Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

993results about How to "Reduce welding distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

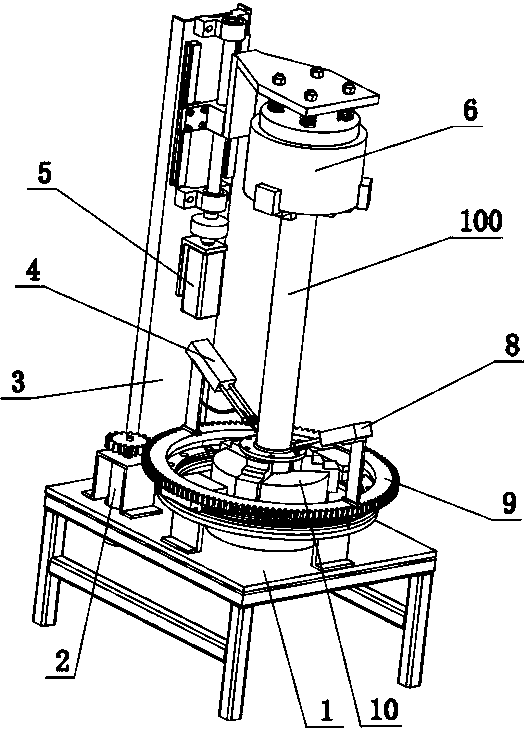

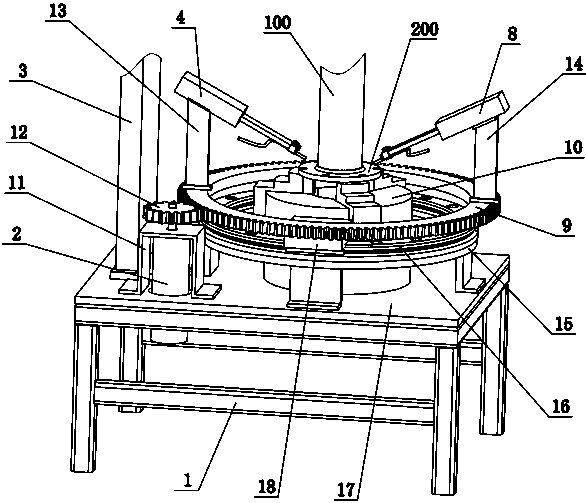

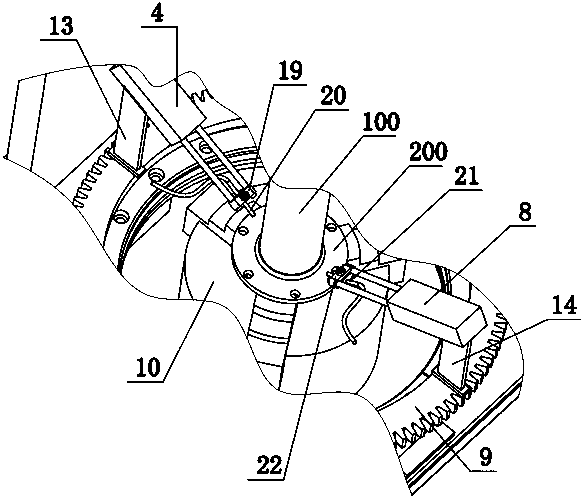

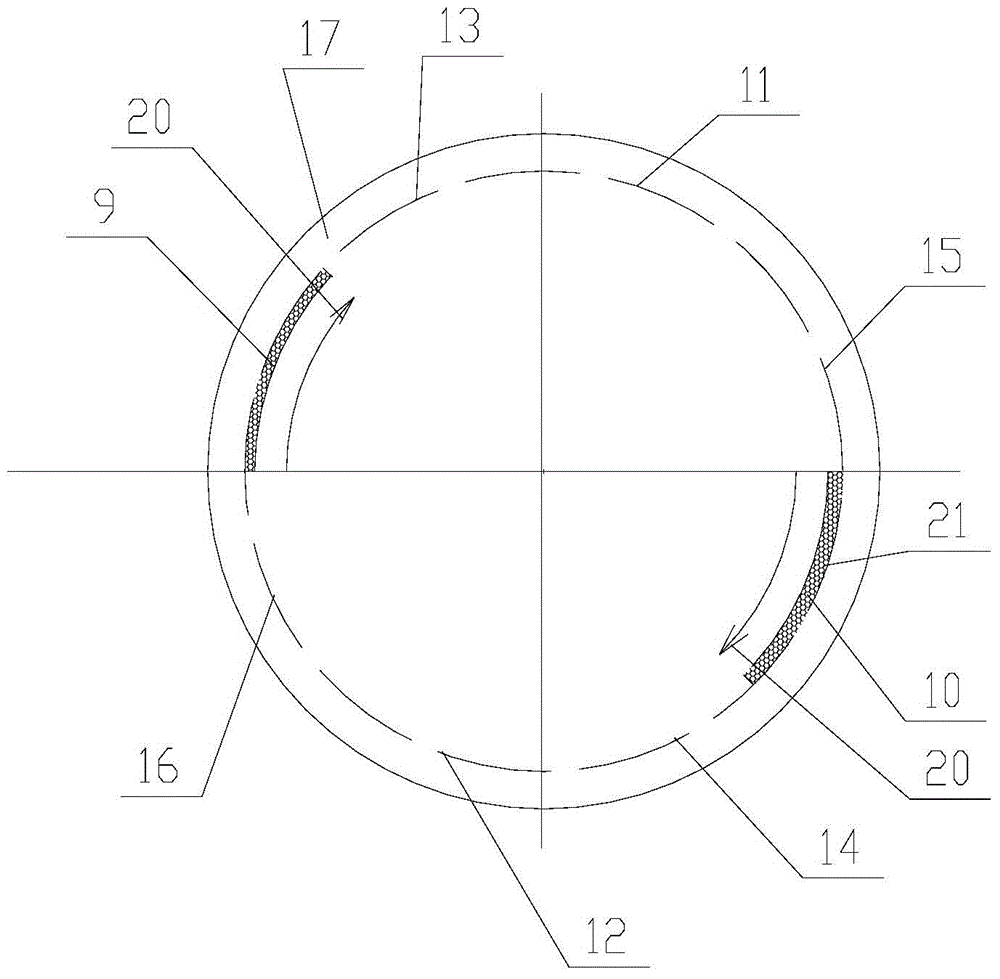

Vehicle supporting bridge pipe and end face flange welding machine and welding method thereof

ActiveCN108032027AReduce welding distortionImprove coaxialityWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationFlange

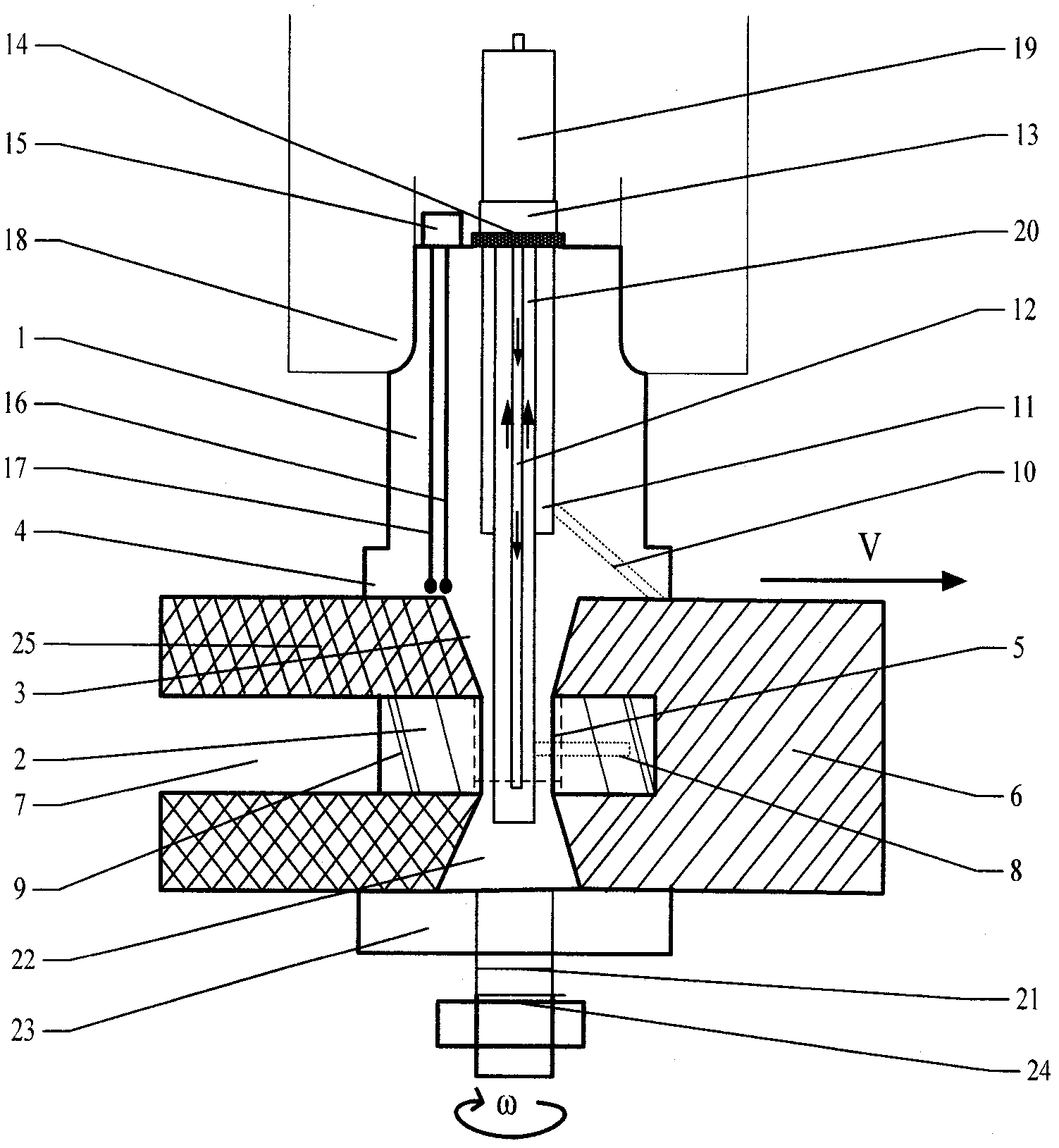

The invention provides a vehicle supporting bridge pipe and end face flange welding machine and a welding method thereof. The welding machine comprises a welding seat, a supporting flange plate is fixed at the upper end of the welding seat, a second three-claw chuck is fixed on the supporting flat plate, a circumferential rotating device coaxial with the second three-claw chuck is arranged on thesupporting flat plate, two welding guns are fixed on two sides of the center of the circumferential rotating device, a vertical beam is fixed on the supporting flat plate, a lifting mechanism is fixedon the vertical beam and fixed to a first three-claw chuck through elastic connection, a second three-claw chuck and the first three-claw chuck are fixed to a flange and a supporting bridge pipe respectively, and the welding guns weld the flange and the bridge pipe when rotating. The welding guns with two circumferential sides in symmetry are adopted to weld a welding position at the same time, welding deformation of the supporting pipe and the flange caused by welding stress is reduced, and coaxiality between the supporting pipe and the flange is improved.

Owner:ANYANG INST OF TECH

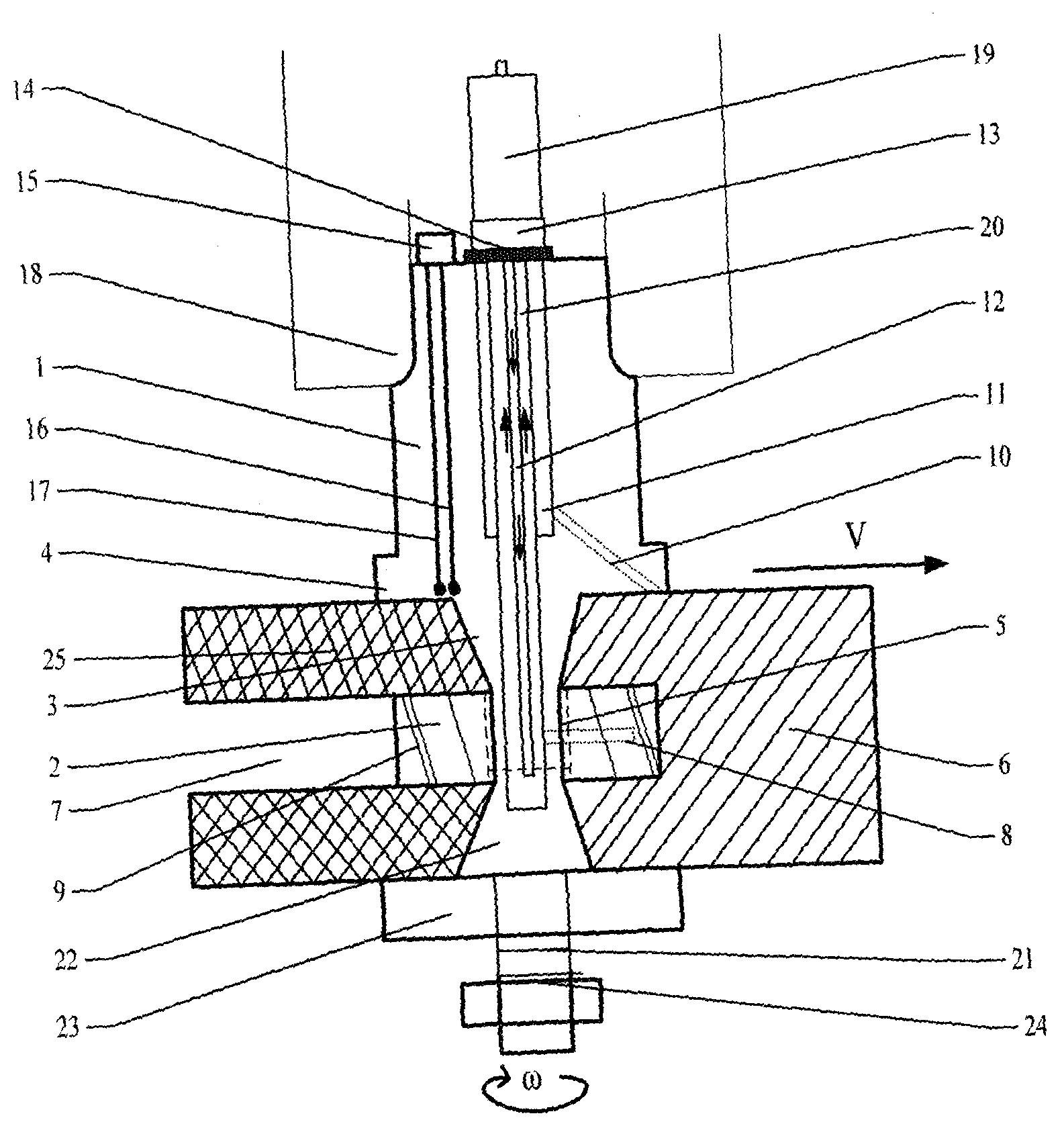

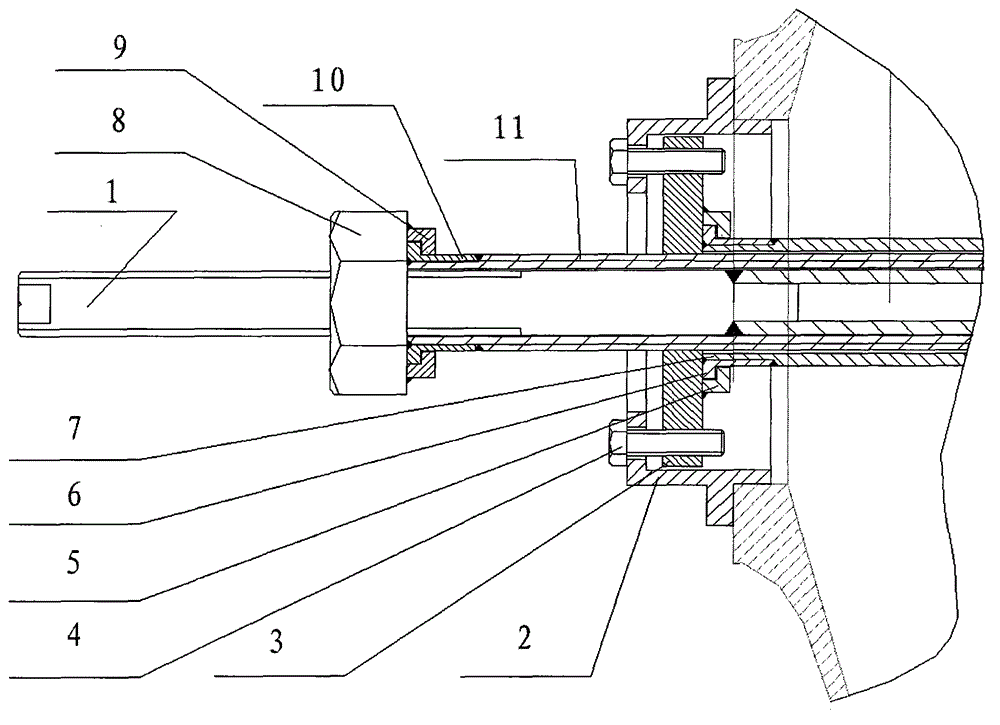

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

ActiveCN102554402AReduce labor intensityEnsure continuous weldingArc welding apparatusFurnace typesNuclear technologyNuclear engineering

The invention discloses welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes, which are suitable for welding and heat treatment of large-diameter and thick-wall pipes. The pipes welded by the welding and heat treatment processes are steady and reliable in the quality of welding lines, and can completely meet the quality requirement of nuclear technology.

Owner:江苏利柏特股份有限公司

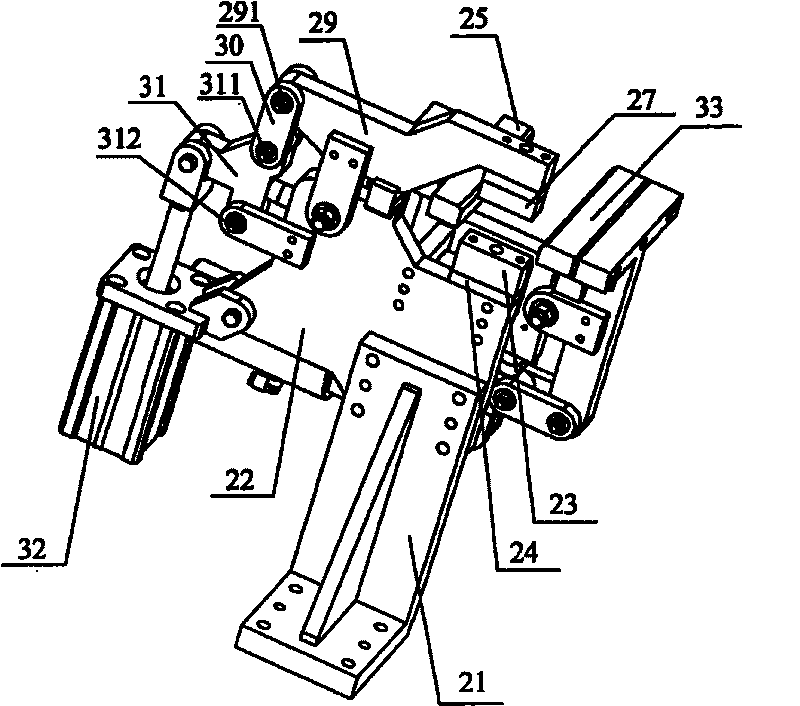

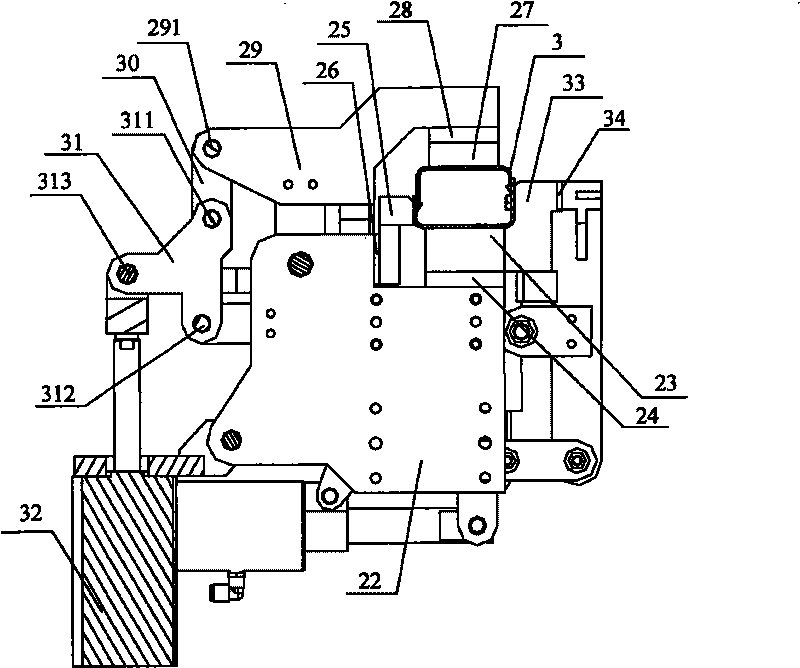

Weld positioning device

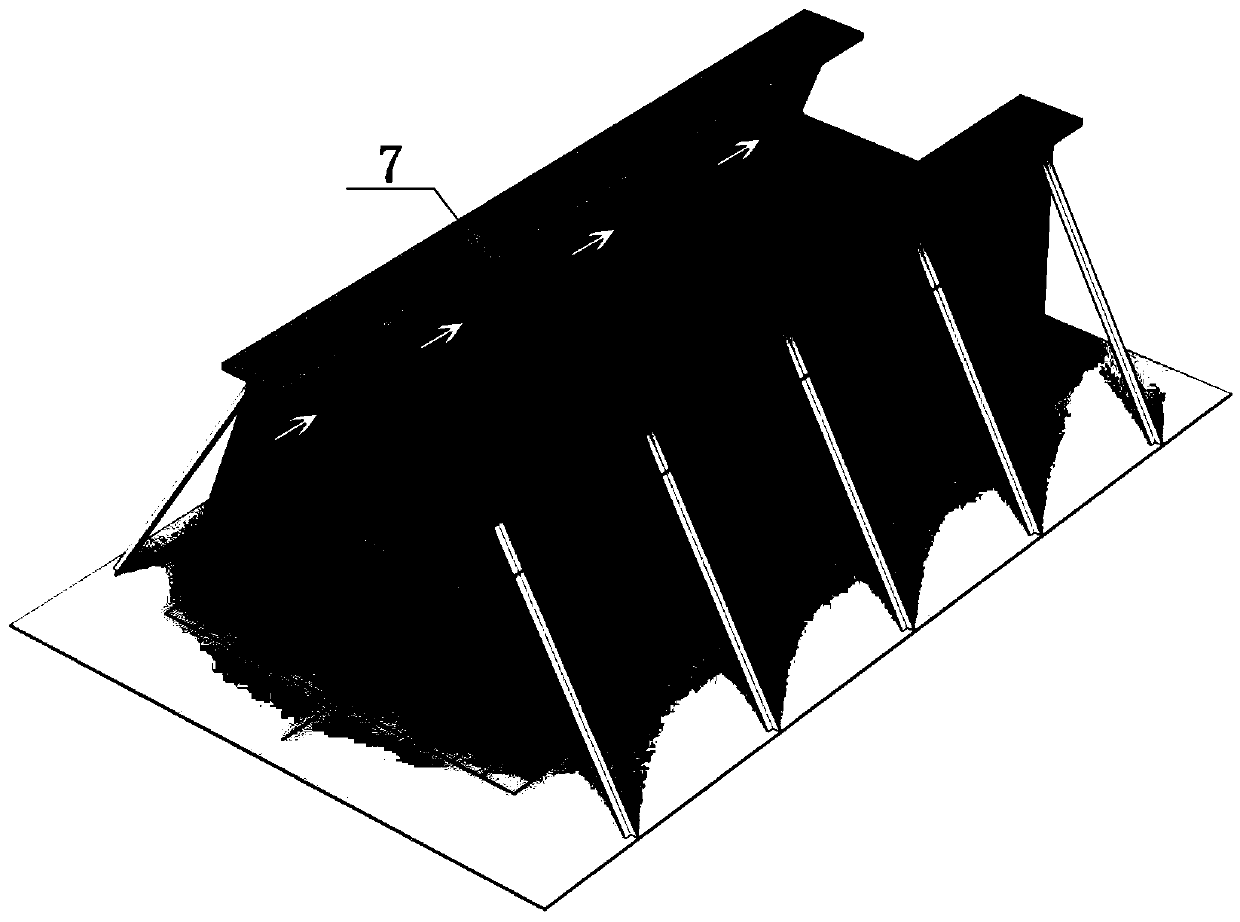

ActiveCN101733606AControlling Distortion ProblemsImprove quality statusWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides a weld positioning device. In order to prevent distortion in the process of welding, a frame rail to be welded is clamped in a positioning track formed by a plurality of positioning mechanisms; and the frame rail is clamped in a split fixing way in an all-surrounding mode. In order to reduce welding deformation in an upward direction and a downward direction of the frame rail in the process of designing the weld positioning device, a reversible deformation measure is designed on the weld positioning device in advance according to deformation tendency. A positioning molded surface in the weld positioning device is arranged into a convex design with higher middle part and lower both ends by aiming at the deformation tendency of bent both ends of a frame rail assembly so as to reduce welding deformation. The weld positioning device can effectively solve the problem of distortion in the process of welding the frame rail and improves quality state of frame rail products.

Owner:BEIQI FOTON MOTOR CO LTD

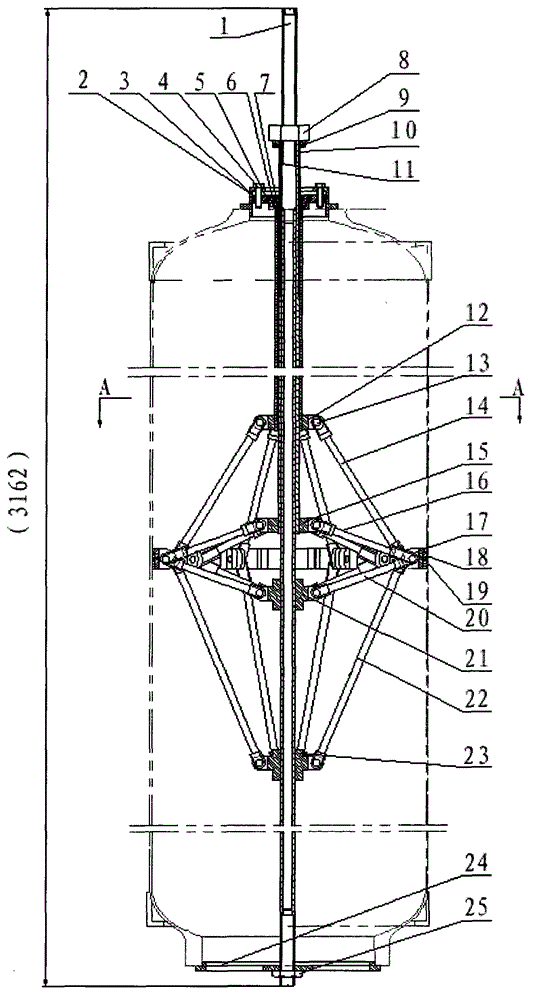

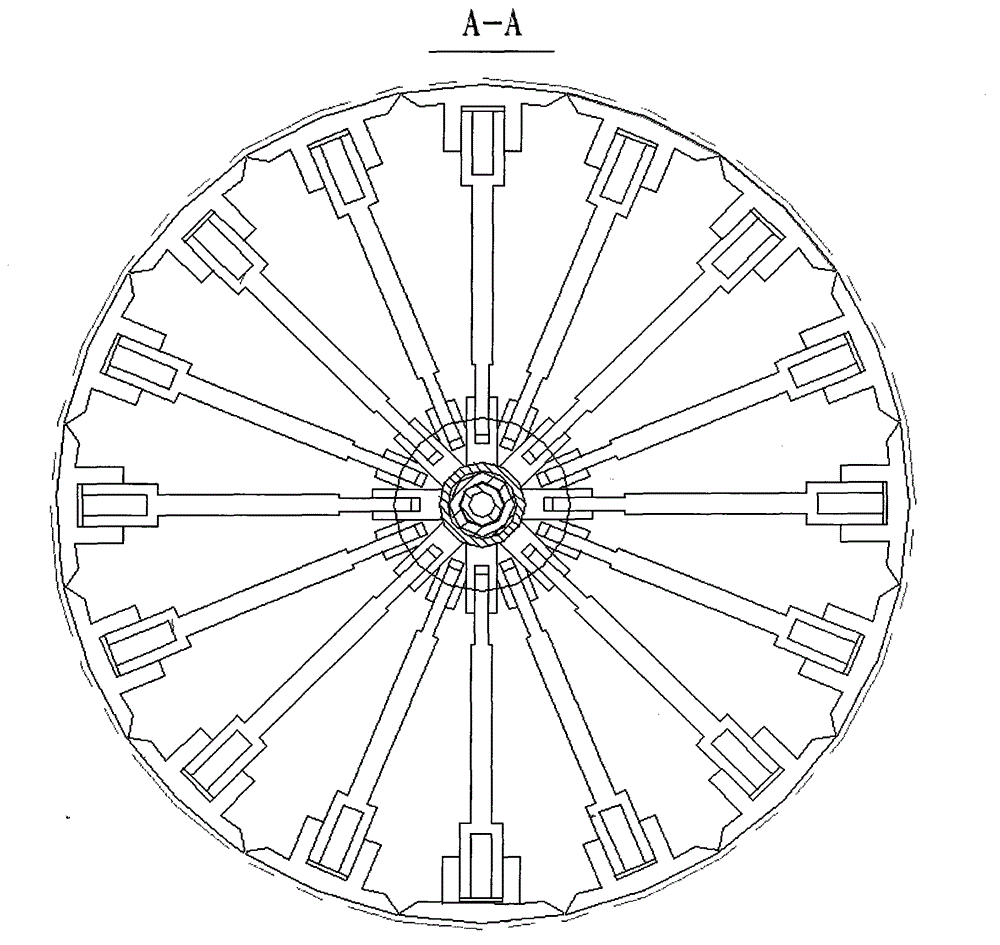

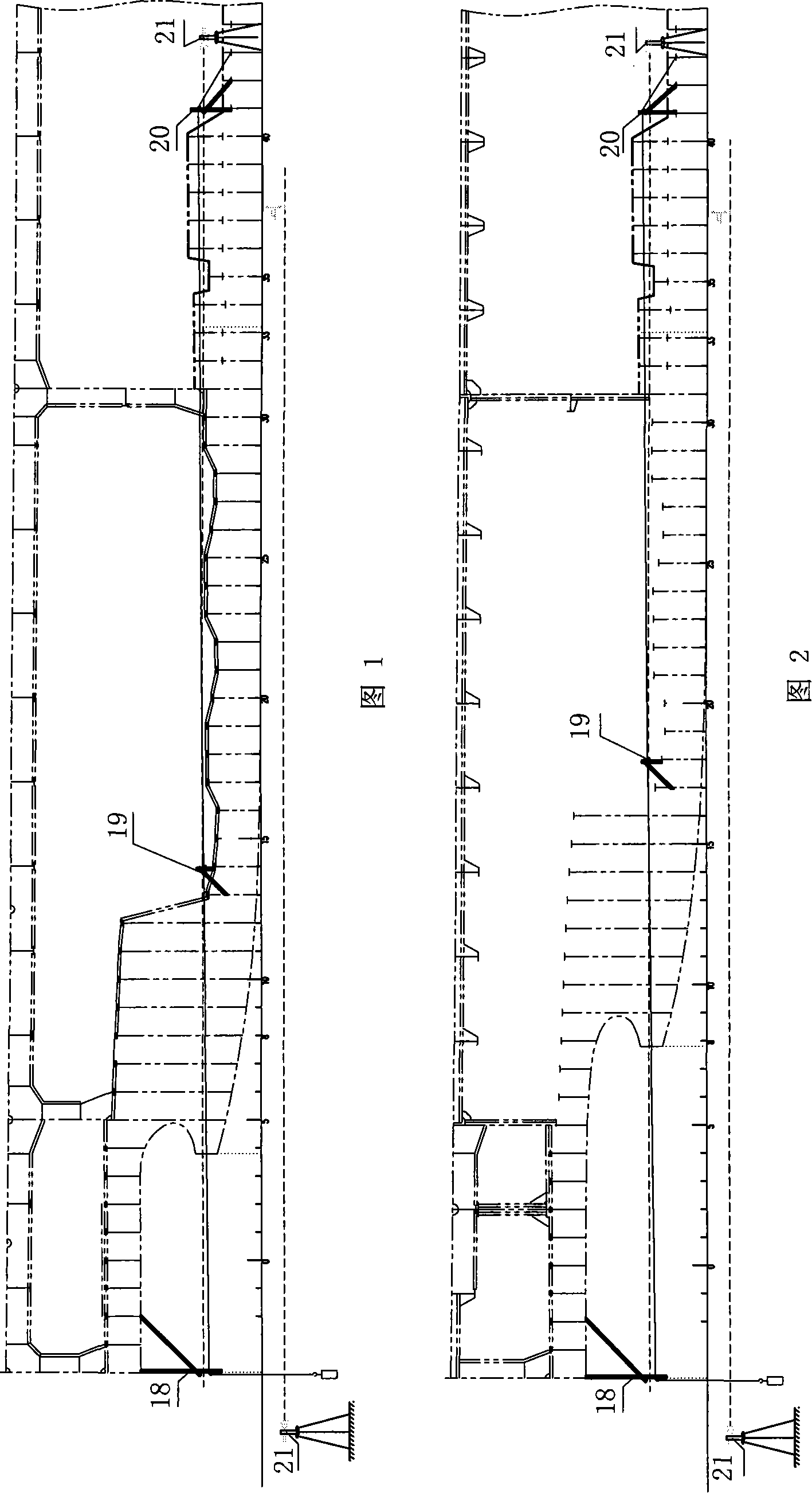

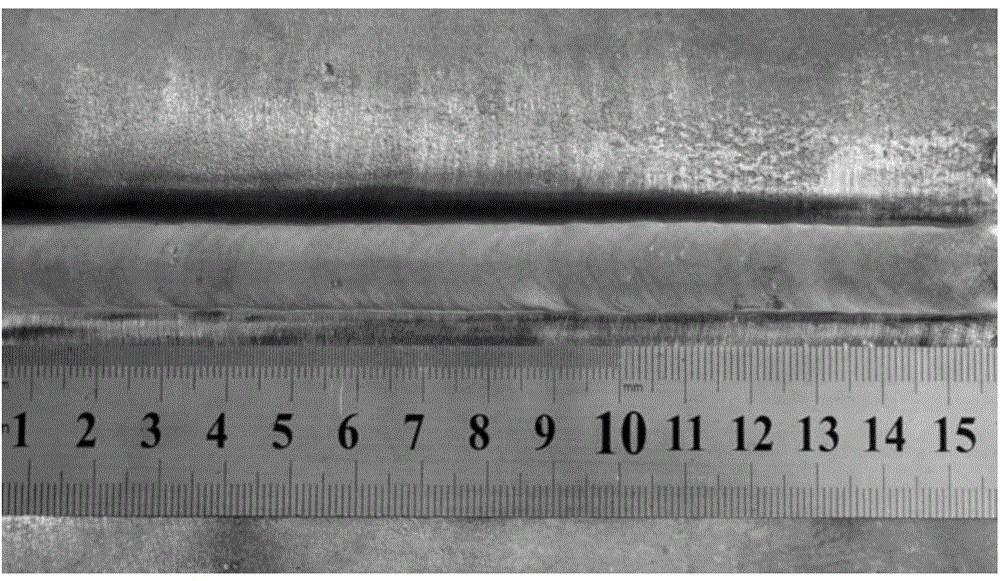

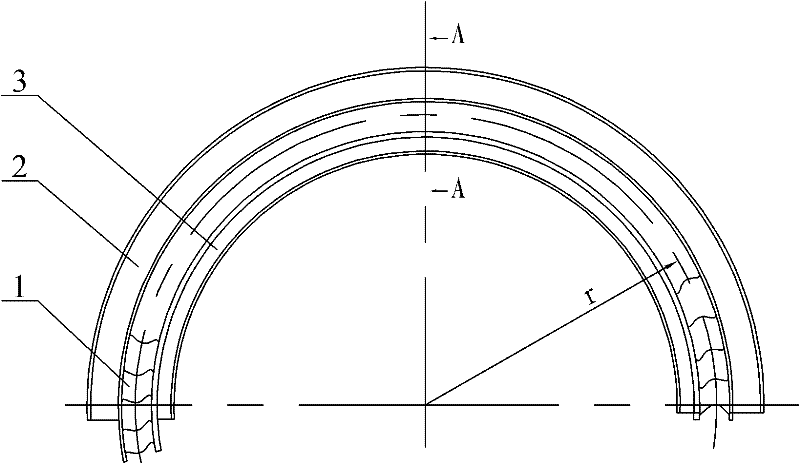

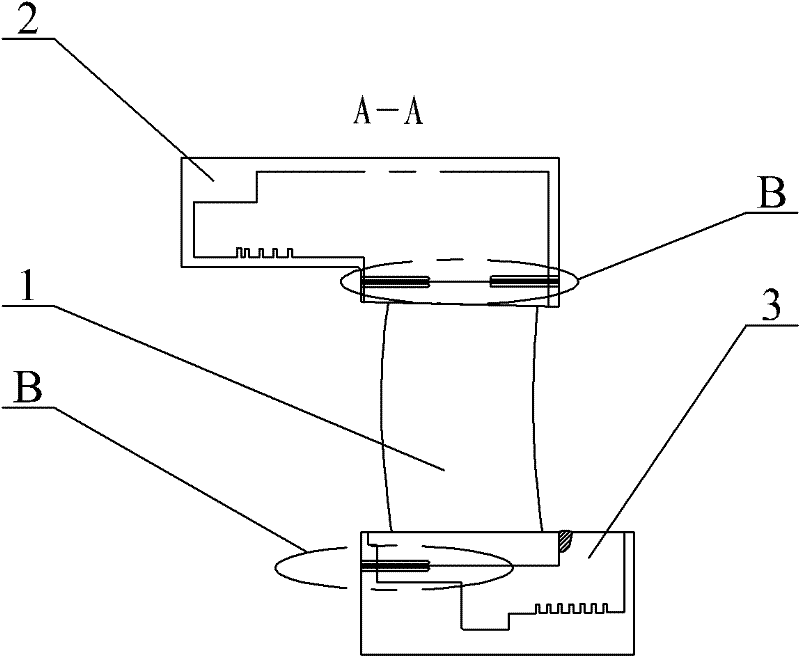

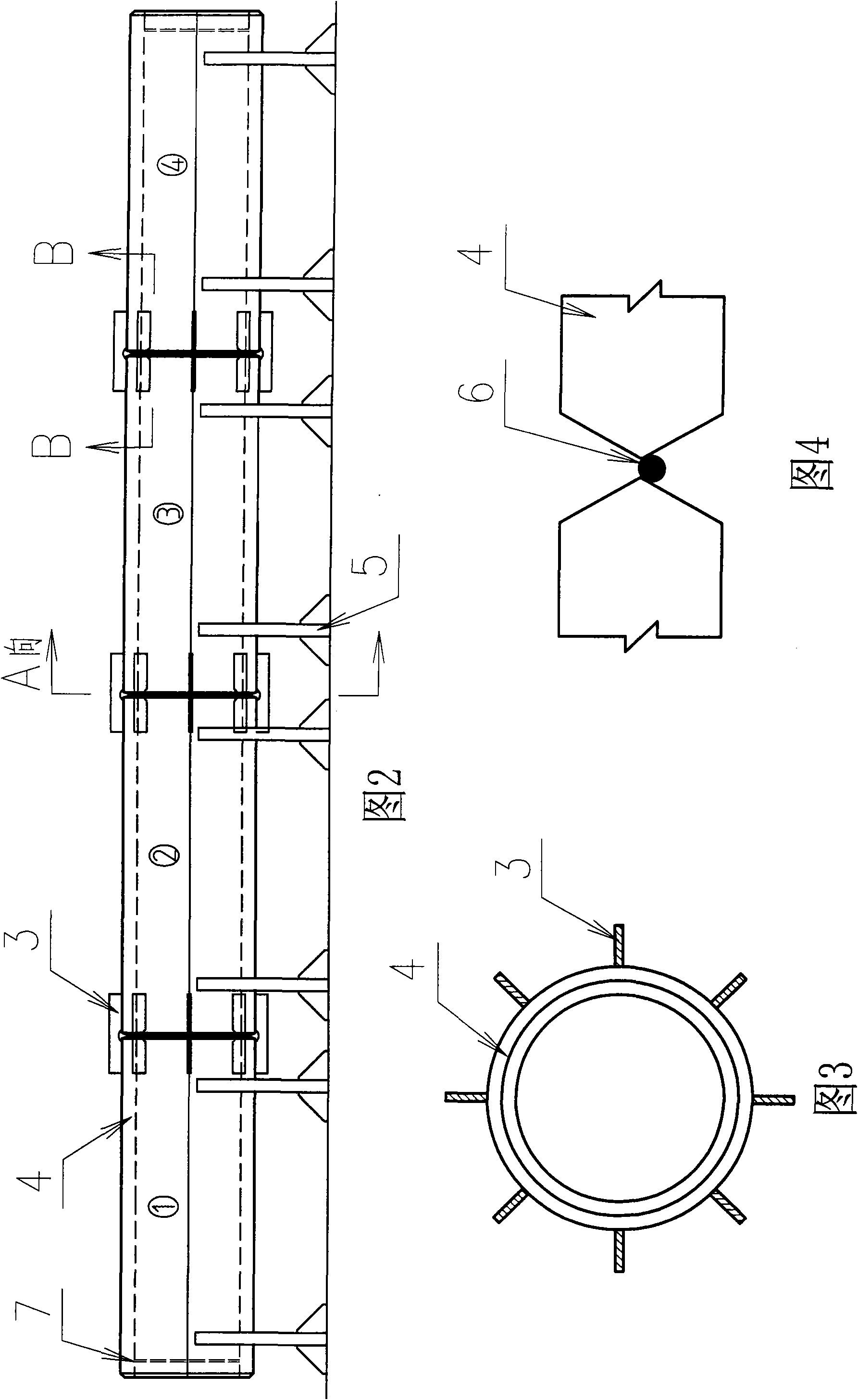

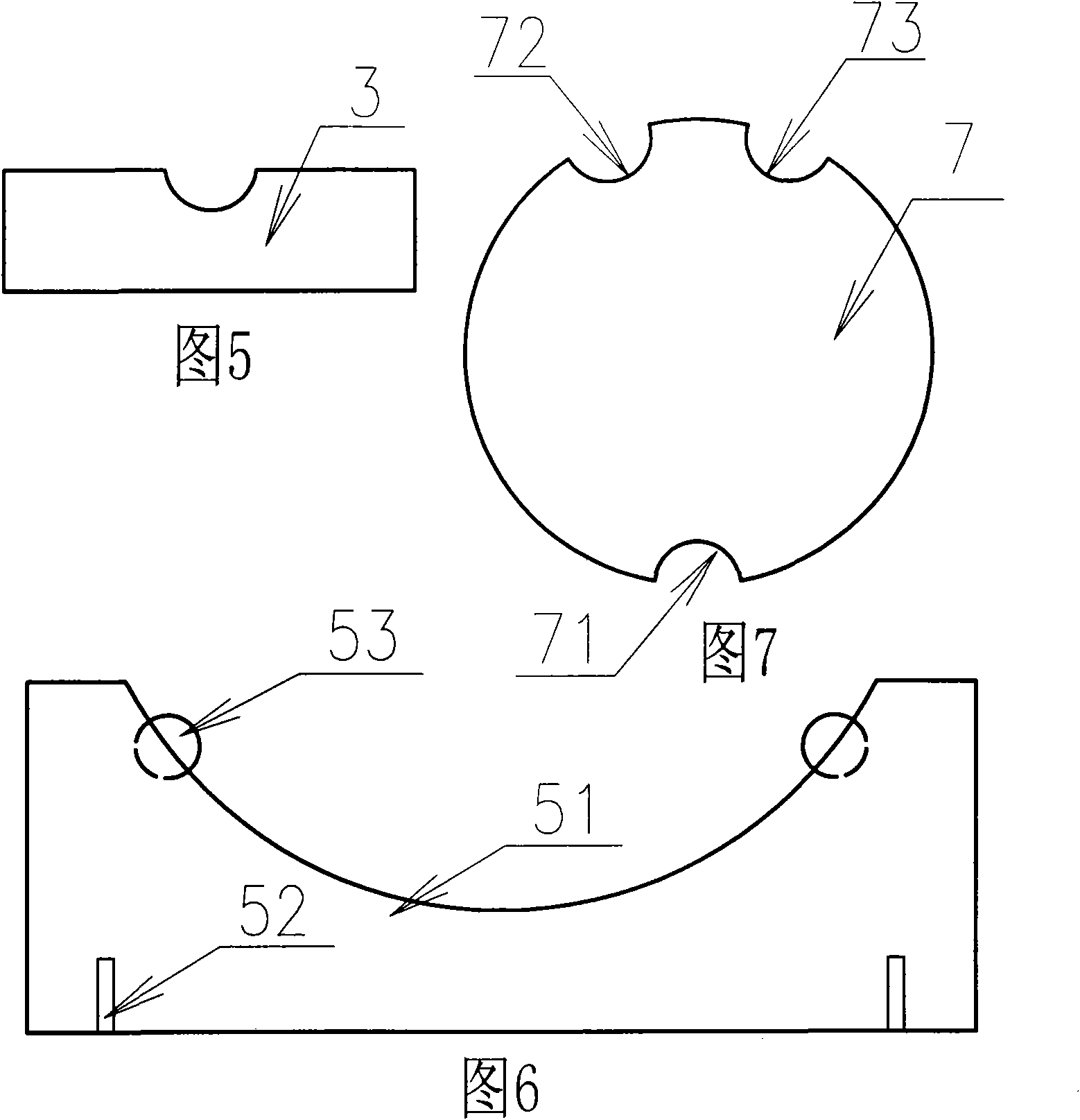

Umbrella-type inner support clamp for annular welding of elongated cylindrical workpieces

ActiveCN102873494AReduce welding distortionMeet straightness requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding joint

The invention discloses an umbrella-type inner support clamp for annular welding of small-diameter cylindrical workpieces and solves the problems of poor welding straightness accuracy and low processing efficiency of workpieces with weld joints located at the center of the elongated cylindrical workpieces or far away from two ends of the elongated cylindrical workpieces. During use, a force-bearing nut and a front plug control a sleeve II and a sleeve I to move back and forth relative to a spindle, the sleeve II and the sleeve I control a base II and a base I to move back and forth, a supporting leg I and a supporting leg II drive a supporting leg III and a supporting leg IV to act to tightly hold a holding assembly, and accordingly the welding joint portion of the workpieces is held tight and circular. An umbrella-type inner support is not demounted during welding so that welding time is saved. The workpieces are restrained and cannot deform easily during welding due to the holding force of the umbrella-type inner support clamp, and accordingly straightness accuracy of the welded workpieces is improved and local welding collapsing deformation is reduced. The umbrella-type inner support clamp has the advantages of being convenient to operate, high in production efficiency, high in accuracy after parts are welded, wide in application range and the like, and is good in application effect.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

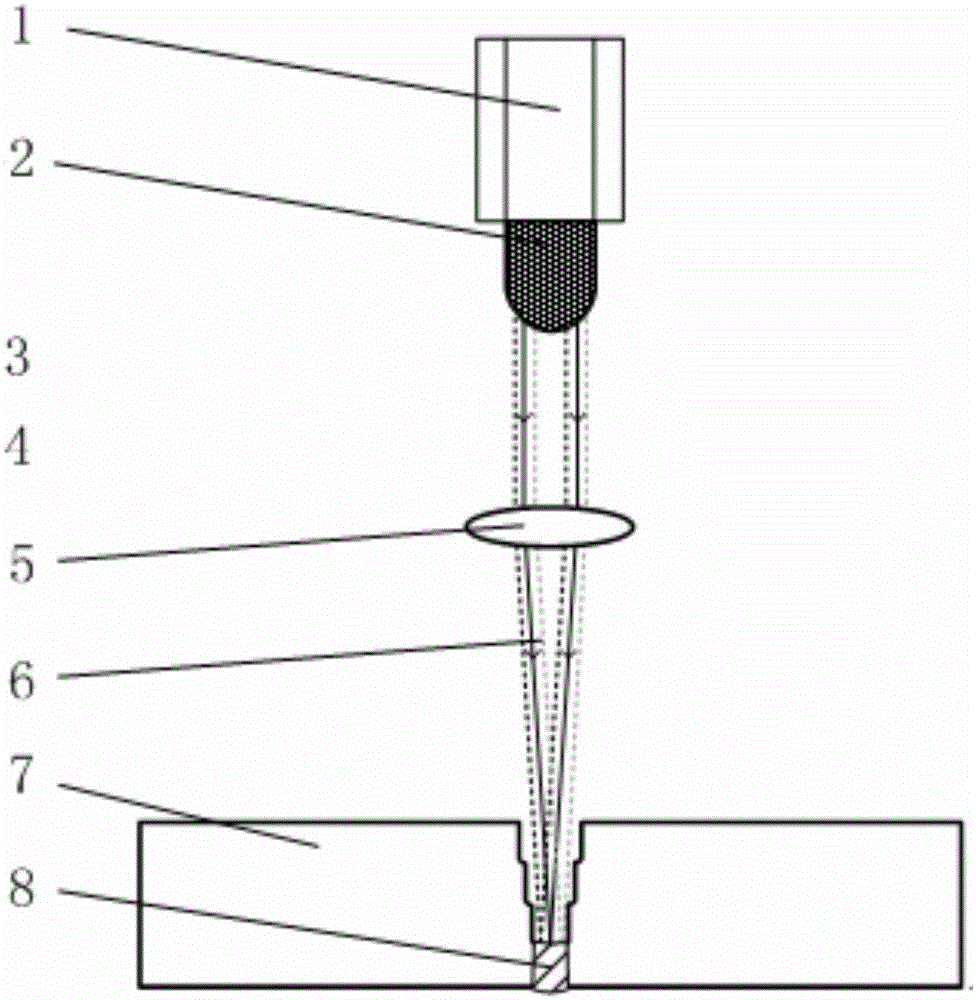

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

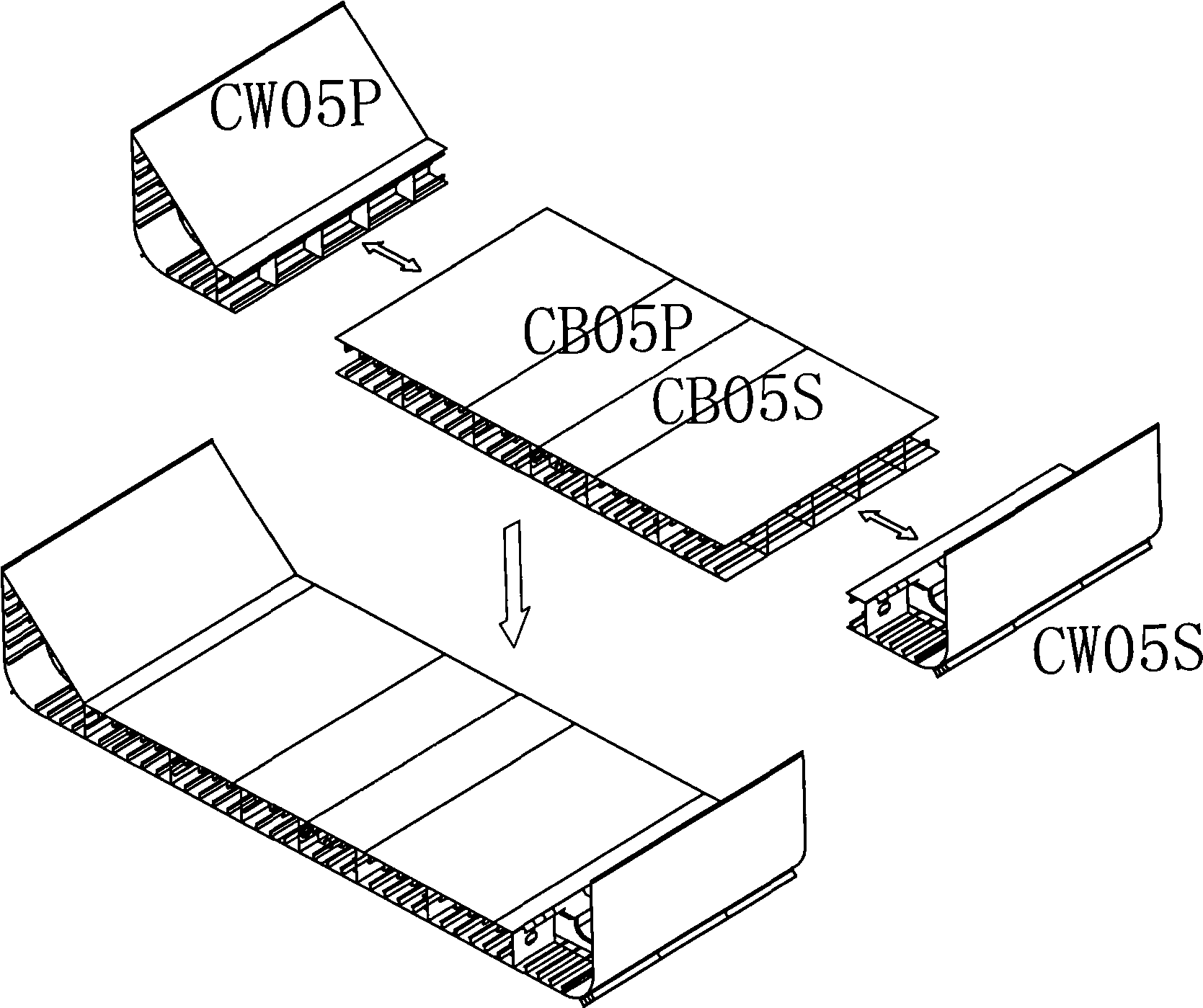

Integrated water-cooled power battery box

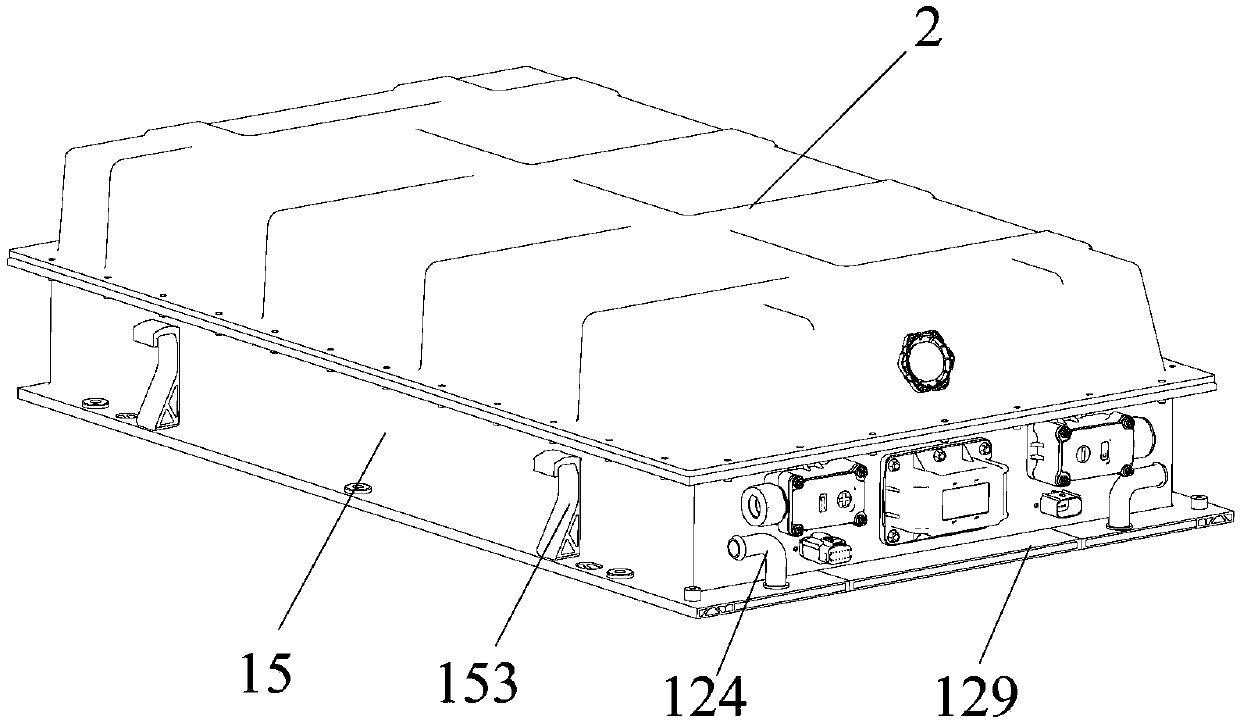

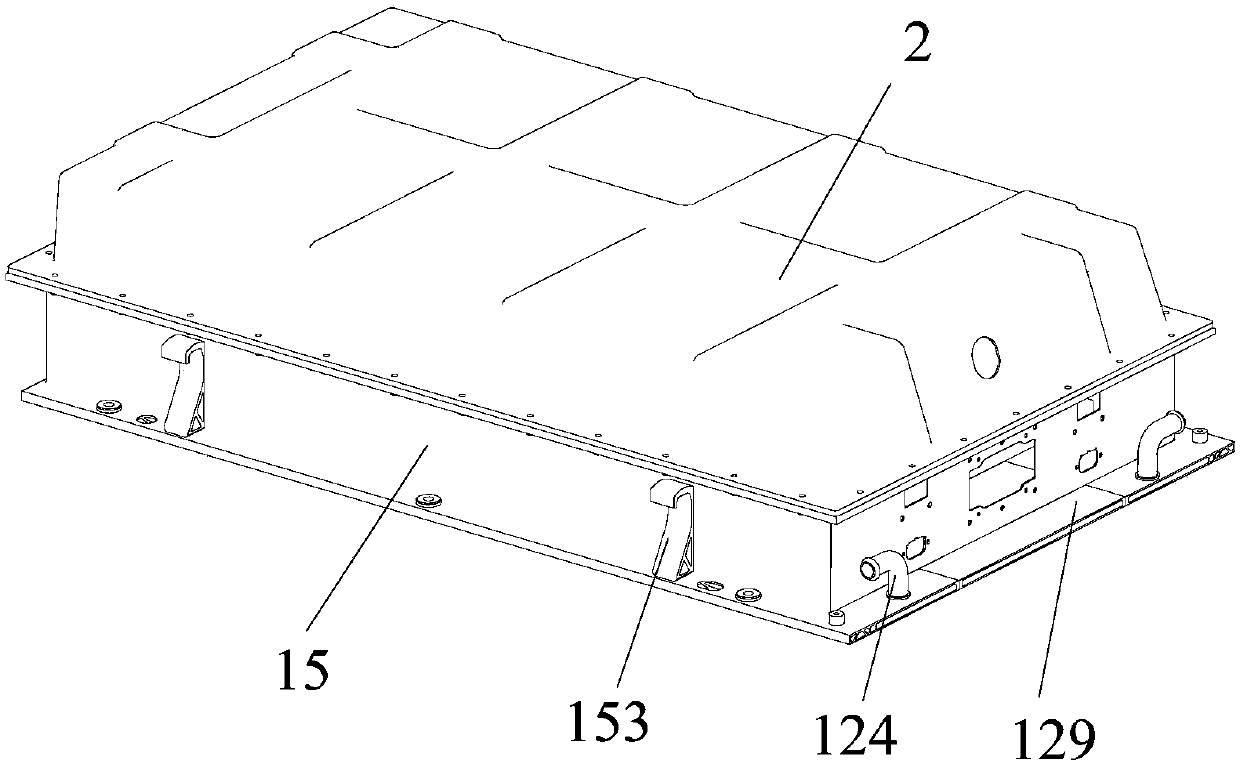

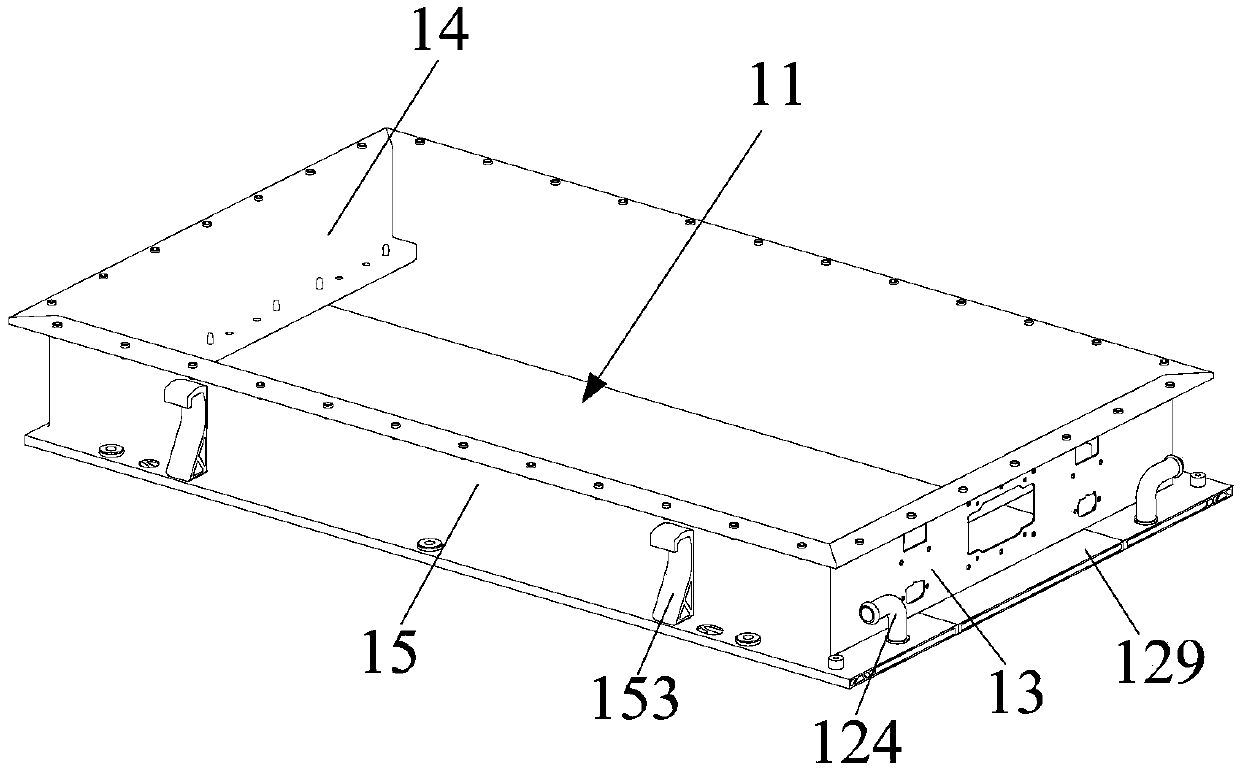

PendingCN108039434AMeet the intensityFulfil requirementsBattery isolationSecondary cellsPower batteryMechanical property

The invention relates to the technical field of electric cars, in particular to an integrated water-cooled power battery box. The integrated water-cooled power battery box provided by the invention comprises a box cover, a box body and a temperature regulating power system, wherein the box body is made of an aluminum alloy material and is manufactured by an extrusion moulding technology; a circulating flow passage is formed in the wall of the box body; a circulating loop for a temperature regulating medium to flow circularly is arranged inside the wall of the box body; and the temperature regulating power system can drive the temperature regulating medium to circularly flow in the circulating loop. In such a way, a water cooling board and a battery box are designed in an integrated manner,a hollow aluminum alloy section is adopted to achieve lightweight design, mechanical properties such as strength and rigidity are met, the integrated water-cooled power battery box is simpler in structure, better in technical performance and smaller in occupied space, and the comprehensive cost can be reduced; the heat-dissipating, cooling and temperature-raising and heating functions can be achieved by using one set of temperature regulating power system, the integrated water-cooled power battery box is simpler in structure, more convenient and fast to use and smaller in occupied space, themanufacturing cost and the using cost can be reduced, and the heat-dissipating efficiency and the heating efficiency can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

Method for mounting ship three-main-engine three-airscrew main frame shafting

The invention relates to a method for mounting ship three-engine three-propeller engine shaft system, belonging to ship main shaft mounting technical field. The invention arranges a target support, tests the central line of the shaft system, positions and mounts stern axle tube, and mounts stern axle and propeller or the like, to confirm the installment accuracy of shaft system, and overcome the defects of prior art as hard control on installment size, large size error, and long installment period, to provide better art technical assurance to ship production.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP +8

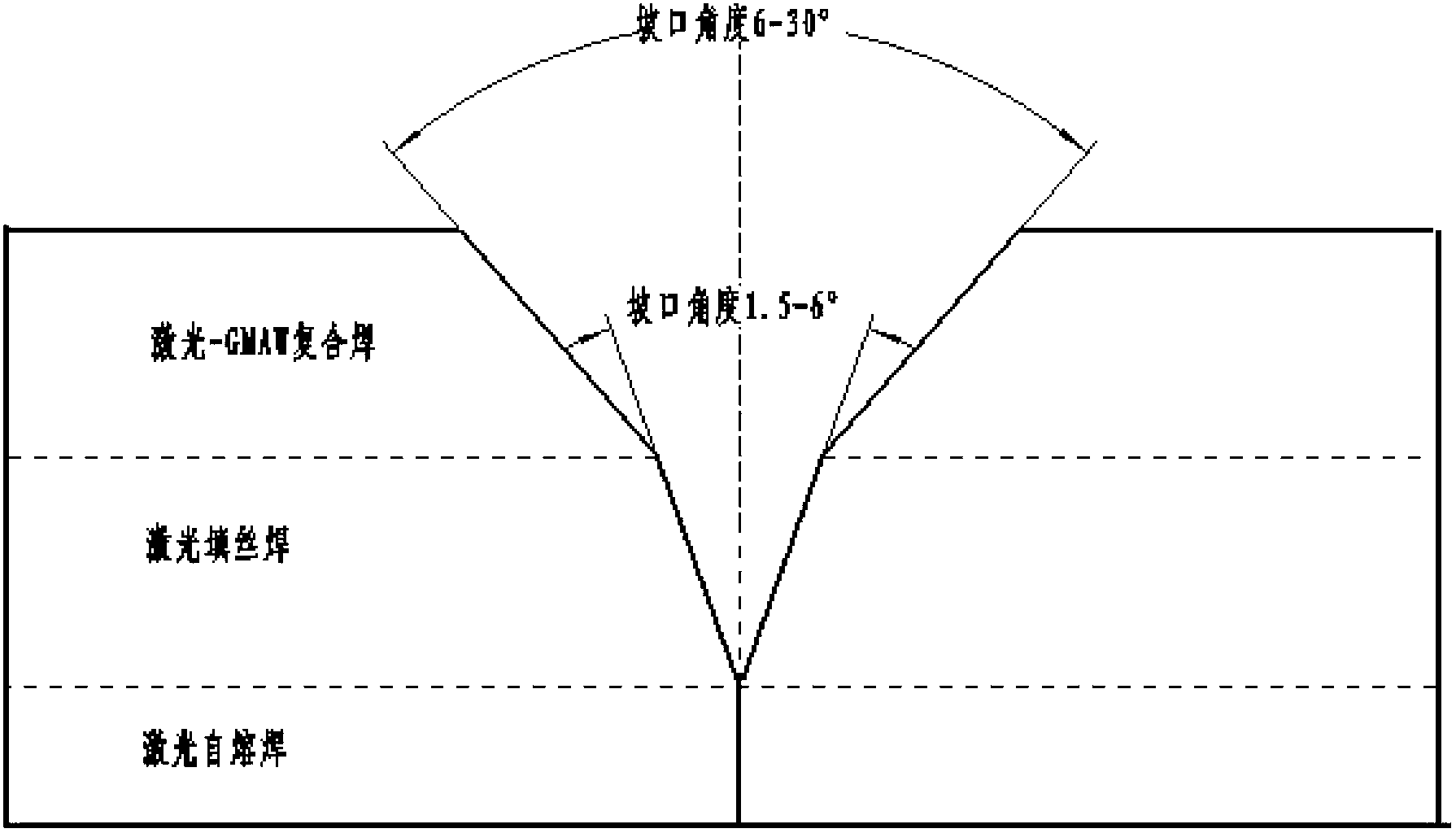

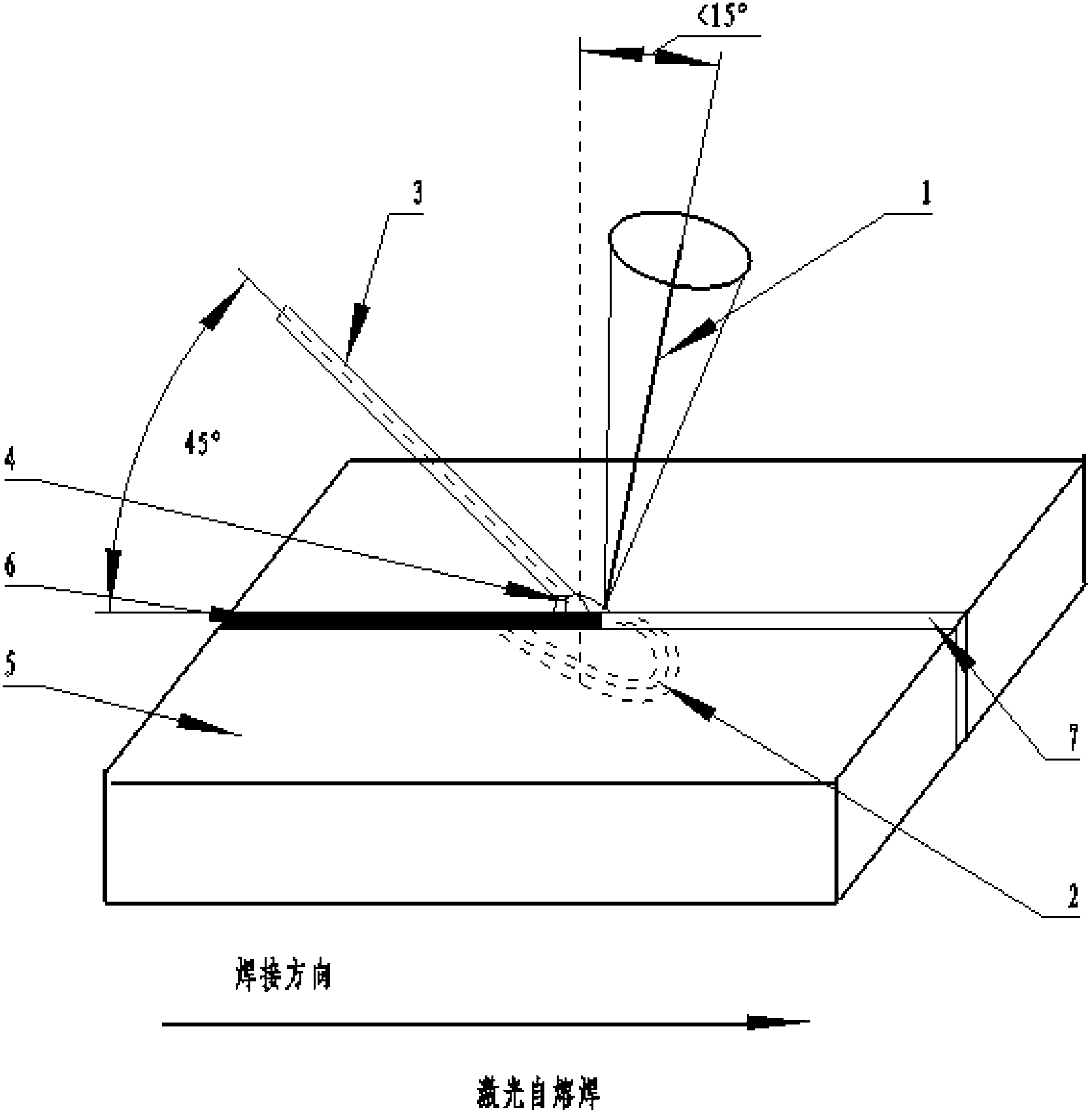

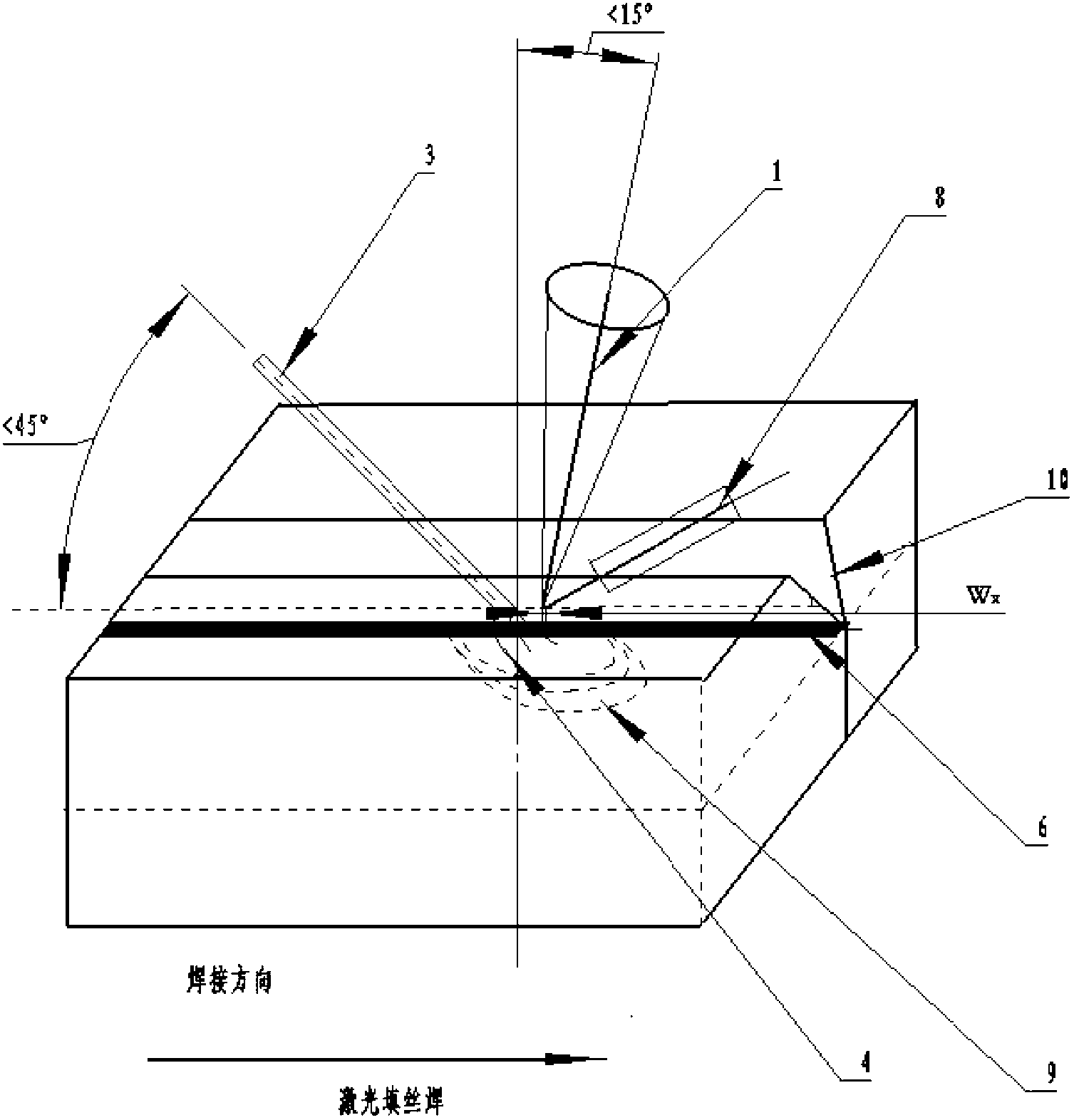

Narrow gap multi-pass laser welding method for thick plate

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

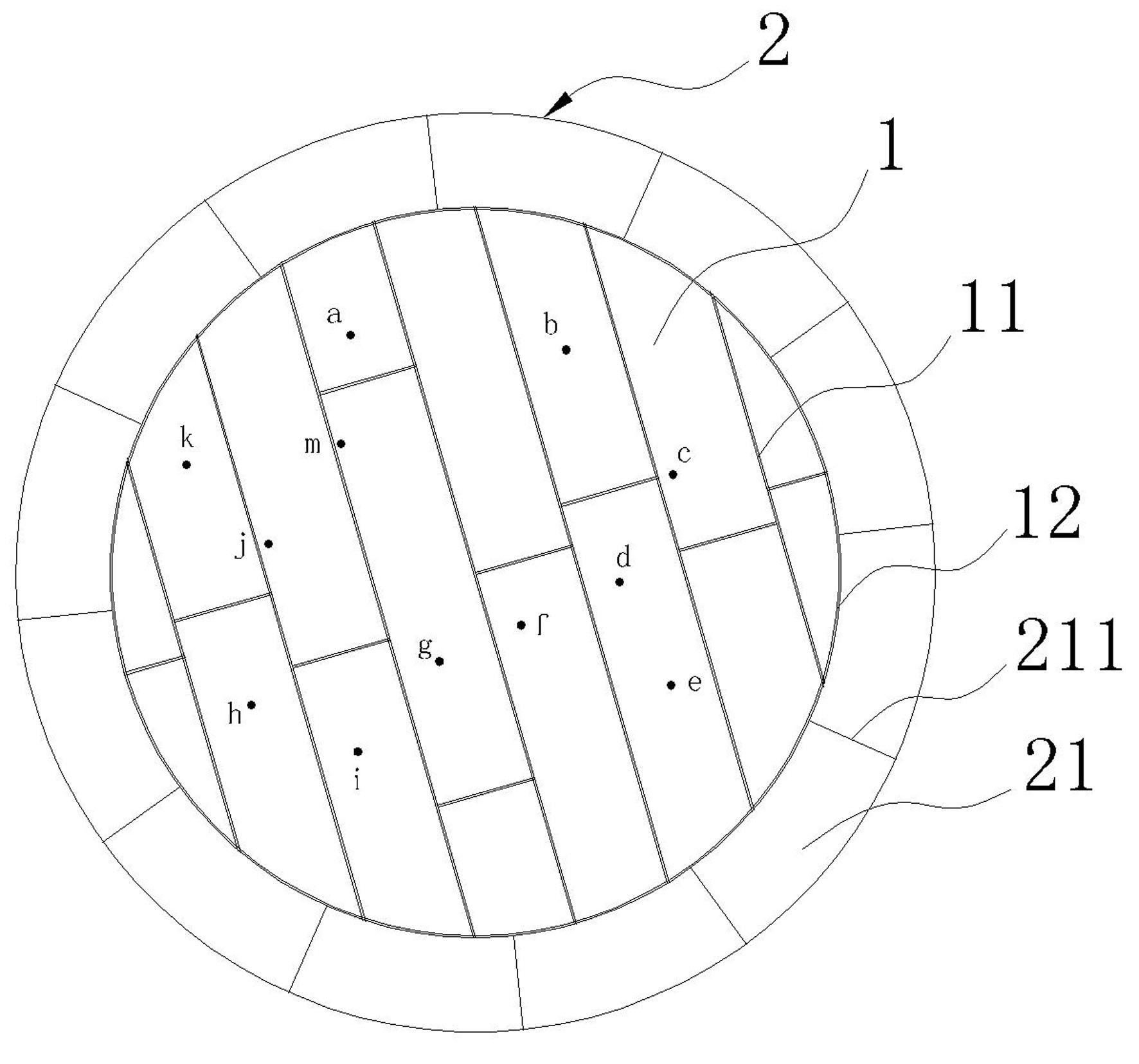

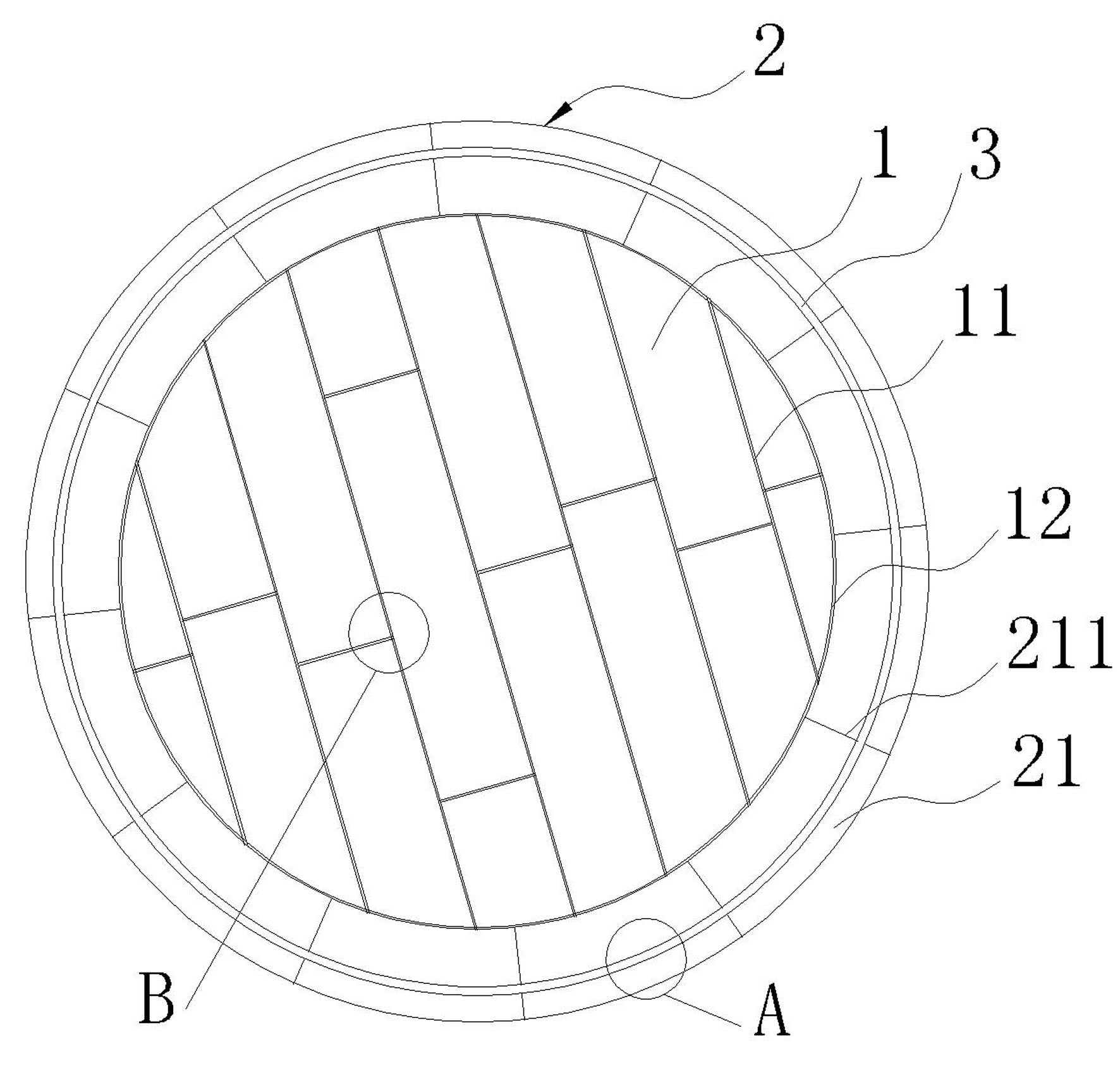

Method for welding bottom plate of large flat-bottom storage tank

InactiveCN102069307AReduce welding distortionEvenly distributedWelding apparatusSteel platesWall plate

The invention discloses a method for welding a bottom plate of a large flat-bottom storage tank, which has the advantage of simple processing process and can effectively reduce the welding deformation of the bottom plate of the large flat-bottom storage tank, improve the evenness of the bottom plate and prolong the service life of the storage tank, solving the technical problems of large bottom plate deformation, poor storage tank strength and rigidity, service life reduction, and the like in the prior art. The method mainly comprises the following steps of: butt jointing or lap jointing a plurality of steel plates to form a bottom plate of a round flat-bottom storage tank; then paving a plurality of fan-shaped steel plates around the circumference of the bottom plate of the flat-bottom storage tank to form an annular edge plate; partially welding adjacent fan-shaped steel plates from outside to inside; then coaxially putting cylindrical wall plates; and welding according to a welding sequence of spot fixing and welding from outside to inside.

Owner:LINDE ENG HANGZHOU

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

Method for combined welding of austenitic stainless steel moderate thickness plate

InactiveCN104858557ALittle thermal impactNo crackWelding/soldering/cutting articlesWelding apparatusButt weldingButt joint

The invention relates to a method for combined welding of an austenitic stainless steel moderate thickness plate. The method comprises the steps of opening a V-shaped groove at the position of the to-be-welded butt joint surface of austenitic stainless steel; polishing and cleaning the surface of a to-be-welded workpiece and the position of the V-shaped groove; performing gapless tight fixed assembly of the workpiece, performing spot welding fixation on a run-on plate, an arc blowout plate and a test plate; pre-leading in protective gas prior to butt welding, guaranteeing that sufficient protective atmosphere is formed on the surface of the stainless steel groove and the bottoms of the weld joints; adopting pulsed plasma arc welding to perform bottoming welding; adopting low carbon welding wires to perform cosmetic welding of pulse wire filling argon tungsten-arc welding, performing the bottoming welding of the pulsed plasma arc welding and cosmetic welding of the pulse wire filling argon tungsten-arc welding simultaneously, and cooling the workpiece while performing the welding. The PC-PAW bottoming welding is adopted, the micropore effect is utilized to achieve one-side welding and double-sided free forming of the moderate thickness plate, the backs of the weld joints are smoothly formed and are free of cracks and edge snapping defects, the process is stable and easy to achieve, and the quality is reliable.

Owner:SHANDONG UNIV

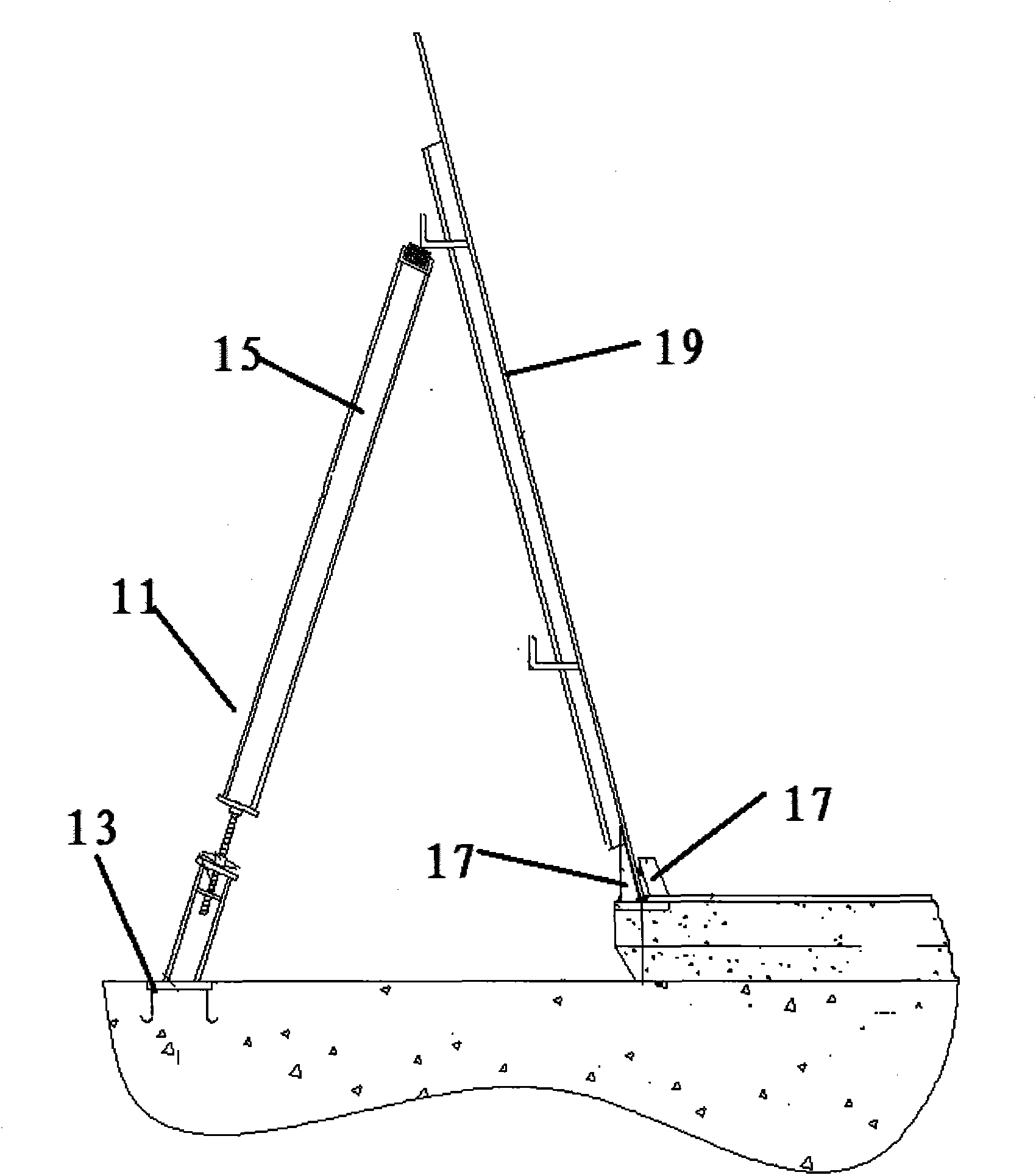

Method for half-breadth double-span total assembling and building in shipbuilding

ActiveCN101544268AReduce upwarping deformationReduce welding distortionVessel partsButt weldingButt joint

The invention relates to a method for half-breadth double-span total assembling and building in shipbuilding, which comprises the following steps: firstly, dividing the half-breadth building at the bottom of a cargo area of a ship into four sections including two double-layer bottom sections and two bottom edge water camber sections; secondly, using one of the double-layer bottom sections as a reference, performing normal total assembling on the two double-layer bottom sections; and thirdly, aligning and welding the two bottom edge water camber sections with the corresponding double-layer bottom sections first, and then performing butt welding on the two adjacent bottom edge water camber sections so as to form a half-breadth type total section. The building method is advantageous for the structural completeness of a shipway, and can speed up the structural submission progress. The pitch point control at a bilge round-turning part can be performed at the total assembling in advance, thus the number of butt joints at the round-turning part of an upper shipway is reduced, the shipway and a total assembling platform are used reasonably, and the utilization rate of the total assembling platform is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

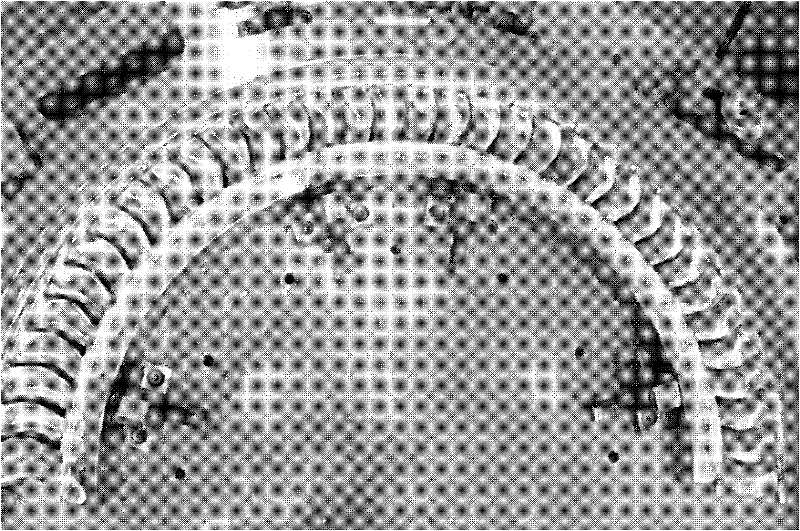

An electron beam welding method for an ultra-supercritical partition

ActiveCN102294541AReduce welding distortionControl pitch circle sizeElectron beam welding apparatusPower flowSeam welding

The invention discloses an electron beam welding method for ultra supercritical partition plates, and relates to a welding method for ultra supercritical partition plates for solving the problems of difficulty in welded seam formation, high welding deformation, difficulty in clearing seams, difficulty in ensuring the welding quality and the like in a manual welding or gas protection welding process during welding the ultra supercritical partition plates. The method comprises the following steps of: ruling, assembling, checking, spot welding, vacuumizing, welding seams, turnover welding, checking, and performing thermal treatment. In the seam welding step, the accelerating voltage is 55 to 60kV, the welding speed is 200 to 800mm / min, the electron beam current is 50 to 350mA, the focusing current is 1,500 to 2,000mA, the scanning oscillation amplitude of electron beams in the X direction is 0 to 5.4, the scanning oscillation amplitude of the electron beams in the Y direction is 0 to 6.0, the gun distance is 220 to 320 millimeters, and the scanning waveform is circular. The method is used for electron beam welding of the ultra supercritical partition plates of a steam turbine.

Owner:HARBIN TURBINE +1

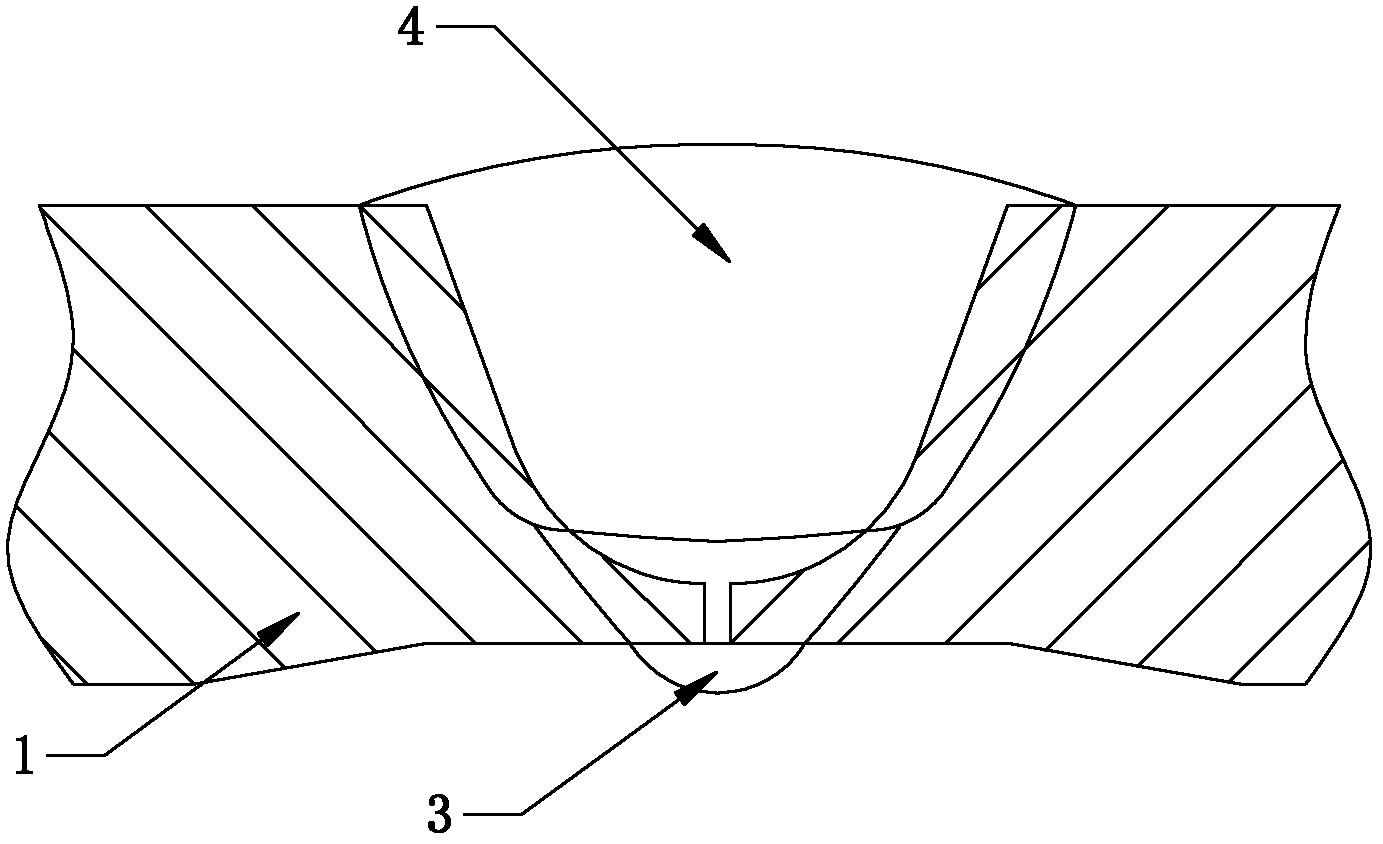

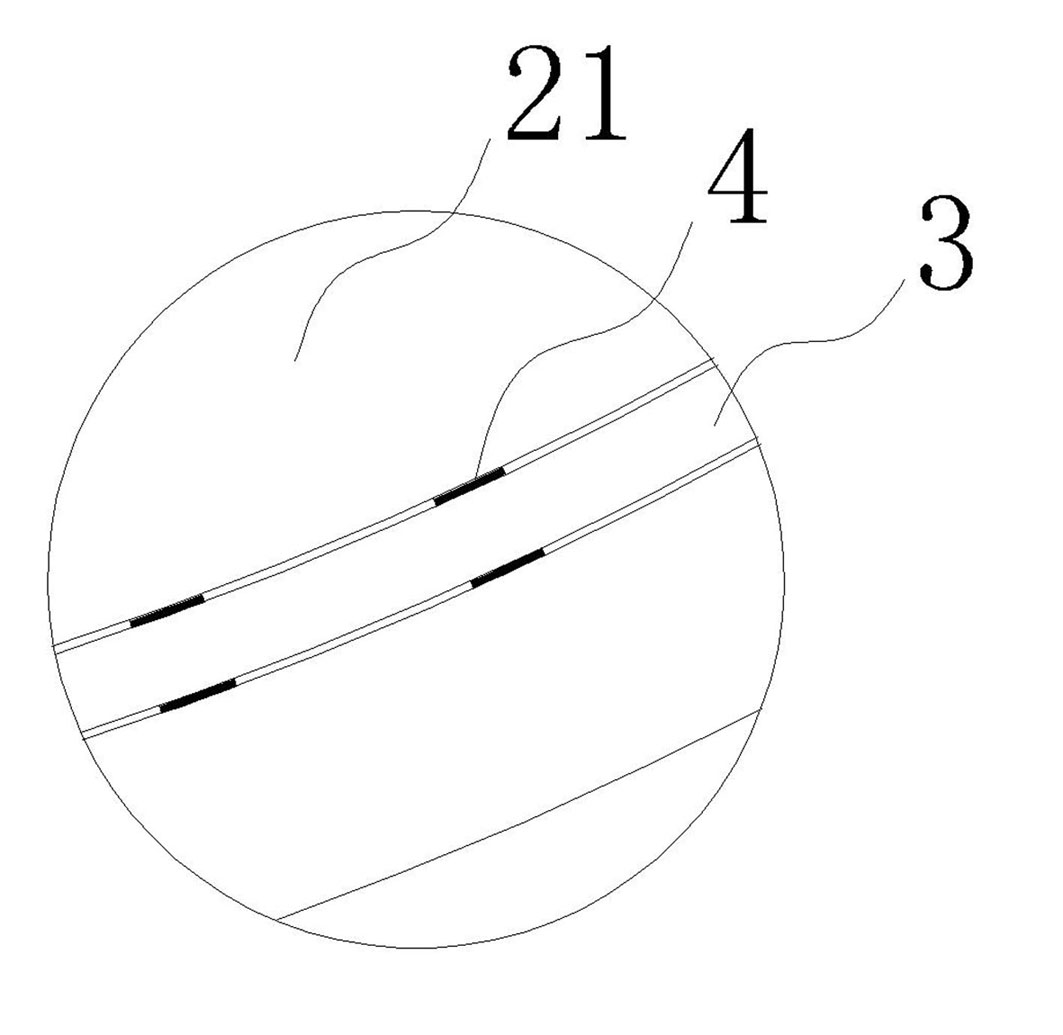

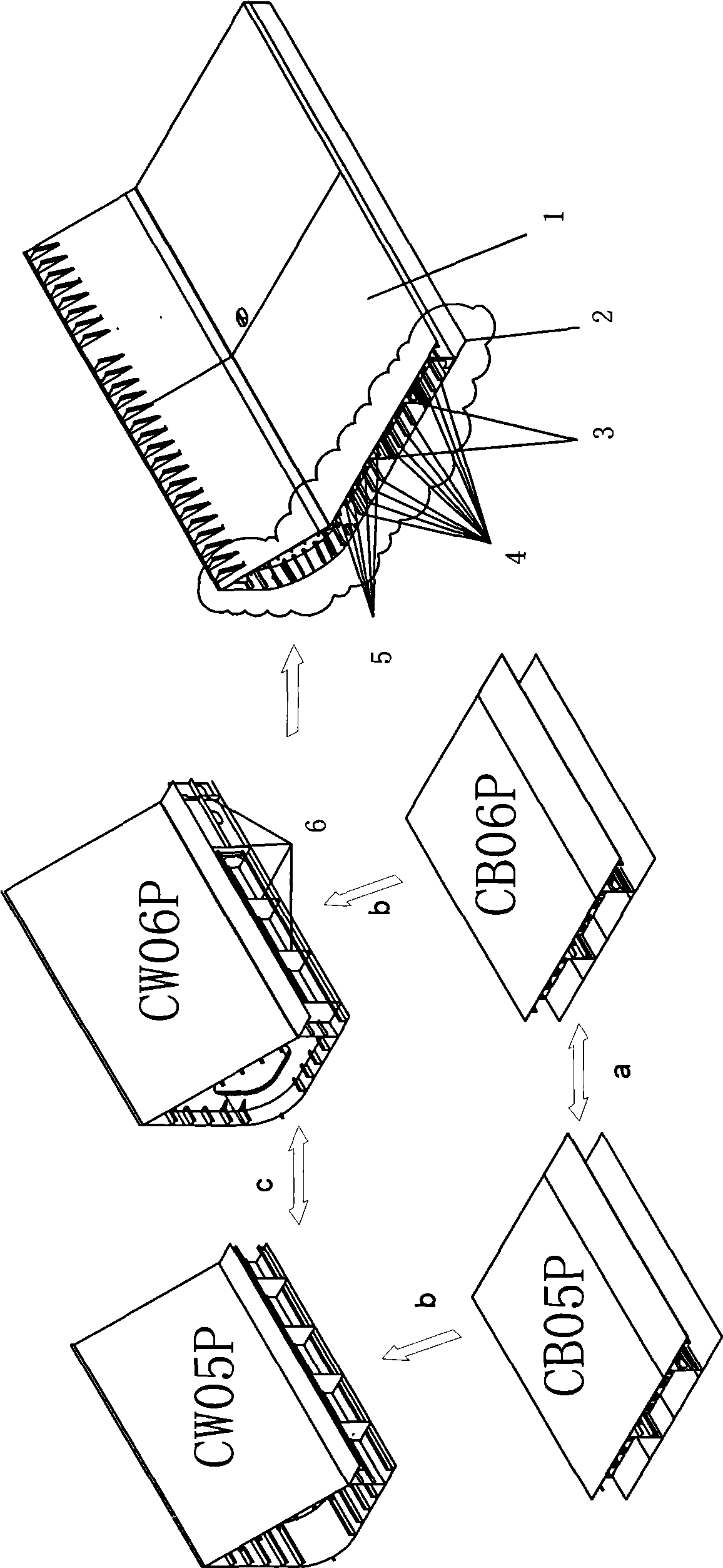

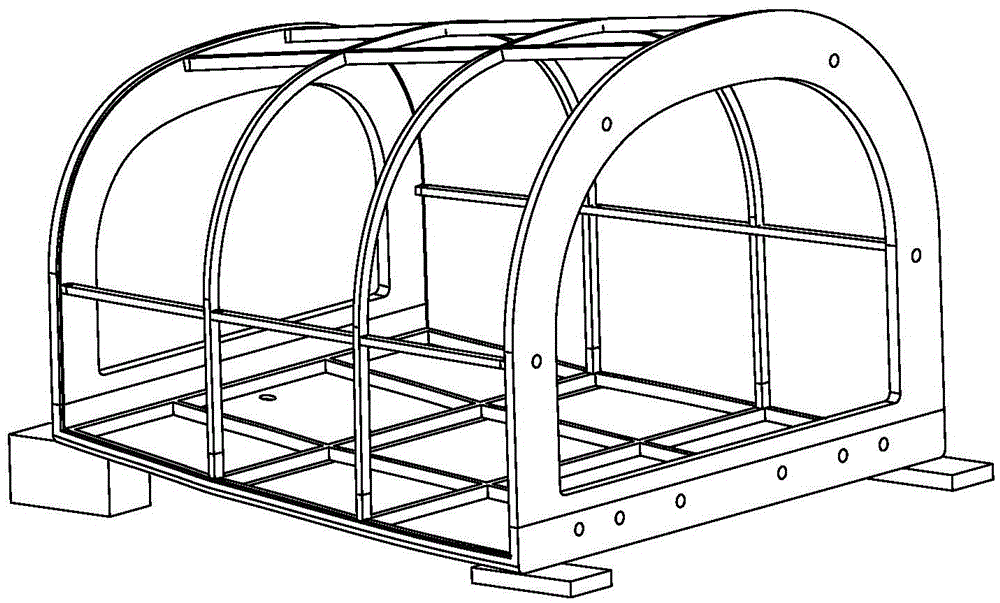

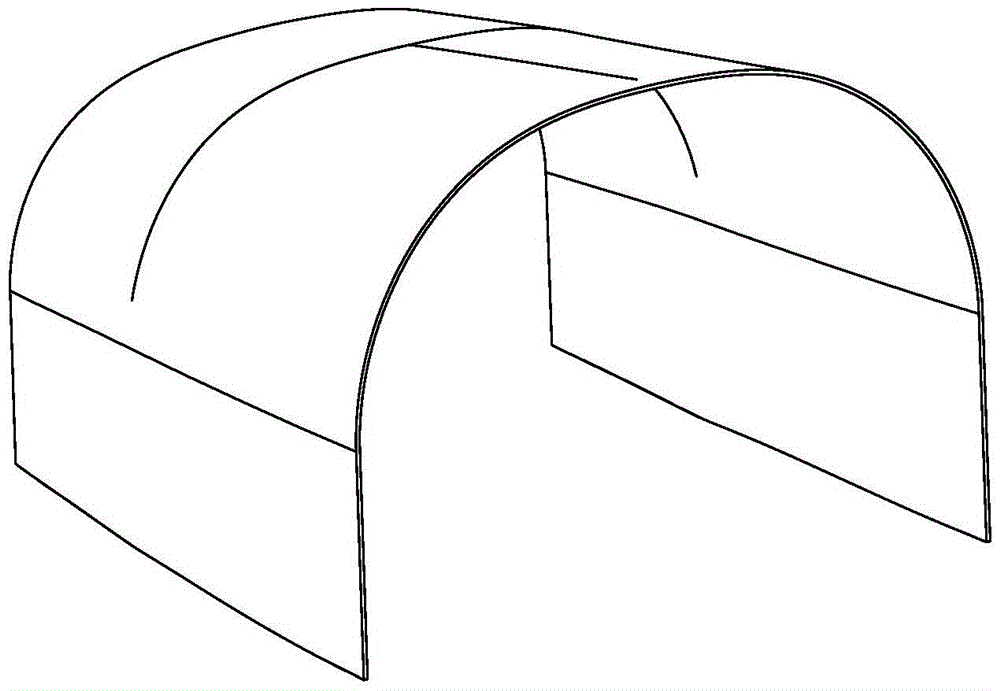

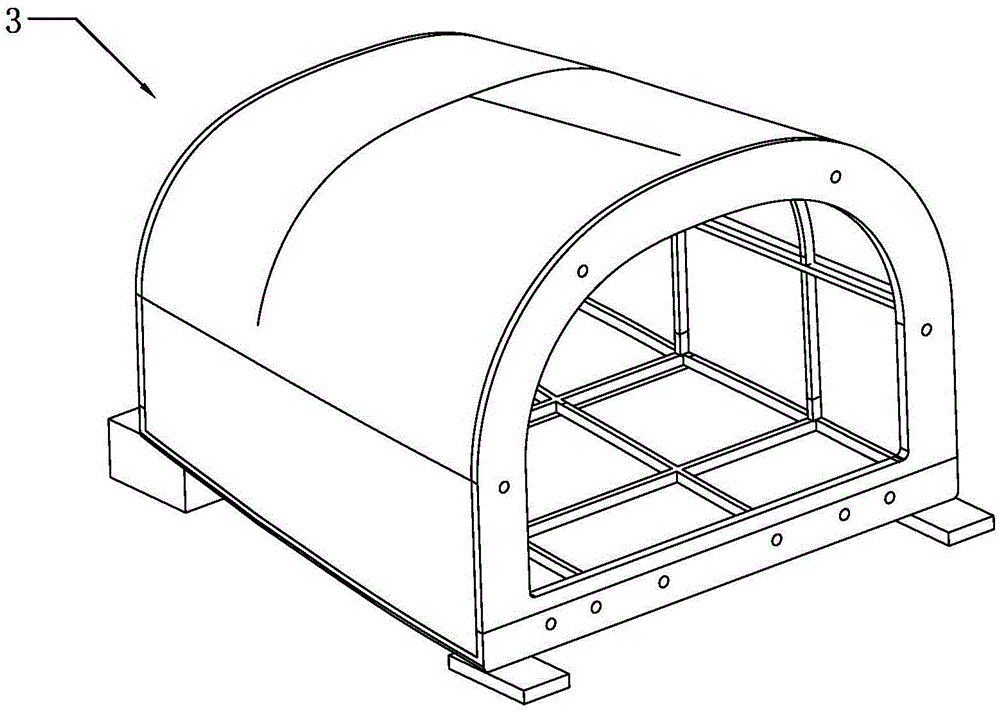

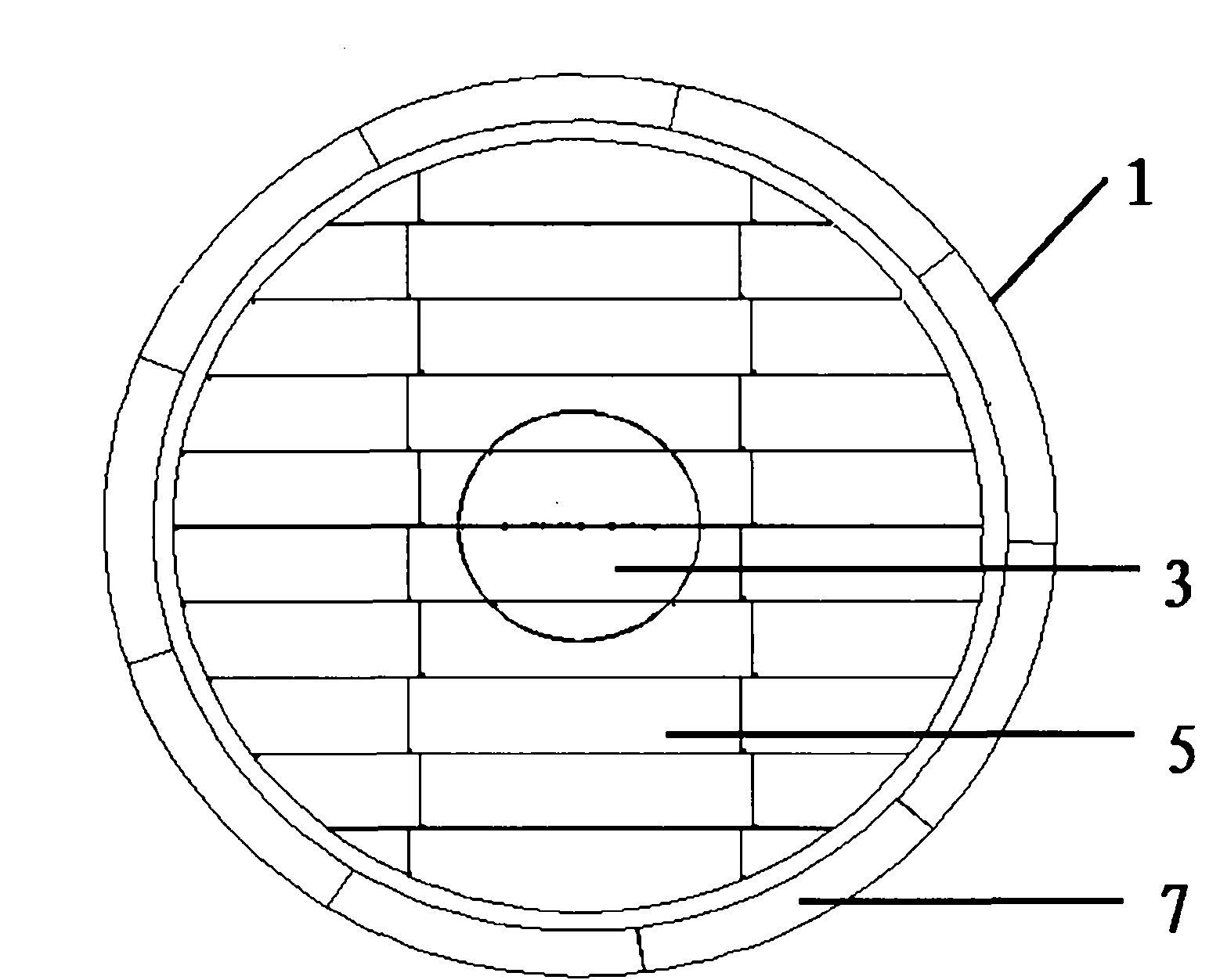

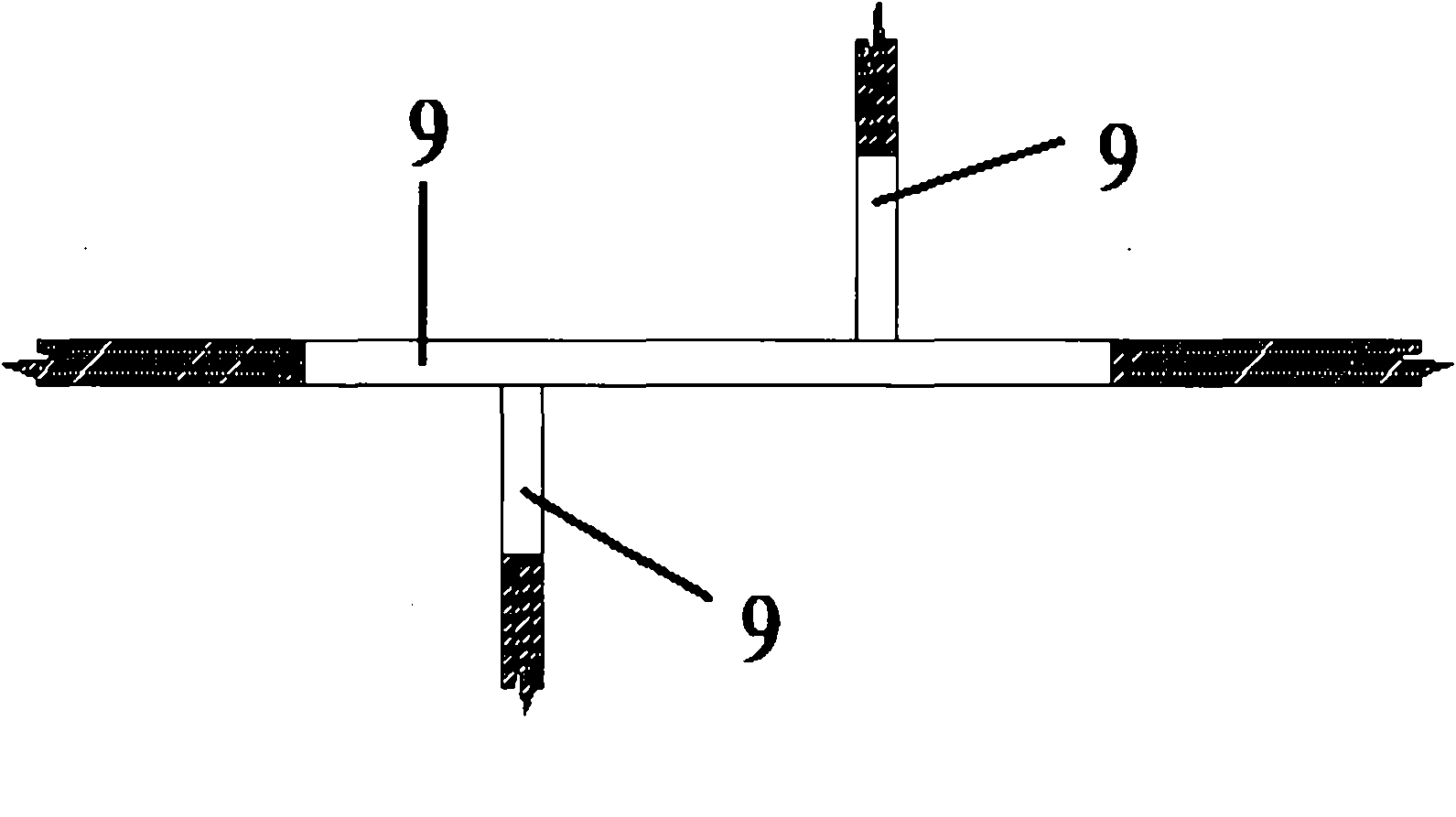

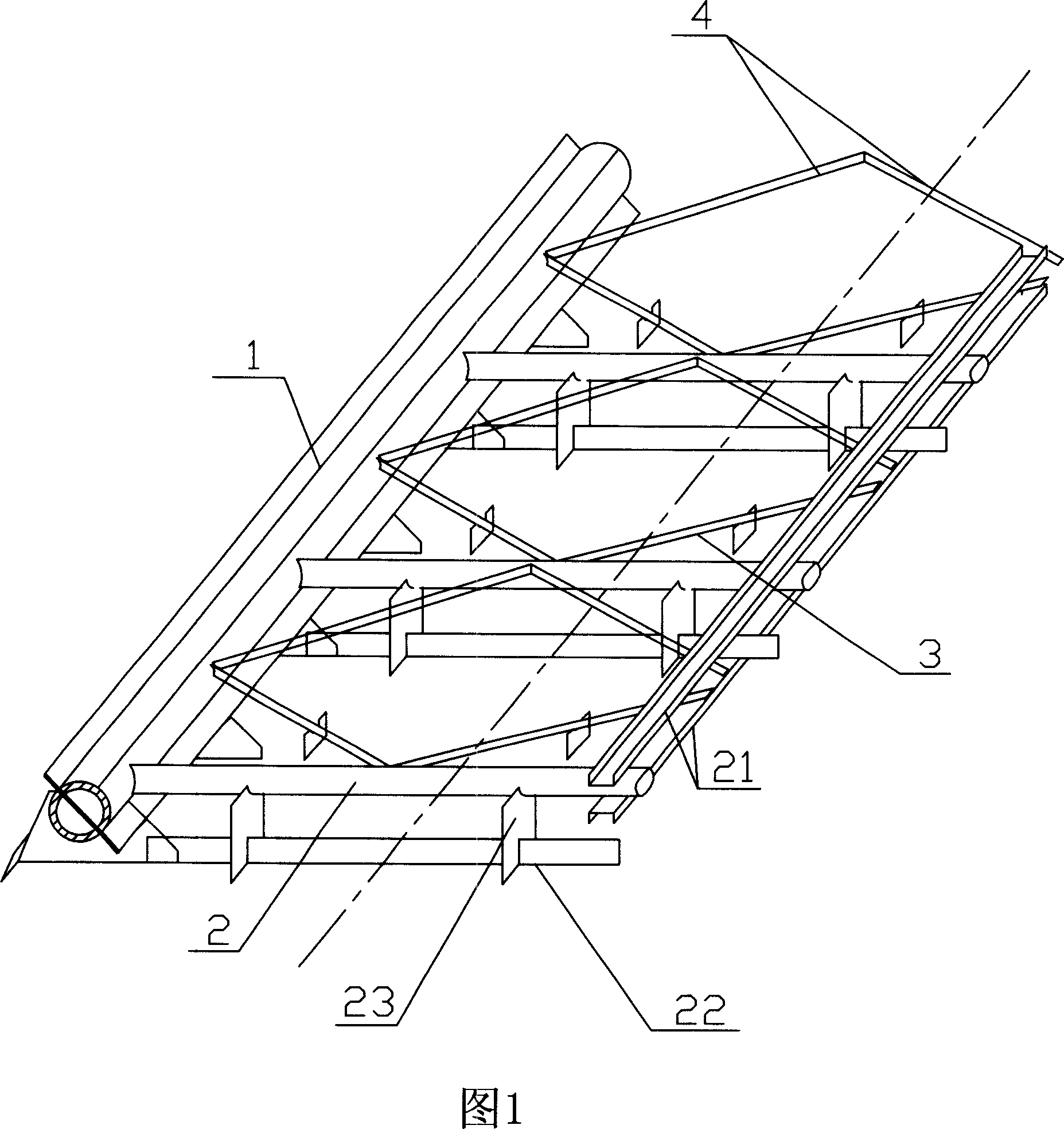

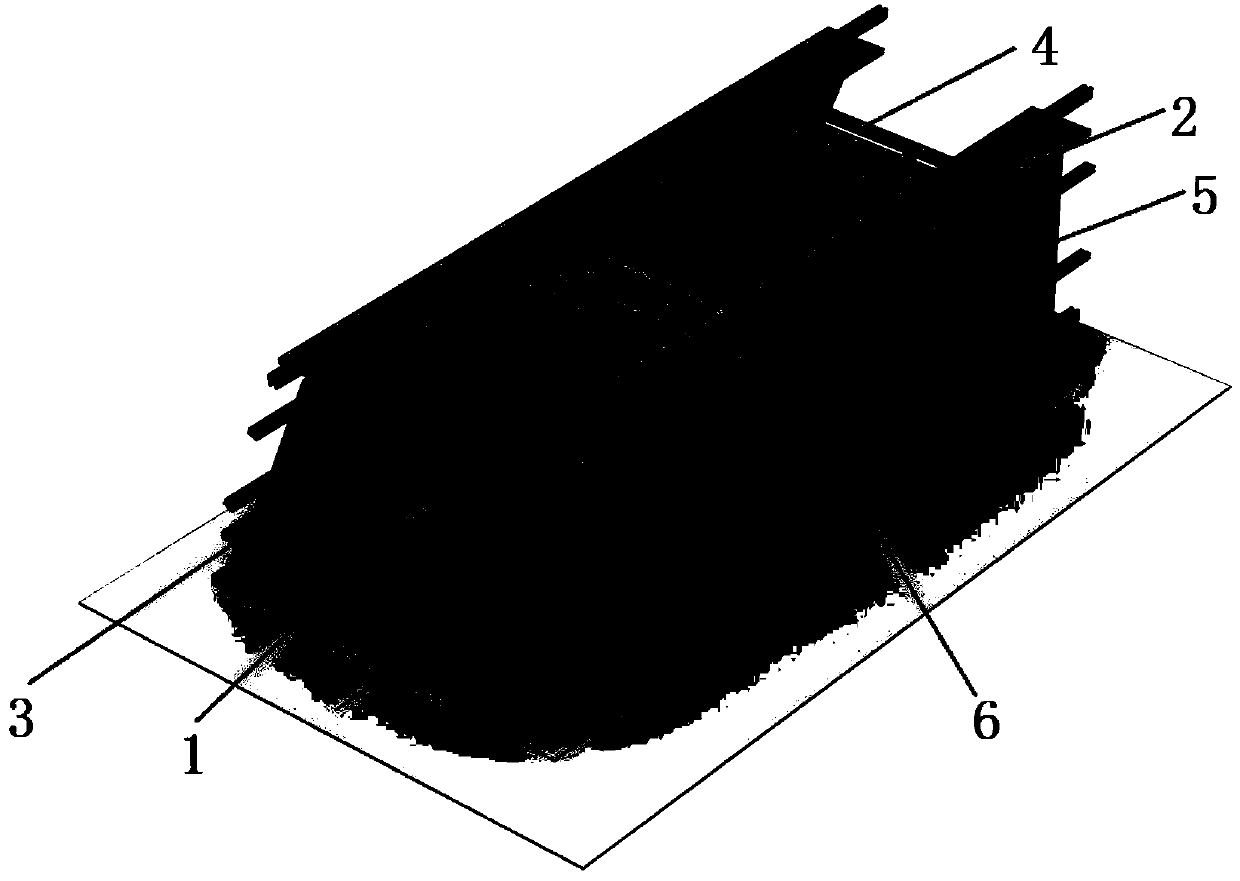

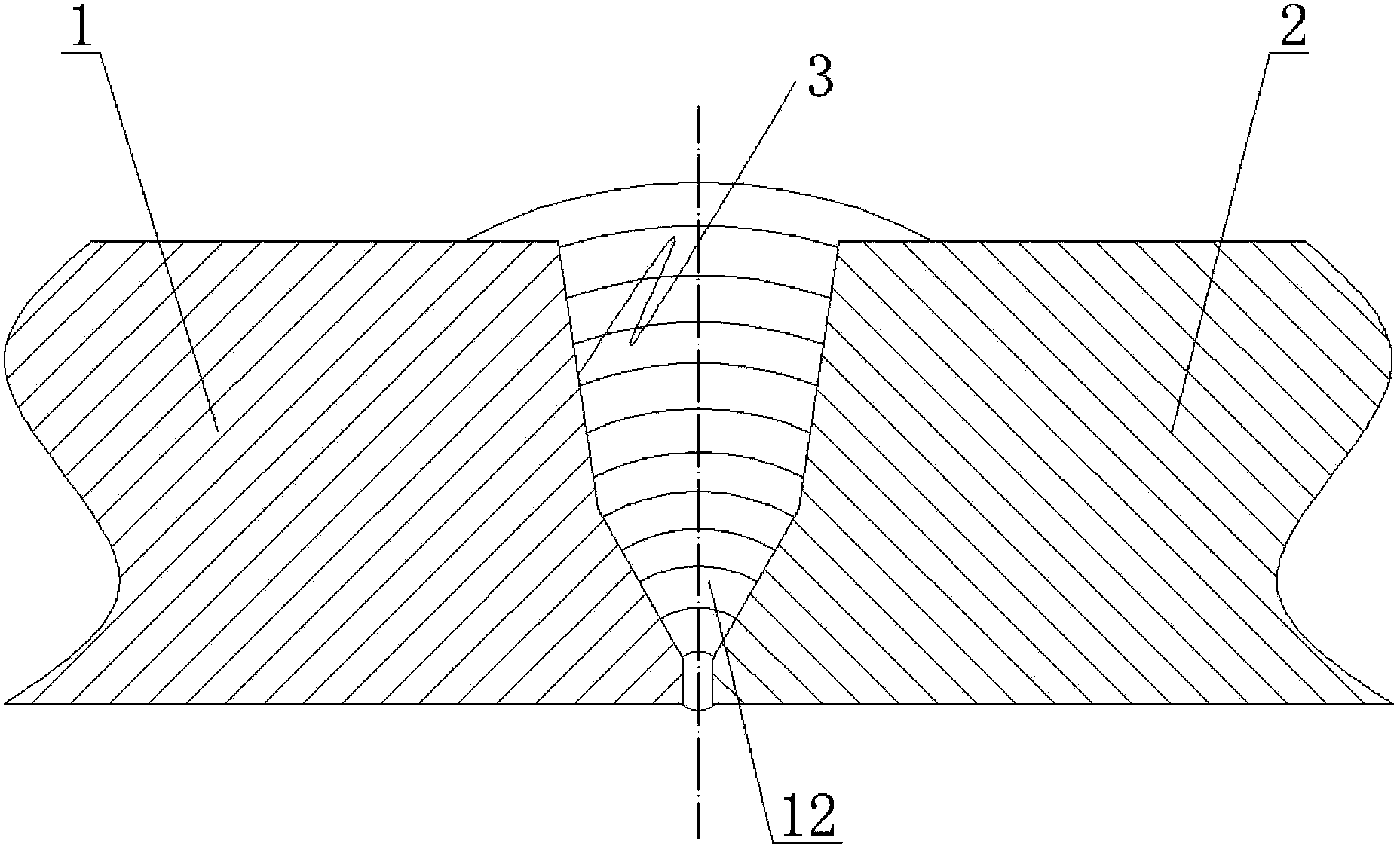

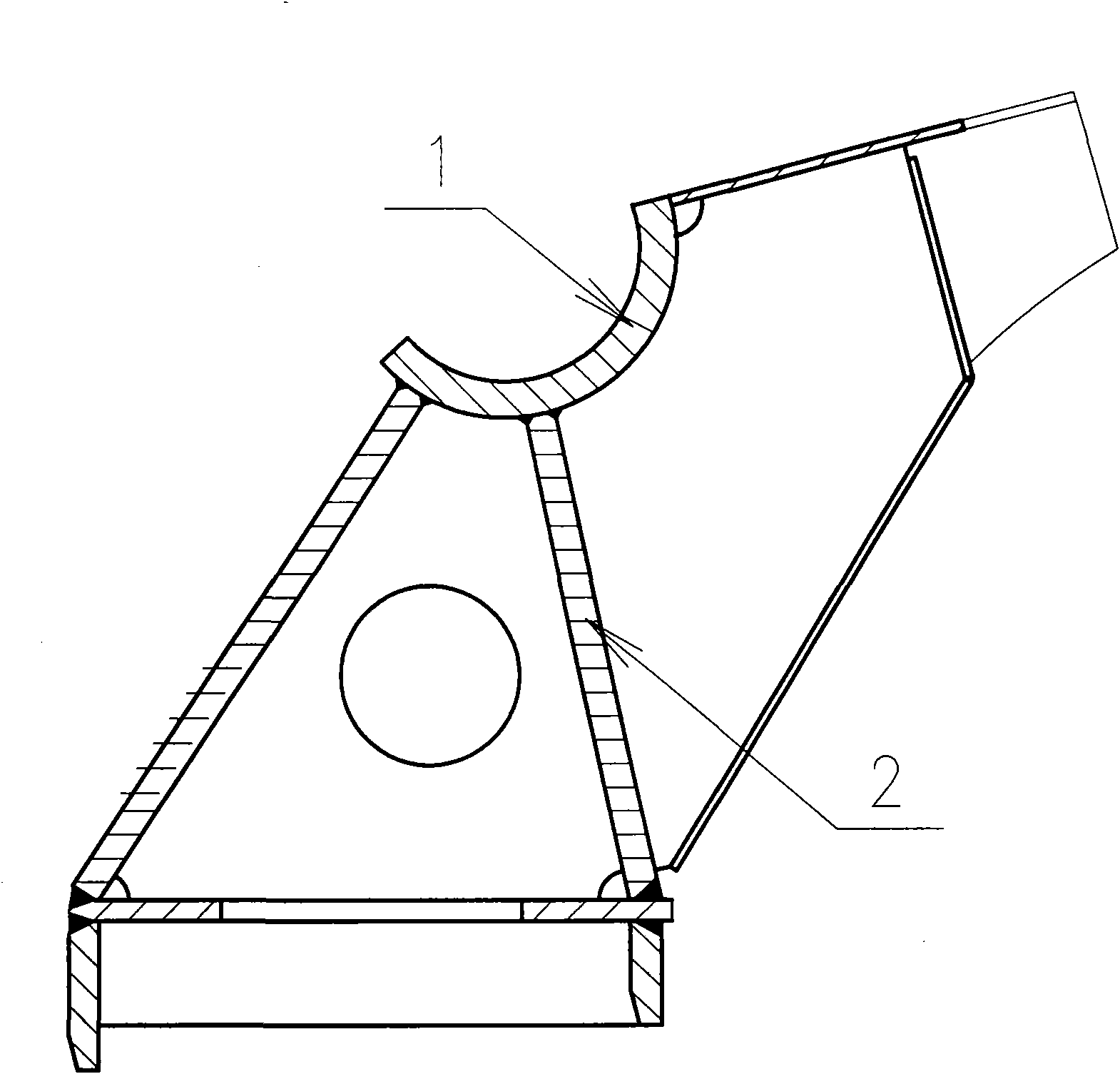

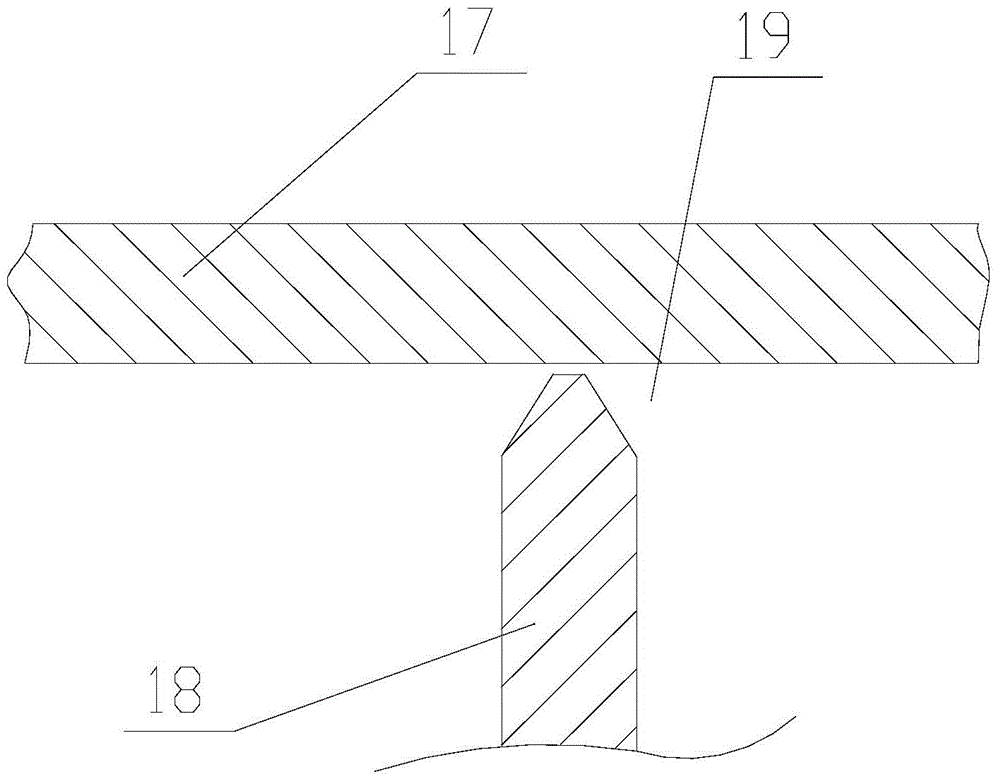

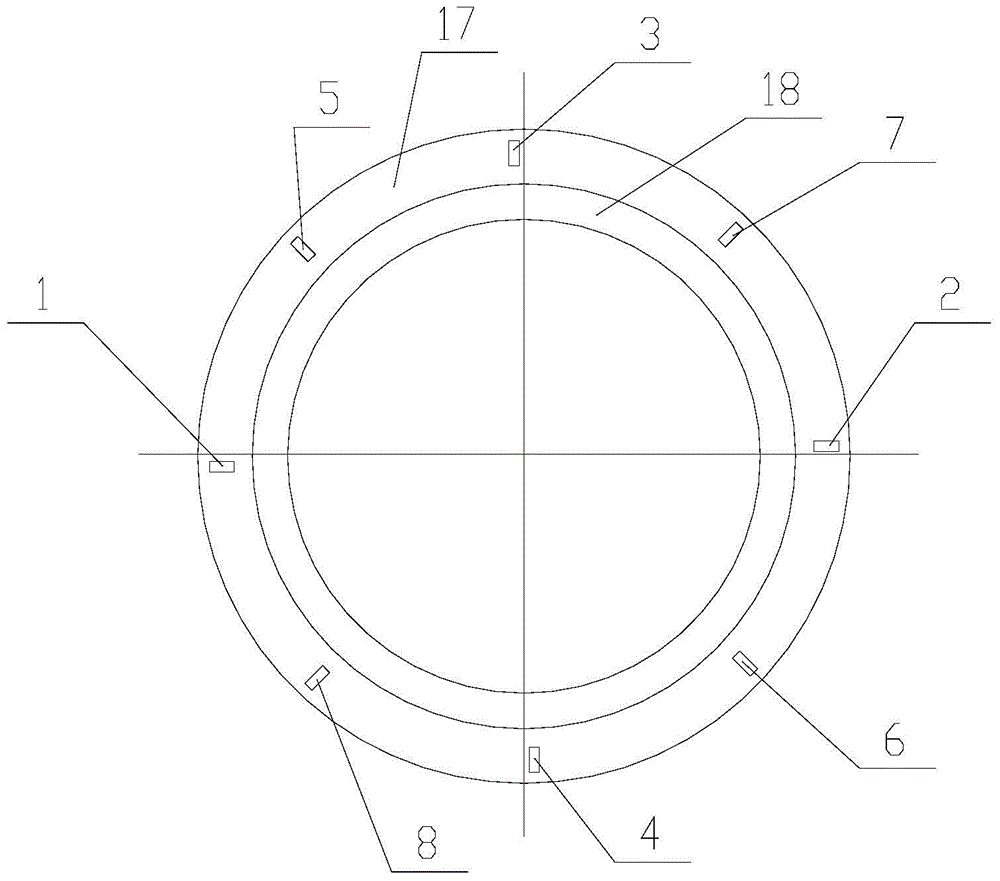

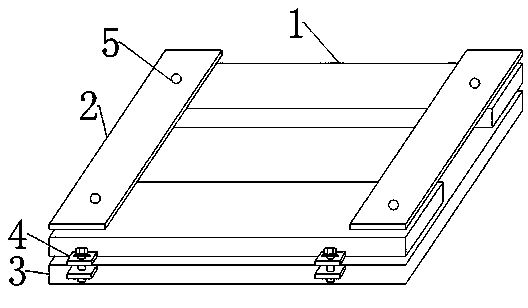

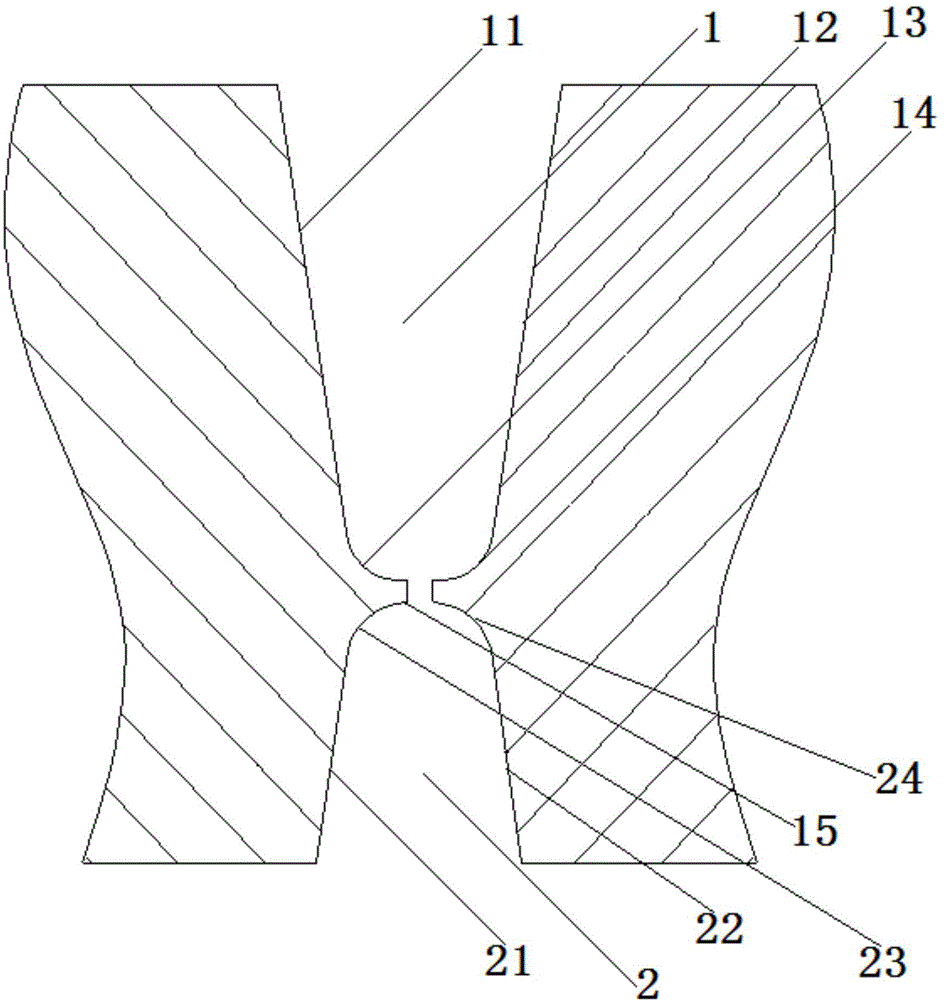

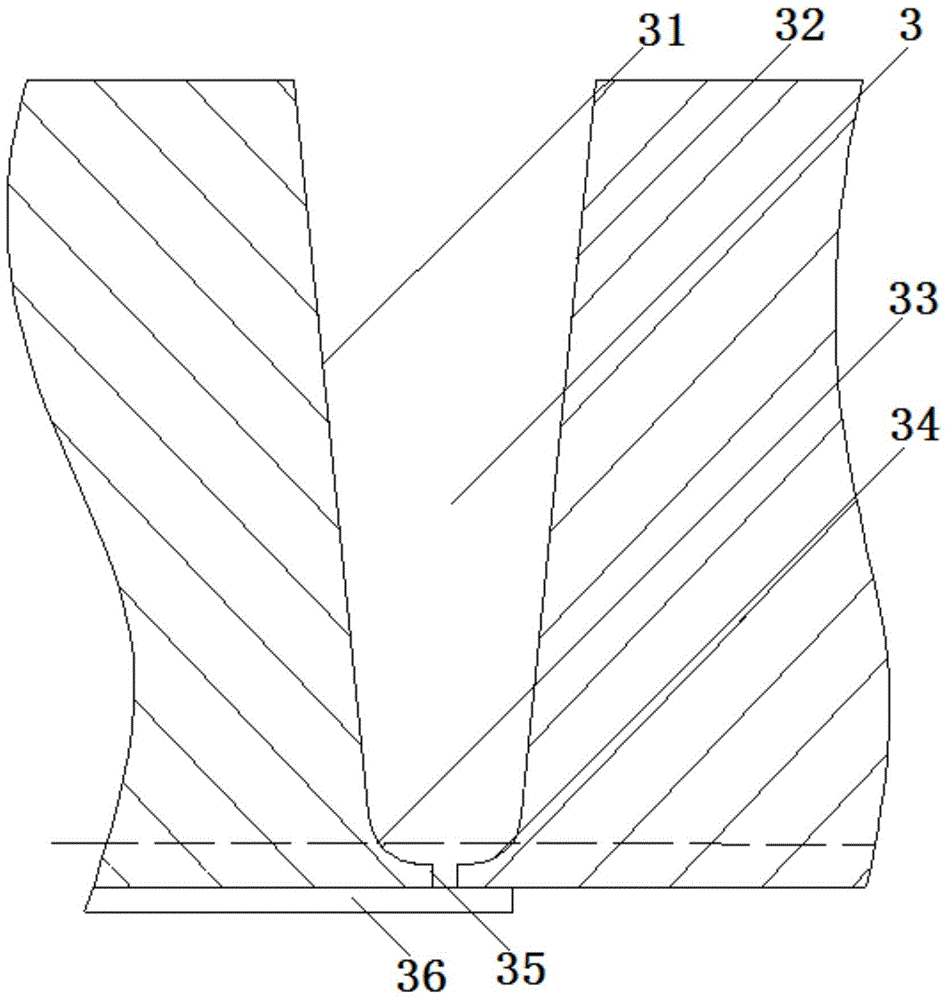

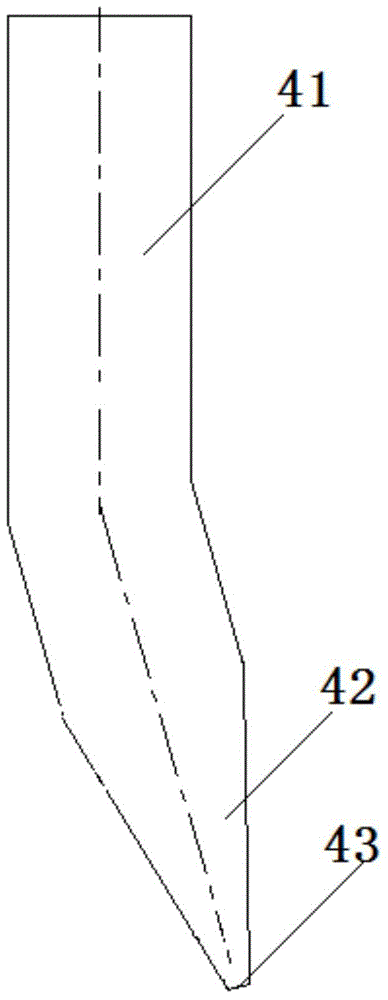

Laser welding tool for thin wall complex surface cabin body and molding method

ActiveCN105458506AIncrease energy densityReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUtilization rate

The invention relates to a laser welding tool for a thin wall complex surface cabin body and a molding method, in particular to the laser welding tool suitable for the thin wall complex surface cabin body and the welding molding method of the laser welding tool and aims at providing the laser welding tool for the thin wall complex surface cabin body and the cabin body molding method. The tool and the method solve the problems that by means of an existing method, the machining cycle is long, the material utilization rate is low, production efficiency is low, cost is high and adaptability is poor. The laser welding tool for the thin wall complex surface cabin body comprises a bearing frame body, wrap belt assemblies and front and rear cover plates (1 and 2). The bearing frame body is used for fixing a cabin body (3). The wrap belt assemblies comprise wrap belts (4) and connecting pieces. The wrap belts are provided with locating through holes (5). The cover plates are provided with gas through holes (7). The thin wall complex surface cabin body molding method adopting the tool includes the steps of cleaning treatment, framework mounting, teaching programming, skin mounting, laser locating and welding, wrap belt assembly detaching and laser continuous welding.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

ActiveCN102061788AShort construction periodShorten the construction periodCovering/liningsArc welding apparatusSupporting systemArchitectural engineering

The invention provides a method for mounting bottom plates and a cylinder of a steel lining of a nuclear power plant. The bottom plates are basically circular, and are divided into circular center bosses, annular intermediate annular plates and annular edge plates which consist of a plurality of precast slabs from inside to outside; the cylinder comprises frustums and cylinder wall plates which are formed by splicing the plurality of precast slabs; and the cylinder wall plates are divided into a plurality of layers. The mounting method sequentially comprises the following steps of: mounting a bottom plate support system; putting the bottom plates on the bottom plate support system; putting the frustums; welding the bottom plates and the frustums in pairs; and mounting each layer of cylinder wall plates from bottom to top respectively. By rationally setting a welding process and a construction assembly process, a mounting construction period of the steel lining is effectively shortened, and the sealability of welding seams of the steel lining is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

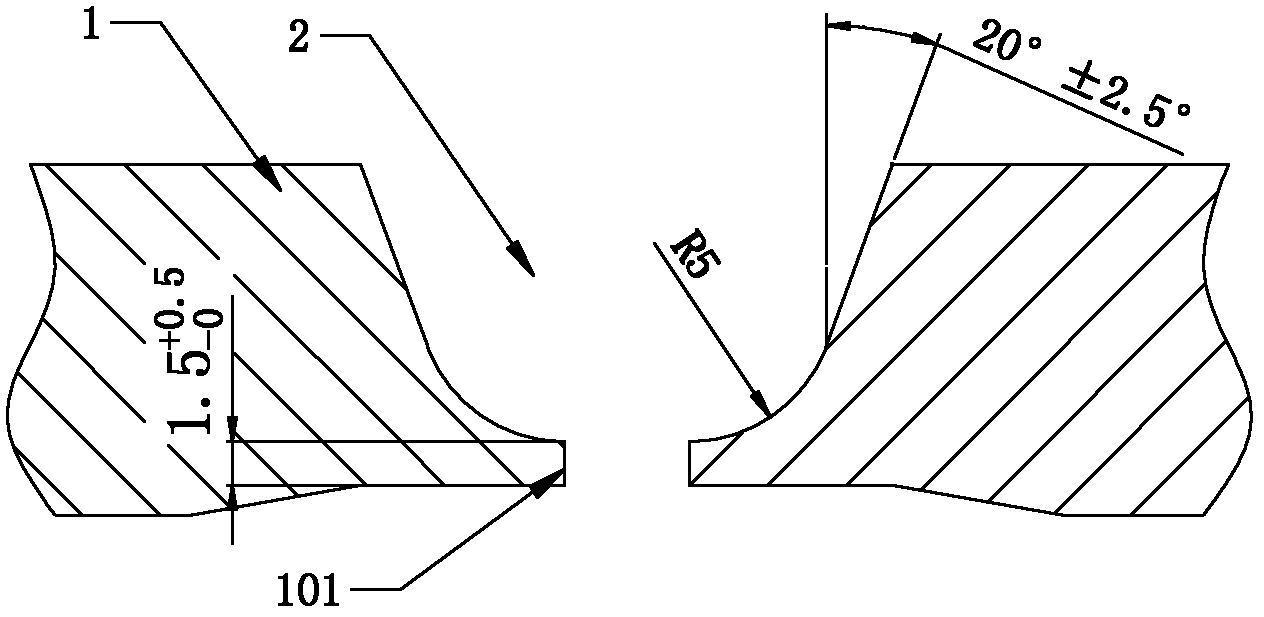

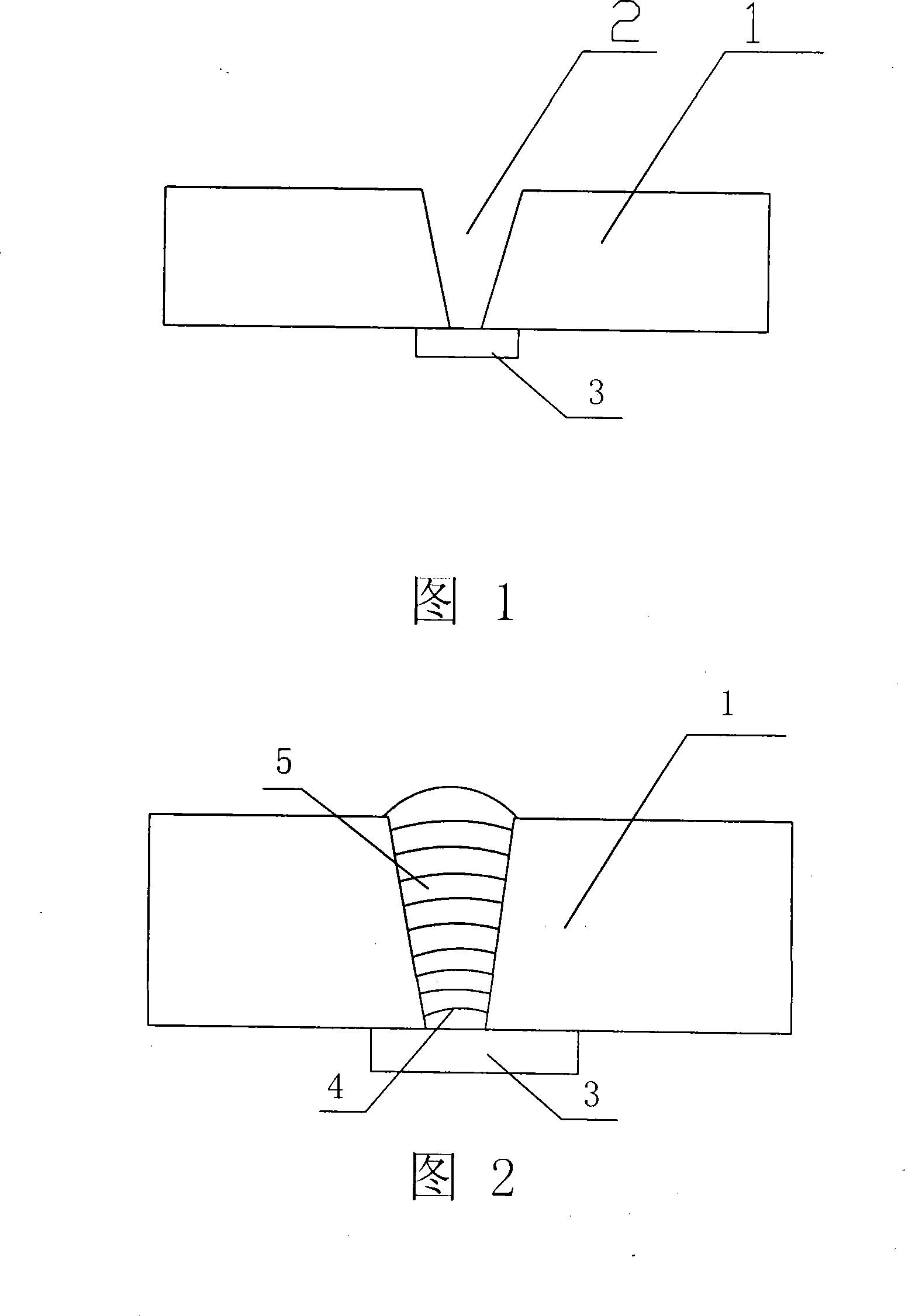

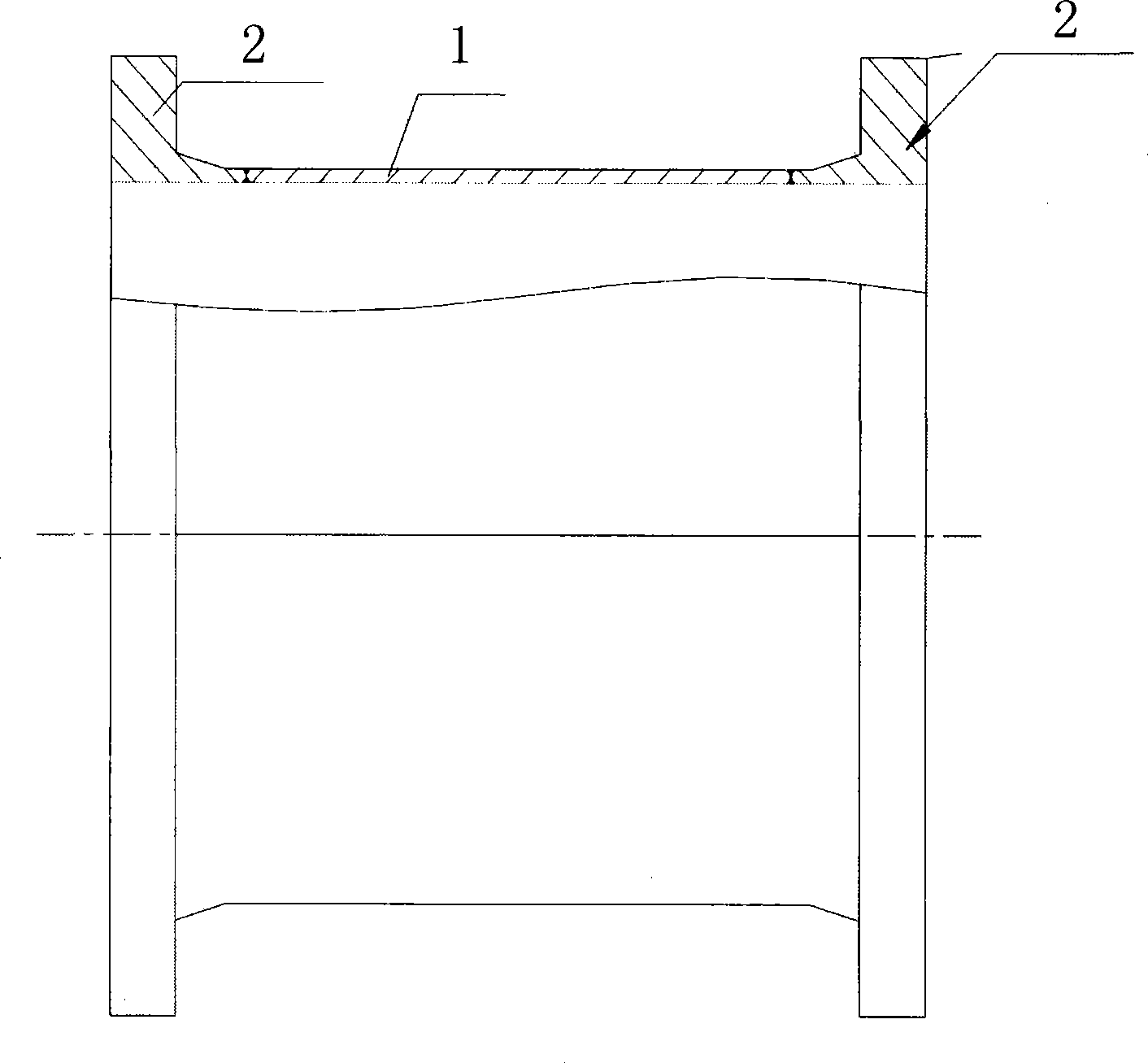

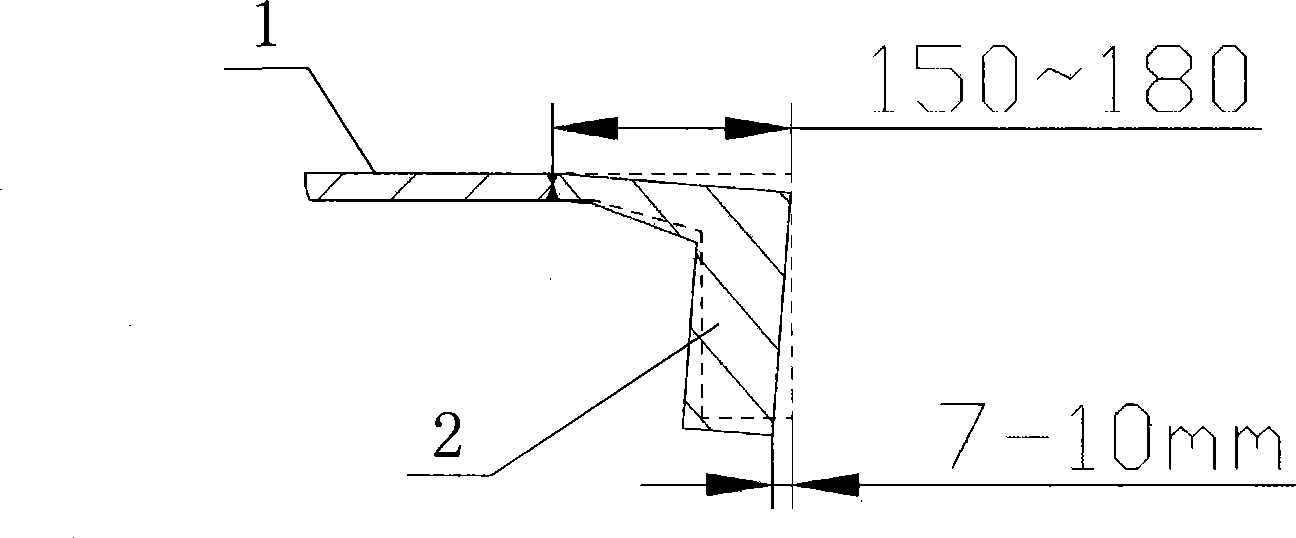

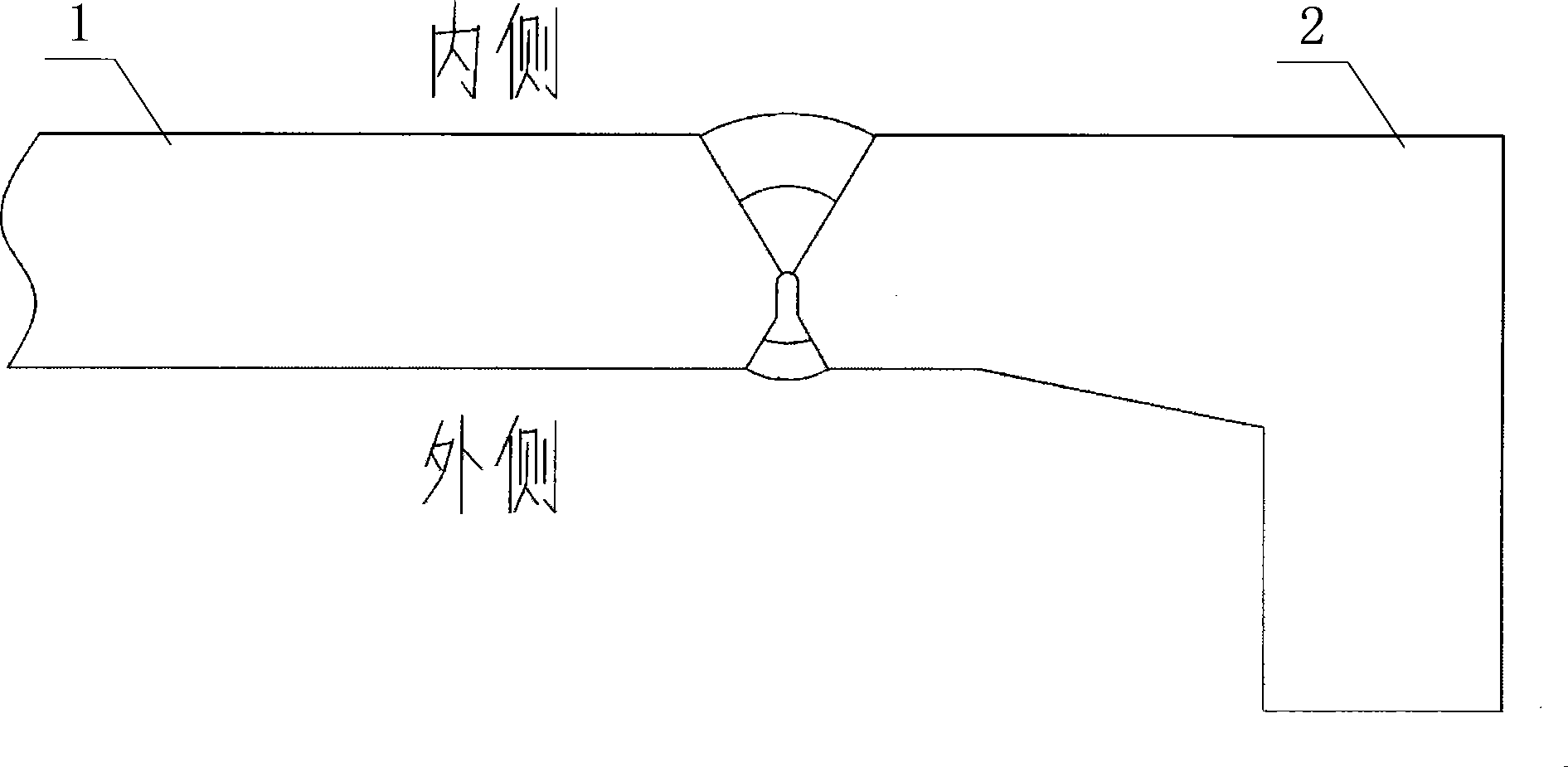

Control method of large-sized mining grinding mill end flange welding deformation

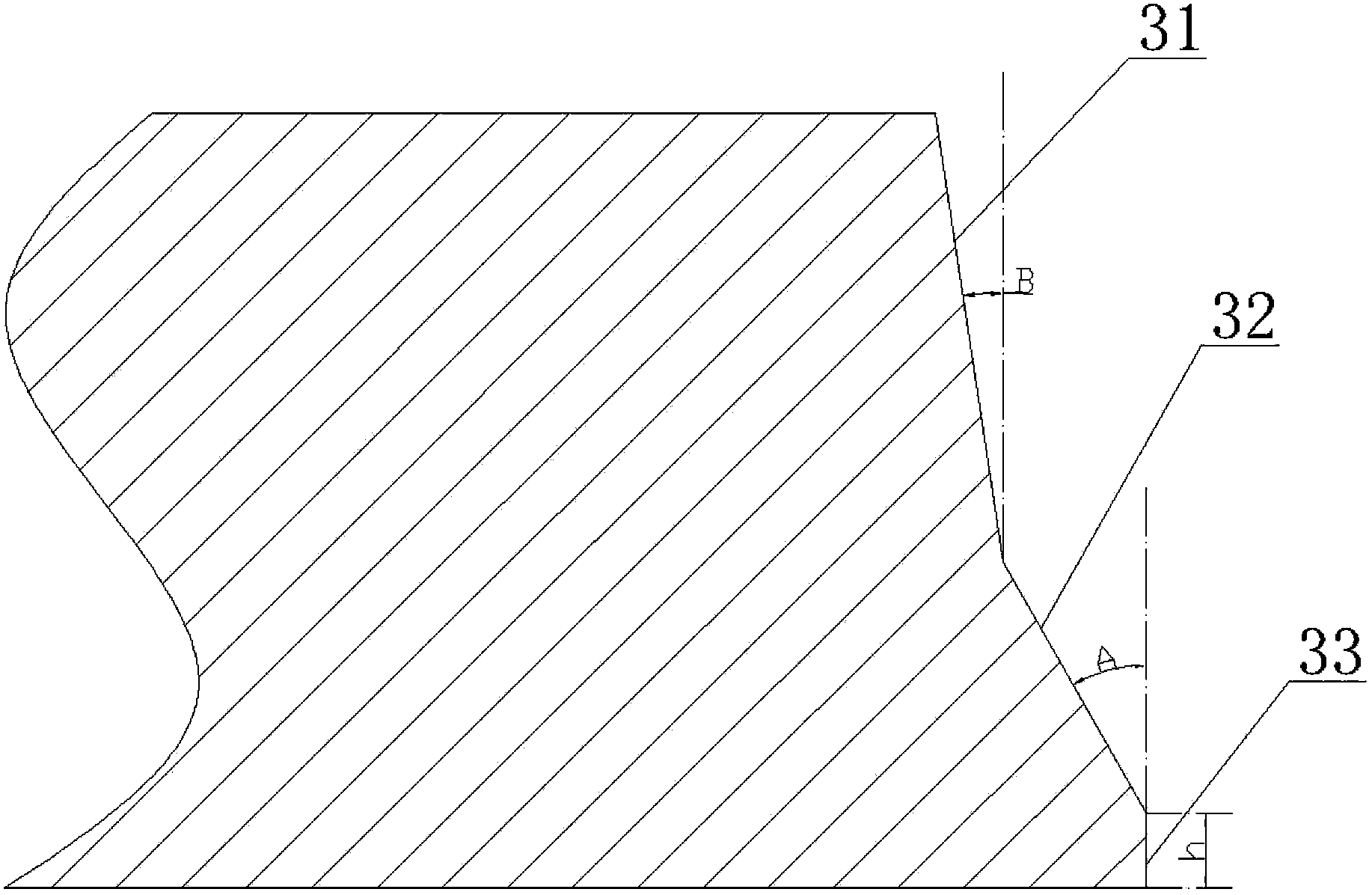

InactiveCN101412157AReduce welding distortionReduce workloadWelding/cutting auxillary devicesArc welding apparatusButt jointPart type

The invention provides a method for controlling welding deformation of an end flange of a large-sized mine mill, which comprises two contents: 1. the groove butt joint mode and welding mode before the end flange(2) and a barrel body(1) are welded are improved, the groove butt joint mode has three types which are small inner part and big outer part type, equal inner part and outer part type and big inner part and small outer part type respectively, and the welding mode correspondingly has three types; and 2. the correction is performed after welding, which has obvious effect, and the product quality is effectively ensured. By utilizing one welding stress to overcome the other welding stress, the welding stresses inside and outside the connecting part between the barrel body and the flange are balanced (i.e. the transverse shrinkages of the welding seams are the same); in the end, when the barrel body of the mill is subjected to relief annealing, the welding stresses inside and outside the barrel body of the mill are equally released, so that the method has the advantages of having little welding deformation, reducing the work load of correction after welding, improving the production efficiency, shortening the production cycle and lowering the production cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD

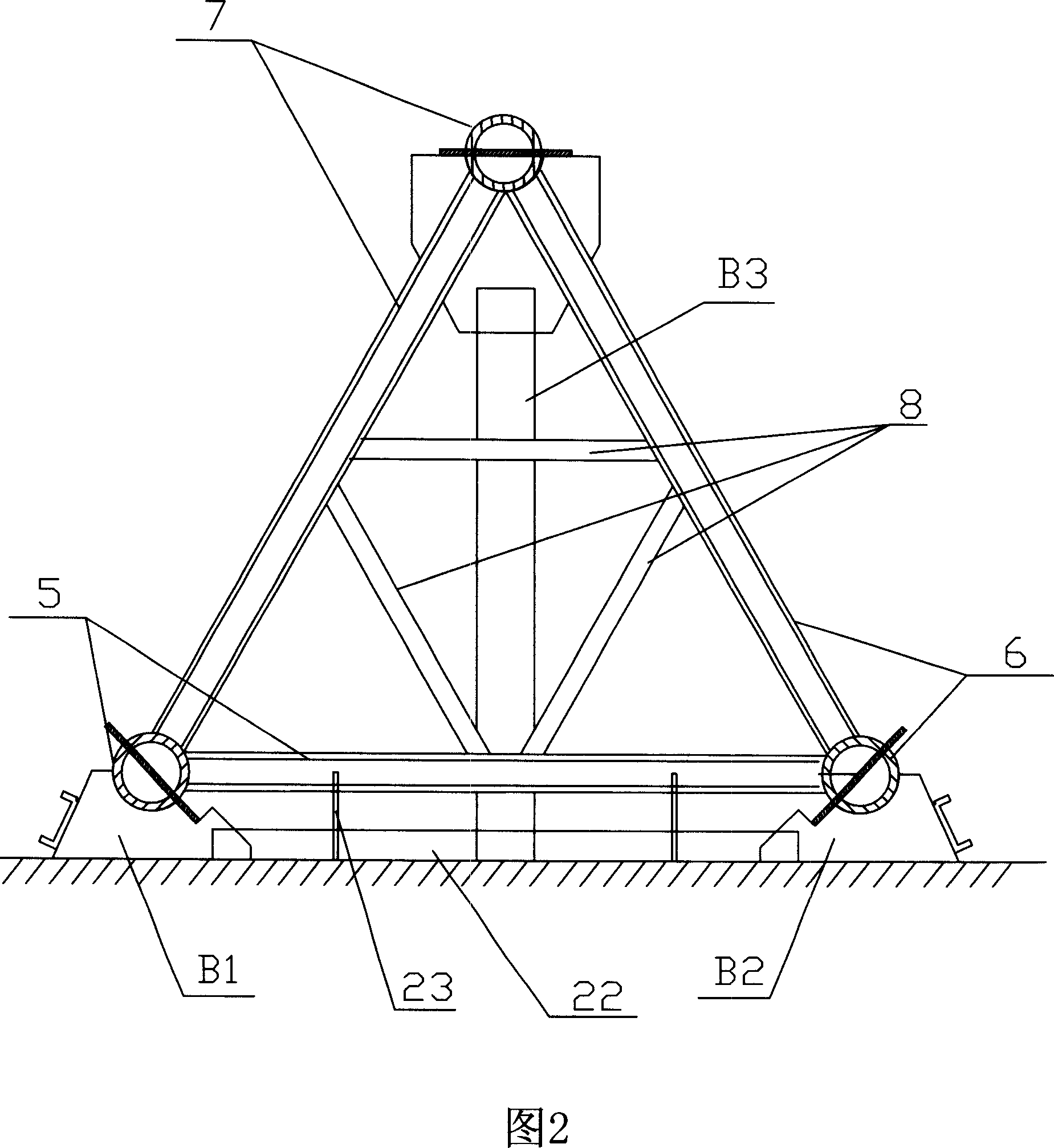

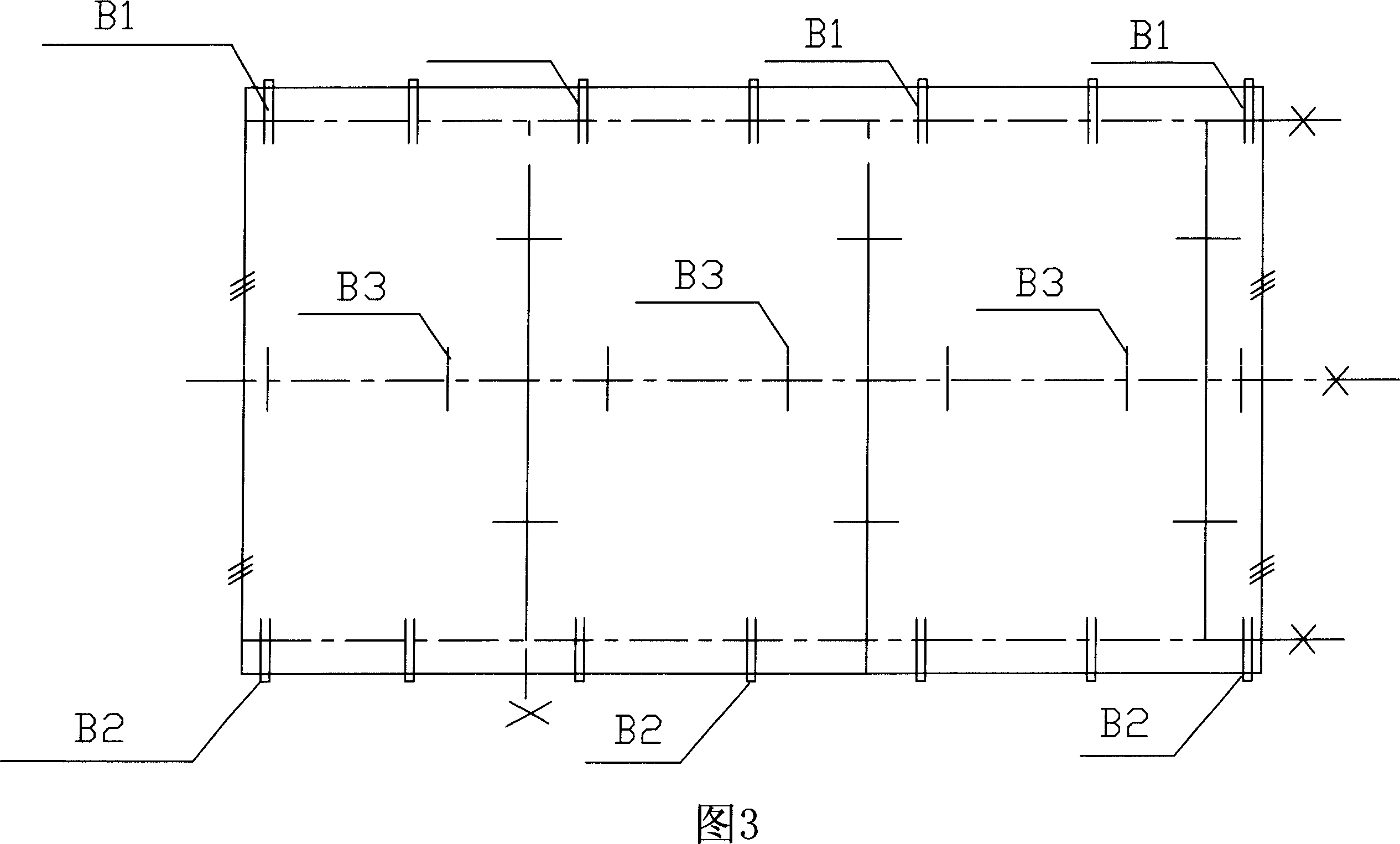

Assembling method for large truss type pile leg structure

ActiveCN1974936AControl build sizeReduce welding distortionArtificial islandsUnderwater structuresSheet structureBuilding construction

The present invention discloses an assembly method of large trussed pile leg structure. Said method includes the following steps: first step, utilizing horizontal construction mode and using main side pipe positioned in one end as reference to assemble single-sheet structure of every pile leg part, the length of every described single-sheet structure is 15-25 meters; second steps, utilizing mould frame to make three identical single-sheet structures be formed into a regular trilateral trussed pile leg part; and third step, assembling all the pile leg parts together so as to obtain the invented large trussed pile leg structure.

Owner:DALIAN SHIPBUILDING IND

Method for welding thick aluminum alloy plate

ActiveCN102922098AReduce welding distortionEasy post-weld calibrationArc welding apparatusProduct gasWelding deformation

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises a cleaning process, a preheating process and a welding process, wherein the cleaning process is carried out in a chemical cleaning way and comprises steps of: dipping a part to be welded in a 8-10% NaOH solution for more than 10 minutes, and then dipping in a 40-50% HNO3 solution for 30 seconds to 1 minute, wherein sensing heating equipment is adopted in the preheating process, and the preheating is carried out at 230 to 250 DEG C; joints in the welding process are in form of angle joint, and the non-melting electrode tungsten electrode gas shielded welding is carried out in the welding method, the welding parameter can be shown as that the current is 250 to 290A, the current polarity is performed by alternating current, Ar with purity not less than 99.99% is adopted as the protective gas, and the gas flow is at 7-13 liters per minute. Through the method, little welding deformation is generated, the correcting is easily carried out after welding, the product quality can be improved, the production efficiency can be increased, and the manufacturing cost can be greatly reduced.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

Ultra-large type combined H-section steel column and manufacturing method thereof

ActiveCN104196166AGuaranteed bearing capacityNovel structural designStrutsPillarsManufactured materialStructural engineering

The invention discloses an ultra-large type combined H-section steel column. The ultra-large type combined H-section steel column comprises two I-section steels and a connecting web; the two I-section steels are respectively arranged at two sides of the connecting web, and the section is of an H shape after installation; the upper end face of the connecting web and the I-section steels at two sides form a concave structure, a stiffening plate is arranged along the concave structure, and a reinforcing rod is arranged on the stiffening plate. Meanwhile, the invention further provides a manufacturing method of the steel column. According to the steel column and the manufacturing method thereof disclosed by the invention, when the bearing capacity of the post is ensured, the structure of the column is maximally simplified, raw materials are saved, the cost is saved, the manufacturing process is simple, the installation precision can be ensured, the effective usable area of a building is increased, the gravity of the structure is reduced, and the seismic response of the structure is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

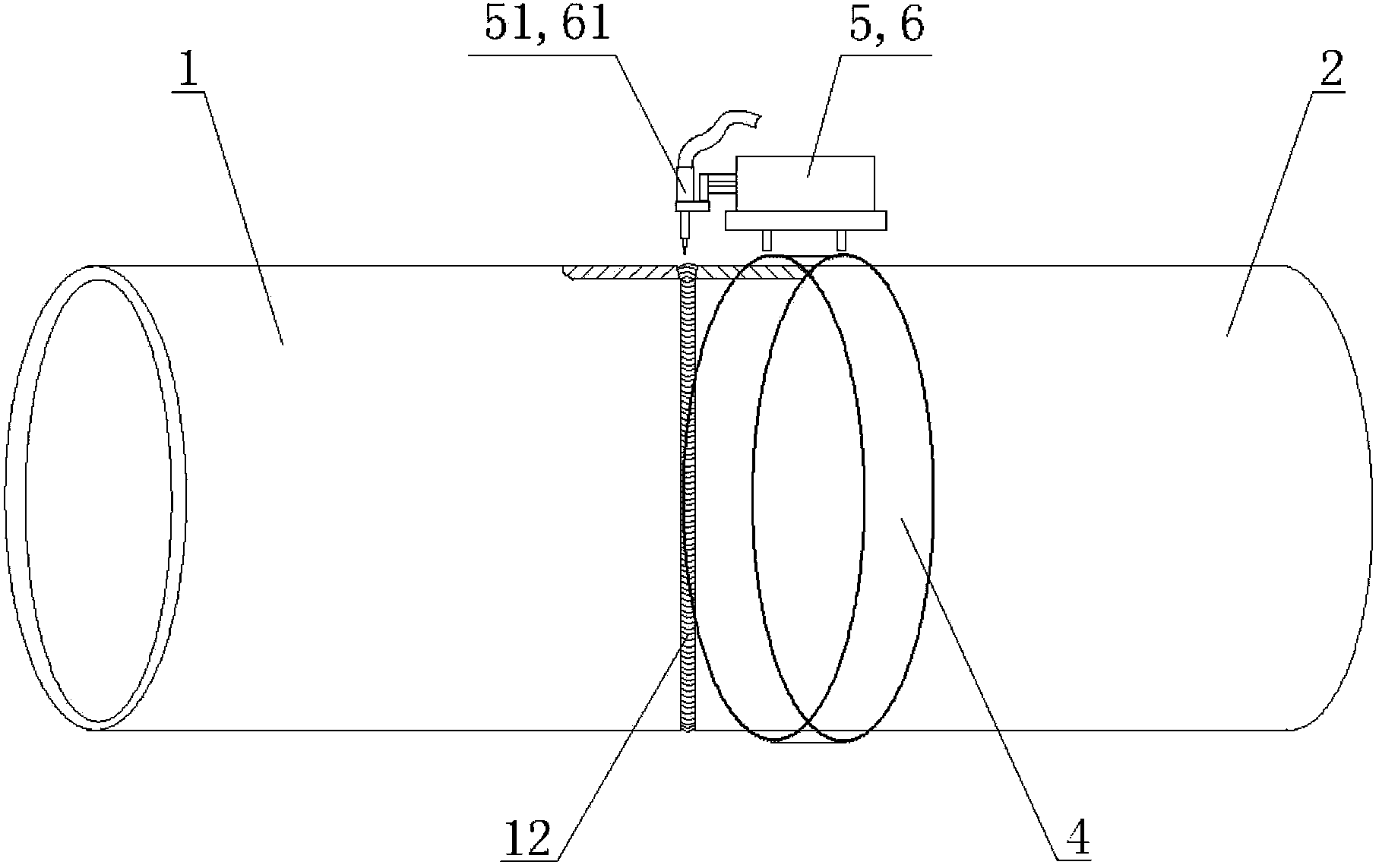

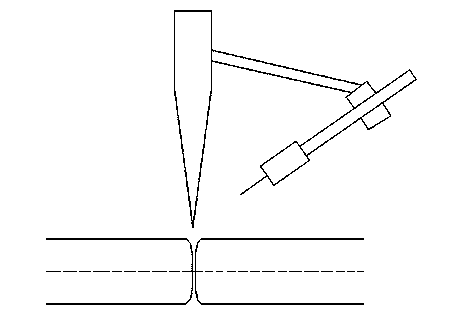

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

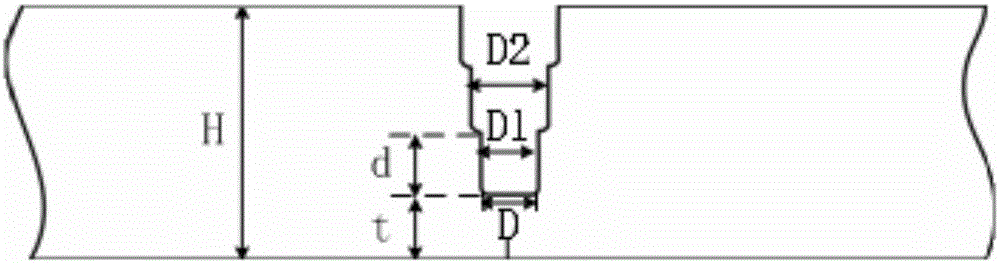

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

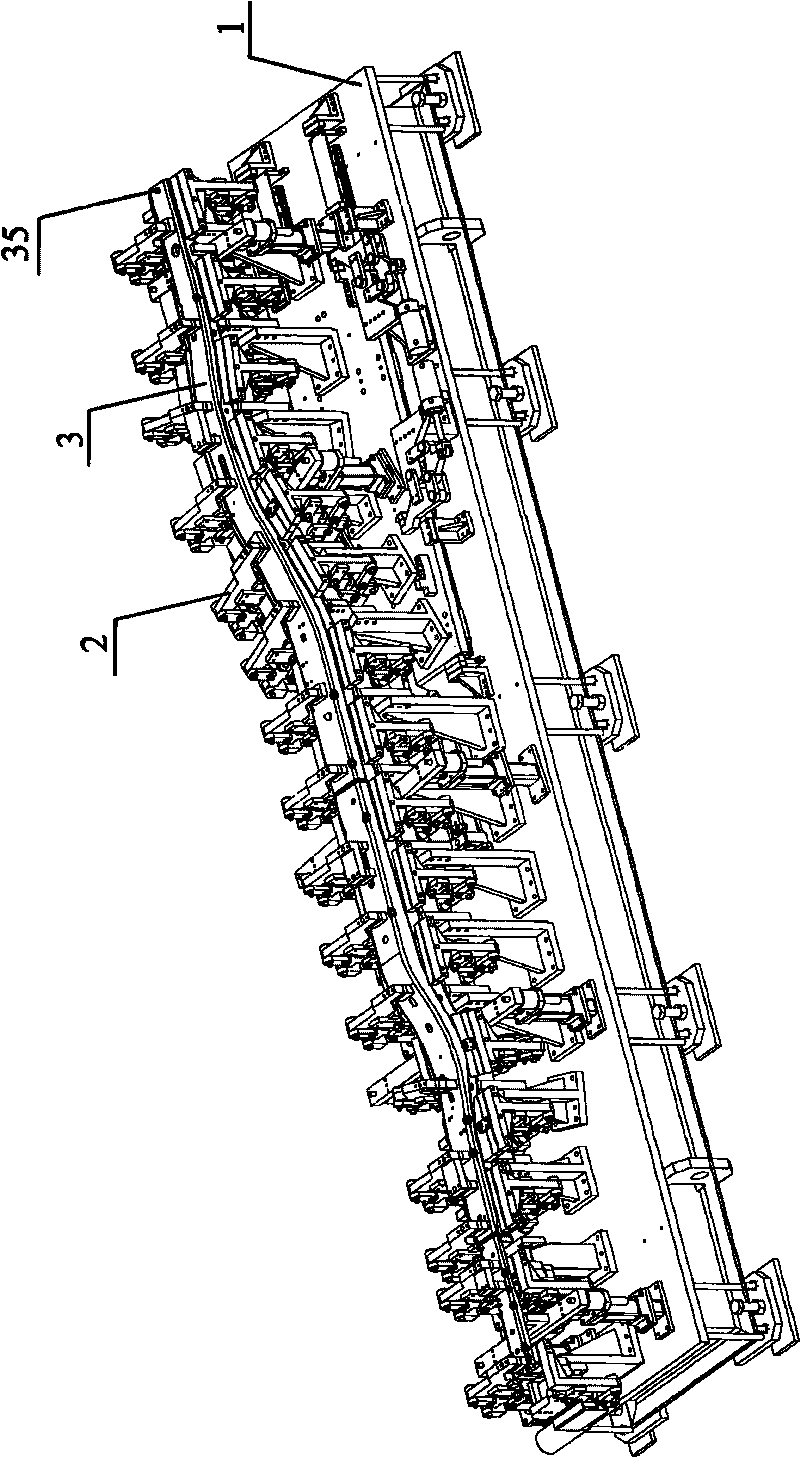

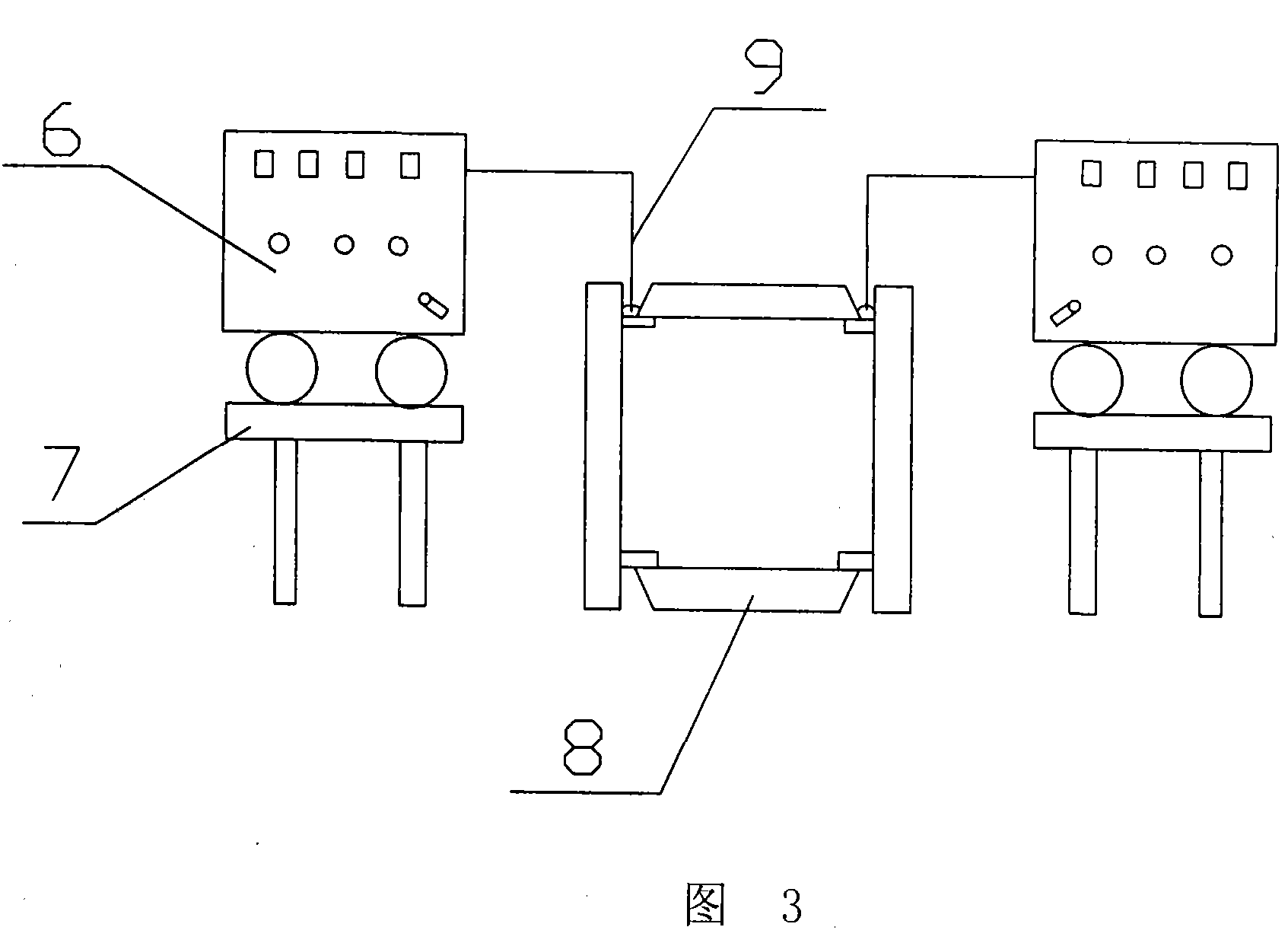

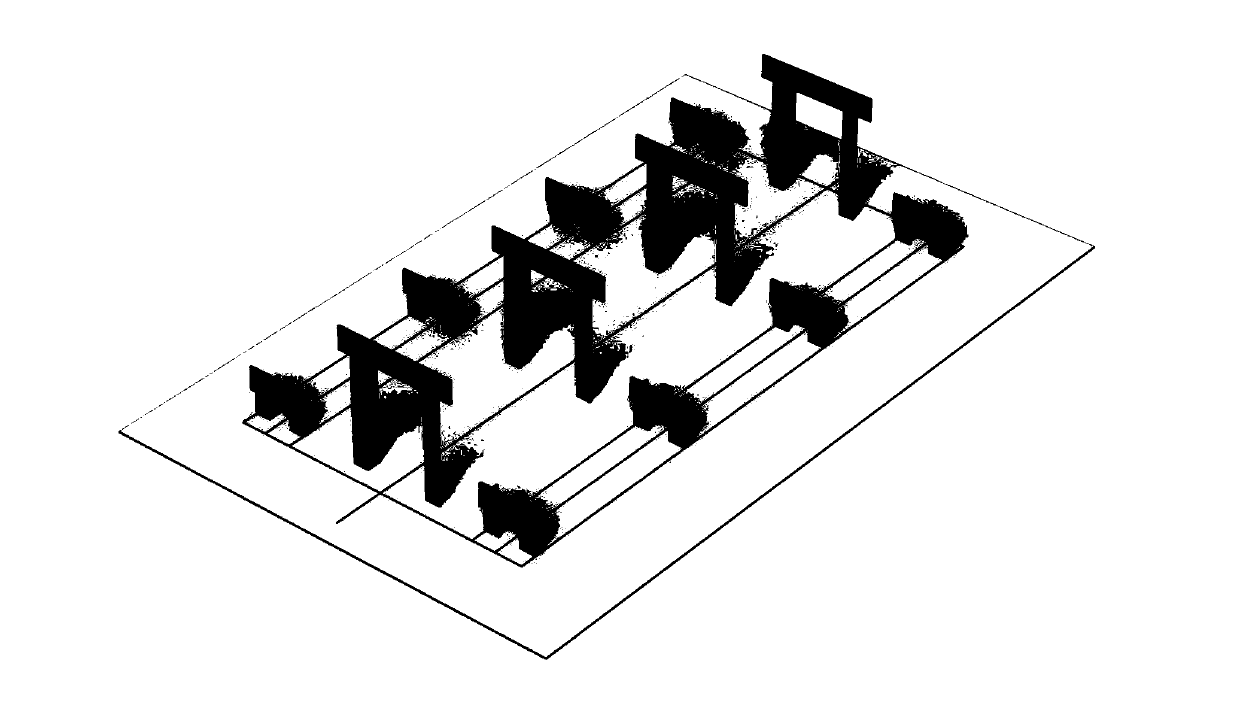

Automatic non-standard steel welding production line

ActiveCN104842083ARealize continuous automatic welding productionReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

An automatic non-standard steel welding production line comprises an automatic wing plate pushing system, wing plate conveying systems, an automatic web discharging and feeding system, an automatic T-steel welding system, an automatic T-steel turnover system, an automatic H-steel welding system and an automatic finished product conveying system. The wing plate conveying systems include an upper wing plate conveying system and a lower wing plate conveying system, and the wing plate conveying systems and the automatic web discharging and feeding system are arranged vertically. In the automatic non-standard steel welding production line, all the devices are simple in structure, easy to operate, stable in mutual connection, continuous automatic welding production of non-standard steel can be realized, weld seams on two sides of a plate are welded at the same time, and the automatic non-standard steel welding production line is small in distortion, less in capital investment, small in space occupation, suitable for non-standard steel manufactures with various scales, timesaving, laborsaving, manpower saving, high in working efficiency and good in product quality.

Owner:LUANXIAN ZHONGXING STEEL STRUCTURE

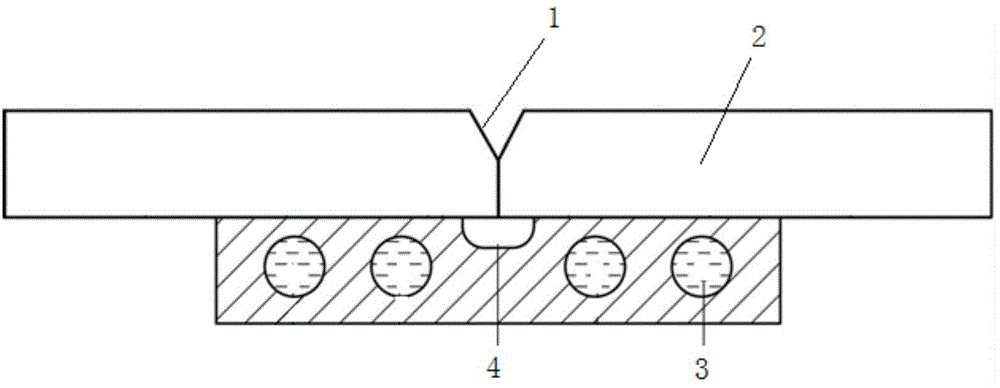

Manufacturing method for ultra-long and ultra-thick circular plate

ActiveCN101579700AImprove mechanical propertiesReduce stressWelding/cutting auxillary devicesArc welding apparatusChemical industryButt welding

A manufacturing method for ultra-long and ultra-thick circular plate is suitable for the steel circular plate which has a length more than 10 meters and has a thickness more than 100 millimeters. The method comprises the following steps: forging a plurality of segments of ultra-thick cylinders; carrying out mechanical processing to make the inner diameter, the wall thickness and the surface roughness accord with the requirements; and processing bevels at two ends. The invention is characterized in that the plurality of segments after procession are placed on a rolling jig bed 5; an interface part is fixed with a fixing plate; then the butt welding is performed after the bevels are added with ceramic gaskets 6; the long cylinder is prepared; the cutting is performed; and the ultra-long ultra-thick circular plate with the required dimension is manufactured. The invention has the advantageous of capability of manufacturing the ultra-long and ultra-thick circular plate with the length of more than 10 meters and the thickness of more than 100 millimeters, having high mechanical property of the manufactured plate, and having simple and convenient manufacturing method, easy operation and reduced manufacturing cost. The manufacturing method for ultra-long and ultra-thick circular plate can be widely used in the watercraft manufacturing industry and other mechanical chemical industry.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

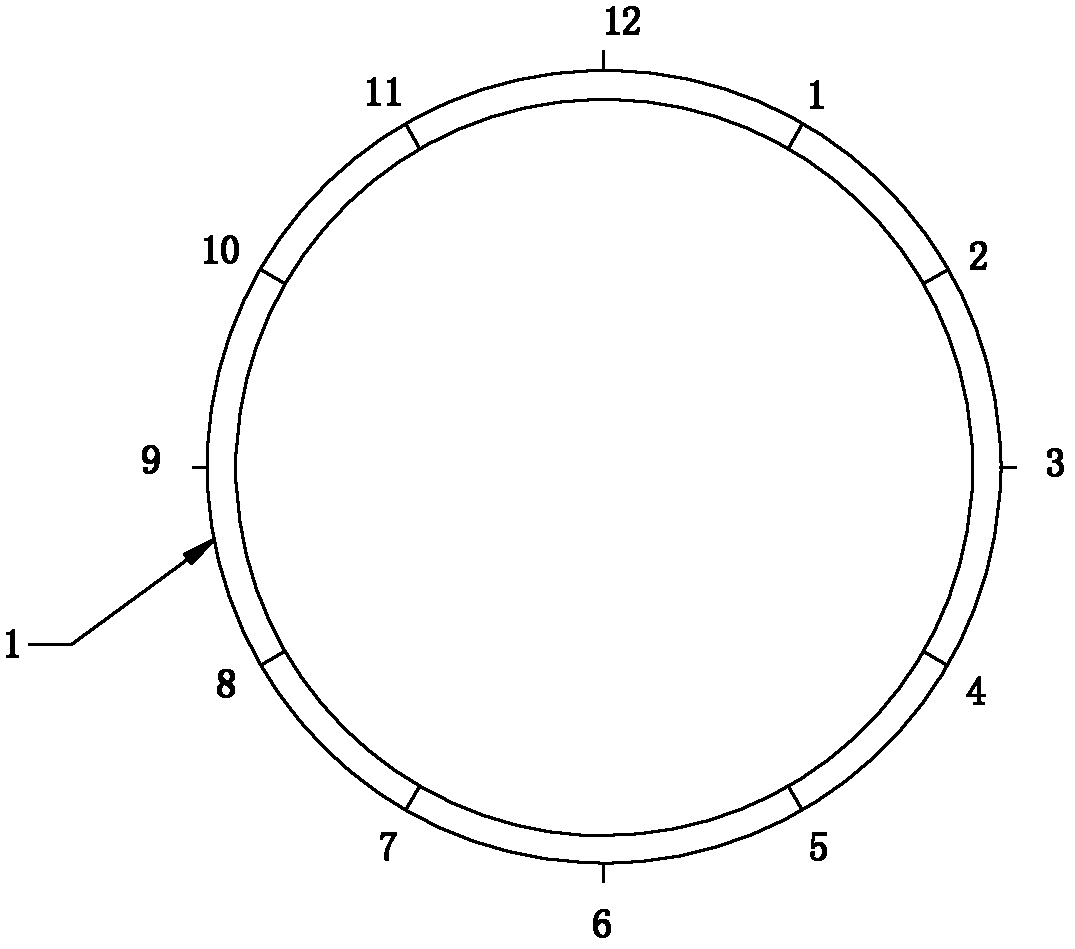

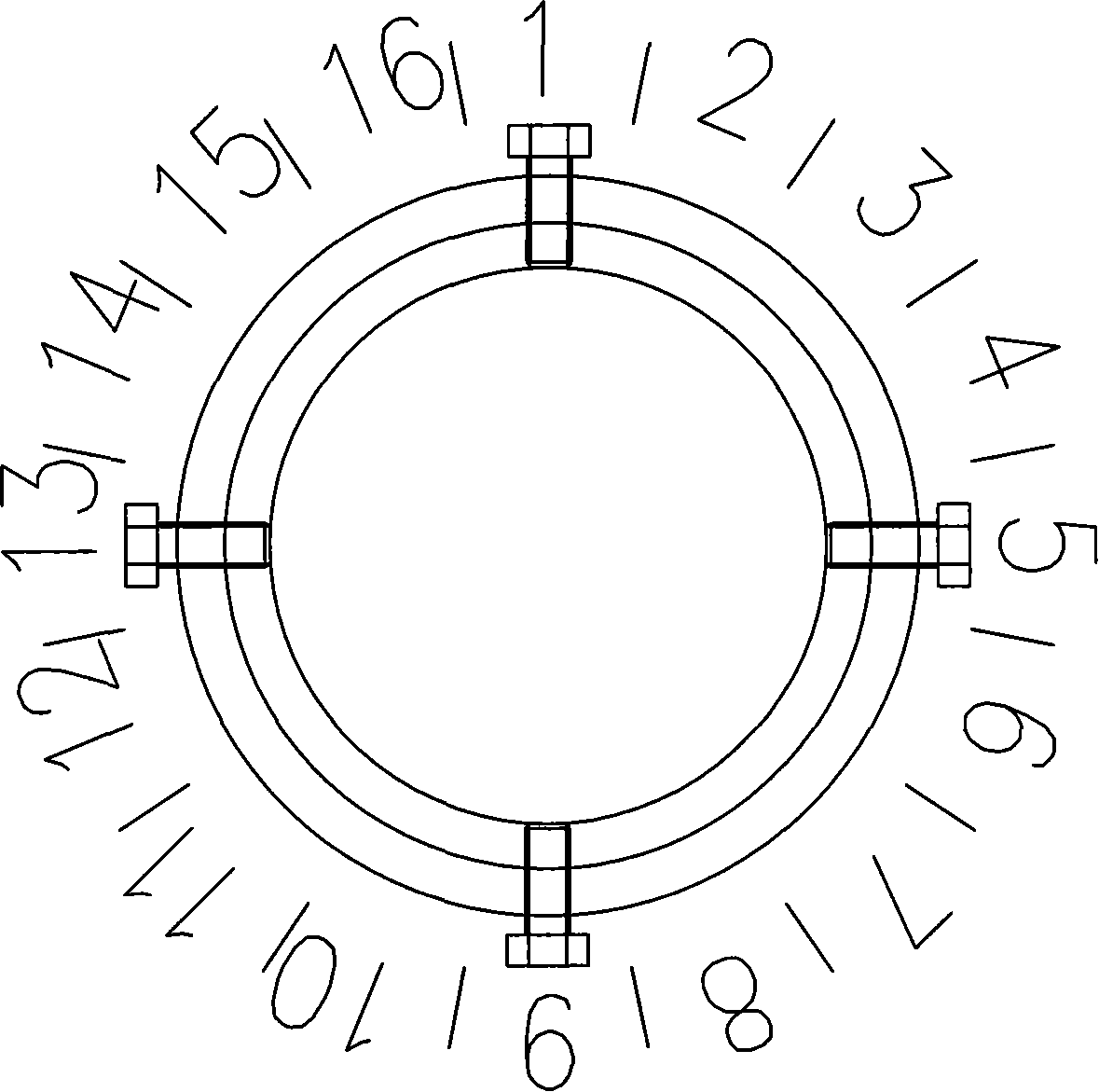

Welding method for furnace top flange of blast furnace

ActiveCN104439740AGuaranteed levelnessReduce welding distortionArc welding apparatusShielded metal arc weldingMarking out

The invention discloses a welding method for a furnace top flange of a blast furnace. The method mainly comprises the following steps that checking and accepting; measuring and paying off; groove preparation; hoisting in position; leveling and centering; scale division and marking out, wherein even scale division and marking out are carried out on the furnace top flange through two or more diameter lines, pitch circles of rib plates arranged on the furnace top flange are equally divided into a plurality of small circular arcs, pitch circles, crossing with a furnace top steel ring, of the furnace top flange are equally divided into a plurality of small circular arcs, and pitch circle face, crossing with the furnace top steel ring, of the furnace top flange are equally divided into a plurality of congruent small sectors; rib plate welding, wherein the two sides of the rib plates are fixedly connected from the inner ends to the other ends through a symmetric welding method, and the welding speed is the same; flange welding, wherein backing weld and layered continuous bead welding are included; according to backing weld, the symmetric welding method is adopted, in the manual electric-arc welding manner, same-direction symmetric welding begins to be carried out on two sides of grooves in the centered and segmented symmetric segments at the same time, and according to the layered continuous bead welding, the number of welding layers is determined according to the thickness of the furnace top steel ring and the thickness of the furnace top flange, and the symmetric welding method is adopted, and same-direction continuous bead welding begins to be carried out on the two sides of the grooves in the centered and segmented symmetric segments at the same time.

Owner:CHINA 19TH METALLURGICAL CORP

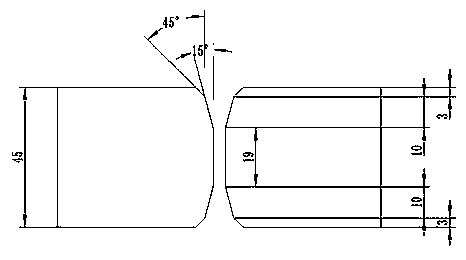

Laser and electric arc combined welding method for thick high-strength steel plates and clamp for method

ActiveCN103406675ANo misalignmentImprove clamping efficiencyWelding/cutting auxillary devicesAuxillary welding devicesThick plateErbium lasers

The invention relates to a laser and electric arc combined welding method for thick high-strength steel plates and a clamp for the method. A 45-mm thick high-strength steel is welded with a 6-KW fiber laser and through a double-sided welding forming method, small double-sided grooves are opened, and a 1mm-1.5mm gap is reserved, accordingly, the 45-mm thick high-strength steel can be completely welded. Compared with traditional multi-layer multi-pass welding which requires at least 20 passes of welding, the combined welding method has the advantages that the progress is apparent, preheating processes are simplified, preheating time is shortened, and welded joint performances reach client required indexes; the production efficiency is improved apparently, consumption of base metal and welding wires is reduced, energy consumption is decreased, the mechanical property of welded joints is improved, the residual stress and the deformation are reduced, automation of production can be easily achieved, and the like. The special clamp is a combined clamp with four pressing plates arranged on the upper portion and a base plate used on the lower portion during welding so as to improve the efficiency and quality of the welding method. By means of the clamp, a workpiece can be positioned and fixed, the welding quality is guaranteed, and the workpiece cannot be abraded.

Owner:NANJING ZHONGKE RAYCHAM TECH

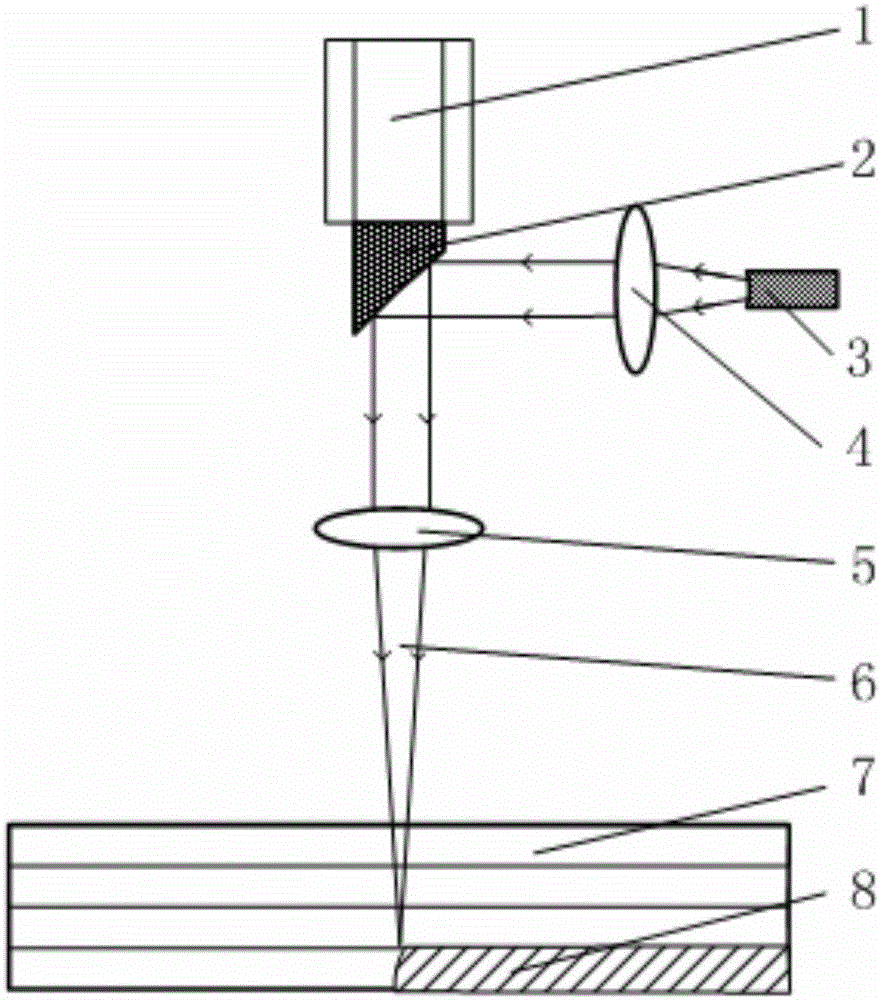

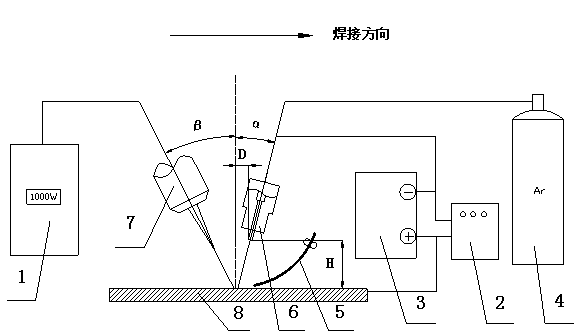

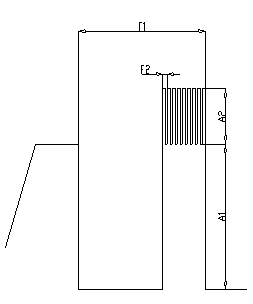

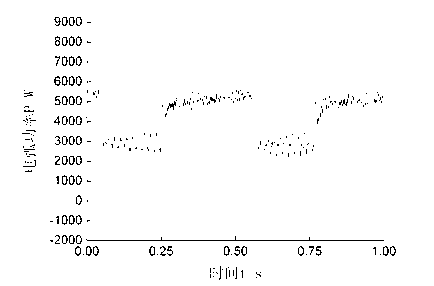

Laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process

InactiveCN103192187AGood compound effectReduce laser powerWelding/soldering/cutting articlesLaser beam welding apparatusAnti stressMolten bath

The invention discloses a laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process. The process comprises the following steps of: constructing a laser high-frequency alternating-current pulse TIG hybrid welding system, and gathering an TIG arc and a semiconductor laser beam on the same welding position of a welded workpiece 8 in the same welding direction, to form a molten bath, wherein an inclined angle alpha of 10-40 degrees is formed between the TIG arc tungsten electrode tip end and a vertical direction, the semiconductor laser beam forms an included angle beta of 10-30 degrees with the vertical direction, the TIG arc tungsten electrode tip end keeps a vertical distance H of 2-4mm with the surface of the welded workpiece 8, and the TIG arc tungsten electrode tip end and the semiconductor laser beam keep a horizontal distance D of 2-5mm with an action point of the surface of the welded workpiece 8. The process disclosed by the invention can refine weld microstructure, remarkably reduce or eliminate pores in melting area and effectively improve mechanical performance and anti-stress corrosion performance of a high-strength aluminous alloy welding joint, and the process is quite practical.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

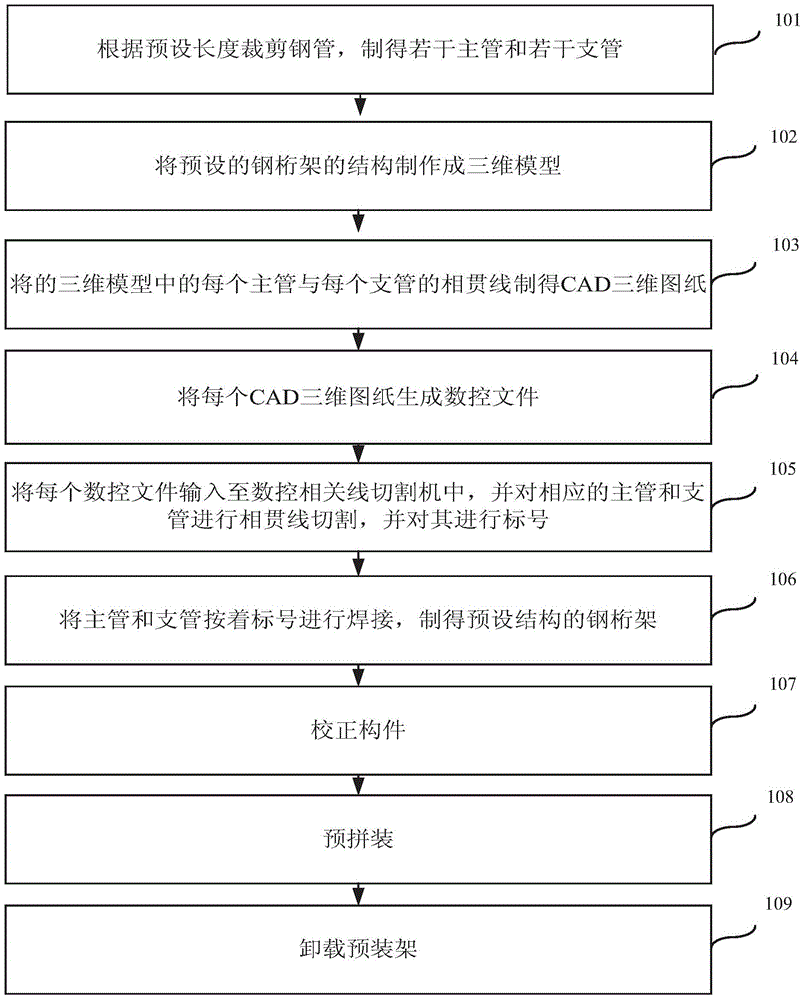

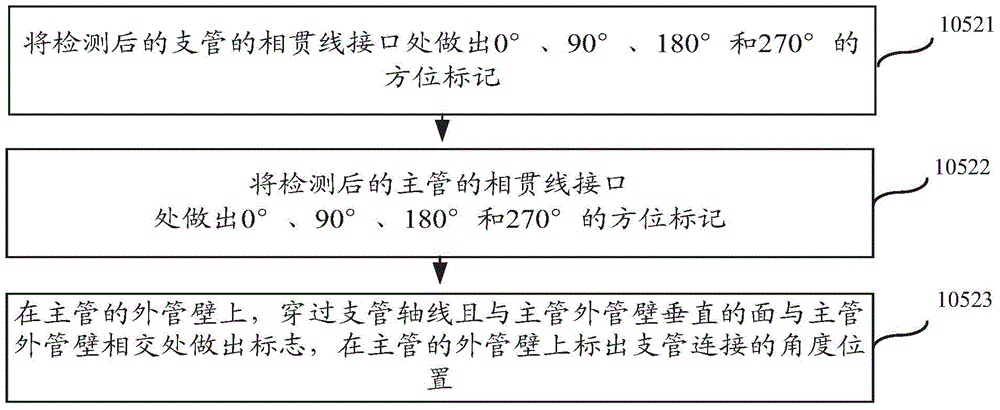

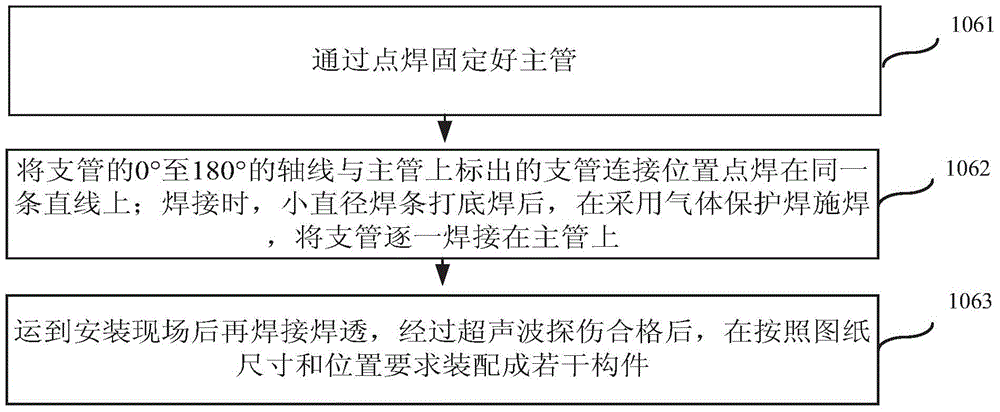

Steel truss manufacture process

ActiveCN104084757AHigh precisionGuaranteed accuracyLoad-supporting elementsNumerical controlEngineering

The invention relates to the field of steel structure building, in particular to a steel truss manufacture process which includes the following steps: shearing a steel pipe according to preset length to obtain a plurality of main pipes and a plurality of branch pipes; manufacturing a three-dimensional model through a preset steel truss structure; manufacturing CAD three-dimensional graphs through intersection lines of all the main pipe and all the branch pipes in the three-dimensional model; generating a numerical control file through each CAD three-dimensional graph; inputting each numerical control file into a numerical control relevant line cutting machine, conducting insertion line cutting on the corresponding main pipes and the corresponding branch pipes and labeling the main pipes and the branch pipes; welding the main pipes and the branch pipes according to labeled numbers to obtain the steel truss of the preset structure. By means of the steel truss manufacture process, connection accuracy and welding quality are improved, welding deformation is reduced, welding seams are continuous and smooth, labor intensity is reduced, manufacturing efficiency is improved, and the accuracy of the steel truss is further ensured.

Owner:KOCEL EQUIP +1

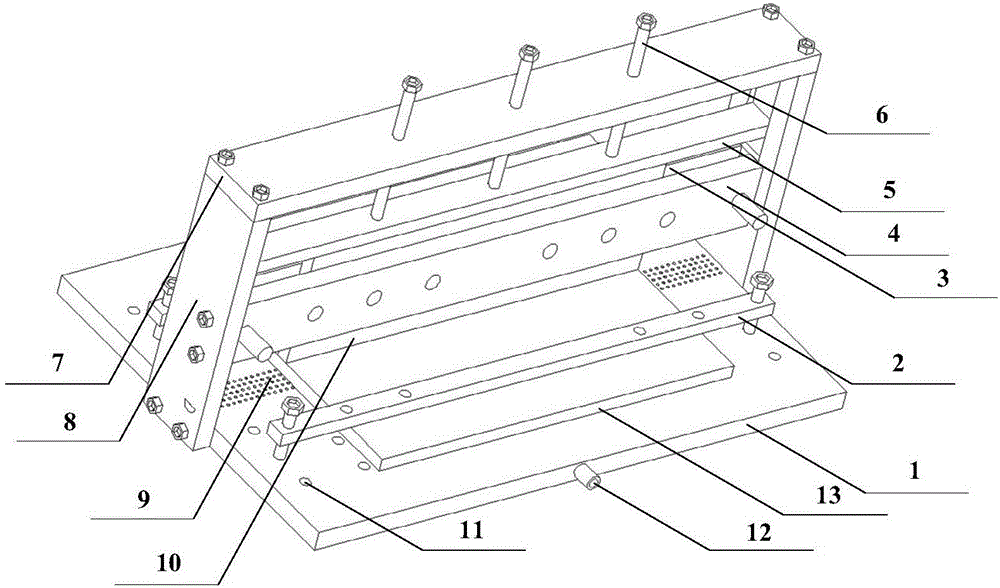

Clamp for laser hybrid welding of T-shaped connector

InactiveCN106425230AImproving the Precision of Laser Hybrid WeldingUniversally applicableWelding/cutting auxillary devicesAuxillary welding devicesLaser-hybrid weldingEngineering

The invention discloses a clamp for laser hybrid welding of a T-shaped connector. The clamp for the laser hybrid welding of the T-shaped connector comprises a base, and frame body vertical beams which are positioned on the two sides of the base; a wing plate is placed on the base and is compressed on the base through a compressing device; the frame body vertical beams are mounted on the base; a first pressing plate is fixedly mounted on the frame body vertical beams; the side surface of the first pressing plate is perpendicular to the upper surface of the base; a web plate is clamped by the first pressing plate through the second pressing plate so that the web plate is vertically intersected with the wing plate; the first pressing plate is connected with the second pressing plate by bolts; a plurality of air holes are formed in the base; the air holes are communicated with a protective gas pipe. The clamp for the laser hybrid welding of the T-shaped connector disclosed by the invention meets the requirement on precision of welding piece assembling, and can ensure the assembling precision in welding, ensure the forming quality, and reduce welding deformation effectively.

Owner:JIANGSU UNIV OF SCI & TECH

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

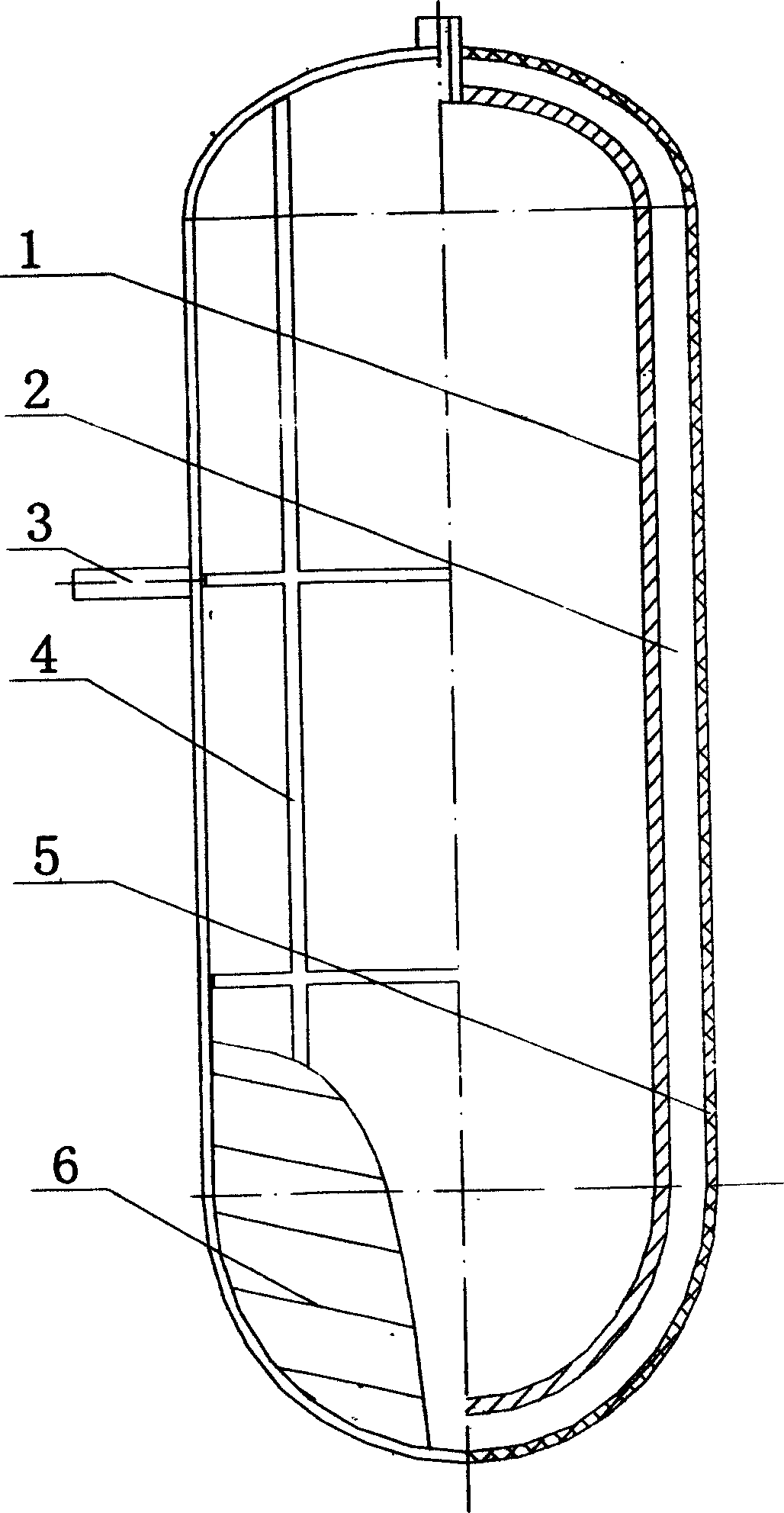

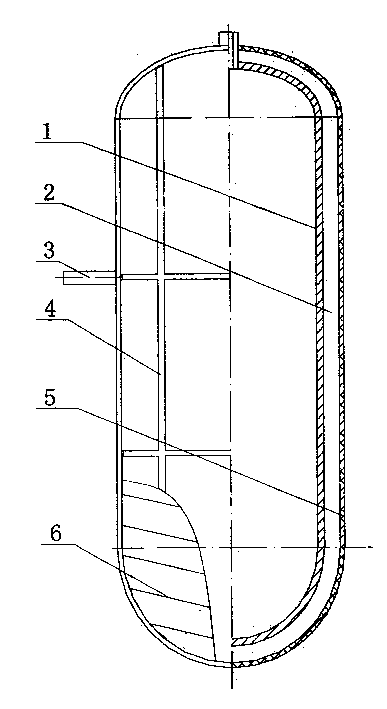

Composite pressure container

The present invention discloses a composite material pressure container for holding liquefied gas, natural gas, liquid hydrogen and liquid oxygen etc. Said container includes internal container made up by high-strength alluminium alloy thin-wall inner liner or plastic thin-wall inner liner, its exterior is covered with a layer of composite material winding band layer which is made up by impregnating prestressed incidence-winded high-strength fibre with epoxy resin base composite material, and on the outer surface of the above-mentioned composite material layer several criss-cross communicated small grooves are cut, and its exterior is covered with closed external protecting layer with leakage-detecting holes which are communicated with above-mentioned small grooves and equipped with sensors mounted on these leakage-detecting holes.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com