Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Great flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

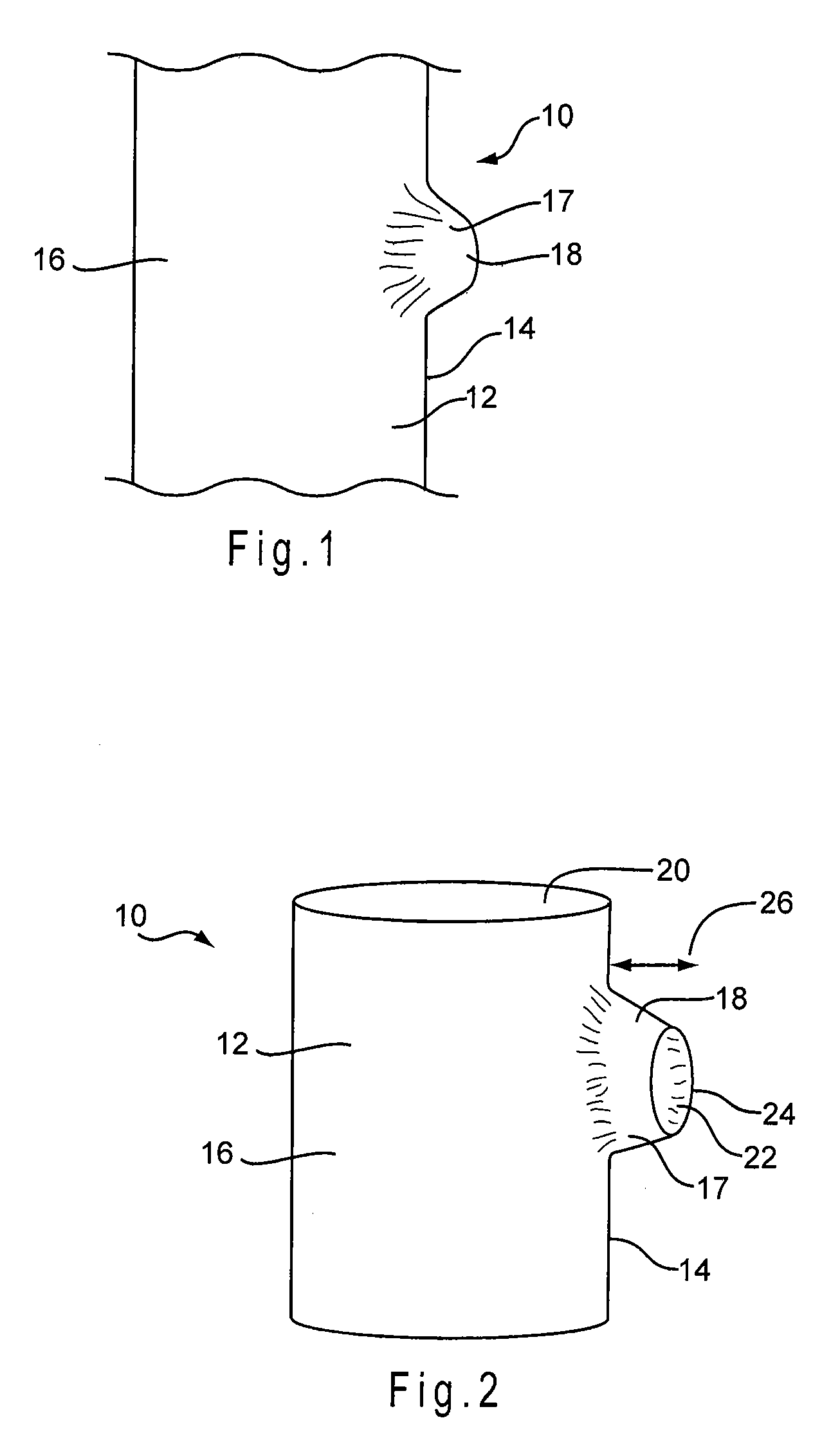

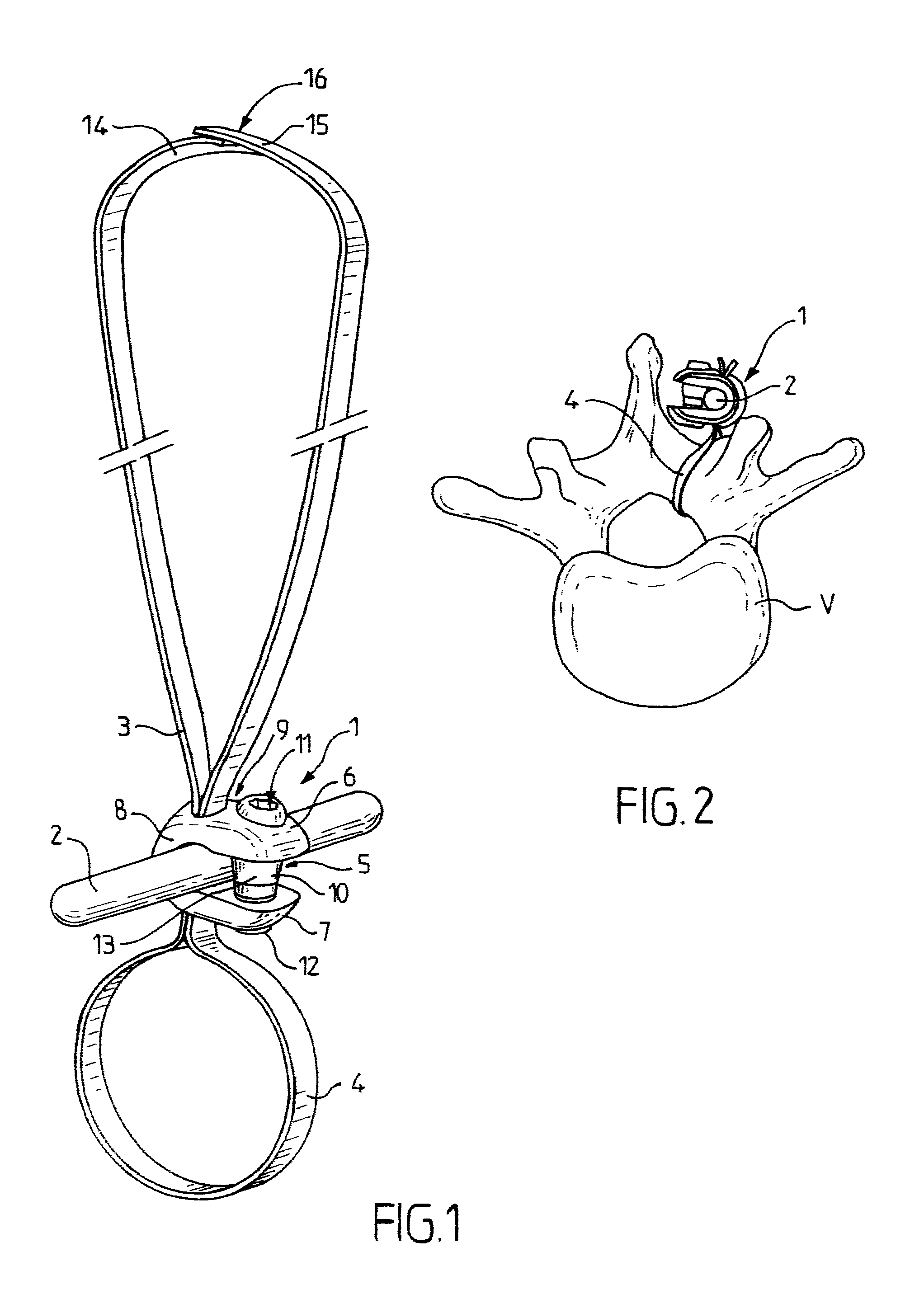

Device and method for inhibiting release of pro-inflammatory mediator

InactiveUS20050075702A1Great flexibilityGreat specificitySpinal electrodesArtificial respirationNervous systemDrug

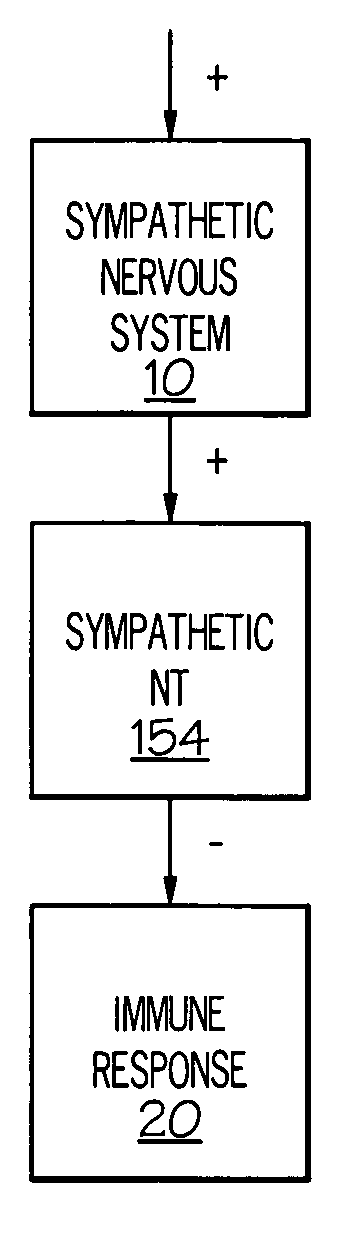

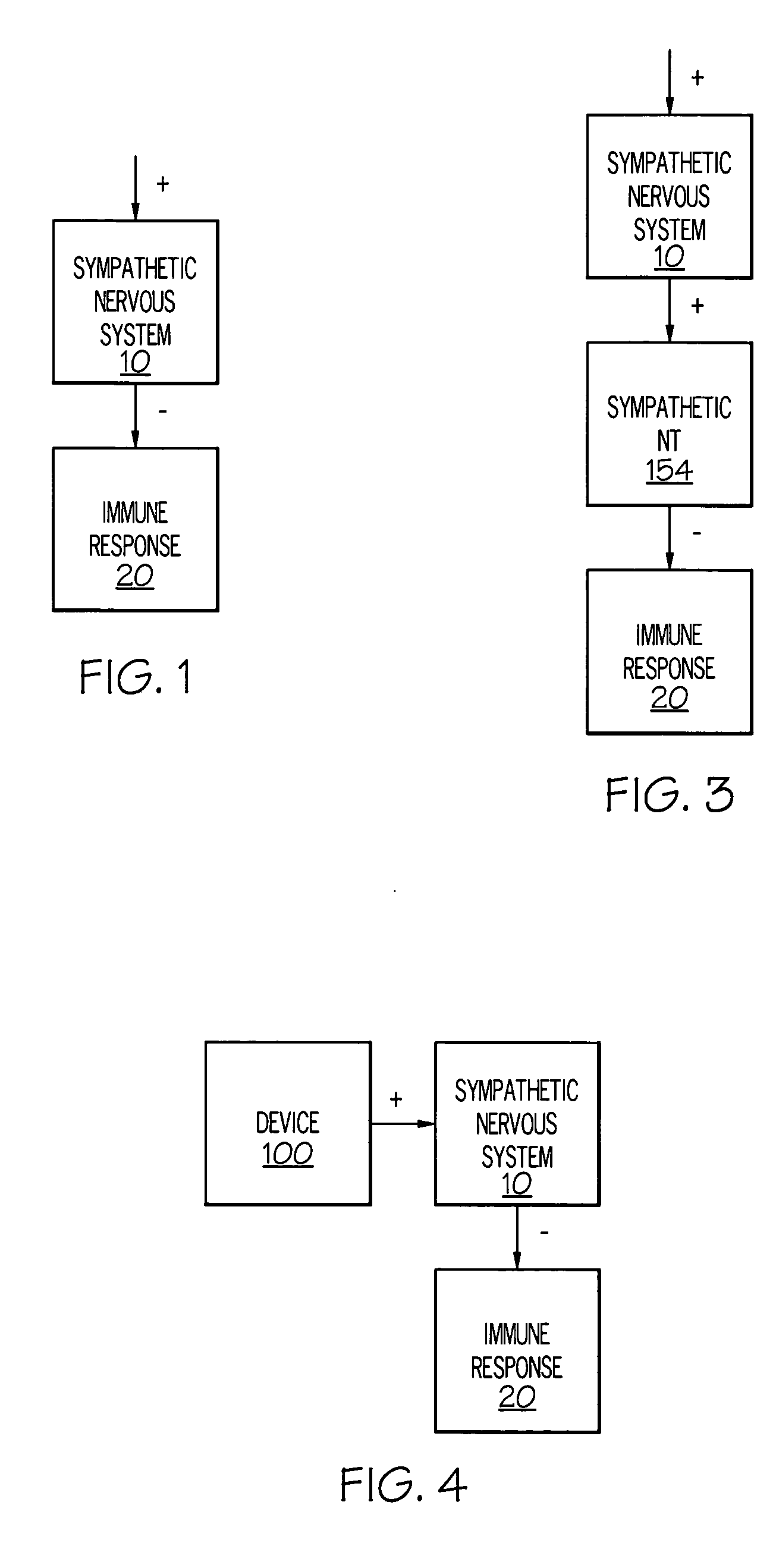

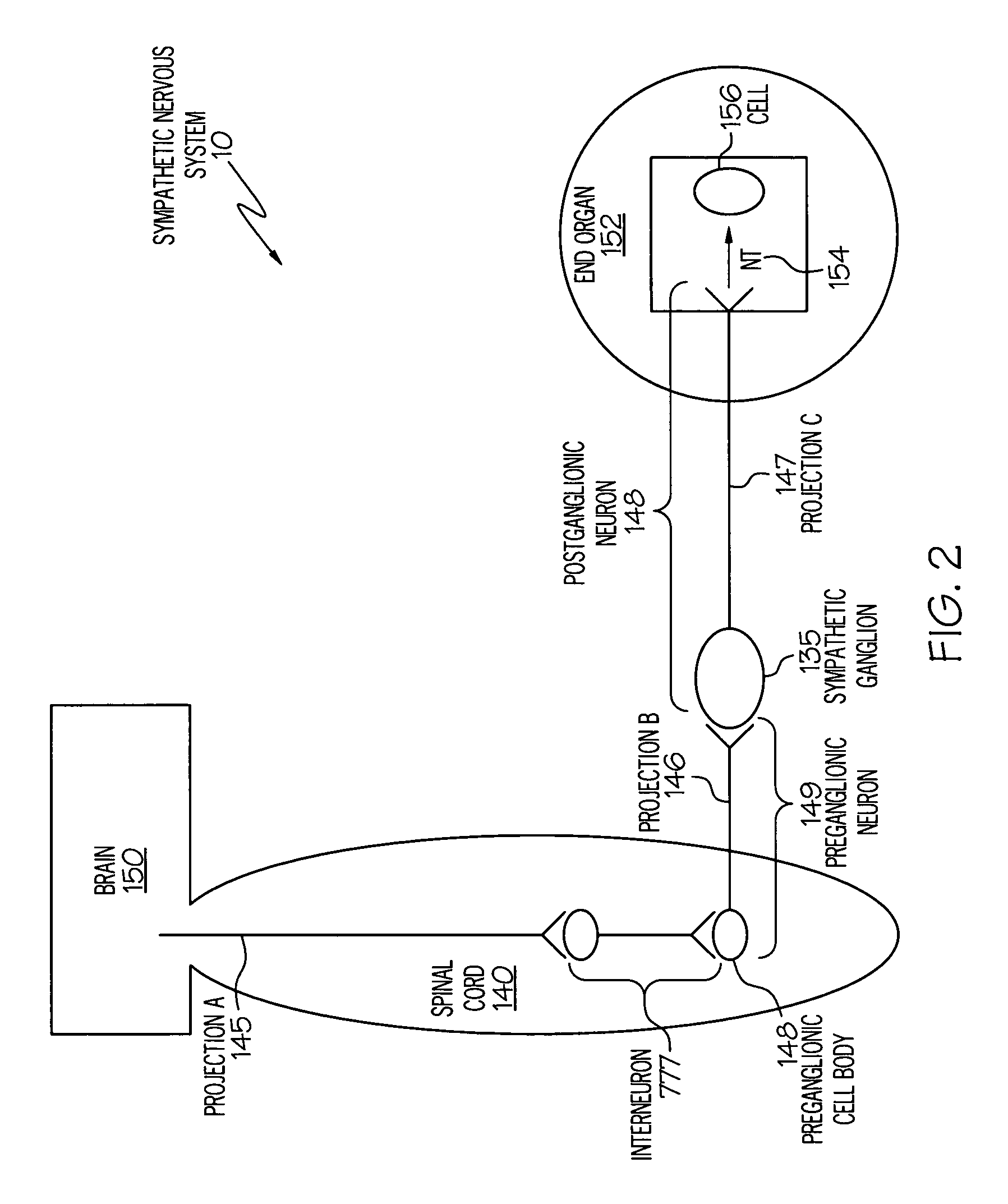

Stimulation of one or more neurons of the sympathetic nervous system, including the splenic nerve, to attenuate an immune response, including an inflammatory immune response, is discussed. Devices and systems to stimulate the sympathetic nervous system to attenuate an immune response are also discussed. Devices discussed include pulse generators and drug pumps. Systems are described as optionally having one or more sensors and operator instructions. In specific examples, stimulation of the splenic nerve of pigs with a pulse generator is shown to be safe and effective in attenuating a lipopolysaccharide-induced immune response.

Owner:MEDTRONIC INC

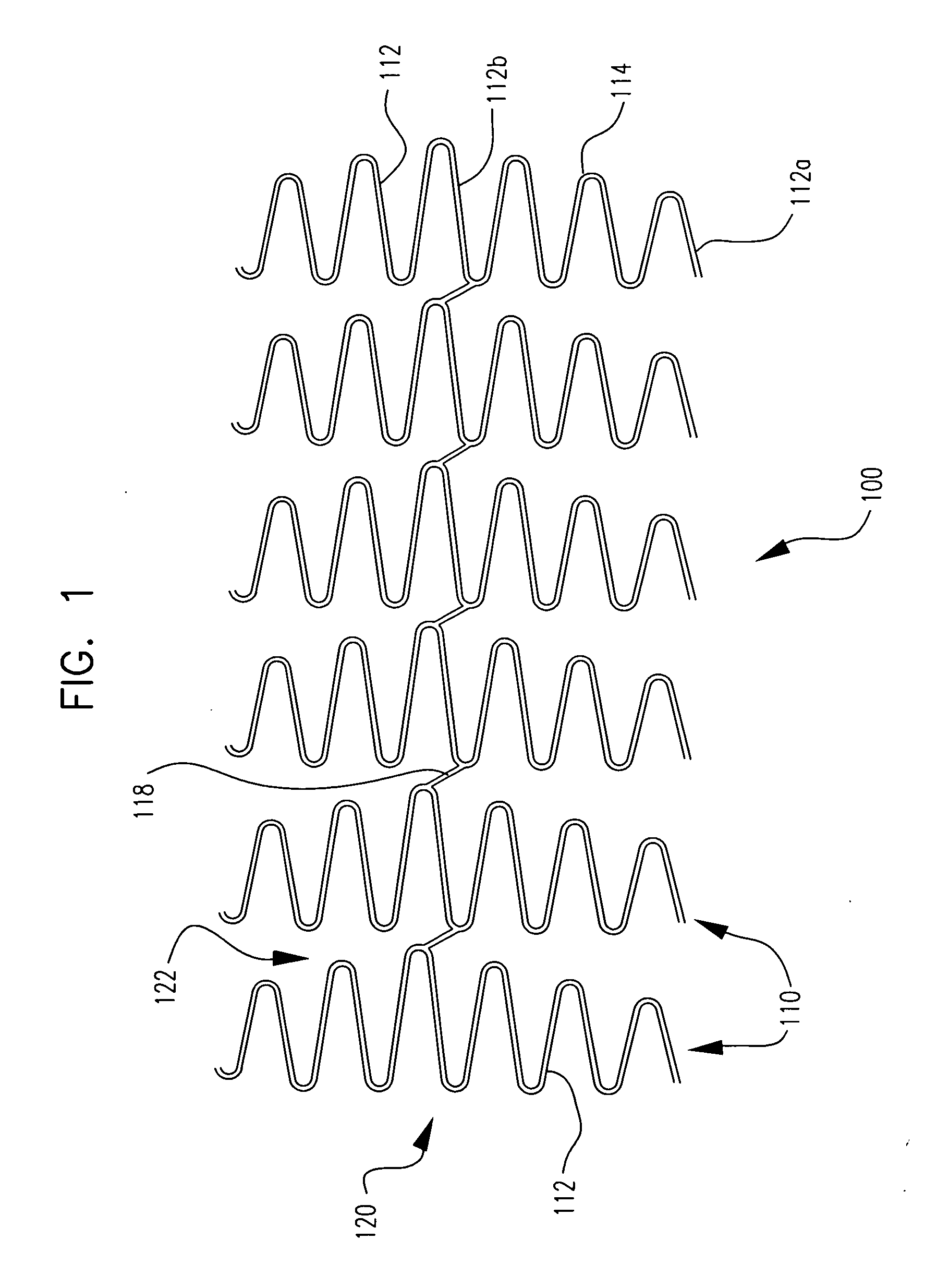

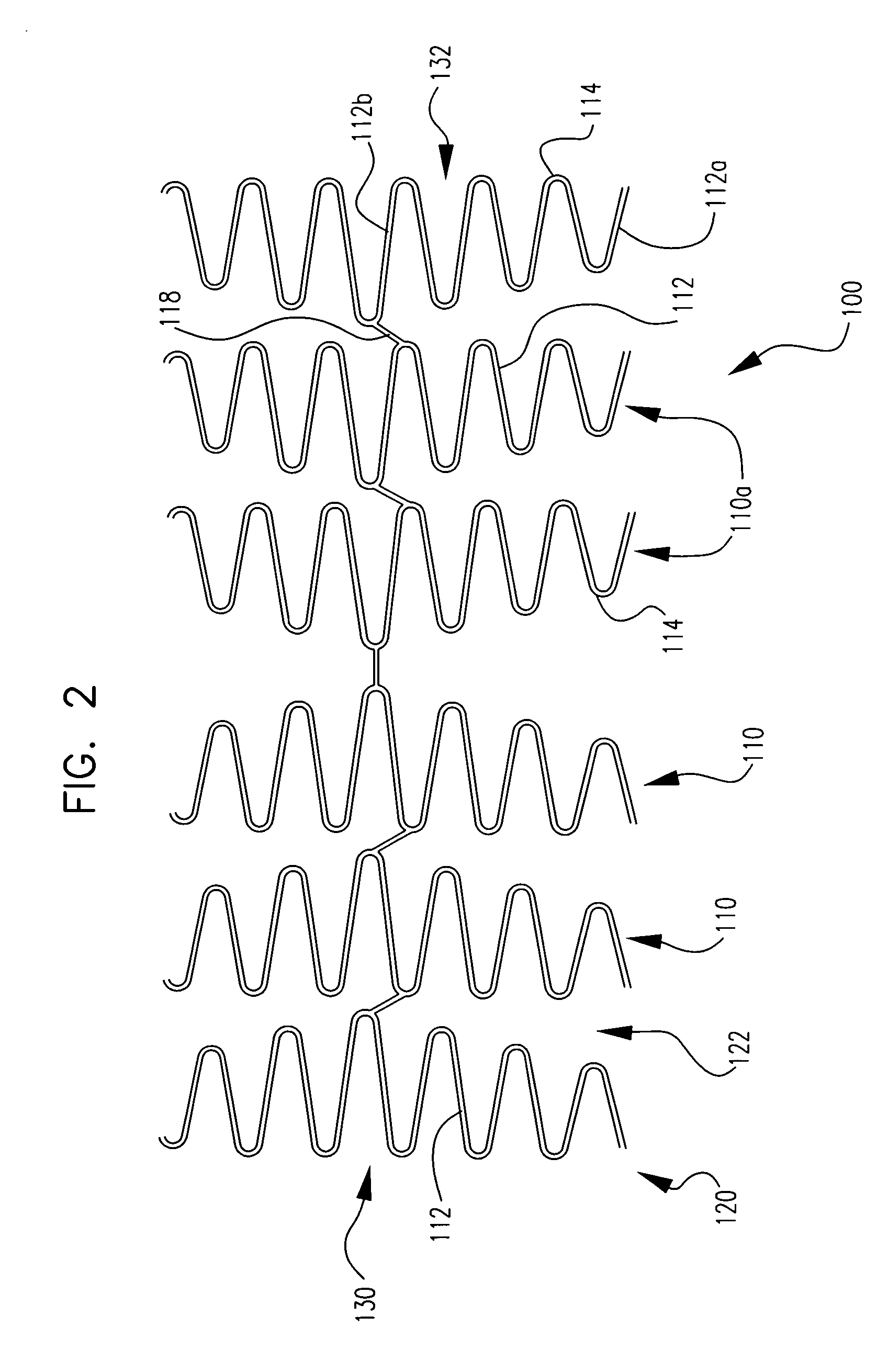

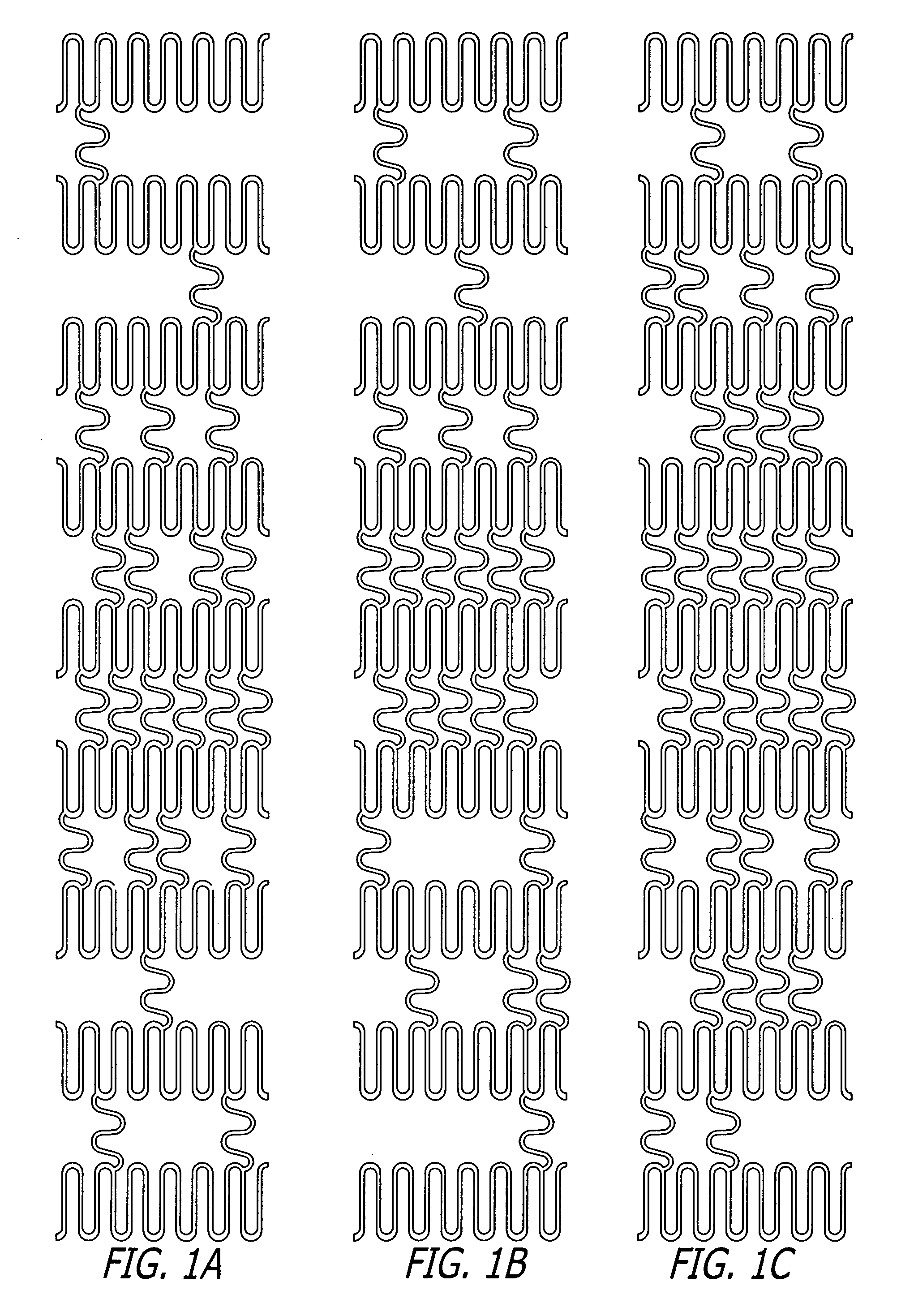

Stent to be deployed on a bend

InactiveUS20050149168A1Great flexibilityGood flexibilityStentsBlood vesselsBiomedical engineeringInsertion stent

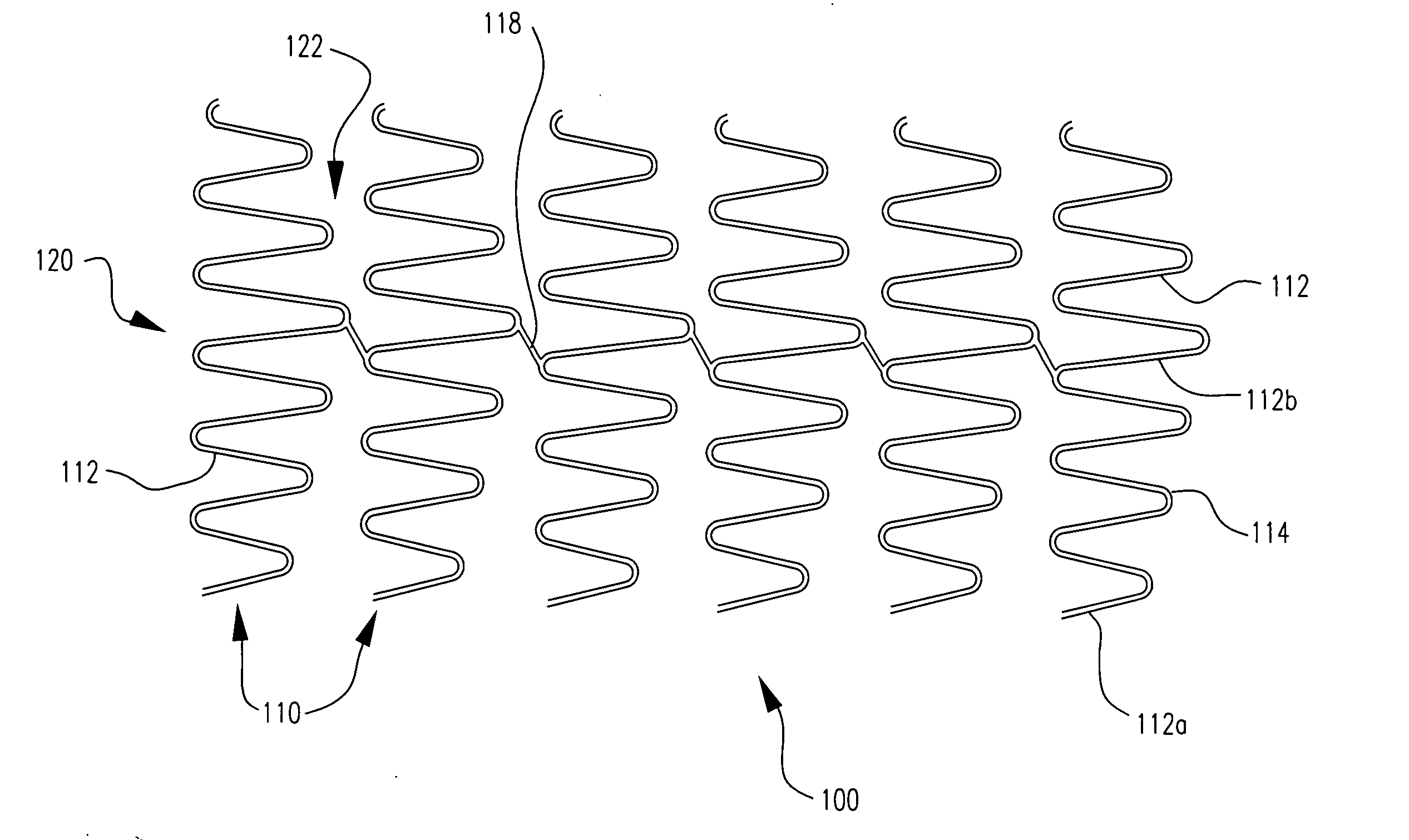

A stent comprises a segment having a plurality of interconnected closed serpentine circumferential bands. Each closed serpentine circumferential band comprises a plurality of struts. Struts which are circumferentially adjacent one another are connected one to the other by a turn. Each strut has a length. The struts generally increase in length from a minimum strut length to a maximum strut length and then generally decrease in length from the maximum length to the minimum length as the circumferential band is traversed in its entirety in a clockwise direction. The maximum length struts of adjacent closed serpentine circumferential bands may be longitudinally aligned.

Owner:BOSTON SCI SCIMED INC

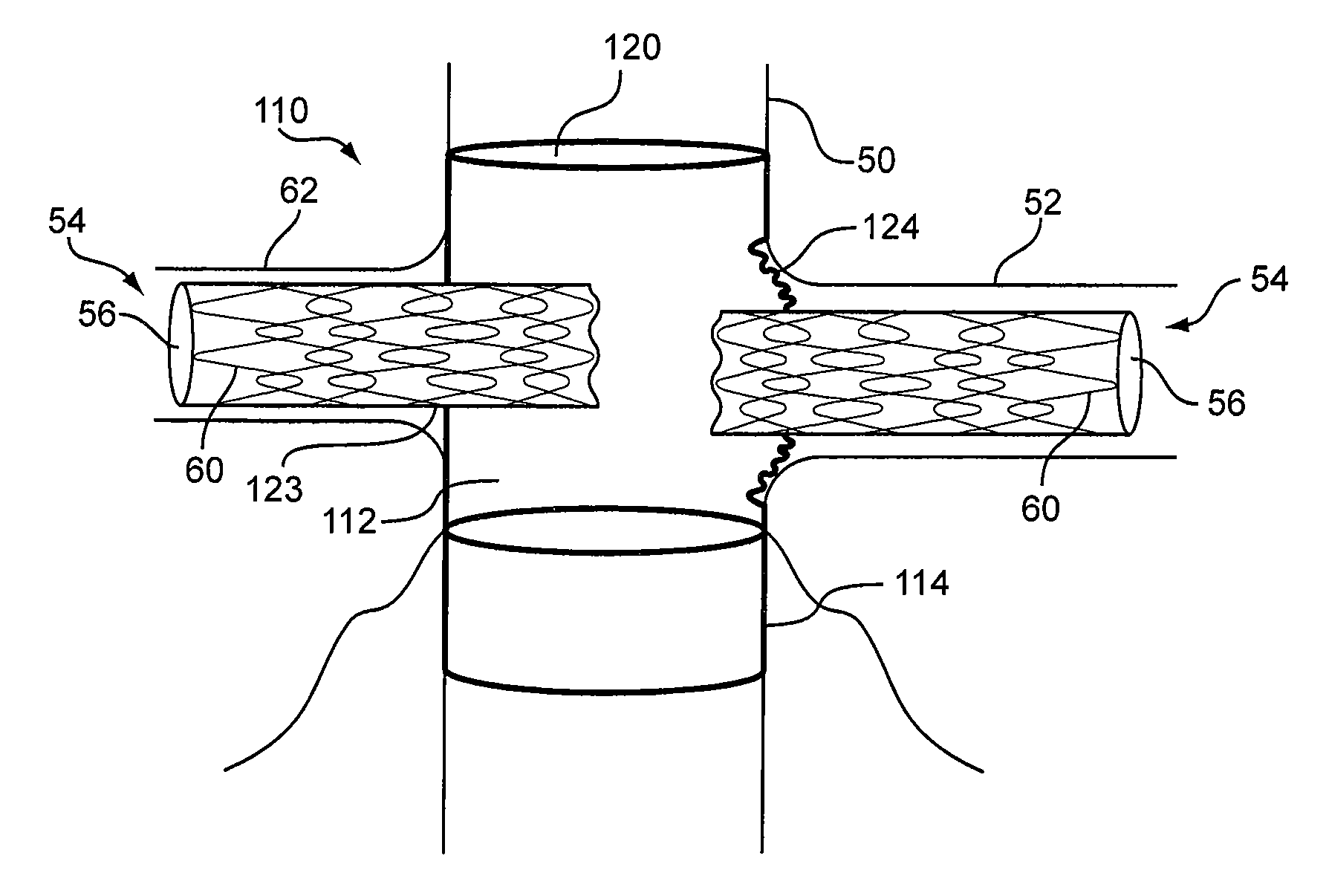

Prosthesis with Moveable Fenestration

An endoluminal prosthesis with a moveable fenestration including a tubular graft body having a proximal end, a distal end, a surface plane at least one fenestration having a perimeter disposed in a sidewall of the tubular body between the proximal end and the distal end, a first biocompatible graft material, and a second biocompatible graft material adjacent to and surrounding the perimeter of the at least one fenestration. The second biocompatible graft material has at least one characteristic different from the first biocompatible graft material and is more flexible than the first biocompatible graft material and is movable relative to the surface plane of the tubular graft body.

Owner:COOK MEDICAL TECH LLC

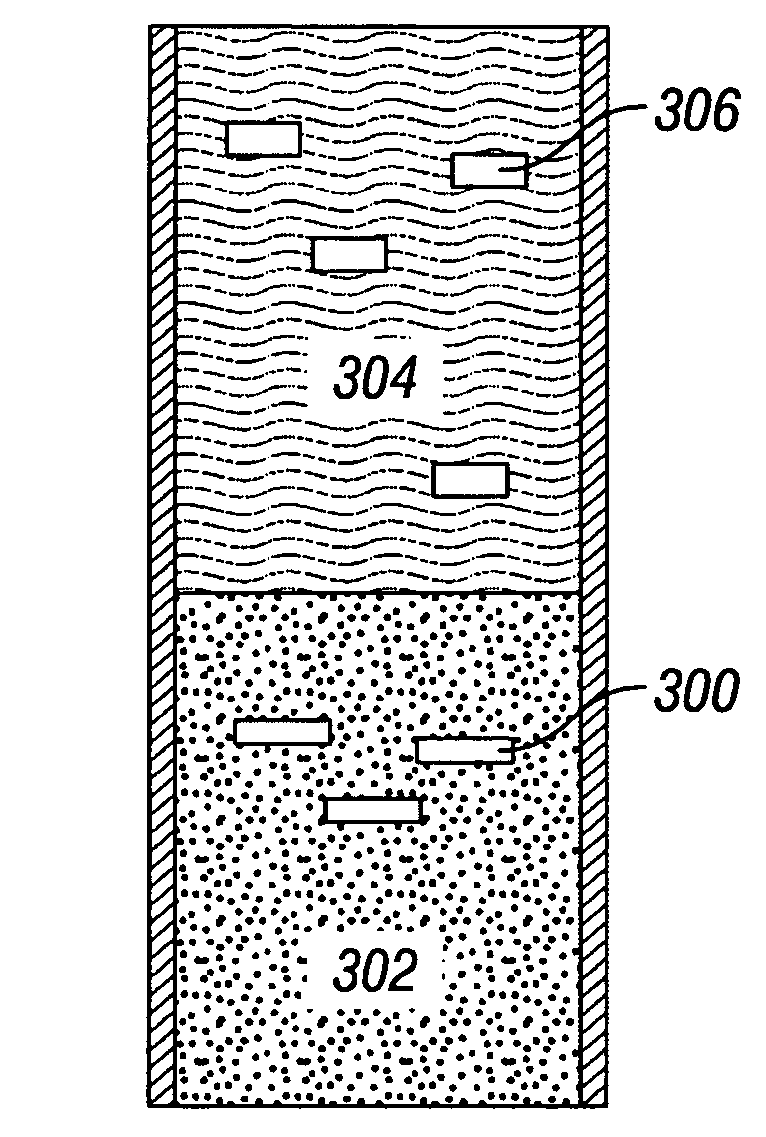

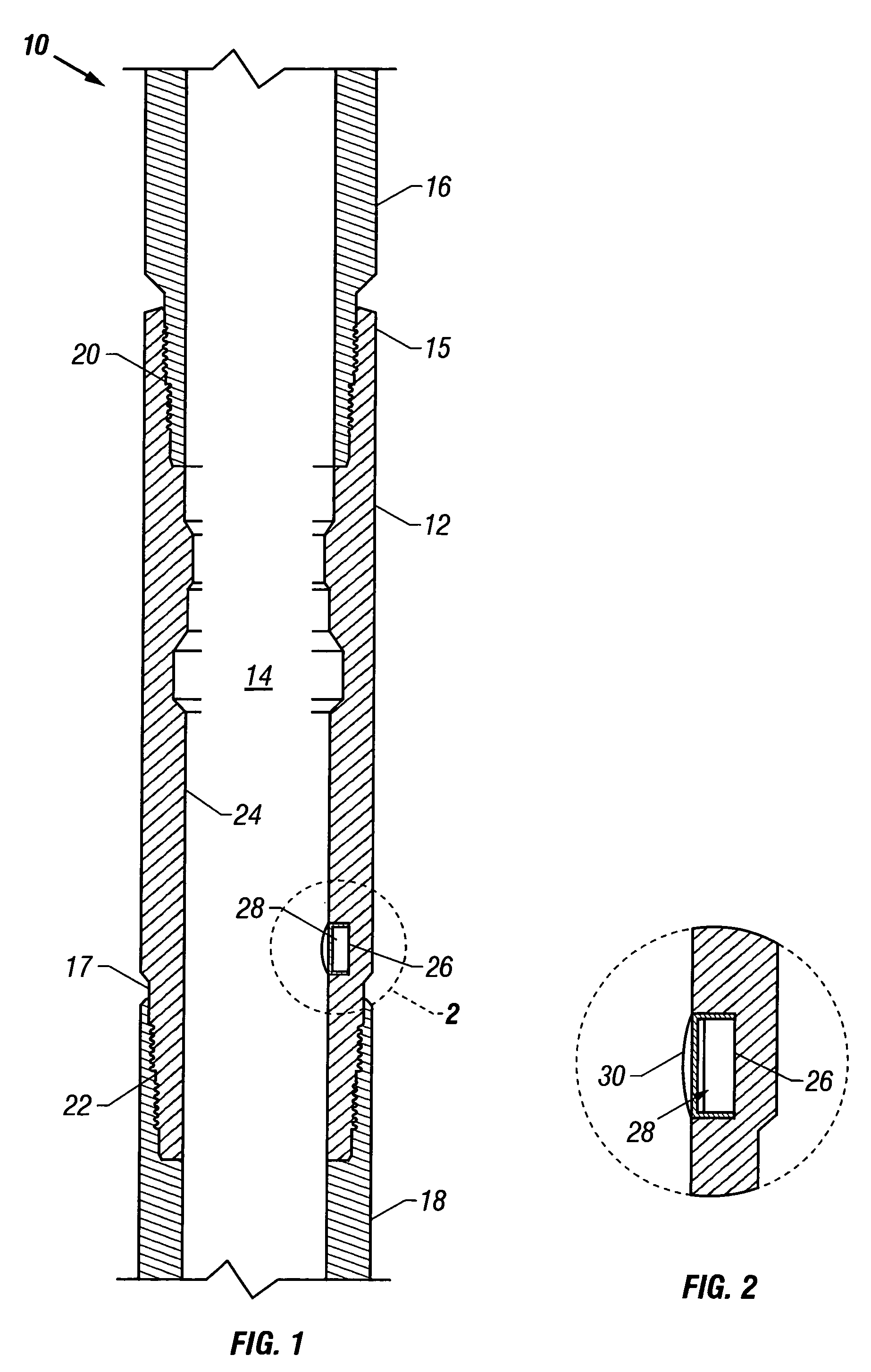

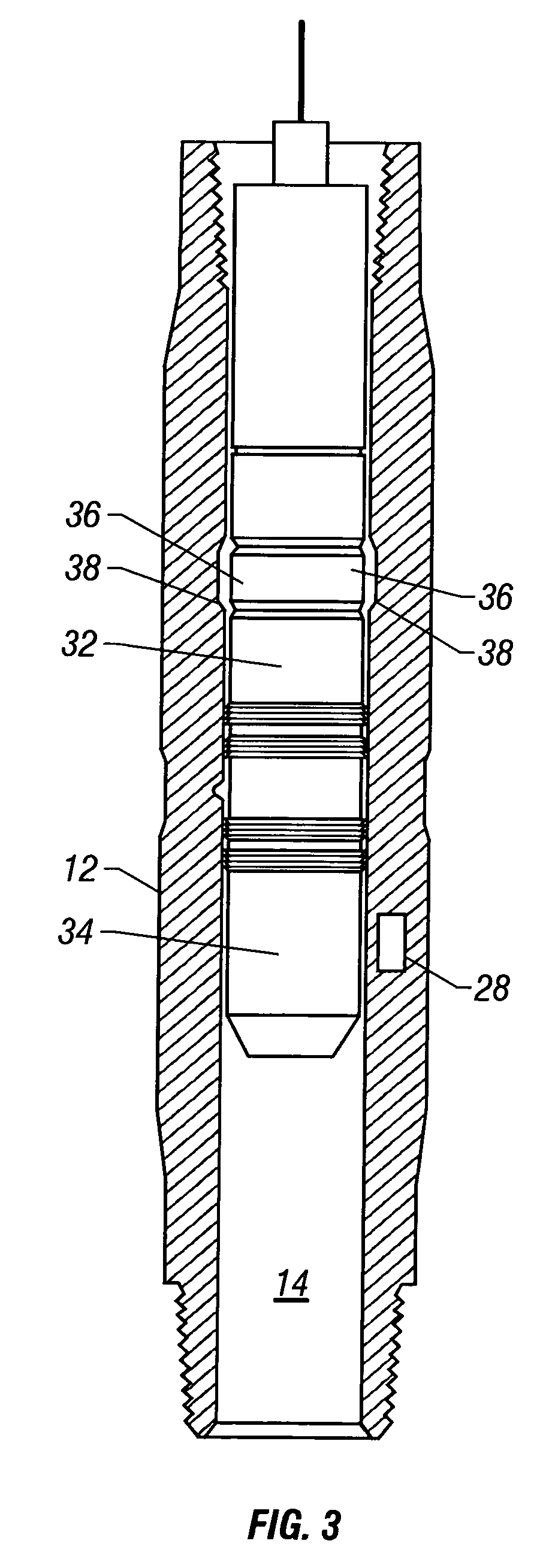

Apparatus and method for downhole well equipment and process management, identification, and actuation

A method for actuating or installing downhole equipment in a wellbore employs non-acoustic signals (e.g., radio frequency signals) to locate, inventory, install, or actuate one downhole structure in relation to another downhole structure. The method comprises the steps of: (a) providing a first downhole structure that comprises a non-acoustic (e.g., radio frequency) identification transmitter unit that stores an identification code and transmits a signal corresponding to the identification code; (b) providing a second downhole structure that comprises a non-acoustic receiver unit that can receive the signal transmitted by the non-acoustic identification transmitter unit, decode the signal to determine the identification code corresponding thereto, and compare the identification code to a preset target identification code; wherein one of the first downhole structure and the second downhole structure is secured at a given location in a subterranean wellbore, and the other is moveable in the wellbore; (c) placing the second downhole structure in close enough proximity to the first downhole structure so that the non-acoustic receiver unit can receive the signal transmitted by the non-acoustic identification transmitter unit; (d) comparing the identification code determined by the non-acoustic receiver unit to the target identification code; and (e) if the determined identification code matches the target identification code, actuating or installing one of the first downhole structure or second downhole structure in physical proximity to the other.

Owner:SCHLUMBERGER TECH CORP

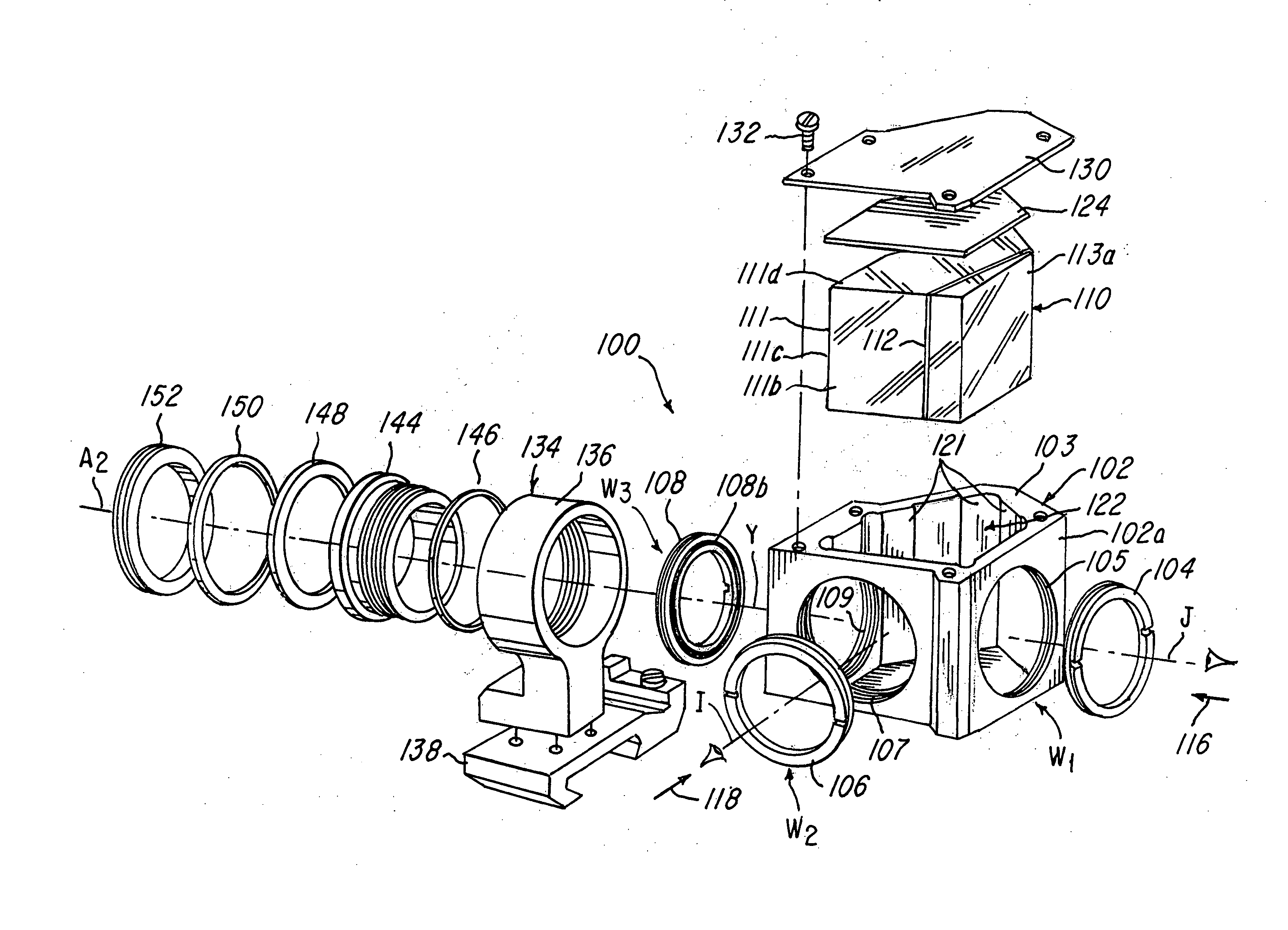

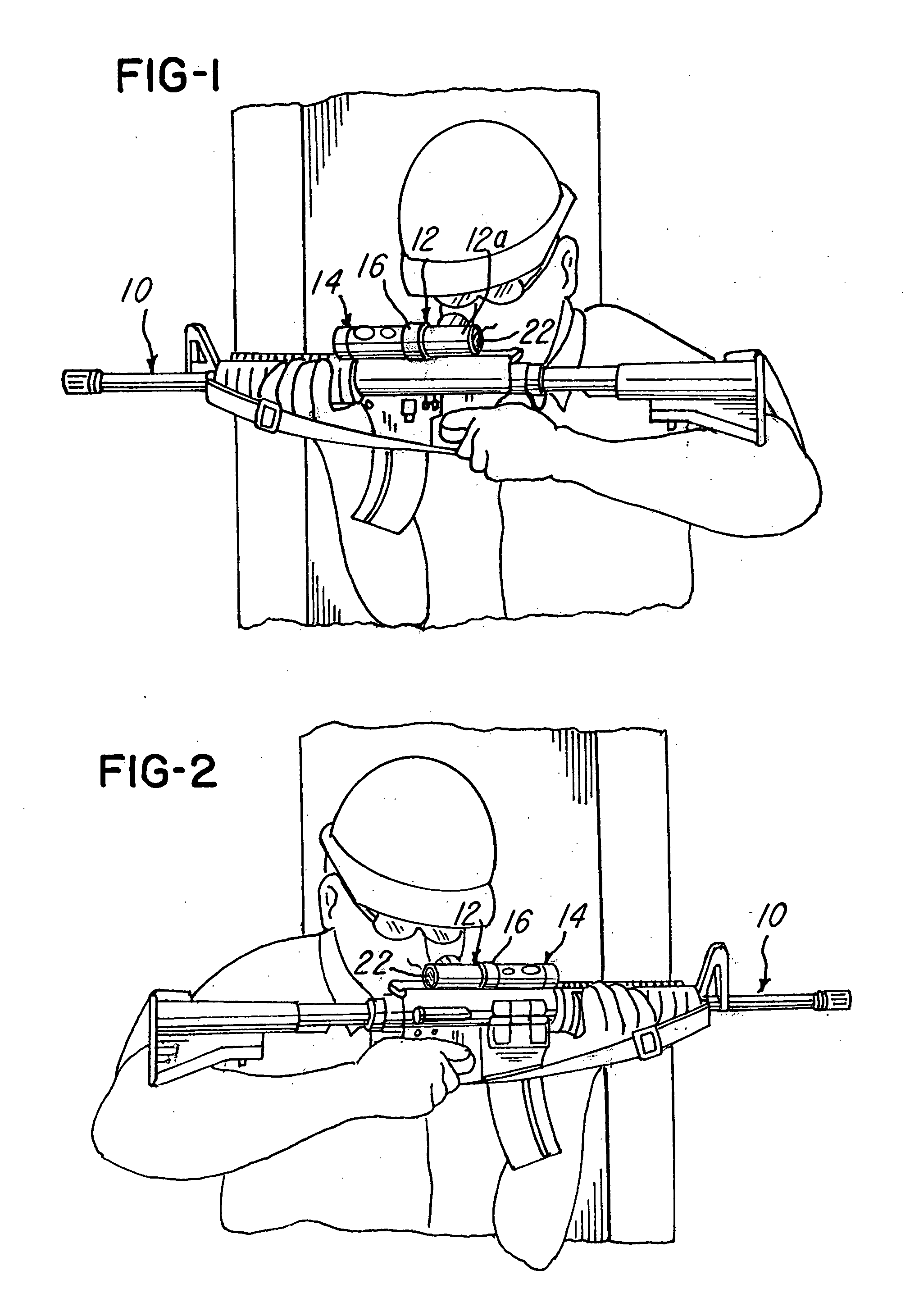

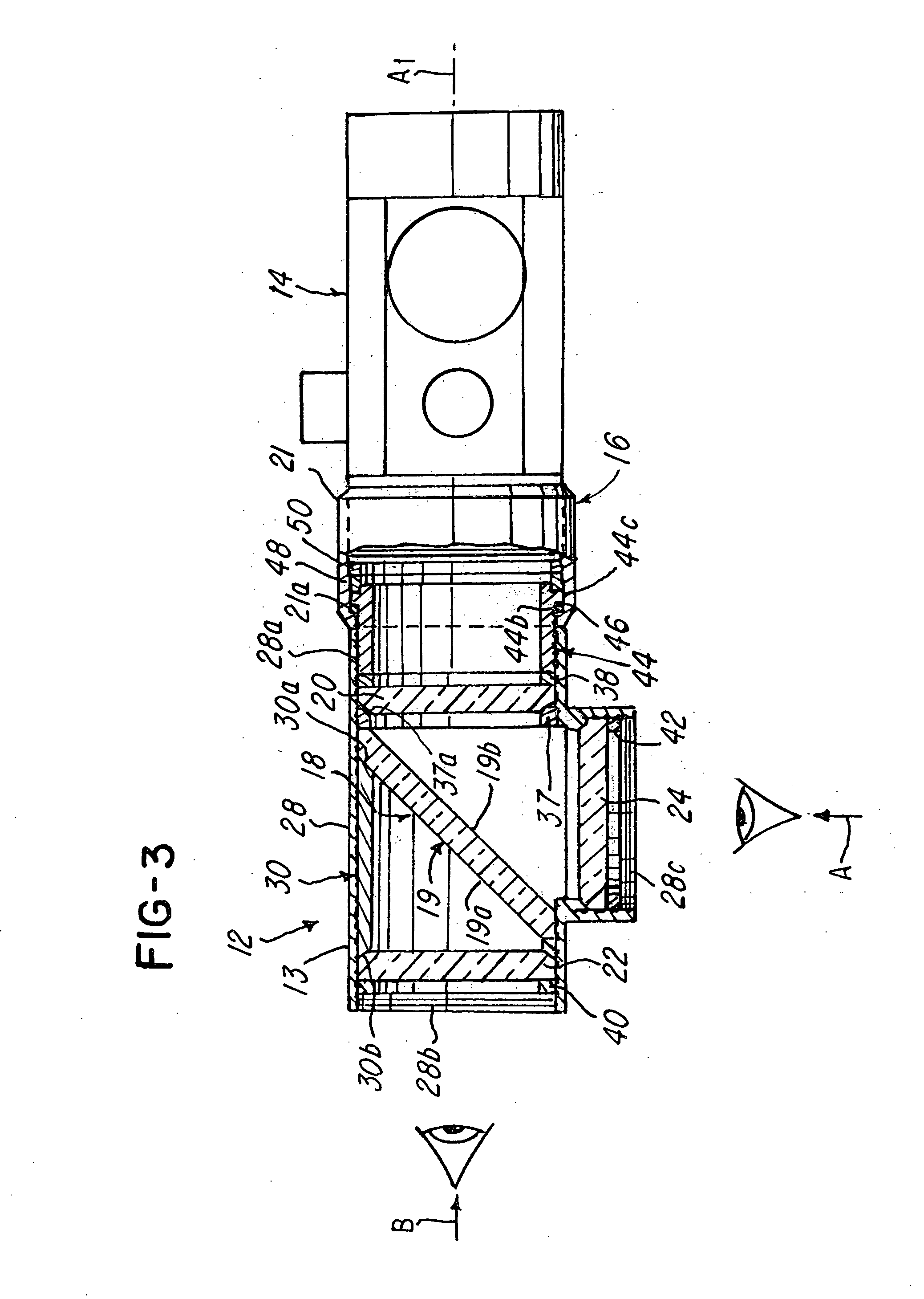

Dual sight scope system and method

A dual sighting optical sight is provided. The sight provides non-inverted images through a rear window and at least one side window so that a user may view a target from either a rear or a side, respectively, of the weapon to which the sight is mounted. The sight is adjustable to a plurality of different positions so that the user can use the sight and weapon from other than directly behind the sight weapon.

Owner:BAE SYST ELECTRONICS SUSTAINMENT

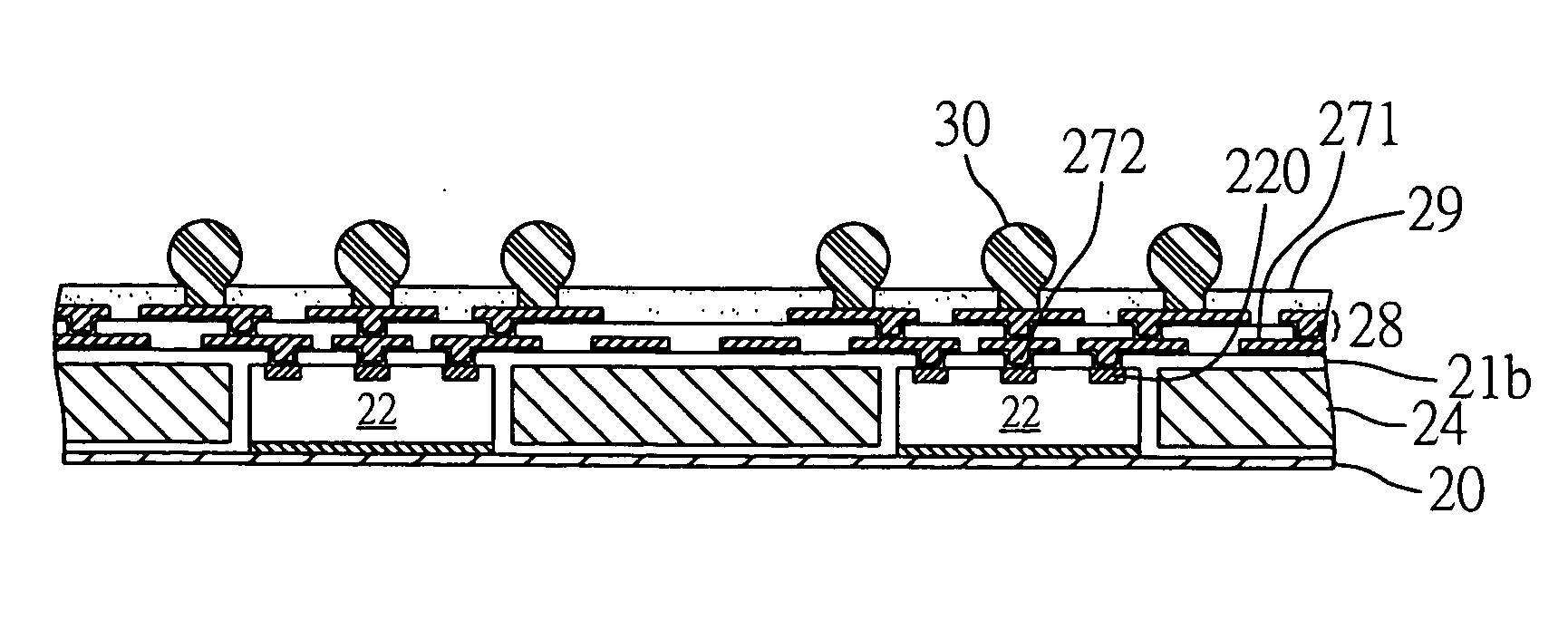

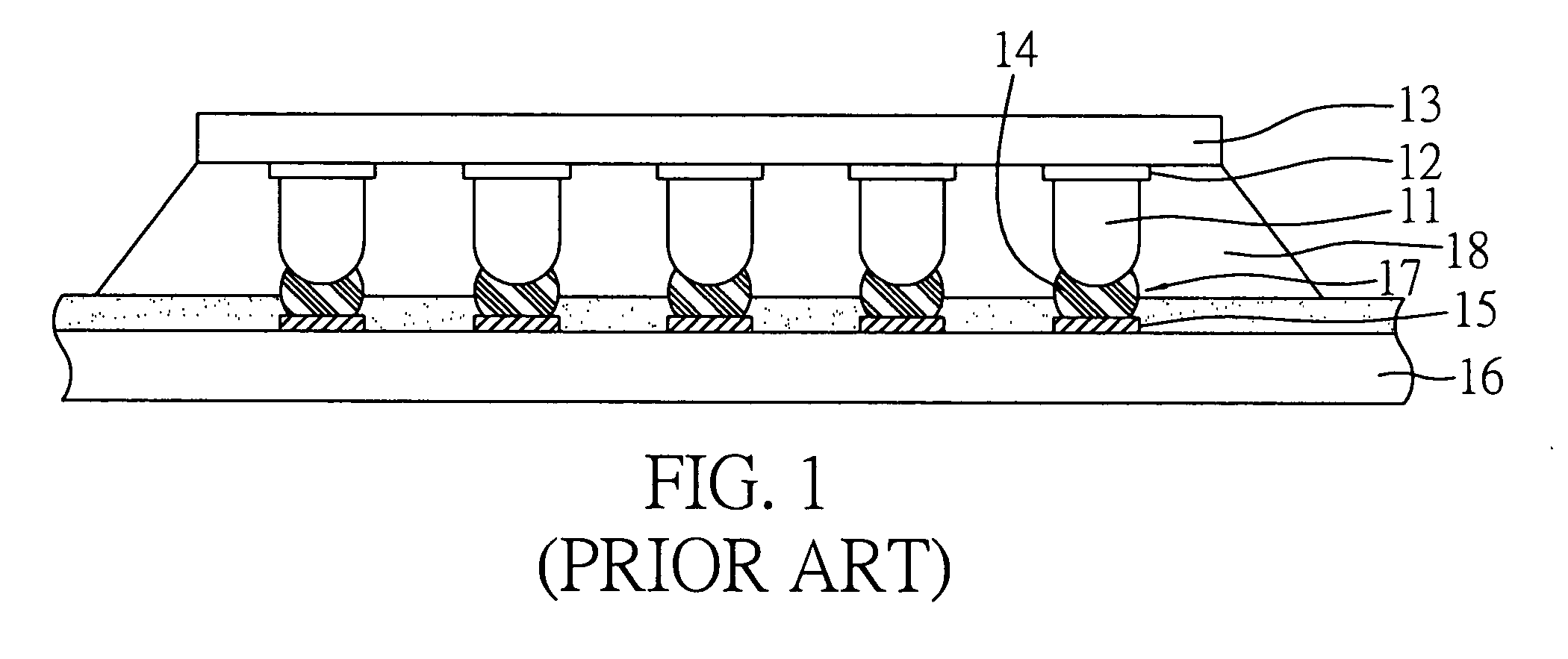

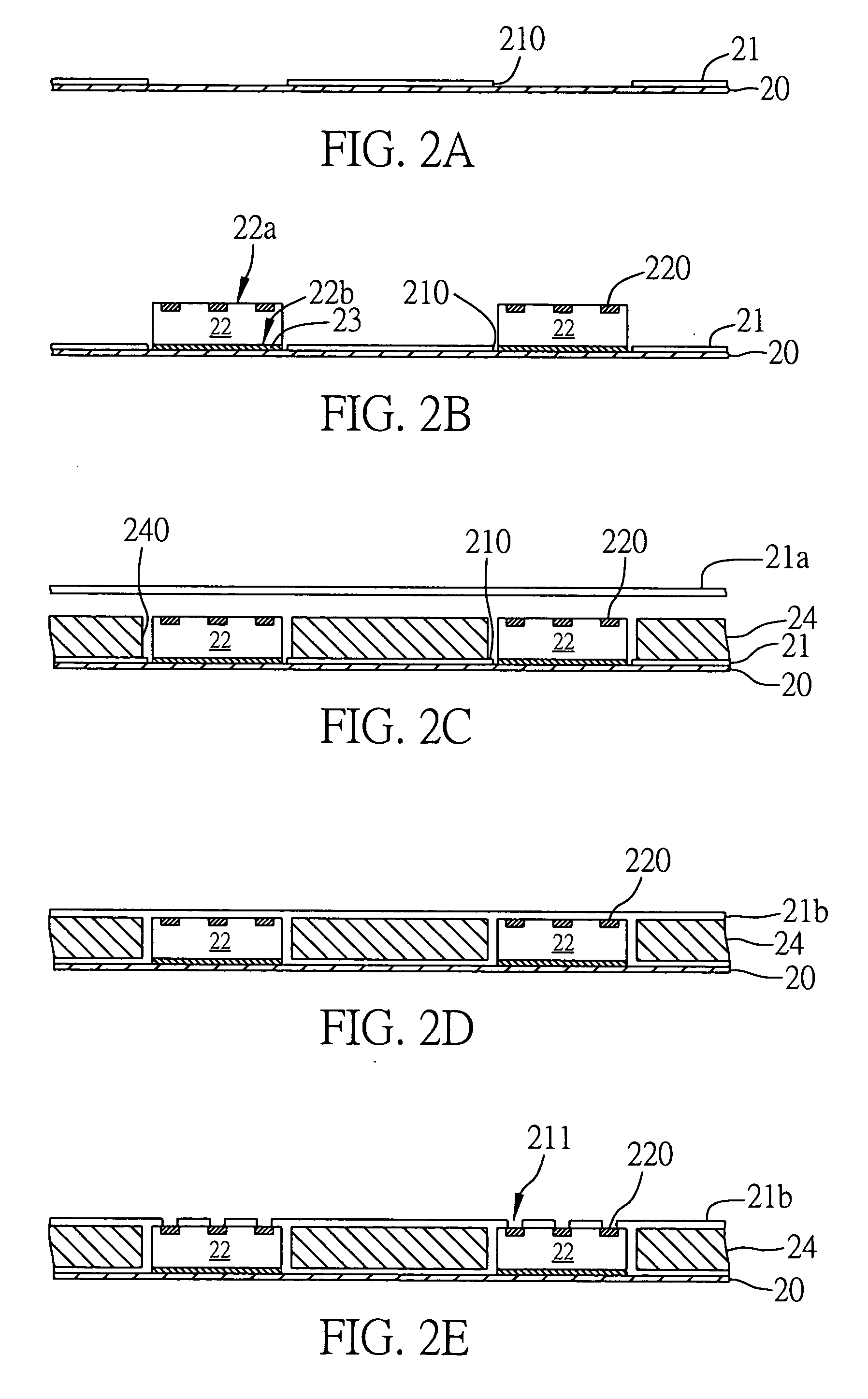

Semiconductor package substrate with embedded chip and fabrication method thereof

ActiveUS20060115931A1Improve performanceGreat flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

A semiconductor package substrate with embedded chip and a fabrication method thereof are provided. A first insulating layer is applied on a metallic board, and formed with at least one opening for exposing a portion of the metallic board. At least one semiconductor chip is mounted on the exposed portion of the metallic board. A support plate is mounted on the first insulating layer, and formed with a through cavity at a position corresponding to the opening of the first insulating layer, for receiving the chip in the through cavity. A second insulating layer is applied on the chip and the support plate. Insulating materials of the insulating layers fill a gap between the chip and the support plate. A circuit layer is formed on the second insulating layer, wherein the circuit layer is electrically connected to the chip by conductive structures formed in the second insulating layer.

Owner:PHOENIX PRECISION TECH CORP

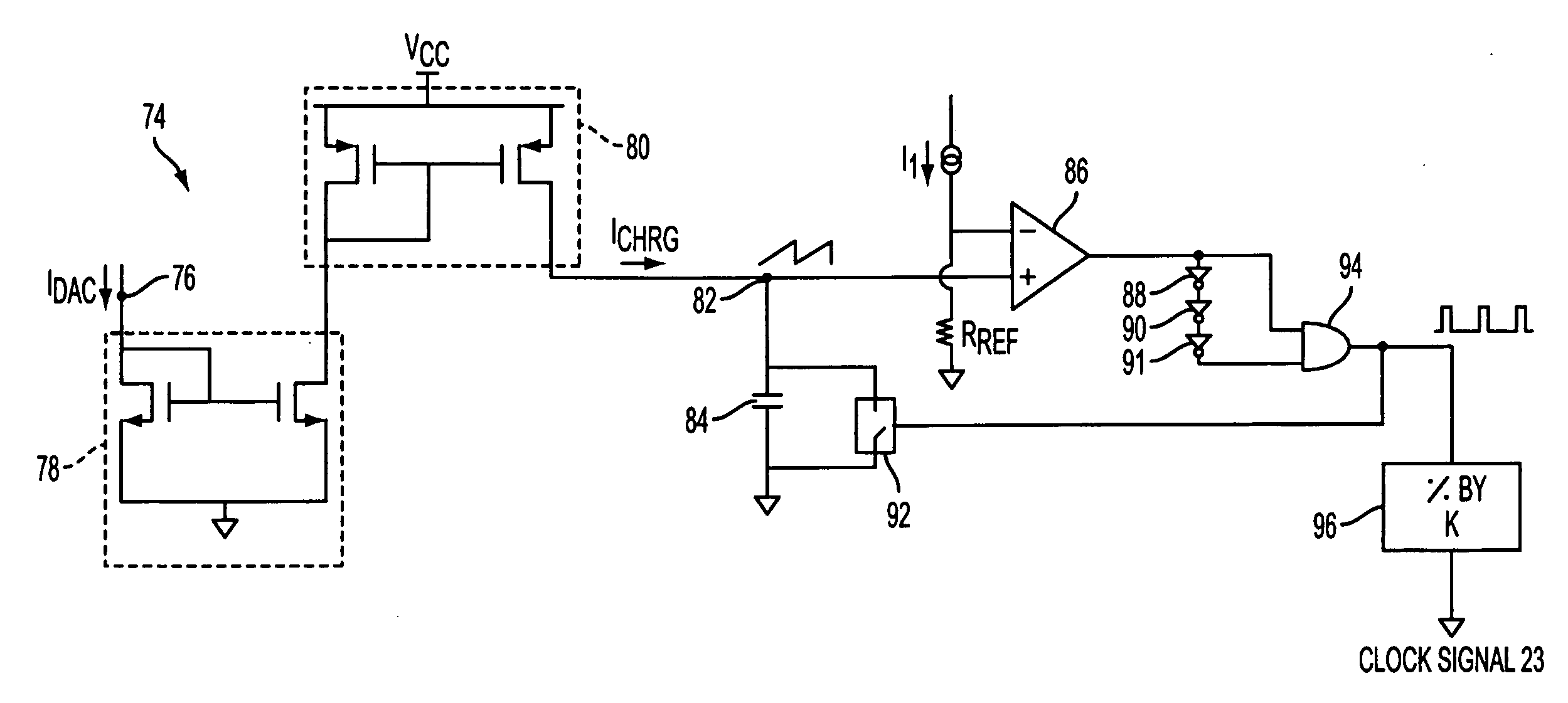

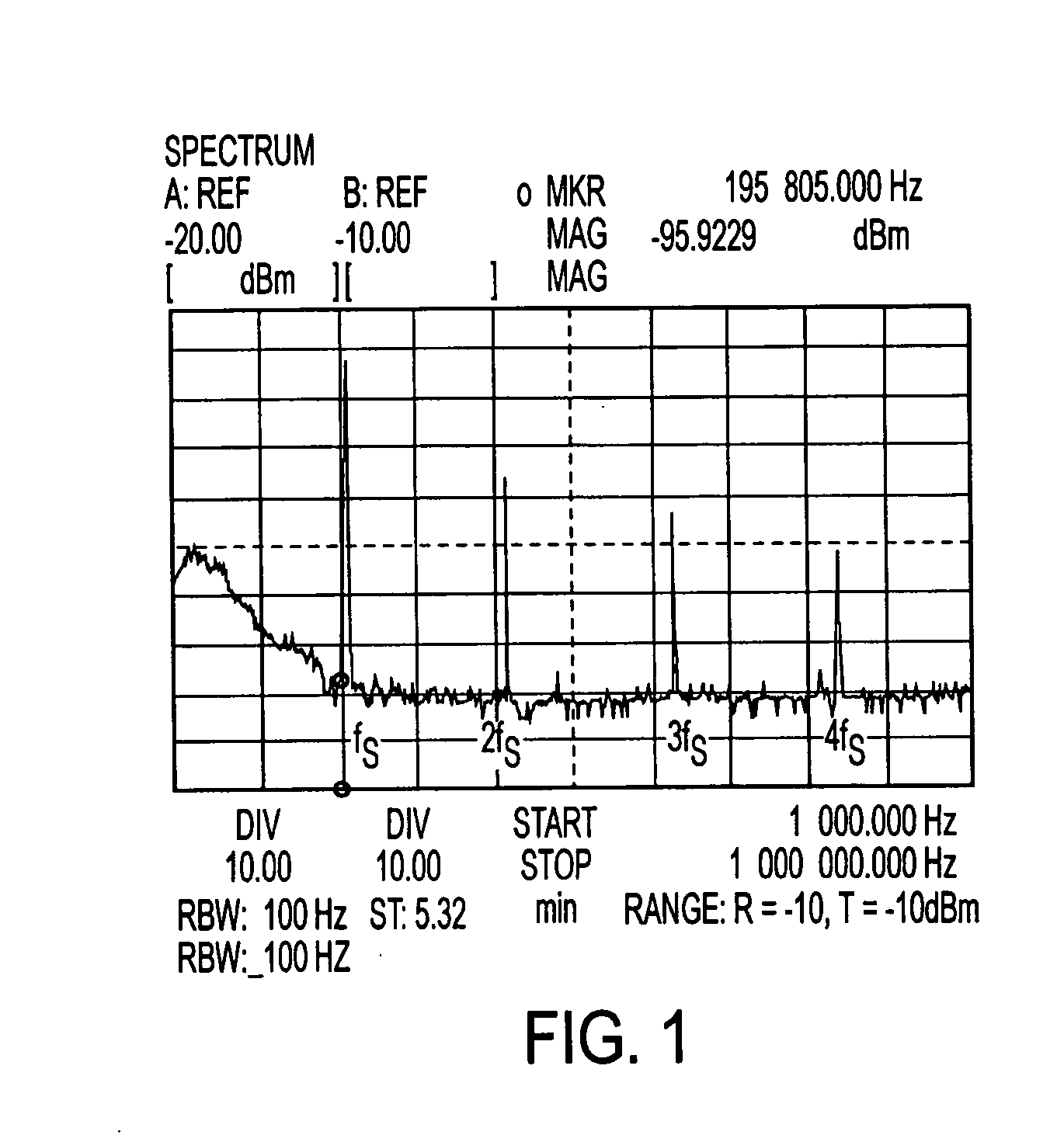

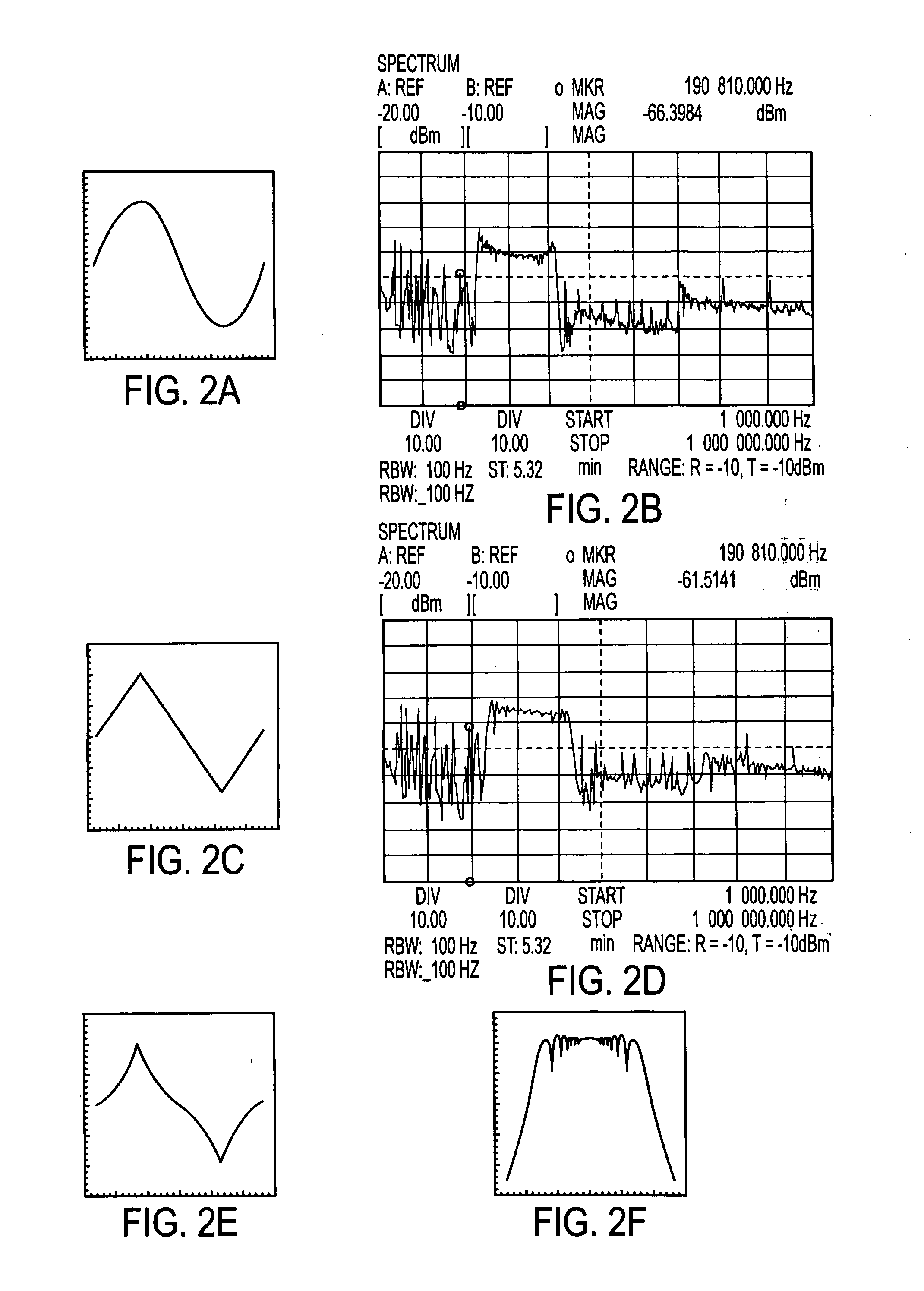

Methods and circuits for frequency modulation that reduce the spectral noise of switching regulators

ActiveUS20050243894A1Great flexibilityLarge amplitudeAc-dc conversionDc-dc conversionPhysicsPeak value

Owner:ANALOG DEVICES INT UNLTD

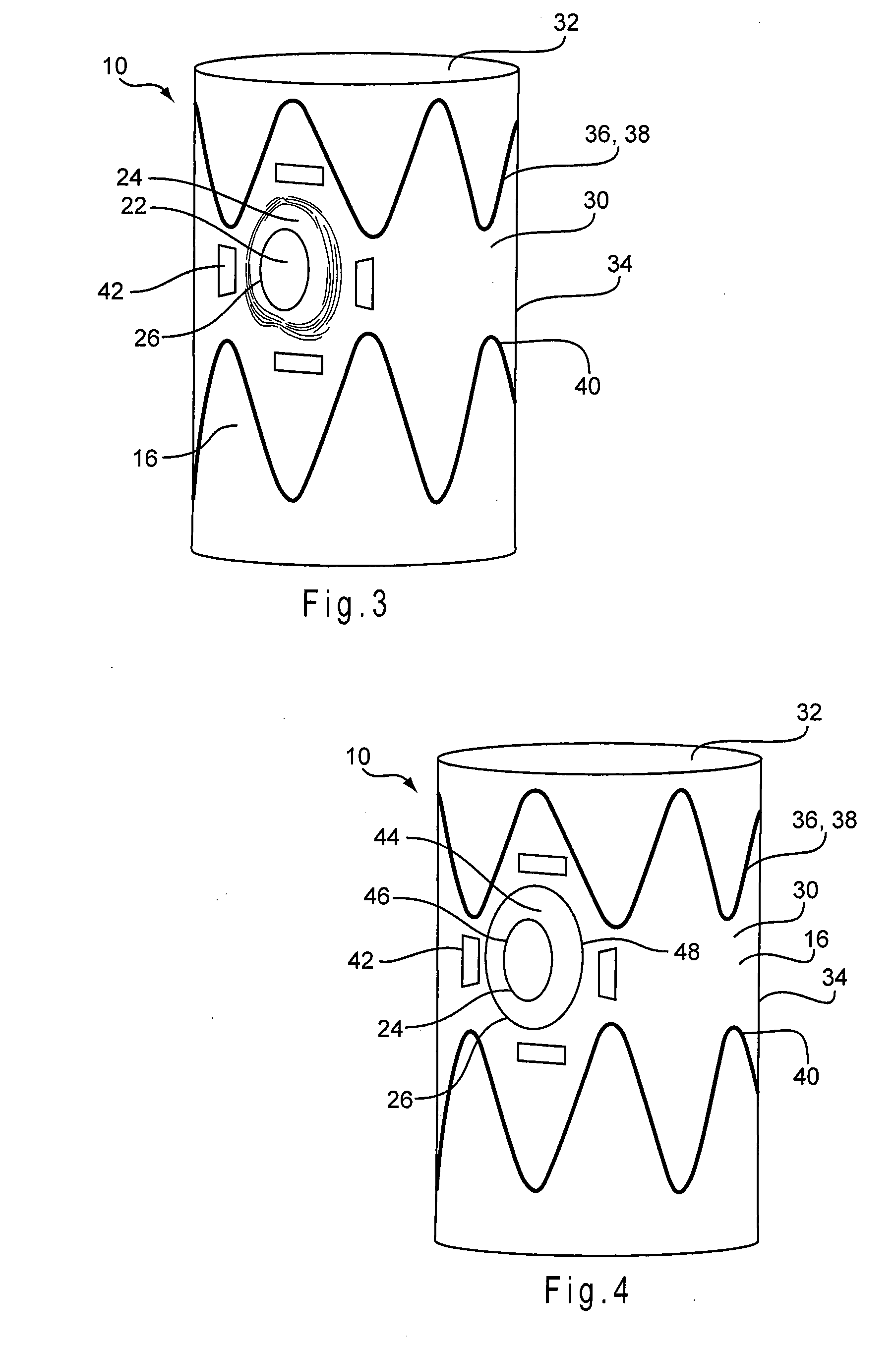

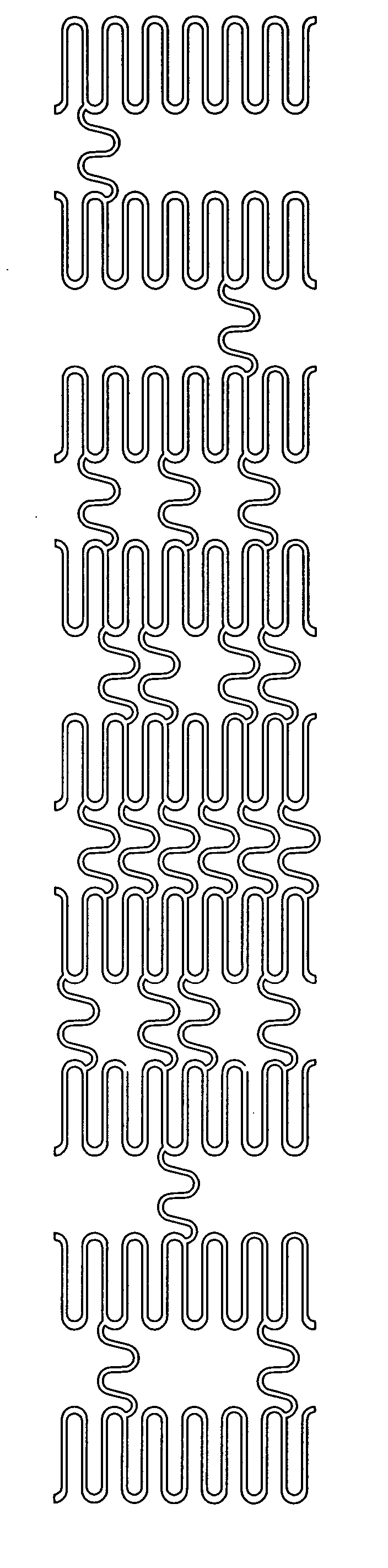

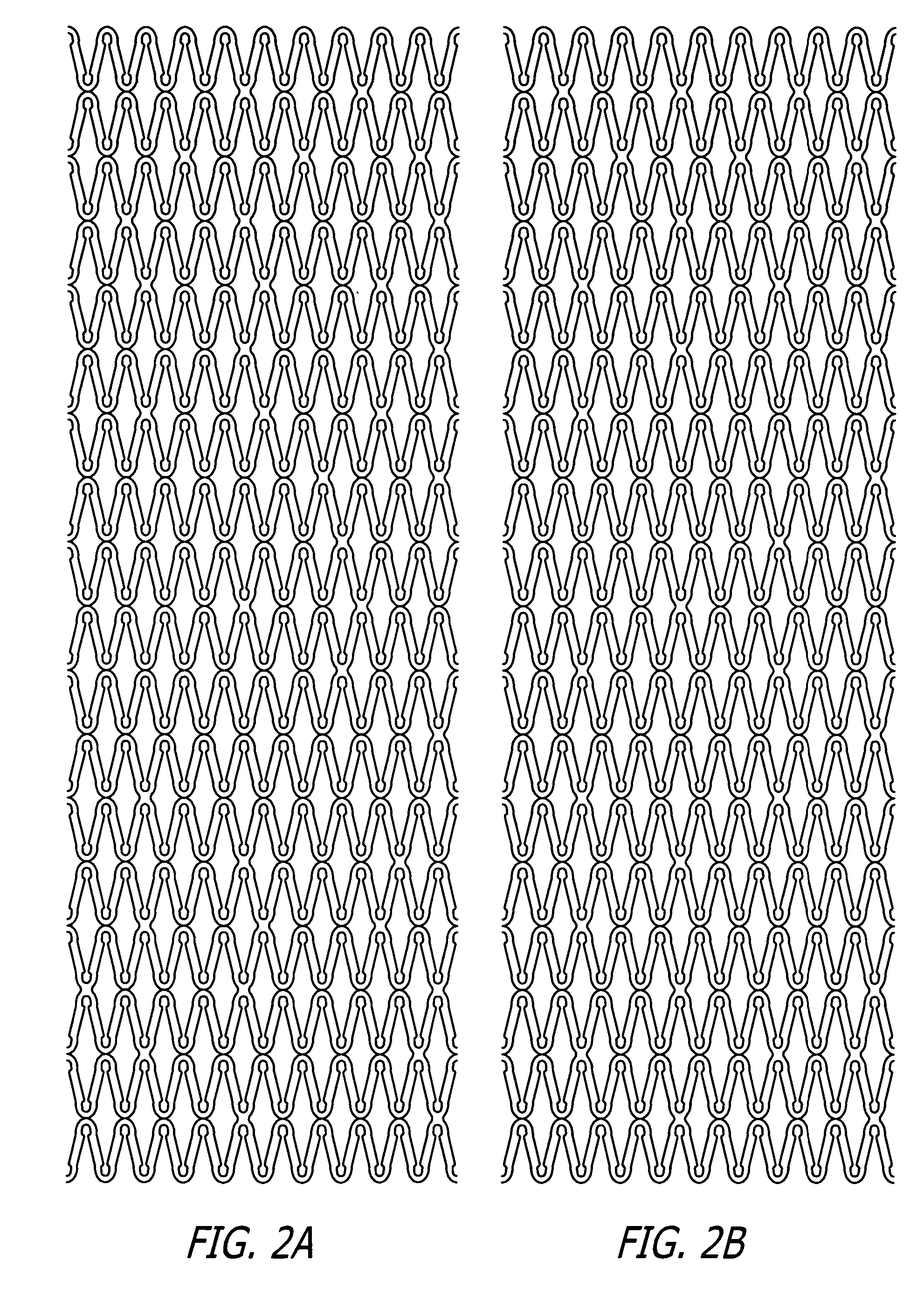

Lumen-supporting stents and methods for creating lumen-supporting stents with various open/closed designs

InactiveUS20070050011A1Great flexibilityImprove deliverabilityStentsBlood vesselsTreatment goalsStent design

Disclosed herein are various open / closed stent designs and methods for creating the same that can be individually adopted depending on particular treatment objectives. Specifically, the stents of the present invention are manufactured to include different open / closed configurations along their length by varying the number of crossovers, connectors or weld points between sections of the stent. Open portions contain less crossovers, connectors or weld points and are more flexible than closed portions which contain more crossovers, connectors or weld points.

Owner:MEDLOGICS DEVICE CORP

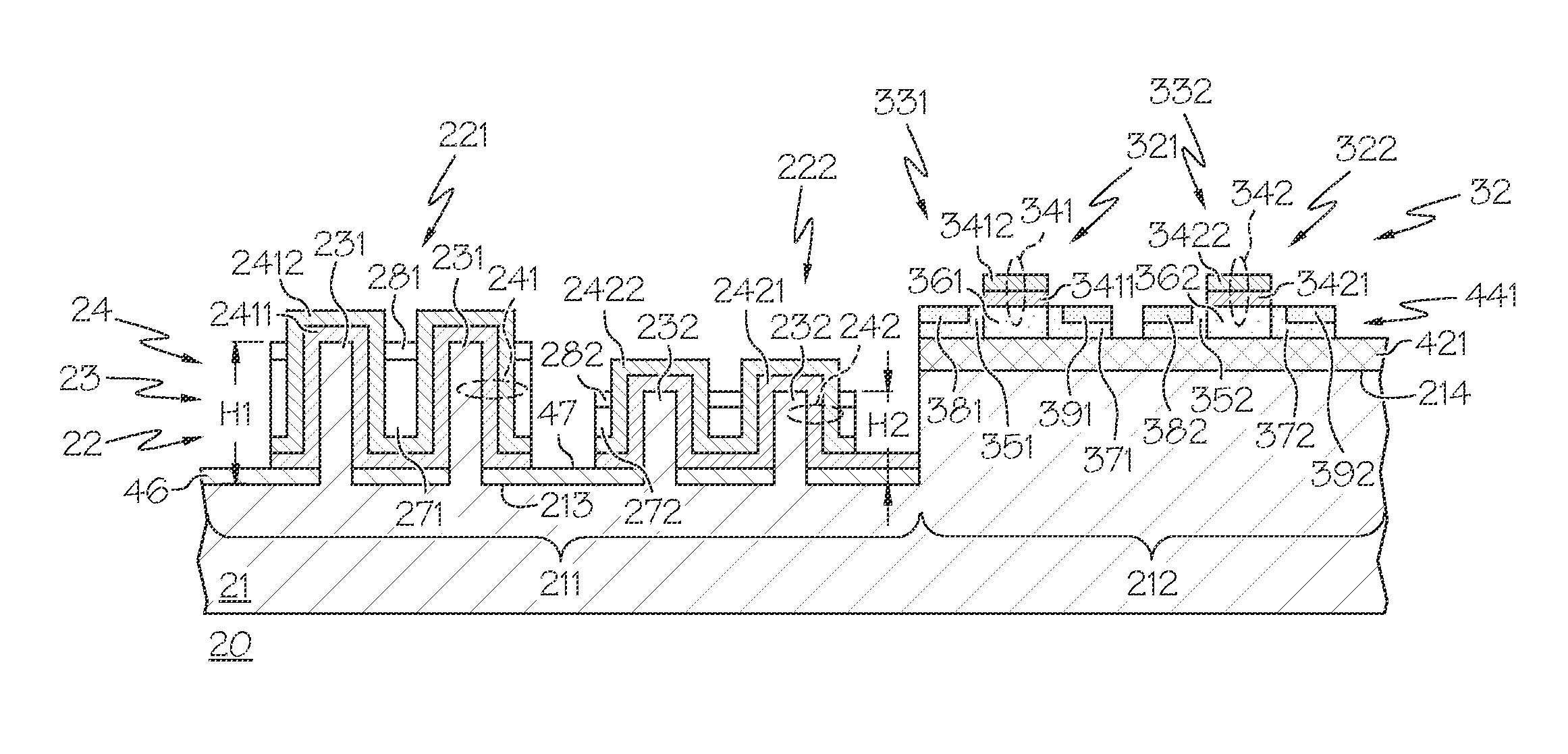

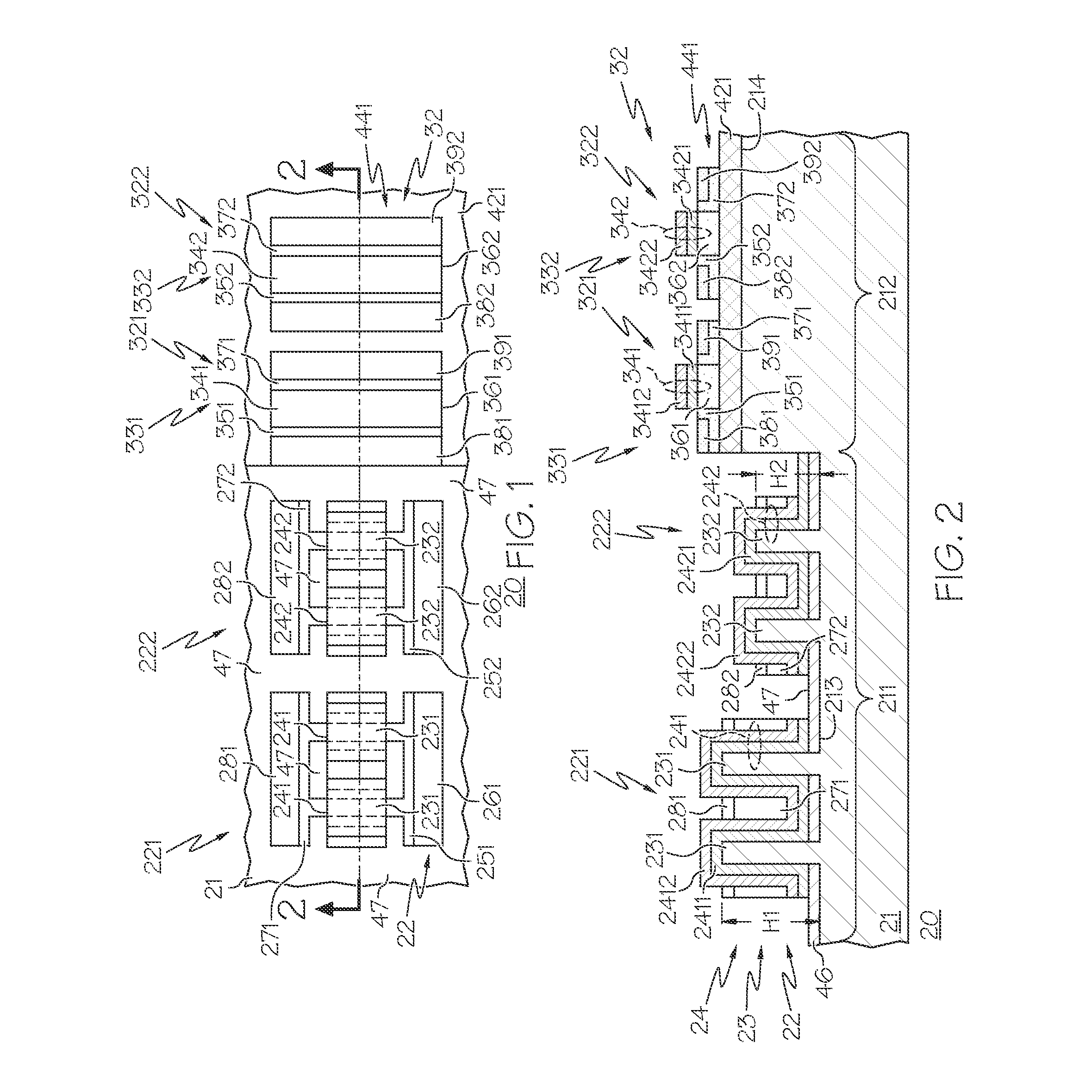

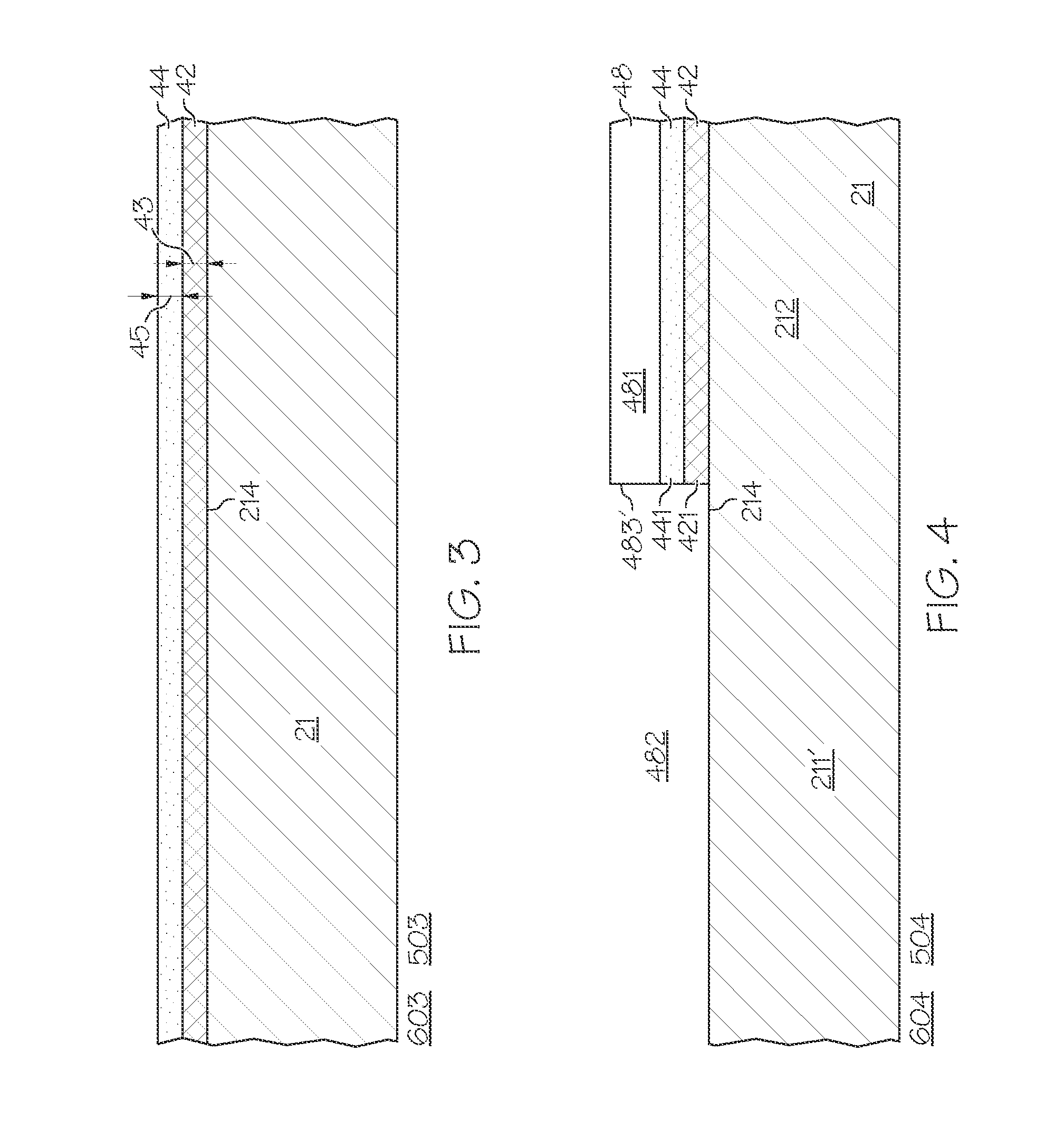

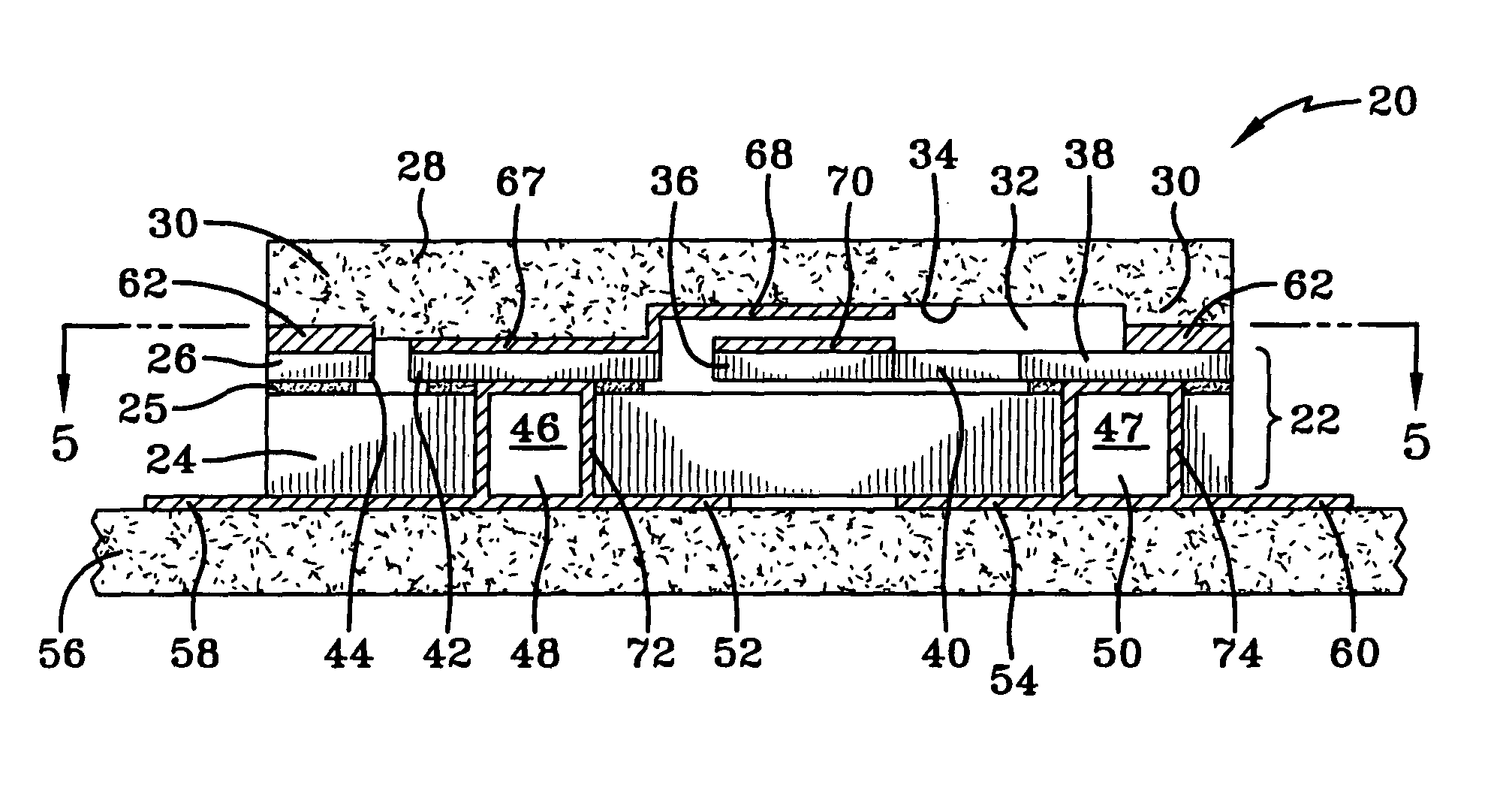

Combined planar fet and fin-fet devices and methods

ActiveUS20130049136A1Improve isolationGreat flexibilityTransistorSolid-state devicesIonChannel width

Electronic devices (20, 20′) of superior design flexibility that avoid channel-width quantization effects common with prior art fin-type (FIN) field effect transistors (FIN-FETS) (22) are obtained by providing multiple FIN-FETs (22) and at least one planar FET (32, 32′) on a common substrate (21), wherein the multiple FIN-FETs (22) have fins (231, 232) of at least fin heights H1 and H2, with H2<H1. The multiple FIN-FETs (22) and the at least one planar FET (32, 32′) are separated vertically as well as laterally, which aids electrical isolation therebetween. Such electrical isolation can be enhanced by forming the planar FET (32) in a semiconductor region (441) insulated from the common substrate (21). In a preferred embodiment, the multiple height fins (231, 232) are obtained by first forming all fins (231, 232′) of common height H1 and then shortening some of the fins (232) to height H2<H1 by differentially etching upper portions thereof that have, preferably, been implanted with etch rate altering ions.

Owner:GLOBALFOUNDRIES US INC

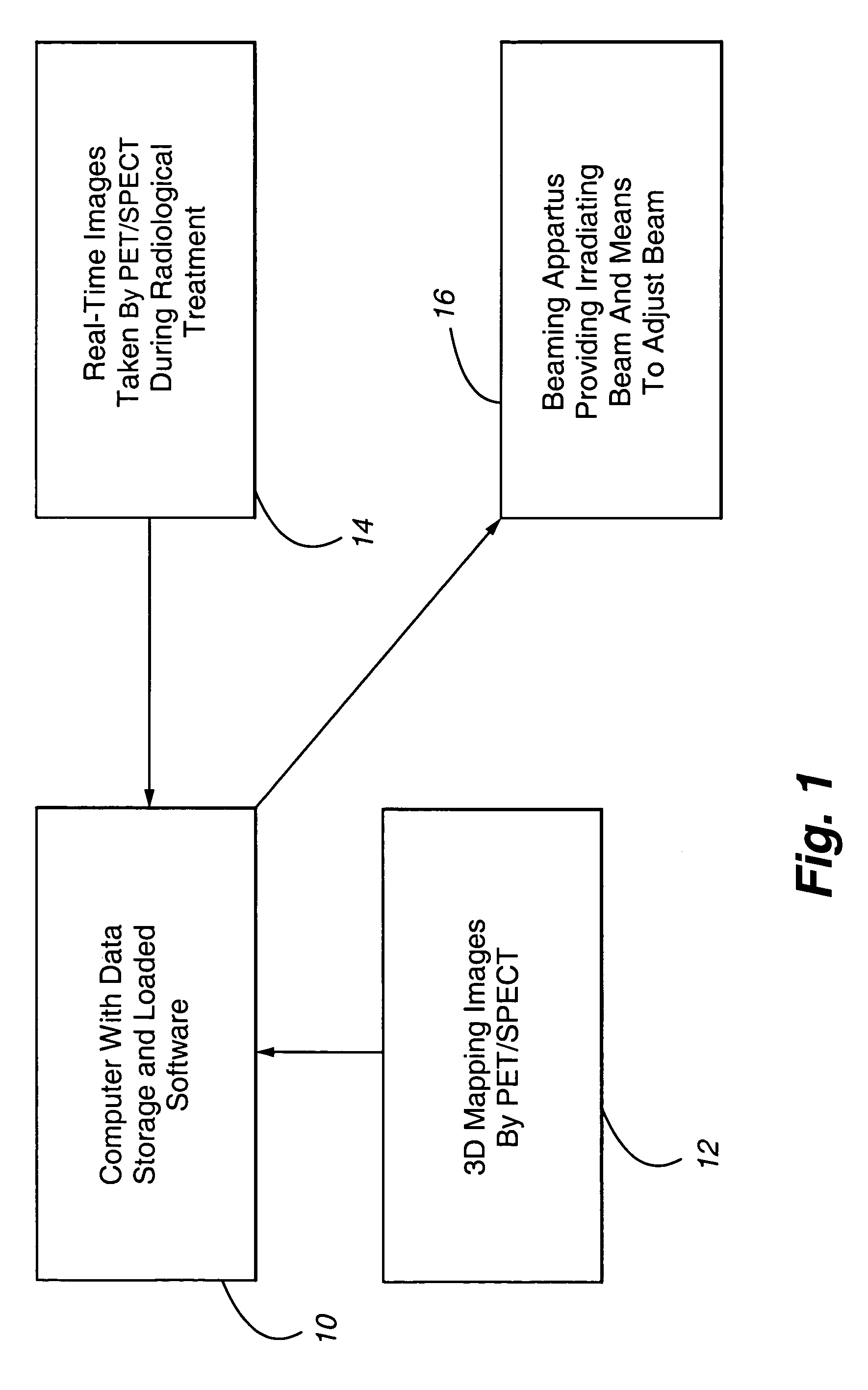

Method of optimizing radiosurgery and radiotherapy with metalloporphyrins

InactiveUS7110808B2Great flexibilityShrink tumor sizeOrganic active ingredientsTelevision system detailsMedical physicsDual delivery

An apparatus and method for subsequent optimization of radiosurgery and radiotherapy is provided. The invention includes administering a metalloporphyrin to the patient, and then creating a 3-dimensional mapping of tissue through use of PET or SPECT. Malignant and pre-malignant tissue has an affinity for the metalloporphyrin. During treatment, real-time images are also provided which are compared to the previous 3-dimensional mapping. Creation of the real-time images is also achieved through PET or SPECT wherein a metalloporphyrin is administered to the patient. Total administration of radiation is calculated by summing radiation from the metalloporphyrins and from the radiosurgery / radiotherapy. The amount of radiation delivered by the metalloporphyrins and by the radiosurgery / radiotherapy are adjustable based on a patient's response to the dual delivery.

Owner:ADAIR

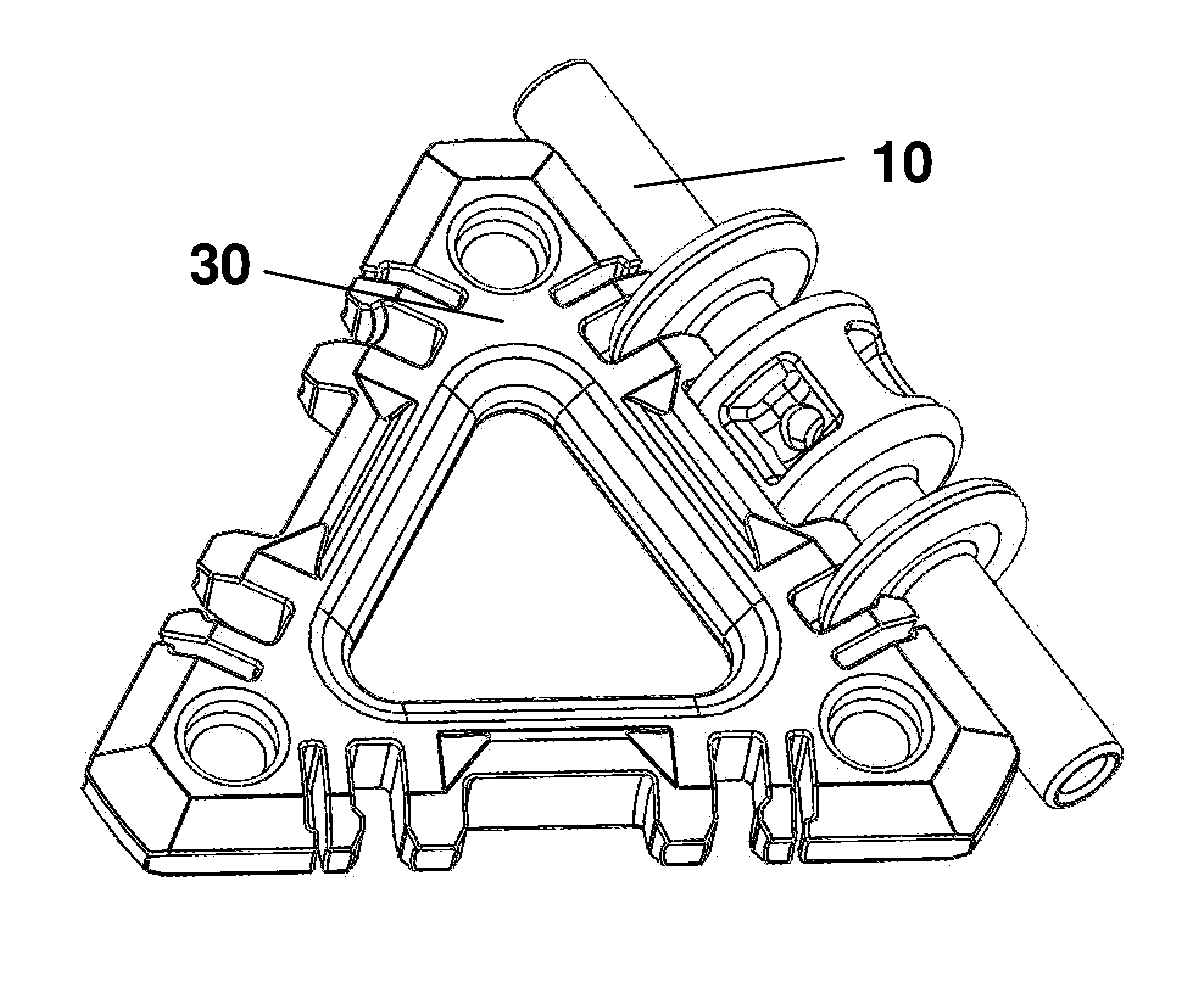

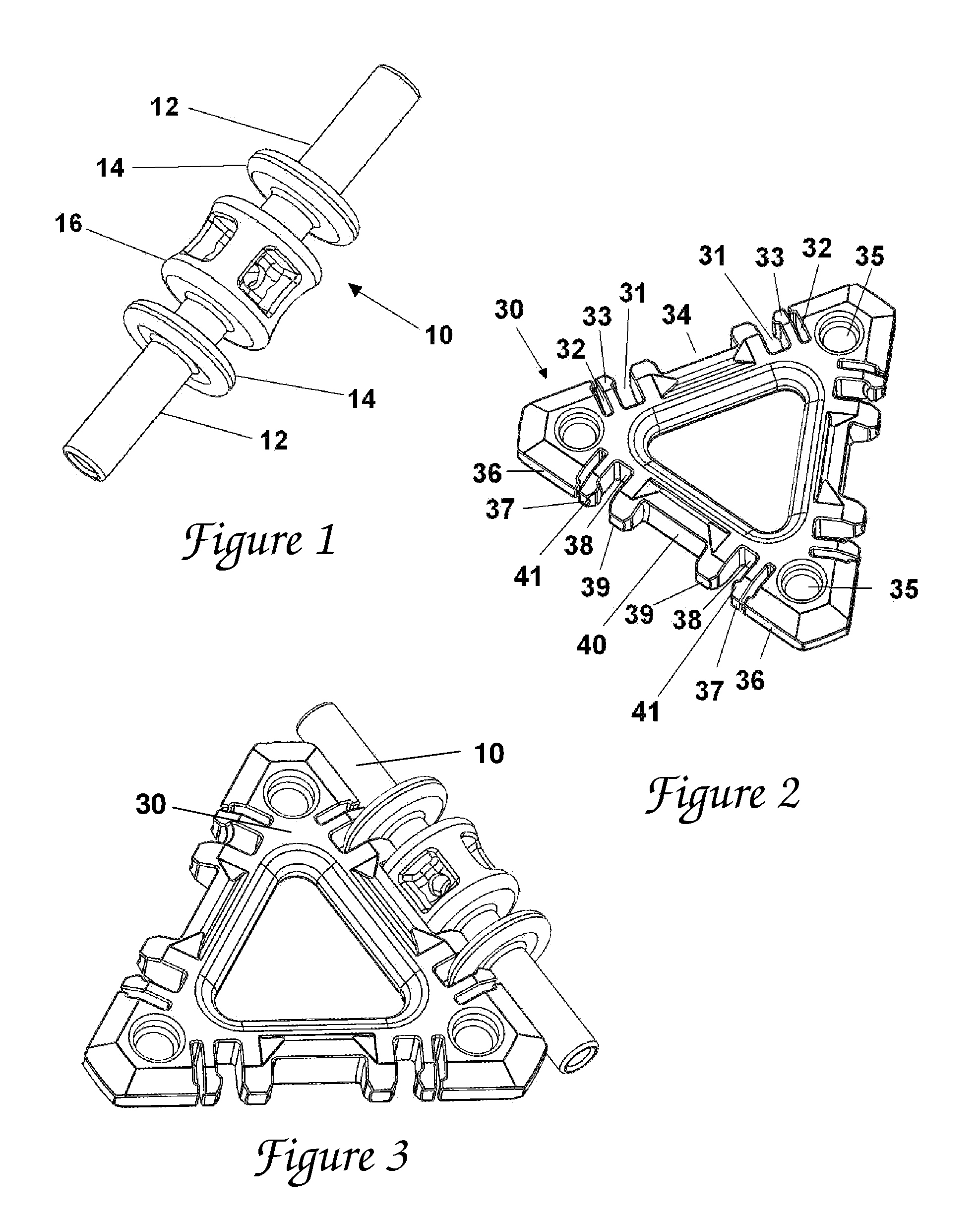

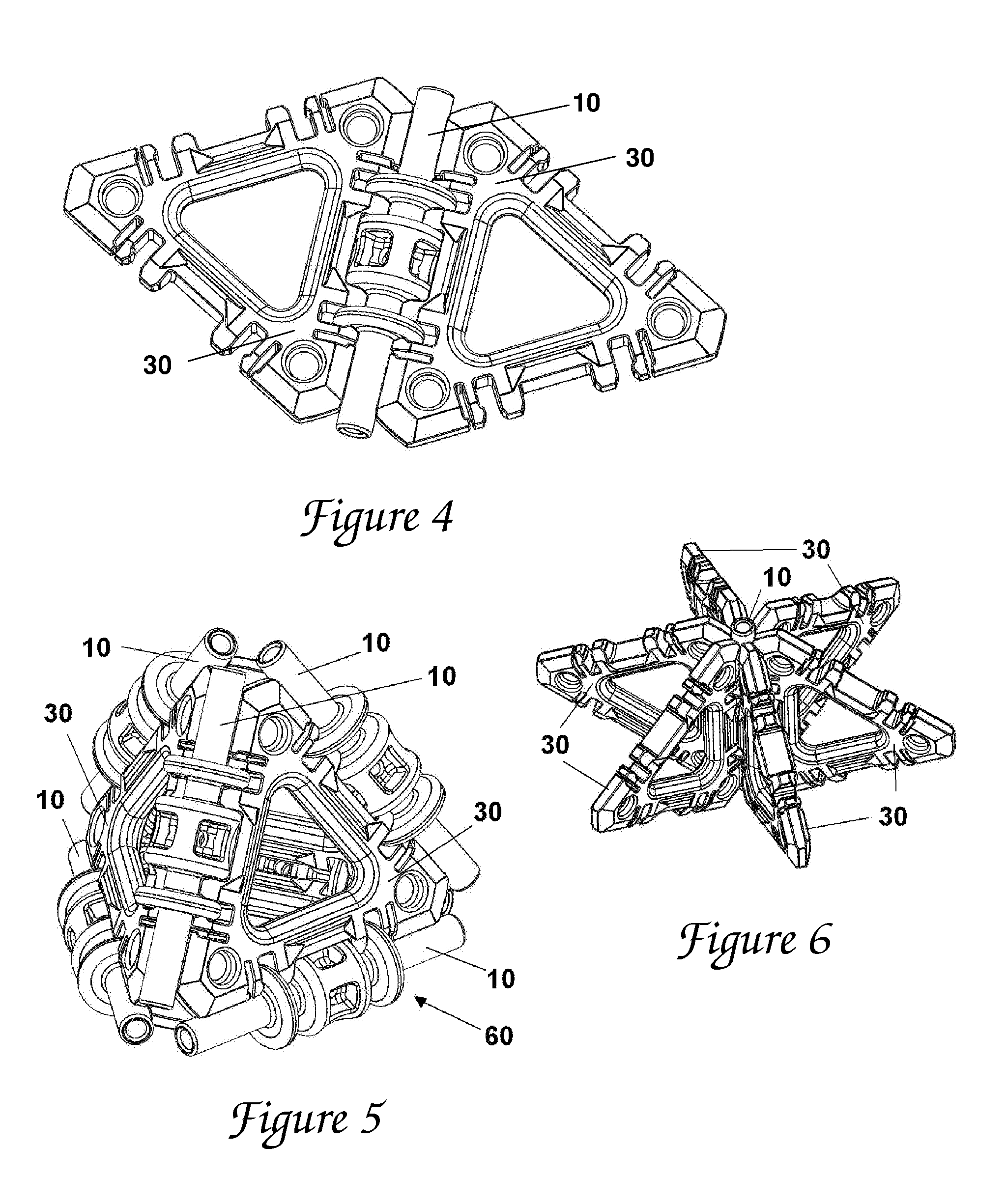

Versatile Robust Construction Toy

ActiveUS20130165012A1Great flexibilityEasily assembleMusical toysBuilding constructionCivil engineering

Owner:CREATIVE TOYS

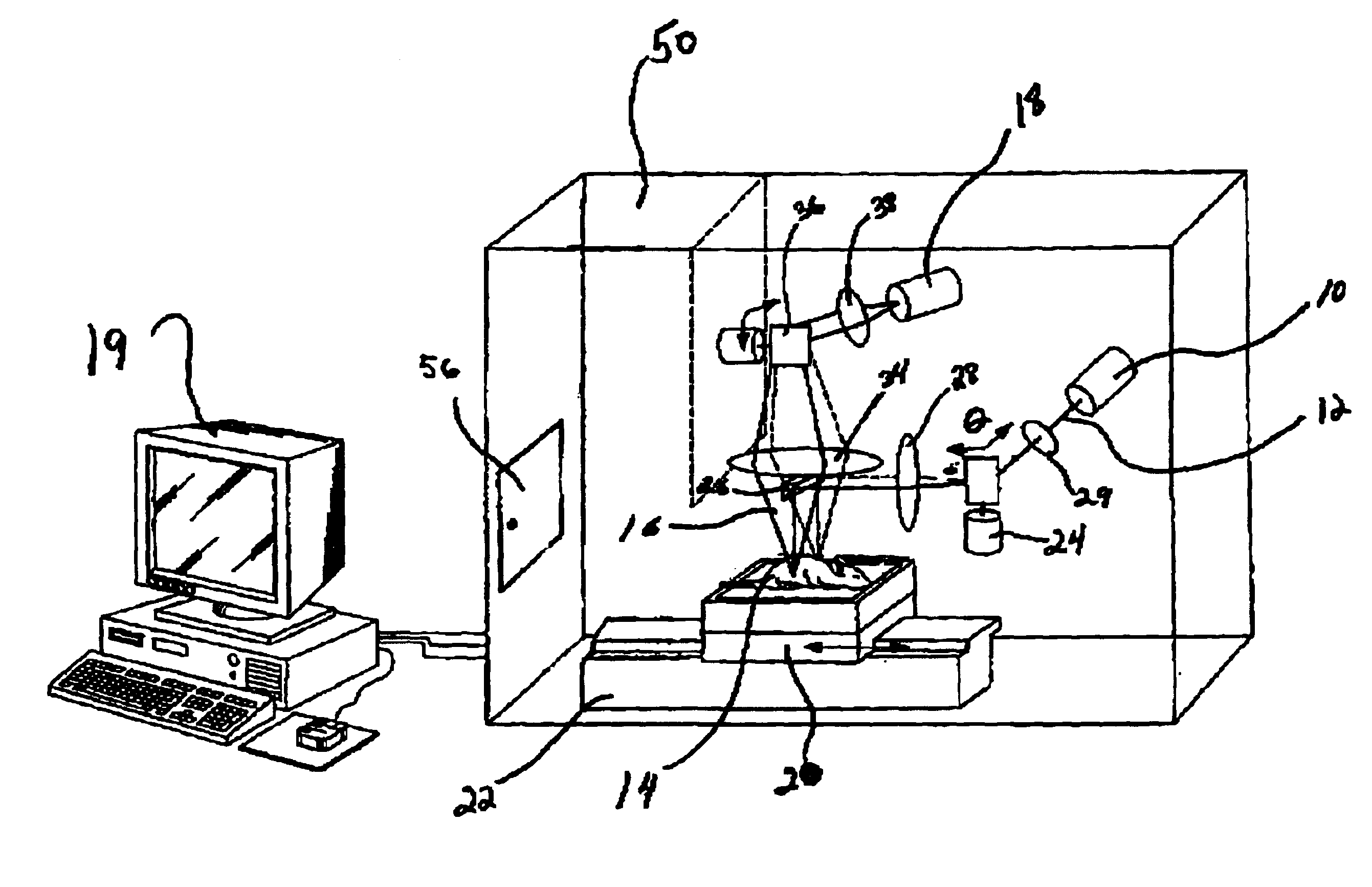

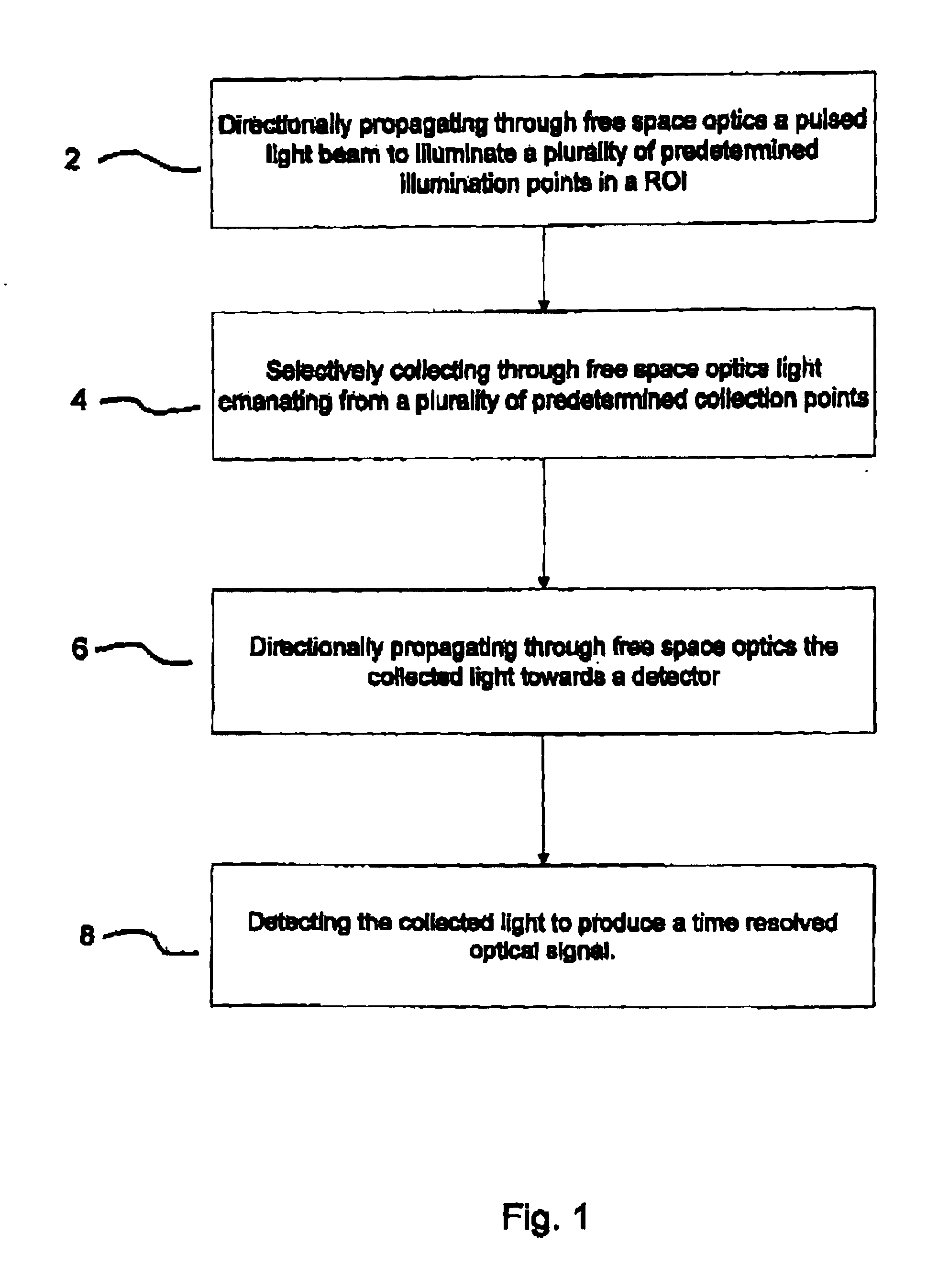

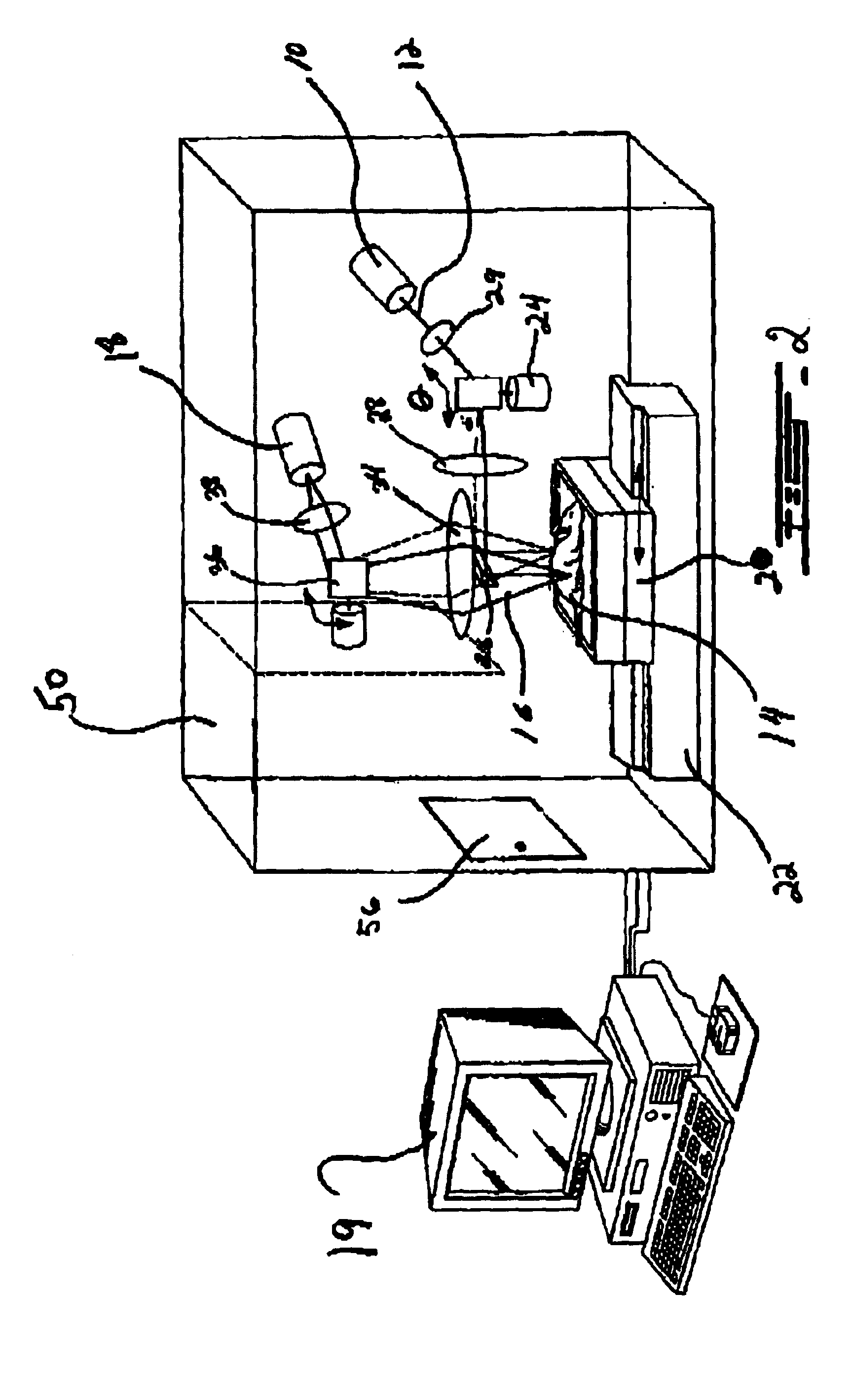

Method and apparatus for time resolved optical imaging of biological tissues as part of animals

ActiveUS6992762B2Great flexibilityGood flexibilityRadiation pyrometrySpectrum investigationBiological tissueOptical Image Reconstruction

There is provided a method and system for collecting optical data for use in time resolved optical imaging wherein light is directionally propagated through free-space optics to impinge on a plurality of illumination at the surface of a biological tissue such as that comprised in small animals. Light re-emitted from the tissue is collected and directionally propagated through free space optics towards a detector to produce time resolved optical signals useful for optical image reconstructions.

Owner:SOFTSCAN HEALTHCARE GROUP

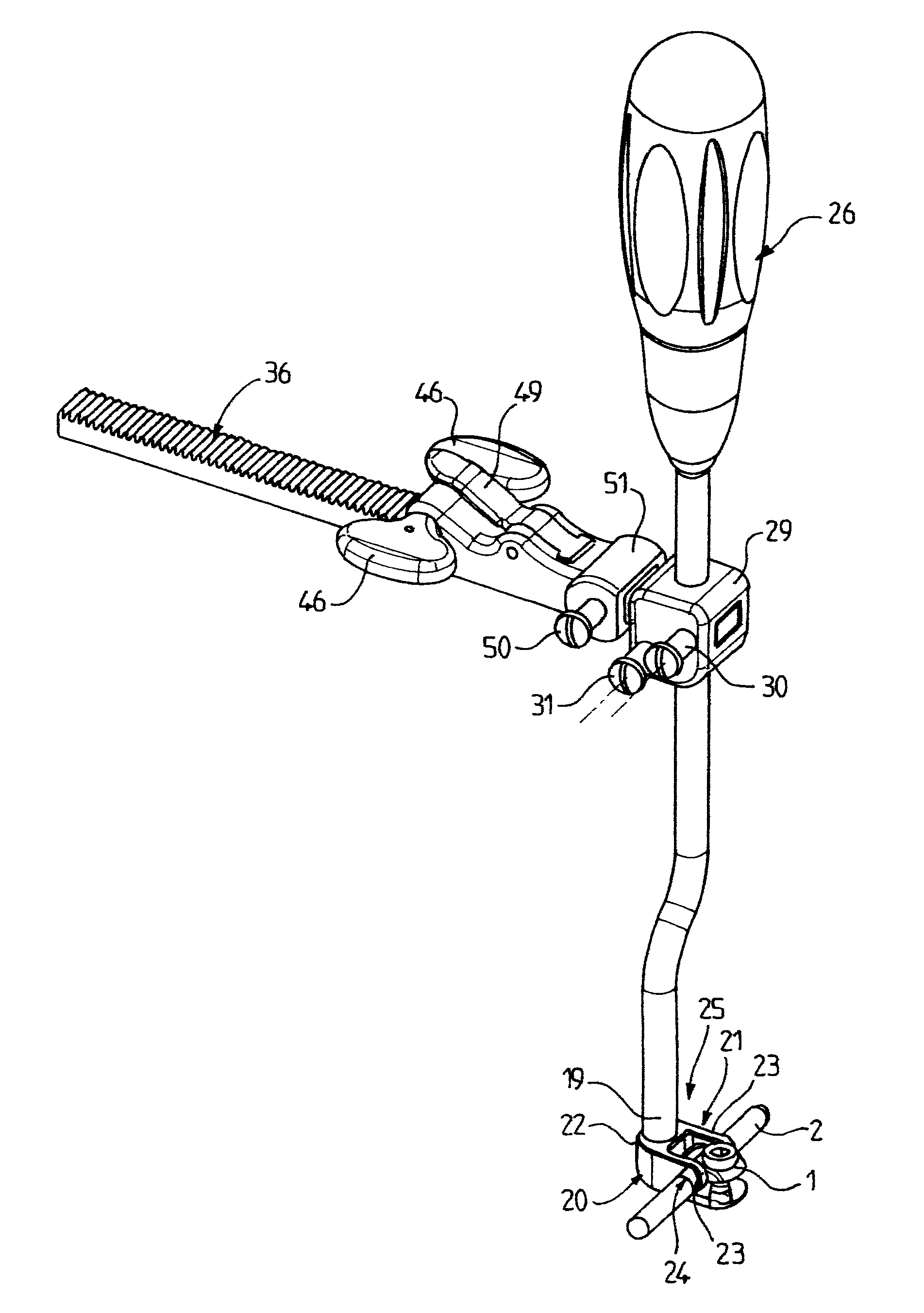

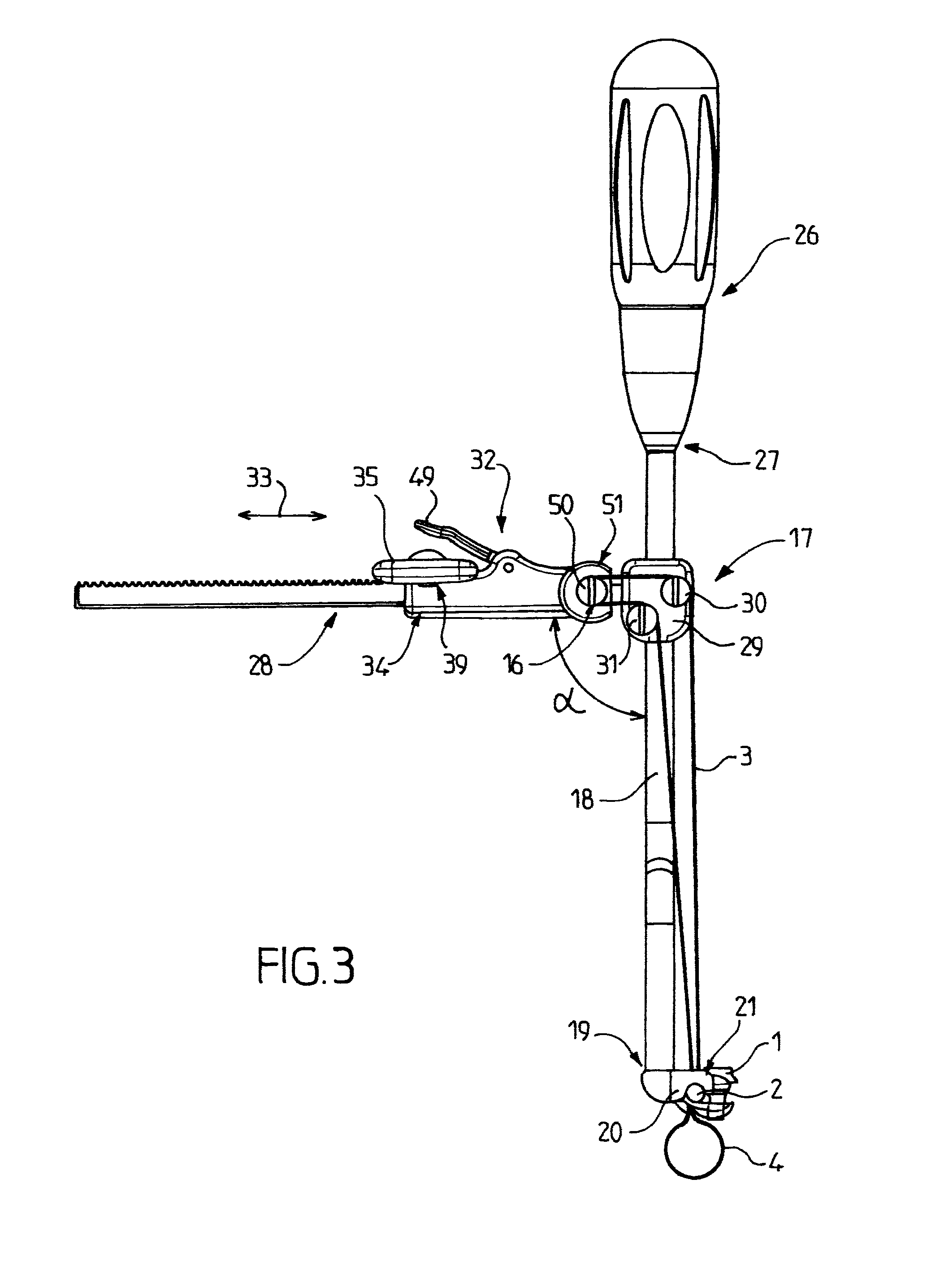

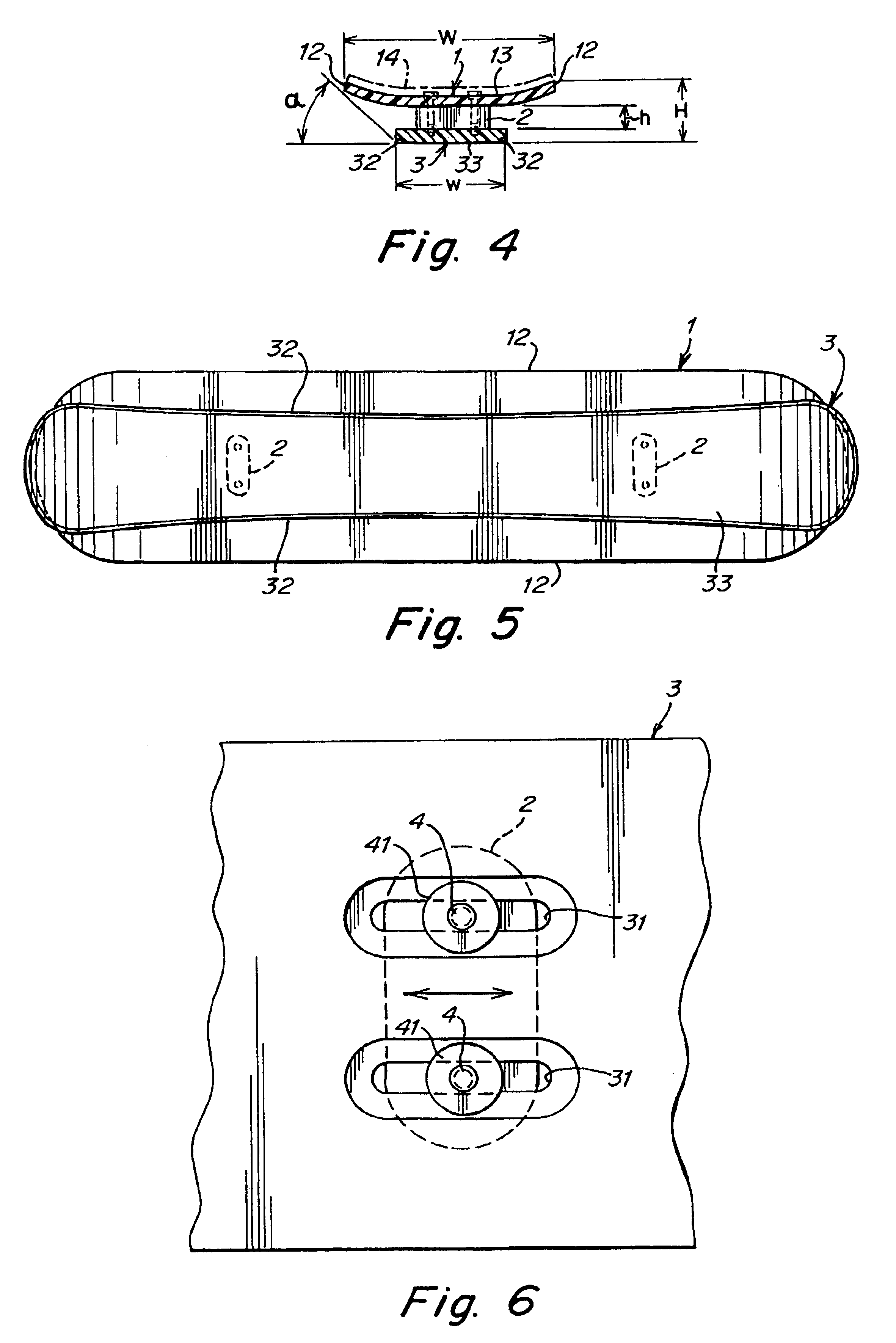

Device for tensioning a flexible band

ActiveUS20130261680A1Great flexibilityGood sensitivityInternal osteosythesisWire toolsBiomedical engineeringDevice form

A device (17) is provided for tensioning a flexible band (3) used to maintain a bone element on an implant. The device includes a rod (18) having a first end (19) provided with means (20) for bearing on the implant, a movable part (32) for hooking the flexible band onto a portion (28) of the device, and means (34) for adjustably locking the movable part in translation in relation to the portion of the device. The rod (18) includes a gripping handle (26) at the second end (27) thereof. The aforementioned portion of the device forms an angle α with the rod (18) to which it is rigidly connected at an intermediary point, the direction of the band being altered at an angle, and the aforementioned adjustable locking means (34) includes manual screwing means (35) for actuating the movable part.

Owner:IMPLANET SA

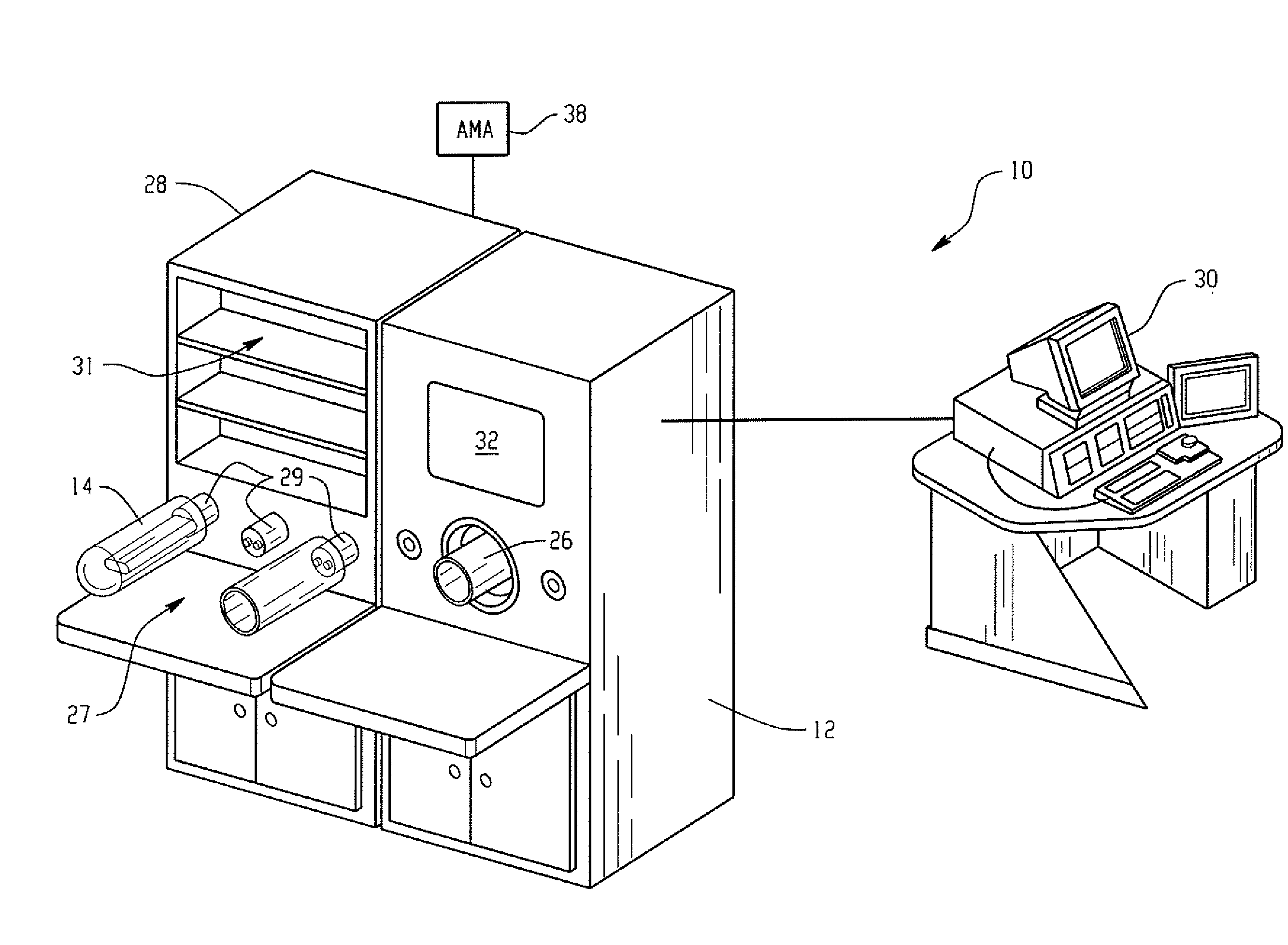

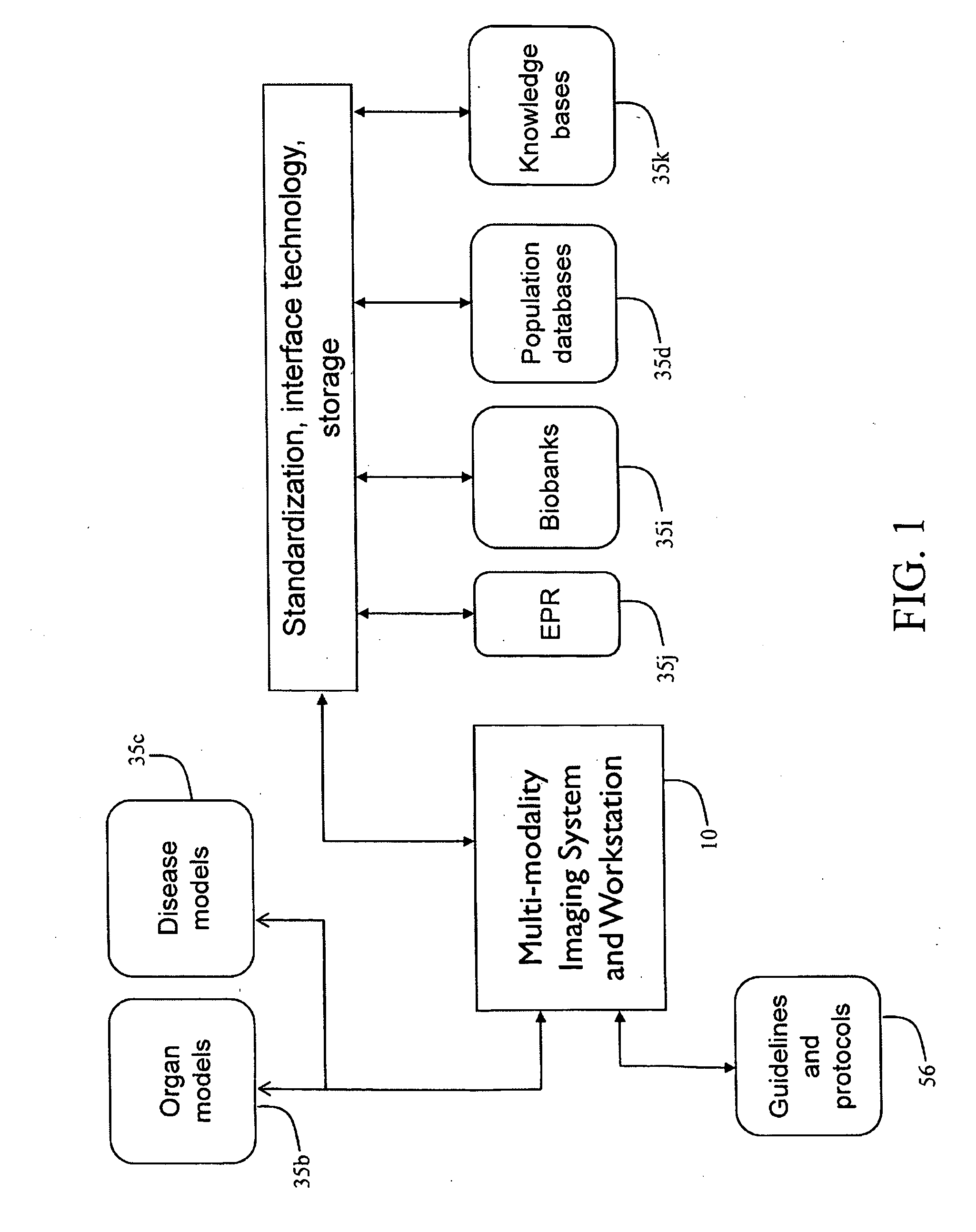

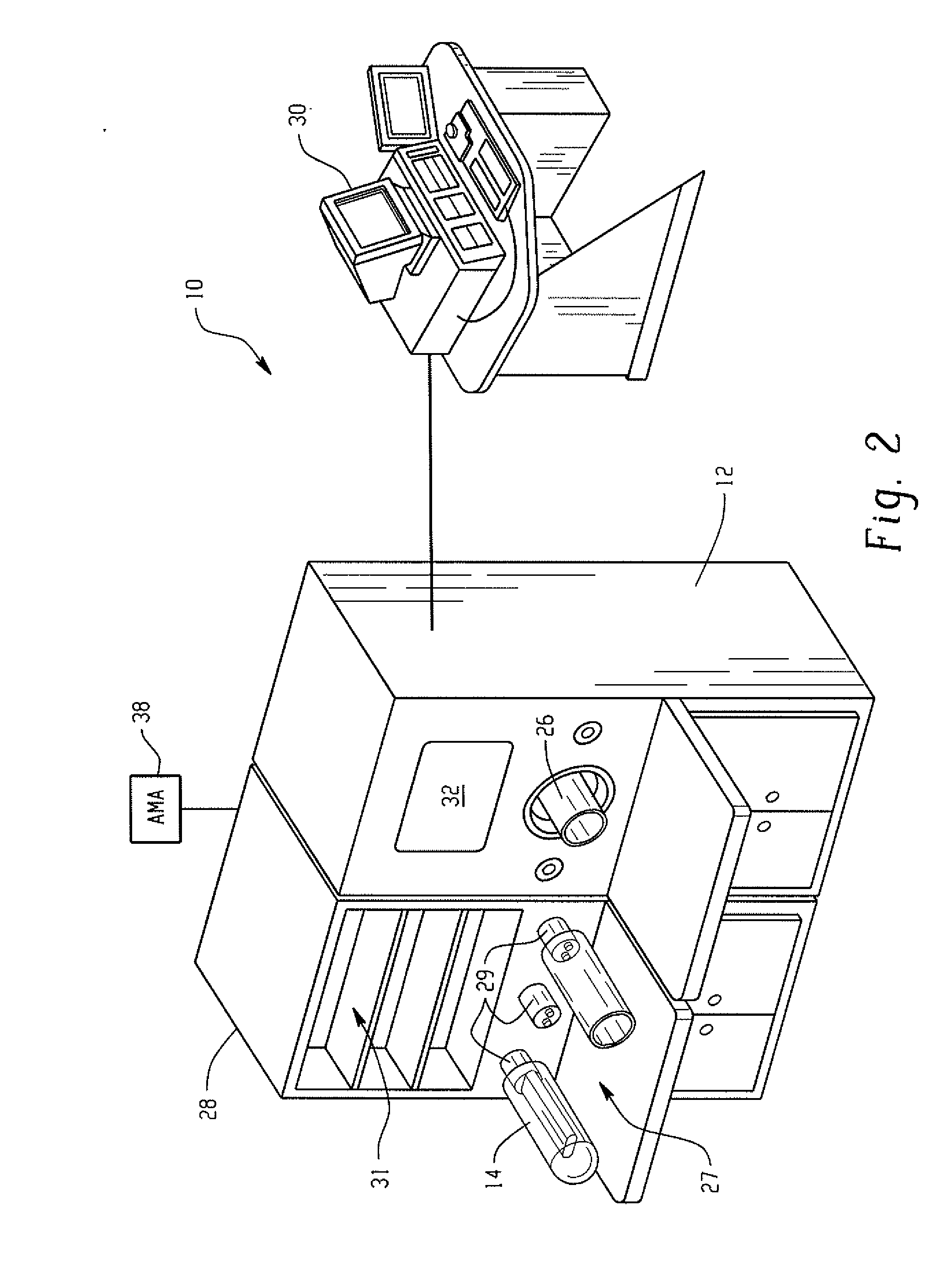

Multi-modal imaging system and workstation with support for structured hypothesis testing

InactiveUS20090043172A1Improve reproducibilityGreat flexibilityRespiratorsSurgeryModularityImaging study

Investigation of in vivo models of disease requires imaging studies involving single subjects in single imaging sessions, serial imaging of individuals or groups of subjects, and integration of data across diverse and heterogeneous experimental methodologies. Each type of experiment is preferably supported by various feature sets that can be rigorously applied to produce quantitative, reproducible results. Current imaging scanners are not equipped with standardized capability that supports an automated and scientifically rigorous workflow suited to hypothesis testing. An imaging system includes a research workstation at which a user can design, execute, study, and report imaging plans. Flexibility that comes along with a modular design of the system allows the user to customize workflow parameters for more robust hypothesis testing.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

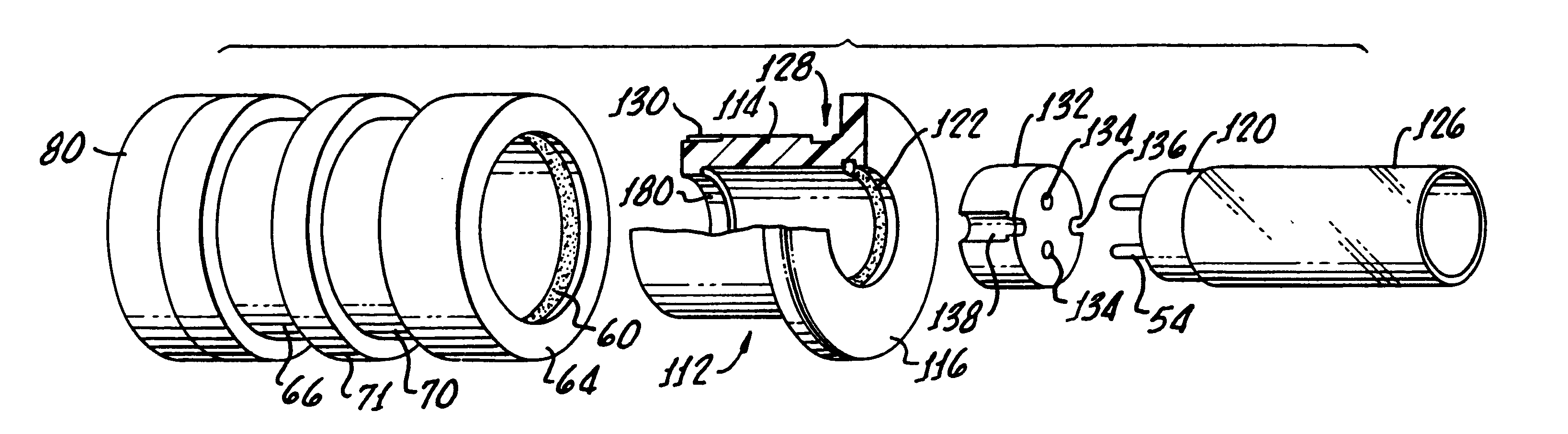

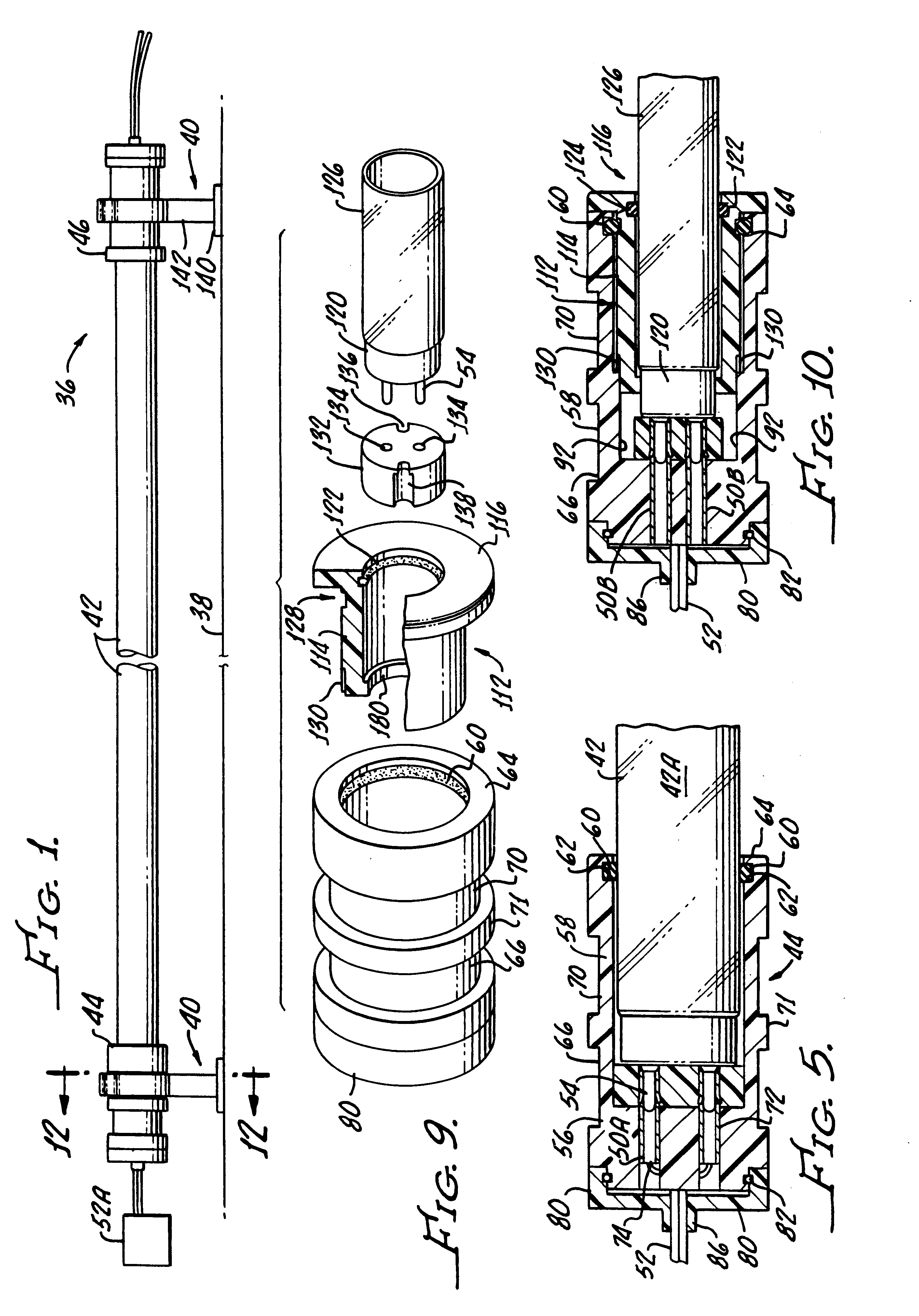

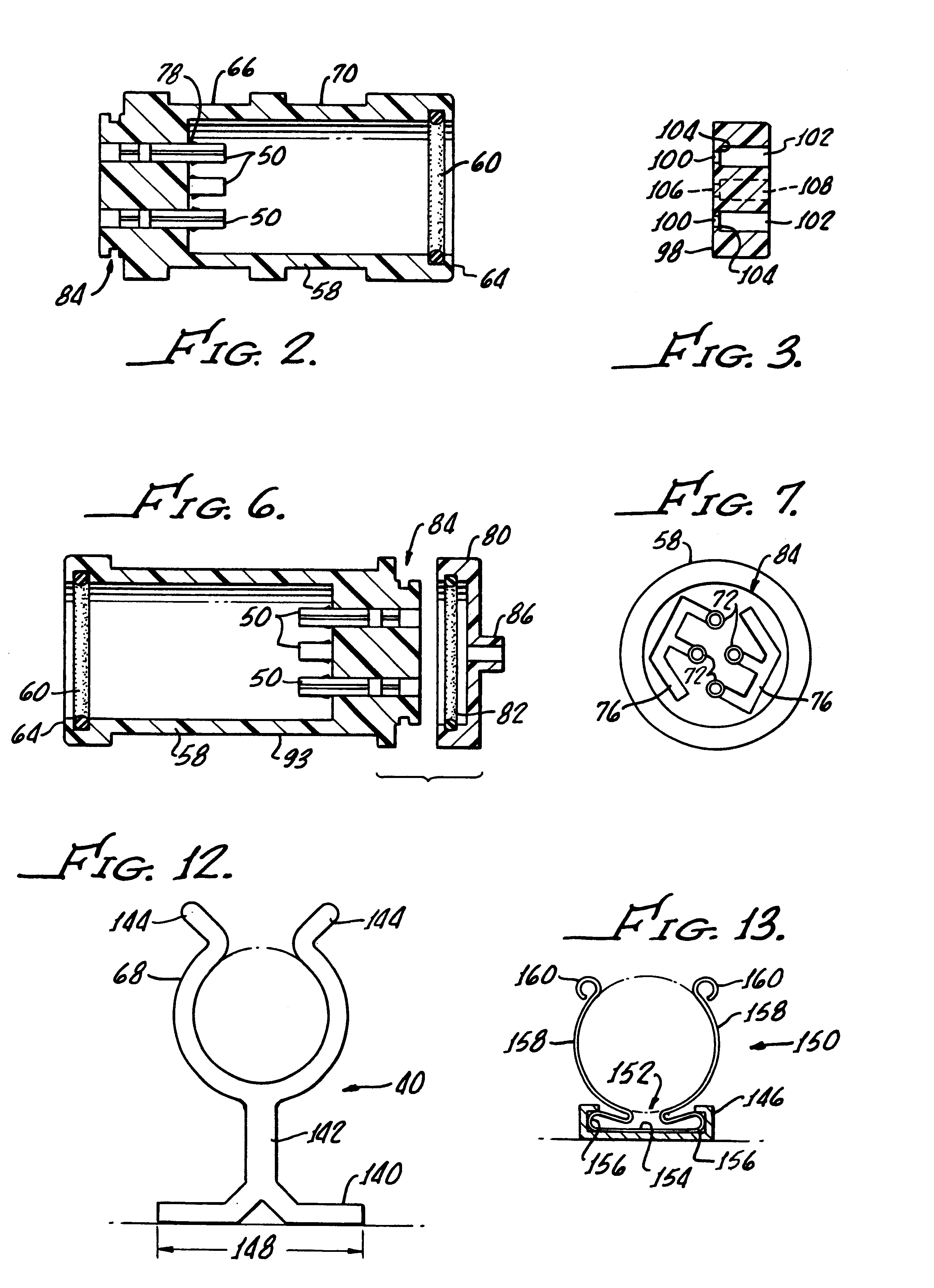

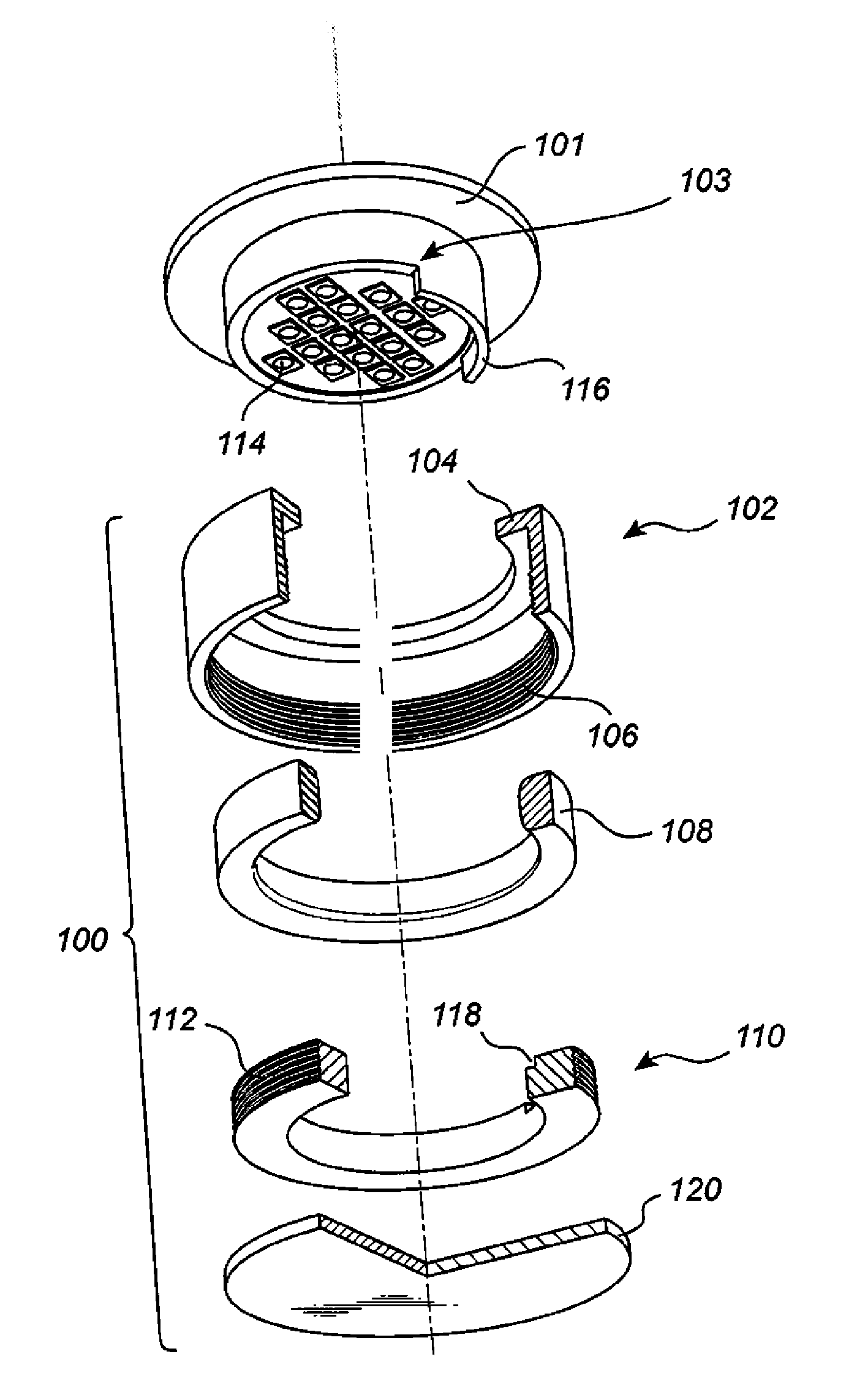

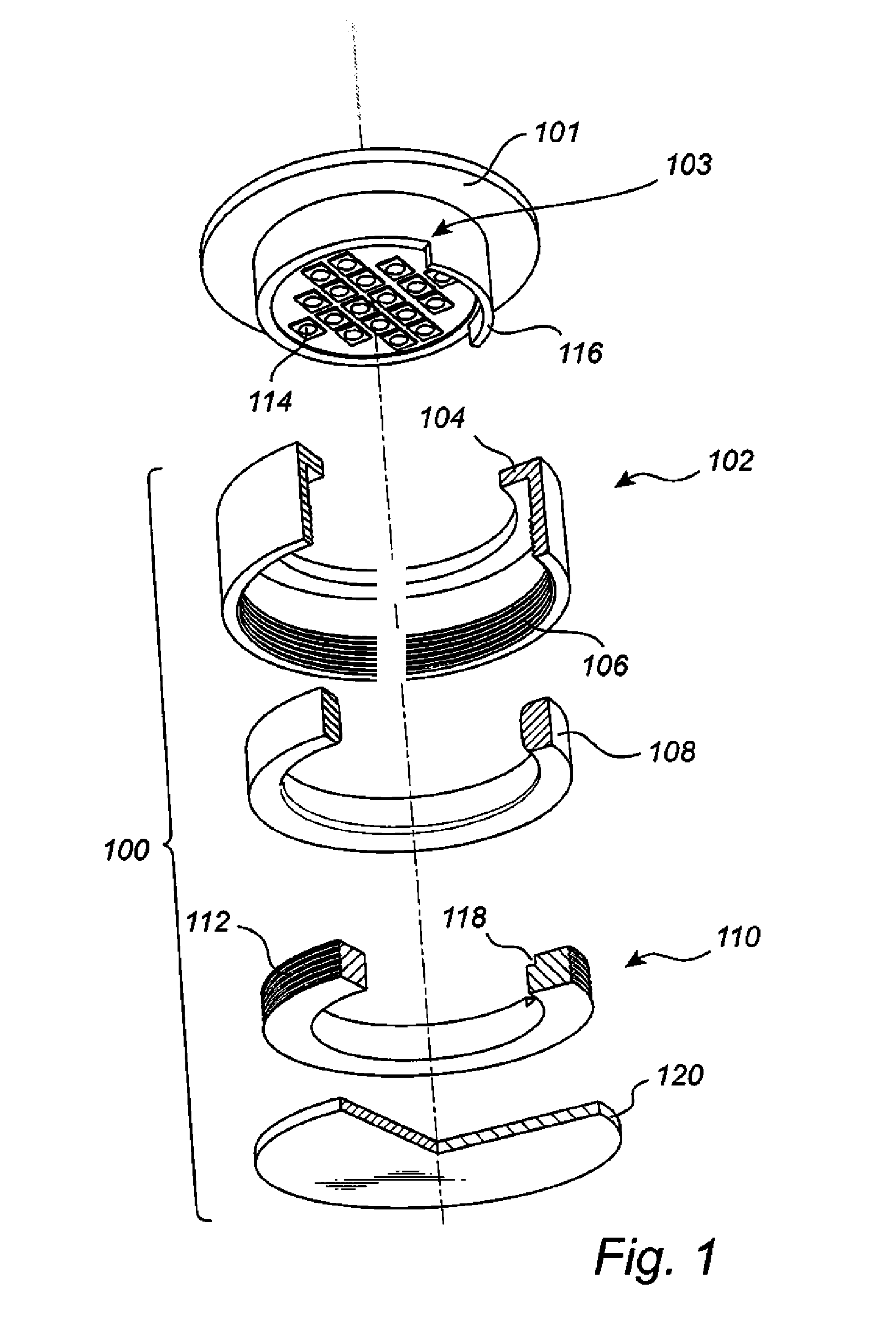

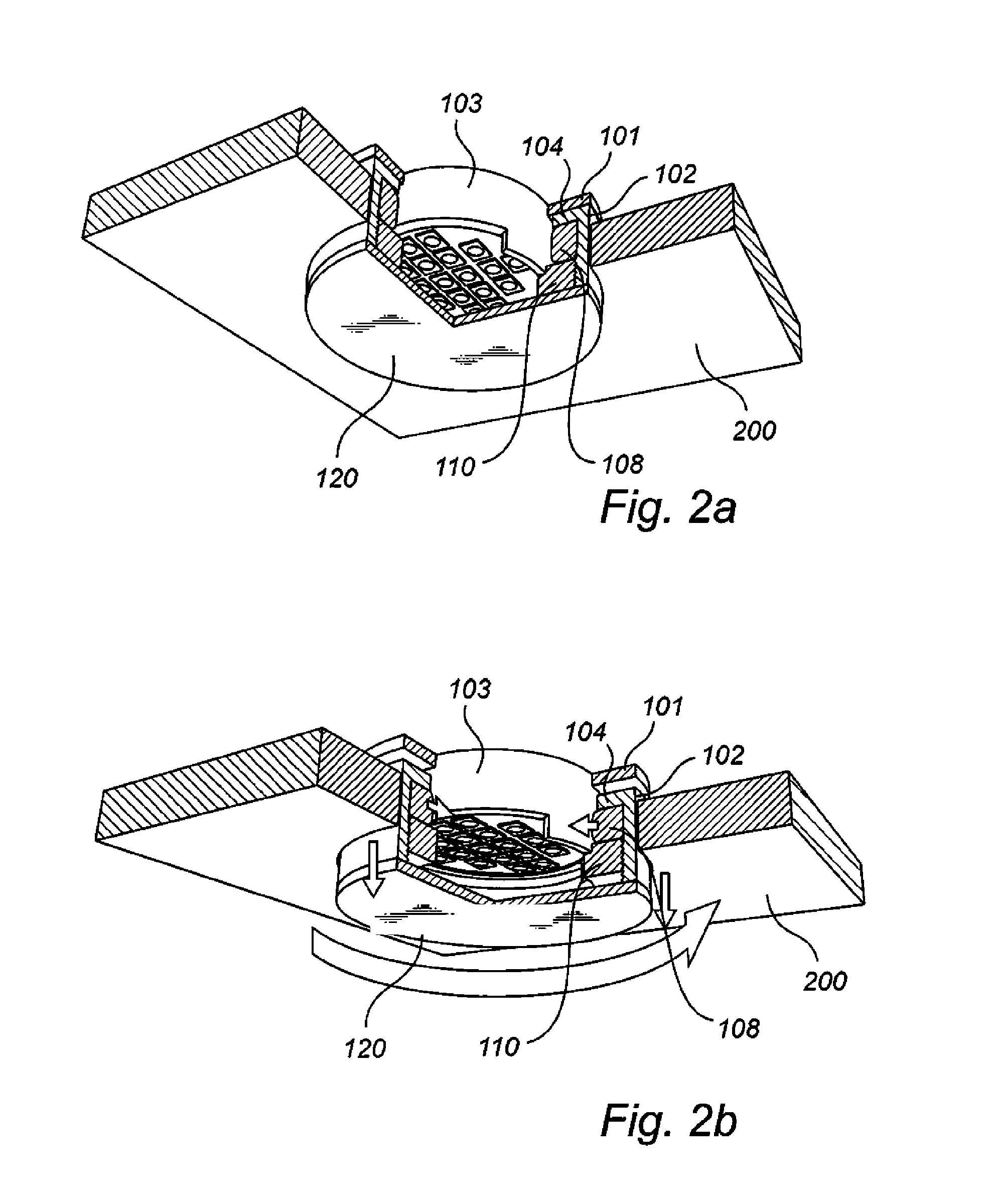

Lighting system method and apparatus socket assembly lamp insulator assembly and components thereof

InactiveUS6632100B1High open circuit voltageGreat flexibilityCoupling device connectionsMechanical apparatusLighting systemEnvironmental effect

A socket is described for a lighting assembly having a socket body and an electrical connector with a seal in the socket to seal around a light source. The socket is preferably configured to be independent of the mounting arrangement for the lighting assembly. An insulator is also disclosed for a lamp such as a fluorescent lamp having a body which covers the contact on the lamp so as to form a recessed lamp conductor. The combination of a socket and lamp insulator is also disclosed for providing a socket and insulator assembly for reducing the possibility of injury or damage due to high open circuit voltage, environmental effects and the like. Additionally, a lighting assembly is disclosed incorporating the insulator, socket and mounting arrangements.< / PTEXT>

Owner:ANTHONY INC

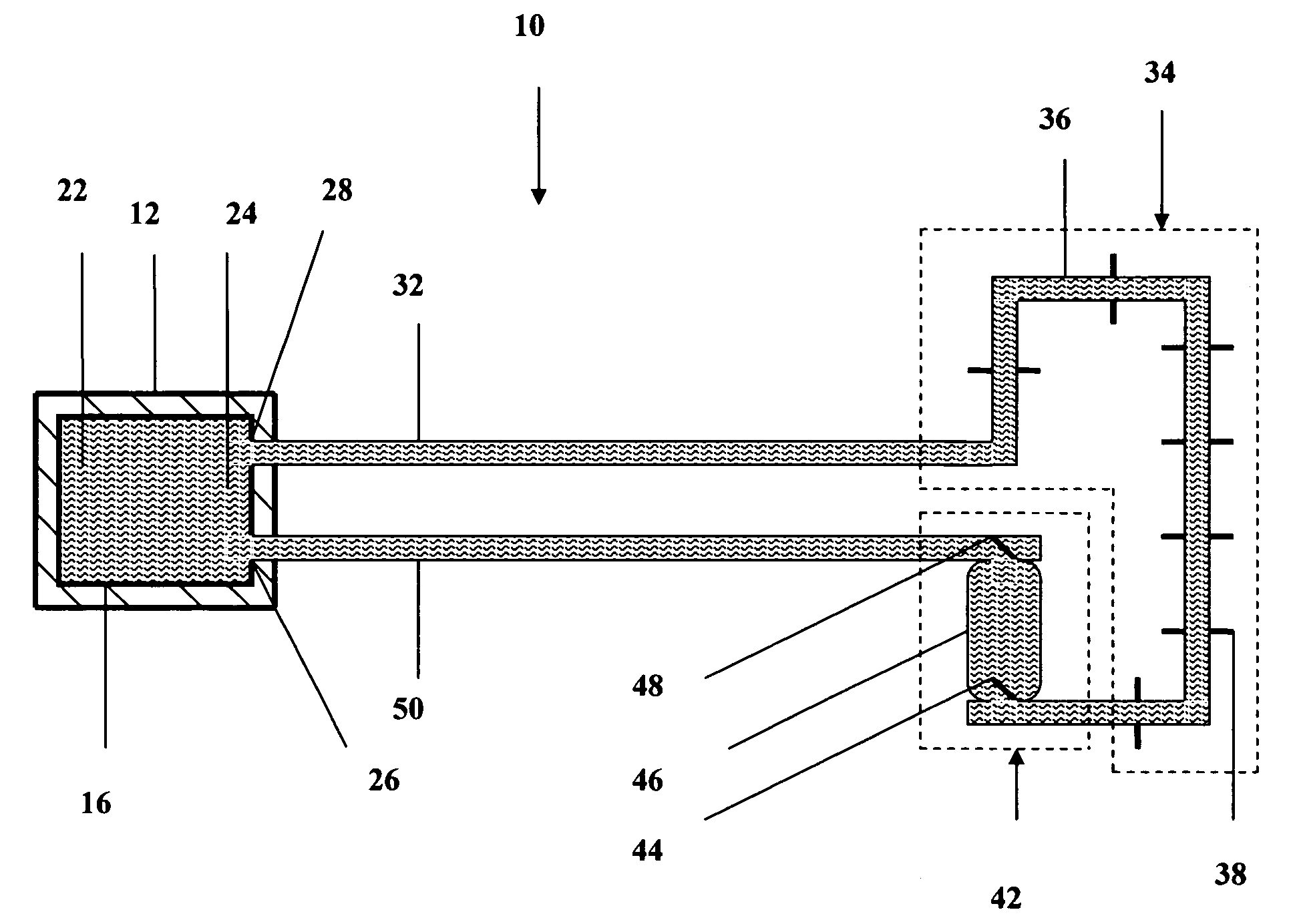

Self-actuating and regulating heat exchange system

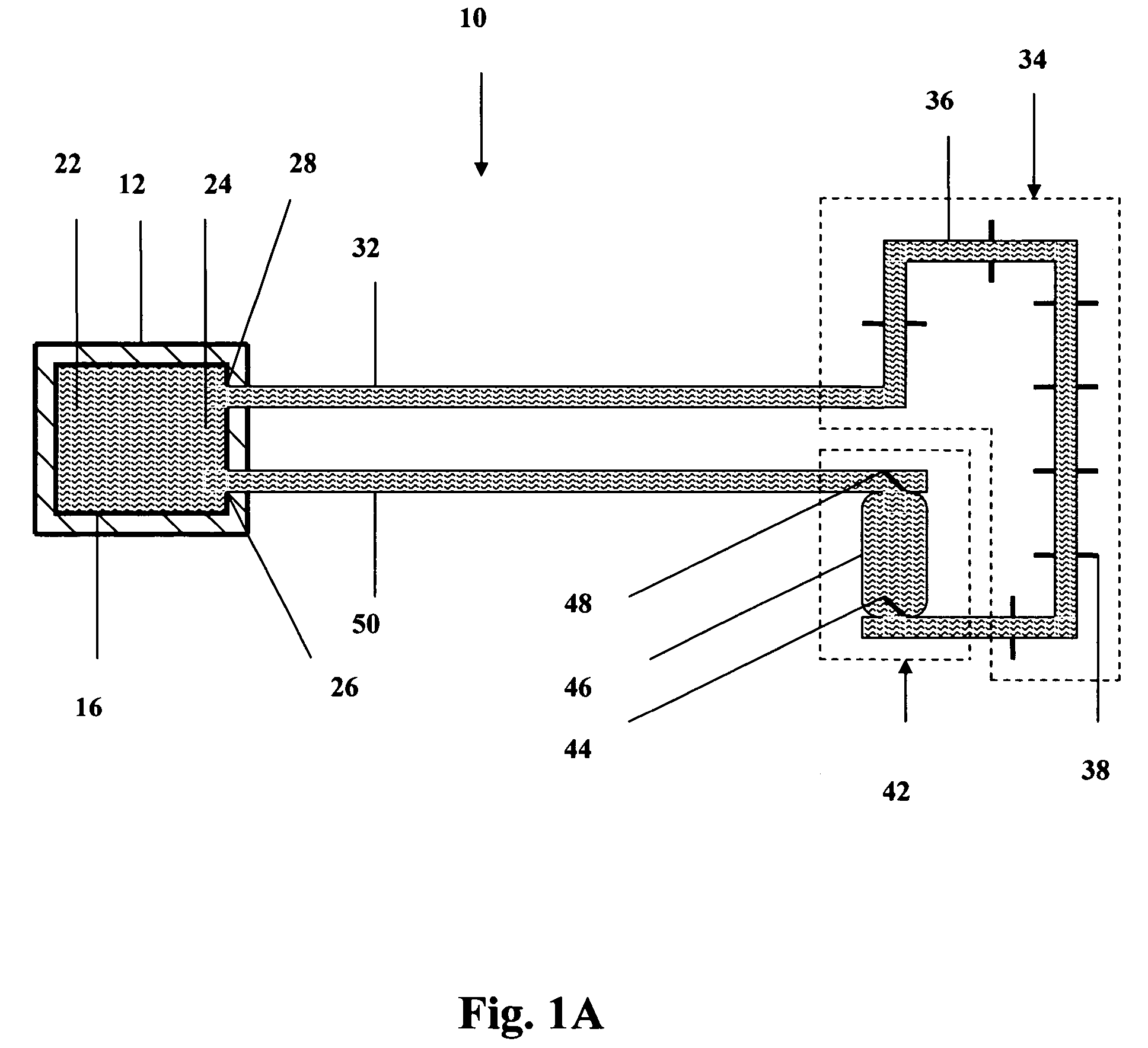

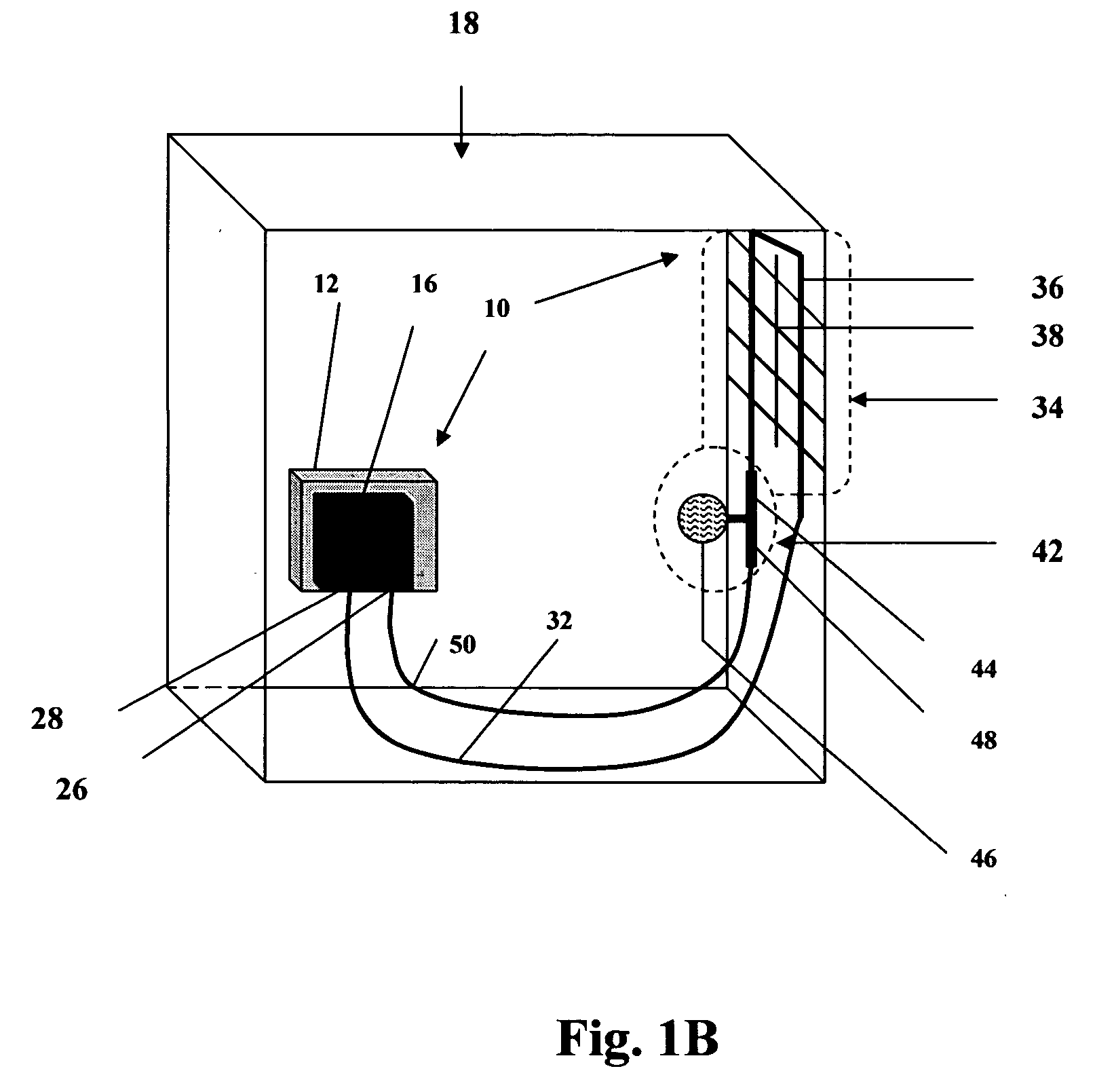

InactiveUS20060065386A1Efficient and convenient for transportGreat flexibilityDigital data processing detailsSemiconductor/solid-state device detailsHot zoneEvaporator

A self-actuating and self regulation heat exchange system comprising: evaporator 16, condenser 34, bladder sub-system 42, phase-change fluid 24 and connecting tubes, is a device and an apparatus useful to transport thermal energy from a relatively hot zone to a relatively cold zone, over distance, and around or through obstructions. The bladder sub system, consisting of an expandable bladder and two one-way check-valves, utilizes the pressure difference in the system created during evaporation and condensation to make the phase-change fluid circulate inside the closed loop system, transferring thermal energy from evaporator to condenser. The operation of the device is self started, self regulated and the device is almost independent of gravity, and the orientation.

Owner:ALAM MOHAMMED

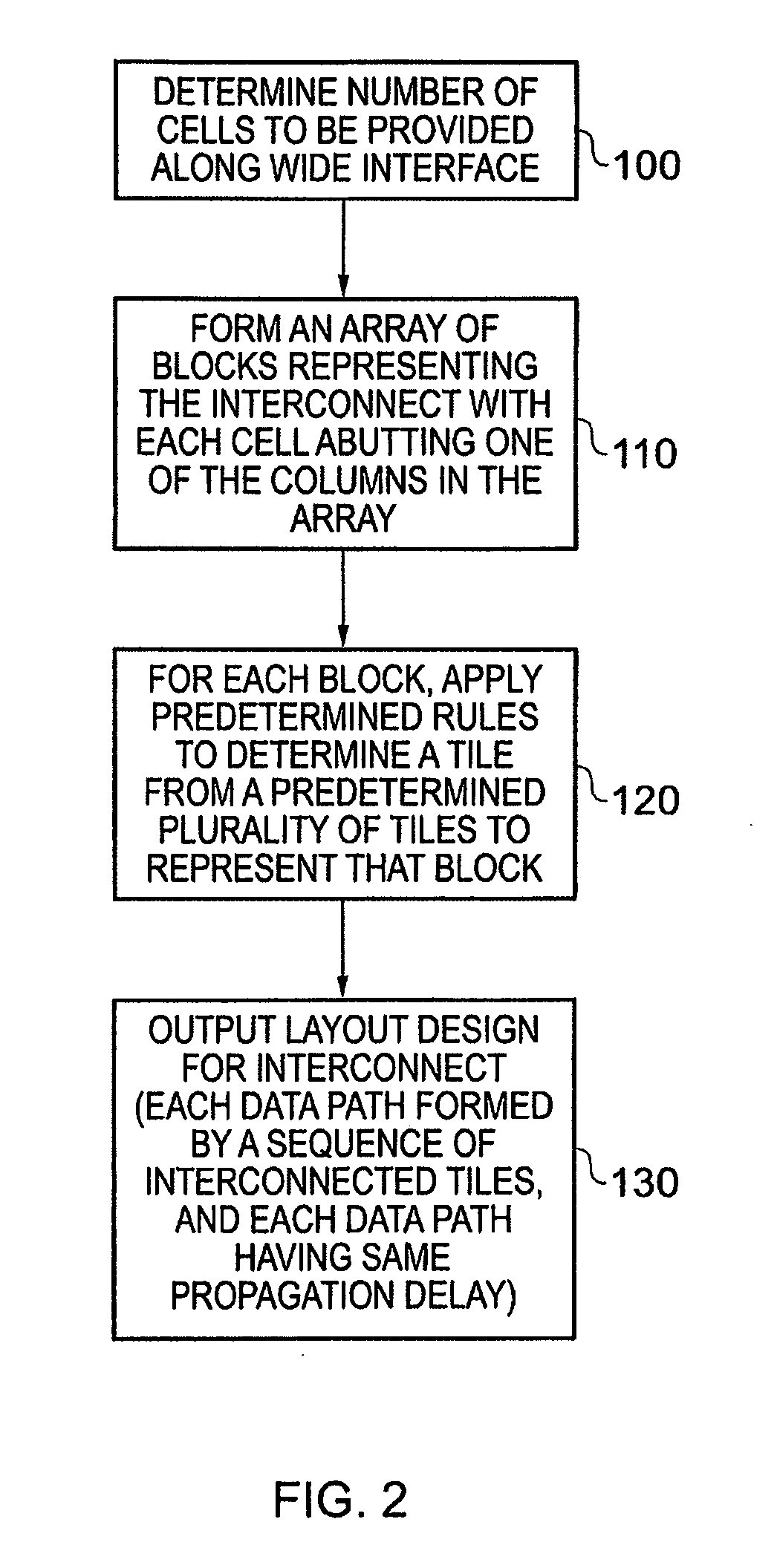

Method, system and computer program product for determining routing of data paths in interconnect circuitry

ActiveUS20090288056A1Great flexibilityImprove flexibilitySolid-state devicesComputer aided designPropagation delayIntegrated circuit

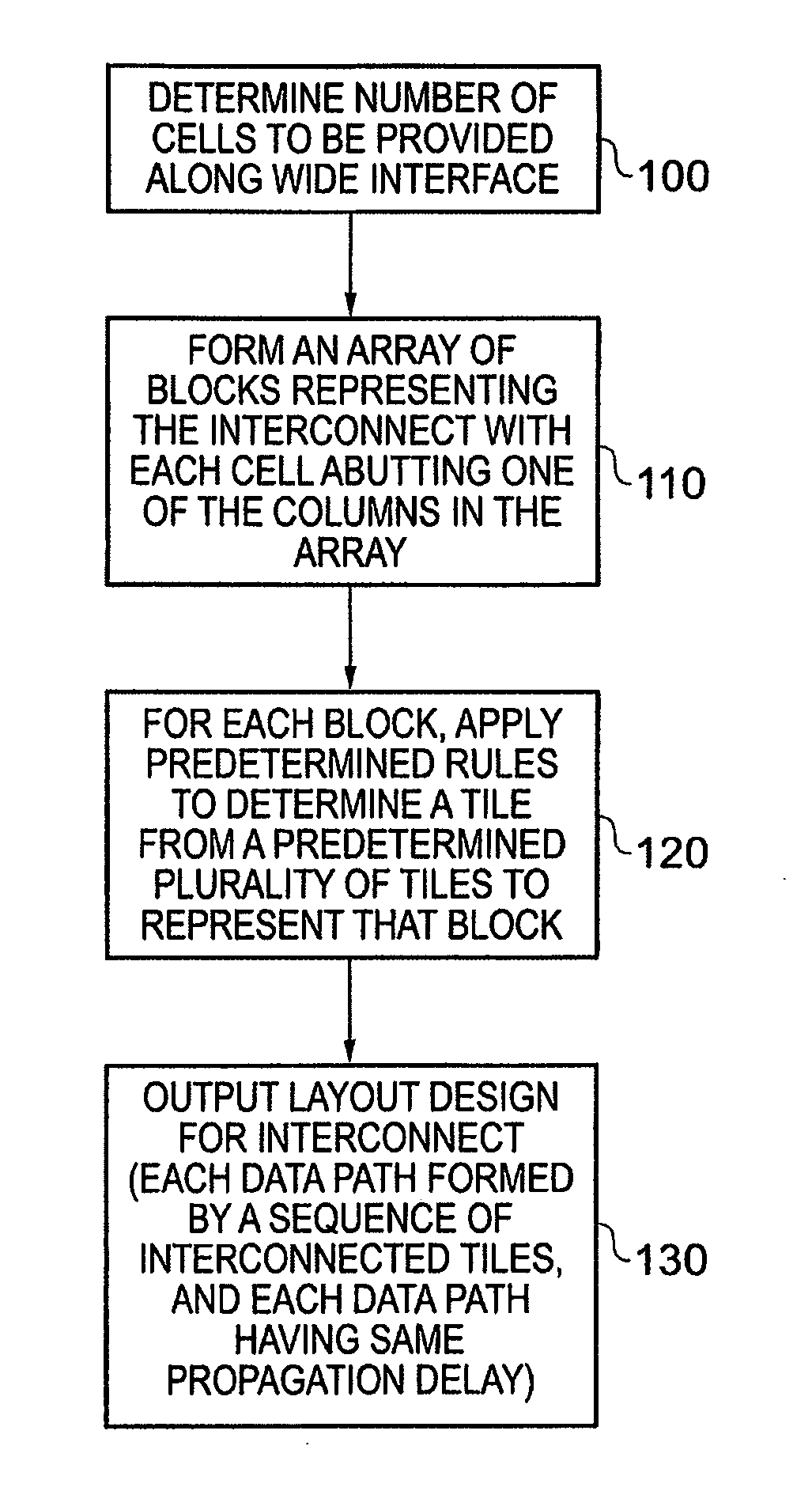

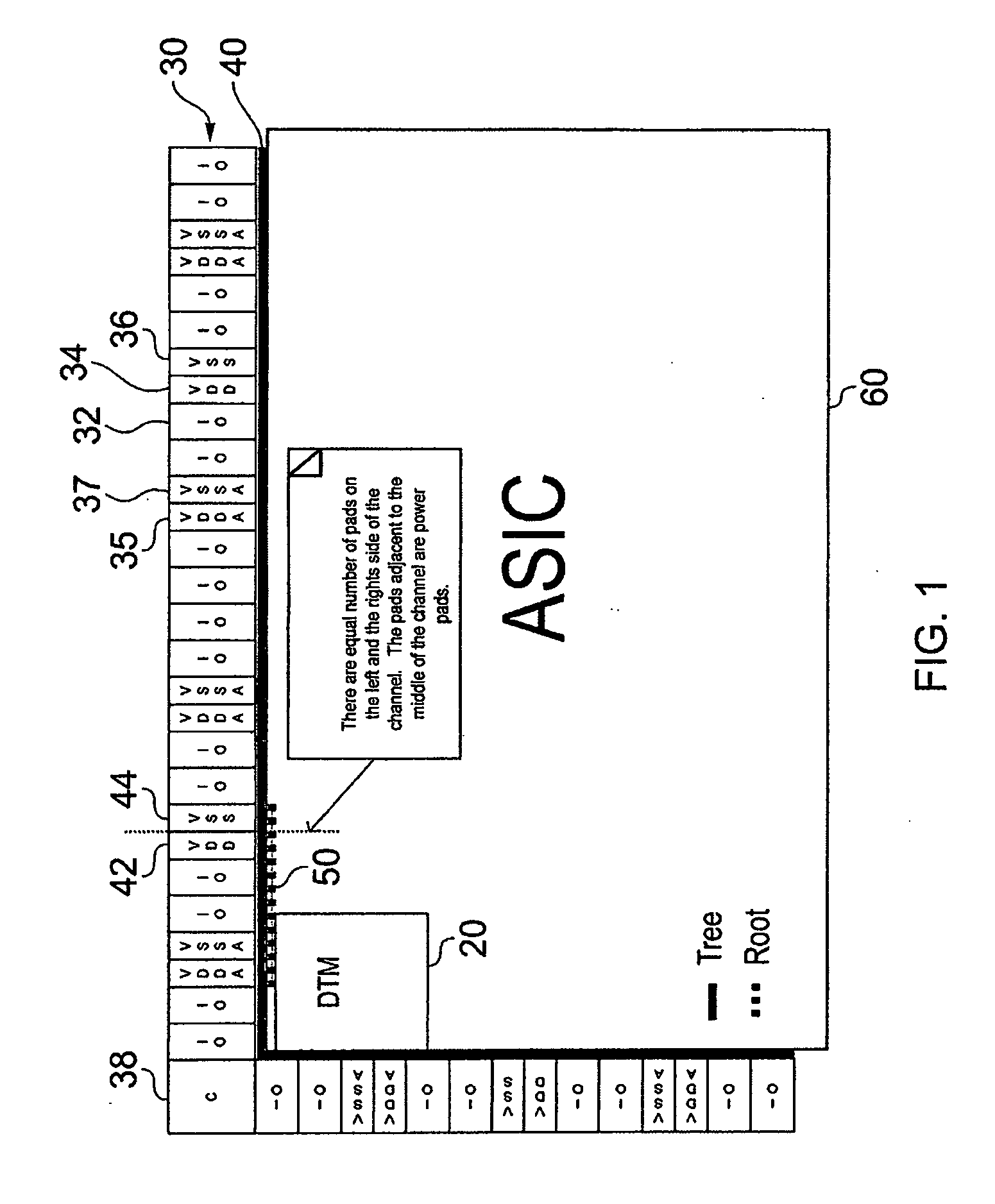

A system, method and computer program product are provided for determining routing of data paths in interconnect circuitry for an integrated circuit. The interconnect circuitry on a first side provides a narrow interface for connection to a first device, and on a second side provides a wide interface for connection to a distributed plurality of further devices. Each data path is associated with one of the further devices and provides a connection through the interconnect circuitry between that associated further device and the first device. The method comprises the steps of defining a plurality of cells to be provided along the wide interface, each of the further devices being associated with at least one of the cells, and defining the interconnect circuitry as an array of blocks formed in rows and columns, with each cell abutting one of the columns. Further, the method includes the steps of providing a predetermined set of tiles, each tile providing a predetermined wiring layout, and for each block, applying predetermined rules to determine one of the tiles to be used to implement that block. The predetermined rules take into account the location of the block in the array and the association between the plurality of further devices and the plurality of cells, ensuring that each data path provided by the interconnect circuitry has the same propagation delay. By such an approach, a structured routing method is provided that uses predetermined tiles enabling a layout design for the interconnect circuitry to be readily produced whilst ensuring that the propagation delays are matched for each of the data paths within the interconnect circuitry.

Owner:ARM LTD

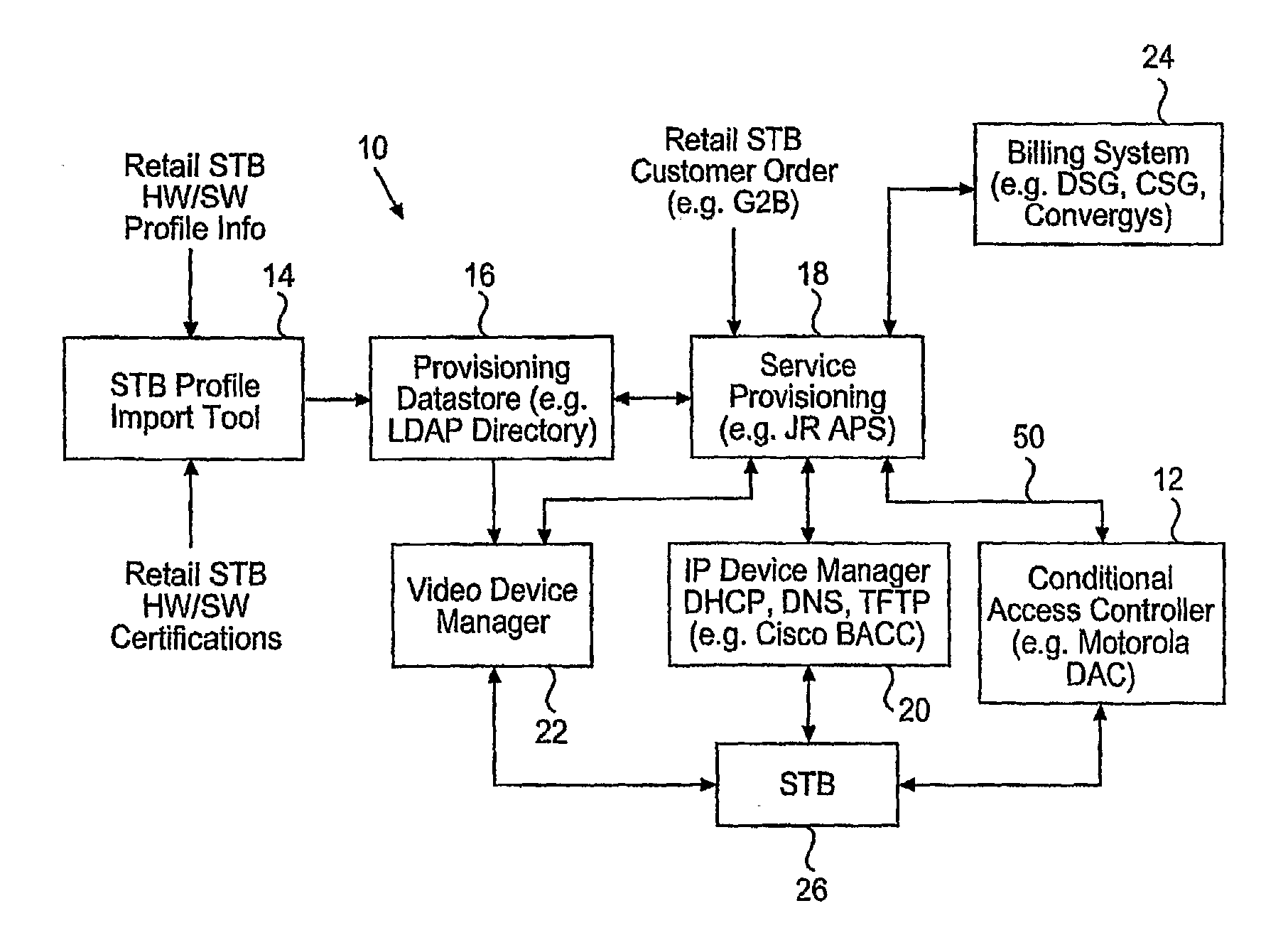

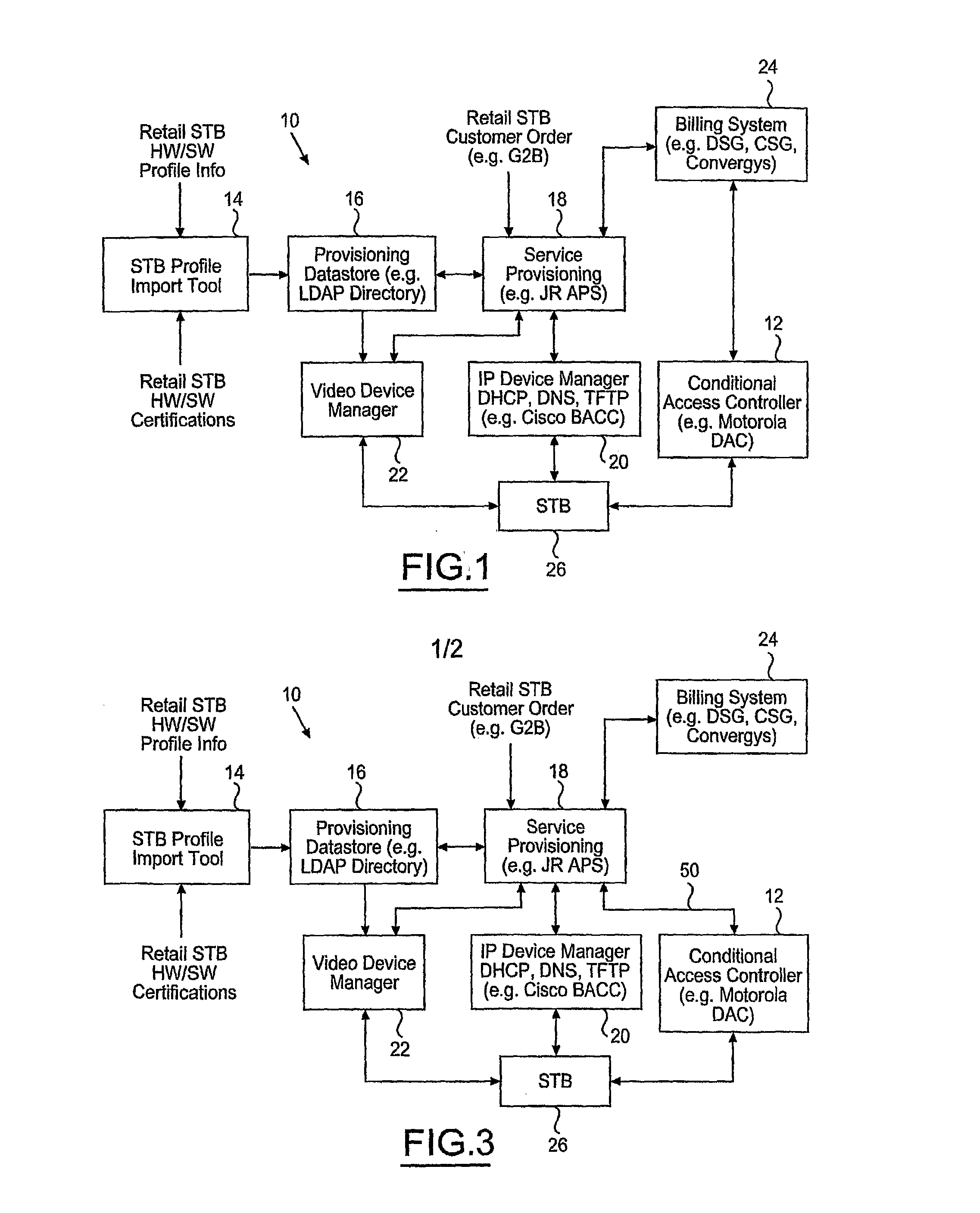

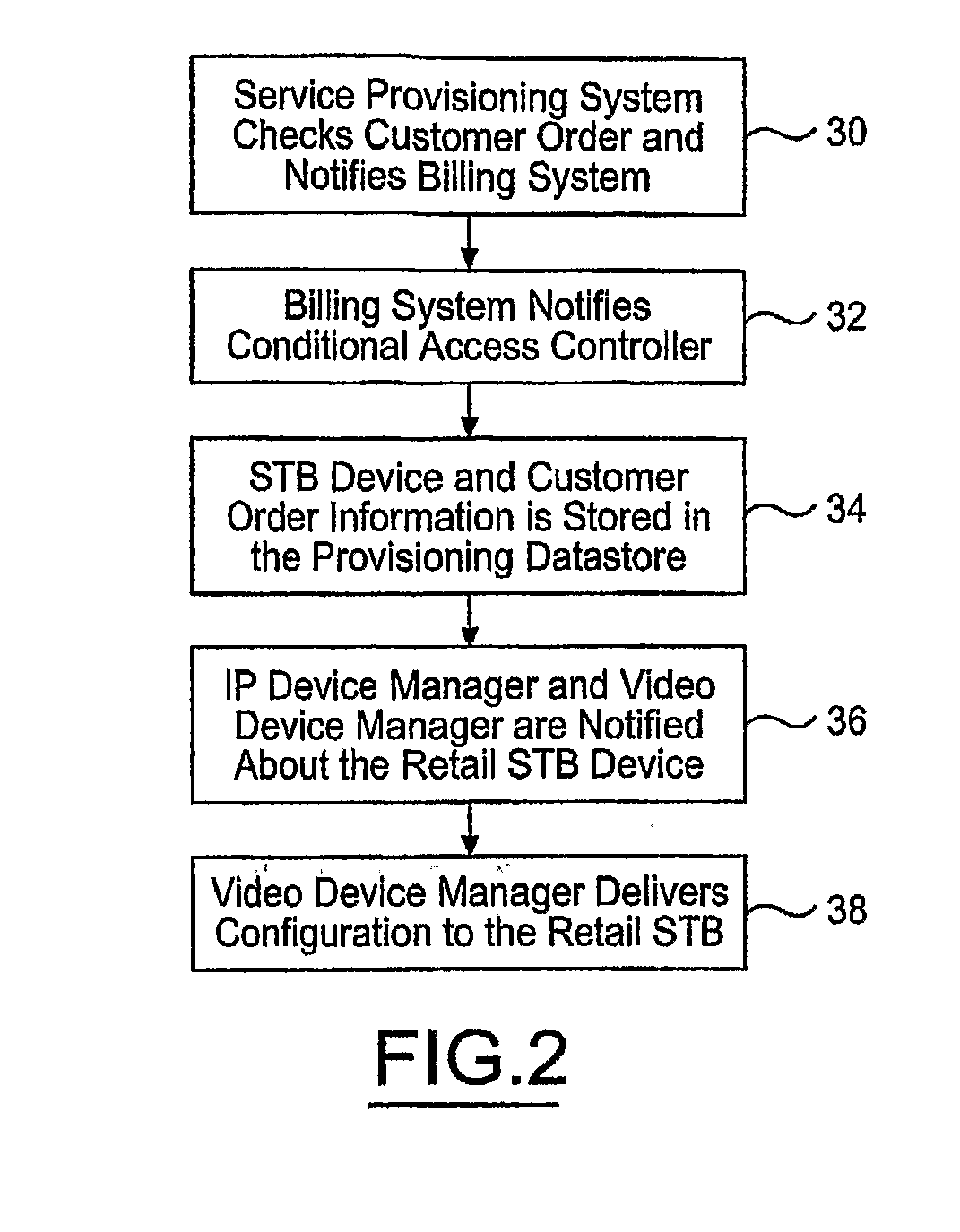

Method and System for Provisioning a Set-Box

ActiveUS20070209052A1Great flexibilityGood flexibilityTelevision system detailsDigital computer detailsBilling systemCustomer order

A method and system of provisioning a set-top box (STB) with a STB provisioning system are provided which include storing STB profile information in a provisioning datastore, receiving a customer order at a service provisioning system, notifying a billing system of the customer order, and notifying a conditional access system of the customer order. The method and system further include storing information from the customer order in a provisioning datastore, notifying a video device manager about the STB, and delivering a cable operator configuration message from the video device manager to the STB, the configuration message being based on information from the provisioning datastore, thereby provisioning the STB without essential involvement of the conditional access system.

Owner:COMCAST CABLE COMM LLC

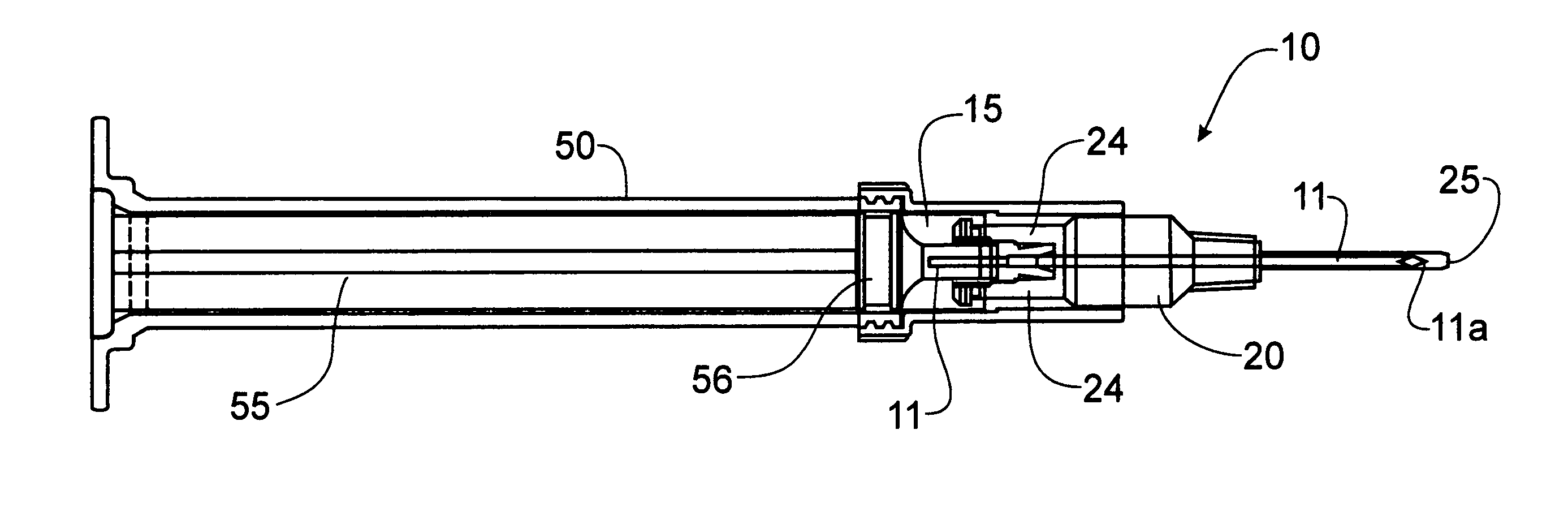

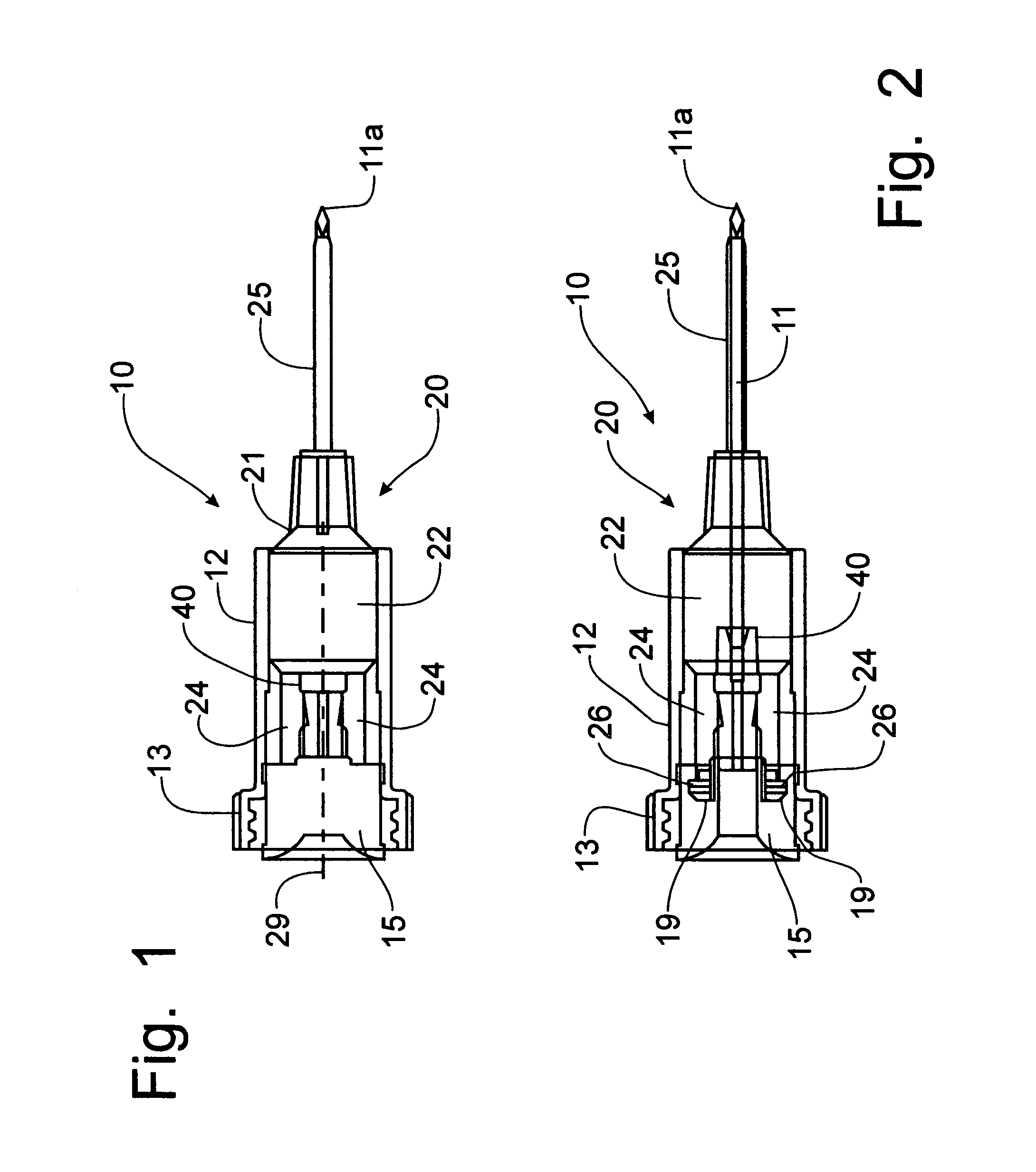

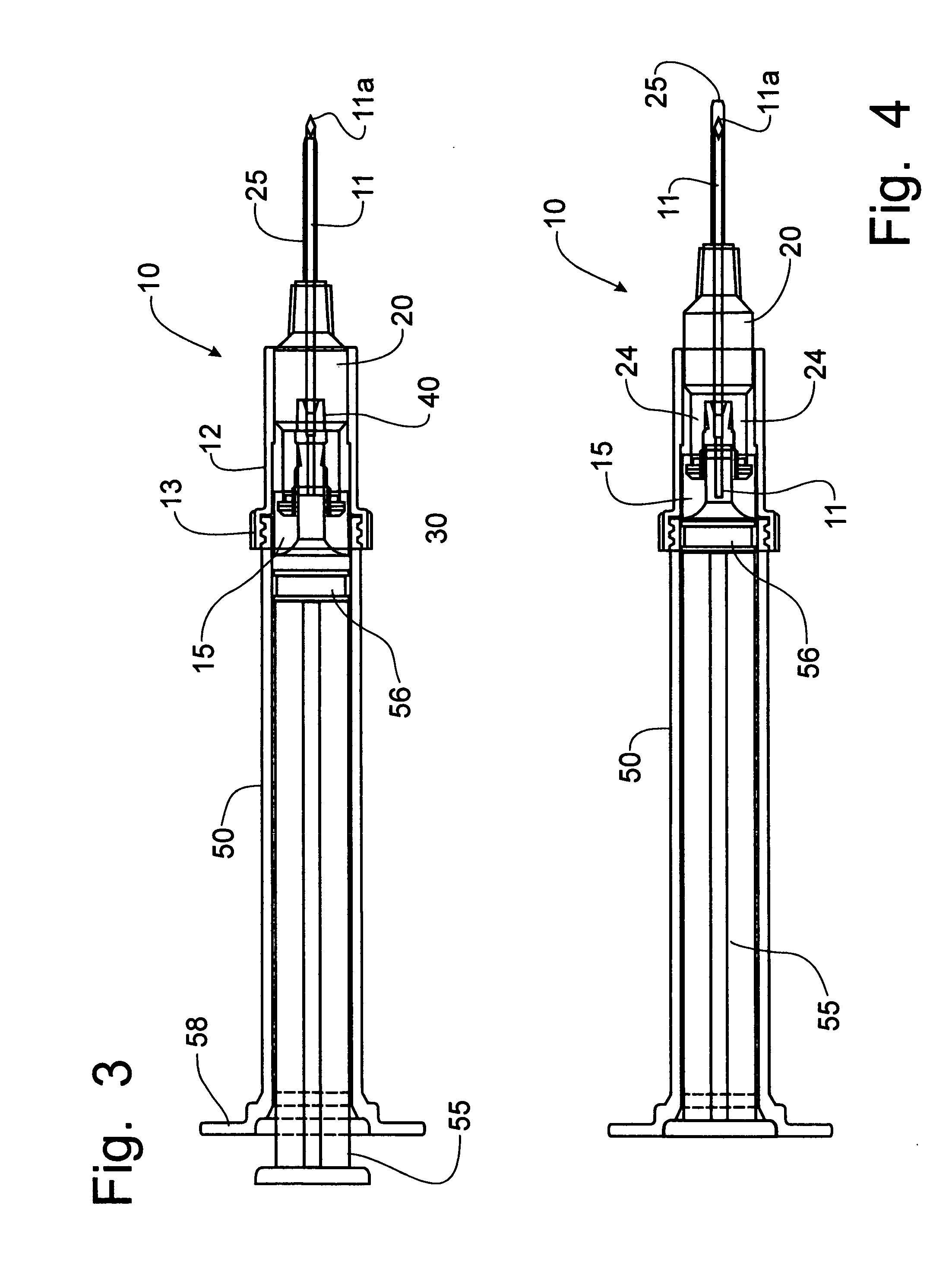

Needle assembly for multiple syringe barrels

InactiveUS20070016145A1Great flexibilityDurable in constructionInfusion syringesInfusion needlesSyringeBiomedical engineering

A safety needle assembly having a rigid housing that encloses a locking mechanism, an actuator that is operable to slide a sheath over the tip of the needle to prevent accidental sticks after the needle has been used, and an actuator that is operable in response to the final end movement of the syringe plunger to effect movement of the actuator over the needle tip. The housing is made in a standard size that is mountable on a connection port formed on a syringe barrel that can have a much greater diameter than the connection port. An adapter is provided for mounting a standard needle having a Luer lock to enable a health care professional the flexibility to use conventional needles to load medicine into the syringe barrel then replacing with a safety needle assembly for injection of the medicine.

Owner:DEVON SAFETY PRODS

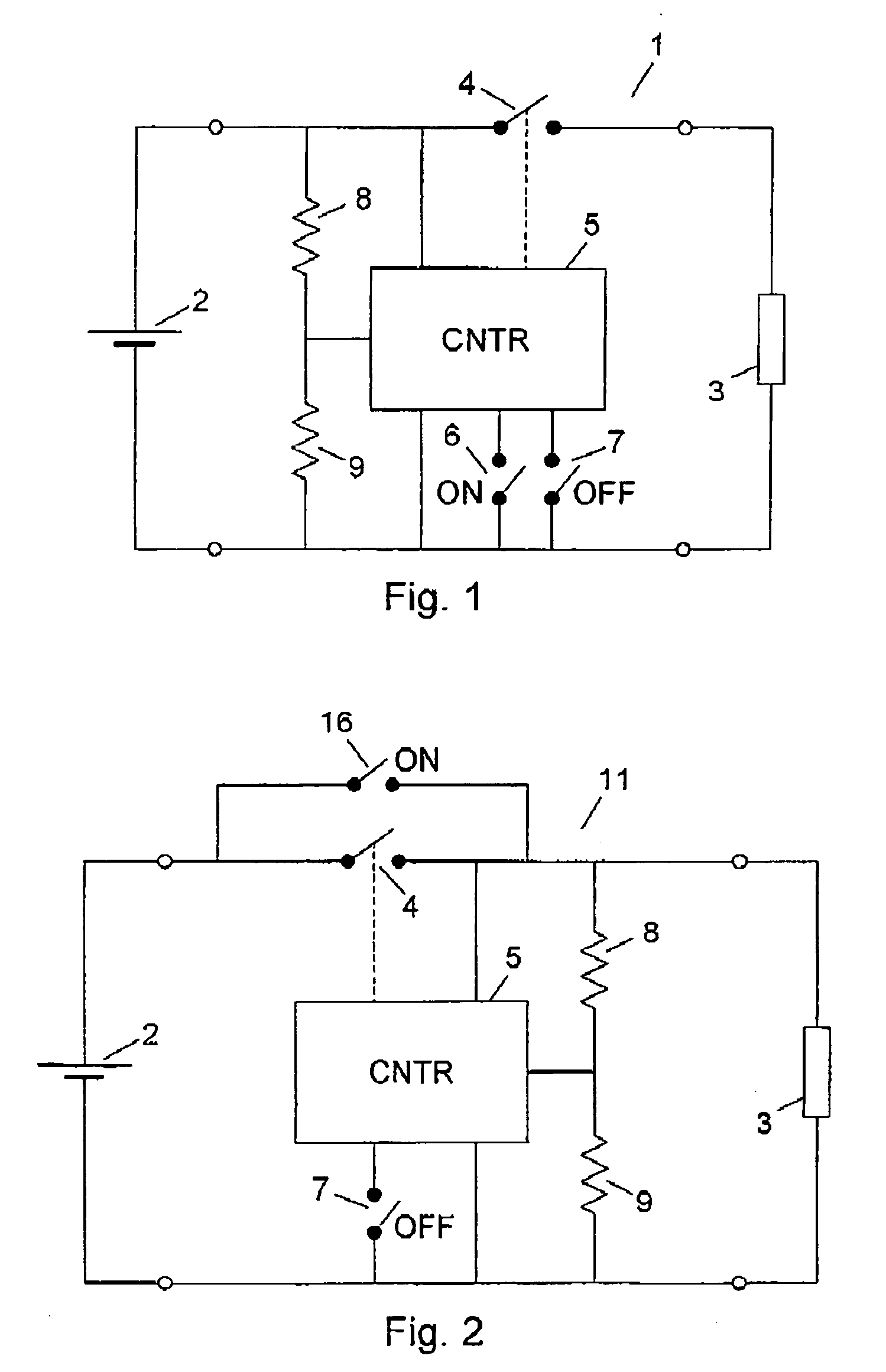

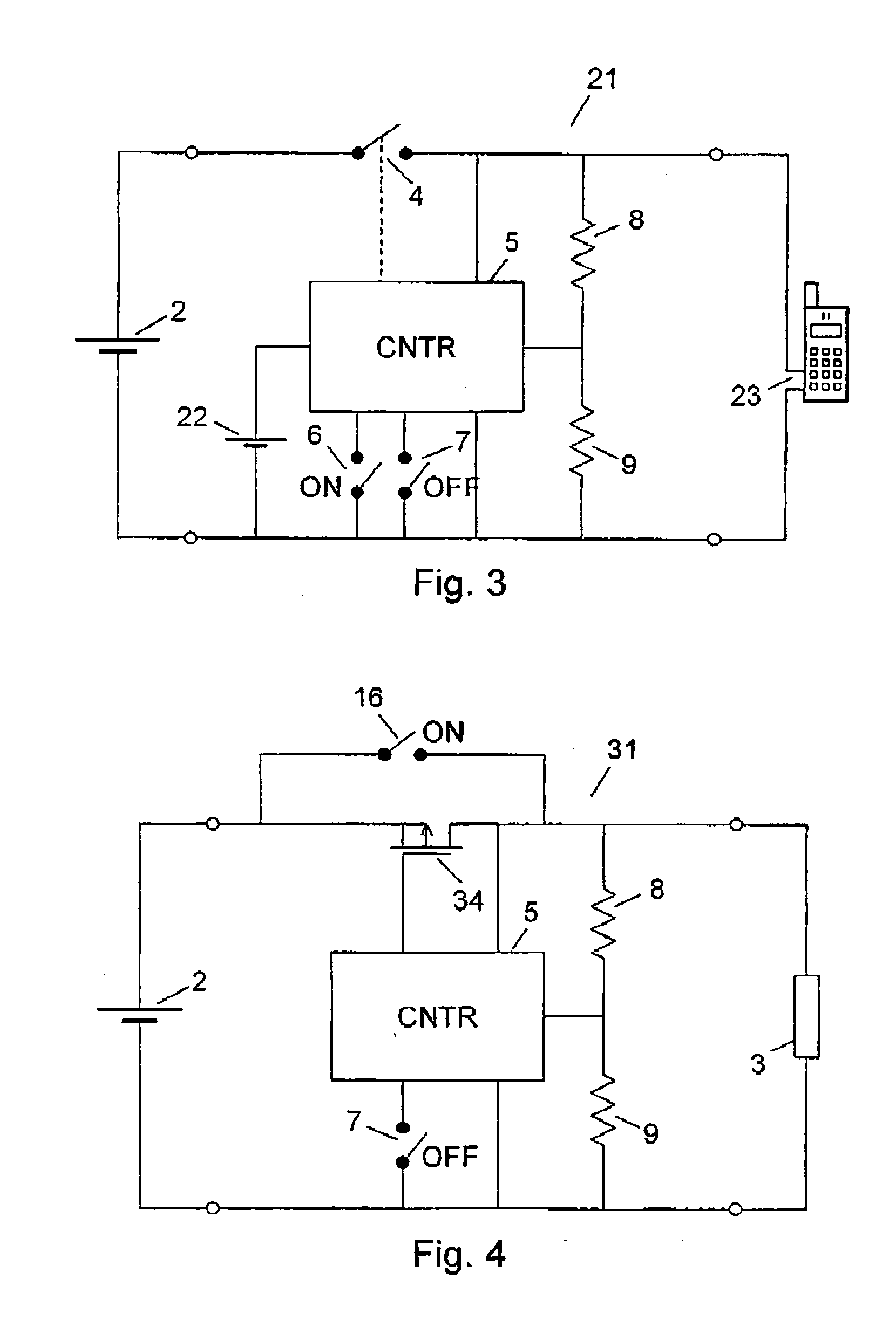

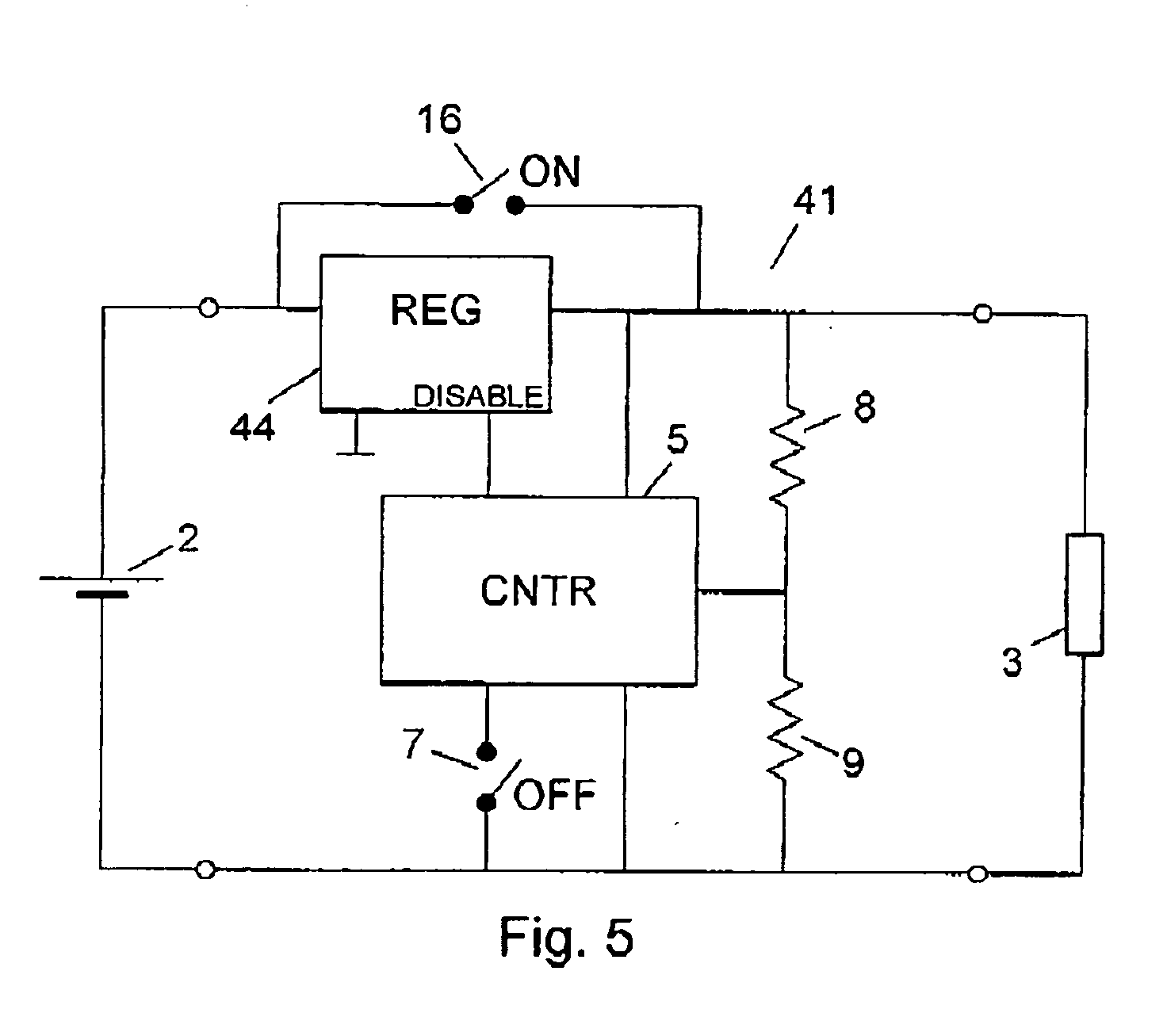

Battery protection circuit

InactiveUS20050088147A1Cost savingGreat flexibilityElectric powerBattery disconnect circuitsElectrical loadControl switch

A power supply arrangement for supplying power from a battery (2) to an electric load (3) comprises a controlled switch (4) having a first state in which a connection is provided from the battery (2) to the load (3), and a second state in which the load (3) is disconnected from the battery (2), and a control circuit (5, 8, 9) for controlling the state of the controlled switch (4). The control circuit (5, 8, 9) is arranged to be disconnected from the battery (2) when the controlled switch (4) is in its second state. By disconnecting not only the electrical load, but also the control circuit from the battery, it is ensured that this circuit cannot draw any leakage current from the battery, when the load is switched off. This means that no over-discharge protection is needed in the battery itself.

Owner:TELEFON AB LM ERICSSON (PUBL)

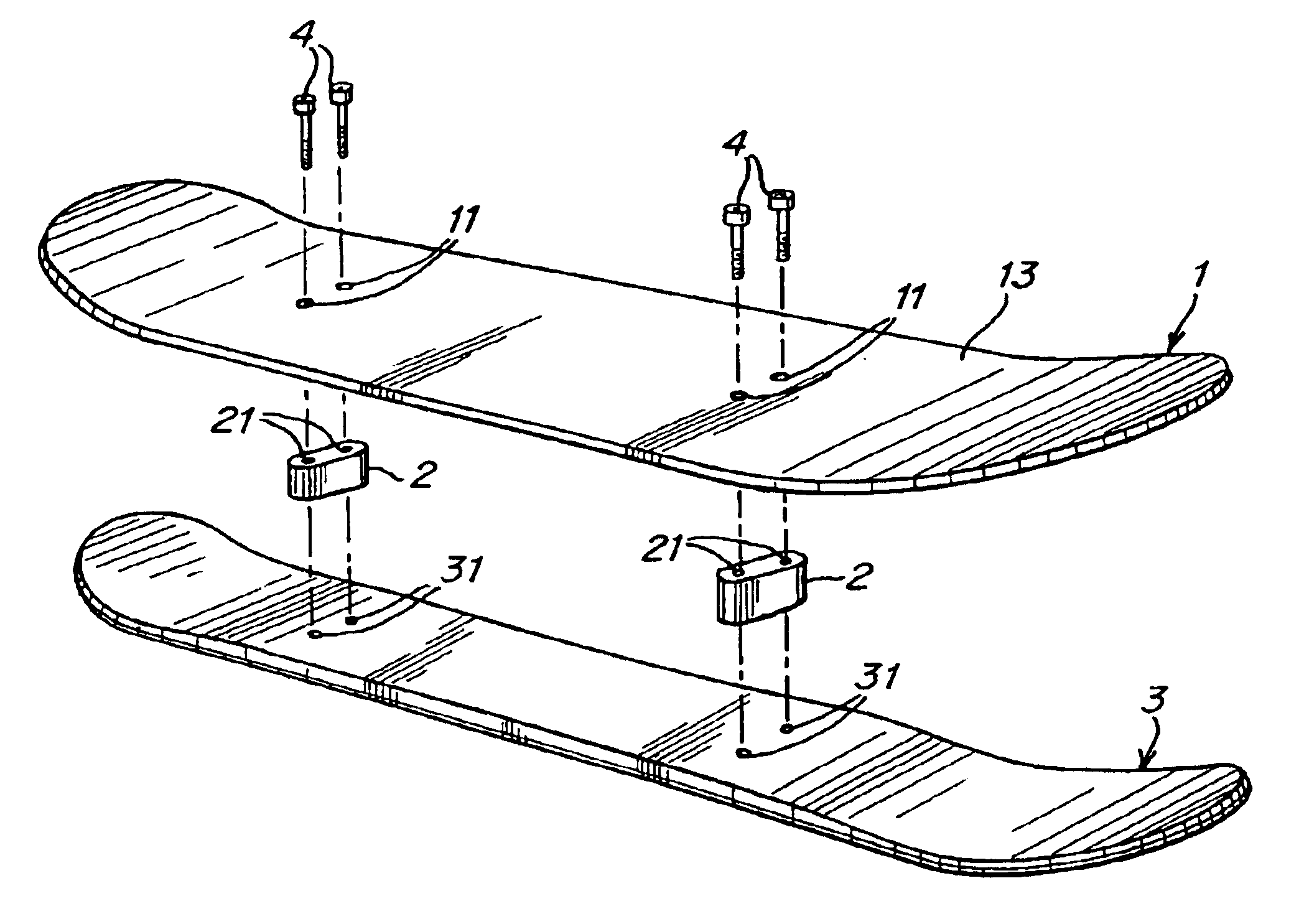

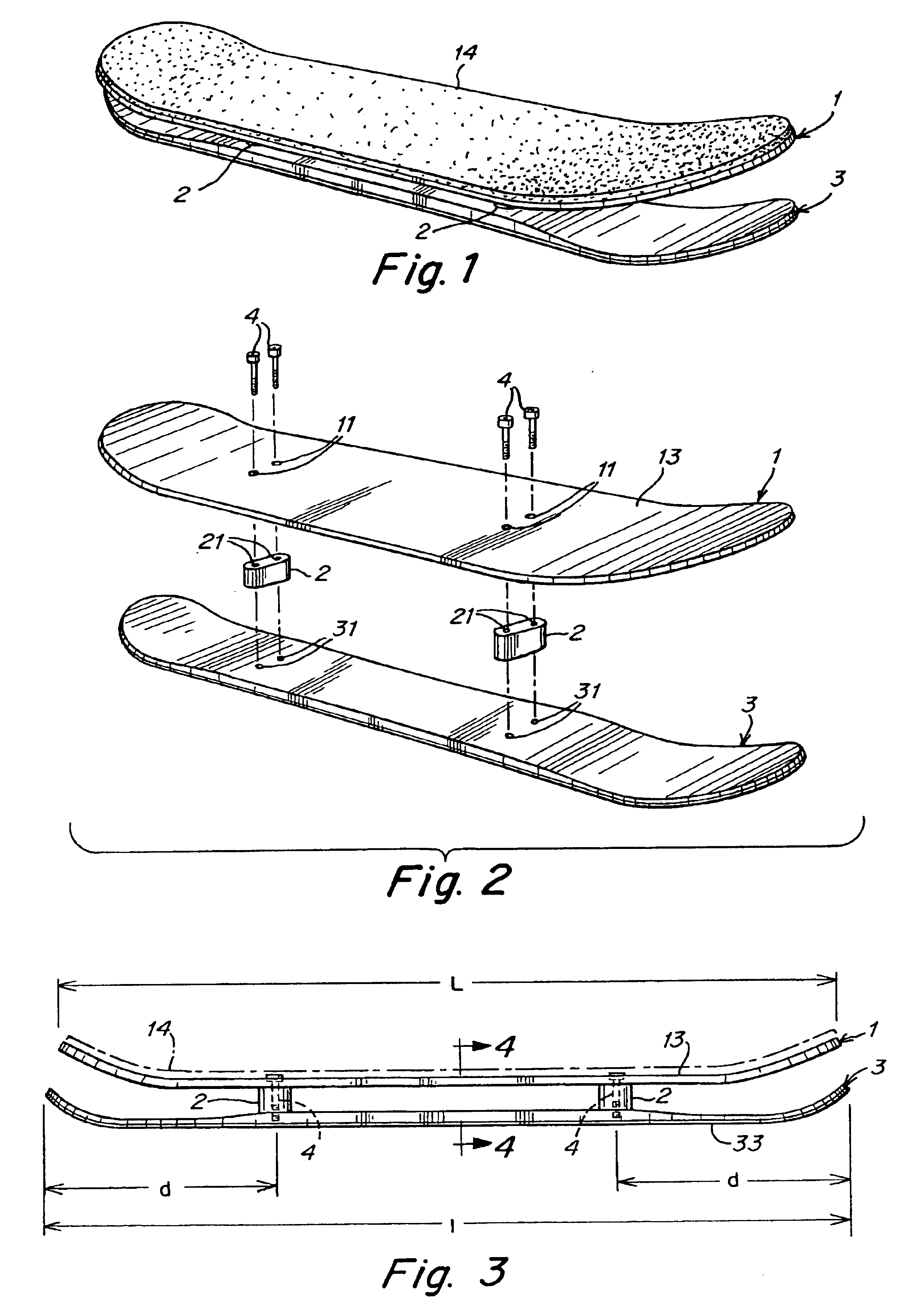

Sliding device

InactiveUS6866273B2Great flexibilityGood flexibilityCarriage/perambulator accessoriesSledgesBiomedical engineeringSnow

A sliding device provides a binding-free apparatus suitable for trick and other riding on snow, sand, ice and other surfaces. An elongated deck to support the rider is elevated from and attached to an elongated runner, which provides a surface that slides on the snow, sand, etc. The runner may be made more narrow than the deck to provide leverage for the rider to tilt the device onto an edge of the runner to steer the device. The device may not have any defined front or back portion and thus be adapted for riding in either direction.

Owner:BURTON USA

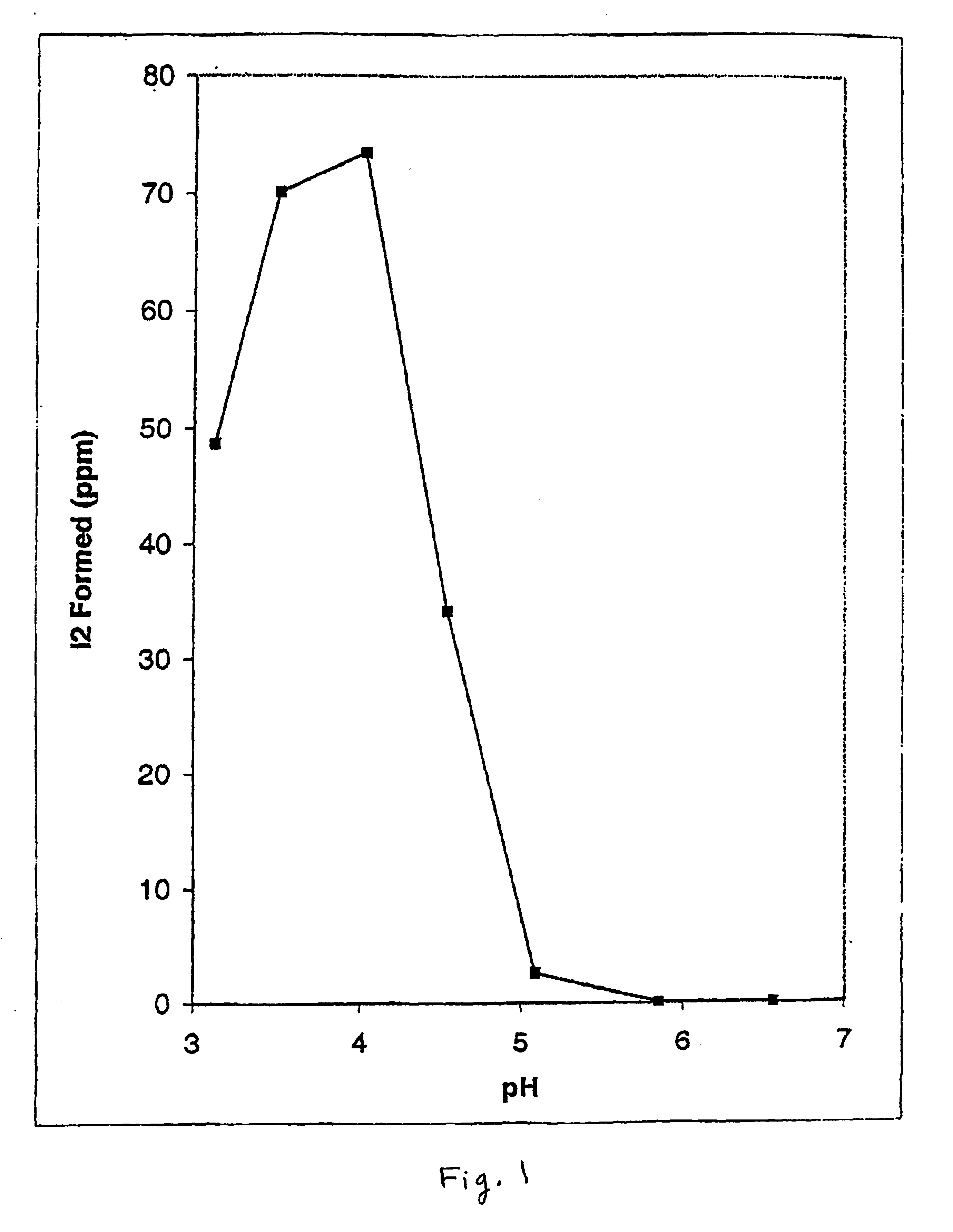

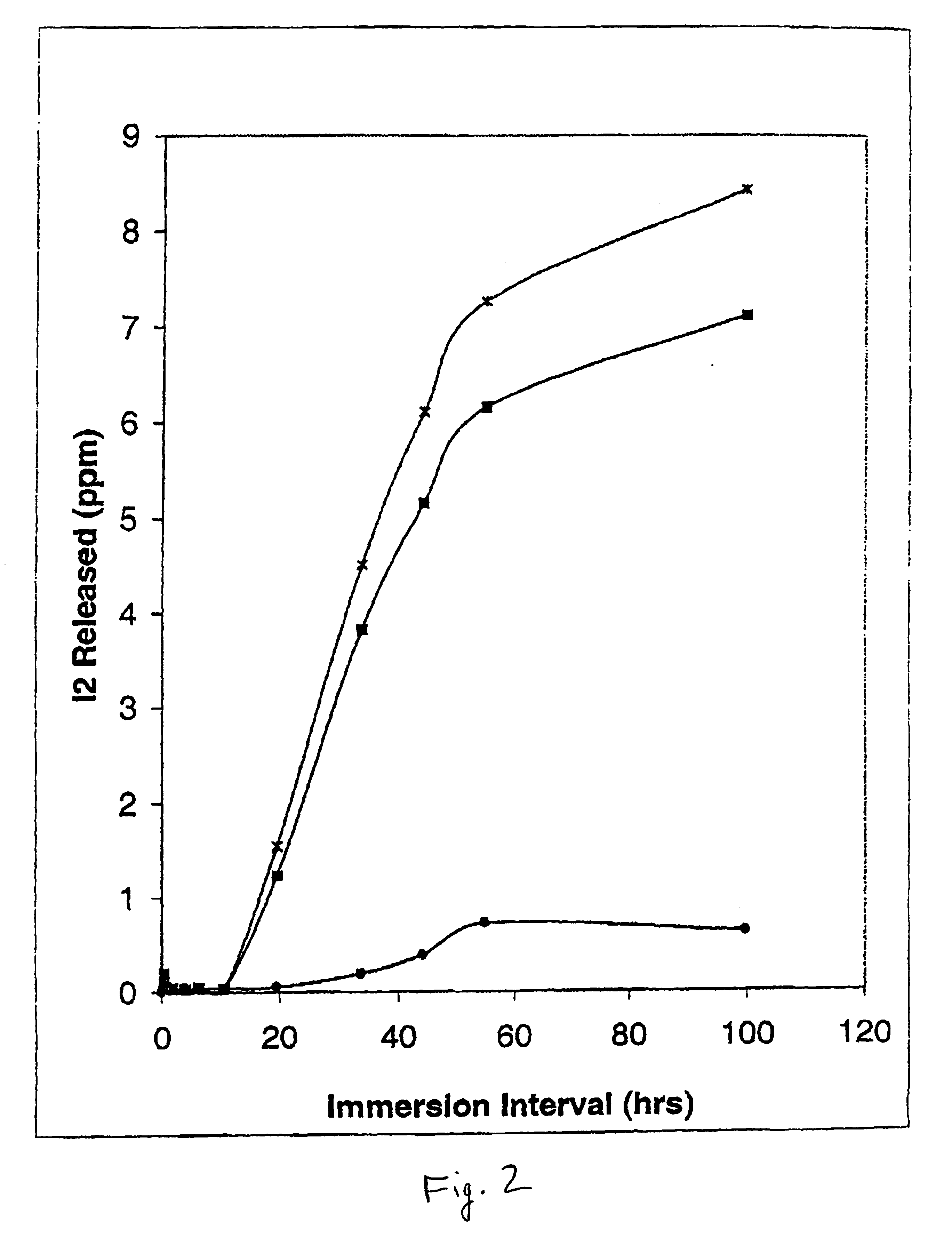

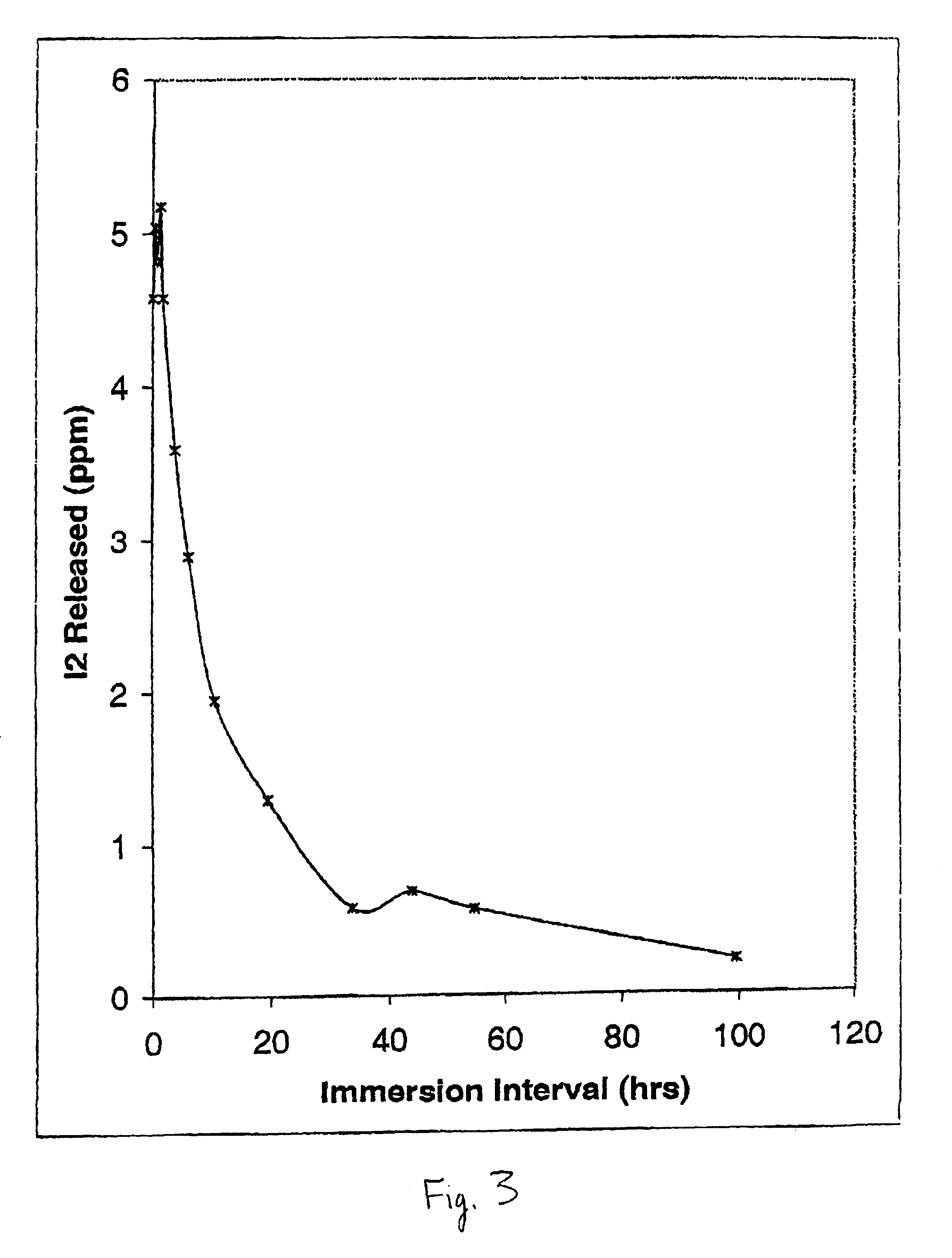

Methods and devices for providing anti-infective activity to a medical device

InactiveUS6838050B1Great flexibilityPromote rapid formationRespiratorsSurgeryAqueous solutionOxidizing agent

Methods of providing anti-infective activity to a medical device including the steps of exposing the medical device to an anti-infective oxidant, and transferring the anti-infective oxidant into a wall of the medical device. One embodiment includes the step of exposing a medical device that is at least in part within a patient to the anti-infective oxidant. Another embodiment includes the steps of exposing a medical device to an aqueous solution which produces the anti-infective oxidant and transferring a sufficient amount of the anti-infective oxidant into the medical device wall to provide the medical device with anti-infective activity. Also provided is an oxidant releasing member that has anti-infective oxidant releasably contained therein and that is configured to be disposed adjacent to the medical device. Exemplary devices include catheters such as venous, arterial, and urinary catheters, generally containing an elongated catheter shaft having a lumen extending therein, and optionally having a balloon on the shaft in fluid communication with the catheter lumen.

Owner:OXIBIO

Releasable optical element

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

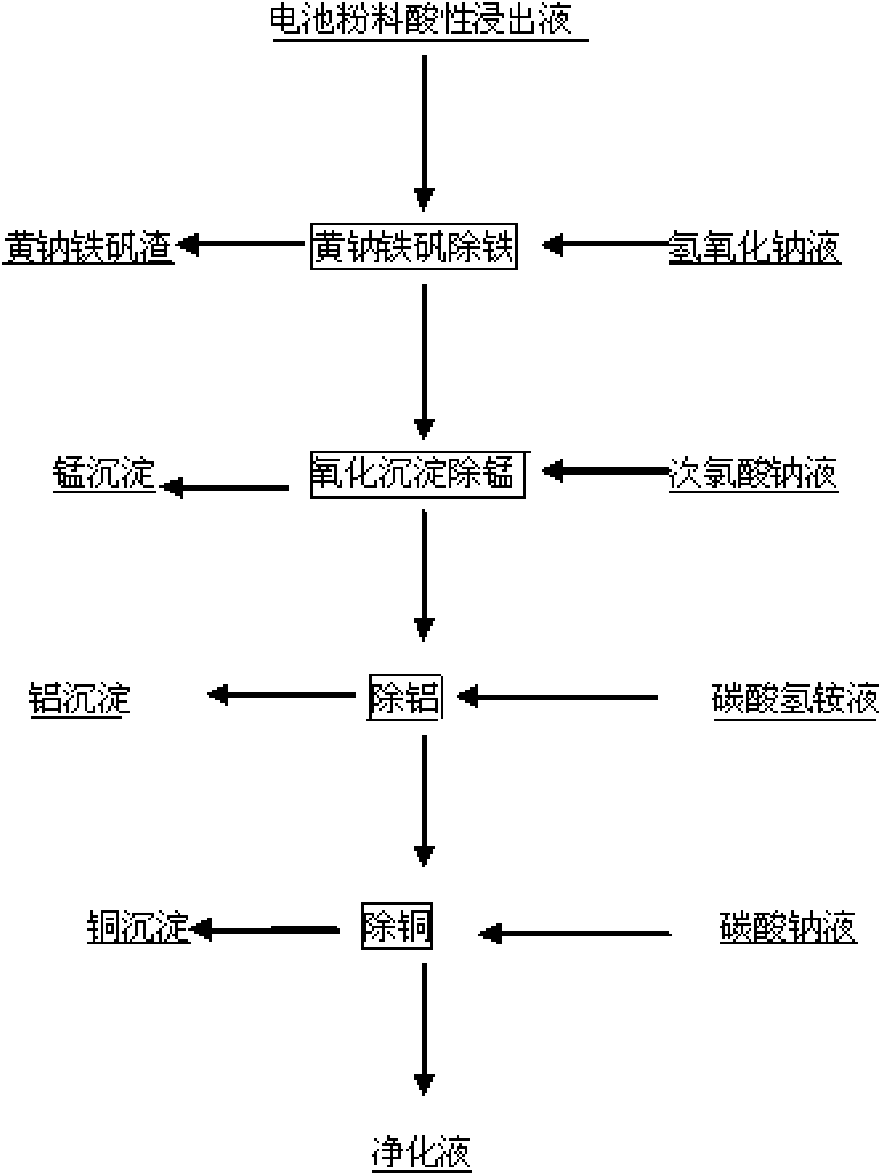

High-efficiency purification process for acid leaching solutions of active substances in waste lithium batteries

InactiveCN101597689ASolve the disadvantages of not being able to comprehensively recover valuable metalsReduce lossesProcess efficiency improvementManganeseTotal recovery

The invention discloses a high-efficiency purification process for acid leaching solutions of active substances in waste lithium batteries. The process comprises working procedures of the purification of the acid leaching solutions of the active materials of positive poles in the waste lithium batteries. The process is mainly characterized by adopting an improved hydrolysis precipitation method and an improved oxidation precipitation method to remove impurity ions in the acid leaching solutions. The process comprises four steps of removing iron by a sodium jarosite method; removing manganese by the oxidation precipitation method; removing aluminum by ammonium bicarbonate; and removing copper by sodium carbonate. A method used by the invention has the advantages of low cost, large operation flexibility, and high cobalt recovery rate, can comprehensively recover valuable metals such as the aluminum, the copper, the manganese and the like, and is suitable for lithium cobalt oxide battery materials which are widely used at present and heavily doped battery materials which may be used in the future. The use of the method can ensure that the total recovery rate of cobalt in waste lithium ion batteries is about 98 percent, and the content of impurities is lower than 2 percent.

Owner:CENT SOUTH UNIV

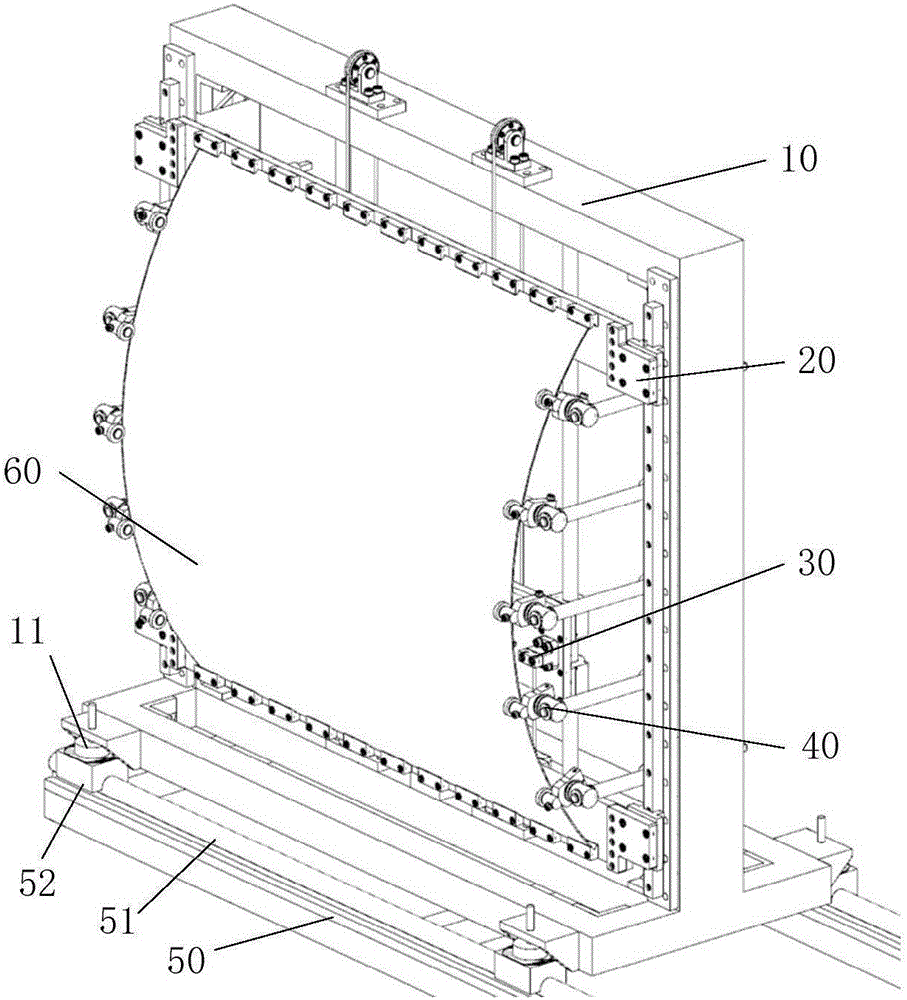

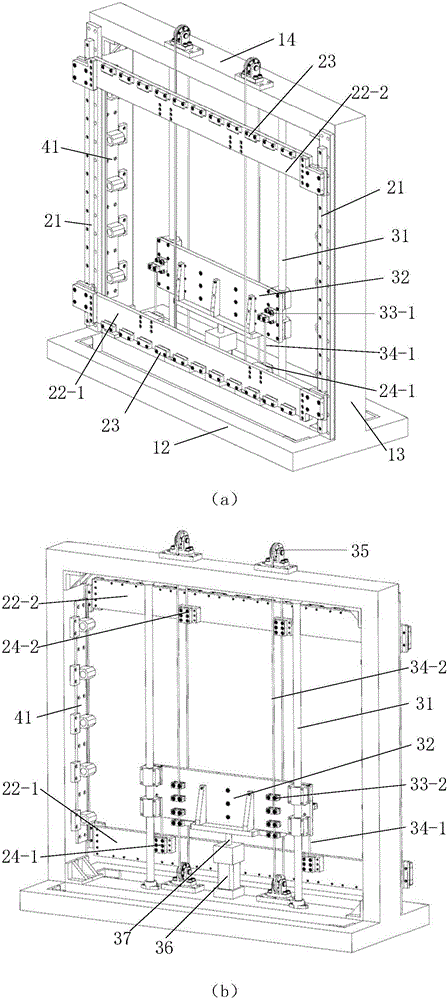

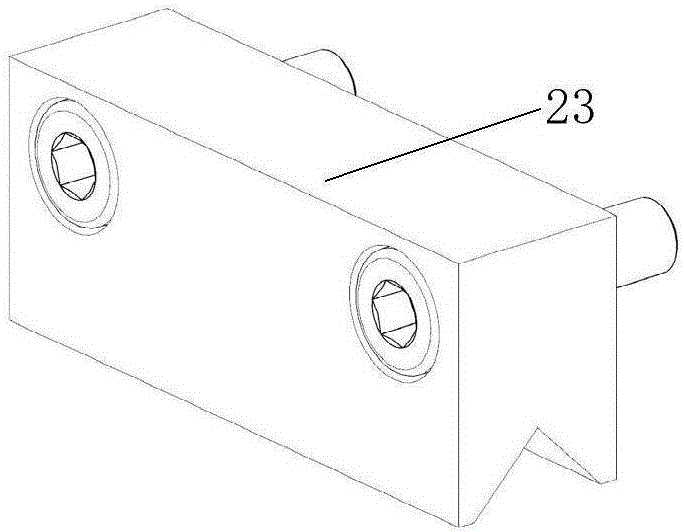

Flexible prestressed clamp for peen forming of large-scale wallboard workpieces

ActiveCN106694724AEasily adjust the layout positionAdjust the placementMetal-working feeding devicesPositioning devicesPre stressEngineering

The invention provides a flexible prestressed clamp for peen forming of large-scale wallboard workpieces. The flexible prestressed clamp comprises a rigid framework used for supporting, an upward and downward extrusion module used for bending the wallboard workpieces, a lifting control module used for controlling the upward and downward extrusion module, an elastic pre-bending module used for controlling the bending shapes of the wallboard workpieces and horizontal guide rails, wherein the upward and downward extrusion module, the lifting control module and the elastic pre-bending module are mounted on the rigid framework; and the rigid framework is arranged on the horizontal guide rails and moves along the horizontal guide rails. The flexible prestressed clamp has the following beneficial effects: the prestressed clamp has extremely high flexibility and universality, and is suitable for implementing elastic pre-bending in various shapes on the wallboard workpieces of various sizes; the bending shapes of the wallboard workpieces can be well controlled; the elastic prestress application is uniform and controllable; clamping and pre-bending are both convenient and labor-saving; the center heights of the workpieces can be kept unchanged in the clamping and pre-bending process; and the positioning performance of the workpieces is extremely good.

Owner:SHANGHAI JIAO TONG UNIV

Hermetically packaged MEMS G-switch

InactiveUS7956302B1Great flexibilityGood flexibilityAcceleration measurementSpeed/acceleration/shock instrument detailsEngineeringOxide

A hermetically packaged G-switch includes a MEMS structure having a bottom substrate layer, a top device layer and an intermediate oxide layer. A mass disposed in the top device layer is connected to one, two or three anchor portions using spring arms. One end of a spring arm is connected to the mass and another end to an anchor portion. The connection to the anchor portion includes a T shaped arrangement, which has a torsional spring cross piece connected to the spring arm. A cap containing a conductive pad is hermetically sealed to the MEMS structure. When a predetermined acceleration is attained, the mass makes electrical contact with the conductive pad to close the G-switch.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

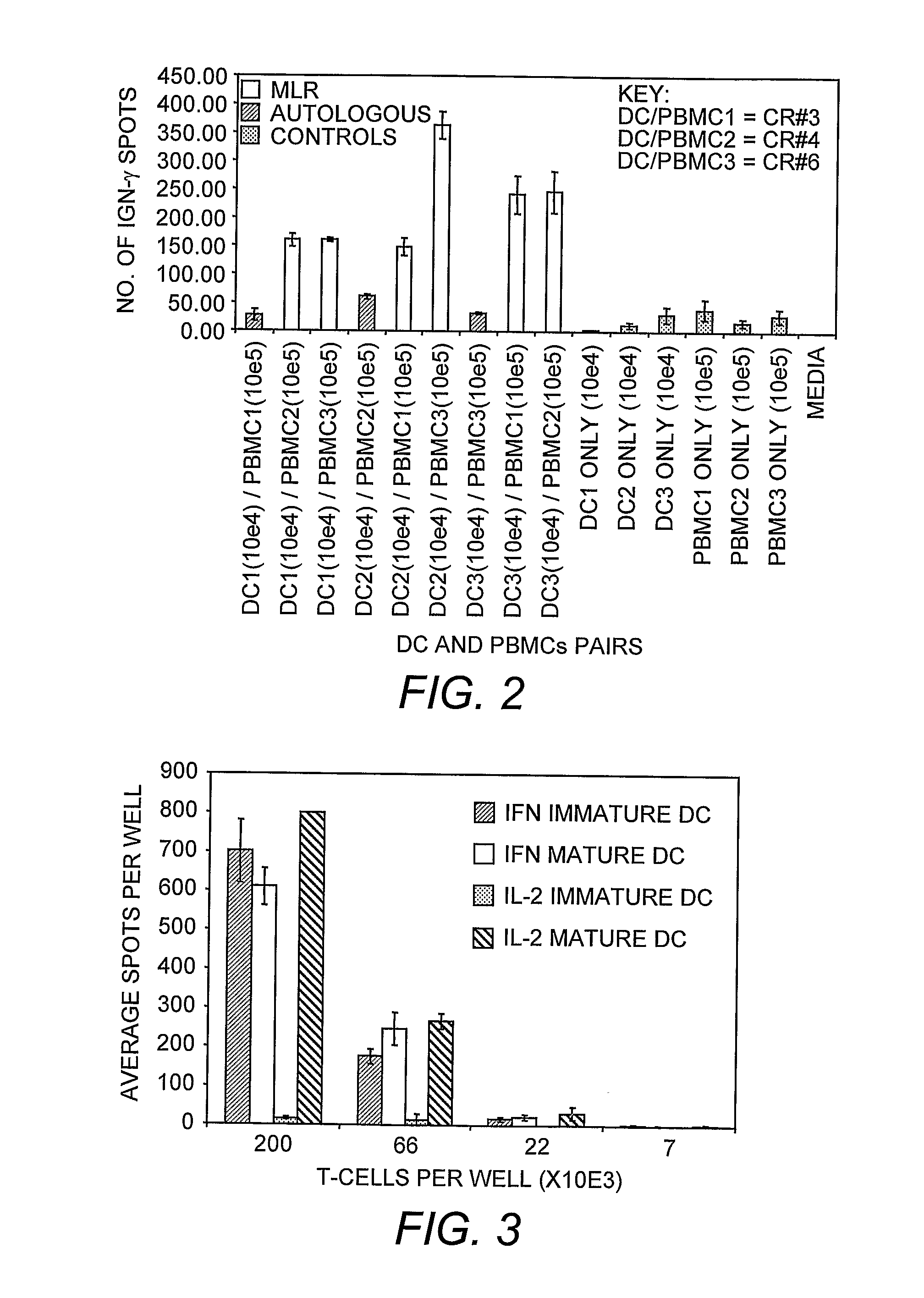

Dendritic Cell Compositions and Methods

ActiveUS20090053251A1Great flexibilityIncrease levelAntibacterial agentsSnake antigen ingredientsIncubation periodCD80

Methods are provided for the production of dendritic cells from monocytes that have been incubated at a temperature of 1° C.-34° C. for a period of approximately 6 to 96 hours from the time they are isolated from a subject. After the incubation period, the monocytes can then be induced to differentiate into dendritic cells. Mature dendritic cells made by the methods of the invention have increased levels of one or more of CD80, CD83, CD86, MHC class I molecules, or MHC class II molecules as compared to mature dendritic cells prepared from monocytes that have not been held at 1° C.-34° C. for at least 6 hours from the time they were isolated from a subject. Dendritic cells made by the methods of the invention are useful for the preparation of vaccines and for the stimulation of T cells.

Owner:COIMMUNE INC

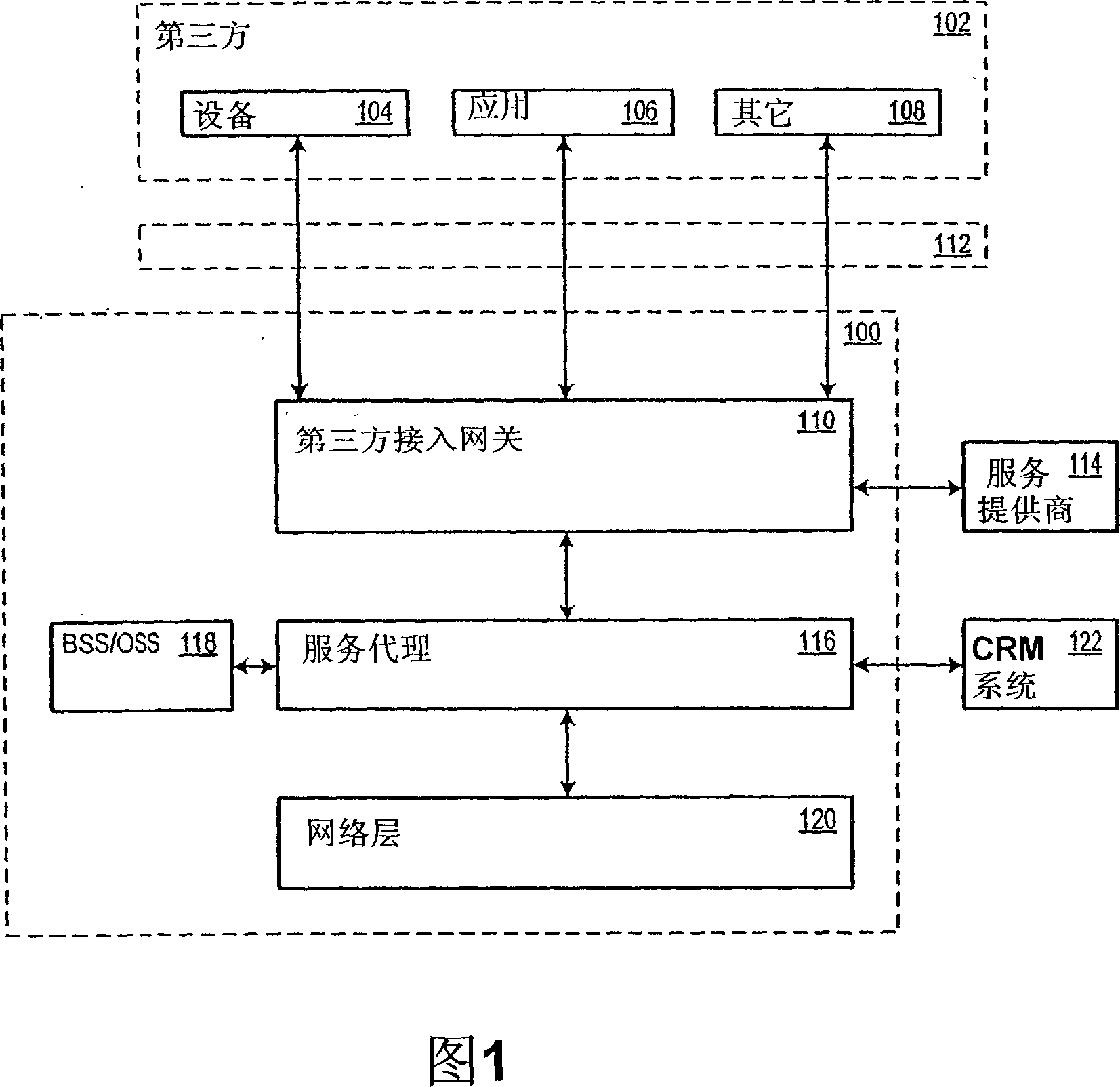

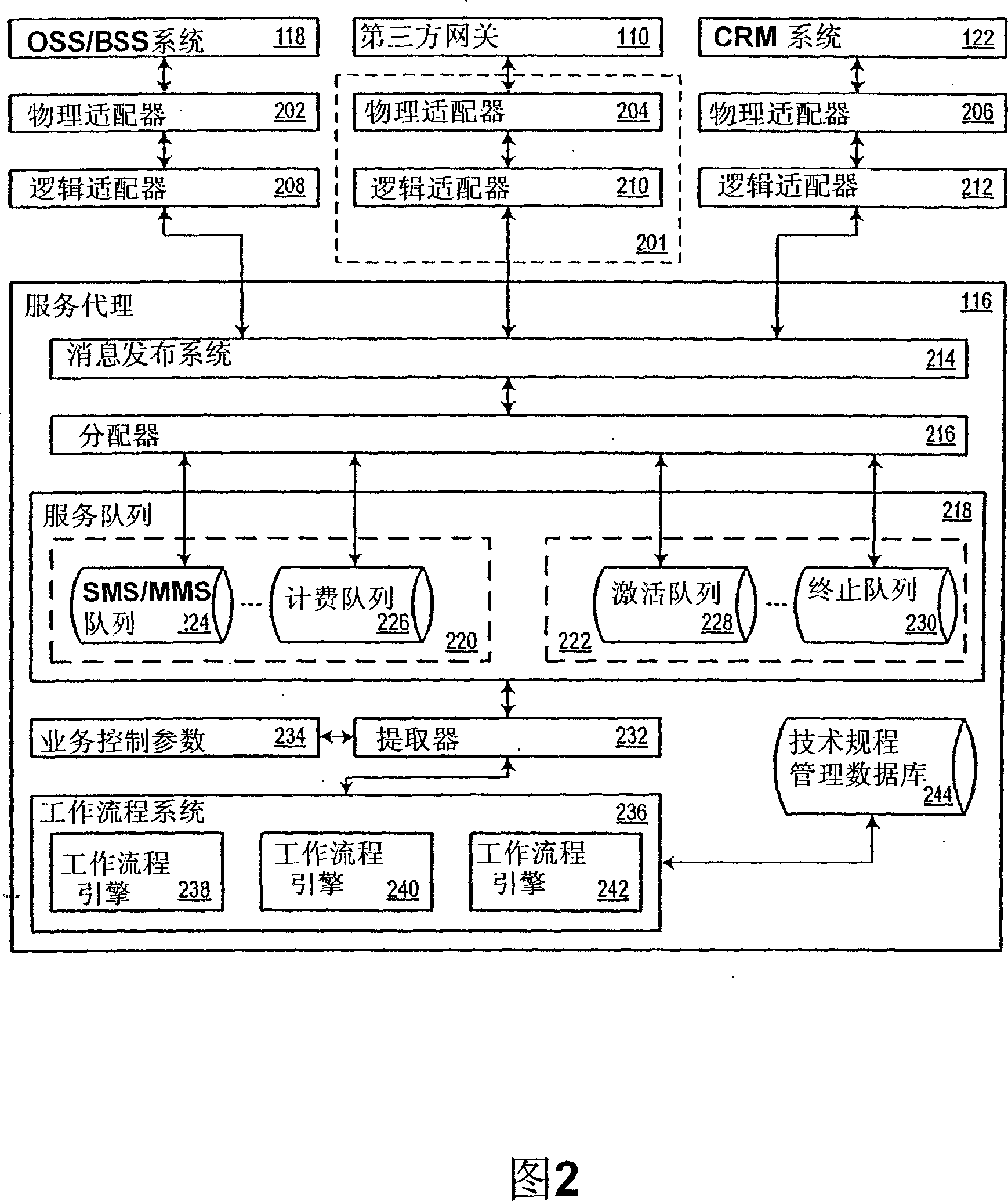

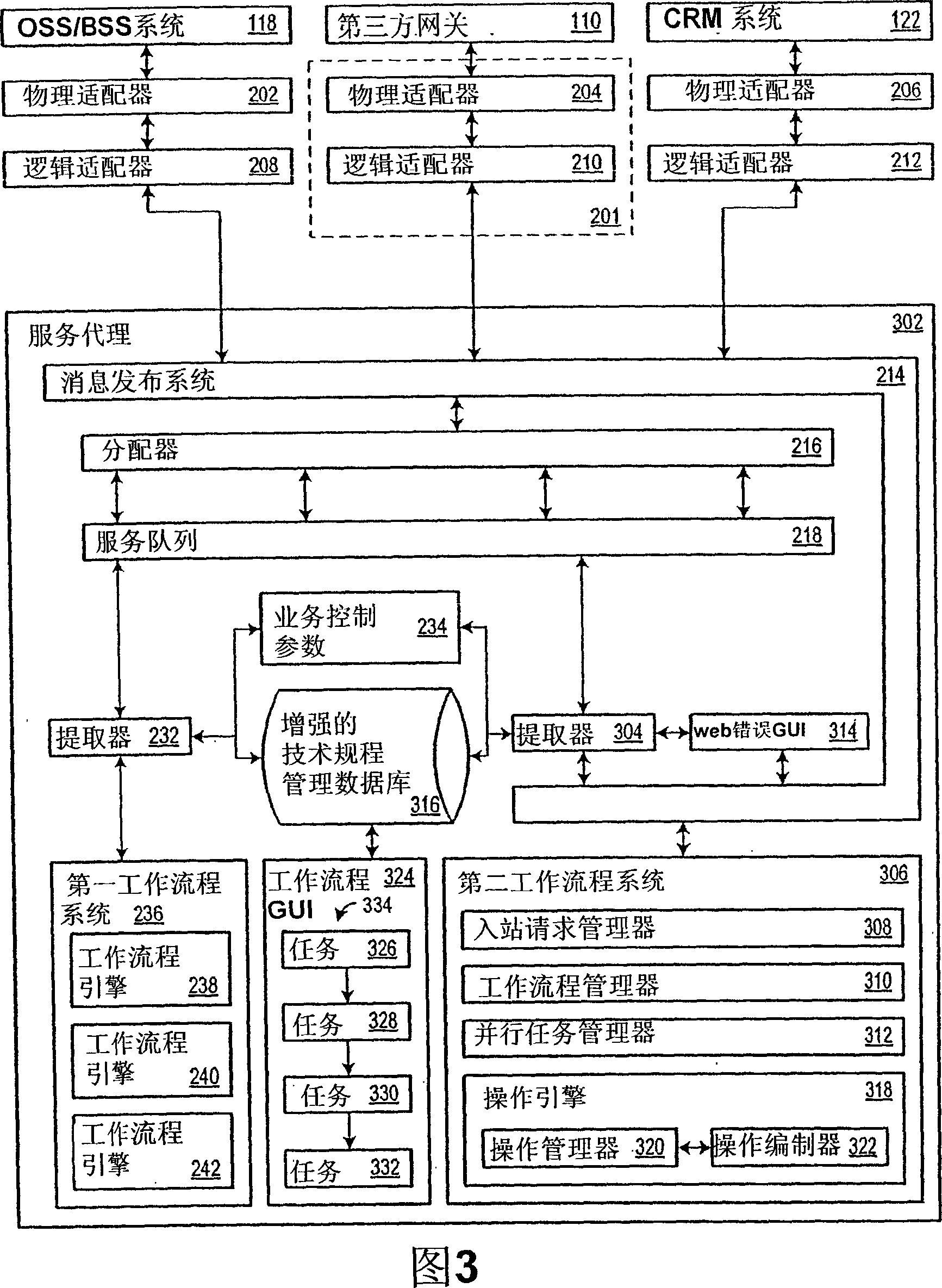

Service broker integration layer for supporting telecommunication client service requests

ActiveCN1980243AGreat flexibilityAvoid hardcodingMetering/charging/biilling arrangementsThird partyApplication service provider

A telecommunications architecture processes telecommunications service requests received from third parties through a secure access gateway. The third parties may be other telecommunications service providers which employ the services to support their own products and services or may be or individual subscribers. The service broker provides a flexible and efficient layer in the telecommunications architecture for processing the service request. The service broker also overcomes the technical problems associated with third party service request processing. In addition to providing technical solutions for efficient and secure processing of service requests for exposed services, the architecture also provides an additional revenue channel for existing telecommunication service providers.

Owner:ACCENTURE GLOBAL SERVICES LTD

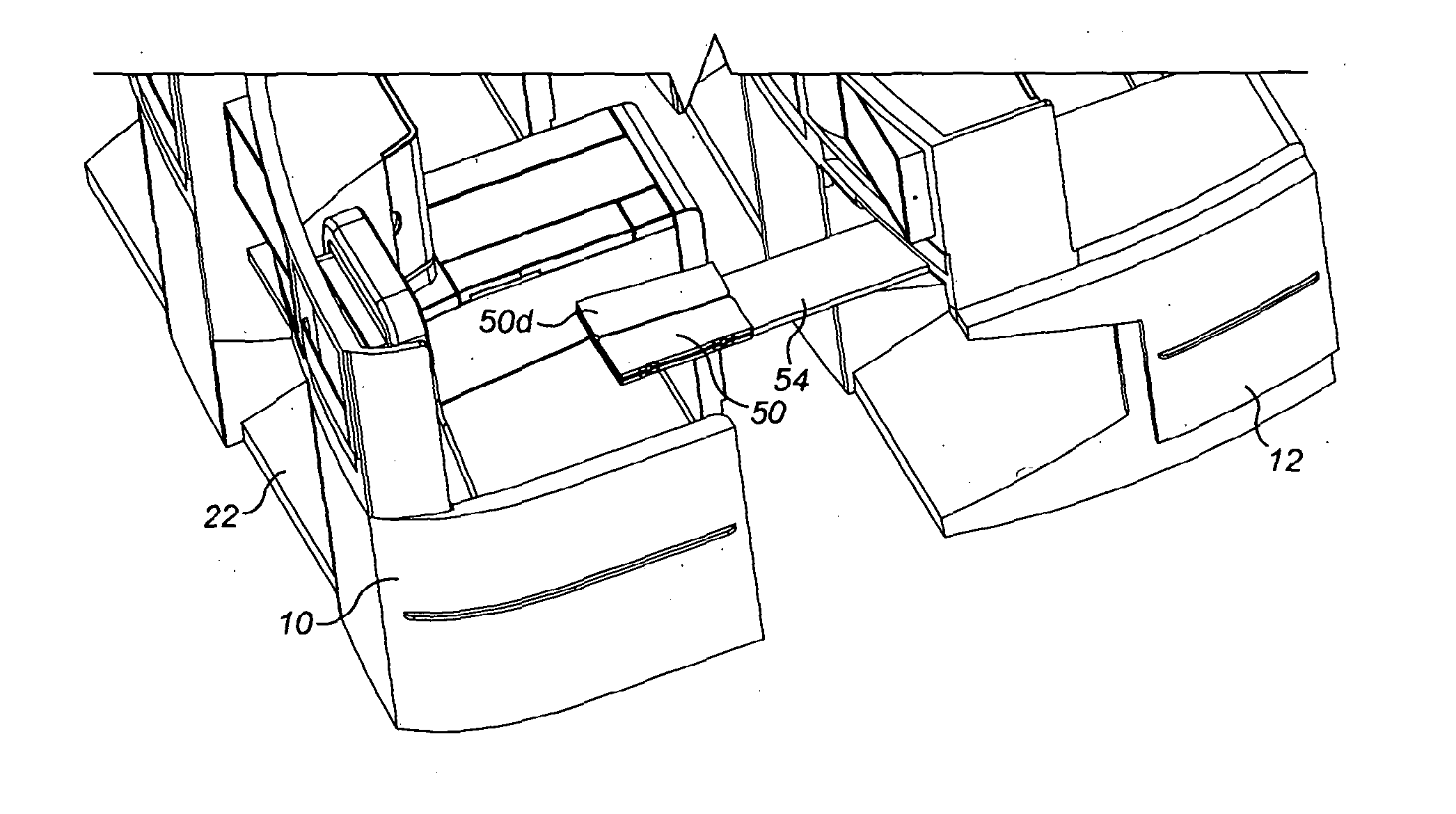

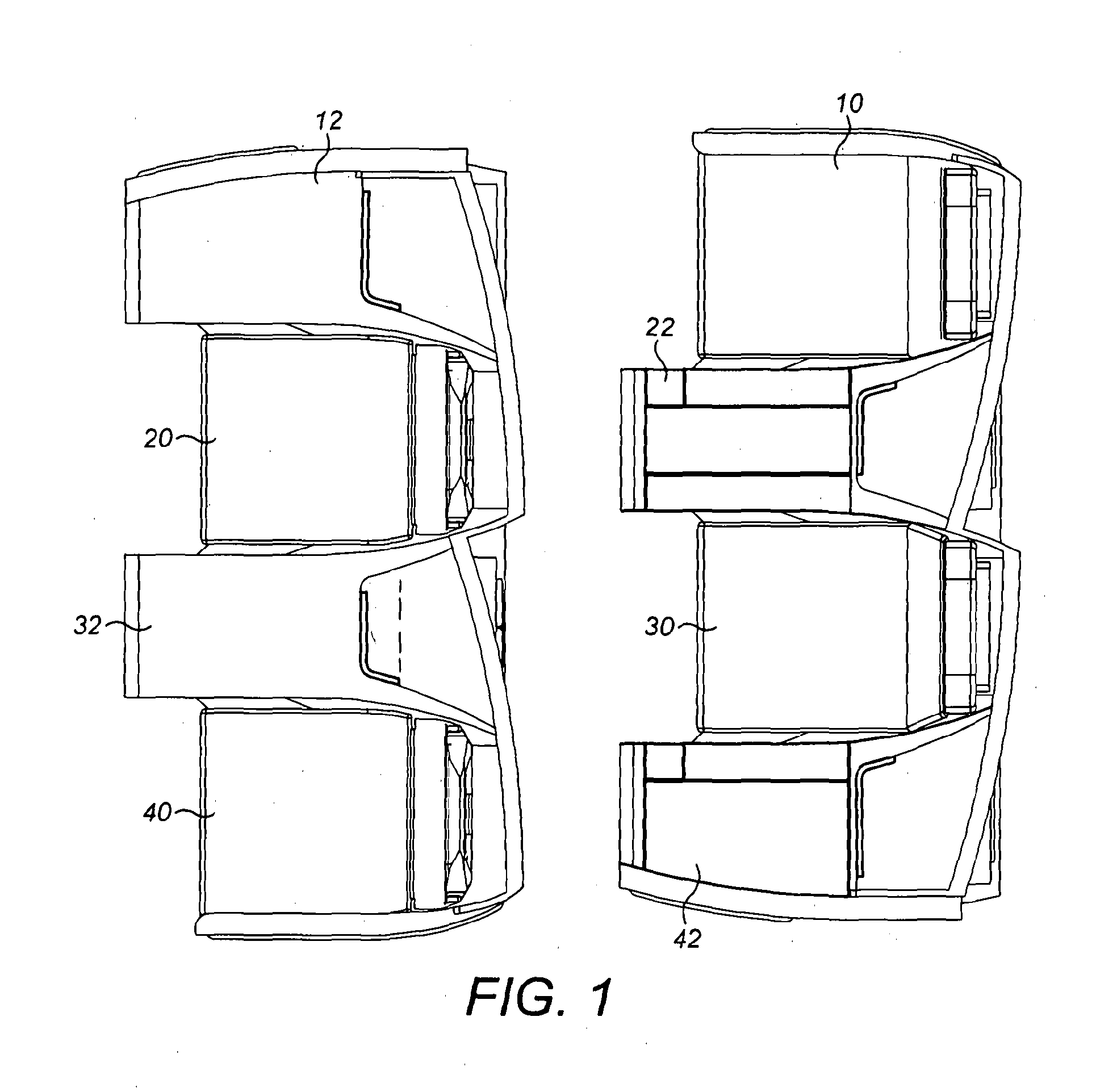

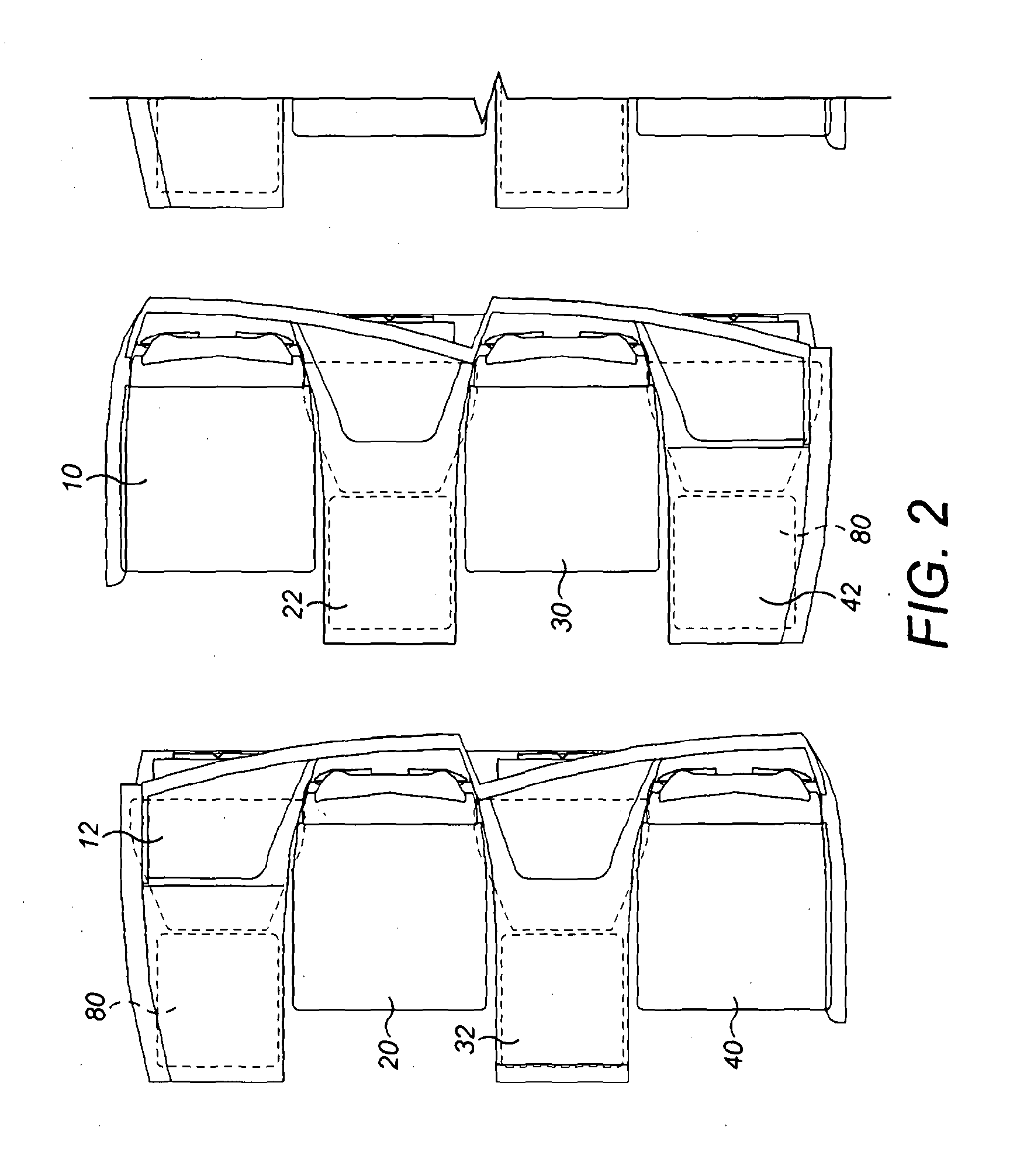

Aircraft seat arrangement including table

ActiveUS20140145477A1Great flexibilityEasy to useVehicle arrangementsSeating arrangementsAirplaneEngineering

Owner:SAFRAN SEATS GB LTD

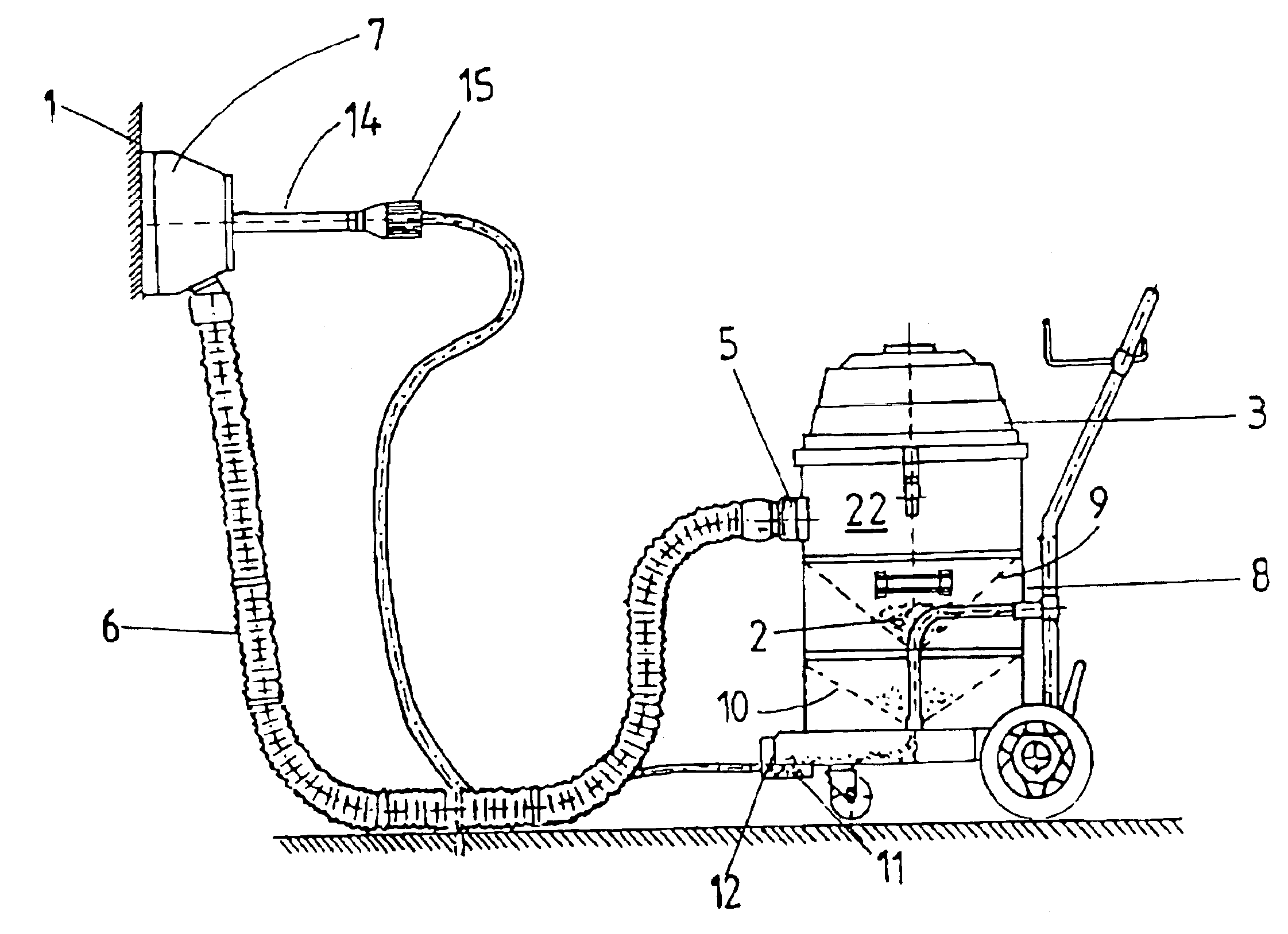

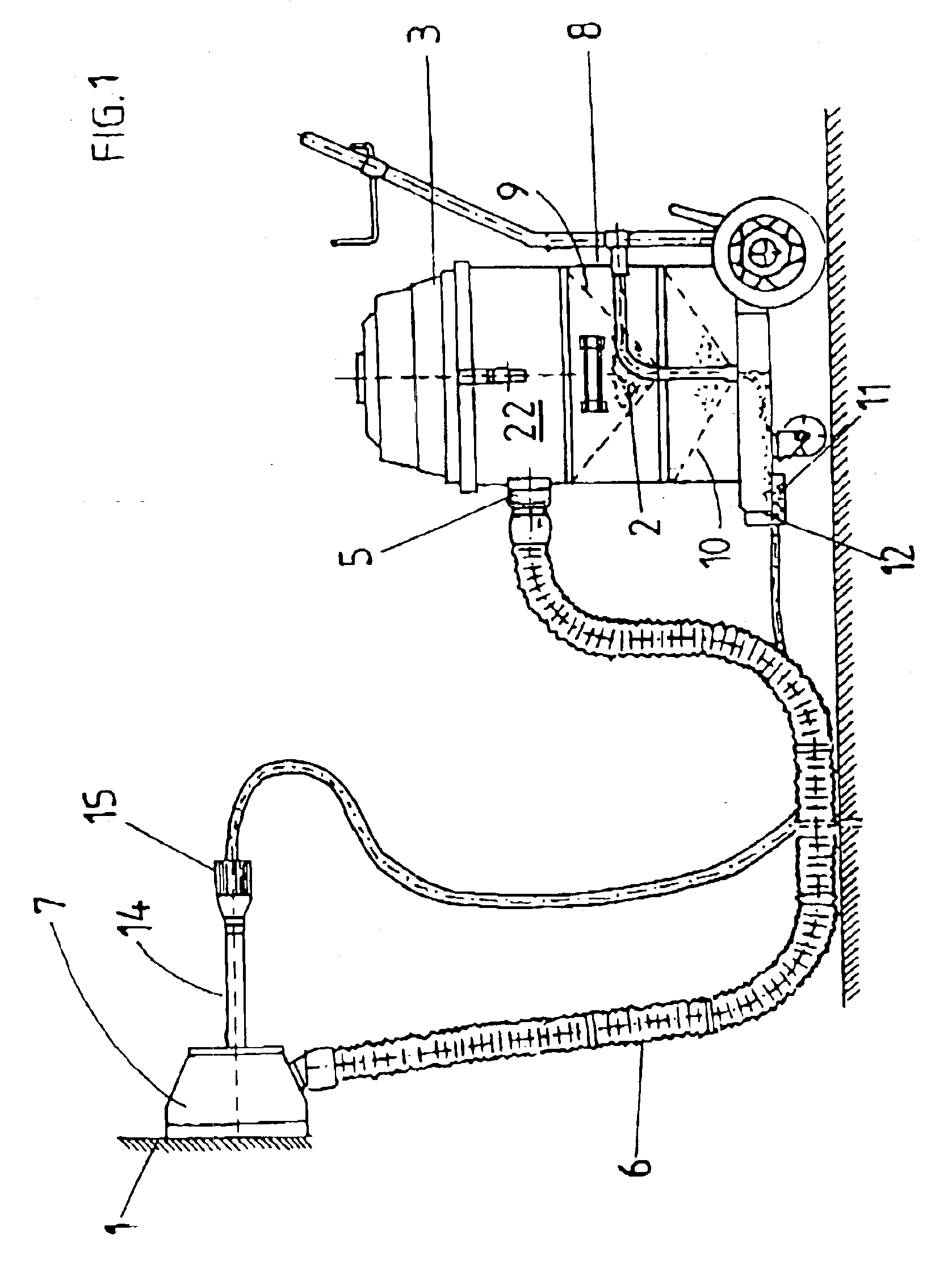

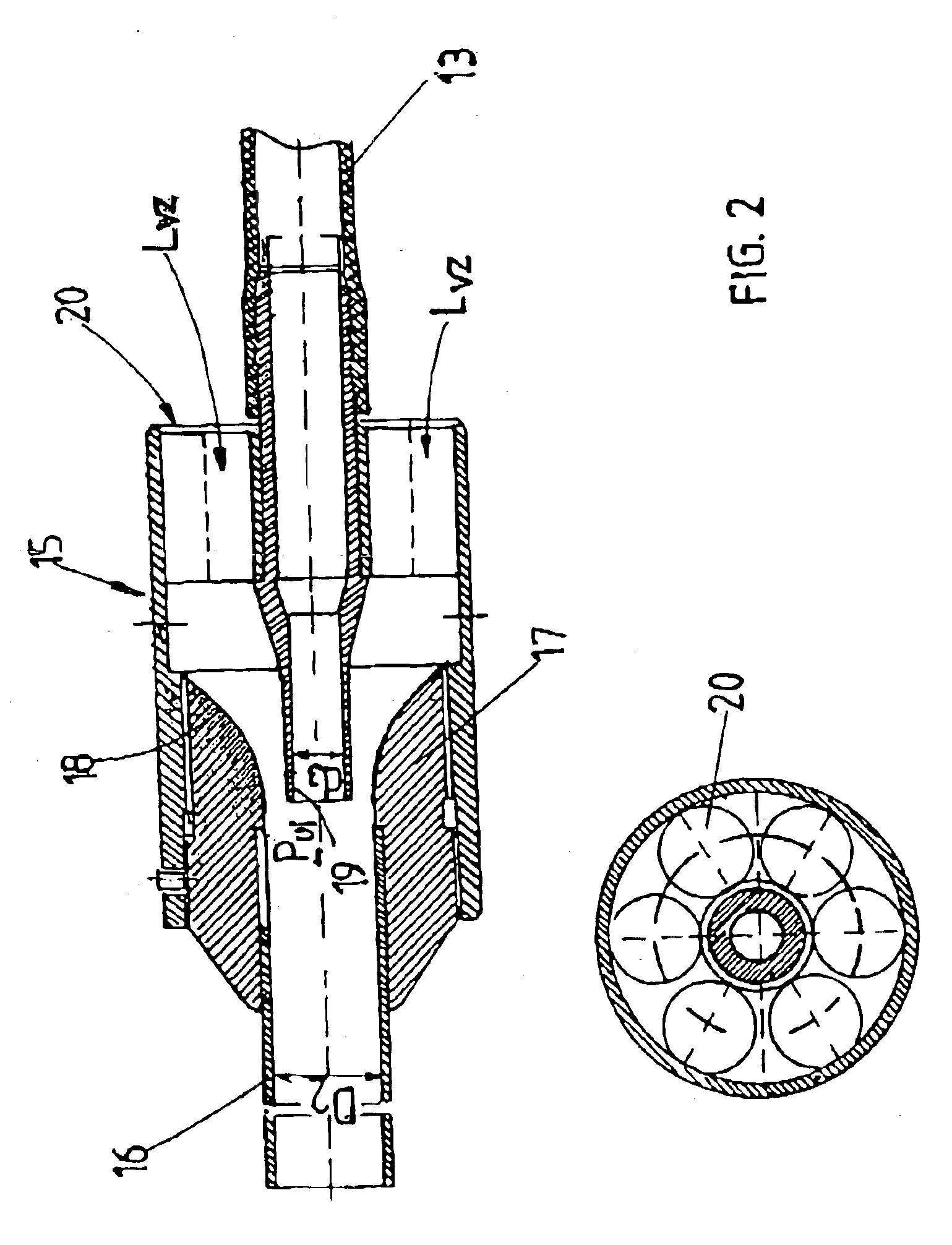

Method and device for sandblasting, especially removing in a precise manner and/or compacting and/or coating solid surfaces

The invention relates to a method and device for sandblasting, especially removing in a precise manner and / or compacting and / or coating solid surfaces, such as removing defective spots of paint from coats of lacquer, smoothing out soldered and welded joints, removal of contaminated concrete coatings or rust coatings, hardening, planing or coating metal surfaces, wherein a sandblasting agent is added by means of gravity and / or due to the effect of an injector to a carrier air flow produced by an underpressure, conveyed in a flexible hose- line system (13) to a jet lance (14) before being guided via a processing surface subject to low pressure by a sandblasting chamber, whereupon it is returned in the air flow, purified and returned to the circuit, whereby acceleration of the sandblasting agent is produced by the low pressure and the sandblasting chamber is displaced from one processing surface to another. The aim of the invention is to increase the sandblasting speed in a significant manner while at the same time economically adjusting the amount of power furnished to the processing surface for various wide-ranging fields of application using as little power as possible yet providing high flexibility and ecologically compatible recovery and reutilization of the sandblasting means. In order to achieve this, the sandblasting agent receives at least one additional energy pulse from a gas flow which is placed at least under atmospheric pressure and suctioned by the low pressure in order to reach a final speed which is significantly greater than the speed of the carrier air flow downstream from the area where dosing occurs. The final speed makes it possible to adjust the amount of power applied to the surface to be processed according to the following parameters: type and forms of the surface to be processed and the sandblasting agent, degree in which the carrier air flow is charged with the sandblasting agent, low pressure in the carrier air flow, and time and temperature of sandblasting.

Owner:PIEPER INNOVATIONSGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com