Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6731 results about "Separation system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

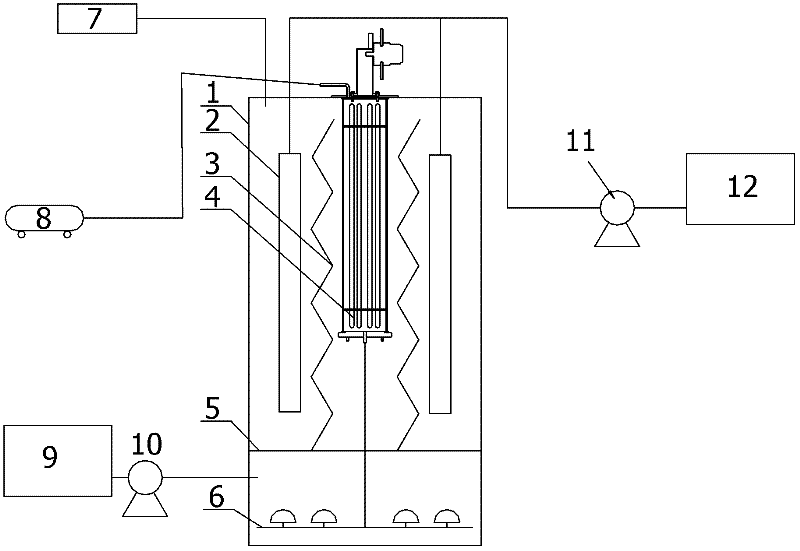

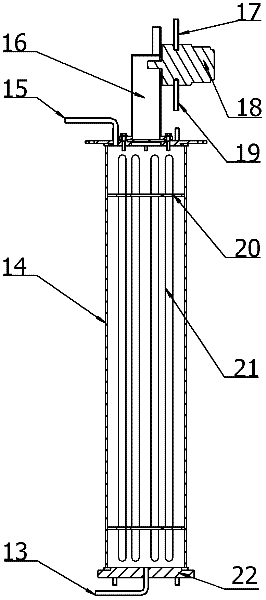

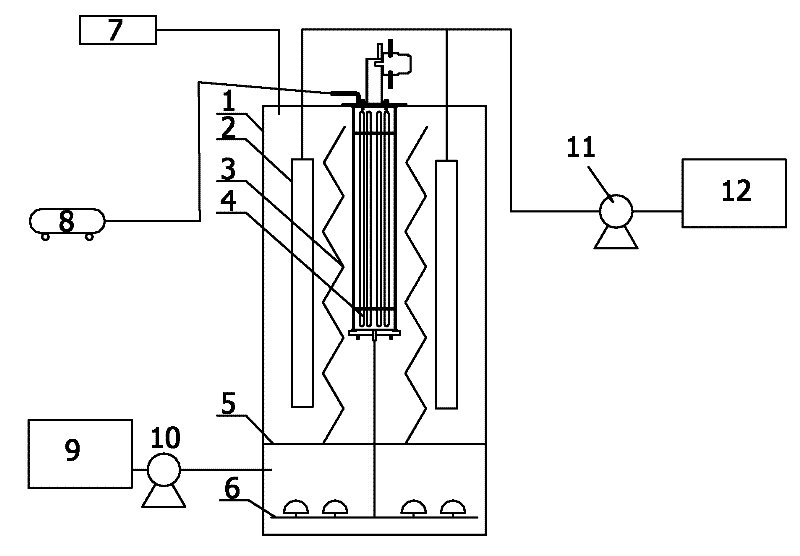

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

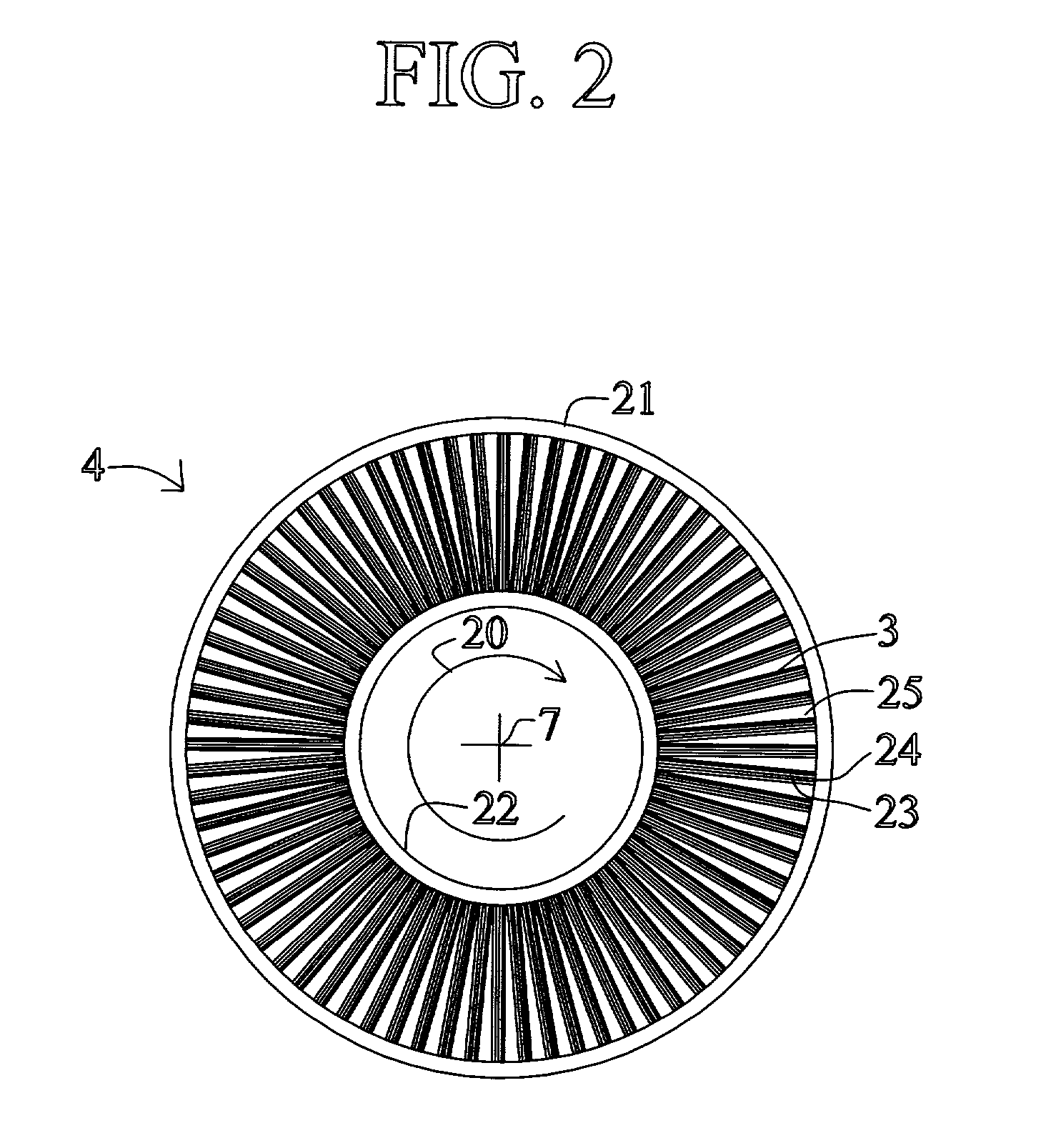

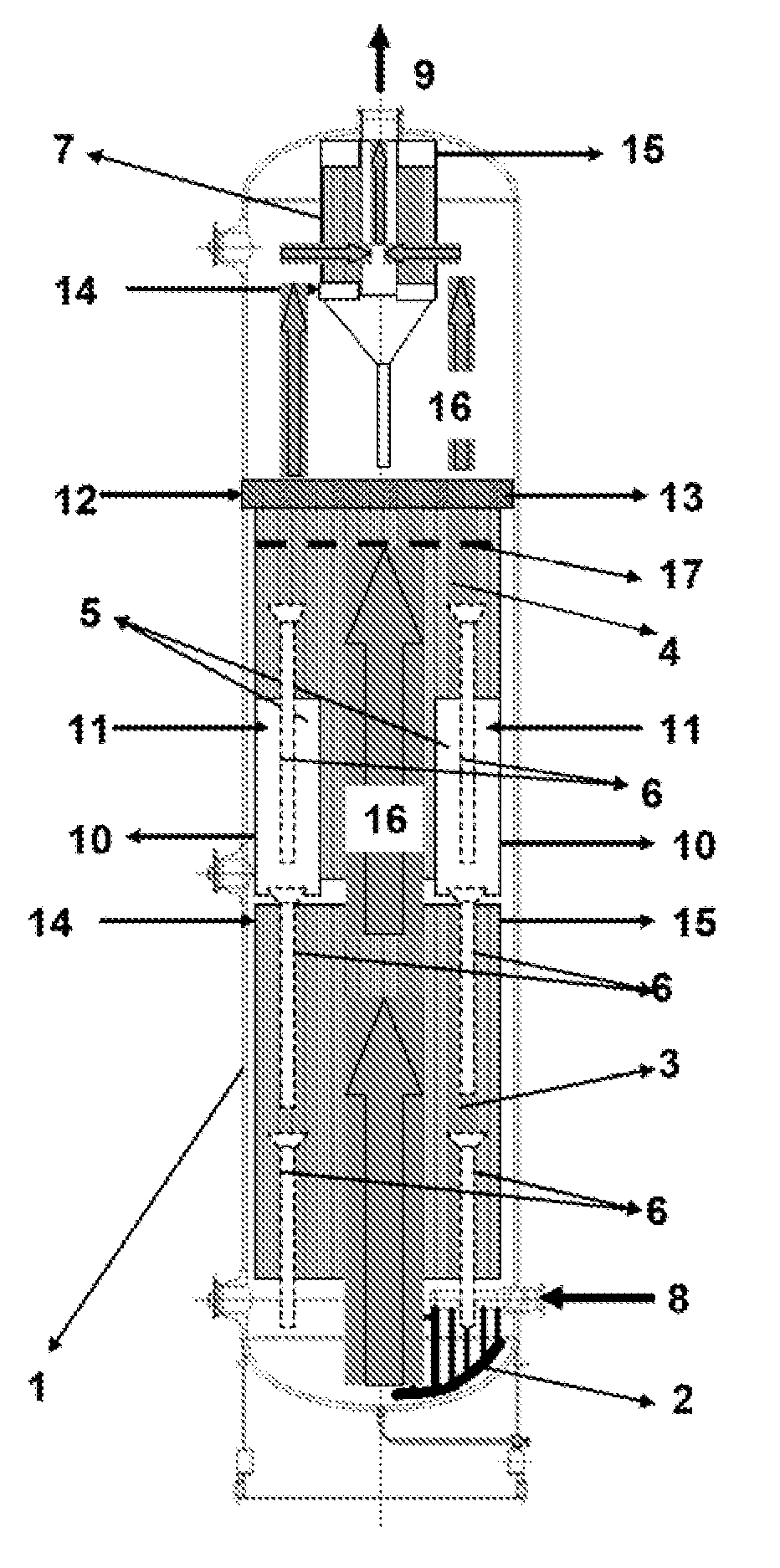

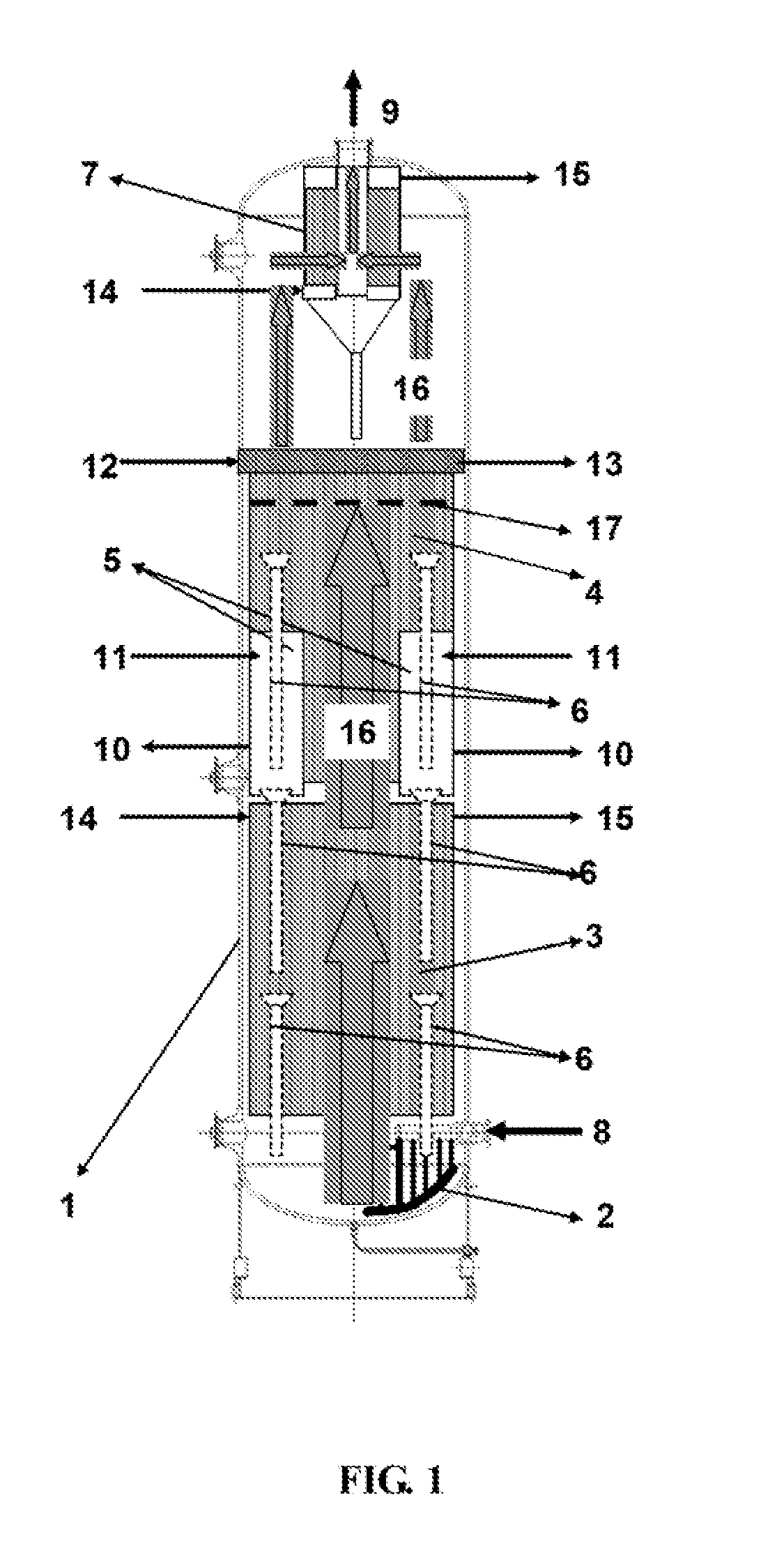

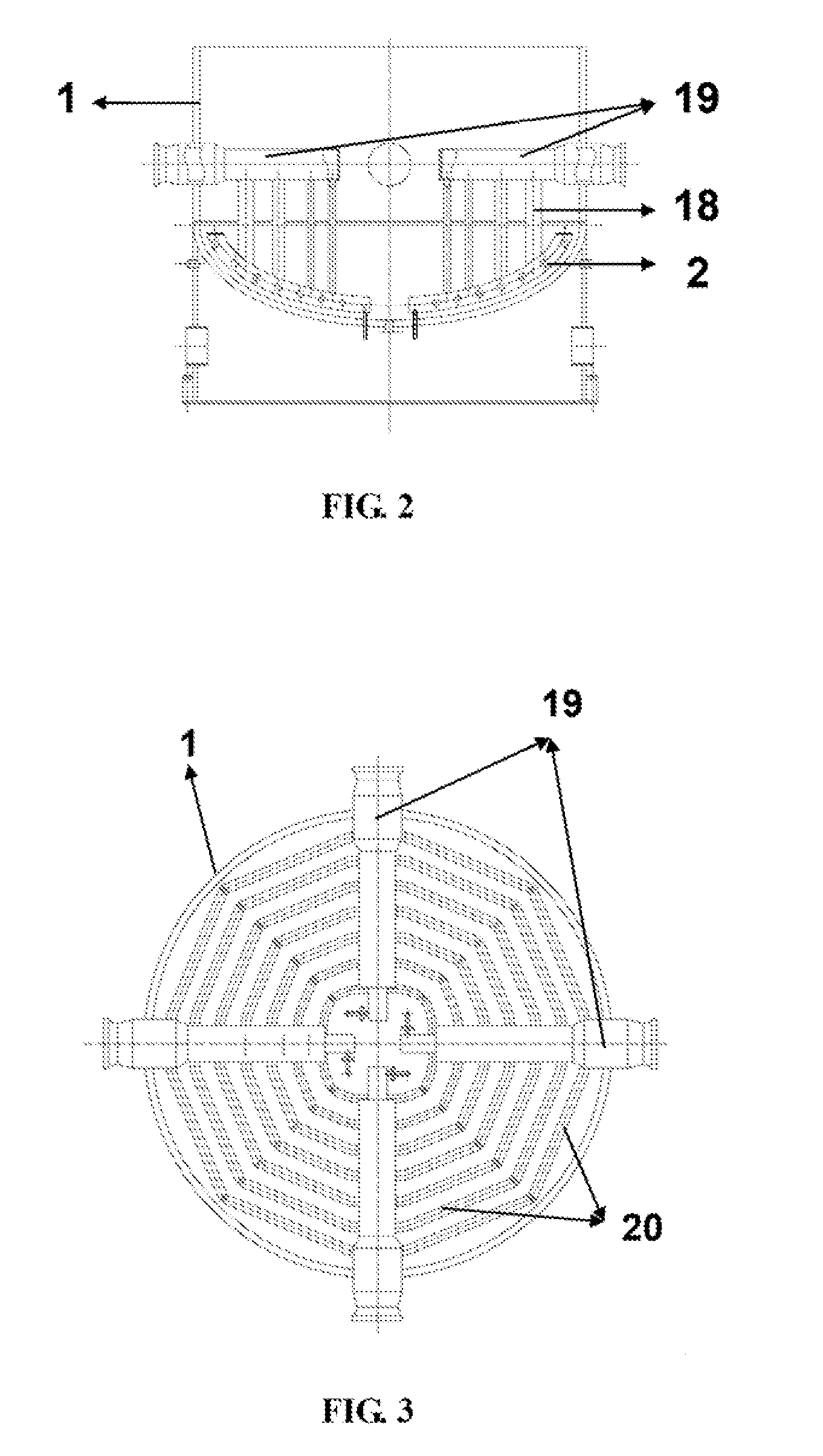

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

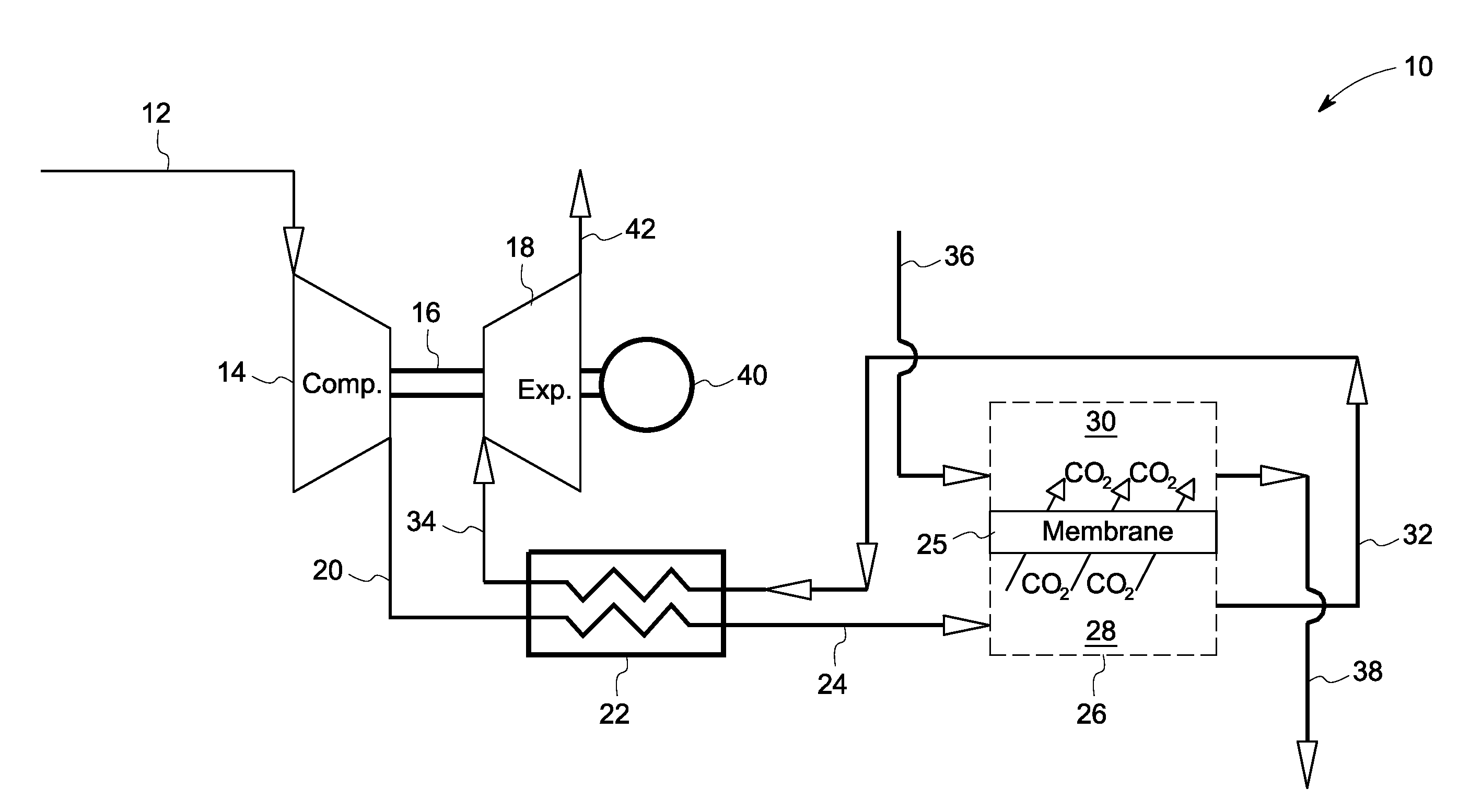

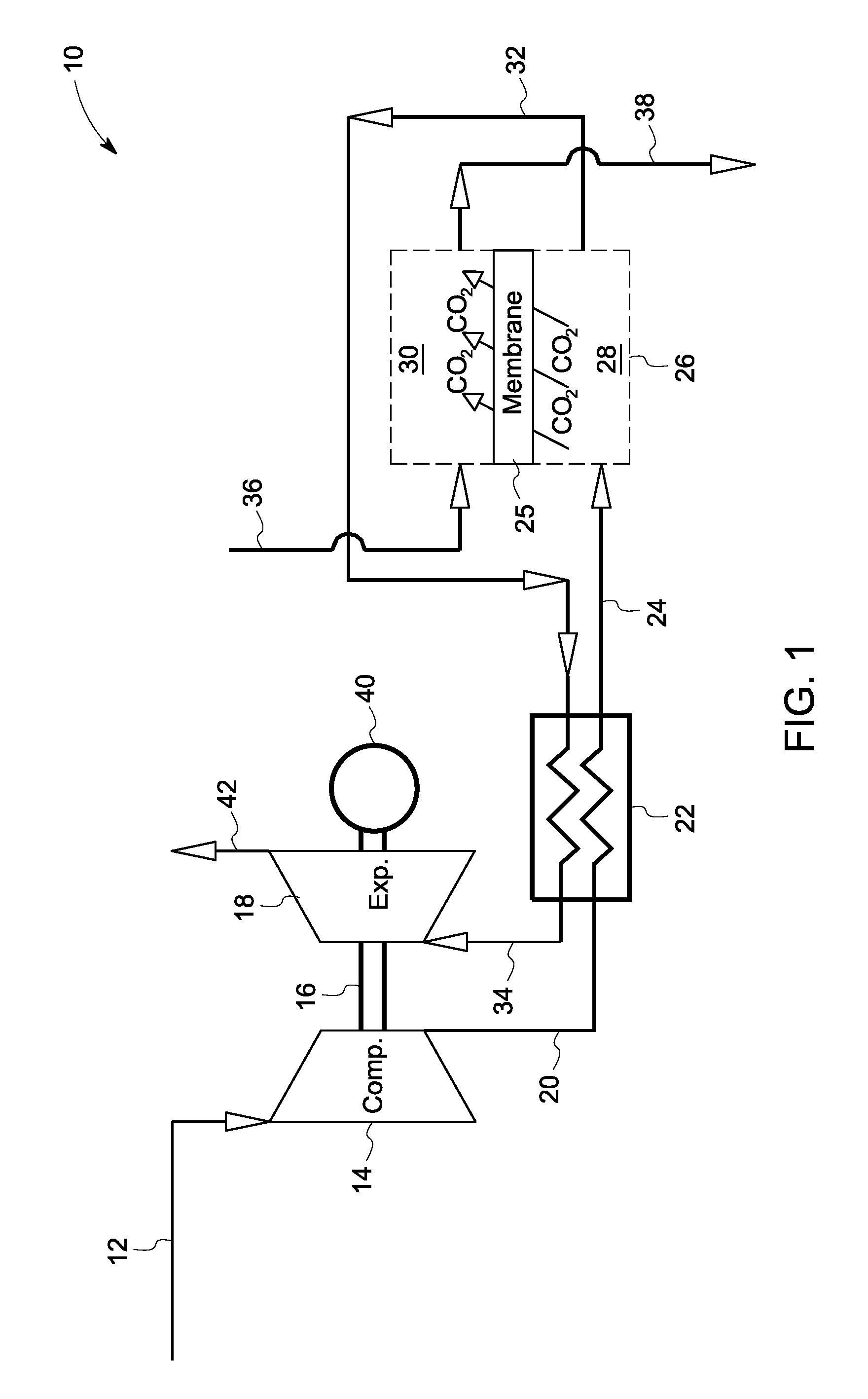

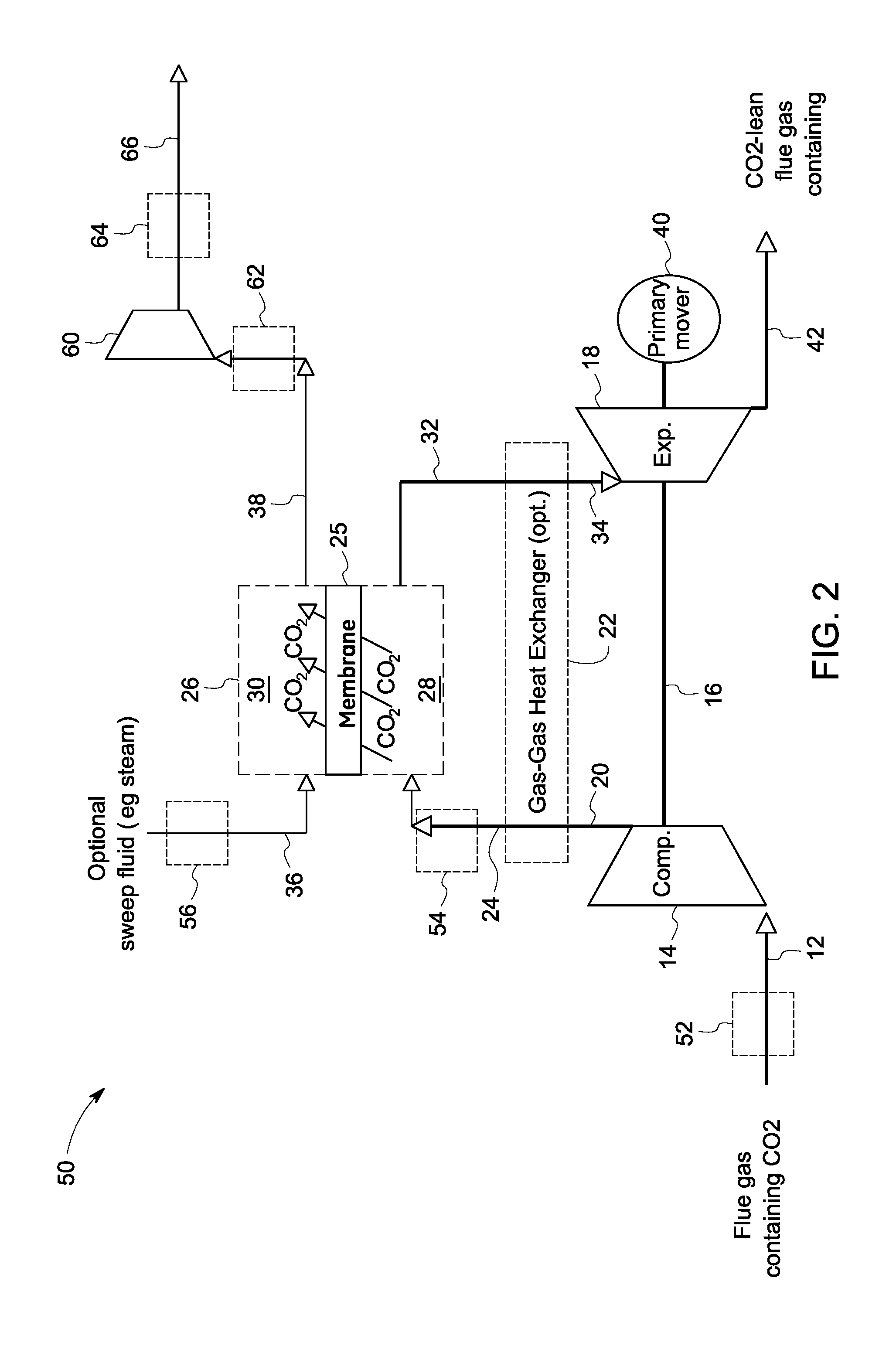

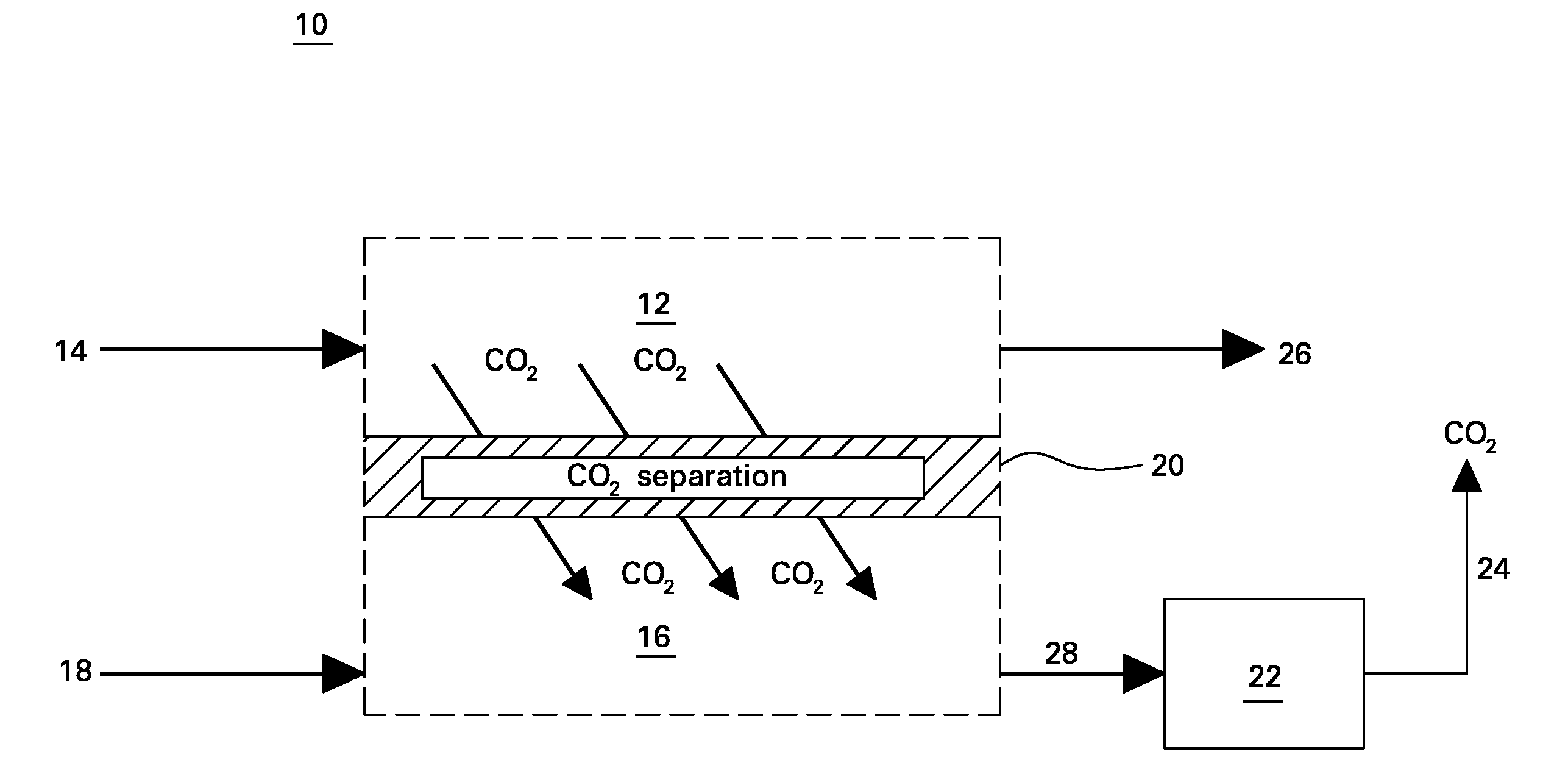

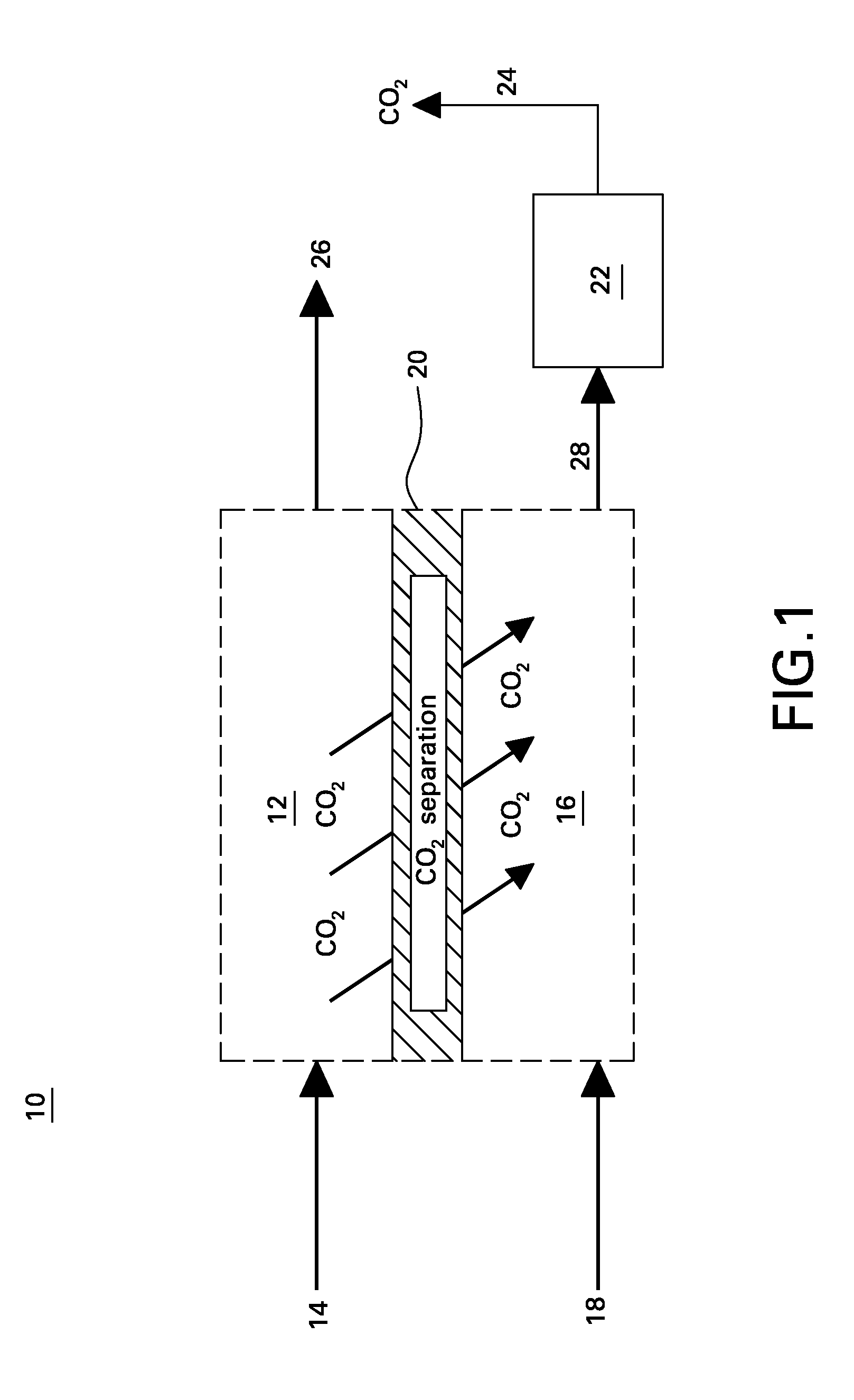

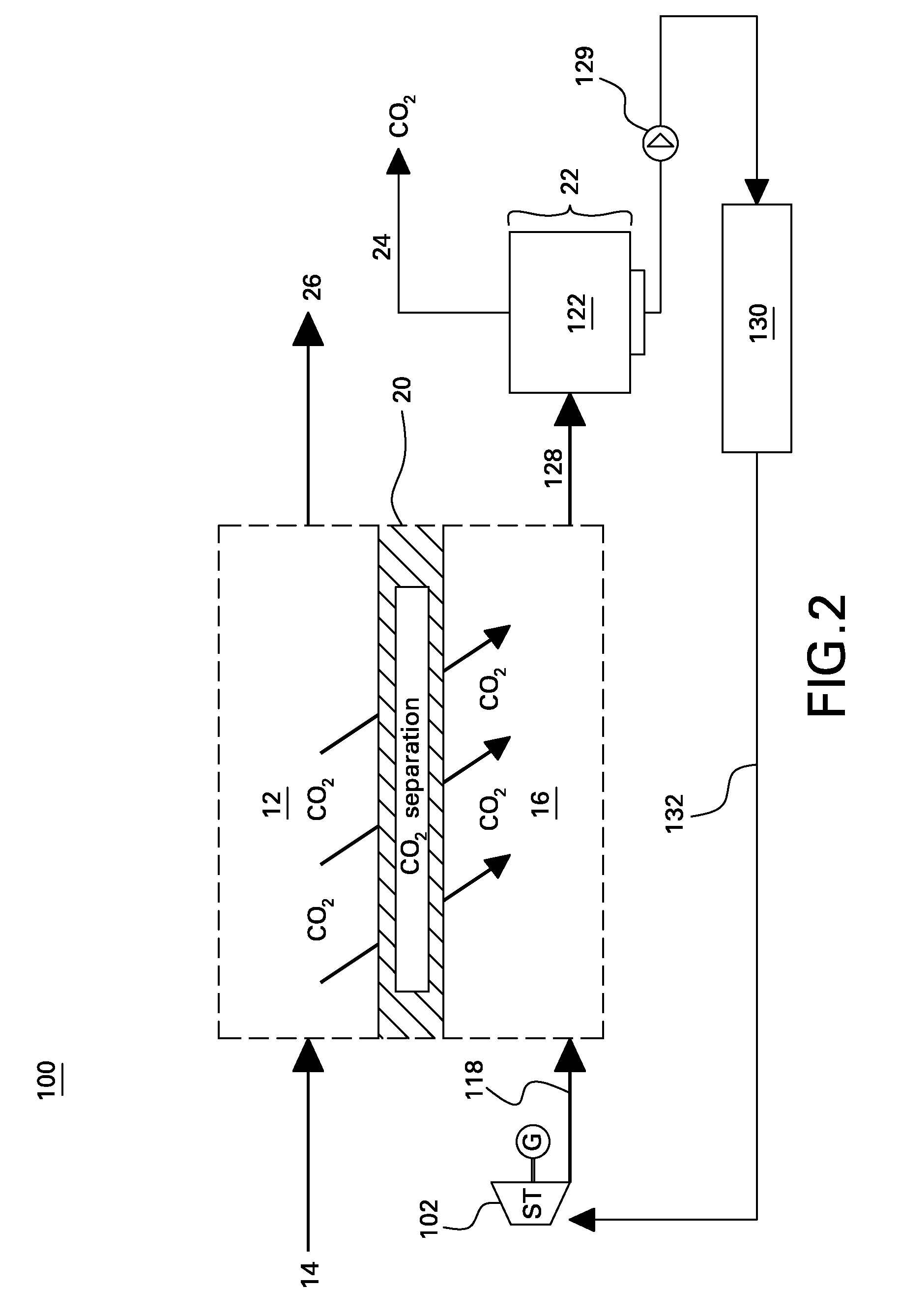

Carbon dioxide capture systems and methods

InactiveUS20080127632A1More cost-effectivelyEasy and cost-effectiveGas treatmentExhaust apparatusCarbon dioxide transportProcess engineering

A carbon dioxide separation system includes a compressor for receiving an exhaust gas comprising CO2 and generate a compressed exhaust gas and a separator configured to receive the compressed exhaust gas and generate a CO2 lean stream. The separator includes a first flow path for receiving the compressed exhaust gas, a second flow path for directing a sweep fluid therethrough, and a material with selective permeability of carbon dioxide for separating the first and the second flow paths and for promoting carbon dioxide transport therebetween. The system further includes an expander coupled to the compressor for receiving and expanding the CO2 lean stream to generate power and an expanded CO2 lean stream.

Owner:GENERAL ELECTRIC CO

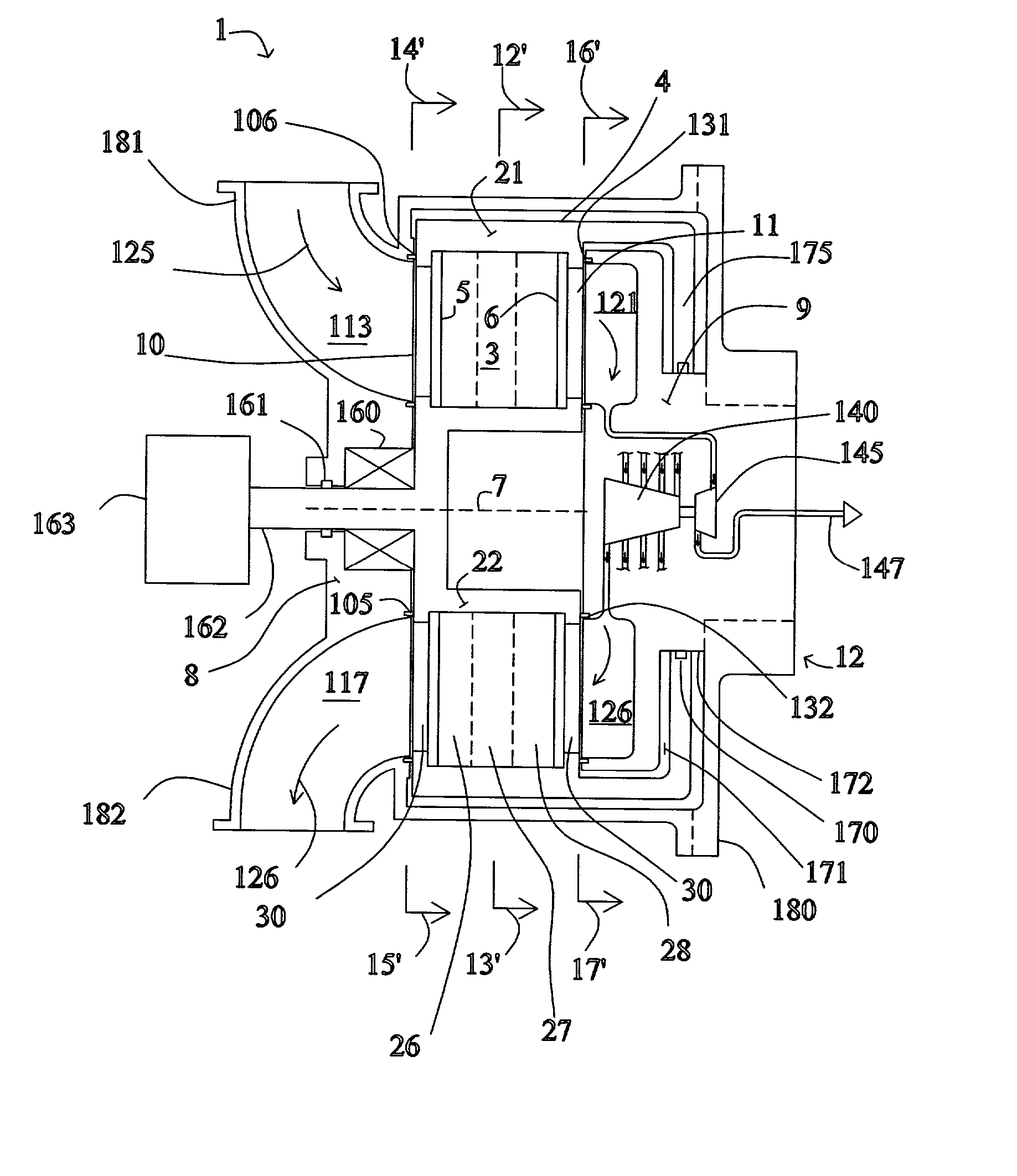

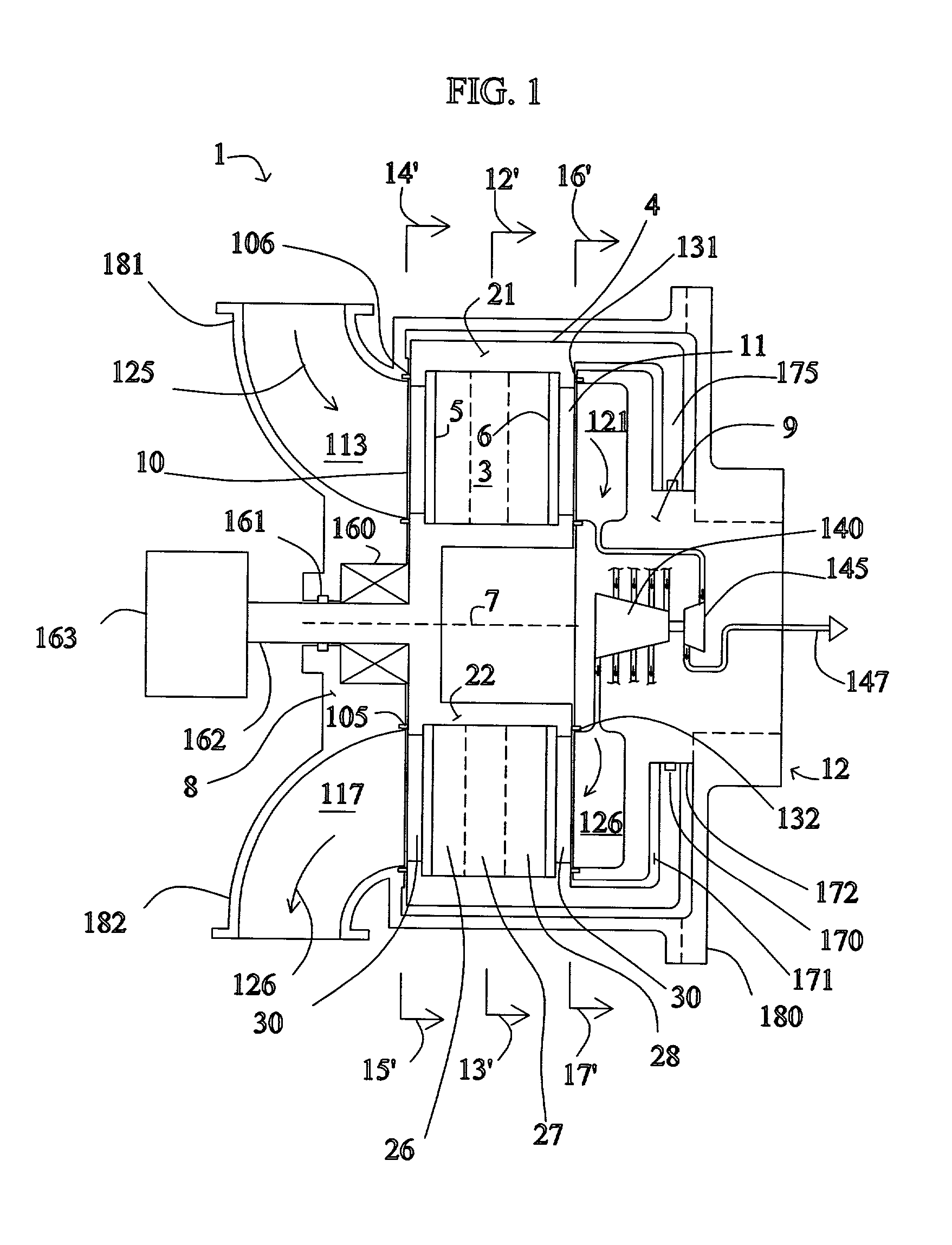

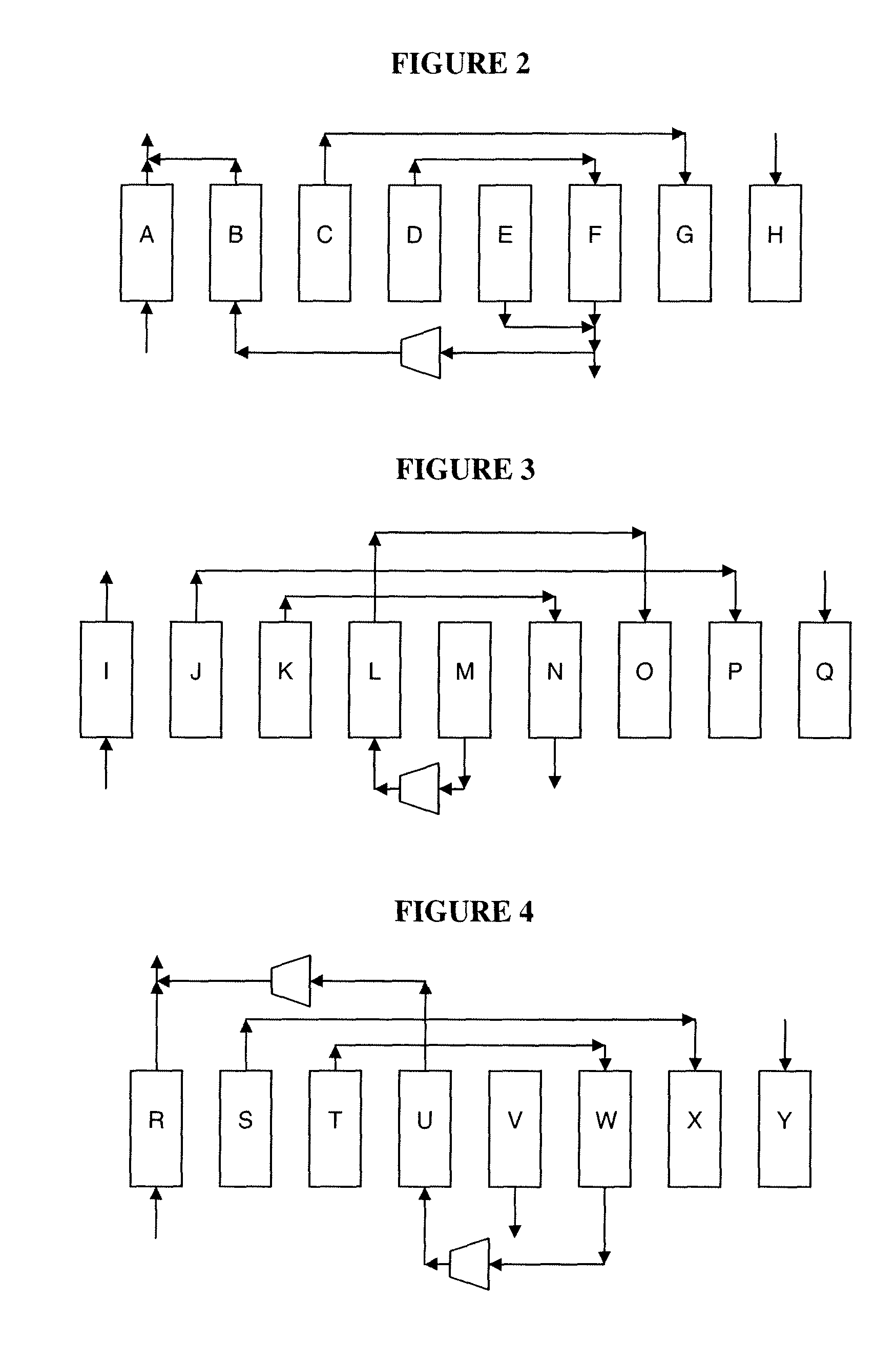

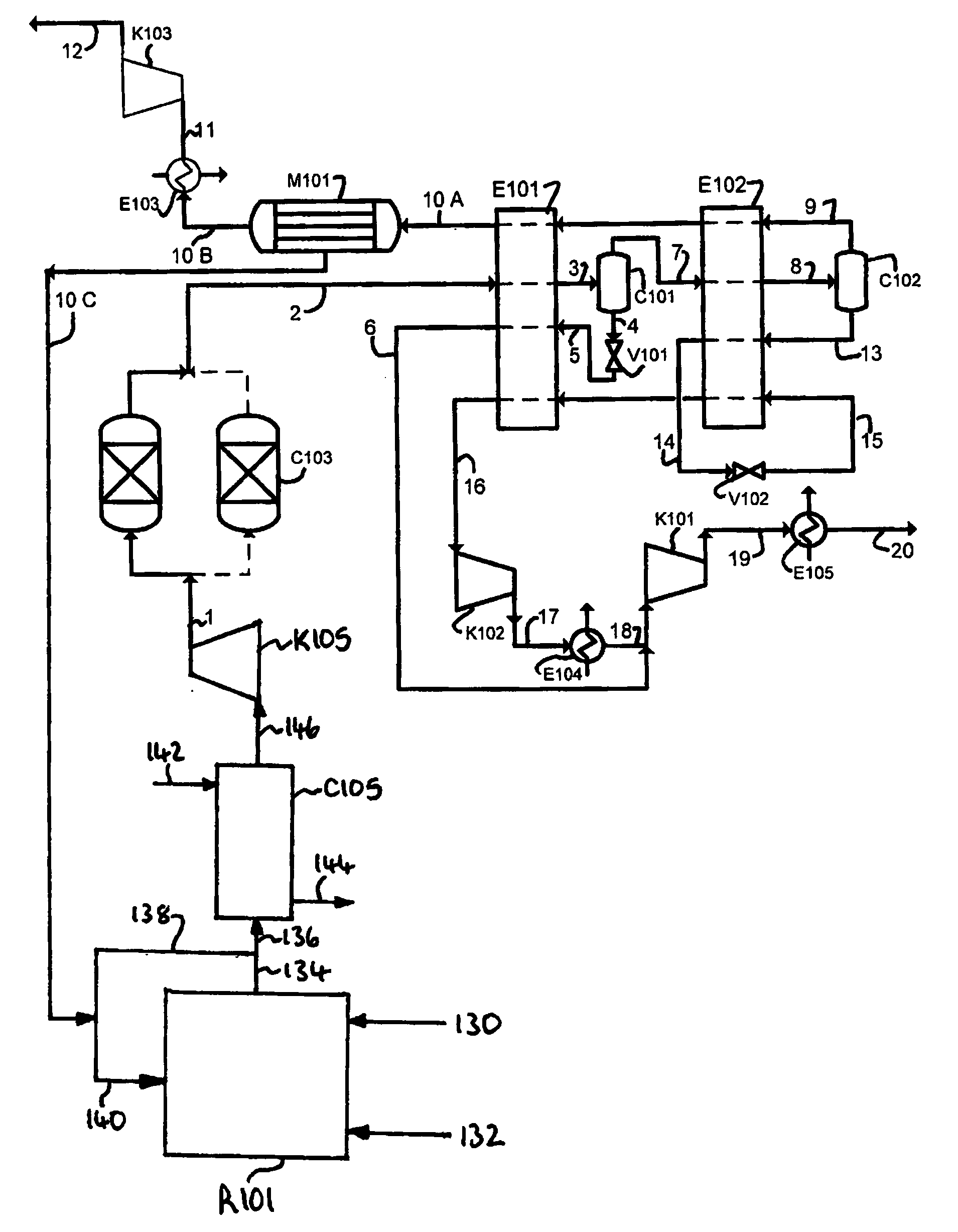

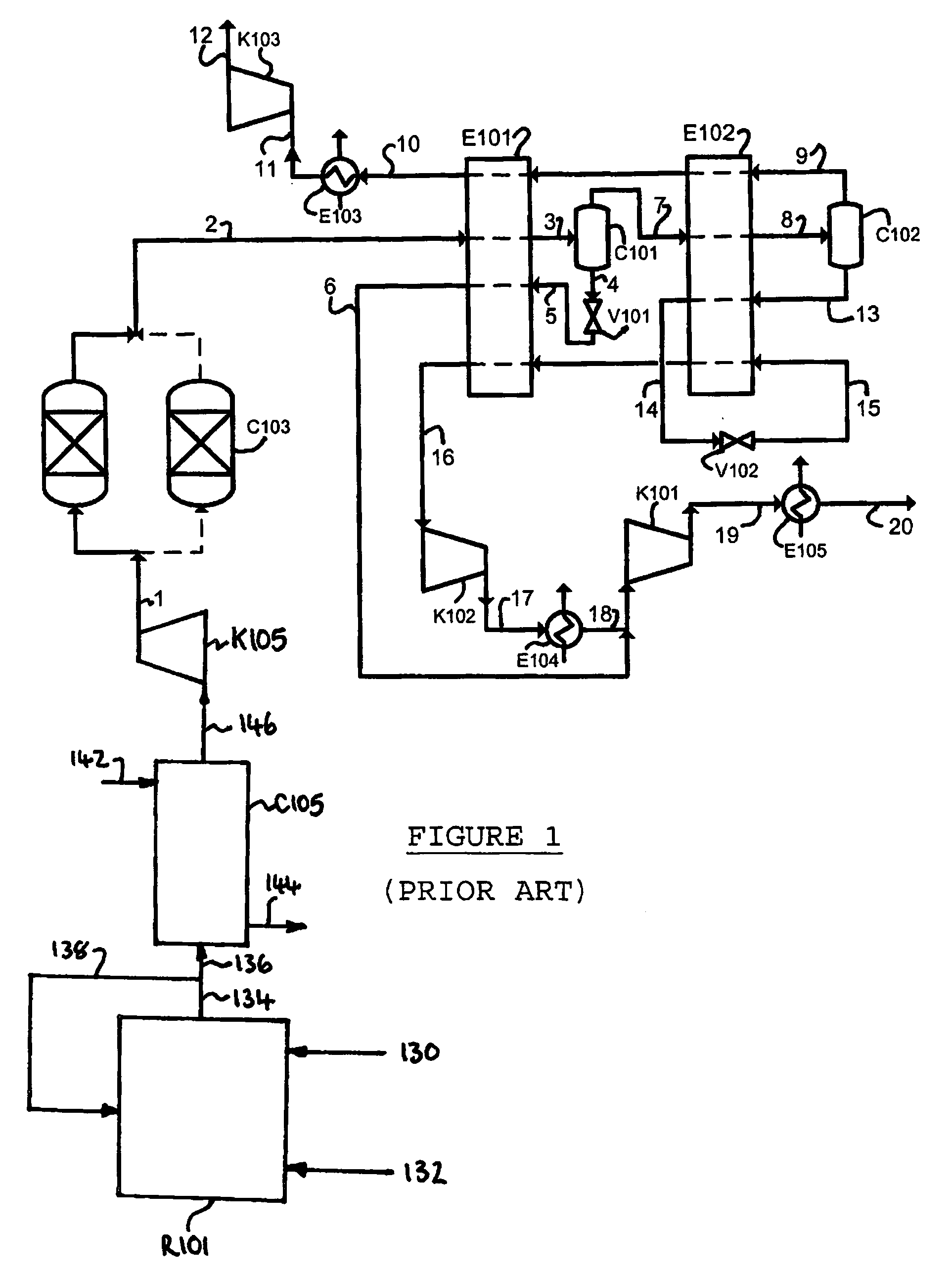

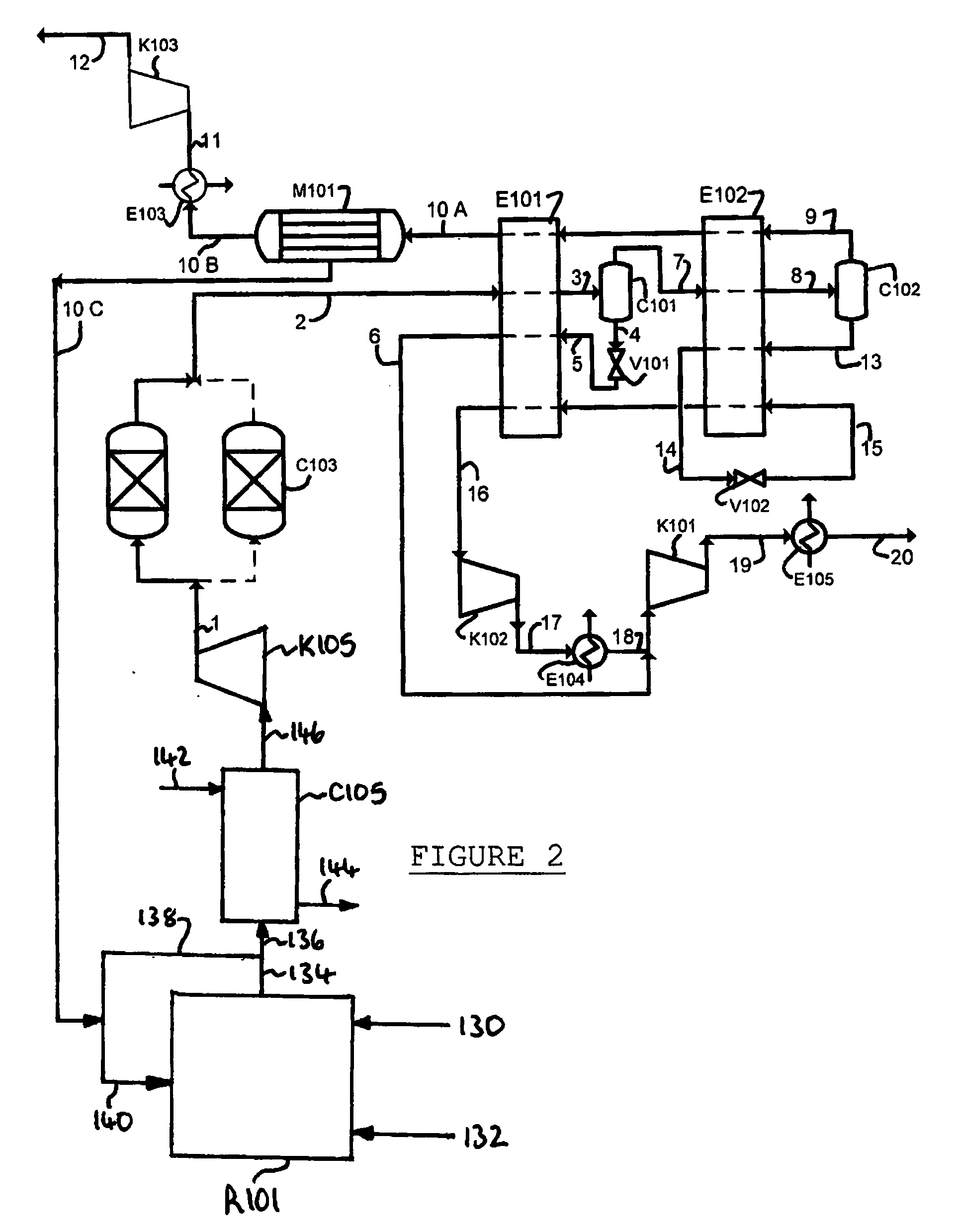

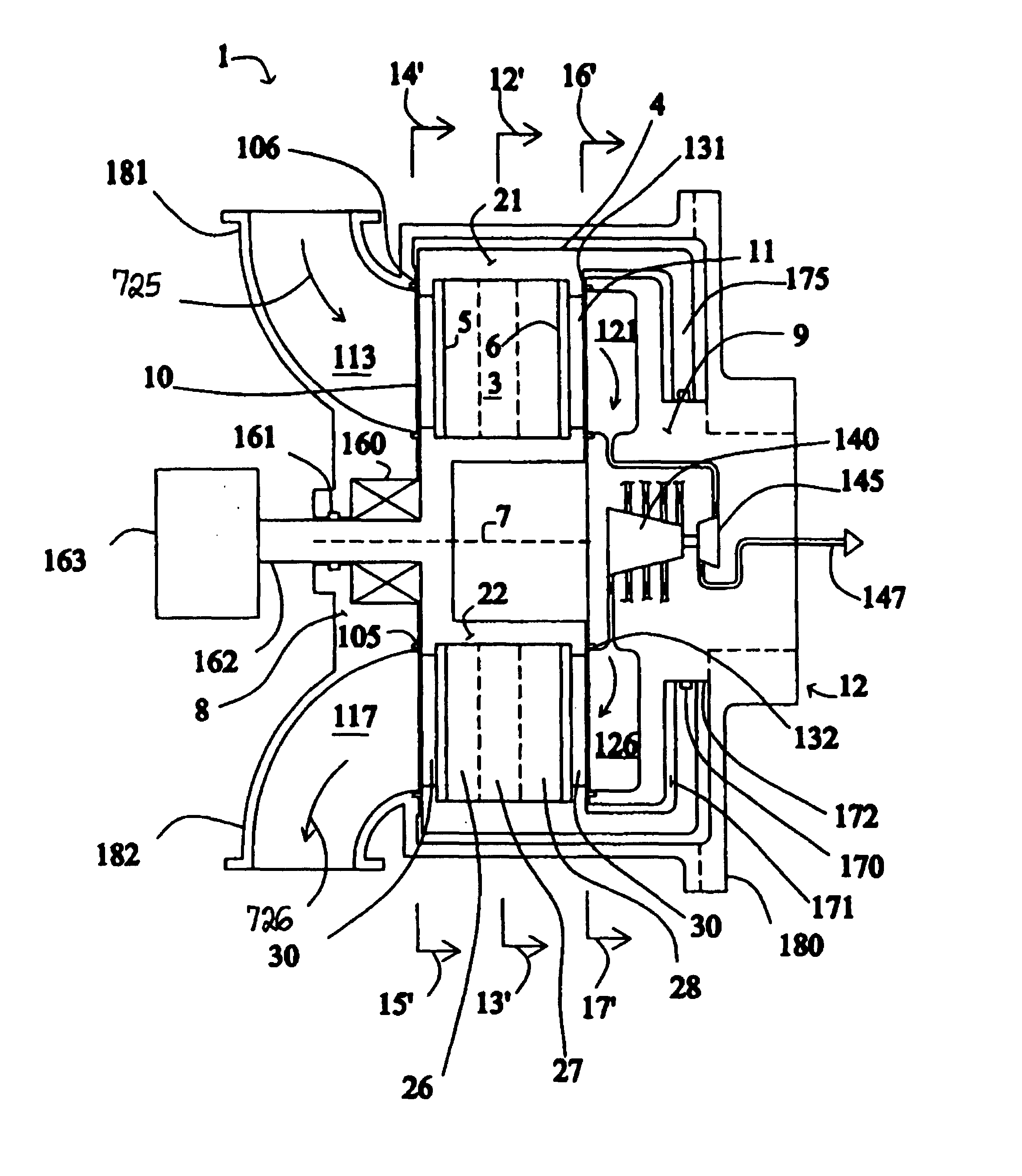

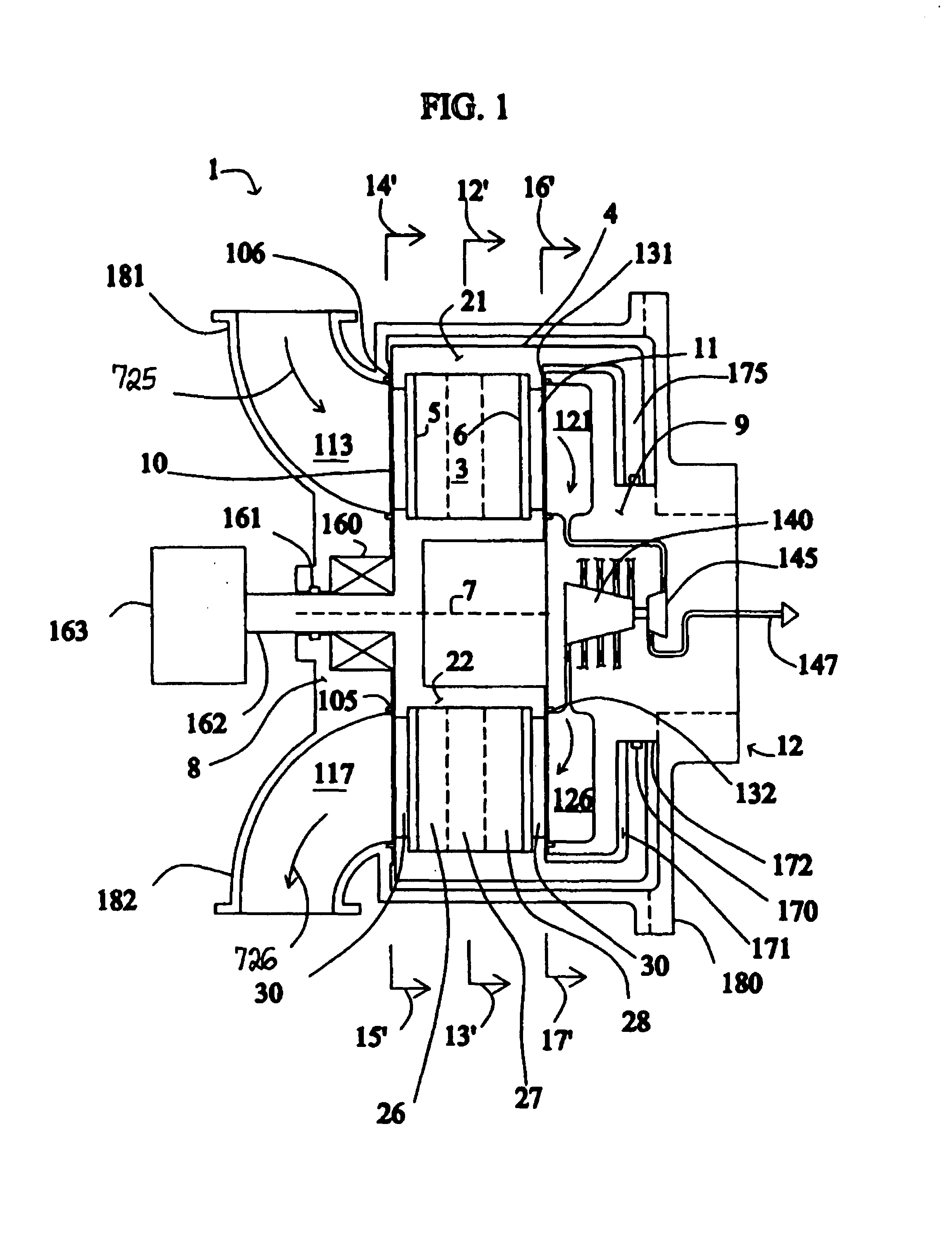

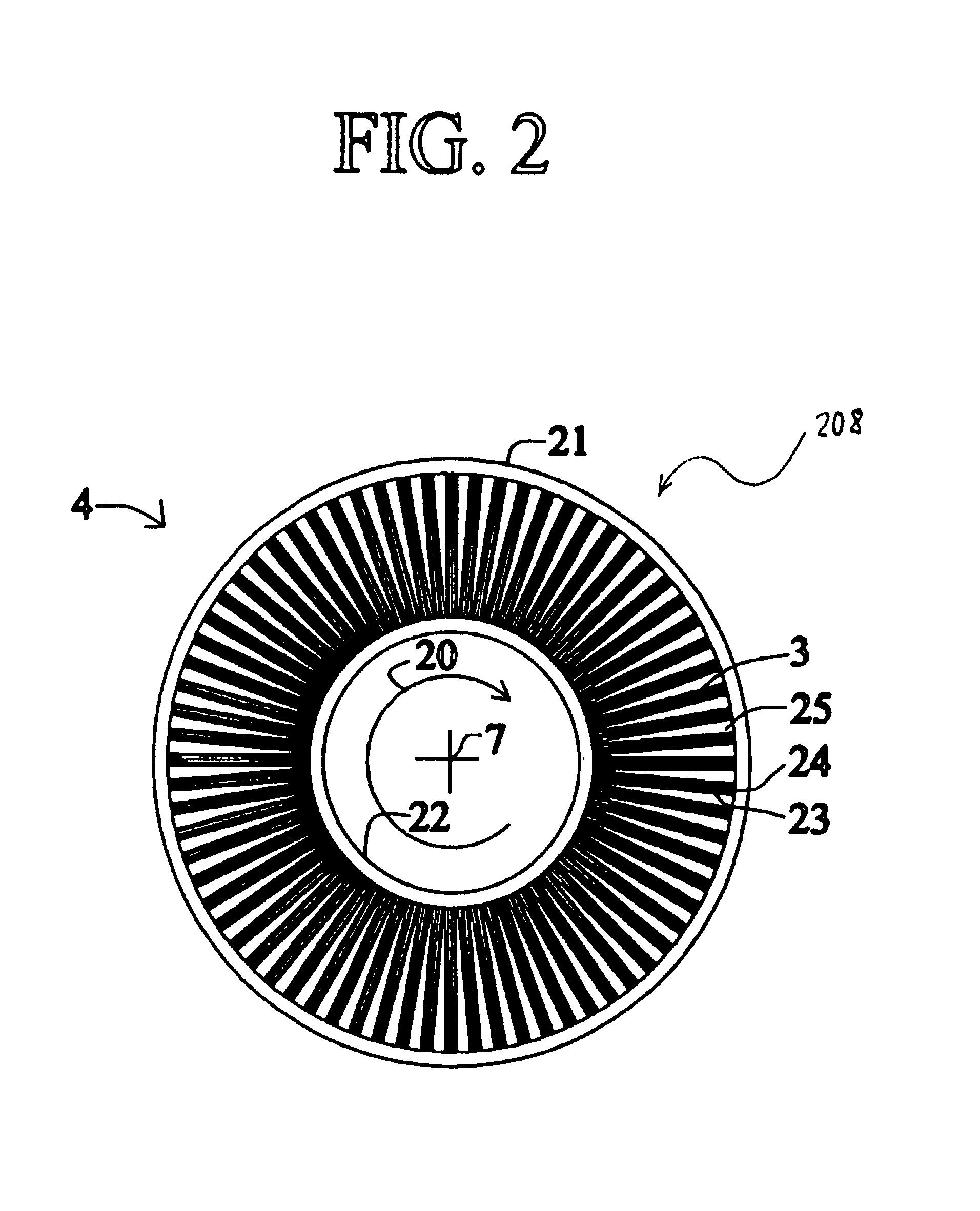

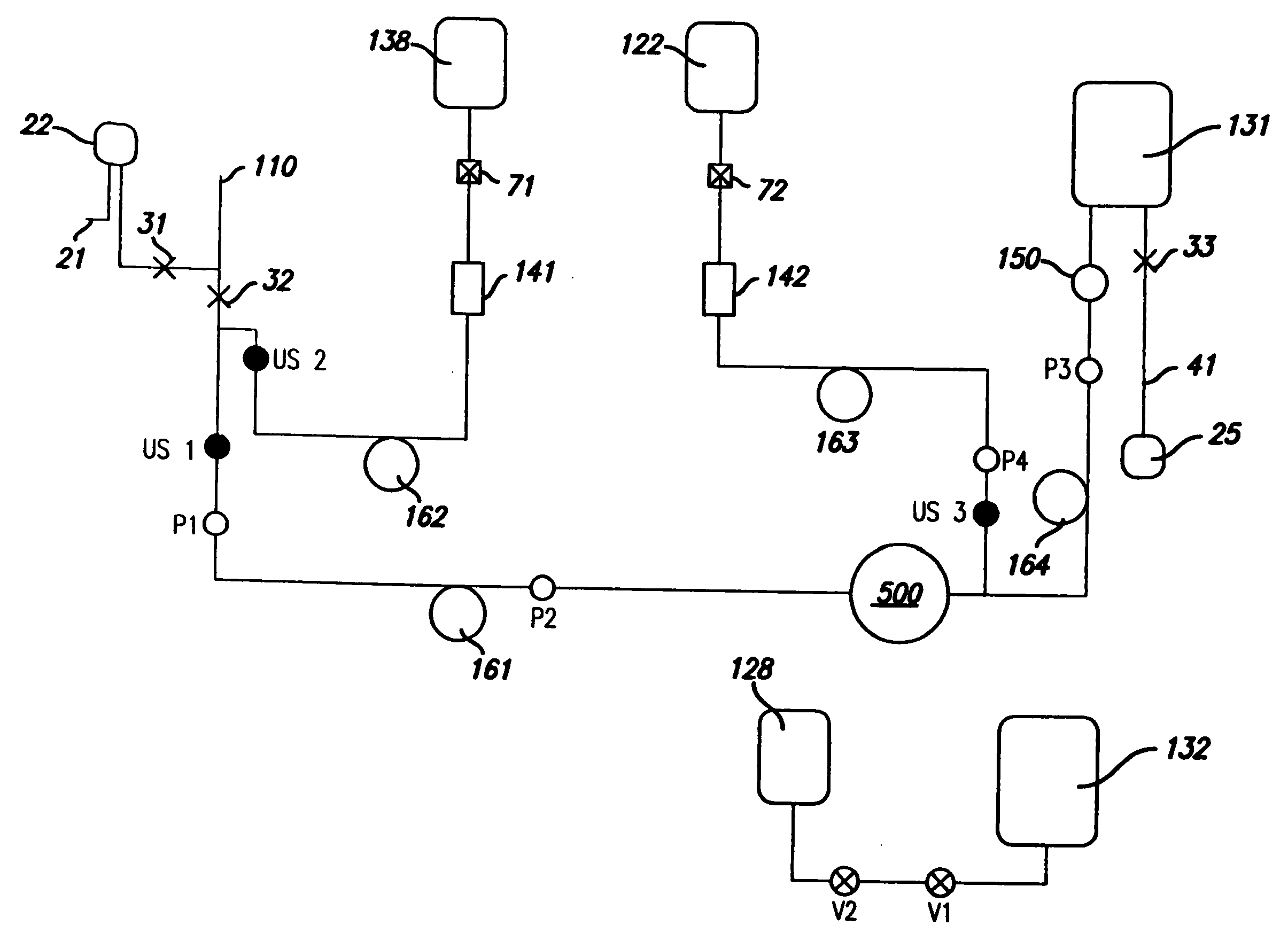

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

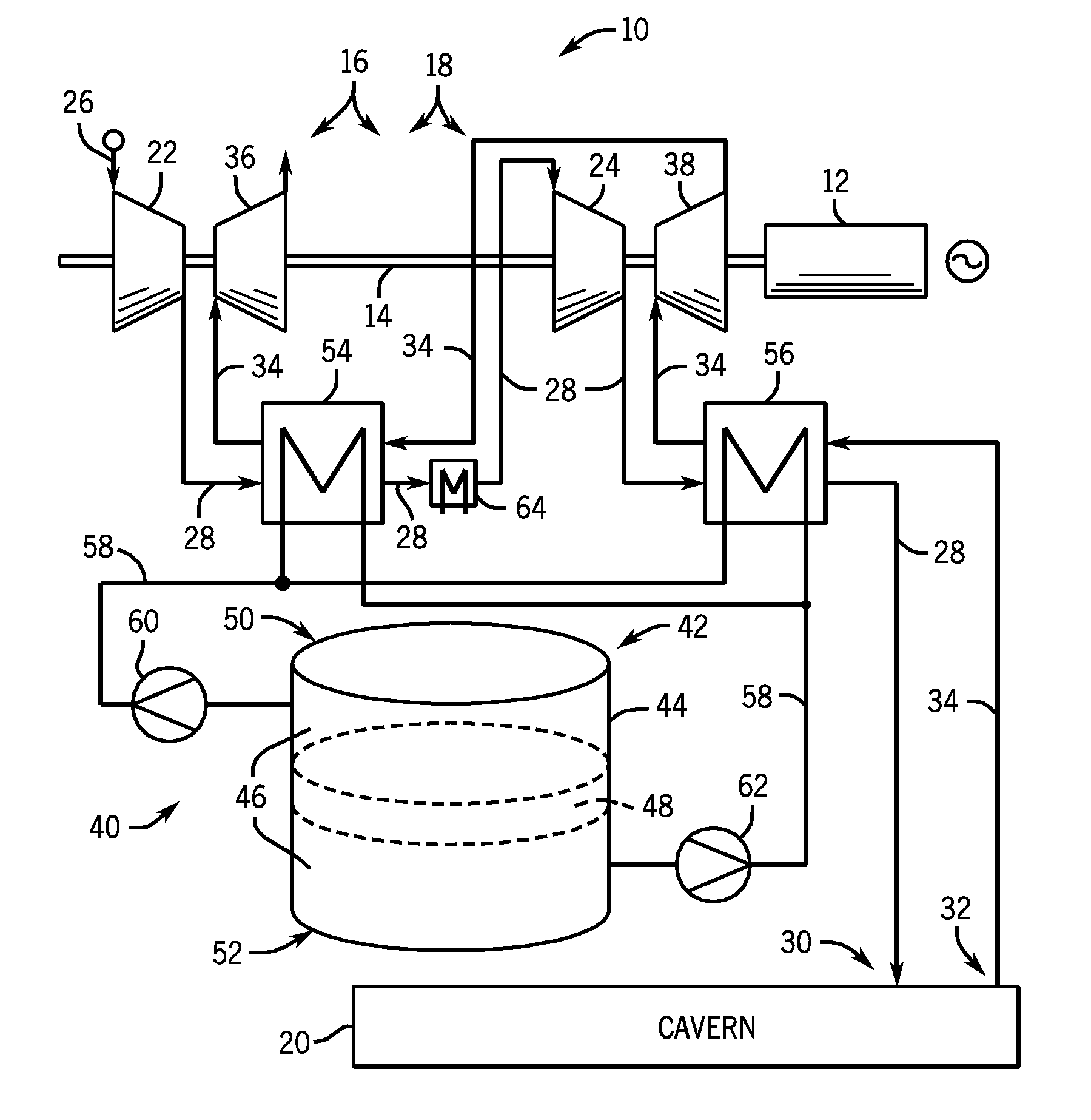

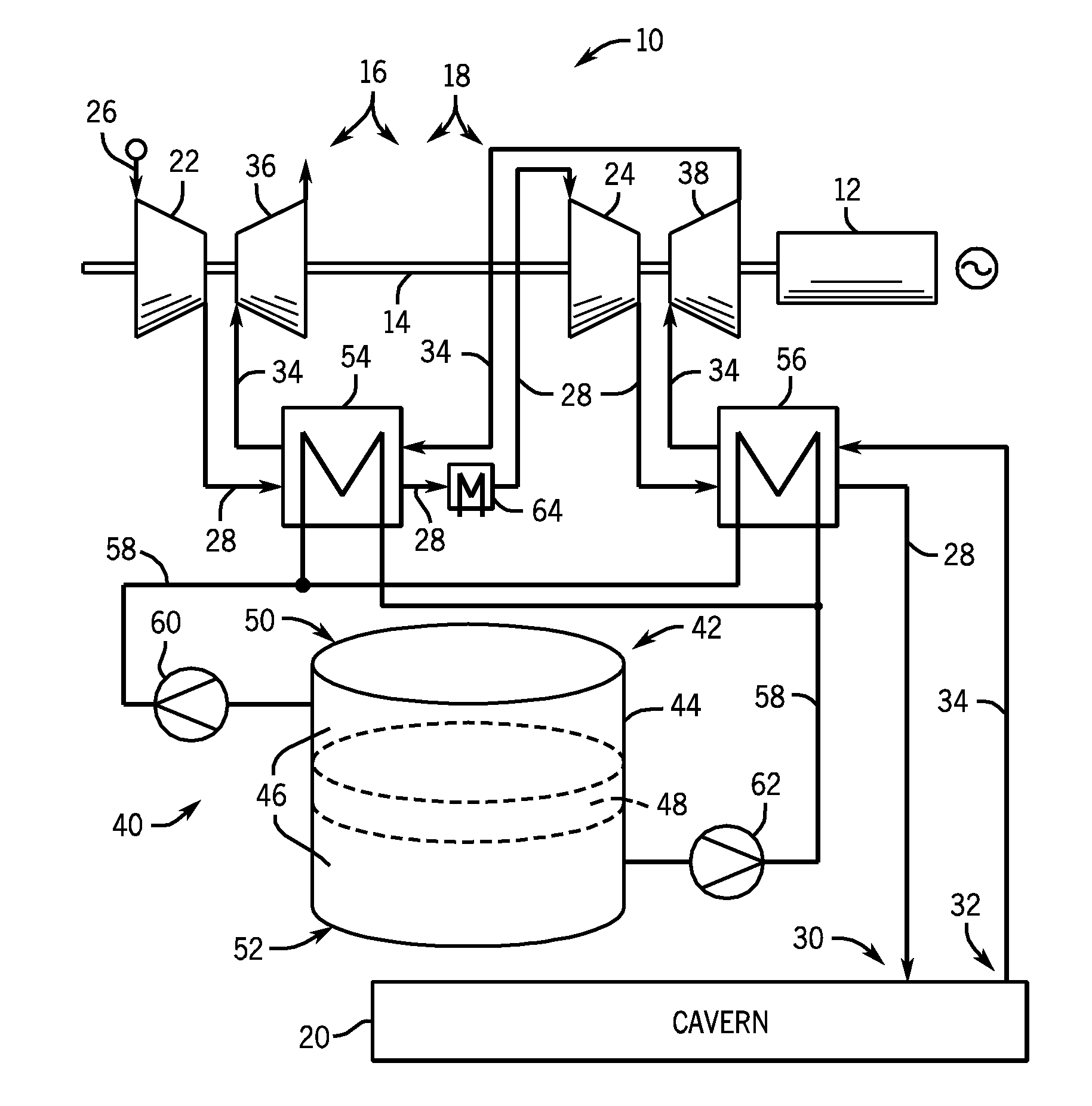

Adiabatic compressed air energy storage system with liquid thermal energy storage

InactiveUS20110100010A1Reciprocating combination enginesCombination enginesThermal energyThermal energy storage

An adiabatic compressed air energy storage (ACAES) system includes a compressor system, an air storage unit, and a turbine system. The ACAES system further includes a thermal energy storage (TES) system that includes a container, a plurality of heat exchangers, a liquid TES medium conduit system fluidly coupling the container to the plurality of heat exchangers, and a liquid TES medium stored within the container. The TES system also includes a plurality of pumps coupled to the liquid TES medium conduit system and configured to transport the liquid TES medium between the plurality of heat exchangers and the container, and a thermal separation system positioned within the container configured to thermally isolate a first portion of the liquid TES medium at a lower temperature from a second portion of the liquid TES medium at a higher temperature.

Owner:GENERAL ELECTRIC CO

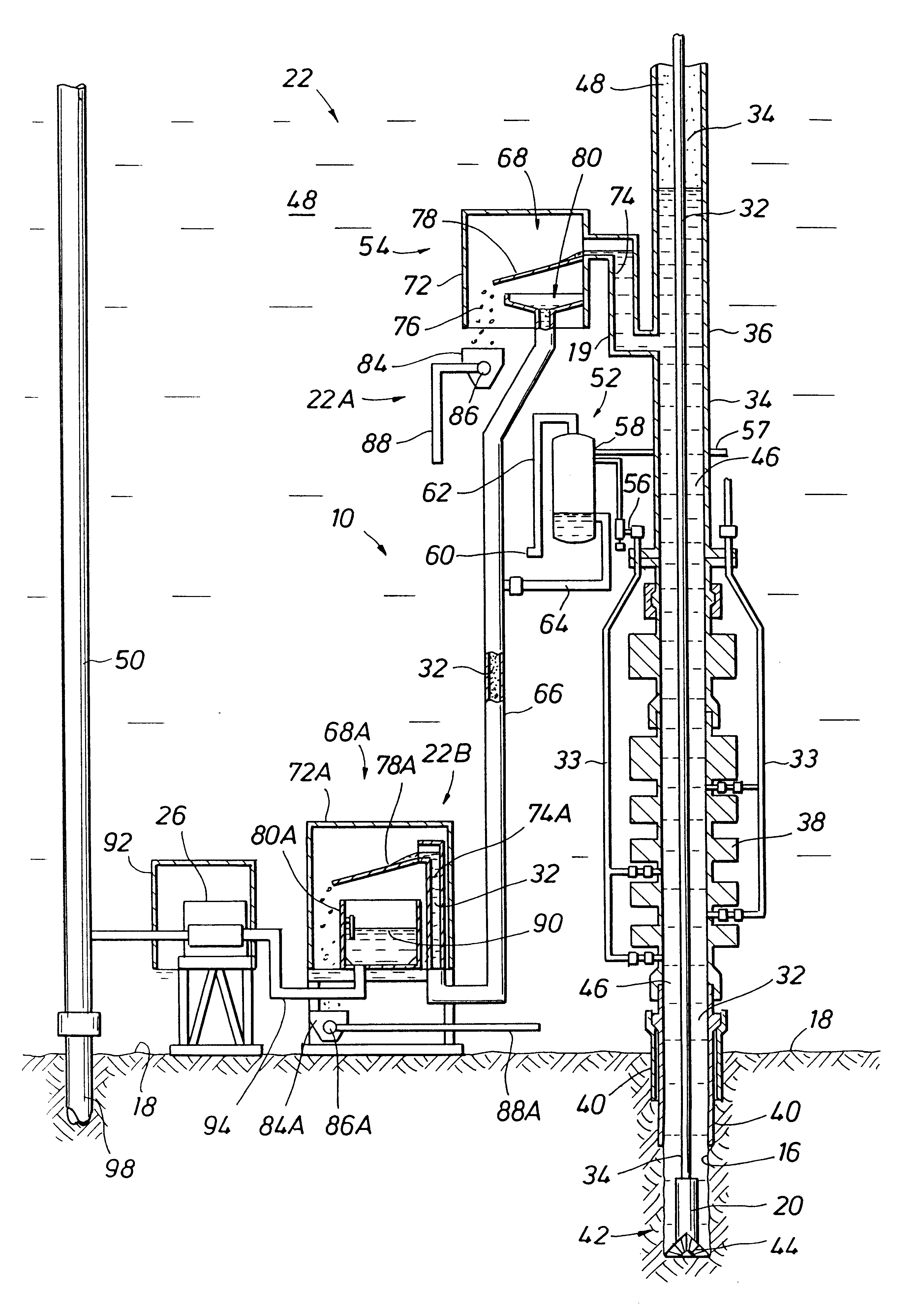

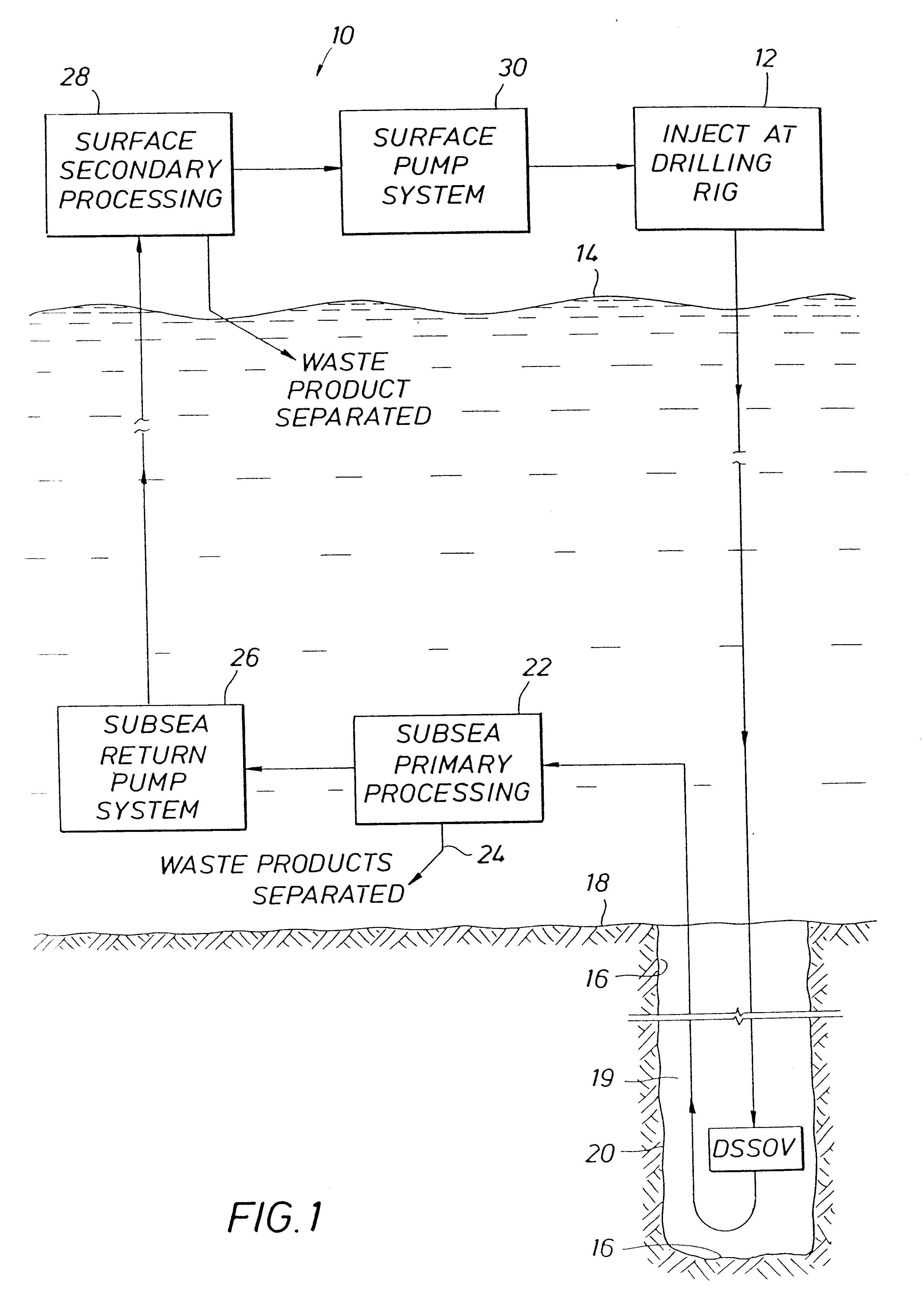

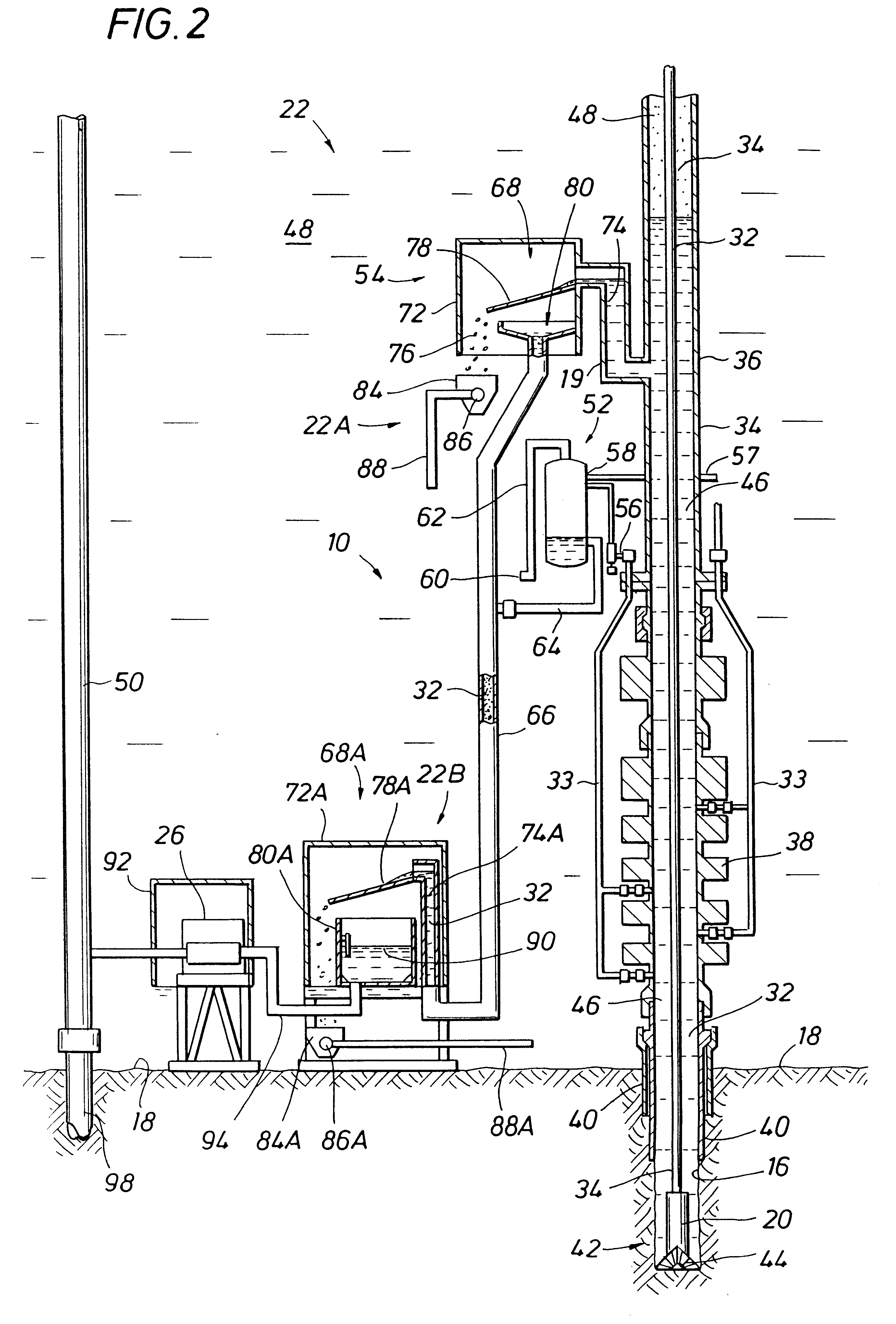

Subsea gas separation system and method for offshore drilling

A subsea gas separation system use in drilling an offshore well includes a subsea blowout preventor connected to the well and a gas separator connected to the blowout preventor near the seafloor. Gas released into the well bore during a well control event is removed at the separator and not returned with the drilling mud recirculated to the surface. A method offshore drilling includes a mud circulation circuit established leading down the drill string, through the drill bit, up the borehole, through a subsea pump, and to the surface through a return riser. The subsea pump is protected during critical well control events by removing gas released into the mud at a gas separator located upstream of the subsea pump and in communication with the blowout preventor.

Owner:SHELL OFFSHORE

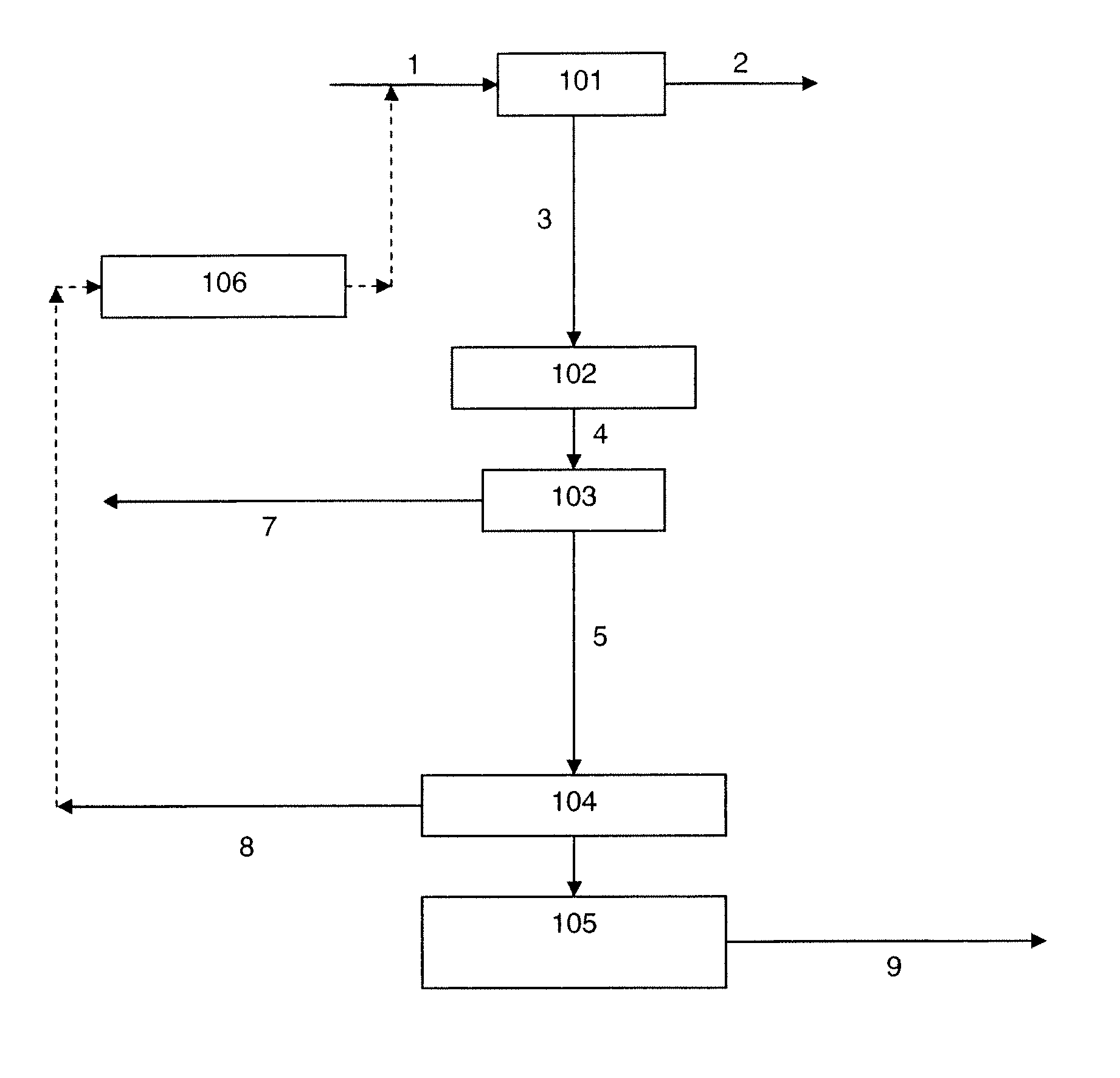

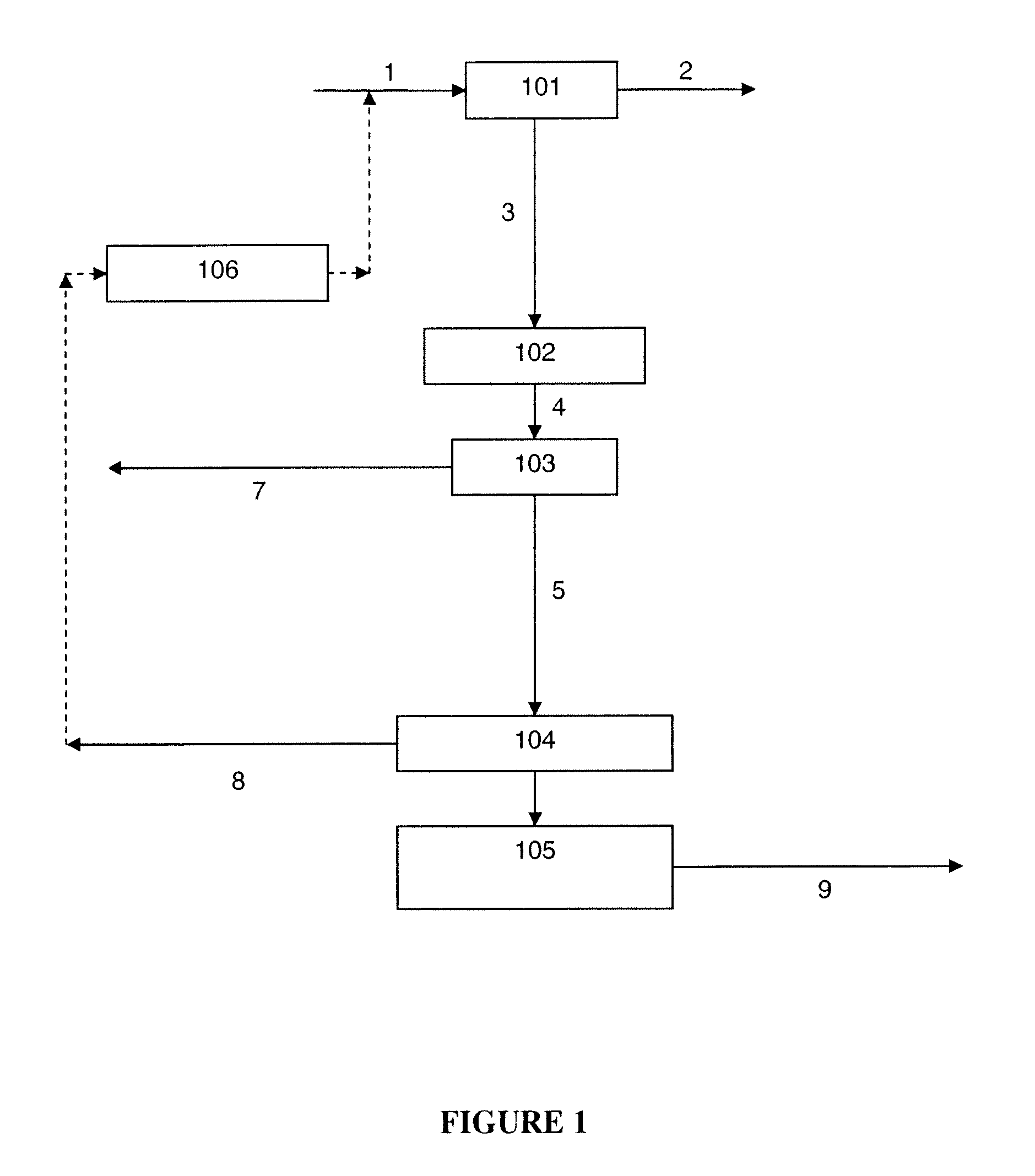

Separation of a sour syngas stream

A feed stream, comprising hydrogen sulphide (H2S), carbon dioxide (CO2), hydrogen (H2) and, optionally, carbon monoxide (CO), is separated into at least a CO2 product stream and an H2 or H2 and CO product stream. The stream is separated using a pressure swing adsorption system, an H2S removal system and a further separation system, which systems are used in series to separate the stream. The method has particular application in the separation of a sour (i.e. sulphur containing) syngas, as for example produced from the gasification of solid or heavy liquid carbonaceous feedstock.

Owner:AIR PROD & CHEM INC

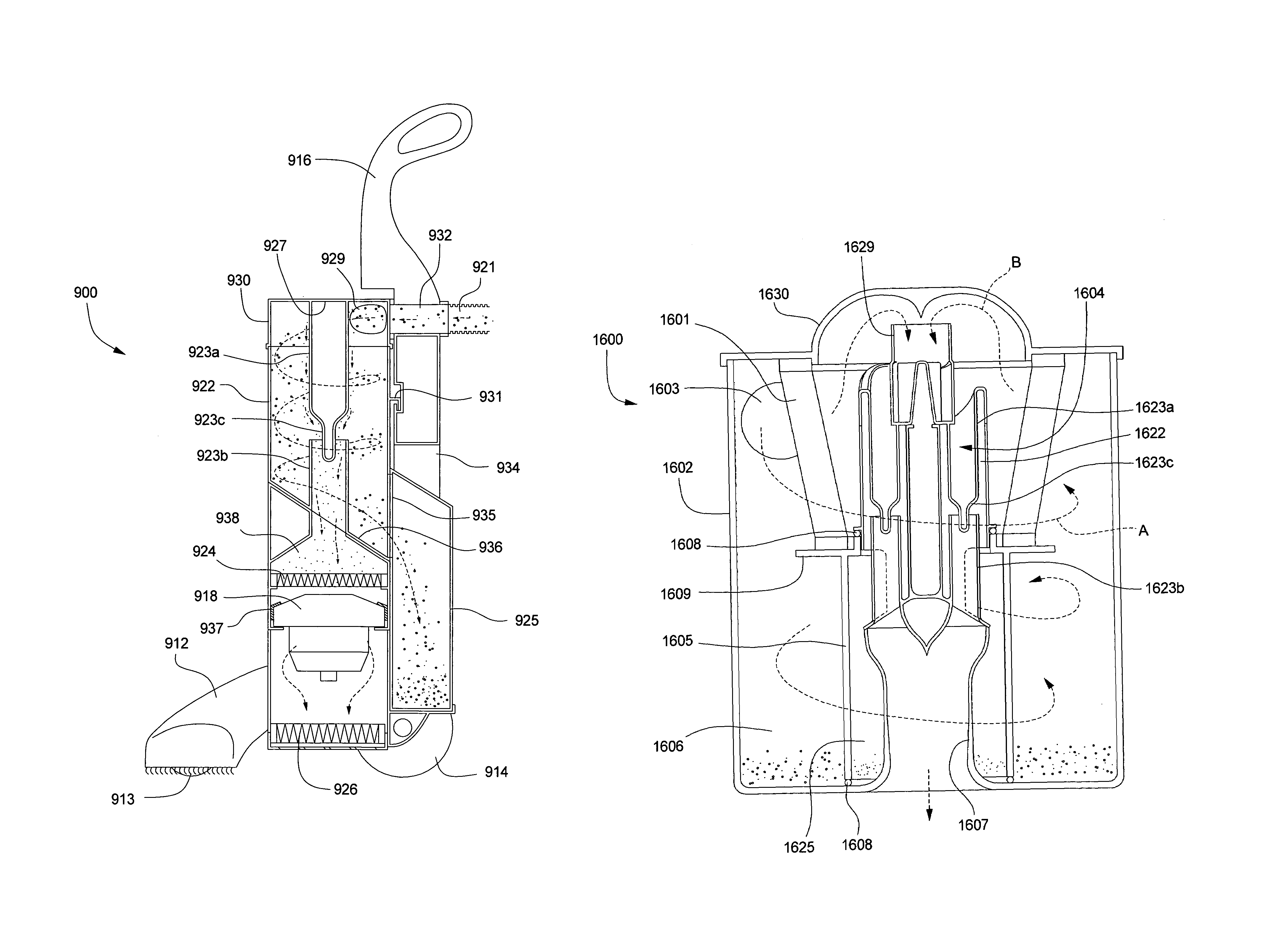

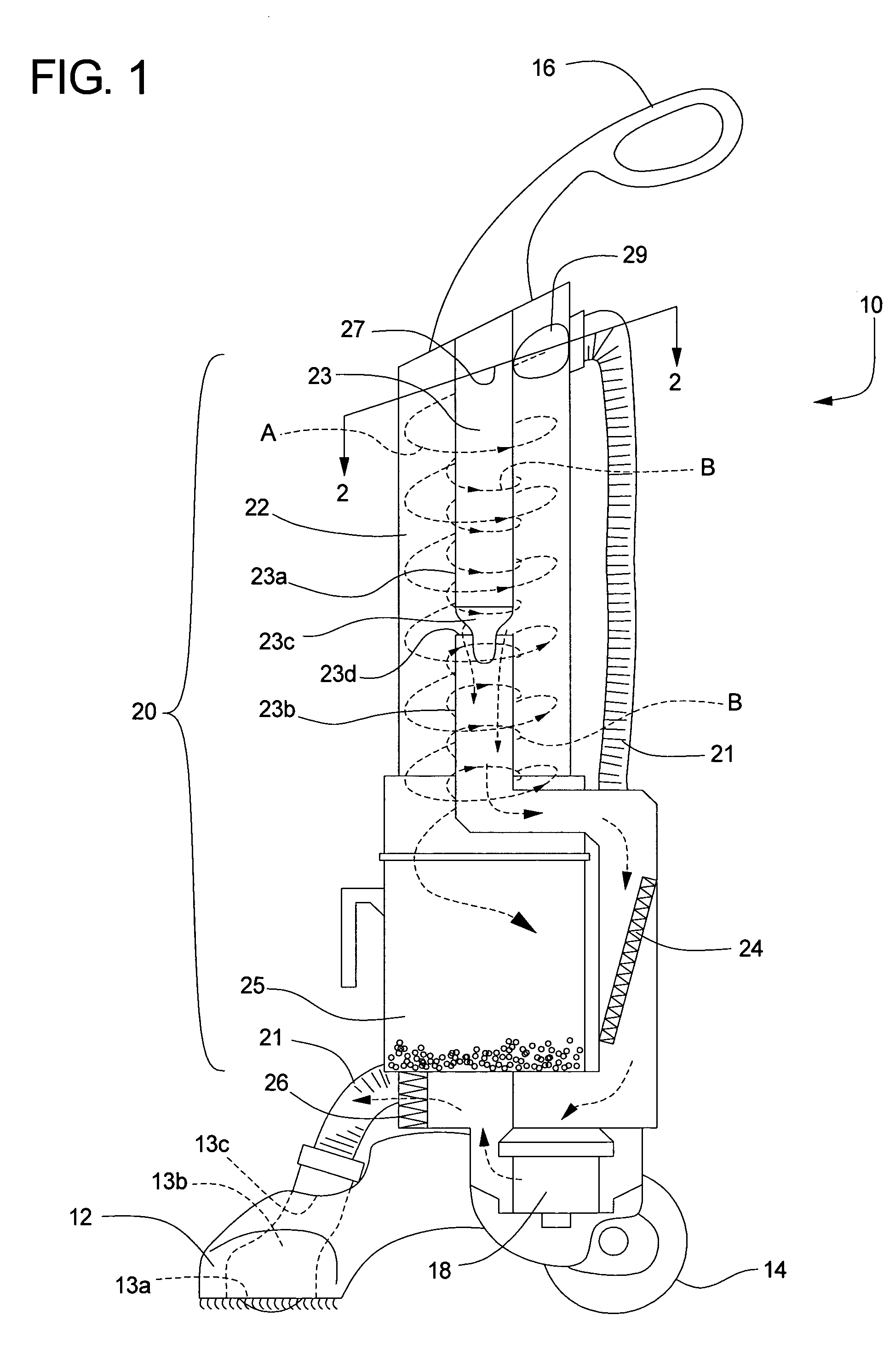

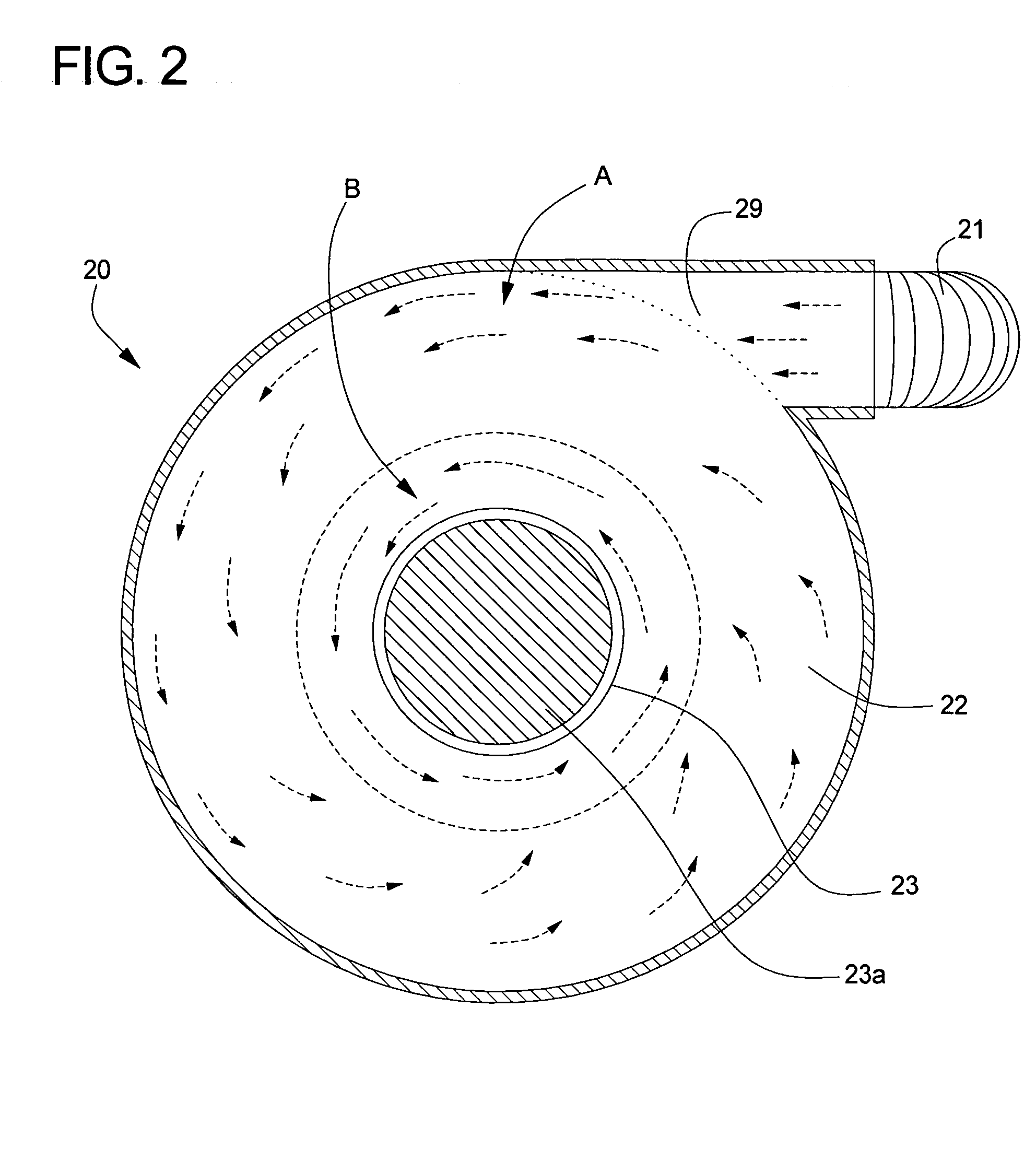

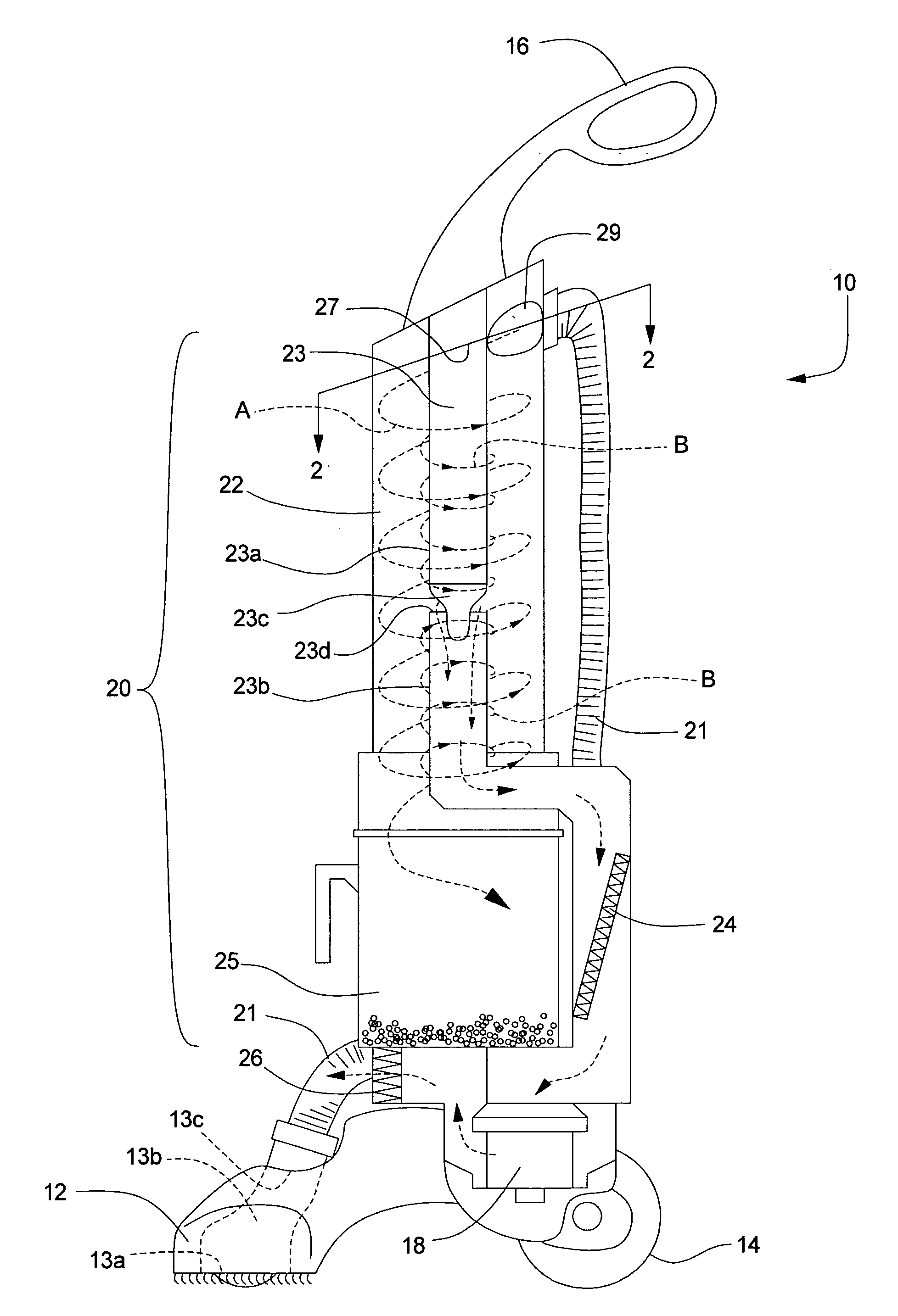

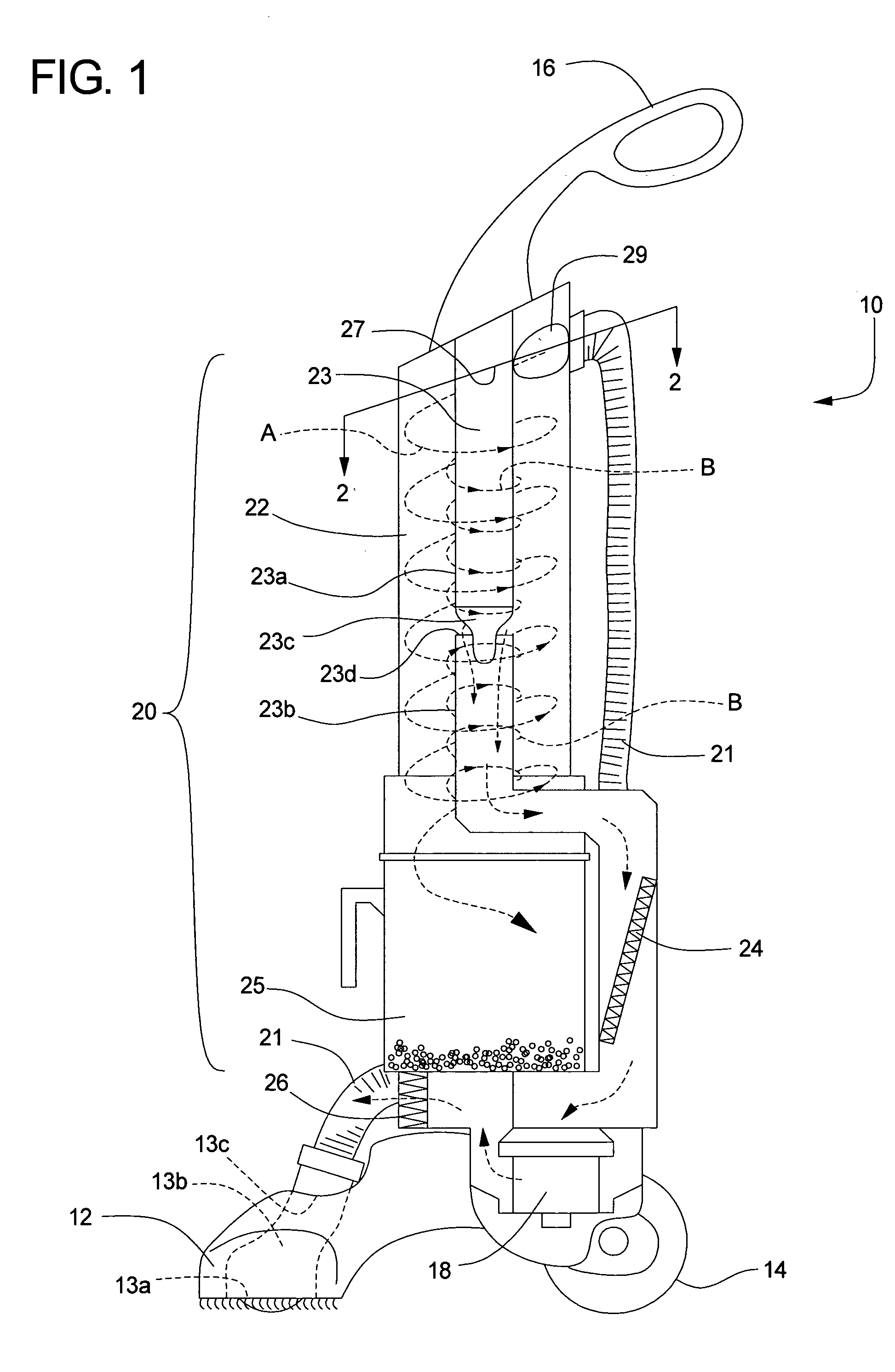

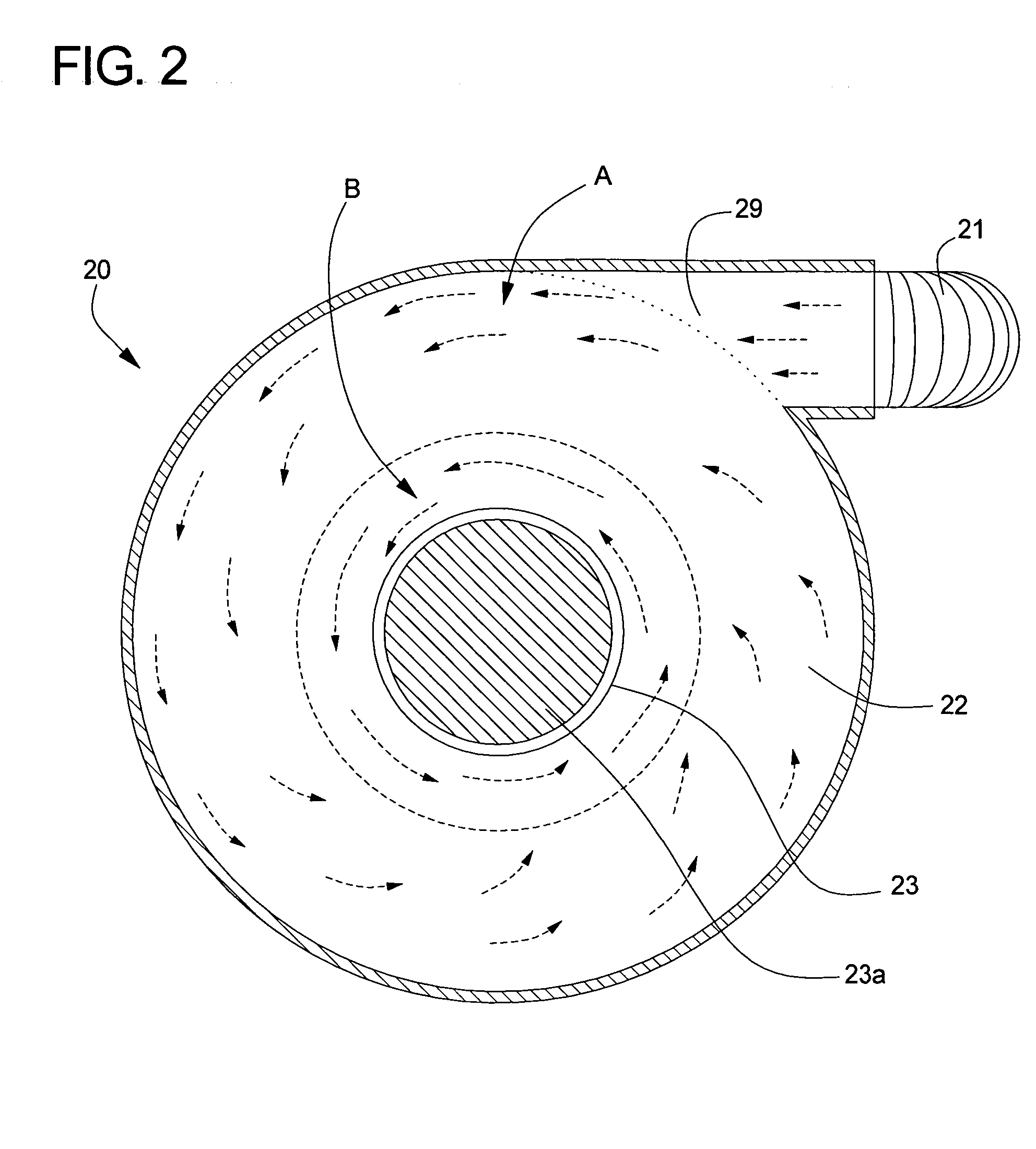

Dust separation system

A vacuum cleaner having a nozzle, a handle pivotally attached to the nozzle, and a suction motor that has an inlet, and is adapted to generate a working air flow through the nozzle. The vacuum includes a separation system having an outer wall and a closed tube having at least a portion of its length located within the wall, and forming a separation chamber between the wall and the closed tube. The separation chamber has an inlet, in communication with the nozzle, that is adapted to impart a tangential component to the air flow as it flows through the separation chamber. A hollow tube is generally coaxially aligned with the closed tube and has a tube inlet at an end adjacent the closed tube and a tube outlet at an end opposite the closed tube. The tube outlet is in fluid communication with the suction motor inlet.

Owner:ELECTROLUX HOME CARE PRODS

Purification of carbon dioxide

Carbon dioxide is separated from a feed gas, preferably derived from flue gas from an oxyfuel combustion process, in a membrane separation system to produce separated carbon dioxide gas which is fed to the oxyfuel combustion process to improve the performance of the process.

Owner:AIR PROD & CHEM INC

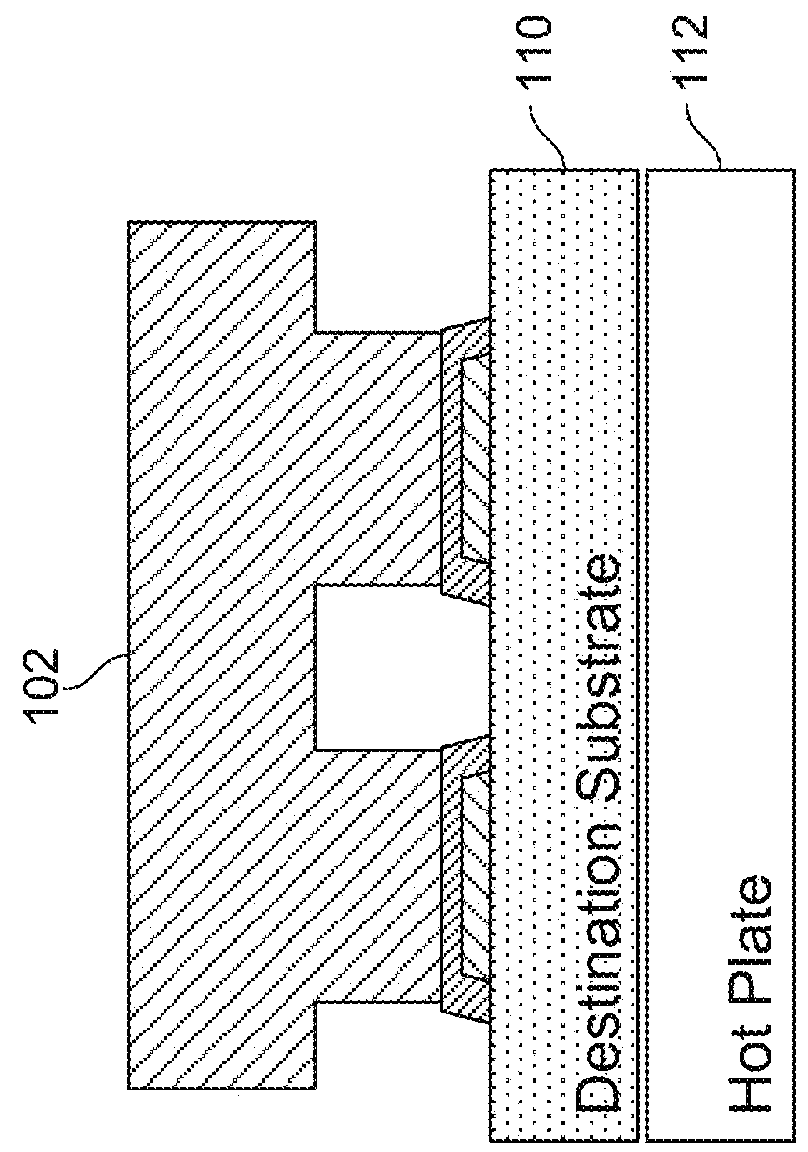

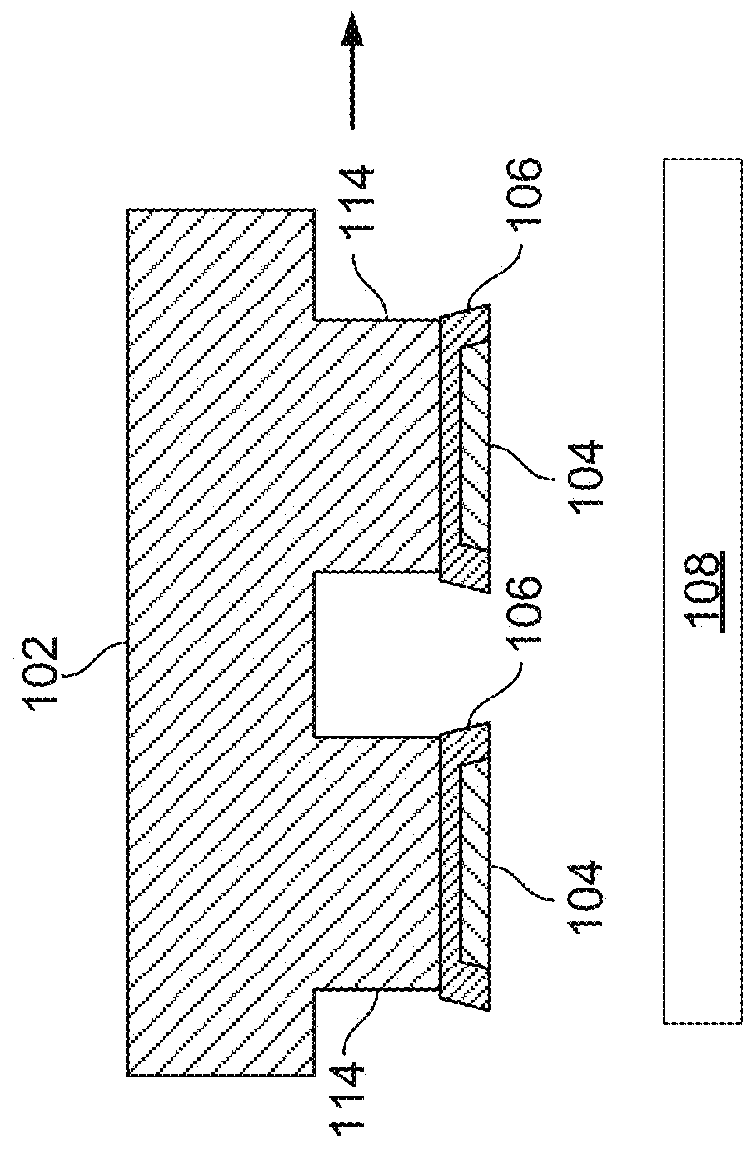

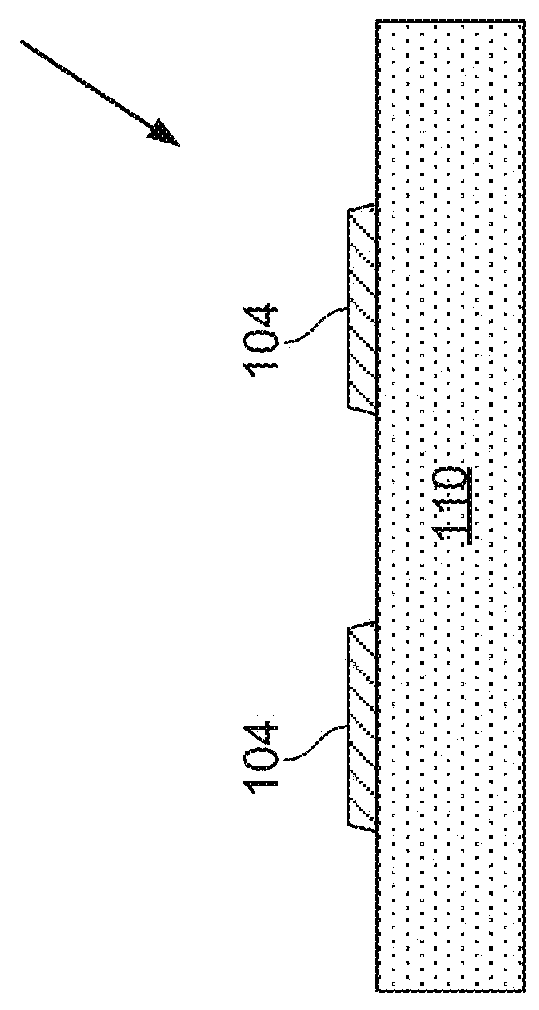

Apparatus and methods for micro-transfer-printing

ActiveUS9358775B2Increase heightImprove adhesionTransfer printingSemiconductor/solid-state device detailsSemiconductorSeparation system

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

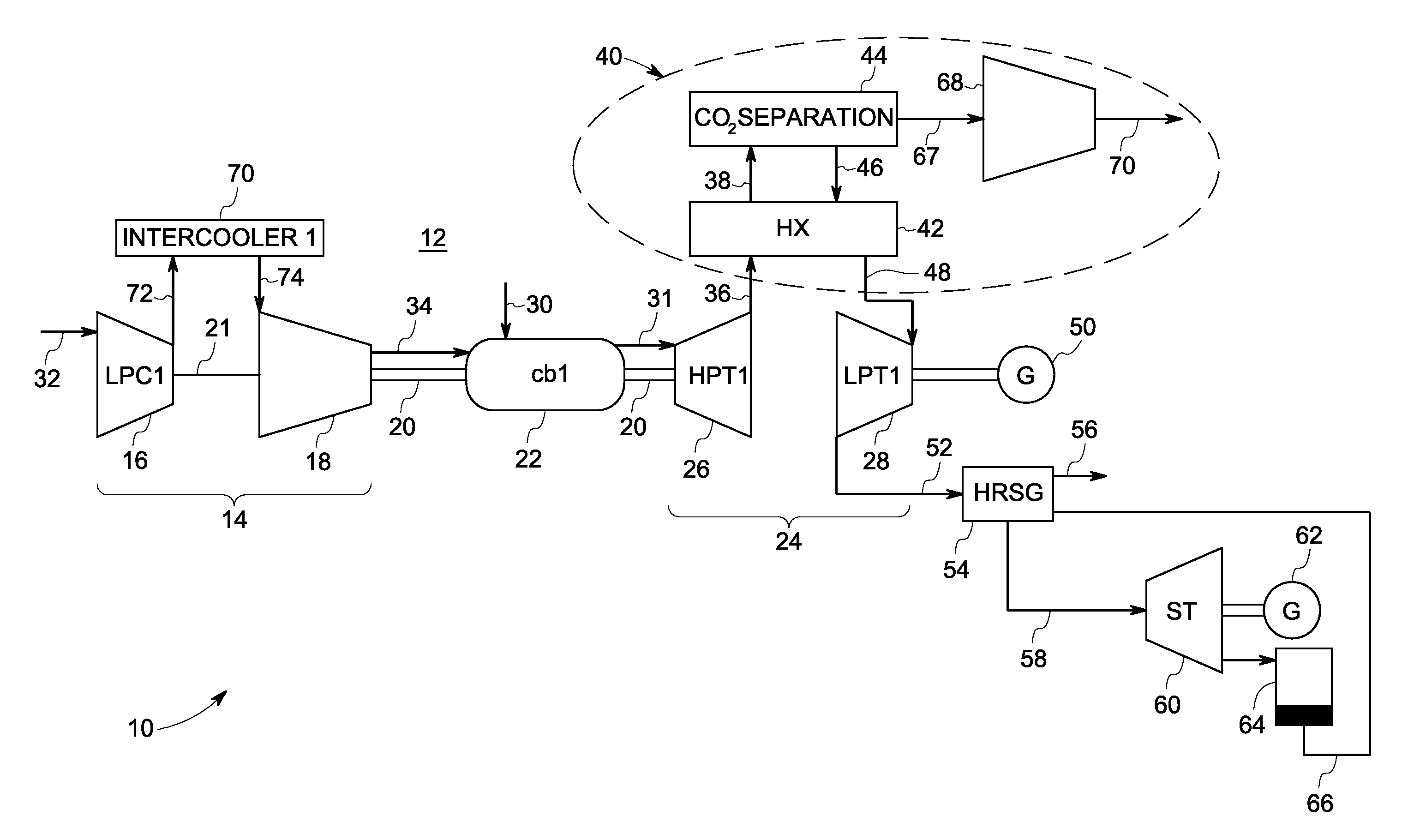

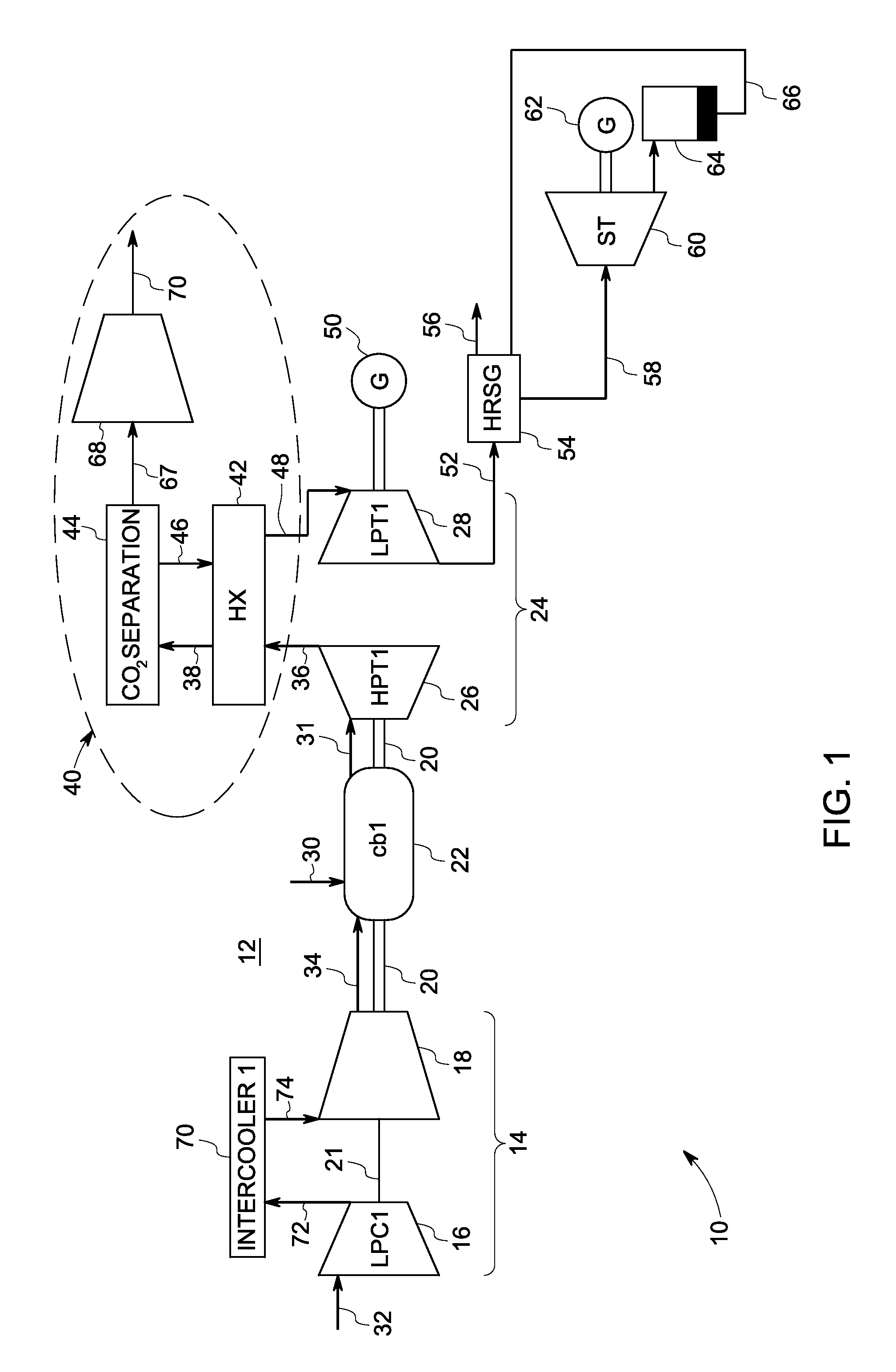

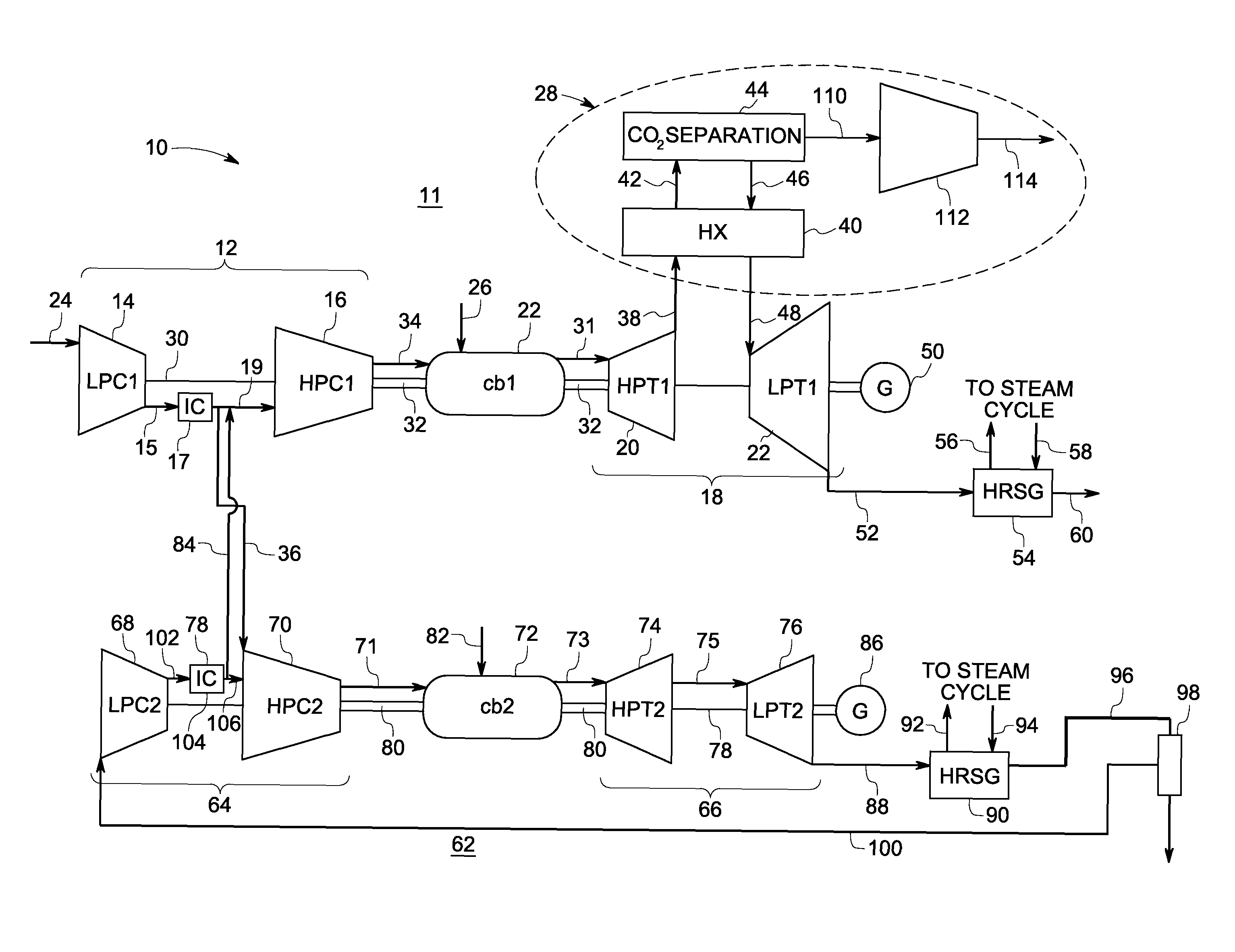

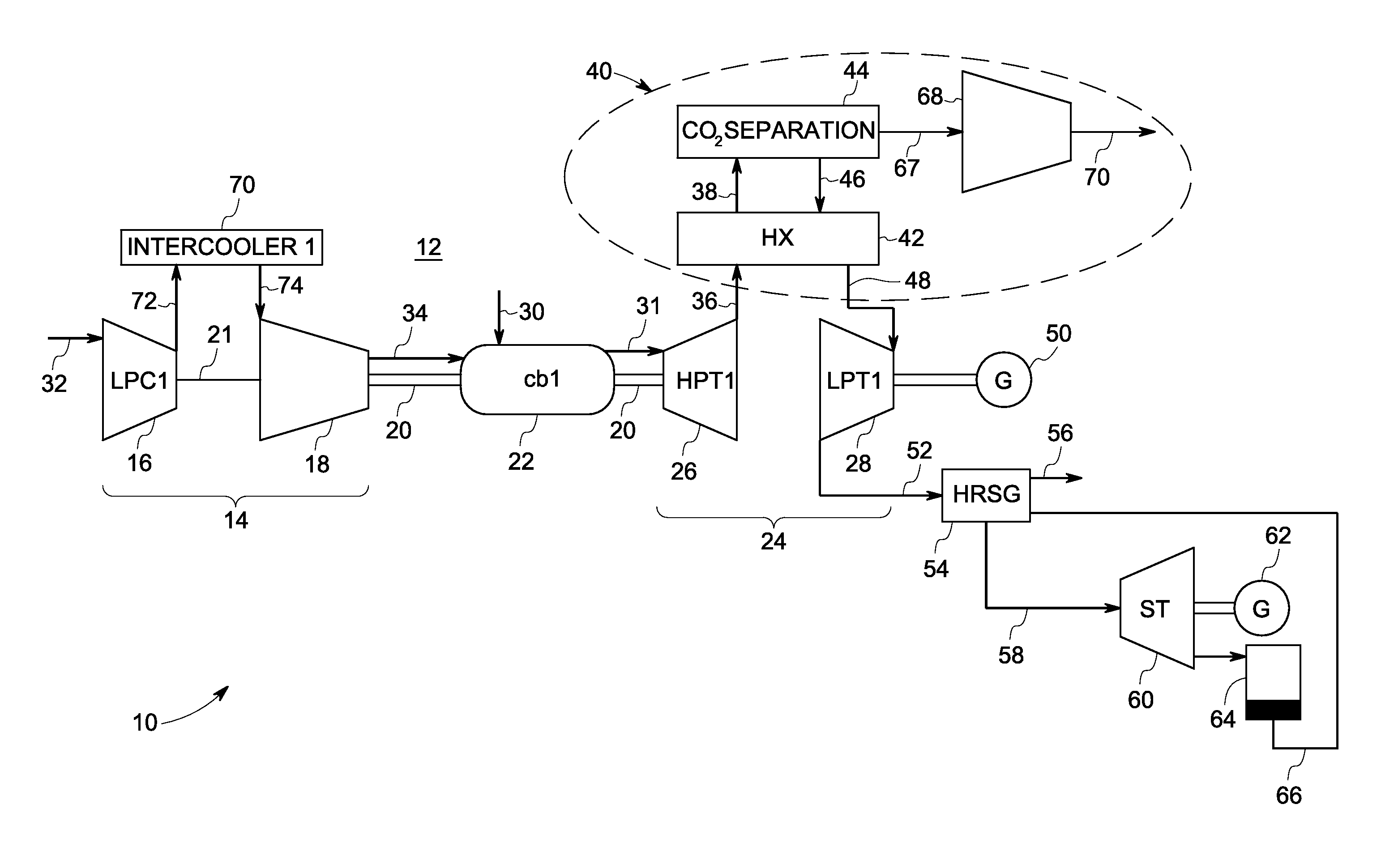

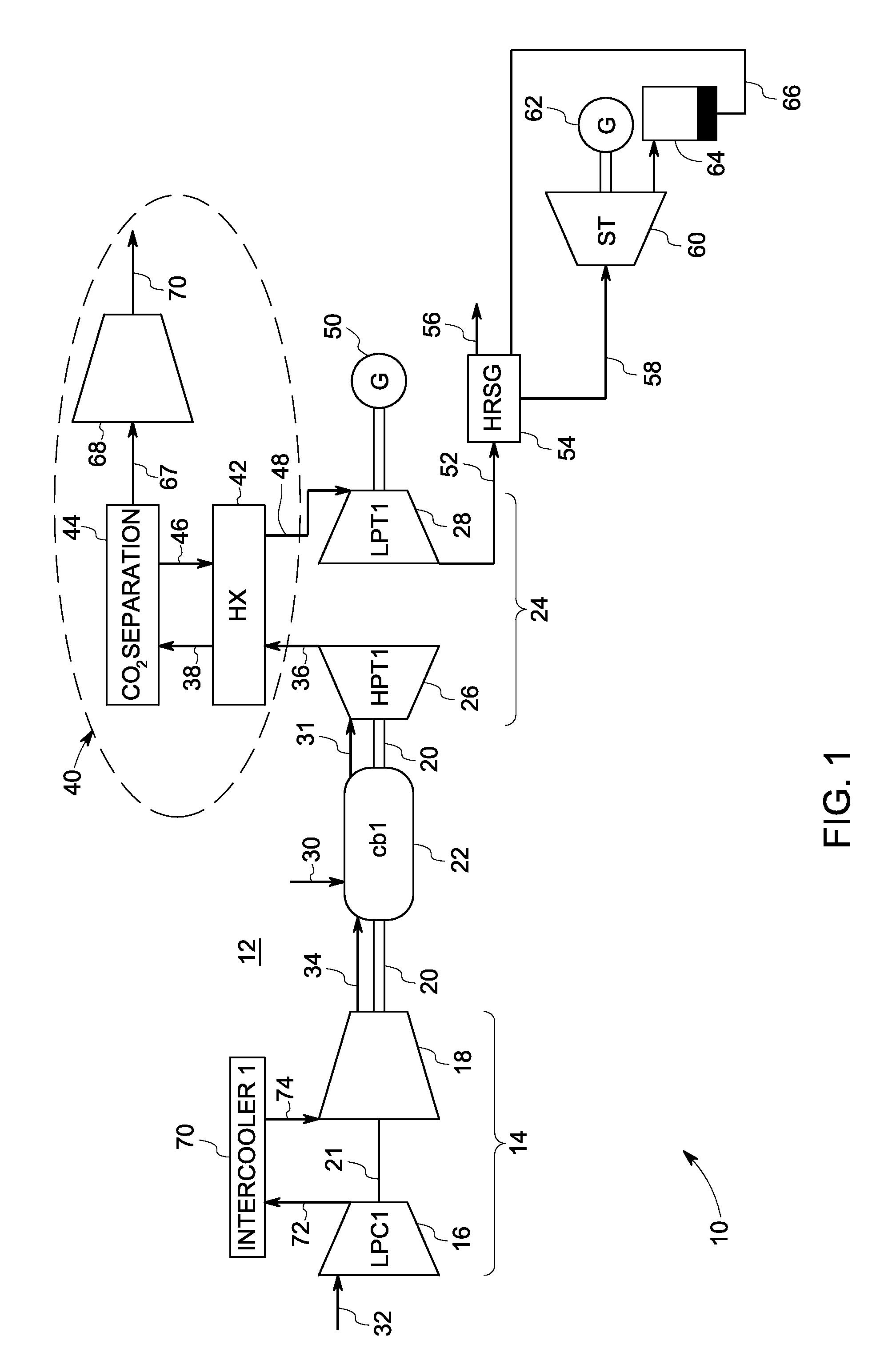

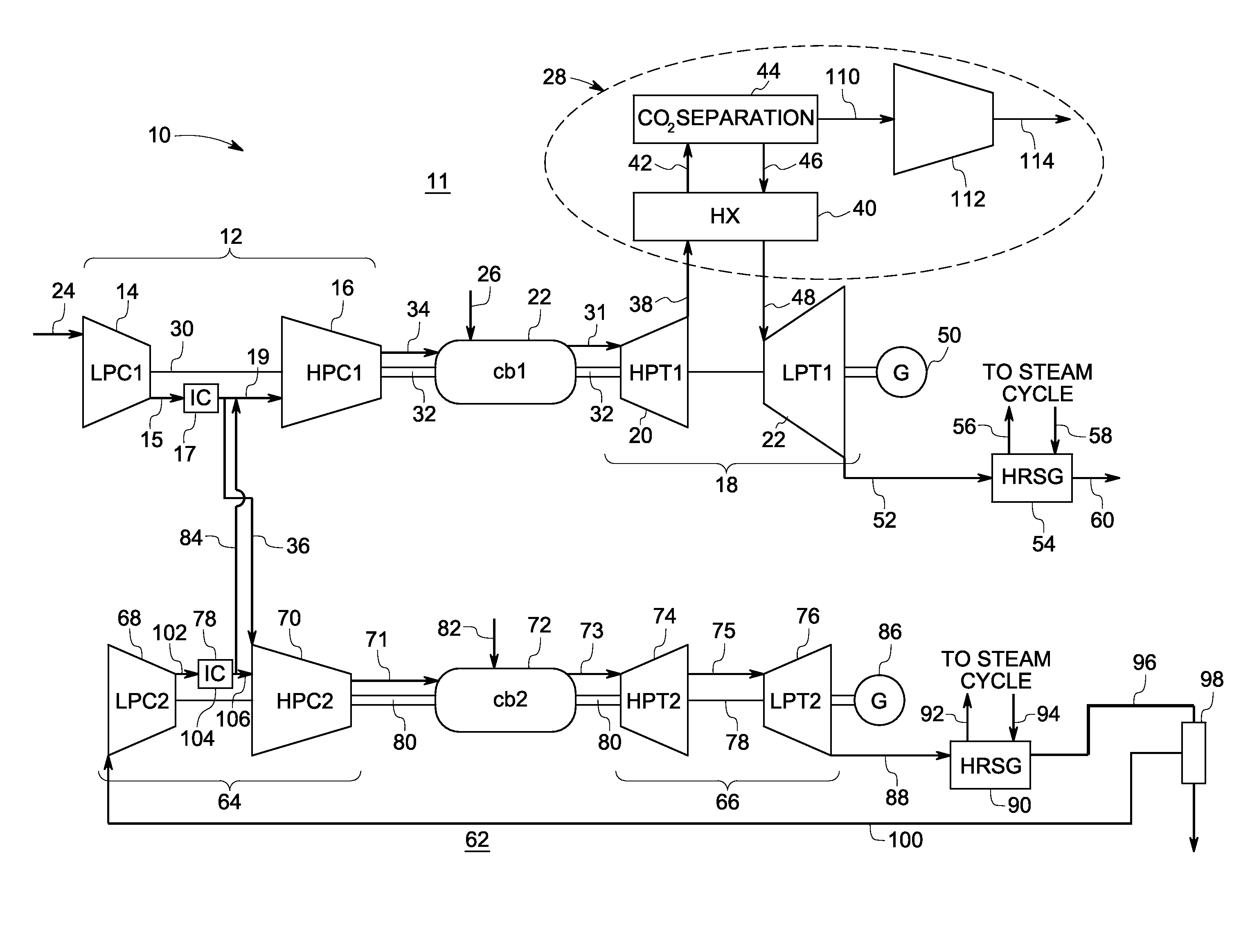

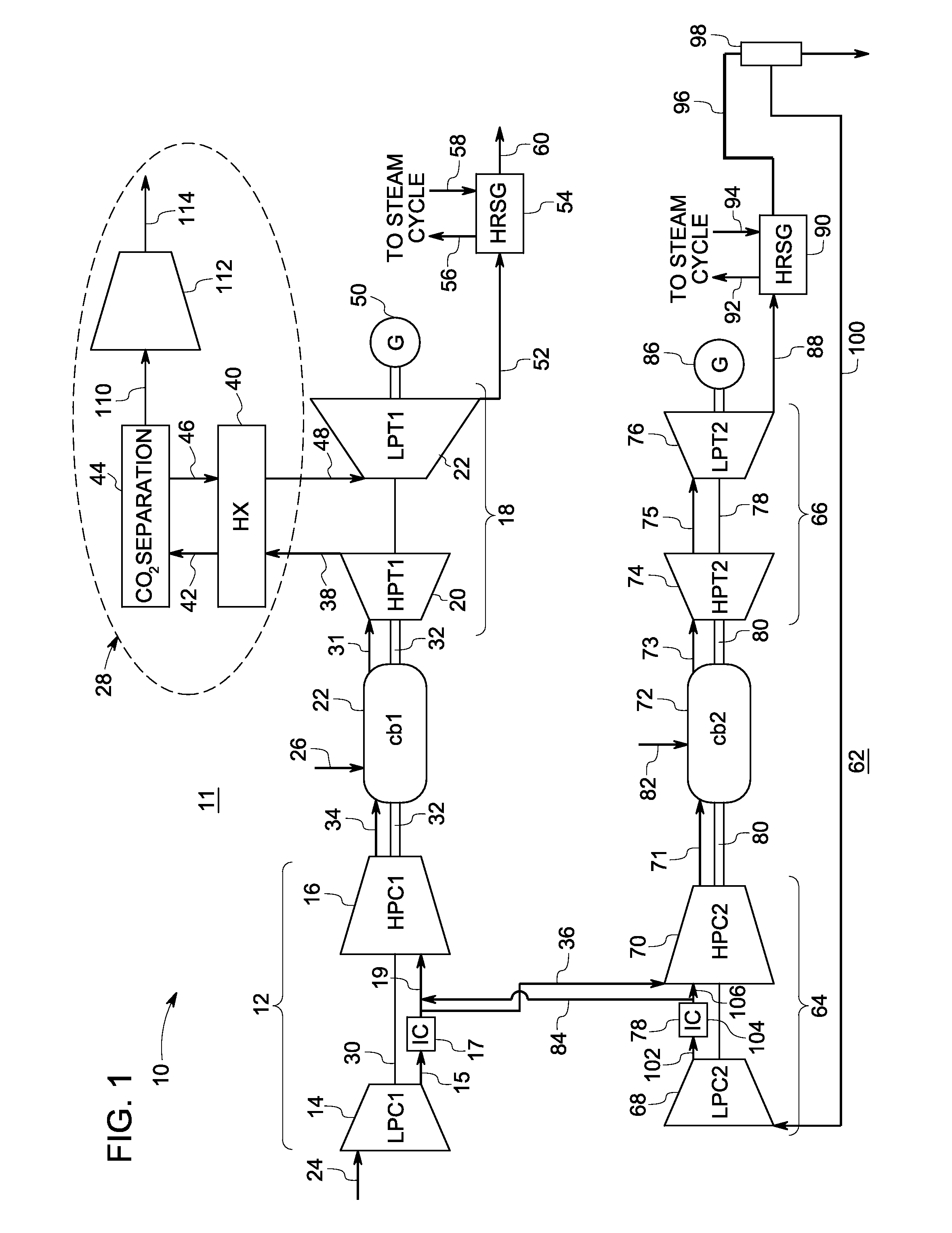

Systems and methods for power generation with carbon dioxide isolation

InactiveUS20080104939A1Dispersed particle separationGas turbine plantsCombustion chamberHigh pressure

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

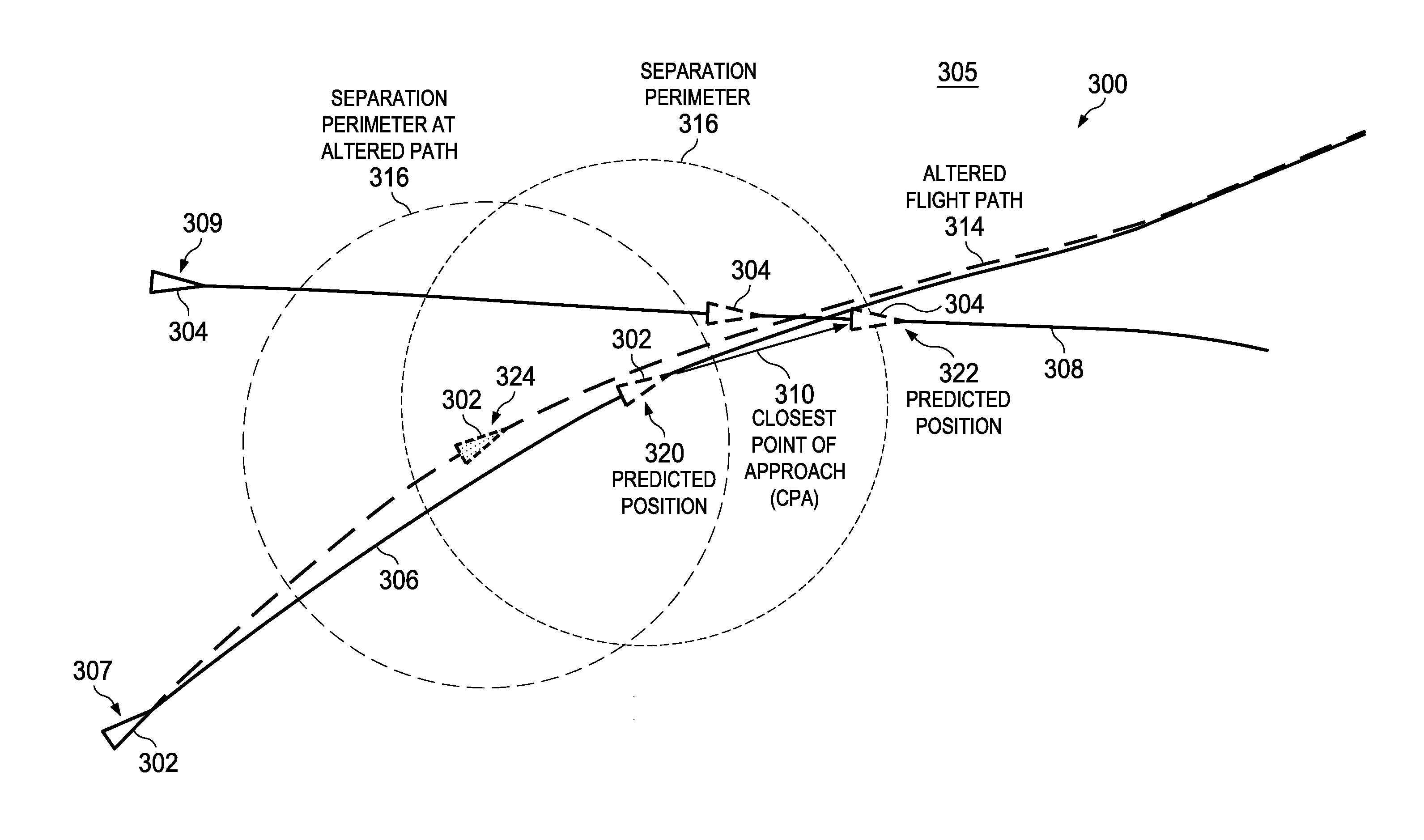

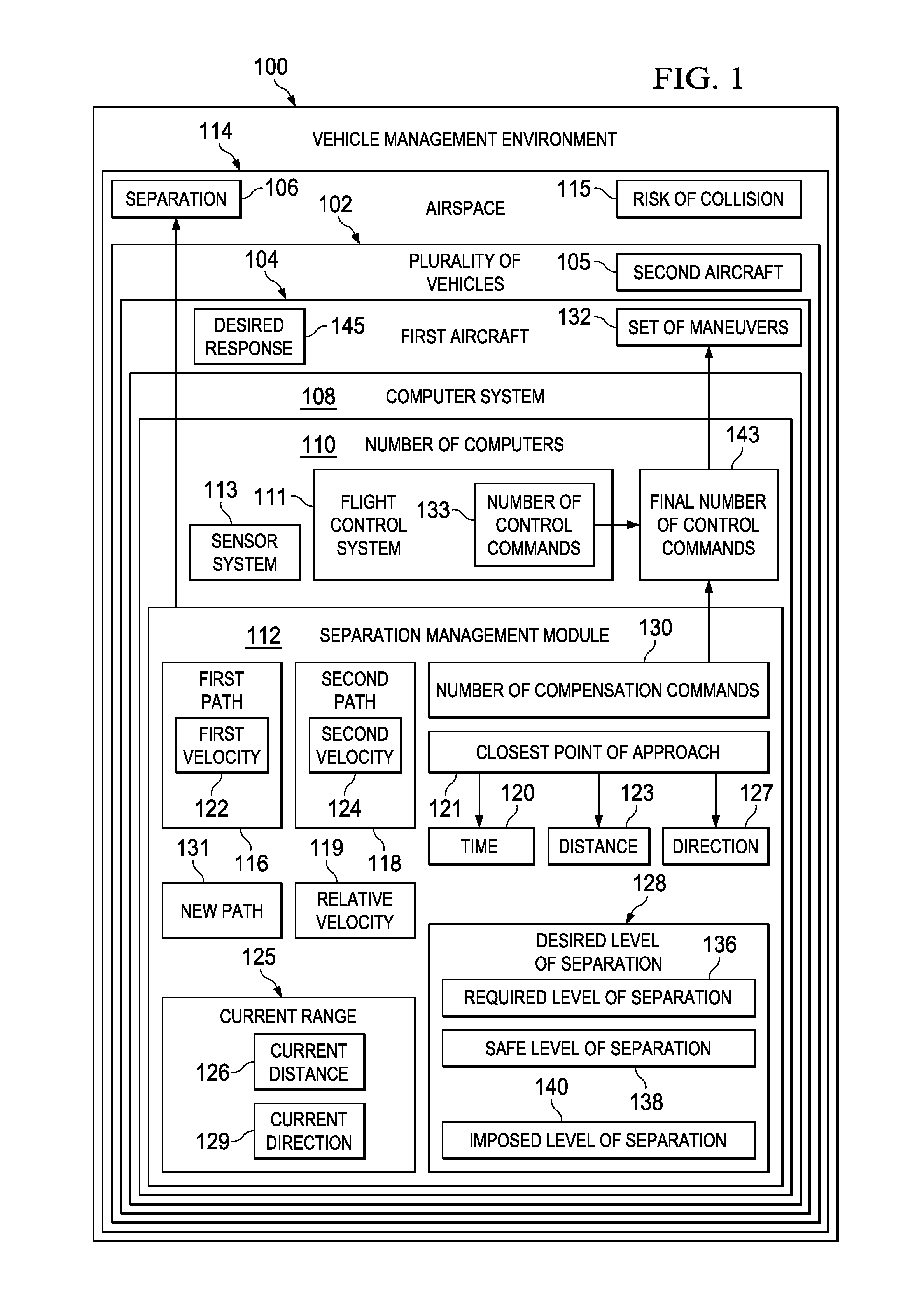

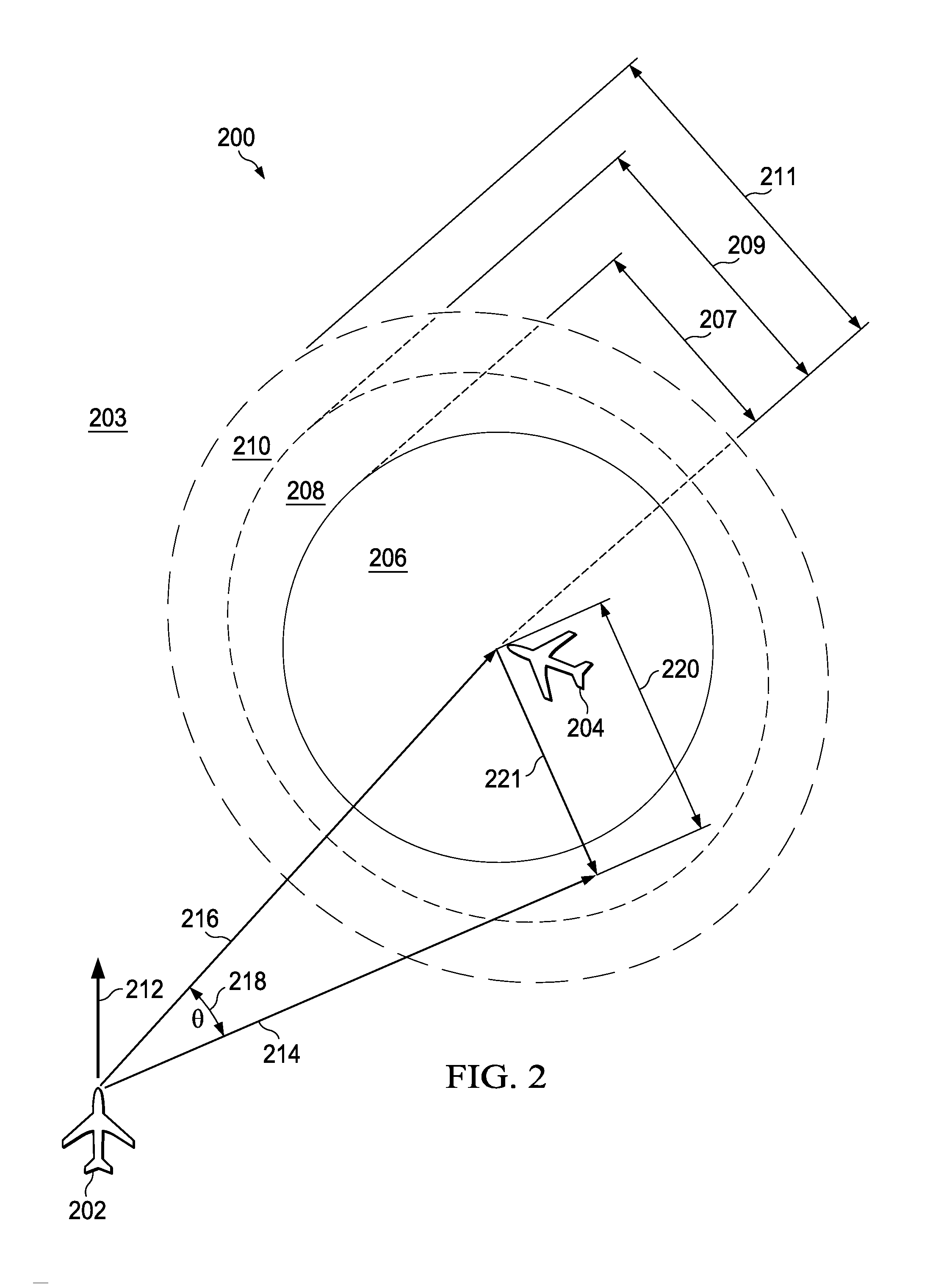

Aircraft Traffic Separation System

ActiveUS20120209457A1Maintain standardAnalogue computers for vehiclesCosmonautic vehiclesClosest pointEngineering

A method and apparatus for managing separation between vehicles. A closest point of approach between a first vehicle traveling along a first path and a second vehicle traveling along a second path is predicted. A number of compensation commands for altering the first path of the first vehicle are generated using the closest point of approach and a desired level of separation between the first vehicle and the second vehicle. The number of compensation commands is integrated with a number of control commands for the first vehicle to form a final number of control commands configured to maneuver the first vehicle to substantially maintain the desired level of separation between the first vehicle and the second vehicle. A response of the first vehicle to the final number of control commands is a desired response.

Owner:THE BOEING CO

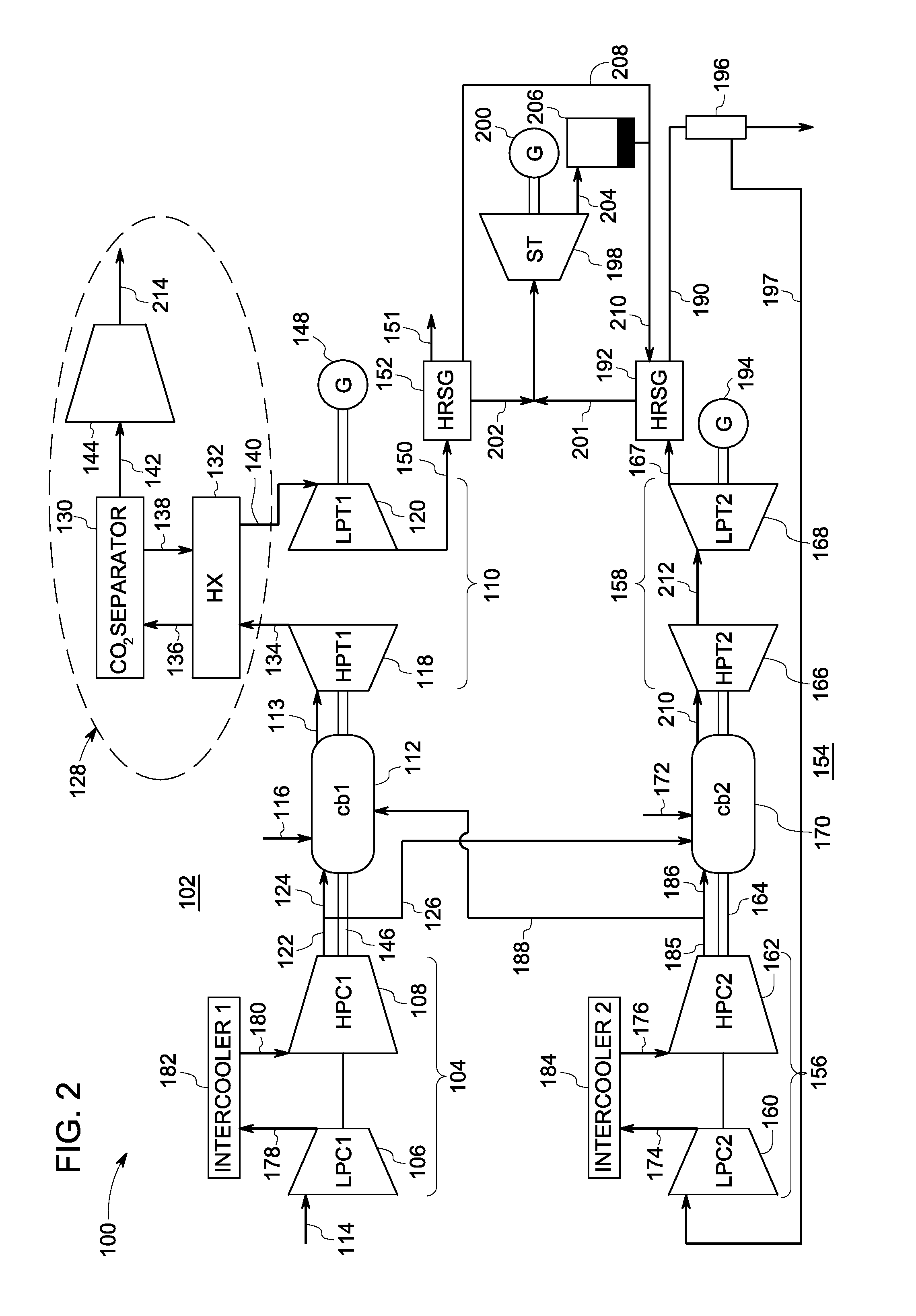

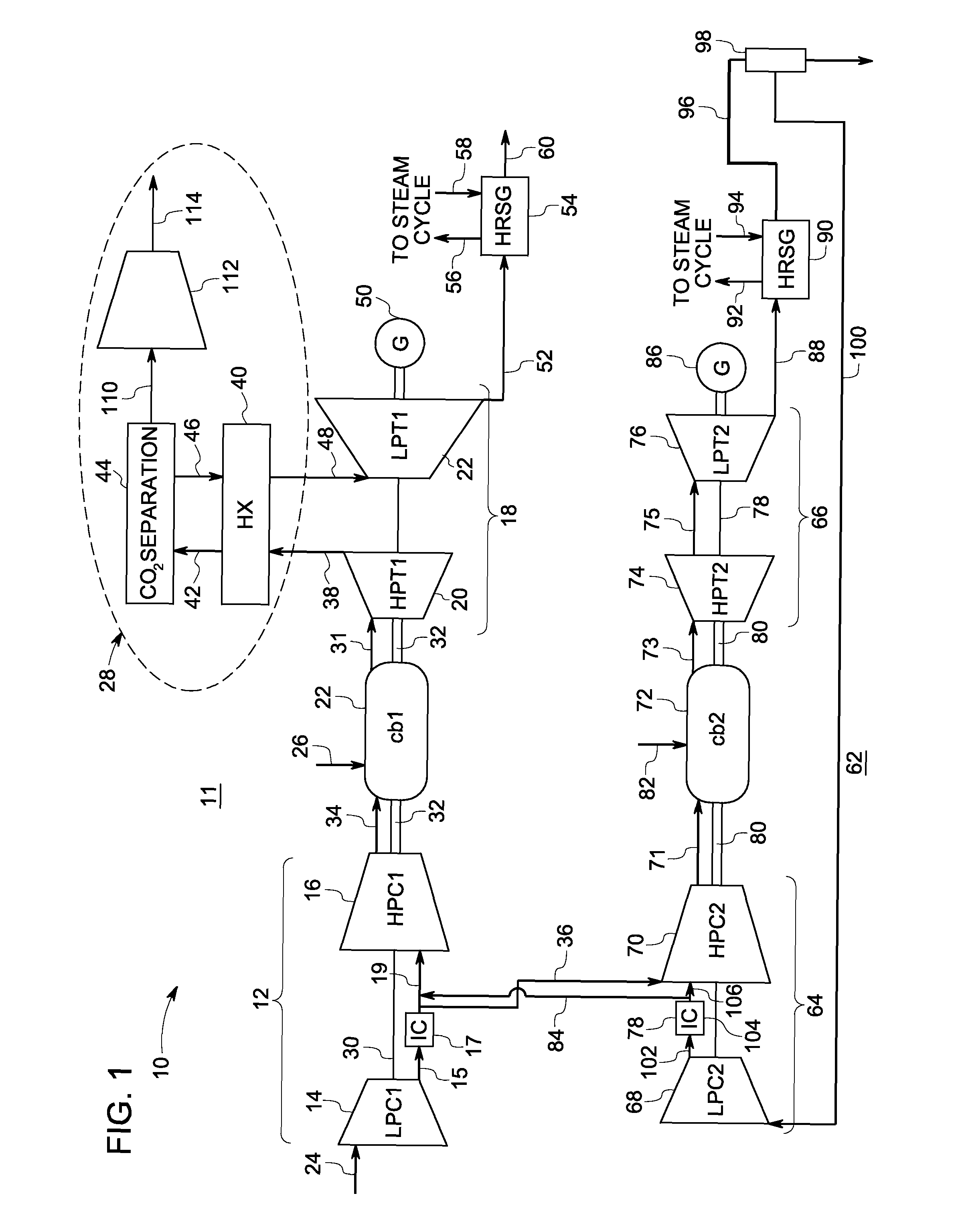

Systems and methods for power generation with carbon dioxide isolation

A power generation system includes first and second turbines. The first turbine including a low-pressure compressor (14) and a high-pressure compressor (16). A combustion chamber (22) combusts compressed oxidant and a fuel stream to generate a hot flue gas (31). The first turbine further includes a high-pressure expander (20) for receiving the flue gas and generating a CO2 rich exhaust gas. A low-pressure expander (22) generates a first final exhaust (52) and electrical energy. A CO2 separation system receives exhaust gas (38) and provides a CO2 lean gas fed to low-pressure expander (22). The second turbine including a compressor section (64) configured to discharge a recycle stream (71) from a high pressure compressor (70) to a second combustion chamber (72) and supply a split stream (84) from a low-pressure compressor (68) to high pressure compressor (16) of the first turbine.

Owner:GENERAL ELECTRIC CO

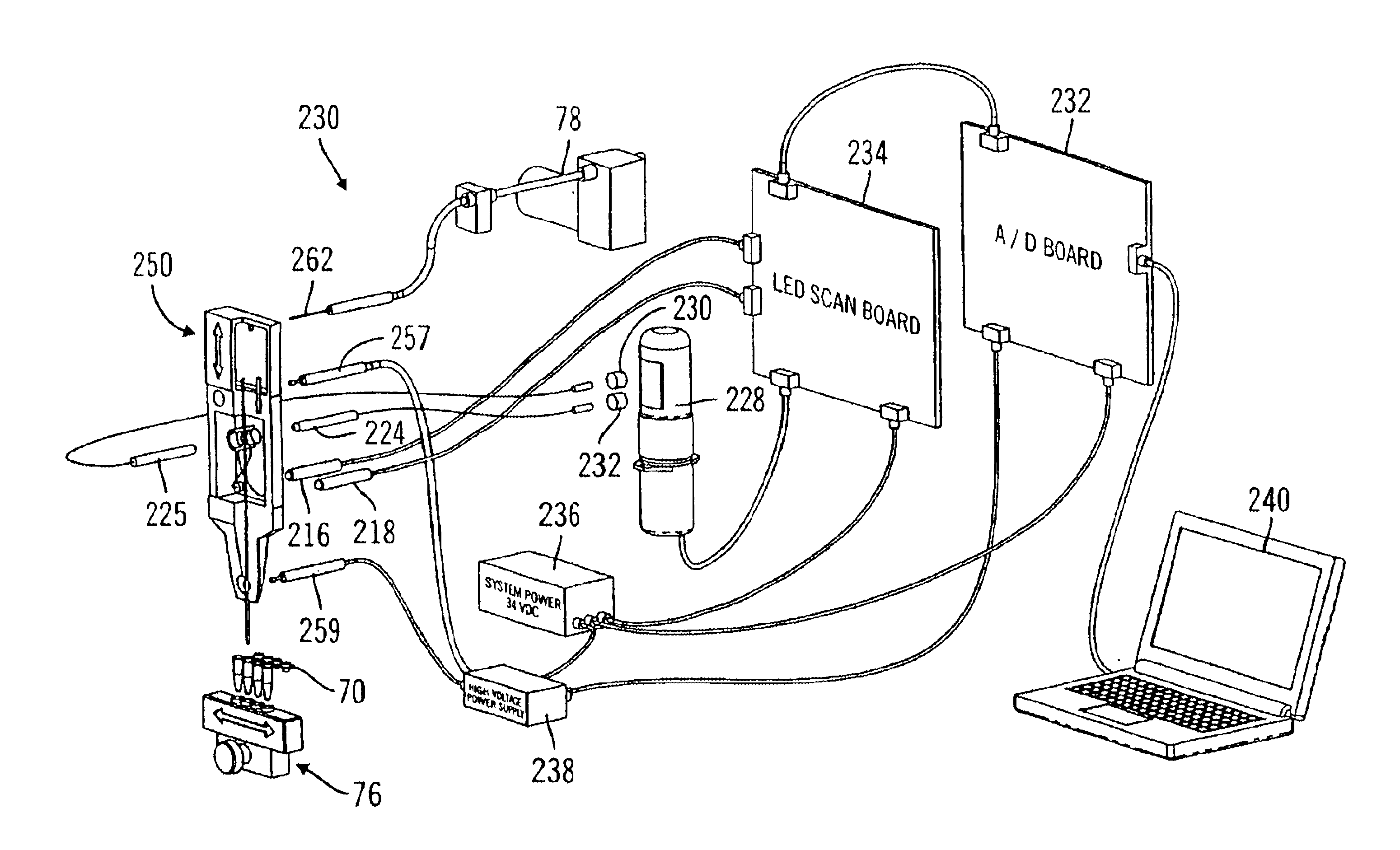

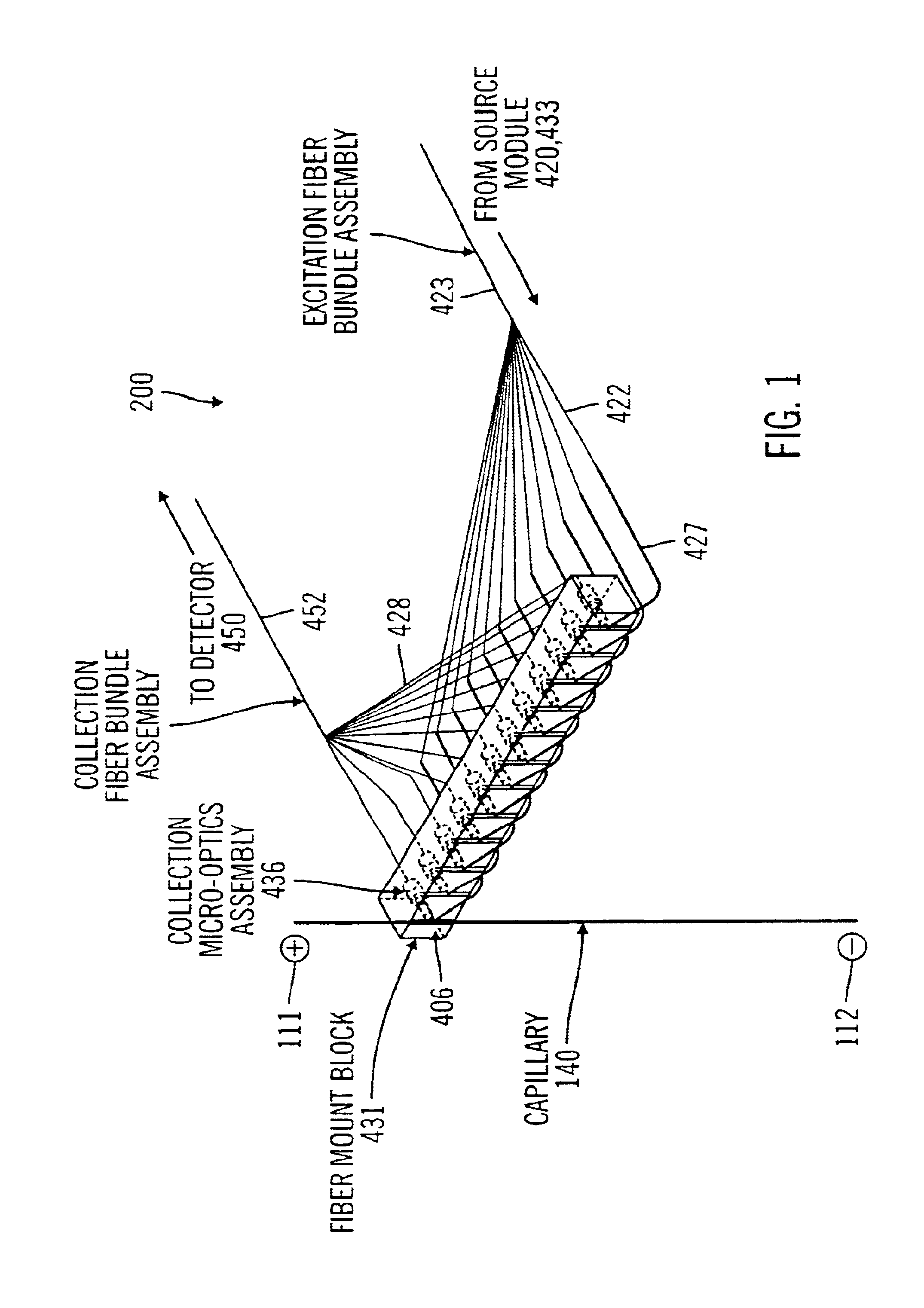

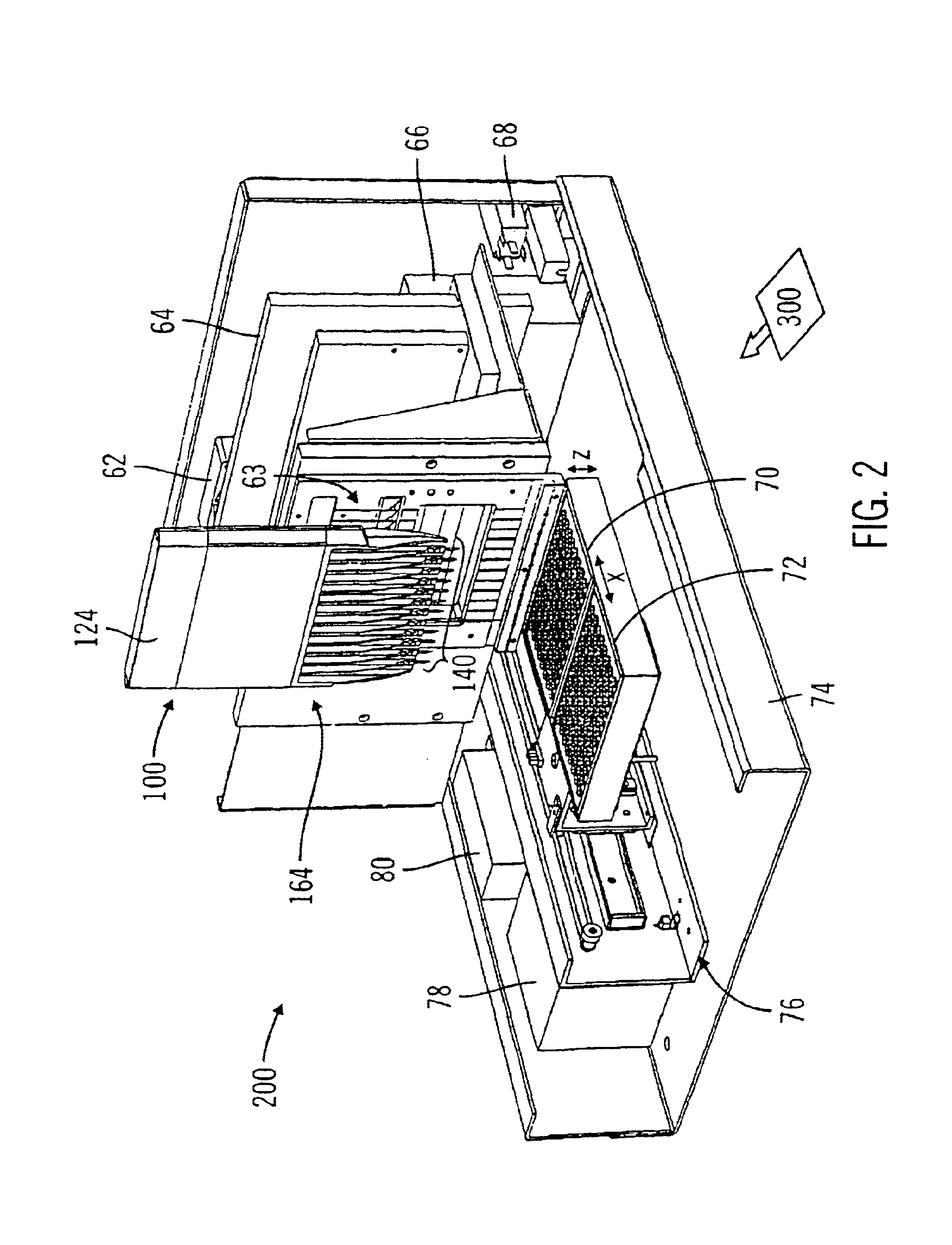

Multi-color multiplexed analysis in a bio-separation system

InactiveUS6870165B2Low costSensitive highOptical radiation measurementSludge treatmentCapillary electrophoresisFluorescence

A multi-channel and multi-color bio-separation detection method and apparatus in which a single detector is coupled to a plurality of radiation sources, in a one detector / many radiation sources configuration. Each radiation source directs radiation at a detection zone of a single separation channel, and a single detector is applied to detect light emissions from the detection zones associated with several radiation sources. The radiation sources are activated to direct radiation at the detection zone in a predetermined sequence and further in a cyclic manner, with the detector output synchronized to the radiation sources by a controller. Bio-separation may be conducted simultaneously in all the channels in parallel, with detection time-staggered and / or time multiplexed with respect to the light sources. In one embodiment, low cost light emitting diodes may be used as radiation sources. In another aspect, the detection scheme is configured for radiation induced fluorescence detection in an capillary electrophoresis instrument.

Owner:QIAGEN SCIENCES LLC

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

Systems and methods for power generation with carbon dioxide isolation

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

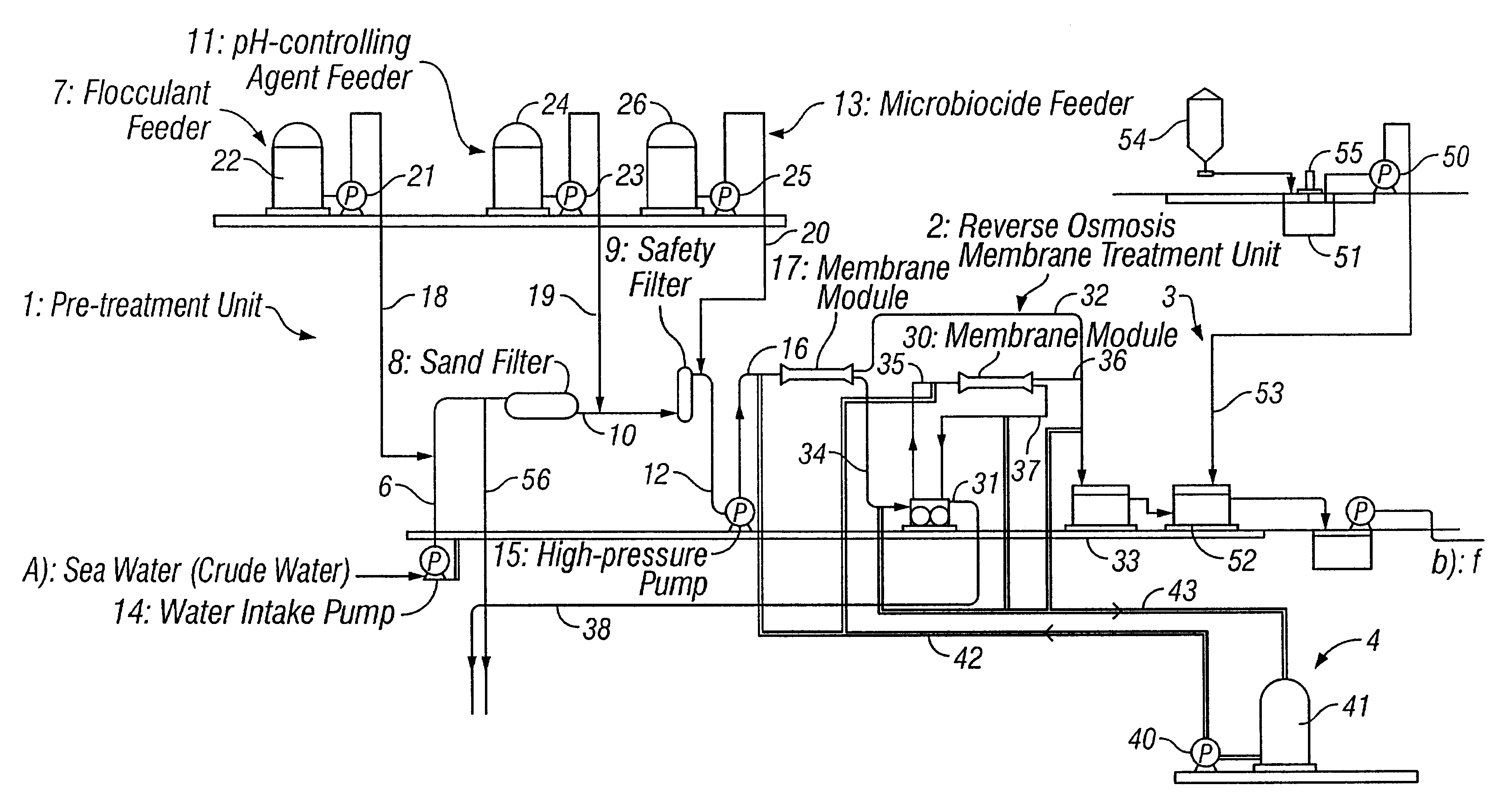

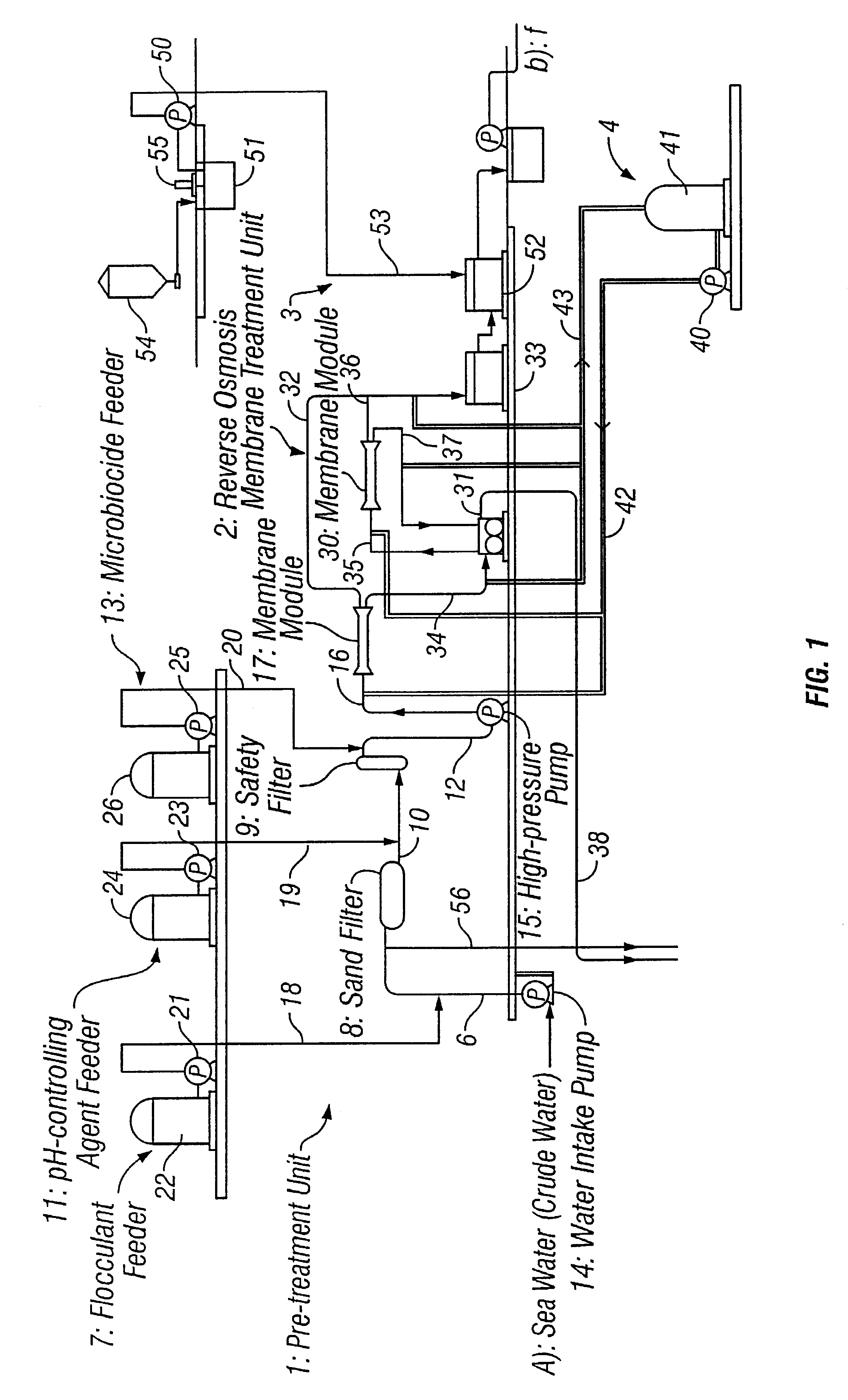

Method for inhibiting growth of bacteria or sterilizing around separating membrane

InactiveUS6468430B1Conserve costReduce the impactMembranesSolid sorbent liquid separationPre treatmentPermselective membrane

In the invention, the pipe lines around permselective membranes and the surfaces of permselective membranes are intermittently disinfected by adding an inexpensive acid such as sulfuric acid or the like to pre-treated crude water so as to make the water have a pH of 4 or lower. Accordingly, the invention provides a method of surely disinfecting the permselective membranes in membrane separation systems.

Owner:TORAY IND INC

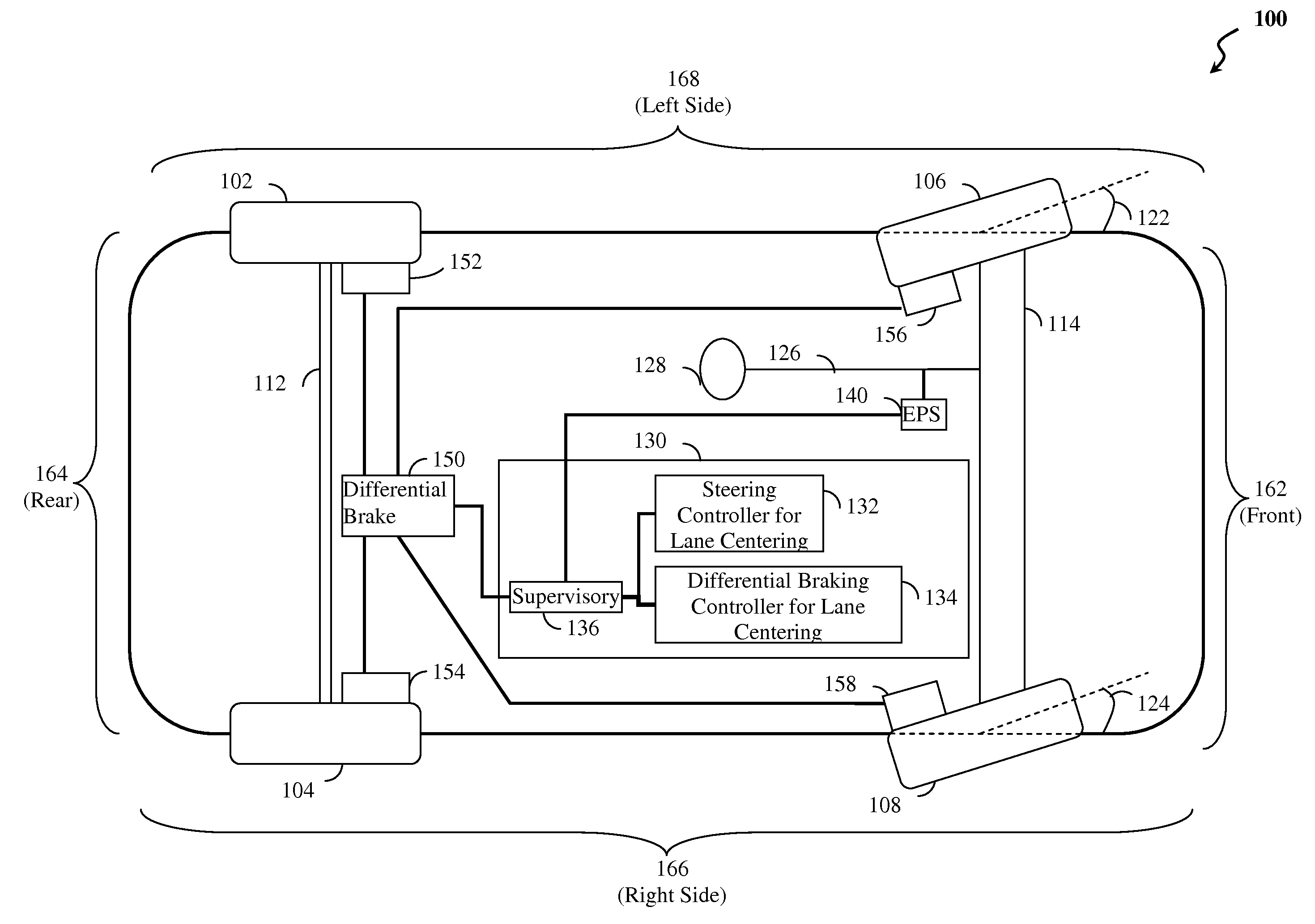

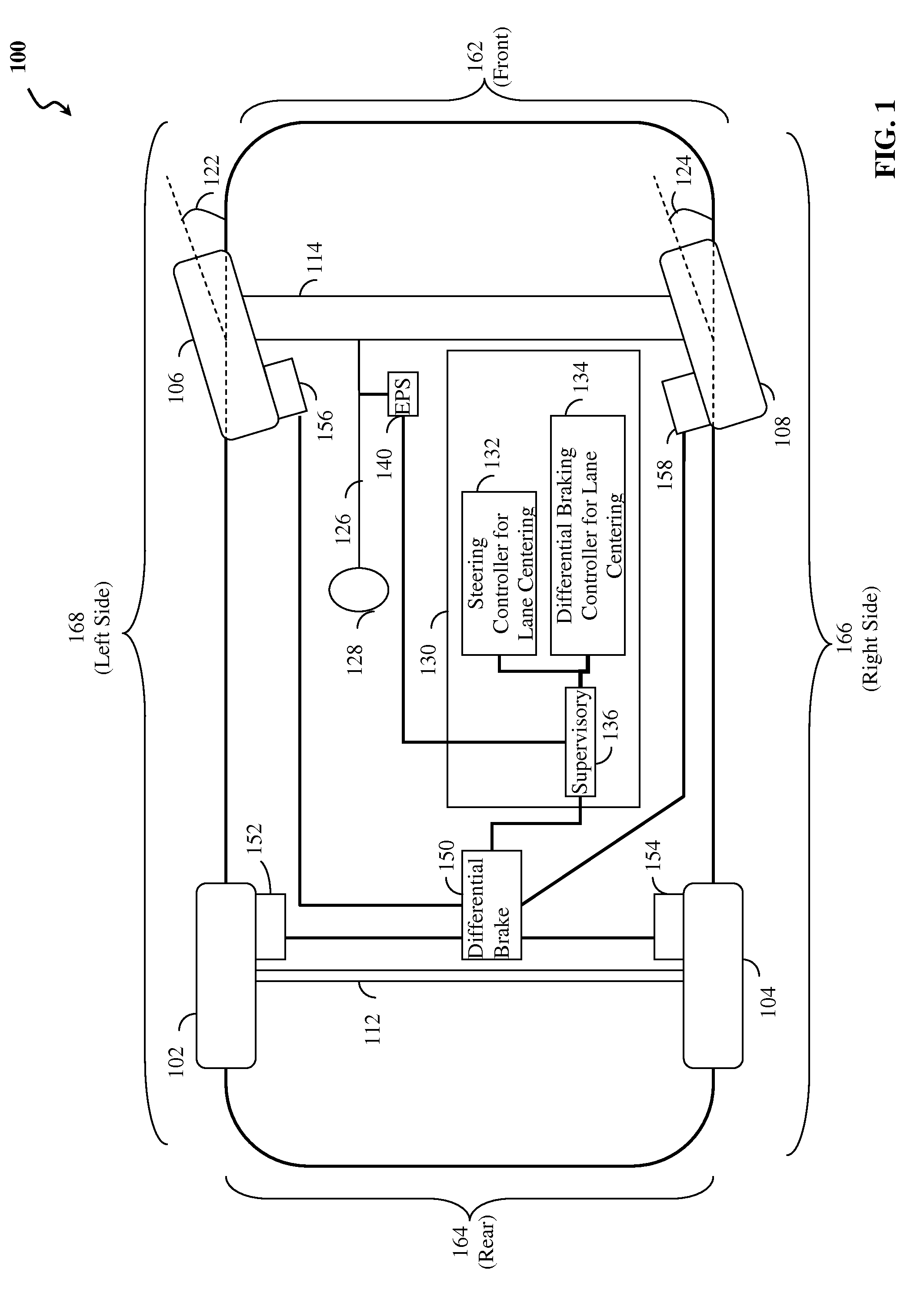

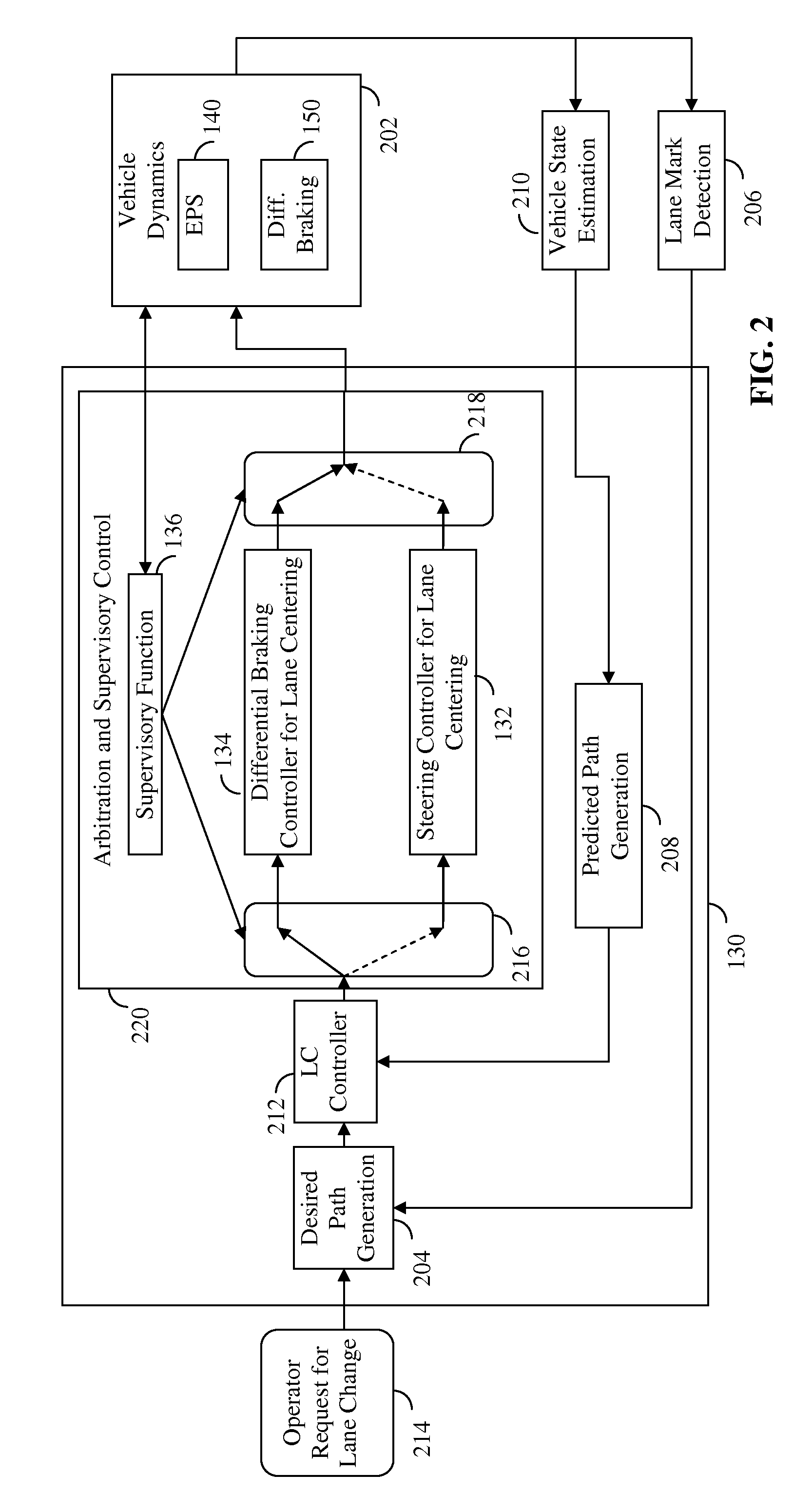

Lane centering fail-safe control using differential braking

ActiveUS20120283907A1Minimize the differenceOffset errorVehicle testingBrake system interactionsElectric power steeringEngineering

Method, system and non-transitory computer-readable medium for fail-safe performance of a lane centering system. An electrical power steering (EPS) system of a vehicle is monitored for a failure and operation of the lane centering system is switched to a differential braking controller to output differential braking commands to a differential breaking system upon determining that a failure of the EPS system has occurred, where the output braking commands direct the differential braking system to apply force a brake for a wheel of vehicle, such by the applied braking force the vehicle follows a desired path determined for a lane centering operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

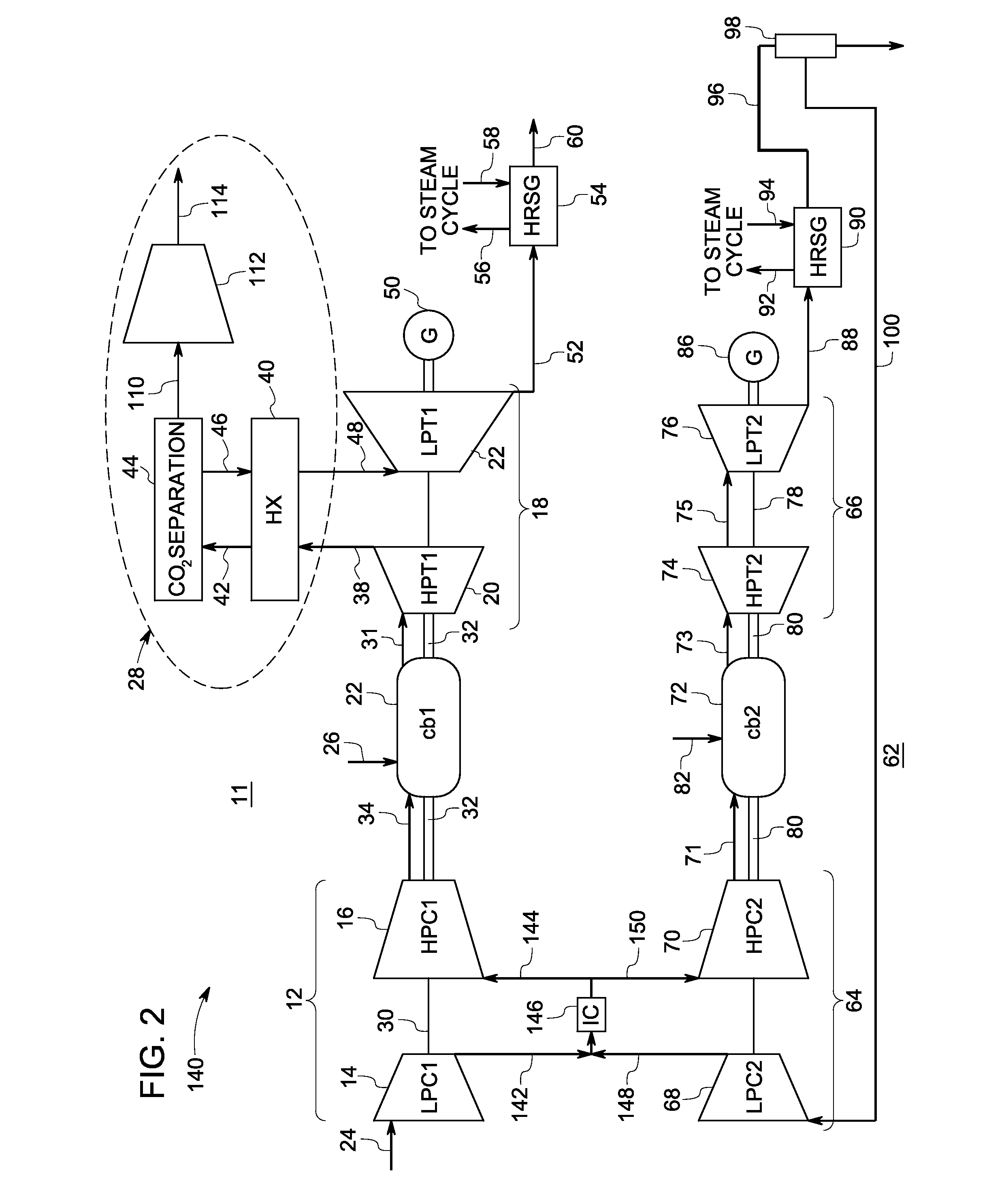

Systems and methods for power generation with carbon dioxide isolation

A power generation system includes a first turbine system. The first turbine system includes a first compressor section comprising at least two stages. The two stages includes a first low pressure compressor fluidly coupled to a first high pressure compressor configured to supply a first portion of compressed oxidant and a second portion of compressed oxidant A first combustion chamber is configured to combust said first portion of compressed oxidant and a first fuel stream comprising carbon-based fuels and to generate a first hot flue gas. The first turbine system further includes a first expander section having an inlet for receiving said first hot flue gas and generating a first expanded exhaust gas rich in CO2. The first high-pressure expander is fluidly coupled to a first low-pressure expander configured to generate a first exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving said first expanded exhaust gas from said first high-pressure expander and provide a CO2 lean gas that is then fed to said first low-pressure expander. The power generation system also includes a second turbine system including a second compressor section comprising at least two stages. The two stages includes a second low-pressure compressor fluidly coupled to a second high pressure compressor, wherein said high pressure compressor is configured to receive said second portion of compressed oxidant. A second combustion chamber is configured to combust a second fuel stream comprising carbon-based fuels and to generate a second hot flue gas and a second expander section is configured to receive said second hot flue gas and to generate a second final exhaust and electrical energy. The second compressor section is configured to receive said second final exhaust comprising carbon dioxide and to discharge a recycle stream from said second high pressure compressor to said second combustion chamber and a split stream from said second low-pressure compressor to said first high pressure compressor.

Owner:GENERAL ELECTRIC CO

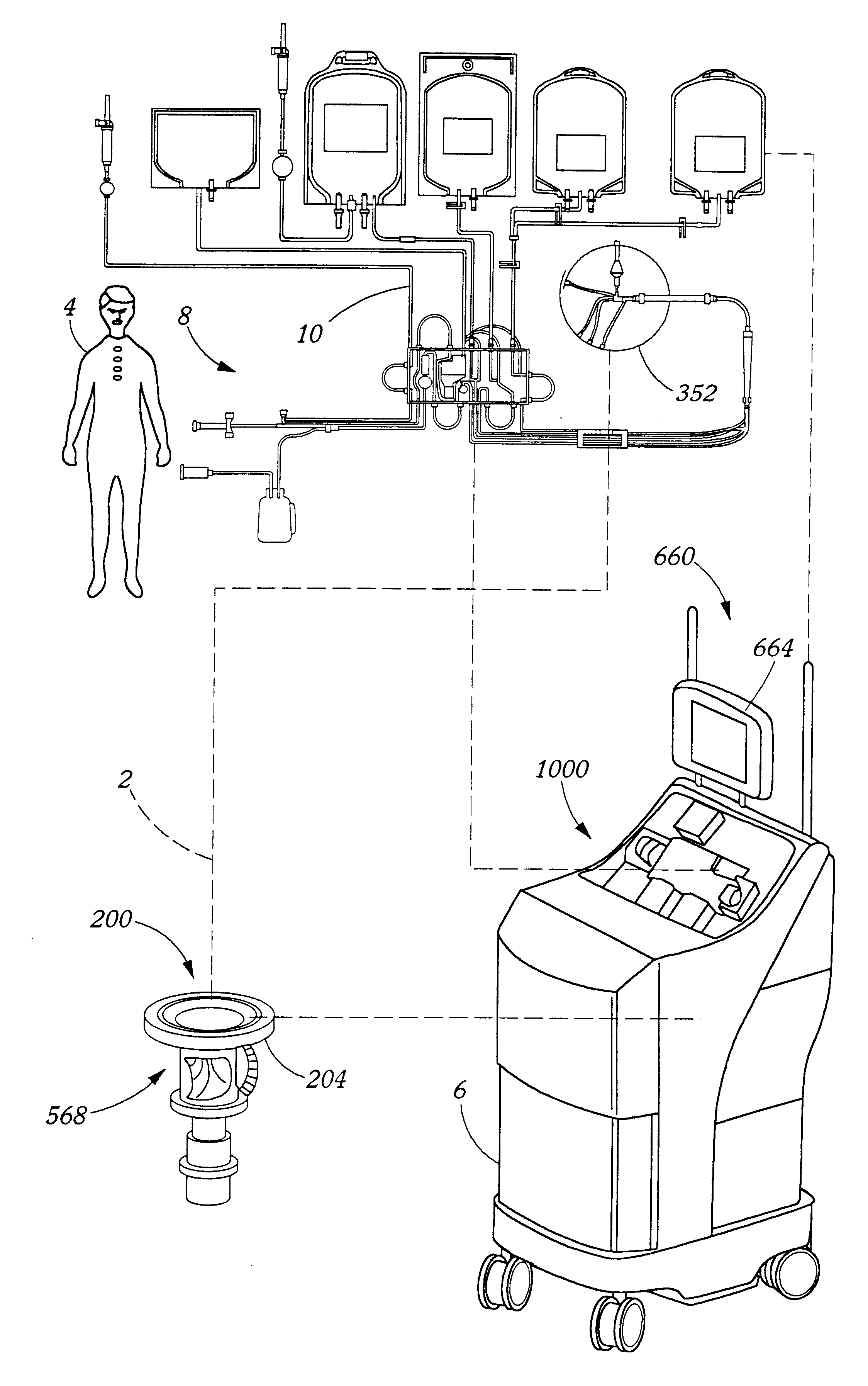

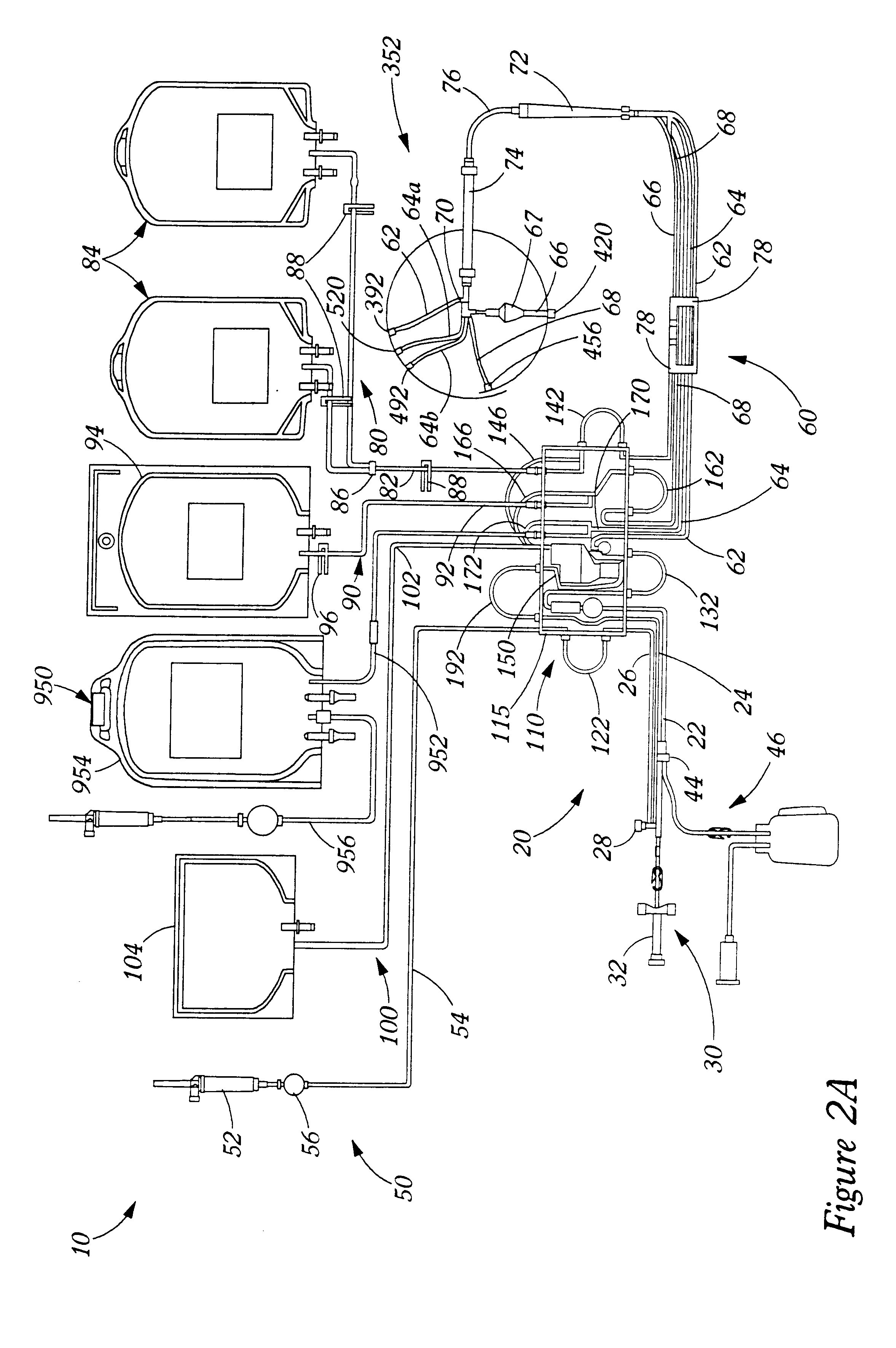

Method and apparatus for blood separations

InactiveUS20060226090A1Reduces direct collectionReduce processing costsWater/sewage treatment by centrifugal separationCentrifugal force sediment separationWhole blood productMedicine

Described herein is a method and apparatus for collecting and separating whole blood into its components, including collecting an amount of plasma and red blood cells. The collection and separation system includes a console and a disposable set. The method may include processing the blood through the centrifuge, collecting plasma, collecting red blood cells and returning red blood cells until a desired plasma volume is reached. Then a final volume of red blood cells and plasma may be collected. The disposable set may include a manifold, a CFC, and various components attached by tubing. These components may include one or more solution bags, blood product bags, bacterial filters, leukofilters, and a donor blood collection tube with access needle.

Owner:TERUMO MEDICAL CORP

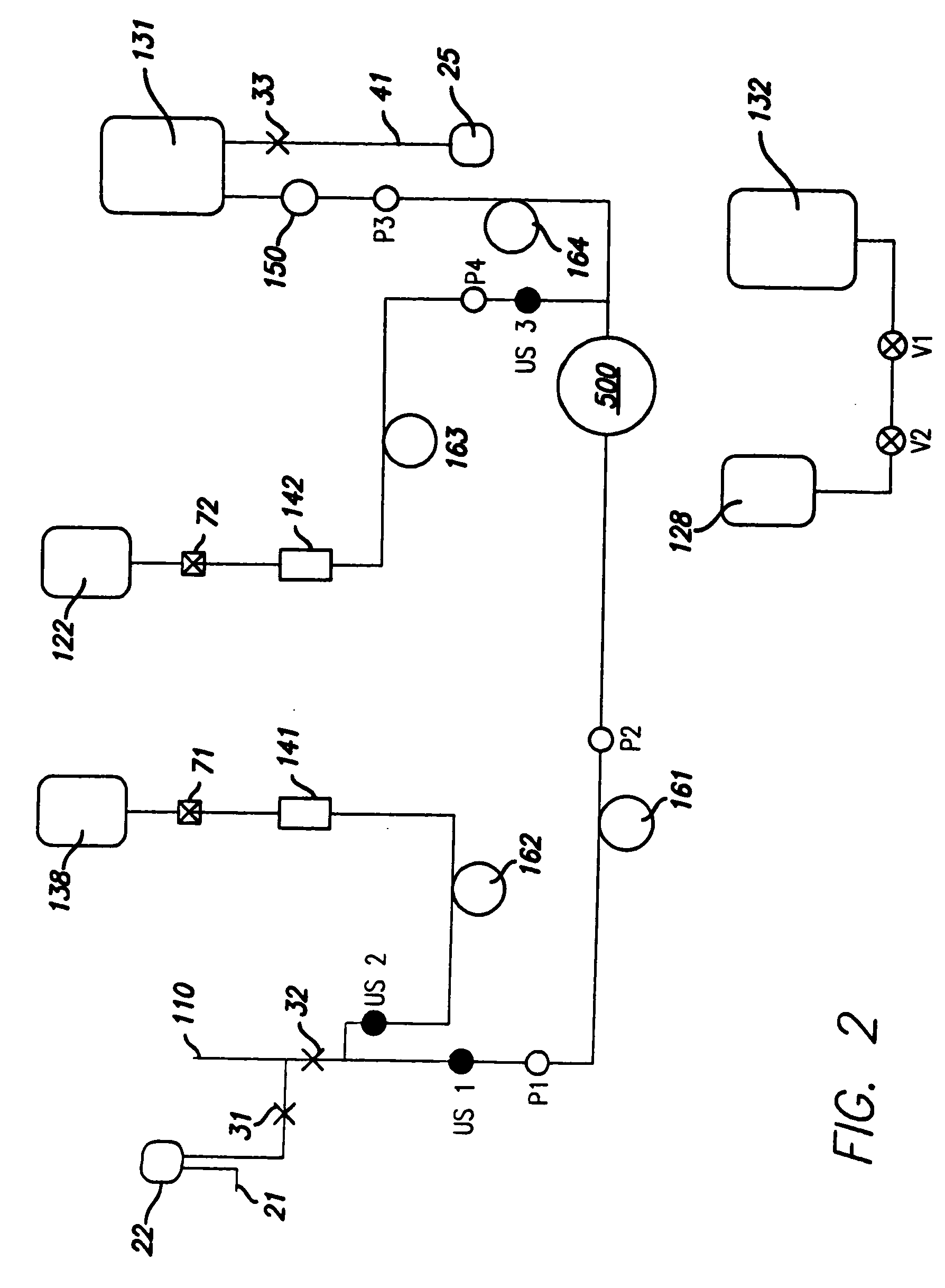

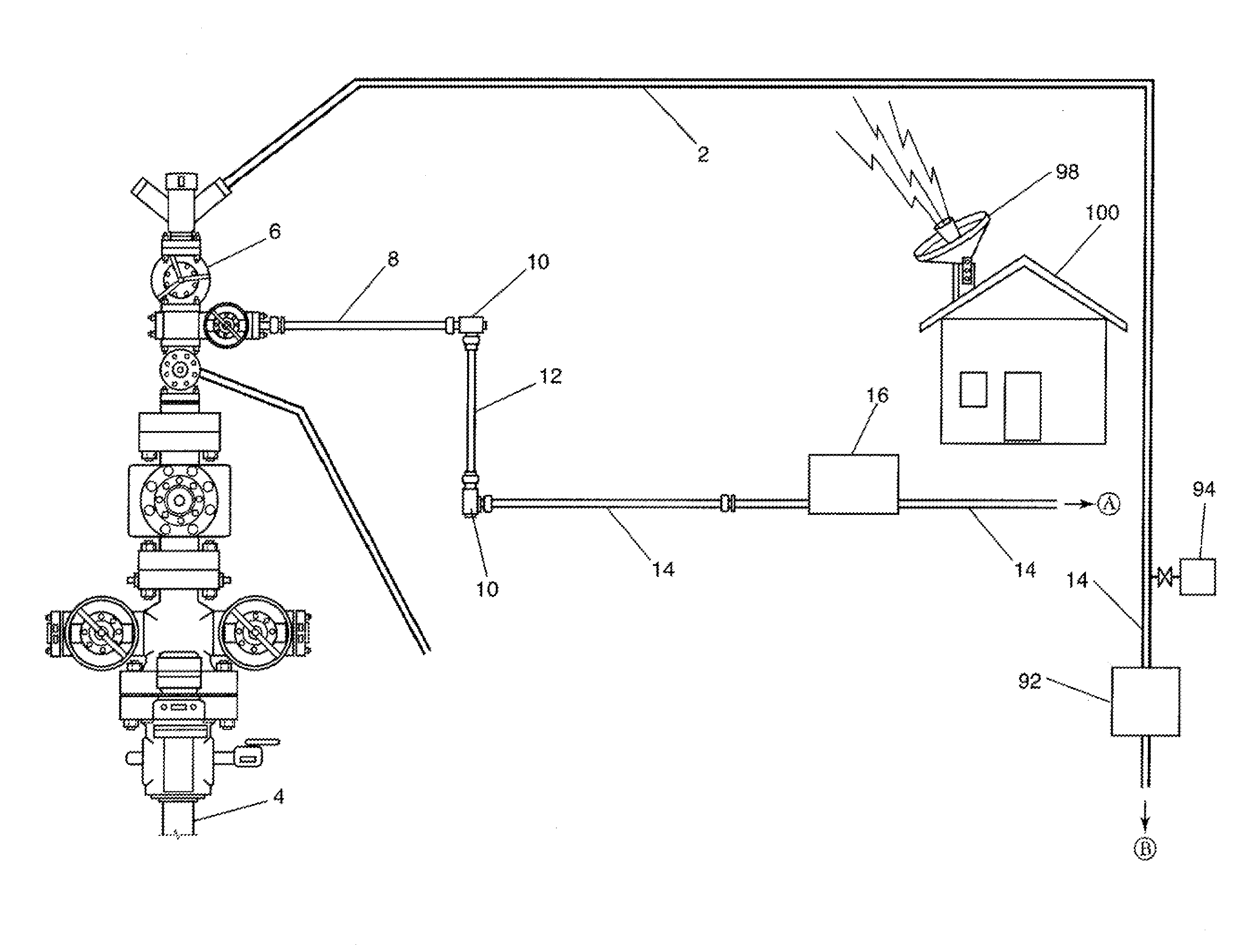

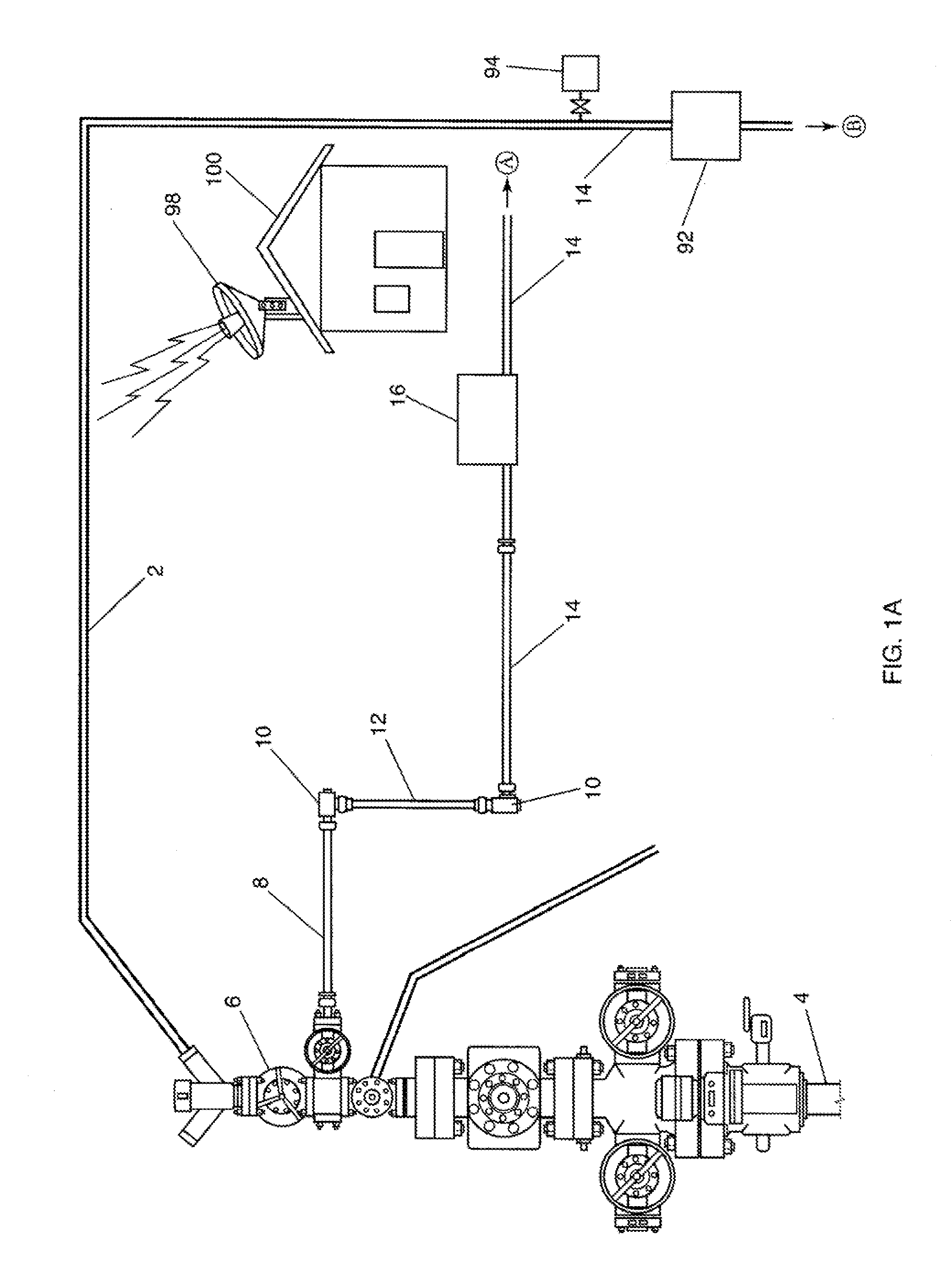

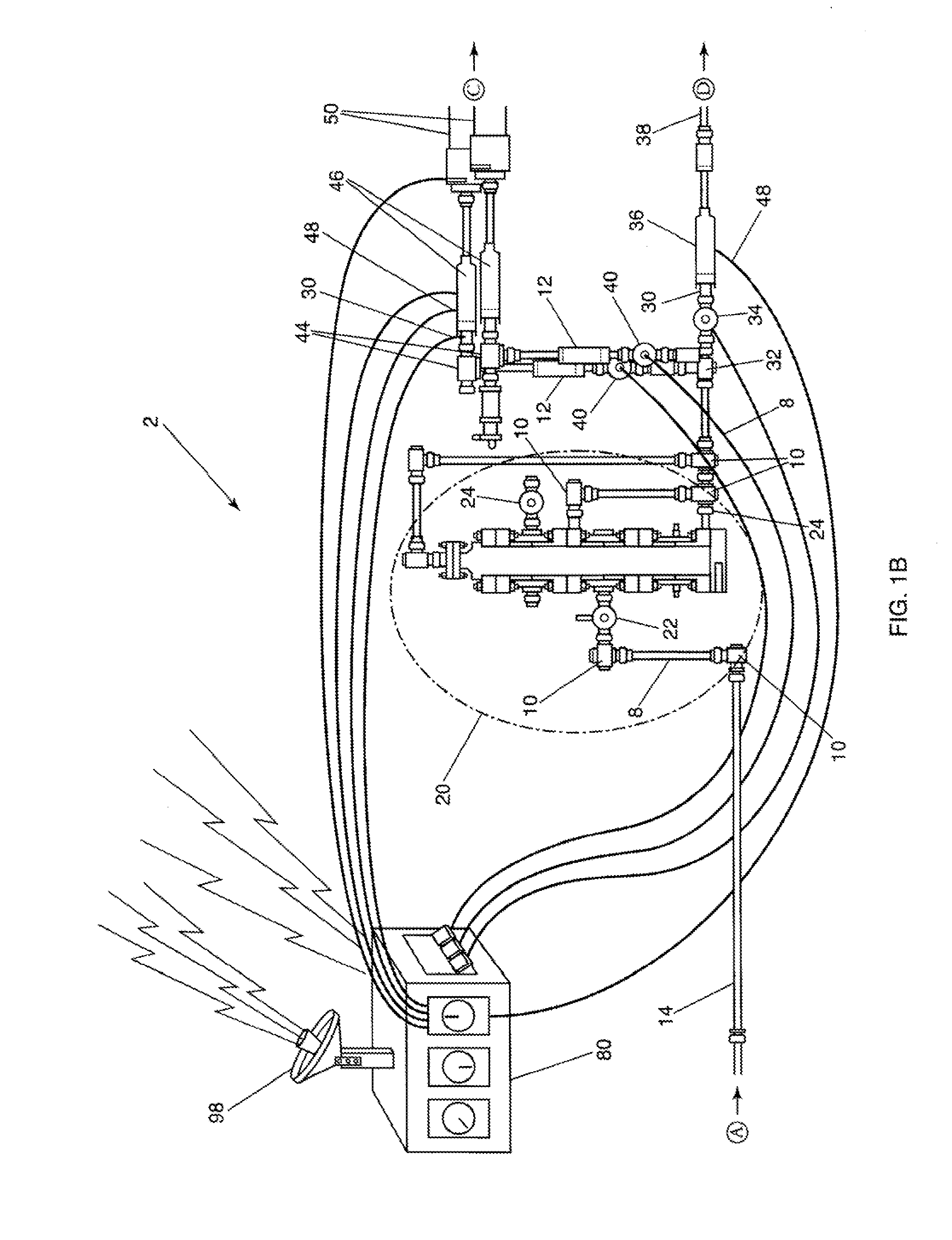

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

Carbon dioxide capture systems and methods

A carbon dioxide separation system comprises a first flow path for directing a fluid comprising carbon dioxide therethrough, a second flow path for directing a sweep fluid therethrough, and a separator comprising a material with selective permeability of carbon dioxide for separating the first and the second flow paths and for promoting carbon dioxide transport therebetween. A carbon dioxide separation unit is in fluid communication with the second flow path for separating the transported carbon dioxide from the sweep fluid.

Owner:GENERAL ELECTRIC CO

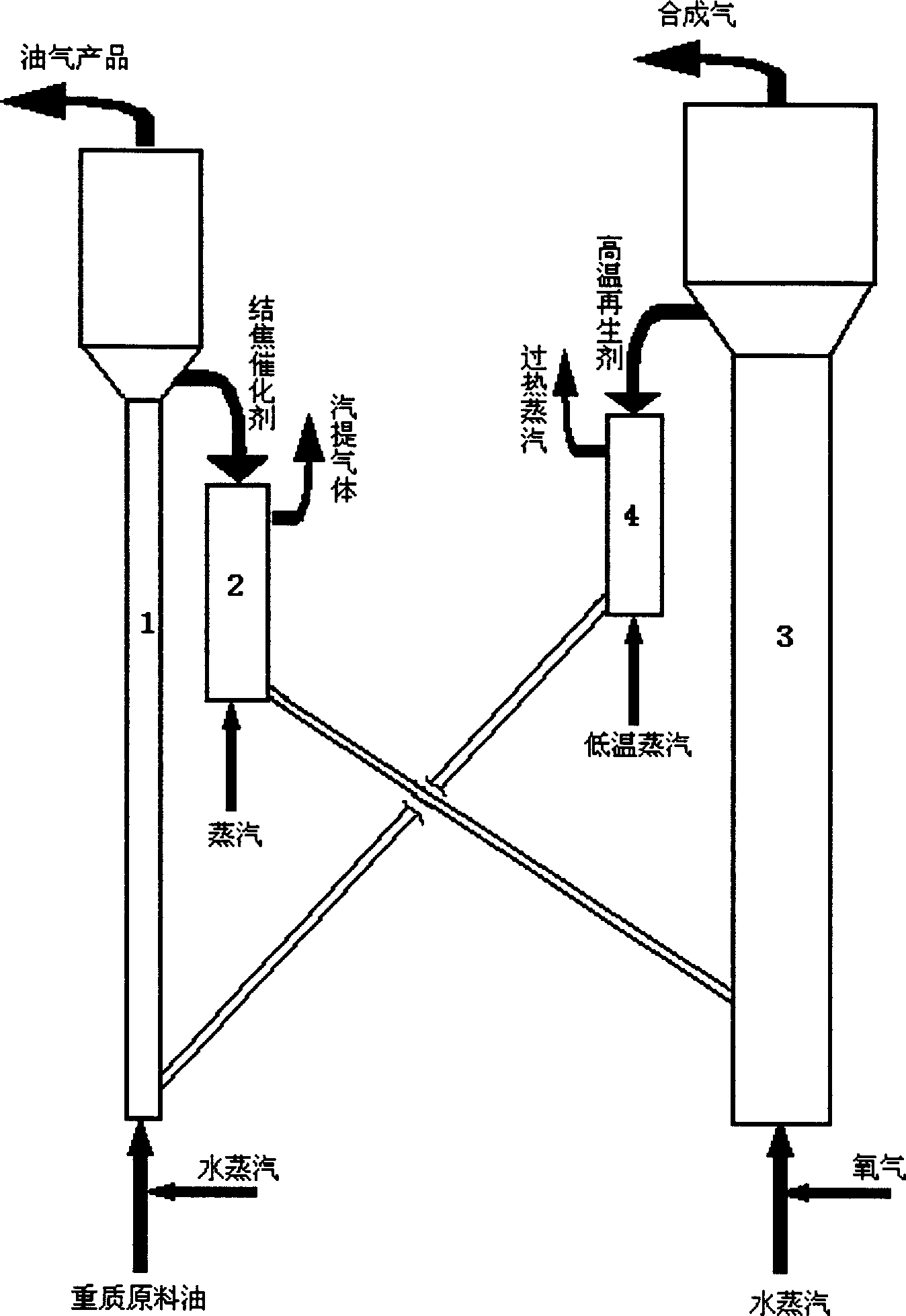

Process combined oil refining and gasification

A process of oil refining and gasification comprising the steps of, (1) petroleum hydrocarbon and coke transfer agent contacting and reacting in reactor, (2) separating produced reaction oil gas and residual coke transfer agent after reaction, (3) coke transfer agent contacting water vapor and oxygen-containing gas under gasification condition to produce formed gas, (4) returning the regenerated coke transfer agent back to reactor in step (1) for circulation use. The process by the invention can not only improve the quality of heavy petroleum hydrocarbon, but also provide cheap raw material gas for hydrogen production process or C1 chemistry.

Owner:CHINA PETROLEUM & CHEM CORP +1

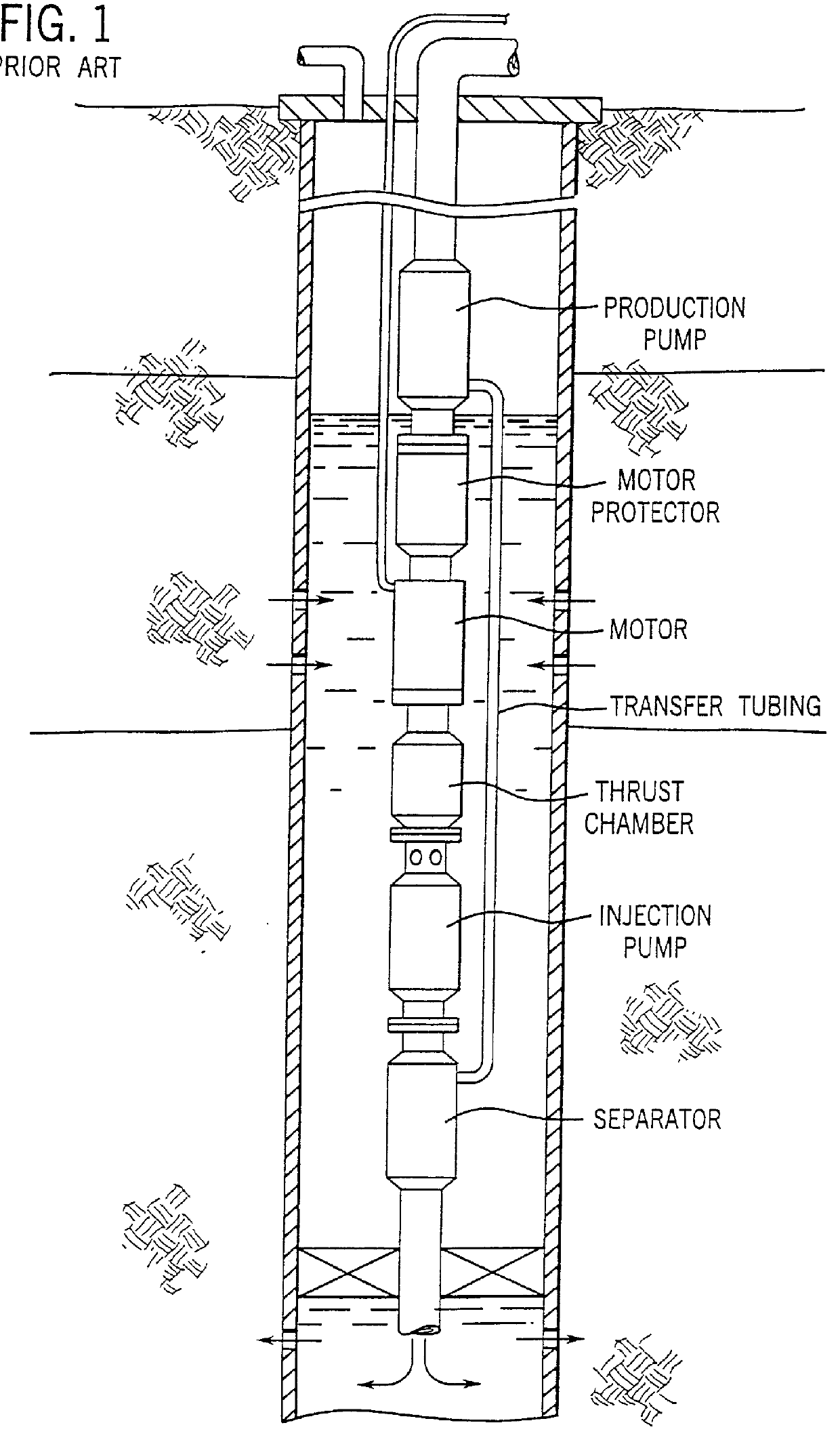

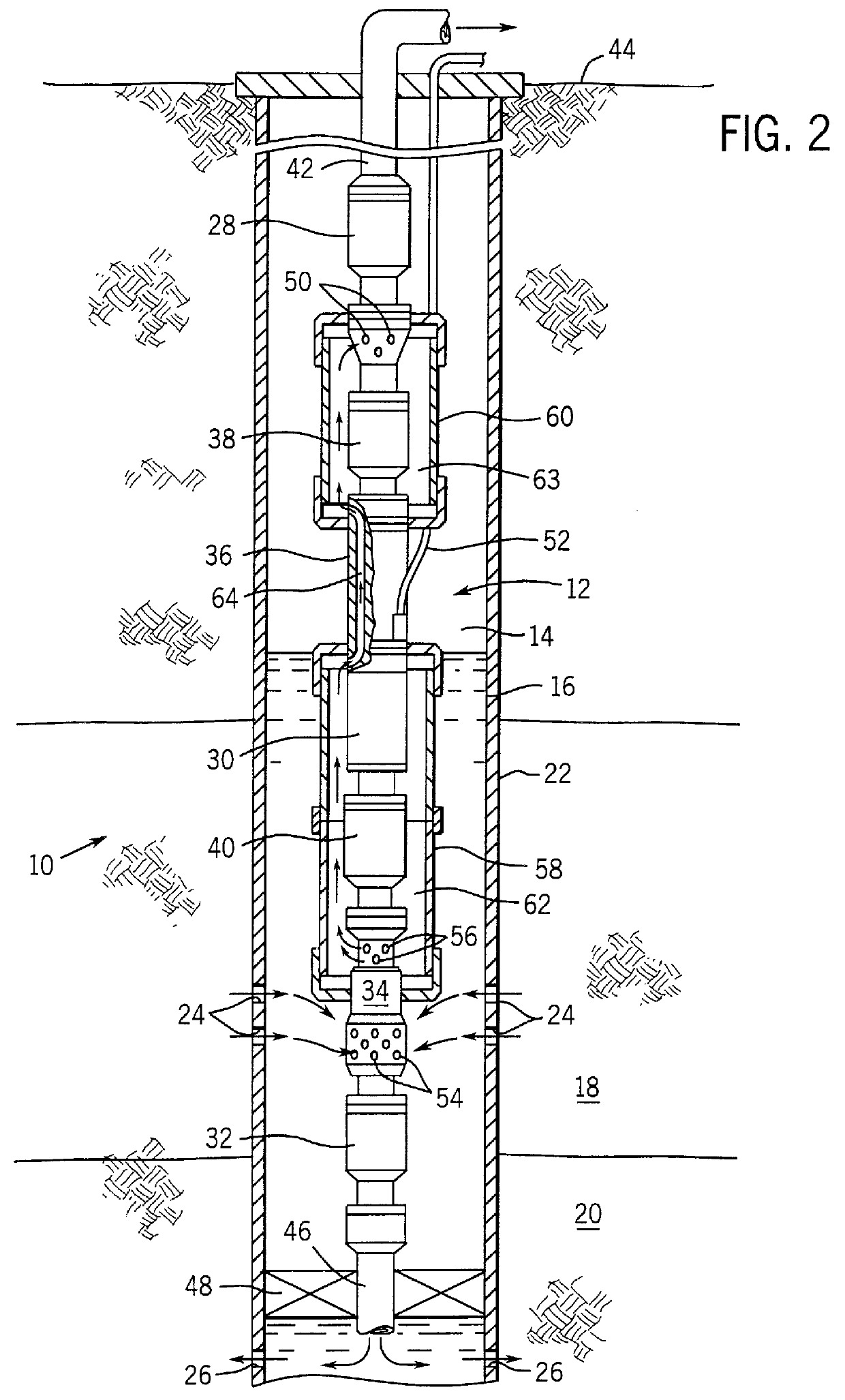

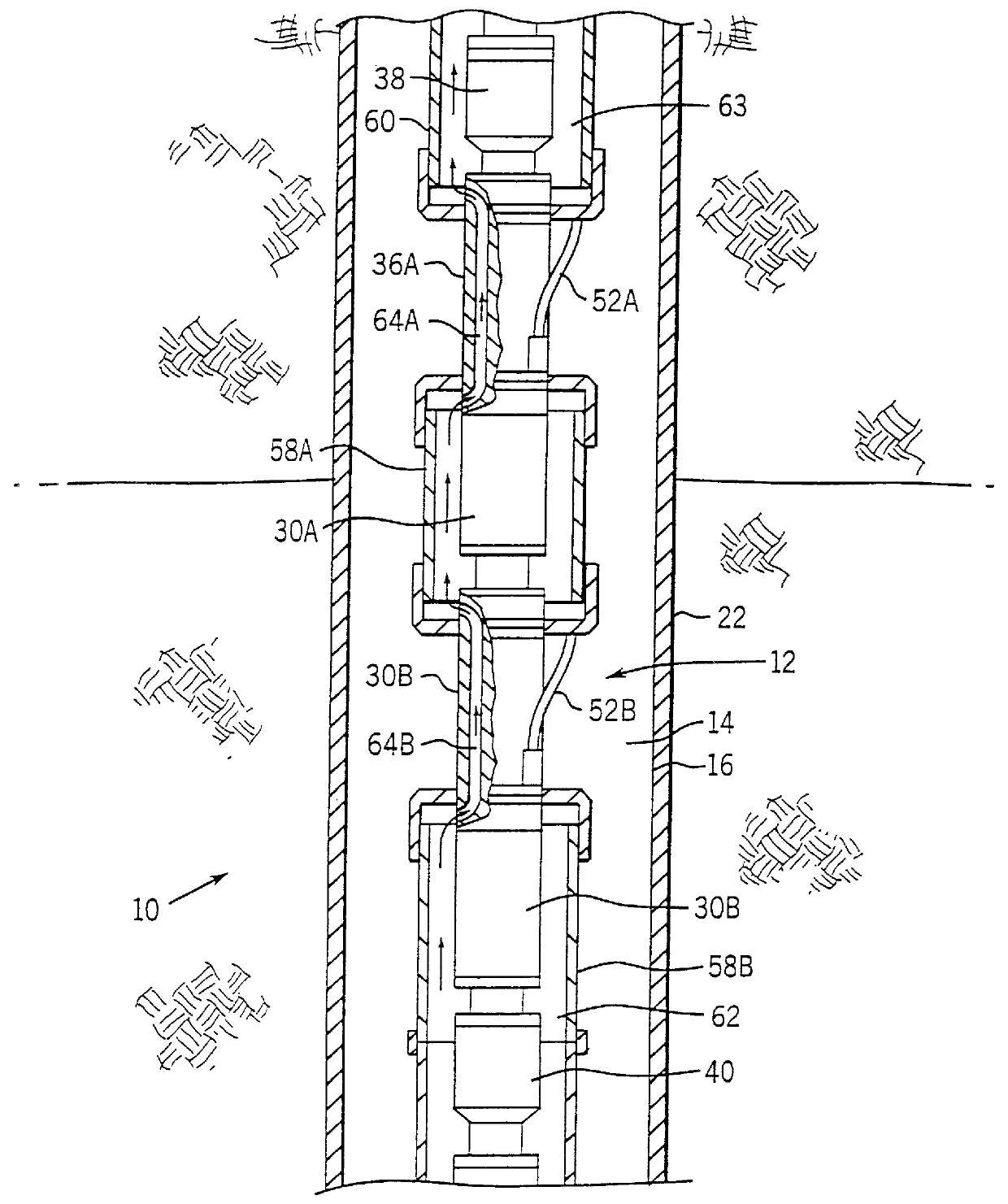

Downhole fluid separation system incorporating a drive-through separator and method for separating wellbore fluids

A fluid separation system is provided for separating wellbore fluids into production fluids and non-production fluids. The system includes a separator adapted for transmitting mechanical power between a drive motor and at least one pump. The separator includes one or more separation units, such as hydrocyclone separators. A drive train traversing the separator is interfaced with drive elements, such as a submergible electric motor, and driven elements such as an injection or production pump. Wellbore fluids are channeled through the separator in either a push-through or pull-through manner. Production fluids are then transferred from the separator to the production pump for removal from the well. Non-production fluids are transmitted from the separator either to the injection pump for reinjection into a subterranean discharge zone, or directly into the discharge zone from the separator. The drive train elements traversing the separator are supported by antifriction bearings in interface plates on either end of the separator. The ability to transmit mechanical power through the separator facilitates assembly of pumping system components in various configurations as well as piping fluid communication paths between the pumping system components.

Owner:CAMCO INT

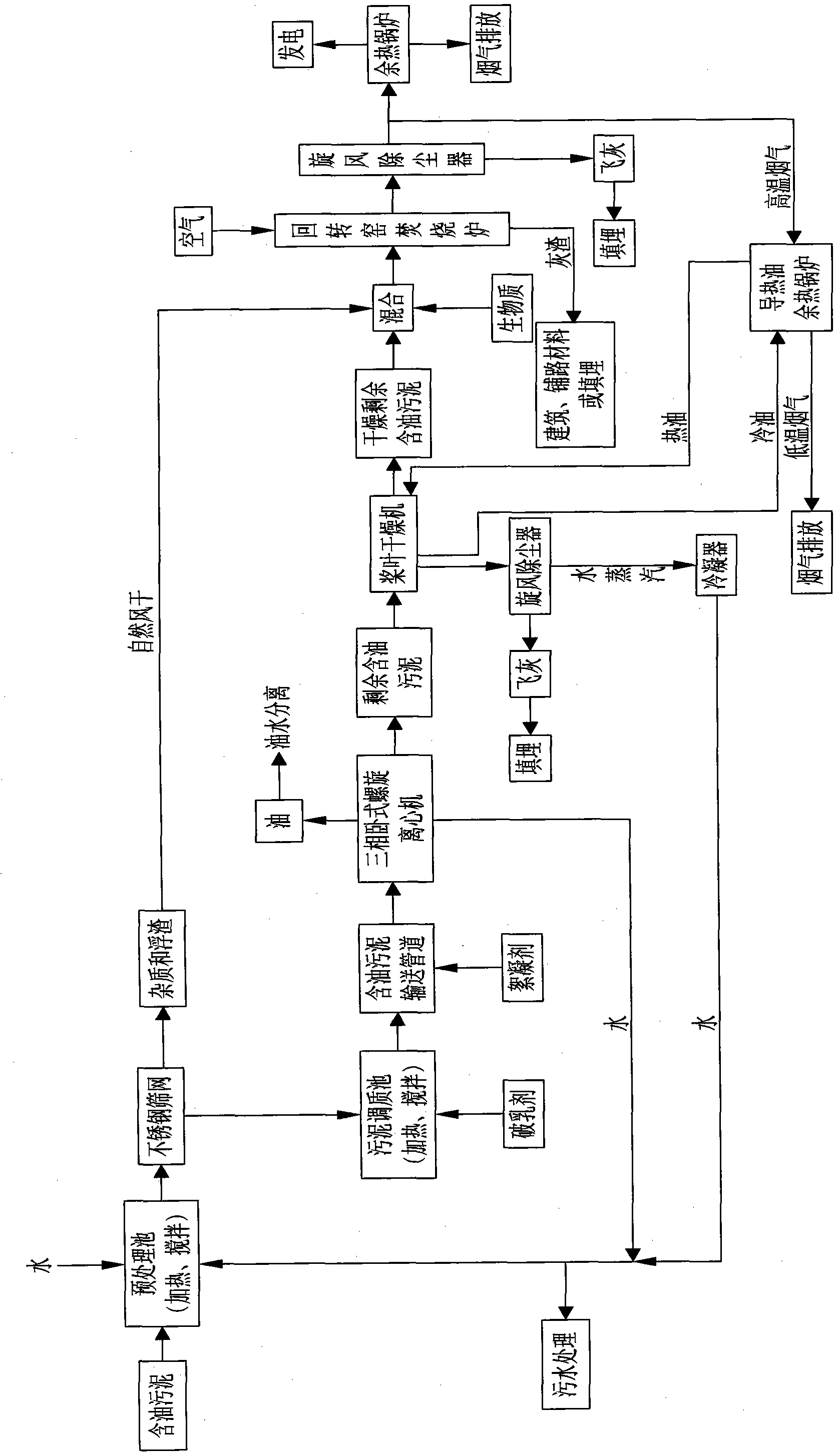

Oily sludge recycling and innocent comprehensive treatment process

InactiveCN102039301APromote resource utilizationEliminate secondary pollutionSolid waste disposalTreatment with plural serial refining stagesSlagOil sludge

The invention provides an oily sludge recycling and innocent comprehensive treatment process, which comprises the following four steps of: 1, pretreating oily sludge: adding water into the oil sludge, heating and stirring to form fluidized sludge, and separating in a stainless steel screen; 2, conditioning the oily sludge, adding a demulsifier and a flocculant into the separated fluidized sludge for conditioning the oily sludge; 3, performing centrifugal separation on three phases of the oily sludge: introducing separated oil into an oil-water separation system for recovering crude oil, conveying separated water to the oily sludge pretreatment step for recycling, drying the separated residual oily sludge, and solid impurities and floating slag which are separated in the oily sludge pretreatment, and introducing the dried substances into a rotary kiln incinerator; and 4, performing mixed combustion on the residual oily sludge and biomass, performing high temperature incineration treatment after the residual oily sludge, the separated solid impurities and floating slag, and the biomass are mixed in a rotary kiln to remove the secondary pollution of the oily sludge, and recovering afterheat from high temperature flue gas.

Owner:KUNMING UNIV OF SCI & TECH

Dust separation system

An upright vacuum cleaner having a nozzle adapted to be traversed on a surface to be cleaned, and having an internal passage defined by a nozzle inlet positioned to be substantially adjacent the surface to be cleaned and a nozzle outlet remote from the nozzle inlet. A handle is pivotally attached to the nozzle, and a suction motor is provided in the nozzle or the handle. The suction motor has a suction motor inlet, and is adapted to generate a working air flow through the nozzle and into the suction motor inlet. The vacuum includes a separation system having an outer wall, a closed tube having at least a portion of its length located within the outer wall and forming a separation chamber between the outer wall and the closed tube, a separation chamber inlet in fluid communication with the nozzle outlet and adapted to impart a tangential component to the working air flow as it flows through the separation chamber, and a hollow tube that is generally coaxially aligned with the closed tube and has a tube inlet at an end adjacent the closed tube and a tube outlet at an end opposite the closed tube. The tube outlet is in fluid communication with the suction motor inlet. The device also includes a collection chamber for receiving dirt separated from the working air flow.

Owner:ELECTROLUX HOME CARE PRODS

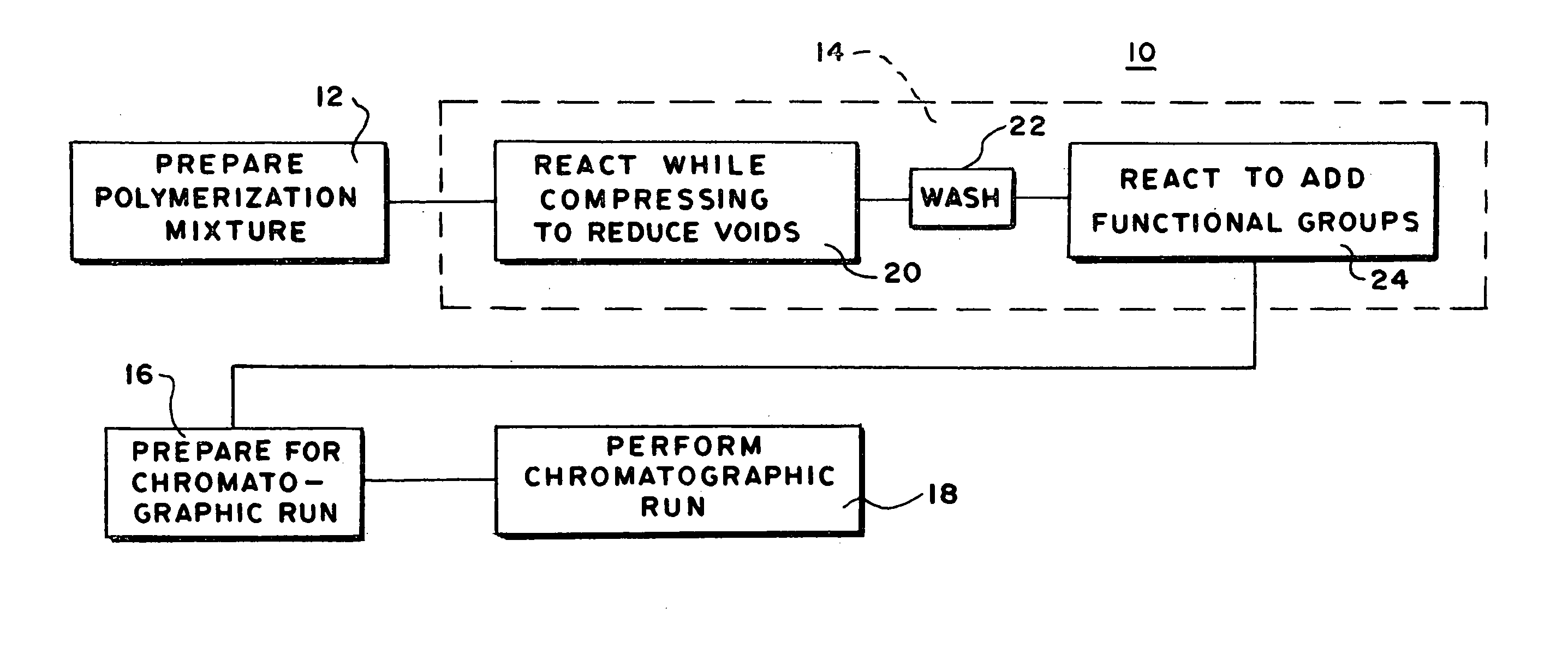

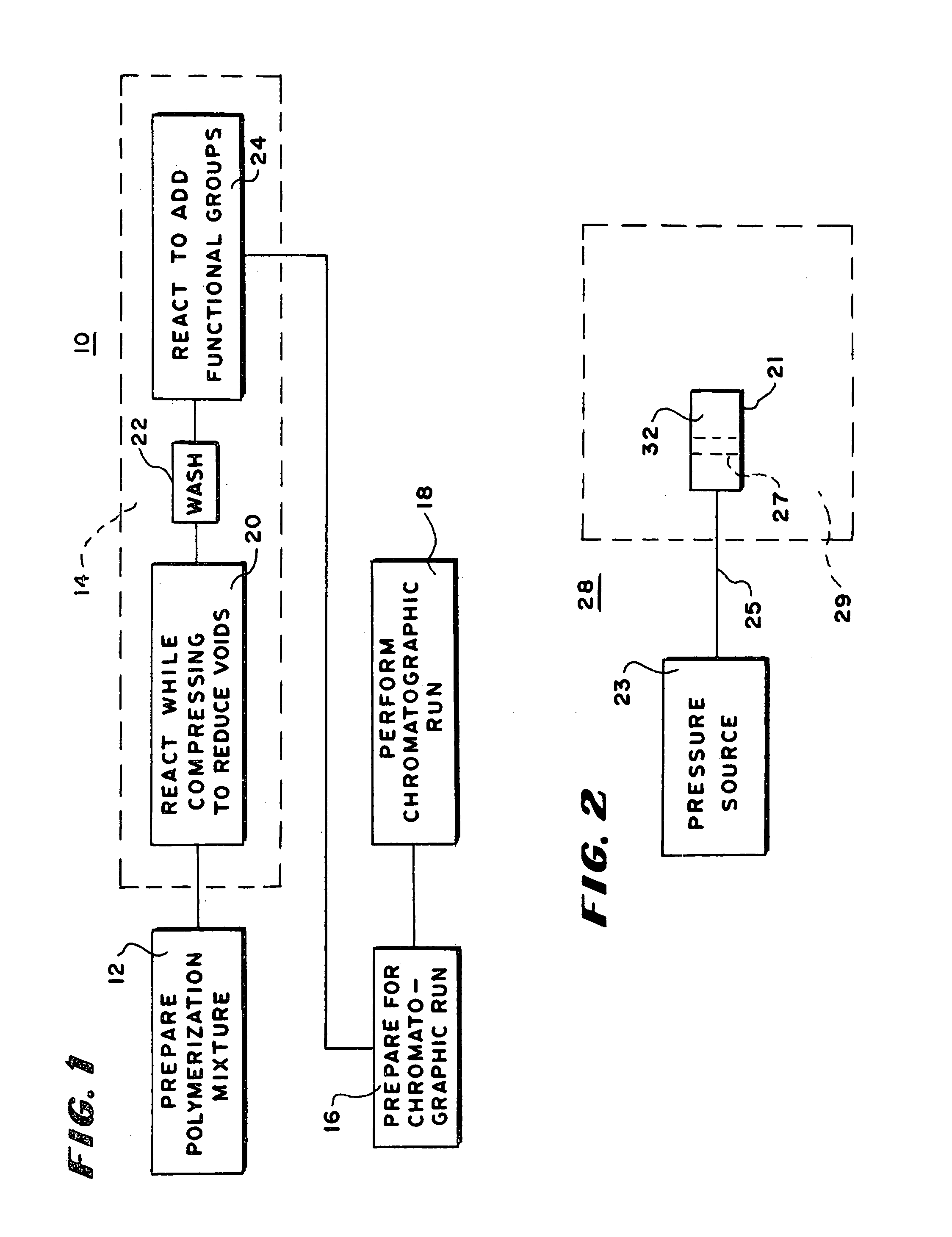

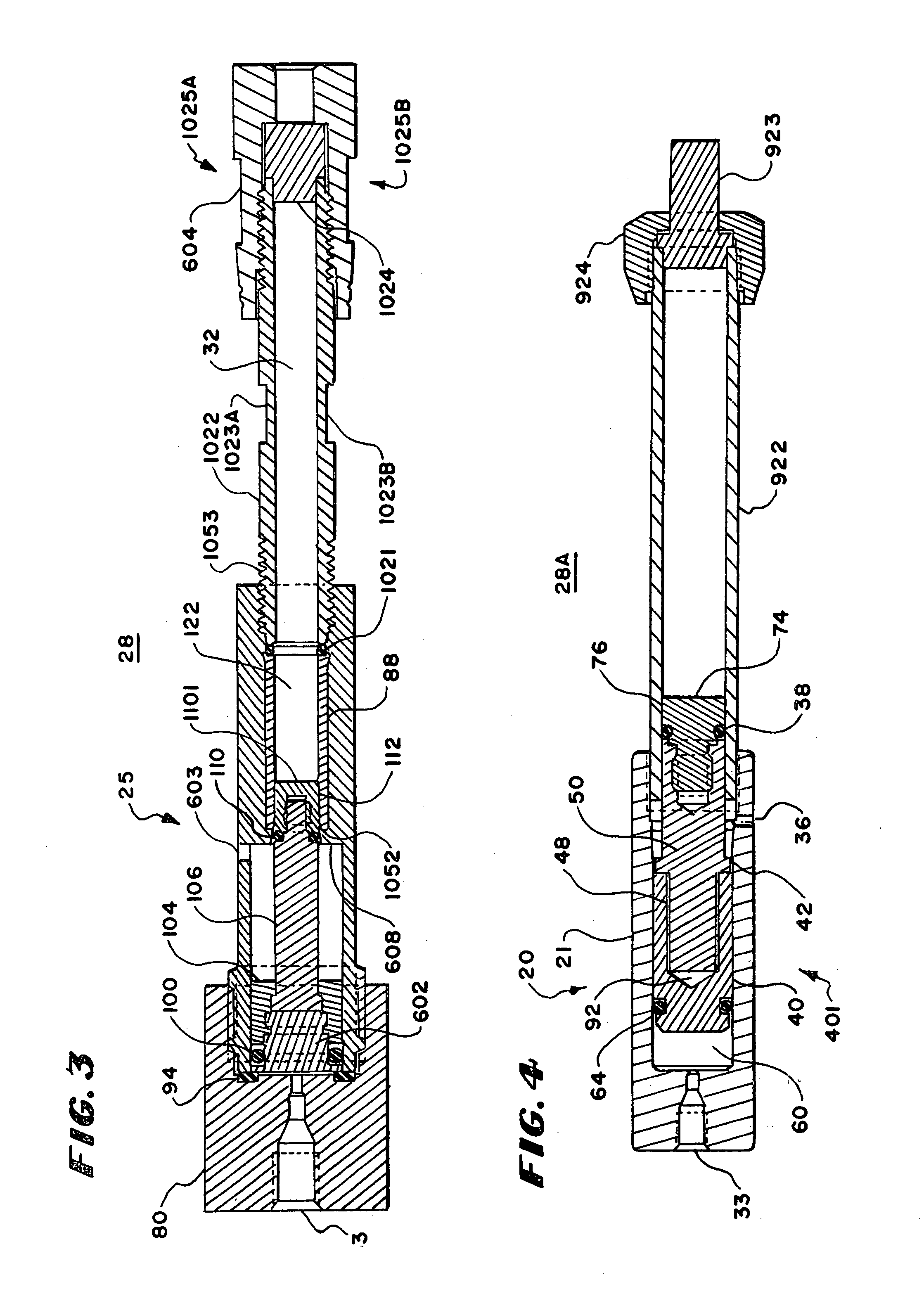

Separation system, components of a separation system and methods of making and using them

InactiveUS7074331B2Improve particle size uniformityHigh resolutionIon-exchange process apparatusComponent separationAqueous solutionChromatography column

Permeable polymeric monolithic materials are prepared in a column casing. In one embodiment, the permeable polymeric monolithic materials are polymerized while pressure is applied through a piston having a smooth piston head in contact with the polymerization mixture. The pressure eliminates wall effect and changes the structure in the column. Similarly, some columns that have a tendency to swell in the presence of aqueous solutions and pressurized while the solution is applied to prevent swelling and wall effect. This procedure also changes the structure in the column. The size of the separation effective openings can be controlled by the amount of the pressure and pores eliminated. Uniformity in the direction flow is improved by controlling polymerization with radiation rather than with conducted heat.

Owner:DIONEX CORP

Extracorporeal blood processing methods and apparatus

InactiveUS6899691B2Improving automated responseImprove responseOther blood circulation devicesHaemofiltrationSpecific volumeEngineering

A method and apparatus for controlling a fluid separation system in response to fluid pressure changes in a fluid flow, said method comprising the steps of sensing a fluid pressure; comparing the fluid pressure to a threshold value, and if the fluid pressure is below the threshold value, then pausing fluid flow for a selected period. During the selected period, either the fluid pressure sensed automatically resolves or the method further comprises a step of setting a fall alarm condition. The method and apparatus may further include interpreting a particular quantity of below threshold fluid pressure occurrences where the fluid pressure is below the threshold value occurring within a particular time period, and then, signalling an alarm. Threshold values may be calculated by the method or apparatus according to a formula such as the following:Threshold Value=Config+75−0.3309*Qin / (1−Hin)−0.3026*Qn / (1−Hn);where,Config=a configuration pre-selected pressure value;Qin=fluid flow rate in the inlet tubing line;Hin=Hematocrit in the inlet tubing line;Qn=fluid flow rate in the needle; andHn=Hematocrit in the needle.

Owner:TERUMO BCT

Gas-liquid-solid three-phase suspension bed reactor for fischer-tropsch synthesis and its applications

ActiveUS20100216896A1High activitySimple structureHydrocarbon from carbon oxidesPhysical/chemical process catalystsGas phaseFiltration

A Fischer-Tropsch synthesis three-phase suspension bed reactor (“suspension bed” also called “slurry bed”) and its supplemental systems, may include: 1) structure and dimension design of F-T synthesis reactor, 2) a gas distributor located at the bottom of the reactor, 3) structure and arrangement of a heat exchanger members inside the reactor, 4) a liquid-solid filtration separation device inside reactor, 5) a flow guidance device inside reactor, 6) a condensate flux and separation member located in the gas phase space at the top of reactor, 7) a pressure stabilizer, a cleaning system for the separation device; an online cleaning system for the gas distributor; an ancillary system for slurry deposition and a pre-condensate and mist separation system located at the outlet of upper reactor. This reactor is suitable for industrial scale application of Fischer-Tropsch synthesis.

Owner:SYNFUELS CHINA TECH CO LTD

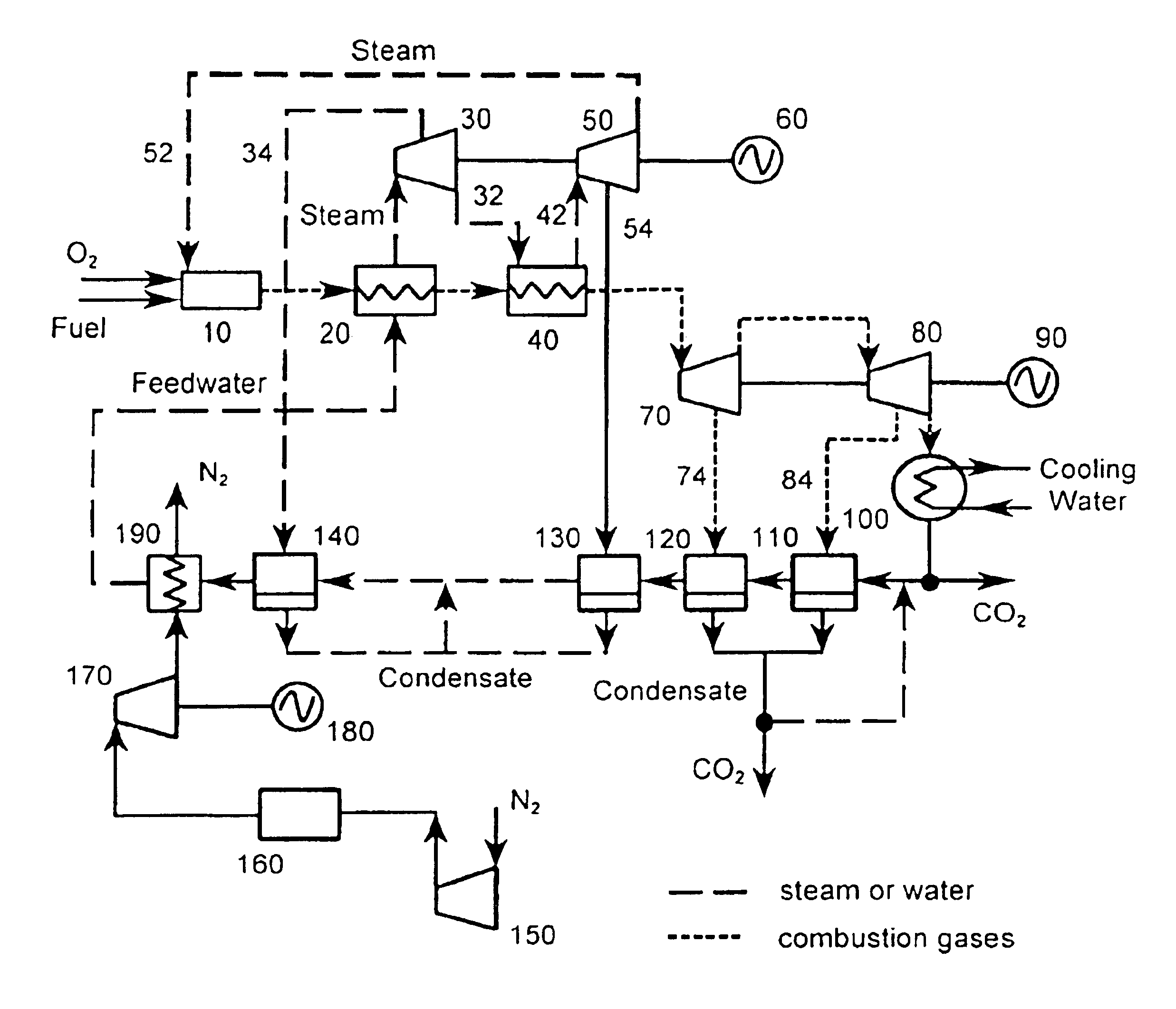

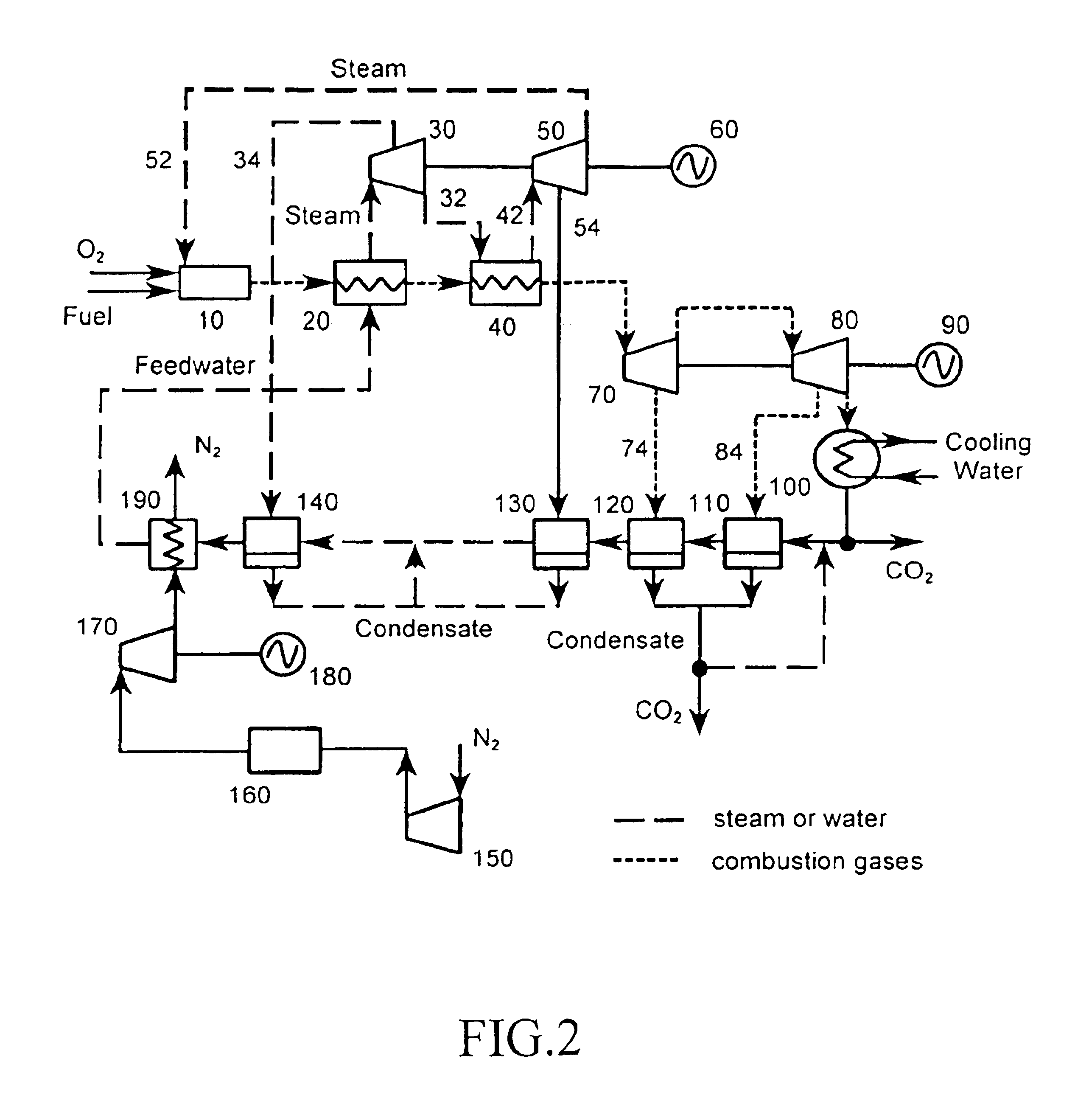

Optimized power generation system comprising an oxygen-fired combustor integrated with an air separation unit

InactiveUS6871502B2Maximize efficiencyImprove efficiencySolidificationLiquefactionHigh pressureCycle efficiency

A novel power generation system, more specifically an integrated power generation and air separation system and an integrated power generation and air separation process is provided. A key component of the system and process is an oxygen-fired combustor designed for gas turbine operating pressures. The combustor produces a high-temperature gas stream that enters one or more heat exchangers to generate / heat steam, and then enters one or more turbines to generate power. The steam from the heat exchanger drives one or more steam turbines to generate power, and the discharged steam is admitted to the combustor. To maximize cycle efficiency, steam extraction and reheat is incorporated in the process. Additional power is generated from a high-pressure nitrogen stream produced by an air separation unit (ASU). This process has the potential to attain high cycle efficiencies with zero emissions, while utilizing existing or near-term steam turbines, and moderate-pressure combustion systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com