Dynamic pressure cavitation jet polishing device of colloidal flow and method

A polishing device and colloid technology, which is applied in the direction of explosion generating device, grinding/polishing equipment, abrasive feeding device, etc., can solve the problems of limited adaptability of workpiece materials, complex equipment, low processing efficiency, etc., and achieve improvement Polishing quality and processing efficiency, enhanced mechanical shear action, and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

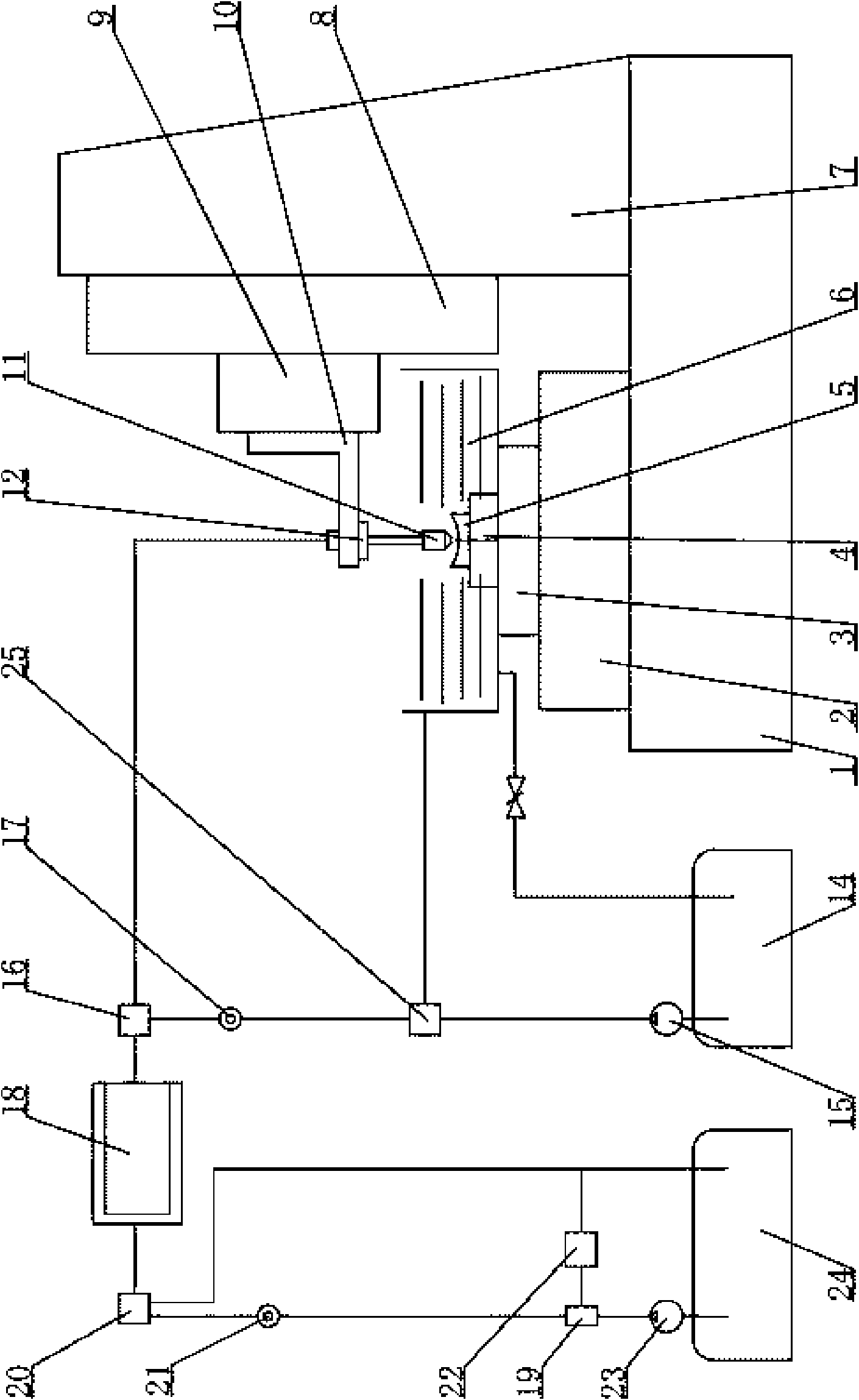

[0008] Specific implementation mode one: combine figure 1Describe this embodiment, this embodiment includes horizontal table base 1, horizontal table transmission mechanism 2, horizontal mobile table 3, rotary table 4, colloidal polishing solution tank 6, vertical table base 7, vertical mobile working table Table 8, vertical rotary table 9, bracket 10, cavitation jet 11, fixture 12, colloidal polishing liquid recovery box 14, peristaltic pump 15, first liquid flow reversing valve 16, colloidal polishing liquid flowmeter 17, capsule type Energy storage device 18, tee 19, second liquid flow reversing valve 20, pressure oil flow meter 21, oil pressure regulating valve 22, high pressure pump 23, pressure oil recovery tank 24 and third liquid flow reversing valve 25, horizontal The workbench transmission mechanism 2 is fixed on the horizontal workbench base 1, the horizontal movement workbench 3 and the rotary workbench 4 are installed on the output end of the horizontal workbench ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described. The cavitation jet 11 of the present embodiment is a Venturi nozzle or an organ pipe self-vibrating cavitation nozzle. The Venturi nozzle is selected from Dongguan Bomei Spray System Co., Ltd. with the model number 2003-L-3 / 8-PP. Venturi nozzles and organ tube self-vibrating cavitation nozzles produce local high temperatures of about 5200K and local high pressures of about 50MPa or more when the cavitation bubbles generated in the cavitation jets are broken. This process is used to strengthen the nanoparticles and particles in the colloidal polishing liquid. The interface chemical reaction process of the workpiece surface is processed, and at the same time, the compression wave and high-speed micro-jet generated by the cavitation effect when the cavitation bubble is broken on the processed surface are used to enhance the mechanical shearing effect of the hydrodynamic pressur...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment mode, this embodiment mode is realized by following steps: 1, inject colloidal polishing fluid: inject colloidal polishing fluid in colloidal polishing fluid tank 6, colloidal polishing fluid level submerges 10~200mm of workpiece to be polished; Pressure: Turn on the high-pressure pump 23, adjust the oil pressure regulating valve 22, and control the oil pressure within the range of 0.5-15MPa; 3. Adjust the cavitation jet pressure: adjust the oil pressure regulating valve 22, and control the cavitation jet pressure at 0.5-15MPa Within the range; 4. Polishing: the nozzle of the cavitation jet 11 is set in the colloidal polishing liquid and aimed at the polishing workpiece 5, and the cavitation jet 11 is continuously sprayed at a speed of 15 to 250 m / s along with the operation of the workpiece 5 After the polishing is completed, the high-pressure pump 23 is turned off, and the workpiece 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com