Gear-box planetary gear shaping die

A technology for planetary gears and forming dies, which is applied in the direction of wheels, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of difficulty in forging, harsh requirements for blanks, and low die life, so as to achieve complete metal flow lines and reduce Requirements for blanking accuracy and the effect of reducing forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

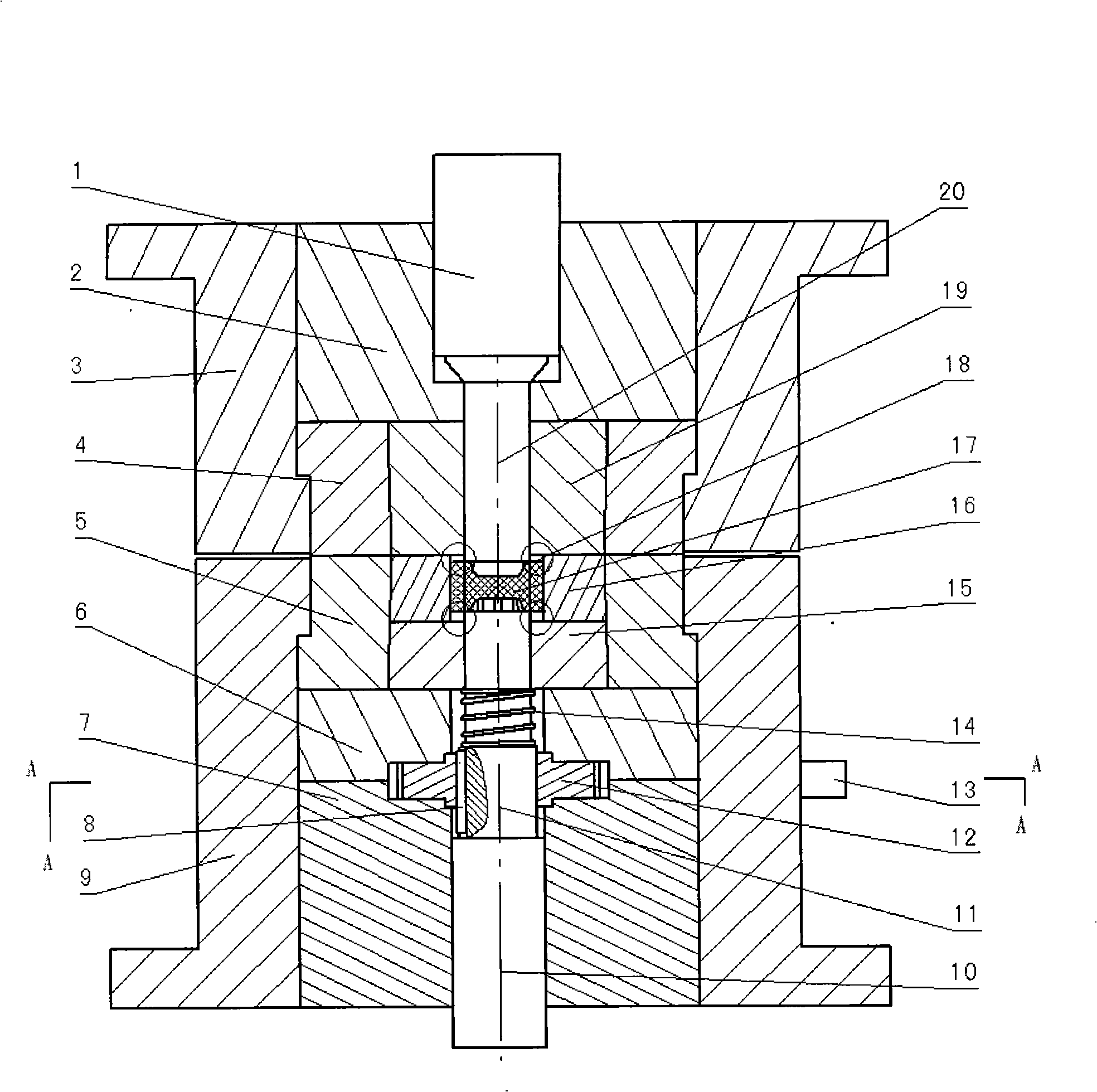

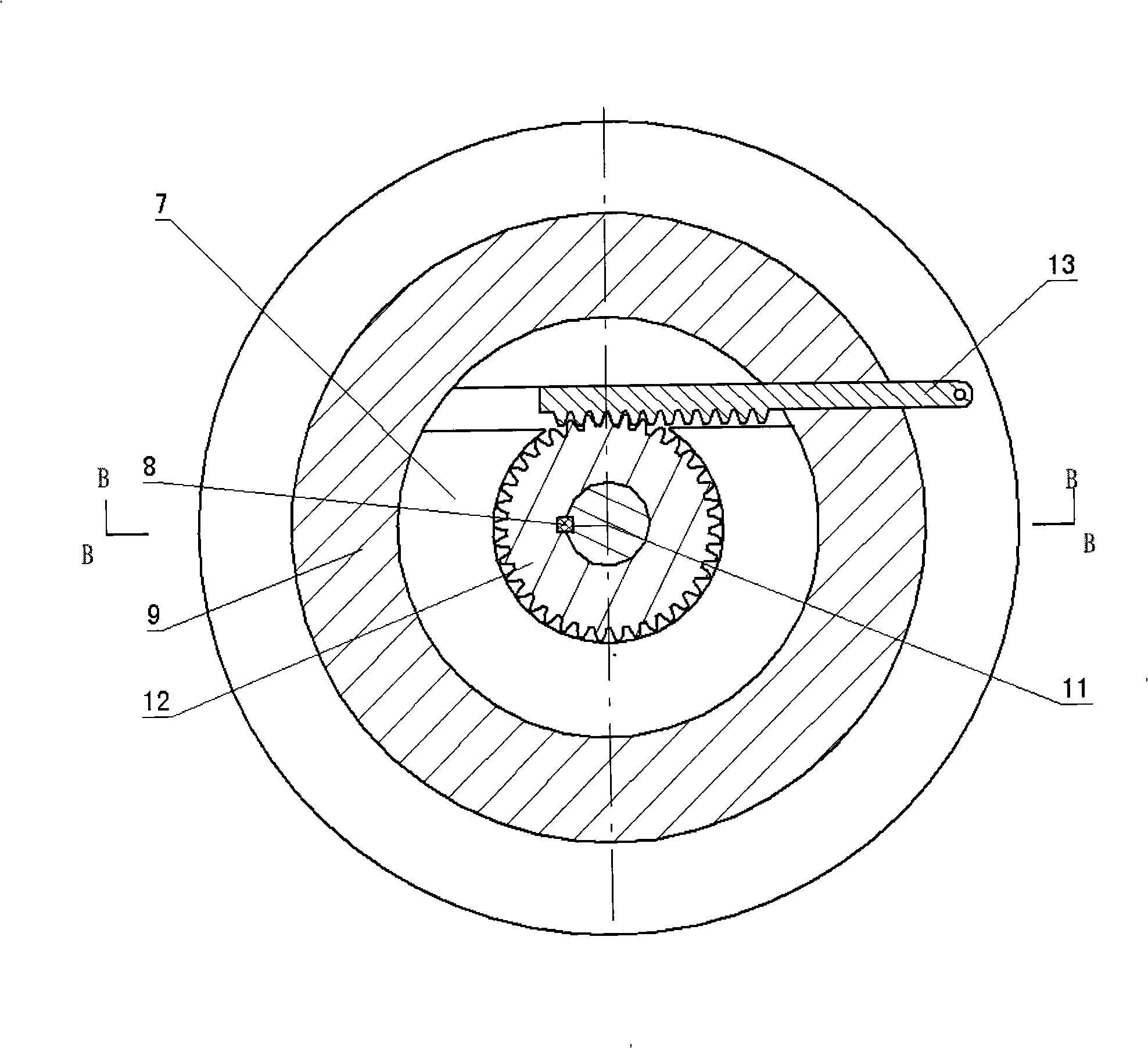

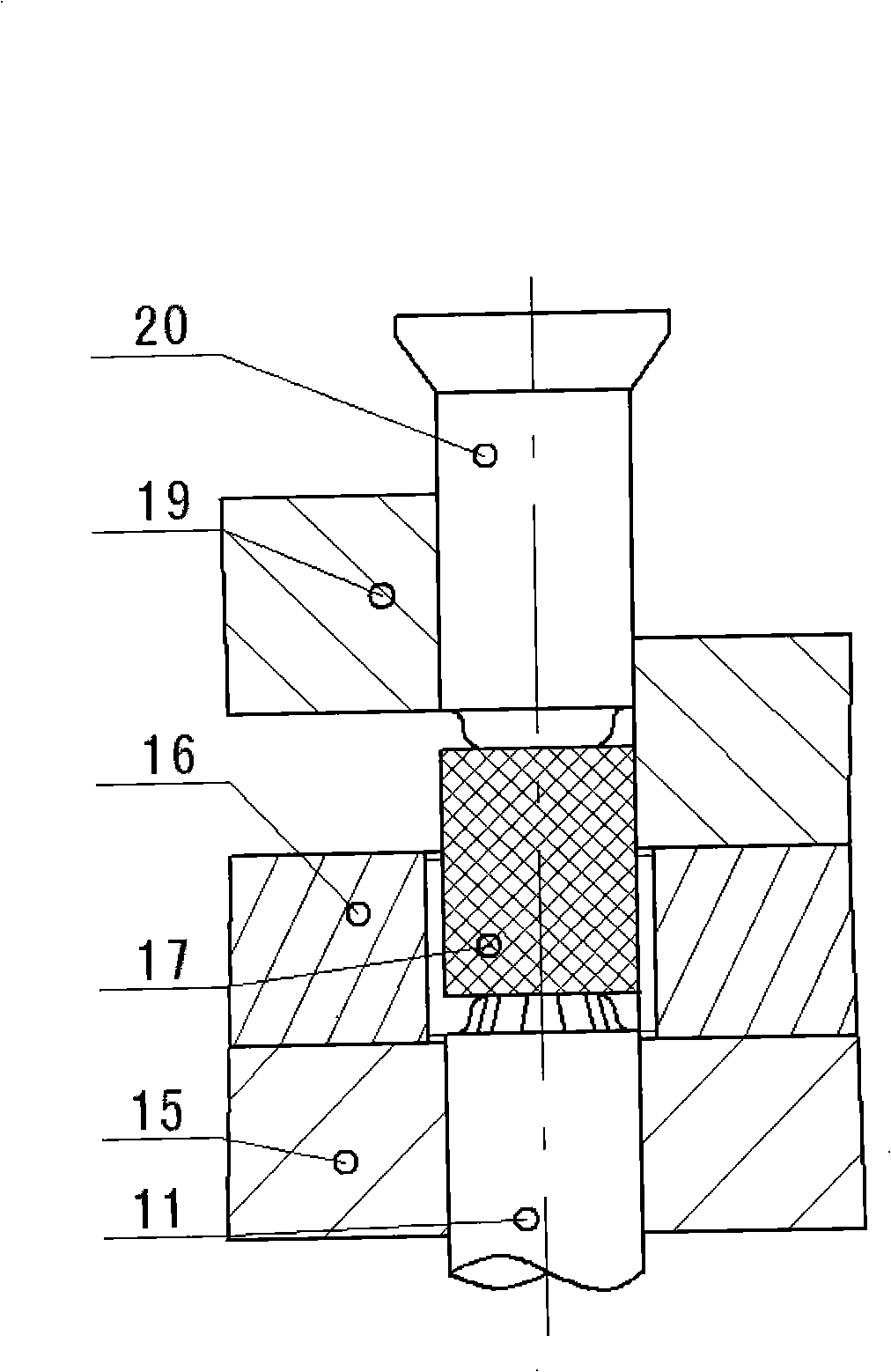

[0021] Such as figure 1 As shown, the mold of the present invention includes an upper push rod 1, an upper mold cushion block 2, an upper mold outer cover 3, an upper die prestressing ring 4, a lower die prestressing ring 5, an upper die upper pad 6, and a lower die lower pad Block 7, guide key 8, lower mold jacket 9, lower push rod 10, lower punch 11, cylindrical gear 12, rack 13, return spring 14, lower barrel 15, tooth-shaped die 16, process compensation space 18, Upper barrel 19, upper punch 20.

[0022] Figure 3(A) and Figure 3(B) show the working process of the die and the forming process of the forging when a single punch is extruded. The left half of Figure 3(A) is the discharging state, and the right half of Figure 3(A) It is the mold closing state; the left half of Figure 3(B) is the mold closing state, and the right half of Figure 3(B) is the final state of extrusion. As shown in the left half of Figure 3 (A), when the upper push rod 1, the upper die cushion block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com