Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

A technology of automatic submerged arc welding and groove angle, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc. It can solve the problems of affecting welding efficiency, affecting the quality of welding seam, and narrowing the welding seam at the root, so as to improve welding efficiency. , Improve production efficiency, small welding deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

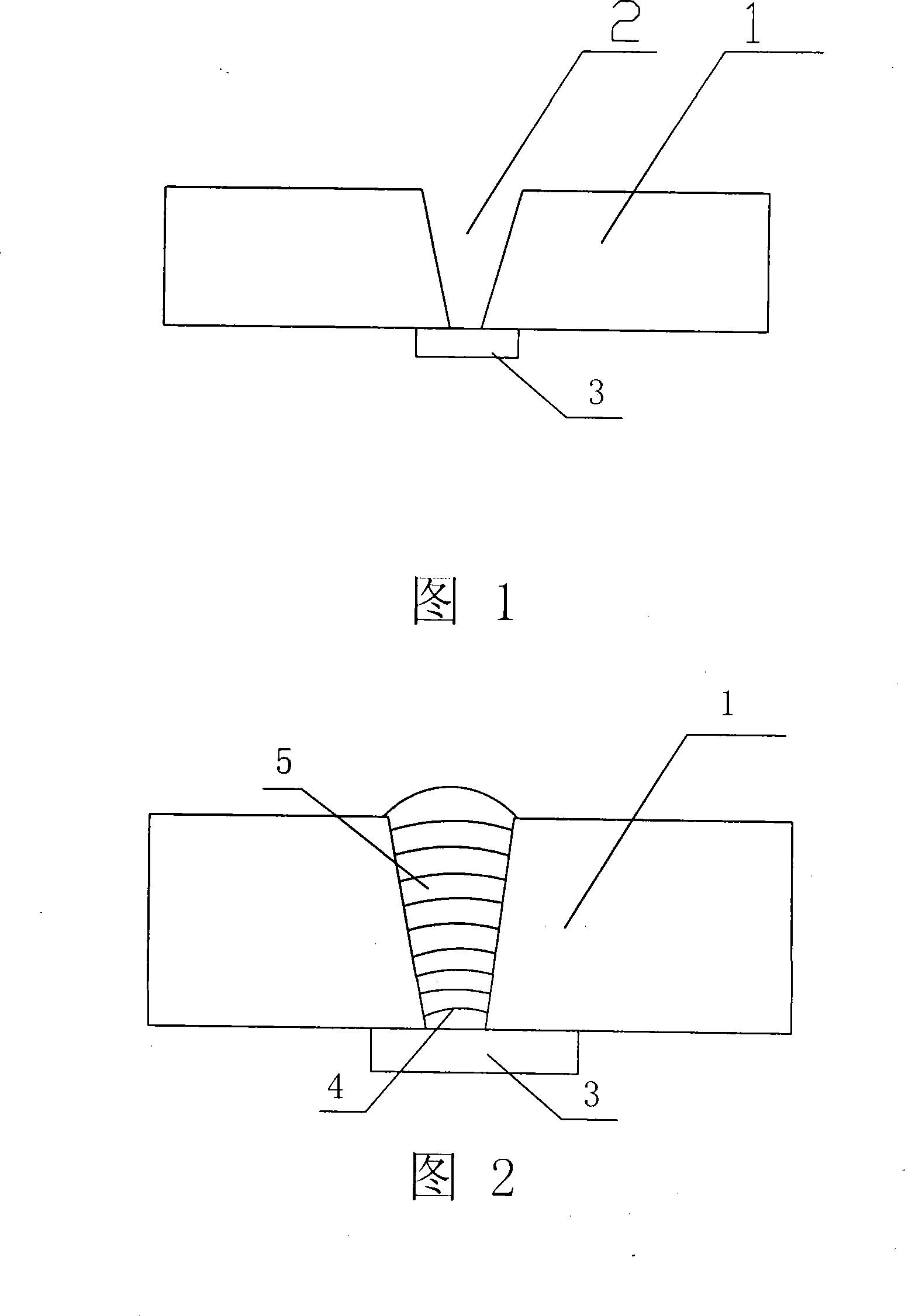

[0025] As shown in Figure 1 and Figure 2, regardless of any weldment 1, a corresponding small-angle groove 2 must be made on the weldment 1 first, and the angle of the groove 2 is 25 +5 0 degree; paired, to ensure that the weld gap is 8 +2 0 mm (that is, the minimum gap of the bottom weld 4); then weld.

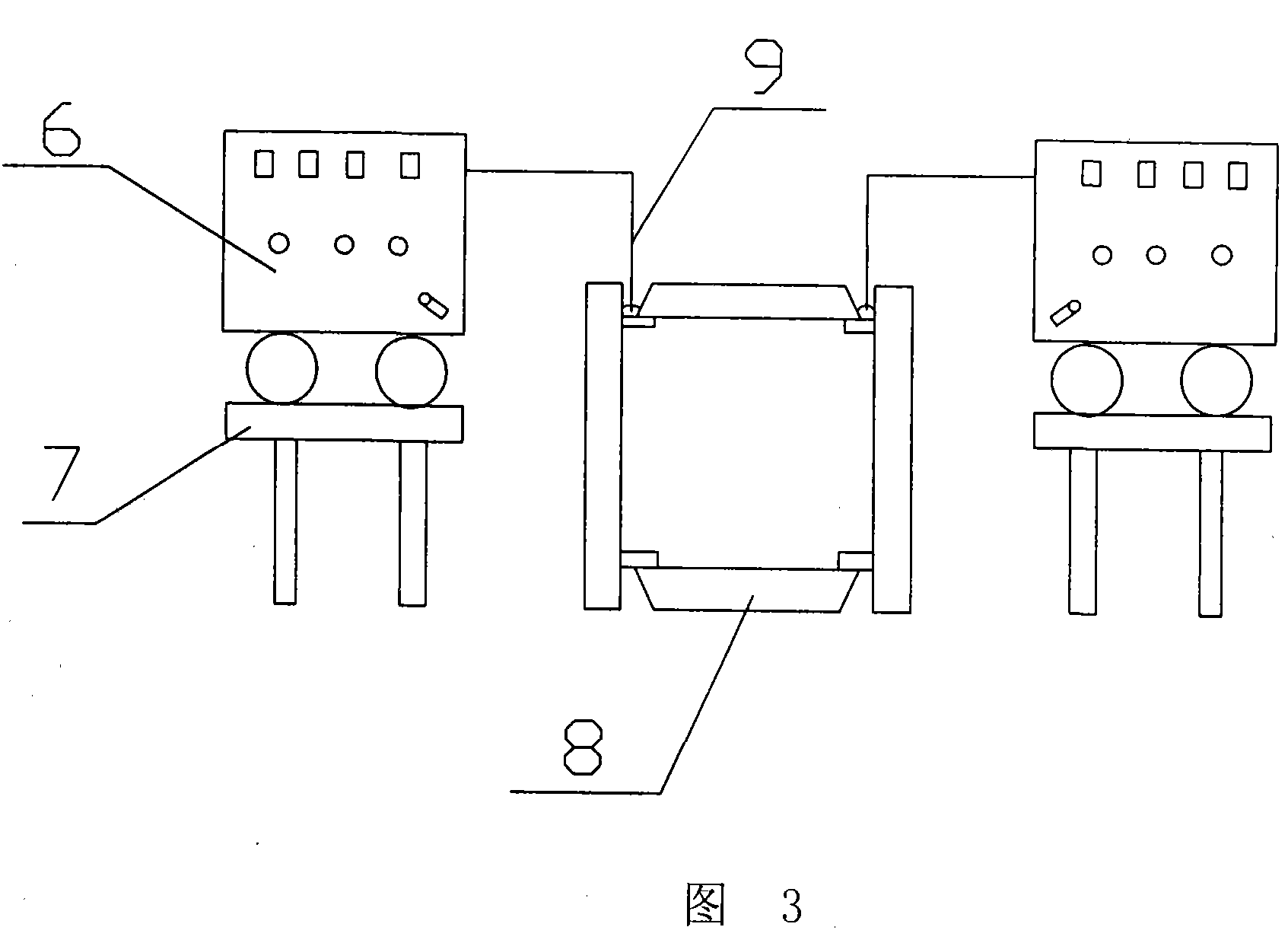

[0026] Figure 3 shows an example of a welded box-shaped weldment 8 . After completing the determination of the small-angle groove 2 and the weld gap, perform welding according to the following steps:

[0027] (1) Fully automatic CO 2 Gas shielded welding is used for bottom welding, that is, welding of the bottom weld seam 4: welding is carried out by a trolley-type walking mechanism, which is composed of a welding trolley 6, a welding table tool 7, and a welding torch 9, and the welding torch 9 is CO 2 Welding torch, the gas is argon-rich prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com