Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3297 results about "Model Number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The identifier assigned to a particular design of a device, usually an alphanumeric text string.

XML-based template language for devices and services

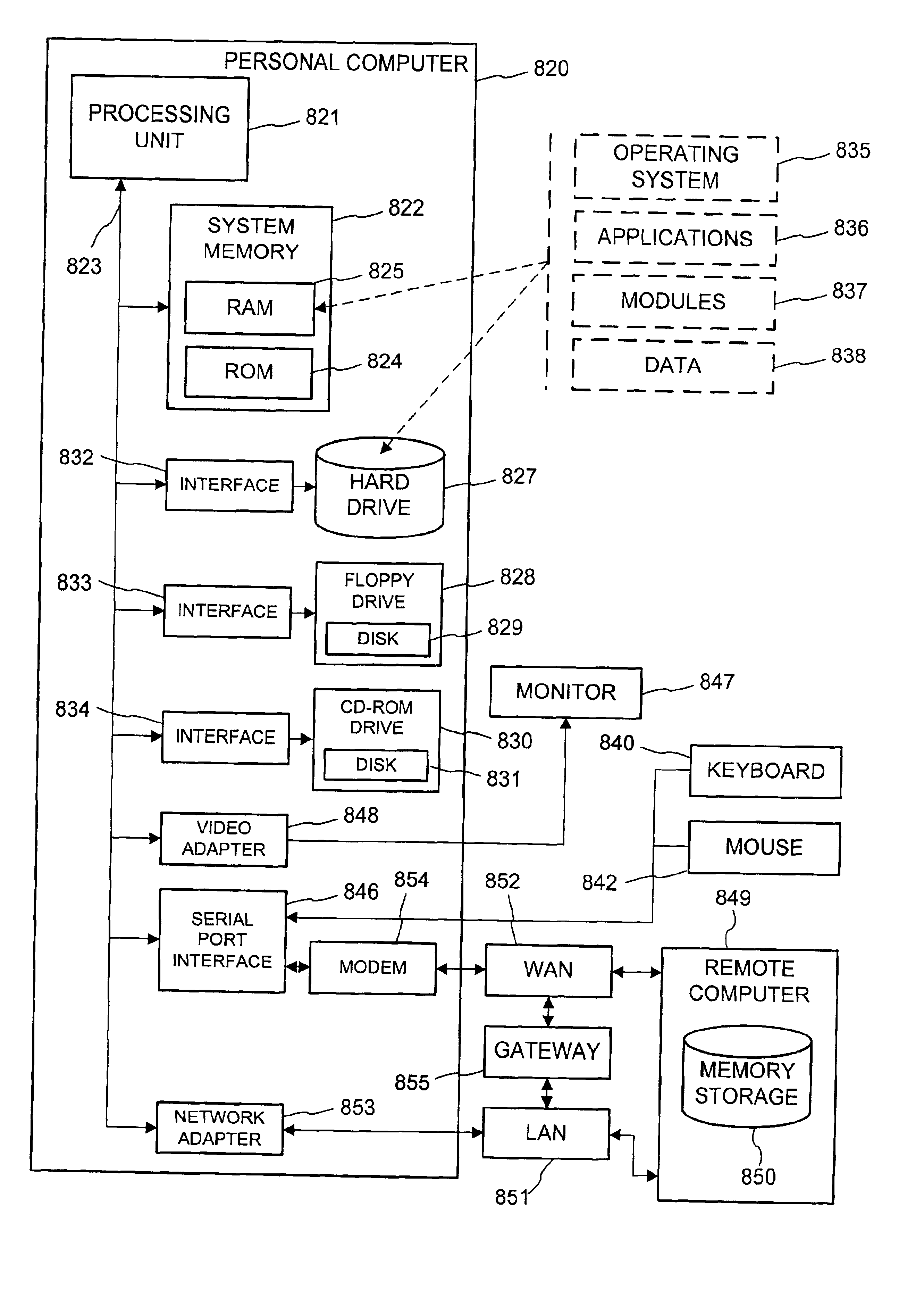

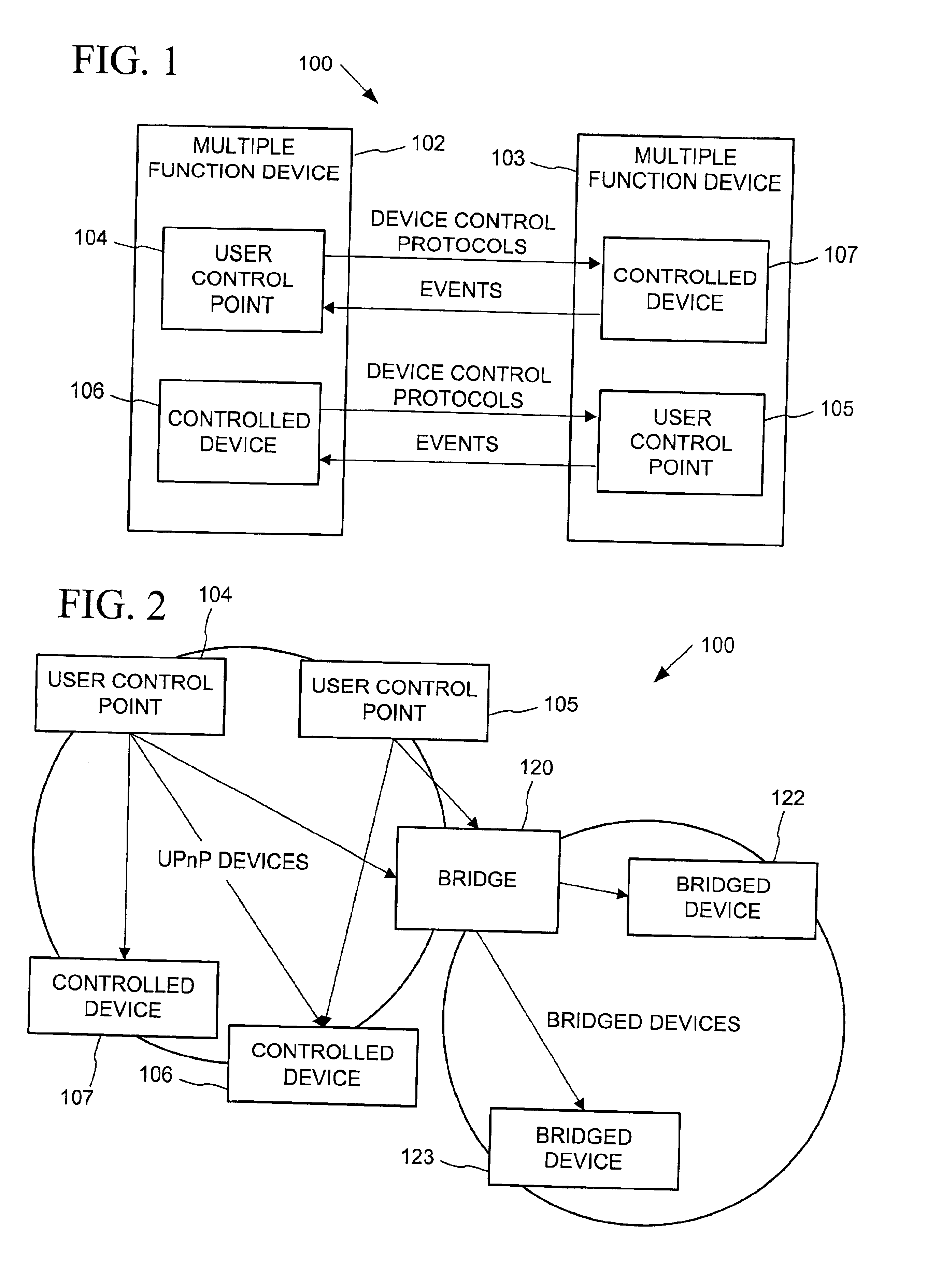

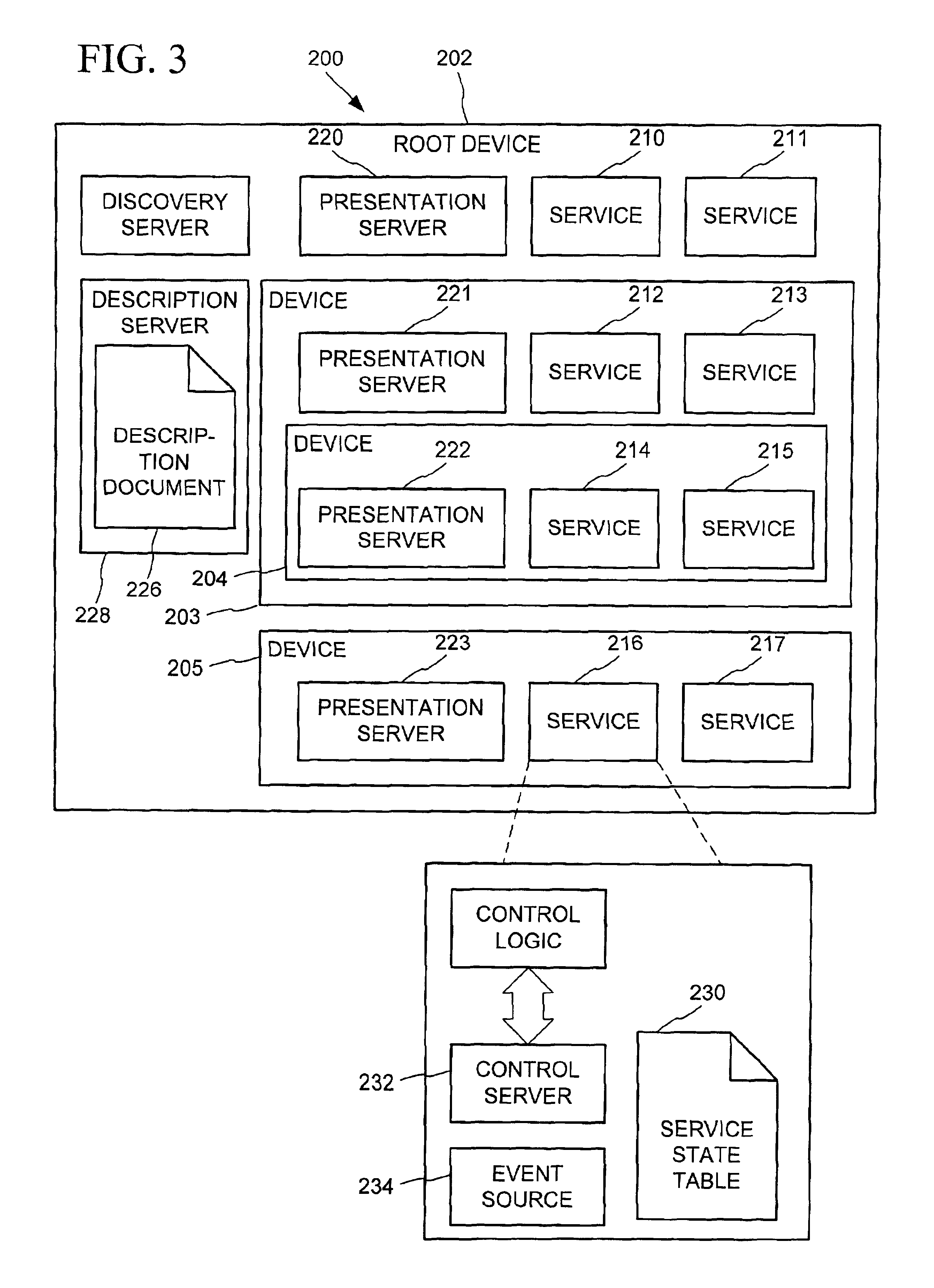

InactiveUS6910068B2CostConnectivity solutionMultiple digital computer combinationsNetworks interconnectionWeb siteProgramming language

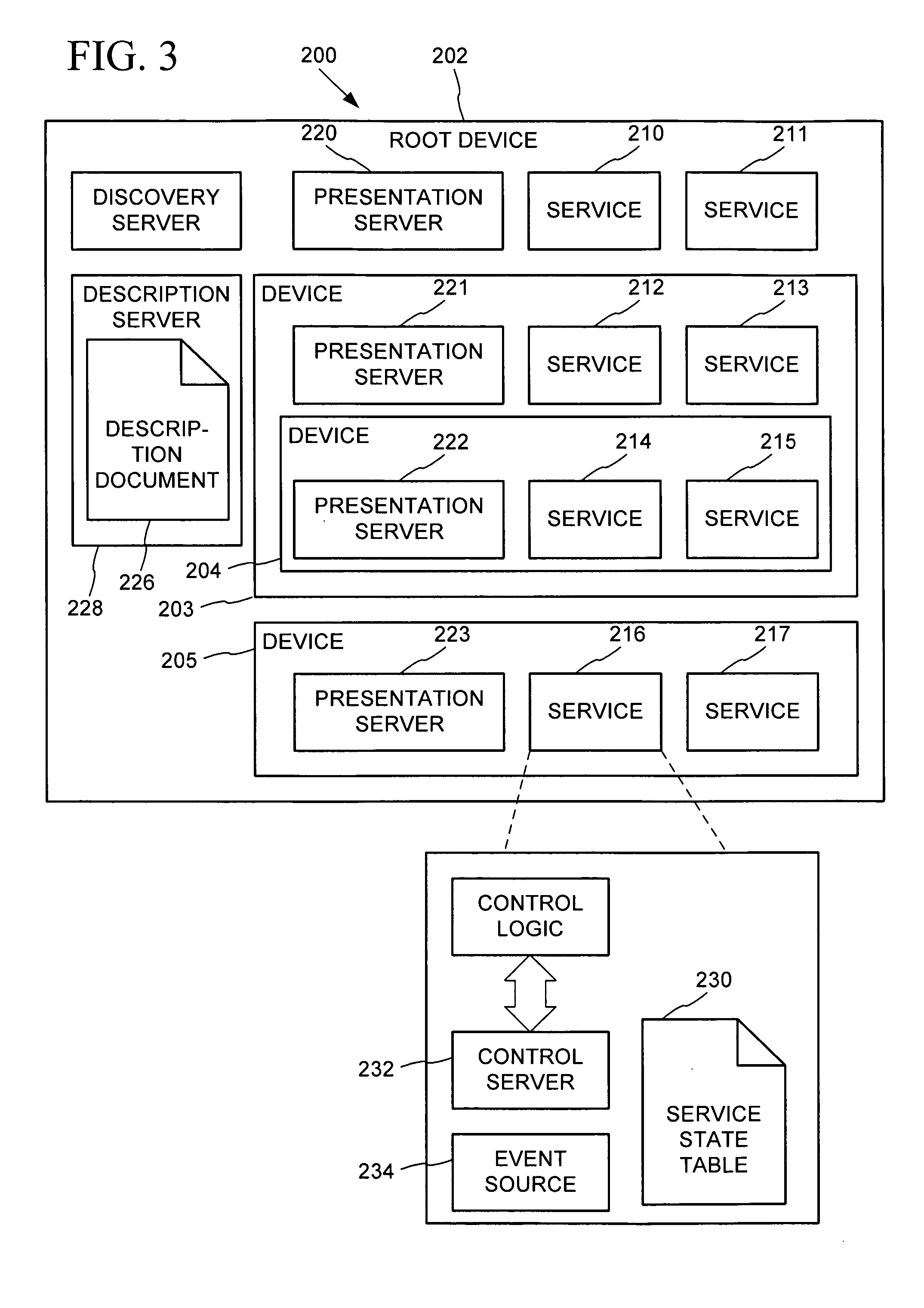

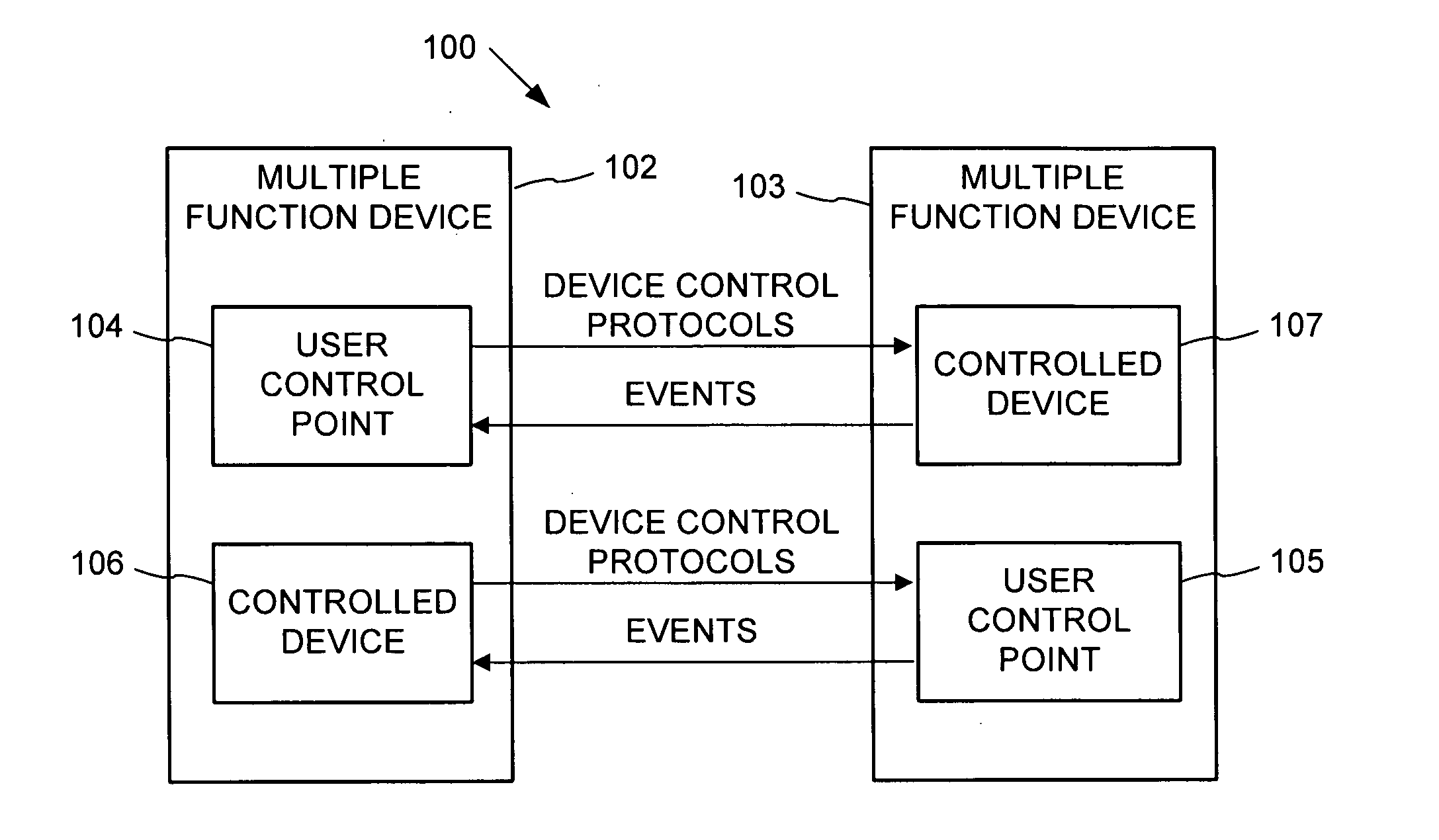

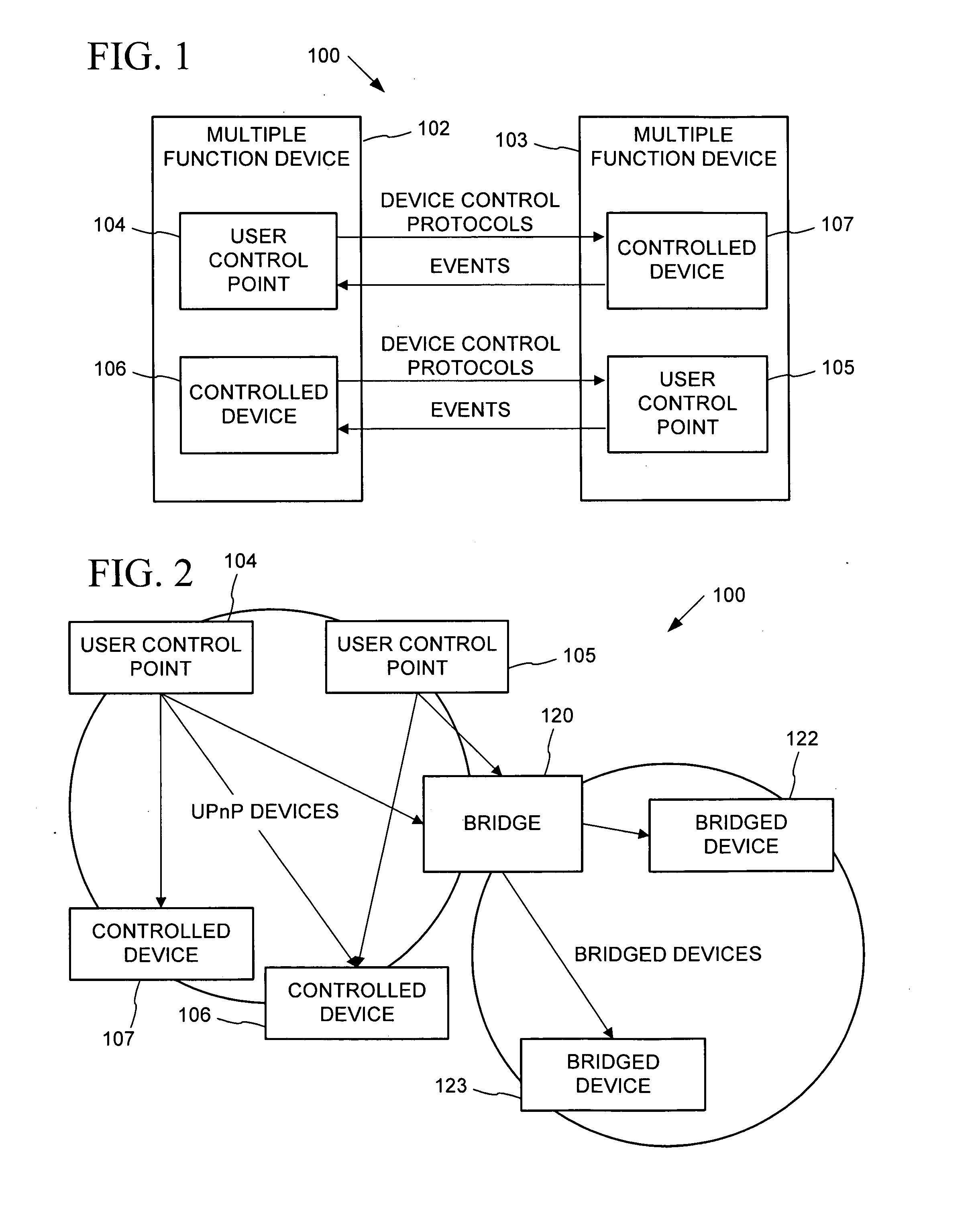

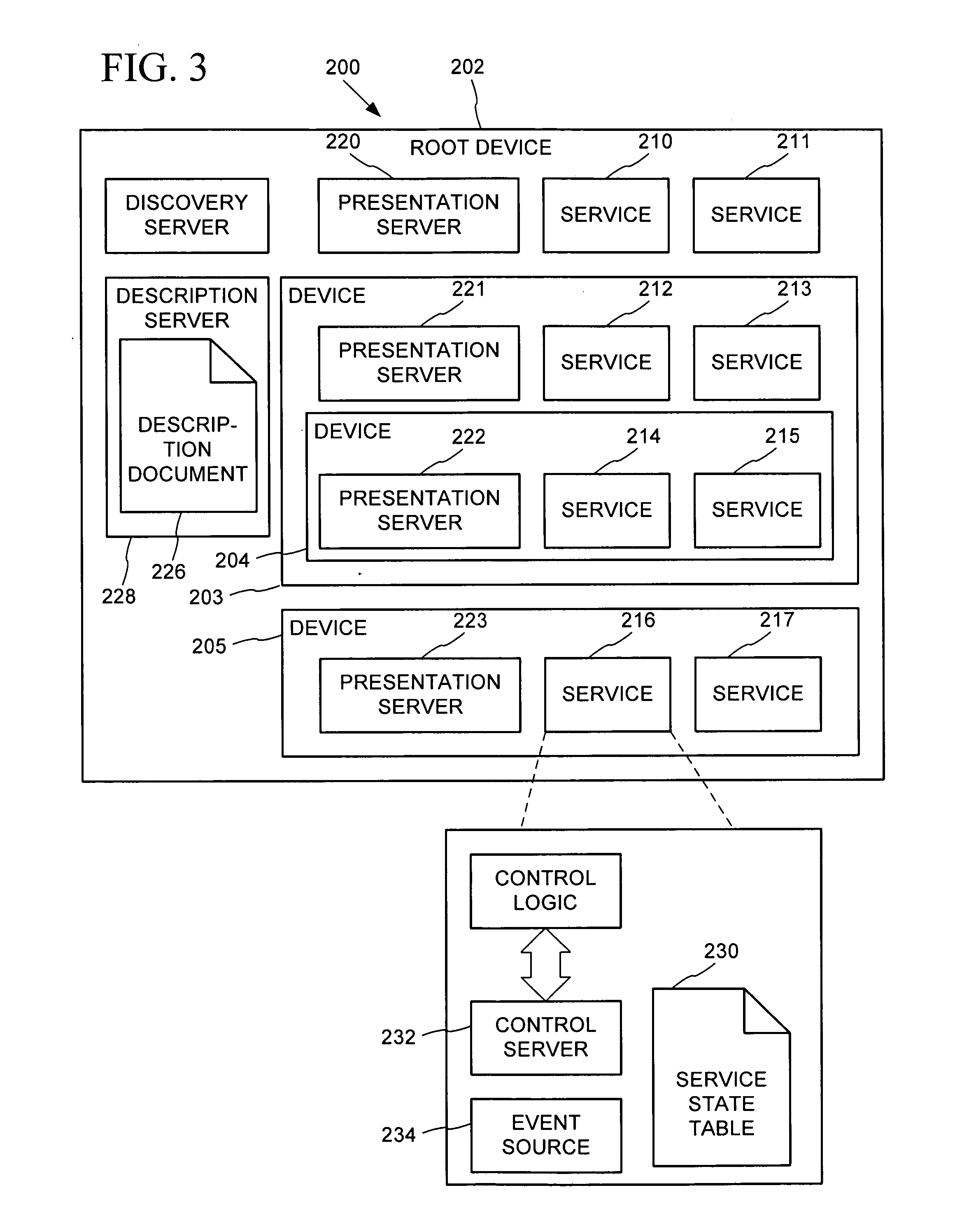

A universal plug and play (UPnP) device makes itself known through a set of processes-discovery, description, control, eventing, and presentation. Following discovery of a UPnP device, an entity can learn more about the device and its capabilities by retrieving the device's description. The description includes vendor-specific manufacturer information like the model name and number, serial number, manufacturer name, URLs to vendor-specific Web sites, etc. The description also includes a list of any embedded devices or services, as well as URLs for control, eventing, and presentation. The description is written by a vendor, and is usually based on a device template produced by a UPnP forum working committee. The template is derived from a template language that is used to define elements to describe the device and any services supported by the device. The template language is written using an XML-based syntax that organizes and structures the elements.

Owner:ROVI TECH CORP

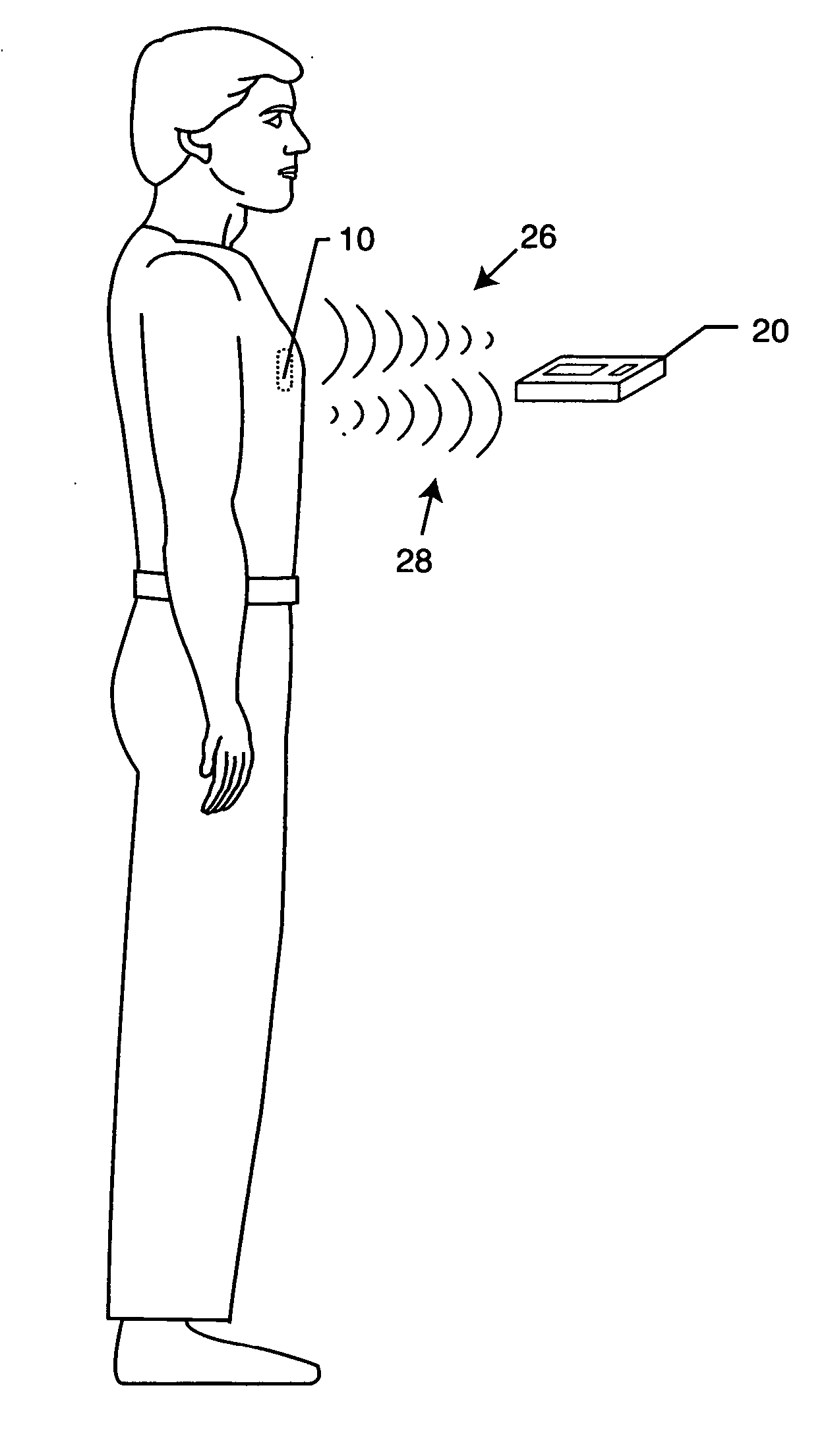

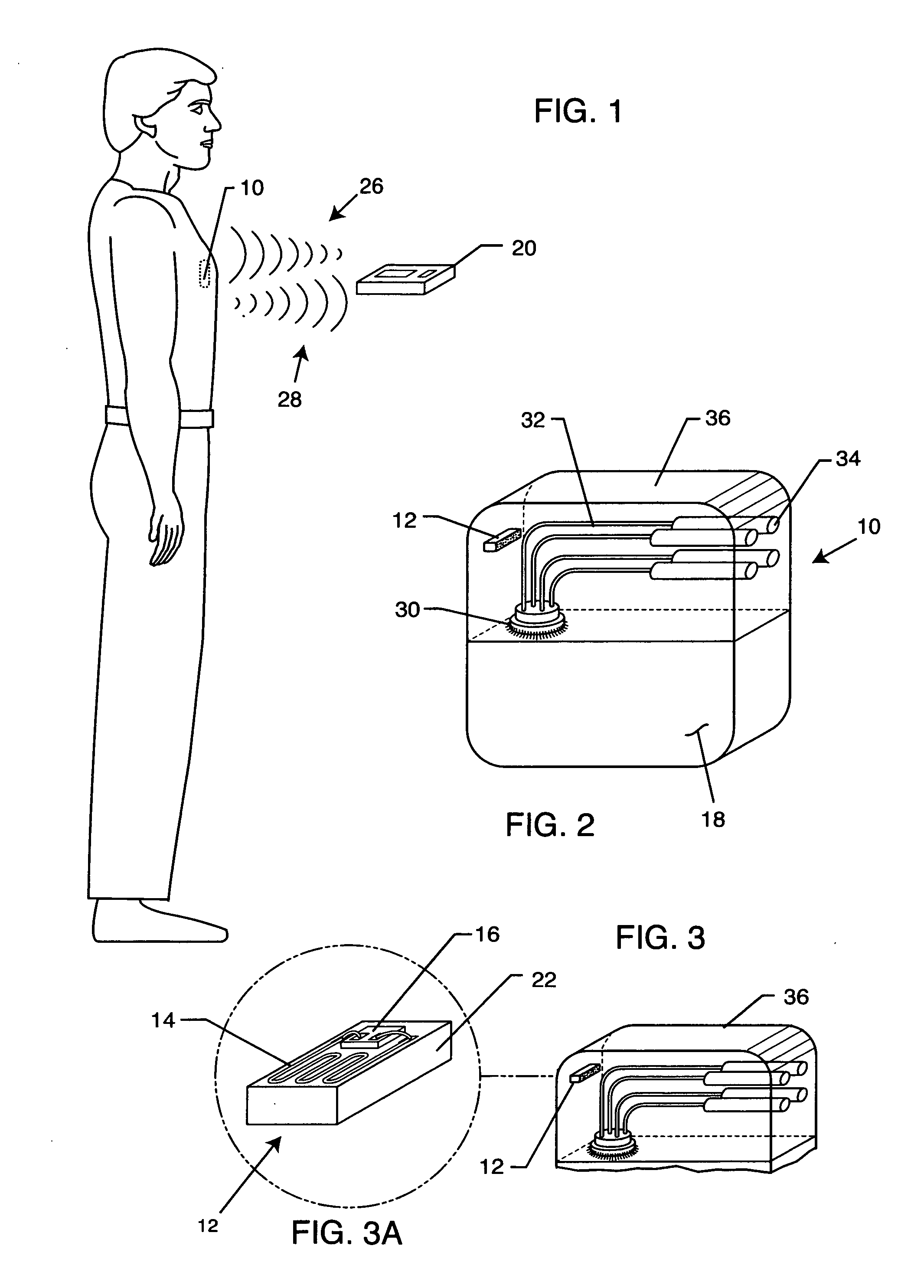

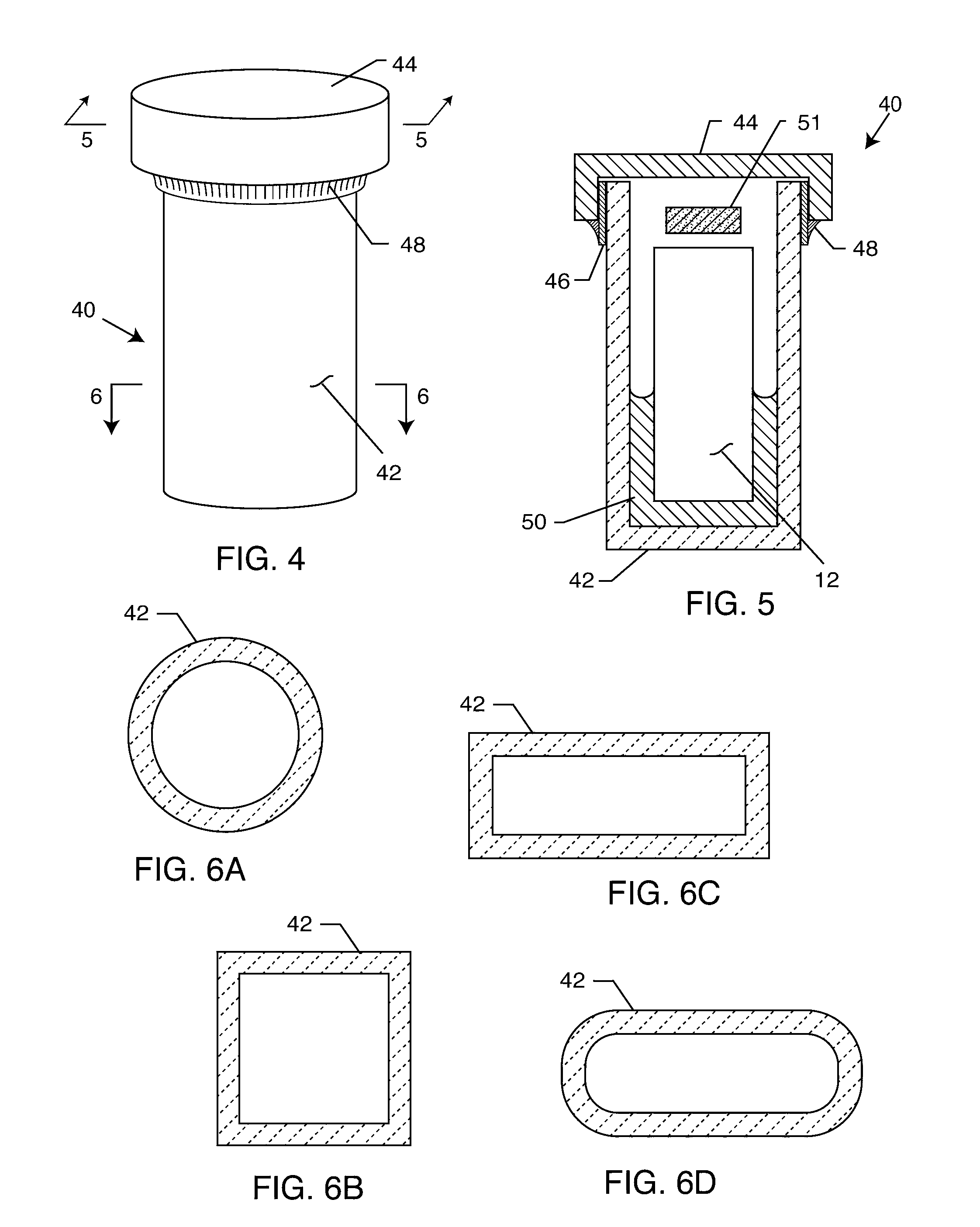

RFID detection and identification system for implantable medical devices

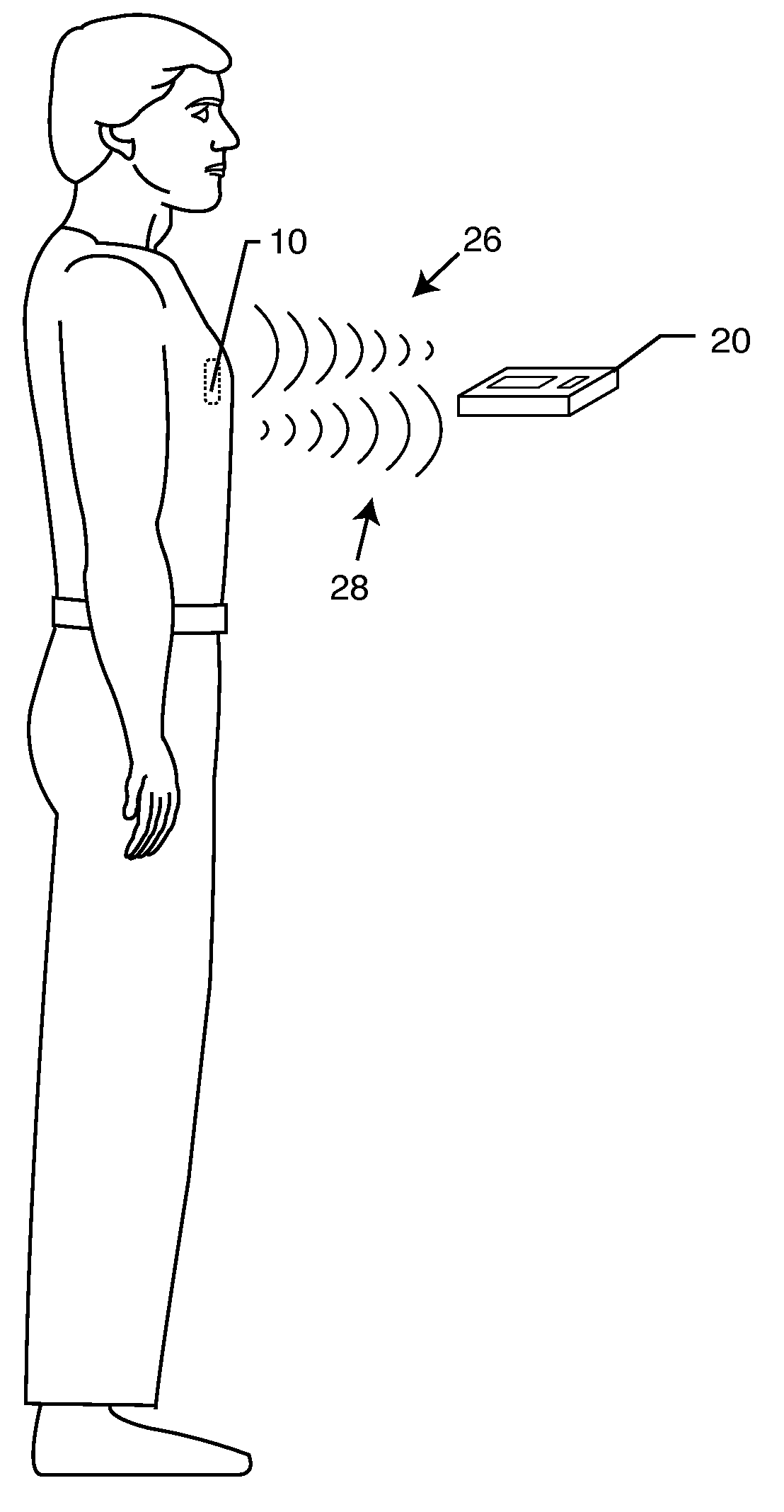

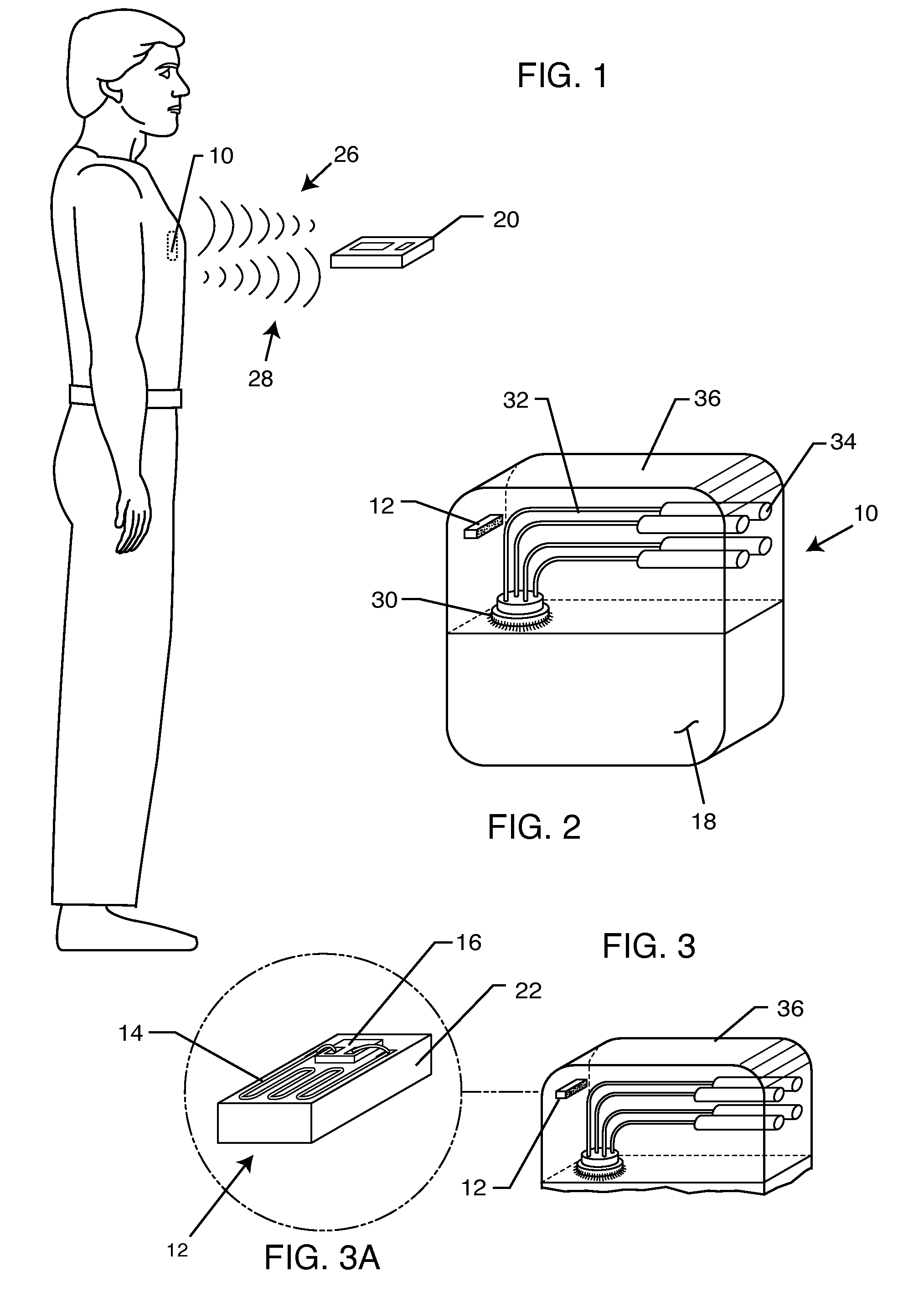

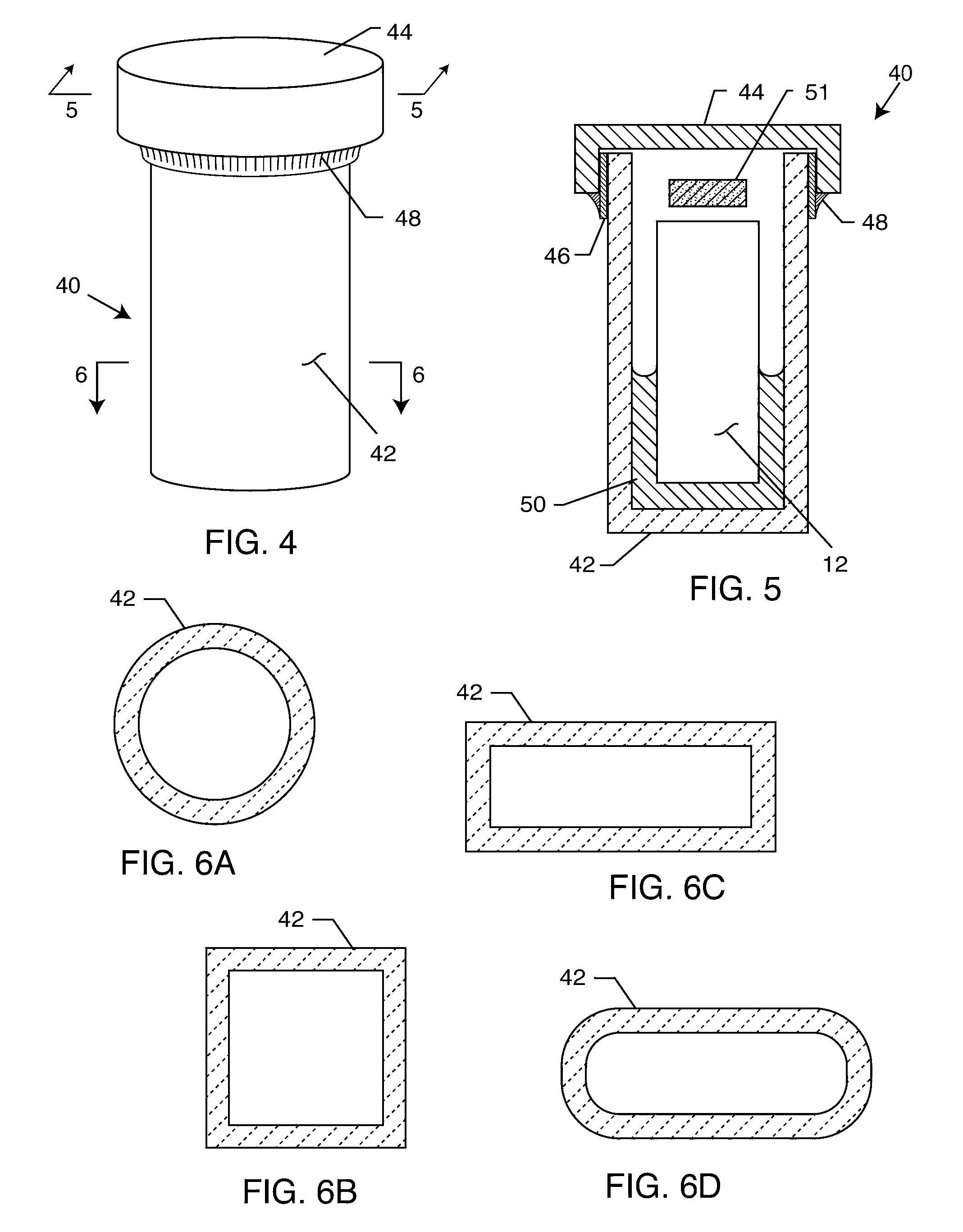

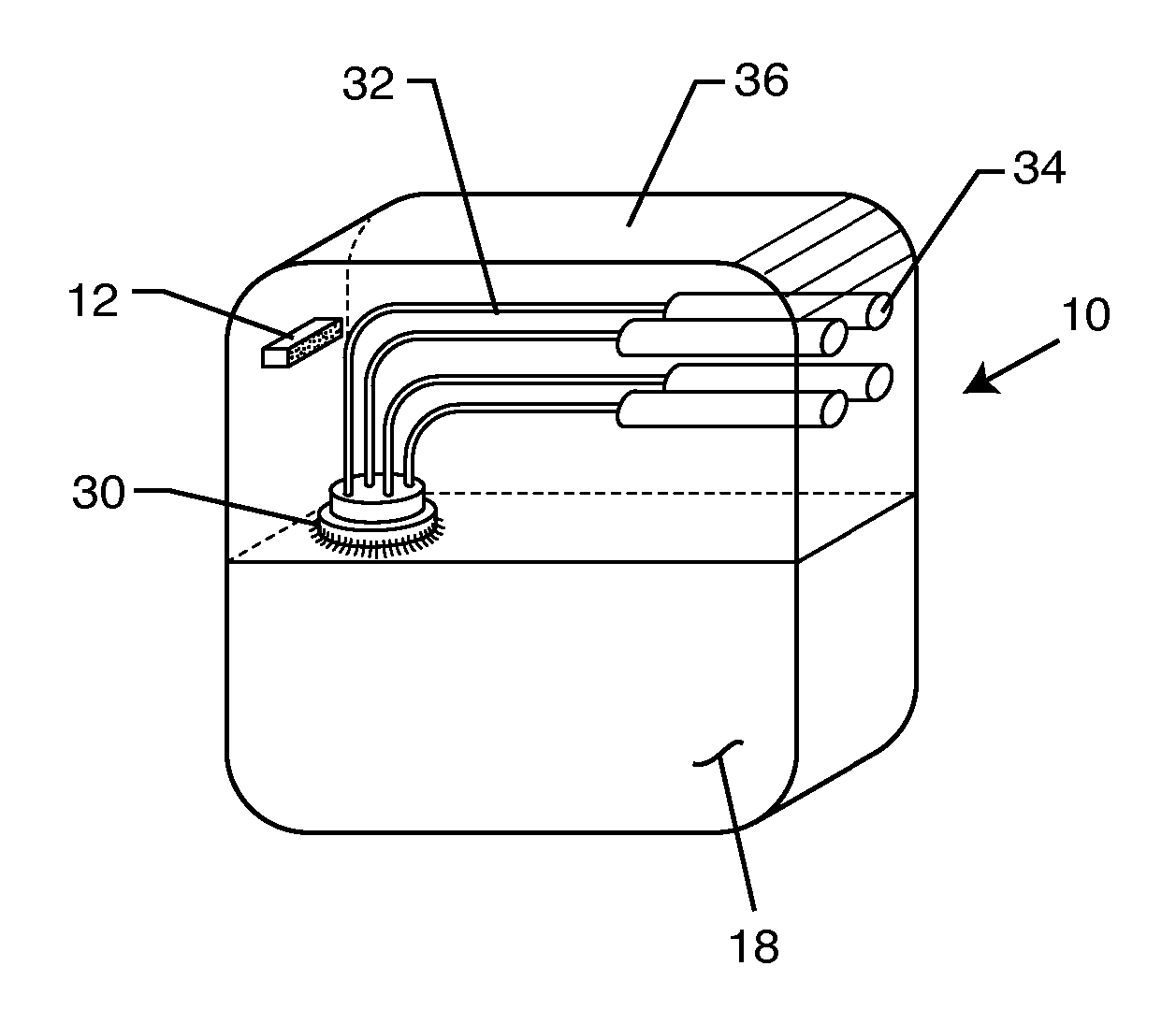

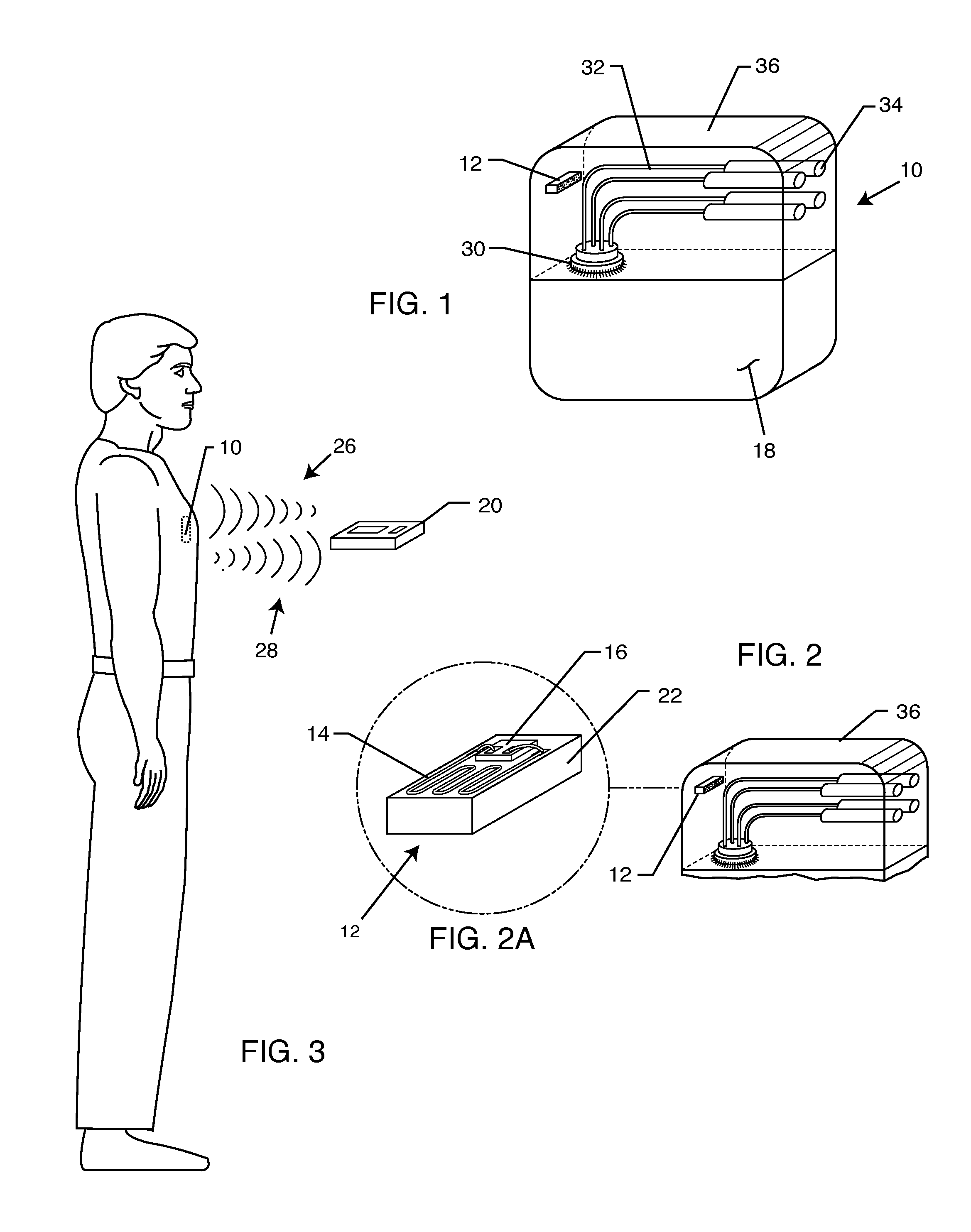

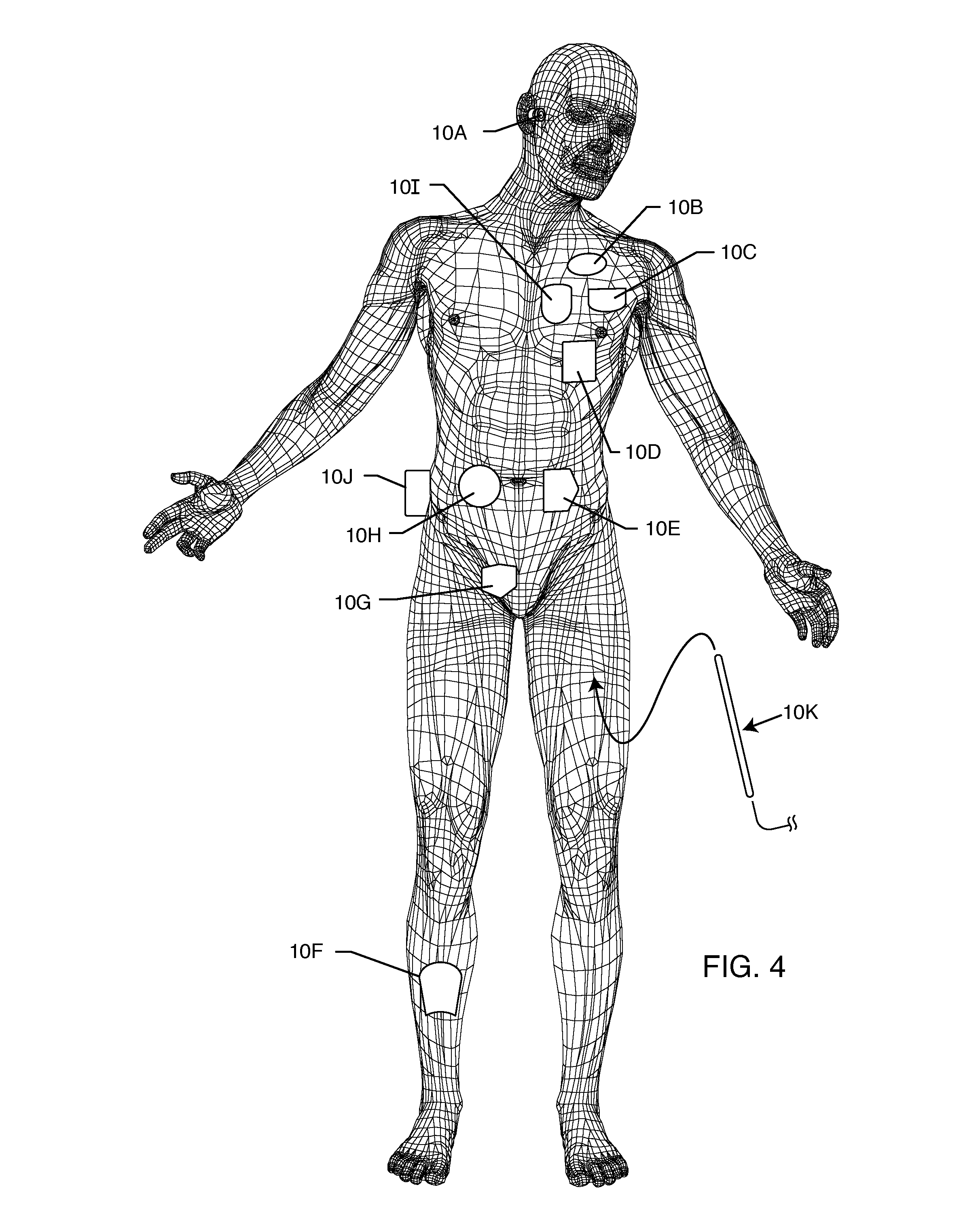

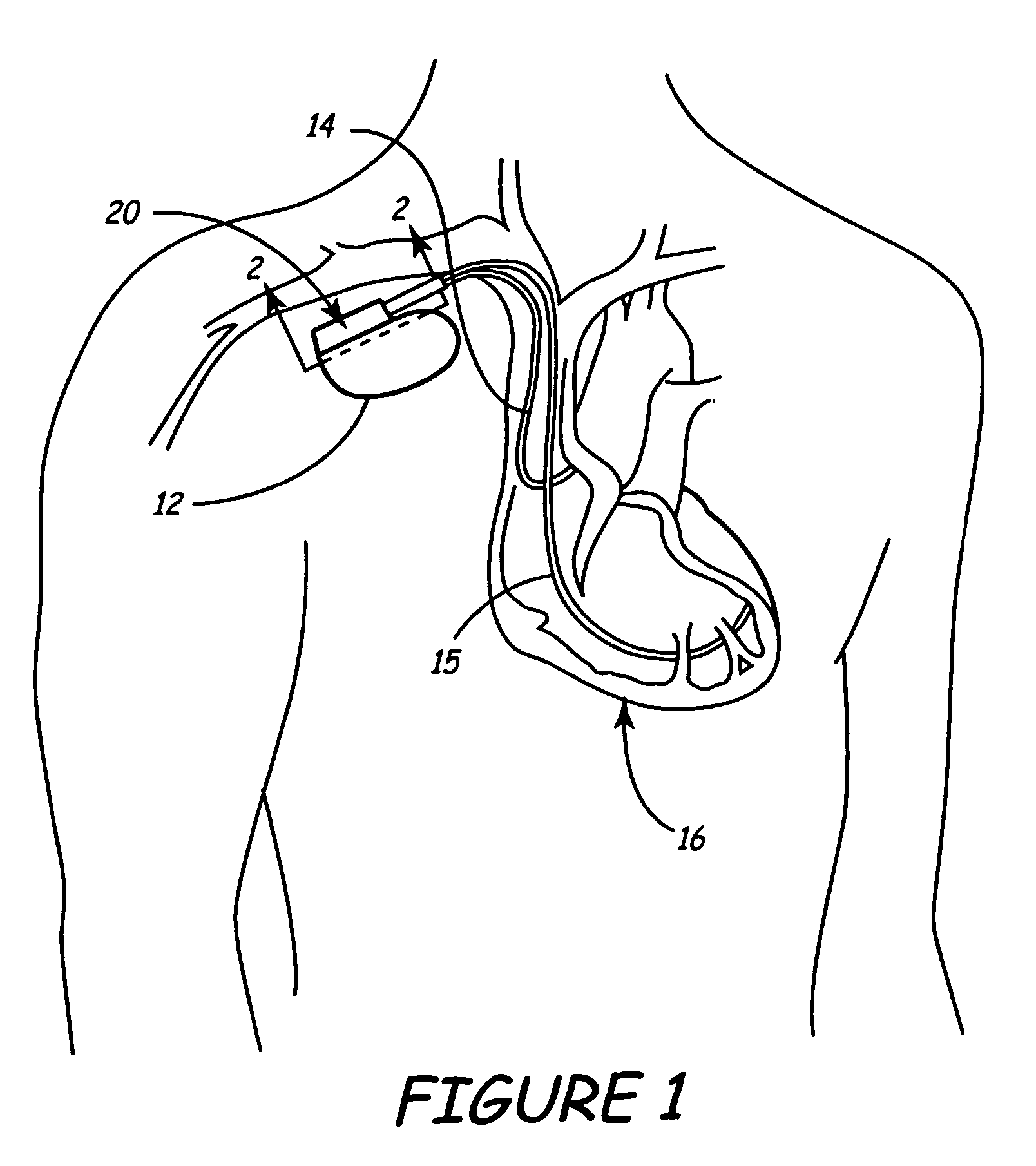

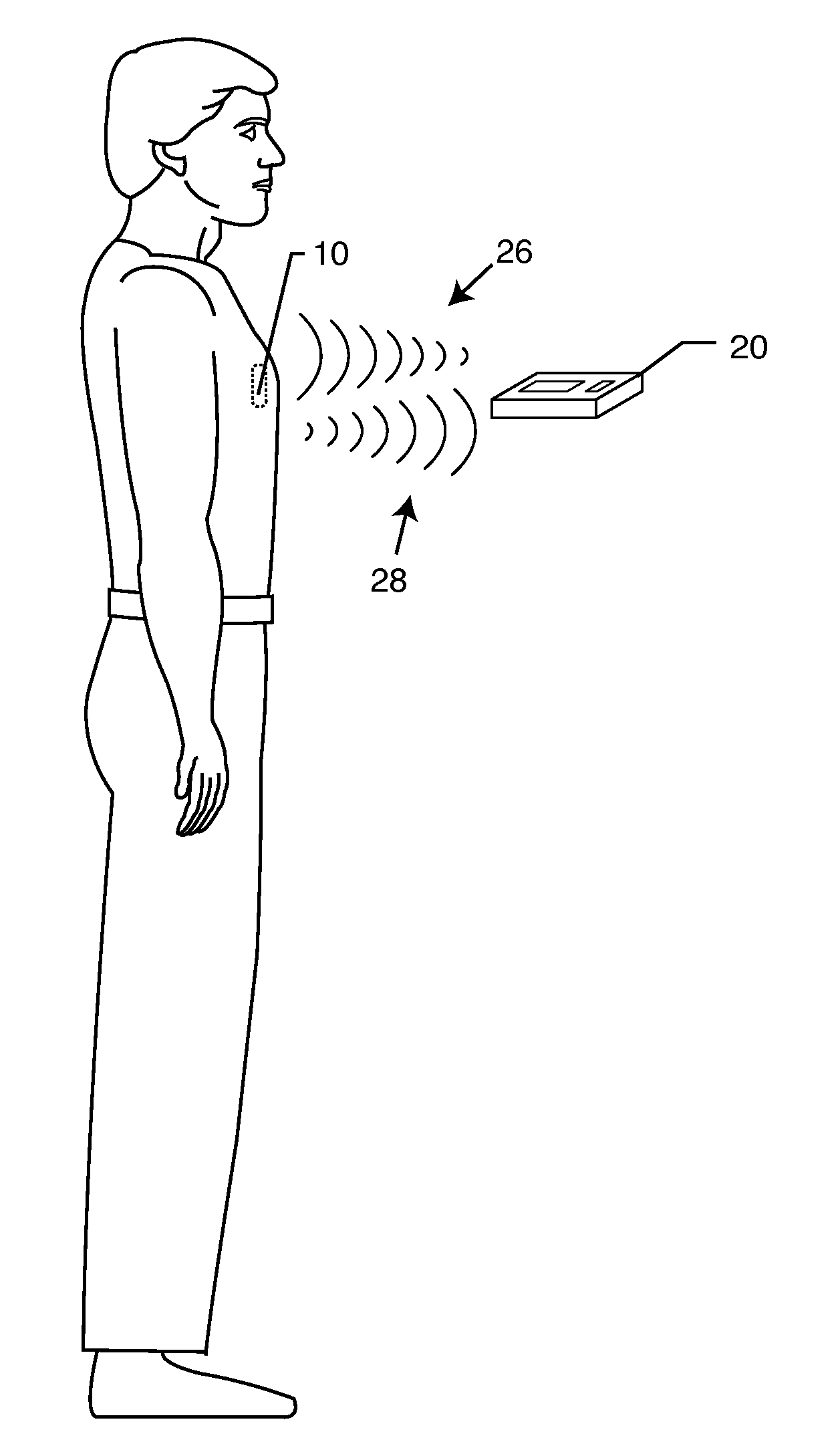

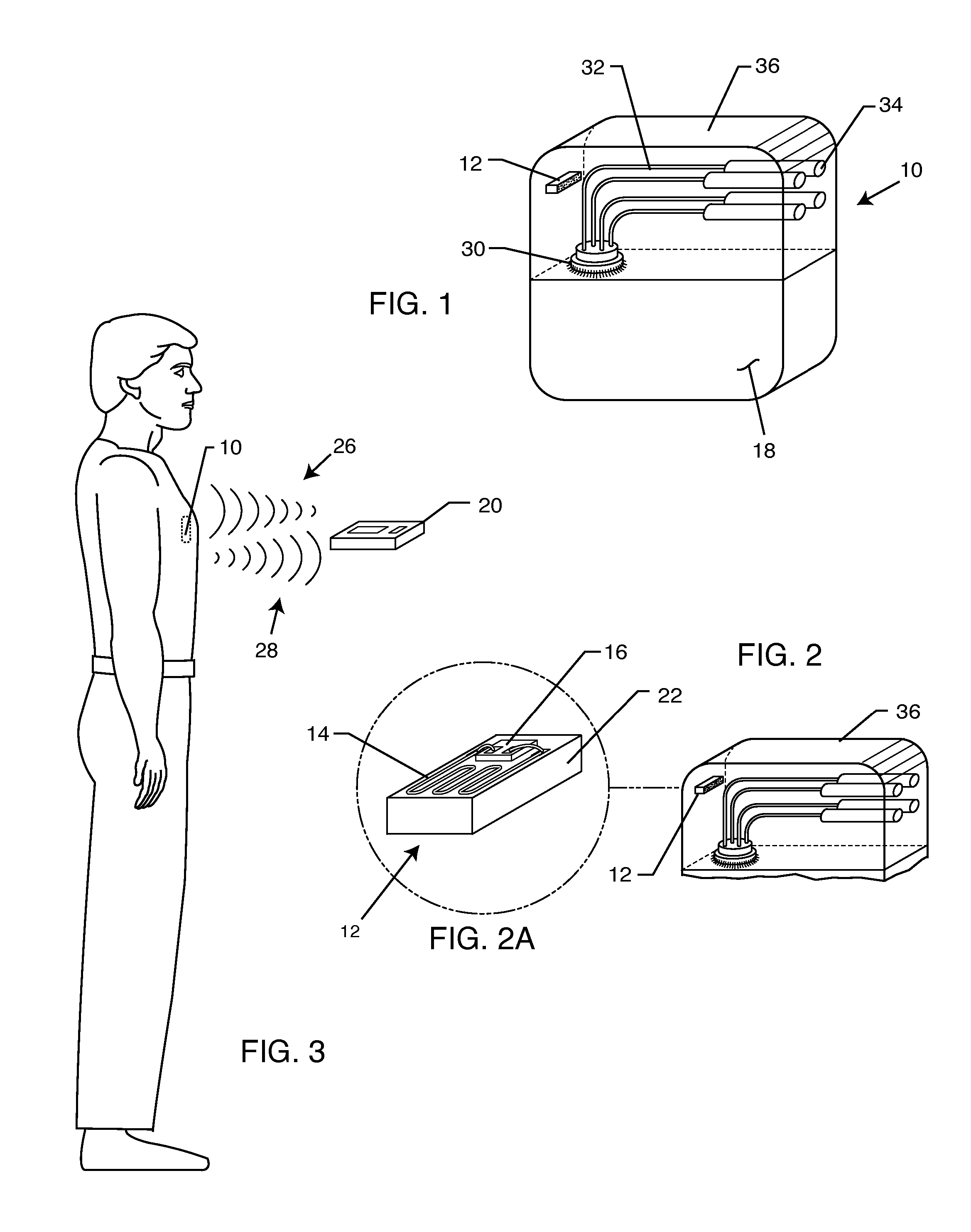

A radio frequency identification (RFID) system for use with active implantable medical devices (AIMD) implanted in a patient comprises an interrogator and an RFID tag comprising a substrate, an RFID chip, and an antenna. The RFID is typically enclosed in a biocompatible and hermetically sealed container comprising a ceramic housing, an end cap and an encapsulant. The RFID tag or sealed container may be affixed to an AIMD or surgically implanted in a patient adjacent to an AIMD. Alternatively, the sealed container may be injected into body tissue by a large needle syringe. The RFID tag may store information about an AIMD including manufacturer, model number and serial number. The RFID tag may also store information about a treating physician and / or patient including the treating physician's name and contact information, the patient's name, contact information, medical condition, treatment and other relevant information.

Owner:WILSON GREATBATCH LTD

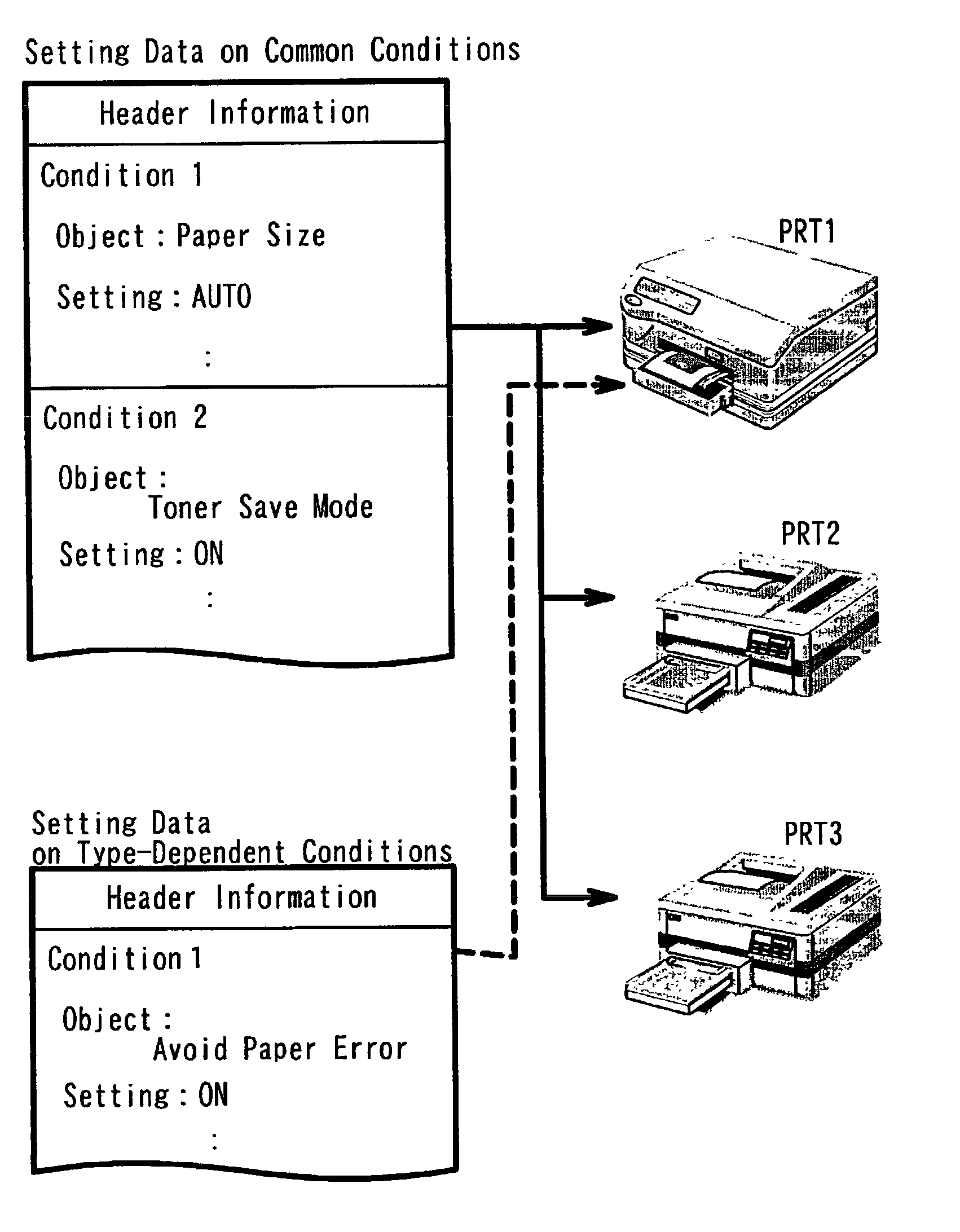

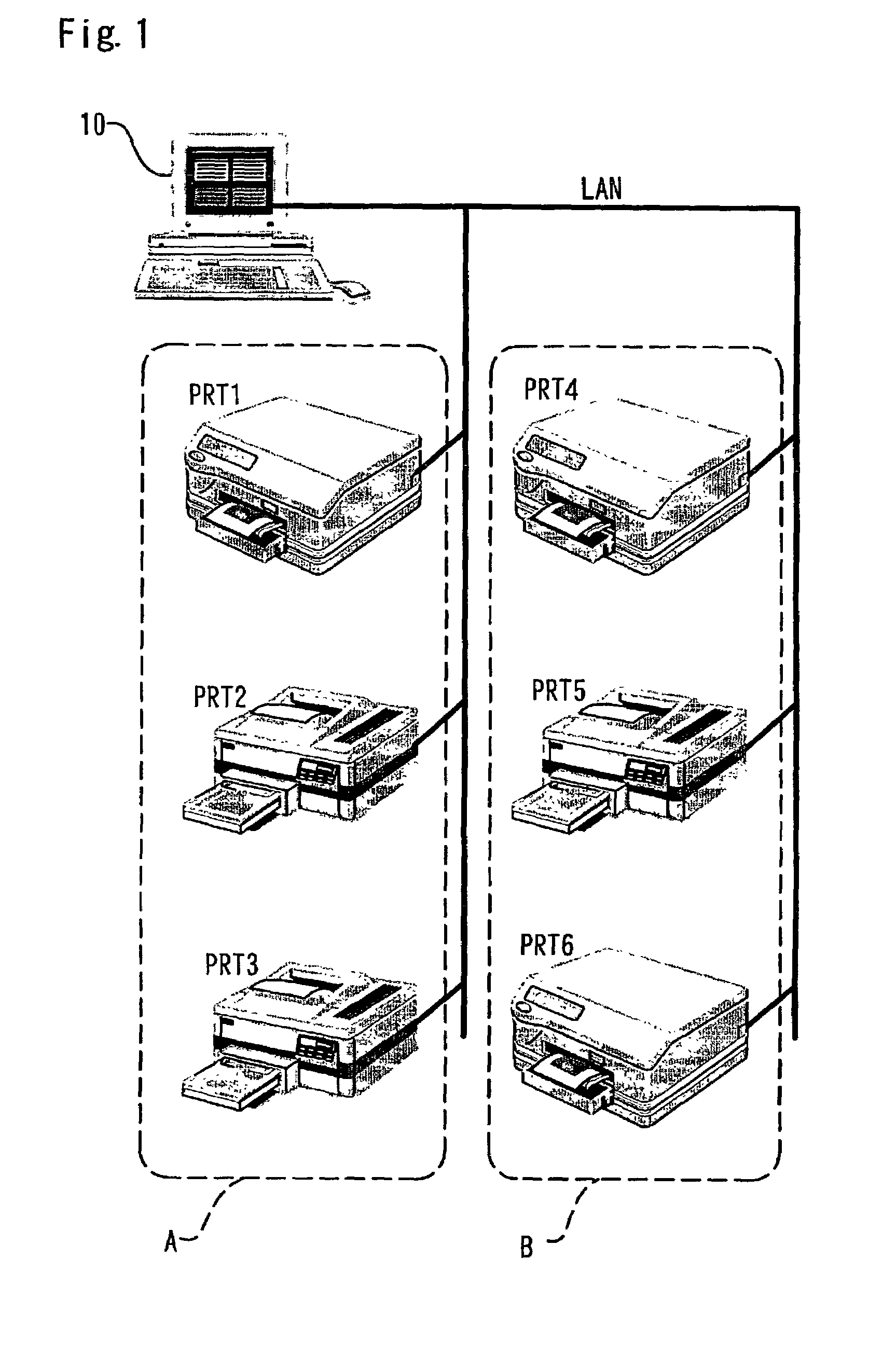

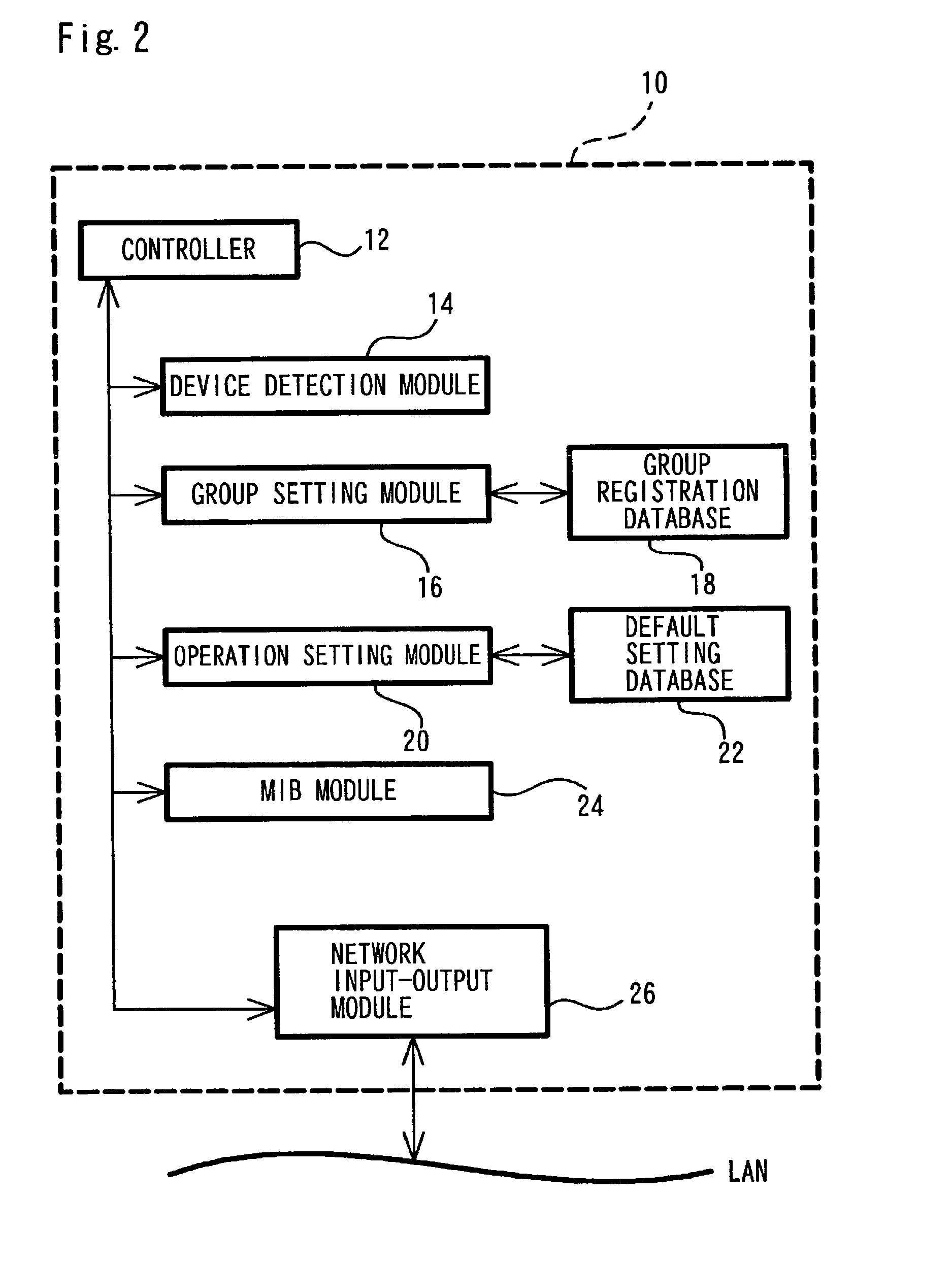

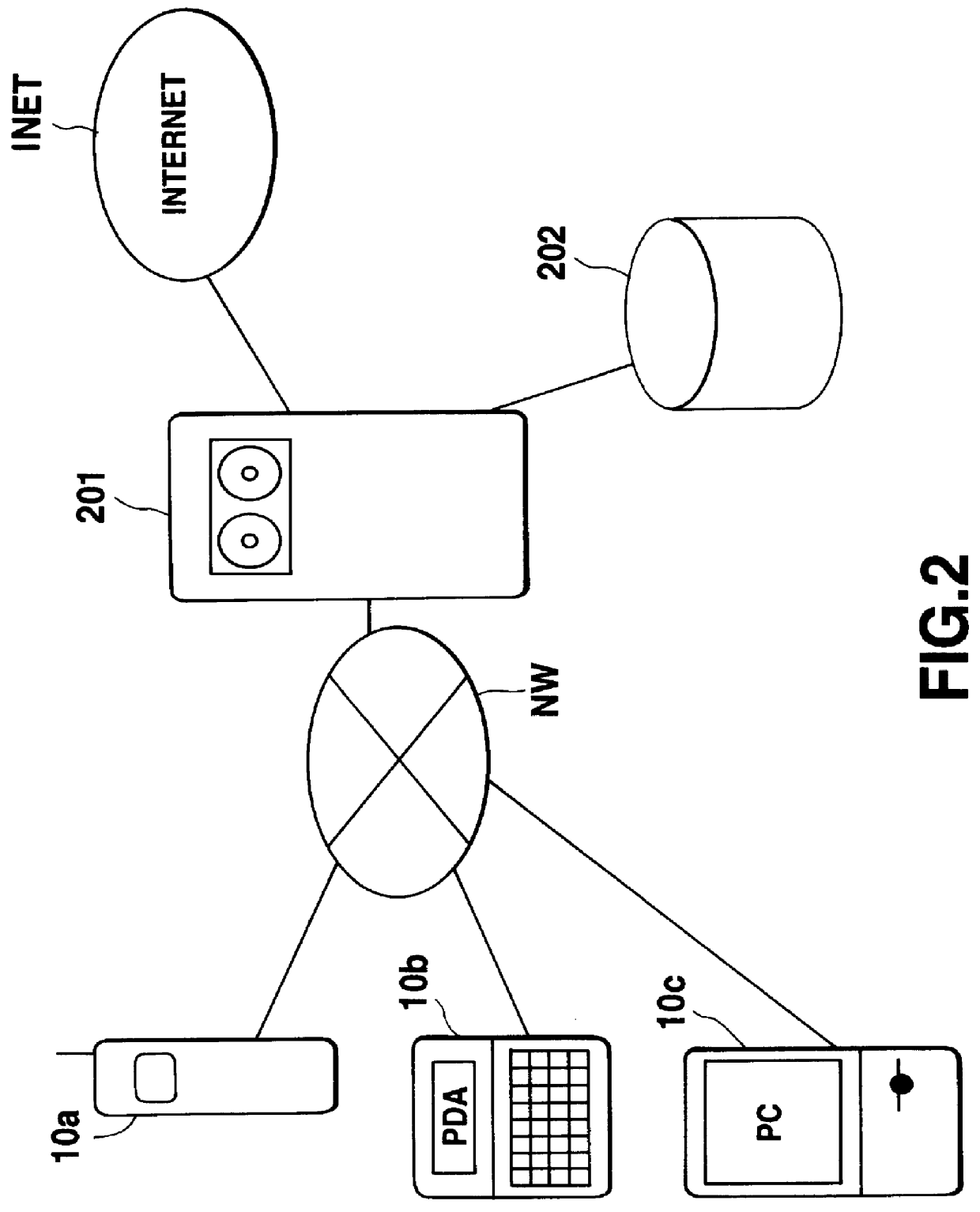

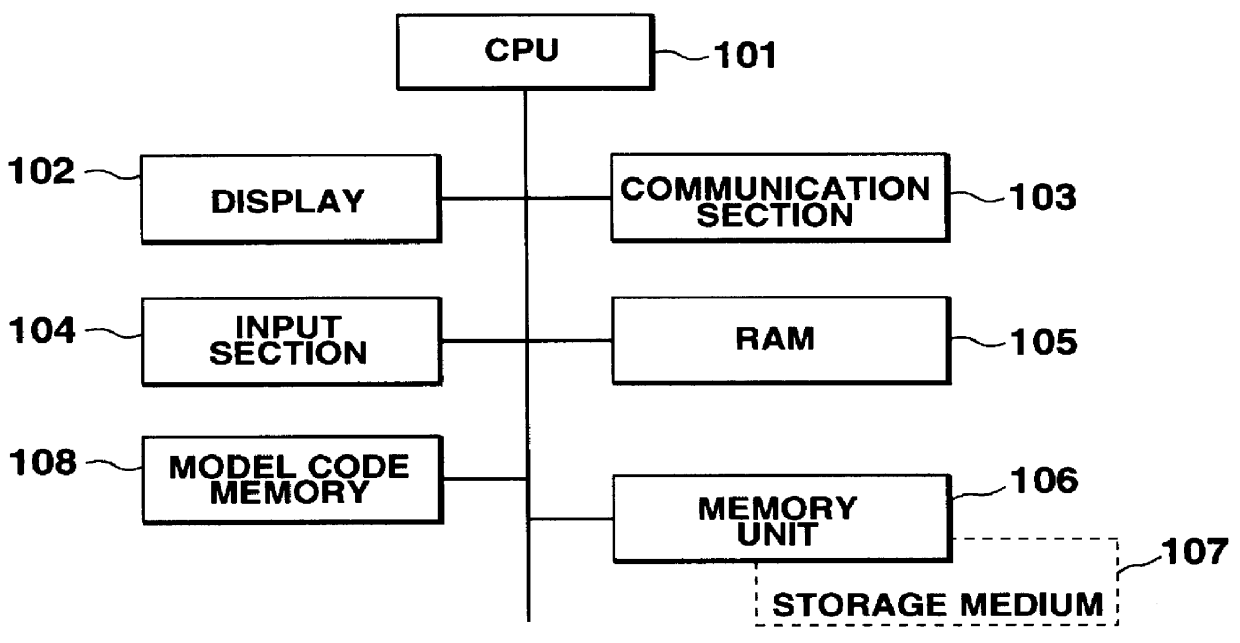

Management system for devices connecting with network

InactiveUS7047088B2Reduce loadDigital computer detailsElectric controllersNetwork connectionModel Number

Owner:SEIKO EPSON CORP

RFID detection and identification system for implantable medical devices

A radio frequency identification (RFID) system for use with active implantable medical devices (AIMD) implanted in a patient comprises an interrogator and an RFID tag comprising a substrate, an RFID chip, and an antenna. The RFID is typically enclosed in a biocompatible and hermetically sealed container comprising a ceramic housing, an end cap and an encapsulant. The RFID tag or sealed container may be affixed to an AIMD or surgically implanted in a patient adjacent to an AIMD. Alternatively, the sealed container may be injected into body tissue by a large needle syringe. The RFID tag may store information about an AIMD including manufacturer, model number and serial number. The RFID tag may also store information about a treating physician and / or patient including the treating physician's name and contact information, the patient's name, contact information, medical condition, treatment and other relevant information.

Owner:WILSON GREATBATCH LTD

RFID detection and identification system for implantable medical lead systems

A system for identifying active implantable medical devices (AIMD) and lead systems implanted in a patient using a radio frequency identification (RFID) tag having retrievable information relating to the AIMD, lead system and / or patient. The RFID tag may store information about the AIMD manufacturer, model number, serial number; lead wire system placement information and manufacturer information; MRI compatibility due to the incorporation of bandstop filters; patient information, and physician and / or hospital information and other relevant information. The RFID tag may be affixed or disposed within the AIMD or lead wires of the lead system, or surgically implanted within a patient adjacent to the AIMD or lead wire system.

Owner:WILSON GREATBATCH LTD

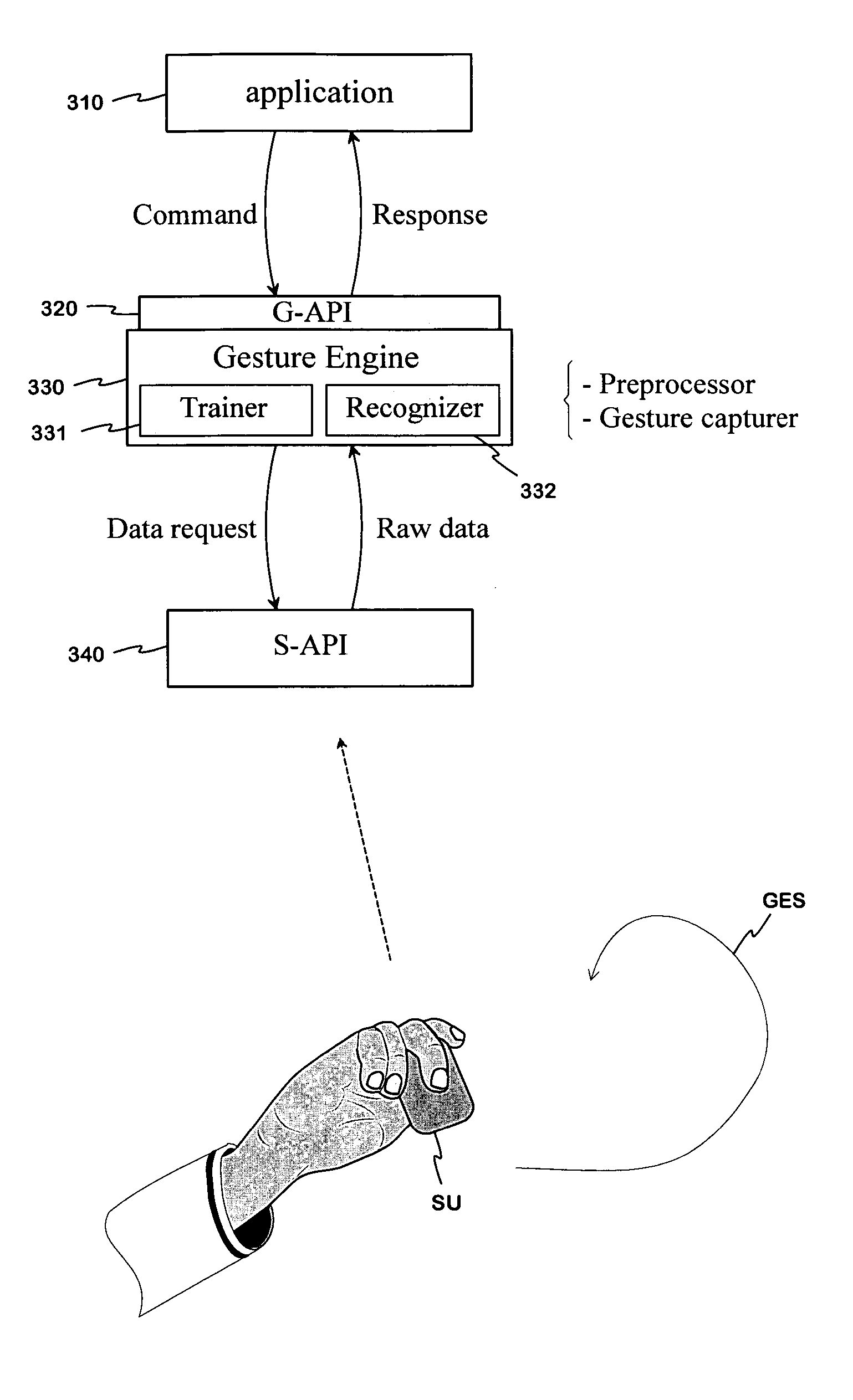

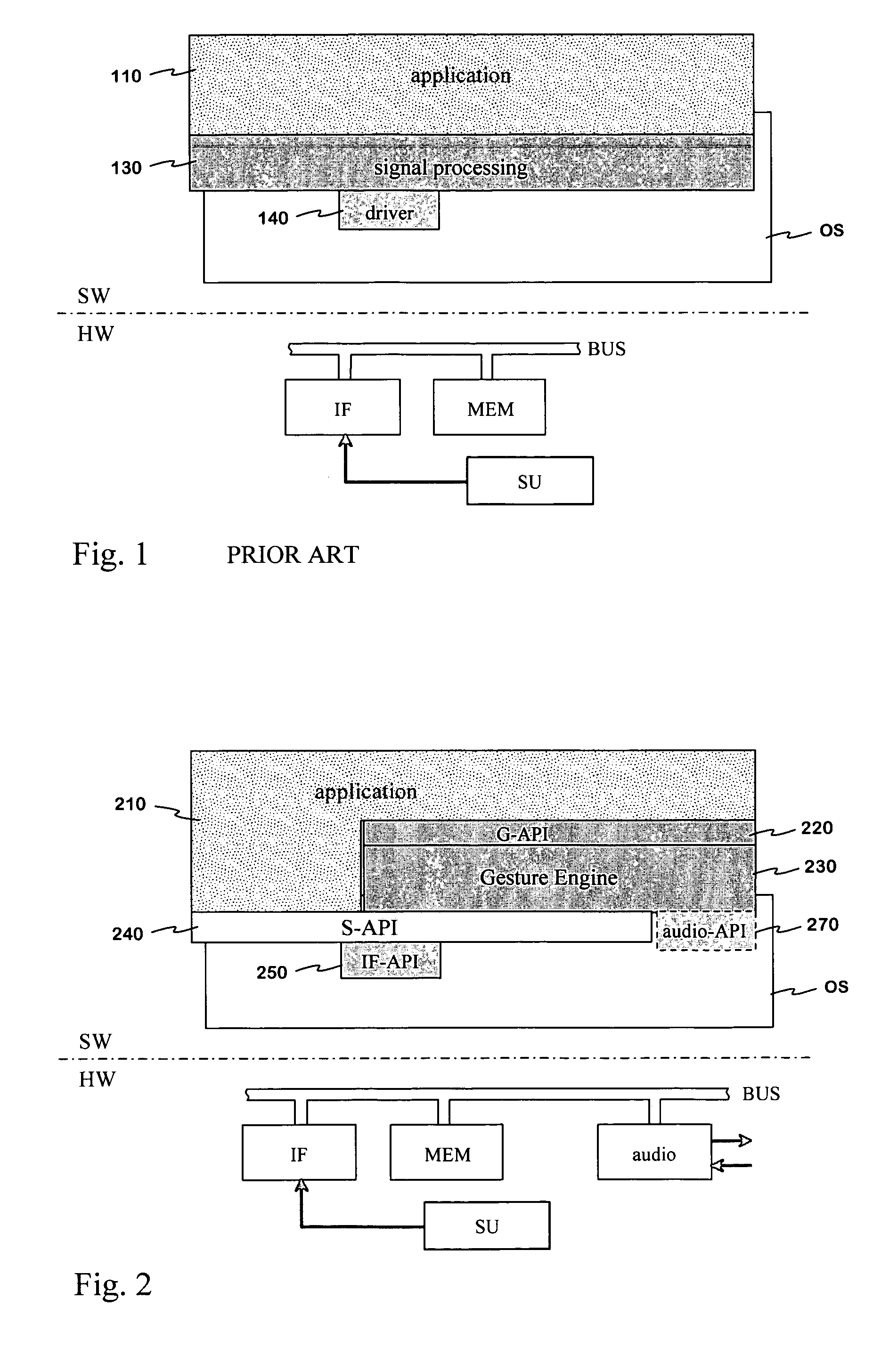

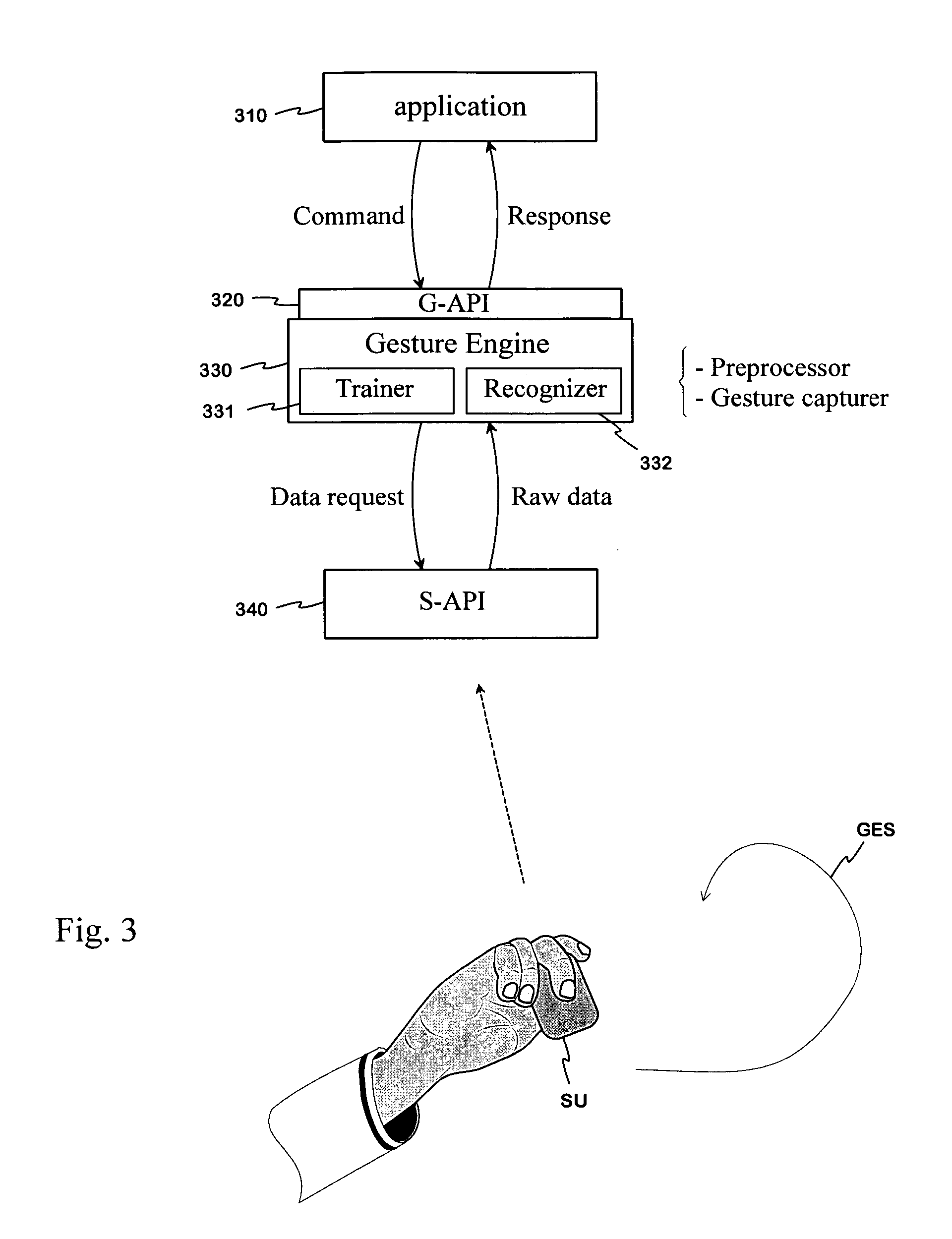

Gesture control system

ActiveUS20050210419A1Easily be formed and put into useRaise the possibilityInput/output for user-computer interactionDigital data processing detailsGeneral purposeControl system

A control system basing on the use of gestures and functioning especially in mobile terminals. The gesture control system is provided with a general purpose interface (320) with its commands for applications (310) to be controlled. The processing software (330) of the gesture signals includes a training program (331), trained free-form gestures made by the user being stored in the gesture library, and a recognizing program (332), which matches a gesture made by the user to the stored gestures and chooses the most similar gesture thereof. Gestures can hence be used as commands for controlling any application configured or programmed to receive the command. One and the same application functions in different models of mobile terminals without matching, and in a certain mobile terminal all applications can be run, which applications use specified interface commands. The application (310) can be e.g. a game or activity being included in basic implementation of a mobile terminal.

Owner:NOKIA TECHNOLOGLES OY

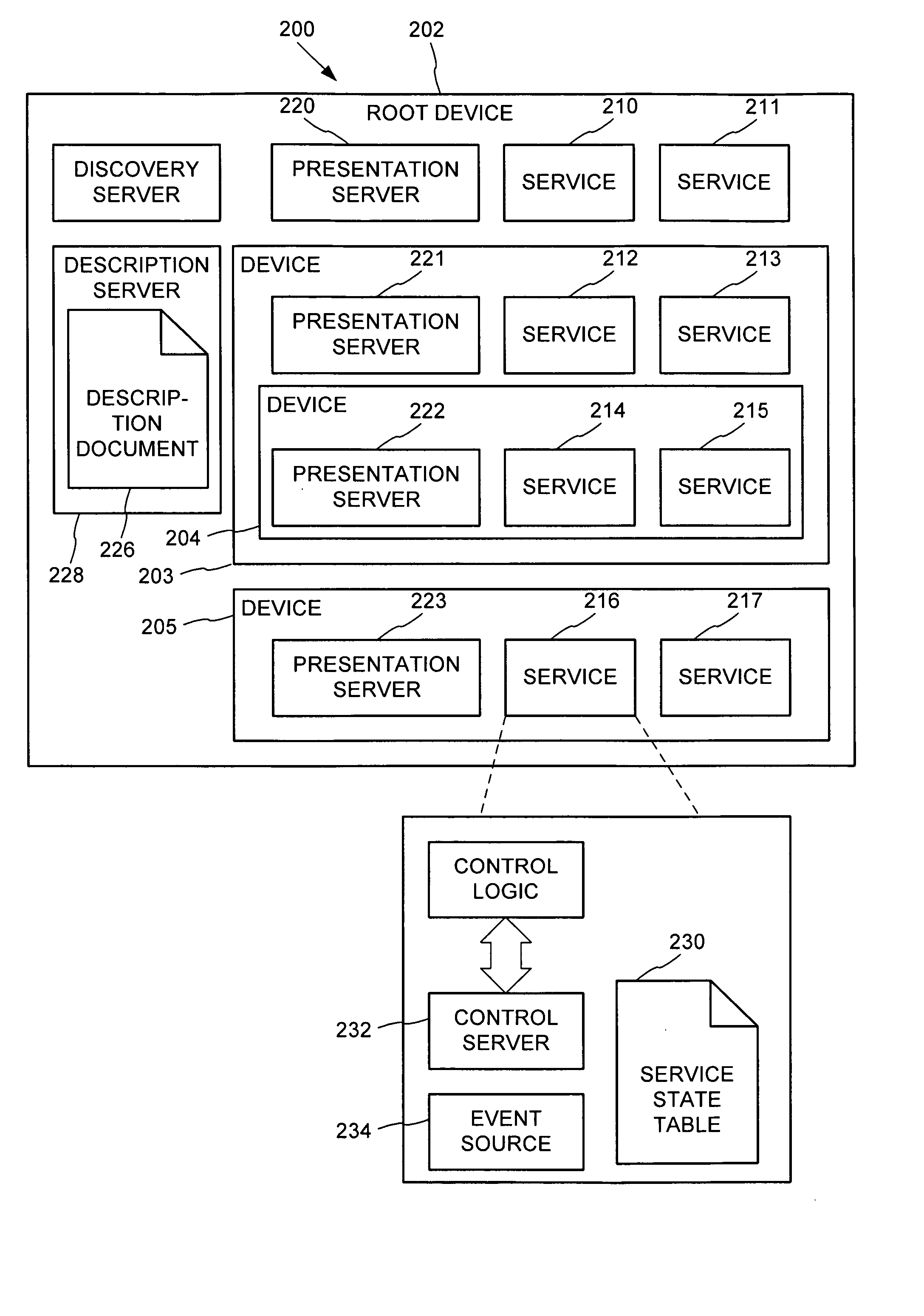

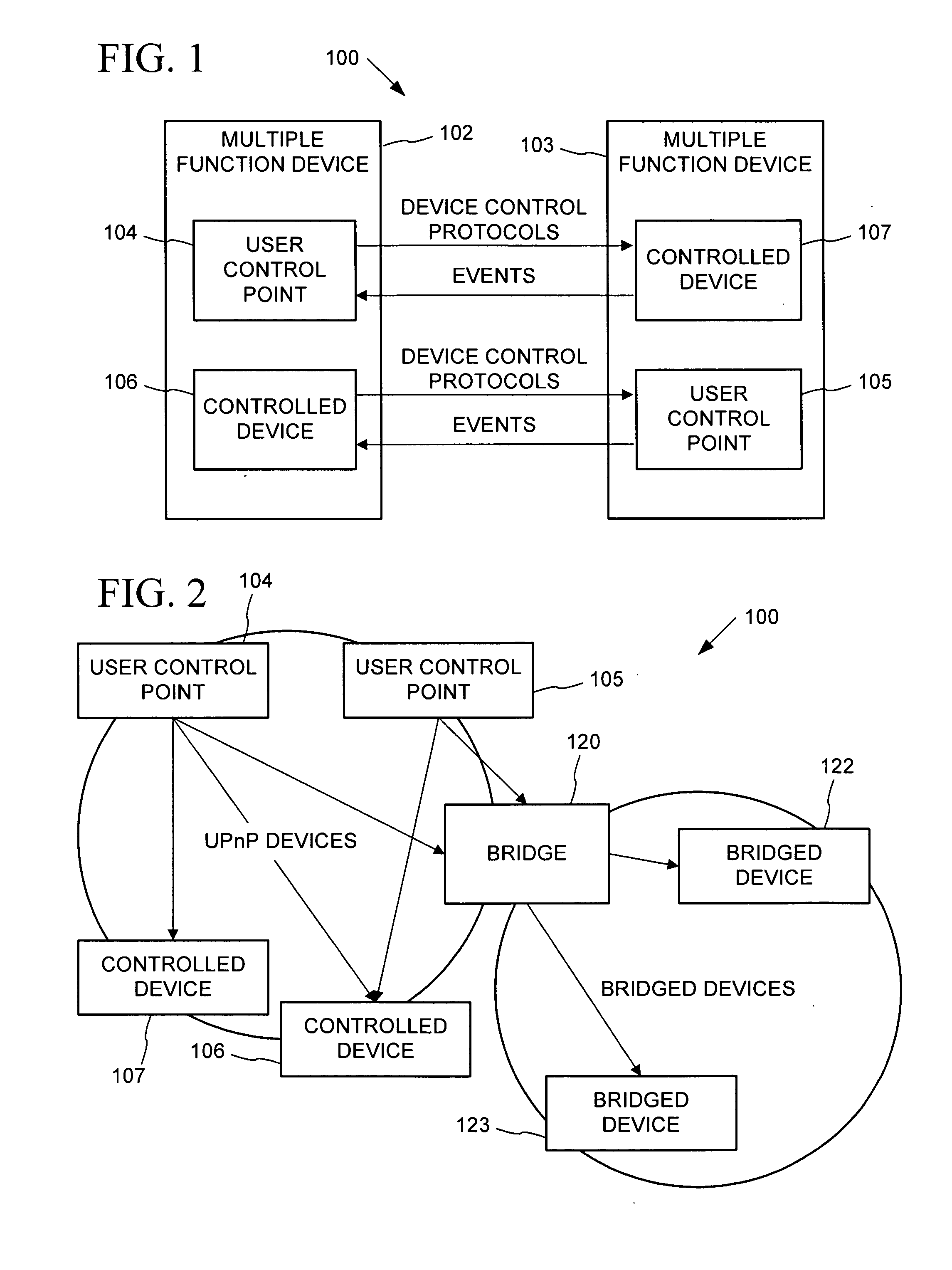

XML-based template language for devices and services

InactiveUS20050097503A1CostConnectivity solutionDigital computer detailsNetworks interconnectionWeb siteProgramming language

A universal plug and play (UPnP) device makes itself known through a set of processes—discovery, description, control, eventing, and presentation. Following discovery of a UPnP device, an entity can learn more about the device and its capabilities by retrieving the device's description. The description includes vendor-specific manufacturer information like the model name and number, serial number, manufacturer name, URLs to vendor-specific Web sites, etc. The description also includes a list of any embedded devices or services, as well as URLs for control, eventing, and presentation. The description is written by a vendor, and is usually based on a device template produced by a UPnP forum working committee. The template is derived from a template language that is used to define elements to describe the device and any services supported by the device. The template language is written using an XML-based syntax that organizes and structures the elements.

Owner:ROVI TECH CORP

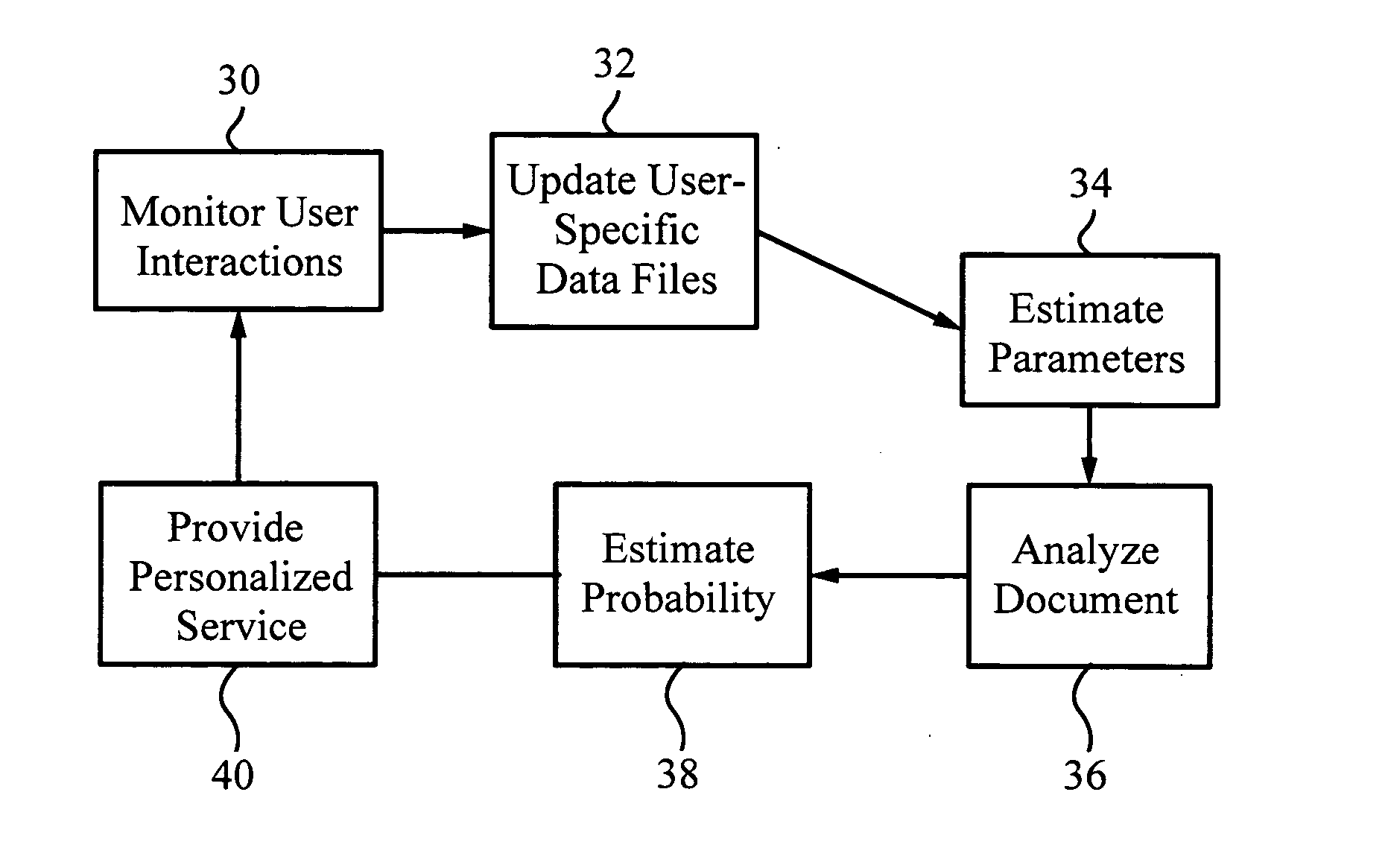

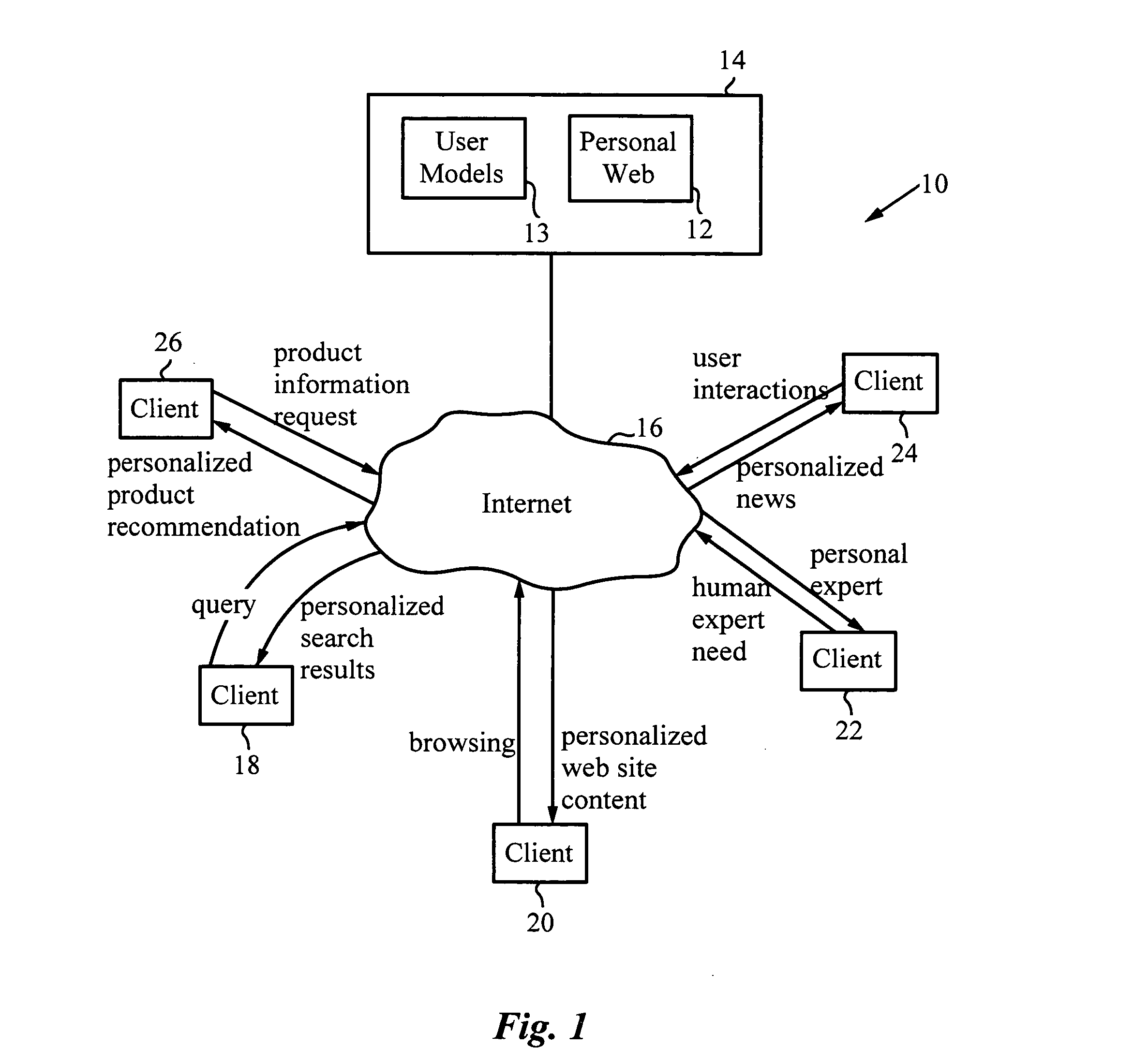

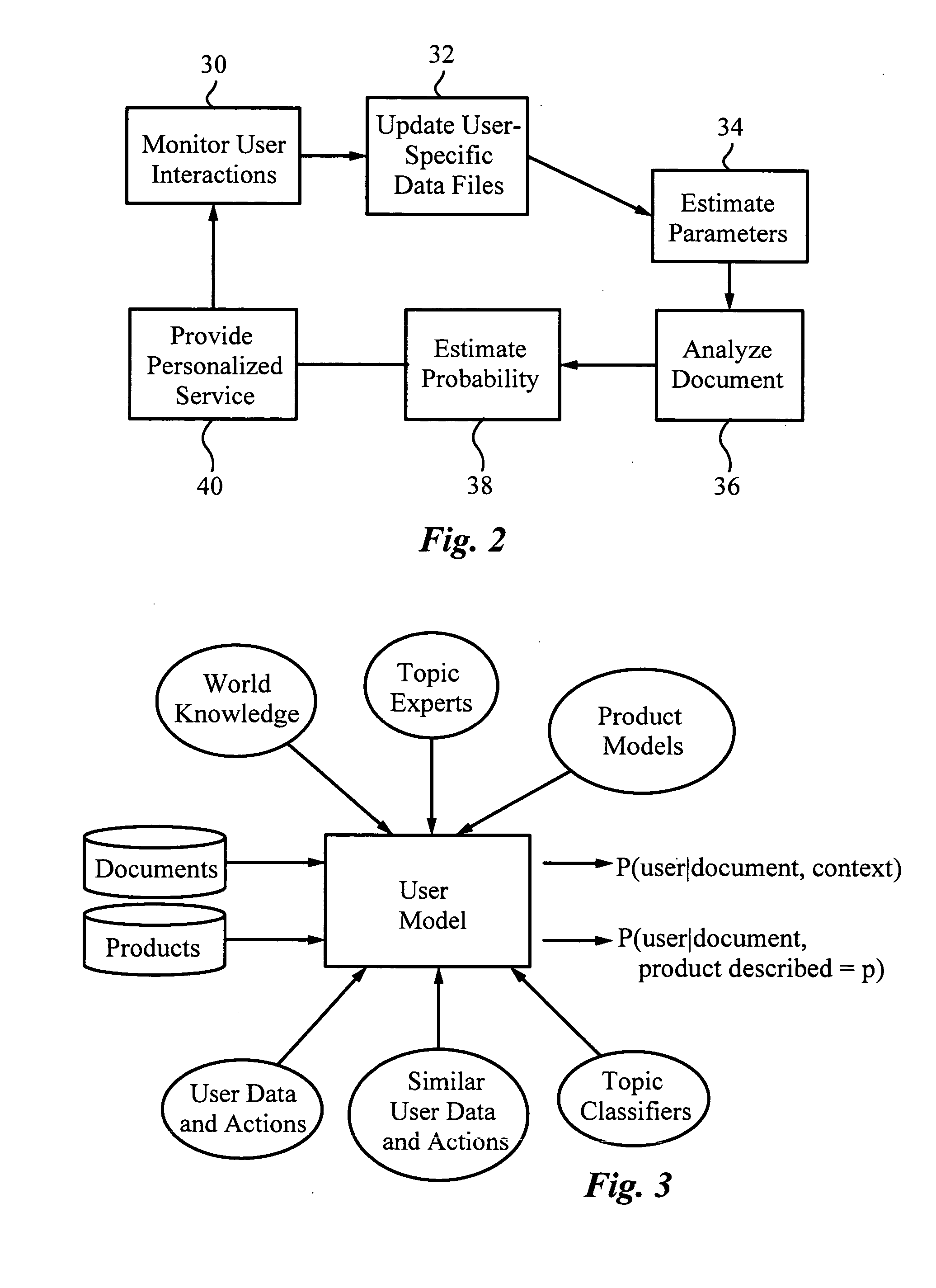

Automatic, personalized online information and product services

InactiveUS20060136589A1Digital data information retrievalDigital computer detailsLearning machineComputer users

Owner:PERSONALIZED USER MODEL PUM

XML-based template language for devices and services

InactiveUS20050074018A1Falling in priceIncrease speedDigital computer detailsNetworks interconnectionWeb siteProgramming language

A universal plug and play (UPnP) device makes itself known through a set of processes—discovery, description, control, eventing, and presentation. Following discovery of a UPnP device, an entity can learn more about the device and its capabilities by retrieving the device's description. The description includes vendor-specific manufacturer information like the model name and number, serial number, manufacturer name, URLs to vendor-specific Web sites, etc. The description also includes a list of any embedded devices or services, as well as URLs for control, eventing, and presentation. The description is written by a vendor, and is usually based on a device template produced by a UPnP forum working committee. The template is derived from a template language that is used to define elements to describe the device and any services supported by the device. The template language is written using an XML-based syntax that organizes and structures the elements.

Owner:ROVI TECH CORP

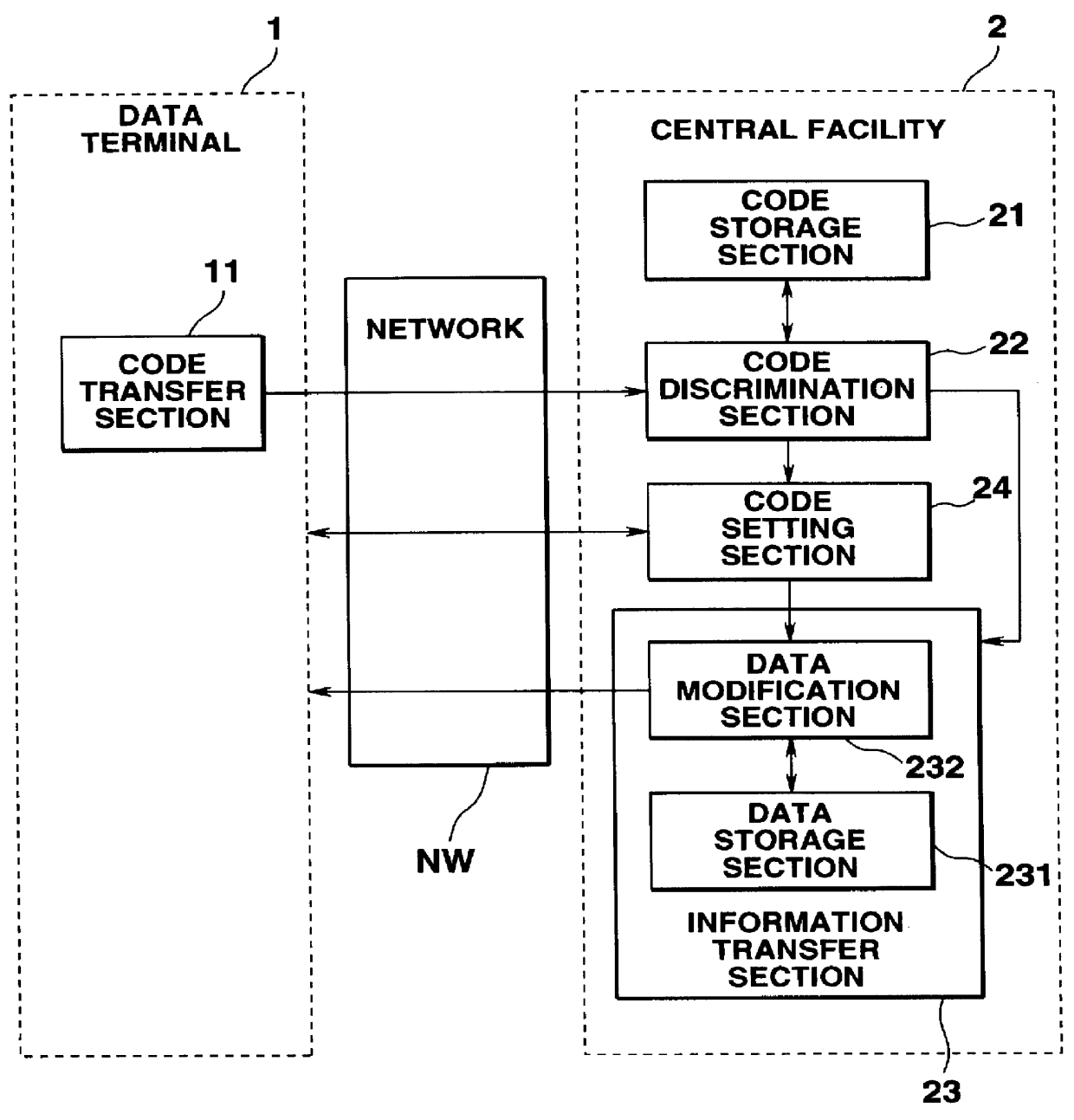

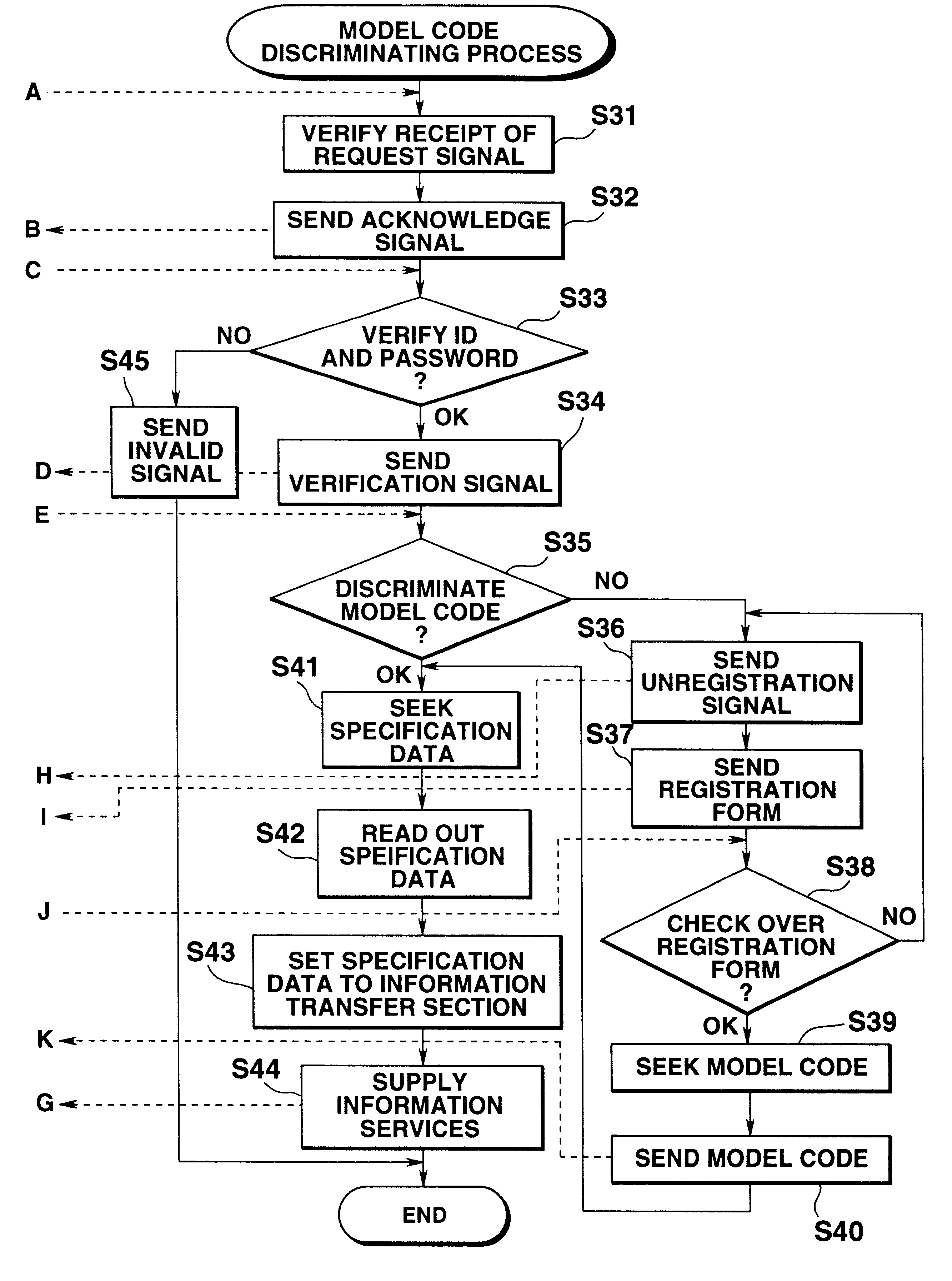

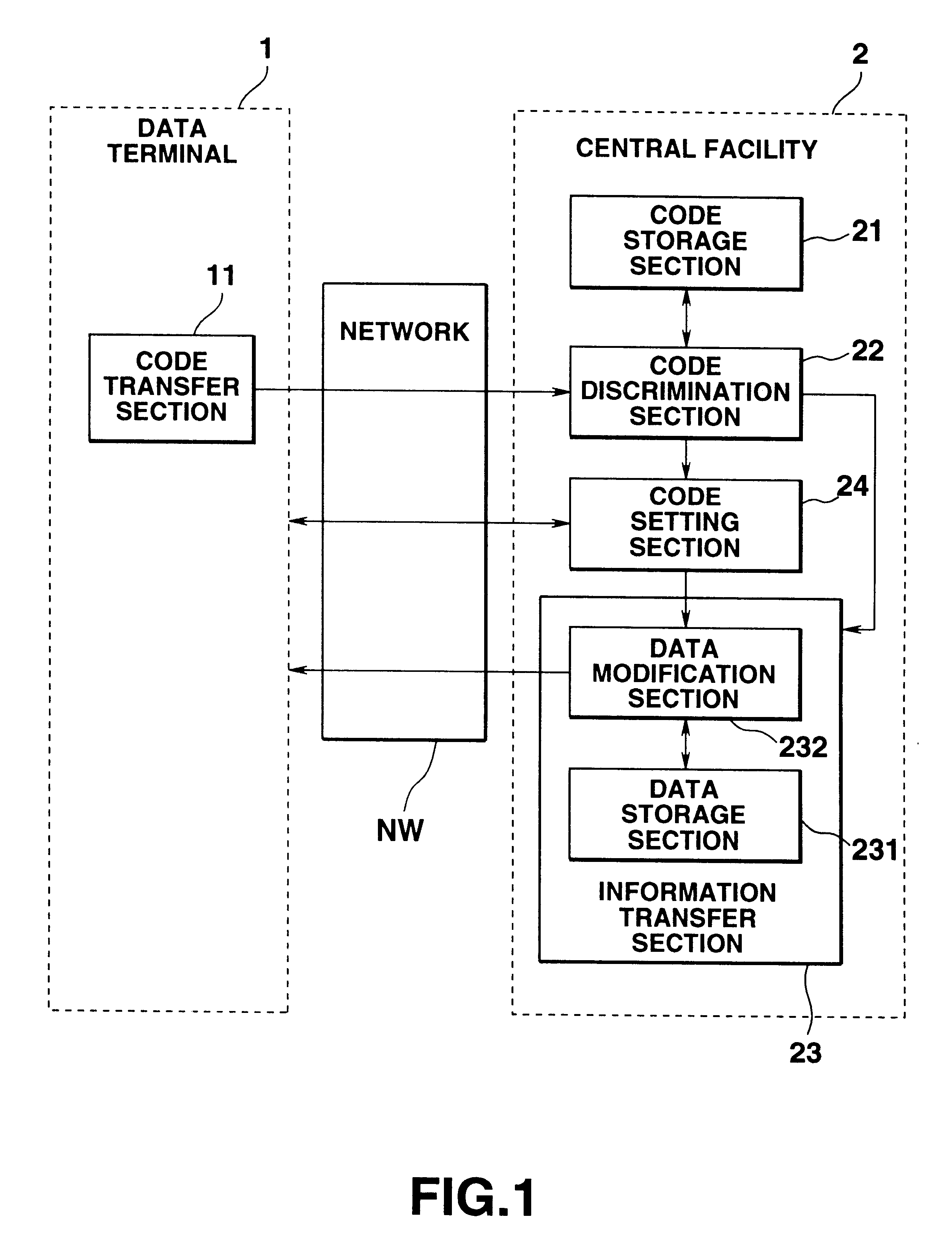

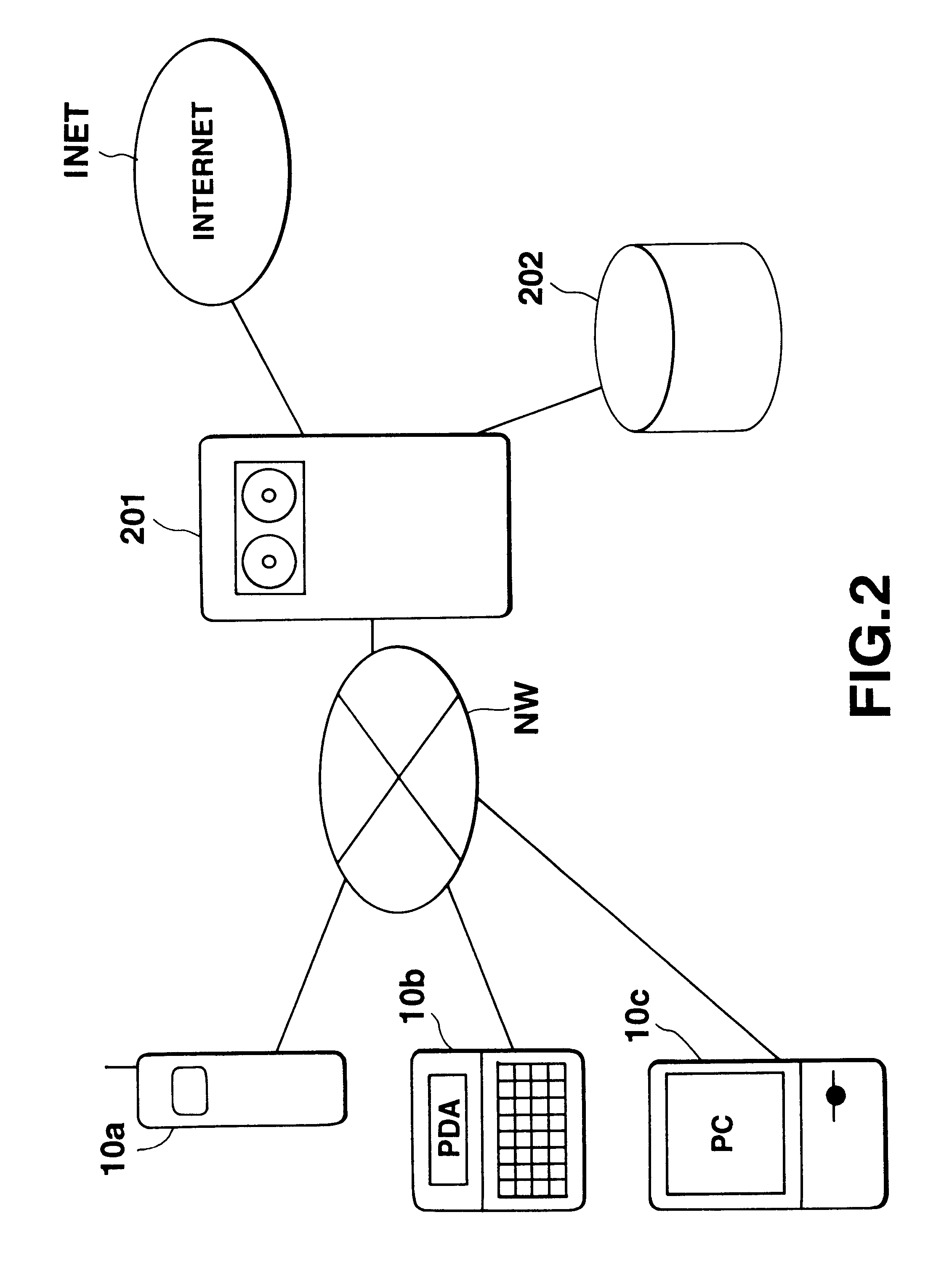

System for transferring information between a server and a data terminal through a network

InactiveUS6161140ADigital data information retrievalMultiple digital computer combinationsData Terminal ReadyData terminal

An information transfer system which includes a data terminal capable of connecting to networks and a central facility capable of connecting to a plurality of the data terminals which may differ from each other in their capabilities and / or features through the network. The data terminal has a model code which indicates its capabilities and / or features and sends the model code to the central facility at every time the data terminal connects to the central facility. The central facility discriminates the model code sent from the data terminal and detects the capabilities and / or the features of the data terminal. Further, the central facility sends information to the data terminal in a manner appropriate to the capabilities and / or features of the data terminal.

Owner:CASIO COMPUTER CO LTD

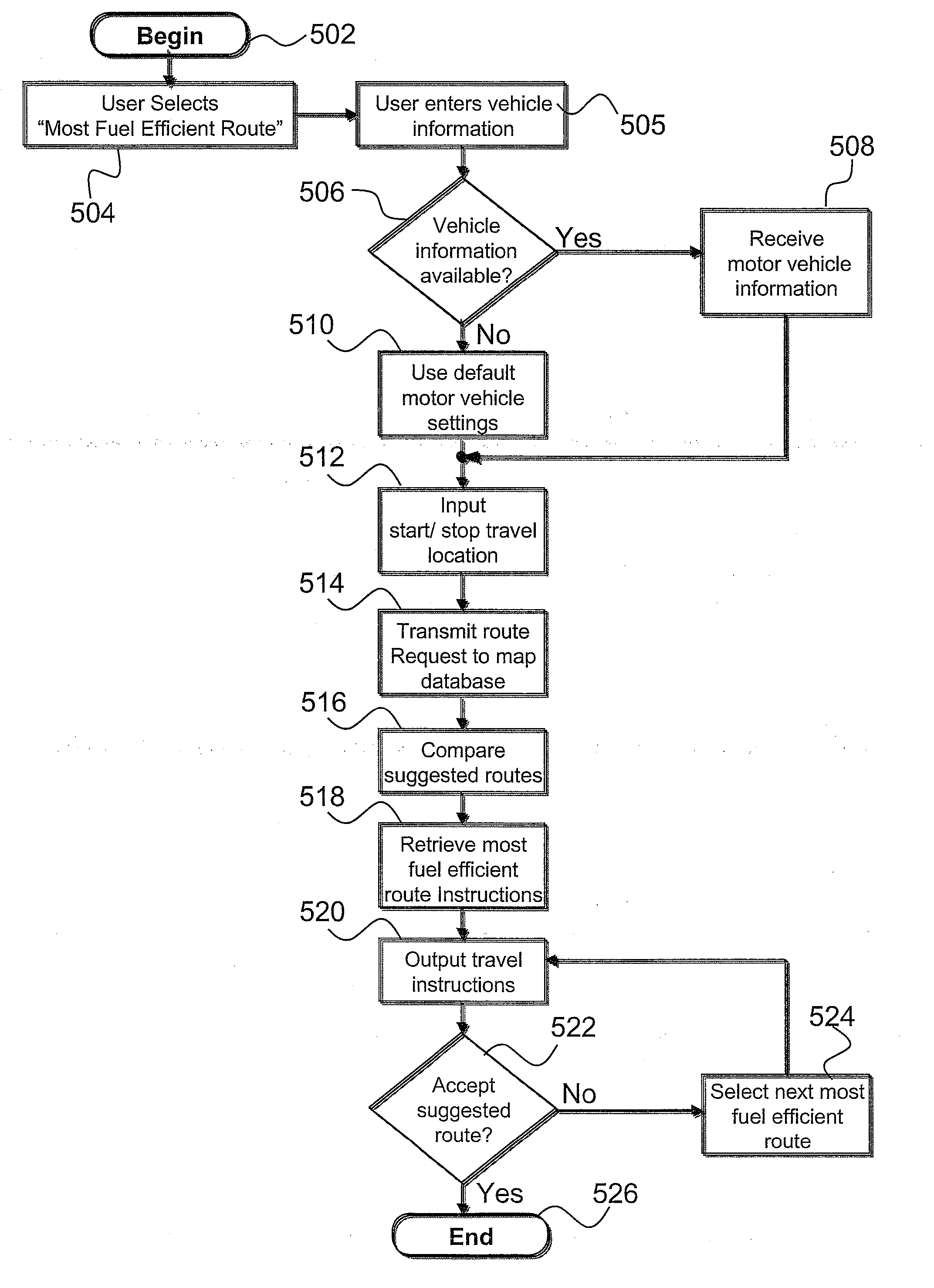

Method for determining and outputting travel instructions for most fuel-efficient route

InactiveUS20080133120A1Improve efficiencyAnalogue computers for vehiclesInstruments for road network navigationTerrainFuel efficiency

A method provides a sequence of travel instructions that reports fuel-efficient routes calculated with regard to vehicle specifications, geography of terrain, and complexity of travel route. An operator selects the desired starting and ending location via a client interface of a software application. When the user selects “most fuel efficient route,” the fuel-efficient route (FER) utility of the application prompts for entry of the make, model, and year of the operator's vehicle. If the FER utility is embedded in an in-car navigation system, the information about the vehicle characteristics is preprogrammed during installation (e.g., at the factory). The FER utility uses a number of metrics and the vehicle's characteristics, to generate an optimal route for efficient fuel consumption. The invention provides means for an operator of a route planning application to optimize the driving directions for optimally predicted fuel usage.

Owner:IBM CORP

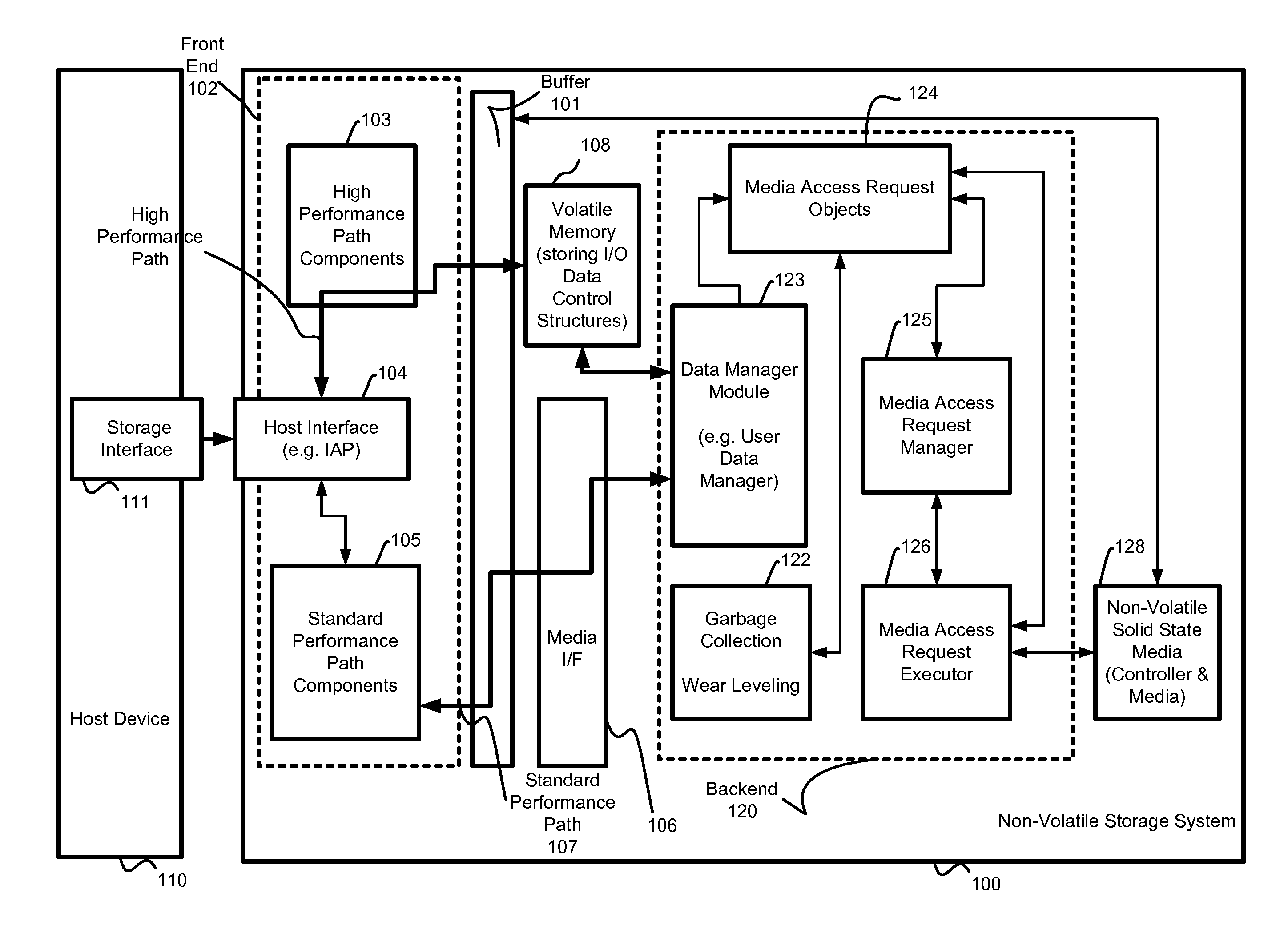

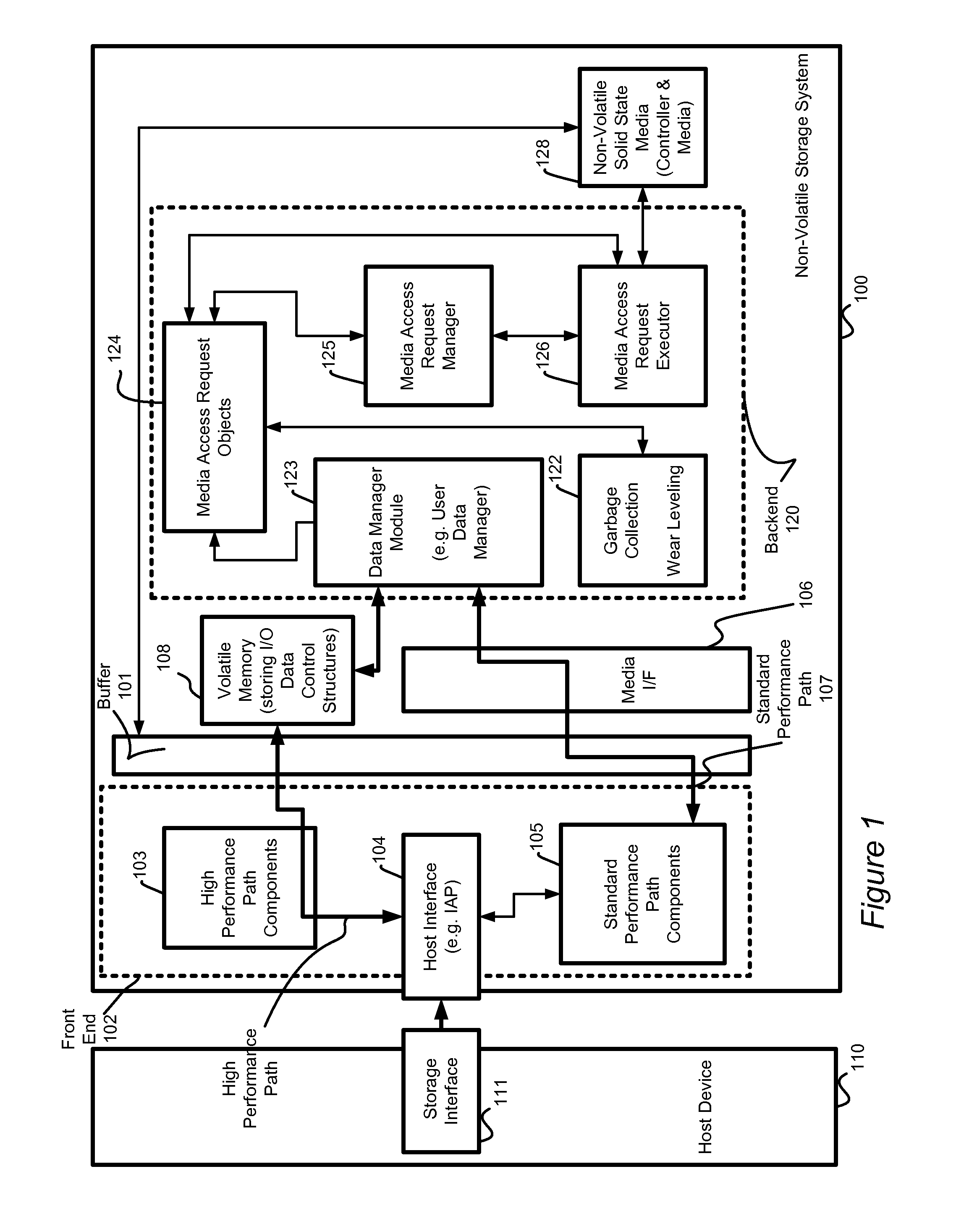

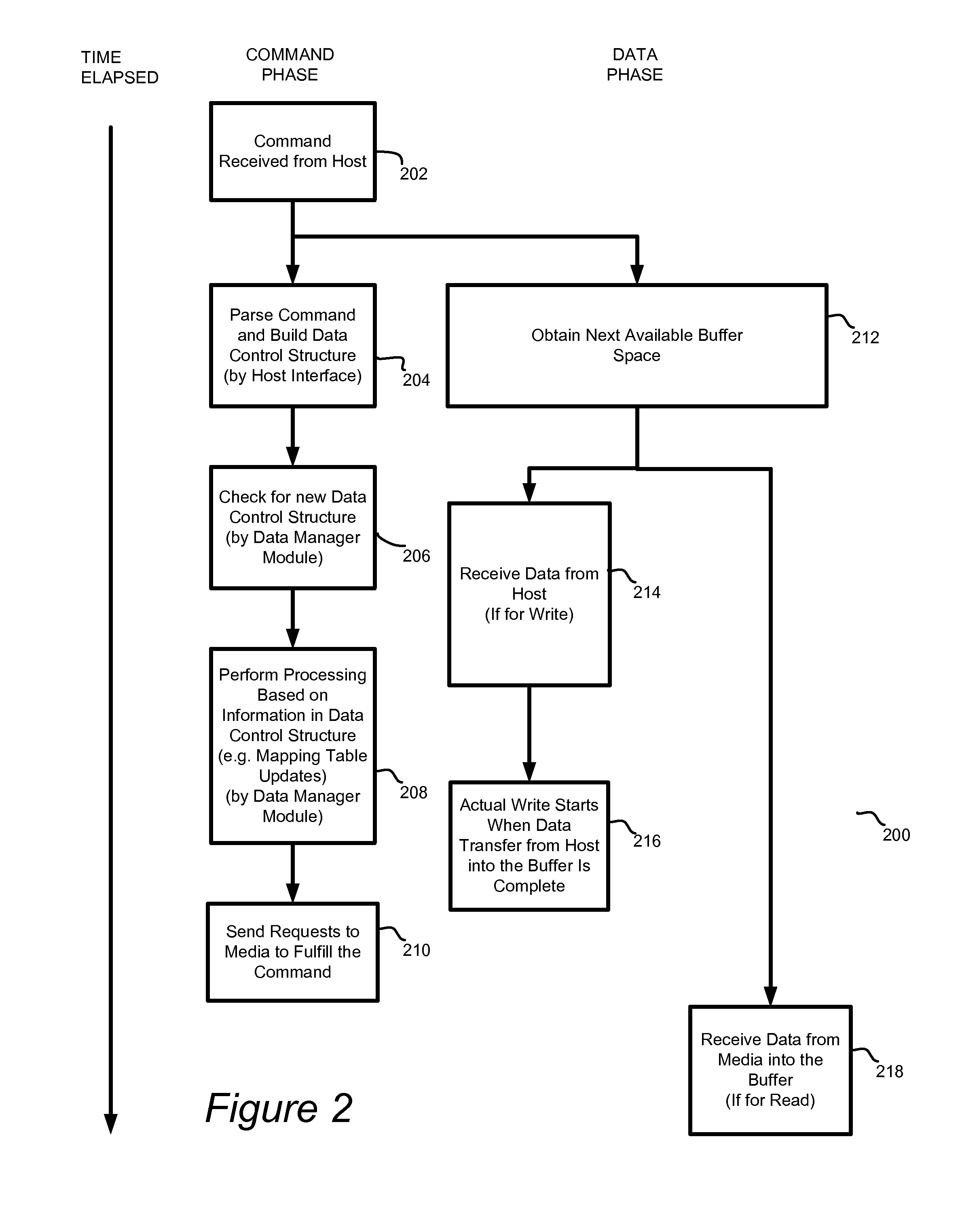

System and method for high performance command processing in solid state drives

ActiveUS8423722B1Improve performanceHigh bandwidthMemory architecture accessing/allocationMemory systemsHard disc driveHigh bandwidth

Solid State Drives (SSD) can yield very high performance if it is designed properly. A SSD typically includes both a front end that interfaces with the host and a back end that interfaces with the flash media. Typically SSDs include flash media that is designed with a high degree of parallelism that can support a very high bandwidth on input / output (I / O). A SSD front end designed according to a traditional hard disk drive (HDD) model will not be able to take advantage of the high performance offered by the typical flash media. Embodiments of the invention provide improved management of multiple I / O threads that take advantage of the high performing and concurrent nature of the back end media, so the resulting storage system can achieve a very high performance.

Owner:WESTERN DIGITAL TECH INC

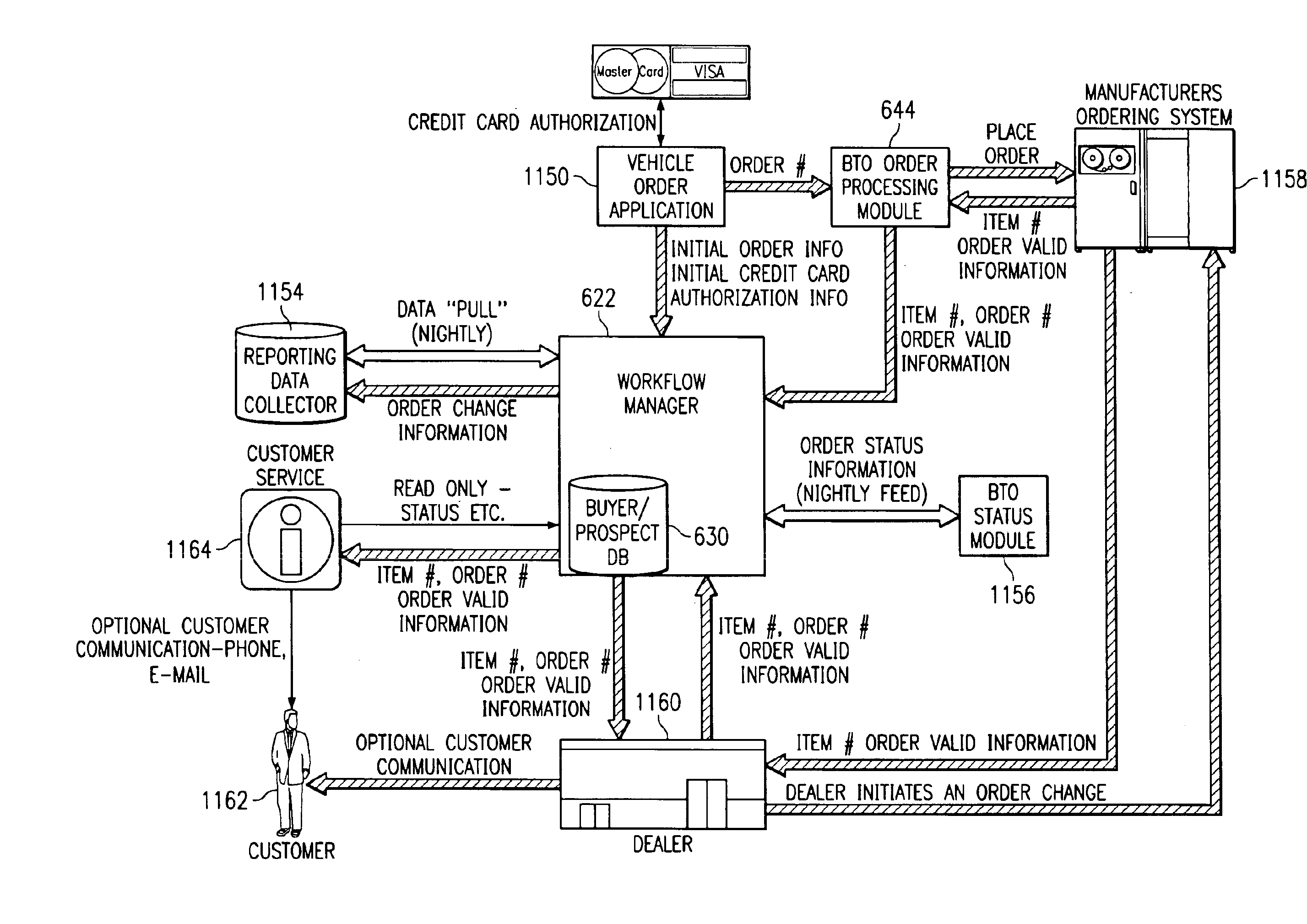

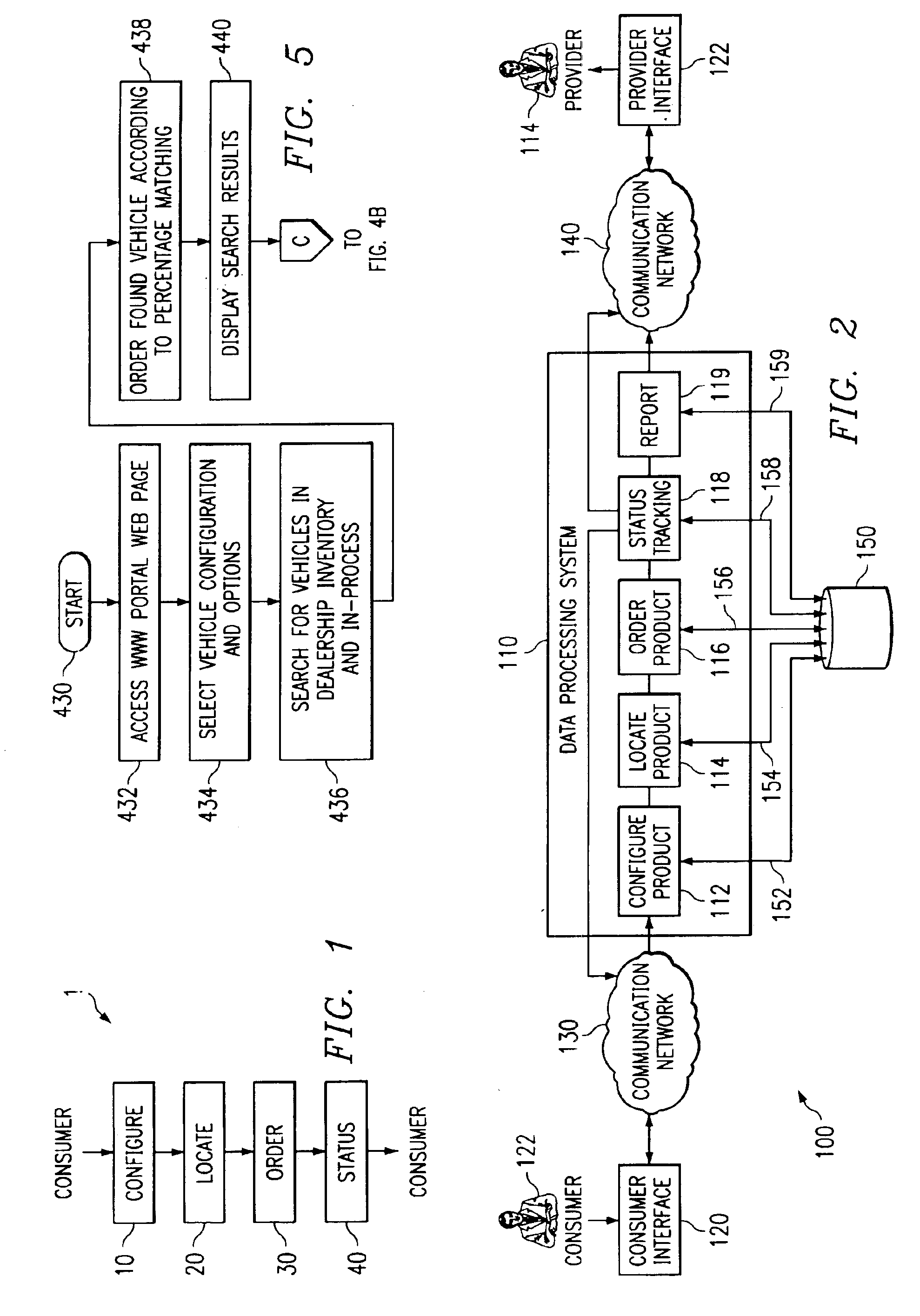

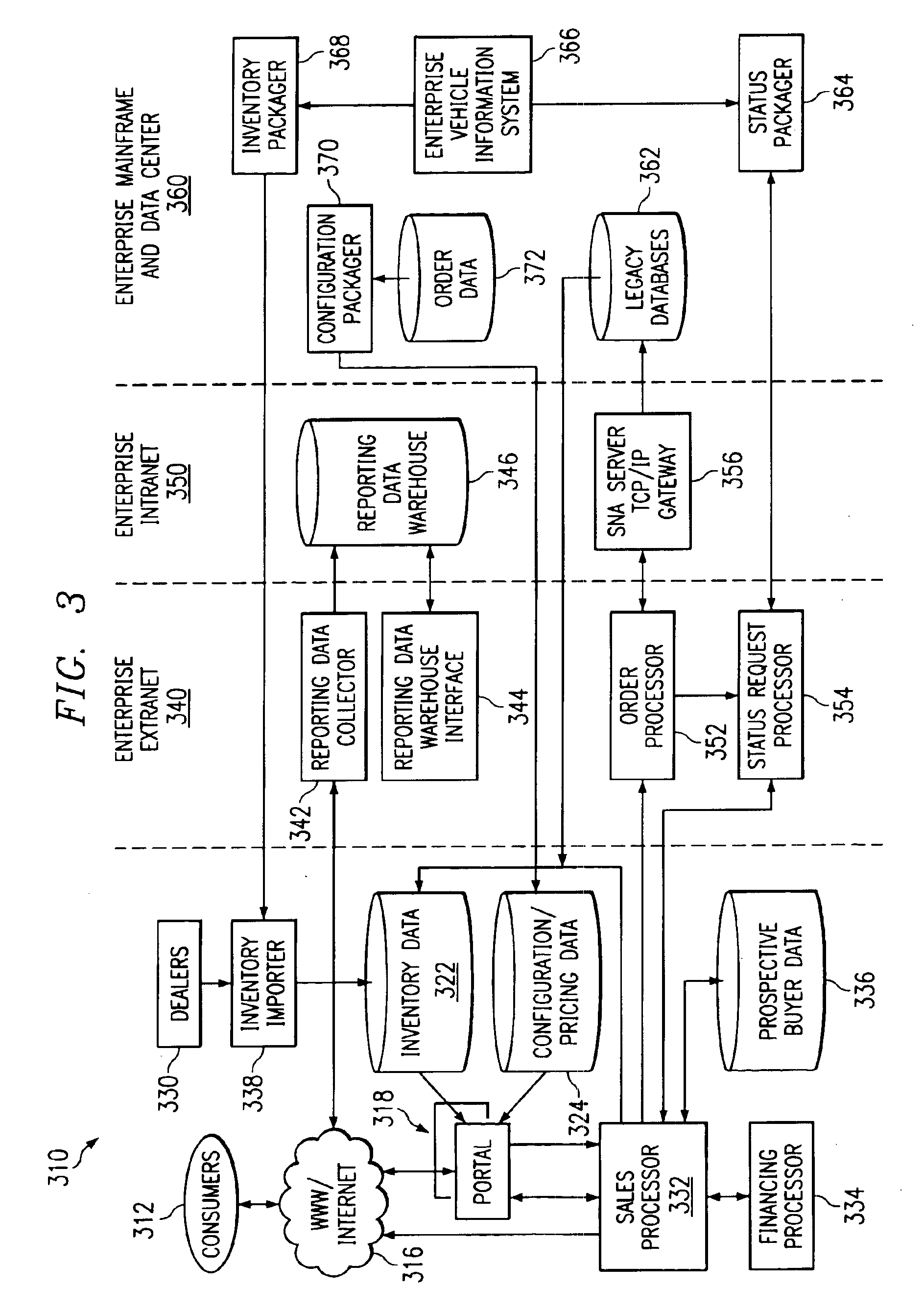

Communication schema of online system and method of locating consumer product in the enterprise production pipeline

InactiveUS6895388B1Shorten delivery timeBuying/selling/leasing transactionsSpecial data processing applicationsModel NumberWorld Wide Web

An online communication schema for an online vehicle ordering and tracking system is provided. The communication schema includes a search request message and a search reply message. The search request message includes at least one search criteria, including make and model of a vehicle, and a weighting of each criterion. The search reply message includes a list of vehicles substantially matching the search criteria, and a plurality of vehicle configuration parameters of the vehicles substantially matching the search criteria, including make, model, dealer identifier, price, and color.

Owner:FORD MOTOR CO

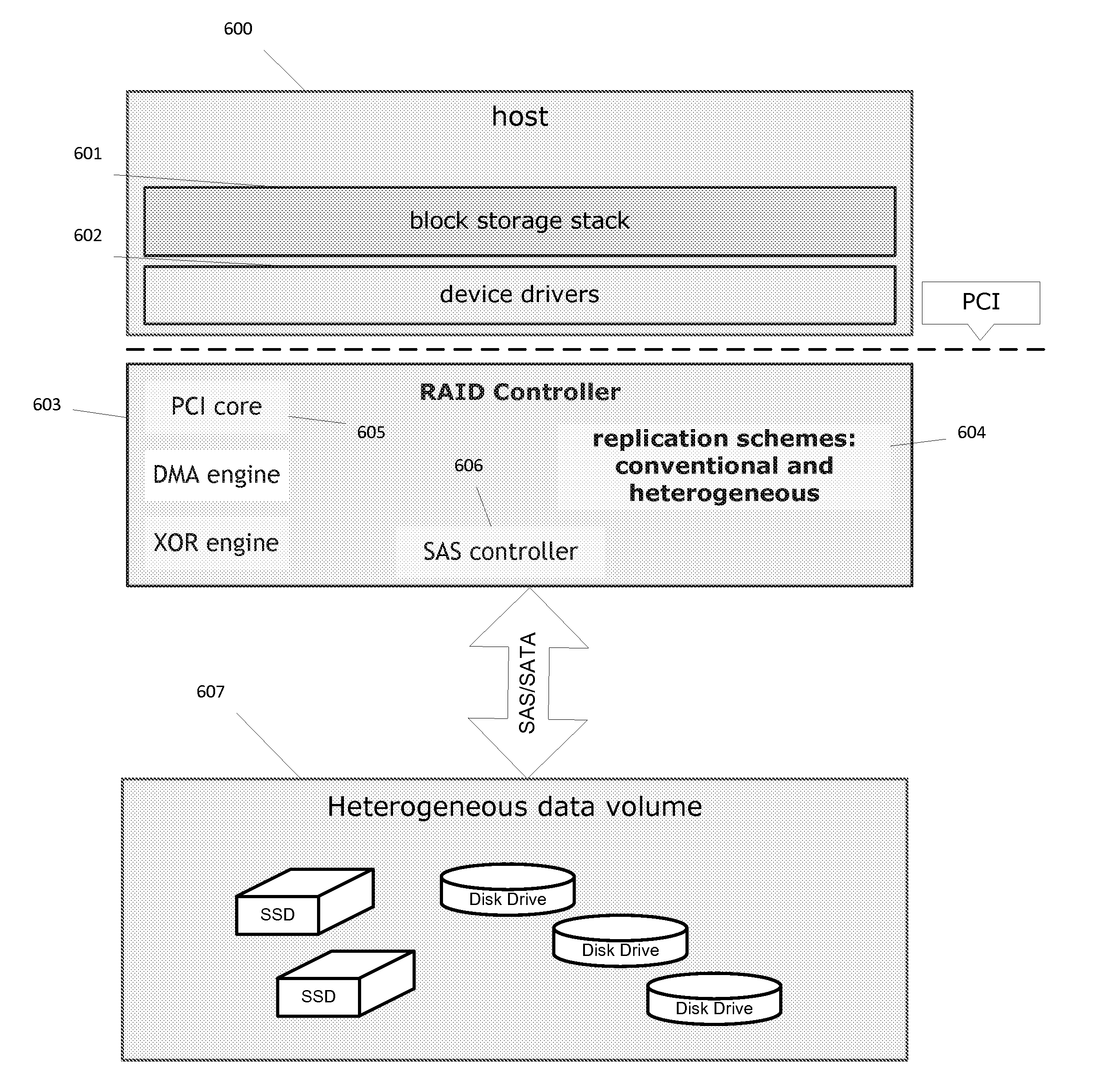

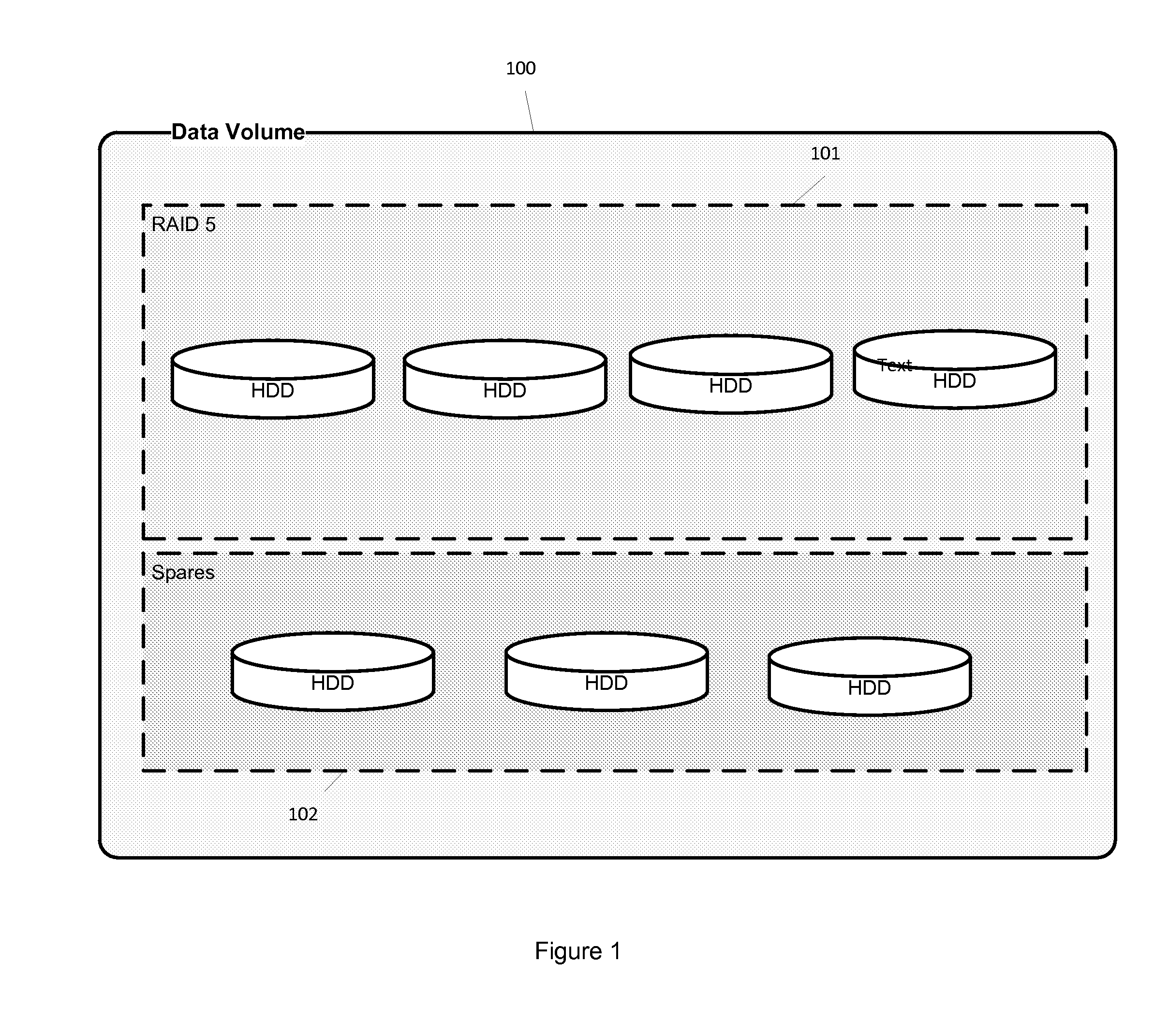

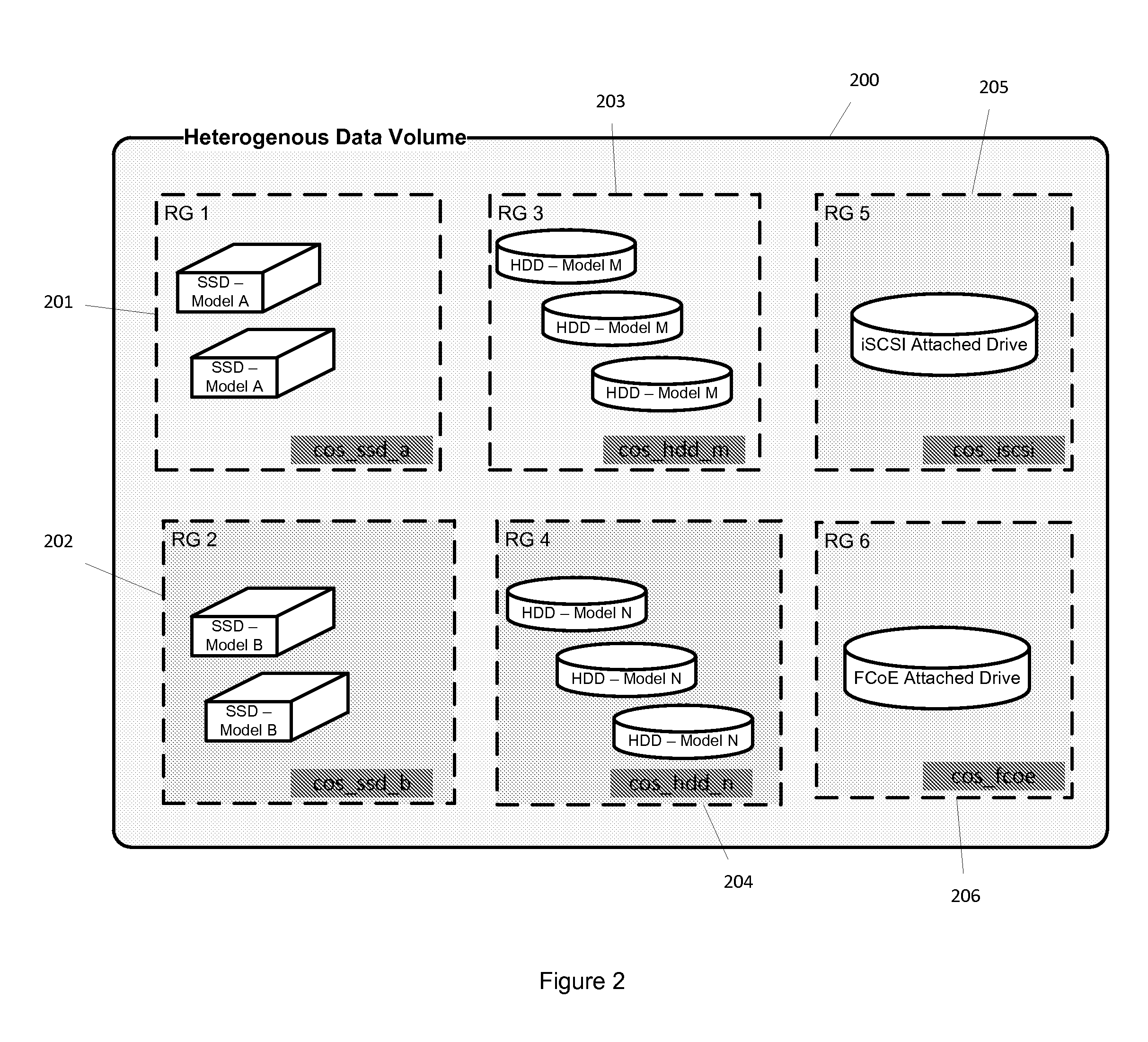

Method and system for heterogeneous data volume

ActiveUS20120017043A1Improve I/O performanceImprove life expectancyDigital data processing detailsError detection/correctionData accessModel Number

A method and system is disclosed for providing a heterogeneous data storage comprising a plurality of storage devices of different types with respect to device vendor, model, capacity, performance and / or function. The present invention employs data access mechanisms specific to the type of underlying storage and the type of data to be stored or retrieved, and provides for integrated remote mirroring, disaster recovery and hierarchical storage management (HSM), as well as improved I / O performance and life expectancy of storage disks. A method of writing to and reading from heterogeneous data volume is also disclosed.

Owner:NEXENTA BY DDN INC

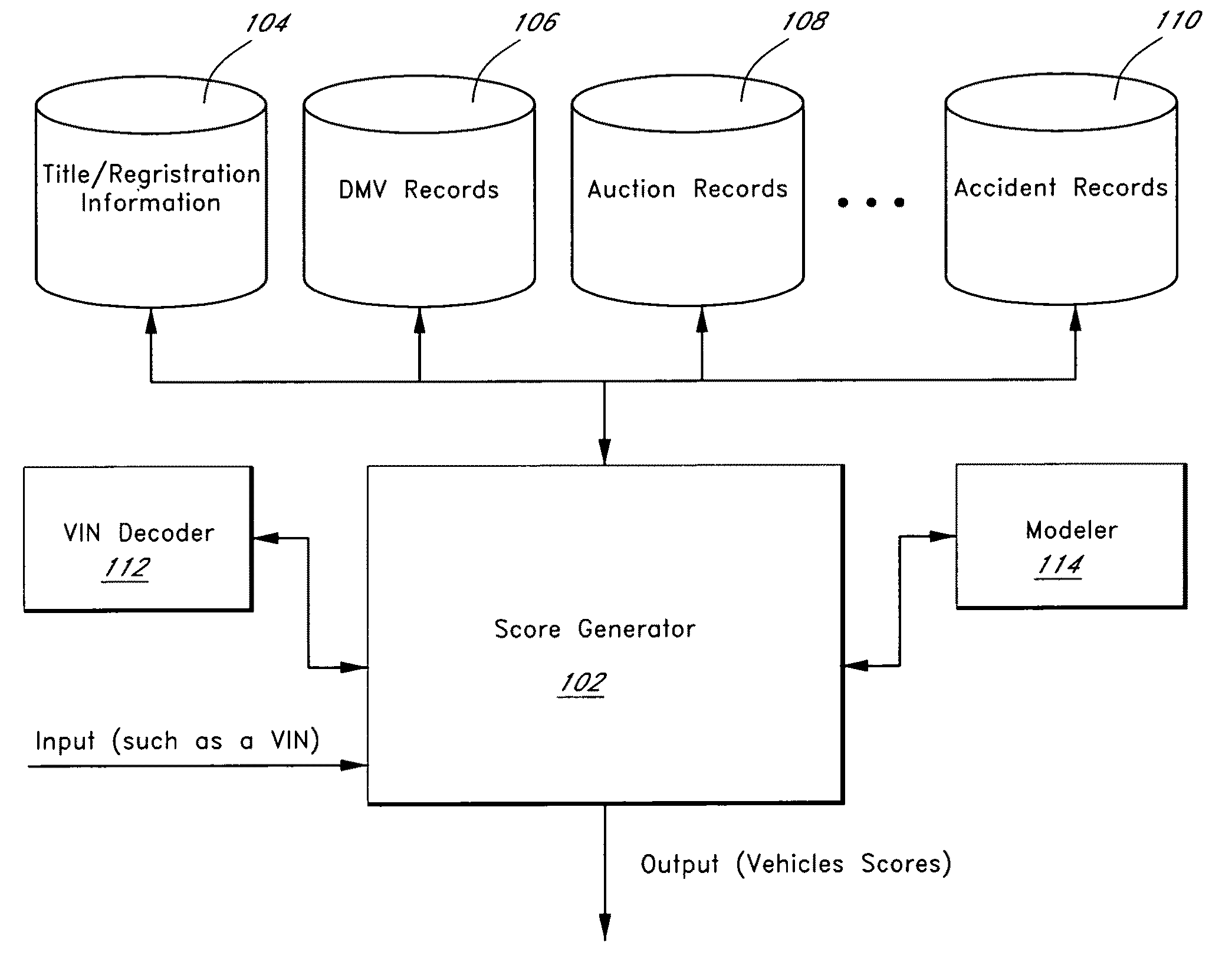

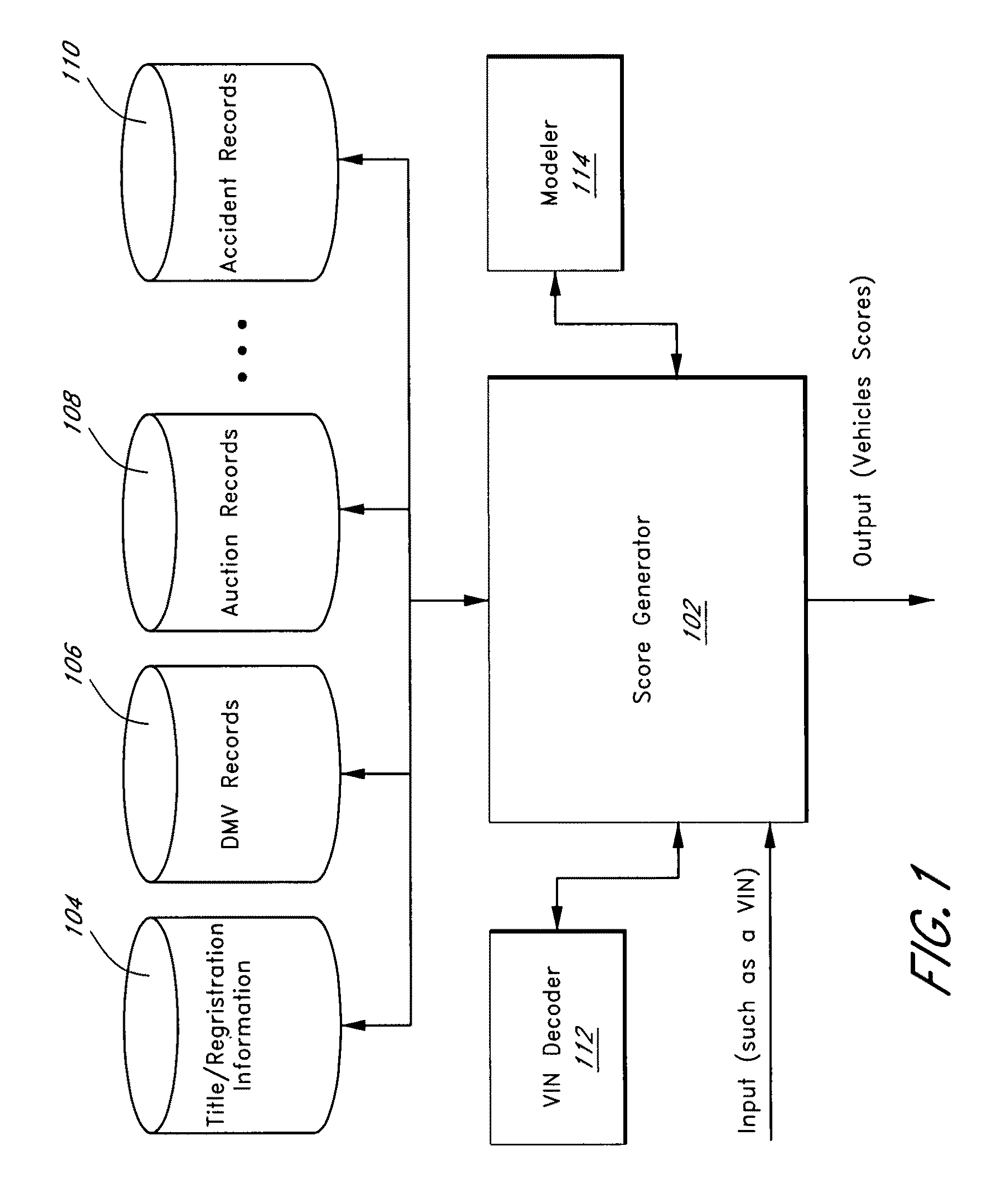

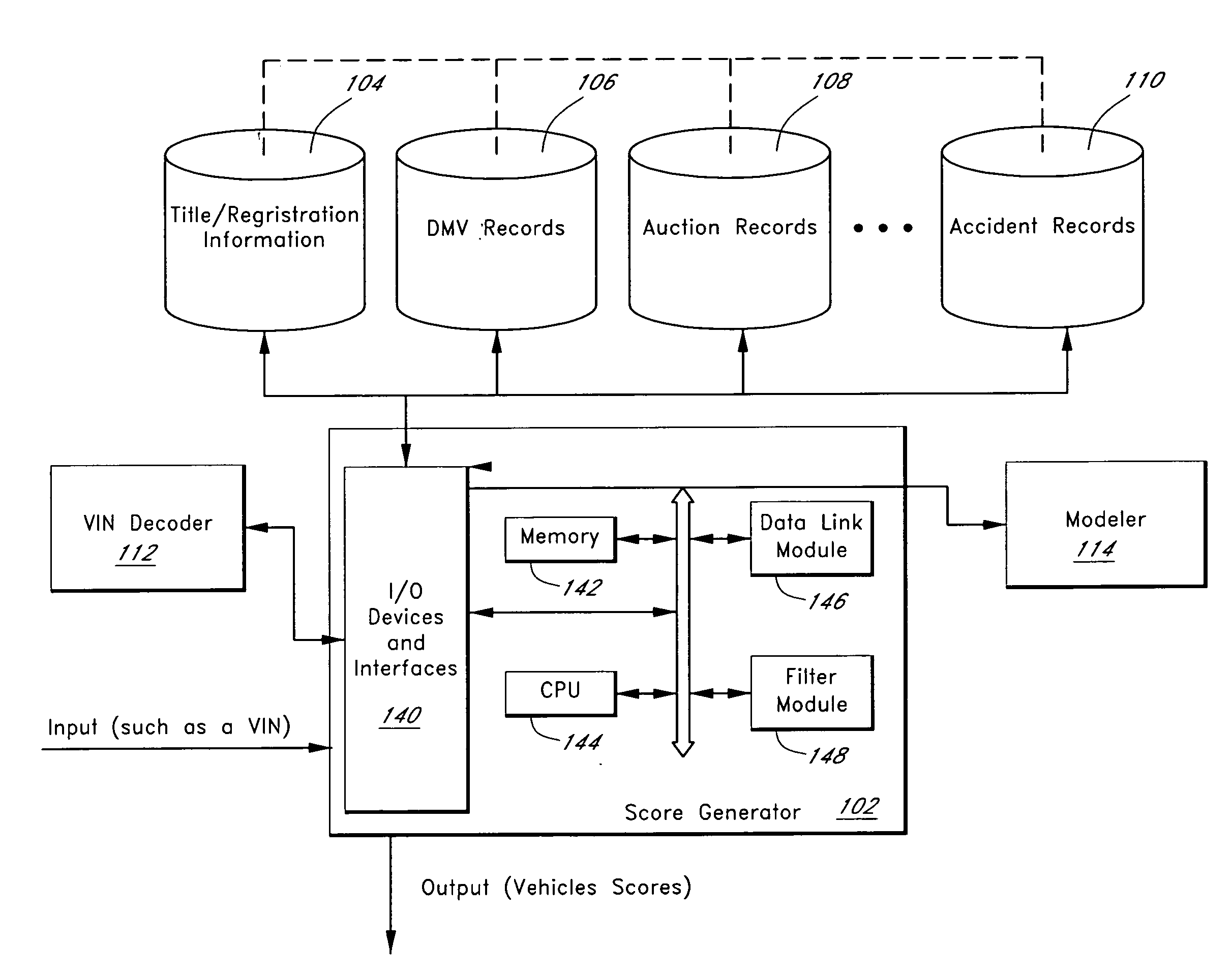

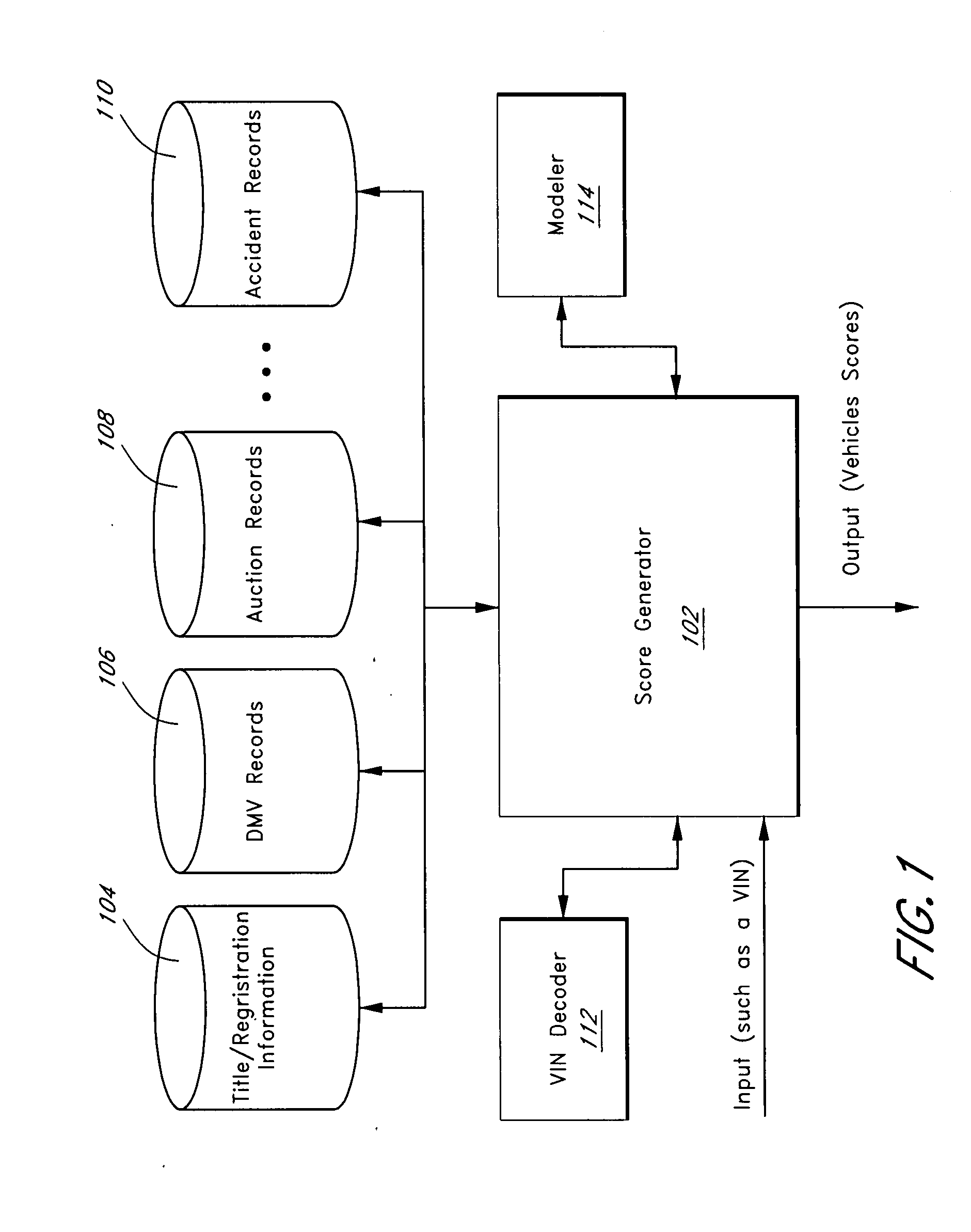

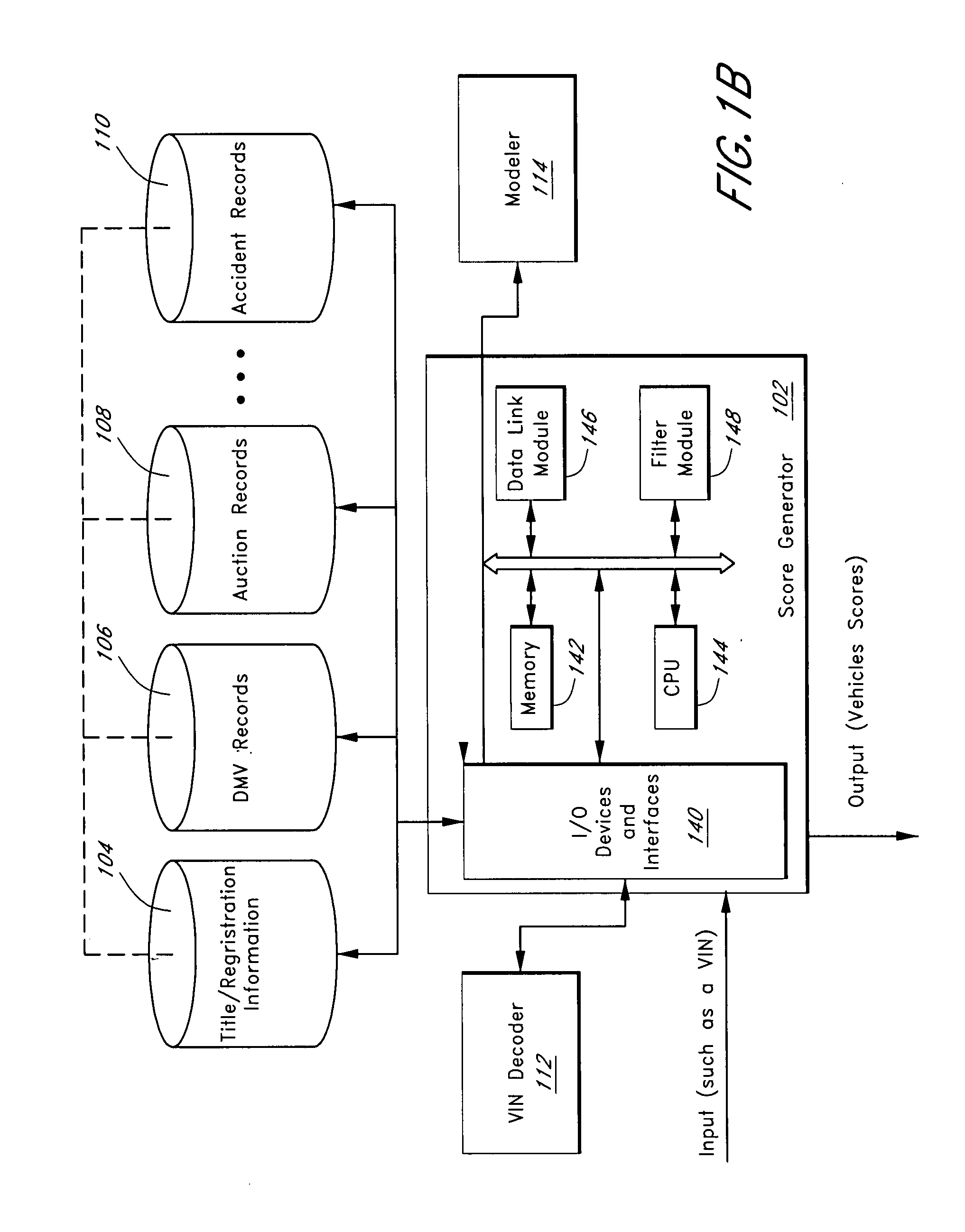

System and method for providing a score for a used vehicle

One embodiment of the system and method described herein provides a score generator system that generates an automated vehicle specific valuation of a used car based on the physical and historical attributes of that vehicle. This score may indicate the likelihood that the vehicle will be on the road in a specific period of time. The score may give an absolute percentage of such likelihood or it may give a value relative to all other used vehicles in a database, all other used vehicles of the same make / model / year, or a certain subset of the vehicles in a database. In one embodiment, the score generator system includes a data link module for linking vehicle data and filter module for applying a multi-level filters that process the linked vehicle data.

Owner:EXPERIAN INFORMATION SOLUTIONS

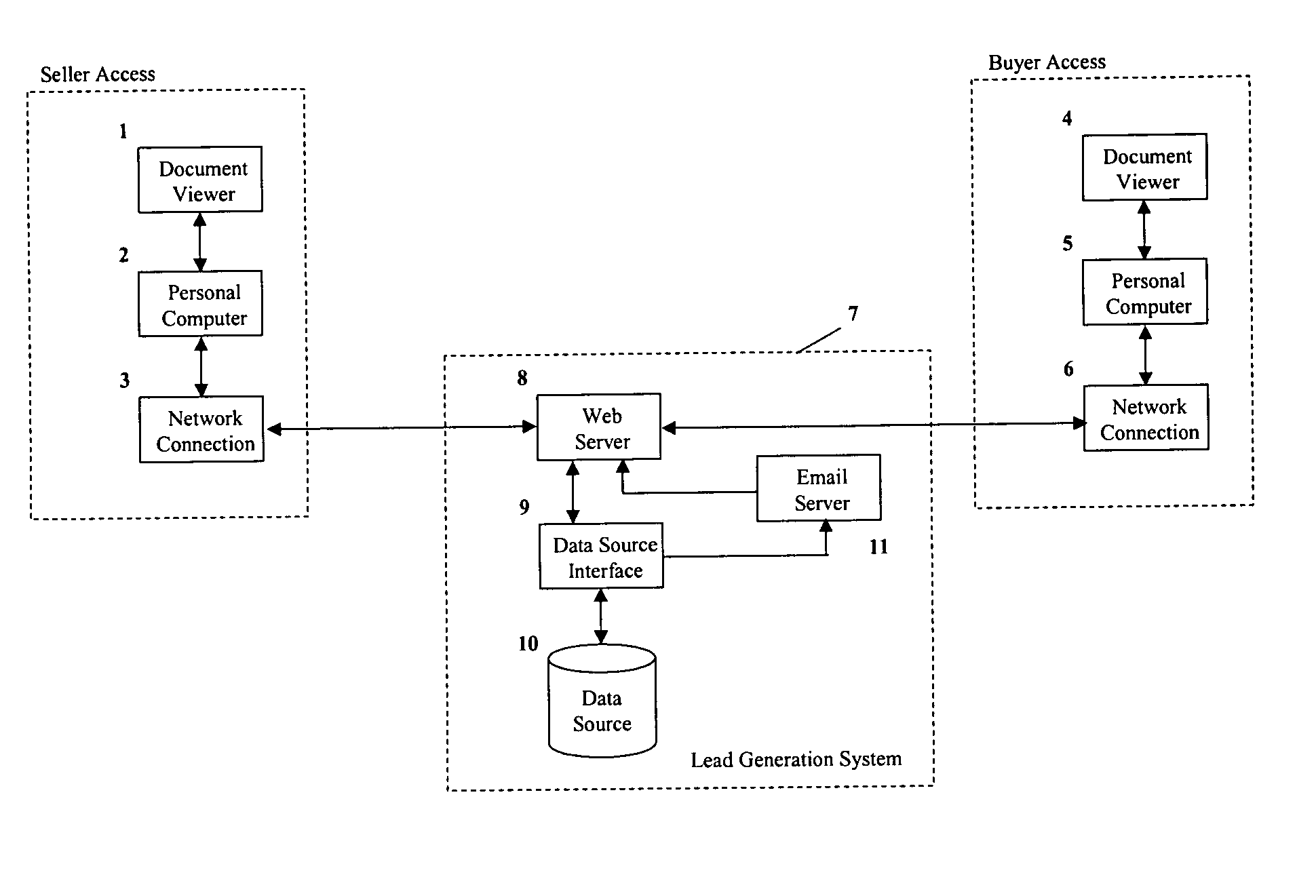

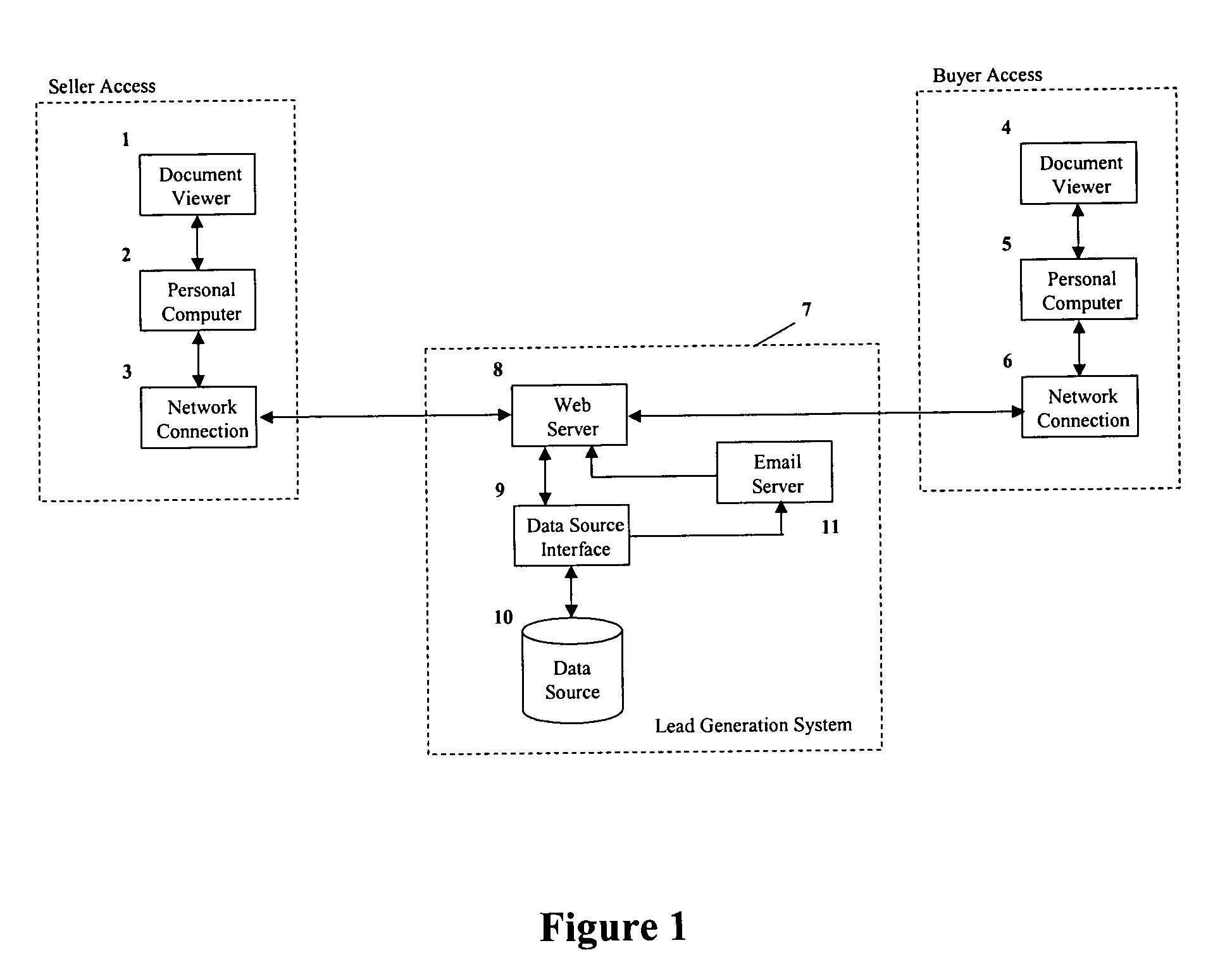

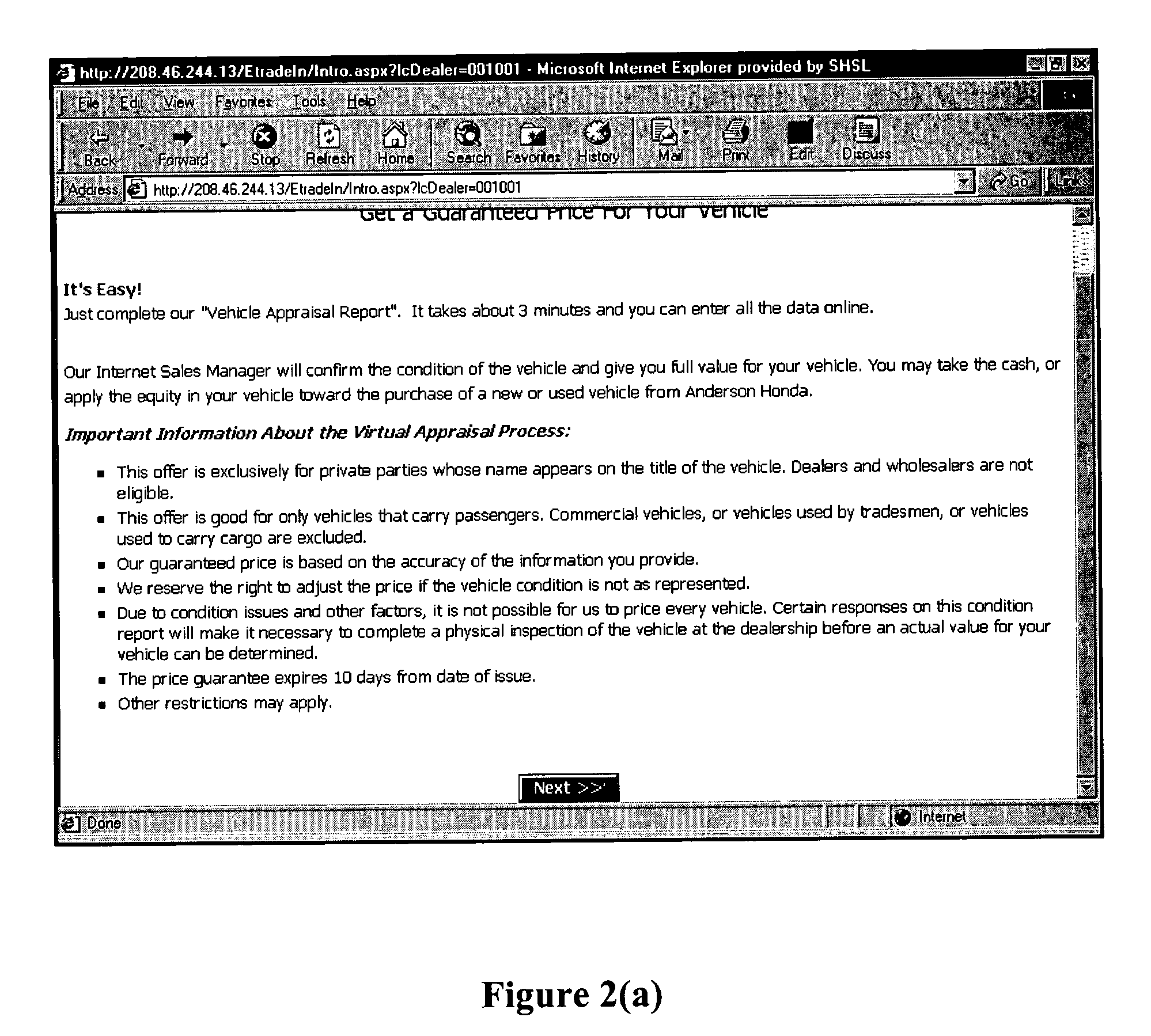

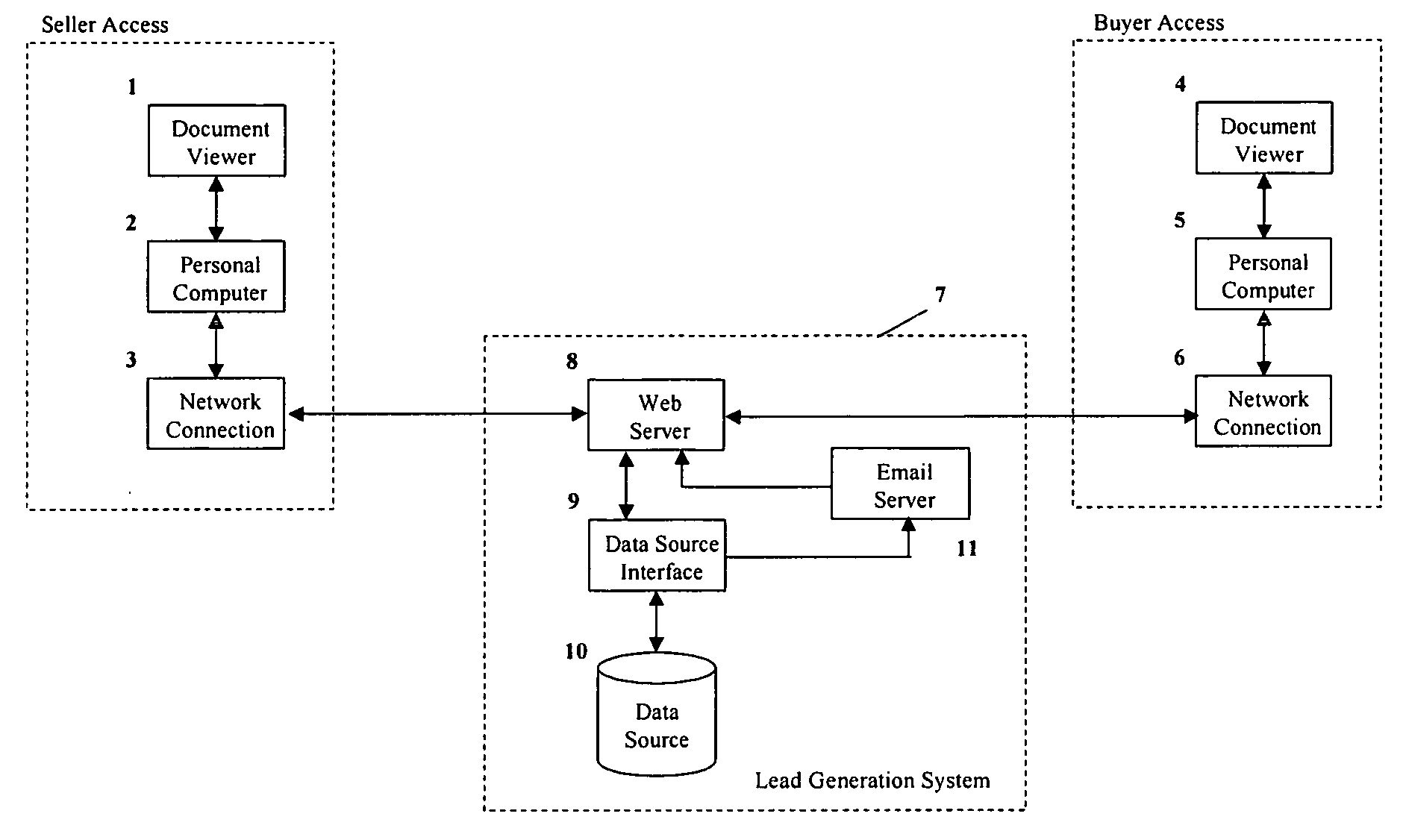

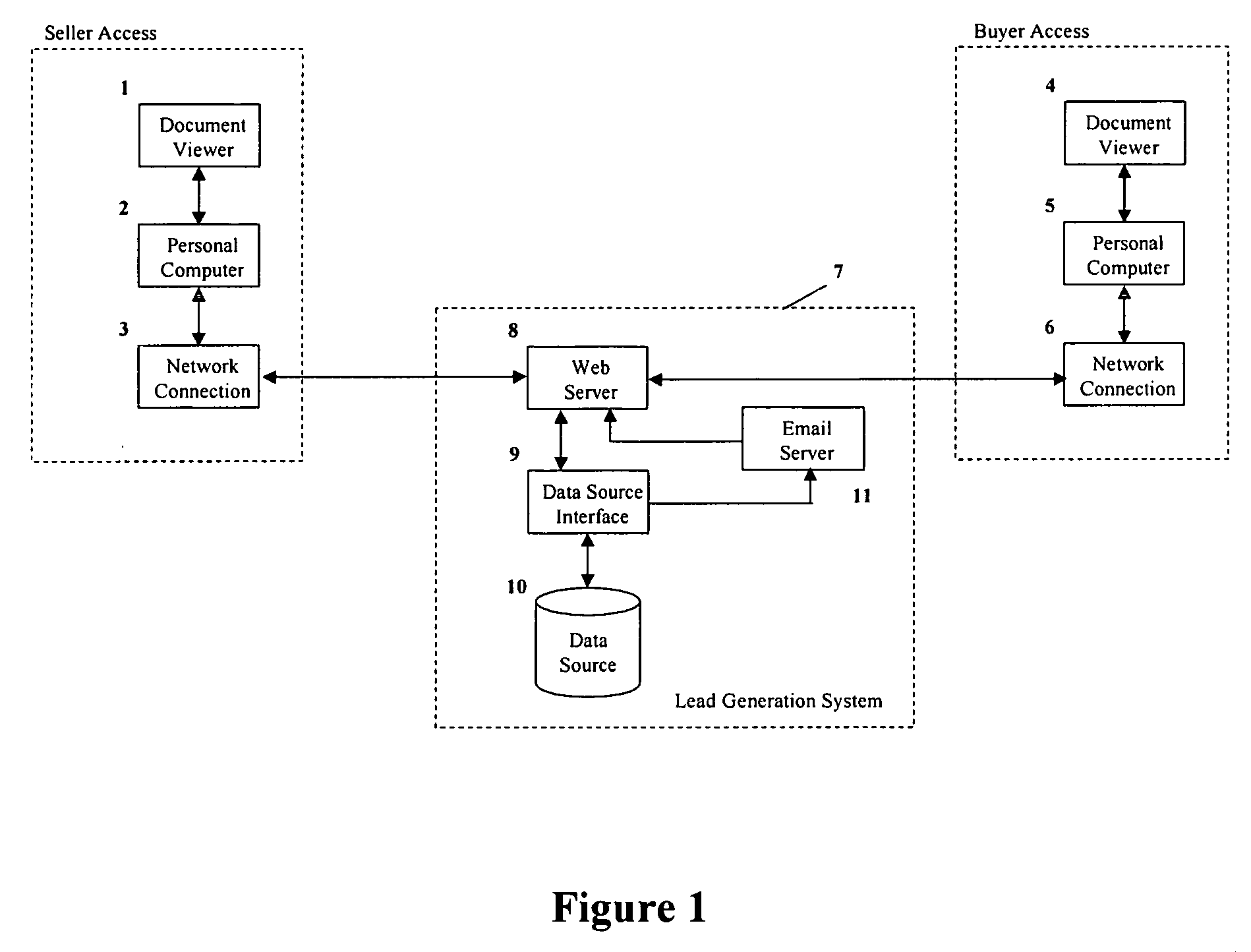

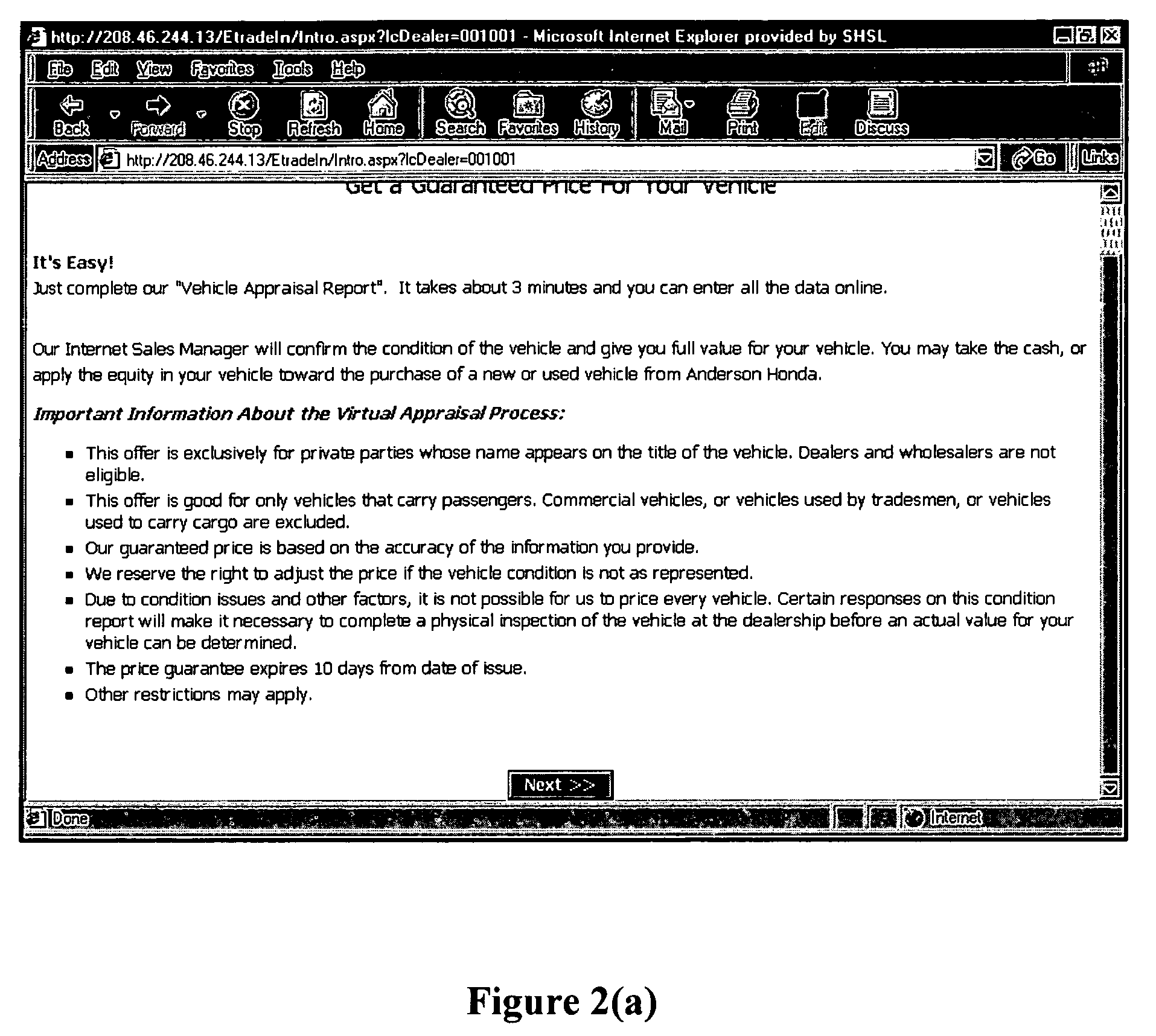

Lead generation system using buyer criteria

The invention is directed to a system for generating a lead by determining an estimated for a vehicle. The system may receive vehicle identifying information; receive seller identifying information; receive information for a sample of vehicles of the same make and model as the vehicle; determine a value for vehicle using the vehicle identifying information and the historical information, wholesale sales through auctions and at dealerships; (and also vehicle condition information if provided), and determine an estimated value, estimated value range, or offer price for the vehicle using predetermined buyer criteria and the determined value. This offer may then be transmitted to the seller in the form of a price certificate, appraisal report, etc., and the seller identifying information may be transmittal to the buyer as a sales lead.

Owner:VERETECH HLDG

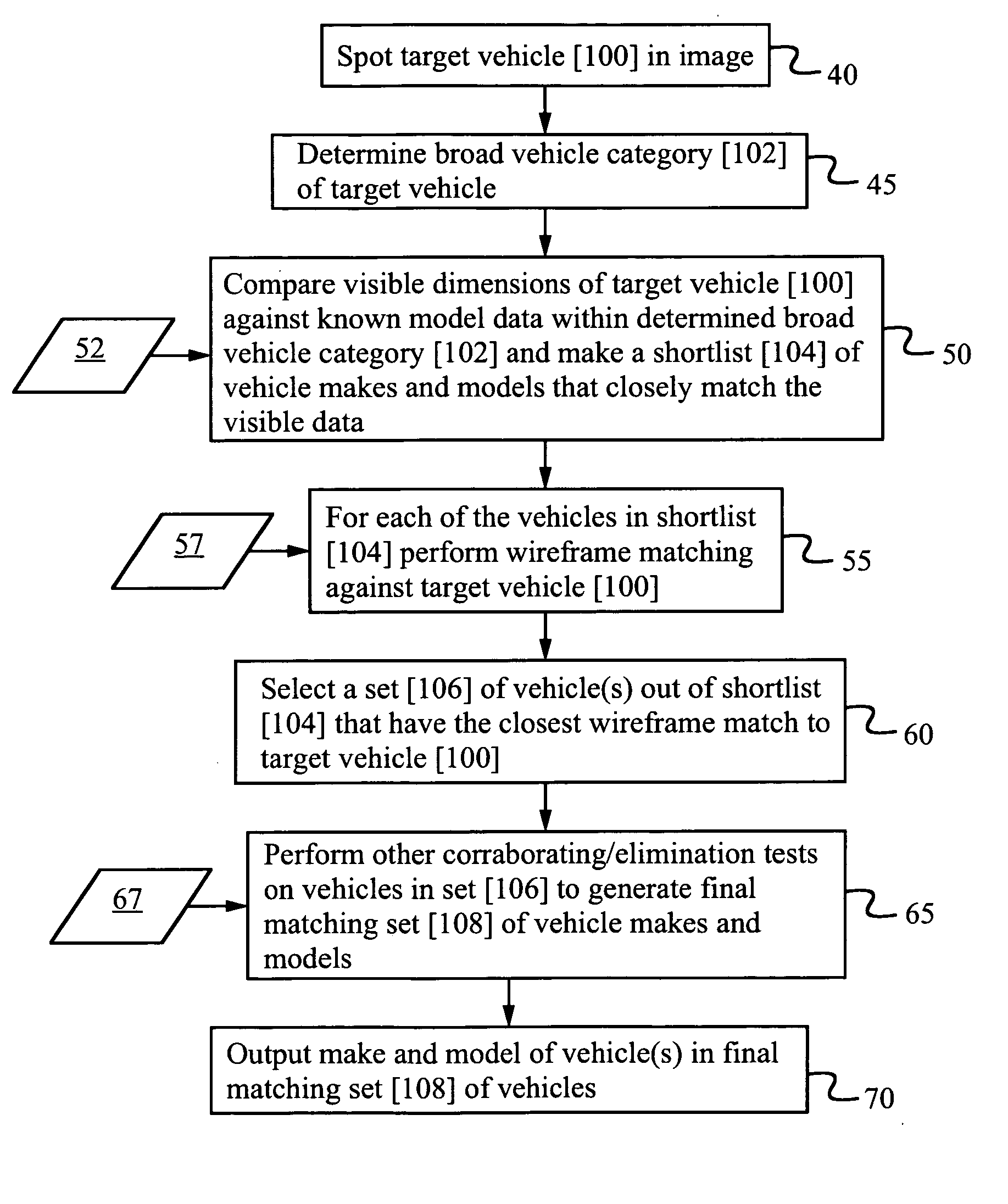

Method for vehicle classification

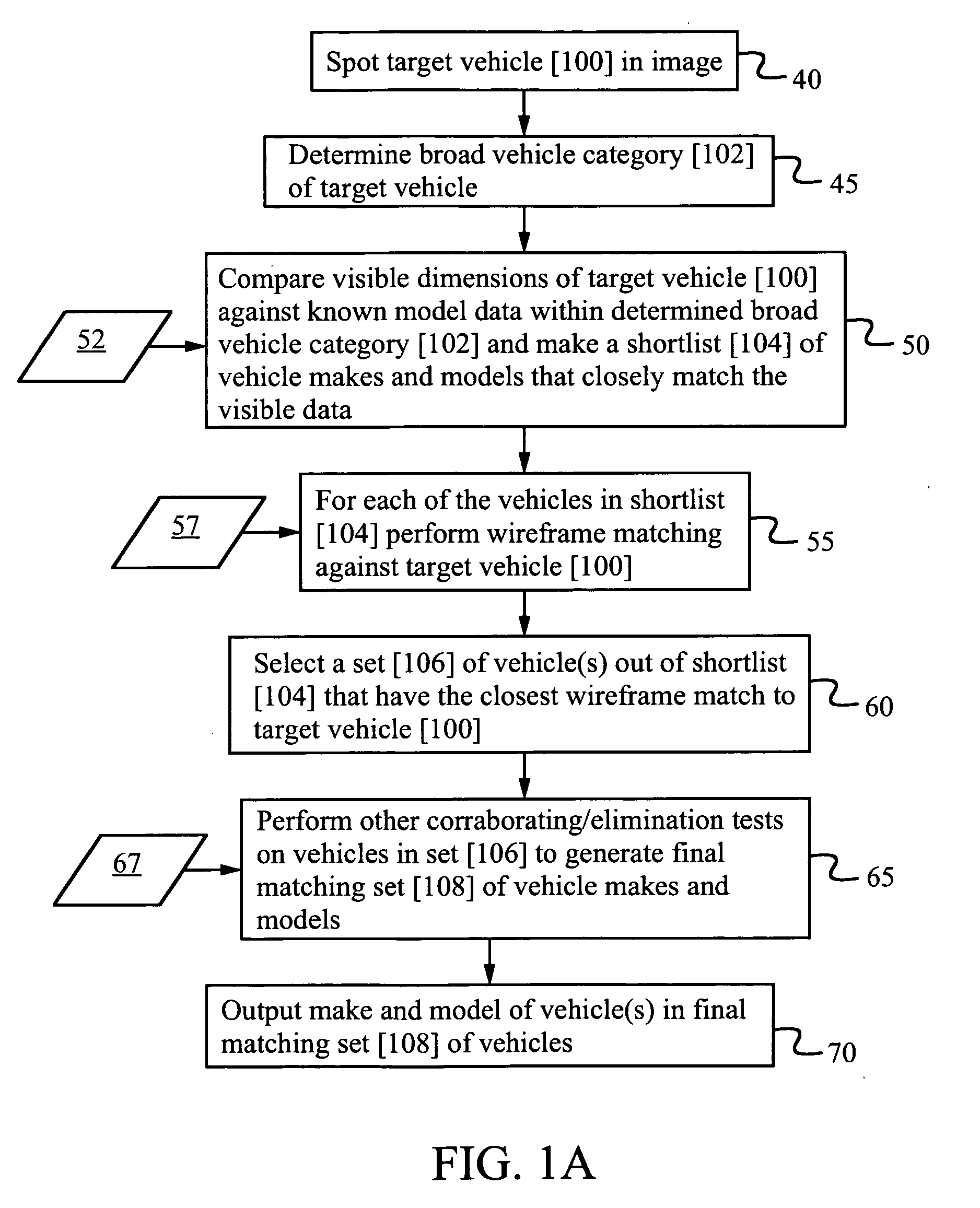

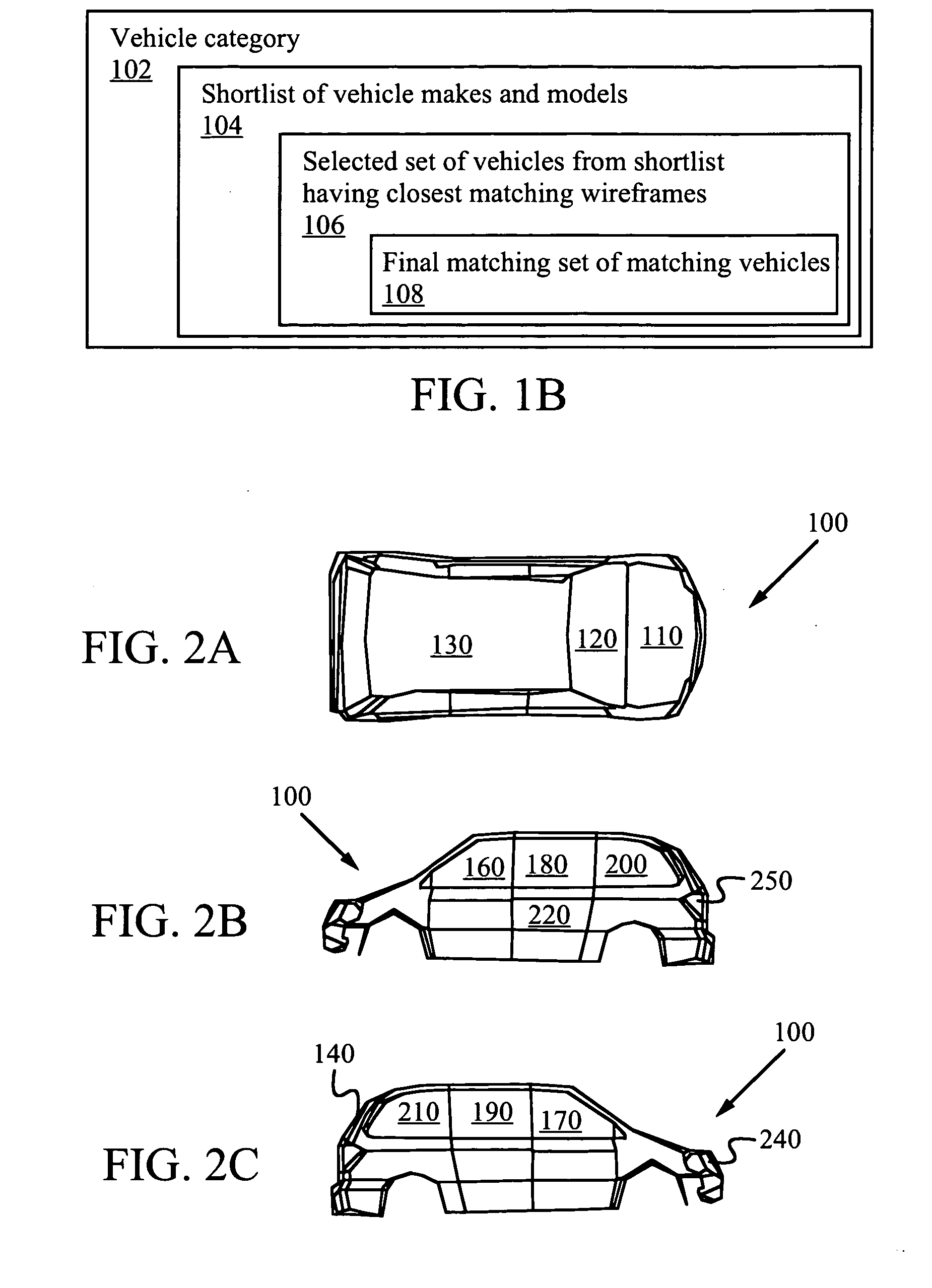

InactiveUS20050267657A1Reduce workloadImprove matchVehicle testingRegistering/indicating working of vehiclesClassification methodsBroad category

A technique for vehicle classification and identification from images successively narrows the classification of a vehicle down to vehicle make, model, and other specific characteristics. This process uses location, size, color, shape, and other image characteristics that help differentiate vehicles from other kinds of objects in an image. A broad categorization of the target vehicle is performed by classifying the vehicle according to a predetermined set of general vehicle types. A short list is then created of potential matching vehicle makes and models within the broad category that have the best chance of matching the target vehicle. Specific visible points on the target vehicle are identified and then a wire-frame matching with pre-recorded wire-frame models of the short listed vehicles is performed to produce a set of selected vehicle makes and models.

Owner:WHITEGOLD SOLUTIONS

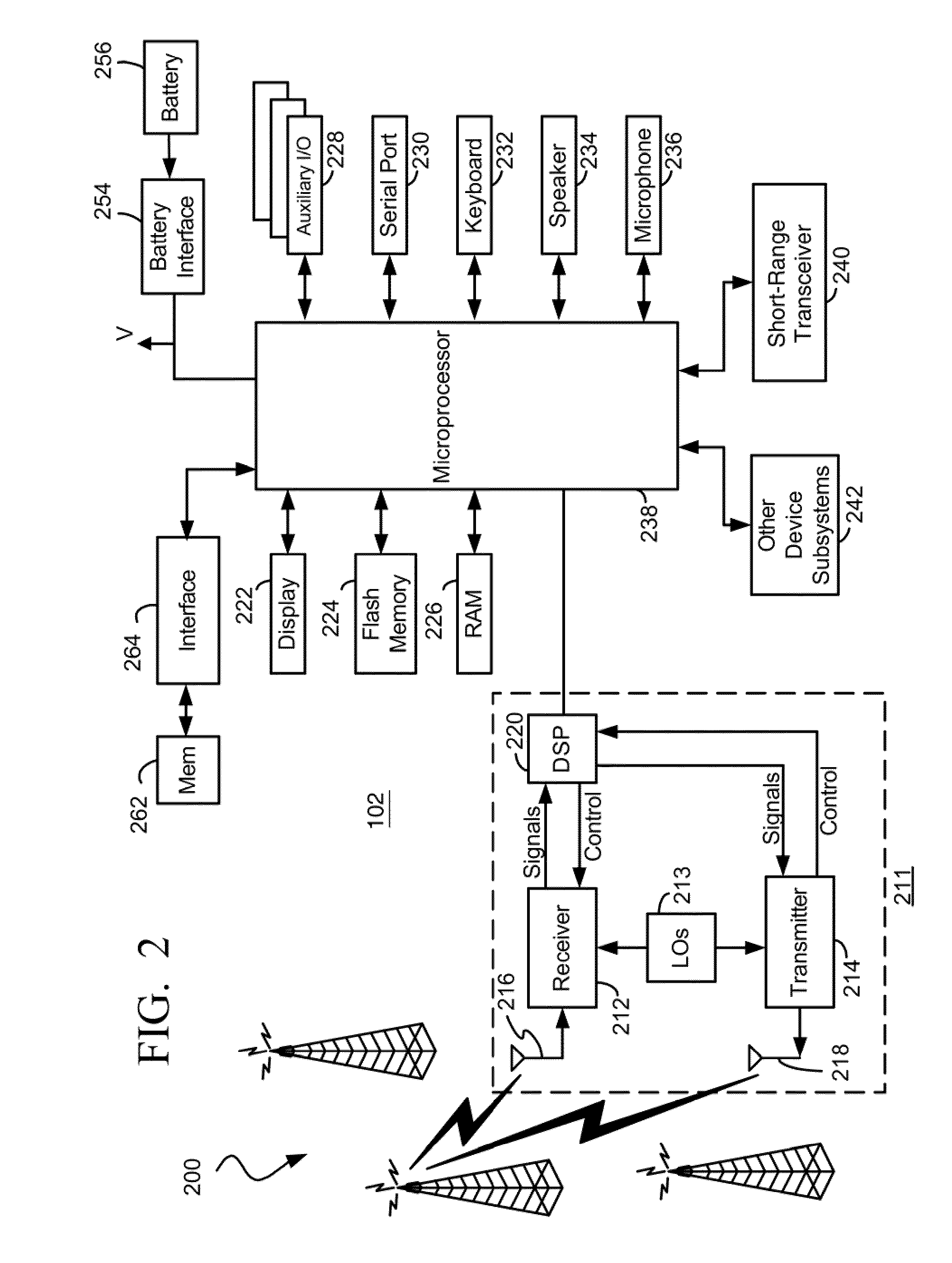

Methods And Apparatus For Use In Selectively Retrieving And Displaying User Interface Information Of A Wireless Peripheral Device

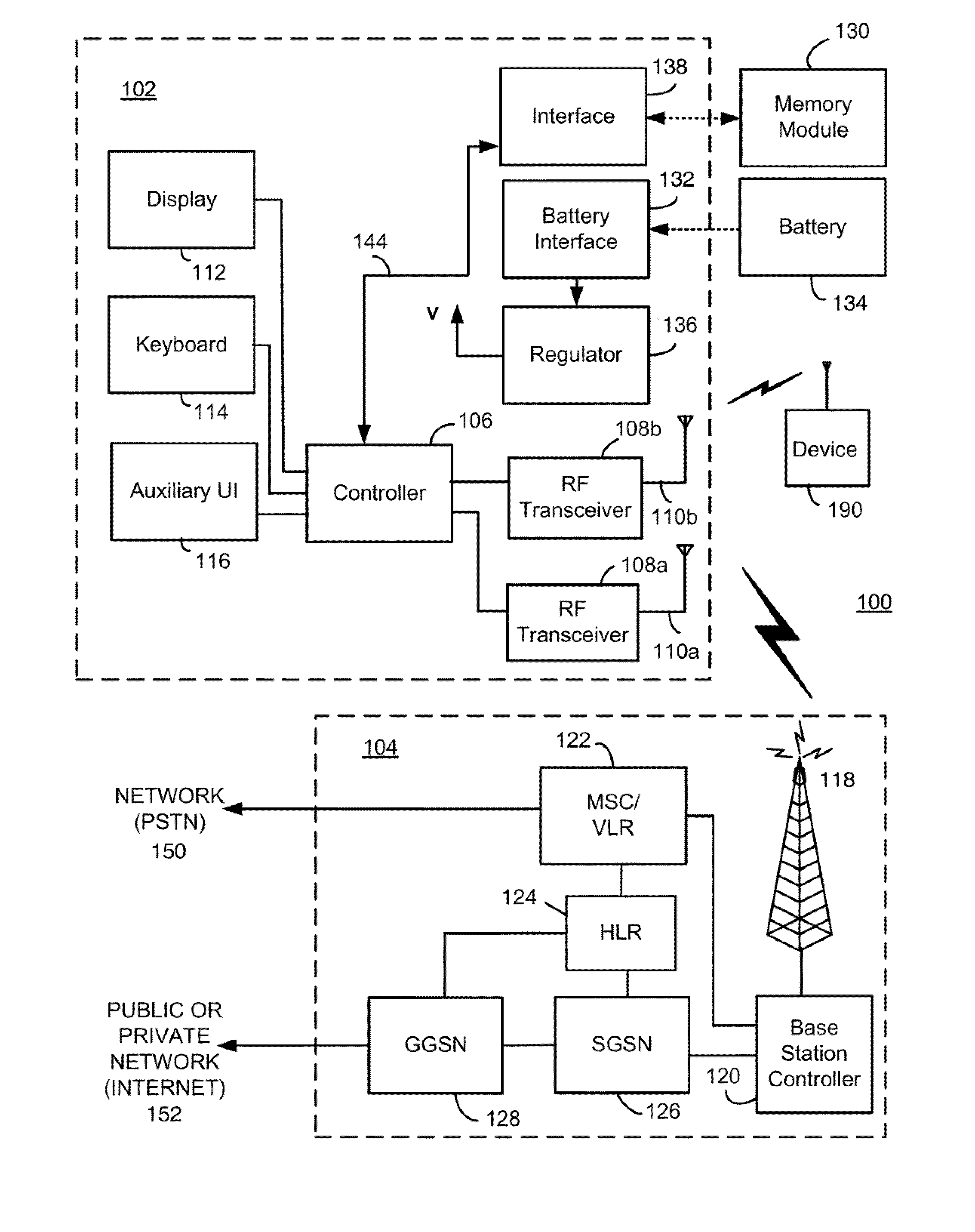

InactiveUS20100222000A1Radio transmissionExecution for user interfacesWireless transceiverTransceiver

A mobile communication device (e.g. a handheld telephone device) has a first wireless transceiver for communications via a wireless communication network and a second wireless transceiver for communications with a wireless peripheral device (e.g. a wireless audio headset or earpiece). The mobile device receives, from the wireless peripheral, an identification of a type or model of the wireless peripheral. The mobile device causes user interface (UI) function mapping information of the wireless peripheral to be selectively retrieved based on the received identification of the type or model. The UI function mapping information is indicative of a plurality of device functions assigned to a plurality of user input controls of the wireless peripheral. UI instruction information which is based on the retrieved UI function mapping information is then displayed at the mobile device. For example, when an incoming call is received, UI instruction information which identifies a first user input control for causing the incoming call to be answered and a second user input control for causing the incoming call to be ignored is displayed. The UI function mapping information may be selectively retrieved by transmitting, via the first wireless transceiver, a request which indicates the type or model of the wireless peripheral, for receipt by a server having different sets of UI function mapping information stored in association with a plurality of different types or models of wireless peripherals.

Owner:RES IN MOTION LTD

Vehicle lead generation system using byer criteria

The invention is directed to a system for generating a lead by determining an estimated for a vehicle. The system may receive vehicle identifying information; receive seller identifying information; receive information for a sample of vehicles of the same make and model as the vehicle; determine a value for vehicle using the vehicle identifying information and the historical information, wholesale sales through auctions and at dealerships; (and also vehicle condition information if provided), and determine an estimated value, estimated value range, or offer price for the vehicle using predetermined buyer criteria and the determined value. This offer may then be transmitted to the seller in the form of a price certificate, appraisal report, etc., and the seller identifying information may be transmittal to the buyer as a sales lead.

Owner:VERETECH

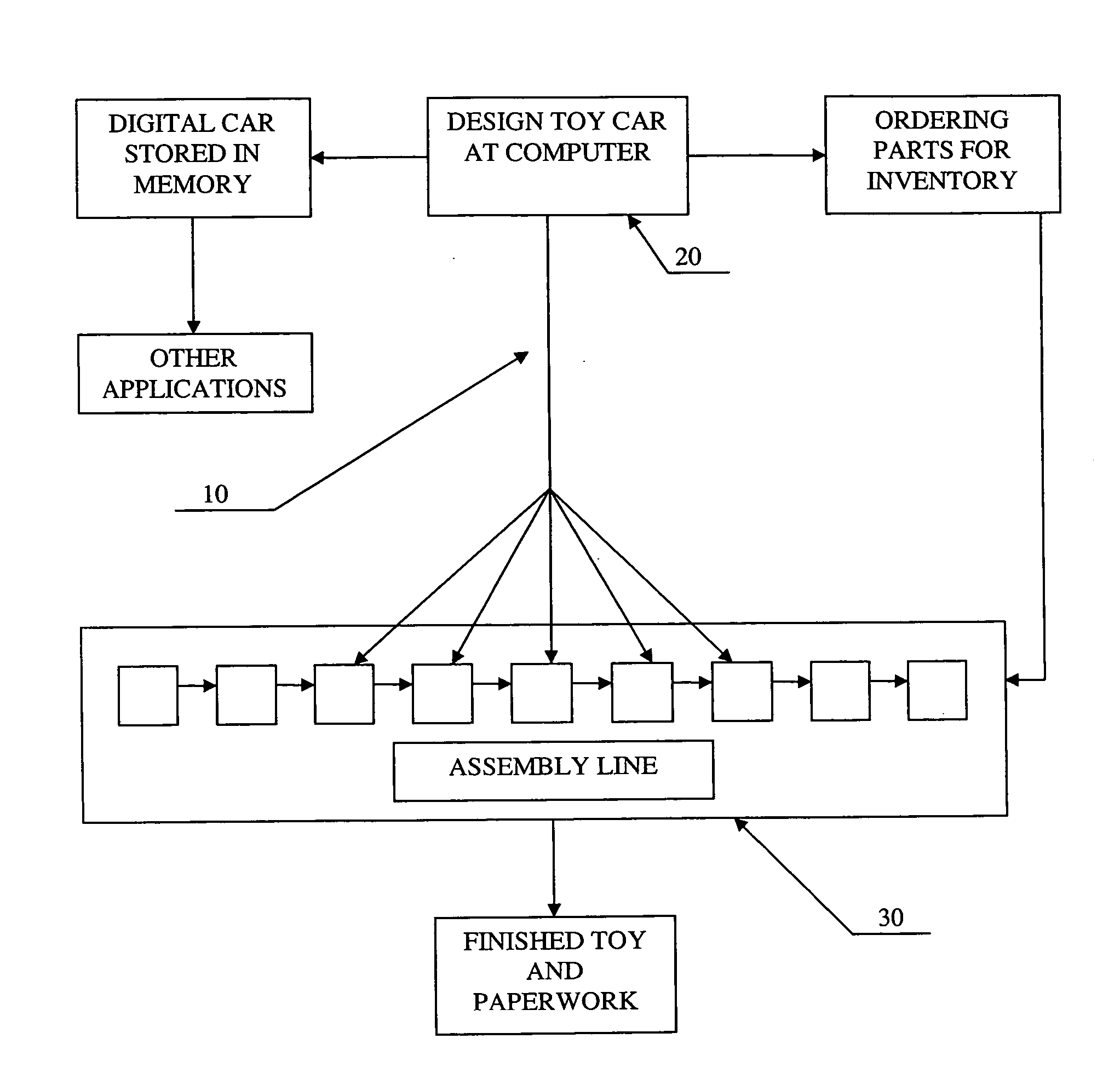

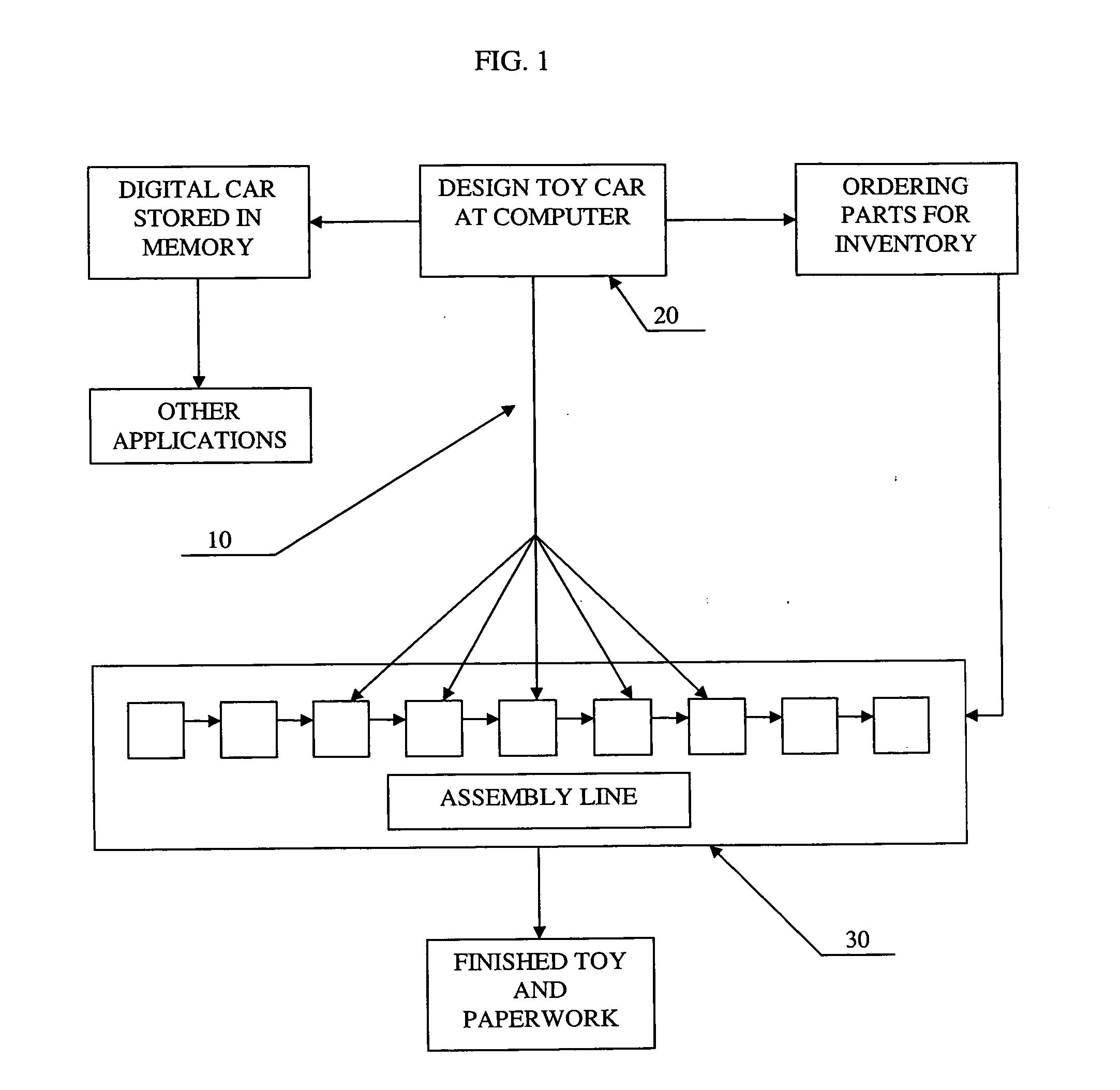

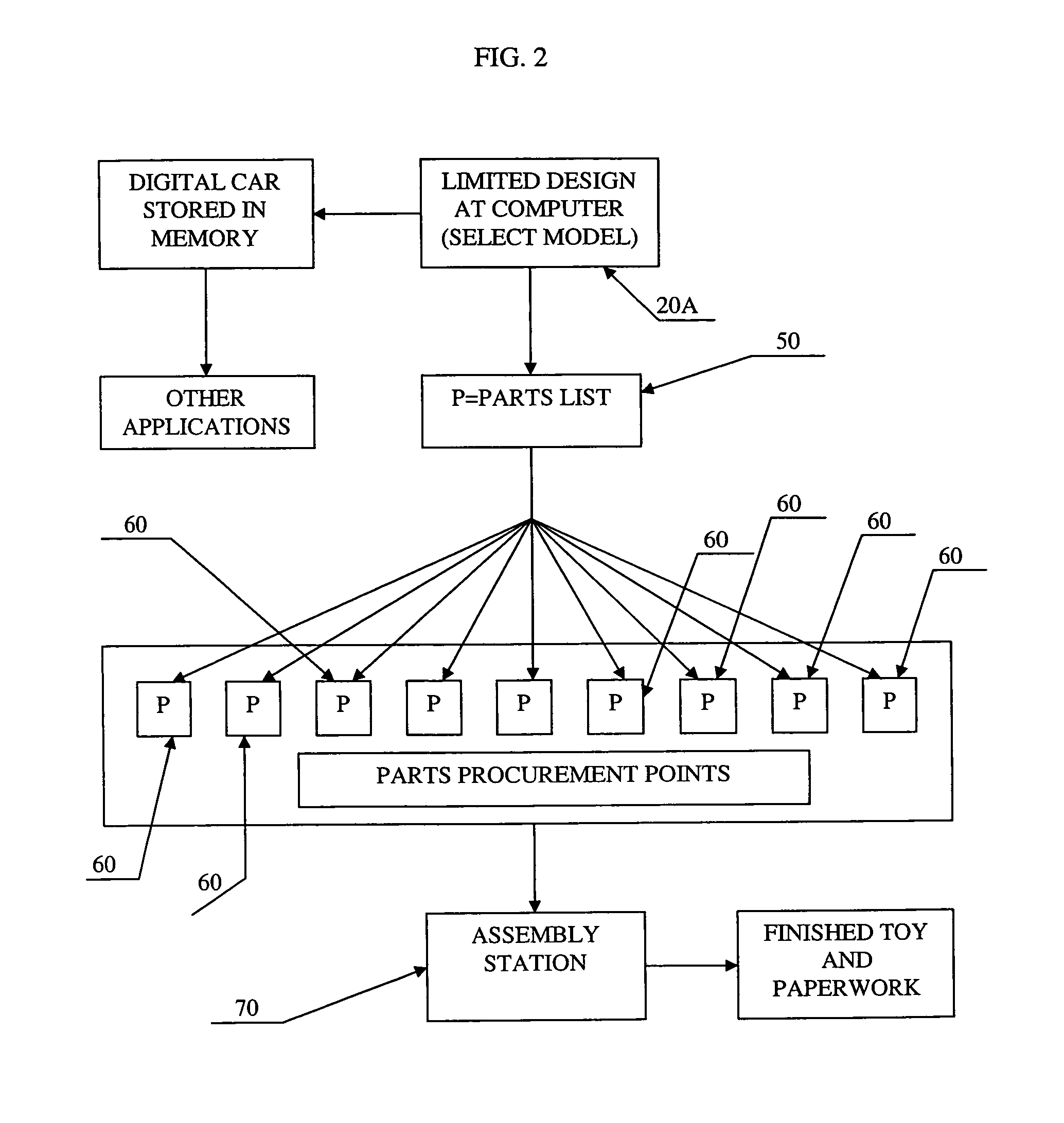

Interactive custom design and building of toy vehicle

InactiveUS20070198117A1Extension of timeIncrease valueSpecial data processing applicationsToy vehiclesDesign softwareComputer terminal

A method and system for custom building a toy vehicle inside a store. A child makes design choices at a computer terminal inside the store that employs design software relating to a design of a toy car, the design software permitting design choices that trigger an ordering of components and an assembly of the toy car that simulates a real car assembly, the assembly commencing while the child interacts with the software and being completed within approximately a half hour of a first design choice. The assembly line located inside the store allows the child to dramatically see assembly of components and permits participating in the assembly by moving assembly objects to make design choices at component installation points. Design choices include style, model, color, front and rear ends, lights, doors, hood, height, wheels, engine, muffler, interior, spoiler, name and logo, and attachments.

Owner:FORDHAM SHARON A +1

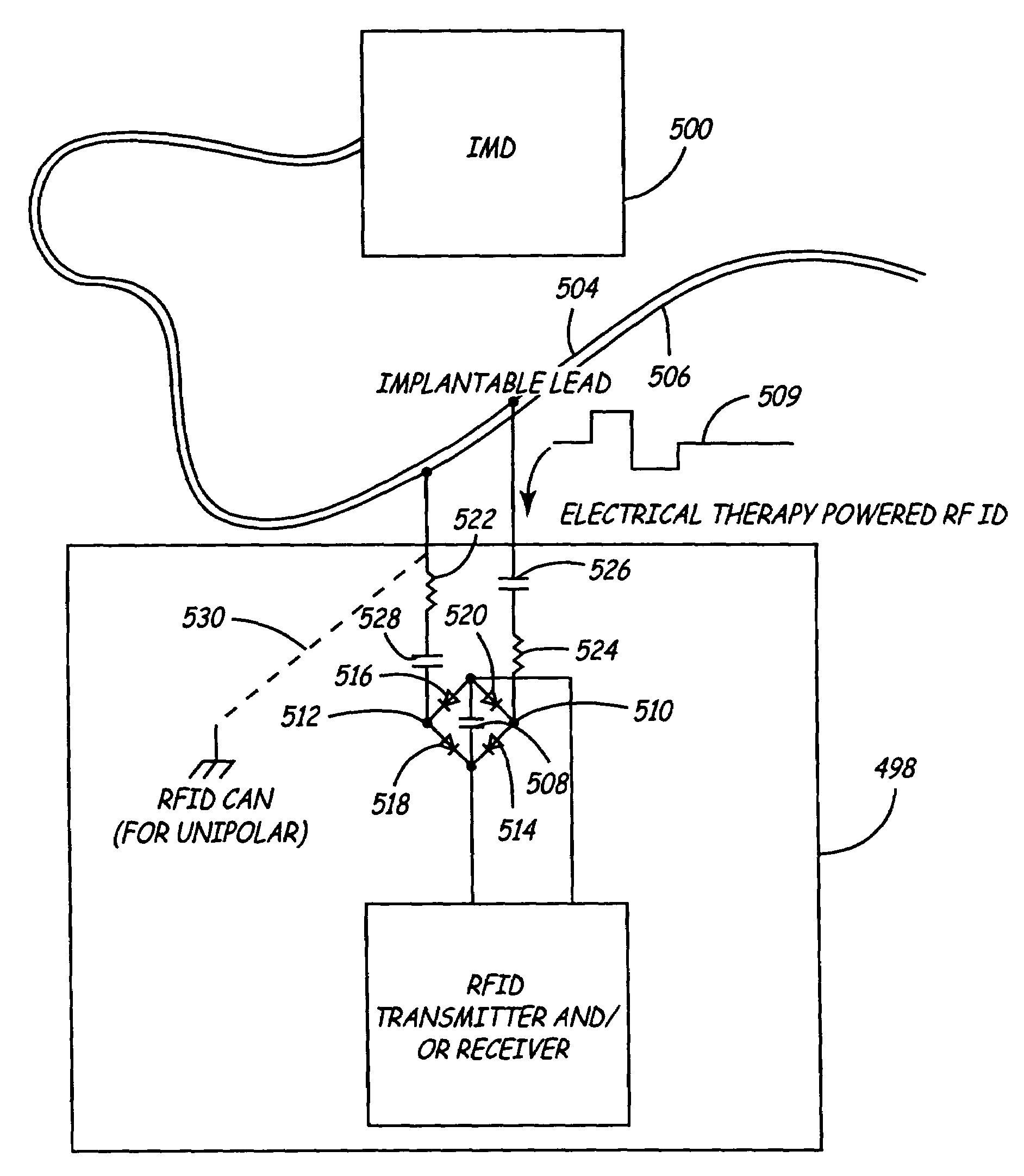

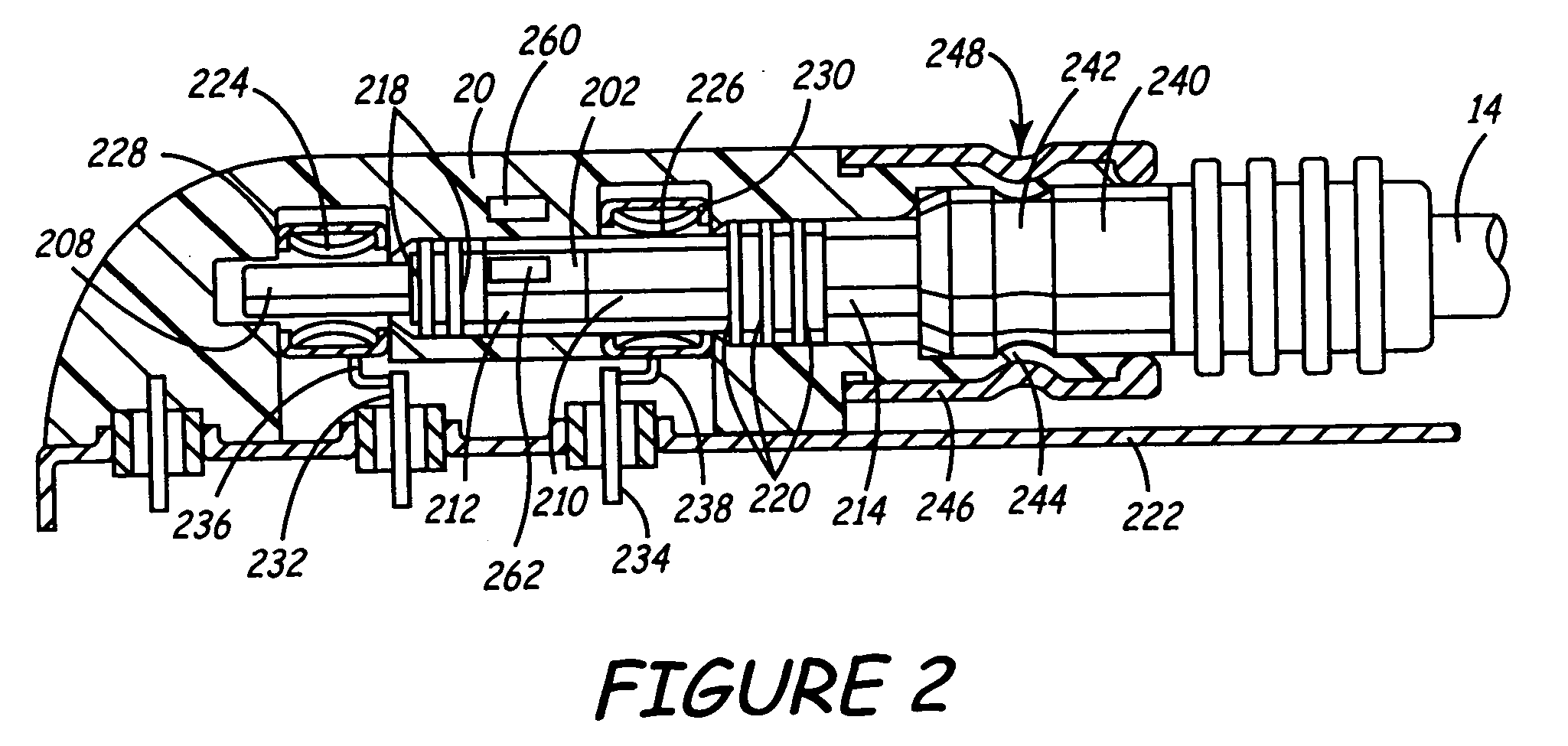

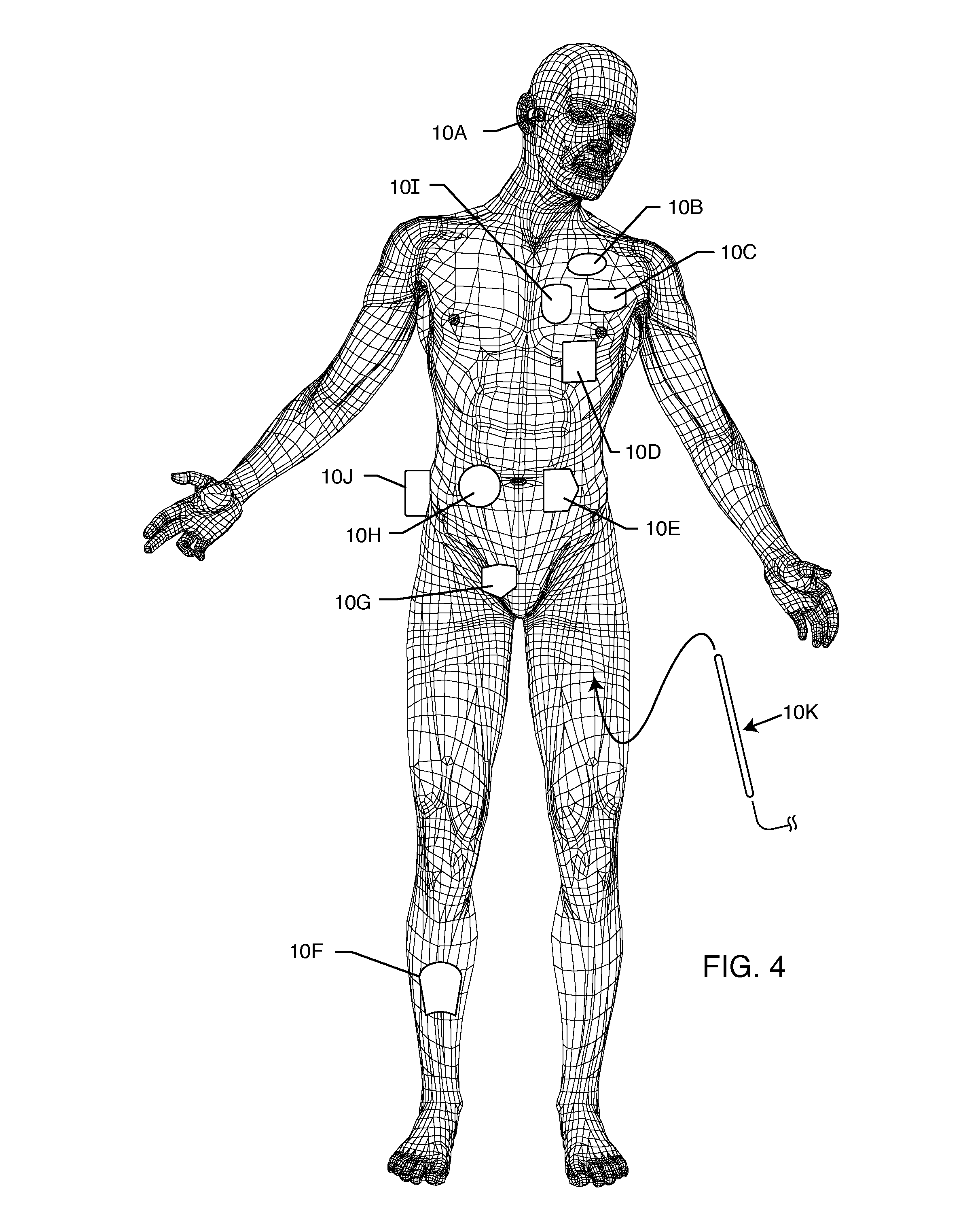

Method and apparatus for automatic implantable medical lead recognition and configuration

InactiveUS7239916B2Simple interfaceTransvascular endocardial electrodesHeart defibrillatorsTransmitterMedical treatment

An automated identification and configuration system for use with an implantable medical device (IMD) is disclosed. The system includes a first communication circuit that is attached to, or otherwise carried by, a detachable component associated with the IMD such as a medical lead. The communication circuit stores data such as model numbers, serial numbers, technical data, and / or calibration information that describes the additional component. This information may be transferred by the first communications circuit to a second communications circuit that is external to the additional component. This transferred data can be used to automatically configure the internal circuitry and connection functions of the IMD to properly interface with, and support, the additional component. For example, the data can be used to automatically adjust amplifier gains or other sensor circuitry, or to configure a connector block to properly couple to the component. The data may further be entered into a patient record on an external programmer, or may be transferred to a central storage location to be generally accessible to health care providers. In one embodiment, the first communication circuit is a passive RF transponder. This first communication circuit may include a receiver as well as a transmitter to allow the circuit to programmably receive data at the time of component manufacture.

Owner:MEDTRONIC INC

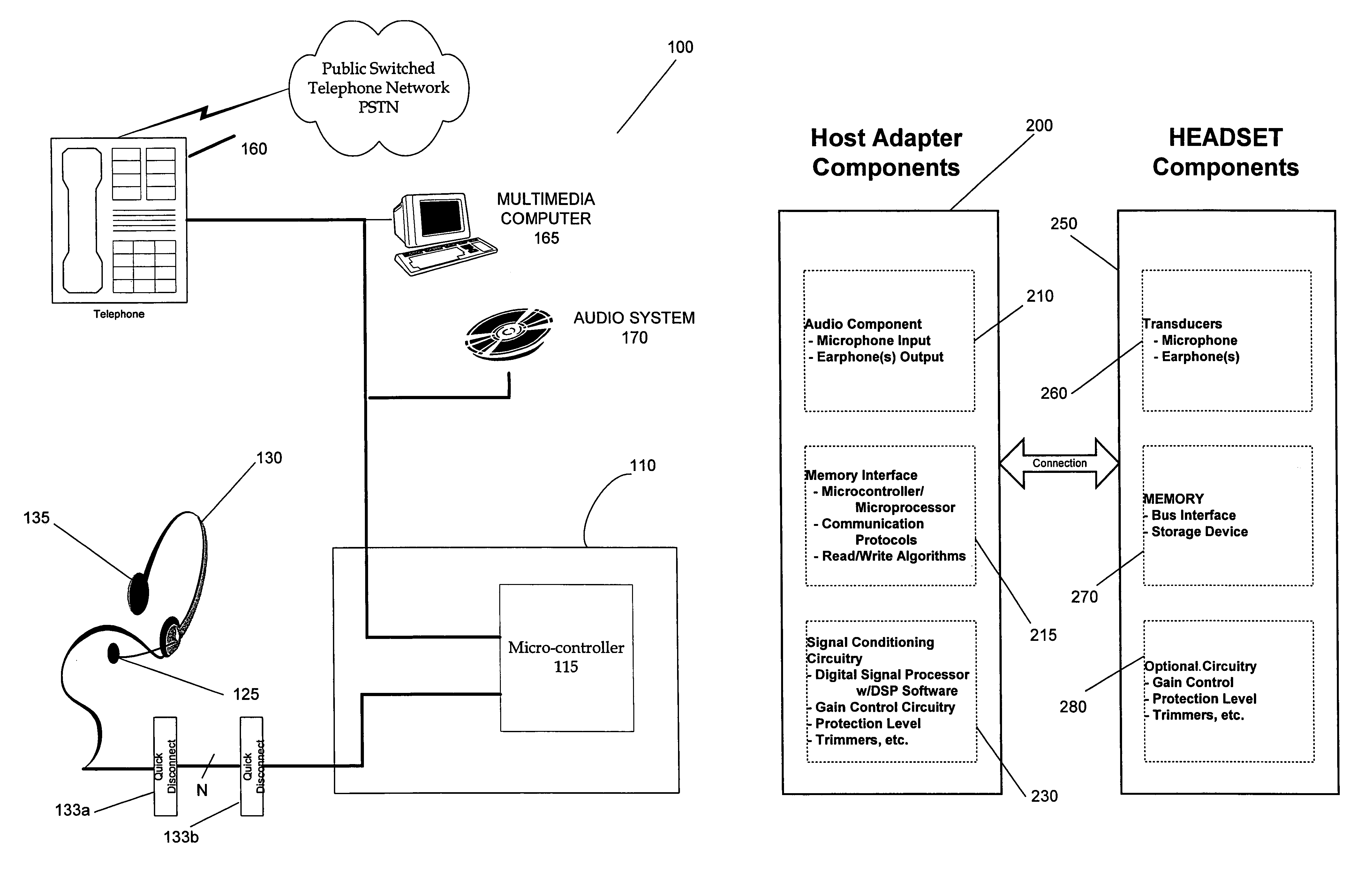

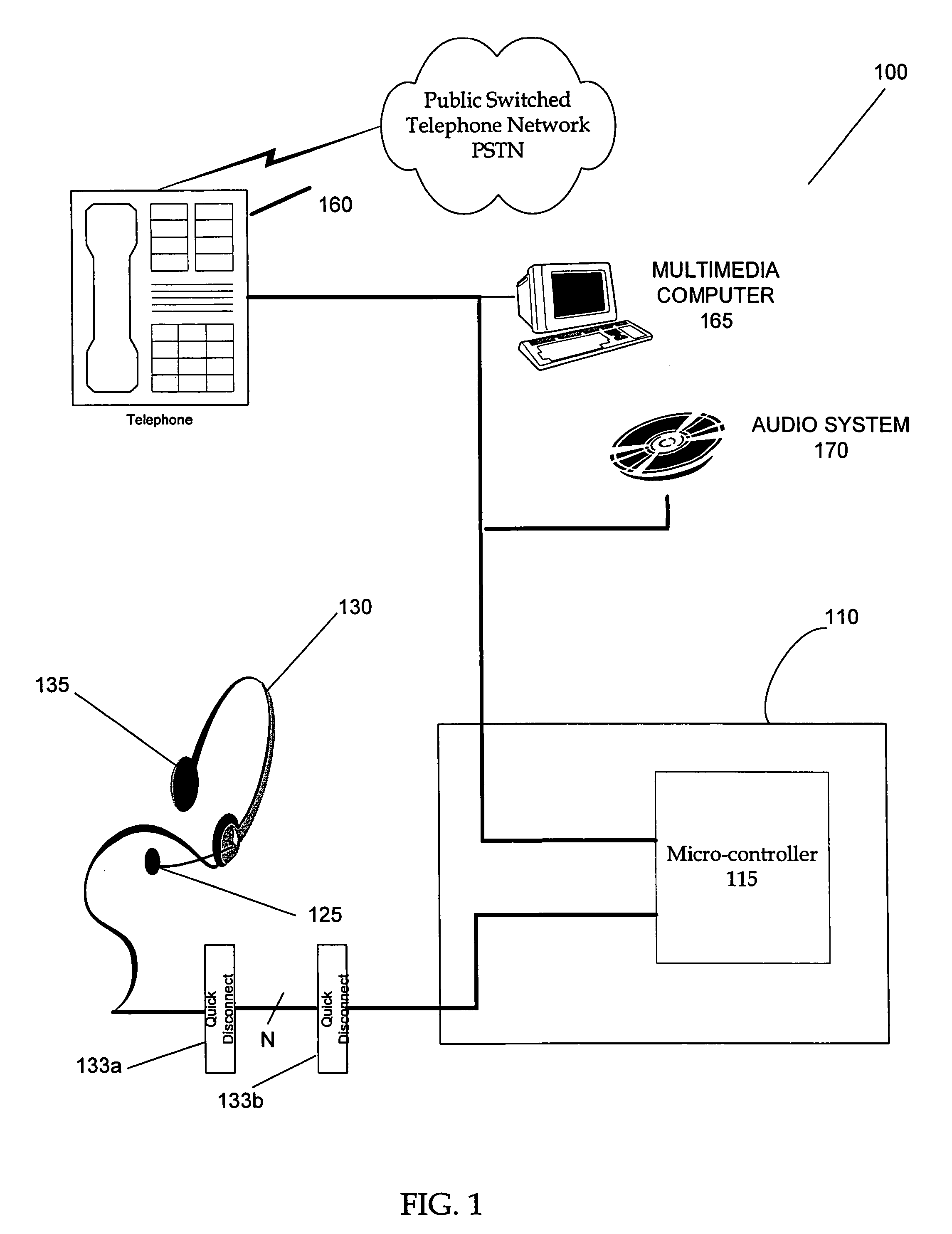

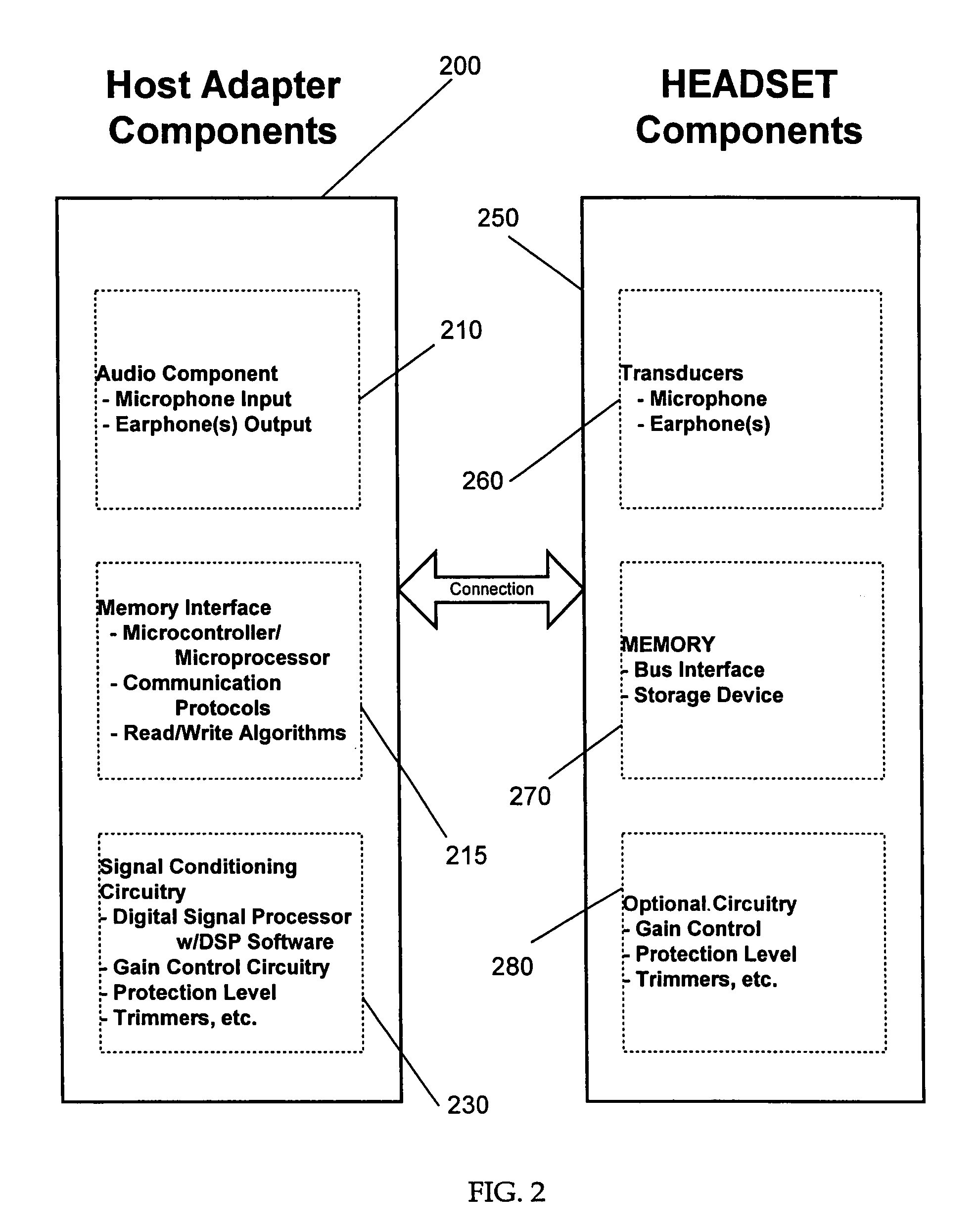

Headset with memory

InactiveUS7283635B1Streamline productionFacilitate future serviceMicrophonesLoudspeakersHeadphonesModel Number

A headset having a built-in memory to store parameter settings relating to headset performance characteristics such as headphone(s) and / or microphone performance characteristics. The performance characteristics can be measured during headset production and stored in the memory. A host adapter may communicate with the headset through a serial communications port of the headset. The host adapter may read the headset performance characteristics and adjust signals transmitted to and received from the headset in accordance thereto. When the headset is used in a system, the system parameters can be manually set and stored in the headset memory. When the headset is used again in the same system, the system parameters can be read from the memory and automatically set. The memory may also store product history information of the headset such as production date, serial and model numbers, and / or any service history.

Owner:PLANTRONICS

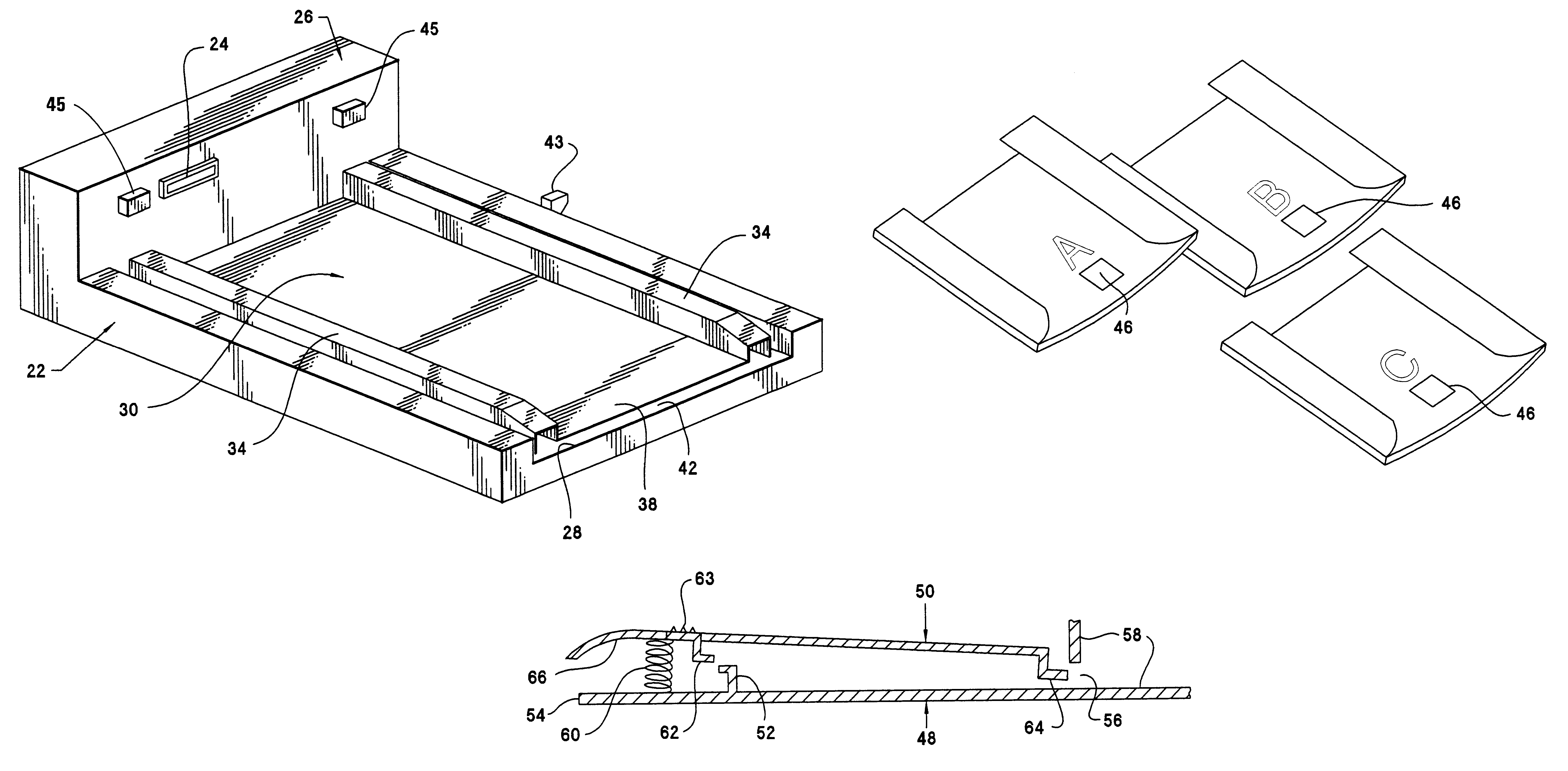

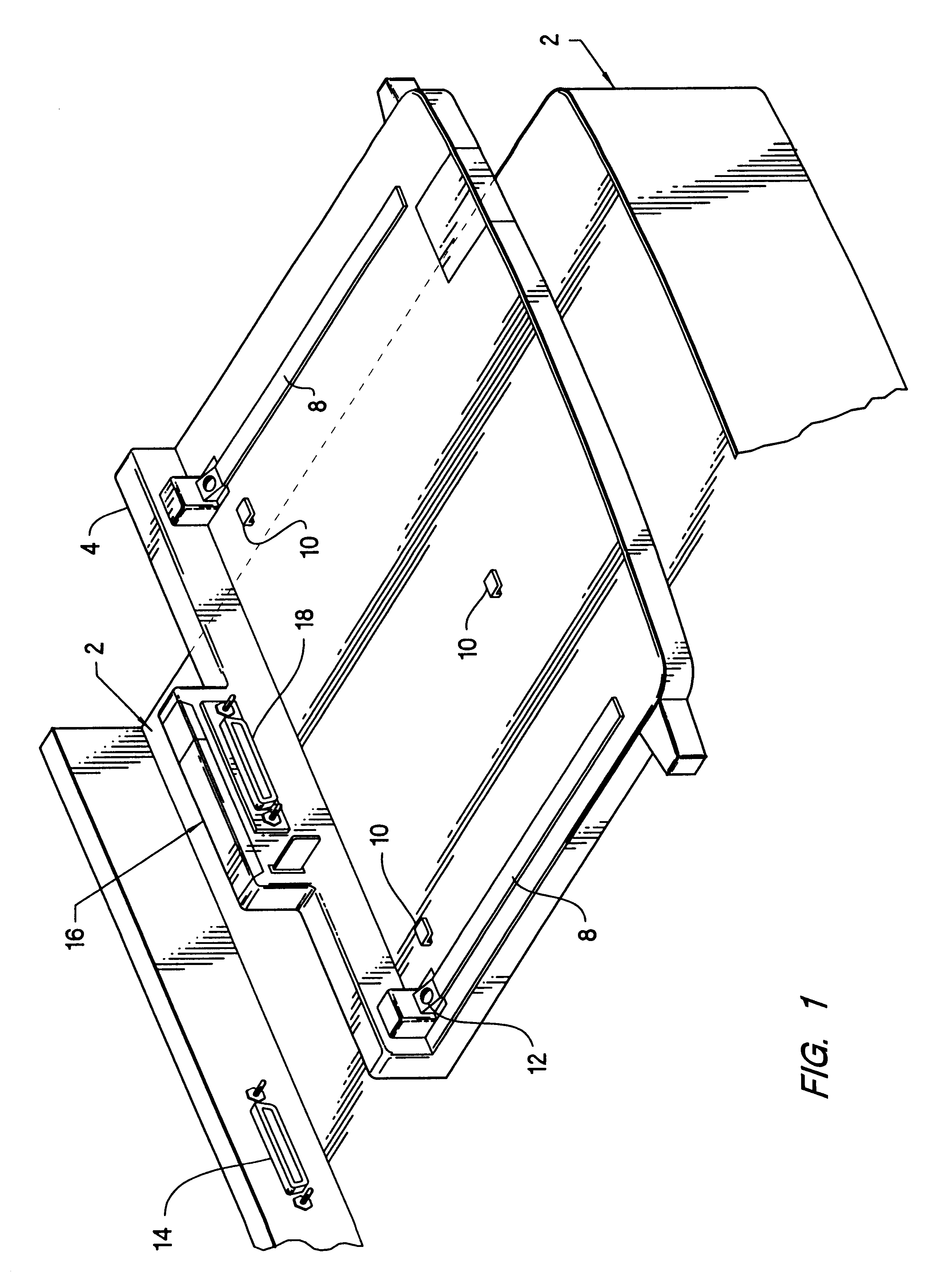

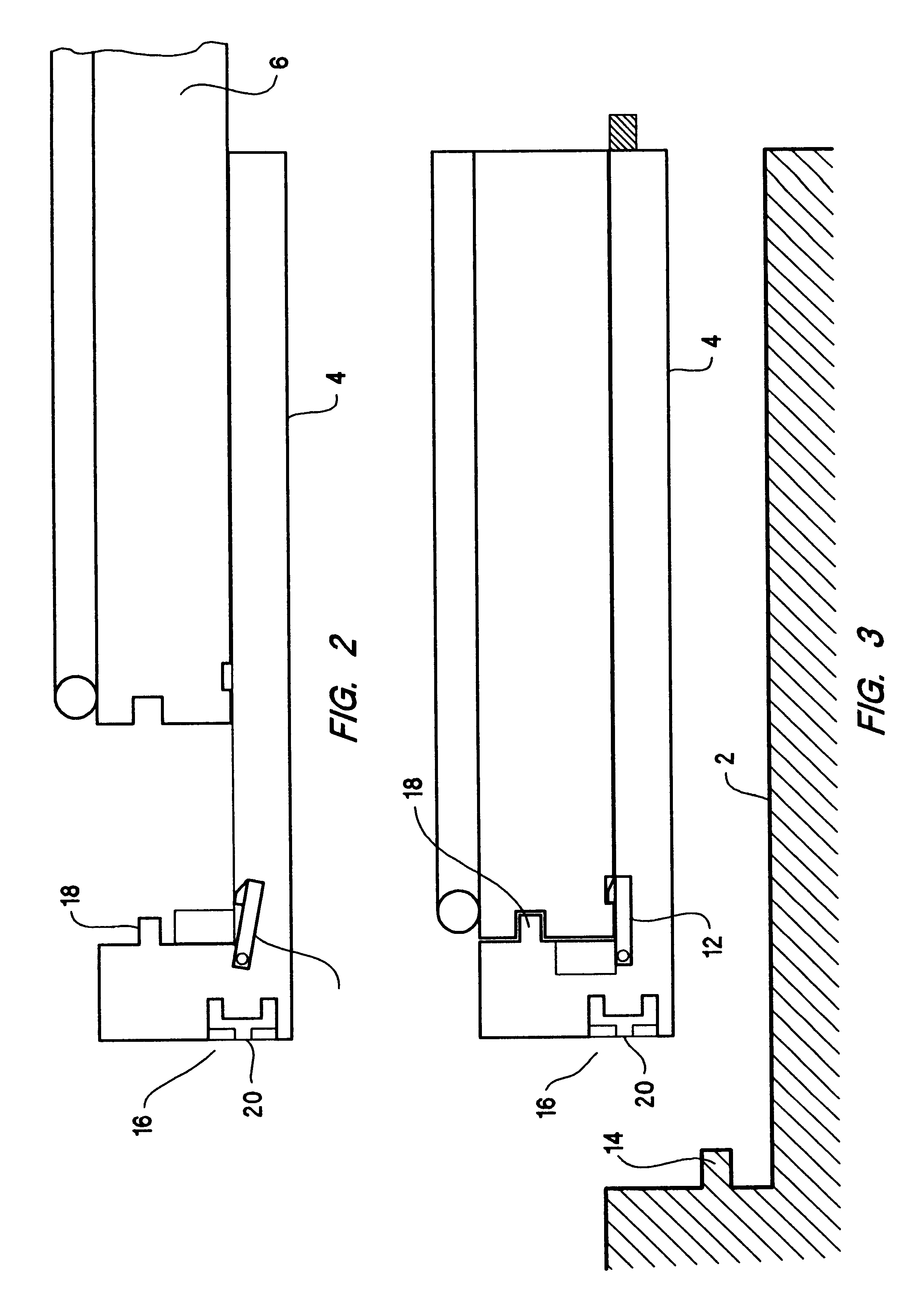

Docking station having a plurality of adapter trays for a plurality of portable computers

InactiveUS6301106B1Few structuresReduce manufacturing costBatteries circuit arrangementsDigital data processing detailsDocking stationProduction line

The invention provides a single docking station structure which is usable for a set of different pieces of equipment having essentially similar interfaces, such as a manufacturer's line of portable ("notebook" or "laptop") computer product models. A common first module supports interfaces with peripheral devices or the like. A model-specific second module, second from a set of second modules that correspond with various models from the line of portable computers, is coupled with the first module to support the portable computer. The second module supports the portable computer, so as to interface it directly with the interface on the first module. The second modules, preferably configured as trays for holding the portable computers, are very simple and inexpensive to manufacture. The trays can be stored next to the docking station (like magazines on a bookshelf). An identification system, which labels the different trays and cross-references them to the corresponding portable computers, allows for future changes in the manufacturer's product line, in which a new model of portable computer requires either a new tray or one of the previously existing trays. The invention is advantageous to manufacturers because it reduces the number and variety of docking station products required for use with the manufacturer's portable computers.

Owner:HEWLETT PACKARD DEV CO LP

System and method for providing a score for a used vehicle

One embodiment of the system and method described herein provides a score generator system that generates an automated vehicle specific valuation of a used car based on the physical and historical attributes of that vehicle. This score may indicate the likelihood that the vehicle will be on the road in a specific period of time. The score may give an absolute percentage of such likelihood or it may give a value relative to all other used vehicles in a database, all other used vehicles of the same make / model / year, or a certain subset of the vehicles in a database. In one embodiment, the score generator system includes a data link module for linking vehicle data and filter module for applying a multi-level filters that process the linked vehicle data.

Owner:EXPERIAN INFORMATION SOLUTIONS

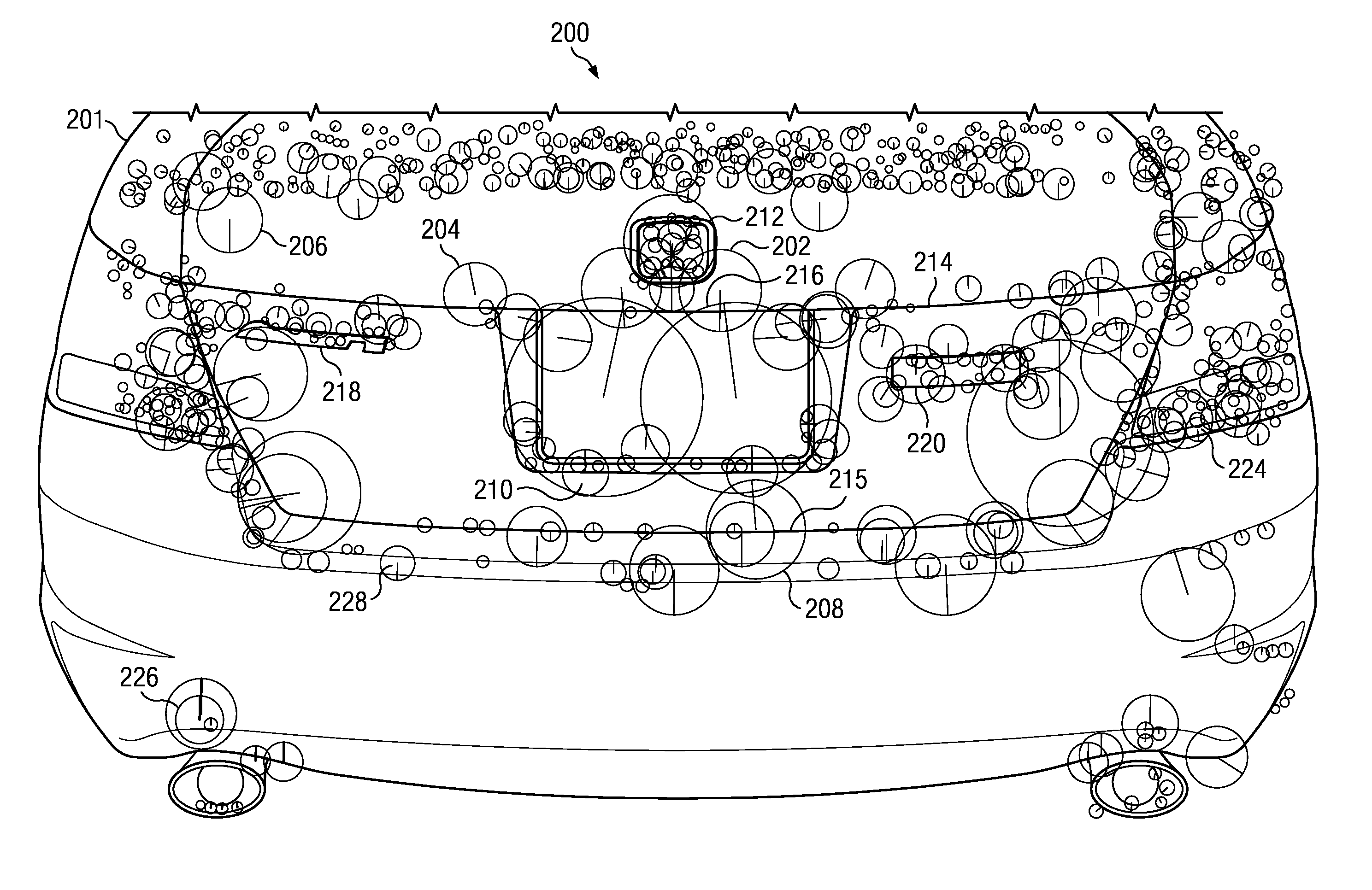

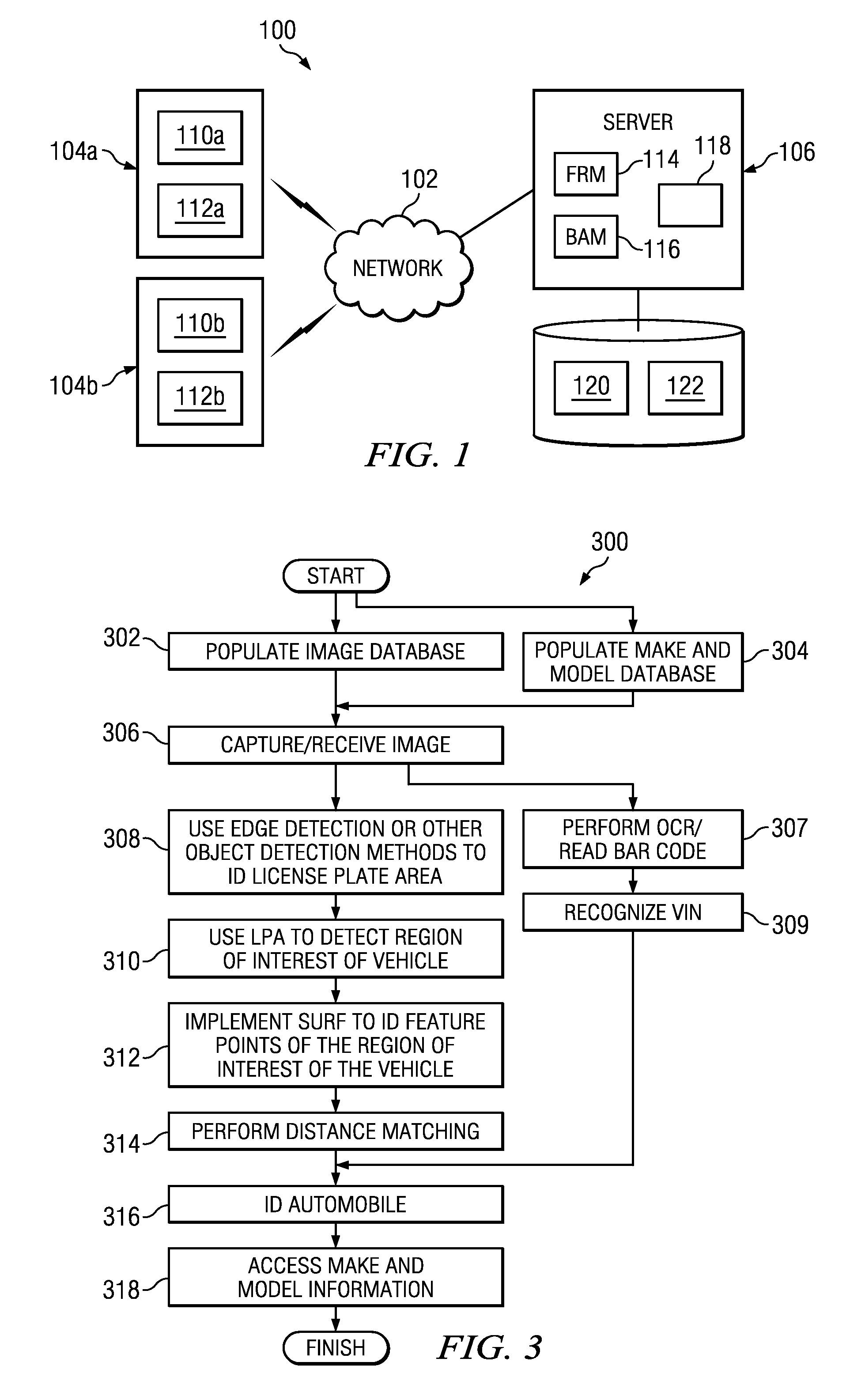

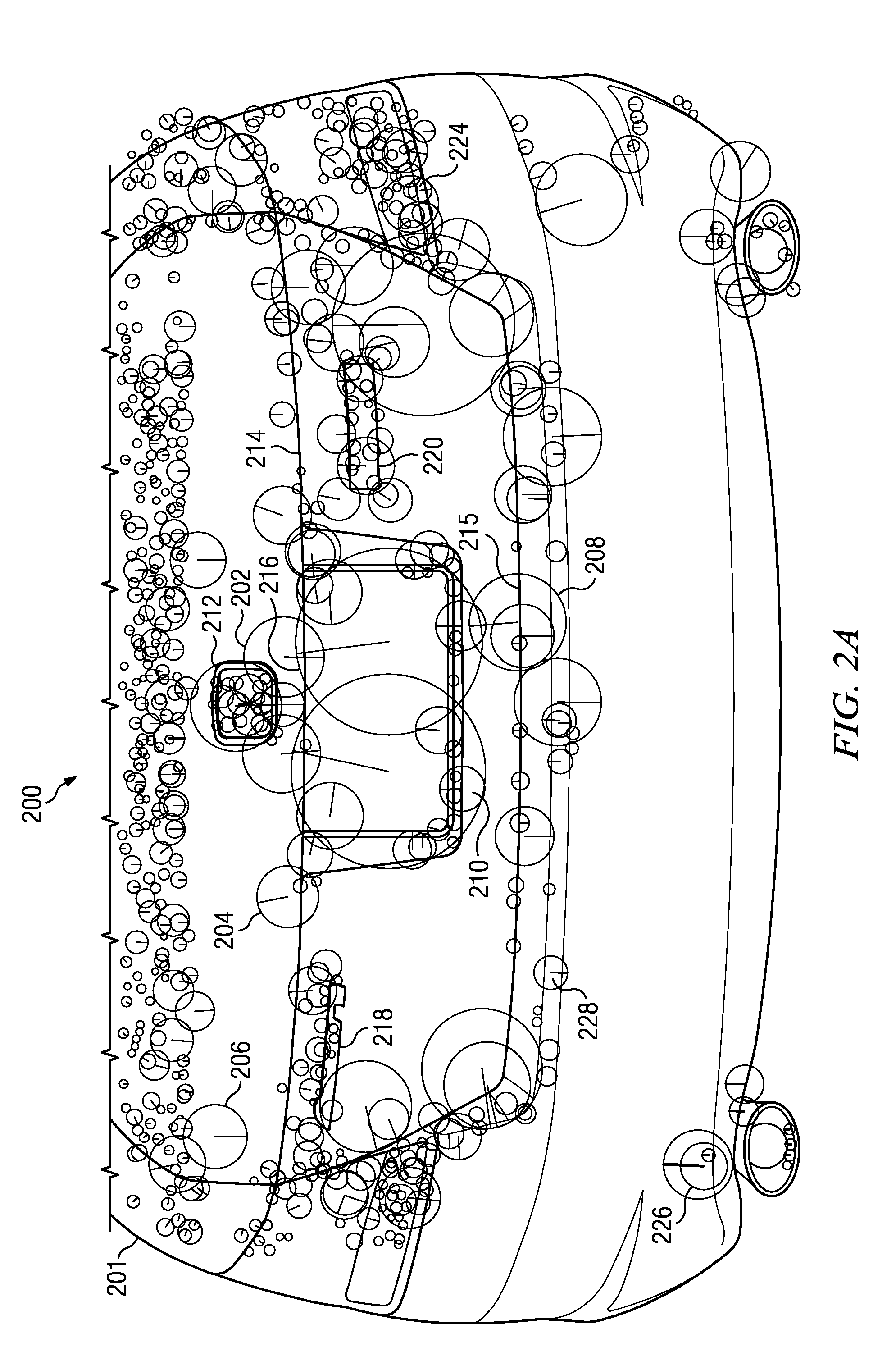

System and method for providing automotive purchase, insurance quote, and vehicle financing information using vehicle recognition

ActiveUS20130329943A1Easy to displayPrecise processingCharacter and pattern recognitionUser deviceService provision

A system for providing vehicle information at an automobile point of purchase includes a user device having a camera or other image capturing device that is used to capture an image of an automobile. An application on or associated with the image capturing device can either transmit the image to a service provider for processing, or can implement one or more steps in a feature recognition process locally, and thereafter transmit the data to a service provider. In either case, the service provider can then complete the feature recognition processing and identify the automobile from the image. The service provider can then communicate with a make and model database to provide useful information on the vehicle, which can then be transmitted to the user device and conveniently displayed.

Owner:STATE FARM MUTUAL AUTOMOBILE INSURANCE

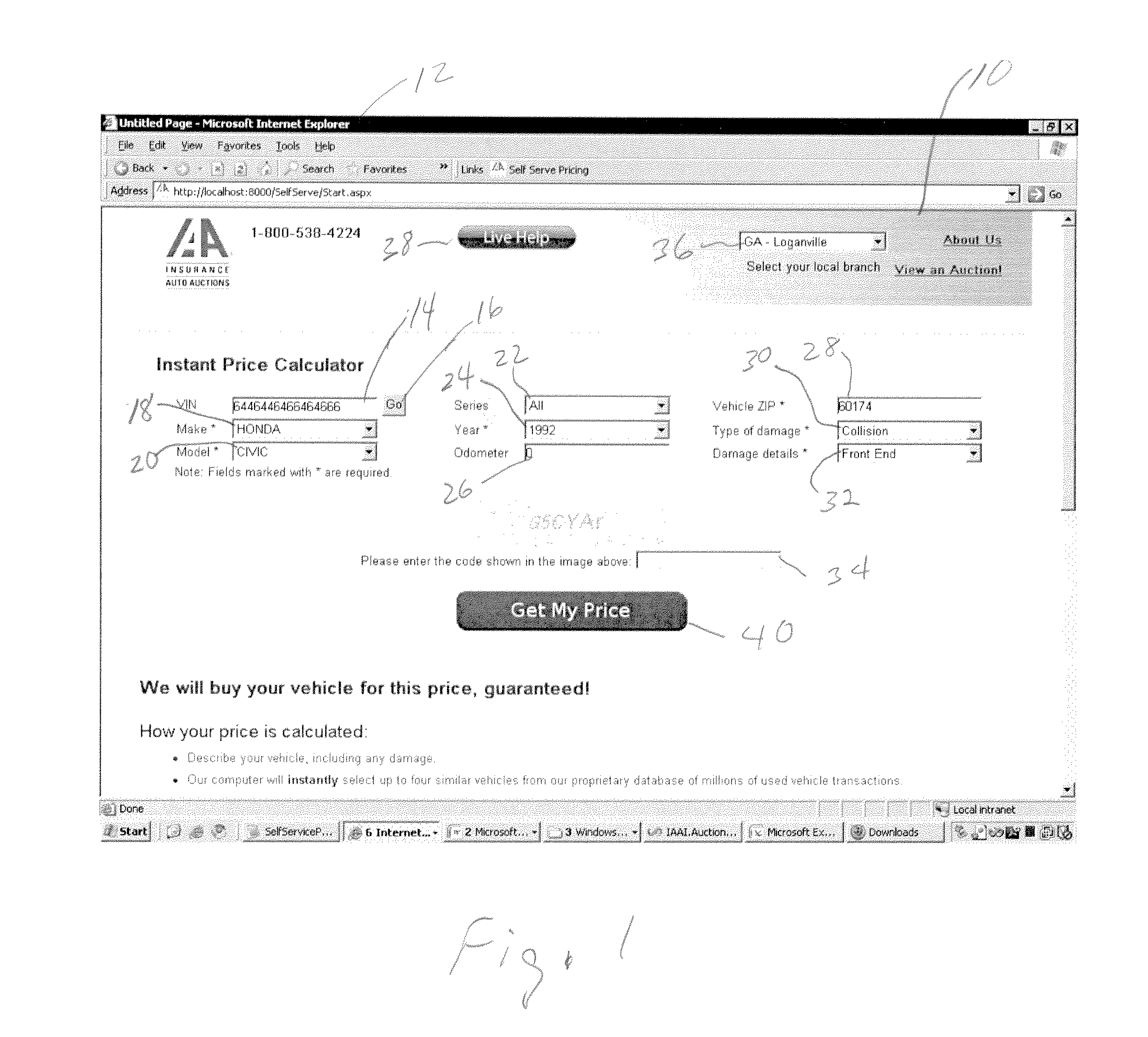

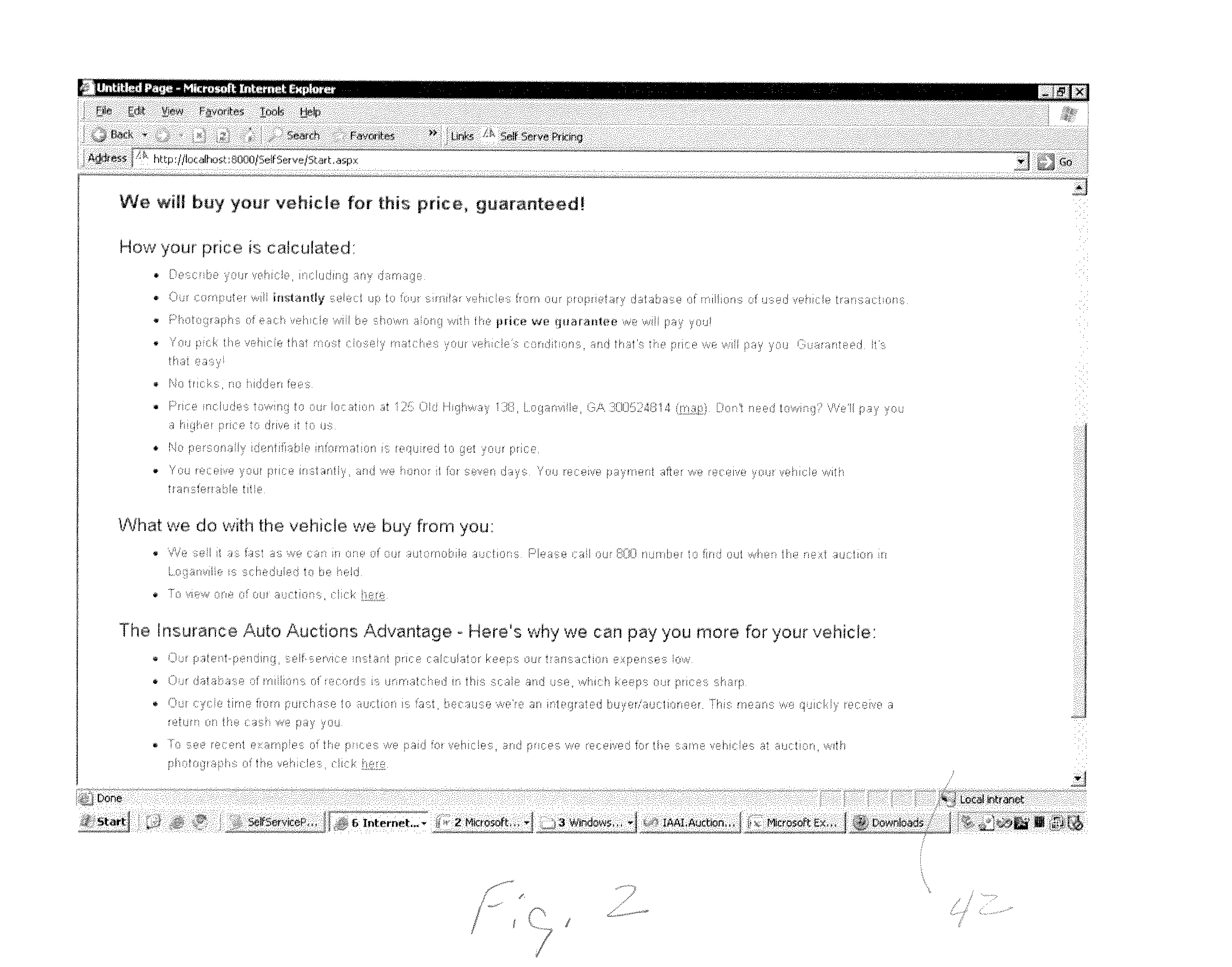

Method and apparatus for estimating value of a damaged vehicle

InactiveUS20110313936A1Product appraisalBuying/selling/leasing transactionsPrice differenceModel Number

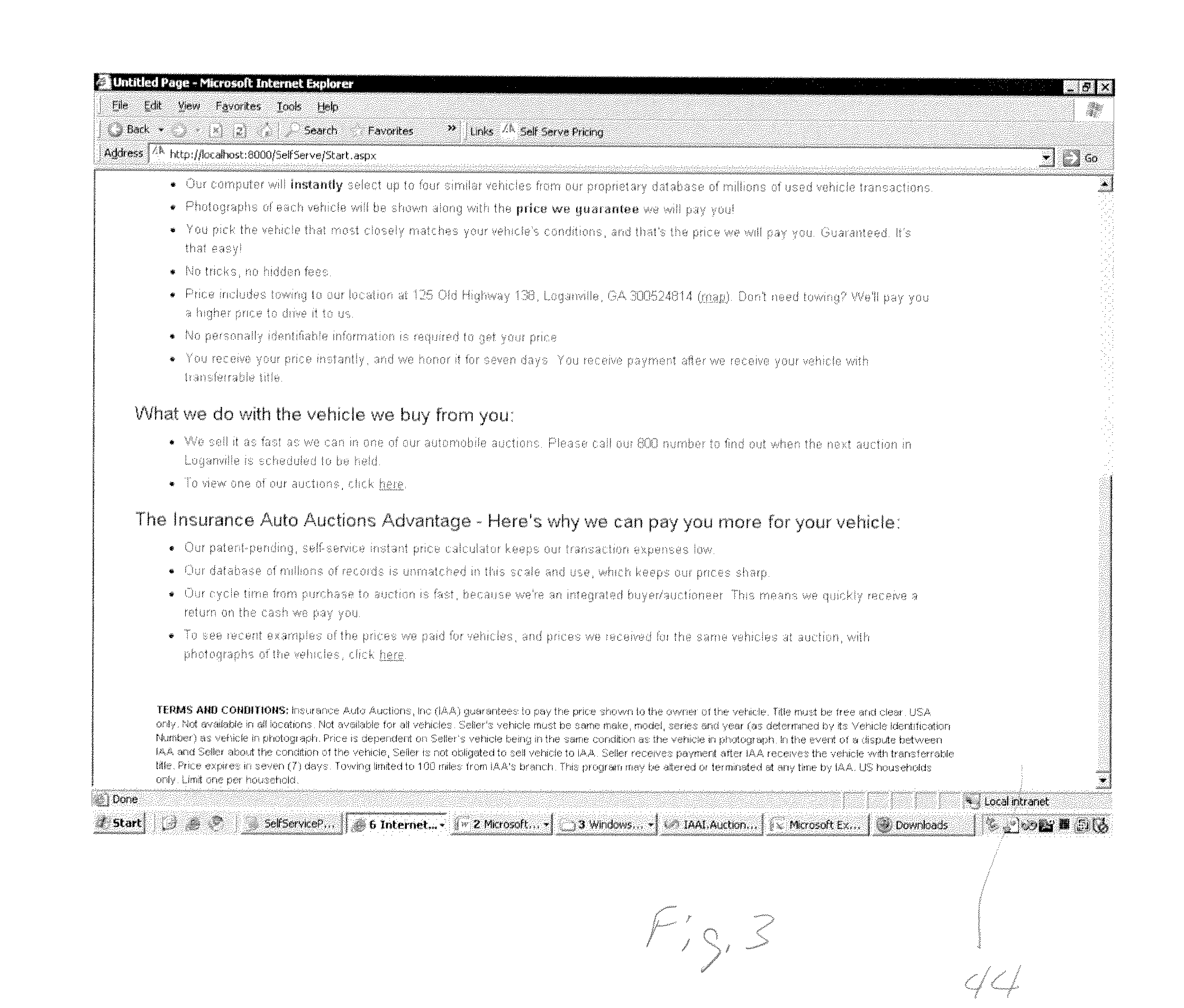

A method and apparatus by which a user who wishes to sell a used or damaged vehicle inputs information about the vehicle including make, model and year. The user is shown images of similar vehicles with various degrees of damage and is shown a purchase price at each level of damage. The purchase prices for the displayed vehicles are calculated to include auction price of the vehicle, regional price differences, title transfer costs, towing costs, etc. By selecting an image of a vehicle with damage as the vehicle to be sold, the user may sell the vehicle at that price. An agent embodiment shows images, prices and percentiles of damaged vehicles at different damage levels so that the agent may determine a price to be offered to the seller for a vehicle.

Owner:INSURANCE AUTO AUCTIONS

RFID detection and identification system for implantable medical lead systems

A system for identifying active implantable medical devices (AIMD) and lead systems implanted in a patient using a radio frequency identification (RFID) tag having retrievable information relating to the AIMD, lead system and / or patient. The RFID tag may store information about the AIMD manufacturer, model number, serial number; lead wire system placement information and manufacturer information; MRI compatibility due to the incorporation of bandstop filters; patient information, and physician and / or hospital information and other relevant information. The RFID tag may be affixed or disposed within the AIMD or lead wires of the lead system, or surgically implanted within a patient adjacent to the AIMD or lead wire system.

Owner:WILSON GREATBATCH LTD

System for transferring information between a server and a data terminal through a network

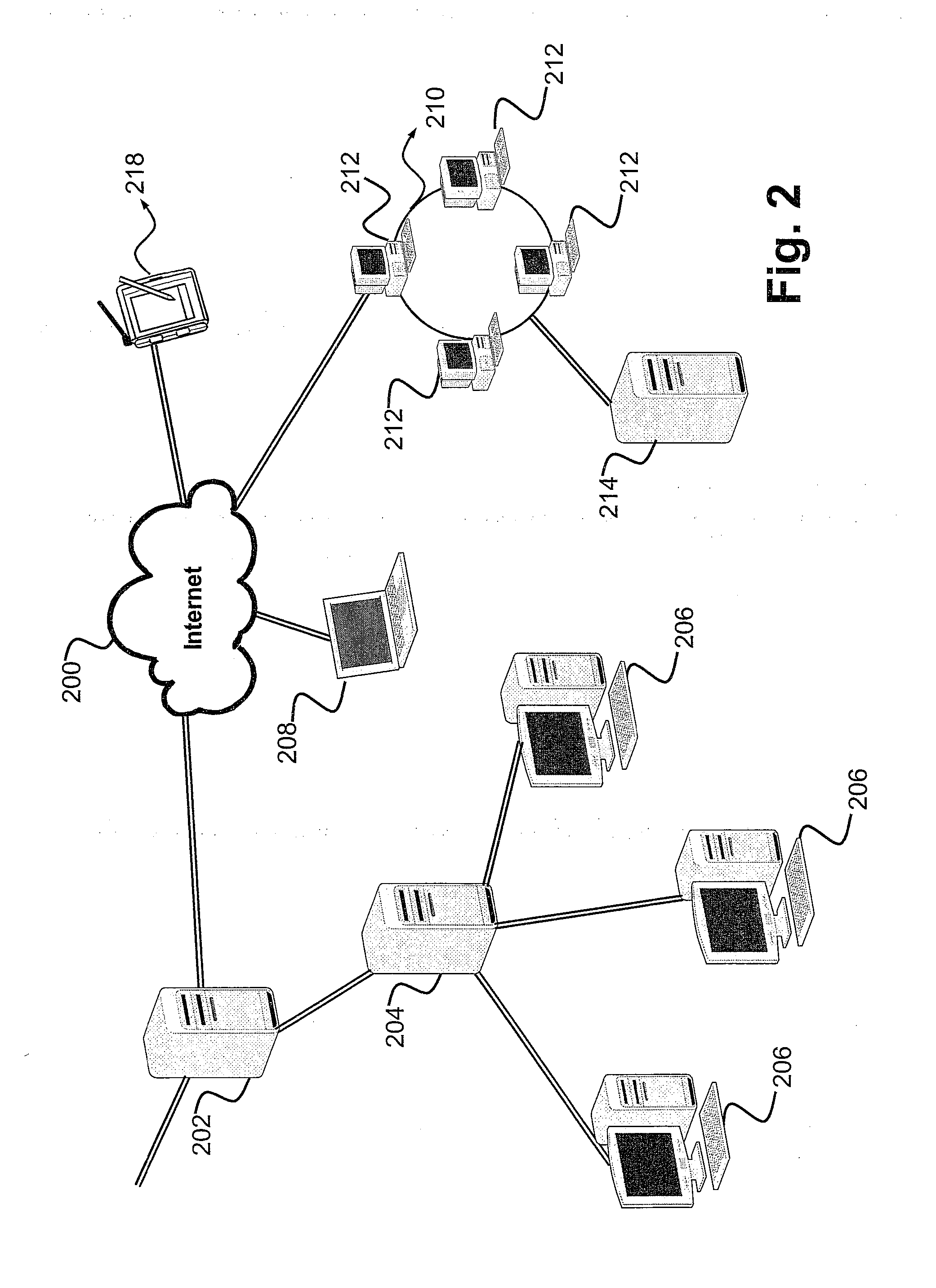

InactiveUS6345298B1Digital data information retrievalMultiple digital computer combinationsData Terminal ReadyData terminal

An information transfer system which includes a data terminal capable of connecting to networks and a central facility capable of connecting to a plurality of the data terminals which may differ from each other in their capabilities and / or features through the network. The data terminal has a model code which indicates its capabilities and / or features and sends the model code to the central facility at every time the data terminal connects to the central facility. The central facility discriminates the model code sent from the data terminal and detects the capabilities and / or the features of the data terminal. Further, the central facility sends information to the data terminal in a manner appropriate to the capabilities and / or features of the data terminal.

Owner:CASIO COMPUTER CO LTD

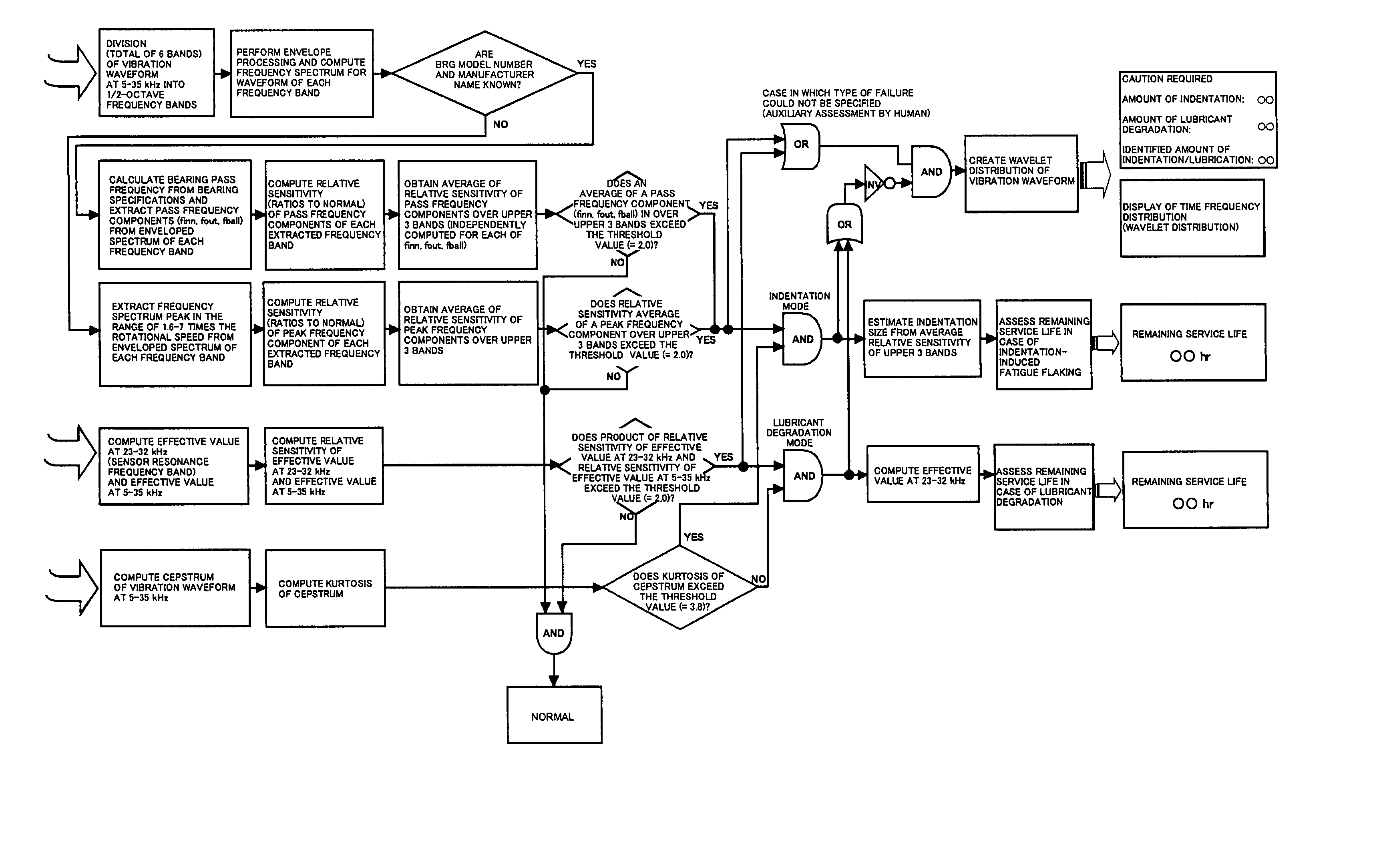

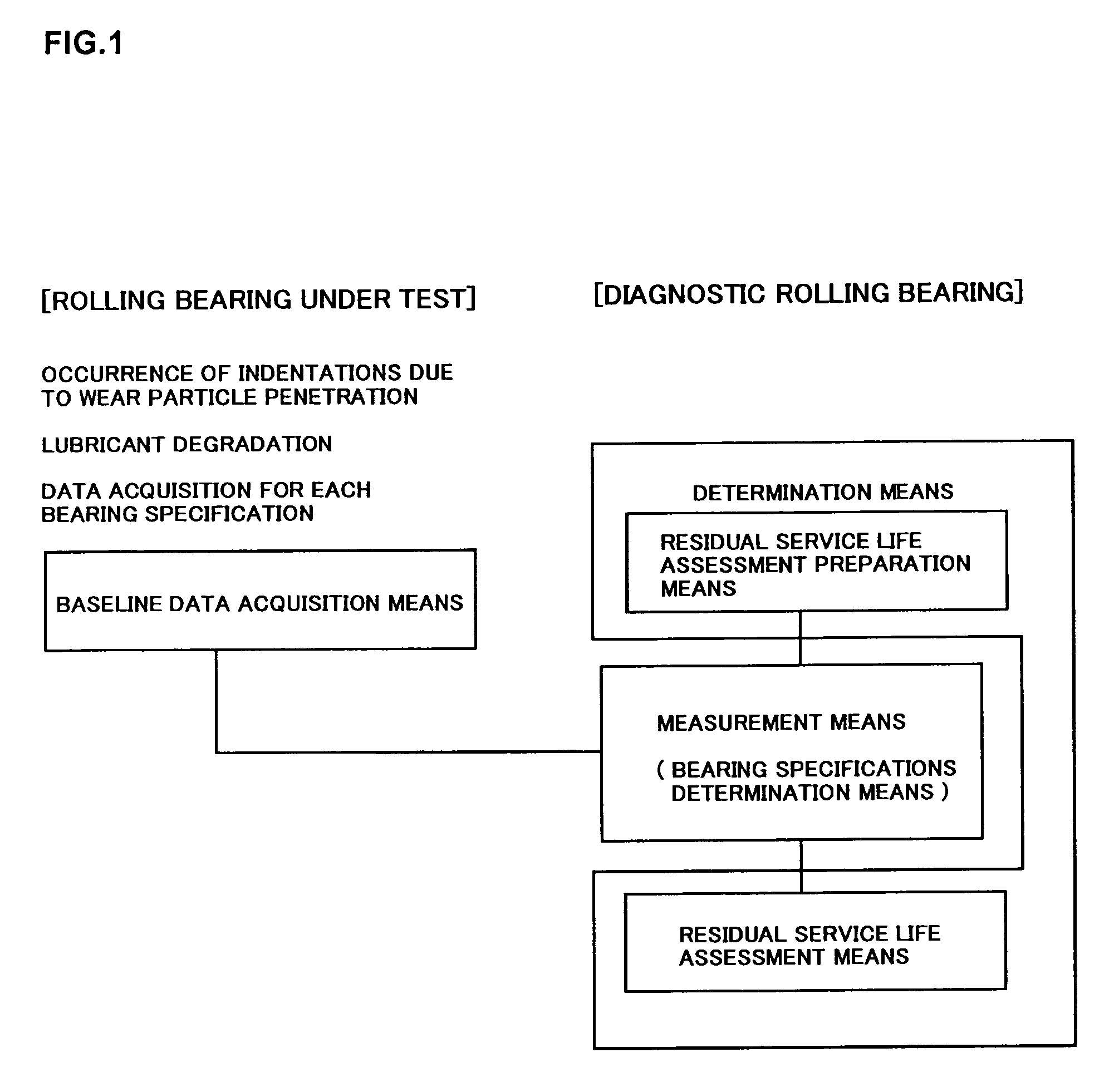

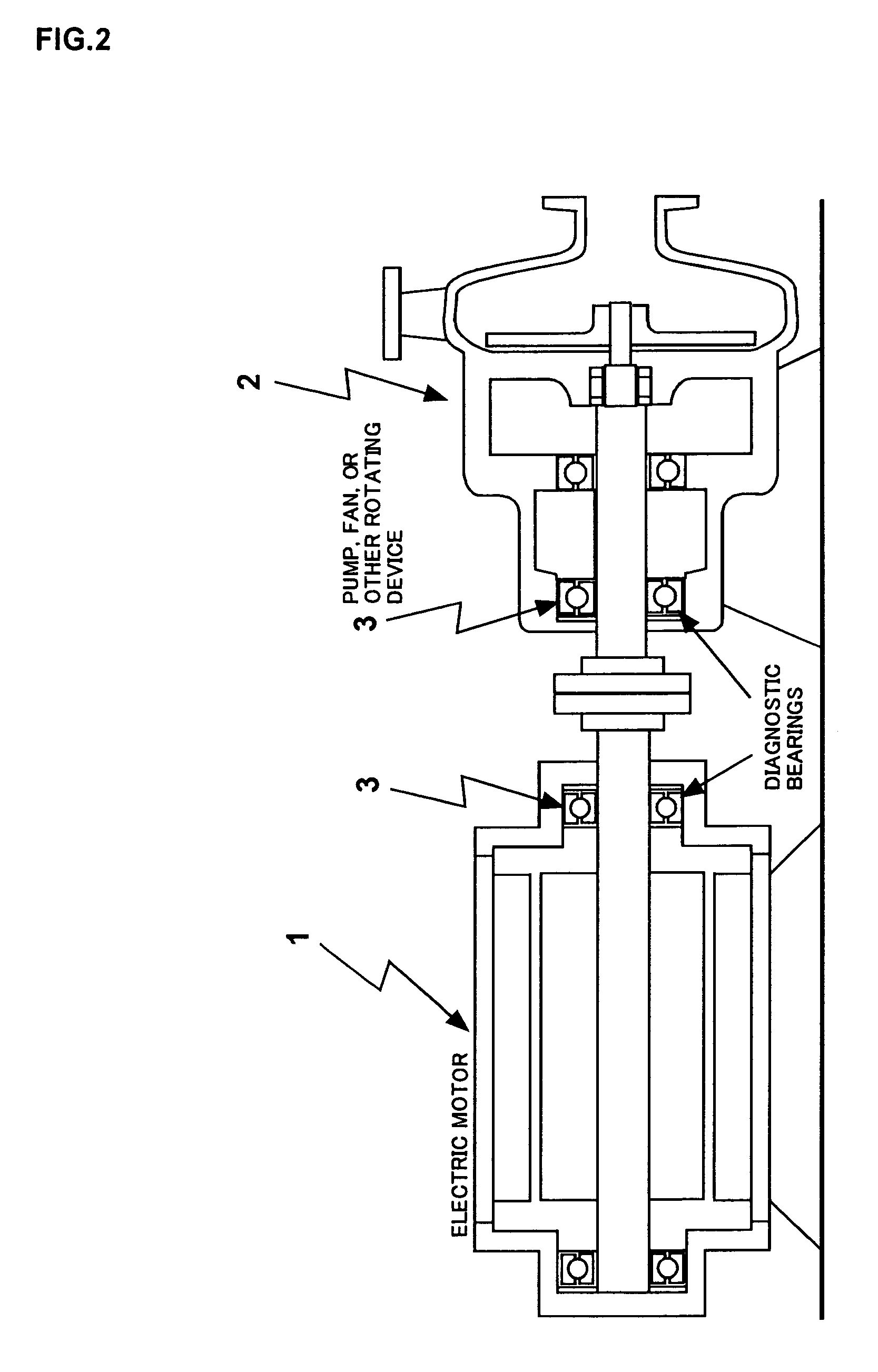

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

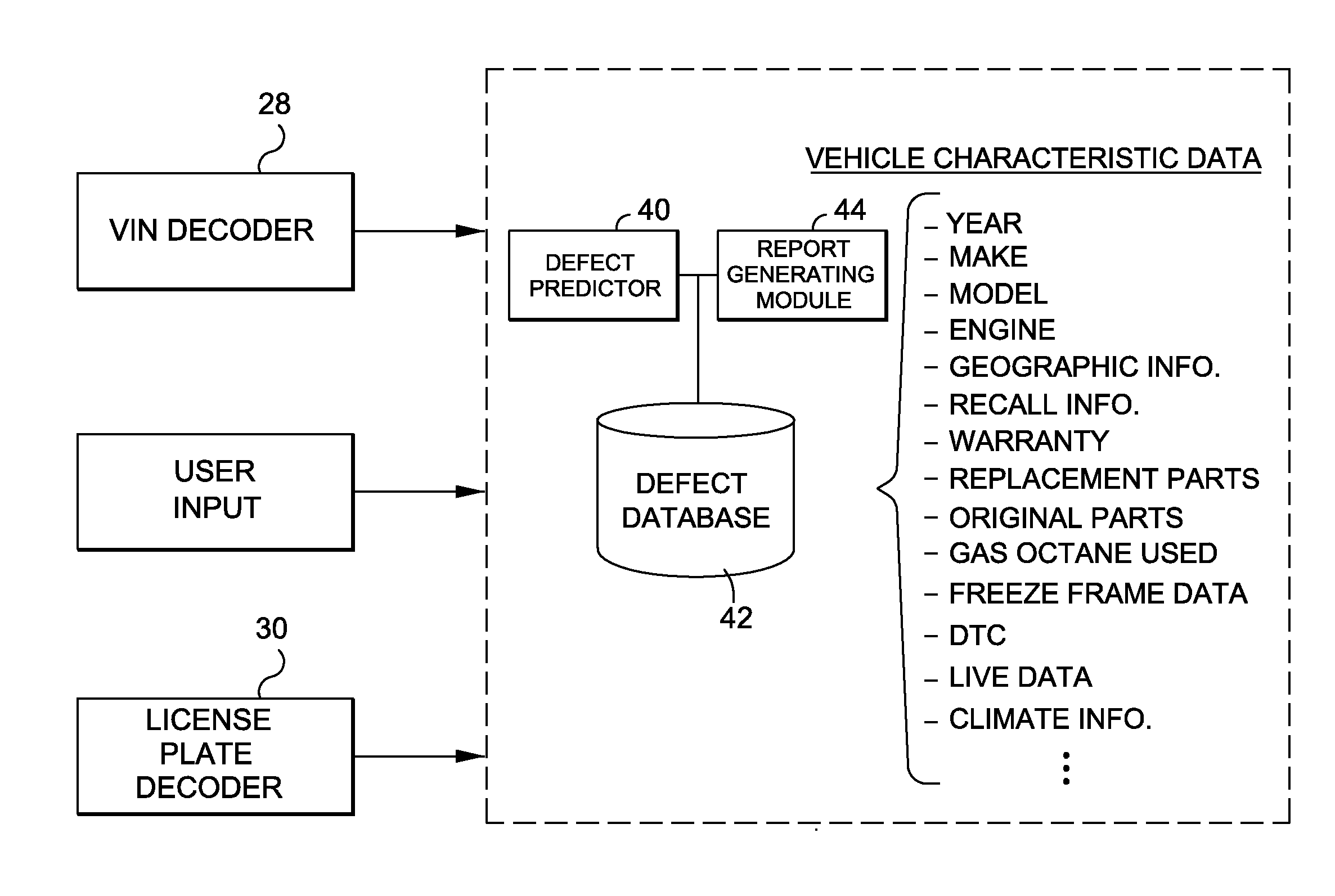

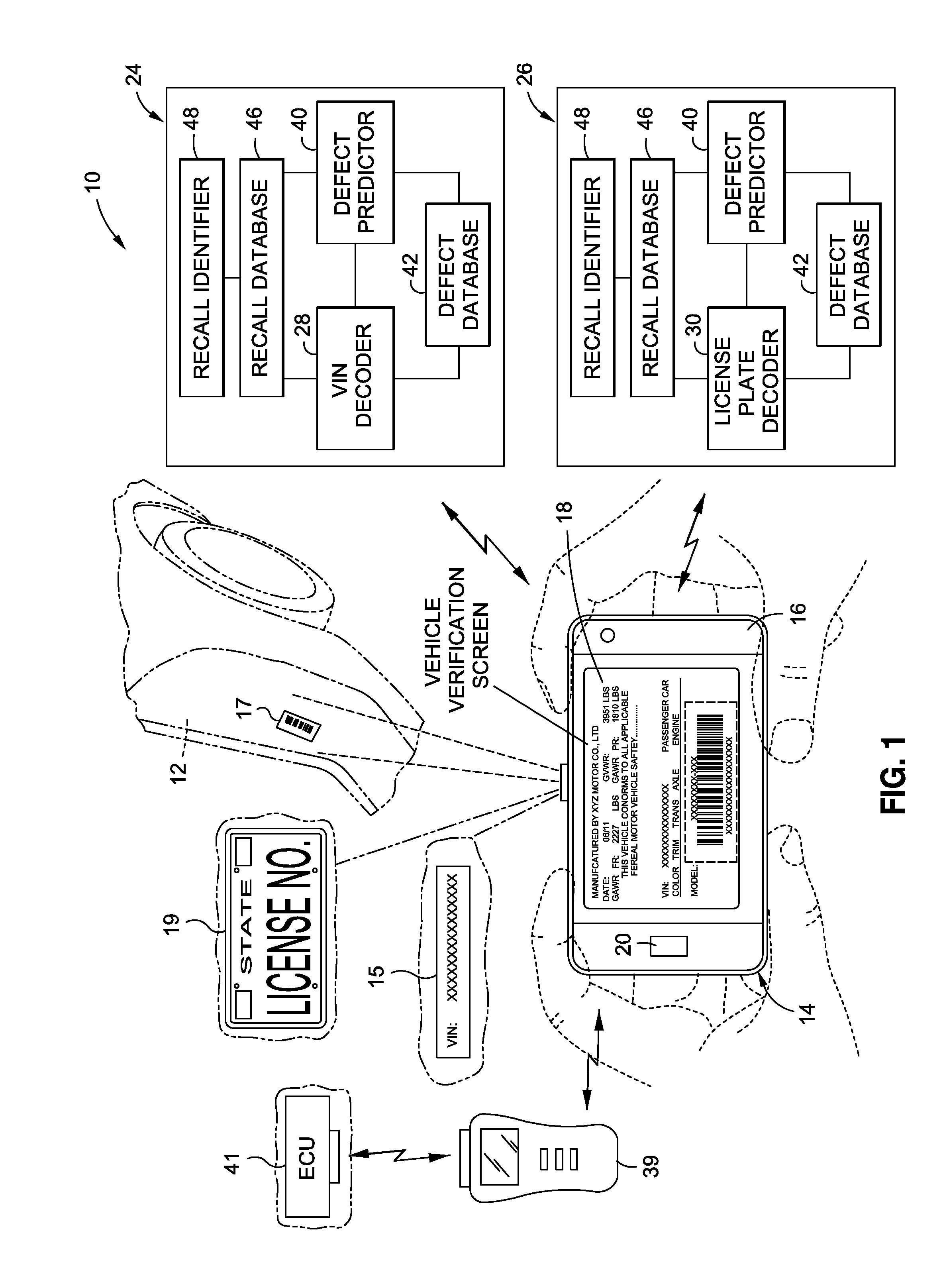

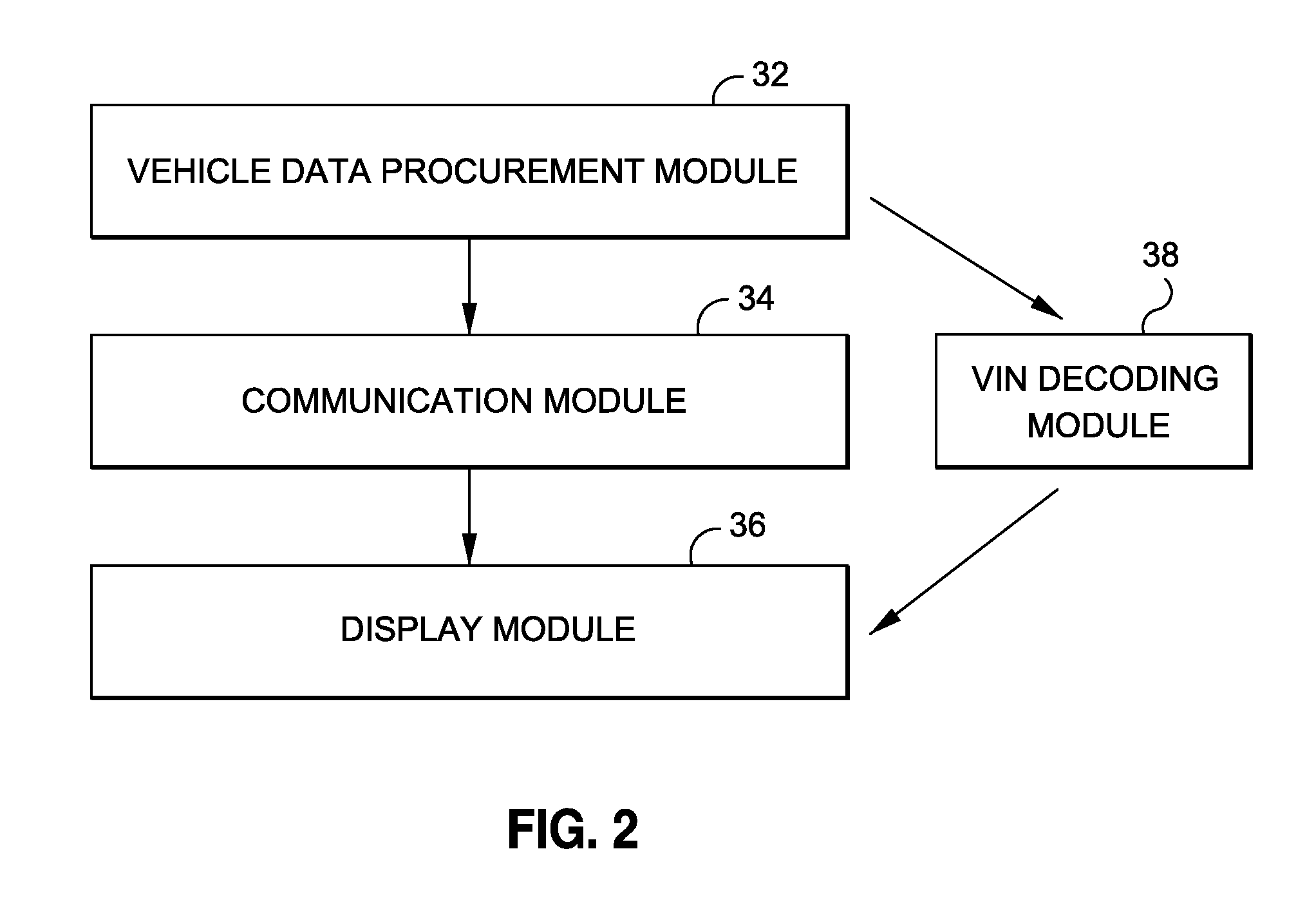

Smart Phone App-Based Method and System of Collecting Information for Purchasing Used Cars

InactiveUS20140046800A1Substation equipmentBuying/selling/leasing transactionsIn vehicleModel Number

Provided is a system for verifying a vehicle for sale on a smart phone. The system includes a VIN decoder capable of decoding a VIN to determine the vehicle year, make, and model of the vehicle for sale. The system further includes a defect predictor and defect database configured to identify defects in vehicles having similar characteristic data to the vehicle associated with the VIN. A computer readable medium is downloadable onto the smart phone to configure the phone to communicate information corresponding to a captured image of the VIN from the vehicle to the VIN decoder. The computer readable medium further configures the smart phone to receive a signal including the characteristic data of the vehicle associated with the VIN, and defects identified by the defect predictor. The computer readable medium further configures the phone to display the received characteristic data and defects.

Owner:INNOVA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com