Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

242results about How to "Small forming force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

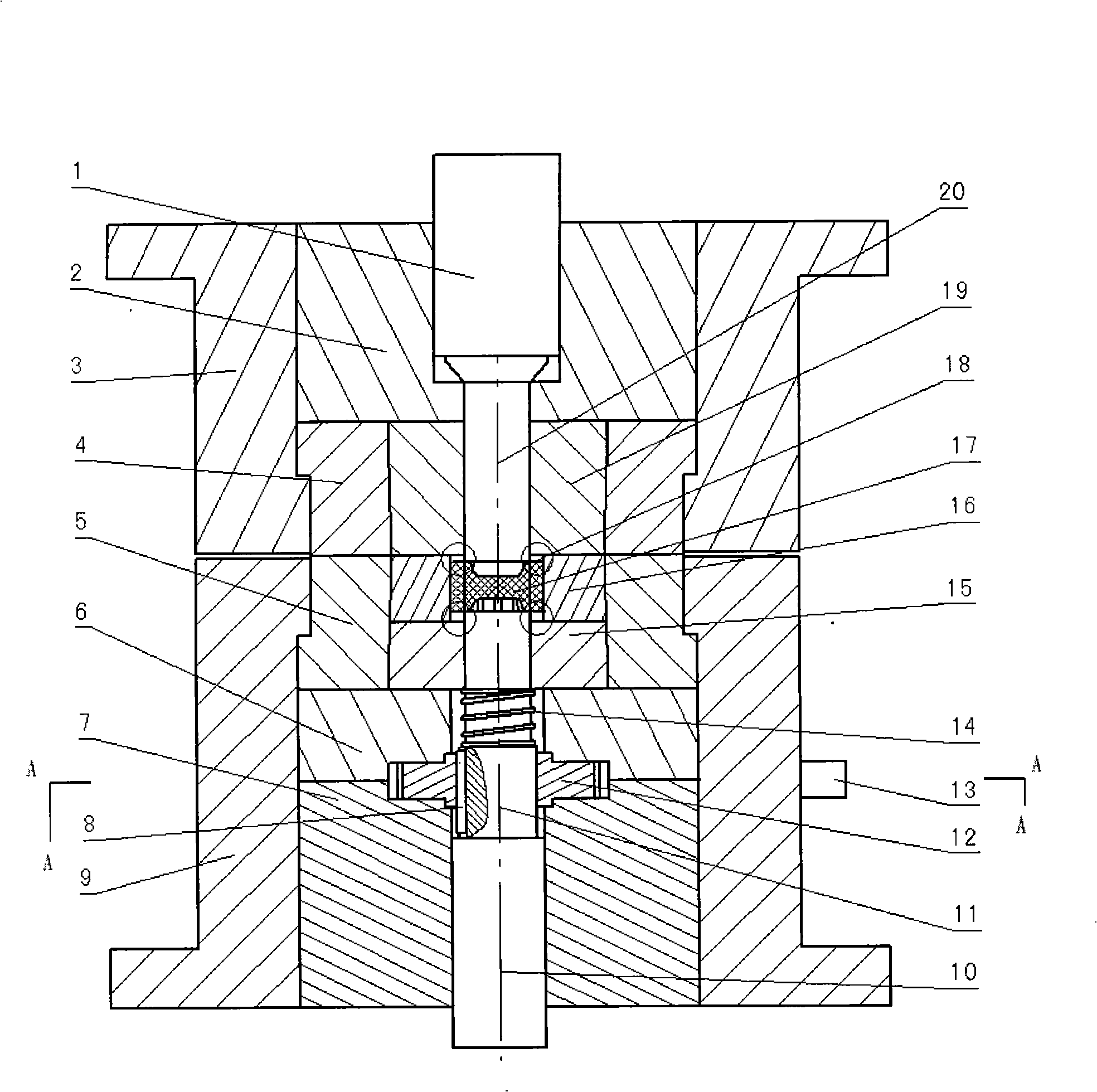

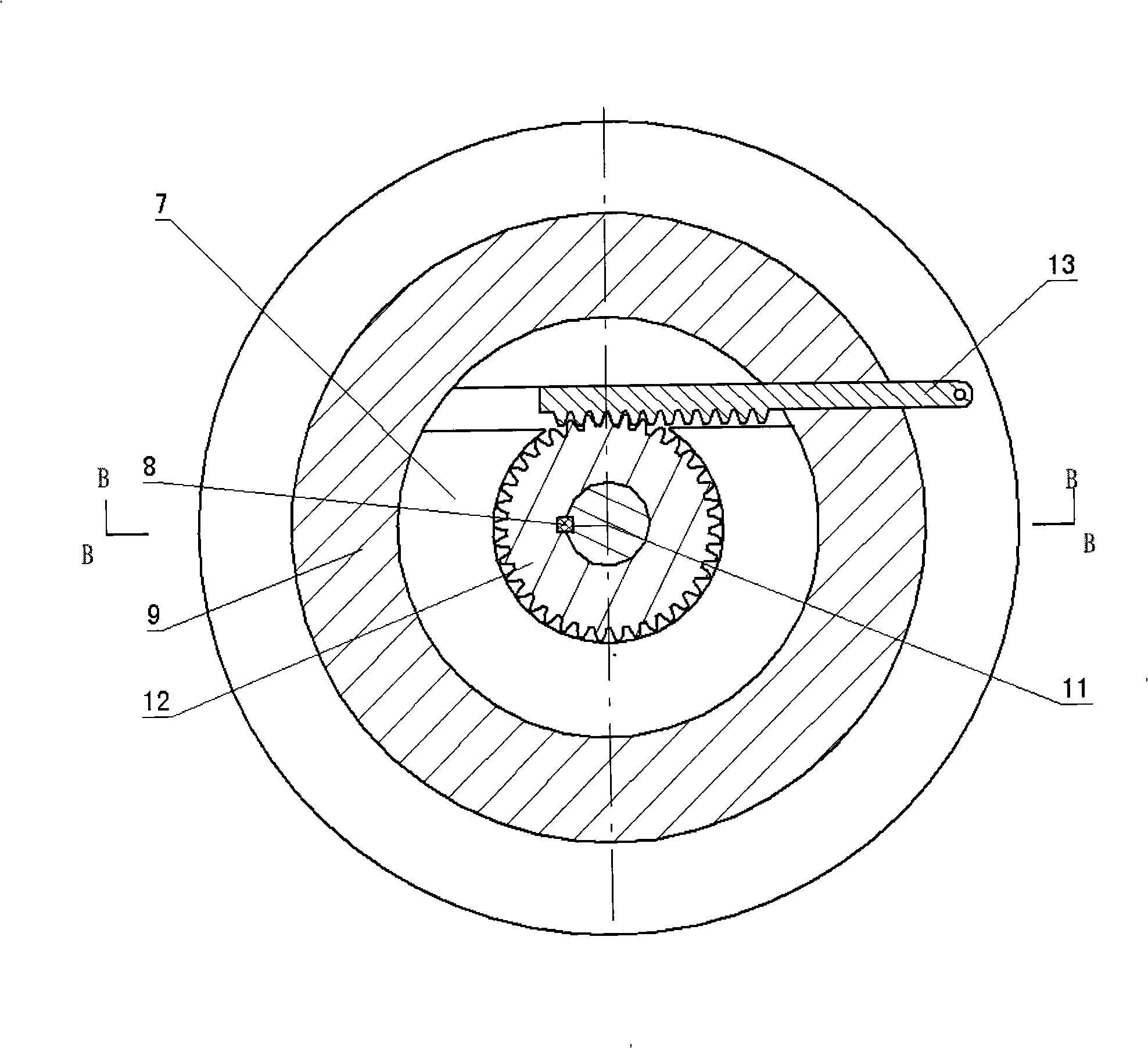

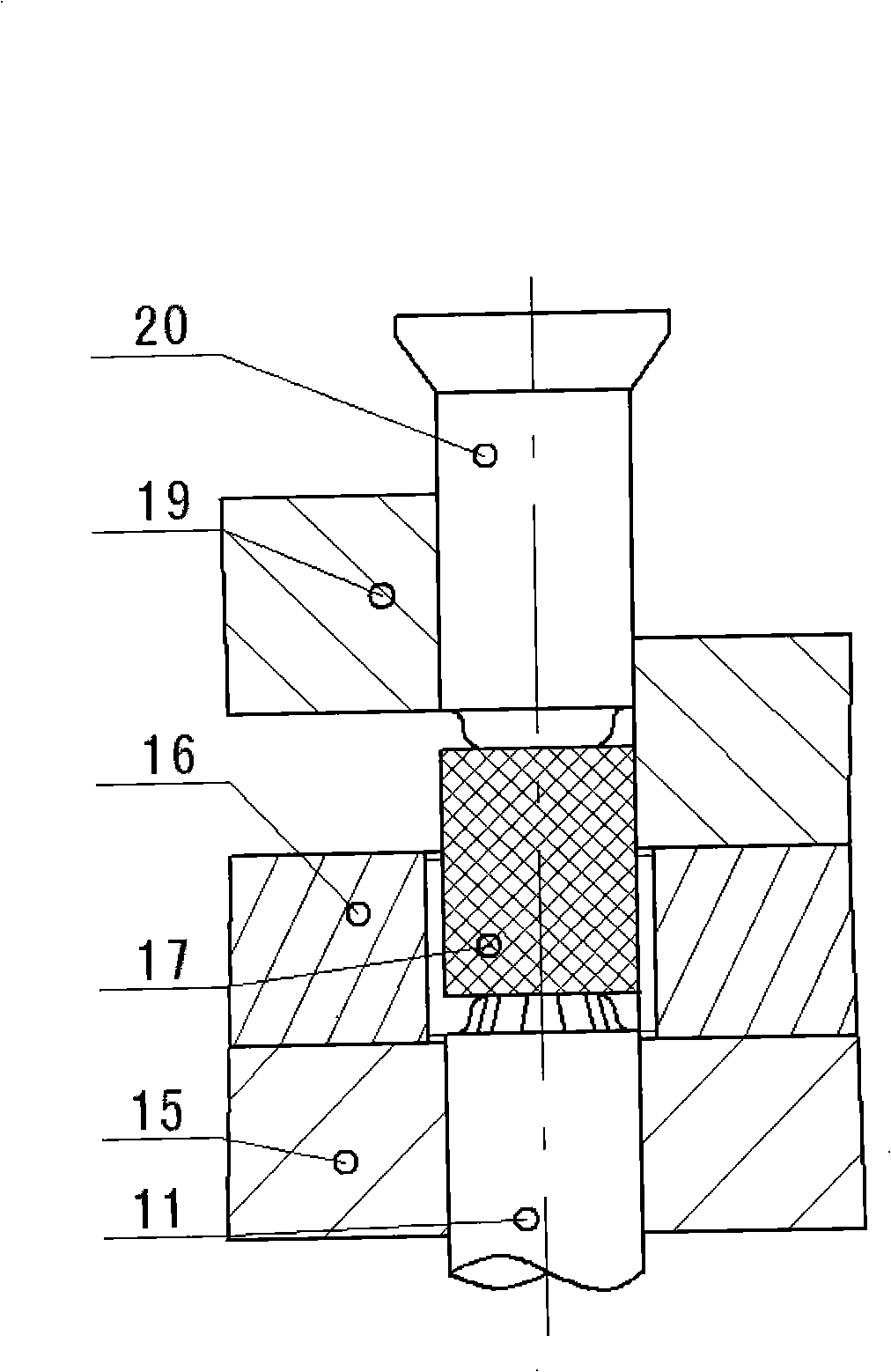

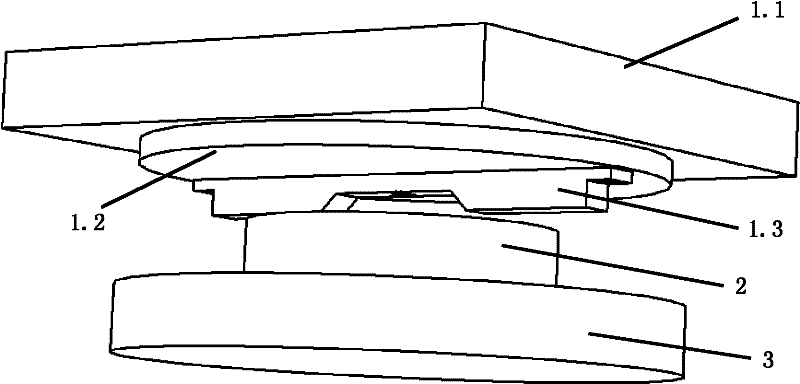

Gear-box planetary gear shaping die

InactiveCN101284299AHigh strengthImprove mechanical propertiesForging/hammering/pressing machinesWheelsGear wheelEngineering

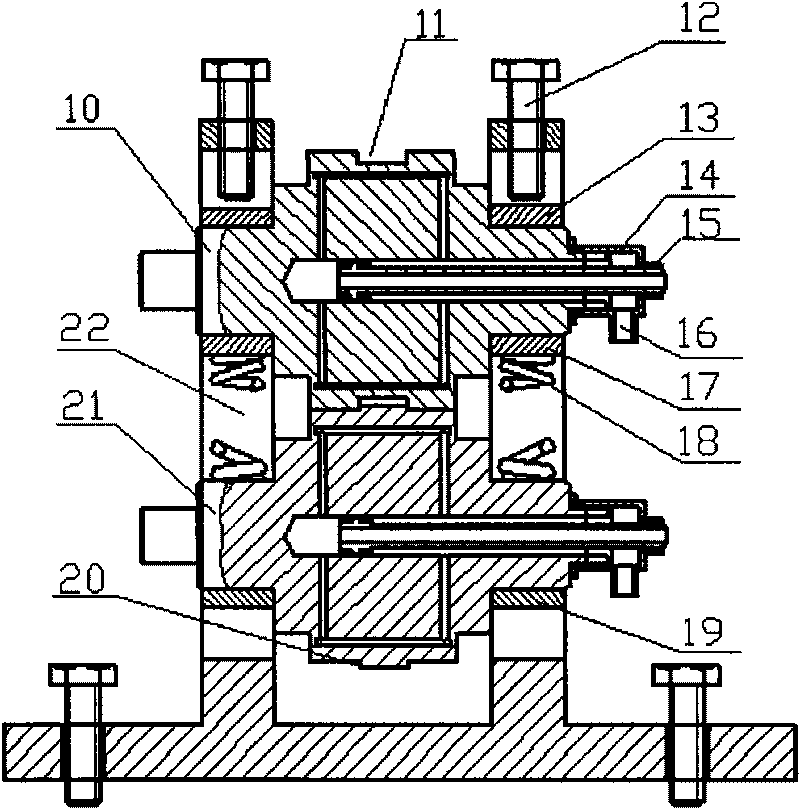

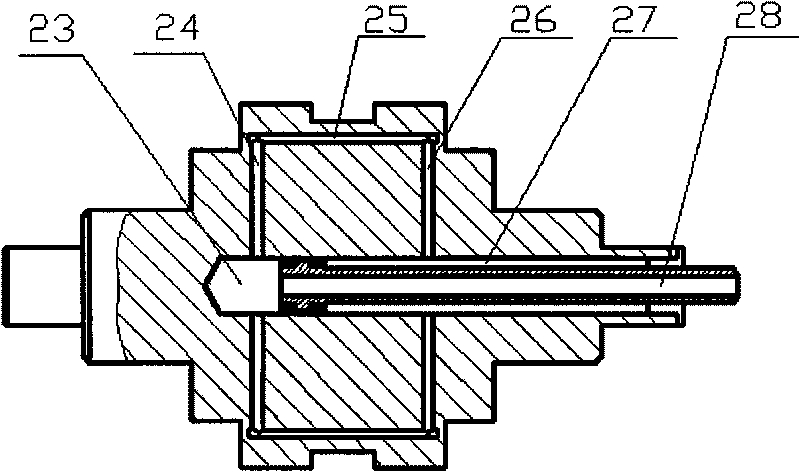

The invention relates to a forming die of a gearbox planet gear, belongs to the processing dies of car automatic gearbox planet gears, solves the problems in prior forging die, including big forging force, rigorous requirement for blanks, and short service life of the die, and satisfies the forming requirement of a car automatic gearbox planet gear. The forming die comprises an upper die and a lower die arranged symmetrically and vertically; the end faces of both an upper punch and a lower punch are bosses; a diffluent trough is formed on the boss of the lower punch; the shoulders of both the upper punch and the lower punch extend into a tooth-shaped cavity die by 1-2mm in the final extrusion state; a rotary ejection mechanism can also be arranged; the lower punch can rotate when being ejected; and a helical cylindrical gear with a bigger helix angle can be forged. The forming die has the advantages of simple structure, easy manufacture and installation, small forming force and low requirement for blanking precision. Furthermore, the forming die can realize single punch extrusion according to different die carriers and equipment, double punch extrusion in opposite directions, as well as the extrusion of the helical cylindrical gear with big helix angle.

Owner:HUAZHONG UNIV OF SCI & TECH +1

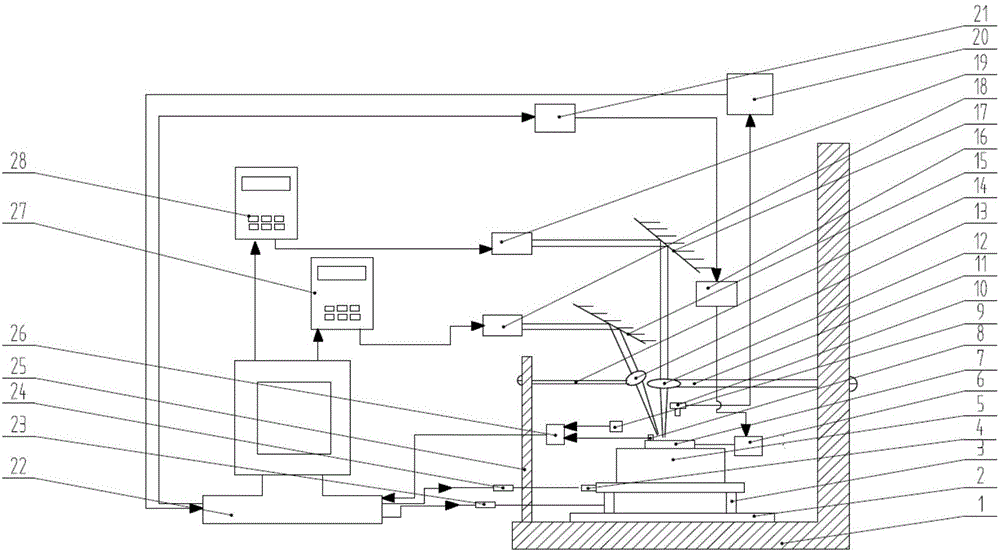

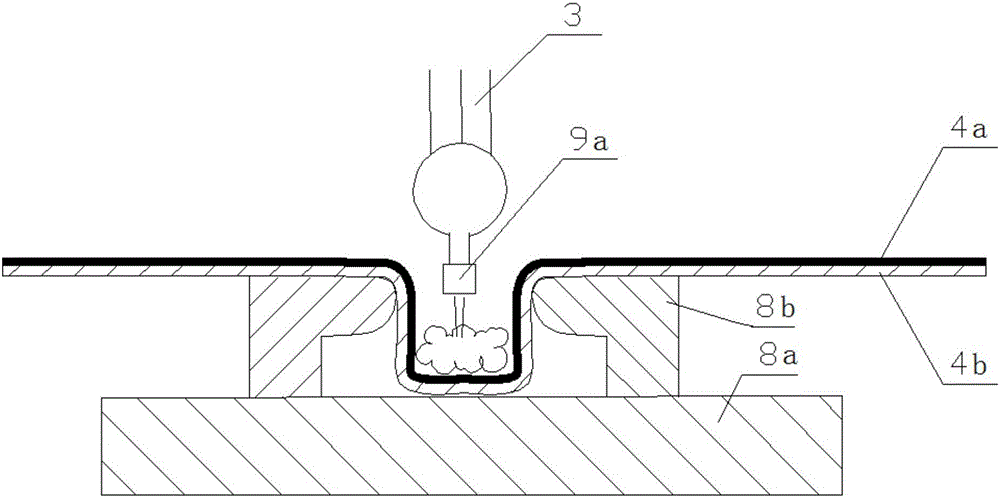

Novel laser indirect impact micro-forming device and method

InactiveCN107520538AGuaranteed forming qualityReduce scrap rateLaser beam welding apparatusControl systemContact type

The invention discloses a novel laser indirect impact micro-forming device and method. The device and method are mainly applied to plastic forming technique and manufacturing of fine micro parts. The device and method solve the problem that a conventional laser impact micro-forming method is difficult in forming, and materials cannot be formed. The device comprises a mold-debug light spot centering assembly, a workpiece positioning assembly, a workpiece assembly, an Nd:YAG pulsed laser system used for impact forming, a CW optical fiber laser system used for heating, an ultrasonic vibration system and a control system. The device can achieve the aim that pulsed laser impact force is adopted to serve as an energy source, meanwhile, ultrasonic vibration is applied to a mold and a workpiece, or, a laser beam sent out by a CW optical fiber laser is used for carrying out non-contact type quasi-static heating on the surface of the workpiece, or, under the joint effect, workpiece micro-forming is achieved; due to the design, work efficiency is improved, design is reasonable, control performance is good, quality and precision of micro-forming parts are ensured, and the device is suitable for industrialized application.

Owner:JIANGSU UNIV

Drawing compound molding die for shell with tooth form on side wall

InactiveCN102626741ASimple structureIncrease productivityShaping toolsStripping-off devicesEngineeringMechanical engineering

Owner:SHANGHAI JIAO TONG UNIV +1

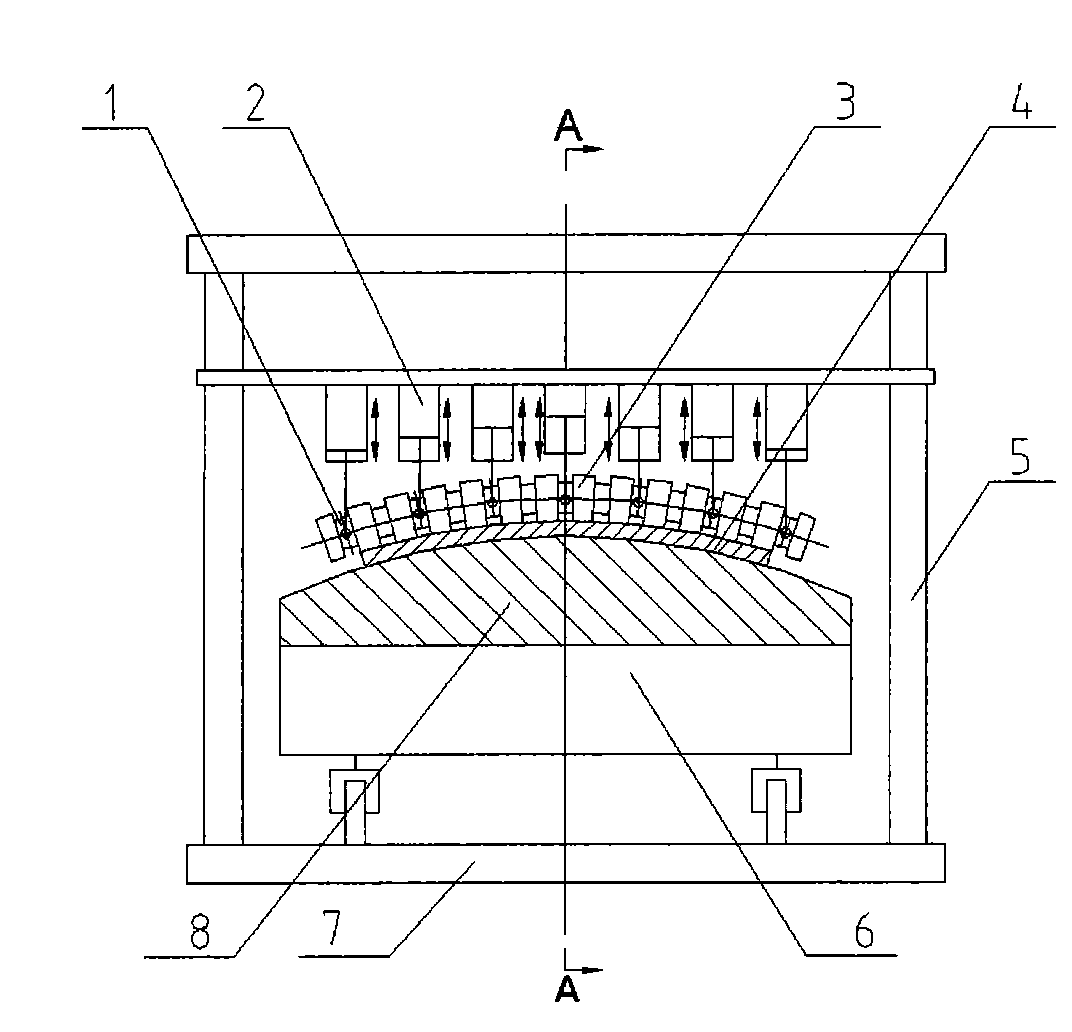

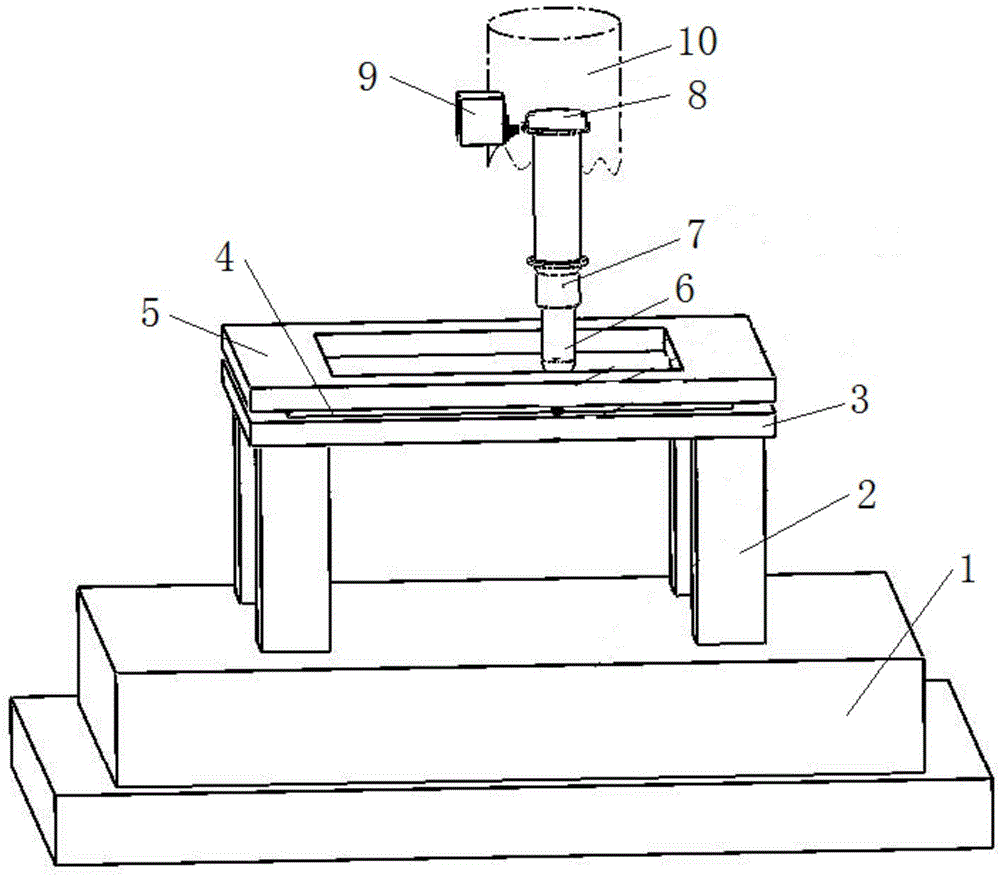

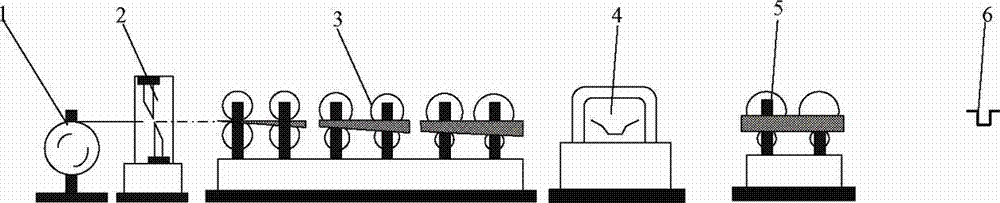

Flexible roller contact molding rolling forming device

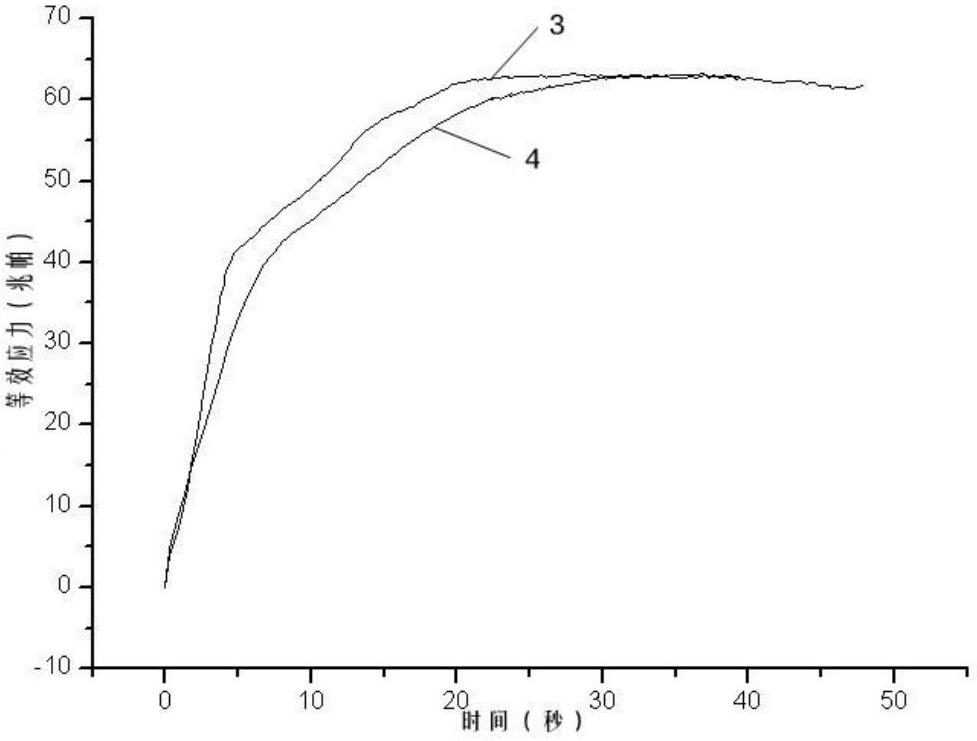

InactiveCN101648235ASmall forming forceReduce manufacturing costShaping toolsMetallic materialsSingle plane mold

The invention relates to a flexible roller contact molding rolling forming device for plastic forming equipment, in particular to a continuous rolling forming device, combining a flexible roller witha single-side mold for processing three-dimensional curved surface workpiece, belonging to the field of mechanical engineering. The invention aims to change the traditional processing mode forming metal materials through an upper mold and a lower mold and to provide the continuous rolling forming device on the basis of a technique combining the flexible roller with the single-side mold. The continuous rolling forming device comprises the flexible rollers, flexible roller support mechanisms, a support frame, a base and a work table and is characterized in that one group or a plurality of groupsof the flexible rollers (1) are arranged on the support frame (5) through a plurality of the flexible roller support mechanisms (2), and axes of the flexible rollers (1) can be bent along the moldedsurface of the single-side mold (8); and the work table (6) is arranged on the base (7), can also move front and back or rotate and is provided with the single-side mold (8).

Owner:JILIN UNIV

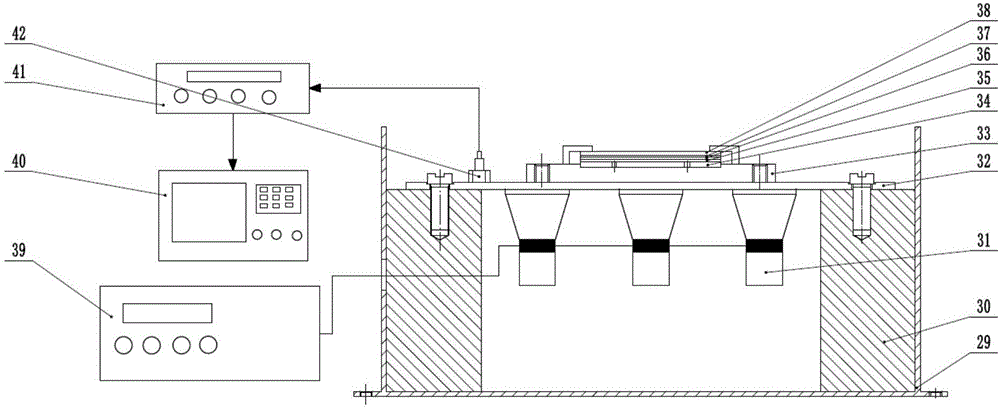

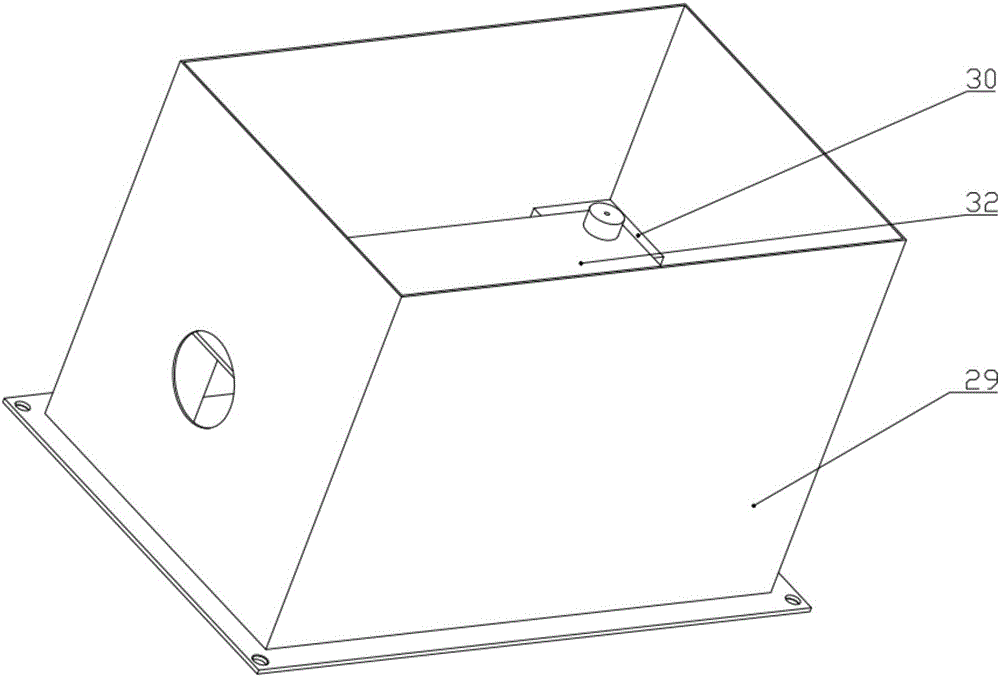

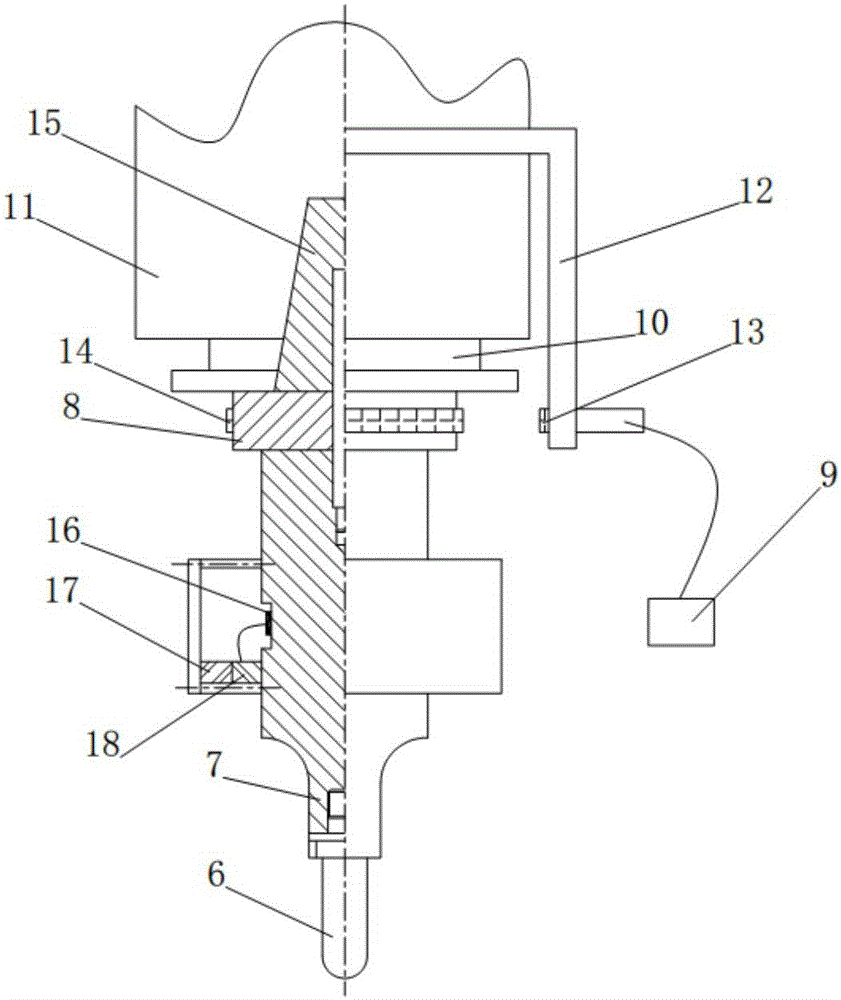

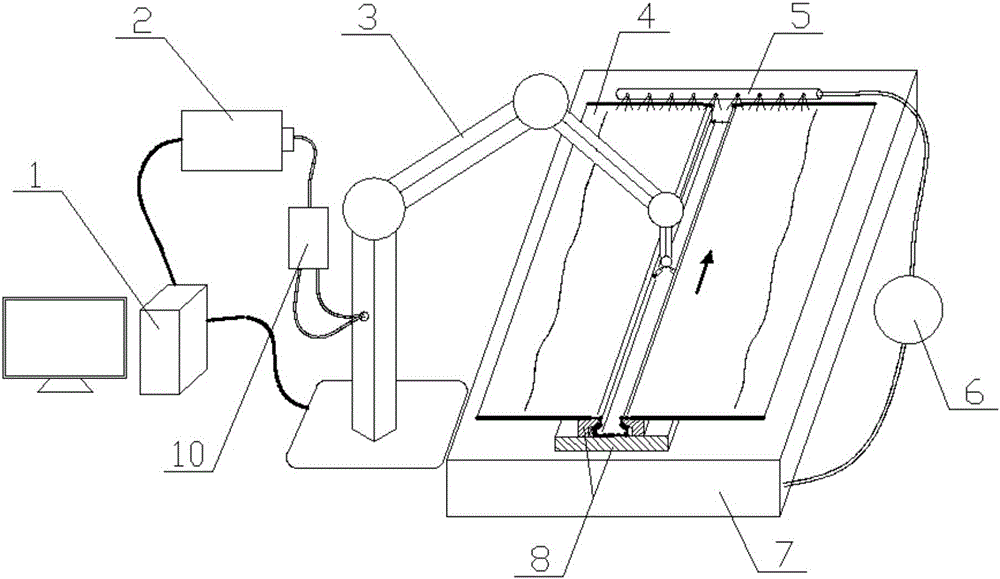

Rotary ultrasonic compound incremental forming device and method based on real-time feedback

ActiveCN106670297AImproved plastic deformation behaviorImprove surface qualityInformation processingPower sensor

The invention discloses a rotary ultrasonic compound incremental forming device and method based on real-time feedback. The rotary ultrasonic compound incremental forming device comprises a plate incremental forming fixture unit. A rotary ultrasonic cutter handle machining unit is arranged above the plate incremental forming fixture unit. The rotary ultrasonic utter handle machining unit comprises a machining main shaft which is connected with an installation taper shank. An ultrasonic energy exchanger is arranged in a cylindrical hole of the installation taper shank. An electrode copper sheet of the ultrasonic energy exchanger is connected with a receiving coil of a magnetic receiver through a wire, a magnetic generator is arranged opposite to the magnetic receiver, and the magnetic generator is connected with the magnetic receiver. The ultrasonic energy exchanger is connected with an amplitude transformer, and the amplitude transformer is connected with a forming tool head. An annular groove is formed in the outer circle of the amplitude transformer, the annular groove is used for sticking a strain gage serving as a power sensor, the strain gage is connected with a signal acquiring and emitting module, and the signal acquiring and emitting module is connected with an information processing and displaying device.

Owner:SHANDONG UNIV

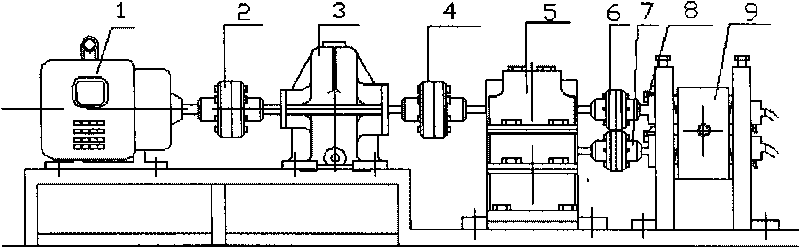

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

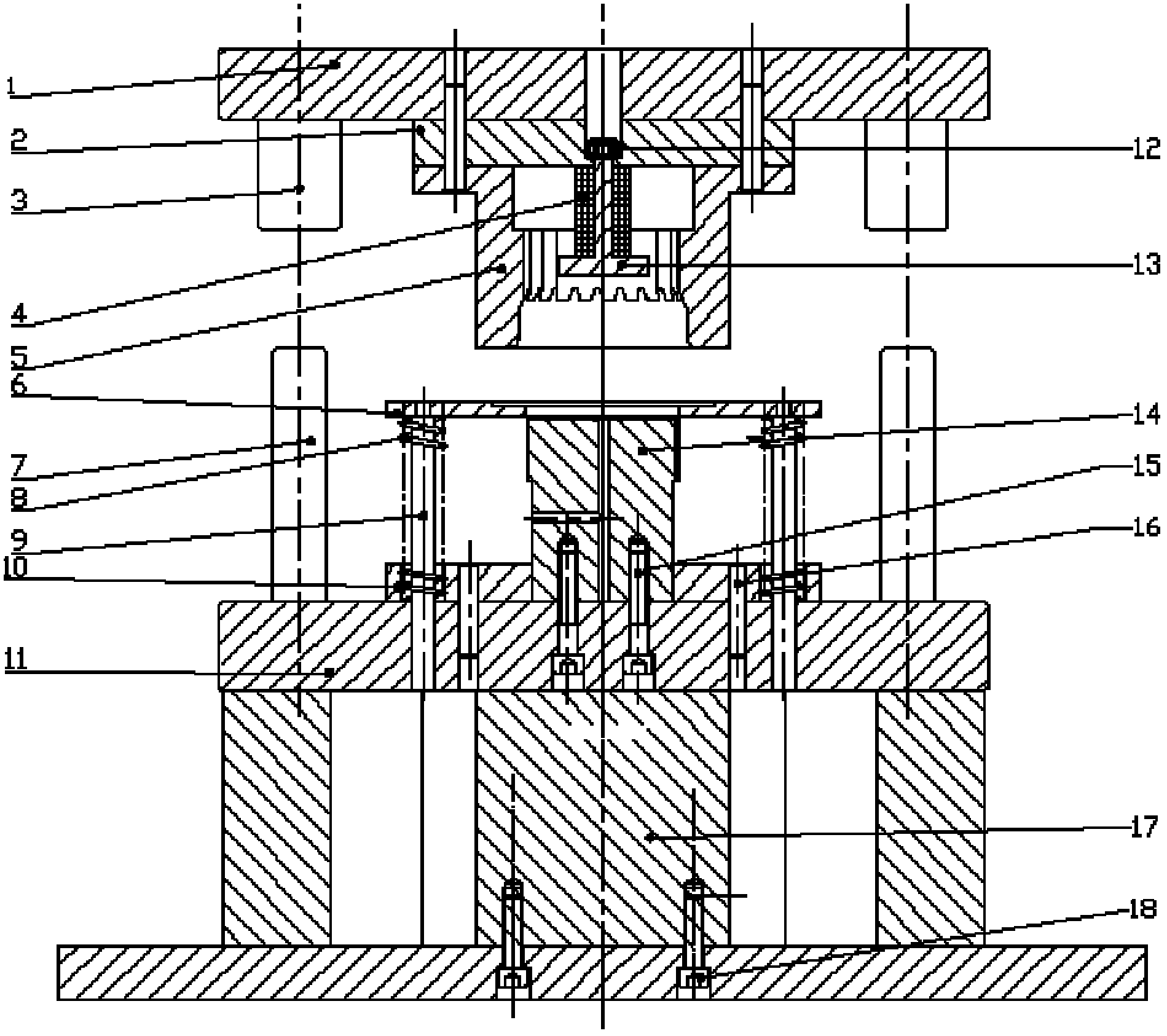

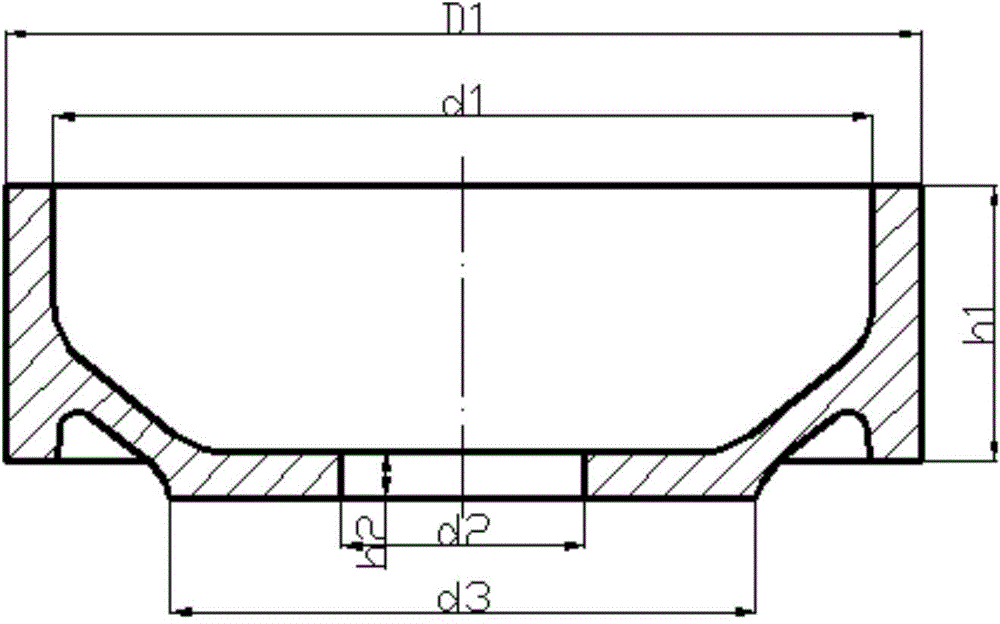

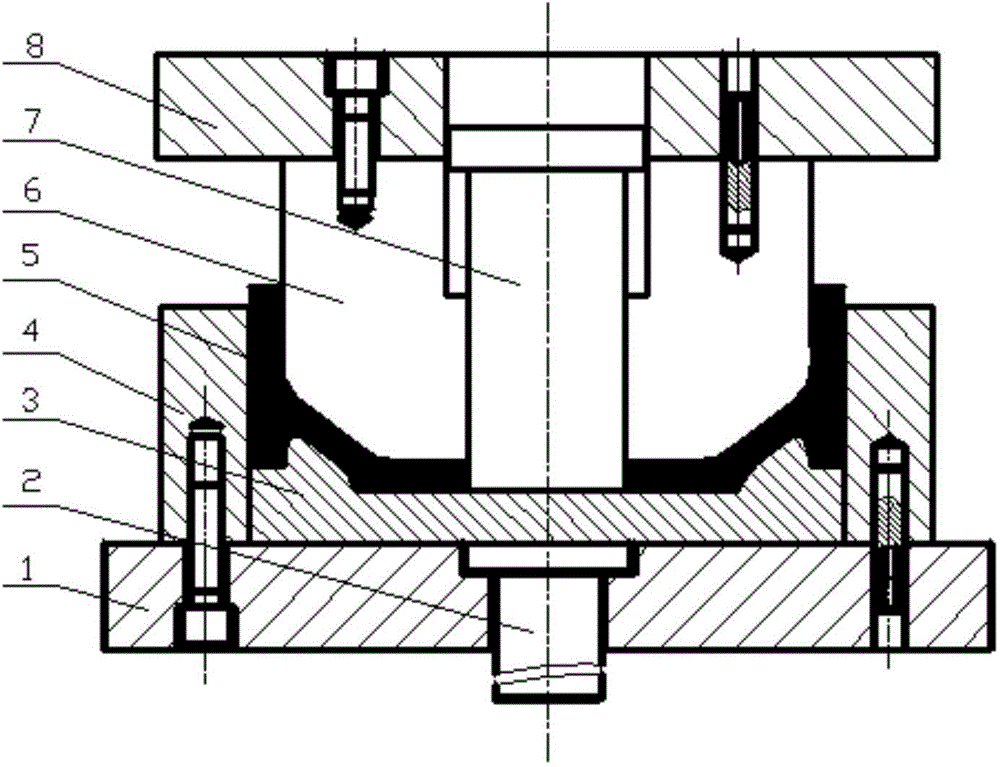

Process and device for forming magnesium alloy loading wheel disc through combined extruding in radial direction and reverse direction

The invention discloses a process and a device for forming a magnesium alloy loading wheel disc through combined extruding in the radial direction and the reverse direction. According to the process and the device, the performance requirements and the structure characteristics of the loading wheel disc and the magnesium alloy deformation characteristic are combined, the device has the main characteristic that a radial-reverse combined extruding mold is adopted; the process is characterized in that the radial-reverse combined extruding process is as follows: an annular blank is prepared by radial and reverse combined extruding of a fixing male die matched with a following male die, metal materials flow towards the directions vertical to and parallel to the movement of the male die simultaneously under the action of the fixing male die, a loading wheel spoke plate is formed due to the metal radial flowing, the metal flowing is limited by the following male die to meet the required size of a bottom hole, a loading wheel disc rim part is formed due to the metal forward and reverse flowing, and the reverse flowing is characterized in that the required height is reached through open type filling; the product performance is improved, the forming force is reduced, and the application of the magnesium alloy loading wheel disc on a crawler can be realized.

Owner:ZHONGBEI UNIV

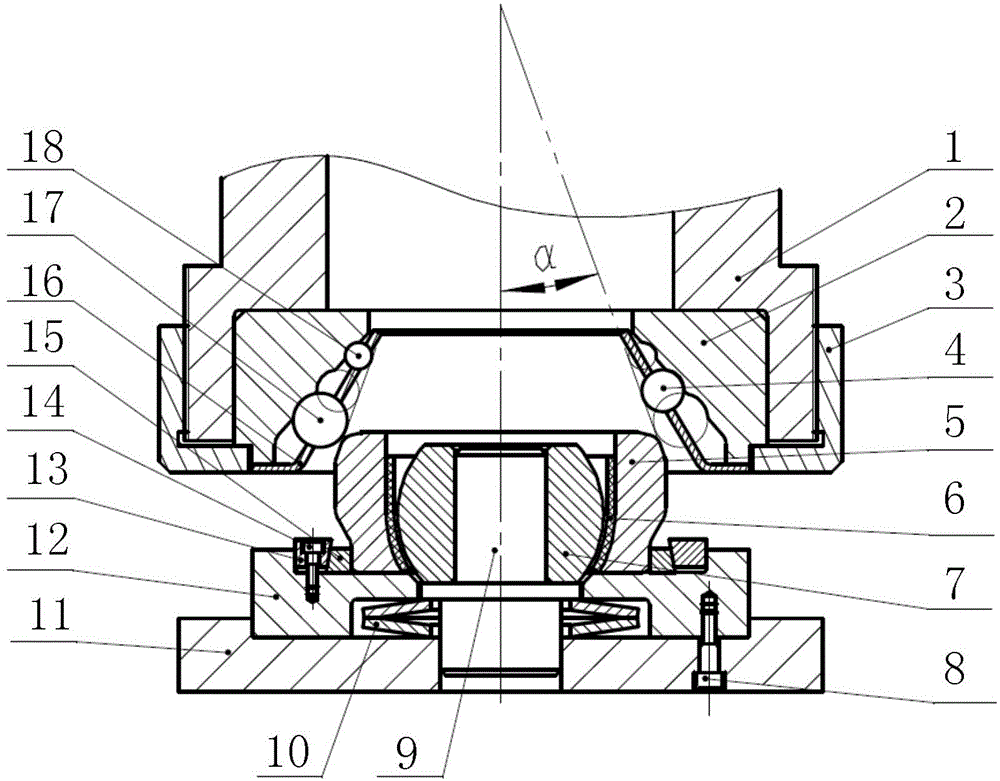

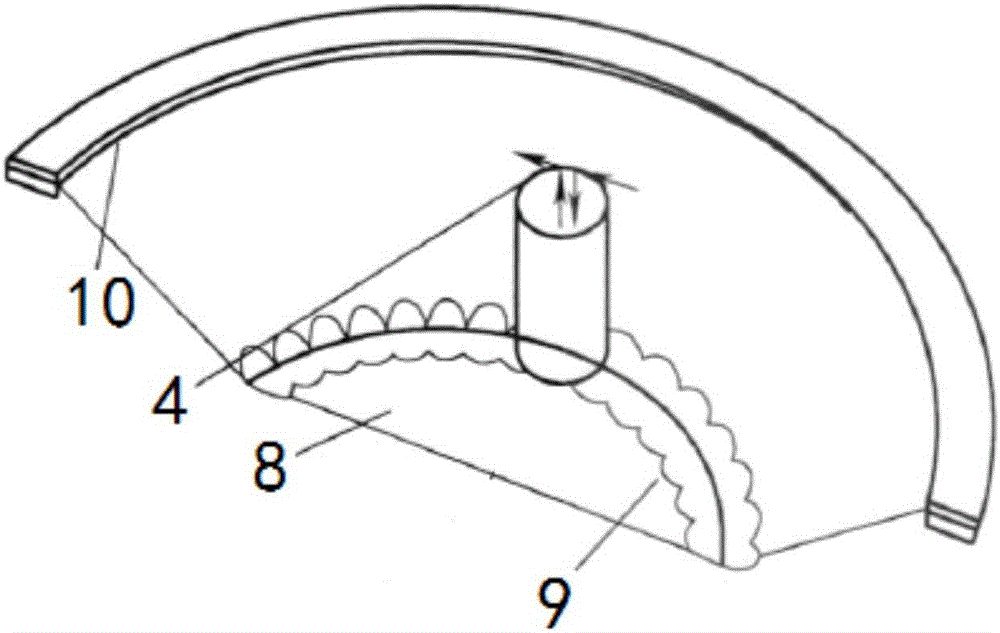

Ball-spinning device and method of integrated outer ring typed self-lubricating spherical plain bearing

The invention relates to a ball-spinning device and a method of integrated outer ring typed self-lubricating spherical plain bearing. An upper die holder of the device is provided internally with inner conical rings, retainers are fixed to the inner conical rings to constrain large, medium and small groups of balls in the corresponding raceways, a mandrel is mounted in a center counter bore of a baseplate, and the baseplate is connected with a lower die through bolts. The method includes processing the inner surface of the outer ring blank of the spherical plain bearing into a process optimized shape, and attaching a self-lubricating layer thereto; allowing the inner surface of the forming side of the outer ring blank to fit on the inner ring of the bearing in a shape follow-up mold by the aid of the forming device; and performing turning and grinding to the end face and the outer surface of the outer ring of the bearing to obtain the integrated outer ring typed self-lubricating spherical plain bearing. During the forming process, the inner ring of the bearing is flexibly contacted with the outer ring of the bearing, thus no damage to the self-lubricating layer occurs, ball flow forming transformation is uniform, forming force is small, and ease in controlling can be achieved.

Owner:QINHUANGDAO HUALIN PRECISION BEARING TECH

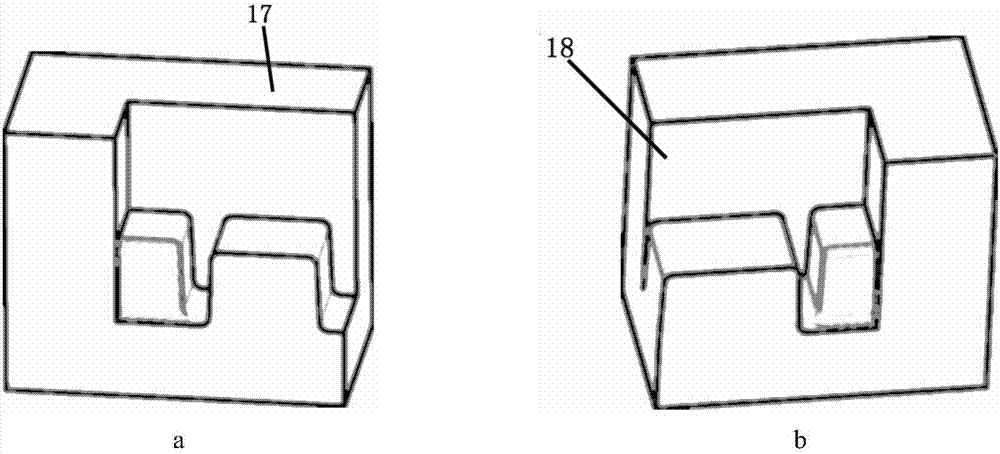

Device and method for preparing magnesium alloy semi-solid blank through repetitive upsetting-extrusion deformation and isothermal annealing

The invention relates to a device and a method for preparing magnesium alloy semi-solid blank through repetitive upsetting-extrusion deformation and isothermal annealing, belonging to the field of metal semi-solid forming technology and mainly aiming at solving the problems that the magnesium alloy semi-solid blank prepared by the existing strain inducement method is greatly changed in shape, has high technology cost, and low production efficiency. The repetitive upsetting-extrusion device mainly comprises a pair of buckled half module female die cavity and upper upsetting lower extruding male die. The method comprises the following steps of putting a cast magnesium alloy bar material into the device for repetitive upsetting extrusion deformation for many times, so as to have enough accumulated inducing strain; and carrying out isothermal annealing treatment on pre-deformed blank, thus obtaining the magnesium alloy semi-solid blank through controlling the annealing temperature and time reasonably. According to the method, the original appearance shape of large strain pre-deformed blank can be guaranteed to be accumulated, the obtained magnesium alloy semi-solid issue has fine and uniform solid phase grains and good degree of sphericity, and the method is simple, has low cost and has high production efficiency.

Owner:HARBIN INST OF TECH

Automobile gearbox P-gear gear manufacturing method

The invention provides an automobile gearbox P-gear gear manufacturing method. An automobile gearbox P-gear gear is finally formed by conducting cold extruding after warm forging is conducted in a warm forging manufacturing mode. The automobile gearbox P-gear gear is characterized in that positive and negative combined extrusion is adopted for cold extruding, and outer teeth are extruded while extrusion forming of the petal portion in a product is finished. The product made through the method is high in accuracy, less in oxidation, good in internal metal organization and more refined in crystalline grain, and harmful structures of coarse crystals, mixed crystals and the like can be avoided; the required equipment is small in tonnage and less in forming force, tooth filling is easier, unit intensity of pressure born by a die is remarkably lowered, the service life of the die is very long, the process can be reduced, and the manufacturing time is greatly shortened (increased by 10 times compared with a gear hobbing machine). The product hardness ranges from HB 140 to HB 180, the tooth profile is fully filled and full, and it is guaranteed that large deformation cannot be generated in subsequent heat treatment of cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

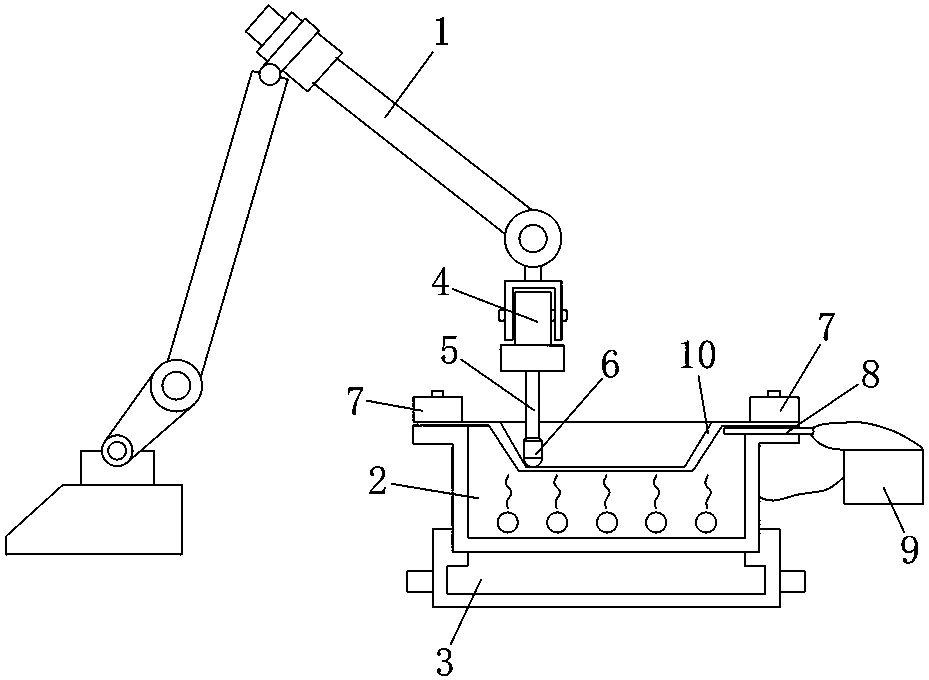

Thermal vibrating integrated incremental forming device for magnesium alloy thin-wall part and forming technology thereof

InactiveCN108435903AReduce tangential frictionImprove deformation internal microstructureShaping toolsIndustrial manipulatorThin walled

The invention relates to a thermal vibrating integrated incremental forming device for a magnesium alloy thin-wall part and a forming technology thereof. The device comprises an industrial manipulator, a heating box, a cooling box, a vibration generator, an amplitude-change pole, a tool head and a blank pressing block, wherein the blank pressing block for pressing the magnesium alloy thin-wall part is screwed to the side edge of a heating port in the upper end of the heating box; the cooling box is mounted at the lower end of the heating box; the vibration generator is mounted at the tail endof the industrial manipulator; the upper end of the amplitude-change pole is fixedly connected to the output end of the vibration generator, and the lower end of the amplitude-change pole is connectedto the tool head which acts on the magnesium alloy thin-wall part. The device is simple and reasonable in structure; the thermal assisted and vibrating assisted plastic processing modes are combined;the low-amplitude vibrating point pressing formation of the magnesium alloy thin-wall part can be realized through a frequency-adjustable and amplitude-adjustable vibration generator. Therefore, theformation limit and the formation quality of a magnesium alloy material can be improved; and moreover, the formation technology chain of the magnesium alloy thin-wall part is shortened, and as a result, the short plastic processing process is achieved.

Owner:FUZHOU UNIV

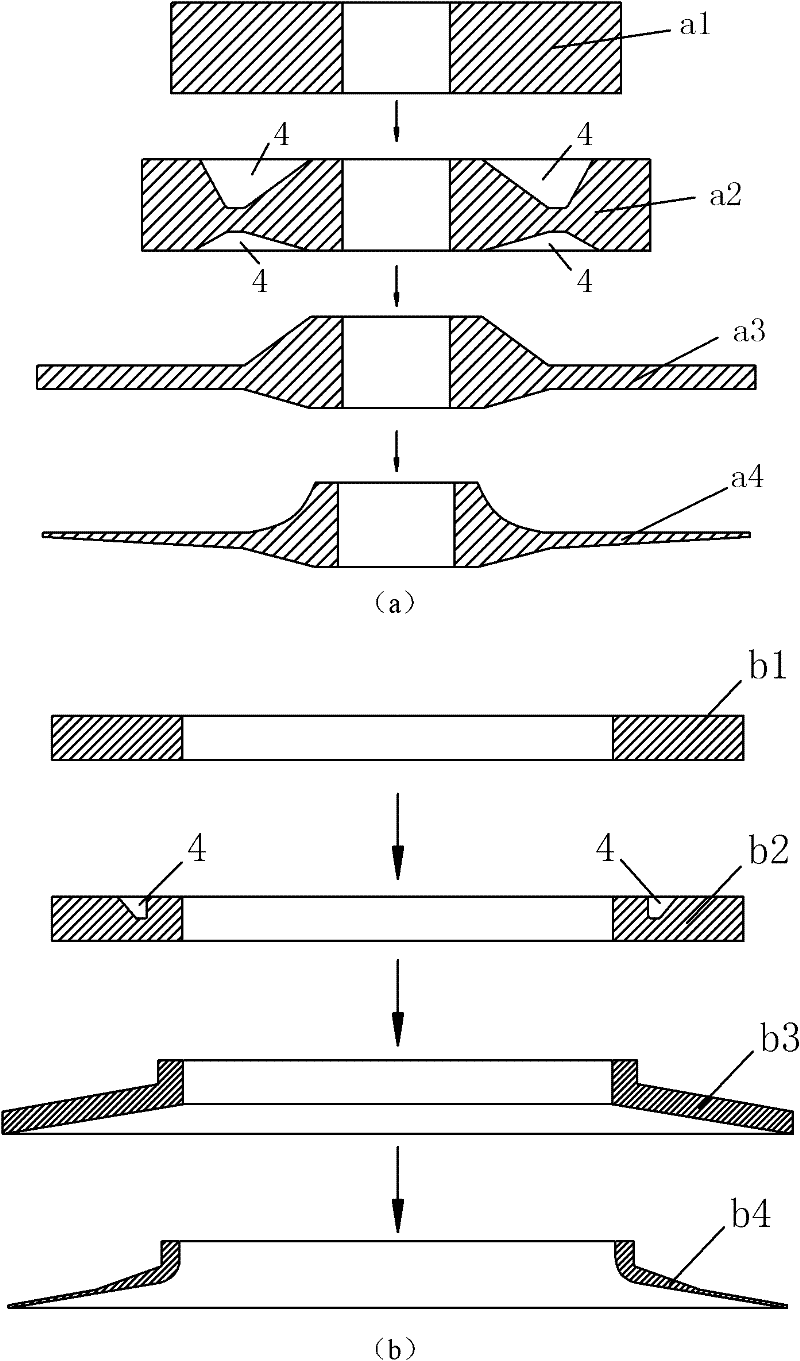

Precision forming method of straight/helical tooth cylindrical gear

ActiveCN102764847AIncrease in sizeReduce volumeMetal-working apparatusWheelsEngineeringProcess conditions

The invention relates to a precise forming method of a straight / helical tooth cylindrical gear. The precise forming method disclosed by the invention is characterized by being realized by the following two steps while a 'diameter-increasing half long ridge-tooth space splitting' way is adopted: firstly, closed die forging is carried out on cylindrical blank to form a pre-formed part, wherein one end of the pre-formed part is larger in radial dimension, sectional area and edge axial dimension and the other end of the pre-formed part is equal to the required value of the sectional area and has slightly smaller radial dimension, the two ends transit in a bevel angle manner, and a cylindrical surface is in a 'diameter-increasing half long ridge' state; and secondly, the pre-formed parts penetrate through a final forming die each tooth space of which is correspondingly provided with a splitting wedge in a sequence from big end to small end, wherein a splitting edge and a working surface of the splitting wedge are in a tilted state, a rim is split, extruded and deforms, and each slot base is deepened and the top of each ridge is lifted, thus a gear tooth with complete tooth profile is obtained. The gear tooth / tooth space obtained by the invention is clear and full, a required forming force is relatively small, an equipment action is simple, a structure of a die is not complex, a workpiece is easy to demould, requirement to technological conditions is low, and adaptability is wide.

Owner:SHENZHEN AIDELI ELECTROMECHANCIAL

Radial forging and gradual-increment forming method for large-tooth-height thread element

ActiveCN103978147AImprove surface strengthHigh surface hardnessForging/hammering/pressing machinesEngine componentsLarge toothEngineering

The invention discloses a radial forging and gradual-increment forming method for a large-tooth-height thread element. According to the method, a hammerhead is gradually increased by a radial compression amount, the hammerhead is provided with a thread-shaped section, the thread shape comprises a gradual-increment-variable thread-shaped section and a gradual-increment-invariable thread-shaped section, a plurality of the hammerheads with the gradual-increment-variable thread-shaped sections are used for synchronously forging, and a workpiece is rotated and axially fed simultaneously, thus reducing a forming force, reducing forging defects, and improving surface accuracy and strength; isovolumetric forging is carried out to realize near-net forming, thus increasing material utilization rate, and shortening production period; forming manufacturing for thread components such as lead screws and screw rods with high performances, large diameters and high tooth heights can be realized.

Owner:XI AN JIAOTONG UNIV

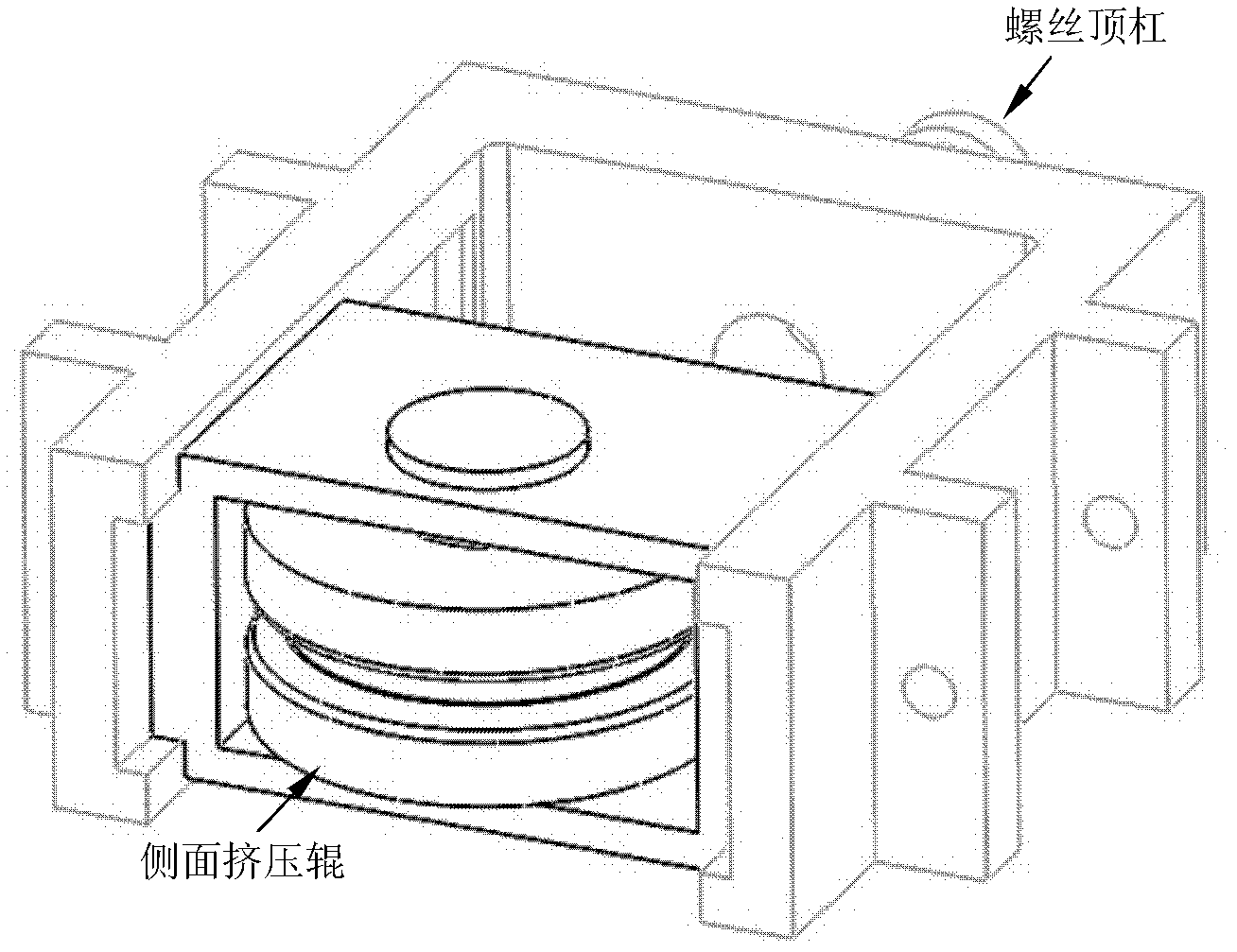

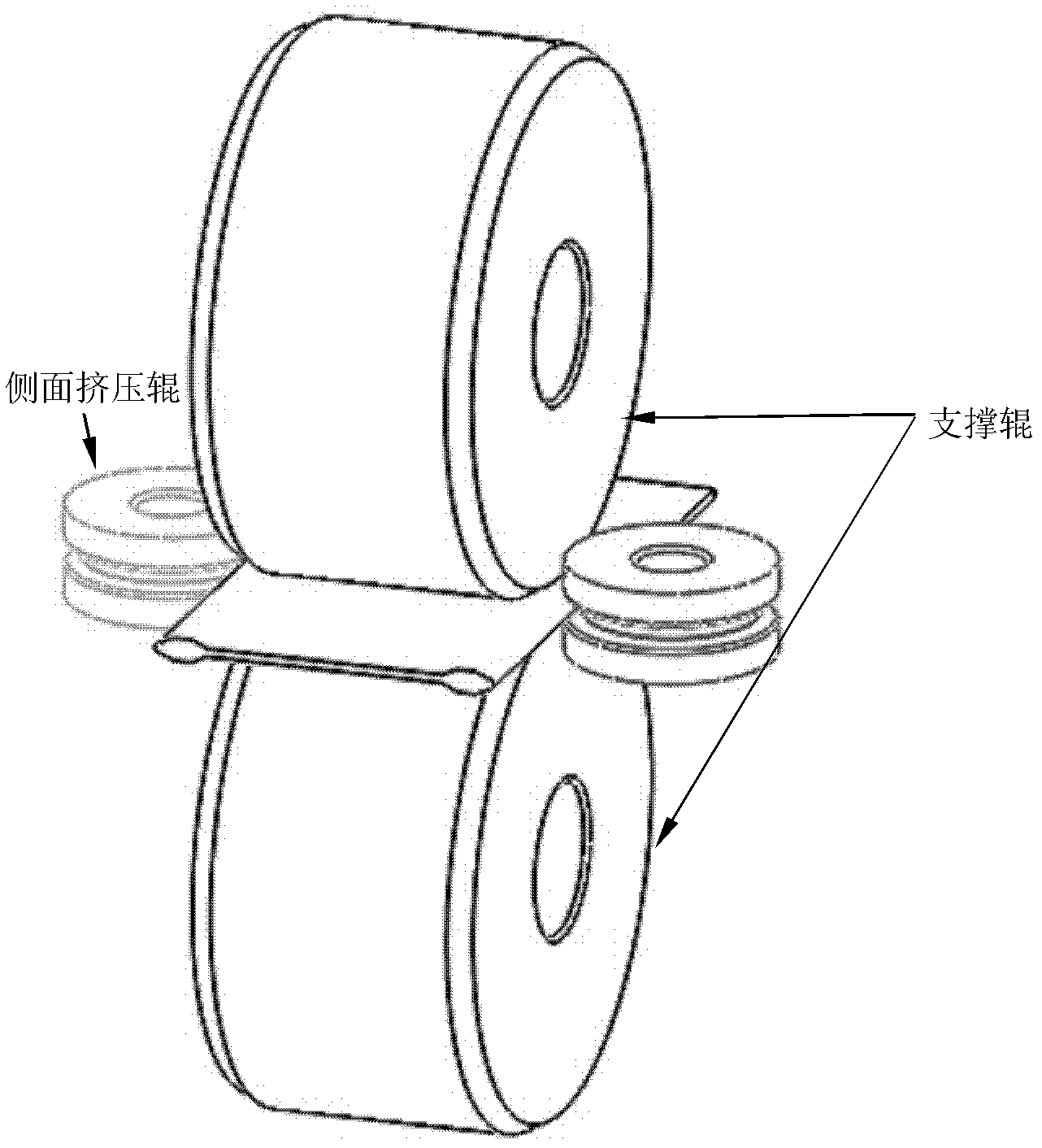

Molding method of cold-bending steel plate pile provided with non-uniform-thickness lock buckle

The invention provides a molding method of a cold-bending steel plate pile provided with a non-uniform-thickness lock buckle, which utilizes induction sensing equipment to heat edge parts of two edges of a flat plate material to 500-900 DEG C to form a molding region with good plasticity; utilizing a side-face extruding roller to gradually extrude the edge parts of the plate material path by path so as to flow the plate material at the edge parts along the thickness direction and further mold a needed non-uniform-thickness transition plate material; utilizing a molding roller to roll the non-uniform-thickness transition plate material into a non-uniform-thickness plate material with a target section; and coldly bending the plate material with the non-uniform-thickness lock buckle by the continuous molding paths to form the steel plate pile provided with the non-uniform-thickness lock buckle. The molding method disclosed by the invention utilizes the side-face extruding roller to gradually extrude the edge parts of the plate material into the non-uniform-thickness lock buckle, and overcomes the problems that the thicknesses of all parts of the traditional cold-bending steel plate pile are the same, the lock buckle part cannot be tightly clamped, the water cannot be stopped and the like.

Owner:UNIV OF SCI & TECH BEIJING

Local loading forming-based optimization method for preformed blank of rib plate part

ActiveCN106971029AImprove carrying capacityAvoid Folding DefectsGeometric CADDesign optimisation/simulationTransitional RegionEngineering

The invention discloses a local loading forming-based optimization method for a preformed blank of a rib plate part. Isothermal local loading forming is realized by controlling material flow and macroscopic defects of a transitional region. The preformed blank subjected to optimization design can effectively improve the uniformity of the material flow, reduce transverse material flow of a cross rib in the transitional region, and improve the filling capability of a rib type cavity. In engineering application, the usage performance of members is improved, the production cost is reduced, and a foundation is laid for forming and integrated manufacturing of large complex members made of titanium alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807BIncrease profitReduce manufacturing costForging/hammering/pressing machinesWheelsProcessing costIndustrial engineering

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

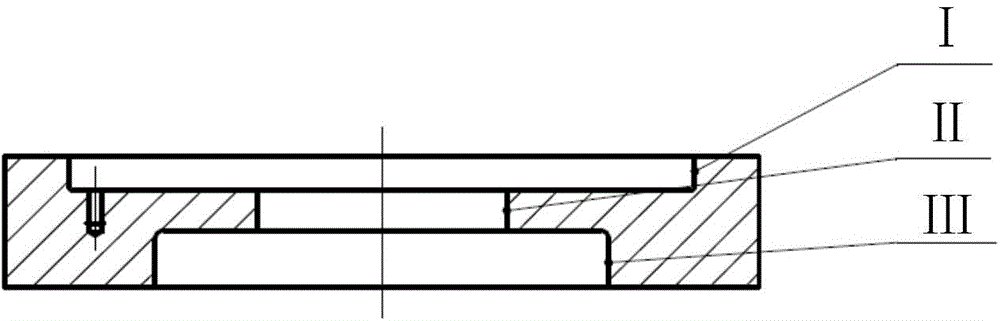

Metal sheet pulse current auxiliary micro punching device and method

ActiveCN108405713ADirect heating is simpleDirect heating is easyShaping toolsPerforating toolsPunchingMetal sheet

The invention discloses a metal sheet pulse current auxiliary micro punching device and method, and relates to a micro punching device and method so as to solve the problems an existing micro punchingtechnology is great in shaping force, a mould service life is short and hole edge defects are multiple. The metal sheet pulse current auxiliary micro punching device comprises a mould assembly and apulse power source system; the mould assembly comprises a die shank, an upper die plate, an upper insulating plate, an upper backing plate, a punch head fixing plate, a punch head, a supporting plate,a heat insulating plate, a female die, a female die fixing plate, a lower insulating plate and a lower die plate which are arranged from top to bottom sequentially; and the female die is arranged inthe female die fixing plate. The metal sheet pulse current auxiliary micro punching method comprises the steps that one, installation and debugging are carried out; two, technological parameters are selected; three blank loading is carried out; four, blank micro punching forming is carried out; and five, micropore piece demoulding is carried out. The metal sheet pulse current auxiliary micro punching device and the metal sheet pulse current auxiliary micro punching method are suitable for micro punching forming on materials, like a titanium alloy, a nickel base alloy and high-strength steel, which are difficult to form or can not be formed by a conventional micro punching method.

Owner:HARBIN INST OF TECH

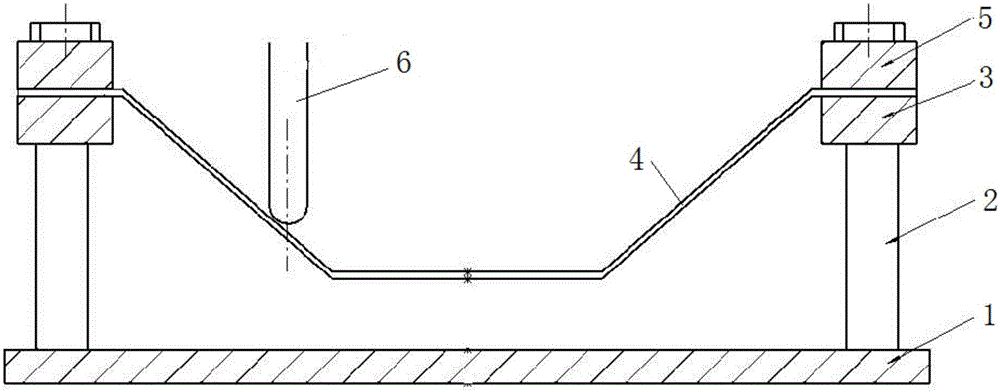

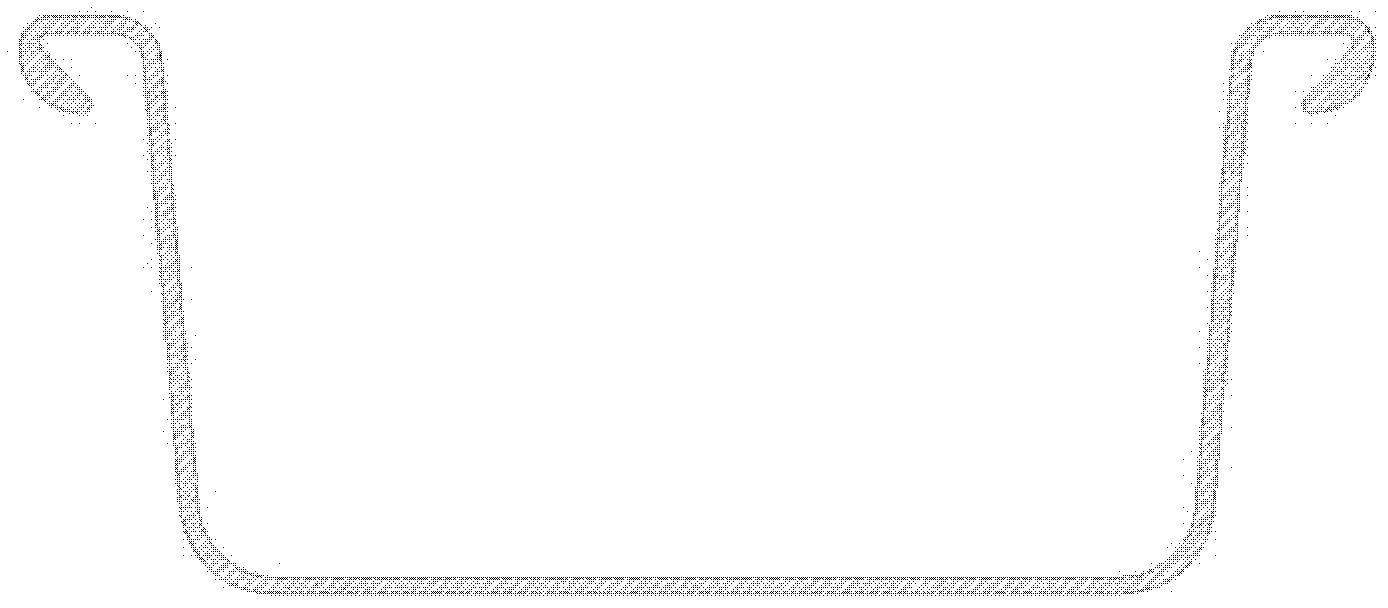

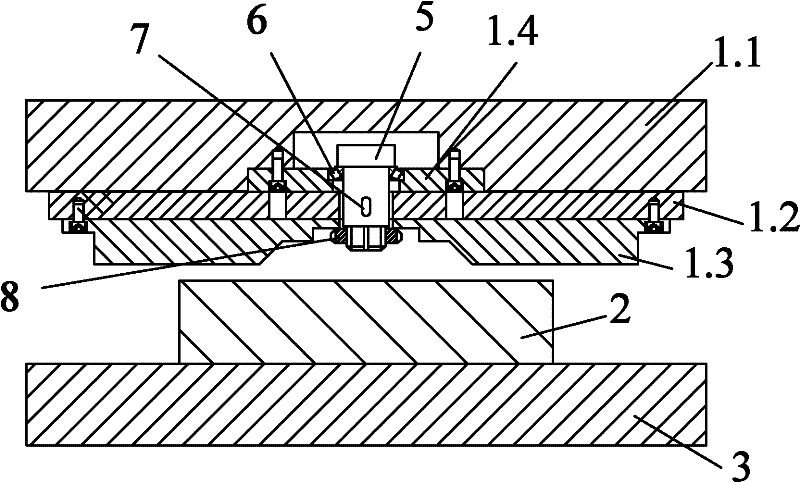

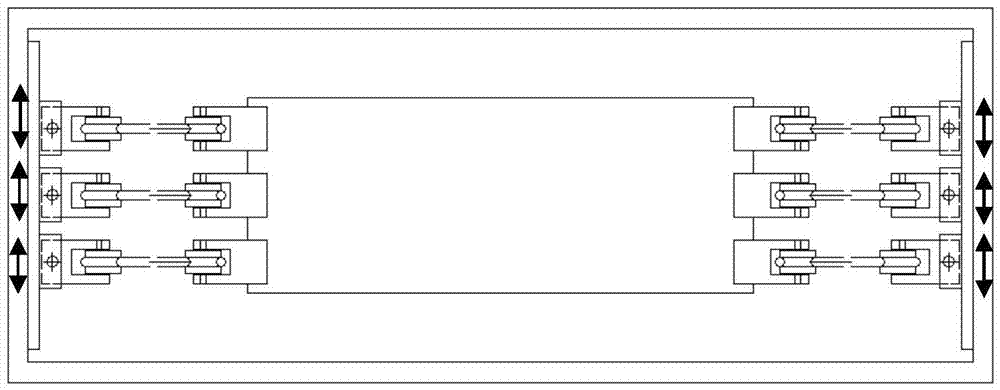

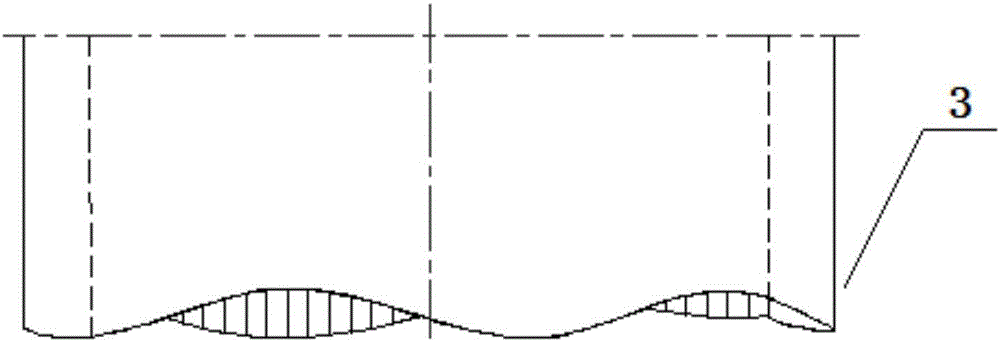

Thin plate tensioning curved surface forming device

InactiveCN103817195BControl Lateral DistortionGood for controlling transverse wrinklingEngineeringEnergy conservation

The invention relates to a thin plate tensioning curved surface forming device which allows tensioning plastic forming of a plate to be achieved on the basis of single-die surface shape matching, and belongs to the field of mechanical engineering. The thin plate tensioning curved surface forming device aims at reducing forming force, saving energy, controlling the transverse change of the plate as well, reducing transverse folds and promoting deformation of the plate to be more even. The thin plate tensioning curved surface forming device is mainly composed of a machine frame (1), a die lifting platform (2), plate stretching systems (3) arranged on the two sides of the die lifting platform (2), and a wire rope stretching and contraction driving system (4). At least three plate stretching systems (3) are arranged on each side of the die lifting platform (2). Each plate stretching system (3) comprises a wire rope (5), a fixed pulley block (6), a movable pulley (7) and a plate clamping device (8), wherein the direction of the wire rope (5) is changed through the fixed pulley block (6), force is transmitted to the plate clamping device (8) through the movable pulley (7), and the movable pulley (7) and the plate clamping device (8) are integrated.

Owner:JILIN UNIV

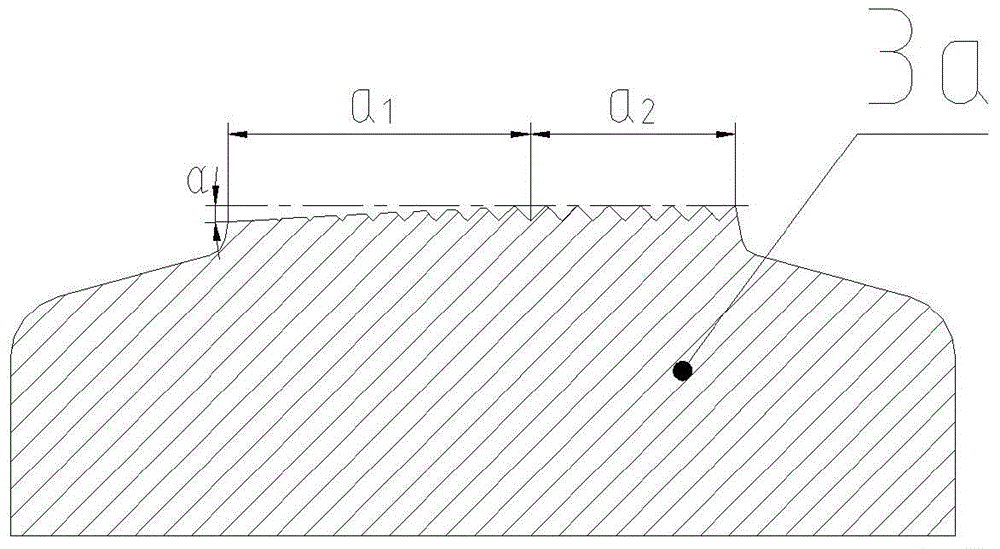

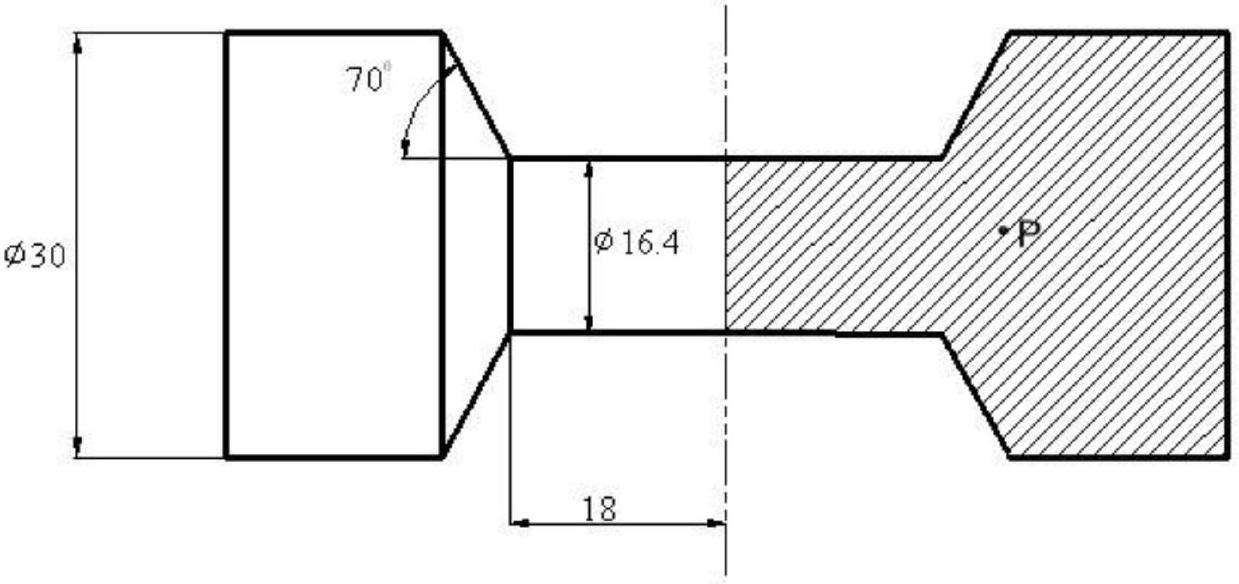

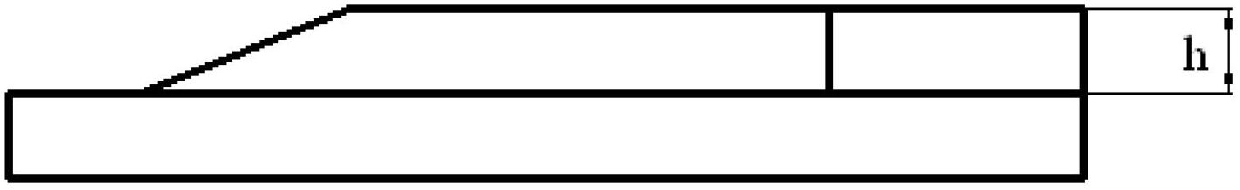

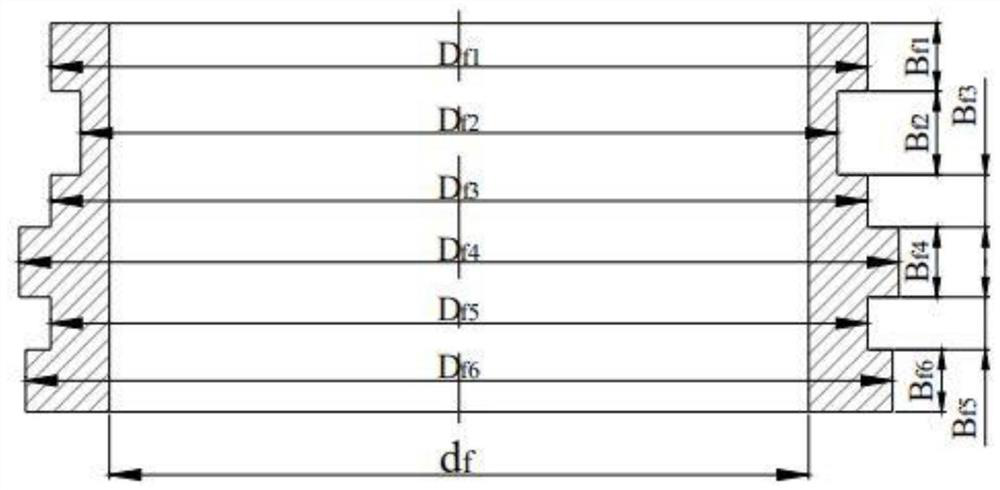

Designing method for cross wedge rolling mould of conical surface stepped shaft part

InactiveCN102688908ASimplify the design processSimplify the manufacturing processExtrusion profiling toolsStructural engineeringDesign methods

The invention discloses a designing method for a cross wedge rolling mould of a conical surface stepped shaft part. The designing method comprises the following steps of: 1, designing a structure of the cross wedge rolling mould, wherein the cross wedge rolling mould consists of four parts, namely a wedge section with the length being L, a first widening section with the length being L1, a second widening section with the length being L2 and a shaping section with the length being L3, and the four parts are connected integrally on a template; and the first widening section, the second widening section and the shaping section have the same thickness, and the thickness is equal to a wedge top height (h) of the wedging section; 2, designing the wedging section with the length being L, wherein L=hcot(alpha)cot(beta), h=r1-r0+delta; 3, designing the first widening section with the length being L1, wherein L1=ecot(beta); 4, designing the second widening section with the length being L2, wherein L2=(L1-e)cot(beta); and 5, designing the shaping section with the length being L3.

Owner:JILIN UNIV

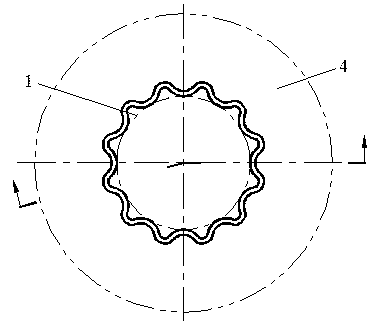

Method for machining thin-wall shell part with inner and outer teeth

The invention discloses a method for machining a thin-wall shell part with inner and outer teeth and relates to a plastic machining method. The method includes the following steps that firstly, slab blank is machined to be cup-shaped prefabricated blank, and the thickness of the wall of the cup-shaped prefabricated blank is equal to that of the wall of the thin-wall shell part with the inner and outer teeth; secondly, a pair of gears which are meshed mutually and are used for forming the inner teeth and the outer teeth of the thin-wall shell part with the inner teeth and the outer teeth respectively are manufactured. The gear for forming the inner teeth of the thin-wall shell part with the inner and outer teeth is a carrier roller, and the gear for forming the outer teeth of the thin-wall shell part with the inner and outer teeth is a compression roller; thirdly, the cup-shaped prefabricated blank is clamped on the carrier roller, and therefore the cup-shaped prefabricated blank and the carrier roller rotate synchronously, and meanwhile, the compression roller synchronously and oppositely rotates with the carrier roller and is fed in the radial direction close to the carrier roller to finish forming of the thin-wall shell part with the inner and outer teeth. According to the method for machining the thin-wall shell part with the inner and outer teeth, the technological steps are simple, the production cost is low, the machining efficiency is high, and high practicability is achieved.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Single-point incremental forming tool head axial vibration device

The invention discloses a single-point incremental forming tool head axial vibration device. The device comprises a supporting frame and a tool head with a push rod. A spring and two guide posts are connected to the inner bottom of the supporting frame. The spring is located in the center. The two guide posts are located on the left side and the right side of the spring correspondingly. The tool head with the push rod is composed of a tool head body arranged horizontally and the protruding push rod perpendicularly and fixedly connected to the tool head body. The upper end of the spring and the upper ends of the two guide posts are all connected with the tool head body. The upper portion of the protruding push rod is connected with a sleeve. A gap is reserved between the tool head body and the bottom surface of the sleeve. The upper portion of the sleeve is clamped to one end of a tool holder of a machine tool. The other end of the tool holder of the machine tool is connected with a rocker arm of the machine tool. According to the single-point incremental forming tool head axial vibration device, the tool head with the push rod is driven through rotation of a machine tool spindle to generate axial vibration, so that original continuous extrusion friction motion is converted into high-frequency point pressure motion, deformation processing is facilitated, and forming force required in the forming process is reduced.

Owner:XIAN UNIV OF TECH

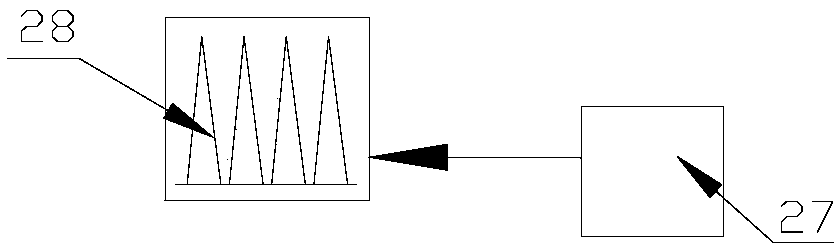

Gradual type laser shock continuous riveting method and device

ActiveCN106041298ASmall forming forceImprove internal organizationLaser beam welding apparatusOptoelectronicsLaser beams

The invention relates to a gradual type laser shock continuous riveting method and device and belongs to the technical field of material connection. The method and device are used for linear riveting between boards. The method includes the steps that A, a laser device is used for directly generating multiple beams of lasers or a beam splitting system is used for generating the multiple beams of lasers; B, a V-shaped included angle is formed between the extending lines of every two laser beams, and the boards are swept through the multiple beams of lasers at the same time; C, when the pulse lasers act on the surfaces of the boards, exploding plasma is generated, and each board gradually deforms to be of a groove structure under the shock effect of the exploding plasma and with the cooperation of the restraint of a forming die; D, the arranging manner of the multiple beams of lasers is adjusted, so that the laser beams are aligned with the two sides of the bottom of each groove structure; and E, the multiple beams of lasers move; under the continuous shock effect of the exploding plasma, the laser beams are matched with the restraint of the forming die, so that the groove structures are gradually shocked into interlocking structures; and the step B to the step E are repeated, the boards are gradually shocked, and therefore the boards are riveted together.

Owner:SHANDONG UNIV

High-pressure gas bulging thermoforming die of boron steel pipe

InactiveCN104438878AHigh strengthBig spaceShaping toolsQuenching devicesHydraulic cylinderHigh pressure

The invention relates to a high-pressure gas bulging thermoforming die of a boron steel pipe. The die comprises an upper die base and a lower die base, and is characterized in that an upper die forming insert is mounted on the lower surface of the upper die base; a lower die forming insert is mounted on the upper surface of the lower die base; the lower surface of the upper die forming insert and the upper surface of the lower die forming insert are the forming surface of a workpiece of the boron steel pipe; seal heads are arranged at the two ends of the workpiece of the boron steel pipe respectively; the front ends of the seal heads are in contact with the pipe ends of the workpiece of the boron steel pipe; an axial hydraulic cylinder or an air cylinder is connected to the rear ends of the seal heads; vent holes are formed in the centers of the seal heads; the front ends of the vent holes are communicated with the interior of the workpiece of the boron steel pipe; a high-pressure gas station is connected to the rear ends of the vent holes; cooling passages are arranged at the lower part of the upper die forming insert and the upper part of the lower die forming insert respectively and directly connected with a water pipe or connected with the water pipe through the upper die base and the lower die base. According to the die, the workpiece which has the material mechanical strength of 1,500 MPa and is variable in cross-section shape and circumference can be produced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and forming method

InactiveCN107052096AImprove processing qualityLow proficiency requirementMetal-working feeding devicesPositioning devicesEngineeringOperability

The invention belongs to the technical field of complex curved-surface steel sheet forming and discloses complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and a forming method. The forming equipment comprises a forming machine tool body, a supporting and adsorption device for performing step-by-step progressive machining and forming on a metal sheet and a tool pressing head set. The supporting and adsorption device comprises a supporting frame, adsorption components for adsorbing the metal sheet and supporting components for adjusting displacement of the adsorption components. The complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment is adopted for the forming method. The method comprises the following steps that a machined piece is divided into a plurality of segments, and the tool pressing head set and the supporting and adsorption device act on the two sides of all segments of the machined piece correspondingly in sequence in a progressive manner. By means of the complex curved-surface steel sheet numerically-controlled flexible progressive forming equipment and the forming method, the metal sheet of multiple shapes can be machined, the structure is stable and reliable, operability is high, machining efficiency is higher, the requirement for the skilled degree of operation workers is low, and the quality of a finished product is high.

Owner:SHENZHEN INST OF ADVANCED TECH

Extrusion forming die for thin-wall near-contoured chevron light alloy member

ActiveCN109530471AUniform wall thicknessDoes not affect separation distanceExtrusion diesAlloyMechanical property

The invention discloses an extrusion forming die for a thin-wall near-contoured chevron light alloy member, which comprises an upper die component, a lower die component, an ejection device, a material ramming device, a fixed component and a movable component, wherein the upper die assembly comprises an upper die plate, a male die fixed ring, a first pass male die and a second pass male die, the first pass male die and the second pass male die are interchangeable, the lower die assembly comprises a lower template, a female die, a middle female die and a mandrel, the middle female die and the mandrel are interchangeable. When the upper die assembly is assembled with the first pass male die, the female die is correspondingly provided with the middle female die, a middle male die is providedwith a discharging channel, and a lower annular wall is extended out of the lower section of the discharging channel. The ejection device comprises an ejection block and an ejector rod. The material ramming device comprises a material ramming plate. The fixed component and the movable component comprise an umbrella cap, a cylindrical pin, a fixed block, a hanging erbium and a chain. According to the extrusion forming die for the thin-wall near-contoured chevron light alloy member, the precise plastic forming of the thin-wall near-contoured complex chevron member is achieved, the problems brought by the traditional processing and manufacturing die are effectively overcome, the formability of the light alloy is improved, the comprehensive mechanical property of the formed member is improved, the material utilization rate is greatly improved, the energy is saved and the consumption is reduced.

Owner:ZHONGBEI UNIV

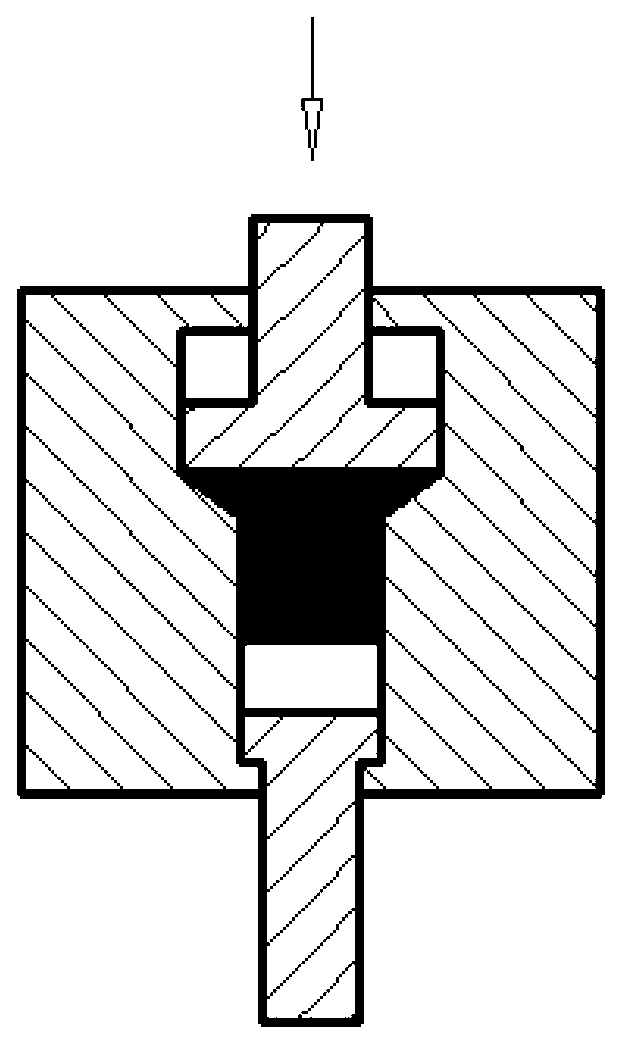

Near-net forming method of high-strength internal hexagon bored bolt

ActiveCN103240359APrevent deviationReduce forming processShaping toolsNutsHigh volume manufacturingHeat treated

The invention discloses a near-net forming method of a high-strength internal hexagon bored bolt. The method includes: firstly, feeding a pipe; secondly, cold-extruding, machining, thermally annealing, surface-treating, and lubricating; thirdly, placing a treated hollow blank into a cavity of a forming die of a forming tool for a high-strength internal hexagon bored bolt, forming an internal hexagon bore and a boss on the bolt, smoothly ejecting an extruded part out of the die; and fourthly, cutting ends and threads on the near-net-shaped extruded part to obtain a standard internal hexagon bored bolt. The method is convenient and simple to operate and high in production efficiency, has fewer machining procedures compared with those of the traditional method, has effectively lowered production cost, and is suitable for batch production.

Owner:ZHONGBEI UNIV

Multi-pass multi-direction rotary rolling forming method of large-scale transversely high-rib thin-wall ring component

ActiveCN110479841ASignificant energy saving and material savingReduce manufacturing costProduction rateRoll forming

The invention relates to a multi-pass multi-direction rotary rolling forming method of a large-scale transversely high-rib thin-wall ring component. The method comprises the following steps that S1, an annular blank and an annular push plate are sleeved on a constraint die, two rotary wheels which are symmetrical about the axial middle surface of the annular blank are in close contact with the twoend faces of the blank correspondingly, so that acting force is generated between the constraint die and the annular blank, and it is guaranteed that the constraint die can drive the annular blank and the rotary wheels to stably rotate; S2, the constraint die drives the annular blank and the rotary wheels to rotate around the self-axes correspondingly, and meanwhile, the two rotary wheels do feeding motion along a track, so that continuous local plastic deformation of the annular blank is generated until the annular blank is integrally formed; and S3, when the shape of a forming part is the shape of the target transversely high-rib thin-wall ring component, the constraint die stops rotating, the two rotary wheels return to the initial position, and the manufactured target transversely high-rib thin-wall ring component is pushed out from the constraint die through the annular push plate. According to the multi-pass multi-direction rotary rolling forming method, the large-scale transversely high-rib thin-wall ring component is locally formed through multiple passes, the method has remarkable effects of saving energy and material, reducing production cost, improving productivity andreducing forming force.

Owner:WUHAN UNIV OF TECH

Rolling-extruding composite near-net forming method for large ring piece having outer contour with abrupt-change section

ActiveCN113084054AInhibit growthPrevent axial movementGeometric CADSpecial data processing applicationsPunchingEnergy consumption

The invention discloses a rolling-extruding composite near-net forming method for a large ring piece having an outer contour with an abrupt-change section. The rolling-extruding composite near-net forming method for the large ring piece having the outer contour with the abrupt-change section comprises the following steps: S1, a blank obtained after upsetting and punching is subjected to pre-rolling forming, and a large-diameter ring blank with the rectangular section and uniform wall thickness is obtained; S2, the ring blank subjected to the pre-rolling forming is placed on an extrusion die, the extrusion die comprises a core die with limiting flanges at the two ends and a plurality of petal dies evenly distributed around the axis, the petal dies are provided with multiple stages of extrusion blocks in the axial direction, each stage of extrusion block is controlled by a respective high-pressure push rod to work, multi-direction continuous local incremental radial extrusion is adopted, and the abrupt-change contour of the outer surface of the ring blank is formed step by step in the axial direction, and a special-shaped ring blank is obtained; and S3, the special-shaped ring blank is subjected to radial closed type near-net rolling forming, and the target ring piece is obtained. The method is smaller in forming force, lower in energy consumption, capable of restraining the outer diameter of the ring piece from being increased, high in material utilization rate and capable of greatly improving the comprehensive performance of products.

Owner:WUHAN UNIV OF TECH

High-strength steel rolling hot-forming technology

The invention relates to a high-strength steel rolling hot-forming technology. The high-strength steel rolling hot-forming technology comprises the following steps of: (a) hot-forming of a steel belt, wherein the steel belt comprises the following components in parts by weight: 0.007-0.33% of C, 0.02-0.05% of Al, 0.001-0.005% of B, 0.16-0.37% of Cr, 0.75-1.21% of Mn, 0.004-0.006% of N, 0.01-0.1% of Ni, 0.20-0.40% of Si, 0.03-0.05% of Ti and the balance of Fe and inevitable impurities; (b) uncoiling: cutting the hot-formed steel belt into sheet materials with the length and width which are required for products; (c) forming: transferring the sheet materials into rolling and forming equipment, and performing the sheet materials into semifinished products at a room temperature; (d) heating: controlling heating temperature to 800-1100 DEG C, and preserving heat for 3-8 minutes; and (e) setting: transferring the semifinished products at a high temperature to setting equipment, carrying out pressure maintaining and quenching under a loading condition, i.e. quenching at a cooling speed of above 27 DEG C / s, cooling to a room temperature, and obtaining a martensitic structure with the tensile strength of above 1500 Mpa by quenching.

Owner:BAOSTEEL METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com