Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

A process pipeline and large diameter technology, which is applied in the field of large diameter and thick wall nuclear process pipeline welding and heat treatment process, can solve the problems of long working cycle, high quality requirements, and inability to complete normal welding work, and achieve guaranteed welding. Quality, to ensure the effect of continuous welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The invention will be further described in detail below through specific examples.

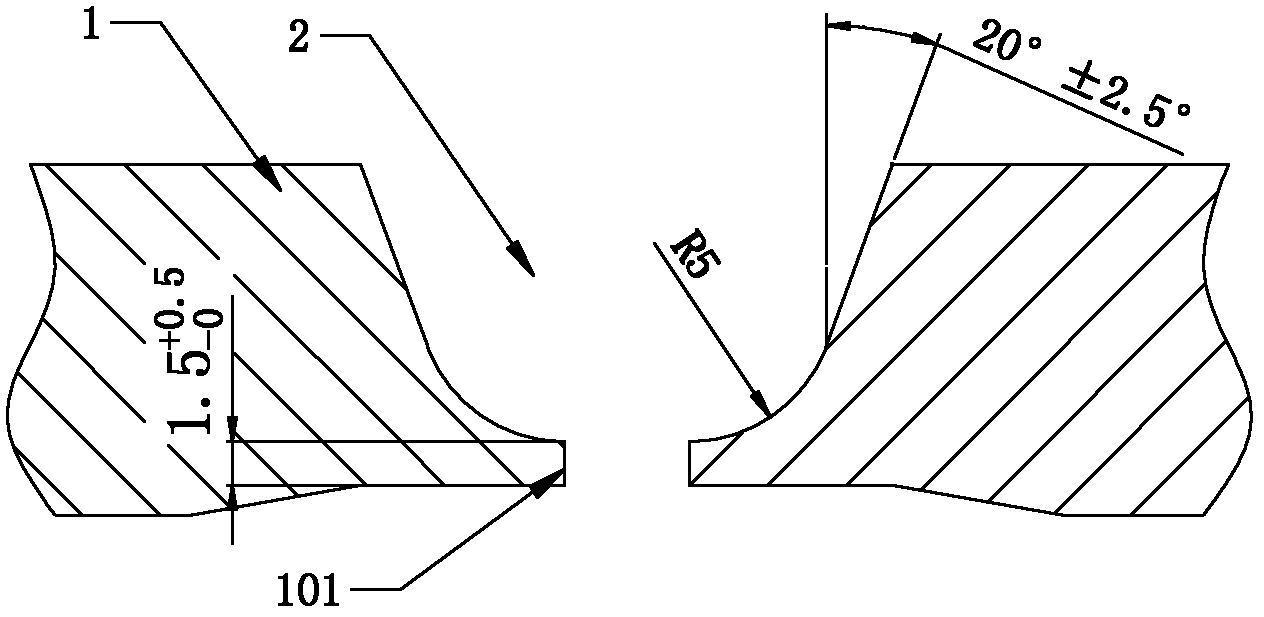

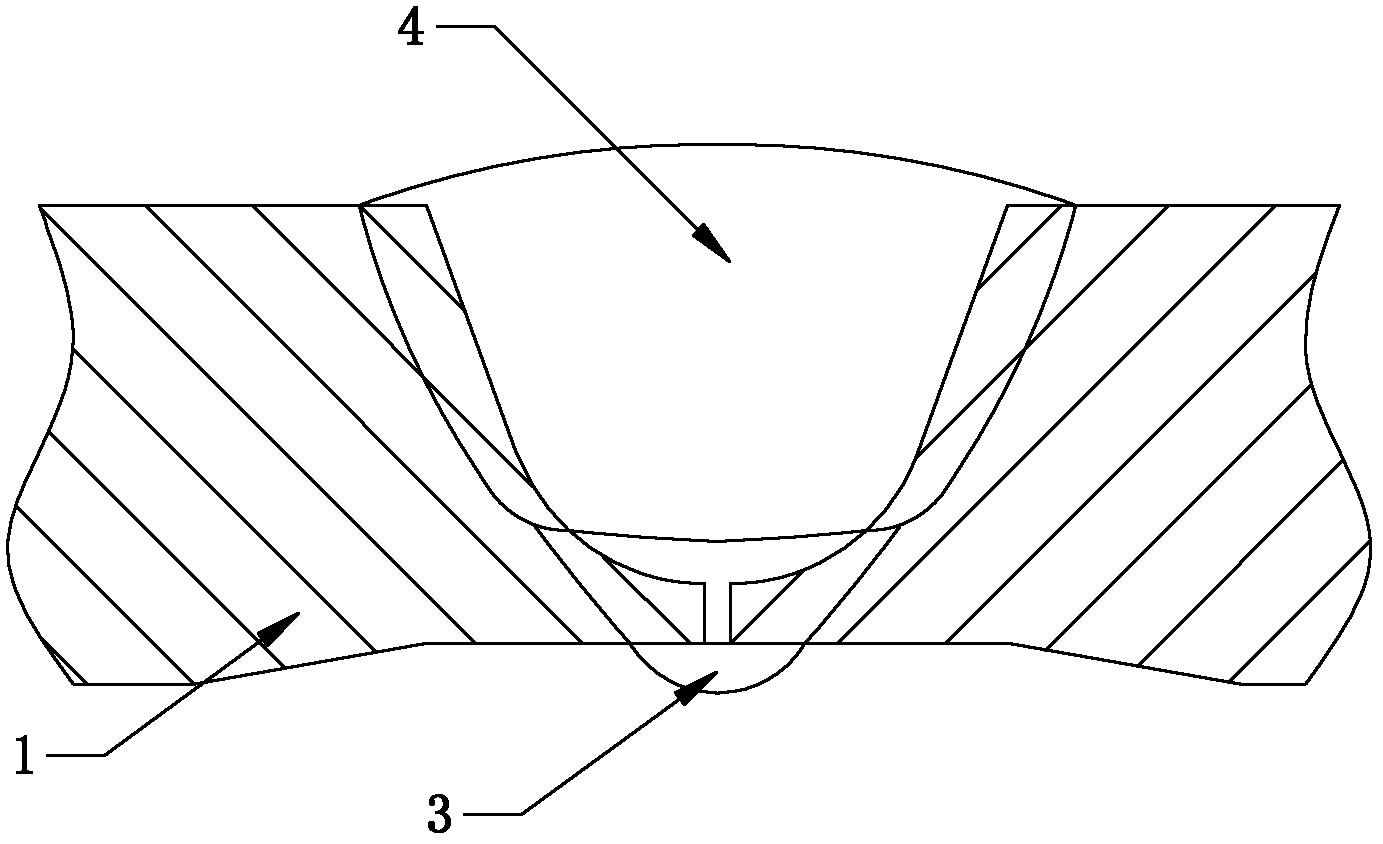

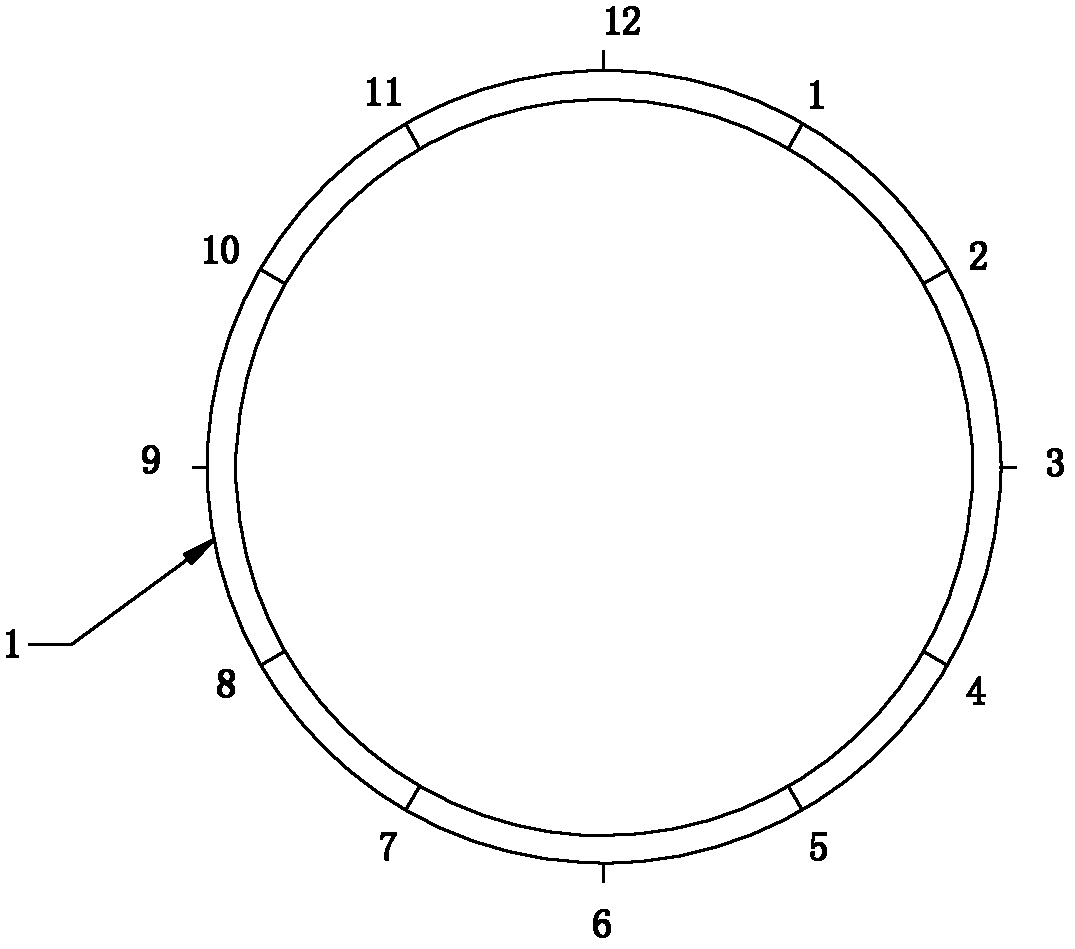

[0052] The term "large pipe diameter and thick pipe wall" in the present invention generally refers to a pipe material 1 with a diameter greater than 114 mm and a wall thickness of 20-46 mm.

[0053] A large-diameter thick-wall nuclear process pipeline welding and heat treatment process, comprising the following steps:

[0054] A. Preparation before welding, including the following sub-steps:

[0055] a1) Determine the execution standard of welding and heat treatment; the execution standard in this embodiment is: "Rules for Design and Construction of Mechanical Equipment for Pressurized Water Reactor Nuclear Island" (addition to RCC-M2000 and RCC-M2002);

[0056] a2) Check whether the specifications, grades, welding material specifications, grades and gas of the pipe 1 meet the standards; in this embodiment, the pipe 1 of P280GHφ812.8×46mm is taken as an example, and Table 1 records th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com