Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2277 results about "Fusion welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fusion welding is a generic term for welding processes that rely on melting to join materials of similar compositions and melting points. Due to the high-temperature phase transitions inherent to these processes, a heat-affected zone is created in the material (although some techniques, like beam welding, often minimize this effect by introducing comparatively little heat into the workpiece).

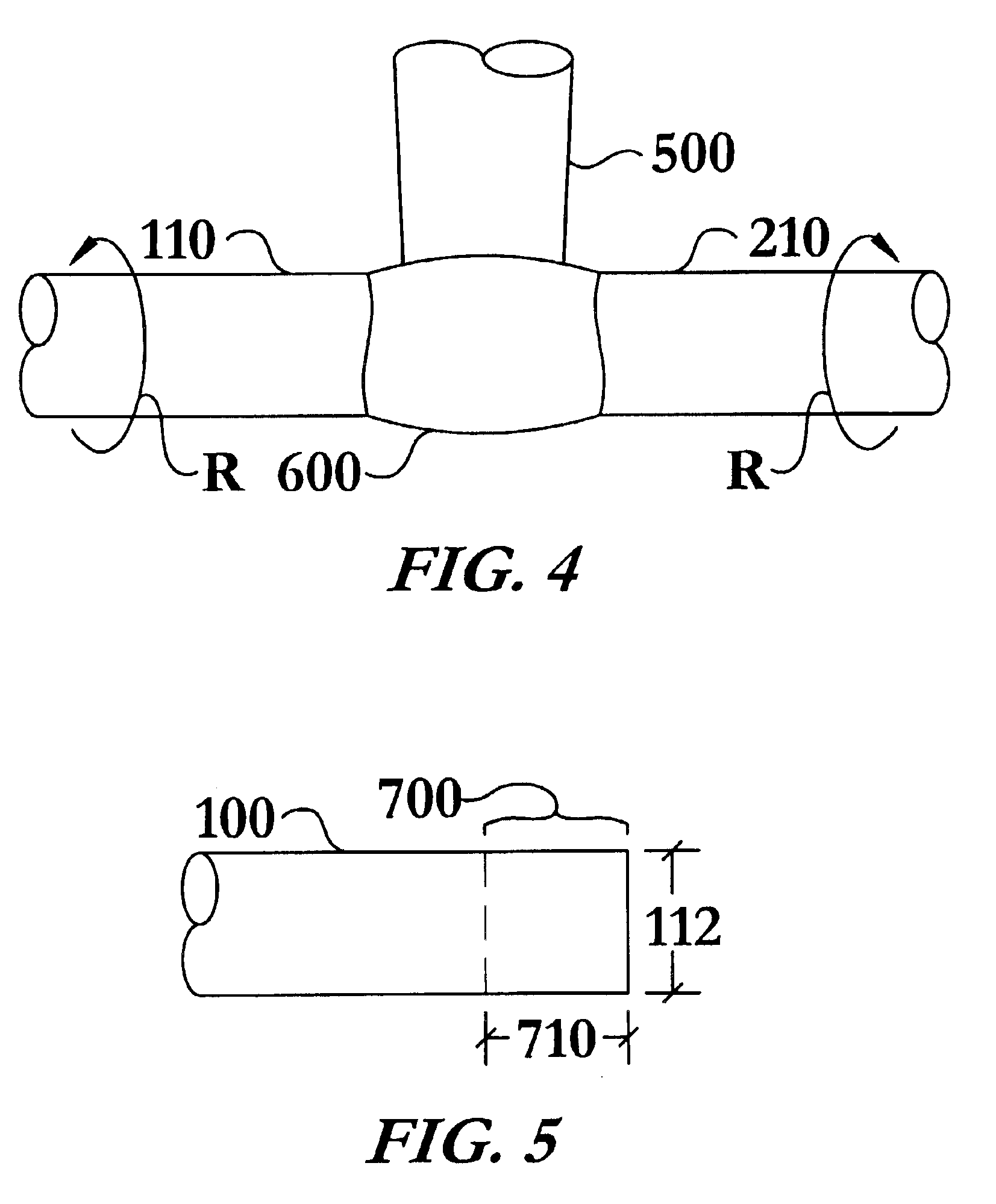

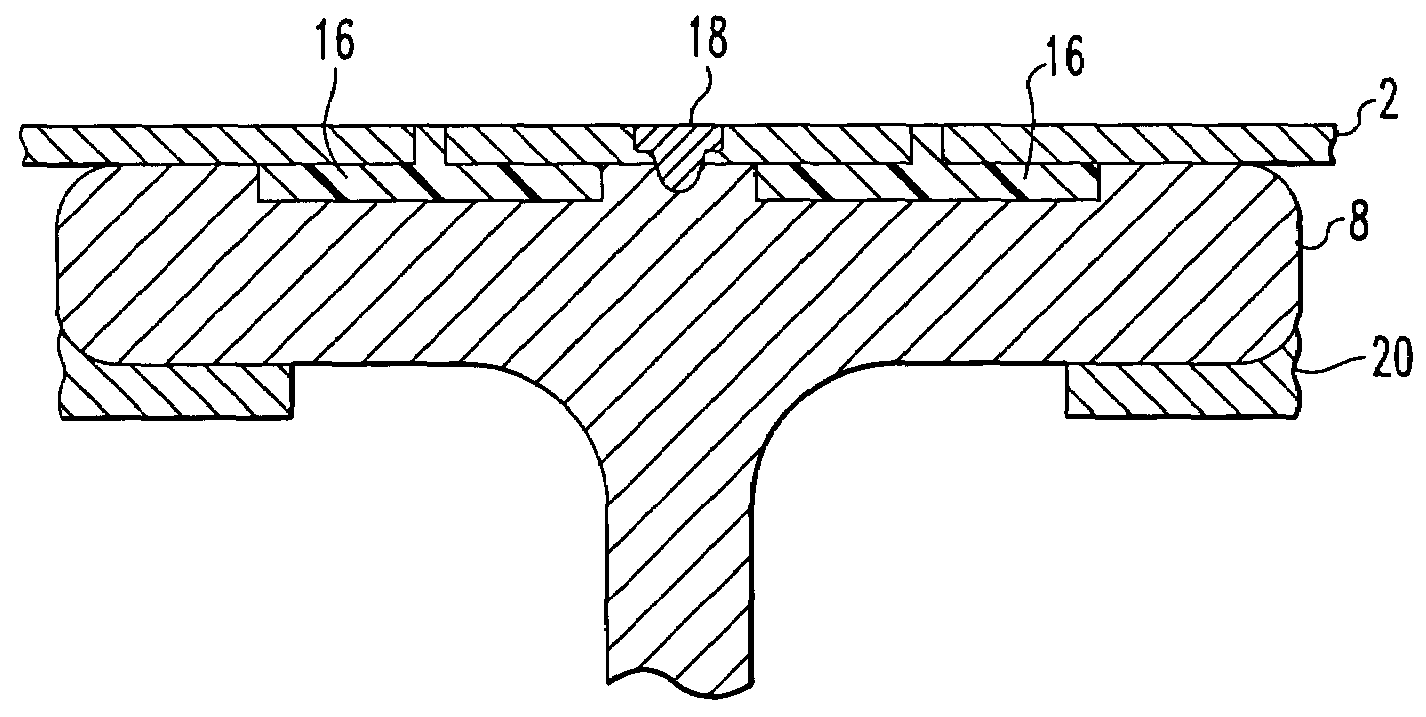

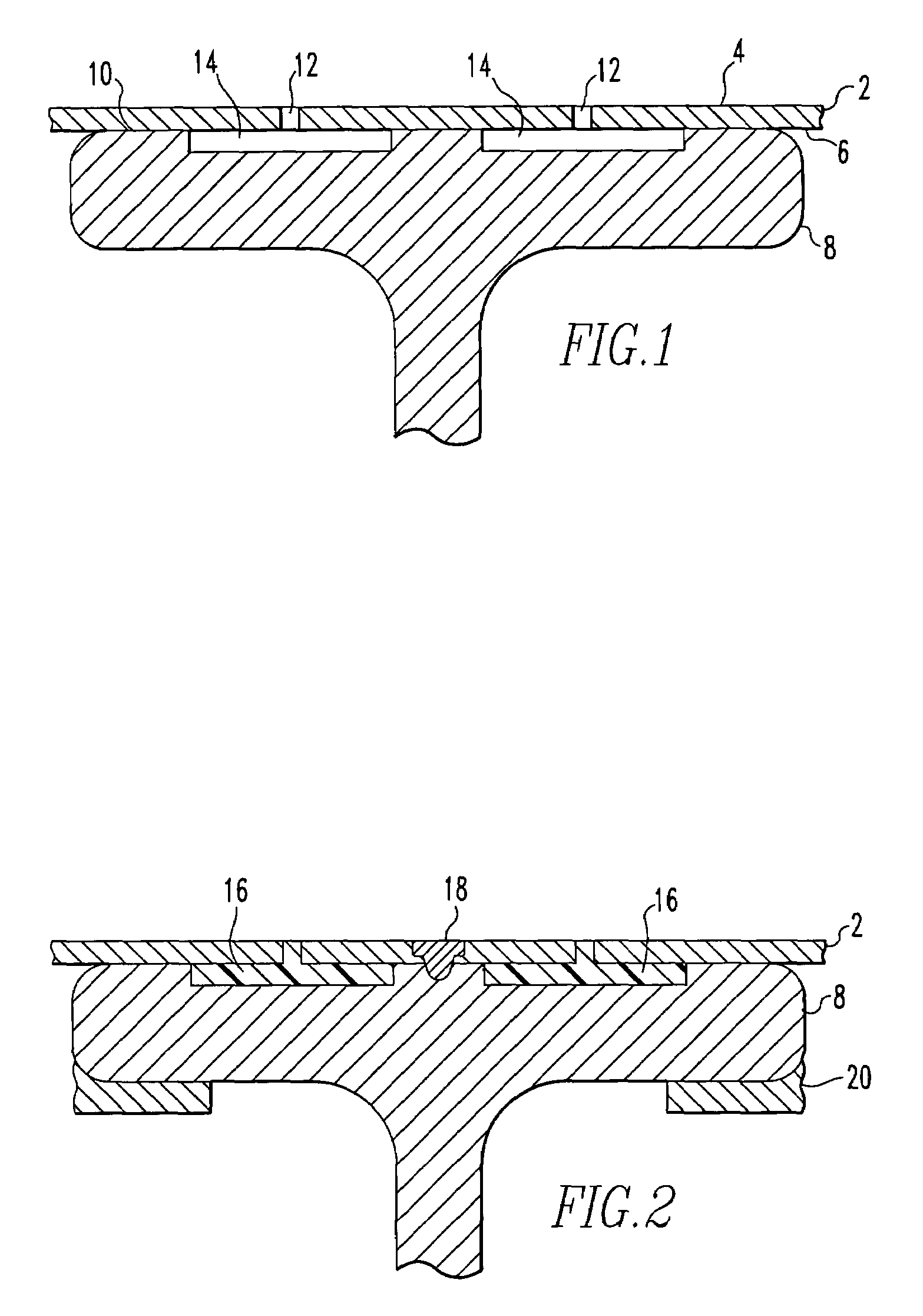

Pipe fittings

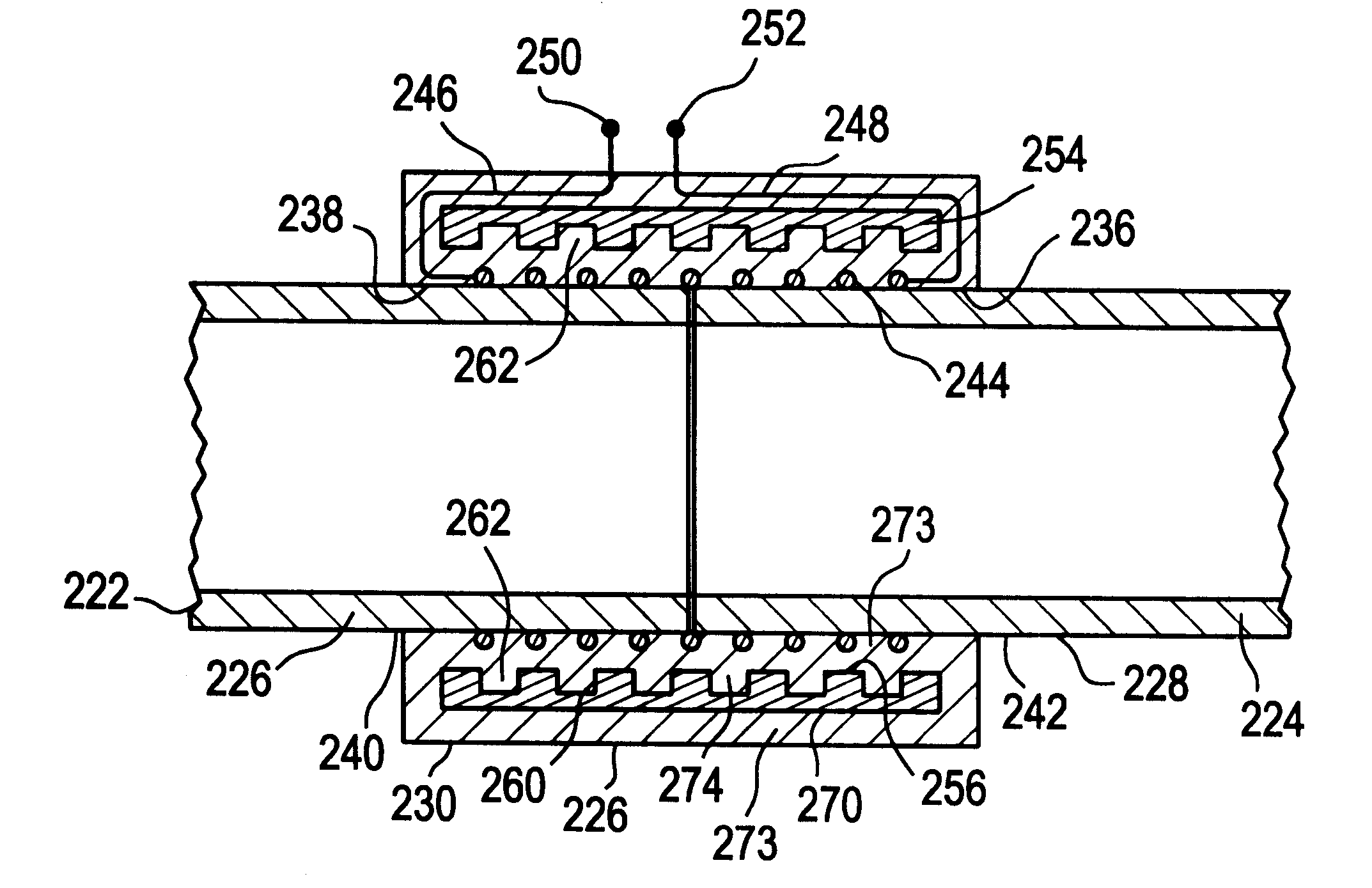

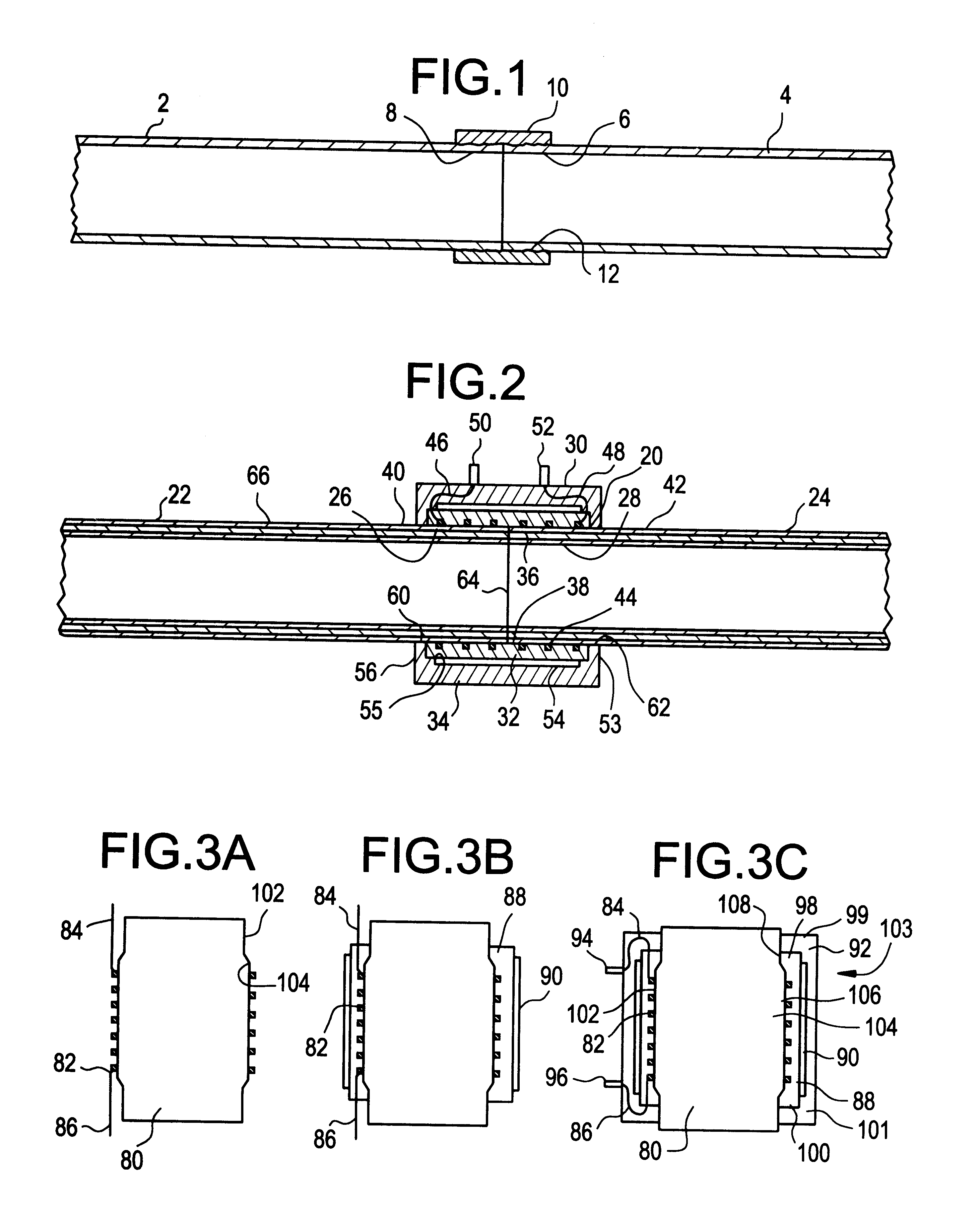

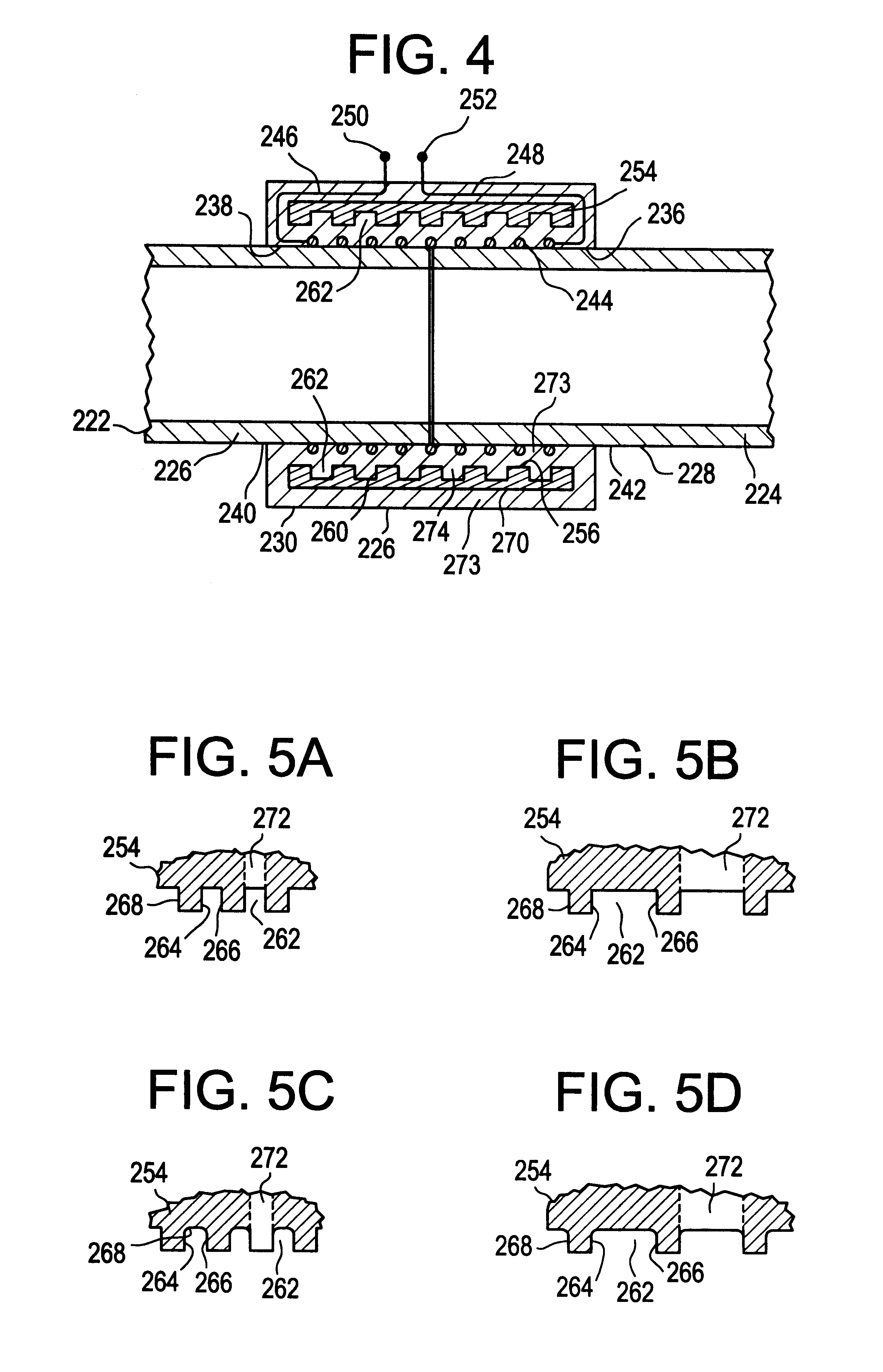

A pipe fitting for coupling together opposed ends of two plastics pipes by fusion welding, the pipe fitting comprising an annular body having an inner cylindrical surface of plastics material surrounding a cylindrical cavity for receiving opposed ends of two plastics pipes to be coupled together, an electrically conductive coil provided in said inner cylindrical surface and surrounding the cylindrical cavity, the coil having opposed ends, a pair of terminals each connected to a respective end of the coil and provided on the body for connection to a source of controlled electrical power, and an annular reinforcing member disposed in the body and surrounding the coil, the annular reinforcing member having a grooved surface which interfaces the annular body, the grooved surface defining a plurality of axially facing surfaces.

Owner:FINA RES SA

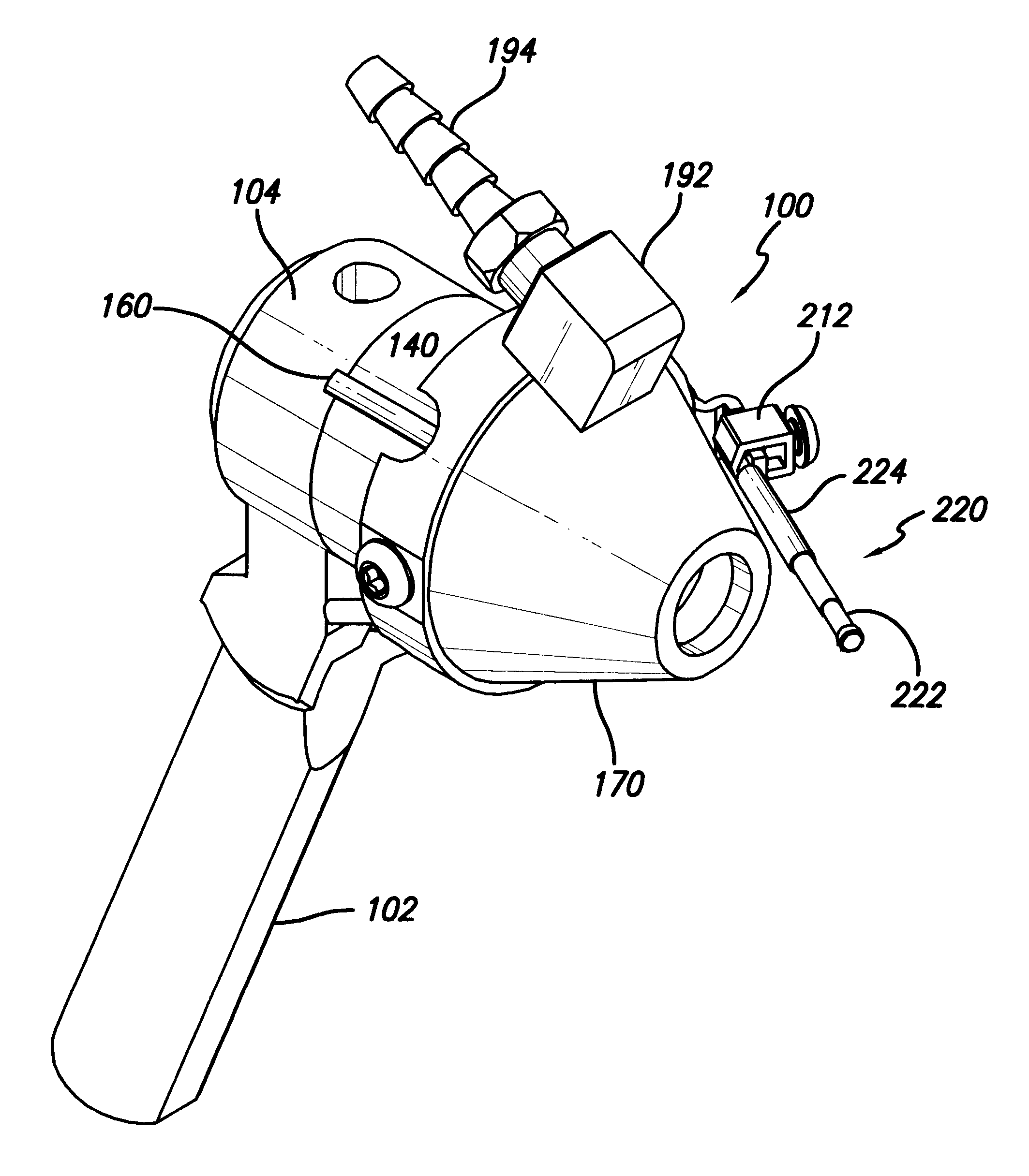

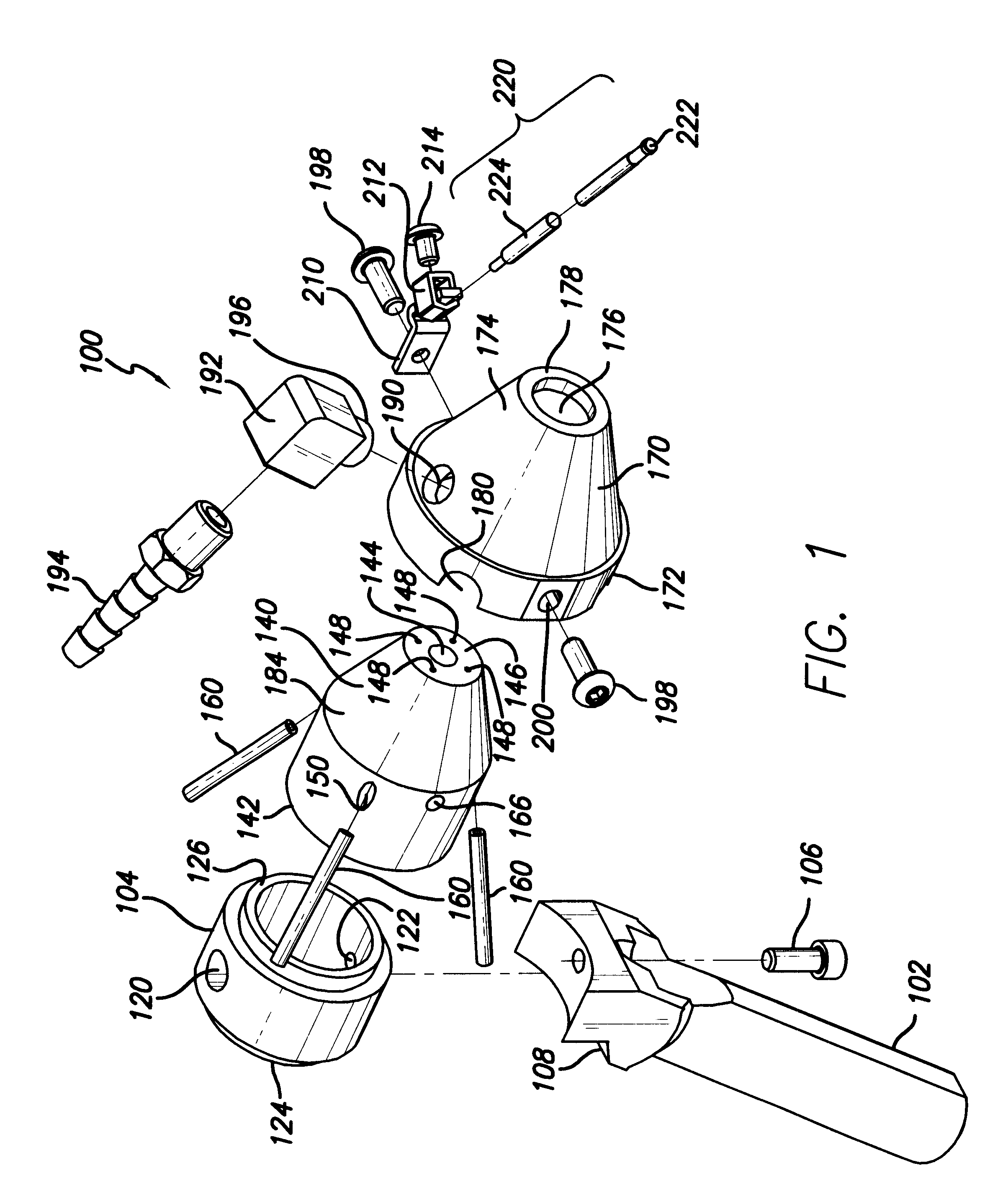

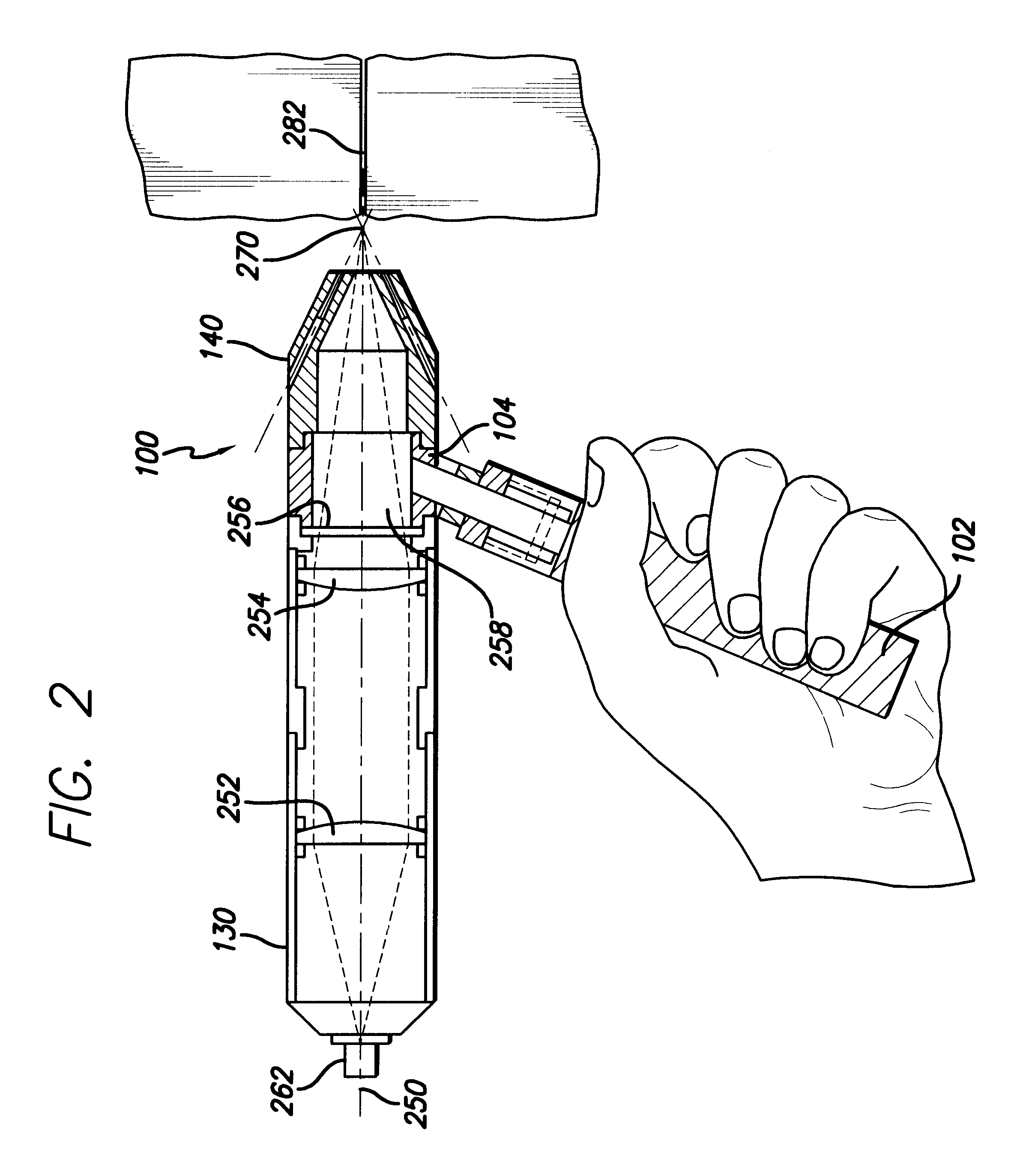

Hand held powder-fed laser fusion welding torch

A novel and inventive hand held powder-fed laser fusion welding torch providing manual flexibility for laser welding with powder-fed material. The hand held laser includes a body, handle, and nozzle assembly. The nozzle may be shrouded by a cover that is slightly spaced apart from the nozzle. The gap between the two may provide space through which inert gas may flow. Laser light from a remote source shines through the nozzle's central aperture. The nozzle aperture may be circumscribed by powder channel outlets aligned upon a working focal point coincident with the laser beam to treat a workpiece. A proximity sensor may enable selective welding torch operation according to the presence of a workpiece.

Owner:HONEYWELL INT INC

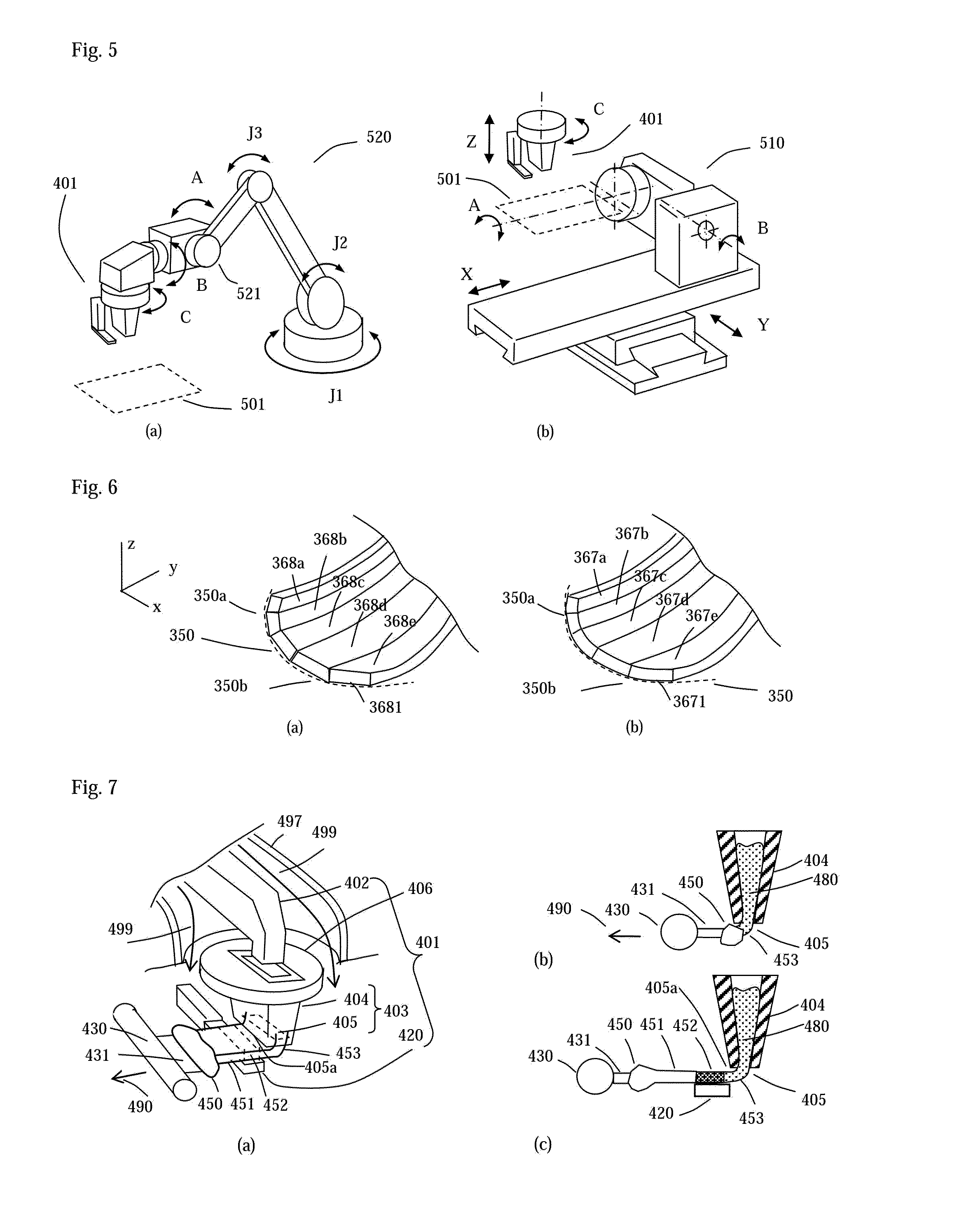

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

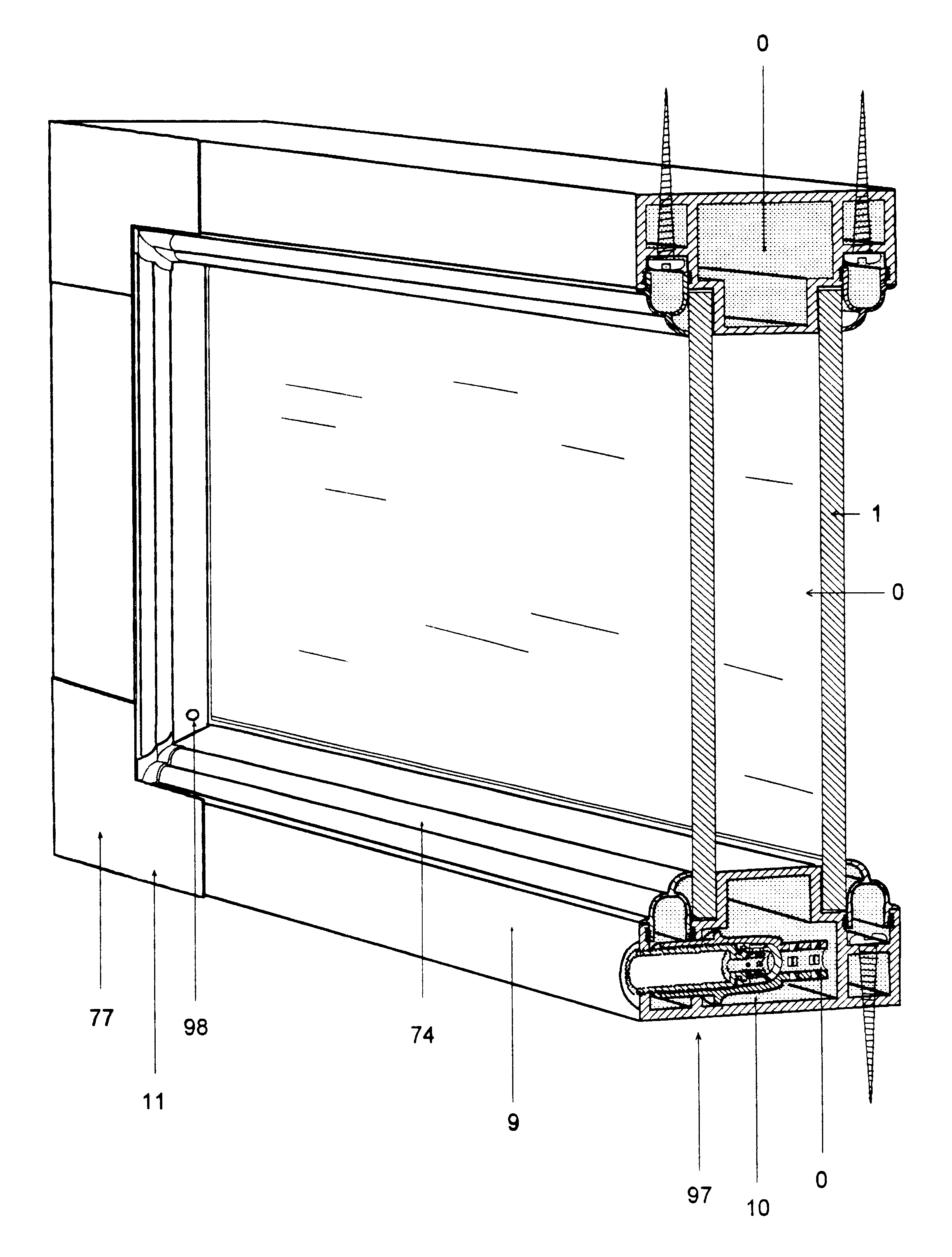

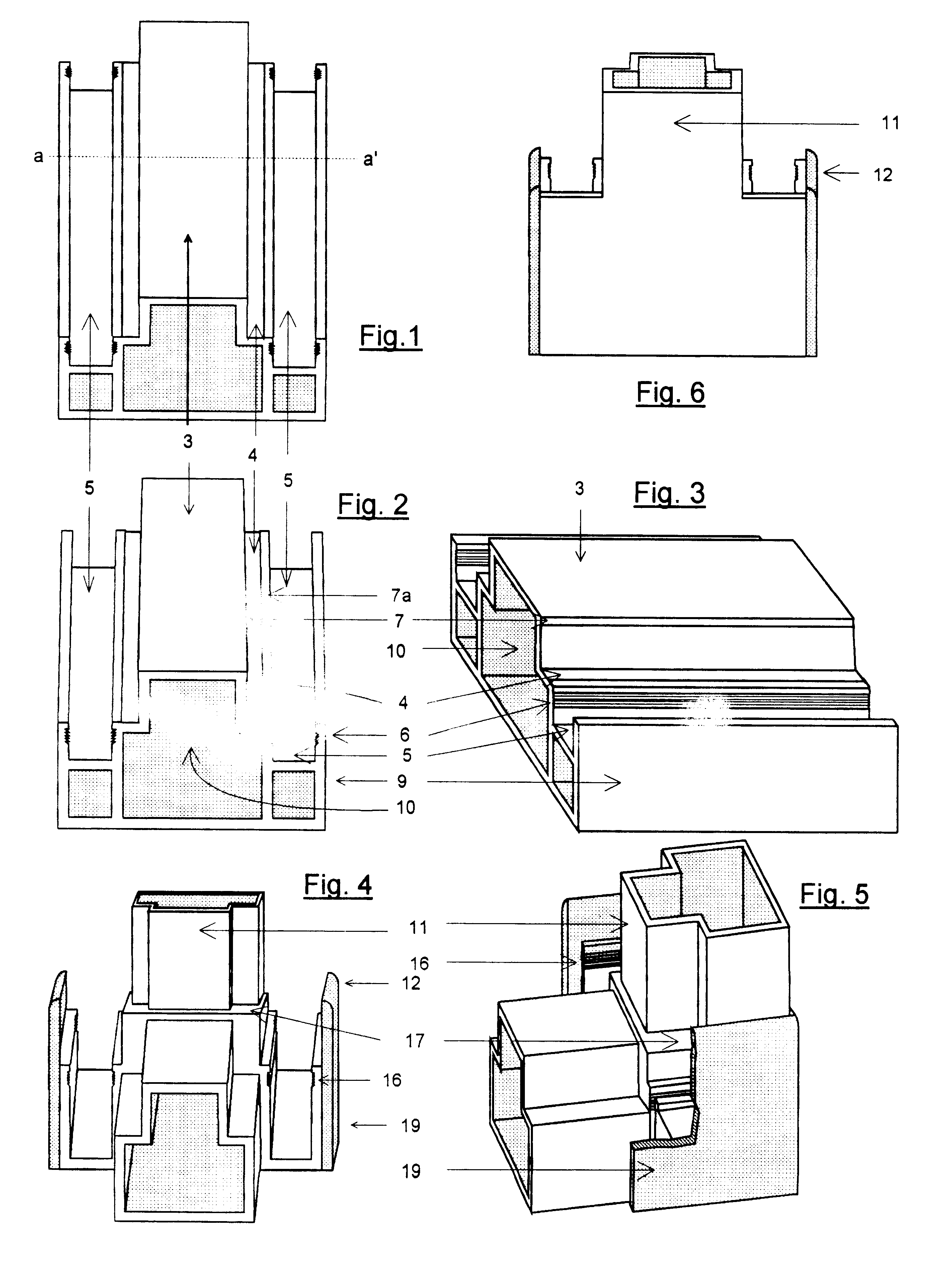

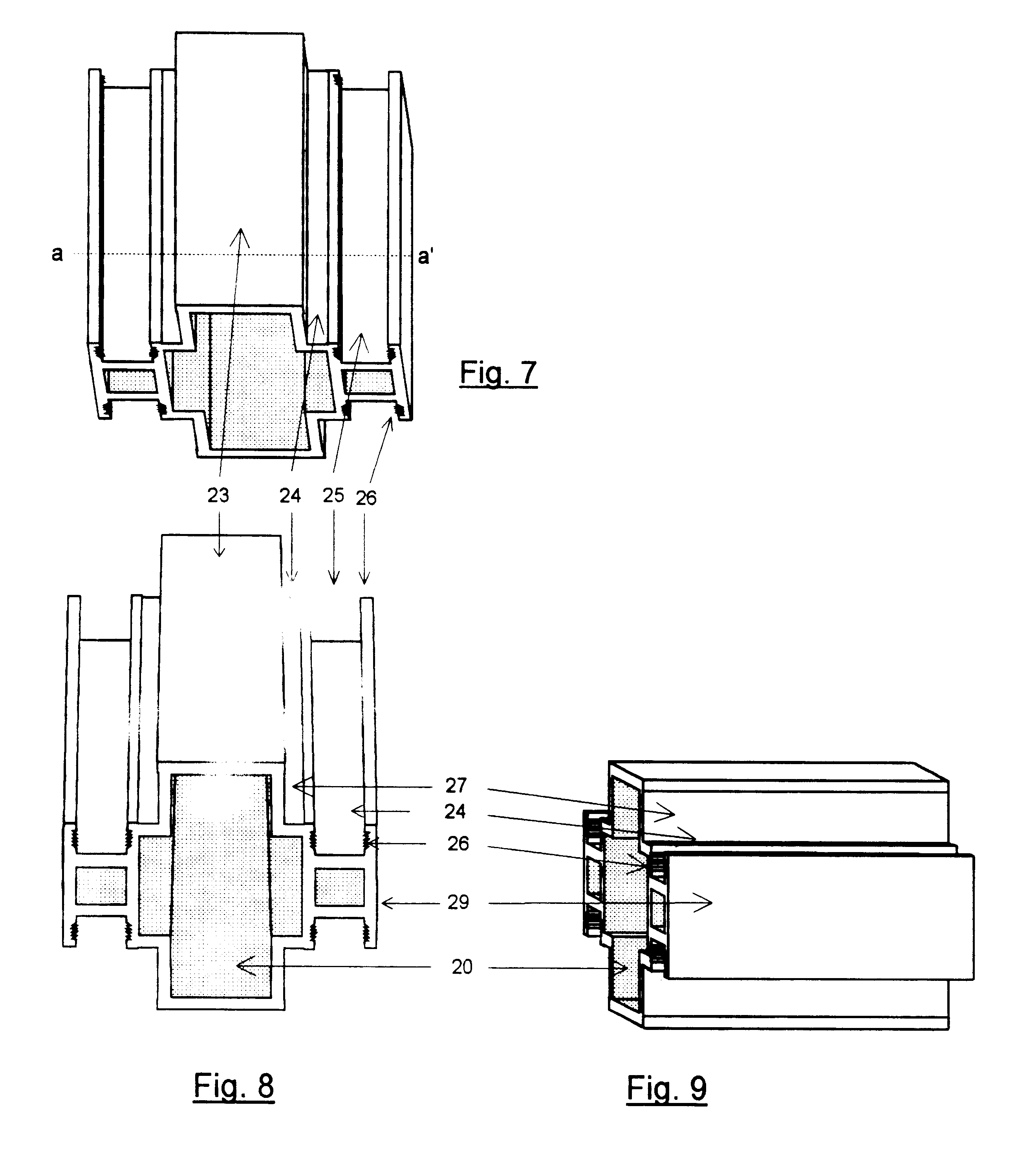

Assembly system for thermoacoustic windows

An assembly system used to build two pane thermoacoustic windows for houses and buildings is provided. The assembly system uses a set of profiles and joints and a permanently installed valve to assemble the window frame without a fusion welding machine. The system creates an airtight chamber directly on the frame. The valve allows the assembler to evacuate the air in the airtight chamber to make a vacuum, or to inflow a gas. The system improves the insulating thermal and acoustic capacity of the window, and allows a supplier to sell the components to build the window, which is then assembled by snapping together profiles and joints. The system can also be applied to assembly one pane window and for other purposes.

Owner:VALDERRAMA MARIO

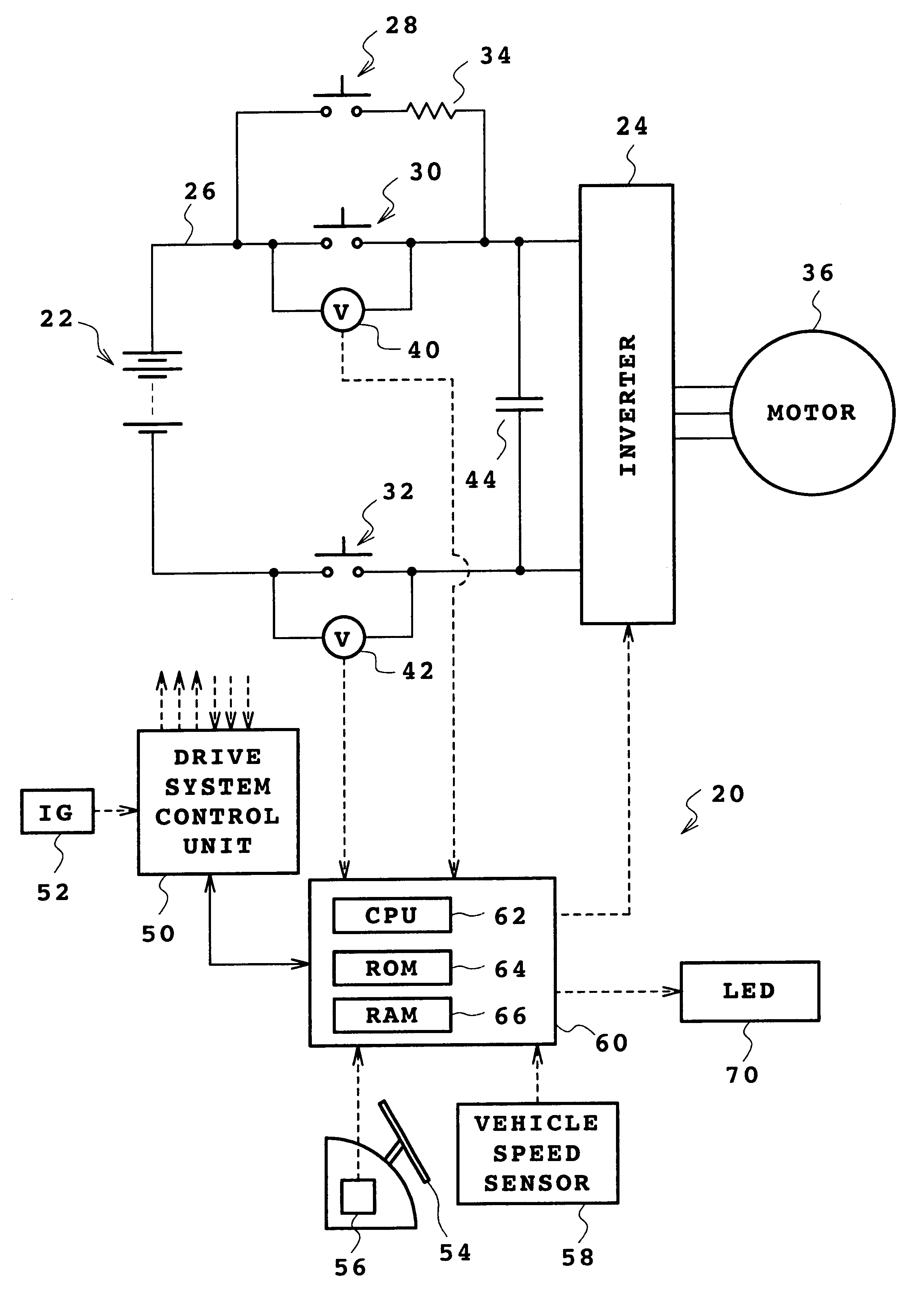

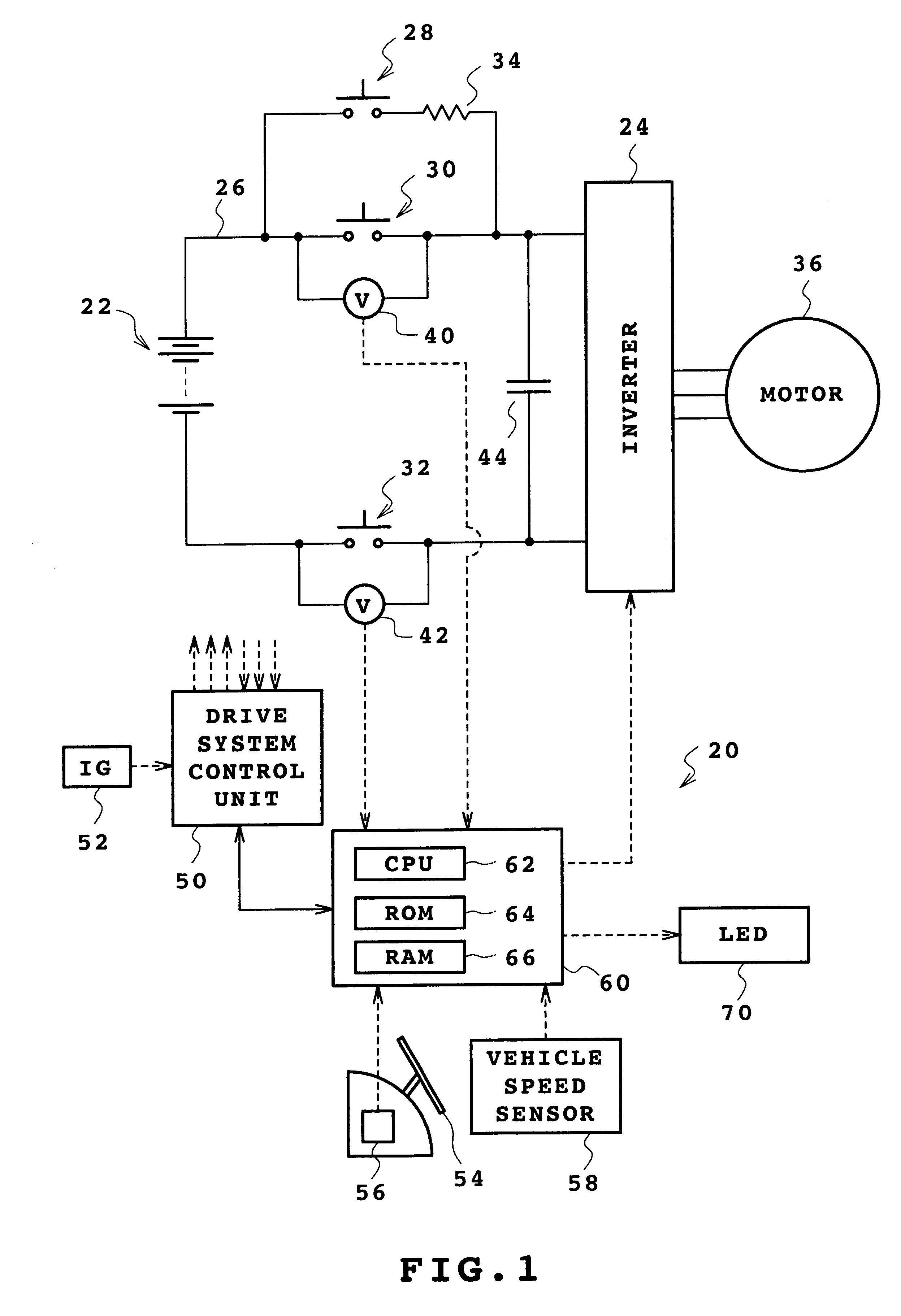

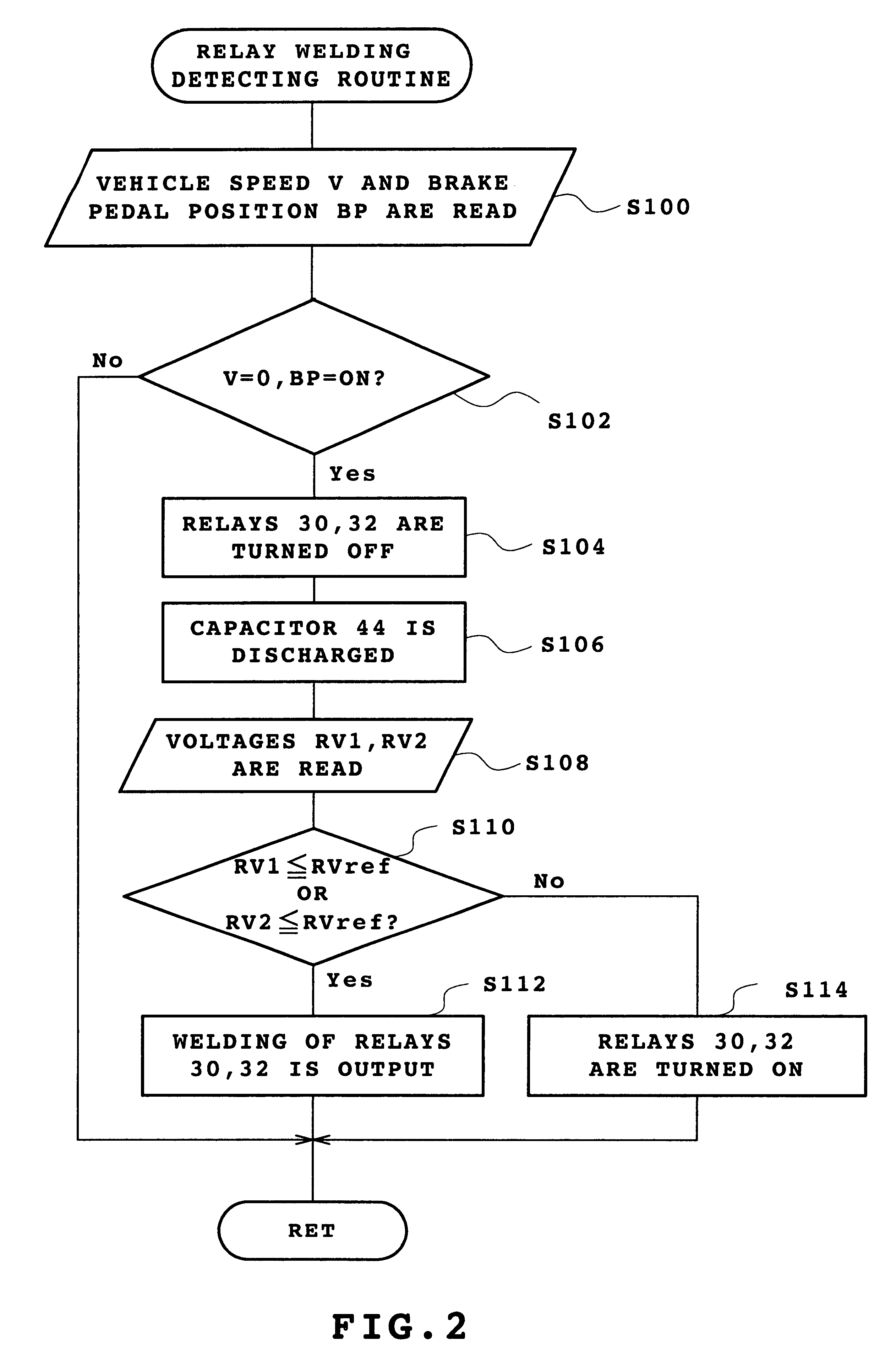

Relay welding detector and detecting method

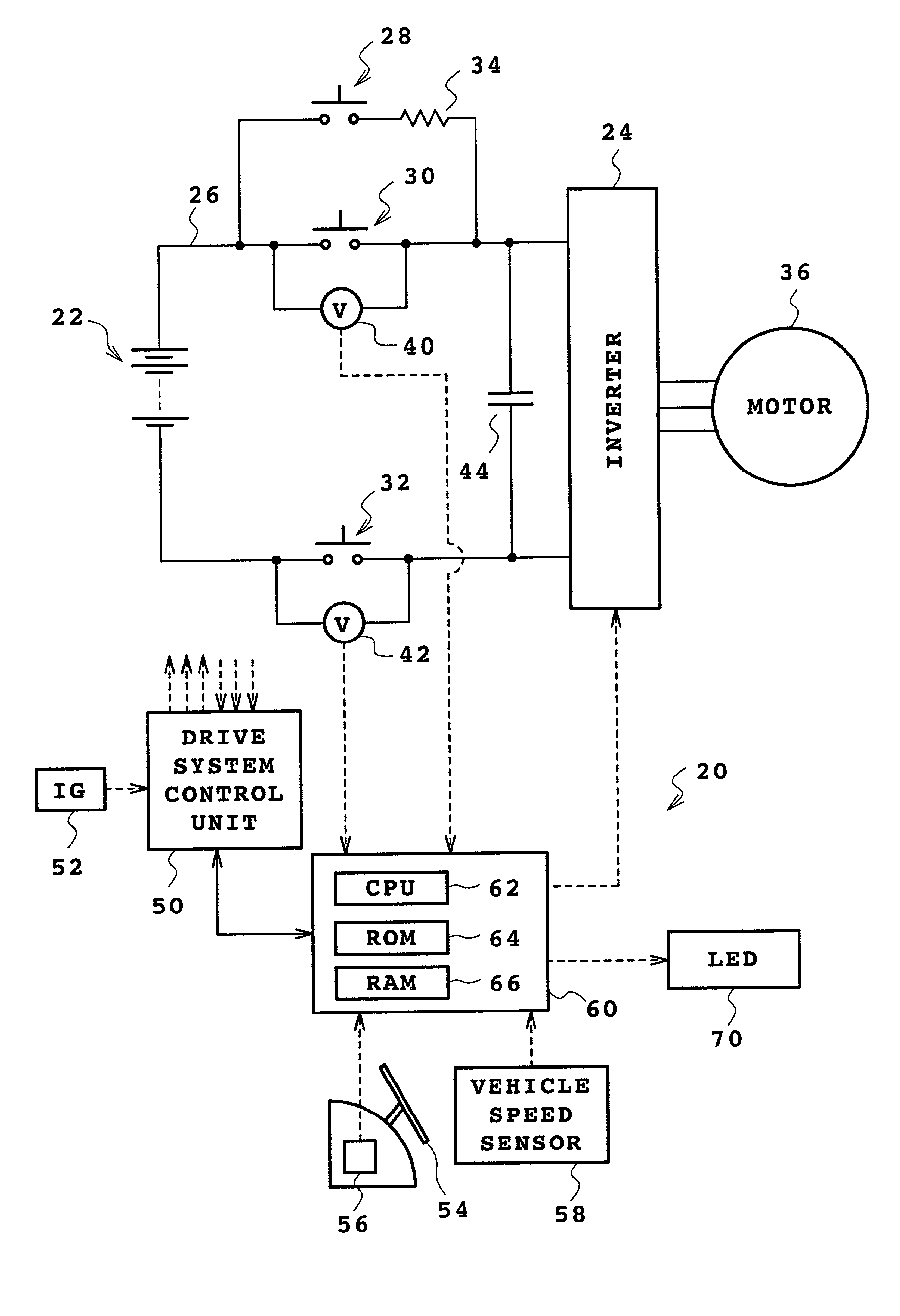

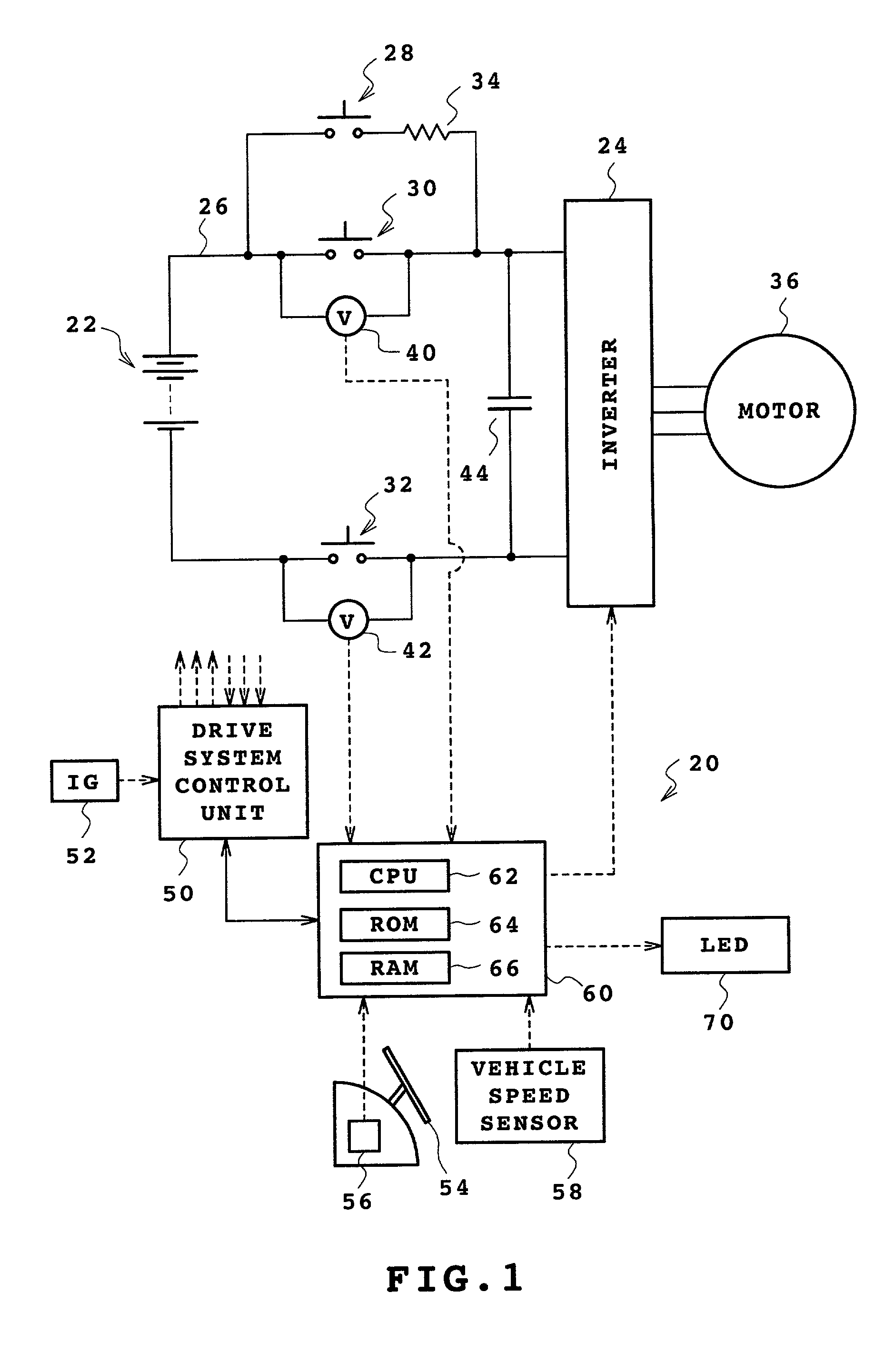

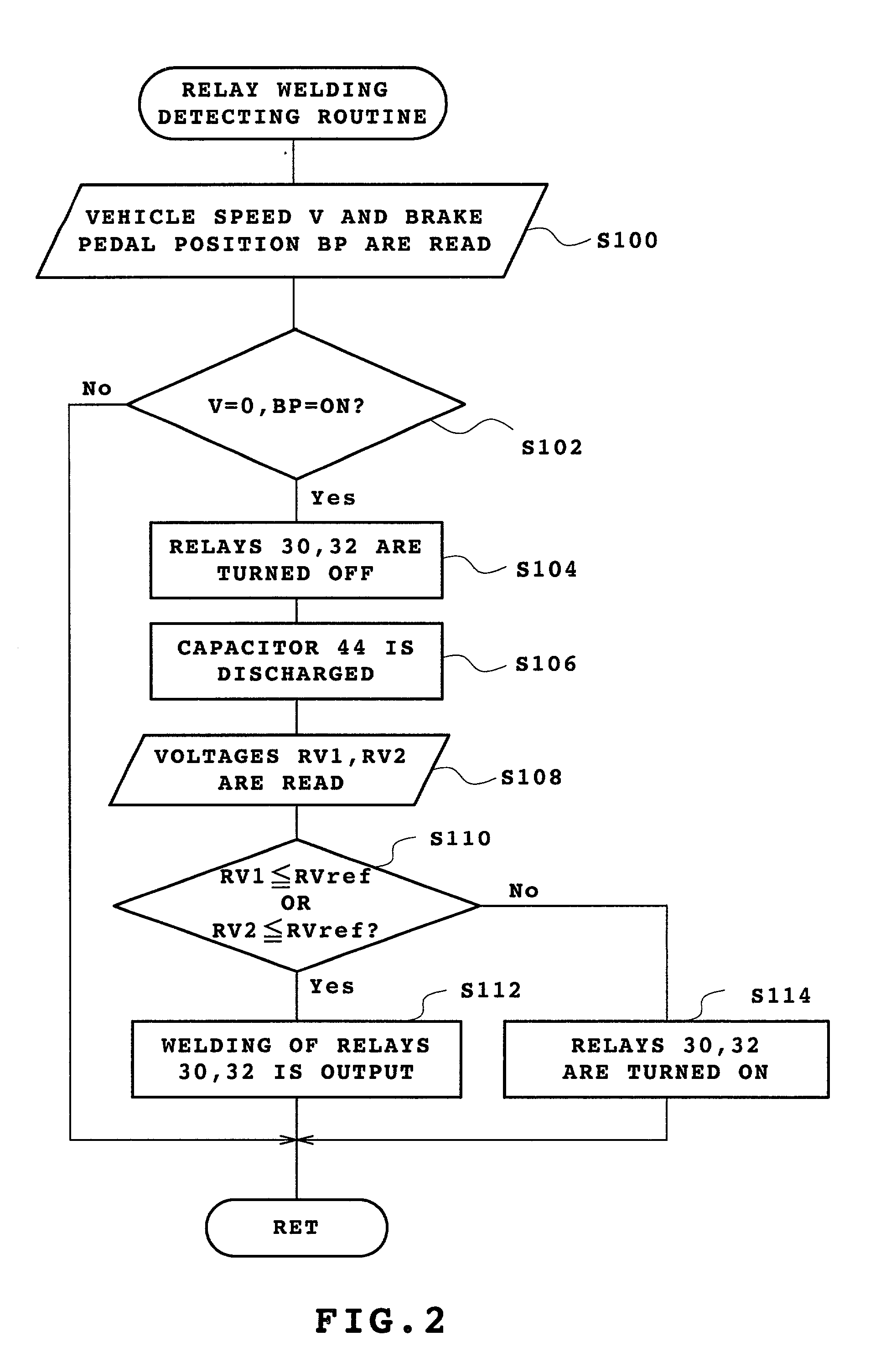

InactiveUS20020070608A1Frequently performedReduce voltageAC motor controlElectric devicesVoltmeterEngineering

Frequency of judgment of welding of relays is increased to increase likelihood of early detection of welding. It is determined that a battery 22 is not being recharged or discharged when a vehicle speed V of an electric vehicle is approximately 0 and a brake pedal 54 is pressed, and a switching element of an inverter 24 is controlled to be switched to discharge electric charges which are stored in a capacitor 44. After discharging, relays 30, 32 are turned off, and voltages RV1, RV2 between the terminals of the relays 30, 32 are detected by voltmeters 40, 42 to judge whether either of the voltages RV1, RV2 has a threshold value RVref (approximate value 0) or less. When it is so determined, it is judged that the relays 30, 32 are welded, and an LED 70 is illuminated.

Owner:TOYOTA JIDOSHA KK

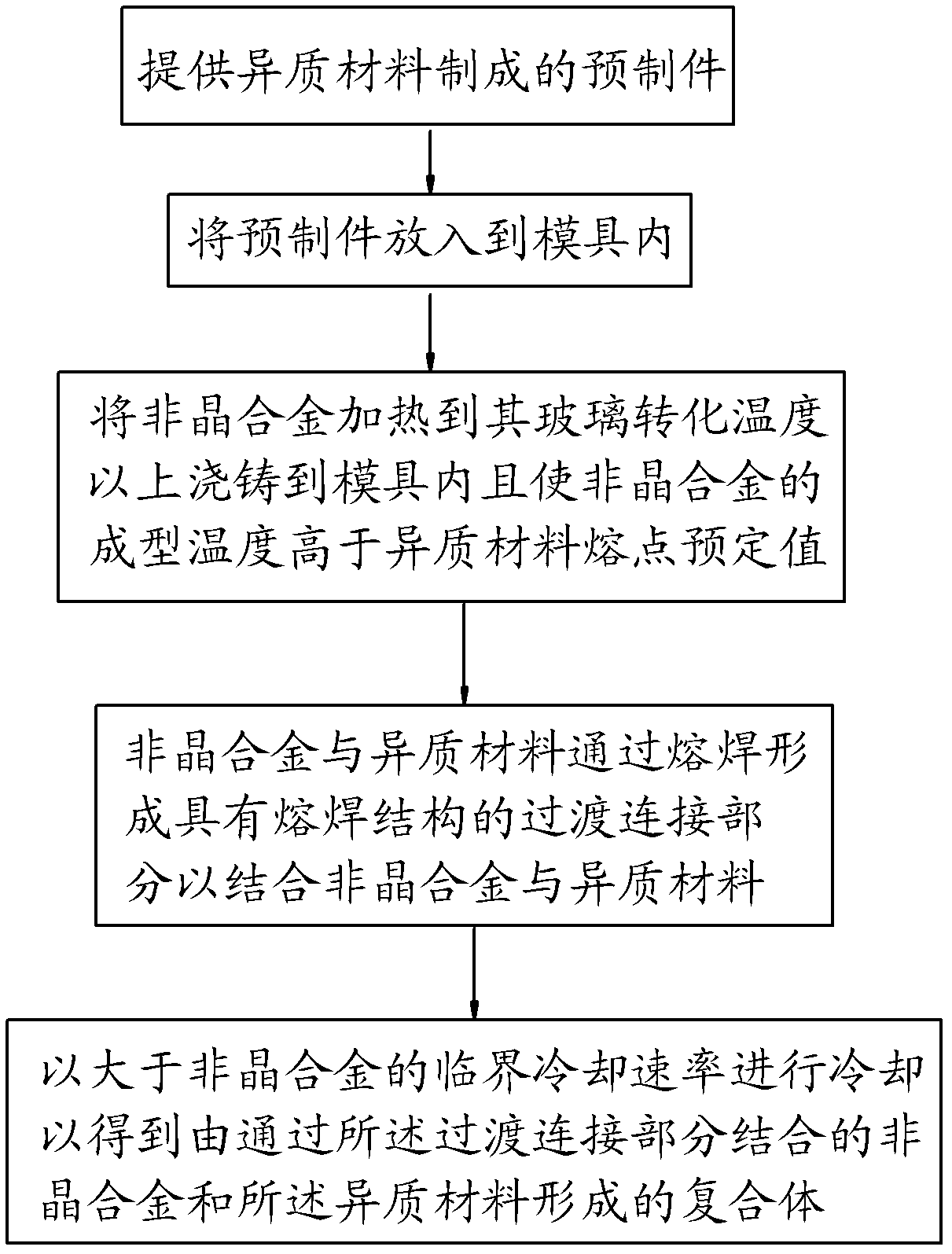

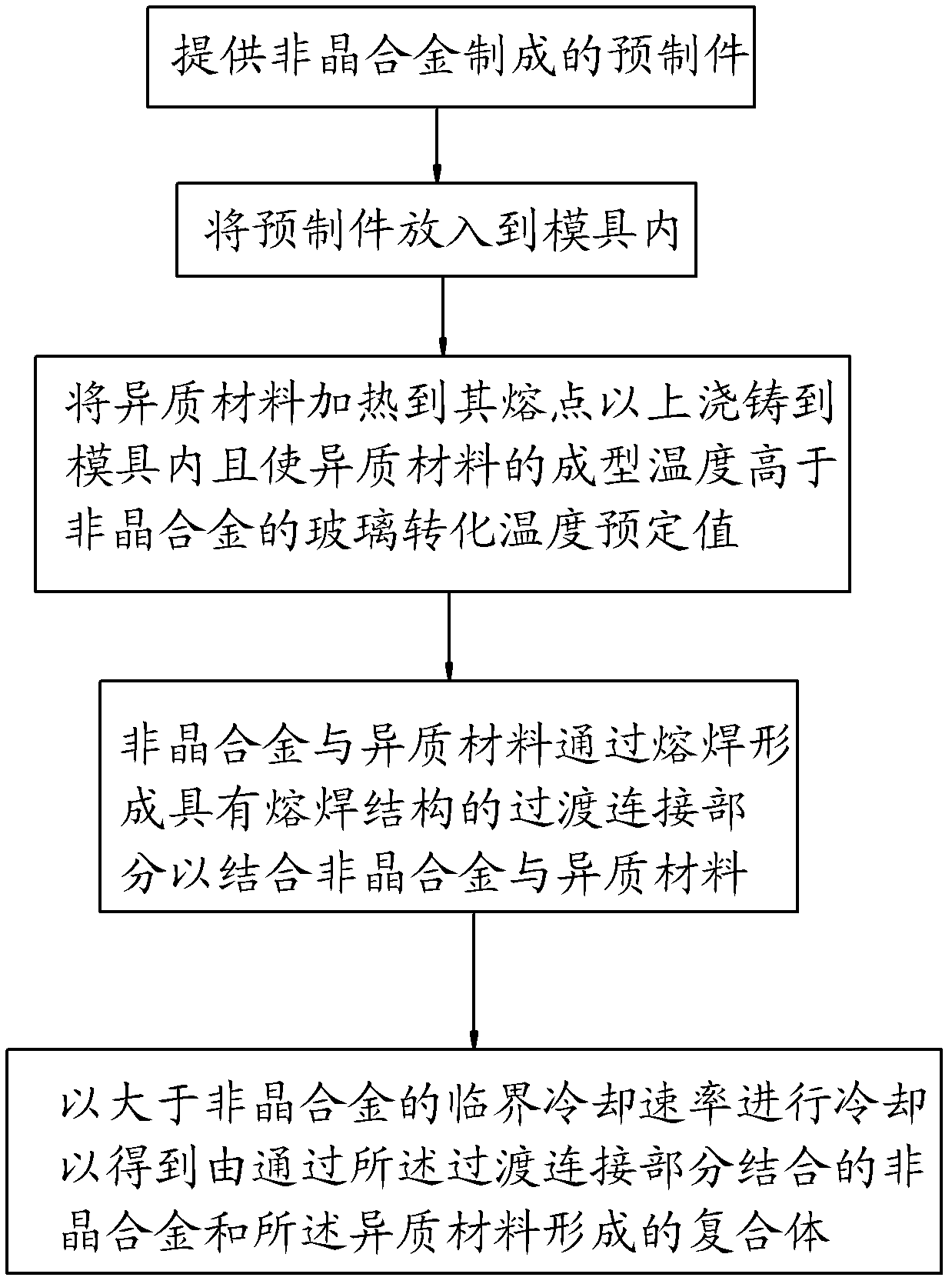

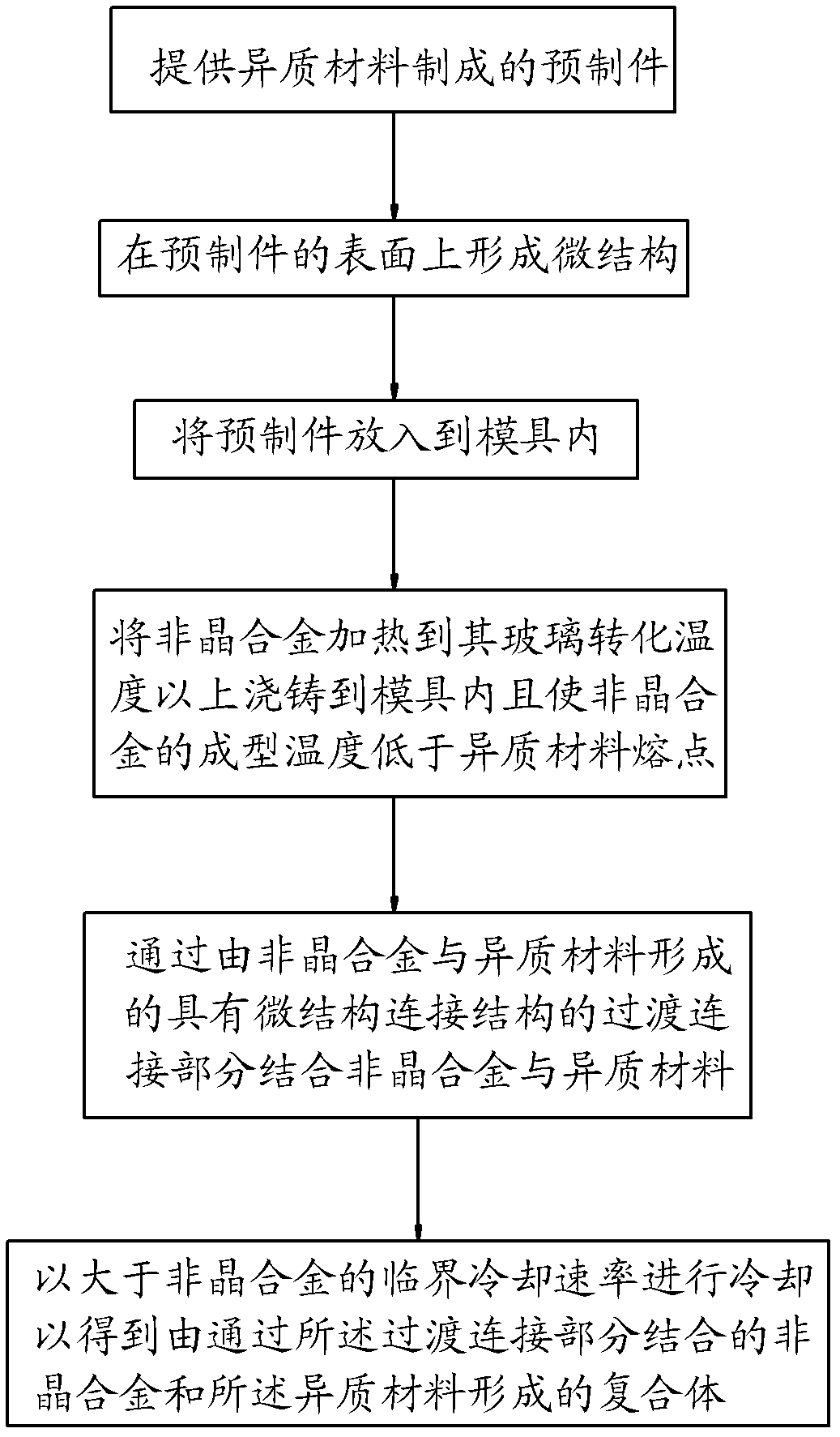

Method for combining amorphous alloy and heterogeneous material and complex

ActiveCN102430745AReduced molding capacityLower requirementThin material handlingMetal layered productsUltimate tensile strengthFusion welding

The invention discloses a method for combining an amorphous alloy and a heterogeneous material and a complex formed thereby. The method comprises the following steps of: putting a prefabricated part made from one of the heterogeneous material and the amorphous alloy into a mould; heating the other one of the heterogeneous material and the amorphous alloy to a predetermined temperature and casting into the mould to form a transitional connection part combining the heterogeneous material and the amorphous alloy, wherein the transitional connection part has a fusion welding structure, a micro structural reinforcing connection structure or a mixed connection structure; and cooling at a speed greater than the critical cooling rate of the amorphous alloy to obtain the complex formed by the amorphous alloy and heterogeneous material. According to the method disclosed by the invention, the combination strength of the amorphous alloy and the heterogeneous material is enhanced, requirements on the forming capability and performance of the amorphous alloy are reduced, requirements on the elastic deformation of the amorphous alloy are reduced, and the applicability of the amorphous alloy is improved.

Owner:BYD CO LTD

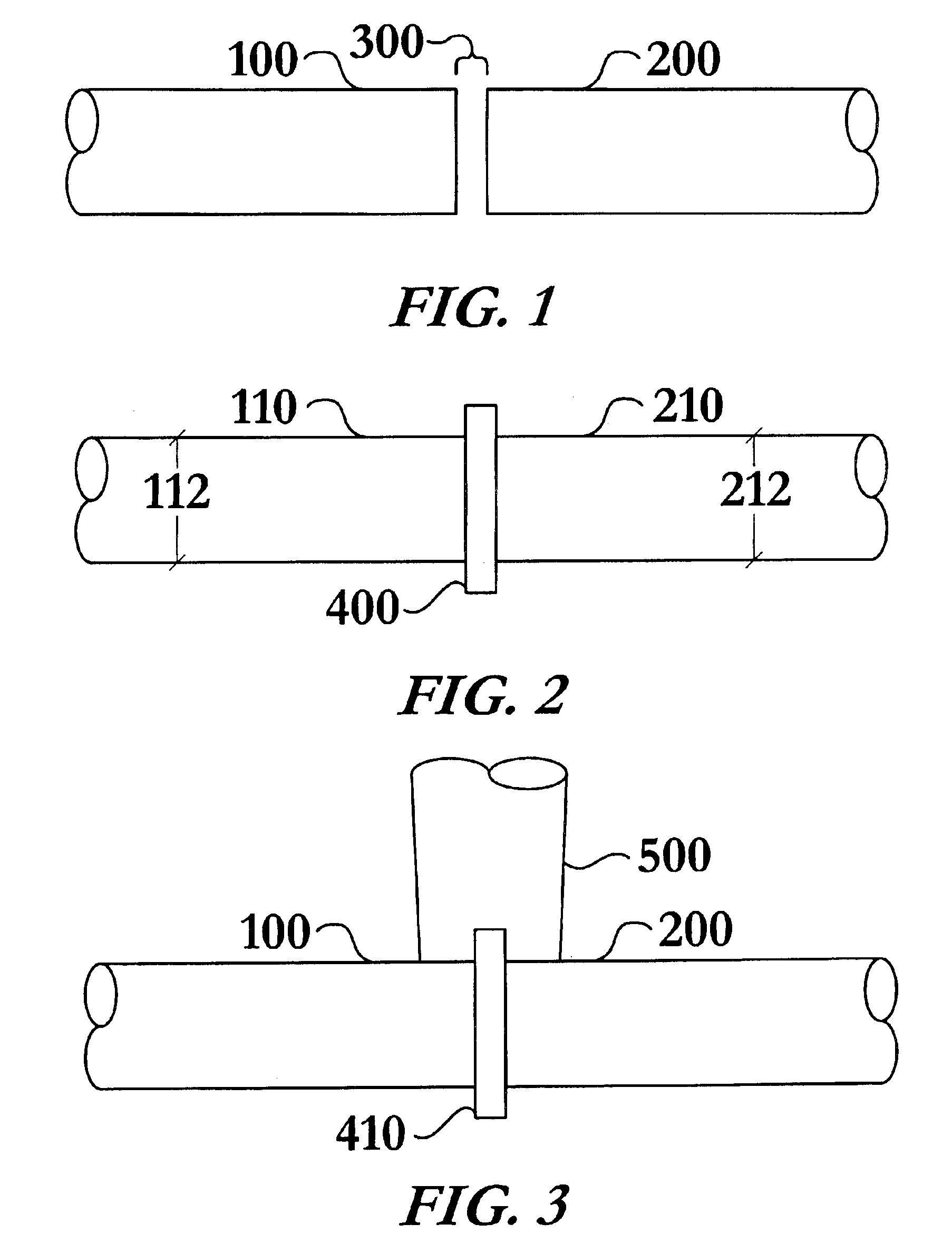

Method of welding titanium and titanium based alloys to ferrous metals

InactiveUS6875949B2Welding/cutting media/materialsWelding/soldering/cutting articlesFull recoveryPoor quality

A method of welding titanium, and titanium based alloys, to ferrous metals is described. Welding of titanium, and titanium based alloys, is plagued with poor quality and highly brittle welds, substantially due to formation of Ti—Fe intermetallics in the weld pool. The instant invention provides supplementary filler material to alter the proportions of various elements in the weld pool. Certain fillers, such as nickel or iron, added to the weld pool enable high quality welds to be fabricated utilizing a wide variety of fusion welding techniques, including laser welding, between titanium, or titanium based alloys, and ferrous metals, including but not limited to the welding of nickel-titanium and stainless steel. Filler material may be supplied in various forms, including foil, wire, powders, preformed gaskets, and numerous others. Optionally, the titanium or titanium based alloy may be stress relieved to achieve full recovery of the shape memory strain prior to welding.

Owner:EDISON WELDING INSTITUTE INC

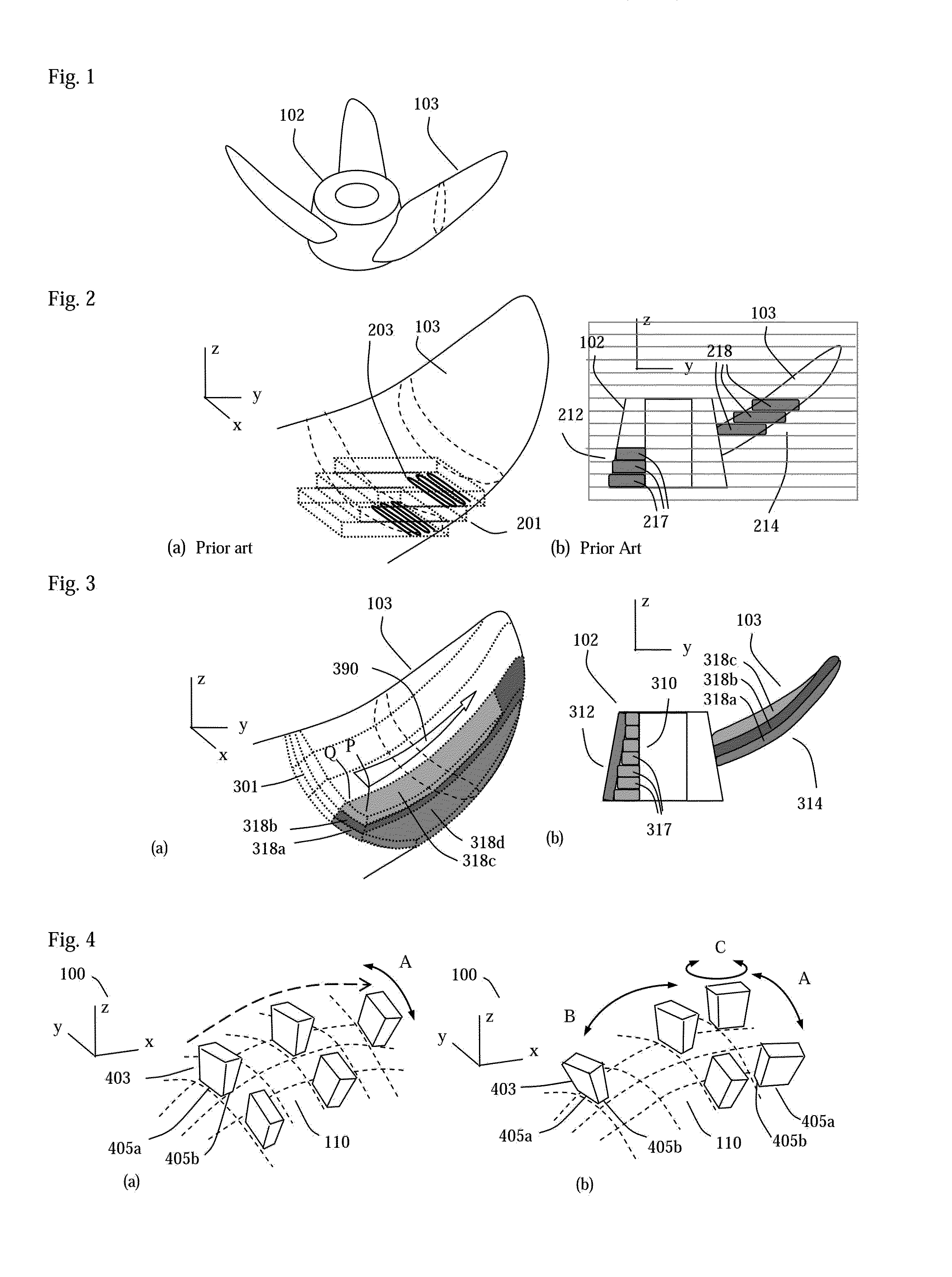

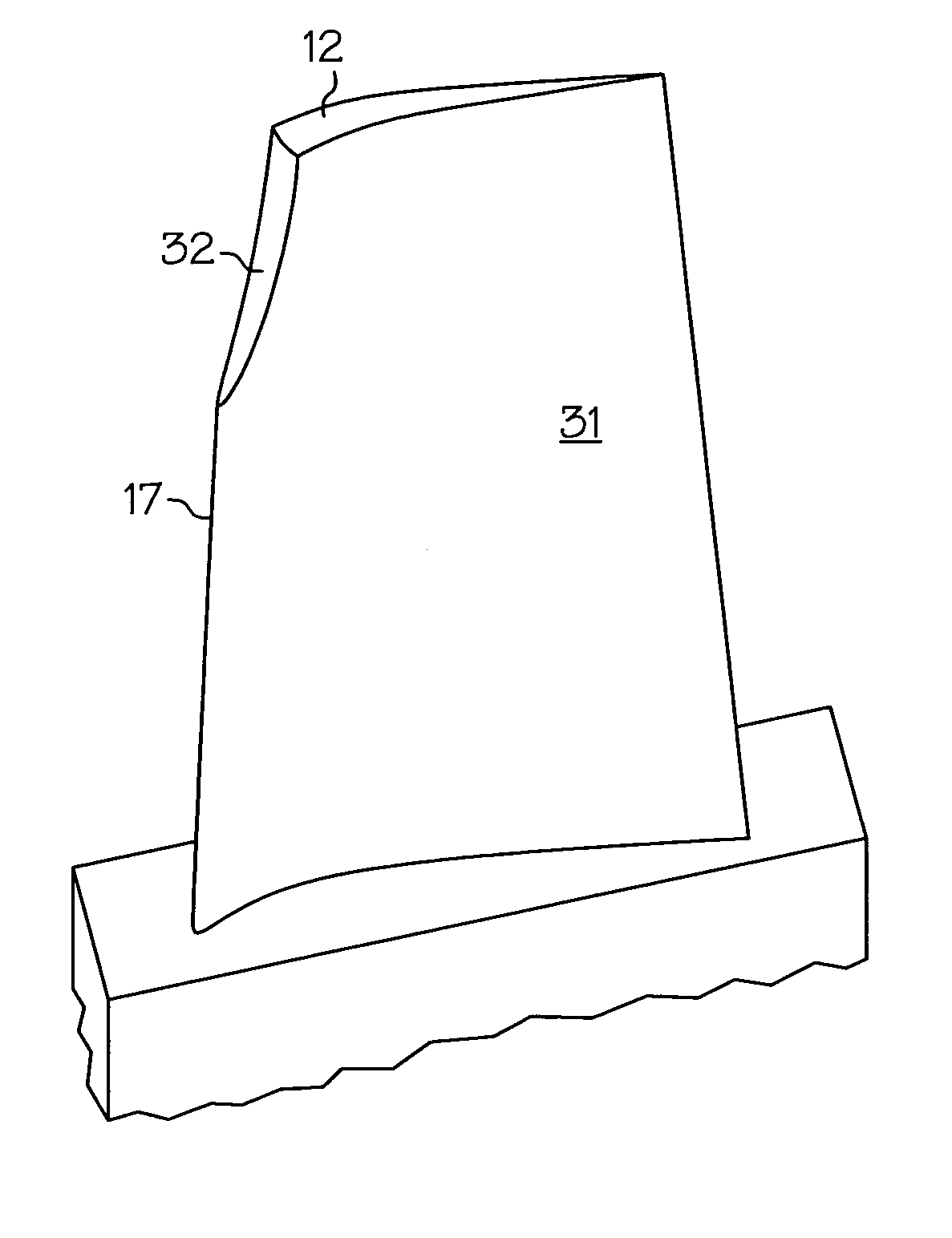

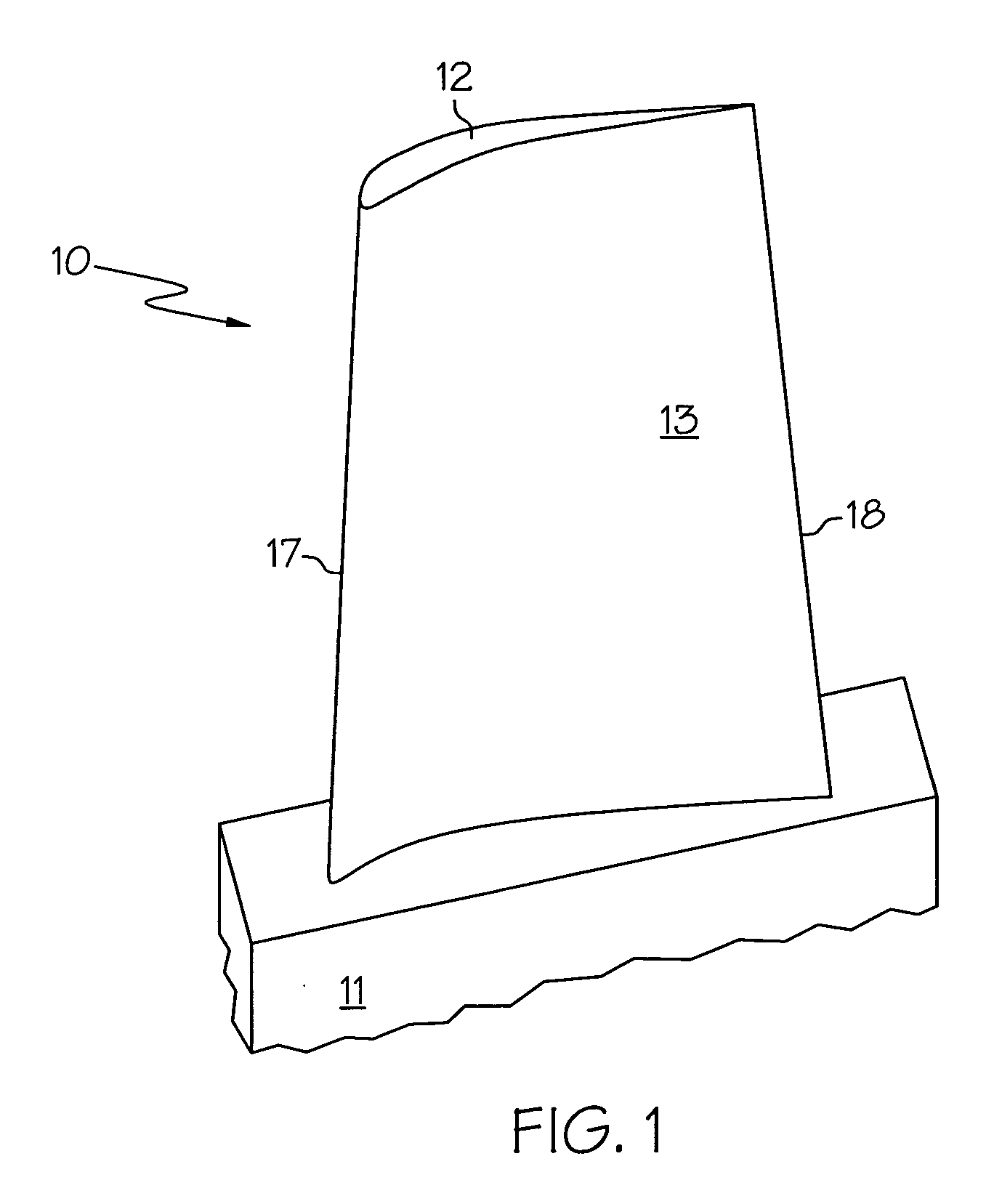

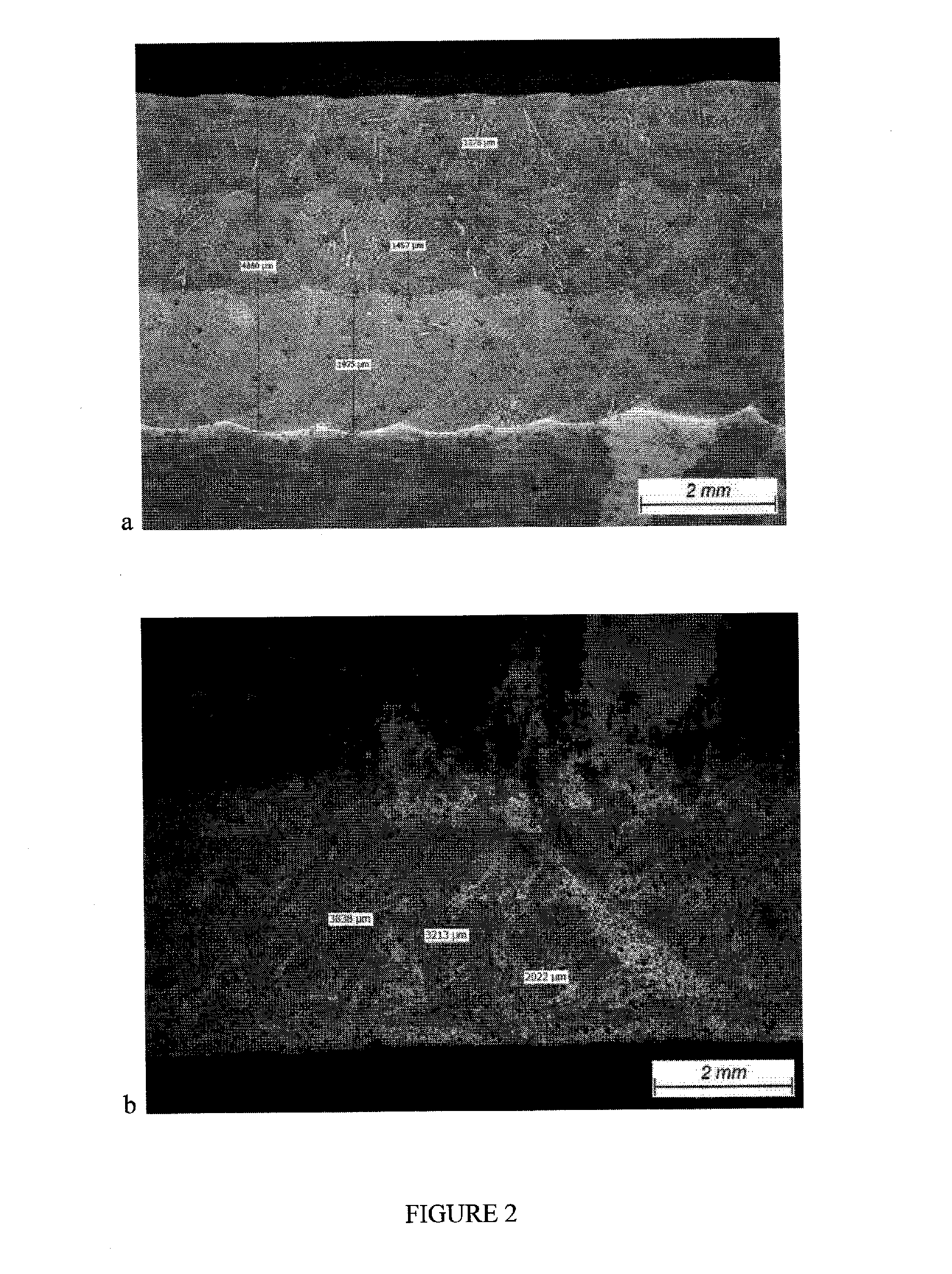

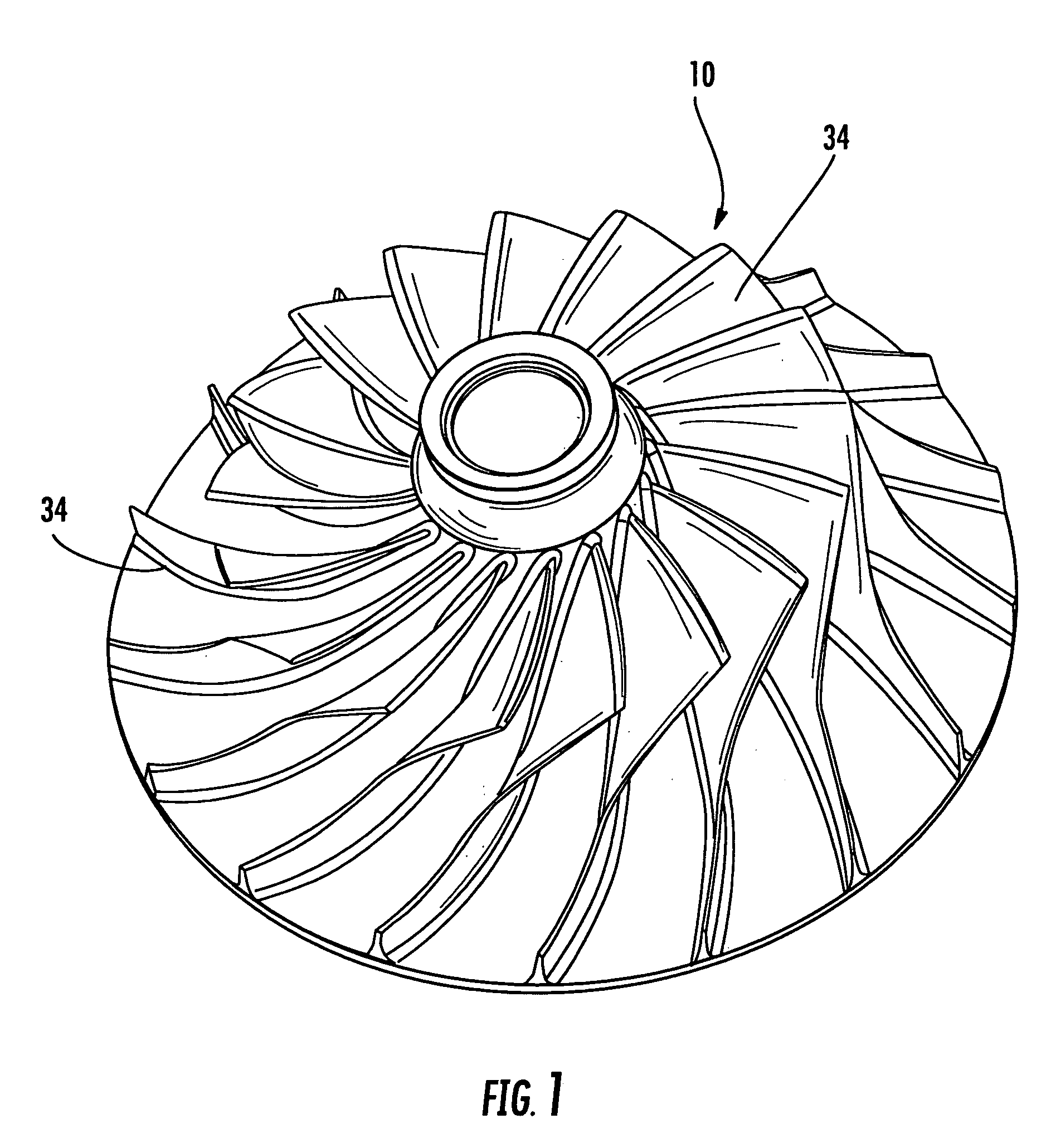

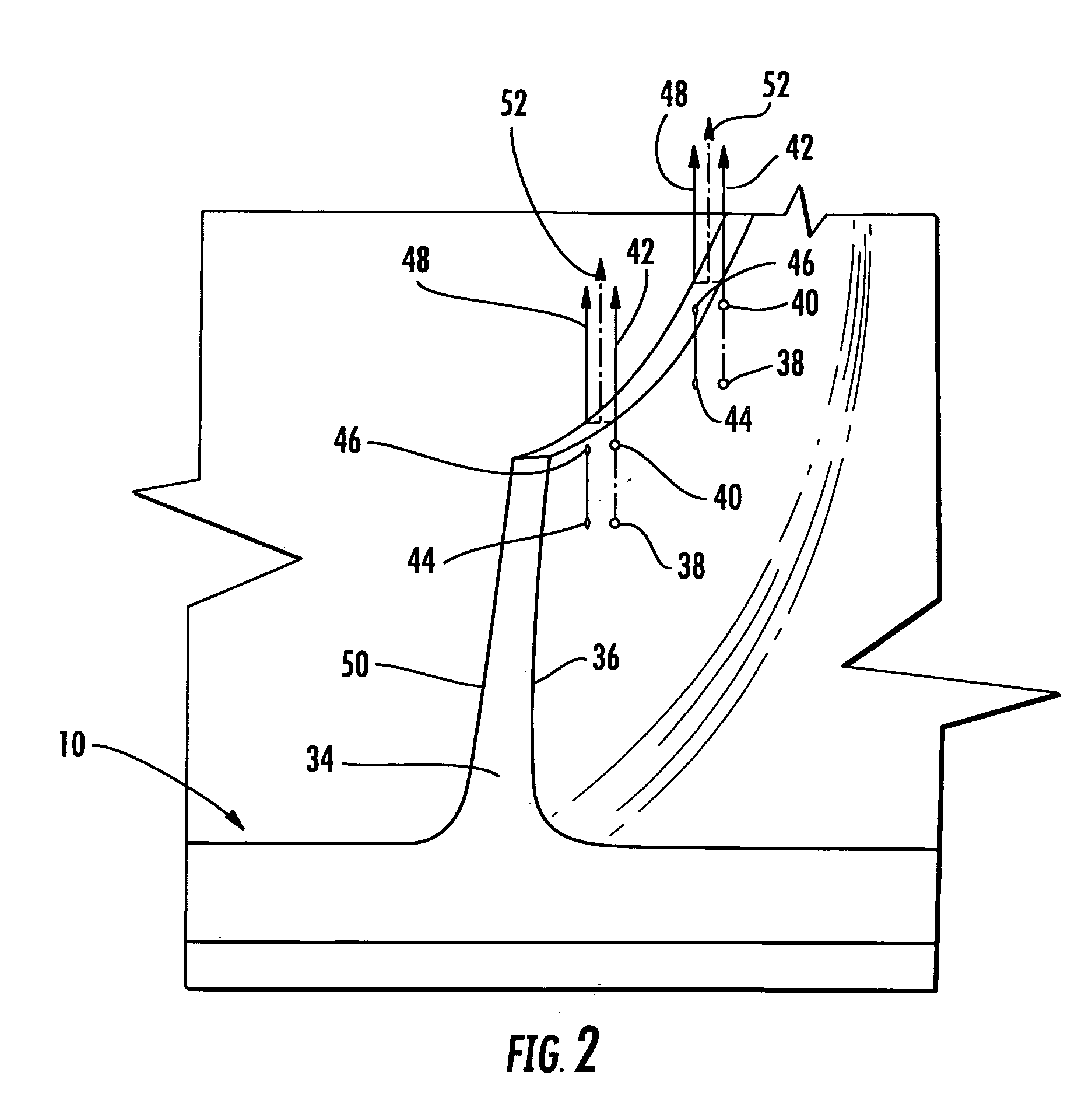

Method to restore an airfoil leading edge

The present invention provides methods and apparatus to restore a blade leading edge on a gas turbine engine component such as an airfoil of a turbine blisk. The method utilizes welding image technology and power control systems in order to provide effective welding with superalloy materials such as Inconel 713 and Inconel 625. The method includes machining away a damaged leading edge and providing a repaired region through successive depositions of superalloy powder filler through laser fusion welding. Deposition material is added until the repaired region exceeds the original dimensions of the airfoil. The airfoil is then machined and finished to return it to original airfoil dimensions.

Owner:HONEYWELL INT INC

Method of cladding, additive manufacturing and fusion welding of superalloys and materialf or the same

The present concept is a method of substantially crack-free cladding, fusion welding and additive manufacturing of superalloys. The method involves the application of a high temperature pre-alloyed filler powder that includes melting point depressants, to a superalloy base material. The base material and pre-alloyed filler powder are heated to a temperature that will fully melt the pre-alloyed filler powder and also melt a surface layer of the base material, thereby forming a weld pool. Upon solidification and cooling of the weld pool, there is coalescence between a weld bead and the base material thereby forming the weld bead which is substantially crack-free. The high temperature pre-alloyed filler powder consists in wt % of the following chemical elements: Co 9-15%; Al 3-6.5%; C 0.1-0.2%; Ti, Zr and Hf with a total content from 1 to 8.5%; Ta and Nb with a total content from 0.5 to 8.5%; W and Mo with a total content from 7 to 20%; Cr and Re with a total content from 6.5 to 18.5%; Fe and Mn with a total content from 0.1 to 1%; B 0.1-0.6% with Ni and impurities to balance.

Owner:LIBURDI ENG

Method of combining welding and adhesive bonding for joining metal components

A method of joining metal components having the steps of depositing adhesive material between the components and welding the components together via solid-state or fusion welding. The welds are spaced apart from the adhesive material and are produced so as to prevent exposure of the adhesive material to the welding. The two types of bonds (adhesive and welding) are produced in the components separated by time and space.

Owner:ARCONIC INC

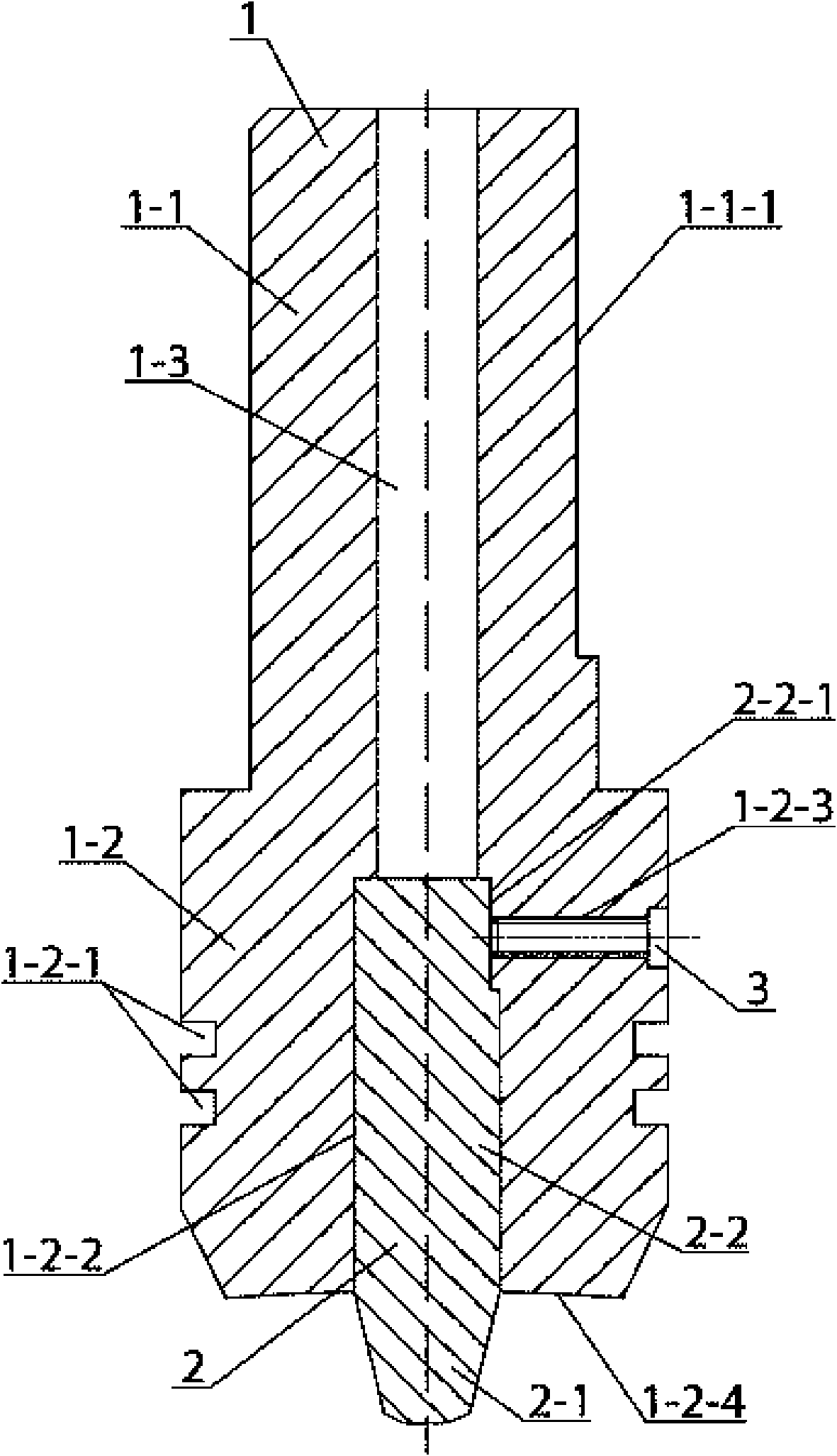

Fill type stirring friction plug repair welding method and welding tool thereof

InactiveCN101670483AReduce distortionAvoid intensityNon-electric welding apparatusFriction weldingEngineering

The invention discloses a fill type stirring friction plug repair welding method and a welding tool thereof, and relates to a stirring friction plug repair welding method and a welding tool thereof. The invention adopts fusion welding or friction plug welding for repair welding and causes the welding joints to reduce strength and have poor mechanical performance. The method comprises the followingsteps: (1) the material of a stirring pin is same as that of the part which repairs welding; (2) a conical preset hole is opened; (3) the size of the stirring pin is determined; (4) positioning is carried out; and (5) welding of the stirring friction plug is repaired. The welding tool is characterized in that the side wall of a clamping hole of a lower cylinder is provided with a thread through hole; a stirring body consists of the stirring pin and a stirring pin seat which are combined into a whole from top to bottom; the outer surface of the stirring pin seat is provided with a stirring pinclamping surface; the stirring pin is a cone; the stirring body is arranged in the clamping hole on the lower cylinder; the stirring pin clamping surface aligns to the thread through hole; and the stirring pin is exposed at the outside of the lower end surface of the lower cylinder. The invention is used for repair welding of the weld defects of stirring friction welding and keyholes.

Owner:HARBIN INST OF TECH

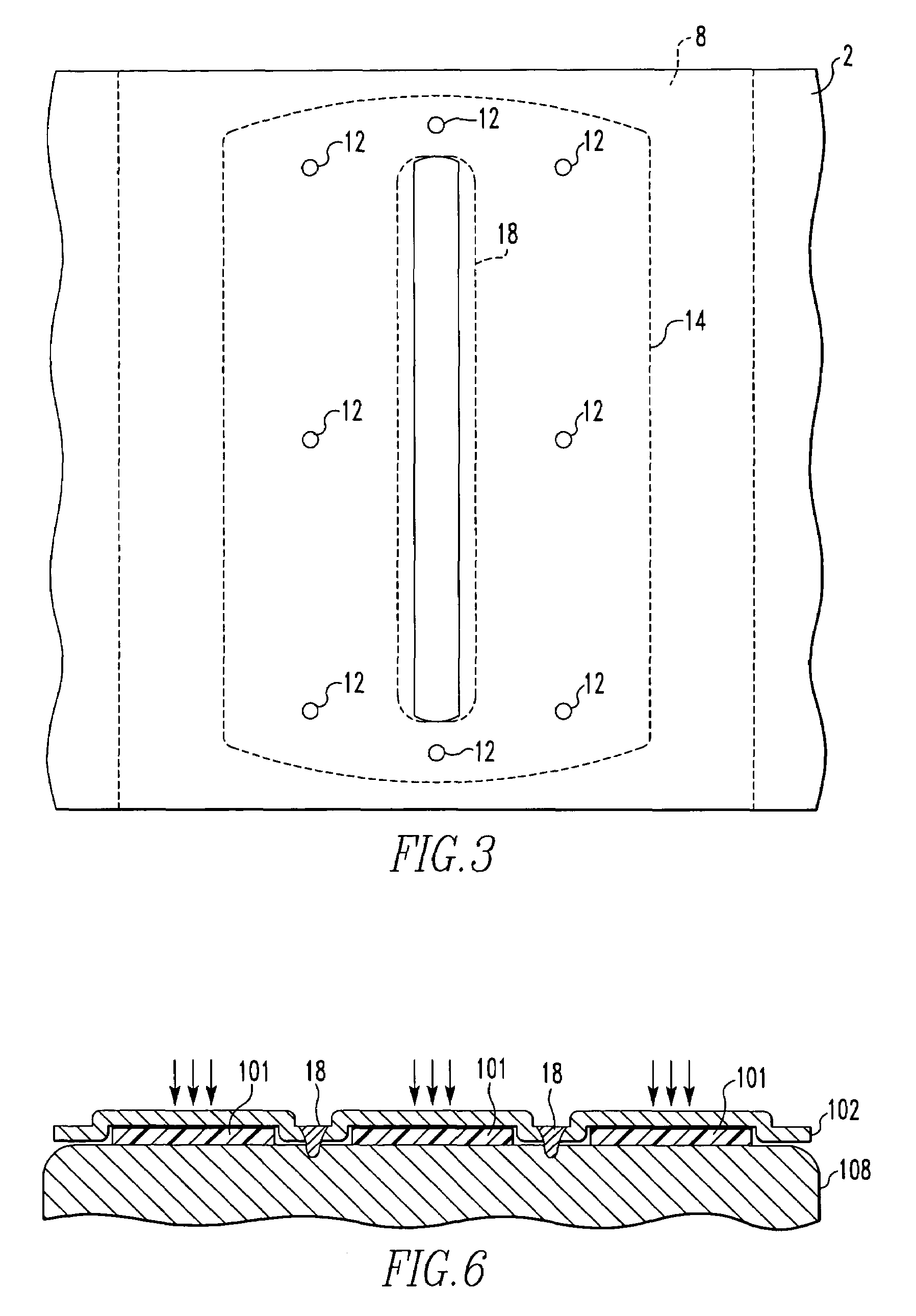

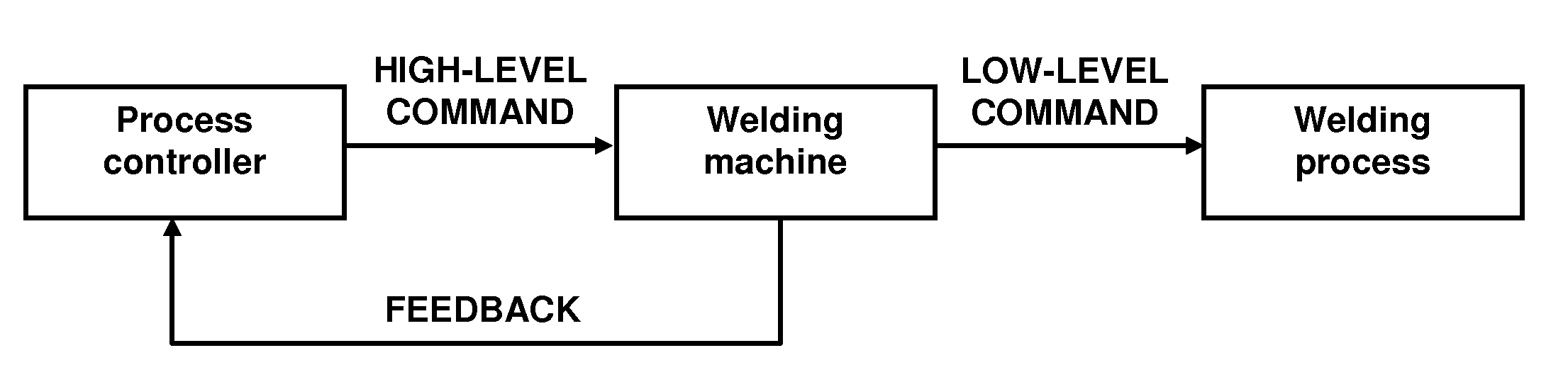

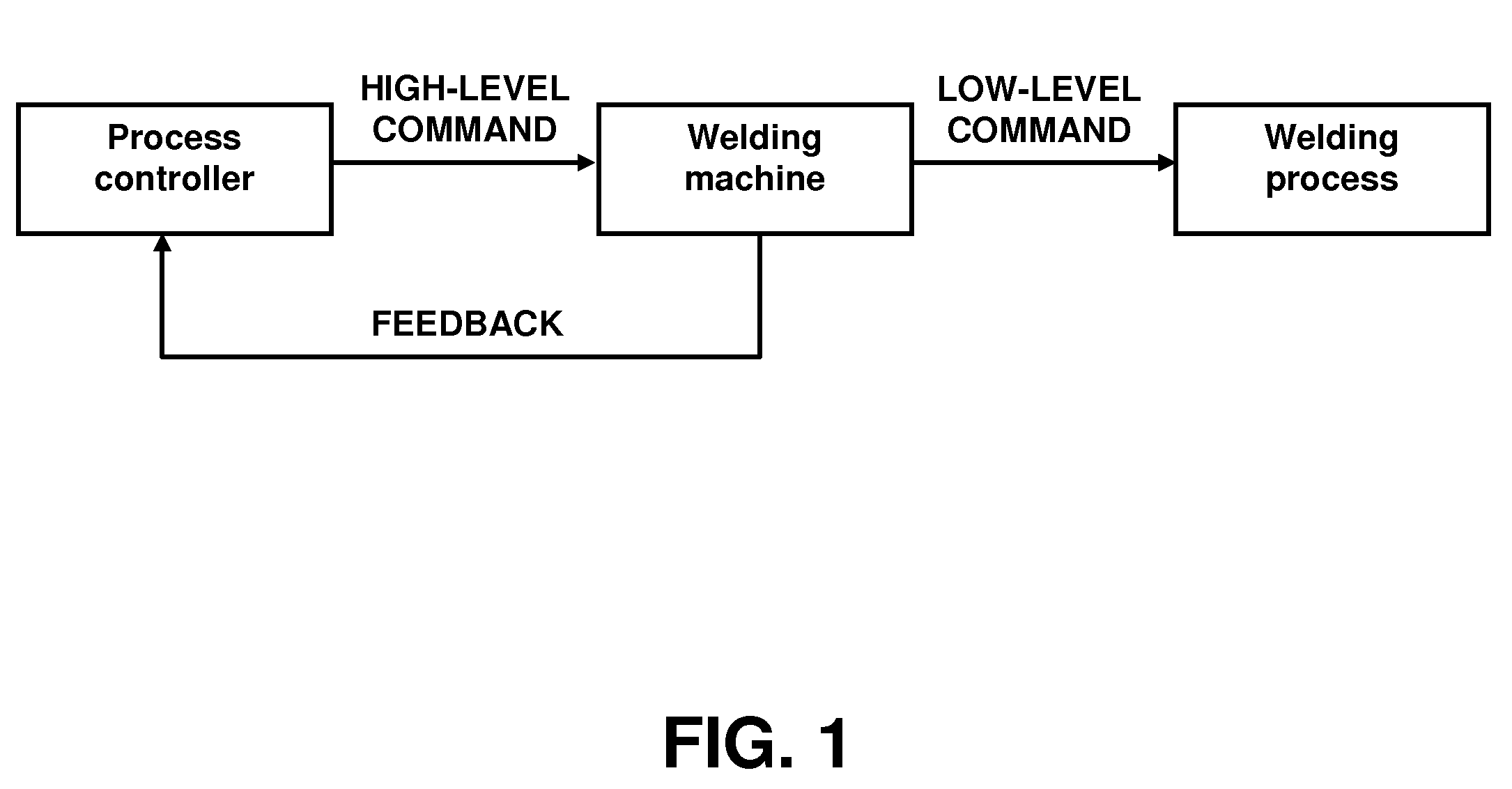

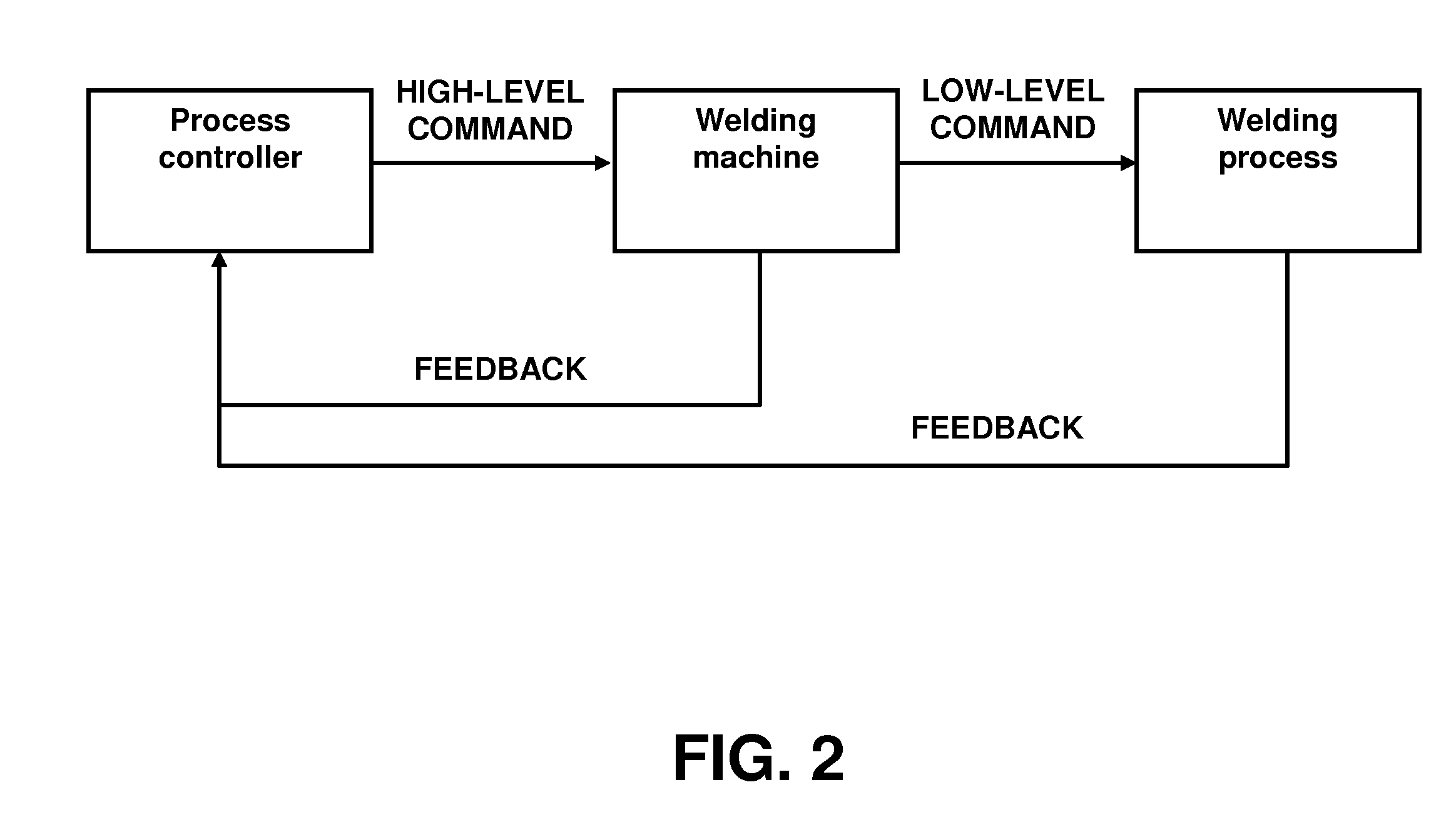

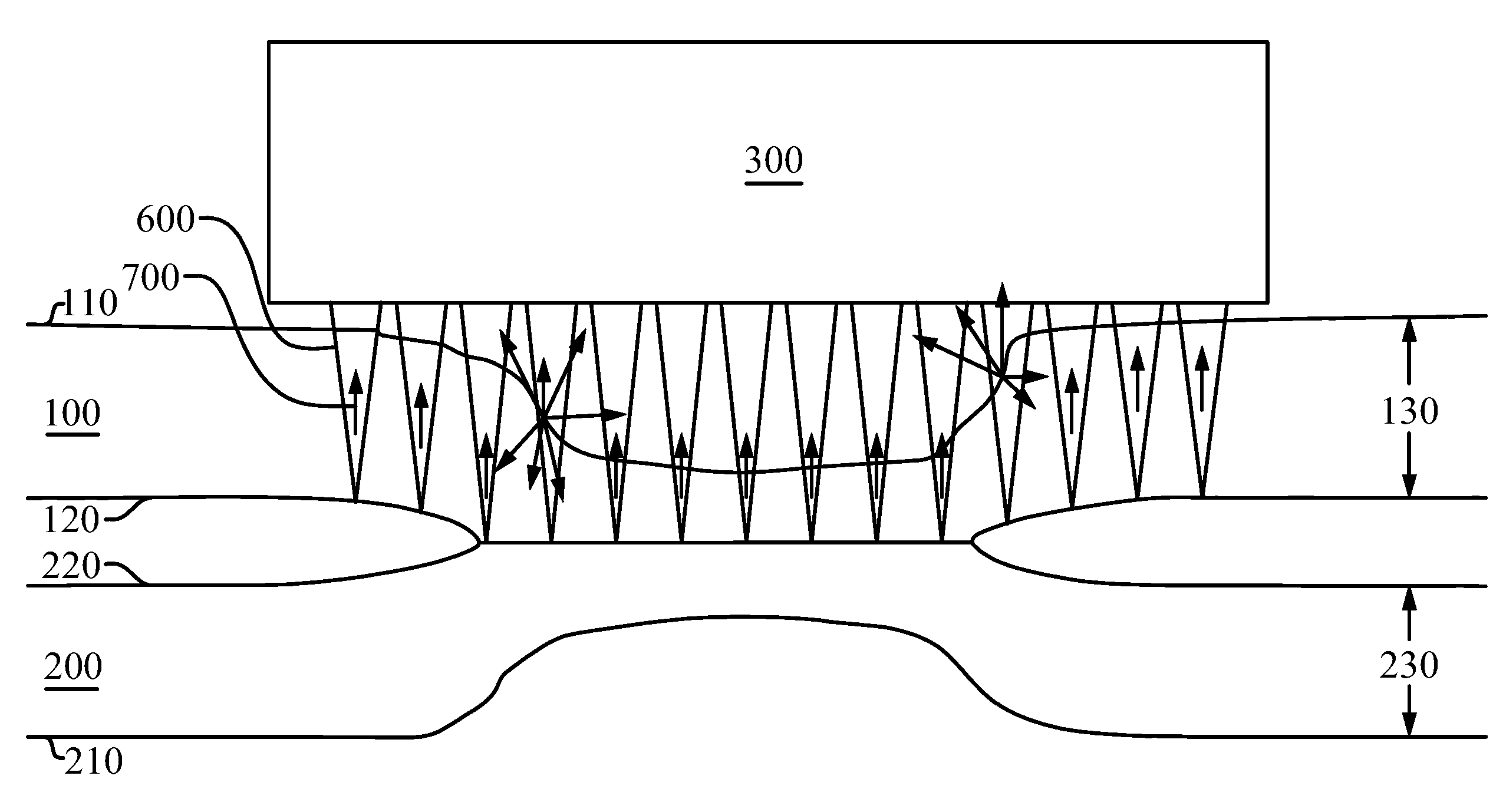

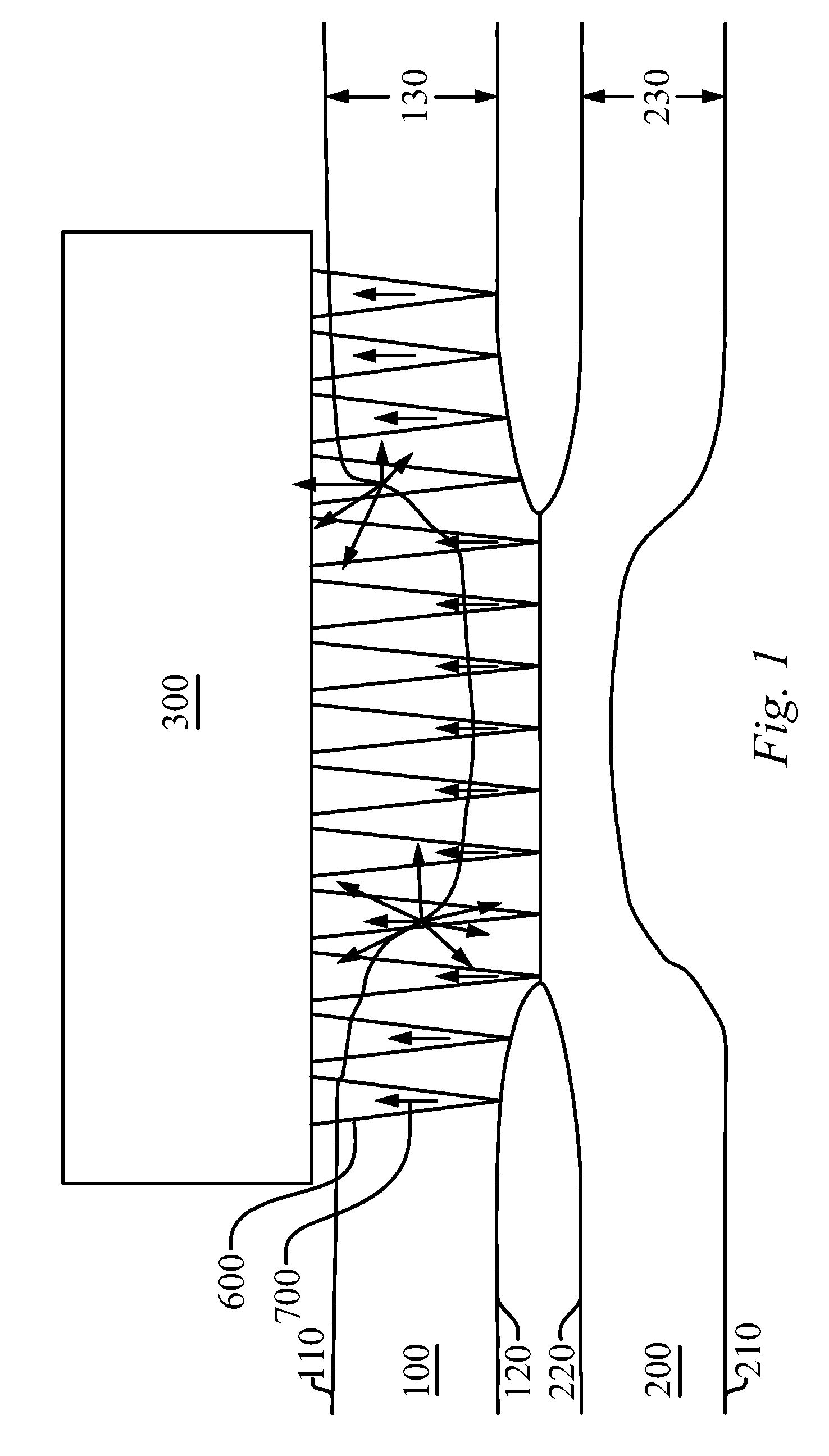

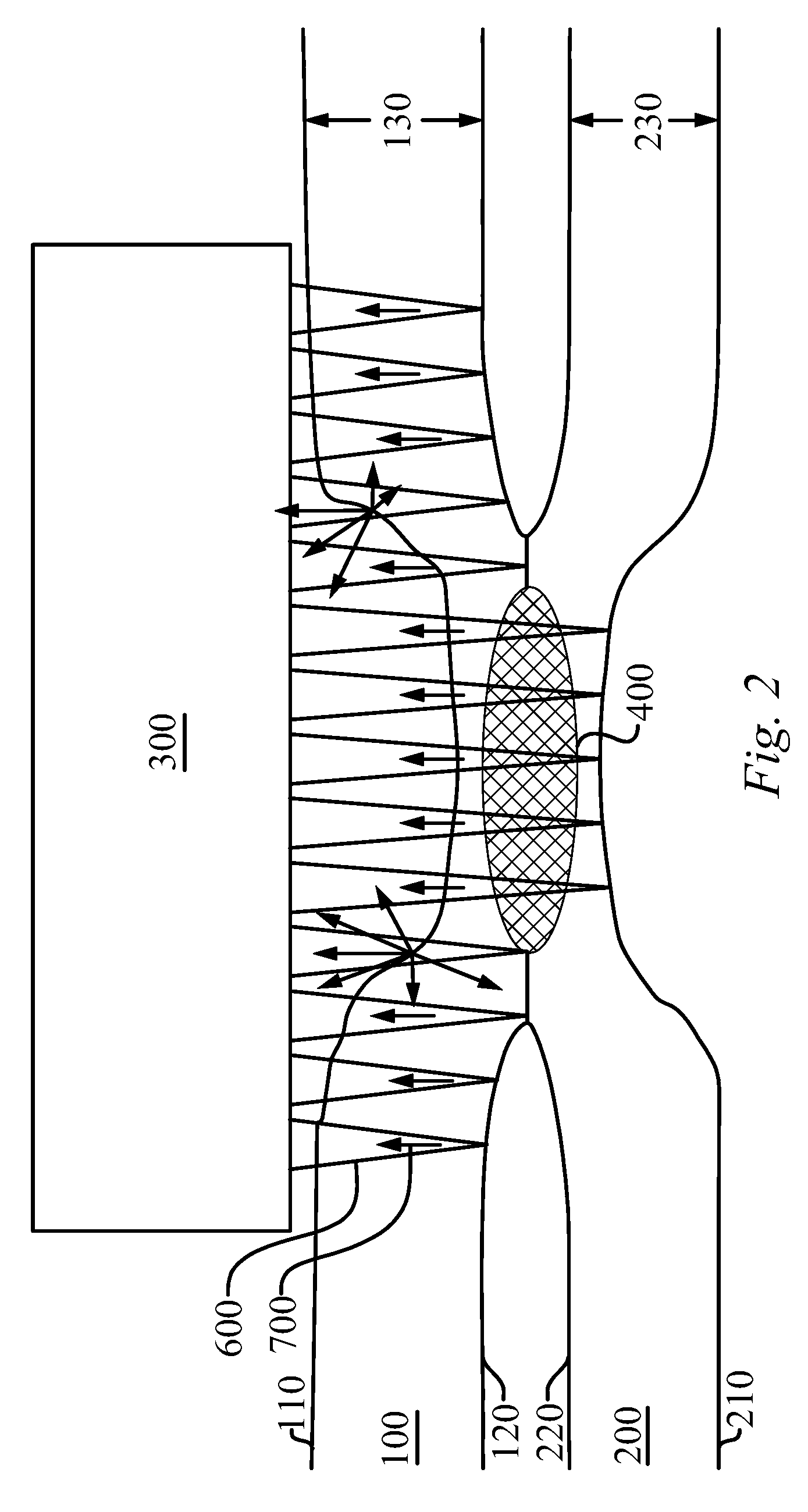

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

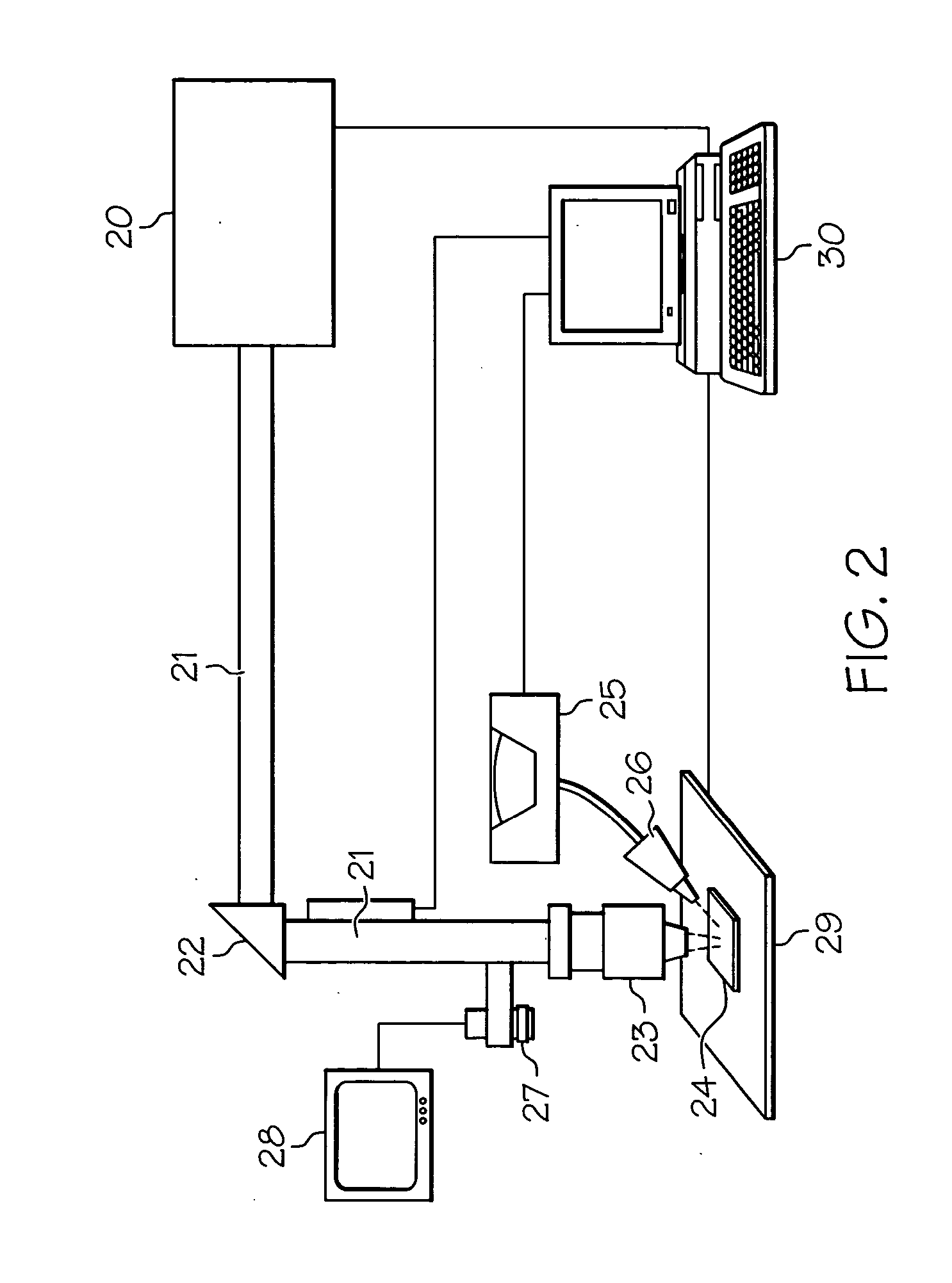

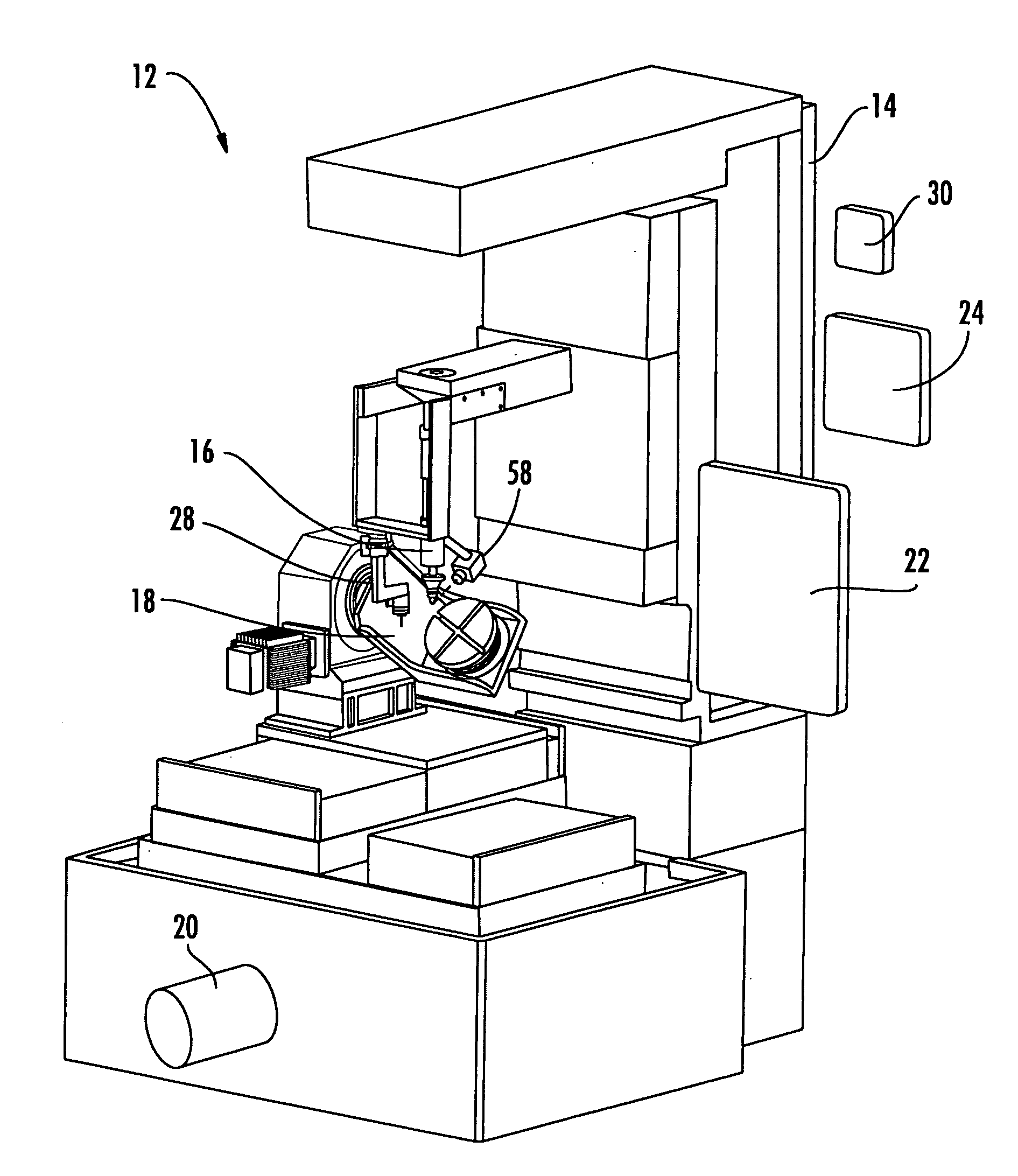

Method and apparatus for repairing turbine components

The present invention includes an apparatus and method by which the three-dimensional form or configuration of a distorted workpiece, such as a turbine component, is reverse engineered, and then this reverse engineering capability is combined with welding equipment, preferably a laser powder fusion welder, all integrally carried within a single machine, whereby a tool path unique to each workpiece is created and the welding machine accurately replaces lost material on the workpiece. The present invention consists of a series of operations or steps, preferably carried out by a single machine.

Owner:OPTOMEC INC

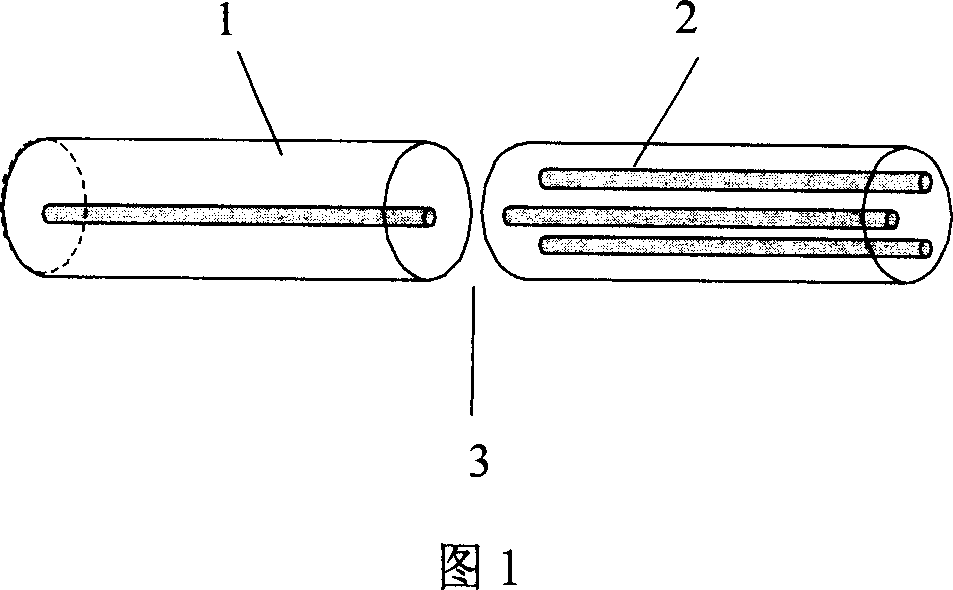

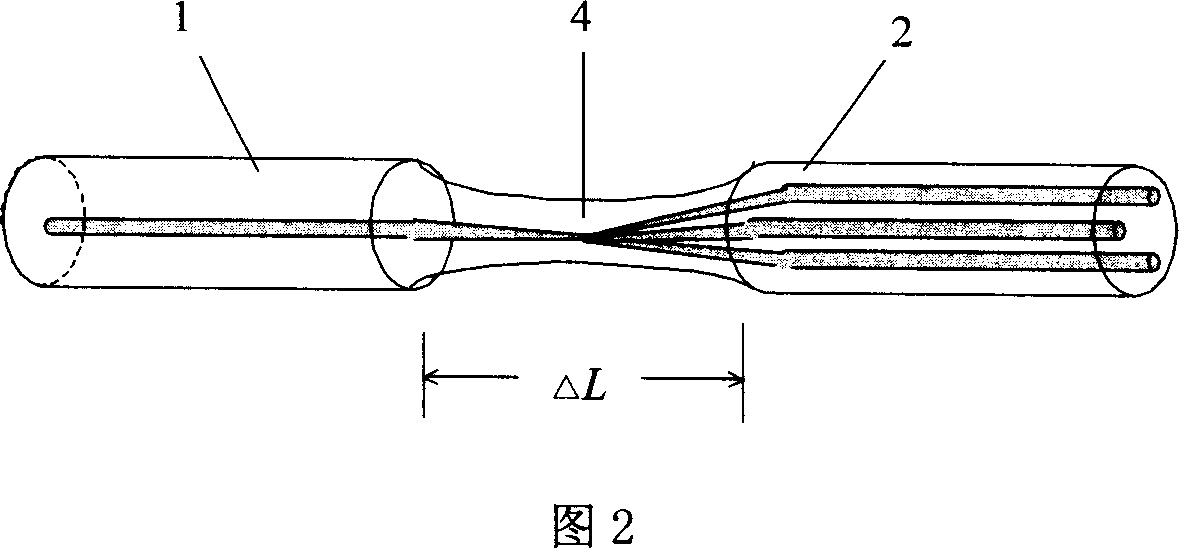

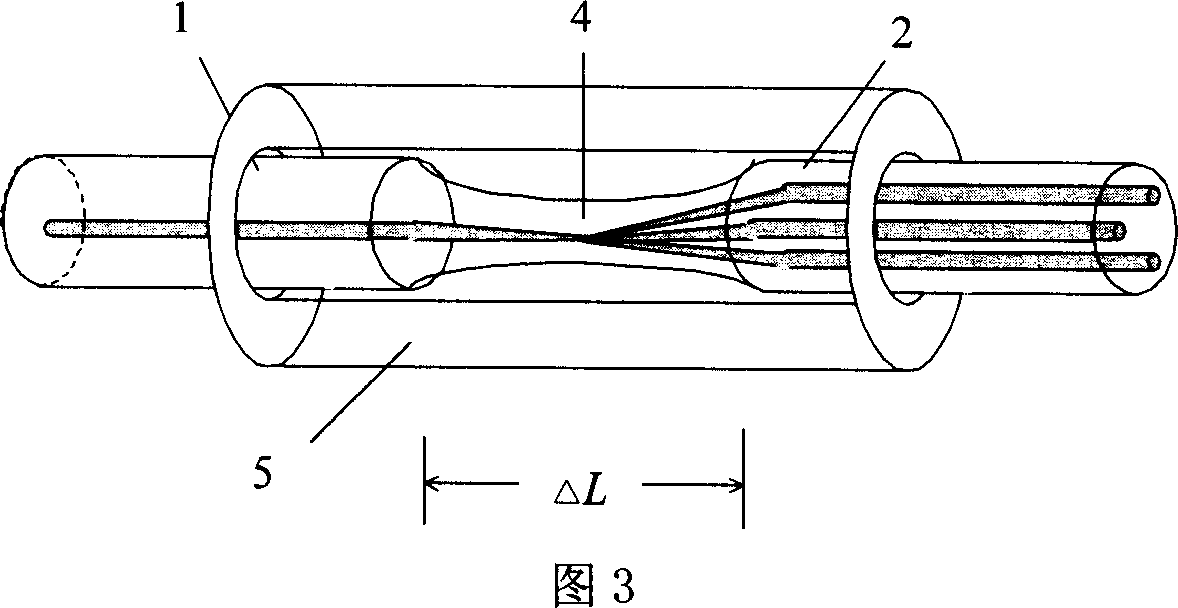

Single fiber and multi-core fiber coupler and fused biconic taper coupling method thereof

InactiveCN1967302ACoupling method improvementsEasy to manufactureCoupling light guidesCouplingOptical power

The invention discloses a single-core and multi-core fiber coupler and fiber access into rafah cone coupling method. It peels the ending coating layer of a single-core optical fibers and a multi-core fiber, direct financial with the fiber welding machine in stripping department, received and in the implementation of solder joint heating department fused biconical taper, monitoring optical power, when cone waist rafah small cone of light power distribution to the target, spectrophotometer stopping widening cone. The method is the technical characteristics of single-core fiber and multi-core fiber fusion welding, the solder joint implemented fused biconical taper, thus forming a cone of light energy distribution, optical power of distribution. The method can be single-core optical fiber distribution of power coupled multi-core optical fiber to each core, or multi-core fiber coupling of light waves to single-core fiber, to achieve optical spectrophotometer and cooperation functions.

Owner:HARBIN ENG UNIV

Metal oxide blended silver-tin dioxide electric contactor material and its preparing method

The present invention belongs to the preparation techonlogy of electric alloy material. The electric contactor material consists of Ag 85-90 wt%, SnO2 5-20 wt% and blended metal oxide 0.5-8 wt%. The blended metal oxide is ZrO2, ZnO, TiO2, MnO2, WO3 or Sb2O3. The electric contactor material is prepared through coating oxide through chemical plating with plating liquid with dispersant, mixing the coated pwoder and silver powder, pressing, sintering, hot extruding, cold drawing or cold rolling, and making rivet or punched product. The present invention has the features of homogeneous oxide dispersion, good fusion welding resistance, high arc corrosion resistance and less electric transfer. The production process is simple, practical, low in cost and suitable for large scale production.

Owner:TIANJIN UNIV

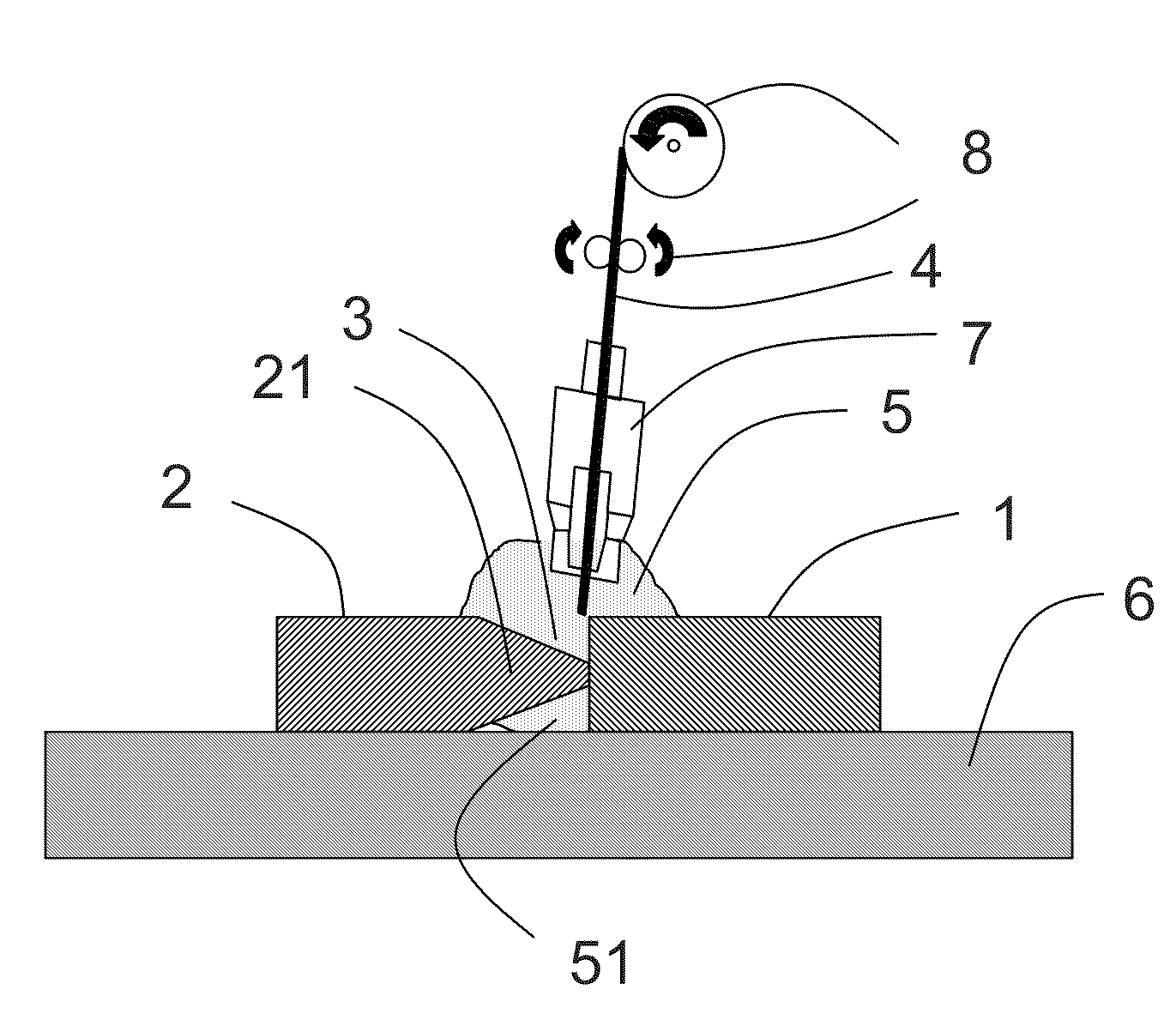

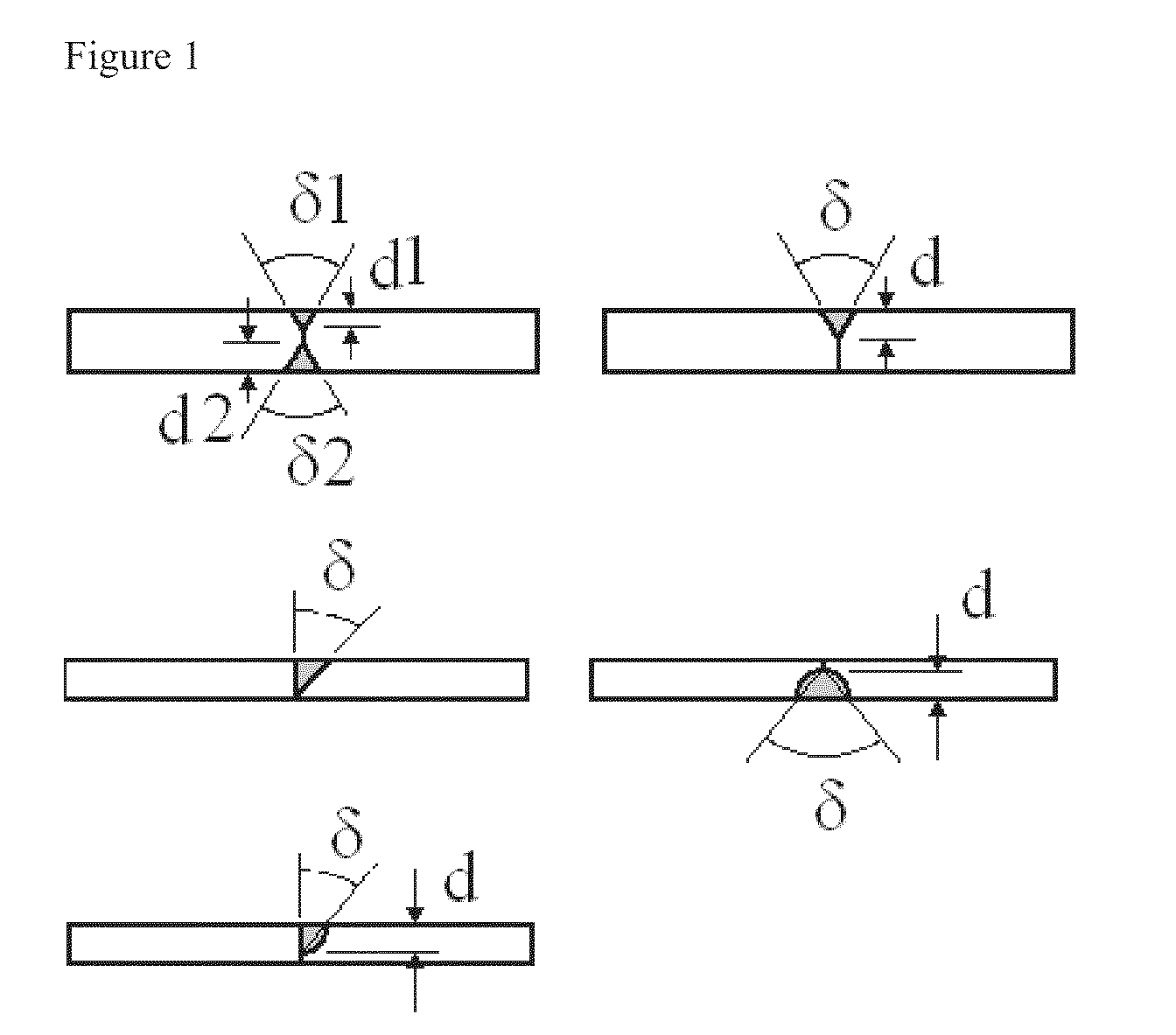

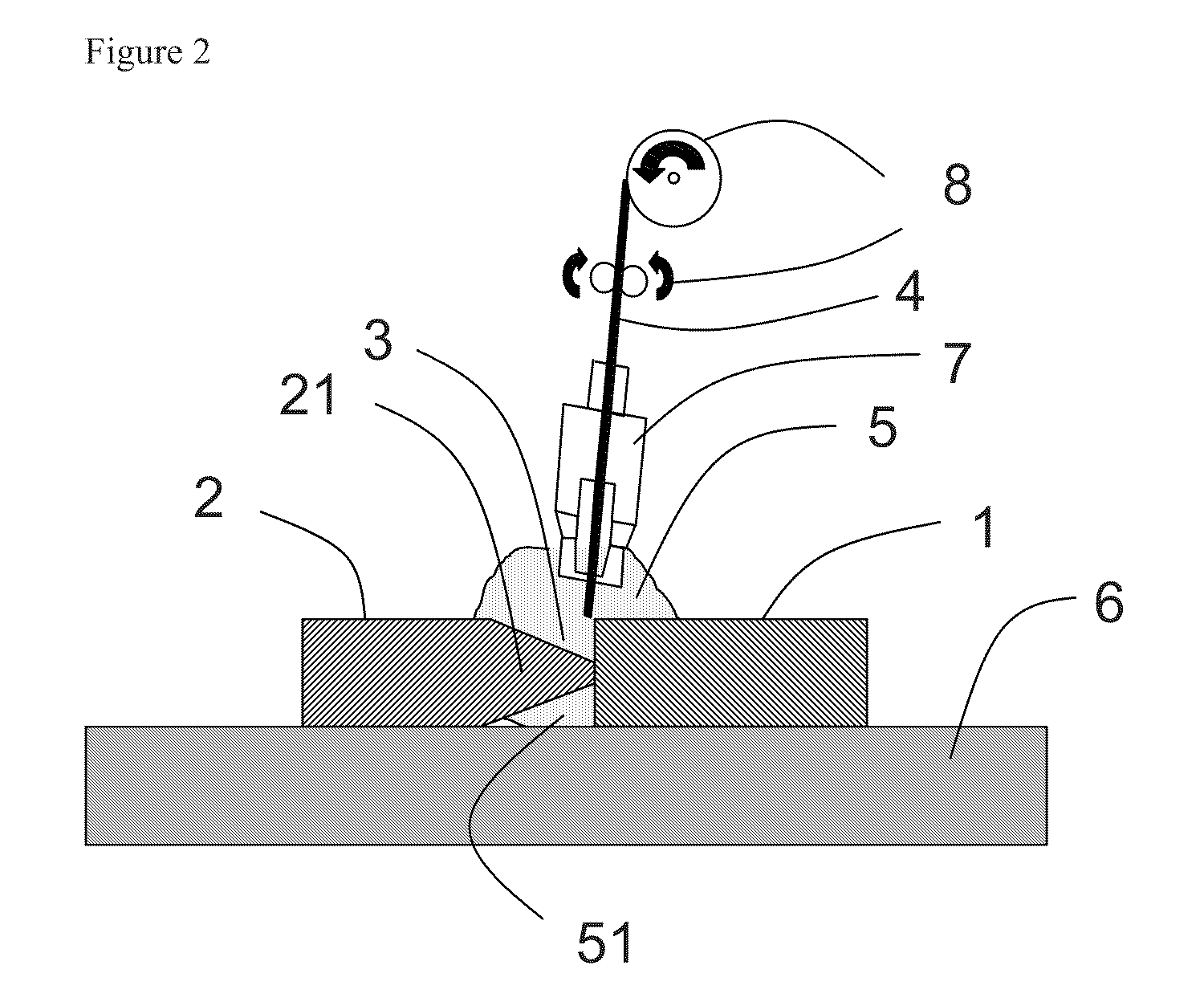

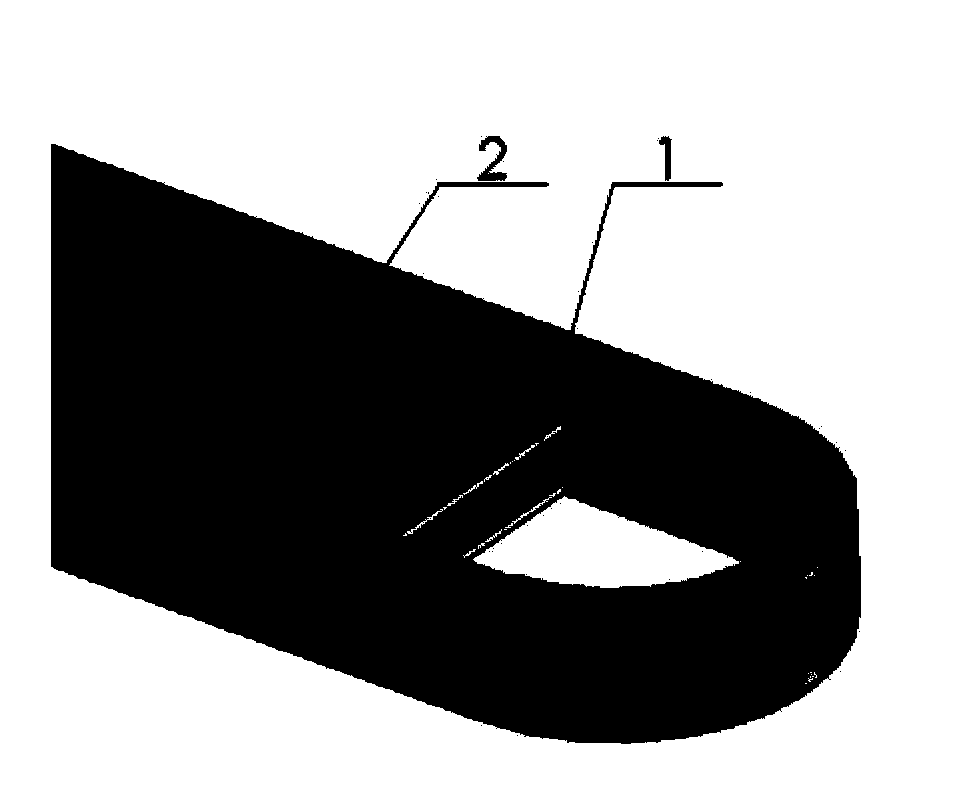

Fusion Welding Process To Join Aluminium and Titanium

The invention concerns a process for joining a first member (1) comprising an aluminum alloy to a second member (2) comprising a titanium alloy and having at least one edge with a thickness e,comprising the steps of(i) chamfering said edge of said second member into a tapered truncated shape having on a first side a first tapering angle α1, on a second side a second tapering angle α2 and a minimum thickness t, wherein α1 and α2 are greater than or equal to zero, the sum of α1 and α2 is between 10° and 50° and t is between 0.05 e and 0.3 e,(ii) placing said first member and said chamfered edge of said second member (21) in an abutting relationship defining a geometry to be weld-brazed (3),(iii) heating the surface areas of said members adjacent the abutment to a temperature above the melting temperature of said aluminum alloy and below the melting temperature of said titanium alloy, in the presence of an inert gas (5) and of a filler metal (4) to obtain a weld-brazed joint.The process of the invention is particularly useful for obtaining high strength weld-brazed joints between aluminum and titanium with a high process output.

Owner:CONSTELLIUM SWITZERLAND

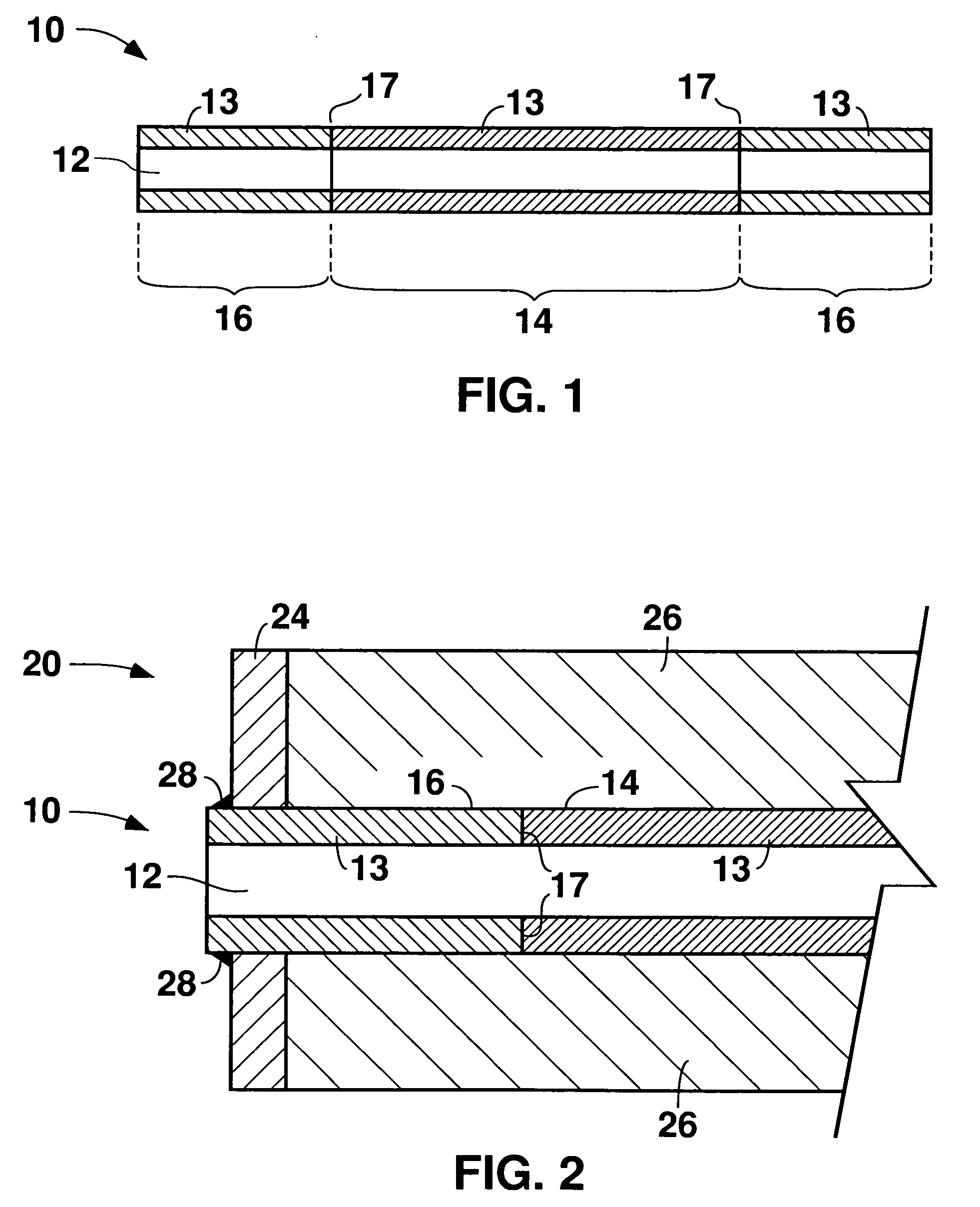

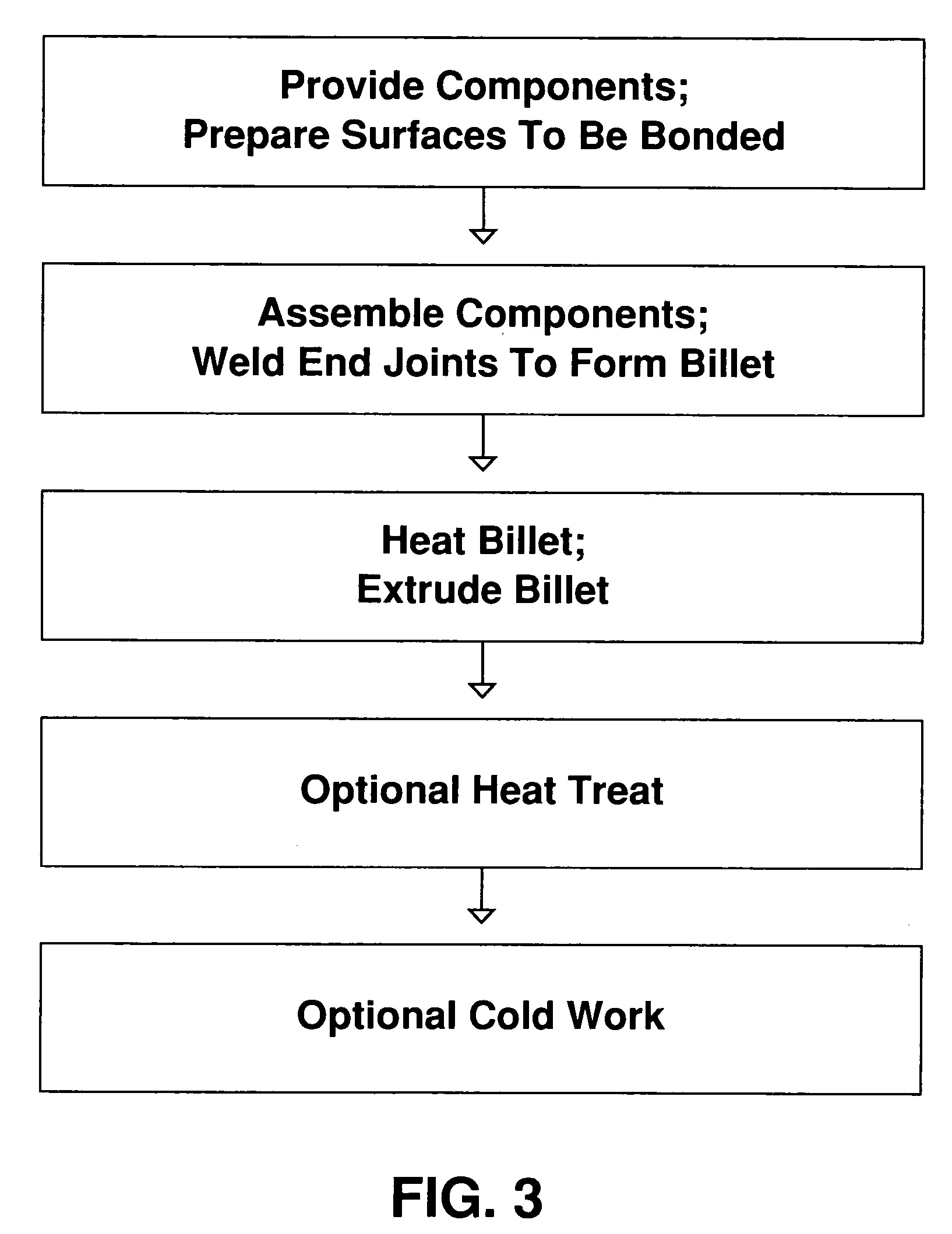

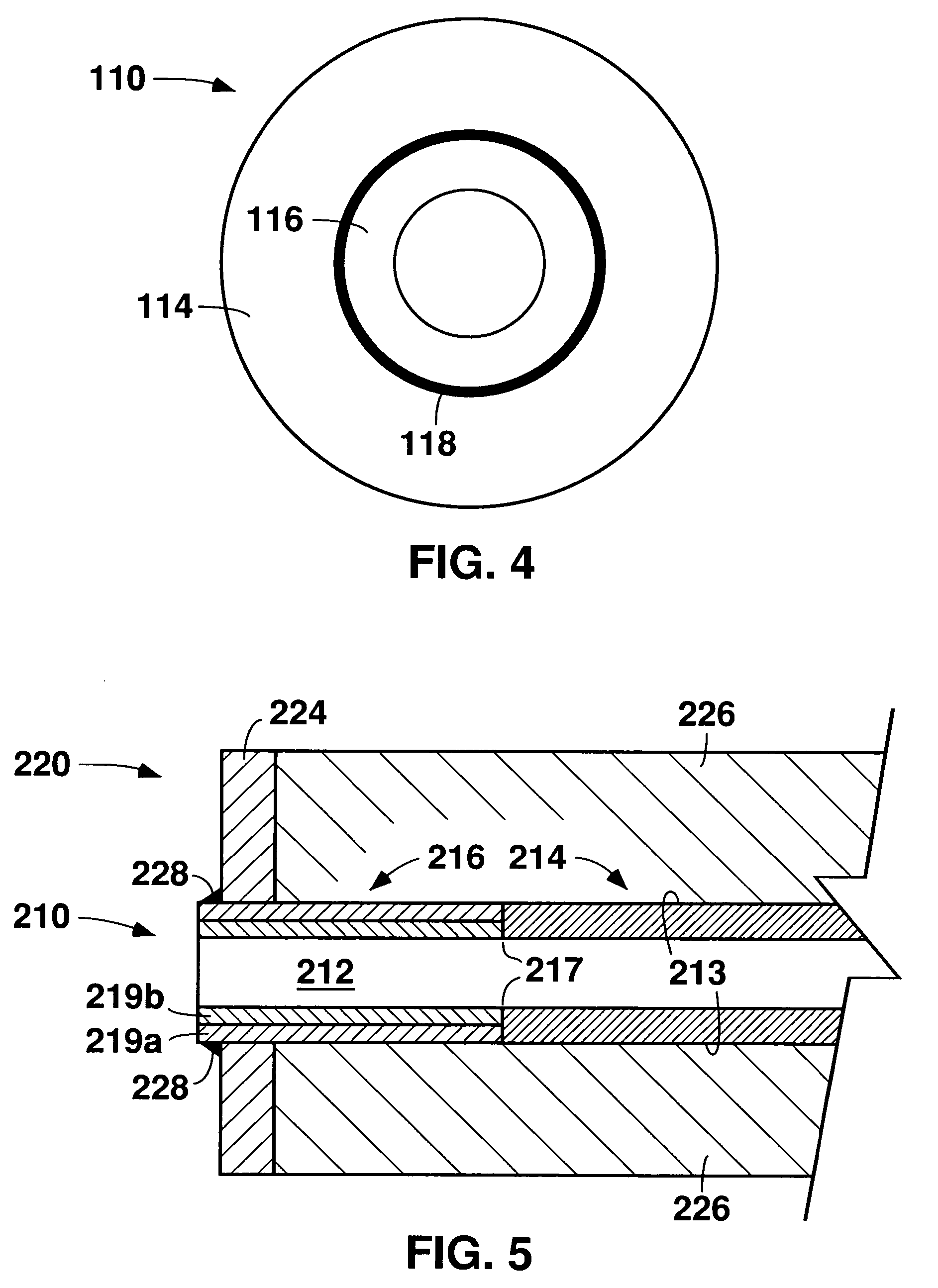

Corrosion resistant fluid conducting parts, methods of making corrosion resistant fluid conducting parts and equipment and parts replacement methods utilizing corrosion resistant fluid conducting parts

ActiveUS20060027628A1Readily cold workedReduced corrosion resistanceWelding/cutting auxillary devicesHeat exhanger sealing arrangementFusion weldingReplacement method

According to one aspect of the present disclosure, a part for an article of equipment includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The first region and the second region are either directly or indirectly joined by solid state welding to form a unitary fluid conducting part. According to another aspect of the present disclosure, a method for replacing at least one fluid conducting part of an article of equipment is disclosed wherein a replacement part is provided that includes a fluid conducting first region including a corrosion resistant first material, and a fluid conducting second region including a second material. The second material is substantially identical to the material of a region of the equipment on which the replacement part is mounted. The first and second regions are either directly or indirectly joined by solid state welding to form a unitary fluid conducting replacement part. The replacement part is secured to the article of equipment by a process comprising fusion welding the second material of the second region of the replacement part to the substantially identical material of the mounting region of the article of equipment.

Owner:ATI PROPERTIES LLC

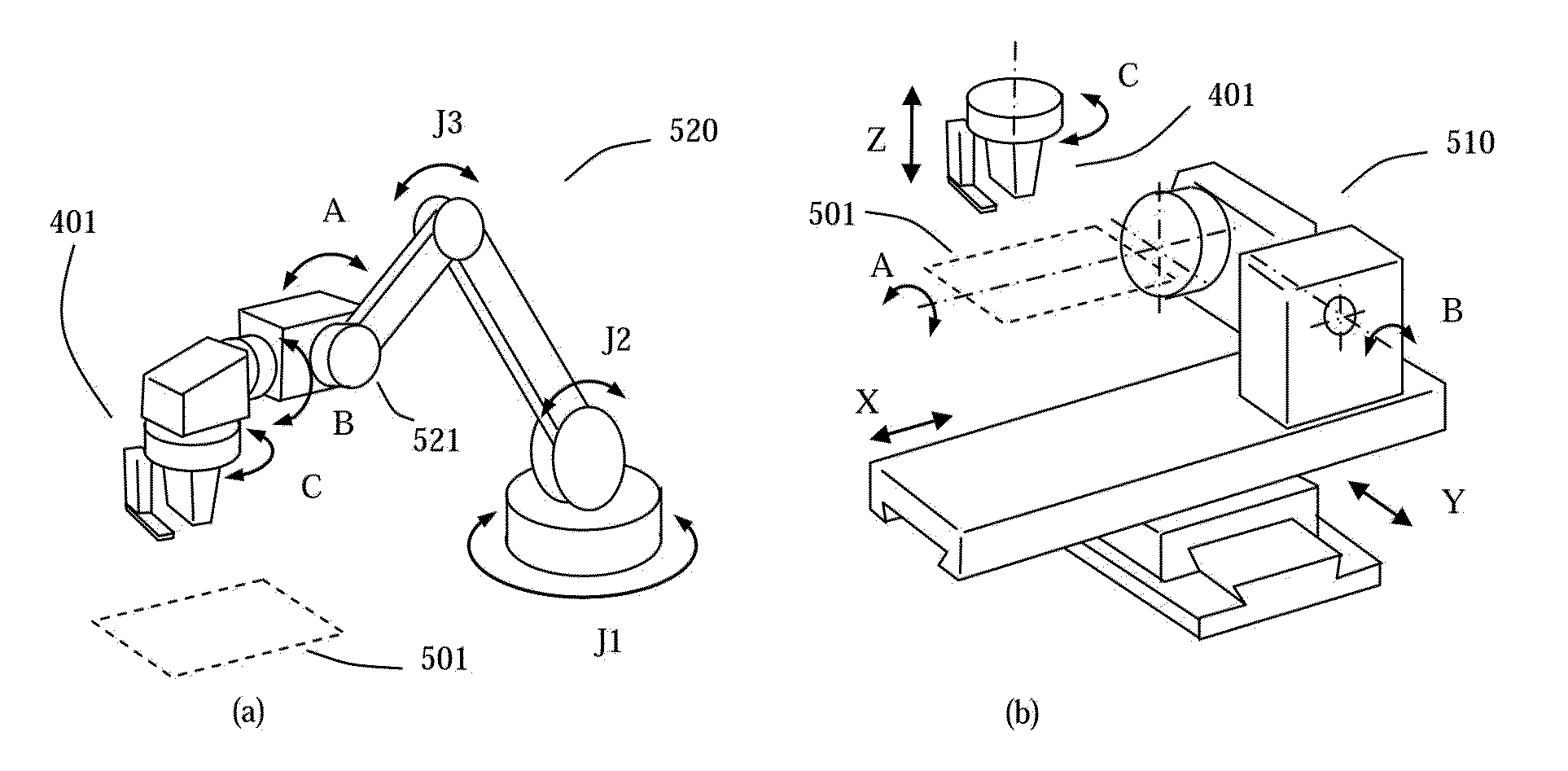

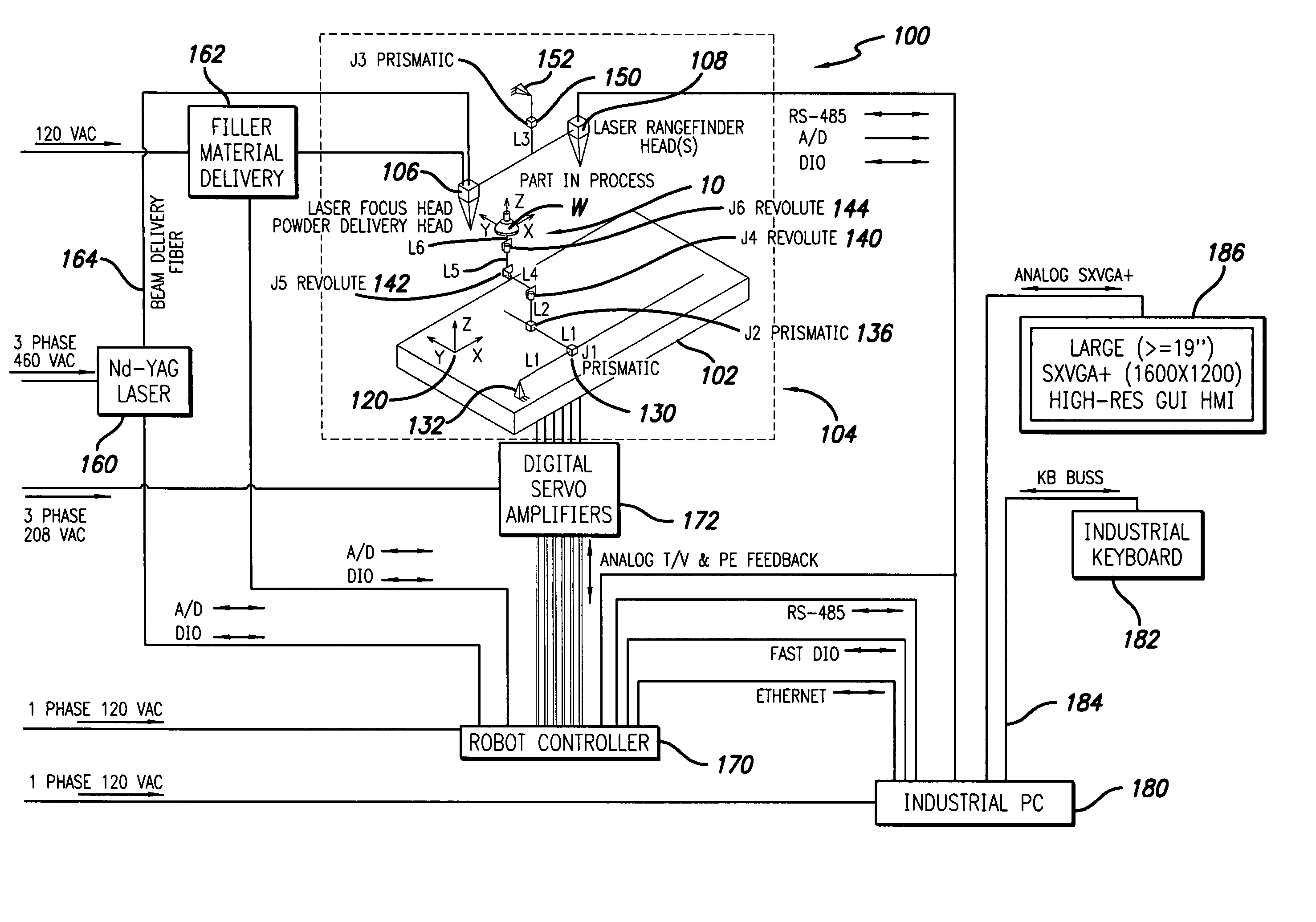

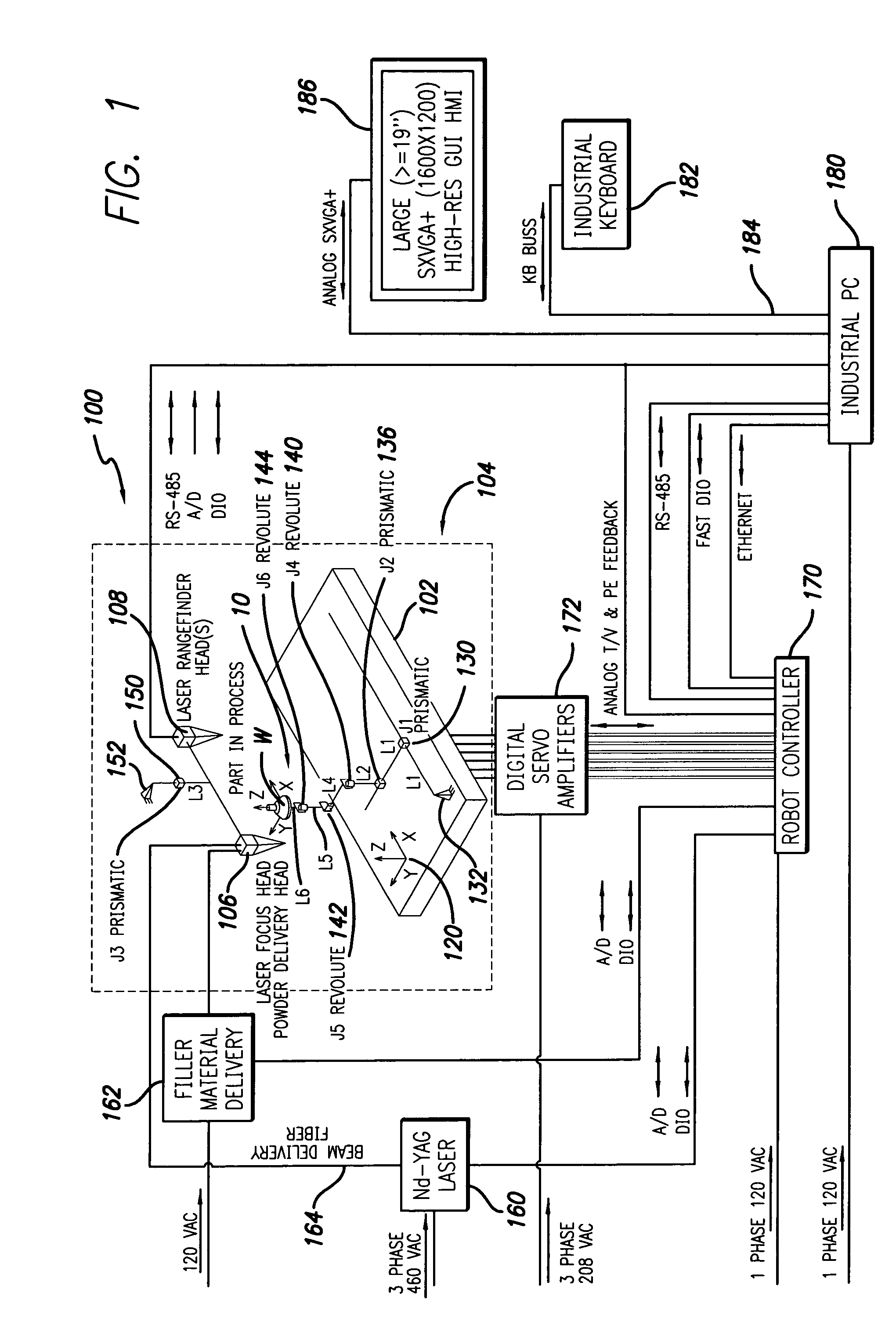

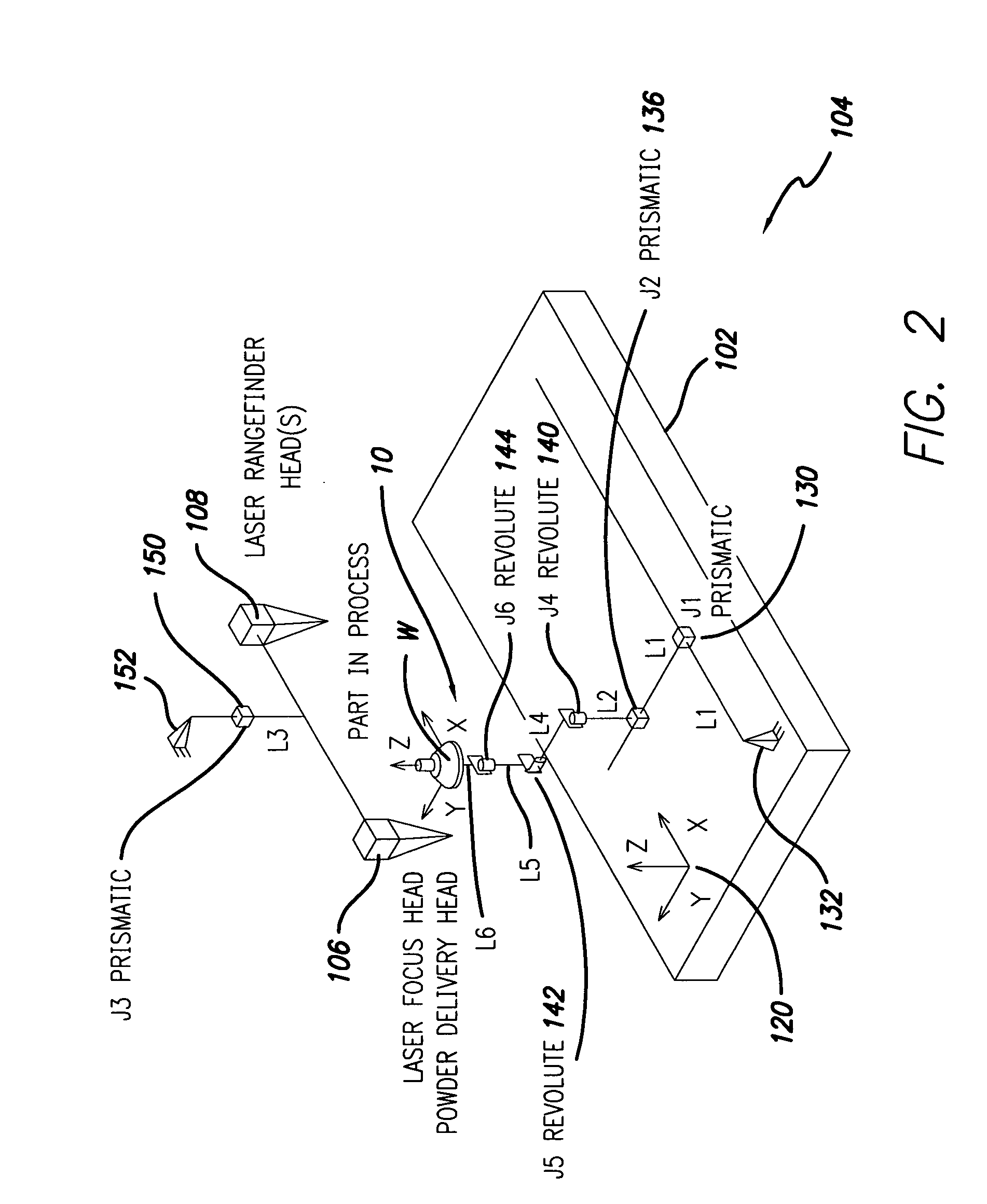

3-D adaptive laser powder fusion welding

InactiveUS20050023256A1Readily and easily achievedReadily availableAdditive manufacturing apparatusIncreasing energy efficiencyLaser rangingSupporting system

A 3-D adaptive laser powder fusion welding system provides for both modeling / gauging of a workpiece as well as repair, restoration, and / or manufacture thereof. By providing a work platform and apparatus support system, five degrees of control in the form of two linear axes and three rotational axes are provided. The sixth linear axis is controlled via the displacement of a laser powder fusion (LPF) welding head and a laser rangefinding head. The laser rangefinding head system enables the workpiece W to be modeled electronically or otherwise. Additionally, the rangefinding system enables a model part to serve as a template from which repairs or construction are affected. The LPF welding head then affects any repairs or manufacture that are needed on the workpiece W. The LPF welding head is powered by filler material. The entire system is generally controlled by computer which enable the operator to be separated from a generally hot and hostile welding environment.

Owner:HONEYWELL INT INC

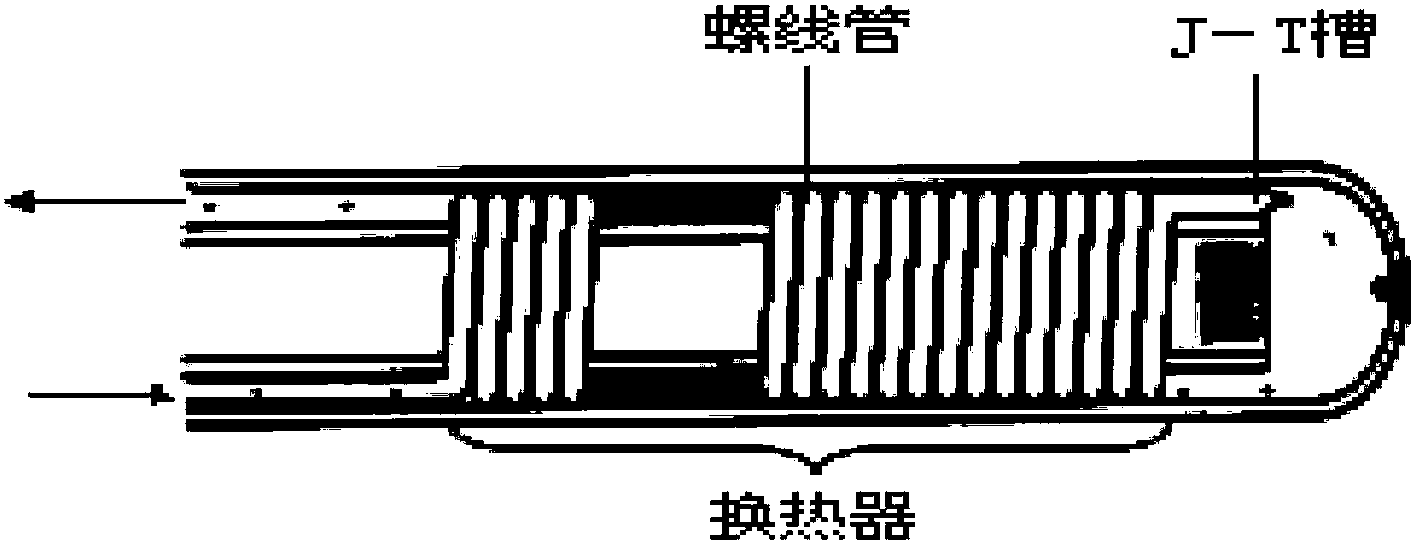

Refrigerator

InactiveCN103423911AImprove cooling effectImprove compactnessMechanical apparatusCompression machinesEngineeringHigh pressure

A refrigerator based on micro-channel regenerative heat exchange technology and Joule-Thomson effect is machined by the aid of atomic diffusion fusion welding technology and comprises an inlet-outlet portion, a regenerative heat exchange portion, a throttling portion and an evaporating cavity. The inlet-outlet portion is provided with an inlet and an outlet, the regenerative heat exchange portion comprises at least one high-temperature layer and at least one low-temperature layer which are pairwise adjacent, each layer is provided with at least one channel, high-temperature and high-pressure gas enters the channels of the high-temperature layers from the inlet, then enters the throttling portion and is cooled in a throttling manner once, and then the high-temperature and high-pressure gas flows to the evaporating cavity with a large space and accordingly is cooled in the throttling manner again. Owing to throttling and cooling, part of the gas is condensed into liquid, the rest gas is low-temperature and low-pressure gas, the liquid and the low-temperature and low-pressure gas are mixed together to form a low-temperature and low-pressure gas liquid mixture, the evaporating cavity keeps the low temperature by the aid of the low-temperature and low-pressure gas liquid mixture, a high-temperature device connected with the evaporating cavity is cooled by the evaporating cavity, and the gas in the evaporating cavity reflows into the channels of the low-temperature layers and is discharged from the outlet after exchanging heat with the high-temperature and high-pressure gas in the channels of the high-temperature layers adjacent to the low-temperature layers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Ut method of identifying a stuck joint

ActiveUS20100031750A1Quickly and easily identifyingAccurate identificationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by using resonanceLight beamUltrasonic testing

An ultrasonic testing method to identify a stuck joint between two workpieces utilizing an ultrasonic probe to transmit ultrasonic (US) beams into the joint area and capture the associated US reflections. The method transmits two separate US beams fired in very close proximity to one another. The probe then captures a plurality of US reflections. The method looks for subtle variations in a high gain A-scan presentation of a high gain reflected beam, while using a low gain US beam to identify the particular region on the high gain A-scan presentation in which to look for signs of a stuck joint. Subtle variations within a particular region of the high gain A-scan presentation identify stuck joints. The method is applicable to metals and nonmetals and is not limited to fusion welding, but may also be used with solid state welds, brazed and soldered joints, and adhesively joined workpieces.

Owner:CUMBERLAND & WESTERN RESOURCES LLC

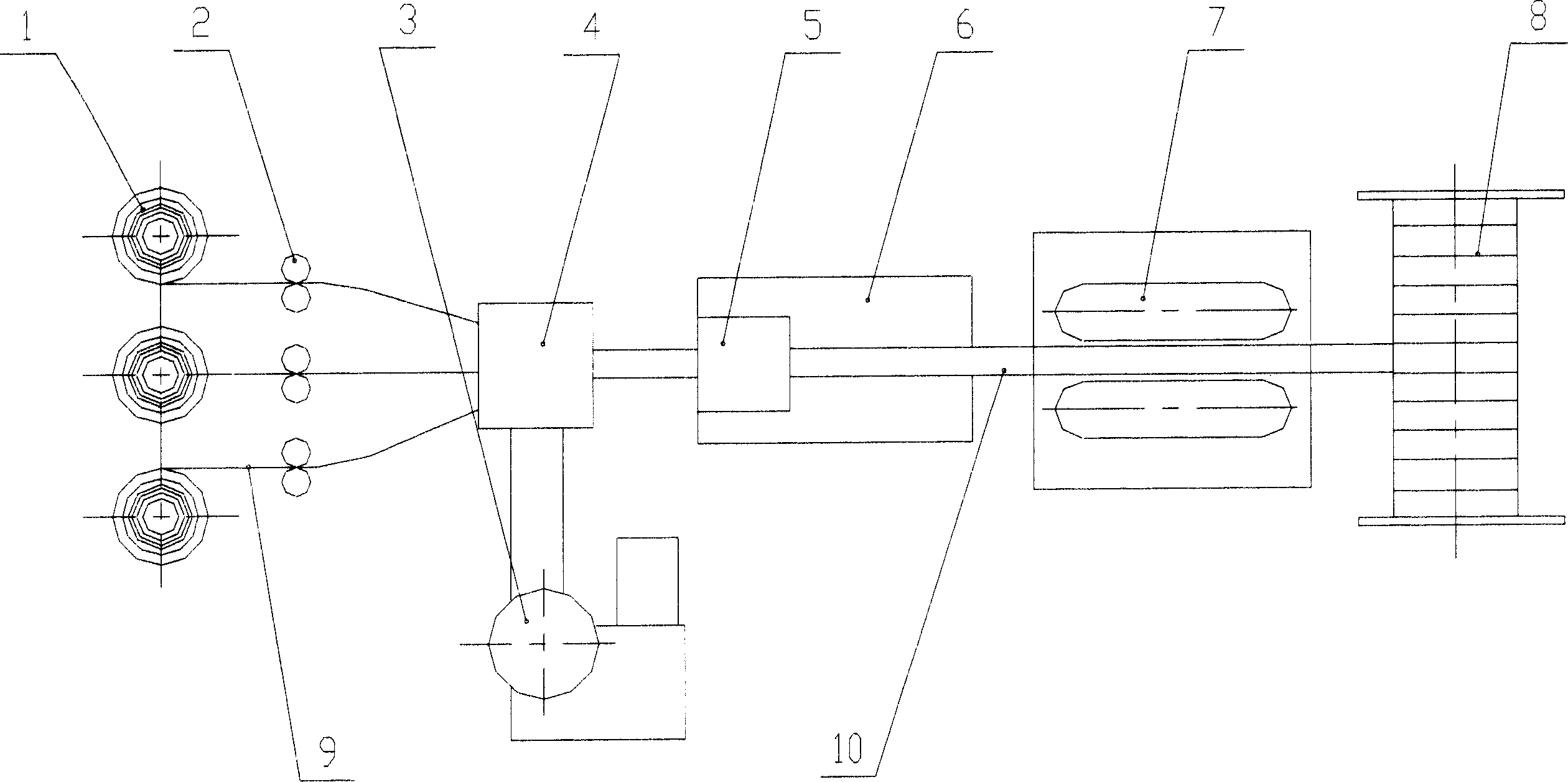

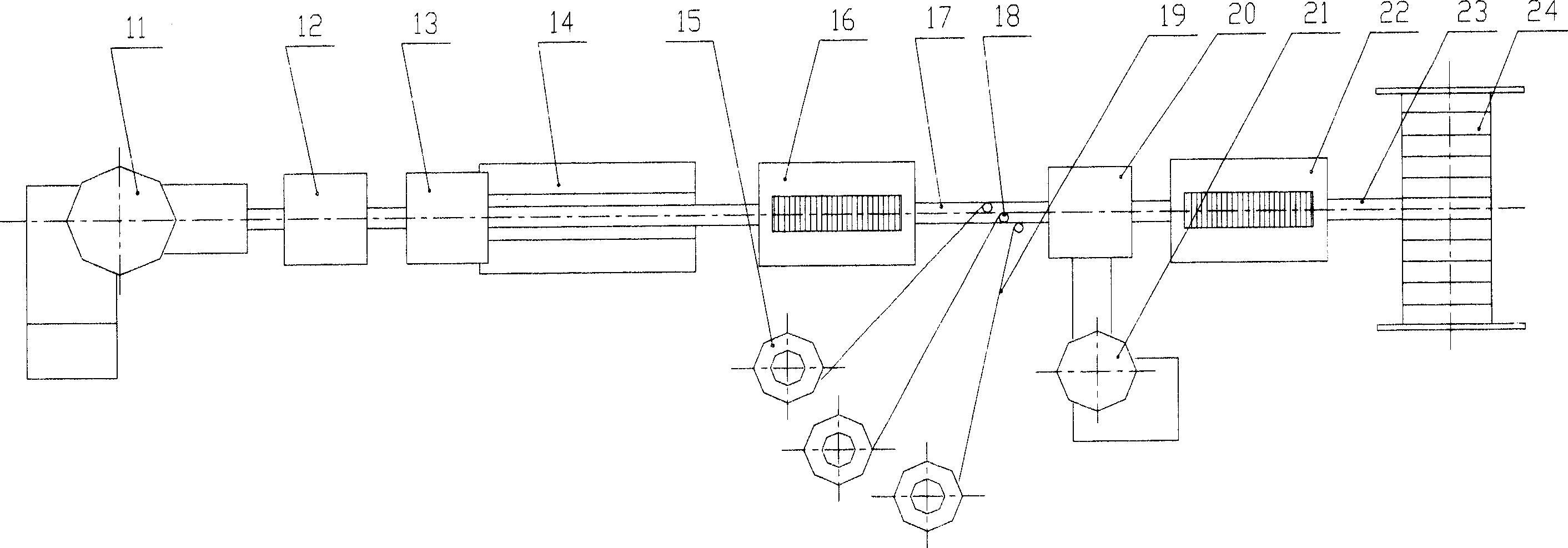

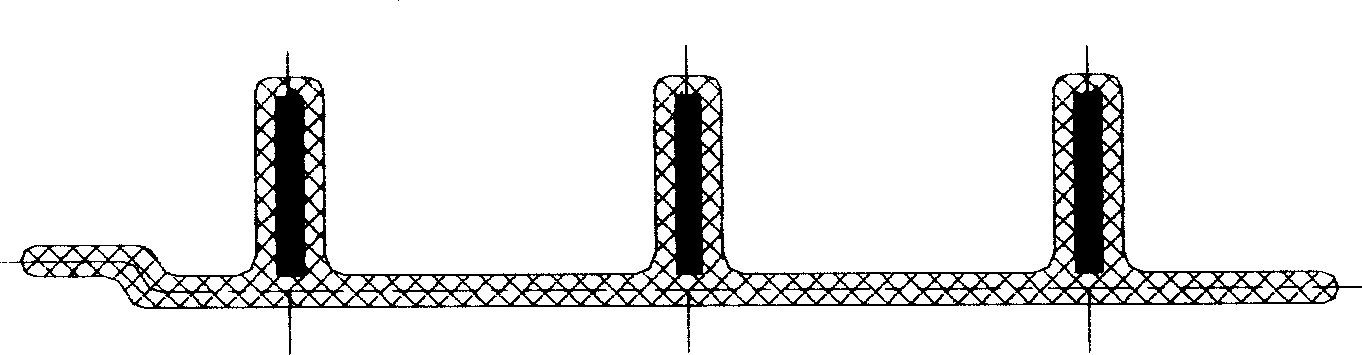

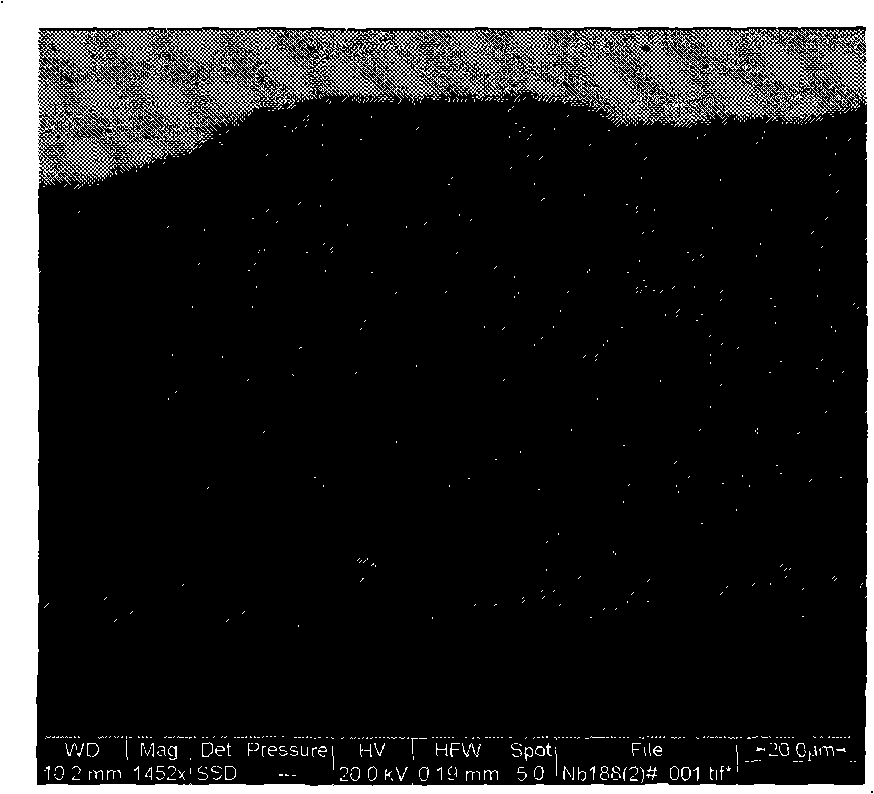

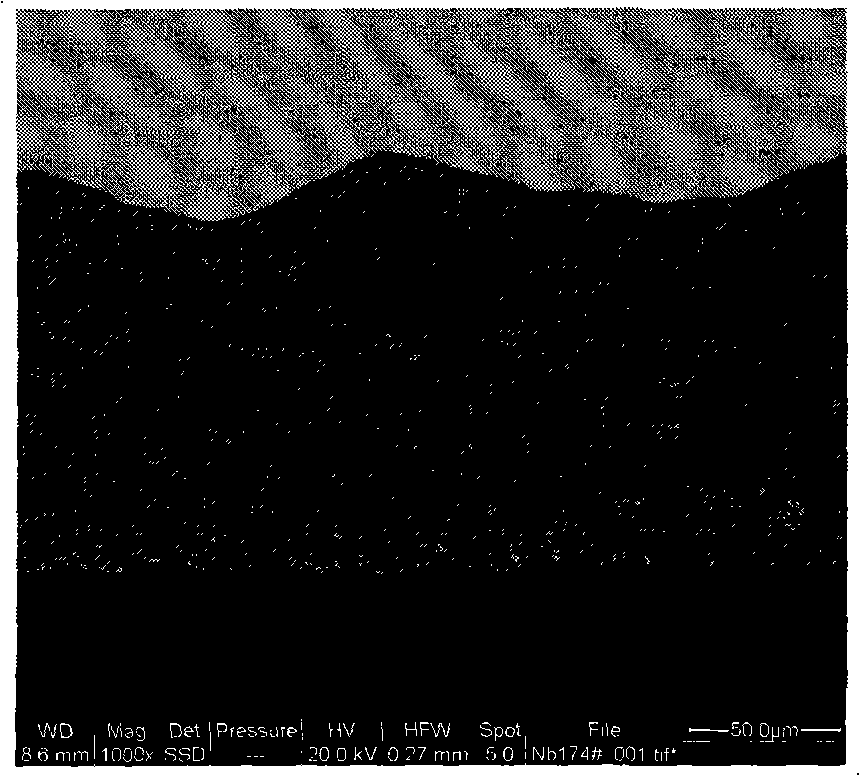

Steel band reinforced plastic drainpipe and method and apparatus for manufacturing the same

Owner:ハルビンスターウェイマシーナリーマニュファクチャリングカンパニーリミテッド

Argon-arc welding-braze welding composite welding method for connecting the titanium alloy and steel

ActiveCN101284336AAvoid crackingAvoid damageSoldering apparatusArc welding apparatusManganeseTitanium

The invention belongs to the welding technology field and relates to an argon-arc welding-composite braze welding method used for welding titanium alloy and steel. When the titanium alloy is welded with the steel, Nb is used as an intermediate layer; arc welding is conducted towards the titanium alloy and the intermediate Nb layer by using a titanium welding wire in an argon chamber; and braze welding is conducted towards the titanium alloy and the intermediate Nb layer. The method uses Nb as the intermediate layer, and utilizes fusion welding and the braze welding to weld Nb with two parent metals of the titanium alloy and the steel respectively, thus avoiding the direct contact of the titanium and iron in the two kinds of parent metal, and preventing cracks from being formed by brittle phase produced when the titanium and the steel are directly welded. Copper manganese matrix solder and silver copper titanium solder are selected for braze welding Nb and the steel, and the corresponding temperature avoids the damage to the property of the parent metals of titanium alloy.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Relay welding detector and detecting method

InactiveUS6657833B2Frequently performedReduce voltageAC motor controlElectric devicesVoltmeterElectric vehicle

Frequency of judgment of welding of relays is increased to increase likelihood of early detection of welding. It is determined that a battery 22 is not being recharged or discharged when a vehicle speed V of an electric vehicle is approximately 0 and a brake pedal 54 is pressed, and a switching element of an inverter 24 is controlled to be switched to discharge electric charges which are stored in a capacitor 44. After discharging, relays 30, 32 are turned off, and voltages RV1, RV2 between the terminals of the relays 30, 32 are detected by voltmeters 40, 42 to judge whether either of the voltages RV1, RV2 has a threshold value RVref (approximate value 0) or less. When it is so determined, it is judged that the relays 30, 32 are welded, and an LED 70 is illuminated.

Owner:TOYOTA JIDOSHA KK

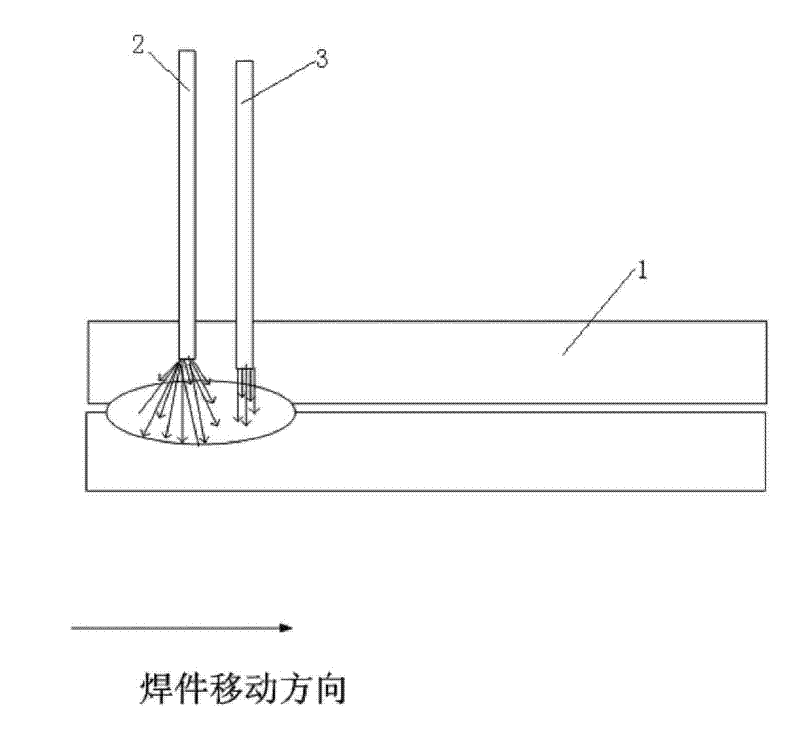

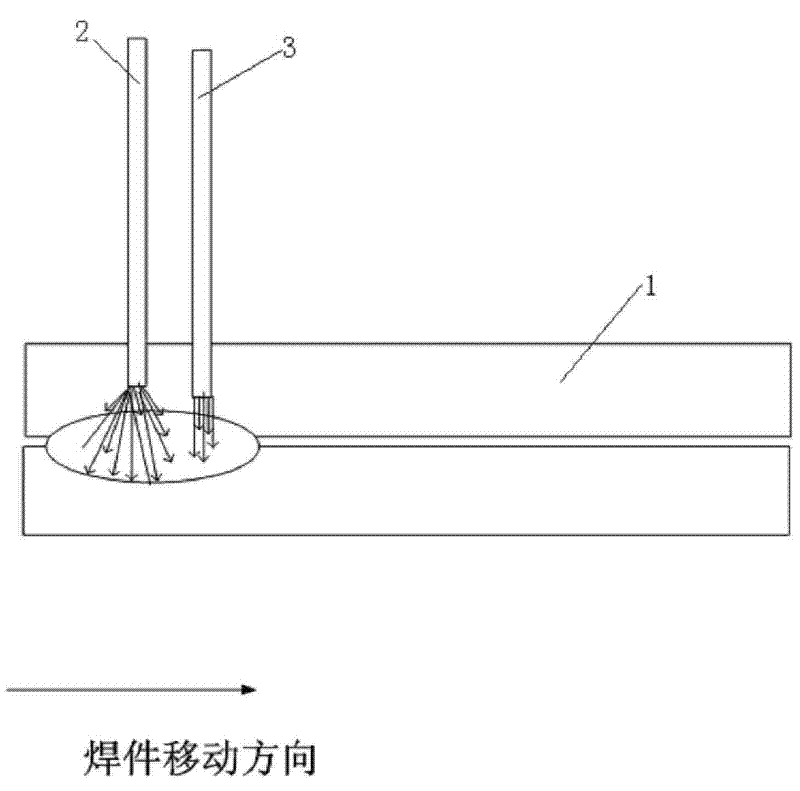

Hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser

The invention relates to a hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser, comprising the following steps: firstly fixing a variable-polarity square-wave tungsten electrode argon arc welding gun and a laser beam transmitting gun, providing a workpiece moving at a constant speed, forming a mode of preposing the variable-polarity square-wave tungsten electrode argon arc welding gun, utilizing the electric arc of variable-polarity square-wave tungsten electrode argon arc welding to remove impurities such as oxide films and the like at the surface zone of the welding workpiece, and leading the workpiece to be in a high-temperature melting state; and then leading laser beams to radiate a welded part, thus deepening the depth of fusion in variable-polarity square-wave tungsten electrode argon arc welding and finishing the welding. By utilizing the welding method adopted by the invention, the reflectivity of metal to the laser can be reduced, and the absorptivity of the metal to the laser energy is improved, so that the effective heating depth of the laser is improved, the depth of fusion of welding seams is enlarged, and the width of the welding seams and the width of heat affected zones are effectively reduced, thus finally a welding piece with deeper depth of fusion, very small heat affected zones and attractive appearance can be obtained.

Owner:CRRC QINGDAO SIFANG CO LTD

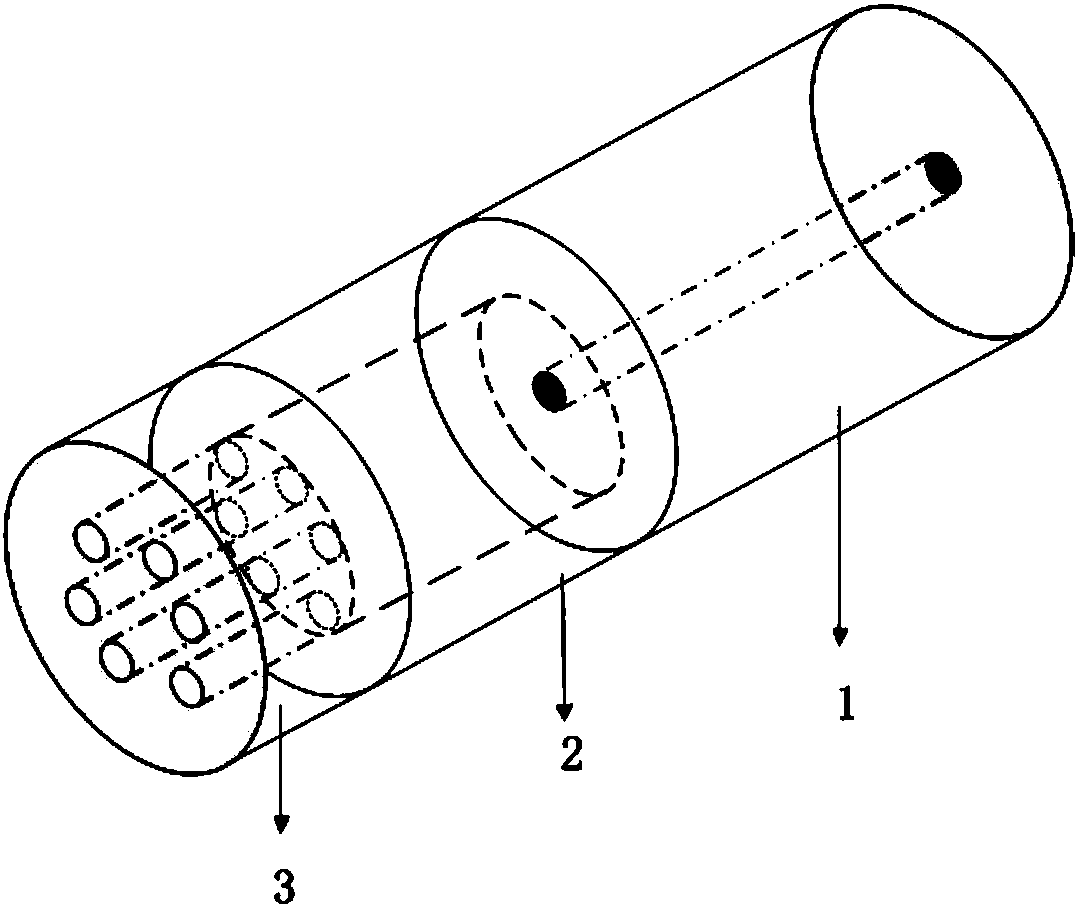

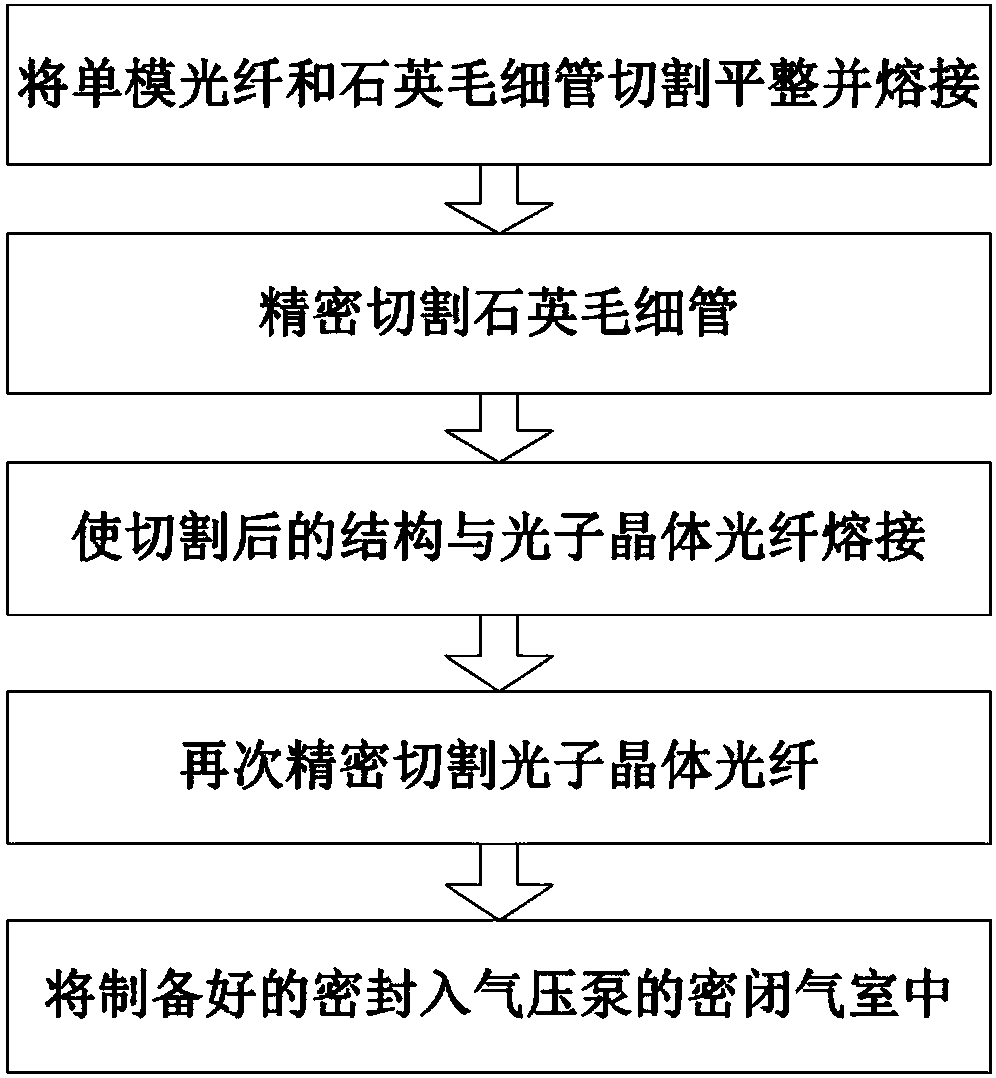

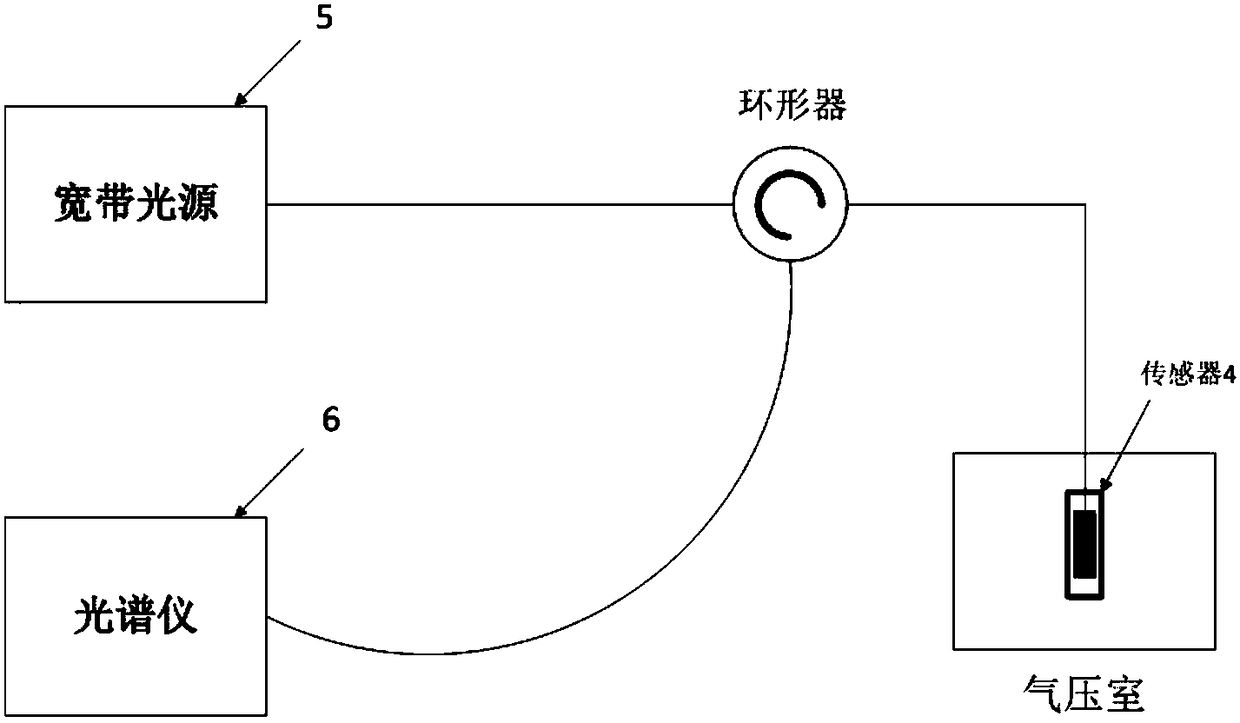

Optical fiber FP (Fabry-Perot) gas pressure sensor with optical vernier effect as well as preparation method thereof

ActiveCN108225657ALarge free spectral rangeHigh test sensitivityFluid pressure measurement by optical meansPhotonGas pressure

The invention discloses an optical fiber FP (Fabry-Perot) gas pressure sensor with optical vernier effect as well as a preparation method thereof. The sensor comprises single-mode optical fiber, a quartz capillary and photonic crystal optical fiber. The two ends of the quartz capillary are connected one end of the single-mode optical fiber and one end of the photonic crystal optical fiber correspondingly by a fusion welding mode; and the other end of the photonic crystal optical fiber is directly connected with the outside, and the pore structure facilitates the outside gas to enter a cavity of an optical fiber FP sensor, so that the quartz capillary and the photonic crystal optical fiber form two Fabry-Perot resonant cavities with vernier effect. During preparation, a commercial optical fiber fusion splicer is used, the discharging time and the discharging intensity of the electrode are controlled, two types of optical fiber are cascaded, a precise cutting device is used for cutting the optical fiber, and the length of the optical fiber is strictly controlled, so that the vernier effect is generated. The optical fiber FP gas pressure sensor is small in volume, simple and convenient to prepare, high in adaptability and high in sensitivity, and has wide application prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

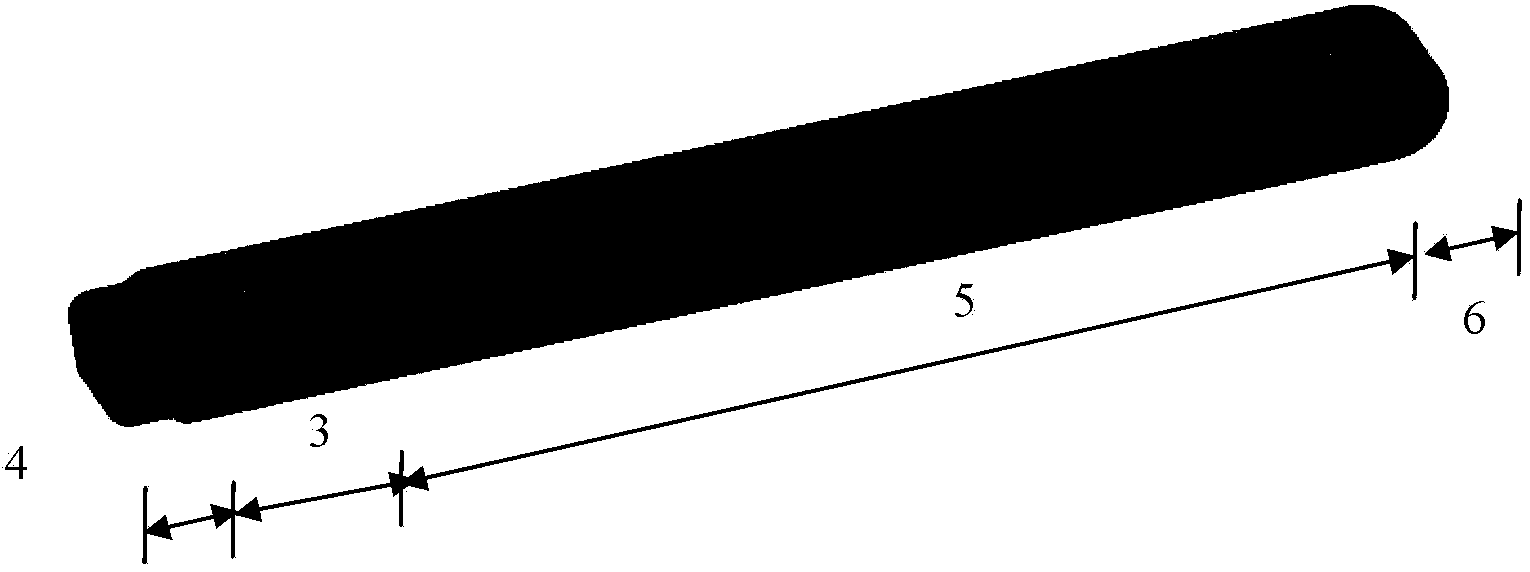

Flux-cored wire for fusion welding butt joint of titanium-steel composite board and preparation method of flux-cored wire

InactiveCN104028917ASmall diameterEffective connectionArc welding apparatusWelding/cutting media/materialsFilling rateMaterials science

A flux-cored wire for fusion welding butt joint of a titanium-steel composite board comprises the components in percentage by mass as follows: 80-81% of vanadium powder and 19-20% of chromium powder, and the sum of the mass percentageof the components is 100%. The invention further discloses a preparation method of the flux-cored wire. The preparation method comprises the steps as follows: the vanadium powder and the chromium powder are dry-mixed to obtain flux core powder, the flux core powder is placed on a charging machine of flux-cored wire production equipment, a copper belt is placed on a belt unwinding machine, ultrasonic cleaning is performed, then U-shaped groove rolling and powder adding operations are performed, the powder filling rate is controlled, sealing of the copper belt is performed through a forming machine, and a wire with the diameter of 3.8 mm is formed; then the flux-cored wire is obtained through six reducing treatment processes and a nine-stage reducing finish drawing treatment process sequentially. By means of the flux-cored wire, a titanium layer and a steel layer weld structure of the composite board can be effectively joined together, and the fusion welding butt joint of the titanium-steel composite board is realized; an obtained weld joint has excellent toughness; and the preparation process is simple, and mass production is facilitated.

Owner:XIAN UNIV OF TECH

TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

InactiveCN101362253ALess loss of shape memory propertiesSmall organizationWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneSurface cleaning

The invention relates to a method for transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel, which belongs to the technical field of the connection of dissimilar materials. In the prior art, the technology of the connection between TiNi shape memory alloy and stainless steel has the problems of welding crack, large crystal grains in the heat affected zone and poor mechanical properties. The transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel is realized through the following steps: after the surfaces of TiNi shape memory alloy and stainless steel to be welded and the surface of AgCuTi foil is cleaned and dried, a TiNi shape memory alloy / AgCuTi metallic foil / stainless steel structure is formed, fixed through a welding clip, and then positioned in a vacuum diffusion oven, and welding pressure and temperature are applied to the structure. The method has the advantages that the welding temperature is low (relative to fusion welding), the influence to the base material is small, the connector has no welding defect, the shearing strength of the connector in the room temperature reaches 250 MPa, and the microhardness of the area near the seam section can reach 670 Hv.

Owner:BEIJING UNIV OF TECH

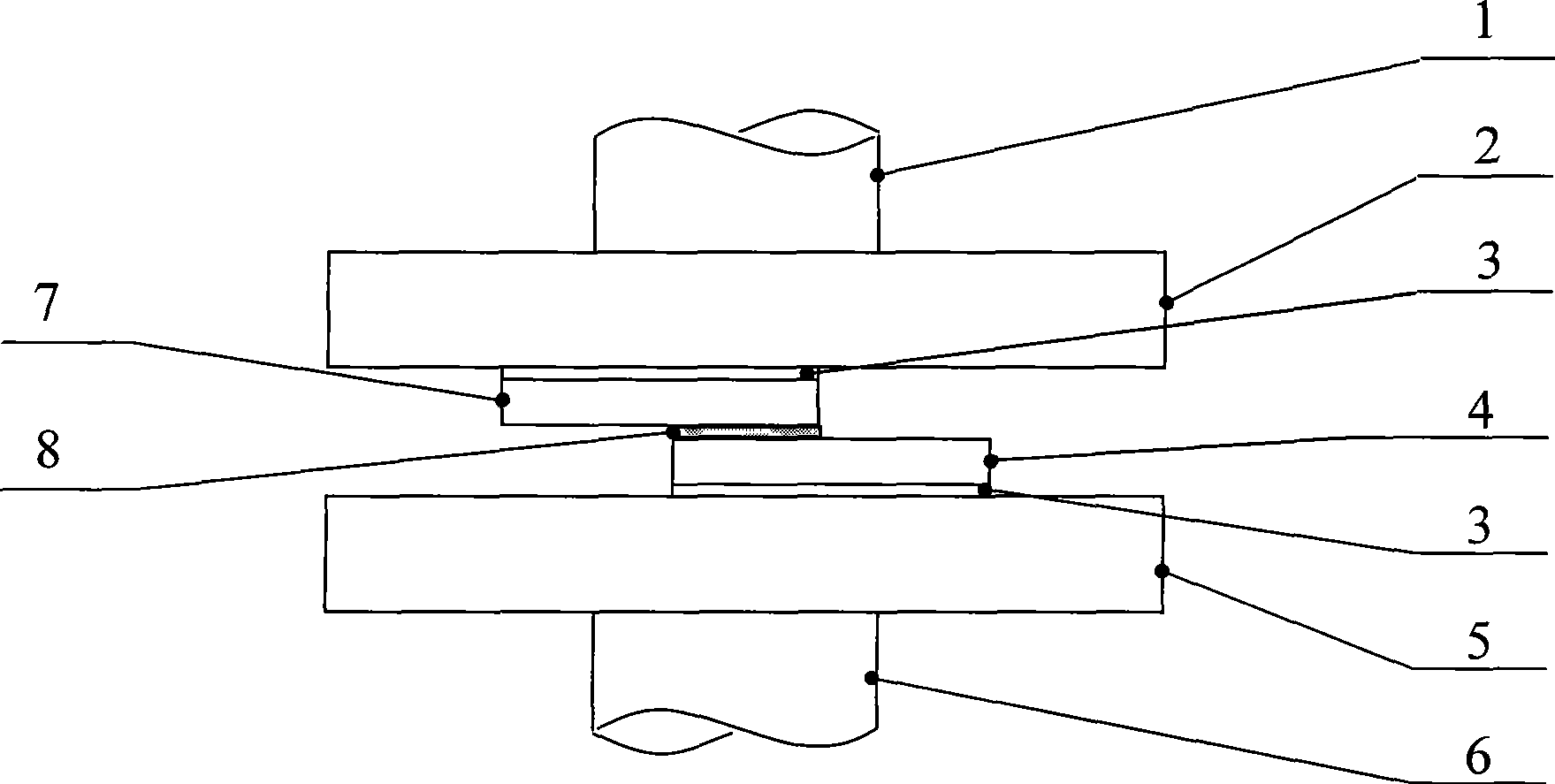

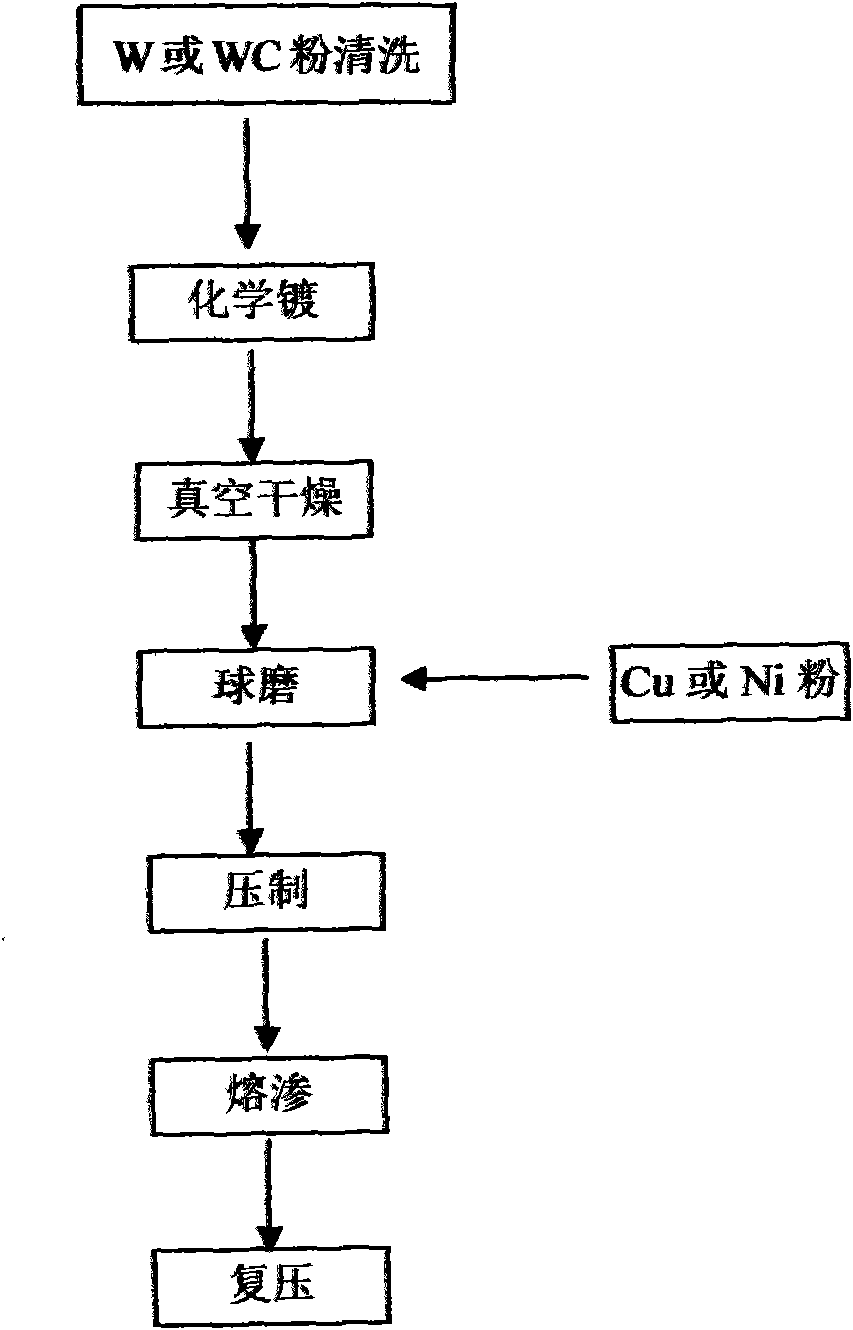

Submicron particle reinforced Ag-based electrical contact material and preparation method thereof

ActiveCN101651050AImprove welding resistanceImprove arc ablation resistanceContactsCopperFusion welding

The invention discloses a submicron particle reinforced Ag-based electrical contact material and a preparation method thereof. The method comprises the following steps: adopting chemical plating method to coat silver on the surface of submicron W particles or WC particles, and then adopting pressing infiltration method to prepare dense micron particle reinforced Ag-based composite material. The material comprises the following components by weight percent: 0.1%<=Ni<=2%, 0.1%<=Cu<=2%, 30%<=W(or WC)<=80% and the balance Ag, wherein the grain size of W or WC powder is 0.01-1mu m. The material ofthe invention has good mechanical and physical properties and the reinforced phase particles are dispersed evenly. Compared with the traditional Ag-W material or Ag-WC material, the material has better fusion welding resistance, lower electric arc burning loss resistance and longer electrical life as the tiny high melting point reinforced phase is distributed evenly in the material substrate in dispersion manner.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

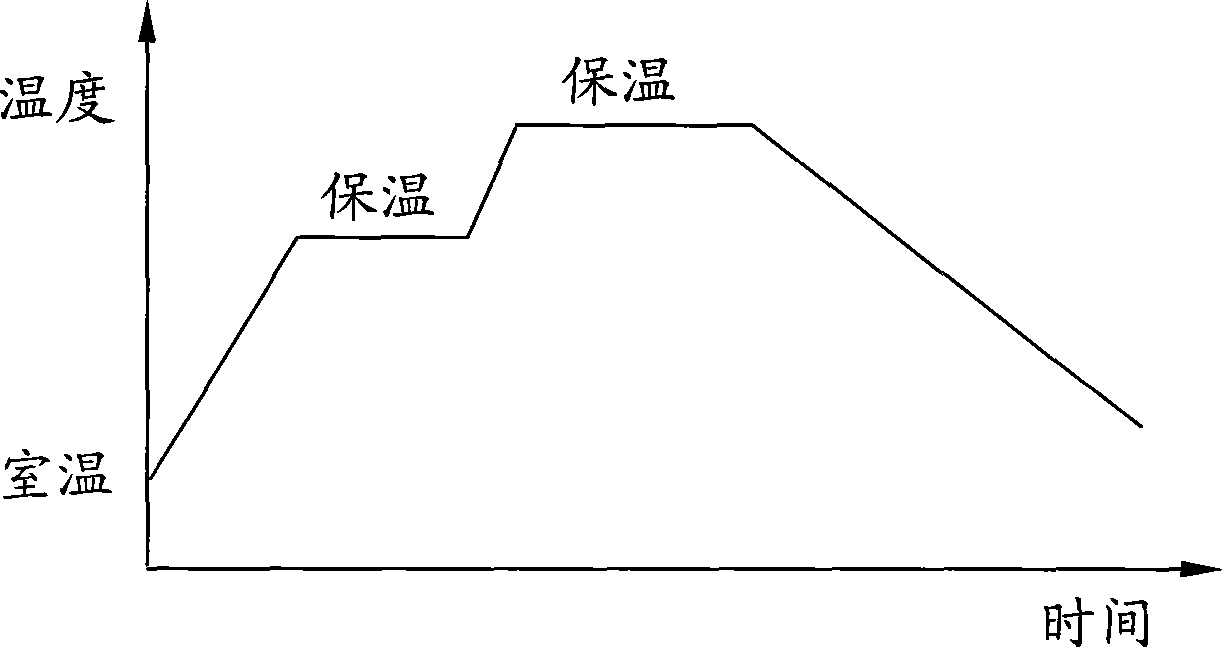

AgWC (wolfram carbide) electrical contact material and manufacturing method thereof

InactiveCN101834070AReduce manufacturing costImprove pass rateContact materialsCarbideHeating furnace

The invention relates to an AgWC (wolfram carbide) electrical contact material and a manufacturing method thereof, in particular to a silver-based electric contact material and a manufacturing method thereof, belonging to the technical field of electrical contact materials. A substrate of the AgWC electrical contact material is infiltrated with silver from upper surface to lower surface. The manufacturing method comprises the following steps of: obtaining Ag and WC mixed powder by applying a powder mixing process; pressing the mixed powder into a powder billet by applying a powder pressing process; then putting a prepared thin silver sheet on the powder billet by applying an infiltration sintering process, conveying into a heating furnace and heating, melting the silver sheet and infiltrating into the powder billet to further obtain an AgWC electric contact; and beautifying the surface of the AgWC electric contact by applying a polishing process. The AgWC electric contact manufactured by adopting the manufacturing process has favorable electric conduction performance and heat conduction performance, high corrosion resistance, strong fusion welding resistance, and the like.

Owner:SHANGHAI DIANKE ELECTRICAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com