Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2699 results about "Weld line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In manufacturing, the Weld line or Knit line or Meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to "knit" together, or "weld", during the molding process. These lines usually occur around holes or obstructions and cause locally weak areas in the molded part. Knit lines are considered molding defects, and occur when the mold or/and material temperatures are set too low: thus the materials will be cold when they meet, so that they do not bond perfectly. This can cause a weak area in the part which can cause breakage when the part is under stress. Weld lines therefore occur during machine start-up, when equilibrium conditions have not been met. Mouldings made in this setting-up period must be rejected.

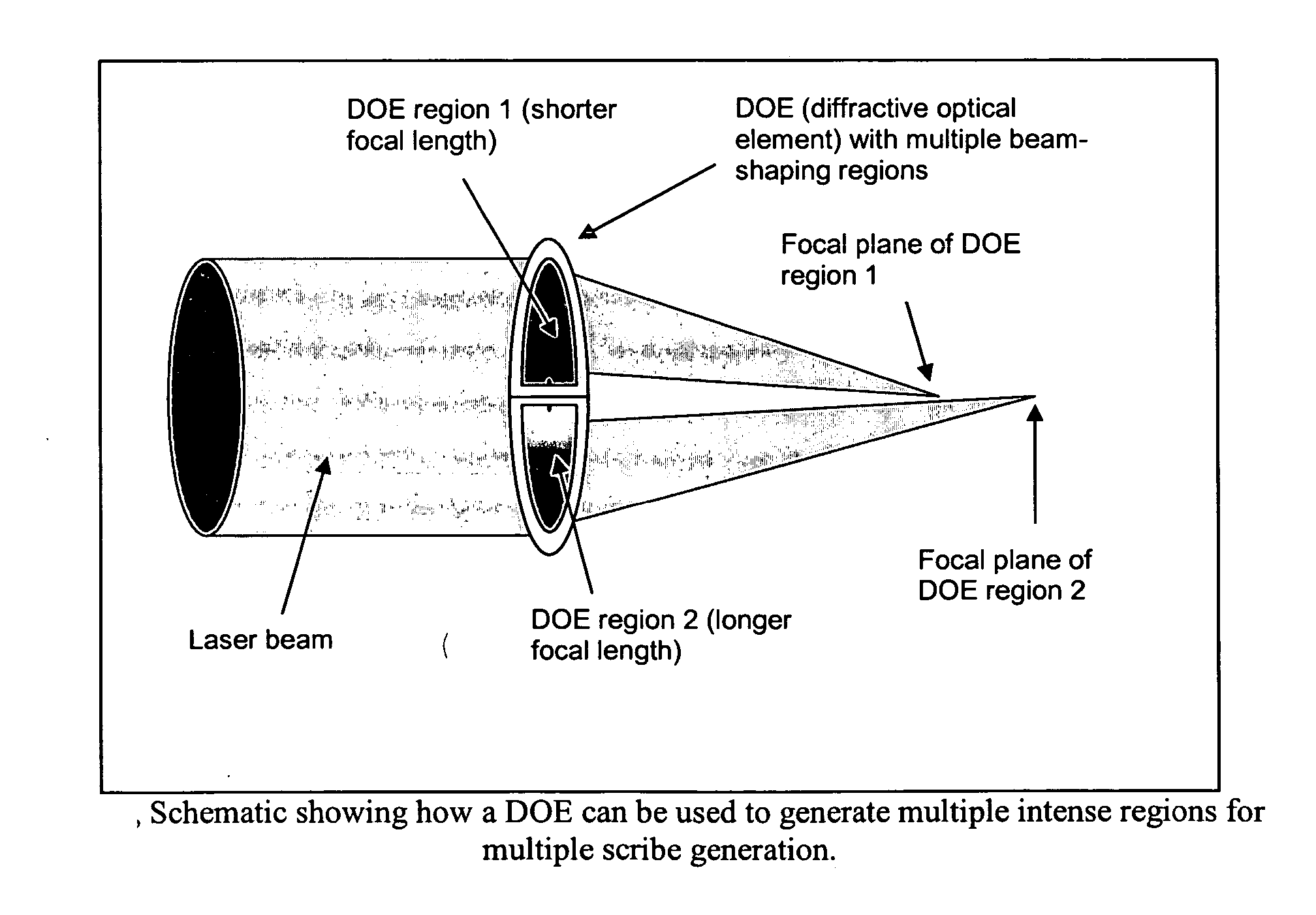

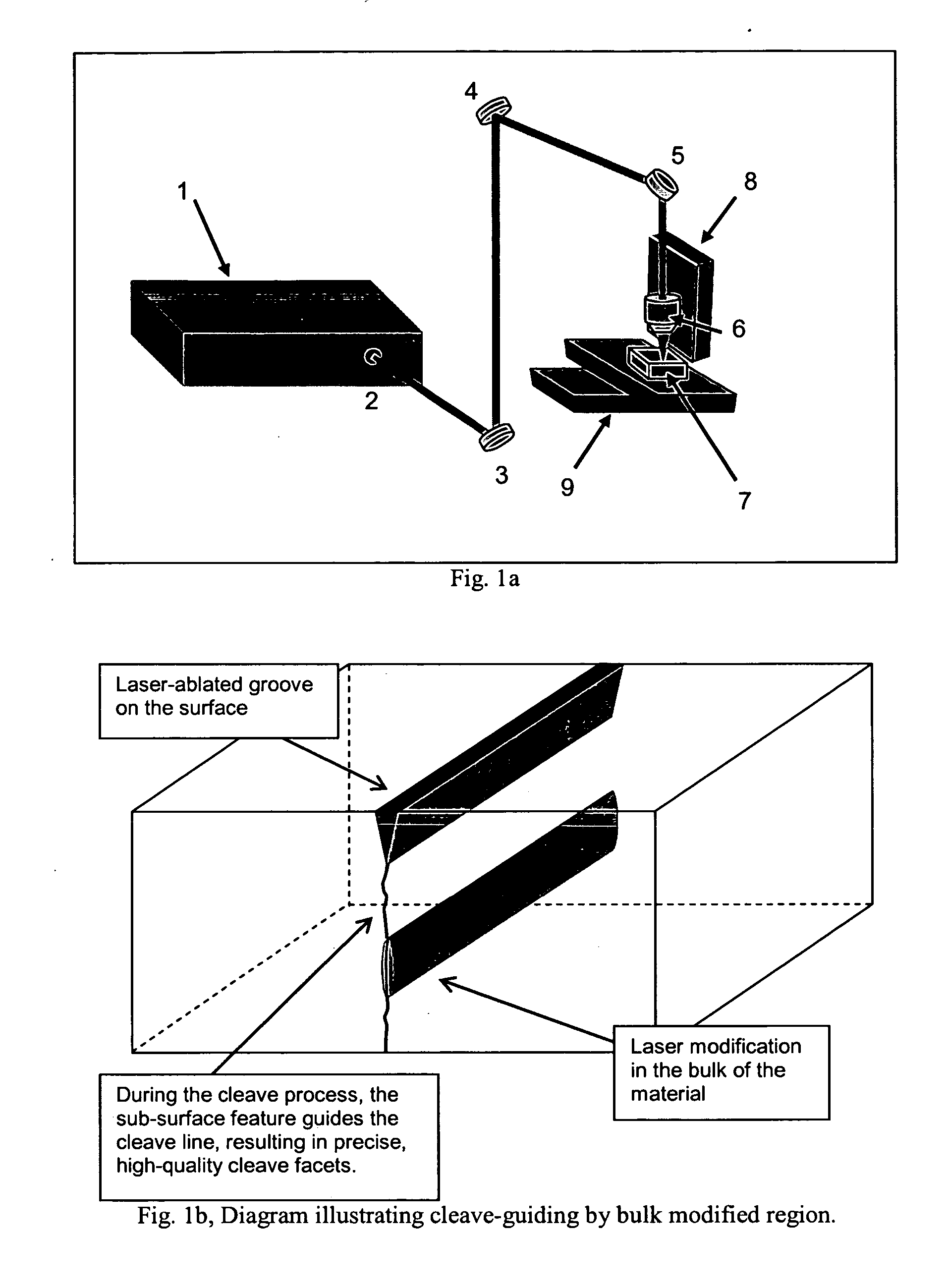

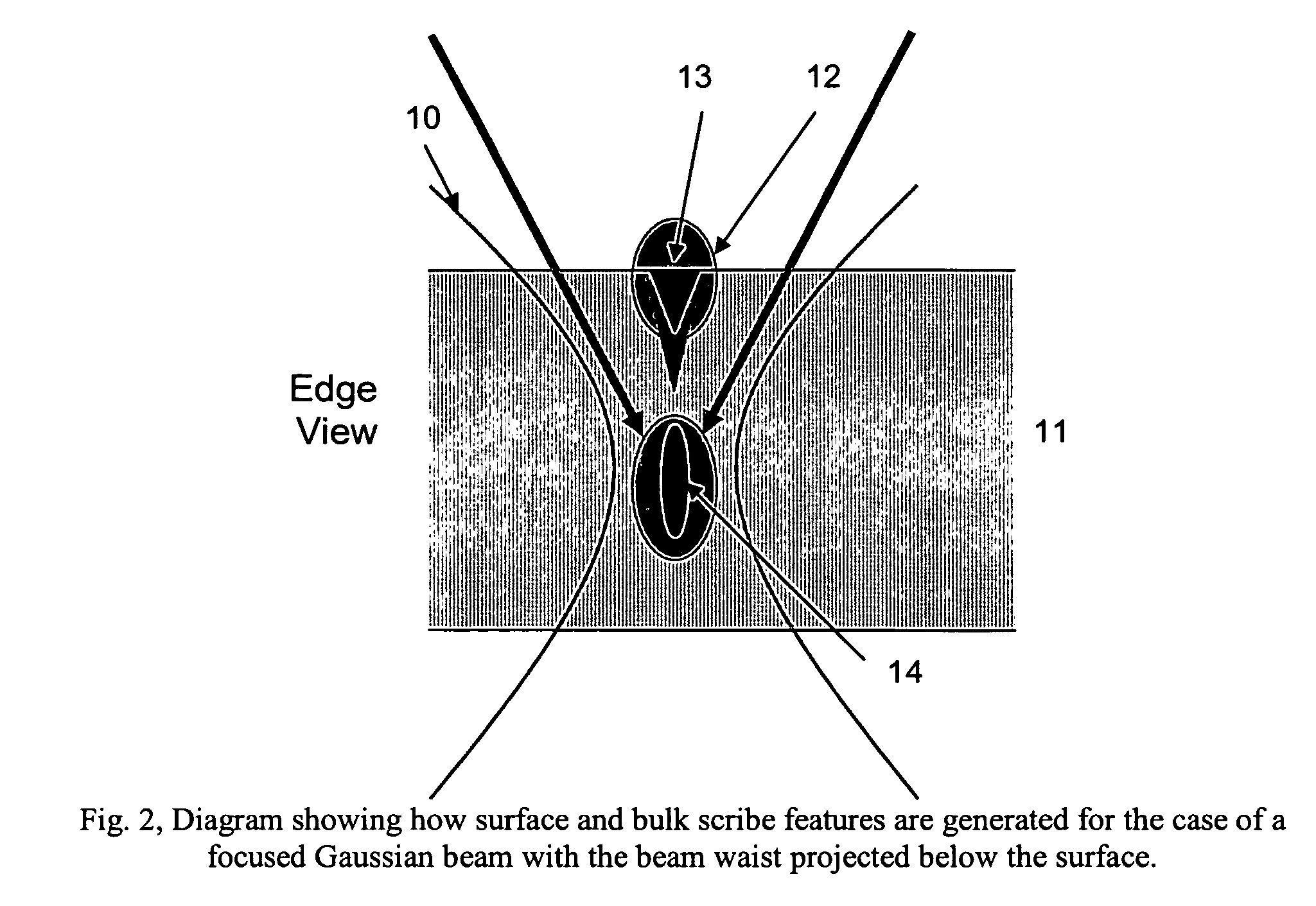

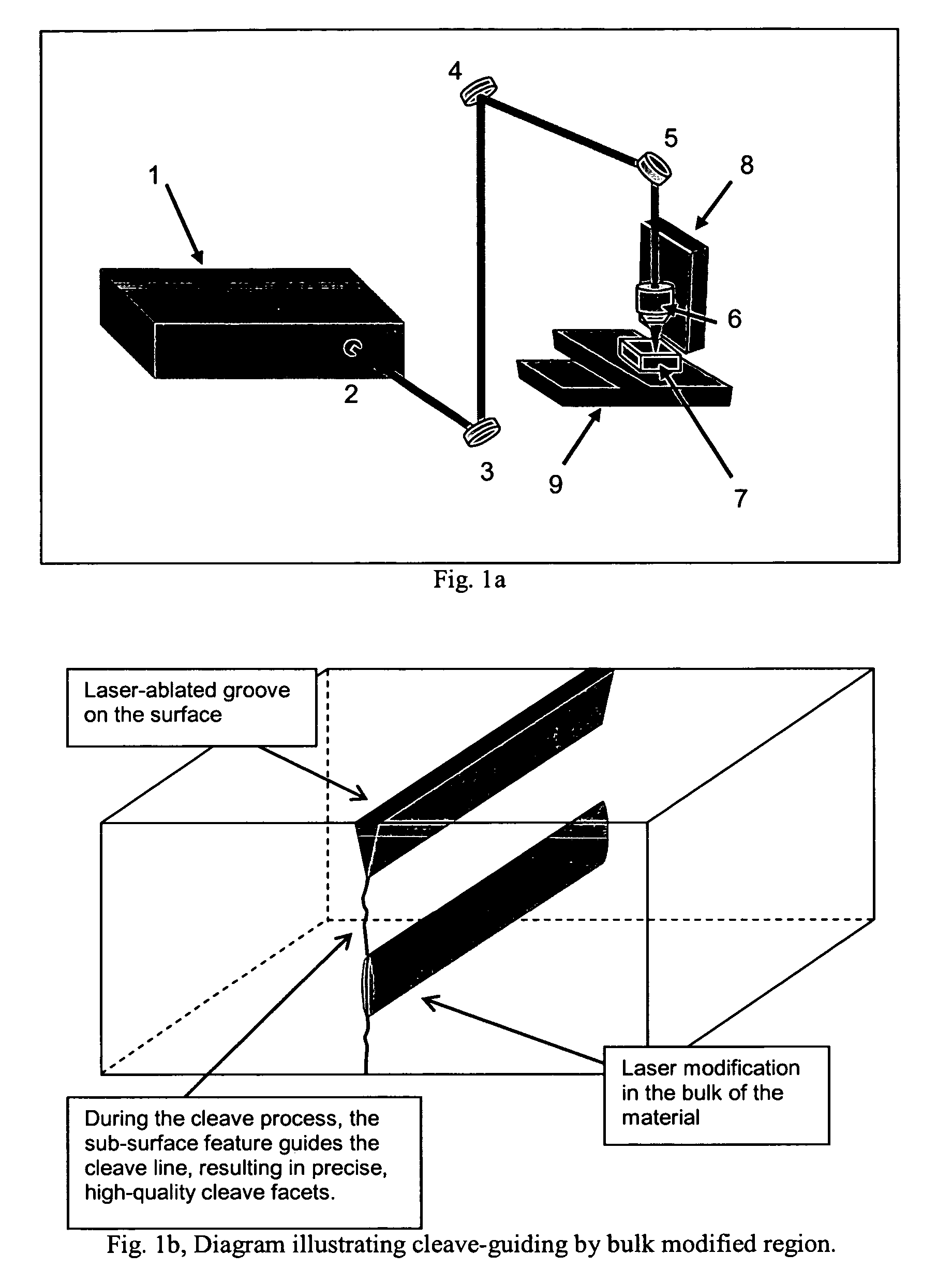

Transparent material processing with an ultrashort pulse laser

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

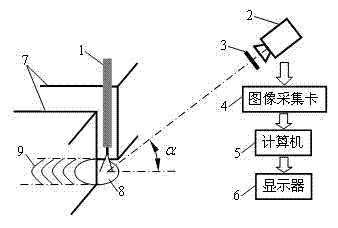

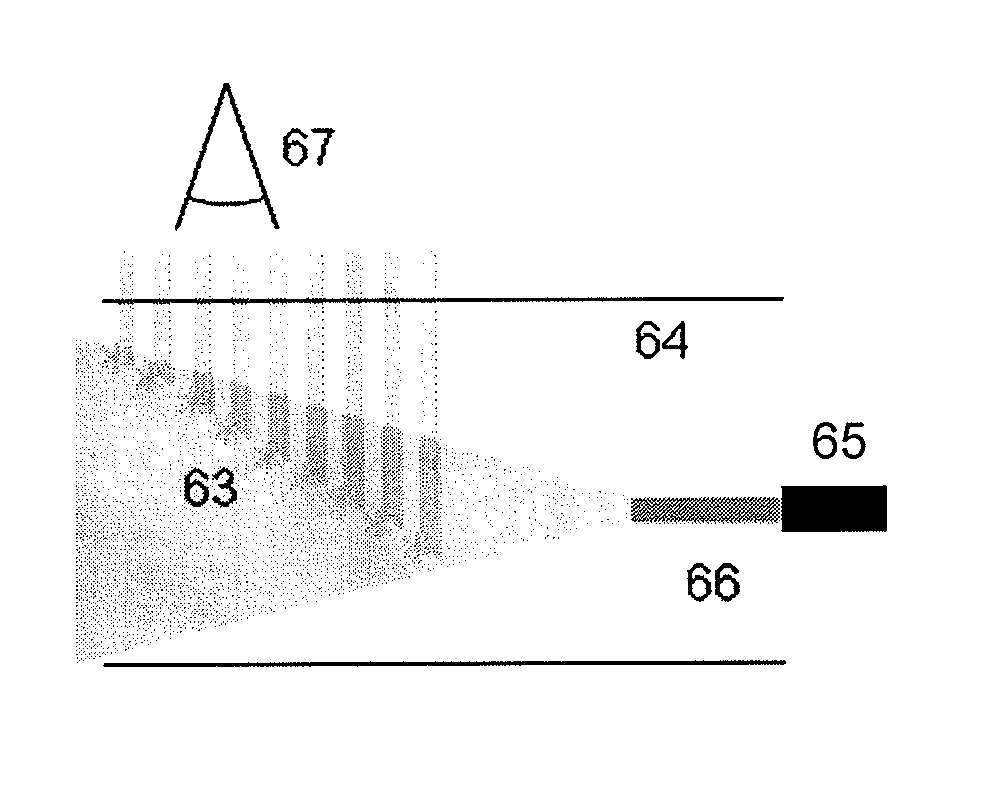

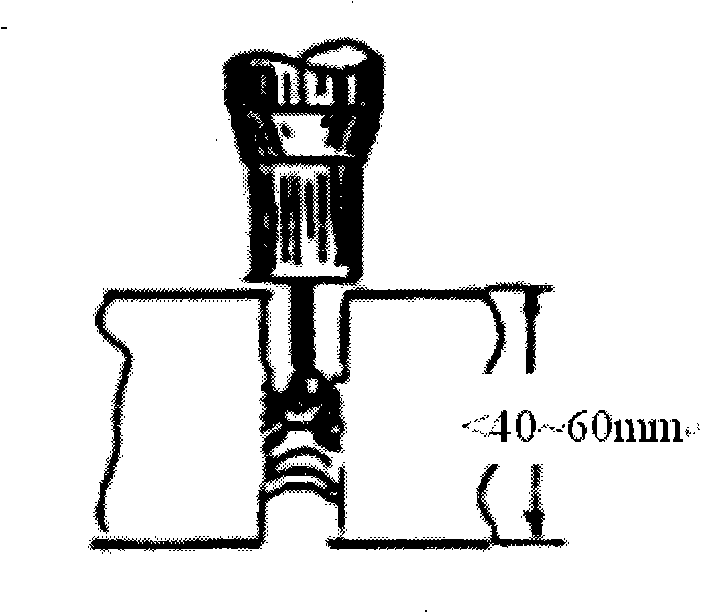

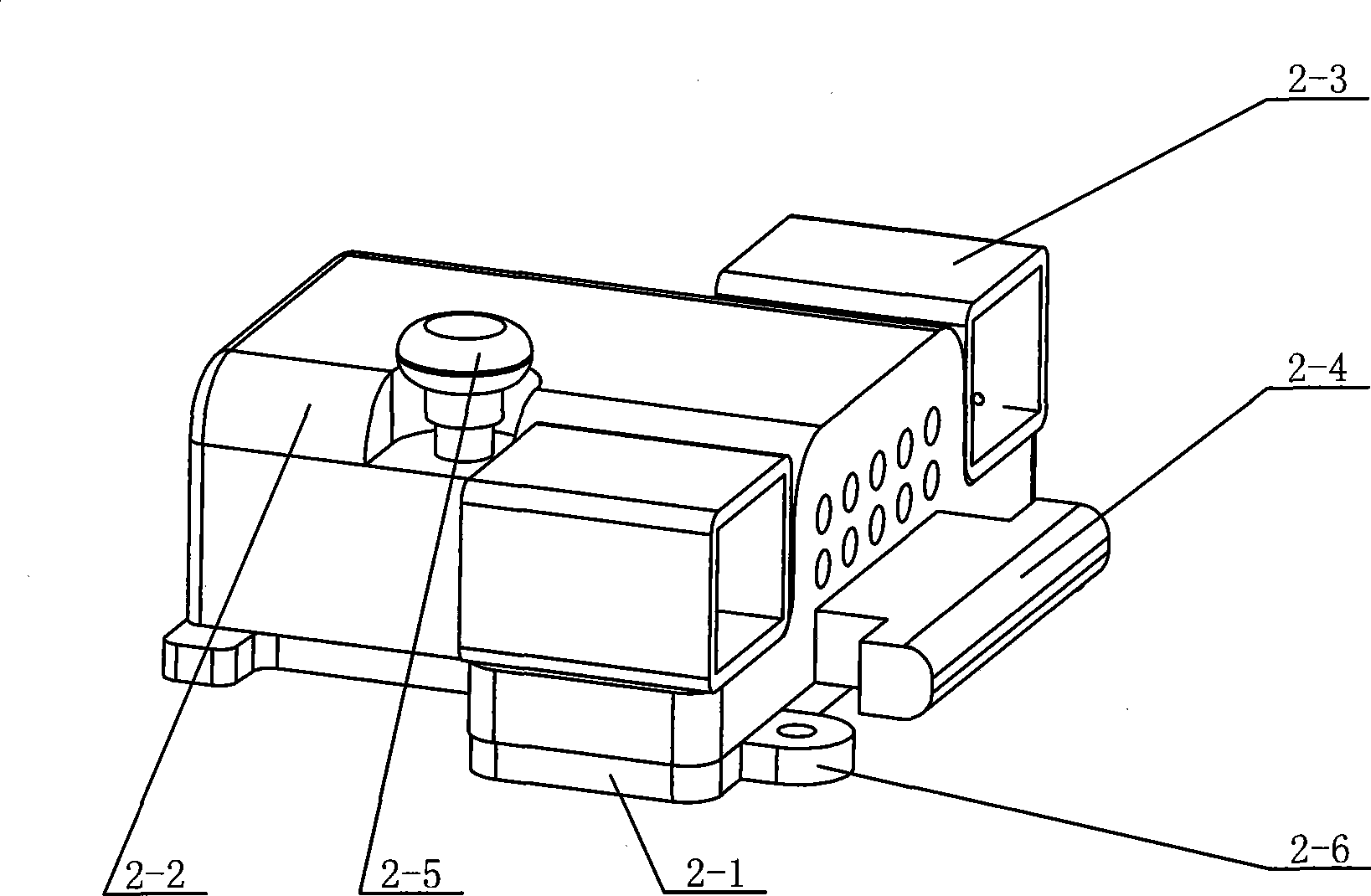

Narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing

ActiveCN102814574AReduce volumeReduce power consumptionArc welding apparatusDisplay deviceEngineering

The invention discloses a narrow gap welding monitoring and welding line deviation detecting method based on infrared vision sensing and belongs to the technical field of welding. An infrared vision sensing system comprises an infrared complementary metal oxide semiconductor (CMOS) camera, a filtering system, an image collecting card, a computer, a display and the like. Narrow gap welding arc light and molten pool radiation light are used as a light source, an infrared narrow belt filtering system is used for filtering interference signals and adjusting light intensity, and the computer collects and displays a welding image obtained through the infrared CMOS camera. An image capturing window is used for capturing an image away from an arc side, the image is processed, welding line deviation information is obtained by extracting a groove single-side edge, and a real-time property of welding line deviation detecting is improved while arc noise is effectively avoided. The system is simple in formation, clear in monitored image, high in welding line deviation detecting precision, strong in anti-interference capacity and good in engineering practicality and can achieve the purposes of real-time monitoring of narrow gap welding and synchronous detecting of welding line deviation.

Owner:JIANGSU UNIV OF SCI & TECH

Appearance-improving spraying-free aesthetic resin and its preparation method

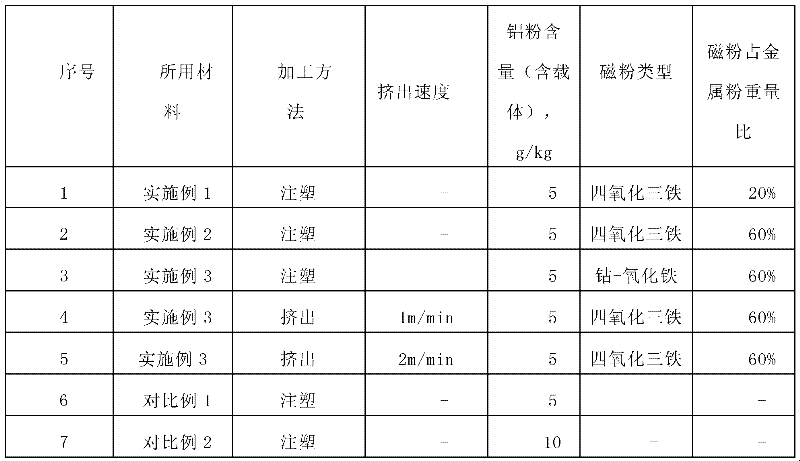

The invention relates to an appearance-improving spraying-free aesthetic resin and its preparation method. The resin comprises the following components by weight part: 90 of matrix resin, 0.1-2.0 of a lubricant, 0.1-1.0 of an antioxidant, and 10-30 of a magnetic metallic pigment masterbatch, which consists of the following components by weight part: 100 of the matrix resin, 1.0-20 of a magnetic metallic pigment, 1.0-30 of a pearlescent pigment, 0.1-2.0 of the lubricant, 0.1-1.0 of the antioxidant. The preparation method includes: preparing the magnetic metallic pigment masterbatch; and mixingthe above raw materials, then conducting mixing, extrusion, bracing, cooling, and pelletizing, thus obtaining the aesthetic resin. The aesthetic resin of the invention can effectively improve the affinity of an aluminum powder pigment and a plastic substrate, mitigate flow marks and weld lines that appear during injection molding or extrusion of aluminum powder pigment-containing aesthetic resin,and simultaneously strengthens the metal effect a made piece, greatly reduces consumption of the aluminum powder pigment, and saves cost. The present invention is green and environmental aesthetics resin instead of traditional paint scheme provides technical support. The aesthetic resin and the preparation method provided in the invention provide technical support for green and environmentally friendly aesthetic resin to substitute traditional paint spraying schemes.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

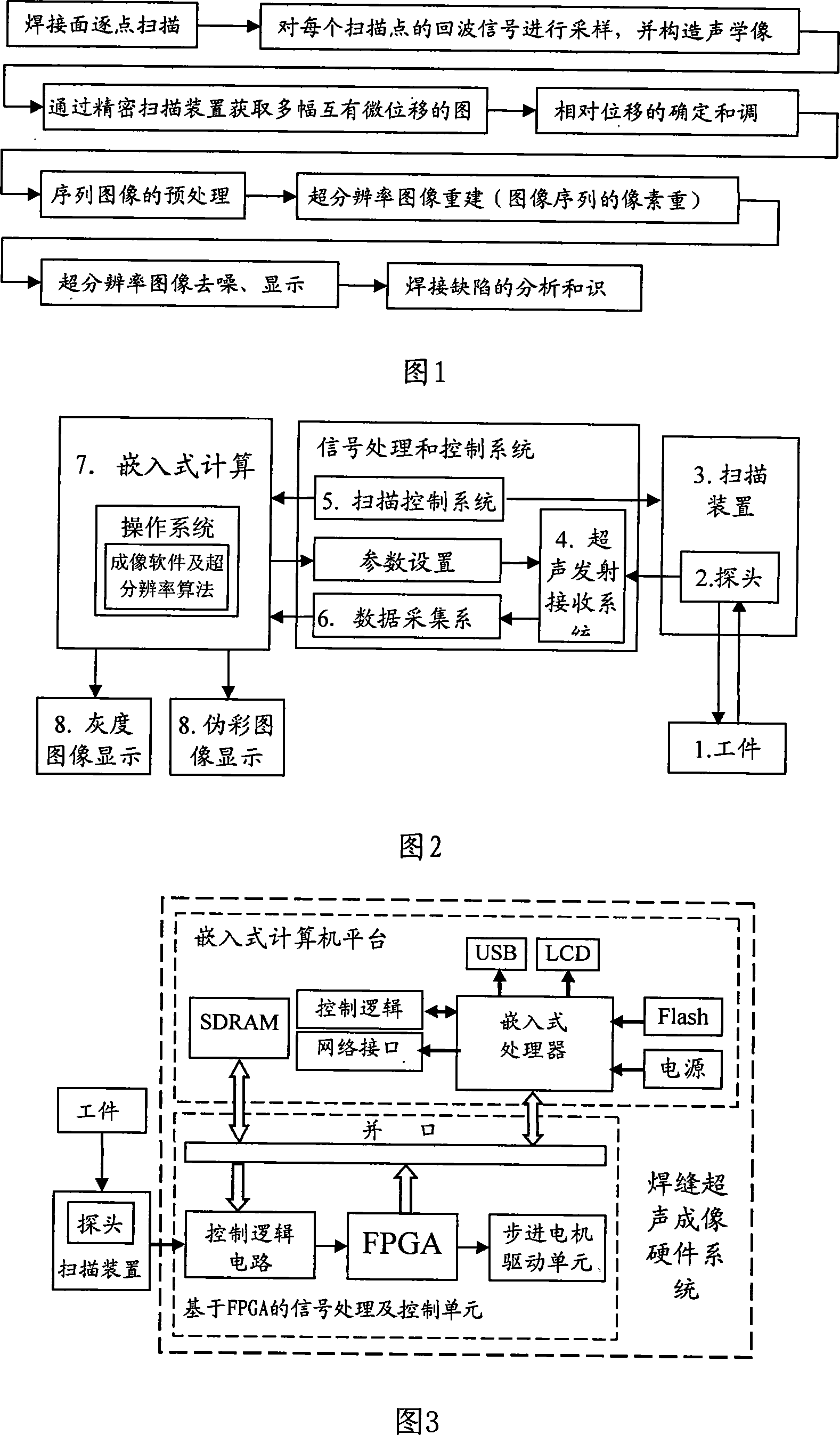

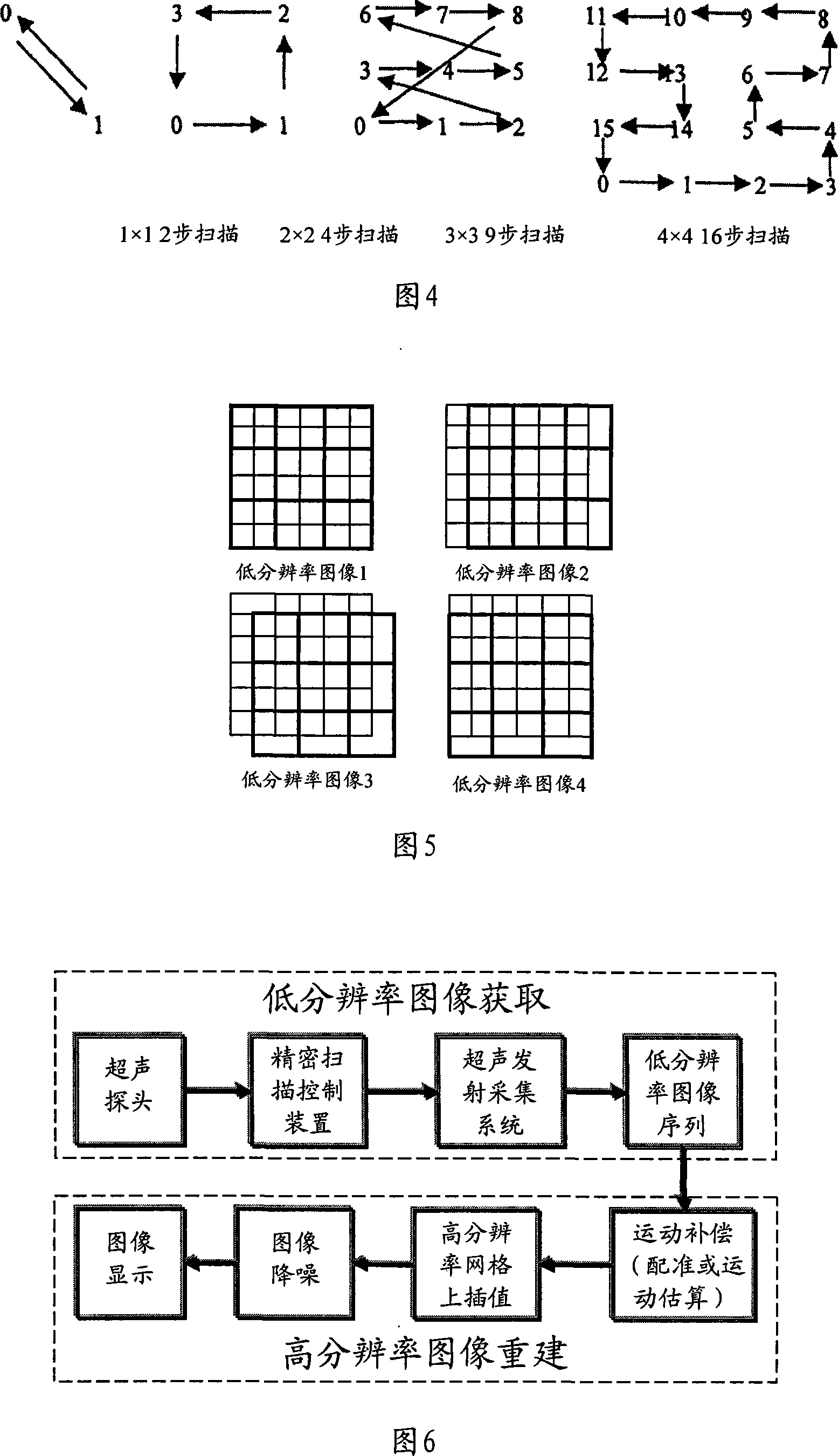

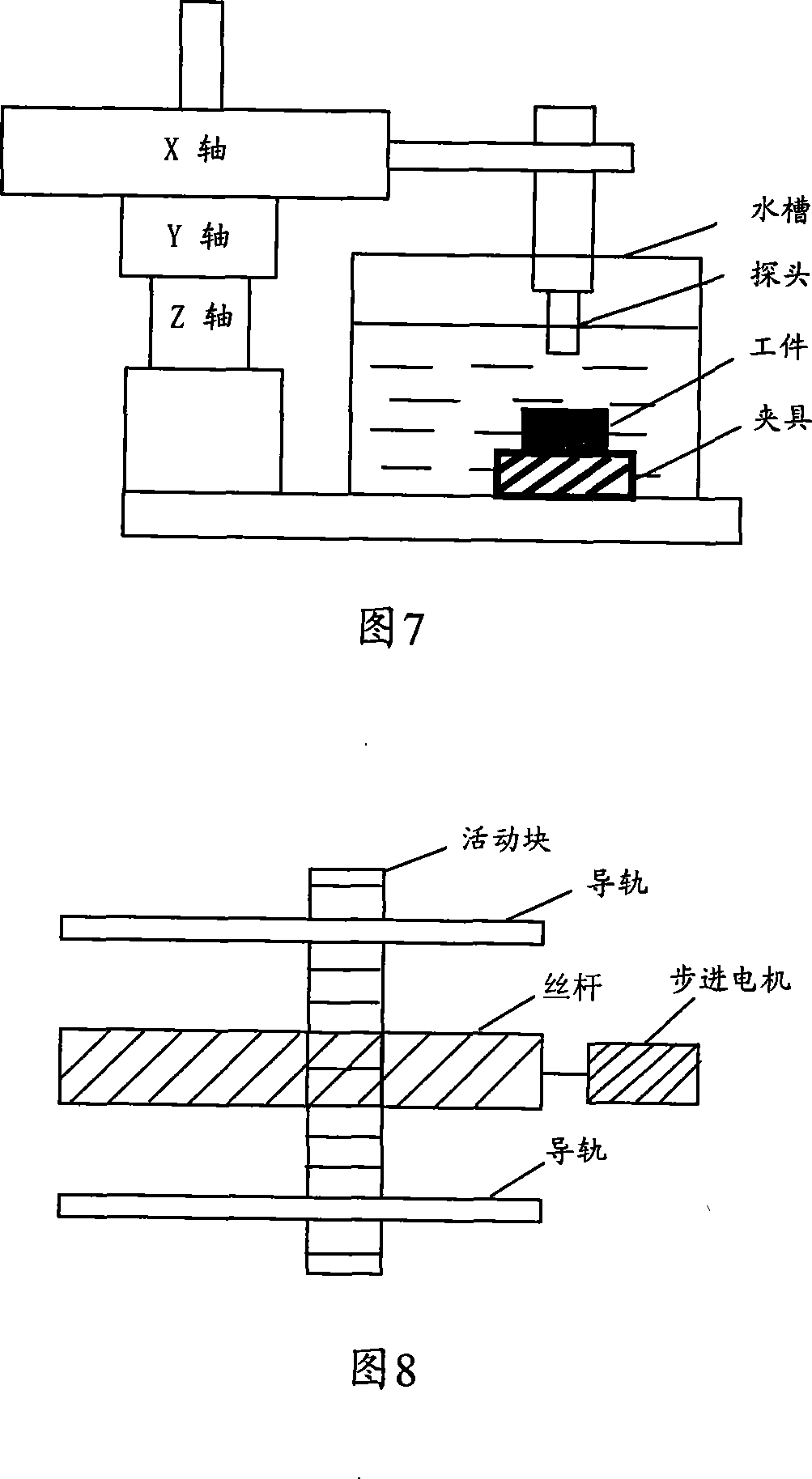

High-resolution welding seam supersonic image-forming damage-free detection method and detection system

InactiveCN101101277AImprove performancePrecise positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound imagingSonification

The invention discloses a high clear weld ultrasound imaging undamaged detection method and detection system, firstly dong point by point scanning with leach focusing probe to welding seam, and sampling detecting signal of ultrasound reflect echo for every bit, composing the ultrasonic scanning image of welding line section, and then realizing to rebuild super-resolution of image by gathering tiny scanning image and multigraph rebuilding super-resolution image. The invention can breach resolution limited of existing equipment of ultrasound imaging, it improves greatly recognizability of equipment of ultrasound imaging for the small bug of welding line by multi-framing rebuilding high resolution and high quality image from fall quality image in the scene.

Owner:SOUTH CHINA UNIV OF TECH

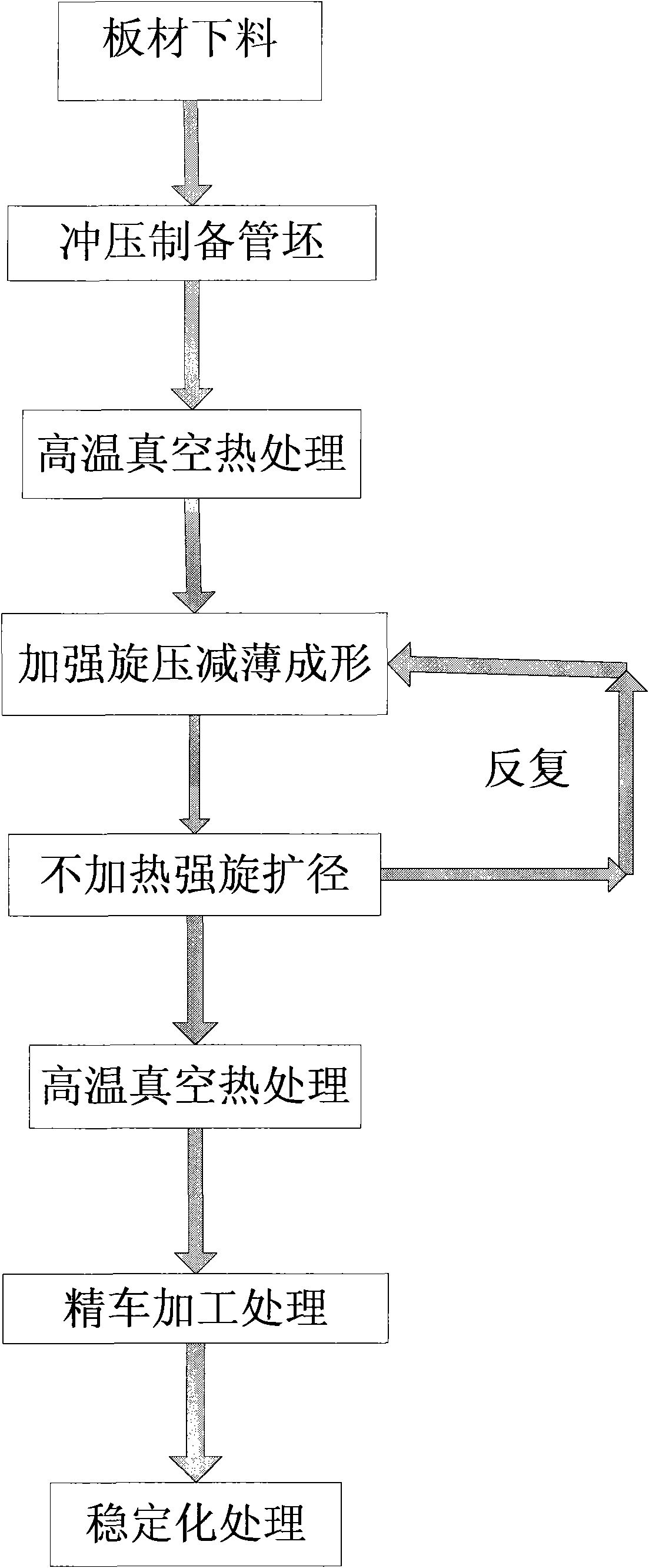

Integral forming method of large size thin-walled titanium alloy cylindrical part without welding line

ActiveCN101579804ASolve UtilizationSolving with longitudinal weldsFurnace typesHeat treatment furnacesThinningLarge size

The invention provides an integral forming method of a large size thin-walled titanium alloy cylindrical part without a welding line. The integral forming method comprises the following steps of: (1) tube blank preparation by stamping; (2) high-temperature vacuum heat treatment; (3) heating power spinning thinning; (4) unheating power spinning diameter expanding; (5) repetitive and alternate conduction of steps (3) and (4) for 2-3 times; (6) high-temperature vacuum heat treatment; (7) finish turning treatment; and (8) stabilizing treatment. The integral forming method prepares the large size thin-walled titanium alloy cylindrical part without the welding line (wall thickness is 1-7mm) which has high precision and high performance by utilizing titanium alloy plates and adopting a composite technique combining a stamping method, a spinning method and a stabilizing treatment method, and solves the problems of low material utilization ratio, having longitudinal welding lines, low precision of tube performance and the like in the forging and roll bending welding forming of the large size titanium alloy thin-walled tubes.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

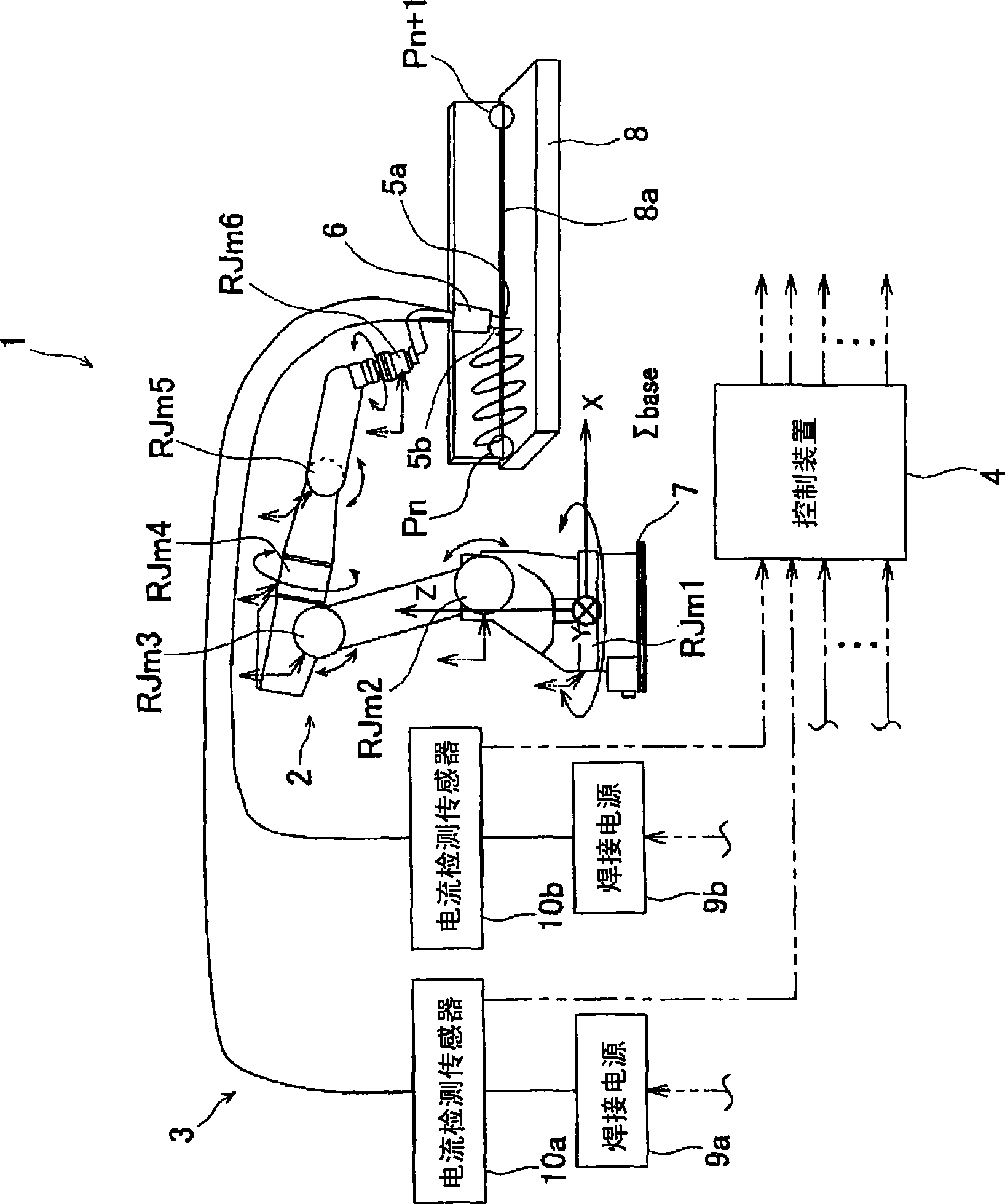

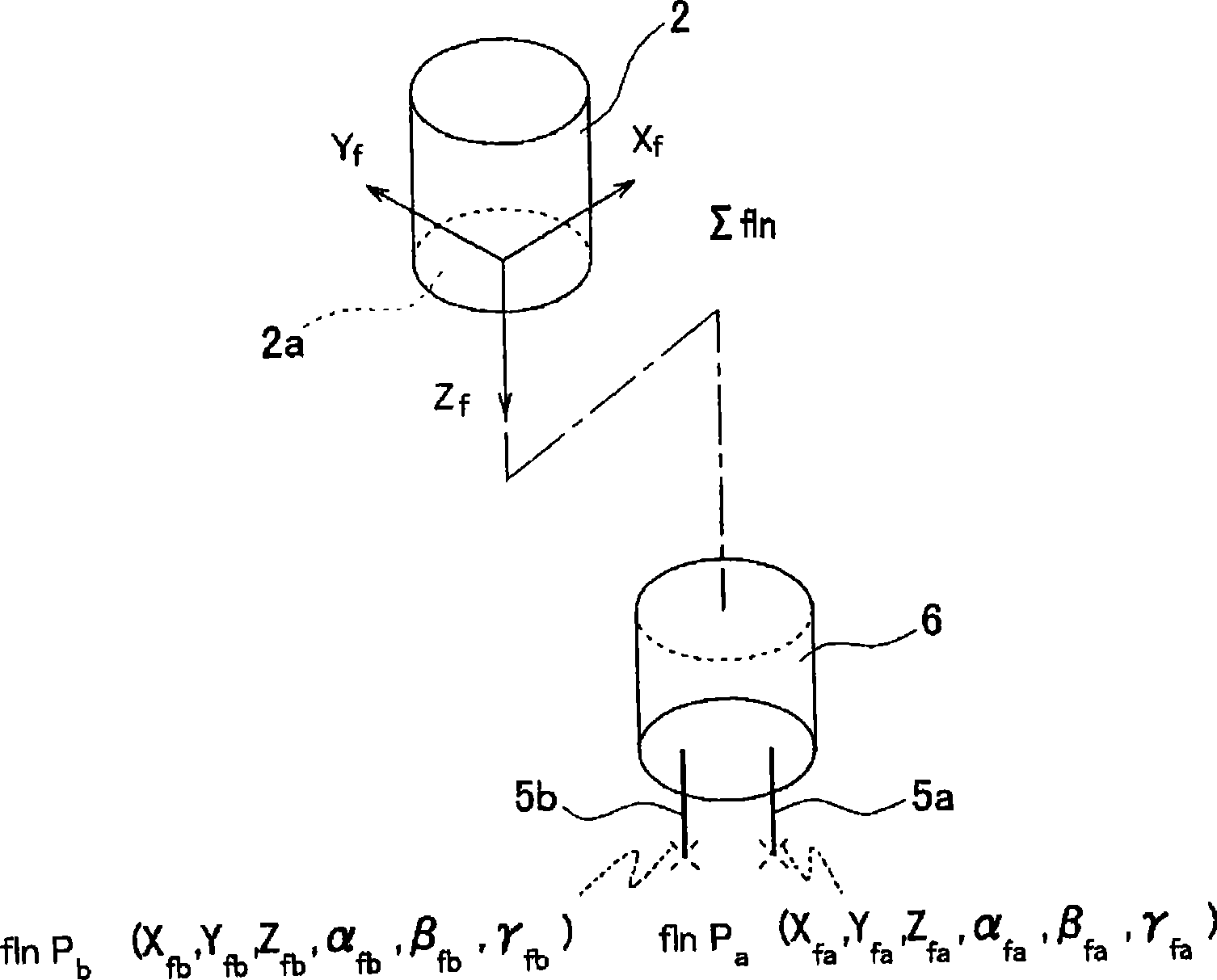

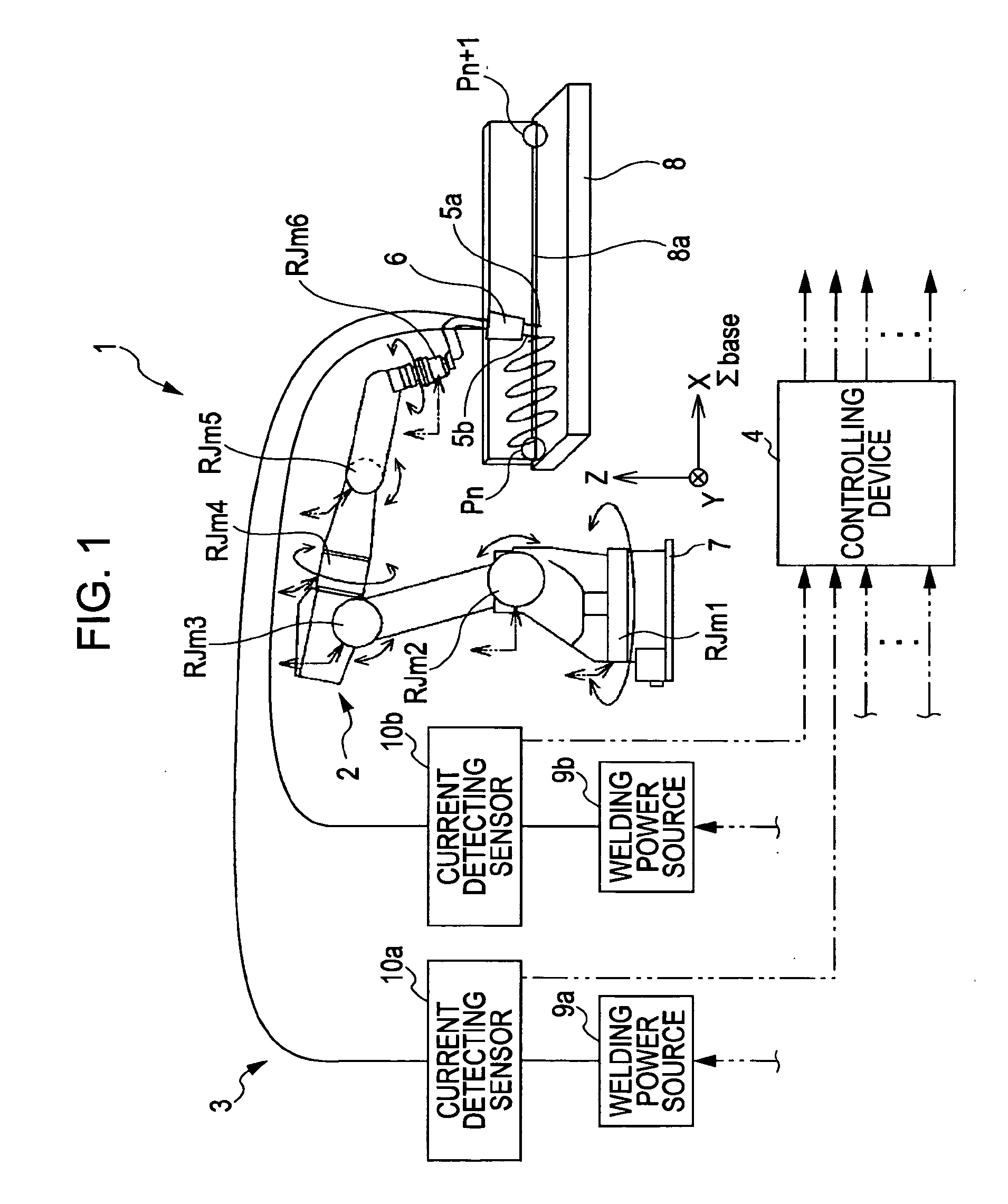

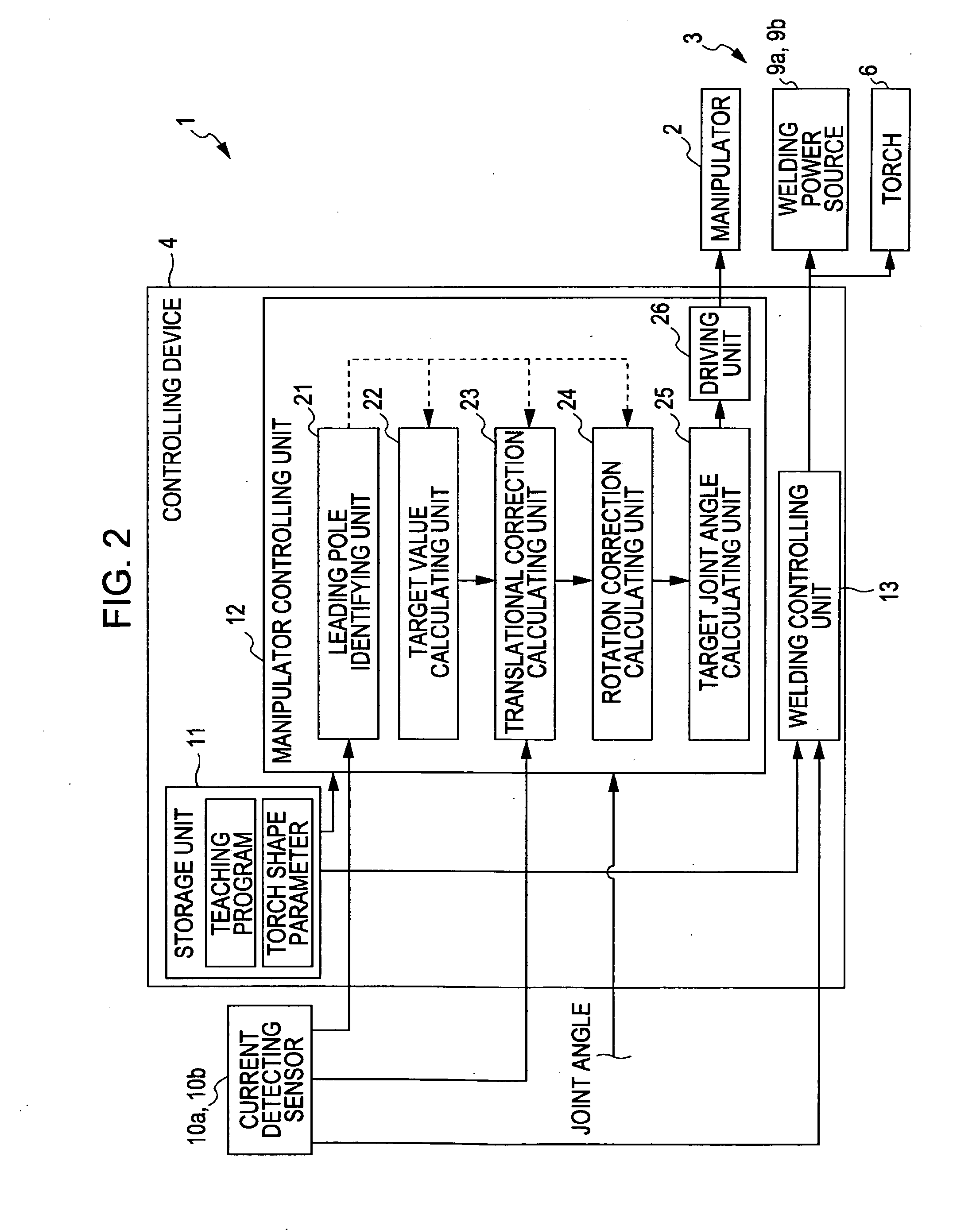

Welding robot

ActiveCN101486123AQuality improvementEfficient Tracking and TracingProgramme-controlled manipulatorArc welding apparatusEngineeringTorch

The invention provides a welding robot which makes it possible to, in a seam tracking operation during tandem welding, realize a high tracking ability, not only for a leading electrode, but also for a trailed electrode. A translational correction calculating unit (23) corrects a target value Plead(t) of the leading electrode (5a) using a translational correction amount Delta P(t) in a base coordinate system Sigmabase for a next time position of the leading electrode (5a), to obtain a primary correction target value Plead(t)'. A rotational correction calculating unit (24) calculates a rotation correction amount Delta theta(t) for correcting displacement of an orientation of a torch (6) around the leading electrode (5a) with respect to a actual weld line Lre generated because of the translational correction amount Delta P(t), and calculates a secondary correction target value Plead(t)'' resulting from correcting the primary correction target value Plead(t)' so that the torch (6) rotates around the leading electrode (5a) by the rotation correction amount Delta theta(t). A manipulator (2) is driven on the basis of the secondary correction target value Plead(t)''.

Owner:KOBE STEEL LTD

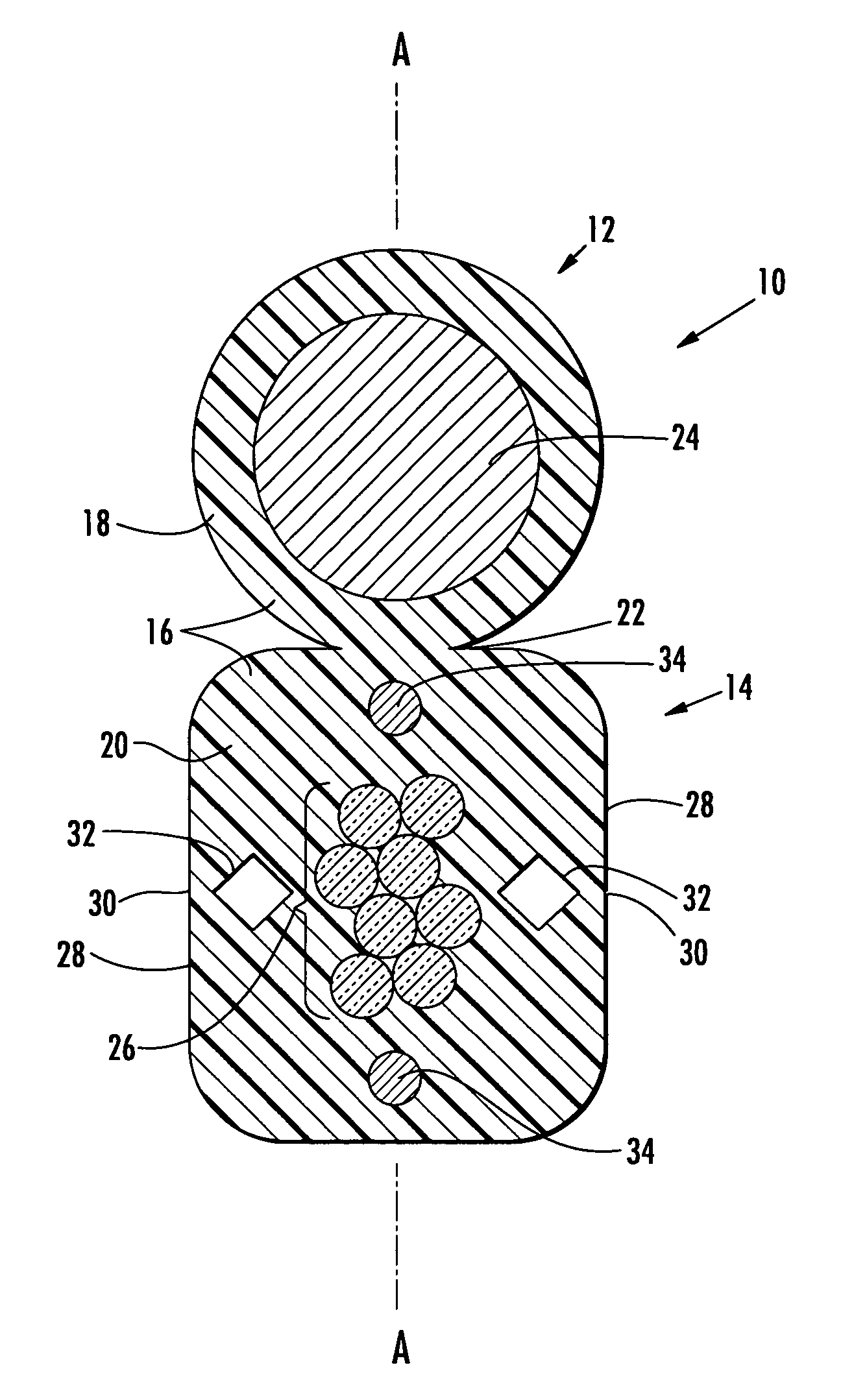

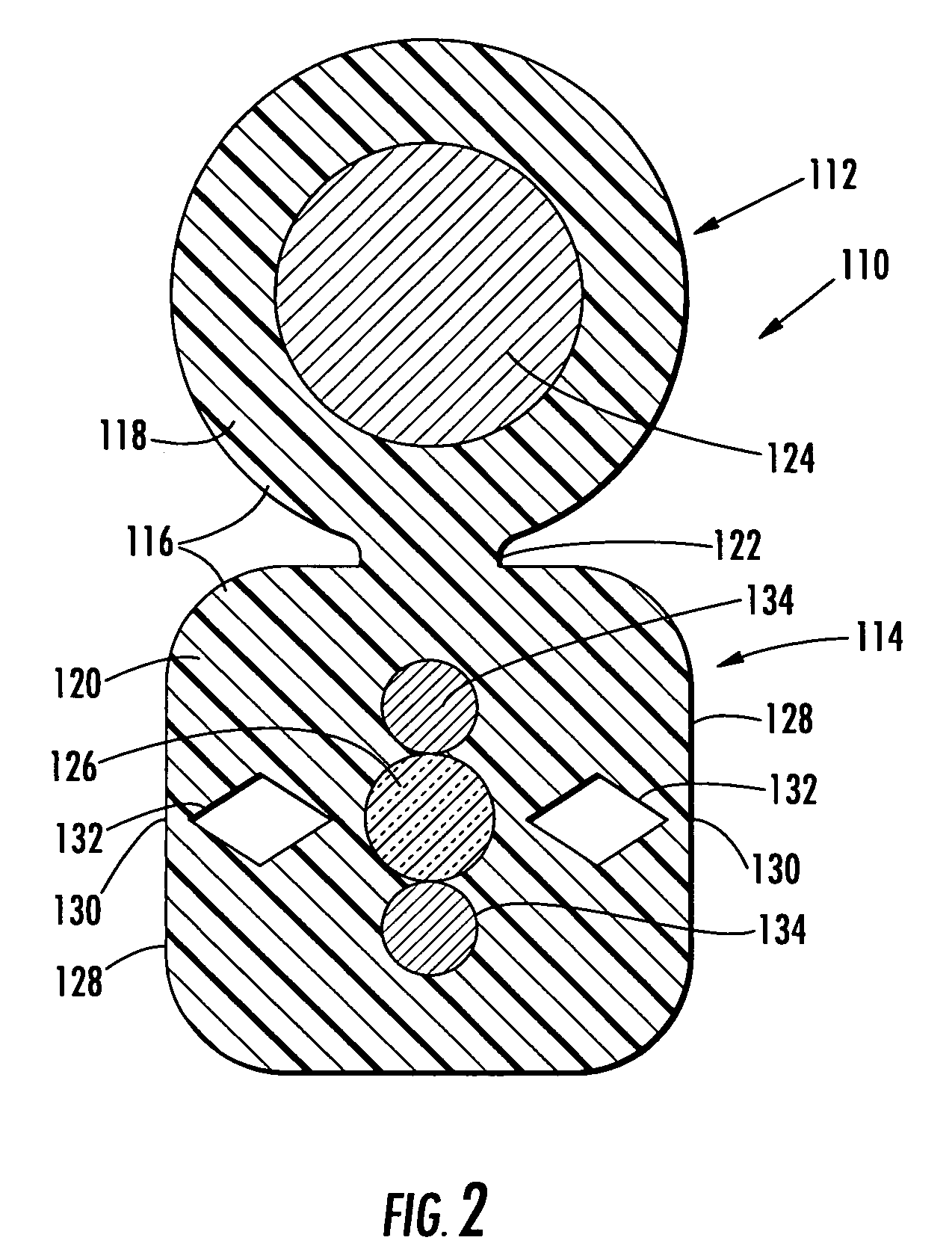

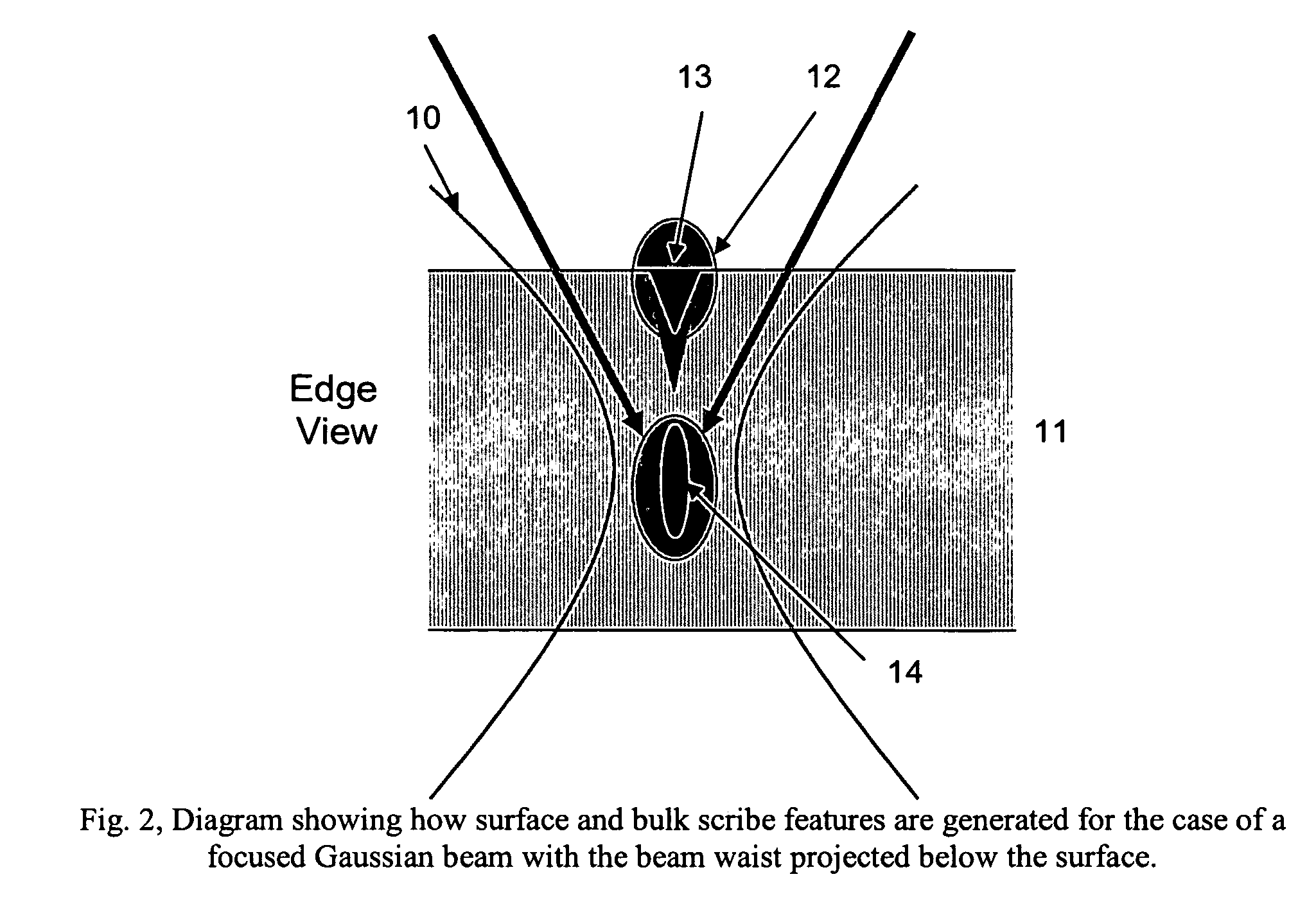

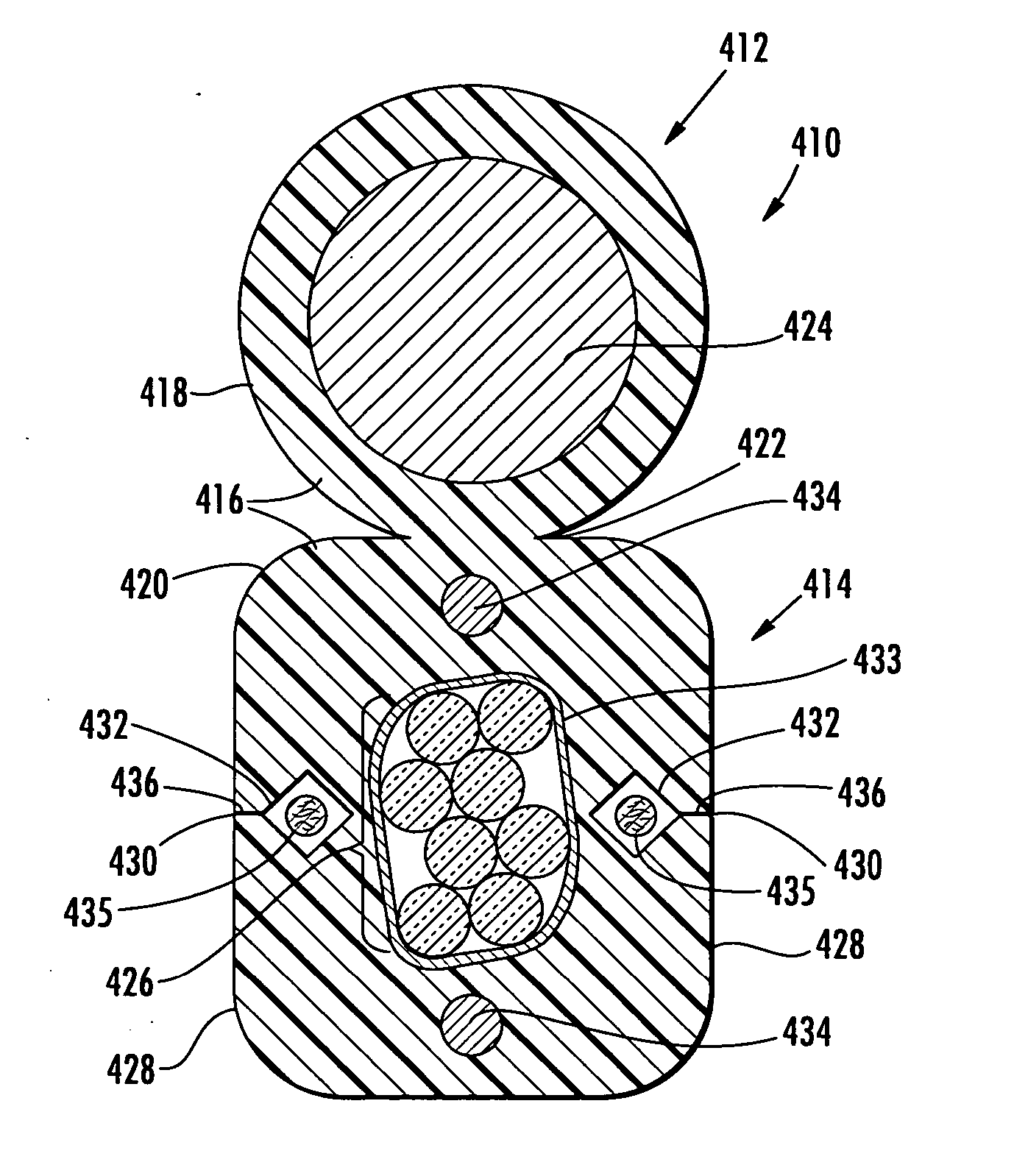

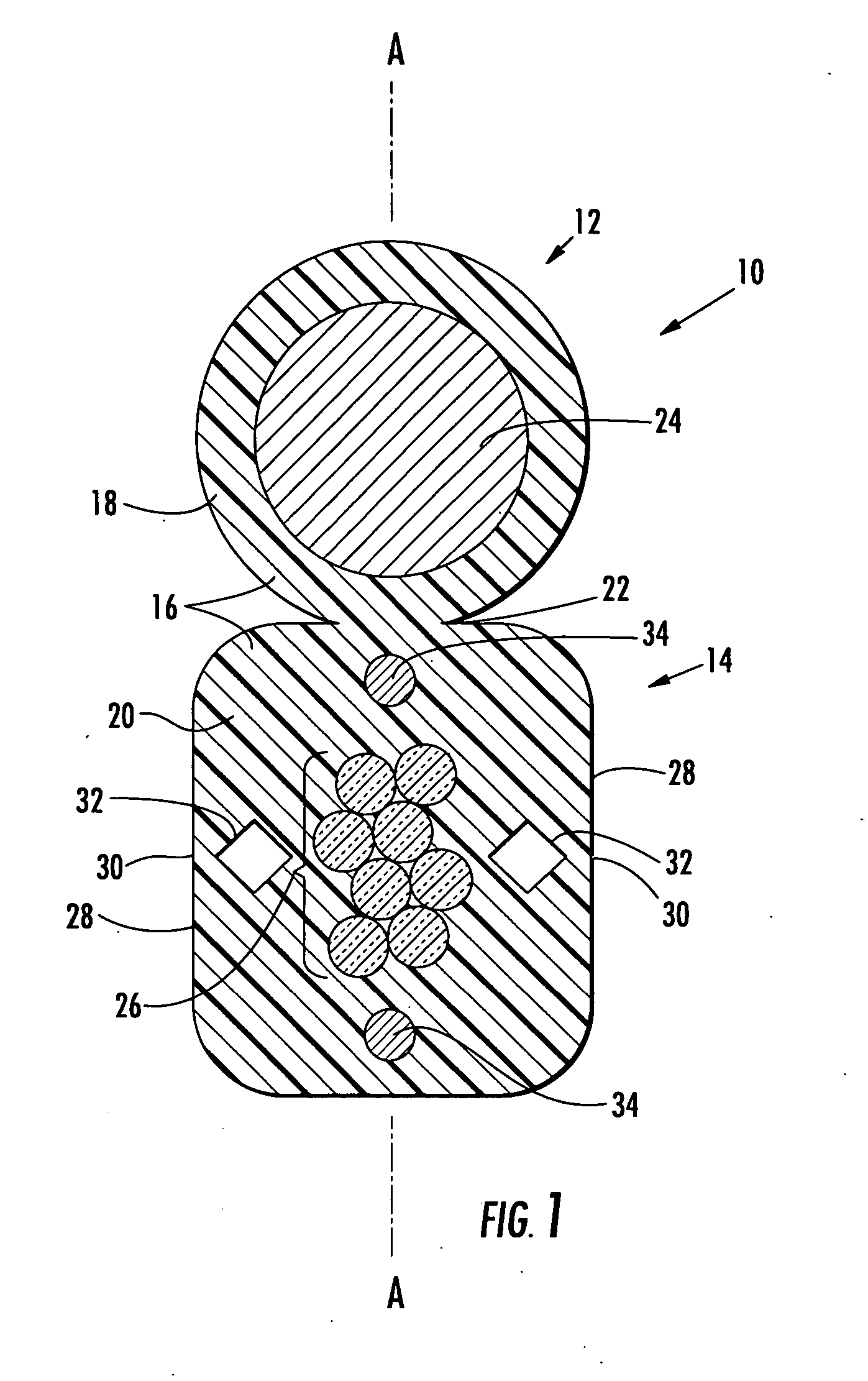

Fiber optic cables that are separable for optical fiber access

InactiveUS7391943B2Reduce the possibilityWeight per lengthFibre mechanical structuresFiberEngineering

A fiber optic cable includes a messenger section having at least one strength member, a carrier section having at least one optical fiber therein, and a common jacket that forms a common jacket. In one embodiment, the carrier jacket has a preferential tear portion adjacent to the at least one optical fiber with a substantially continuous outer surface in the carrier jacket adjacent to the preferential tear portion. The preferential tear portion may be defined by at least one of: at least one internal void, at least one weld line, and at least one wing extending from a tape disposed about the one or more optical fibers. Various alternatives are possible. For example, the carrier jacket may also or alternatively include at least one gripping area extending for enhancing the gripping of the carrier section when pulling apart the carrier section and messenger section.

Owner:CORNING OPTICAL COMM LLC

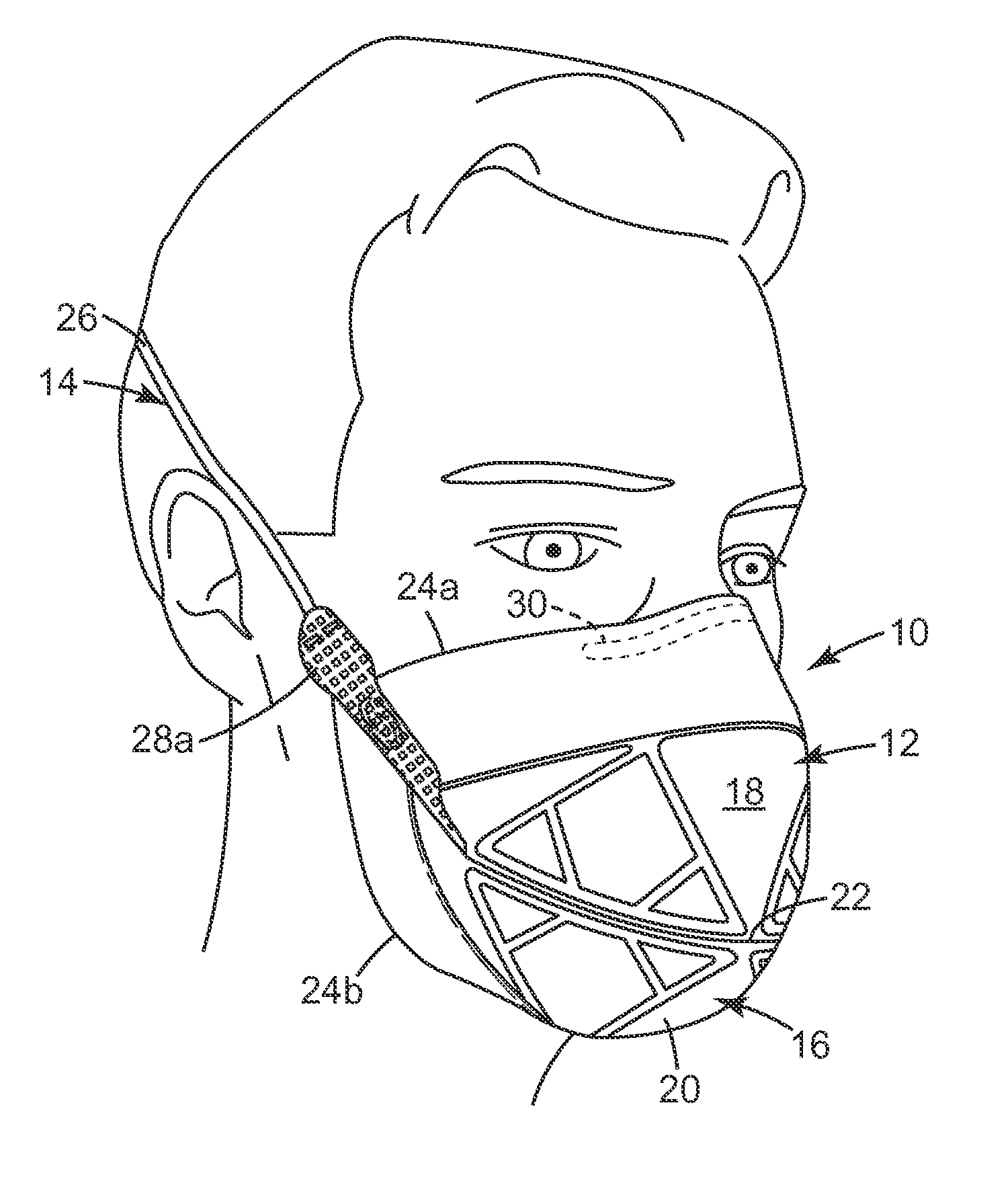

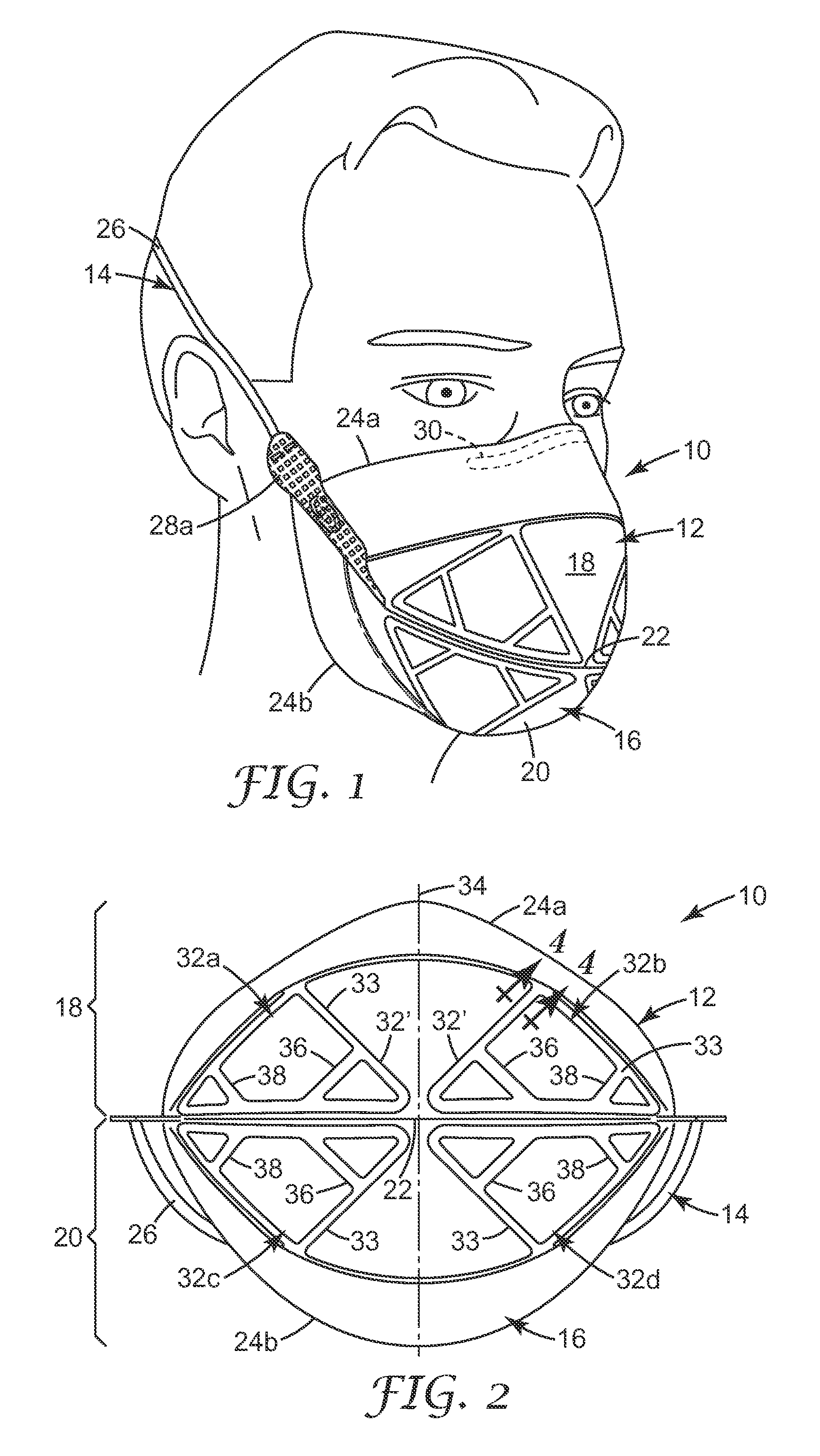

Filtering face-piece respirator having parallel line weld pattern in mask body

ActiveUS20110094515A1Reduce usageDeformation MinimizationBreathing filtersBreathing masksRespiratorEngineering

A respirator 10 that has a harness 14 and a mask body 12 that is joined to the harness 14. The mask body 12 includes a filtering structure 16 that may contain a plurality of layers of nonwoven fibrous material 58, 60, 62. The layers of nonwoven fibrous material 58, 60, 62 have a thickness A and are welded together by at least two parallel weld lines 34′, 34″ that are spaced at 0.5 to 6 times A. A mask body that uses parallel weld lines may exhibit better resistance to collapse and may be manufactured at faster speeds than similar structures which use single weld lines of comparable width.

Owner:3M INNOVATIVE PROPERTIES CO

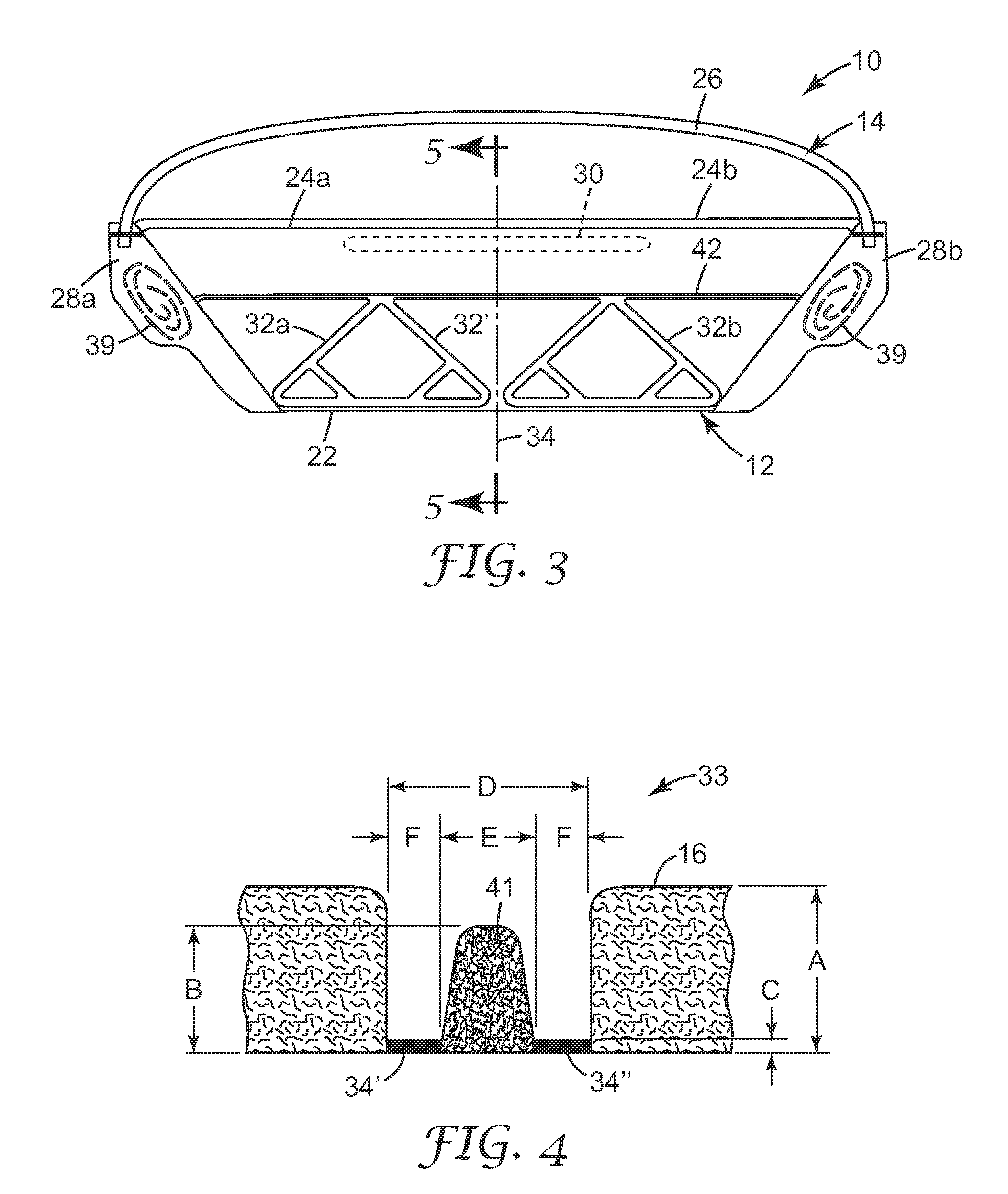

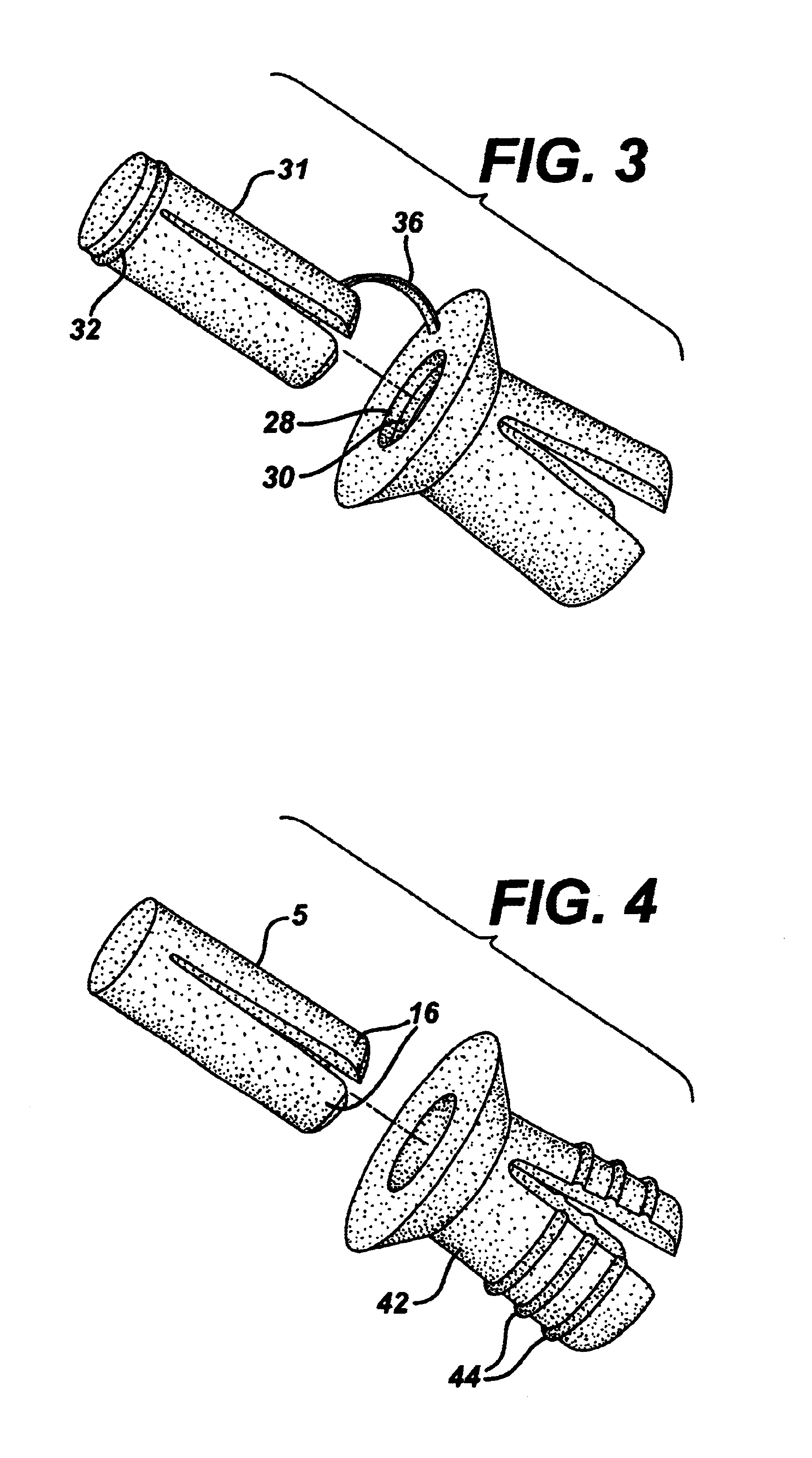

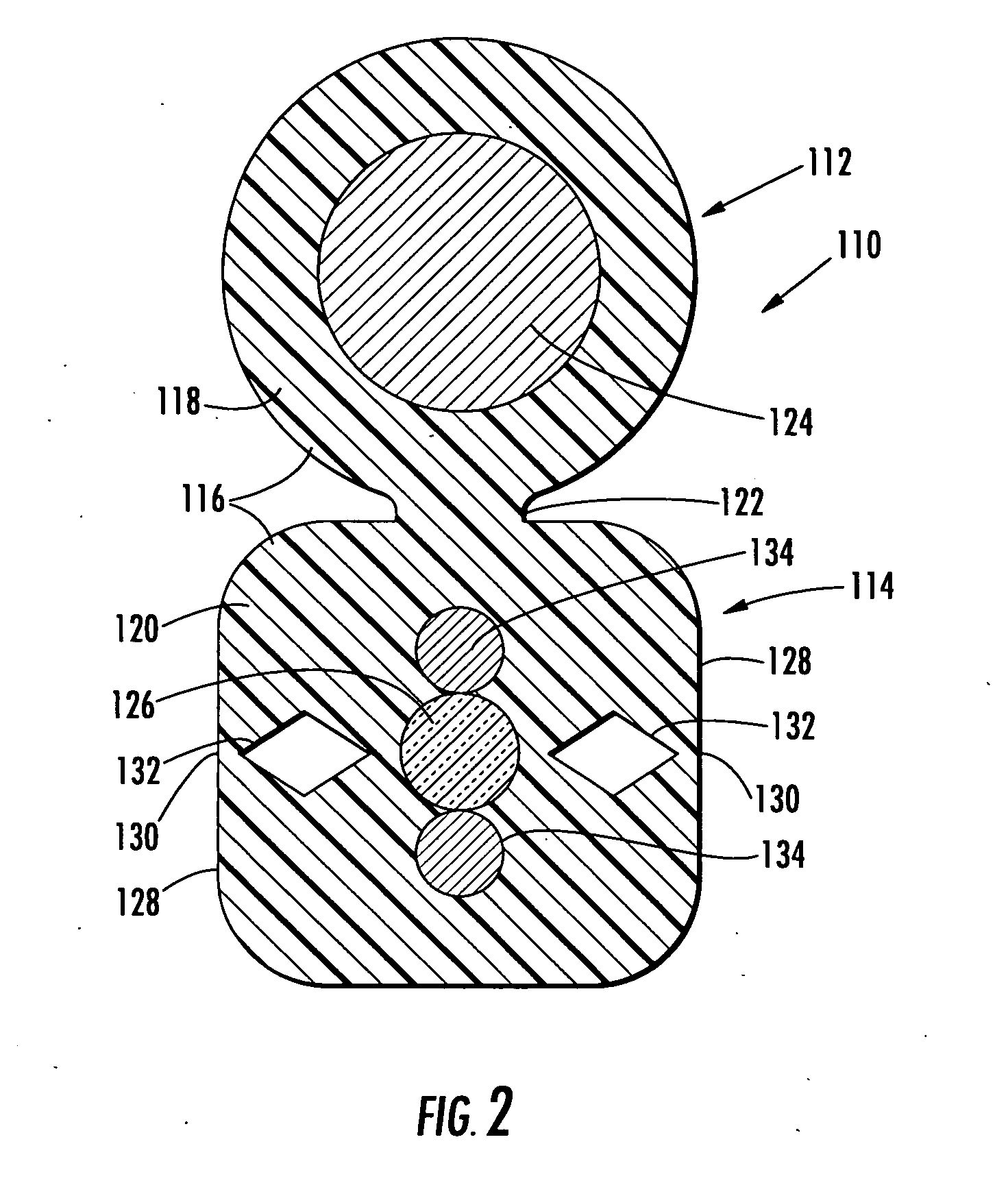

One-piece biocompatible absorbable rivet and pin for use in surgical procedures

InactiveUS6846313B1Easy to handleConveniently installedSuture equipmentsInternal osteosythesisEngineeringWeld line

A bioabsorbable rivet and pin fastener is formed as an elongated unit that may be used for anchoring, or for attachment of a fixation plate. The rivet has a head mechanically connected to two or more legs that extend generally distally from the head and may flex outwardly from a central rivet axis. The pin is integral with the rivet and oriented along the central axis by a connection such as a web or a plurality of braces, forming an integral, aligned, one-piece assembly that may, for example, be molded as a single piece. The connection breaks under force as the pin is driven into the rivet, so that the pin contacts internal surfaces of the legs and pushes the legs outward into frictional engagement with the surrounding bone. The one-piece assembly may be formed in a gated mold having a central pin with a relief passage that defines the braces between upper and lower portions of the rivet. The braces so formed at the weld line readily part from the mold, and are easily sheared when the pin is advanced during installation of the rivet.

Owner:CODMAN & SHURTLEFF INC

Transparent material processing with an ultrashort pulse laser

InactiveUS7626138B2Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

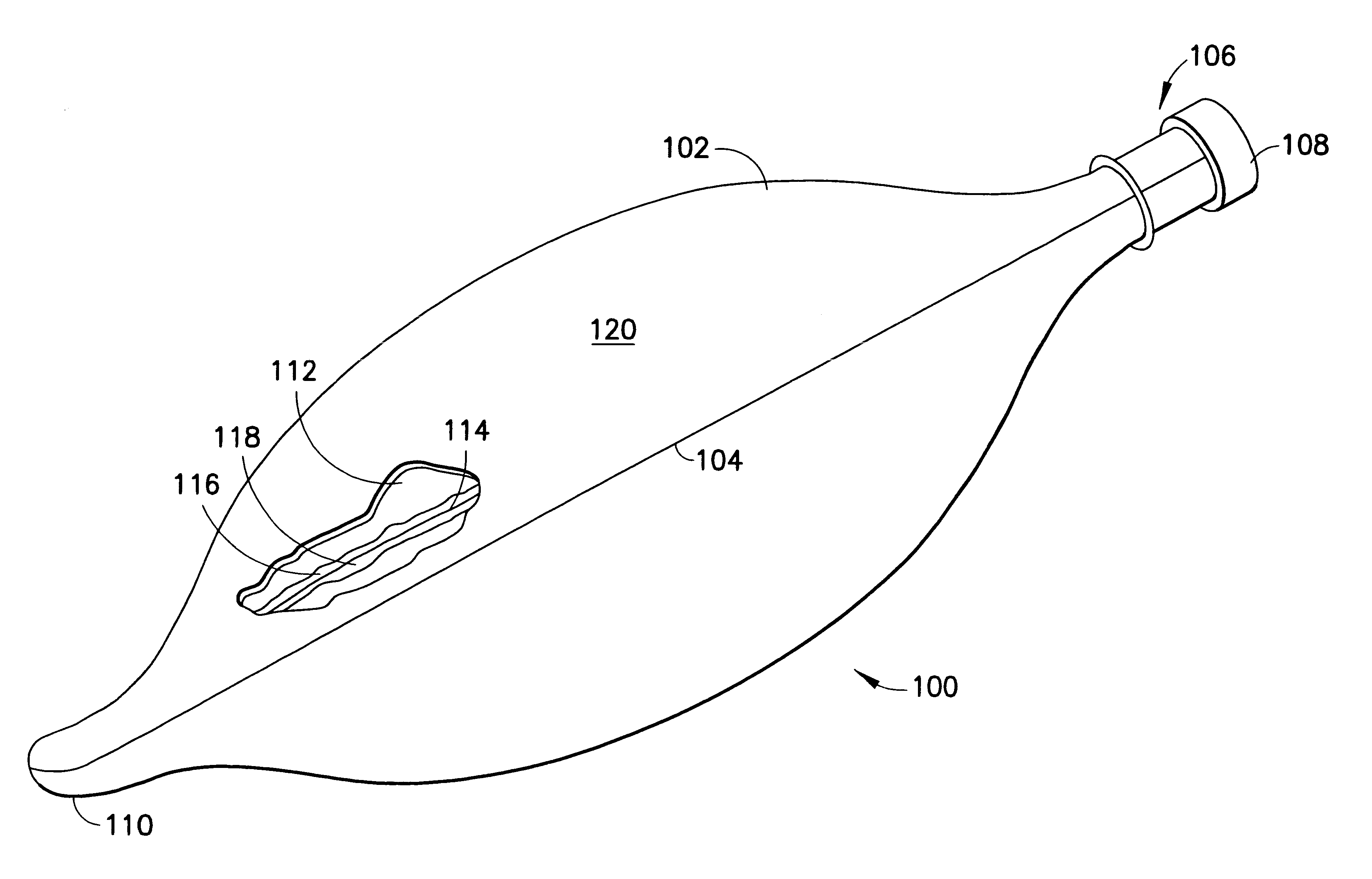

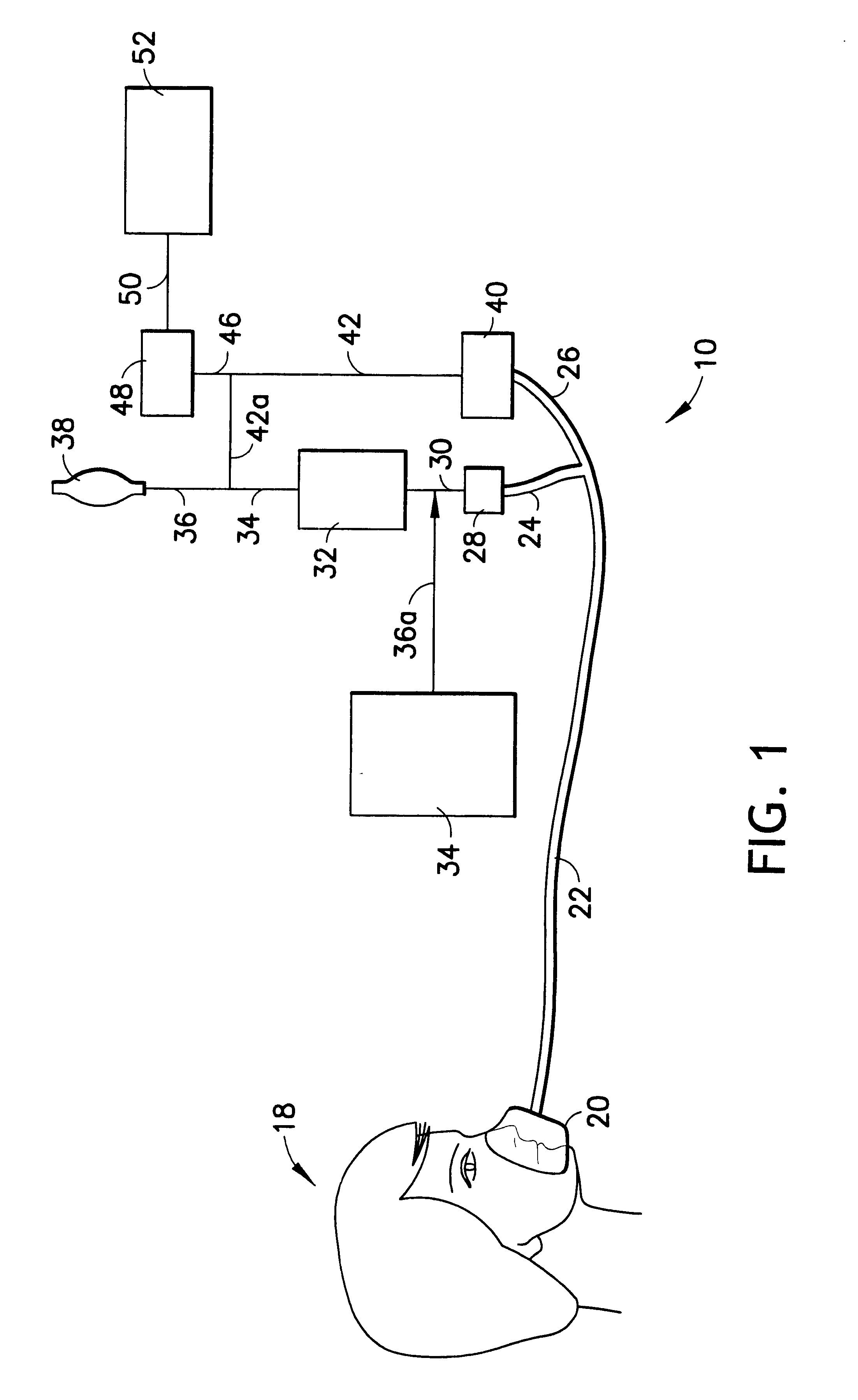

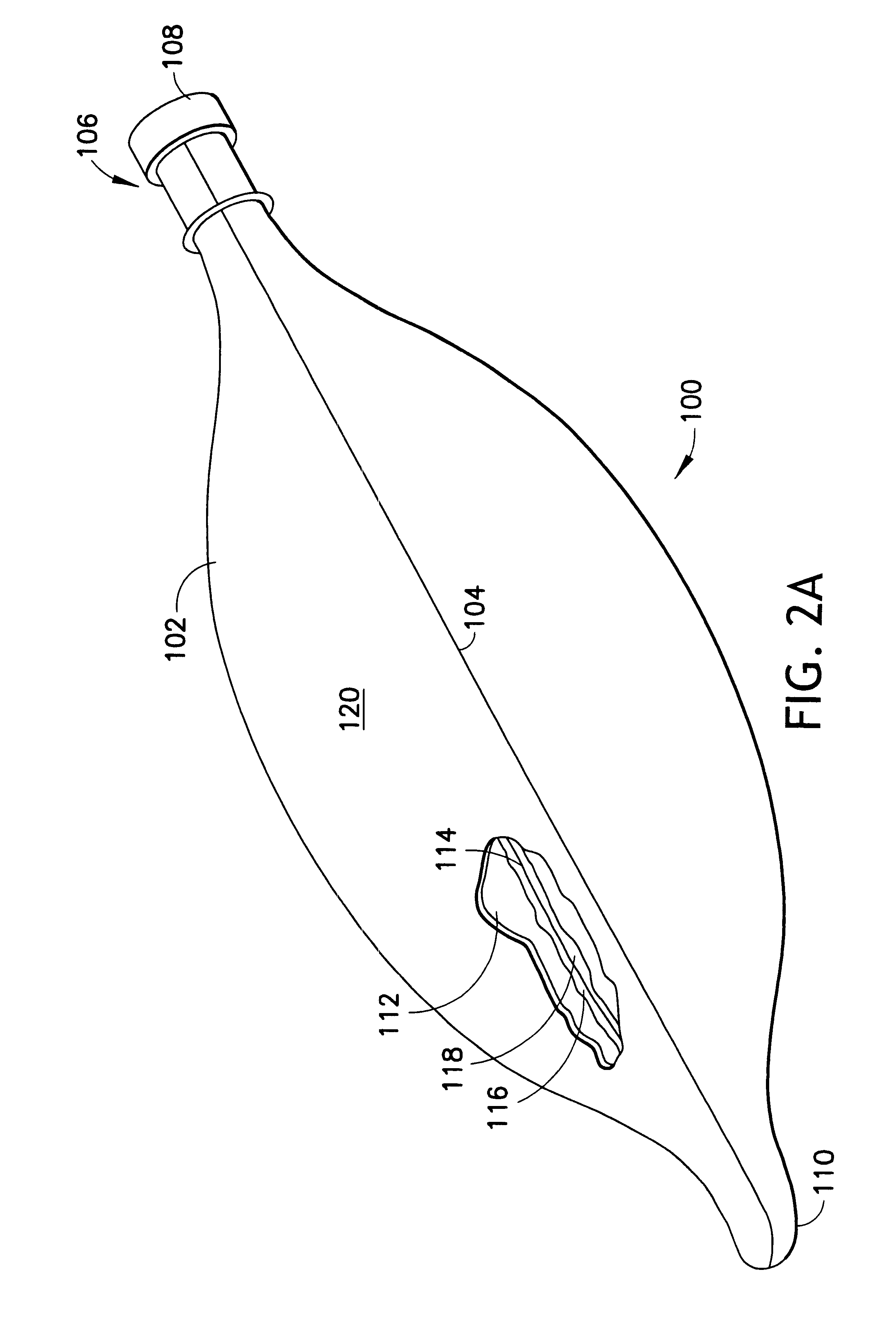

Film welded reservoir bag for breathing circuit and method of making the same

A pulmonarily sized bag formed of a non-latex material, including a bag body formed of panels of resin film material welded to one another along a weld line defining a seam of the bag body bounding an interior volume of the bag. The seam includes an interior seam portion in the interior volume, and an exterior seam portion at an exterior surface of the bag. One of the interior seam portion and exterior seam portion comprises free edges of the seam, and the other one of such seam portions is devoid of free edges. The bag is formable by various techniques, including radio frequency welding, impulse heating, solvent bonding, etc., and is usefully employed in a breathing circuit to obviate the necessity of using latex breathing bags.

Owner:POLYZEN INC

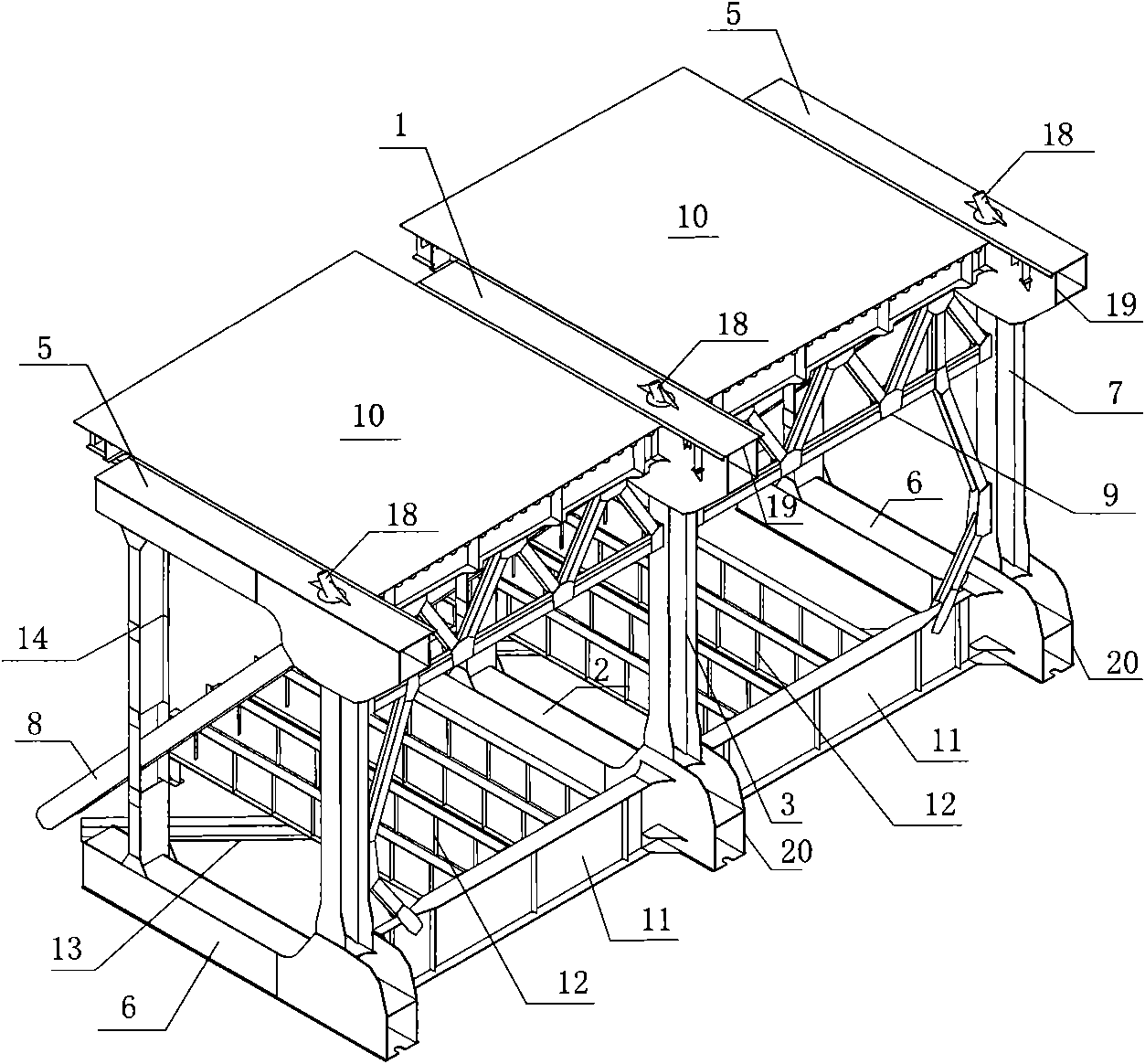

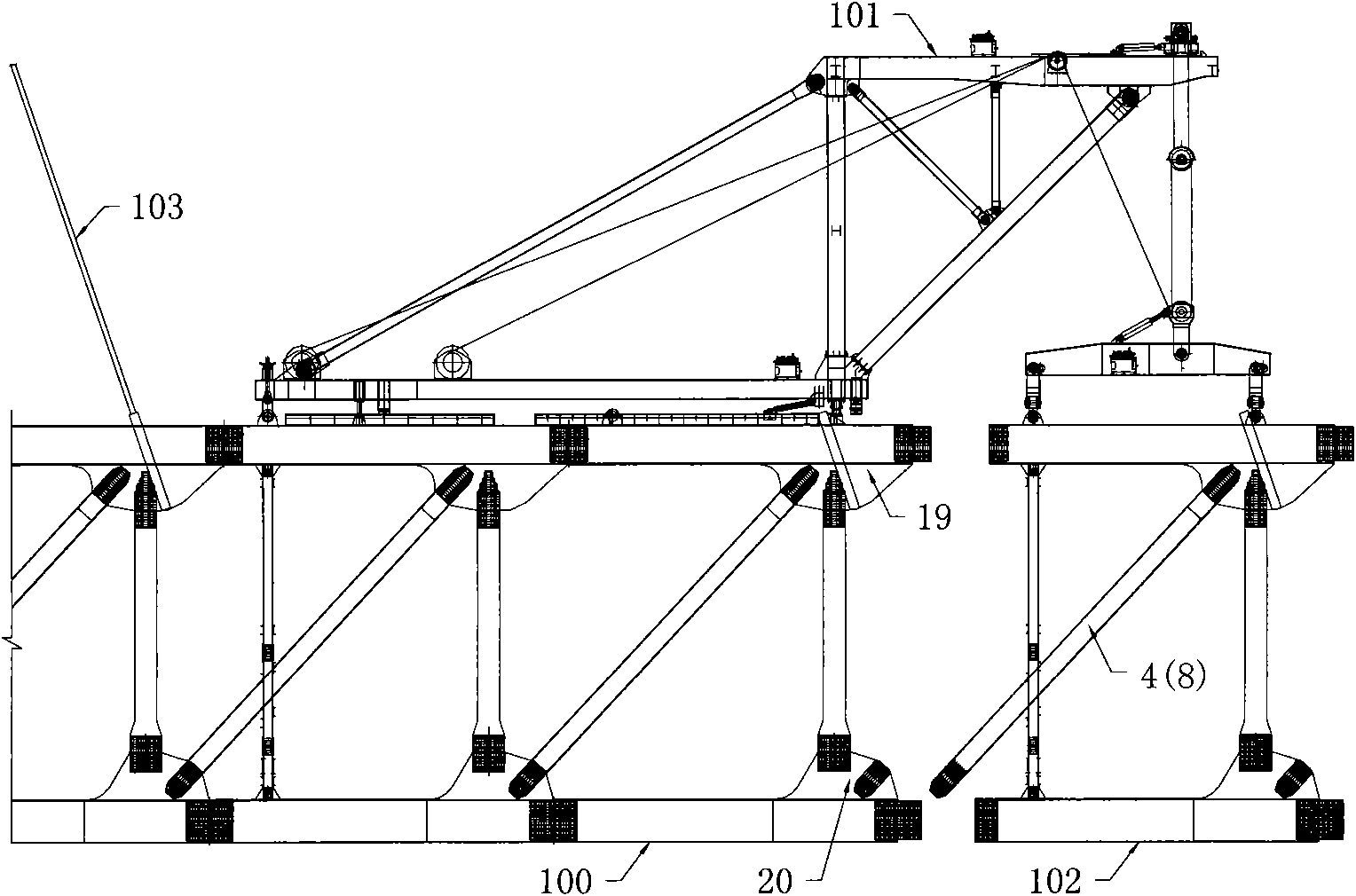

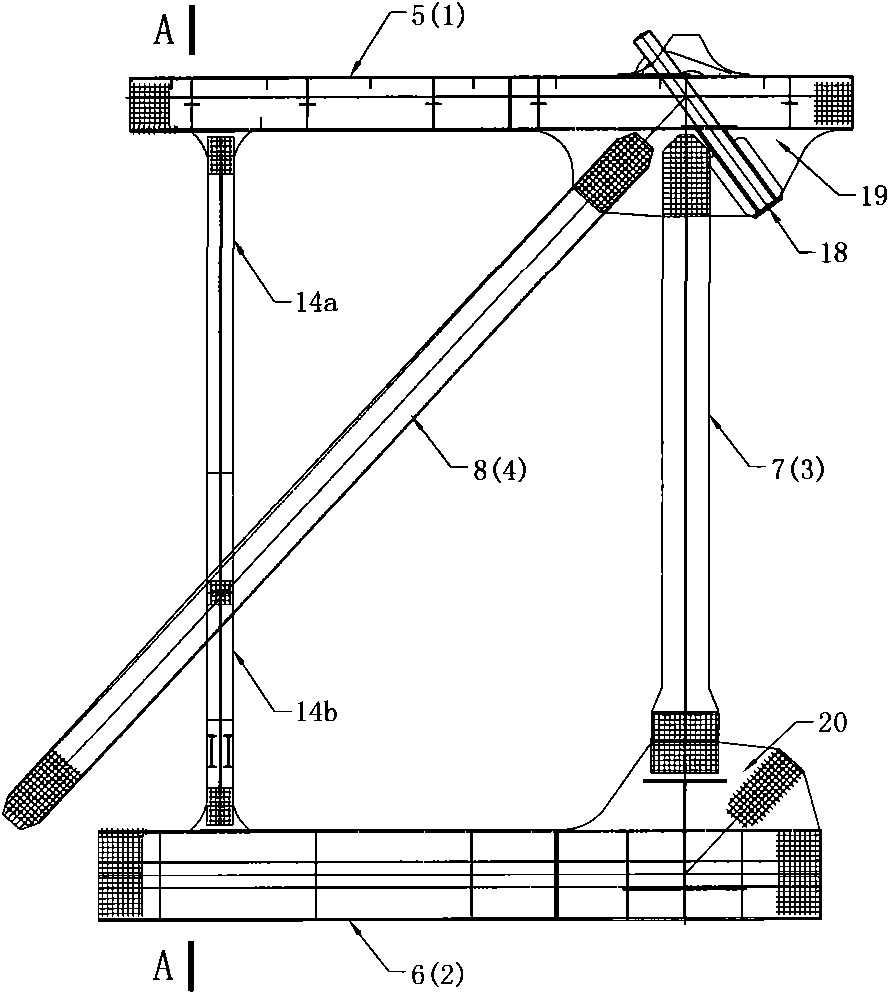

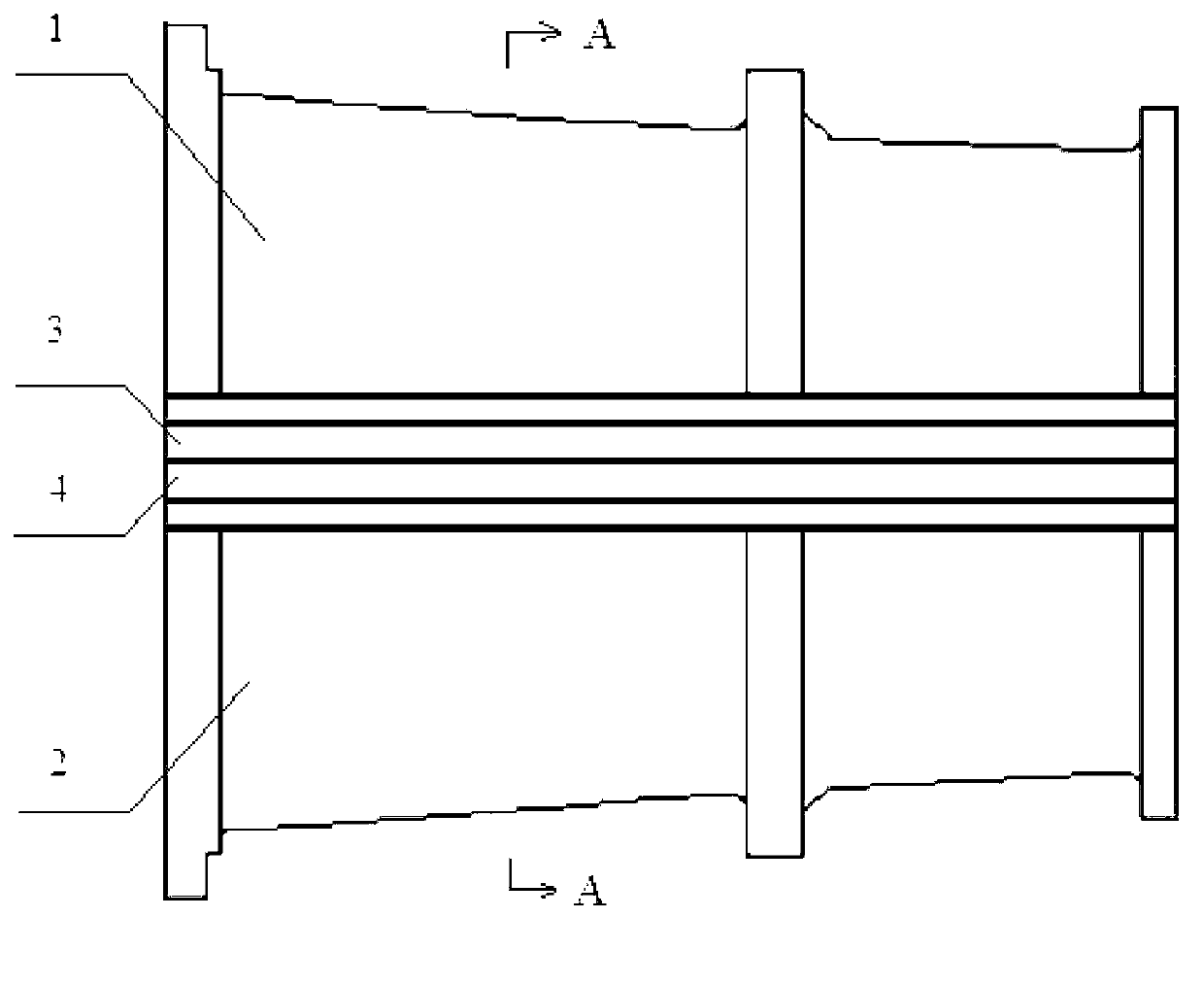

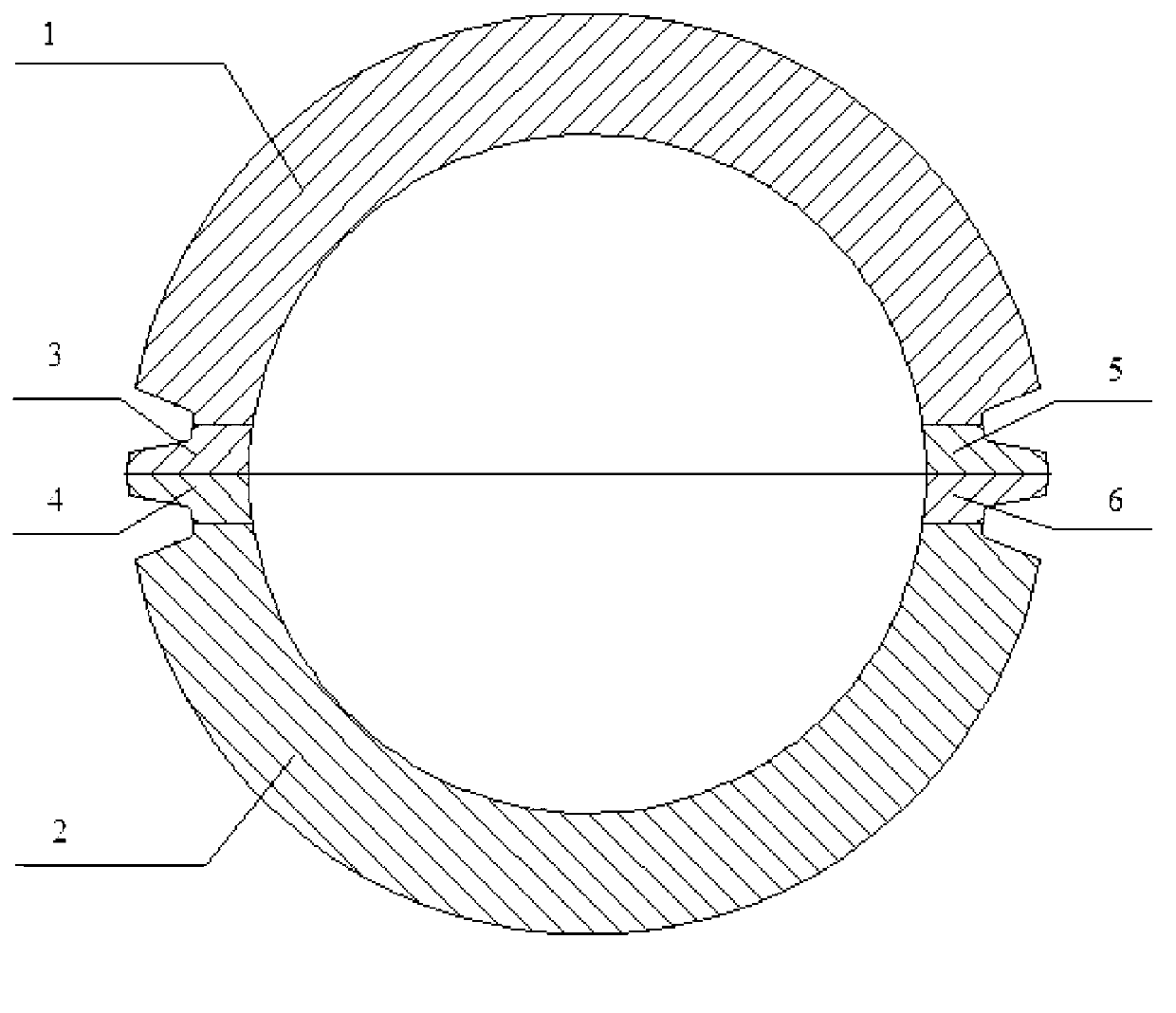

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

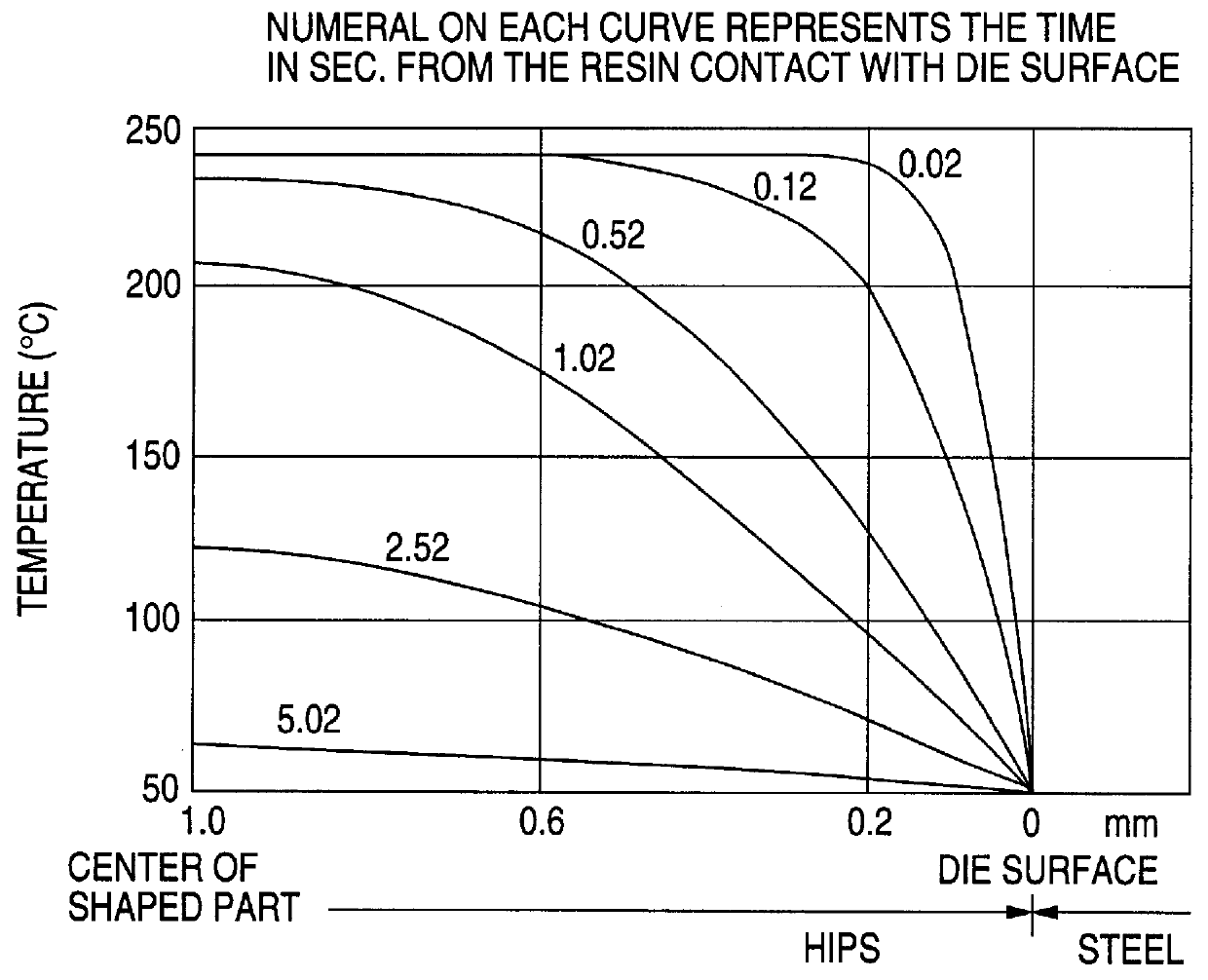

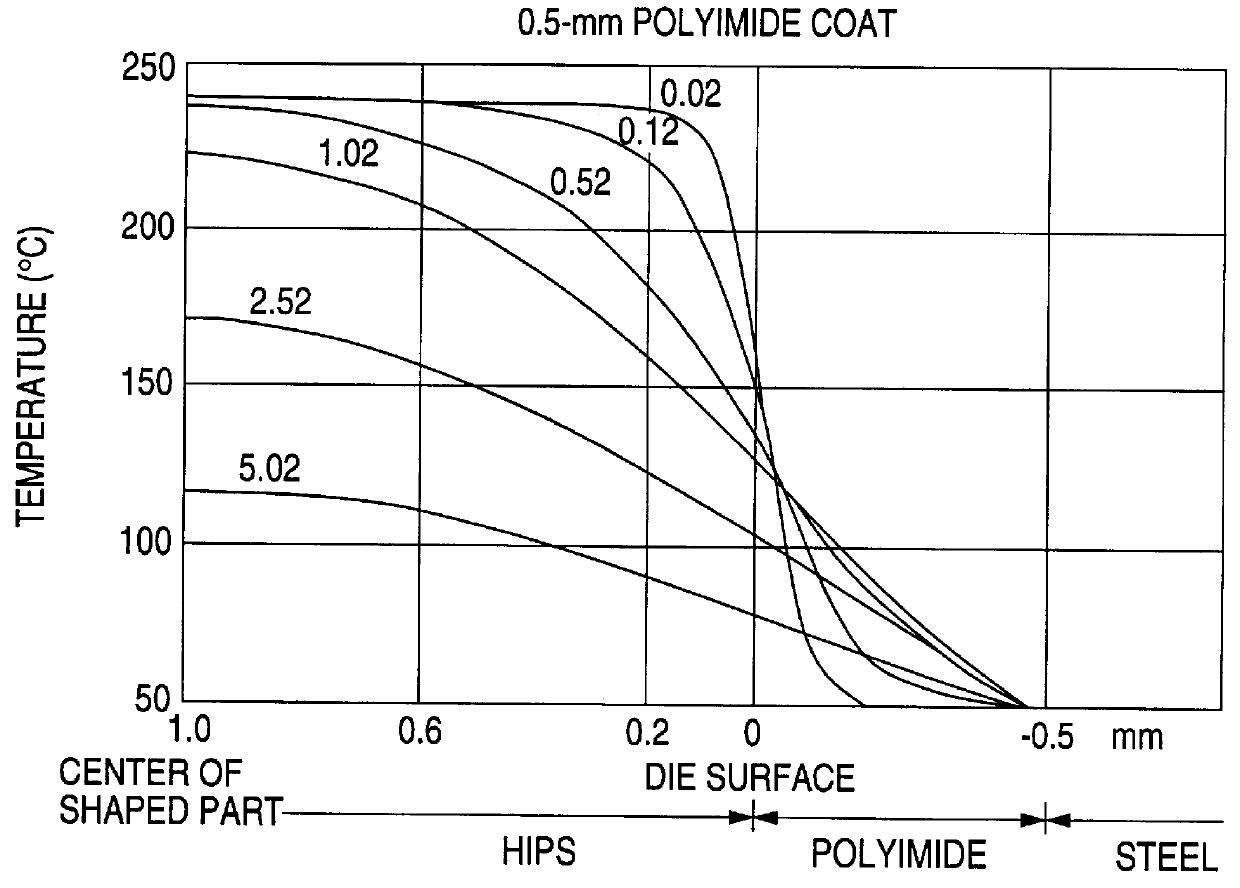

Dull-surfaced, injection molded synthetic resin articles and a method of shaping them

InactiveUS6077472AEfficient platingDiminished plating rateRecord information storageMagnetic recordingPolymer scienceShell molding

PCT No. PCT / JP95 / 01241 Sec. 371 Date Dec. 20, 1996 Sec. 102(e) Date Dec. 20, 1996 PCT Filed Jun. 21, 1995 PCT Pub. No. WO95 / 35194 PCT Pub. Date Dec. 28, 1995The purpose of the invention is to produce a shaped article having a uniform dull surface with less noticeable weld line and other surface detects. The injection molded synthetic resin article of the invention has a weld portion and is characterized in that the weld line on the surface of the injection molded article has a dent of no more than 2 mu m, the surface of the injection molded article is a dull surface with no more than 30% gloss, the general portion, the weld portion and the resin flow end portion of the surface of the injection molded article provide a uniform dull surface, said dull surface having such abrasion resistance that no visible flaws develops at a hardness of 2B and below in a pencil scratch test. Such molded article can be produced without post-molding paint application and yet it has practical utility, thus presenting a maximum economic advantage.

Owner:ASAHI KASEI KK

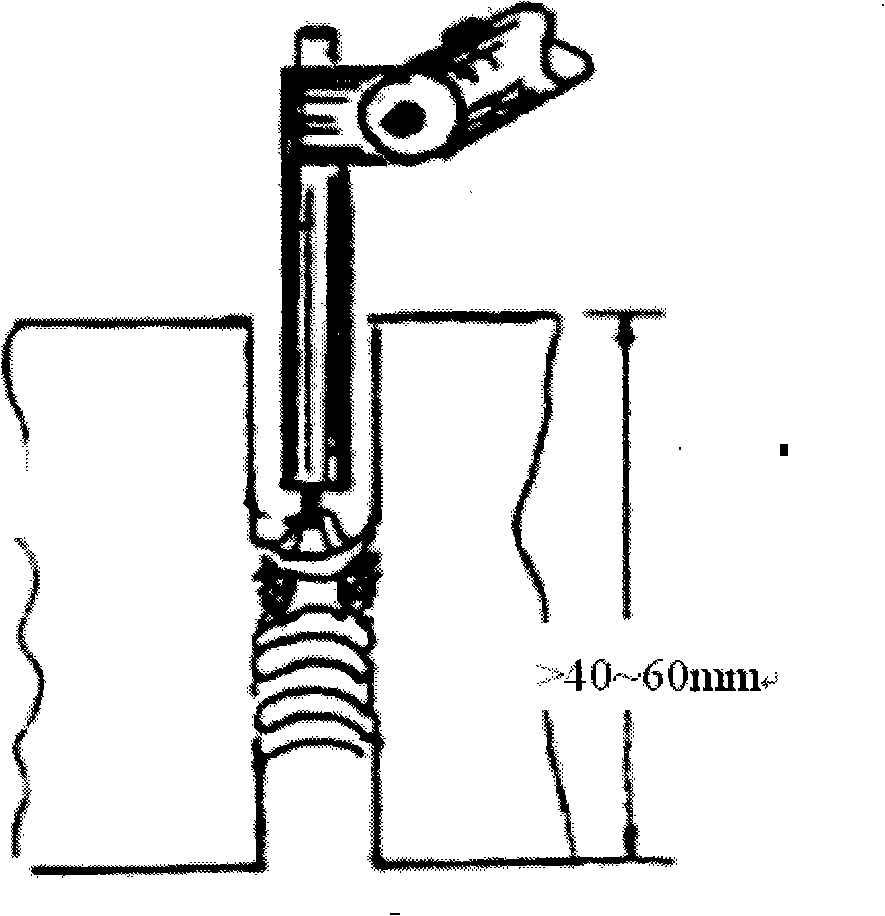

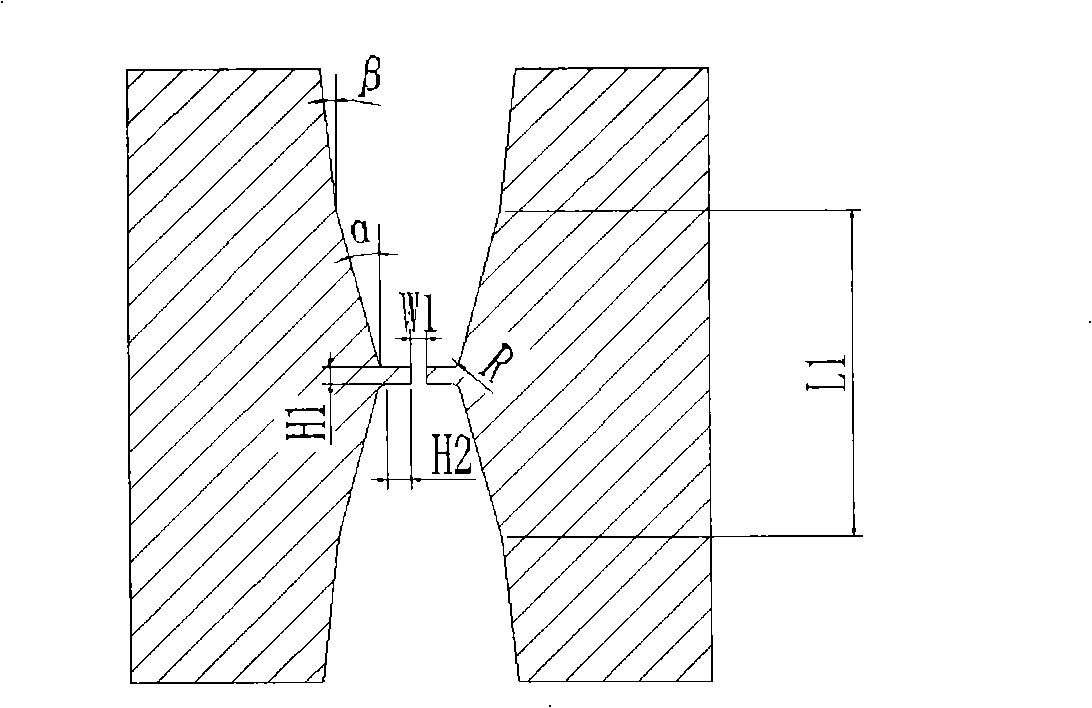

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

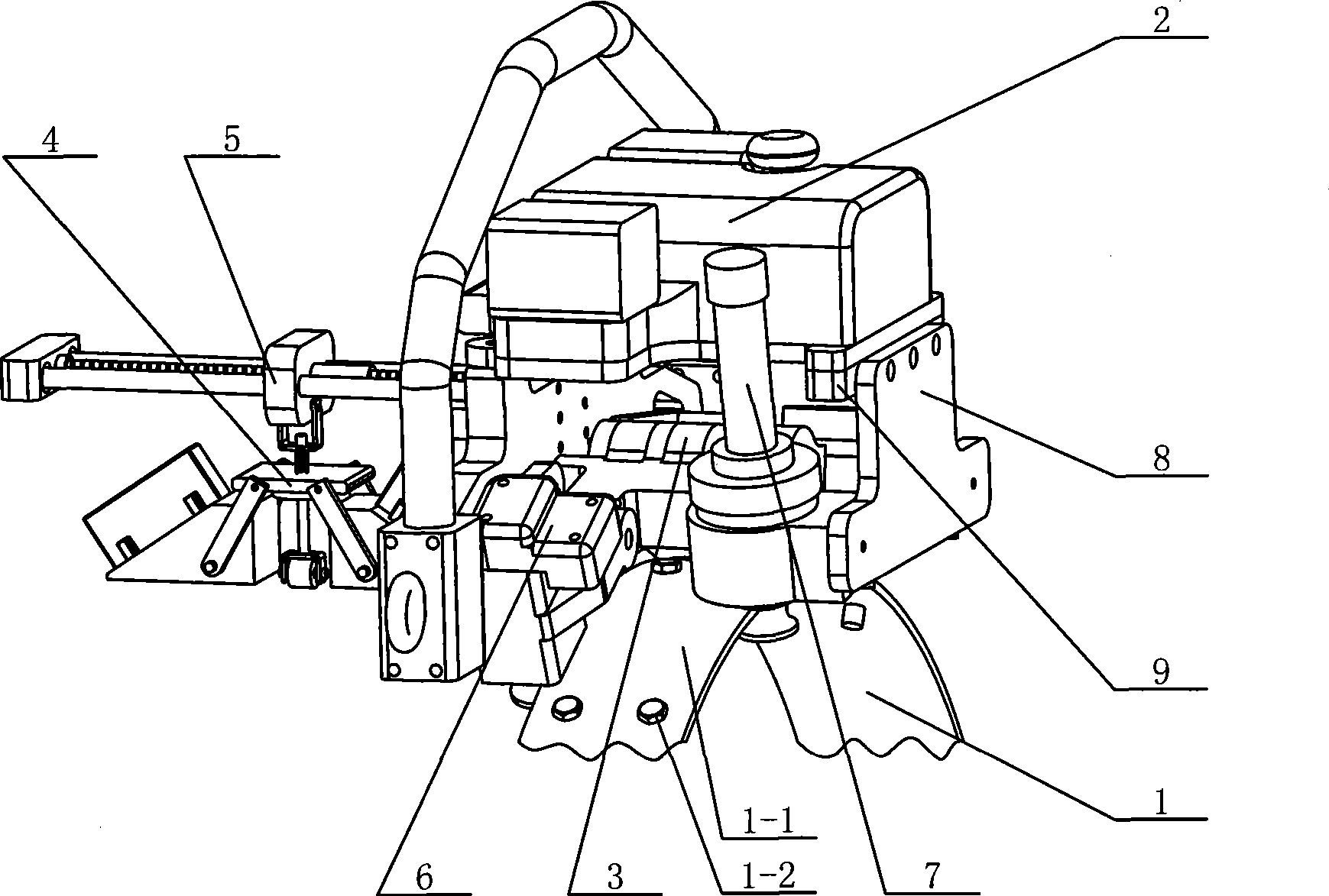

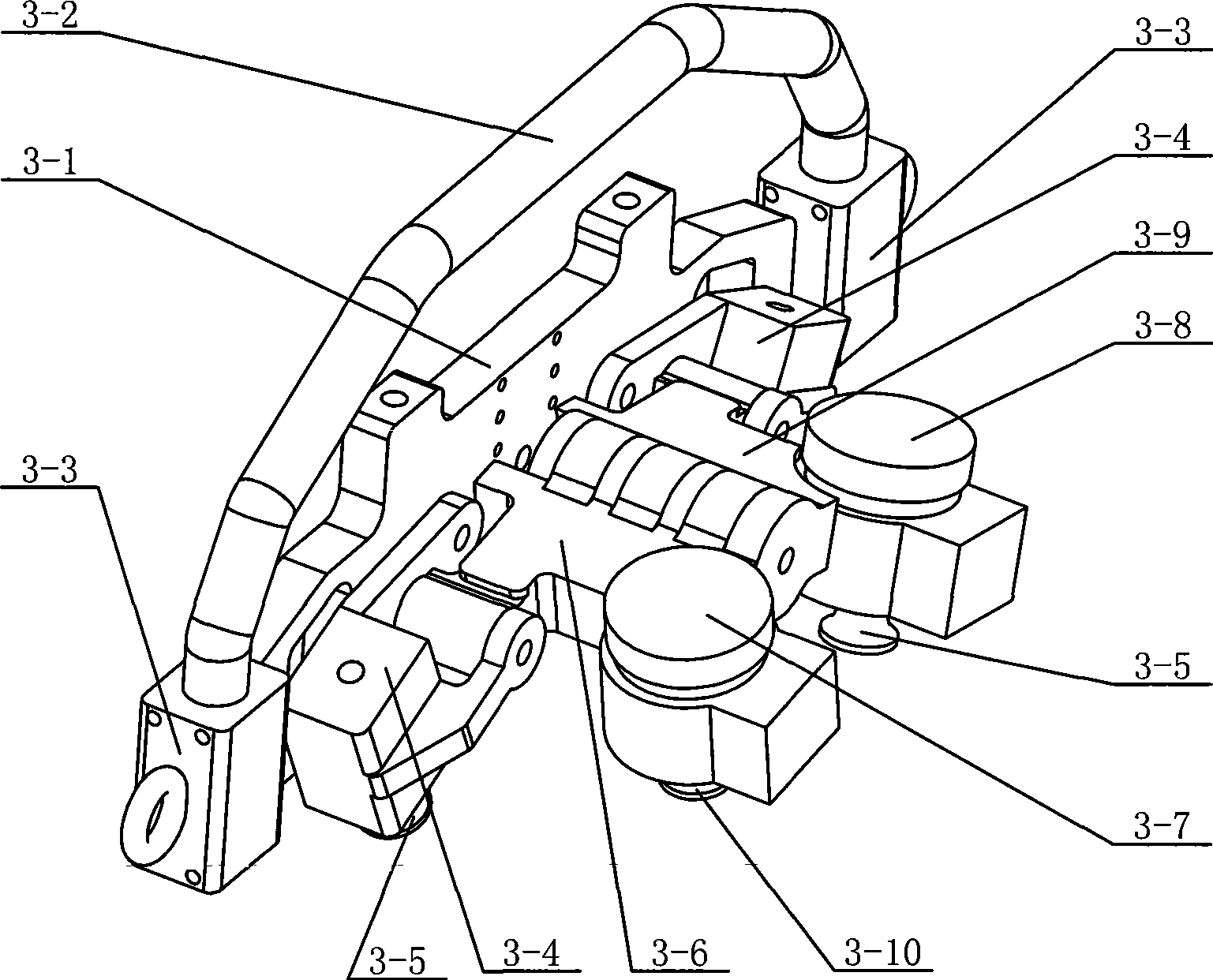

Full-automatic detection apparatus suitable for multi-diameter pipe welding seam

InactiveCN101368932AReduce radiation pollutionReduce misjudgmentMaterial analysis using sonic/ultrasonic/infrasonic wavesNon destructiveWeld seam

The invention provides an automatic detection device suitable for multi-diameter pipeline welding lines. A carrier dolly module (3) of the invention is arranged on a flexible track module (1); a scanner module (2) is fixed on the upper part of the carrier dolly module (3) through a vertical plate (8) and a horizontal plate (9); a probe combination module (4) is fixed on the lateral side of the carrier dolly module (3) through a tracking module (5); an encoder (6) is fixedly arranged on an angle adjusting block (3-4) of the carrier dolly module (3); and a motor (7) is fixedly arranged on a reduction gearbox (3-7) of the carrier dolly module (3). The invention can be applied to the diameter welding line detection of a series of pipelines; the efficiency of the detection technique of the invention in the pipeline girth welding line non-destructive detection is much higher than that of manual ultrasonic detection; and the invention is obviously superior in detection speed, environmental radiation pollution reduction and labor intensity decrease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

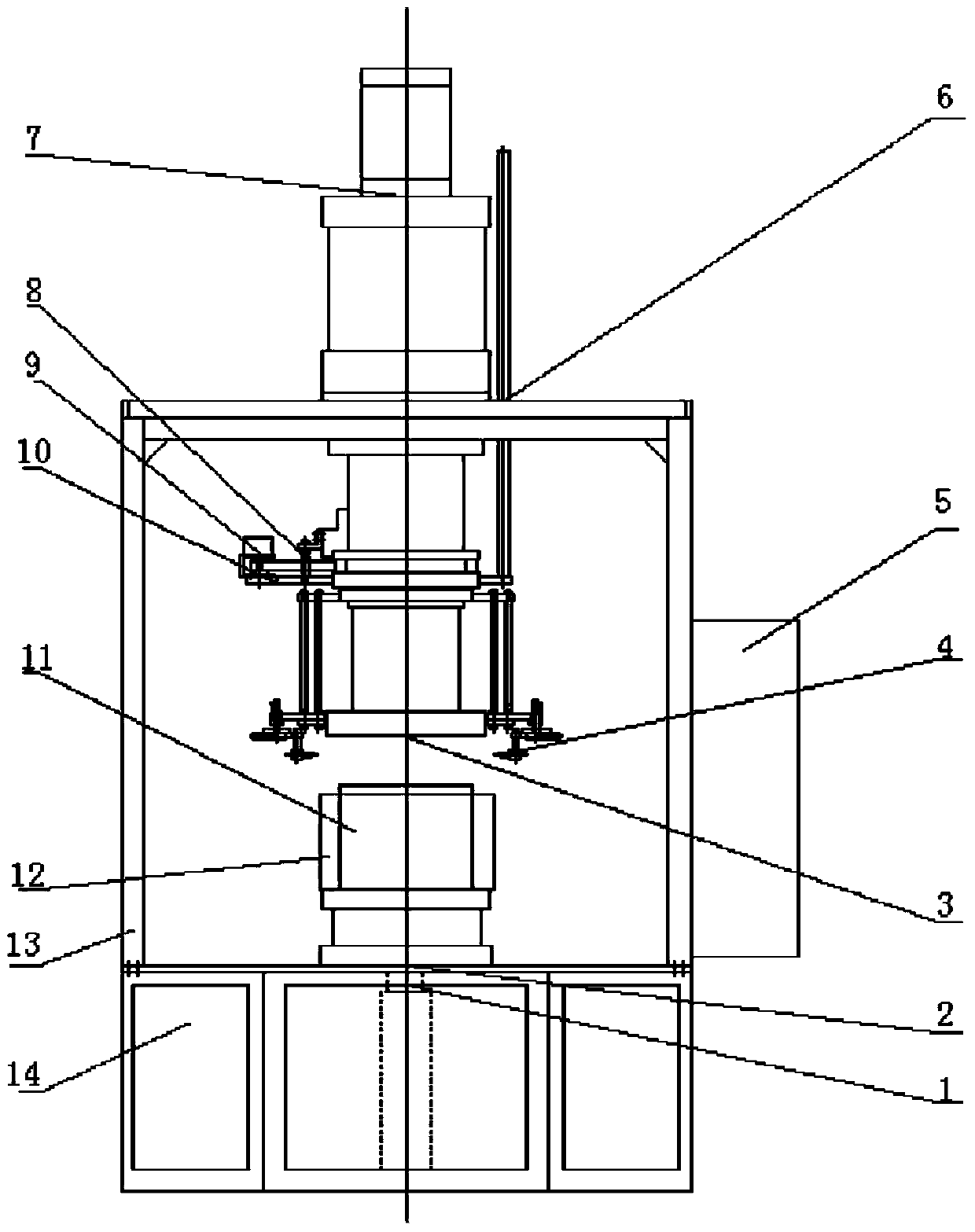

Automatic welding device and welding method for stators

InactiveCN103433637AHigh yieldWith station rotation functionWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderRotation function

The invention discloses an automatic welding device and welding method for stators. The automatic welding device comprises a shell body, a base, a rotary table, a lifting mechanism, a compressing device, welding guns, an electrical cabinet, a guide rod, a hydraulic cylinder, a lead screw, a servo motor, dabber fixtures and a servo control system, wherein the rotary table is installed on the base through a rotary shaft, the lifting mechanism is installed in a rectangular tank of the base, the two dabber fixtures which are the same in structure are installed on the horizontal plane of the rotary table, and the welding guns are evenly distributed on the outer circumference of the compressing device. The rotary table is provided with the two dabber fixtures and has the work station rotating function, and two stators can be installed at the same time and then are welded and machined through rotation of the rotary table; meanwhile, the welding guns are installed at the same time, welding of multiple passes of welding lines can be conducted, and accordingly working efficiency is improved. A servo motor of the automatic welding device is controlled by the servo control system, and machining speed and position are accurate.

Owner:DALIAN JIAOTONG UNIVERSITY

Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

ActiveCN102554402AReduce labor intensityEnsure continuous weldingArc welding apparatusFurnace typesNuclear technologyNuclear engineering

The invention discloses welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes, which are suitable for welding and heat treatment of large-diameter and thick-wall pipes. The pipes welded by the welding and heat treatment processes are steady and reliable in the quality of welding lines, and can completely meet the quality requirement of nuclear technology.

Owner:江苏利柏特股份有限公司

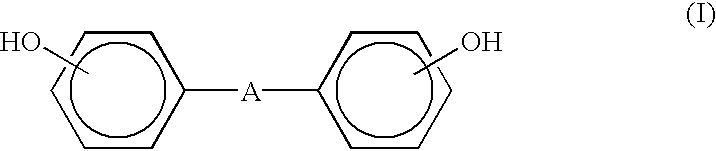

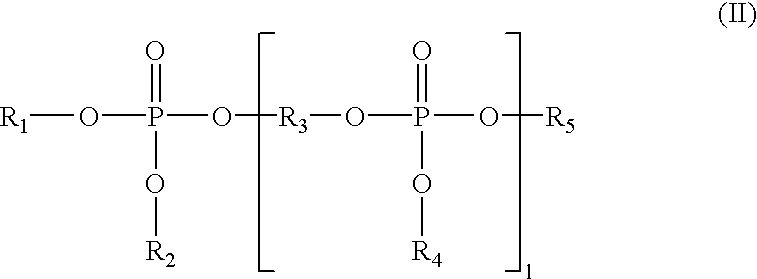

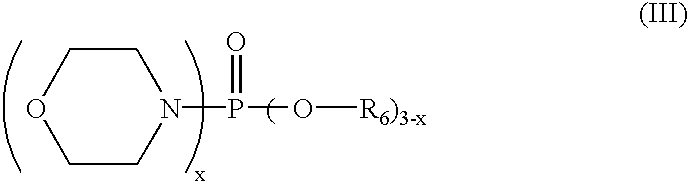

Flame retardant polycarbonate resin composition

InactiveUS6437029B1Improve flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsLiquid carbonaceous fuelsPhosphoric Acid EstersMeth-

The present invention relates to a flame retardant thermoplastic resin composition that comprises a polycarbonate resin, a rubber modified styrene-grafted copolymer, a styrene-containing copolymer, a (meth)acrylic acid ester copolymer, a phosphoric acid ester as a flame retardant and a fluorinated polyolefin resin, which does not show coalescence of the domain resin that might be caused by the low viscosity at a high temperature, and poor flame retardancy, weld-line strength and mechanical properties such as impact strength, and which has a good balance of physical properties such as impact strength, heat resistance, heat stability, processability and appearance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

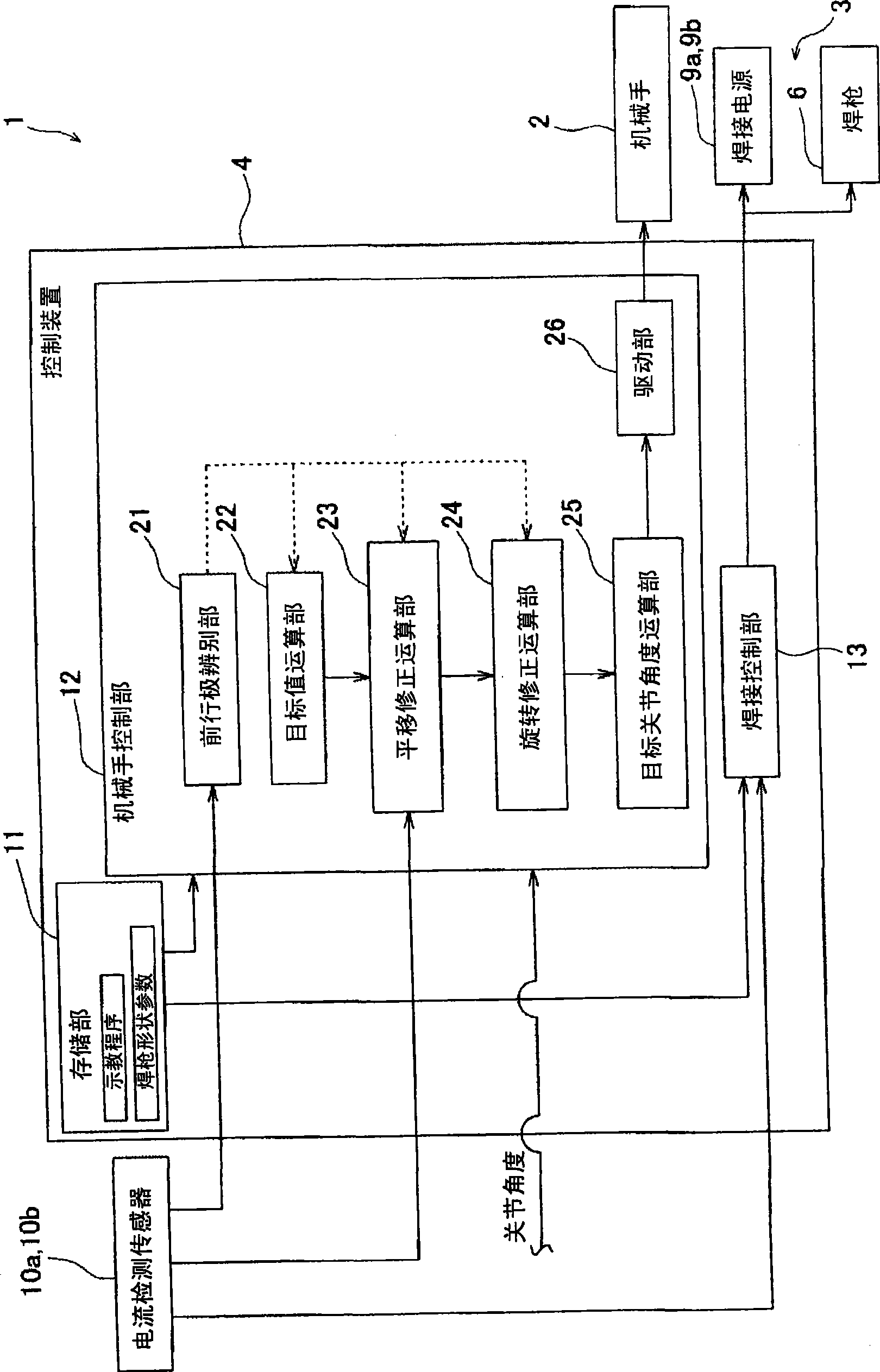

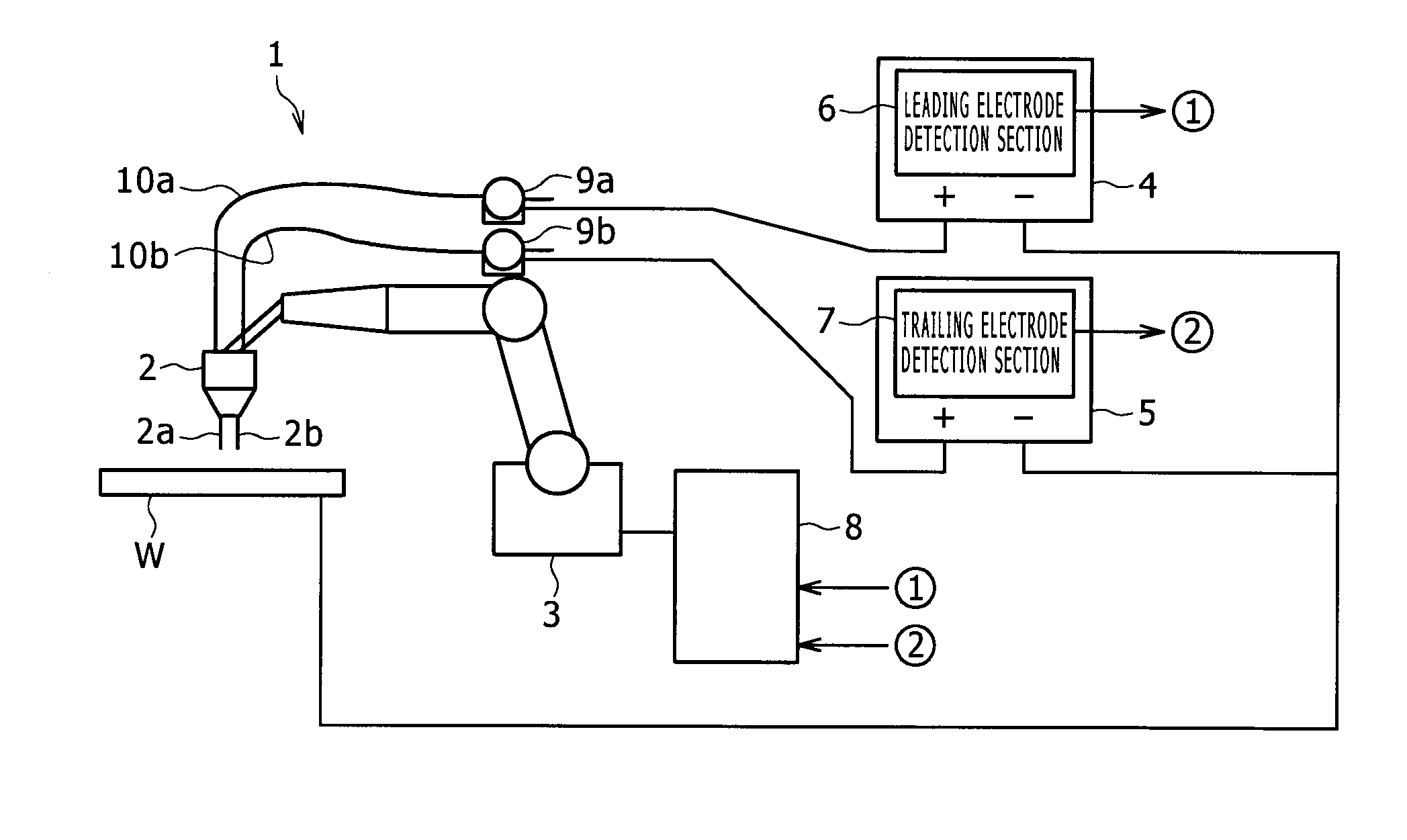

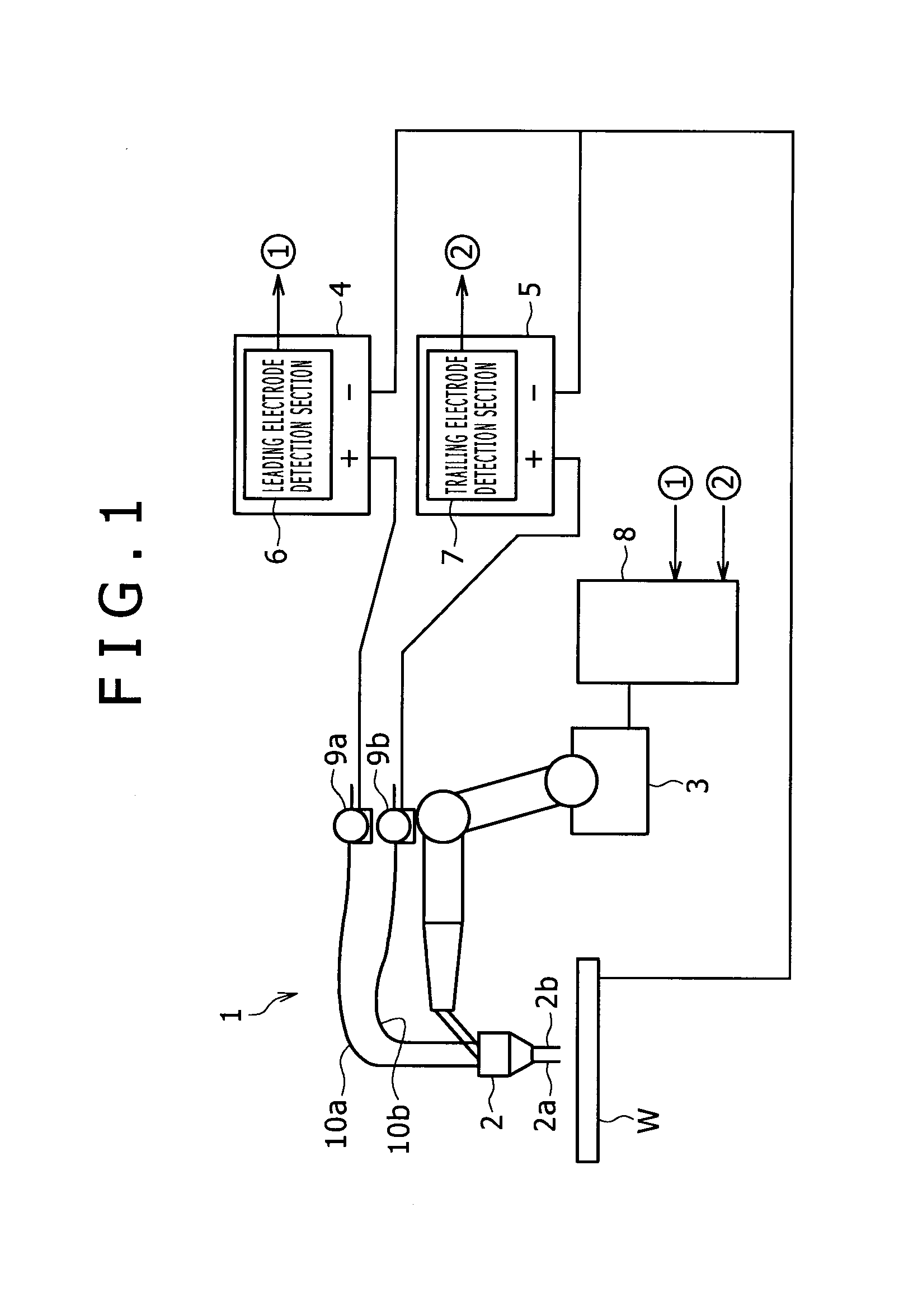

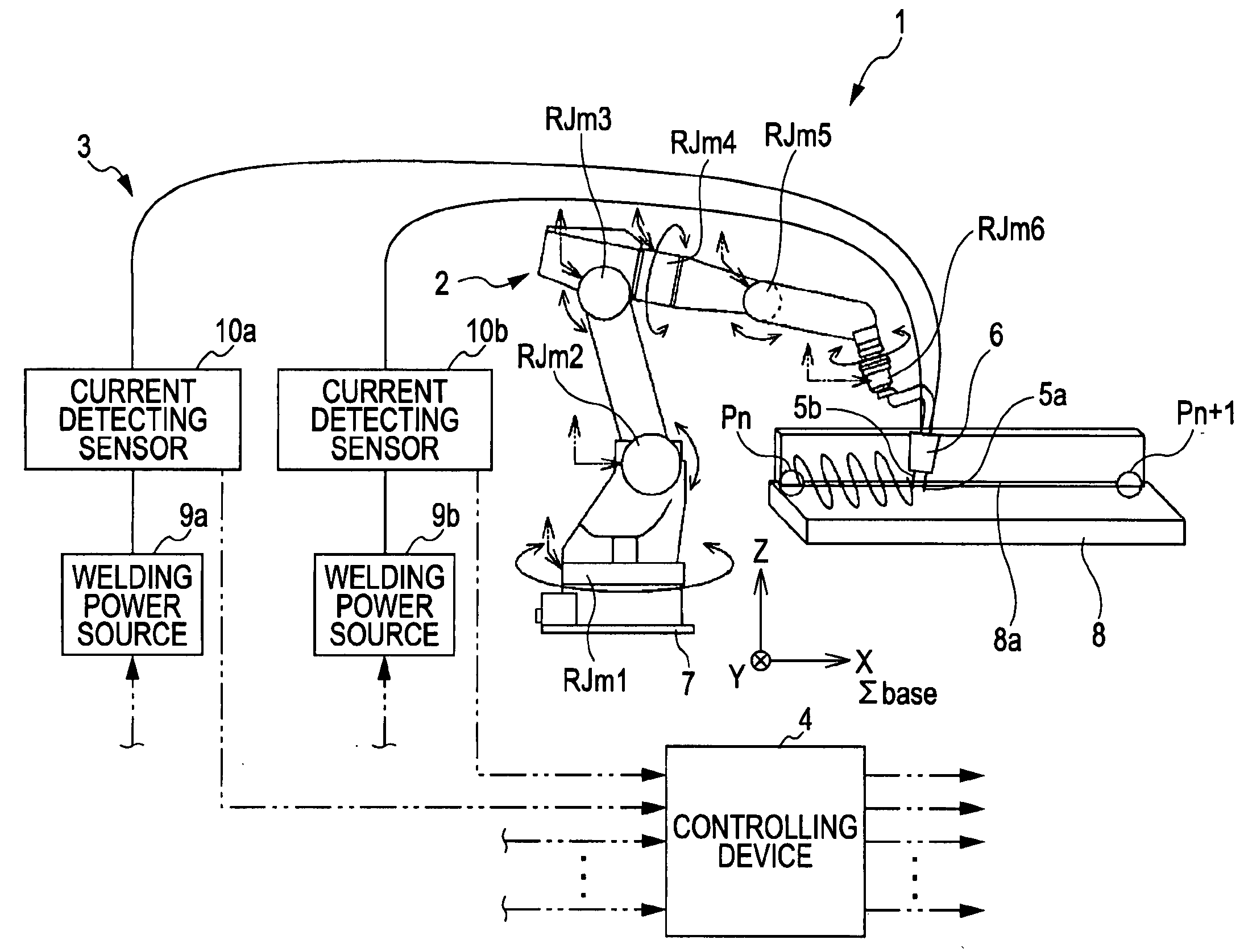

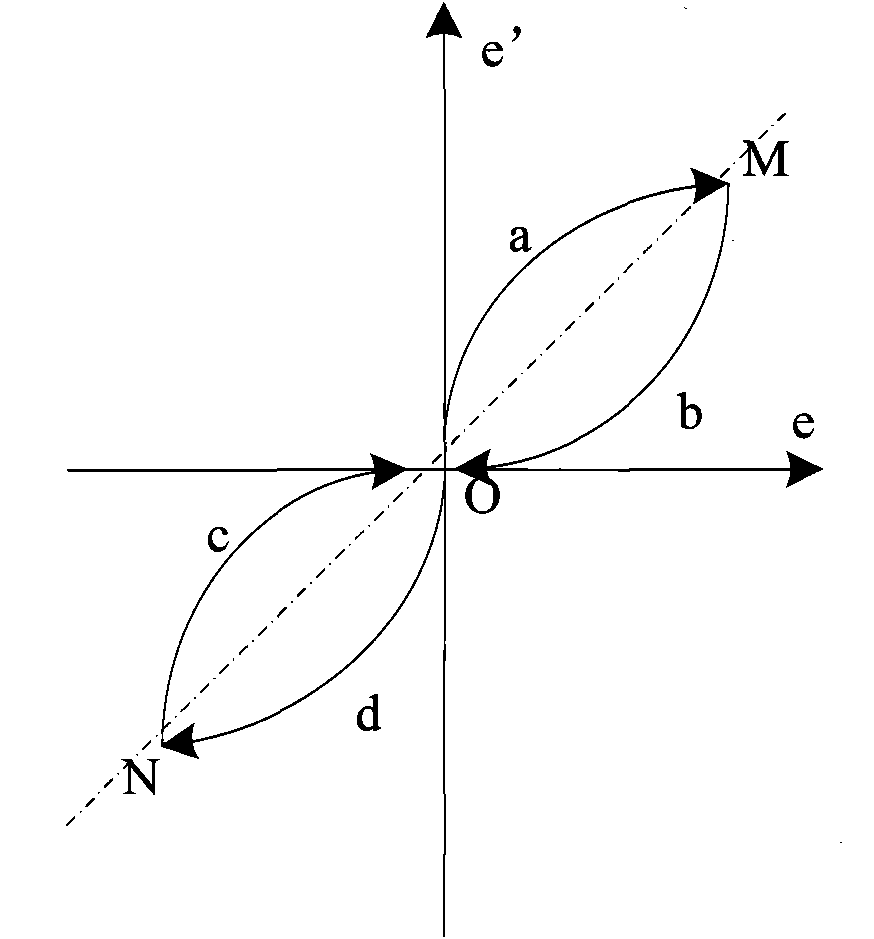

Robot control unit for controlling tandem arc welding system, and arc-sensor control method using the unit

ActiveUS20080083716A1Improve calibration accuracyImprove accuracyComputer controlSimulator controlRobot controlWelding defect

A robot control unit for controlling a tandem arc welding system, which has a welding torch, a robot for weaving the welding torch, a leading electrode power supply, and a trailing electrode power supply, includes a leading electrode detection section and a trailing electrode detection section for detecting quantity of welding state during weaving; a leading electrode processing section for calculating amounts of electrical change; a leading electrode correction section for calculating correction amounts for correcting displacement in horizontal and vertical directions from a weld line of a weaving center trajectory based on the amounts of electrical change; a trailing electrode processing section for calculating an amount of electrical change; and a trailing electrode correction section for calculating a correction amount for correcting displacement in a rotational direction from the weld line of the weaving center trajectory based on the amount of electrical change. According to the robot control unit, arc welding can be performed, which is excellent in accuracy of arc-sensor control, and hardly produces welding defects.

Owner:KOBE STEEL LTD

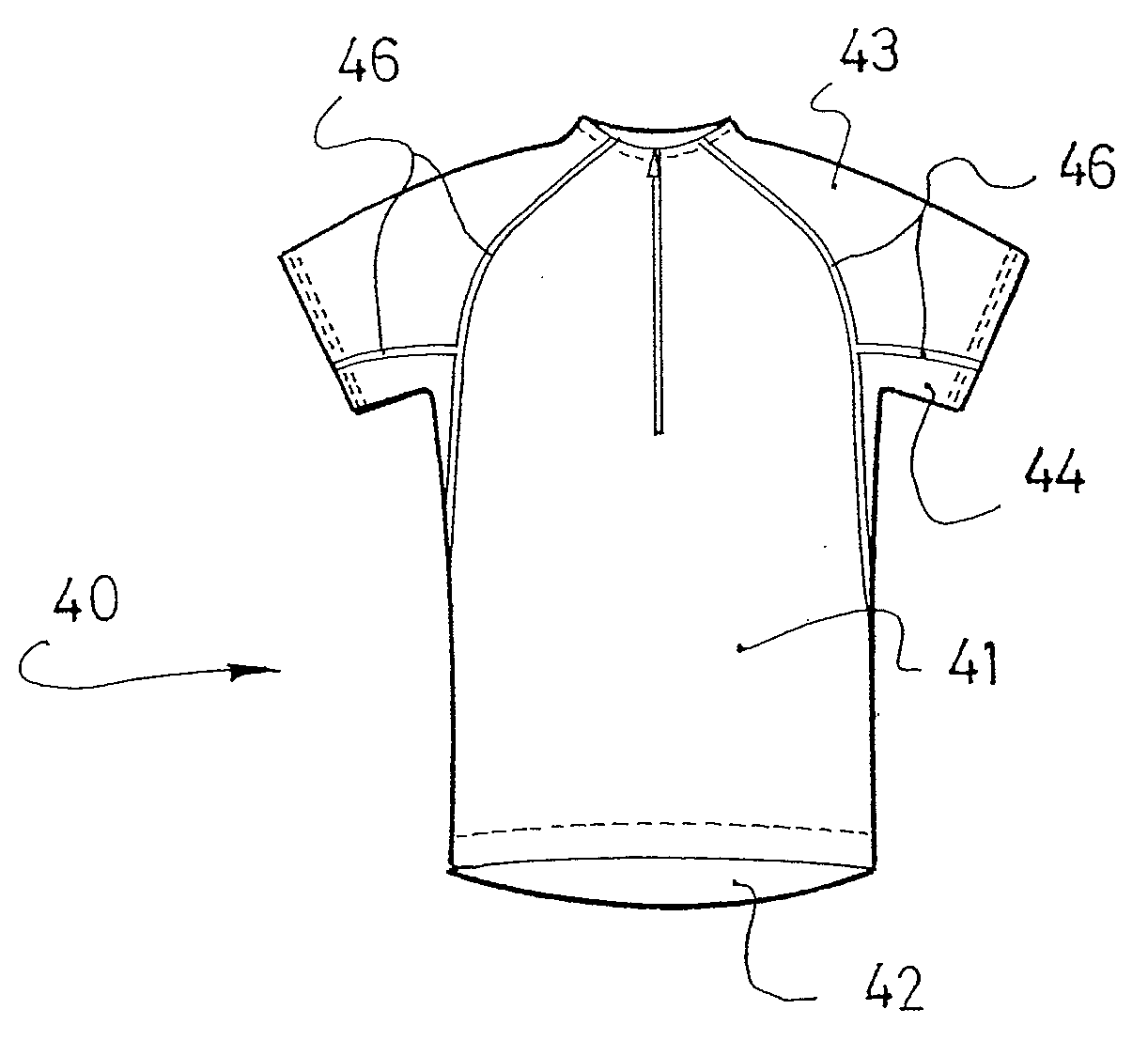

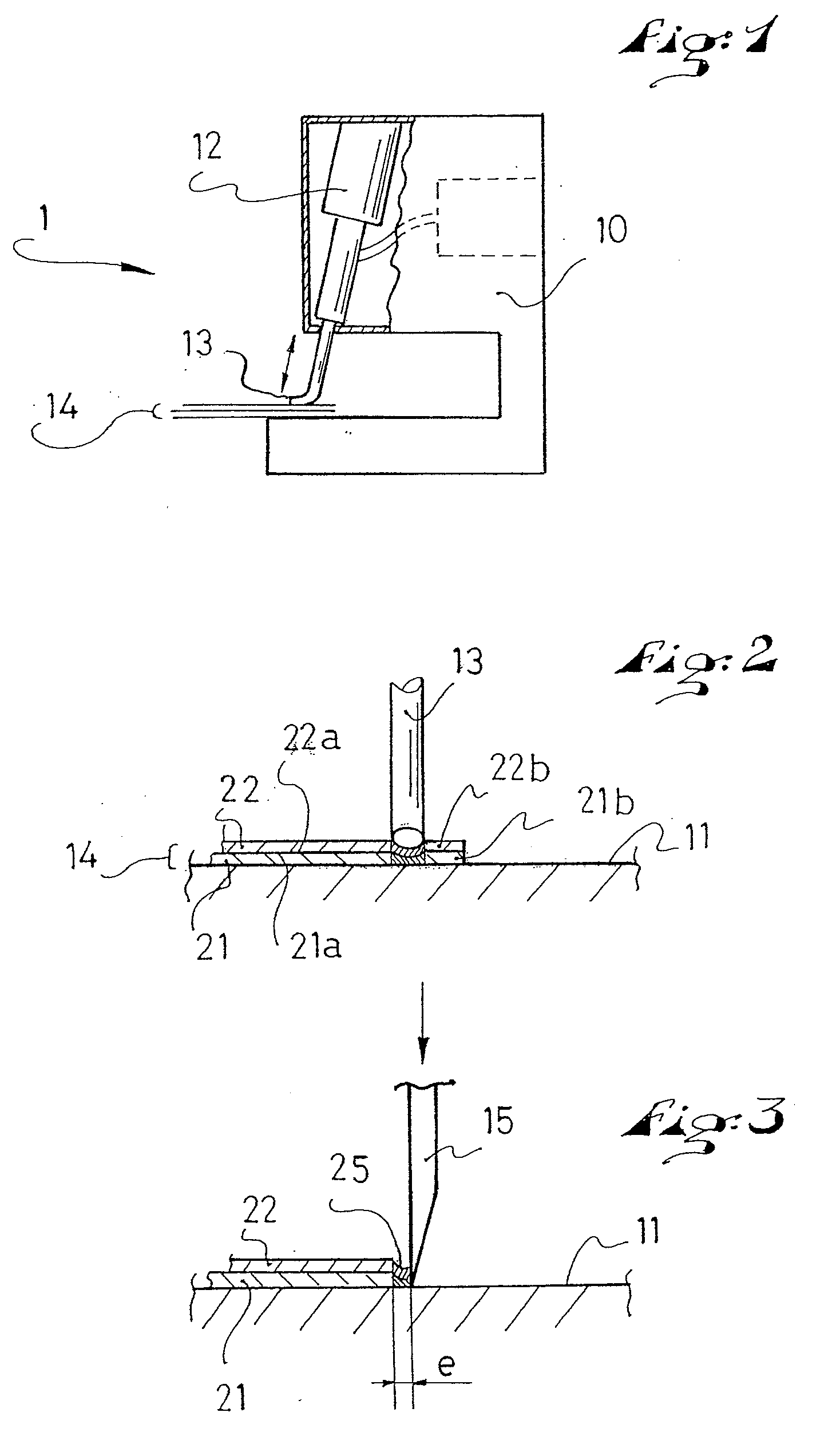

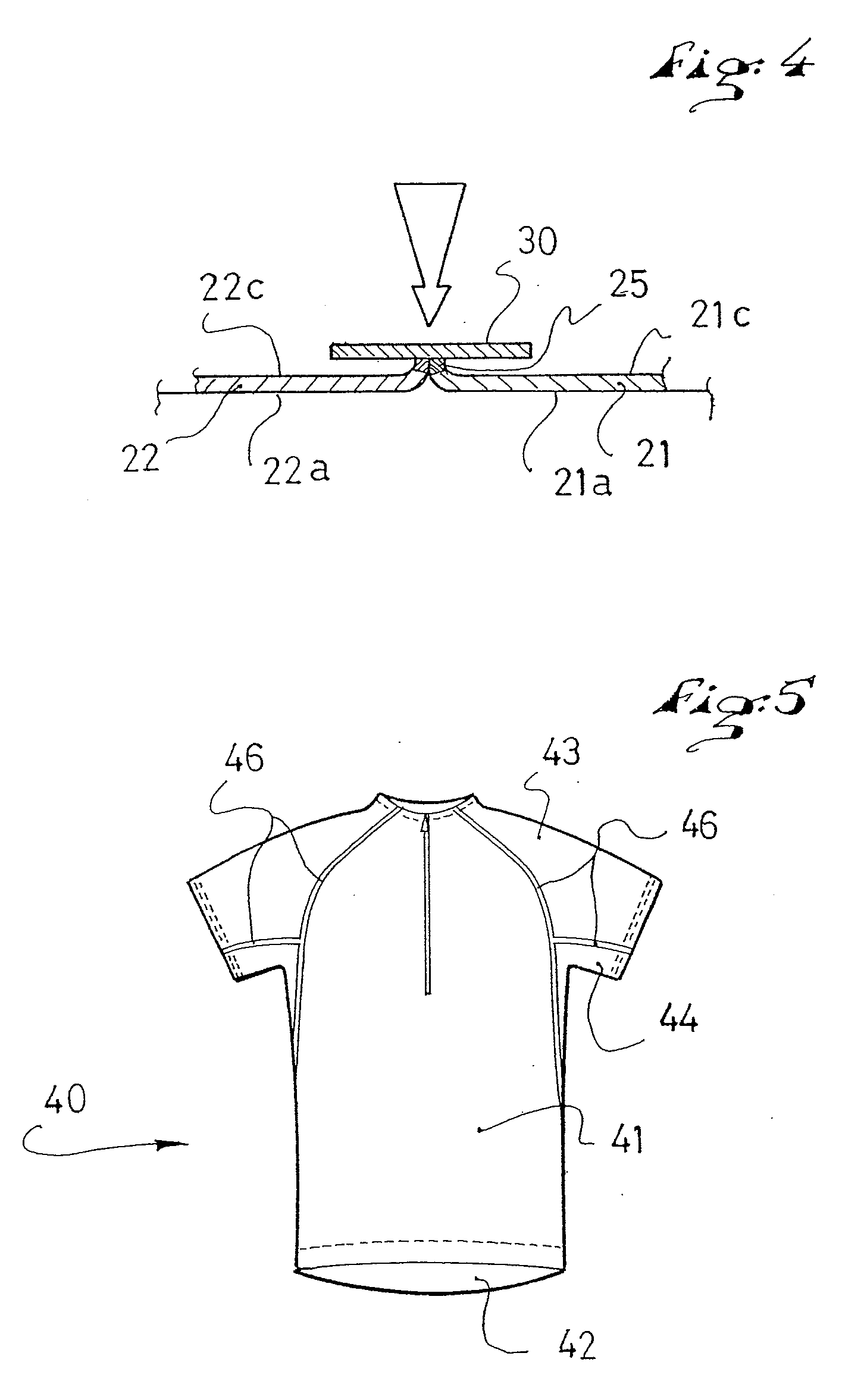

Laminated Fabric Panels and Method of Assembling Same

InactiveUS20080196136A1Easy to weldMinimizing abrasionLayered productsDomestic articlesEngineeringWeld line

Laminated fabric panels and a method of assembling such panels. A garment, for example, is made of first and second parts assembled to one another by superimposing the first part and the second part so that their inner surfaces face one another; welding the two parts along a weld line; flattening the two parts, the weld line being arranged on the outer side; applying a reinforcement strip to the welding line on the outer side of the garment.

Owner:SALOMON SA

Welding robot

InactiveUS20090179021A1Improve tracking performanceAvoid mistakesProgramme-controlled manipulatorArc welding apparatusEngineeringTorch

A welding robot in which a translational correction calculating unit corrects a target value of a leading electrode using a translational correction amount, to obtain a primary correction target value. The translational correction amount is a correction amount of a position of the leading electrode in a translational direction in a base coordinate system at a next time. A rotational correction calculating unit calculates a rotation correction amount for correcting displacement of an orientation of a torch around the leading electrode with respect to a actual weld line, and calculates a secondary correction target value resulting from correcting the primary correction target value so that the torch rotates around the leading electrode by the rotation correction amount. The displacement is caused by the correction using the translational correction amount. A manipulator is driven on the basis of the secondary correction target value.

Owner:KOBE STEEL LTD

Polymeric coextruded multilayer articles

InactiveUS6949283B2Improve adhesionSynthetic resin layered productsThin material handlingFiberEngineering

Described is a polymeric coextruded multilayer web, the web comprising: at least two layers that are discontinuous in the cross-web direction, each layer comprising a plurality of distinct phases that are substantially continuous in the down-web direction; and at least one layer that is substantially continuous in both the cross-web and down-web directions; wherein said web has an x-axis that is in the cross-web direction of the web, a y-axis that is in the down-web direction of the web and a z-axis that is in the thickness direction of the web, and wherein the substantially continuous layer(s) lacks weld lines in the y-z plane of the web.

Owner:3M INNOVATIVE PROPERTIES CO

Fiber optic cables that are separable for optical fiber access

InactiveUS20060269198A1Reduce the possibilityWeight per lengthFibre mechanical structuresFiberEngineering

A fiber optic cable includes a messenger section having at least one strength member, a carrier section having at least one optical fiber therein, and a common jacket that forms a common jacket. In one embodiment, the carrier jacket has a preferential tear portion adjacent to the at least one optical fiber with a substantially continuous outer surface in the carrier jacket adjacent to the preferential tear portion. The preferential tear portion may be defined by at least one of: at least one internal void, at least one weld line, and at least one wing extending from a tape disposed about the one or more optical fibers. Various alternatives are possible. For example, the carrier jacket may also or alternatively include at least one gripping area extending for enhancing the gripping of the carrier section when pulling apart the carrier section and messenger section.

Owner:CORNING OPTICAL COMM LLC

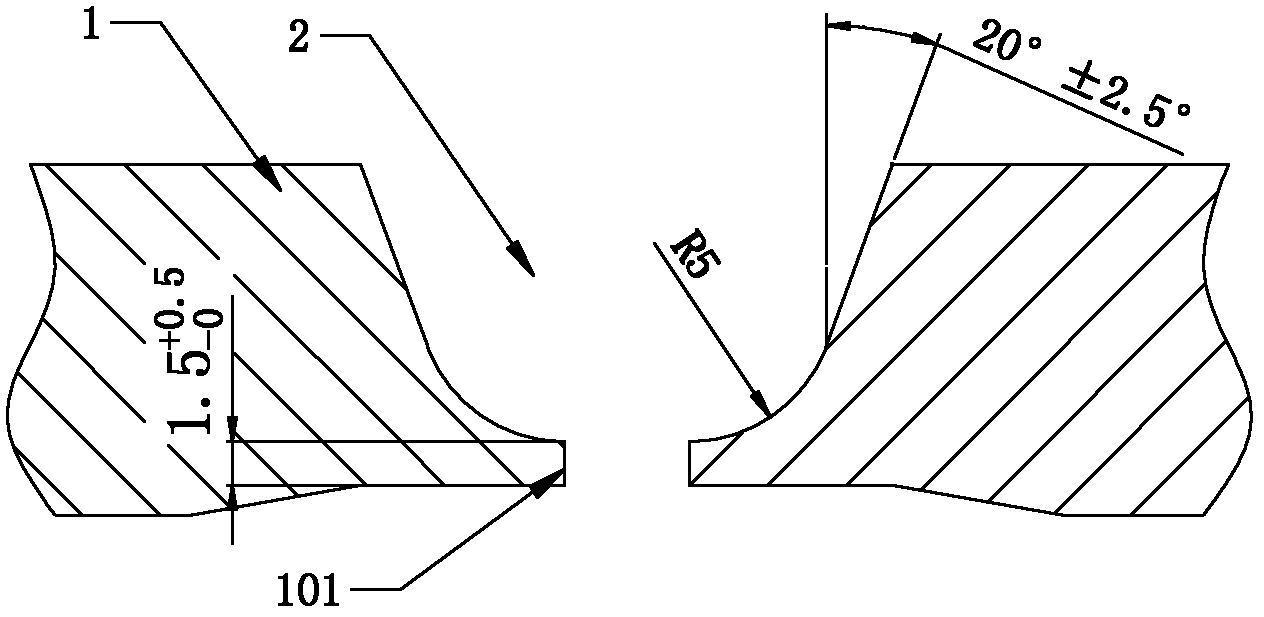

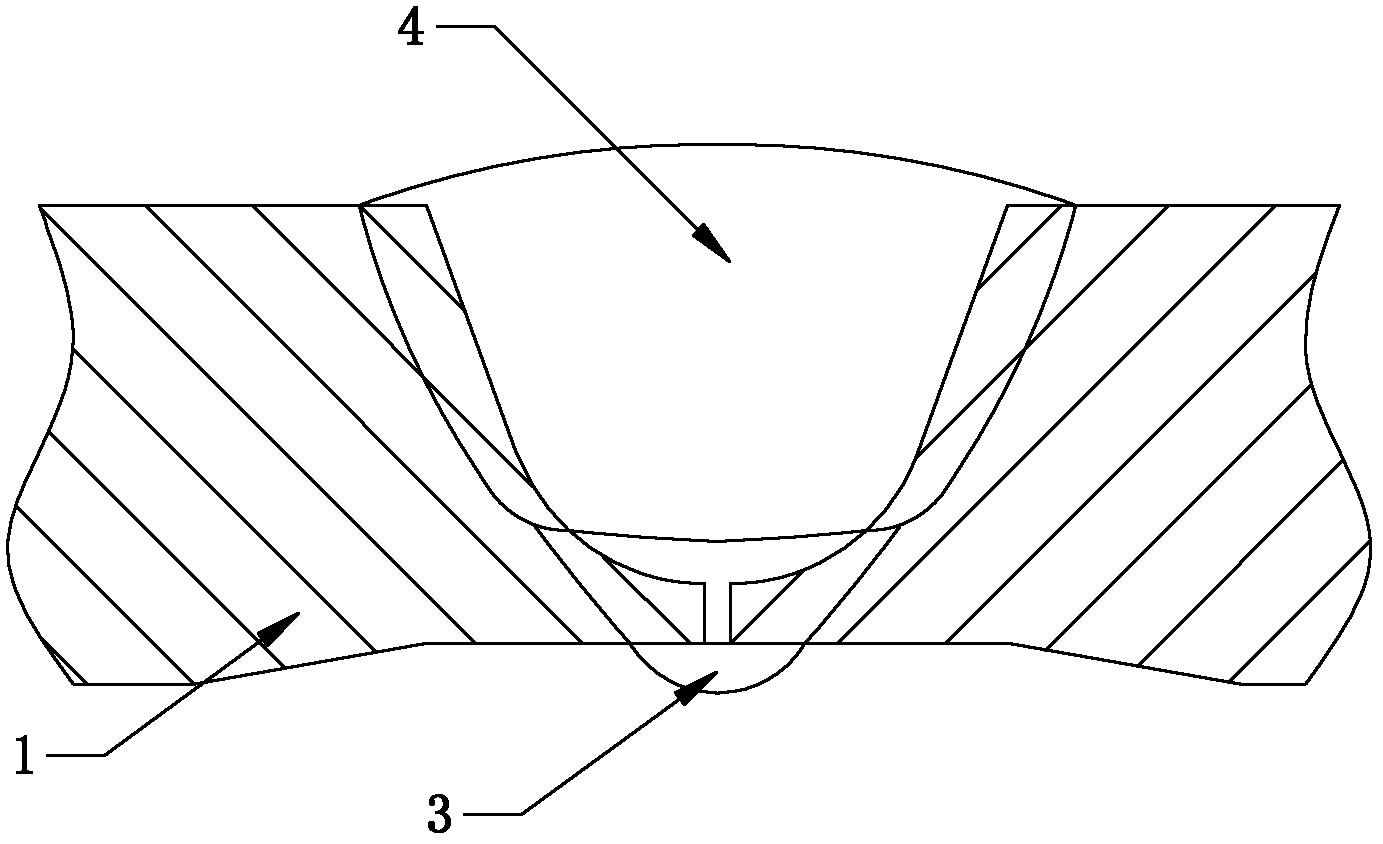

Overlaying welding technology of ductile cast iron roller

ActiveCN101543926ASolve the problem of repairing welding defects such as small and medium cracksAvoid Weld CrackingWelding/soldering/cutting articlesWelding accessoriesEconomic benefitsDuctile iron

The invention relates to an overlaying welding technology of an iron casting, in particular to an overlaying welding technology of a ductile cast iron roller. The technology comprises the following steps: (1), post-welding preparation: a, detecting cracks; b, controlling a welding material; and c, selecting a welding beveling; (2), welding: a, preheating the beveling within a range of 120mm to 180mm at a temperature range of 130 DEG C to 170 DEG C; b, adopting a DC reverse-connected arc welding machine for welding, using welding rods with the diameter of 3.2mm for welding a first-layer welding line and using welding rods with the diameter of 4mm for welding lines on subsequent layers; and (3), post-welding detection. The invention adopting the technologies, such as small currents, a plurality of stages, sectional welding, welding line hammering after welding, cooling speed reduction, and the like prevents welding line cracks and fusion region cracks from generating, prolongs the service life of products, obtains favorable economic benefits and solves the problems for the overlaying welding of mid-small cracks, and the like on the surface of the ductile cast iron roller.

Owner:CHANGZHOU HAIJIE METALLURGICAL MACHINERY MFG

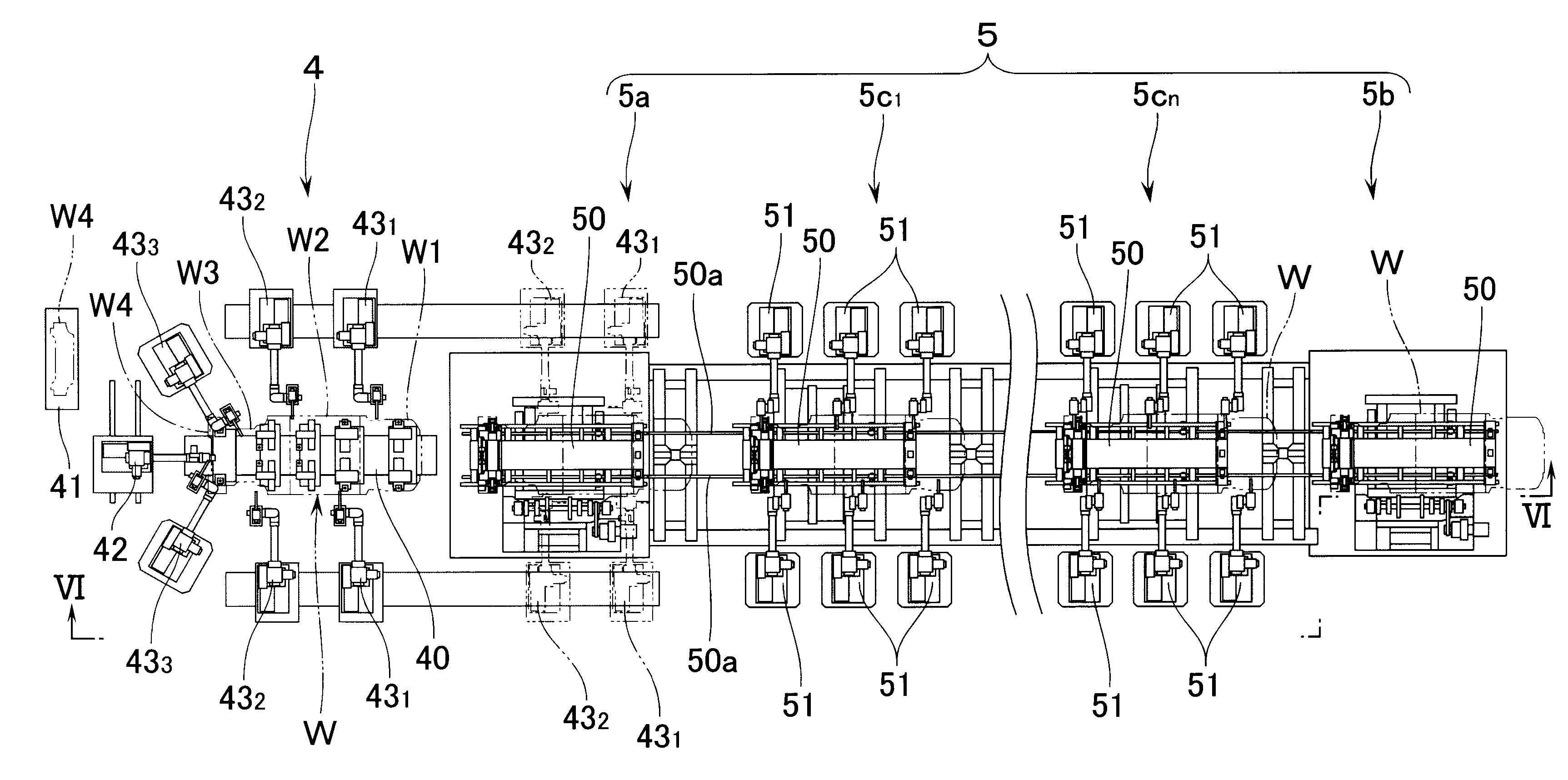

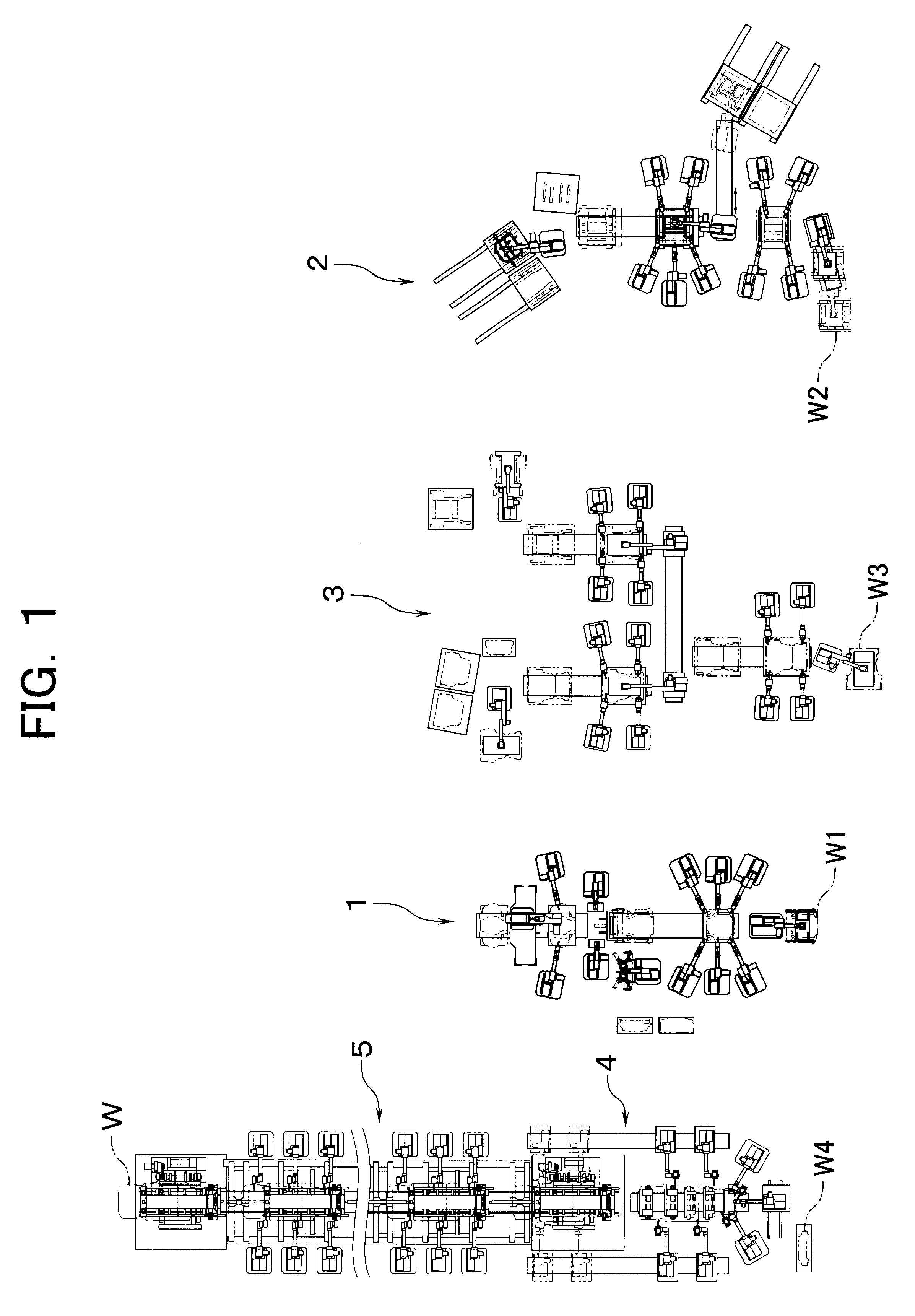

Method of manufacturing multiple kinds of products in arbitrarily selected order in one manufacturing line

InactiveUS6336582B1Rate of operationReduce the numberExhaust apparatusWelding/cutting auxillary devicesProduction rateProduction line

In a method of manufacturing multiple kinds of products in an arbitrarily selected order in one manufacturing apparatus, the rate of operation of the welding robots to be disposed in each of assembly lines for each of parts is improved, the cost for equipment investment is reduced, and the time required to introduce a new kind of motor vehicle into the manufacturing apparatus is shortened, whereby the productivity is improved. The manufacturing apparatus is made up of: a plurality of part assembly lines for assembling a plurality of parts; a combining station for tack-welding these parts to thereby assemble a product; and a reinforce-welding line for reinforce-welding the product. The number of welding points for welding each of the parts in the respective assembly lines is made equal to one another for all kinds of vehicles. Those welding points of each of the parts which fall short of a required number of welding points are welded in the reinforce-welding line.

Owner:HONDA MOTOR CO LTD

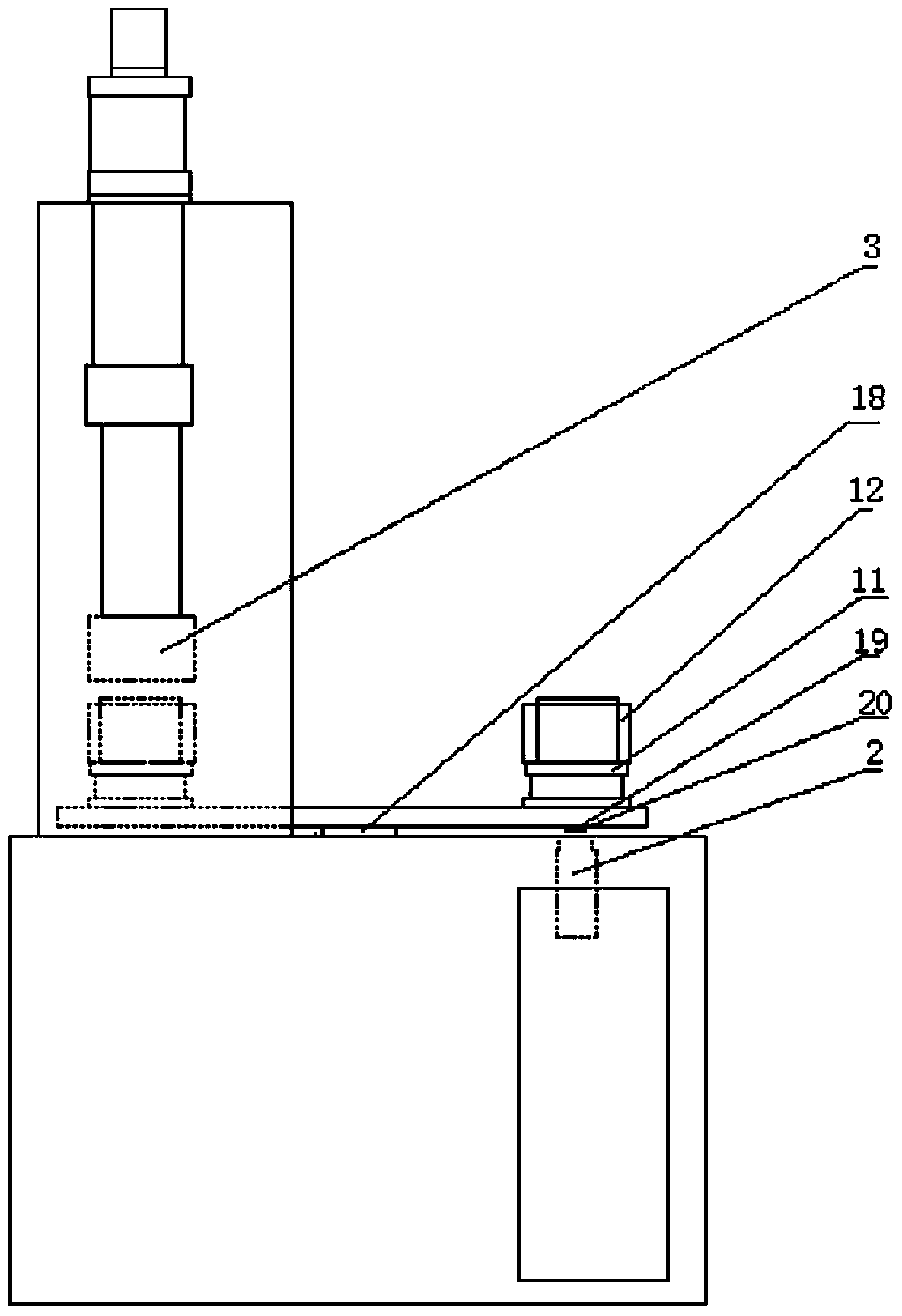

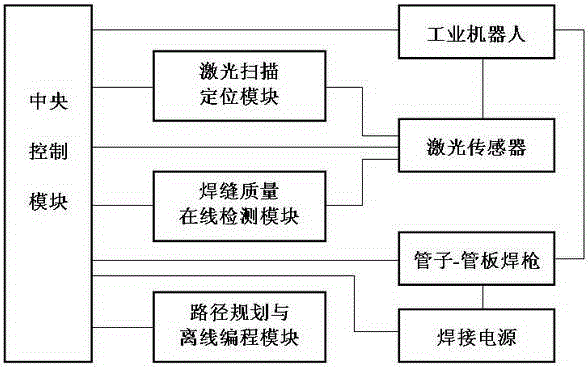

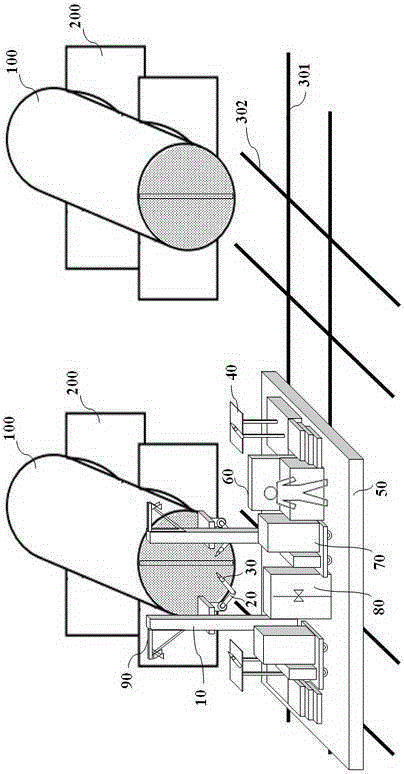

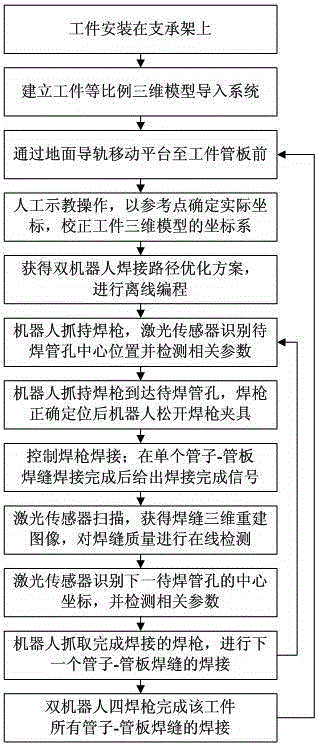

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

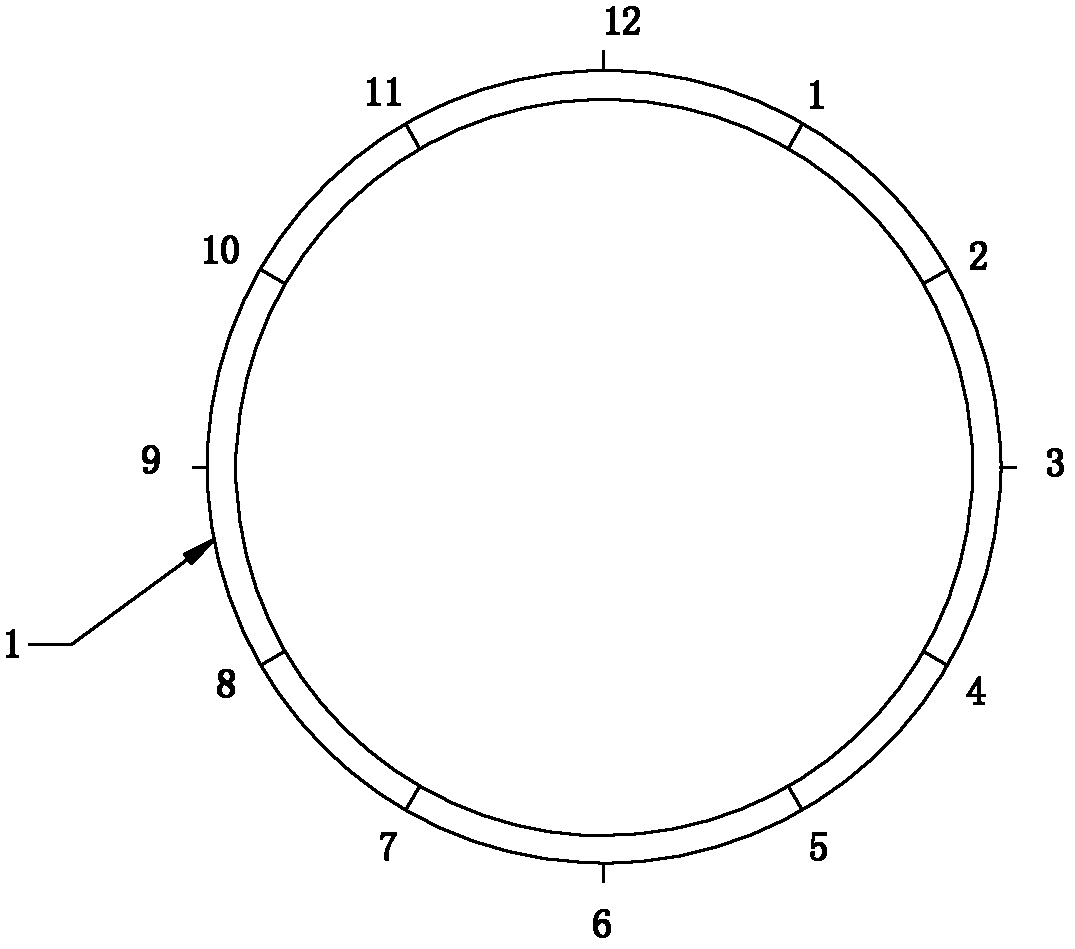

Electron beam welding method of gas turbine casing with horizontal flange structure

ActiveCN102990217AImprove manufacturing levelLow costElectron beam welding apparatusStructural engineeringSpot welding

The invention discloses an electron beam welding method of a gas turbine casing with a horizontal flange structure, and relates to the welding method of the casing with horizontal flanges. The invention aims at solving the technical problems of large deformation, complicated tooling design and manufacture, low repetition usage rate of the tooling and low production efficiency after the horizontal flanges are welded by the existing half-ring gas turbine casing welding method. The welding method comprises the following steps of: 1, machining; 2, cleaning the surfaces of parts to be welded; 3, spot welding; 4, scribing; 5, assembling; 6, spot welding at fixed positions; 7, centering; 8, interpolating, and 9, welding the electron beam. Once vacuum electron beam welding of four horizontal flanges is achieved by the welding method disclosed by the invention; the deformation after welding is small; the production efficiency is doubled; X-ray flaw detection non-destructive testing is carried out; a welding line does not generate the defects such as lack of penetration, air holes, cracks and puncture; the quality of the welding line meets the requirements; and the electron beam welding method is simple in tooling design and manufacture, and high in repetition usage rate of the tooling, and can be used for welding the horizontal flanges of the gas turbine casing.

Owner:HARBIN TURBINE

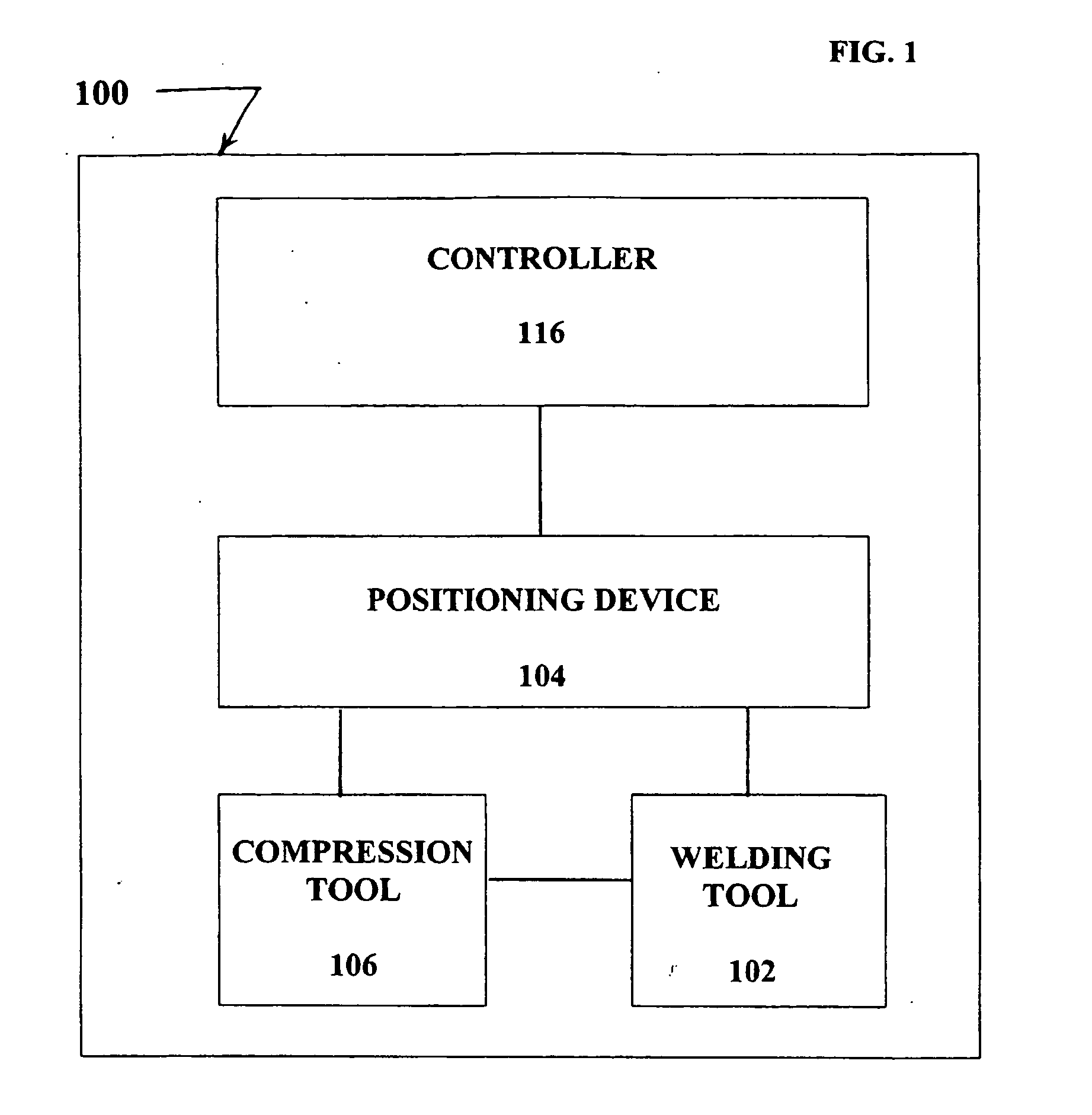

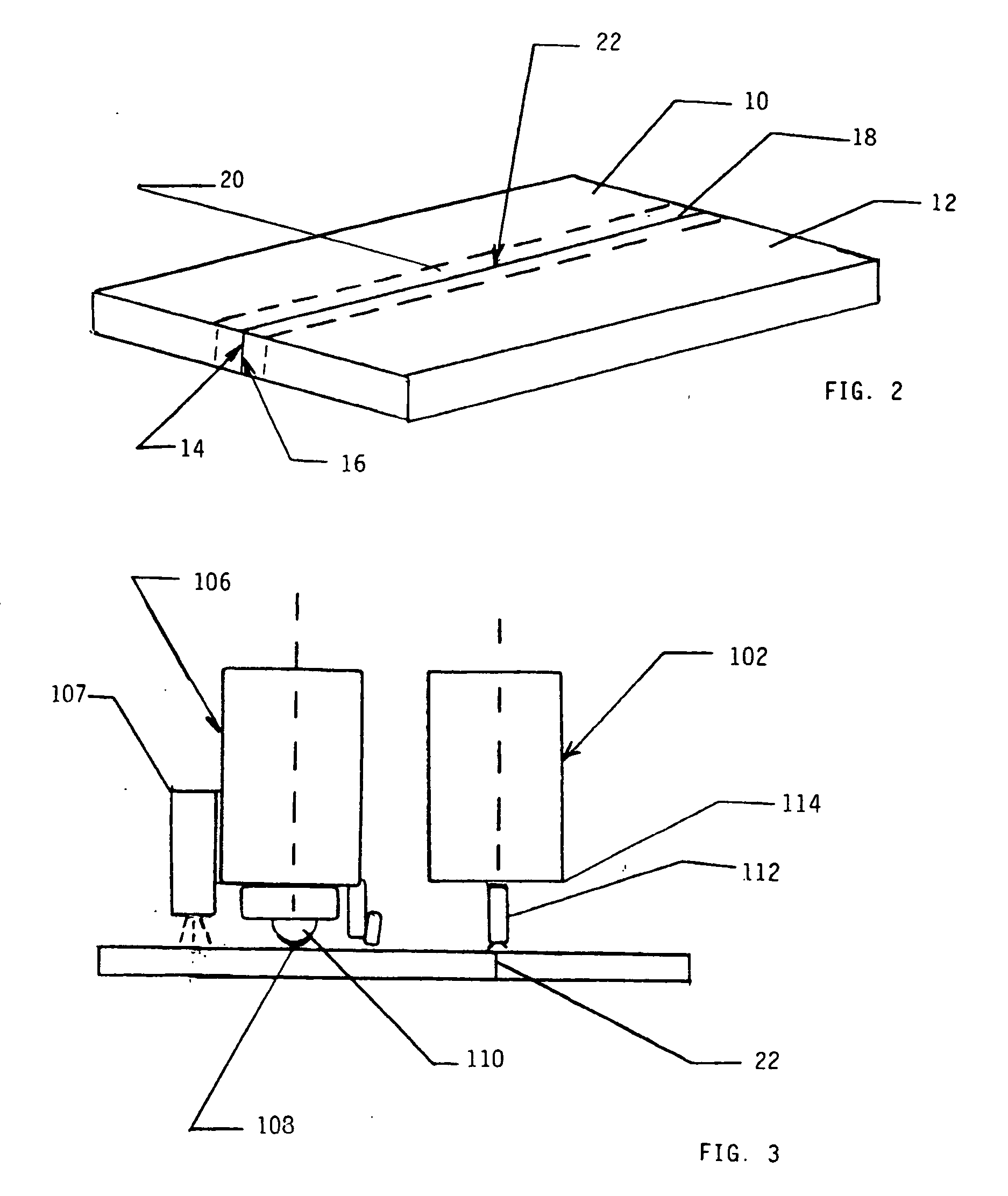

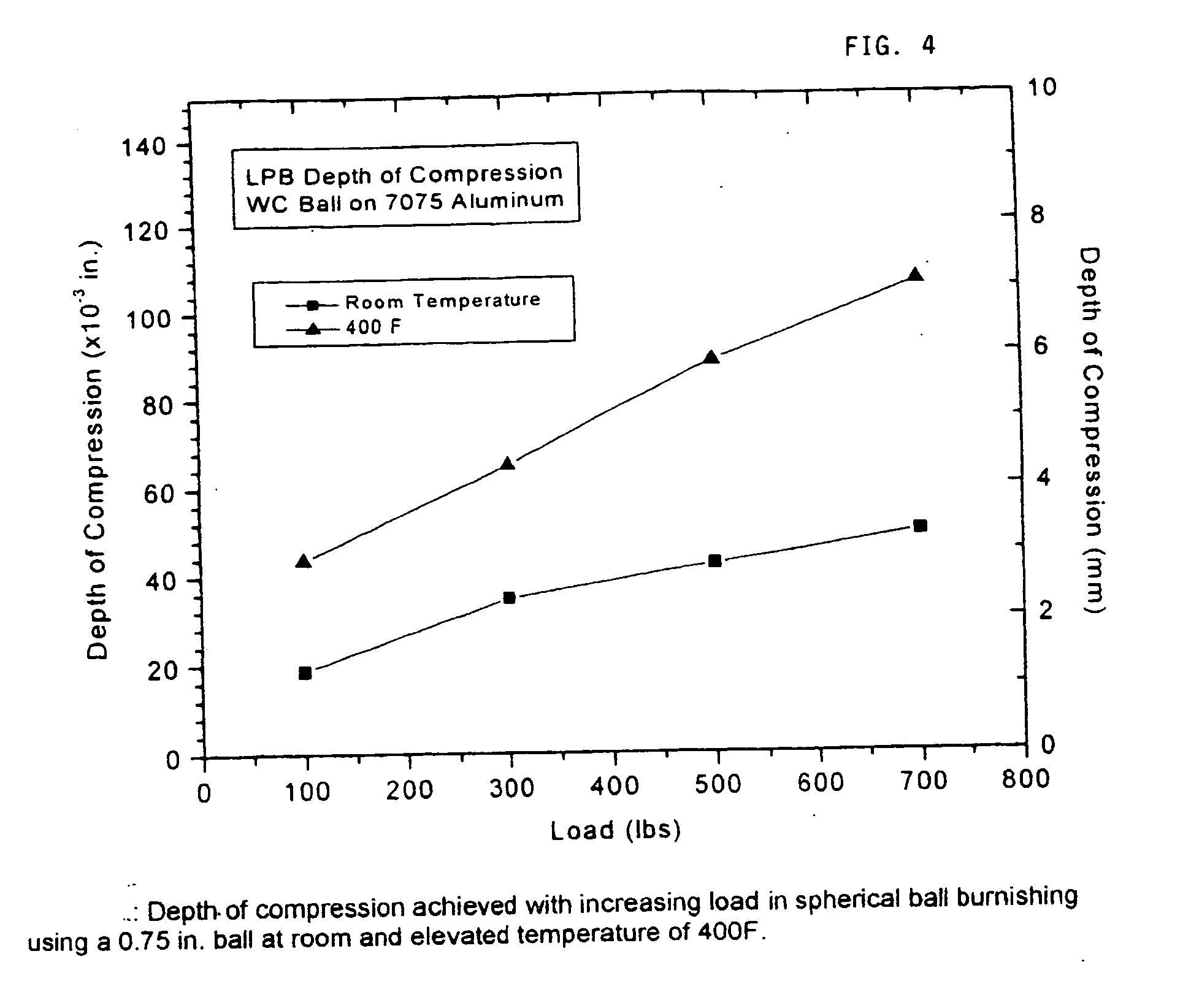

Apparatus and method for forming a weld joint having improved physical properties

InactiveUS20050224562A1Improve material performanceDeep compressionArc welding apparatusFurnace typesHeat-affected zoneEngineering

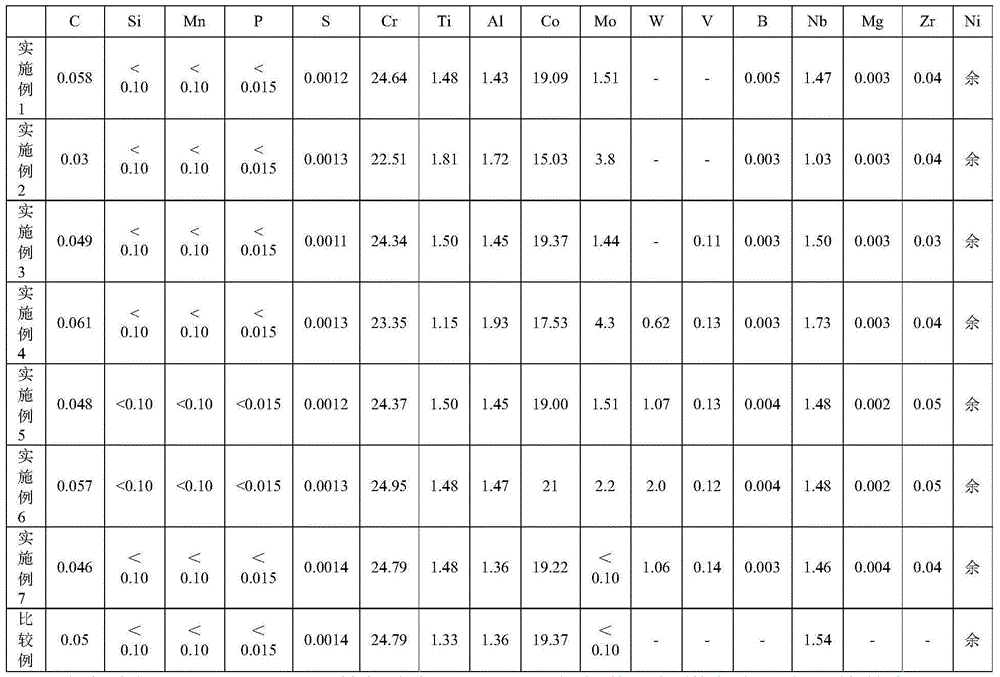

The method and apparatus for performing the method of forming a weld joint of the present invention utilizes welding apparatus (100) having welded tool (102) and a compression tool (106) for inducing a layer of residual compressive stress along the surface of the weld line (18) and any heat affected regions with a controlled amount of cold working and surface hardening. In a preferred embodiment of the invention the compression tool (106) utilizes a single-point burnishing process to provide deep compression within the weld joint (20) with a minimal amount of cold working and surface hardening.

Owner:SURFACE TECH HLDG

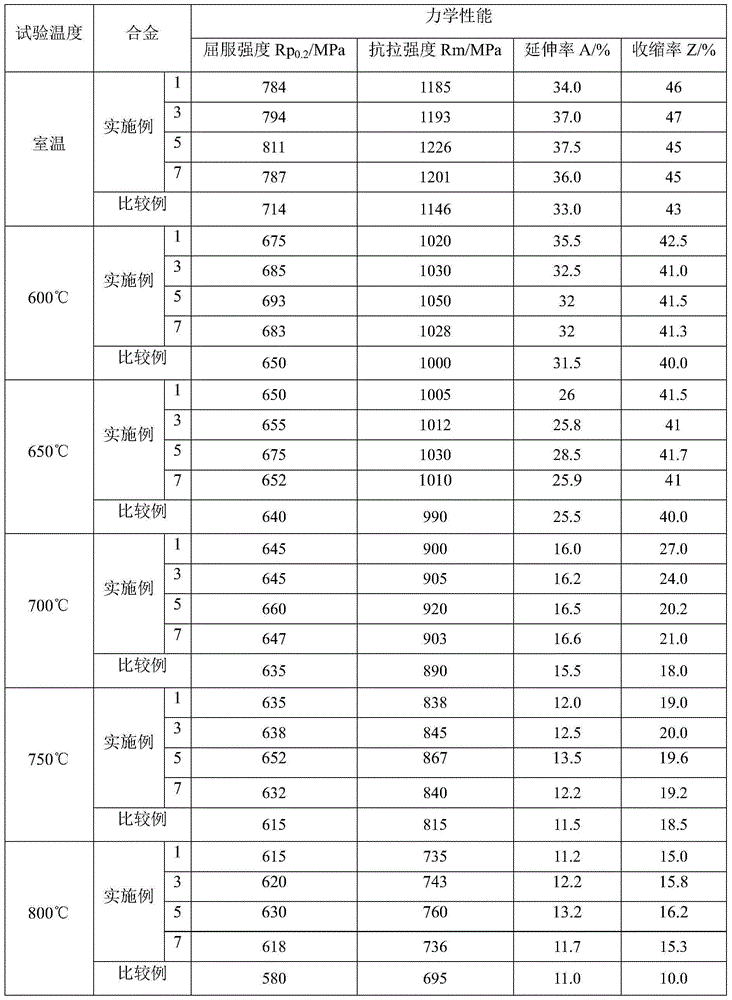

Nickel-base superalloy welding wire for 700 DEG C-above ultra-supercritical coal power generation equipment

InactiveCN105014258AImproved hot and cold processing performanceImprove high temperature strengthWelding/cutting media/materialsSoldering mediaMelting tankChemical composition

The invention discloses a nickel-base superalloy welding wire for 700 DEG C-above ultra-supercritical coal power generation equipment, and belongs to the technical field of nickel-base superalloys. The nickel-base superalloy welding wire comprises the following chemical components: 0.005-0.08 wt% of C, 22-25 wt% of Cr, 12-22 wt% of Co, 0.5-2.0 wt% of Ti, 1.0-2.5 wt% of Al, 0.5-2.0 wt% of Nb, 0.5-4.5 wt% of Mo, 0.1-3.0 wt% of W, 0.01-0.3 wt% of V, 0.001-0.05 wt% of Zr, no more than 0.02 wt% of Mg, 0.001-0.006 wt% of B, no more than 1.5 wt% of Fe, and the balance Ni and inevitable impurity elements. As such elements as Co, Cr, Mo, W, Al, Ti and Nb and proper amounts of other microelements are added in a nickel-base alloy, the cold / hot machinability, the high-temperature strength and in particular the high-temperature durability of the alloy welding wire are all improved. The alloy welding wire is better in high-temperature strength and durability, and is more excellent in welding process performance; and in the welding process, a molten pool is better in fluidity, and the welding line formability is excellent.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

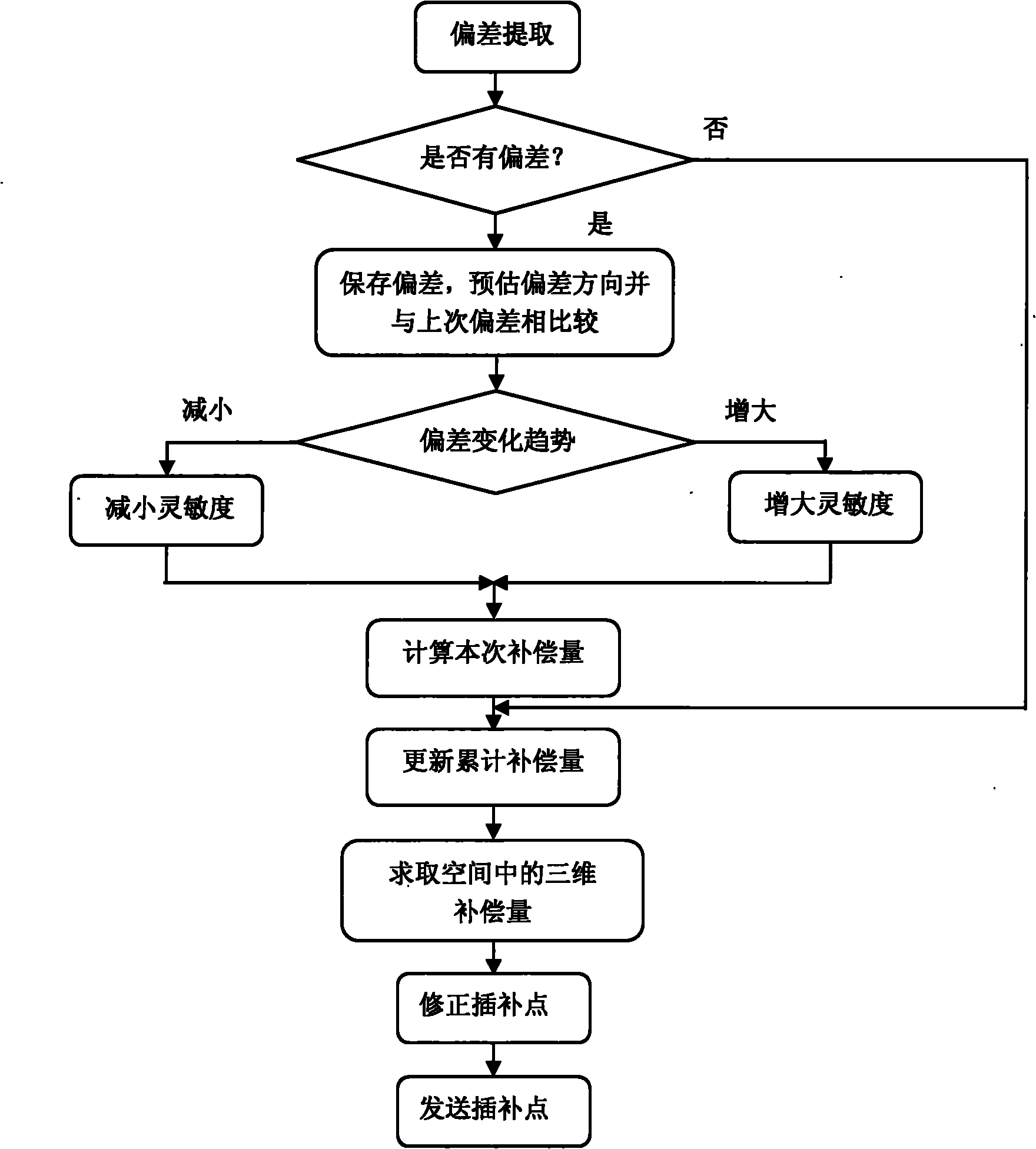

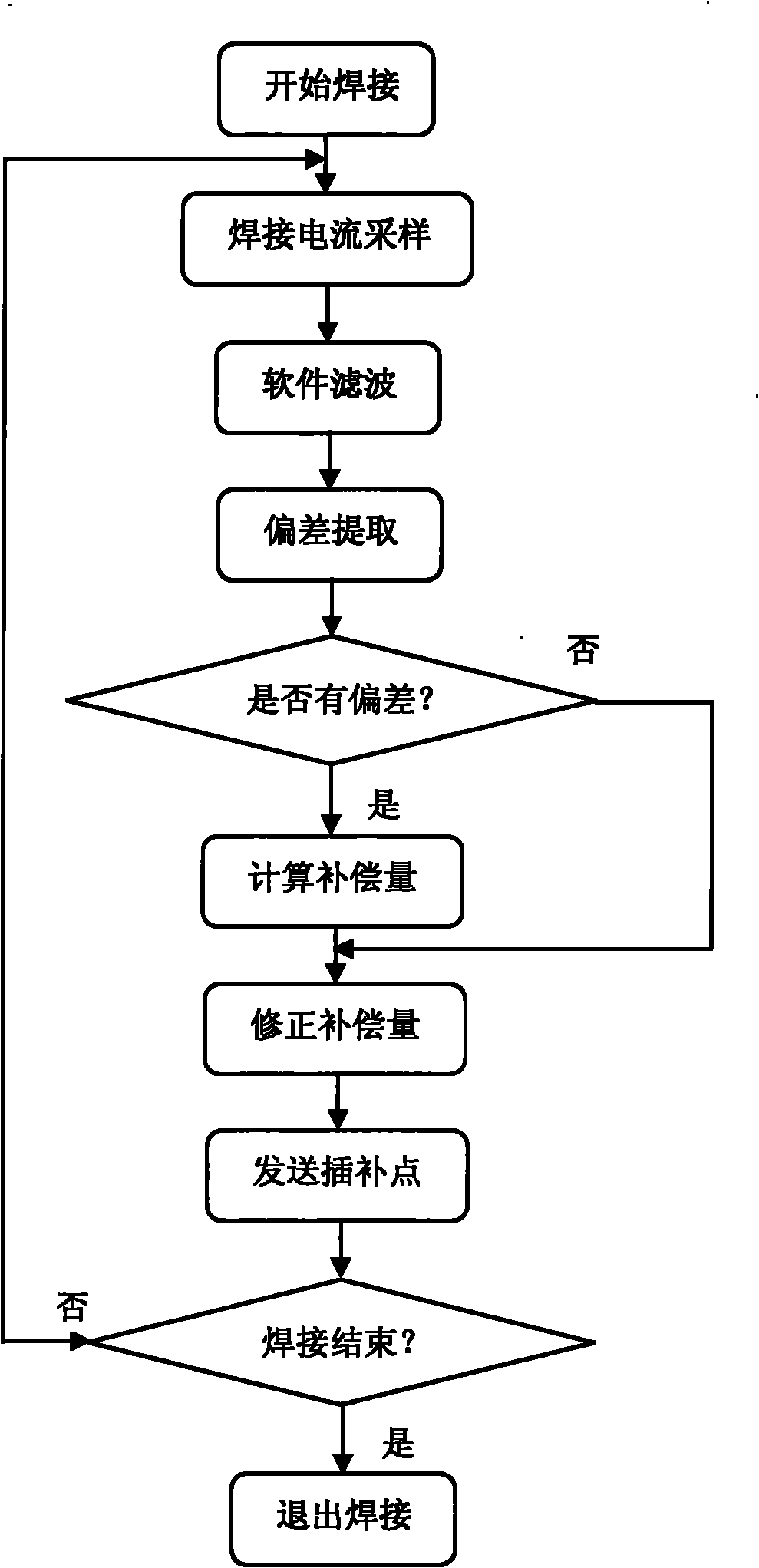

Robot welding line tracking deviation compensation method

The invention relates to a robot welding line deviation compensation method based on arc oscillation welding line tracking, comprising the steps of: 1, detecting a welding current, sampling, filtering collected welding current data; 2, extracting deviation of the filtered current data, fitting a deviation direction, extracting according to an integral differential method, obtaining a compensation dosage and a transverse deviation value of a height deviation direction; 3, storing the transverse deviation value, adjusting the sensitivity; 4, computing a compensation dosage of the deviation by combining with the transverse deviation value and the sensitivity; 5, updating and accumulating deviation compensation dosages along the height direction and the transverse direction; 6, converting a three-dimensional compensation dosage into interpolation points of x axis, y axis and z axis; and 7, sending the compensated interpolation points to a control part of the robot. The invention can not generate jump change aiming at the compensation dosages, can ensure the stability of the system at a certain degree, and has better molding of a welding line subjected to the deviation compensation and tracking error of generally within + / -mm.

Owner:昆山华恒机器人有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com