Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

665 results about "Parent material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parent material is the underlying geological material (generally bedrock or a superficial or drift deposit) in which soil horizons form. Soils typically inherit a great deal of structure and minerals from their parent material, and, as such, are often classified based upon their contents of consolidated or unconsolidated mineral material that has undergone some degree of physical or chemical weathering and the mode by which the materials were most recently transported.

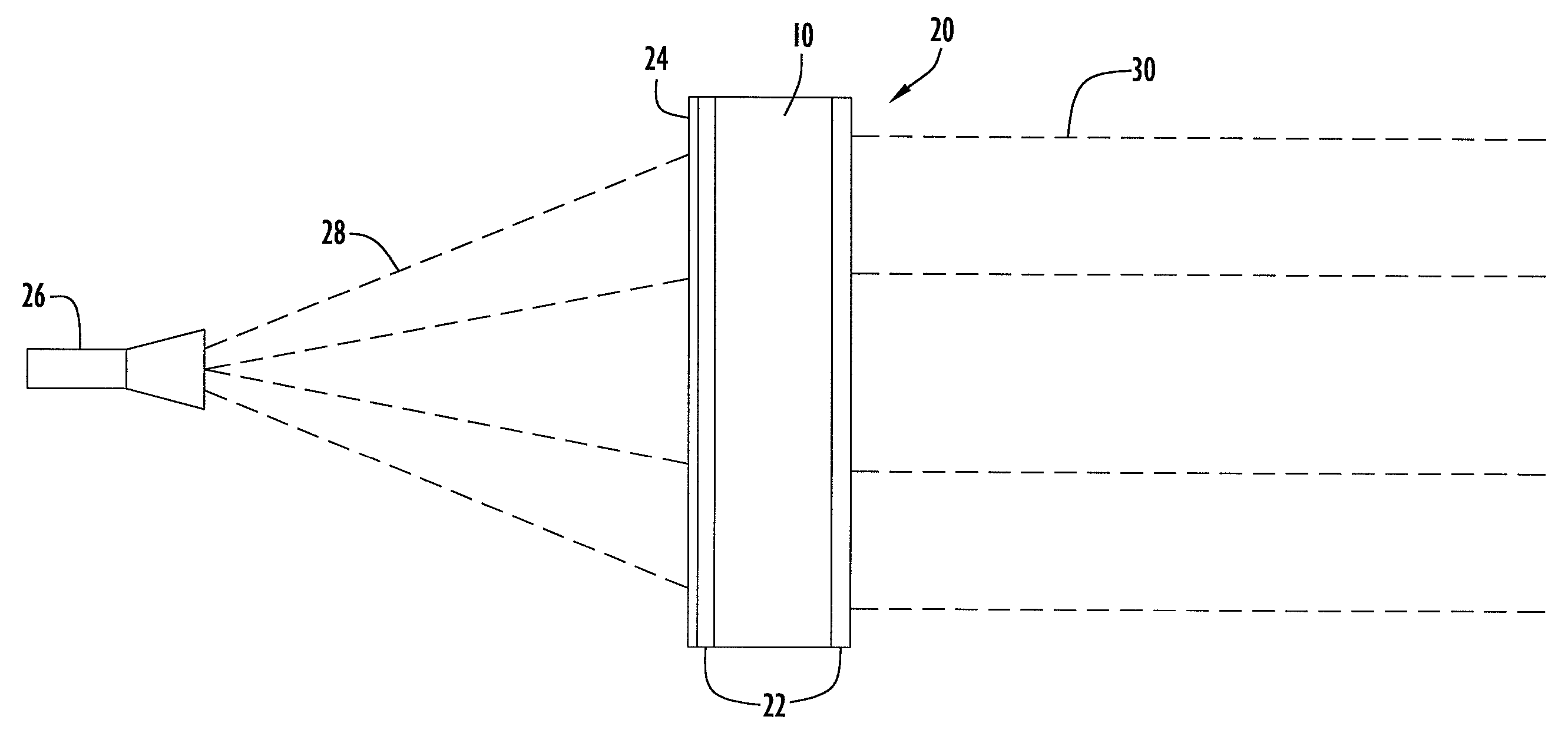

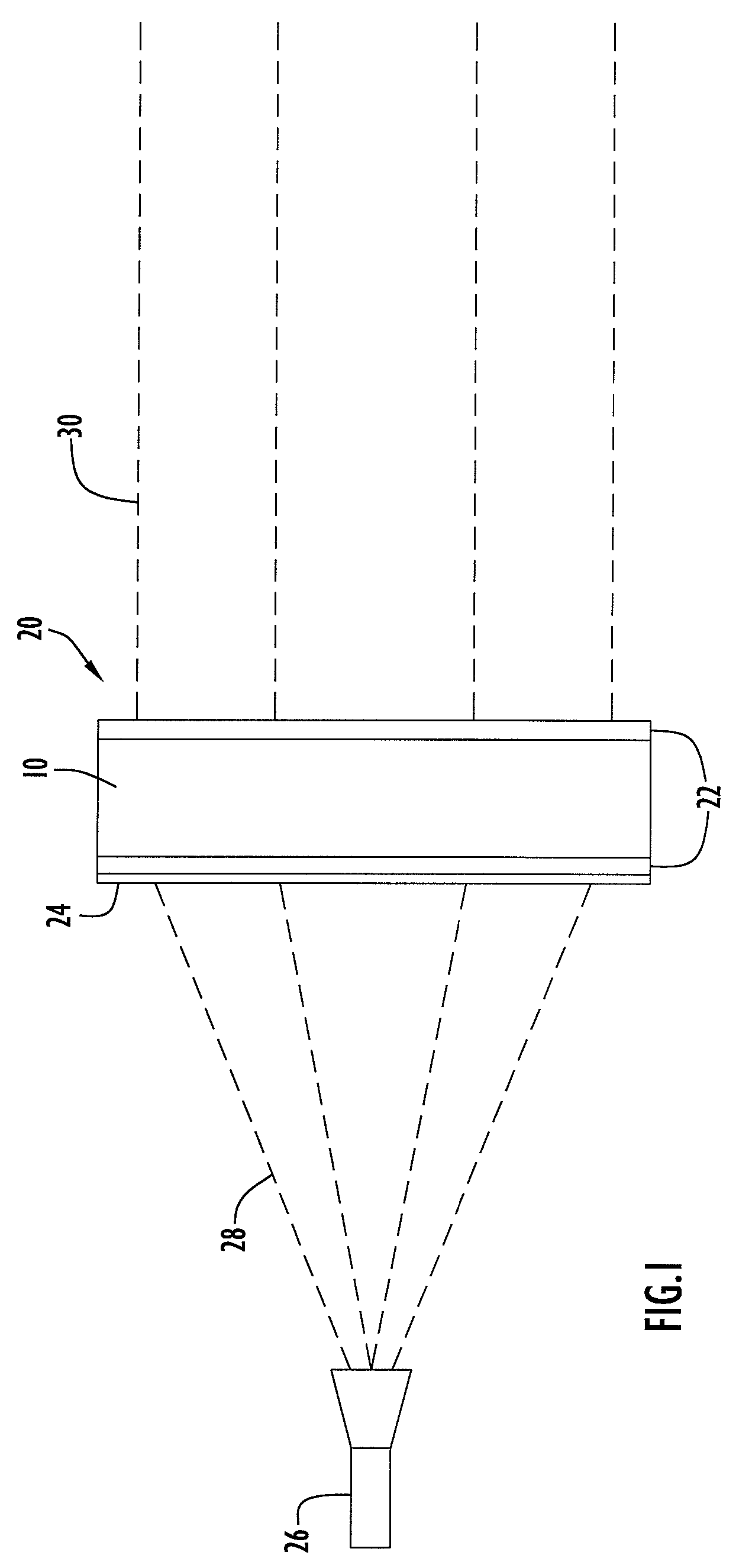

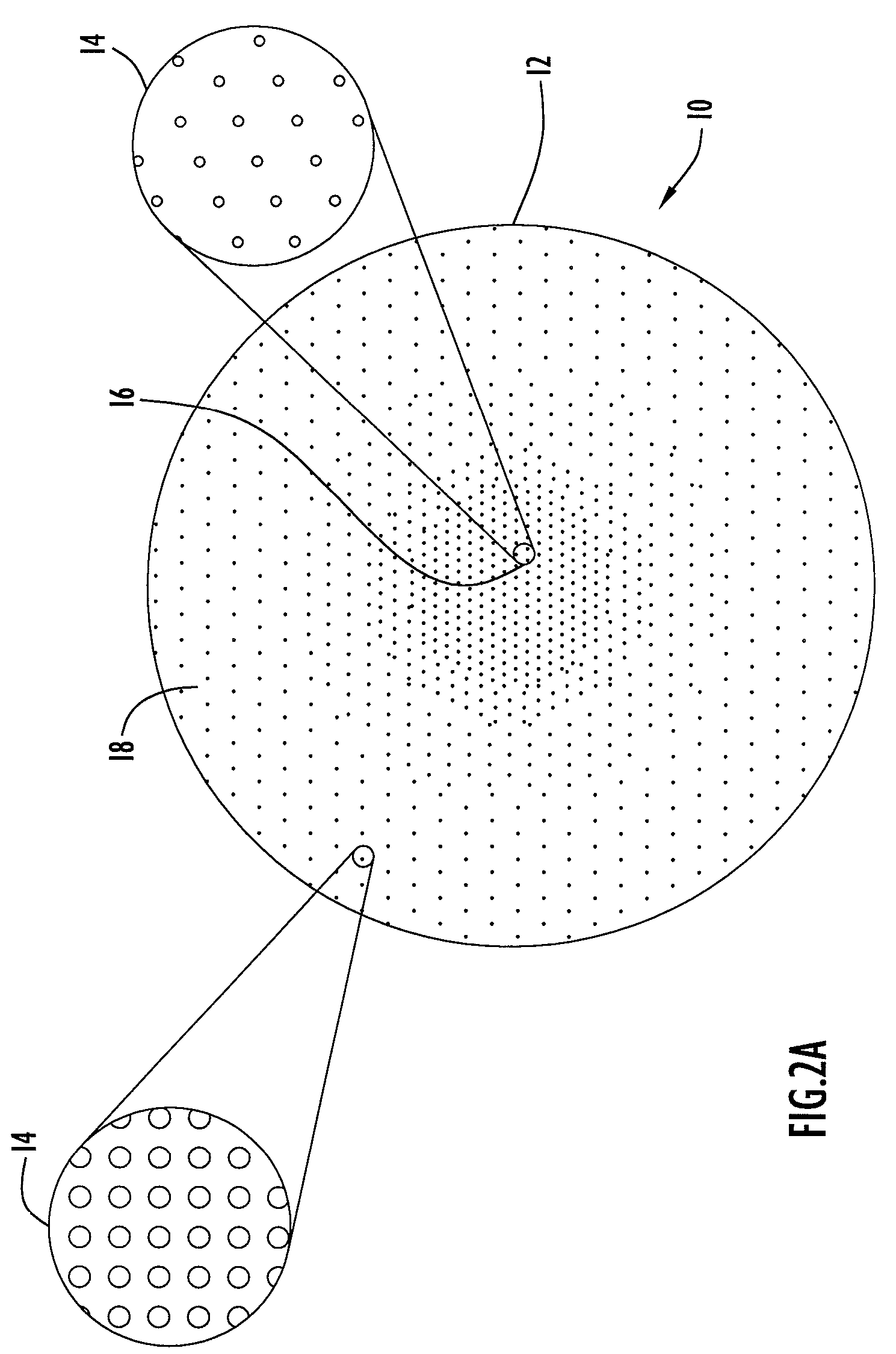

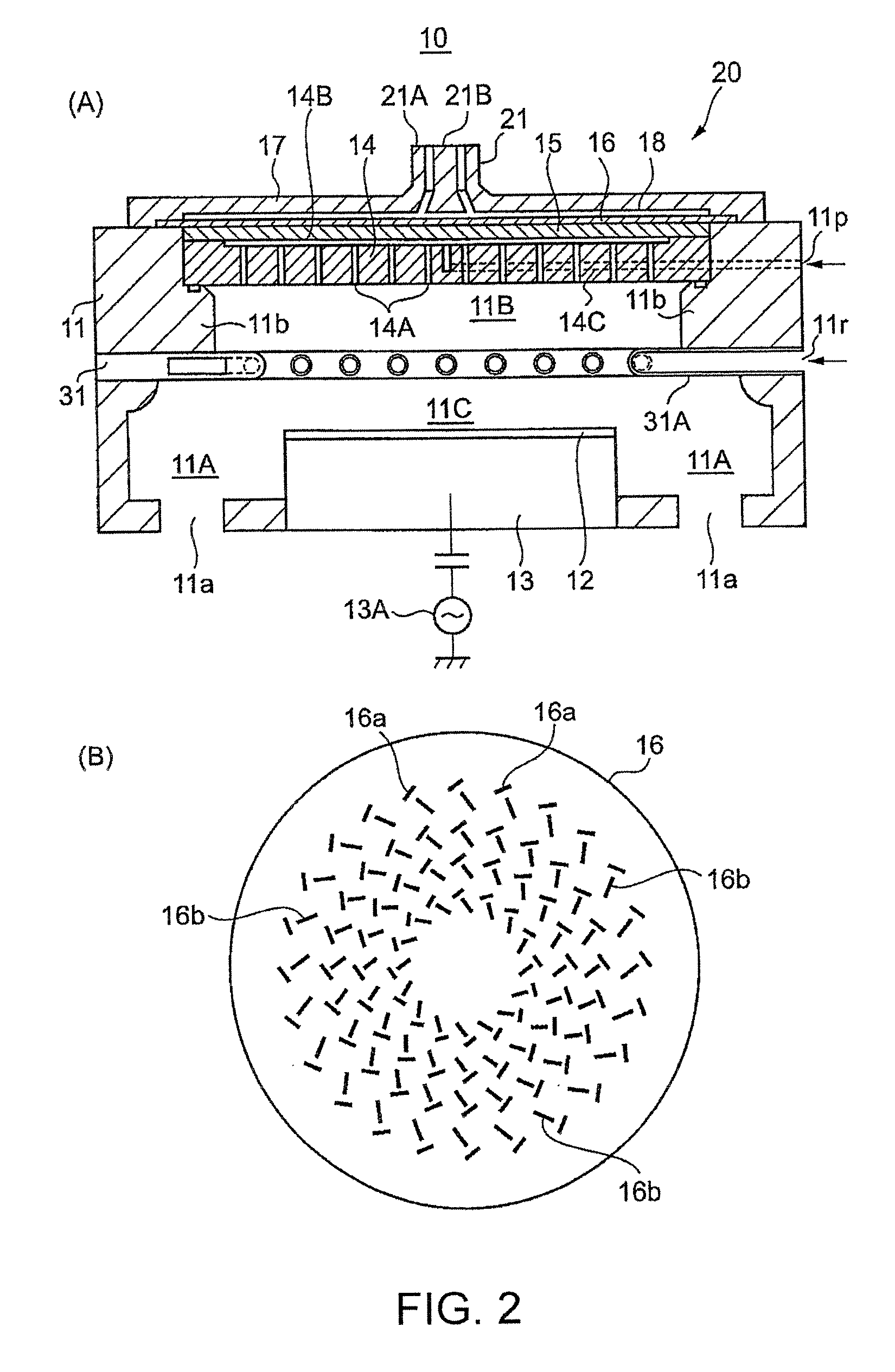

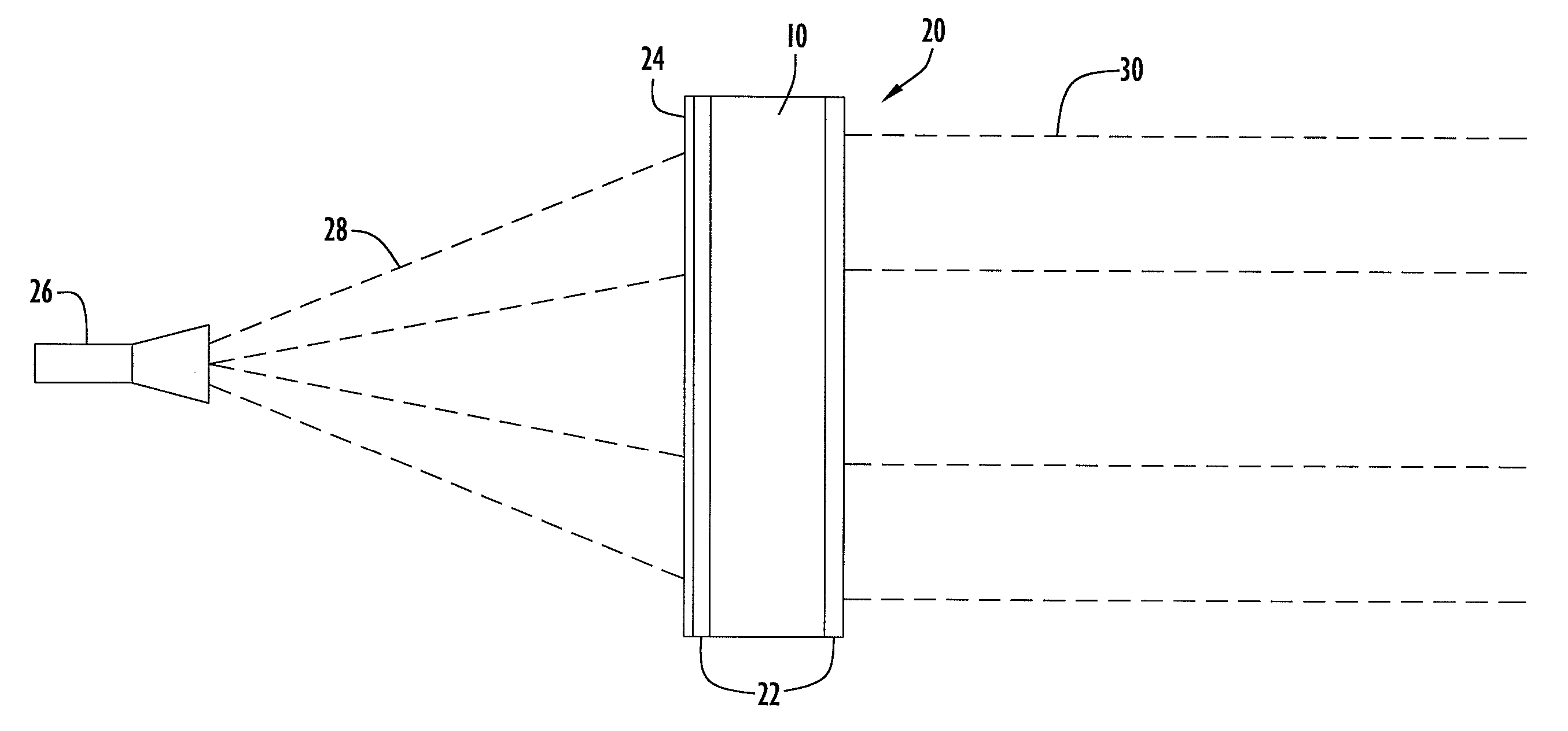

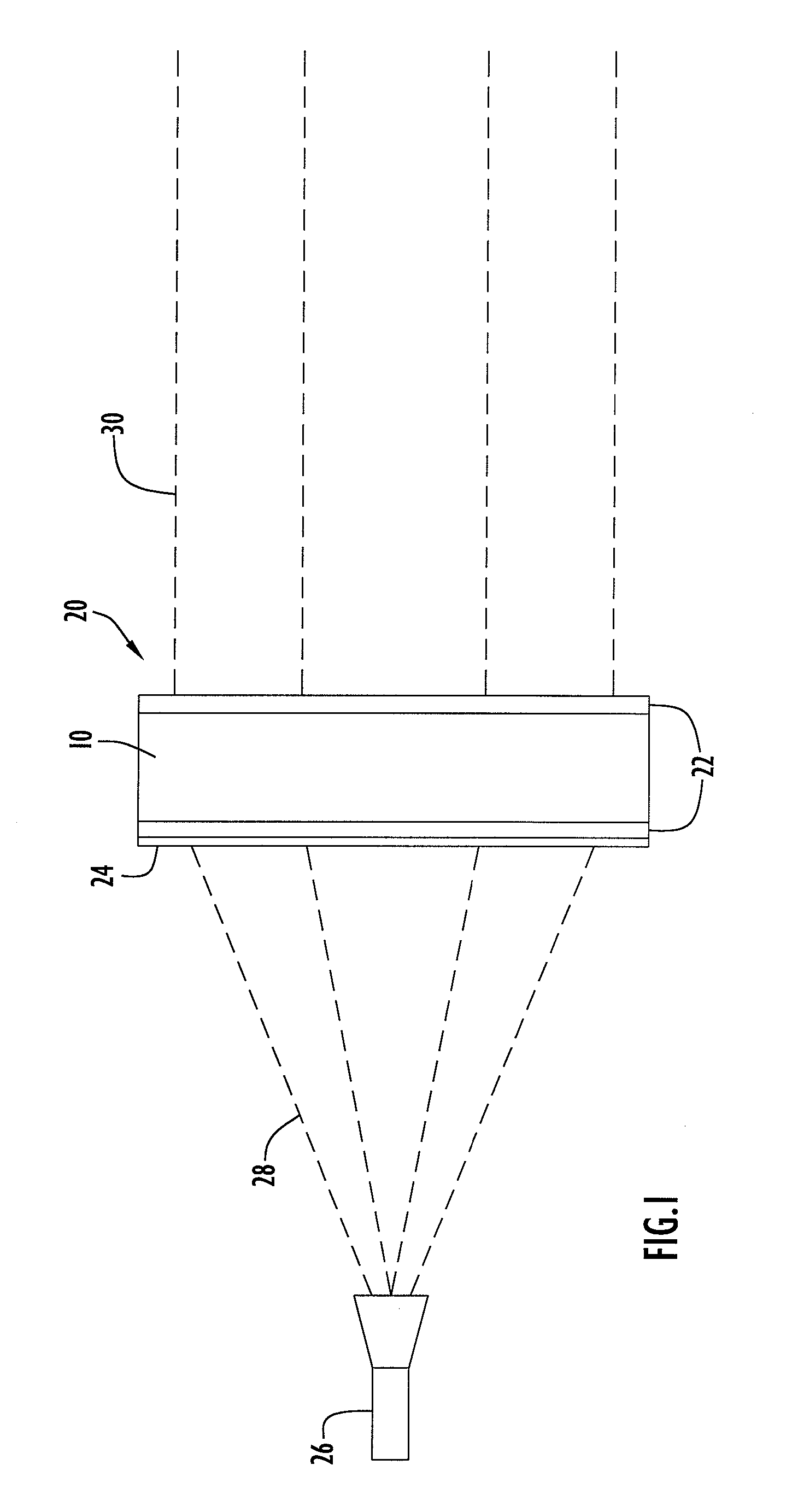

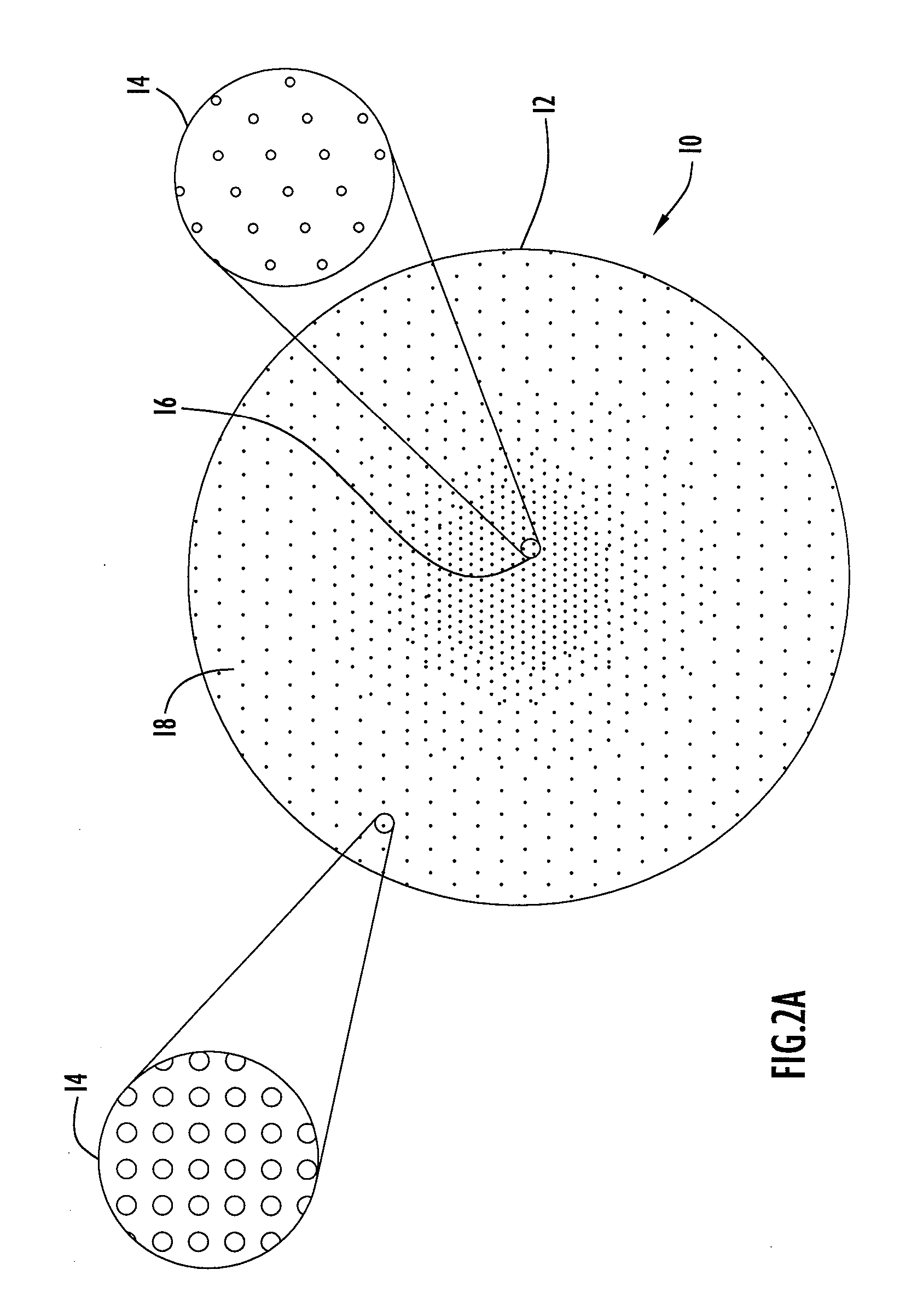

Radio frequency lens and method of suppressing side-lobes

ActiveUS7777690B2Weaken energyImproves Structural IntegrityAntennasPhotonic crystal structureCrystal structure

An RF lens according to the present invention embodiments collimates an RF beam by refracting the beam into a beam profile that is diffraction-limited. The lens is constructed of a lightweight mechanical arrangement of two or more materials, where the materials are arranged to form a photonic crystal structure (e.g., a series of holes defined within a parent material). The lens includes impedance matching layers, while an absorptive or apodizing mask is applied to the lens to create a specific energy profile across the lens. The impedance matching layers and apodizing mask similarly include a photonic crystal structure. The energy profile function across the lens aperture is continuous, while the derivatives of the energy distribution function are similarly continuous. This lens arrangement produces a substantial reduction in the amount of energy that is transmitted in the side-lobes of an RF system.

Owner:HARRIS CORP

Method for repairing defect in tungsten copper-copper integral electric contact material

InactiveCN101635210AImprove mechanical propertiesLow costElectric switchesHigh energy laser beamVolumetric Mass Density

The invention provides a method for repairing a defect in a tungsten copper-copper integral electric contact material. The method comprises the following steps: firstly, eliminating impurities in the part of the defect; secondly, weighting metal powders containing the materials identical to that of the electric contact in the part of the defect, wherein the mass of the metal powders is 1.2 times the product of the volume of part of the defect and the density of the electric contact material in the part of the defect; thirdly, uniformly mixing the weighed metal powders with a glycerin solution to produce a filling material, and then coating the filling material in the part of the defect in the electric contact part; after the part of the defect is filled up with the filling material, in the circumstance of taking nitrogen as a protective atmosphere, scanning and remelting the filling material in the part of the defect with a high-energy laser beam; in the remelting process, complementing the filling material in the part of the defect blown away due to spraying nitrogen is replaced at the same time, and melting the refilled filling material with a parent material until the part of the defect is full and slightly convex; and finally, grinding and polishing the repaired electric contact part. The method is easy to operate, the product rate is high and the repaired product has stable performance and high quality.

Owner:NANTONG YONGDA PIPE IND

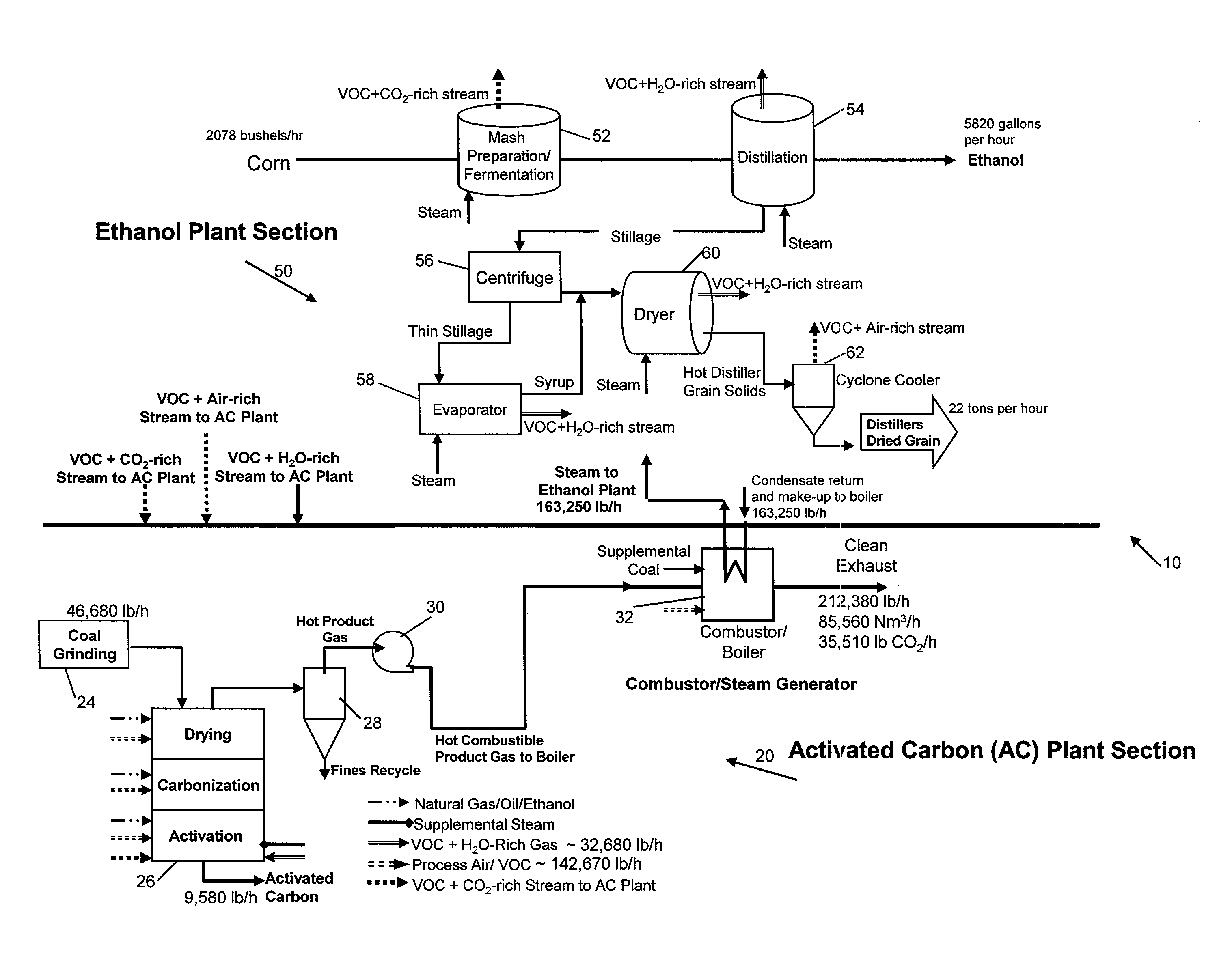

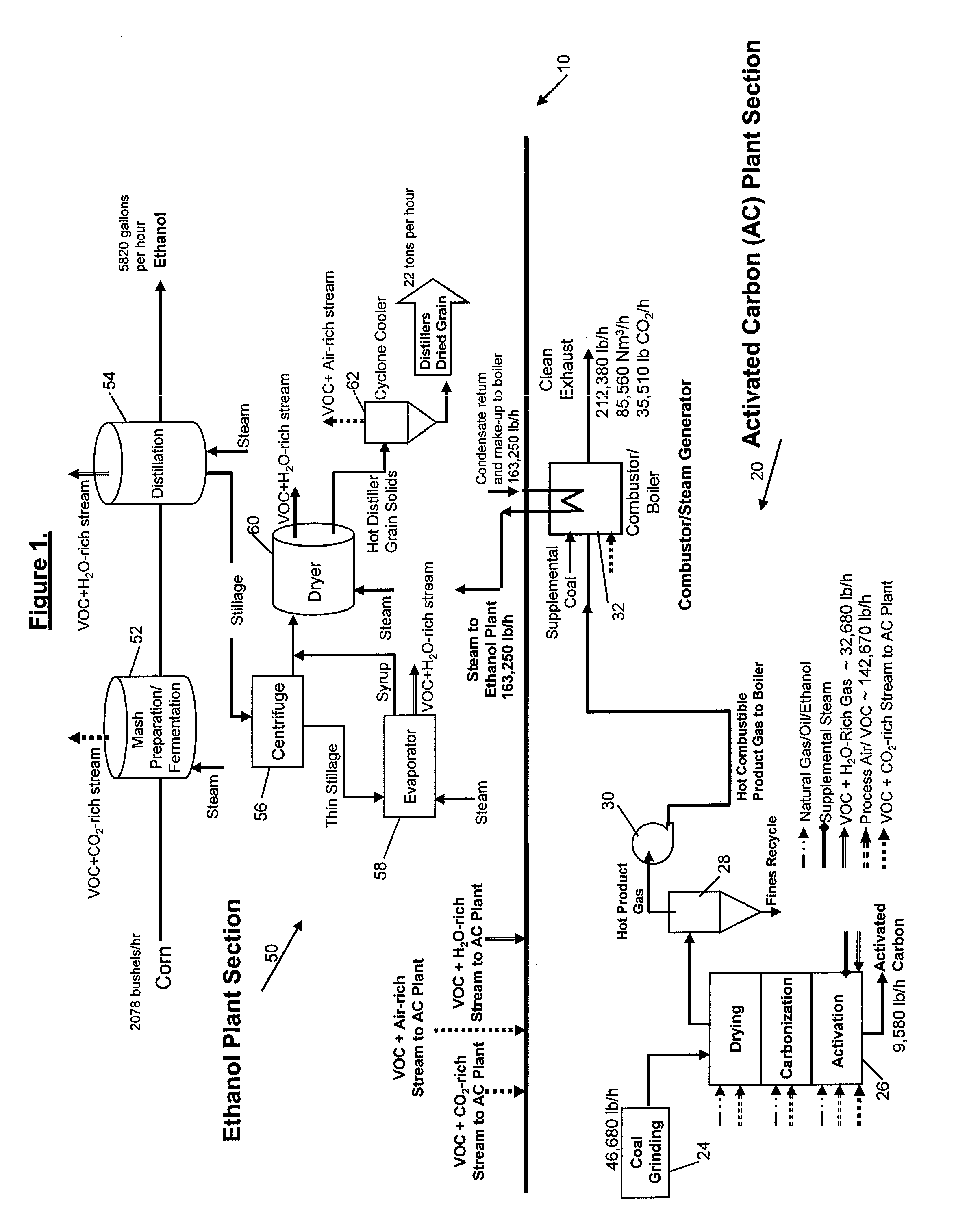

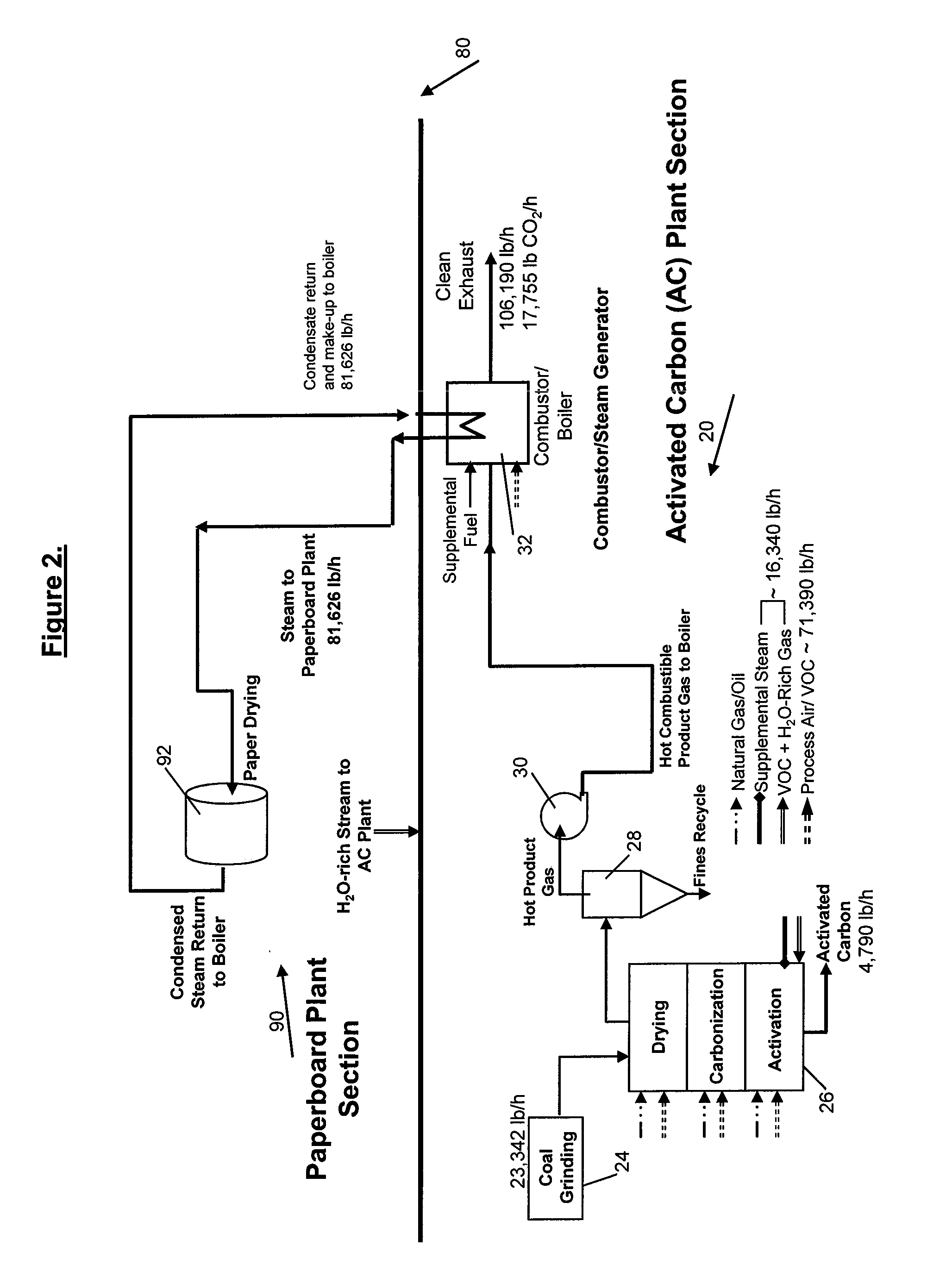

Method of Manufacturing Carbon-Rich Product and Co-Products

ActiveUS20100178624A1Simple and cost-effectiveImprove efficiencyBioreactor/fermenter combinationsGaseous fuel feeder/distributionWater vaporHigh carbon

A method in which a parent hydrocarbon-rich material is processed so as to produce both a carbon-rich solid material that has a higher carbon to hydrogen ratio than that of the parent material and a carbon-deficient combustible gas that has a lower carbon to hydrogen ratio than the parent material. In the process, the material is activated by exposing it to a hot gas stream having elevated levels of one or both of carbon dioxide and water vapor. The combustible gas is combusted to produce heat. At least about 80% of the heat is used in one or more endothermic steps that include drying coal or biomass.

Owner:SRINIVASACHAR SRIVATS

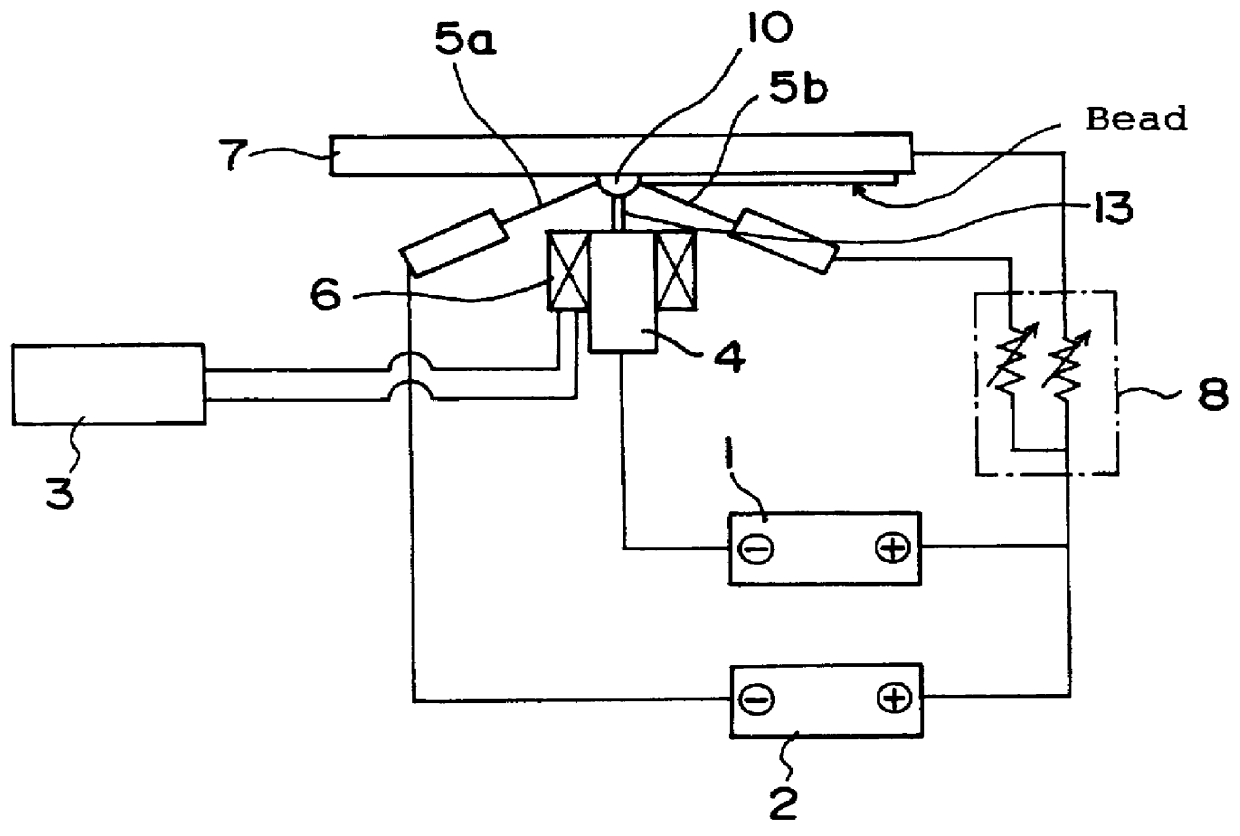

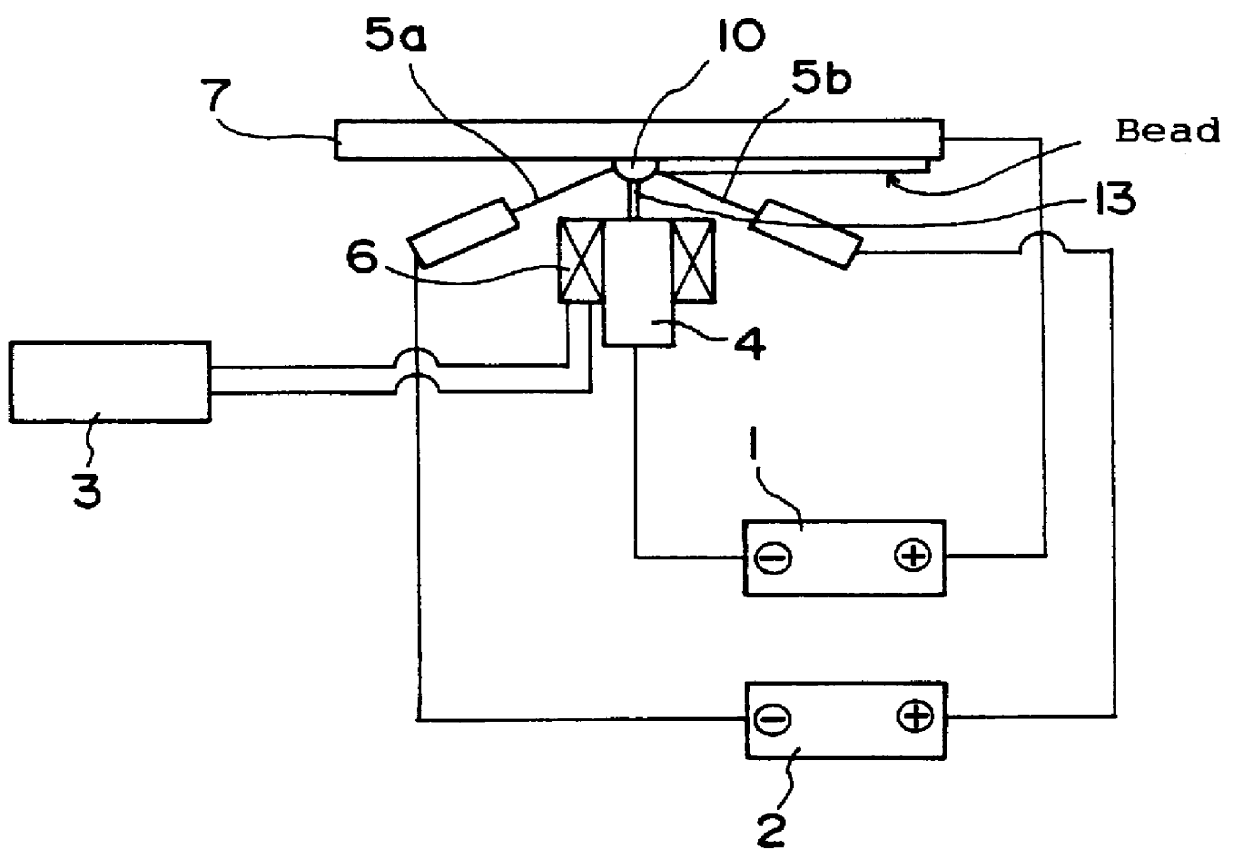

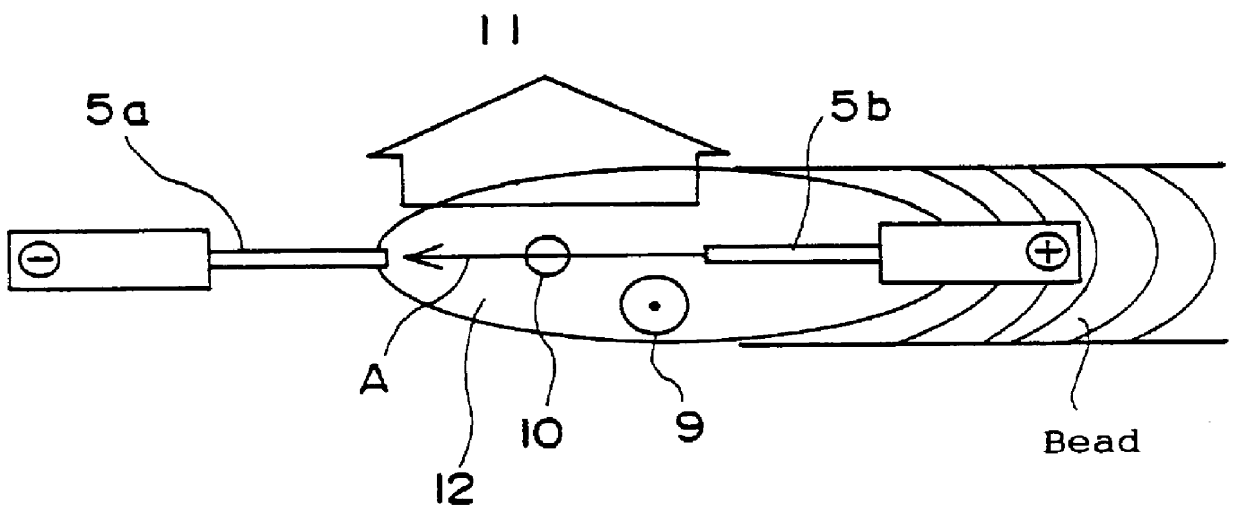

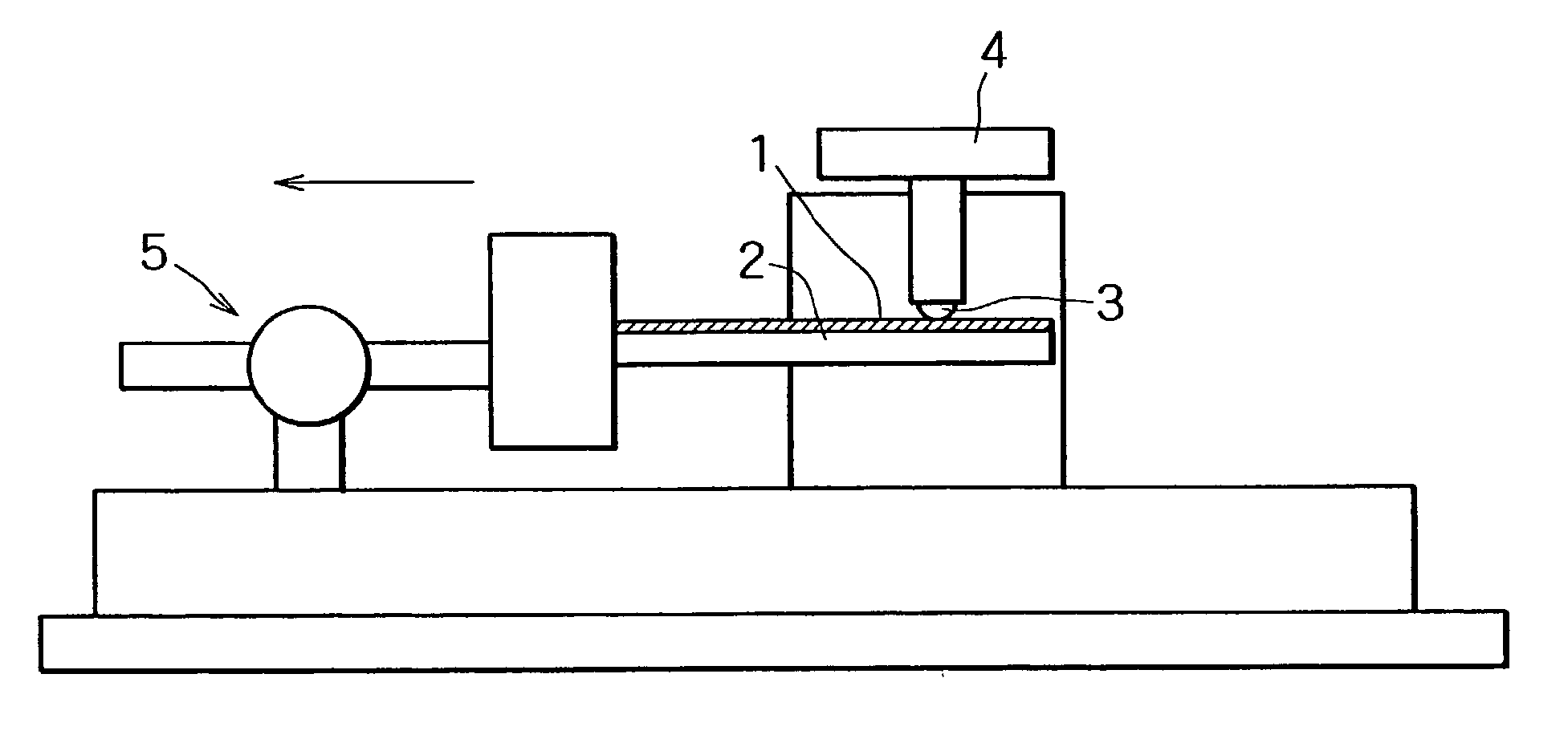

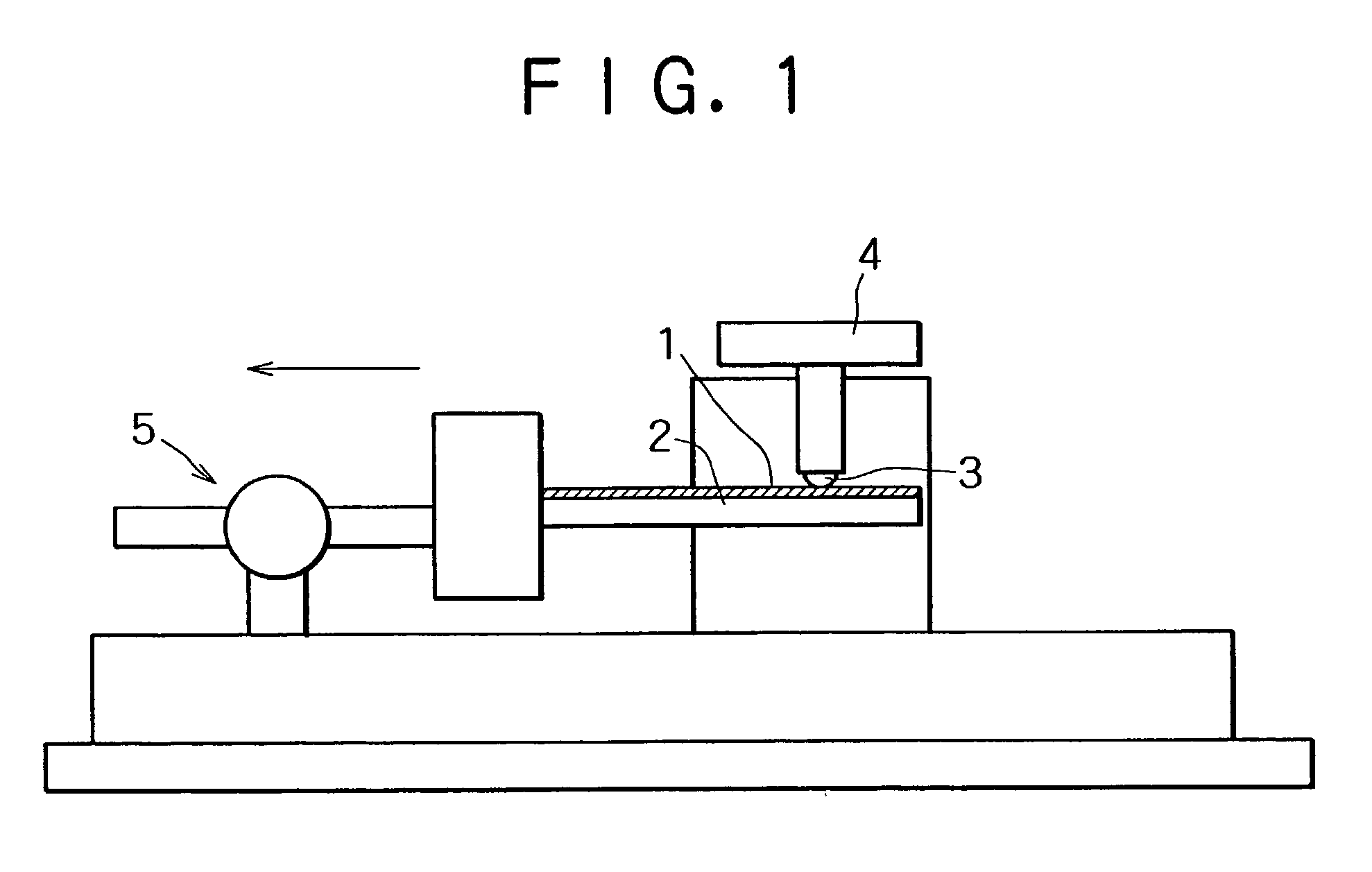

Method of welding in the horizontal position and welding apparatus therefor

InactiveUS6023043ABetter-shaped beadWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding defect

PCT No. PCT / JP97 / 01533 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed May 7, 1997 PCT Pub. No. WO97 / 43073 PCT Pub. Date Nov. 20, 1997The object of this invention is to prevent the occurrence of welding defects such as undercuts, overlaps and faulty angles of fusion, and to increase the efficiency of welding in the horizontal position. Auxiliary wires 5a and 5b are inserted into molten pool 12, and a unidirectional current is made to flow between them. A magnetic field 9 is induced which is approximately orthogonal to the surface of the parent material so as to generate an upward Lorentz force (opposite the pull of gravity) in molten pool 12. This force supports the molten metal and prevents it from dripping, resulting in a better-shaped bead.

Owner:MITSUBISHI HEAVY IND LTD

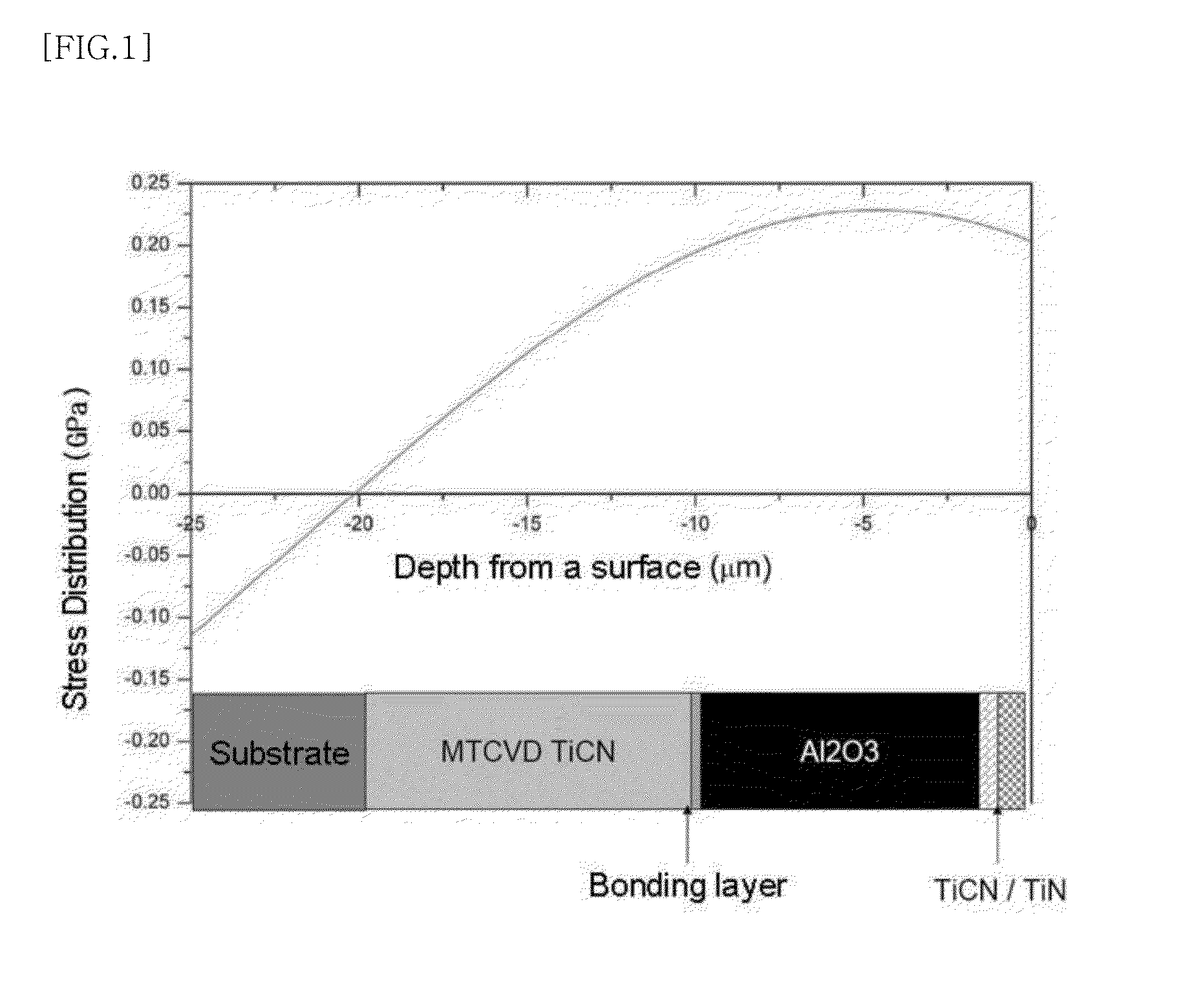

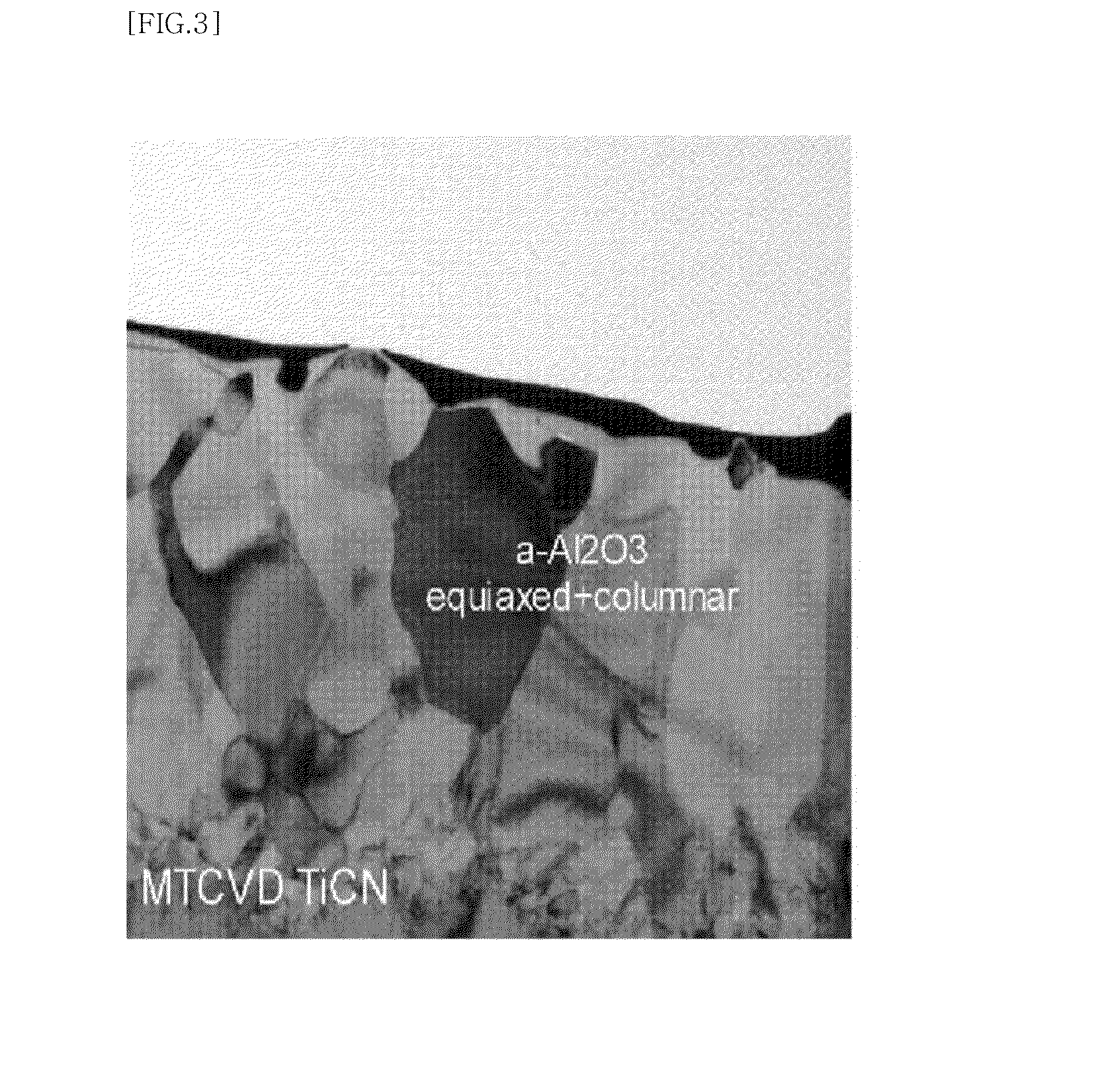

Coating layer for cutting tools

InactiveUS20130149527A1Tool lifetime be significantly increasedExtended service lifeRecord information storageTurning toolsGas phaseWear resistant

Provided is a coating layer for cutting tools, as a hard coating layer stacked and formed in the sequence of a TiN layer, a TiCN layer, a bonding layer, an alumina (Al2O3) layer, and a cover layer from the bottom by using a chemical vapor deposition (CVD) method on a parent material, able to improve cutting performance, because surface residual stress of the coating layer may be maintained in a compressive stress state by adjusting a composition of the cover layer without using a separate additional process, such as a blasting operation, or a mixed process of CVD and physical vapor deposition (PVD), and simultaneously the cover layer may also be used as a wear-resistant layer.The coating layer according to present invention is formed on a surface of a parent material by using a CVD method, in which the coating layer includes an alumina layer formed of an α-phase, disposed on the parent material and composed of a composite structure having a columnar crystal structure and an equiaxed crystal structure mixed therein, and a cover layer formed of AlxTiySizCrwN (herein, x+y+z+w=1, x≧0.75, y≧0.2, 0≦z≦0.06, 0≦w≦0.08) and disposed on the alumina layer.

Owner:KORLOY

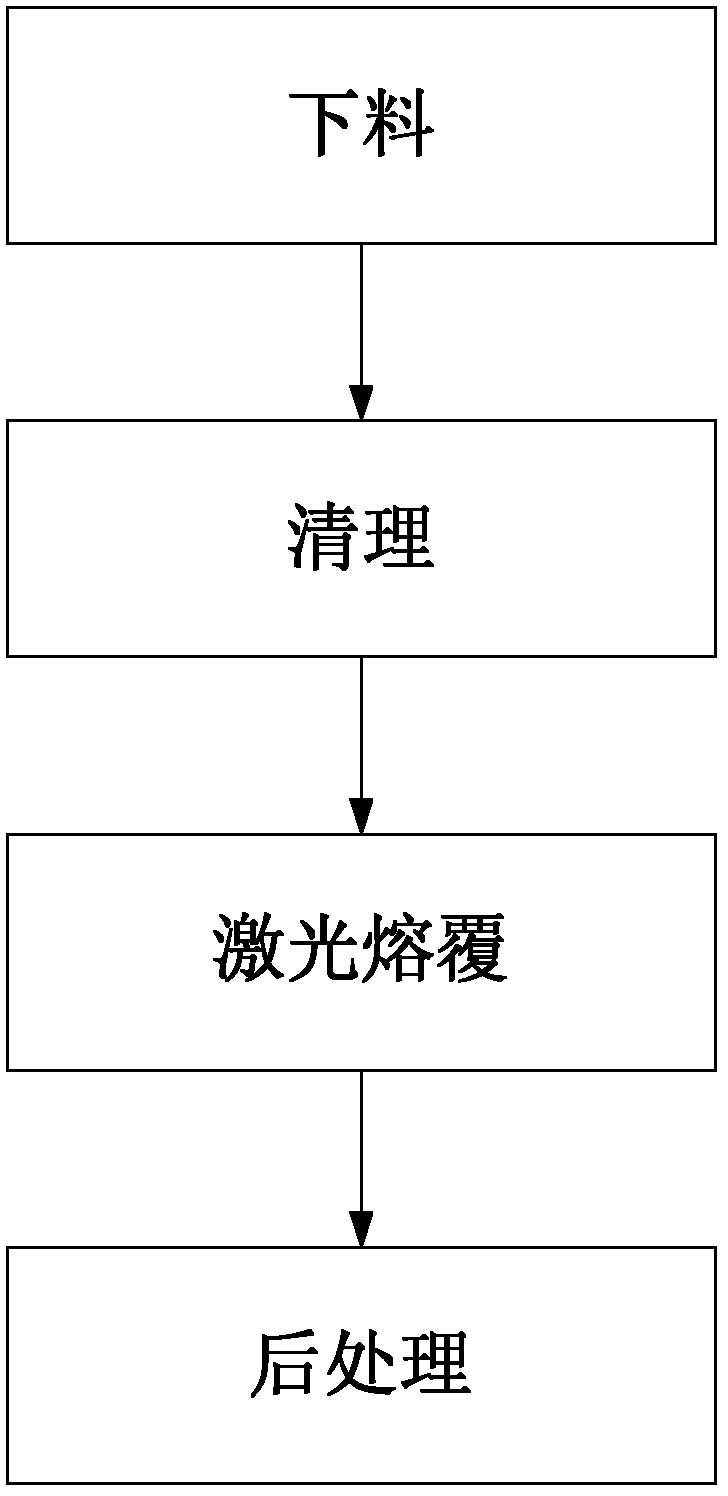

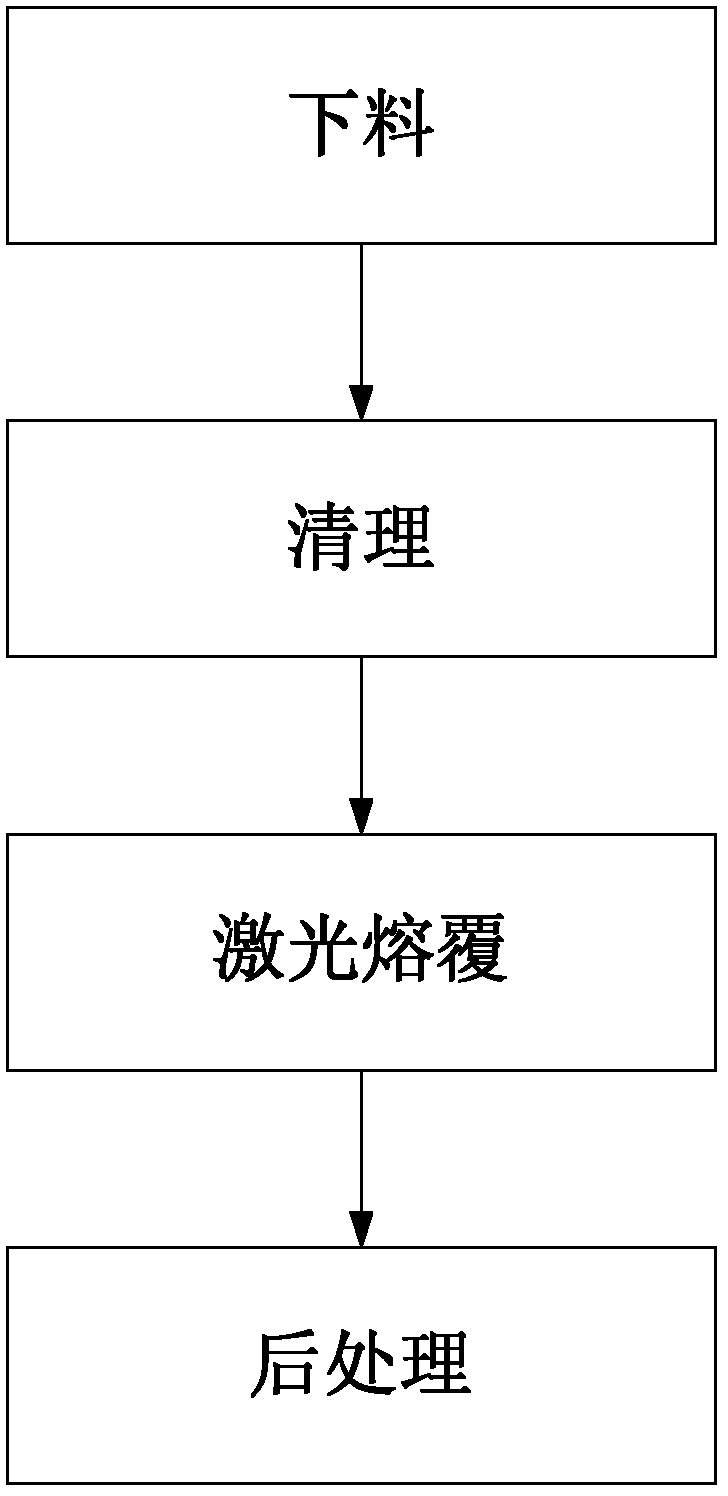

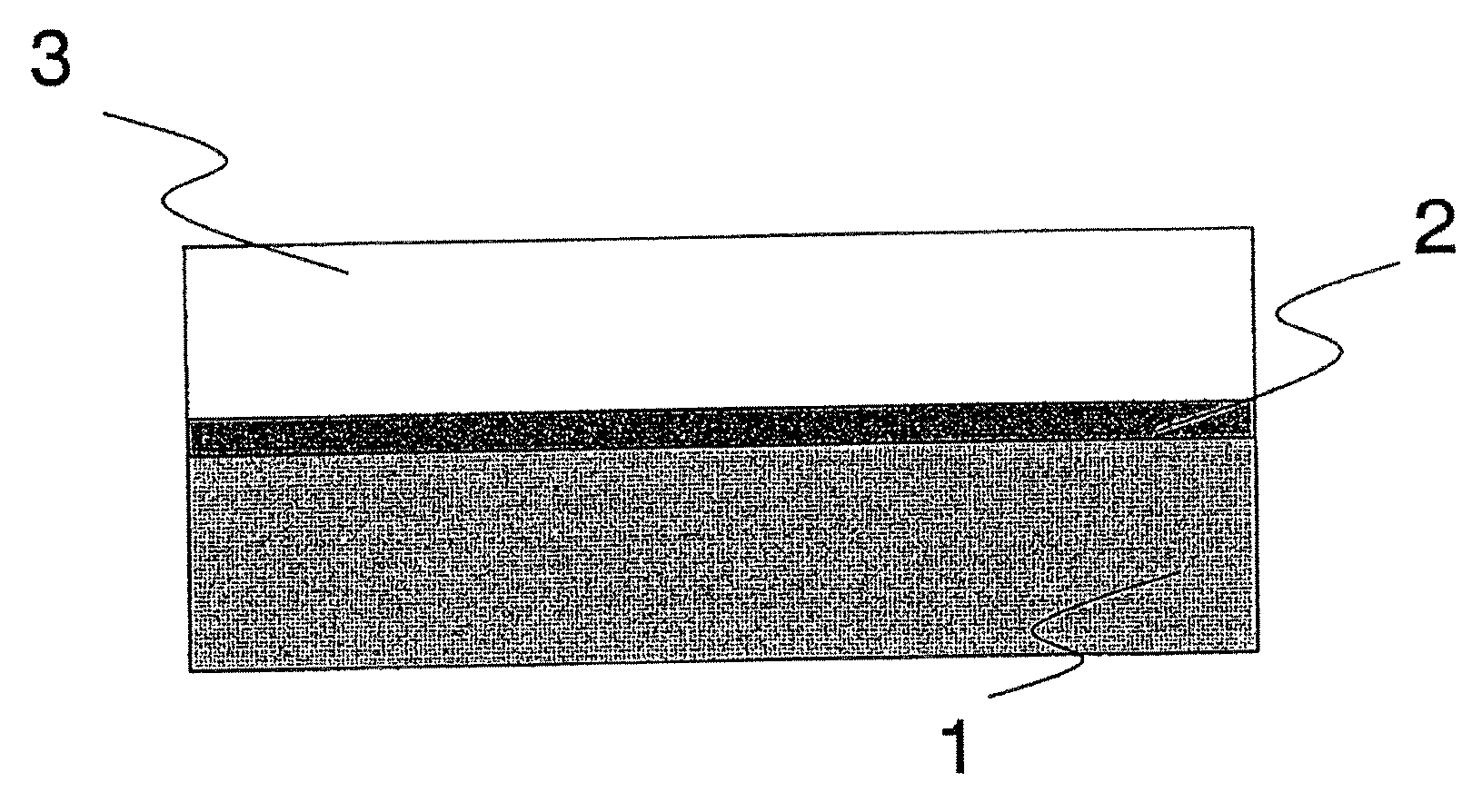

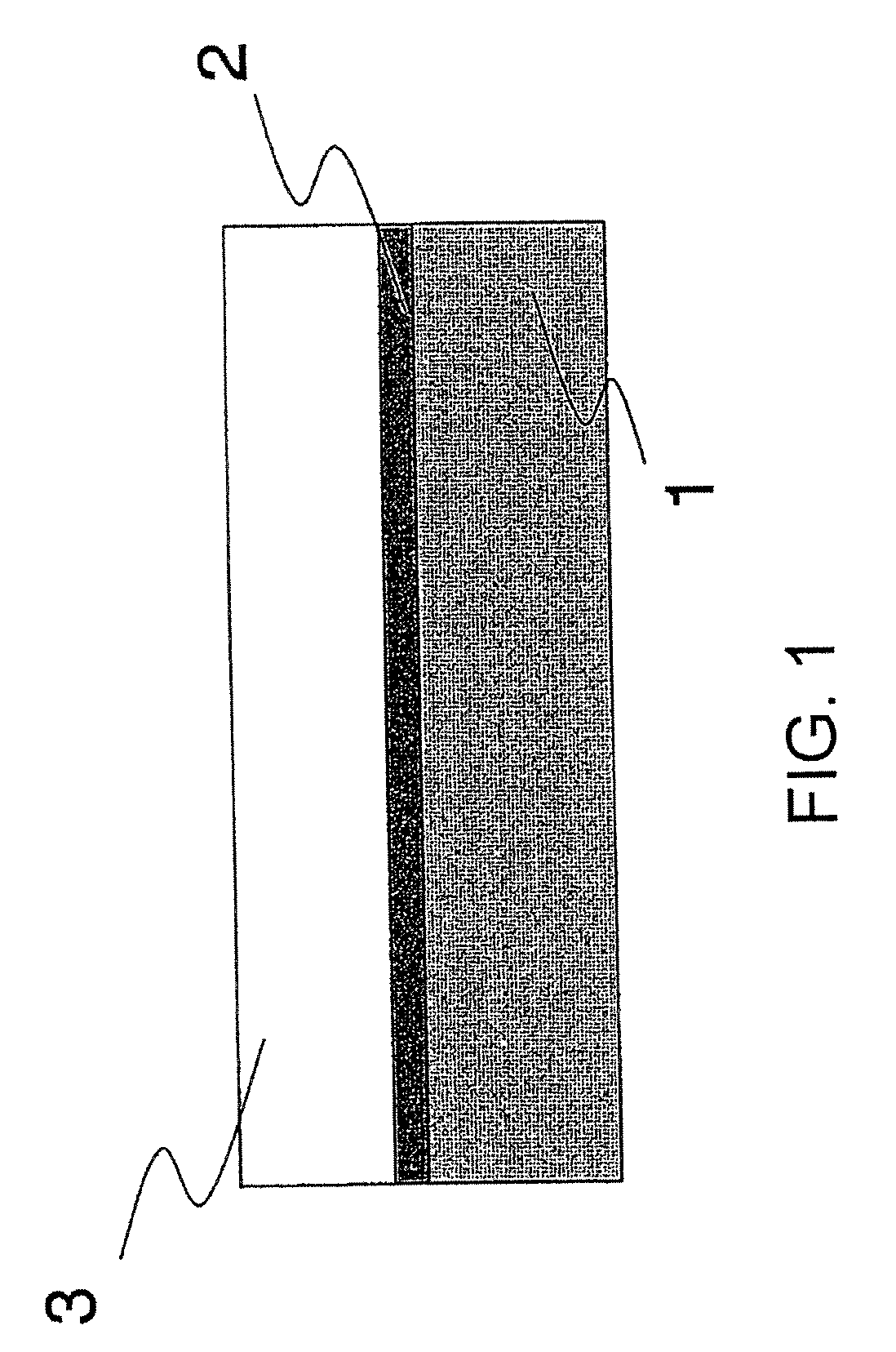

Laser cladding method

ActiveCN102560478AQuality controllableSmall heat affected zoneMetallic material coating processesHeat-affected zoneOptoelectronics

The invention provides a laser cladding method which comprises the steps of: blanking, preparing cladding material according to a workpiece to be cladded; and laser cladding, melting parent material by laser, fusing the cladding material and the melted parent material onto the parent material and forming a cladding layer. According to the laser cladding method, the cladding layer is bonded with the parent material in a metallurgical bonding way; and the cladding speed is rapid, the heat affected zone is small, and the quality of the cladding layer is more easily controlled, so that quality defect such as a brittle point or a crack is not easily caused, and the bonding force between the cladding layer and the parent material is strong.

Owner:ZOOMLION HEAVY IND CO LTD

Polyethylene membrane

The invention relates to the technical field of high molecular material, in particular to a light weight polyethylene film. In order to solve the technical problem, the invention discloses the light weight polyethylene film which is prepared through the following raw materials by weight portion: 2 to 50 portions of polyethylene film composite parent material, and 50 to 98 portions of polyethylene, wherein the polyethylene film composite parent material is prepared through the following raw materials by weight portion: 80 to 100 portions of filler, 5 to 25 portions of polyolefin, 10 to 15 portions of poly-modifier, 11 to 15 portions of fatty acid, 2 to 8 portions of mineral oil, 2 to 3 portions of coupling agent, and 0.1 to 0.08 portions of crosslinking agent. The specific gravity of the light weight polyethylene film is between 0.8 and 0.95g / cm. The key physical properties of the light weight polyethylene film are not reduced while the cost of the finished product film is reduced simultaneously. The fracture elongation rate is more than or equal to 150 percent; the tensile property is more than or equal to 25MPa; and the thermal sealing strength is more than or equal to 6.0.

Owner:SHANGHAI RUNLONG PACKING

Protective Film Structure of Metal Member, Metal Component Employing Protective Film Structure, and Equipment for Producing Semiconductor or Flat-Plate Display Employing Protective Film Structure

InactiveUS20090142588A1Avoid Surface CorrosionReduce pollutionAnodisationMolten spray coatingTectorial membraneMetallic materials

Multifunction production equipment enabling a plurality of processes in which deposition of reaction products on the inner wall of the processing chamber of equipment for producing a semiconductor or a flat-plate display, metal contamination due to corrosion of the inner wall, or the like, and fluctuation of the process due to discharged gas are suppressed, and a protective film structure for use therein. On the surface of a metal material, a first coating layer having an oxide coating of 1μ thick or less formed as an underlying layer by direct oxidation of a parent material, and a second coating layer of about 200 μm thick are formed. With such an arrangement, corrosion resistance against irradiation with ions or radicals can be imparted to a second layer protective film, and the effect of a protective layer for preventing corrosion of the surface of parent metal caused by diffusing molecules or ions into the second layer protective film can be imparted to the first layer oxide film. Consequently, contamination of the substrate with metals generated from each metal member and the inner surface of the process chamber is reduced, and stripping of the second layer protective film due to lowering in adhesion of the second layer protective film due to corrosion of the interface between the parent material and the second layer protective film can be suppressed.

Owner:NGK SPARK PLUG CO LTD +2

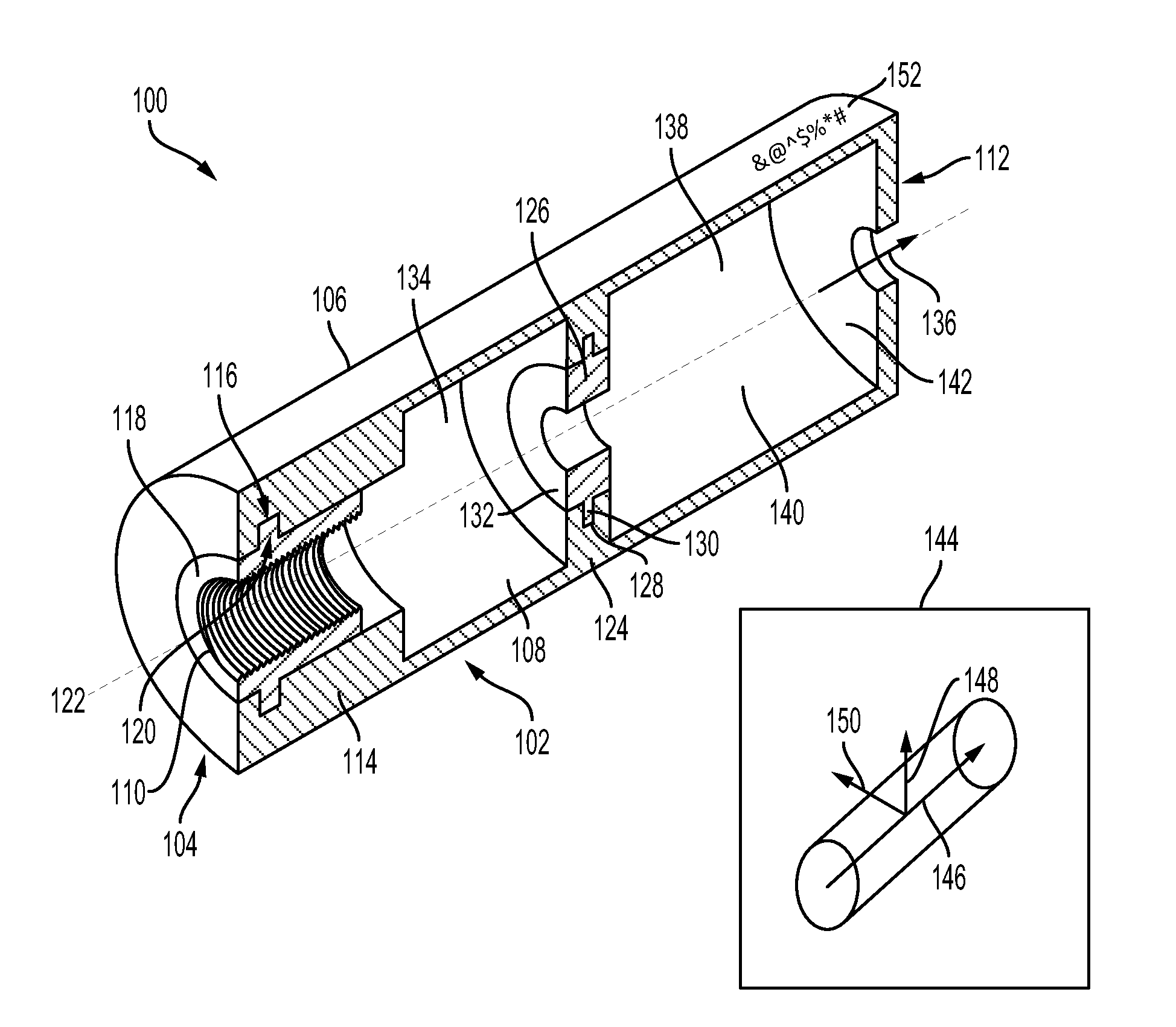

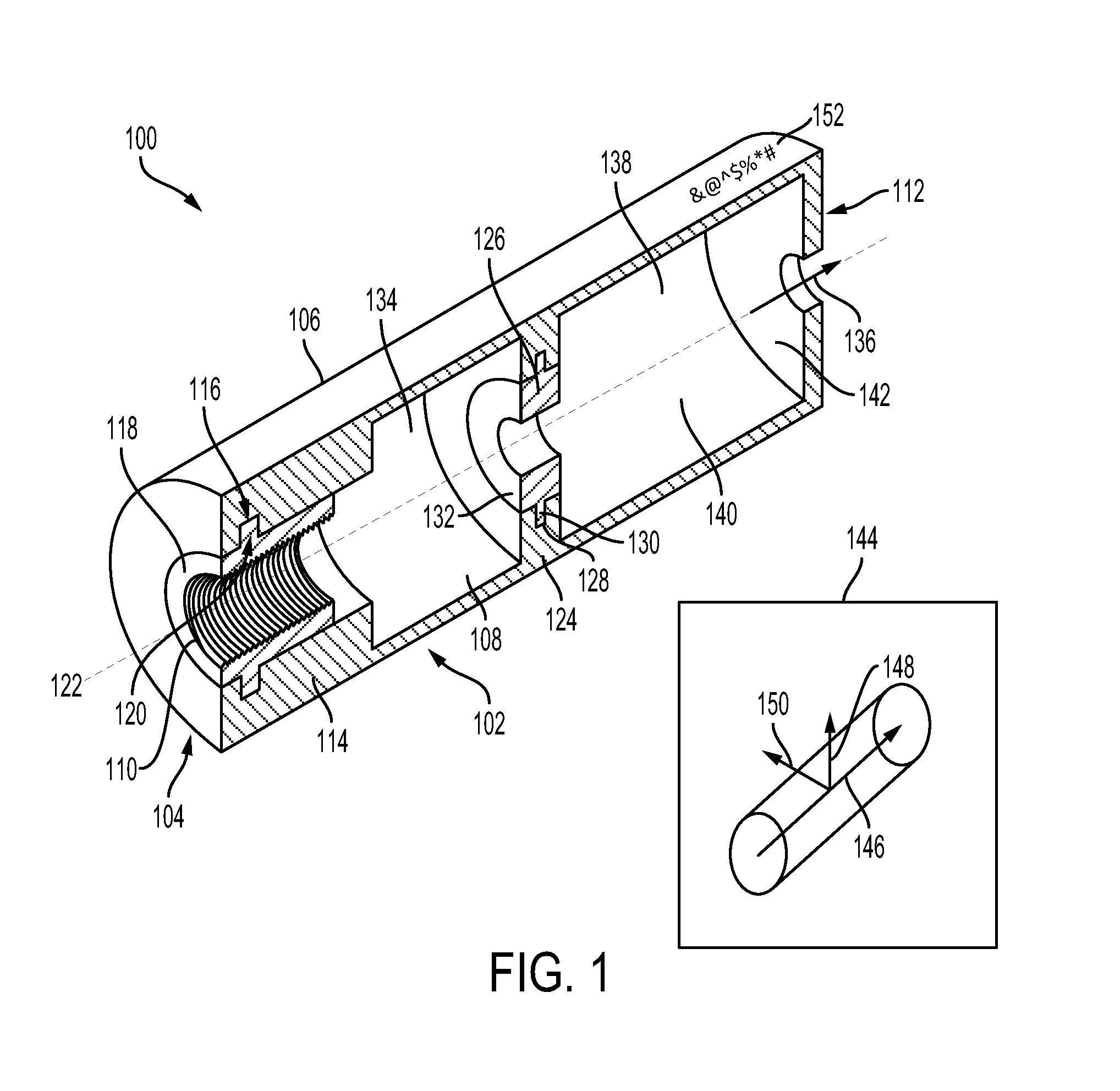

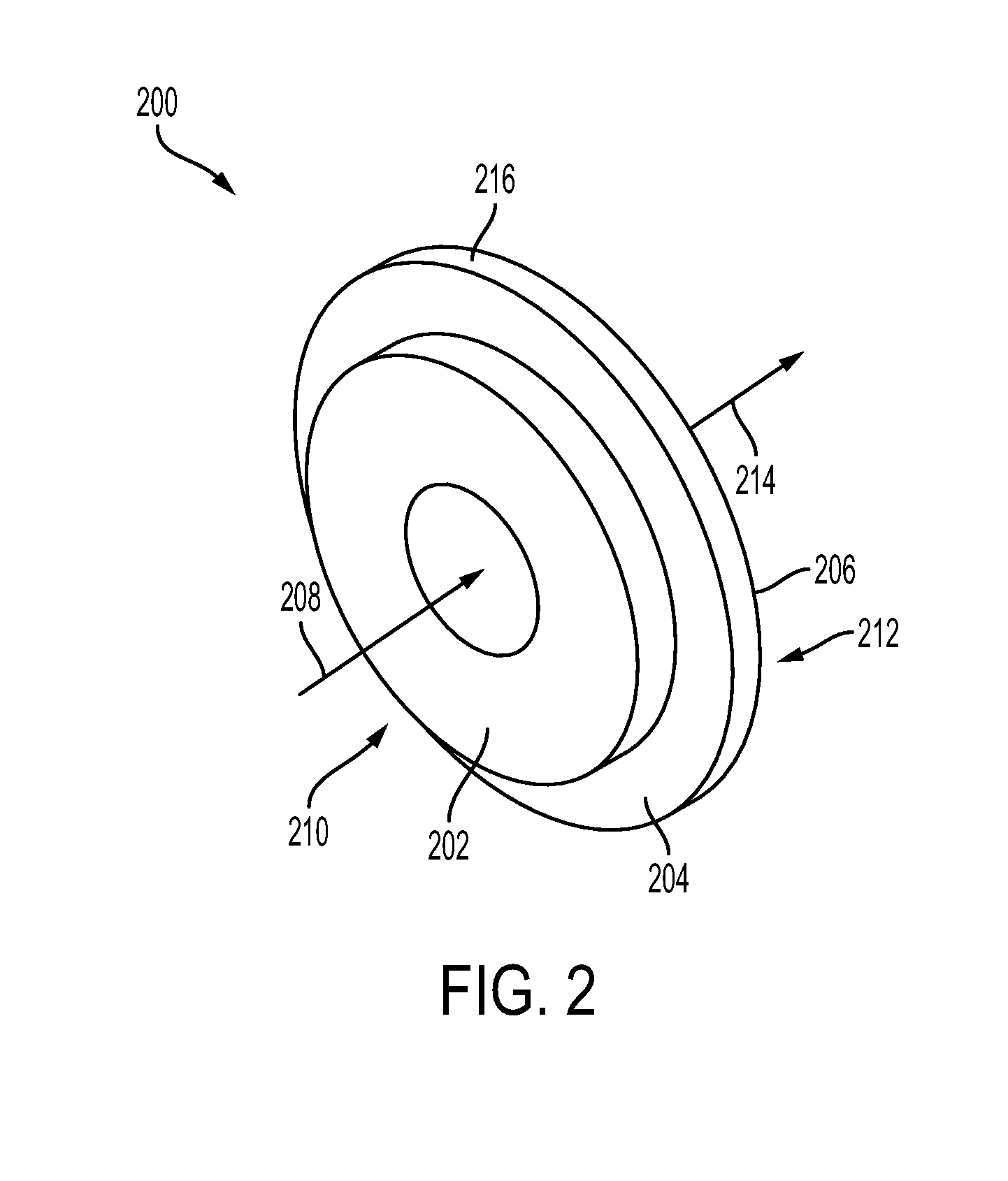

Firearm suppressor insert retained by encapsulating parent material

Methods and systems are provided for a sound suppressor adapted to be coupled to a firearm and including one or more inserts positioned within a body of the suppressor. In one embodiment, a sound suppressor comprises a unitary single-piece body, where an insert is positioned within the body and encapsulated by the body, the body and the insert forming one or more chambers, where the body and insert are bonded to one another via only interfacing surfaces of the body and insert. In this way, a more robust suppressor is constructed that is not vulnerable to the attrition that arises when using replaceable inserts bonded to the suppressor housing via welding.

Owner:DELTA P DESIGN

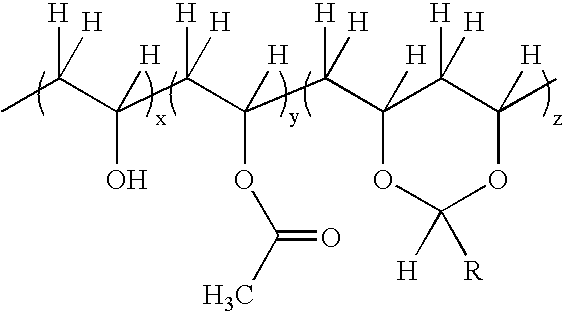

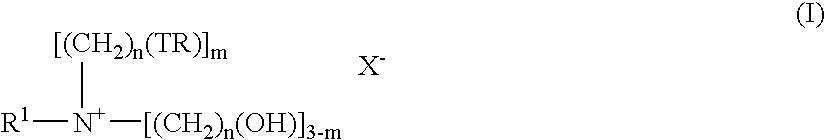

Polymeric film for water soluble package

InactiveUS7083047B2Organic detergent compounding agentsSolid separationPolymer thin filmsBackbone chain

Owner:HENKEL IP & HOLDING GMBH +1

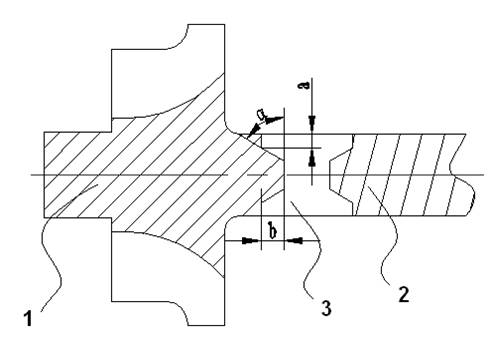

Method for connecting titanium-aluminum alloy turbine with 42CrMo steel shaft

InactiveCN102211249AImprove supercharging efficiencyIncrease the effective contact areaWelding/cutting auxillary devicesFurnace typesFriction weldingPollutant emissions

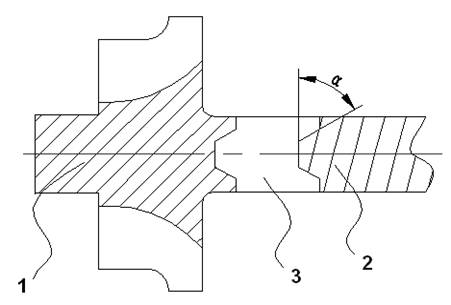

The invention discloses a method for connecting a titanium-aluminum alloy turbine with a 42CrMo steel shaft. The turbine members consist of a titanium-aluminum alloy turbine, an intermediate transitional shaft and a 42CrMo steel shaft, wherein the titanium-aluminum alloy turbine and the intermediate transitional shaft, the intermediate transitional shaft and the 42CrMo steel shaft are respectively combined in a friction welding mode. A friction welding contact part is designed into a mode that a lug boss and a concave groove are combined with each other, the axial cross sections of the lug boss and the concave groove are isosceles trapezoids, an included angle between a base and a hypotenuse of each trapezoid is 30-60 DEG, the length ratio of a top edge to the base of the trapezoid is 0.3-0.7, and the ratio of the flat area formed by the top edge of the trapezoid to the cross sectional area of the shaft is 0.01-0.1. According to the method disclosed by the invention, the bonding strength of the whole structure is effectively improved through increasing the effective contact area of the welding surface; after welded, all materials are ruptured in a titanium-aluminum parent material region; the turbocharging efficiency can be greatly increased; the engine transient responsiveness is enhanced; and the pollutant discharge is reduced; in addition, the method has a simple process and can be used for realizing mass production.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

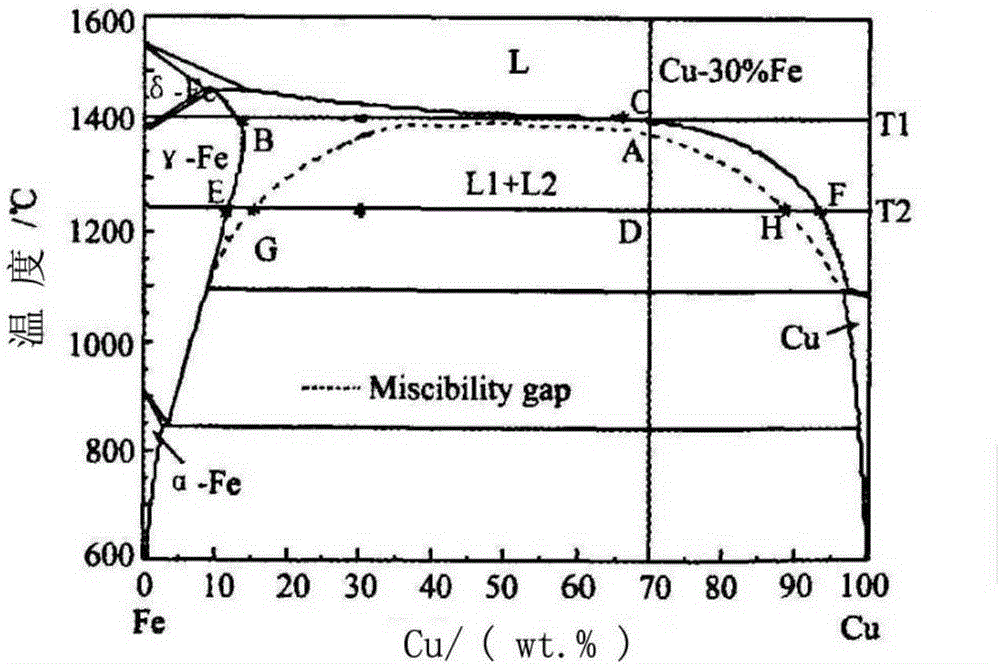

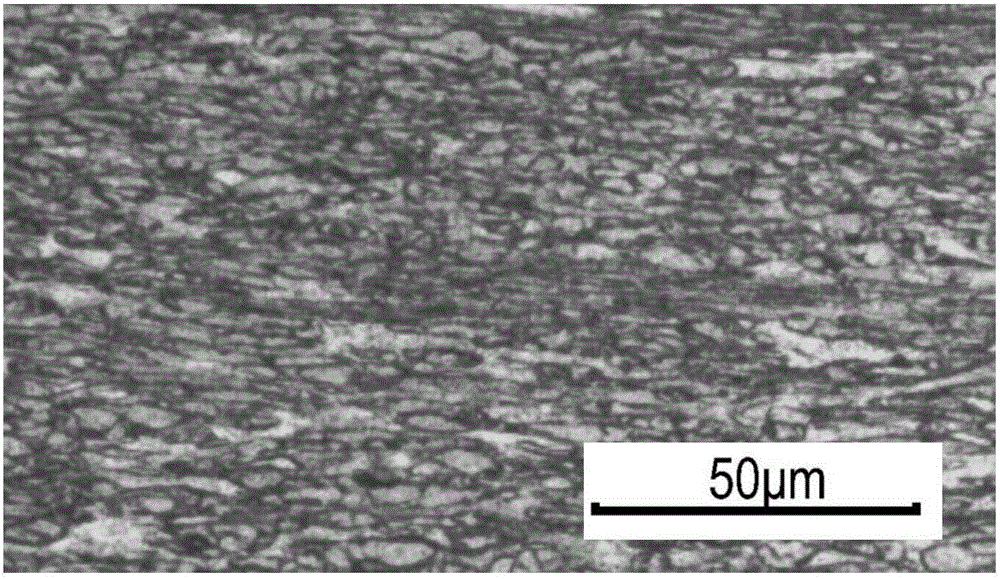

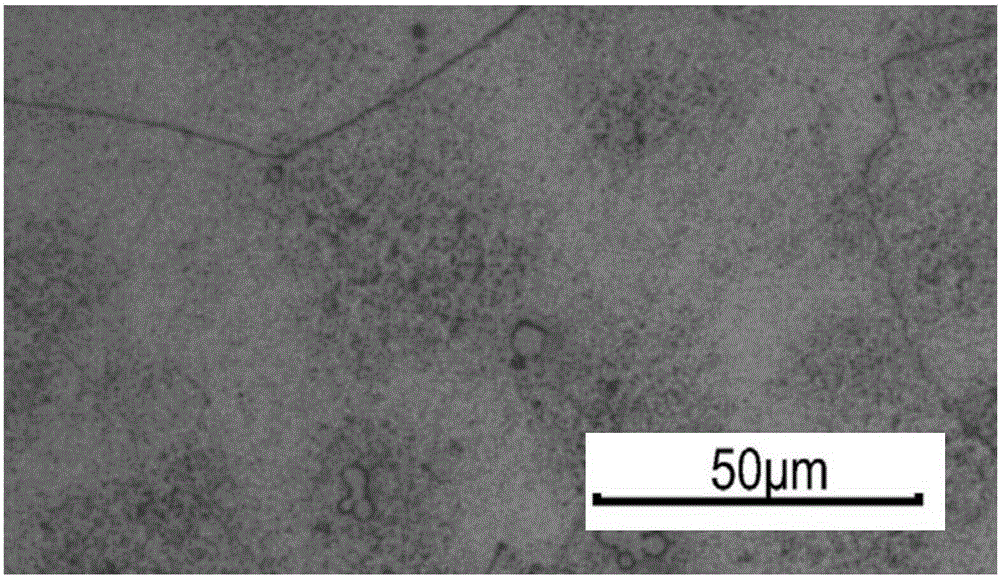

Cu-Fe alloy wire and preparing method thereof

The invention discloses a Cu-Fe alloy wire and a preparing method thereof, and belongs to the technical field of non-ferrous alloy. The preparing method includes the steps that an intermediate alloy with even ingredients is used as parent materials, wherein the ingredients of the parent materials comprise 45% to 60% of Fe, 0.20% to 0.35% of Ni, not smaller than 0% of RE and the balance Cu; and then cathode copper and the intermediate alloy parent materials serve as raw materials, and a casting-state alloy ingot is obtained through vacuum melting and further machined into the Cu-Fe alloy wire, wherein the wire is prepared from 8.0% to 13.0% of Fe and the balance Cu and unavoidable impurities. When the prepared Cu-Fe alloy is in the casting state and the forging state, Fe-Cu solid solution is good, Fe elements are evenly distributed without segregation, and good machinability is achieved. The diameter phi of the further-machined finished wire ranges from 0.05 mm to 0.1 mm, the tensile strength of the finished wire is larger than or equal to 440 N / mm<2>, and the elongation of the finished wire is larger than or equal to 10%. The Cu-Fe alloy further has the excellent electromagnetic shielding effect.

Owner:张连仲

Plated copper alloy material and process for production thereof

InactiveUS20030129441A1Improve corrosion resistanceForce is smallDomestic articlesConductive pattern reinforcementCopper platingContact resistance

A plated copper alloy material for connecting terminals is provided which comprises a parent material of copper or copper alloy, a nickel layer and a copper-tin alloy layer. The nickel layer has a thickness of 0.1-1.0 .mu.m. The copper-tin alloy layer has a thickness of 0.1-1.0 .mu.m and contains 35-75 at % of copper. The material may additionally have a tin layer no thicker than 0.5 .mu.m for an engaging type terminal containing 0.001-0.1 mass % of carbon, or thicker than 0.5 .mu.m for a non-engaging type connector. The material meets requirements for capability of insertion with a small force, good electric reliability (due to low contact resistance) in a high-temperature atmosphere, workability for sharp bending without cracking, good solder wettability and good corrosion resistance to sulfur dioxide gas.

Owner:KOBE STEEL LTD

Electroless welding type welding rod and preparation and welding method thereof

InactiveCN102990240ASolving Quick Weld RepairsTackling Emergency Welding RepairsWelding/cutting media/materialsAlumino-thermic welding apparatusEmulsionThermite

The invention discloses an electroless welding type welding rod and a preparation and welding method thereof. The electroless welding type welding rod comprises a plug, a grain, a paper pipe, an igniting cap, a pipe plug and a sleeve pipe, wherein the plug and the paper pipe are coaxially adhered together through emulsions; the grain and the igniting cap are formed in the paper pipe; the sleeve pipe is sleeved on the paper pipe; one end of the sleeve pipe is connected with the plug in a close fit way, and the other end of the sleeve pipe is sealed through the pipe plug. According to the electroless welding type welding rod, a welding material is manufactured into a special hand-held pencil, the special hand-held pencil can initiate reaction by being only ignited through matches, a reaction product and a parent material are molten by taking the self-releasing chemical energy of a thermite as a welding heat source, and the firm connection of the welded parent material is realized through mechanisms such as wetting, diffusion and reaction crystallization.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Carbon fiber enhanced polylactic acid 3D printing material and preparation method thereof

ActiveCN105385124AImprove interfacial composite performanceRaise the ratioAdditive manufacturing apparatusFiberCarbon fibers

The invention provides a carbon fiber enhanced polylactic acid 3D printing material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 60 to 80 parts of polylactic acid, 5 to 15 parts of toughening agent, 2 to 10 parts of compatibilizing agent, 5 to 25 parts of modified carbon fibers, 0.1 to 2 parts of antioxidant, 0.5 to 2 parts of anti-hydrolysis agent, 0.05 to 1 part of crystallizing nucleating agent, 0.5 to 3 parts of mobile regulating agent and 0.2 to 2 parts of melt fusion enhancing agent. By adopting a surface modification technology of carbon fibers, the interface compounding performance with polylactic acid is improved; aiming at FDM (frequency division multiplex) 3D printing characteristics, the mobile regulating agent and the melt fusion enhancing agent are added so that the specific value between the strength of a printing material and the strength of a parent material is effectively improved; aiming at a phenomenon that the printing material is not dried before utilization, the anti-hydrolysis agent is used for inhibiting a problem that polylactic acid is easy to hydrolyze in a printing process; the whole performance of the material is improved through the coordination of the components in the formula.

Owner:吉林庭然景观材料科技有限公司

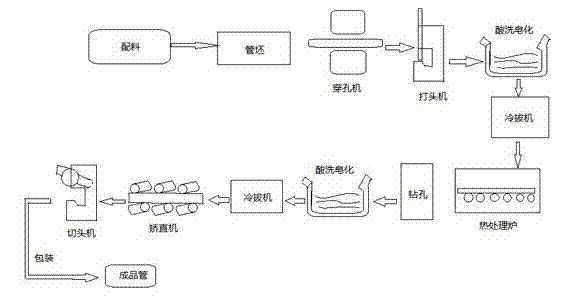

High intensity straight-line joint pipeline steel tube fabrication technique using high-frequency electric resistance welding

InactiveCN101474644AHigh geometric accuracy of appearanceImprove mechanical propertiesHigh frequency current welding apparatusManufacturing technologyPerformance index

The invention relates to the manufacturing technical field of steel pipes for long-distance transport pipes for petroleum, natural gas, mineral powder and the like, in particular to a pipeline steel pipe manufacturing technology employing straight high-frequency resistance welding. Raw materials meeting requirements are purchased, wherein, the requirements comprise physical properties, chemical compositions and mechanical properties of the raw materials. The raw materials are inspected to determine whether the physical properties, the chemical compositions and the mechanical properties meet the requirements. The technology comprises steel pipe manufacturing preparation, determination of production line moulding process parameters, determination of welding process parameters and determination of auxiliary material parameters. The pipeline steel pipe manufacturing technology employing the straight high-frequency resistance welding can help manufacture 632.2X11.1-60 pipeline steel pipes, various performance indexes of the steel pipes meet the requirements of pipeline steel pipes (USA API SPEC 5L PSL2 44 Standard), the heights of an inside seam and an outside seam are identical with the pipe wall of a parent material, and the technology perfectly solves the engineering anti-corrosive difficulties. The straight high-frequency pipeline pipe manufacturing technology has the advantages of high manufacturing efficiency, fast speed and low cost.

Owner:中冶辽宁德龙钢管有限公司

Polyethylene membrane composite master batch

The invention relates to the technical field of high molecular material, in particular to a polyethylene film composite parent material. The invention discloses the polyethylene film composite parent material which is prepared through the following raw materials by weight portion: 80 to 100 portions of filler, 5 to 25 portions of polyolefin, 10 to 15 portions of poly-modifier, 11 to 15 portions of fatty acid, 2 to 8 portions of mineral oil, 2 to 3 portions of coupling agent, and 0.1 to 0.08 portion of crosslinking agent. The specific gravity of the light weight polyethylene film prepared from the polyethylene film composite parent material is between 0.8 and 0.95g / cm<3>. The key physical properties of the light weight polyethylene film are not reduced while the cost of the finished product film is reduced simultaneously. The fracture elongation rate is more than or equal to 150 percent; the tensile property is more than or equal to 25MPa; and the thermal sealing strength is more than or equal to 6.0.

Owner:SHANGHAI RUNLONG PACKING

Radio Frequency Lens and Method of Suppressing Side-Lobes

ActiveUS20080238810A1Weaken energyImproves Structural IntegrityAntennasPhotonic crystal structureCrystal structure

An RF lens according to the present invention embodiments collimates an RF beam by refracting the beam into a beam profile that is diffraction-limited. The lens is constructed of a lightweight mechanical arrangement of two or more materials, where the materials are arranged to form a photonic crystal structure (e.g., a series of holes defined within a parent material). The lens includes impedance matching layers, while an absorptive or apodizing mask is applied to the lens to create a specific energy profile across the lens. The impedance matching layers and apodizing mask similarly include a photonic crystal structure. The energy profile function across the lens aperture is continuous, while the derivatives of the energy distribution function are similarly continuous. This lens arrangement produces a substantial reduction in the amount of energy that is transmitted in the side-lobes of an RF system.

Owner:HARRIS CORP

Novel brake pad material of truck

InactiveCN101555399AStable coefficient of frictionStable recovery performanceOther chemical processesFriction liningLow speedEngineering

The invention relates to a frictional material, in particular to a novel brake pad material of truck. The invention provides a novel brake pad material of a truck, wherein the novel brake pad material is used in a dry one-step hot press molding process applied to a nanocopper modified phenolic resin agglutination technology and a parent material modifying and adjusting technology. The raw material mixing ratio of the novel brake pad material is as below: 15%-20% of binder, 30%-50% of framework material, 10%-15% of friction enhancing agent, 5%-10% of anti-friction agent and 20%-30% of filling material. The binder is nanocopper modified phenolic resin, the framework material is mineral fibre and the like, the friction enhancing agent is great-hardness chromium ore power, and the like, the anti-friction agent is low-hardness graphite, and the like, the filling material is BaSO4, coarse whiting, and the like. The novel brake pad material has the advantage that a brake lining has a stable friction factor, stable recovery performance, good heat resistance, no crack performance, low speed sensitivity, good wearability and no braking noise.

Owner:SHANDONG DAWANG XINYI AUTOMOBILE FITTING

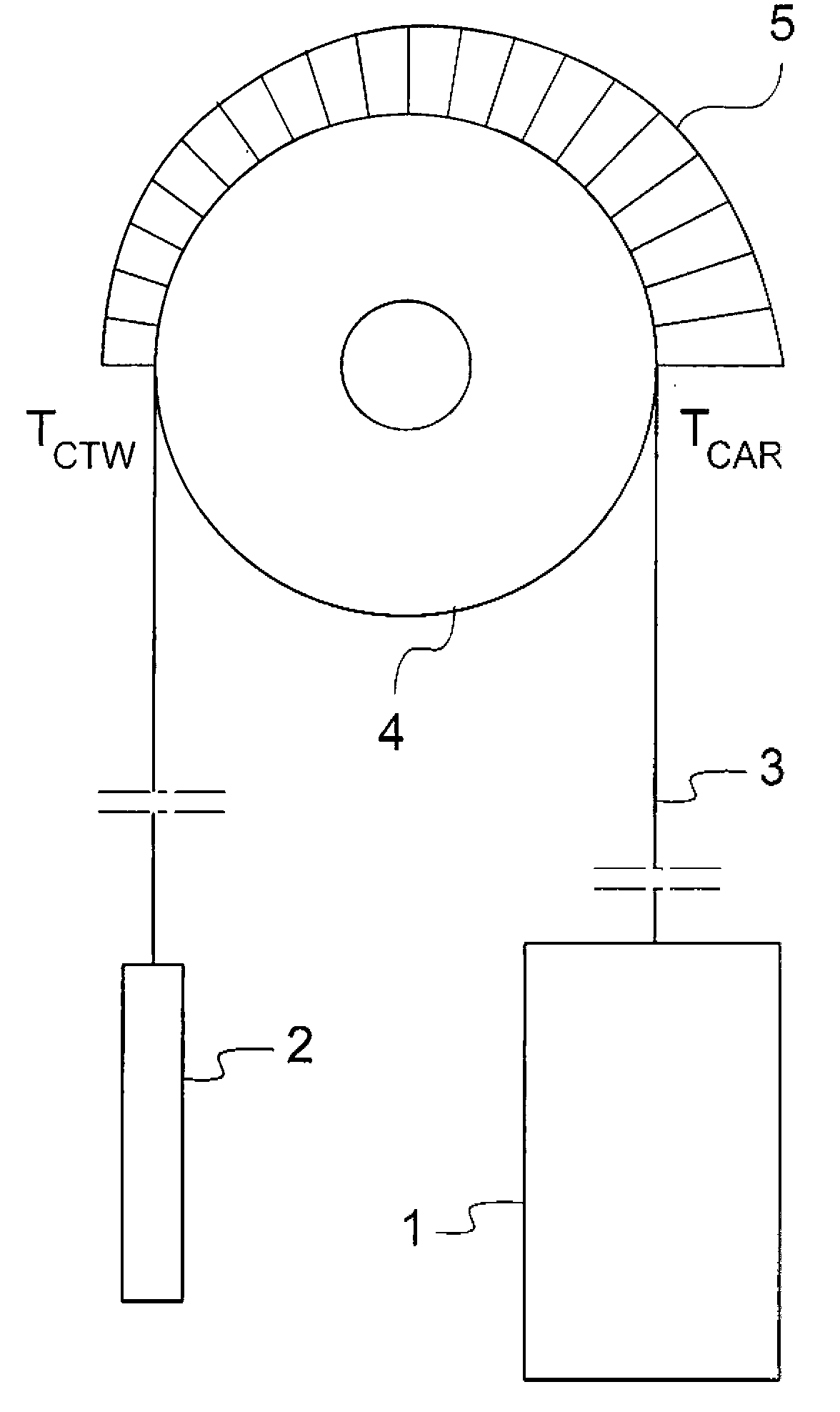

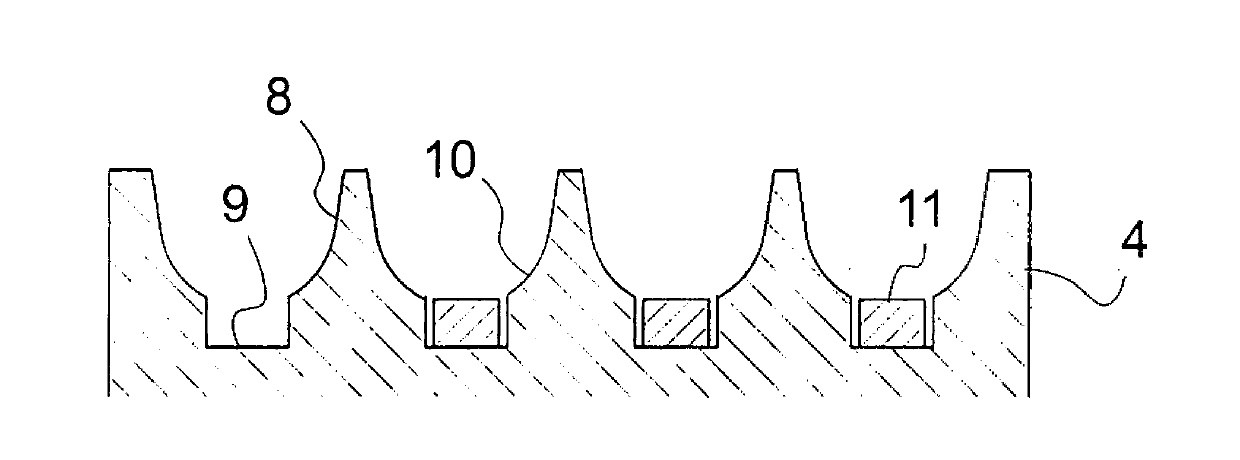

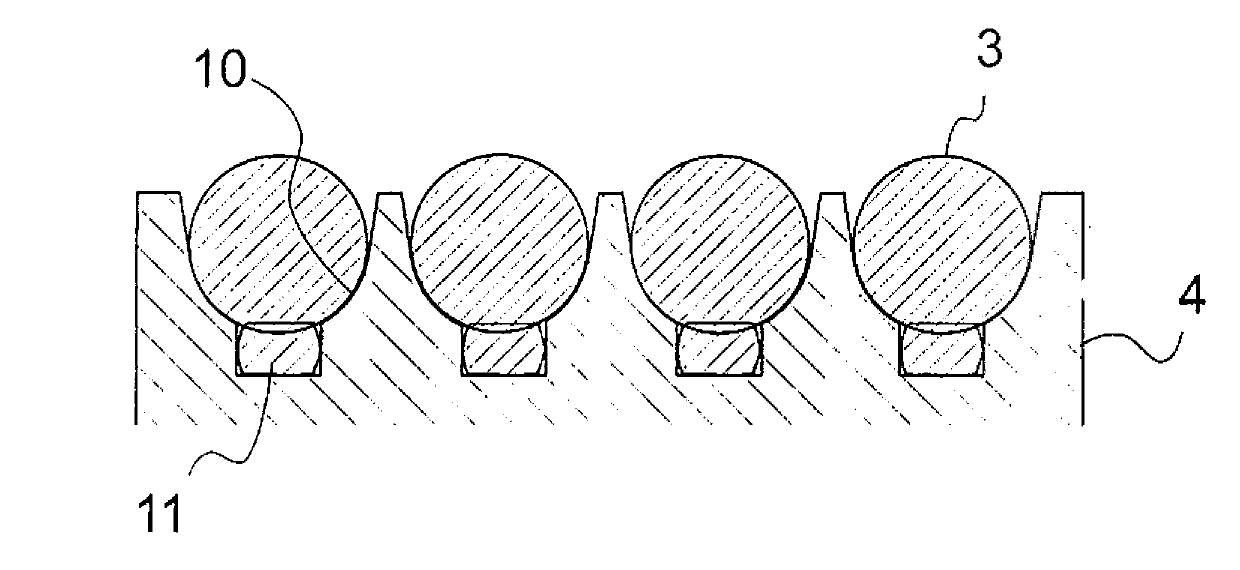

Method for manufacturing or modernizing a traction sheave elevator, and traction sheave elevator

ActiveCN102892702ANo added stressExtended service lifePortable liftingWinding mechanismsAutomotive engineeringParent material

The object of the invention is a method for modernizing an elevator, and a traction sheave elevator, which elevator comprises at least an elevator car (1) and a traction sheave (4) that moves the elevator car (1) by means of elevator ropes (3), the rim of which traction sheave comprises one or more rope grooves (8). In connection with modernization a traction sheave is installed as the traction sheave (4) of the elevator, the rope grooves (9) of which traction sheave (4) comprise a material, the frictive traction achieved by which is greater than the frictive traction between the parent material of the metallic traction sheave and the elevator ropes (3).

Owner:KONE CORP

Silver-loaded zirconium phosphate/nano-titanium dioxide composite antibacterial agent and preparation method thereof

ActiveCN101720787AGood compatibilitySimple production methodBiocideDisinfectantsLead phosphatePhosphoric acid

The invention discloses a silver-loaded zirconium phosphate / nano-titanium dioxide composite antibacterial agent and a preparation method thereof, and the composite antibacterial agent consists of 70-95 parts of silver-loaded zirconium phosphate with the silver content of 0.5-3.5% and 5-30 parts of SiO2 modified nano-TiO2 with the silver content of 0.5-3.5%. The preparation method comprises the steps of firstly leading phosphate or phosphoric acid to be reacted with soluble zirconium salt for generating zirconium phosphate, washing the zirconium phosphate, then preparing 10-60% suspension, then adding silver nitrate into a system, aging for 2-36 hours, then adding titanium salt, further adding silicate ester or silica sol after completing the addition of the titanium salt, finally adding the silver nitrate, aging for 1-24 hours, then filtering, and carrying out high-temperature calcination for preparation. The composite antibacterial agent has excellent antibacterial performance, the compatibility between the antibacterial agent and a parent material is better, and the production method is simple and easy to control.

Owner:WENGFU (GRP) CO LTD

Polymers anti-cracking mortar

The invention provides polymer crack-resistant mortar, which is prepared with 25 to 35 percent of cement, 55 to 65 percent of sand, 5 to 10 percent of pulverized fuel ash, 2 to 4 percent of soluble powdered gum, 0.1 to 0.5 percent of wood fiber, and 0.2 to 0.5 of hydroxypropyl methylcellulose through mixing. All of the indices of the polymer crack-resistant mortar meet the standard requirements of the Material for Exterior Wall Thermal Insulation System of Buildings (DBJ04-234-2005); the distortion resulting from drying shrinkage of the polymer crack-resistant mortar is small; the cohesive strength is high with high crack resistance, placeability and moisture retention; the hardened polymer crack-resistant mortar can be bonded to the wall or other parent materials well, and can prevent internal wall and external wall from cracking. The beating uniformity is high; the quality is stable; and the quality of building construction is guaranteed by adopting the polymer crack resistant mortar for construction.

Owner:闵博干

Polyester thermal contraction film with balanced thermal contraction performance and production method thereof

The invention discloses a polyester thermal contraction film with balanced thermal contraction performance and production method thereof, the film is of three-layer construction: a top layer, a core layer and a bottom layer, wherein the component of the core layer is polyethylene terephthalate; the top layer and the bottom layer comprise parent material 15-25% wt and copolymerized modified polyester. The vertical, horizontal thermal contractions of the film are balanced and the vertical thermal contraction is about 65% and the horizontal thermal contraction is about 70% at 90-100DEG C; the vertical, horizontal tensile strengths are 240-260MPa. The process is mature with very strong operability, especially suitable for two-step tensile polyester film production line.

Owner:ANHUI GUOFENG PLASTIC

Modified super-fine cool-ash composite plastic

InactiveCN101024712AQuality is not affectedDoes not affect the production processPolymer sciencePolystyrene

The invention relates to modified refined coal compound plastic. It includes plastic 100 portions, polyvinyl chloride and the matched plasticizer 1-95 portions, stabilizer 2-7 portions; plastic 100 portions and polyethylene, polypropylene, ethane acetic acid ethylene copolymer, polystyrene or ABS, and bulk additive 5-90 portions. The physical and chemical indexes are: carbon content >=90%, 18um screenings <=1%, dispersant and coupling agent 0.5-6 portions. The parent material carbon content of the invention could be over 70%. When being used in polyethylene and polyvinyl chloride cable material, it could make cable material ageing resistance, reinforcing action and equally black.

Owner:JIANGSU JINKEN TECH IND

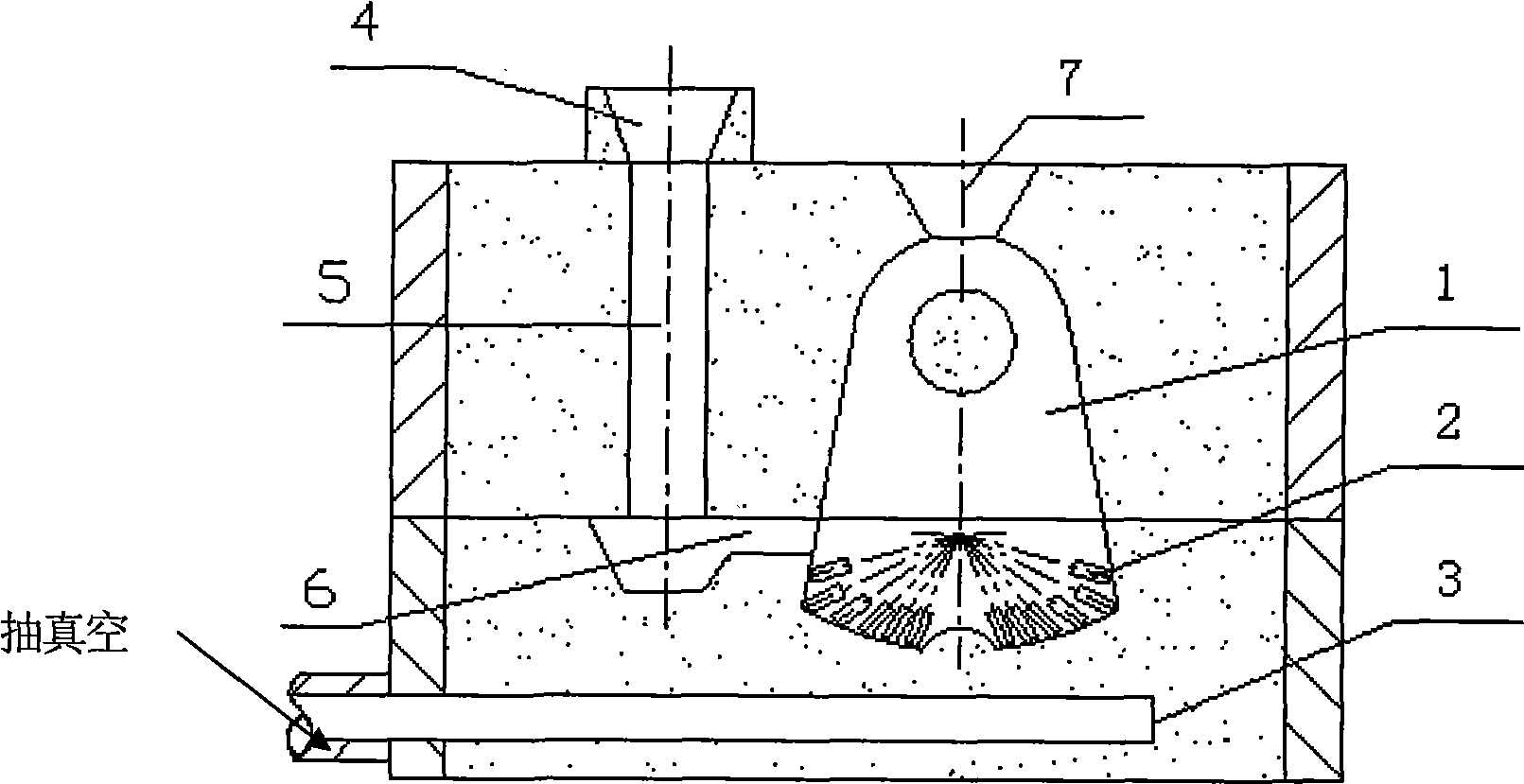

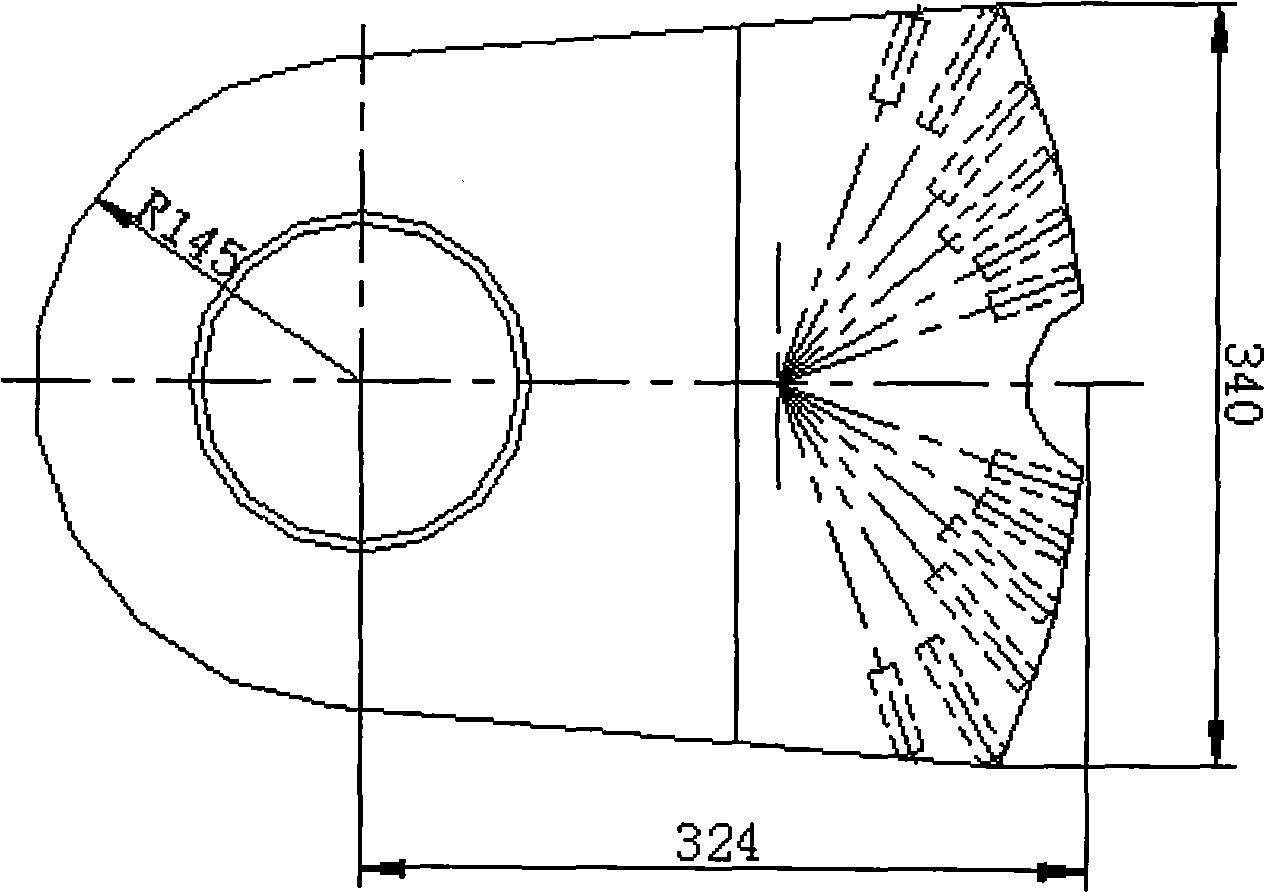

Composite material hammerhead of crusher and negative pressure casting method thereof

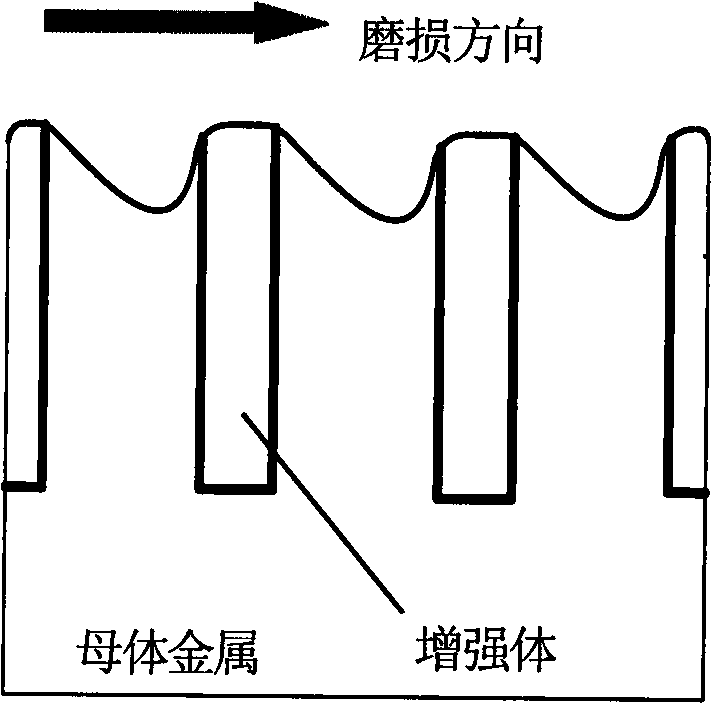

The invention discloses a composite material hammerhead of a crusher and a negative pressure casting method thereof. The negative pressure casting method comprises that: firstly, a metal parent material is subjected to electric smelting to form molten metal; WC particles and a bonding agent are mixed and prepared into paste, the paste is filled in a columnar metal screen which is then baked in a sealed mode to form a prefabricated body, and the prefabricated body is placed on the end face side of a mould cavity; a vacuum pump is started 5 minutes earlier than the tapping of the molten metal, and then the molten metal is tapped off for casting; and the vacuum pump is switched off after 4 minutes of the casting completion. The composite material hammerhead hammer body obtained by the preparation method is made of high manganese steel, alloy steel or common carbon steel; a hammer end, namely a working face or a striking face consists of a metal matrix and columnar reinforcers uniformly distributed in the metal matrix, wherein the columnar reinforcers are made of a composite material formed through infiltration of a ceramic particle prefabricated body and mother liquor metal, and have the hardness of HRC55-67 and excellent impact abrasion resistance; and the interface of the columnar reinforcers and the metal matrix, and the interface of the WC particles in the reinforcers and a substrate have good metallurgical bonding and high bonding strength.

Owner:XI AN JIAOTONG UNIV

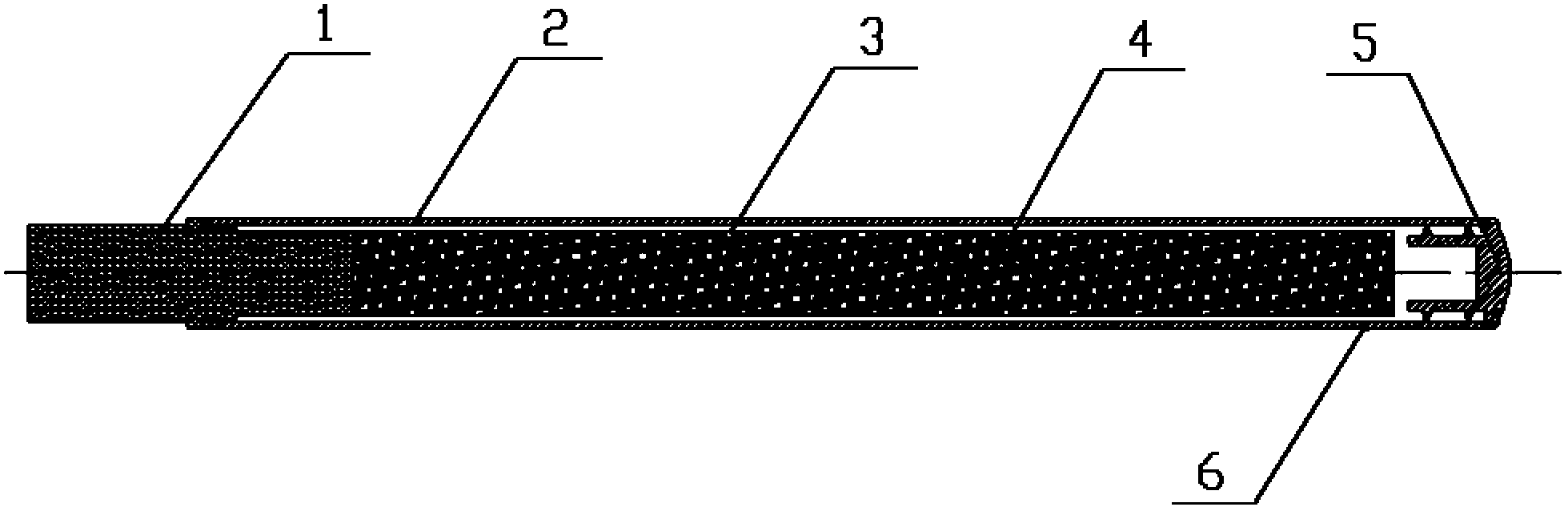

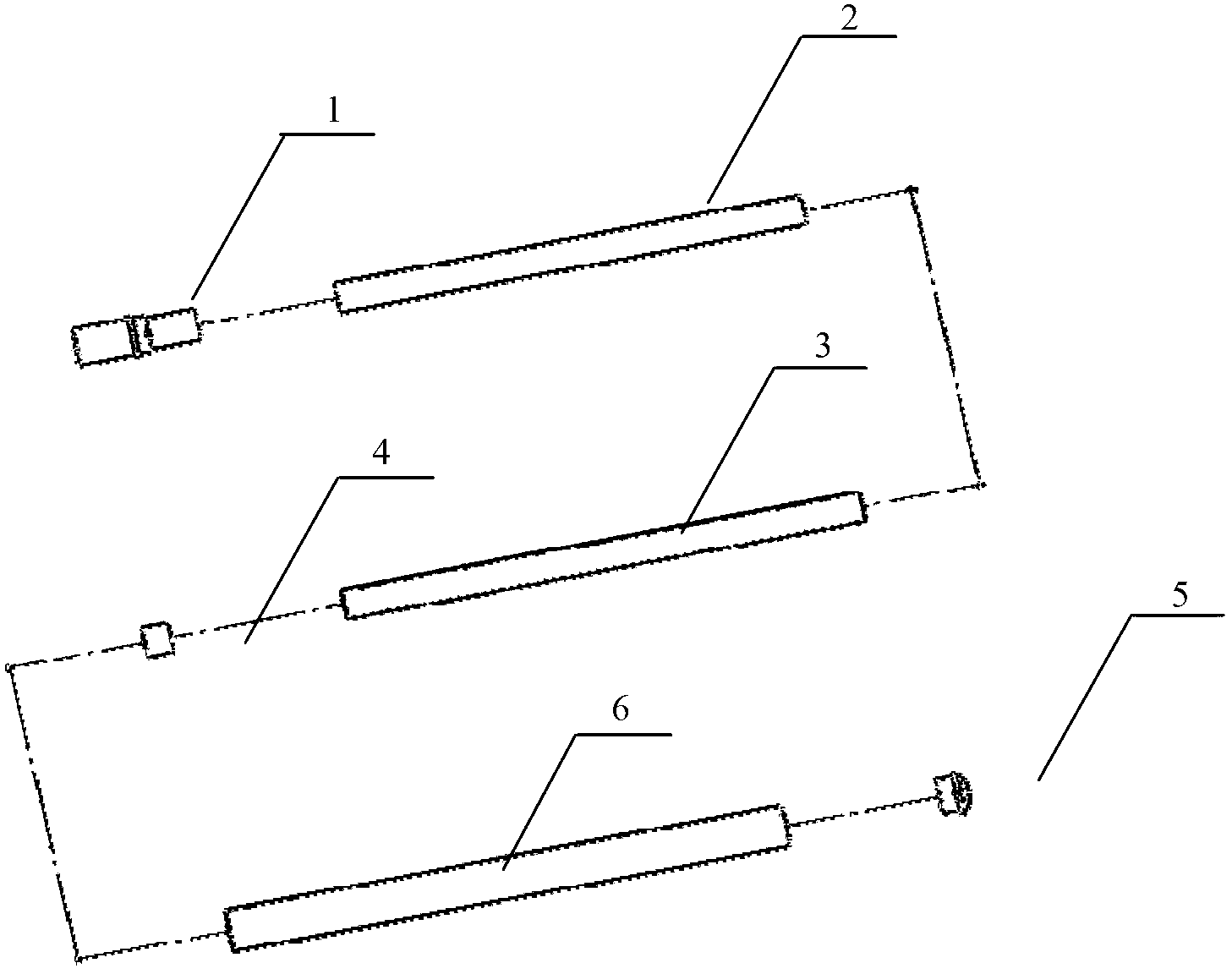

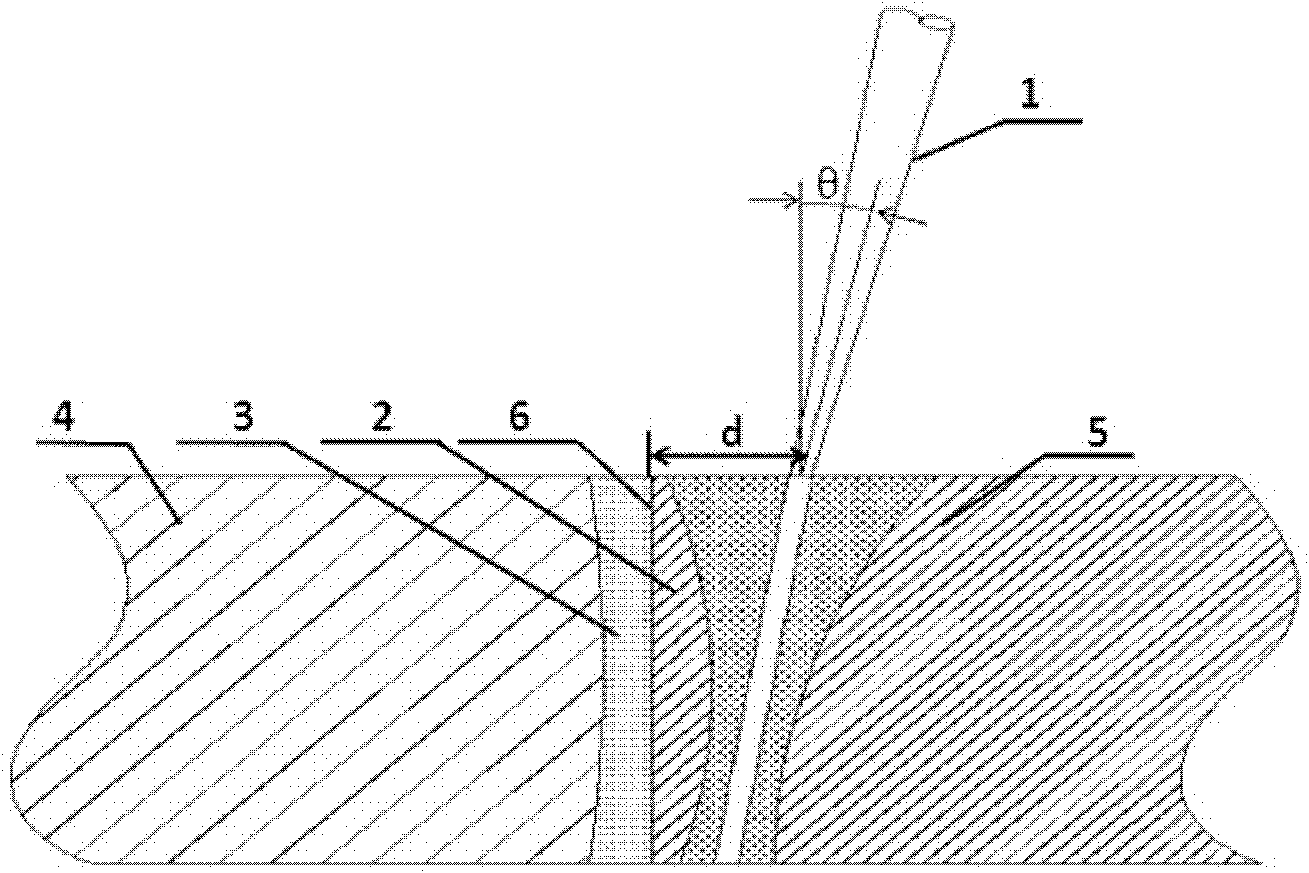

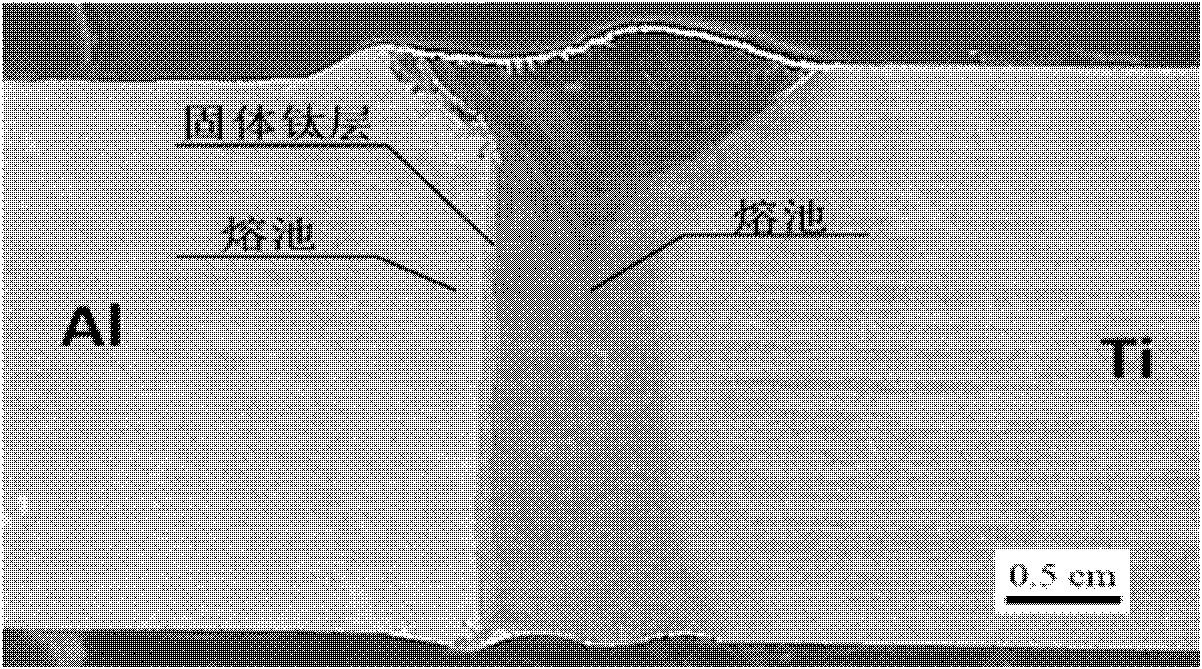

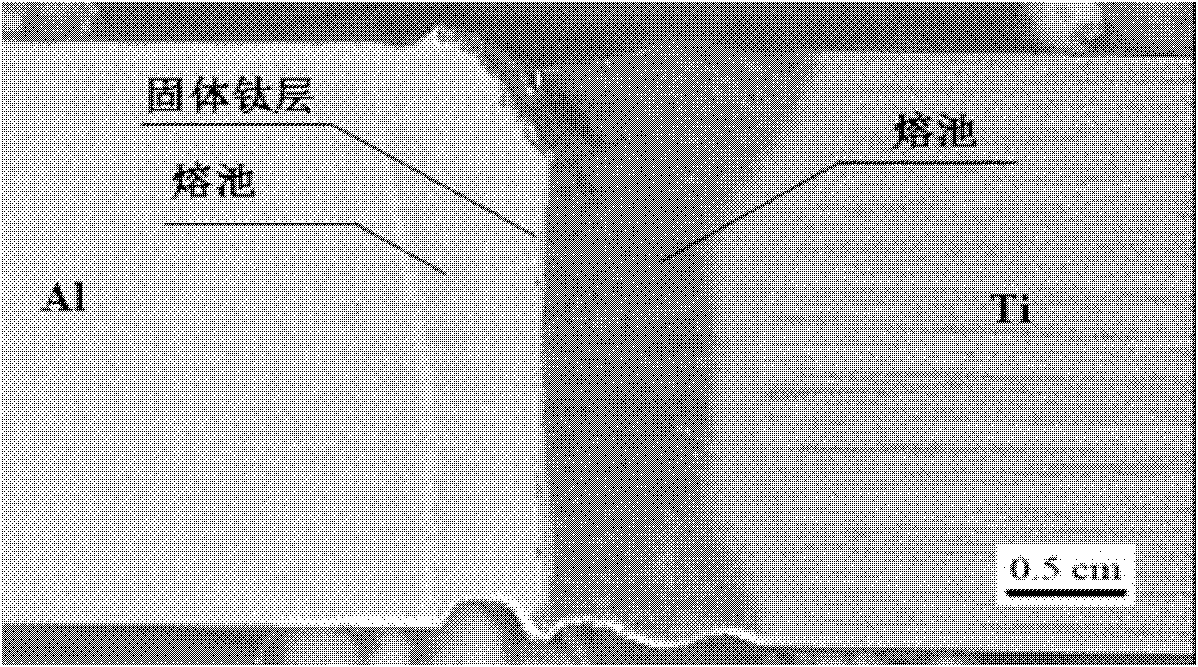

Laser penetration brazing method for dissimilar alloy

InactiveCN102145420AThe effect of improving wettabilityUncontrollable formationSoldering apparatusAlloyMaterials processing

The invention discloses a laser penetration brazing method for dissimilar alloy and belongs to the technical field of laser material processing. The method comprises the following steps of: during welding, allowing a focused laser beam (1) to act on one side of a high-melting-point parent material (5) to realize penetration fusion welding; and controlling a distance d of the laser beam (1) and an interface (6) on the surface of the high-melting-point parent material and an included angle theta between the laser beam (1) and a normal line, forming a high-melting-point parent material solid state intermediate layer (2) on the high-melting-point parent material side close to the interface (6), melting a low-melting-point parent material (4) through the heat conduction of the high-melting-point parent material solid state intermediate layer (2), and spreading and soaking the high-melting-point parent material (5) on a melted low-melting-point parent material layer (3) to realize the laser penetration brazing of the dissimilar alloy. The laser energy utilization rate and welding efficiency are obviously improved, and the welding of a dissimilar alloy plate with a certain thickness can be realized. The influence of mixing two kinds of metal liquid states at the interface to generate a complex and brittle intermetallic compound on joint quality is avoided.

Owner:BEIJING UNIV OF TECH

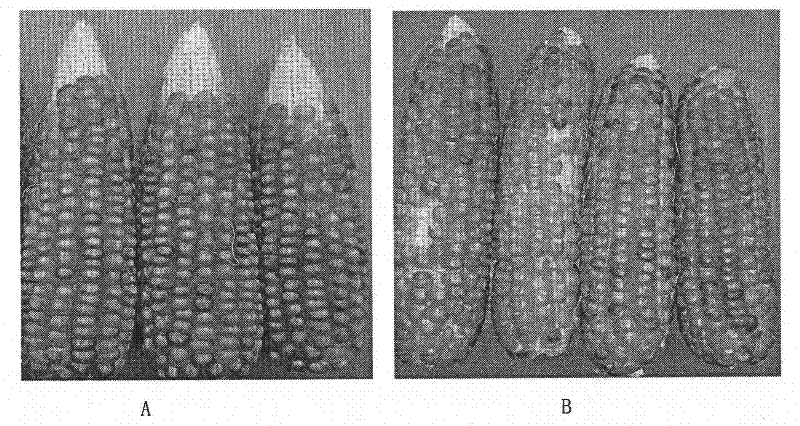

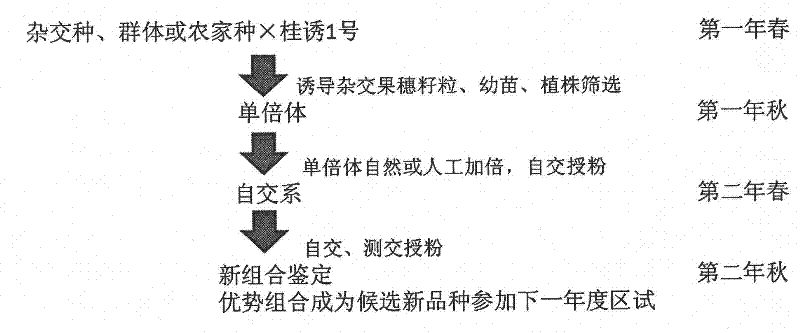

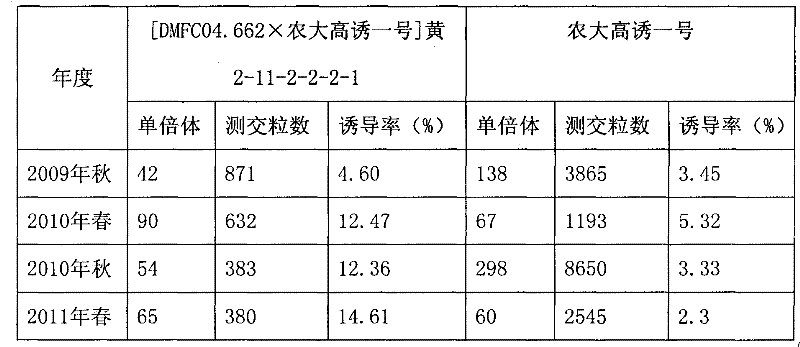

Breeding method of maize parthenogenesis inducer and its application in maize inbred line breeding

InactiveCN102440179AShorten breeding timeSimple procedurePlant genotype modificationAgricultural scienceParthenogenesis

The invention discloses a breeding method of a maize parthenogenesis inducer and its application in maize inbred line breeding. Employment of a maize parthenogenesis inducer can induce a female parent material to perform parthenogenesis and generate a female parent haploid, thus realizing a method able to rapidly breed a highly homozygous maize inbred line in a large-scale through simple process and create a lot of new maize breeding resources. And the application of a maize parthenogenesis inducer consists of: using a high frequency parthenogenesis inducer Guiyou No.1 as a male parent to hybridize with an excellent maize breeding germplasm resource, making use of an obvious seed purple marker to pick out a haploid grain, and utilizing the purple marker of a plant to distinguish a non-haploid plant, subjecting a haploid plant to chromosome doubling so as to become a normal diploid, then conducting inbreeding so as to generate a new highly homozygous maize inbred line, which can be applied in maize hybrid combination preparation for breeding new maize varieties. Compared with a traditional pedigree breeding method, the method provided in the invention can shorten the breeding time of an inbred line by 3-4 years, thus shortening the breeding period of new maize varieties.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION CORN RES INST

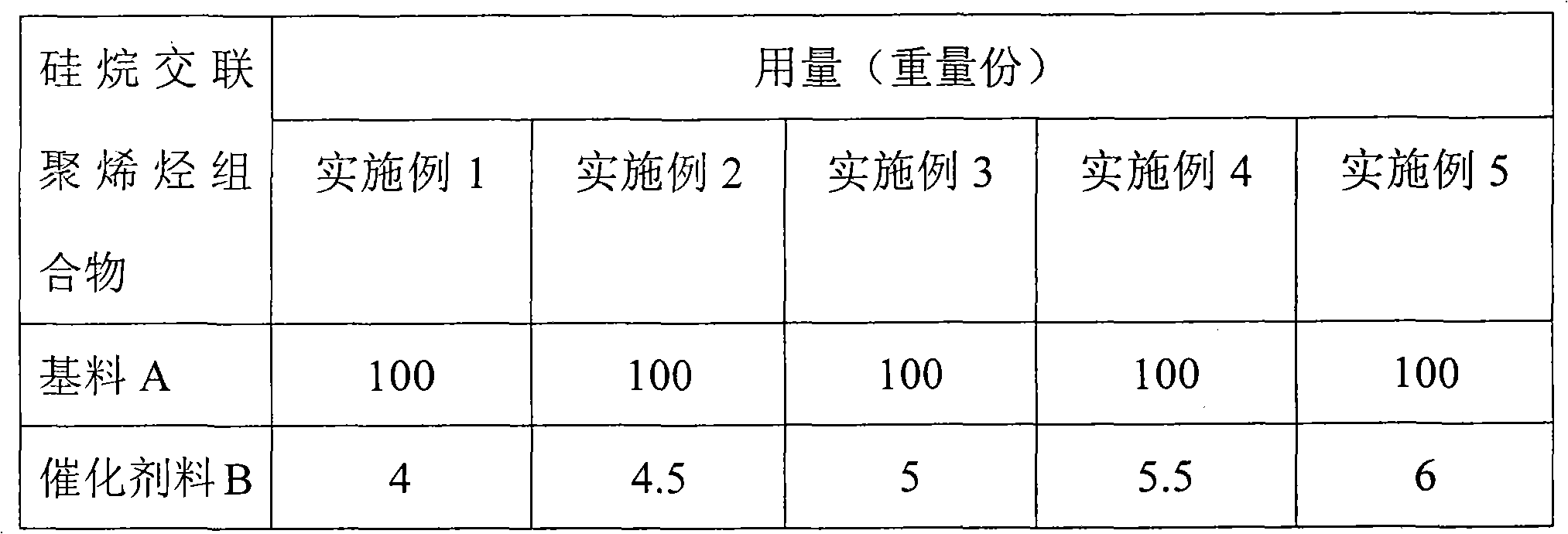

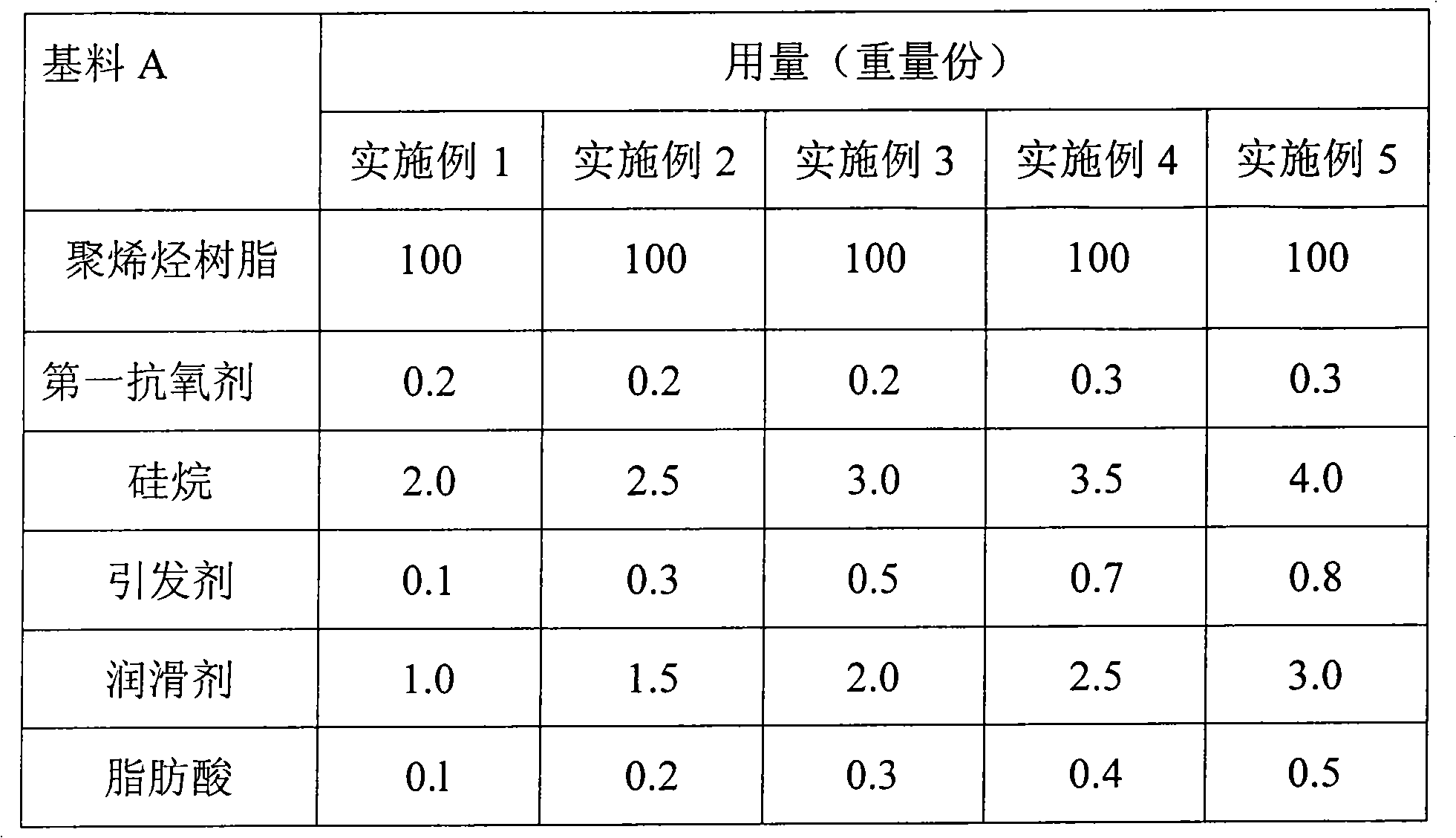

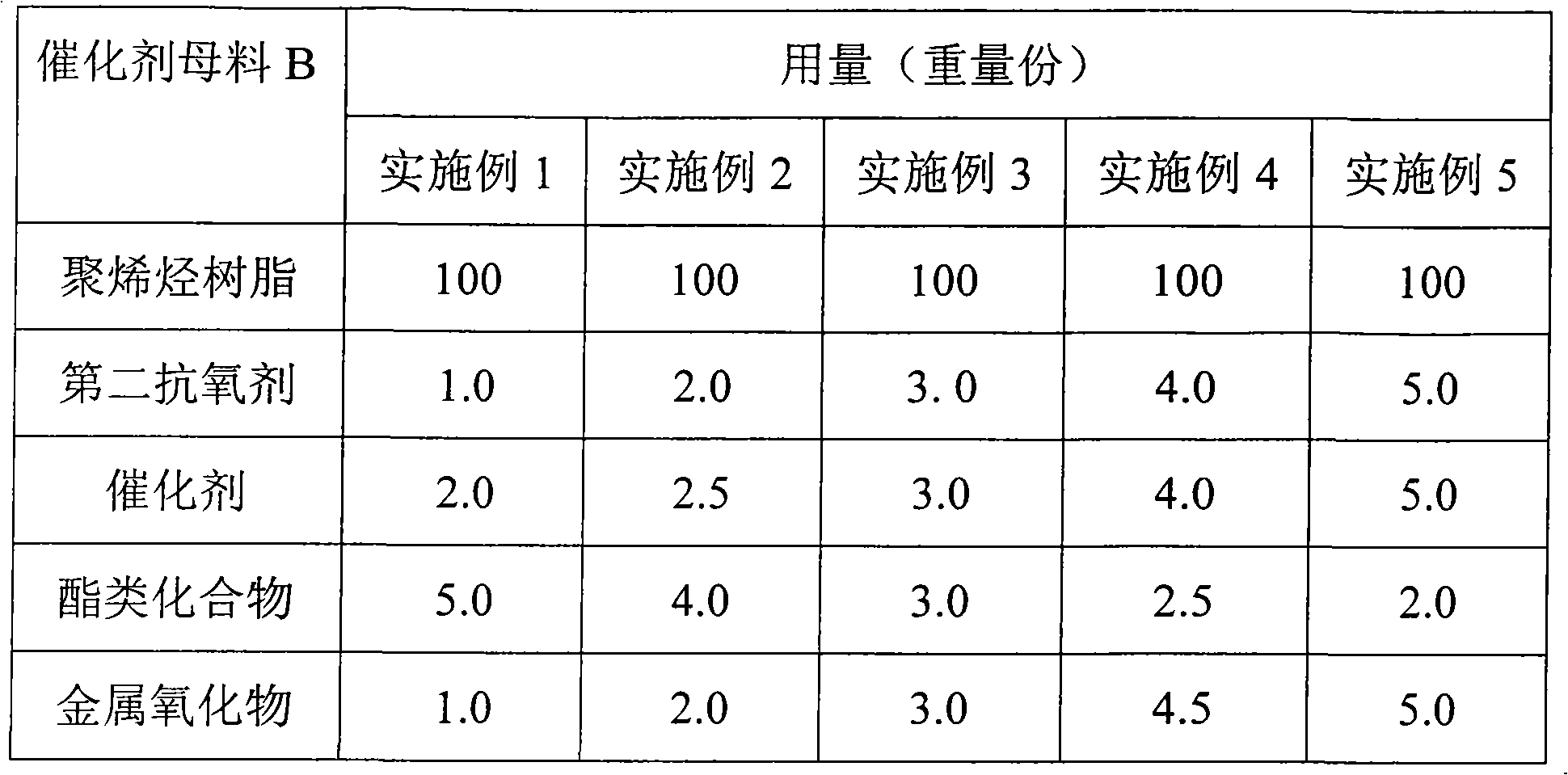

Boiling-free silicane cross-linking polyolefin composition

The invention provides a warm-water-free silane crosslinking polyolefines composition, comprising base material A and catalyst parent material B, the weight ratio thereof being :100:4-6, wherein the base material A is composed of (by weight parts): polyolefine rsin 100 parts, first antioxidant 0.2-0.3 parts, silicane 2.0-4.0 parts, initiator 0.1-1.0 parts, lubricant 1.0-3.0 parts, fatty acid 0.1-0.5 parts, the catalyst parent material B is composed of (by weight parts): polyolefine resin 100 parts, second antioxidant 1.0-5.0 parts, catalyst 2.0-5.0 parts, ester compound 2.0-5.0 parts, metal oxide 2.0-5.0 parts. The preparation method is uniformly mixing the above material. The silane crosslinking polyolefines composition can be linkable under natural conditions not through boiling or vapor bathing, with property corresponding the operational requirement, especially silane crosslinking polyolefines cable material .

Owner:JIANGSU DEWEI ADVANCED MATERIALS +1

Directed cultivation method for drought-resisting water-saving variety of winter wheat

ActiveCN102197784AIncreased yield potentialImprove qualityPlant genotype modificationHorticultureEarly generationWater saving

The invention discloses a directed cultivation method for a drought-resisting water-saving variety of winter wheat. The directed cultivation method mainly comprises the following steps: A, selectively pairing and hybridizing excellent complementary parent materials; and B, carrying out directed cultivation to select a new strain with strong drought resistance and high yield, wherein the step B iscarried out according to the following operations: B-1, planting early-generation F1-4 materials under high water and fertilizer conditions, and selecting based on yielding ability; and B-2, taking higher-generation materials (above generation F5) in duplicate, respectively planting under high water and fertilizer conditions and drought stress conditions in an inter-generation water-drought alternation manner, and selecting the new strain with strong drought resistance and high yield. The selected new variety of winter wheat has outstanding drought resistance and water-saving property, and has the characteristics of high yielding potential and strong stress resistance.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Manufacturing method of vehicle seamless steel tubes

The invention relates to a manufacturing method of vehicle seamless steel tubes. Surface quality of finished products can be improved through twice phosphorus acid saponification processing and secondary cold drawing processing; during manufacturing, external and internal quality of the products can be guaranteed through twice test, performance index of the steel tubes with the tensile strength larger than or equal to 500Mpa and extension larger then or equal to 10% and internal and external surface roughness smaller than or equal to 0.4 micrometers can be achieved by directly using saw cutting without heat treatment and mechanical machining, requirements of the steel tubes of vehicle parts on strength, toughness and surface quality are met, and meanwhile, technical requirement of processing-free steel tube parent materials of the vehicle parts can be met.

Owner:泰州双马节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com