Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Continuous wave laser beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

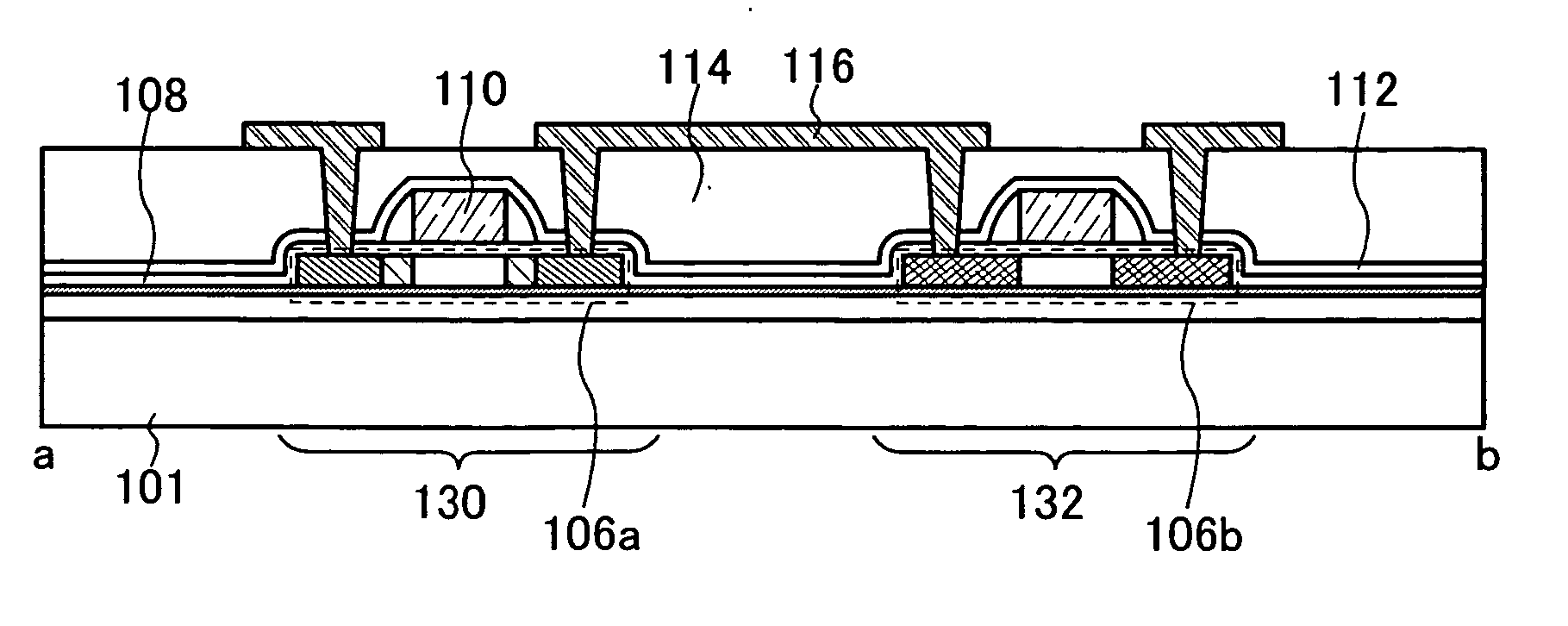

Semiconductor device and manufacturing method thereof

InactiveUS20060275710A1Reduce light intensityImprove routing densitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialContinuous wave laser beam

To provide a semiconductor device having a circuit with high operating performance and high reliability, and improve the reliability of the semiconductor device, thereby improving the reliability of an electronic device having the same. The aforementioned object is achieved by combining a step of crystallizing a semiconductor layer by irradiation with continuous wave laser beams or pulsed laser beams with a repetition rate of 10 MHz or more, while scanning in one direction; a step of photolithography with the use of a photomask or a leticle including an auxiliary pattern which is formed of a diffraction grating pattern or a semi-transmissive film having a function of reducing the light intensity; and a step of performing oxidation, nitridation, or surface-modification to the surface of the semiconductor film, an insulating film, or a conductive film, with high-density plasma with a low electron temperature.

Owner:SEMICON ENERGY LAB CO LTD

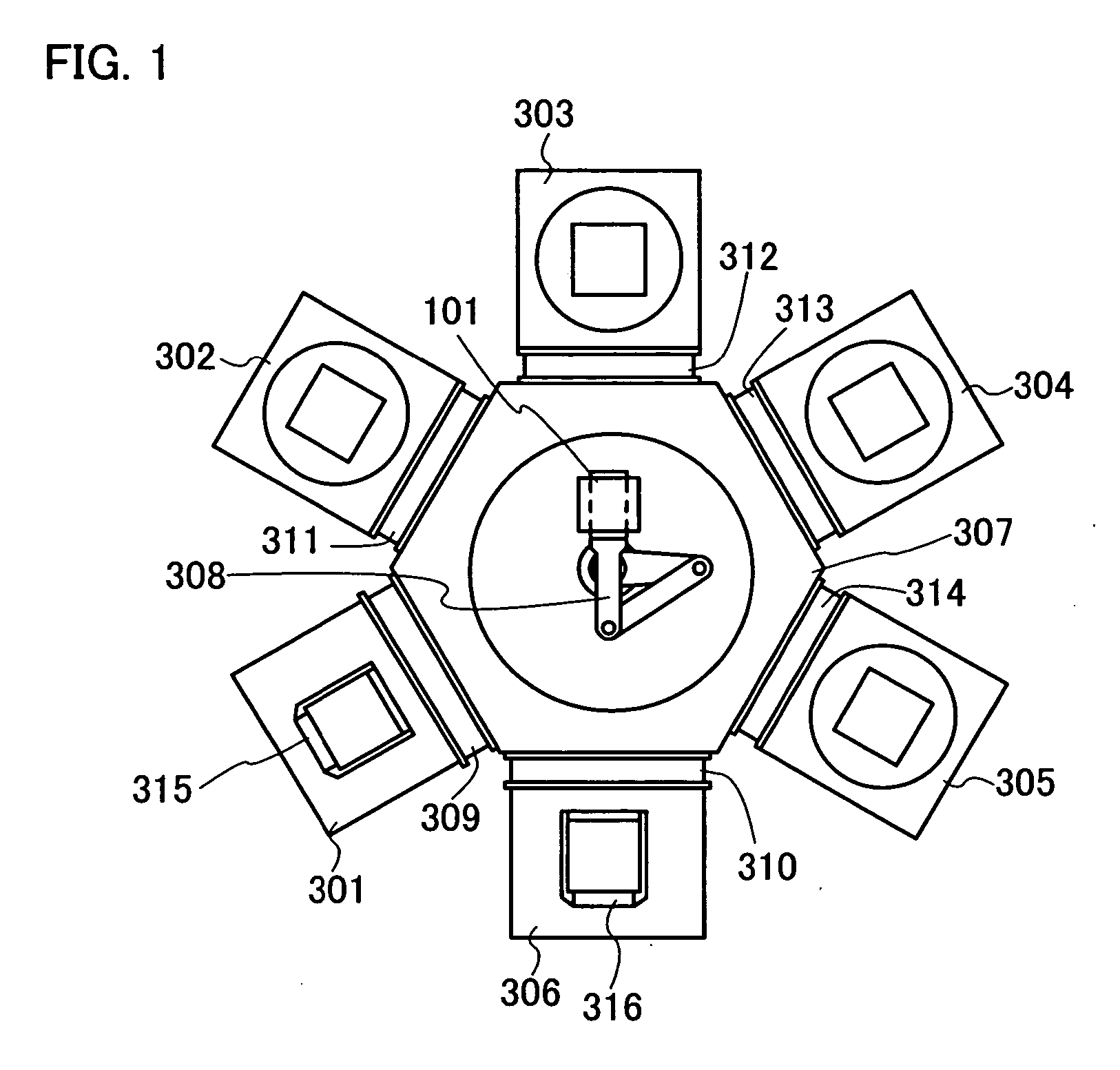

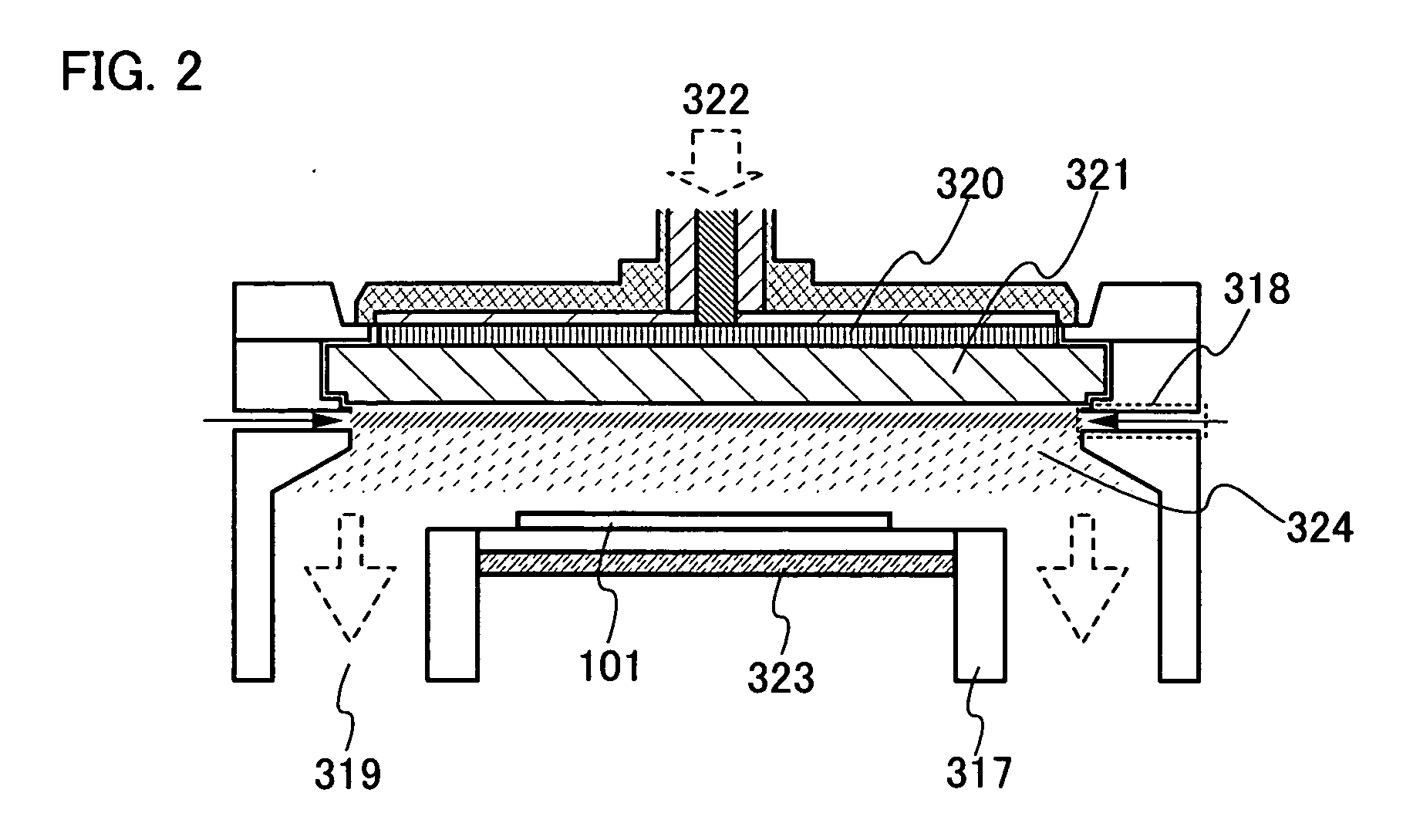

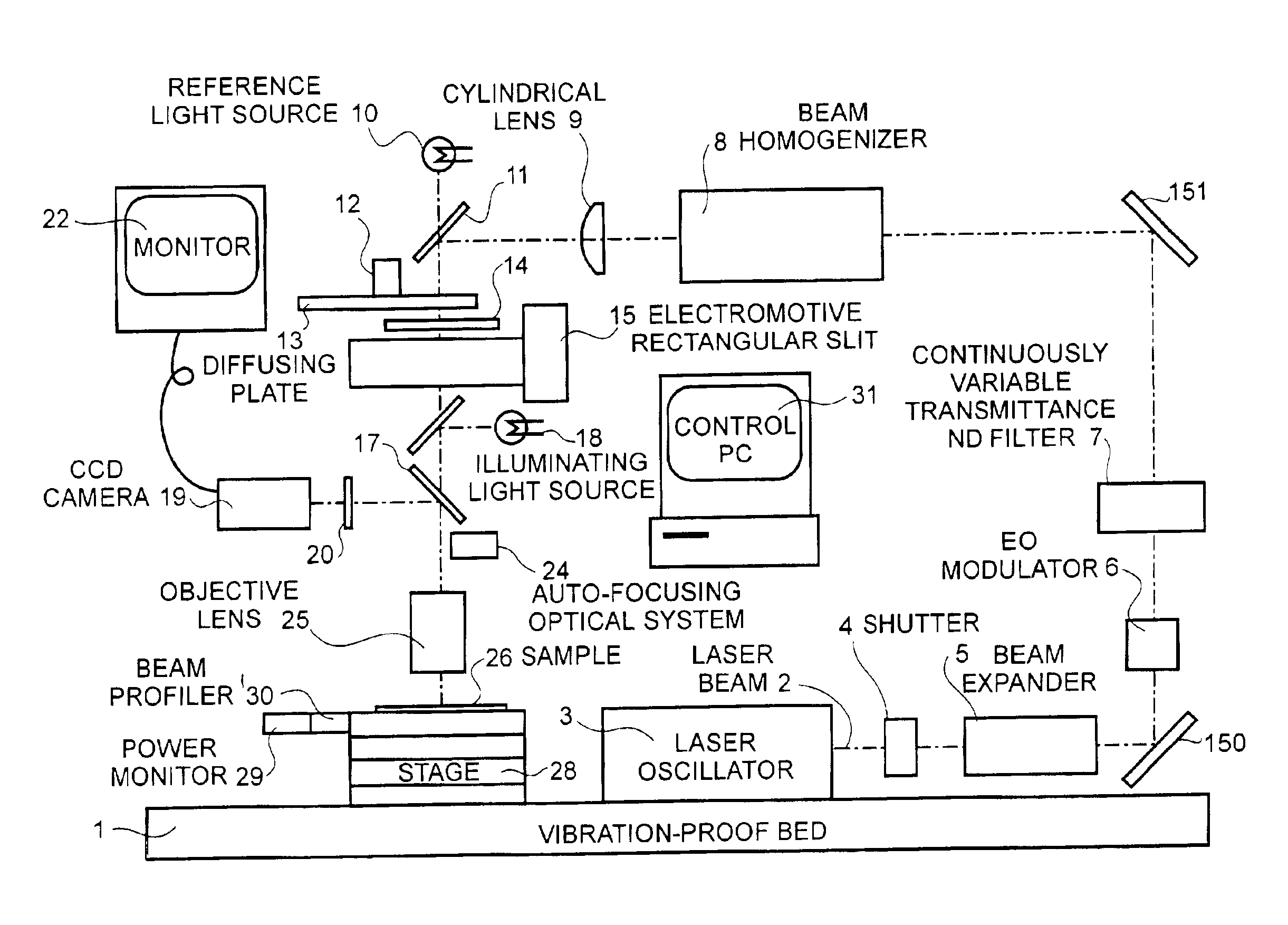

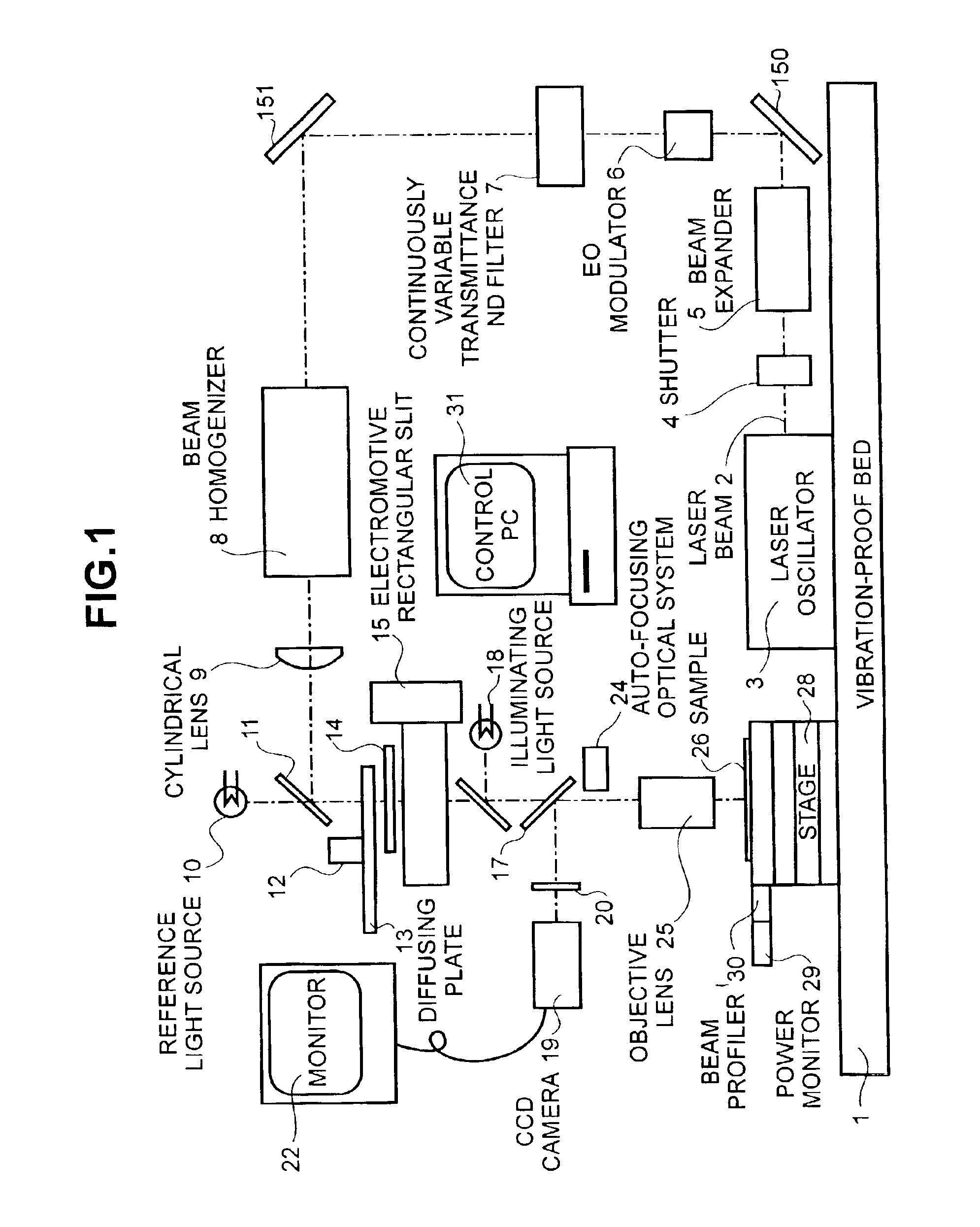

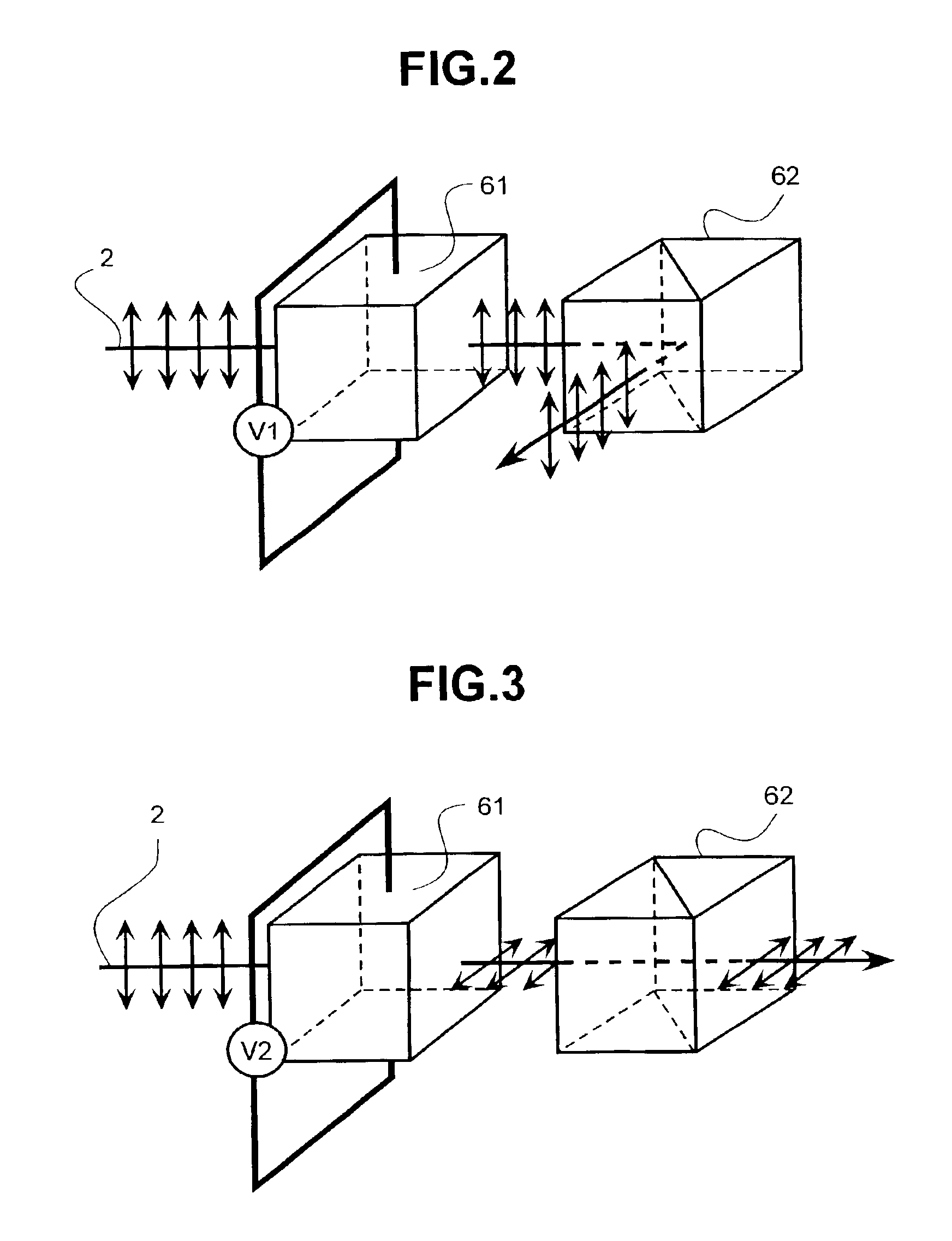

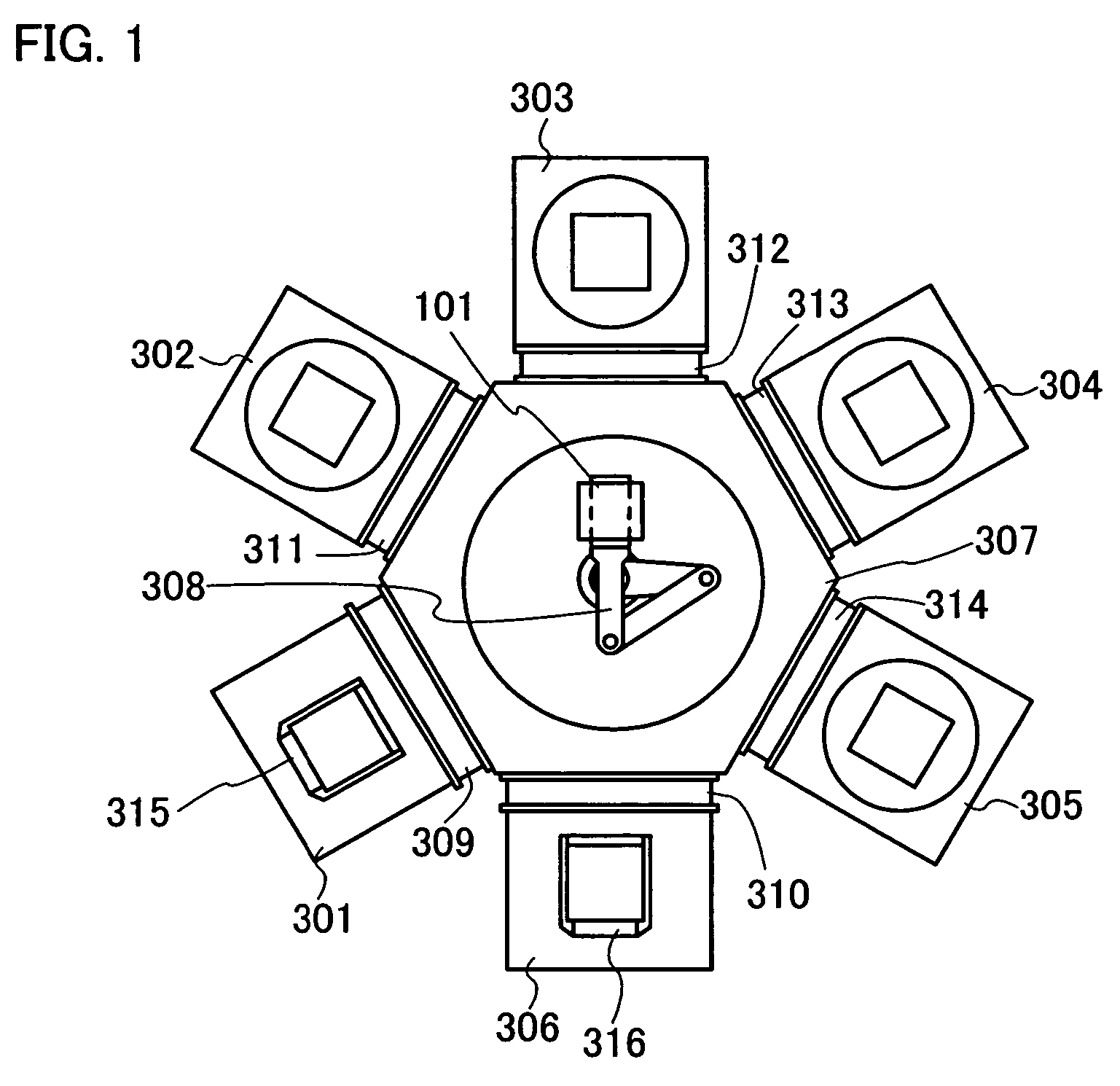

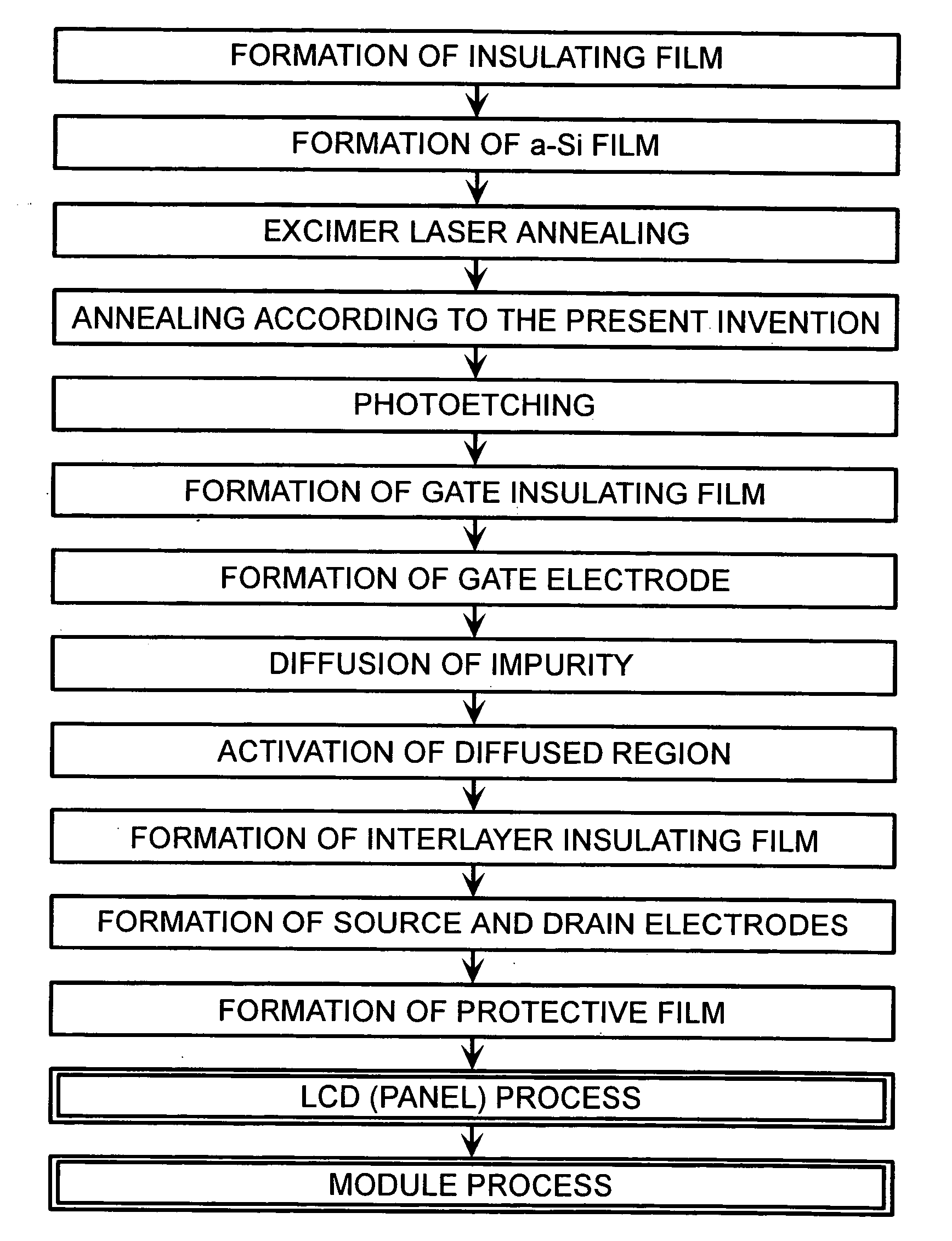

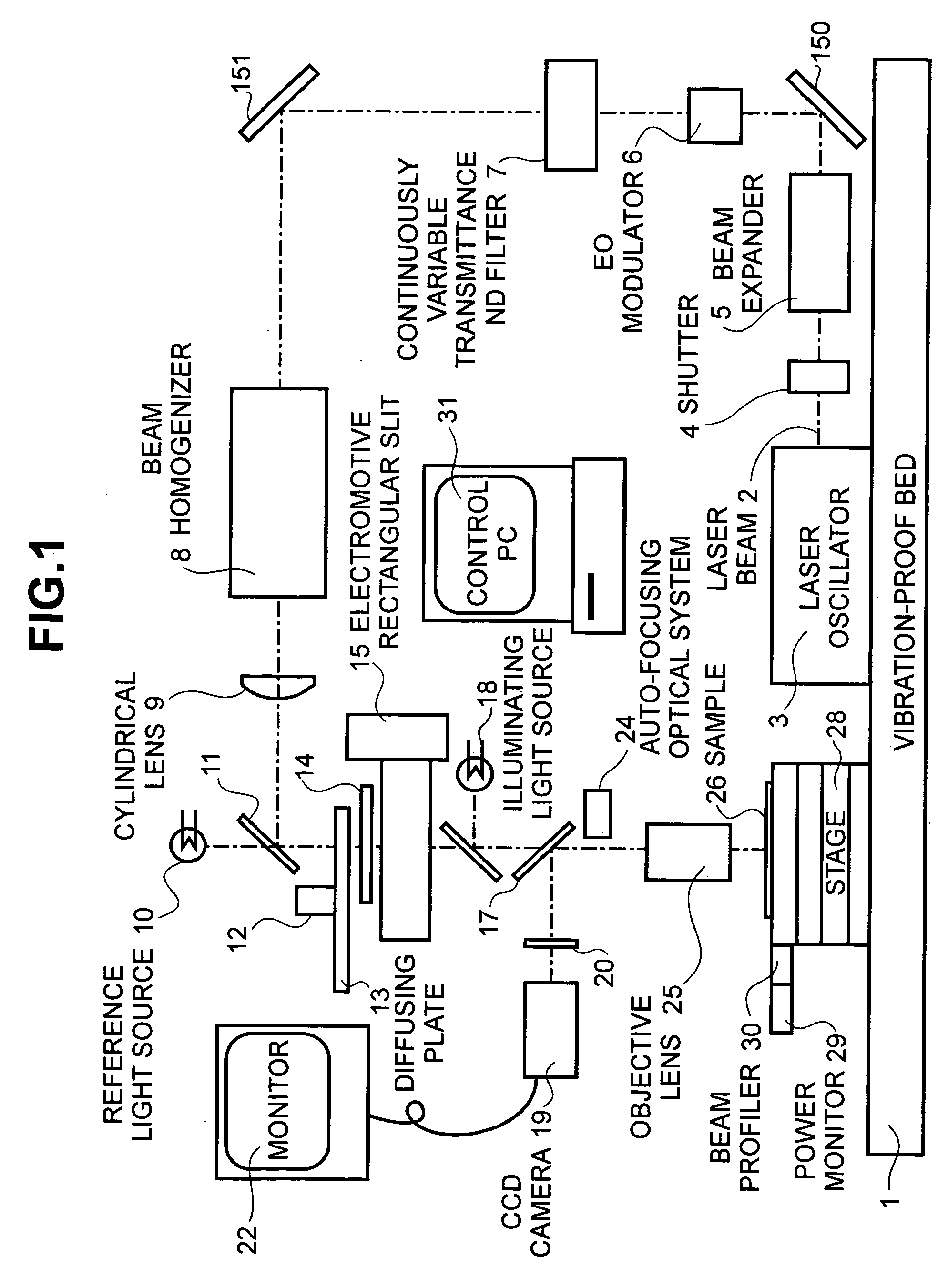

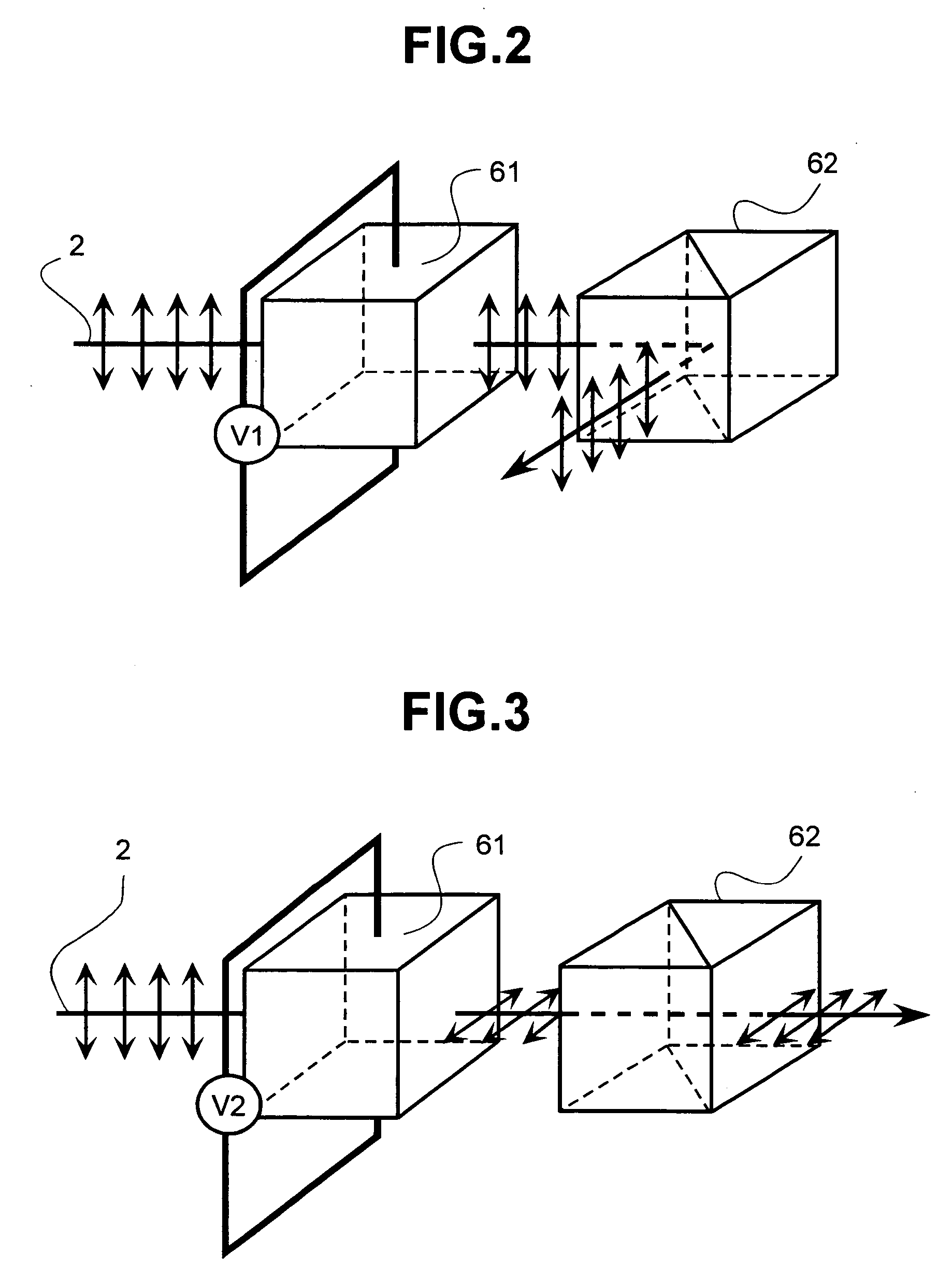

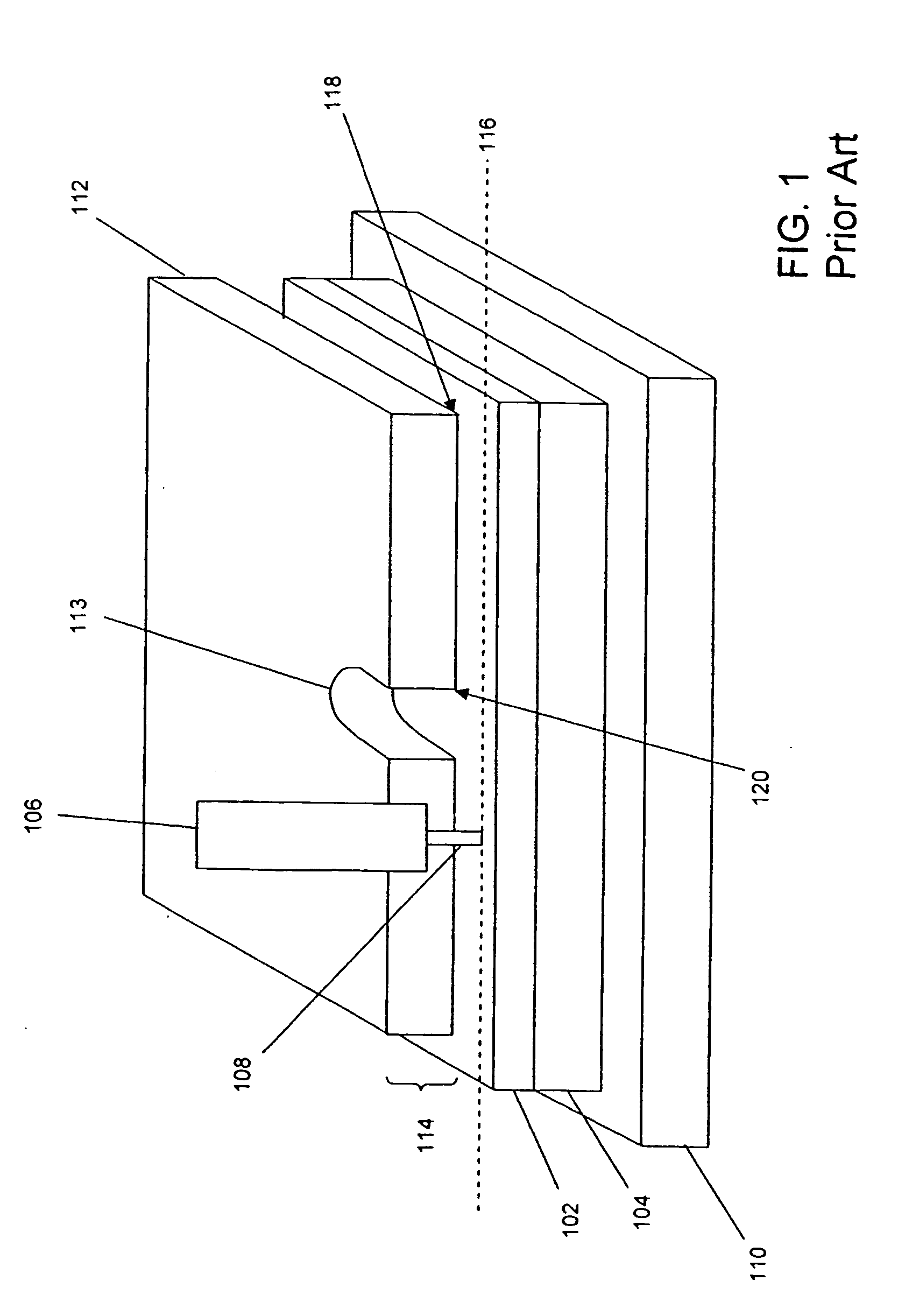

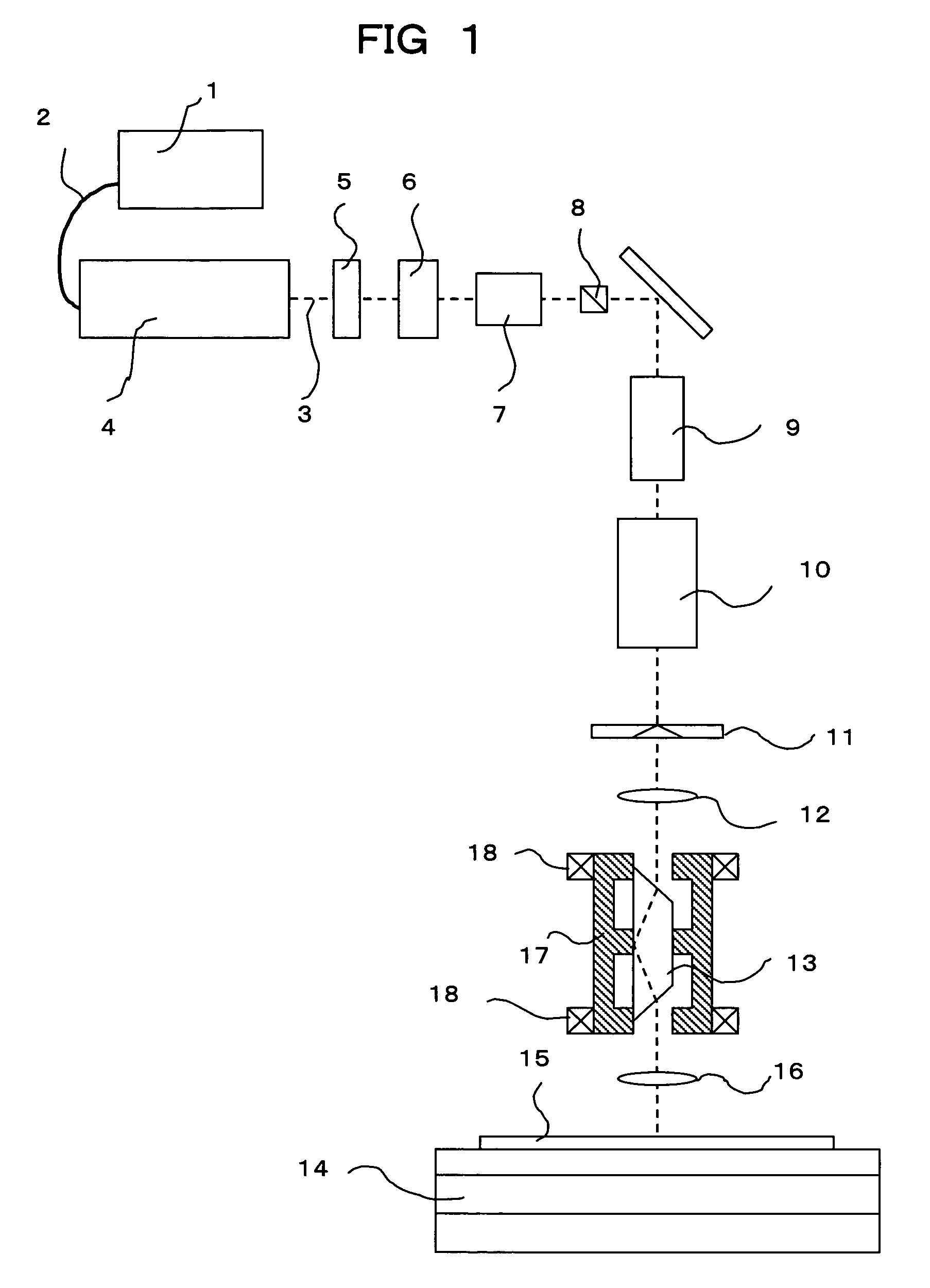

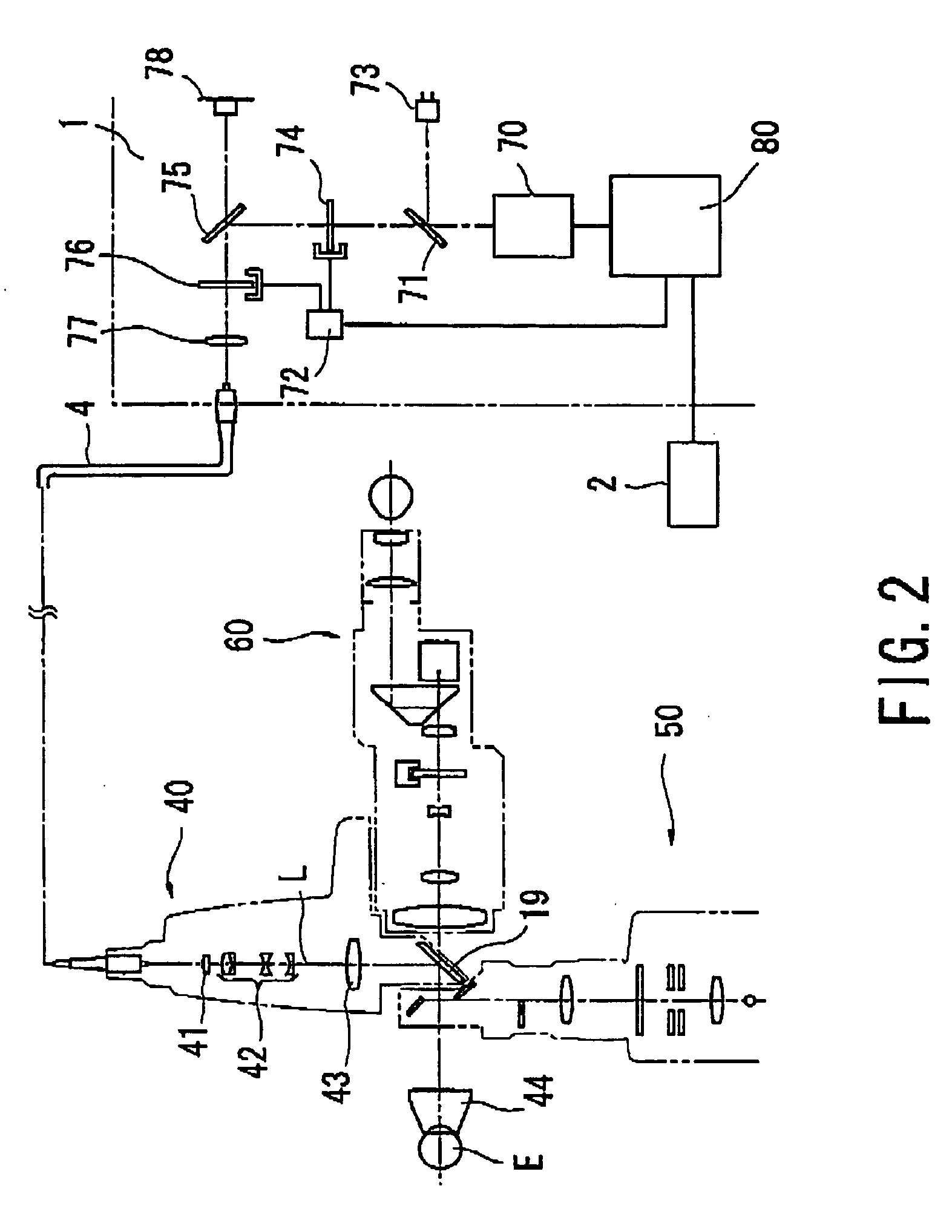

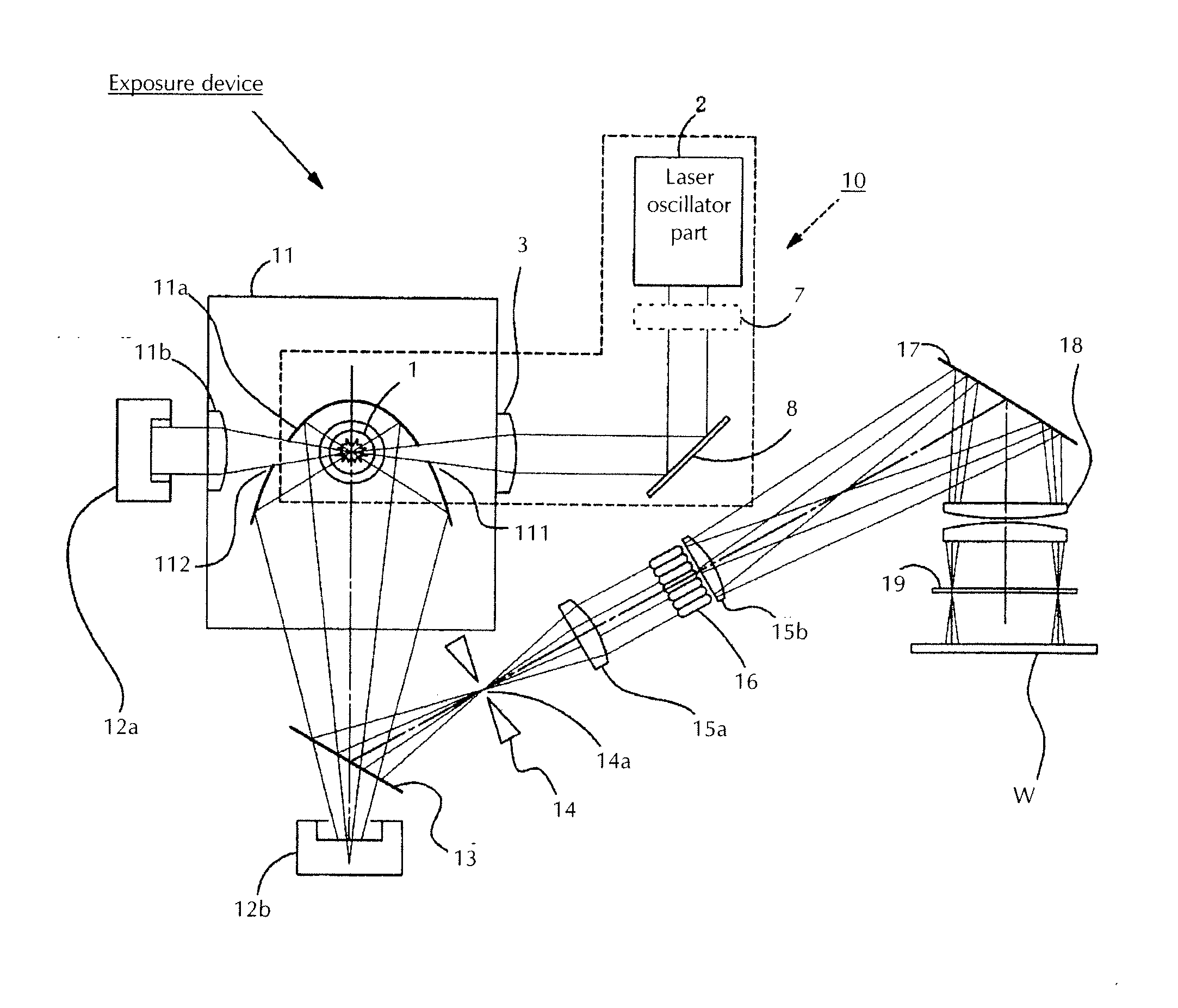

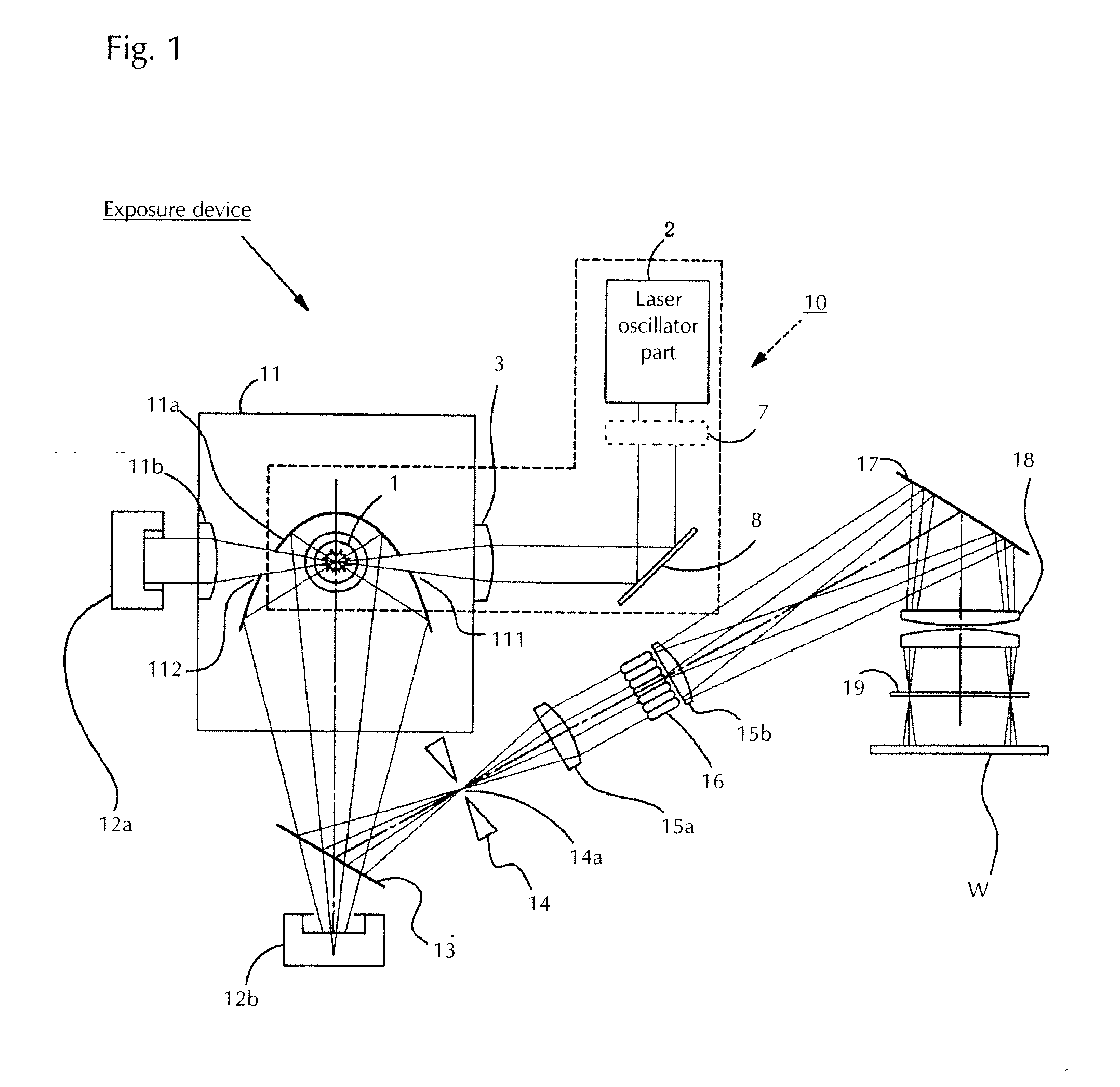

Laser annealing apparatus, TFT device and annealing method of the same

InactiveUS6943086B2Reducing and eliminating influenceTransistorSolid-state devicesEnergy variationSingle crystal

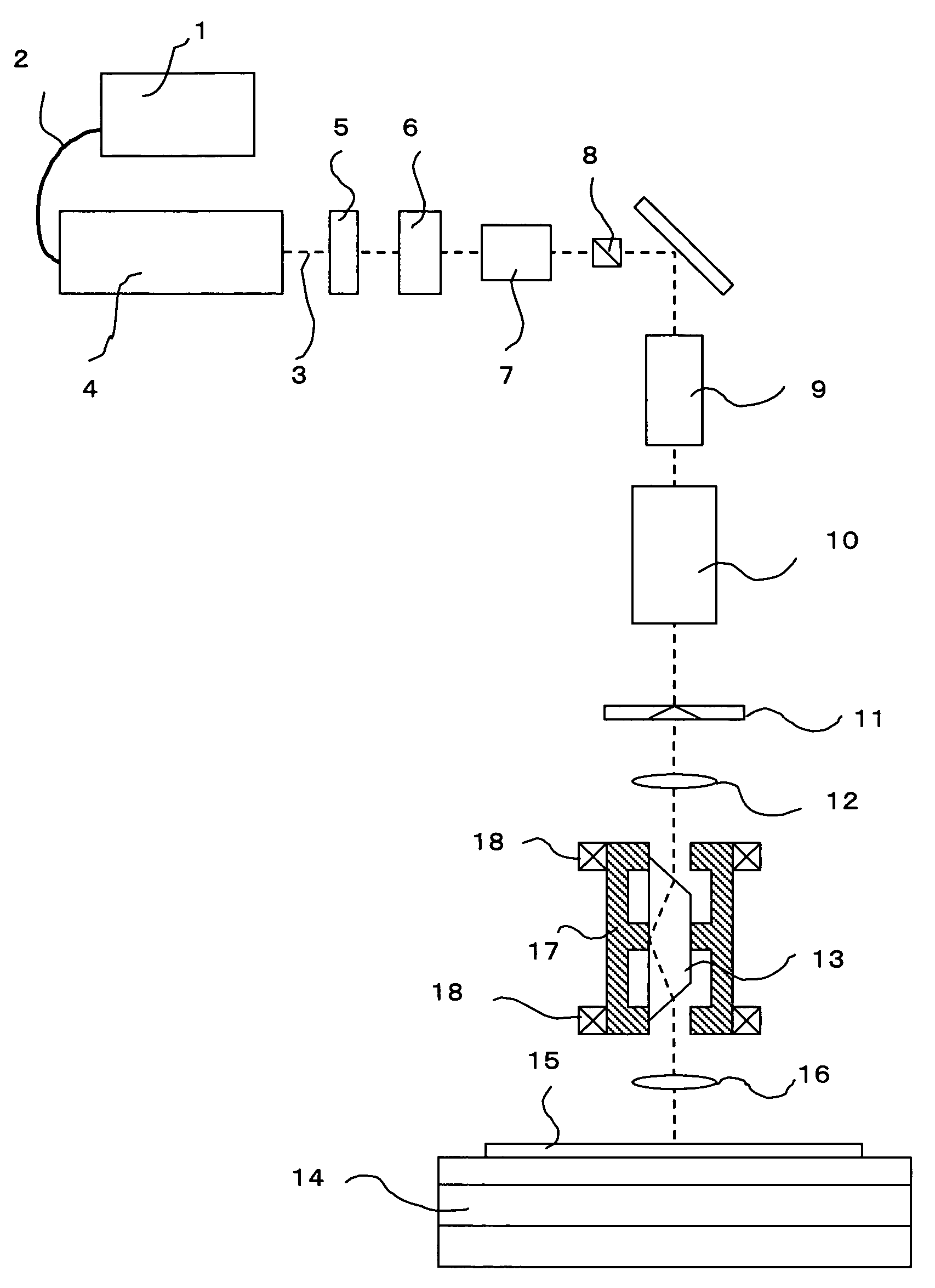

A laser beam is concentrated using an objective lens and radiated on a amorphous silicon film or polycrystalline silicon film having a grain size of one micron or less, the laser beam being processed from a continuous wave laser beam (1) to be pulsed using an EO modulator and to have arbitrary temporal energy change while pulsing ; (2) to have an arbitrary spatial energy distribution using a beam-homogenizer, filter having an arbitrary transmittance distribution, and rectangular slit; and (3) to eliminate coherency thereof using a high-speed rotating diffuser. In this manner, it is possible to realize a liquid crystal display device in which a driving circuit comprising a polycrystalline silicon film having substantially the same properties as a single crystal is incorporated in a TFT panel device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

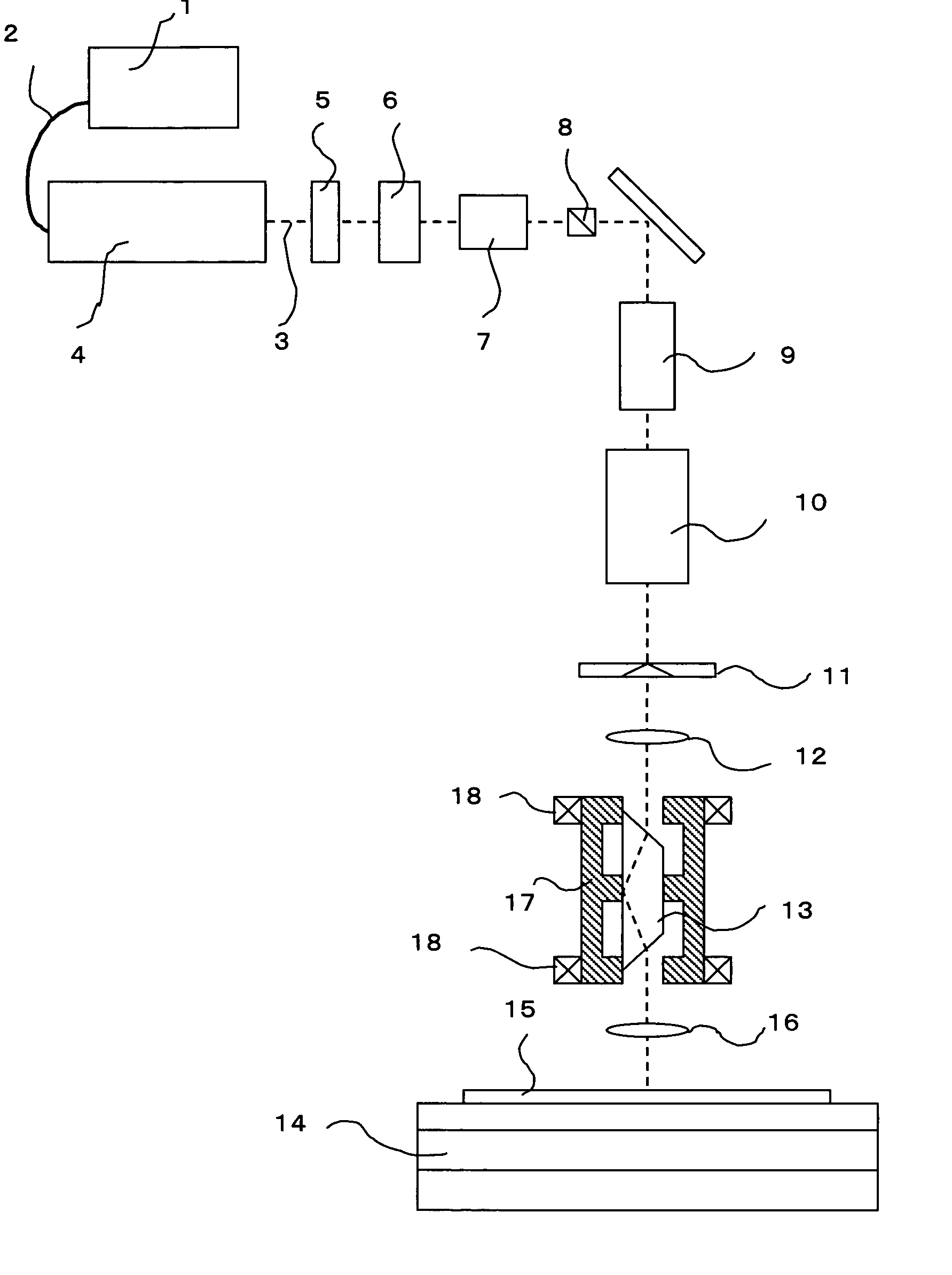

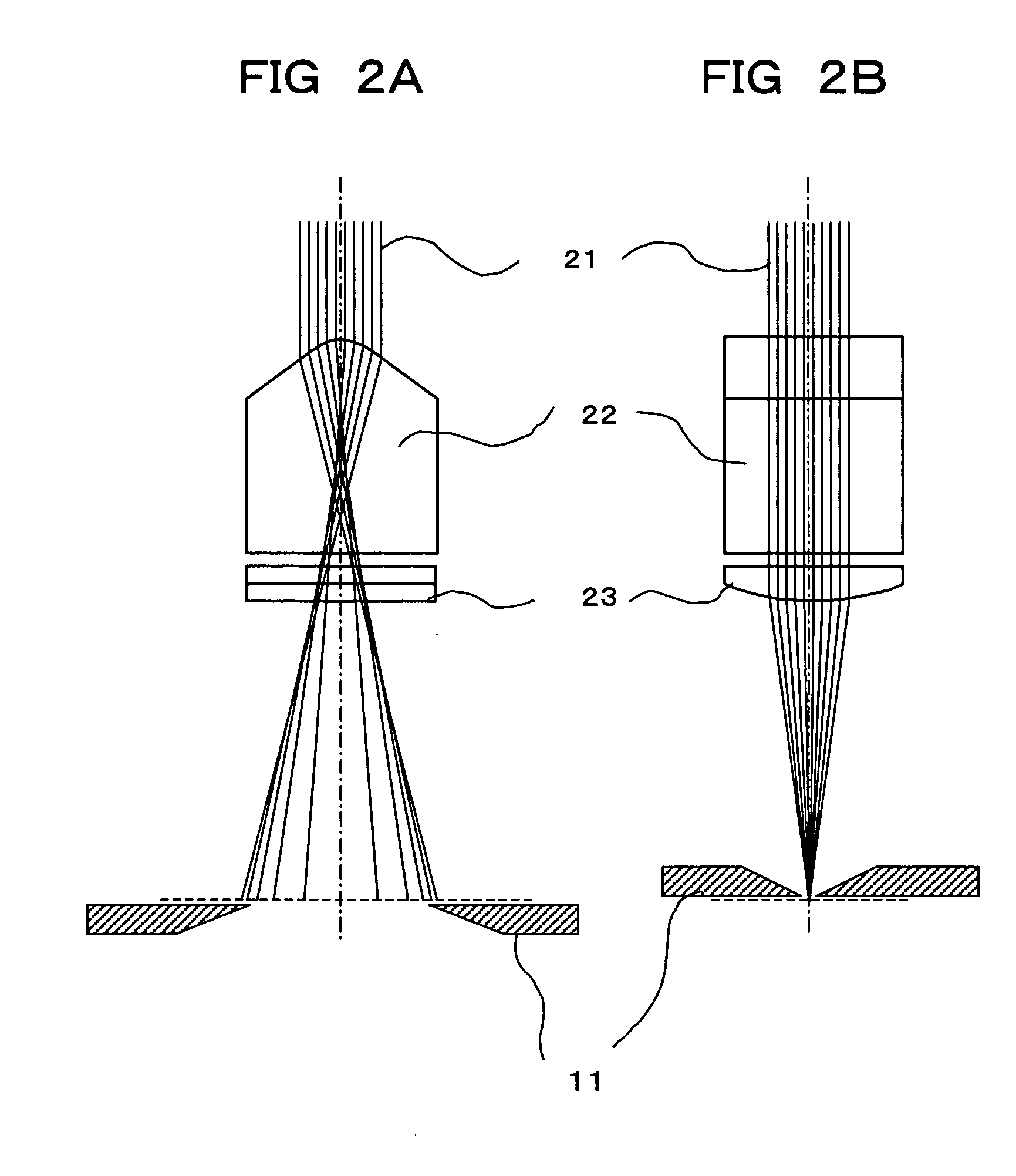

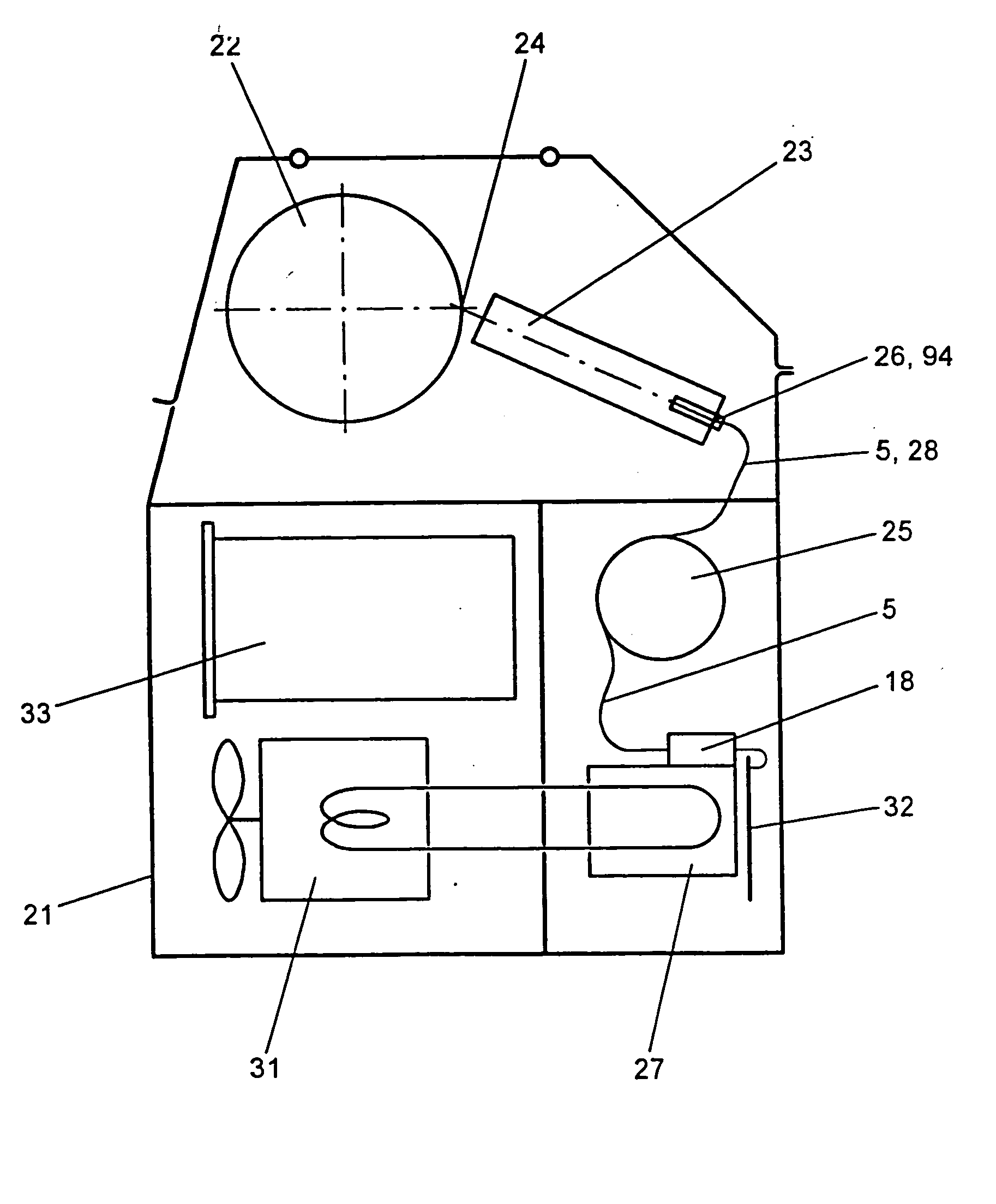

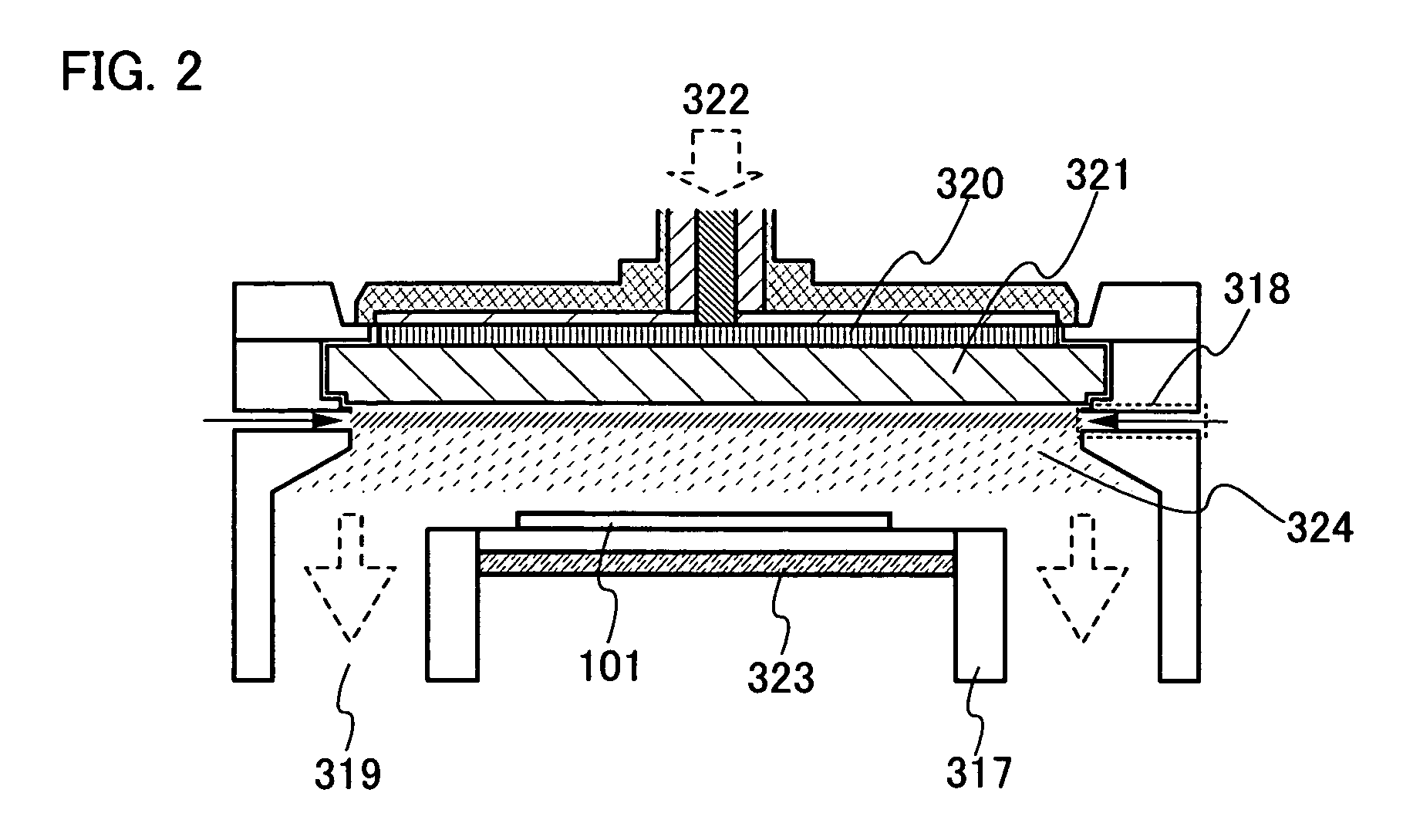

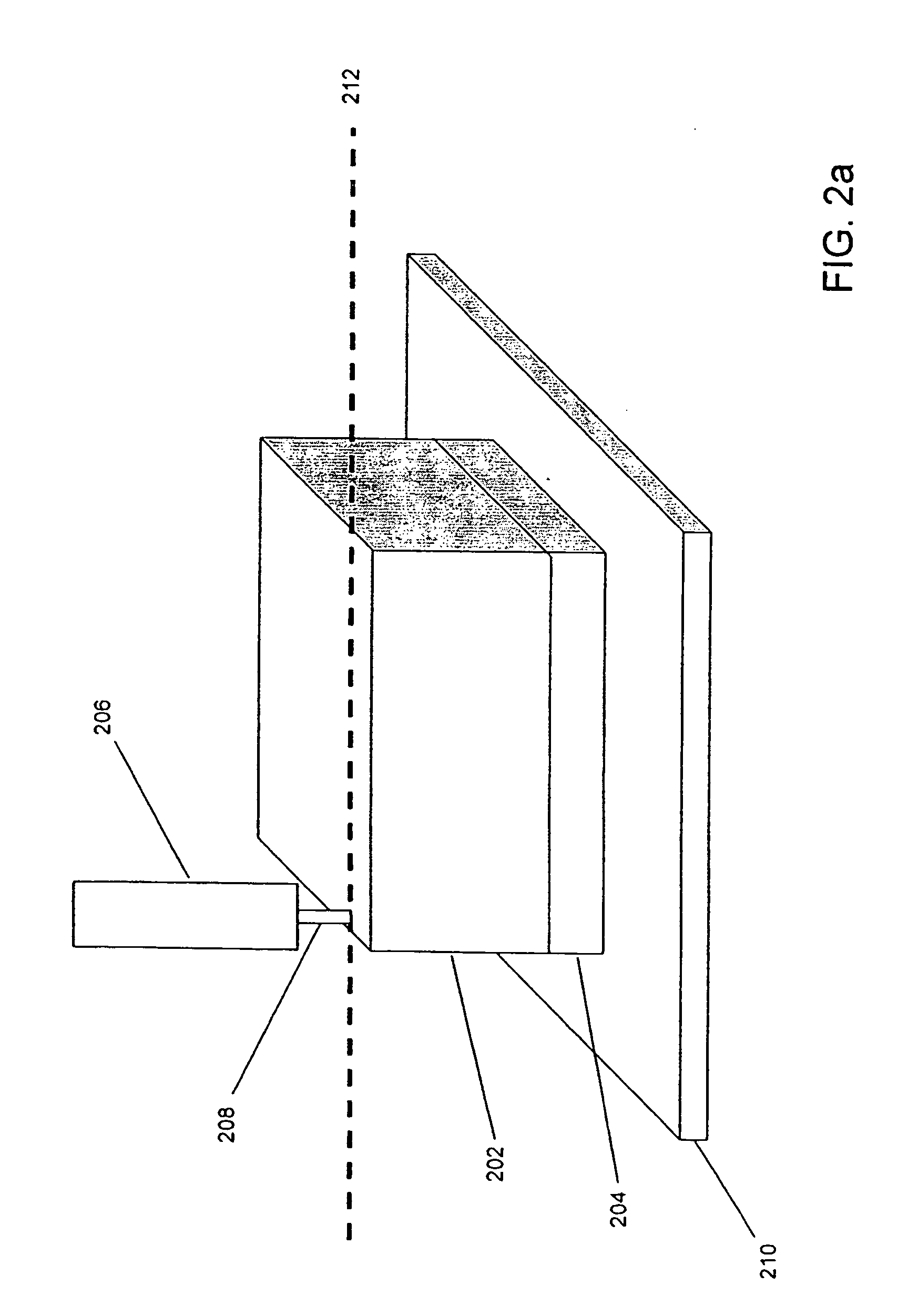

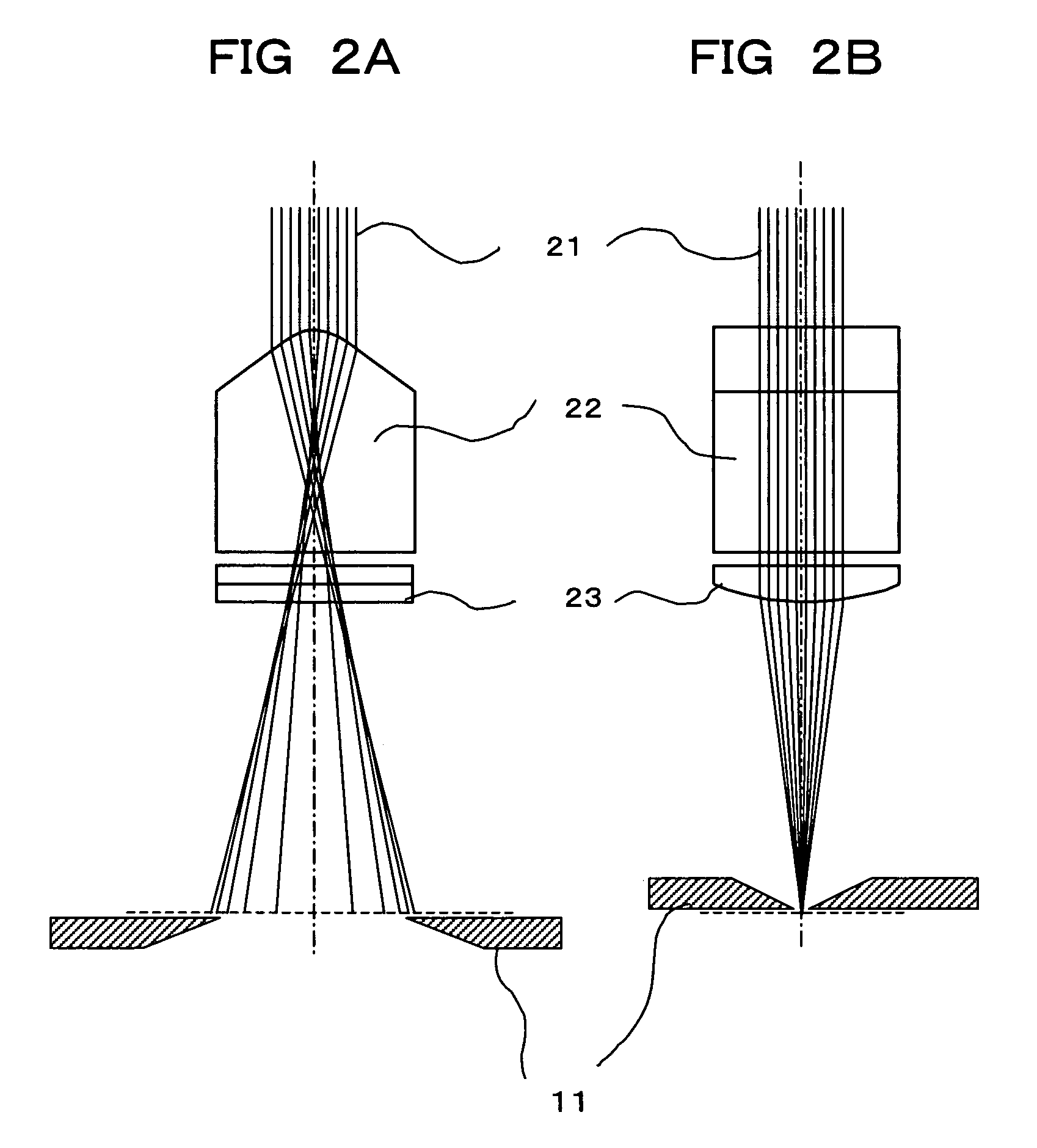

Laser annealing apparatus and annealing method of semiconductor thin film using the same

InactiveUS20050170572A1Prolong lifeCost of apparatus can be reducedLaser detailsElectrode and associated part arrangementsOptical axisLight beam

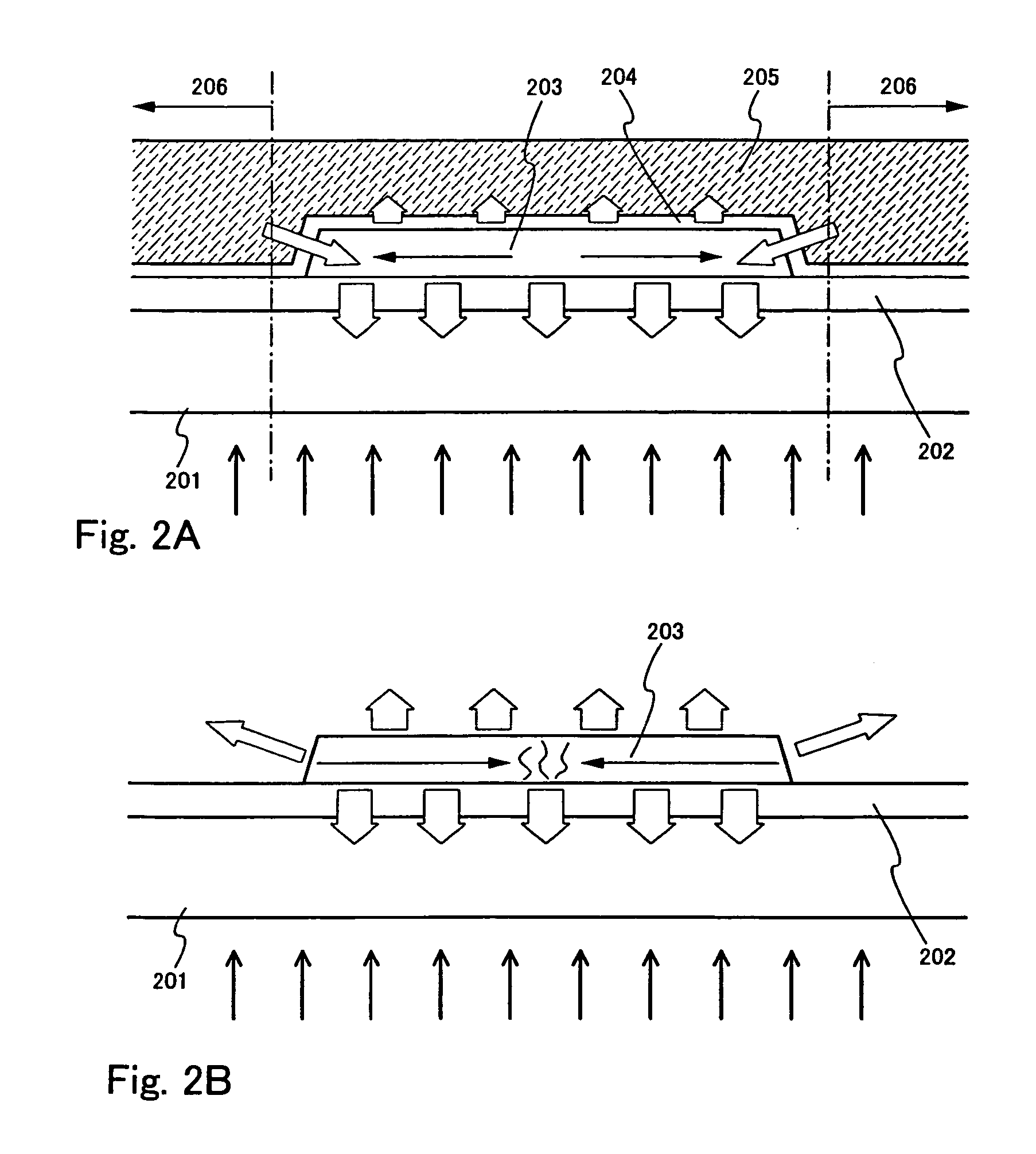

A laser beam temporally modulated in amplitude by a modulator and shaped into a long and narrow shape by a beam shaper is rotated around the optical axis of an image rotator inserted between the beam shaper and a substrate. Thus, the longitudinal direction of the laser beam having the long and narrow shape is rotated around the optical axis on the substrate. In order to perform annealing in a plurality of directions on the substrate, the laser beam shaped into the long and narrow shape is rotated on the substrate while a stage mounted with the substrate is moved only in two directions, that is, X- and Y-directions. In such a manner, the substrate can be scanned at a high speed with a continuous wave laser beam modulated temporally in amplitude and shaped into a long and narrow shape, without rotating the substrate. Thus, a semiconductor film can be annealed.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

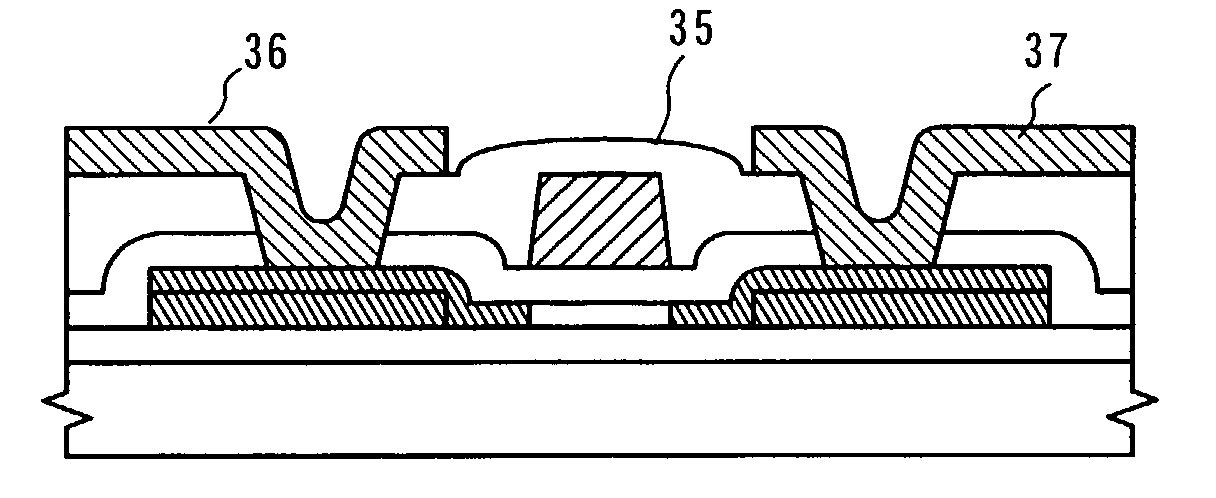

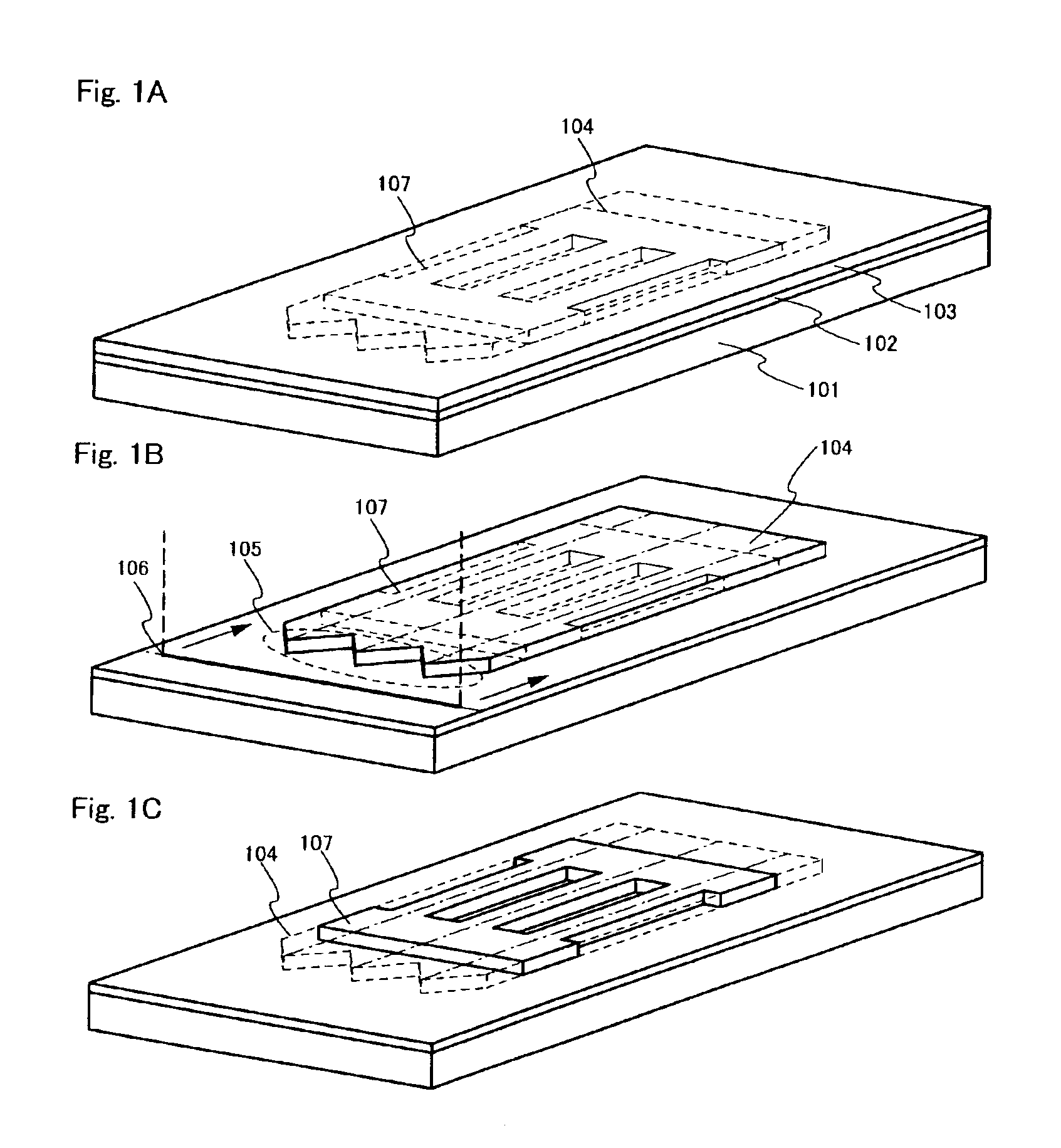

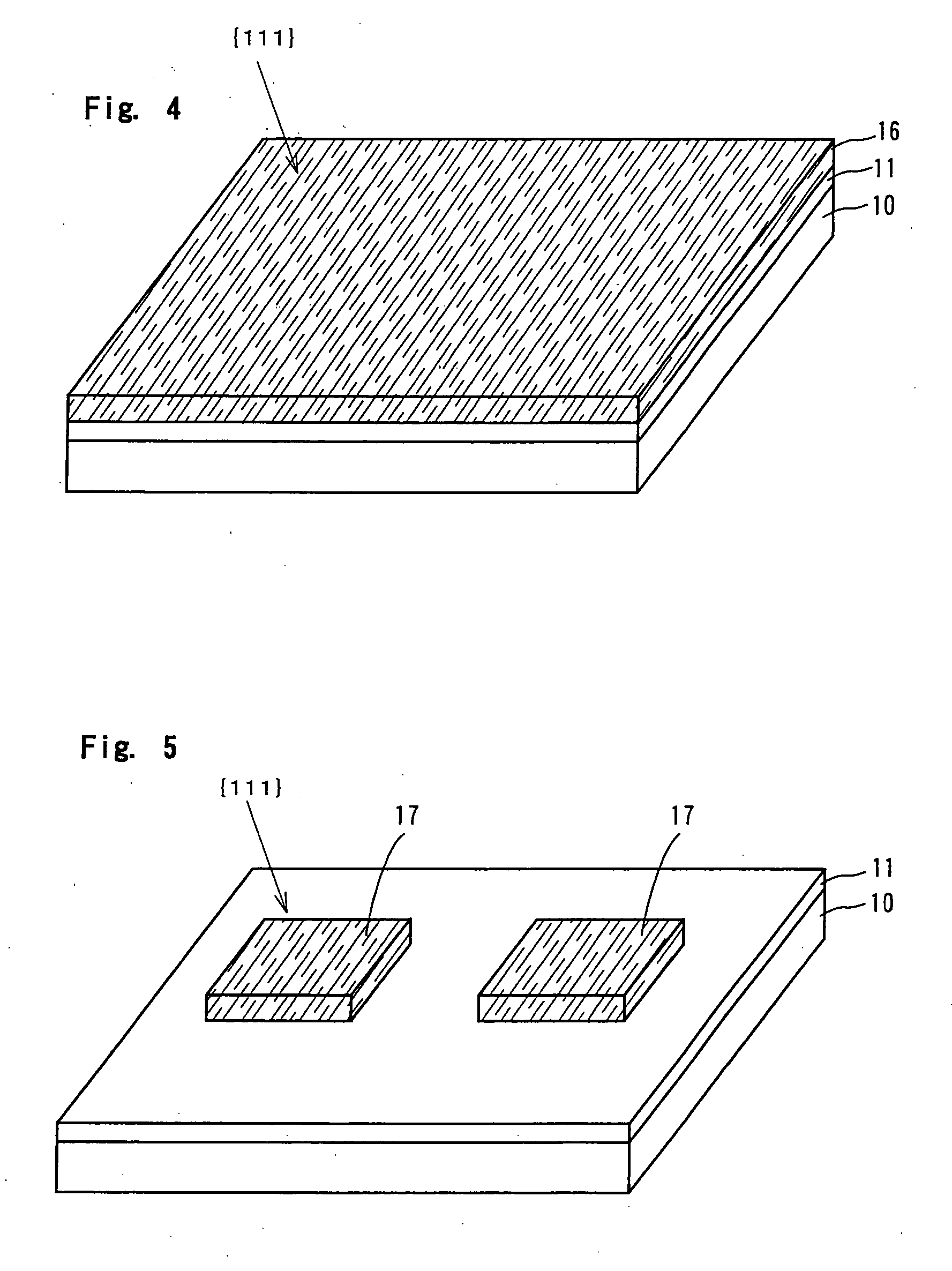

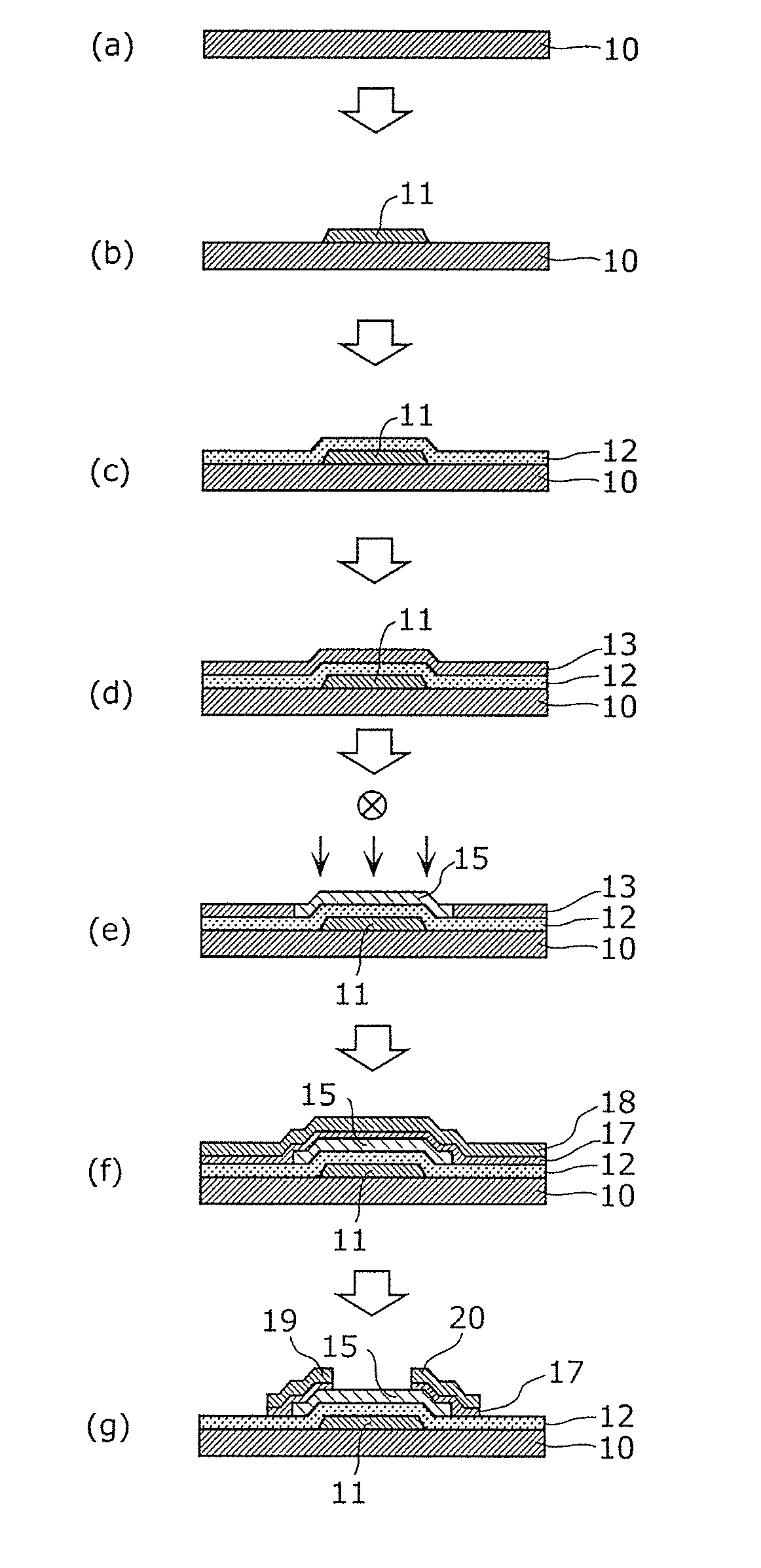

Semiconductor device and method of fabricating the same

InactiveUS7238557B2Improve mobilityImprove featuresTransistorSolid-state devicesDevice materialHigh field

To provide a thin film transistor having a high field effect mobility and a small variation in characteristics thereof, a second amorphous semiconductor layer patterned in a predetermined shape is formed on a first crystalline semiconductor layer 17 for constituting source and drain regions. By irradiating an irradiated region 21 of continuous wave laser beam while scanning along a channel length direction, the second amorphous semiconductor layer is crystallized to form a second crystalline semiconductor layer 22. The first crystalline semiconductor layer 17 is crystallized by selectively adding nickel and therefore, an orientation rate of {111} is increased. By irradiating laser beam, crystals of the second amorphous semiconductor layer grow by constituting a seed by the first crystalline semiconductor layer 17 oriented to {111} and therefore, a region 22a for constituting a channel forming region is also oriented highly to {111} and a direction of a crystal grain boundary becomes parallel with the channel length direction.

Owner:SEMICON ENERGY LAB CO LTD

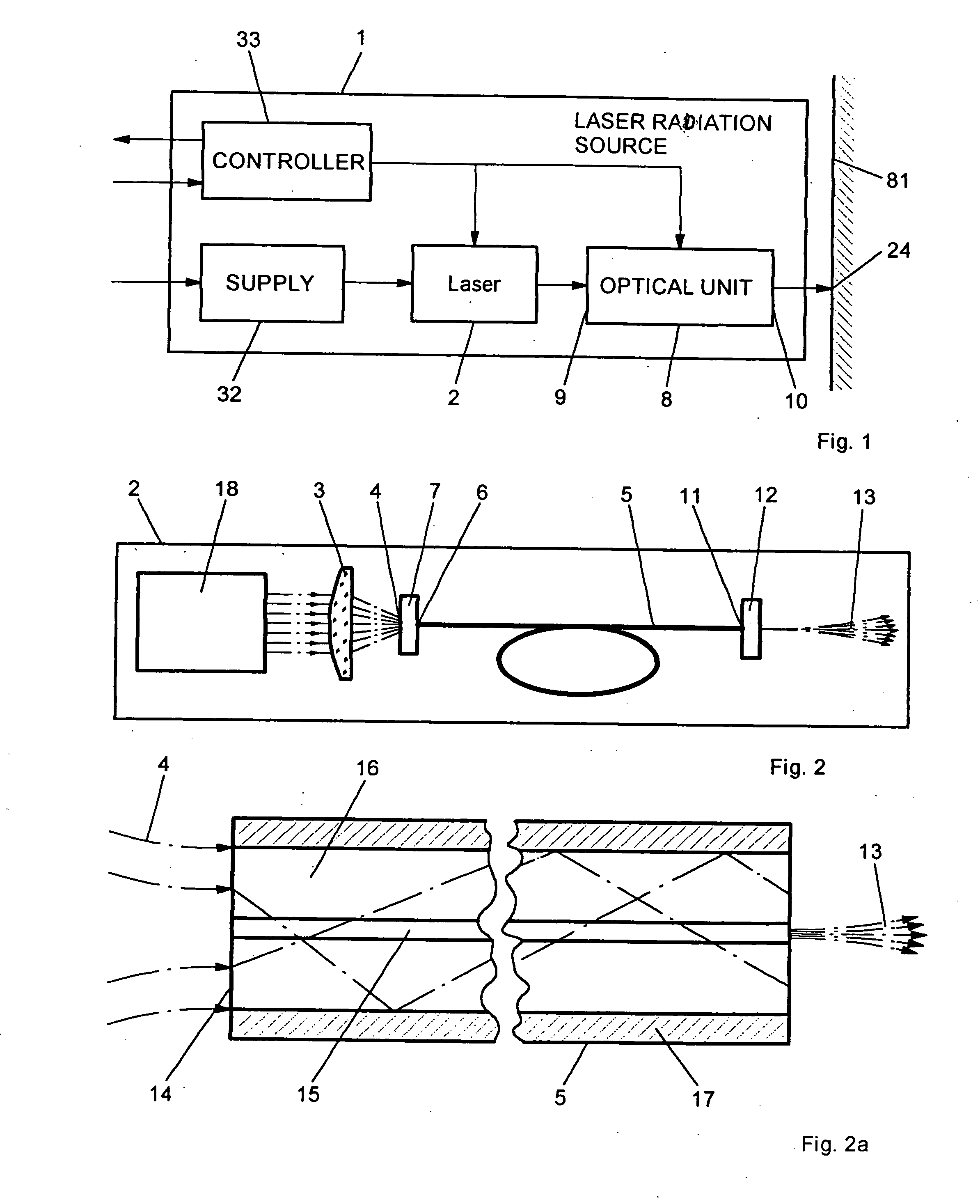

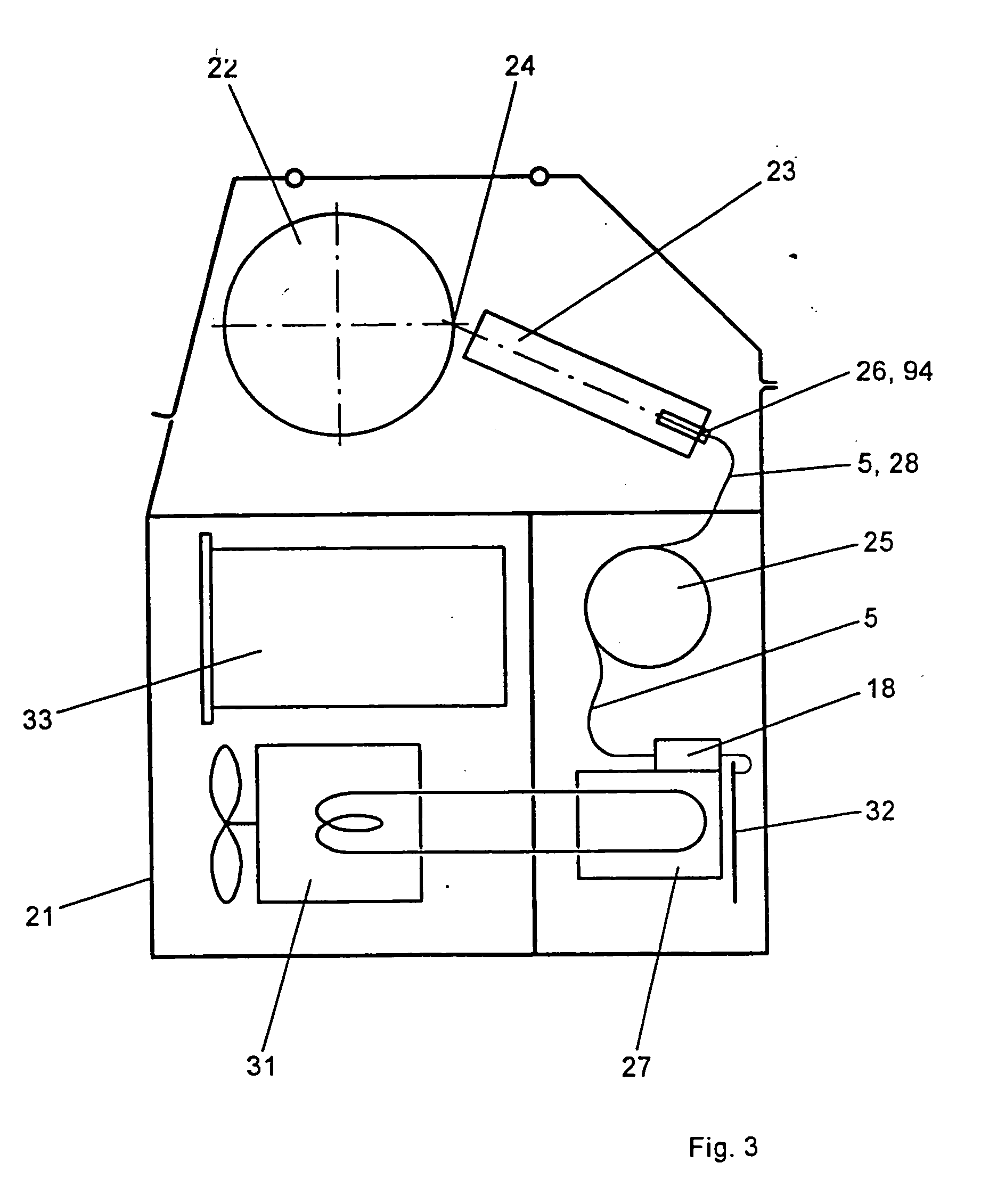

Laser radiation source

InactiveUS20050013328A1High energyImprove power densityLaser using scattering effectsLaser arrangementsFine structureLight beam

In a method and system for processing a processing surface of a material, a mounting receives the material with the processing surface. At least one fiber laser comprising a pump source and a laser fiber has an infeed end, an outfeed end, and a core surrounded by a pump core, the pump source being positioned at the infeed end, and the laser fiber outputting a continuous wave laser beam at the outfeed end. At least one of the laser beam and the processing surface are laterally movable with respect to each other. A focusing optics is provided through which the laser beam passes. The laser beam output from the laser fiber is diffraction-limited to permit the focusing optics to focus the laser beam onto the processing surface as a spot having a spot size sufficiently small to create a fine structure by processing material at the processing surface.

Owner:HELL GRAVURE SYST

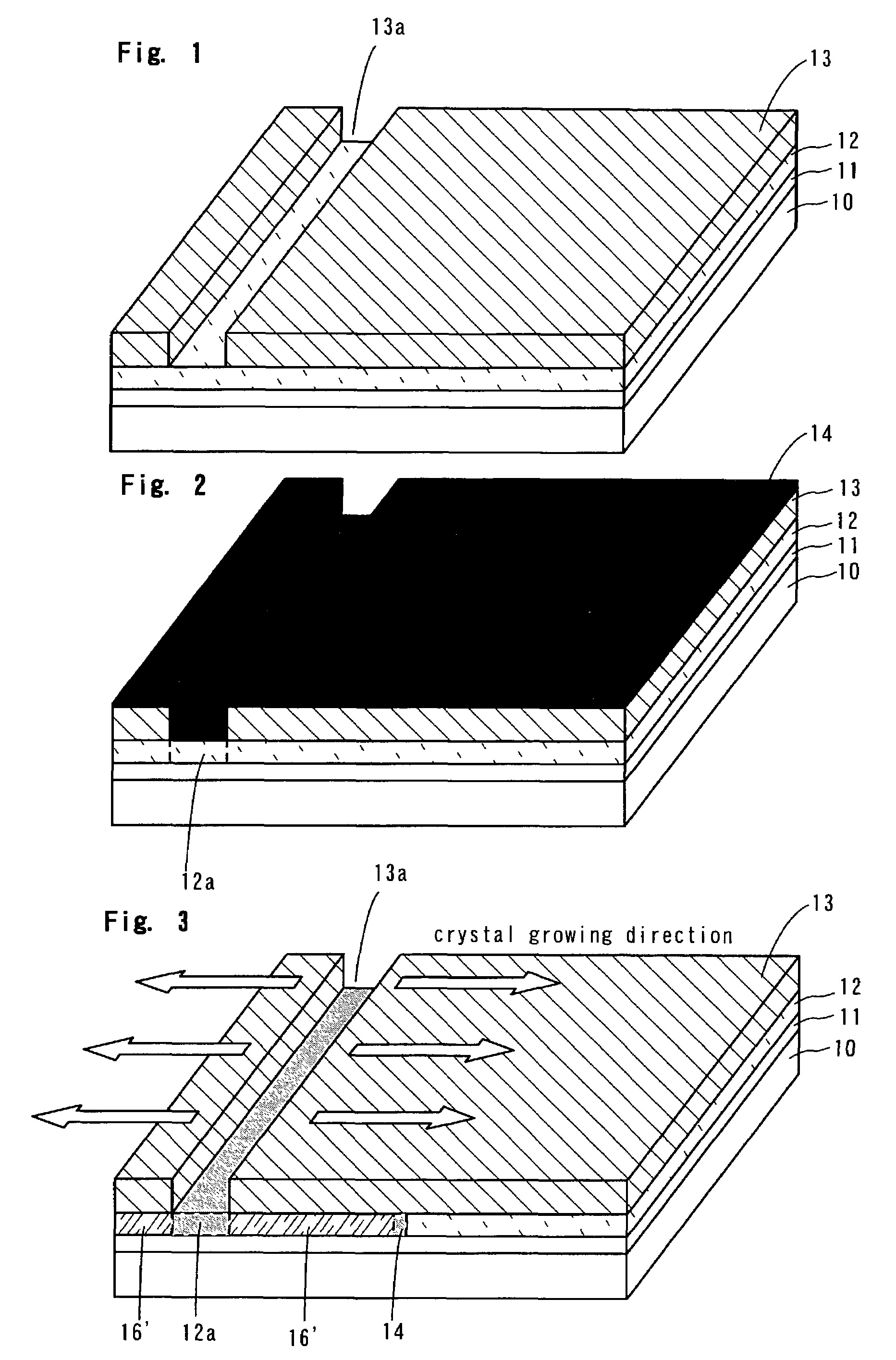

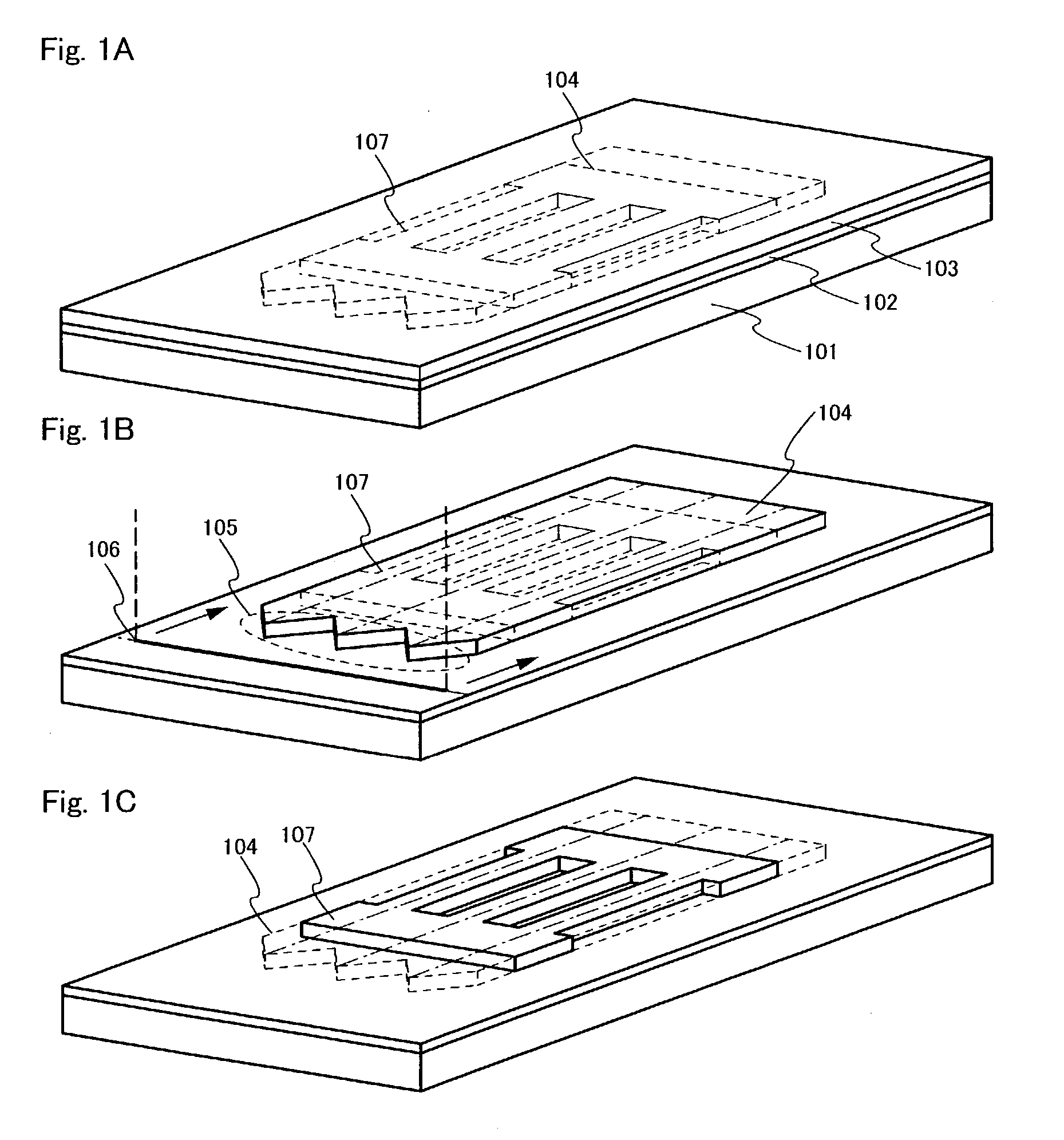

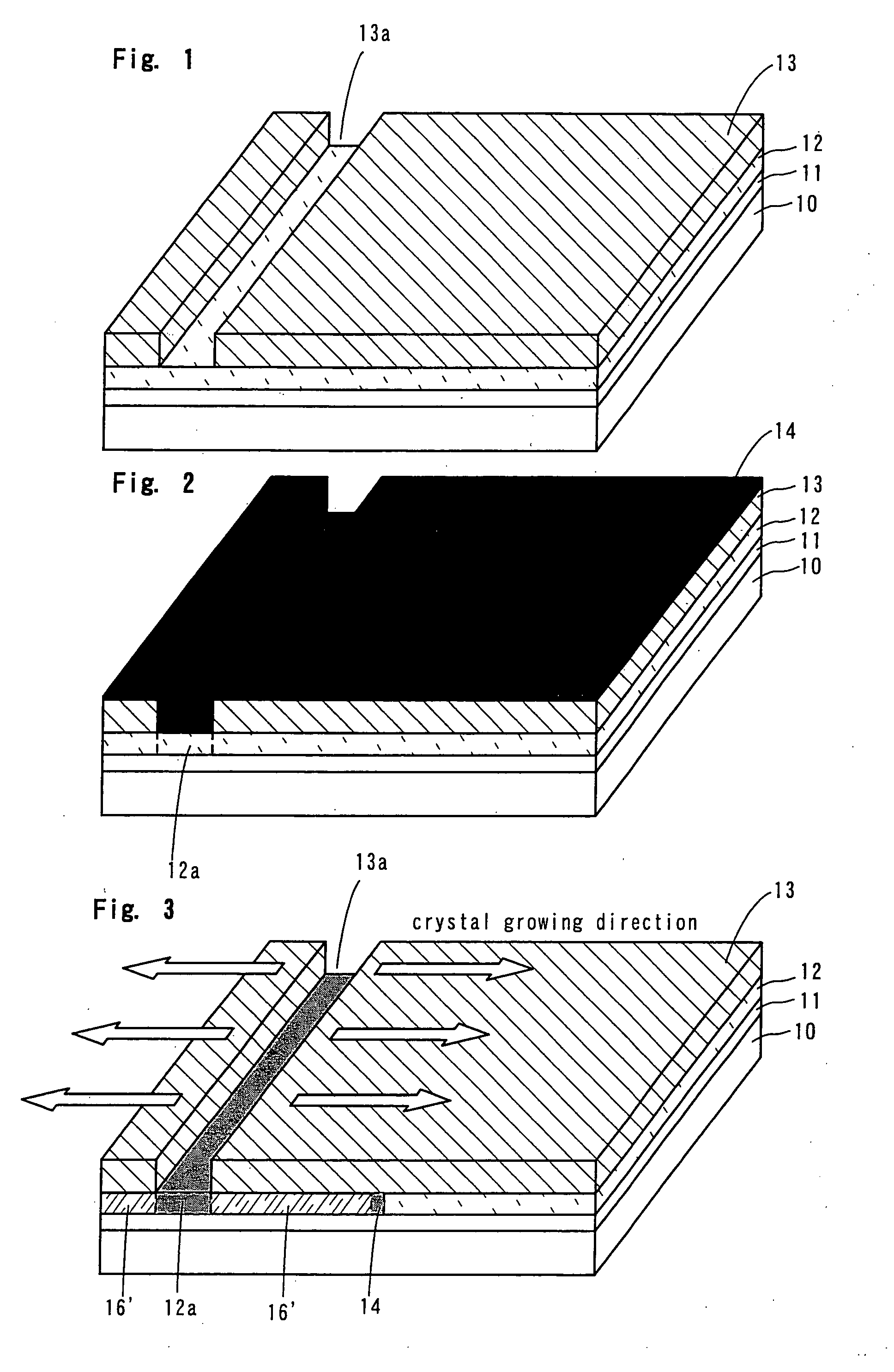

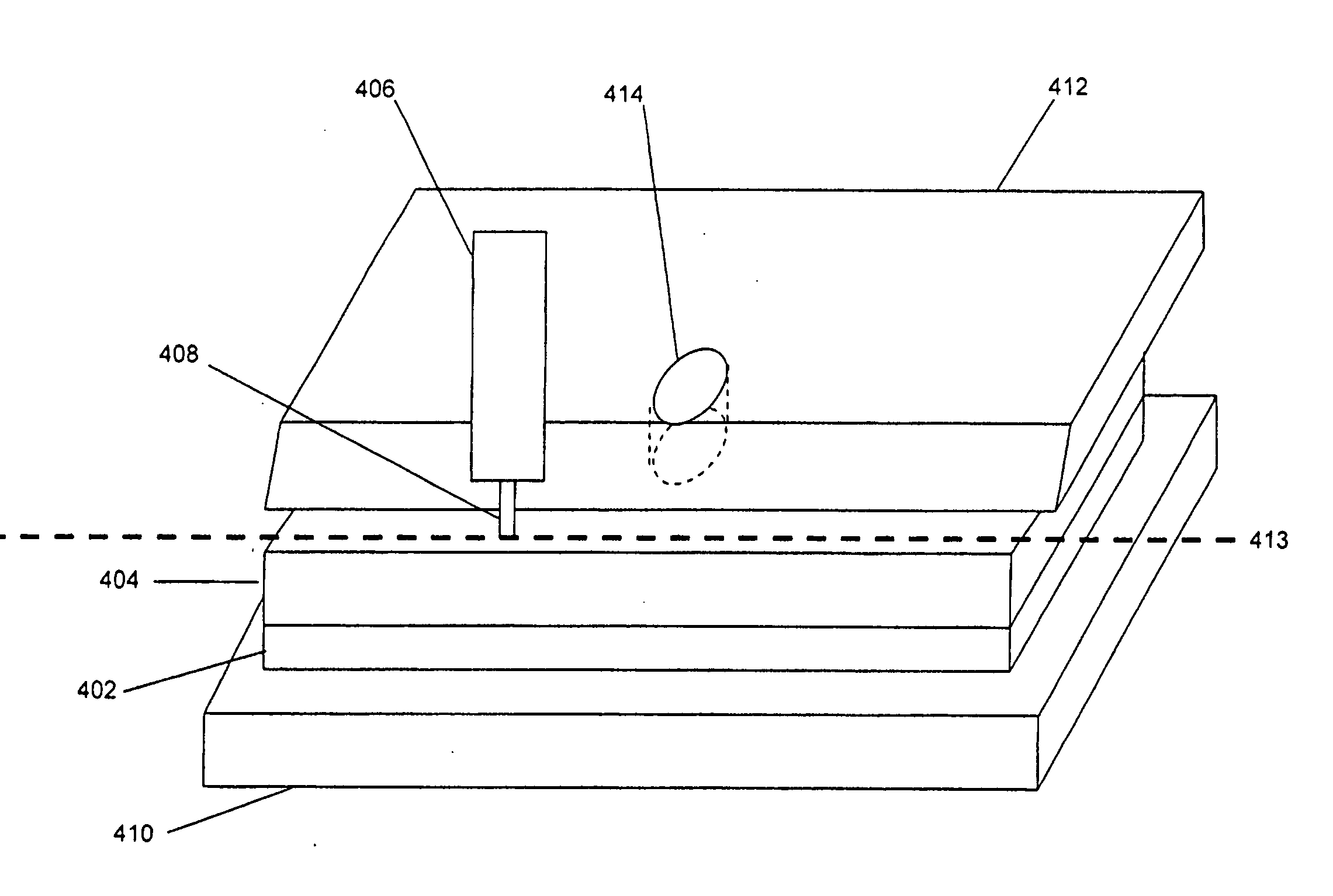

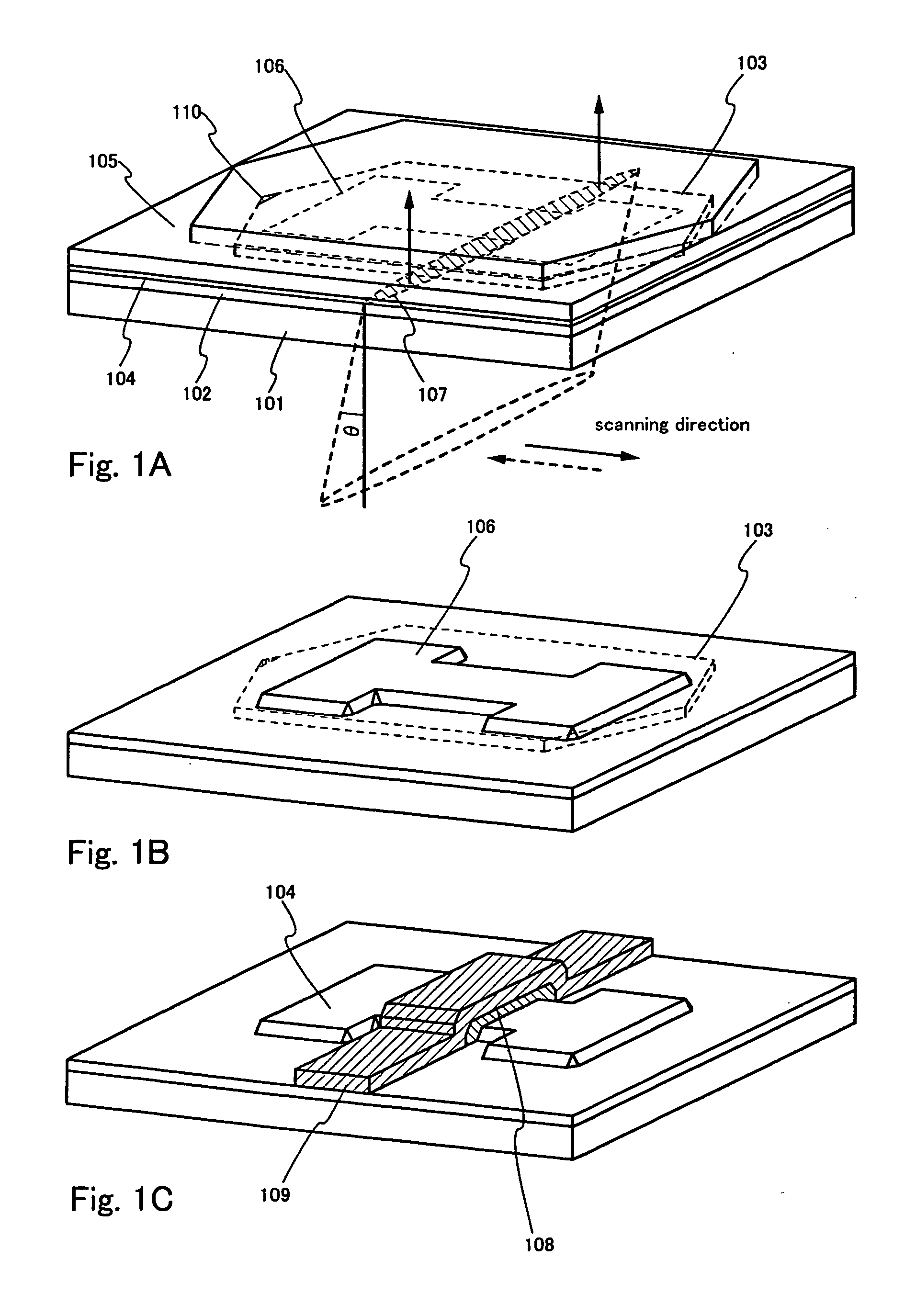

Method of manufacturing a semiconductor device by crystallization of a semiconductor region by use of a continuous wave laser beam through the substrate

InactiveUS7132375B2Enlarge regionImprove featuresTransistorSolid-state devicesCrystal orientationActive layer

A technique is provided for forming a crystalline semiconductor film whose orientation is uniform by control of crystal orientation and obtaining a crystalline semiconductor film in which concentration of an impurity is reduced. A configuration of the invention is that a first semiconductor region is formed on a substrate having transparent characteristics of a visible light region, a barrier film is formed over the first semiconductor region, a heat retaining film covering a top and side surfaces of the first semiconductor region is formed over the barrier film, the first semiconductor region is crystallized by scanning a continuous wave laser beam from one edge of the first semiconductor region to the other through the substrate, then the heat retaining film and the barrier film are removed and a second semiconductor region is formed as an active layer of TFT by etching the crystallized first semiconductor region. A pattern of the second semiconductor region formed by etching is formed in a manner that a scanning direction of the laser beam and a channel length direction of the TFT are arranged in almost the same direction in order to smooth drift of carriers.

Owner:SEMICON ENERGY LAB CO LTD

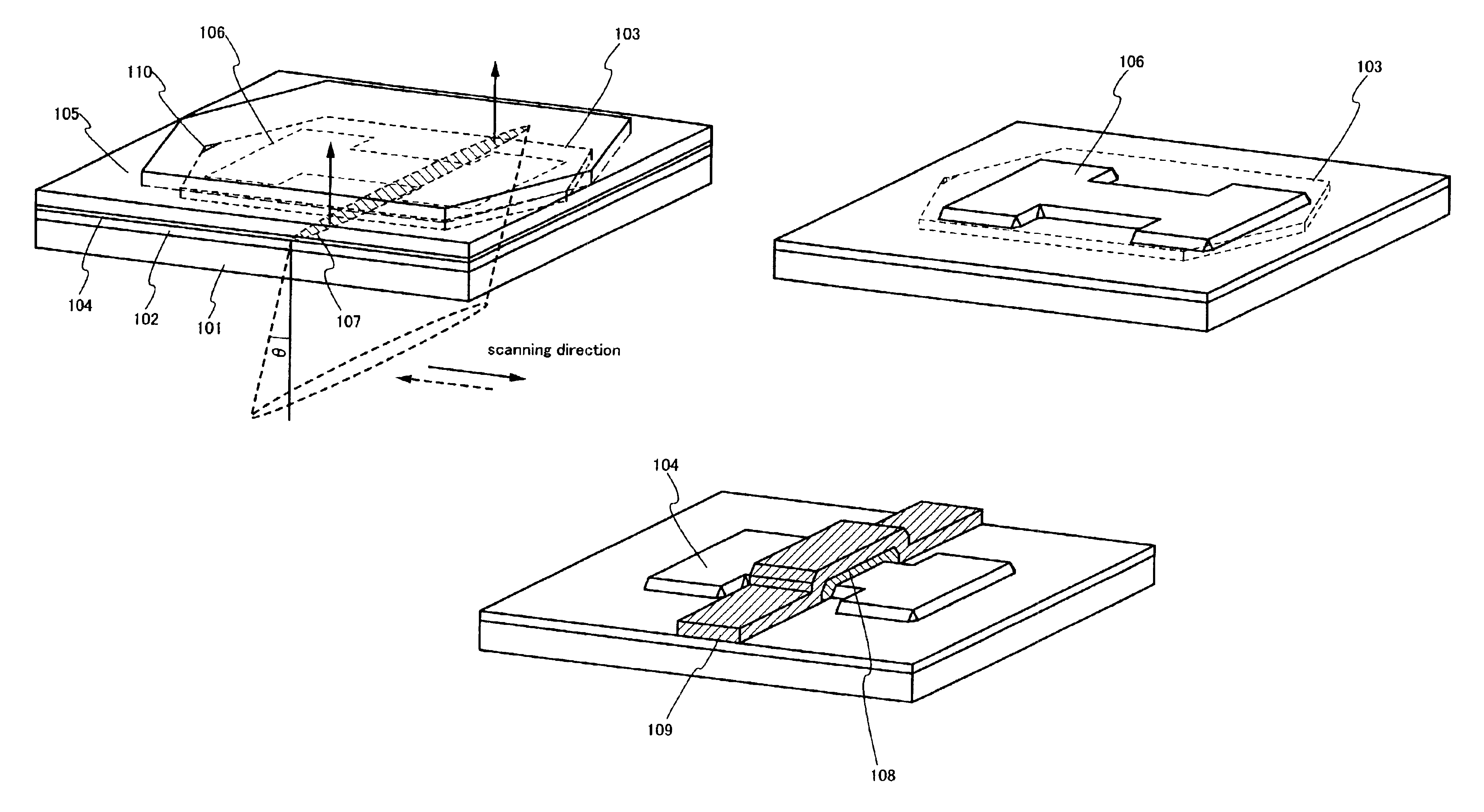

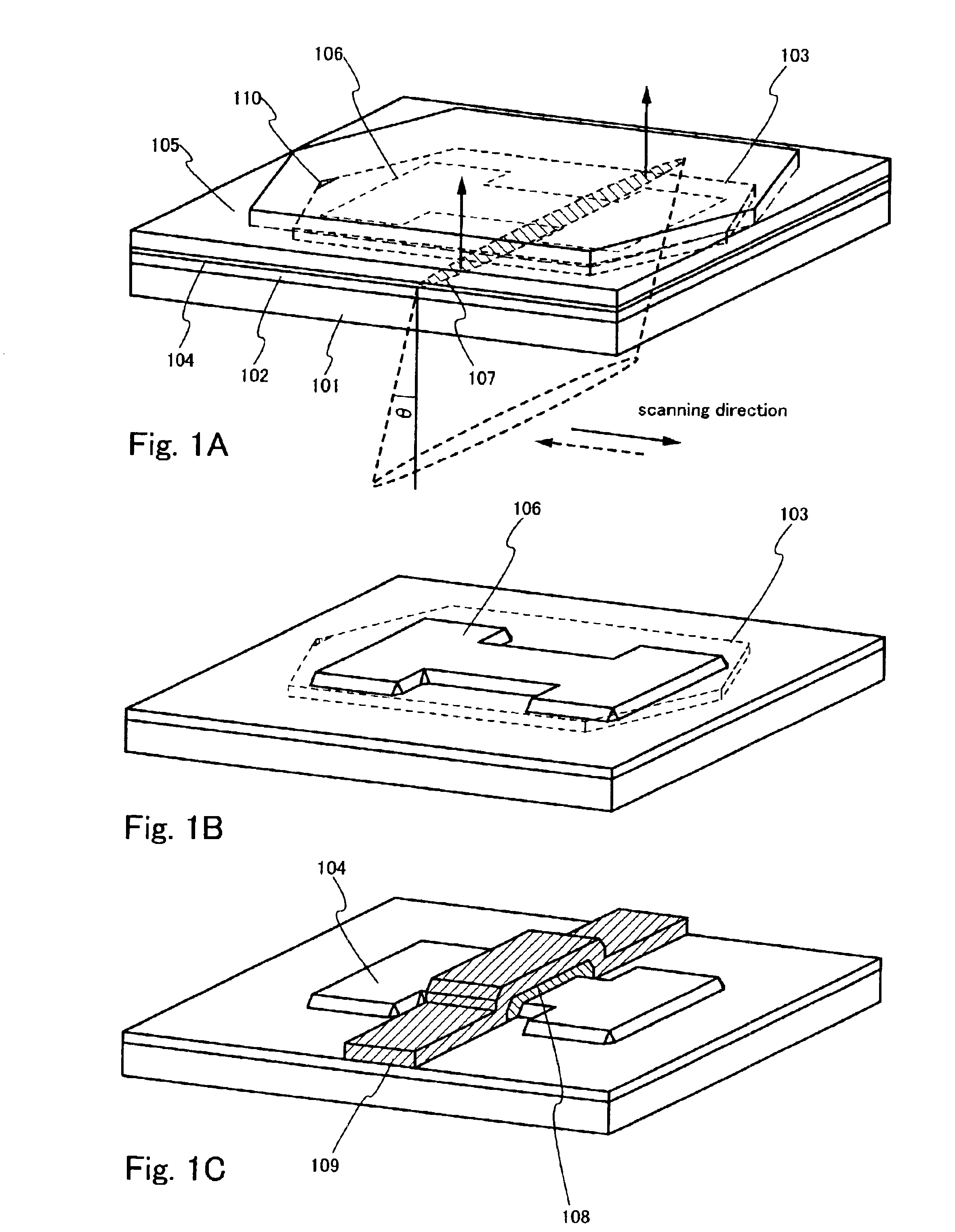

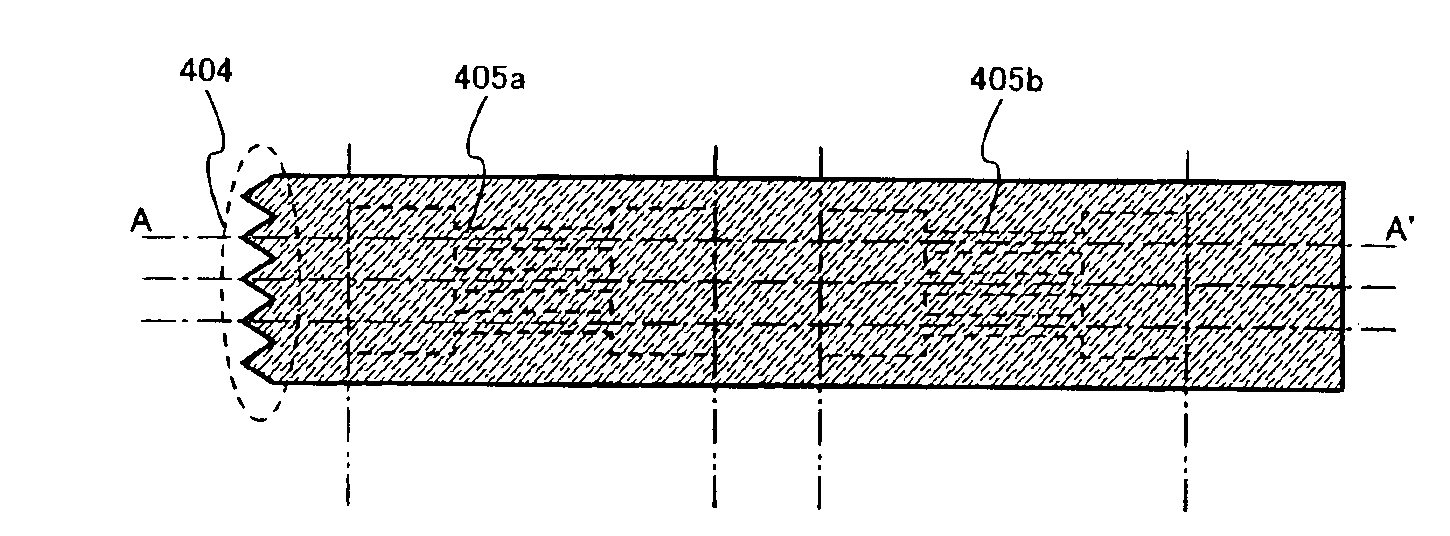

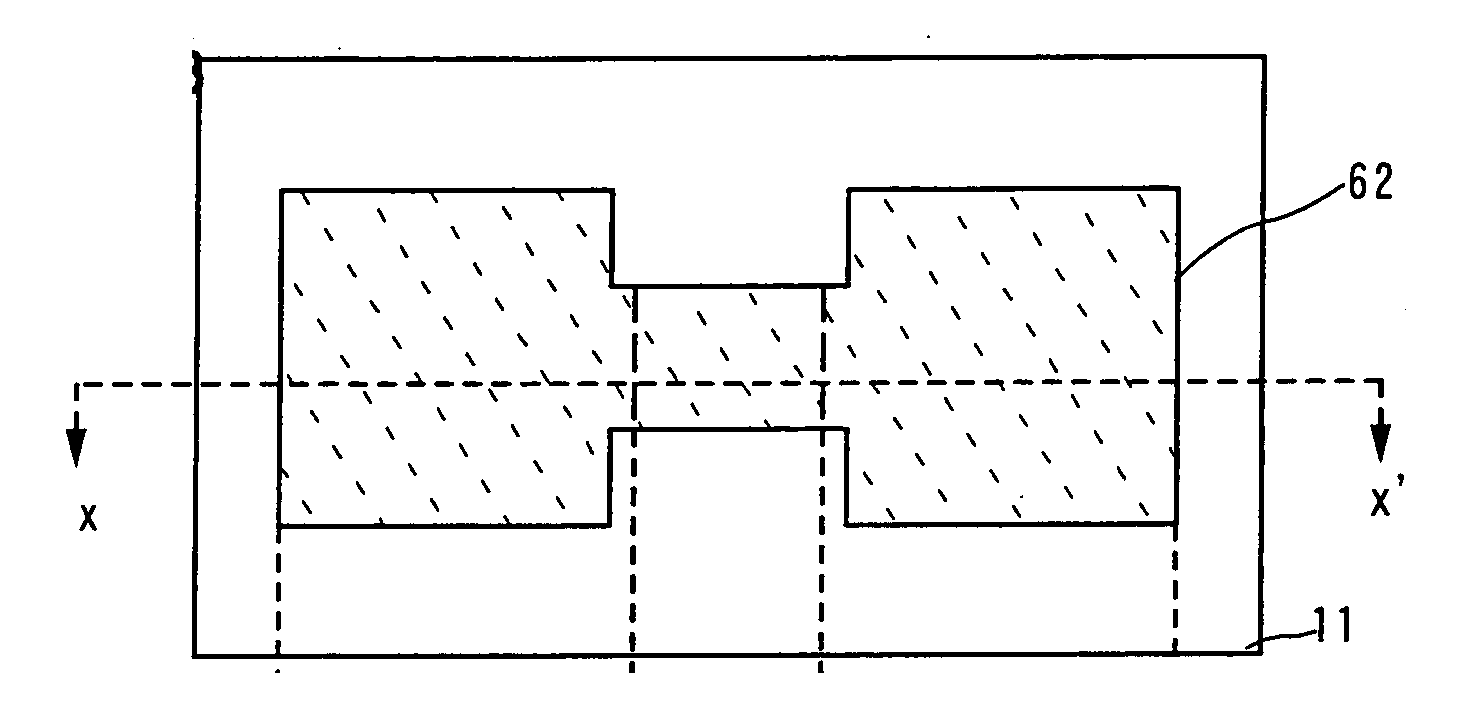

Semiconductor device and method of manufacturing the same

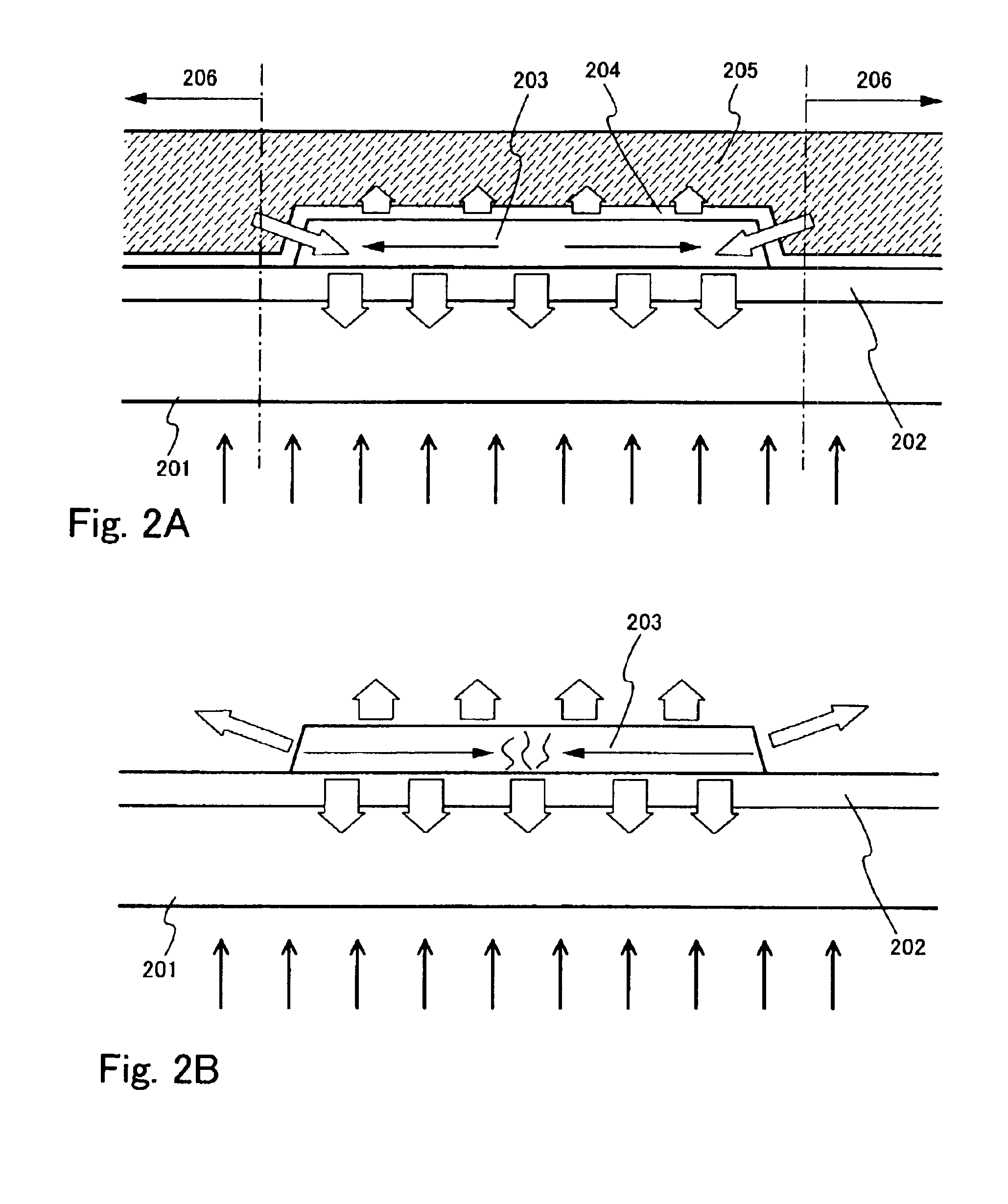

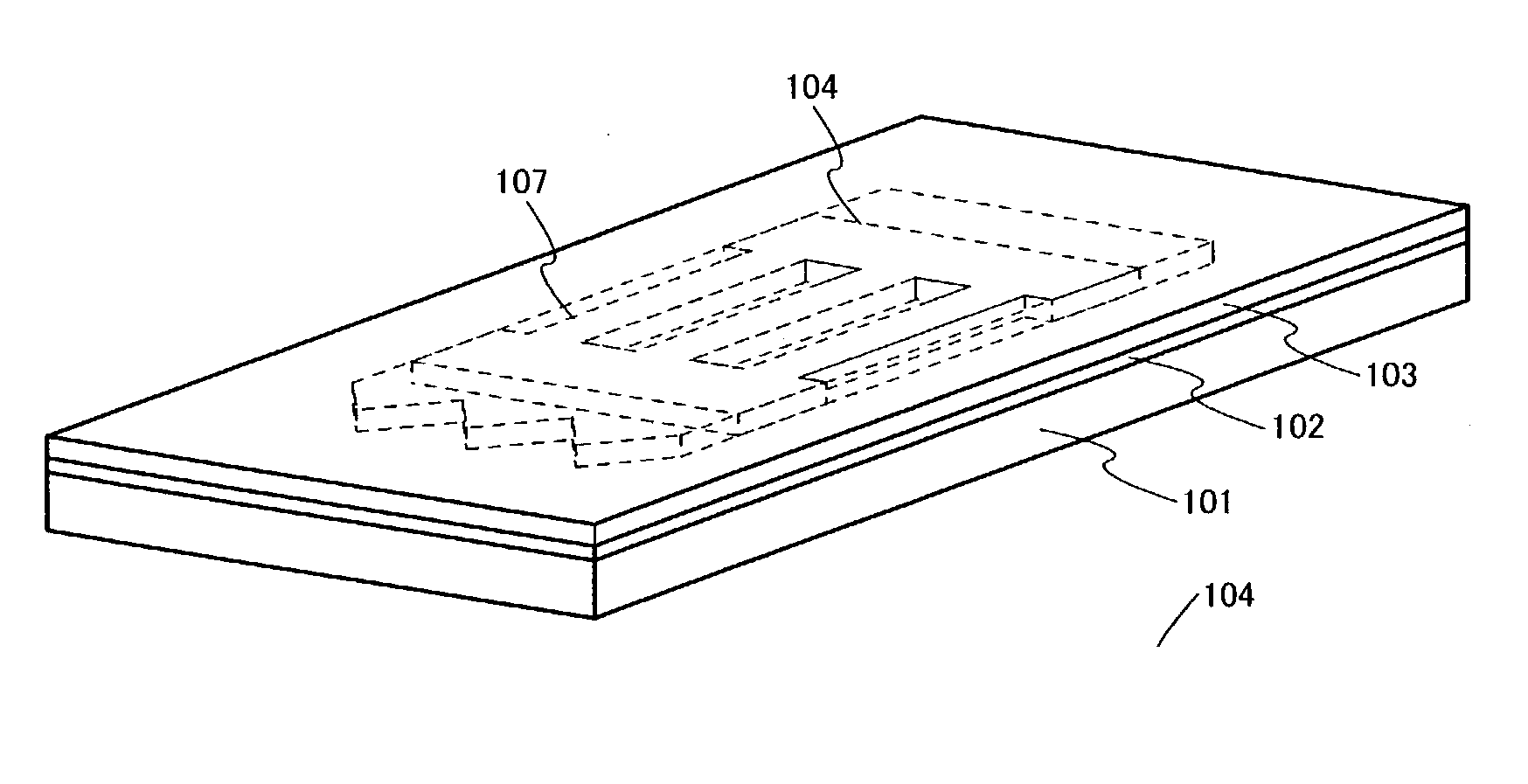

InactiveUS20030234395A1High crystallinityImprove mobilityTransistorSolid-state devicesSemiconductorContinuous wave laser beam

In a conventional method of crystallization using a laser beam, variance (or dispersion) in a TFT characteristic becomes large, which causes various functions of a semiconductor device comprising TFTs as components of its electronic circuit to be restrained. A first shape of semiconductor region having on its one side a plurality of sharp convex top-end portions is formed first and a continuous wave laser beam is used for radiation from the above region so as to crystallize the first shape of semiconductor region. A continuous wave laser beam condensed in one or plural lines is used for the laser beam. The first shape of semiconductor region is etched to form a second shape of semiconductor region in which a channel forming region and a source and drain region are formed. The second shape of semiconductor region is disposed so that a channel forming range would be formed on respective crystal regions extending from the plurality of convex end portions. A semiconductor region adjacent to the channel forming region is eliminated.

Owner:SEMICON ENERGY LAB CO LTD

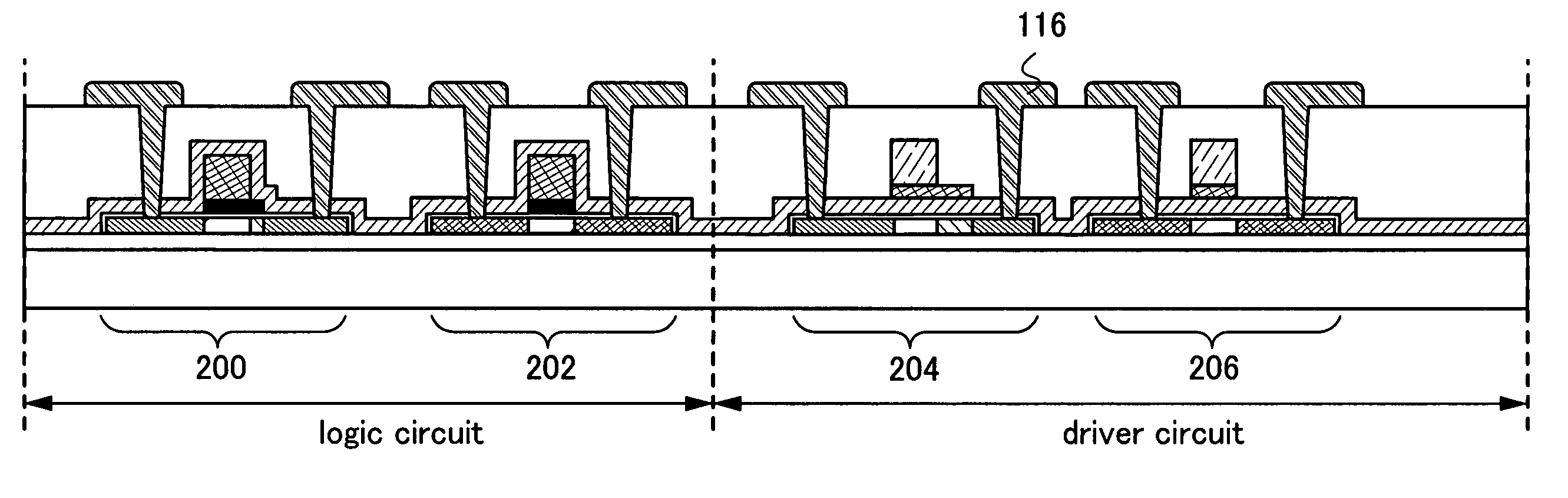

Semiconductor device and manufacturing method thereof

InactiveUS7608490B2Improve performanceImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhotolithographyContinuous wave laser beam

Owner:SEMICON ENERGY LAB CO LTD

Directional electromagnetic steel plate and method for manufacturing same

InactiveCN102834529AReduced electrical insulationHigh build productivityInorganic material magnetismWelding/soldering/cutting articlesLength waveUltimate tensile strength

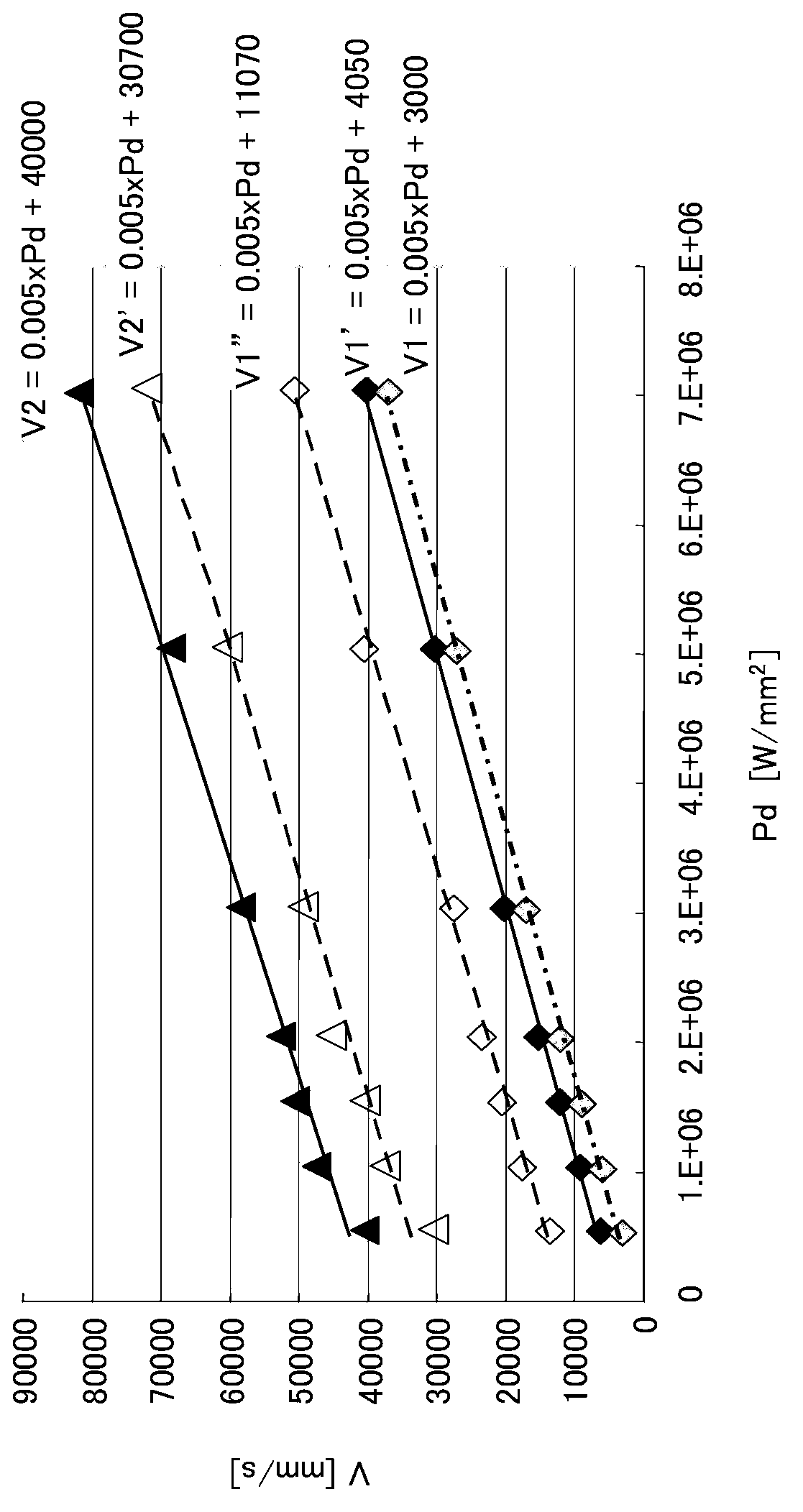

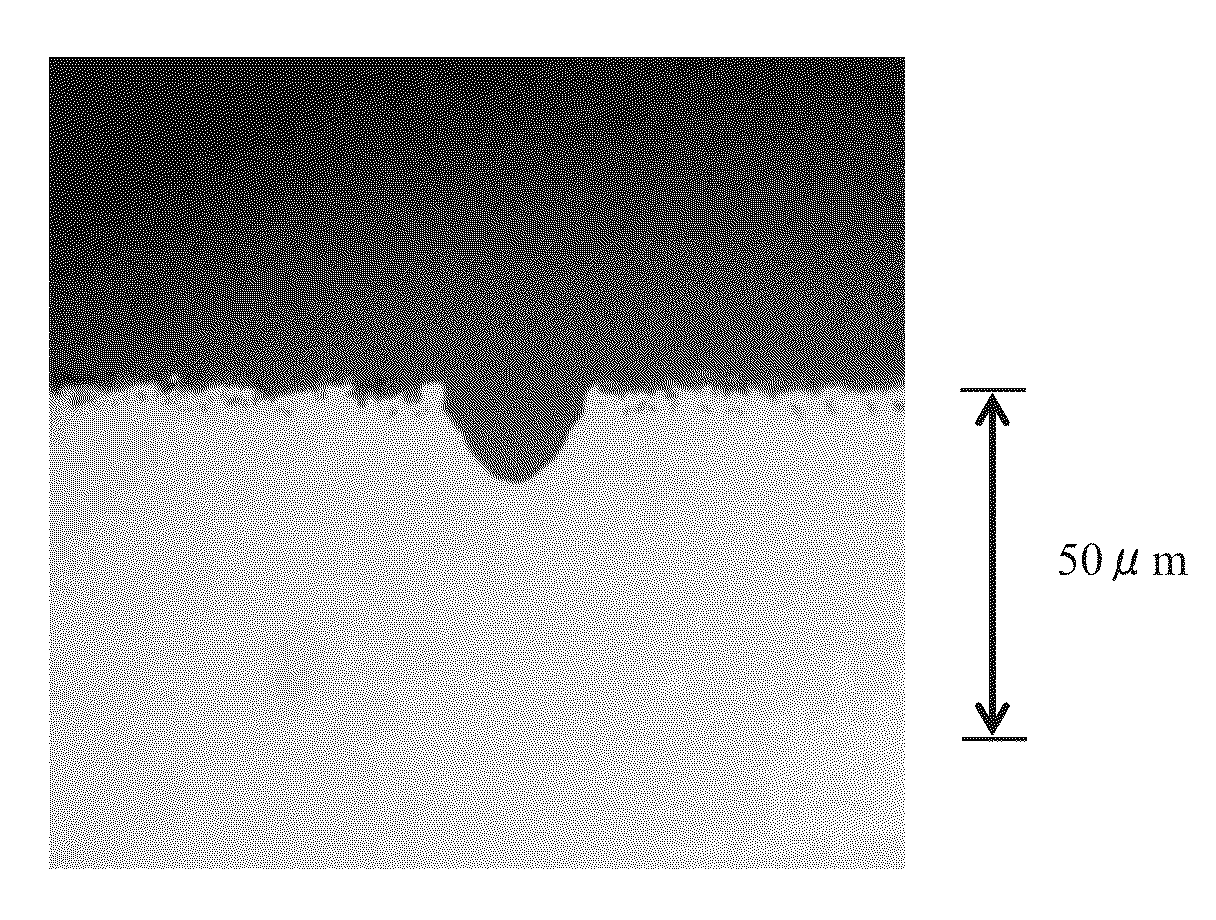

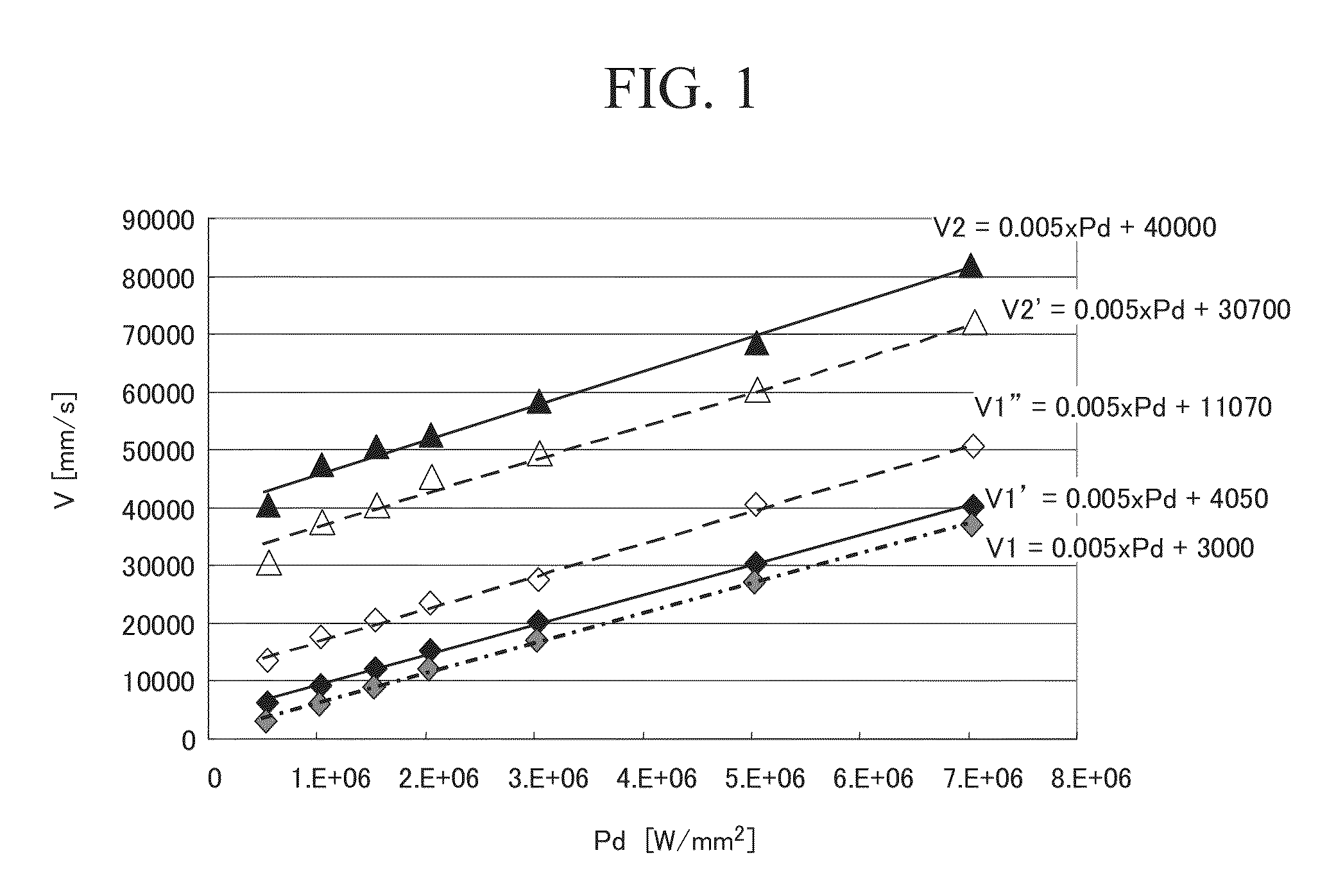

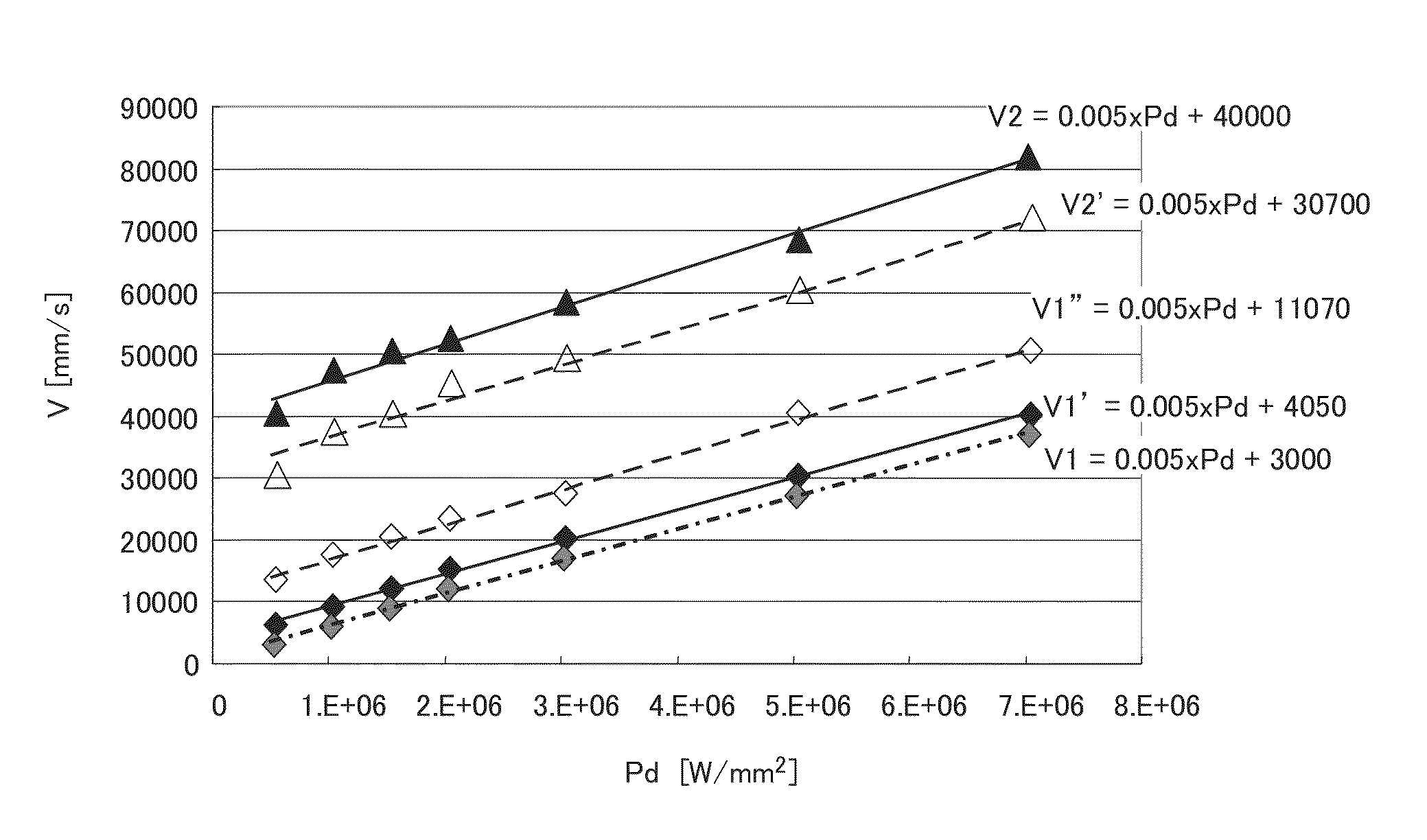

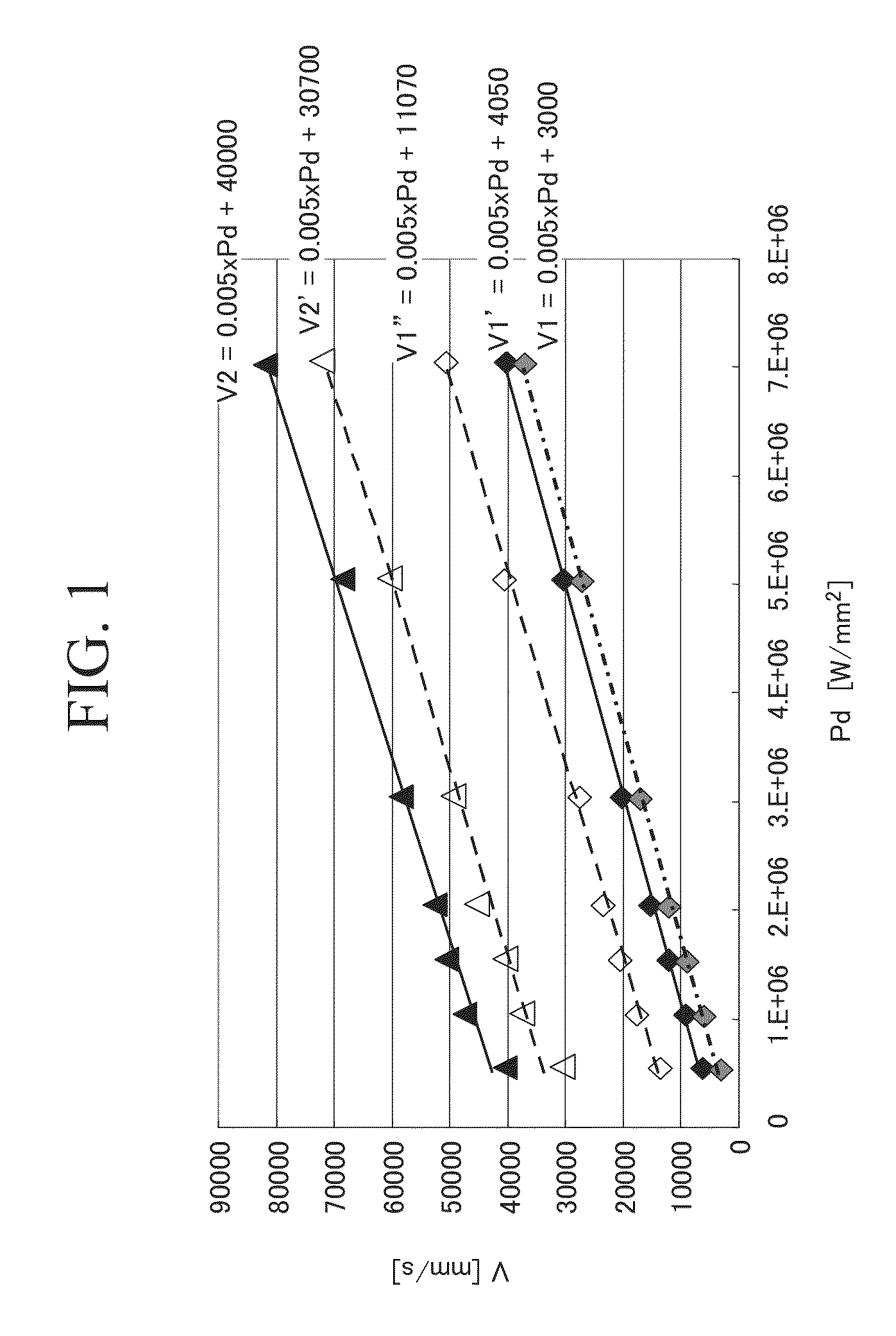

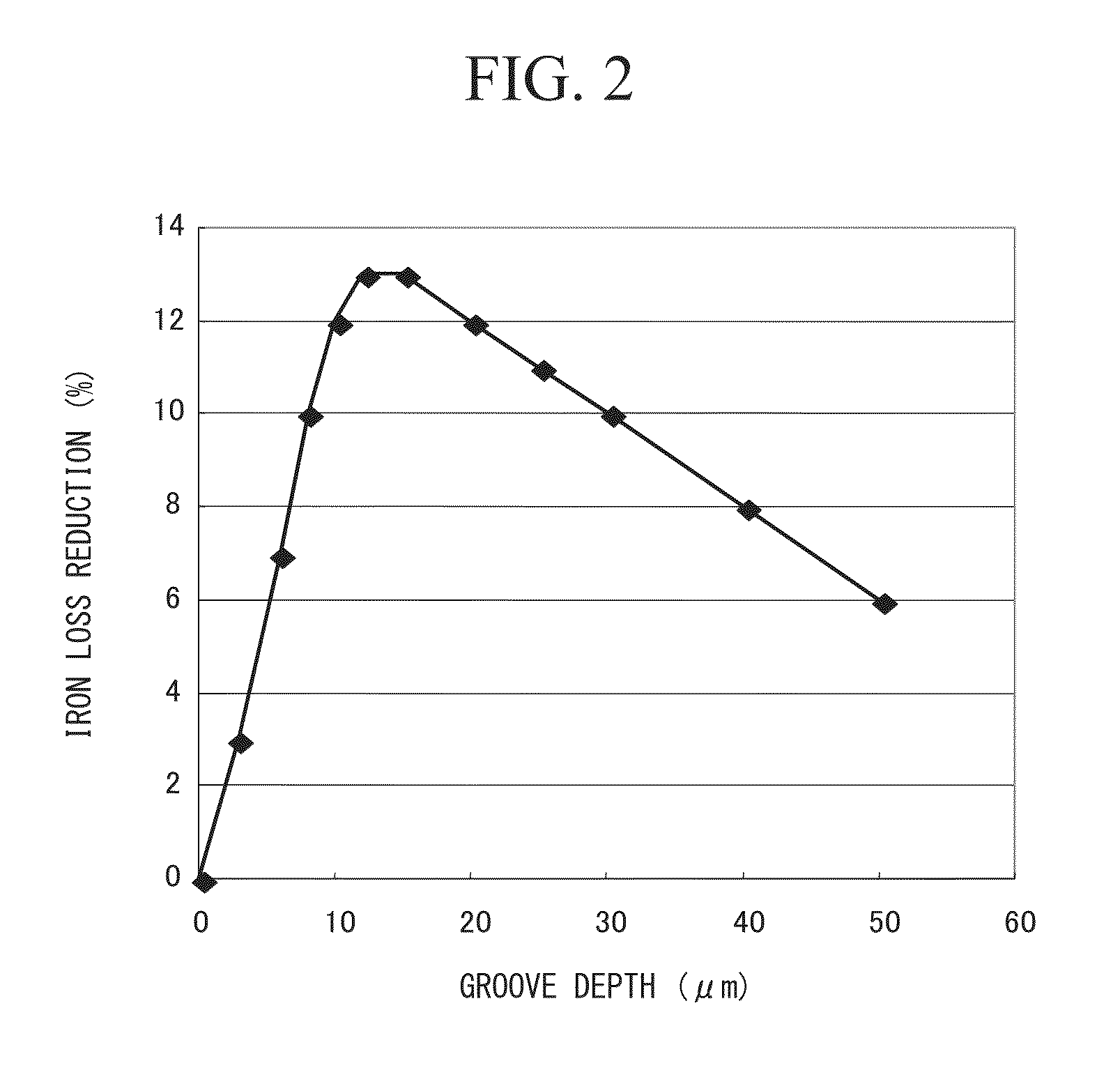

In a method for manufacturing a directional electromagnetic steel plate, grooves which extend in directions including a direction perpendicular to the conveying direction of the directional electromagnetic steel plate and have a predetermined length are formed at predetermined intervals in the conveying direction by applying a laser beam to the surface of the directional electromagnetic steel plate while scanning the laser beam over the surface thereof. Further, in the method for manufacturing the directional electromagnetic steel plate, the laser beam is a continuous-wave laser beam with a laser wavelength (?) of 1.0-2.1 [mu]m inclusive, the power density (Pd) [W / mm2] obtained by dividing the laser beam intensity (P) by the focused beam area (S) is 5105 W / mm2 or more, and the power density (Pd) [W / mm2] and the scan speed (V) [mm / s] of the focused spot of the laser beam on the surface of the directional electromagnetic steel plate satisfy 0.005Pd+3000=V=0.005Pd+40000.

Owner:NIPPON STEEL CORP

Method of laser-welding metal materials by double lasers

ActiveCN103753022AChange the surface morphologyImprove absorption rateWelding/soldering/cutting articlesLaser beam welding apparatusShielding gasMetallic materials

A method of laser-welding metal materials by double lasers includes the steps: 1, cleaning welding material and fixing the welding material; 2, generating two laser beams by two lasers and allowing the two laser beams to focus on the surface of the welding material; 3, laterally blowing protective gas to the surface of the welding material; 4, generating the first laser beam by the quasi-continuous laser, and melting the surface of the welding material into a bath; 5, focusing the second laser beam to the area of melted welding material; 6, allowing the laser beams to synchronously move at a given scanning speed to form a weld seam on the surface of the welding material, and finishing welding. The method has the advantages that surface microstructure of aluminum alloy can be changed, the surface of the aluminum alloy is melt into the bath to increase the rate of the aluminum alloy absorbing continuous wave laser beams, and welding quality is improved.

Owner:JIANGSU ZHONGKE DAGANG LASER TECH

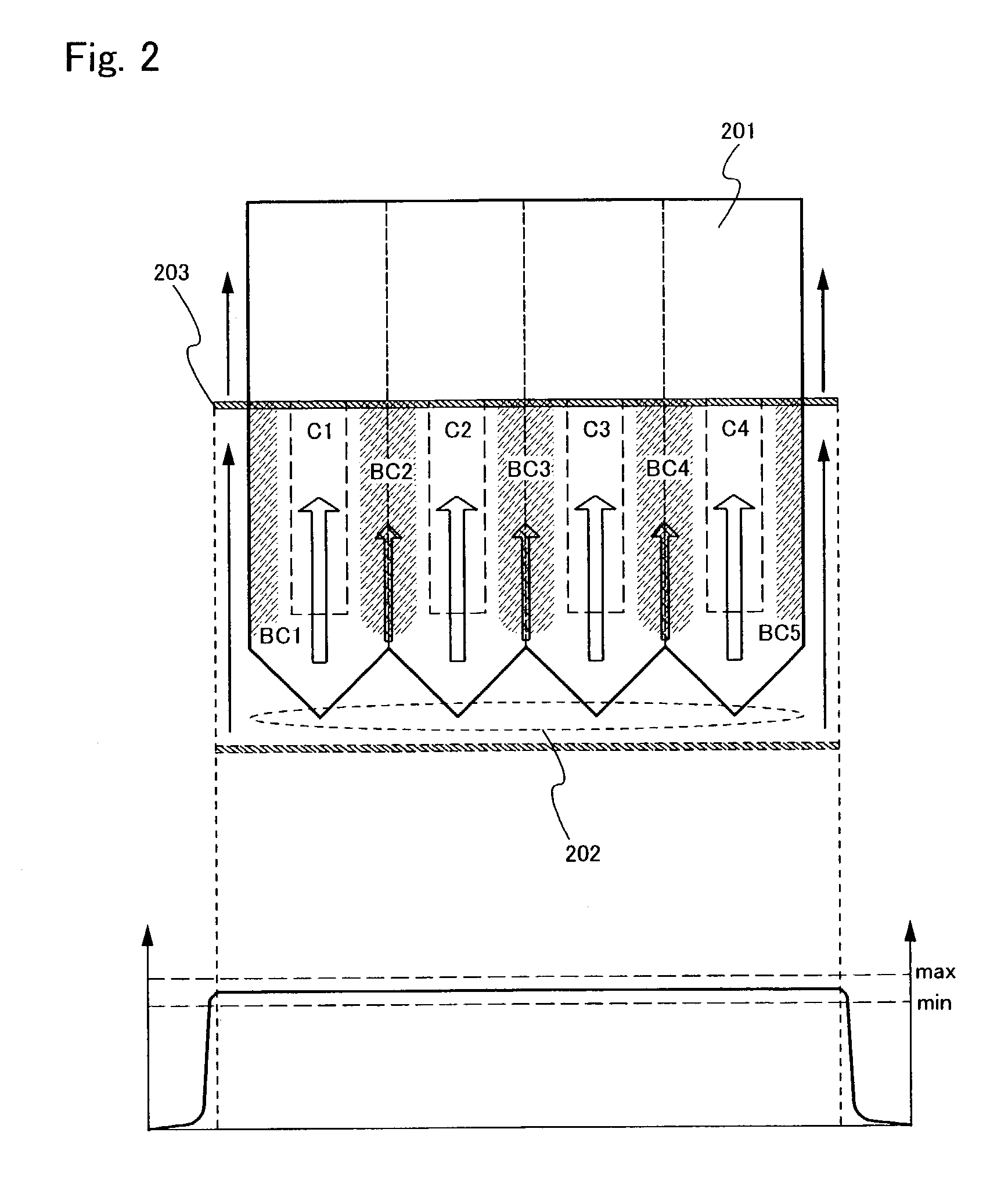

Method of manufacturing display device

InactiveUS20060003478A1Reducing and eliminating influenceReduce and eliminate interferenceTransistorLaser detailsDisplay deviceOptoelectronics

Arrangements (e.g., methods) for manufacturing a display device, including irradiating an amorphous semiconductor film formed on a substrate with an excimer laser beam to convert the amorphous semiconductor film into a polycrystalline semiconductor film; and irradiating predetermined areas of the polycrystalline semiconductor film intermittently with a continuous wave laser beam while a position of the substrate with respect to the continuous wave laser beam is scanned, crystal grains larger than those of the polycrystalline semiconductor film other than the predetermined areas are formed in each of the predetermined areas locally in the polycrystalline semiconductor film, wherein first thin film transistors are formed in the predetermined areas while second thin film transistors are formed in the polycrystalline semiconductor film other than the predetermined areas thereof.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Semiconductor device and method of manufacturing the same

InactiveUS7109069B2High crystallinityIncrease speedTransistorSolid-state devicesSemiconductorContinuous wave laser beam

In a conventional method of crystallization using a laser beam, variance (or dispersion) in a TFT characteristic becomes large, which causes various functions of a semiconductor device comprising TFTs as components of its electronic circuit to be restrained.A first shape of semiconductor region having on its one side a plurality of sharp convex top-end portions is formed first and a continuous wave laser beam is used for radiation from the above region so as to crystallize the first shape of semiconductor region. A continuous wave laser beam condensed in one or plural lines is used for the laser beam. The first shape of semiconductor region is etched to form a second shape of semiconductor region in which a channel forming region and a source and drain region are formed. The second shape of semiconductor region is disposed so that a channel forming range would be formed on respective crystal regions extending from the plurality of convex end portions. A semiconductor region adjacent to the channel forming region is eliminated.

Owner:SEMICON ENERGY LAB CO LTD

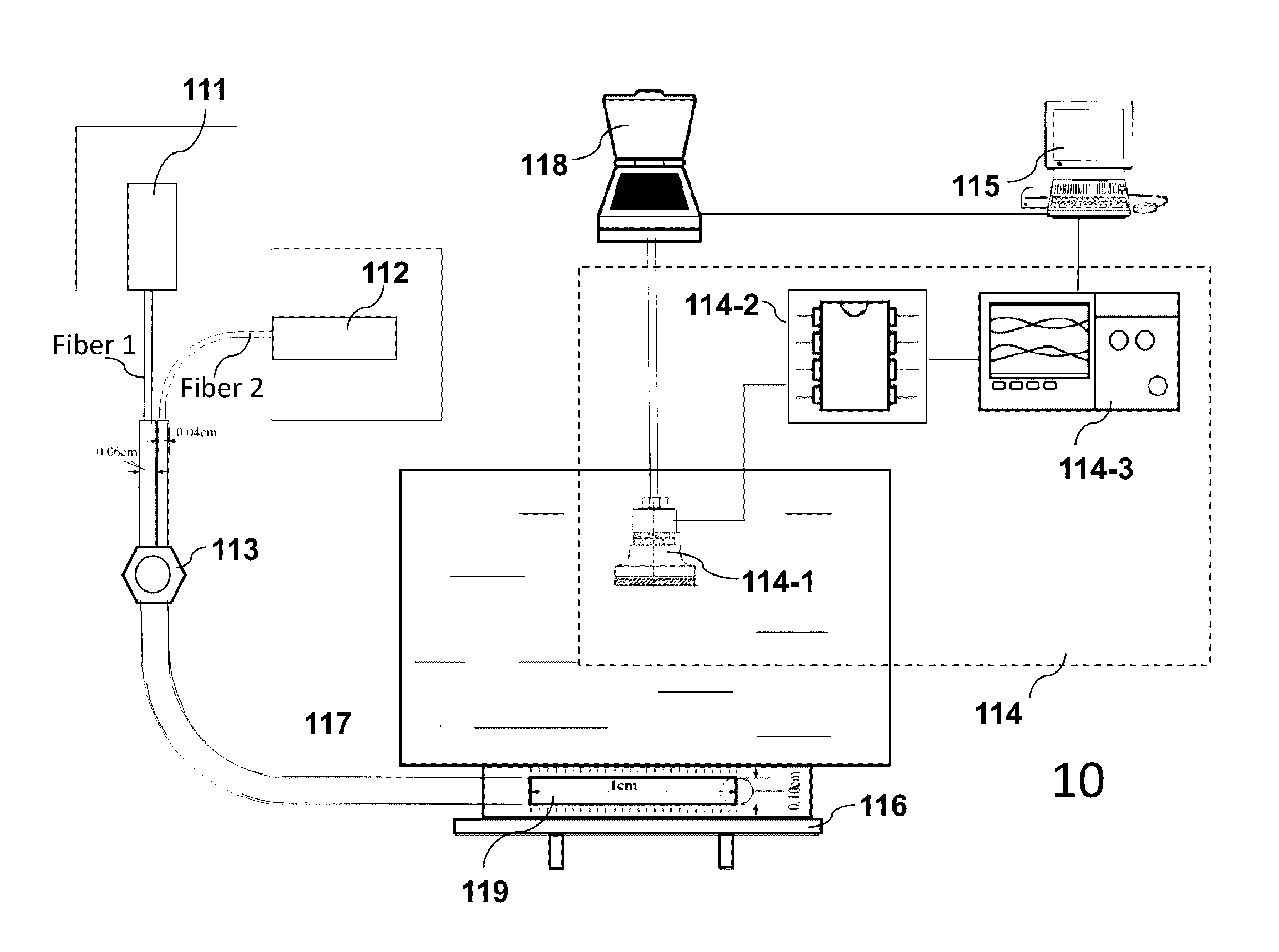

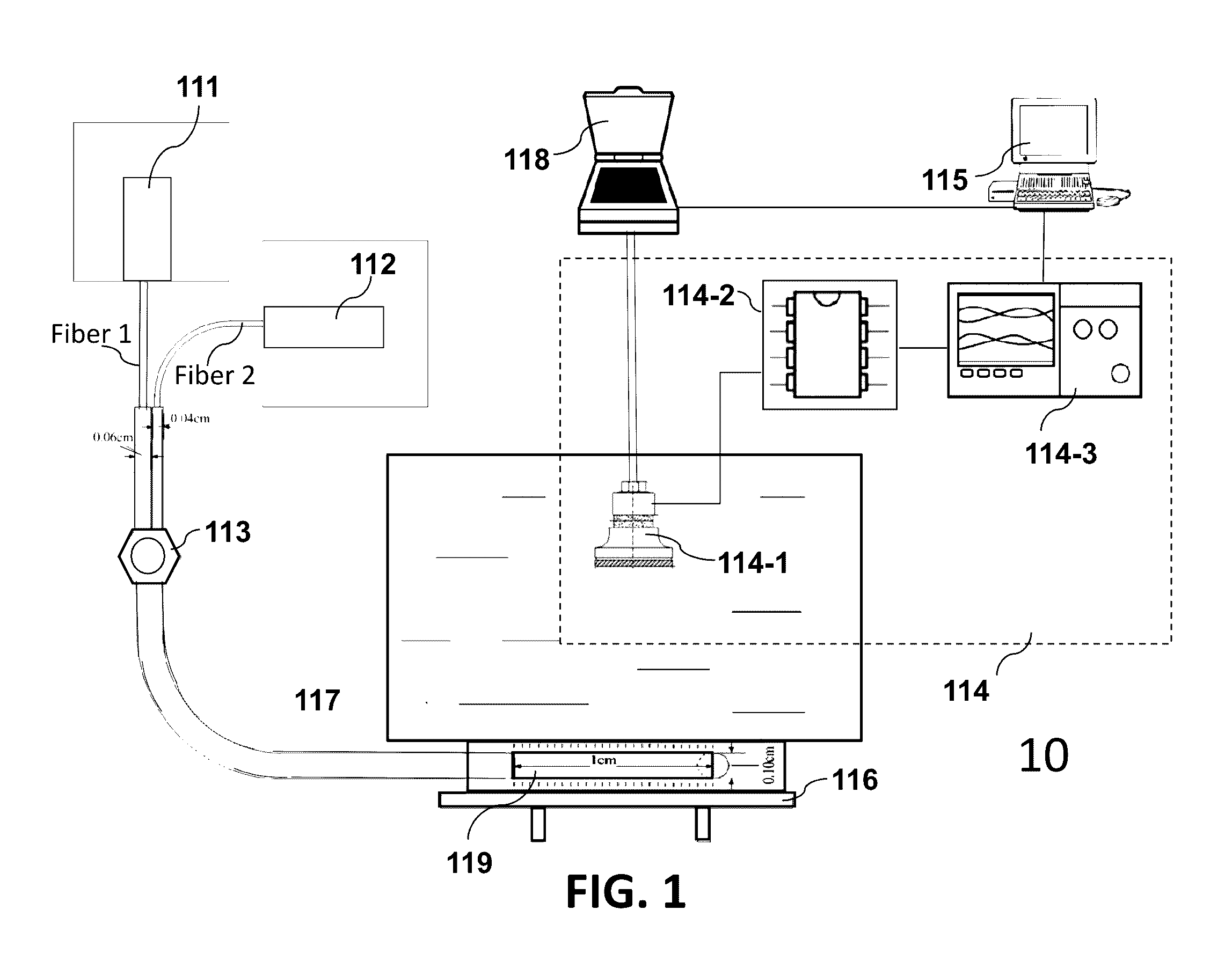

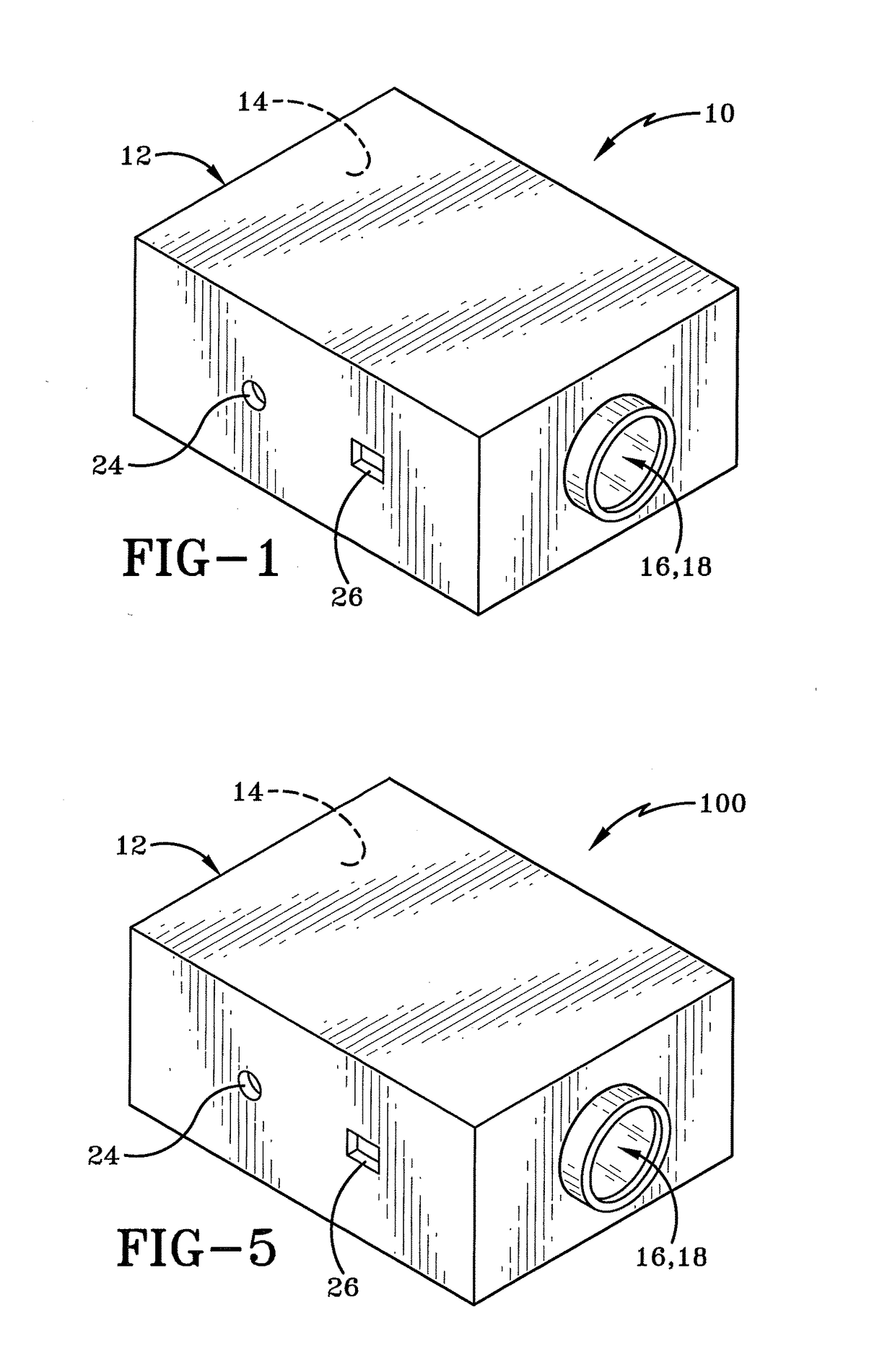

Device and a method for imaging-guided photothermal laser therapy for cancer treatment

ActiveUS20170014186A1Good photothermal effectIncrease temperatureSurgical needlesSurgical instrument detailsHigh power lasersLaser light

This invention relates to a device and a method for monitoring and optimizing photothermal therapy, using a high-power continuous-wave laser beam and a pulsed laser beam, both transmitted through a single soft, multi-mode optical fiber with a diffuse active tip, to interstitially irradiate the target tissue at the same time. The continuous-wave laser light induces photothermal effect and increases tissue temperature and the pulsed laser light produces a photoacoustic signal. The photoacoustic signal intensity is used to monitor the temperature changes in the target tissue and to guide the irradiation of the high-power laser to optimize the photothermal effect by adjusting the light intensity and irradiation time.

Owner:UNIVERSITY OF CENTRAL OKLAHOMA

Semiconductor device and method of fabricating the same

InactiveUS20070228374A1Improve mobilityImprove featuresTransistorSolid-state devicesDevice materialOptoelectronics

To provide a thin film transistor having a high field effect mobility and a small variation in characteristics thereof, a second amorphous semiconductor layer patterned in a predetermined shape is formed on a first crystalline semiconductor layer 17 for constituting source and drain regions. By irradiating an irradiated region 21 of continuous wave laser beam while scanning along a channel length direction, the second amorphous semiconductor layer is crystallized to form a second crystalline semiconductor layer 22. The first crystalline semiconductor layer 17 is crystallized by selectively adding nickel and therefore, an orientation rate of {111} is increased. By irradiating laser beam, crystals of the second amorphous semiconductor layer grow by constituting a seed by the first crystalline semiconductor layer 17 oriented to {111} and therefore, a region 22a for constituting a channel forming region is also oriented highly to {111} and a direction of a crystal grain boundary becomes parallel with the channel length direction.

Owner:SEMICON ENERGY LAB CO LTD

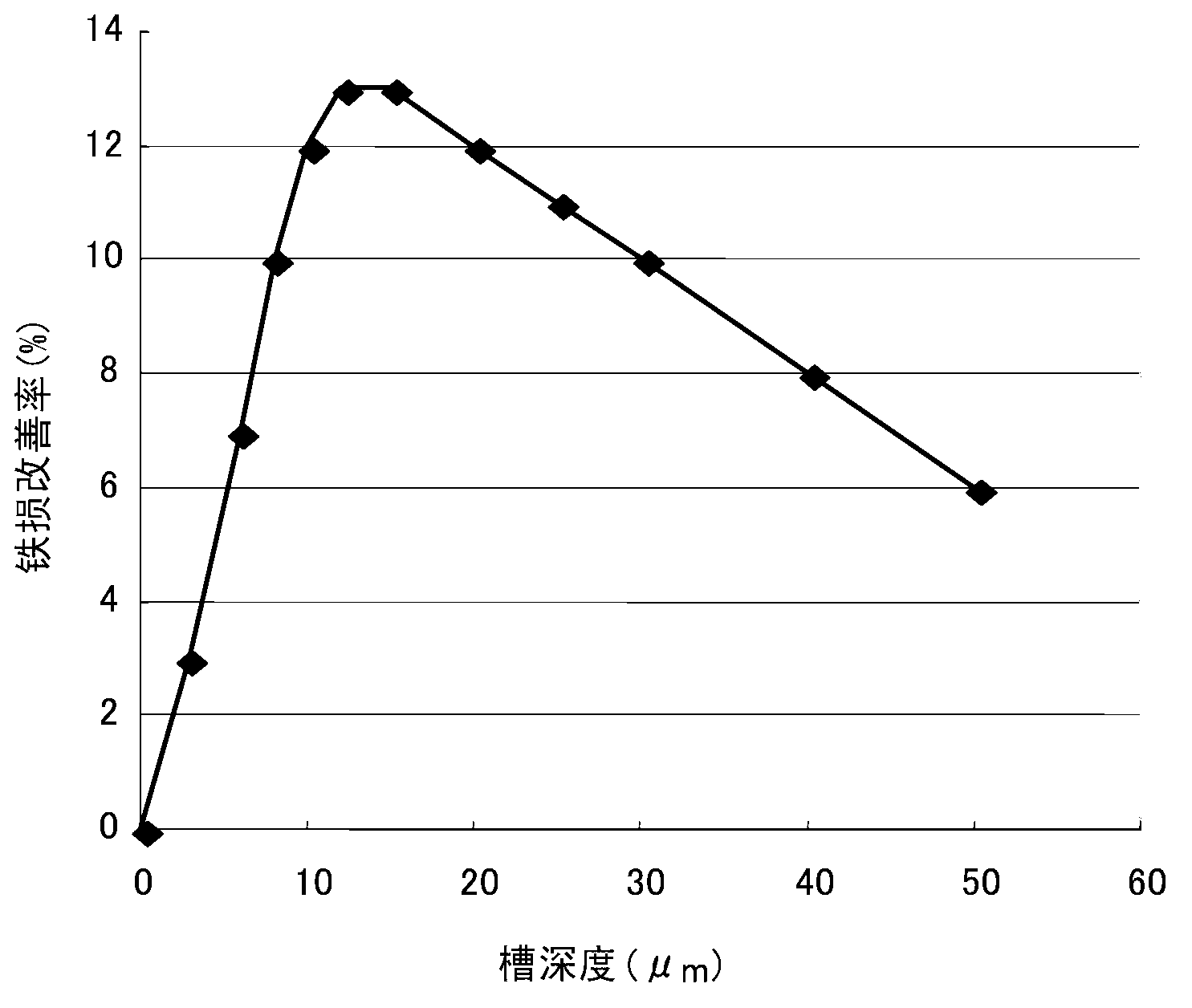

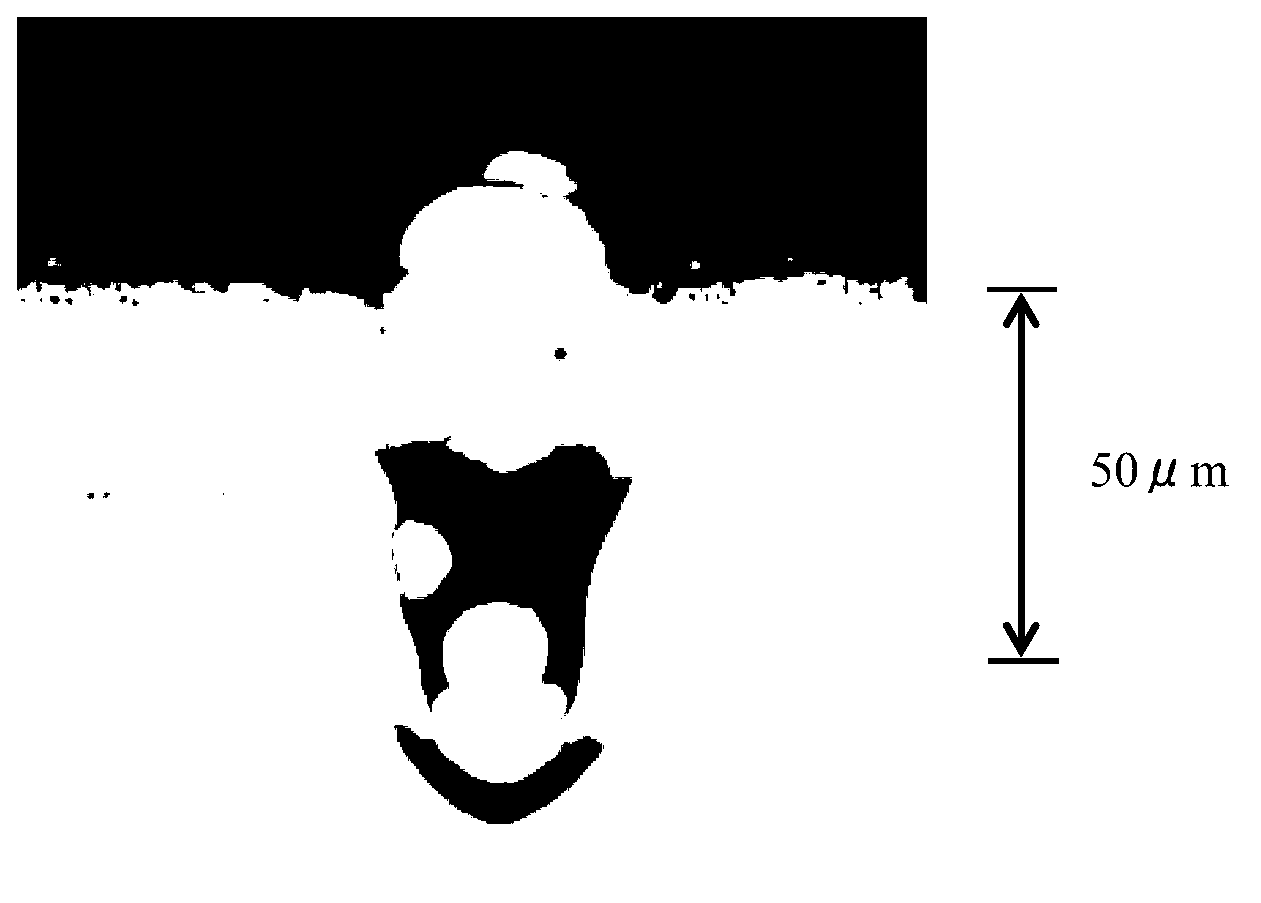

Grain-oriented electrical steel sheet and method for producing same

ActiveUS20130017408A1Increase strainExcellent iron loss characteristicLayered productsInorganic material magnetismElectrical steelLight beam

In a method for producing a grain-oriented electrical steel sheet, grooves each having a given length and extending in a direction including a direction perpendicular to a transportation direction of the grain-oriented electrical steel sheet are formed at given intervals in the transportation direction by irradiating the surface of the grain-oriented electrical steel sheet with a laser beam while scanning the surface of the grain-oriented electrical steel sheet with the laser beam. Further, in the method for manufacturing a grain-oriented electrical steel sheet, the laser beam is a continuous-wave laser beam having a laser wavelength λ of 1.0 μm to 2.1 μm, power density Pd [W / mm2] which is obtained by dividing laser beam intensity P by a focused beam area S is 5×105 W / mm2 or more, and the power density Pd [W / mm2] and scanning speed V [mm / s] of a focused spot of the laser beam on the surface of the grain-oriented electrical steel sheet satisfy a relationship of 0.005×Pd+3000≦V≦0.005×Pd+40000.

Owner:NIPPON STEEL CORP

System and method for laser welding foils

InactiveUS20070170158A1Welding/soldering/cutting articlesLaser beam welding apparatusThin metalThermocouple

A method and apparatus, for welding together a pair of metal foils of different thickness. The method includes the steps of positioning a thin metal foil adjacent a thick metal foil and applying a continuous wave laser beam to the thick metal foil to weld at least a portion of the thick metal foil and the thin metal foil together. A thermally conductive plate is positioned proximate the weld line in order to limit the thick foil melt pool and to function as a laser beam block. Accordingly, appropriate materials may be chosen for the foils and top plate so that the continuous wave laser beam couples optimally into the thick foil material and minimally into the top plate material. A thermocouple may be placed proximate the weld line to obtain measures of temperature used to vary the laser beam power and / or the slew rate.

Owner:PANASONIC CORP

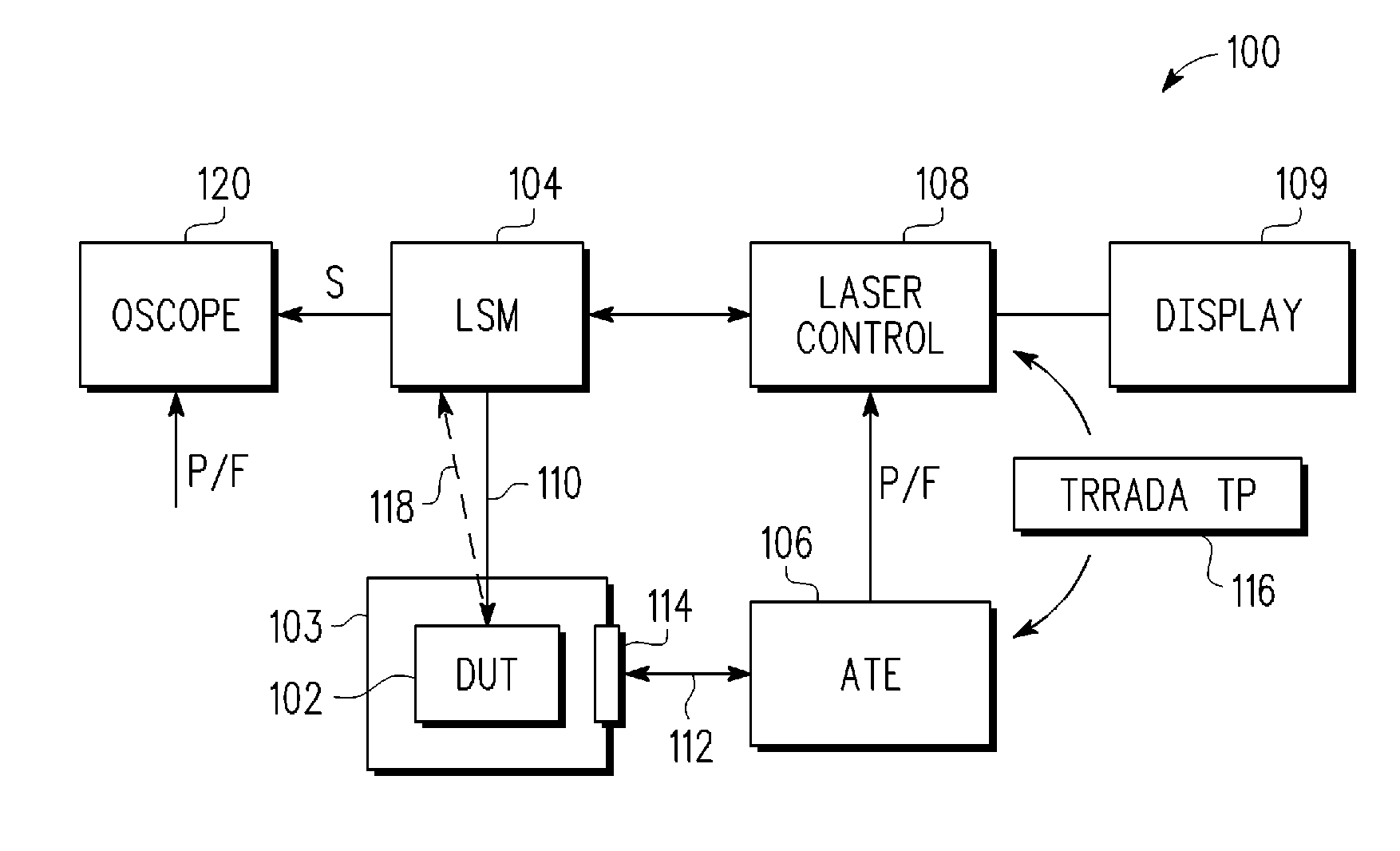

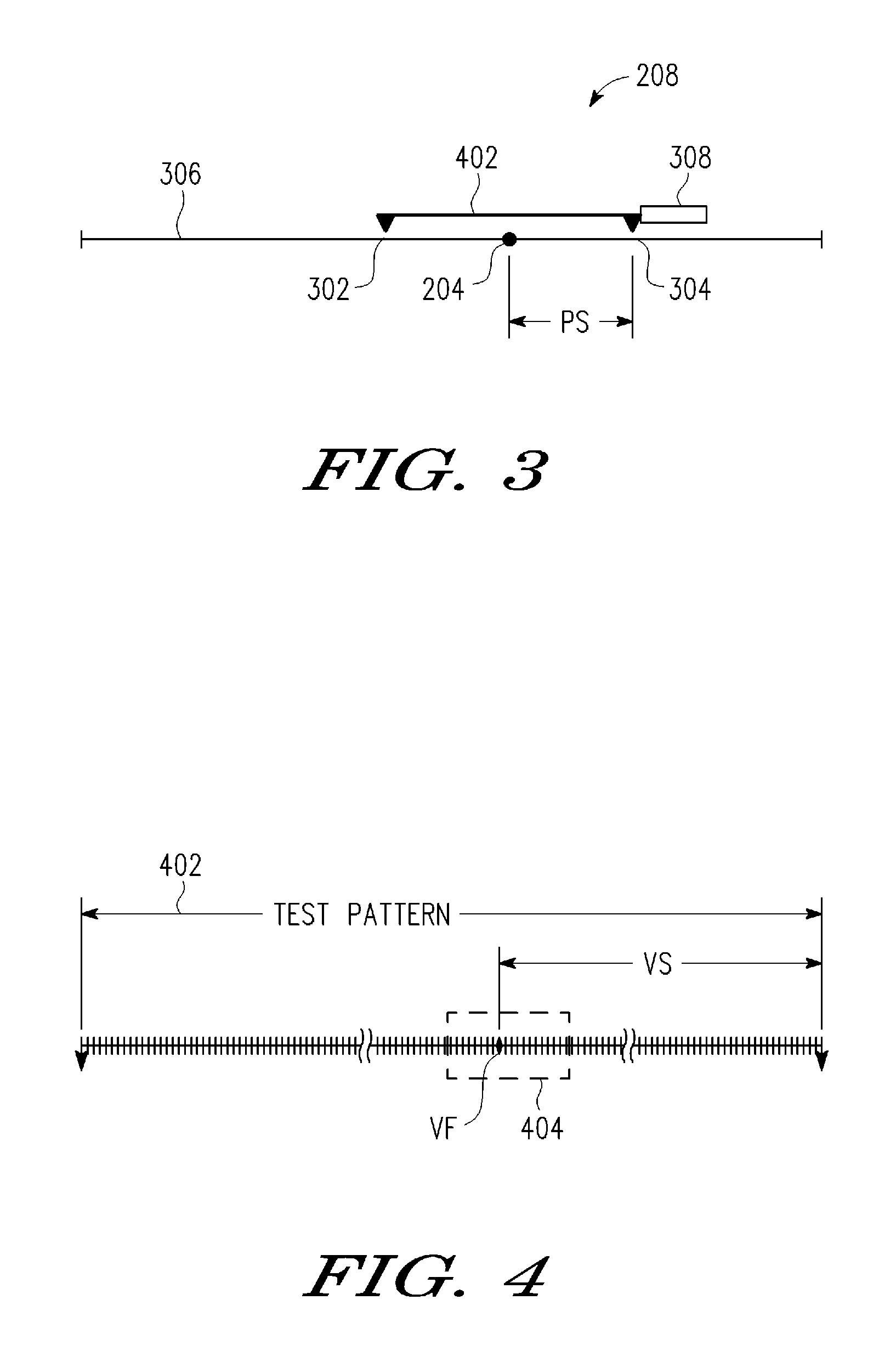

Time resolved radiation assisted device alteration

A method of time resolved radiation assisted device alteration testing of a semiconductor circuit which includes performing spatially resolved radiation assisted circuit testing on the semiconductor circuit while applying a test pattern to determine a pass-fail modulation location, asynchronously scanning the semiconductor circuit with radiation while repeatedly applying the test pattern and providing pass-fail results, combining corresponding pass-fail results provided during the asynchronously scanning to determine a shifted pass-fail modulation indication, determining time shift information between the pass-fail modulation location and the shifted pass-fail modulation indication, and identifying at least one of the test vectors based on the time shift information. The radiation may be a continuous wave laser beam. The time shift information may be determined by scanning an image, incorporating graphics into the image indicating the pass-fail modulation location and the shifted pass-fail modulation indication, and measuring a pixel shift on the scanned image.

Owner:NXP USA INC

Micro integrated non-cooperative target detection device

The invention provides a micro integrated non-cooperative target detection device, and belongs to the technical field of micro electro mechanics. The device is characterized by comprising a laser emission part, an optical scanning part and a signal receiving and processing part, which are integrated in a 100mm*35mm*50mm module box; the continuous wave laser beam undergoing signal modulation passes through a diaphragm and a beam splitter and then is irradiated on an MEMS micro reflection mirror serving as the optical scanning part, the continuous wave laser beam undergoes two-dimensional scanning, and the beam reflected back by a non-cooperative target is reflected by the MEMS micro reflection mirror and the beam splitter respectively and then processed by the signal receiving and processing part so as to output the information about the relative distance and orientation of the non-cooperative target. The micro-integration non-cooperative target detection device of the invention is more compact in structure and much smaller in volume.

Owner:TSINGHUA UNIV

Method for manufacturing semiconductor device

InactiveUS20070020826A1Reduce cooling ratePromote growthTransistorSolid-state devicesDevice materialCrystal orientation

It is an object of the invention to provide a technique forming a crystalline semiconductor film whose orientation is uniform by control of crystal orientation and obtaining a crystalline semiconductor film in which concentration of an impurity is reduced. A configuration of the invention is that a first semiconductor region is formed on a substrate having transparent characteristics of a visible light region, a barrier film is formed over the first semiconductor region, a heat retaining film covering a top and side surfaces of the first semiconductor region is formed through the barrier film, the first semiconductor region is crystallized by scanning of a continuous wave laser beam from one edge of the first semiconductor region to the other through the substrate, the heat retaining film and the barrier film are removed, then a second semiconductor region is formed as an active layer of TFT by etching the first semiconductor region. A pattern of the second semiconductor region formed by etching is formed in a manner that a scanning direction of the laser beam and a channel length direction of the TFT are arranged in almost the same direction in order to smooth drift of carriers.

Owner:SEMICON ENERGY LAB CO LTD

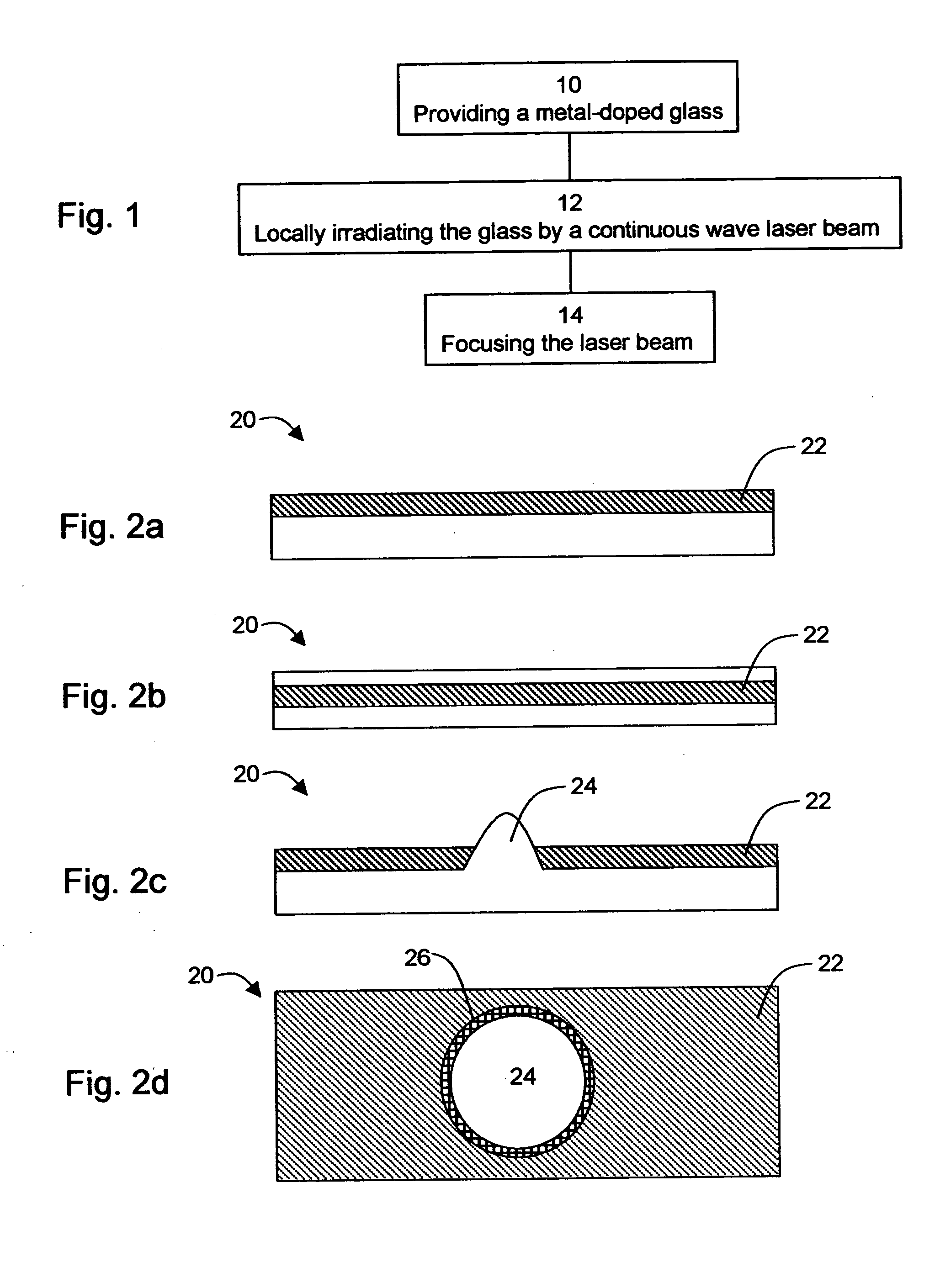

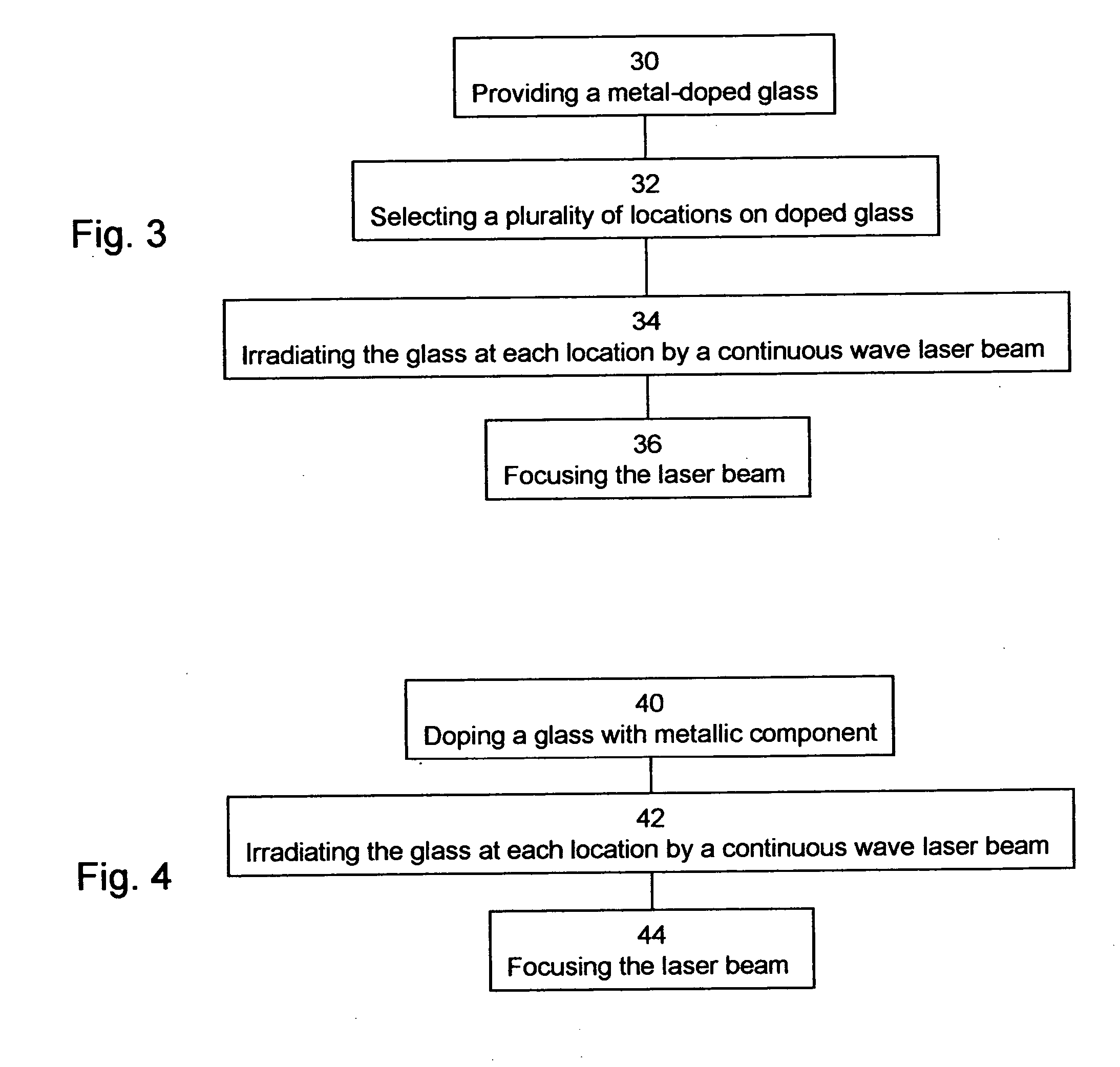

Microlens and method of marking same

A method of forming a microlens, comprising providing a doped glass having at least one metallic component other than copper, and locally irradiating the doped glass by a continuous wave laser beam, so as to melt a portion of the doped glass, thereby to form the microlens.

Owner:BAR ILAN UNIV

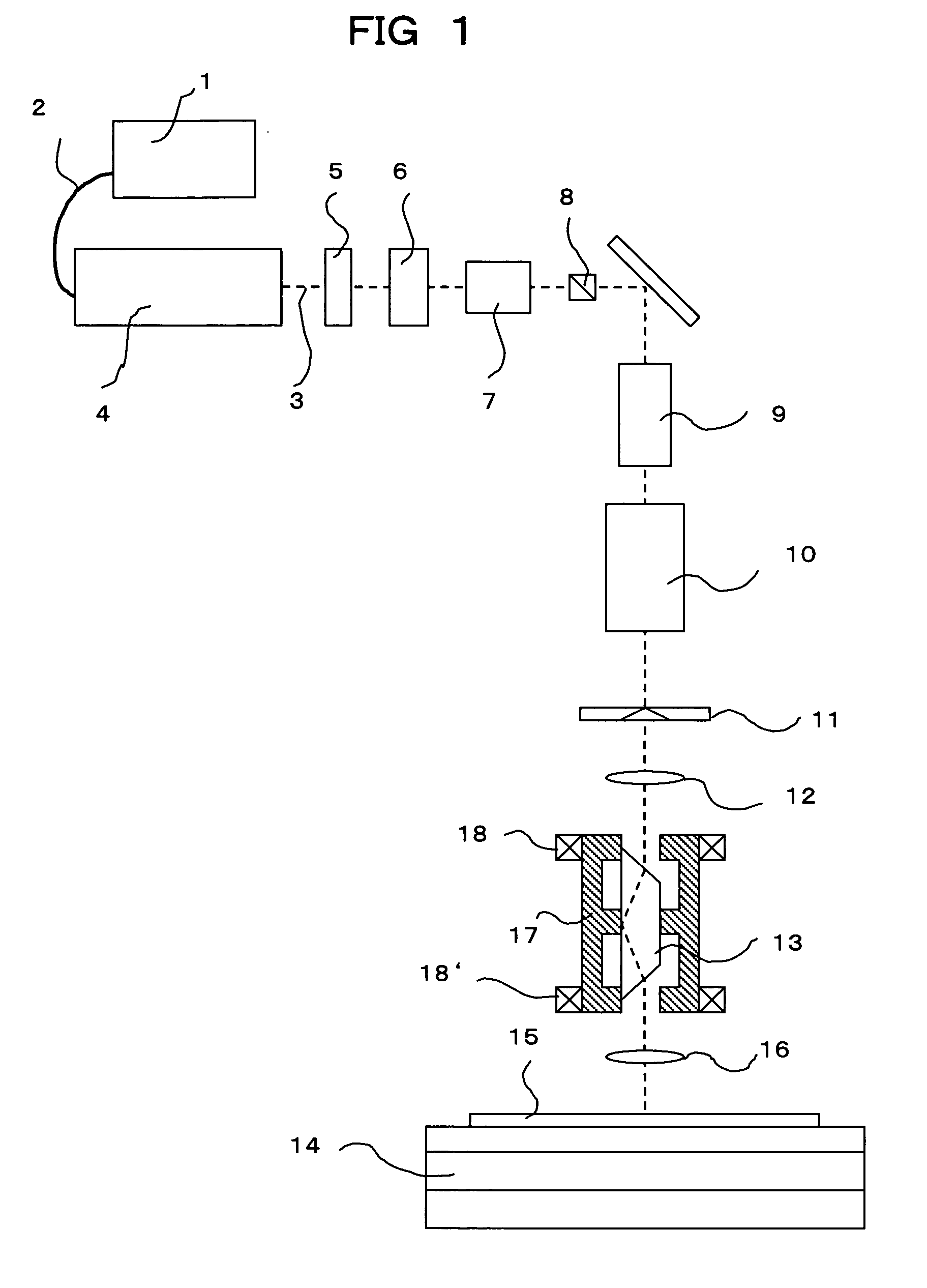

Laser annealing apparatus and annealing method of semiconductor thin film using the same

InactiveUS7397831B2Increased size and weightIncrease in sizeLaser detailsSolid-state devicesOptical axisLight beam

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

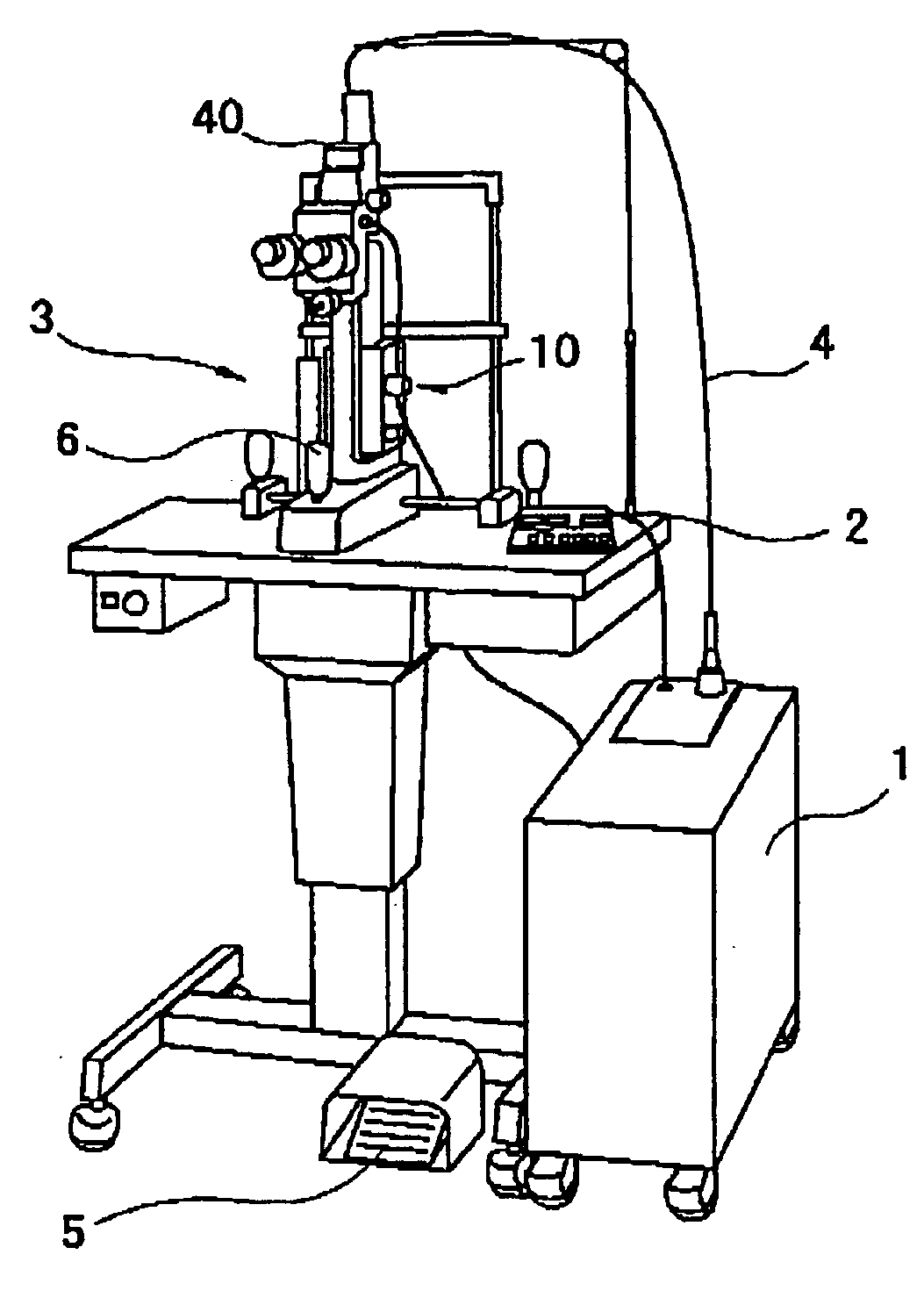

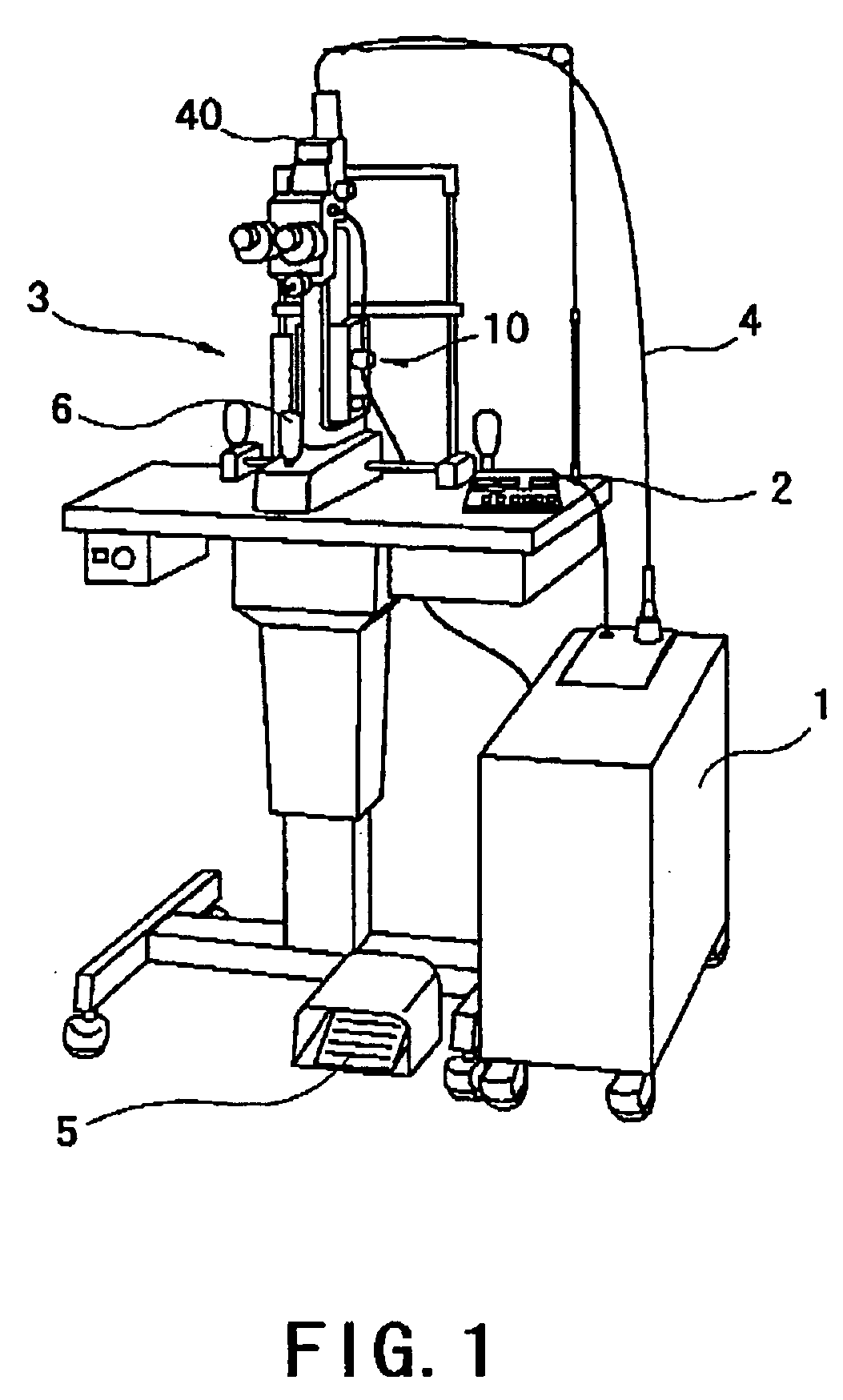

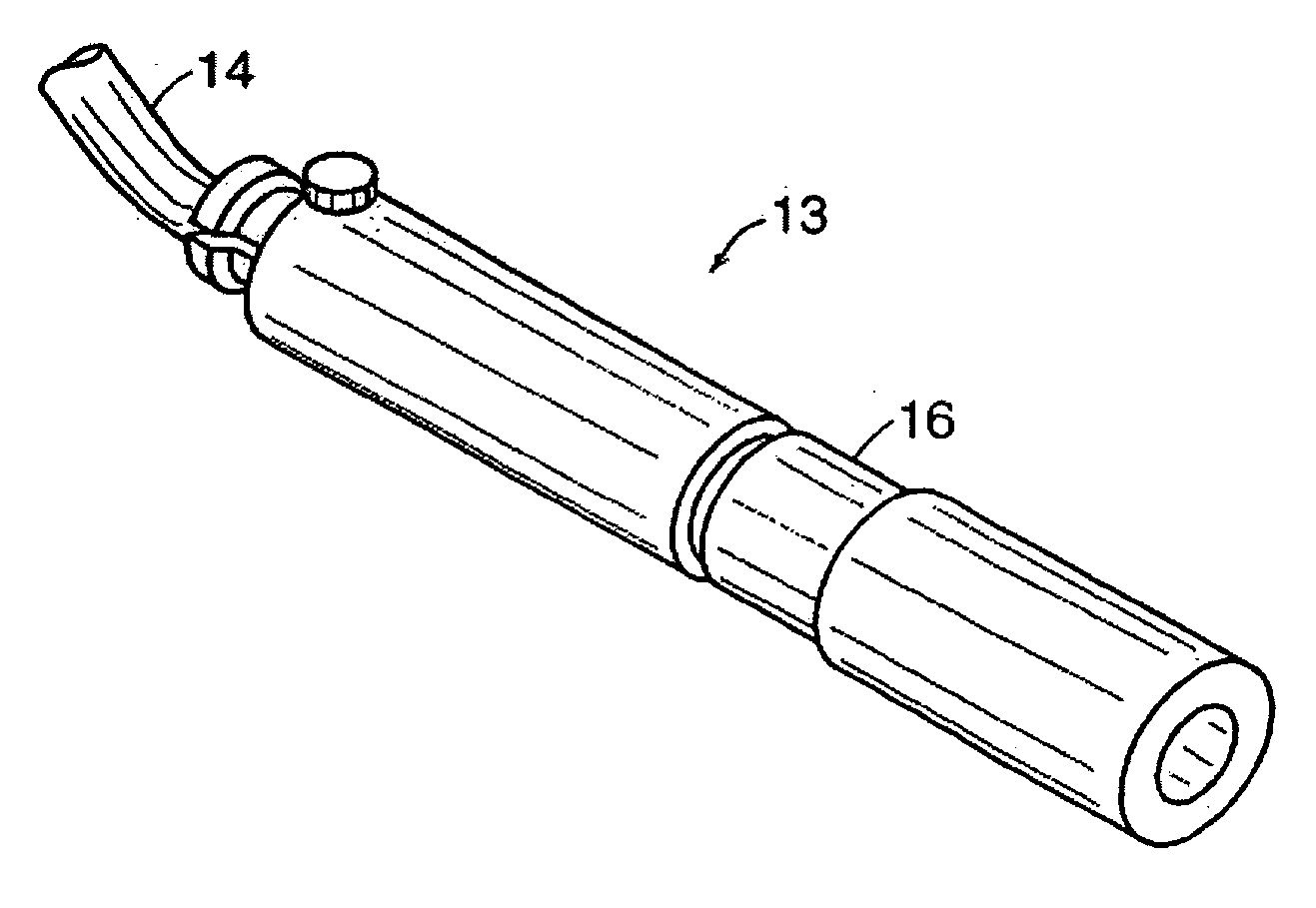

Ophthalmic laser treatment apparatus

ActiveUS20080188838A1Laser surgerySurgical instrument detailsContinuous waveSelective laser trabeculoplasty

An ophthalmic laser treatment apparatus, which allows SLT to be performed by a laser source not having a Q-switch which emits a continuous wave laser beam, has a laser source capable of emitting a continuous wave visible laser beam to be absorbed into pigment cells of trabecular meshwork, an irradiation optical system for directing the laser beam to a patient's eye so as to irradiate the eye with the laser beam, a device for pulsing the laser beam by controlling a driving duration of the laser source or opening and closing durations of a shutter in the irradiation optical system, a device capable of setting an irradiation duration of the laser beam within a range of 0.1 msec to 5 msec in order to perform Selective Laser Trabeculoplasty, and a device capable of setting irradiation energy density of the laser beam within a range of 1 J / cm2 to 8.5 J / cm2.

Owner:NIDEK CO LTD

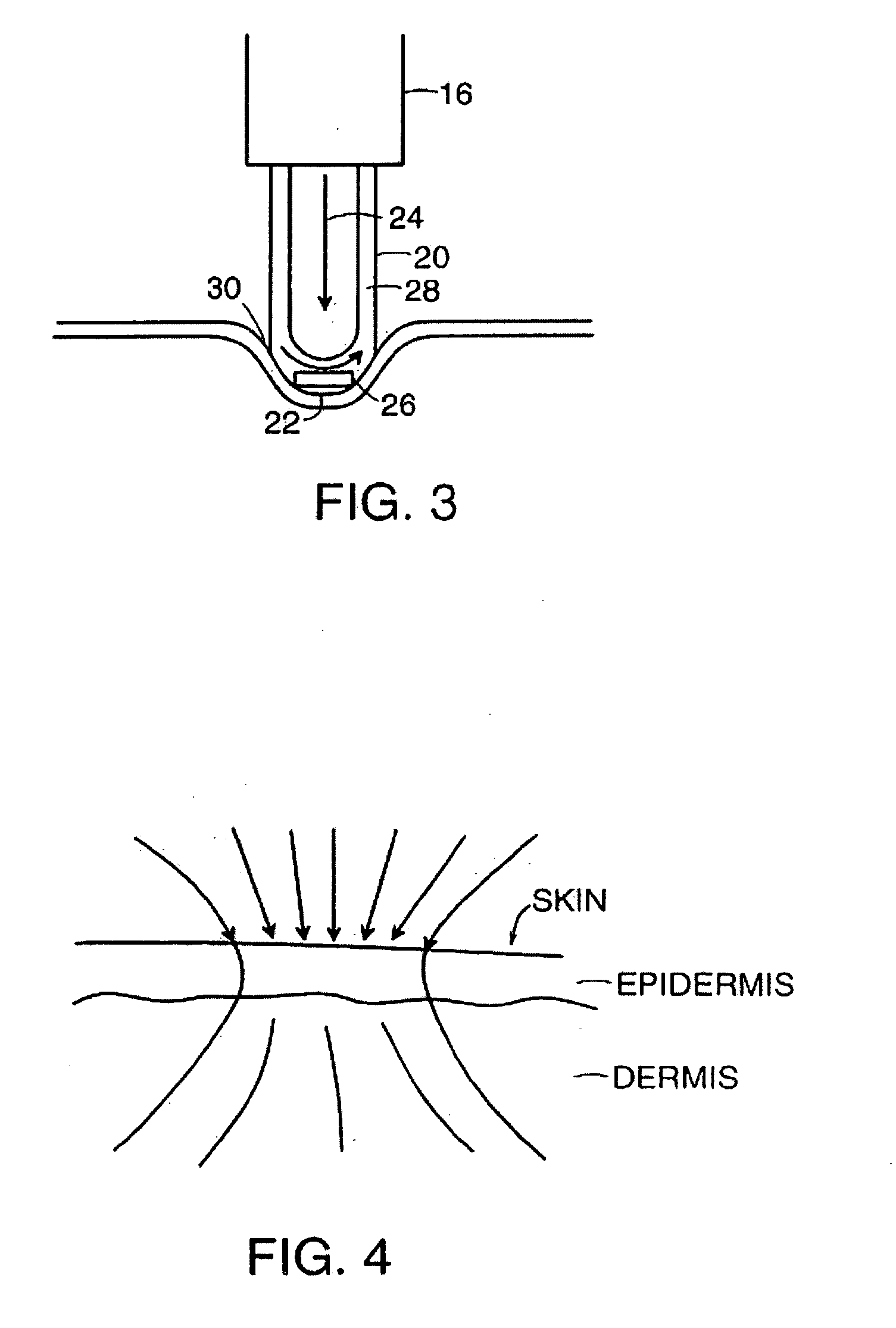

Method and apparatus for treating wrinkles in skin using radiation

InactiveUS20080269733A1Avoid injuryPigmentary disturbances are minimizedSurgical instrument detailsLight therapyWrinkle skinContinuous wave

Owner:CANDELA CORP +1

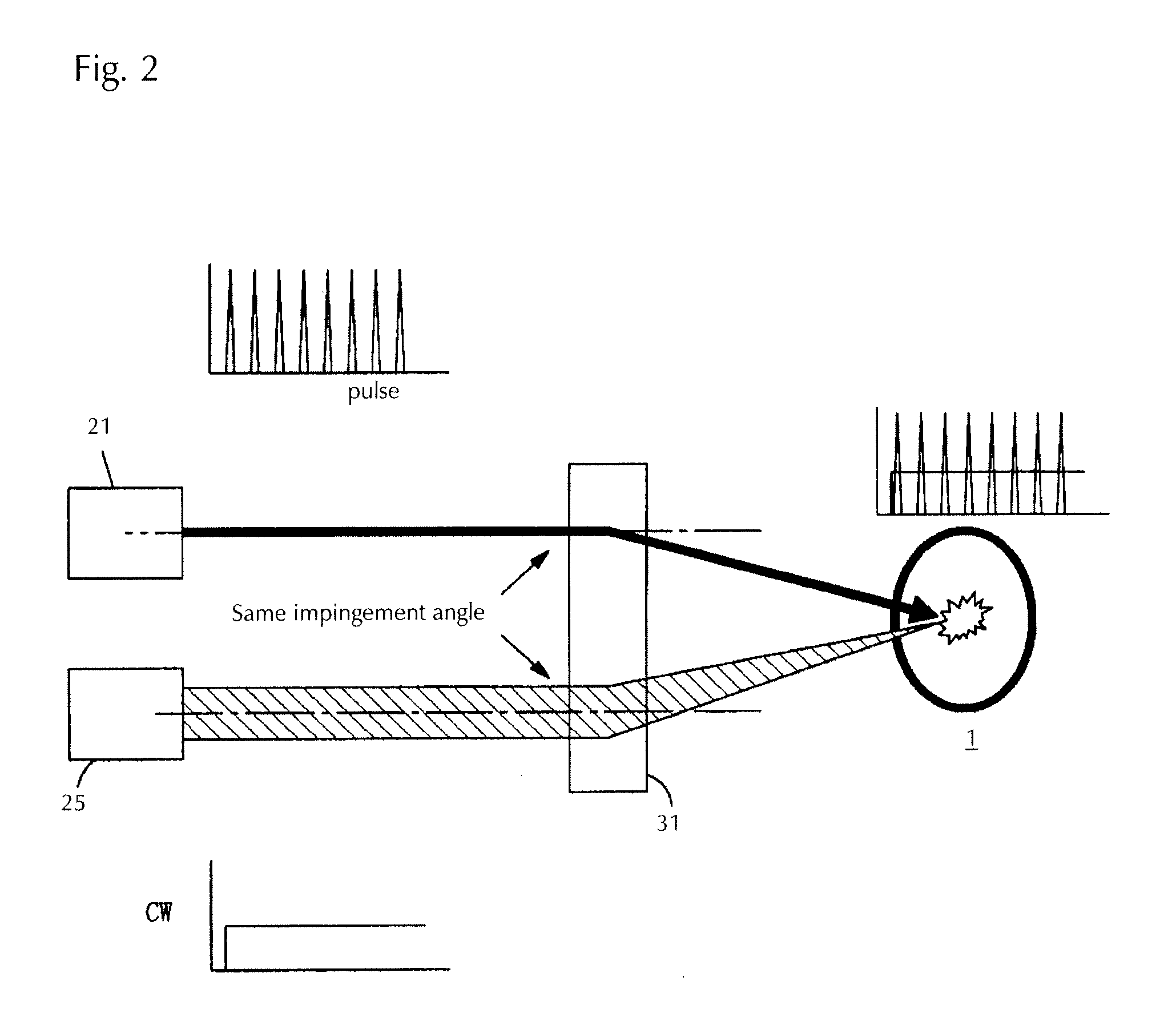

Light source device

ActiveUS20110026547A1Process stabilityReduce lightExcitation process/apparatusPhotomechanical apparatusLight beamPulsed laser beam

A light source device wherein the high-temperature plasma state after the start of the lighting is maintained stably and the light emission can be maintained stably and a decrease of the lighting life cycle by means of a heating of the light emission tube is suppressed comprises a light emission tube, in which a light emitting means is enclosed, and a pulsed laser oscillator part emitting a pulsed laser beam towards said light emission tube, wherein a continuous-wave laser oscillator part is provided emitting a continuous-wave laser beam towards said light emission tube.

Owner:ENERGETIQ TECH

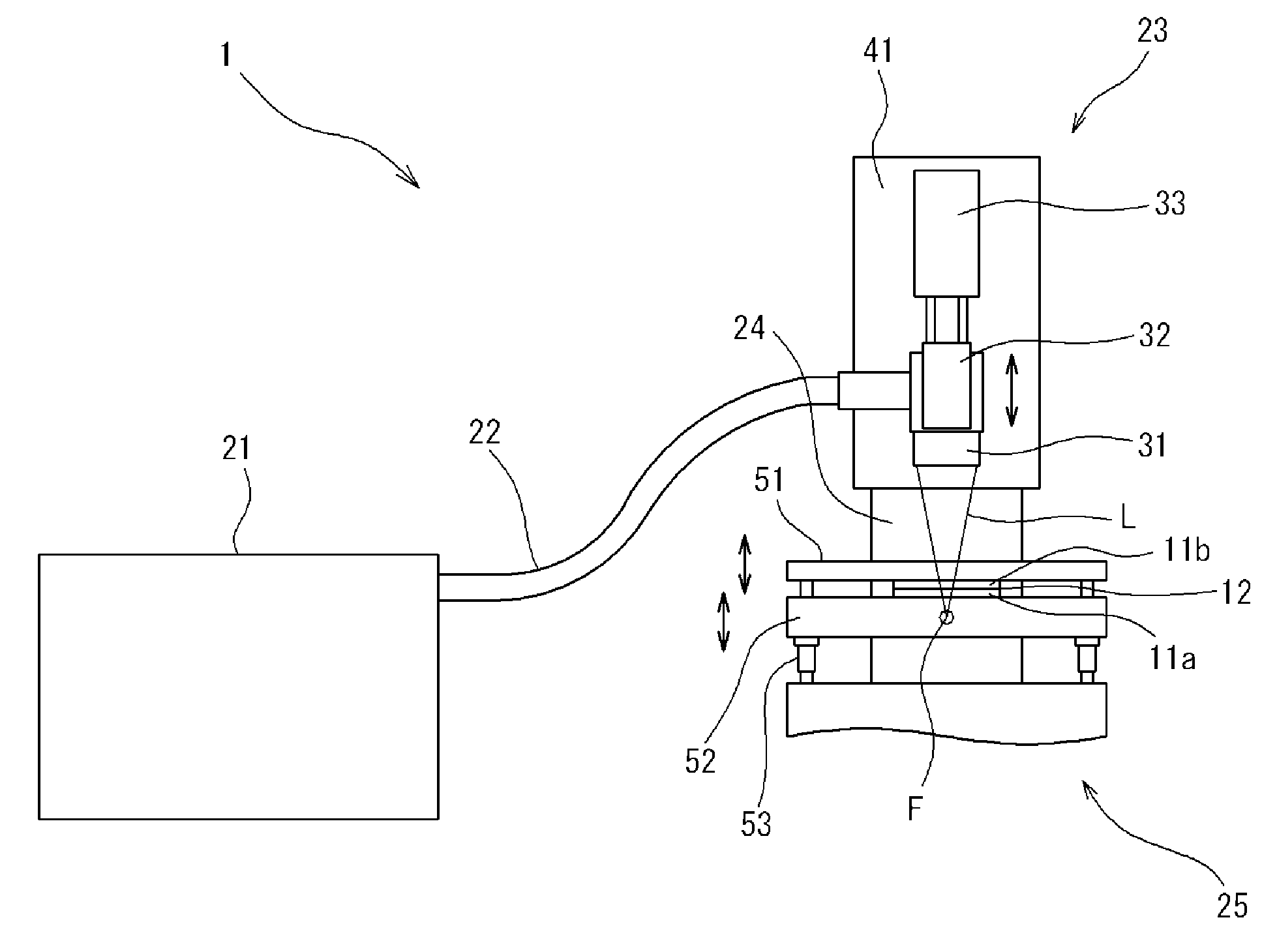

Method for joining members to be joined and joining apparatus used therefor

InactiveUS20110072854A1Easily and inexpensively joinedRaise the gradeGlass blowing apparatusGlass reforming apparatusLaser lightEngineering

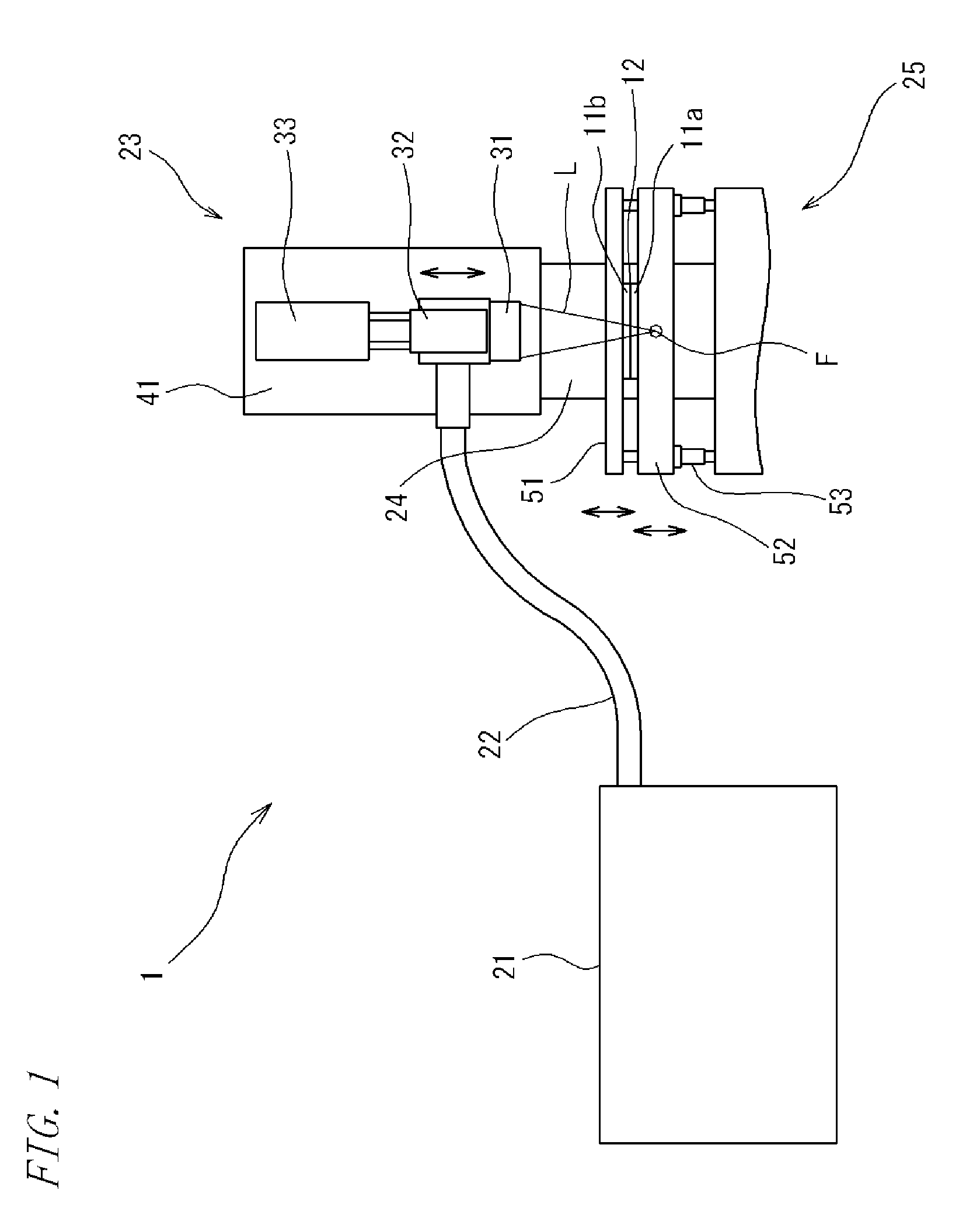

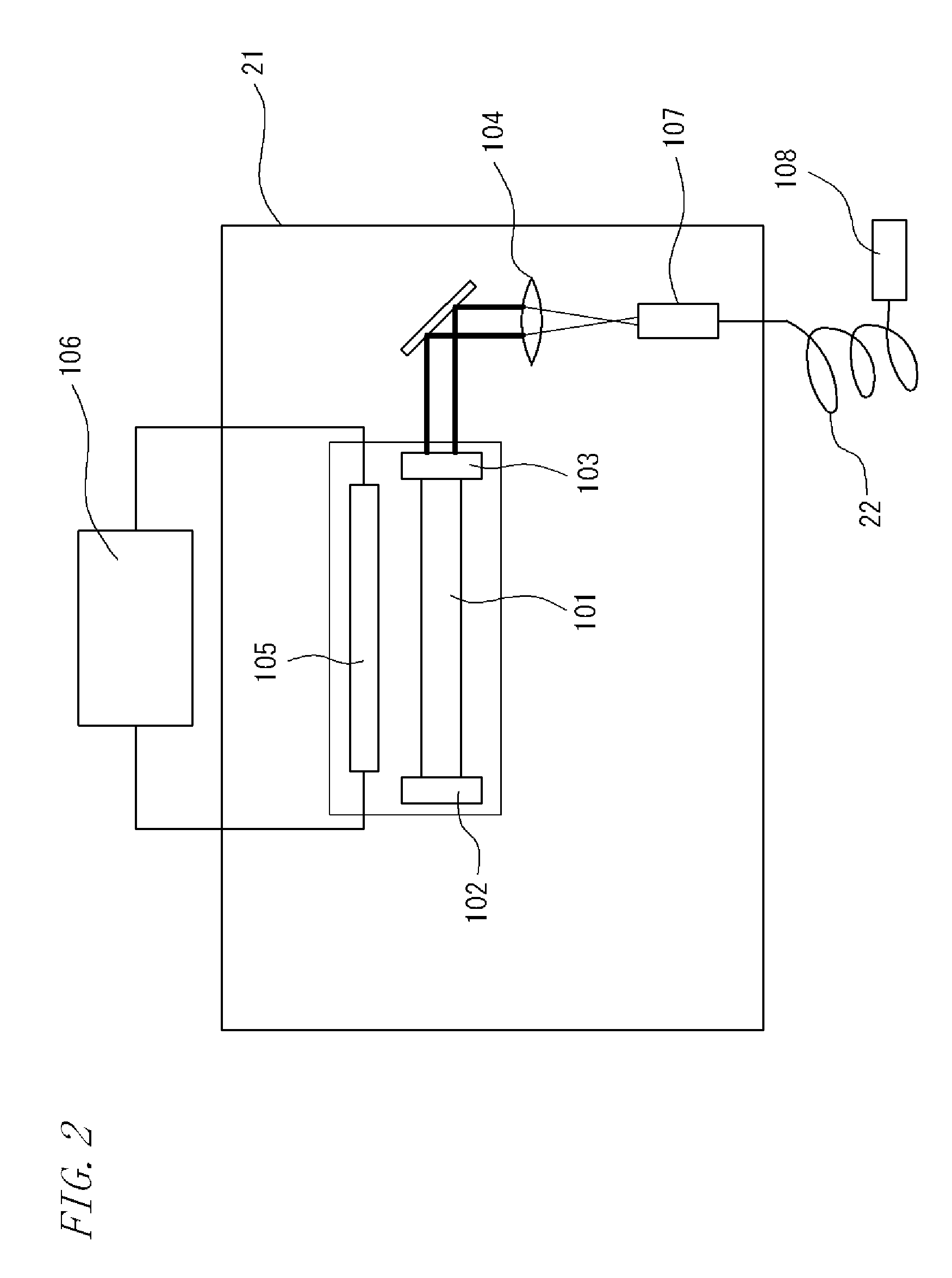

Provided are a method for joining members to be joined and a joining apparatus used therefor, which can easily and inexpensively join members to be joined such as glass members can be together with good finish.A joining apparatus 1 adapted to apply a laser beam to a joint interface (laser light absorbent layer 12) between two members to be joined 11a and 11b is provided with: a laser-applying unit 23 for applying a continuous wave laser beam with a focal point thereof spaced a predetermined distance away from the laser light absorbent layer; and a retainer 25 including a pressing portion 51 for applying in a compressing direction a substantially uniform surface pressure to the entire contact surfaces of the two members to be joined 11a, 11b at the time of applying the laser beam. Thus, the members to be joined 11a and 11b are easily and inexpensively joined together with good finish by applying the continuous wave laser beam to the laser light absorbent layer with the focal point thereof spaced the predetermined distance away from the laser light absorbent layer while applying in the compressing direction the substantially uniform surface pressure to the entire contact surfaces of the members to be joined.

Owner:KYOEI AUTOMATIC CONTROL TECH

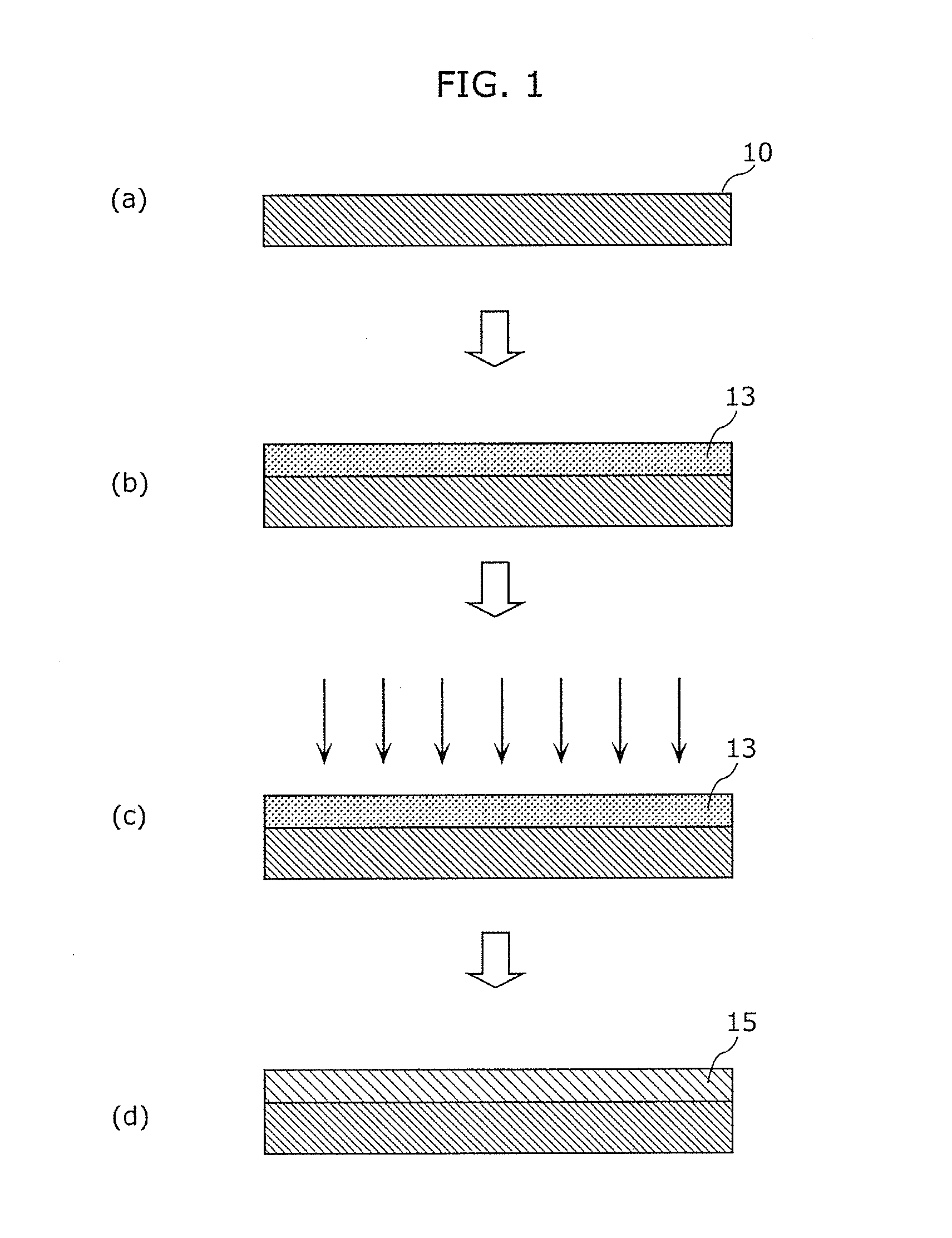

Crystalline semiconductor film manufacturing method, substrate coated with crystalline semiconductor film, and thin-film transistor

InactiveUS20110297950A1Improve in-plane uniformityTransistorSolid-state devicesIn planeOptoelectronics

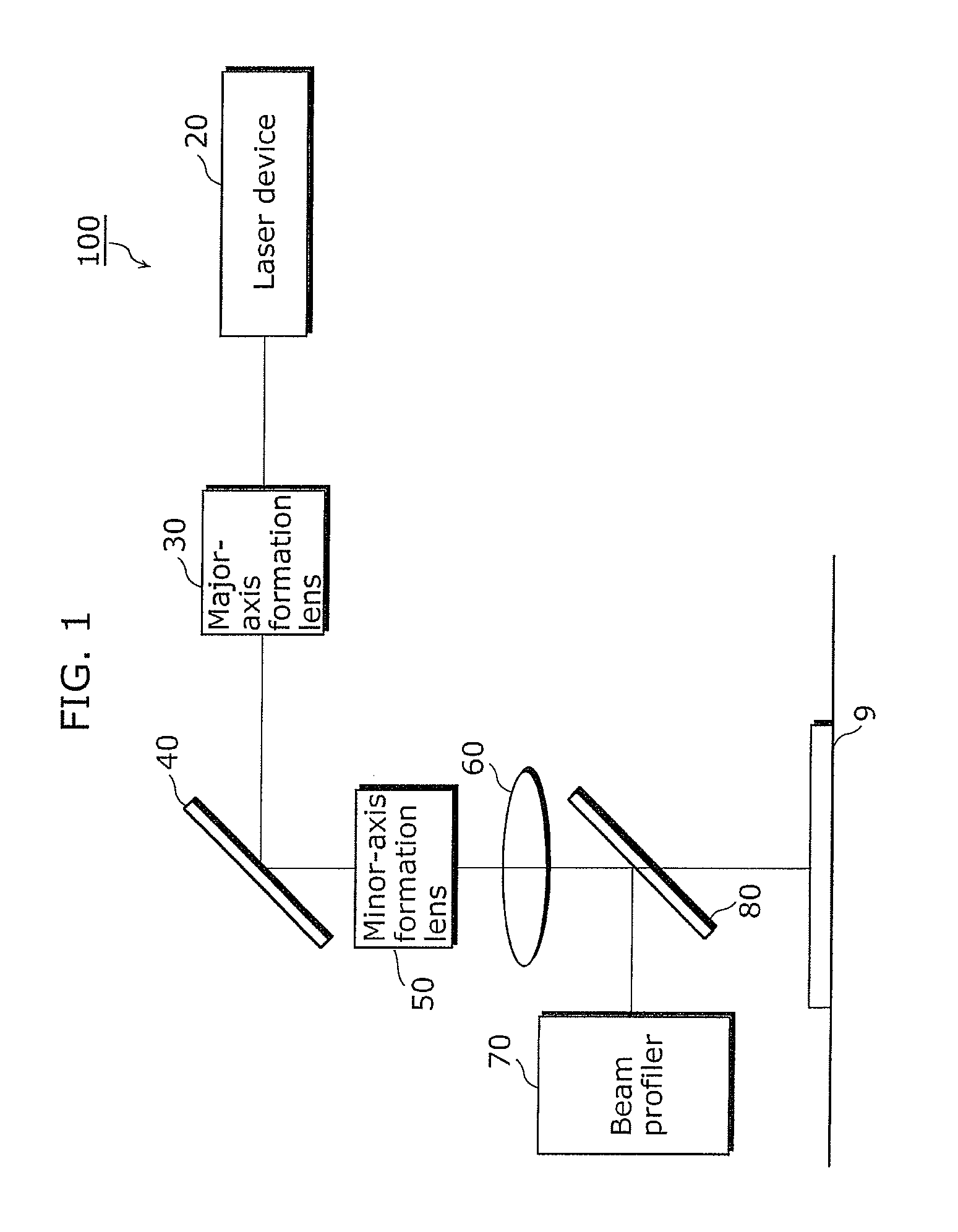

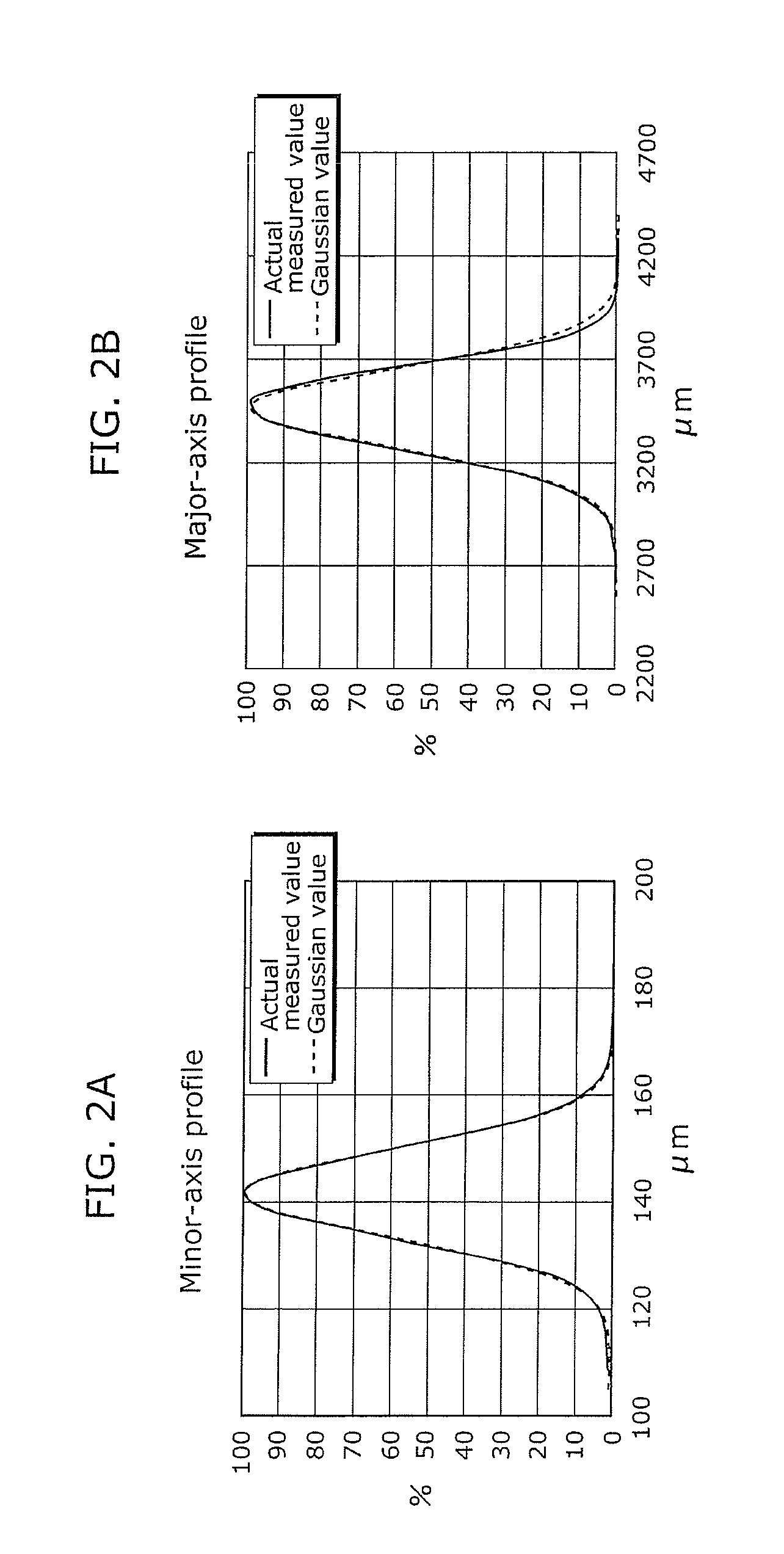

To provide a method of manufacturing a crystalline semiconductor film having a crystal structure with favorable in-plane uniformity. The method includes: irradiating an amorphous semiconductor film with a continuous-wave laser beam to increase a temperature of the amorphous semiconductor film to a range of 600° C. to 1100° C., the continuous-wave laser beam having a light intensity distribution continuously convex upward on each of major and minor axes; crystallizing the amorphous semiconductor film at the temperature increased to the range of 600° C. to 1100° C.; and increasing a crystal grain size of the crystallized amorphous semiconductor film, as a result of an increase in an in-plane temperature of the crystallized amorphous film to a range of 1100° C. to 1414° C. by latent heat released in the crystallizing of the amorphous semiconductor film.

Owner:JOLED INC +1

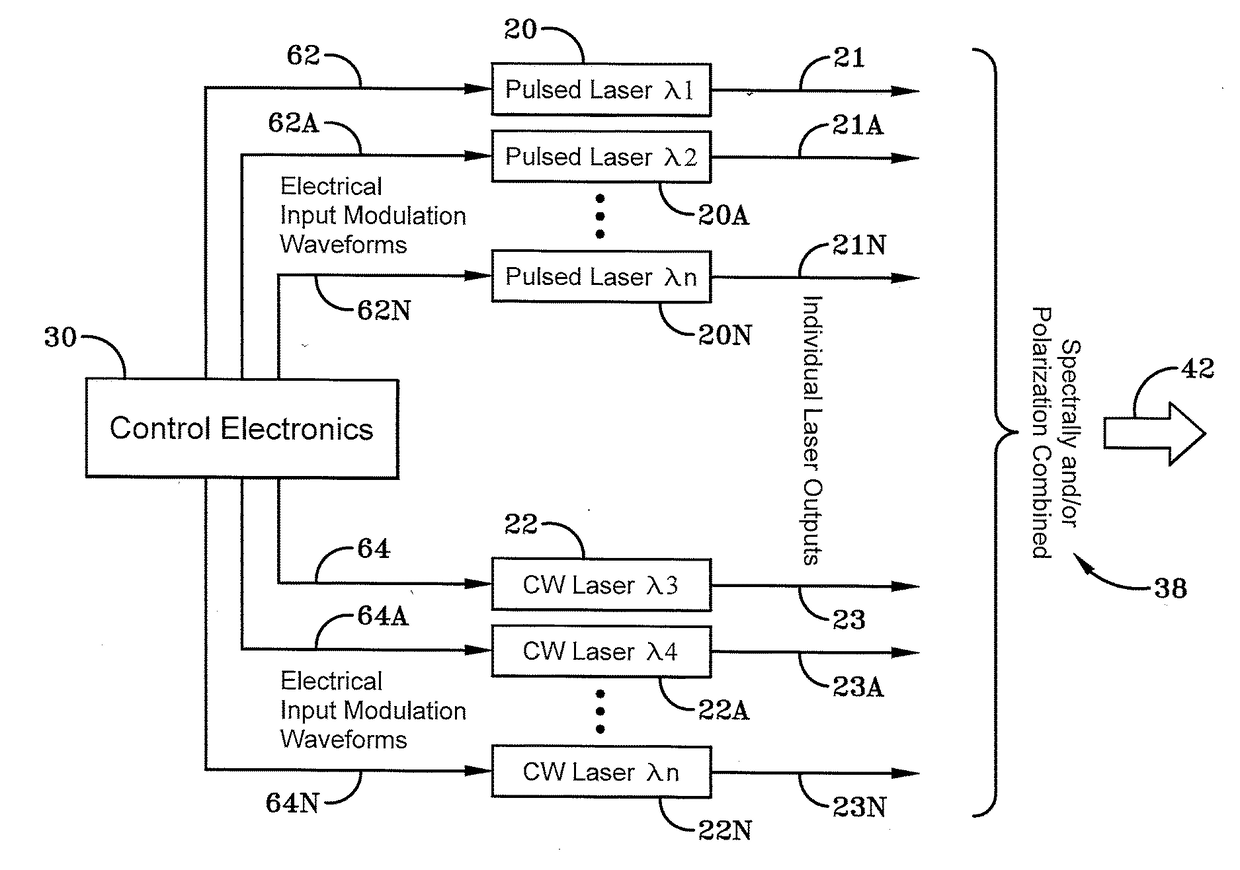

Hybrid laser countermeasure line replaceable unit and method of upgrading therewith

ActiveUS20170102212A1Improve rendering capabilitiesWave based measurement systemsDirection controllersCountermeasureLight beam

A hybrid laser countermeasure line replaceable unit and method of upgrading therewith is provided. The unit includes two generable laser beams, namely, a first pulsed laser beam and a second continuous wave laser beam. Further embodiments may have multiple pulsed and continuous wave laser beams as necessary. The two beams in this single unit either may be generated from a single gain medium or may be generated from multiple gain mediums inside the line replaceable unit. The two beams may be combined if necessary to provide greater likelihood of success as a countermeasure to defend against optically guided incoming threats to a vehicle, such as military aircraft.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Manufacturing method for thin film semiconductor device, manufacturing method for thin film semiconductor array substrate, method of forming crystalline silicon thin film, and apparatus for forming crystalline silicon thin film

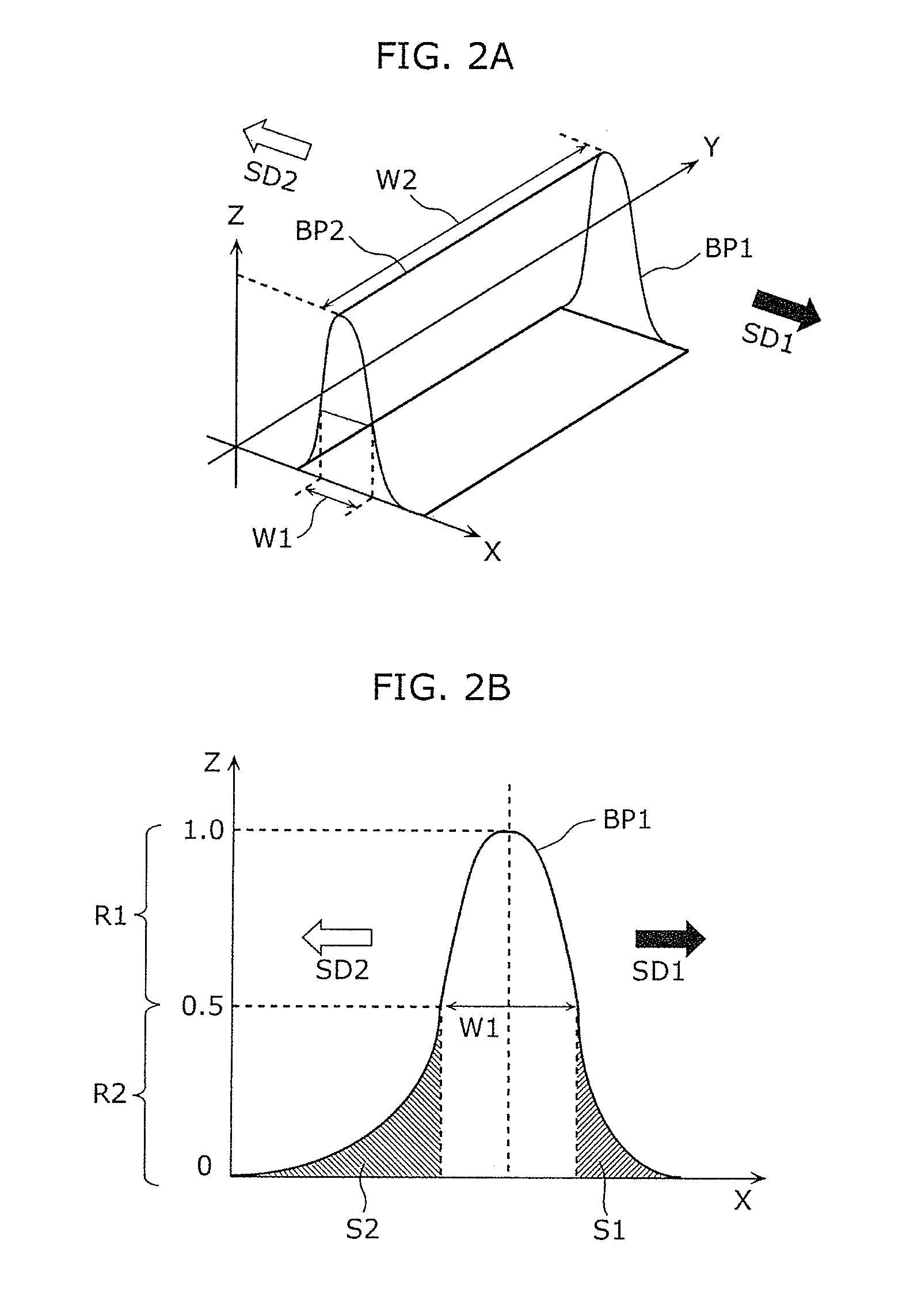

InactiveUS20120309140A1Improve conduction characteristicsDrive fastSolid-state devicesMaterial analysis by optical meansLight beamSilicon thin film

A crystalline silicon thin film is formed by irradiating a silicon thin film with a laser beam. The laser beam is a continuous wave laser beam. An intensity distribution of the laser beam in a first region about a center of the intensity distribution is symmetric on an anterior side and a posterior side of the center. The intensity distribution in a second region about the center is asymmetric on the anterior side and the posterior side. The first region is from the maximum intensity of the laser beam at the center to an intensity half of the maximum intensity. The second region is at most equal to the half of the maximum intensity of the laser beam. In the second region, an integral intensity value on the posterior side is larger than on the anterior side.

Owner:JOLED INC

Grain-oriented electrical steel sheet and method for producing same

ActiveUS9139886B2Increase strainExcellent iron loss characteristicLayered productsInorganic material magnetismElectrical steelSheet steel

In a method for producing a grain-oriented electrical steel sheet, grooves each having a given length and extending in a direction including a direction perpendicular to a transportation direction of the grain-oriented electrical steel sheet are formed at given intervals in the transportation direction by irradiating the surface of the grain-oriented electrical steel sheet with a laser beam while scanning the surface of the grain-oriented electrical steel sheet with the laser beam. Further, in the method for manufacturing a grain-oriented electrical steel sheet, the laser beam is a continuous-wave laser beam having a laser wavelength λ of 1.0 μm to 2.1 μm, power density Pd [W / mm2] which is obtained by dividing laser beam intensity P by a focused beam area S is 5×105 W / mm2 or more, and the power density Pd [W / mm2] and scanning speed V [mm / s] of a focused spot of the laser beam on the surface of the grain-oriented electrical steel sheet satisfy a relationship of 0.005×Pd+3000≦V≦0.005×Pd+40000.

Owner:NIPPON STEEL CORP

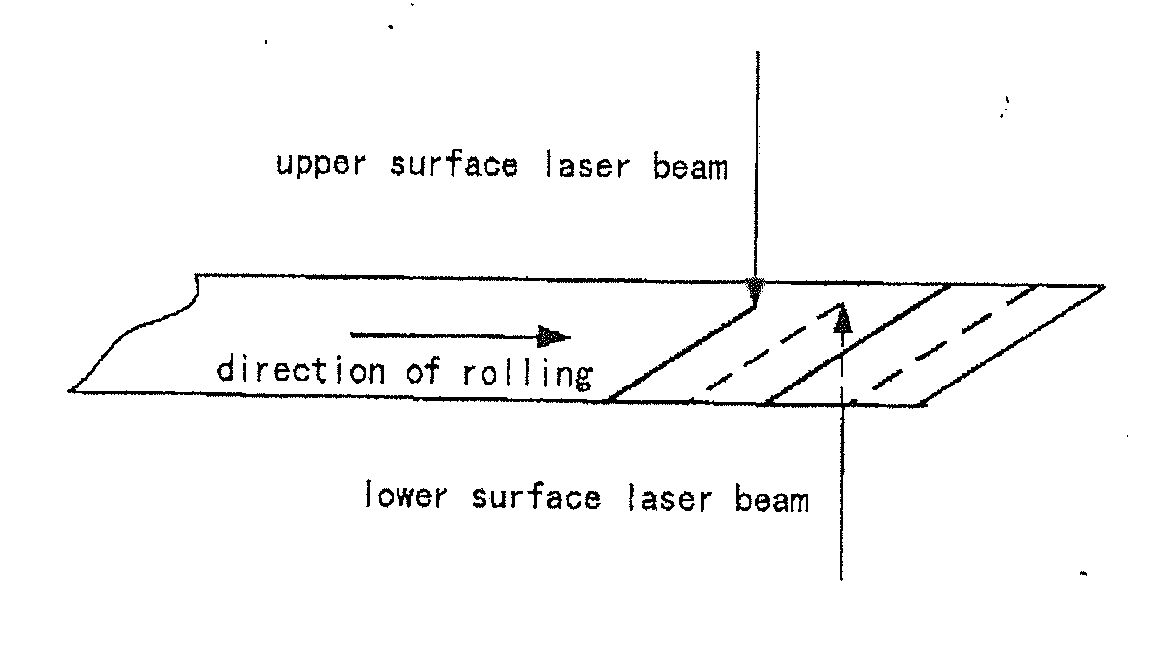

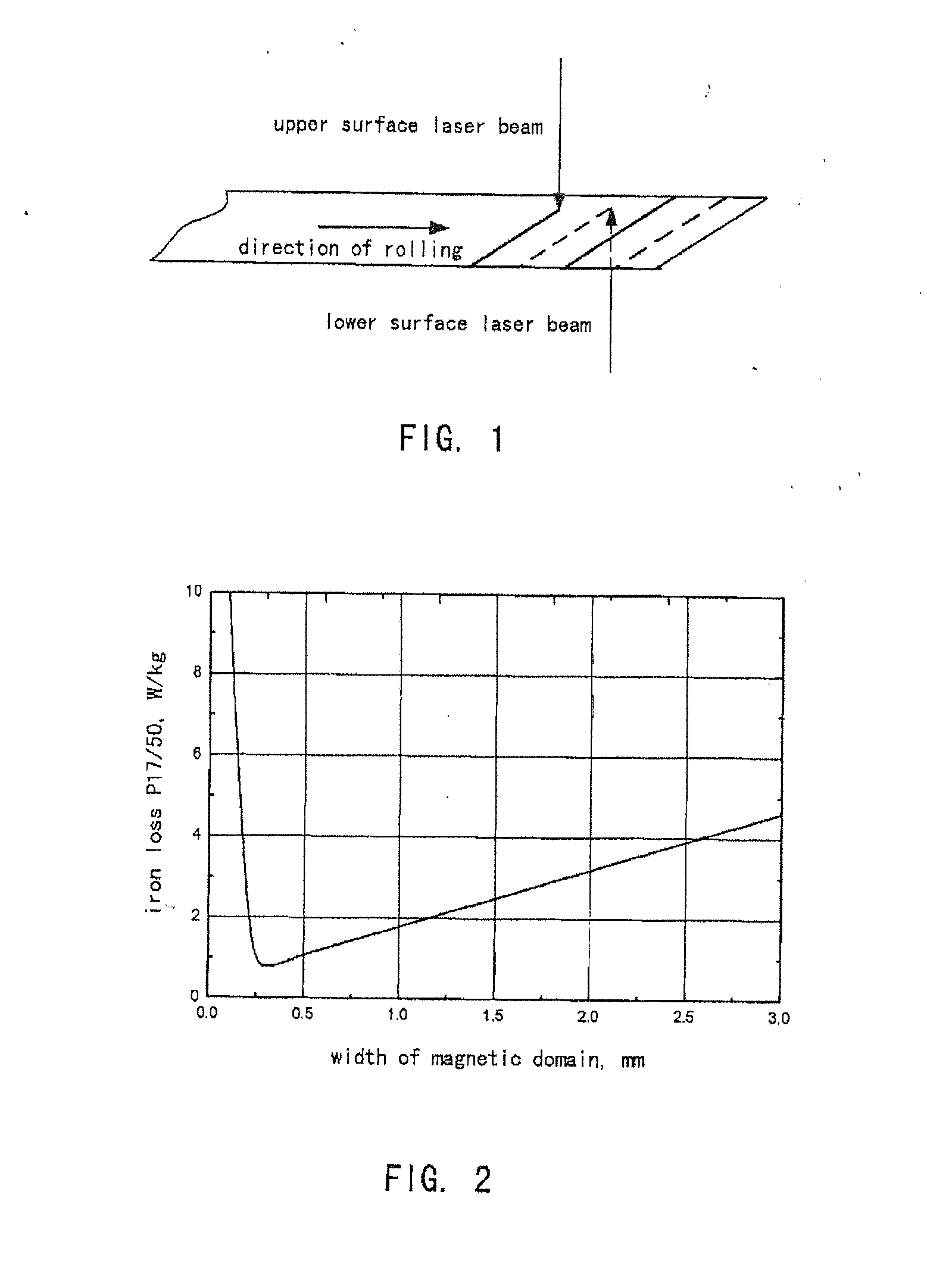

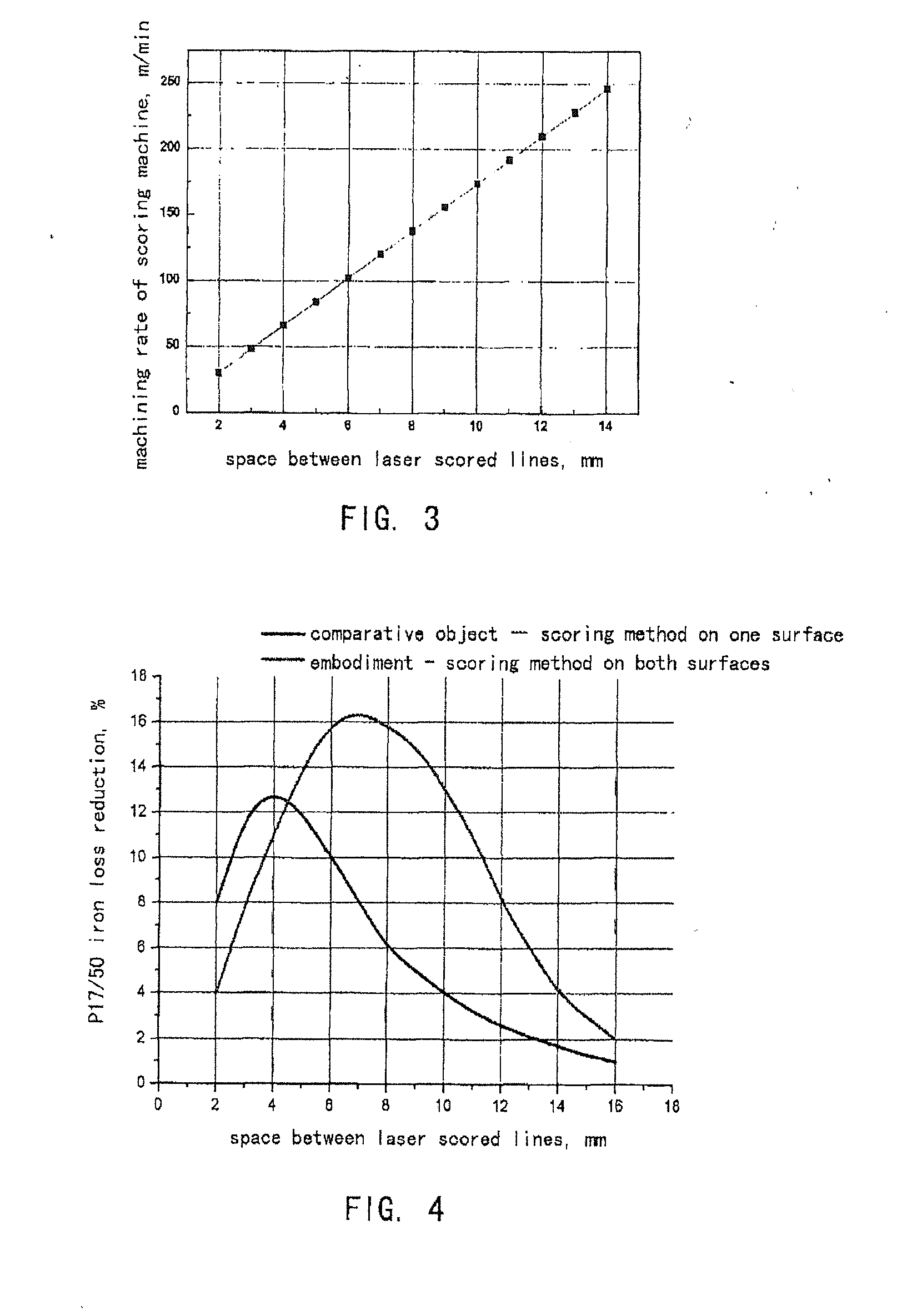

Fast-speed laser scoring method

ActiveUS20130284711A1Reducing iron lossRapid mass productionLaser beam welding apparatusProduction lineScore method

A fast-speed laser scoring method is provided, in which a set of related laser scoring device is used to simultaneously score lines on the upper surface and the lower surface of an oriented silicon steel strip, which is being fed and traveling forwards on a production line, with high-focalized continuous wave laser beam; the lines scored on the upper surface and the lines scored on the lower surface have the same space between every two adjacent scored lines but are staggered each other in order to reduce iron loss evenly. The space between every two adjacent scored lines on the same surface is 6-12 mm, laser power is 1000-3000 W and scanning speed is 100-400 m / min. The machining rate of the scoring method and device attains 1.5-2 times the one of conventional scoring methods which can not simultaneously score the upper and lower surfaces of a steel strip at a time. The lines scored on a steel strip by the method can reduce iron loss of the strip by 10-16%.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com