Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1139 results about "Tungsten electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

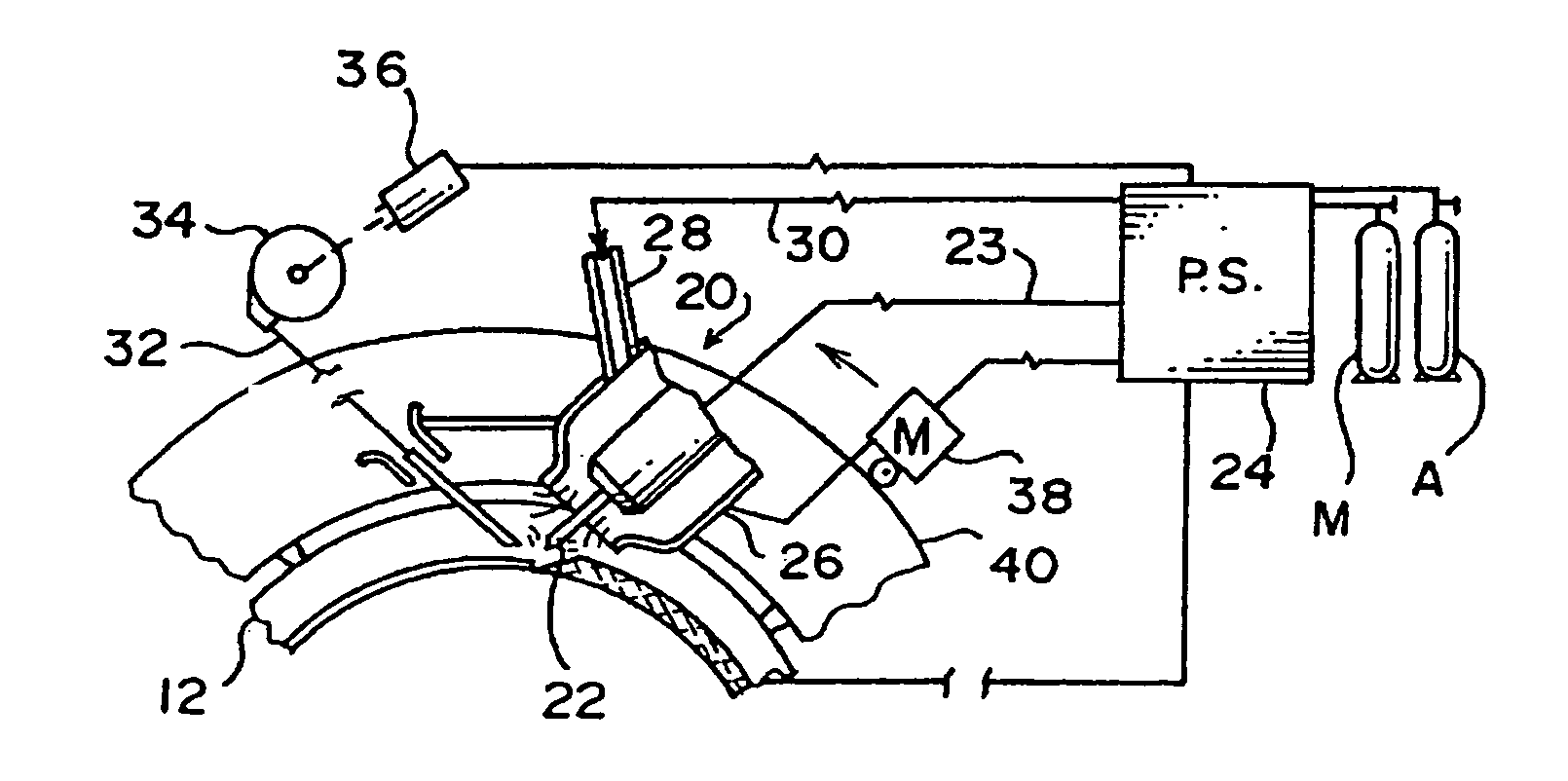

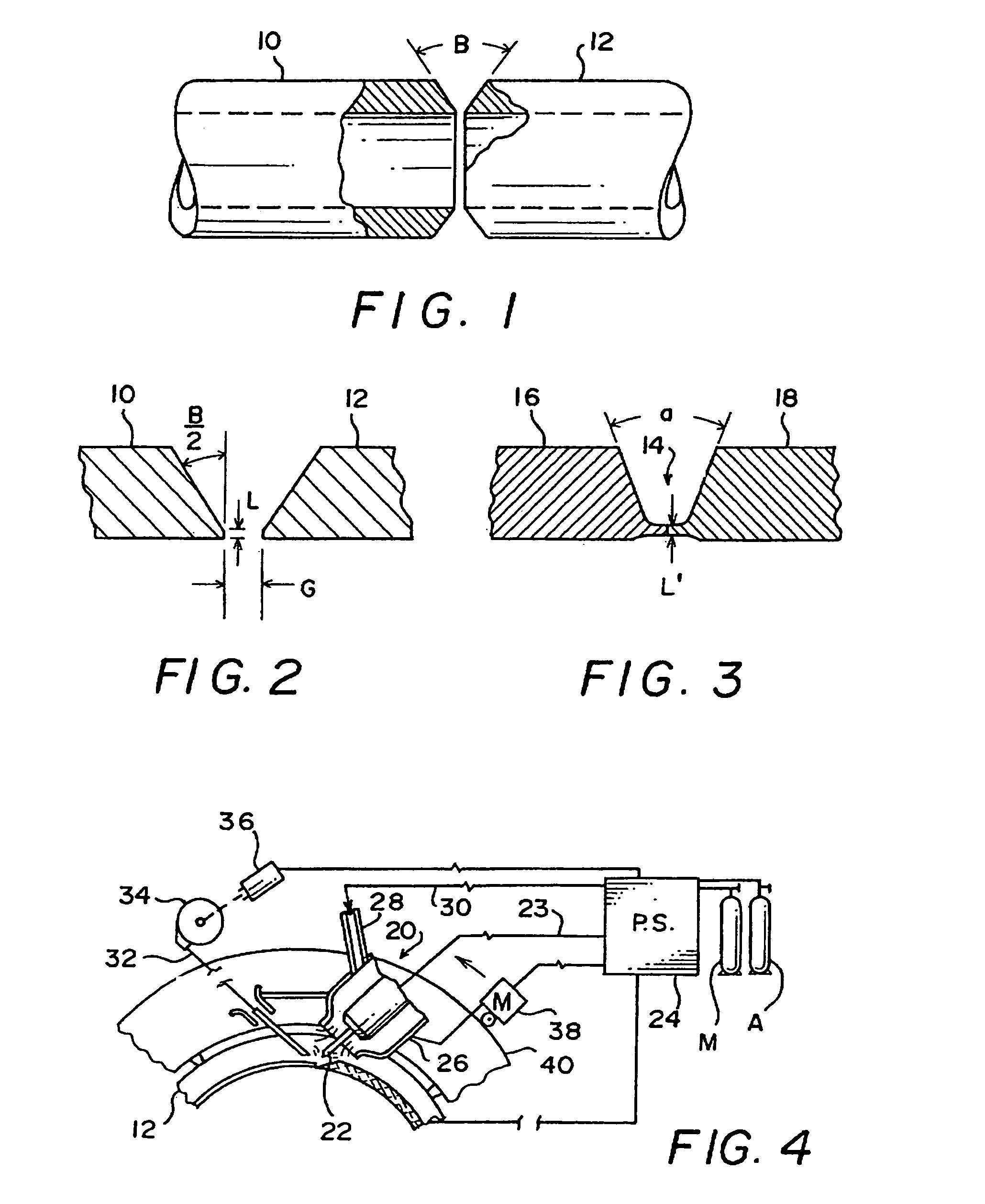

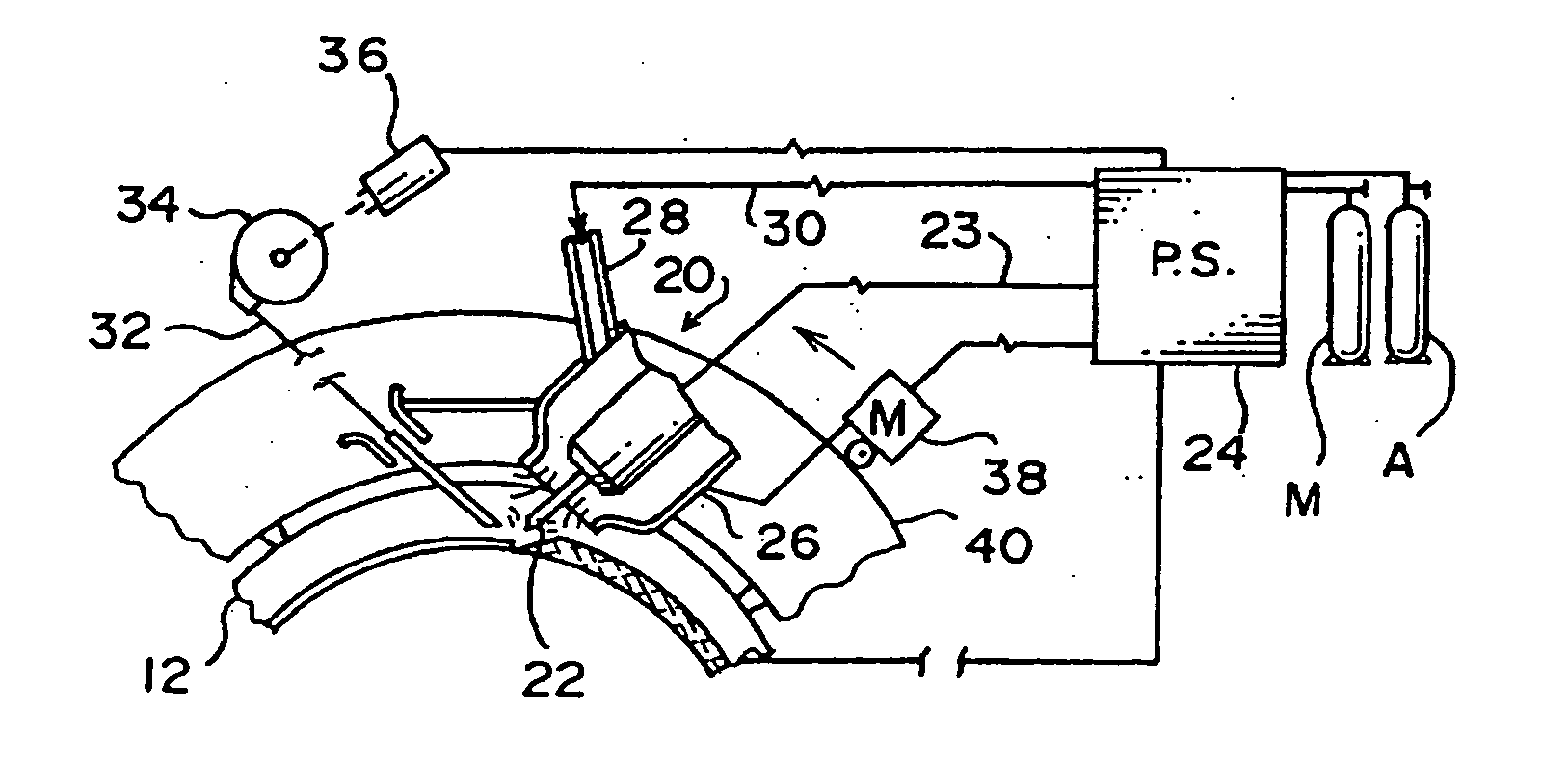

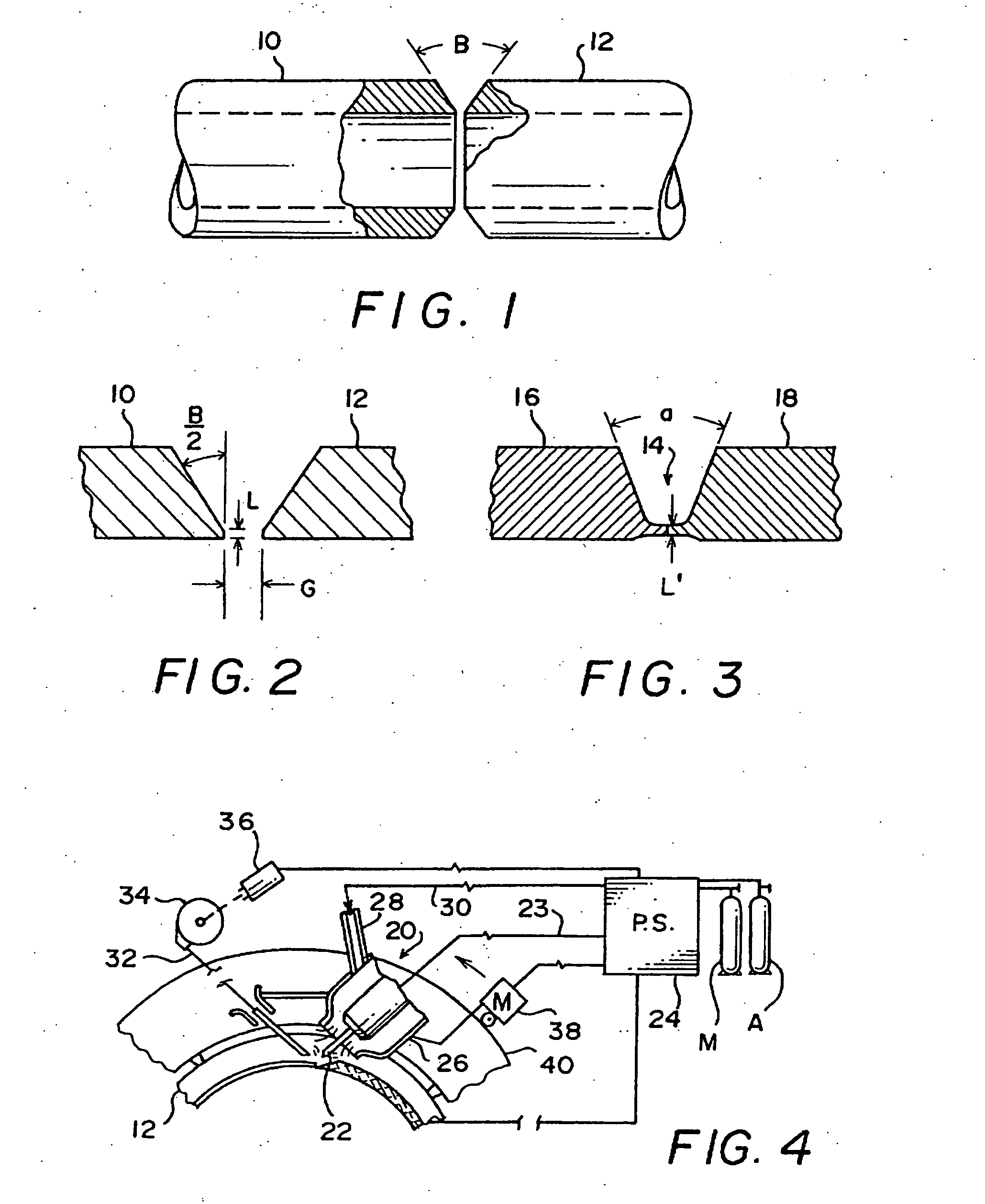

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

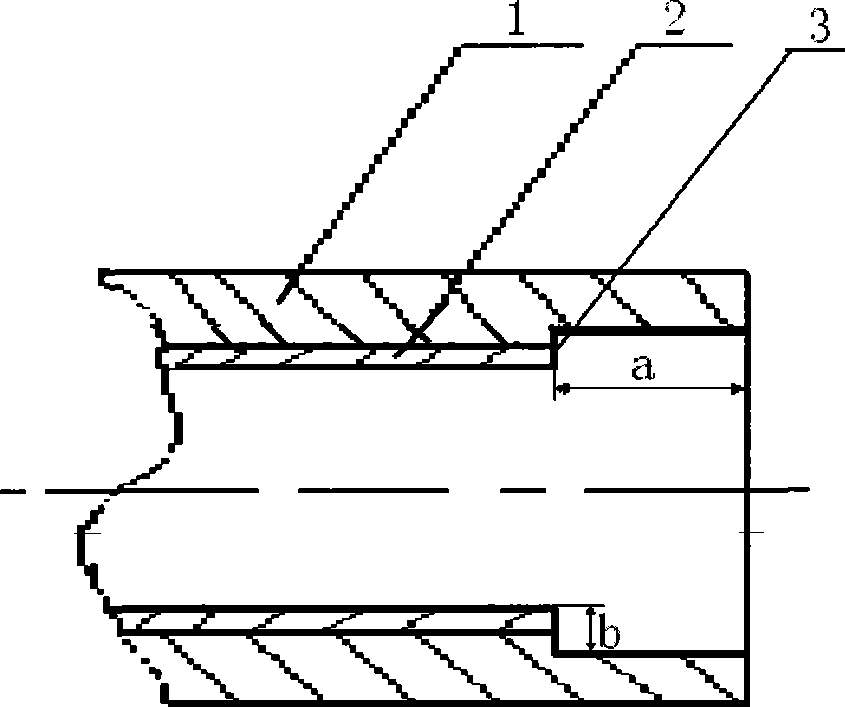

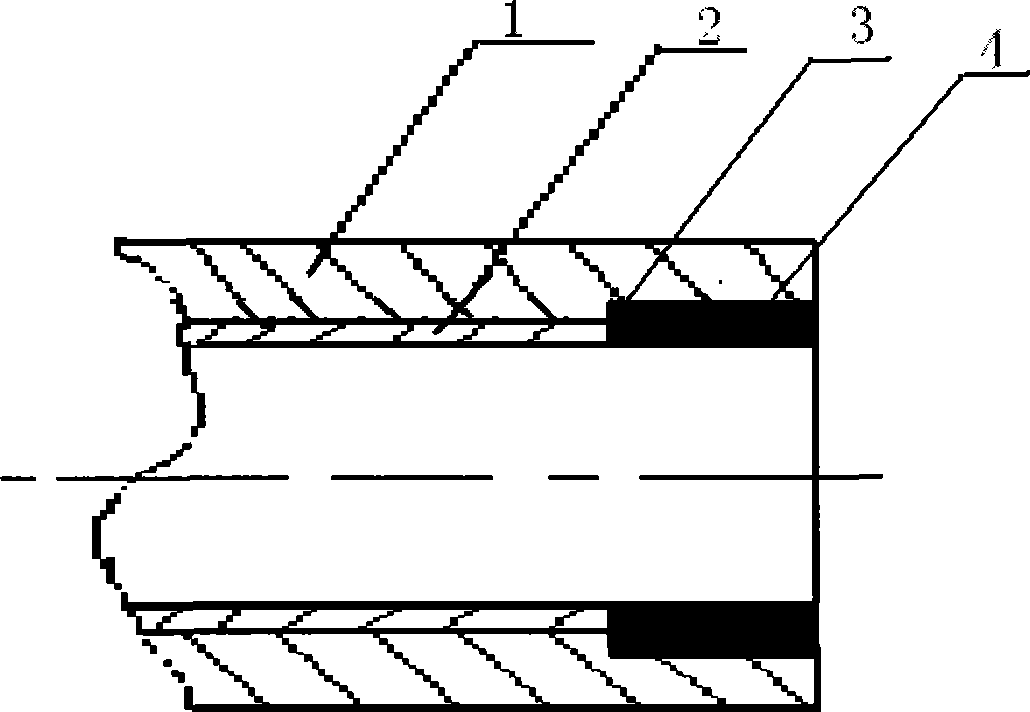

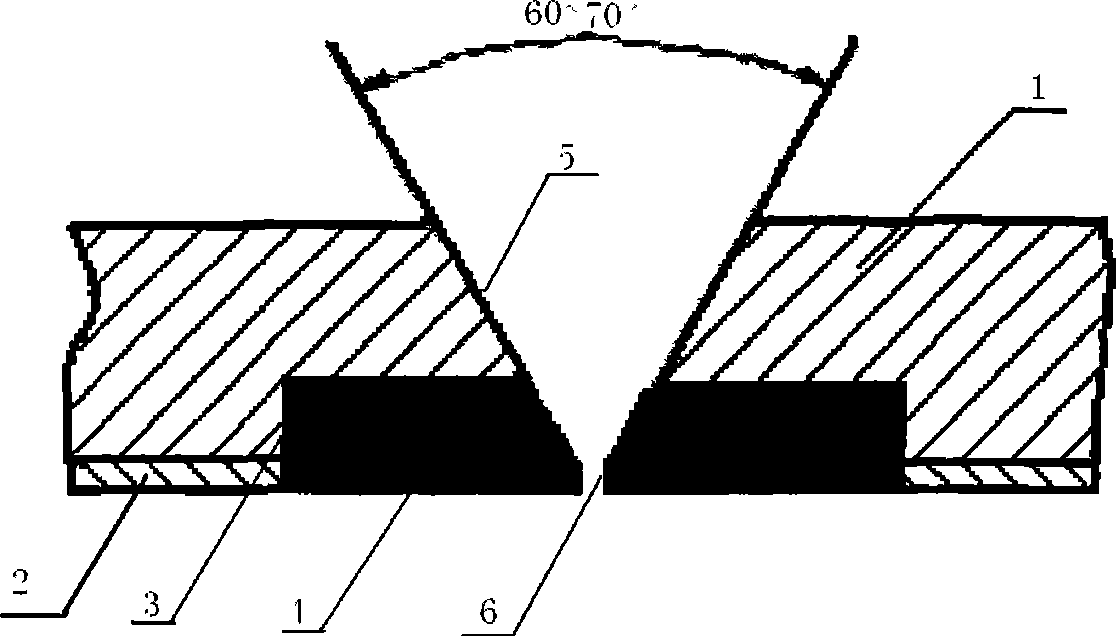

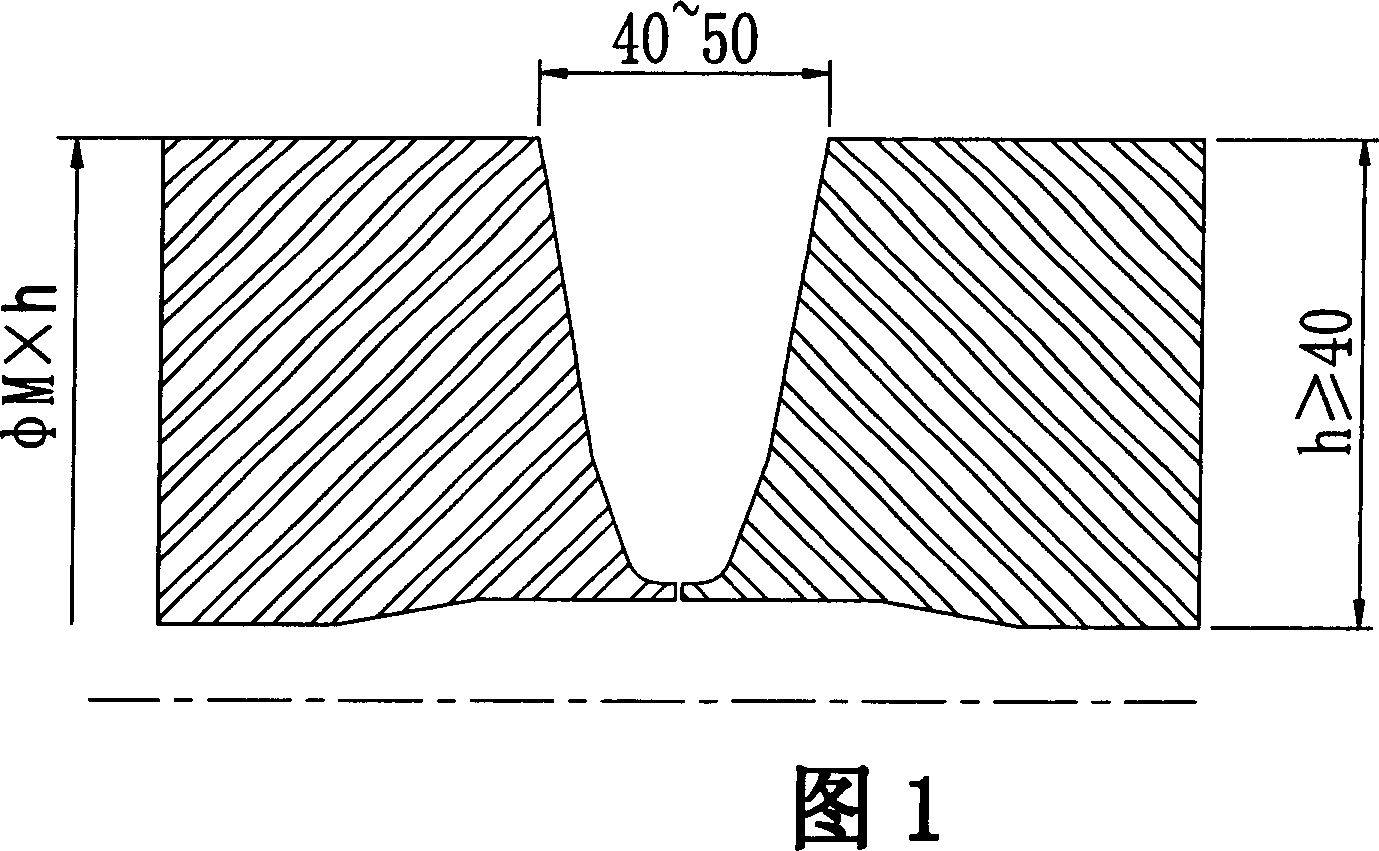

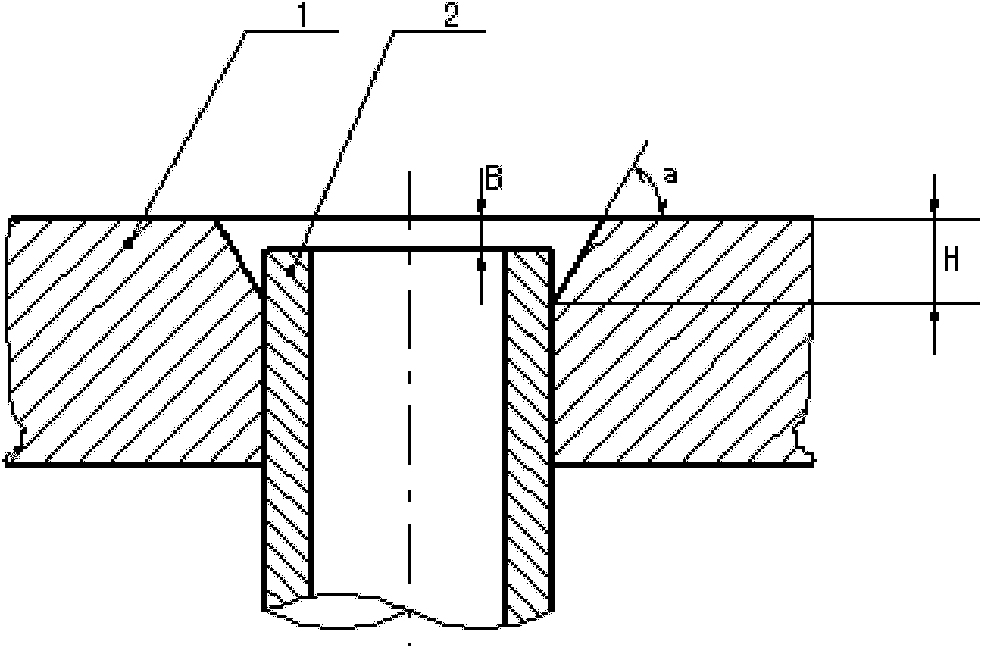

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

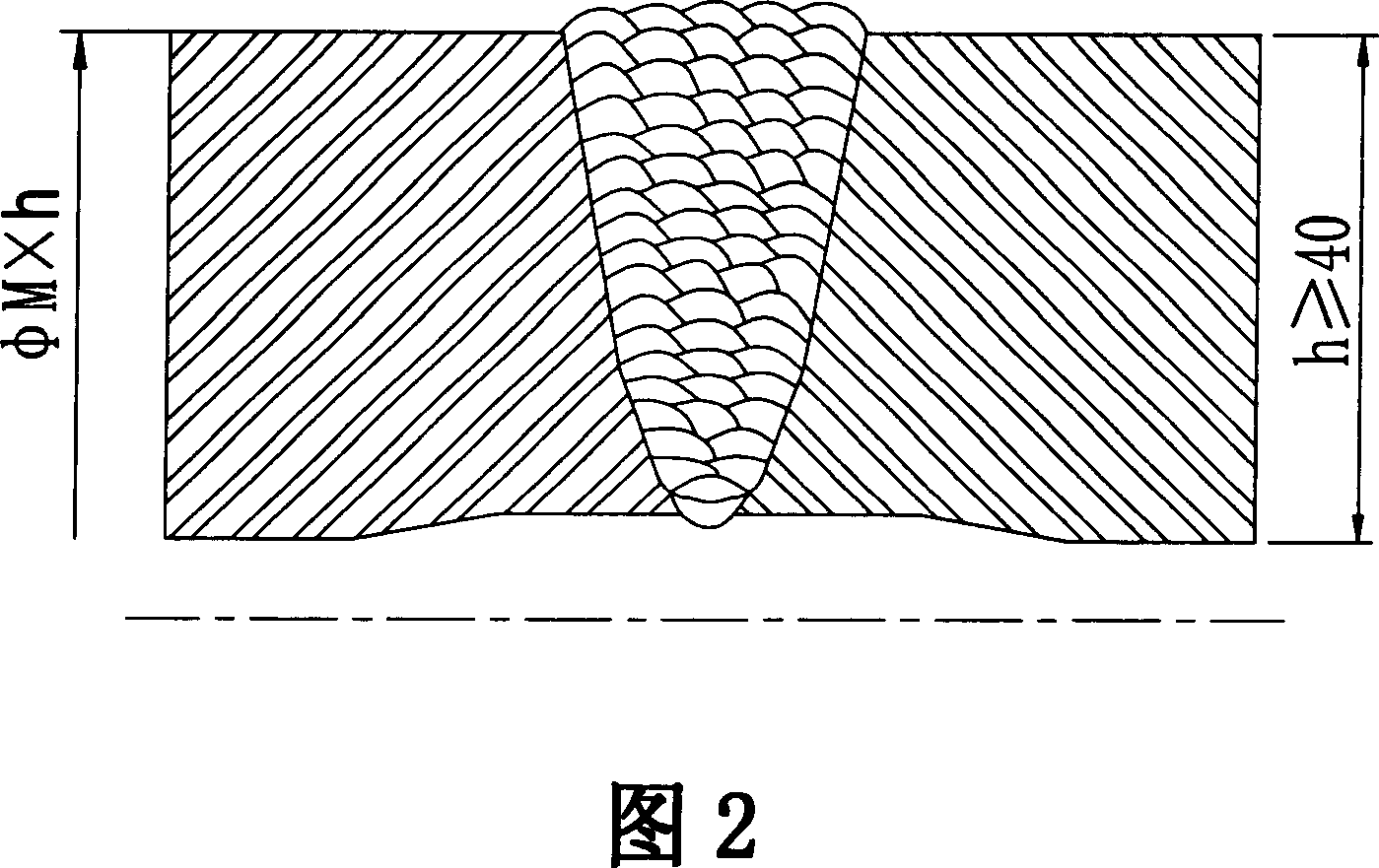

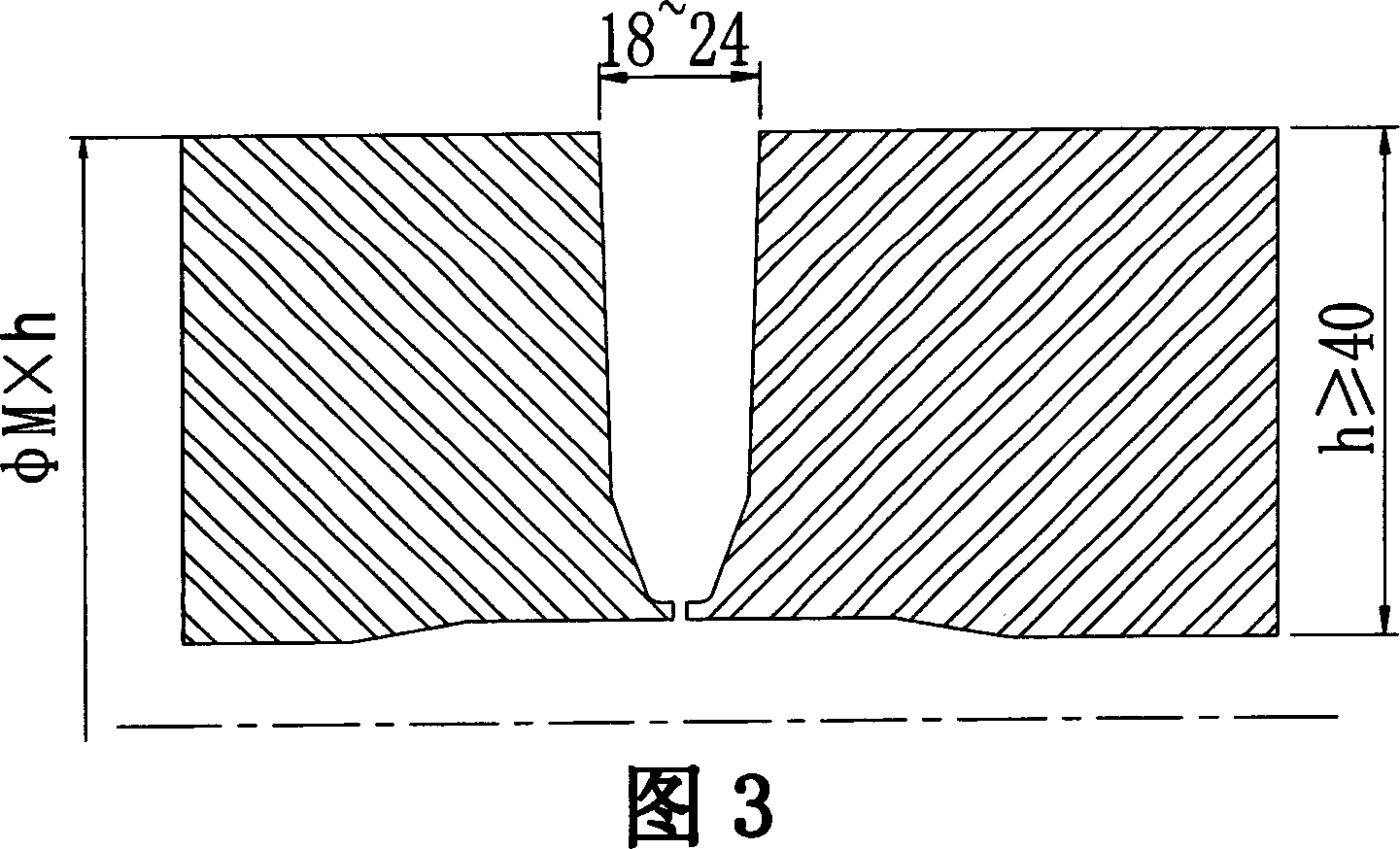

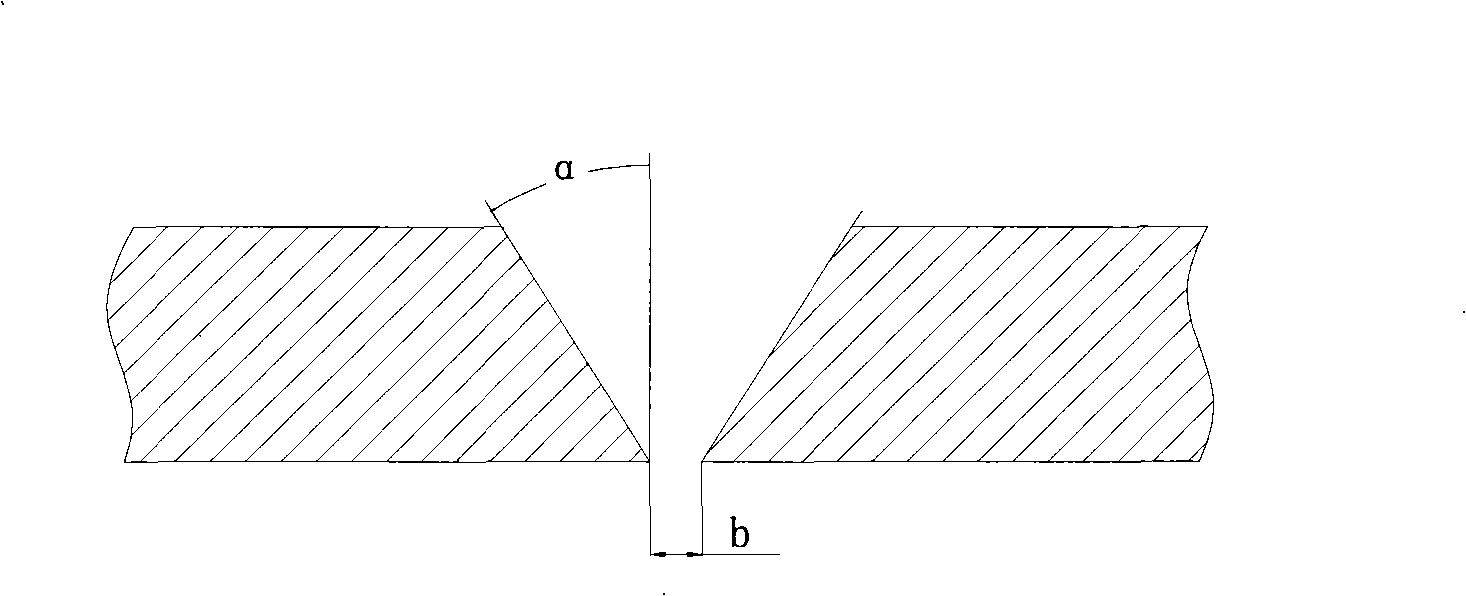

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

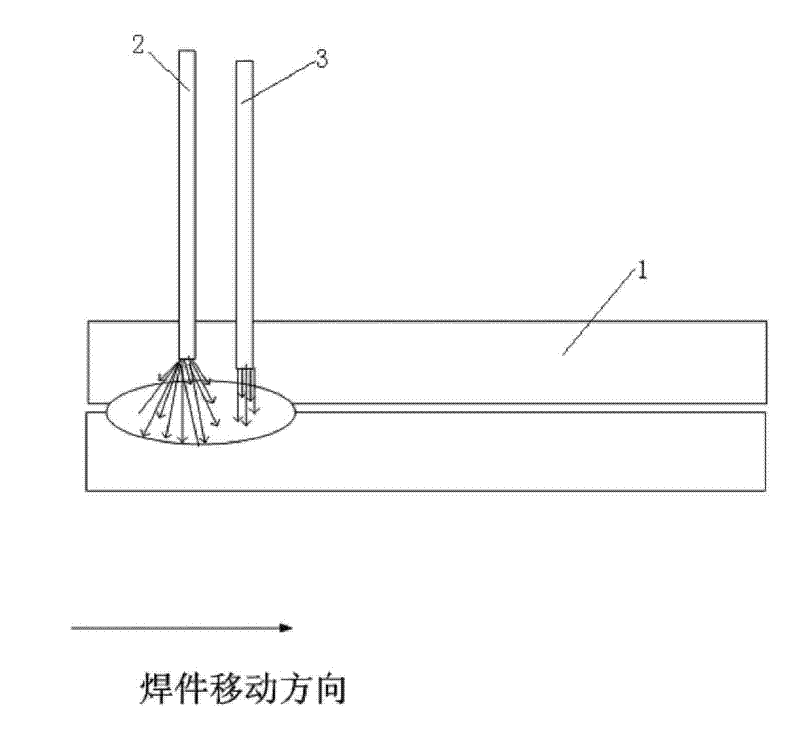

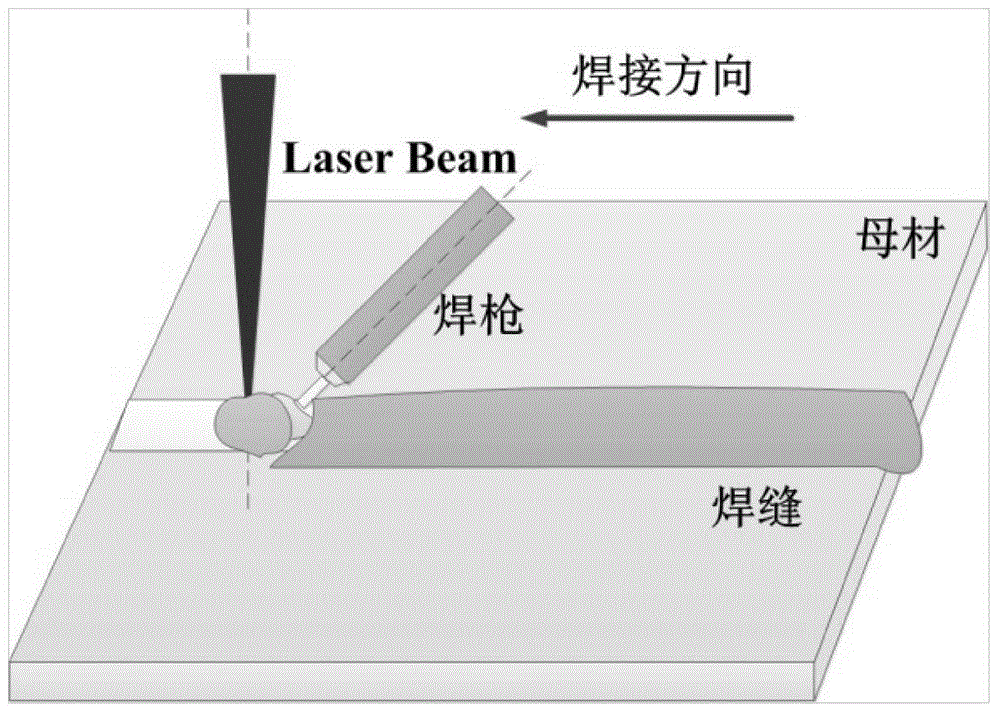

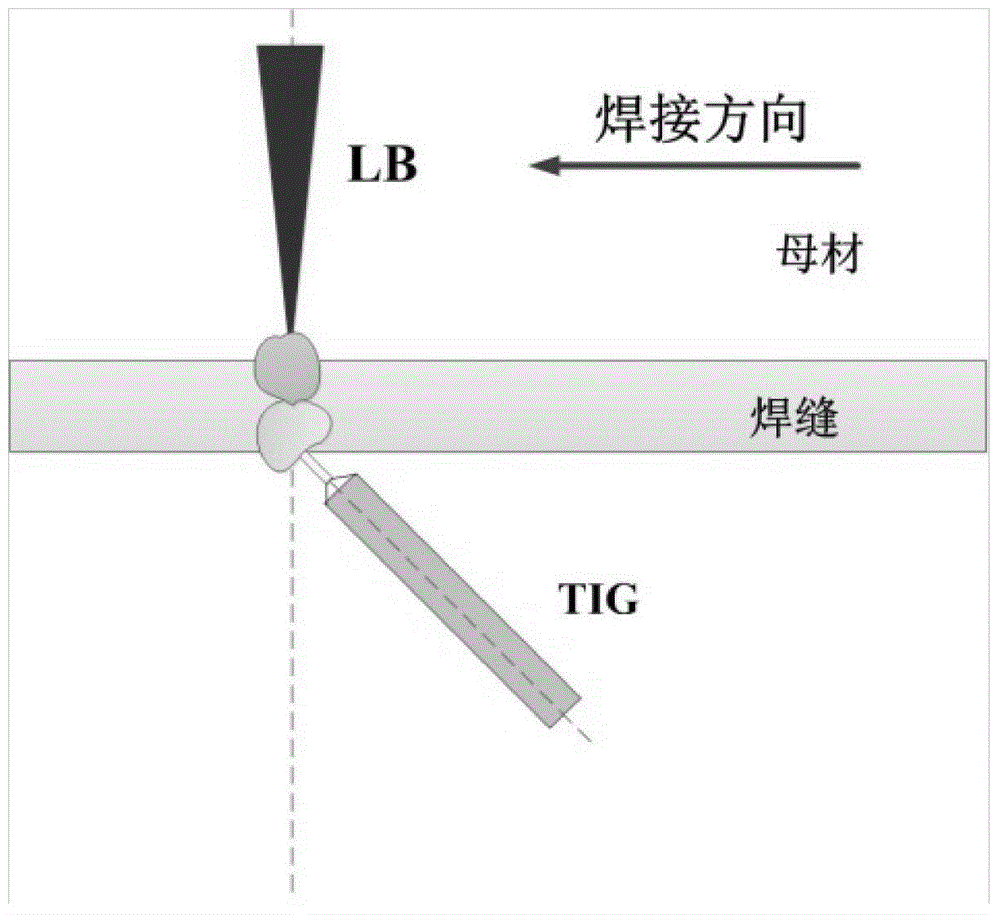

Laser-TIG electric arc hybrid welding technology for spaceflight aluminum alloy plate with medium thickness and high strength

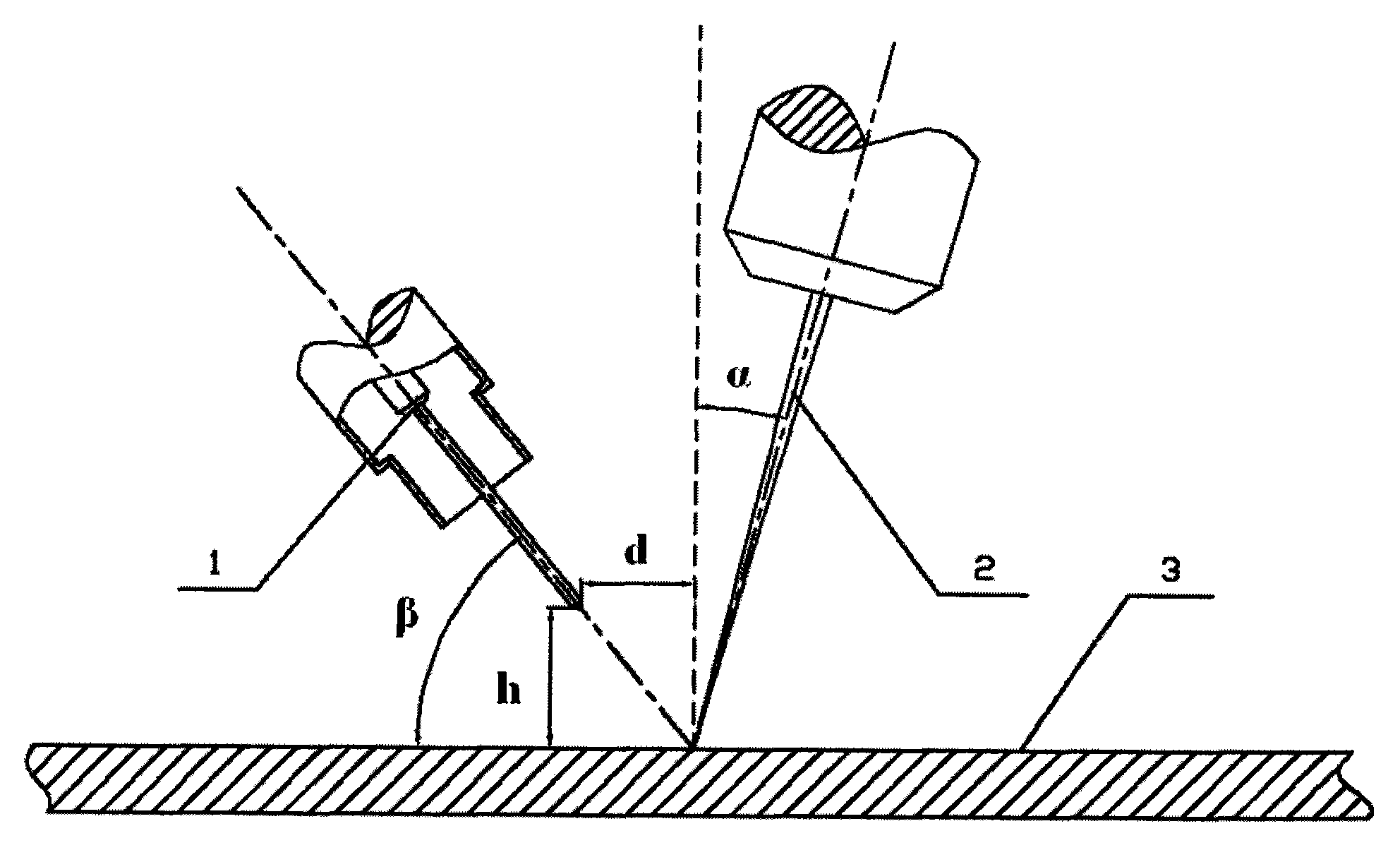

InactiveCN101670495AIncrease profitReduce metallurgical damageLaser beam welding apparatusSpaceflightLaser beams

The invention discloses a laser-TIG electric arc hybrid welding technology for a spaceflight aluminum alloy plate with medium thickness and high strength and belongs to the technical field of weldingengineering. In the hybrid welding technology, a non-consumable TIG electric arc and laser beams emitted by a optical fiber laser are gathered at the same welding position on a workpiece along weldingdirection so as to jointly form a molten pool; when in welding, the laser beams are in the front and the non-consumable TIG electric arc is in the back; the distance form between the focus of the laser beams and the workpiece is sharp defocus, a dip angle between the laser beams and vertical direction is 15-17 degrees, the vertical distance from the tungsten electrode point end of the TIG electric arc to the surface of the workpiece is 3-5mm, the horizontal distances between the tungsten electrode point end of the TIG electric arc and from the laser beams to an action point on the surface ofthe workpiece are 3-5mm, and a dip angle between the tungsten electrode point end of the TIG electric arc and the horizontal direction of the workpiece is 45-55 degrees. The hybrid welding technologynot only improves the utilization ratio of laser energy, but also obviously enhances welding speed, and reduces metallurgical damage of a spaceflight aluminum alloy welding joint with high strength.

Owner:BEIJING UNIV OF TECH

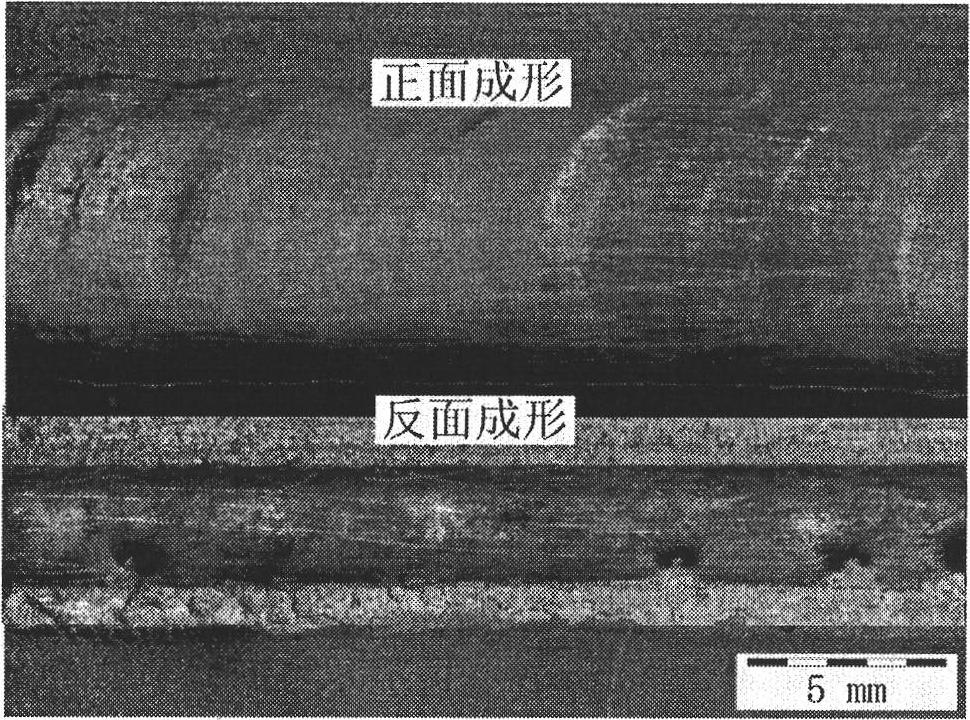

Large caliber aluminium alloy pipeline non-pad tungsten electrode argon arc single face welding and double face shaping method

InactiveCN101301699ABeautiful weldWell formed inside and outArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

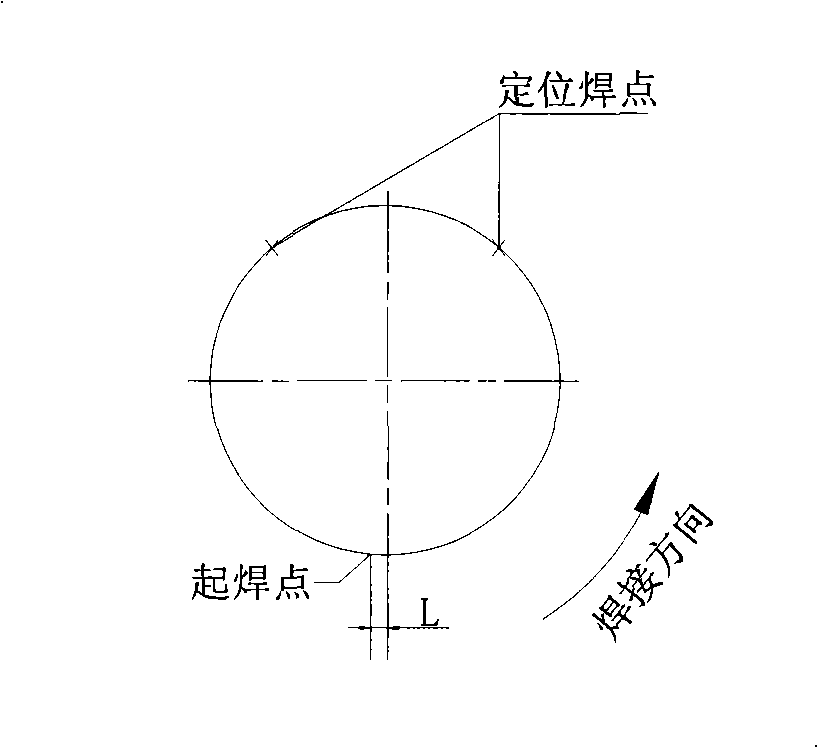

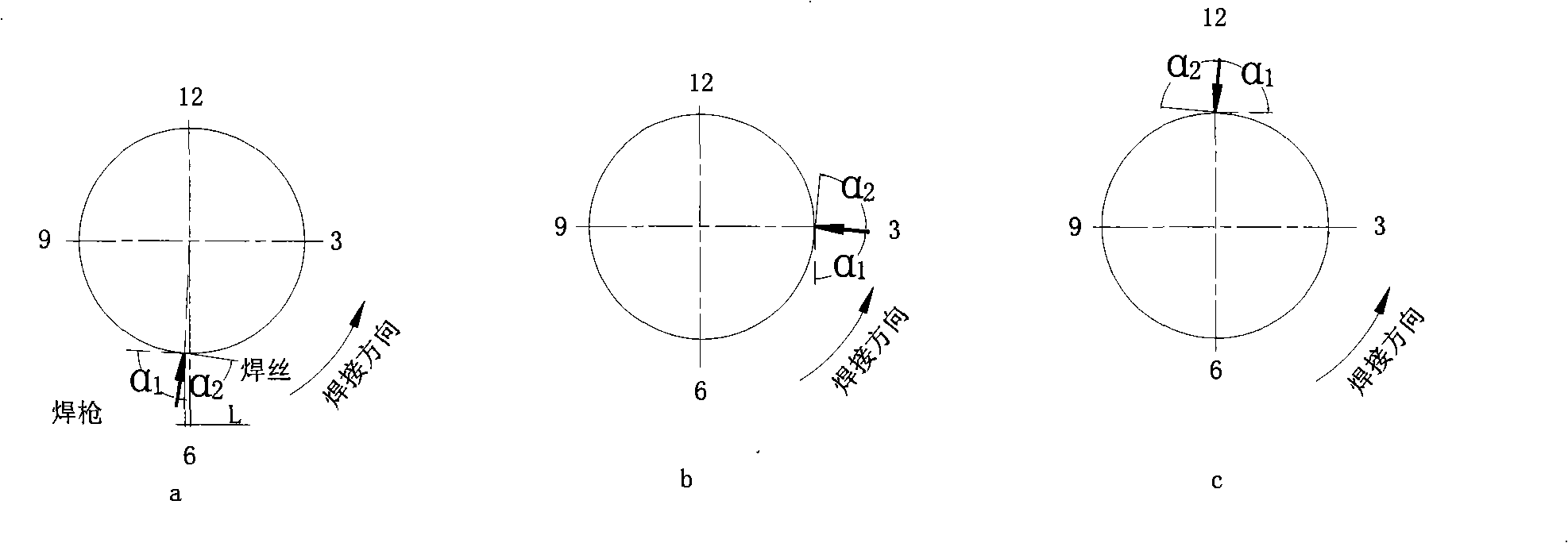

The invention discloses a method for large-calibre aluminium-alloy pipeline no-liner tungsten electrode argon arc one-side welding both-side formation, comprising the following steps of: assembling of groove angle and clearance, grinding of tungsten electrode, cleaning before welding, adjusting welding process parameters, tack welding, and welding of a bottom coating, a filling layer and a covering layer. The pipe is horizontally fixed and the position is marked by hour; the welding sequence is left half-ring and right half-ring; each half-ring comprises overhead welding, vertical position welding and downhand welding; the welding is started at a position where L is equal to 5-10mm close to six of the overhead welding; the vertical position welding is then carried out; finally, the front half-ring is ended at 12 of the downhand welding; before the rear half-ring starts welding, the connection is grinded as a slope; the welding seam formed by the connection and the front half-ring welding position is overlapped by 3-5mm; the welding of the rear half-ring is started from 6 of the overhead welding and ended at 12 of the downhand welding through the vertical position welding; the welding is carried out by a continuous feeding method. The surface of the welding seam of the method has no pores or cracks, is completely welded and beautiful, and has good internal and external forming; by the non-destructive testing, the first-time qualification rate achieves 100%, the welding seam achieves the class-1 quality, the construction procedures are reduced, and the construction cost is reduced.

Owner:ANGANG CONSTR CONSORTIUM

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

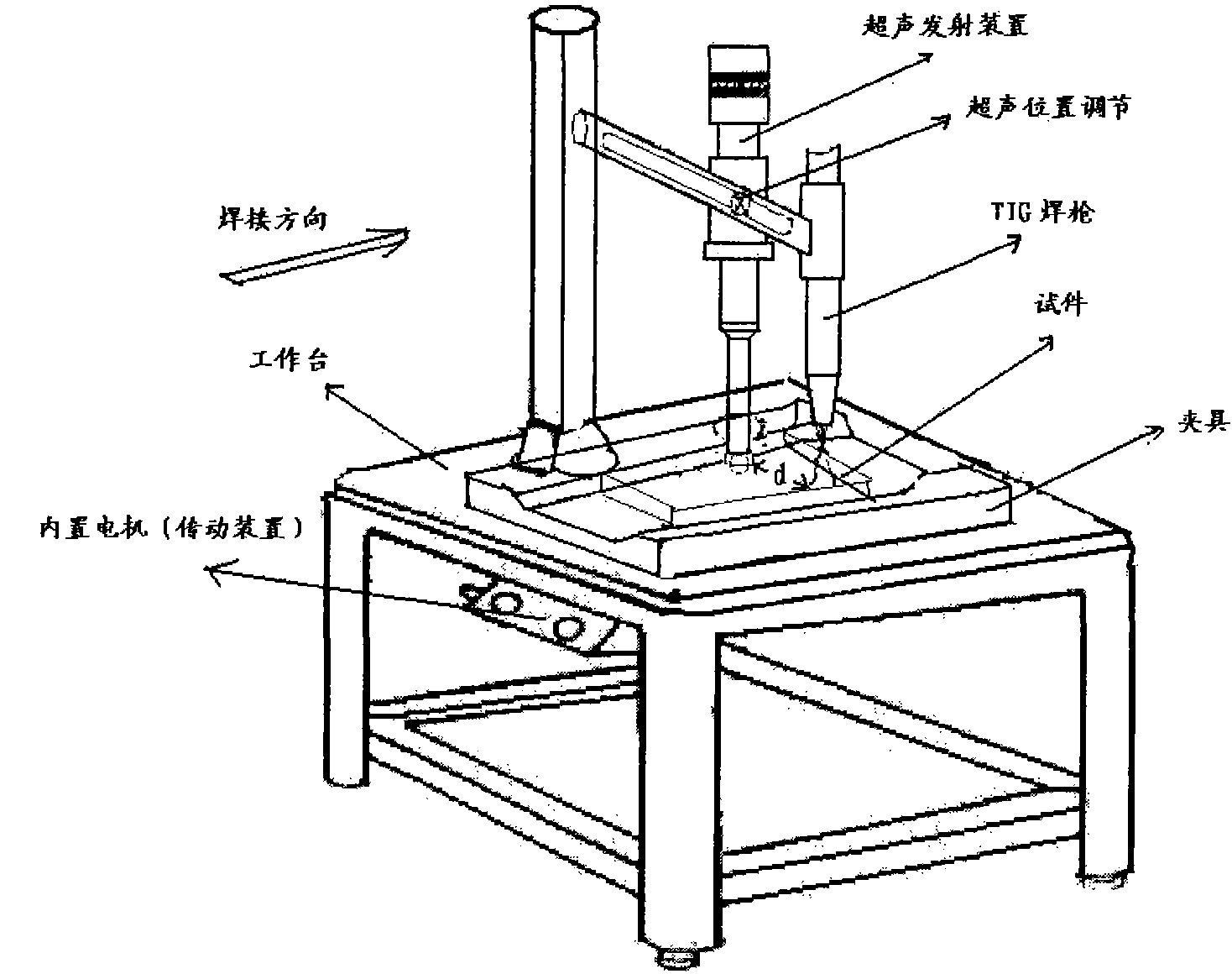

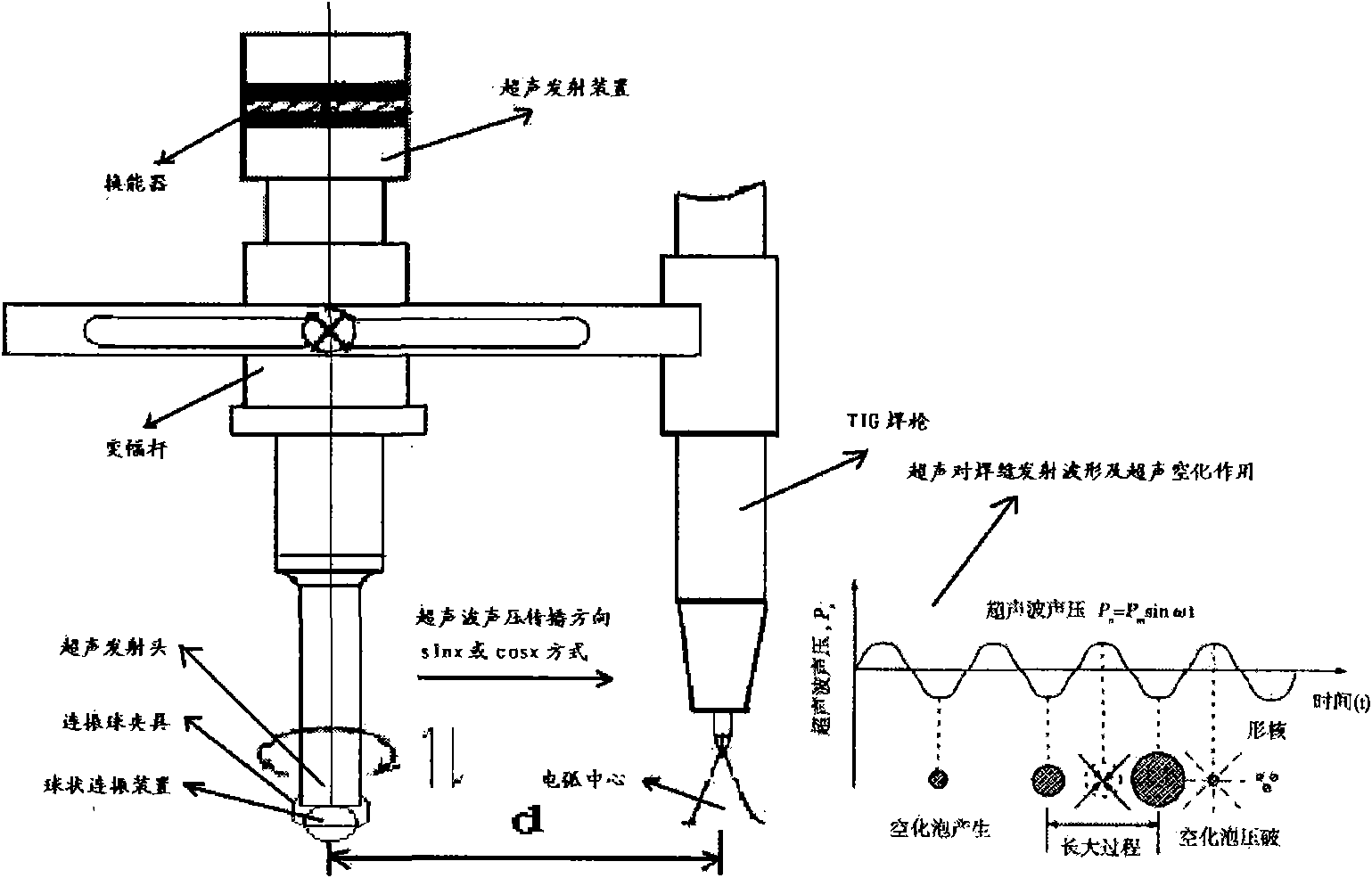

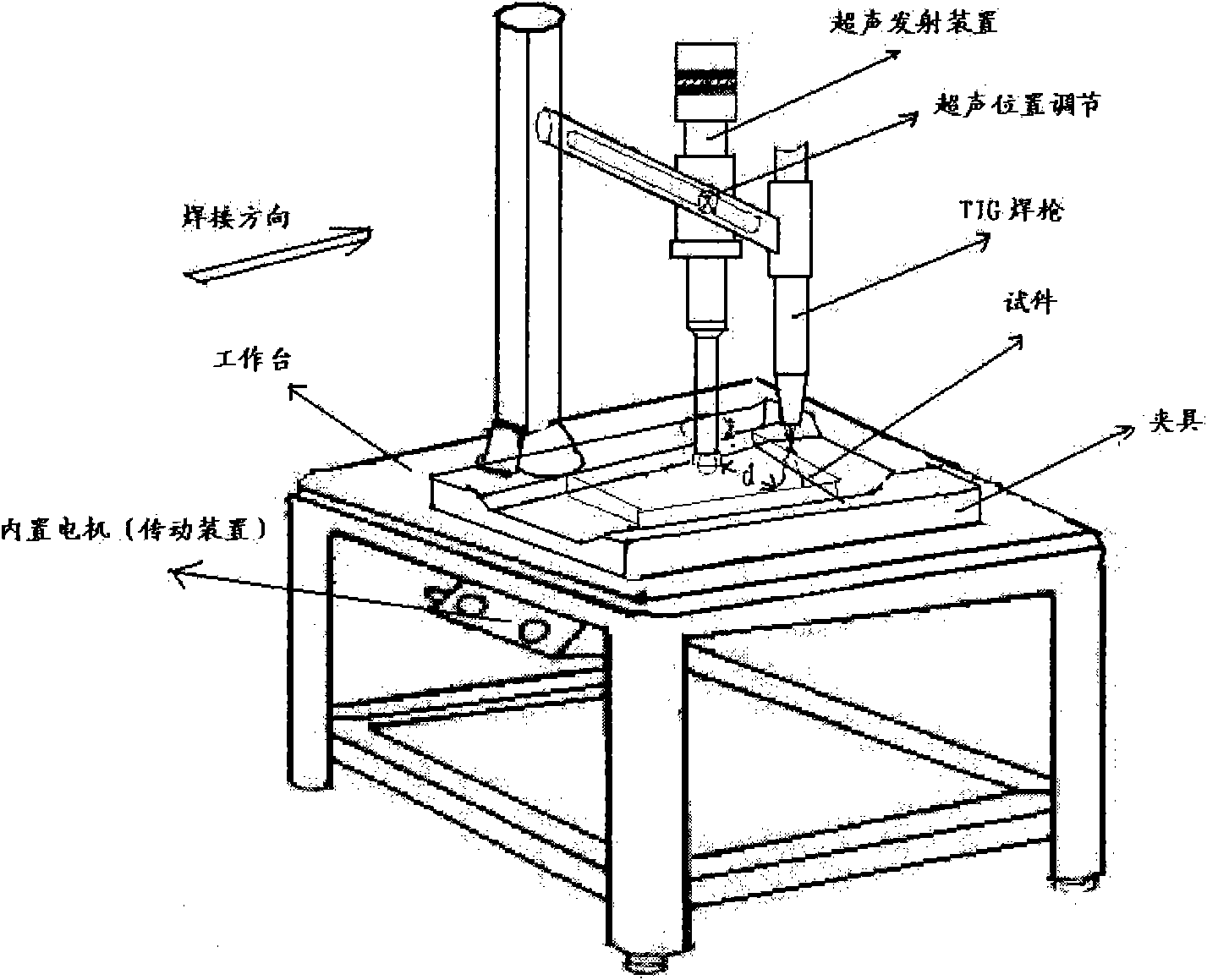

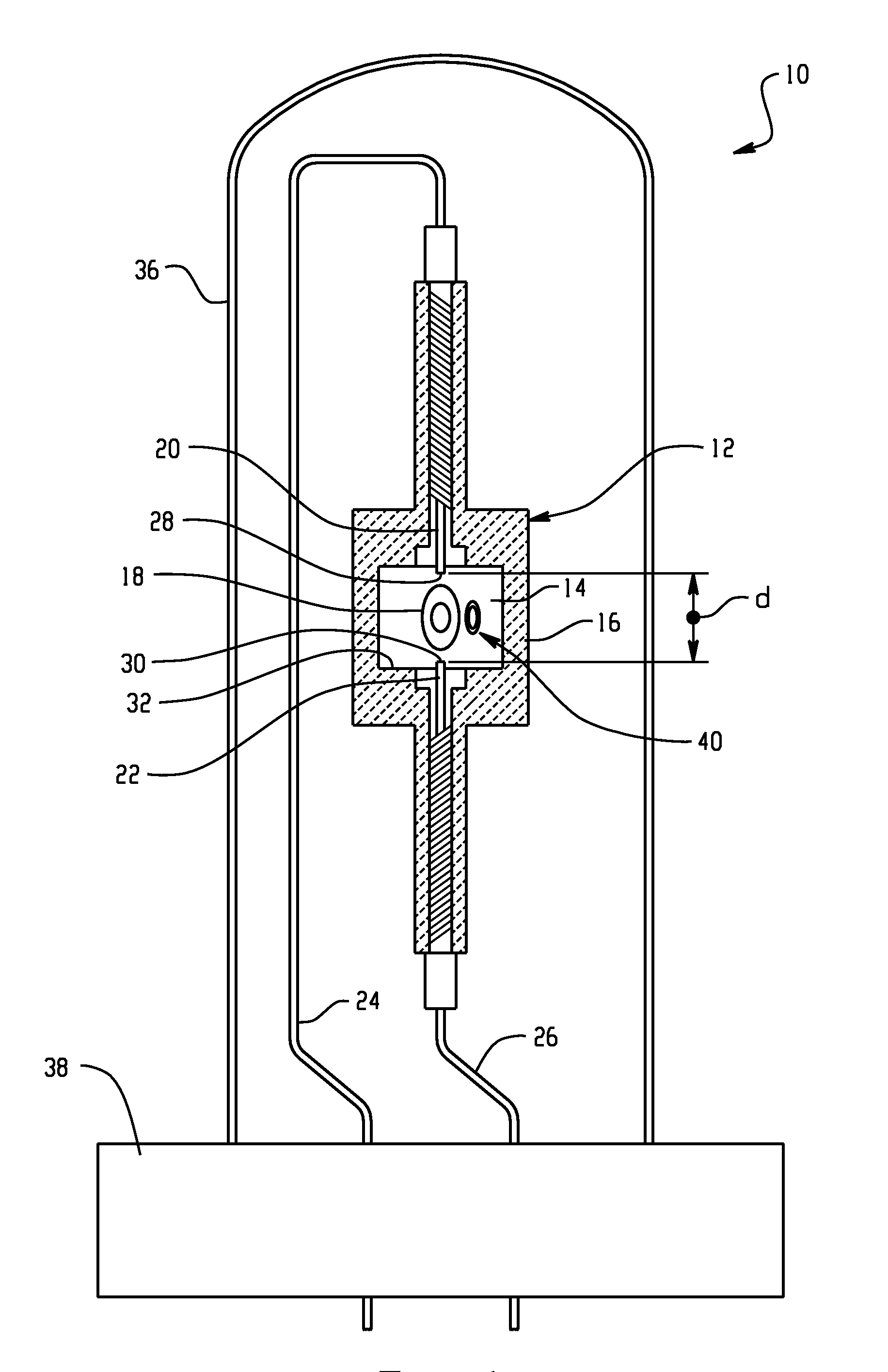

Ultrasonic welding method of Al/Ti dissimilar metal TIG (Tungsten Inert Gas) electrical arc micro-melting brazing and following welding

The invention provides an ultrasonic welding method of Al / Ti dissimilar metal TIG electrical arc micro-melting brazing and following welding, wherein an isochronous and stable ultrasonic vibration system is added in the TIG micro-melting brazing process, and the simultaneous and equi-directional welding of TIG micro-melting brazing and following welding is realized through a spherical interlinking device. The method comprises the following steps of: enabling a welding gun tungsten electrode and a test piece to reach reasonable welding height by vertically adjusting the position of a welding gun; enabling a continuous vibration ball to cling to the surface of the test piece by vertically adjusting an ultrasonic transmitting device; measuring the distance d from the contact point of the continuous vibration ball and the surface of the test piece to a TIG welding gun tungsten electrode by horizontally adjusting an ultrasonic generating device to enable d to satisfy welding requirements; and reasonably matching an ultrasonic vibration device and a TIG welding gun by adjusting d, and adjusting the acting position of ultrasonic vibration by adjusting d. The invention has strong process applicability and good stability, realizes the semi-automatic welding of Al / Ti dissimilar metal connection, and has wider usability and good improving action for the welding joints of TIG micro-melting brazing for various dissimilar metals.

Owner:HARBIN INST OF TECH

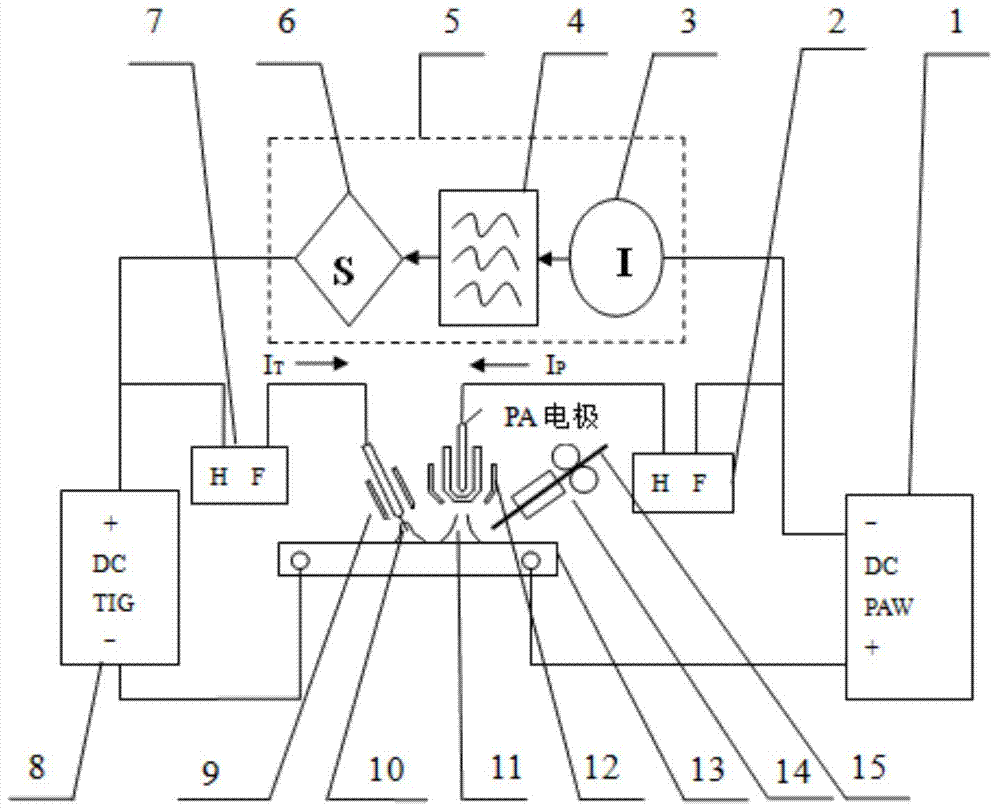

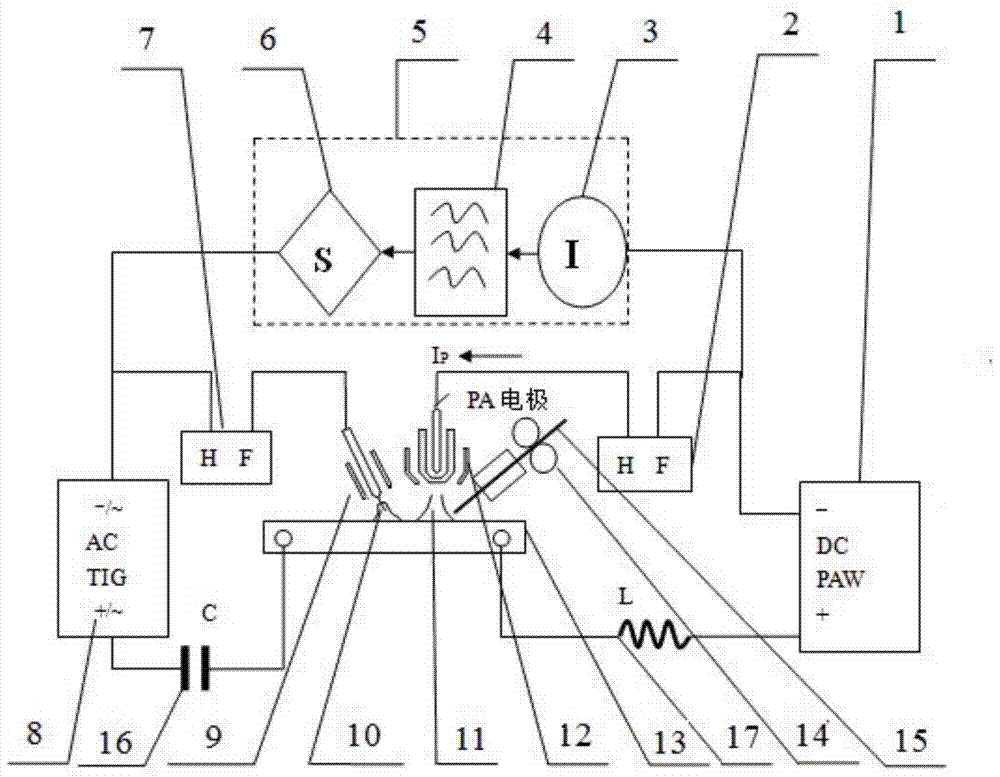

Aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control

ActiveCN103567652AAchieve cleanupRealize DC piercing plasma arc weldingArc welding apparatusPlasma welding apparatusHalf wavePlasma arc welding

The invention aims to provide an aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control. A tungsten electrode argon arc welding gun is exerted on one side of a plasma arc welding gun, in the welding process, the tungsten electrode argon arc welding gun is utilized to remove oxidation films on the surface of aluminum alloy in front of the direct current plasma welding gun, and the direct current plasma welding gun is utilized to conduct welding behind the tungsten electrode argon arc welding gun. In order to avoid electromagnetic interference between plasma arcs and tungsten electrode argon arcs in the welding process, when a plasma arc current is in a pulse basic value pilot arc stage, a pulse signal controller is triggered, and a tungsten electrode argon arc current is adjusted to be in a negative half wave crest value for removing the oxidation films on the surface of the aluminum alloy; when the plasma arc current is in a pulse crest value welding stage, the pulse signal controller is utilized to adjust the tungsten electrode argon arc current to be in pulse basic value output, and the steps are repeatedly executed in this way. According to the method, the current pulse wave form of the tungsten electrode argon arcs and the current pulse wave form of a plasma arc power supply are reasonably adjusted, the effect of cleaning the oxidation films on the surface of the aluminum alloy and weld penetration are controlled, and therefore weld formation is guaranteed, tungsten electrode burning losses are reduced, and welding efficiency is improved.

Owner:哈尔滨哈船特装科技发展有限公司

Laser electrical arc complex welding method for intensifying current magnetohydrodynamics effect

InactiveCN101176954AEasy to shapeImprove energy coupling efficiencyArc welding apparatusLaser beam welding apparatusARC complexEnergy coupling

The invention relates to a laser-arc hybrid welding method which reinforces dynamic effect of current and magnetic fluid, belonging to technical field of laser material processing. The invention is characterized in that: a synergistic arrangement of laser and electric arc is adopted and a filler wire is added simultaneously; wherein, the electric arc and the wire are arranged at both sides of a laser beam; the wire is arranged in the front and is contacted with a workpiece, and the electric arc is arranged at the back; the two polarities of the welding power are connected with a tungsten electrode and the wire respectively; the welding power forms a current loop by flowing through a weld pool and the electric arc by the wire, and most of the welding power flows through the weld pool and produces electromagnetic force. The invention has the advantages that the energy coupling efficiency and the stability in the welding process are both highly improved by fully utilizing influence of dynamic effect of arc current and magnetic fluid on the heat exchange situation and the flowing state of the weld pool, and the surface forming state of a weld joint is greatly improved because of the significantly improved tolerance of the electric arc arranging at the back of the weld pool to the wire fluctuation.

Owner:BEIJING UNIV OF TECH

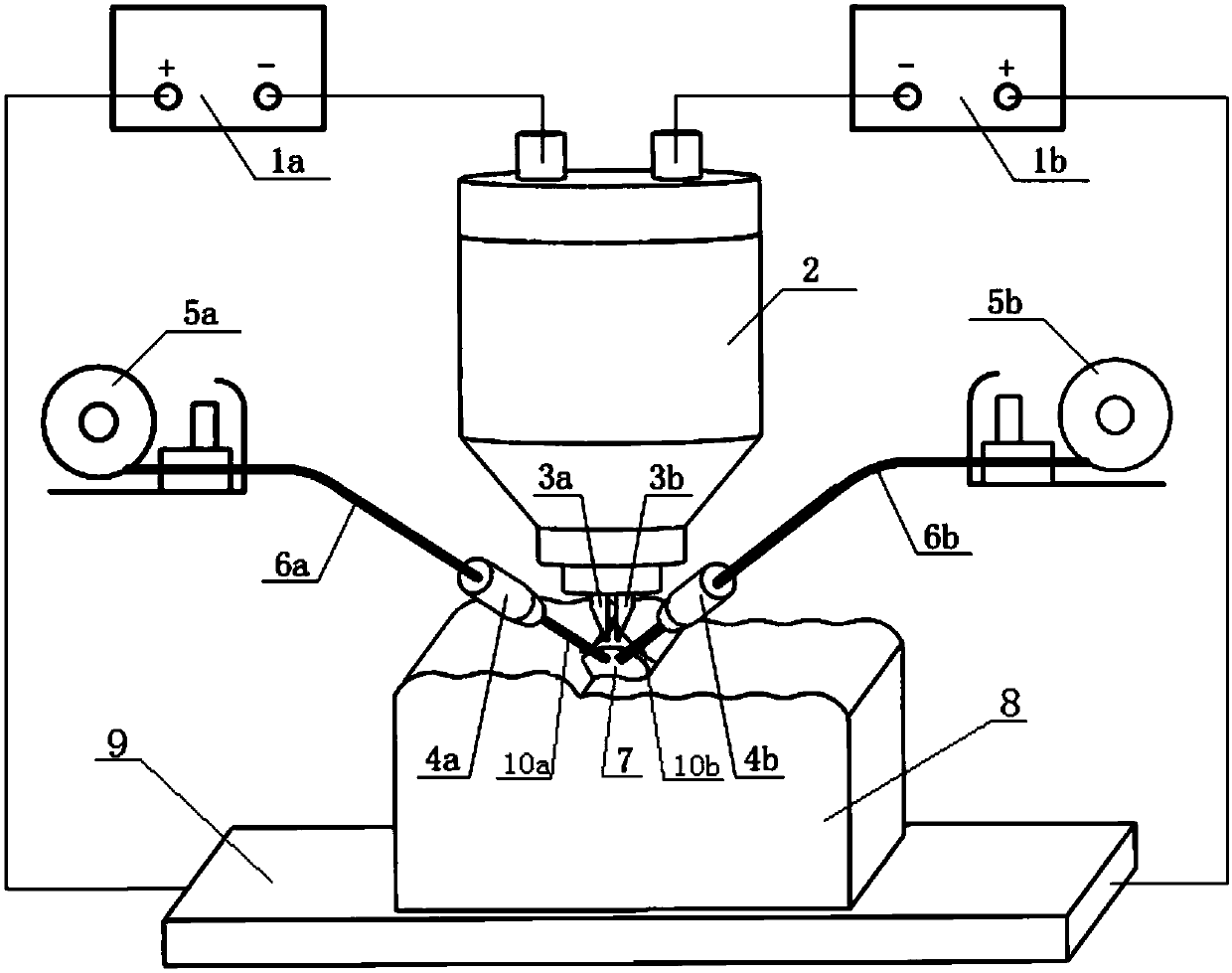

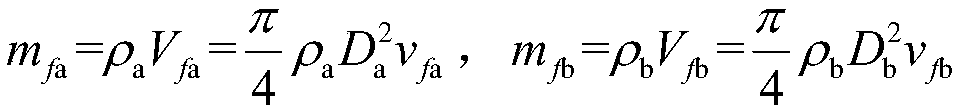

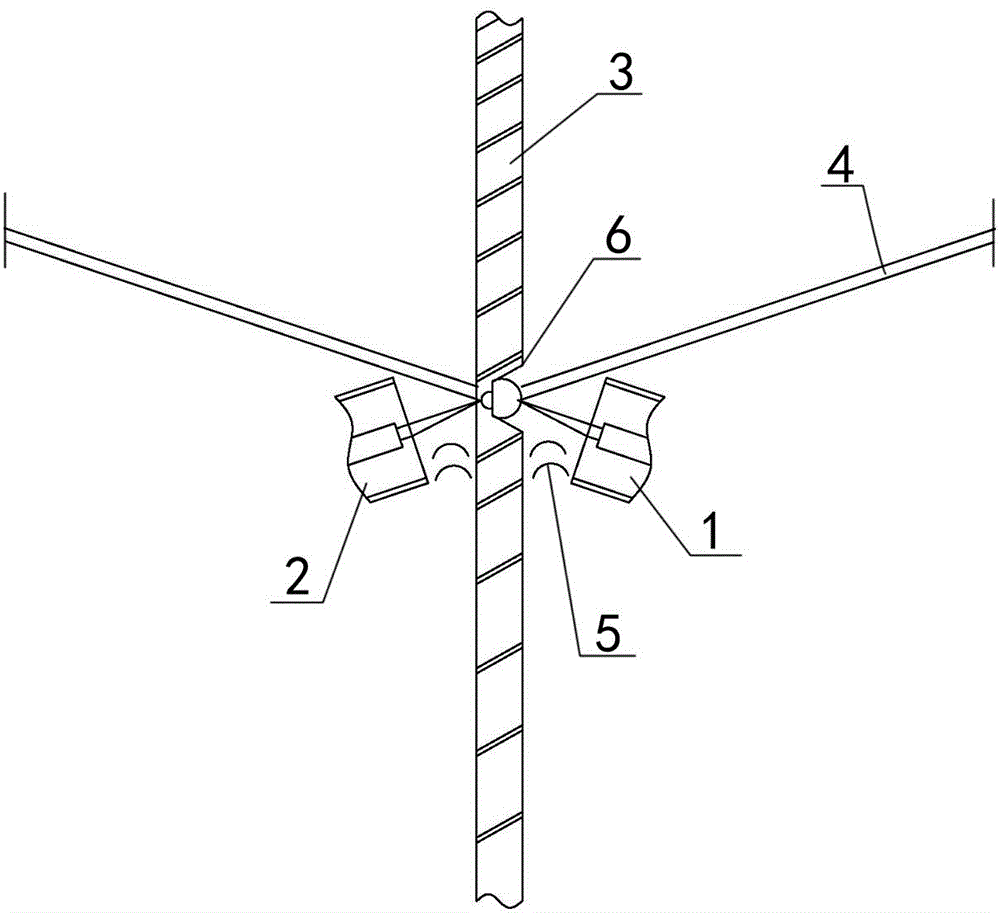

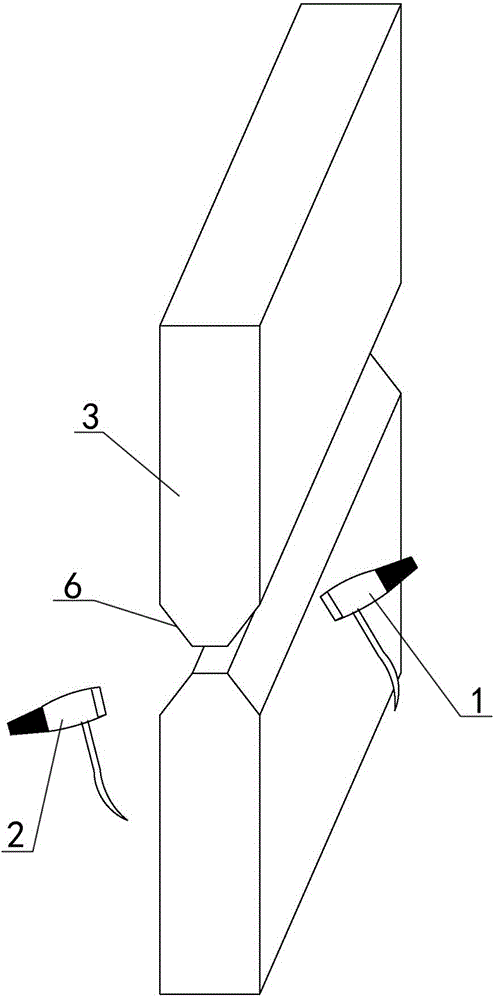

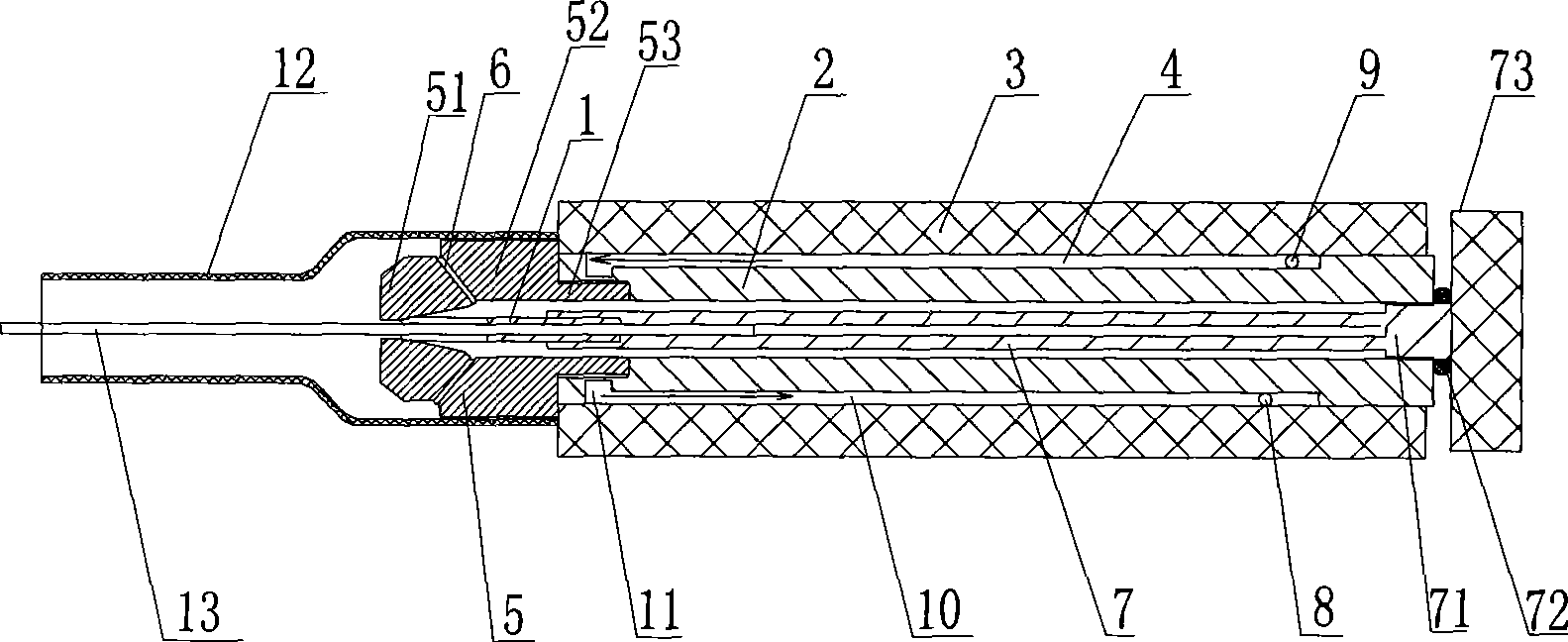

Device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc

InactiveCN108788389ABroaden process specification windowImprove deposition efficiencyAdditive manufacturing apparatusArc welding apparatusMelting tankPower flow

The invention provides a device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc. A first partial tungsten electrode and a second partial tungsten electrode are installed below a two-tungsten-electrode argon arc additional material manufacturing gun of the device, and are vertically arranged above a base plate. A first wire guide nozzle and a second wire guide nozzle are arranged in front of the two-tungsten-electrode argon arc additional material manufacturing gun. In the deposition process, two metal wires of dissimilar compositions are conveyed to a melting bath at the same time, the composition and performance of a deposition bead are controlled by adjusting the feeding proportion of the metal wires, and thus manufacturingof the gradient material arc additional material is achieved. It is ensured that excellent forming can still be achieved in the deposition process with large current and high wire feeding speed, thecomposition of the prepared gradient material formed part can be continuously transited from the composition of one metal wire to the composition of the other metal wire without replacement of the welding wires, and the deposition efficiency is up to 330 cm<3> / h; and in addition, the deposition bead is more uniform in composition, and the relative error between the components of the deposition bead and target set compositions is smaller than 10%.

Owner:HARBIN INST OF TECH

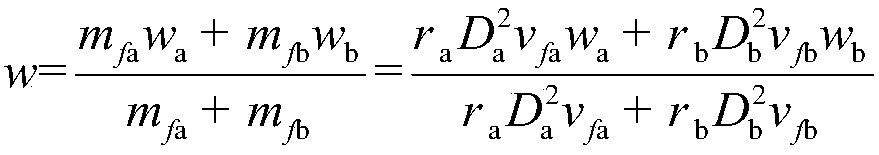

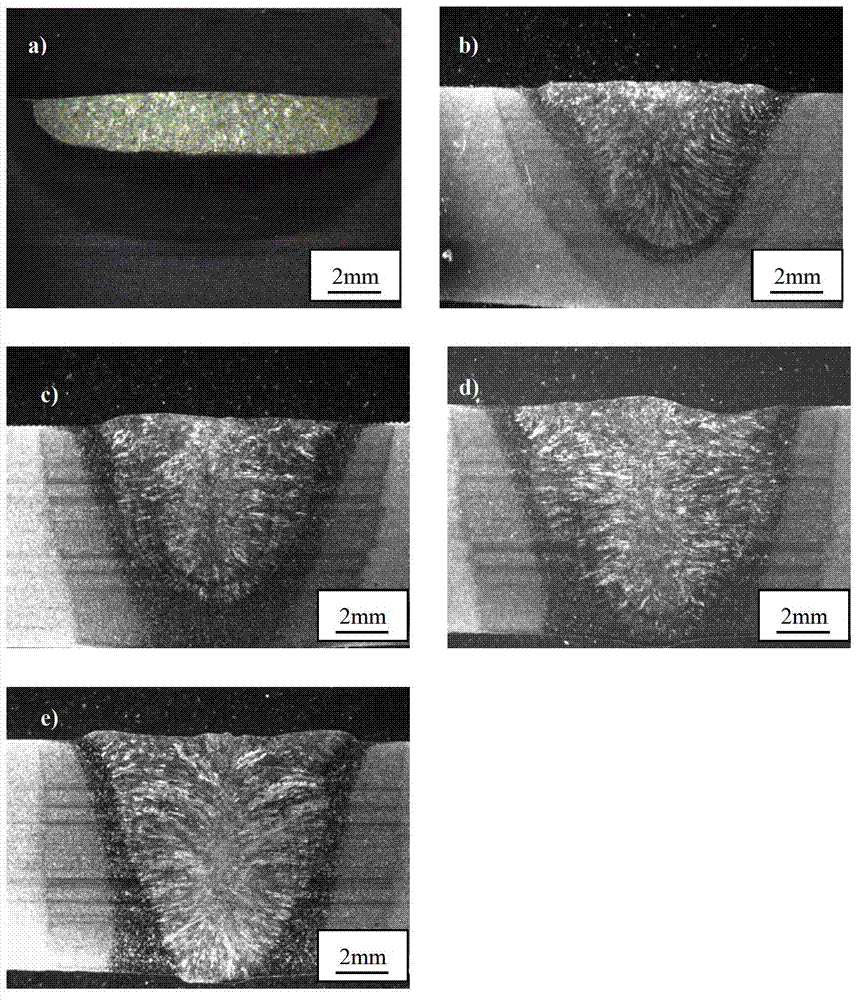

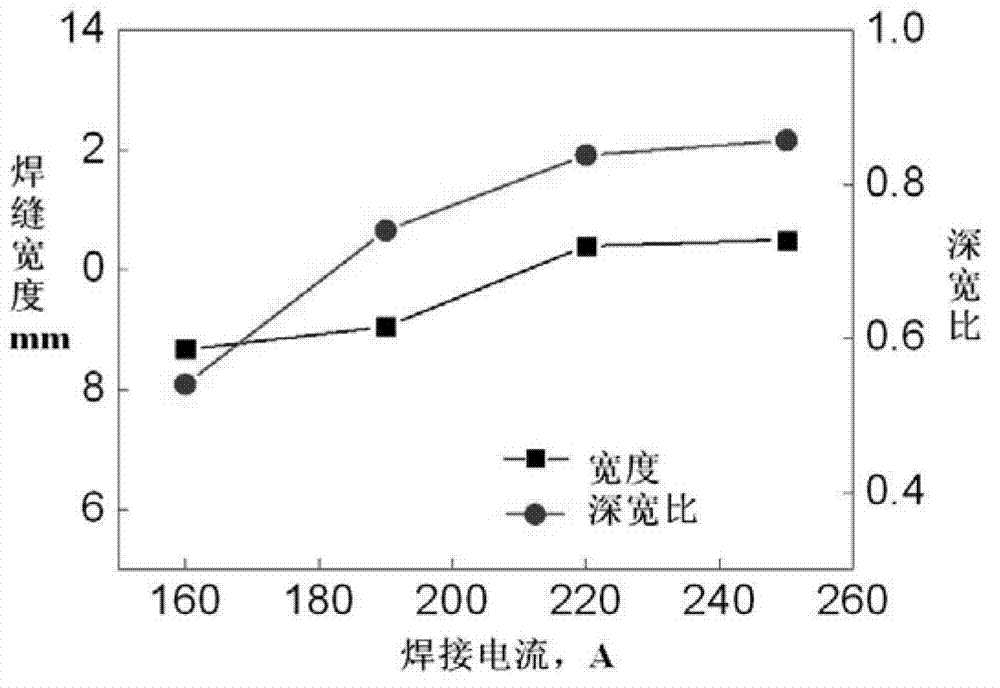

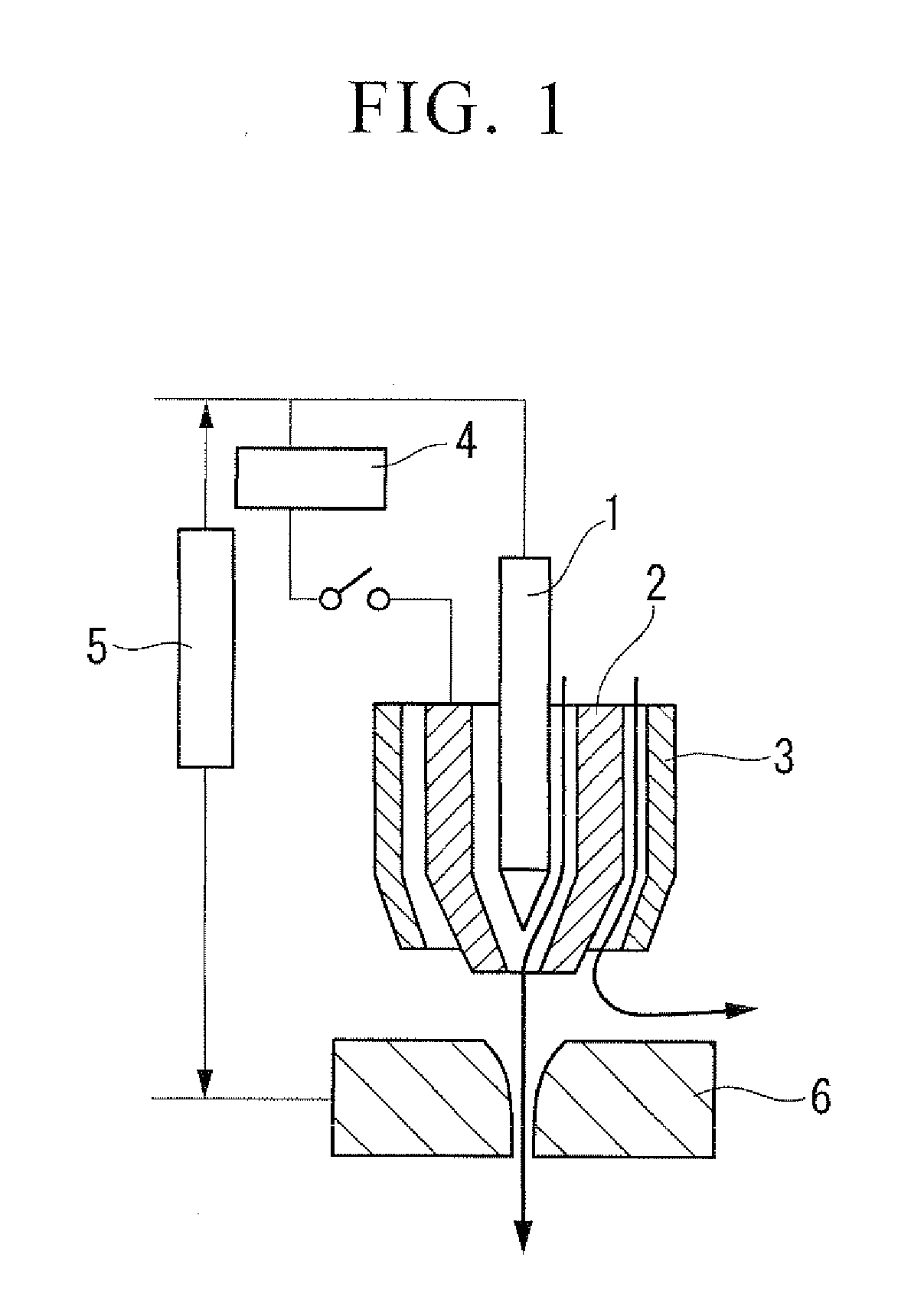

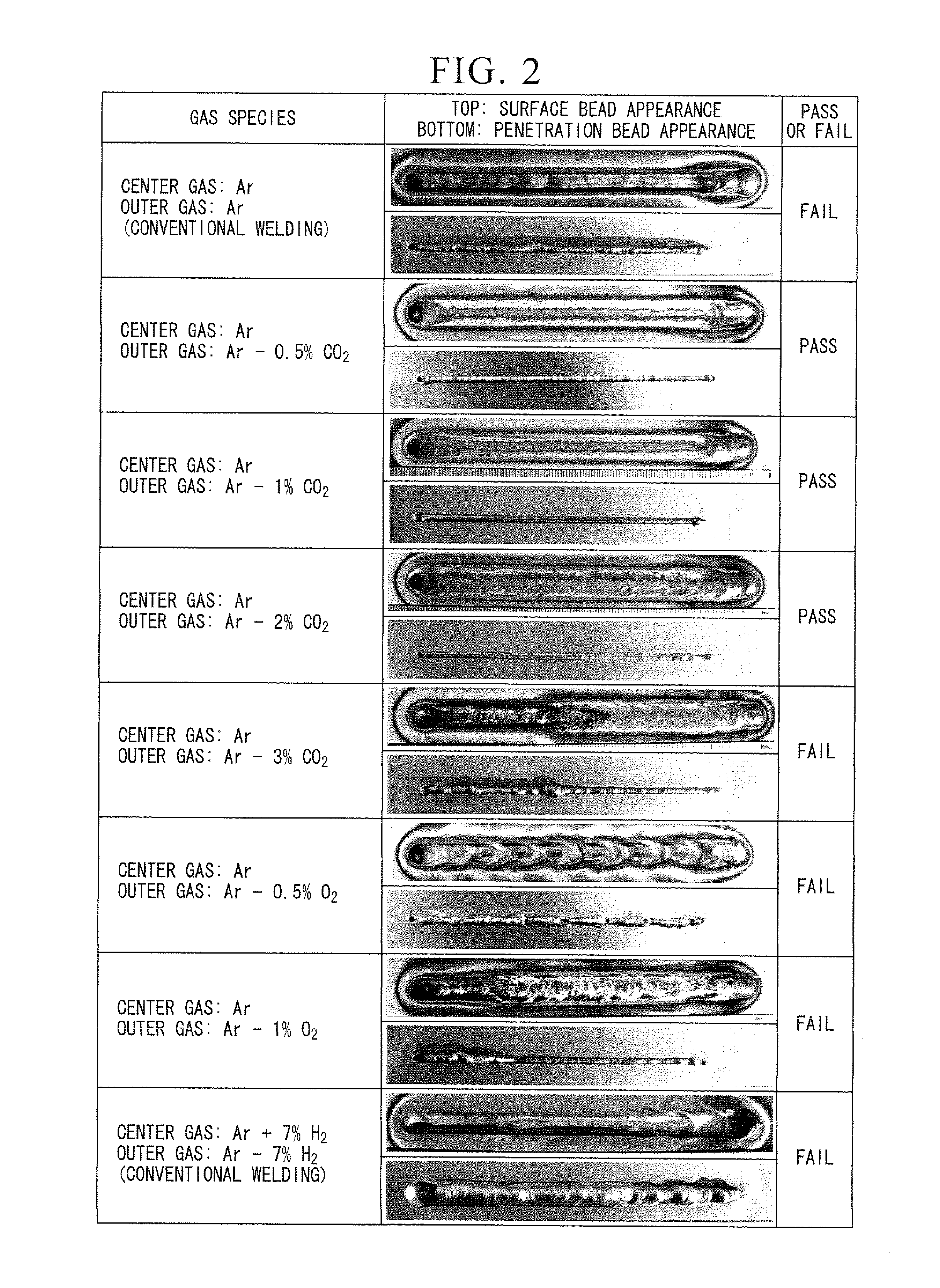

TIG (tungsten inert gas) welding method for high-nitrogen steel under double-layer gas flow shielding

ActiveCN102764930AChange the heat transfer and convection modeEasy transferArc welding apparatusMixed gasAustenitic stainless steel

The invention belongs to the technical field of welding, and particularly relates to a TIG (tungsten inert gas) welding method for high-nitrogen steel under double-layer gas flow shielding. The TIG welding method is applicable to a welding process of high-nitrogen austenitic stainless steel (the high-nitrogen steel), and solves problems that a weld pool is shallow and nitrogen elements in weld joints leak when tungsten inert gas welding is carried out for high-nitrogen steel in the prior art. The TIG welding method includes that double layers of protective gas channels including an inner-layer gas channel and an outer-layer gas channel are arranged on the outer side of a tungsten electrode, pure inert gas is filled in the inner-layer gas channel, mixed gas containing inert gas and active gas is filled in the outer-layer gas channel, electric arcs are generated via the electrode, and tungsten inert gas welding is carried out for high-nitrogen steel parent metal. Active components are transited to a weld pool, so that a convection mode for heat transfer of the weld pool is changed, and the depth of the weld pool is increased; and the width of the surface of the weld pool is reduced, so that overflow of nitrogen elements in weld joints is reduced. Besides, the depth of the weld pool for welding the high-nitrogen steel is increased by 2-3 times of that of a common arc weld pool while overflow of the nitrogen elements at the weld joints is further effectively reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Tungsten electrode argon arc welding active flux for increasing welding fusion depth

InactiveCN1555957AImprove molding qualityEasy to remove slagArc welding apparatusWelding/cutting media/materialsAlloyHigh intensity

An active welding flux of W-electrode argon arc welding for increasing the welded depth contains Cr2O3, TiO2 and metallic fluoride. It can increase the welded depth by more than 3 times. Its advantages are narrow width being affected by welding heat, high productivity and low cost.

Owner:国营七四一四厂

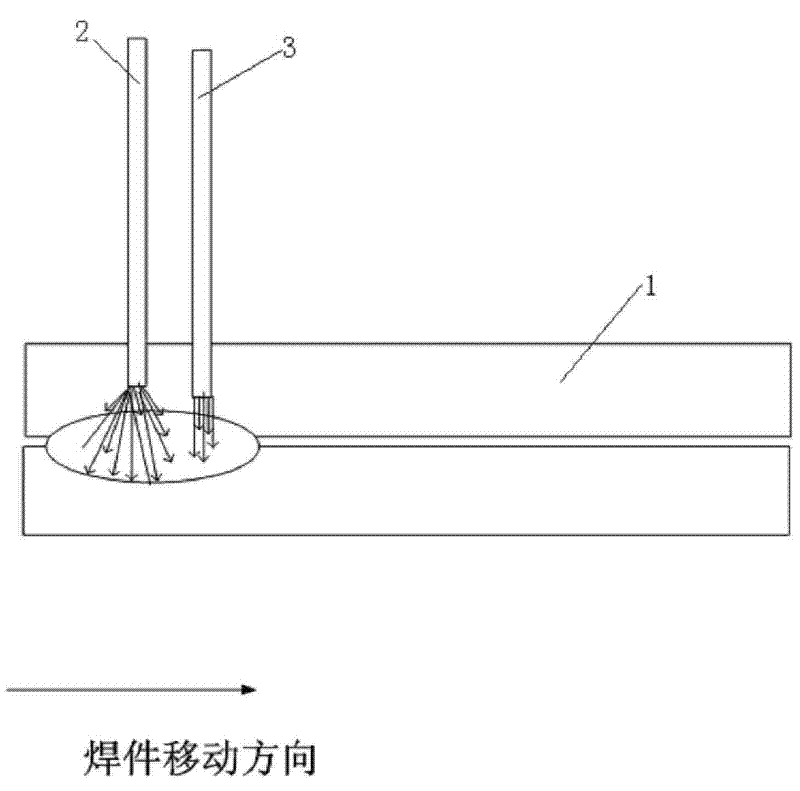

Hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser

The invention relates to a hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser, comprising the following steps: firstly fixing a variable-polarity square-wave tungsten electrode argon arc welding gun and a laser beam transmitting gun, providing a workpiece moving at a constant speed, forming a mode of preposing the variable-polarity square-wave tungsten electrode argon arc welding gun, utilizing the electric arc of variable-polarity square-wave tungsten electrode argon arc welding to remove impurities such as oxide films and the like at the surface zone of the welding workpiece, and leading the workpiece to be in a high-temperature melting state; and then leading laser beams to radiate a welded part, thus deepening the depth of fusion in variable-polarity square-wave tungsten electrode argon arc welding and finishing the welding. By utilizing the welding method adopted by the invention, the reflectivity of metal to the laser can be reduced, and the absorptivity of the metal to the laser energy is improved, so that the effective heating depth of the laser is improved, the depth of fusion of welding seams is enlarged, and the width of the welding seams and the width of heat affected zones are effectively reduced, thus finally a welding piece with deeper depth of fusion, very small heat affected zones and attractive appearance can be obtained.

Owner:CRRC QINGDAO SIFANG CO LTD

Molybdenum copper and stainless steel argon tungsten argon arc welding process

InactiveCN101284330AReduce temperature differenceReduce welding stressArc welding apparatusWelding/soldering/cutting articlesSurface cleaningAlloy

The invention discloses an argon tungsten arc process of molybdenum copper and a dissimilar stainless steel material. The method comprises the steps of cleaning the surface of the molybdenum copper and the surface of the stainless steel, which are to be connected, and the surface the Cr-Ni alloy system welding wire used for filling before welding; preheating by using a tungsten electrode argon arc inclining to the molybdenum copper first after arc starting; adopting pure argon protection; keeping down the argon arc to control heat distribution and to conduct filler rod argon tungsten-arc welding. The method has the advantages of convenient operation and strong applicability. Furthermore, the obtained welding joint of the molybdenum copper and the stainless steel has higher strength and stable property, and can be widely used for welding the molybdenum copper and the stainless steel and other dissimilar materials, thus being worth popularization and application.

Owner:SHANDONG UNIV

Method for welding heat exchanger tube plate and welding joint of heat exchange tube

InactiveCN102151958AInhibition retentionExtended service lifeArc welding apparatusHeat exchange apparatusEngineeringWelding defect

The invention relates to a method for welding a heat exchanger tube plate and a welding joint of a heat exchange tube. During assembling of the heat exchange tube and the tube plate, a structure which is sunken into the surface of the tube plate 0.5 to 1 millimeter is adopted; during welding, a welding sequence from bottom to top is adopted, and a 3-shaped or S-shaped welding running line is adopted; during welding, each heat exchange tube is welded with a half of a cycle, and after 8 to 10 heat exchange tubes are welded disposably without arc quenching, the tube plate is subjected to the arc quenching; and according to the same method, the other half of the cycle is welded from bottom to top. Therefore, the frequency of arc stopping and arc starting can be reduced, the welding efficiency is improved, and the number of arc starting and stopping points and the probability of generating welding defects can be reduced. During welding, a tungsten electrode can be stretched into the root part of an included angle between the heat exchange tube and the tube plate easily; during autogenous welding, an electric arc can get to a sharp corner position, and the root part can be penetrated totally without any hollow cavity, so retention of shell side corrosion media is prevented, interval corrosion is avoided and the service life of a welding line is prolonged.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

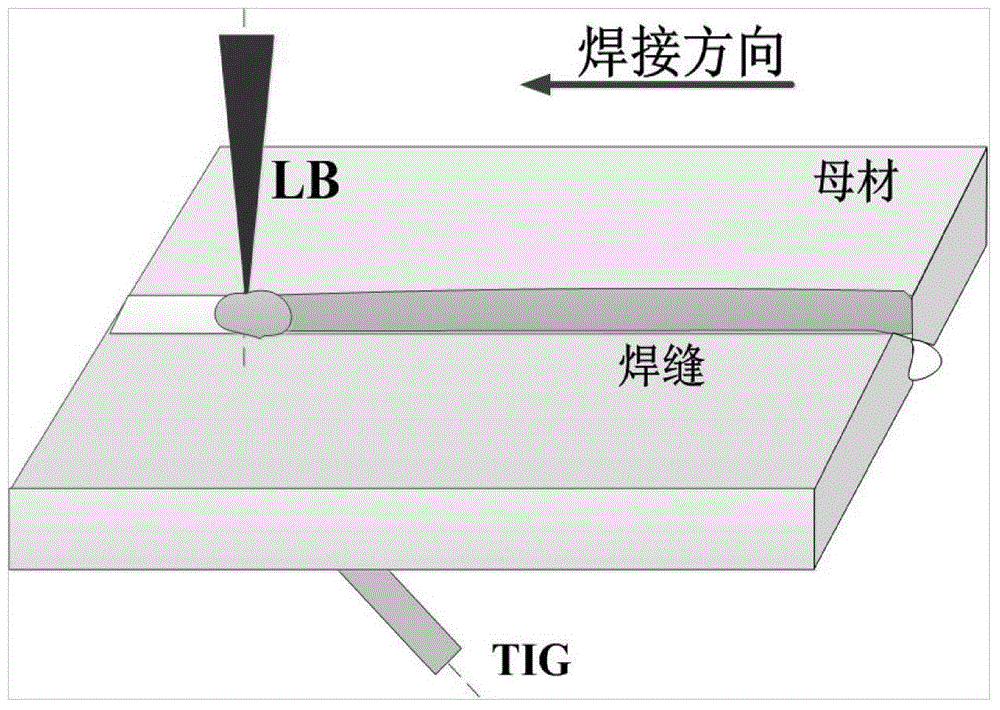

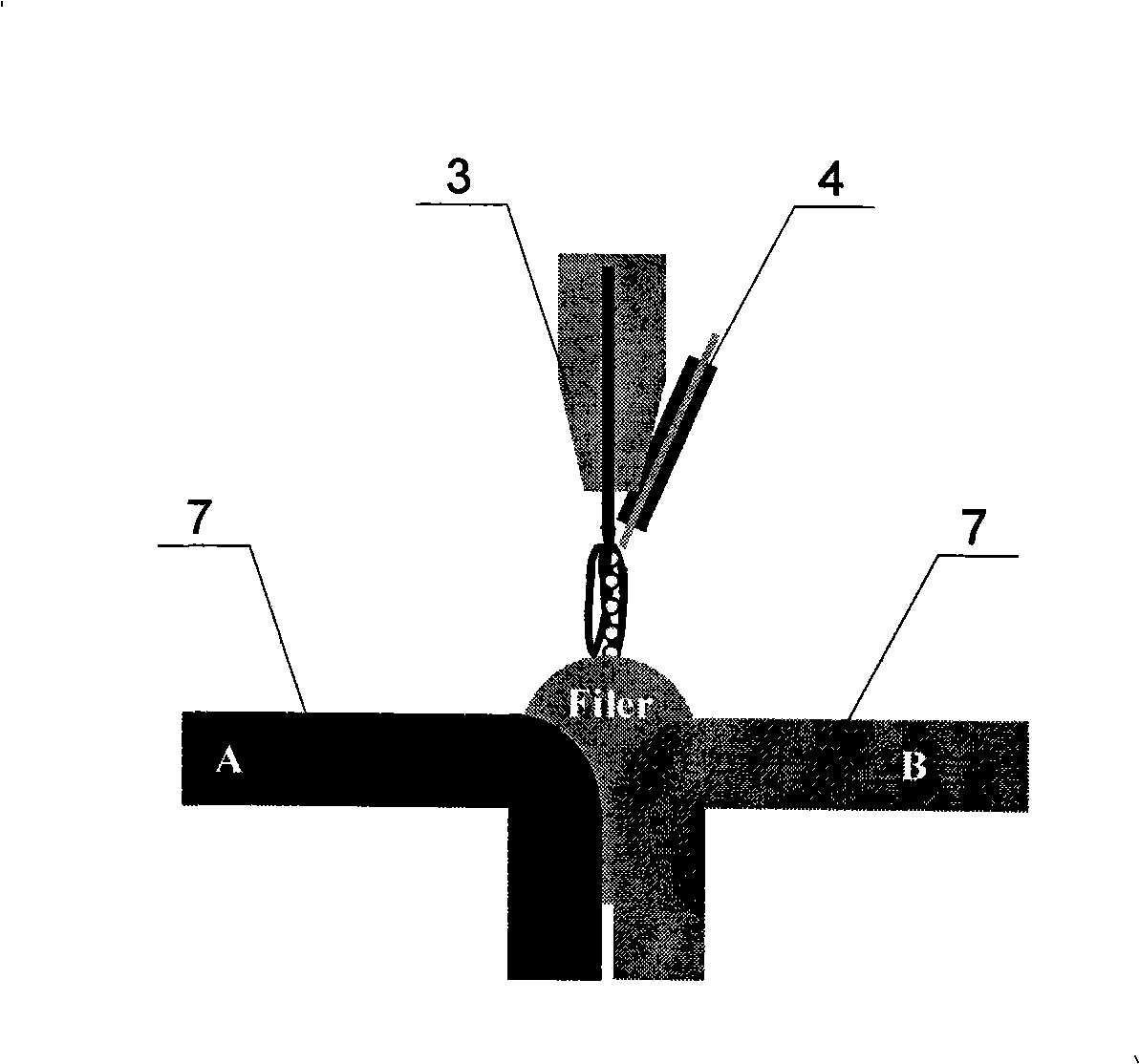

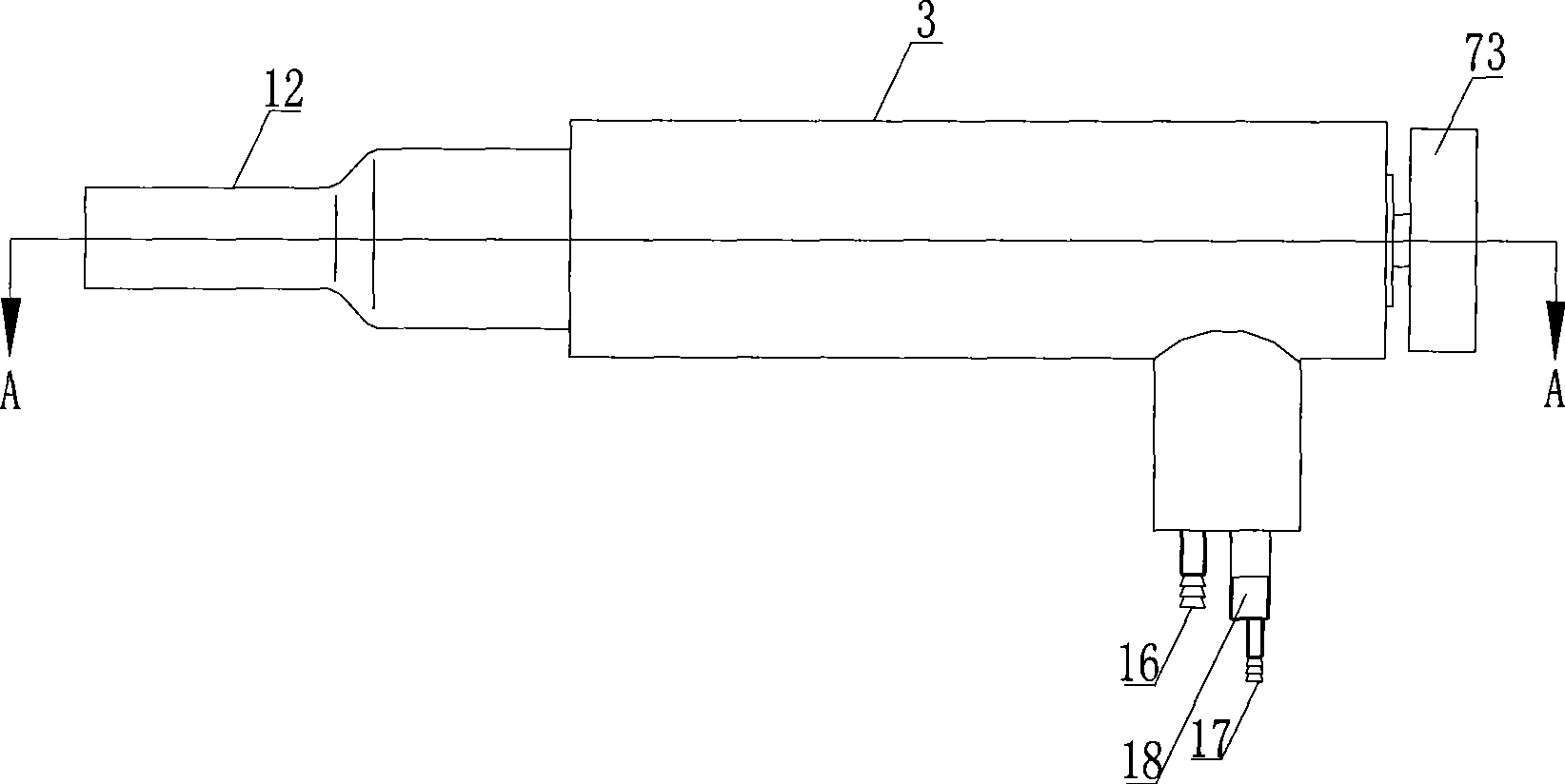

Double-sided laser-TIG (Tungsten Inert Gas) electric arc compound welding method

ActiveCN104400226AGuaranteed accuracyImprove accessibilityMetal working apparatusLaser beam welding apparatusEngineeringLaser beams

The invention provides a double-sided laser-TIG (Tungsten Inert Gas) electric arc compound welding method, relating to a compound welding method. The method comprises the following steps of firstly, implementing groove processing on a to-be-welded workpiece, and cleaning a tool fixture; secondly, arranging two sets of relatively independent laser TIG electric arc systems on two sides of the to-be-welded workpiece, and adjusting the positions; thirdly, setting welding technology parameters; fourthly, starting the systems to implement welding. According to the new double-sided laser-electric arc compound welding method, the grooves are formed in two side faces when a medium plate is welded, the laser-electric arc compound welding method is simultaneously implemented on two faces of the plate to weld, shown as Figure 4; as a welding gun is integrally designed with a laser working head, the precision of welding is guaranteed; the end part of a tungsten electrode and the extension line of a laser beam are intersected at one point of the welding centre together; the double-sided laser-electric arc welding process is synchronously implemented along the same direction.

Owner:HARBIN INST OF TECH

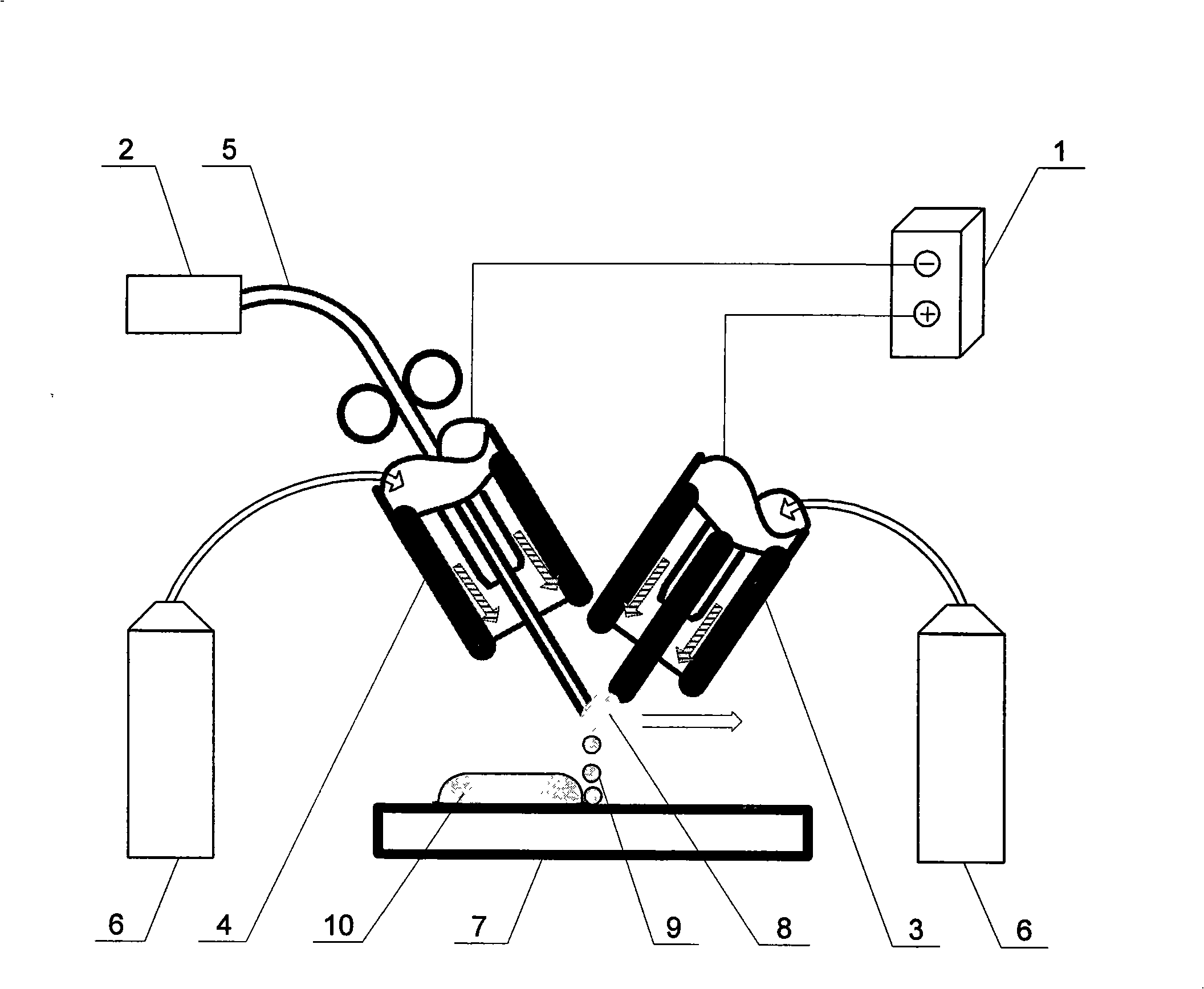

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

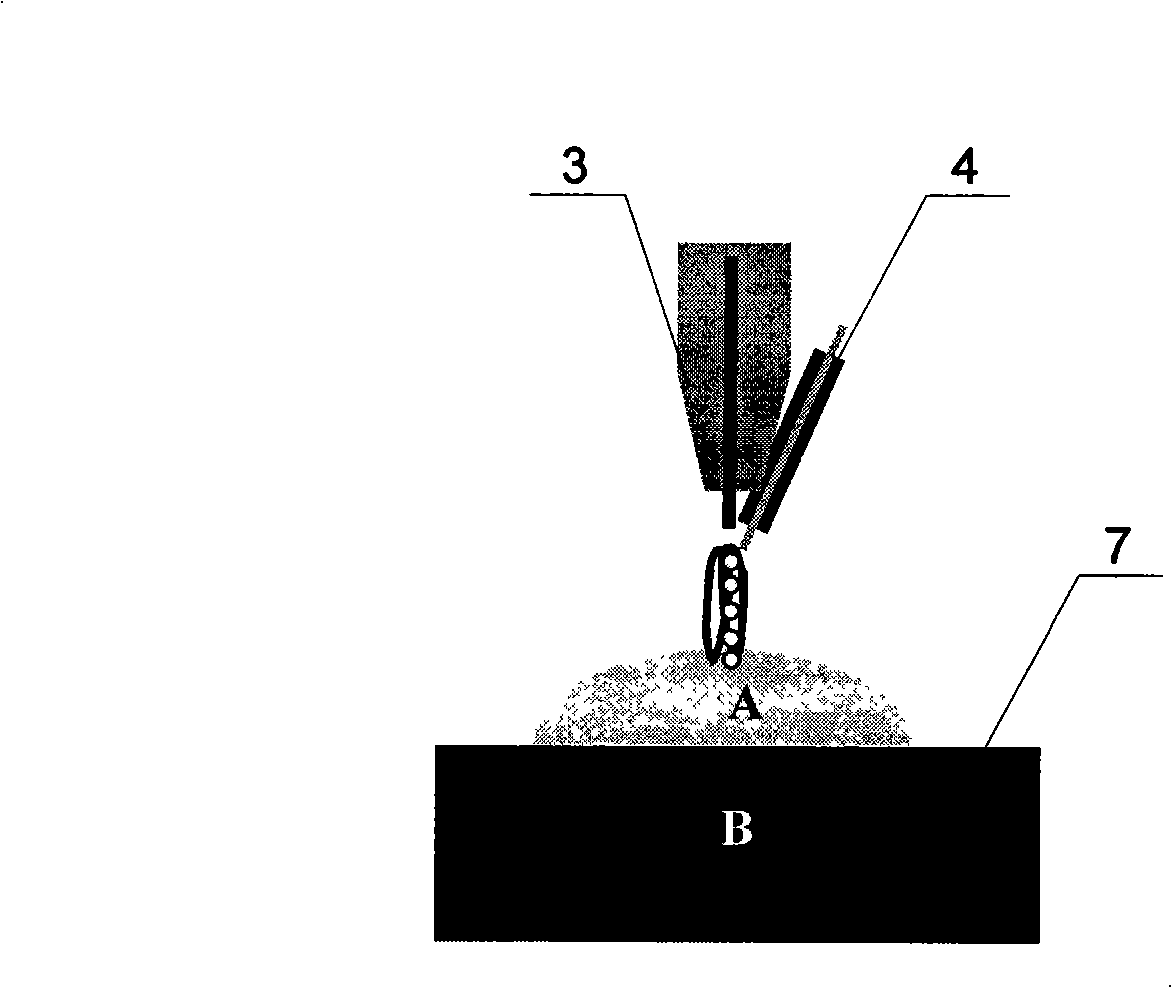

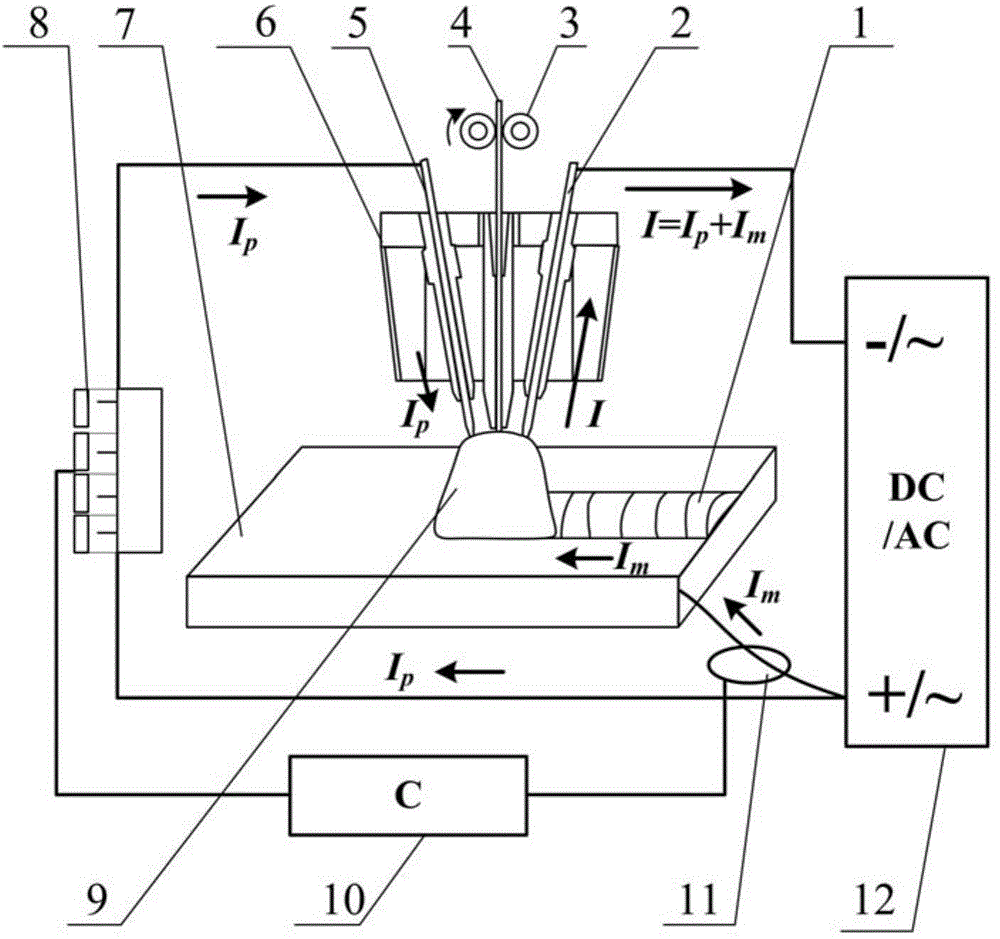

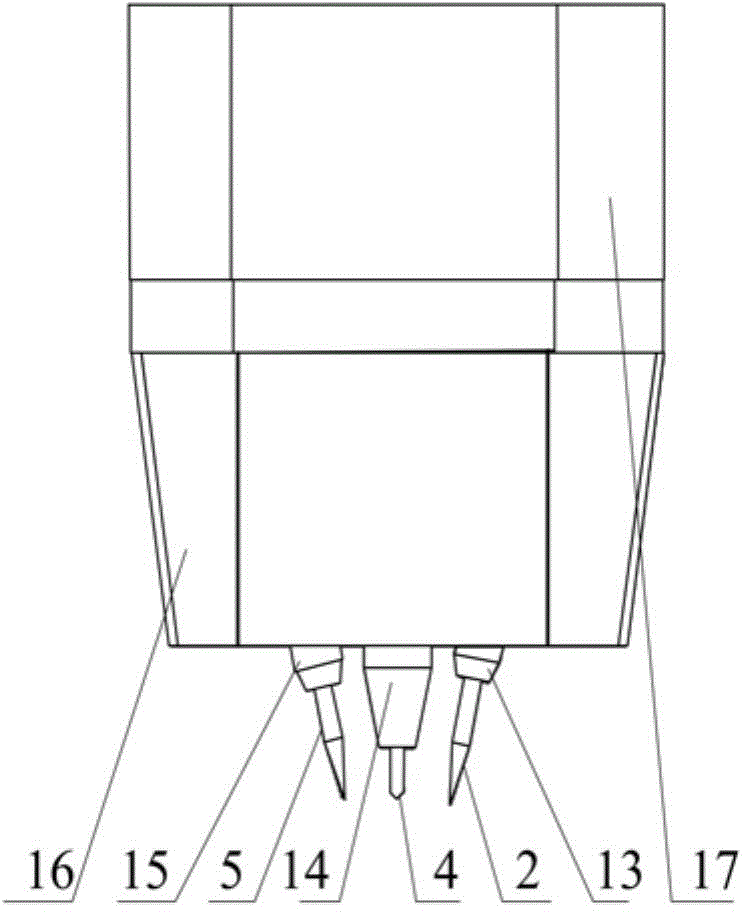

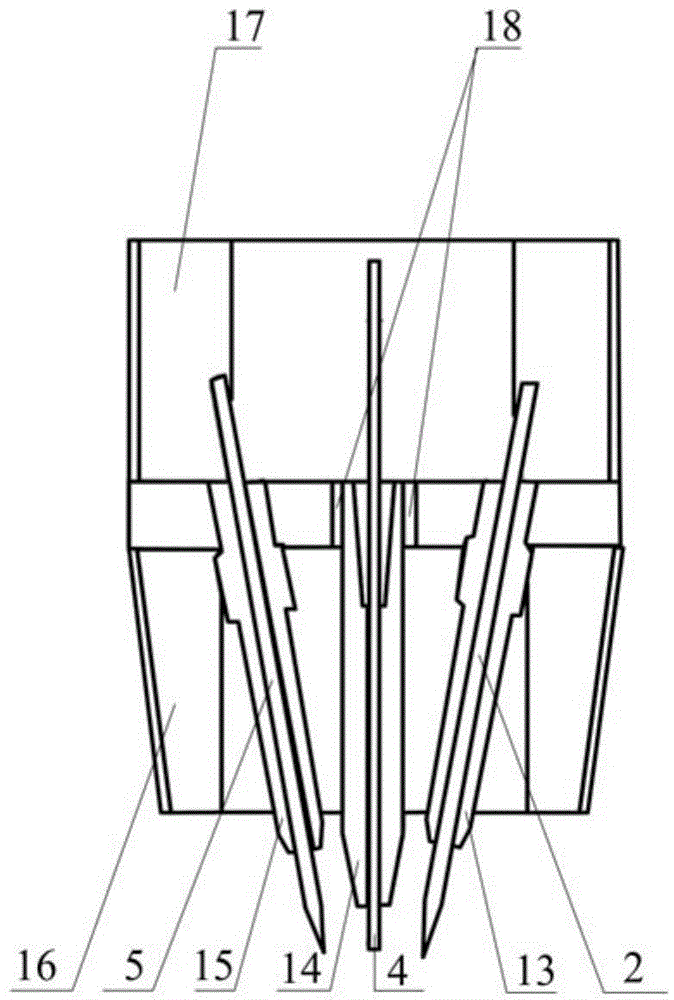

Controllable shunt double-tungsten electrode coupling electric arc welding gun device based on center filler wire and welding method thereof

ActiveCN104148785AIncrease profitHigh wire melting efficiencyArc welding apparatusFilling materialsInput control

The invention provides a controllable shunt double-tungsten electrode coupling electric arc welding gun device based on a center filler wire and a welding method thereof. Two tungsten electrodes are symmetrically arranged in a welding gun body in a small included angle mode, so that a bypass shunt coupling electric arc is formed through an IGBT control module, the filler wire is fed directly from the center of the coupling electric arc, the melting efficiency of the welding wire can be improved through the hottest part of the electric arc, and heat input of the welding wire and a base material can be accurately controlled through the bypass shunt. By means of the controllable shunt double-tungsten electrode coupling electric arc welding gun device based on the center filler wire and the welding method thereof, a filling material can be heated efficiently and stably, the melting quantity of the welding wire and the base material can be effectively and accurately controlled as well, and thus accurate welding heat input control can be achieved while high efficiency welding is guaranteed; the controllable shunt double-tungsten electrode coupling electric arc welding gun device based on the center filler wire and the welding method thereof not only are suitable for high efficiency and high quality welding of materials of the same type but also are suitable for reliably connecting dissimilar materials such as nickel base alloy, stainless steel and copper which have a strict requirement for dilution rate control.

Owner:HARBIN ENG UNIV

Double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method

InactiveCN104096954AAvoid drippingImprove liquidityArc welding apparatusDomestic vesselsButt weldingEngineering

A double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method is implemented by the following steps: cleaning up sundry, carrying out groove processing on the welding position of a wall plate of a stainless steel storage tank, welding position welding, choosing welding torch equipment, aligning a same weld pool by a main welding torch and an auxiliary welding torch from the inside and outside of a weld joint respectively synchronously, arcing synchronously by the main welding torch and the auxiliary welding torch, enabling the auxiliary welding torch to be moved synchronous to the main welding torch, welding along the same direction at the same speed, and stopping arcing by the main welding torch and the auxiliary welding torch synchronously. By adopting the double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method, the inner side forming of the weld joint is protected and penetrated, the defects of oxidation, overlap, lack of penetration and the like of the weld joint are avoided, the processes of root clearing, grinding and re-welding on the inner side are omitted, compared with the prior art, the method has the advantages of simple method and easy implementation, the production efficiency is greatly improved, and the labor intensity of workers is lowered.

Owner:中建一局集团安装工程有限公司 +1

Perforated TIG (Tungsten Inert Gas) arc melting brazing method of dissimilar metal

InactiveCN102615398AEvenly distributedReduce temperature gradientArc welding apparatusMelting tankLiquid metal

The invention provides a perforated TIG (Tungsten Inert Gas) arc melting brazing method of a dissimilar metal. The perforated TIG (Tungsten Inert Gas) arc melting brazing method of the dissimilar metal comprises the following steps that: a steel / aluminum or titanium / aluminum plate is clamped by a rigid clamp and a copper base plate to be assembled into butt joints, and the matching between a gap and the size of a molding groove is ensured; a guidewire mouth of a wire feeder and a welding gun are assembled into a whole, the wire feeding angle is 30 to 45 degrees, the wire is fed at a low-melting-point metal side, and the distance between a tungsten electrode and a workpiece is controlled in a range of 2-3mm; after small perforated holes obviously grow up, welding wires are sent to the small perforated holes along the low-melting-point metal side in an inching wire feeding mode, and continuously flow along a groove until a molten pool is spread at the front and back of the groove, and the inching wire filing is continuously carried out after the obvious small perforated holes are formed; and the steps are repeated until the melting brazing process is finished. The plasma pressure in the perforated holes promotes the spreading of liquid metal to the back of a high-melting-point metal to realize one-side welding with back formation. Complex equipment and structure do not exist, the operation is simple, the cost is low, and the process stability is good.

Owner:HARBIN INST OF TECH

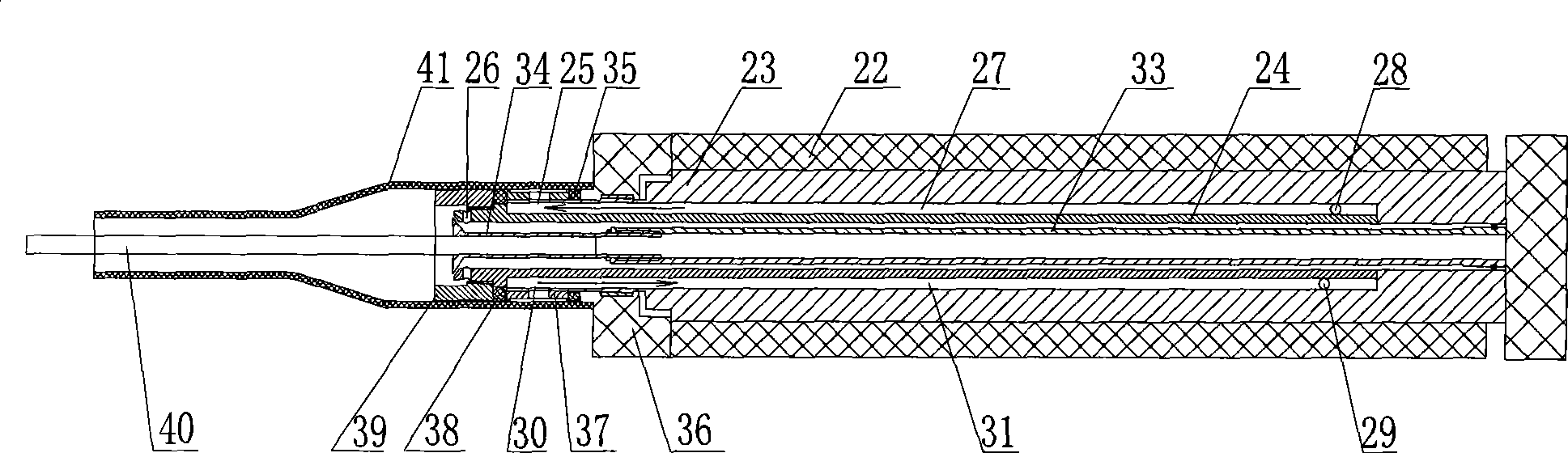

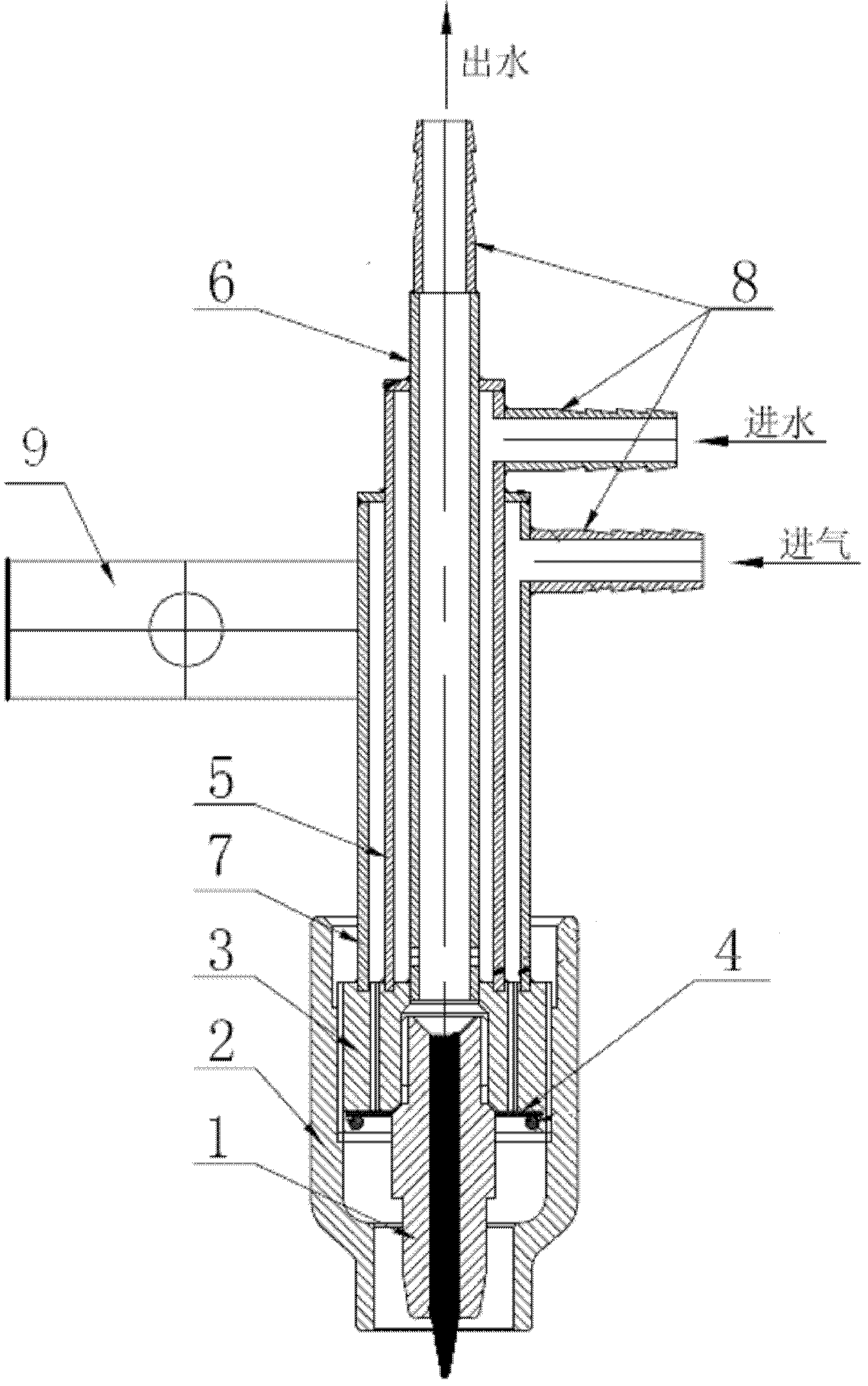

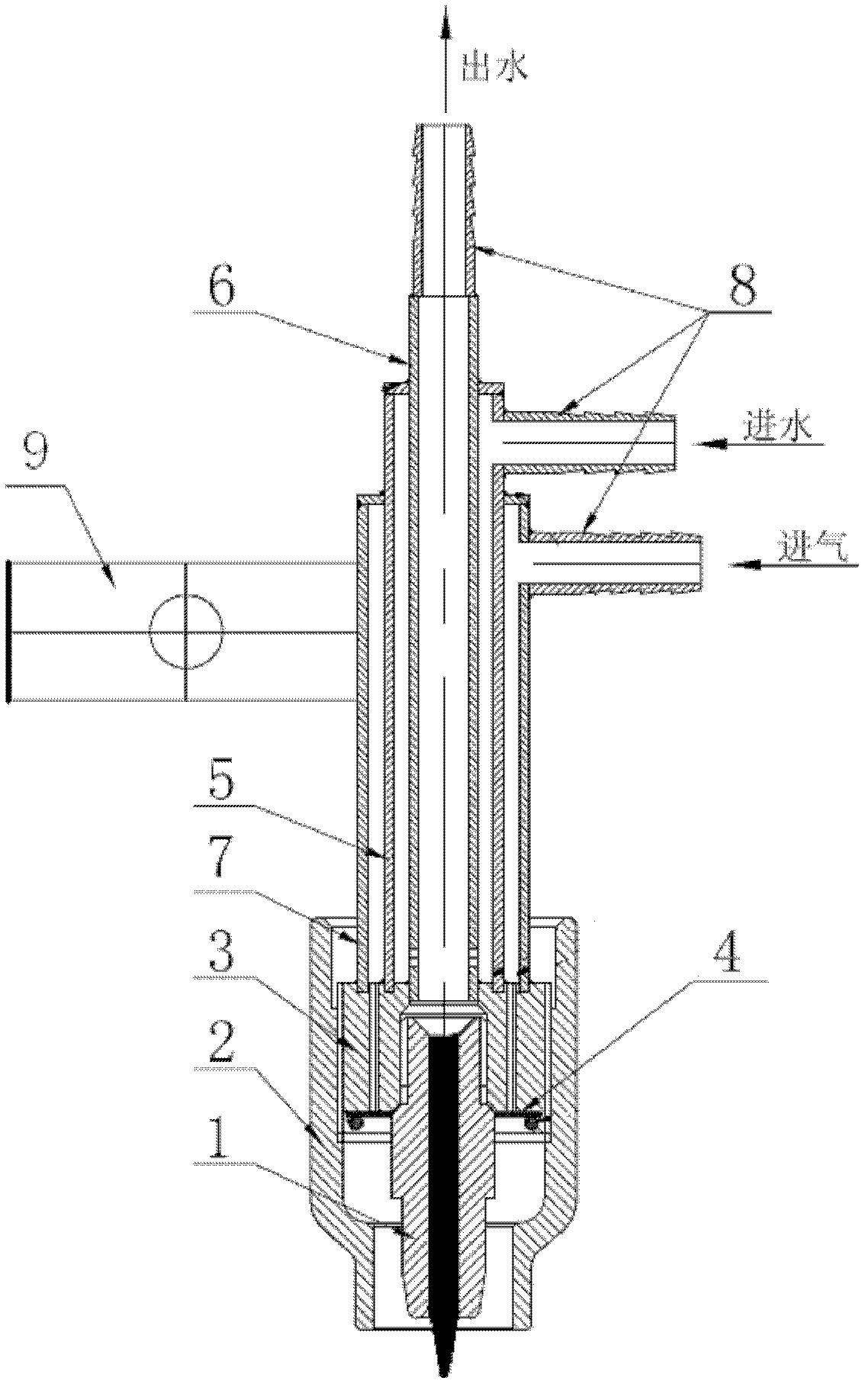

TIG welding gun and welding cooling method

ActiveCN101380690ANo leakageExtended service lifeElectrode supporting devicesWelding accessoriesAcute angleShielding gas

The invention discloses a TIC welding torch; a torch head includes a tungsten electrode, a shielding gas hood and a fixing seat; a torch body includes an insulating liner, a cooling tube cylinder, a tungsten electrode clamp and a compression adjusting rod which are coaxially sheathed from the outside to the inside; the front end of the tungsten electrode clamp is against to the position of a conical hole in front of a through hole in the fixing seat; the shielding gas hood is sheathed in the periphery of the fixing seat body; the front end of the cooling tube cylinder is sheathed to the connection part of the fixing seat; a cooling water channel is formed between the insulating liner and the cooling tube cylinder; an annular gas chamber used as a shielding gas channel is formed in the torch body; gas distribution holes arranged in an acute angle with the coaxial direction are uniformly arranged along the circumferential direction on the fixing seat. In the welding cooling method, the torch body is cooled by the cooling water; the shielding gas firstly cools the tungsten electrode and the surrounding parts and then carries out protection to a welding line during a welding process. The welding torch and the welding cooling method can effectively cool the welding torch and the torch body, the tungsten electrode and the surrounding parts, and can avoid the leakage of the cooling water; the welding torch has a simple structure and is easily dismounted, thus improving the welding quality and the service life of the welding torch.

Owner:TAICANG CIMC REEFER LOGISTICS EQUIP CO LTD +2

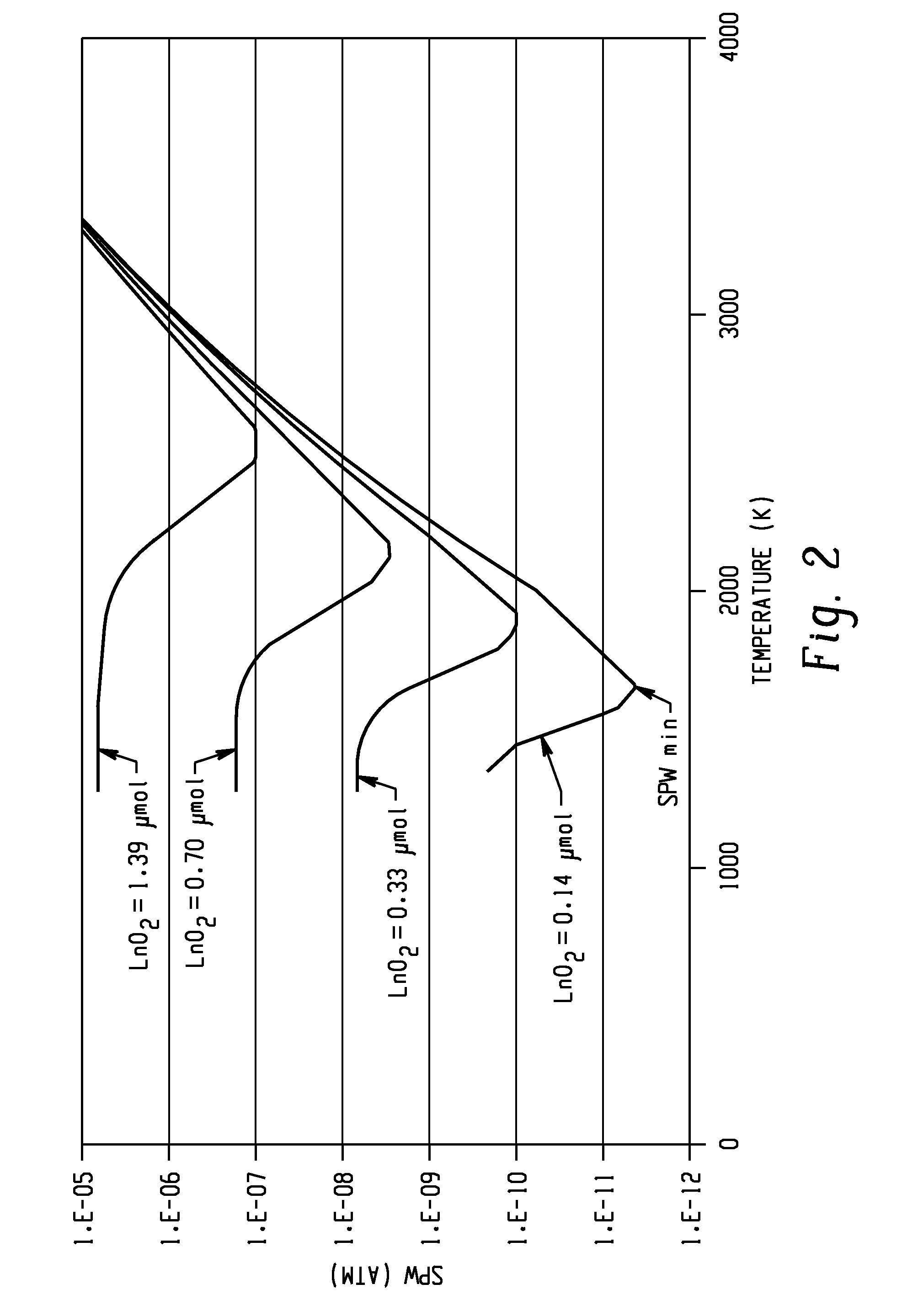

Lanthanide oxide as an oxygen dispenser in a metal halide lamp

InactiveUS20090146570A1Improve lumen maintenanceImprove performanceElectric lighting sourcesX-ray tube gas fillingMetal-halide lampRare earth

A lamp includes a discharge vessel. Tungsten electrodes extend into the discharge vessel. An ionizable fill is sealed within the vessel. The fill includes a buffer gas and a halide component that includes a rare earth halide. A source of oxygen which includes a lanthanide oxide is present in the discharge vessel. The source of oxygen provides oxygen for a regenerative cycle which reduces blackening of the lamp walls by tungsten from the electrodes.

Owner:GENERAL ELECTRIC CO

Welding method of high-nickel alloy and stainless steel dissimilar metal

InactiveCN101508053AMeet performance requirementsImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsImpulse frequencyAustenite

The invention discloses a dissimilar intermetallic welding method for high nickel alloy and stainless steel, which adopts pulsed tungsten argon arc welding, and welding technological parameters comprise that: the background current is between 20 and 50A, the impulse current is between 28 and 60A, the impulse duration is between 5 and 10s, the impulse frequency is between 35 and 75Hz, the welding voltage is between 8 and 12V, the welding speed is between 1.0 and 2.6mm / s, the inert gas flow rate is between 5 and 12L / min, the distance between a nozzle of a welding torch and a workpiece is between 5 and 10mm, and the included angle between a tungsten electrode of the welding torch and a weldment is between 70 and 85DEG. The method adopted has the advantages of high welding efficiency, low cost and convenient and flexible operation, can obtain welding joints without defects of cracks, pores and the like, and can meet the use requirement of a heterogenous composite structure of high nickel casting alloy and austenitic stainless steel.

Owner:SHANDONG UNIV

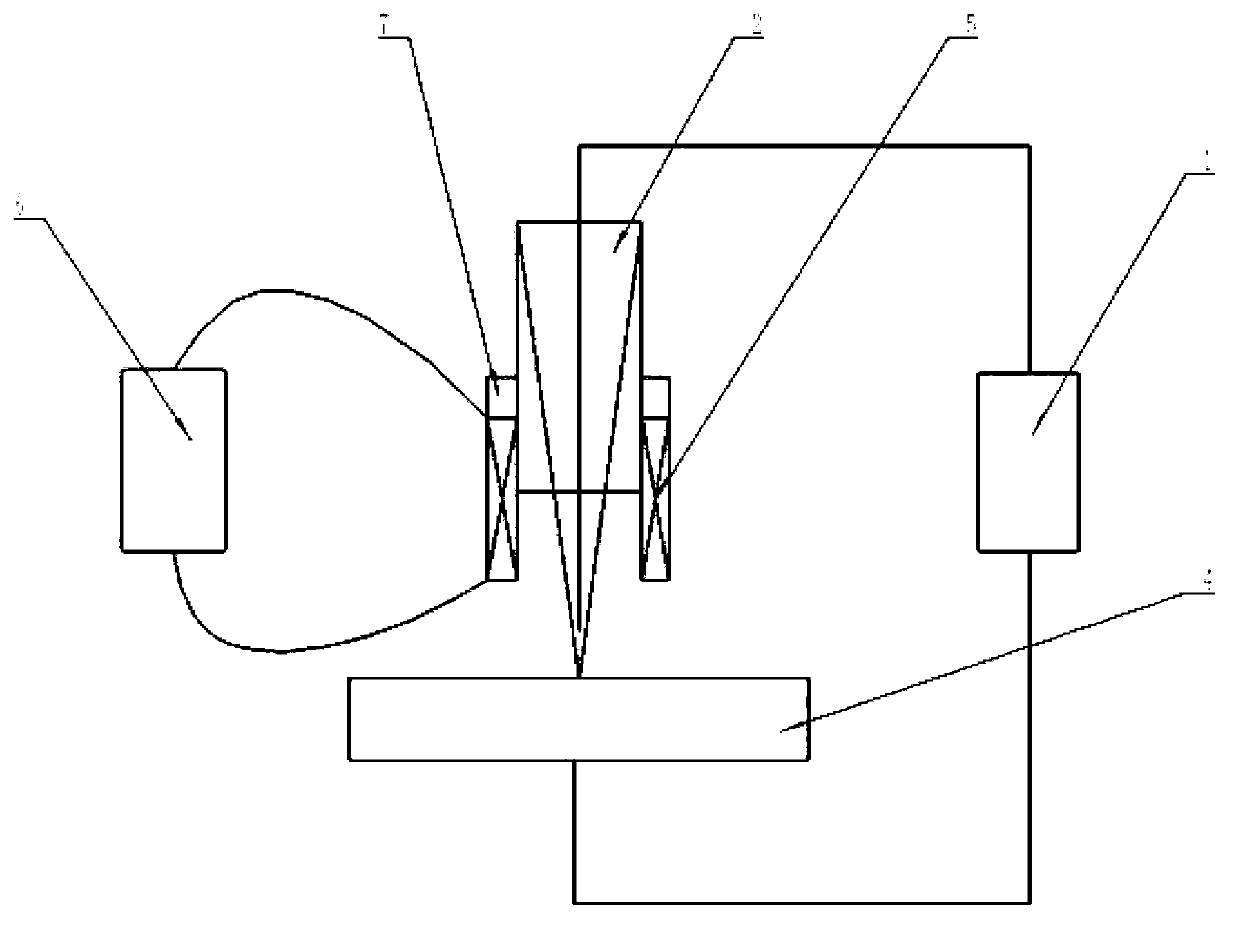

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

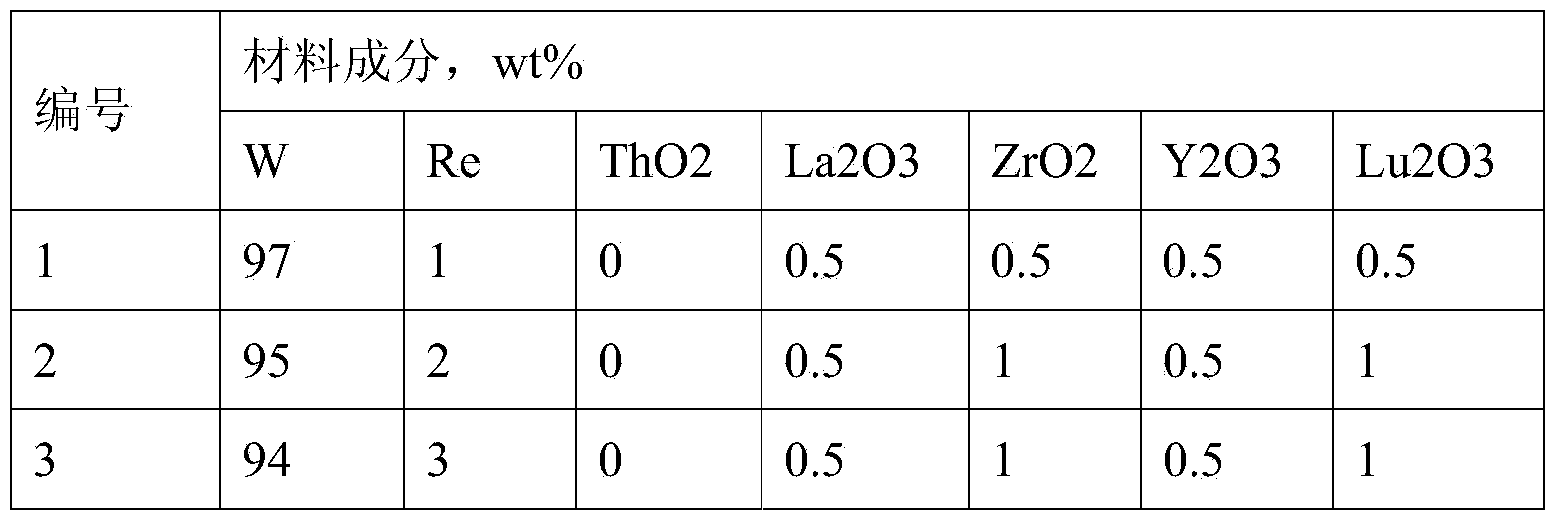

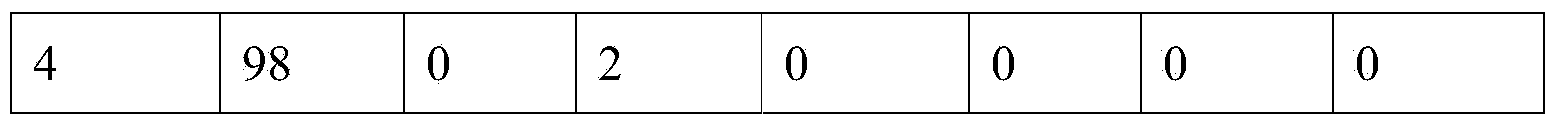

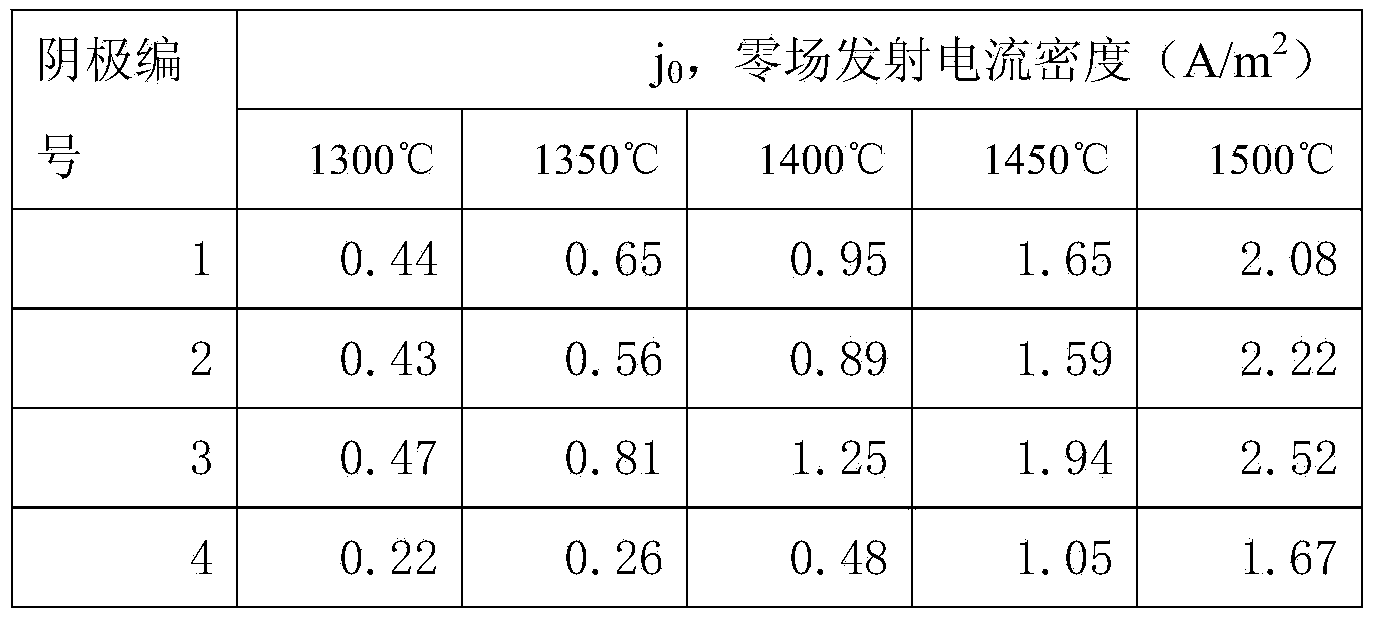

Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

InactiveCN103849804AImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumLutetium

The invention discloses a non-radiative multi-component composite tungsten negative material for a microwave oven magnetron and a preparation process of the negative material. The tungsten cathode material comprises lanthanum oxide, zirconium oxide, yttrium oxide, lutetium oxide, rhenium and tungsten, wherein the mass percent of each rare-earth oxide in the tungsten electrode material is 0.5%-1.5%, the mass percent of the total rare-earth oxides in the tungsten electrode is 2%-3%, the mass percent of the alloy element rhenium in the tungsten electrode material is 1%-4%, and the tungsten accounts for the rest mass percent. The tungsten cathode material is non-radiative, excellent in thermal emission performance, excellent in high-temperature creep resistance, thermal shock resistance and sag resistance, and long in service life. The preparation method of the non-radiative multi-component composite tungsten cathode material for the microwave oven magnetron comprises the steps of solution preparation, drying, reducing, isostatic cool pressing, sintering, incipient fusion, medium-frequency induction annealing, press working, winding and mechanical straightening. The non-radiative multi-component composite tungsten negative material for the microwave oven magnetron is better in usability. When heated periodically for a long time at a high temperature, the multi-component composite tungsten wire produced by virtue of the process is capable of going through large deformational resistance, and has the sag resistance.

Owner:深圳市威勒科技股份有限公司

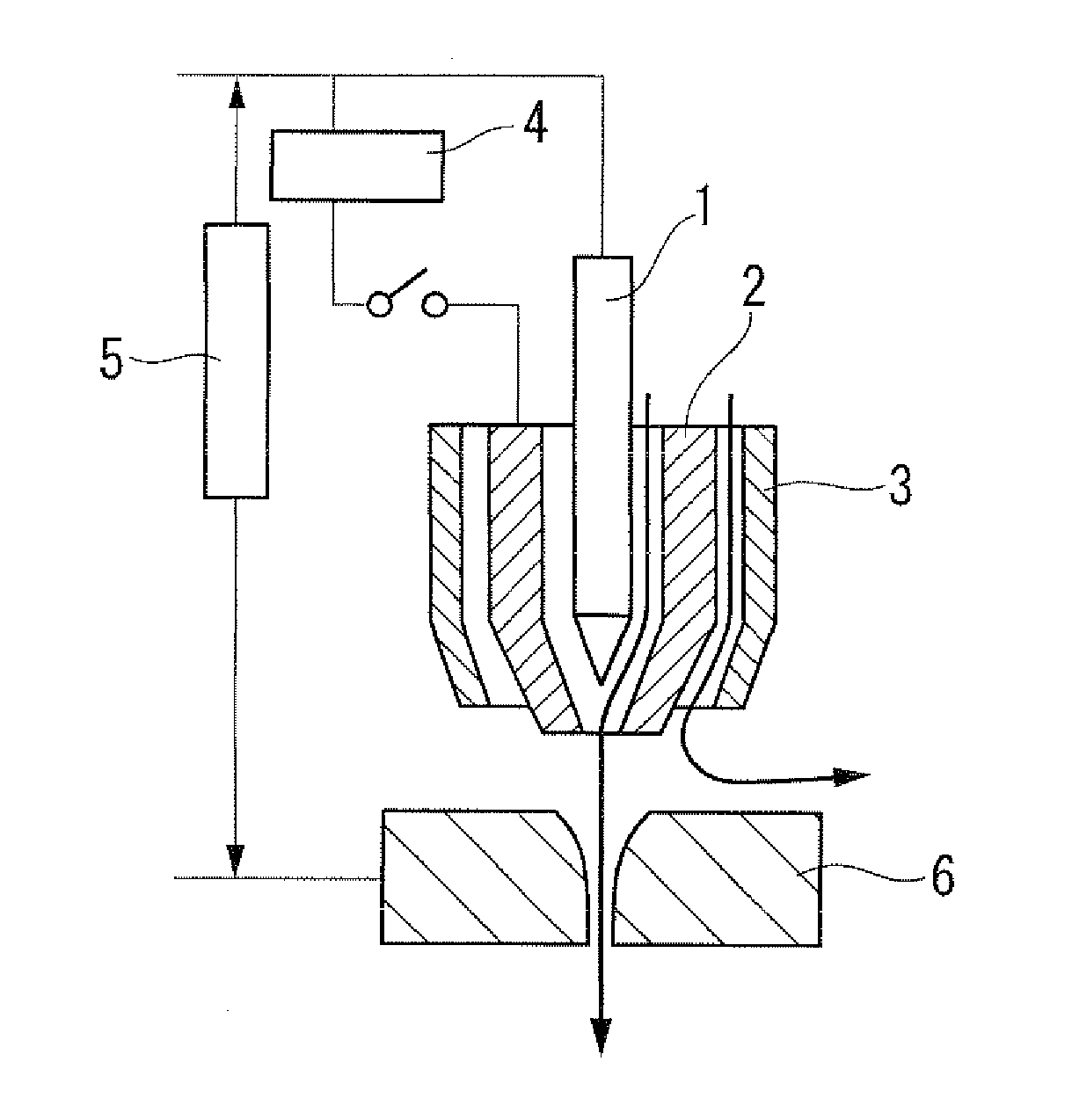

Plasma welding process and outer gas for use in the plasma welding process

ActiveUS20110017712A1Easy to weldUnnecessary costOther chemical processesArc welding apparatusEngineeringMixed gas

An outer gas for plasma welding of the present invention is used in plasma welding of a stainless steel with use of a plasma welding torch in which an insert tip (2) is provided in the periphery of a tungsten electrode (1), a shield cap (3) is provided in the periphery of this insert tip (2), a front end part of the tungsten electrode (1) is located inside from a front end part of the insert tip (2), a center gas comprising an inert gas is allowed to flow into a gap between the tungsten electrode (1) and the insert tip (2), and the outer gas is allowed to flow into a gap between the insert tip (2) and the shield cap (3), wherein the outer gas is a mixed gas containing 0.5 to 2% by volume of a carbon dioxide gas with the balance of an inert gas.

Owner:TAIYO NIPPON SANSO CORP

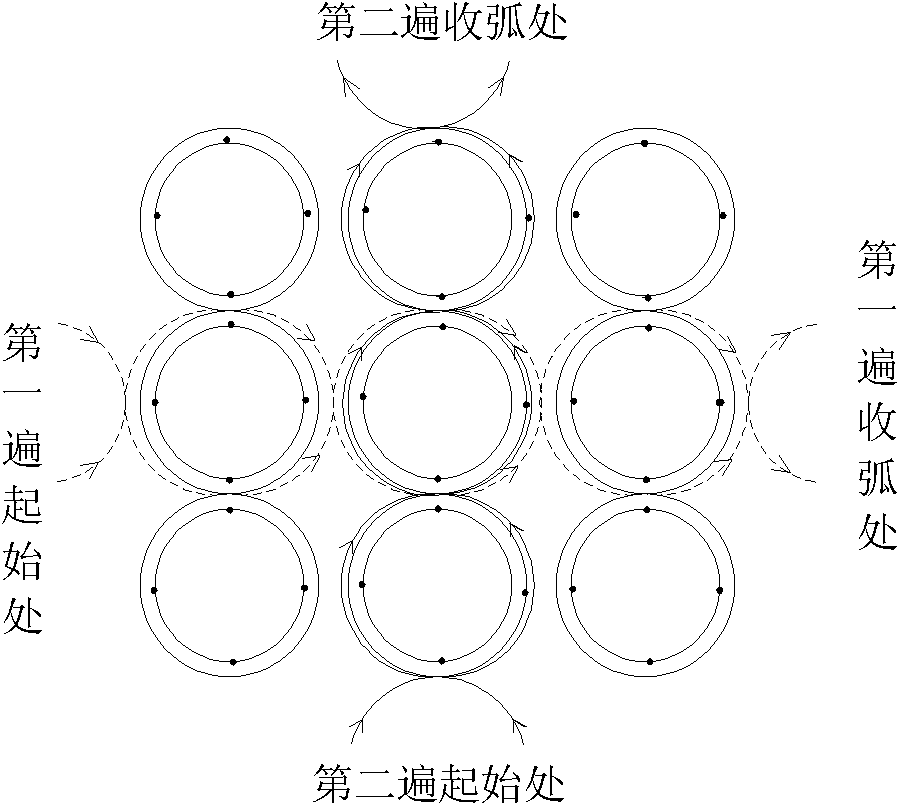

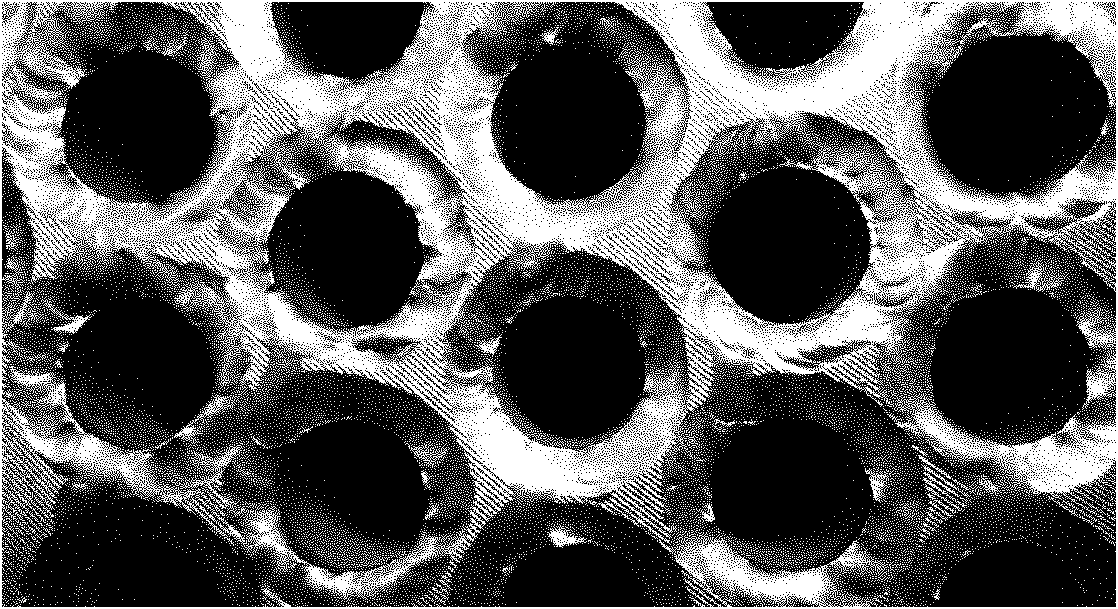

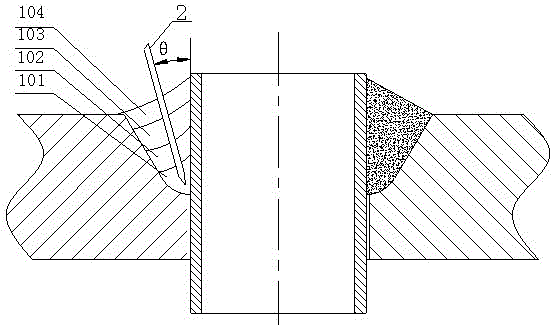

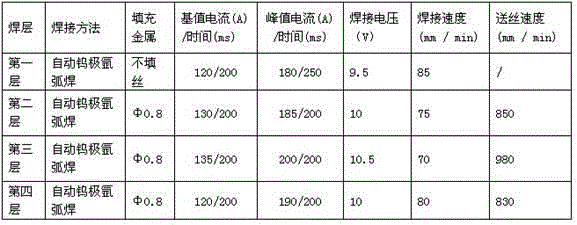

Automatic argon arc seal welding method for narrow gap between deep grooves of tube plate and heat exchange tube

ActiveCN102717175ASolve the problem of automatic weldingStrong penetrating powerArc welding apparatusHeat exchange apparatusWeld seamTungsten electrode

The invention discloses an automatic argon arc seal welding method for a narrow gap between deep grooves of a tube plate and a heat exchange tube. The method comprises the following steps that the groove is subjected to polishing cleaning and washing; the tube plate and the heat exchange tube are assembled; a positioning pneumatic expansion sleeve of an automatic tungsten argon-arc welding gun is inserted into the inner wall of the heat exchange tube and is inflated to be expanded; an included angle between a tungsten axis of the welding gun and an axis of the heat exchange tube is adjusted to 12.5-17.5 degrees; after adjustment, the tungsten end part of the welding gun is positioned in the middle of the groove and points to the roots of the grooves of the tube and the tube plate; in the groove, four layers of weld passes are distributed from the bottom of the groove to the surface of the groove, wherein the first layer of backing weld is self fluxing without welding wires, and other three layers are filled with metal wires; in each layer of single-pass weld, a tungsten electrode adopts a cerium tungsten electrode; and after the first layer is welded, welding is stopped, the next layer of welding is carried out step by step until the welding is finished after the weld joint quality is not abnormal. According to the automatic argon arc seal welding method, the quality of deep and narrow groove seal welding is increased, the welding work efficiency is increased, the appearance of weld joints is attractive, the fusing is good, and the inner parts of the weld joints do not have any defect.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

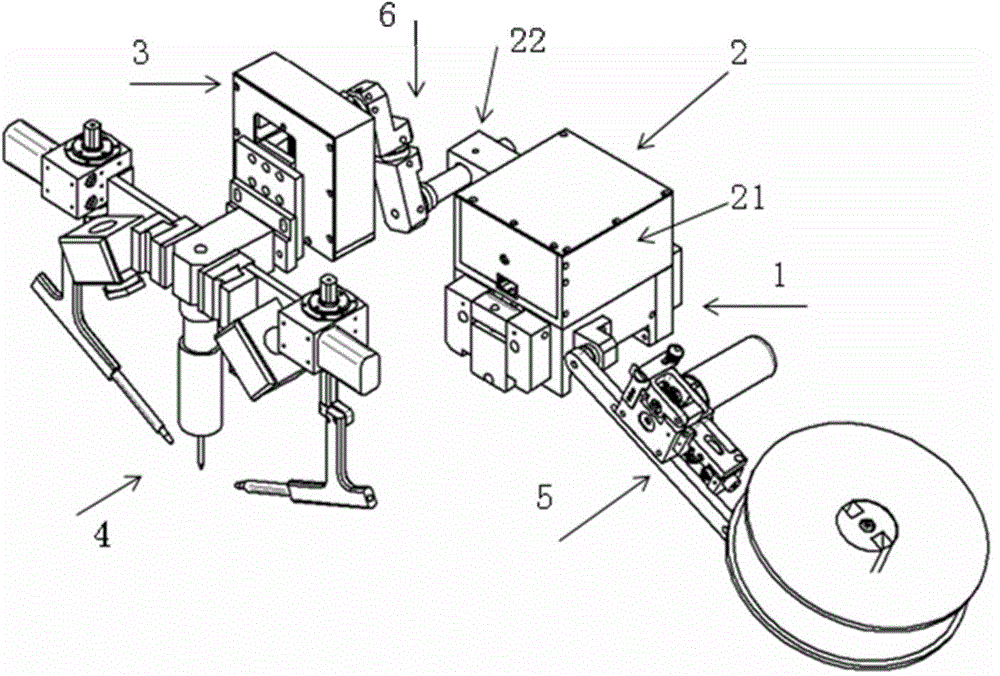

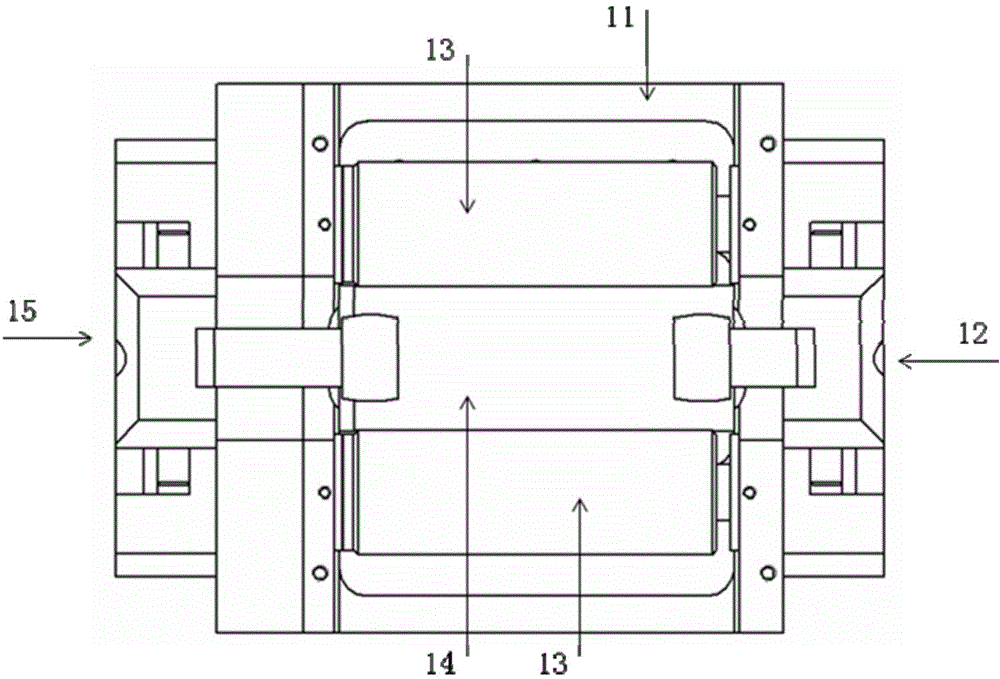

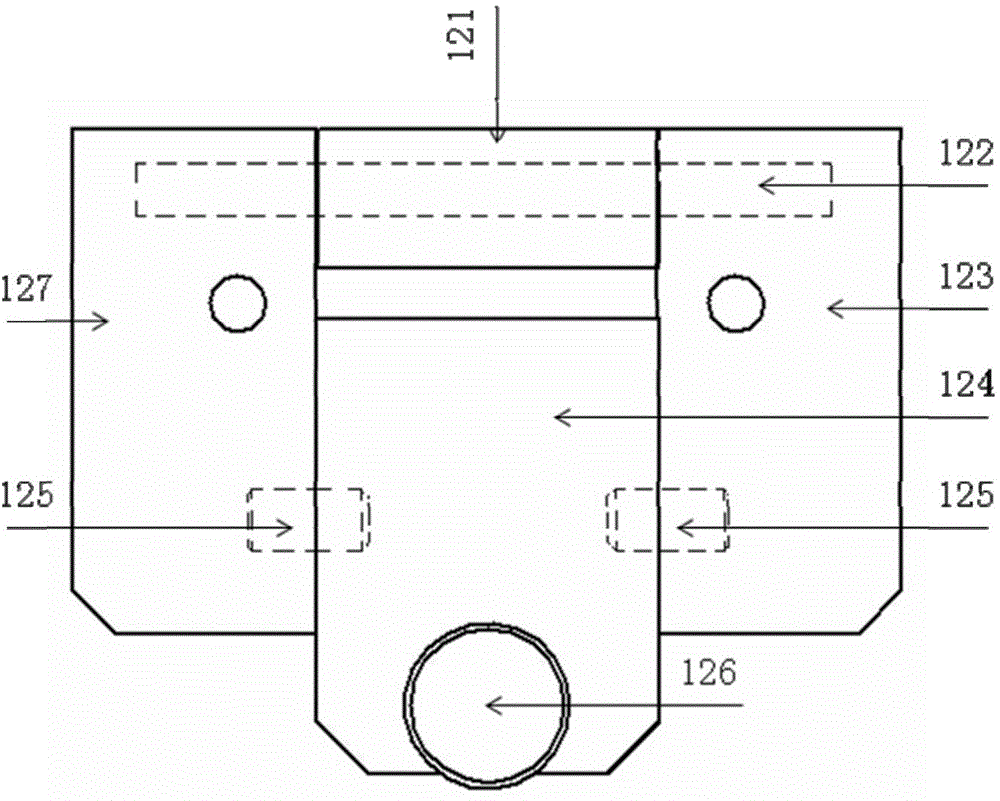

TIG welding head with multi-axis servo movement mechanism and welding method

The invention discloses a TIG welding head with a multi-axis servo movement mechanism and a welding method. A walking mechanism is installed on a walking track so that the TIG welding head can move along the walking track. A wire feeding mechanism is installed on one side of the walking mechanism and used for feeding a welding wire when the TIG welding head performs welding. A swinging mechanism is fixed to the upper portion of the walking mechanism and connected with one side of a vertical adjusting mechanism through a welding gun angle adjusting arm, the other side of the vertical adjusting mechanism is connected with a front-end welding mechanism, and therefore a welding gun can swing in a reciprocating mode in the width direction of a welding seam when the TIG welding head performs welding. The vertical adjusting mechanism is used for adjusting the distance between the welding gun and a workpiece. The front-end welding mechanism is used for adjusting the position of the welding wire and the position of a tungsten electrode. The TIG welding head is economical, practical, compact in structure, small, portable, convenient to clamp, convenient to disassemble and maintain due to modularization, high in automation degree and capable of achieving remote monitoring and control in the welding process.

Owner:BEIJING XINGTONG SCI & TECH DEV CO LTD

Condensation electric arc welding gun

InactiveCN102528249AIncrease energy densityAbility to control shapingElectrode supporting devicesElectrical conductorShielding gas

The invention discloses a condensation electric arc welding gun, which belongs to the technical field of welding equipment. A tungsten electrode is closely embedded in the center of an electrode holder; the electrode holder is sleeved in the center of a main connector through thread; the root part of the electrode holder is mutually engaged with the main connector by using an inclined surface, so that water cooling effect to the electrode and no leakage are guaranteed; a ceramic nozzle is sleeved on the periphery of the main connector through threaded connection; a protective gas laminar flow screen is a stainless steel wire net which is fixed on the other end face of the main connector through an O-shaped steel wire spring, so that protective gas forms laminar flow; a water outlet pipe, a water inlet bushing or a gas inlet bushing is provided with a cable connecting end; the water inlet bushing is coaxially sleeved outside a water outlet straight pipe; and the gas inlet bushing is sleeved outside the water inlet bushing, a water inlet passage is remained in the middle of the gas inlet bushing and the water inlet bushing, and the gas inlet bushing and the water inlet bushing are welded on the same end face of the main connector to form a water cooling passage and a gas protection passage. Apart from the ceramic nozzle, all the remaining materials are conductors. According to the condensation electric arc welding gun, the free electric arc energy intensity can be improved, and better capacity of controlling welding joint formation is achieved.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com