Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

A multi-component compound, tungsten cathode technology, applied to the cathode of the time-of-flight electronic tube, etc., can solve the problems of increasing manufacturing costs, adverse effects on human health, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

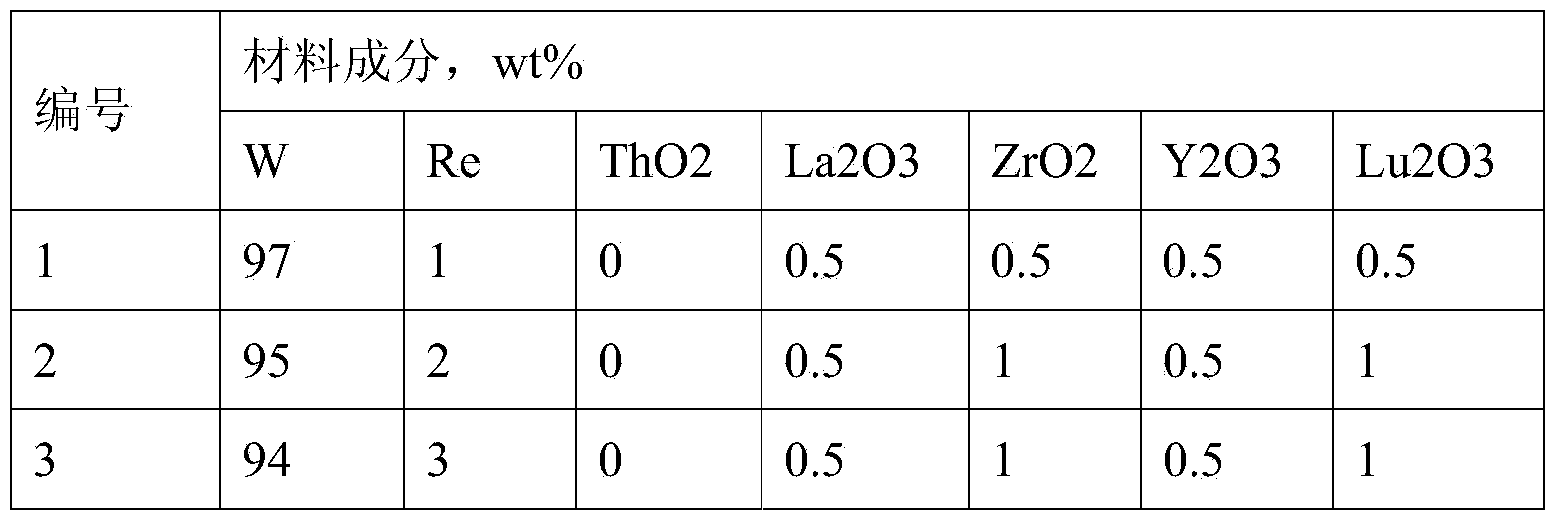

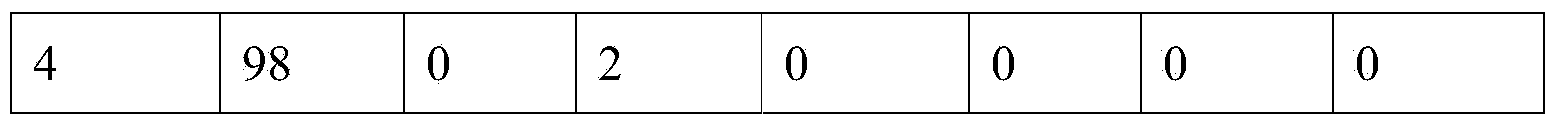

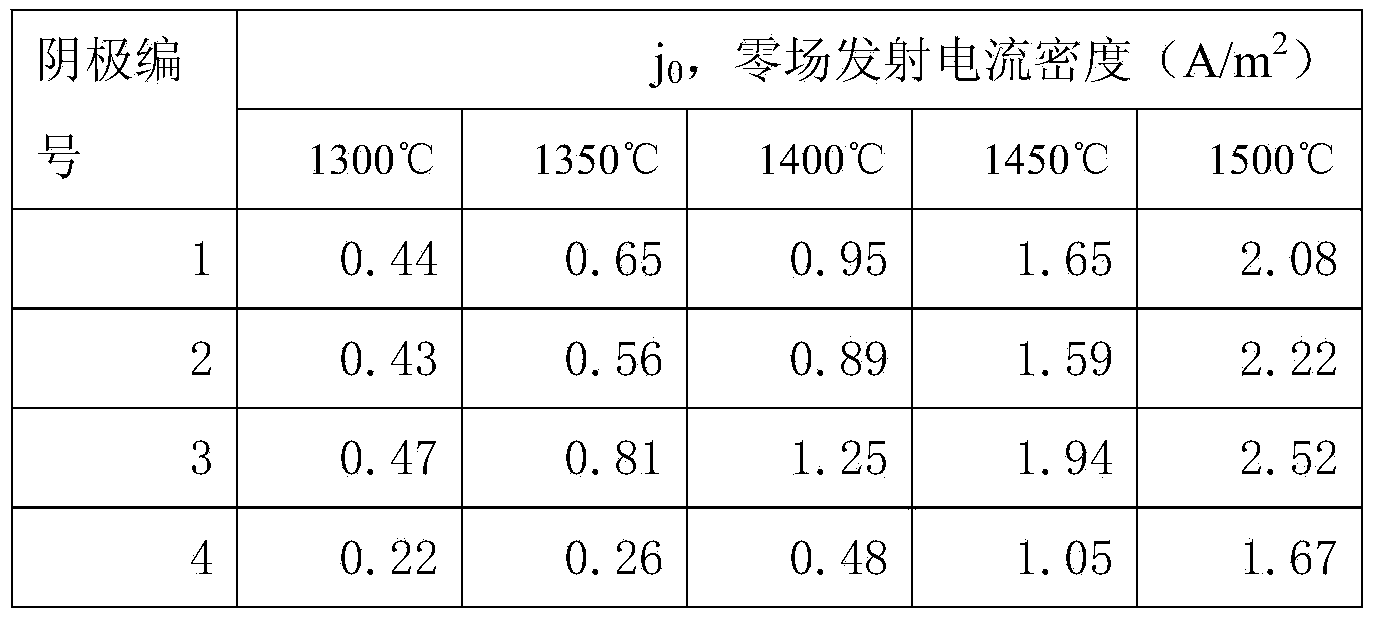

Examples

Embodiment 1

[0026] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate, and 64.82g of ammonium rhenate powder to form a mixed solution, add 1778.0g of tungsten trioxide powder, fully stir and evaporate to dryness and dry , first reducing by passing hydrogen for 45 minutes in an environment with a temperature of 400°C, and then reducing by passing hydrogen for 45 minutes in an environment with a temperature of 700°C to obtain a mixed powder that meets the requirements and has good processability.

[0027] Wash the above-mentioned reduced mixed powder with hydrochloric acid and hydrofluoric acid successively, that is, first add deionized pure water to the pickling pot lined with acid-resistant glue, and at the same time add hydrochloric acid with a mass content of 3%, start stirring, and load the mixed powder Washing, precipitation for 2 hours after washing, and then removing the waste liquid, then adding hydrofluoric acid wit...

Embodiment 2

[0029] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate, and 64.82g of ammonium rhenate powder to form a mixed solution, add 1778.0g of tungsten trioxide powder, fully stir and evaporate to dryness and dry , first reducing by passing hydrogen for 60 minutes in an environment with a temperature of 500°C, and then reducing by passing hydrogen for 60 minutes in an environment with a temperature of 800°C to obtain a mixed powder that meets the requirements and has good processability.

[0030] Wash the above-mentioned reduced mixed powder with hydrochloric acid and hydrofluoric acid successively, that is, first add deionized pure water to the pickling pot lined with acid-resistant glue, and at the same time add hydrochloric acid with a mass content of 4%, start stirring, and load the mixed powder After washing, precipitate for 2 hours, then remove the waste liquid, then add hydrofluoric acid with a mass content of...

Embodiment 3

[0032] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate, and 64.82g of ammonium rhenate powder to form a mixed solution, add 1778.0g of tungsten trioxide powder, fully stir and evaporate to dryness and dry , first reducing with hydrogen for 75 minutes in an environment with a temperature of 700°C, and then reducing with hydrogen for 75 minutes in an environment with a temperature of 1000°C to obtain a mixed powder that meets the requirements and has good processability.

[0033] Wash the above-mentioned reduced mixed powder with hydrochloric acid and hydrofluoric acid successively, that is, first add deionized pure water to the pickling pot lined with acid-resistant glue, and at the same time add hydrochloric acid with a mass content of 5%, start stirring, and load the mixed powder Washing, precipitation for 3 hours after washing, and then removing the waste liquid, then adding hydrofluoric acid with a mass co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com