Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

770 results about "Metal flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

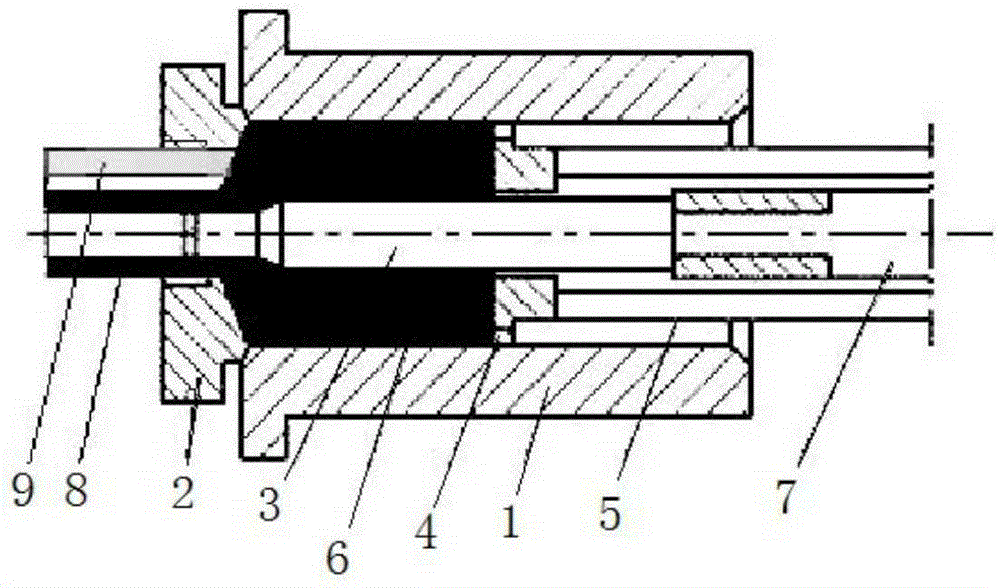

Small-diameter snare

InactiveUS20050234474A1Maximize supportReduced cross sectionDiagnostic markersExcision instrumentsDistal portionEngineering

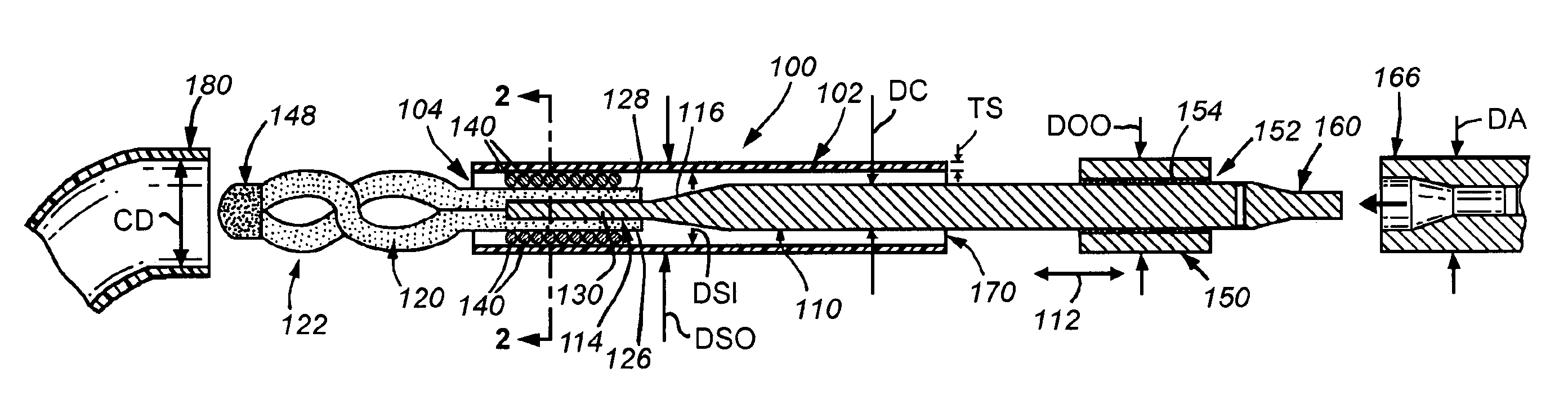

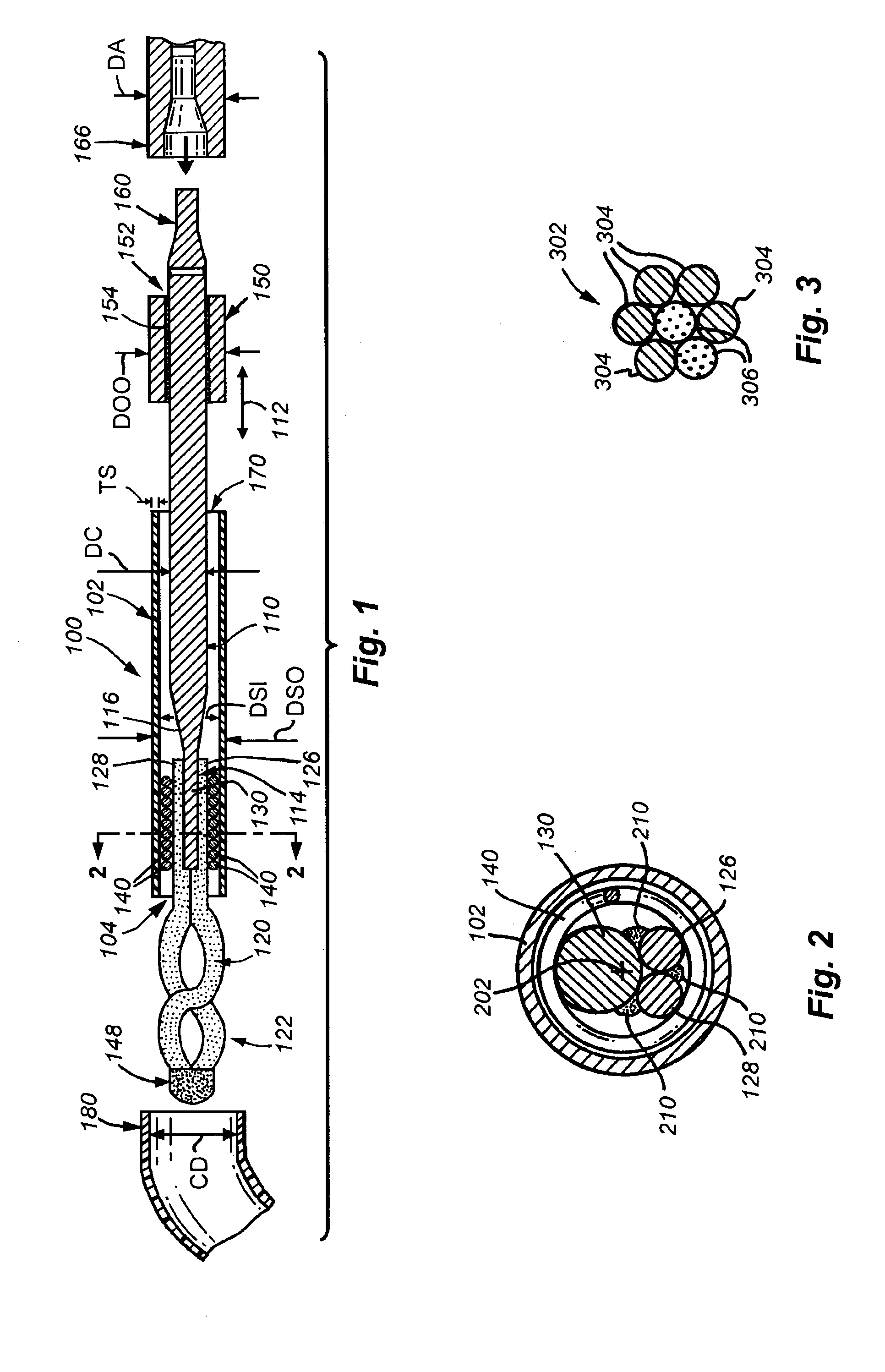

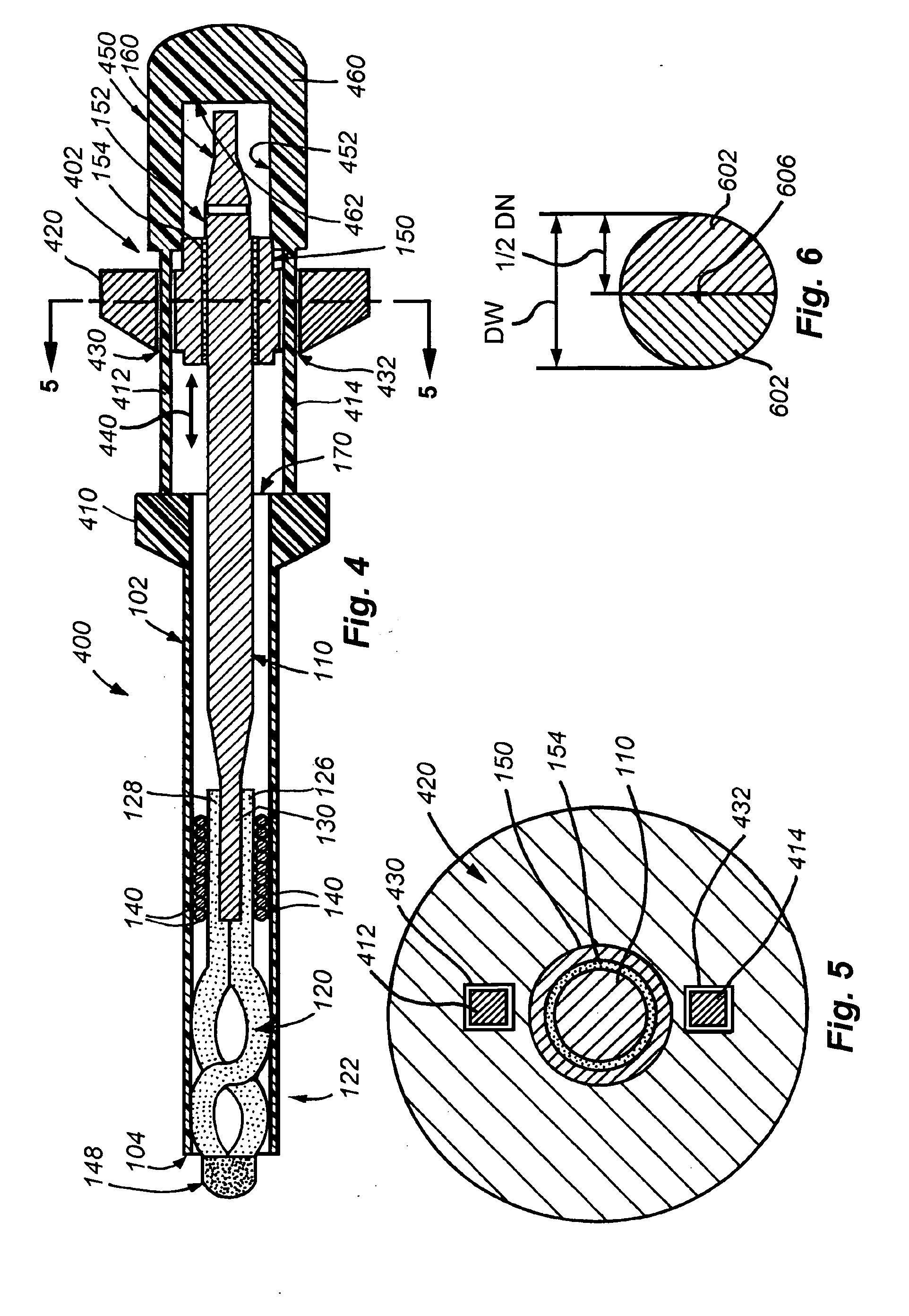

This invention provides a small diameter snare device consisting of a hollow, elongate, thin-walled polymer outer sheath. A single central core wire extends through the entire length of the sheath. The outer diameter of the core wire is sized close to the inner diameter of the sheath while allowing for axial sliding, in order to maximize the support to the body portion of the snare device. The distal end of the core wire has a tapered section of reduced diameter or cross section to provide a “guidewire-like” flexibility to the distal portion of the device. A second wire of about fifty percent of the inner diameter of the sheath is shaped to form a snare loop and the two ends are attached to the distal most portion of the central core wire via welding, soldering, or brazing. After assembly of the core and sheath, a second short, hollow tube is fitted over the proximal end of the central core and attached thereto to provide an actuating handle to slideably move the central core within the sheath, thus exposing and retracting the snare loop from the open distal end of the sheath. The loop is typically circular or oval shaped and can also be multiplanar (for example, a twisted, figure eight shape) so as to increase the ability to ensnare and capture objects. The loop attachment to the core wire is facilitated and strengthened by a wrapped coupling coil formed typically of 0.001-inch platinum wire applied to secure the loop prior to soldering (brazing or other metal-flowing joining techniques), and through which solder flows to permanently secure the loop to the core wire.

Owner:VASCULAR SOLUTIONS

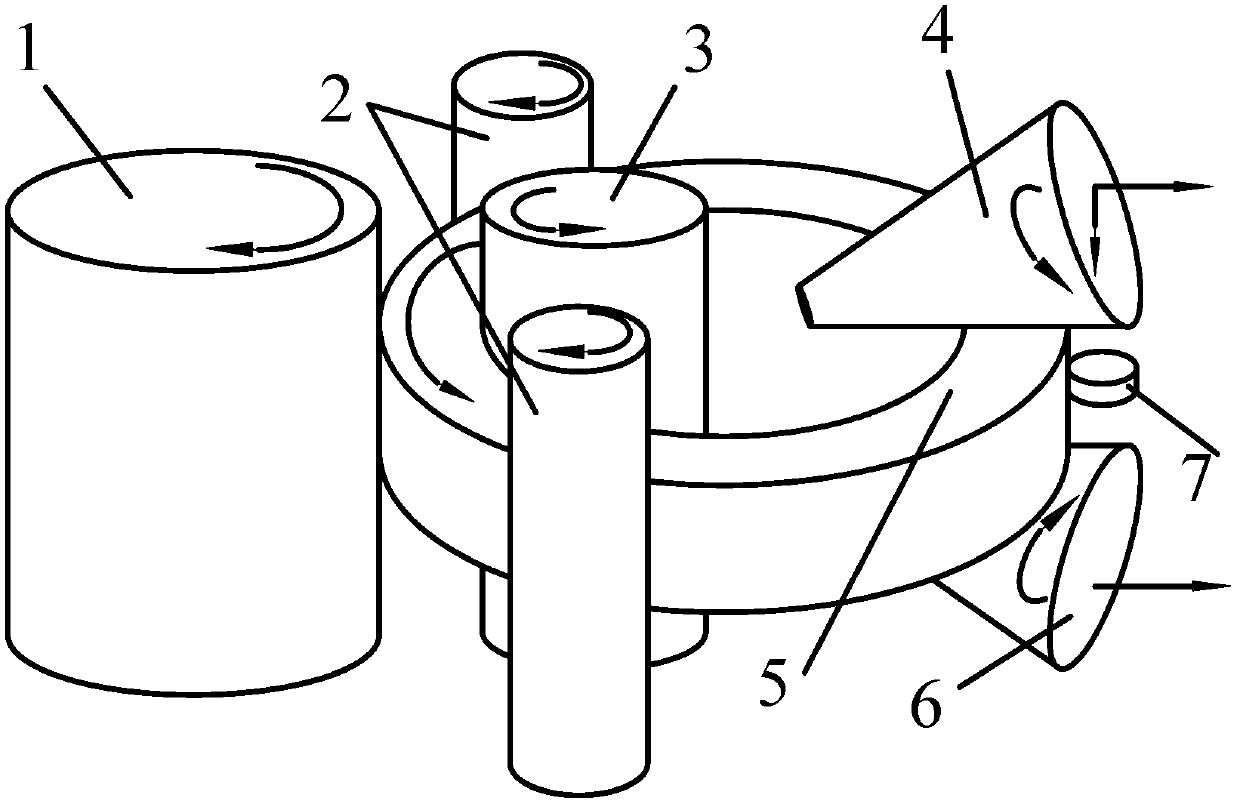

Backfill type friction stir welding method and device

The invention relates to a backfill type friction stir welding method and device. According to the technical scheme, a novel friction stir spot welding device is used for achieving backfill type keyhole-free welding. The method comprises that a stir head is pushed down to press a part to be machined, the position of an outer sleeve of the stir head is invariant, a shaft shoulder rotates at a high speed to stab into a welding bead, a stir needle moves far away from the welding bead direction, the shaft shoulder begins to perform welding after stabbing for certain depth into the welding bead, softened metal flows into space formed by the welding bead, the stir needle and the shaft shoulder, the shaft shoulder is withdrawn from the part to be welded, the stir needle pushes the metal in the space to press the part to be welded, and accordingly, a key hole is filled, welding is completed, and the stir head is unloaded and withdrawn. Compared with the prior art, the backfill type friction stir welding method and device have the advantages that uneven welding beads caused by key holes are eliminated, and the welding penetration depth evenness is guaranteed during discontinuous welding beads.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

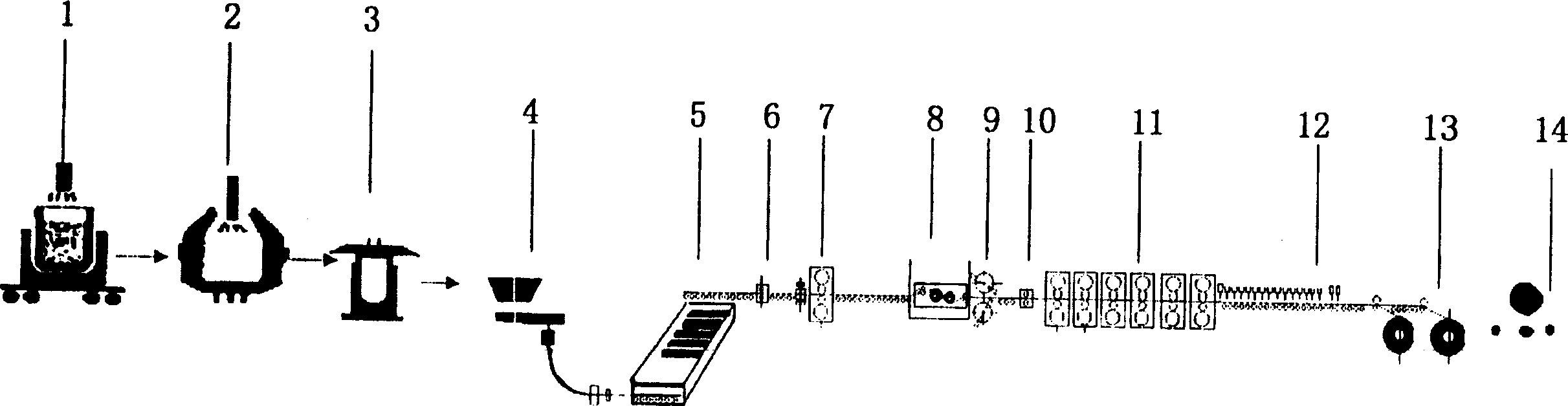

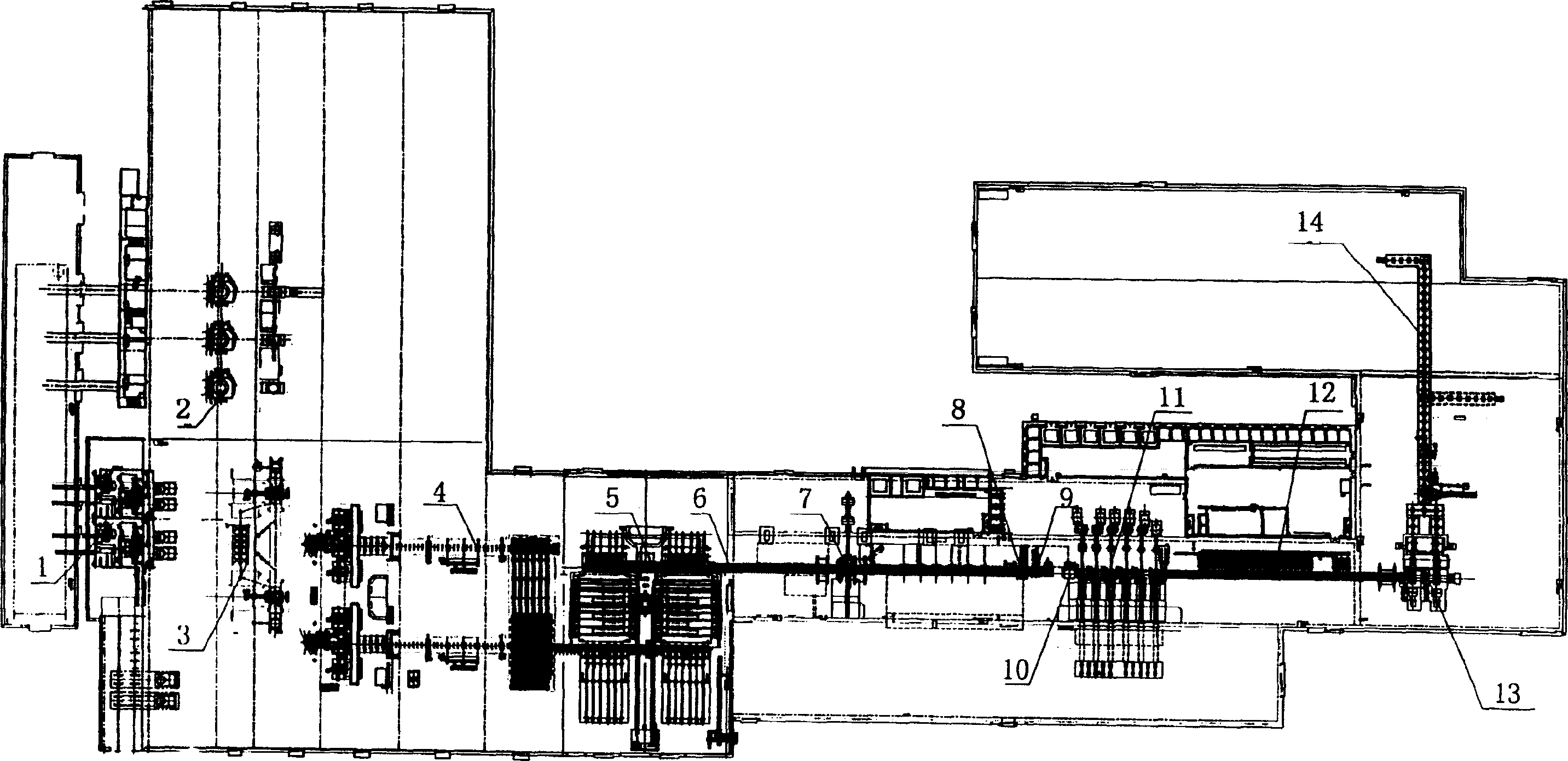

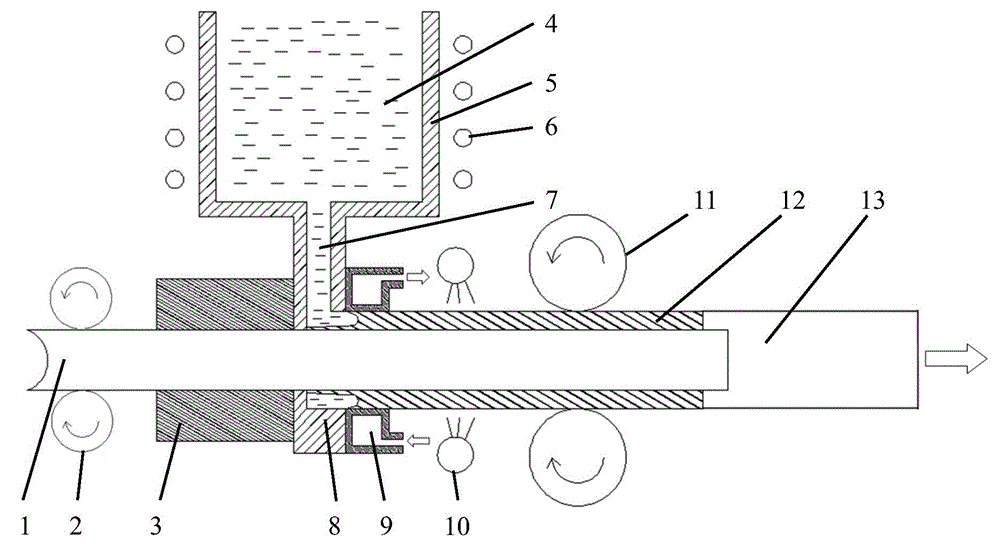

Compact medium-width strip steel production process

ActiveCN1864878AThe process is compact and reasonableSmooth logisticsMetal rolling arrangementsEconomic productionHigh pressure water

The invention relates to a compact method for producing middle-wide strip steel, which comprises: using melt iron to process pretreatment; smelting liquid steel; refining liquid steel; continuously casting the middle-thin plate blank; step beam heater heats uniformly; high-pressure water scale breaker breaks scale; one-frame four-roller reversible roughing mill mills; hot winding box winds; cutting the head and end of middle blank; the high-pressure water scale breaker breaks scale; the finishing roll machine continuously rolls; cooling the interlayer flow; the underground winder winds; and transporting steel coil. Wherein, all processes are inside one workshop or connected workshops. The invention can be used in middle steel factory with 1-2 million ton / year yields to match the metal flow, temperature flow and time flow effectively, to feed the high-temperature non-defect sheet blank at 920Deg. C into step beam heater, to save energy more than 60%, improve 1-2% of metal yield, reduce the producing cost and reduce the transport cost of middle process.

Owner:BERIS ENG & RES CORP +2

All fiber forging process for load-carrying vehicle hub axle and die therefor

InactiveCN1628921AHigh geometric accuracyGrain refinementForging/hammering/pressing machinesWheelsSurface finishFiber

This invention relates to a load automobile hub axle tube whole fiber forging and shaping process and its mould. It is characterized by the following: adopting solid material; finishing hub axle tube surface and deep hole extrusion shaping to get the whole fiber metal flow wire along axle direction and the inner hole is shaped by extrusion without process.

Owner:李克敏 +3

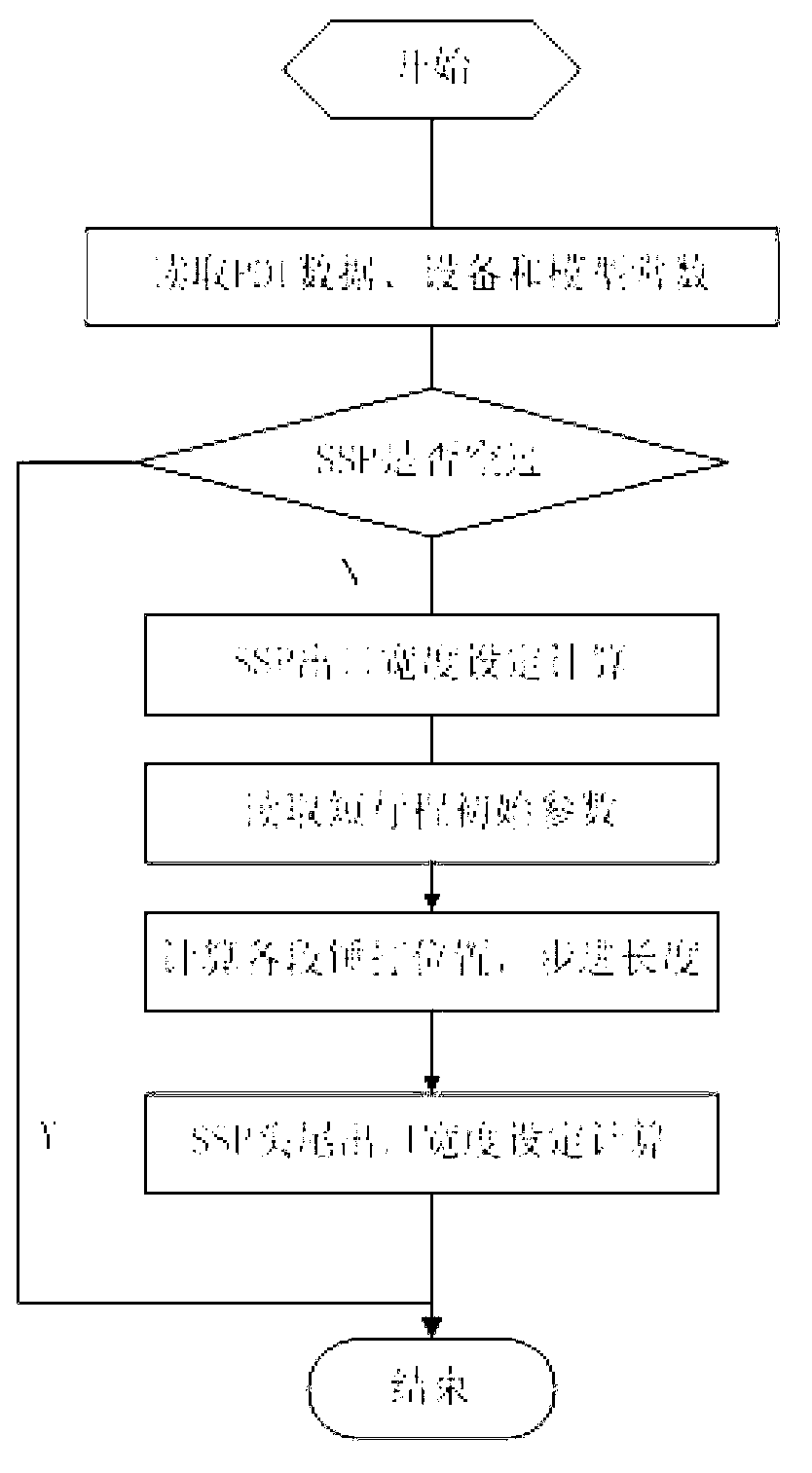

Fixed-width press plate blank width control method

ActiveCN102989784APrecise calculation of adaptive positionImplement width control methodMetal rolling stand detailsAutomatic controlEngineering

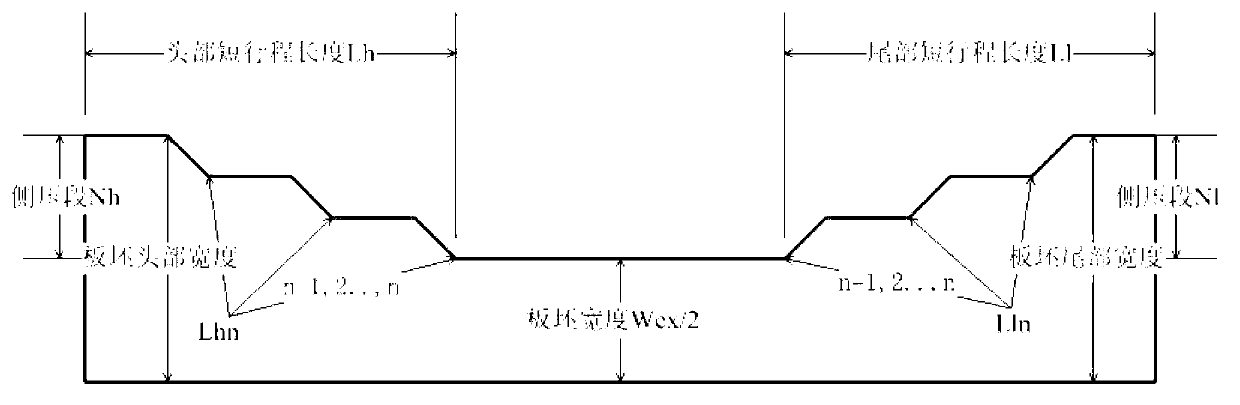

The invention discloses a fixed-width press plate blank width control method, and belongs to the technical field of steel rolling automatic control. During the process of laterally rolling the head and the tail of a plate blank by a fixed-width press, the head part and the tail part of the plate blank are in plane stress states; according to the metal flow principle of the head part and the tail part of the plate blank, and tongue and fishtail phenomena can be generated. In order to improve the condition, the widths of the head and the tail of the plate blank are controlled in short stroke by adopting the fixed-width press; under the working condition that stripe steel rolling temperature and rolling cycle are ensured, the severe width failure of the head and the tail of the stripe steel can be improved, and the final rolling target width index is ensured effectively; a pass band guarantees the width index deviation range to be 0-8mm, the yield is improved, and the production cost is saved; and when the plate blank is pressed greatly, similar to the small lateral pressing amount, the outlet width is obtained through pressing one time, the rolling temperature of the stripe steel is ensured, and the rolling cycle is improved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

Line focusing metal flow passage solar vacuum heat-collecting tube and fabrication technology thereof

InactiveCN101063559ATechnical Defects to Reduce External Heat LossImprove the mechanical strength of the sealGeneral water supply conservationSolar heat devicesMechanical stabilityHeat losses

The invention relates to line focus metal flow passage solar vacuum heat collecting tube and its manufacturing technique, mainly to solve the problem of the prior art that the large external heat loss and sealing mechanical stability of the sealing terminal of the metal flow passage solar vacuum heat collecting tube. The line focus metal flow passage solar vacuum heat collecting tube comprises a glass outer tube, a metal inner tube, an external unloading device and a tube connecting element. The adjusted indirect sealing connecting method of The invention apparently improves the connecting mechanical intensity of the metal flow passage solar vacuum heat collecting tube, and the stability of the metal flow passage solar vacuum heat collecting tube is improved. The invention could be widely used in the solar medium-high-temperature heat collecting device of the groove style solar heat power generation, solar air conditioner refrigeration, solar sea water desalting and so on.

Owner:中金盛唐新能源科技(北京)有限公司

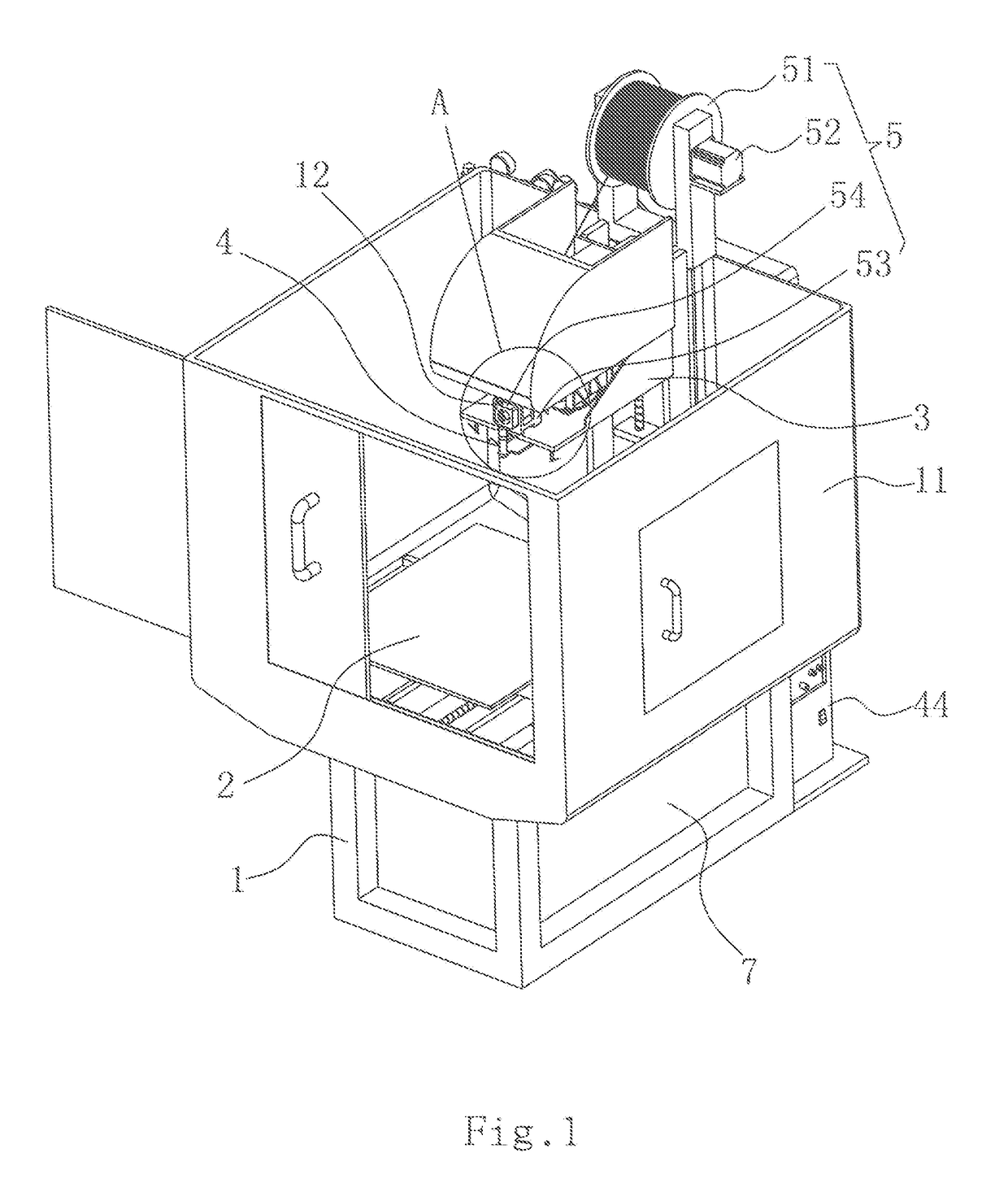

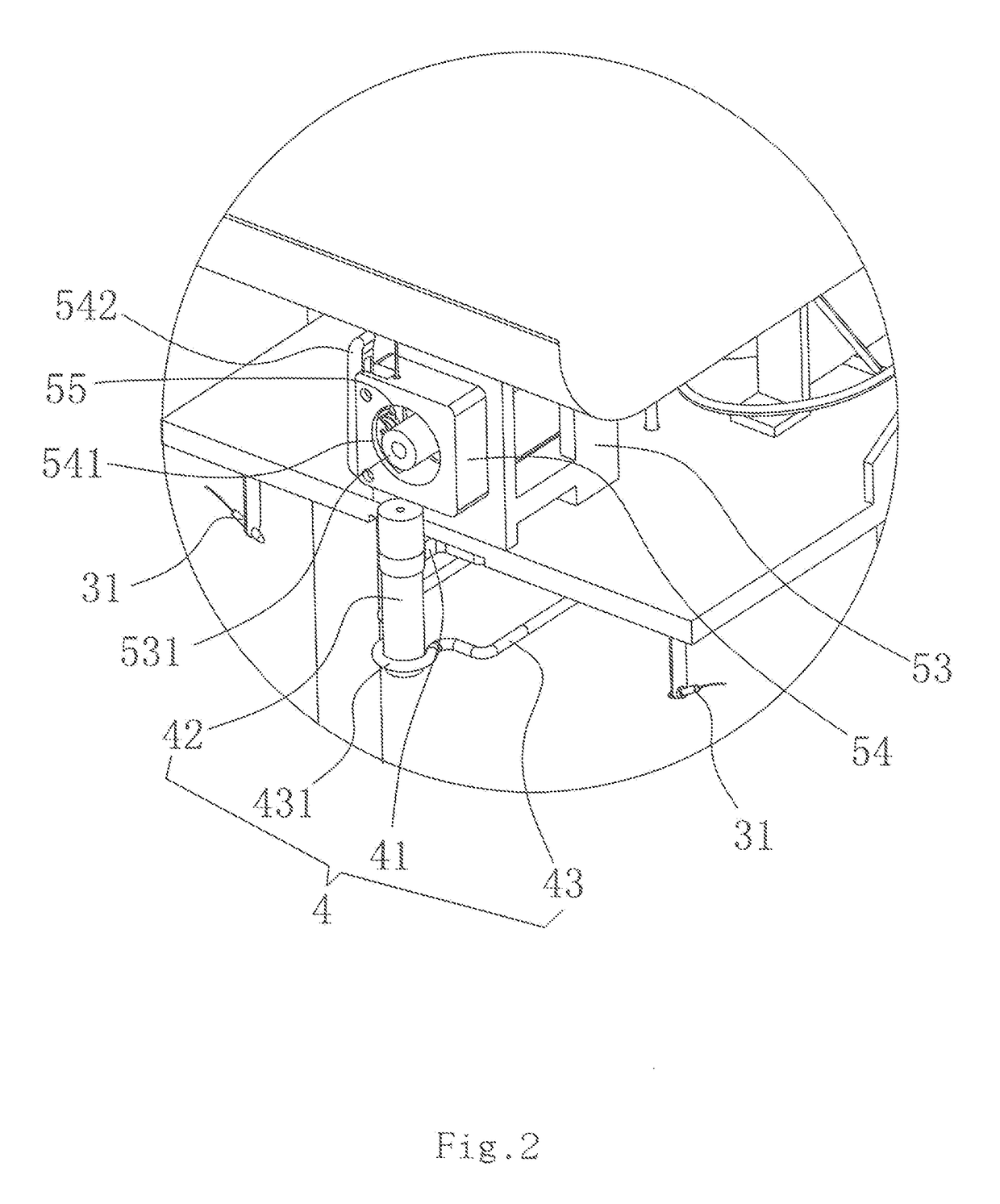

Extruded metal flow 3D printer

ActiveUS20170274454A1Good molding effectSimple structureAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingErbium lasers

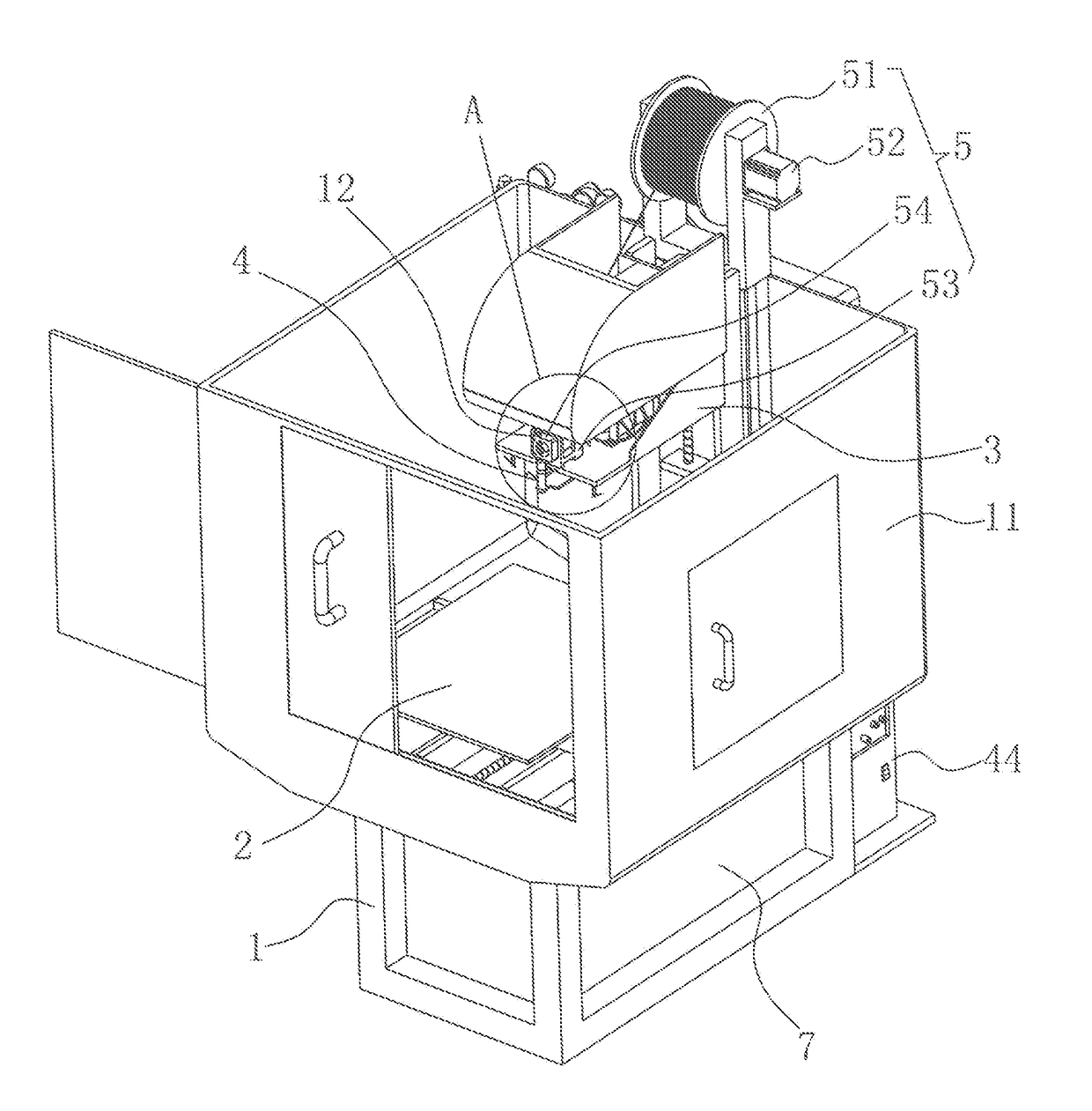

an extruded metal flow 3D printer comprising a rack including a workbench capable of moving along n X-axis and Y-axis direction, and a head capable of moving along an Z-axis direction; a printing device including a printing head, a highfrequency coil and a high frequency electric induction heating device; the printing heal including a tungsten steel nozzle, a ceramic tube bank, a high temperature resistant ceramic protective sleeve, and a stainless steel end cover; the tungsten steel nozzle having an extrusion hole; a feeding device; the head comprising at least one laser mounted on a lower end face thereof and configured to locally preheat and melt a metal layer printed from the metal wire or enhance a binding force between metal layers, so that the print effect and model molding effect of the present invention can be improved, enhancing the marketability.

Owner:ASIA AMERICA IND MFG INC

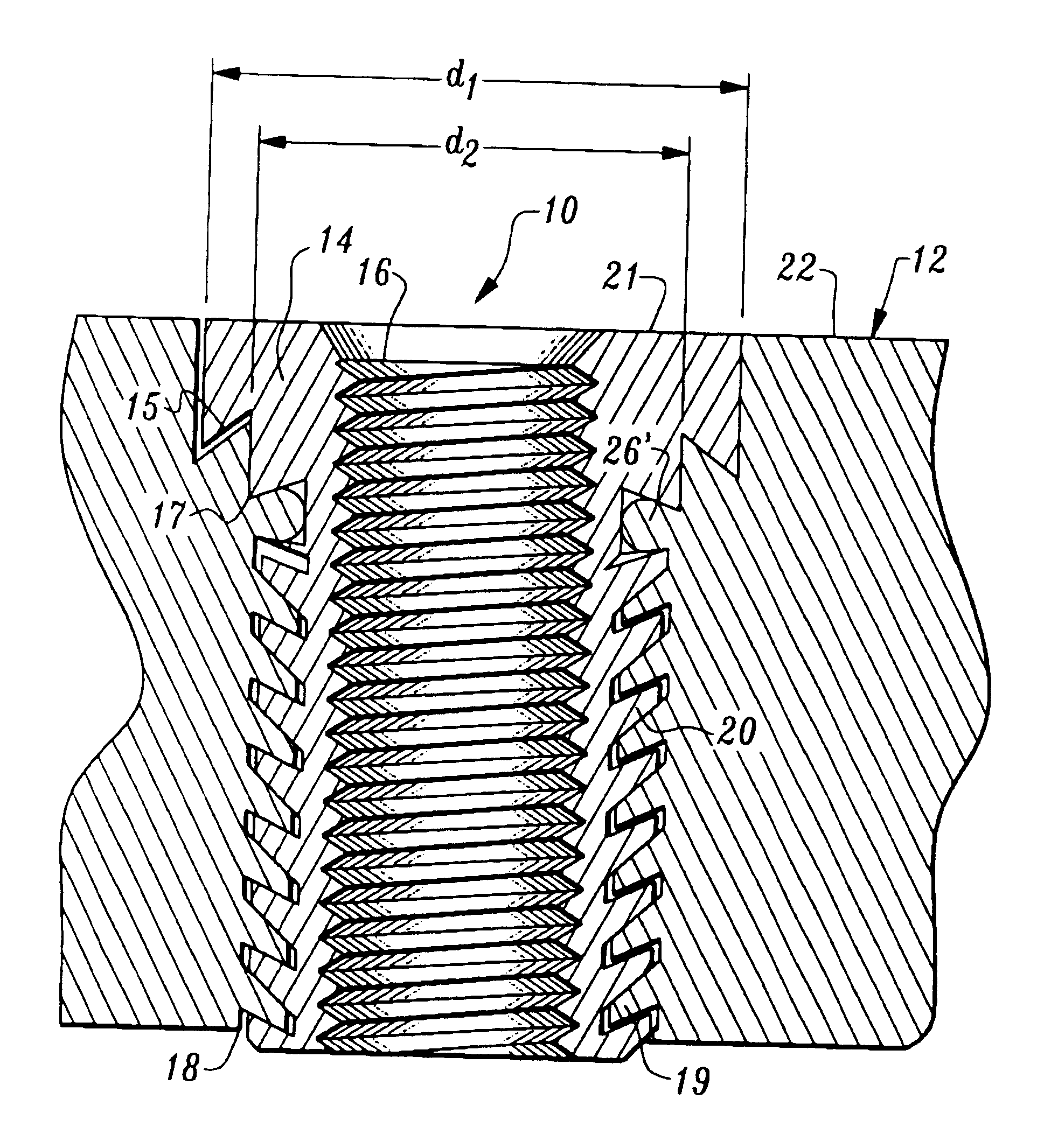

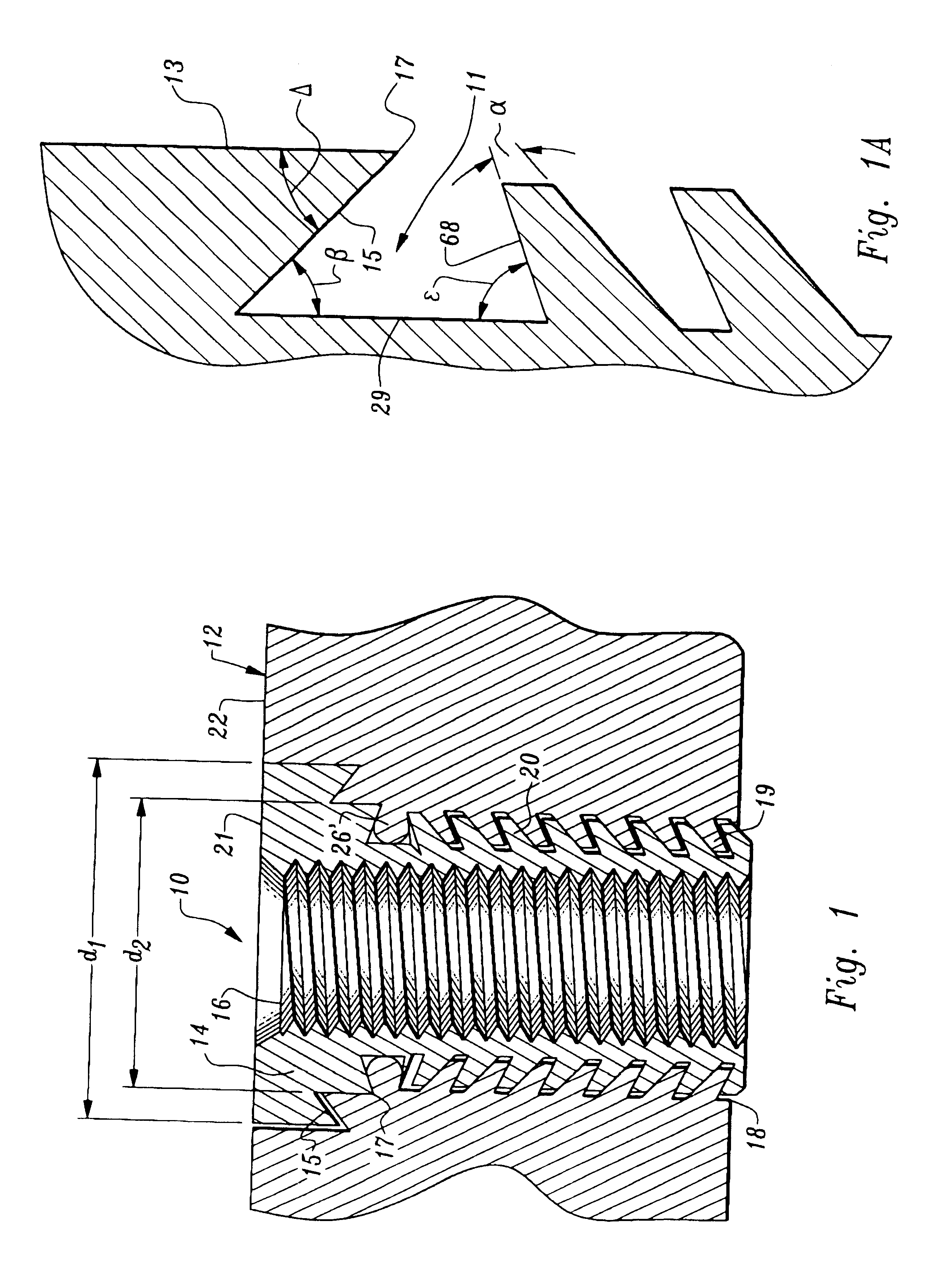

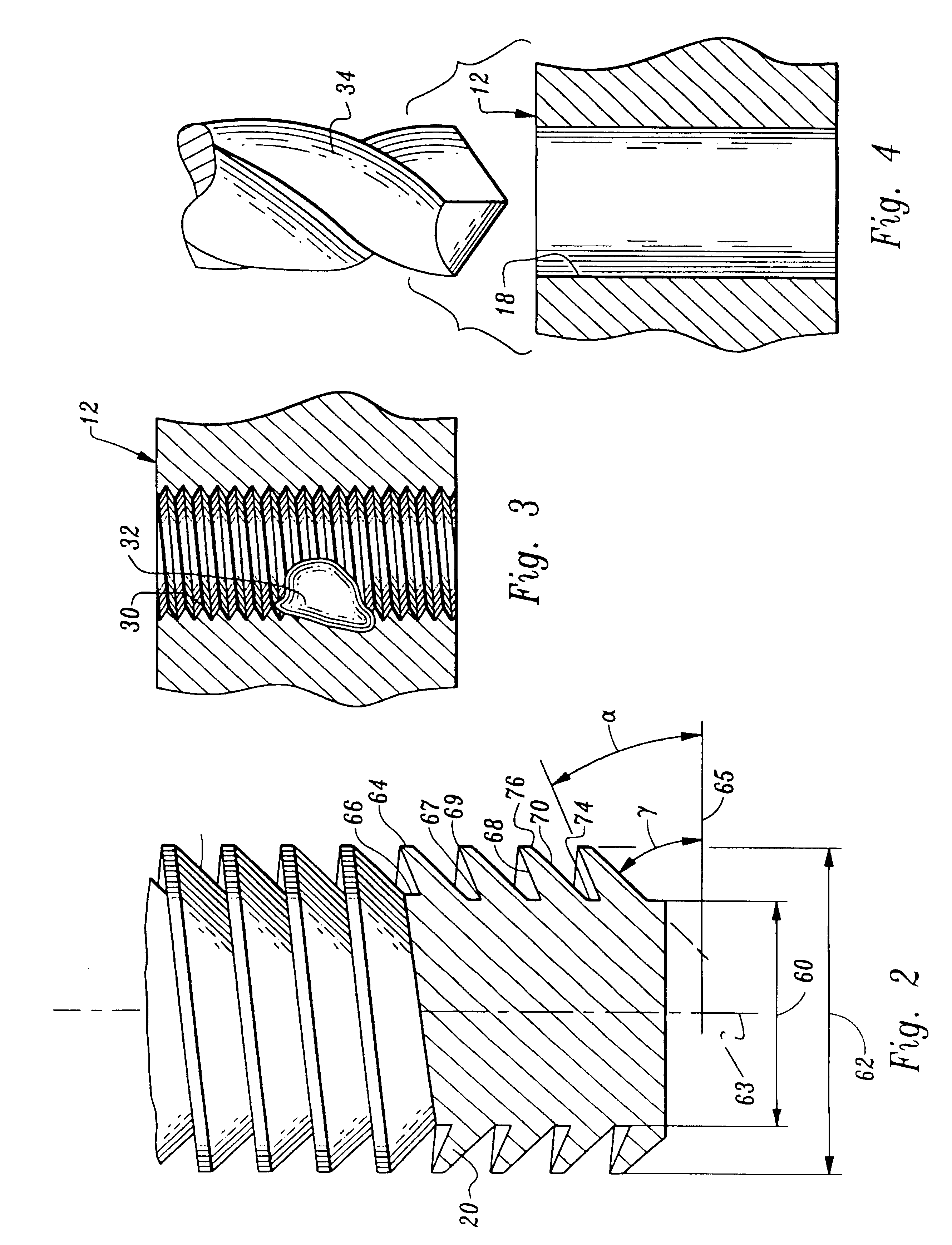

Thread replacement system and device

InactiveUS6382893B1Minimal thicknessSimple and inexpensive to manufactureNutsBoltsEngineeringScrew thread

The present invention relates to a system and device which allows the replacement of a damaged thread in an object with a thread identical to the damaged thread by enlarging the original threaded hole and inserting a thread-insert in a newly threaded hole in the object which has an internally threaded hole identical to the original threaded hole. The thread-insert is fastened into the enlarged hole using a thread that securely holds it in place. When the thread-insert is threaded into the enlarged threaded hole, a pocket formed below the drive head of the thread-insert causes metal flow into the pocket to create a seal between the thread-insert and the object.

Owner:LOCK N STITCH INC

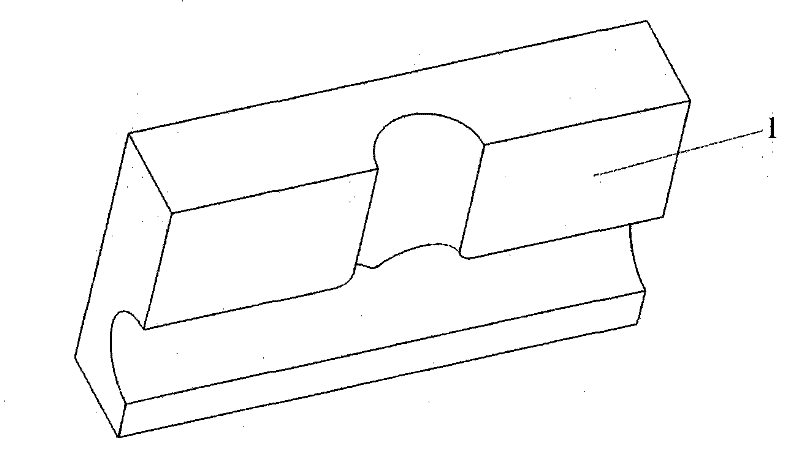

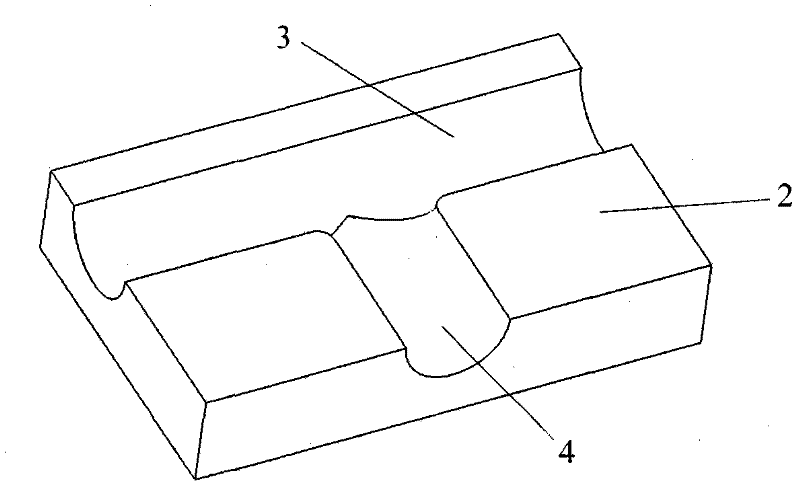

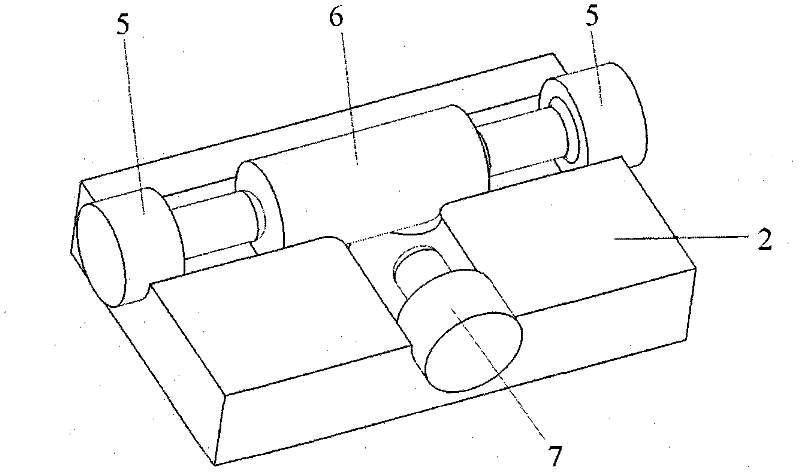

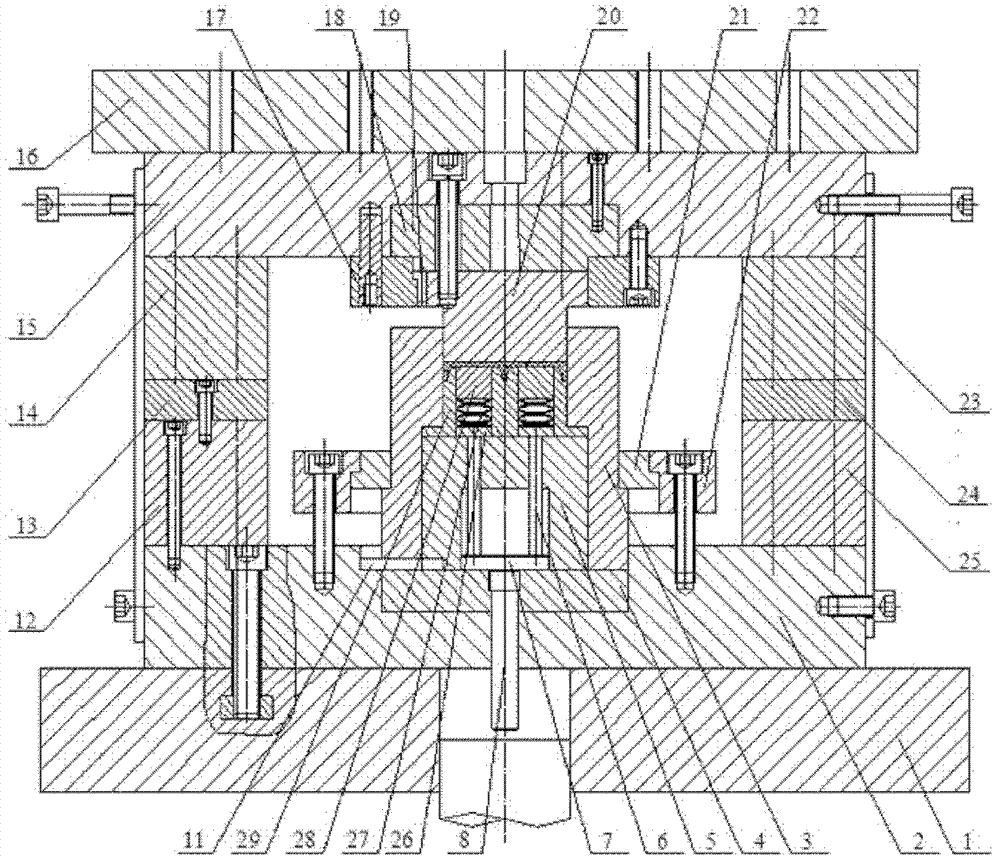

Method for integrally forming aluminum alloy equal-diameter three-way member

ActiveCN102248102ARealize one-time formingReduce processing stepsForging/hammering/pressing machinesEngine componentsTime integralMachining process

The invention discloses a method for integrally forming an aluminum alloy equal-diameter three-way member. In the method, the aluminum alloy equal-diameter three-way member is integrally formed by using a three-way die; a multidirectional active loading and forming technology is adopted, the loading and forming process is as follows: a horizontal male die moves first, side male dies move latterlyand three male dies move together to reach a final forming position. By adopting a method that the side male dies move in advance to inhibit metal from violently flowing towards a support tube die cavity, the defects in the prior art are eliminated, the one-time integral forming of the aluminum alloy equal-diameter three-way member is realized and the process flow is simplified. In the method disclosed by the invention, by coordinating the loading sequences of dies in different directions, the metal flowing in the forming process is actively controlled and the defects in causing a cavity and folding are avoided. In addition, according to the method, the welding and machining processes are reduced, the defects of the corrosion of a welding joint, the cutting off of a stream line and the like are avoided, the reliability of the member is improved, and the utilization rate of materials is increased simultaneously; and the invention has the characteristics of simpleness and convenience for operation and easiness for implementation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

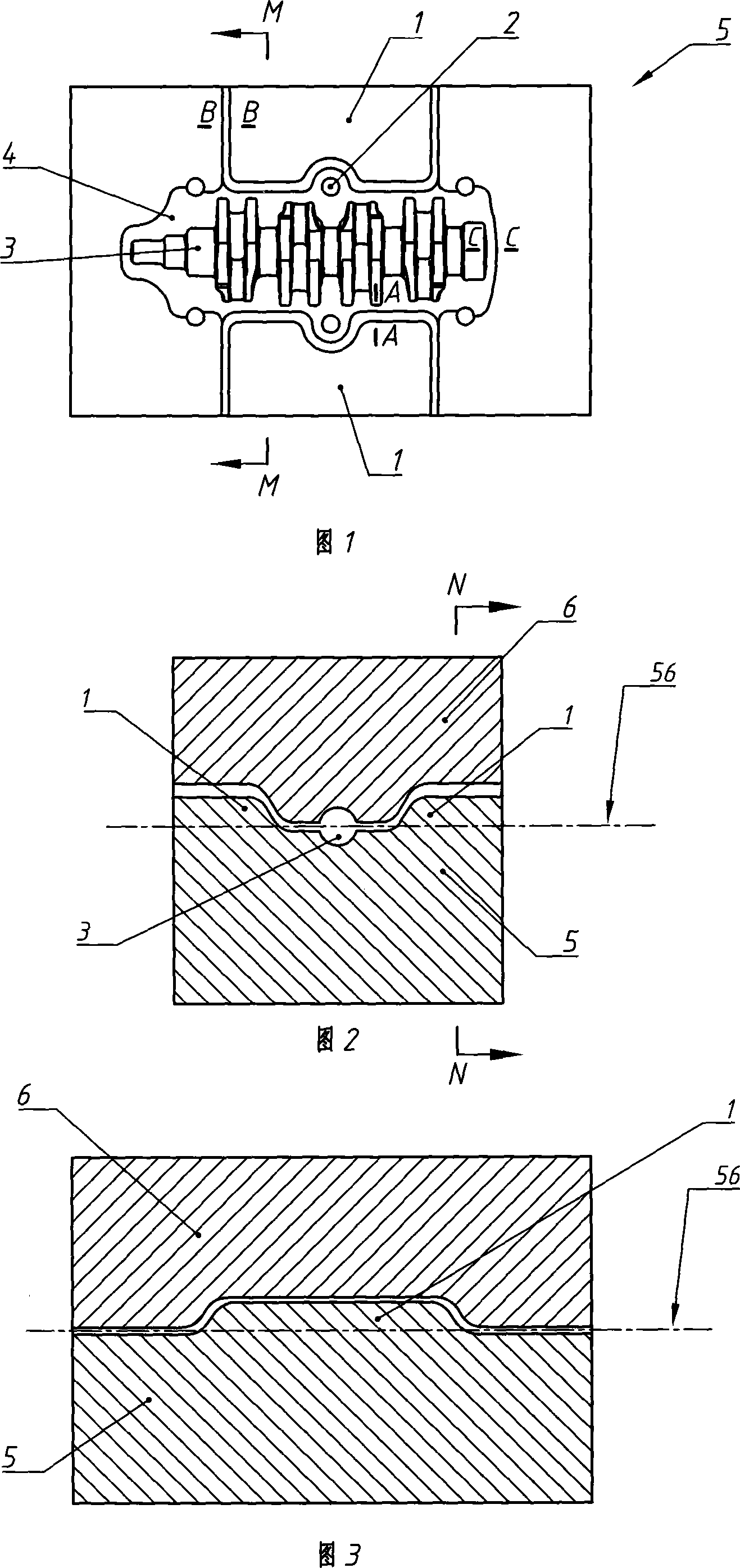

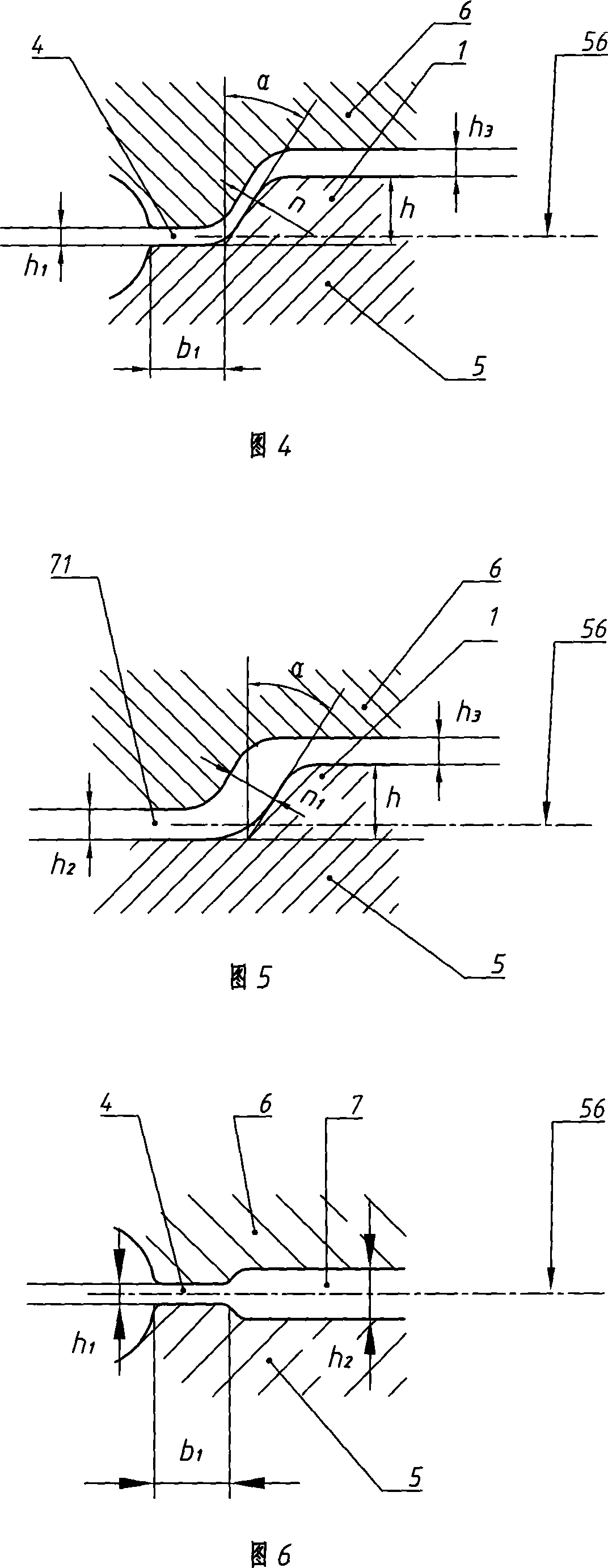

Crankshaft forging die

InactiveCN101020224AStrong horizontal flow resistanceIncrease profitForging/hammering/pressing machinesEngine componentsEngineeringBinding force

The crankshaft forging die has one flash gutter comprising one flash bridge and one flash bin set around the die cavity and in the die joint between the upper die and the lower die. Inside the flash gutter, one raised wall beyond the die joint is set in one side of the upper die or the lower die and in the location corresponding to the flash bin of die cavity for the crankshaft balancing block. Compared with available technology, the wall structure alters the metal flow direction and increases the horizontal flow resistance, and this results in the possibility of adopting relatively small size blank, raised material utilization rate and lowered energy source consumption.

Owner:CHONGQING UNIV

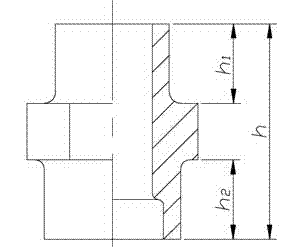

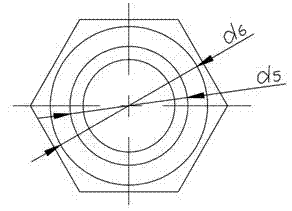

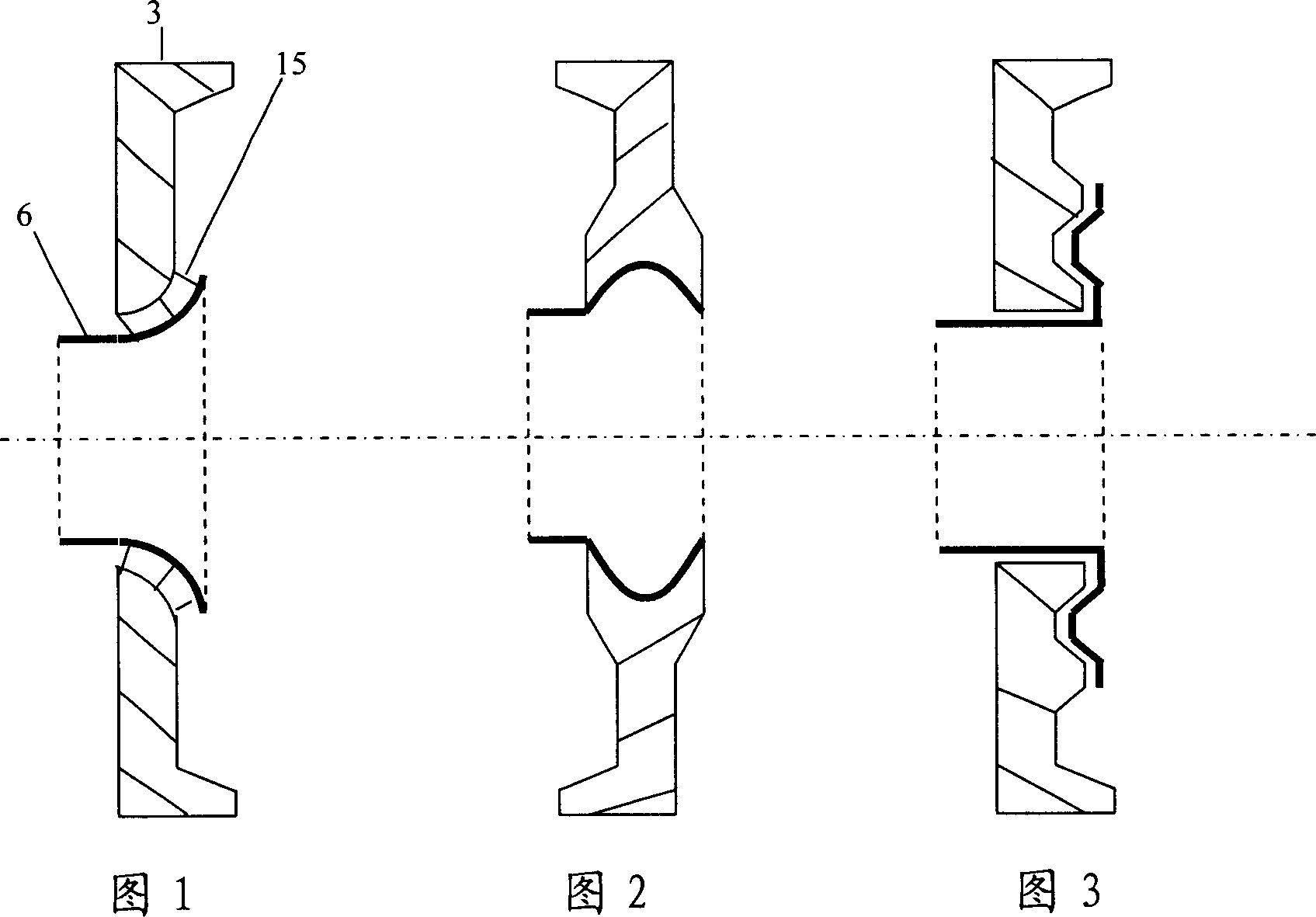

Fabrication process of hexagonal flange toothed bolt

The invention discloses a fabrication process of hexagonal flange toothed bolt. In the fabrication process, medium carbon cold heading steel wires are used. The fabrication process mainly comprises the steps of: (1) shearing blanking; (2) preliminarily heading; (3) pressing to form a circular top; (4) pulling to produce a hexagonal product; (5) molding; (6) thread rolling; (7) heating; and (8) electroplating. In the fabrication process of hexagonal flange toothed bolt disclosed by the invention, the cold heading forming technology is adopted to carry out processing, thus the material utilization rate is over 98%, the material is saved, the cost is reduced; by the use of multi-position extrusion, the volumetric deformation and metal flow are more reasonable, fins produced in deformation process are removed, and the resistance to deformation is reduced; by undergoing thermal processing, the bolt has uniform grain and hardness, and is free of cracks; the qualification rate is up to 100%; by electroplating cadmium and titanium, the strength of the bolt is greatly improved, as well as the safety in use.

Owner:苏州新凌电炉有限公司

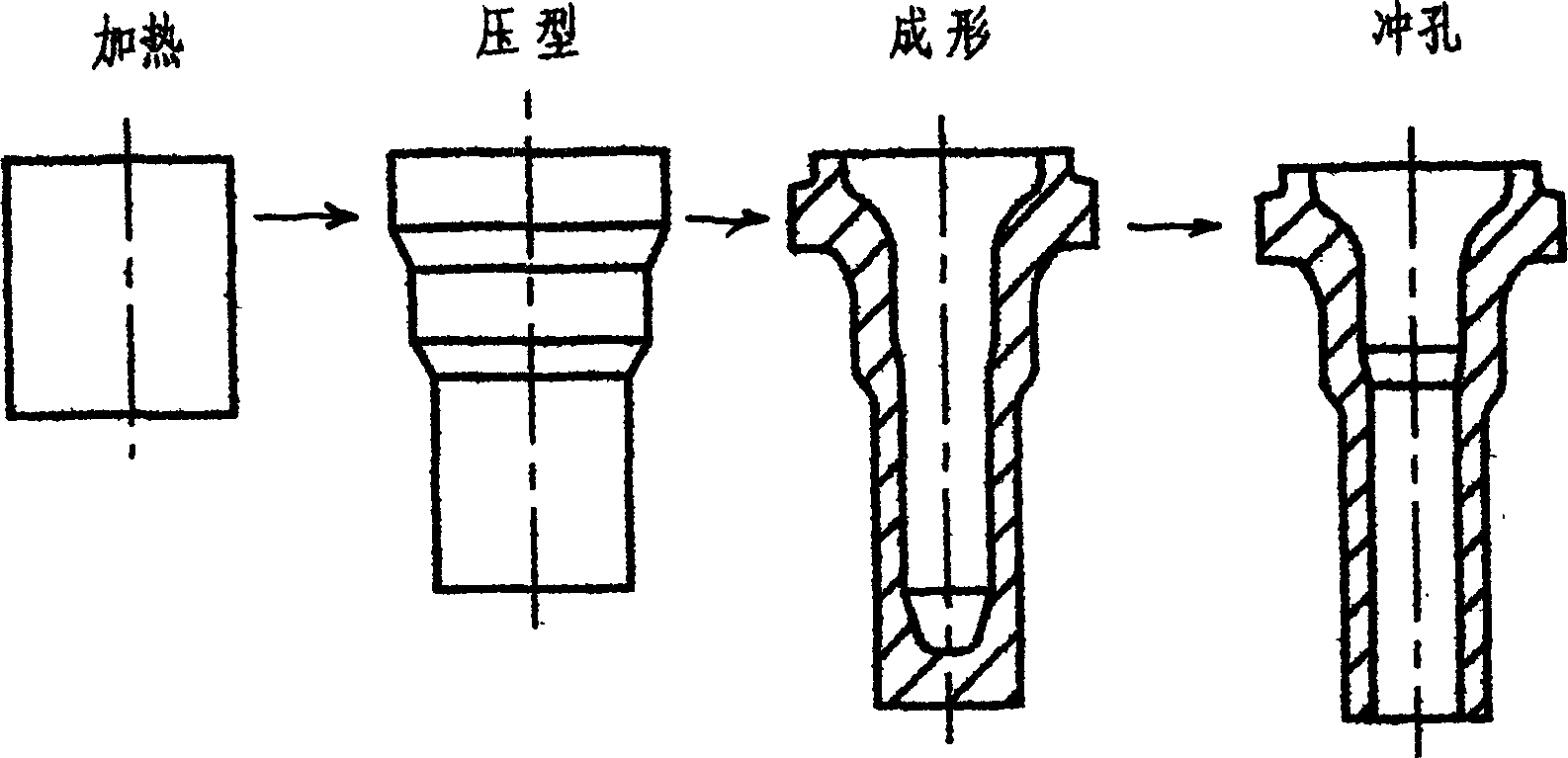

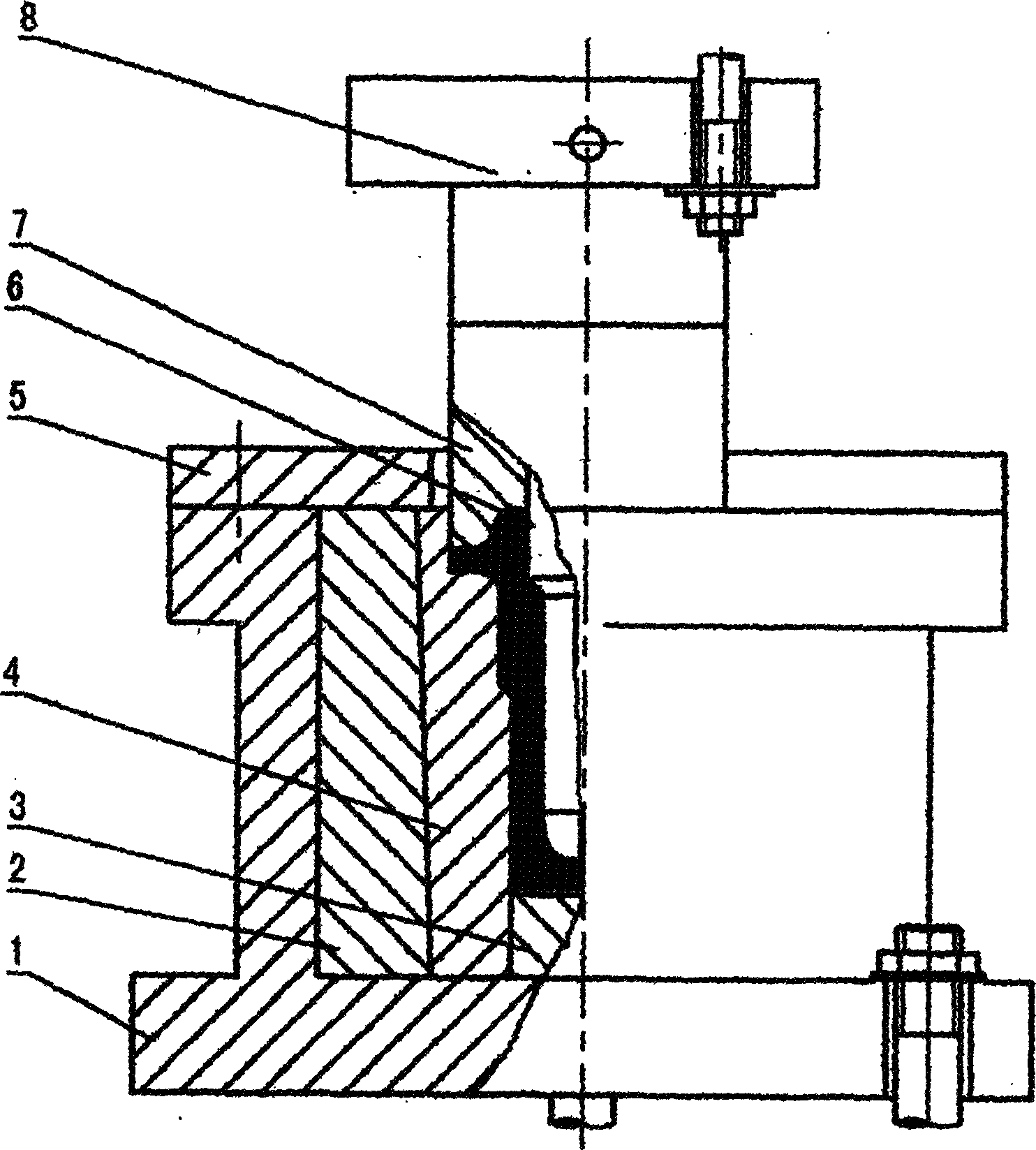

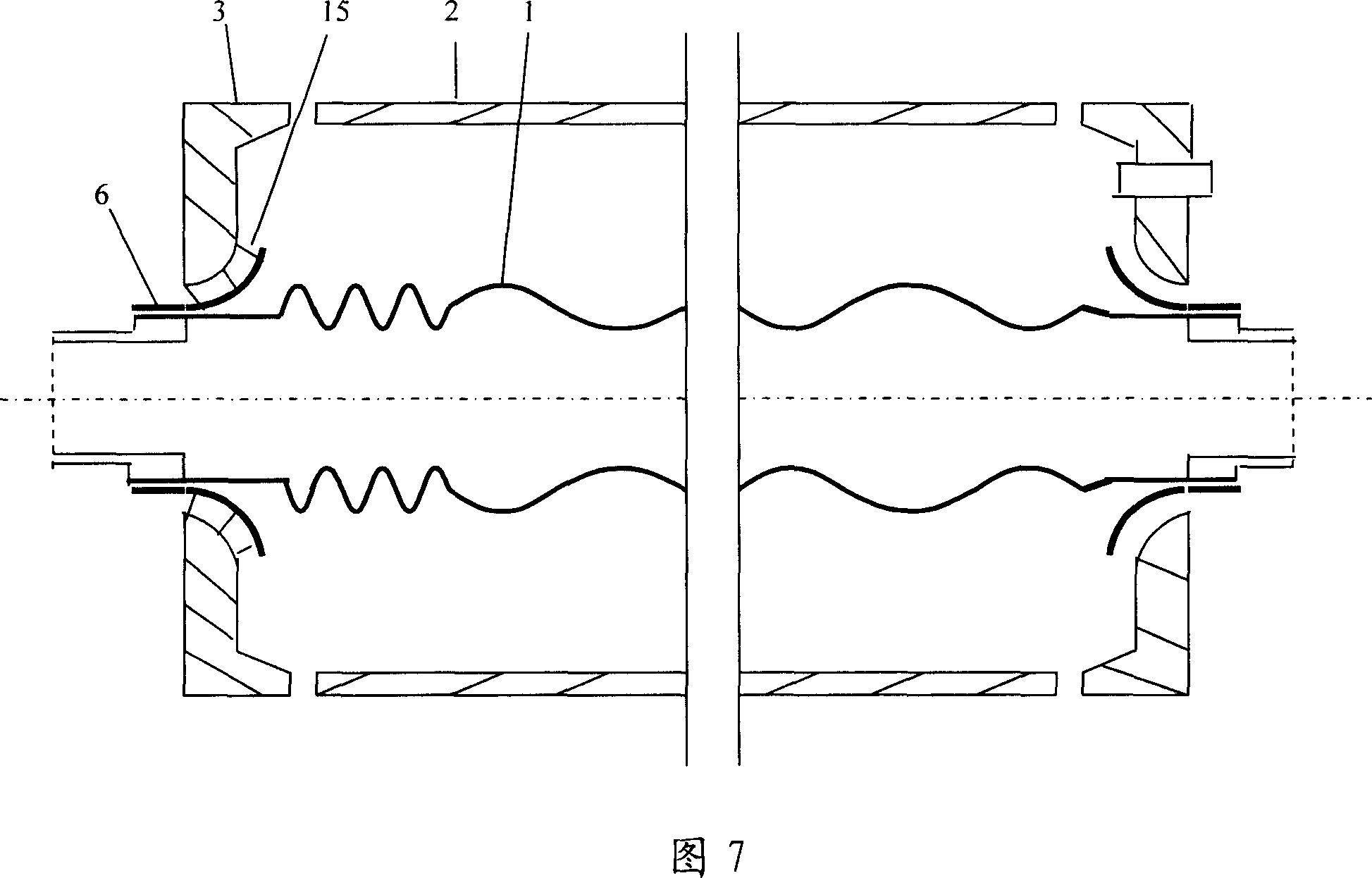

Device and method for forming central flange pipe joint from round rod material in one-step, multidirectional and composite manner

InactiveCN102357645AGive full play to the characteristics of multi-directional flowImprove liquidityExtrusion diesForging/hammering/pressing machinesEngineeringHigh pressure

The invention discloses a method for forming a central flange pipe joint from a round rod material in a one-step, multidirectional and composite manner. The method comprises the following steps of: using the round rod material as a blank; after perforating a conical head male die, upsetting, extruding and forming the central flange part of the pipe joint; simultaneously, upwardly and reversely extruding and downwardly and forwardly extruding to form the upper end and the lower end of the pipe joint. According to the method disclosed by the invention, metal can flow in multiple directions, such as upward, downward and radial simultaneously; the deformation force is small; fewer work stations are required; compared with the pipe joint cutting, the material utilization rate is high; the production efficiency is high; the metal flow organization is good; and the method is especially applied to production of high-pressure pipe joints.

Owner:JIANGSU UNIV

Middle-high-temperature solar vacuum heat-collecting tube glass end cap packaging structure and fabrication technology

InactiveCN101063560AImprove use reliabilityThe connection is airtight and reliableSolar heating energySolar heat devicesHeat conductingEngineering

The invention relates to medium-high-temperature solar vacuum heat collecting tube glass end cap packing structure and manufacture technique. The invention primarily solves the problem that the high external heat loss and complicate packing technique of the sealing terminal of the high temperature metal flow passage solar vacuum heat collecting tube under high pressure and high temperature condition, to provide new technical method to produce solar medium-high-temperature heat collecting tube. The glass end cap packing structure is composed by glass caps with different structure and relative nickel iron alloy strike component. The glass end cap component produced by The invention is useful to improving the mechanical connecting intensity of the glass metal solar vacuum heat collecting tube, to reduce the heat loss caused by heat radiating, heat convection, and heat conducting, to improve the stability of the vacuum heat collecting, it is useful to realizing specialized production.

Owner:中金盛唐新能源科技(北京)有限公司

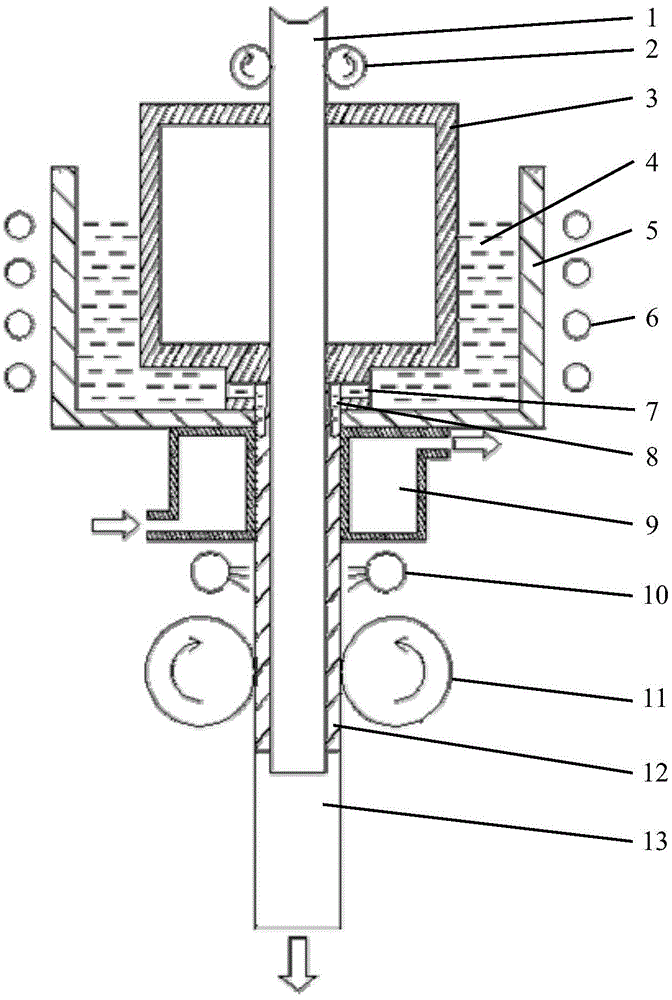

Clad material solid/liquid composite horizontal continuous casting and forming equipment and method

The invention discloses clad material solid / liquid composite horizontal continuous casting and forming equipment and method, and belongs to the technical field of clad material continuous casting. According to the clad material solid / liquid composite horizontal continuous casting and forming equipment and method, the measures that a core material protection device, a flow guide pipe, an inversion solidification device and the like are adopted and mounted below a crucible, core materials are not heated in advance, the inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of the crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through horizontal continuous casting, and the equipment and the method are especially suitable for horizontal continuous casting forming of the large-size clad materials which are hard to reel up and has the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, production efficiency is high, investment is small, automatic control is easy to achieve, large-scale industrial production is facilitated, the procedure of the forming process is short, energy is saved, environment is protected, efficiency is high, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

Crawler shoe with peening pads in roller path

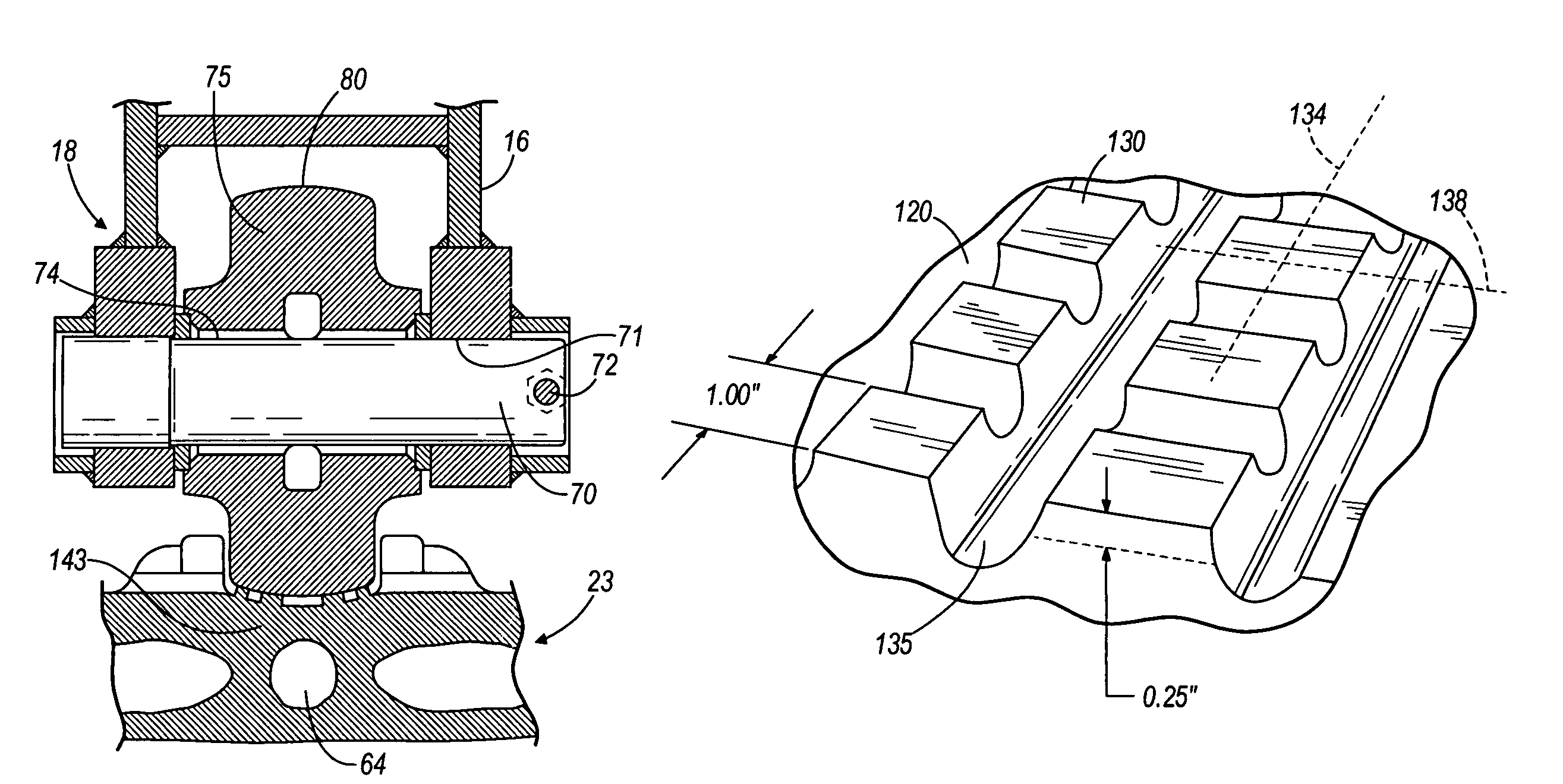

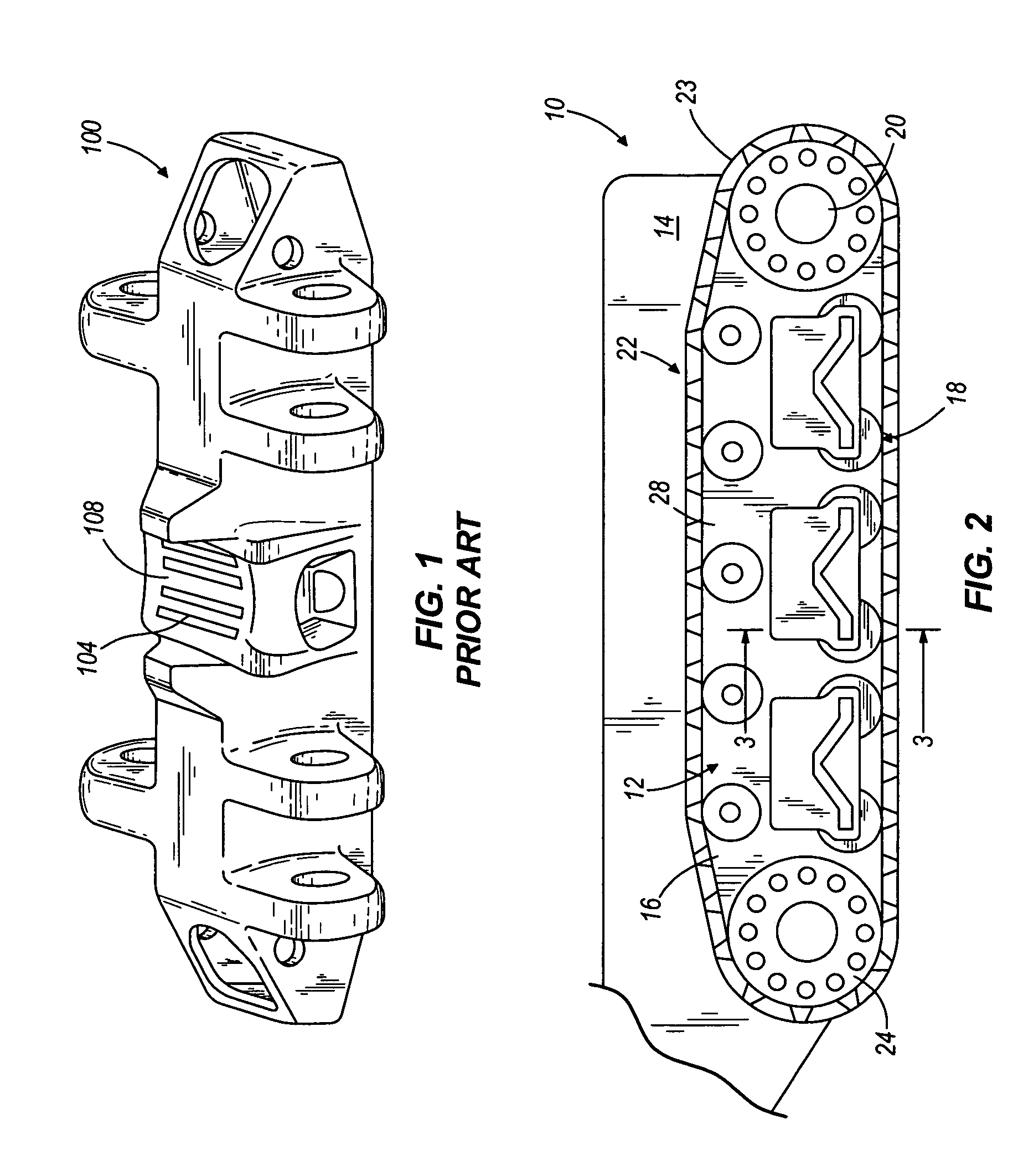

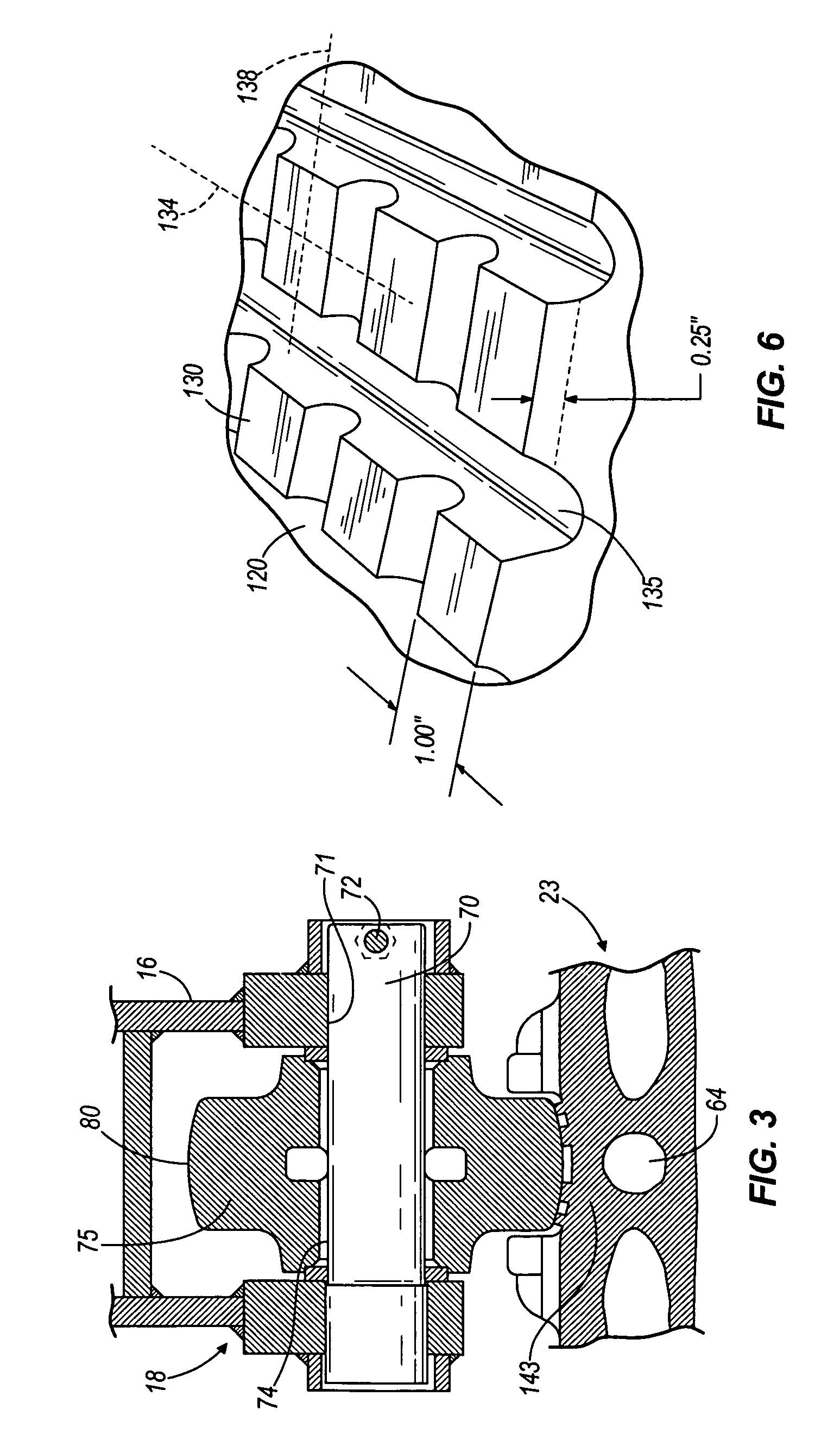

ActiveUS20050151421A1Eliminate high compressive residual stressEliminate severe elongationPortable liftingEndless track vehiclesEngineeringMechanical engineering

Each crawler shoe comprises a main body having an upper surface, a lower surface, and opposite lateral sides and opposite front and rear sides. Each crawler shoe further includes a mechanism on the main body for articulately and releasably connecting the crawler shoe to an adjacent crawler shoe. Each crawler shoe further includes a roller path on the upper surface of the main body and drive lugs attached to the upper surface of the main body on opposite sides of the roller path. Each crawler shoe further includes an upward extending peening portion so that when a downward force is applied to the peening portion, unrestricted metal flow at the peening portion can occur in a first horizontal direction and in a second horizontal direction greater than 45 degrees from the first horizontal direction. More particularly, the peening portion is greater than 0.1 inch tall, and, in the preferred embodiment, about 0.25 inches tall.

Owner:JOY GLOBAL SURFACE MINING INC

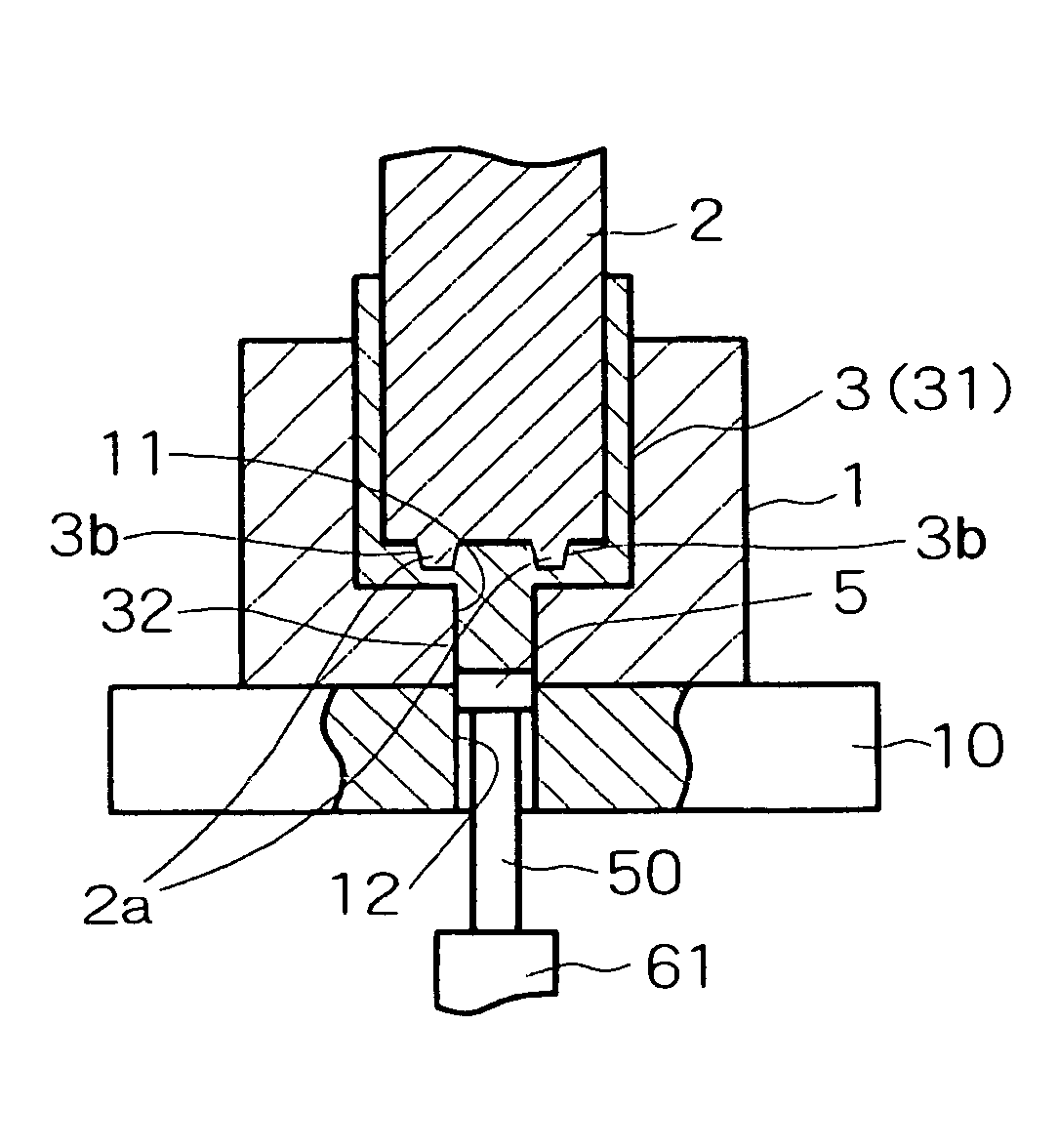

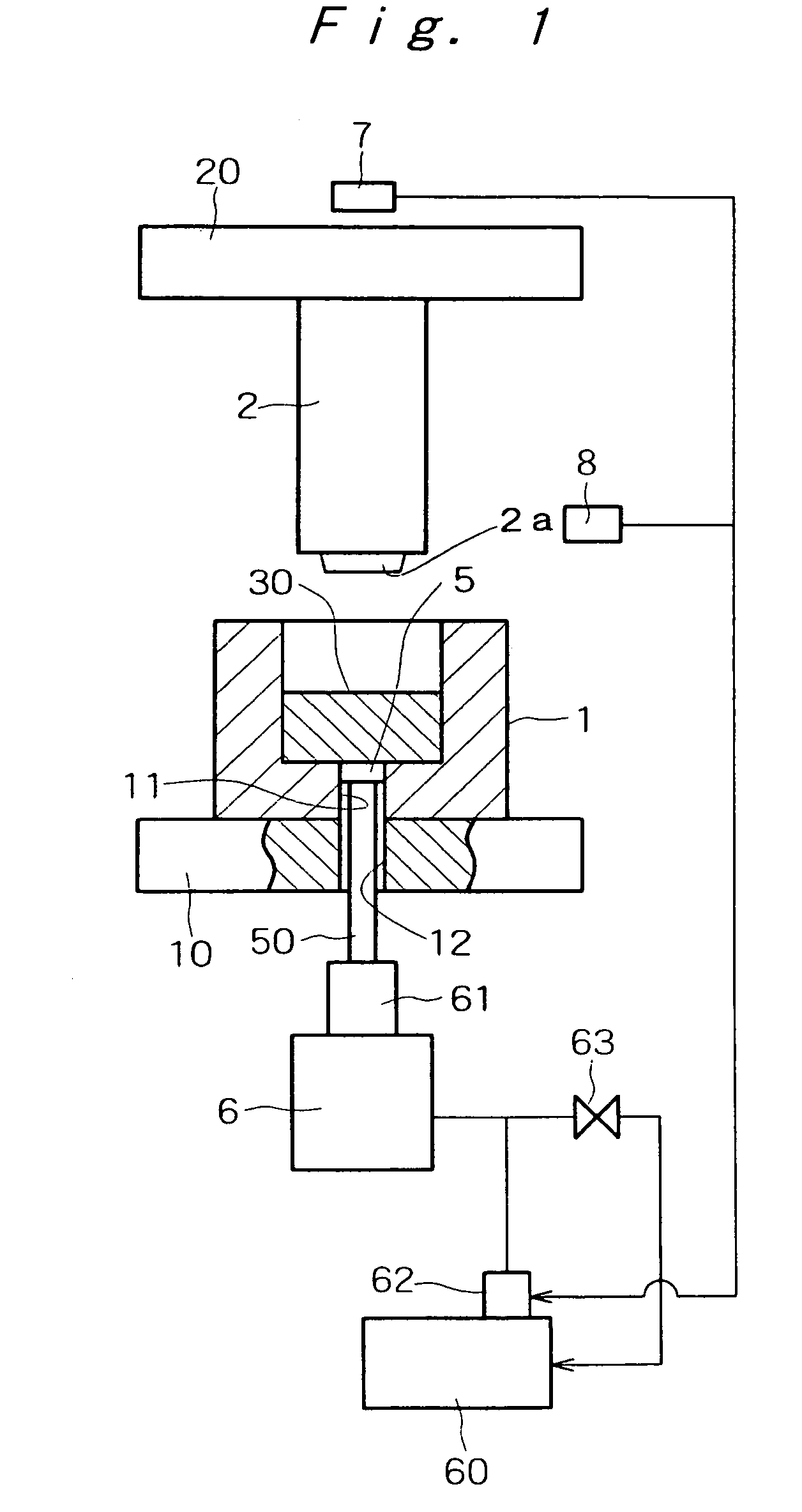

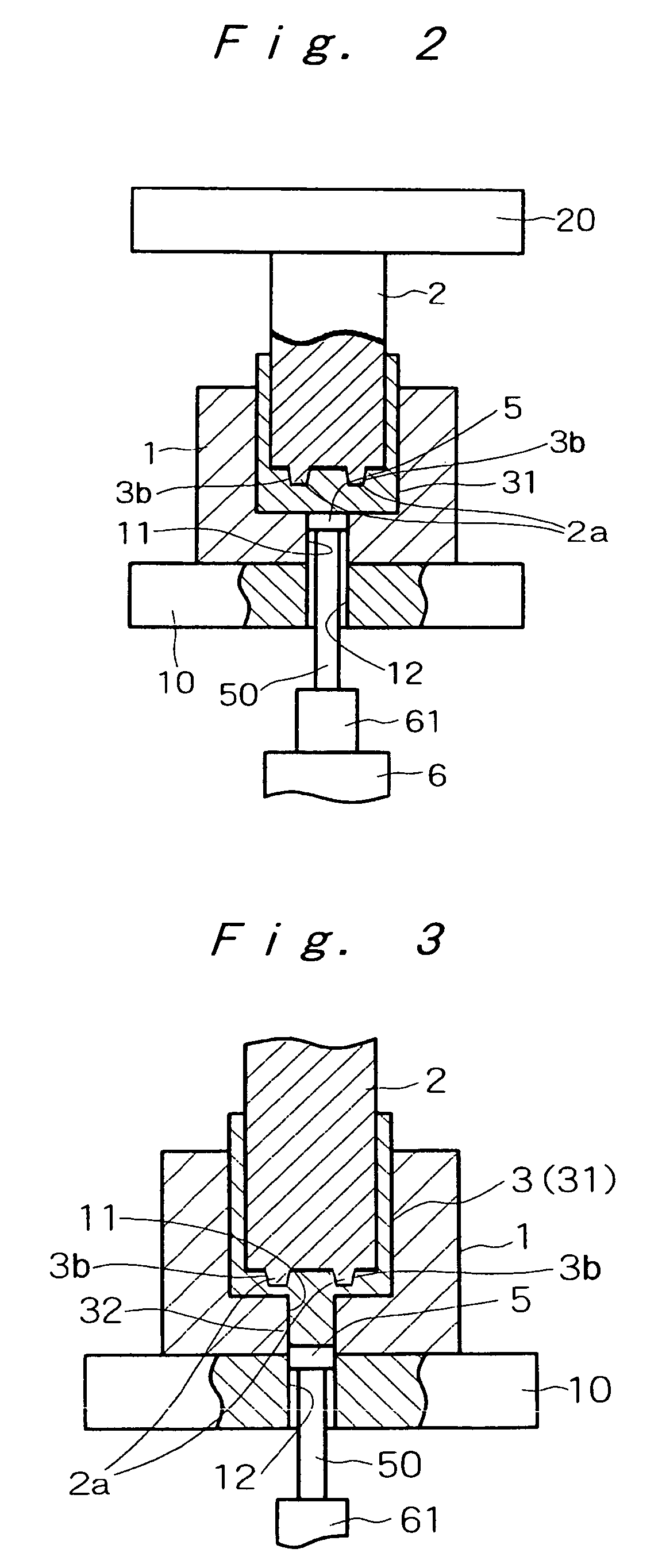

Impact extrusion molded article, and impact extrusion molding method, and an impact extrusion molding apparatus

An impact extrusion molded article that is molded while the metal-flow from a bottom of a slug set in a dice toward the side of the molded product article is suppressed; an impact extrusion molding method for manufacturing the impact extrusion molded article, and an impact extrusion molding apparatus used for the impact extrusion molding method, are provided.

Owner:FURUKAWA SKY ALUMINUM CORP

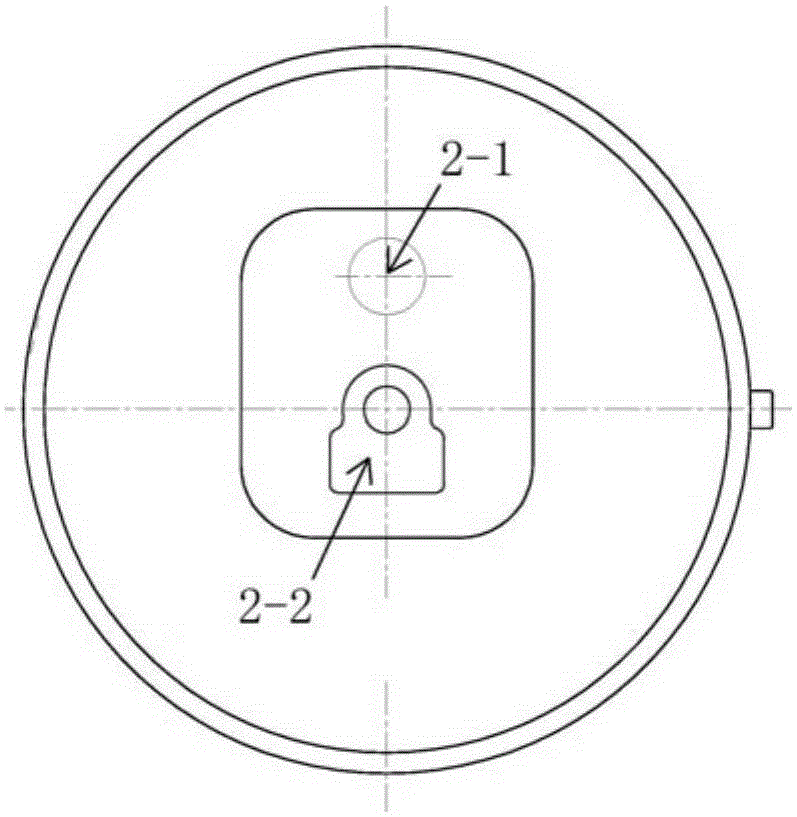

Extrusion forming mould for annular ribs of magnesium alloy shell parts

The invention discloses an extrusion forming mould for annular ribs of magnesium alloy shell parts. The extrusion forming mould mainly comprises an upper mould plate, a mandrel, a split male mould pull rod, split male moulds, tension springs, a male mould sliding guide rail, a split male mould sliding bottom plate, a supporting plate and a cylindrical female mould, wherein the head part of the mandrel is conical, a center hole is formed in the axial direction of the mandrel, one end of the split male mould pull rod is inserted in the center hole, the other end of the split male mould pull rod is fixed on the split male mould sliding bottom plate, the at least two split male moulds are symmetrically arranged around the split male mould pull rod, are fixedly connected with the split male mould pull rod through the tension springs and are arranged in a radial sliding groove of the split male mould sliding bottom plate through the male mould sliding guide rail, a wedge-shaped inclined plane adapting to the conical head part of the mandrel is arranged at the inner side of each split male mould, an arc-shaped extruding bulge is arranged at the arc-shaped wall surface of the outer side of each split male mould, and the arc length of each extruding bulge is more than the distance between each two adjacent extruding bulges. According to the extrusion forming mould, all the split male moulds do radial movement by virtue of the axial movement of the mandrel, metal flows in the radial direction, and thus the annular ribs are generated.

Owner:ZHONGBEI UNIV

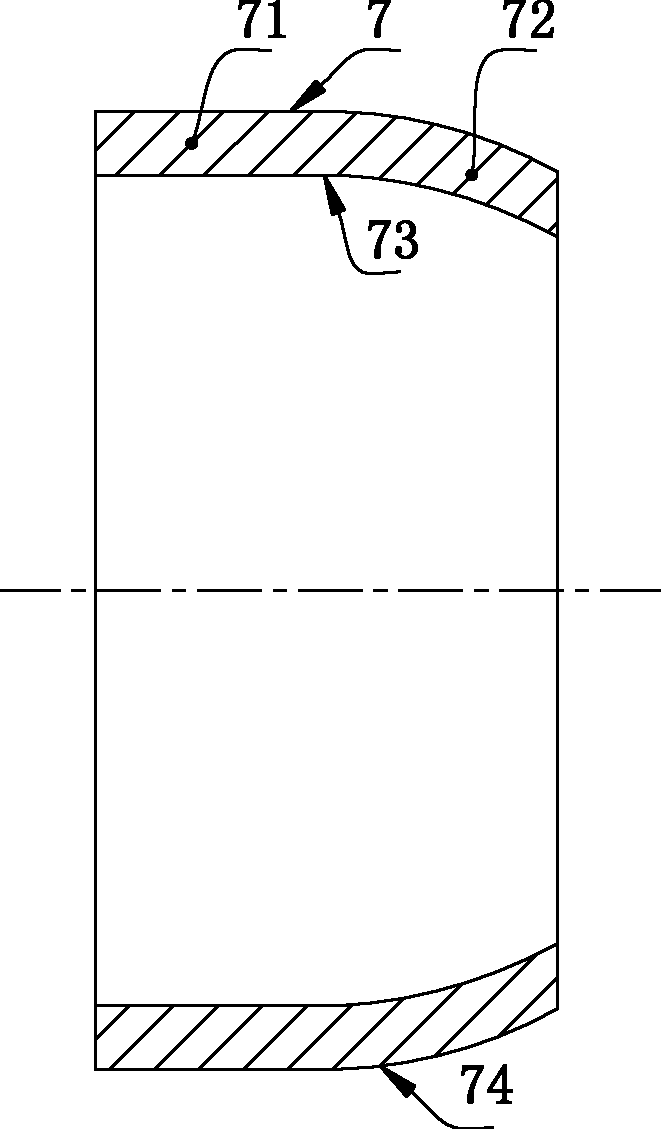

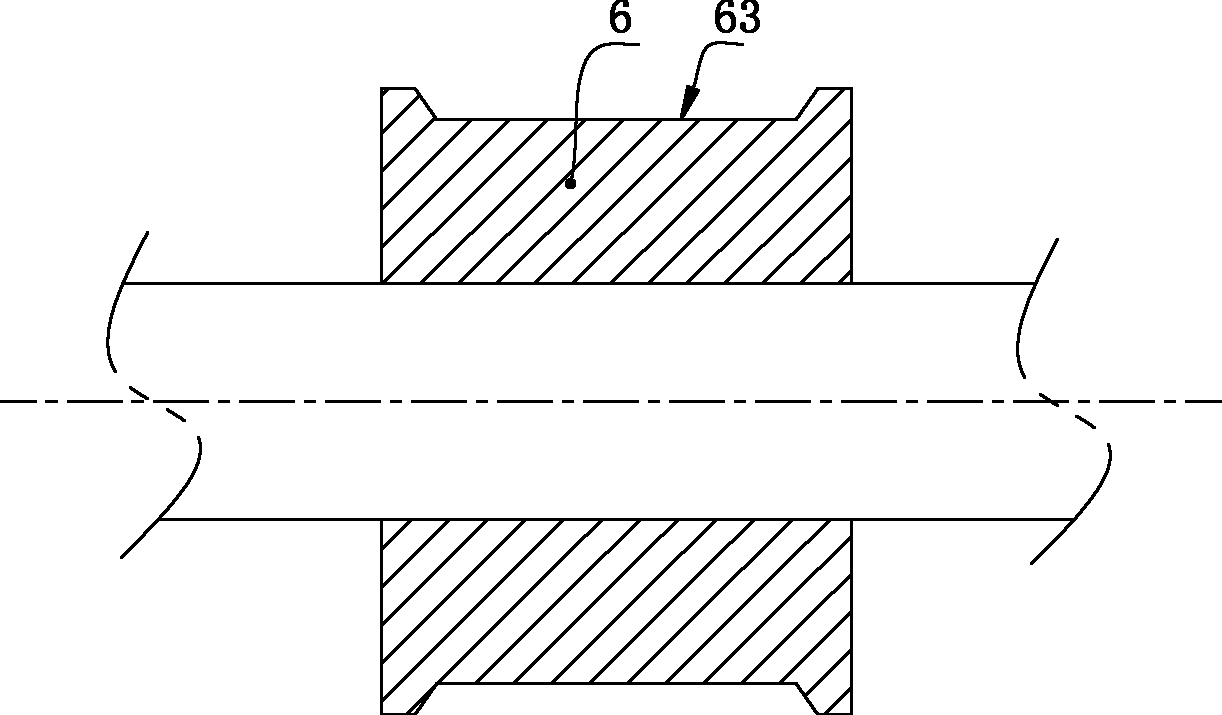

Metal components with inert vapor phase coating on internal surfaces

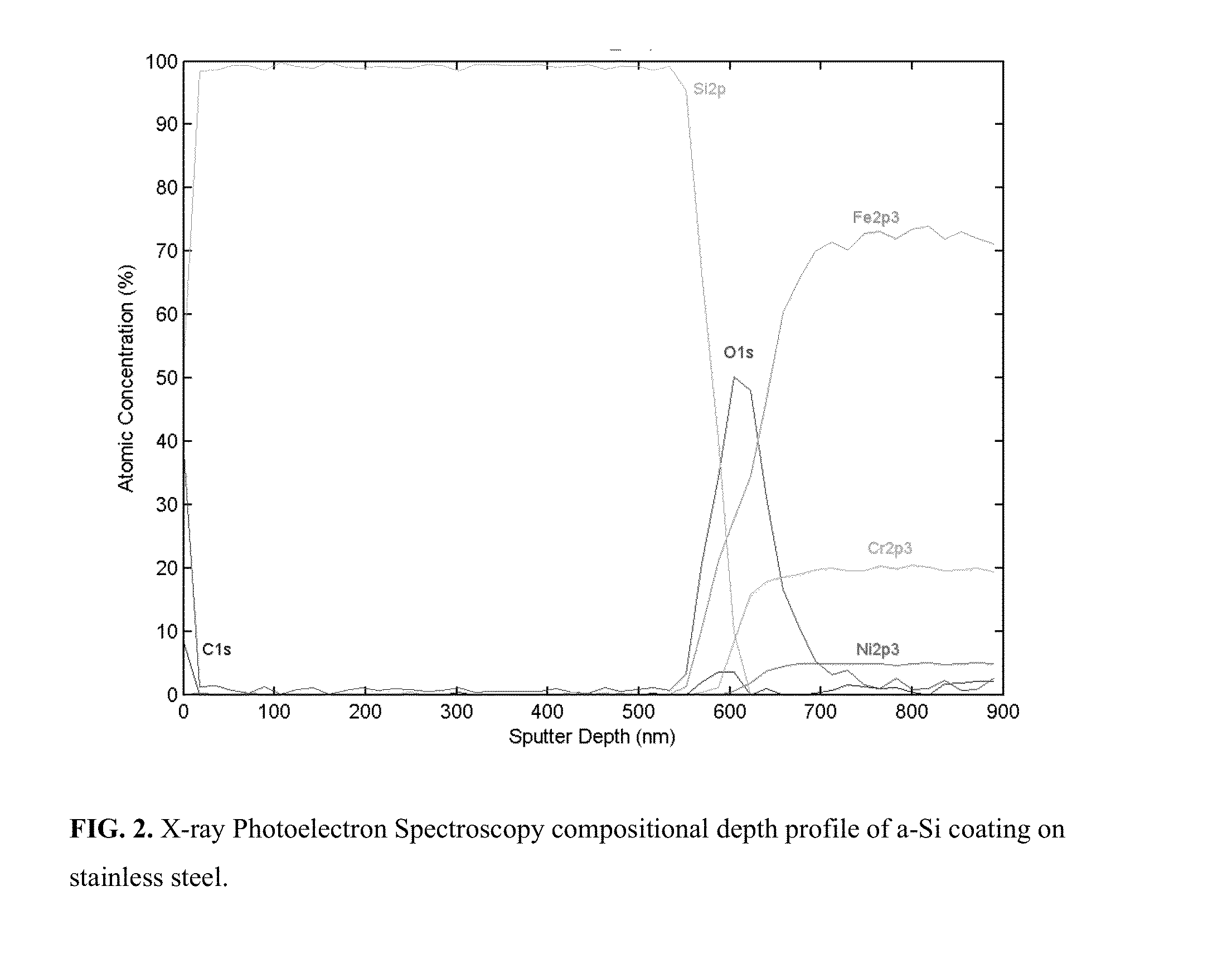

InactiveUS20150024152A1Efficient solutionEnvelopes/bags making machineryLiquid surface applicatorsGas phaseDeposition process

The invention provides metal liquid chromatography components with uniformly coated internal surfaces and methods for achieving the same. The invention addresses the problem of corrosion or interference of metal components in the flow path for LC analyses in which the sample interacts with metal ions or surfaces. The invention also alleviates the difficulties in coating very long metal tubes and very small metal channels with an inert, continuous coating that adheres well to metal surfaces. The metal flow path is rendered inert by the coating, and thus compatible with bioanalytical separations, for example, by using a vapor phase deposition process to coat the inner surfaces with a coating that continuously covers all metal surfaces in the flow path.

Owner:AGILENT TECH INC

Forging forming process of heteromorphic transition section of super large pressure vessel

The invention relates to a forging process of super large workpieces and provides a forging forming process of a heteromorphic transition section of a super large pressure vessel. The process comprises the following steps of: 1) punching; 2) drawing out; and 3) reaming with a special lower reaming anvil by adopting free forging, wherein the forming surface of the special lower reaming anvil is raised along the low and middle parts of the two axial ends of a forging stock; aiming at forming of each indexing region of the forging stock, firstly the two axial ends of the indexing region are deformed through forging and pressing and are matched with the middle raise of the special lower reaming anvil to form bidirectional axial limits; and after reaming, the inner circumferential surface of the forging stock comprises an inner concave surface formed through the middle raise of the special lower reaming anvil. The process has the following beneficial effects that: through the final inner concave surface of the inner circumferential surface of the forging stock, the dressing metals are saved, the raw material consumption can be reduced, the machining allowance is reduced, the metal flow lines are prevented from being cut off and the forging block quality is improved; and the process is suitable for manufacturing the heteromorphic transition section forging of the super large pressure vessel.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

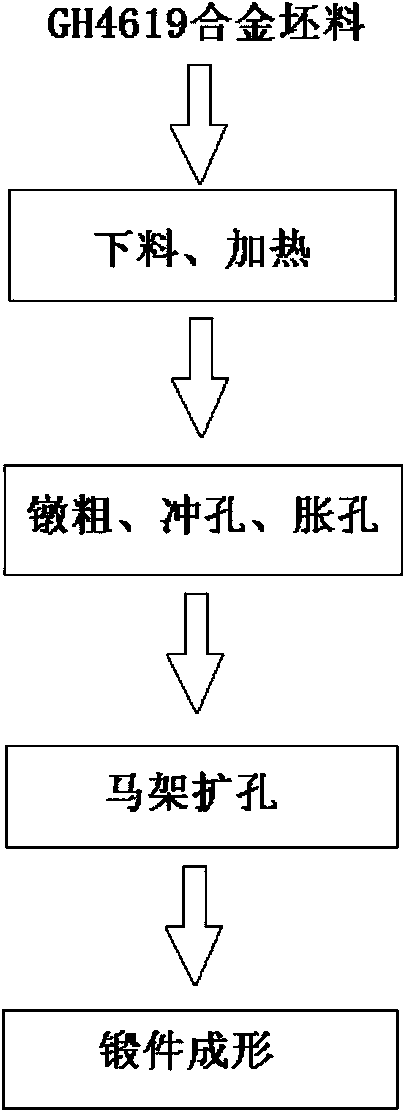

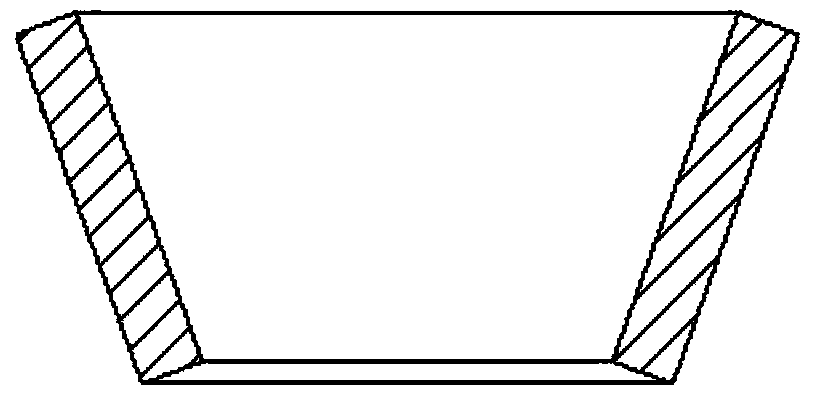

Method for manufacturing box shell of large special-shaped low-pressure turbine used for aircraft engine

The invention discloses a method for manufacturing a box shell of a large special-shaped low-pressure turbine used for an aircraft engine. A GH 4169 alloy blank is chamfered by R20mm and is heated in a three-section heating mode at the temperature of 845-855 DEG C, 975-985 DEG C and 1015-1025 DEG C, the heat-preservation time of each heating temperature section is 6min / 10mm, then upsetting, punching, hole expanding and trestle chambering are carried out, and ultimately the box shell is finished through forged forming. According to the method, a large special-shaped bearing ring supercritical rolling technique replaces a traditional rectangular ring rolling technique, part metal flow lines are complete, large amounts of mechanical machining is needless, performance is excellent, the use rate of materials is high, raw materials are saved, manufacturing cost is low, the manufacturing cycle is short, structural stress inside a product is basically eliminated, and follow-up machining performance of the product is guaranteed.

Owner:GUIZHOU AVIATION TECHN DEV

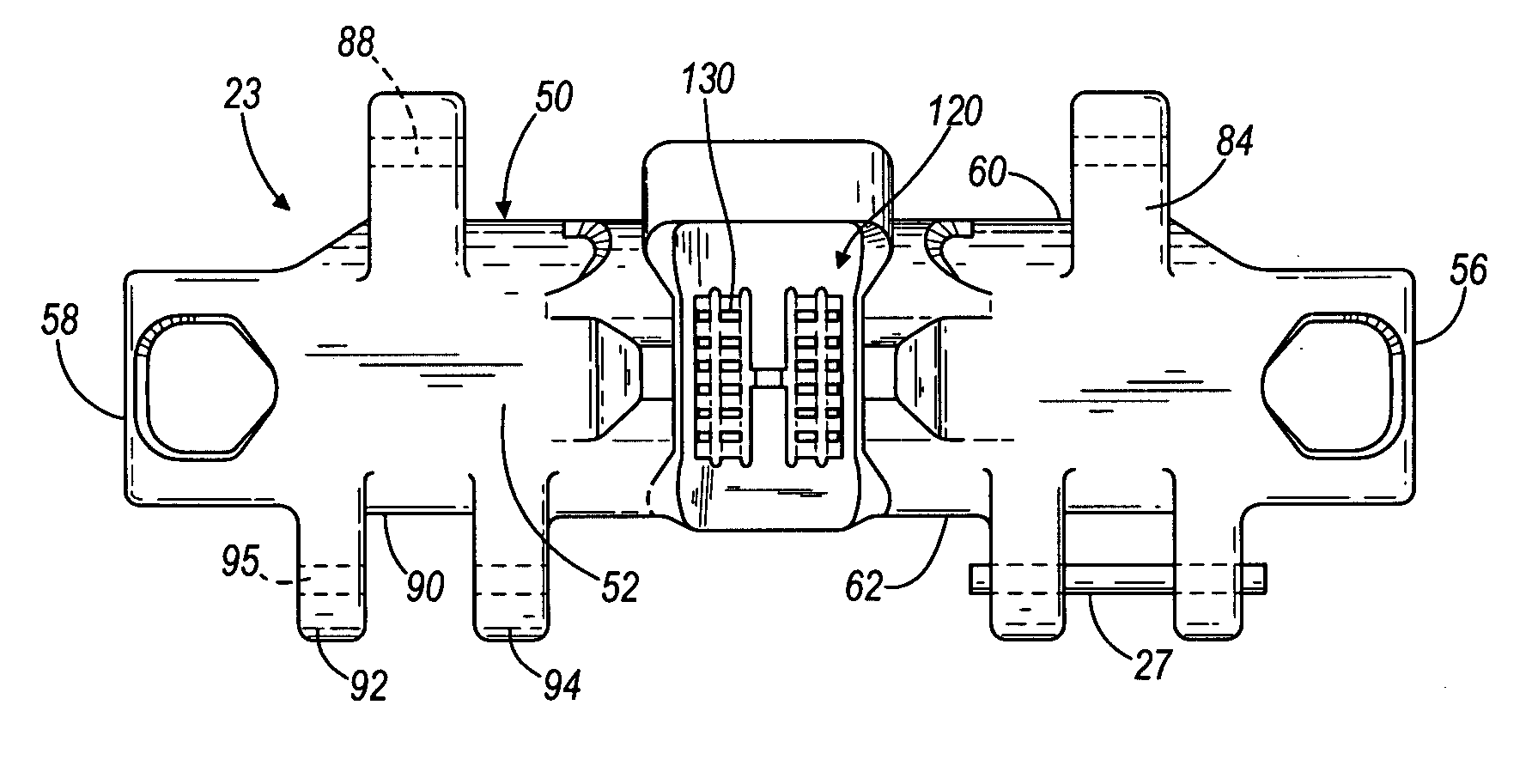

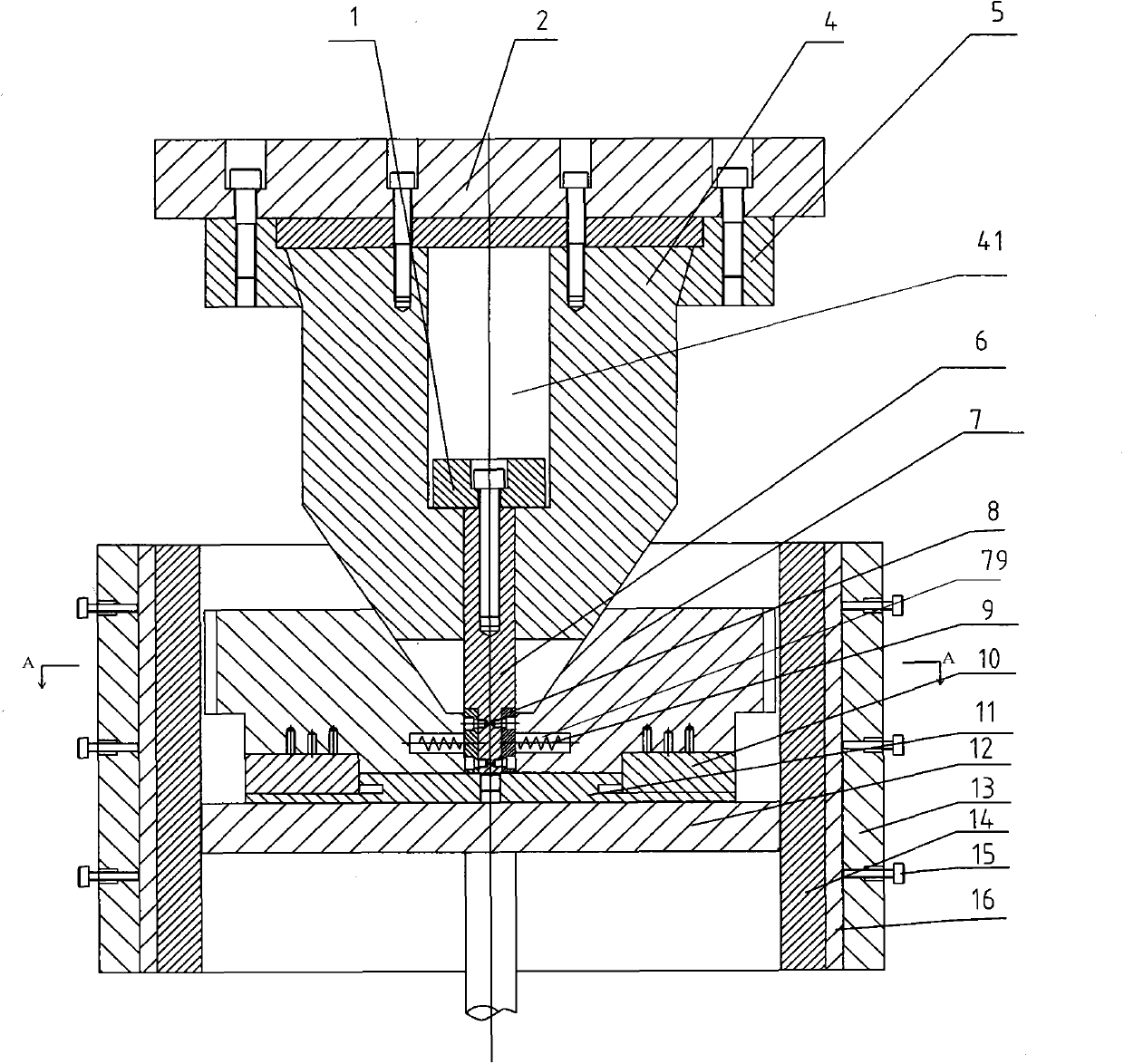

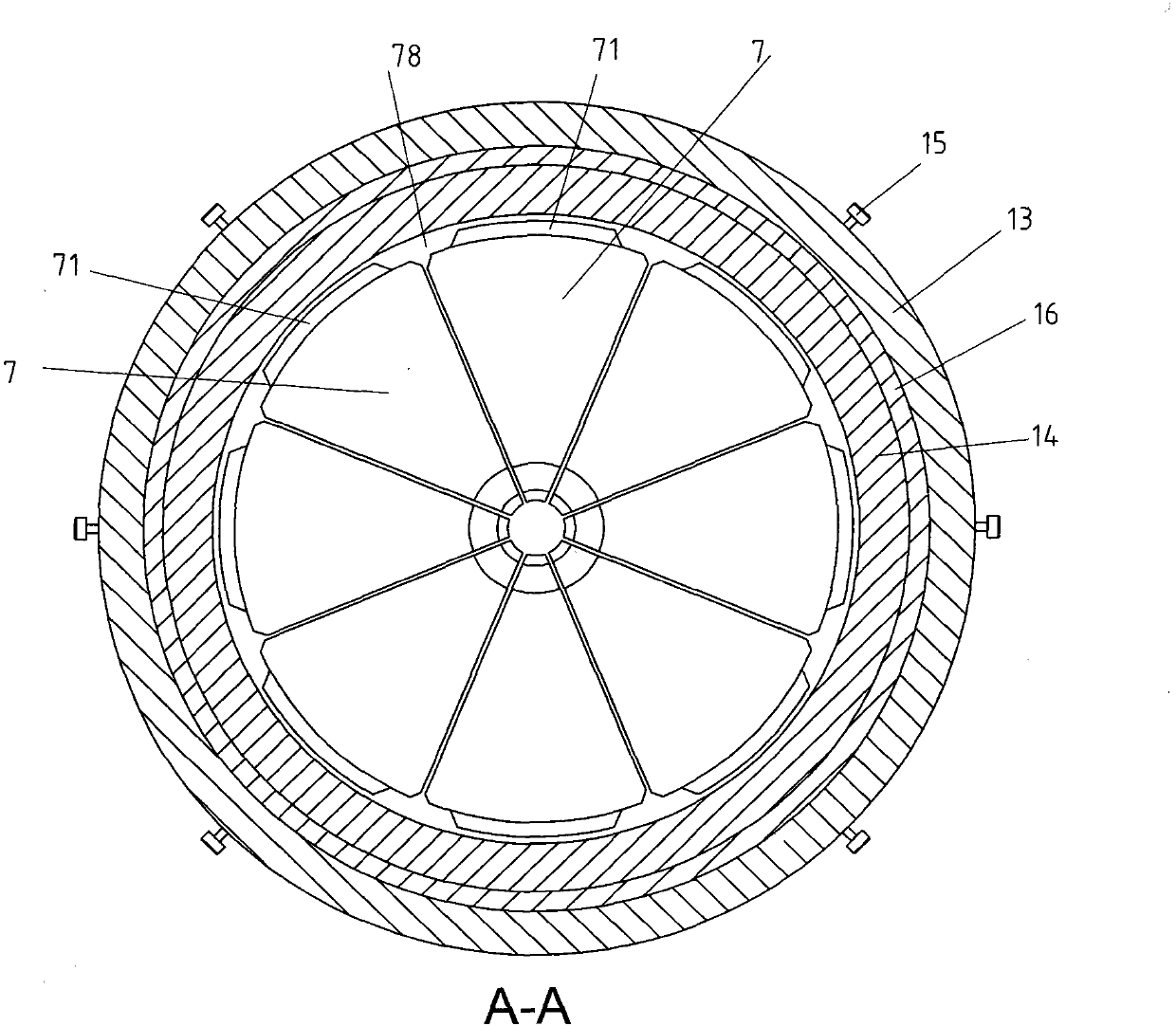

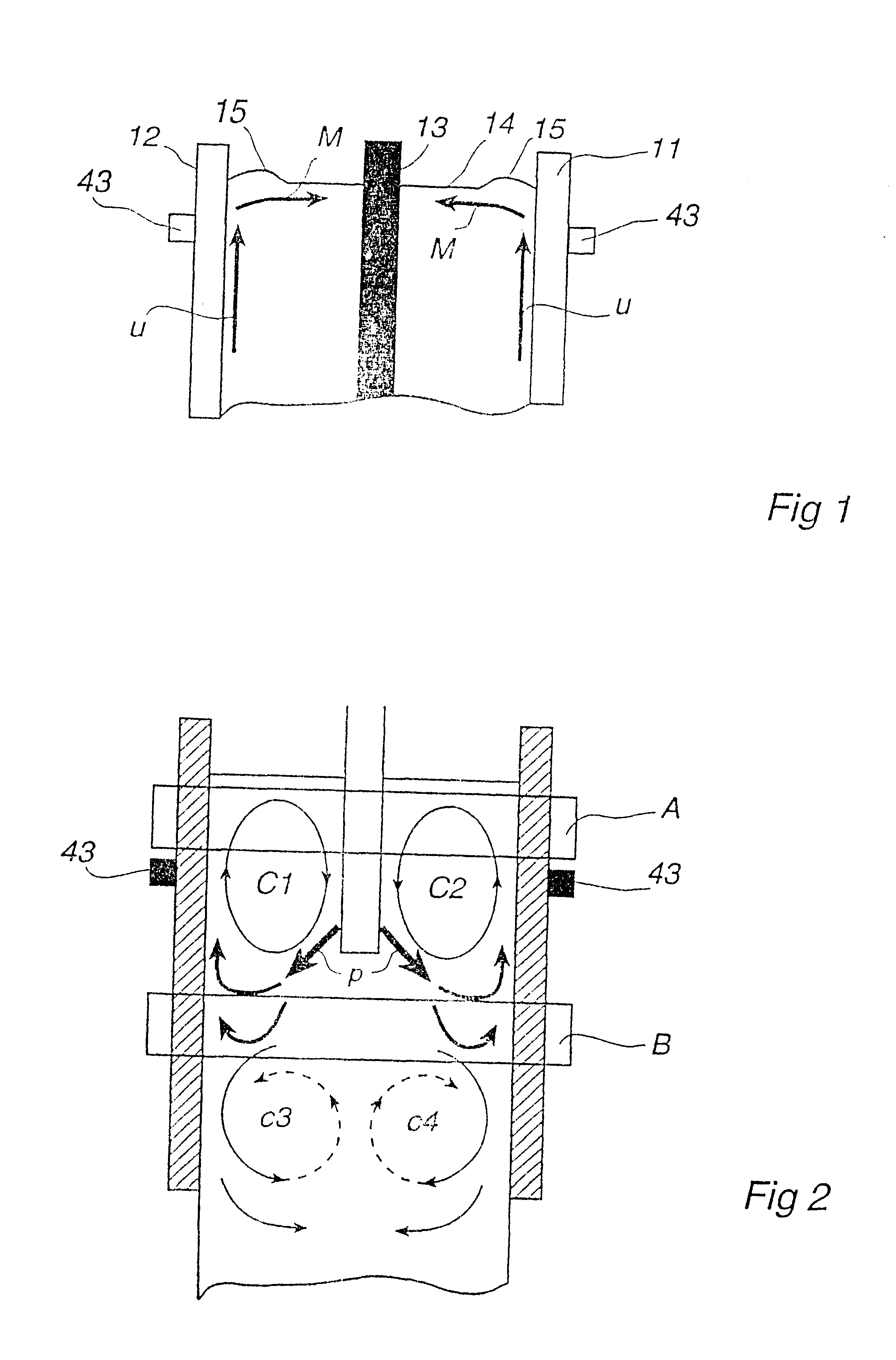

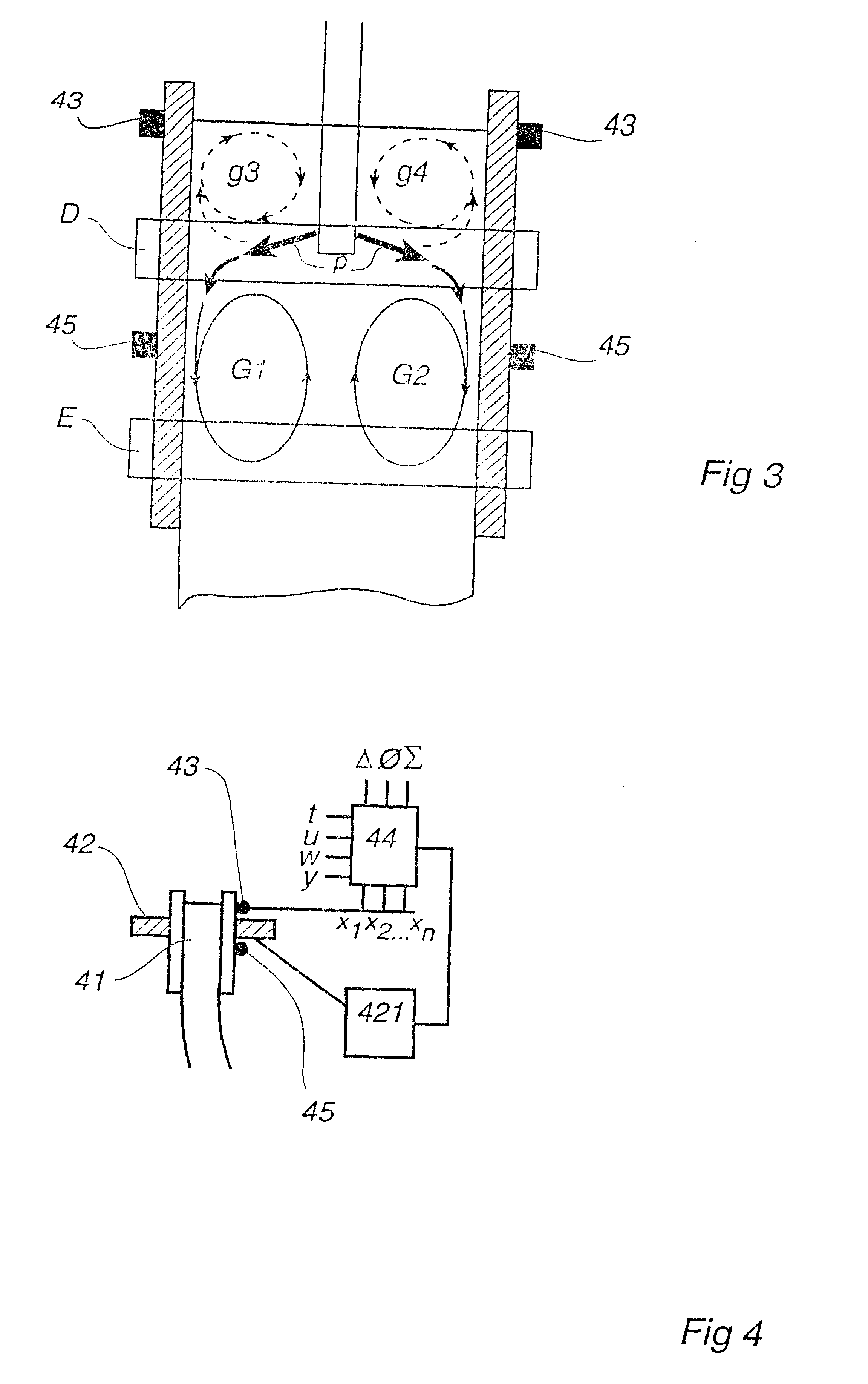

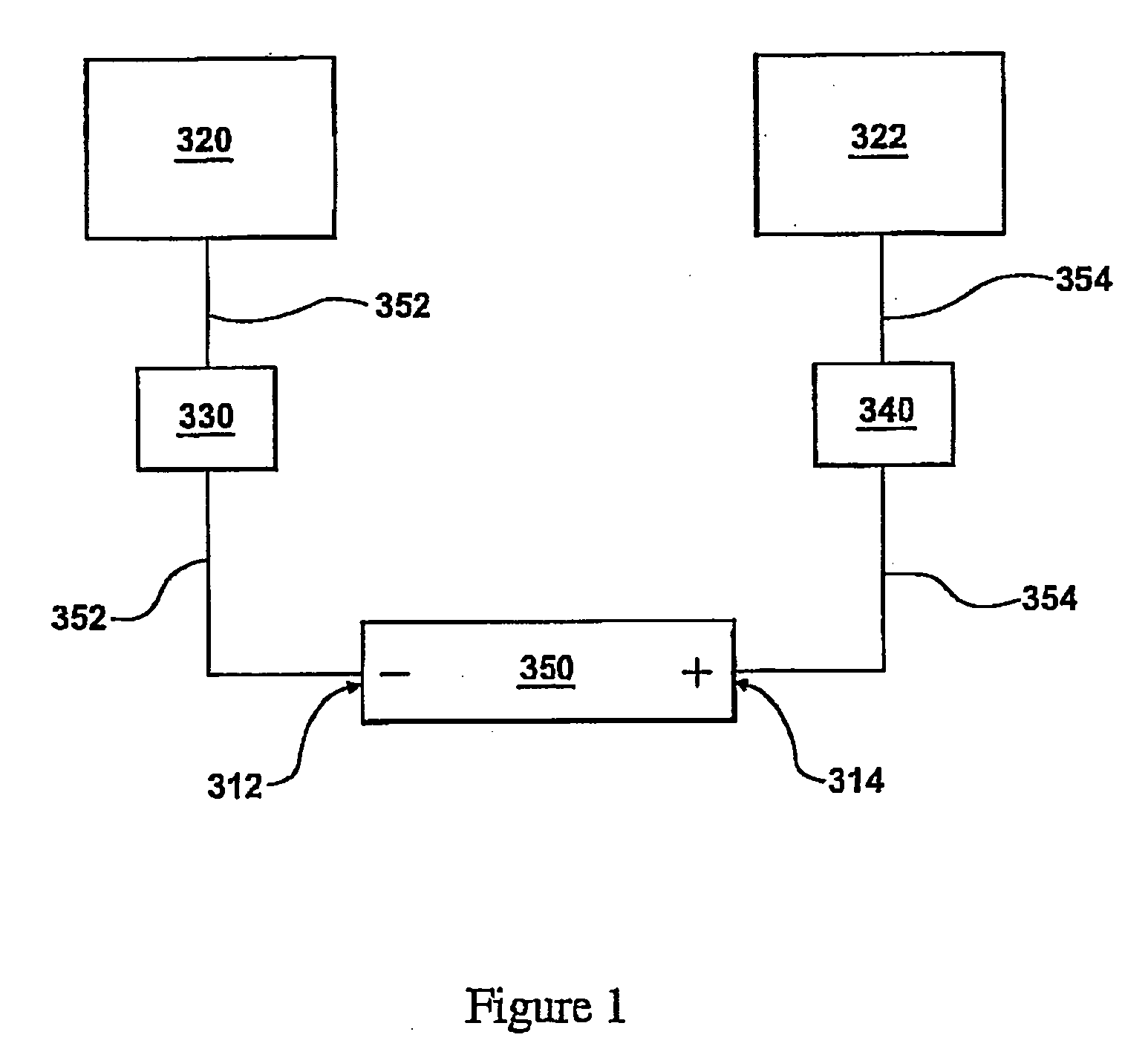

Method and device for control of metal flow during continuous casting using electromagnetic fields

InactiveUS6494249B1Improve productivityImprove abilitiesCasting safety devicesMould controlling devicesVolumetric Mass DensityElectromagnetic field

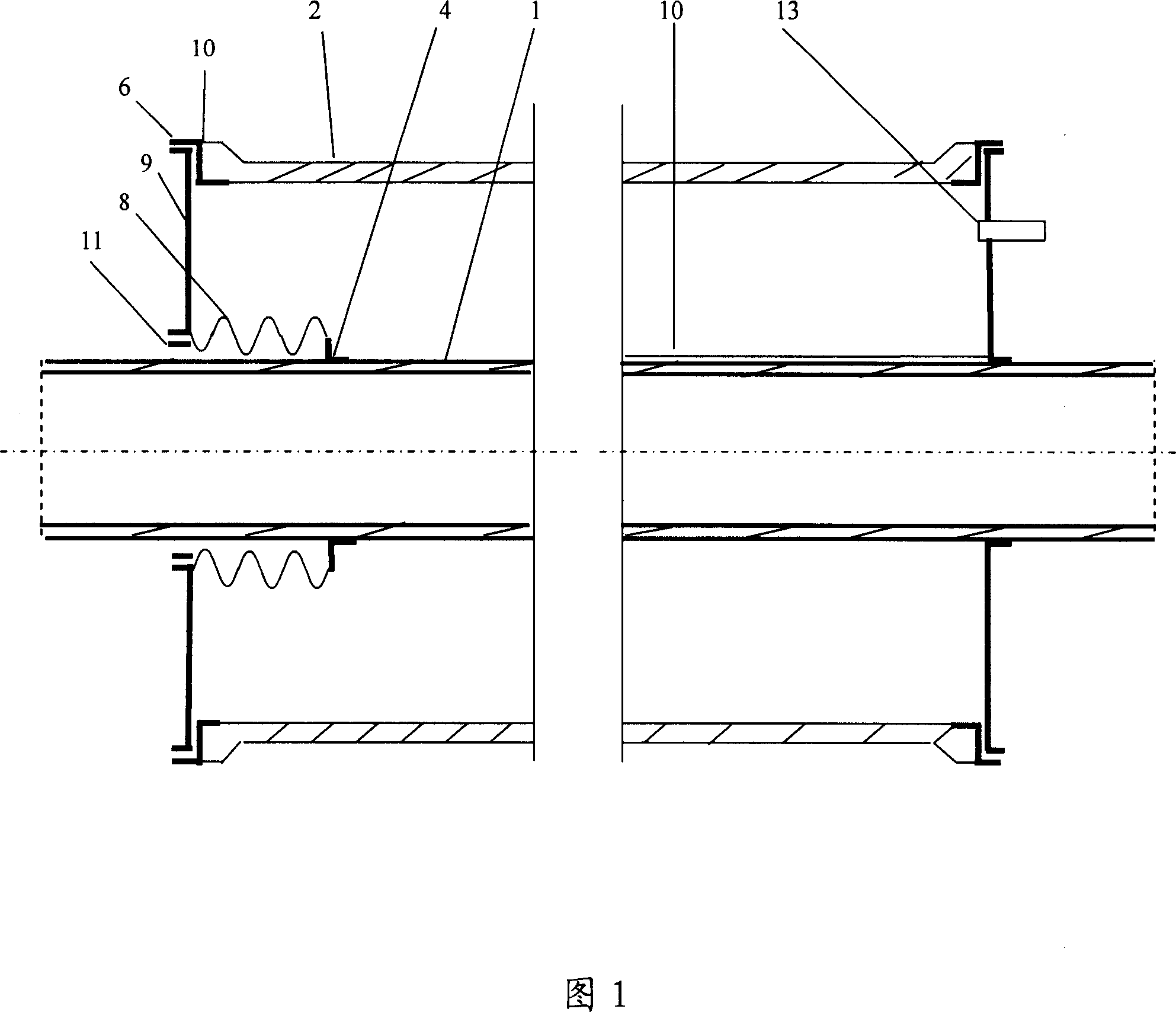

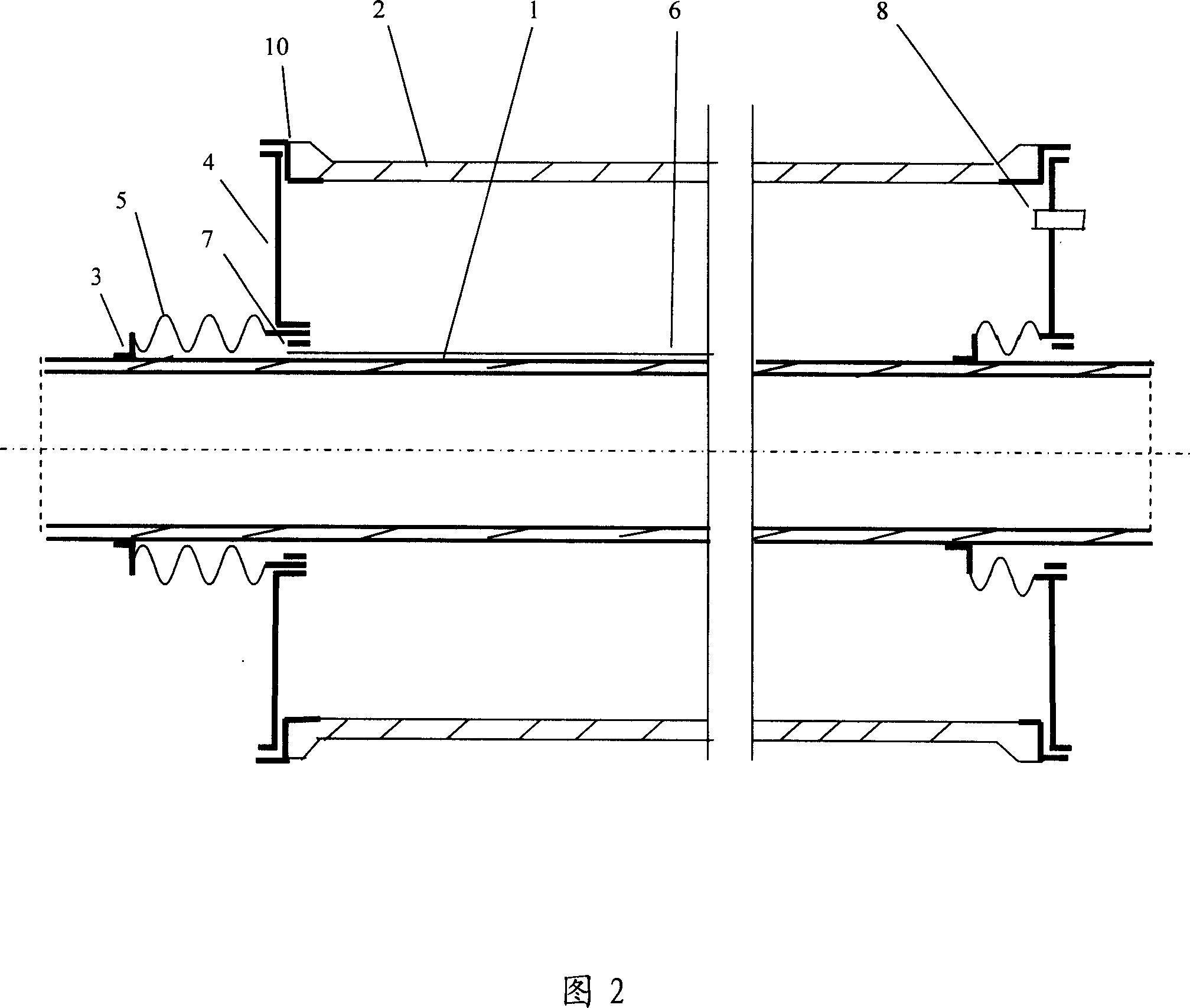

A method and a device for continuous or semi-continuous casting of metal. A primary flow (P) of hot metallic melt supplied into a mold is acted upon by at least one static or periodically low-frequency magnetic field to brake and split the primary flow and form a controlled secondary flow pattern in the non-solidified parts of the cast strand. The magnetic flux density of the magnetic field is controlled based on casting conditions. The secondary flow (M, U, C1, C2, c3, c4, G1, G2, g3, g4, O1, O2, o3, o4) in the mold is monitored throughout the casting and upon detection of a change in the flow, information on the detected change monitored flow is fed into a control unit (44) where the change is evaluated and the magnetic flux density is regulated based on this evaluation to maintain or adjust the controlled secondary flow.

Owner:ABB (SCHWEIZ) AG

Clad material solid/liquid composite dual-solidification continuous casting and forming equipment and method

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

Electromagnetic vibrating, stirring and friction-welding stirring-head and welding method thereof

InactiveCN101574756ALarge plastic deformationChanging the plastic flow modeNon-electric welding apparatusFriction weldingEngineering

The invention discloses an electromagnetic vibrating, stirring and friction-welding stirring-head and a corresponding welding method thereof. An electromagnetic vibrating device is adopted to assist electromagnetic vibration during the process of stirring, and friction-welding to lead the stirring-head to vibrate at high frequency simultaneously when the stirring-head rotates at a high speed to transfer energy to the metals in a stirring and friction area so as to lead the metals to achieve plastic state more quickly; the thermoplastic metals receive the composite effects of a friction force and the high-frequency vibrating energy during the rotating process of a stirring needle, thus being capable of effectively improving the velocity of the thermoplastic metal flow, improving the forming efficiency and quality of welding seams and being more effectively used for the welding and processing of high-melting point materials and thick boards.

Owner:CHONGQING UNIV

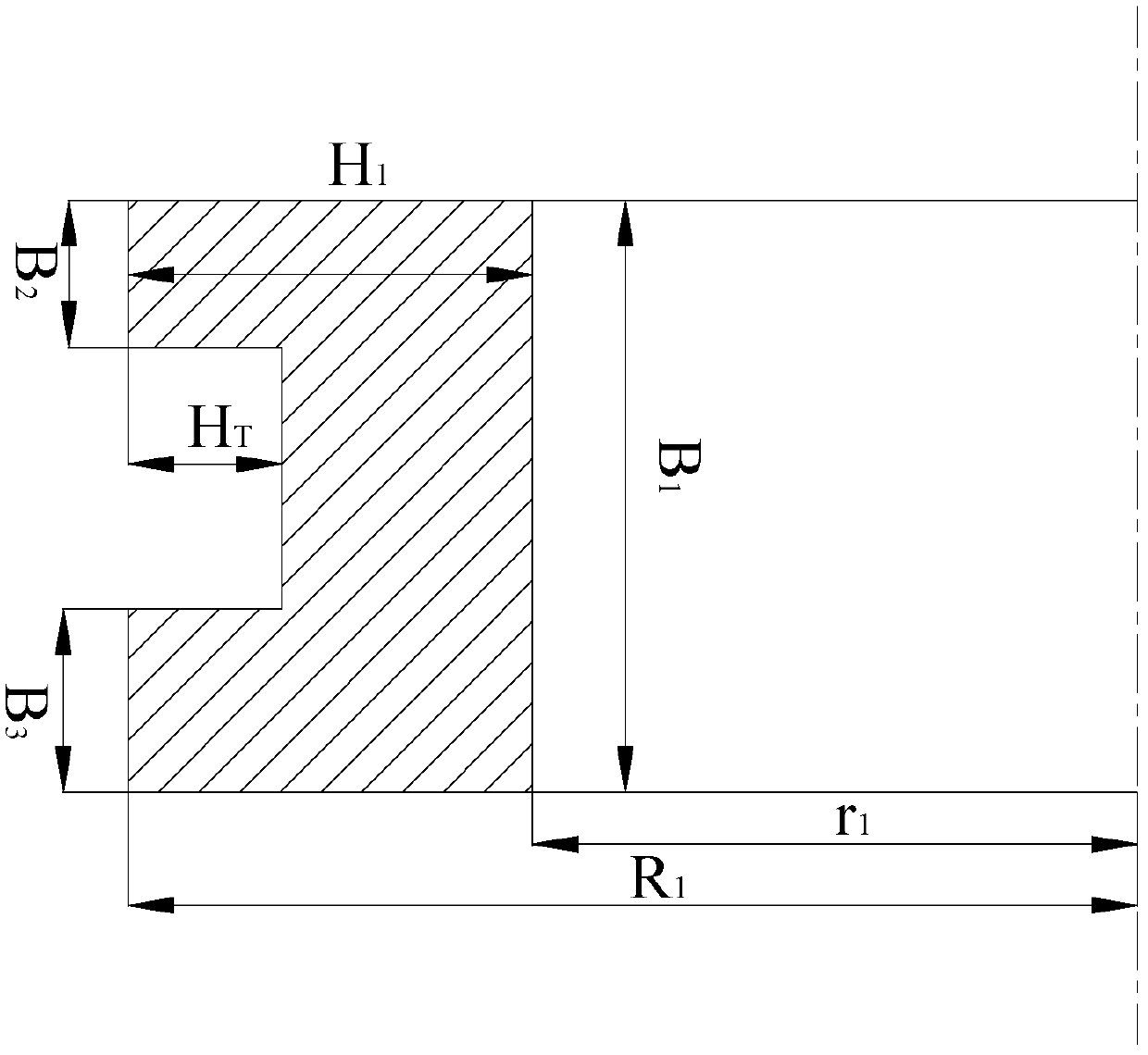

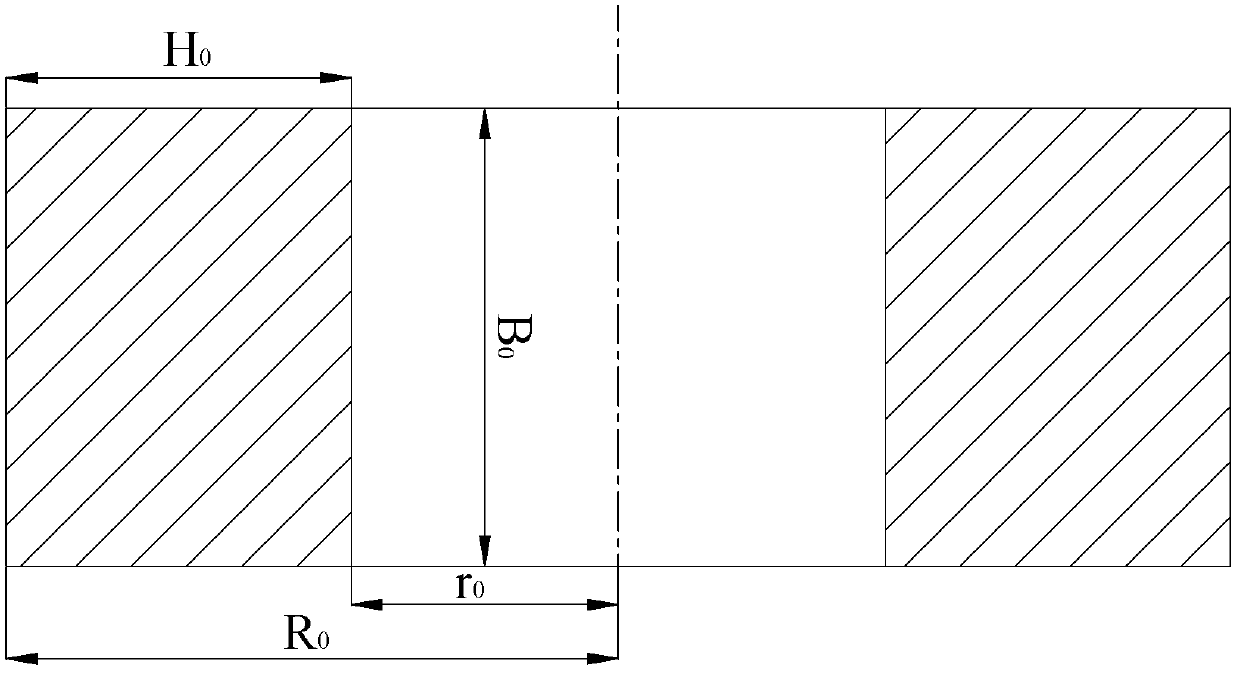

Method for radially and axially rolling and forming large-sized double-edge stepped ring parts

ActiveCN102601278AAvoid damageIncrease productivityMetal rollingStructural engineeringMechanical engineering

The invention relates to a method for radially and axially rolling and forming large-sized double-edge stepped ring parts. The method includes reasonably designing a ring part blank and a rolled hole, controlling a rolling process, directly rolling the rectangular ring part blank to form a double-edge stepped ring part, rolling the hole by a working surface of a driving roll and a working surface of a core roll, and determining the size of the working surface of the driving roll and the size of the working surface of the core roll according to rolling linear speed, equipment parameters, rolling deformation conditions, the size of the ring part blank and the size of the ring part; controlling the rolling process according to a pre-rolling stage, a main rolling stage and an integral rolling stage; and completing the rolling process when the measured outer diameter of the ring part reaches a preset value. By the aid of accumulation of continuous local plastic deformation, the diameter of the ring part is enlarged, the outline of the double-edge stepped section of the ring part is integrally formed, energy, material and working hour consumption is effectively reduced, metal flow line distribution of the ring part is improved, production efficiency and performances of the product are enhanced, and production cost is reduced.

Owner:WUHAN UNIV OF TECH +1

Laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method

ActiveCN102922153ASuppression of drippingEliminate undercut defectsLaser beam welding apparatusVertical planeArchitectural engineering

The invention provides a laser guide GMAW (Gas Metal Arc Welding) electric arc compound transverse welding method, relates to a transverse welding method and solves the problem of the existing welding method that fused metal flows down when transverse welding is carried out in a vertical plane so as to cause undercut and deviation of a central line of a welding line. The laser guide GMAW electric arc compound transverse welding method is carried out by the following steps of: 1, carrying out oil-removing and oxidization-film-removing treatment on a work piece to be welded; 2, filling a welding wire; and 3, starting a laser device and a GMAW electric arc welding machine. With the adoption of the laser guide GMAW electric arc compound transverse welding method, the flowing of the fused metal can be controlled under the condition with a large welding current, so that the undercut defect of the welding line is eliminated and the central line of the welding line is rightly centered. The laser guide GMAW electric arc compound transverse welding method is applicable to the field of metal transverse welding engineering.

Owner:哈尔滨工大焊接科技有限公司

Crawler shoe with peening pads in roller path

ActiveUS6929335B2Eliminate high compressive residual stressInhibit the shoes from hingingPortable liftingEndless track vehiclesMechanical engineeringPeening

Each crawler shoe comprises a main body having an upper surface, a lower surface, and opposite lateral sides and opposite front and rear sides. Each crawler shoe further includes a mechanism on the main body for articulately and releasably connecting the crawler shoe to an adjacent crawler shoe. Each crawler shoe further includes a roller path on the upper surface of the main body and drive lugs attached to the upper surface of the main body on opposite sides of the roller path. Each crawler shoe further includes an upward extending peening portion so that when a downward force is applied to the peening portion, unrestricted metal flow at the peening portion can occur in a first horizontal direction and in a second horizontal direction greater than 45 degrees from the first horizontal direction. More particularly, the peening portion is greater than 0.1 inch tall, and, in the preferred embodiment, about 0.25 inches tall.

Owner:JOY GLOBAL SURFACE MINING INC

Damping type flow control forming process and die for aluminium-alloy rib-plate forging

ActiveCN103357804ASmall forming forceEffective control of flow directionForging/hammering/pressing machinesDecompression chamberEngineering

The invention provides a damping type flow control forming process for an aluminium-alloy rib-plate forging. The process comprises two forming steps of pre-forging and finish-forging, a forming load is reduced through a decompression chamber during pre-forging, and the damping force is applied to a web portion of the forging during finish-forging, so that the web portion is prevented from plastic deformation, and deformation only occurs in rib portions. The invention also provides a die for implementing the method. A damper is arranged inside a concave die to apply the acting force to the web portion of the forging. According to the process and the die, metal flow is controlled through the damping force, so that metal distribution is adjusted reasonably during forming, and the forming load is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing process of asymmetric seamless hollow profile

ActiveCN105149372AImprove surface qualityDimensionally stableExtrusion diesNon symmetricHigh probability

The invention relates to a manufacturing process of an asymmetric seamless hollow profile. The manufacturing process comprises the following steps: a, prefabricating an extrusion die, adopting the dual-hole design that a balancing rod extrusion hole and a profile extrusion hole are formed in a squeezing die, and arranging an extrusion hole forming pin in the inner chamber of an extrusion shaft; b, performing center adjustment of the extrusion die, and conducting matching adjustment of the extrusion hole forming pin and the center of the squeezing die; c, preheating the extrusion die; d, preheating an ingot; e, charging the ingot into the extrusion die for extrusion molding to obtain an aluminium alloy profile and a round bar which serves as a balancing rod; f, performing on-line quenching; g, performing on-line stretching, straightening and finishing; and h, performing artificial ageing treatment. The manufacturing process is suitable for producing the 6A02 aluminium alloy seamless non-centrosymmetric specially-shaped hollow profile on a 75 MN large-scale extruder and solves the problems of non-uniform metal flow rate, eccentricity, high probabilities of surface scratching and peeling and the like, which are caused by large difference between the wall thicknesses on two sides of the profile.

Owner:TIANJIN HEXING AERONAUTICAL MATERIAL CO LTD

Ex vivo antimicrobial devices and methods

A method and device for destroying and inhibiting exposure to microbes and infection includes a first element and a second element, and a power source. At least one of the elements includes antimicrobial metal, which, when energized by the power source, produces ions that are lethal to microbes. The device can be incorporated into virtually any useful object. During normal use of the object, electrical communication is established between the two elements, causing current supplied from the power source to flow through the antimicrobial metal. The two elements are configured and arranged to ensure that ions flowing from the antimicrobial metal flow through the region in which it is desired to kill microbes. The antimicrobial metal can be on the surface of the element, incorporated into the material making up the element, or provided in any other way that allows the antimicrobial effect to be achieved.

Owner:AIONX ANTIMICROBIAL TECH INC

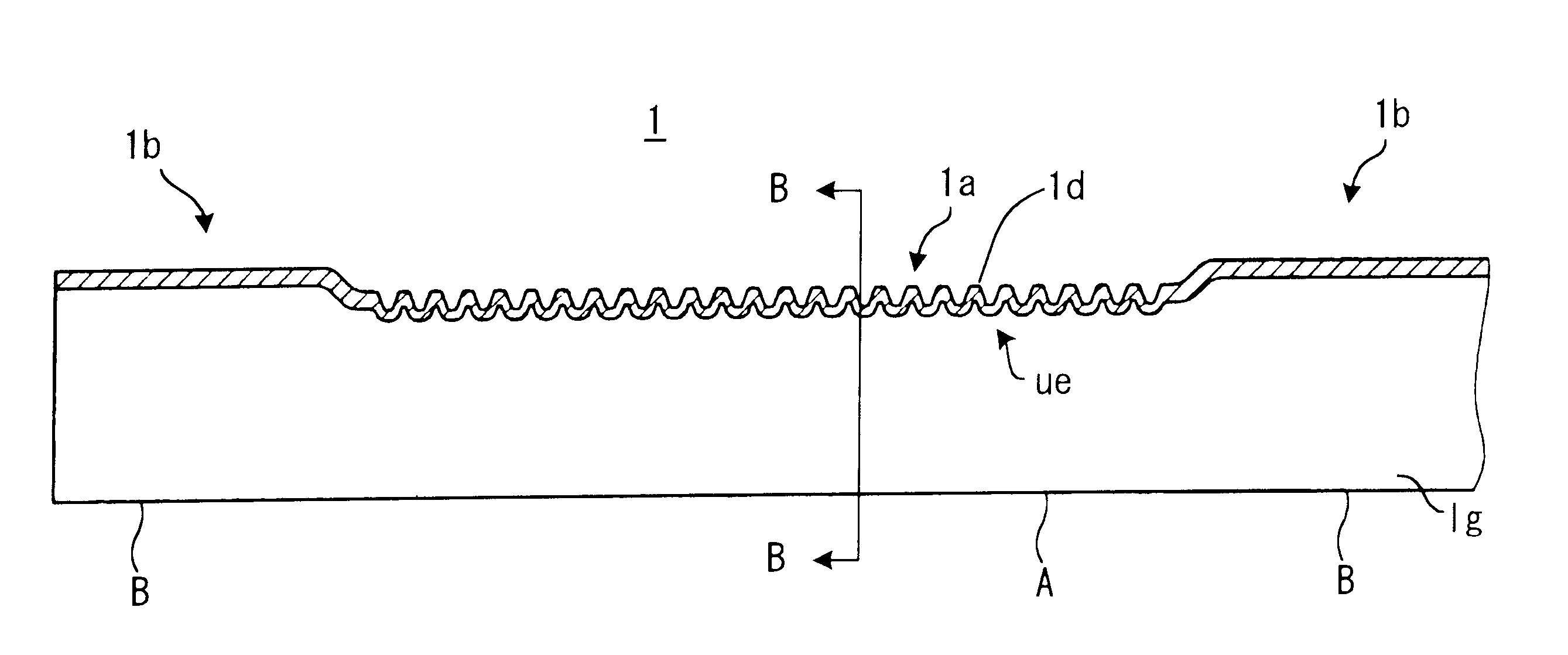

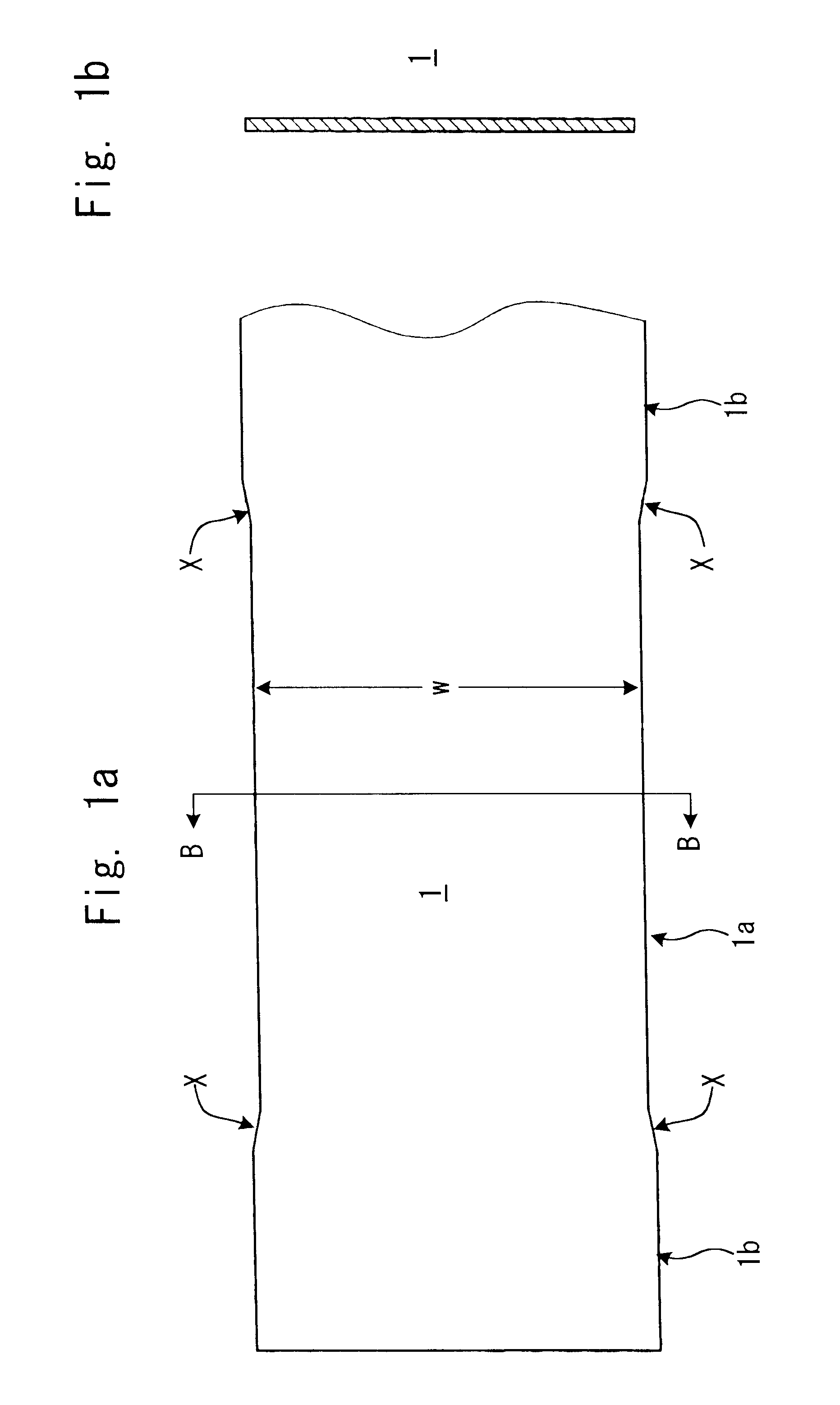

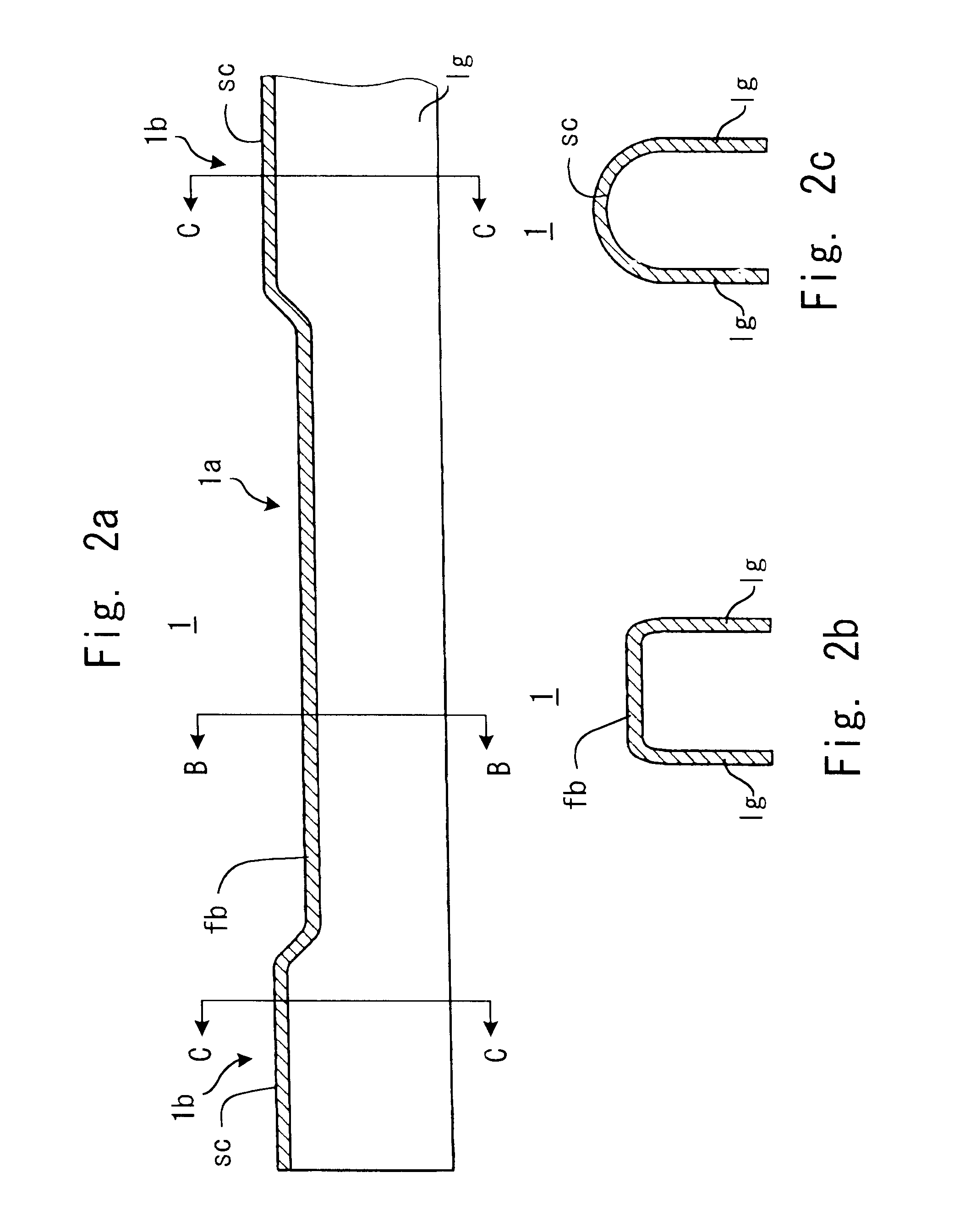

Hollow rack shaft

A hollow rack shaft is produced by forming a plate work piece and has continuous metal flow along the contour of rack teeth surface without being cut. A series of wave-like concave-convex sections is formed on the inner surface of the shaft. Thickness of tooth body and tooth bottom of the rack teeth is adjusted by dimensions of the unevenness. Thereby, stress concentration at each point of the rack shaft is prevented and the shaft is strengthened and its weight reduced.

Owner:NSK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com