Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

505 results about "Weld penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A full penetration weld is a type of weld that has completely consumed the root of the joint. A full penetration weld is often a requirement for joints that will be subjected to high stresses because it typically has higher strengths than a partial penetration weld.

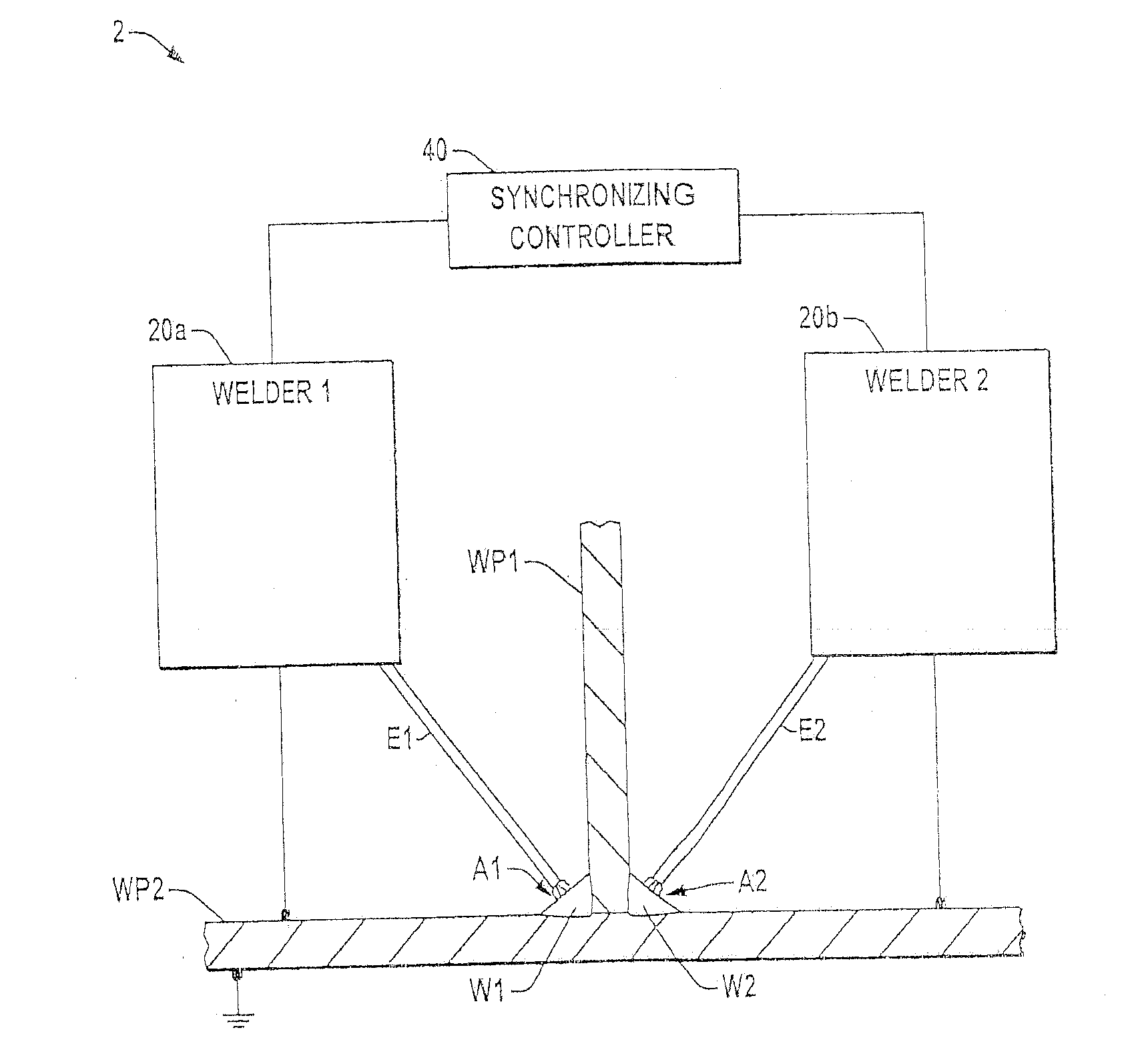

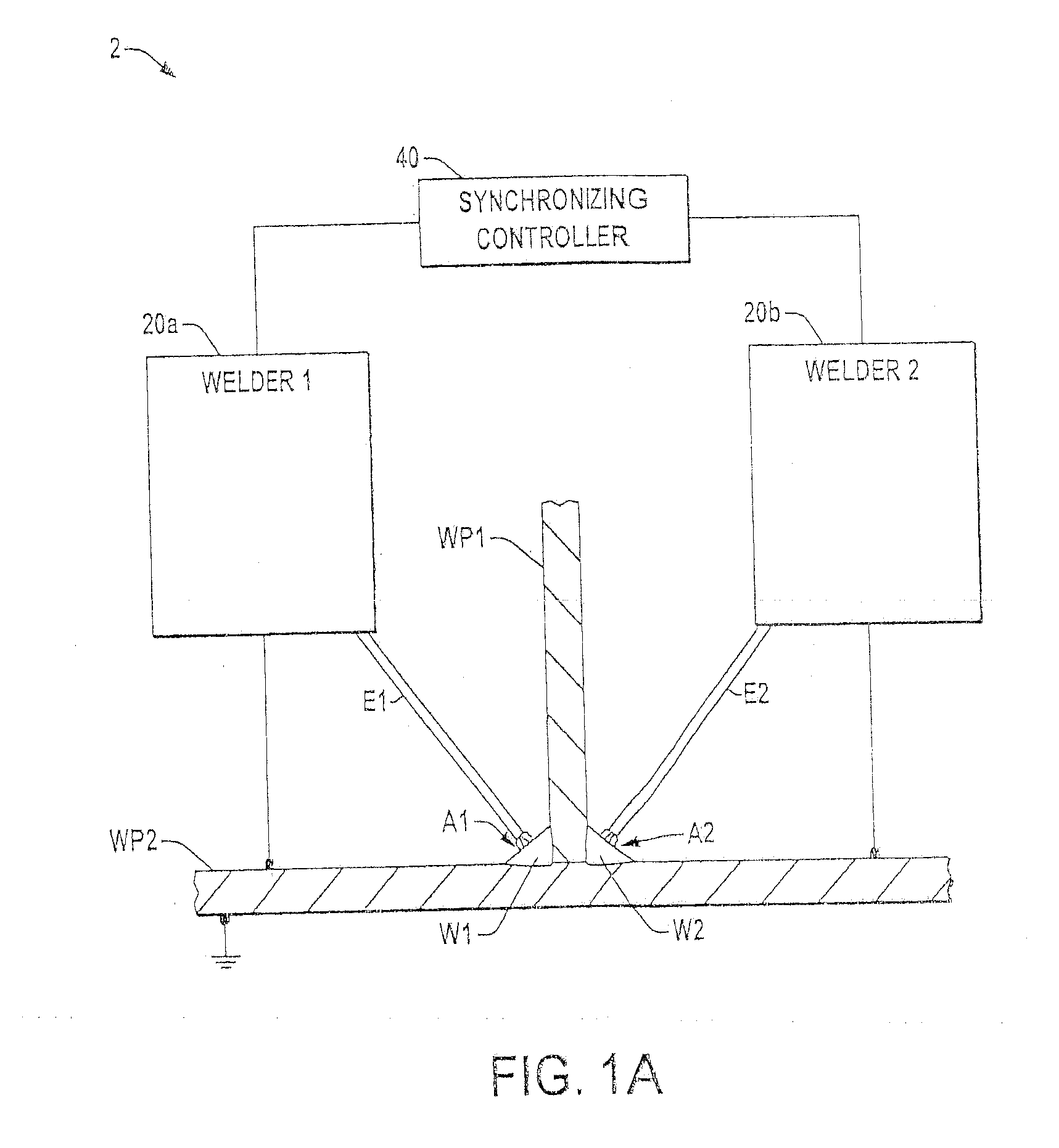

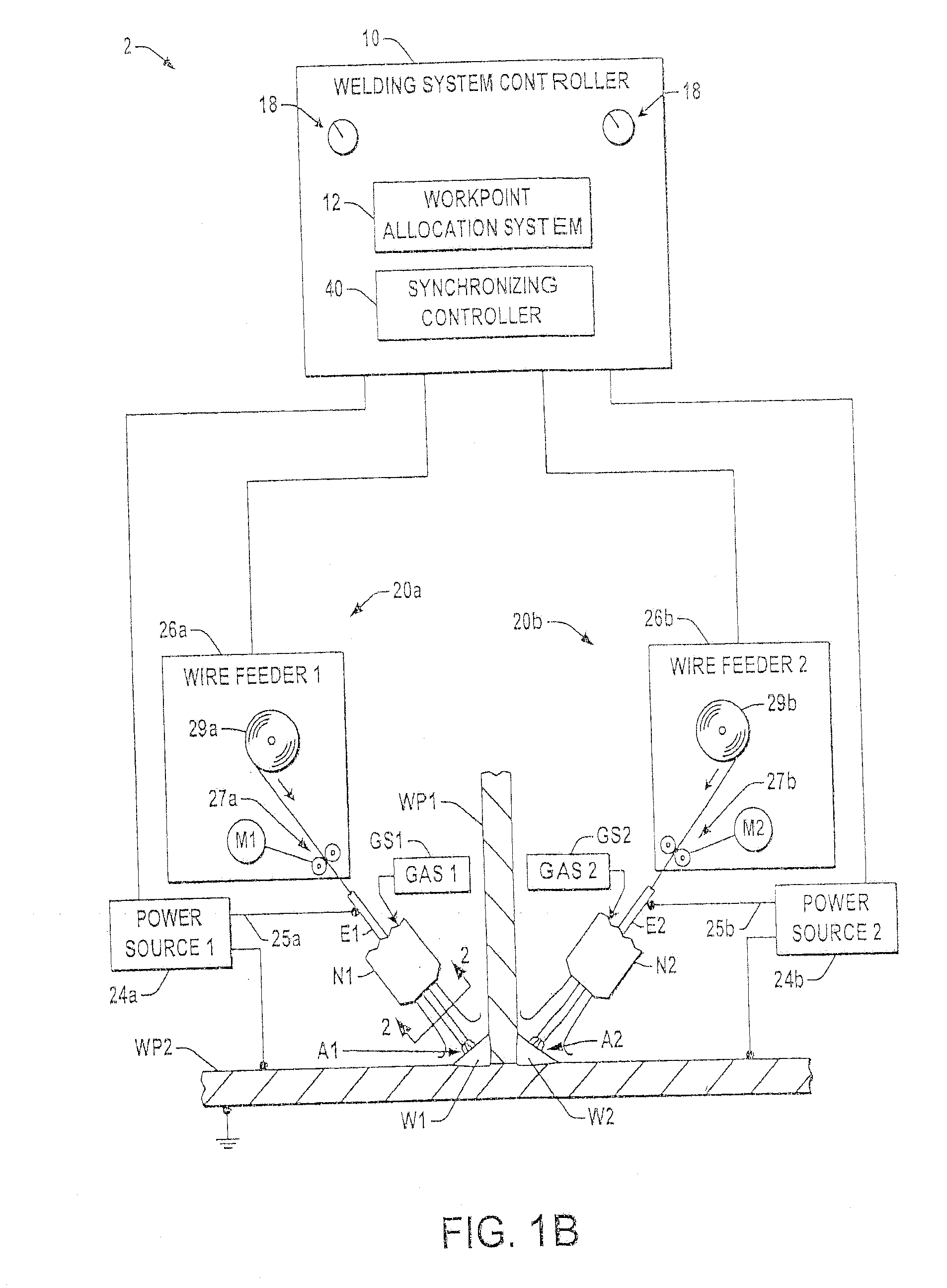

Welding methods and systems

A welding system is provided, in which two electrodes are directed at a joint between two work pieces and the electrodes are energized with DC pulse or AC welding waveforms at a controlled waveform phase angle. The systems include a synchronizing controller to synchronize the welding waveforms, and a work point allocation system provides one or more work point values to the welding machines to provide synergic control of the welding according to a user selected system work point value or parameter. The systems and methods further provide for synchronized work point value modulation for the opposite sides of a dual fillet weld. The system and method further provide a high energy heat source that directs intense heat at a portion of the weld joint to improve weld penetration.

Owner:LINCOLN GLOBAL INC

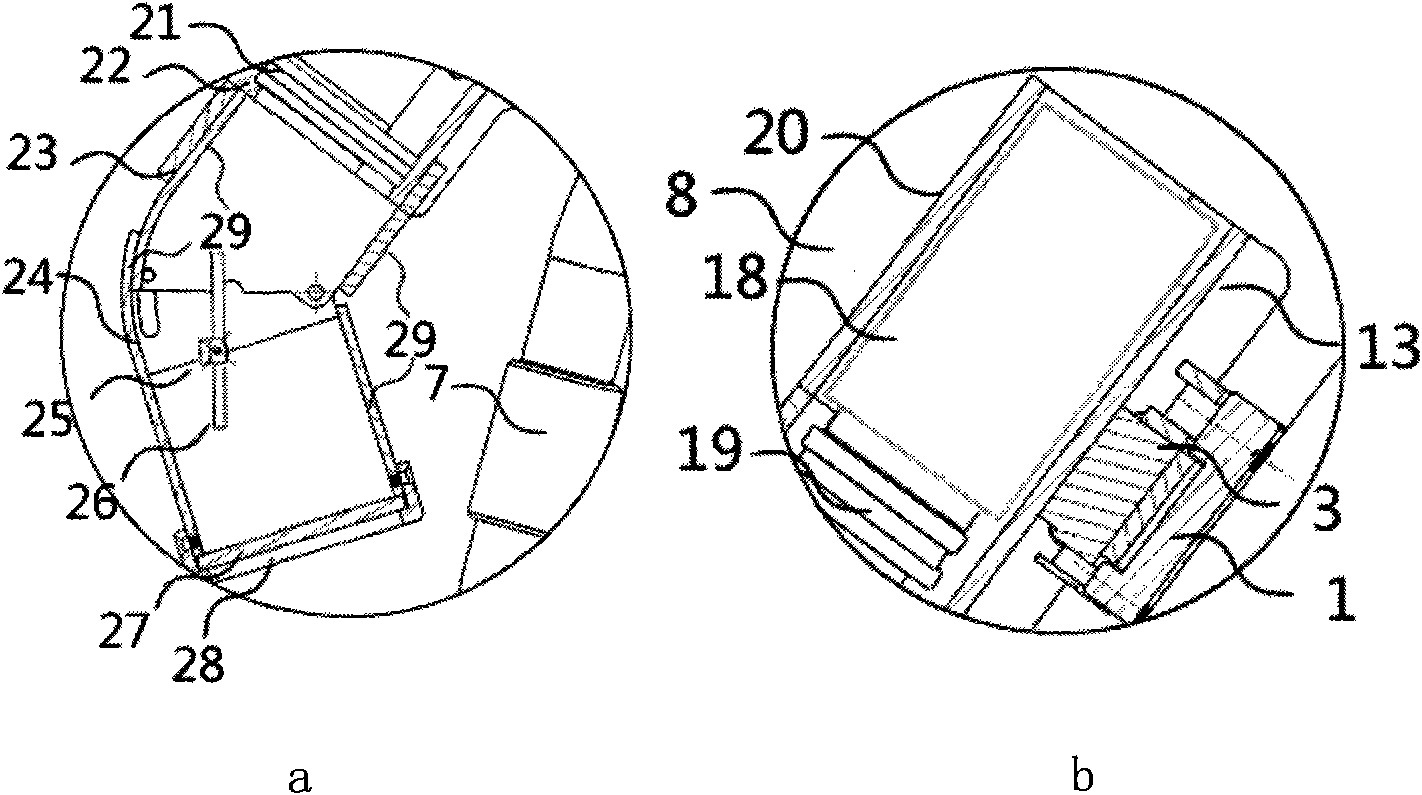

Backfill type friction stir welding method and device

The invention relates to a backfill type friction stir welding method and device. According to the technical scheme, a novel friction stir spot welding device is used for achieving backfill type keyhole-free welding. The method comprises that a stir head is pushed down to press a part to be machined, the position of an outer sleeve of the stir head is invariant, a shaft shoulder rotates at a high speed to stab into a welding bead, a stir needle moves far away from the welding bead direction, the shaft shoulder begins to perform welding after stabbing for certain depth into the welding bead, softened metal flows into space formed by the welding bead, the stir needle and the shaft shoulder, the shaft shoulder is withdrawn from the part to be welded, the stir needle pushes the metal in the space to press the part to be welded, and accordingly, a key hole is filled, welding is completed, and the stir head is unloaded and withdrawn. Compared with the prior art, the backfill type friction stir welding method and device have the advantages that uneven welding beads caused by key holes are eliminated, and the welding penetration depth evenness is guaranteed during discontinuous welding beads.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

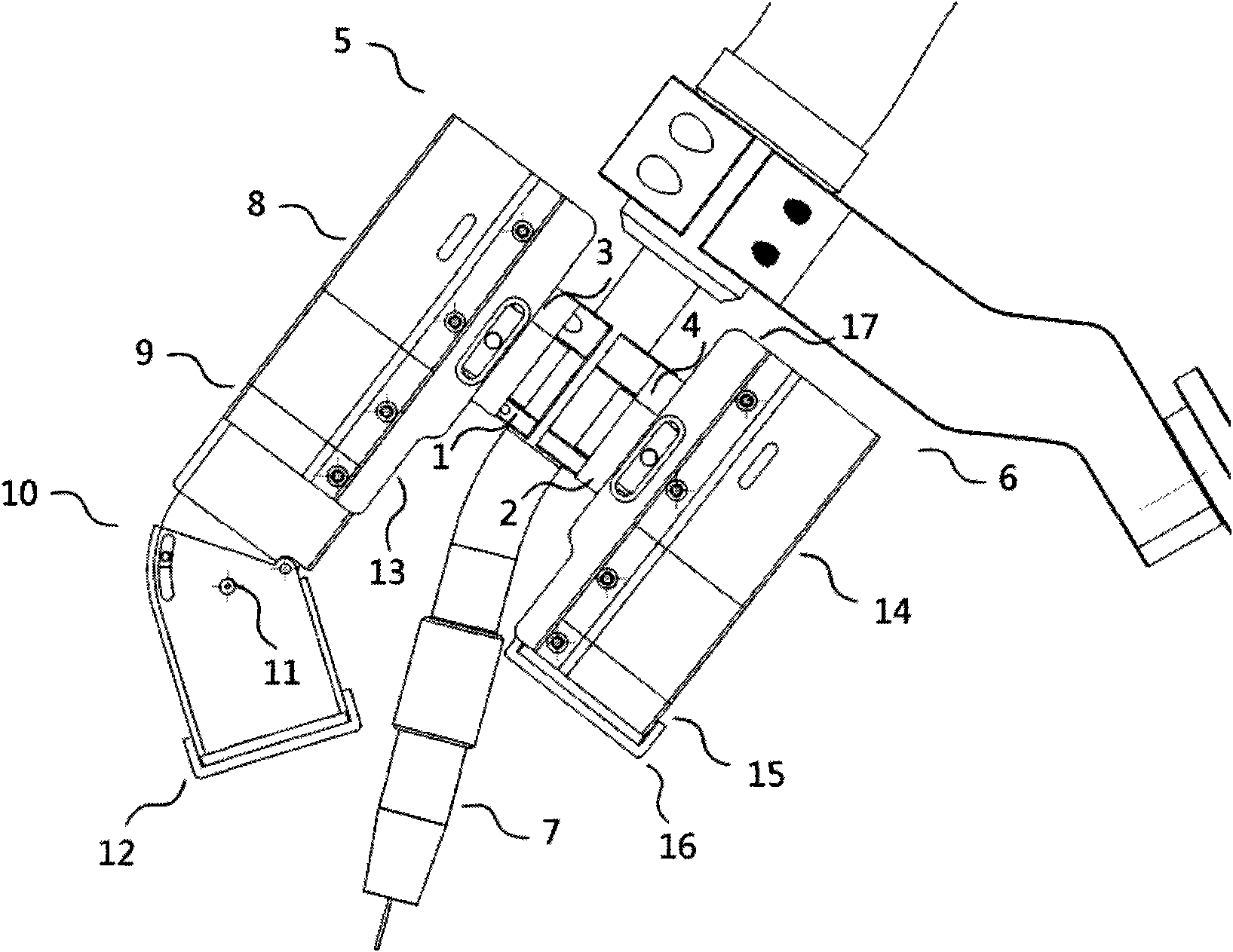

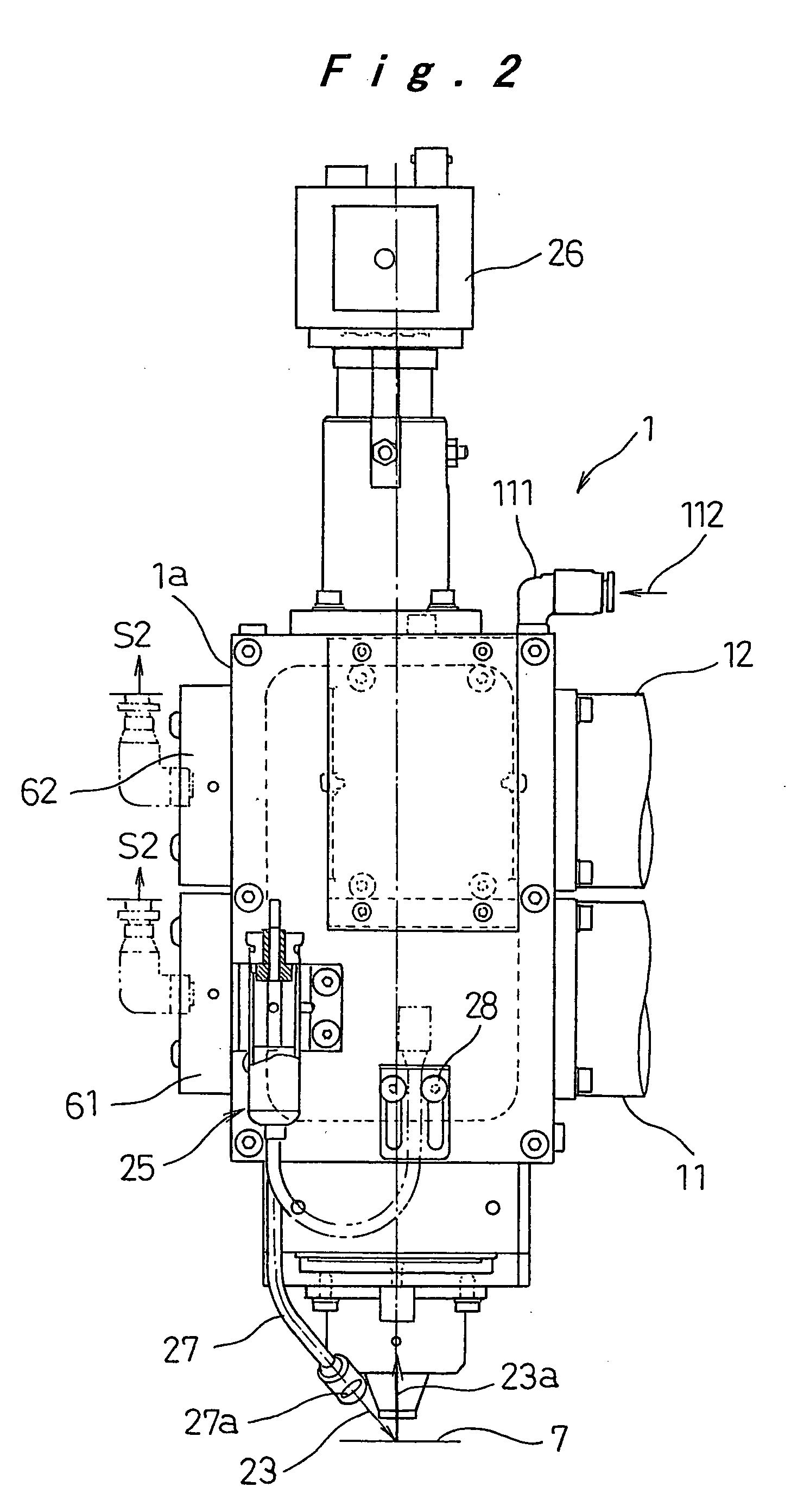

Robot MIG welding binocular vision sensing system

InactiveCN101612736AReduce bearing pressureImprove versatilityPrintersProjectorsComputer moduleHearth

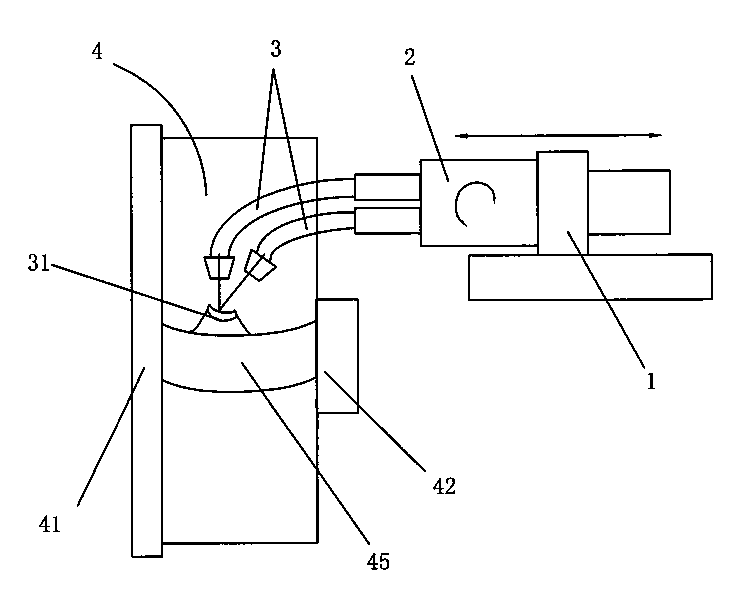

A robot MIG welding binocular vision sensing system in the technical field of automated welding equipment comprises two welding torch fixed sleeves, two sensor sleeve connection blocks, a furnace hearth observation module and a seam tracking module; wherein the furnace hearth observation module and the seam tracking module are respectively fixed on the respective welding torch fixed sleeve and are respectively connected with the two sensor sleeve connection blocks, the sensor sleeve connection blocks are arranged on the welding torch fixed sleeves in a rotary way, and the welding torch fixed sleeves are fixedly connected with an MIG welding torch. The invention obtains clear images by adjusting the angle between a sensor main module and the welding torch as well as the angle between a reflector assembly and the sensor main module, and ensures the welding quality by weld penetration control.

Owner:SHANGHAI JIAO TONG UNIV

Composite welding method of ultrasound wave and non-melt pole electrical arc

InactiveCN101219499AImprove straightnessImproved arc stabilityElectrode vibration holdersTransformerEngineering

The invention discloses a welding method of compounding ultrasonic and nonconsumable electrode voltaic arc. Under the welding condition of protection of nonconsumable electrode gas, the ultrasonic is conducted into welding arc through the conductive electrode and the voltaic arc obviously contracts after ultrasound is carried on. The invention not only has the advantages of stable welding process and high welding and forming quality which normal TIG welding has, but also can improve weld penetration of single-pass welding and therefore the method can realize high quality welding under normal welding condition. The invention converts the high frequency electrical signals of ultrasound supply into mechanical vibration through an energy conversion device and the mechanical vibration is amplified by an amplitude transformer, and then is transmitted to an electrode studded in the amplitude transformer so as to generate supersonic vibration of corresponding frequency on the electrode. The input power of the ultrasound can be adjusted at will between 1W to 1000W and then welding is carried out by the method of normal gas metal arc welding. When voltaic arc is applied to processing pieces, the energy is concentrated, thereby effectively improving utilization ratio of voltaic arc during welding.

Owner:HARBIN INST OF TECH

Non-penetration laser welding apparatus and non-penetration laser welding method

InactiveCN104002044AAdaptableImprove anti-interference abilityLaser beam welding apparatusControl systemLaser light

The invention relates to a non-penetration laser welding apparatus. The non-penetration laser welding apparatus comprises a laser welding head (1), a transmitting optical fiber (2), a laser (3), a feedback control system (6), a computer (7) and an infrared temperature acquisition system (8); the non-penetration laser welding apparatus is characterized in that the laser light output by the laser (3) is transmitted to the laser welding head (1) by virtue of the optical fiber (2), a laser beam (4) focused by a focusing lens in the welding head acts on the surface of a welding material (5) to weld the material, the infrared temperature acquisition system (8) is used for capturing the temperature of the back surface of a weld joint in the welding process online, obtaining the present welding penetration condition of the material and transferring control information to the feedback control system (6), and the feedback control system (6) is used for controlling the laser (3) to adjust the power of the laser light in real time. The non-penetration laser welding apparatus is capable of performing accurate control on non-penetration welding adopted in industries so that the welded joint can be protected against non-fusion and back burn; the non-penetration laser welding apparatus is high in practicability.

Owner:HUNAN UNIV

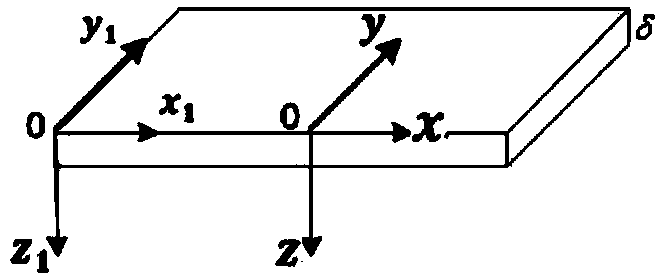

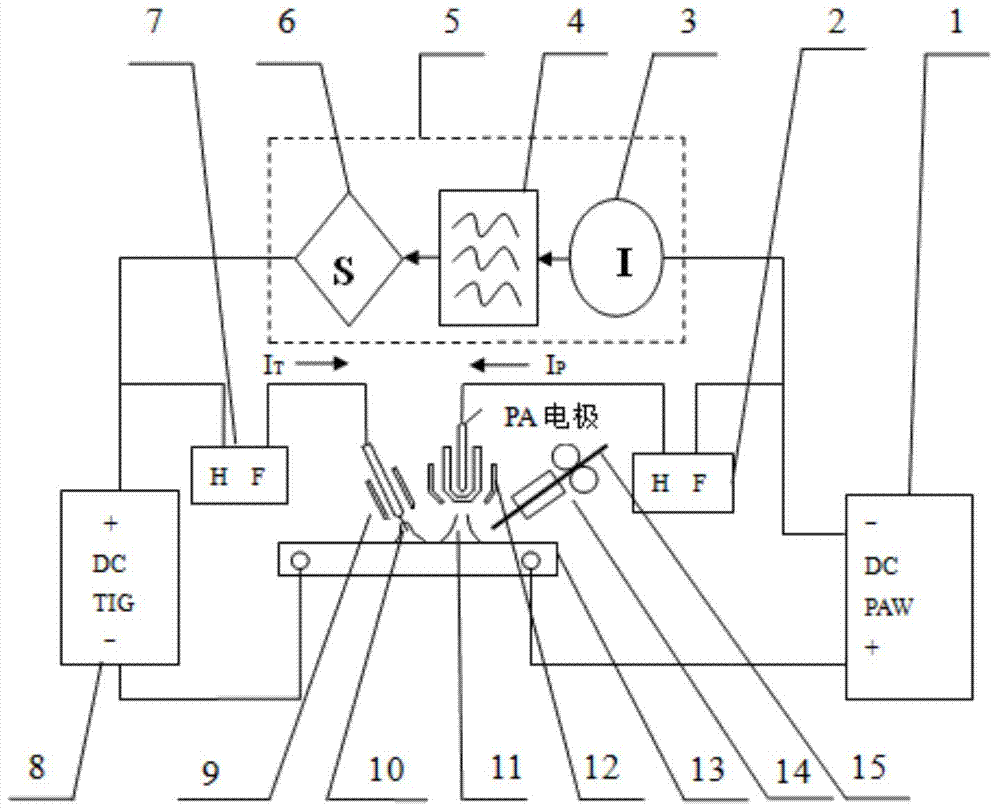

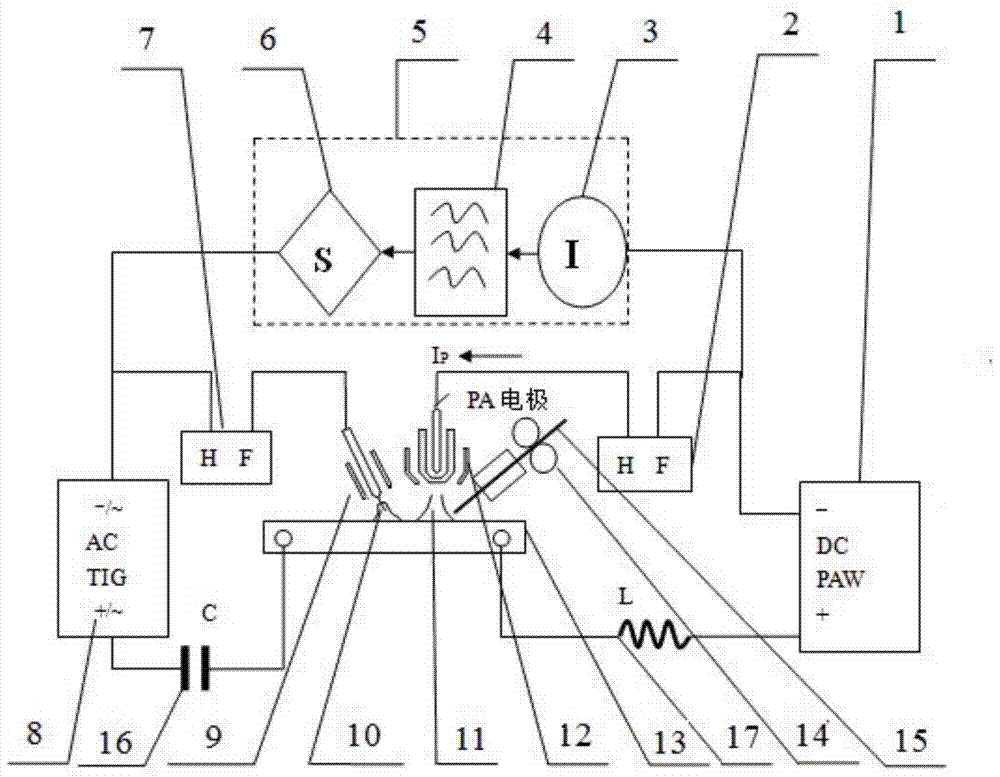

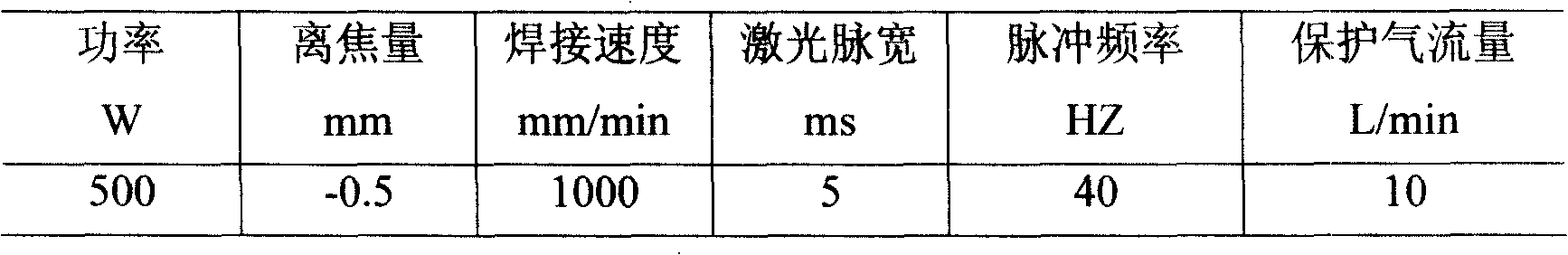

Aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control

ActiveCN103567652AAchieve cleanupRealize DC piercing plasma arc weldingArc welding apparatusPlasma welding apparatusHalf wavePlasma arc welding

The invention aims to provide an aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control. A tungsten electrode argon arc welding gun is exerted on one side of a plasma arc welding gun, in the welding process, the tungsten electrode argon arc welding gun is utilized to remove oxidation films on the surface of aluminum alloy in front of the direct current plasma welding gun, and the direct current plasma welding gun is utilized to conduct welding behind the tungsten electrode argon arc welding gun. In order to avoid electromagnetic interference between plasma arcs and tungsten electrode argon arcs in the welding process, when a plasma arc current is in a pulse basic value pilot arc stage, a pulse signal controller is triggered, and a tungsten electrode argon arc current is adjusted to be in a negative half wave crest value for removing the oxidation films on the surface of the aluminum alloy; when the plasma arc current is in a pulse crest value welding stage, the pulse signal controller is utilized to adjust the tungsten electrode argon arc current to be in pulse basic value output, and the steps are repeatedly executed in this way. According to the method, the current pulse wave form of the tungsten electrode argon arcs and the current pulse wave form of a plasma arc power supply are reasonably adjusted, the effect of cleaning the oxidation films on the surface of the aluminum alloy and weld penetration are controlled, and therefore weld formation is guaranteed, tungsten electrode burning losses are reduced, and welding efficiency is improved.

Owner:哈尔滨哈船特装科技发展有限公司

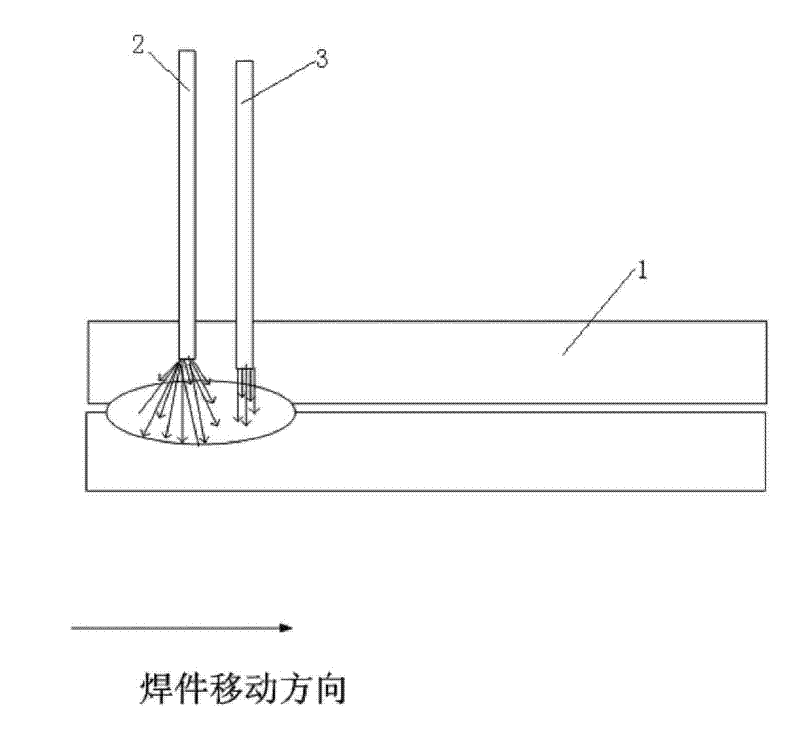

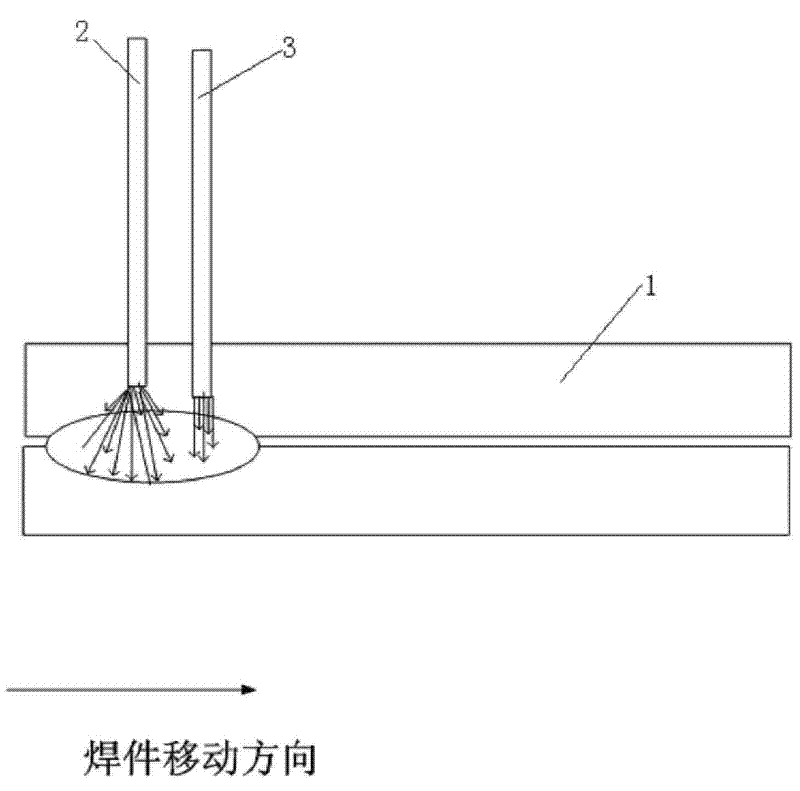

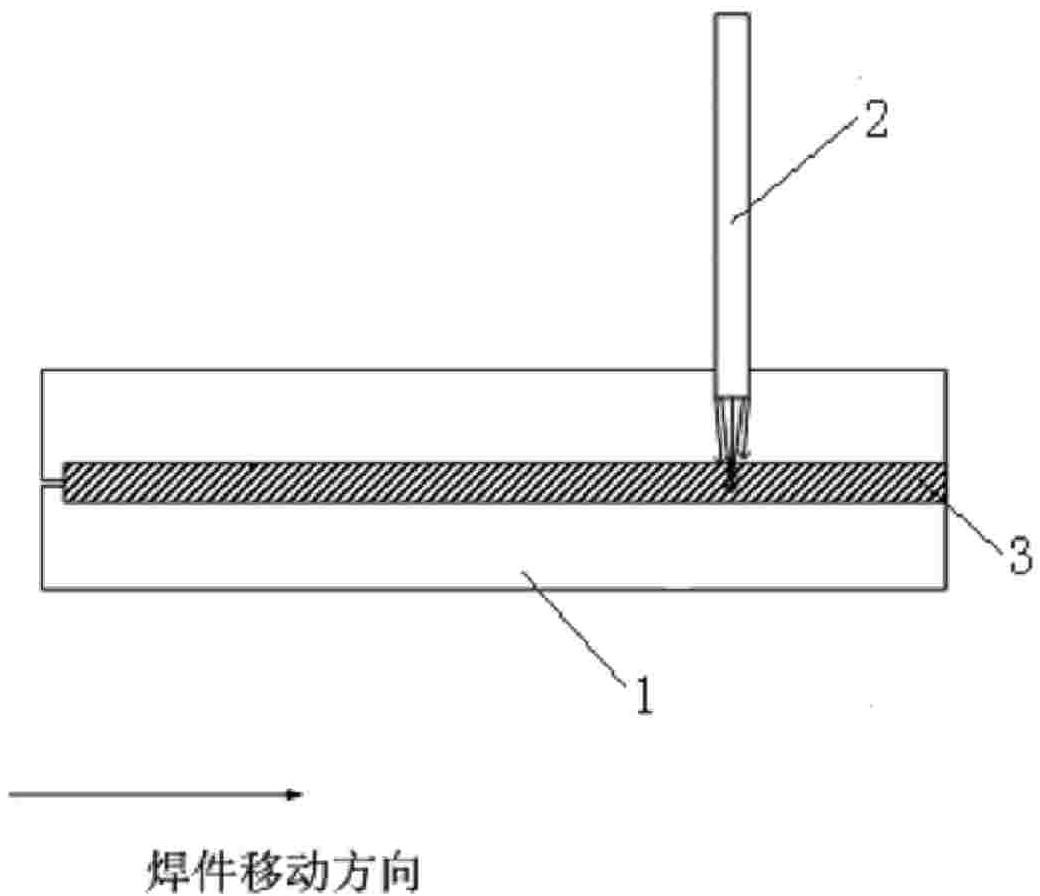

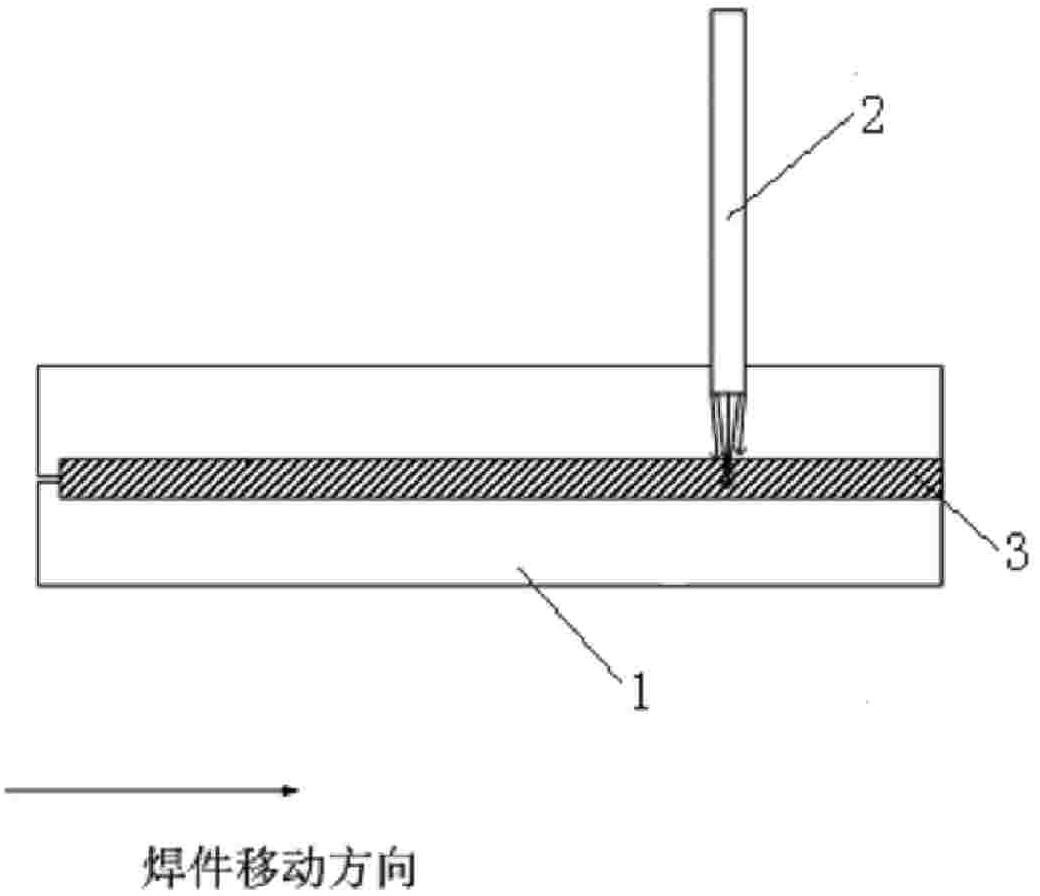

Hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser

The invention relates to a hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser, comprising the following steps: firstly fixing a variable-polarity square-wave tungsten electrode argon arc welding gun and a laser beam transmitting gun, providing a workpiece moving at a constant speed, forming a mode of preposing the variable-polarity square-wave tungsten electrode argon arc welding gun, utilizing the electric arc of variable-polarity square-wave tungsten electrode argon arc welding to remove impurities such as oxide films and the like at the surface zone of the welding workpiece, and leading the workpiece to be in a high-temperature melting state; and then leading laser beams to radiate a welded part, thus deepening the depth of fusion in variable-polarity square-wave tungsten electrode argon arc welding and finishing the welding. By utilizing the welding method adopted by the invention, the reflectivity of metal to the laser can be reduced, and the absorptivity of the metal to the laser energy is improved, so that the effective heating depth of the laser is improved, the depth of fusion of welding seams is enlarged, and the width of the welding seams and the width of heat affected zones are effectively reduced, thus finally a welding piece with deeper depth of fusion, very small heat affected zones and attractive appearance can be obtained.

Owner:CRRC QINGDAO SIFANG CO LTD

Aluminum alloy laser welding method

InactiveCN102079013AImprove absorption rateImprove organizationLaser beam welding apparatusHeat-affected zoneYttrium

The invention relates to an aluminum alloy laser welding method. The method comprises the following steps: firstly carrying out nanometer metal oxide pretreatment on a part to be welded, namely, coating or spraying a nanometer metal oxide layer on the welding bead of an aluminum alloy weldment, wherein the nanometre metal oxide is nanometer yttrium oxide preferably; and then carrying out laser welding. By utilizing the method, the absorptivity of the aluminum alloy surface for laser can be greatly increased up to about 90%, thereby increasing the effective heating depth of the laser, deepening the weld penetration of a welding seam, effectively decreasing the width of the welding seam and the width of a thermal influence area, and improving the structure of the welding seam metal; the crystalline grain of an aluminum alloy welding joint under the action of the nanometre metal oxide can be refined, and finally the weld penetration can be relatively deep. Moreover, the thermal influence area is very small, and the weldment is beautiful in appearance and has fine inner structures.

Owner:CRRC QINGDAO SIFANG CO LTD

Hybrid laser processing method and hybrid laser torch used in the method

InactiveUS20060157457A1Reduce glareEasy and correct visual recognitionLaser beam welding apparatusLaser processingMetallic materials

First and second laser beams from two different laser systems are superposed and irradiated as a hybrid laser beam on a workpiece. The effective spot size of second laser beam on the workpiece is smaller than that of the first laser beam. Thereby, a workpiece of a metal material having high reflectivity is processed with a sufficient weld penetration depth and width, and at high speed.

Owner:PANASONIC CORP

Laser welding with filler wire method of aluminum alloy T-type shapes for boat

InactiveCN101007370AReduced precision requirementsImprove performanceWelding/soldering/cutting articlesLaser beam welding apparatusLight beamMaterials processing

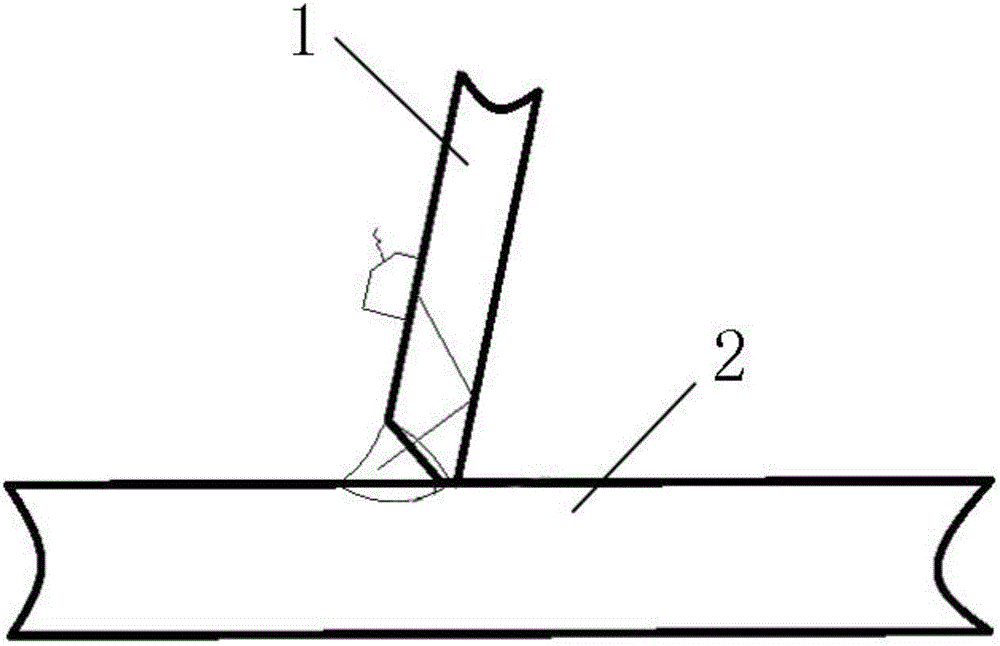

The invention is a laser filler wire welding method of marine aluminum alloy T-shaped section bar which belongs to laser materials processing technology field. Fix the vertical plate (5) and horizontal plate (4) rigidly in 90degreebefore welding, the laser beam (2) incidents obliquely in the angle of 30degree-45degreewith horizontal plate (4), welding wire (1), laser beam (2) and nozzle (3) are in same surface and in 30 degree to 60 degreeeach other, the incident laser beam and the working point of workpiece are on vertical board and have a slippage of 0.3 to 0.8mm on the horizontal plate surface, the laser beam and the photoproduced plasma body melts welding wire and generates deep weld penetration between vertical plate (5) and horizontal plate (4), it realizes the welding and shaping of marine aluminum alloy T-shaped section bar through twice welding. The method improves the stability of welding process, process is simple, can create a variety of marine aluminum T-shaped section bar, the prepared aluminum alloy T-shaped section bar has small deformation, stable dimension and excellent overall performance.

Owner:BEIJING UNIV OF TECH

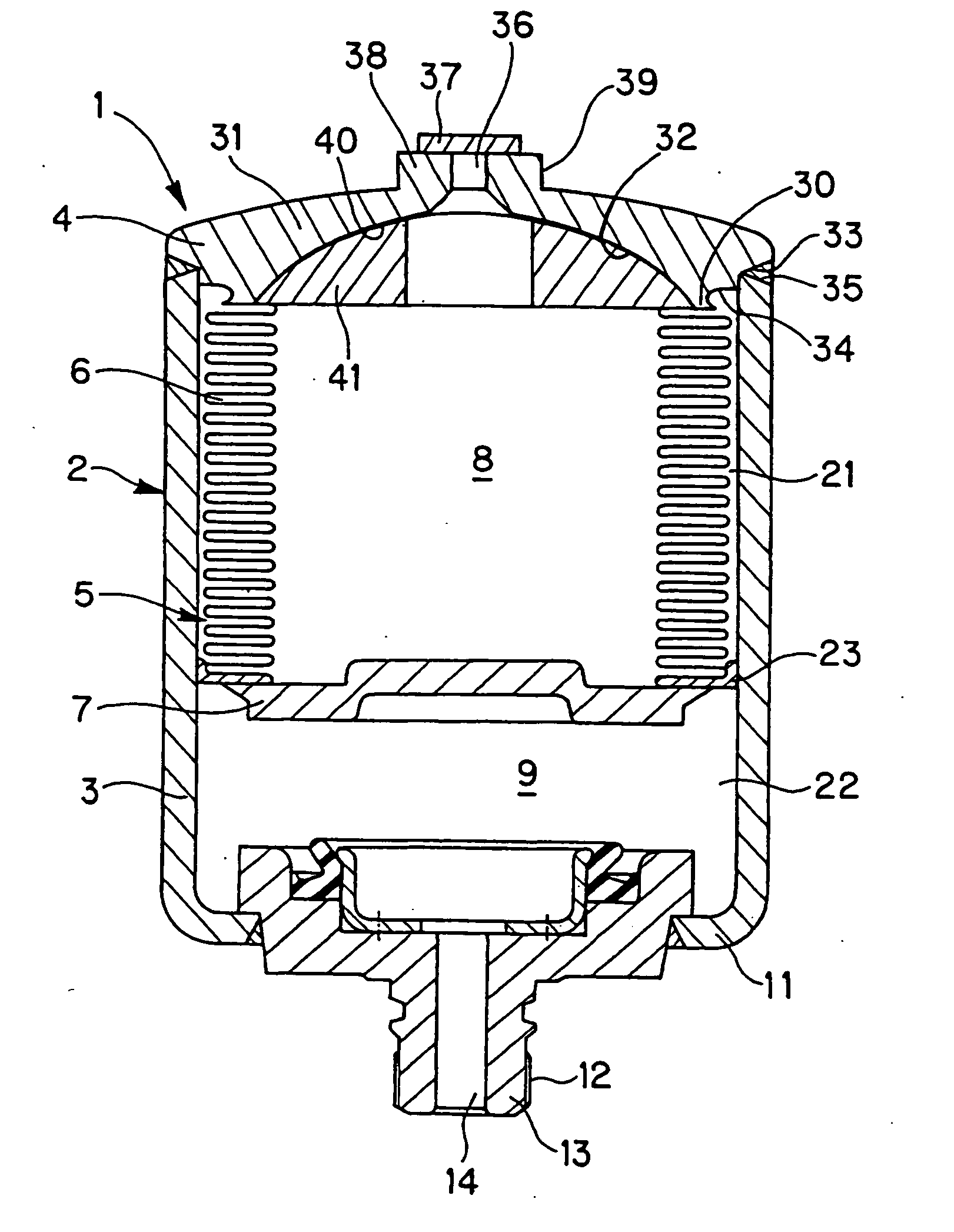

Accumulator

InactiveUS20070102052A1Made smallSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

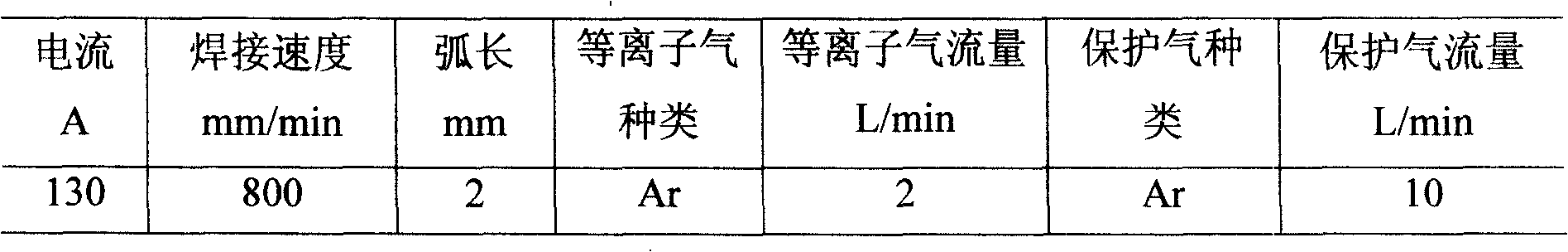

Niobium based superconducting radio frequency(SCRF) cavities comprising niobium components joined by laser welding, method and apparatus for manufacturing such cavities

InactiveUS20120094839A1Improve performanceIncrease costWelding/cutting auxillary devicesSuperconductor detailsSurface finishAlloy

Niobium or its alloy based Superconducting Radio Frequency (SCRF) Cavities involving atleast one laser beam welded components in the SCRF cavity welded from inside surface of the wall of cavity directed to achieving more than half the thickness to full depth penetration with minimum HAZ, minimizing distortion and shrinkage. The method ensures improved weld quality and surface finish substantially free of any weld defects. Also disclosed is the welding nozzle system and welding rigs adapted to facilitate such laser welding of the Niobium or its alloy based Superconducting Radio Frequency (SCRF) Cavities. The invention is thus directed to enhancing productivity, ensuring consistent quality and reliability, enhanced weld penetration with minimum HAZ, smooth finish of weld joints at possible reduced costs.

Owner:SEC DEPT OF ATOMIC ENERGY

TIG welding method of titanium alloy and pure aluminum plates

InactiveCN102896406AReduce processingReduce welding costsArc welding apparatusWelding/cutting media/materialsActive agentTitanium alloy

The invention provides a TIG (tungsten arc inert gas) welding method of a titanium alloy and pure aluminum plates. The method adopts a welding wire at specific ratio, an active agent is coated on the welding wire, argon tungsten-arc welding to titanium and the pure aluminum plates is performed, not only pre-alumetizing treatment related in a vacuum diffusion welding technology is avoided, but also welding cost in a vacuum environment or a laser condition is reduced. Filling material and pure aluminum plate parent metal are sufficiently molten and mixed during a welding process and then are solidified to form a welding line, and an obvious fusion area exists; a high-melting-point titanium alloy and a molten welding wire filling metal have mutual effect to form brazed connection, so that two metal liquid phase Ti and Al are prevented from being mixed, a large amount of fragile Ti-Al intermetallic compound is prevented from being produced, and simultaneously, the active agent on the surface of the welding wire has an effect of welding penetration increasing, so that the an artistic welding connector without cracks is formed through the welding line. The welding method has the advantages that production efficiency is improved, a performance of the connector is improved, and the welding method is convenient to operate.

Owner:夏雨

Large tank singe-face-weld double-face-forming method and weld joint forming pad

InactiveCN102489830AHigh technical levelReduce consumptionWelding accessoriesEngineeringWeld penetration

The invention provides a large tank singe-face-weld double-face-forming method, which comprises arranging a weld joint forming pad on the back face of a weld joint of a weld part, wherein the weld joint forming pad is provided with a weld joint forming groove with the shape matched with that of the weld joint; fixedly and tightly attaching the weld joint forming pad on the back face of the weld joint to enable the center of the weld joint to align at the center of the weld joint forming groove; welding the front face of the weld joint; using large weld current for weld penetration of a weld part at one step; and enabling a weld puddle to be cooled and solidified on the weld joint forming groove. Compared with a traditional double-face-weld method, the weld joint is formed by one step, weld quality is better, production efficiency is improved, and production cost is reduced.

Owner:CHONGQING POLYCOMP INT

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

Hybrid laser machining method and hybrid laser torch used therein

InactiveCN1785575AAvoid interferenceStrong penetrating powerActive medium materialLaser beam welding apparatusMetallic materialsOptoelectronics

The invention discloses a hybrid laser processing method and a hybrid laser head used in the method. Even for metal materials with high reflectivity, it is possible to weld with sufficient penetration depth and penetration width, and at a higher speed. The different first and second lasers from the two laser systems A and B are superimposed to form a mixed laser (6) and focused, if the second laser (5) and the first laser ( 3) The effective light spot sizes on the processed object (7) are respectively set to D2 and D1, so that D2 is smaller than D1, so that the processed object 7 is irradiated for processing, so as to achieve the above purpose.

Owner:PANASONIC CORP

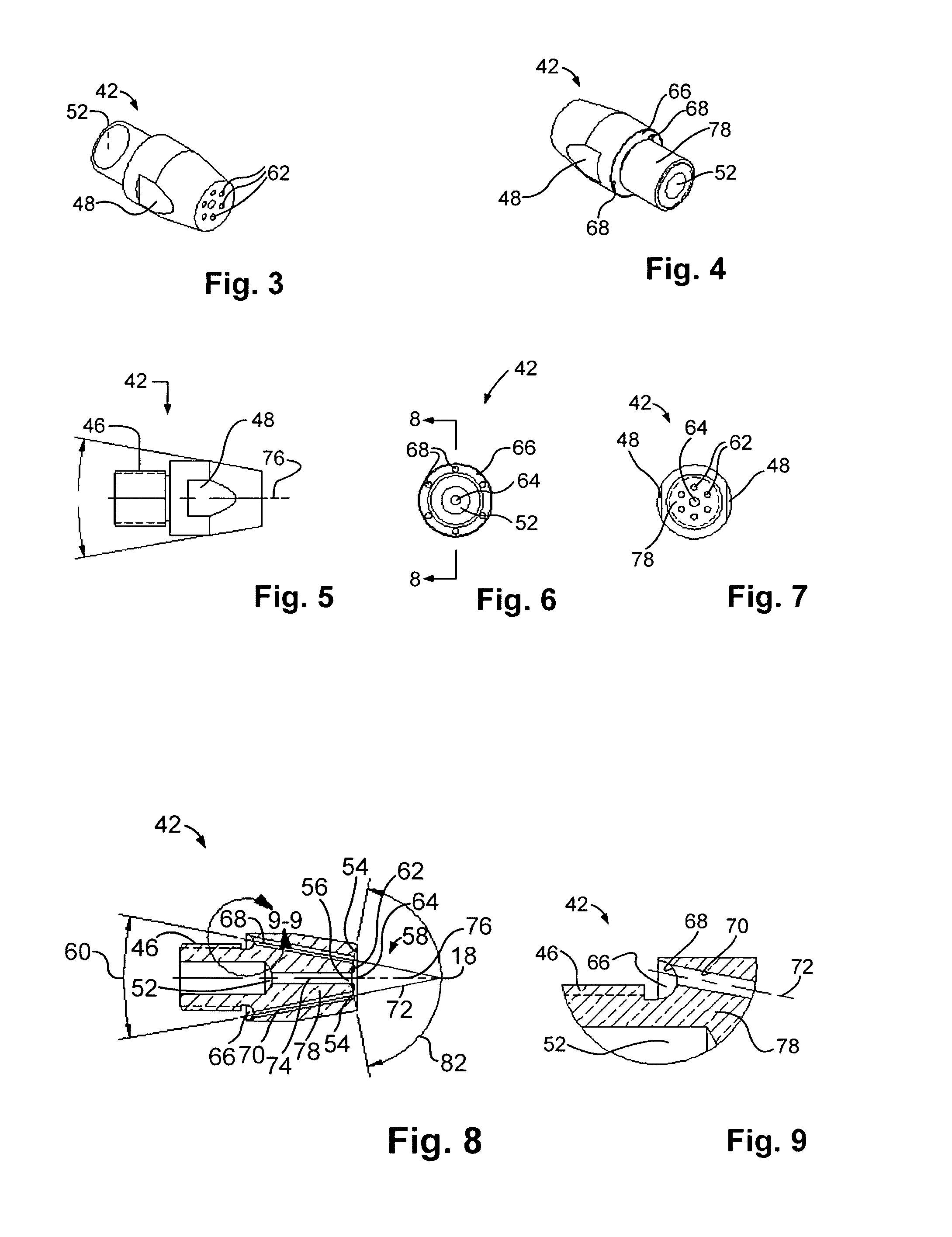

Method & apparatus for laser welding with mixed gas plasma suppression

ActiveUS20130233836A1Easy to solveIncrease weld penetrationLaser beam welding apparatusAngle of incidenceLight beam

Machinery and process are disclosed for laser welding. A beam is generated and focused on a discrete work surface, with a distinctive nozzle provided for delivering plasma suppression gas toward the surface. The nozzle has first and second inlets for receiving first and second sources of different plasma suppression gases, respectively. The nozzle has first and second outlets in fluid communication with the first and second inlets, respectively, together directing an externally mixed stream of the gases from the nozzle at an angle of incidence of 35 degrees to 50 degrees relative to the surface to impinge upon the generated plasma. The impinging stream intersects the beam at or above the surface, as the mixed gases are deflected across the beam. The invention saves on helium costs and demonstrably increases weld penetration.

Owner:DACKSON CHRISTOPHER

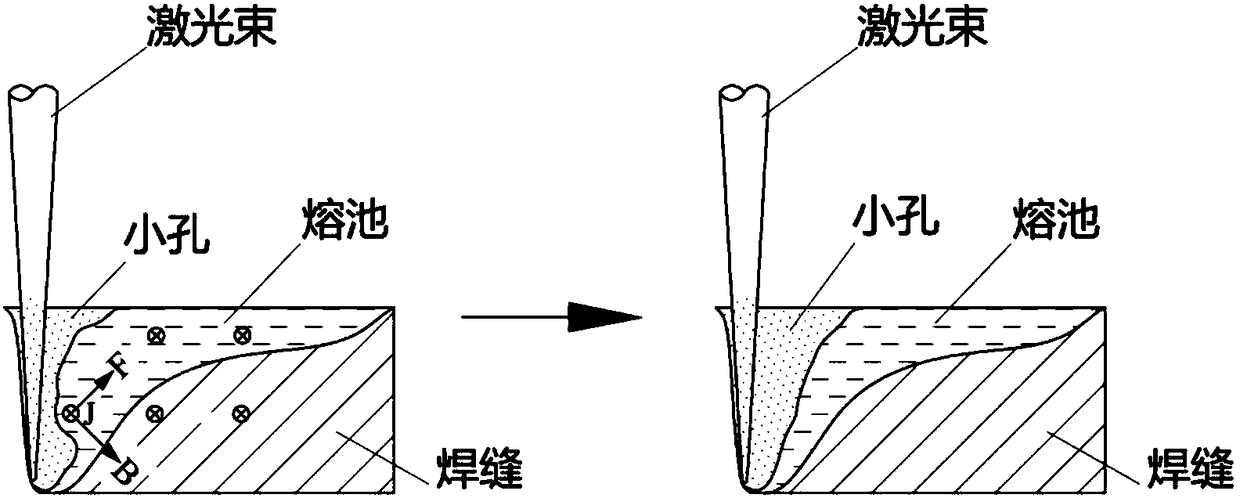

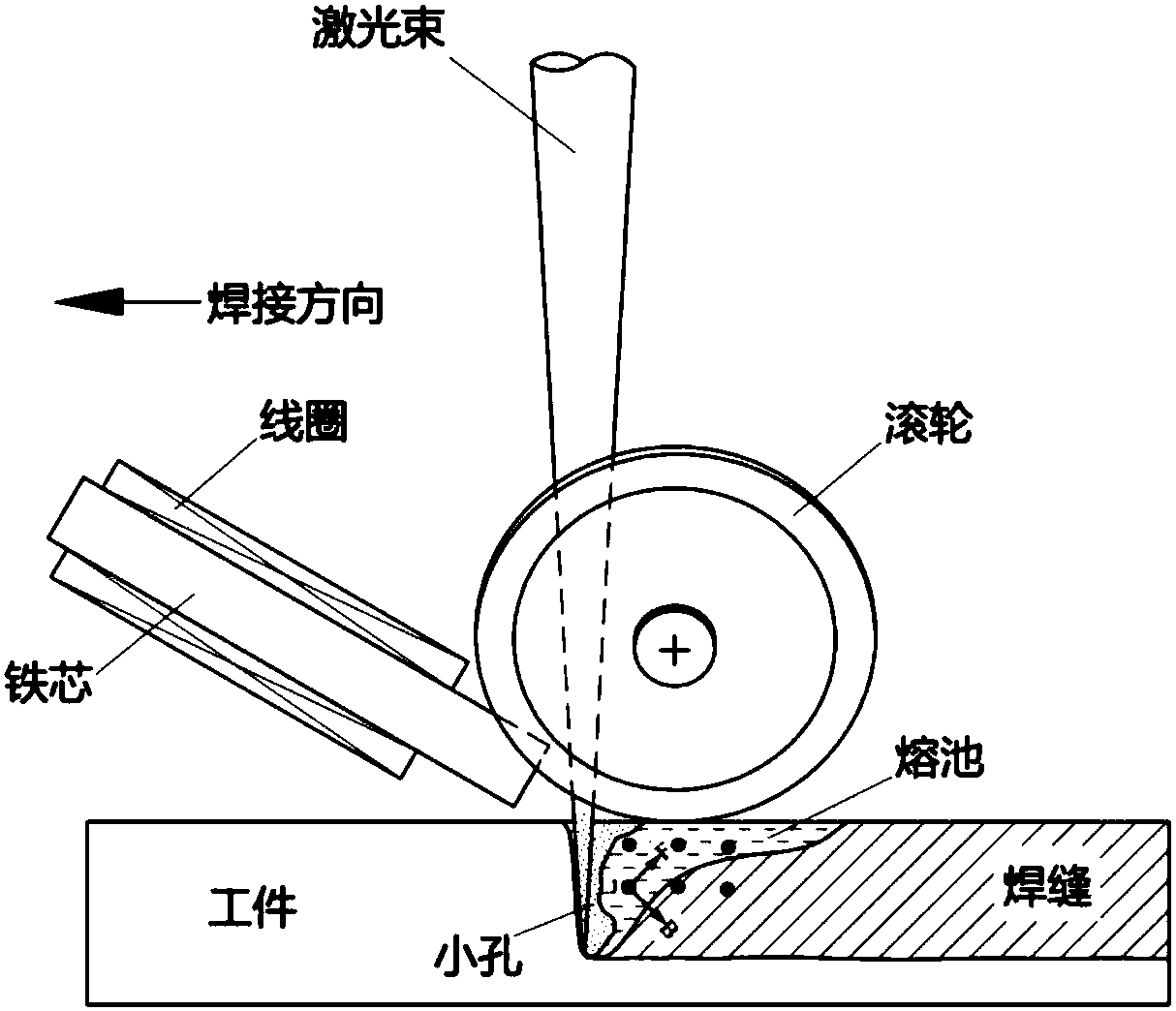

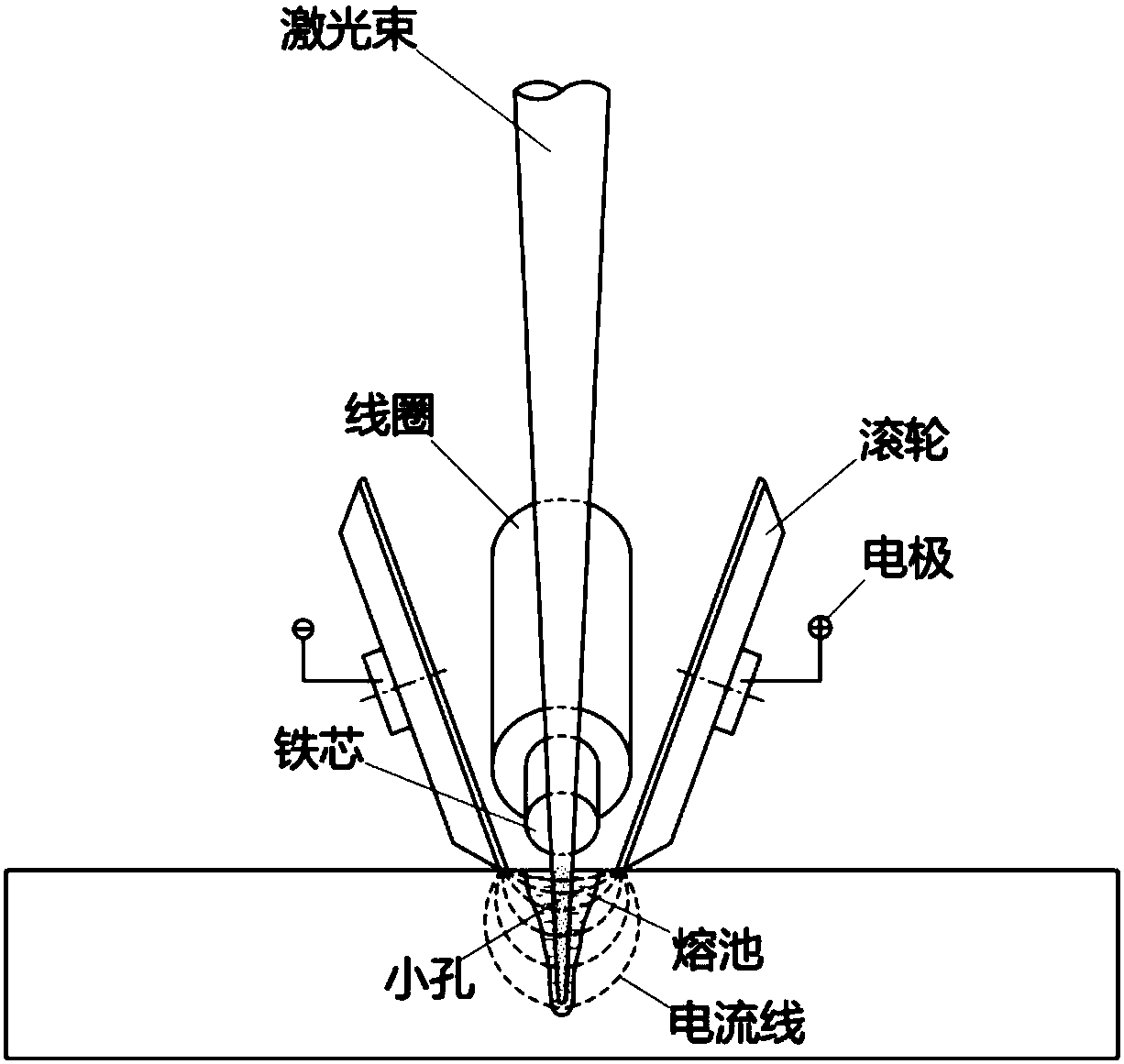

Lorentz-force-based laser welding pool control method

ActiveCN108247226AAffecting the physical laws of interactionImprove controllabilityLaser beam welding apparatusEngineeringStressed state

The invention provides a Lorentz-force-based laser welding pool control method and belongs to the technical field of laser processing. According to the method, current and a magnetic field which are perpendicular to each other are applied to a laser welding pool to generate Lorentz force following the ampere left-hand law in the welding pool; the stress state, the flow behavior and the solidification process of a melt are actively controlled through the Lorentz force. The backward Lorentz force is applied to the welding pool to make a welded tiny hole be deepened and stretched, so that metal vapor / plume in the tiny hole escape smoothly. A solution in the welding pool flows smoothly. The effects of increasing the weld penetration depth increase, improving the welding stability and optimizing welding formation are achieved. If AC or pulse wave modulation is conducted on parameters of the applied current and the applied magnetic field, the Lorentz force can have the effects of stirring, vibrating and directionally driving the solution in the welding pool. The adjustment functions of the weld microstructure and performance can be achieved while the welding defects such as pores, cracks, undercut and poor formation are controlled.

Owner:BEIJING UNIV OF TECH

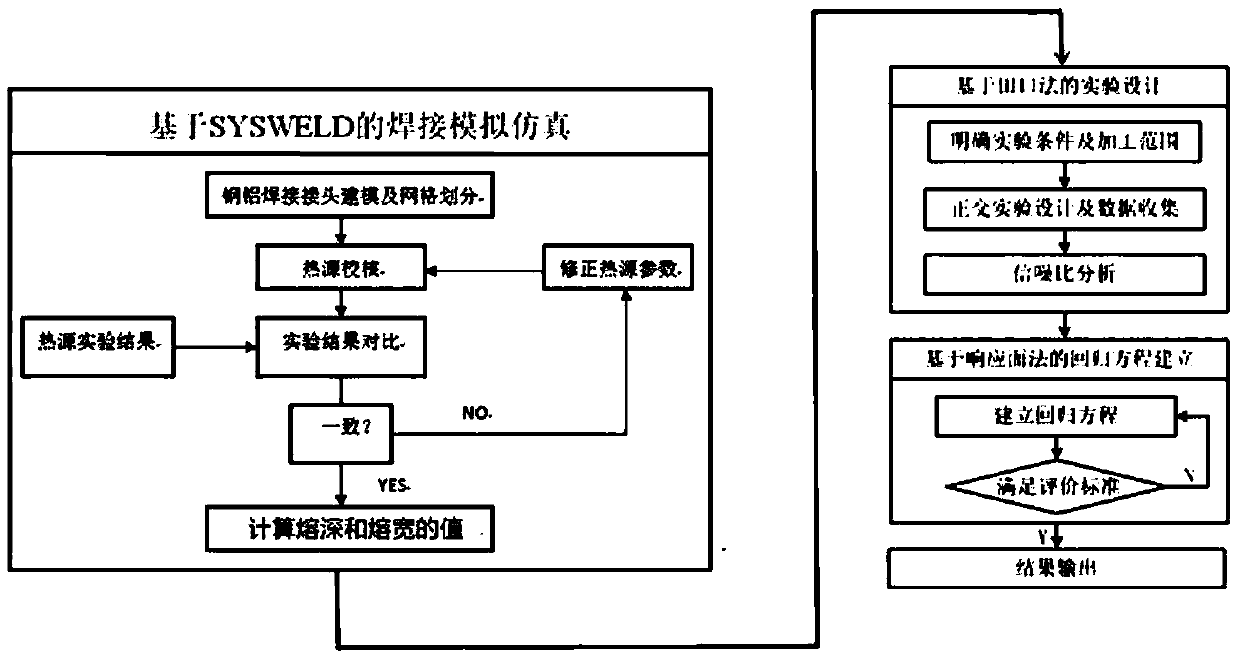

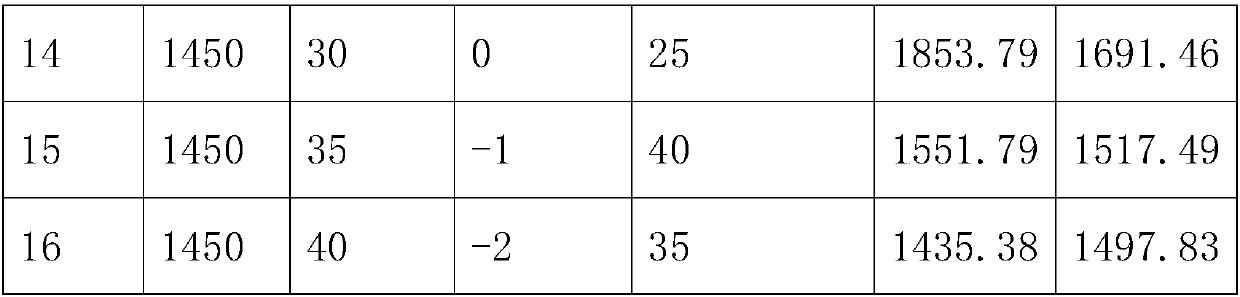

Steel-aluminum laser welding technique optimizing method

ActiveCN107598370AImprove forecast accuracyHigh-efficiency steel/aluminum laser welding performance with excellent predictive accuracyLaser beam welding apparatusFinite element analysis softwareWeld penetration

The invention discloses a steel-aluminum laser welding technique optimizing method. The steel-aluminum laser welding process is simulated through finite element analysis software SYSWELD, and a steel-aluminum dissimilar metal laser welding temperature field distribution cloud picture, the weld penetration depth and the weld width are obtained. The mapping relation between laser technique parameters and the weld penetration depths and the weld widths is built through the Taguchi experiment and a response surface method, accordingly, the weld penetration depths and the weld widths under the different technique parameters are predicted, the ideal weld penetration depth is obtained under the condition that the good weld formability is comprehensively considered, and thus the optimal laser welding technique parameters are obtained. The steel-aluminum laser welding technique optimizing method is applied to selecting of the steel-aluminum laser welding technique parameters, the difficulty that the steel-aluminum laser welding technique parameters have to be selected by means of rich experience of workers and a large number of experiments is overcome, thus, the large quantity of time and consumed materials are saved, selection of the technical parameters is easier and more reliable, the production efficiency is improved, and the production cost is saved.

Owner:WENZHOU UNIVERSITY

Ultrasonic flaw detection method of weld joint at U-shaped angle of rib of steel bridge plate unit

InactiveCN102721742AImprove fatigue strengthIncreased durabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringStructural engineering

The invention discloses an ultrasonic flaw detection method of a weld joint at a U-shaped angle of rib of a steel bridge plate unit. The method comprises the steps of: weld joint flaw detection: using a panel of the U-shaped angle of rib as a detection surface, and adopting an RB-2 test block as a reference sensitivity calibration block and adopting an angle probe of 2.5-5MHz and K1.5 to detect; weld penetration detection: respectively arranging grooves which are different in depths along the thickness direction on an 8mm thick steel plate, wherein the probe is 5MHz9*9K2.5 or 2.5MHz 13*13K2.5 during detection; placing the probe on a reference block to find the maximum reflective signal of each groove and record the equivalent dB values; and making a dB-weld penetration curve through relations between the equivalent dB values and dB values in the corresponding depths of the reference block to judge the actual penetration of the weld joint at the U-shaped angle of rib. The method provided by the invention solves the problems that near surface nondestructive detection is just performed on the U-shaped angle of rib of the steel bridge plate unit by using magnetic powder, and the flaws in the weld joint cannot be detected.

Owner:中铁宝桥(扬州)有限公司

Welding device for compounding ultrasonic focusing sound field with molten pole arc welding

InactiveCN101947696AStrong penetrating powerEasy to shapeArc welding apparatusNon-electric welding apparatusUltrasonic sensorTransformer

The invention provides a welding device for compounding an ultrasonic focusing sound field with molten pole arc welding for improving the energy density of ultrasonic, changing the arc shape and the energy density and realizing high-efficiency high-quality welding. The welding device comprises a molten pole welding wire, a conductive pole, an ultrasonic transducer, an axle center through hole ultrasonic amplitude transformer, a welding nozzle, a focusing surface, a welding arc, a workpiece to be welded, a welding power supply and an ultrasonic power supply, wherein the molten pole welding wire passes through the conductive pole and is in sliding contact with the conductive pole, the ultrasonic power supply is connected with the ultrasonic transducer through a cable, the ultrasonic transducer is connected with the ultrasonic amplitude transformer through a bolt, and the focusing surface is positioned at the lower end part of the ultrasonic amplitude transformer. The invention ensures that the arc is compressed to improve the arc energy density, increase weld penetration and improve weld formation. The invention can change the arc shape and the heat generation characteristic and the transition form of molten metal, realizes the high-efficiency high-quality welding, and enlarges the application range of the arc welding.

Owner:HARBIN INST OF TECH

Welding gun swinging device for vertical electrogas welder

ActiveCN102423827AStrong penetrating powerImprove mechanical propertiesArc welding apparatusLinear motionReciprocating motion

The invention provides a welding gun swinging device for a vertical electrogas welder, which comprises a horizontal sliding mechanism for leading a welding gun to carry out linear motion along the direction of a vertical weld seam and a serrated swinging mechanism for leading the welding gun to swing in a groove clearance of the vertical electrogas welder, wherein the serrated swinging mechanism on which the welding gun is mounted is arranged on the horizontal sliding mechanism. Thus, the invention has the beneficial effects that a welding electric arc can move back and forth and be welded between a forming cushion plate on the back surface of the weld seam and a water-cooled forming slide block on the front surface of the weld seam as well as between a left side plate and a right side plate of a groove of the vertical electrogas welder; the side wall of the weld seam can be effectively ensured to be fully fused with a welding pool; the depth of a weld penetration can be remarkably increased, so that the mechanical property of the weld seam can be remarkably improved; and even if the melting speed of a welding wire is improved and the welding heat input is reduced, the side wall of the weld seam can still be fully fused with the welding pool to avoid interruption or mutation, even crack.

Owner:SHENZHEN RILAND IND

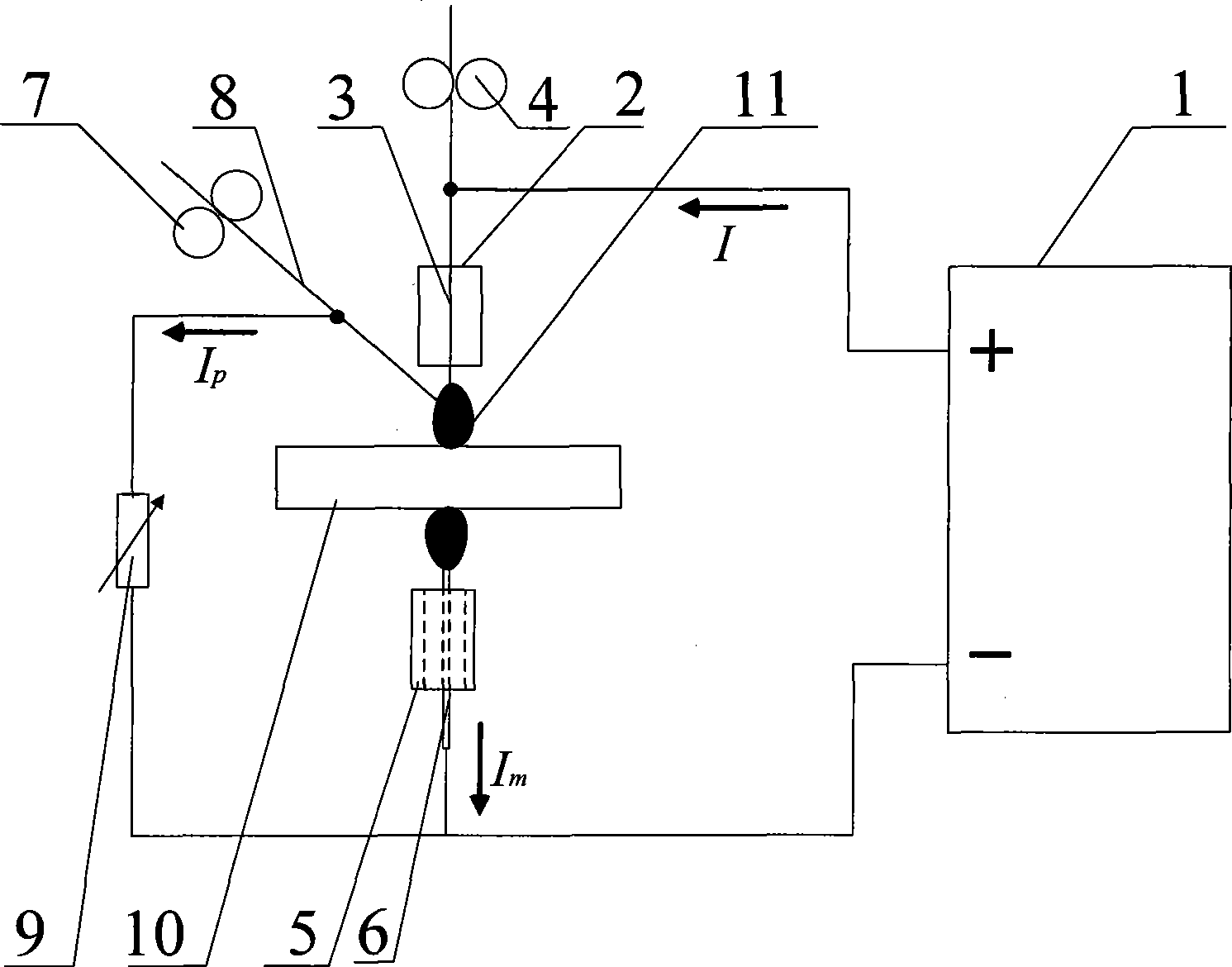

Two-sides arc-welding device based on welding wire diffluence and welding method thereof

InactiveCN101391331ASolve the prone to overburning of weldsSolve weld penetrationElectrode supporting devicesHeat-affected zoneWelding power supply

The invention provides a double-sided arc welding device and a welding device, which are based on welding wire current shunting. The invention comprises a power supply, a welding torch I, a welding torch II, a wire feeder and a slide rheostat. At least one of the welding torch I and the welding torch II is a non-melt electrode welding torch. The welding torch I and the welding torch II are symmetrically arranged on the upper and lower side of a workpiece. The electric connection ends of the welding torch I and the welding torch II are respectively connected with a positive electrode and a negative electrode of the power supply. The wire feeder deliver the filling welding wire to the electric arc or melting pool formed by the welding torch, and the filling welding wire is connected with the power supply through the slide rheostat. The adoption of the invention can solve the problems of shallow welding penetration depth, wide heat-affected zone and low deposition rate, and also solve the double-sided arc welding prone weaknesses of the welding seam being overheated and penetrated, electrodes being badly destroyed and narrow welding parameter range. The invention has distinct advantages that the welding penetration depth and the deposition rate are enhanced, the welding process is stabilized, and the quality of the welding seam is improved.

Owner:HARBIN ENG UNIV

Method for improving weld structure and performance of magnesium alloy

The invention provides a method for improving a weld structure and performance of a magnesium alloy, which comprises the following steps: firstly, placing an magnesium alloy welding plate in a heat treatment furnace to carry out stress relief annealing for a certain time at a temperature of 250 DEG C to 350 DEG C; then, polishing and flattening a weld joint by adopting abrasive paper for metallograph to enable the magnesium alloy welding plate to be at the same height with a base material; and heating the magnesium alloy to a certain temperature higher than a recrystallization temperature and carrying out hot rolling after carrying out heat preservation for a certain time. The method is generally suitable for weld penetration magnesium alloy plates such as an AZ31 magnesium alloy plate, an AZ61 magnesium alloy plate, an AZ80 magnesium alloy plate and the like. Intensity of the weld joint and a heat affected zone of the welded magnesium alloy plate is obviously lower than that of the base material. By a means of carrying out hot rolling after carrying out heat preservation at a certain temperature, the method can effectively improve intensity of a magnesium alloy welding part and enables tissues and performance of the weld joint, the heat affected zone and a base metal to be consistent.

Owner:CHONGQING UNIV

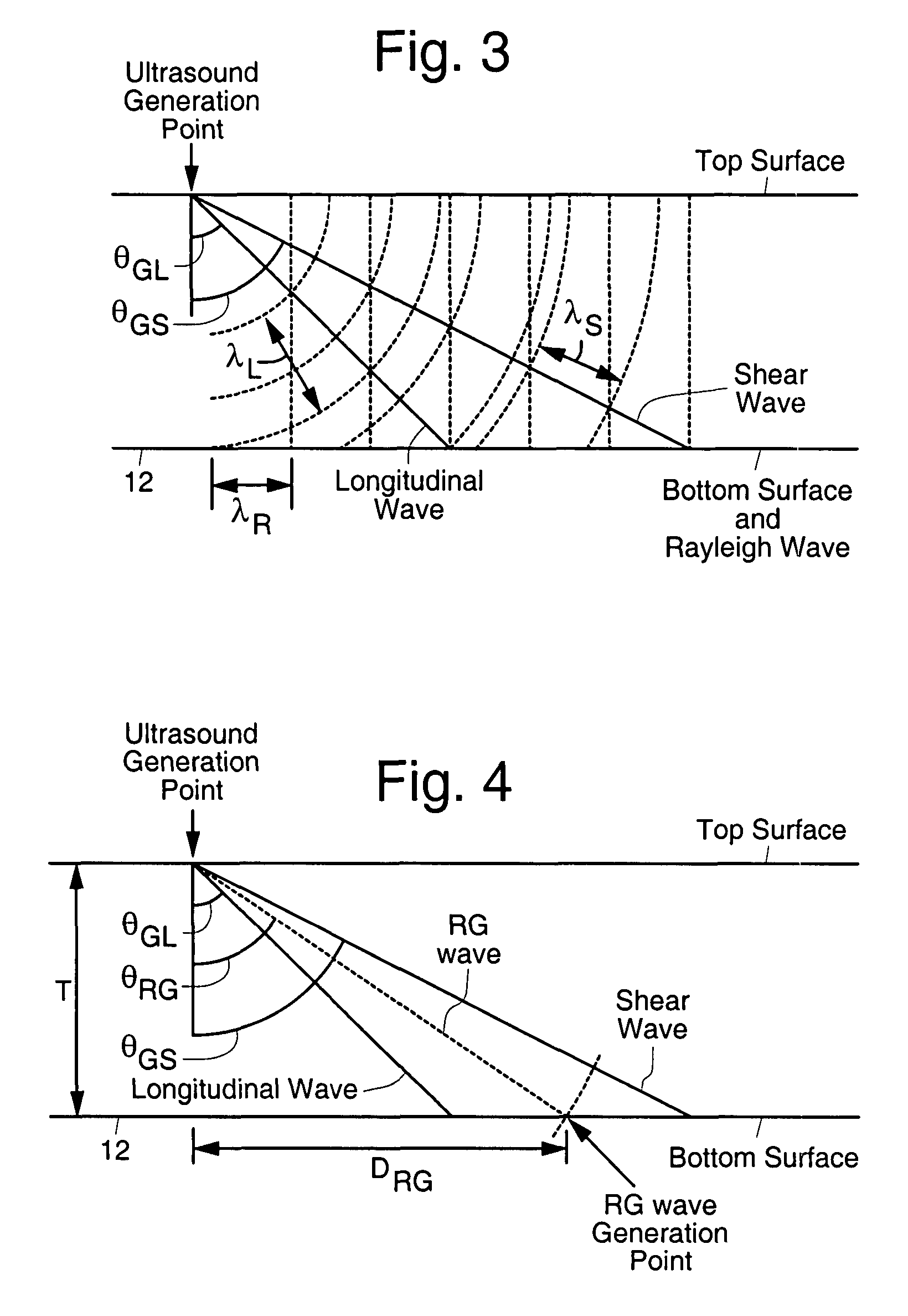

Ultrasound systems and method for measuring weld penetration depth in real time and off line

InactiveUS7762136B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorSonification

Disclosed are systems and methods that permit both real-time, and off-line, measurement of weld penetration depth. Exemplary systems and methods comprise an ultrasound source, such as a pulsed Nd:Yag laser, that simultaneously generates longitudinal and shear waves that radiate adjacent one side of a weld joining two specimens. An ultrasonic sensor, such as an electro-magnetic acoustic transducer or a piezo-electric transducer, capable of detecting shear and / or longitudinal waves, is disposed on an opposite side of the weld from the source. A signal processor is coupled to the sensor that processes time of flight signals for selected longitudinal or shear waves transmitted across the weld seam. The signal processor implements an algorithm that computes the weld penetration depth from the time of flight signals.

Owner:GEORGIA TECH RES CORP

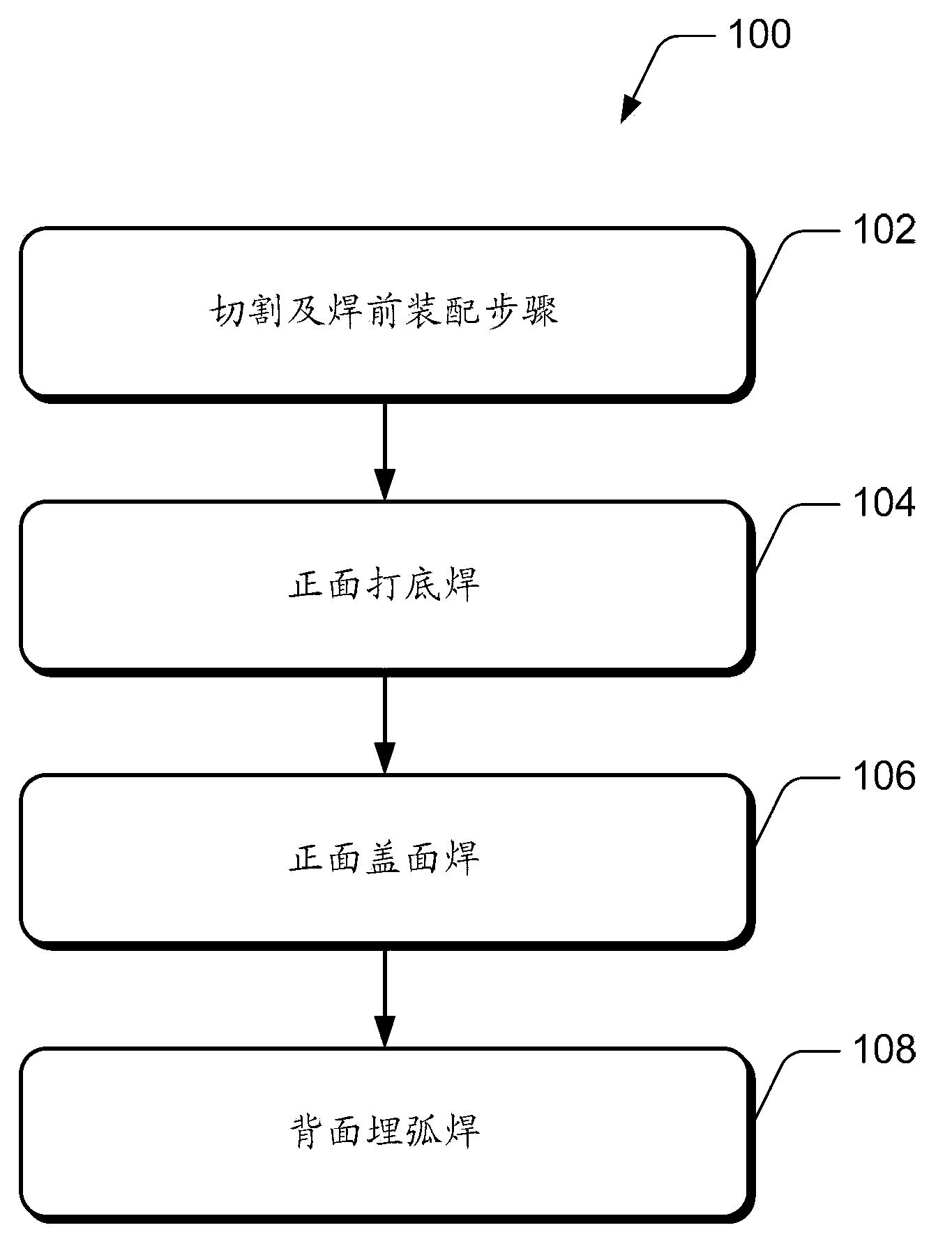

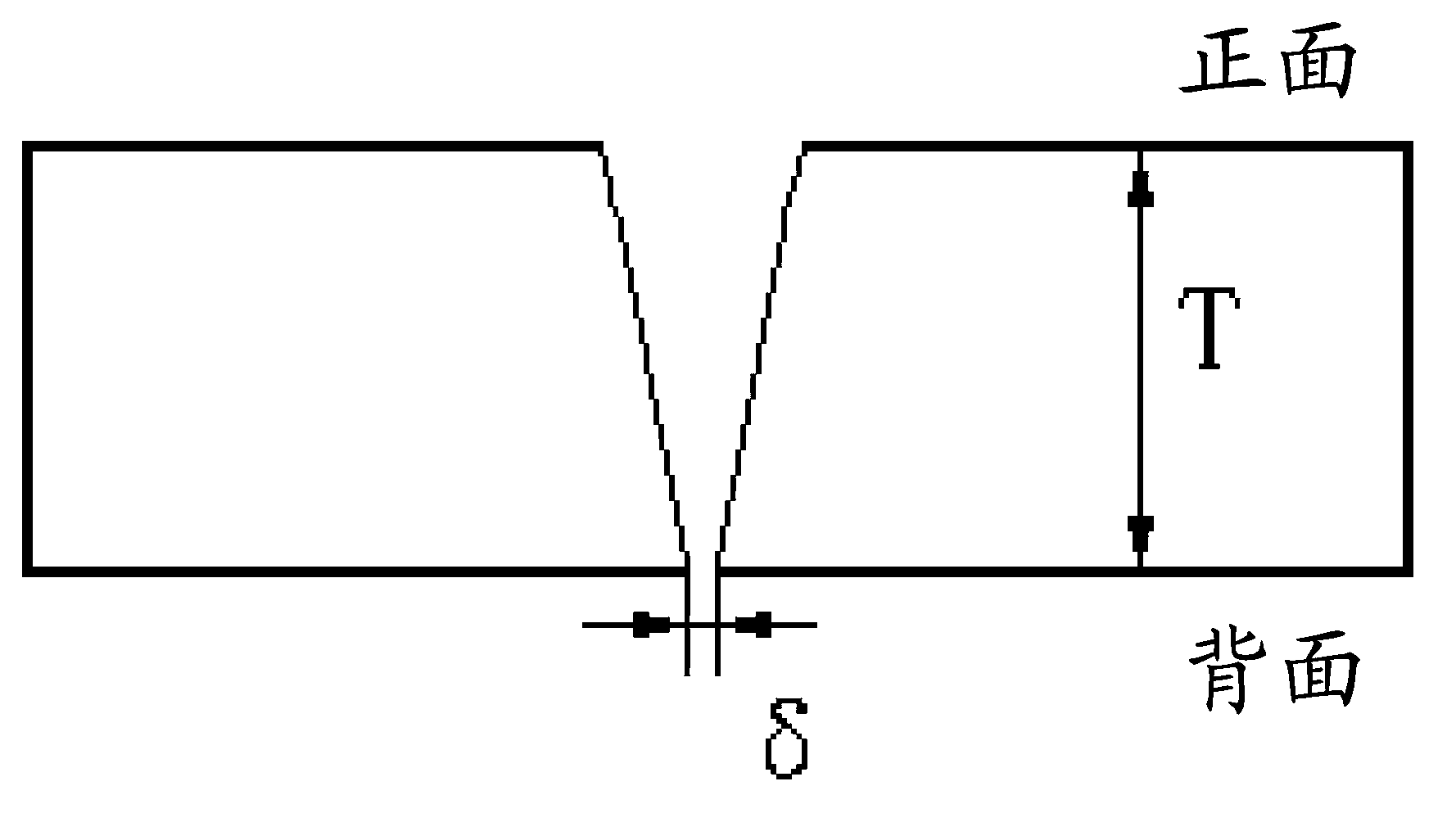

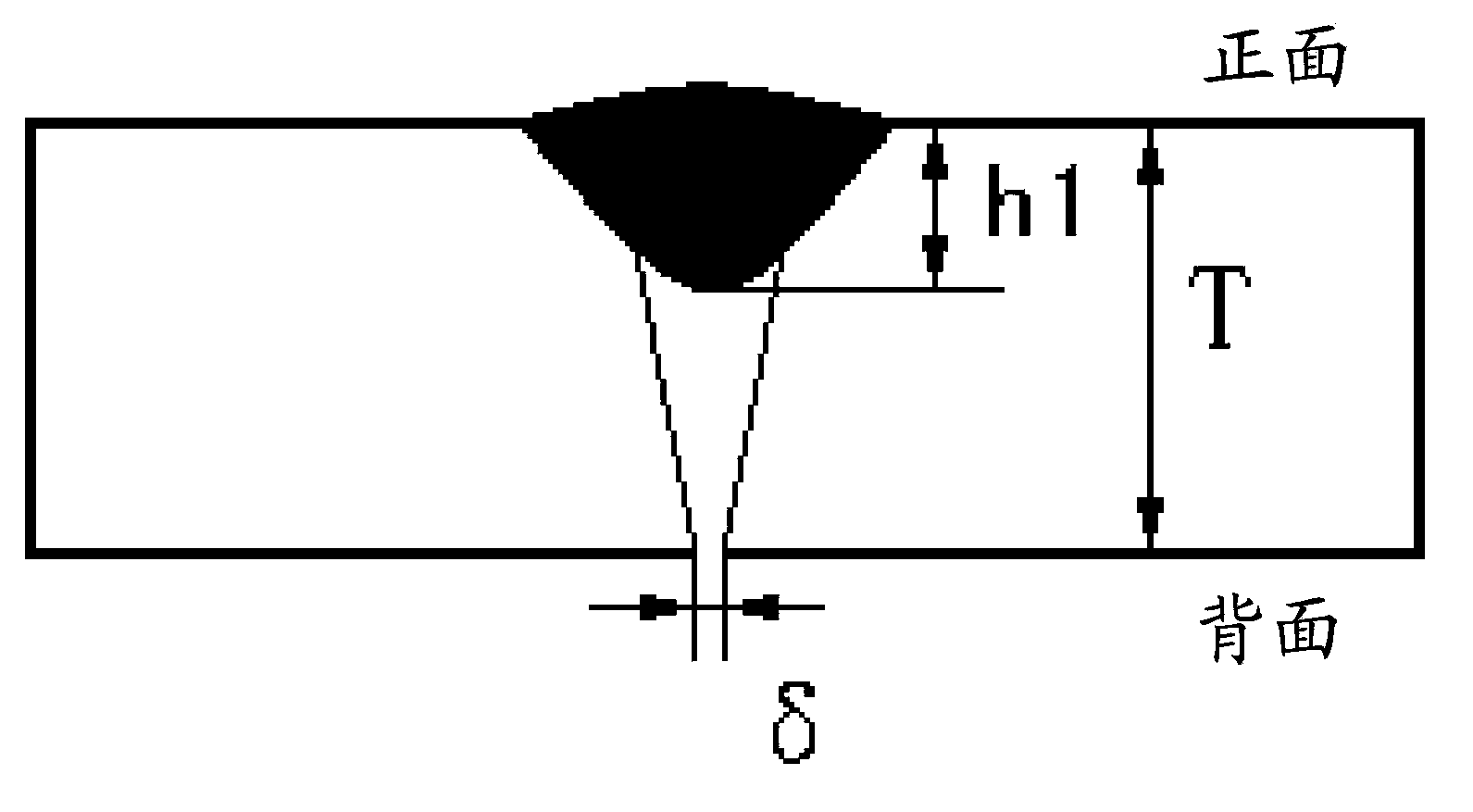

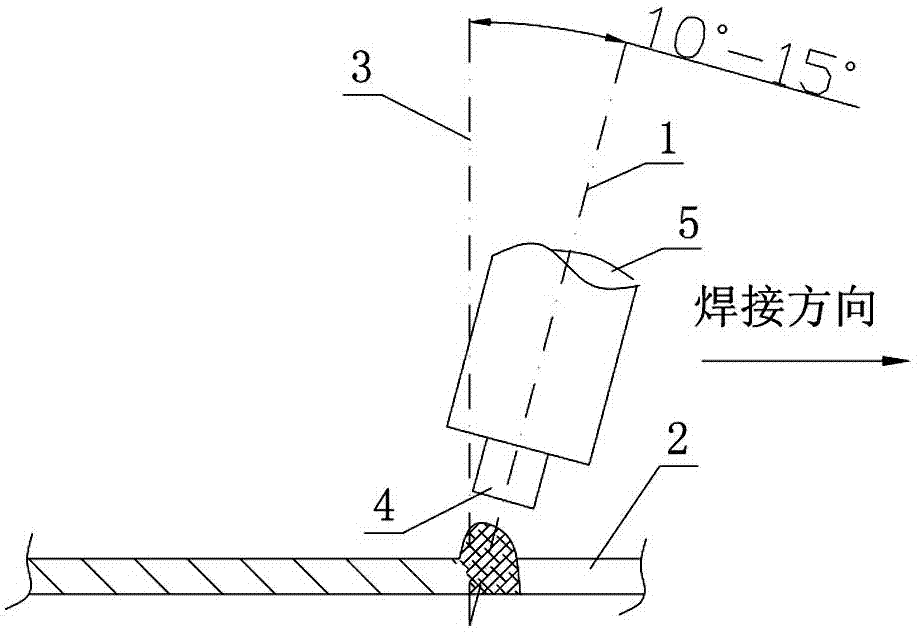

Large-gap back-chipping-free welding process for I-shaped groove of middle thick plate

ActiveCN103785932AImprove applicabilityImprove welding productivityArc welding apparatusPlasma welding apparatusPower flowThick plate

The invention discloses a large-gap back-chipping-free welding process for an I-shaped groove of a middle thick plate. The process includes the following steps: cutting and assembling before welding, namely adopting plasma to cut the middle thick plate and assembling the middle thick plate to form the I-shaped groove, wherein root gap of the groove is smaller than or equal to 3mm, and front gap of the groove is small than or equal to 5mm; performing front back welding, namely performing back welding on the front of the groove by means of small-current oscillation welding to form a welding seam in a large gap without welding penetration; performing front cosmetic welding, namely performing cosmetic welding on the front of the groove in a small-current manner, wherein the welding seam of front back welding is not burnt through in the process of front cosmetic welding; performing back submerged arc welding, namely directly performing submerged arc welding on the back of the groove without through carbon gouging and back chipping, wherein current of back submerged arc welding enables weld penetration depth h3 of back submerged arc welding to be three fourths of thickness of the middle thick plate.

Owner:SHANGHAI ZHENHUA HEAVY IND

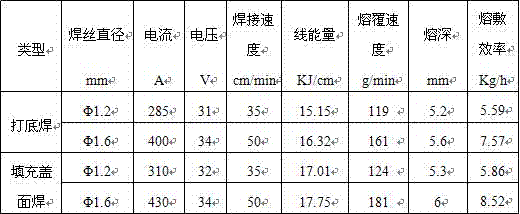

Method for automatically welding hydraulic support structural component through welding wires with diameter being 1.6 mm

ActiveCN106914686AMeet the requirements of the weldSolve serious burn damageArc welding apparatusFillet weldButt welding

The invention discloses a method for automatically welding a hydraulic support structural component through welding wires with the diameter being 1.6 mm. The method includes the steps that firstly, the part tolerance and the splicing precision of the hydraulic support structural component are checked before welding, and the depth tolerance of a welding groove and the angle tolerance of the welding groove are controlled; secondly, the two sides of a weld bead are ground before welding till metallic luster appears; thirdly, all to-be-welded weld joints of the hydraulic support structural component are located at flat welding or flat fillet welding positions; fourthly, off-line programming or on-site programming teaching is conducted on a welding robot; and fifthly, multi-layer and multi-channel welding is conducted on the to-be-welded weld joints through the welding robot by means of the welding wires with the diameter being 1.6 mm in a gas shielded welding manner. According to the method, robot welding is conducted through the welding wires with the diameter being 1.6 mm, and compared with traditional welding conducted through welding wires with the diameter being 1.2 mm, under the condition that the ton cost of the welding wires is not changed and all mechanical properties of the weld joints can meet requirements, the weld penetration of the weld joints is increased, efficiency is improved by 40% or above, and the comprehensive cost of welding conducted through each ton of welding wires is saved by RMB 1500 yuan or above.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

Method for reducing laser welding pores of cast magnesium alloy

InactiveCN101502918AImprove uniformityReduce porosityWelding/soldering/cutting articlesLaser beam welding apparatusPorosityHigh power lasers

The invention relates to a method for reducing casting magnesium alloy laser welding porosity which belongs to the technical field of high-power laser processing, in particular to laser welding of casting magnesium alloy. The method is characterized in that the laser power P and the defocusing amount are firstly adjusted to ensure the sufficient weld penetration and weld width. Then the welding wire can be melted down stably before filled in a weld puddle through adjusting the distance d and the height h between a welding wire and a spot and the angle a formed by the welding wire and a workpiece; the wire feed speed V1 and the welding speed V2 are then adjusted to ensure the entry of appropriate amount of welding wire into the weld puddle. In addition, the porosity is further reduced through adjusting the clearance D between two plates. During the welding process, the protective atmosphere with Ar gas in the inner layer and He gas in the outer layer is provided by a nozzle. For metals with the base metal of great shrinkage porosity rate such as magnesium alloy, the purpose of adding the welding wire is essentially to improve the uniformity of the seam structure configuration, 'dilute' the over saturated hydrogen and reduce the porosity of the seam structure.

Owner:BEIJING UNIV OF TECH

Active agent for titanium alloy tungsten electrode argon arc welding

InactiveCN102626839AEffective contractionStrong penetrating powerArc welding apparatusWelding/cutting media/materialsPorosityMetallurgy

The invention discloses an active agent for titanium alloy tungsten electrode argon arc welding, which aims to increase the weld penetration, reduce the input of welding heat, thin a weld structure and reduce the weld porosity. In percent by weight, the active agent comprises the following components: 20-30% of CaF2, 10-20% of CrCl3, 10-20% of KF and 40-50% of Te.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

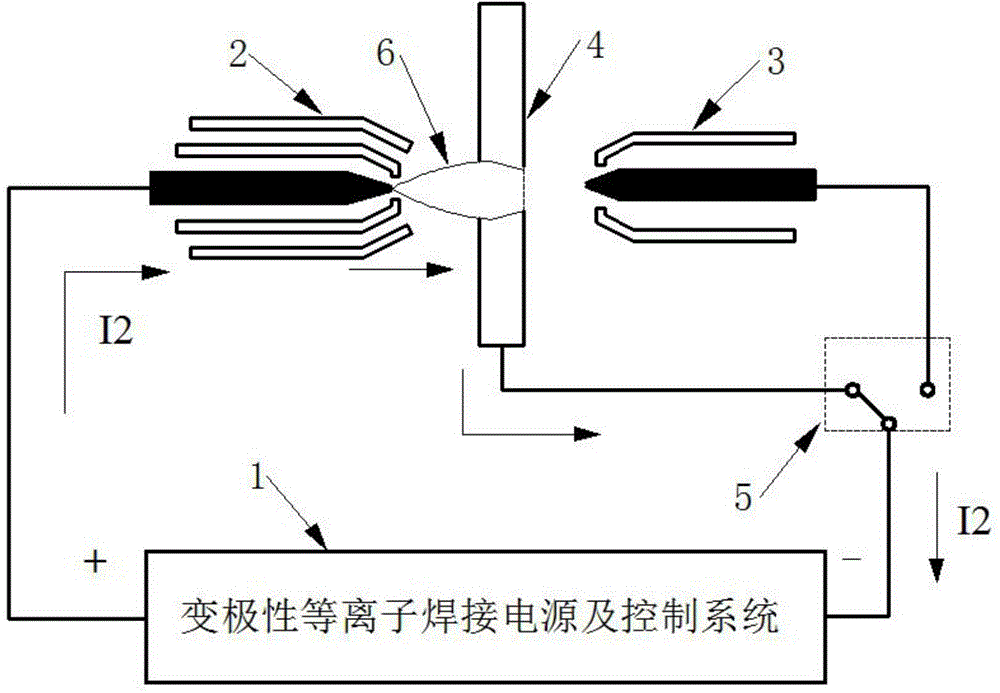

Single-power-source VPPA-GTAW binary electric-arc punching welding method

ActiveCN103600177AStrong penetrating powerRealize one-time welding double-sided formingArc welding apparatusPlasma welding apparatusThick plateControl system

The invention relates to a single-power-source VPPA-GTAW binary electric-arc punching welding method and belongs to the technical field of welding. The method includes that a welding current loop is changed through a welding control system, and binary electric arcs which are composed of conventional plasma electric arcs and penetrating electric arcs and constantly change are formed; the conventional plasma electric arcs complete heat input of plasma arc side parent metal and play a role in cathode atomization; the penetrating electric arcs penetrate a workpiece, energy is centralized, heating efficiency is improved, and welding deformation can be effectively reduced; respective adjusting and accurate control of heat input of the binary electric arcs on parent metal on two sides of a welded workpiece can be realized by adjusting variable-polarity plasma arc welding parameters. By the method, variable-polarity plasma arc welding equipment is ensured not to be changed, welding penetration depth can be increased remarkably, heat input of the parent metal can be effectively reduced, welding quality of medium and thick plates can be improved, and high-efficiency and high-quality welding can be realized.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com