Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1829results about "Blast guns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

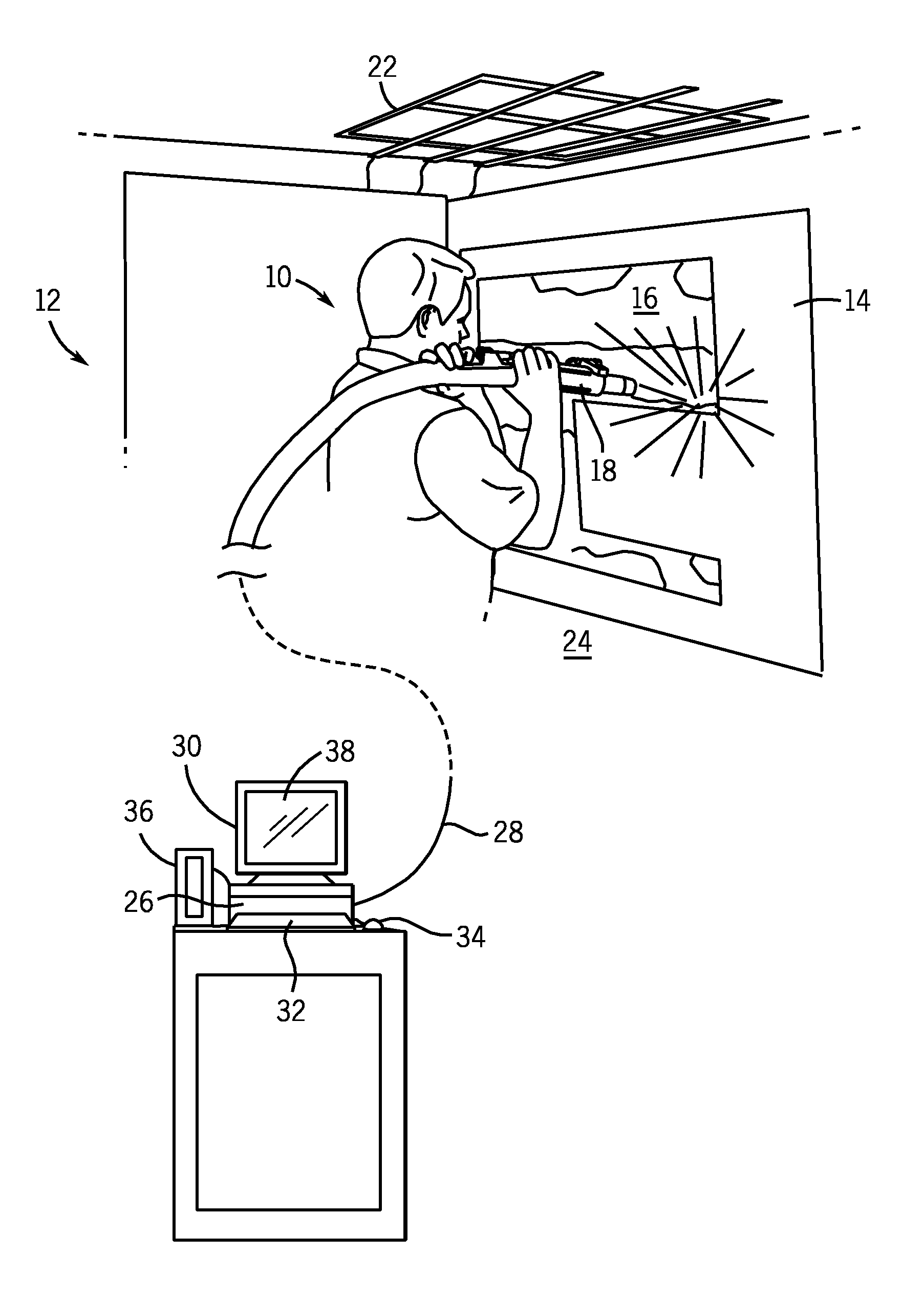

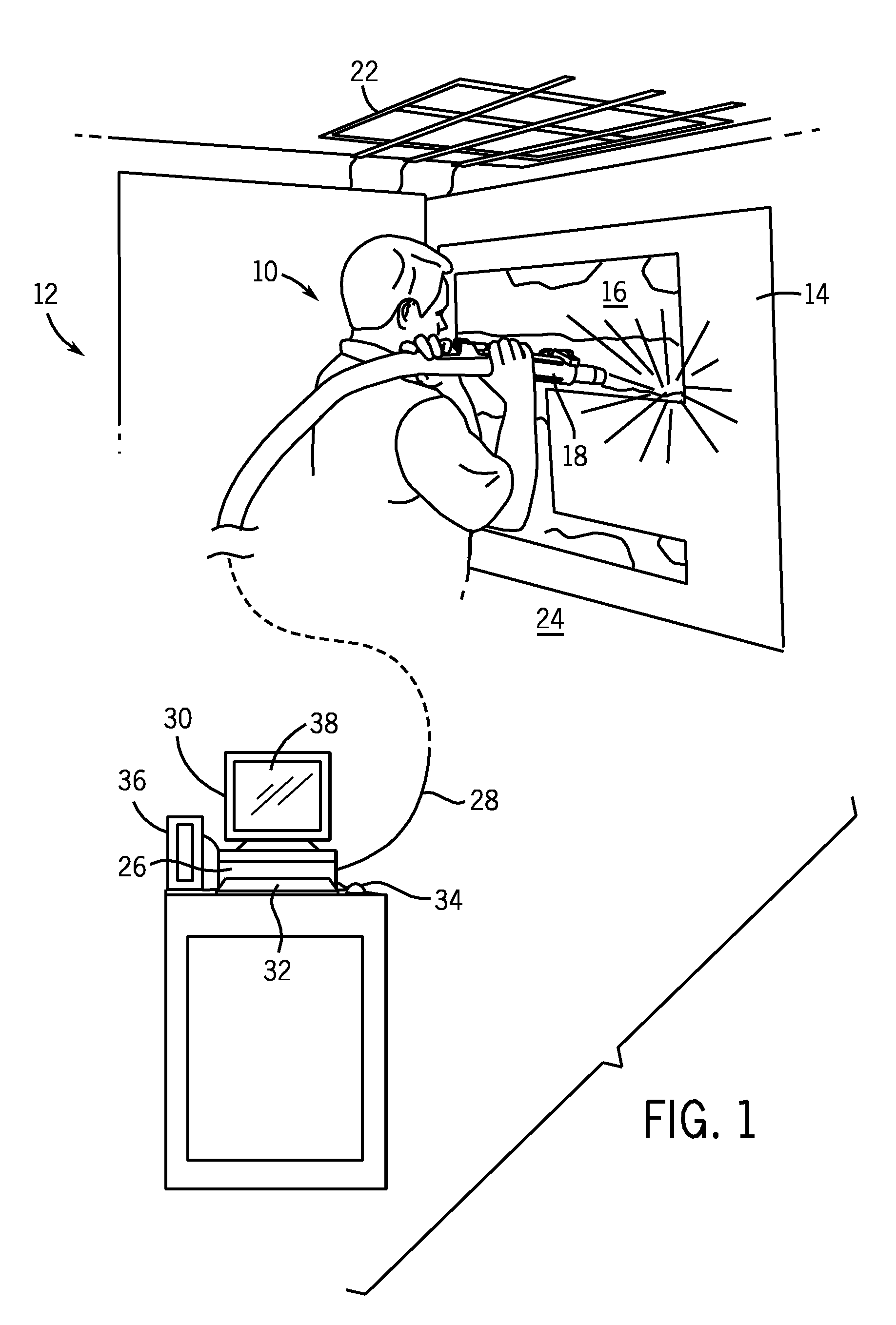

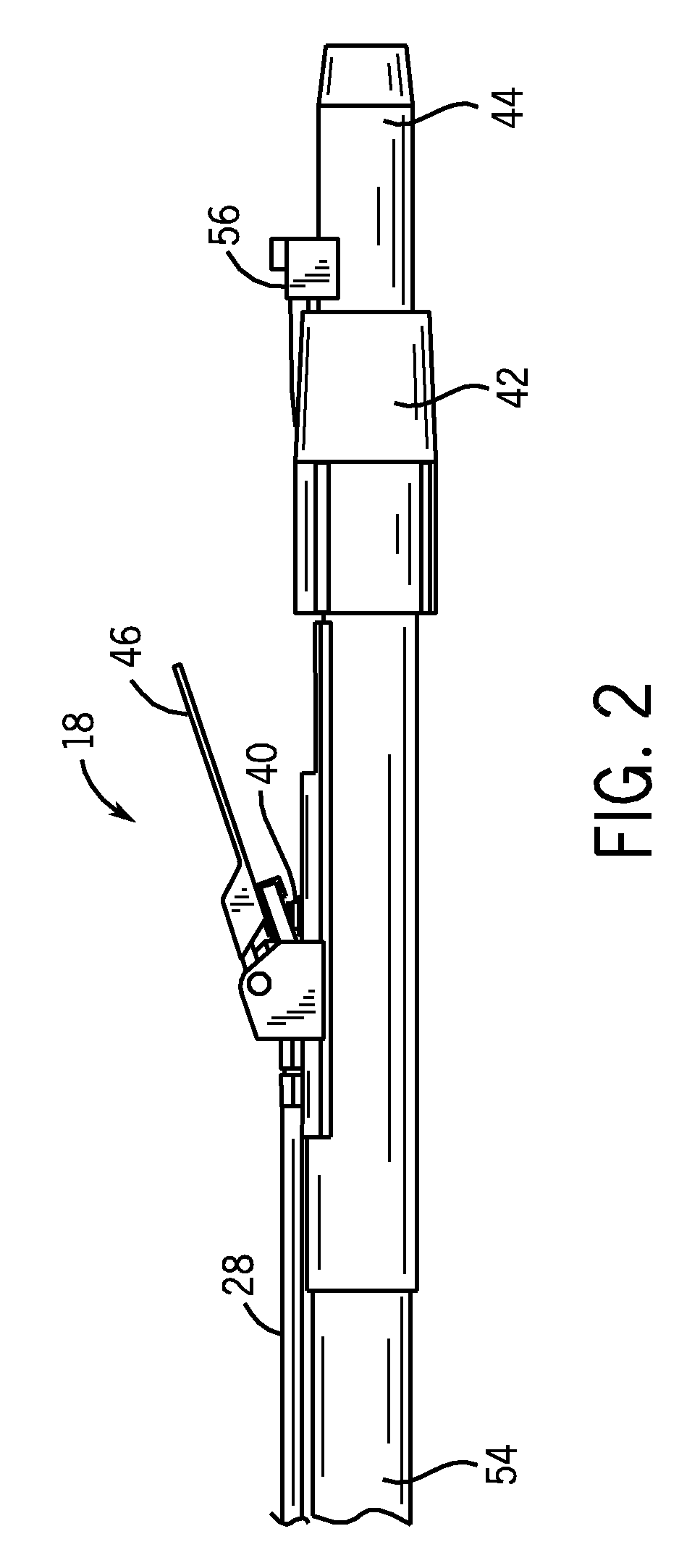

Virtual blasting system for removal of coating and/or rust from a virtual surface

InactiveUS7817162B2High simulationImprove realismCathode-ray tube indicatorsEducational modelsAbrasive blastingElectronic controller

A computer simulation and virtual reality system simulates the use of a blasting nozzle to remove one or more coatings and / or rust from a virtual surface. The user operates an electronic controller in the form of a blasting nozzle that outputs a signal indicating whether the blasting nozzle controller is in an “on” position or in an “off” position. The system also has a motion tracking system that tracks the position and orientation of the blasting nozzle controller with respect to the virtual surface defined on the display screen. Simulation software in a computer generates virtual blast pattern data, and the removal of the virtual coating(s) and / or rust image from the virtual surface is displayed in real time on the display screen.

Owner:UNIV OF NORTHERN IOWA RES FOUND

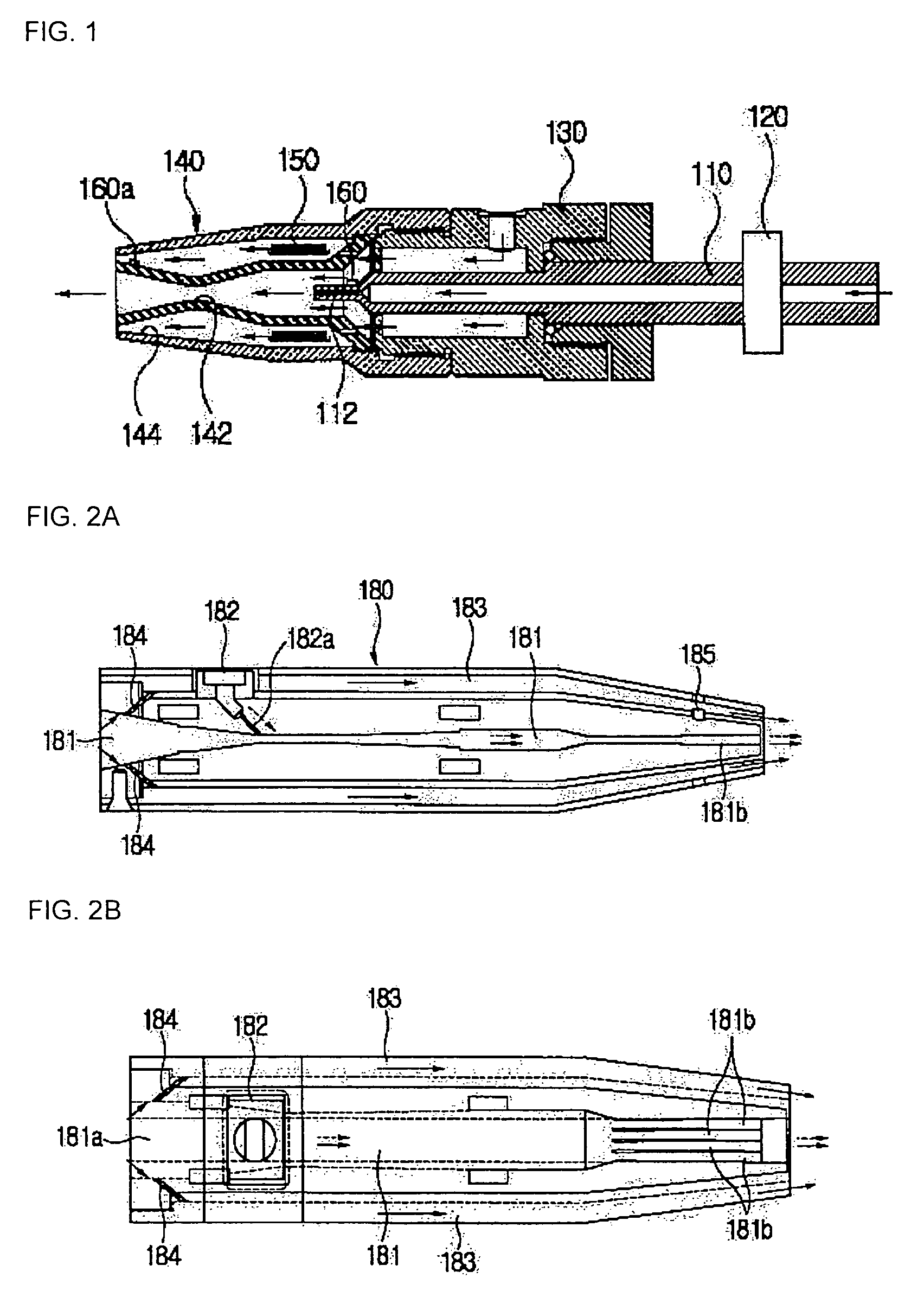

Method and system for cold gas spraying

InactiveUS7143967B2Simple spraying particle injection methodSpeed up the gas flowBurnersMolten spray coatingMaterials scienceAirflow

Owner:SULZER METRO AG

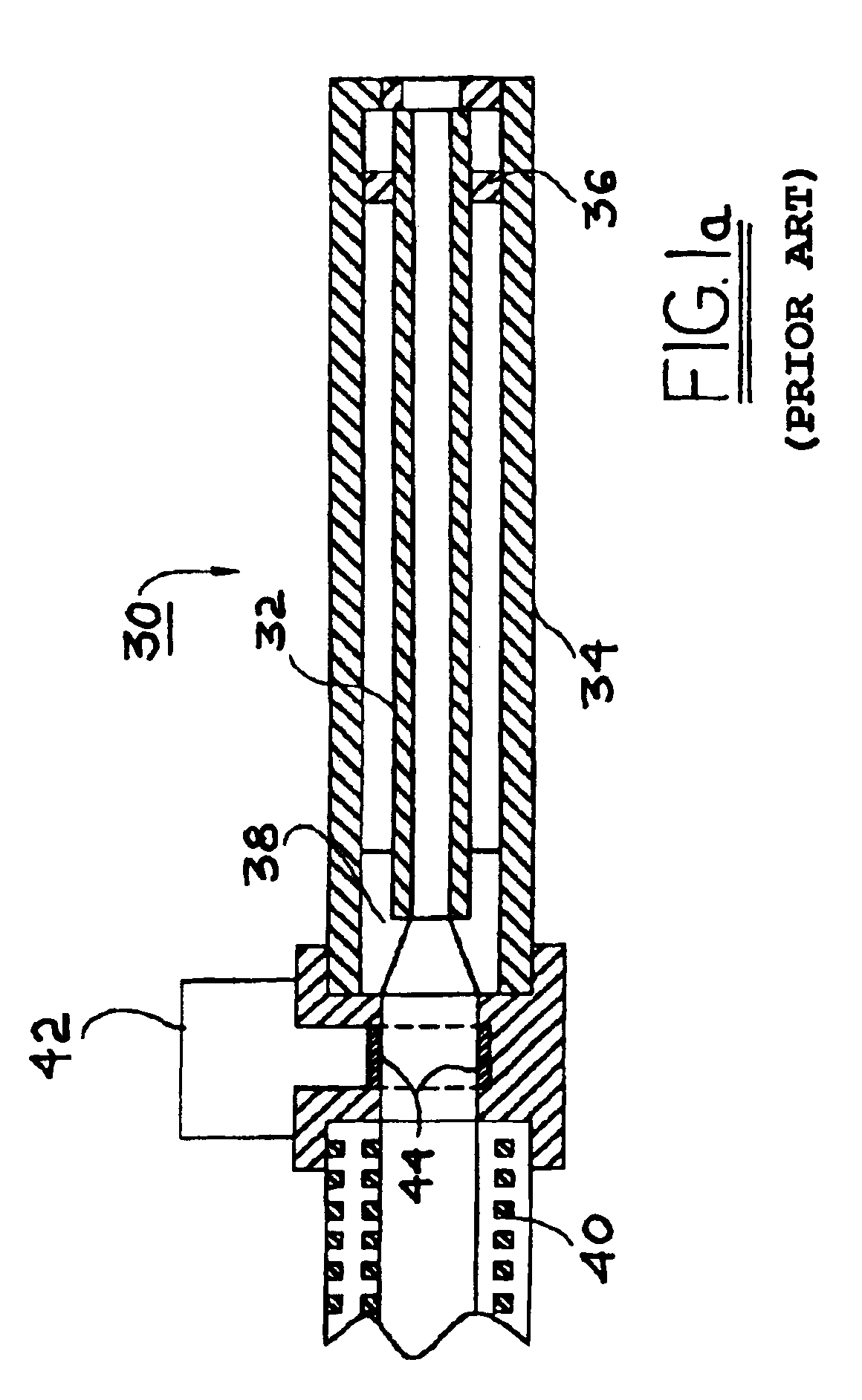

Dry ice blasting cleaning apparatus

The invention is an apparatus used for cleaning equipment including extremely high voltage energized electrical equipment using a dry ice blasting stream as the cleaning agent. The apparatus comprises a cleaning wand and a heating mechanism for impeding the formation of condensation and / or frost on the outer surface of the wand, thereby enabling the wand to operate for prolonged periods of time.

Owner:BRITISH COLUMBIA HYDRO & POWER AUTHORITY

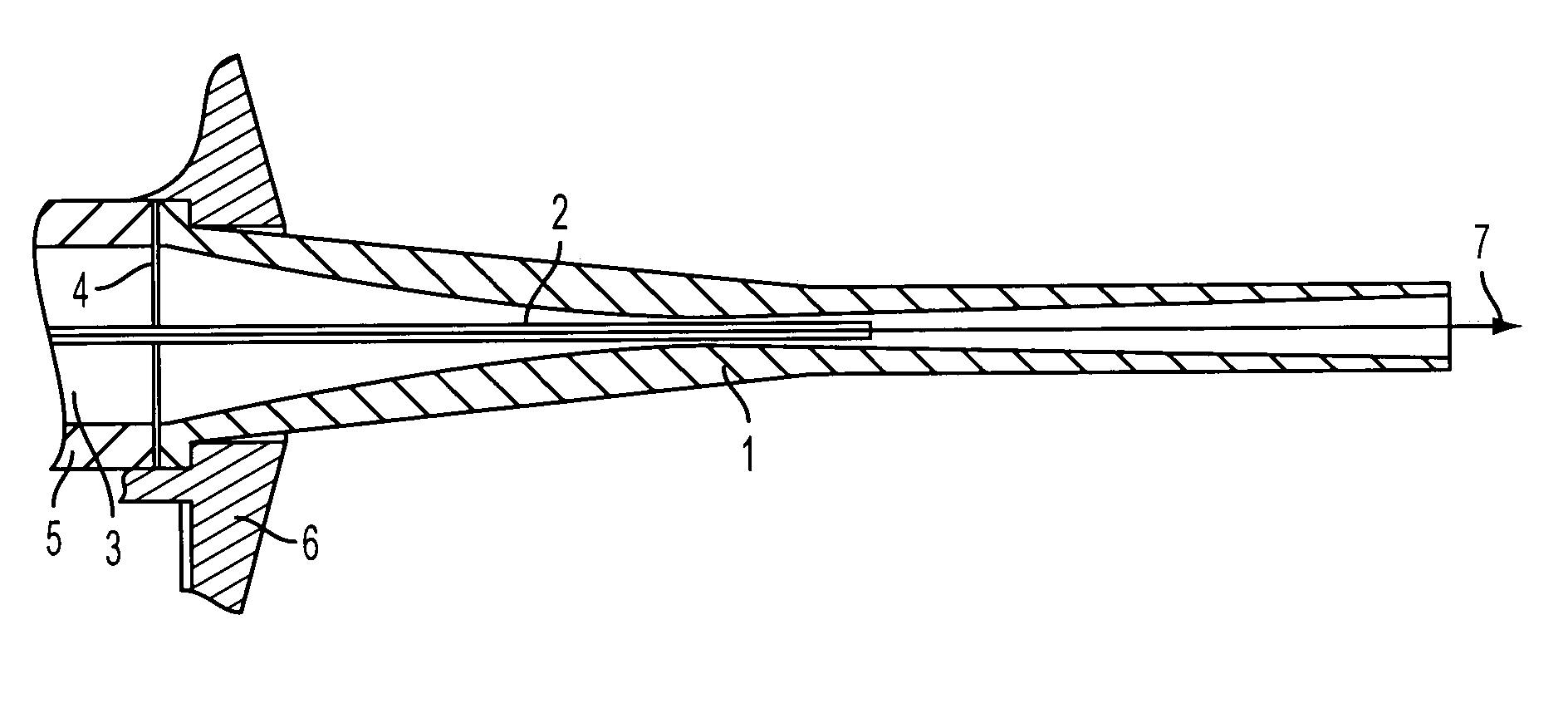

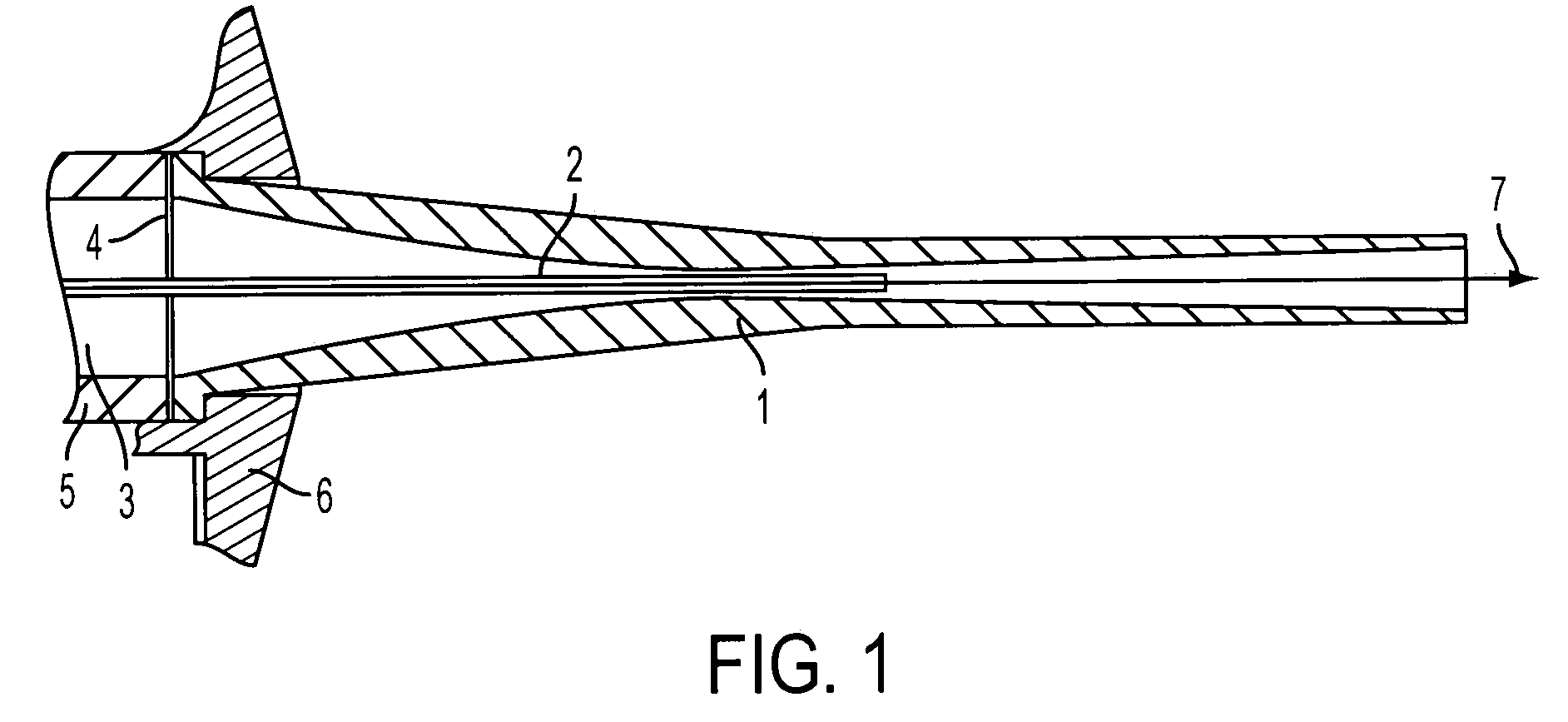

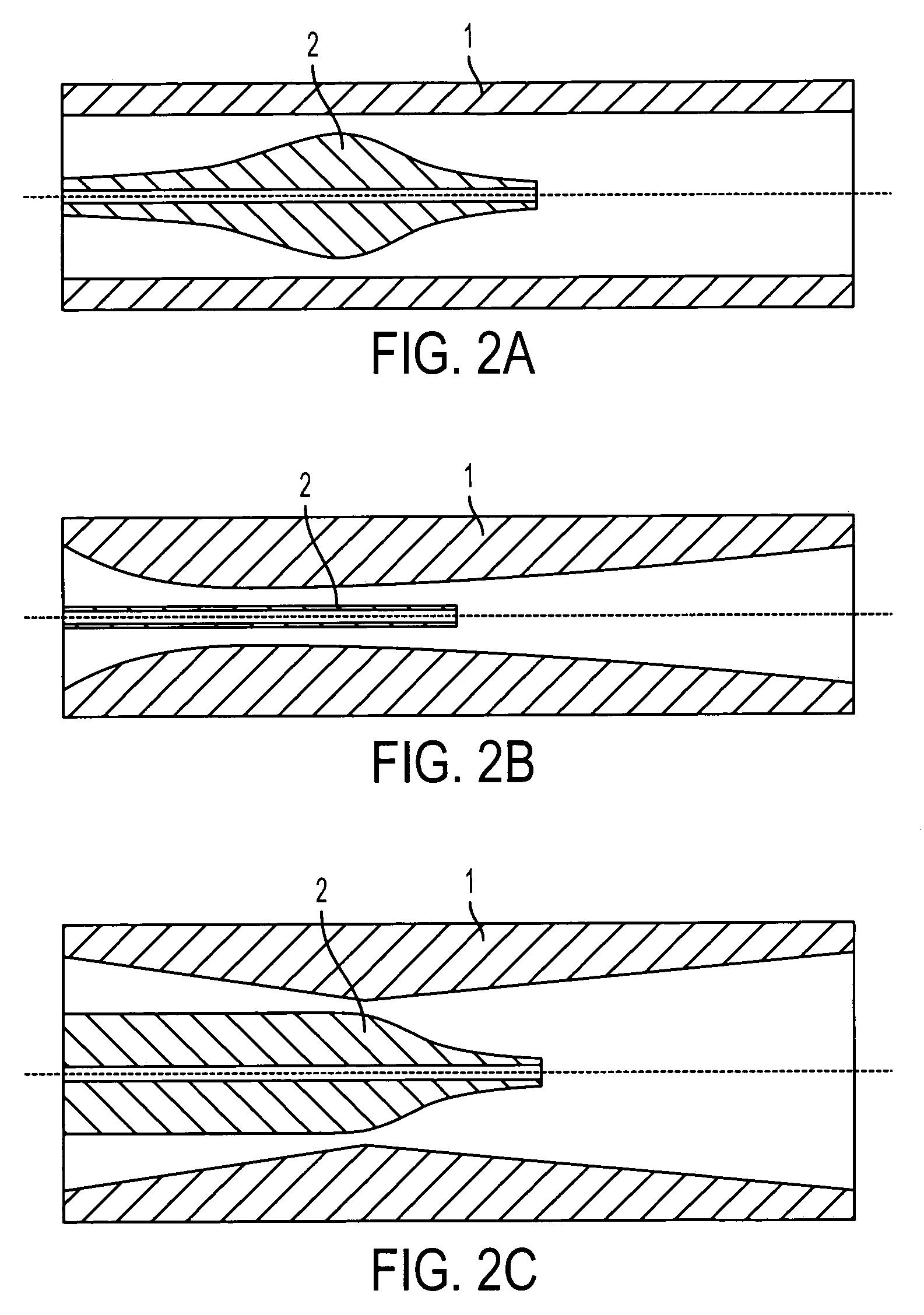

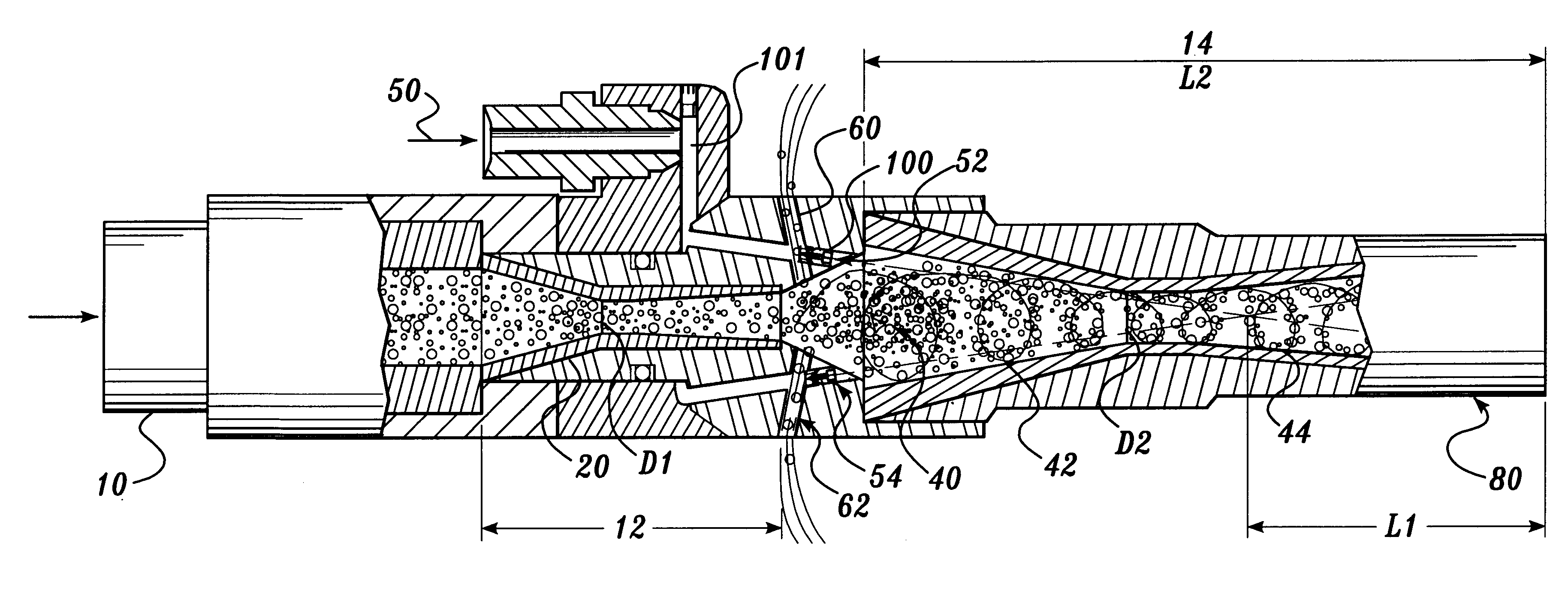

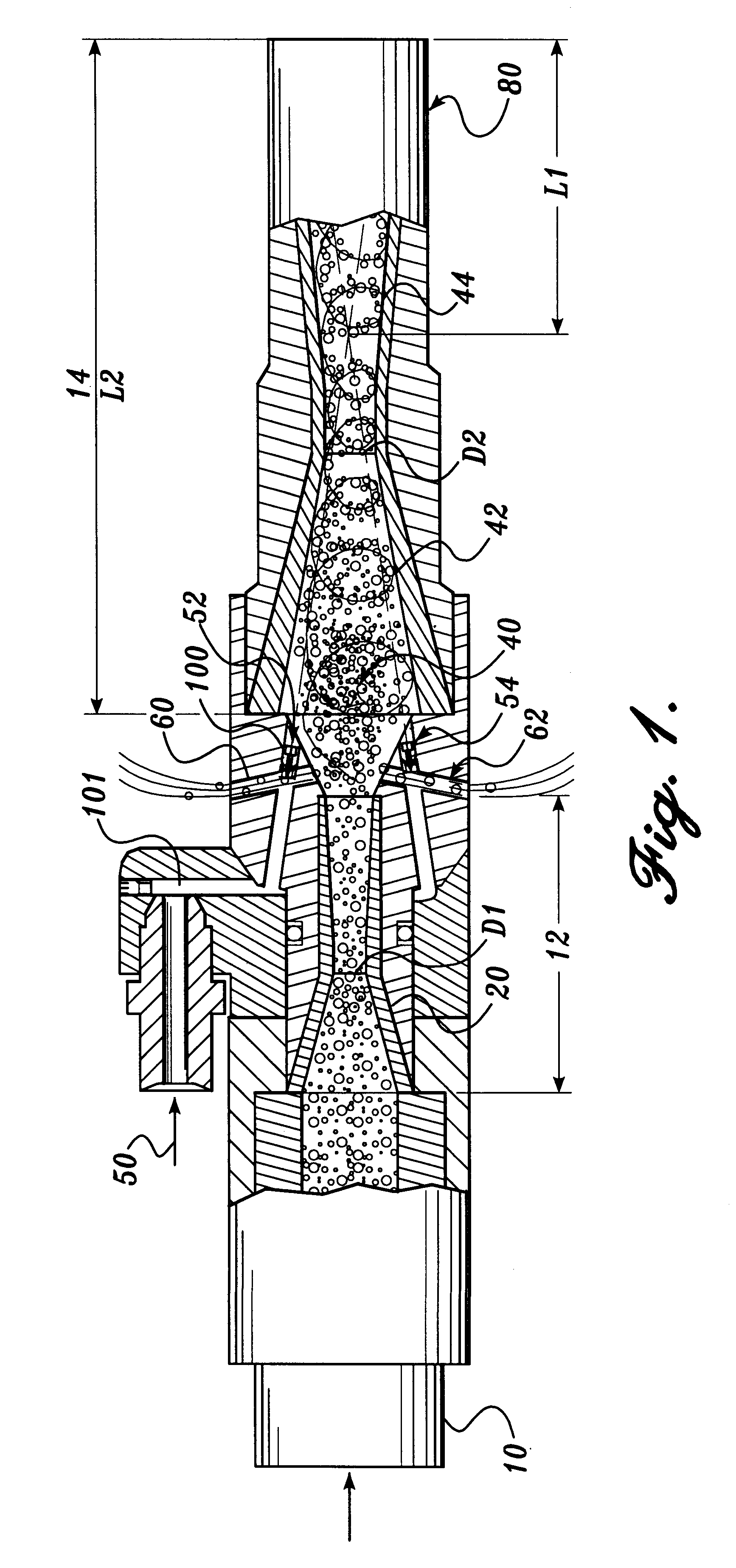

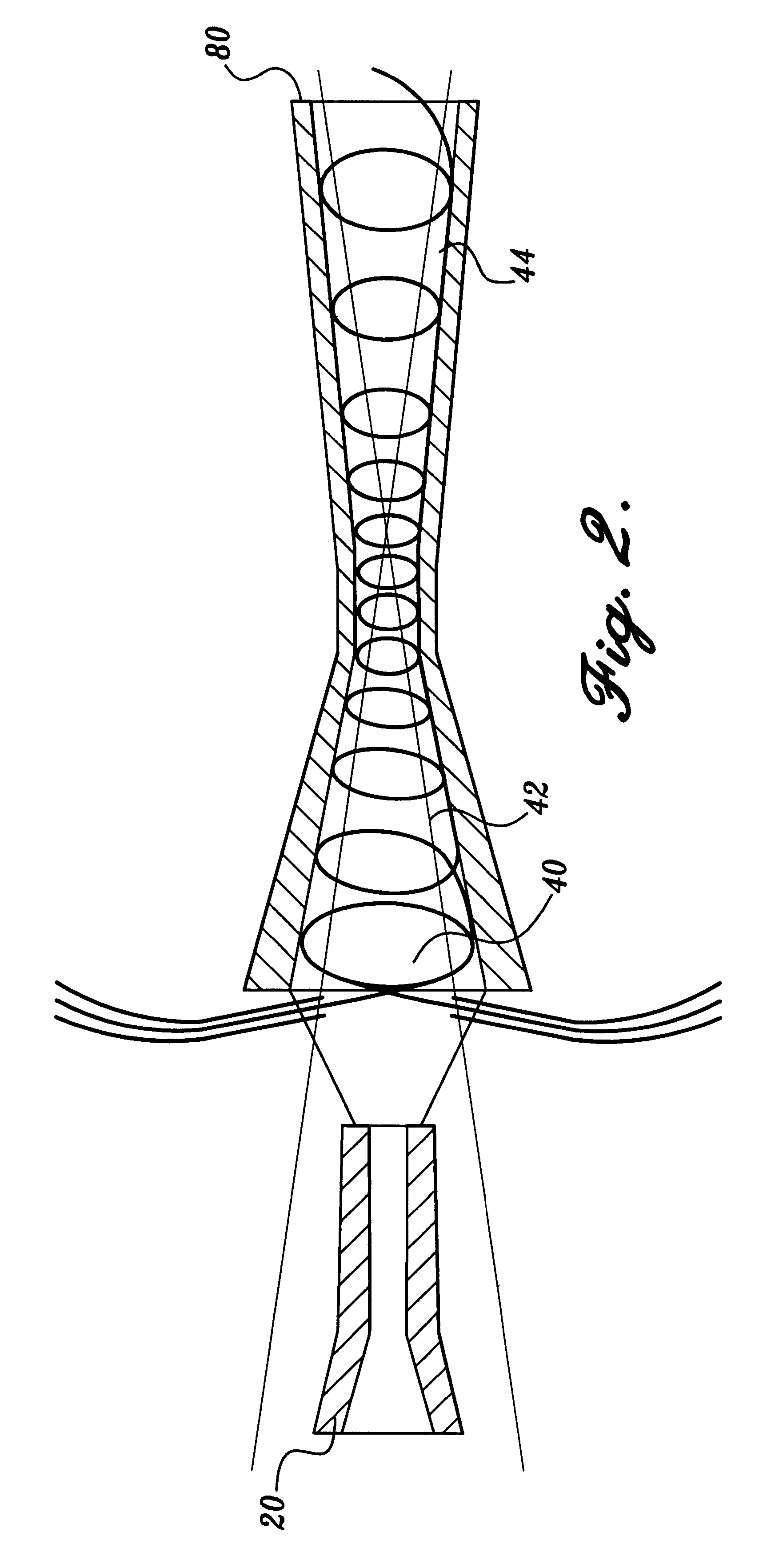

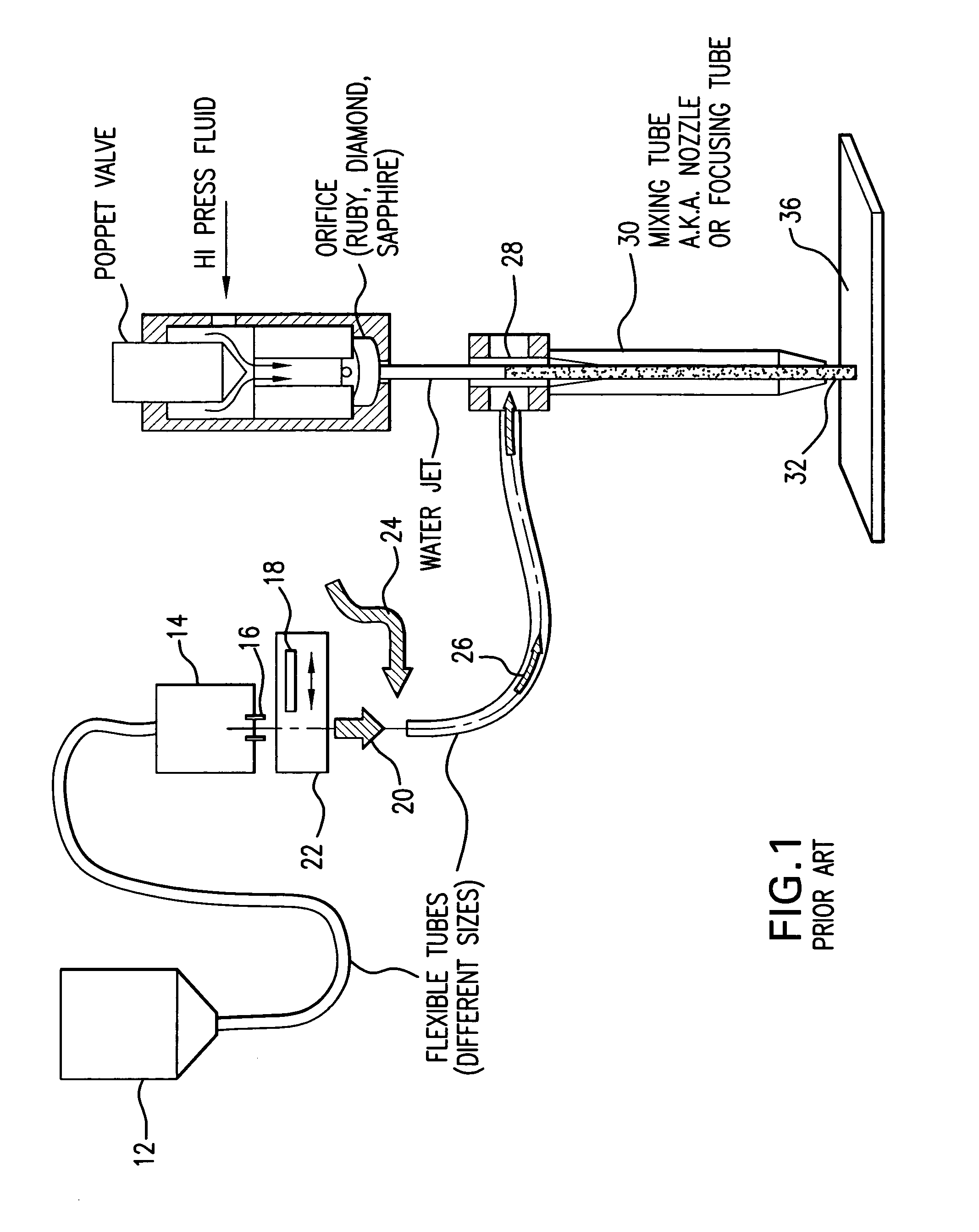

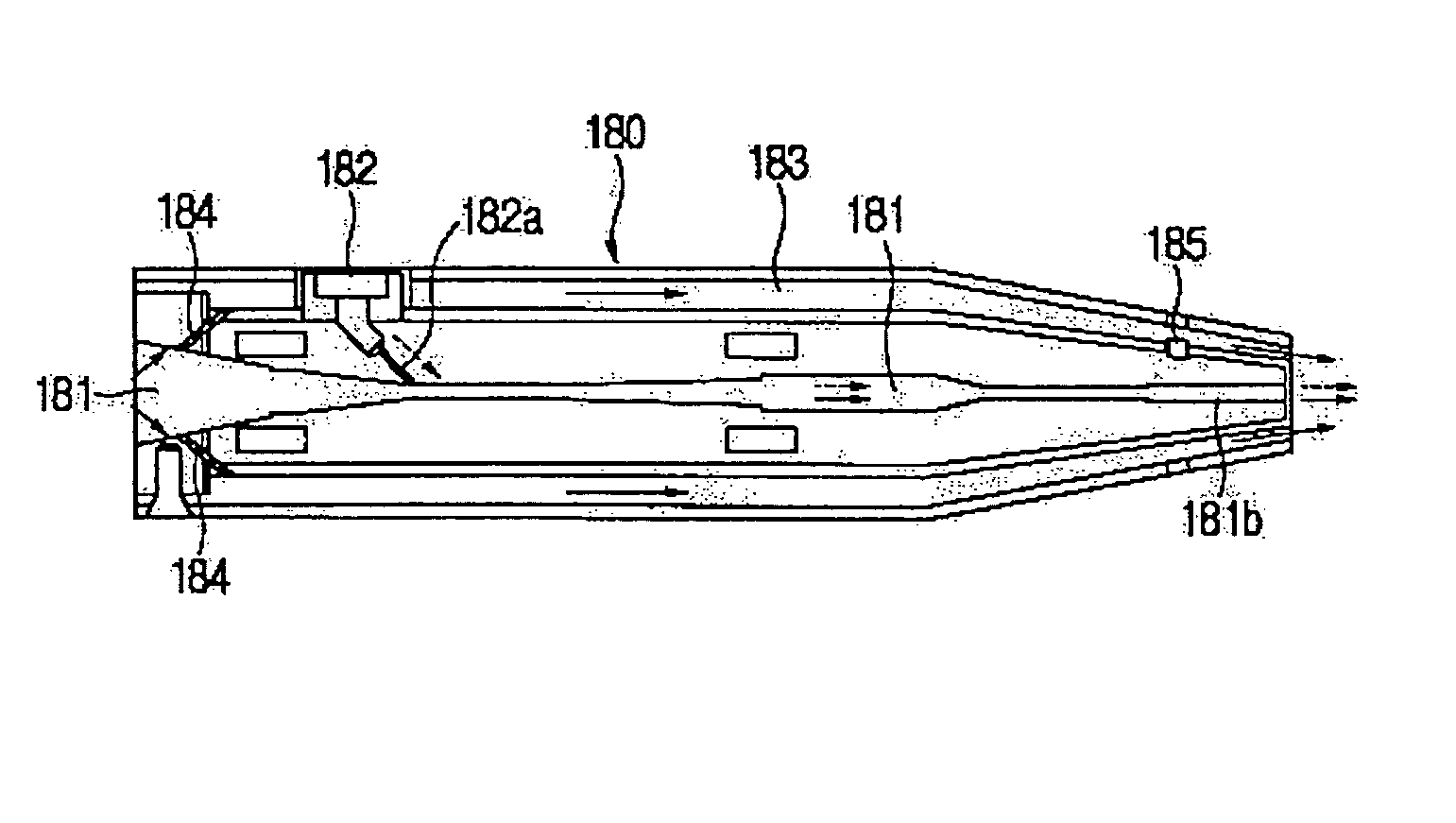

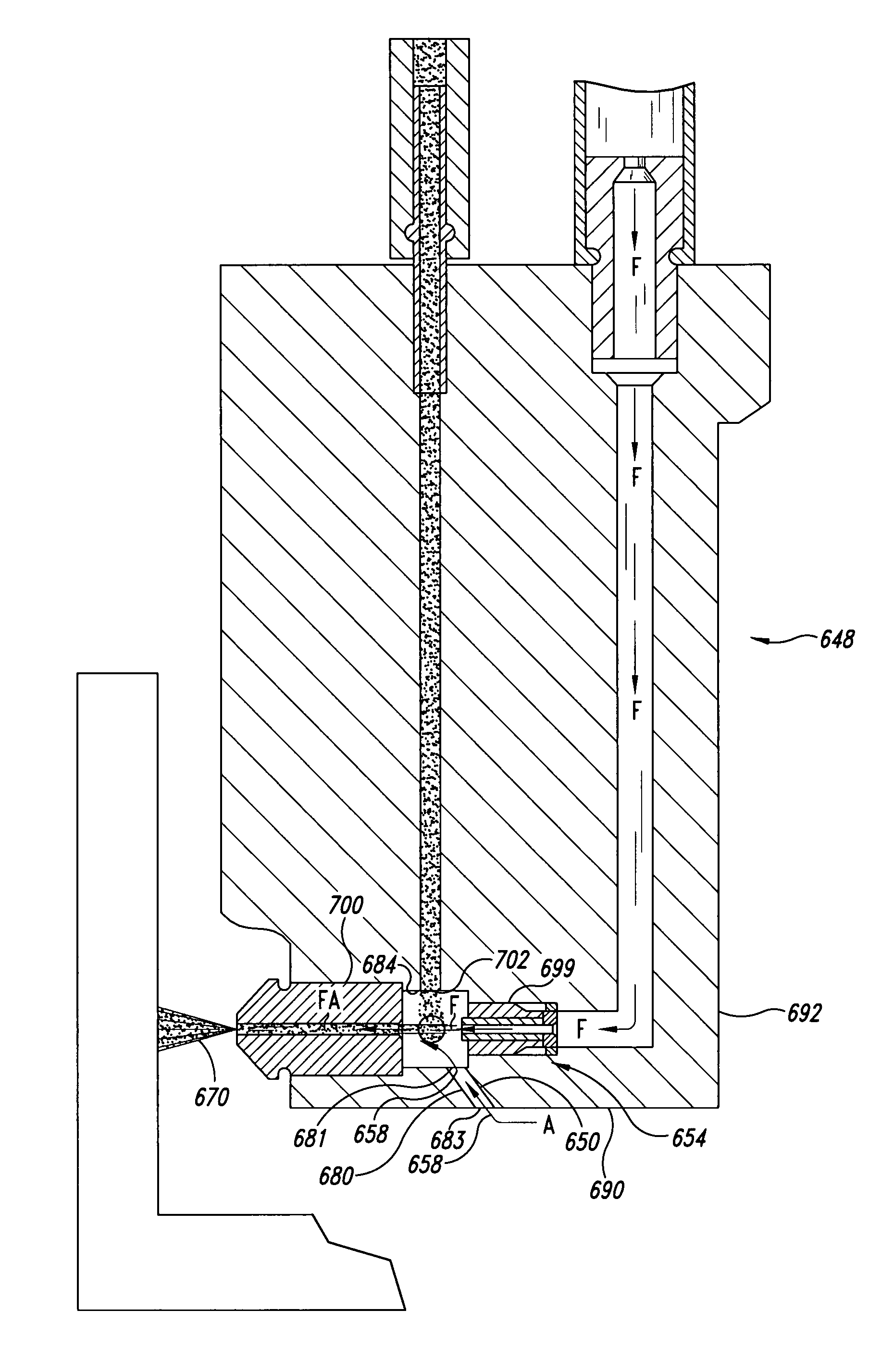

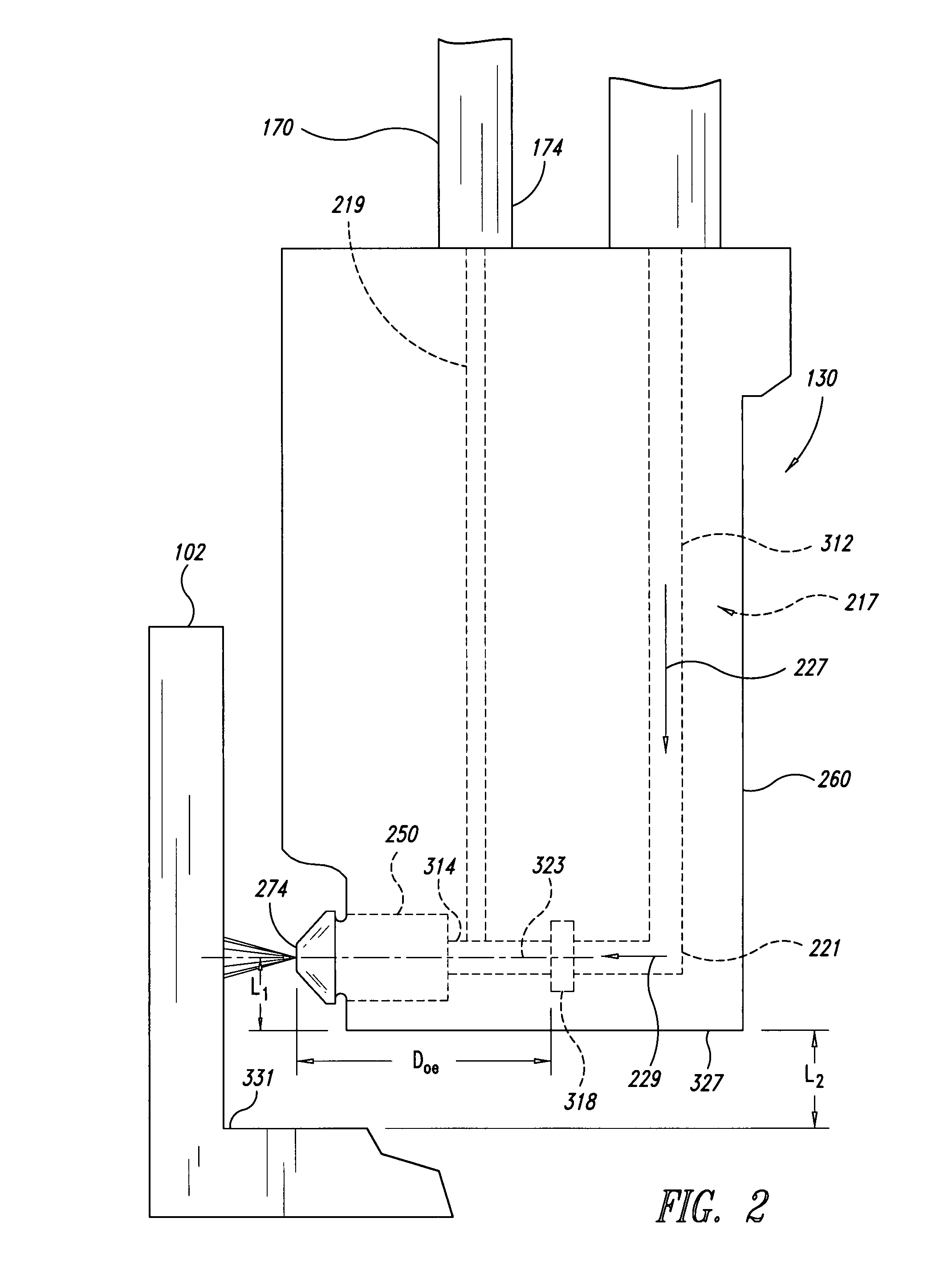

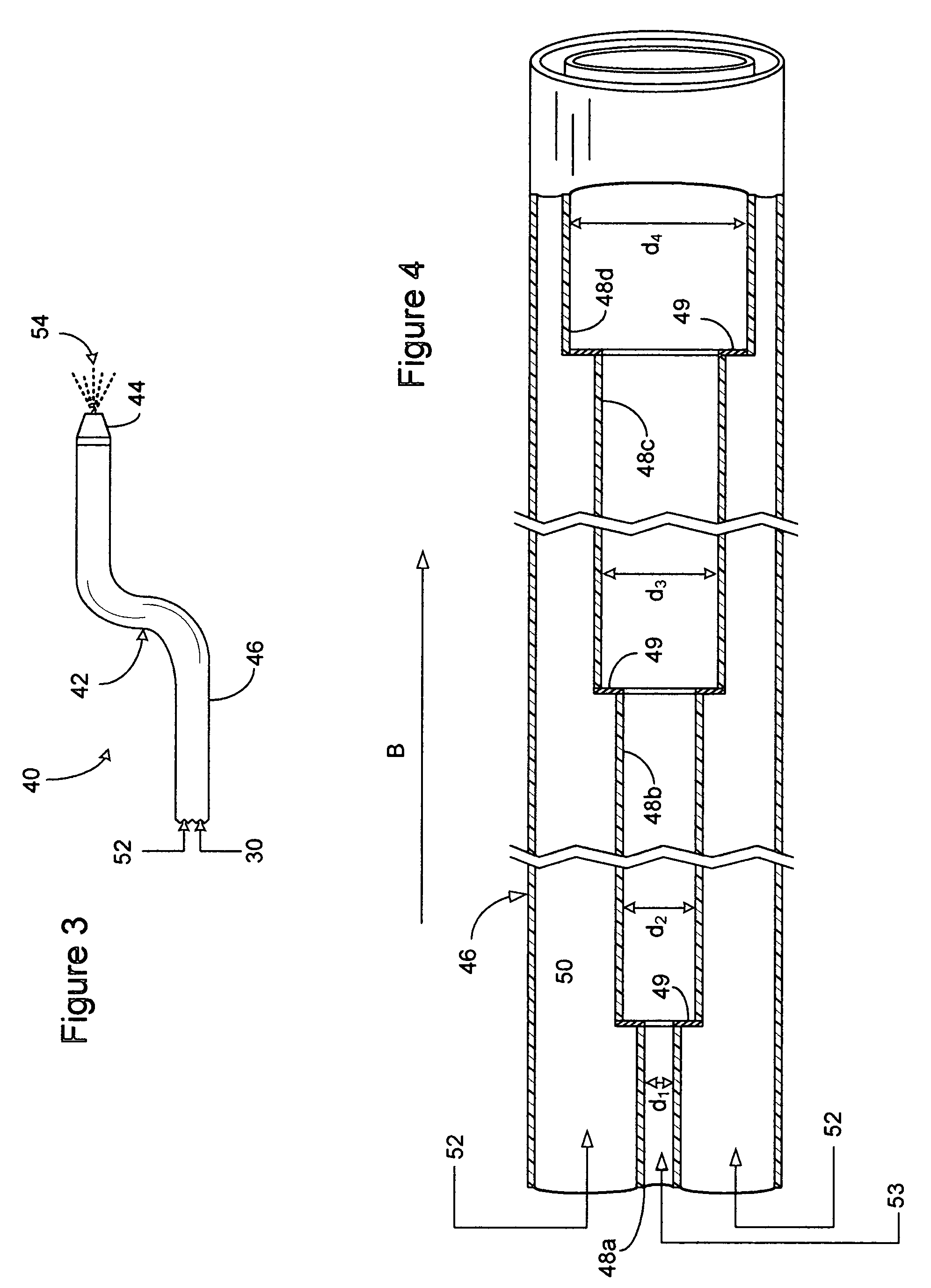

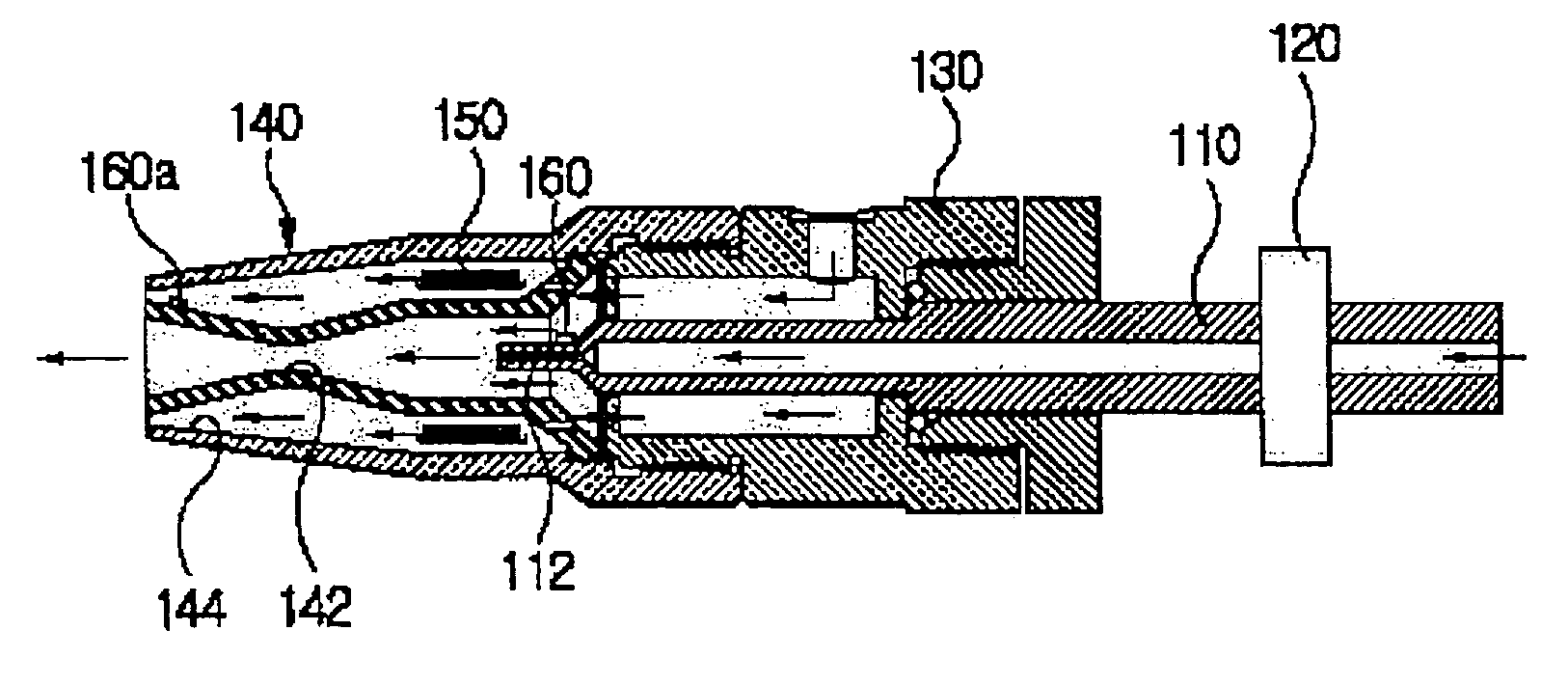

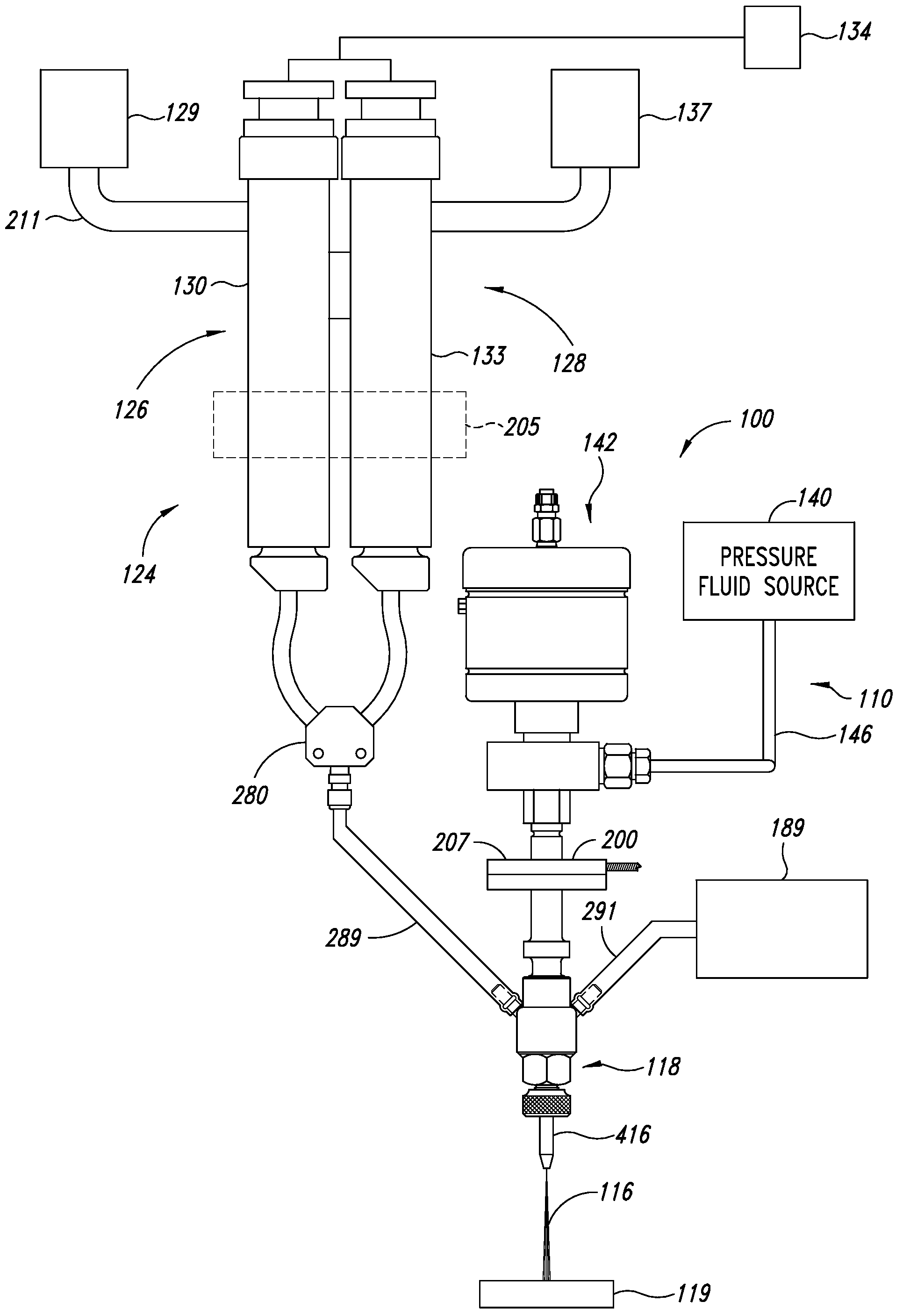

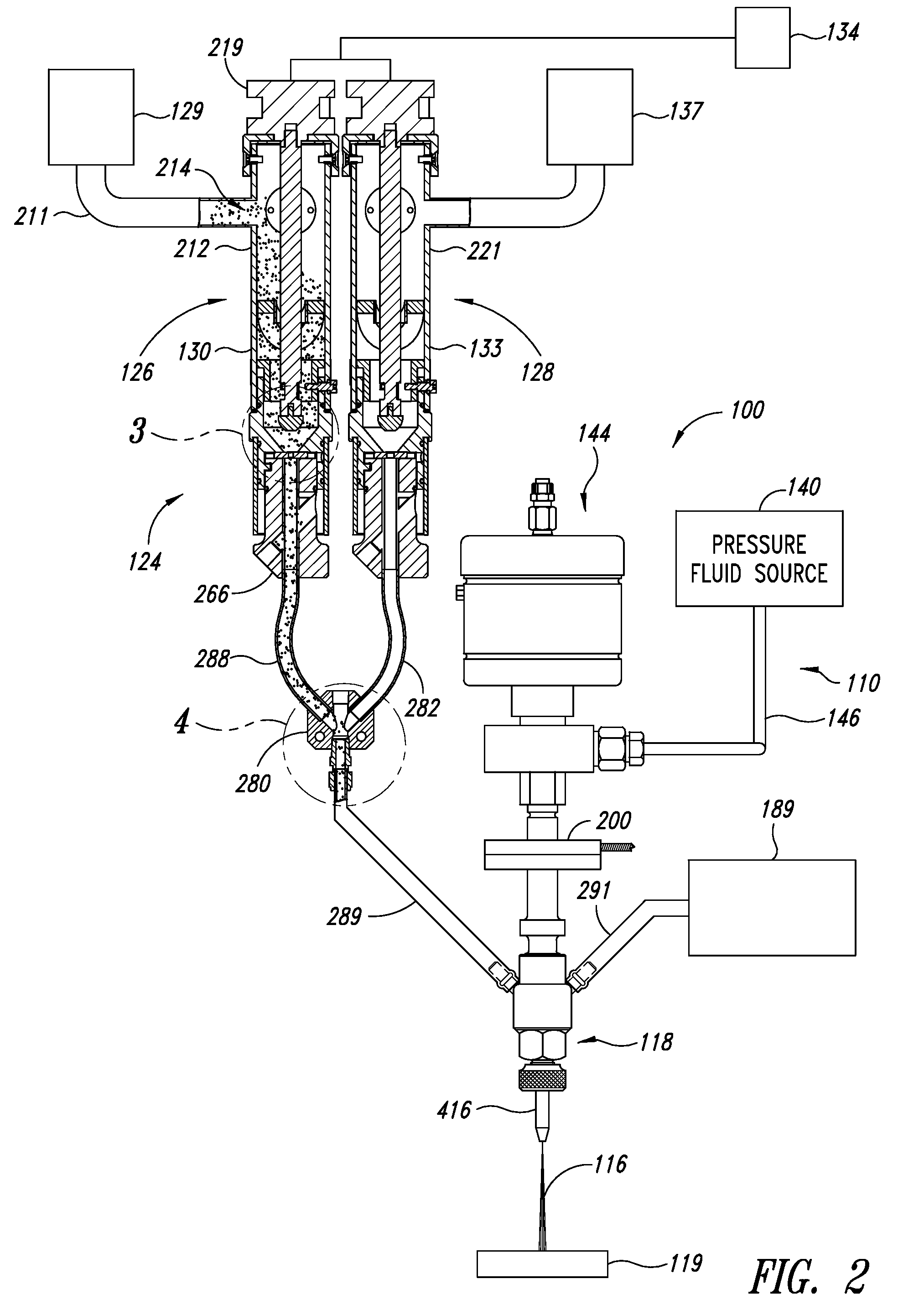

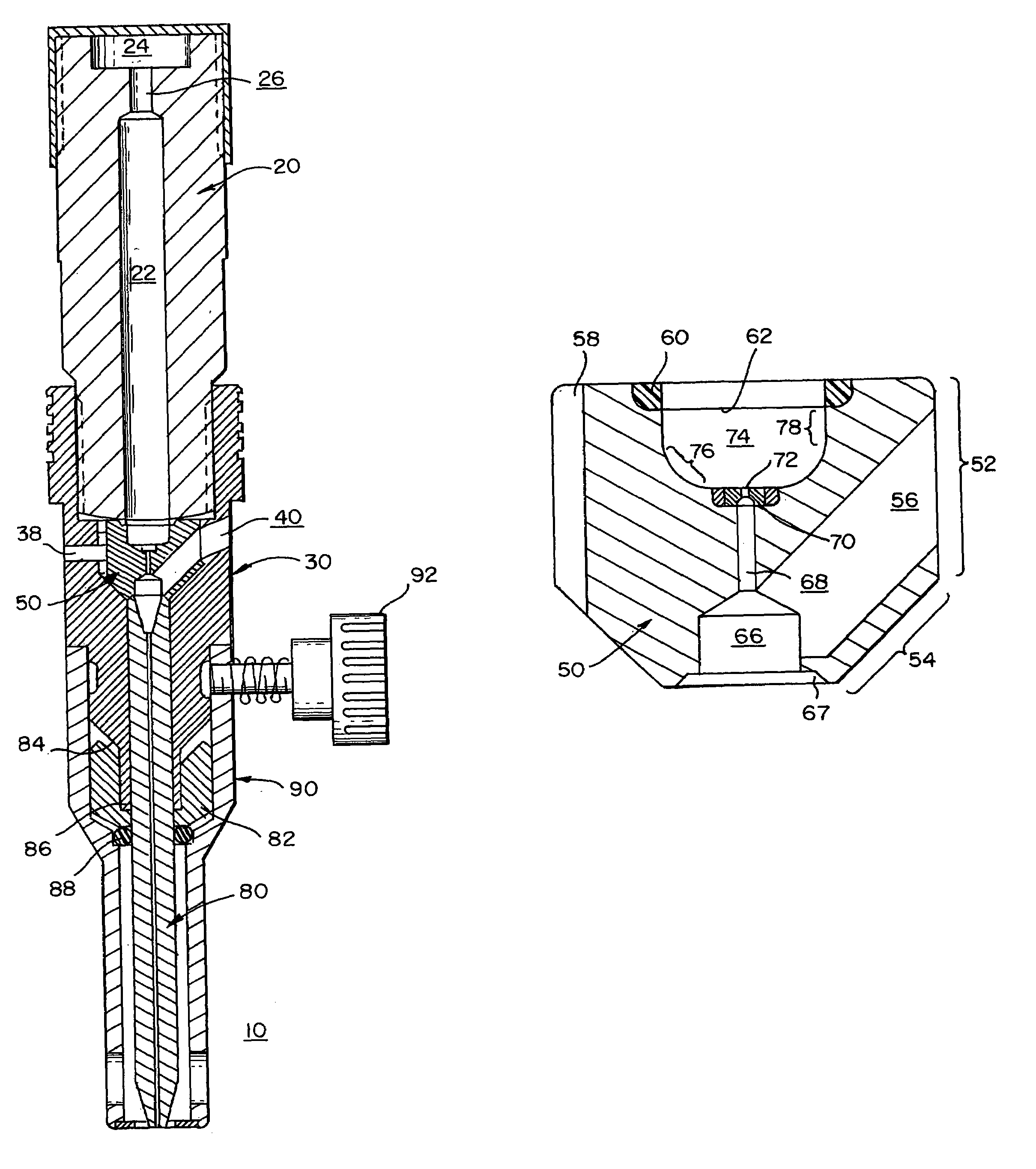

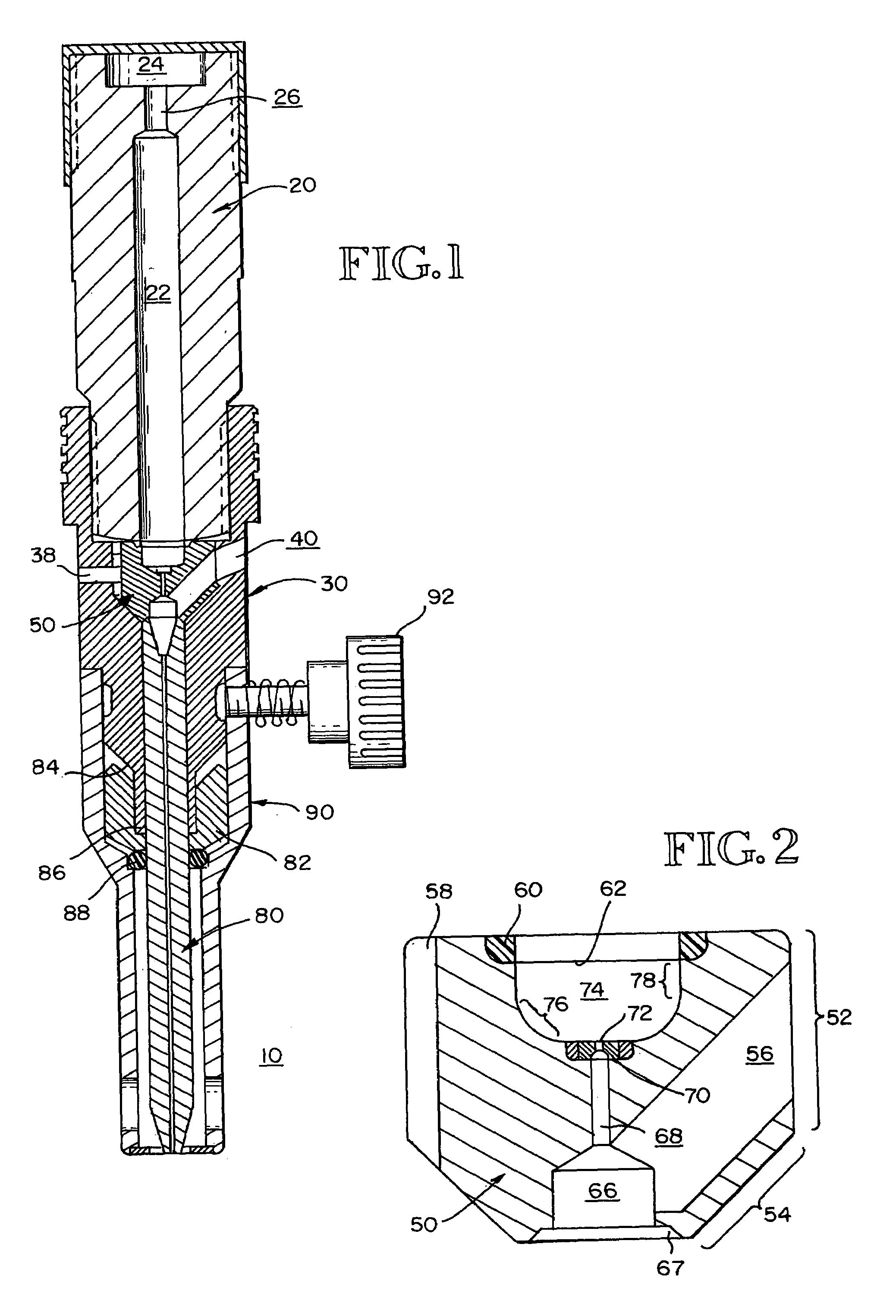

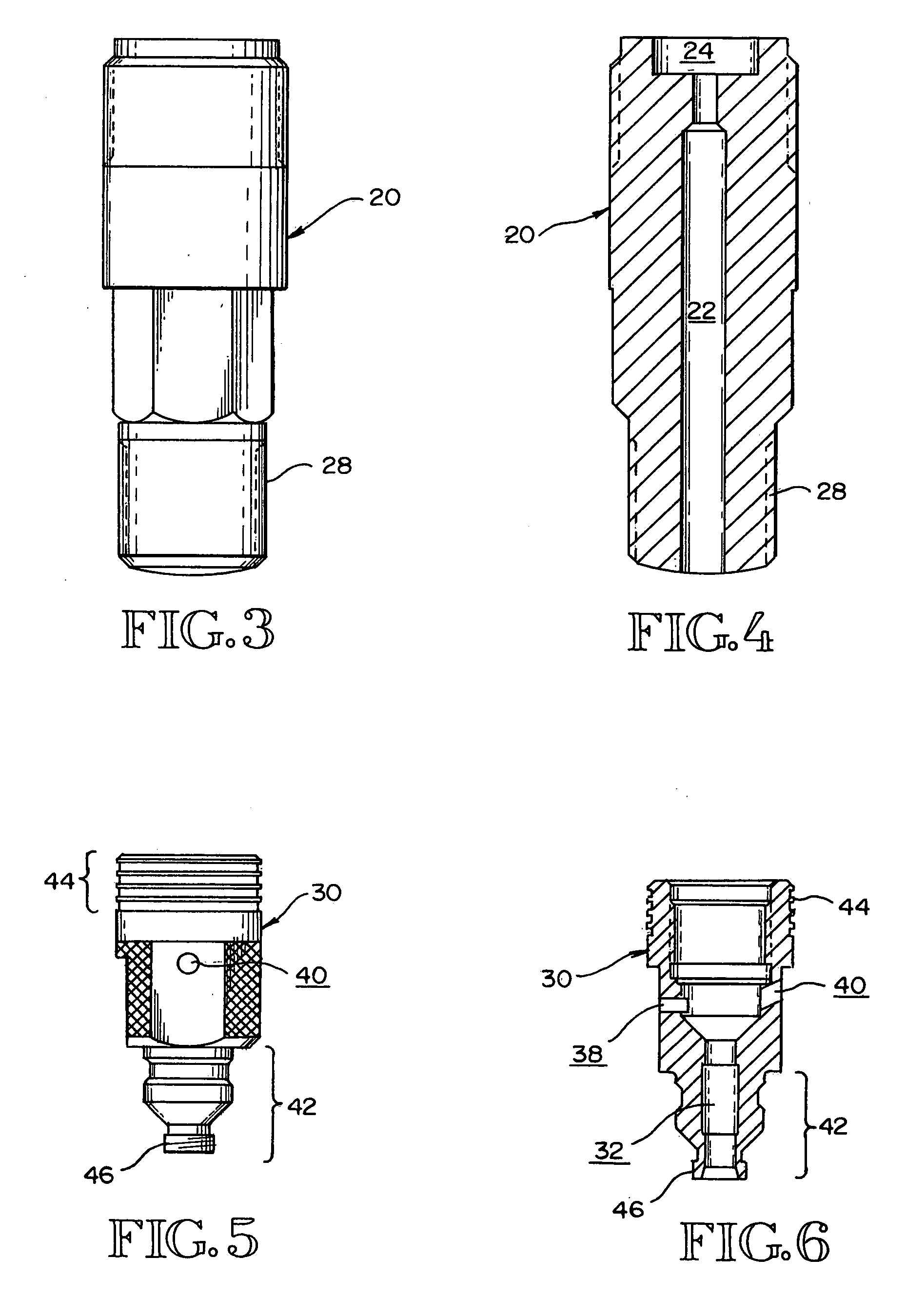

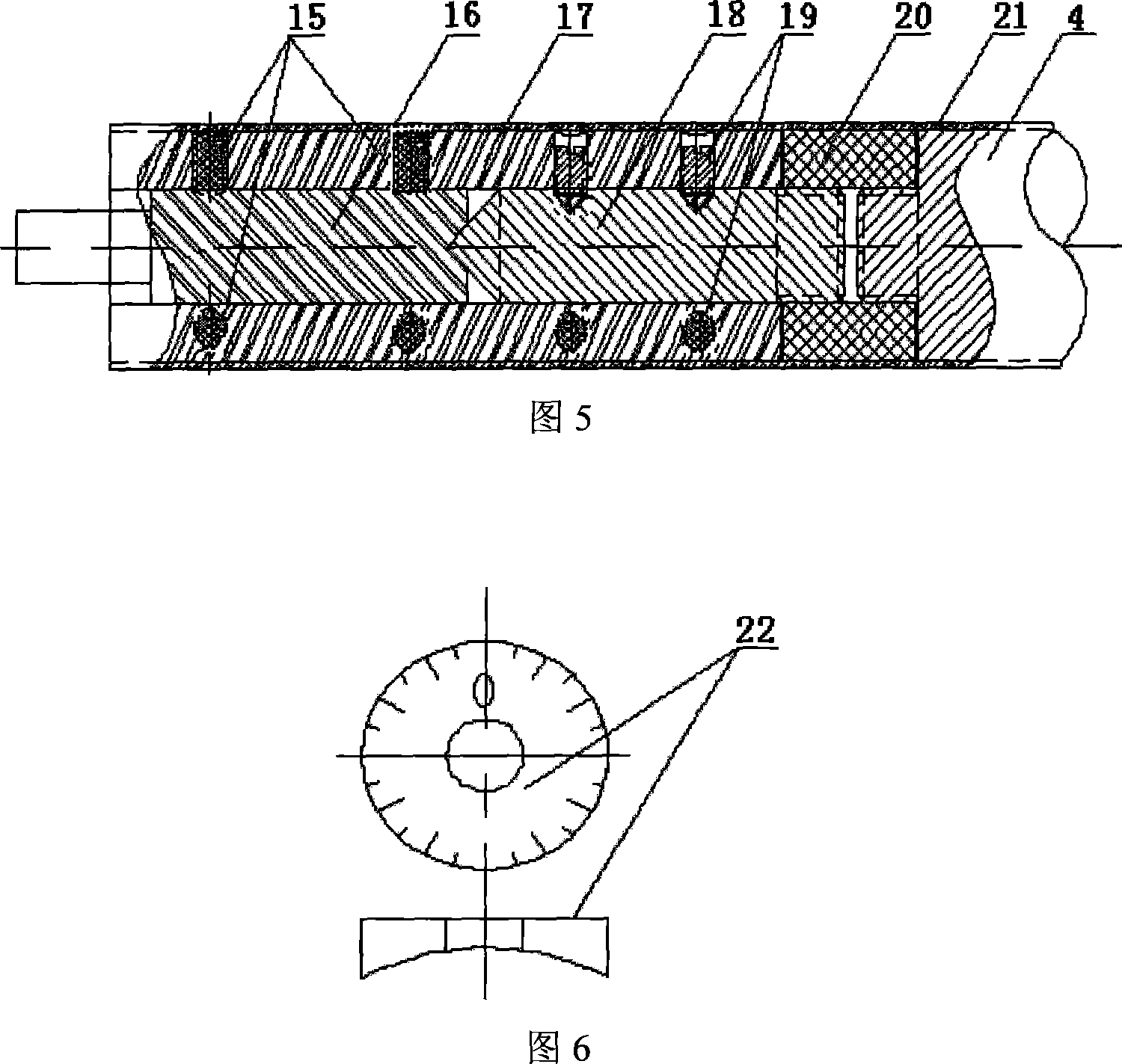

Method and apparatus for producing a high-velocity particle stream

InactiveUS6283833B1Uniform particle spreadingImprove productivityBlast gunsLiquid spraying apparatusJet flowClassical mechanics

A method and apparatus for producing a high-velocity particle stream at low cost through multi-staged acceleration using different media in each stage. The particles are accelerated to a subsonic velocity (with respect to the velocity of sound in air) using one or more jets of gas at low cost, then further accelerated to a higher velocity using jets of water. Additionally, to enhance particle acceleration, a vortex motion is created, and the particles introduced into the fluid having vortex motion, thereby enhancing the delivery of particles to the target.

Owner:FLOW INT

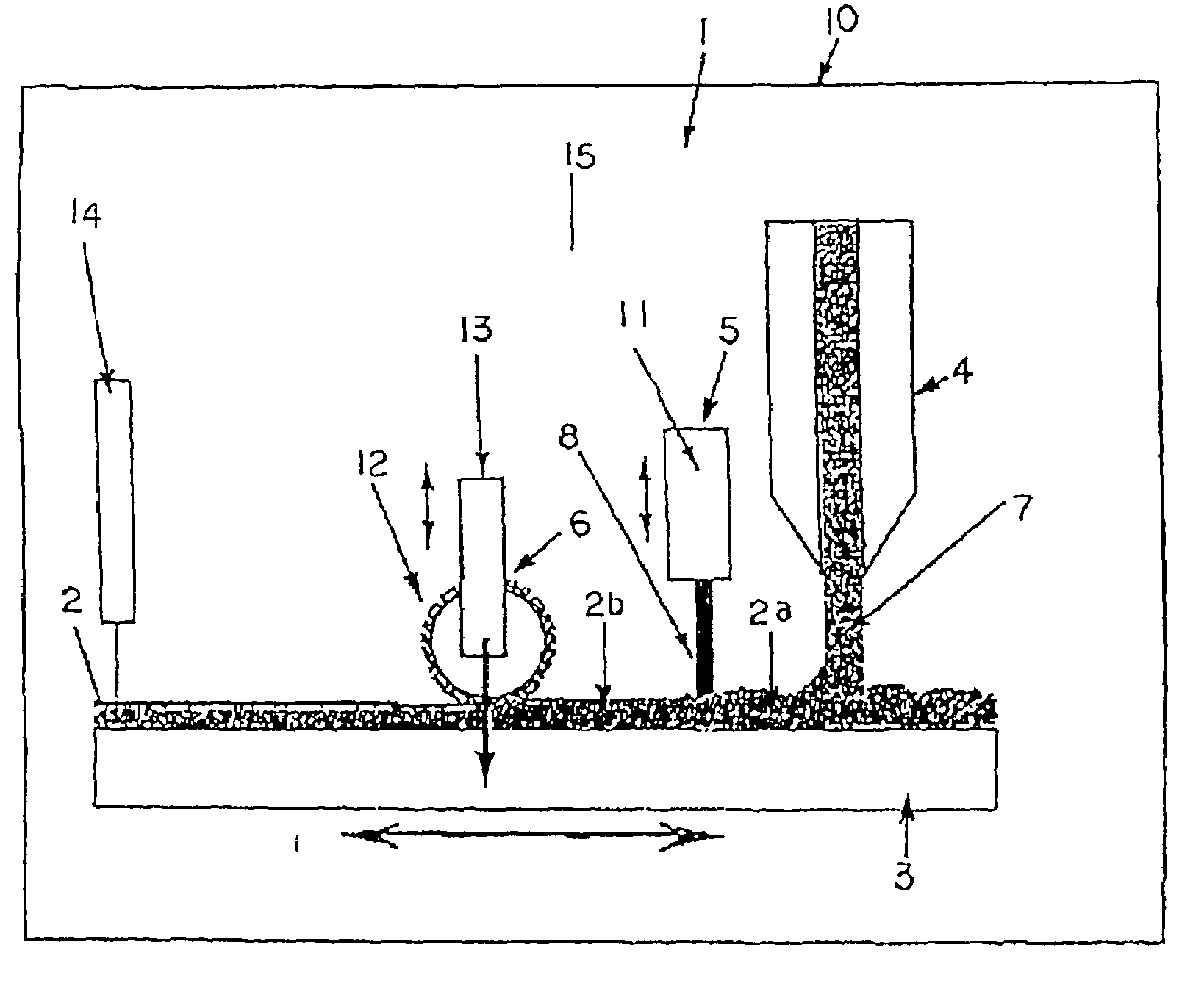

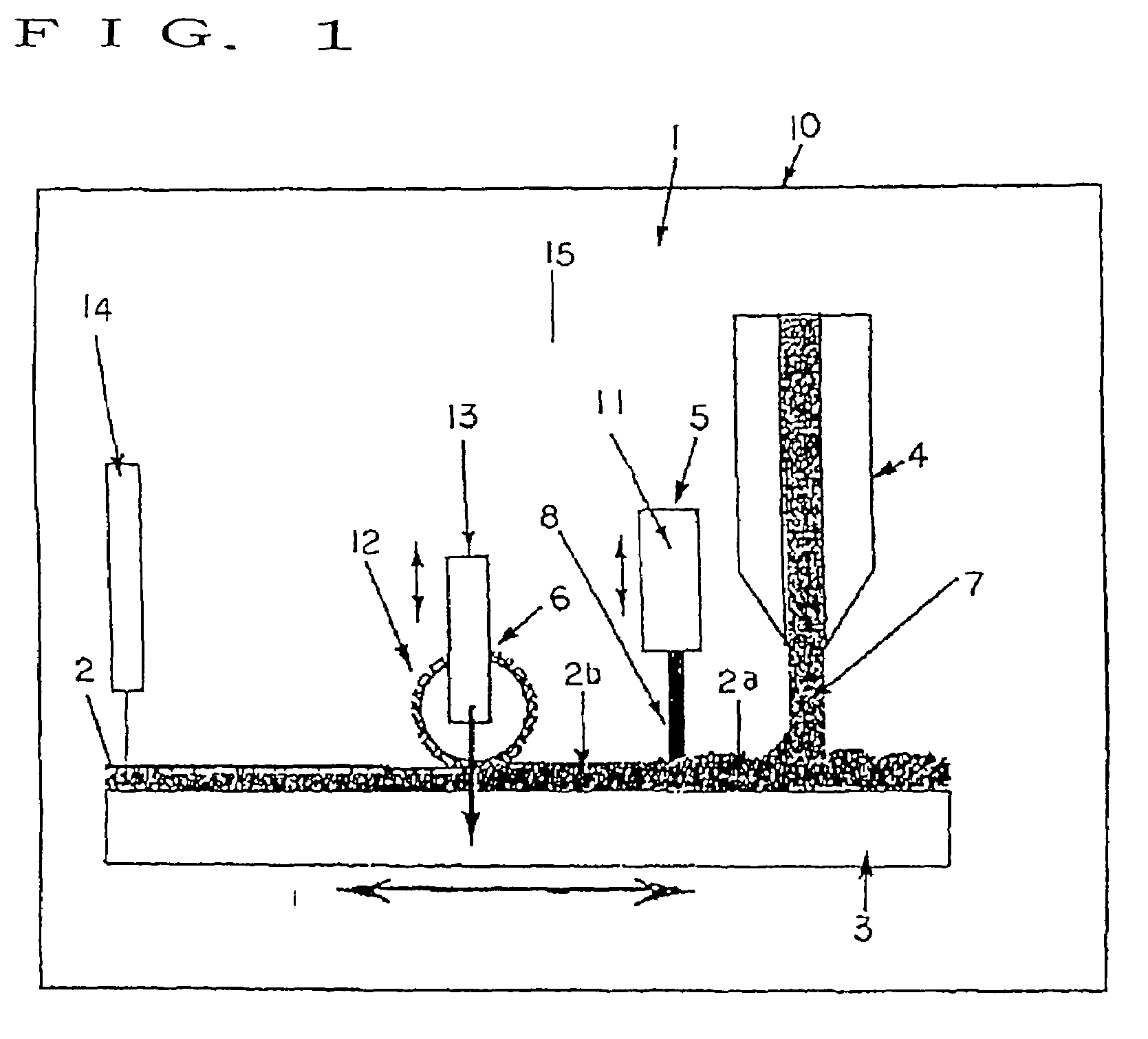

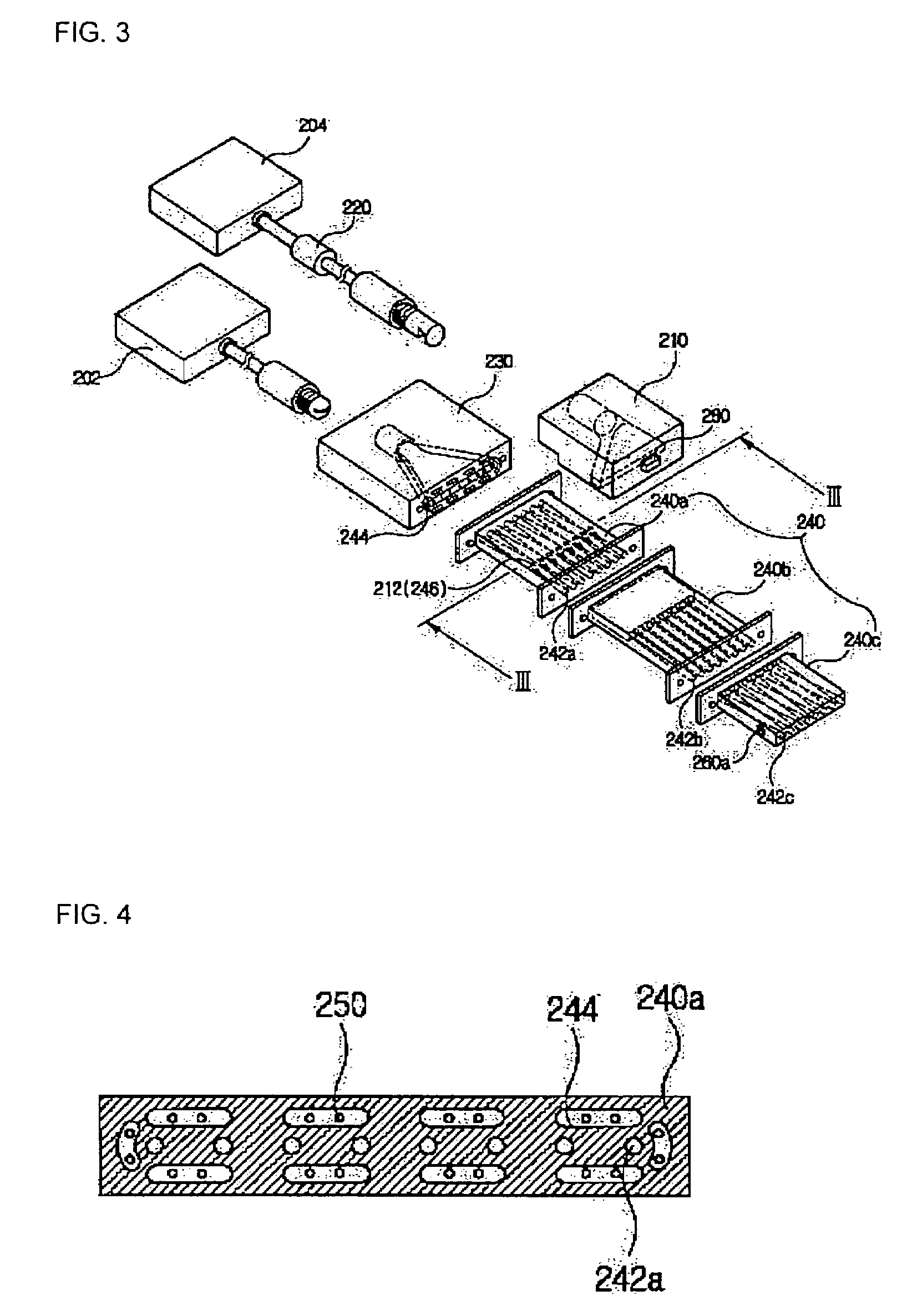

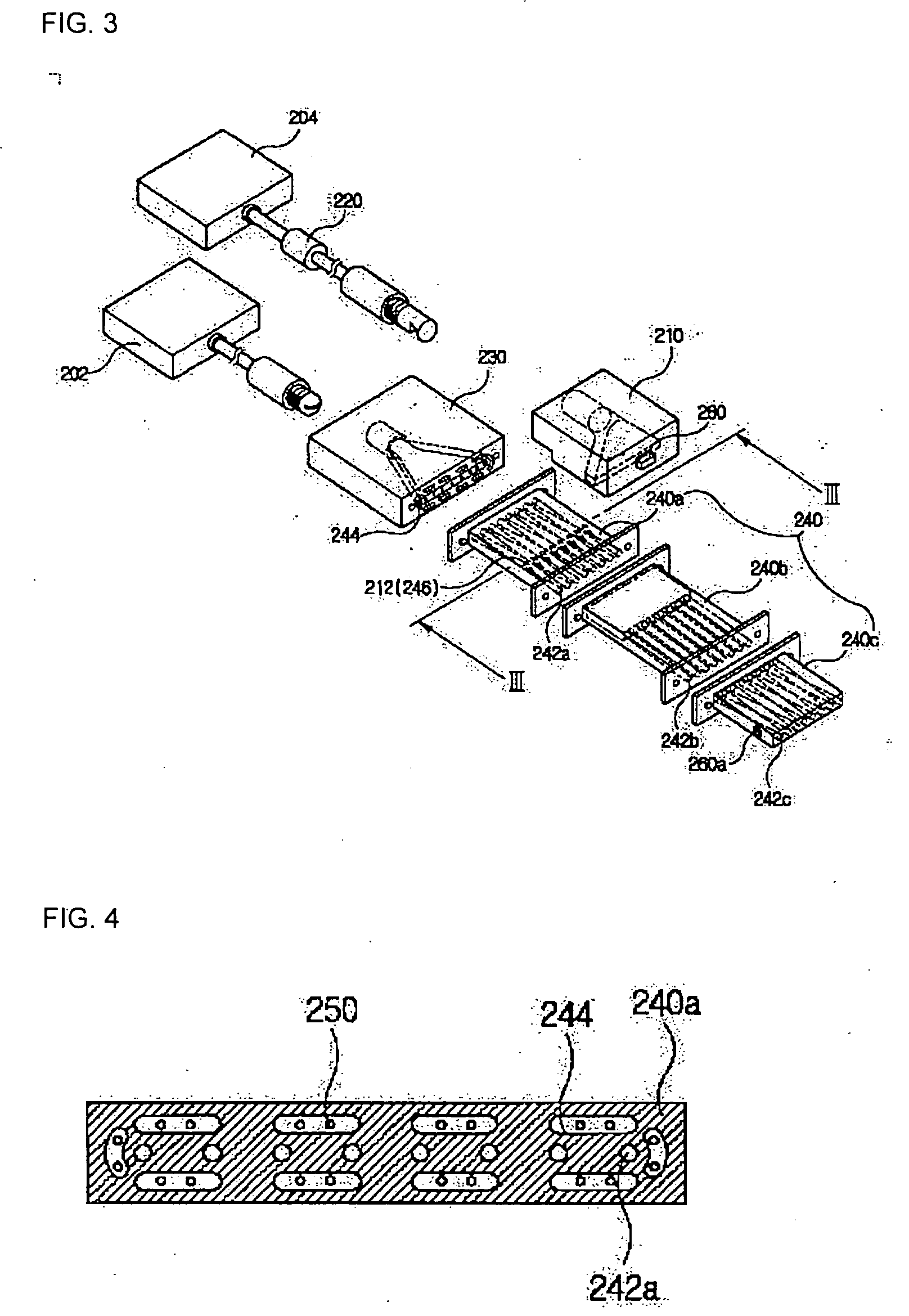

Ultra fine particle film forming method and apparatus

A ultra fine particle film forming apparatus is provided which is capable of forming a ultra fine particle film which has ultra fine particles sufficiently bonded together, sufficient density, flat surface and uniform density. A planarized ultra fine particle film forming method for forming a planarized ultra fine particle film from a deposited film of ultra fine particles formed by supplying the ultra fine particles to a substrate, the method comprising one or more of a planarizing step of planarizing a surface of the deposited film of the ultra fine particles supplied to the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Device for comminuting dry ice granules, and dry ice dispensing arrangement having such a device

The invention relates to a device for comminuting dry ice granules, comprising a housing having a flow channel for dry ice granules which can be applied, by means of compressed gas, to a surface to be cleaned, and also comprising a first comminution member for comminuting the dry ice granules which are to be dispensed. In order to provide a device of this kind with which different degrees of comminution of dry ice granules can be achieved in a simple manner, it is proposed according to the invention that the device has at least one second comminution member which can be disposed in the housing in a position in which a total degree of comminution, which is greater than the individual degree of comminution which can be achieved solely by the first comminution member, can be achieved in combination with the first comminution member. A dry ice dispensing arrangement for dispensing a mixture of compressed gas and dry ice granules is also proposed, having a device of the above kind.

Owner:ALFRED KARCHER GMBH & CO KG

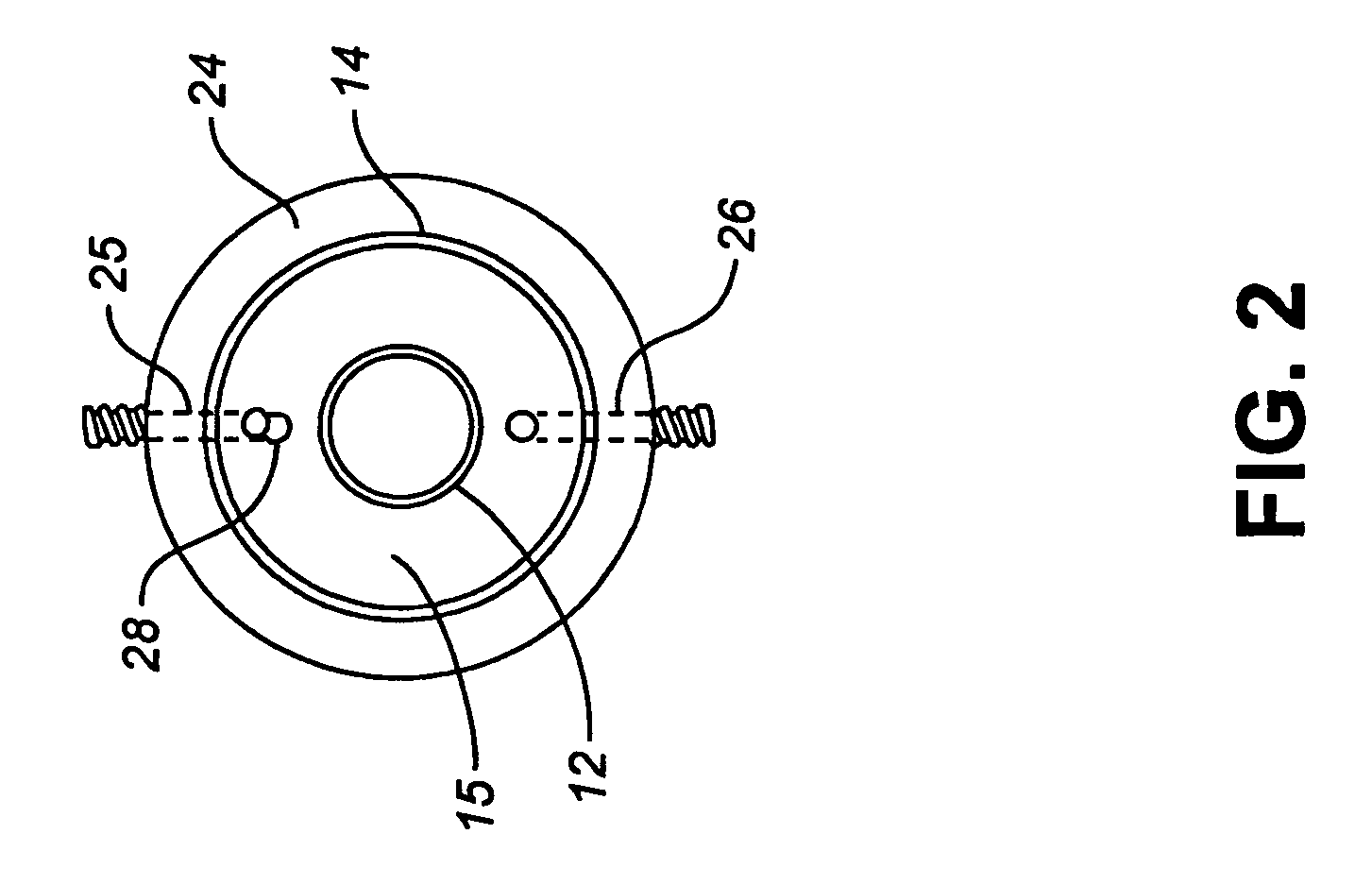

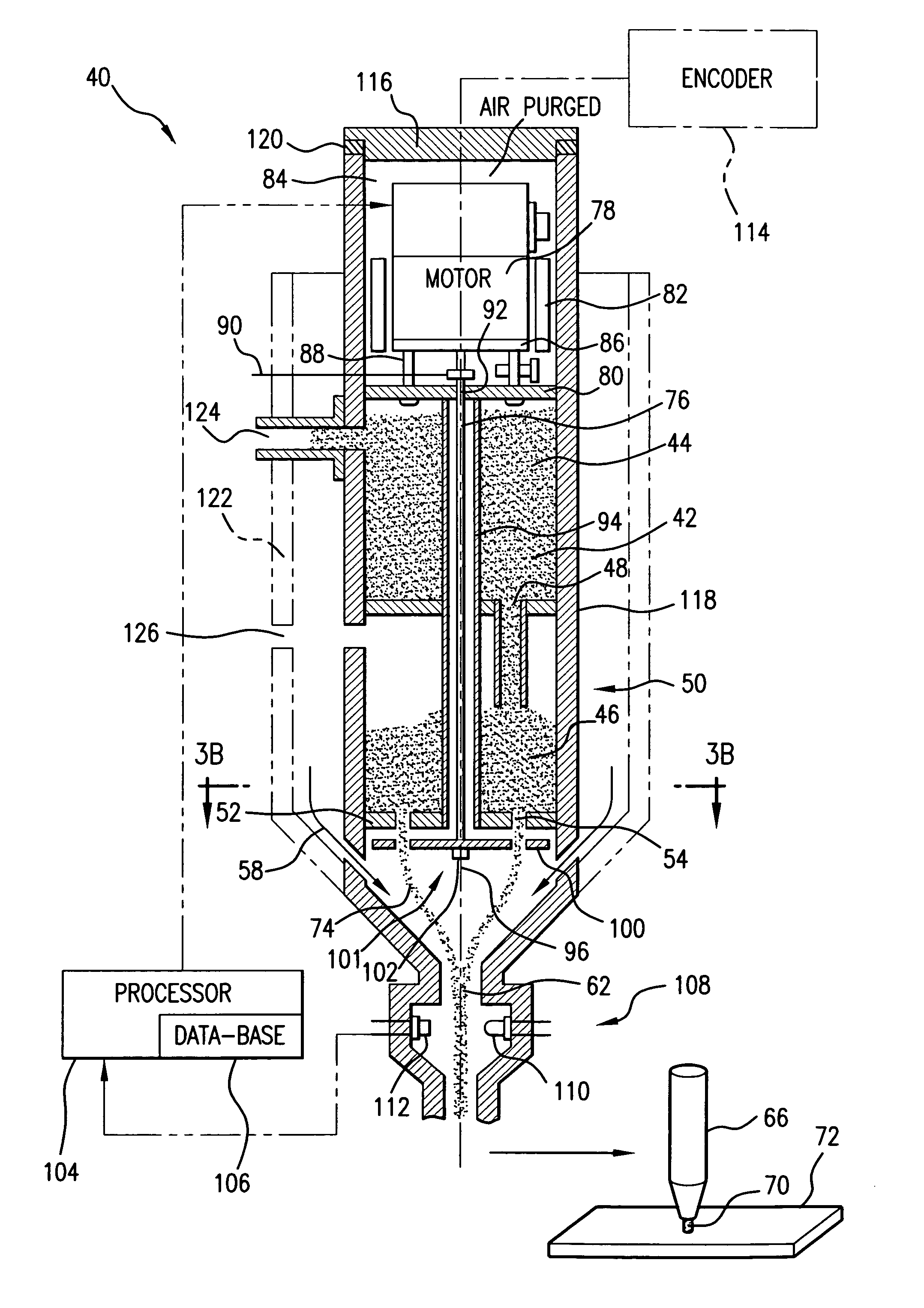

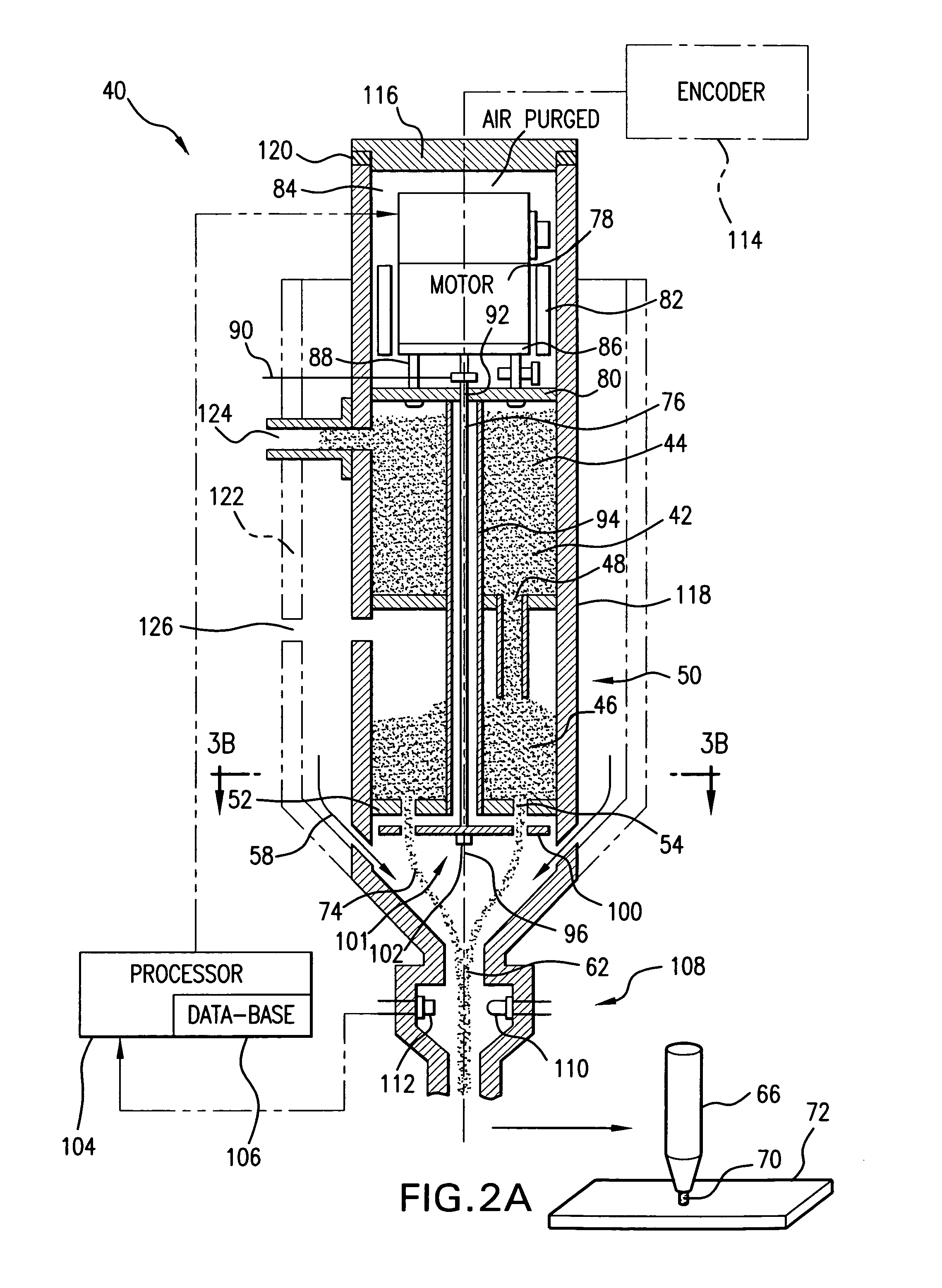

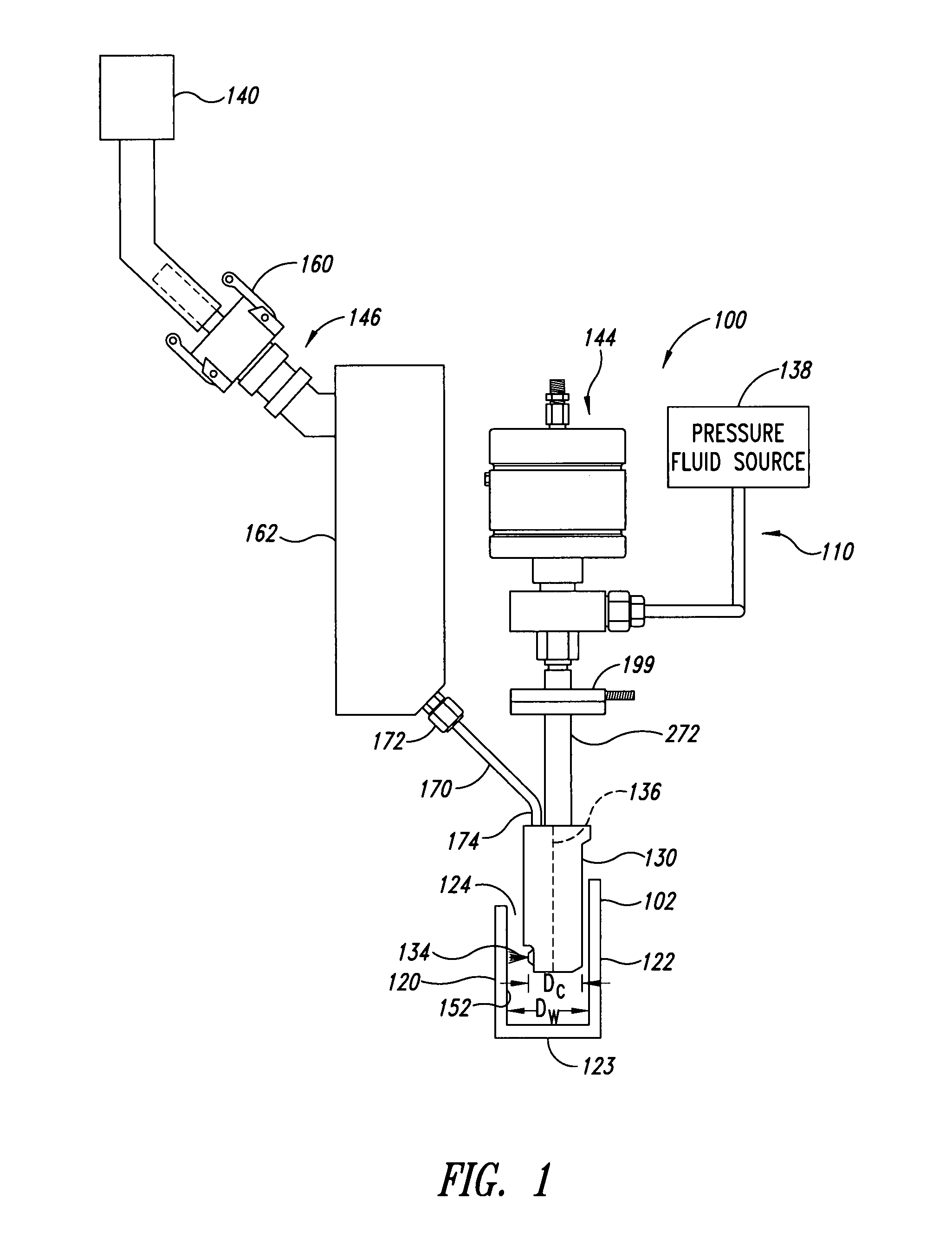

Variable rate dispensing system for abrasive material and method thereof

InactiveUS7040959B1Accurate and reliable yet efficientBlast gunsGrinding feed controlEngineeringActuator

An abrasive jet apparatus is provided which includes an abrasive dispenser defining a compartment for storing a granular abrasive material and at least one metering orifice disposed in open communication therewith for dispensing the granular abrasive material. The apparatus also includes a shutter assembly disposed adjacent the metering orifice, which includes a shutter member angularly displaceable between first and second positions relative to the metering orifice. The shutter member has formed therethrough at least one shutter opening which in the first position is substantially fully aligned with the metering orifice, and in the second position is substantially fully offset therefrom. The apparatus further includes a position actuator operatively coupled to the shutter mechanism for reversibly displacing the shutter member to the first and second positions and a plurality of intermediate positions therebetween for occluding a selective portion of the metering orifice. A flow rate of the abrasive material dispensed through said metering orifice is thereby maintained at a predetermined level.

Owner:LAI INT

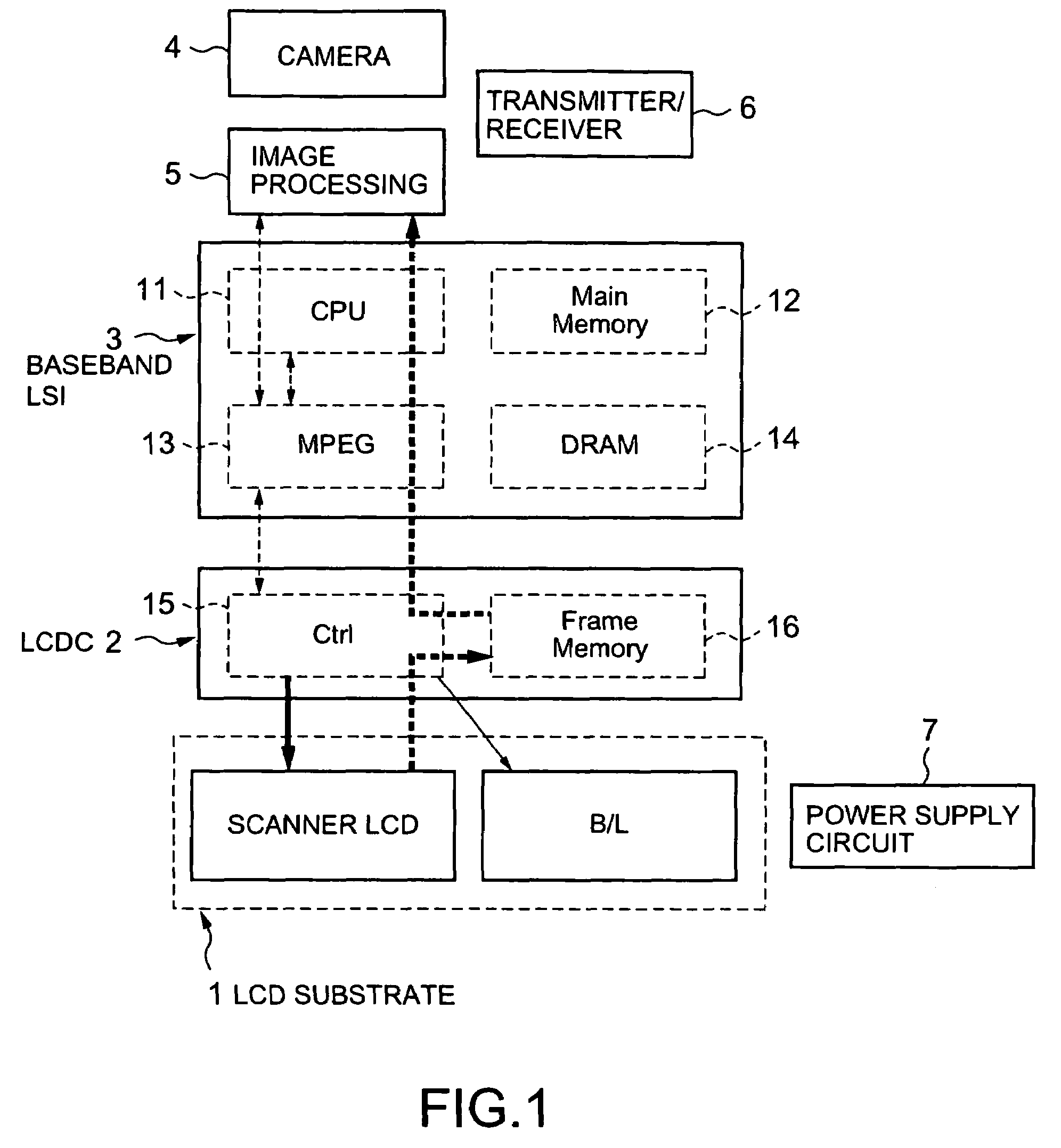

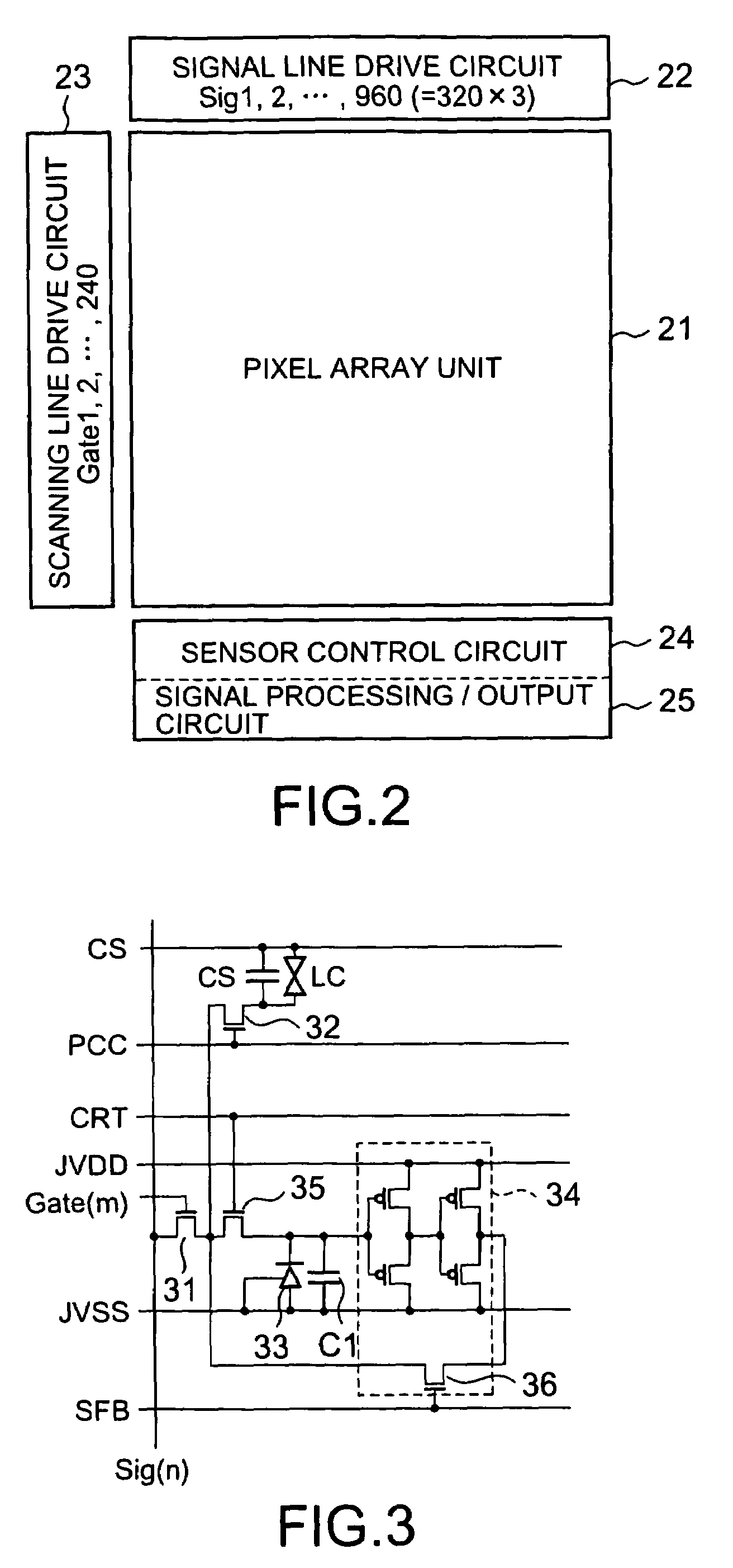

Display device

InactiveUS7450105B2Simple configurationSimplified mannerBlast gunsStatic indicating devicesImaging processingComputer graphics (images)

A display device, comprising: a pixel array unit having display elements formed in vicinity of intersections of signal lines and scanning lines arranged in length and breadth, image pickup units and an output unit which outputs binary data corresponding to image picked up by said image pickup unit; a image pickup device provided separate from said image pickup unit; a first image processing unit configured to generate multiple gradation data based on multiple binary data picked up by said image pickup units based on multiple image pickup conditions; and a second image processing unit configured to receive either the image pickup data picked up by said image pickup device or the multiple gradation data generated by said first image processing unit, to conduct a prescribed image processing.

Owner:JAPAN DISPLAY CENT INC

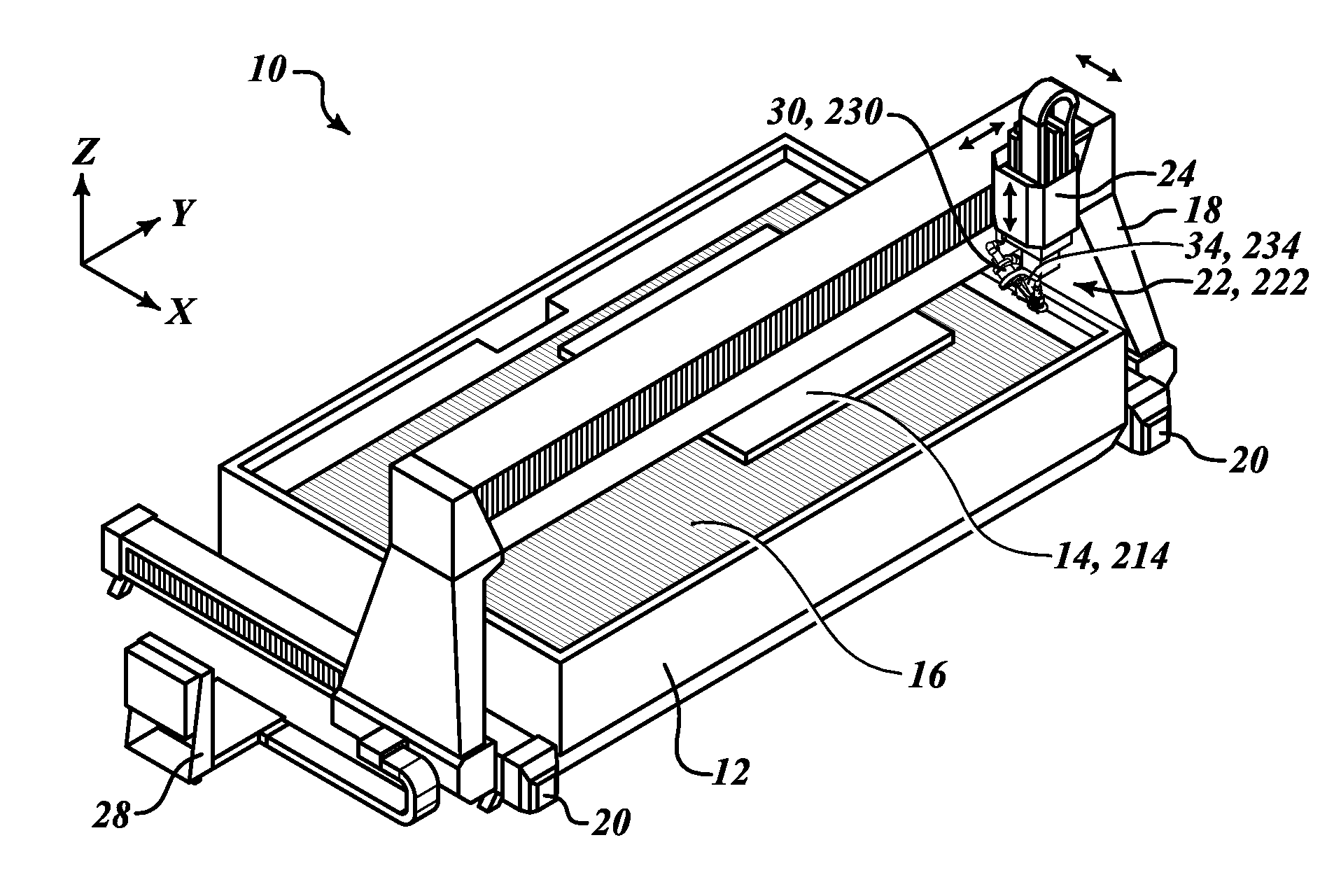

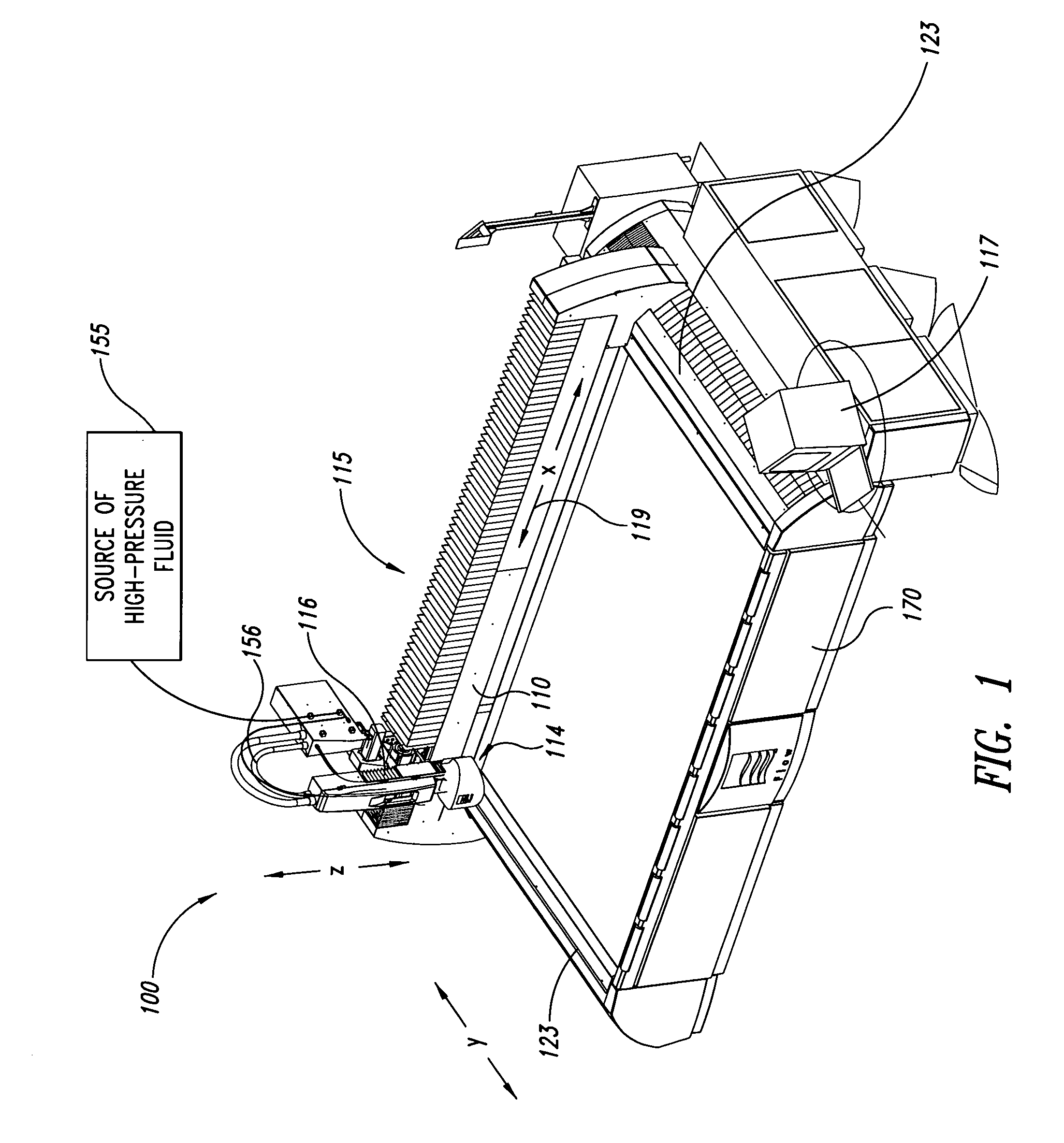

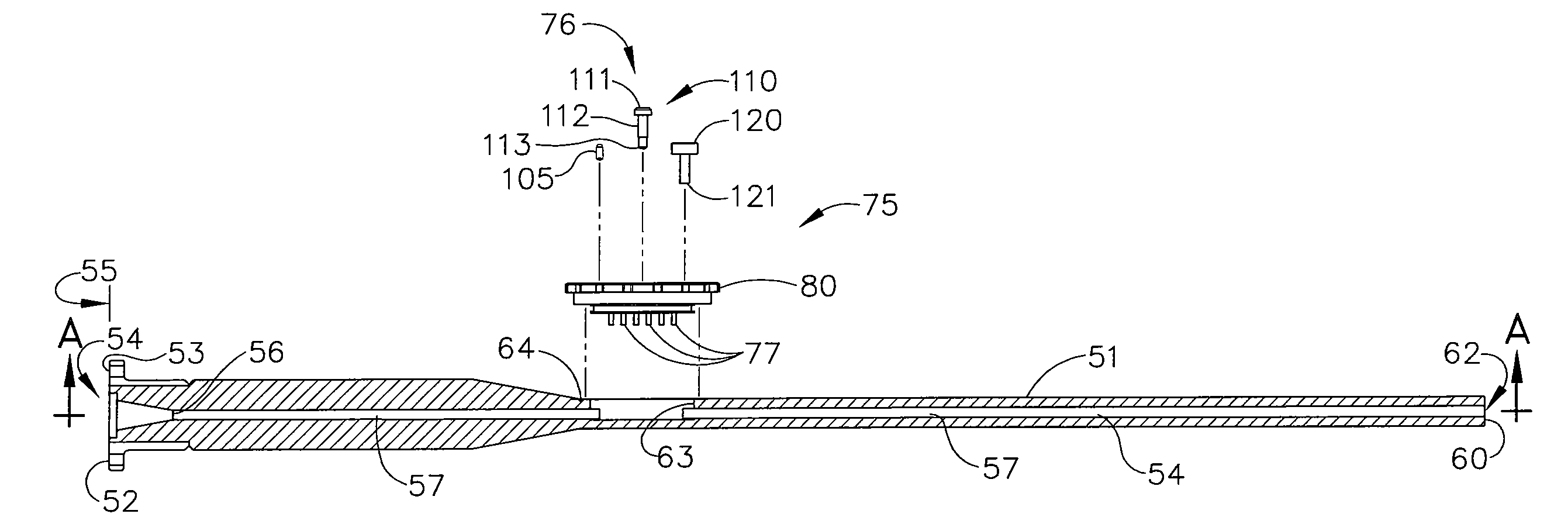

Waterjet cutting system with standoff distance control

ActiveUS20130025422A1Efficient and accurate mannerBlast gunsAbrasive machine appurtenancesMeasurement deviceControl system

A cutting head of a waterjet cutting system is provided having an environment control device and a measurement device. The environment control device is positioned to act on a surface of a workpiece at least during a measurement operation to establish a measurement area on the surface of the workpiece substantially unobstructed by fluid. The measurement device is positioned to selectively obtain information from within the measurement area indicative of a position of the cutting head relative to the workpiece. A control system is further provided and operable to position the cutting head relative to the workpiece at a standoff distance based at least in part on the information indicative of the position of the cutting head relative to the workpiece obtained by the measurement device. A method of operating a waterjet cutting system is also provided.

Owner:FLOW INT

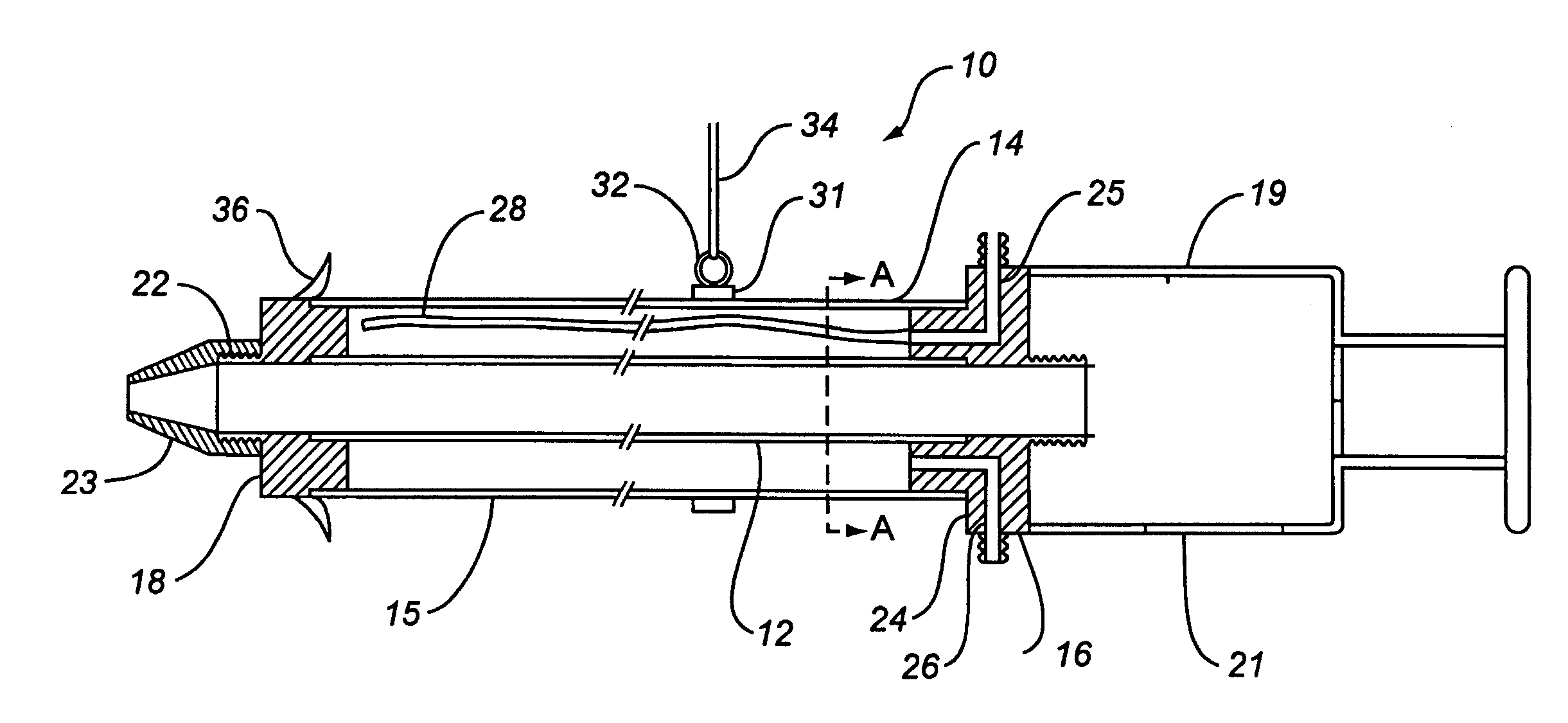

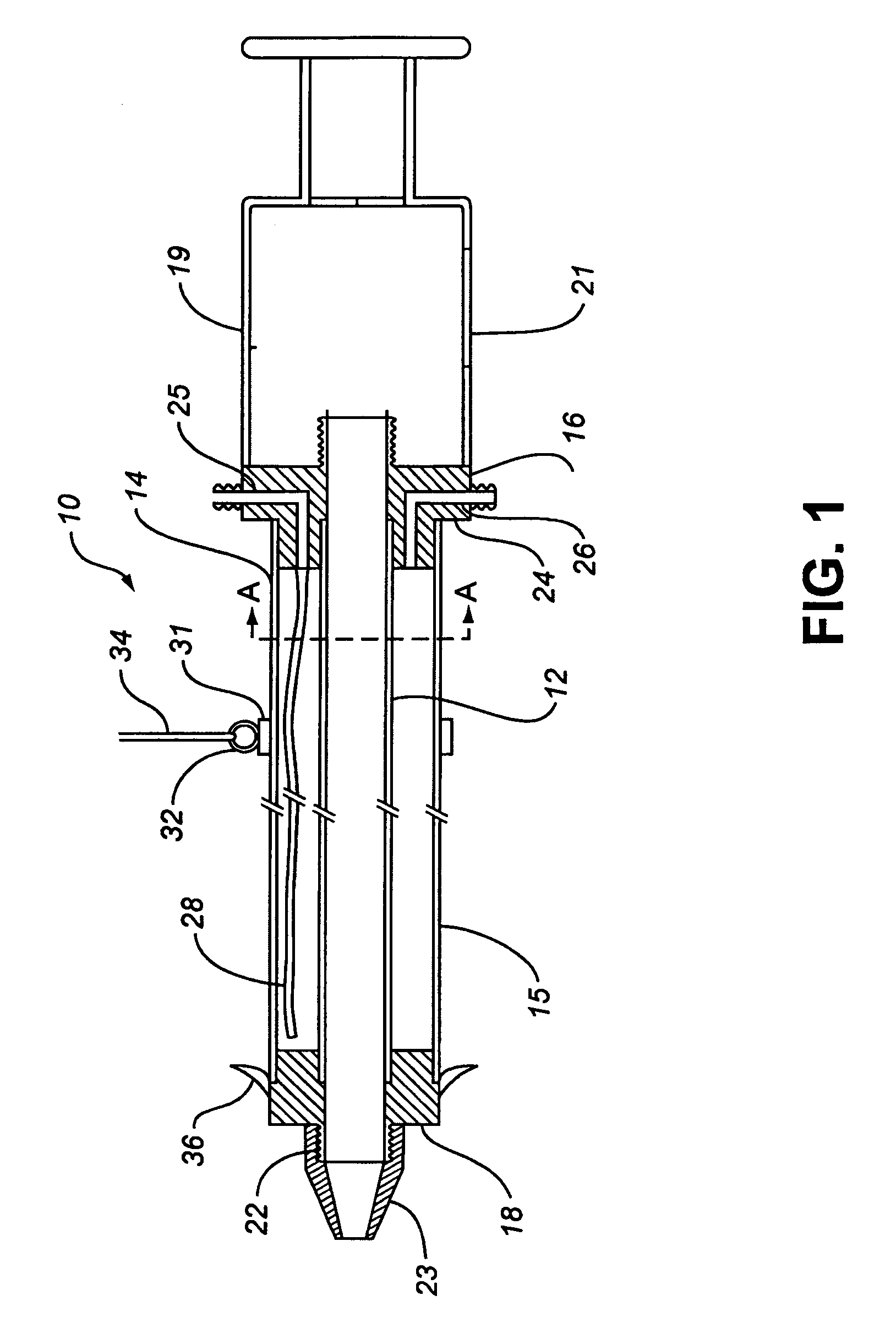

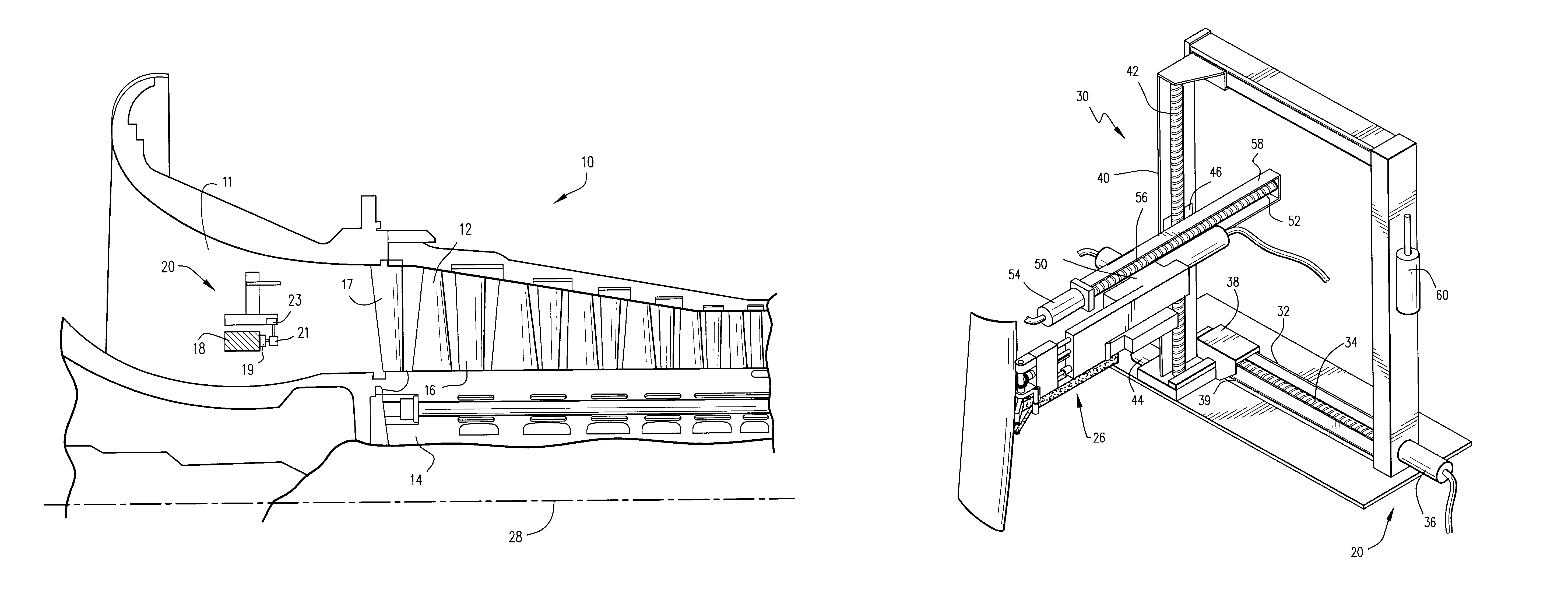

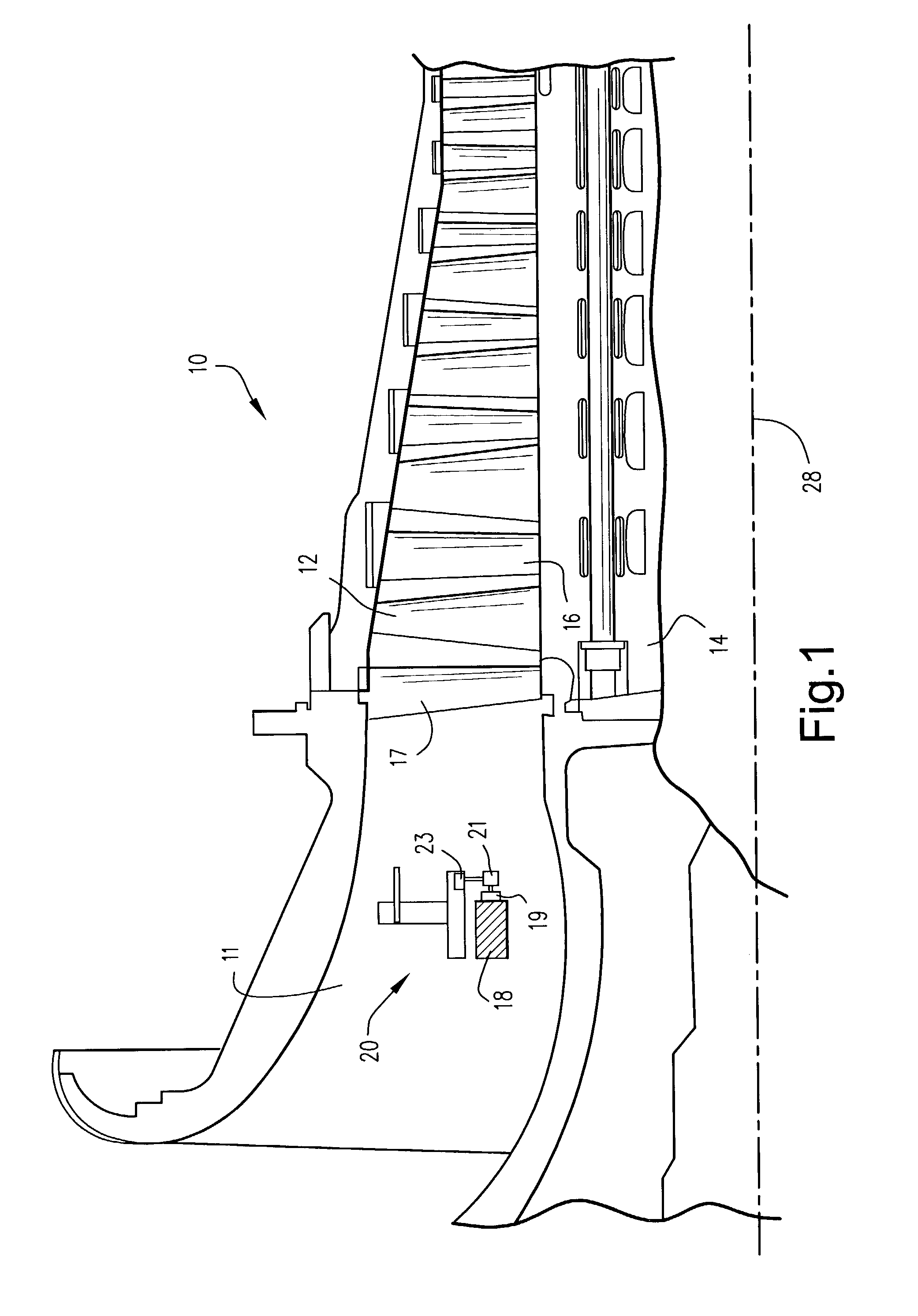

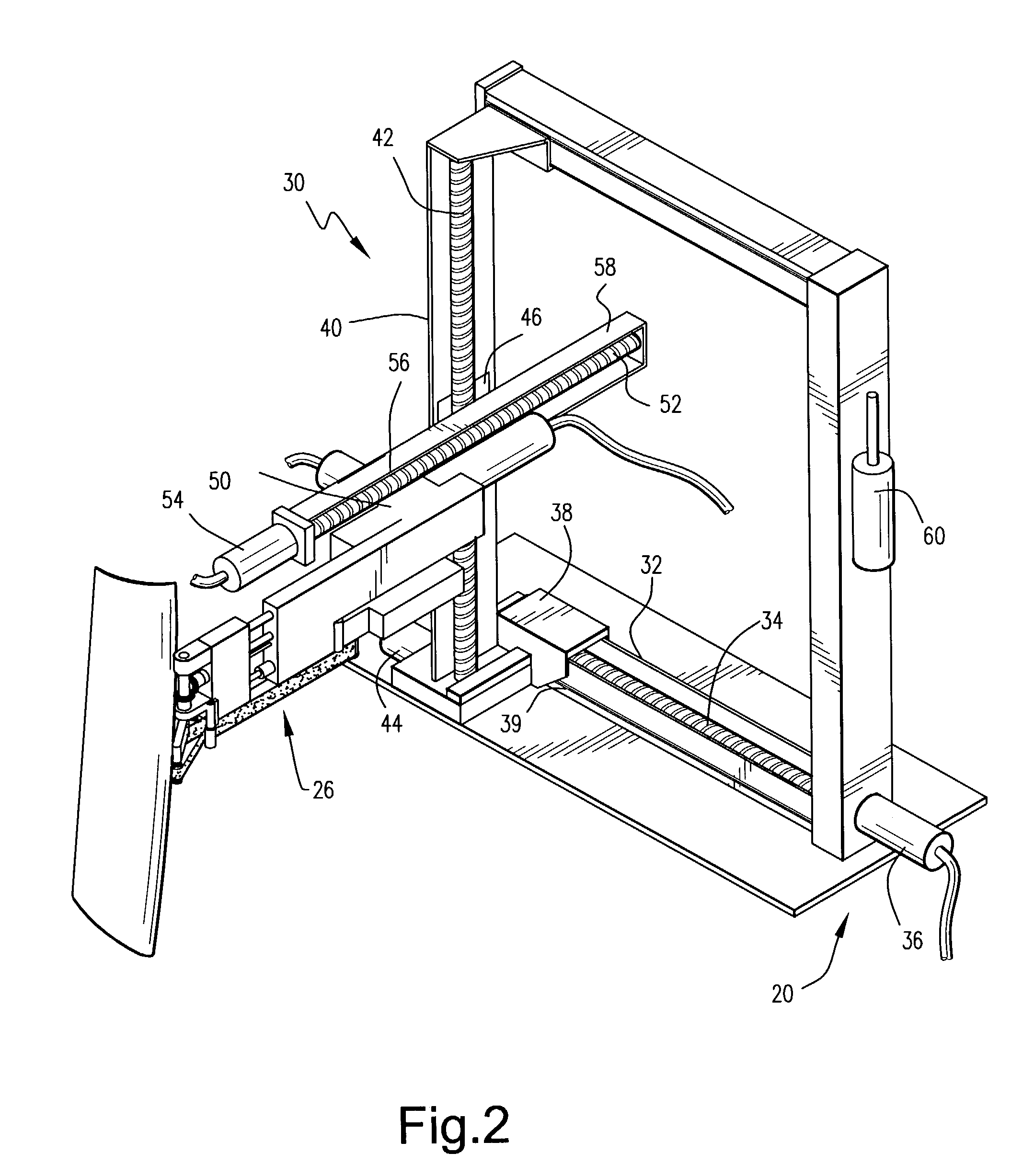

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

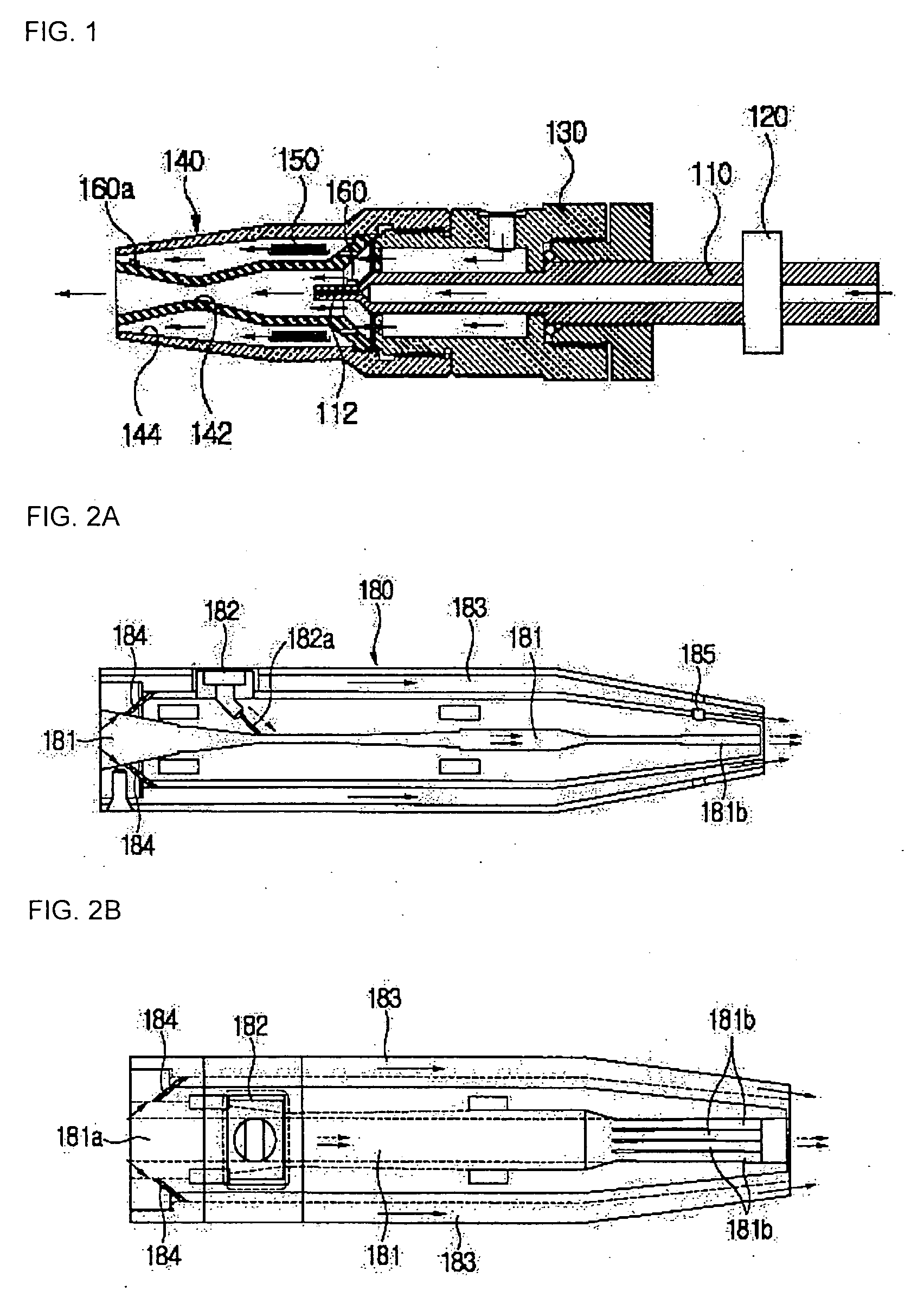

Nozzle for spraying sublimable solid particles entrained in gas for cleaning surface

ActiveUS7442112B2Blast gunsSemiconductor/solid-state device manufacturingSolenoid valveSolid particle

A nozzle for spraying sublimable solid particles and preventing frost from forming at surfaces of the nozzle. The nozzle includes: a cleaning agent block for phase-changing a cleaning agent into a snow containing sublimable solid particles; a nozzle block for growing the cleaning agent snow through adiabatic expansion and spraying the grown cleaning agent snow onto a surface of an object; a carrier gas block for supplying a carrier gas to the nozzle block to mix with the cleaning agent snow; and a heater for heating at least a portion of the carrier gas supplied from the carrier gas supply source. Fine dry ice particles and liquid CO2, passing through a solenoid valve from a CO2 reservoir tank and a pressure drop of a flow rate regulation valve, are introduced into the spray nozzle and then mixed with the carrier gas, such as N2 or purified air, and discharged.

Owner:K C TECH

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

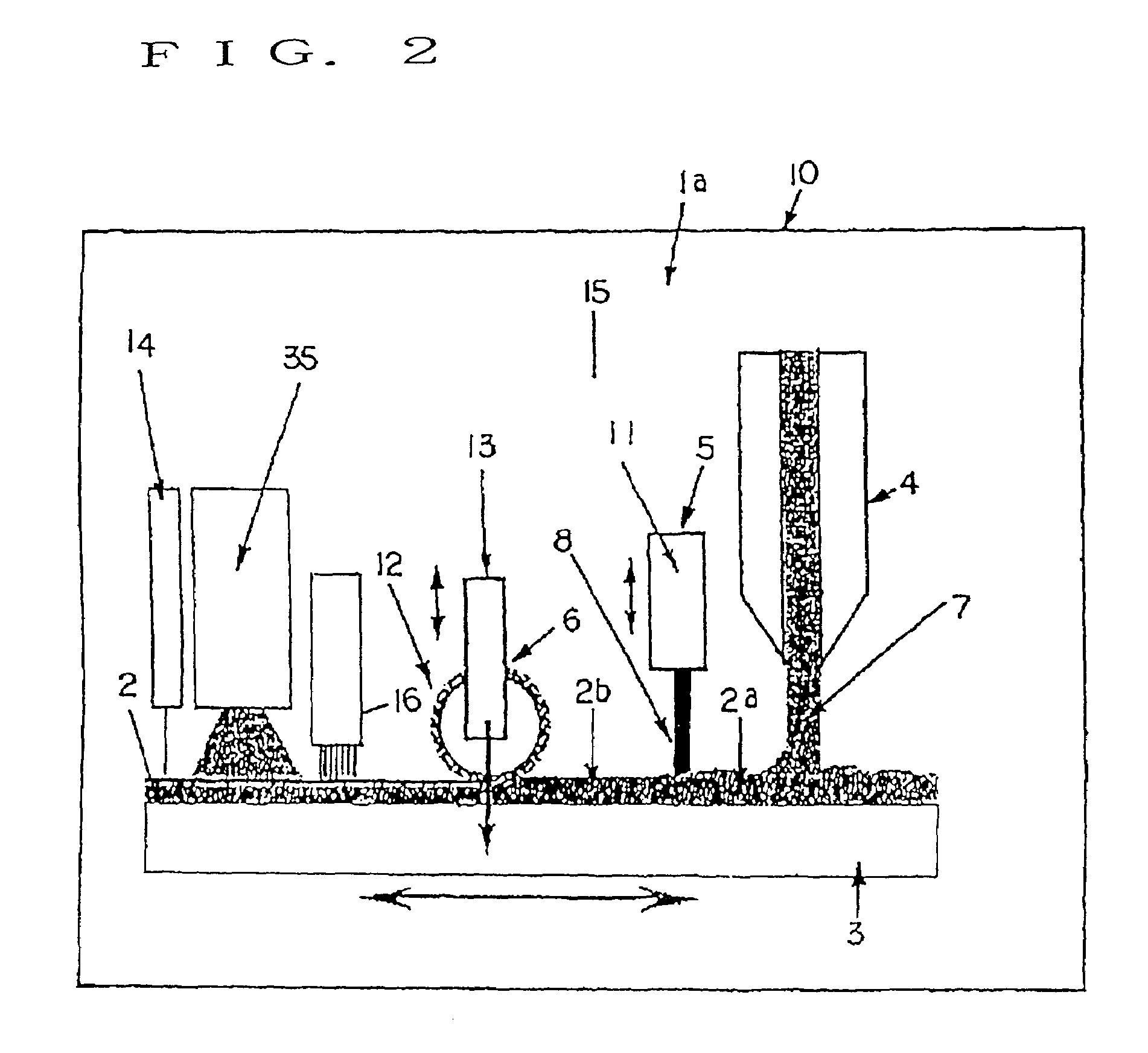

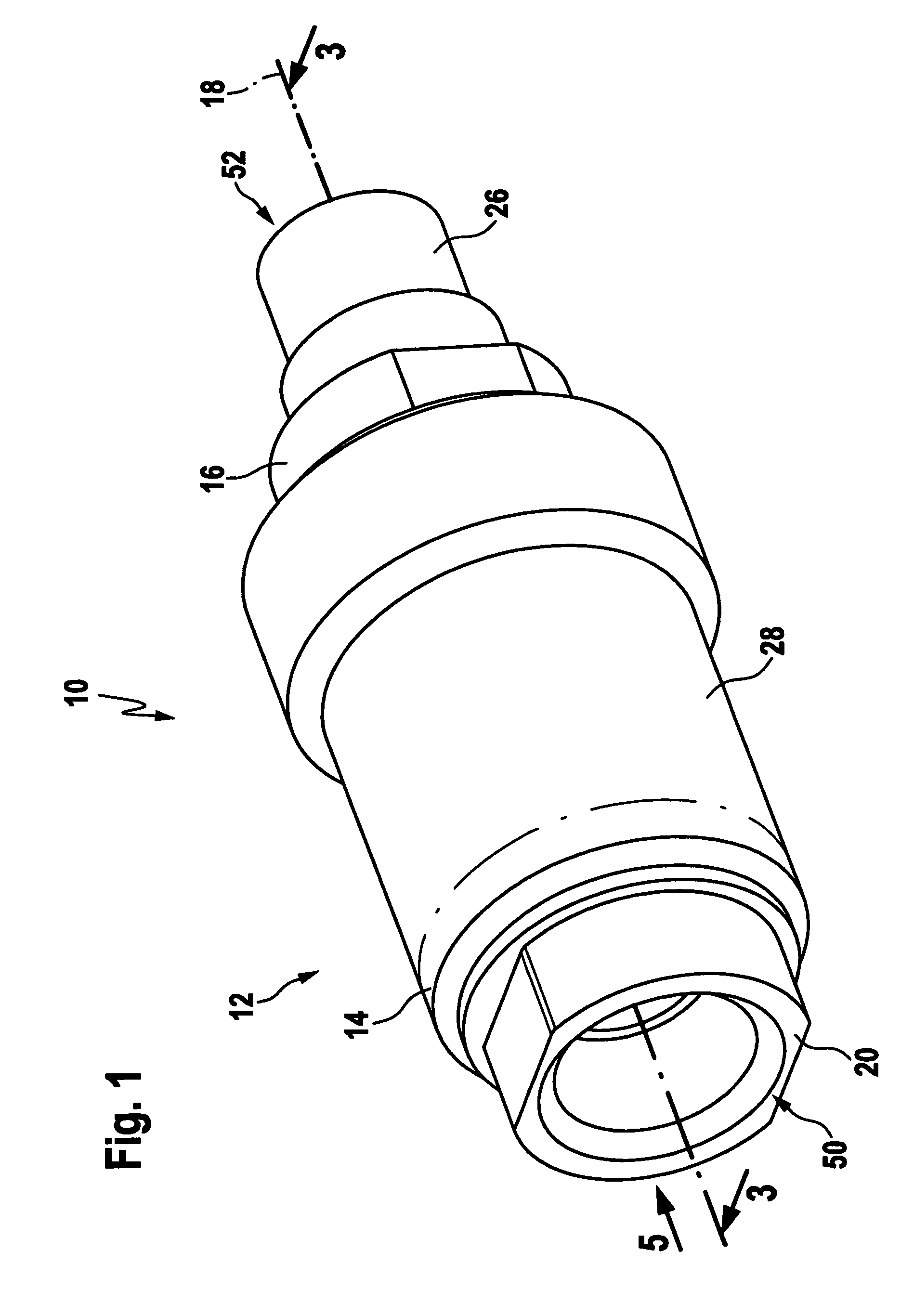

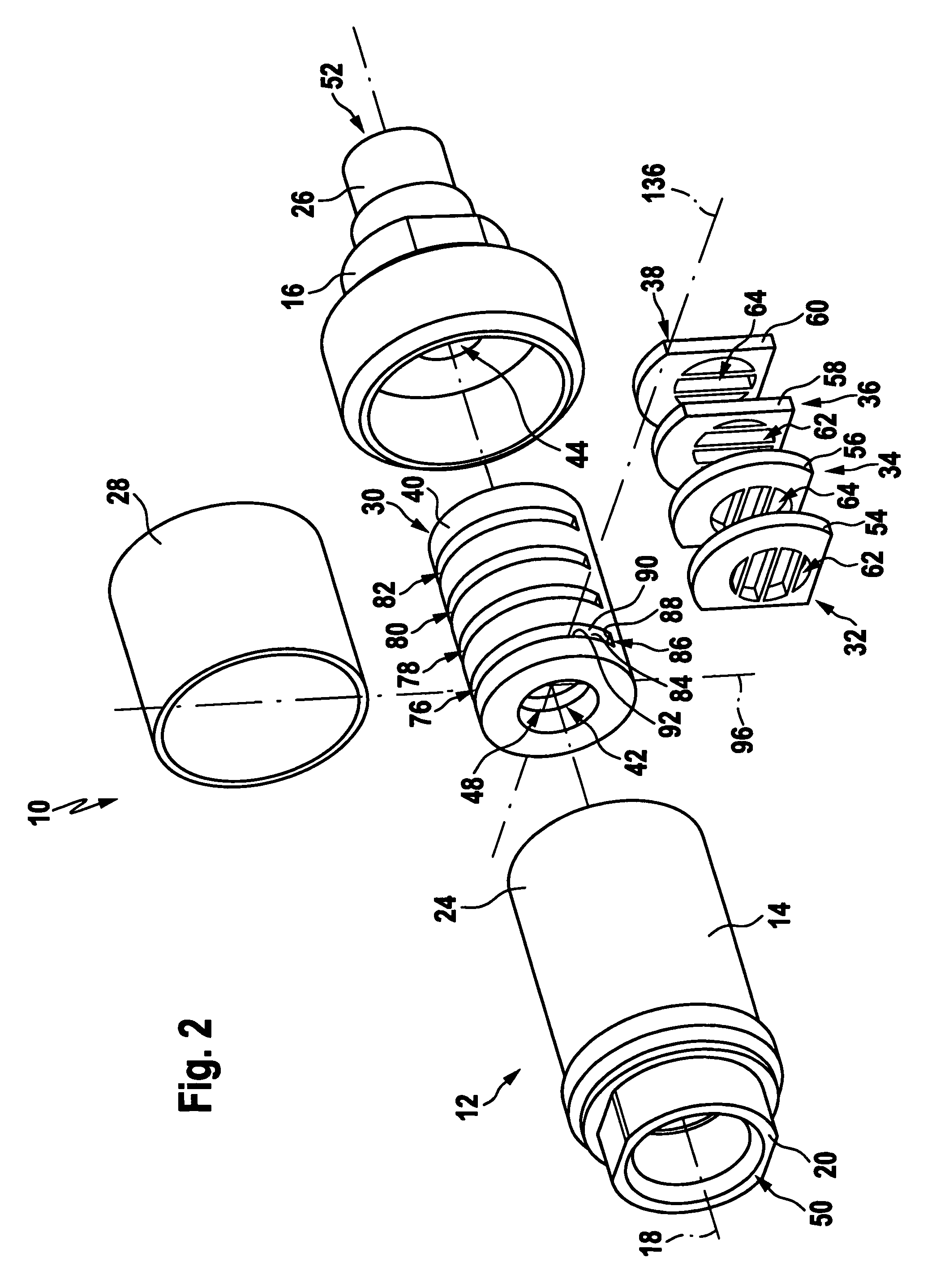

Mixing tube for a waterjet system

A waterjet system for generating and delivering fluid jets suitable for processing a workpiece has a cutting head body and a mixing tube. The cutting head body includes a mixing chamber and a bore. The bore is positioned downstream of the mixing chamber, and an abrasive fluid jet from the mixing chamber passes through the mixing tube. The mixing tube has a first coupler adapted to magnetically couple the mixing tube to the cutting head body when the mixing tube is installed. The cutting head body has a second coupler positioned to engage the first coupler of the mixing tube to keep the mixing tube properly positioned during operation of the waterjet system.

Owner:FLOW INT

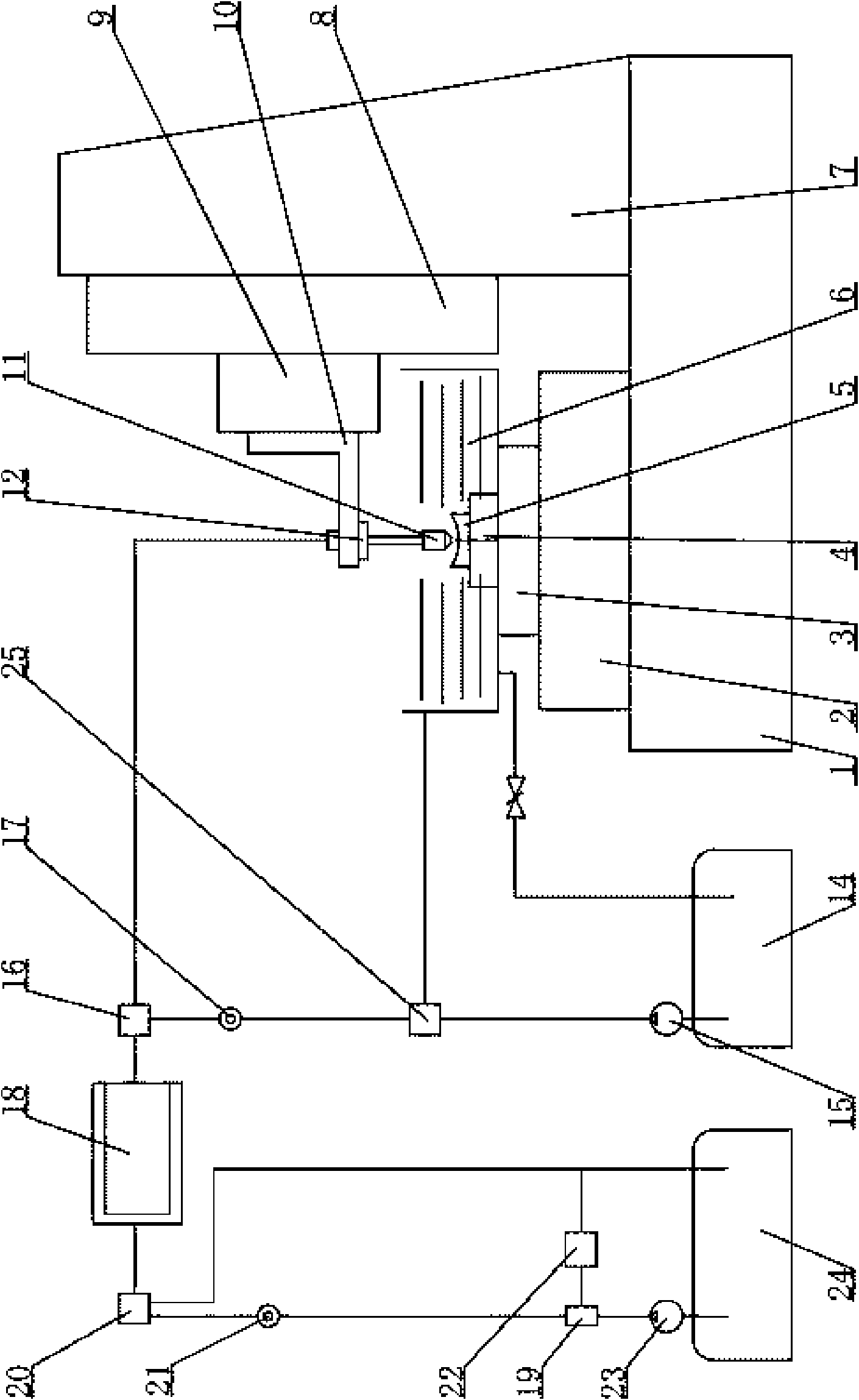

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

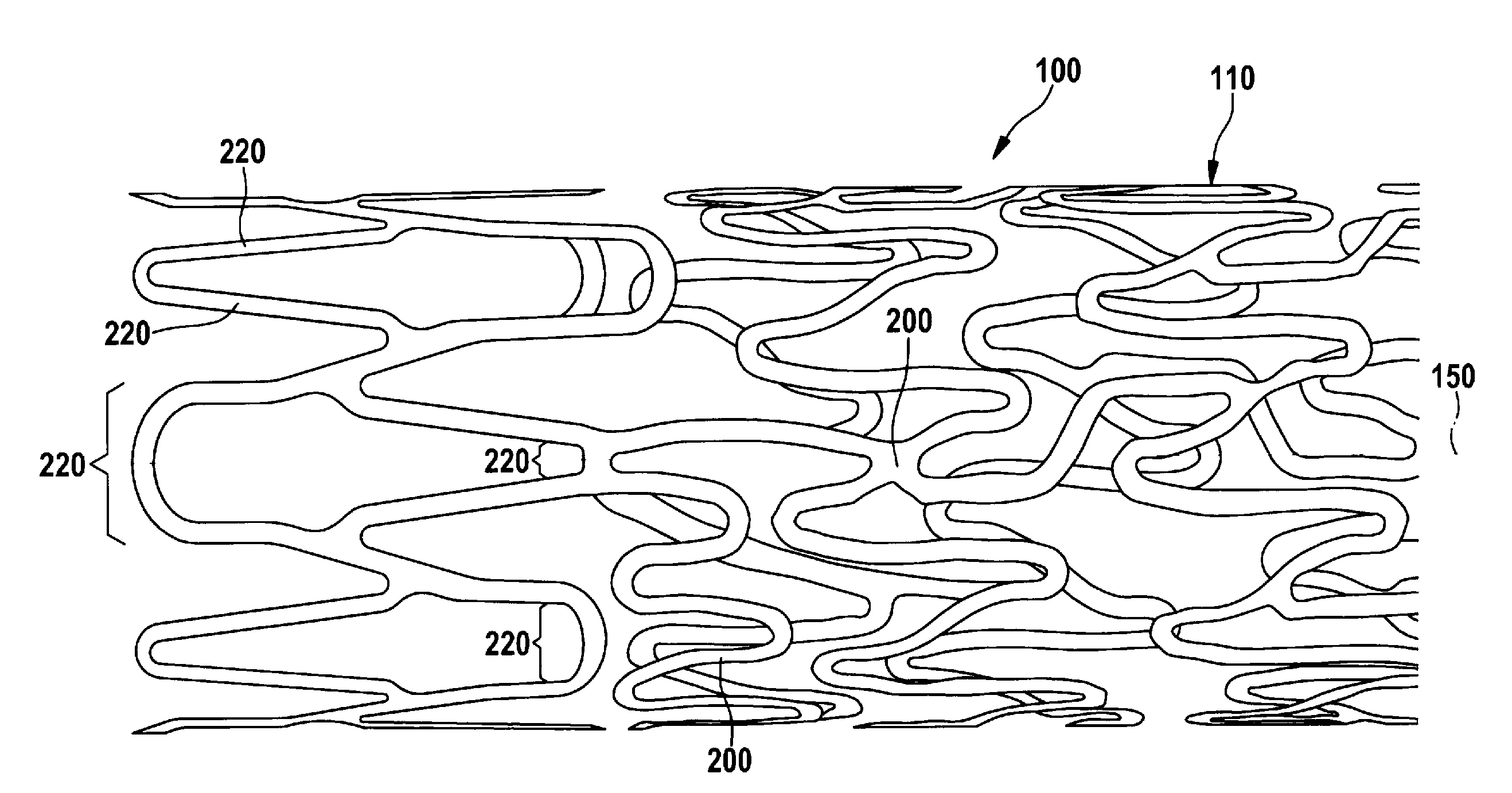

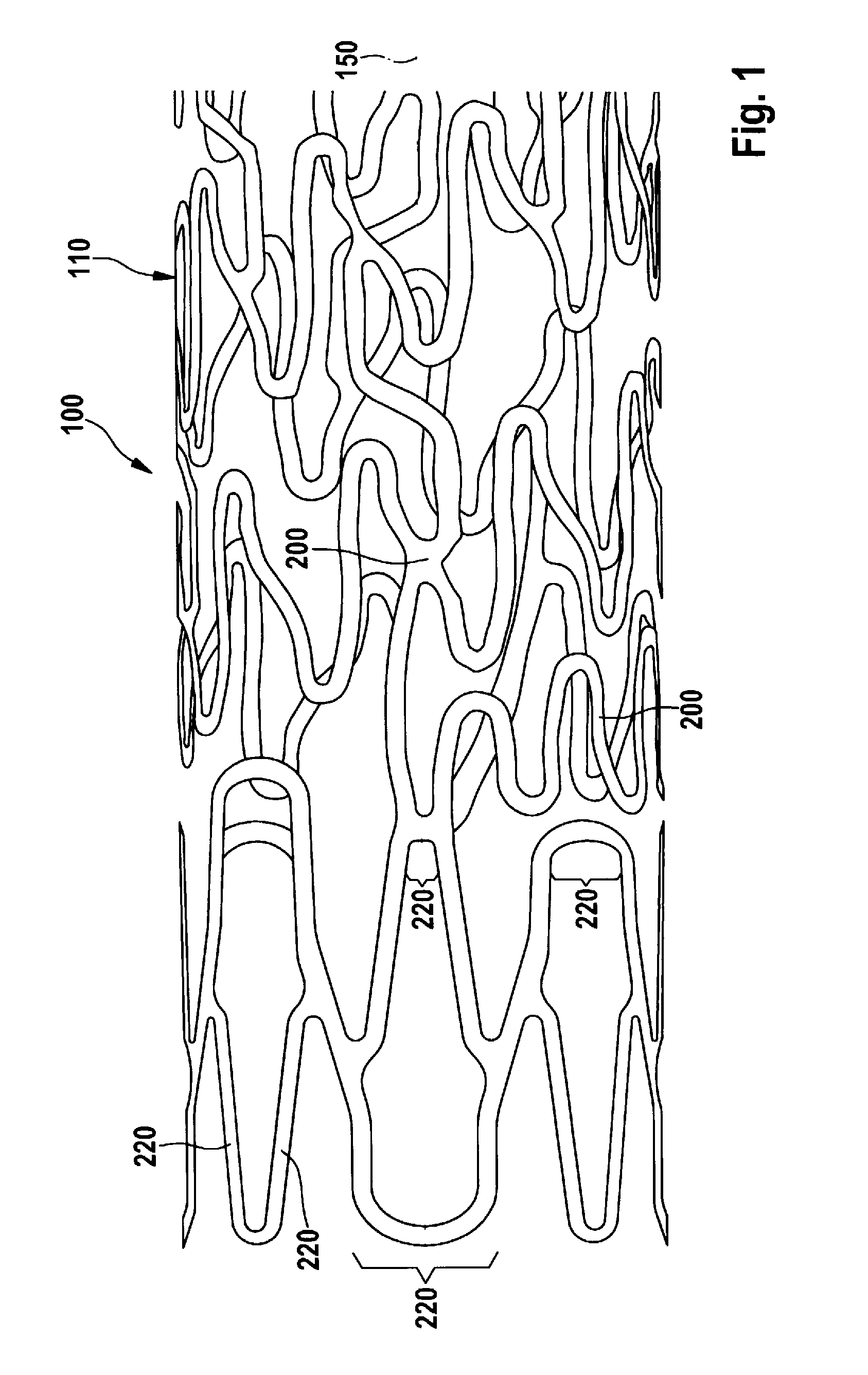

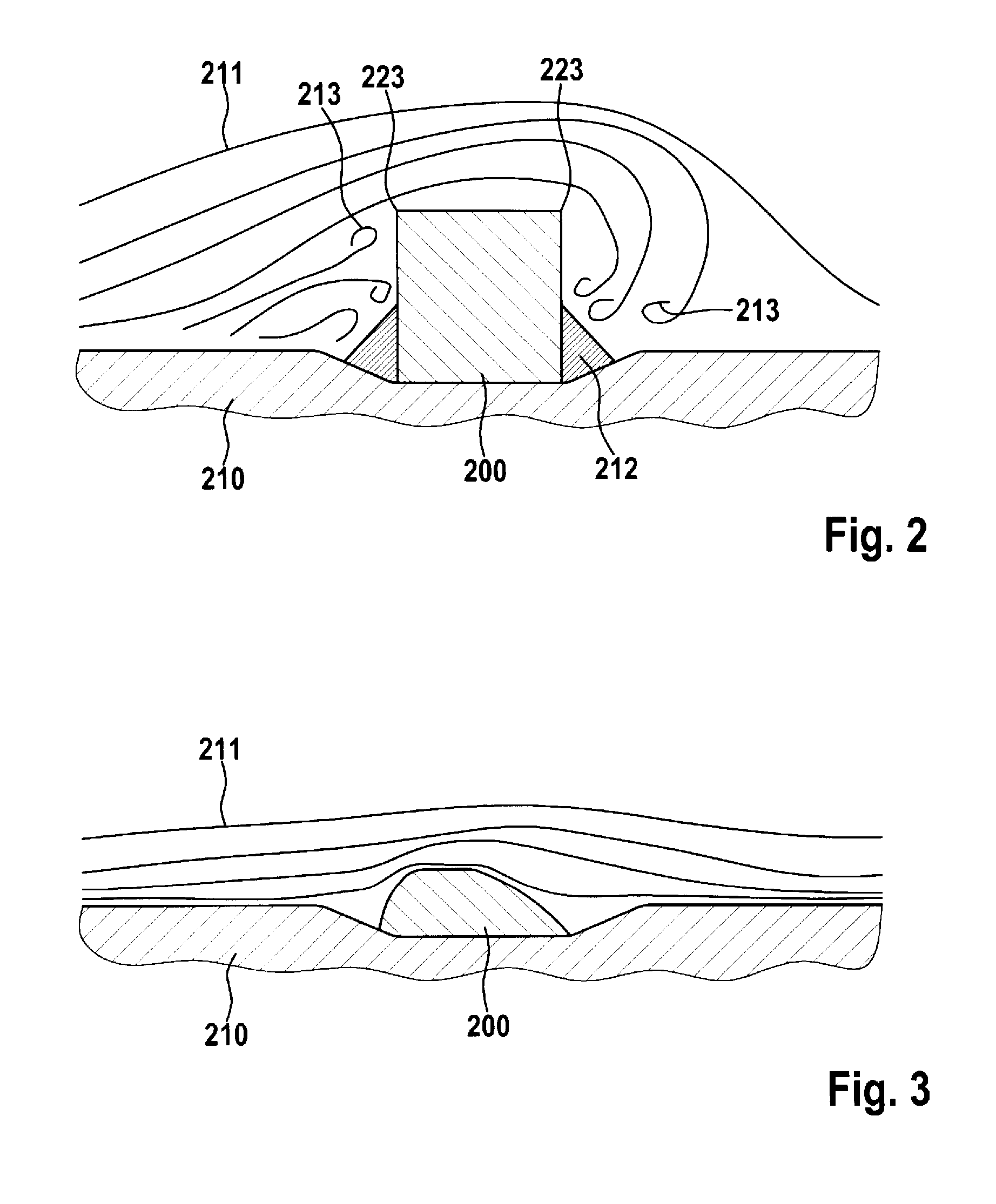

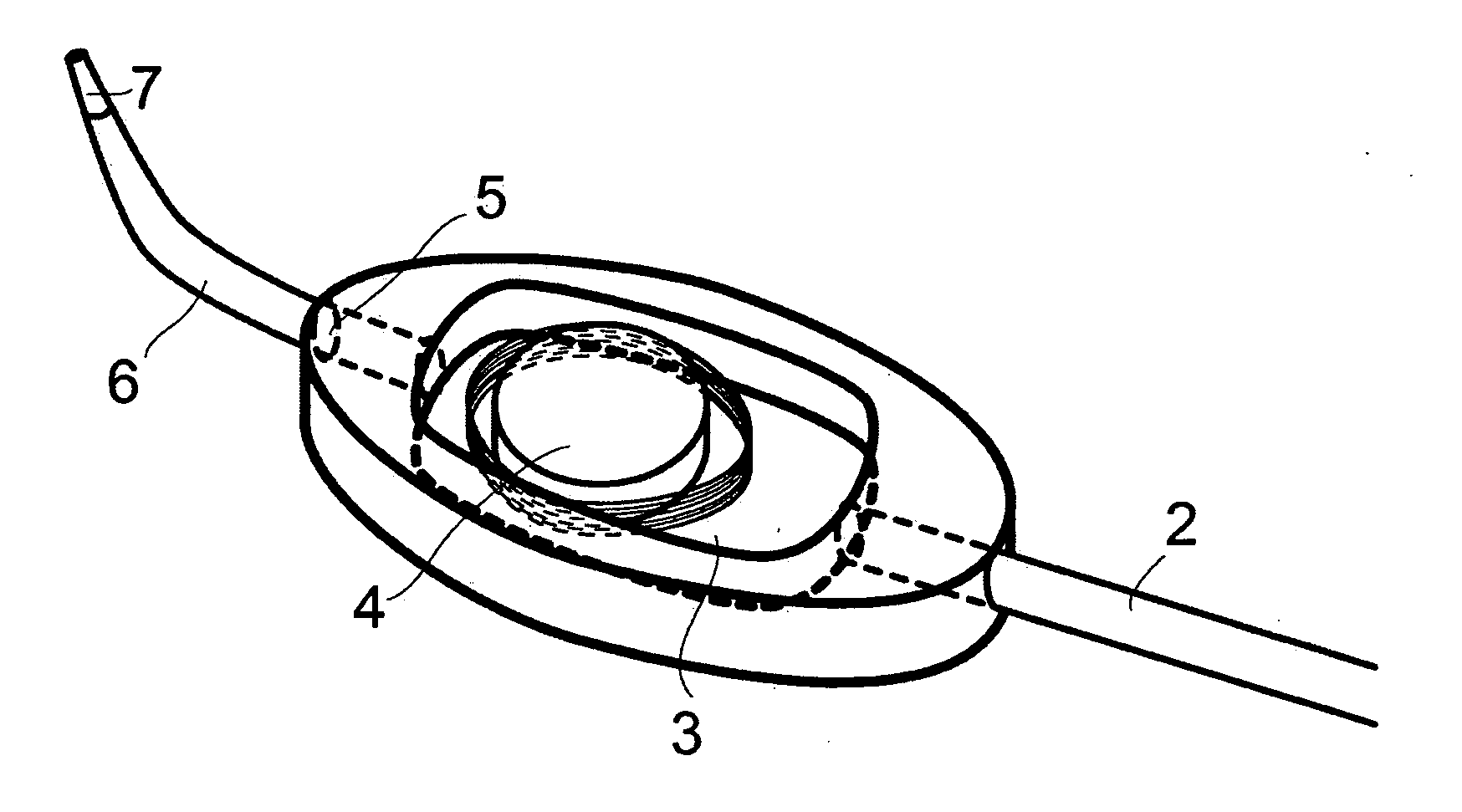

Stent and Method and Device for Fabricating the Stent

ActiveUS20100049300A1Stress minimizationAvoid injuryStentsElectrolysis componentsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

Apparatus and process for formation of laterally directed fluid jets

ActiveUS20090071303A1Liquid surface applicatorsGrinding machine componentsSpray nozzleMechanical engineering

A processing apparatus is provided to process a workpiece. The processing apparatus can have a low-profile nozzle system capable of navigating through spaces in order to process target regions with relatively small clearances. A fluid jet outputted from the nozzle system is used to cut, mill, or otherwise process the target region of the workpiece.

Owner:FLOW INT

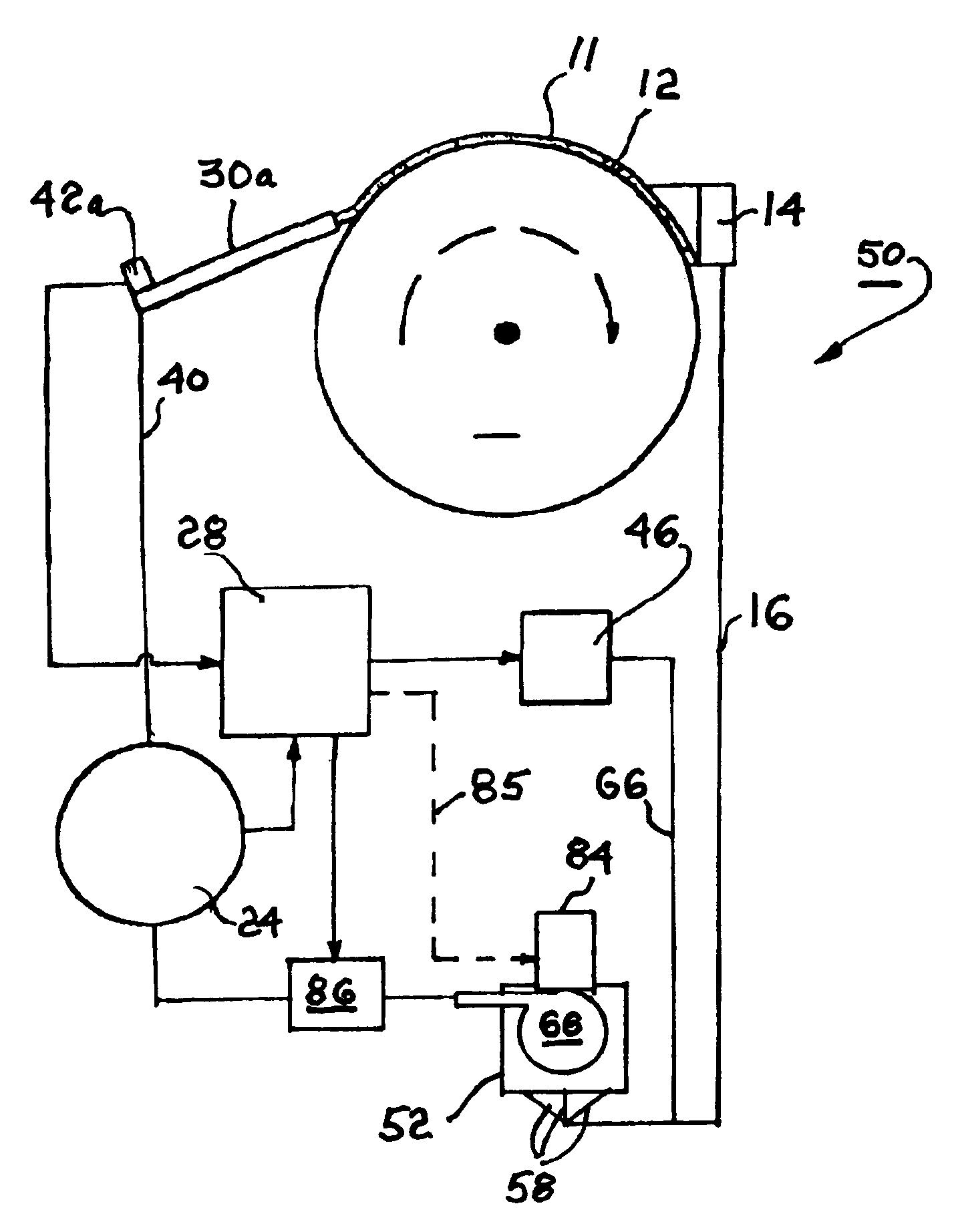

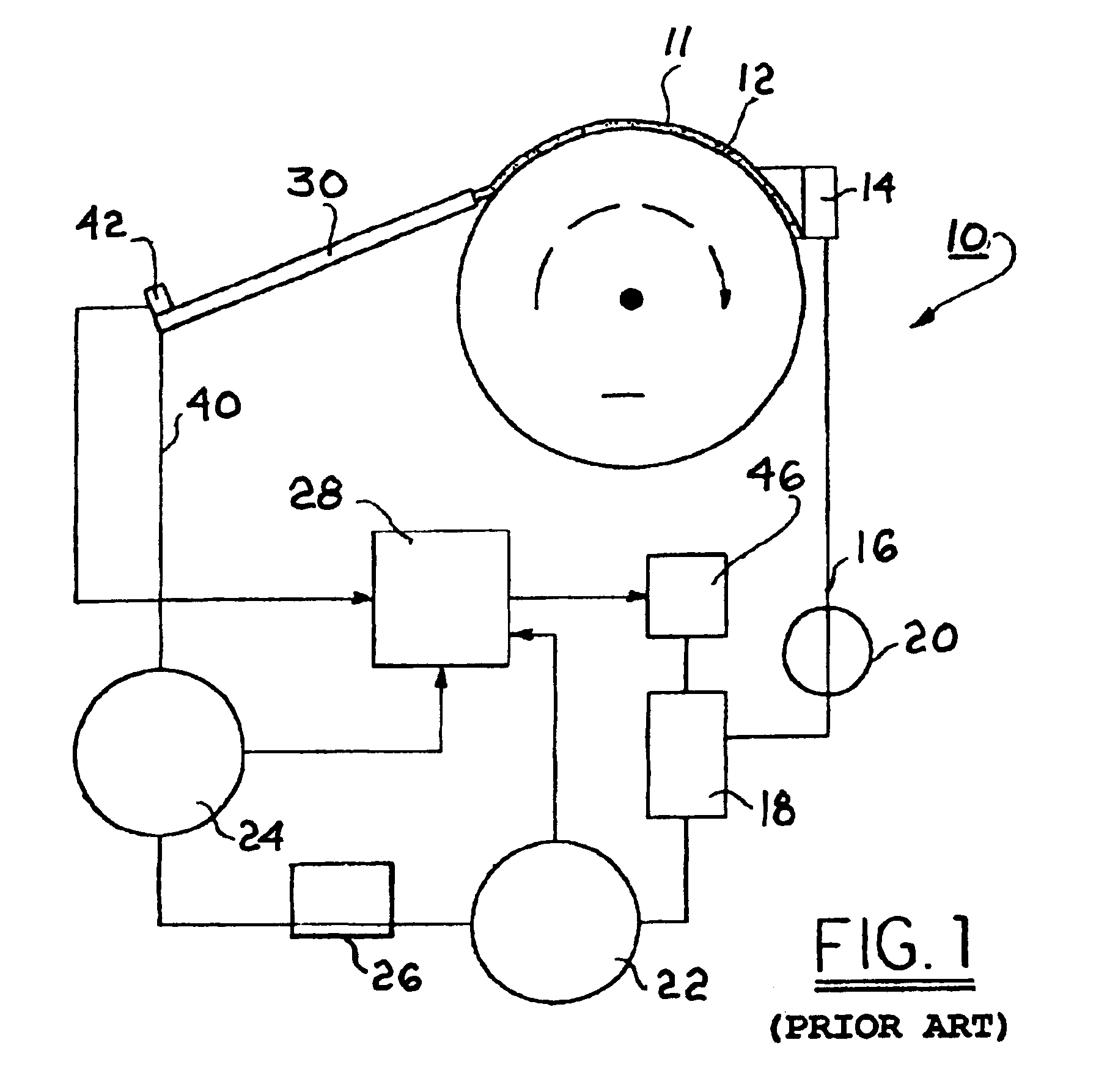

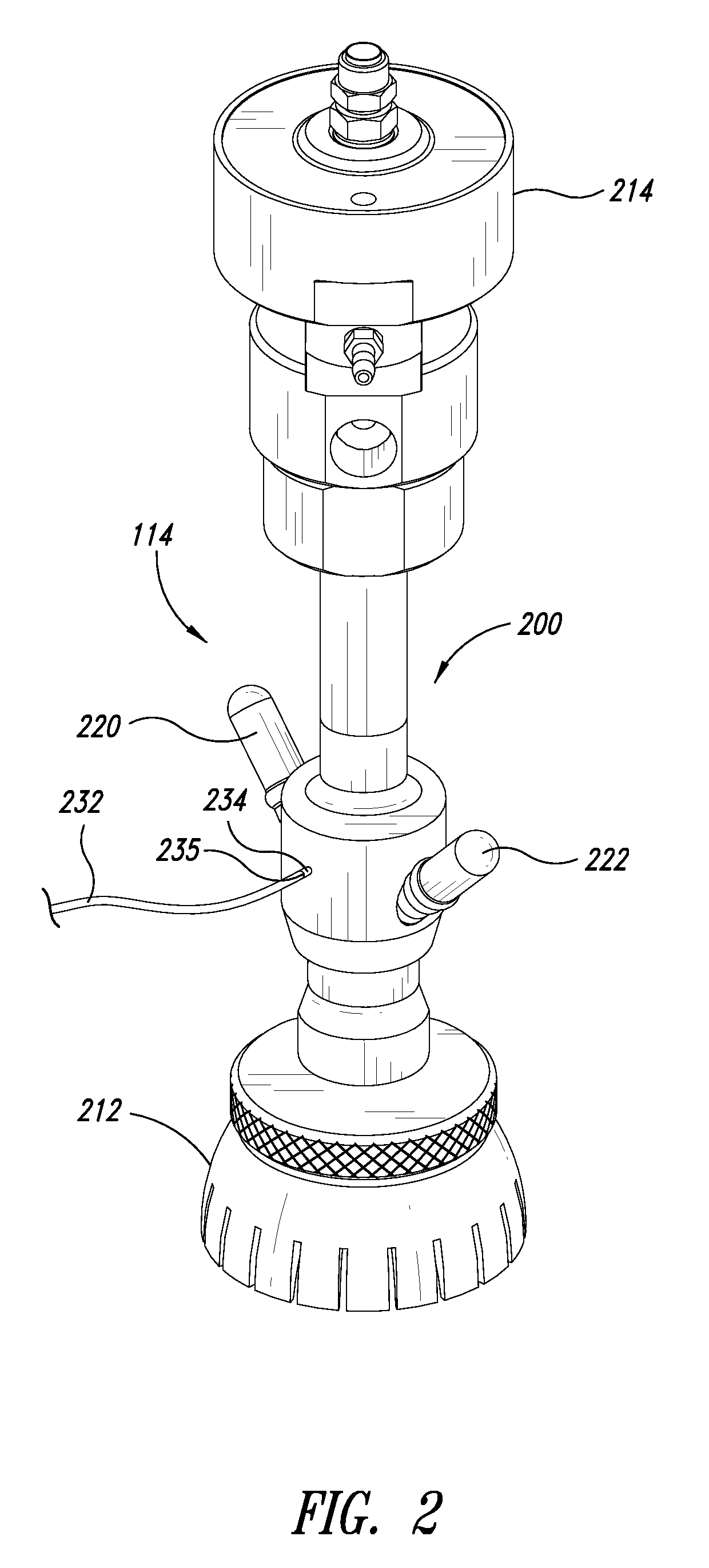

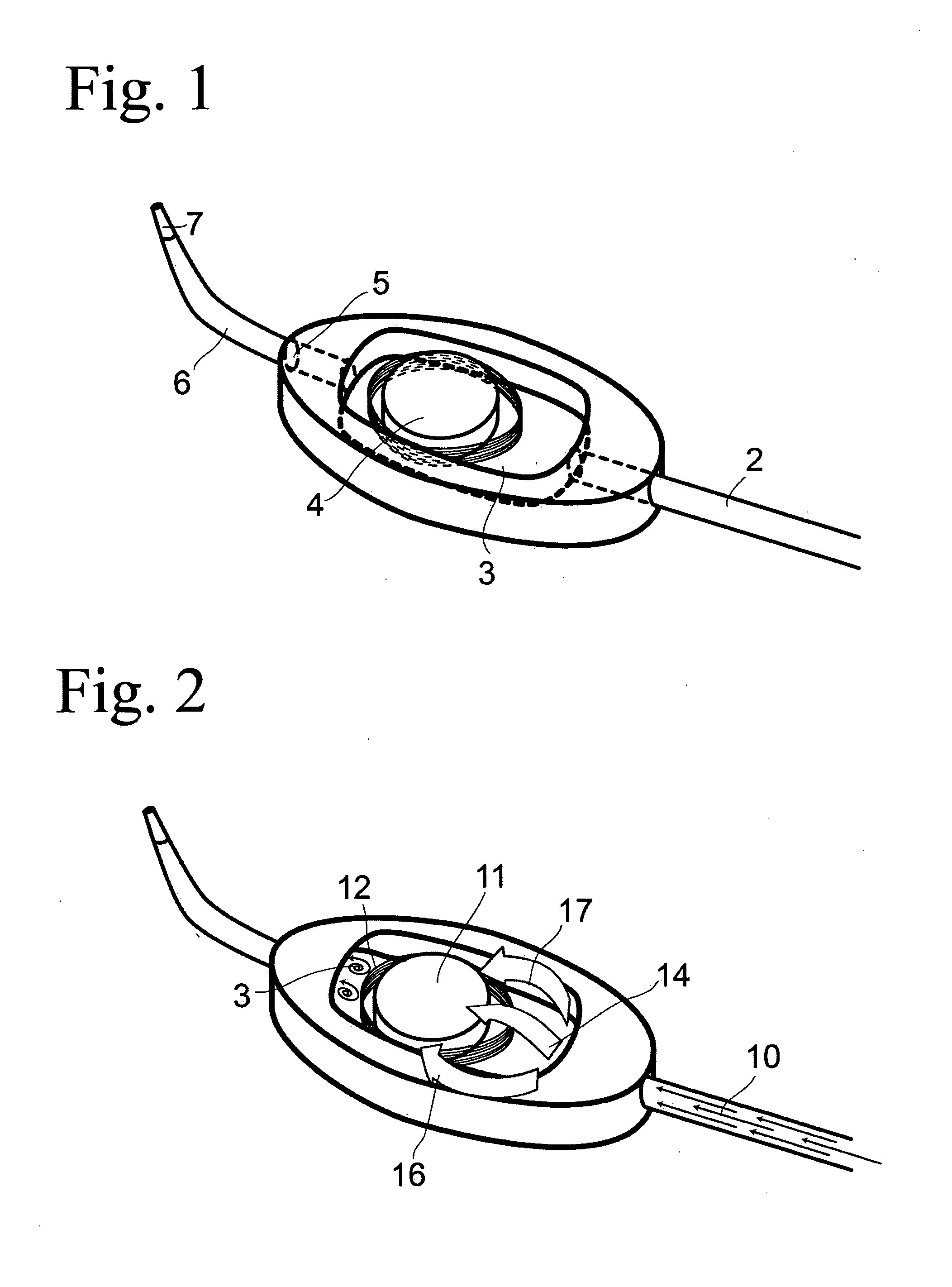

Microdermabrasion and suction massage apparatus and method

Microdermabrasion and suction massage apparatus are included in a single unit and alternatively connectable through a mode switch to a source of vacuum. The microdermabrasion section of the unit includes a crystal pick up station operating with a venturi effect to draw crystals through a hole into an air stream. The size of the hole is variable to control crystal density. A bleed valve is provided to control crystal velocity without controlling crystal density, while a bypass valve is provided to control crystal density without controlling crystal velocity. In an associated method, a microdermabrasion procedure is performed on the skin of a patient at an operative site. The mode switch is operated to activate the suction massage apparatus within the unit. This step is followed by performing a suction massage procedure at the operative site in order to promote healing of the abraded skin. The unit can be back flushed by connecting various portions of the unit to a pressurized output of the source of vacuum.

Owner:EDGE SYST CORP

Delivery system for magnetorheological fluid

A magnetorheological fluid delivery system includes a mixing and tempering vessel. Fluid is admitted to the vessel via a plurality of tangential ports, creating a mixing of the fluid in the vessel and promoting homogeneity. Fluid may be reconstituted in the vessel by metered addition of carrier fluid. A fixed-speed centrifugal pump disposed in the vessel pressurizes the system. Fluid is pumped through a magnetic-induction flowmeter and a magnetic flow control valve having solenoid windings whereby MR fluid is magnetically stiffened to restrict flow. A closed-loop feedback control system connects the output of the flowmeter to performance of the valve. A nozzle having a slot-shaped bore dispenses MR fluid for re-use in the work zone. A planar-diaphragm flush-mounted pressure transducer at the entrance to the nozzle and flowmeter inferentially measure relaxed viscosity and provide signals to a computer for dispensing metered amounts of carrier fluid into the mixing vessel to assure correct composition of the reconstituted fluid as it is dispensed.

Owner:QED TECH INT

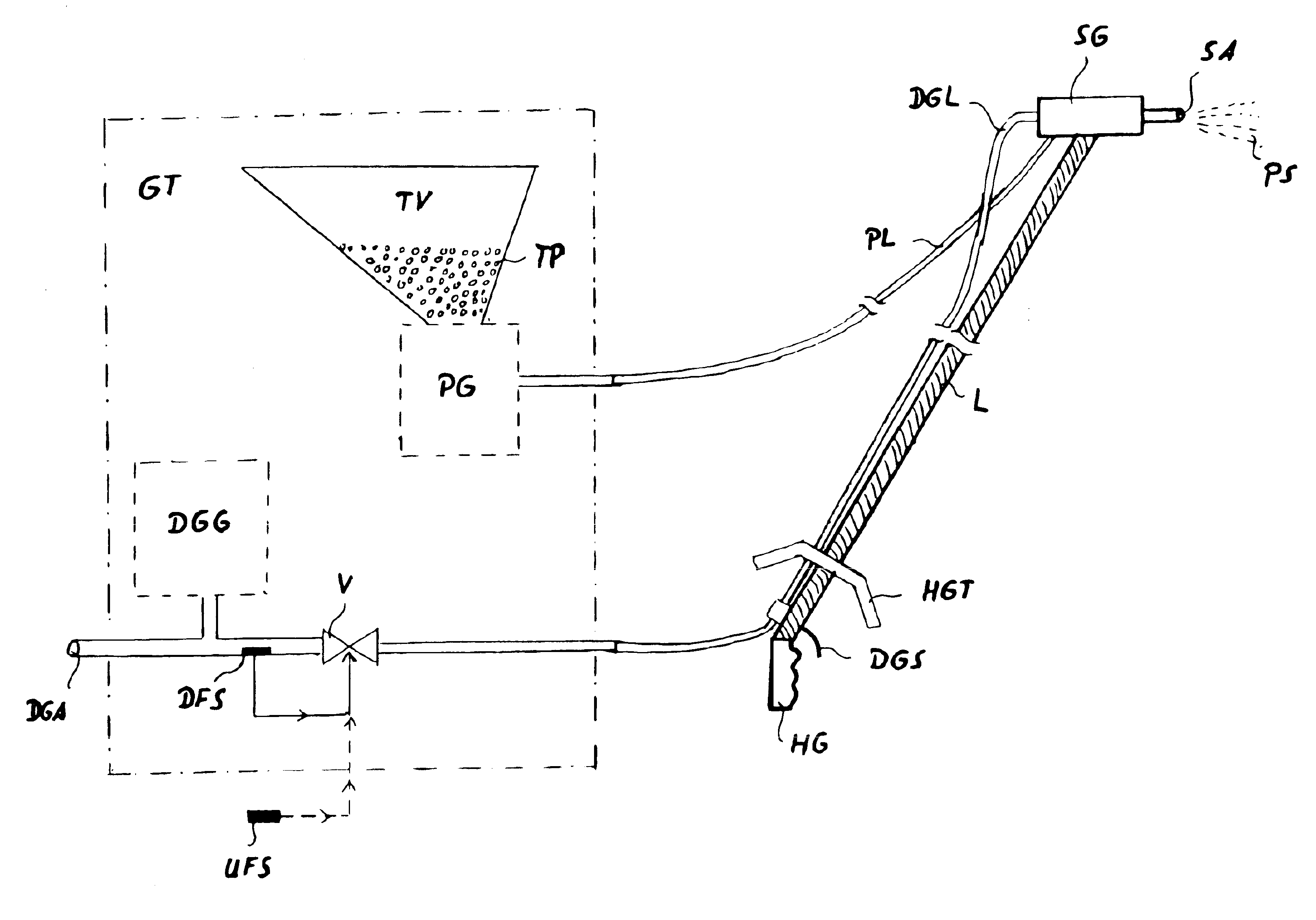

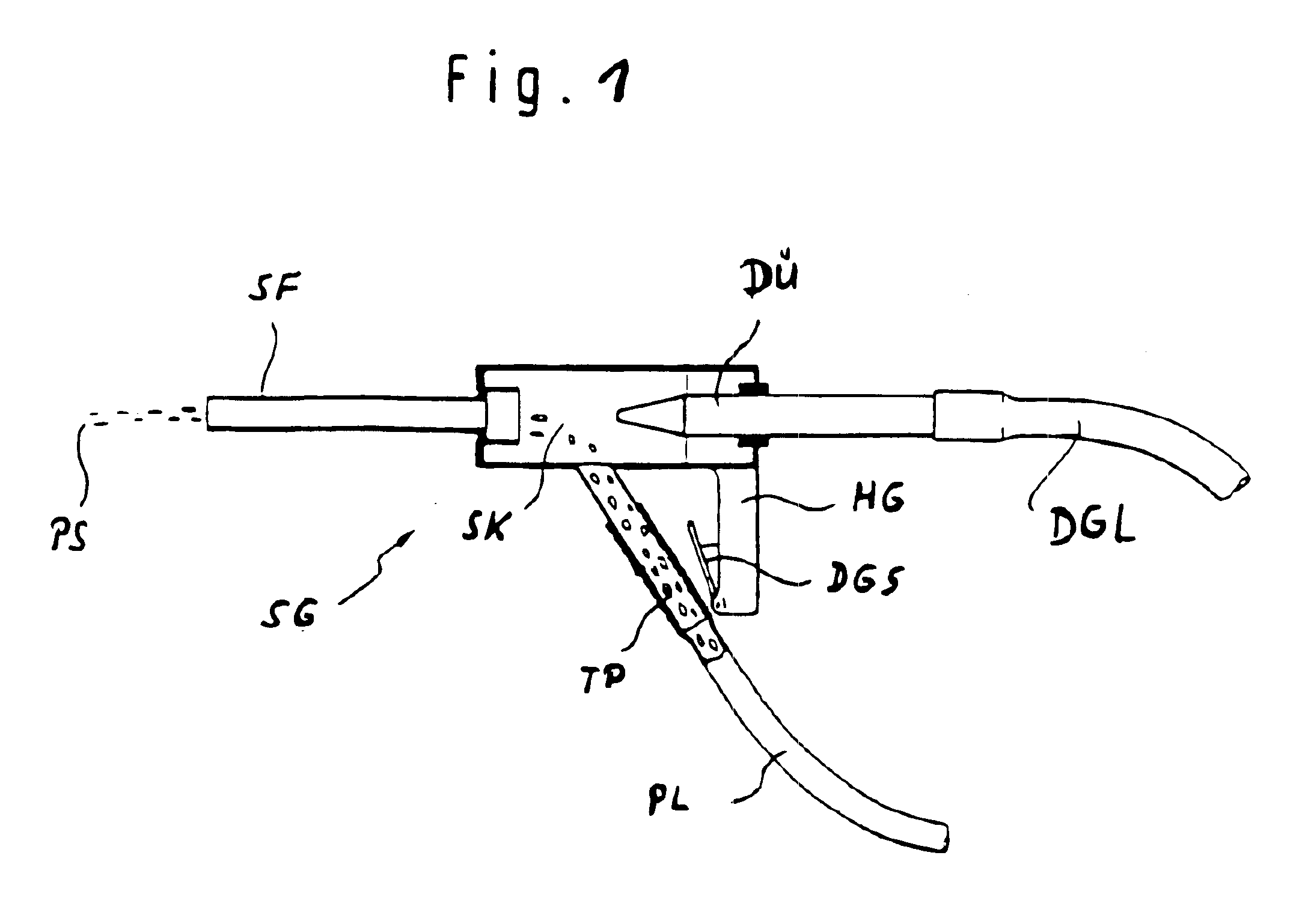

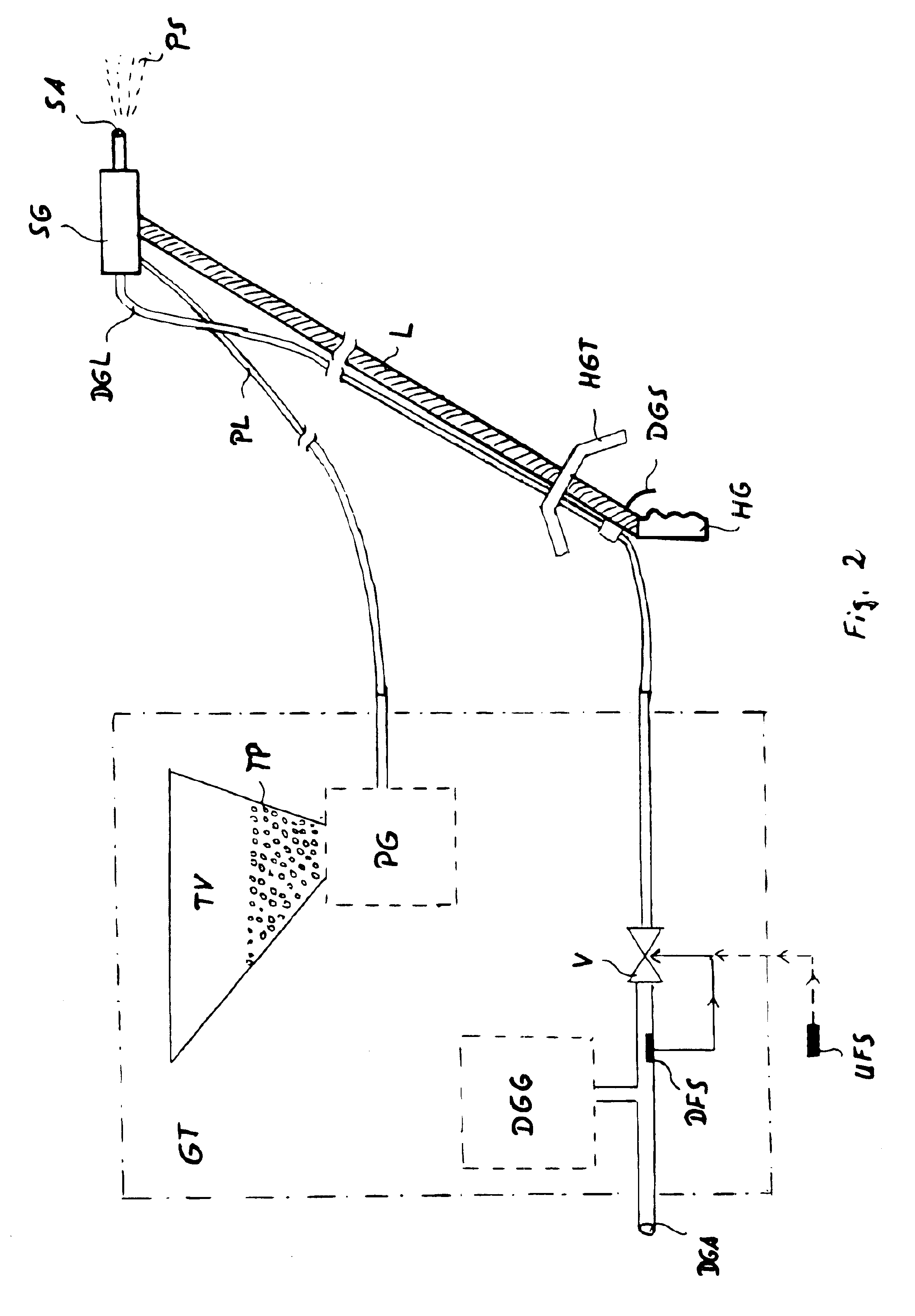

Method and device for cleaning high-voltage carrying installation component parts

InactiveUS6863594B2Without endangering safetyProtected installationBlast gunsPipeline systemsEngineeringCleaning methods

A cleaning method and a corresponding cleaning device offer adequate protection to individuals, devices and installations, for cleaning component parts of installations that carry an electrical high-voltage and which are not disconnected during cleaning. Towards this end, the component parts to be cleaned are subjected to the action of a two-phase particle stream (PS) consisting of a compressed gas (DGA) serving as a carrier medium and of carbon dioxide ice particles (TP) carried therein. Possible superficial accumulations of dirt are removed from the component parts by way of low-temperature embrittlement and by the kinetic energy of the impacting carbon dioxide particles. The carbon dioxide ice particles themselves sublimate without leaving residues. A sufficiently safe distance of cleaning personnel from the high-voltage carrying insulation component parts is ensured by the provision of an electrically insulating distance mechanism (L, SFR) that is provided approximately in the form of a lance (L) or of a stream guided tube (SFR). A further increase in protection is offered by monitoring the quantity of moisture of compressed gas and / or ambient air, whereby the cleaning device is immediately shut off when predetermined limiting values are exceeded.

Owner:PREISING PAUL ERIC

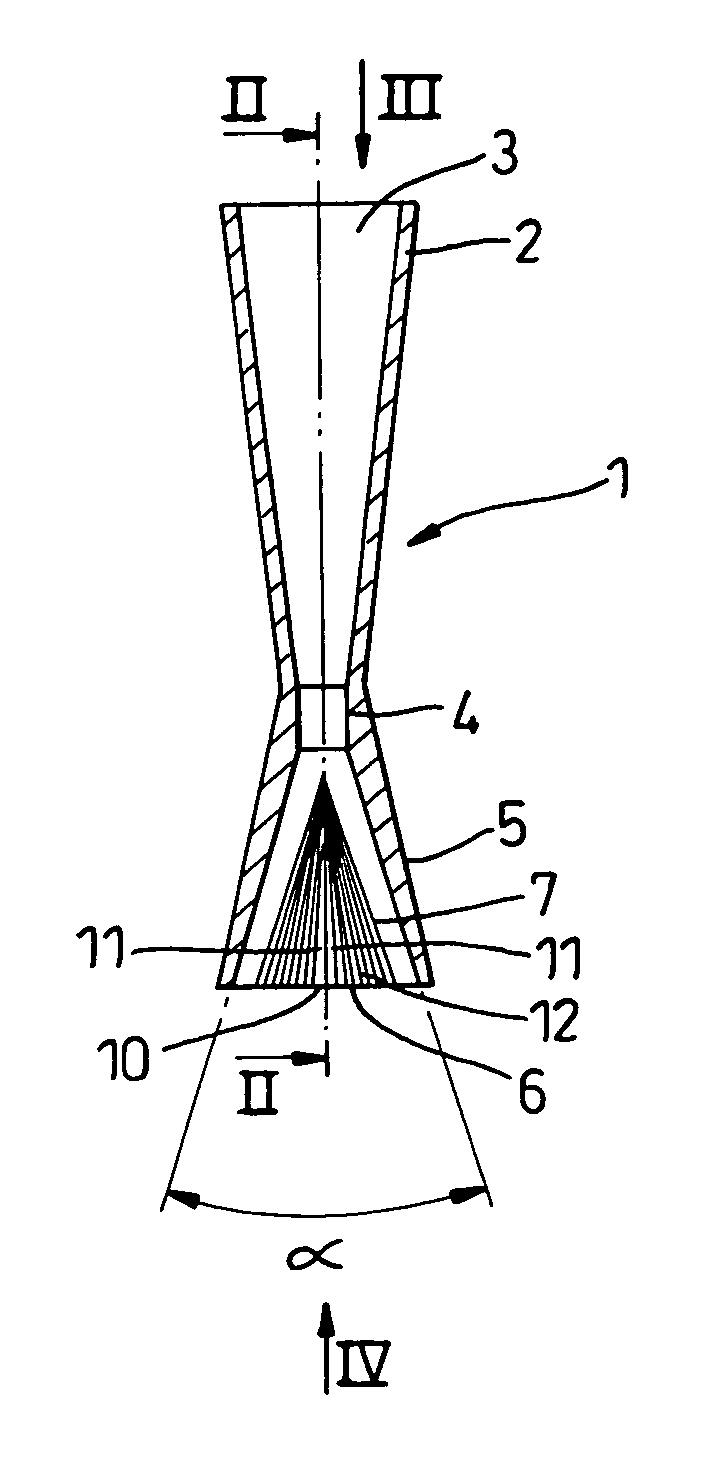

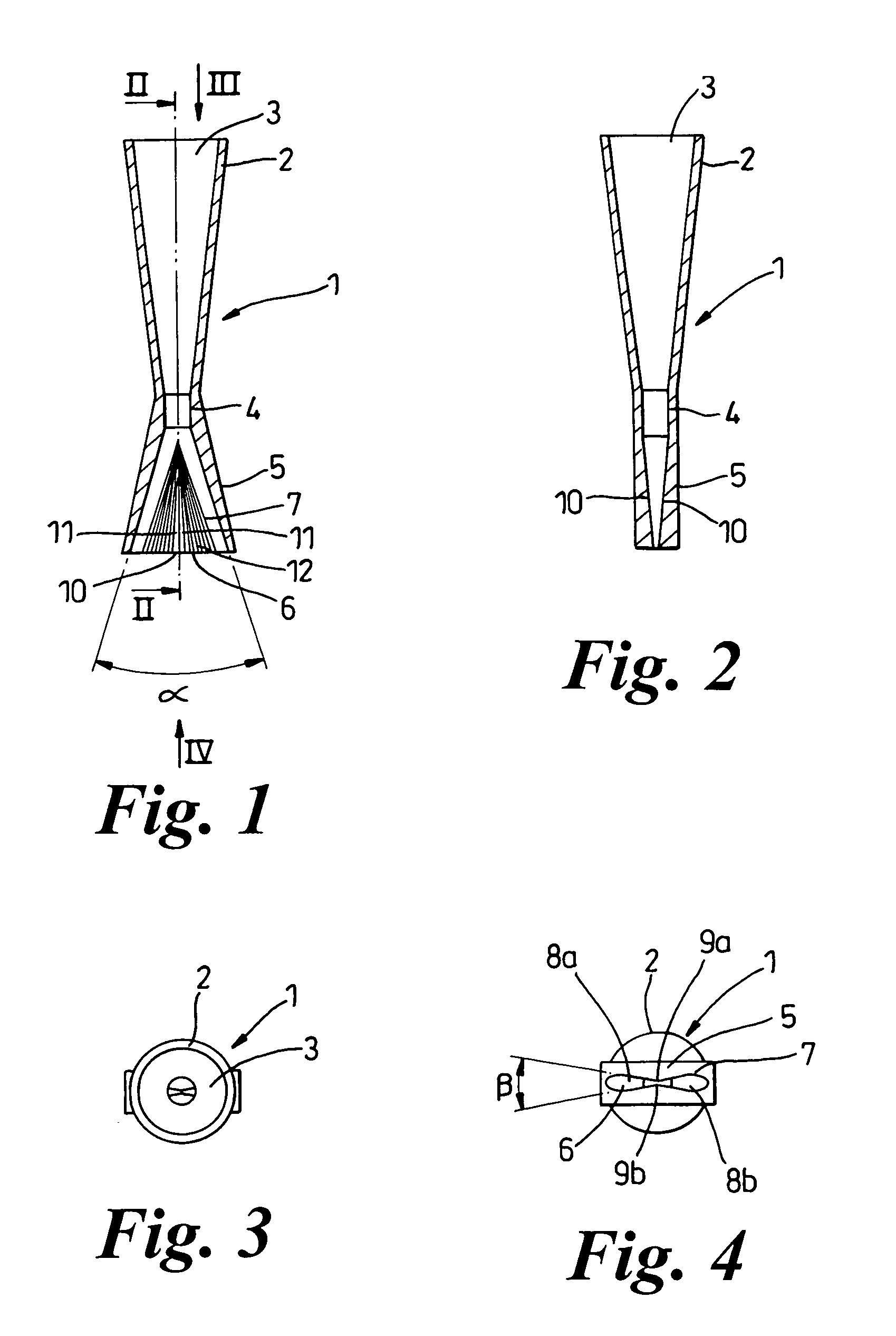

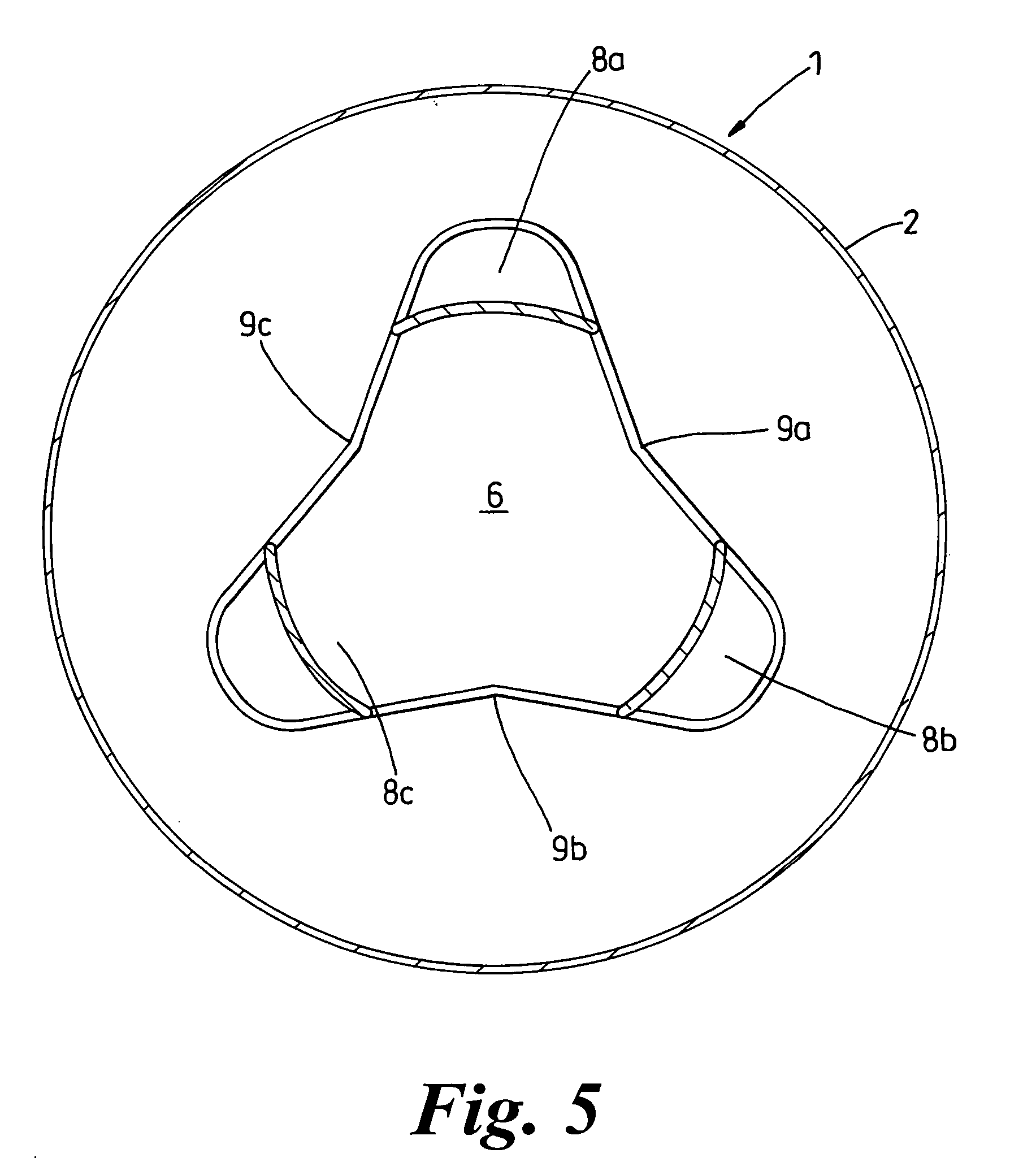

Blasting nozzle

InactiveUS20060063476A1Optimize quantityEasy to cleanBlast gunsSpray nozzlesAbrasive blastingEngineering

A blasting nozzle for a blasting apparatus includes an inlet for attachment to the outlet hose of the blasting apparatus, an accelerating portion, and an outlet portion through which an accelerated abrasive-laden jet can be ejected. The outlet portion has an interior surface that flares outwards to define a single outlet orifice but that also defines a transverse cross-section profile having at least two lobes between which is at least one splitter element. In use, the abrasive within the jet is directed by the splitter element into one or other of the two lobes within the single egressing jet. The overall effect is such that the abrasive distribution transversely across the jet is much more even than in a conventional blasting nozzle.

Owner:QUILL INTERNATIONAL INDUSTRIES PLC

Carbon dioxide snow apparatus

ActiveUS7293570B2Increased Joule-Thompson coolingReduce cloggingBlast gunsSpray nozzlesLiquid carbonMachining process

A carbon dioxide snow apparatus of the present invention includes a carbon dioxide snow generation system and a propellant generation system connected to a common carbon dioxide gas source. The carbon dioxide snow generation system includes a condenser having a at least two connected segments, wherein a first segment has a lesser diameter than the a second segment to provide a stepped expansion cavity for cooling and condensing liquid carbon dioxide into solid carbon dioxide snow. Several snow generation systems, each separately controllable with separate condensers, may be integrated with the propellant generation system and common carbon dioxide source to provide for a multiplicity of carbon dioxide snow applicators for integration into both manual and automated machining processes.

Owner:COOL CLEAN TECH

Vented cutting head body for abrasive jet system

An abrasive waterjet assembly has a cutting head assembly with a venting system for controlling the flow of abrasive within a cutting head body. The venting system includes one or more vents for regulating the pressure within a cutting head body to minimize, limit, or substantially eliminate any abrasive from reaching a jewel orifice. The vents include venting ports positioned between an orifice mount that retains the jewel orifice and a mixing region in which abrasive is mixed with a fluid jet produced by the jewel orifice. An isolator retained in the cutting head body further inhibits the upstream flow of abrasive, if any.

Owner:FLOW INT

Nozzle for spraying sublimable solid particles entrained in gas for cleaning surface and method of cleaning surface using the same

ActiveUS20050266777A1Blast gunsSemiconductor/solid-state device manufacturingSolenoid valveEngineering

A nozzle for spraying sublimable solid particles and preventing frost from forming at surfaces of the nozzle. The nozzle includes: a cleaning agent block for phase-changing a cleaning agent into a snows containing sublimable solid particles; a nozzle block for growing the cleaning agent snow through adiabatic expansion and spraying the grown cleaning agent snow onto a surface of an object; a carrier gas block for supplying a carrier gas to the nozzle block to mix with the cleaning agent snow; and a heater for heating at least a portion of the carrier gas supplied from the carrier gas supply source. Fine dry ice particles and liquid CO2, passing through a solenoid valve from a CO2 reservoir tank and a pressure drop of a flow rate regulation valve, are introduced into the spray nozzle and then mixed with the carrier gas, such as N2 or purified air, and discharged.

Owner:K C TECH

Processes and apparatuses for enhanced cutting using blends of abrasive materials

ActiveUS20100124872A1Composition is limitedBlast gunsControlling ratio of multiple fluid flowsEngineeringDelivery system

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT

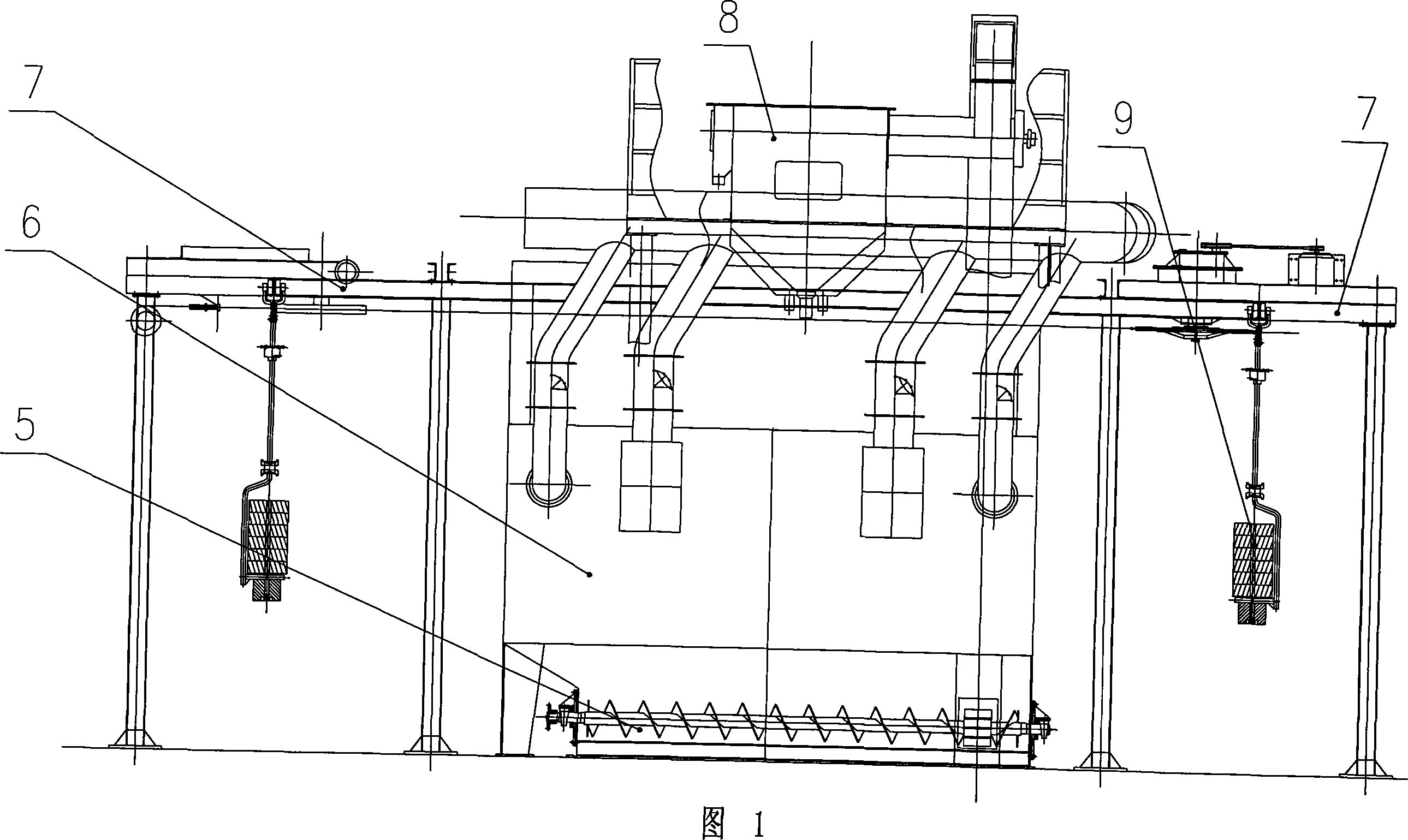

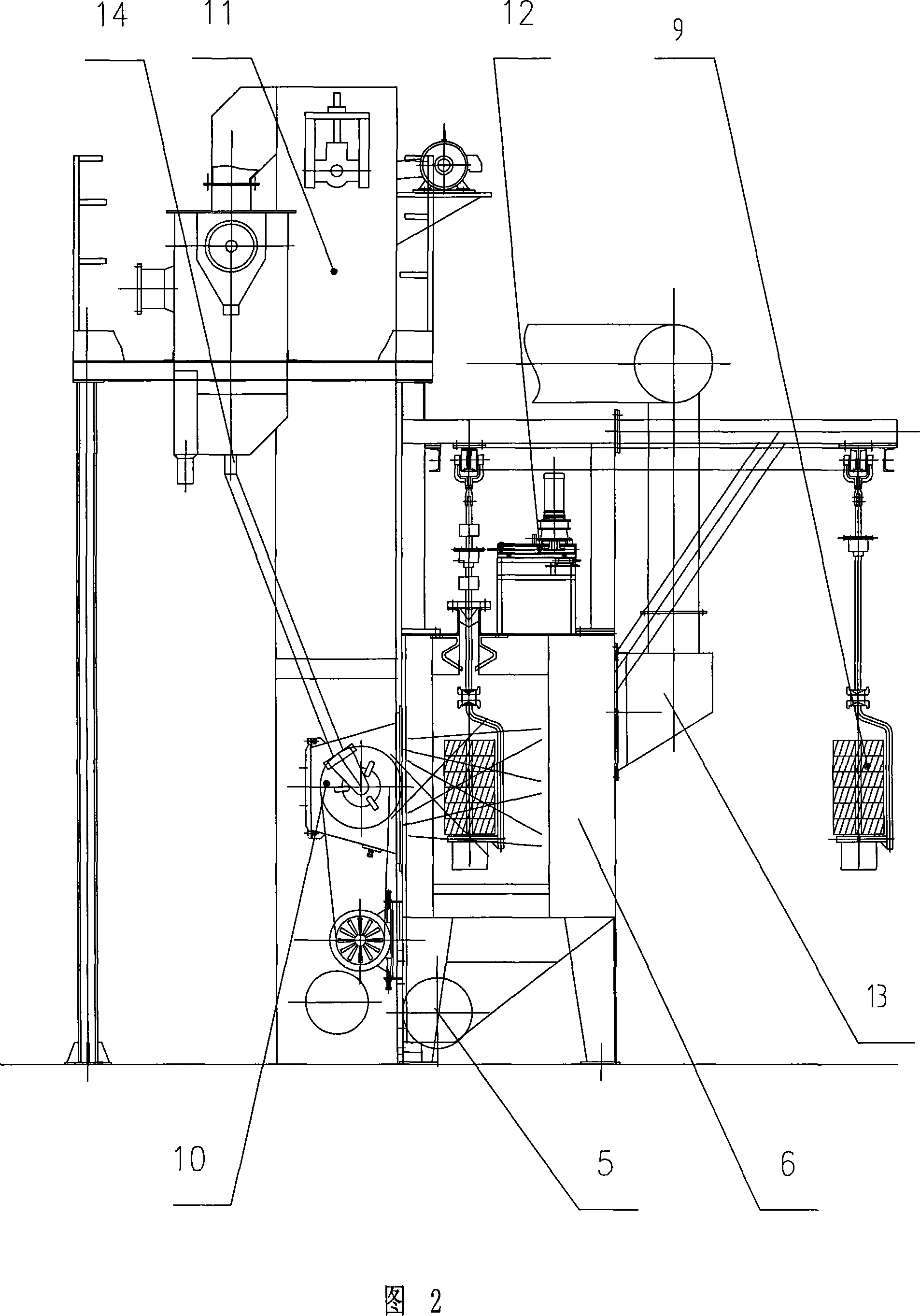

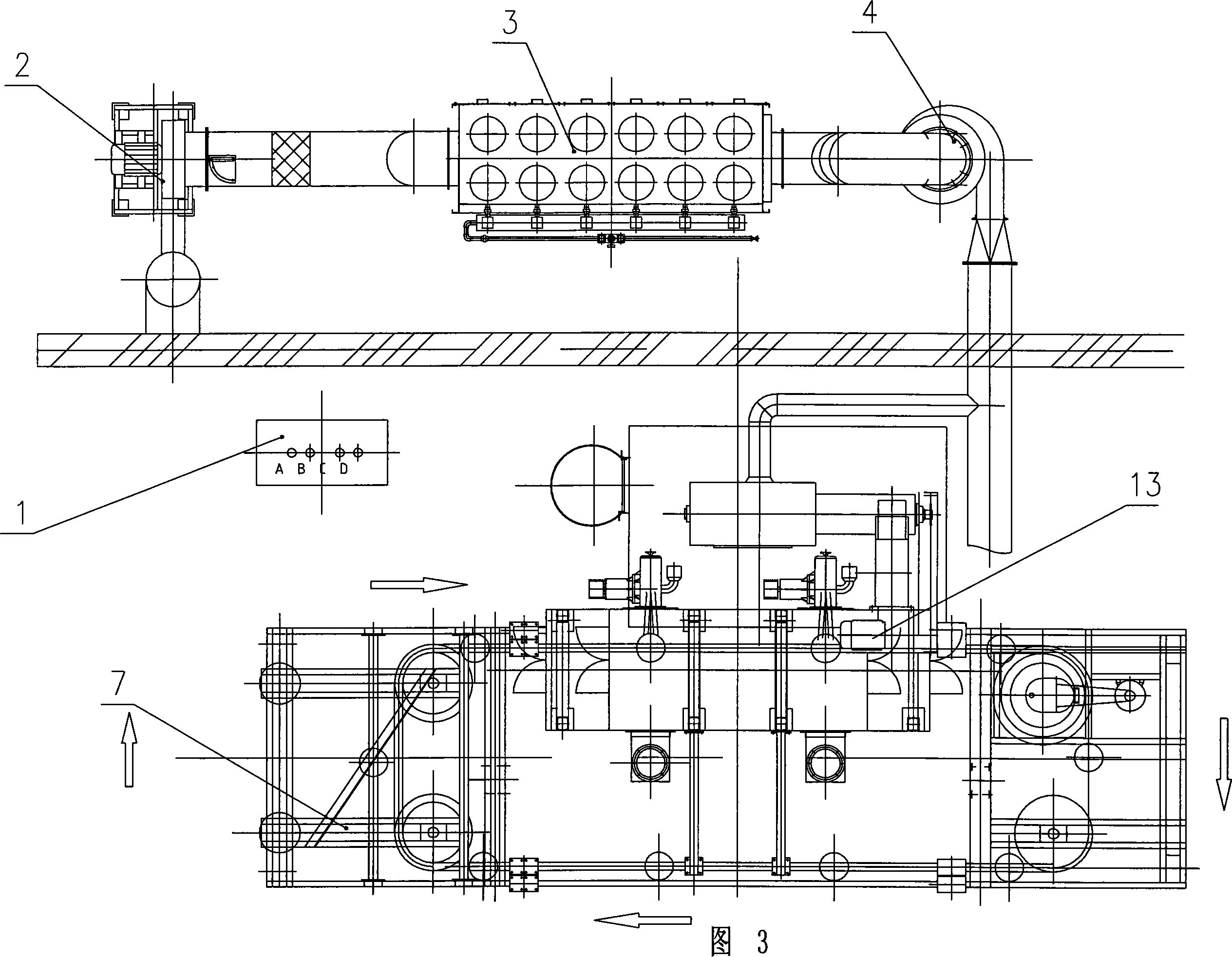

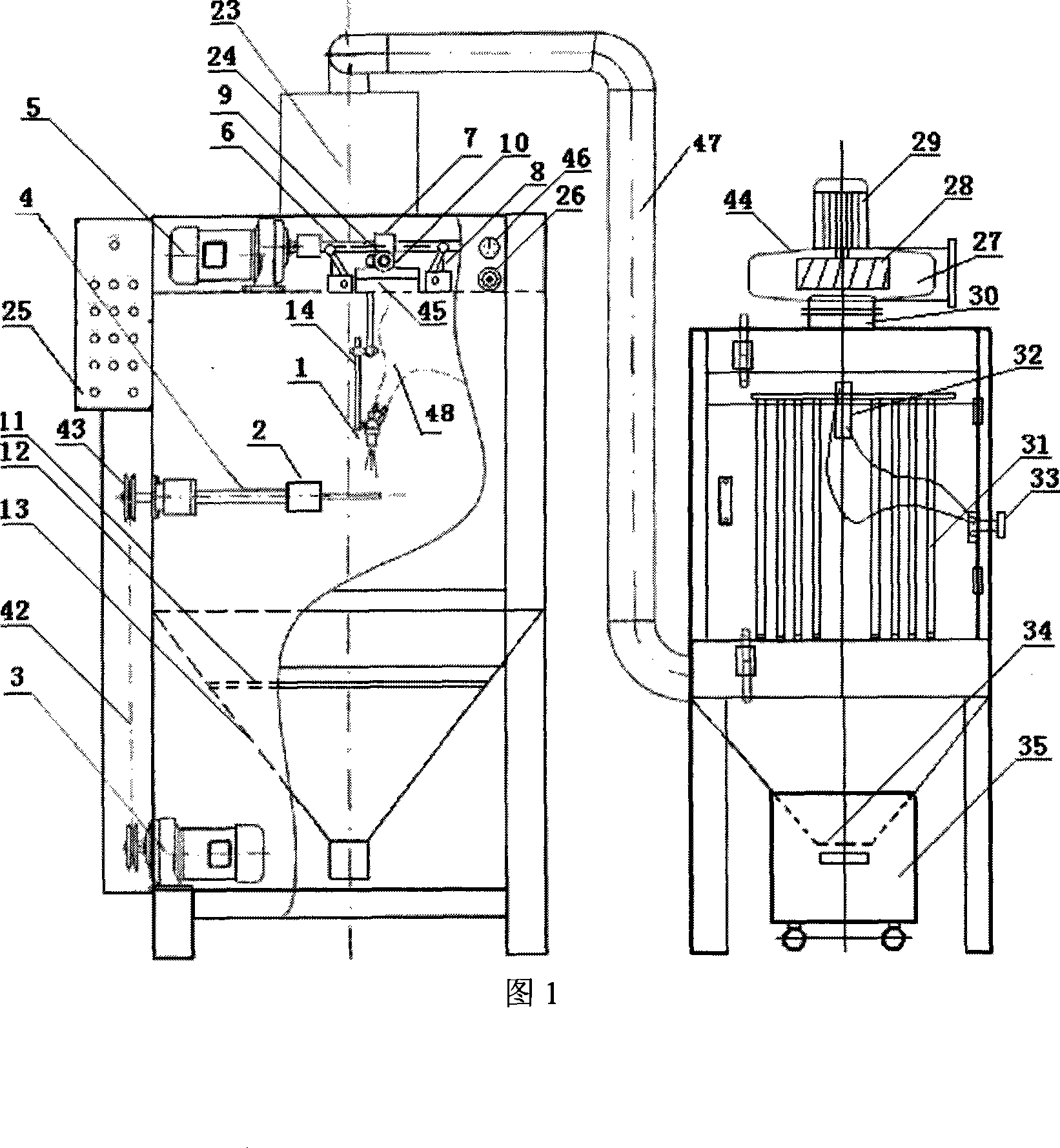

Automobile gear ruggedization shot-blasting machine

InactiveCN101157203AReduce energy consumptionImprove work efficiencyImpeller wheelsBlast gunsGear wheelEngineering

The invention belongs to equipment for cleaning the surface of a machine element by utilizing a shot blasting method, in particular to an automotive gear enhanced shot blasting machine. According to the technical proposal provided by the invention, the shot blasting machine is arranged on a shot blasting cleaning chamber. The invention is characterized in that a suspend conveyer installed on a supporting bracket is arranged at the upper part of the shot blasting cleaning chamber, the suspend conveyer is in a sealed state and circled around the shot blasting cleaning chamber, and one section passes through the shot blasting cleaning chamber, a plurality of rotating racks which can rotate under the driving of the suspend conveyer are suspended on the suspend conveyer, a curtain separator is arranged above / on the shot blasting cleaning chamber, a chamber hoisting gear is arranged on the flank of the shot blasting cleaning chamber, and a worm conveyer is arranged at the bottom of the shot blasting cleaning chamber. The input end of the curtain separator is connected with the output end of the chamber hoisting gear, and the output end of the worm conveyer is connected with the input end of the chamber hoisting gear. The invention can improve the effect of the shot blasting cleaning and the quality of the product.

Owner:无锡国达机械设备有限公司

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

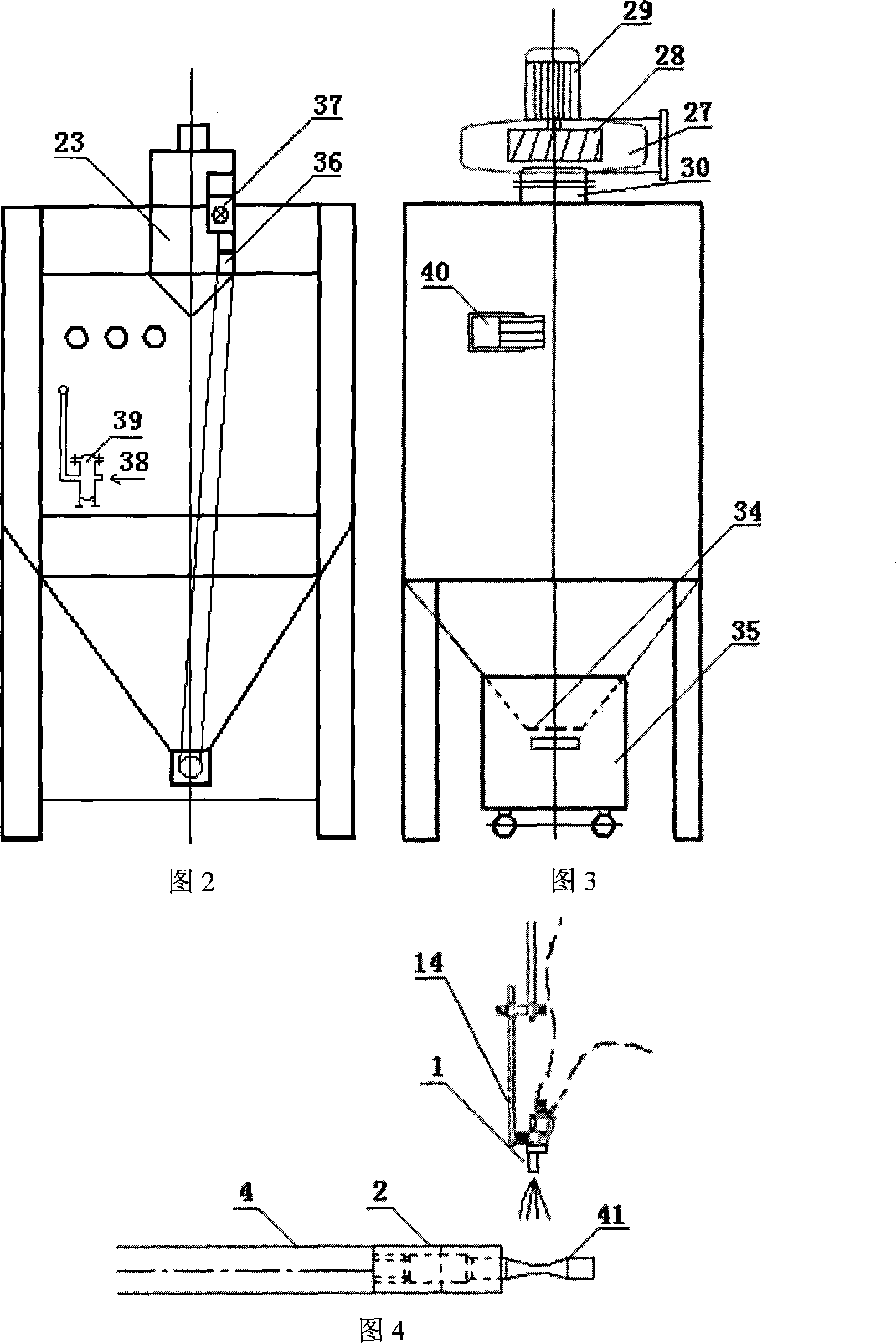

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

Toothcleaning Device

Equipment for daily dental care: teeth are cleaned by water jet with admixed softly abrasive media for the dissolution of plaques. A particular mixing chamber for the transfer of the ingredients from tabs may be branched either to by passes on faucets or showering mixing taps or to hereditary water jet pumping systems. Pressure and spray characteristics of the jet can be adjusted with a spiral nozzle.

Owner:DENTAL CARE INNOVATION

Blast nozzle

A blast nozzle apparatus which includes a circular inlet to an entry portion with converging top and bottom surfaces and diverging side surfaces which terminate in a throat portion and an outlet portion including diverging side surfaces and top and bottom surfaces terminating in a substantially rectangular outlet opening.

Owner:PAULI ROBERT

Blast nozzle with blast media fragmenter

A media blast nozzle for cleaning a surface with compressed air and ejected particles of a sublimating blast media comprises a media size changer to change a size of the blast media particles. The media blast nozzle has an entrance and an exit and a throat therebetween. A converging passageway extends from the entrance to the throat, and a diverging passageway extends from the throat to the exit. The media size changer is operably located in the diverging passageway and has one or more media size changing members to fragment moving blast media particles by impact therewith. The blast media particles are provided to the media blast nozzle in an initial consistent size, and when a moving blast media particle impacts with one or more media size changing members, two or more fragments of reduced size are created from the initial blast media particle for ejection from the nozzle device. The media size changer can be adjusted by an operator to eject whole particles or fragments of particles. The size of the ejected particle fragments can also be adjusted with the media size change

Owner:COLD JET

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com