Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1480 results about "Pulsed laser beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulsed laser deposition (PLD) is a physical vapor deposition (PVD) technique where a high-power pulsed laser beam is focused inside a vacuum chamber to strike a target of the material that is to be deposited. This material is vaporized from the target (in a plasma plume) ...

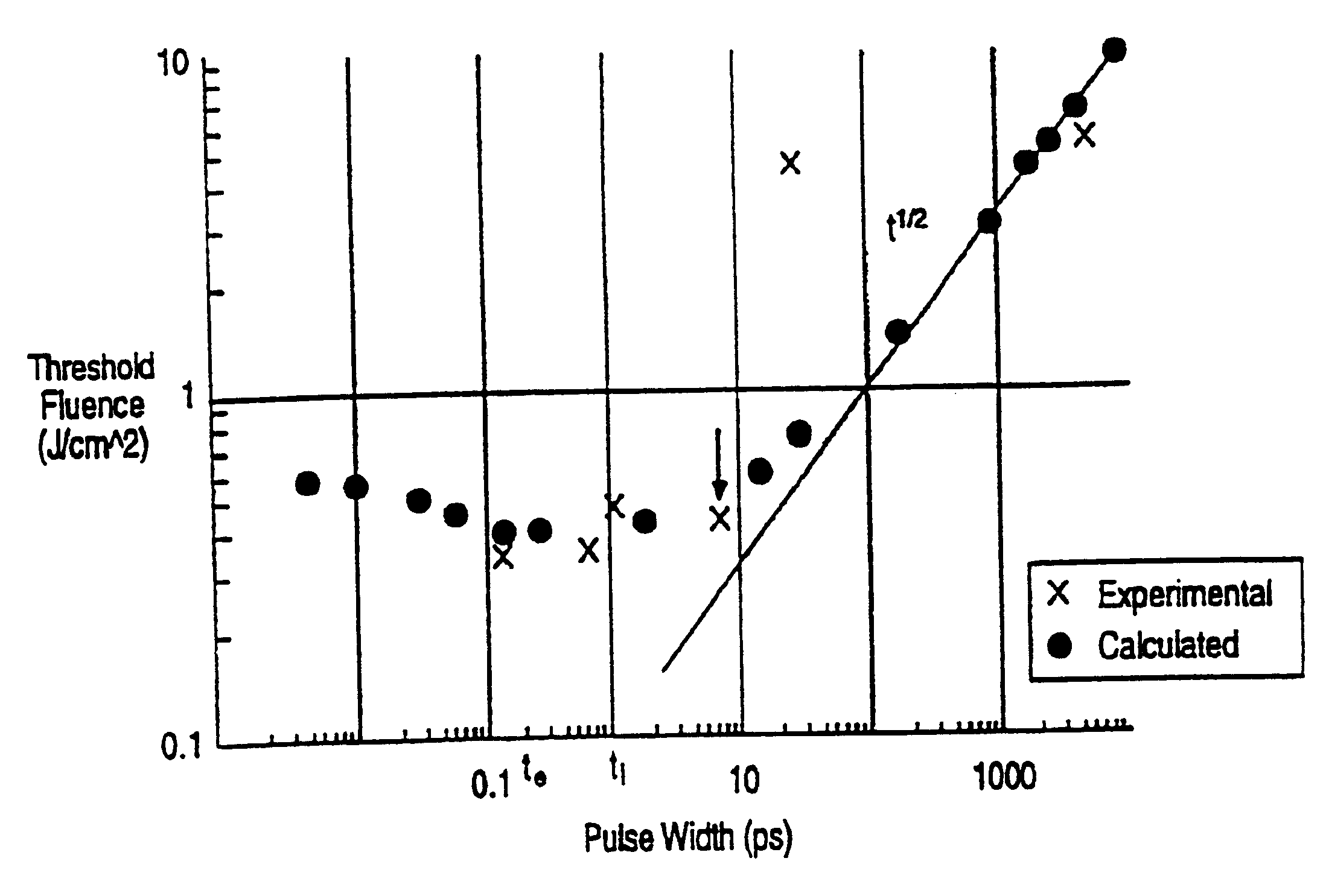

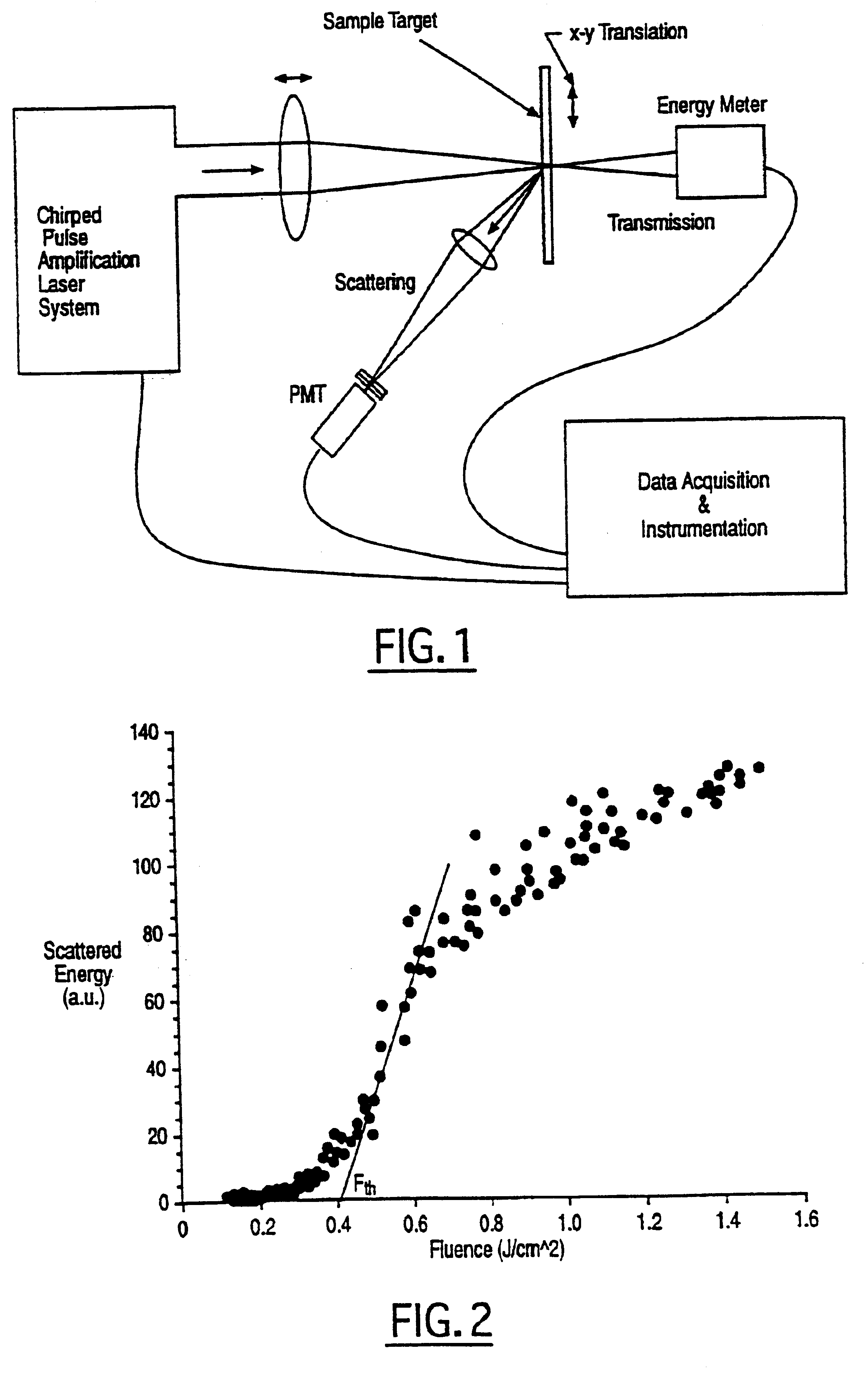

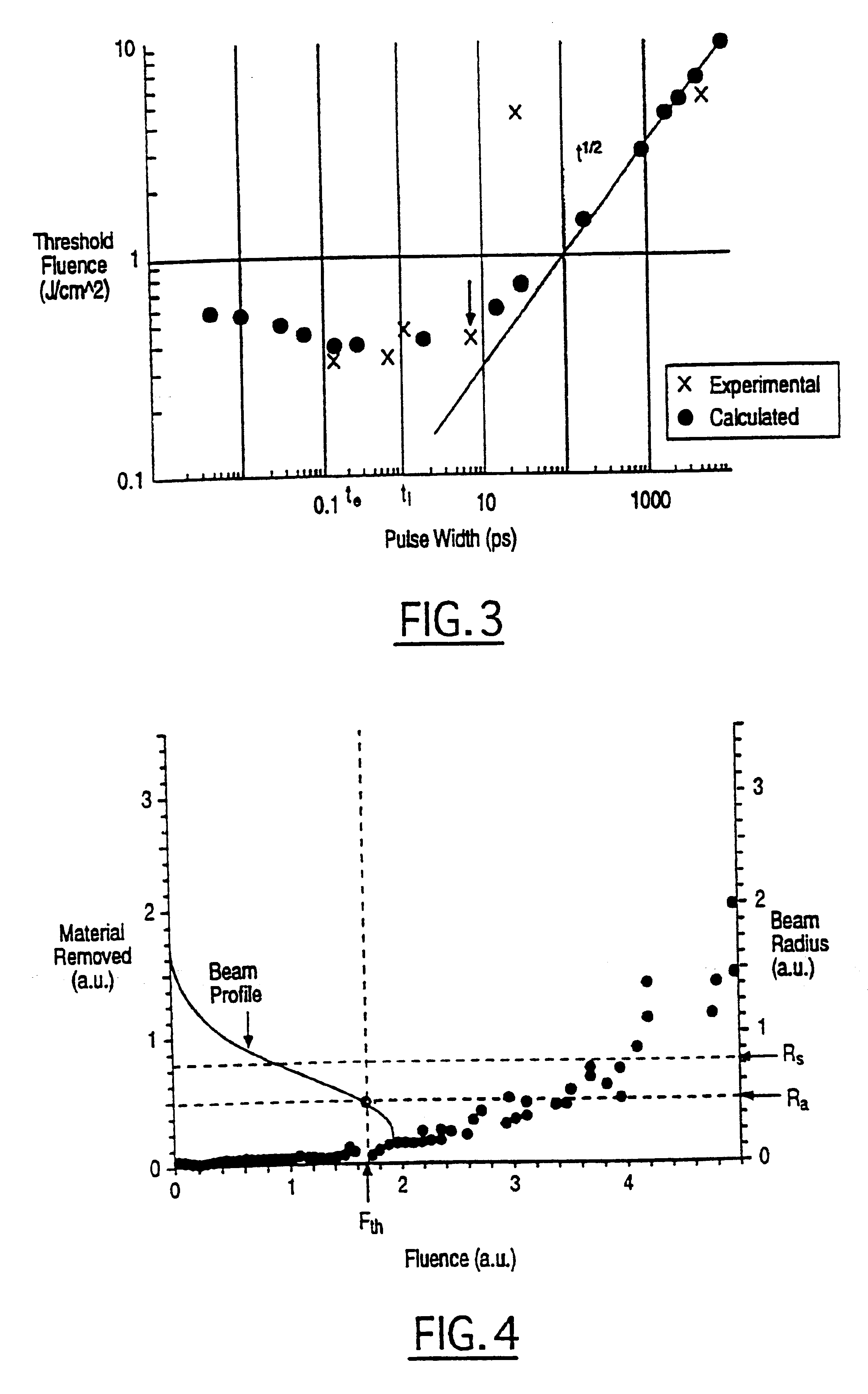

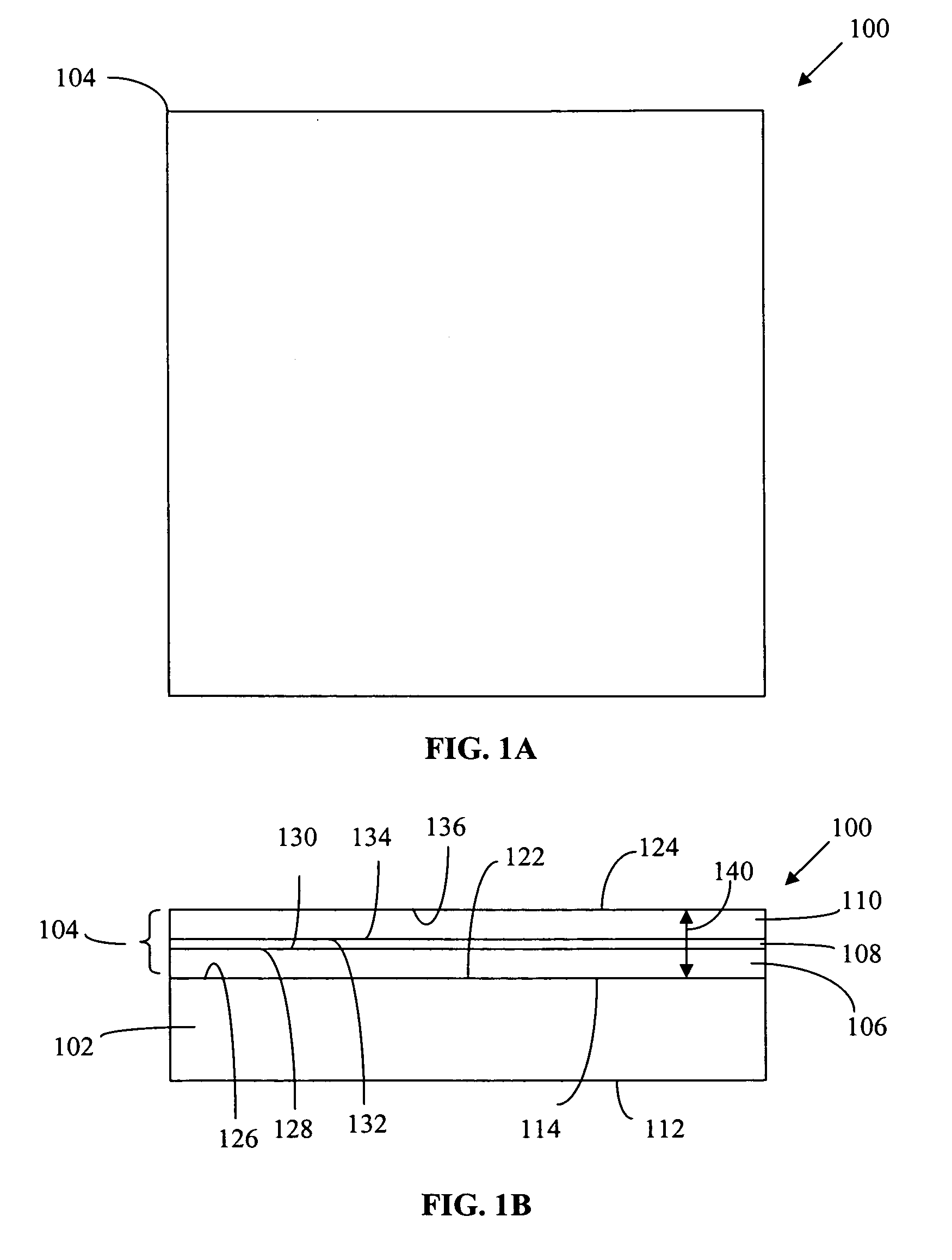

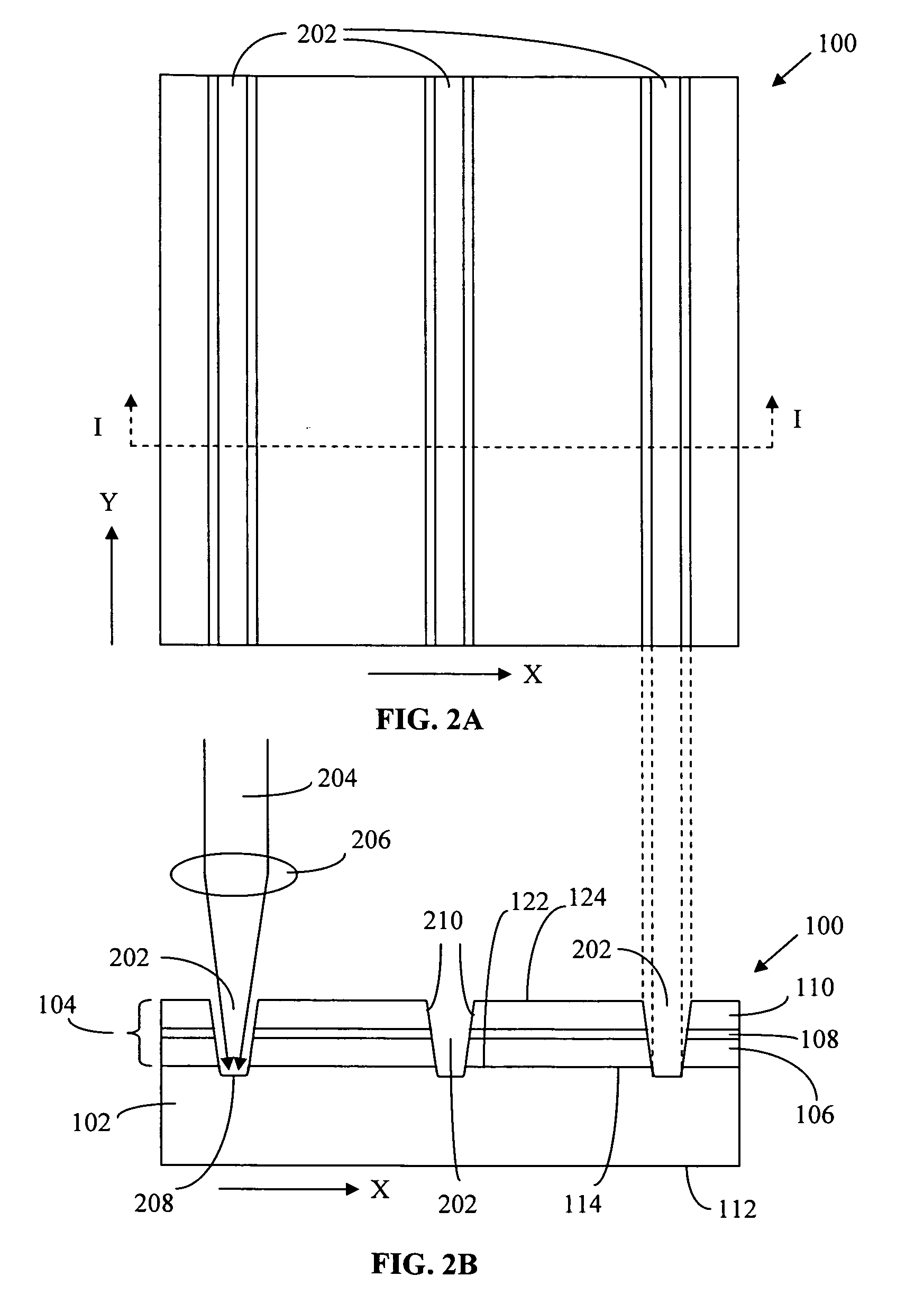

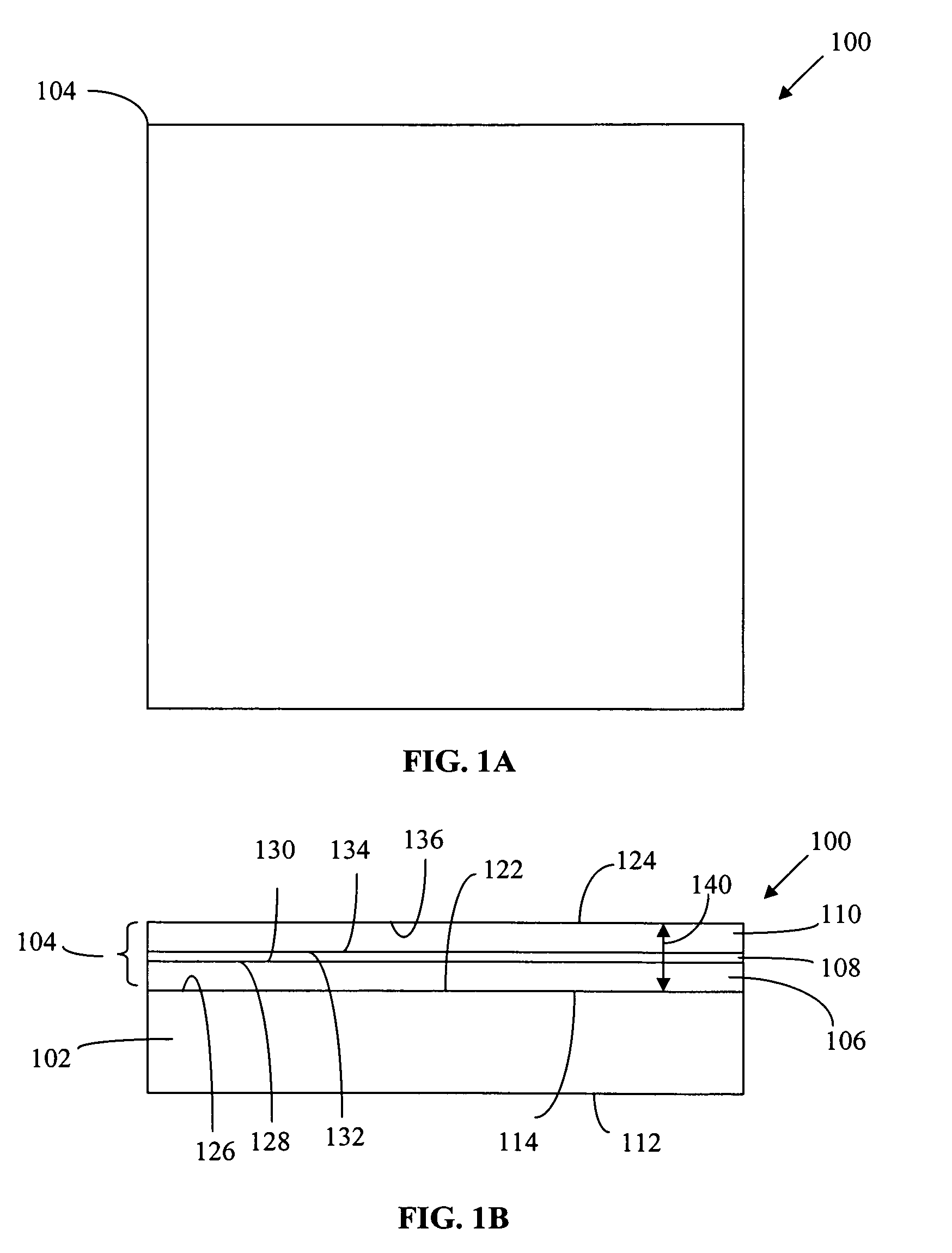

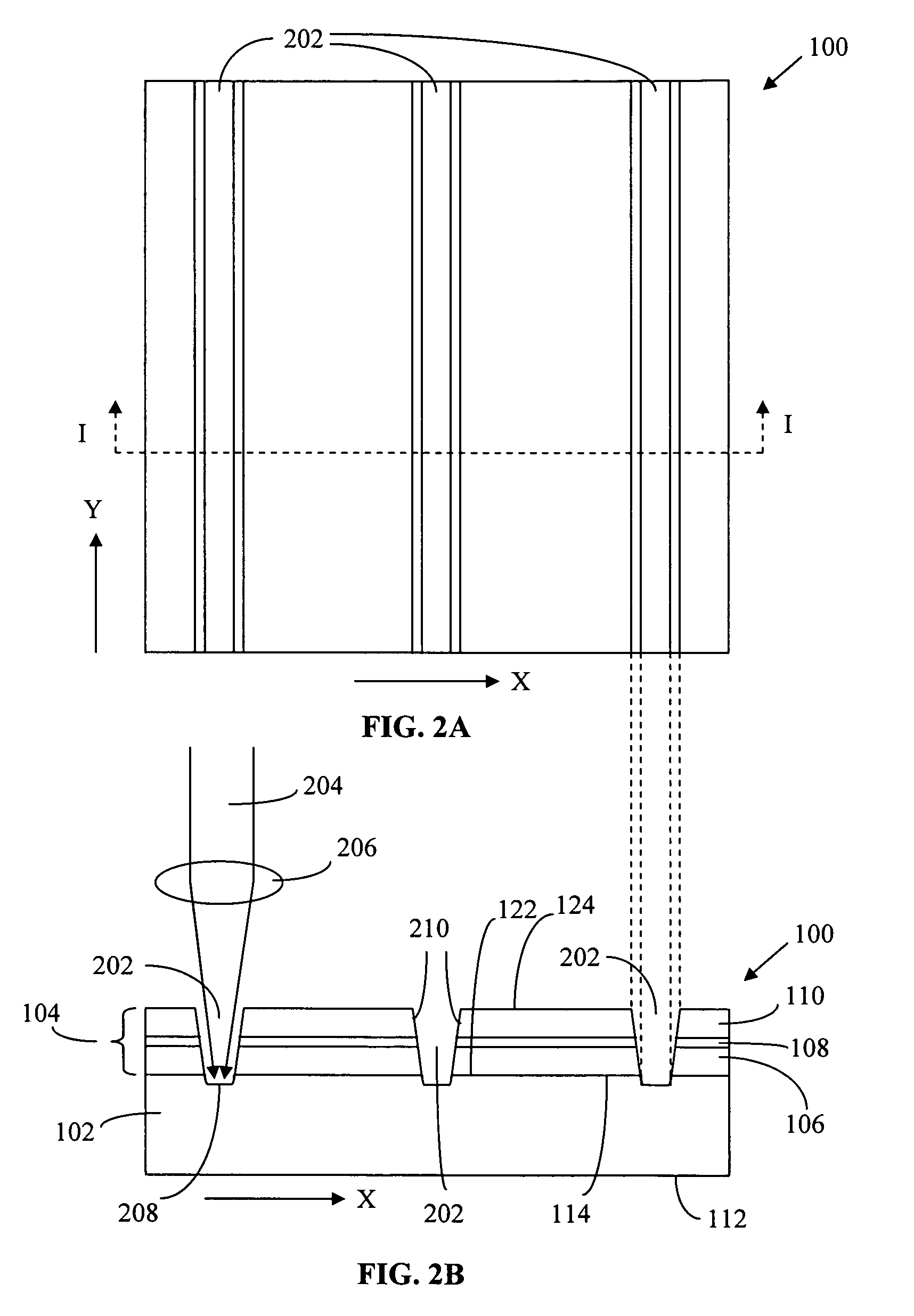

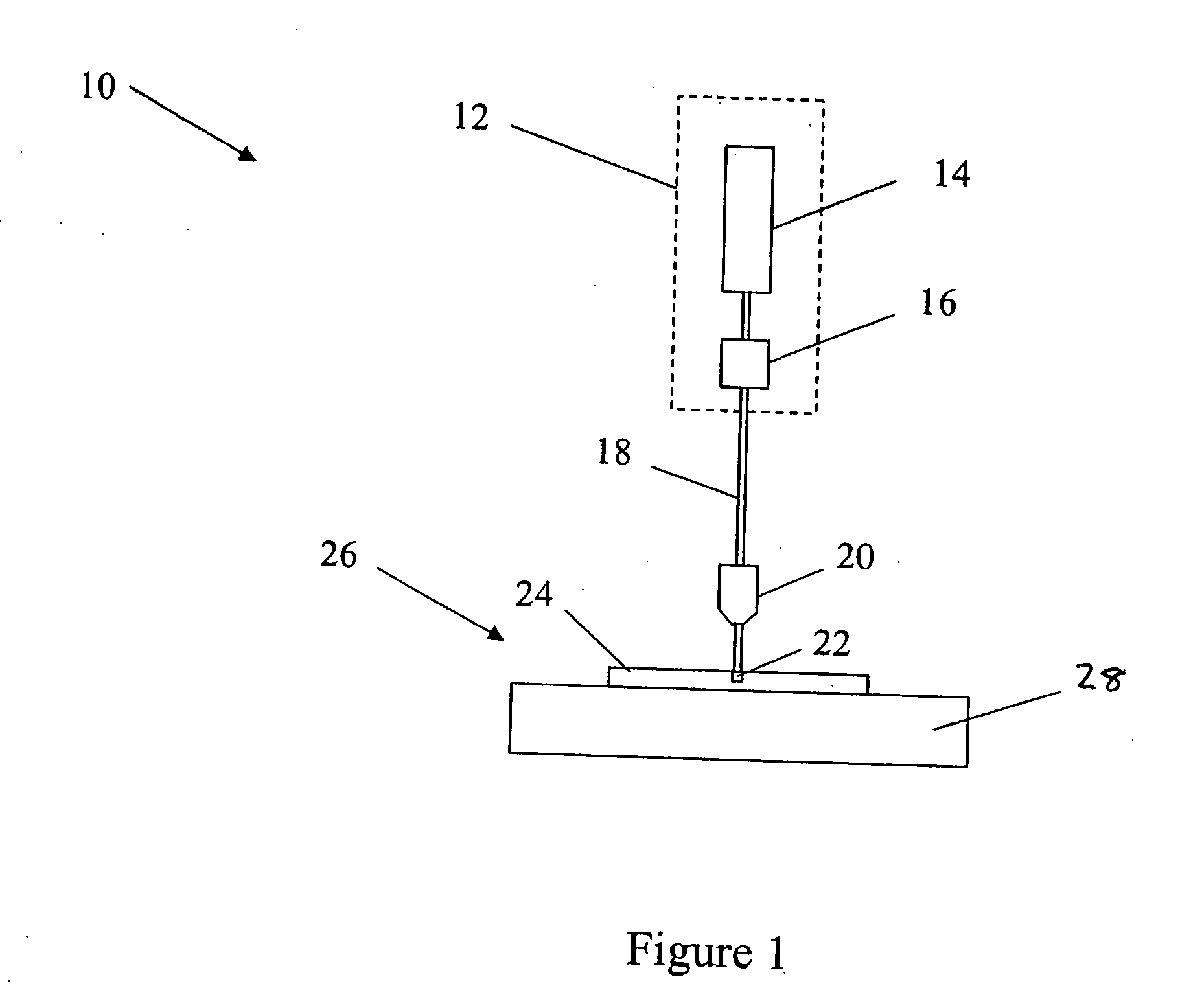

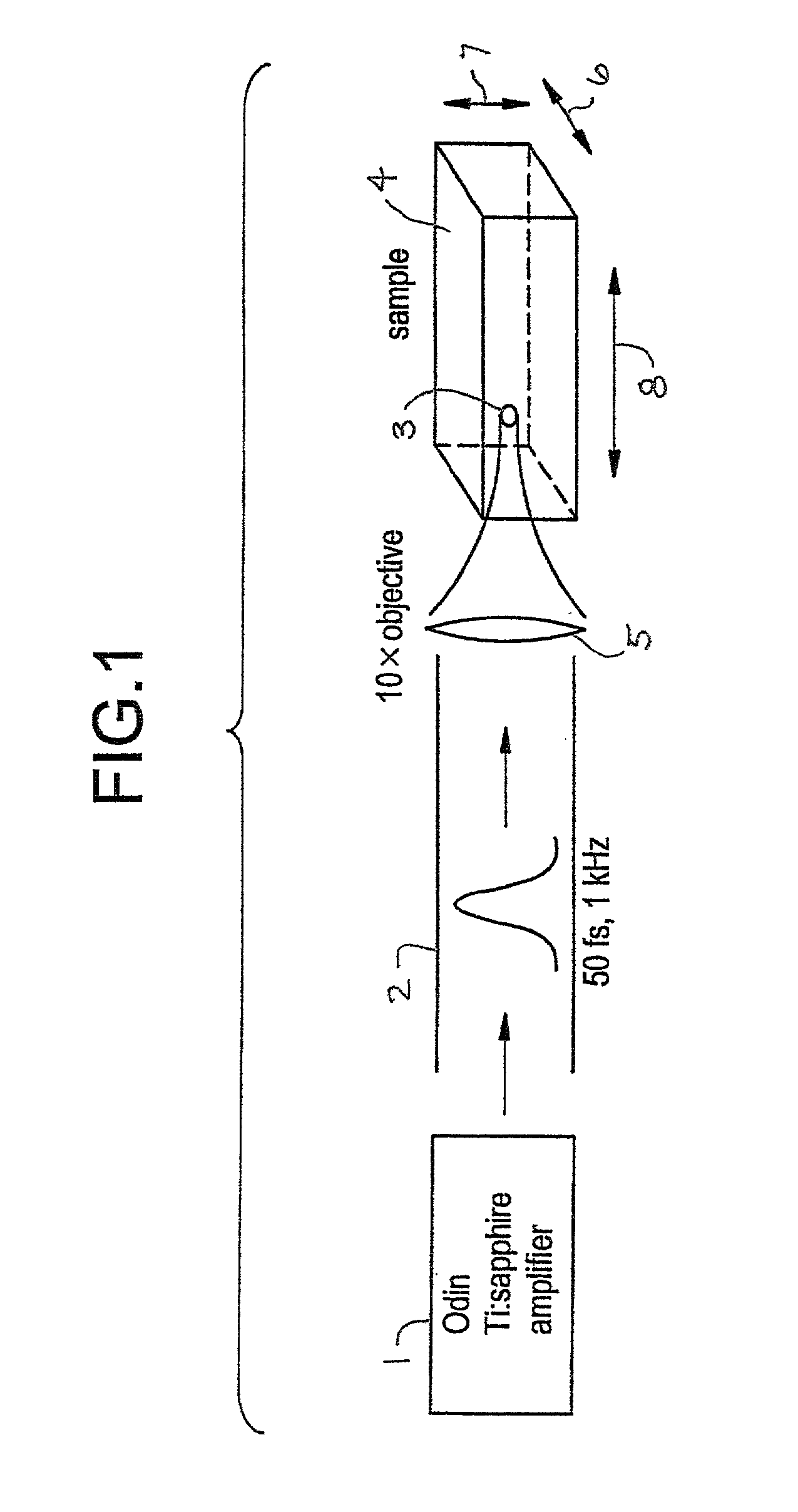

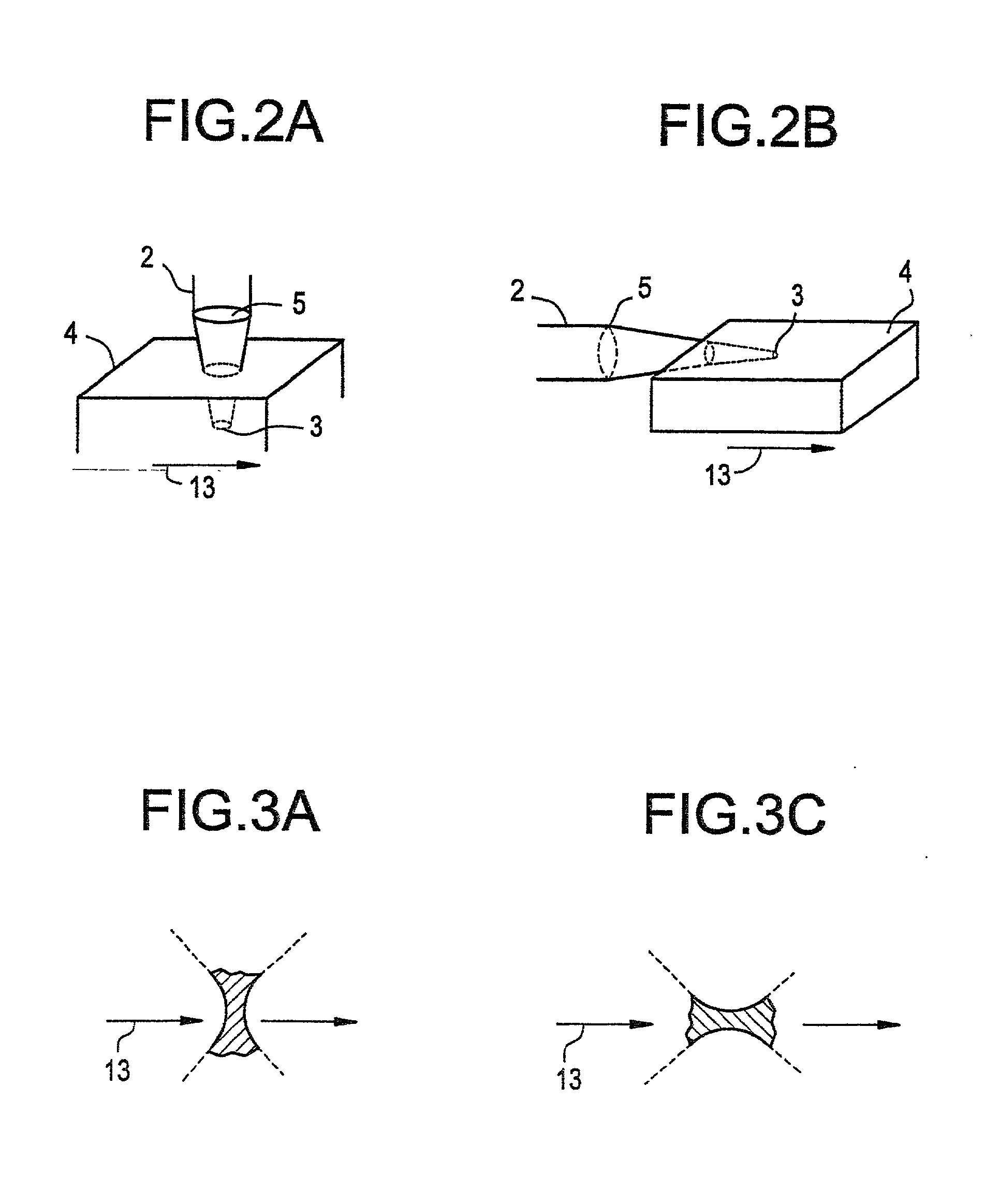

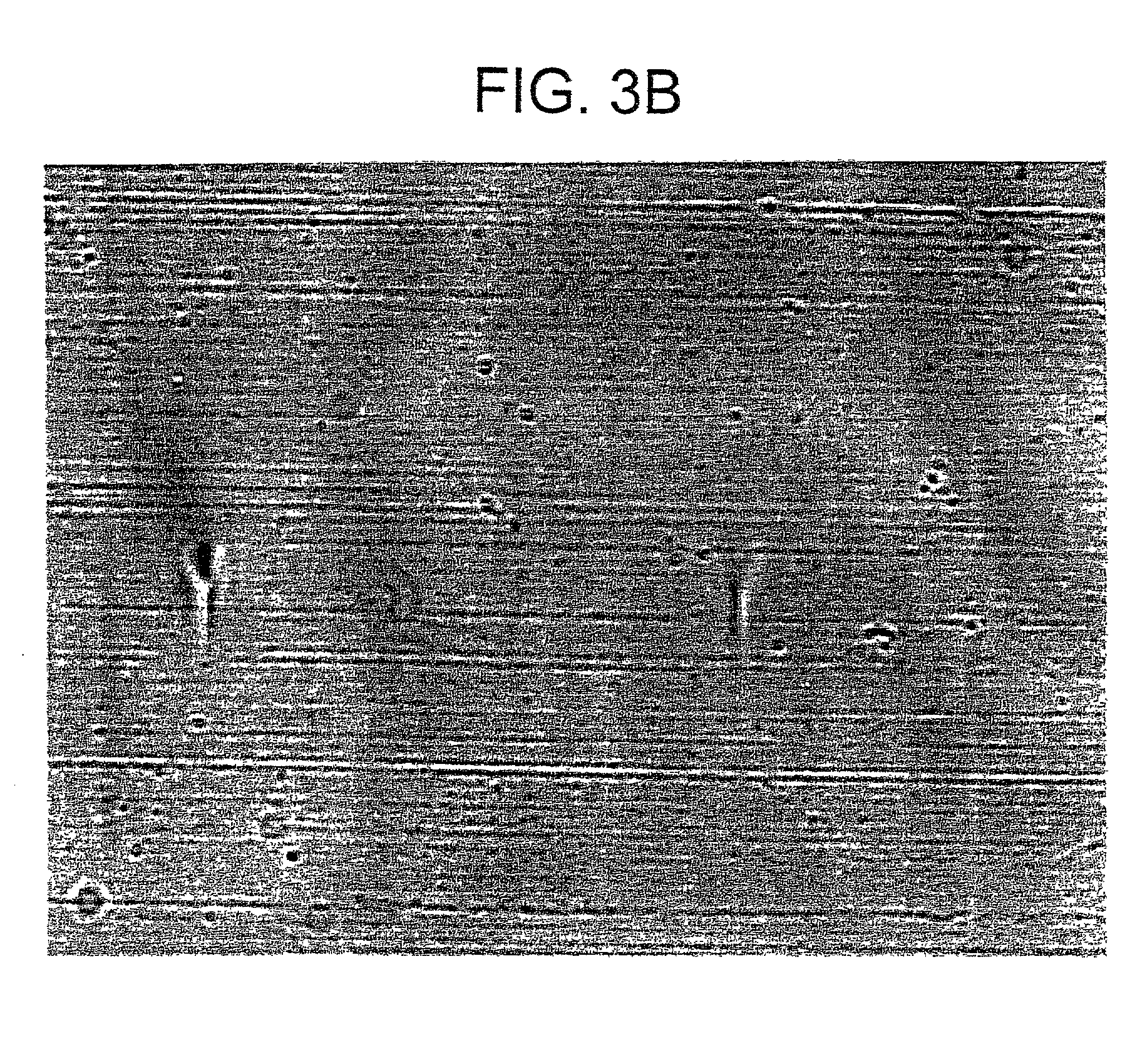

Method for controlling configuration of laser induced breakdown and ablation

In one aspect the invention provides a method for laser induced breakdown of a material with a pulsed laser beam where the material is characterized by a relationship of fluence breakdown threshold (Fth) versus laser beam pulse width (T) that exhibits an abrupt, rapid, and distinct change or at least a clearly detectable and distinct change in slope at a predetermined laser pulse width value. The method comprises generating a beam of laser pulses in which each pulse has a pulse width equal to or less than the predetermined laser pulse width value. The beam is focused to a point at or beneath the surface of a material where laser induced breakdown is desired.The beam may be used in combination with a mask in the beam path. The beam or mask may be moved in the x, y, and Z directions to produce desired features. The technique can produce features smaller than the spot size and Rayleigh range due to enhanced damage threshold accuracy in the short pulse regime.

Owner:AMO DEVMENT

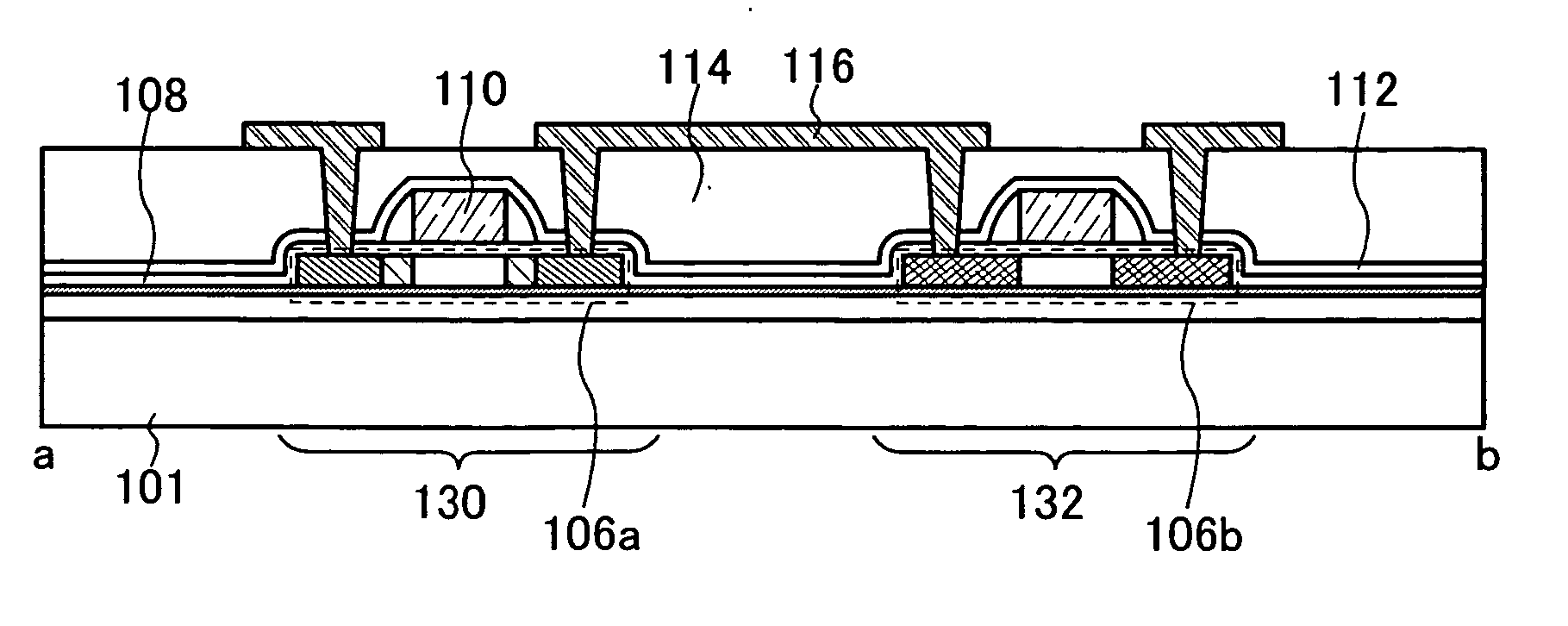

Semiconductor device and manufacturing method thereof

InactiveUS20060275710A1Reduce light intensityImprove routing densitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialContinuous wave laser beam

To provide a semiconductor device having a circuit with high operating performance and high reliability, and improve the reliability of the semiconductor device, thereby improving the reliability of an electronic device having the same. The aforementioned object is achieved by combining a step of crystallizing a semiconductor layer by irradiation with continuous wave laser beams or pulsed laser beams with a repetition rate of 10 MHz or more, while scanning in one direction; a step of photolithography with the use of a photomask or a leticle including an auxiliary pattern which is formed of a diffraction grating pattern or a semi-transmissive film having a function of reducing the light intensity; and a step of performing oxidation, nitridation, or surface-modification to the surface of the semiconductor film, an insulating film, or a conductive film, with high-density plasma with a low electron temperature.

Owner:SEMICON ENERGY LAB CO LTD

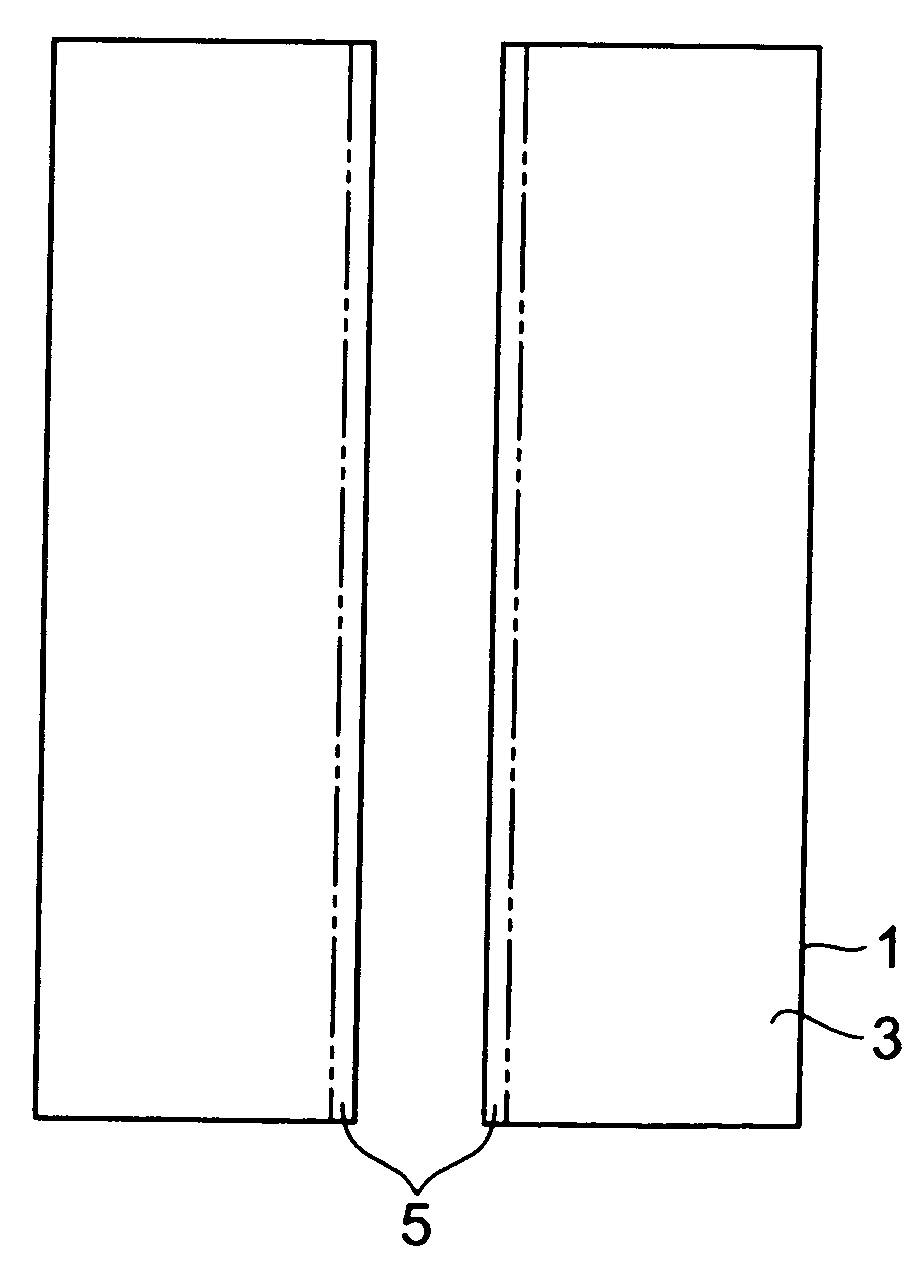

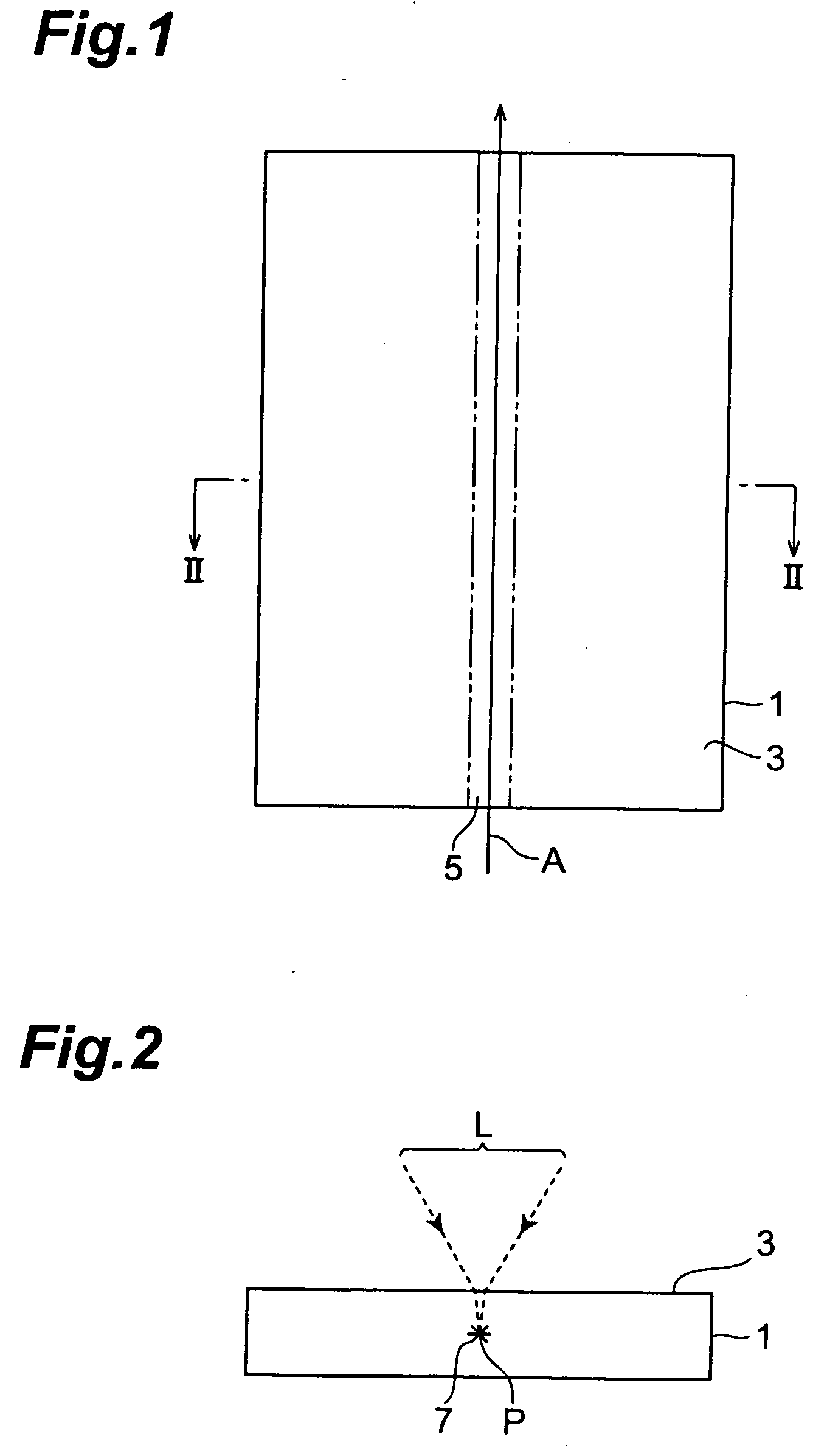

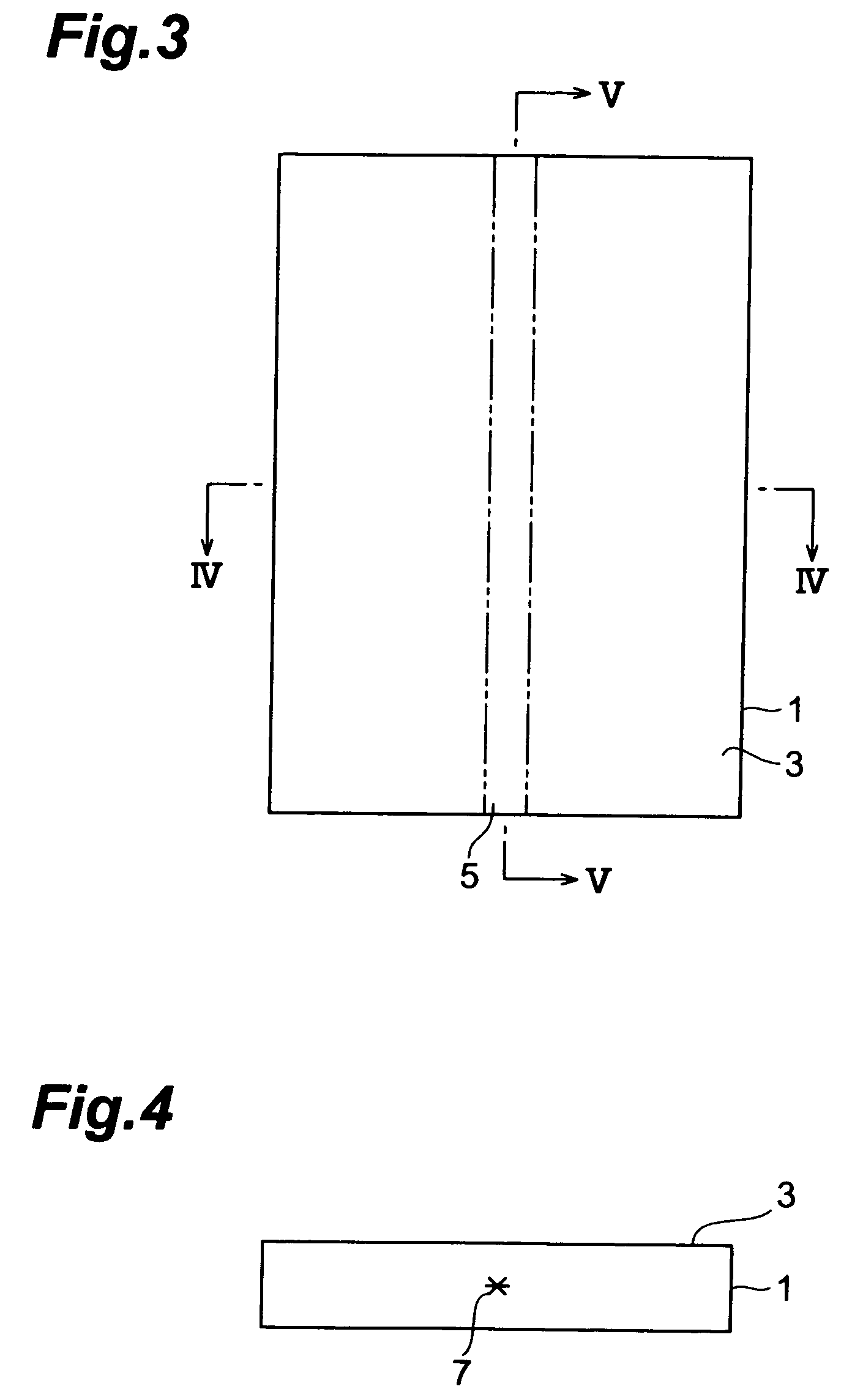

Chip manufacturing method

ActiveUS20150343559A1Efficiently formGlass reforming apparatusGlass severing apparatusLight beamUltrasonic vibration

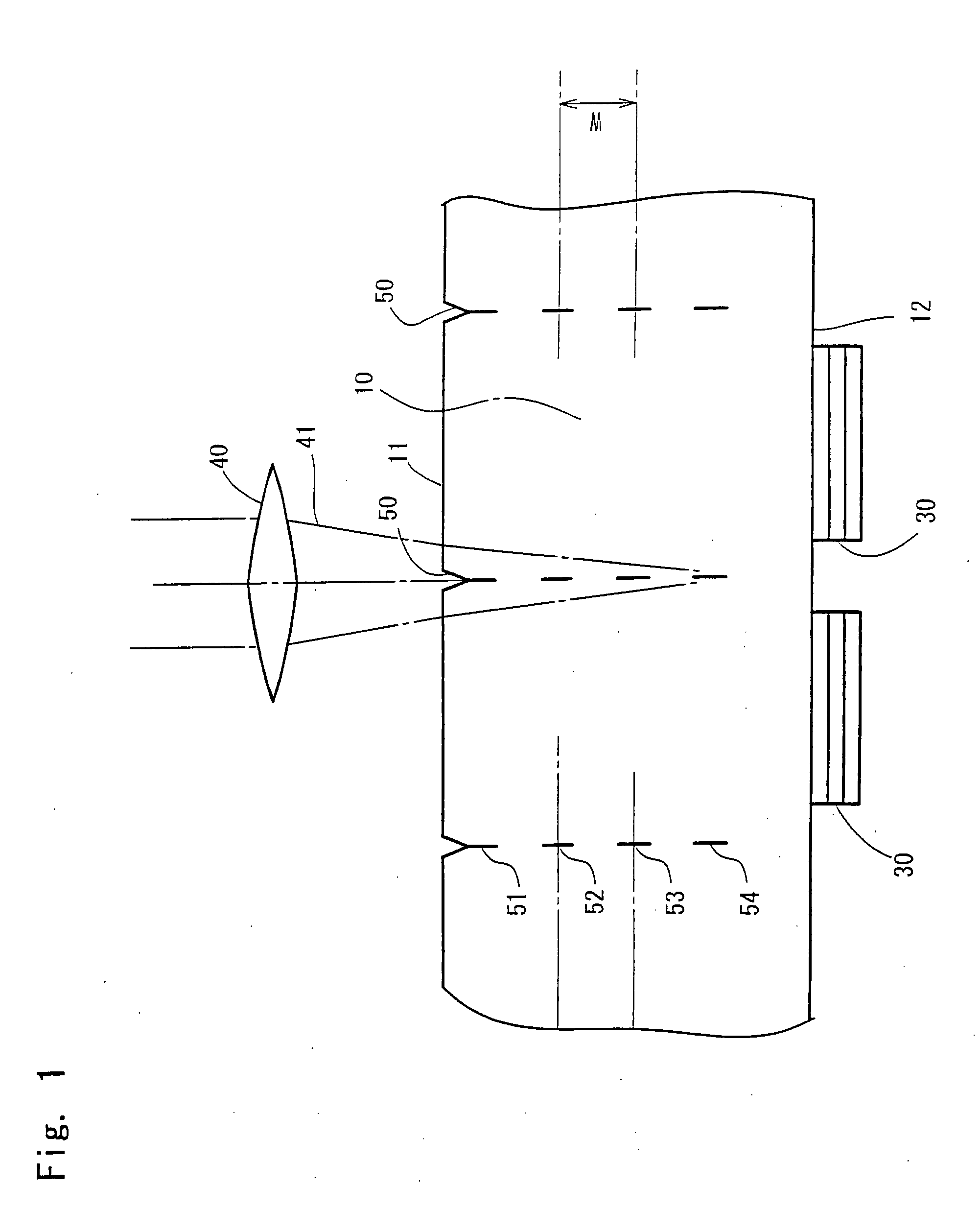

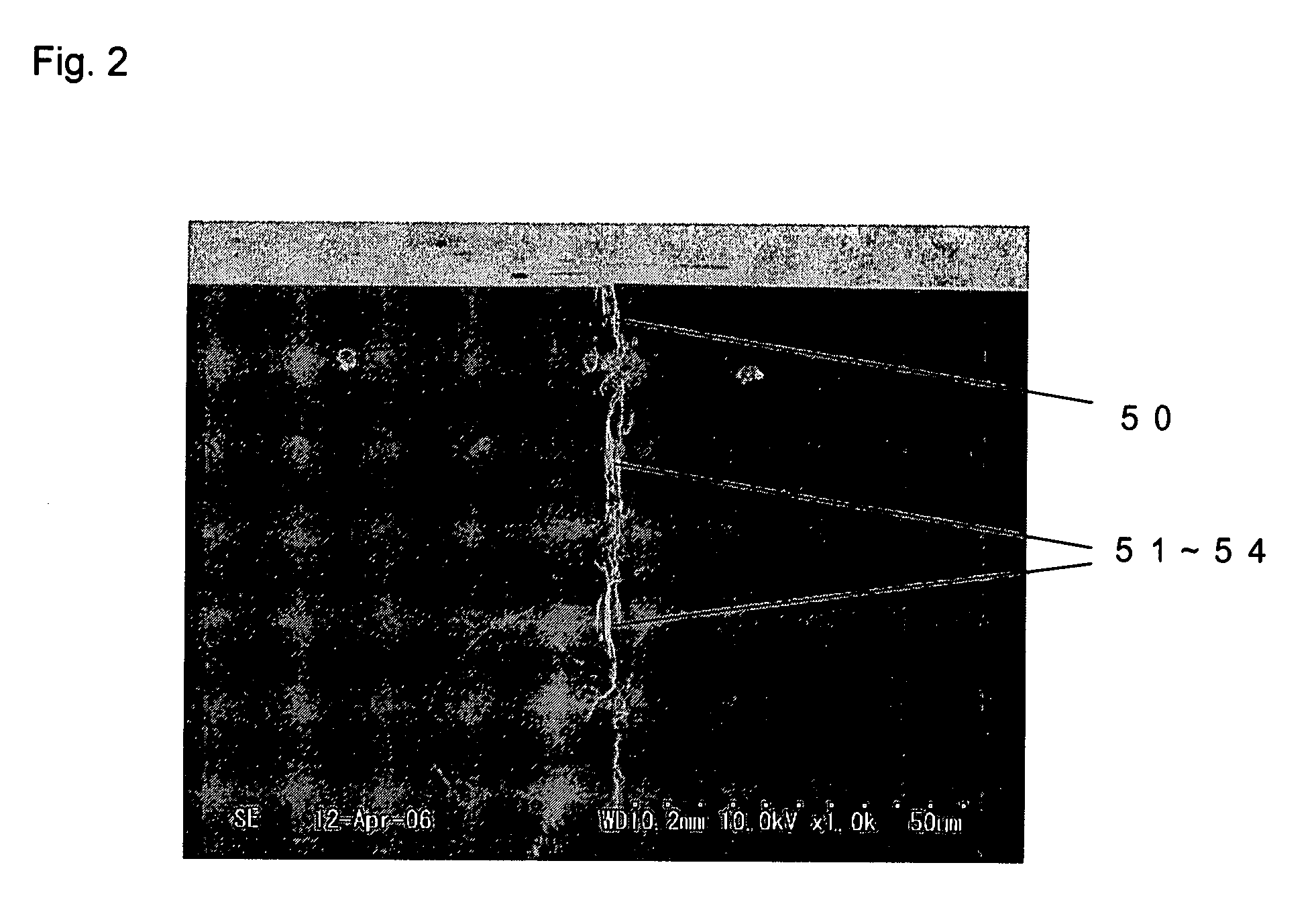

A chip having a desired shape is formed from a platelike workpiece. The chip manufacturing method includes a shield tunnel forming step of applying a pulsed laser beam to the workpiece from a focusing unit included in a pulsed laser beam applying unit along the contour of the chip to be formed, with the focal point of the pulsed laser beam set at a predetermined depth from the upper surface of the workpiece, thereby forming a plurality of shield tunnels inside the workpiece along the contour of the chip to be formed. Each shield tunnel has a fine hole and an amorphous region formed around the fine hole for shielding the fine hole. In a chip forming step, ultrasonic vibration is applied to the workpiece to break the contour of the chip where the shield tunnels have been formed, thereby forming the chip from the workpiece.

Owner:DISCO CORP

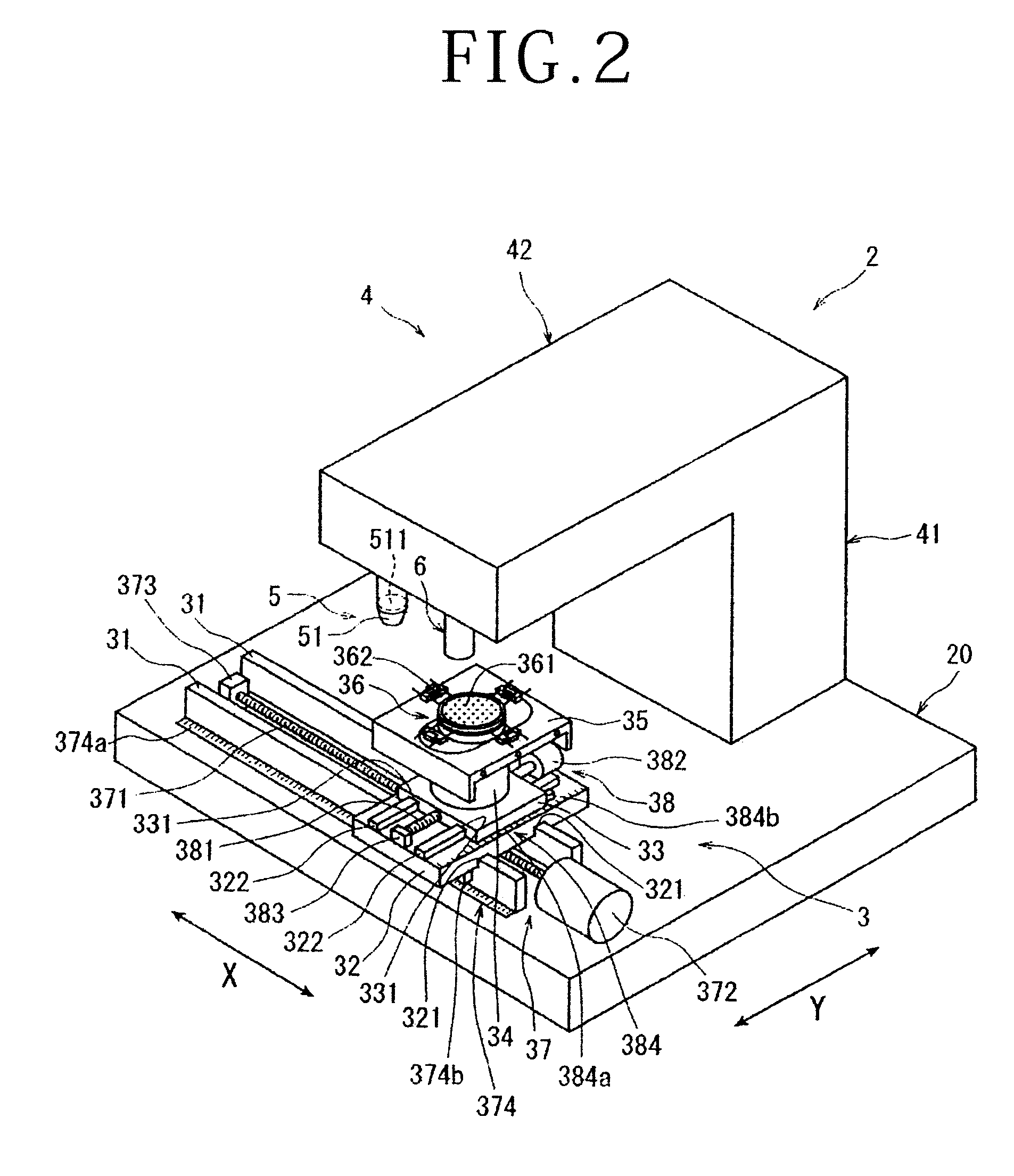

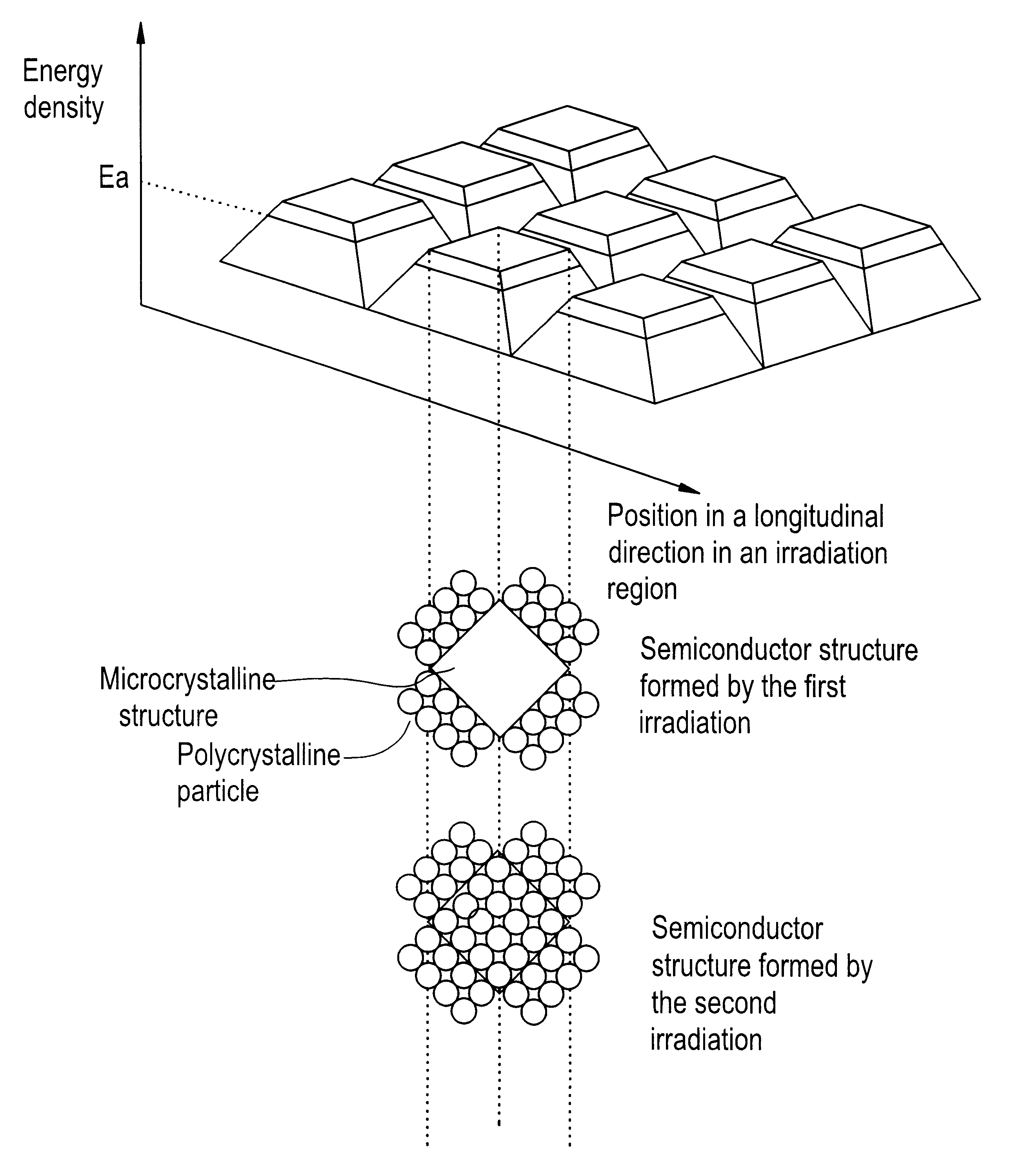

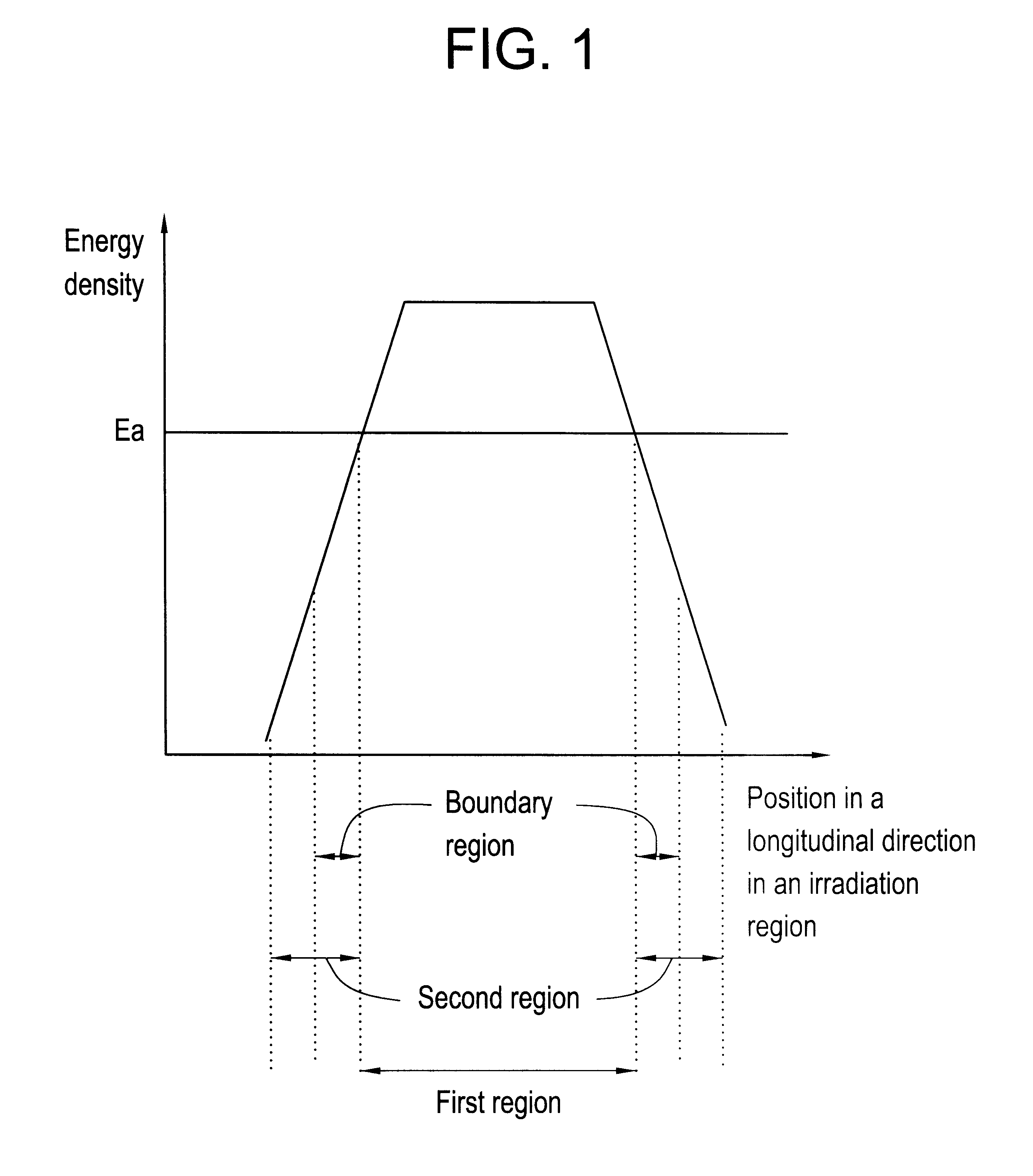

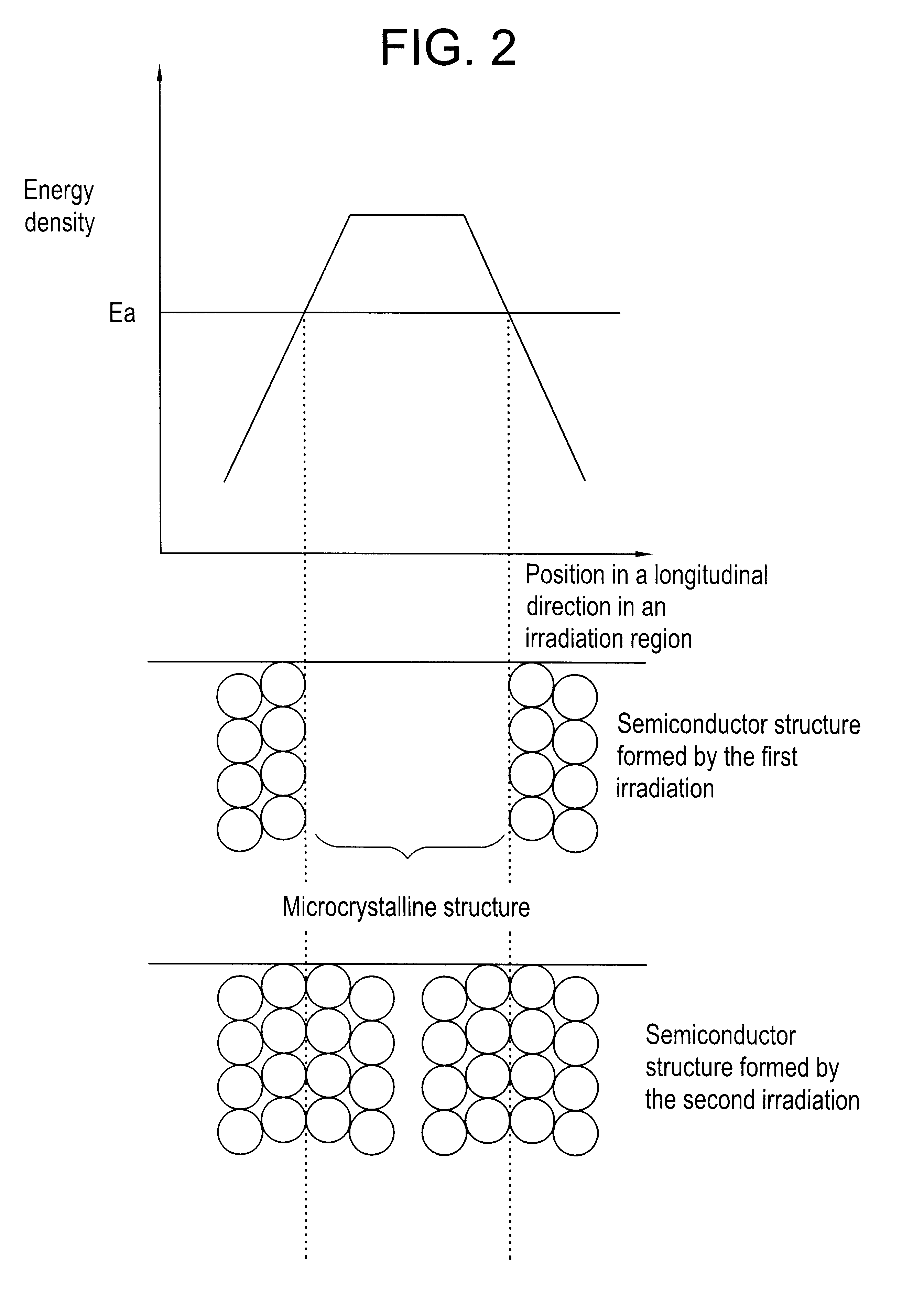

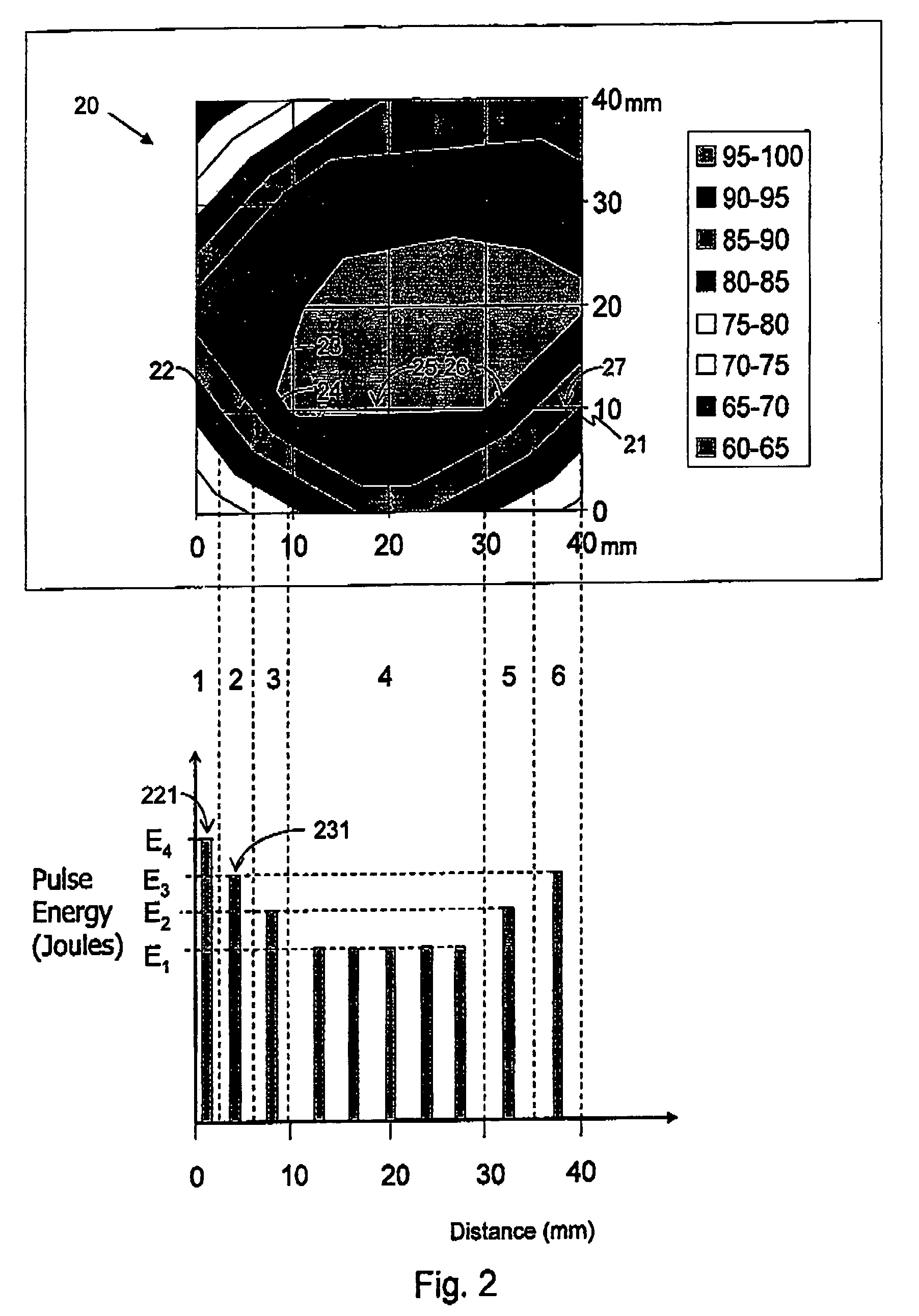

Laser irradiation process

A pulse laser beam having a rectangular irradiation region is irradiated on the same point in a non-single crystal semiconductor film multiple times. The pulse laser beam has an energy profile in a longitudinal direction in the beam irradiation region as follows: (a) there are the first region having an energy density of Ea or higher and the second regions on both sides of the first region having an energy density of less than Ea, and (b) an energy density slope has an absolute value of 20 to 300 J / cm3 in a boundary region extending to 1 mum from the boundary line between the first and the second regions.

Owner:GOLD CHARM LTD

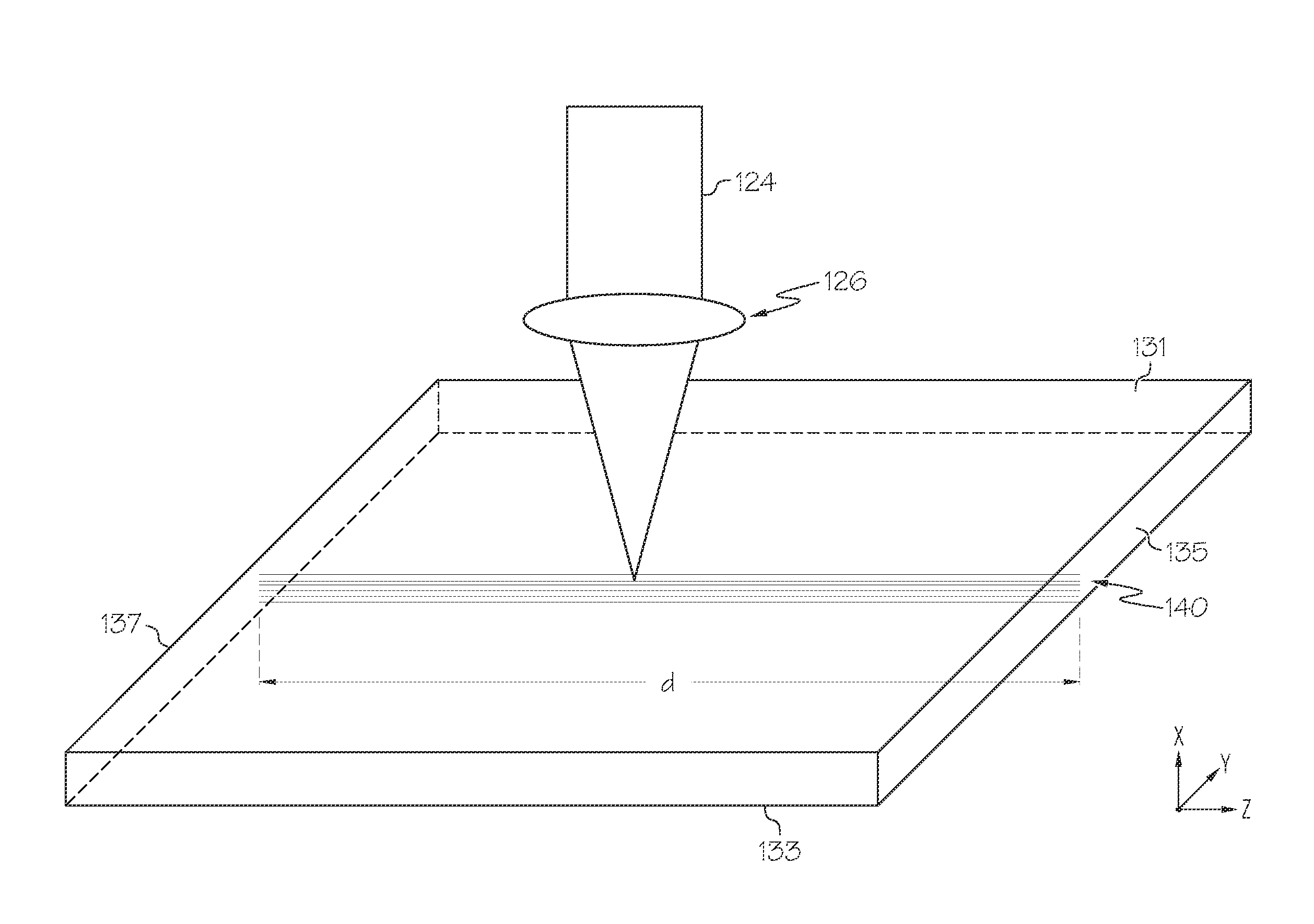

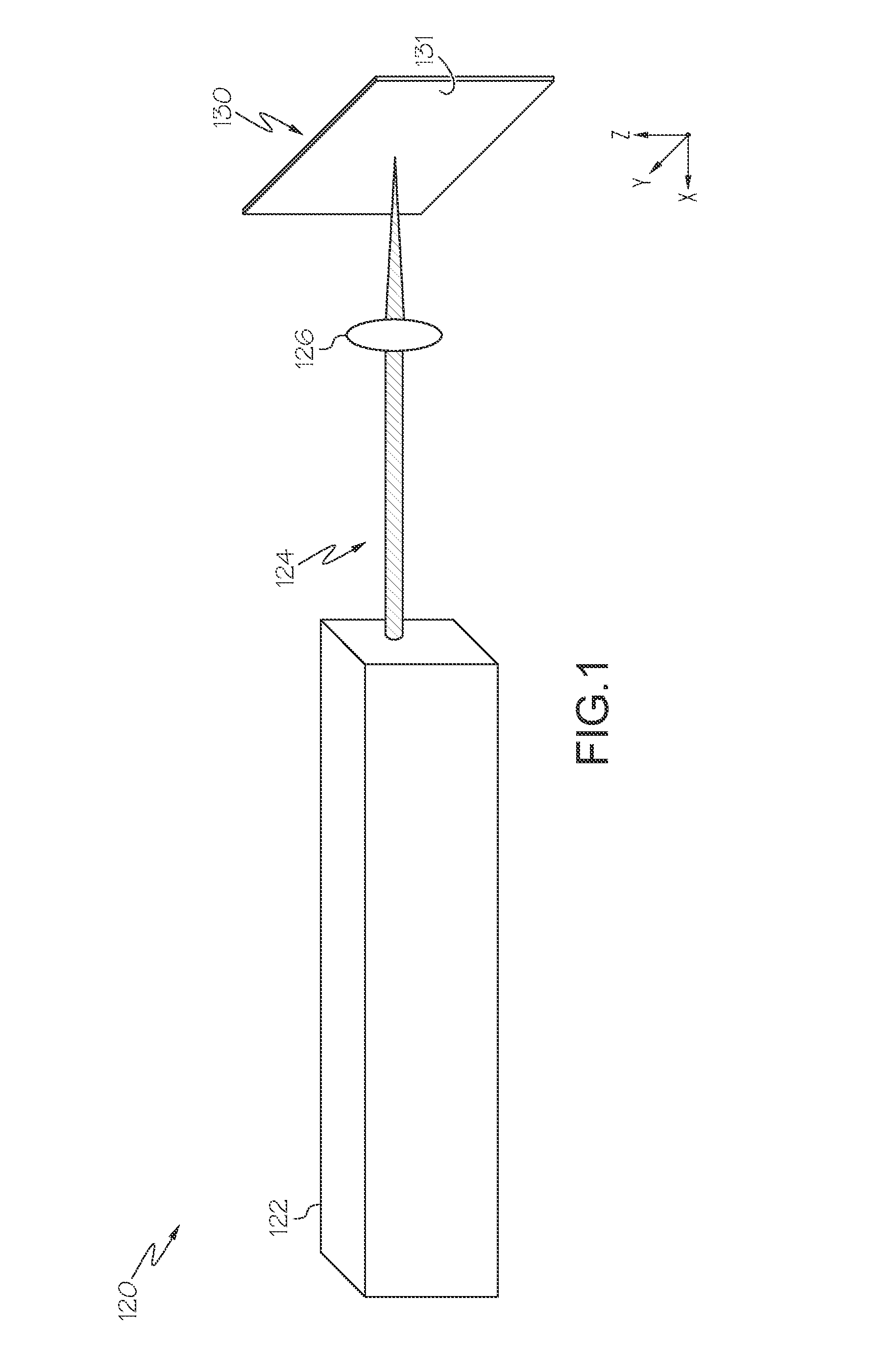

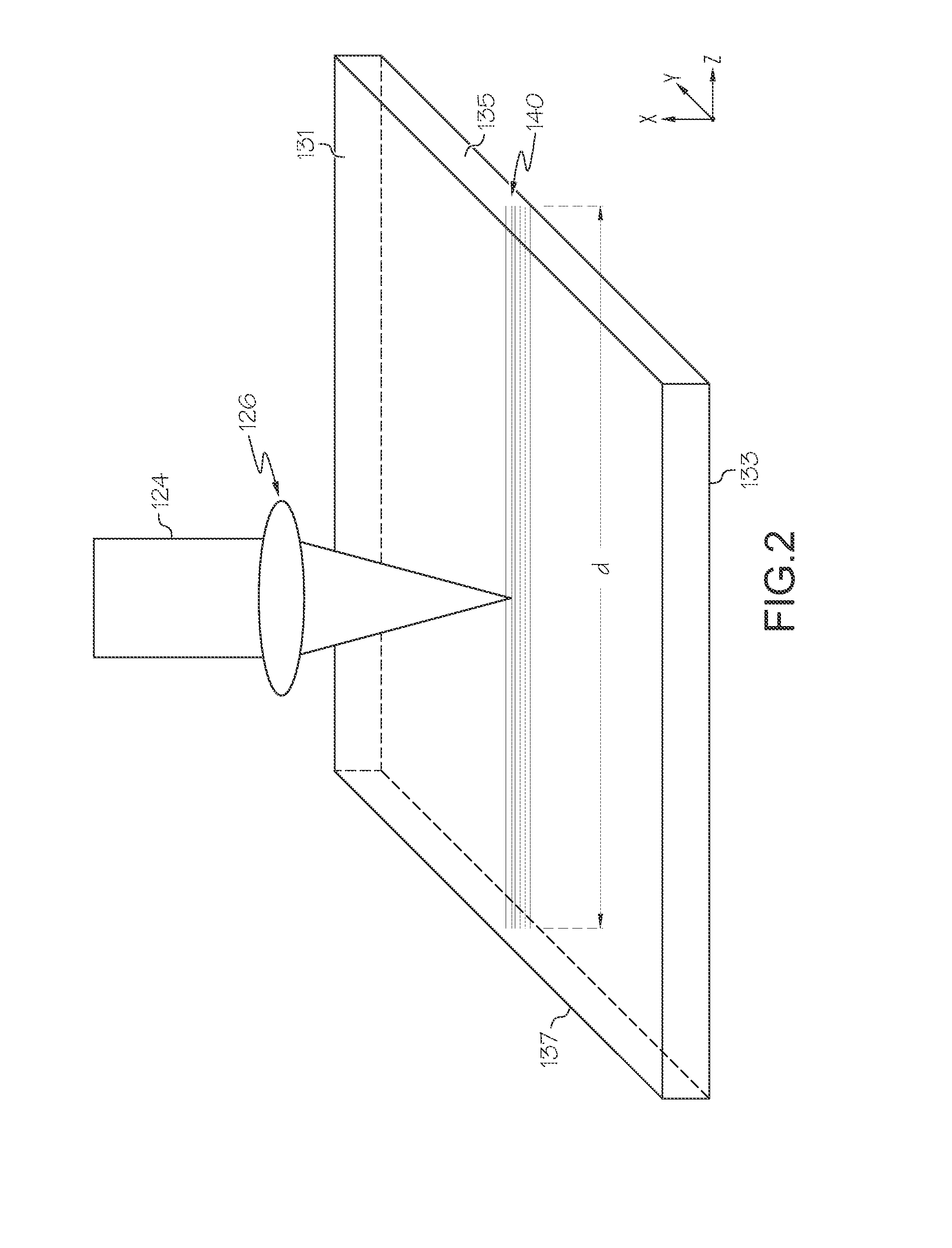

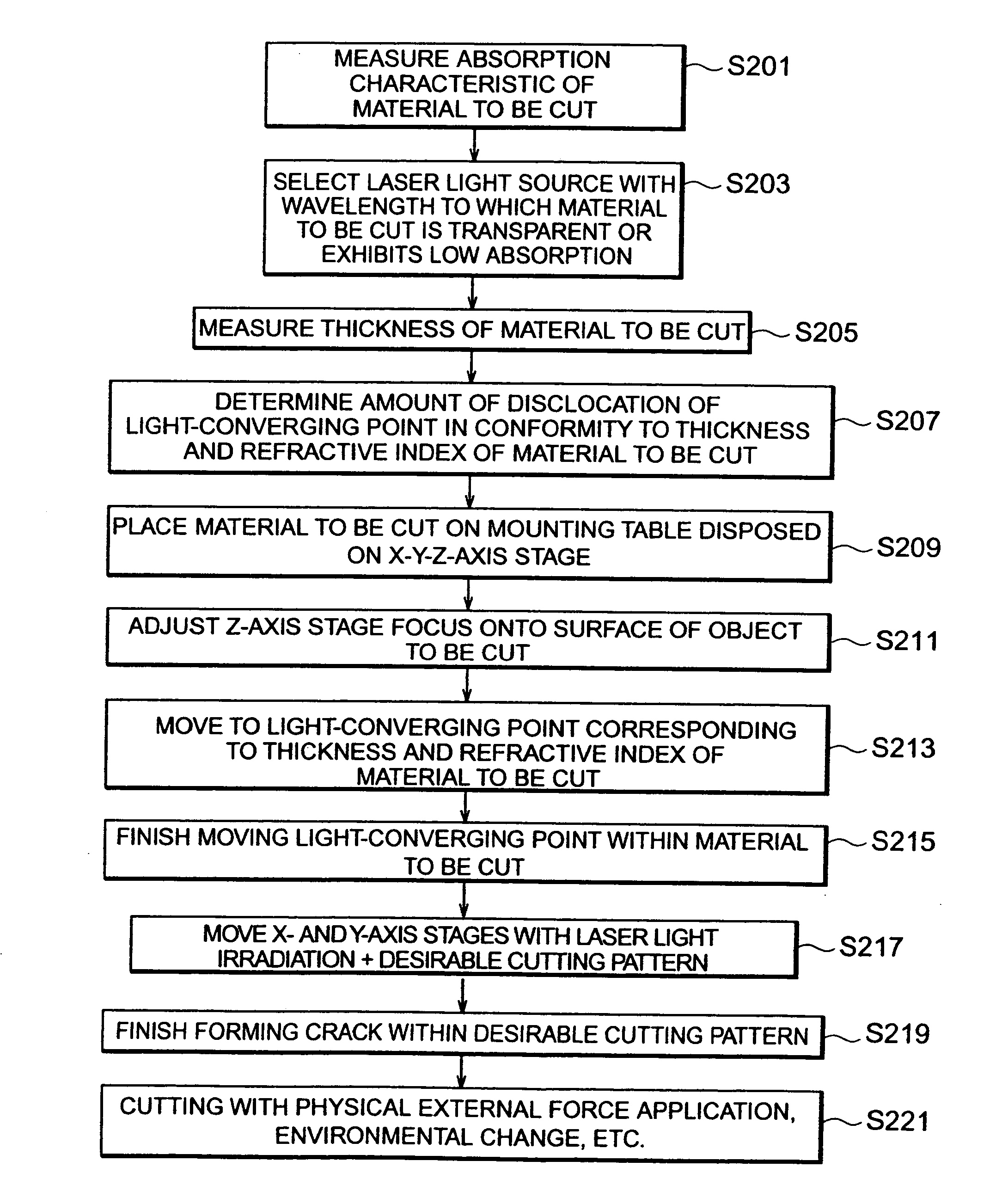

Laser processing method and laser processing apparatus

InactiveUS20050173387A1No unnecessary fracture in surfaceNo unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

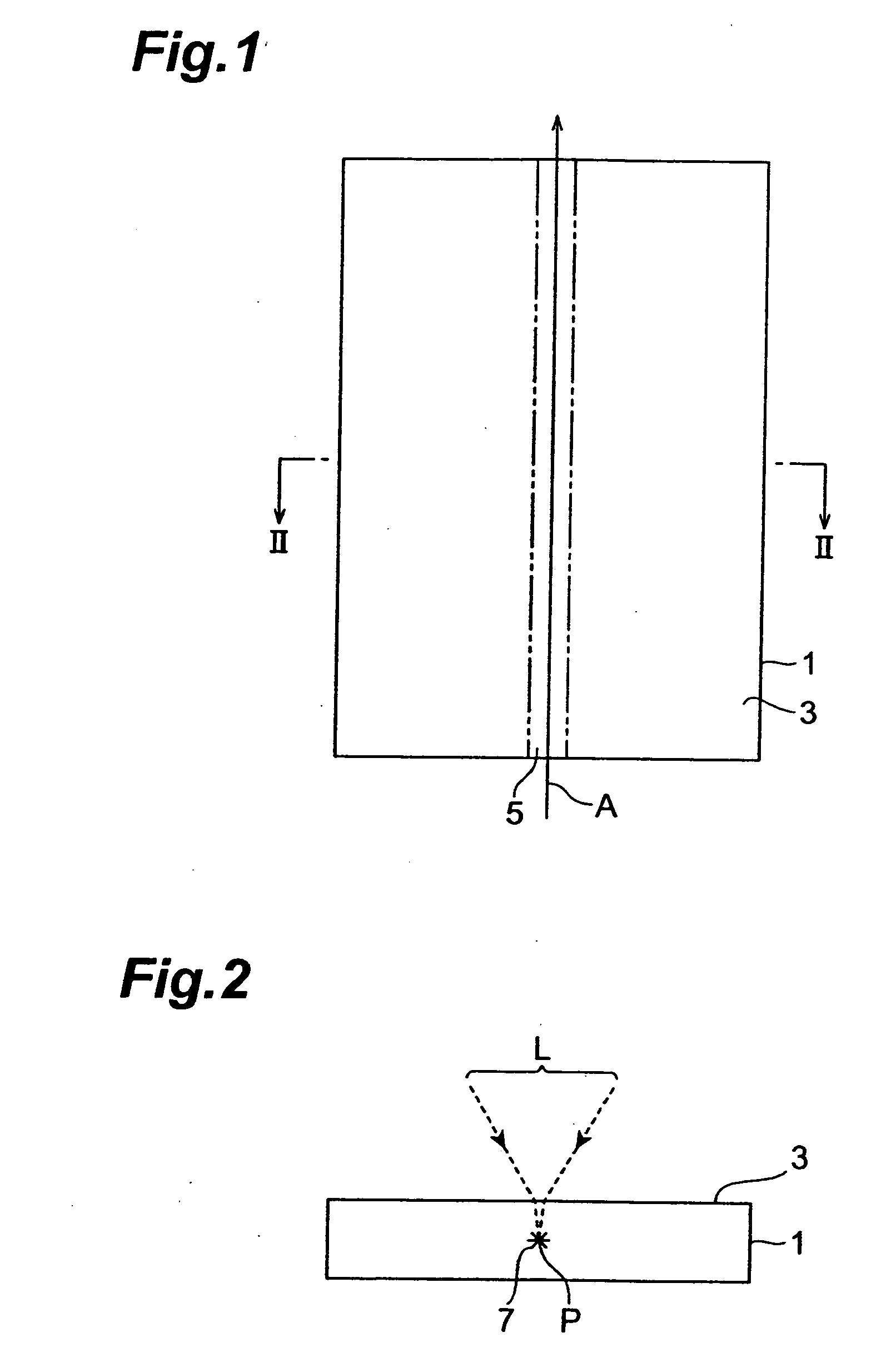

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

Semiconductor light-emitting device and method for separating semiconductor light-emitting devices

InactiveUS20070298529A1Reliably splitLight absorptionSolid-state devicesSemiconductor/solid-state device manufacturingSplit linesPulsed laser beam

The invention provides a method for separating semiconductor light-emitting devices formed on a substrate. In the method, a pulse laser beam having a pulse width less than 10 ps in a substrate is focused on the substrate, to thereby cause multi-photon absorption in the substrate. Through multi-photon absorption, a groove is formed through the pulse laser beam along a split line predetermined on a surface of the substrate, the groove being substantially continuous in the direction of the predetermined split line. In addition, internal structurally changed portions are formed through the pulse laser beam at a predetermined depth of the substrate on a predetermined split face, the structurally changed portions being discontinuous in the direction of the predetermined split line. Subsequently, an external force is applied to thereby form a split face along the continuous groove and the discontinuous internal structurally changed portions, whereby the semiconductor light-emitting devices are separated from one another

Owner:TOYODA GOSEI CO LTD

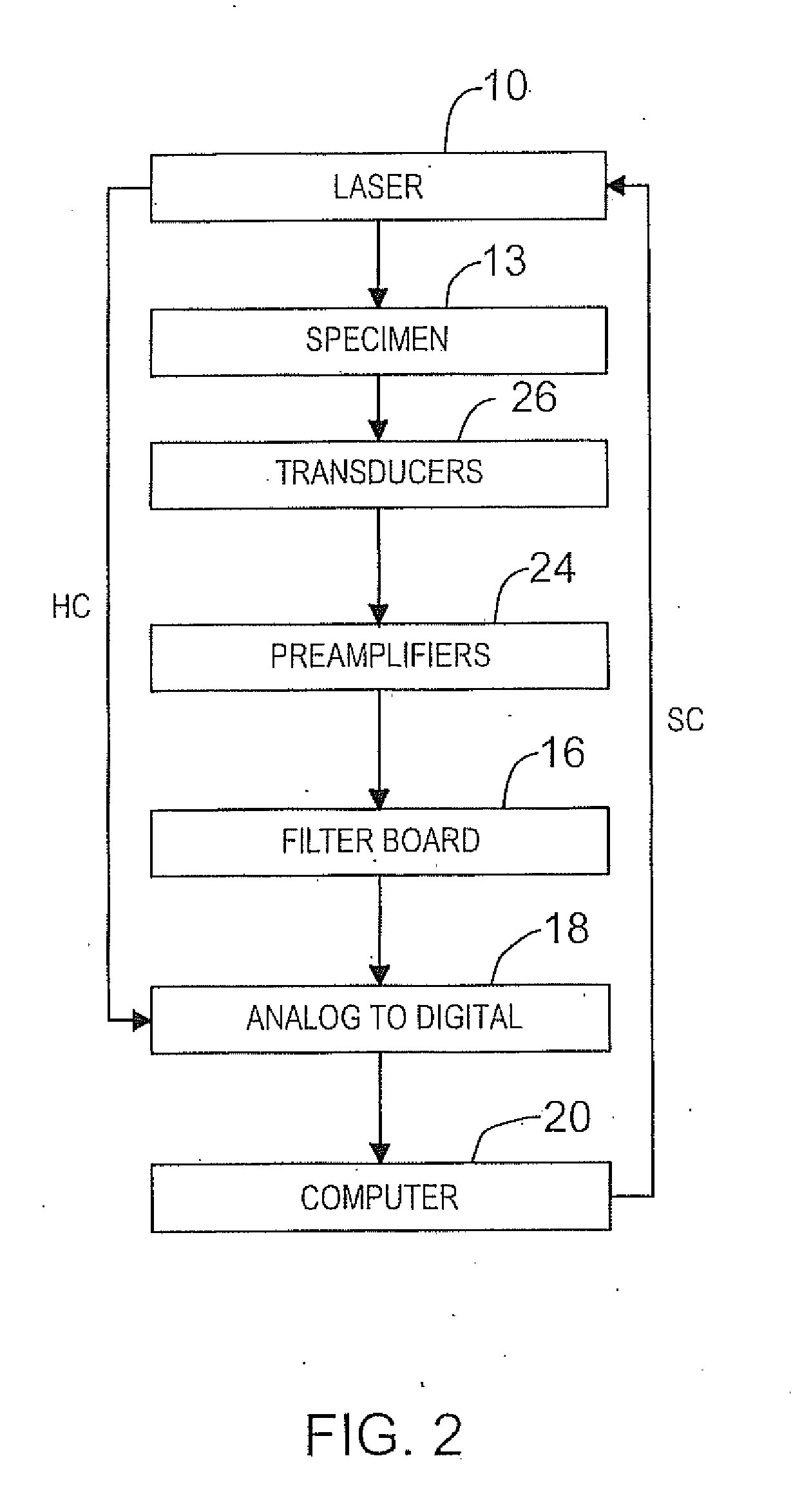

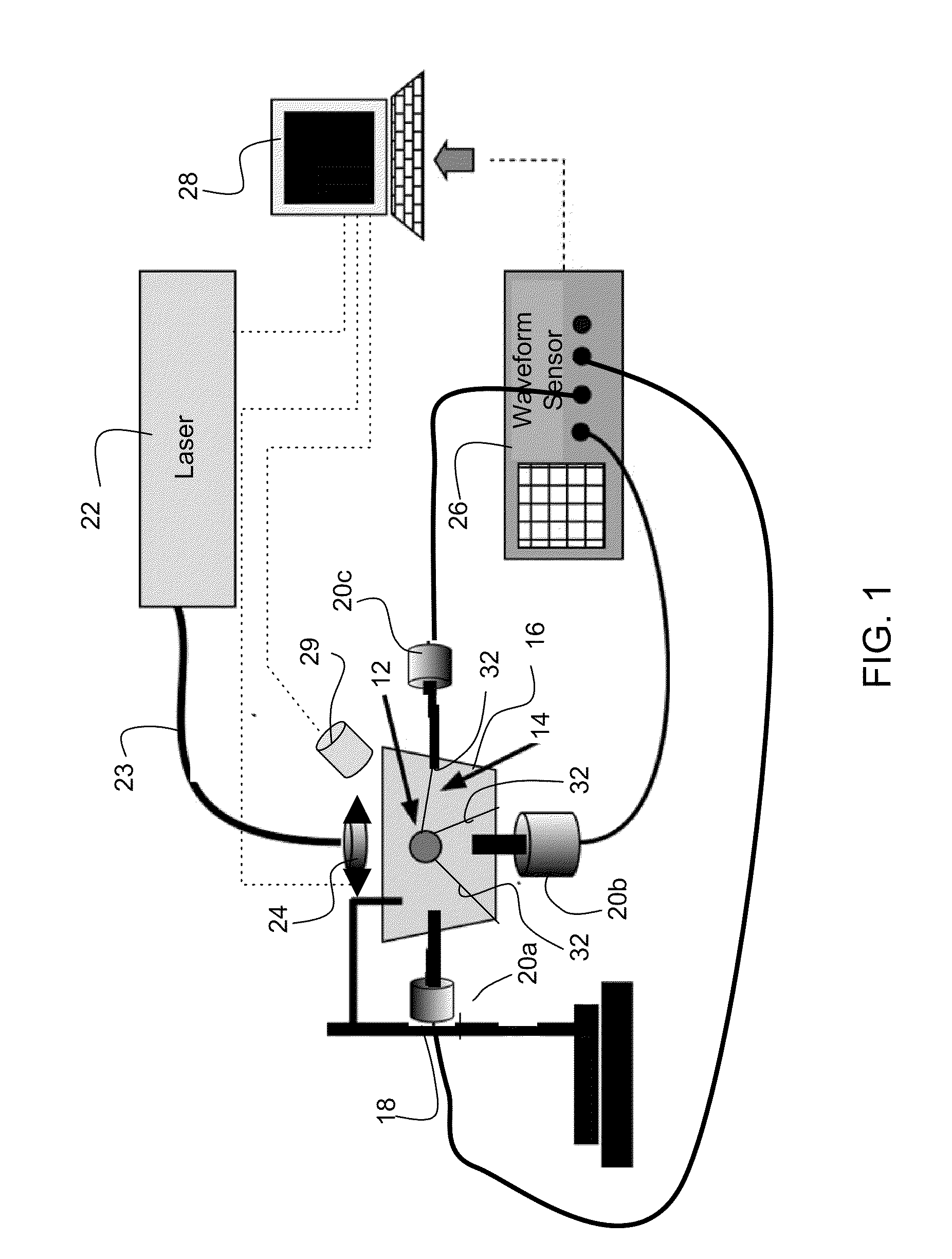

Three-dimensional photoacoustic imager and methods for calibrating an imager

InactiveUS20100249570A1Illuminating subjectUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesData acquisitionReconstruction algorithm

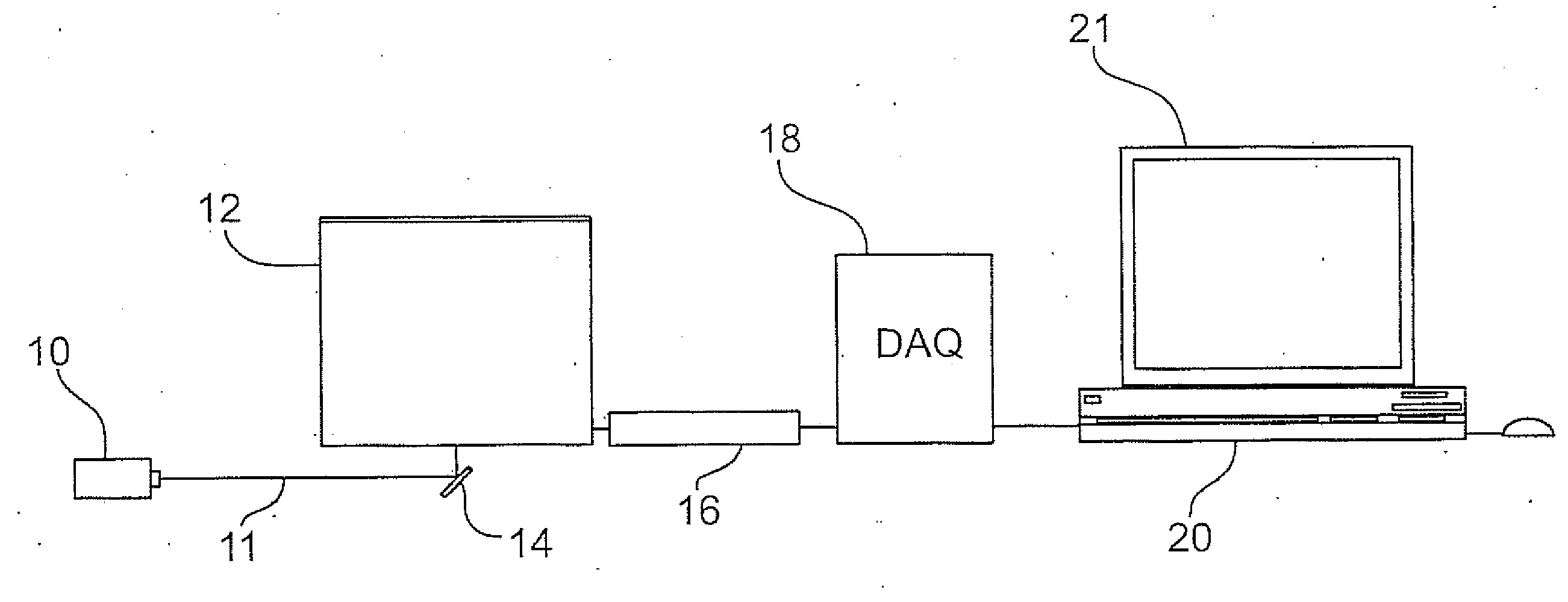

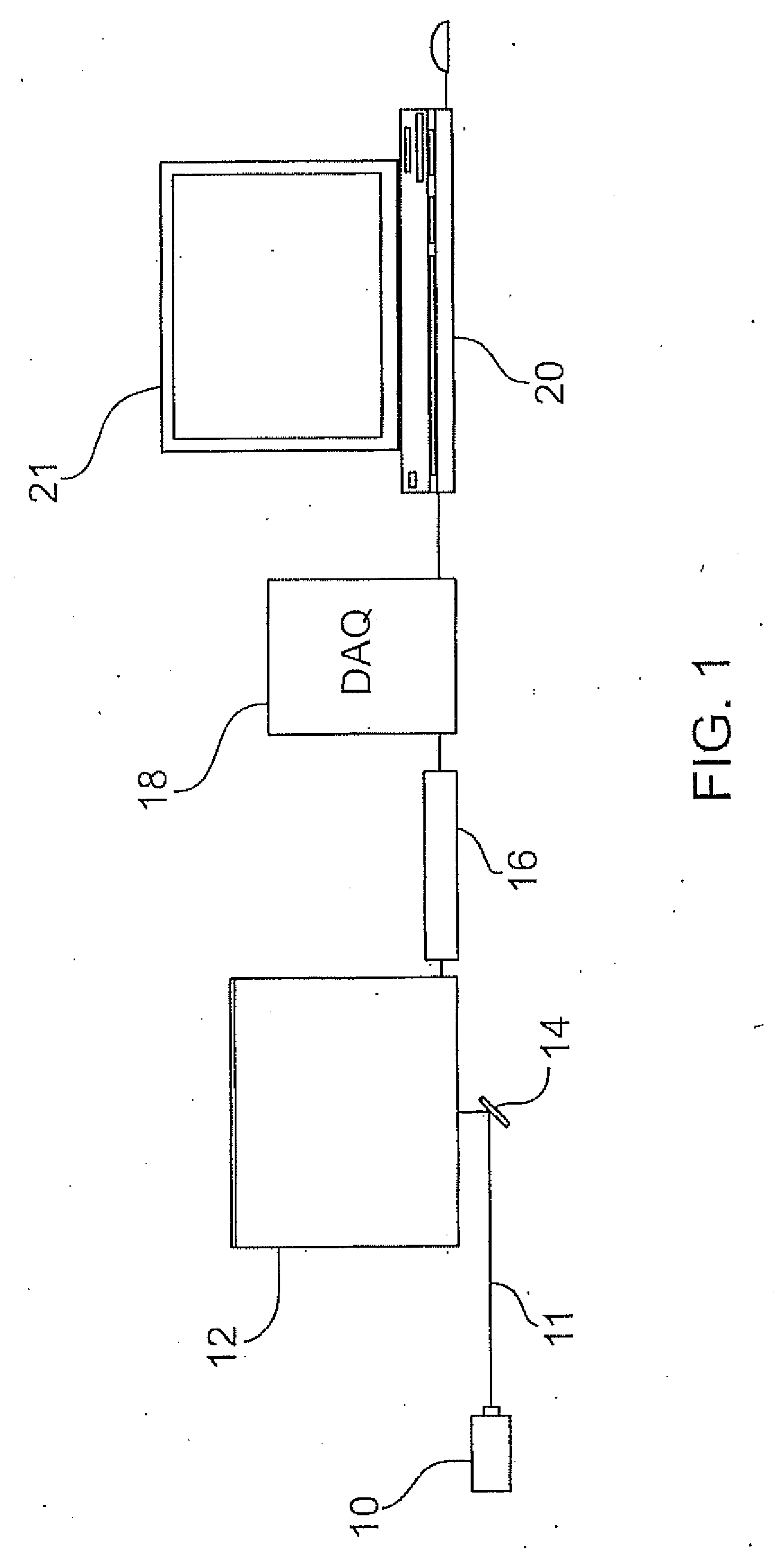

A photoacoustic imaging apparatus is provided for medical or other imaging applications and also a method for calibrating this apparatus. The apparatus employs a sparse array of transducer elements and a reconstruction algorithm. Spatial calibration maps of the sparse array are used to optimize the reconstruction algorithm. The apparatus includes a laser producing a pulsed laser beam to illuminate a subject for imaging and generate photoacoustic waves. The transducers are fixedly mounted on a holder so as to form the sparse array. A photoacoustic (PA) waves are received by each transducer. The resultant analog signals from each transducer are amplified, filtered, and converted to digital signals in parallel by a data acquisition system which is operatively connected to a computer. The computer receives the digital signals and processes the digital signals by the algorithm based on iterative forward projection and back-projection in order to provide the image.

Owner:MULTI MAGNETICS

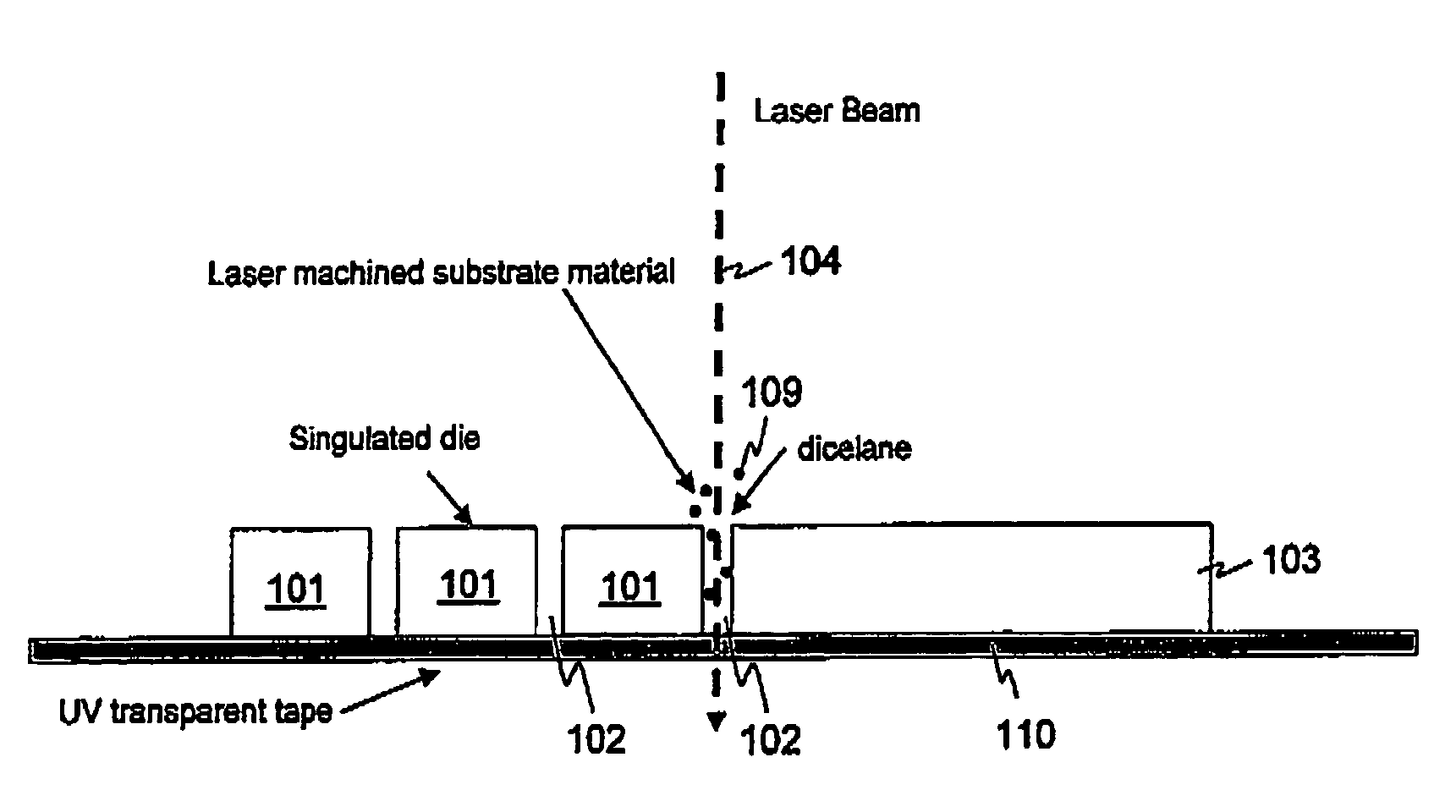

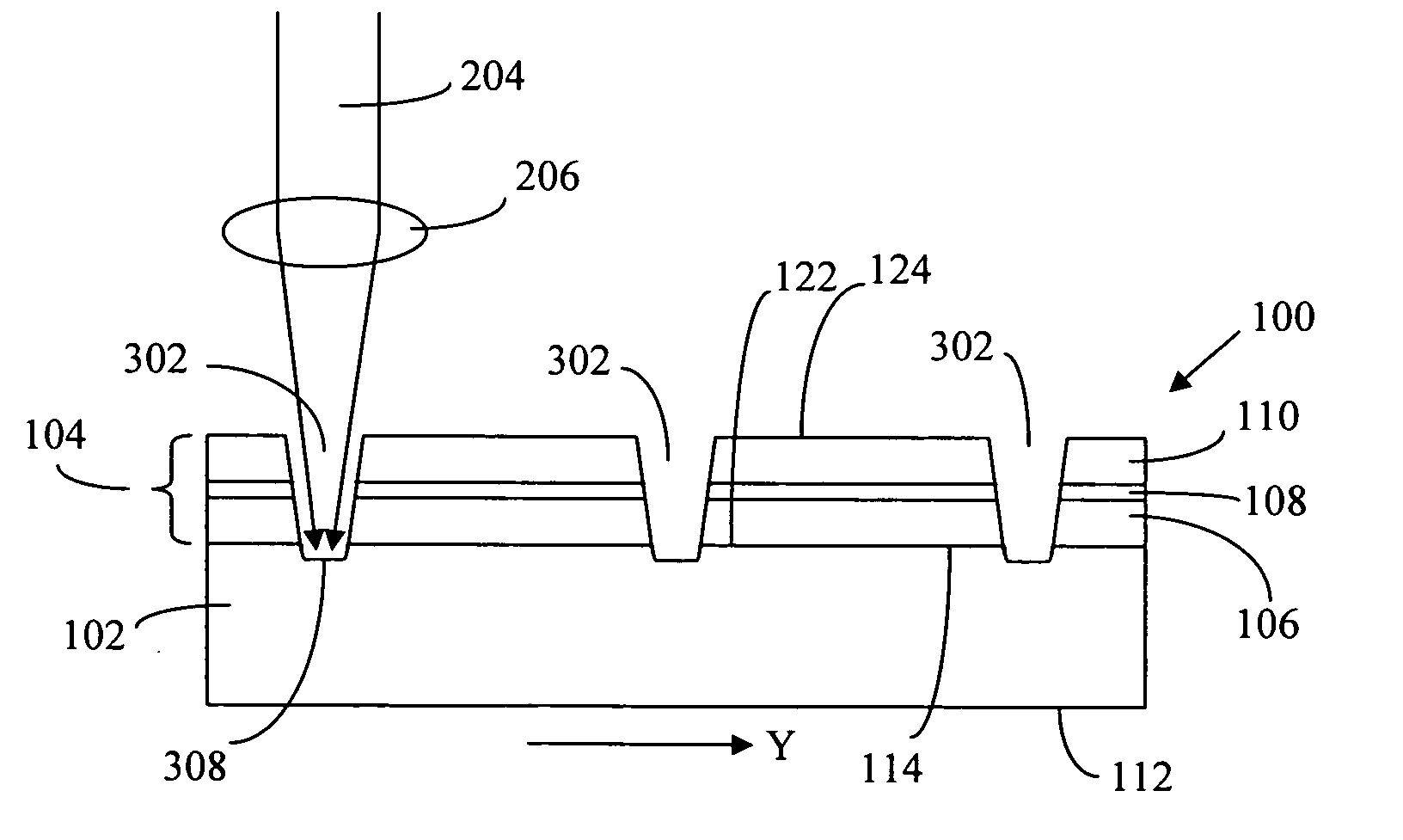

Program-controlled dicing of a substrate using a pulsed laser

InactiveUS7776720B2Facilitate dicing of the substrateControl damageSemiconductor/solid-state device manufacturingPrinted circuit manufactureChemical reactionPulse rate

A substrate is diced using a program-controlled pulsed laser beam apparatus having an associated memory for storing a laser cutting strategy file. The file contains selected combinations of pulse rate Deltat, pulse energy density E and pulse spatial overlap to machine a single layer or different types of material in different layers of the substrate while restricting damage to the layers and maximising machining rate to produce die having predetermined die strength and yield. The file also contains data relating to the number of scans necessary using a selected combination to cut through a corresponding layer. The substrate is diced using the selected combinations. Gas handling equipment for inert or active gas may be provided for preventing or inducing chemical reactions at the substrate prior to, during or after dicing.

Owner:XSIL TECH

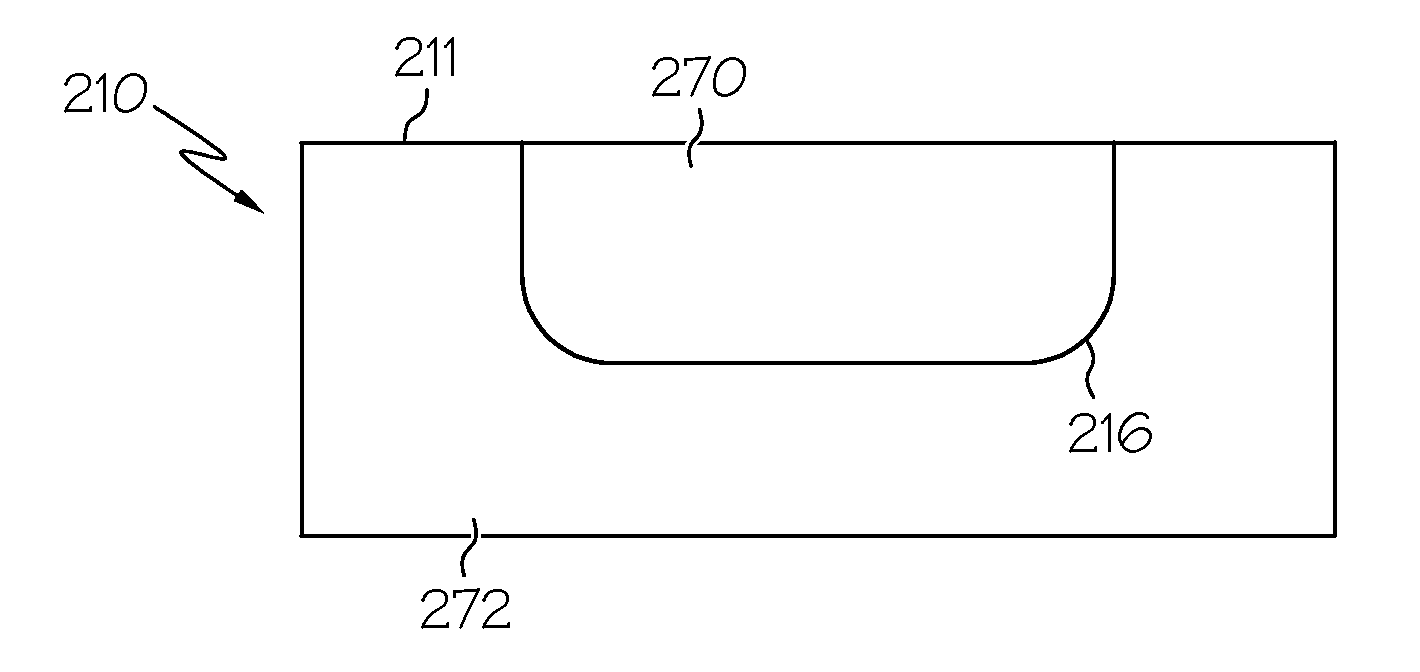

Methods of Fabricating Glass Articles by Laser Damage and Etching

Methods of forming a glass article are disclosed. In one embodiment, a method of forming a glass article includes translating a pulsed laser beam on a glass substrate sheet to form a laser damage region between a first surface and a second surface of the glass substrate sheet. The method further includes applying an etchant solution to the glass substrate sheet to remove a portion of the glass substrate sheet about the laser damage region. The method may further include strengthening the glass substrate sheet by an ion-exchange strengthening process, and coating the glass substrate sheet with an acid-resistant coating. Also disclosed are methods where the laser damage region has an initial geometry that changes to a desired geometry following the reforming of the glass substrate sheet such that the initial geometry of the laser damage region compensates for the bending of the glass substrate sheet.

Owner:CORNING INC

Laser processing method and laser processing apparatus

InactiveUS20050181581A1No unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

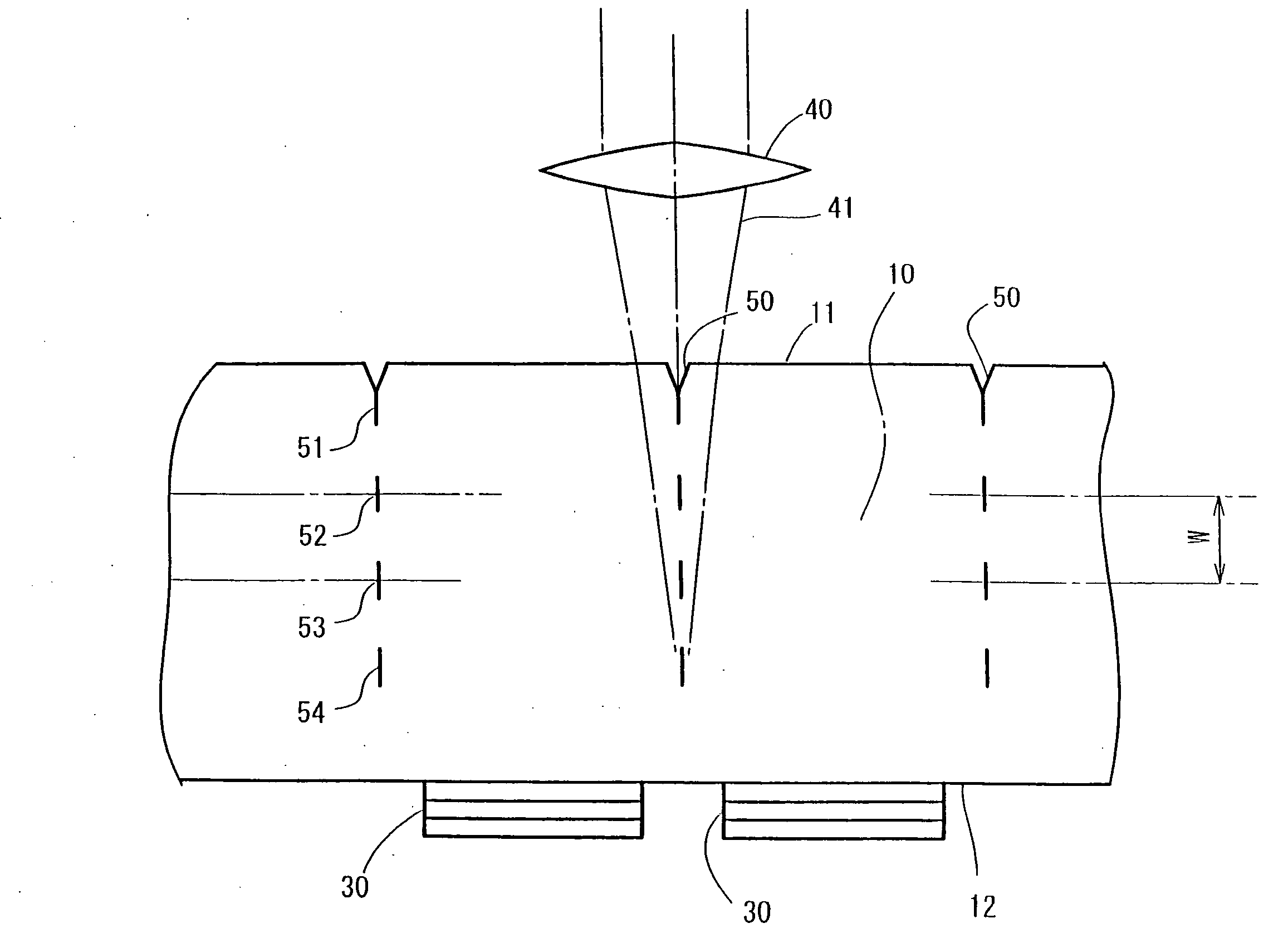

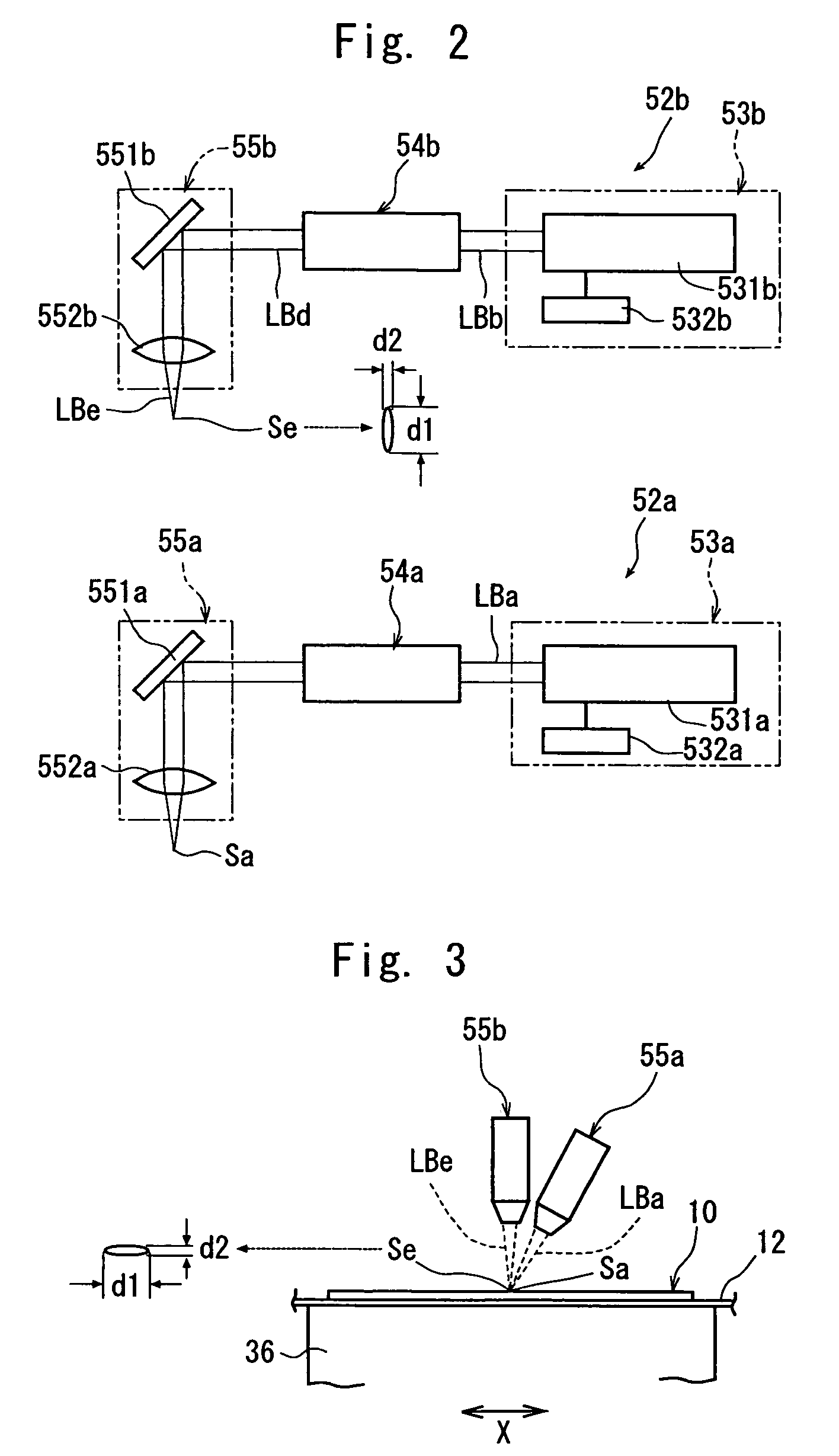

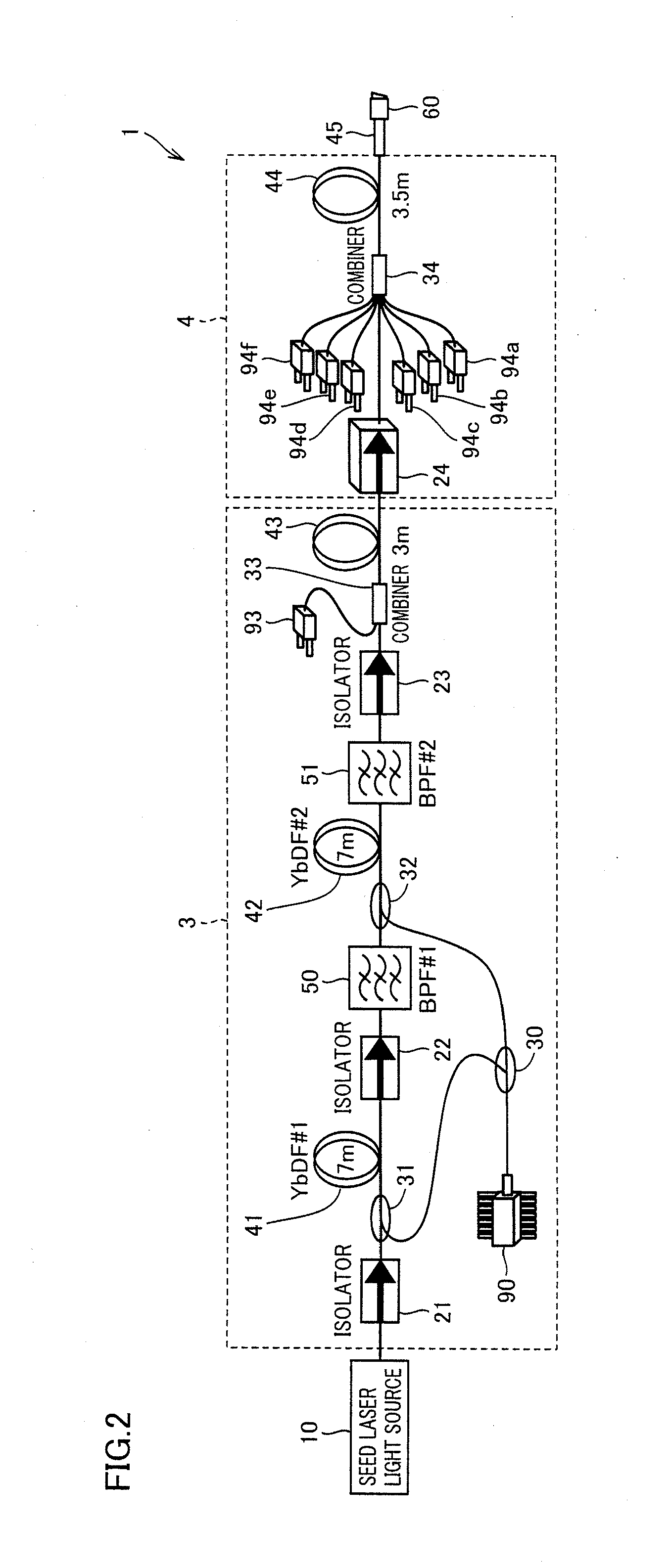

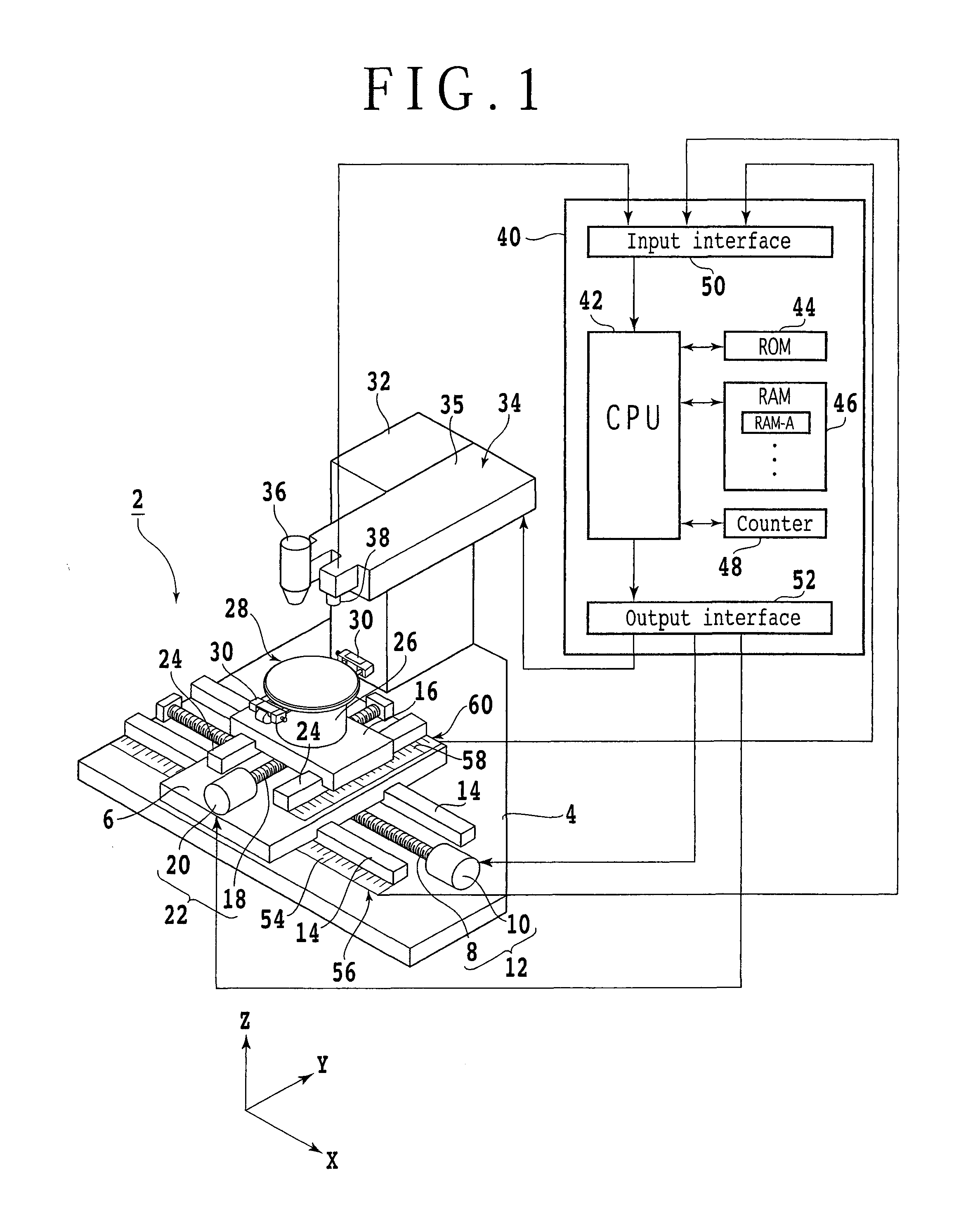

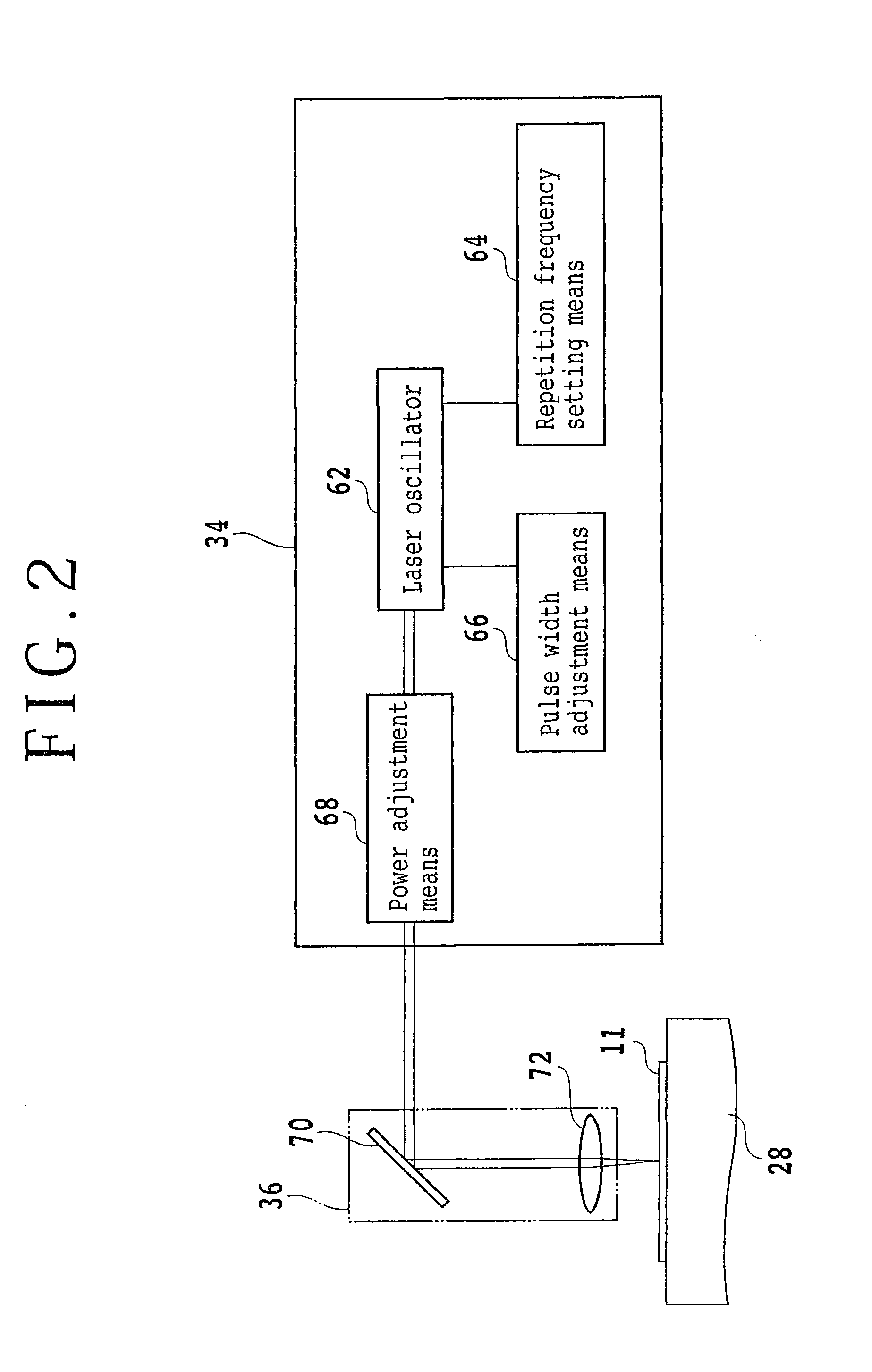

Laser processing apparatus

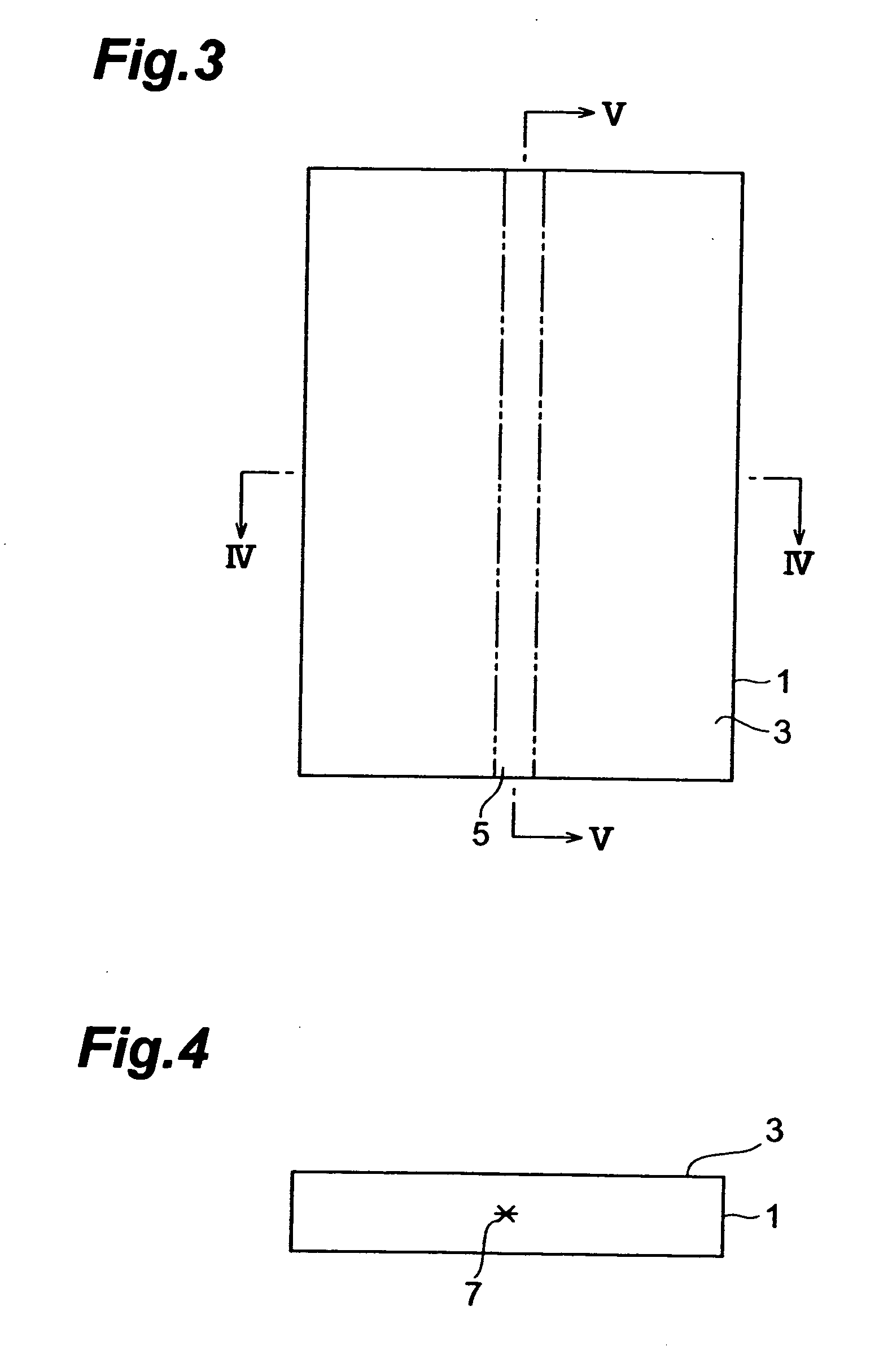

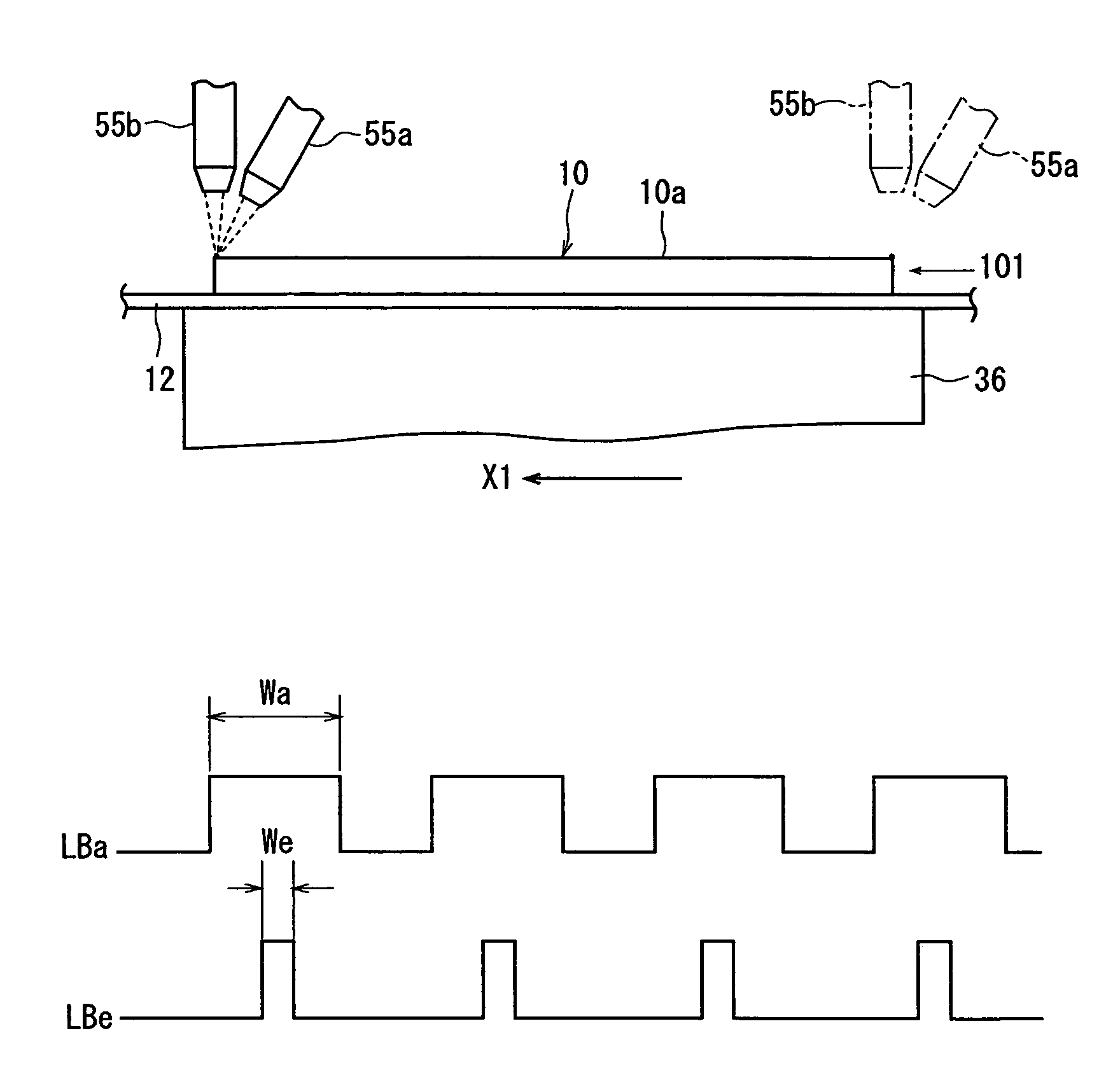

ActiveUS7473866B2Soften the processing area of the workpieceProcessing area is softenedPhotometrySemiconductor/solid-state device manufacturingLaser processingLight beam

A laser processing apparatus comprising a chuck table, laser beam irradiation means for irradiating a workpiece held on the chuck table with a laser beam, and processing feed means for processing-feeding the chuck table and the laser beam irradiation means relative to each other. The laser beam irradiation means includes first laser beam irradiation means for throwing a first pulsed laser beam having a wavelength in the intermediate-infrared radiation region, and second laser beam irradiation means for throwing a second pulsed laser beam having a wavelength in the ultraviolet radiation region. The first laser beam irradiation means and the second laser beam irradiation means are set such that at least a part, in the processing feed direction, of the focus spot of the second pulsed laser beam overlaps the focus spot of the first pulsed laser beam.

Owner:DISCO CORP

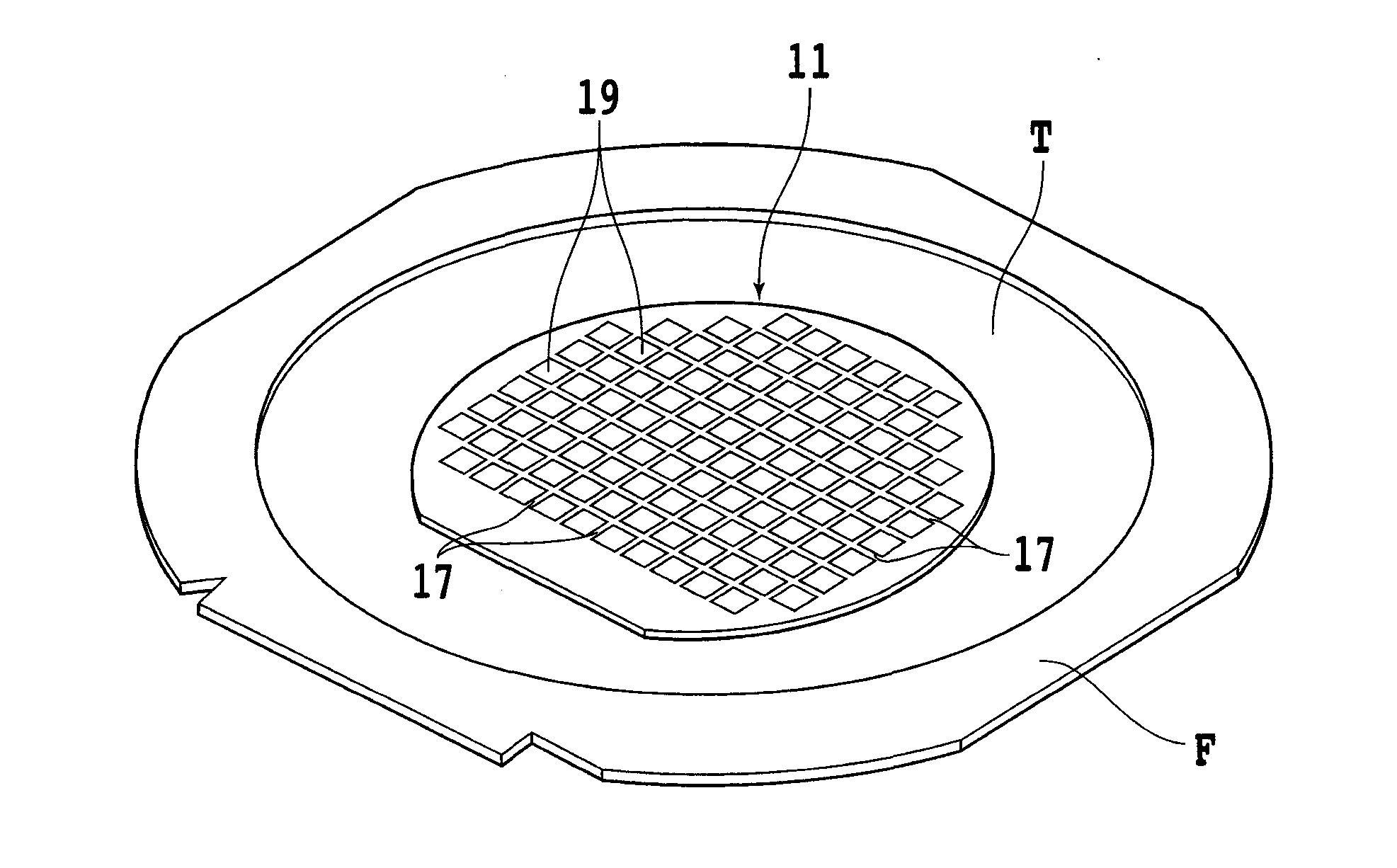

Method of wafer laser processing using a gas permeable protective tape

ActiveUS7435607B2Exclude influenceDecline in wafer holding force is eliminatedSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingPulsed laser beam

A laser processing method for forming a deteriorated layer, which has been once molten and then re-solidified, in the inside of a wafer by applying a pulse laser beam capable of passing through the wafer to the wafer along a dividing line formed on the wafer, comprising: a protective tape affixing step for affixing a protective tape having gas permeability to one side of the wafer; a wafer holding step for holding the wafer having the protective tape affixed thereto on the chuck table of a laser beam machine in such a manner that the surface side onto which the protective tape has been affixed comes into contact with the chuck table; and a laser beam application step for applying a pulse laser beam capable of passing through the wafer from the other surface side of the wafer held on the chuck table with its focusing point set to a position near the one surface of the wafer to form the deteriorated layer exposed to the one surface along the dividing line in the inside of the wafer.

Owner:DISCO CORP

Laser processing method

ActiveUS20120255935A1Good body shapeReduce processing costsSemiconductor/solid-state device manufacturingFine working devicesLaser processingOptoelectronics

There is obtained a laser processing method by which an excellent shape of a cut surface can be achieved and an increase in cost can be suppressed. A laser processing method includes the steps of: preparing a material to be processed; and forming a modified area in the material to be processed, by irradiating the material to be processed with laser beam. In the aforementioned step, pulsed laser beam having a continuous spectrum is focused with a lens, thereby forming a focusing line constituted by a plurality of focuses that are obtained by predetermined bands forming the continuous spectrum of the laser beam, and the material to be processed is irradiated with the laser beam such that at least a part of the focusing line is located on a surface of the material to be processed, thereby forming the modified area on an axis of the focusing line.

Owner:SUMITOMO ELECTRIC IND LTD +1

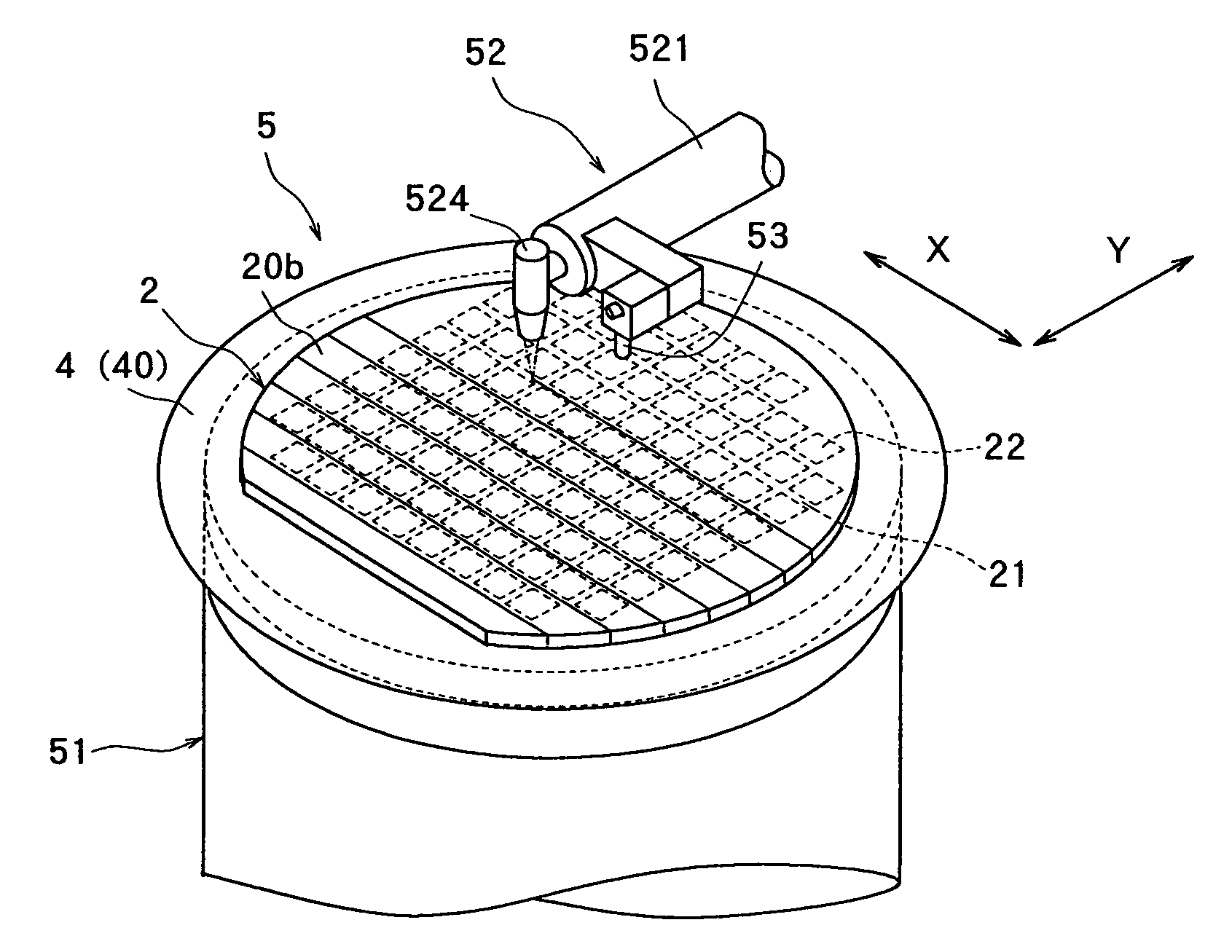

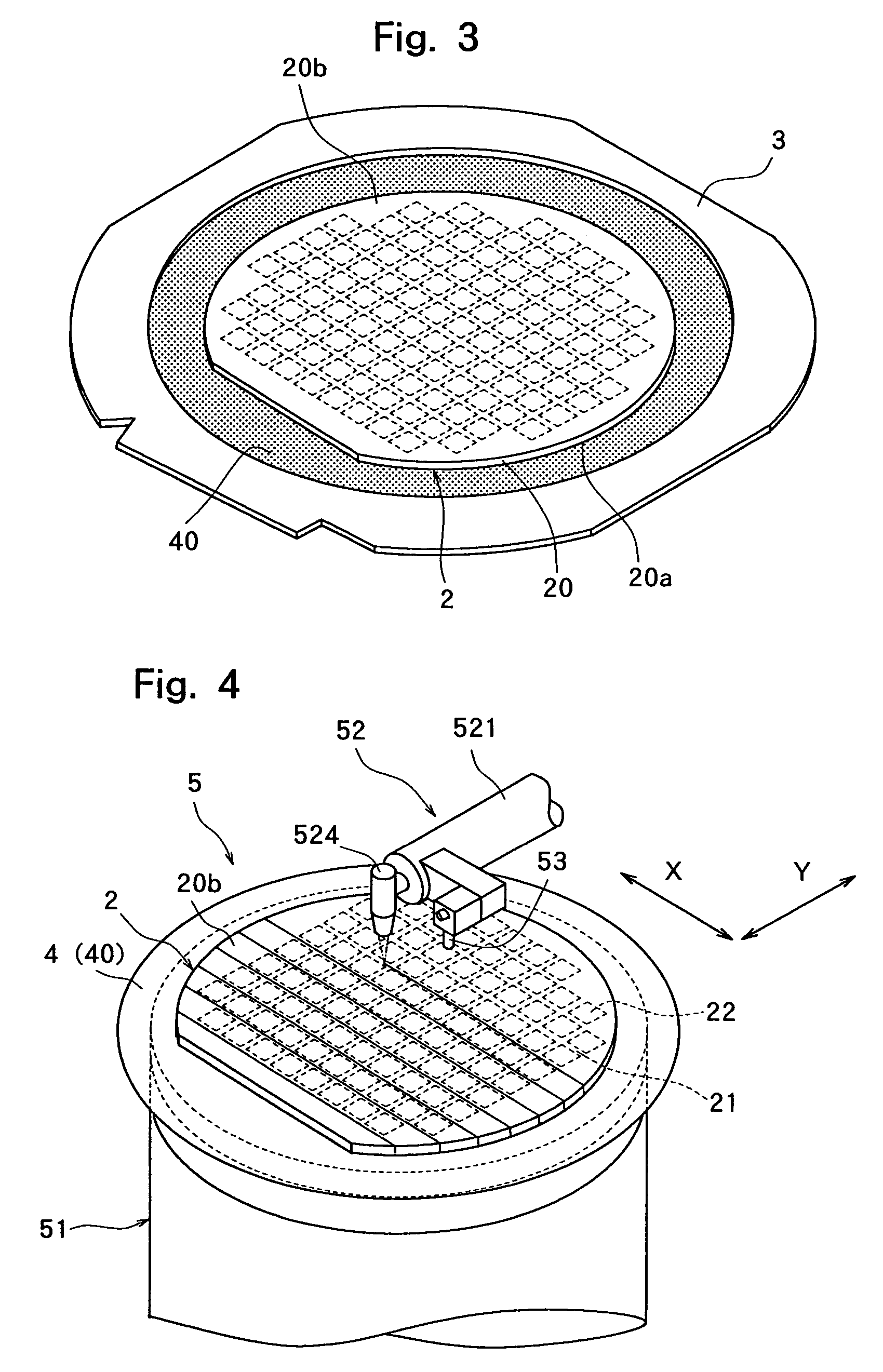

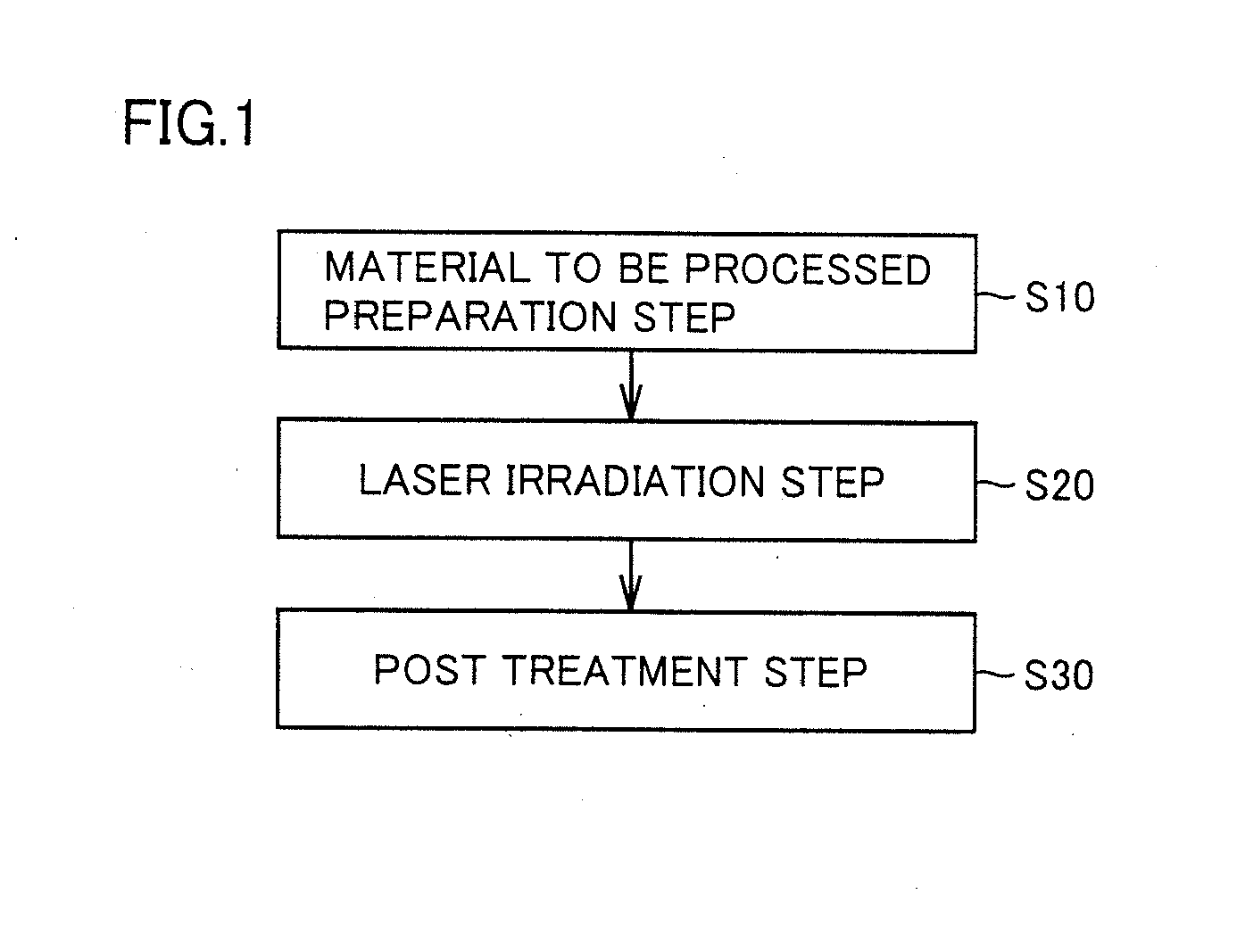

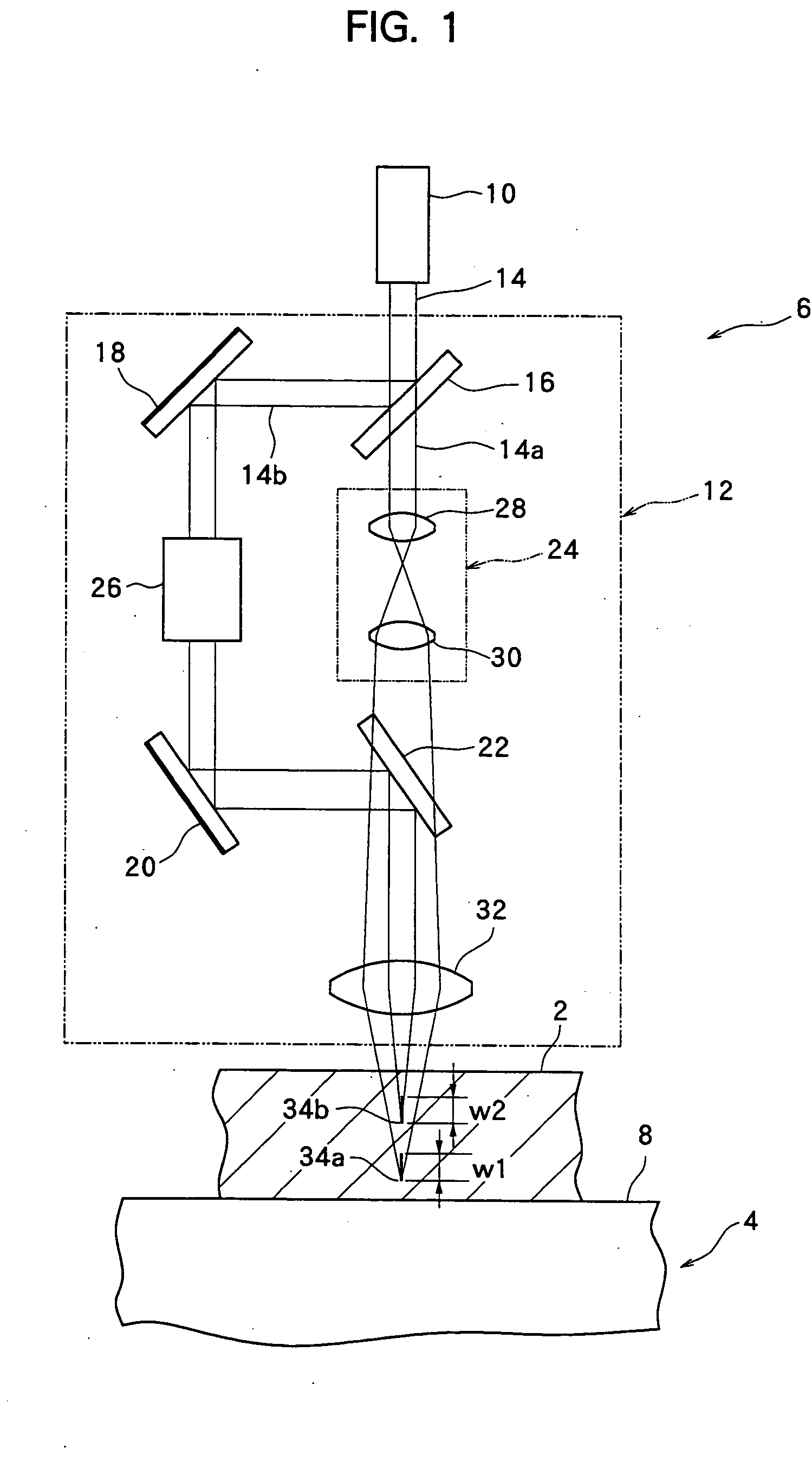

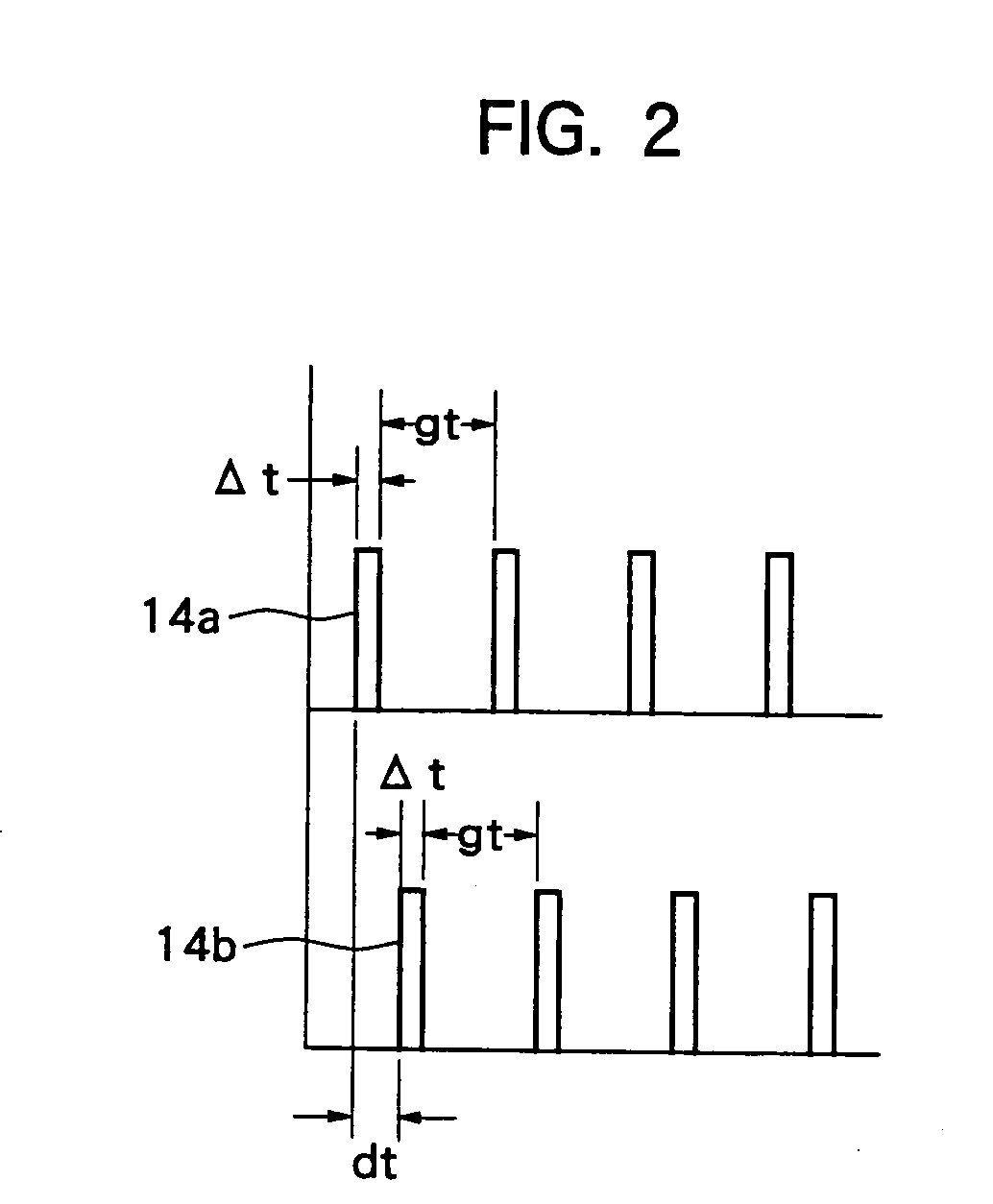

Processing apparatus using laser beam

ActiveUS20050098548A1Semiconductor/solid-state device manufacturingFine working devicesOptical axisLight beam

A processing apparatus using a laser beam, which comprises holding means for holding a workpiece, and laser beam application means for irradiating the workpiece, held by the holding means, with a pulsed laser beam capable of passing through the workpiece, thereby deteriorating the workpiece. The laser beam application means includes pulsed laser beam oscillation means and transmitting / focusing means for transmitting and focusing the pulsed laser beam oscillated by the pulsed laser beam oscillation means. The transmitting / focusing means focuses the pulsed laser beam, with a time difference provided, to at least two focus points displaced in the optical axis direction.

Owner:DISCO CORP

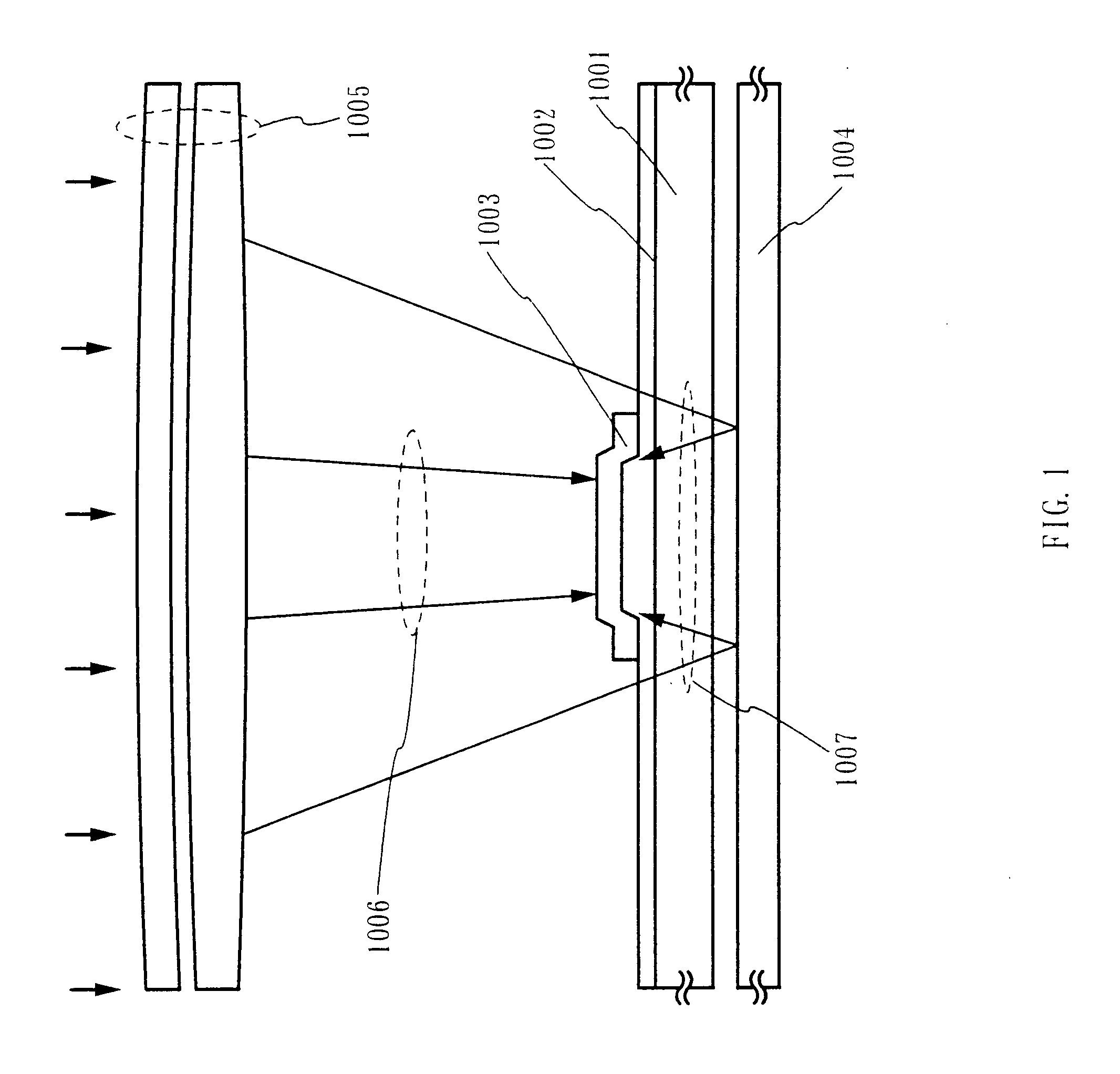

Semiconductor device and method of fabricating the same

A crystalline semiconductor film in which the position and size of a crystal grain is controlled is fabricated, and the crystalline semiconductor film is used for a channel formation region of a TFT, so that a high performance TFT is realized. An island-like semiconductor layer is made to have a temperature distribution, and a region where temperature change is gentle is provided to control the nucleus generation speed and nucleus generation density, so that the crystal grain is enlarged. In a region where an island-like semiconductor layer 1003 overlaps with a base film 1002, a thick portion is formed in the base film 1002. The volume of this portion increases and heat capacity becomes large, so that a cycle of temperature change by irradiation of a pulse laser beam to the island-like semiconductor layer becomes gentle (as compared with other thin portion). Like this, a laser beam is irradiated from the front side and reverse side of the substrate to directly heat the semiconductor layer, and heat conduction from the semiconductor layer to the side of the substrate and heat conduction of the semiconductor layer in the horizontal direction to the substrate are used, so that the increase in the size of the crystal grain is realized.

Owner:SEMICON ENERGY LAB CO LTD

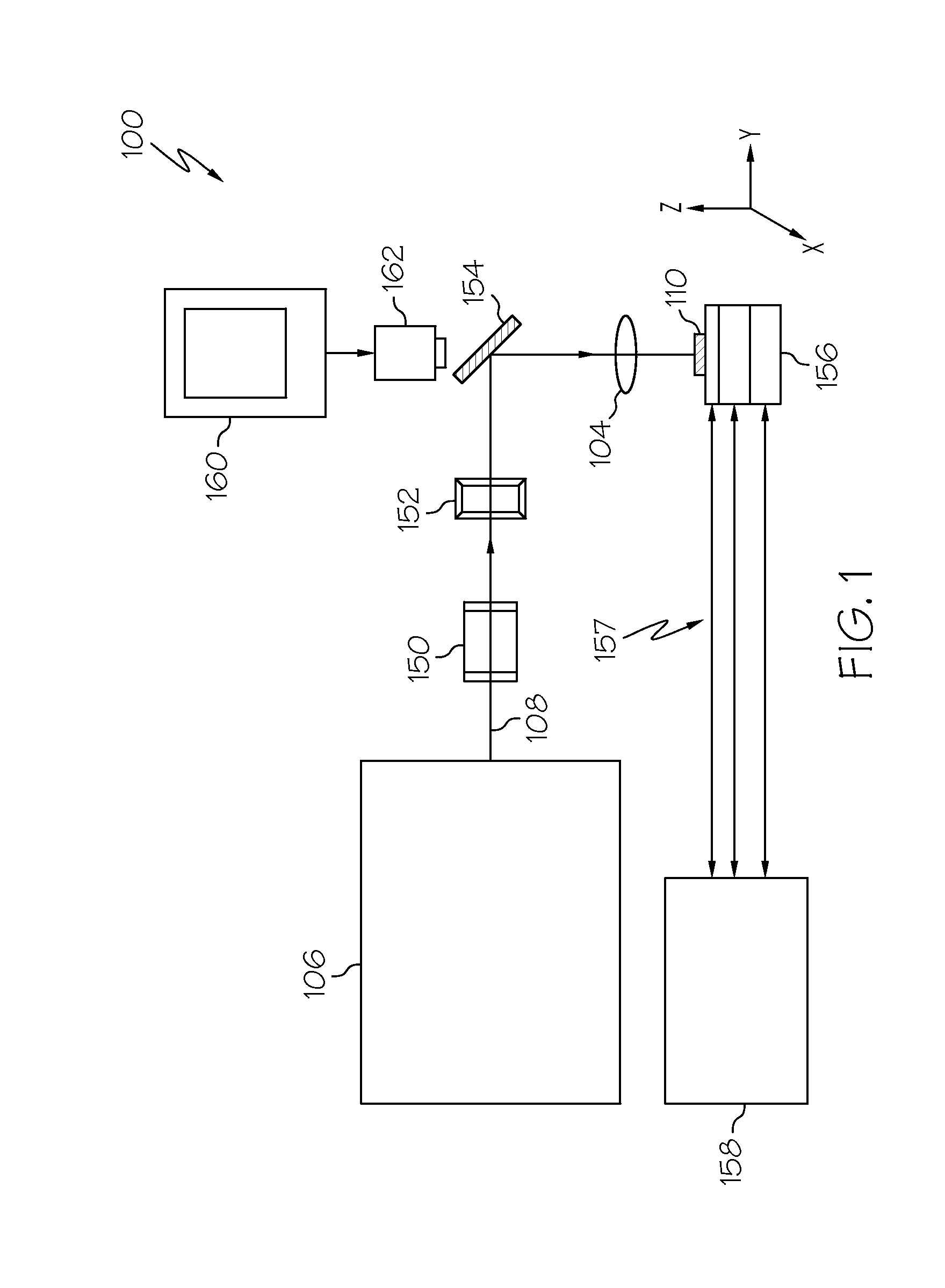

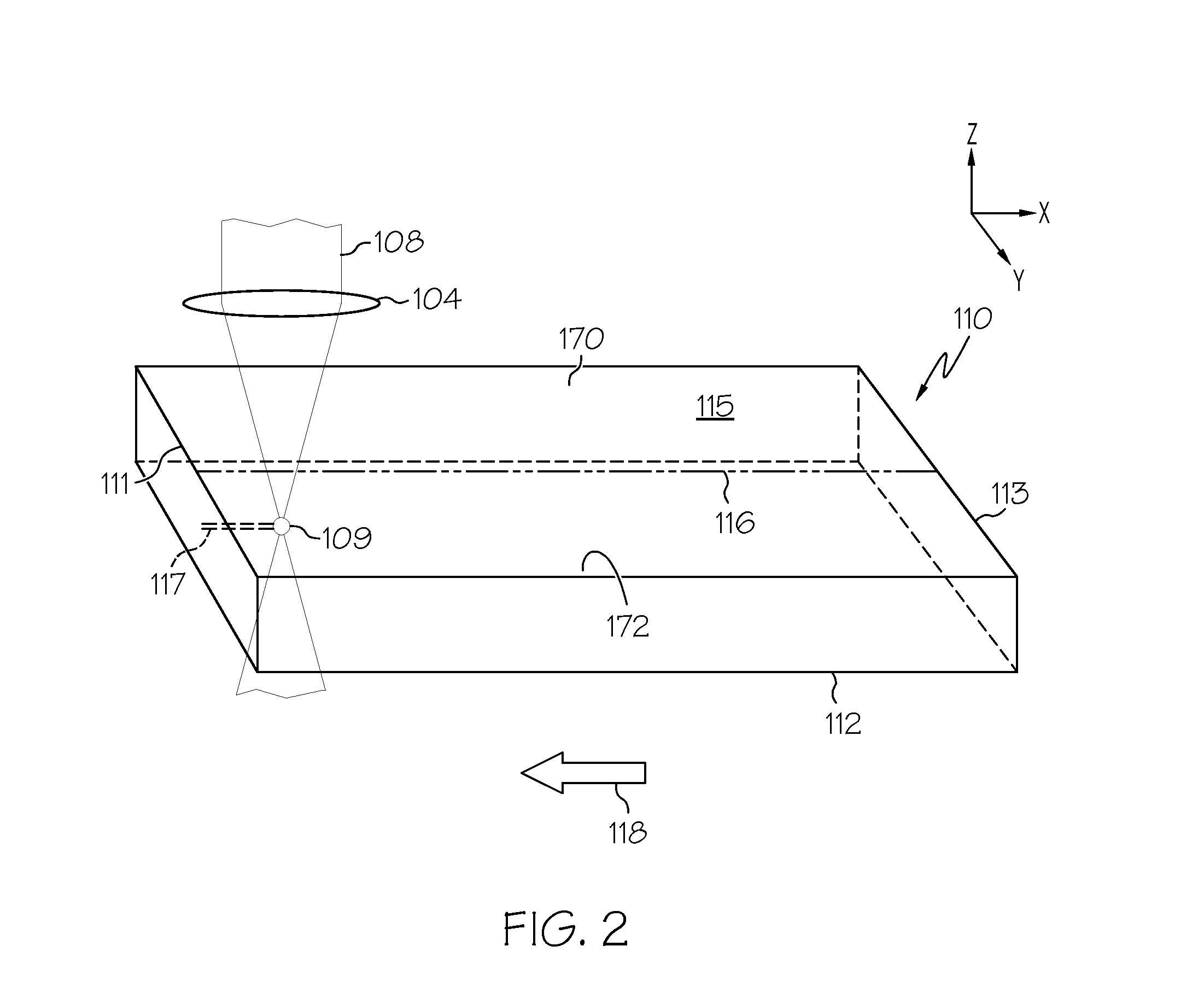

Methods for laser cutting articles from ion exchanged glass substrates

ActiveUS20120145331A1Increase the tensile stressGlass reforming apparatusGlass severing apparatusIon exchangeLaser cutting

A method of cutting an article (172) from a chemically strengthened glass substrate (110) includes generating a pulsed laser beam (108) from a laser source (106). The pulsed laser beam (108) may have a pulse duration of less than about 1000 fs and an output wavelength such that the chemically strengthened glass substrate (110) is substantially transparent to the pulsed laser beam (108). The pulsed laser beam (108) may be focused to form a beam waist (109) that is positioned in the same horizontal plane as an inner tensile region (124) of the chemically strengthened glass substrate (110). The beam waist (109) may be translated in a first pass along a cut line (116), wherein the beam waist (109) traverses an edge (111) of the chemically strengthened glass substrate. The beam waist (113) may then be translated in a second pass along the cut line (116) such that a crack (119) propagates from the edge (113) along the cut line (116) ahead of the translated beam waist (109) during the second pass.

Owner:CORNING INC

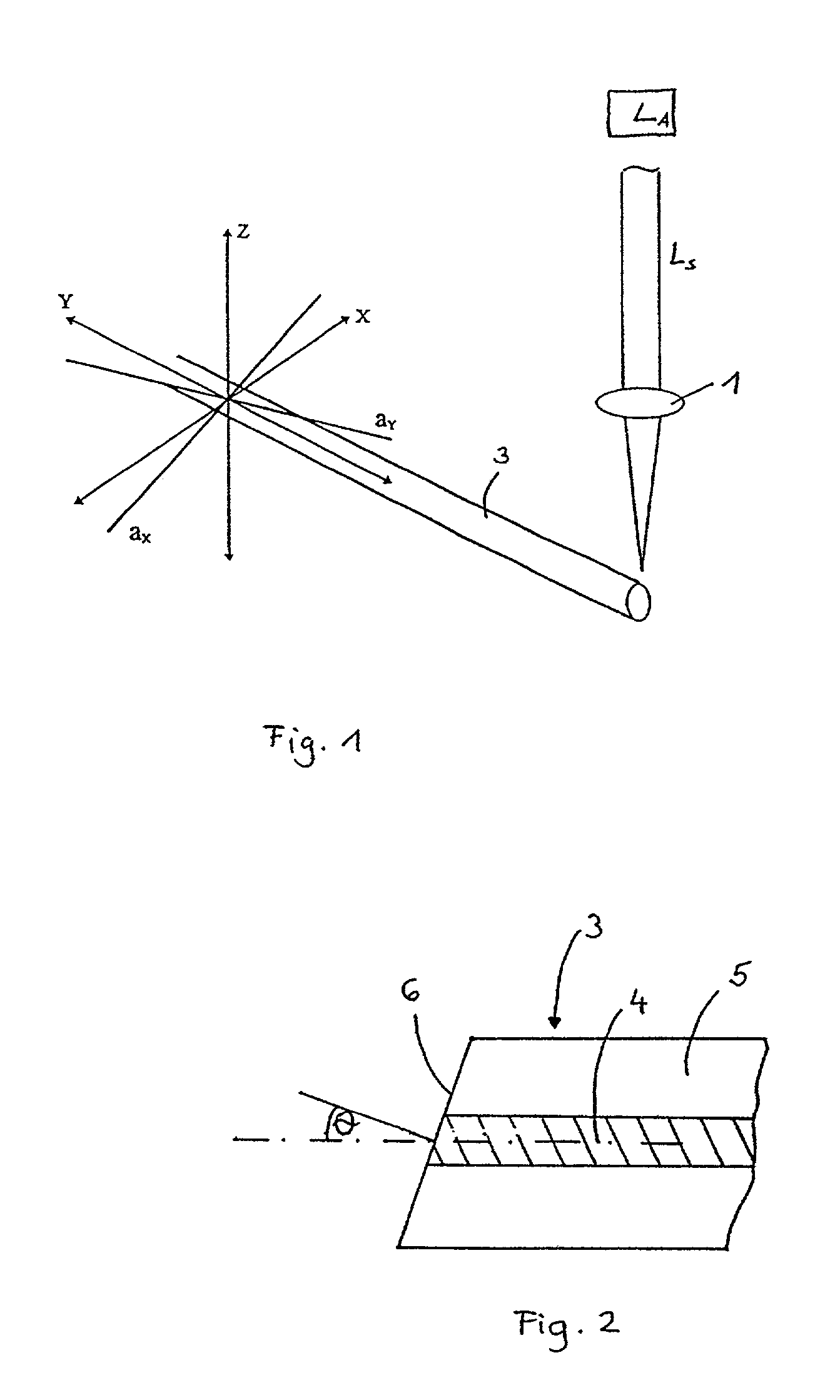

Process for cutting an optical fiber

InactiveUS6963687B2Enhance optical coupling performance of fiberUnprecedented accuracyGlass making apparatusCladded optical fibreFiberEngineering

A process for cutting or splitting at least one optical fiber at a predetermined angle, wherein the fiber is introduced into a holding and positioning device and is cut by a pulsed laser beam.

Owner:THE WHITAKER CORP

Method for fabricating a light emitting diode chip

InactiveUS20080261341A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structurePulsed laser beam

A method for fabricating substrate-free LED chips has a multilayer semiconductor structure at least 10 microns thick provided on a growth substrate. One or more arrays of parallel streets are etched into the multilayer semiconductor structure using a first pulsed laser beam. By scanning a second pulsed laser beam through the growth substrate to the multilayer semiconductor structure, the LED chips are detached from the growth substrate while simultaneously forming surface features on the chips.

Owner:GOLDENEYE

Light emitting diode chip

InactiveUS20080258165A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structurePulsed laser beam

A substrate-free LED chip has a multilayer semiconductor structure at least 10 microns thick provided on a growth substrate. One or more arrays of parallel streets are etched into the multilayer semiconductor structure using a first pulsed laser beam. By scanning a second pulsed laser beam through the growth substrate to the multilayer semiconductor structure, the LED chips are detached from the growth substrate while simultaneously forming surface features on the chips.

Owner:GOLDENEYE

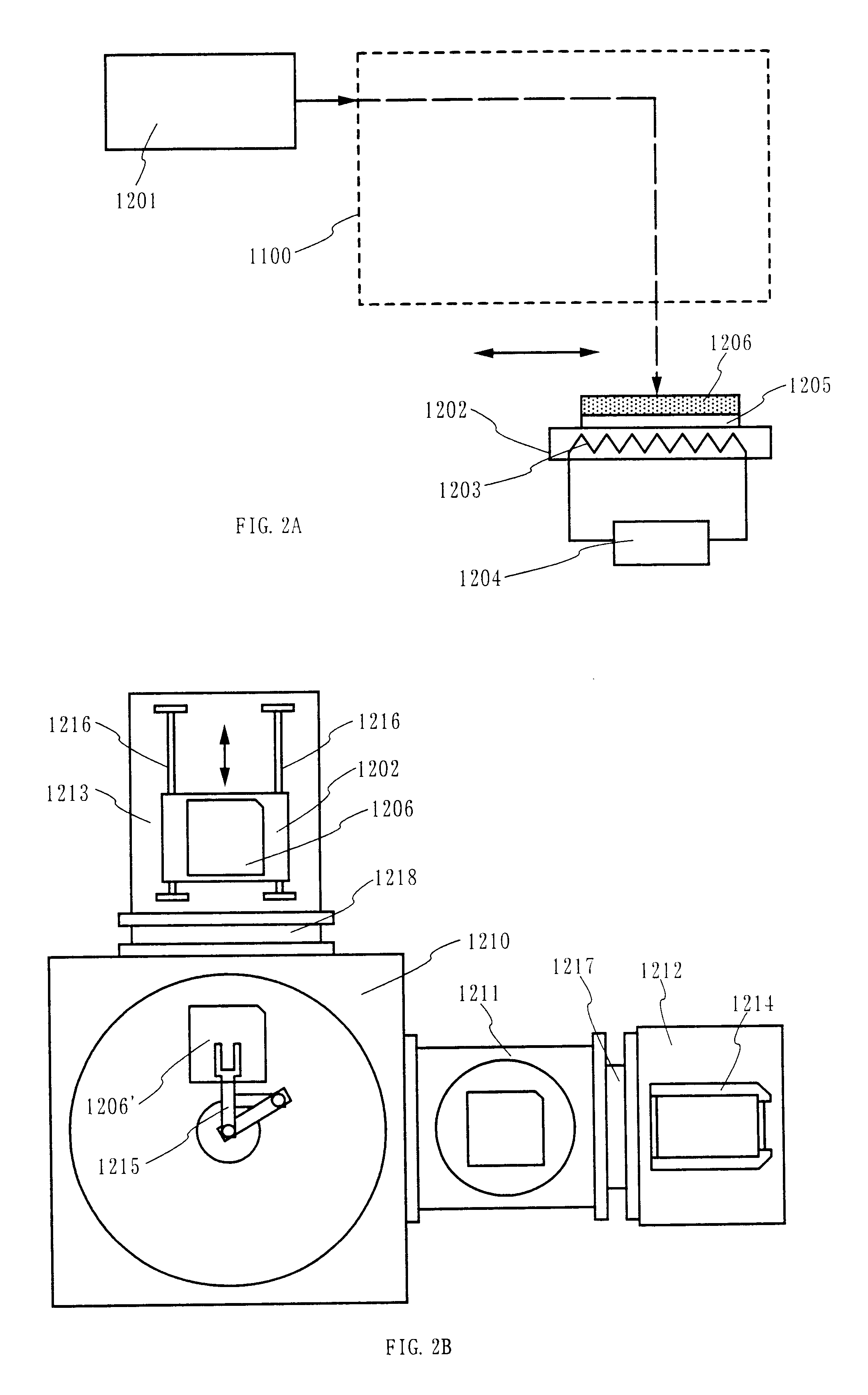

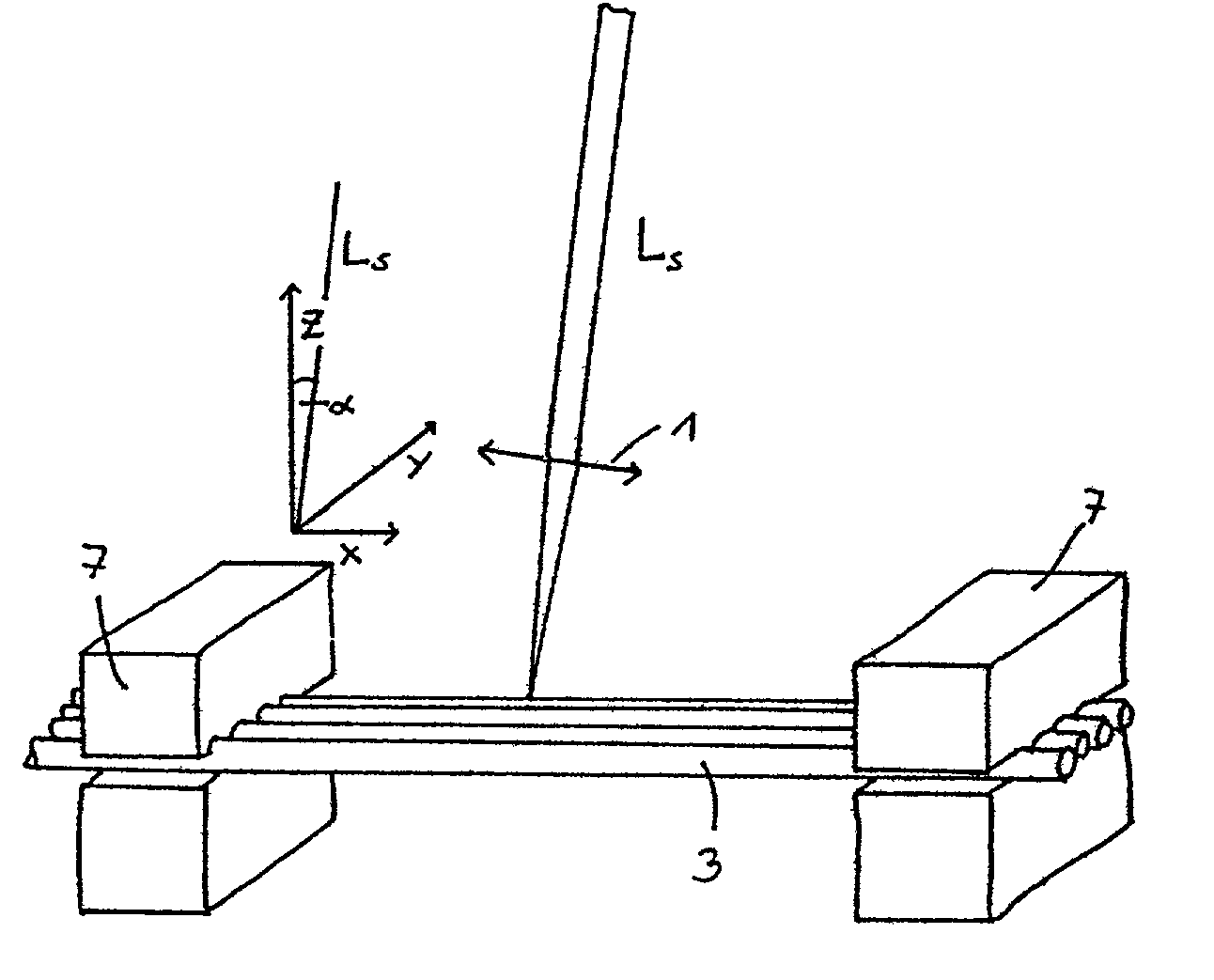

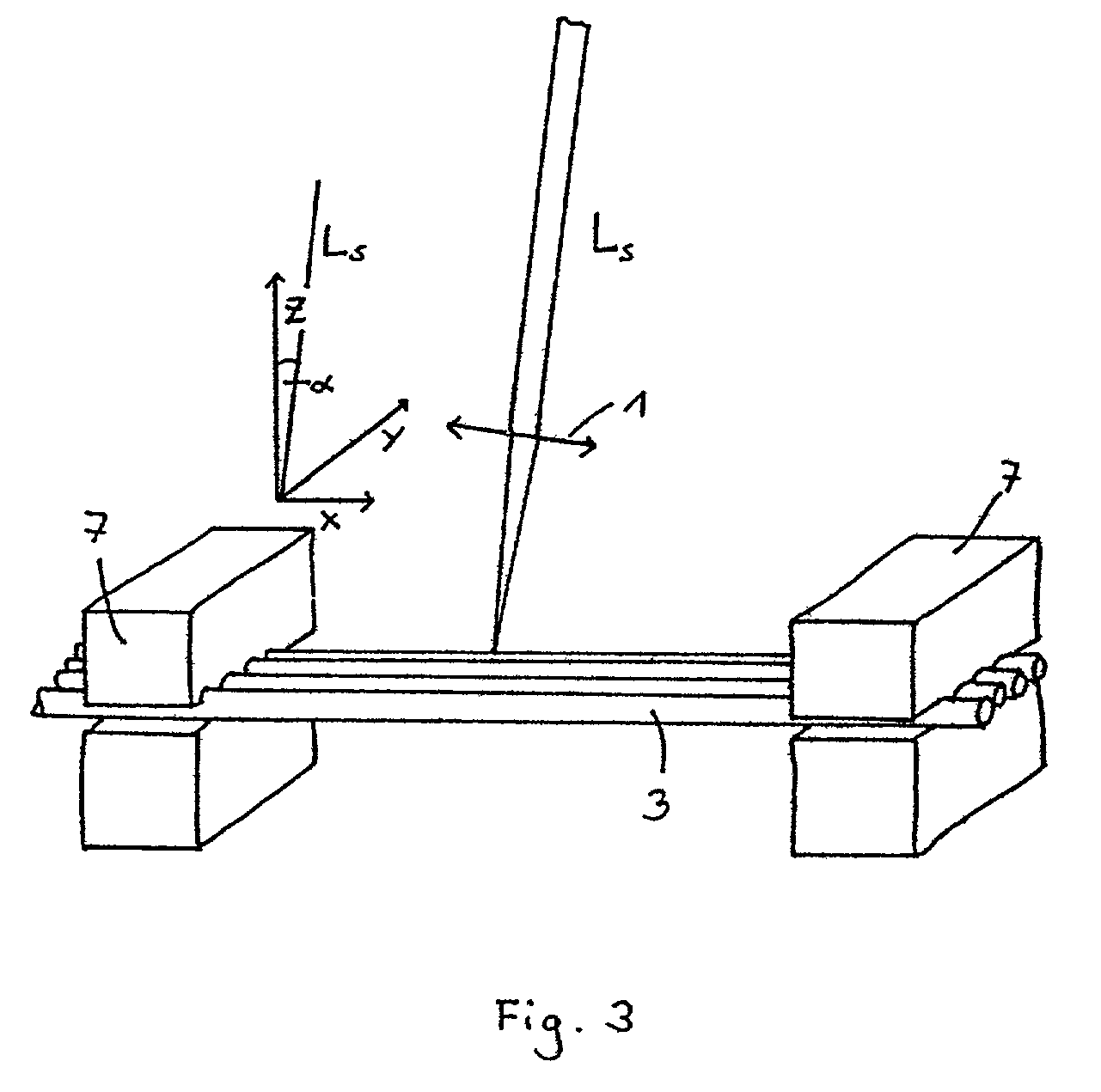

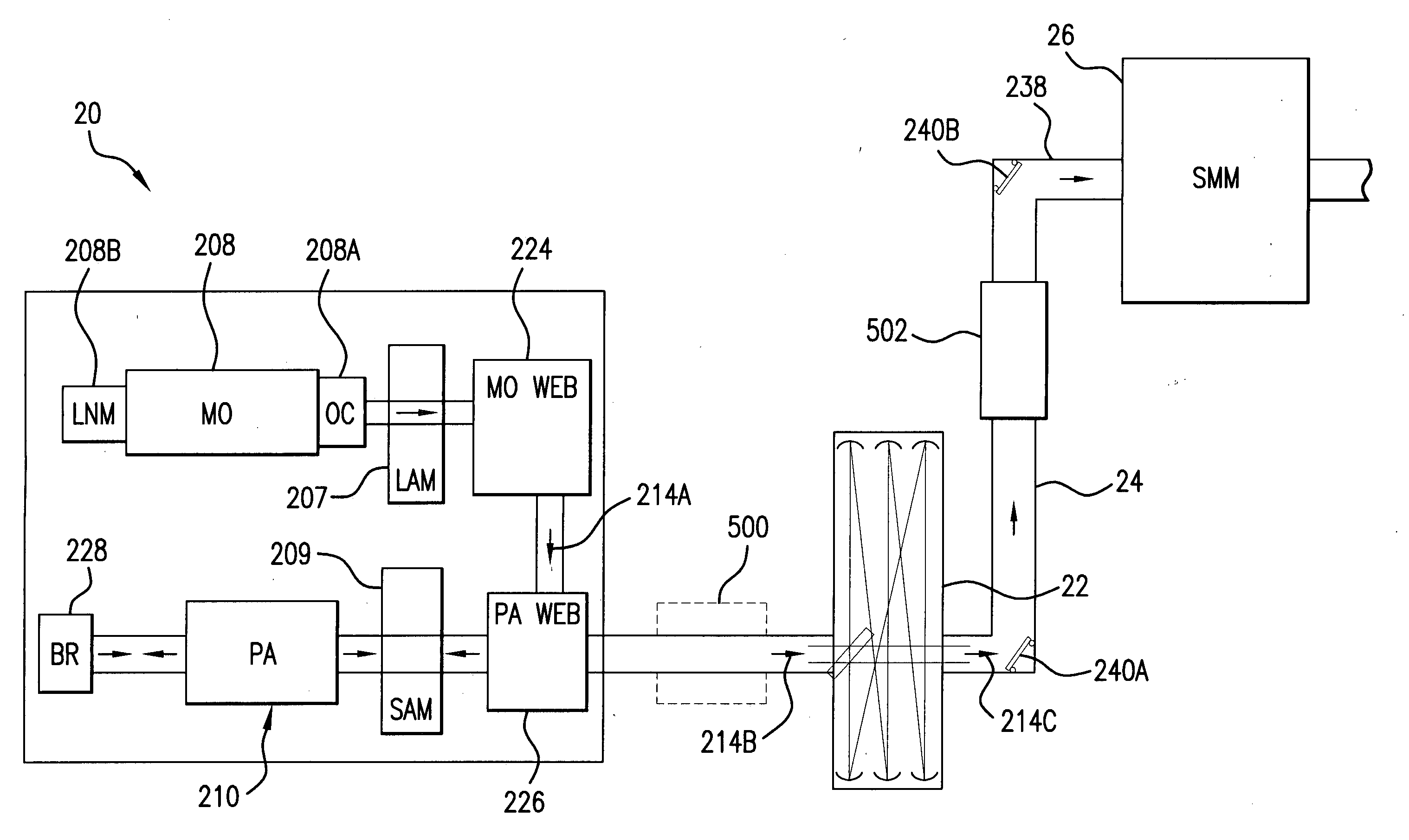

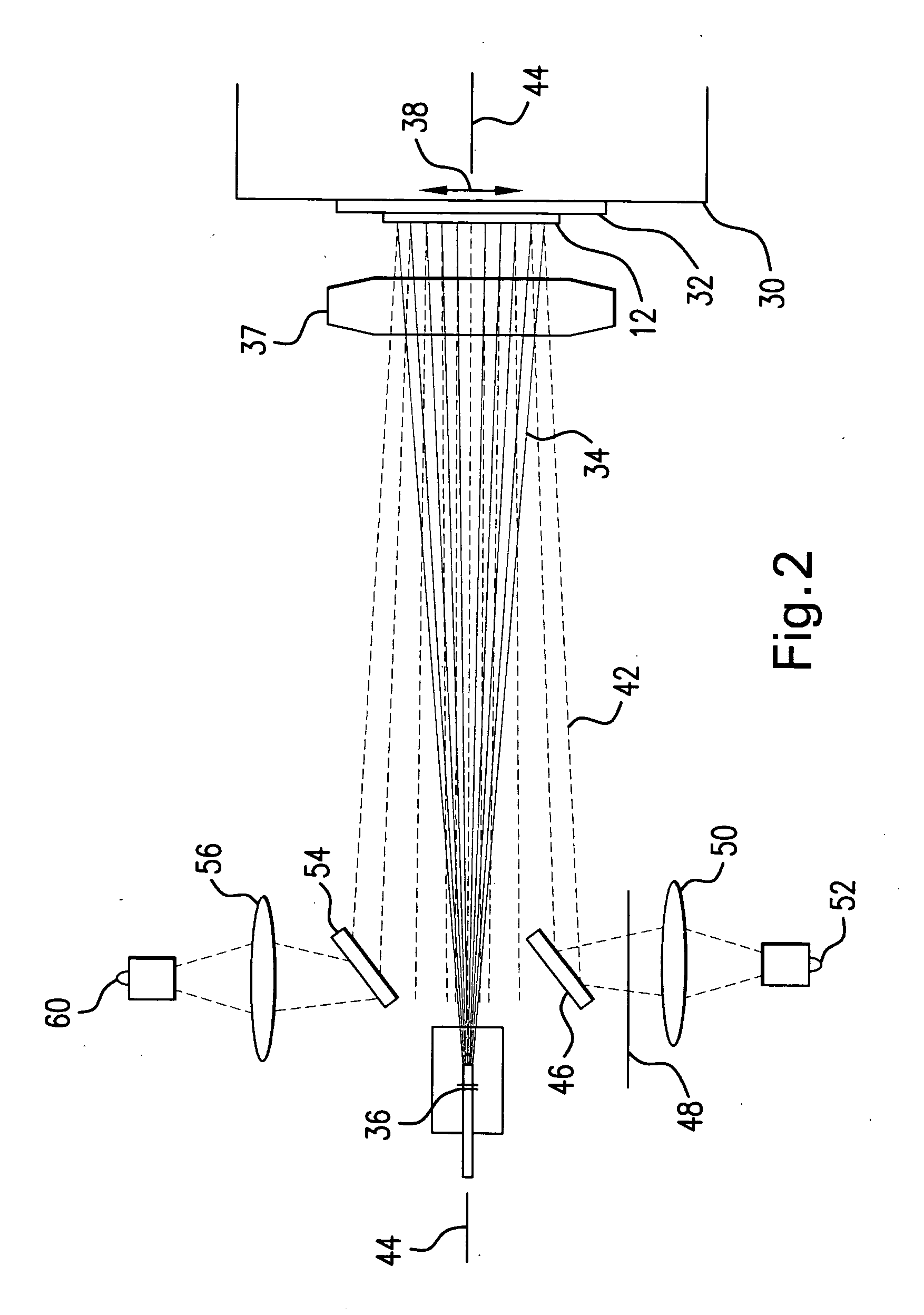

Systems and methods for implementing an interaction between a laser shaped as a line beam and a film deposited on a substrate

InactiveUS20050259709A1Maintain energy densityFrom solid stateBy zone-melting liquidsLaser crystallizationLight beam

A laser crystallization apparatus and method are disclosed for selectively melting a film such as amorphous silicon that is deposited on a substrate. The apparatus may comprise an optical system for producing stretched laser pulses for use in melting the film. In still another aspect of an embodiment of the present invention, a system and method are provided for stretching a laser pulse. In another aspect, a system is provided for maintaining a divergence of a pulsed laser beam (stretched or non-stretched) at a location along a beam path within a predetermined range. In another aspect, a system may be provided for maintaining the energy density at a film within a predetermined range during an interaction of the film with a shaped line beam.

Owner:CYMER INC

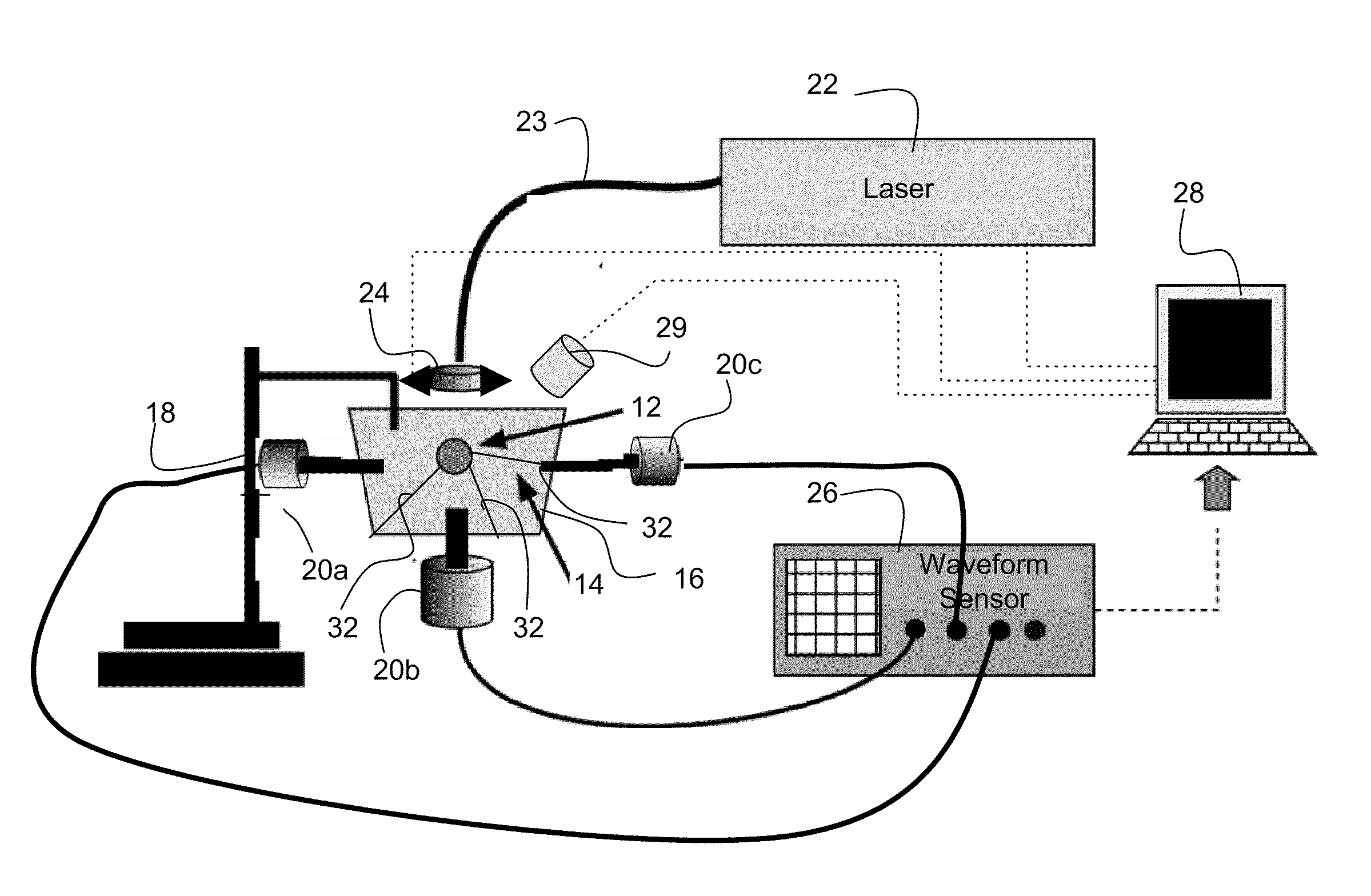

Photoacoustic detection of analytes in solid tissue and detection system

InactiveUS20100285518A1Ultrasonic/sonic/infrasonic diagnosticsBioreactor/fermenter combinationsAnalyteThree-dimensional space

A preferred system for detecting an analyte in solid tissue, such as an intact lymph node, in vitro includes a laser arranged to generate a pulsed laser beam into solid tissue, which can be a fully intact lymph node. An acoustic sensor, and preferably at least three acoustic sensors are arranged in different positions to span a three dimensional space, such as in an X, Y and Z coordinate system, to detect photoacoustic signals generated within the lymph node. At least one computer receives signals from the acoustic sensor(s). The computer determines the presence or absence of, and preferably the position of analyte, from the signals and the timing of the signals. A preferred method for detecting an analyte in a lymph node in vitro includes exposing an extracted lymph node to a pulsed laser beam. A photoacoustic signal is sensed. The photoacoustic signal is analyzed to confirm the presence or absence of an analyte in the lymph node. Preferably, multiple photoacoustic signals are sensed from sensors that span a three dimensional space and the position of analyte is also determined.

Owner:UNIVERSITY OF MISSOURI

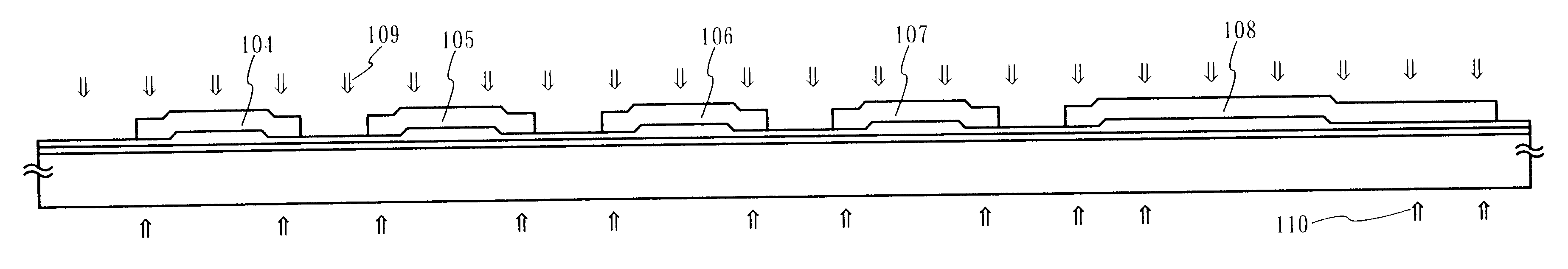

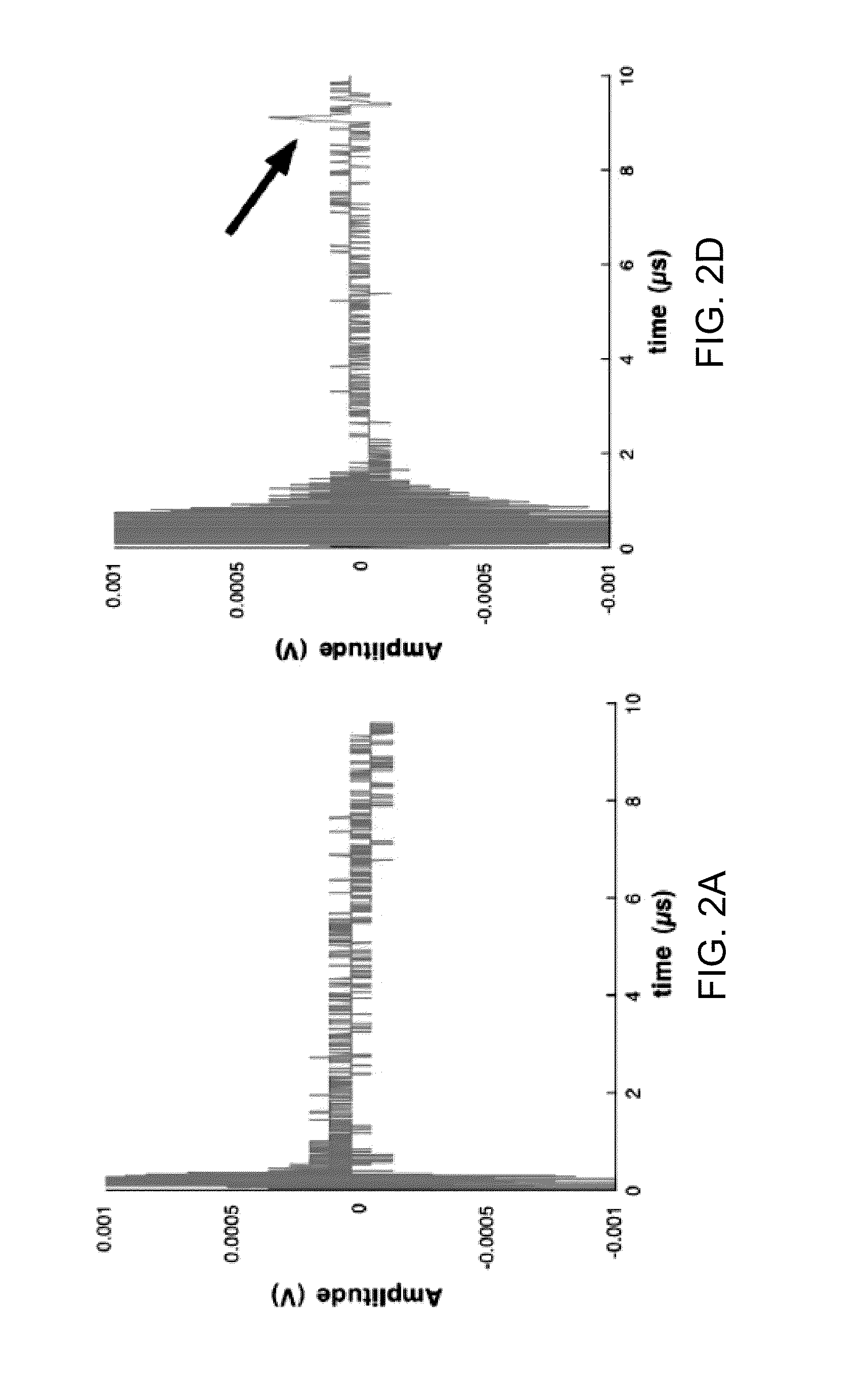

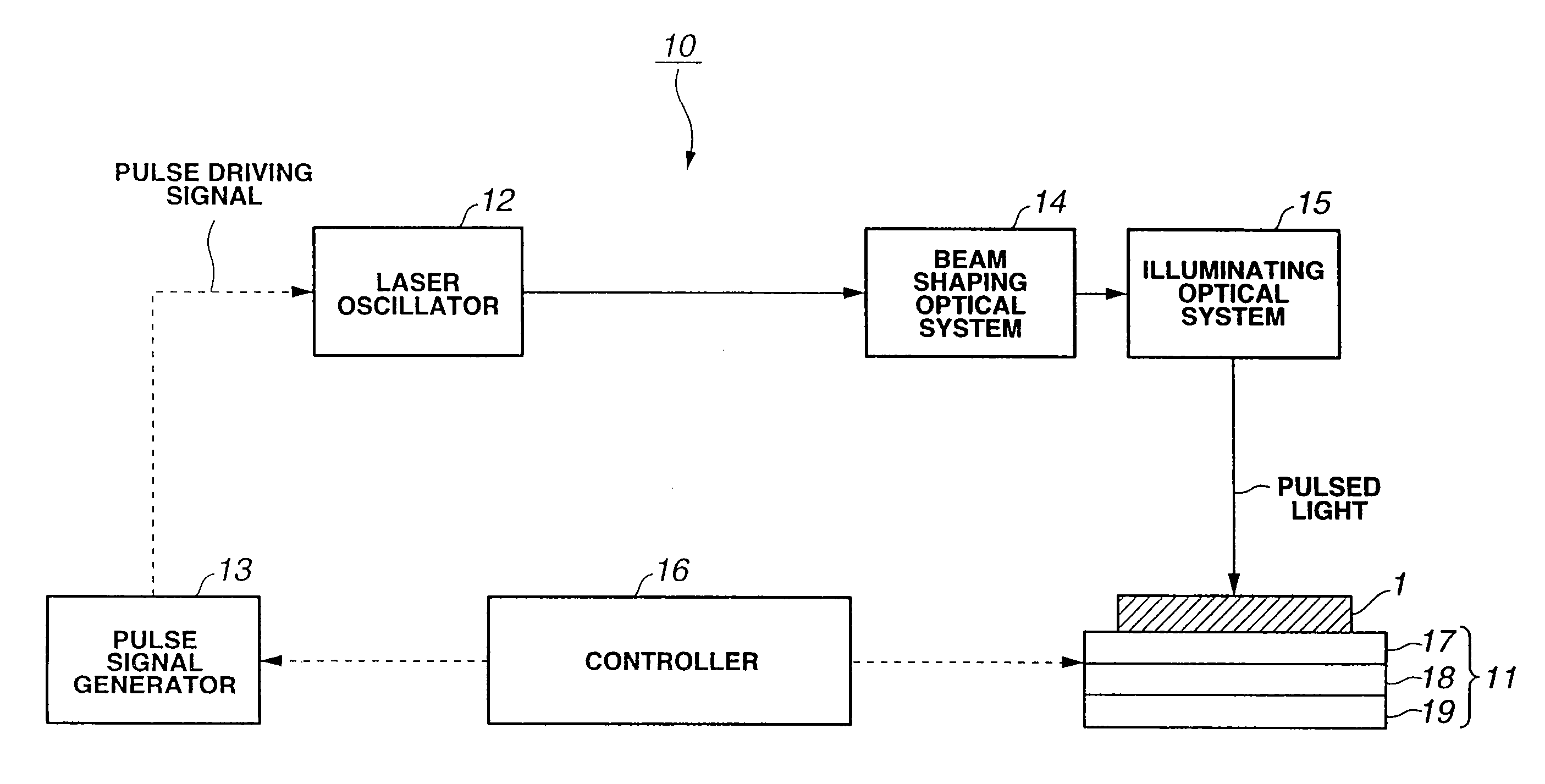

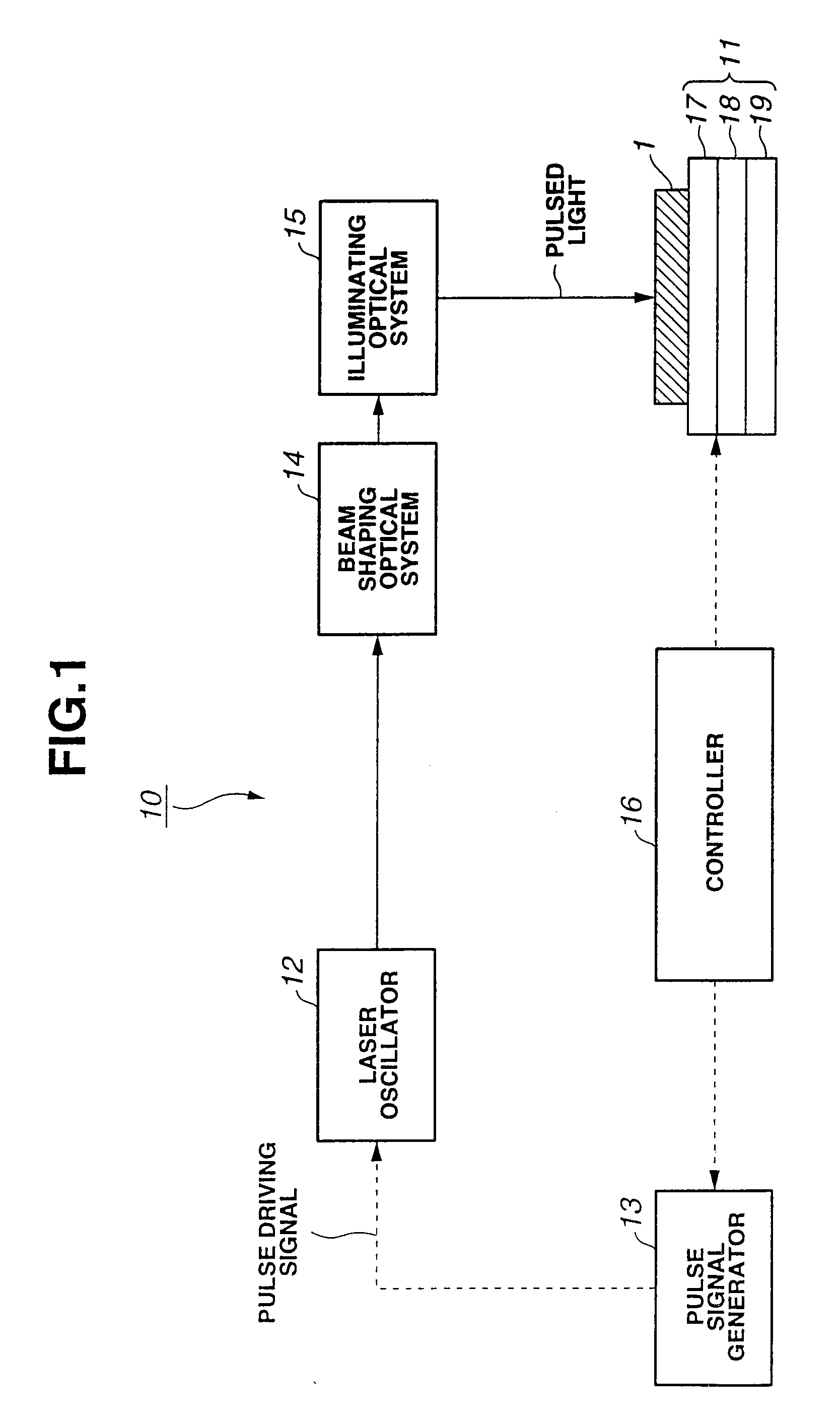

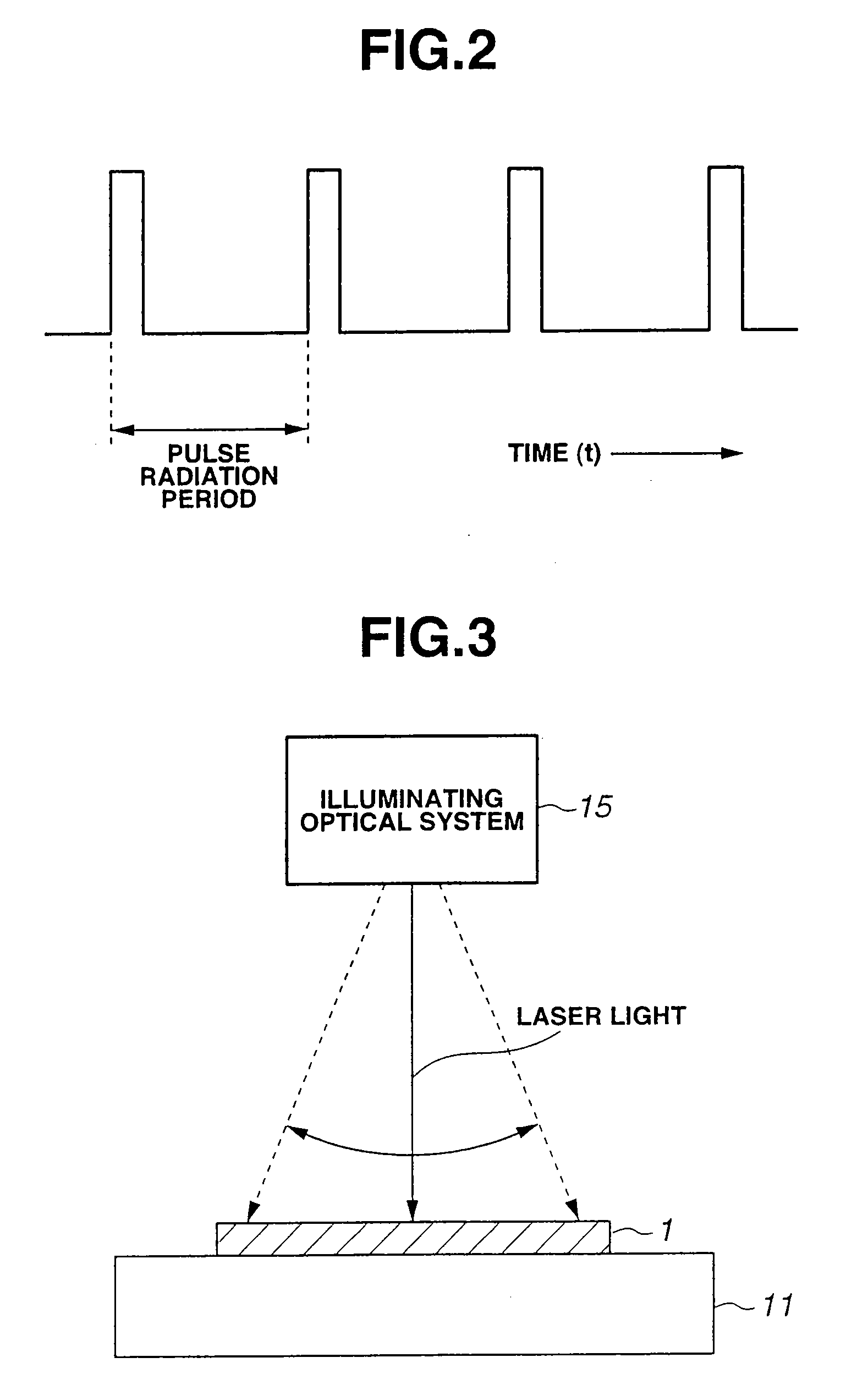

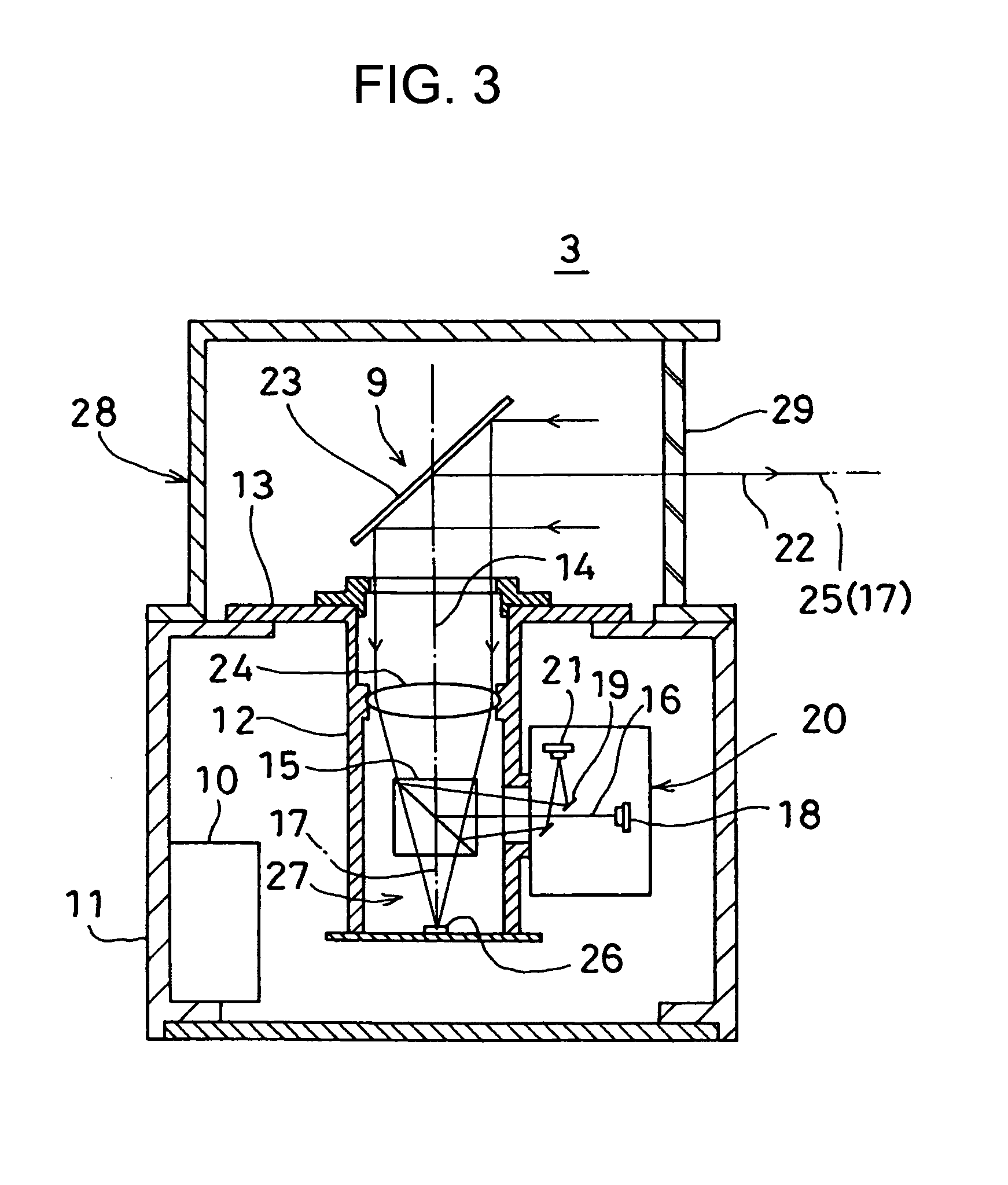

Laser annealing device and method for producing thin-film transistor

InactiveUS20070178674A1Increase in sizeTransistorSolid-state devicesReference PeriodAmorphous silicon

A laser annealing device (10) includes a laser oscillator (12), radiating a pulsed laser light beam of a preset period, and an illuminating optical system (15) for illuminating a pulsed laser light beam to an amorphous silicon film (1). The illuminating optical system (15) manages control for moving a laser spot so that a plural number of light pulses will be illuminated on the same location on the amorphous silicon film (1). The laser oscillator (12) radiates a laser light beam of a pulse generation period shorter than the reference period. The reference period is a time interval as from the radiation timing of illumination of a pulsed laser light beam on the surface of the film (1) until the timing of reversion of the substrate temperature raised due to the illumination of the laser light beam to the original substrate temperature.

Owner:SONY CORP

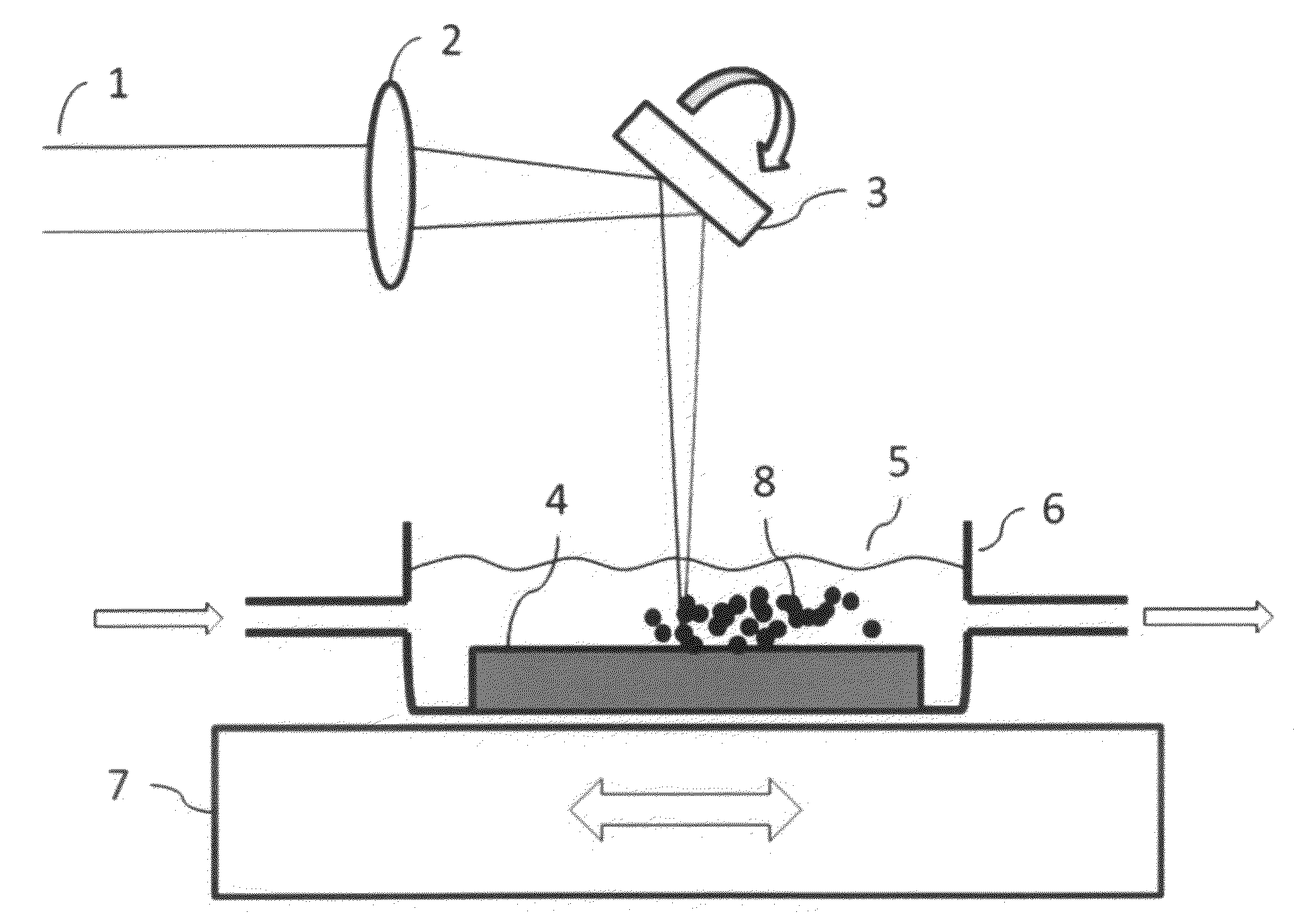

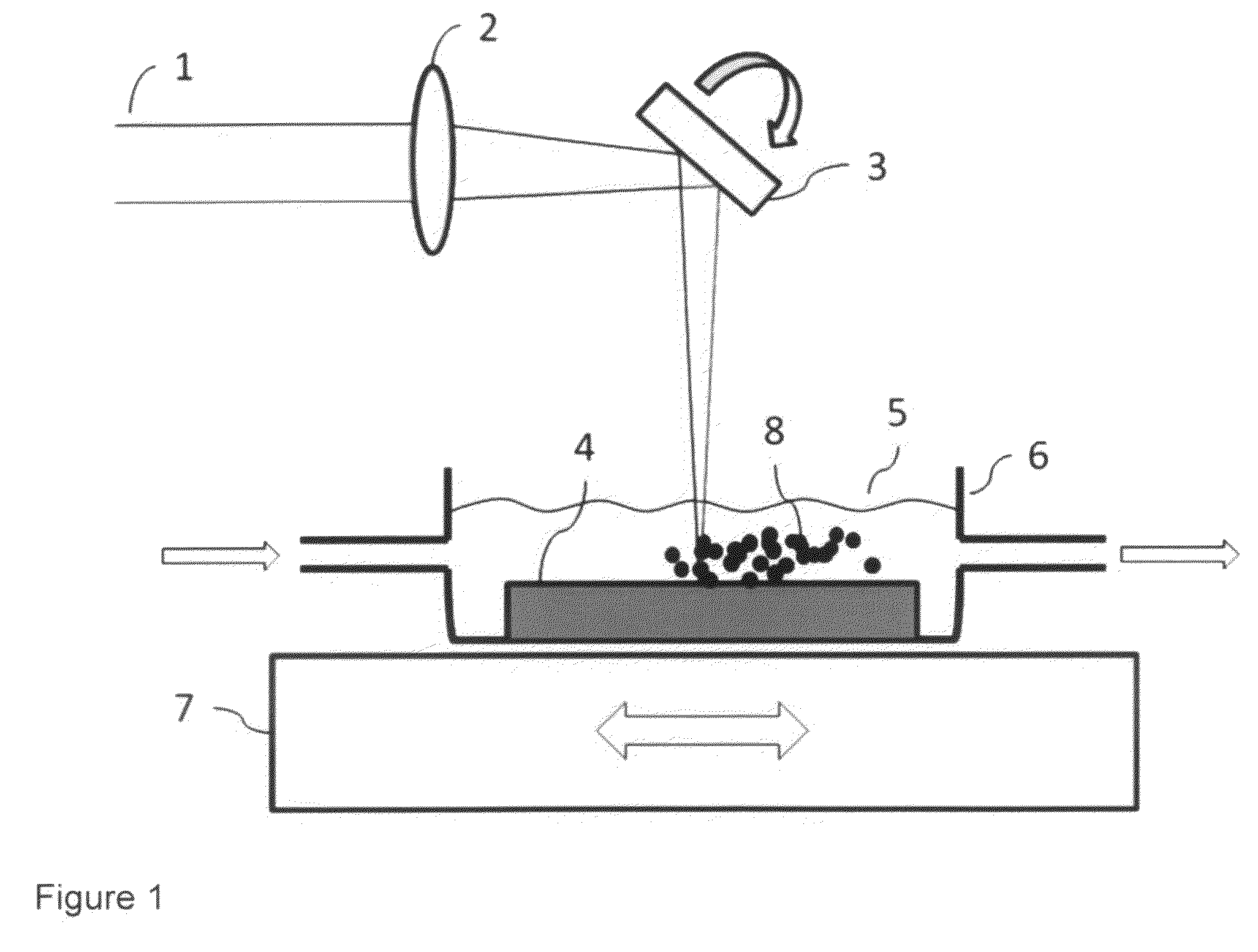

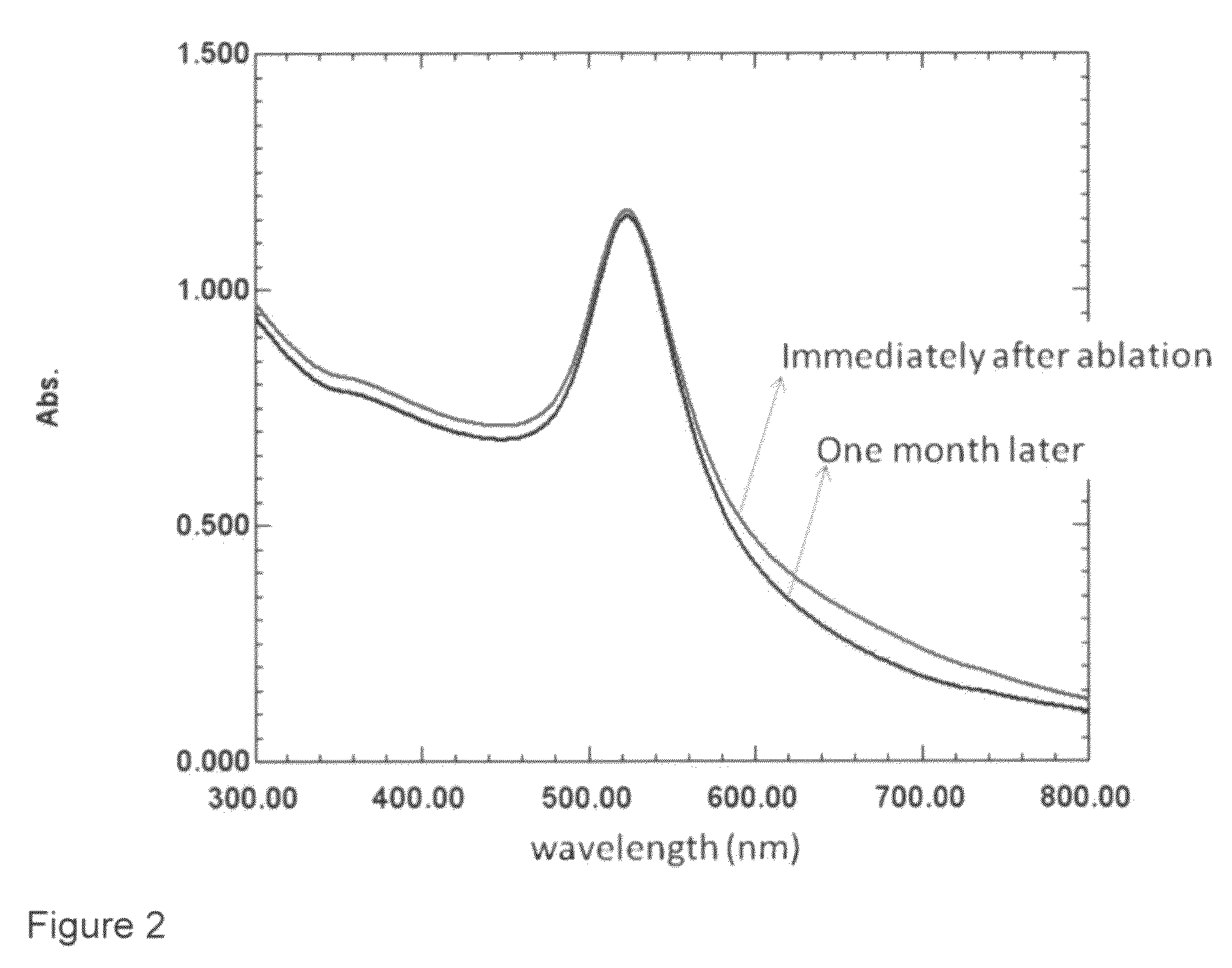

Production of metal and metal-alloy nanoparticles with high repetition rate ultrafast pulsed laser ablation in liquids

ActiveUS20100196192A1Prevent coagulationFaster throughputMaterial nanotechnologyOther chemical processesUltrashort laserFocal volume

Various embodiments include a method of producing chemically pure and stably dispersed metal and metal-alloy nanoparticle colloids with ultrafast pulsed laser ablation. A method comprises irradiating a metal or metal alloy target submerged in a liquid with ultrashort laser pulses at a high repetition rate, cooling a portion of the liquid that includes an irradiated region, and collecting nanoparticles produced with the laser irradiation and liquid cooling. The method may be implemented with a high repetition rate ultrafast pulsed laser source, an optical system for focusing and moving the pulsed laser beams, a metal or metal alloy target submerged in a liquid, and a liquid circulating system to cool the laser focal volume and collect the nanoparticle products. By controlling various laser parameters, and with optional liquid flow movement, the method provides stable colloids of dispersed metal and metal-alloy nanoparticles. In various embodiments additional stabilizing chemical agents are not required.

Owner:IMRA AMERICA

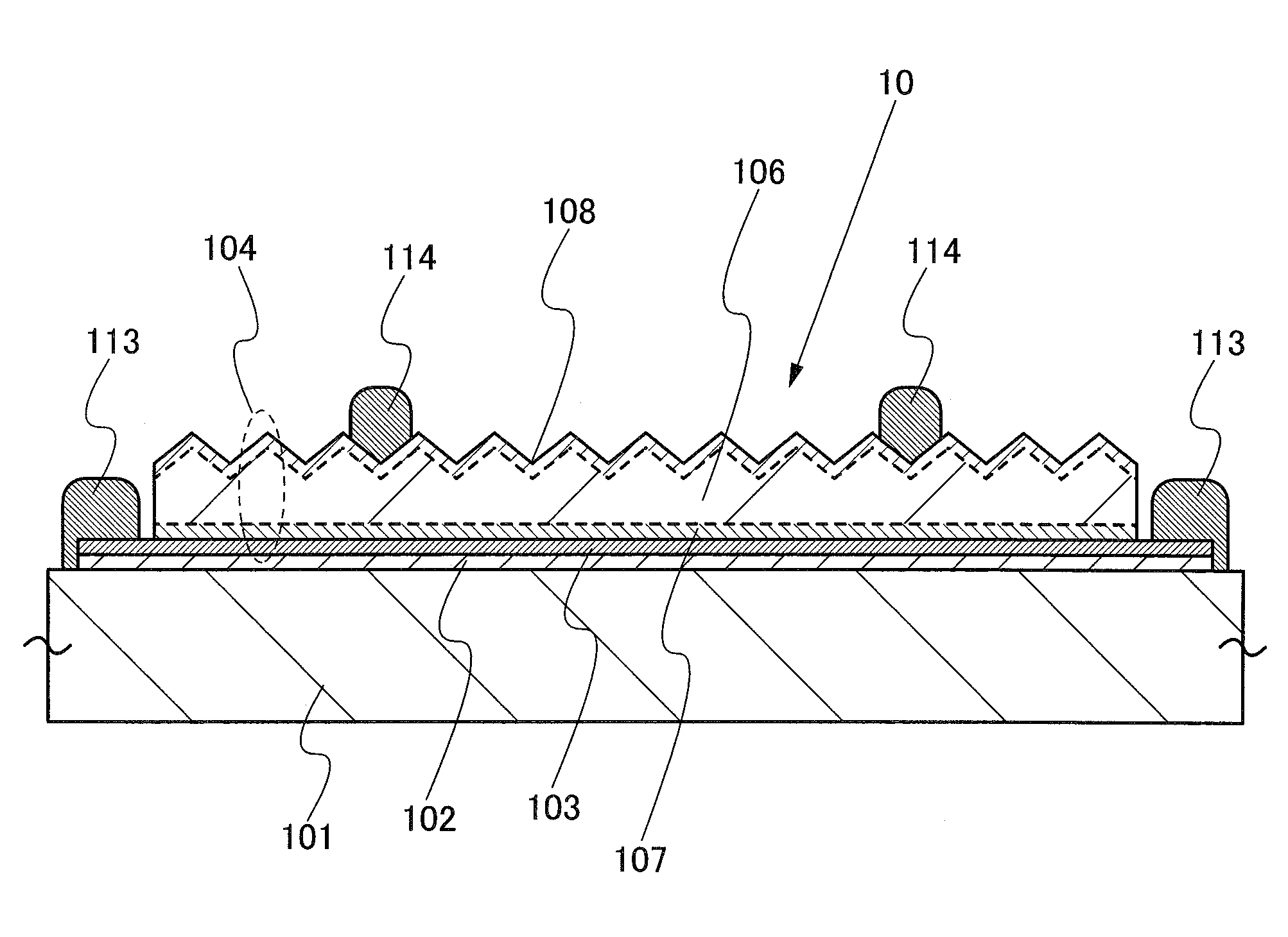

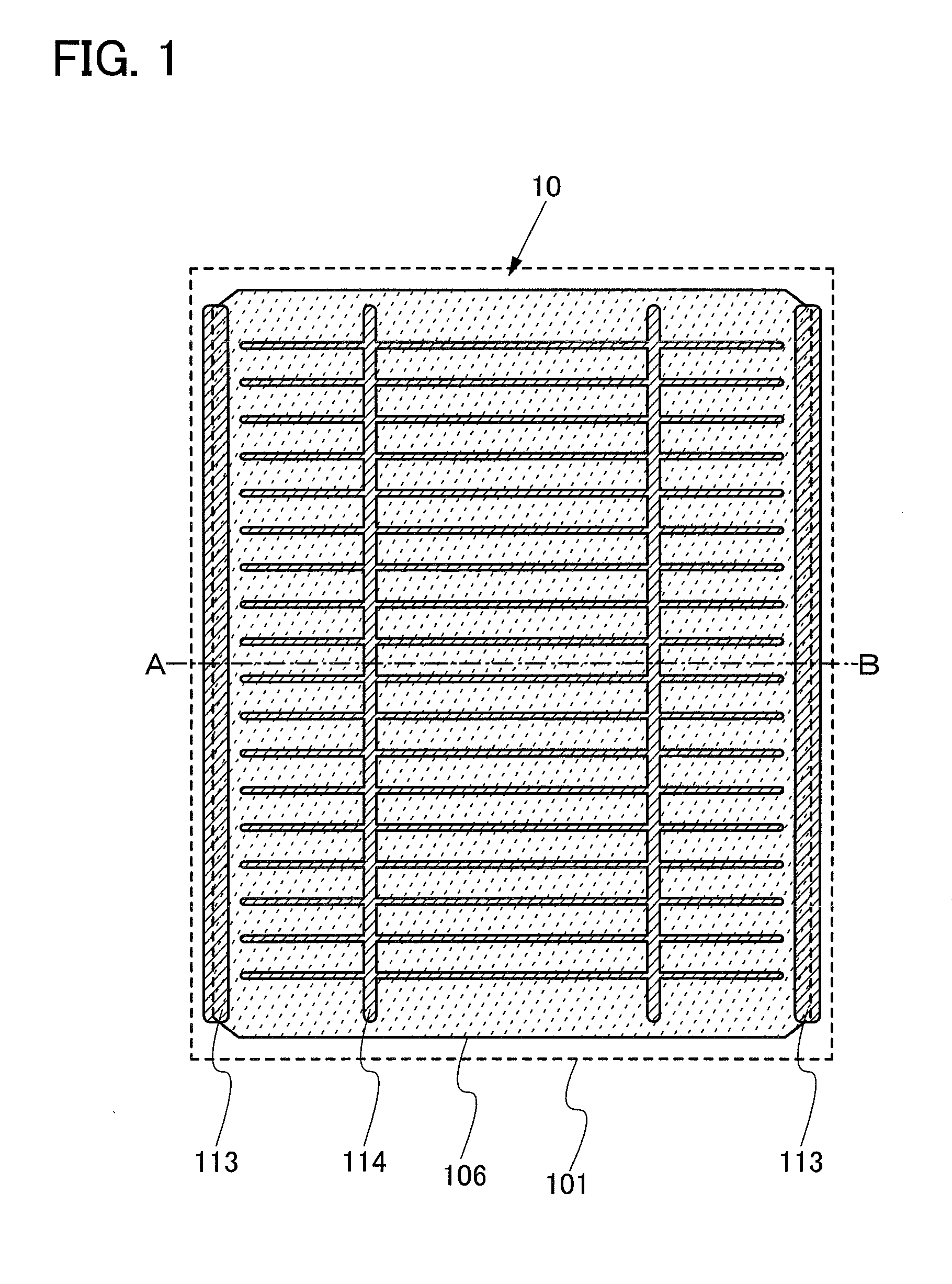

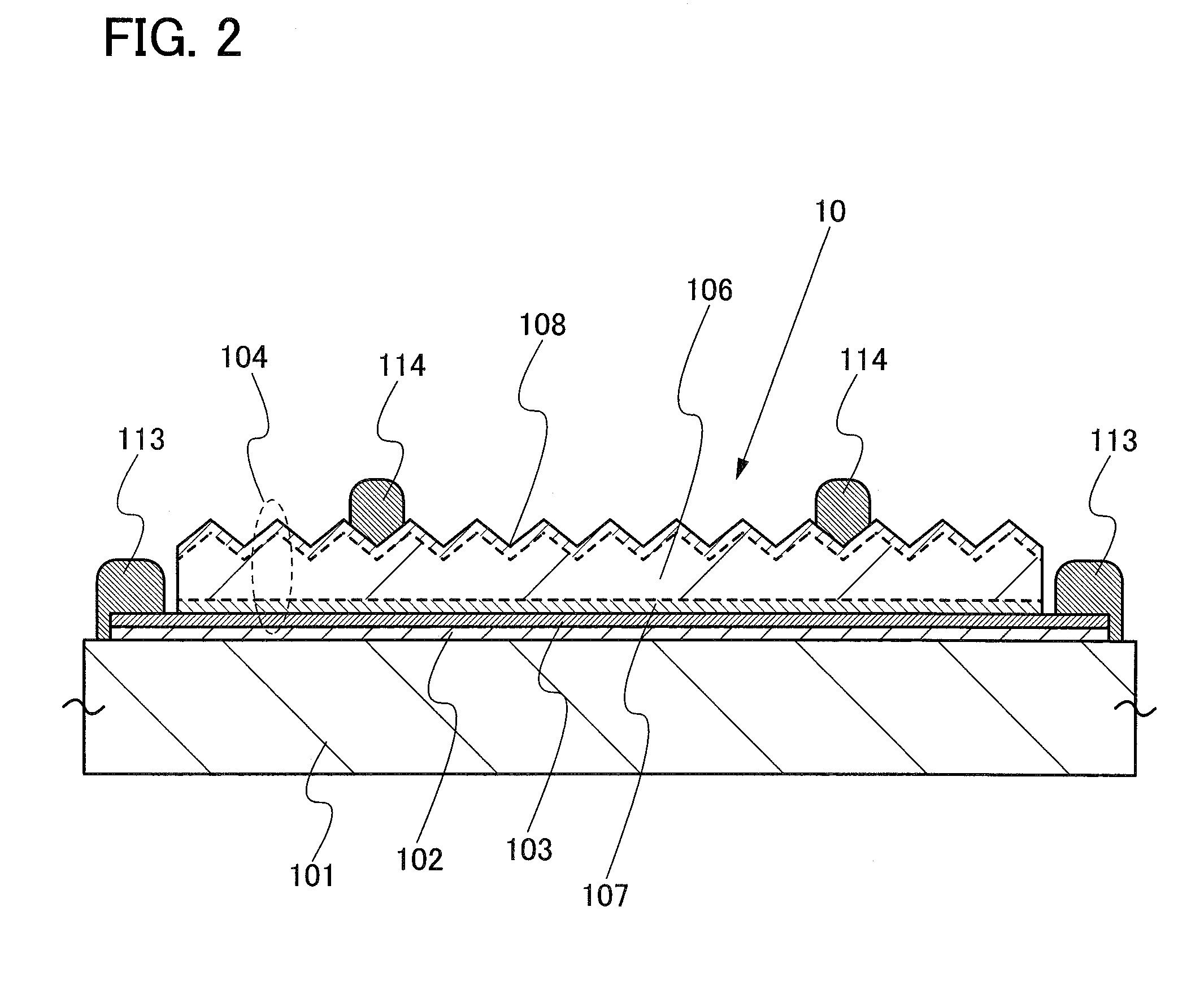

Method for manufacturing photoelectric conversion device

InactiveUS20090142874A1Reduce surface reflectivityImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPath lengthSemiconductor materials

A method for manufacturing a photoelectric conversion device typified by a solar cell, having an excellent photoelectric conversion characteristic with a silicon semiconductor material effectively utilized. The point is that the surface of a single crystal semiconductor layer bonded to a supporting substrate is irradiated with a pulsed laser beam to become rough. The single crystal semiconductor layer is irradiated with the pulsed laser beam in an atmosphere containing an inert gas and oxygen so that the surface thereof is made rough. With the roughness of surface of the single crystal semiconductor layer, light reflection is suppressed so that incident light can be trapped. Accordingly, even when the thickness of the single crystal semiconductor layer is equal to or greater than 0.1 μm and equal to or less than 10 μm, path length of incident light is substantially increased so that the amount of light absorption can be increased.

Owner:SEMICON ENERGY LAB CO LTD

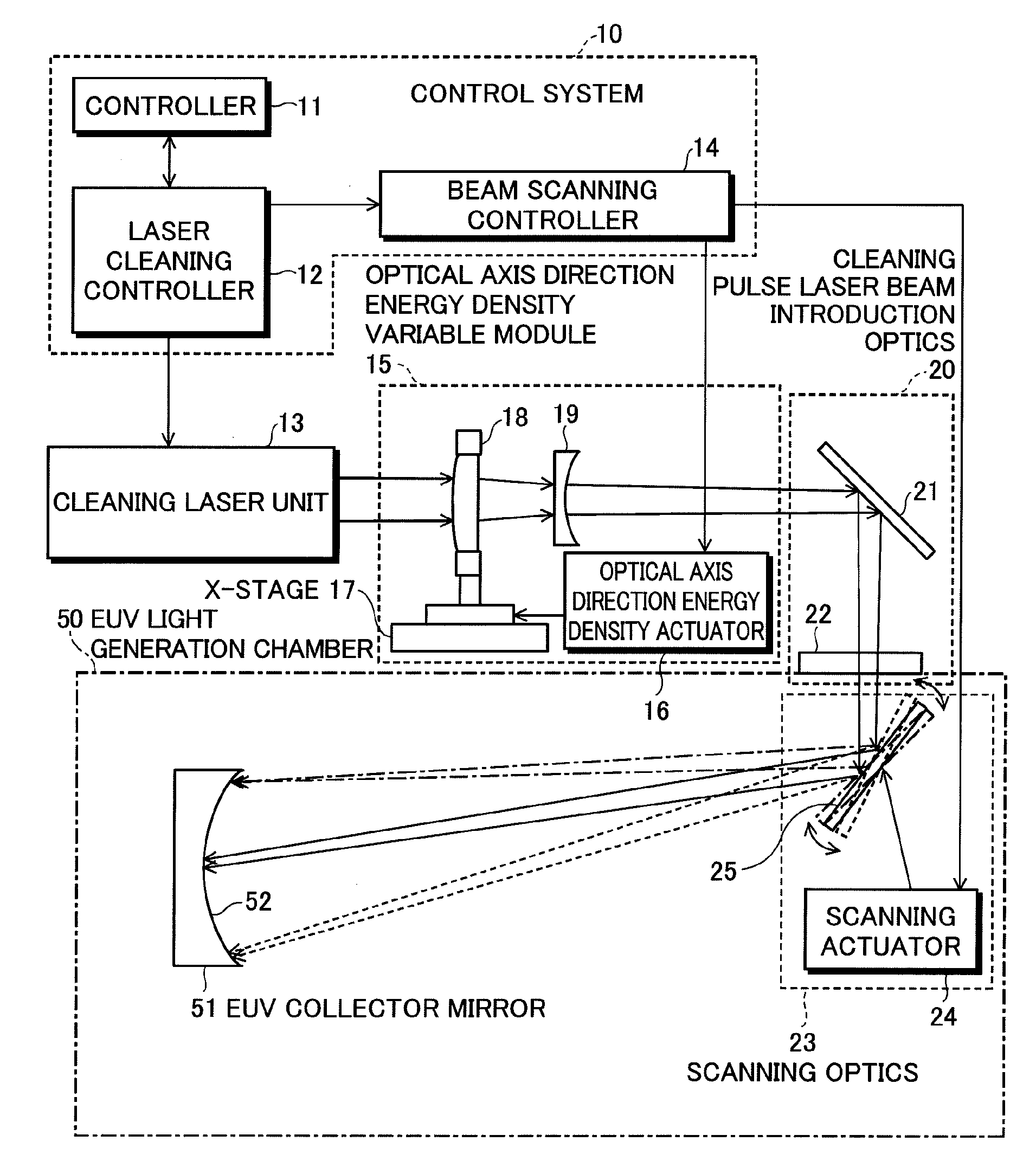

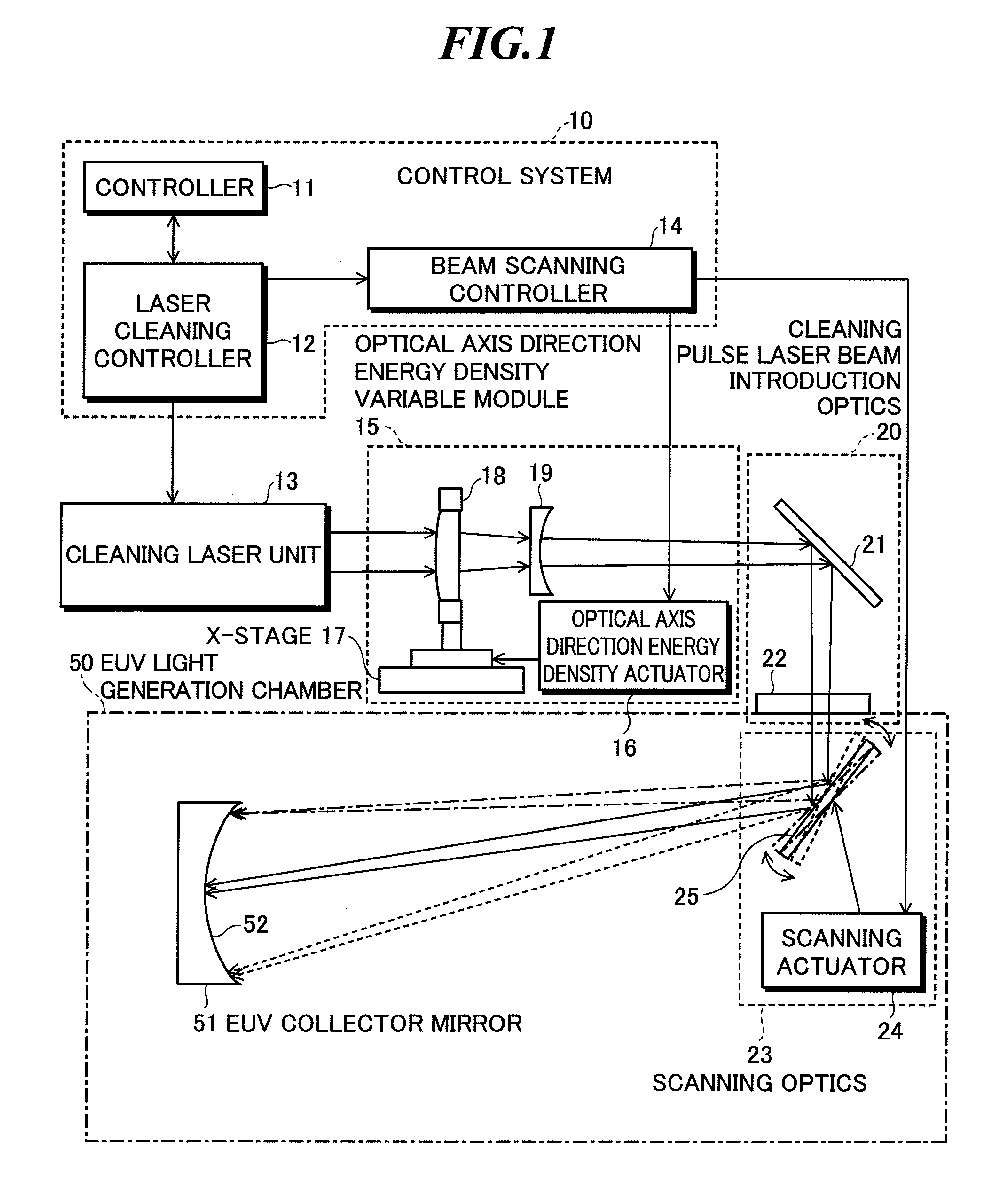

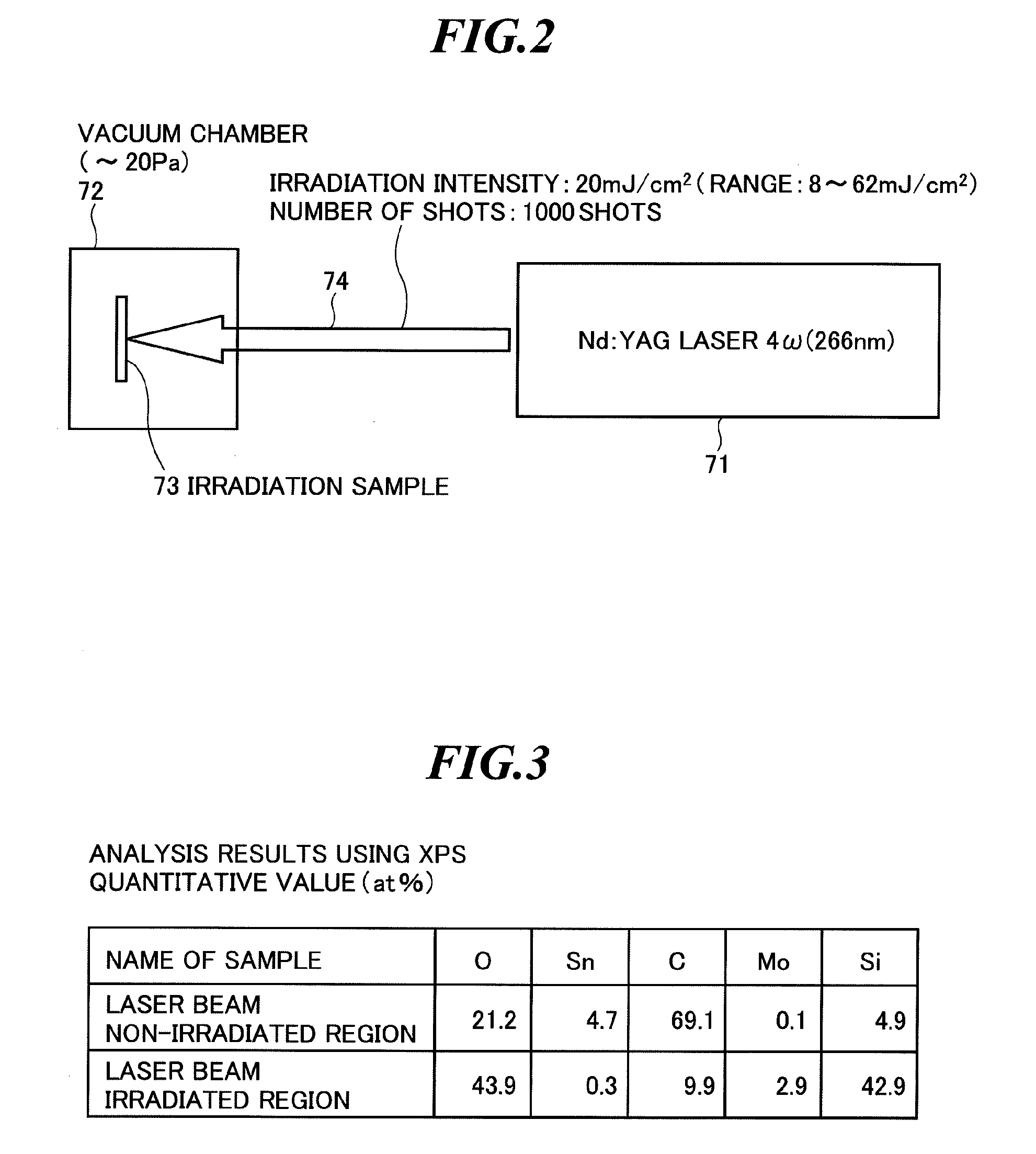

Extreme ultraviolet light source apparatus and cleaning method

InactiveUS20100192973A1Eliminate adhesionEfficient removalSimulator controlPhotomechanical apparatusLight beamPulsed laser beam

An extreme ultraviolet light source apparatus that can eliminate debris adhering to a component such as optical elements provided within a chamber. The extreme ultraviolet light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target material supply unit for supplying a target material into the chamber; a driver laser unit for irradiating the target material with a driver pulse laser beam to generate plasma; a cleaning laser unit for emitting a cleaning pulse laser beam; and a control unit for controlling an irradiation position of the cleaning pulse laser beam emitted from the cleaning laser unit so as to irradiate a component provided within the chamber with the cleaning pulse laser beam to remove debris adhering to a surface of the component.

Owner:GIGAPHOTON

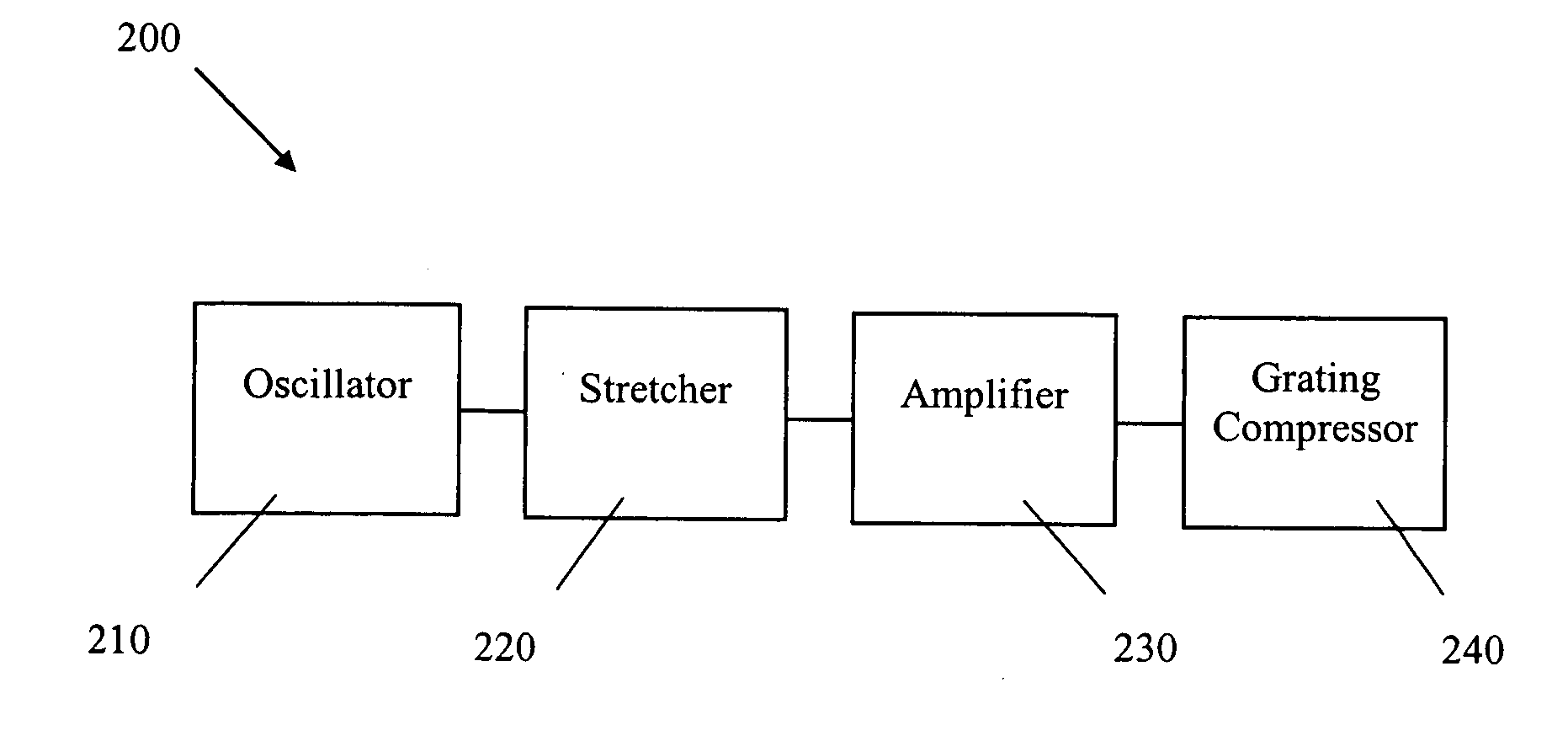

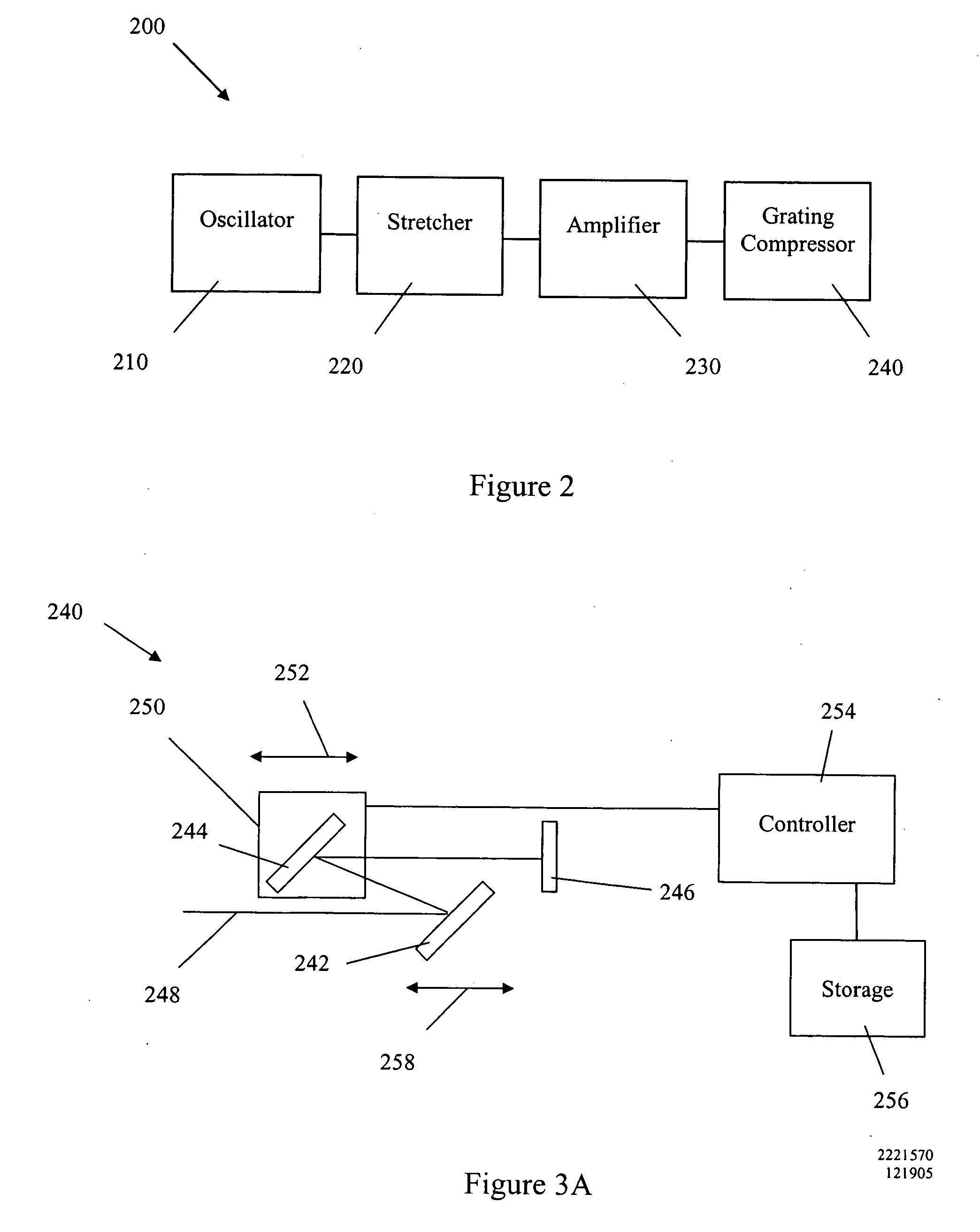

Pulsed laser source with adjustable grating compressor

ActiveUS20060159137A1Optimal pulse compressionOptical resonator shape and constructionOptical waveguide light guideFiberGrating

Various embodiments described herein relate to a laser source for producing a pulsed laser beam comprising a plurality of ultrashort optical pulses having a variable repetition rate. In one embodiment, the laser source comprises a fiber oscillator, which outputs optical pulses and a pulse stretcher disposed to receive the optical pulses. The optical pulses have an optical pulse width. The pulse stretcher has dispersion that increases the optical pulse width yielding stretched optical pulses. The laser source further comprises a fiber amplifier disposed to receive the stretched optical pulses. The fiber optical amplifier has gain so as to amplify the stretched optical pulses. The laser source includes an automatically adjustable grating compressor having dispersion that reduces the optical pulse width. The grating compressor automatically adjusts this dispersion for different repetition rates.

Owner:IMRA AMERICA

Direct writing of optical devices in silica-based glass using femtosecond pulse lasers

InactiveUS20020076655A1Efficient rateHigh sensitivityPhotography auxillary processesRadiation applicationsLight guideRefractive index

The invention relates to methods of writing a light-guiding structure in a bulk glass substrate. The bulk glass substrate is preferably made from a soft silica-based material having an annealing point less than about 1380°K. A pulsed laser beam is focused within the substrate while the focus is translated relative to the substrate along a scan path at a scan speed effective to induce an increase in the refractive index of the material along the scan path. Substantially no laser-induced physical damage of the material is incurred along the scan path. Various optical devices can be made using this method.

Owner:CORNING INC

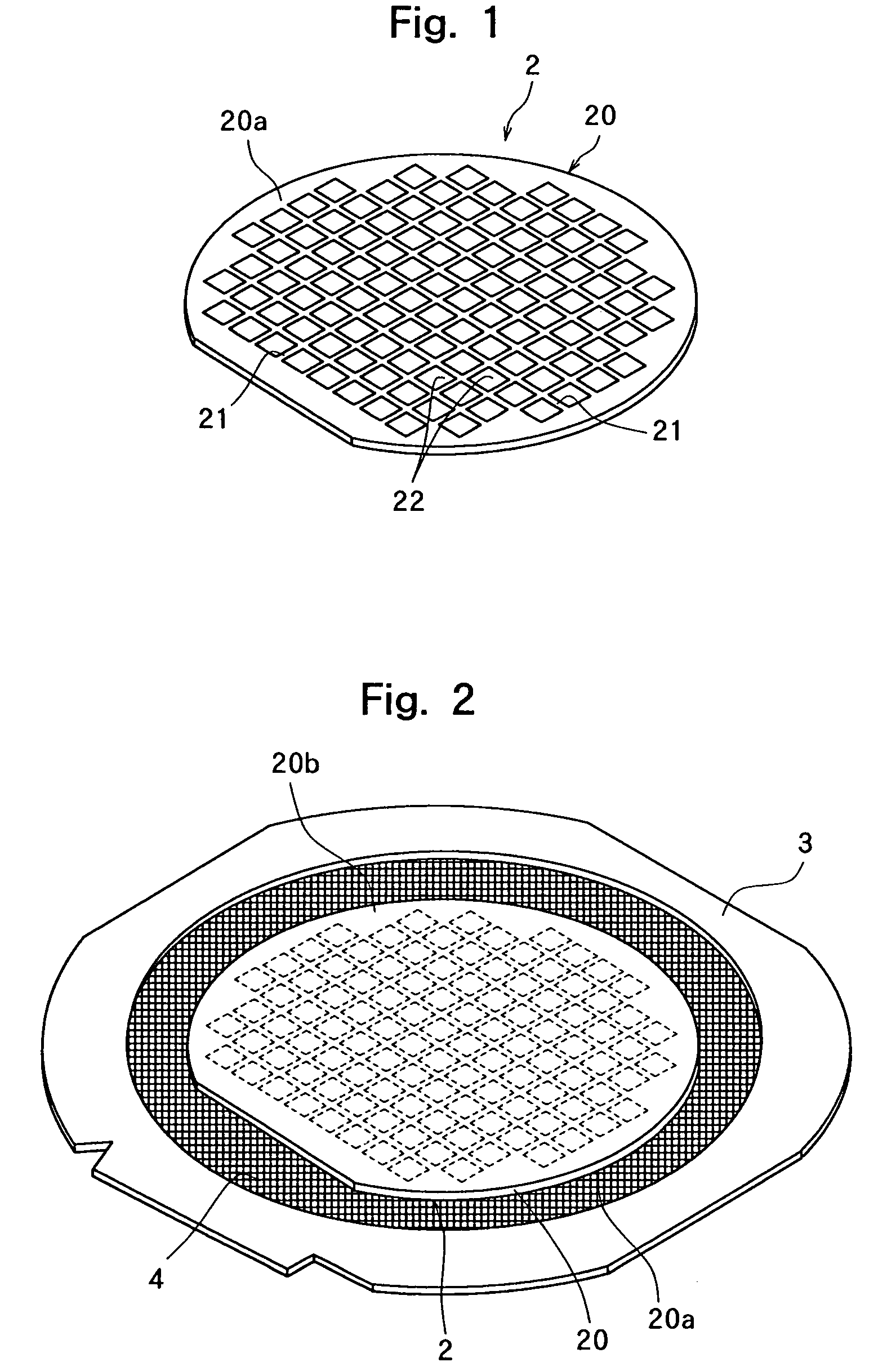

Processing method for wafer

ActiveUS20130189806A1So as not to breakSemiconductor/solid-state device manufacturingFine working devicesSplit linesLight beam

A wafer has, on a front face thereof, a device region in which a device is formed in regions partitioned by a plurality of scheduled division lines. An outer peripheral region surrounds the device region. A reflecting film of a predetermined width is formed from the outermost periphery of the wafer on a rear face of the wafer corresponding to the outer peripheral region. The front face side of the wafer is held in a chuck table, and a focal point of a pulsed laser beam of a wavelength having permeability through the wafer is positioned in the inside of the wafer corresponding to the scheduled division lines. The pulsed laser beam is irradiated from the rear face side of the wafer to form modified layers individually serving as a start point of division along the scheduled division lines in the inside of the wafer.

Owner:DISCO CORP

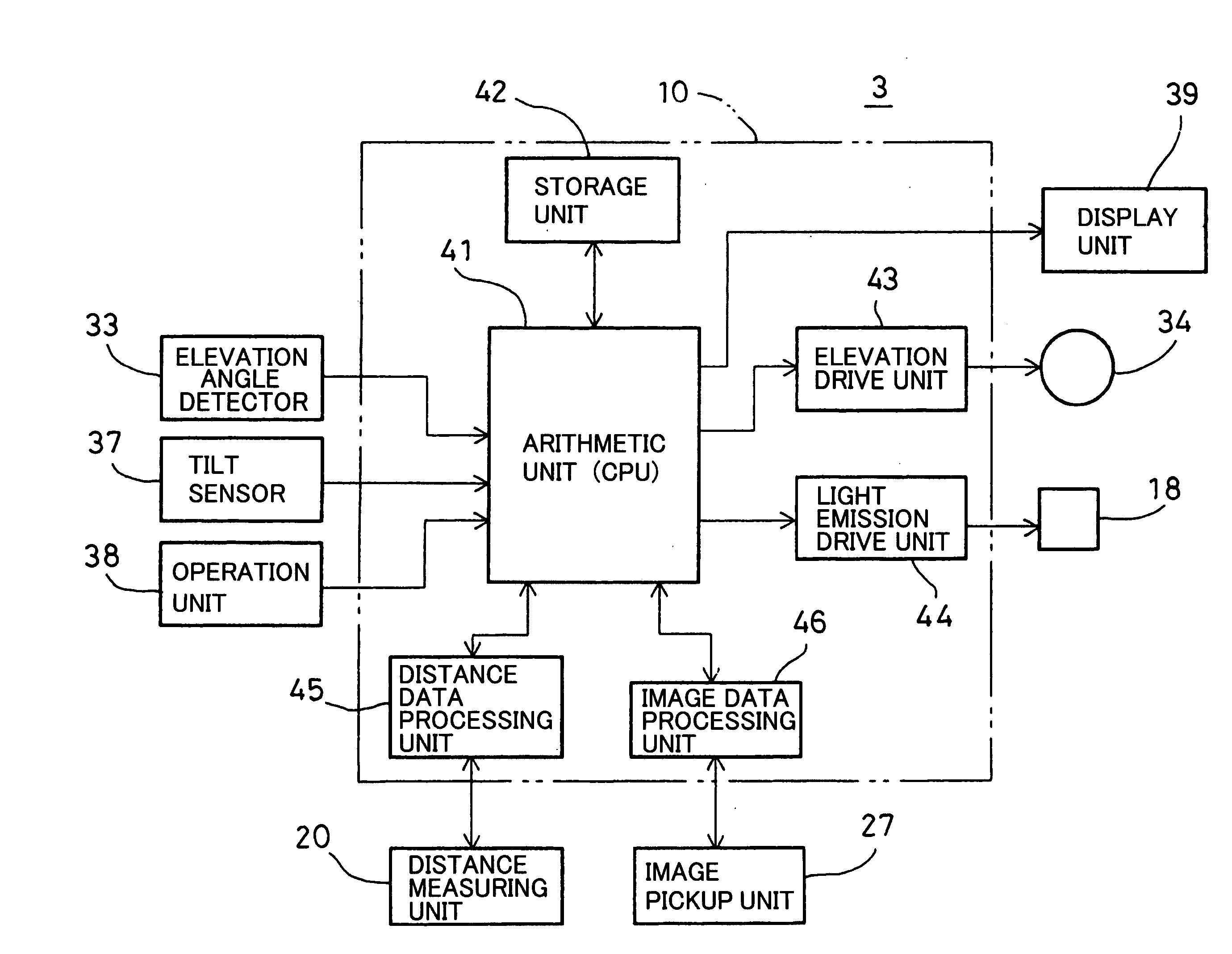

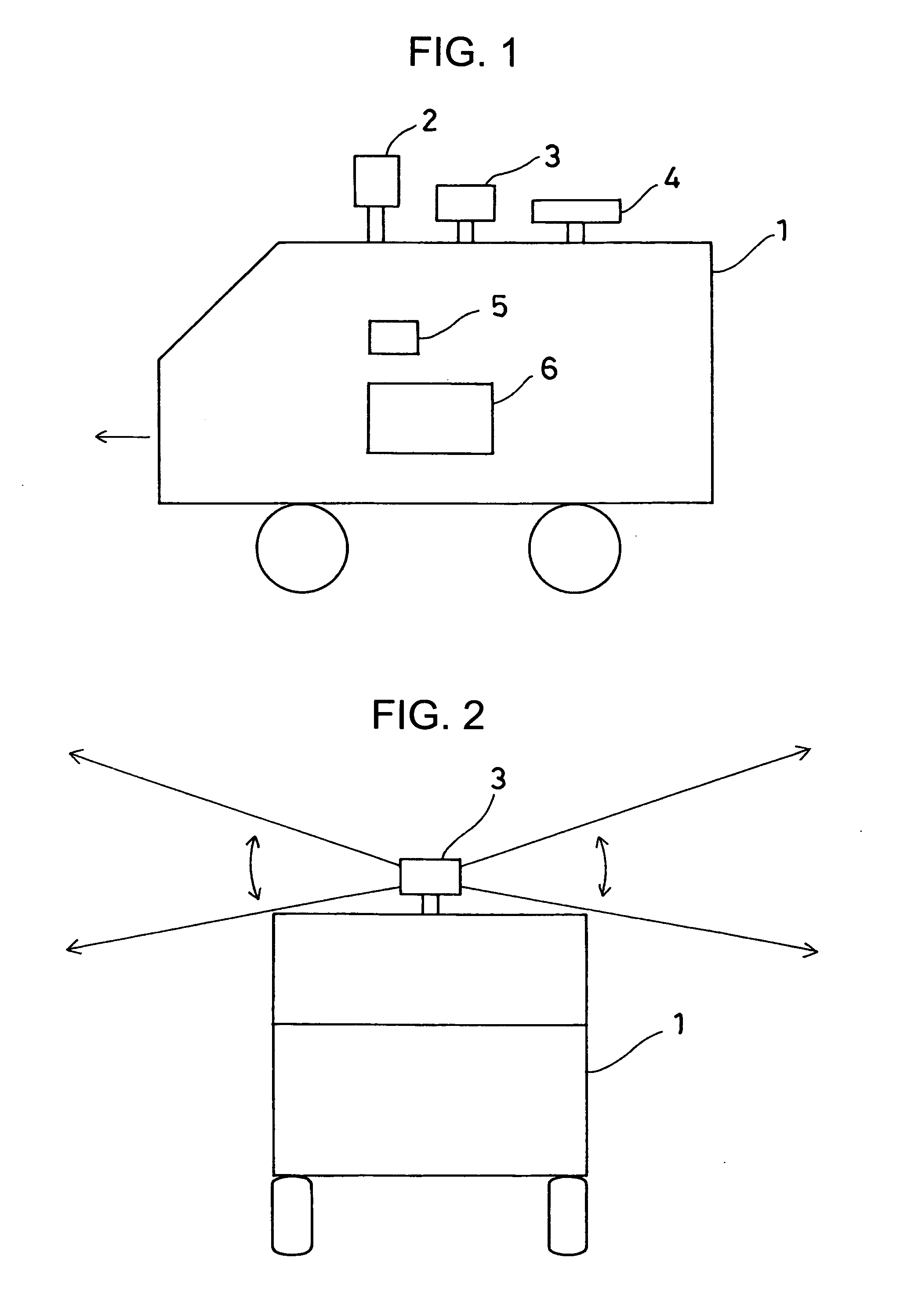

Laser scanner, laser scanner measuring system, calibration method for laser scanner measuring system and target for calibration

ActiveUS20100256940A1Easy to associateEasy to detectPhotometry using reference valueOptical rangefindersLaser scanningLight beam

According to the present invention, a laser scanner measuring system, which has a laser scanner and a calibration target, wherein the laser scanner comprises a light emitting element for emitting a pulsed laser beam, a rotary projecting unit for projecting the pulsed laser beam for scanning, a distance measuring unit, which has a distance measuring light receiving unit, for measuring a distance by receiving a reflection light from an object to be measured, and a control unit for driving and controlling the light emitting element and the distance measuring unit, and wherein the calibration target has a reflection sector with a known shape and with high reflectance and is installed at a known position, comprising a step for judging a reflected pulsed laser beam from the reflection sector as received by the distance measuring light receiving unit by detecting a level of light quantity, a step for determining a center position of the reflection sector based on the result of the judgment, and a step for calibrating the laser scanner measuring system based on the determined center position and on the known position.

Owner:KK TOPCON

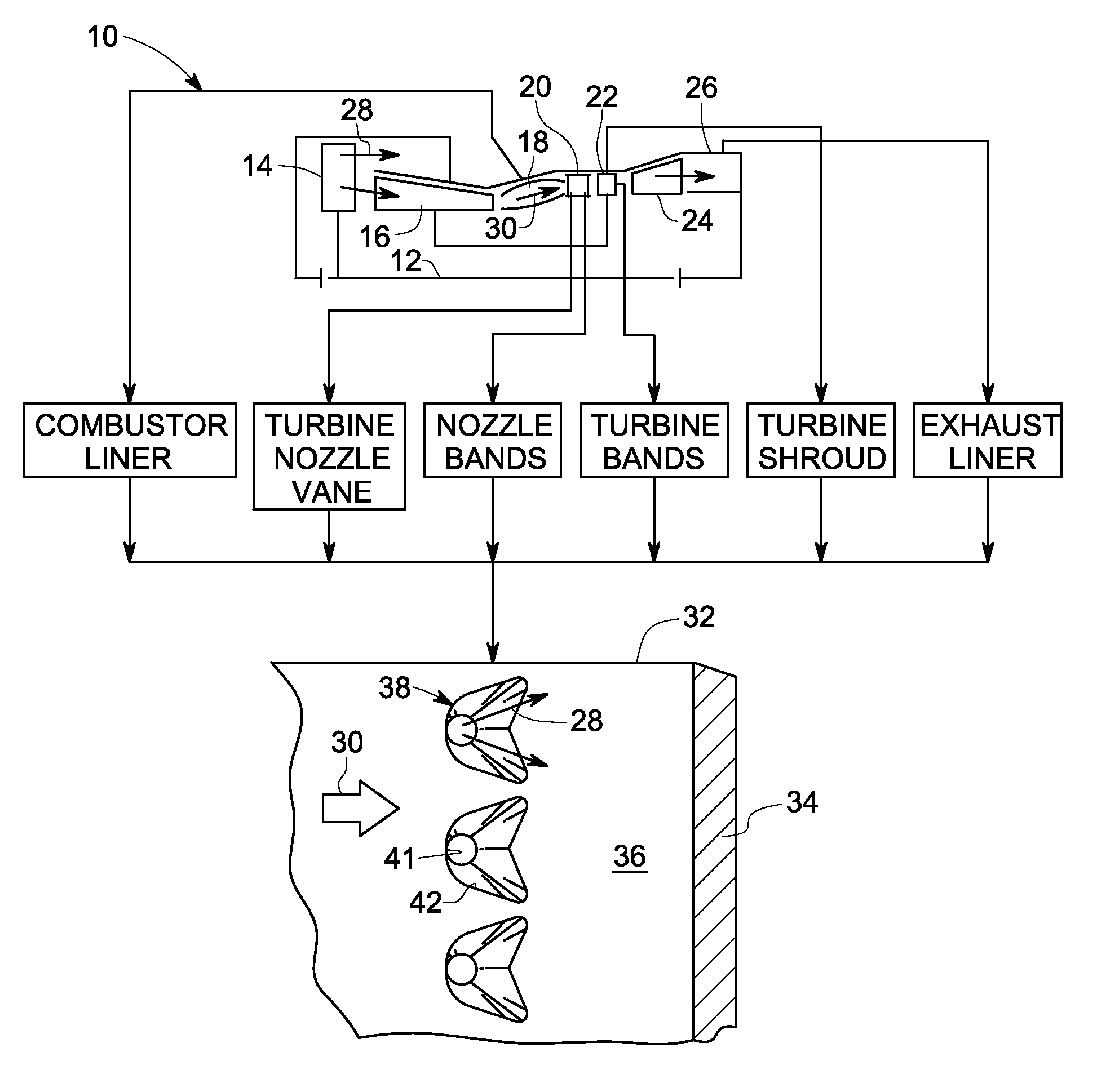

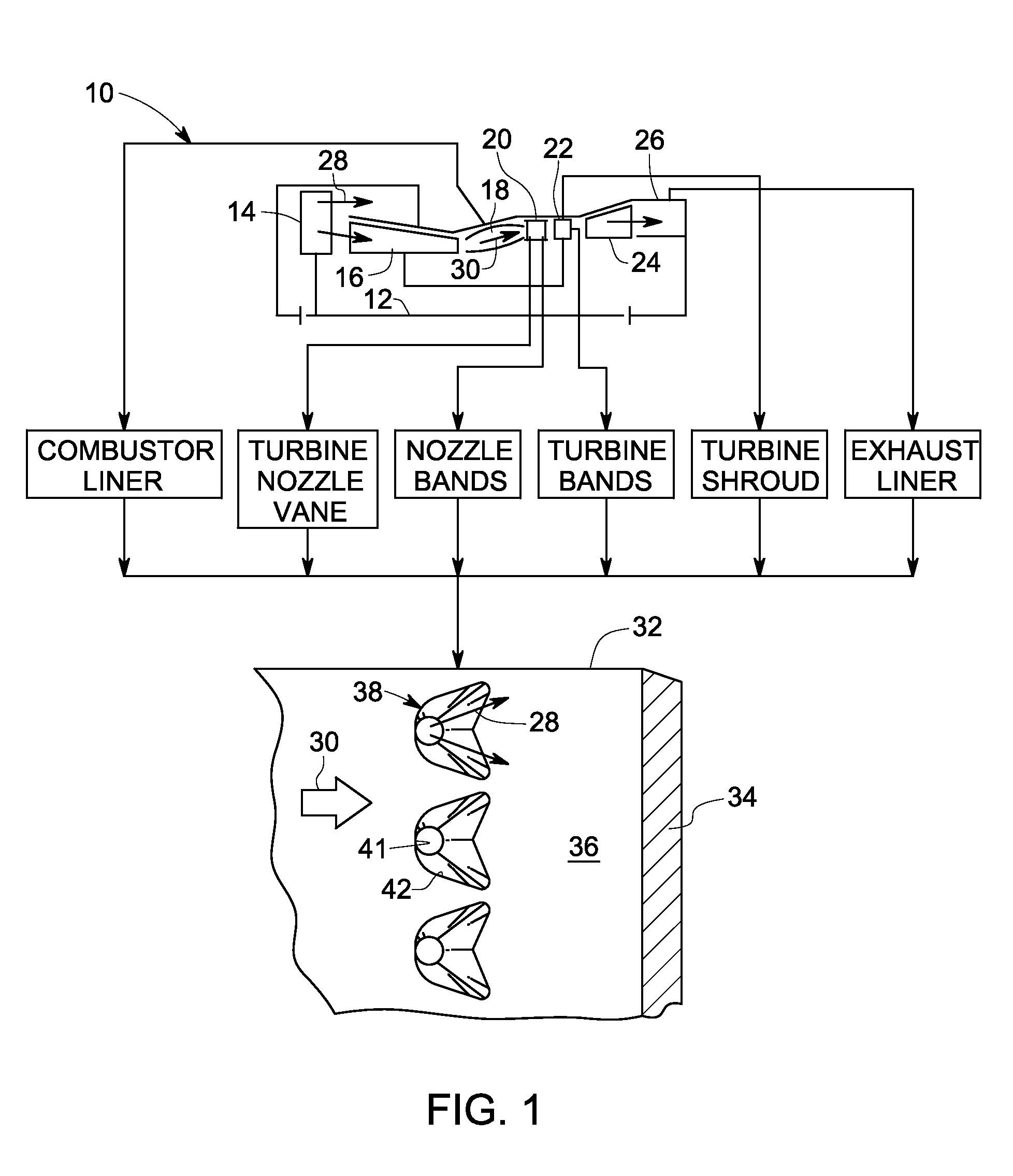

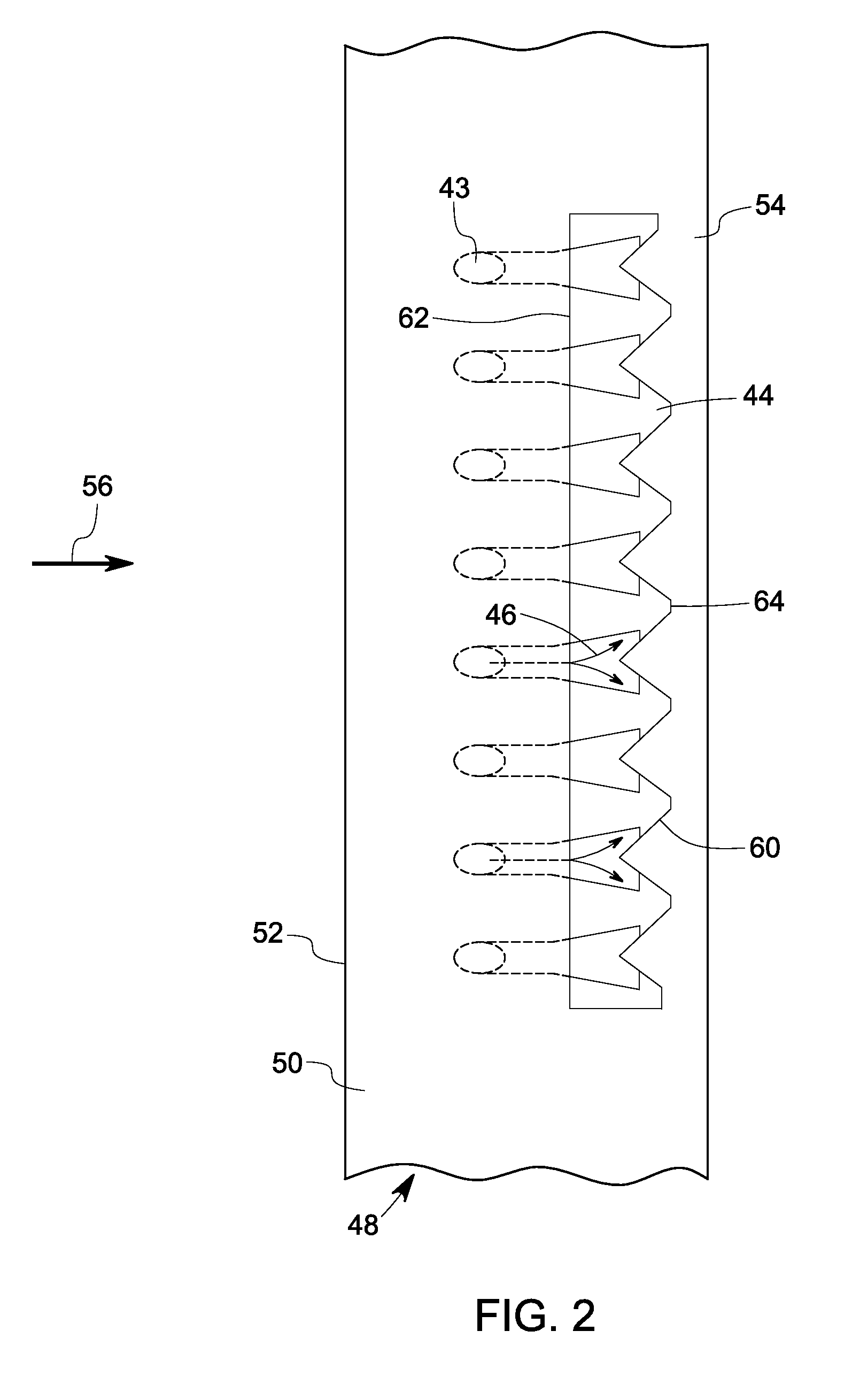

System and method for improved film cooling

ActiveUS20100282721A1Prolongs effectiveness of coolerSimple technologyEngine fuctionsEfficient propulsion technologiesLight beamSystem configuration

A system for producing at least one trench to improve film cooling in a sample is provided. The system includes at least one laser source outputting at least one pulsed laser beam. The pulsed laser beam includes a pulse duration including a range less than about 50 μs, an energy per pulse having a range less than about 0.1 Joule, and a repetition rate with a range greater than about 1000 Hz. The system also includes a control subsystem coupled to the laser source, the control subsystem configured to synchronize a position of the sample with the pulse duration and energy level in order to selectively remove at least one of a thermal barrier coating, a bondcoat and a substrate metal in the sample to form the at least one trench.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com