Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

300 results about "Co product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

We called that Co product and By product. Co-Product: Co-product is a product, we getting this product while manufacturing finished material or main material. Same material might be used in other material manufacturing process. By-product By-product is a product, we getting this product while manufacturing finished material or main material.

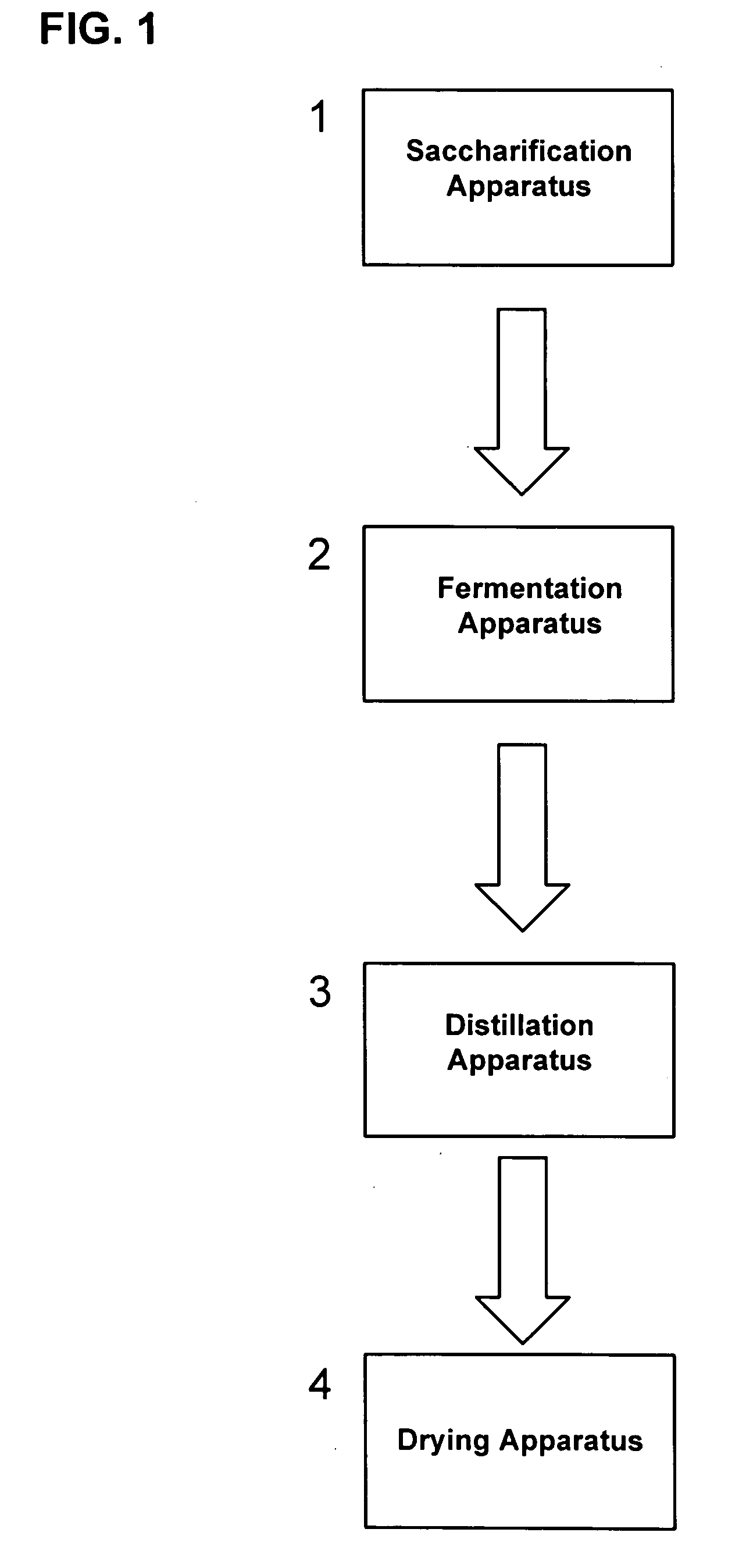

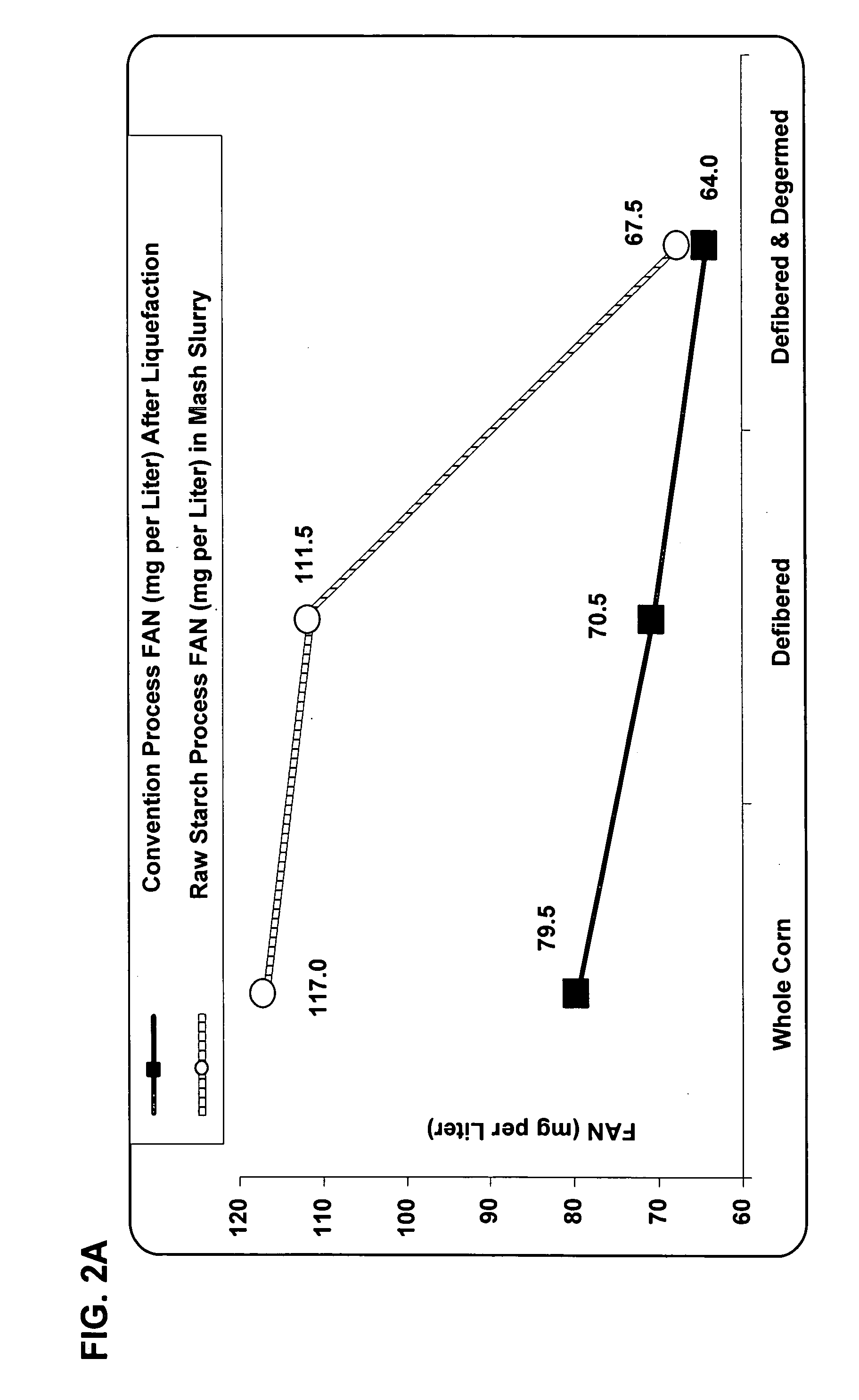

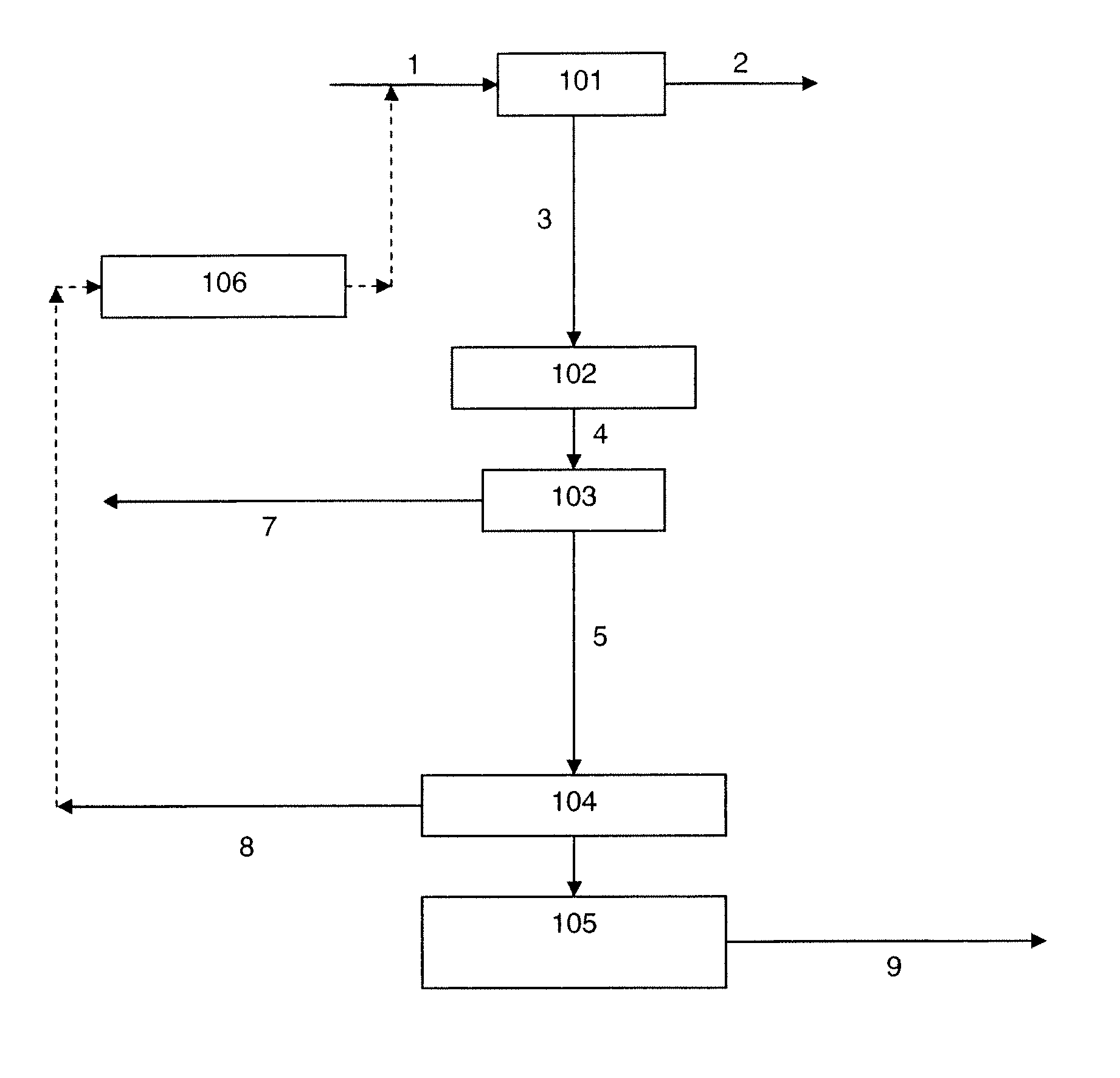

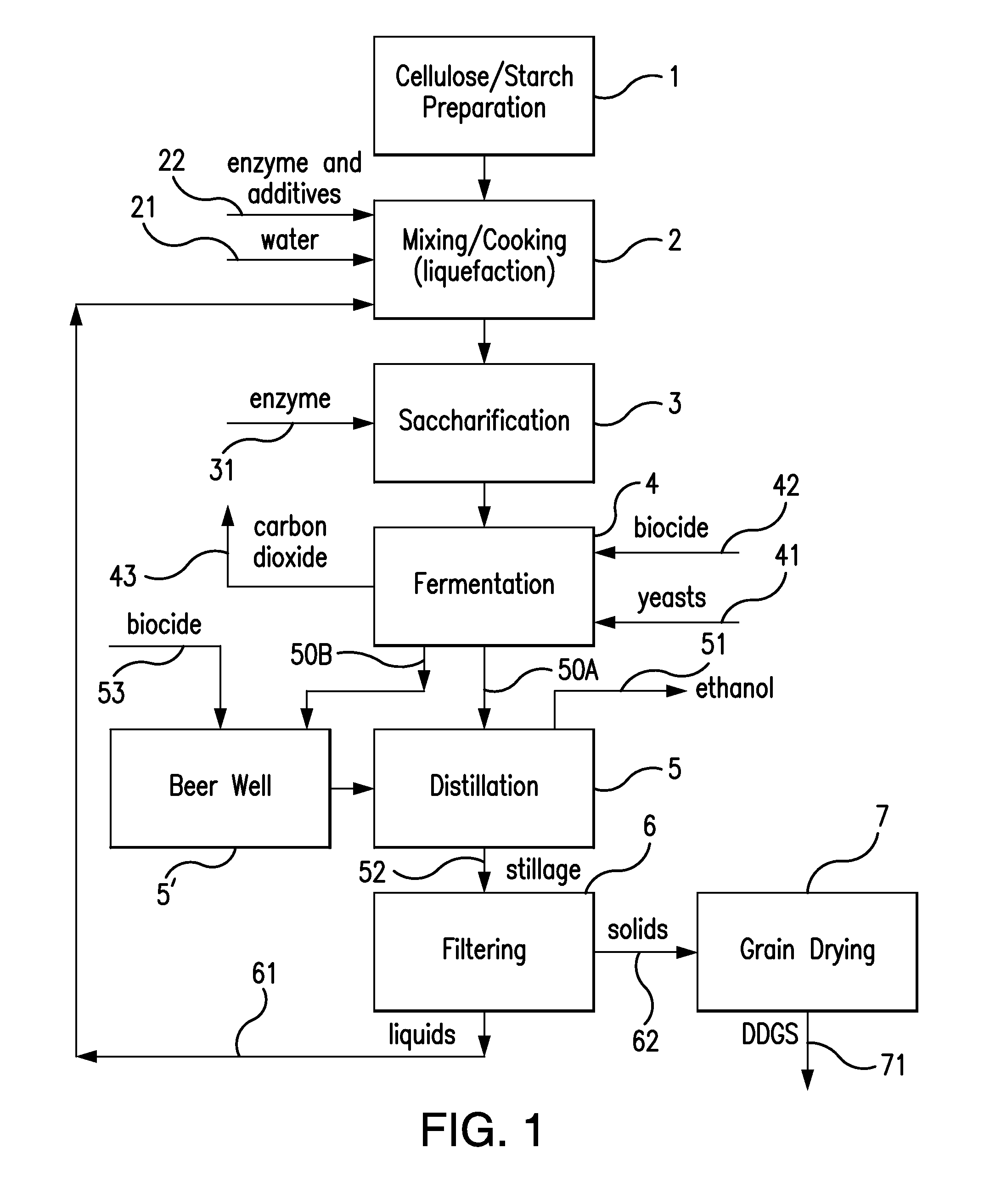

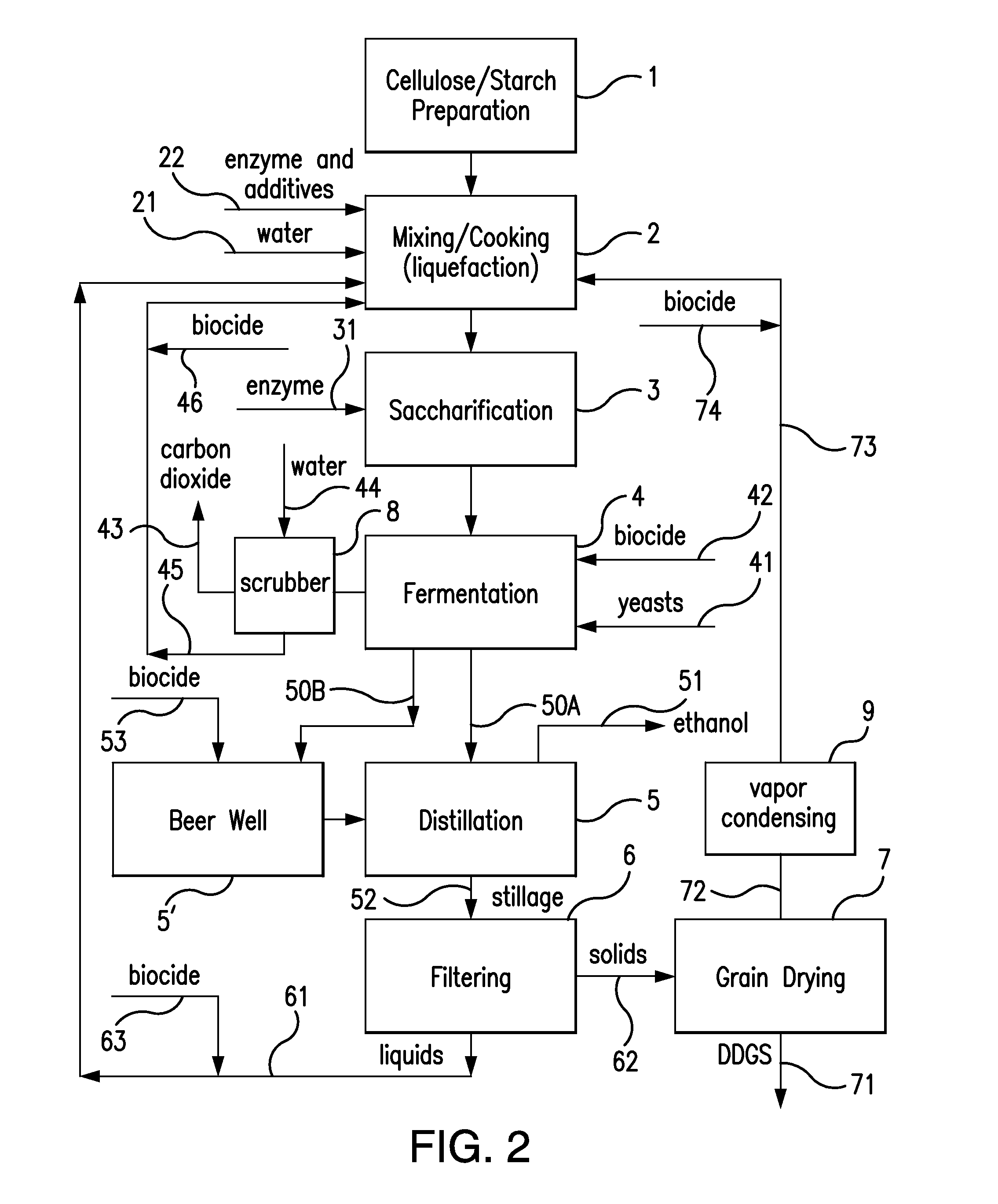

Methods and systems for producing ethanol using raw starch and fractionation

InactiveUS20070037267A1Improve the level ofImprove the immunityBiofuelsFermentationFluidized bed dryingHigh alcohol beer

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include fractionating the plant material. The present invention also relates to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The method can include drying a co-product by ring drying, flash drying, or fluid bed drying. The present invention further relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:BROIN & ASSOC

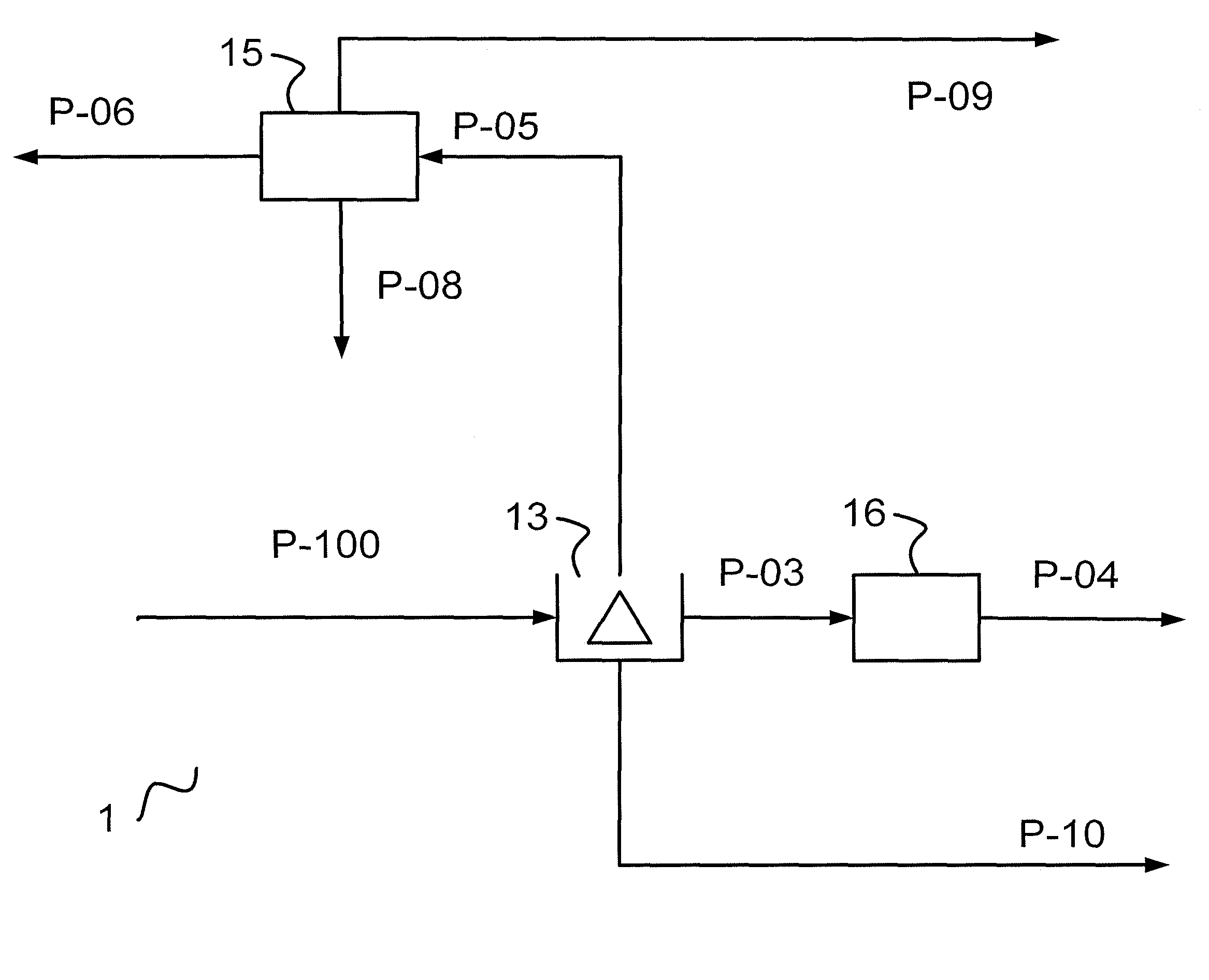

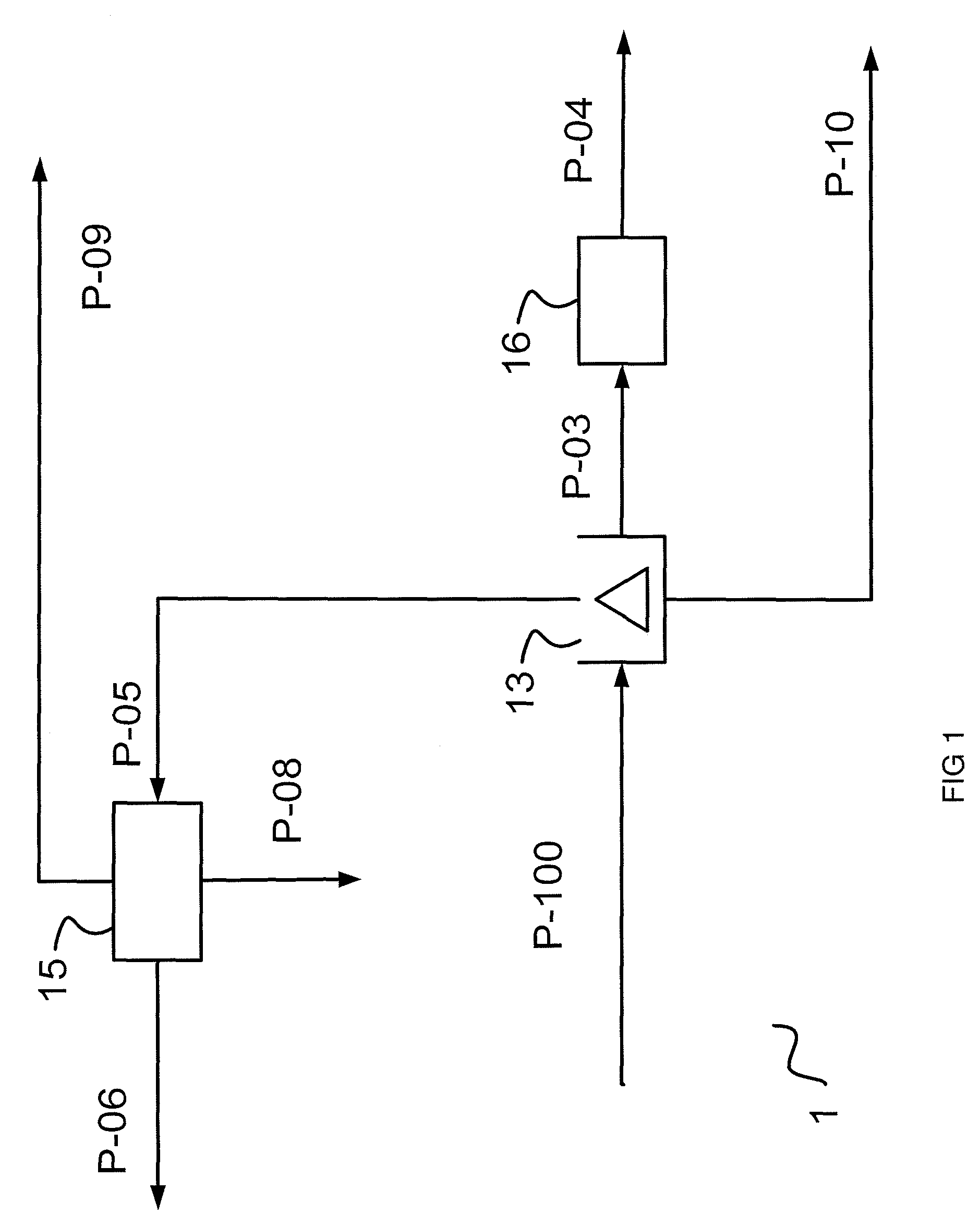

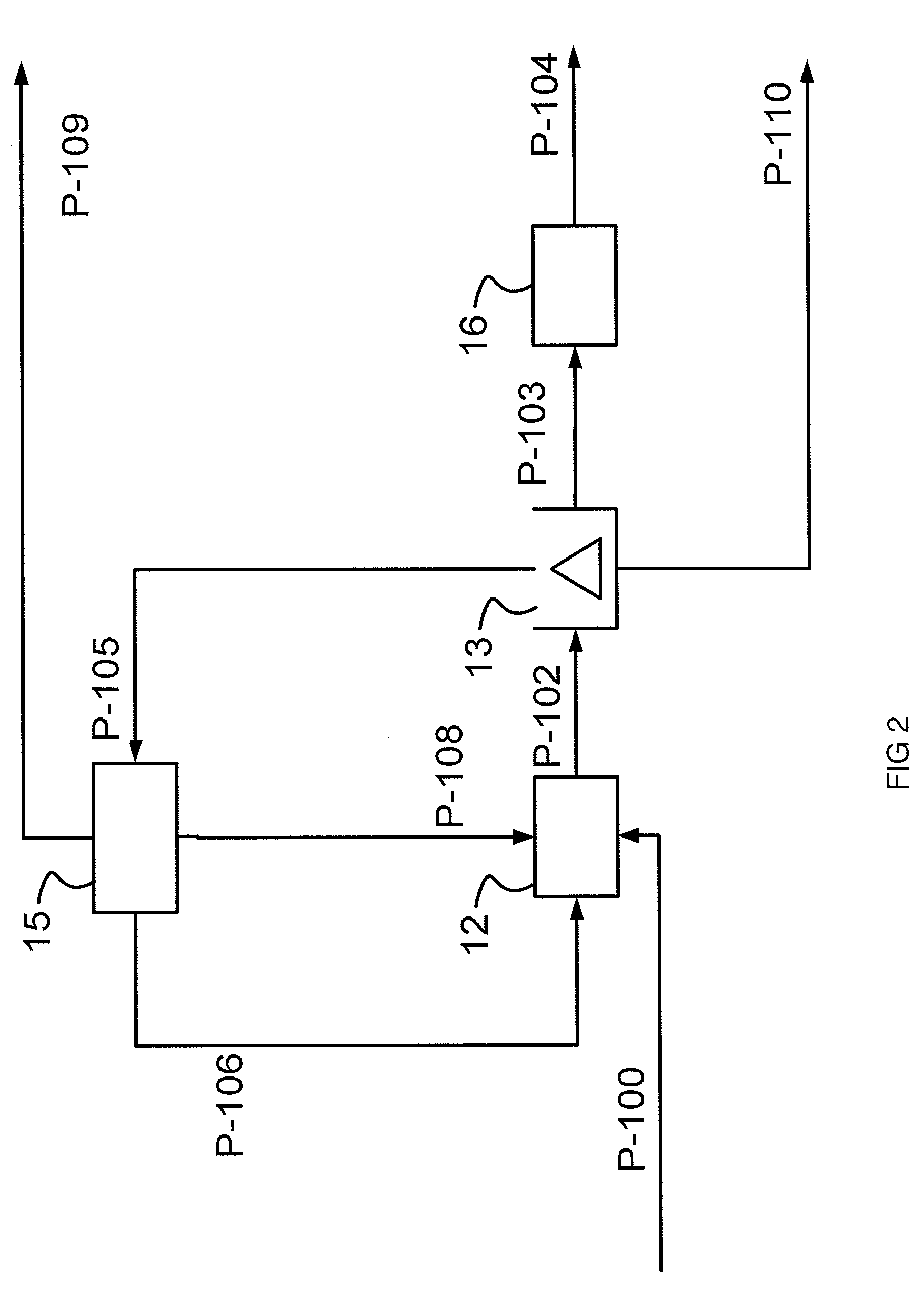

Separation of a sour syngas stream

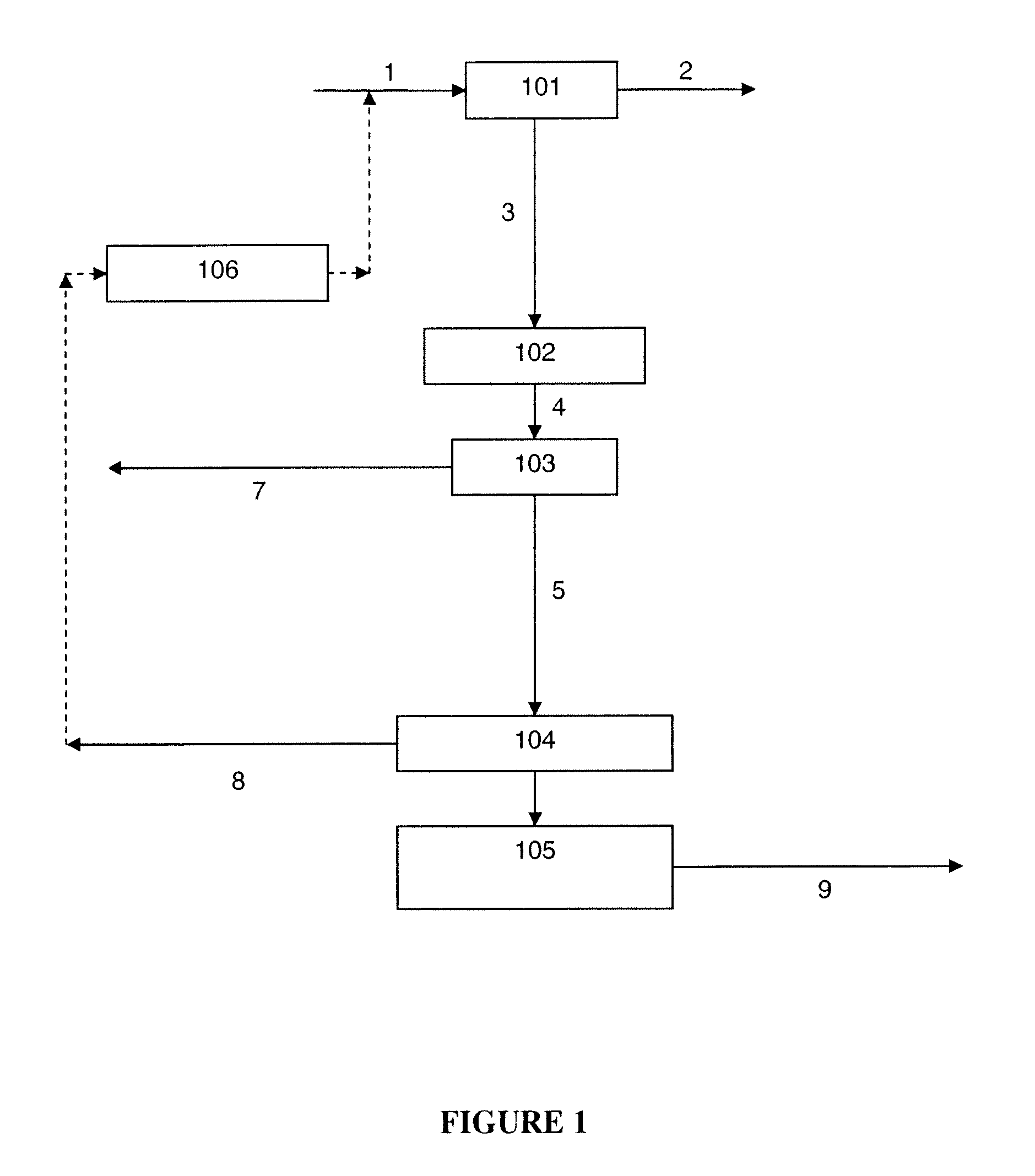

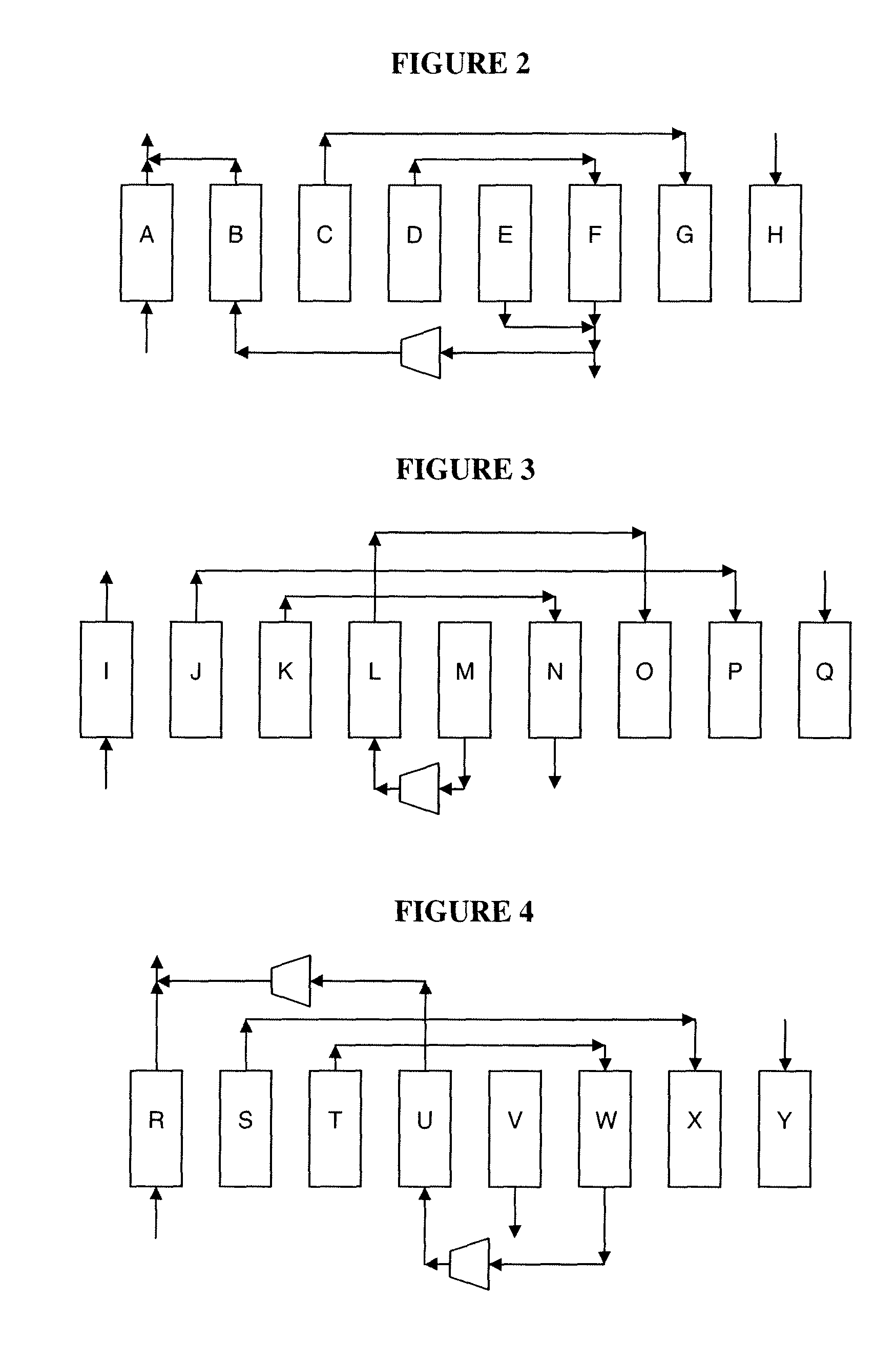

A feed stream, comprising hydrogen sulphide (H2S), carbon dioxide (CO2), hydrogen (H2) and, optionally, carbon monoxide (CO), is separated into at least a CO2 product stream and an H2 or H2 and CO product stream. The stream is separated using a pressure swing adsorption system, an H2S removal system and a further separation system, which systems are used in series to separate the stream. The method has particular application in the separation of a sour (i.e. sulphur containing) syngas, as for example produced from the gasification of solid or heavy liquid carbonaceous feedstock.

Owner:AIR PROD & CHEM INC

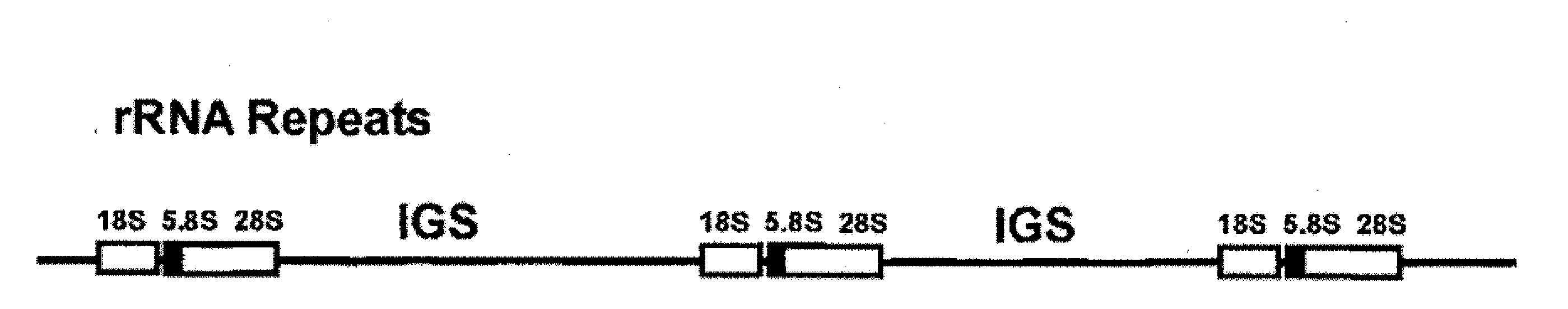

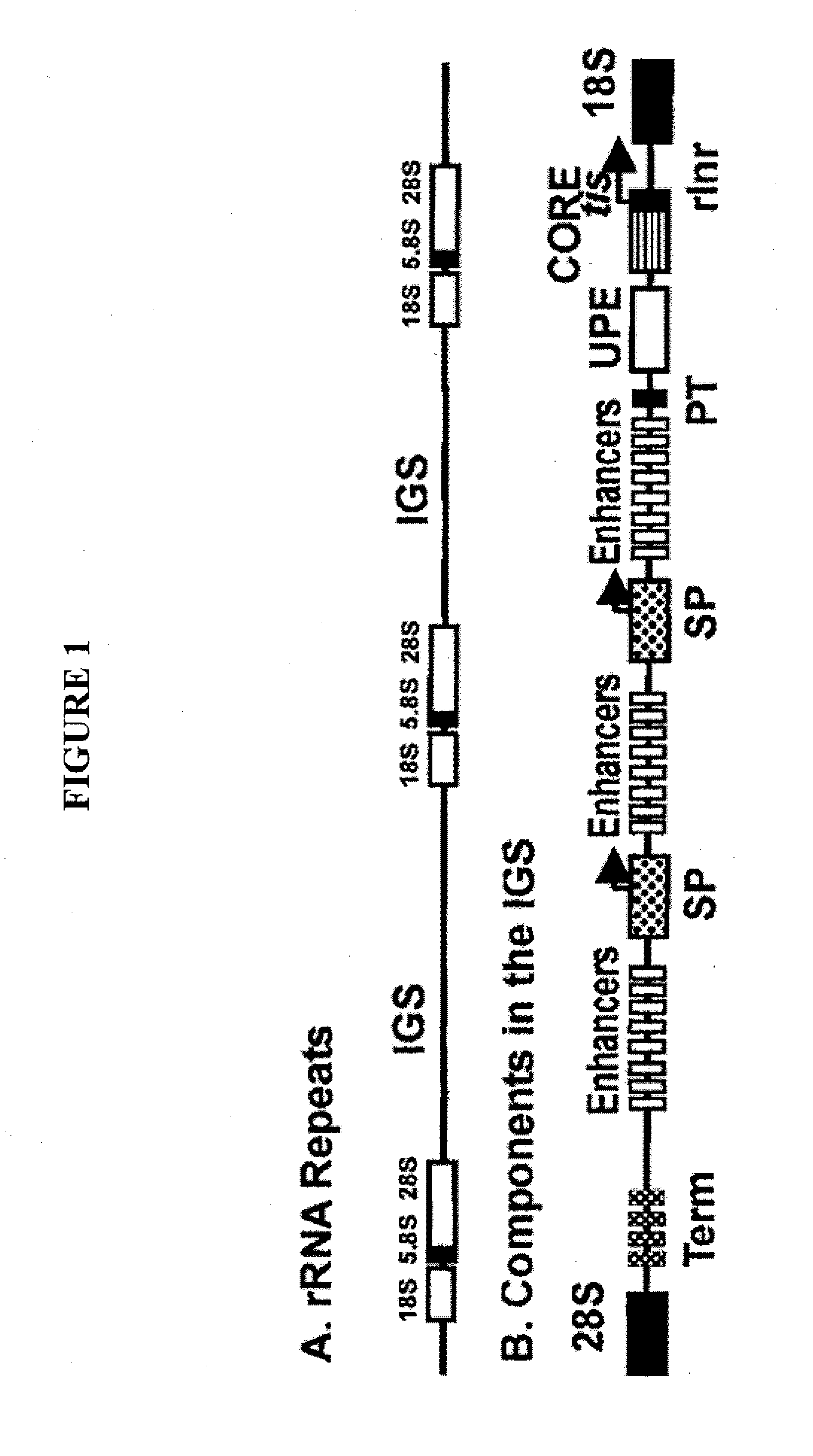

Nuclear based expression of genes for production of biofuels and process co-products in algae

Various embodiments provide, for example, vectors, expression cassettes, and cells useful for transgenic expression of nucleic acid sequences. In various embodiments, vectors can contain nuclear-based sequences of unicellular photosynthetic bioprocess organisms for the production of food- and feed-stuffs, oils, biofuels, starches, raw materials, pharmaceuticals or fine chemicals.

Owner:KUEHNLE AGROSYST

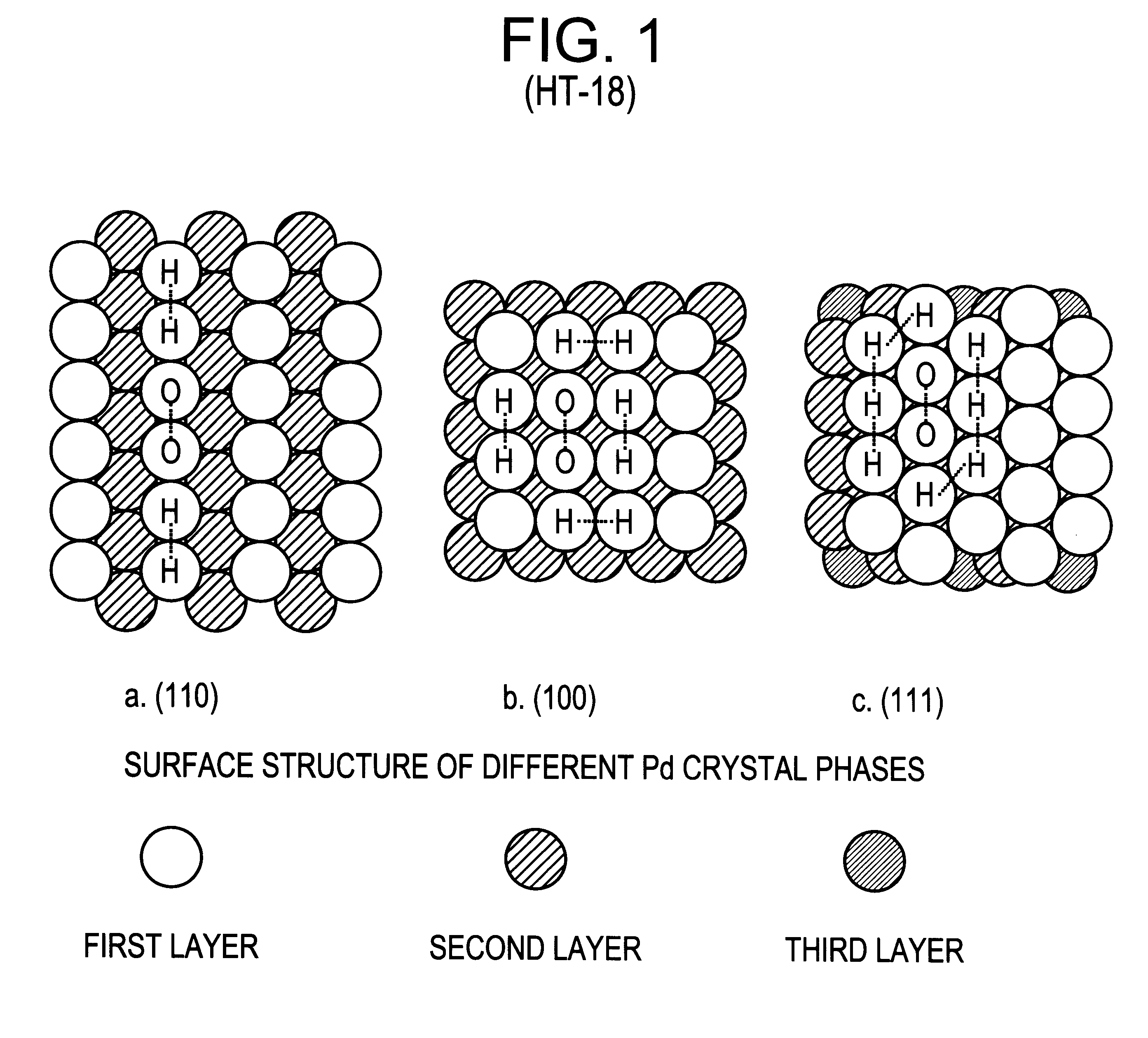

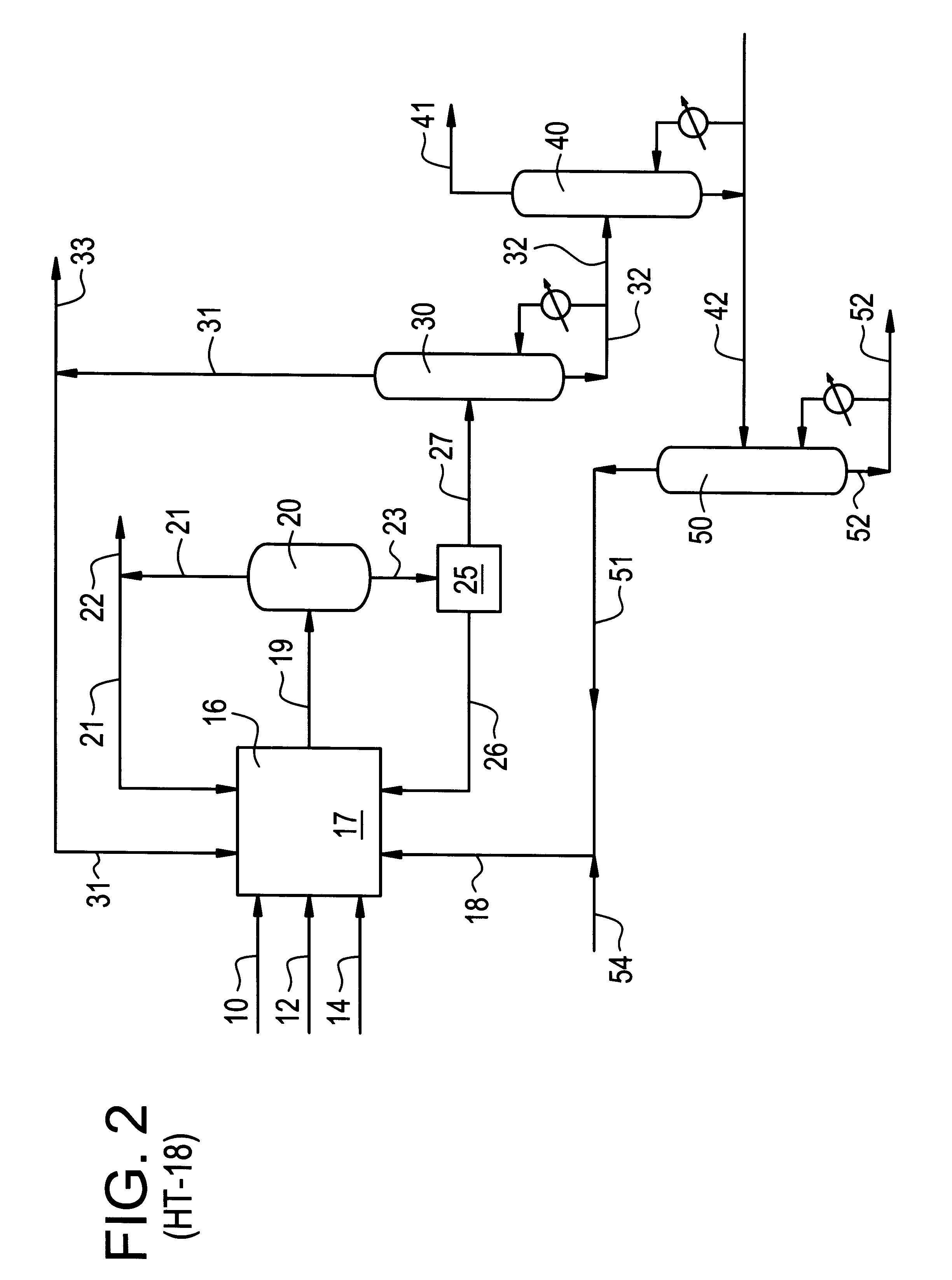

Integrated process and dual-function catalyst for olefin epoxidation

The invention discloses a dual-functional catalyst composition and an integrated process for production of olefin epoxides including propylene oxide by catalytic reaction of hydrogen peroxide from hydrogen and oxygen with olefin feeds such as propylene. The epoxides and hydrogen peroxide are preferably produced simultaneously in situ. The dual-functional catalyst comprises noble metal crystallites with dimensions on the nanometer scale (on the order of <1 nm to 10 nm), specially dispersed on titanium silicalite substrate particles. The dual functional catalyst catalyzes both the direct reaction of hydrogen and oxygen to generate hydrogen peroxide intermediate on the noble metal catalyst surface and the reaction of the hydrogen peroxide intermediate with the propylene feed to generate propylene oxide product. Combining both these functions in a single catalyst provides a very efficient integrated process operable below the flammability limits of hydrogen and highly selective for the production of hydrogen peroxide to produce olefin oxides such as propylene oxide without formation of undesired co-products.

Owner:HEADWATERS TECH INNOVATION GRP

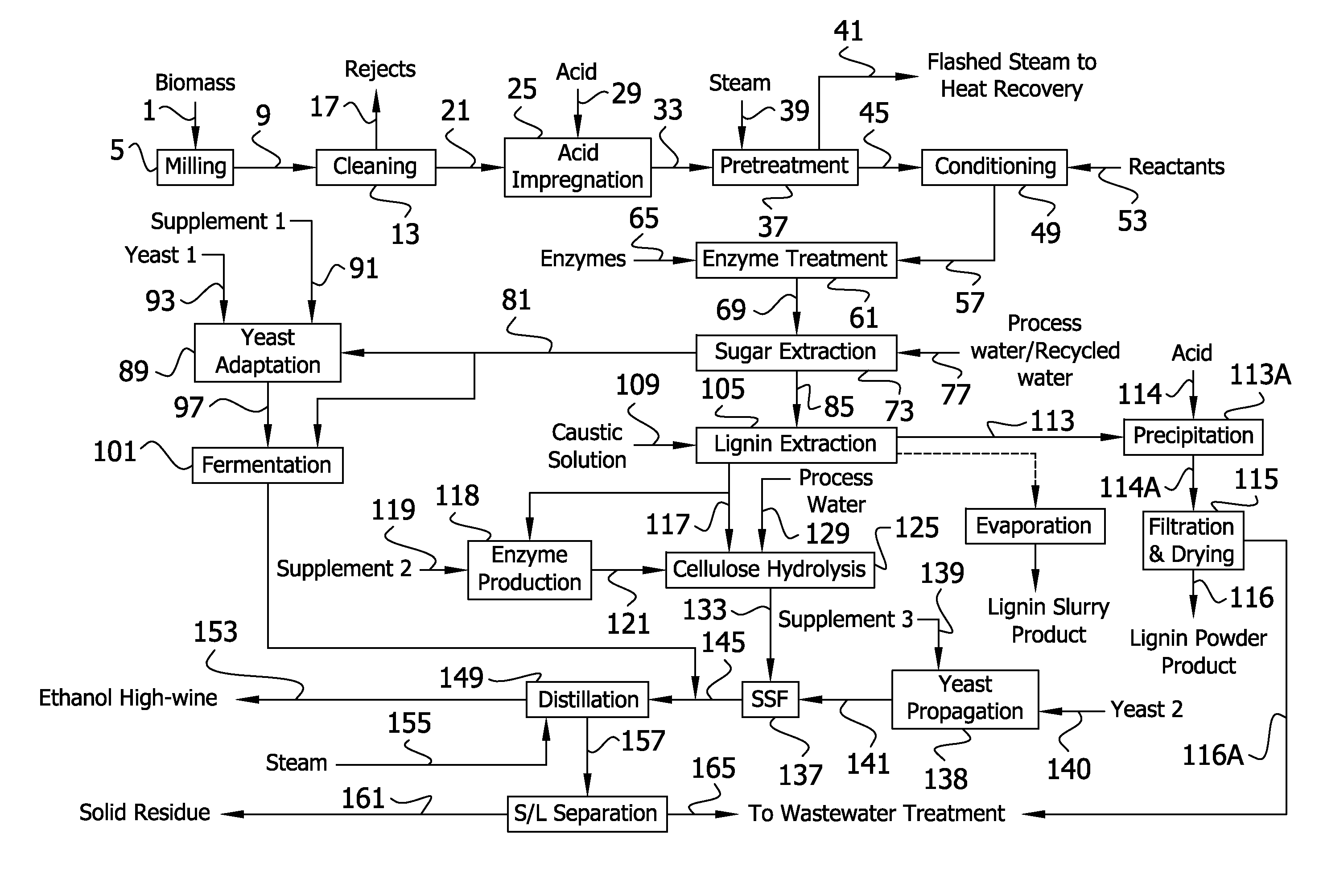

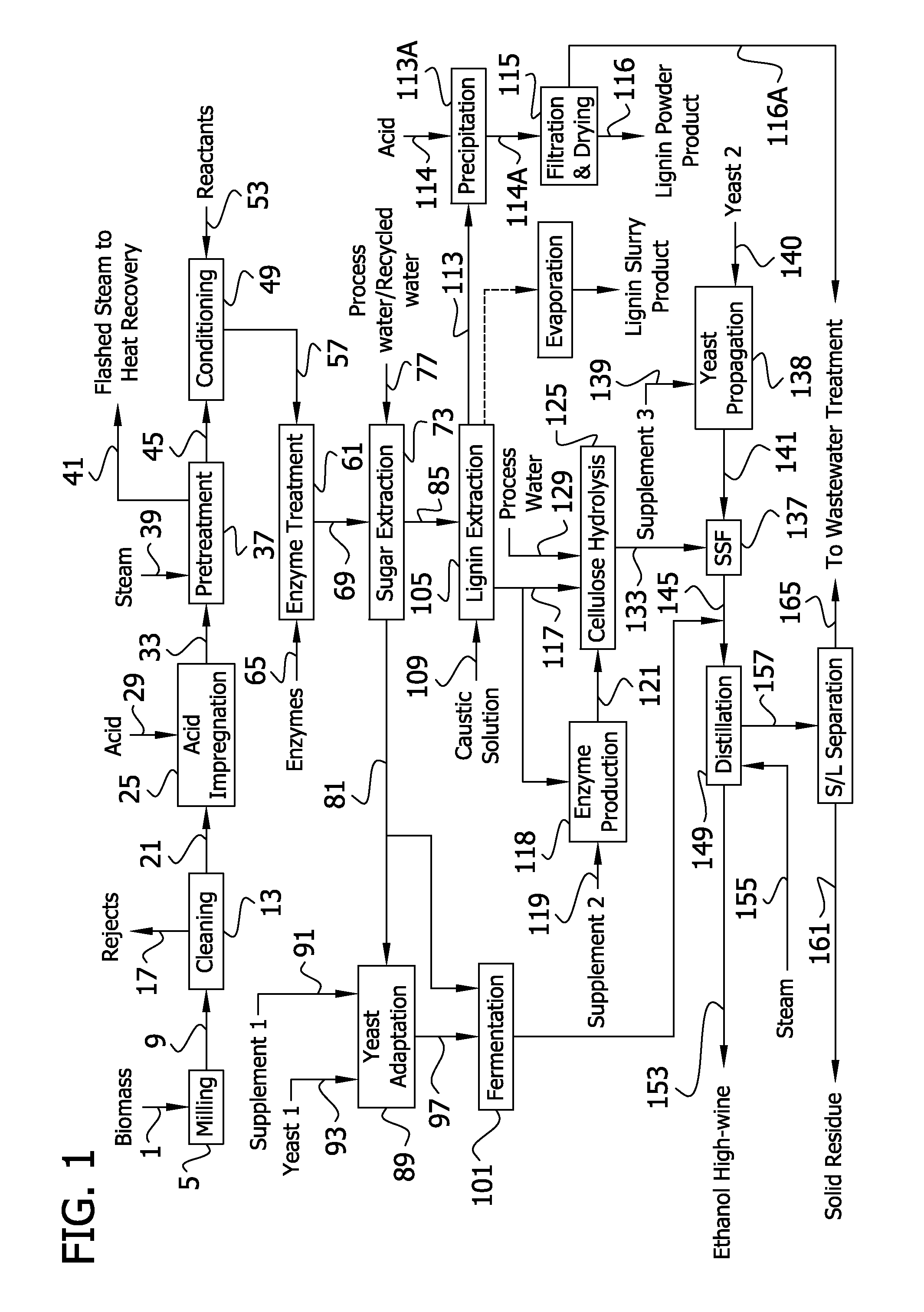

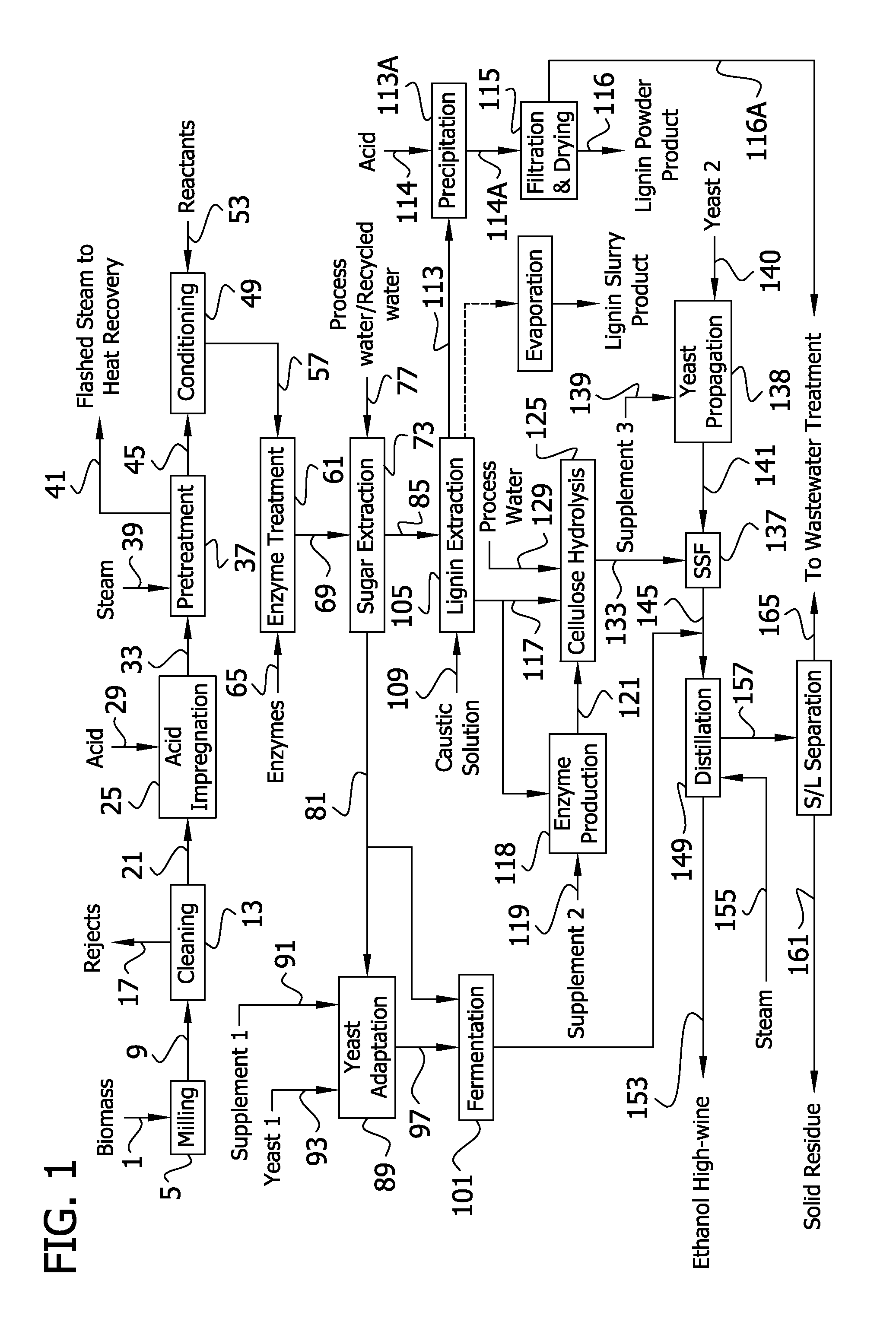

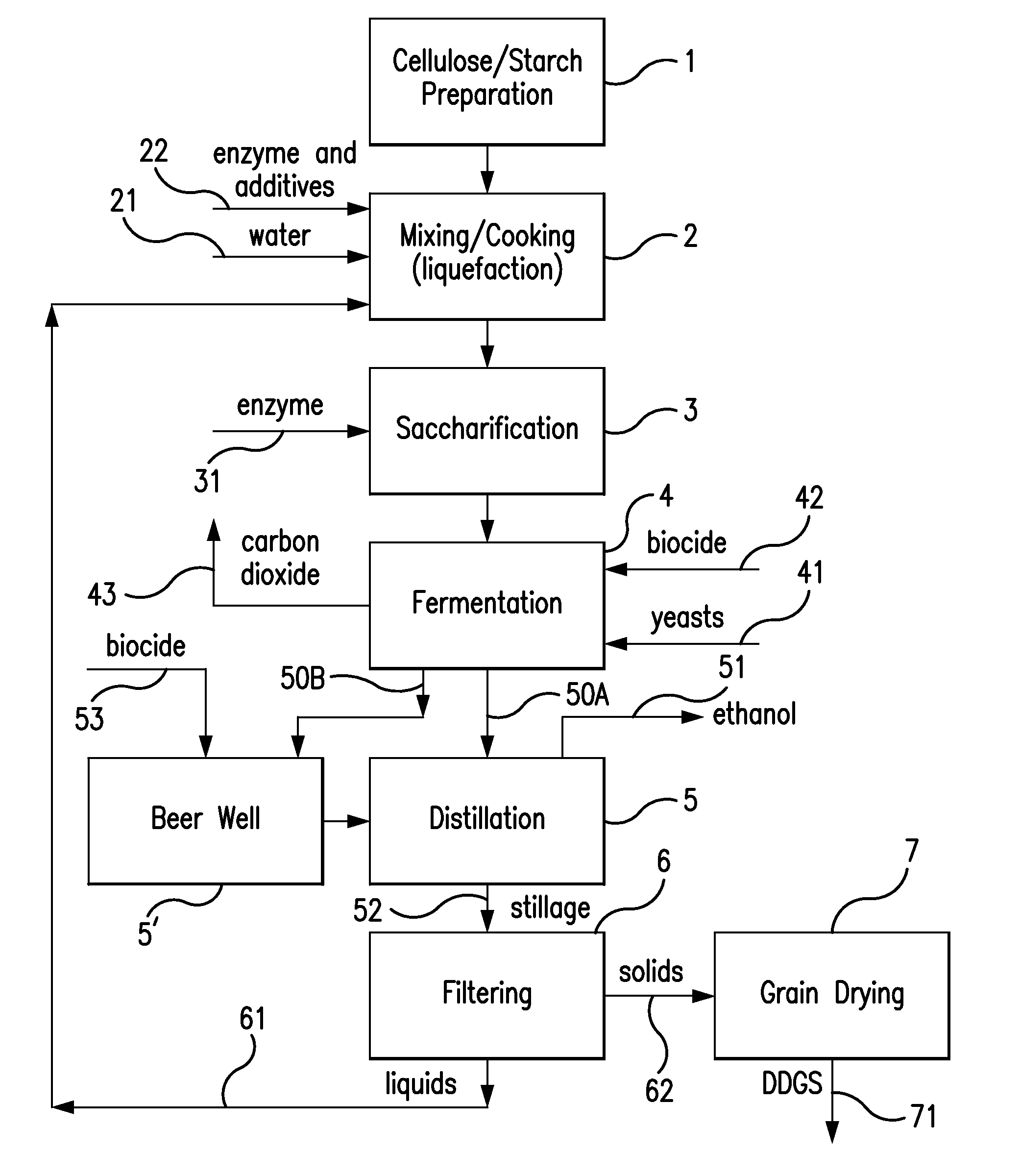

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

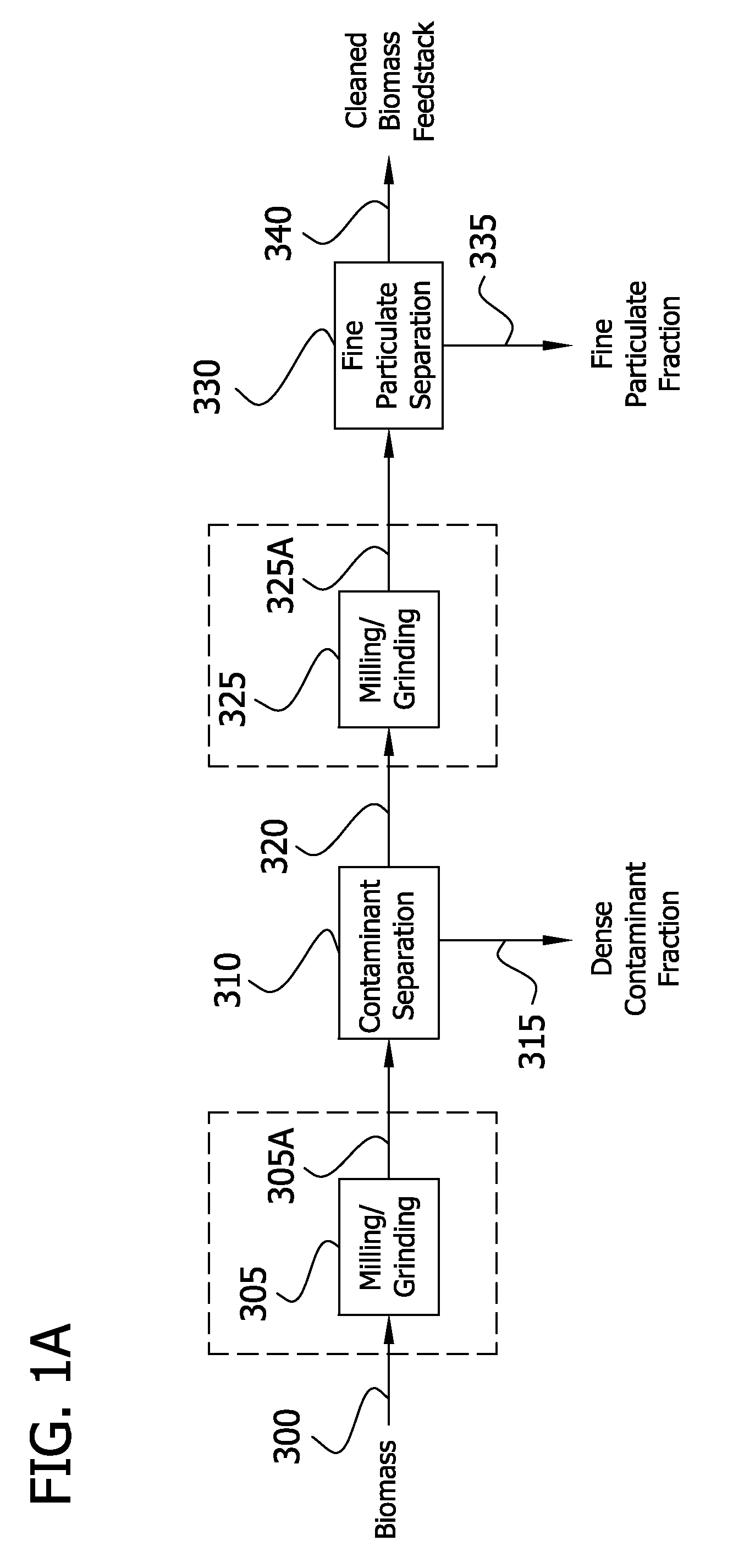

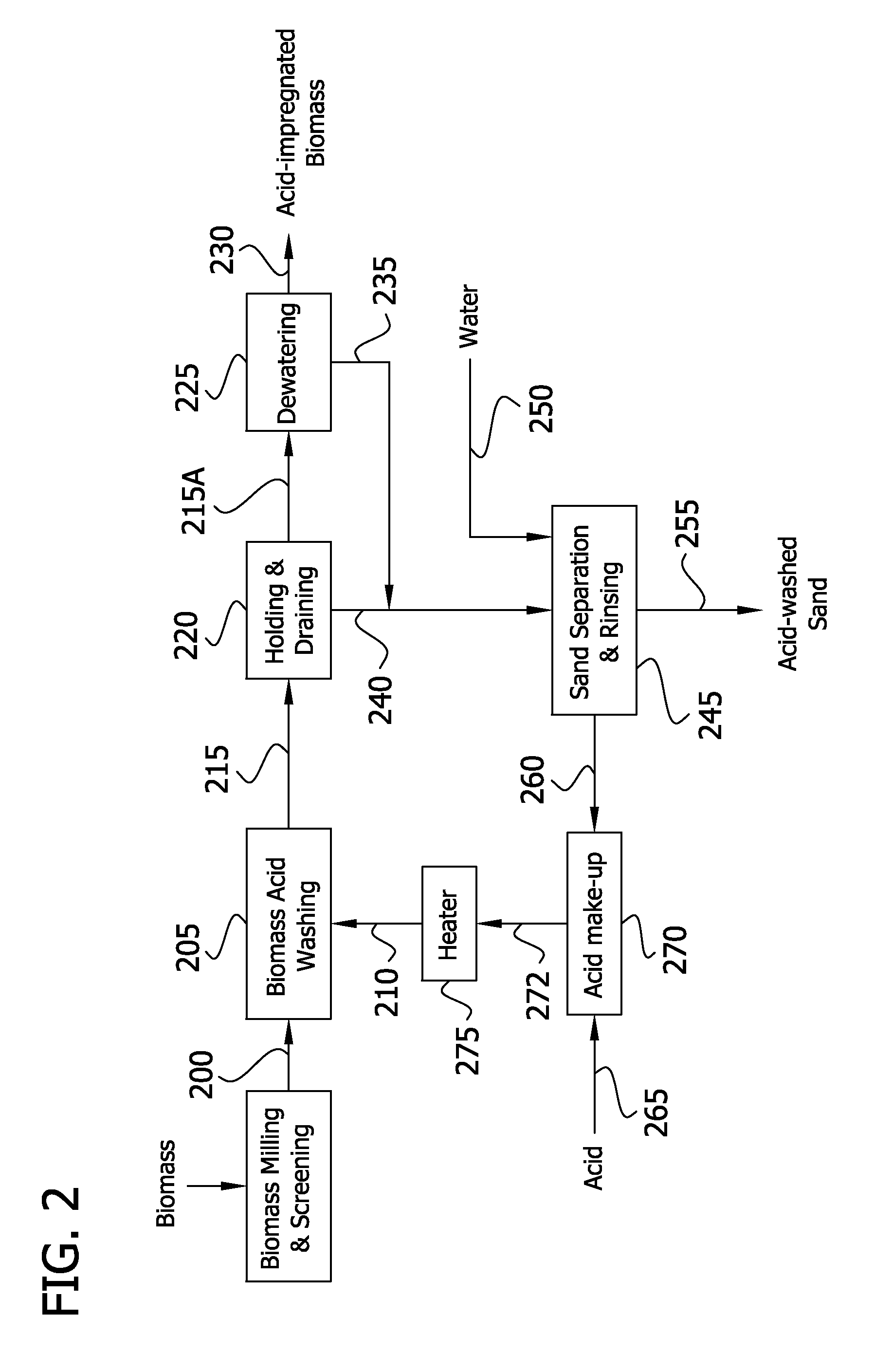

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

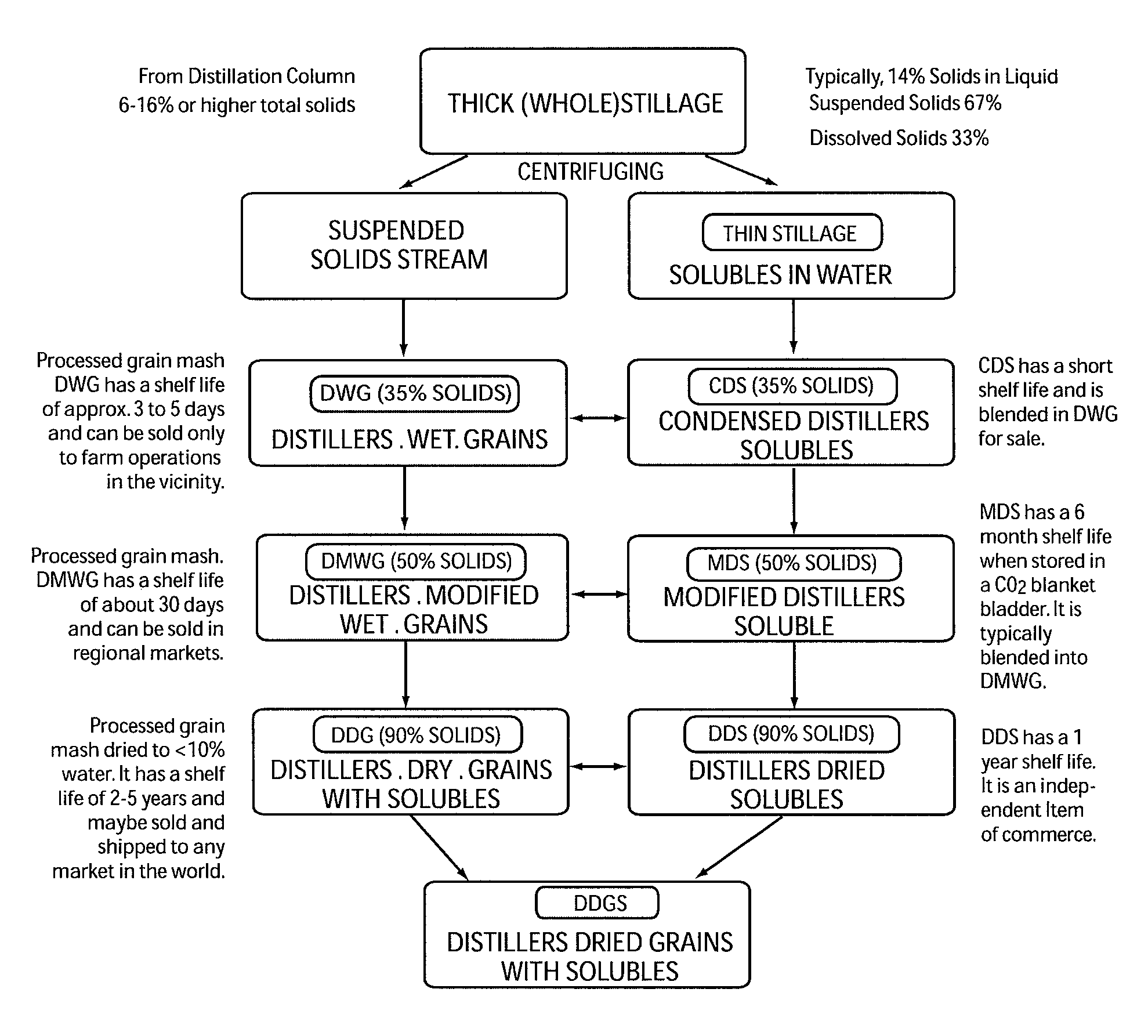

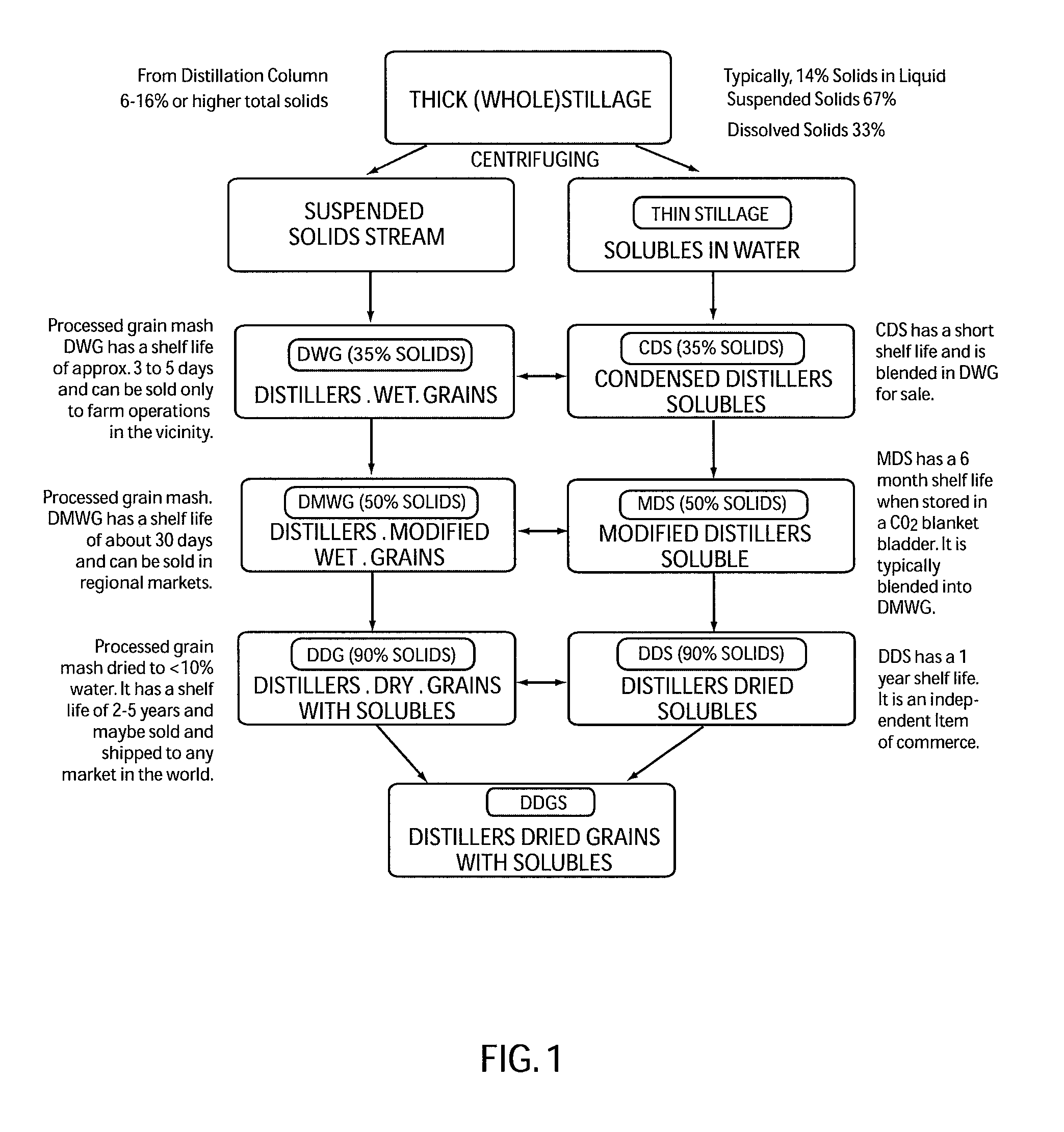

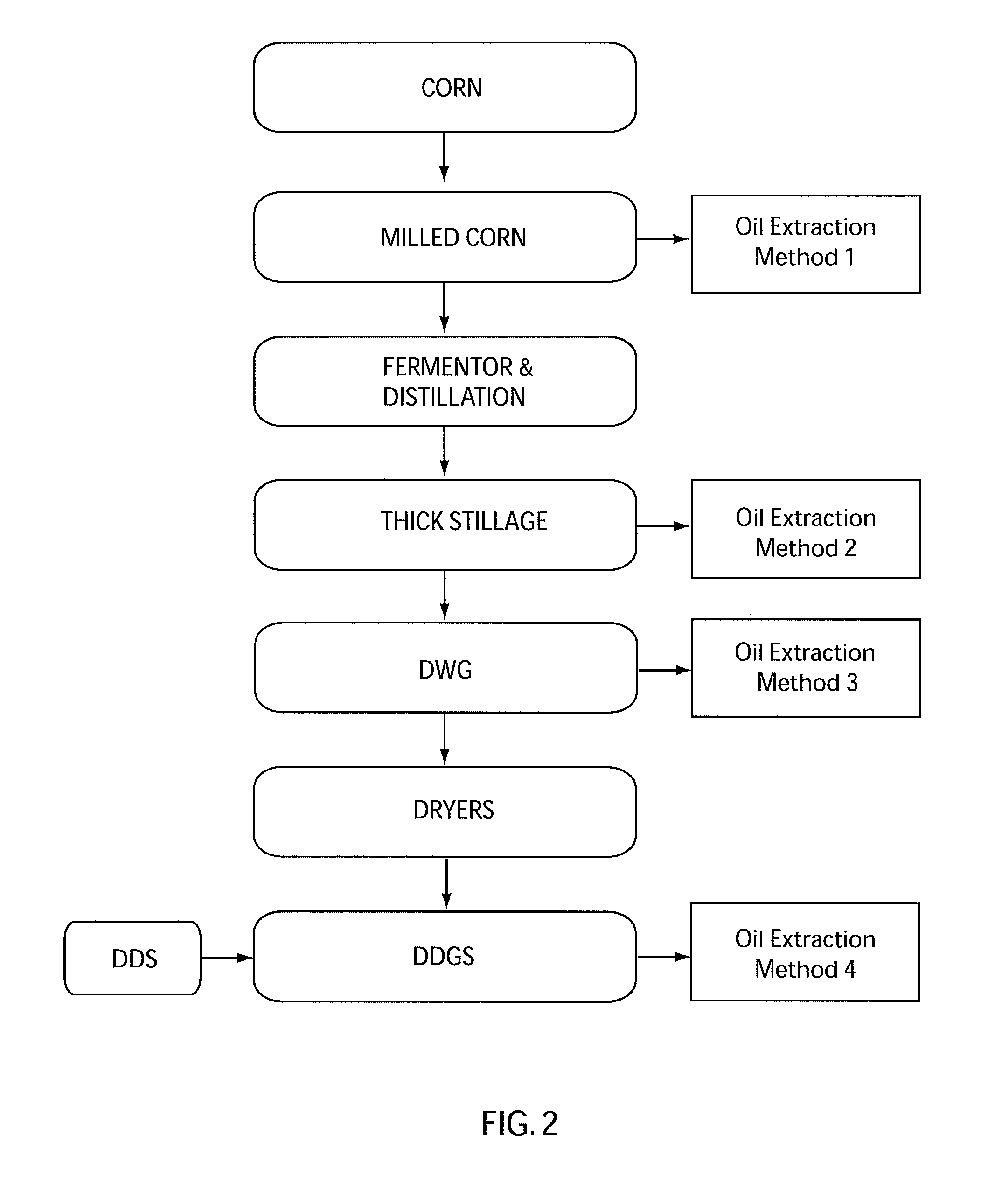

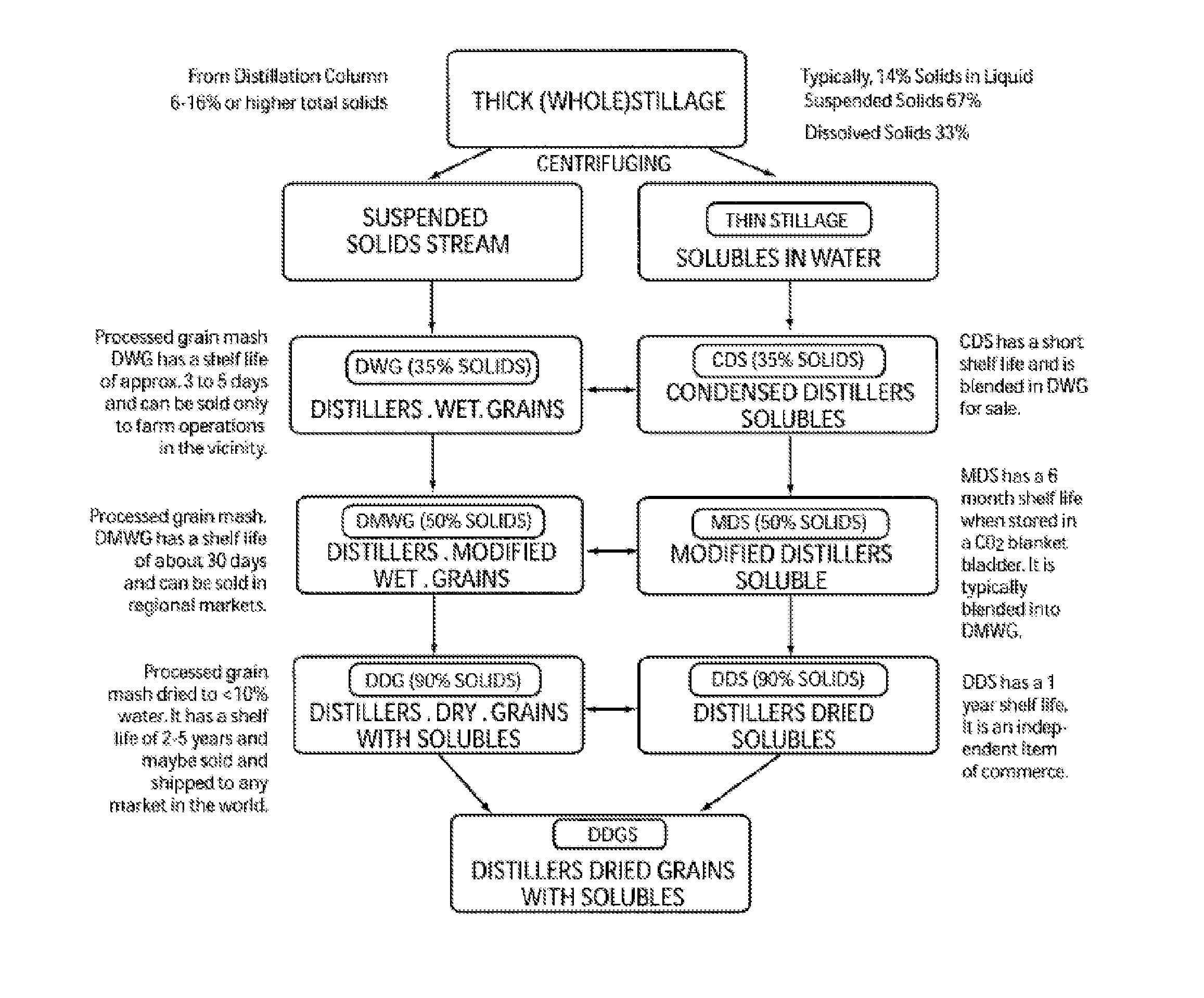

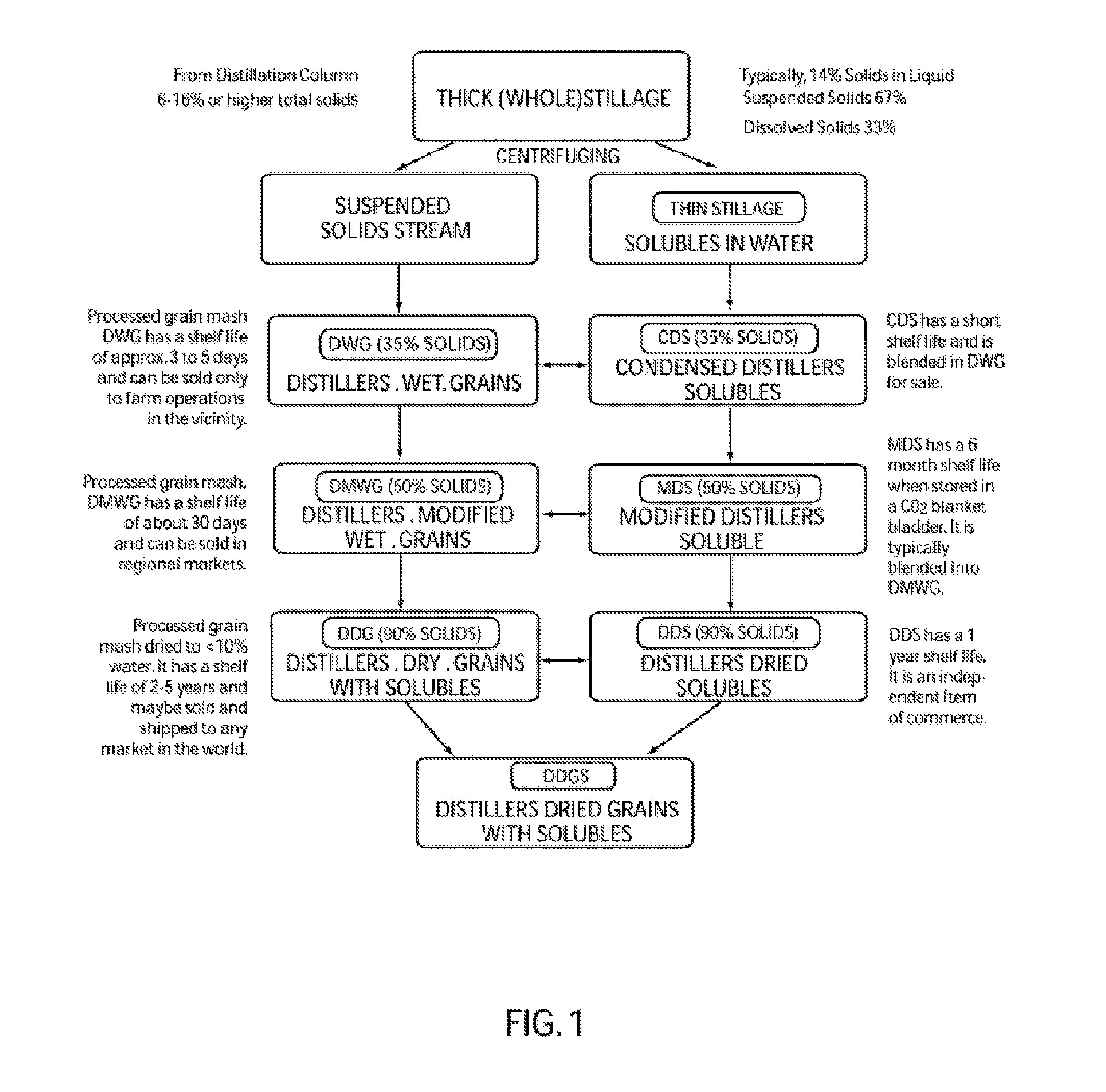

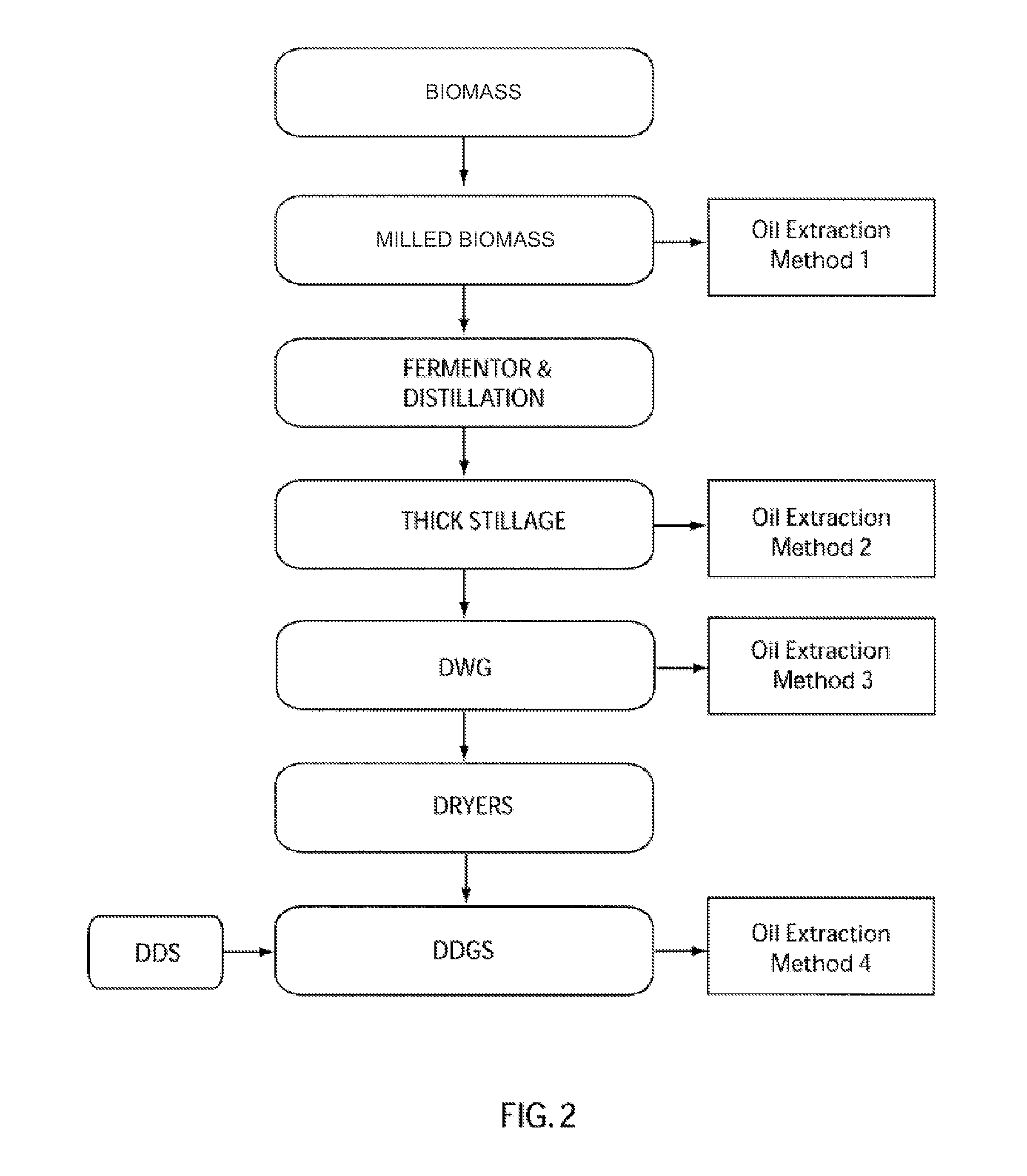

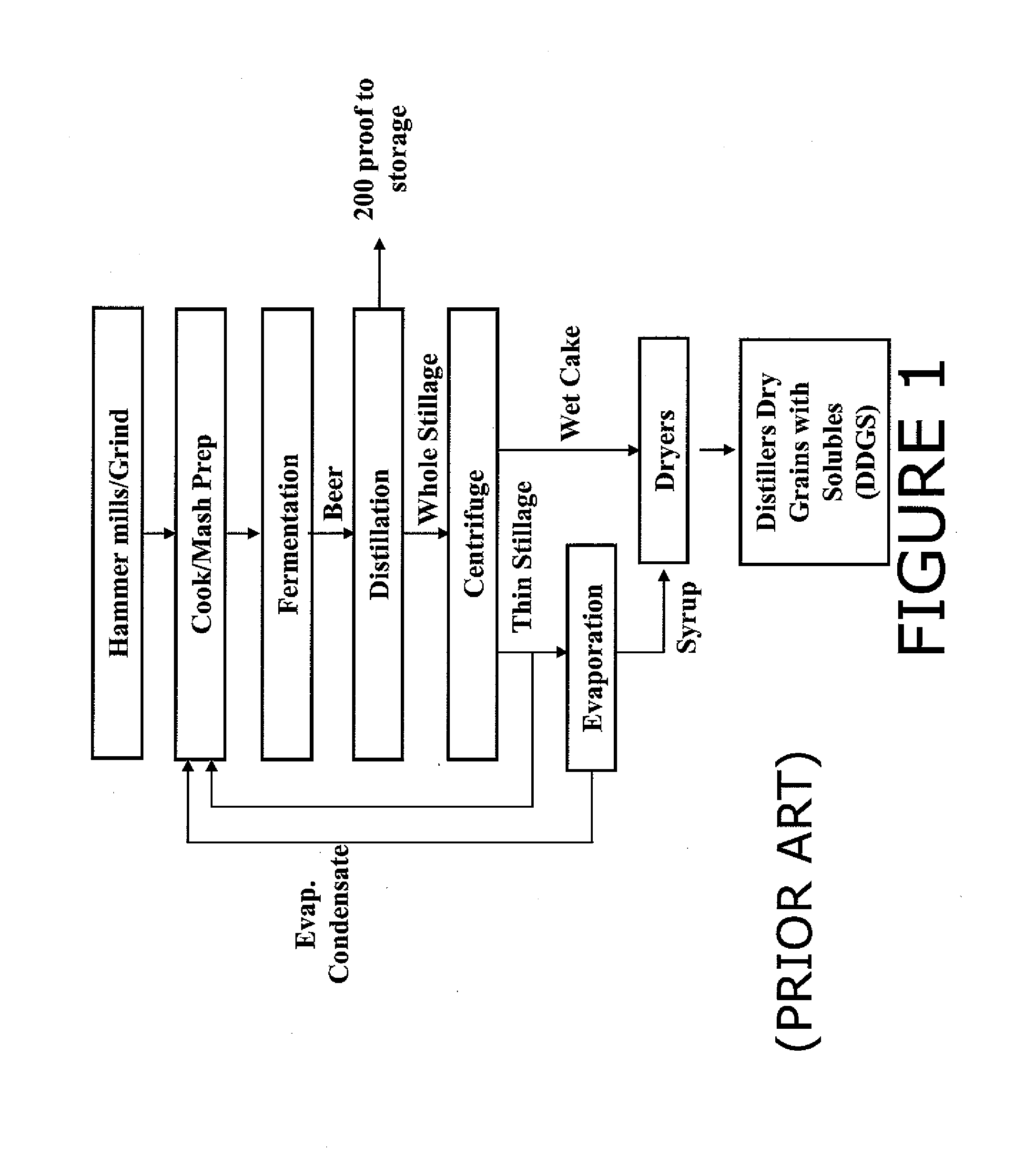

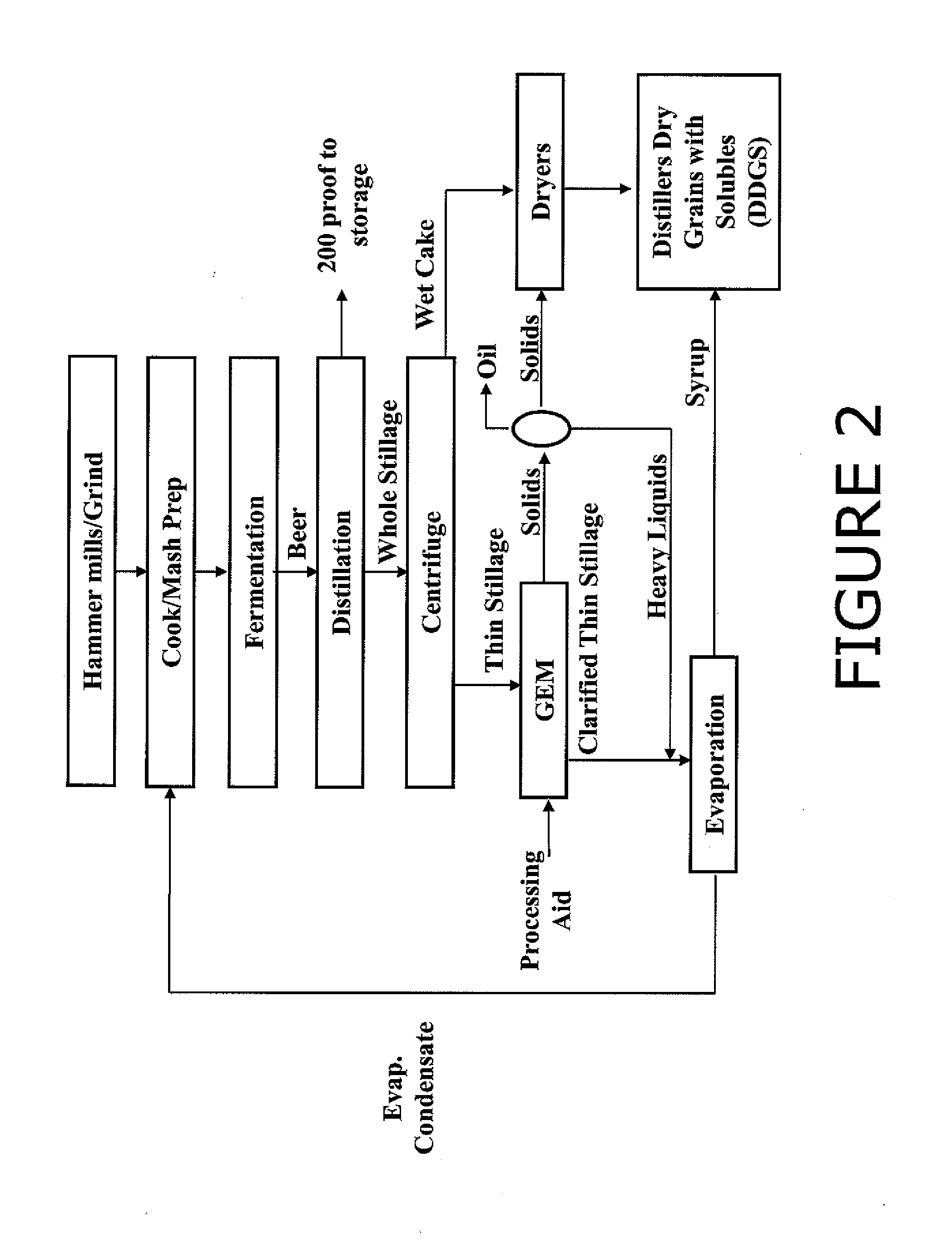

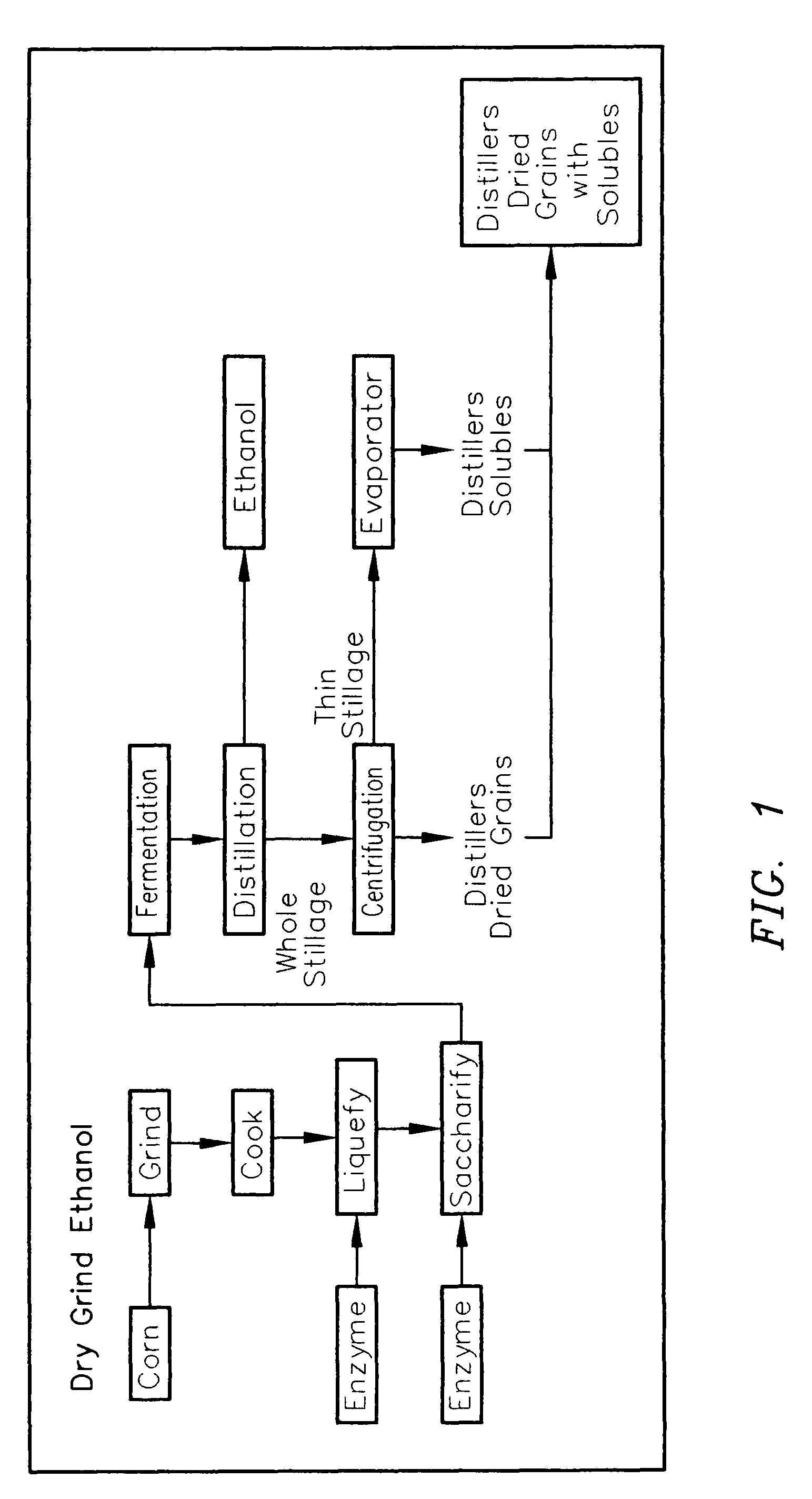

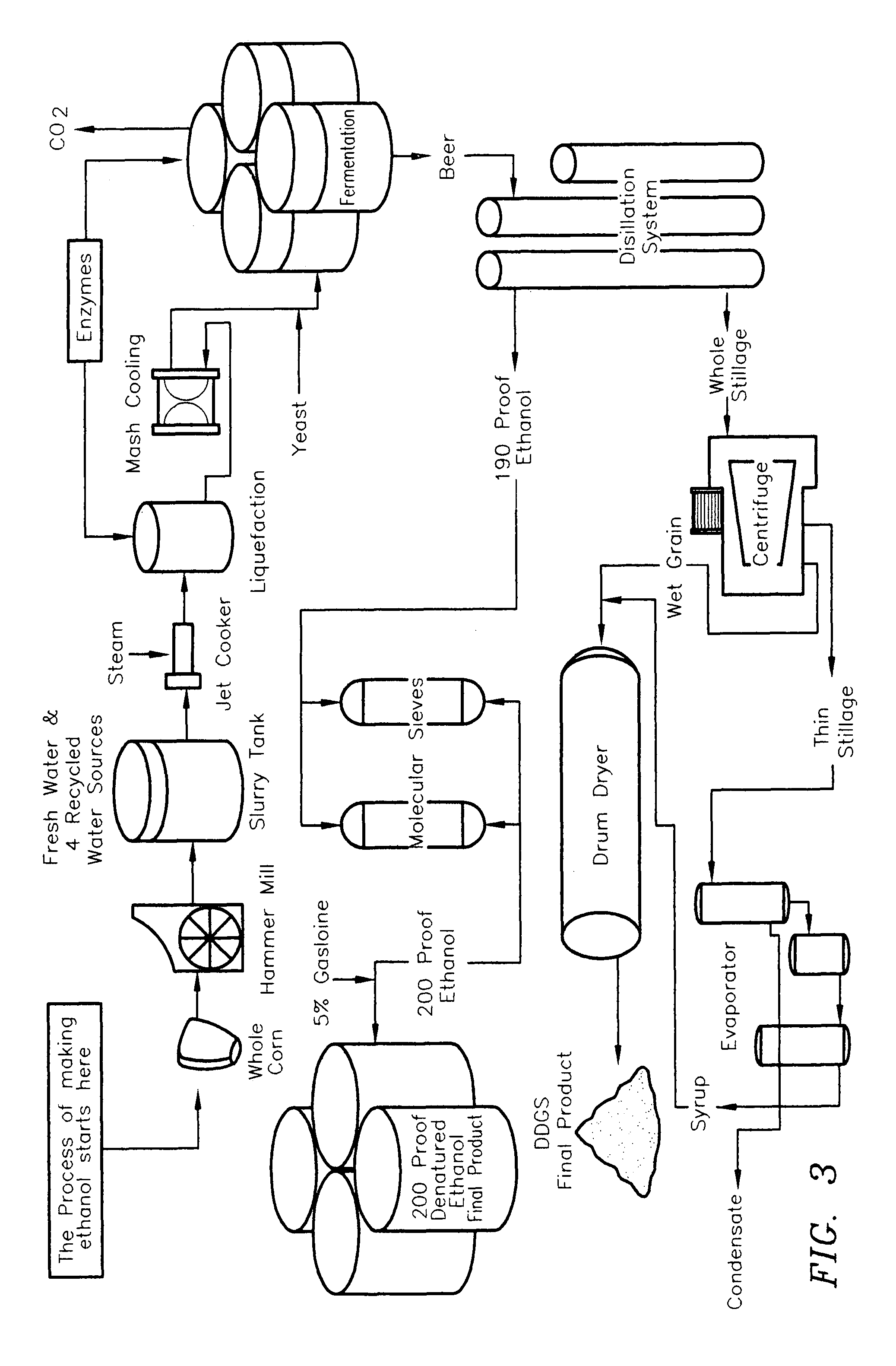

Oil recovery from dry corn milling ethanol production processes

A corn oil extraction process is disclosed. The process includes the recovery of corn oil and other co-products, including but not limited to steam, electric power and chemicals, from an ethanol production process and in particular, a process that involves dry corn milling methods. The process involves extraction of oil from milled corn and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed.

Owner:GROWMARK

Method of treating a gaseous mixture comprising hydrogen, carbon dioxide and hydrogen sulphide

A gaseous mixture, comprising CO2, H2, H2S and optionally CO, is separated into an H2 or H2 and CO product stream (H2 / CO product stream), and a CO2 enriched stream containing at least one combustible component selected from H2S, H2, CO and any additional combustible components present in the gaseous mixture. A support fuel stream, comprising one or more combustible components, is combusted to form a stable flame, and the CO2 enriched stream and flame are contacted in the presence of sufficient O2 to combust all or substantially all of the combustible component(s) present in said CO2 enriched stream. A CO2 product stream is formed from said combustion effluent. The support fuel stream may be generated from the process of generating or separating the gaseous mixture or from the H2 / CO product stream. Where the CO2 enriched stream contains H2S, the support fuel stream may also be a stream obtained off-site that comprises H2S.

Owner:AIR PROD & CHEM INC

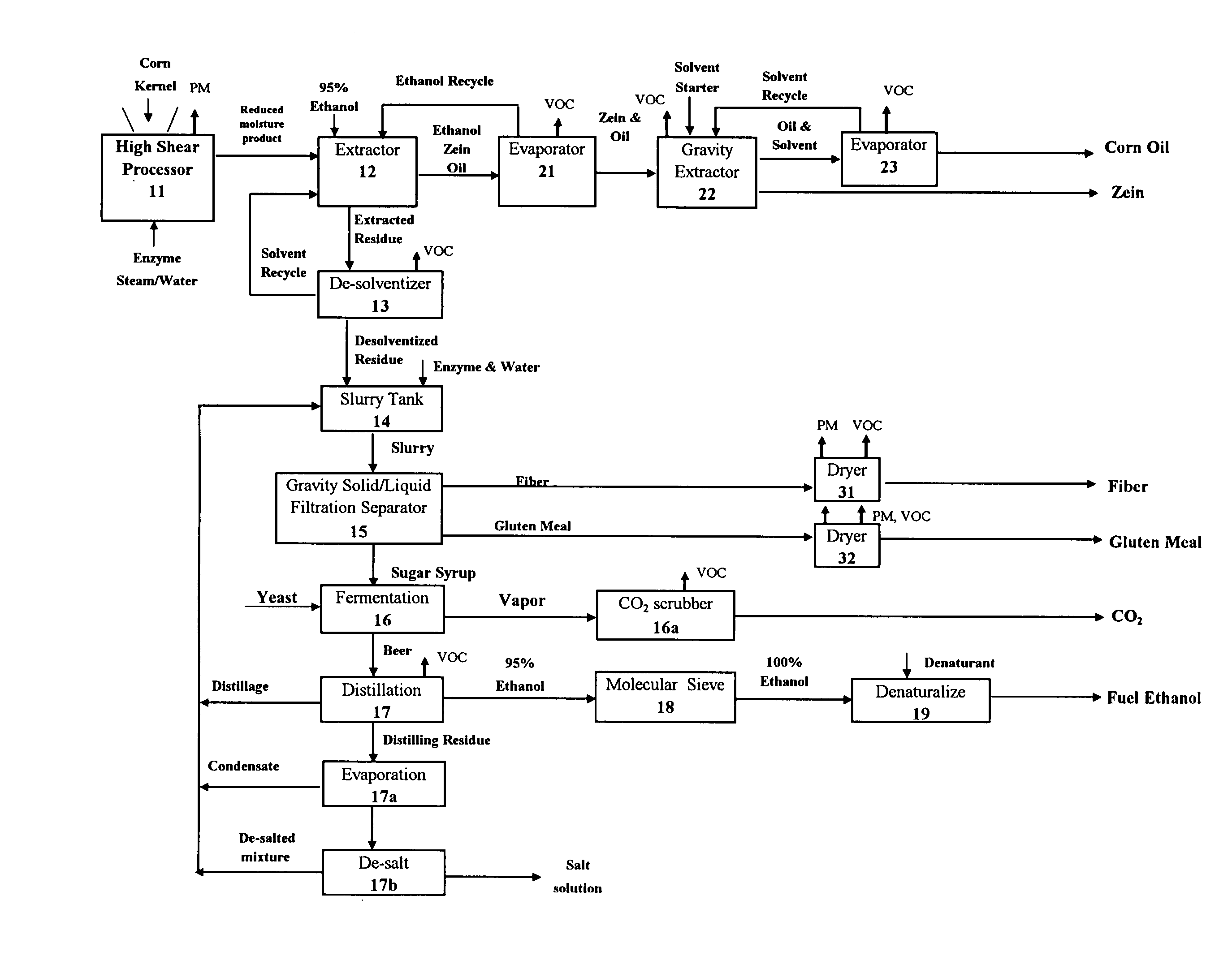

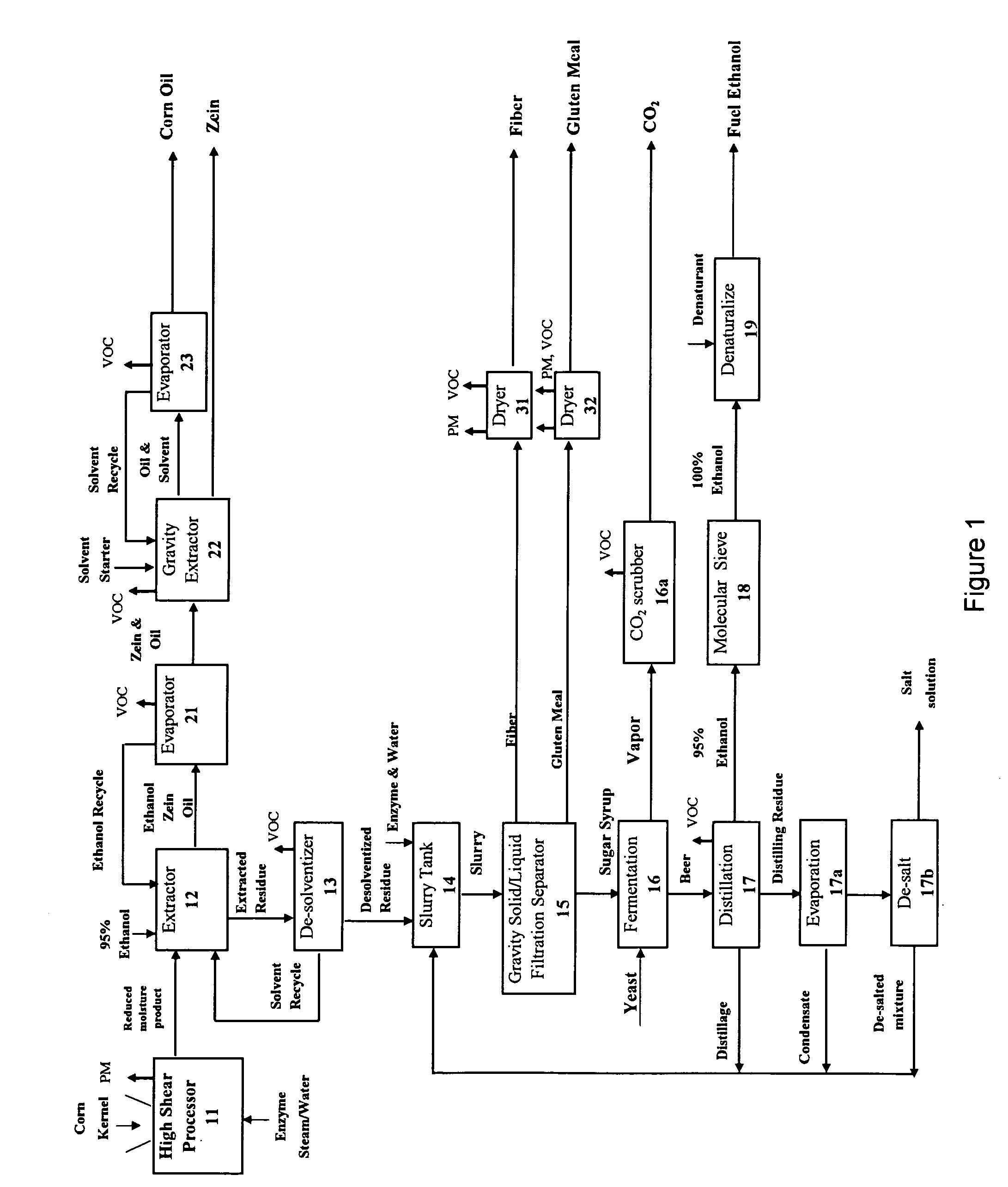

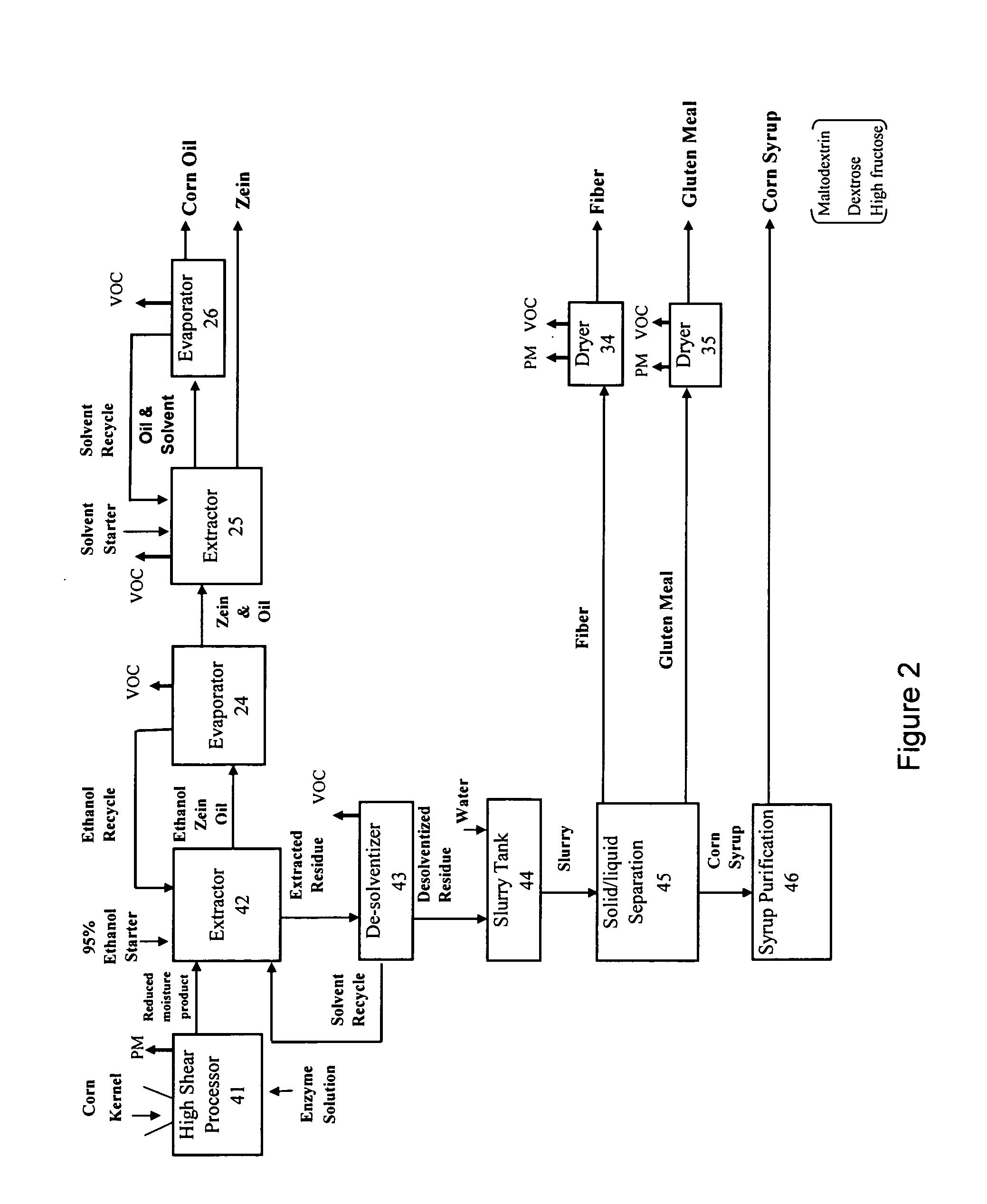

Starchy material processed to produce one or more products comprising starch, ethanol, sugar syrup, oil, protein, fiber, gluten meal, and mixtures thereof

InactiveUS20070014905A1Reduce processIncrease shearProtein composition from eggsConfectioneryFiberFood grade

The invention provides a method and system of processing a starchy material that can advantageously produce ethanol, sugar syrup, or starch as the chief products along with food-grade co-products such as, but not limited to oil, protein, fiber, and gluten meal. The invention can apply such a force to a starchy material that is at a superambient temperature with a high shear processor to mill, mix, and gelatinize some of the starch. A liquefaction enzyme can be introduced into the high shear processor to liquefy the processed product. The moisture content of the processed starchy material can be reduced, which preferably occurs in the high shear processor. Some of the co-products such as the oil, protein, fiber and gluten meal can be separated prior to the sugar syrup purification or ethanol fermentation steps.

Owner:PURDUE RES FOUND INC

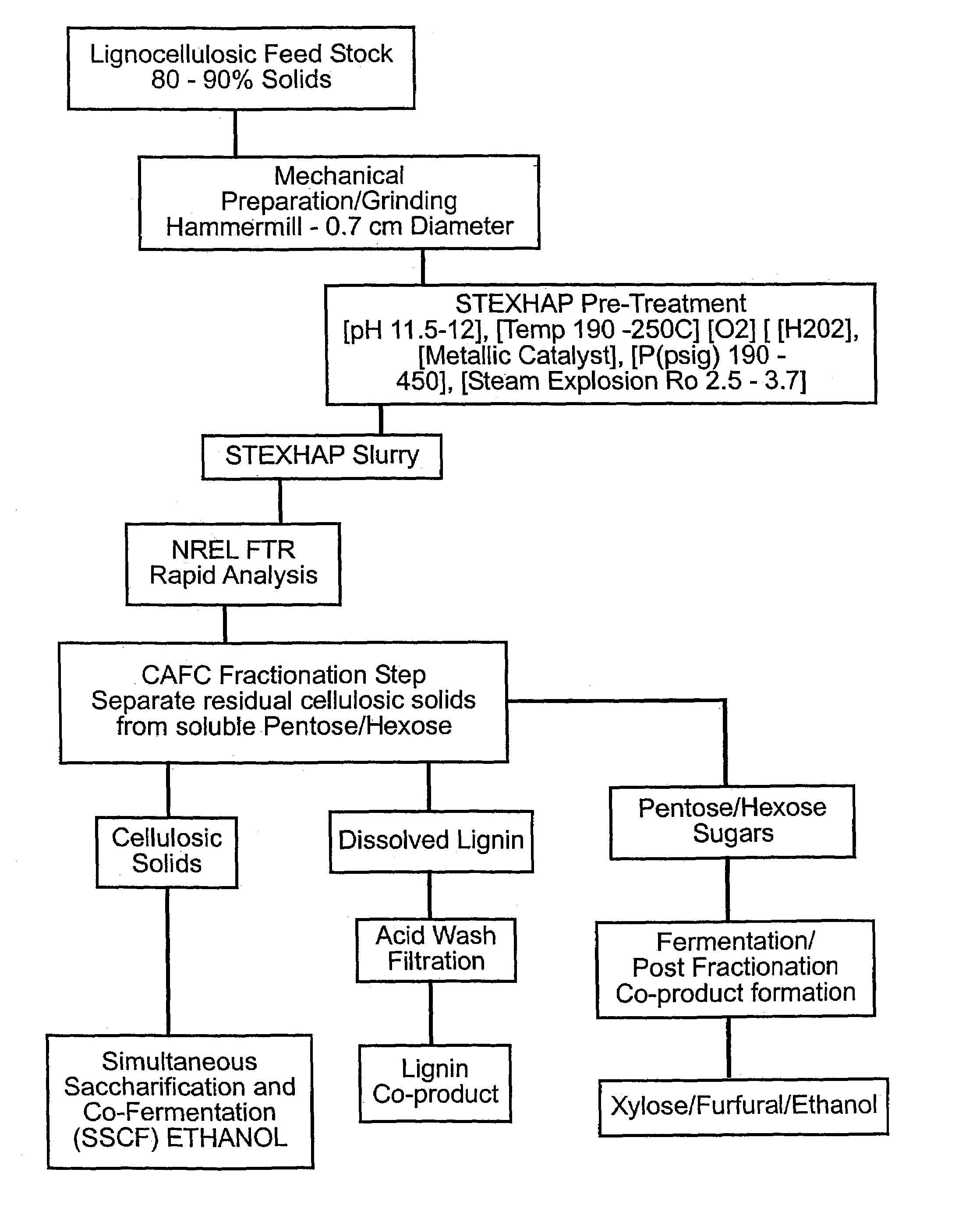

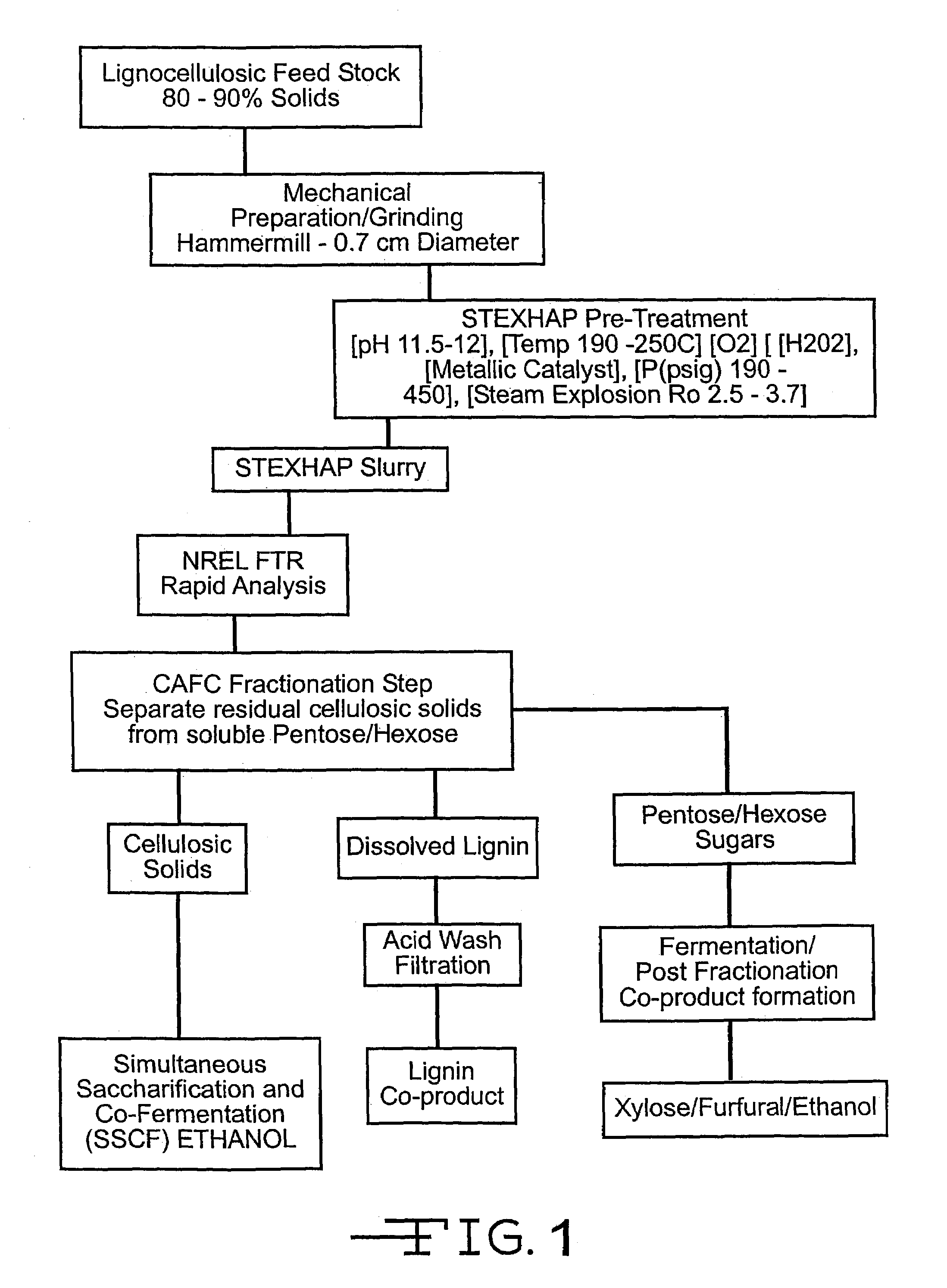

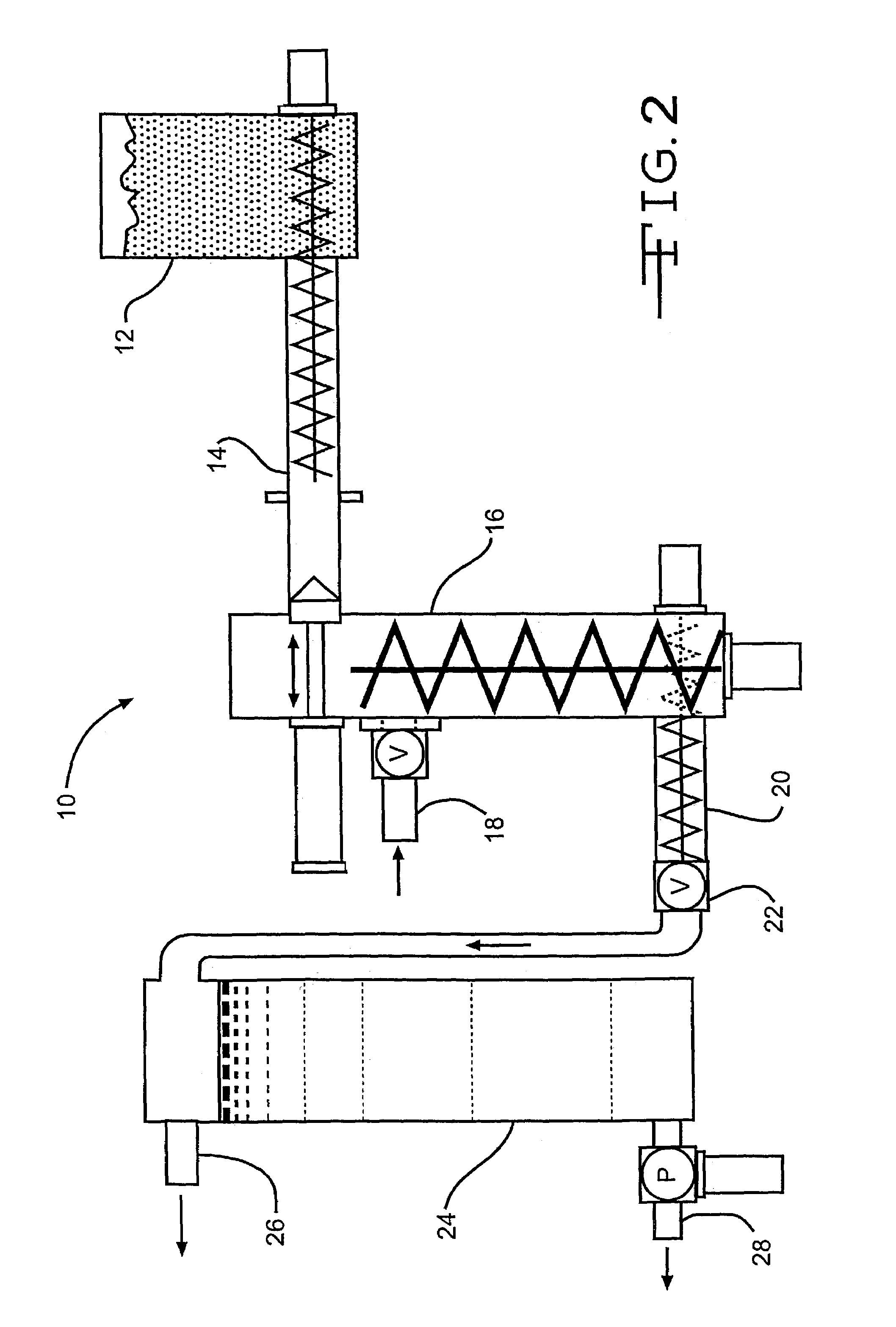

Process of treating lignocellulosic material to produce bio-ethanol

InactiveUS7189306B2Separation efficiency can be improvedEasy to separatePretreatment with water/steamPulp liquor regenerationSide productCo product

This invention relates to a process of treating a lignocellulosic material to produce bio-ethanol. The process includes the steps of: (a) exposing the lignocellulosic material to conditions including a pH not less than about 8, and steam at a first pressure, to produce a step (a) product; (b) explosively discharging the step (a) product to a second pressure less than the first pressure to produce a step (b) product; and (c) further processing the step (b) product to produce bio-ethanol and other co-products. In another embodiment, the invention relates to a conical auger fractionation column. The fractionation column includes a column body having an input and an output. A conical filter is positioned inside the column body, the filter having a larger diameter end directed toward the input and a smaller diameter end directed toward the output. A conical auger is positioned inside the conical filter, the conical auger having an outer diameter which is approximately the same as an inner diameter of the conical filter. The auger and filter are adapted to cooperate to separate cellulosic solids from a liquid stream in a process of producing bio-ethanol from a lignocellulosic material.

Owner:GERVAIS GIBSON W

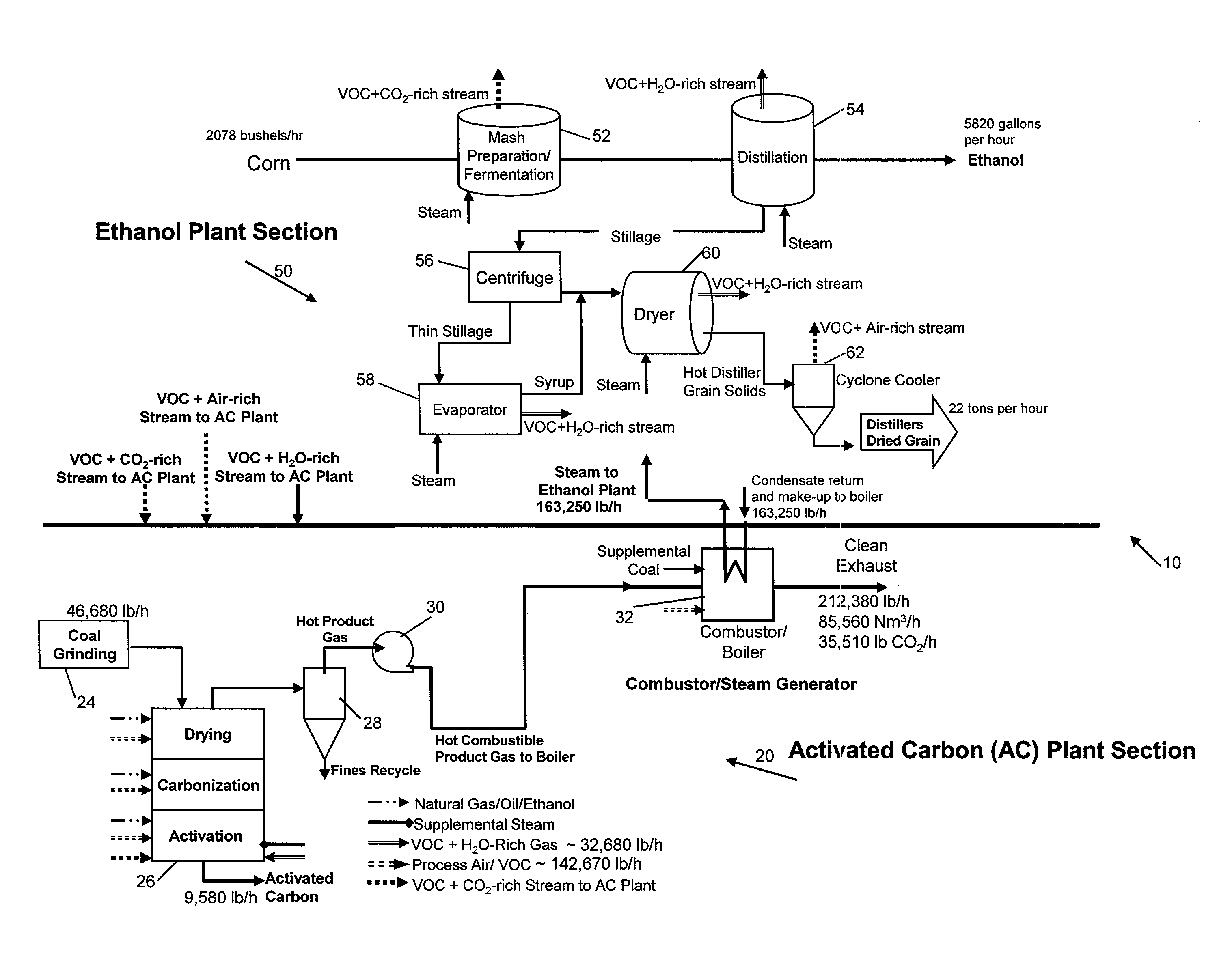

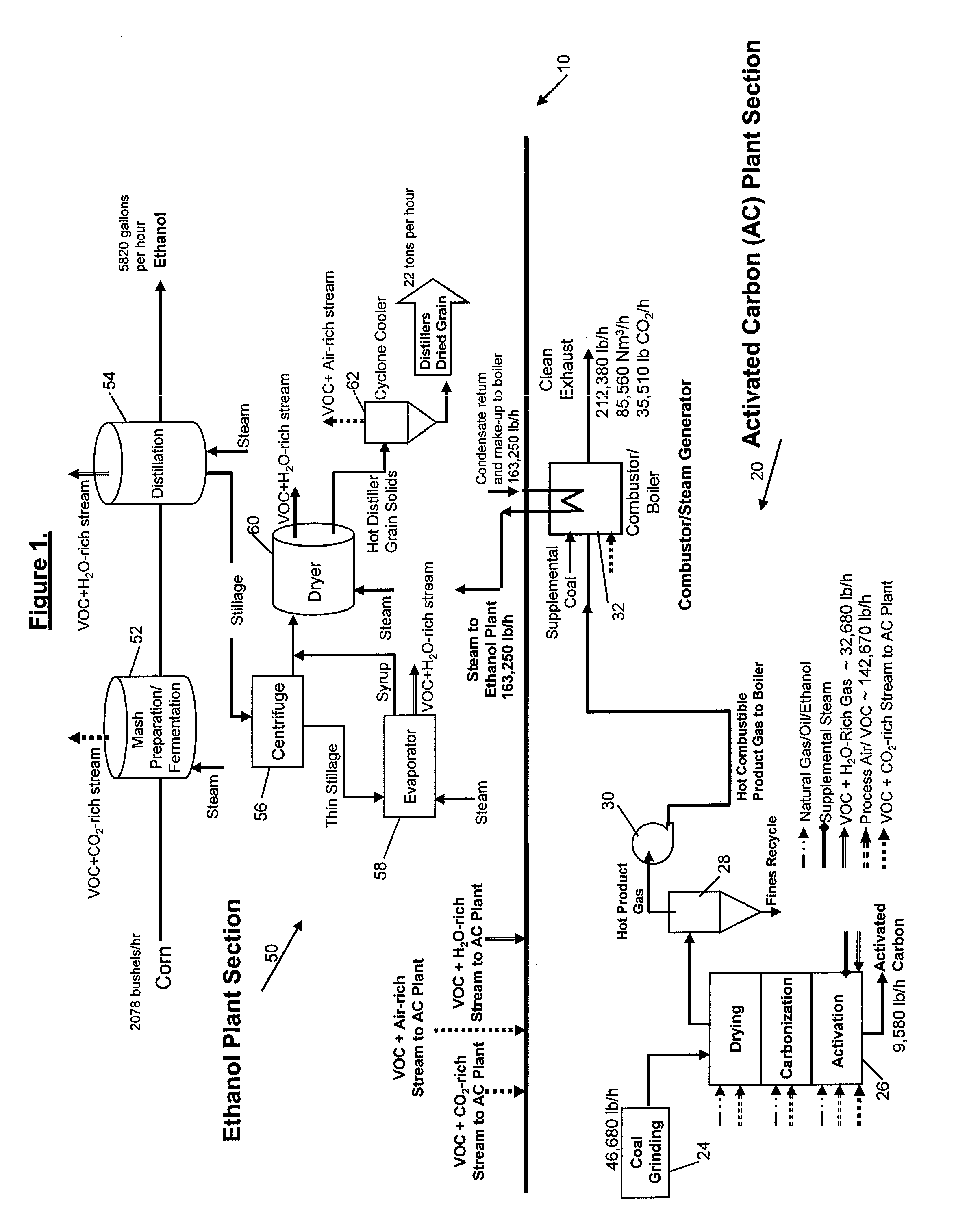

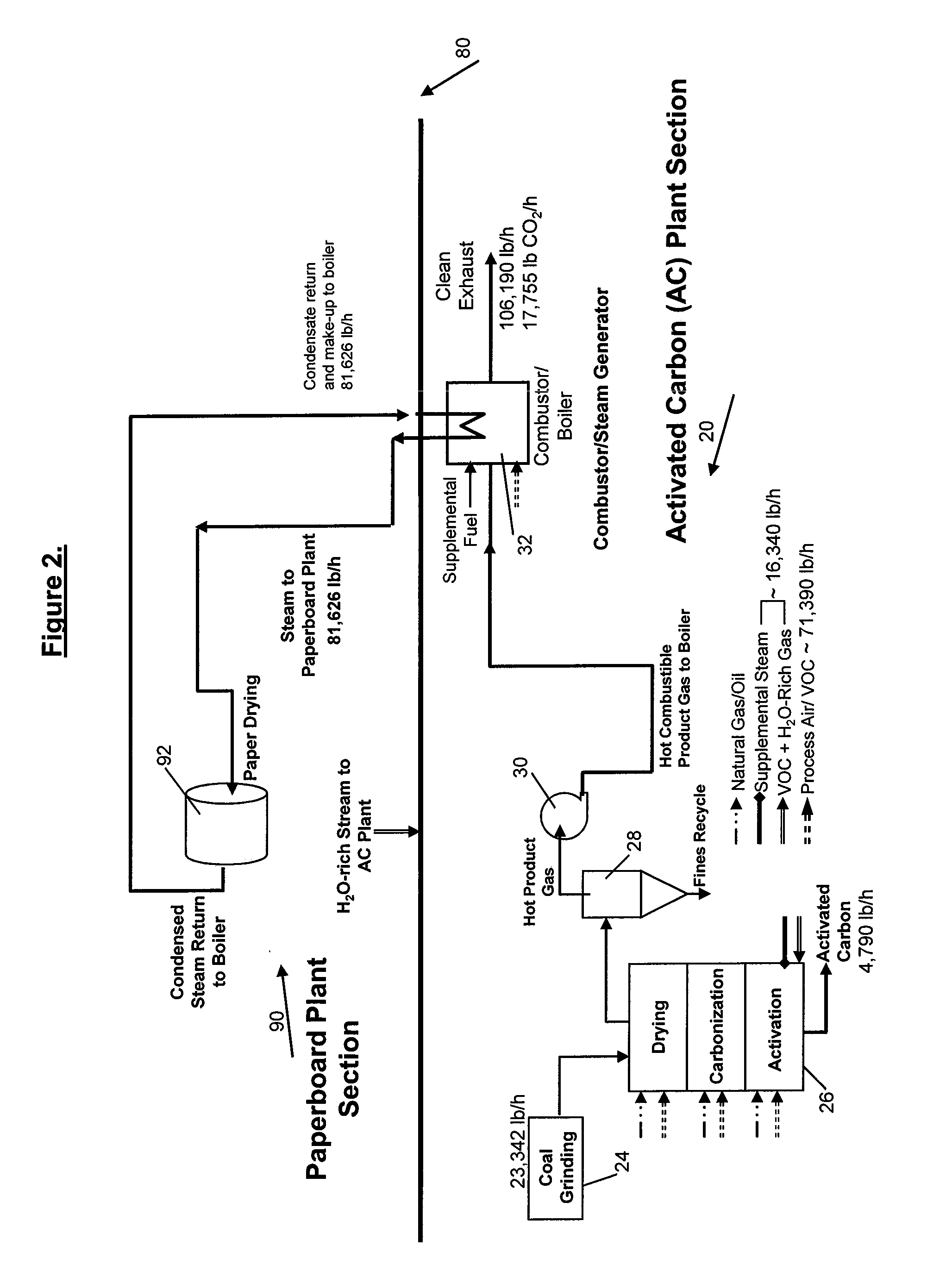

Method of Manufacturing Carbon-Rich Product and Co-Products

ActiveUS20100178624A1Simple and cost-effectiveImprove efficiencyBioreactor/fermenter combinationsGaseous fuel feeder/distributionWater vaporHigh carbon

A method in which a parent hydrocarbon-rich material is processed so as to produce both a carbon-rich solid material that has a higher carbon to hydrogen ratio than that of the parent material and a carbon-deficient combustible gas that has a lower carbon to hydrogen ratio than the parent material. In the process, the material is activated by exposing it to a hot gas stream having elevated levels of one or both of carbon dioxide and water vapor. The combustible gas is combusted to produce heat. At least about 80% of the heat is used in one or more endothermic steps that include drying coal or biomass.

Owner:SRINIVASACHAR SRIVATS

Oil recovery and syngas production from biomass-based processes

InactiveUS20100331580A1Small sizeSolvent extractionCombustible gas catalytic treatmentSyngasCompound (substance)

A biomass-based oil extraction process is disclosed. The process includes the recovery of biomass-based oil and other co-products, including but not limited to steam, electric power and chemicals, from various biomass processes and in particular, a process that involves dry biomass milling methods. The process involves extraction of oil from milled biomass-based products and residues from the fermentation step, including thick stillage, distillers wet grain, distillers dry grain and distillers dry grains with solubles, by the application of an alkyl acetate, phase separation and recovery of the separated matter. A process of drying wet co-product using ethanol and carbon dioxide from the production facility is also disclosed. Also a process for the production of syngas from oil containing or deoiled biomass-based products in a pressurized gasifier is disclosed.

Owner:FS FINANCIAL SERVICES

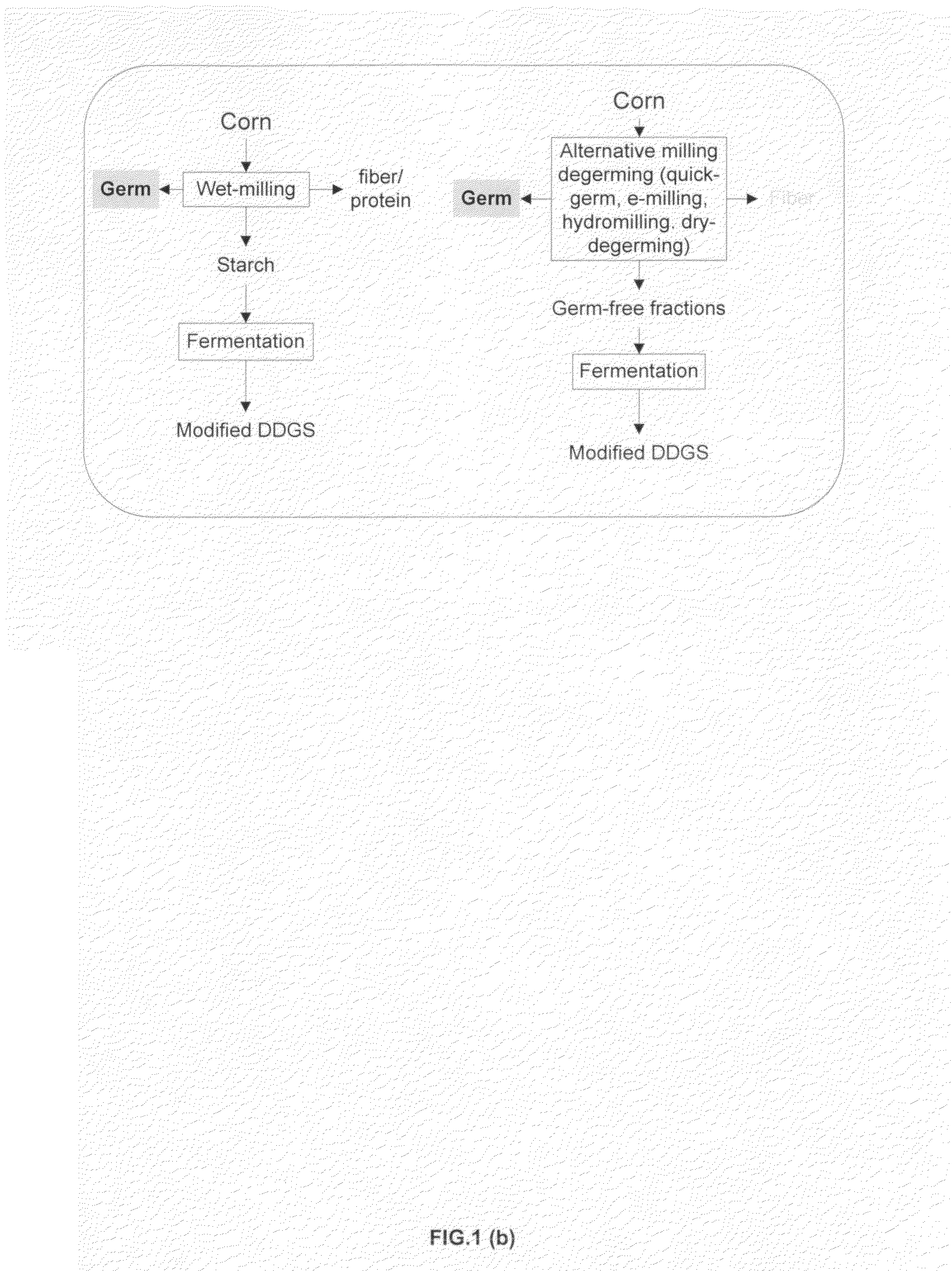

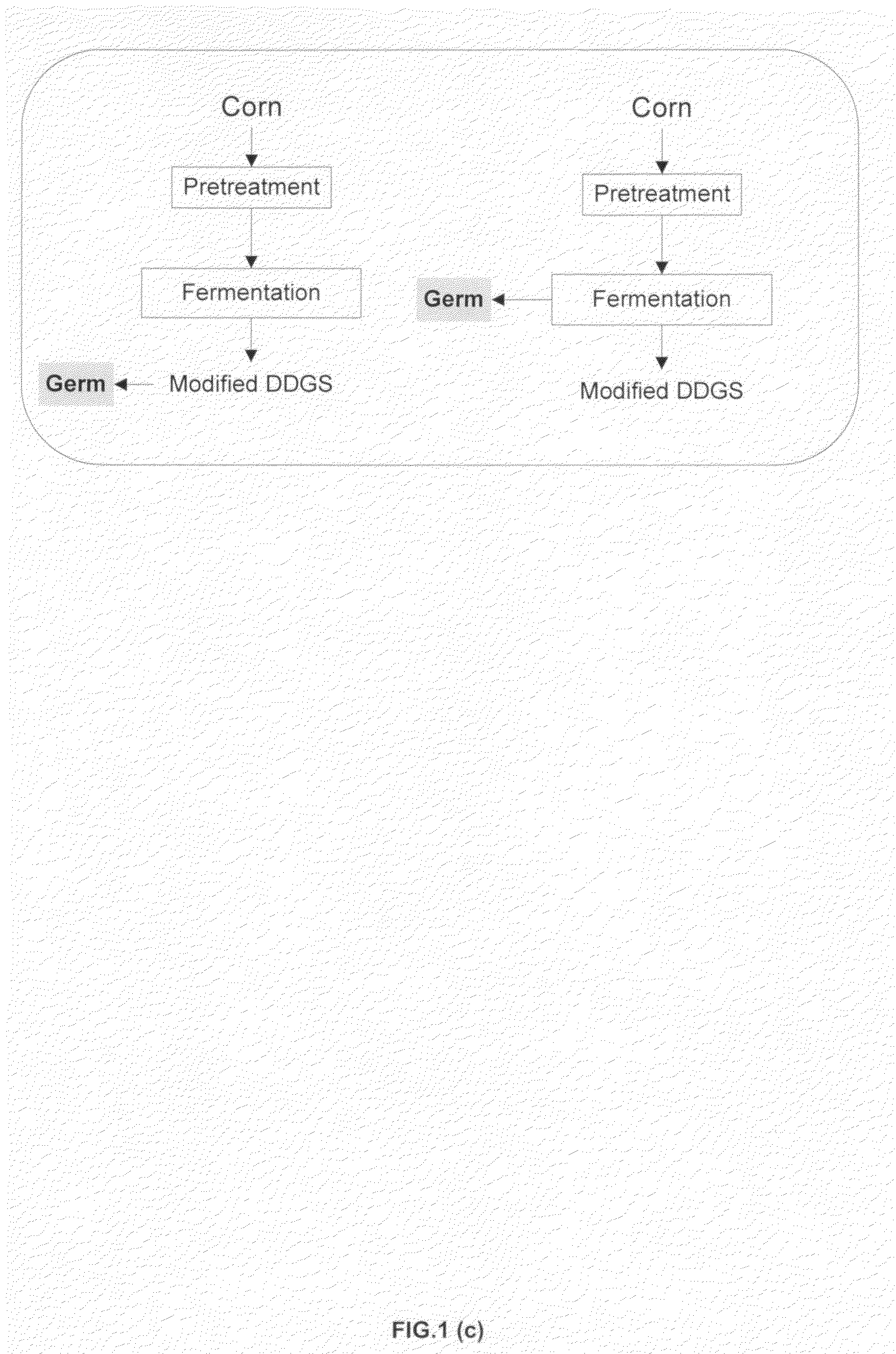

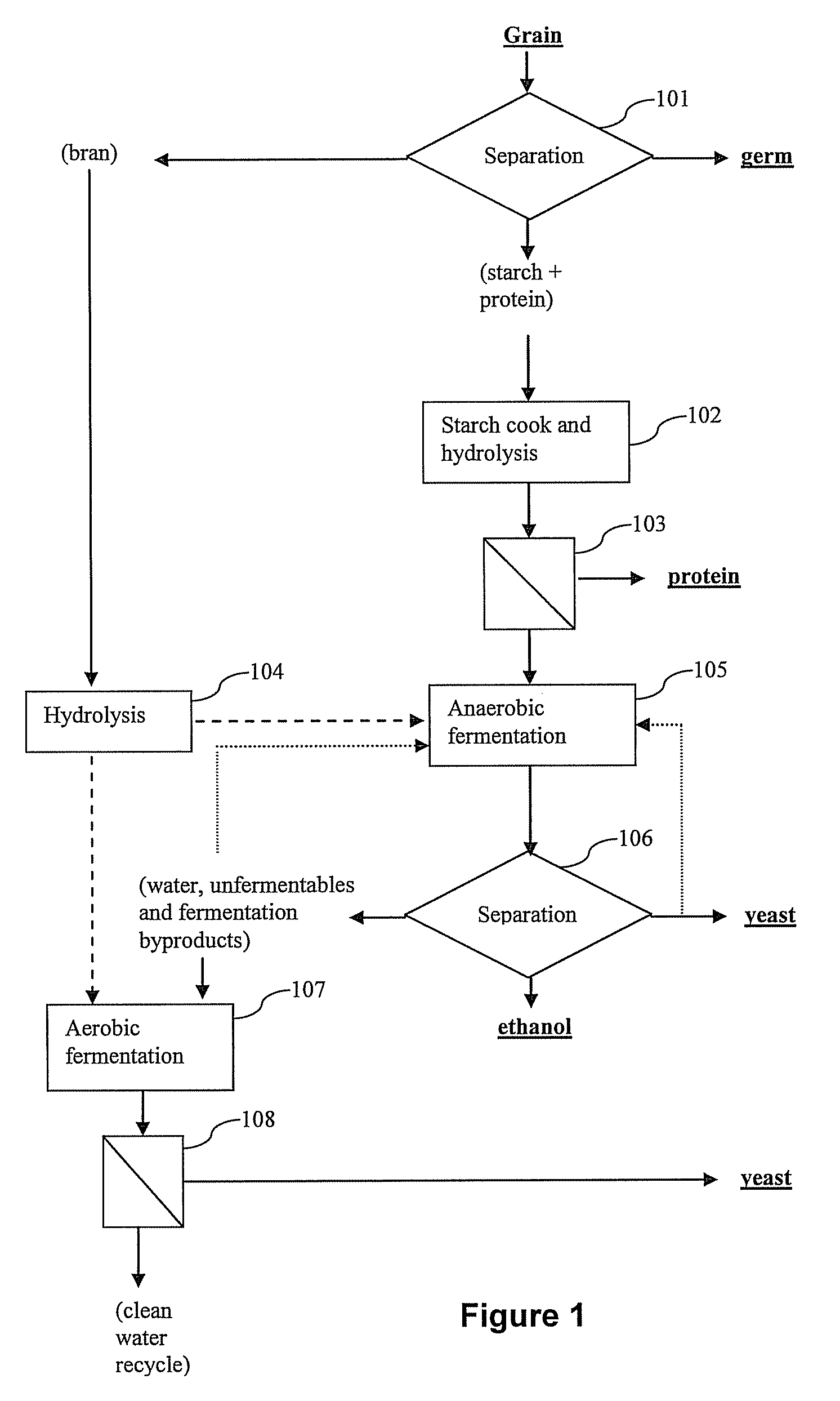

Novel corn degerming Ethanol fermentation processes

The invention presents novel corn fermentation processes that remove the oil-rich fraction either during or after fermentation instead of before fermentation as usual. Besides recovery of high value oil-rich fraction of the corn, the processes also produce other value-added co-products such as that with high fiber or high protein but low oil contents.

Owner:WANG HUI

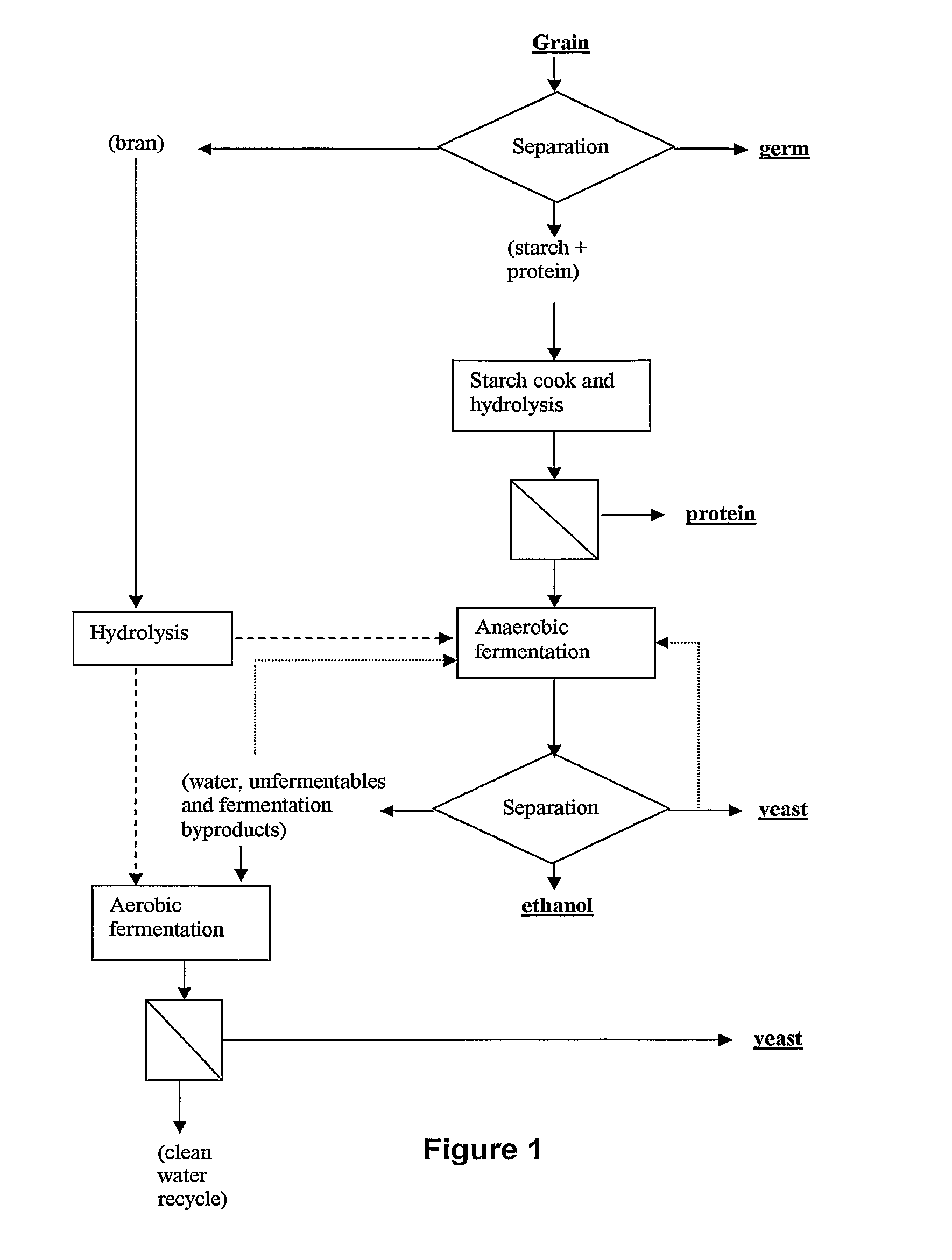

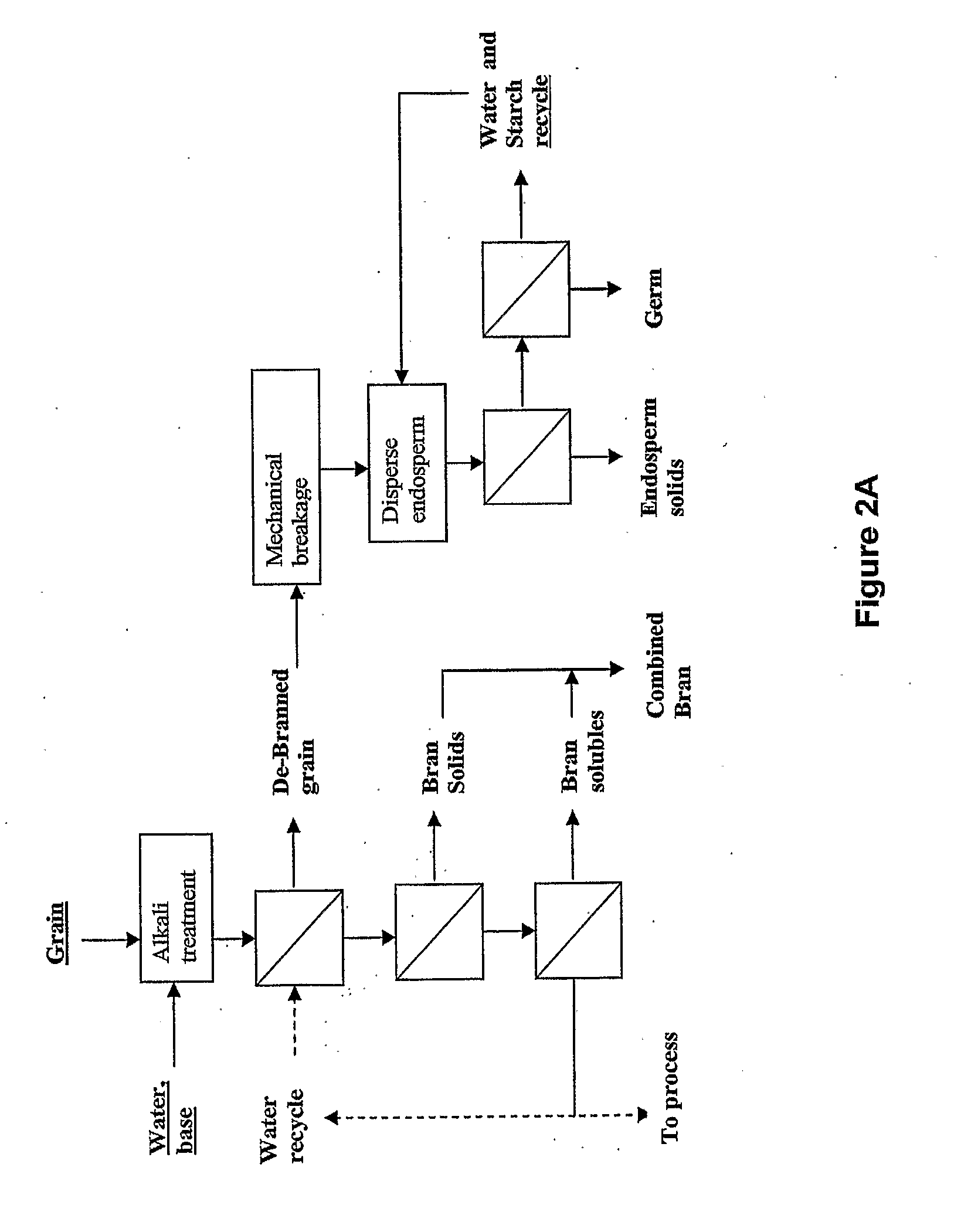

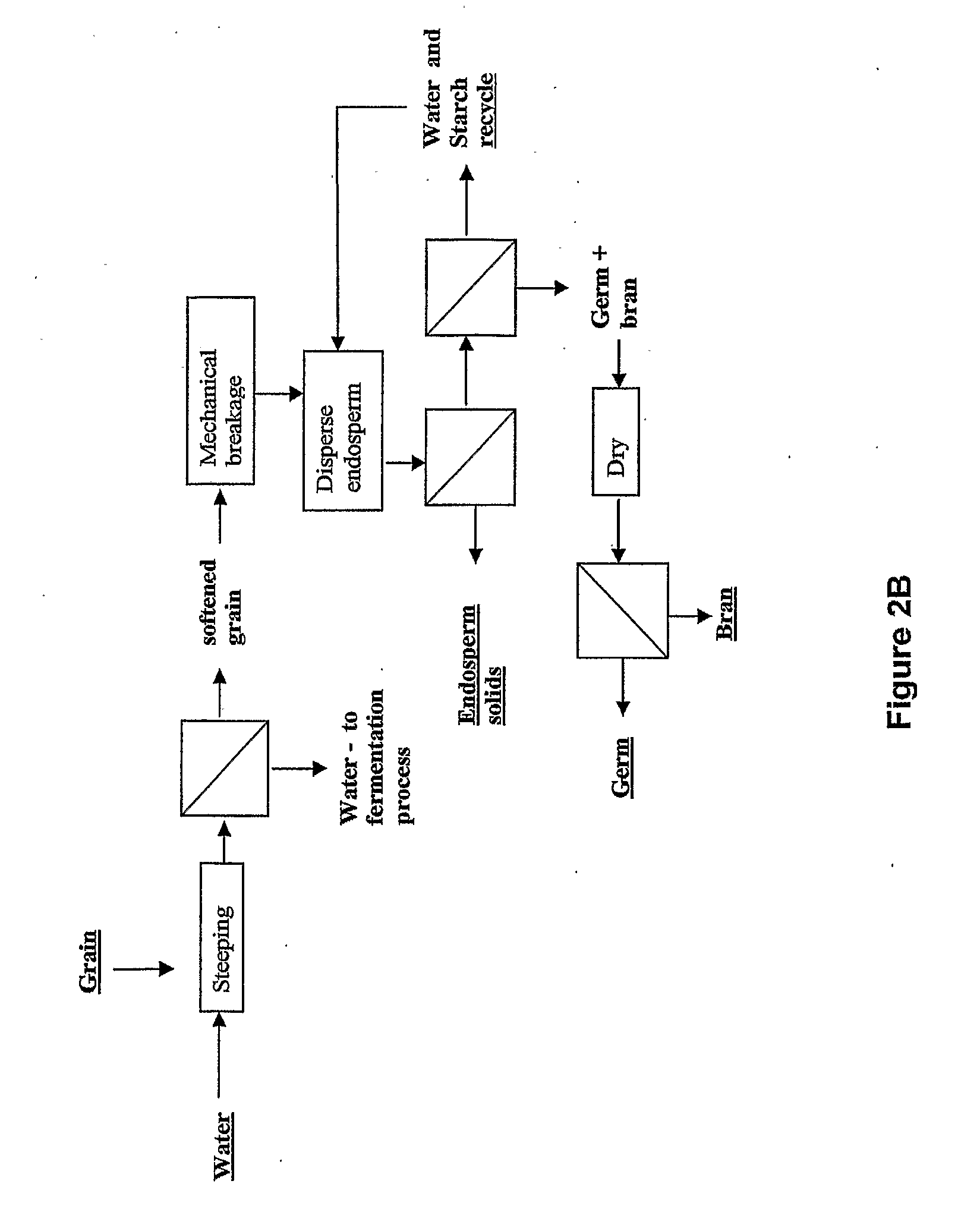

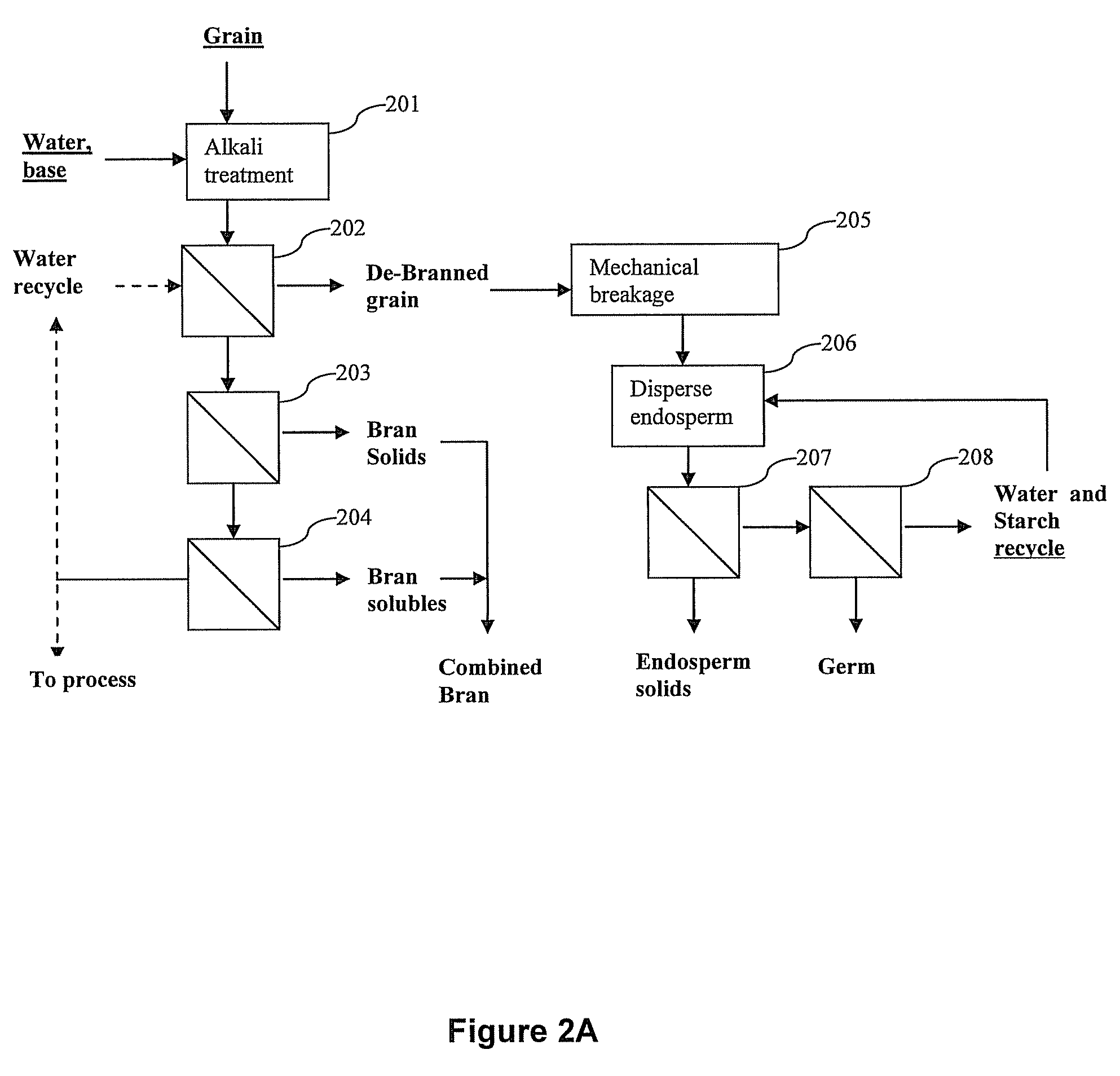

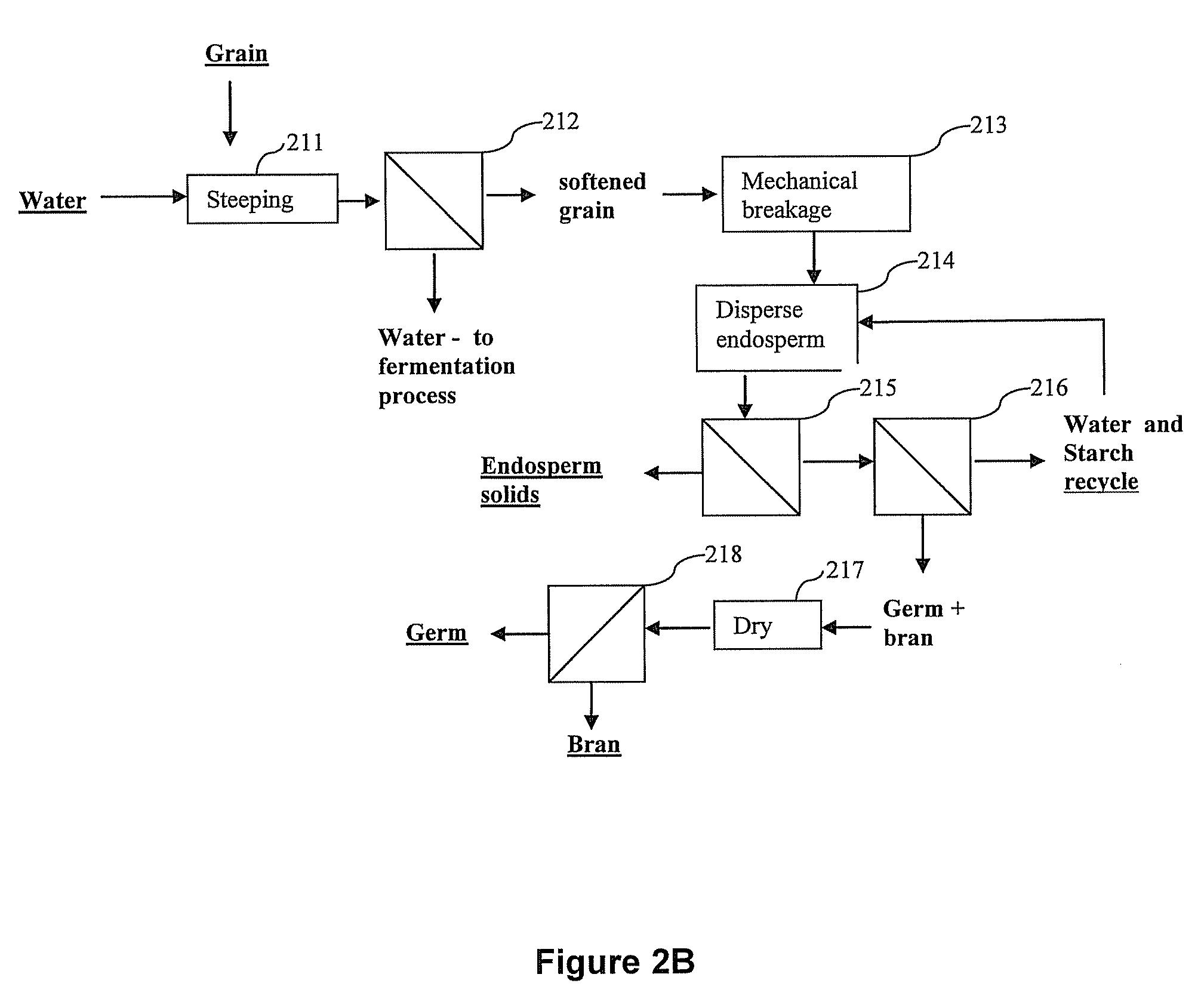

Corn fractionation method

InactiveUS20070184541A1Avoid fermentationContributing to air pollutionMicroorganismsBiofuelsFractionationFermentable sugar

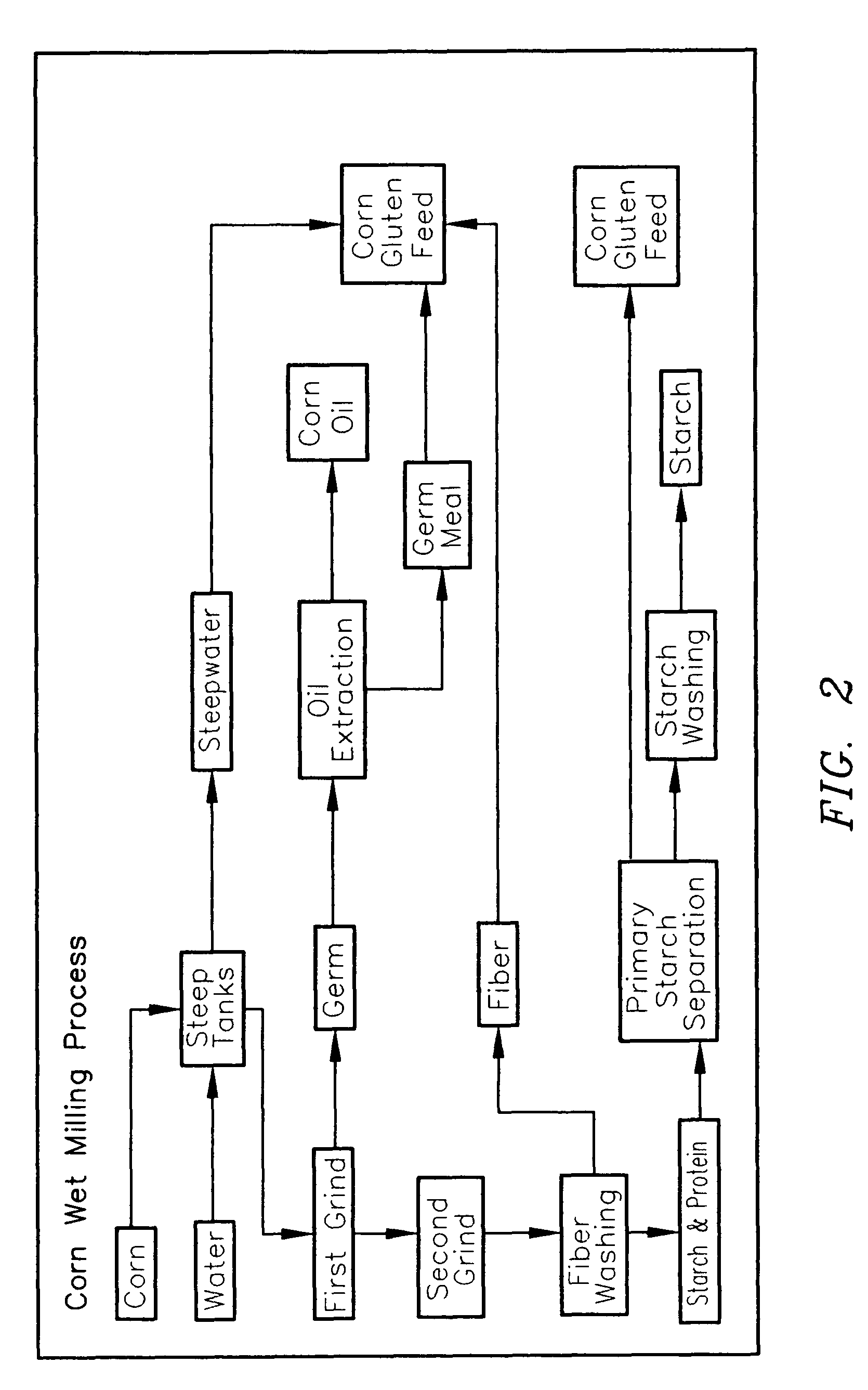

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

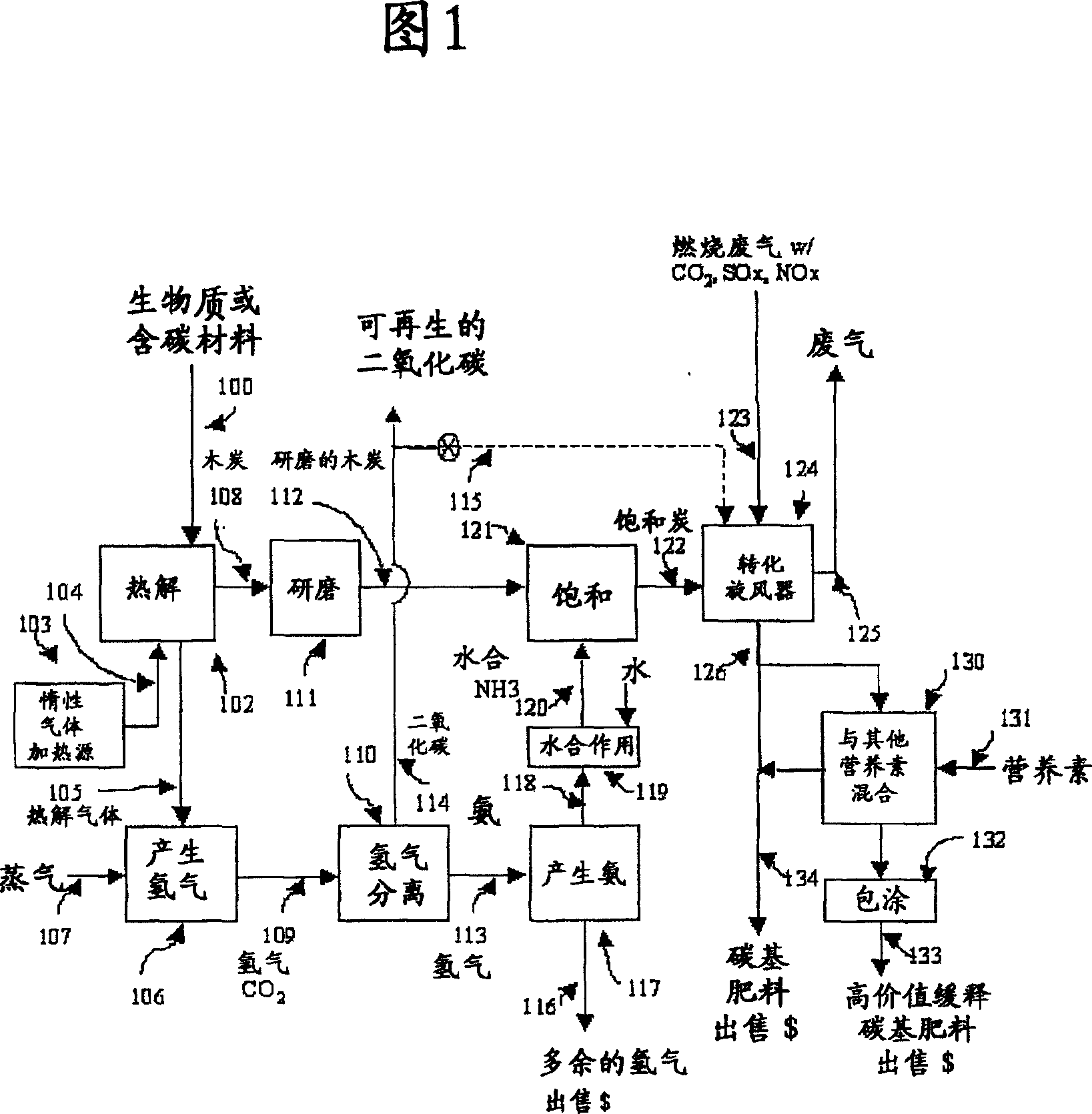

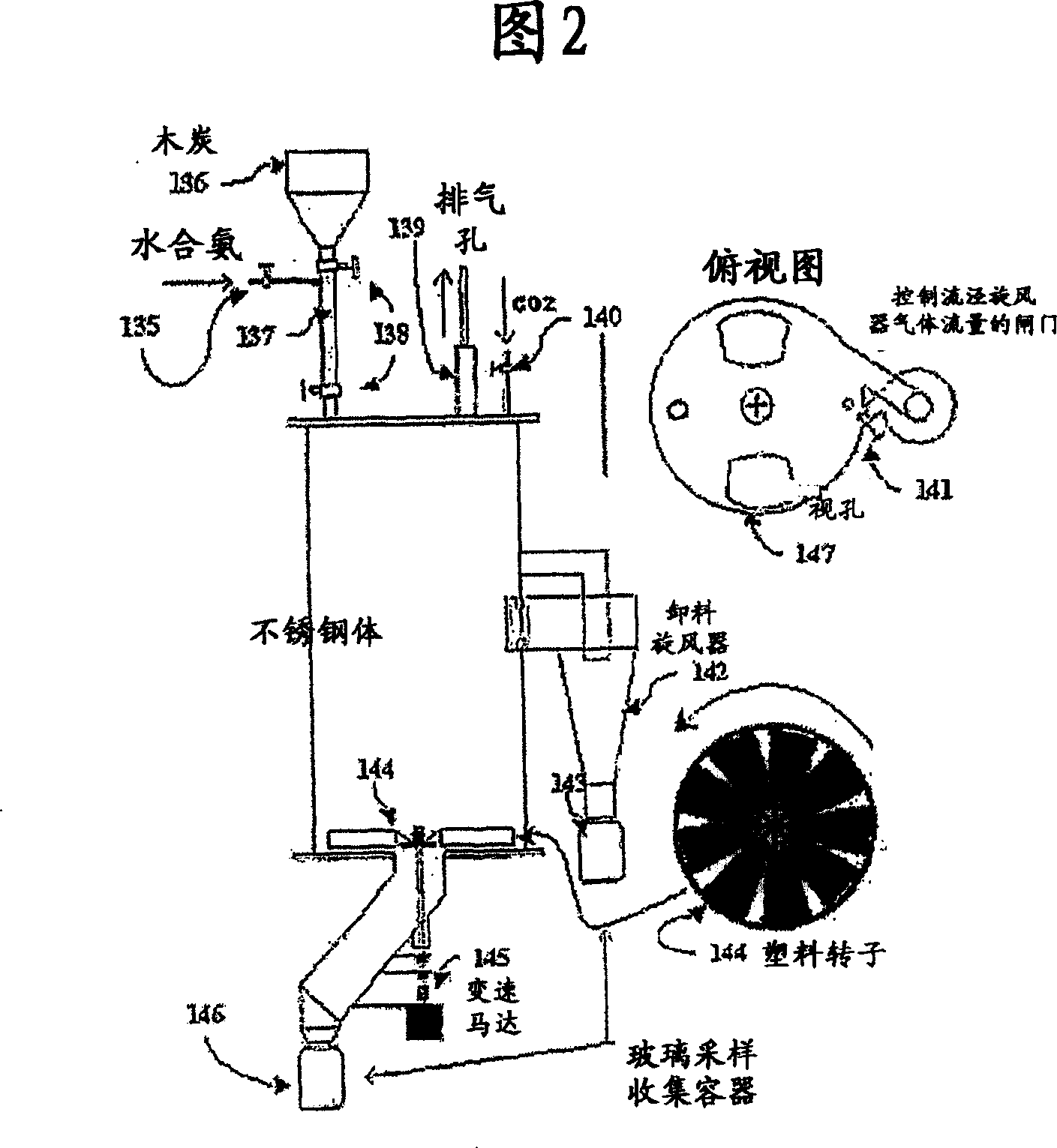

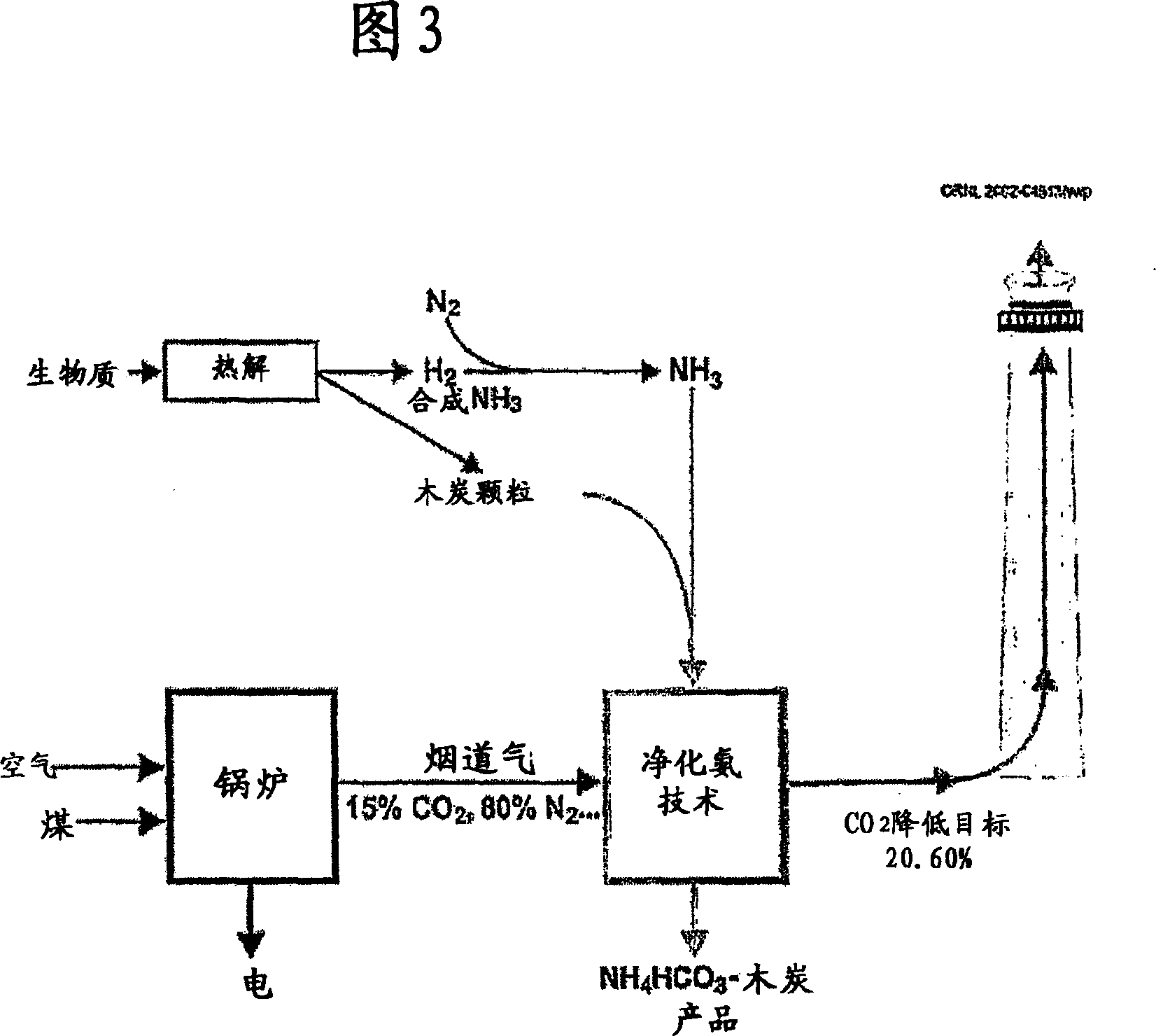

Production and use of a soil amendment made by the combined production of hydrogen, sequestered carbon and utilizing off gases containing carbon dioxide

InactiveCN1997590AHigh carbon contentReduce churn rateNitrous oxide captureMethane captureBiofuelCo product

This invention relates a series of steps to provide an economical production of a carbon based fertilizer and soil amendment made during the capture of greenhouse gases from the combustion of fossil and non fossil fuels. The invention uses biomass and other carbonaceous sources through pyrolytic conversion to gases and charcoal, to allow for the further production of co-products, such as hydrogen and ammonia. The invention also relates to the combination of hydrated ammonia, combustion flue gas exhaust, and charcoal, provide for the conversion of the charcoal into a valued added soil amendment to return essential trace minerals and plant nutrients to the soil. The ability to produce a large volume carbon co-product while removing mandated emissions and producing renewable based hydrogen provides an economic gain to a large number small and large businesses and increase the chance of achieving significant reductions in greenhouse gas emissions.

Owner:丹尼·马歇尔·戴 +1

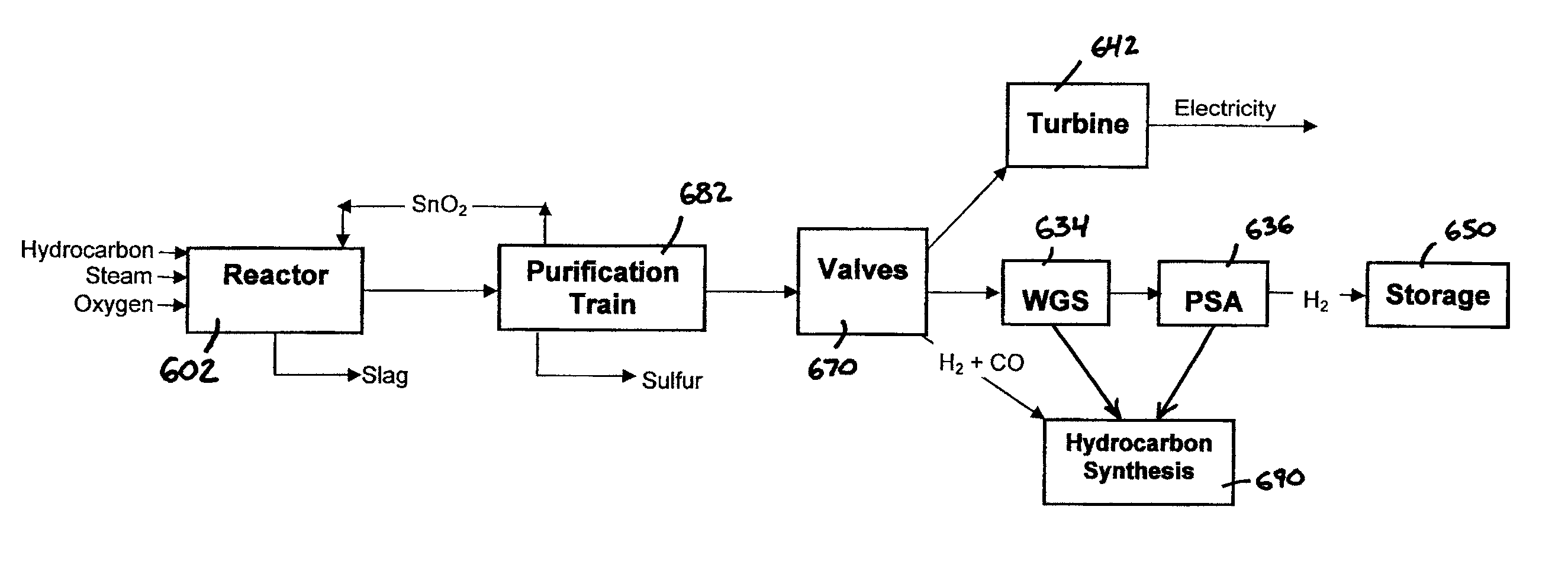

Method for the gasification of hydrocarbon feedstocks

InactiveUS20070256361A1Lower cost of capitalReduce productionBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasAmmonia

A method for the gasification of a hydrocarbon-bearing feedstock to produce useful co-products such as high-value hydrocarbon fuels, pure H2, electricity, and / or ammonia. The method advantageously gasifies the carbon in the feedstock to carbon monoxide (CO) without producing large quantities of carbon dioxide (CO2). Supplemental hydrogen (H2) is also produced by reacting steam (H2O) with a metal. The method can advantageously produce two separate syngas streams, one that is CO-rich and one that is H2-rich.

Owner:ALCHEMIX CORP

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20110262984A1Increased ethanol productionImproved co-productsPretreatment with acid reacting compoundsBiofuelsCelluloseCo product

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

Method for conditioning and processing whole or thin stillage to aid in the separation of and recover protien and oil fractions

ActiveUS20120125859A1Lower energy requirementsFatty/oily/floating substances removal devicesSpecific water treatment objectivesProcedure AgentsProcess engineering

The invention provides a method and apparatus for reducing the energy needed to process stillage in an ethanol refining operation. The method involves adding to stillage an effective amount of at least one processing aid. The flocculant induces the separation of insoluble material that would otherwise remain suspended in water but which impose a high shear energy cost on the refining processes. This allows for the removal of insoluble material that would otherwise be overlooked but which increase energy costs. This allows for more efficient and effective separation and recovery of insoluble fractions of the concentrated thin stillage that would otherwise be overlooked and lost in the process. Loss of these valued fractions as a result of traditional processing techniques and those requiring extensive additional energy input results in the loss of high value co-products to low revenue process streams. This allows stillage to be processed more rapidly with a lower energy cost and improved co-product recovery economics.

Owner:ECOLAB USA INC

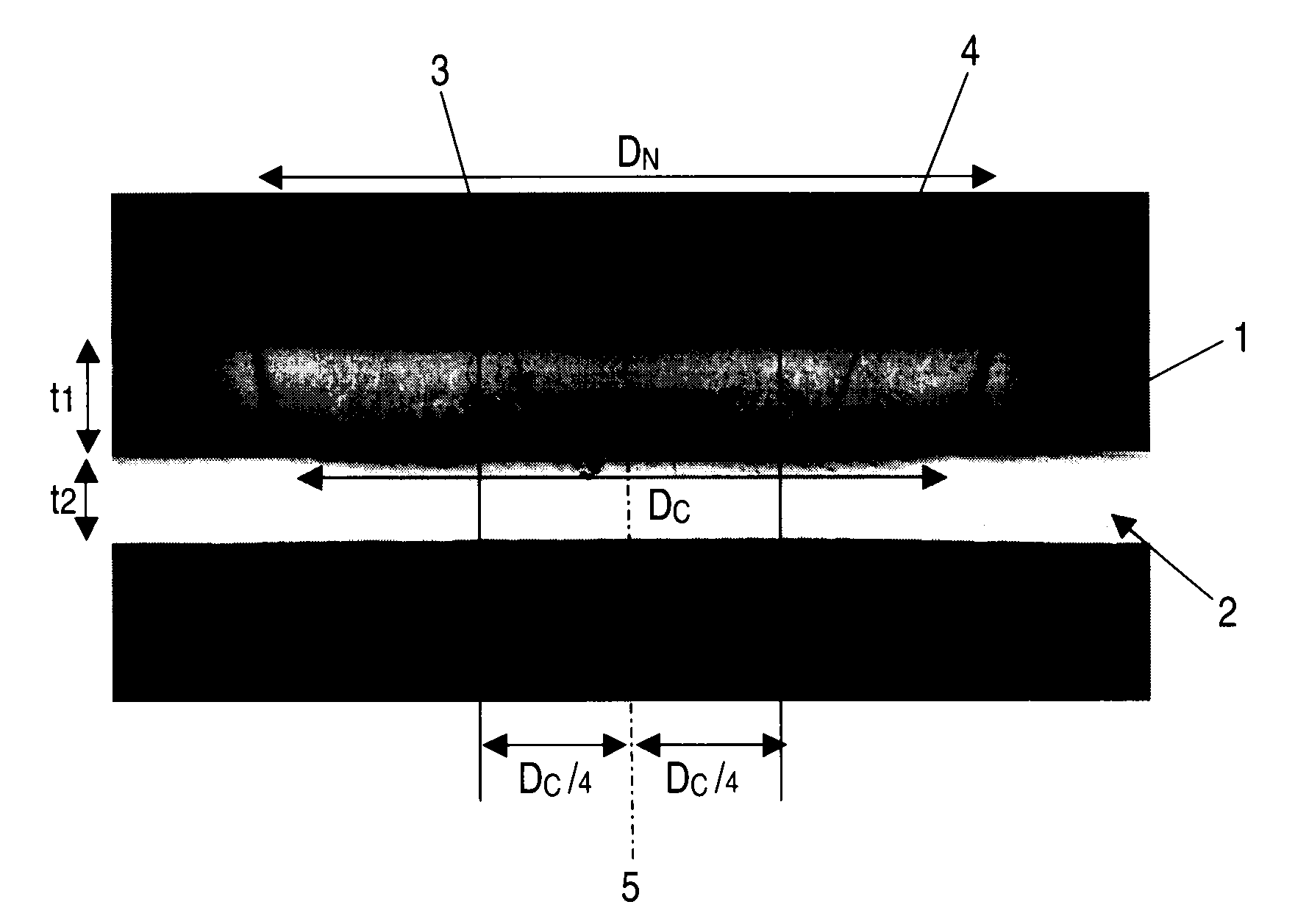

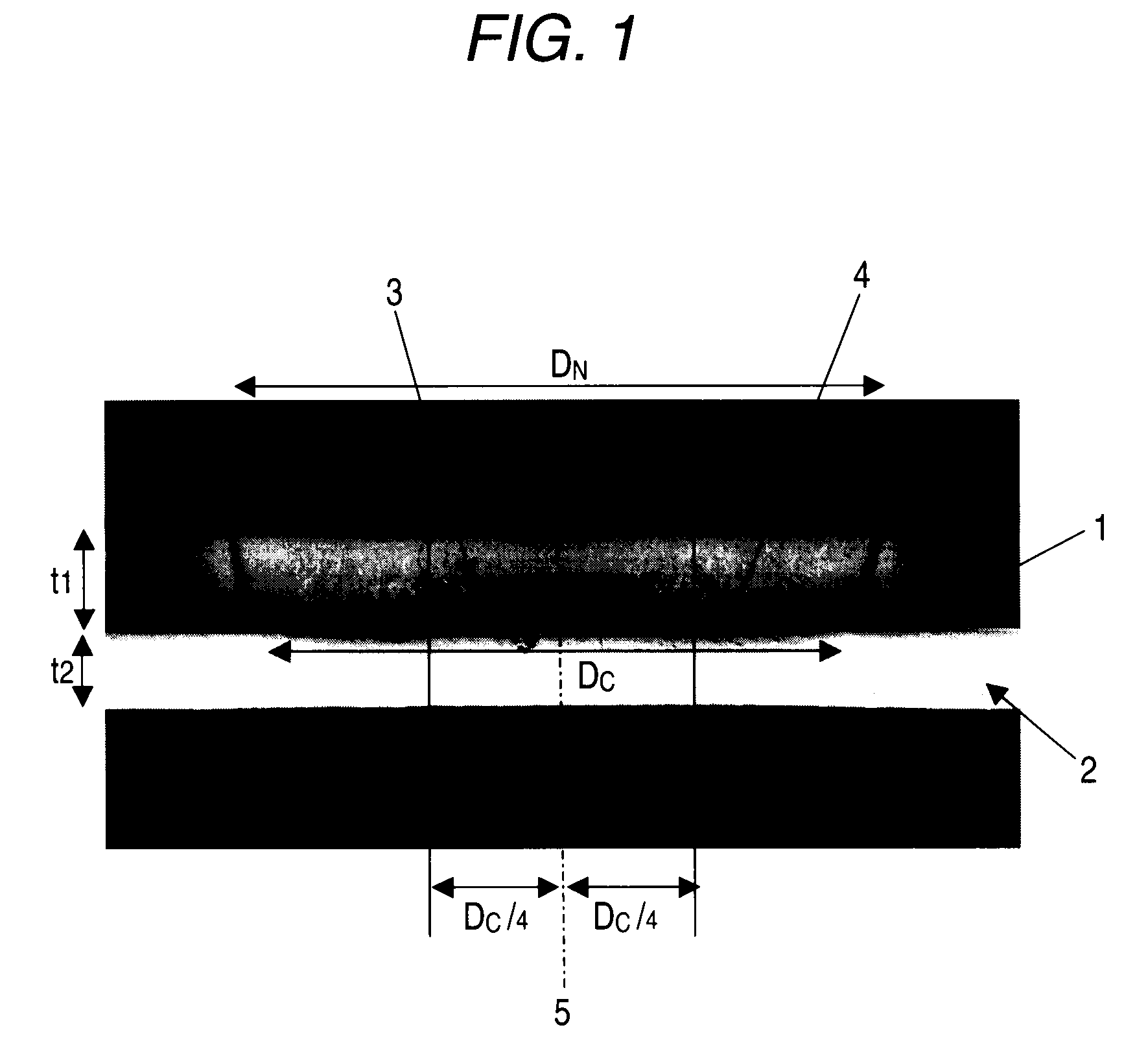

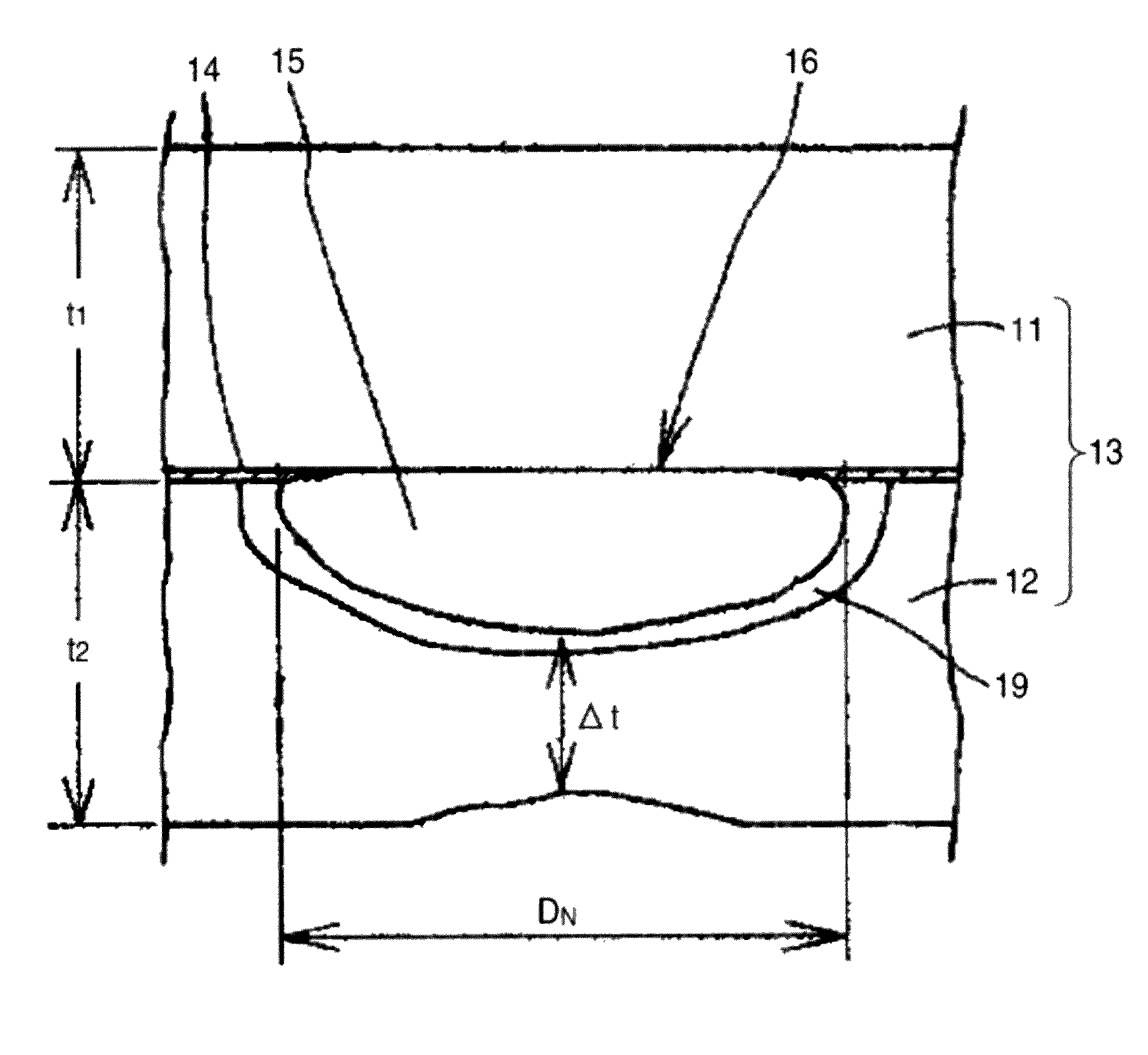

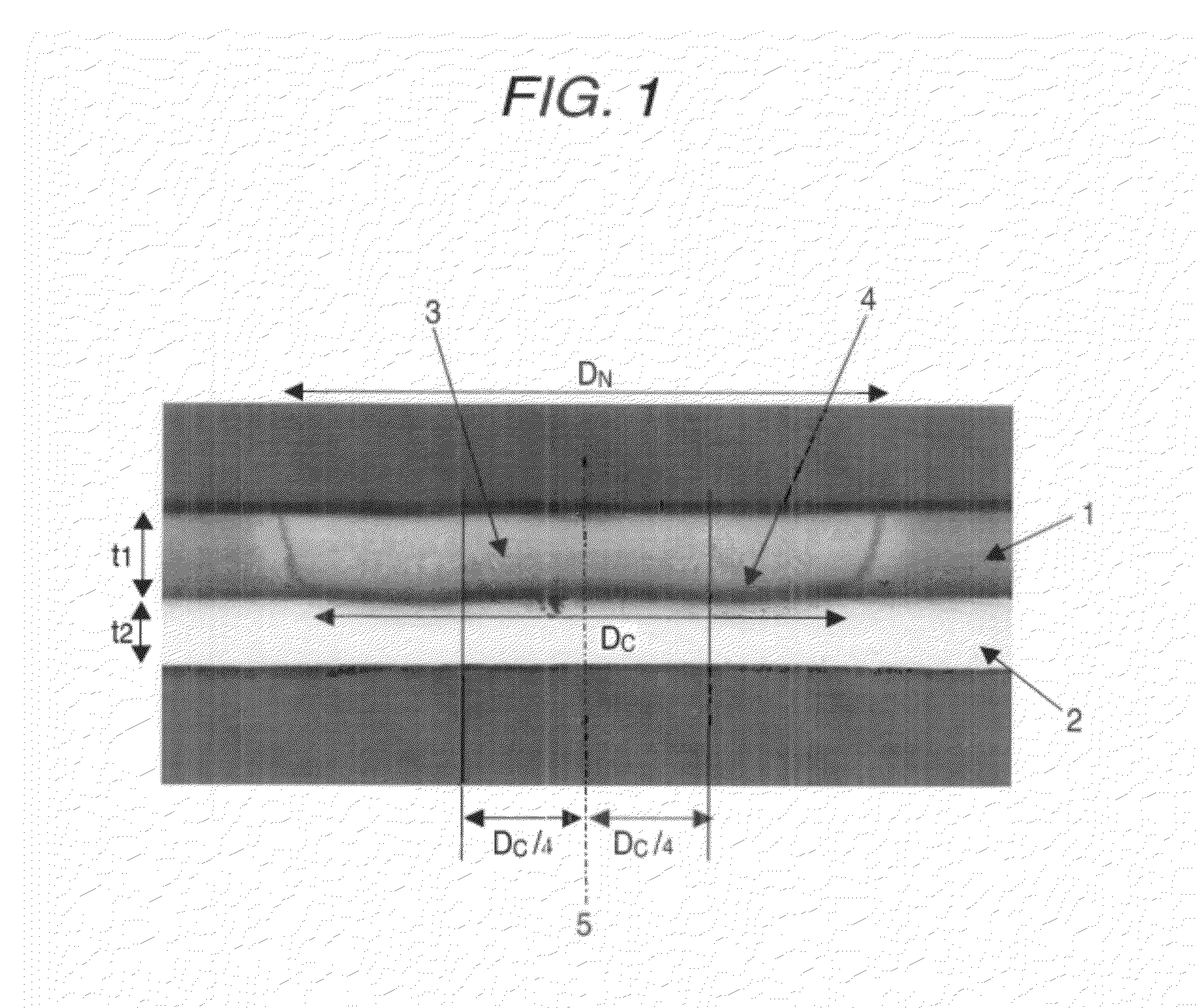

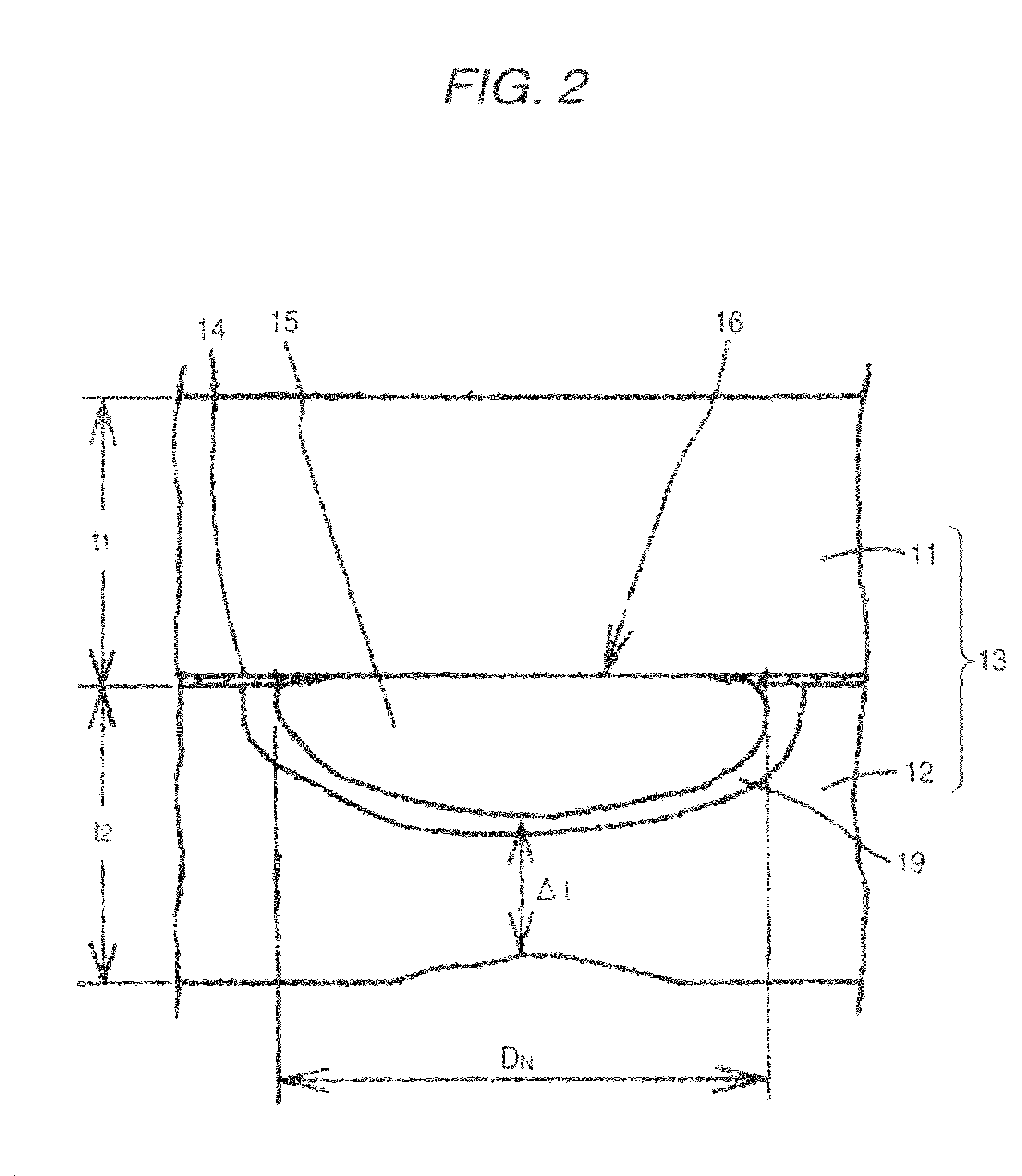

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

InactiveUS20090011269A1High bonding strengthLow costOhmic-resistance electrodesOther manufacturing equipments/toolsReaction layerSpot welding

To provide a joint product of a steel product and an aluminum material, and a spot welding method for the joint product, ensuring that spot welding with high bonding strength can be performed. In one embodiment, a steel product 1 having a sheet thickness t1 of 0.3 to 3.0 mm and an aluminum material 2 having a sheet thickness t2 of 0.5 to 4.0 mm are joined together by spot welding to form a joint product of a steel product and an aluminum produce. In this joint product, the nugget area in the joint part is from 20×t20.5 to 100×t20.5 mm2, the area of a portion where the thickness of the interface reaction layer is from 0.5 to 3 μm is 10×t20.5 mm2 or more, and the difference between the interface reaction layer thickness at the joint part center and the interface reaction layer thickness at a point distant from the joint part center by a distance of one-fourth of the joint diameter Dc is 5 μm or less. According to this construction, there can be provided a dissimilar material joint product with excellent bonding strength, which can be formed by an existing spot welding apparatus at a low cost without newly using other materials such as clad material or without newly adding a separate step, and a spot welding method for the dissimilar material joint product.

Owner:KOBE STEEL LTD

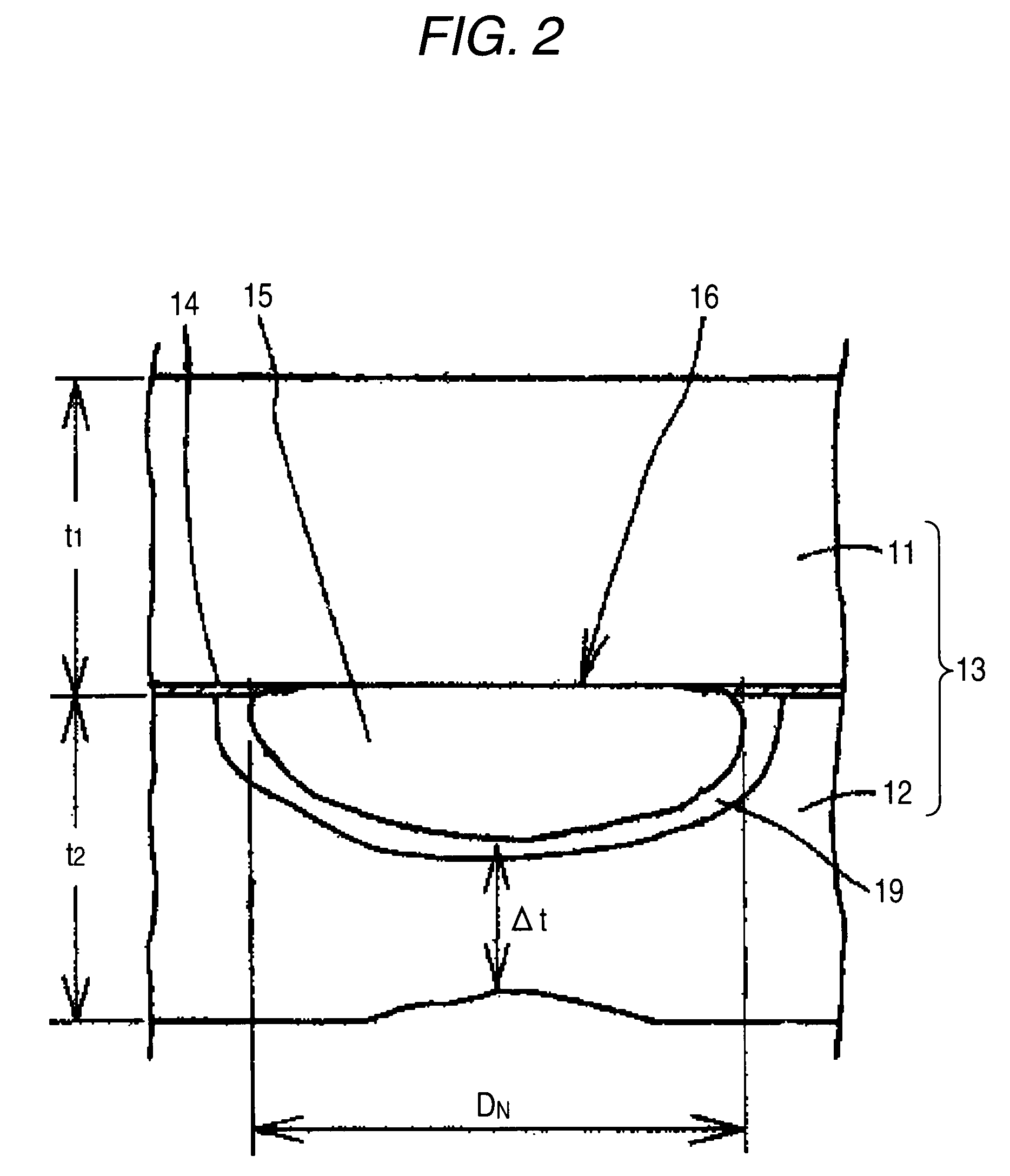

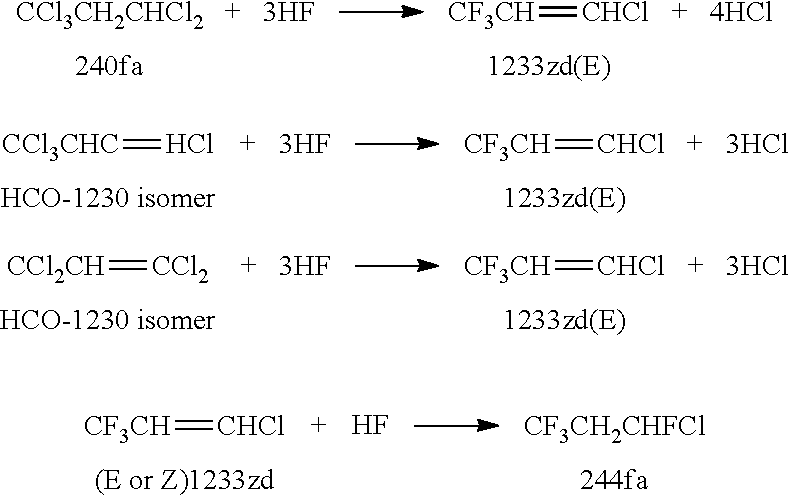

Integrated Process to Co-Produce Trans-1-Chloro-3,3,3-Trifluoropropene and Trans-1,3,3,3-Tetrafluoropropene

ActiveUS20110245549A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offDistillation1,3,3,3-Tetrafluoropropene

The disclosed integrated manufacturing process includes a combined liquid phase reaction and purification operation which directly produces trans-1-chloro-3,3,3-trifluoropropene and 3-chloro-1,1,1,3-tetrafluoropropane which is a precursor to the manufacture of trans-1,3,3,3-tetrafluoropropene. The mixture of co-products is easily separated by conventional distillation and 3-chloro-1,1,1,3-tetrafluoropropane is then dehydrochlorinated to produce trans-1,3,3,3-tetrafluoropropene by contacting in the liquid phase with a caustic solution or in the vapor phase using a dehydrochlorination catalyst.

Owner:HONEYWELL INT INC

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

ActiveUS8487206B2High bonding strengthLow costOther manufacturing equipments/toolsVehicle componentsReaction layerSpot welding

Provided is a joint product of a steel product and an aluminum material, the joint product being formed by joining the steel product having a sheet thickness t1 of 0.3 to 3.0 mm with the aluminum material having a sheet thickness t2 of 0.5 to 4.0 mm by spot welding, wherein a nugget area in a joint part is from 20×t20.5 to 100×t20.5 mm2, an area of a portion where a thickness of an interface reaction layer is from 0.5 to 3 μm is 10×t20.5 mm2 or more, and a difference between the thickness of the interface reaction layer at a joint part center and the thickness of the interface reaction layer at a point distant from the joint part center by a distance of one-fourth of a joint diameter is 5 μm or less, and wherein the aluminum material is pure aluminum or an aluminum alloy material.

Owner:KOBE STEEL LTD

Corn fractionation method

InactiveUS7820418B2Good amino acid balanceAvoid fermentationMicroorganismsBiofuelsFractionationFermentable sugar

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

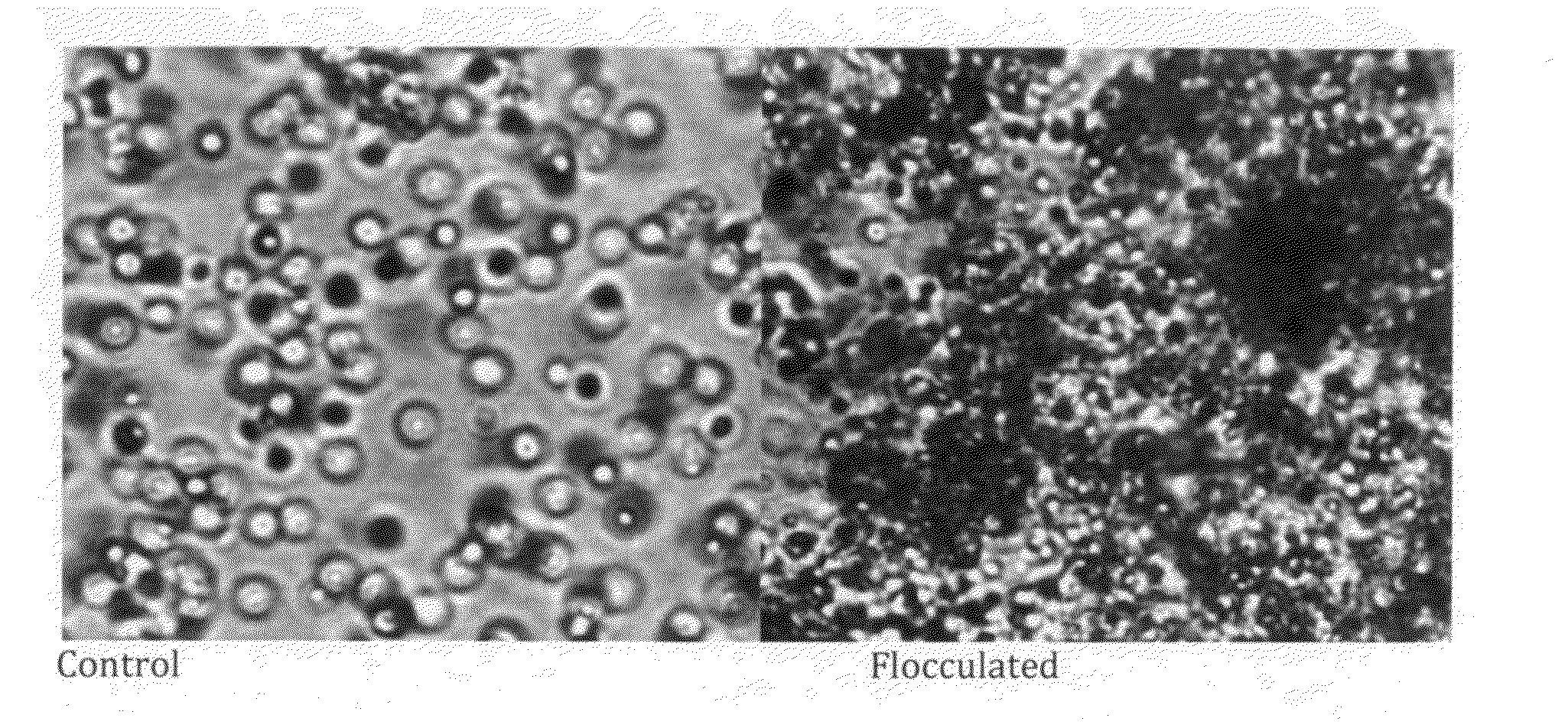

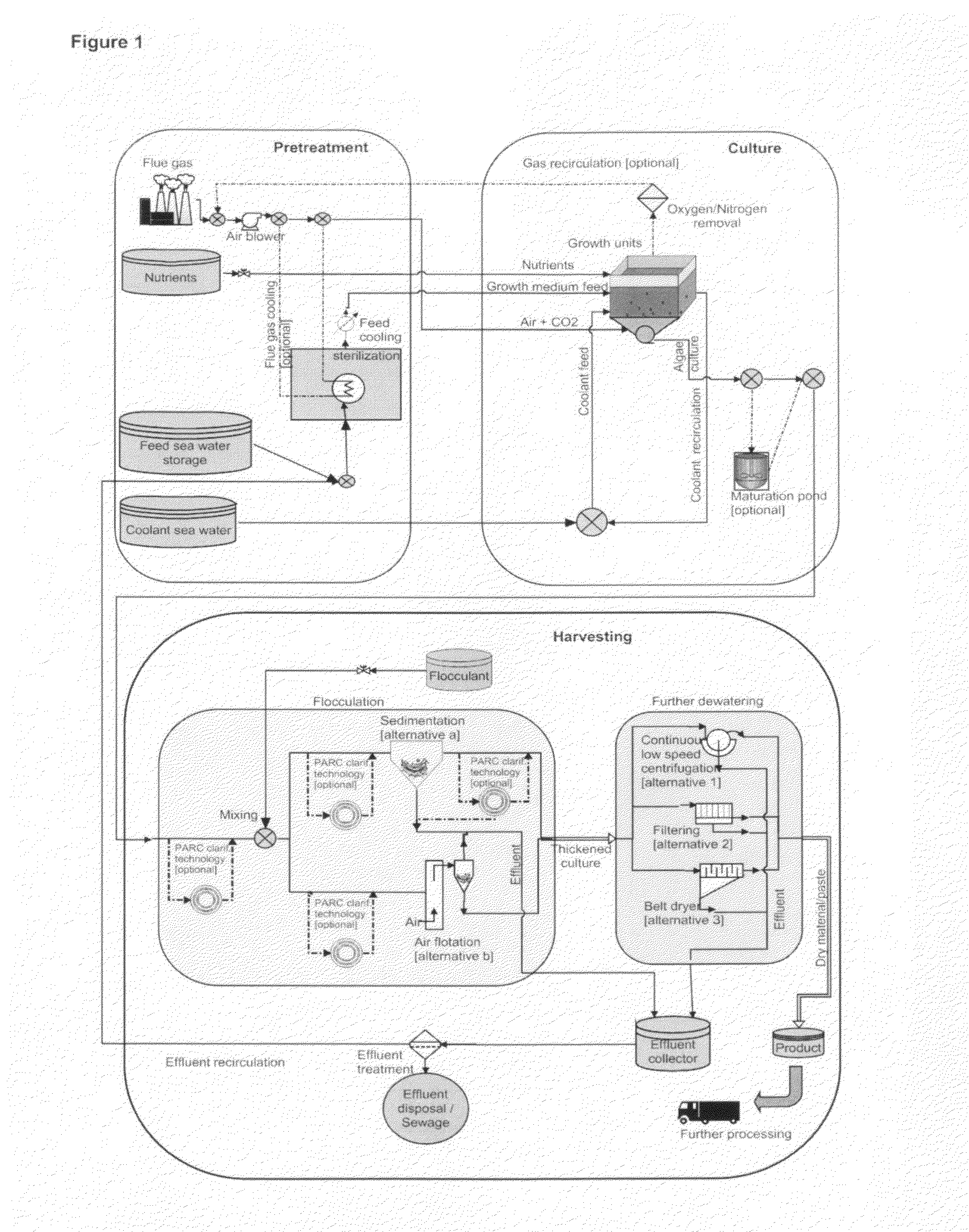

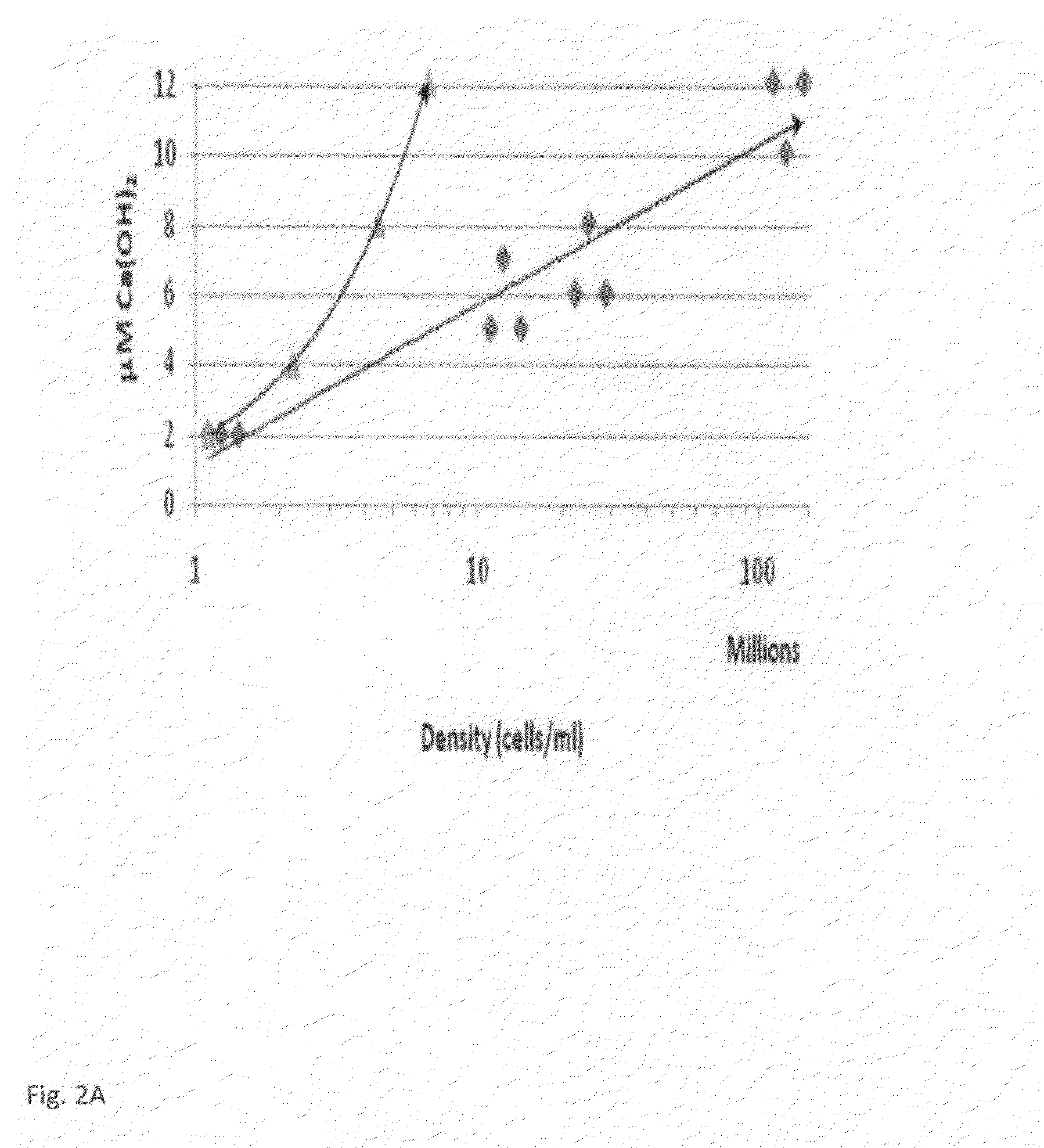

Method and system for efficient harvesting of microalgae and cyanobacteria

The high-speed centrifugation heretofore required for harvesting micro algae and cyanobacteria cultured for biofuels and other co-products is a major cost constraint. Mixing algae / cyanobacteria at high-density culture with far less alkali than previously assumed is sufficient to flocculate the cells. The amount of flocculant required is a function of the logarithm of cell density, and is not a linear function of cell density as had been thought. The least expensive alkali treatments are with slaked limestone or dolomite (calcium hydroxide and magnesium hydroxides). Further water can be removed from the floc by sedimentation, low speed centrifugation, dissolved air flotation or filtration, prior to further processing to separate oil from valuable co-products.

Owner:TRANSALGAE ISRAEL

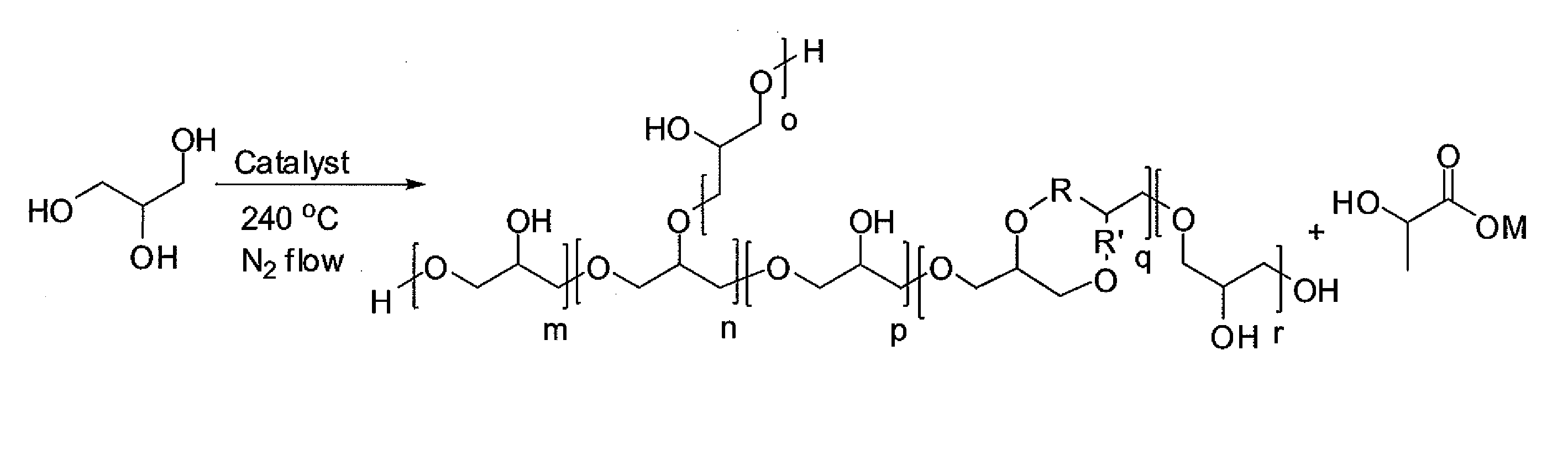

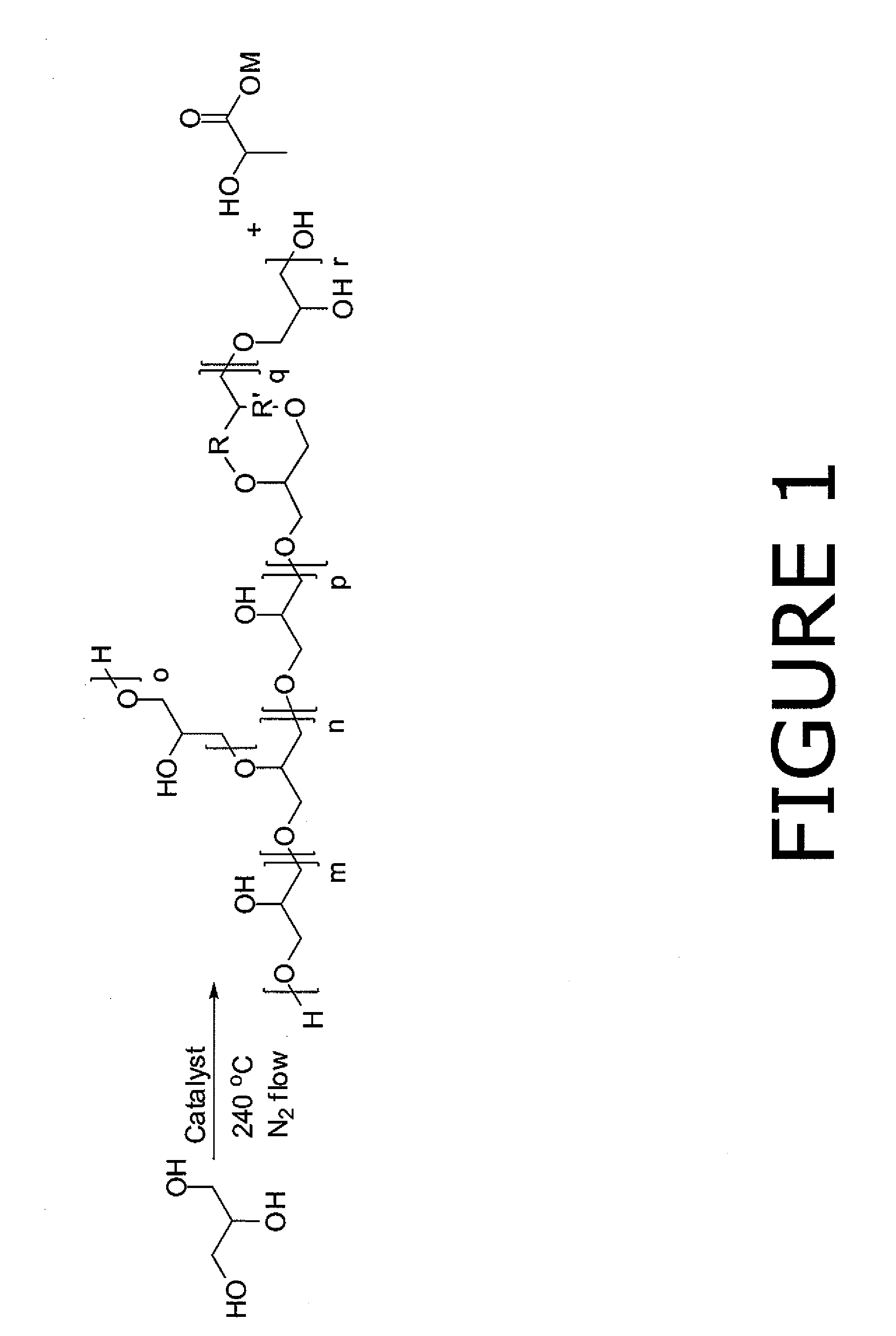

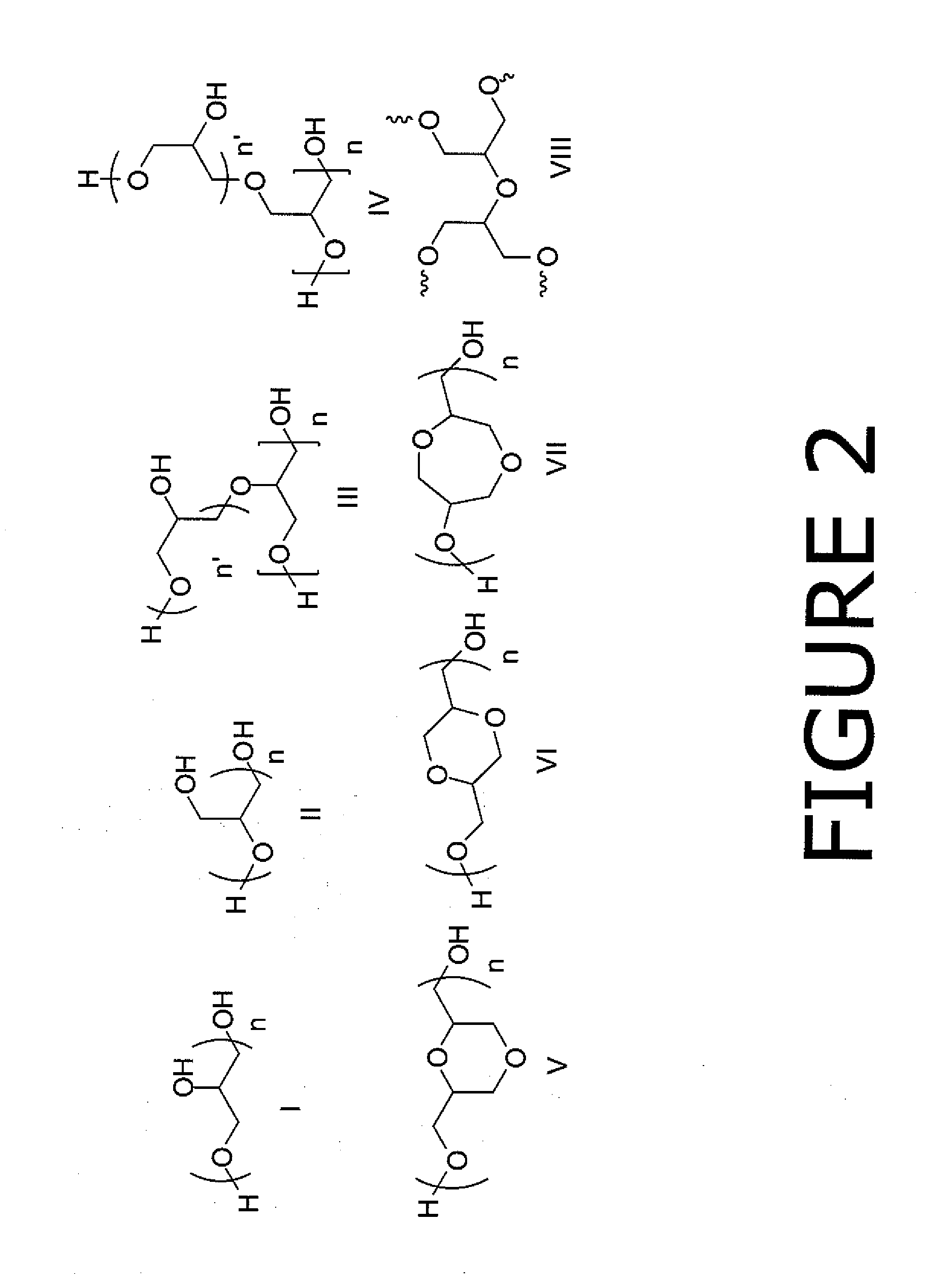

Production and composition of glycerol based polyols

ActiveUS20110092743A1Protection is in progressHigh proportionOrganic compound preparationCarboxylic acid salt preparationDistillationGlycerol

The invention provides a method of efficiently producing branched, cyclic glycerol-based polyols with a co-product as anti-biodegrading agent from inexpensive readily available glycerol monomer. The method involves polymerizing glycerol or glycerol with at least another monomer to multiple other monomers in the presence of particular amount of a strong base as the catalyst under a particular distillation environment. The polyol produced by the inventive method is beneficial of reducing scales in Bayer liquid for aluminum production process and improving brightness of coated paper substrates without greening effect.

Owner:ECOLAB USA INC

Recovery of desired co-products from fermentation stillage streams

ActiveUS8236977B2Reduce pressureFatty oils/acids recovery from wasteWater/sewage treatment by centrifugal separationCo productChemistry

Processes and methods of recovering desired products from fermentation stillage are presented, including processes and methods of recovering lipids and aqueous materials.

Owner:EDENIQ INC

System and method for isolation of gluten as a co-product of ethanol production

The present invention is a method for protein isolation as a co-product of alcohol production. The method includes receiving grain product at a holding receptacle, the grain product being at least one of whole stillage, dried distillers grain, and wet distillers grain. The method further includes directing the grain product from the holding receptacle over a plurality of screens, thereby allowing a fiber-containing portion of the grain product to be collected on the plurality of screens and further allowing a protein-containing portion of the grain product and an oil-containing portion of the grain product to pass through the plurality of screens. The method further includes directing the protein-containing portion and the oil-containing portion over a finishing screen, thereby allowing remaining fiber fractions from the protein-containing portion and the oil-containing portion to be collected on the finishing screen and further allowing the protein-containing portion and the oil-containing portion to pass through the finishing screen. Further, the method includes centrifuging the protein-containing portion and the oil-containing portion for isolating a protein fraction, an oil fraction, and a water and minerals fraction.

Owner:VALICOR SEPARATION TECH

Processes Using Antibiotic Alternatives In Bioethanol Production

ActiveUS20110230394A1Increase productionLow and no adverse environmental impactAntibacterial agentsBiocideEthanol yieldAntibacterial peptide

Methods for controlling the growth of bacteria in ethanol fermentation systems with antibiotic alternatives, which can be nonoxidizing biocides, stabilized oxidizers, or any combinations thereof, are described. As an option, a process or composition of the present invention can include one or more polycyclic antibacterial peptides. The methods can provide improvements, such as increased ethanol yields with minimal carryover of biocide into co-products of the processes.

Owner:BUCKMAN LAB INT INC

Method for the gasification of moisture-containing hydrocarbon feedstocks

InactiveUS20070256360A1Lower cost of capitalRaise the ratioBioreactor/fermenter combinationsBiological substance pretreatmentsHydrogenAmmonia

A method for the gasification of a hydrocarbon feedstock that has a high moisture content to produce useful co-products such as high-value hydrocarbon fuels, pure H2, electricity, and / or ammonia. The method advantageously gasifies the carbon in the feedstock to carbon monoxide (CO) without producing large quantities of carbon dioxide (CO2). Supplemental hydrogen (H2) is co-produced by reacting steam (H2O) generated from the moisture in the hydrocarbon feedstock with a molten metal.

Owner:ALCHEMIX CORP

Process for combined preparation of p-xylene and low carbon olefin by methylation of toluene

The method of toluene methylating to produce p-xylene and co-product low carbon olefin is that one kind of catalyst is used in producing p-xylene in high selectivity while co-producing ethylene and propylene. During the production, toluene and methylated reagent are fed simultaneously and different operation conditions are adopted so as to reach the selectivity of p-xylene in p-xylene isomers as high as 85-95 %, the selectivity of ethylene and propylene in C1-C5 low carbon hydrocarbons as high as 70-85 %, and the regulation of the molecular ratio between p-xylene and ethylene in the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

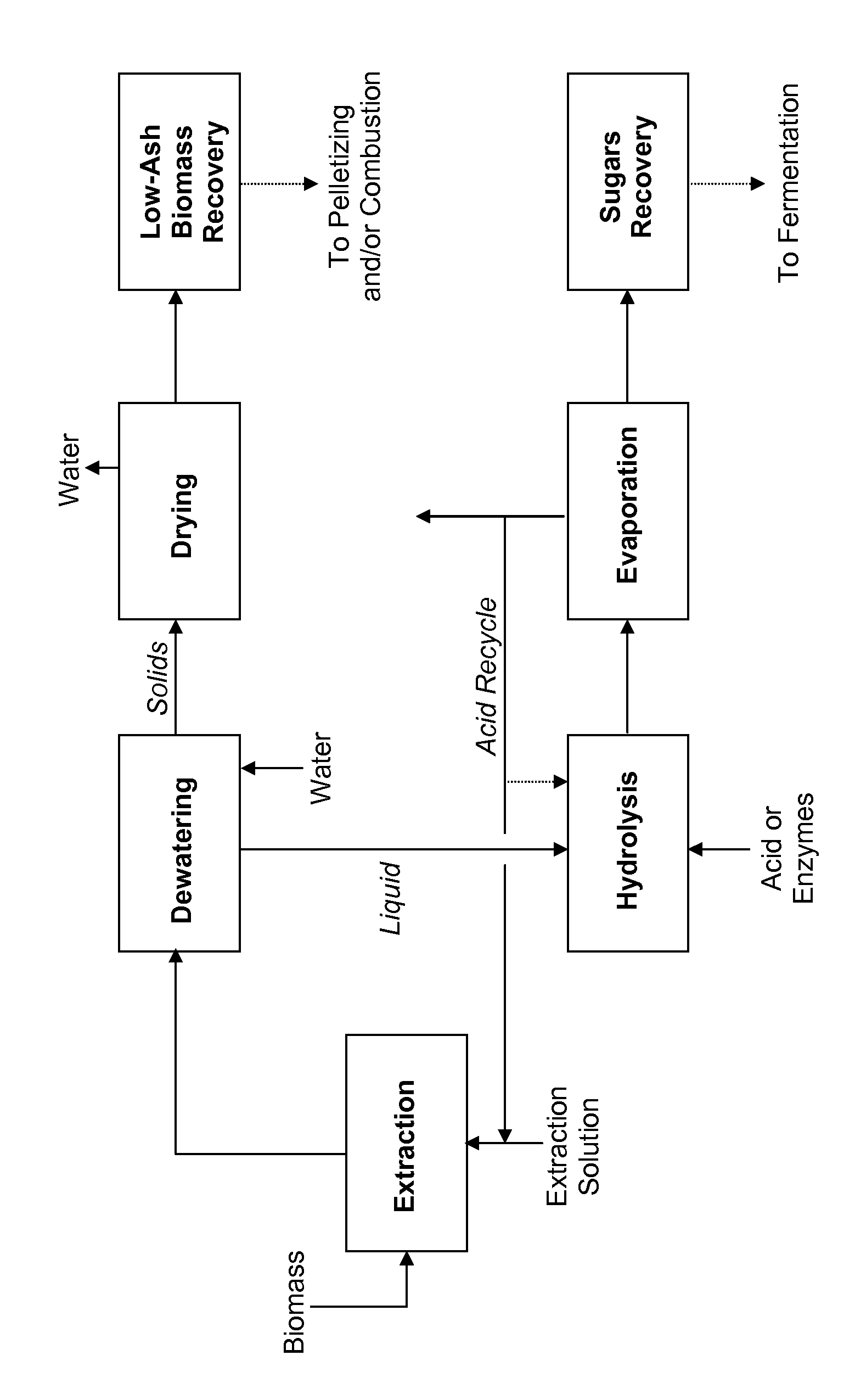

Processes for producing fermentable sugars and low-ash biomass for combustion or pellets

This invention provides processes and apparatus to convert biomass, including wood and agricultural residues, into low-ash biomass pellets for combustion, alone or in combination with another solid fuel. Some embodiments provide processes for producing hemicellulosic sugars and low-ash biomass from cellulosic biomass, comprising providing an aqueous extraction solution with acetic acid; extracting the feedstock to produce an extract liquor containing soluble ash, hemicellulosic oligomers, acetic acid, dissolved lignin, and cellulose-rich solids; dewatering and drying the cellulose-rich, lignin-rich solids to produce a low-ash biomass; hydrolyzing the hemicellulosic oligomers to produce fermentable hemicellulosic sugars, wherein additional acetic acid is generated; removing a vapor stream comprising vaporized acetic acid from the extract; recycling the vapor or its condensate to provide some starting acetic acid for the extraction solution; and recovering fermentable hemicellulosic sugars. The disclosed processes can produce clean power from biomass. Co-products include fermentation products such as ethanol, fertilizers, and lignin.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Two-stage high-temperature preheated steam gasifier

InactiveUS20110078951A1Undesired dilution is to minimumMinimization requirementsCombustible gas coke oven heatingGasifier mechanical detailsActivated carbonSyngas

A gasifier combines two reactors using externally generated preheated high temperature steam injection into the first reactor, where the heating demand for gasification is supplied by the sensible energy from the steam. The gasifier can produce a medium and higher LCV syngas. The first reactor is a fixed bed gasification section where the coarse feedstock is gasified, and the second reactor is an entrained-bed gasification section where the liquid and fine feedstock is gasified. Solid coarse feedstock is devolatilized in the first fixed bed reactor of the gasifier with high-temperature steam, and subsequently, in the second reactor subjected to a higher temperature sufficient to crack and destroy tars and oils. Activated carbon may be formed as co-product. The gasifier may be used with various solid and liquid feedstocks. The gasifier is capable of gasifying such different feedstocks simultaneously.

Owner:BOSON ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com