Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7266 results about "Epicyclic gearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

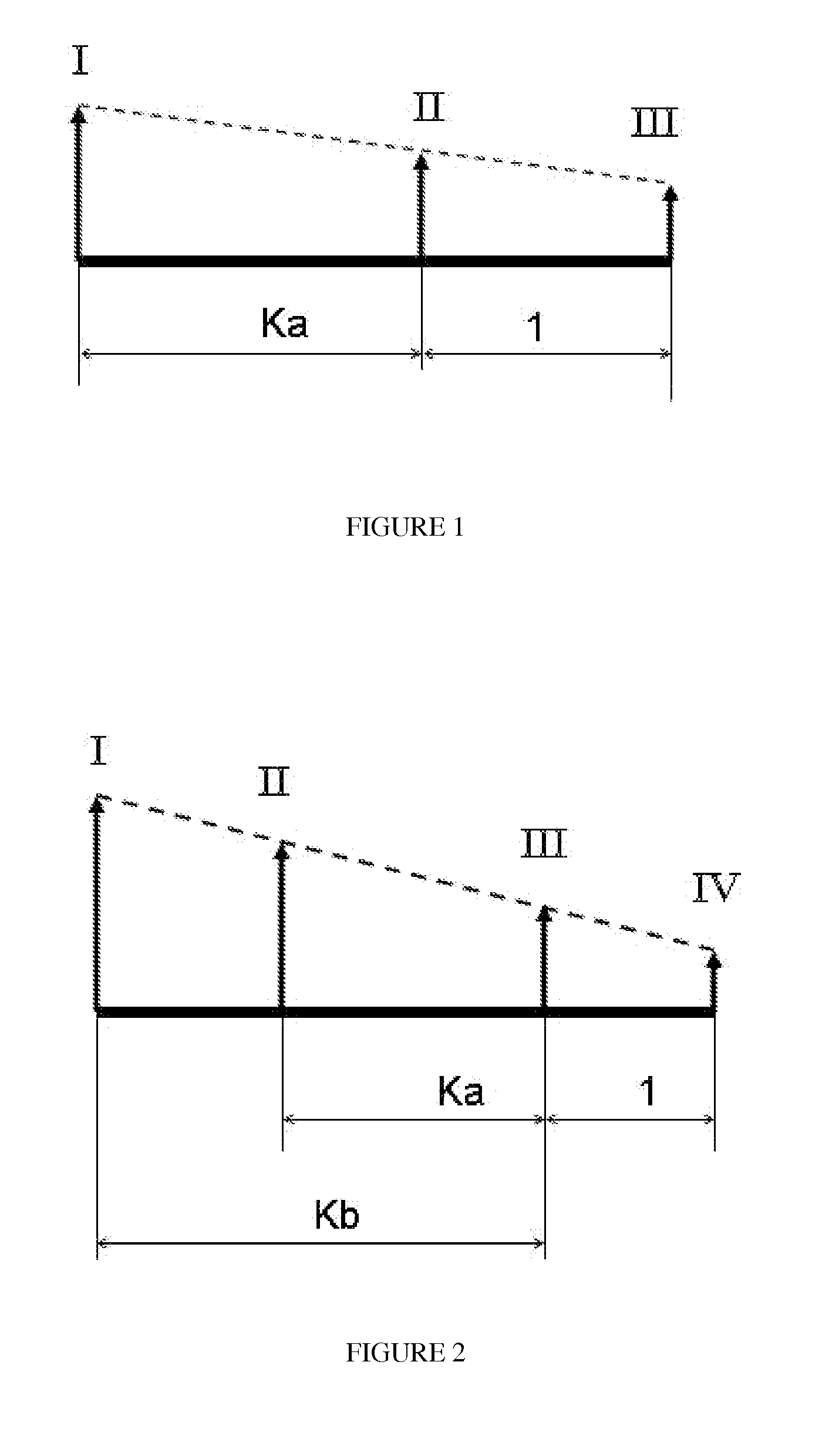

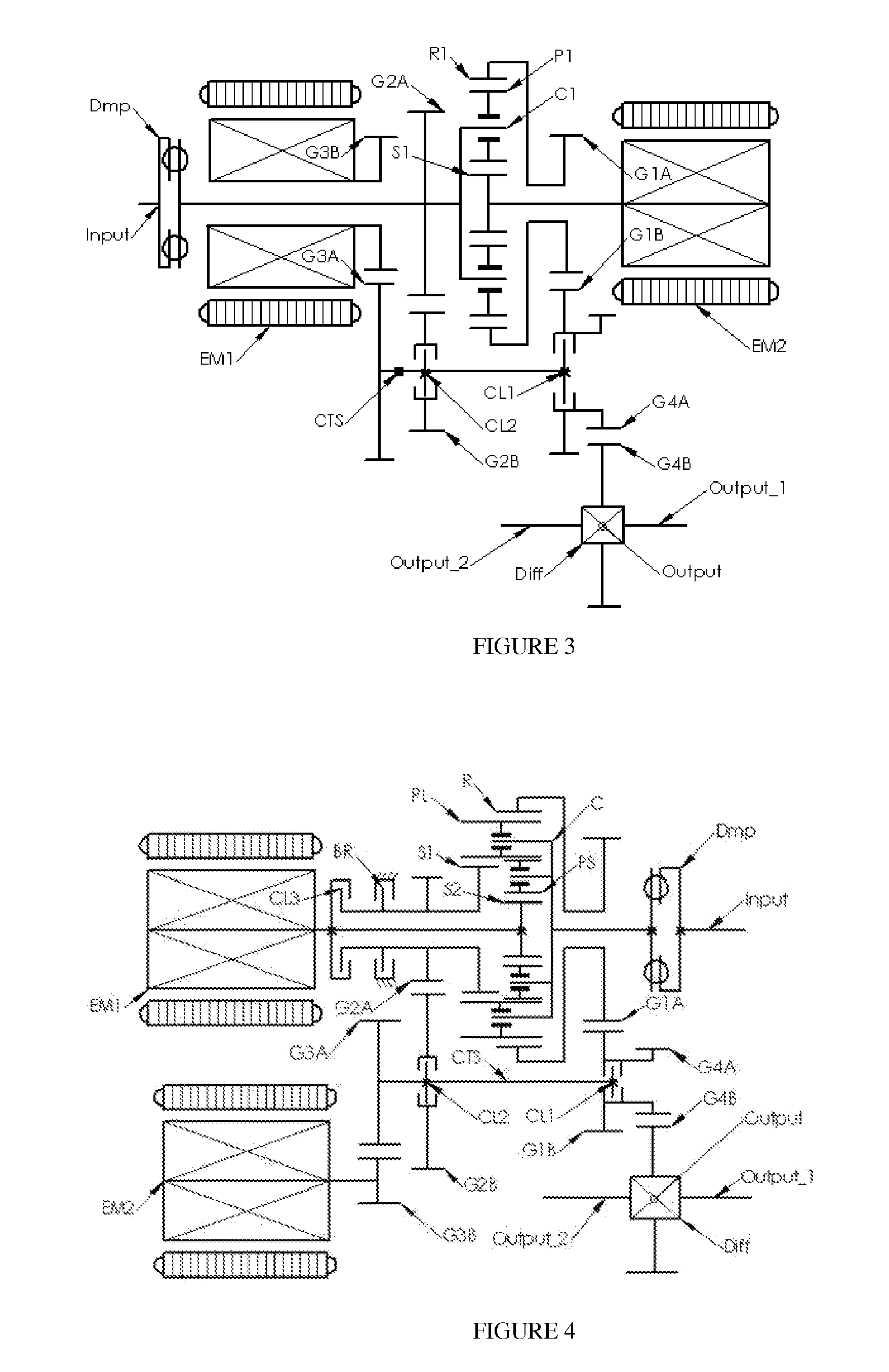

An epicyclic gear train (also known as planetary gear) consists of two gears mounted so that the centre of one gear revolves around the centre of the other. A carrier connects the centres of the two gears and rotates to carry one gear, called the planet gear or planet pinion, around the other, called the sun gear or sun wheel. The planet and sun gears mesh so that their pitch circles roll without slip. A point on the pitch circle of the planet gear traces an epicycloid curve. In this simplified case, the sun gear is fixed and the planetary gear(s) roll around the sun gear.

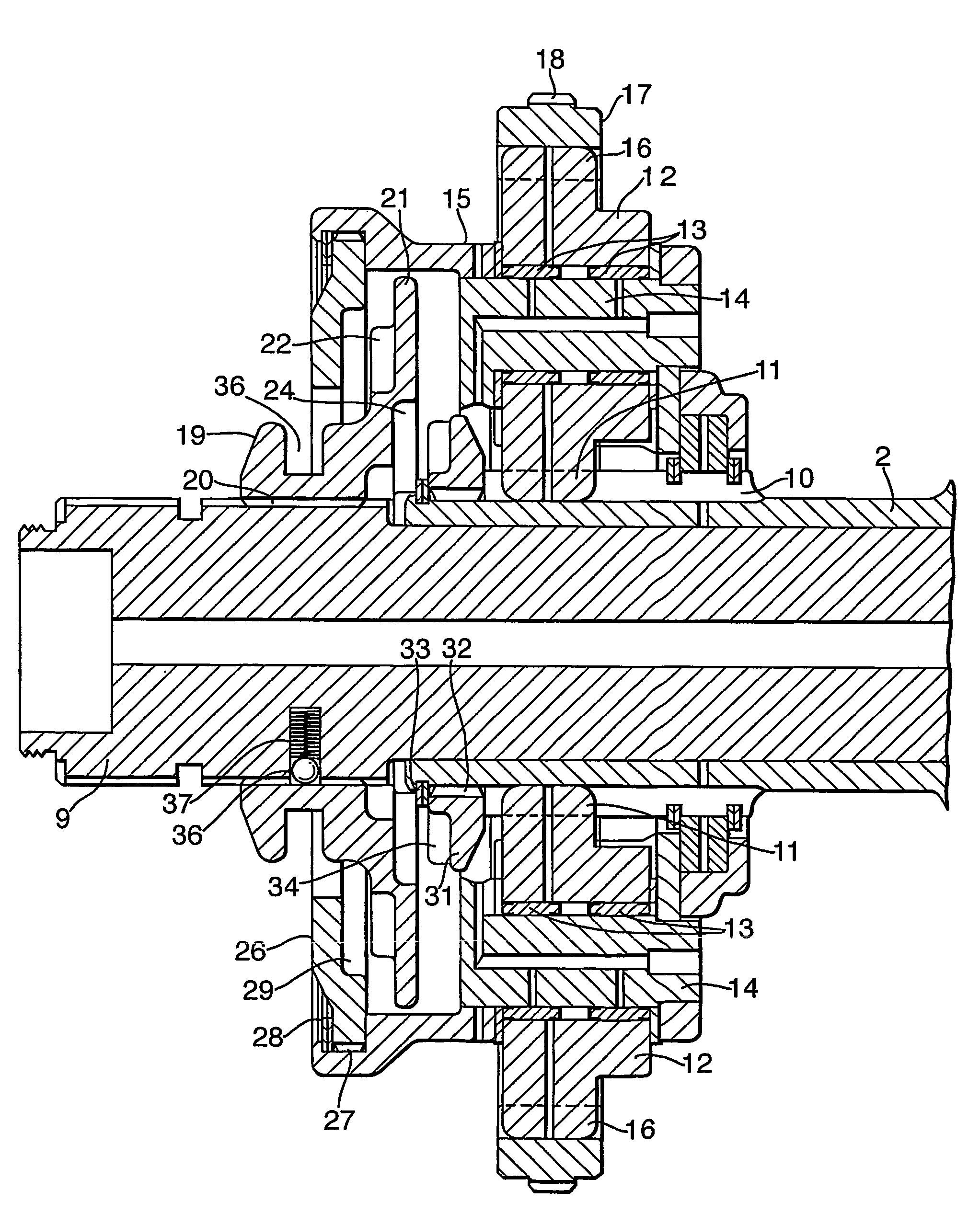

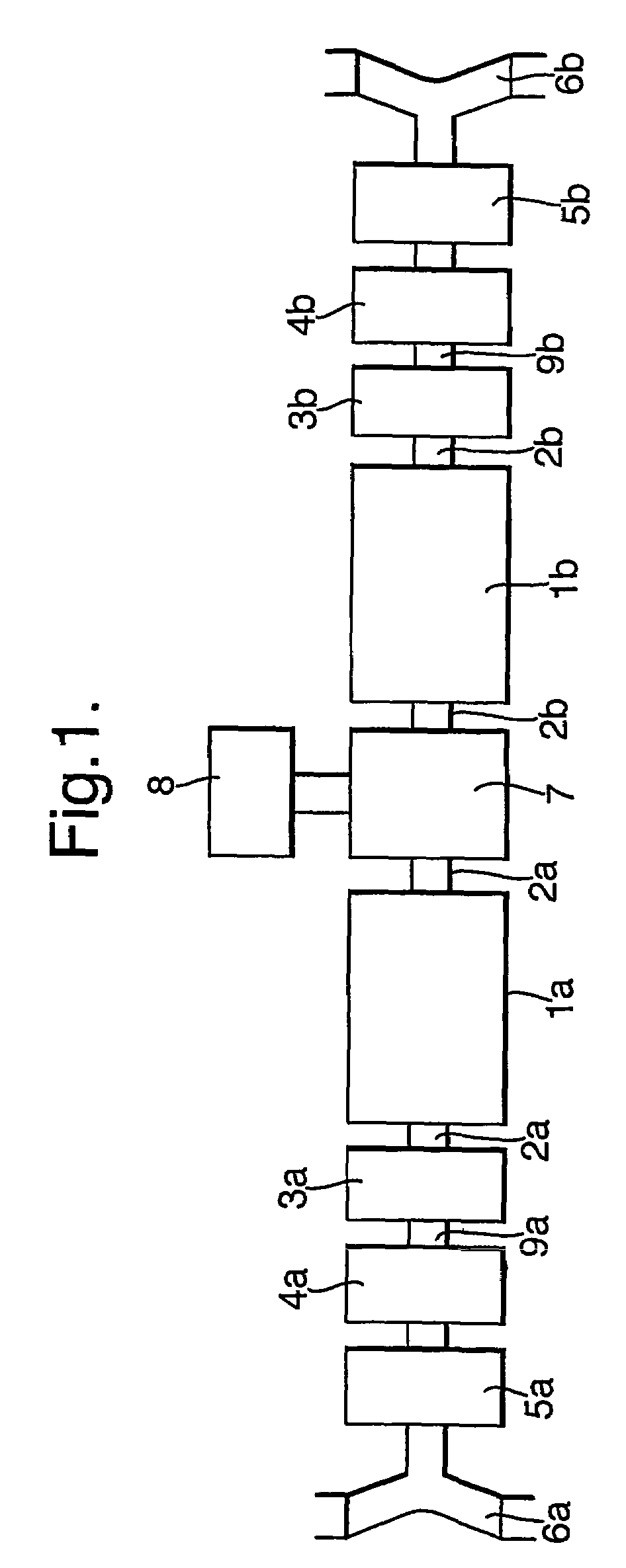

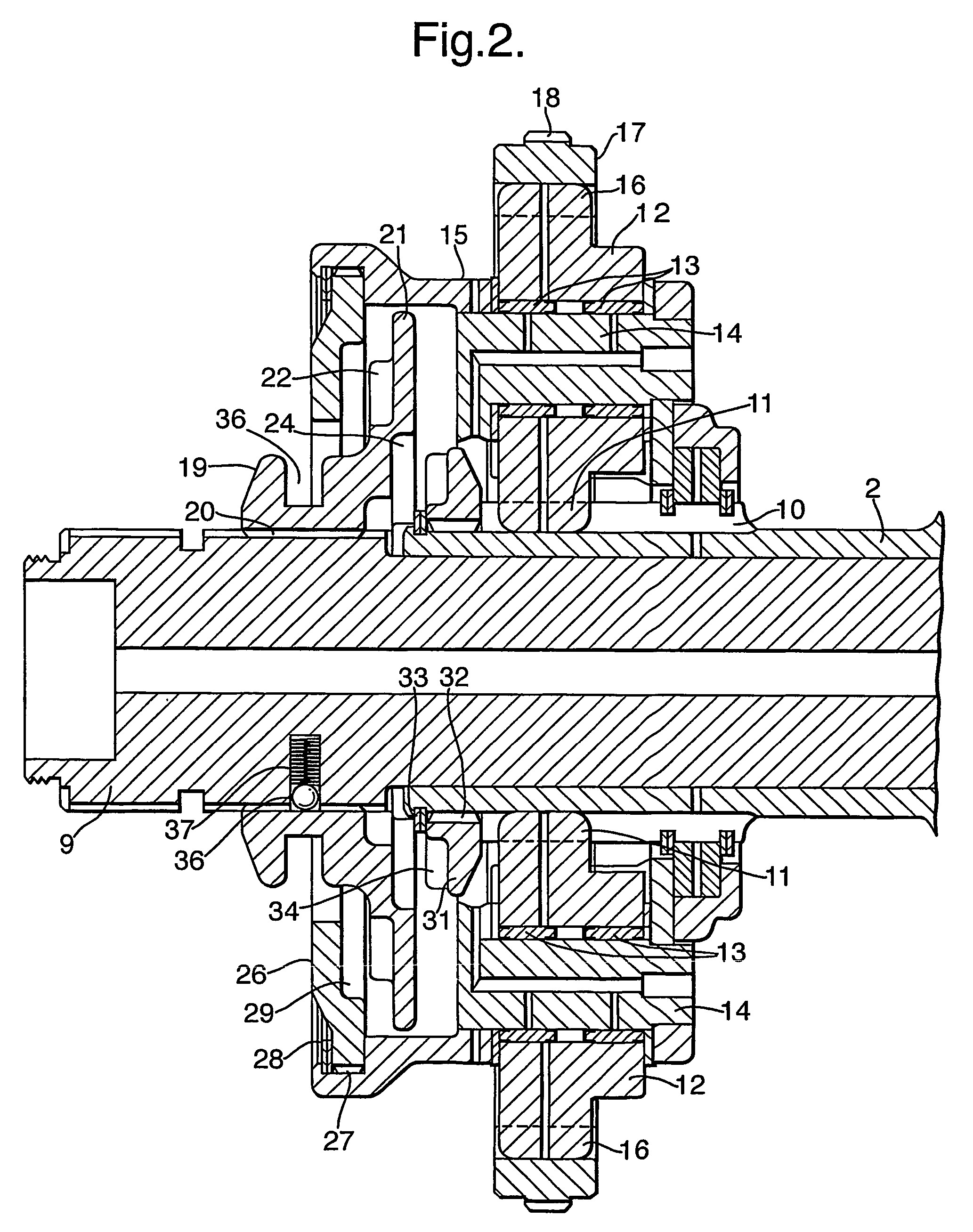

Gear change mechanism

ActiveUS7303502B2Easy to participateSpace minimizationToothed gearingsInterengaging clutchesEngineeringDog clutch

A gear change mechanism coupling a pair of shafts employs a planetary gear set comprising a sun gear fast with a first of the shafts, planet gears in a planet carrier, and an annulus or ring gear, the latter being fixed. A selector hub slidable on the other of the shafts has sets of radially spaced dogs to engage with corresponding dogs on the planet carrier and sun gear respectively, so as to couple the shafts at two different ratios depending on the axial position of the selector hub. This results in a more axially compact package than conventional dog clutch gear changers. In an alternative embodiment a reversing mechanism is provided by fixing the planet carrier and engaging the selector hub with the sun gear or annulus depending on its axial position.

Owner:QINETIQ LTD

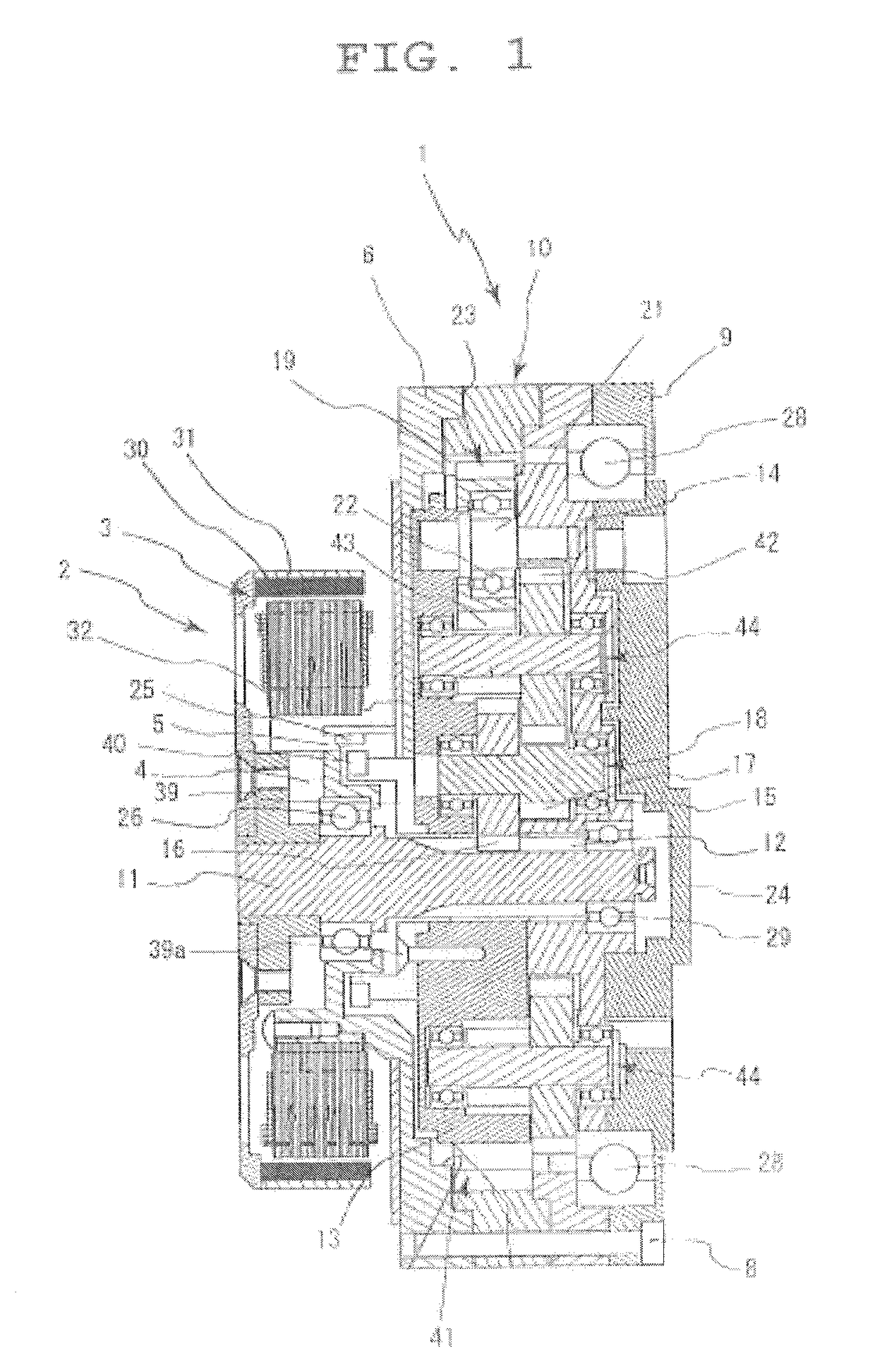

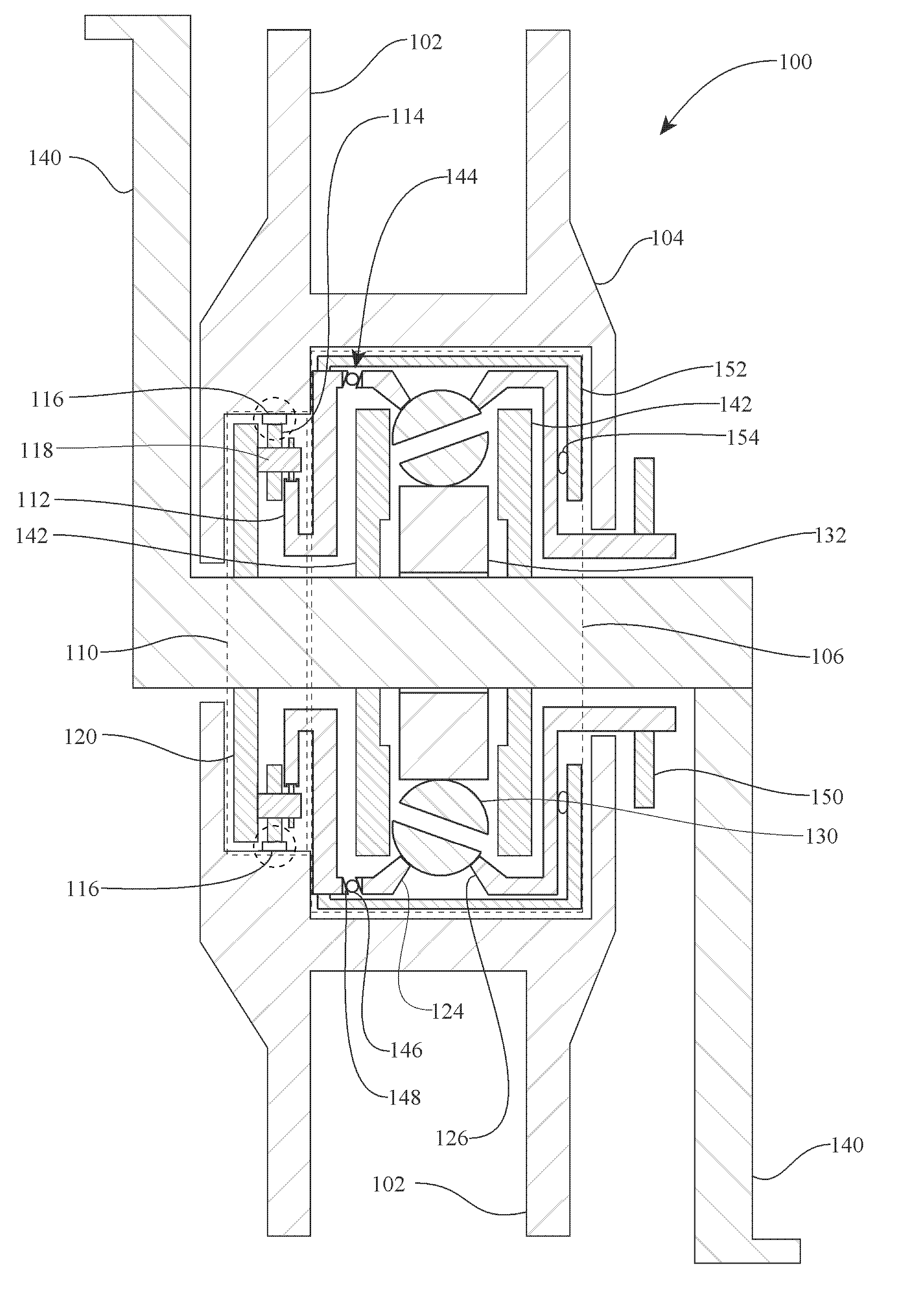

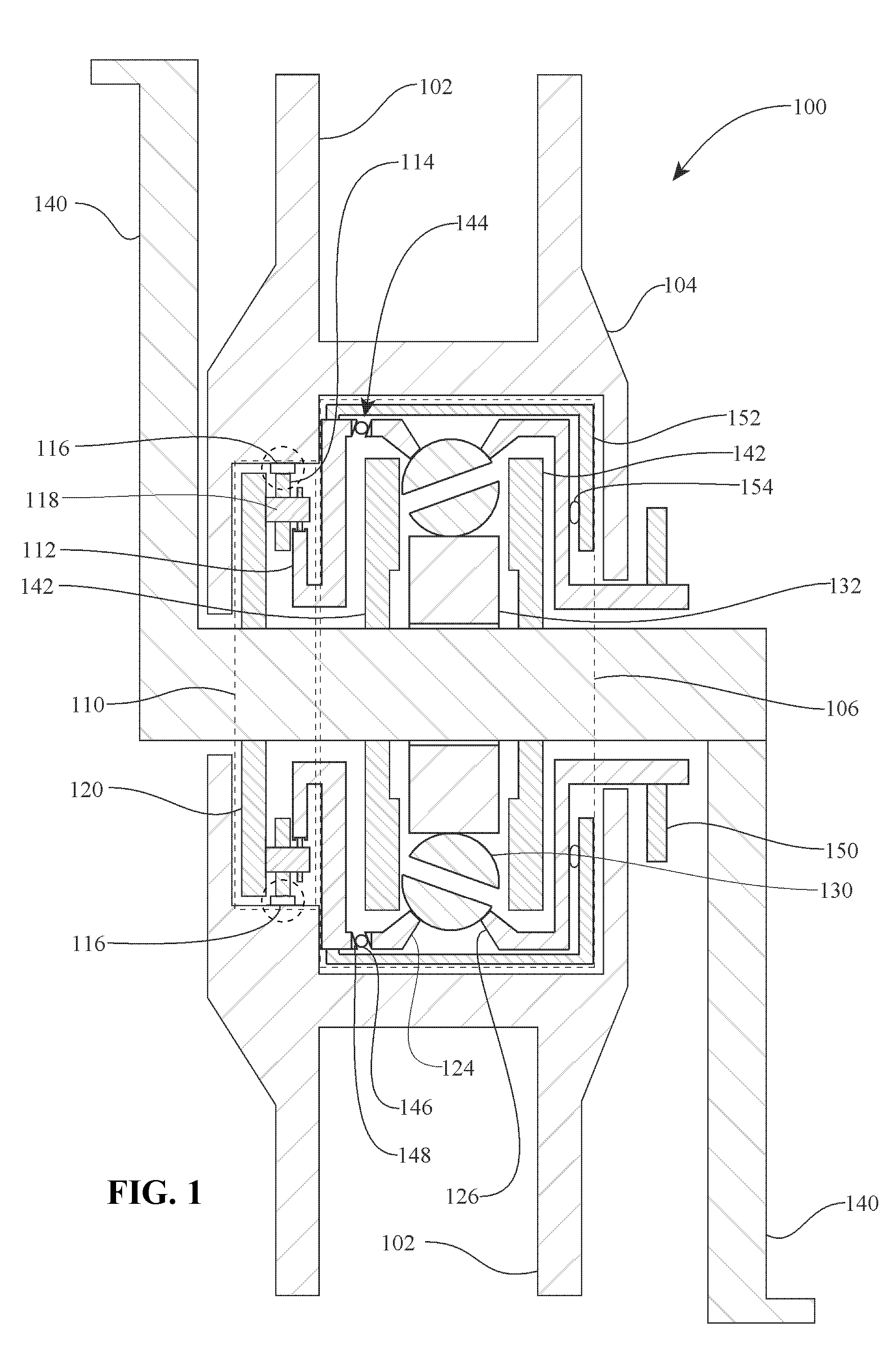

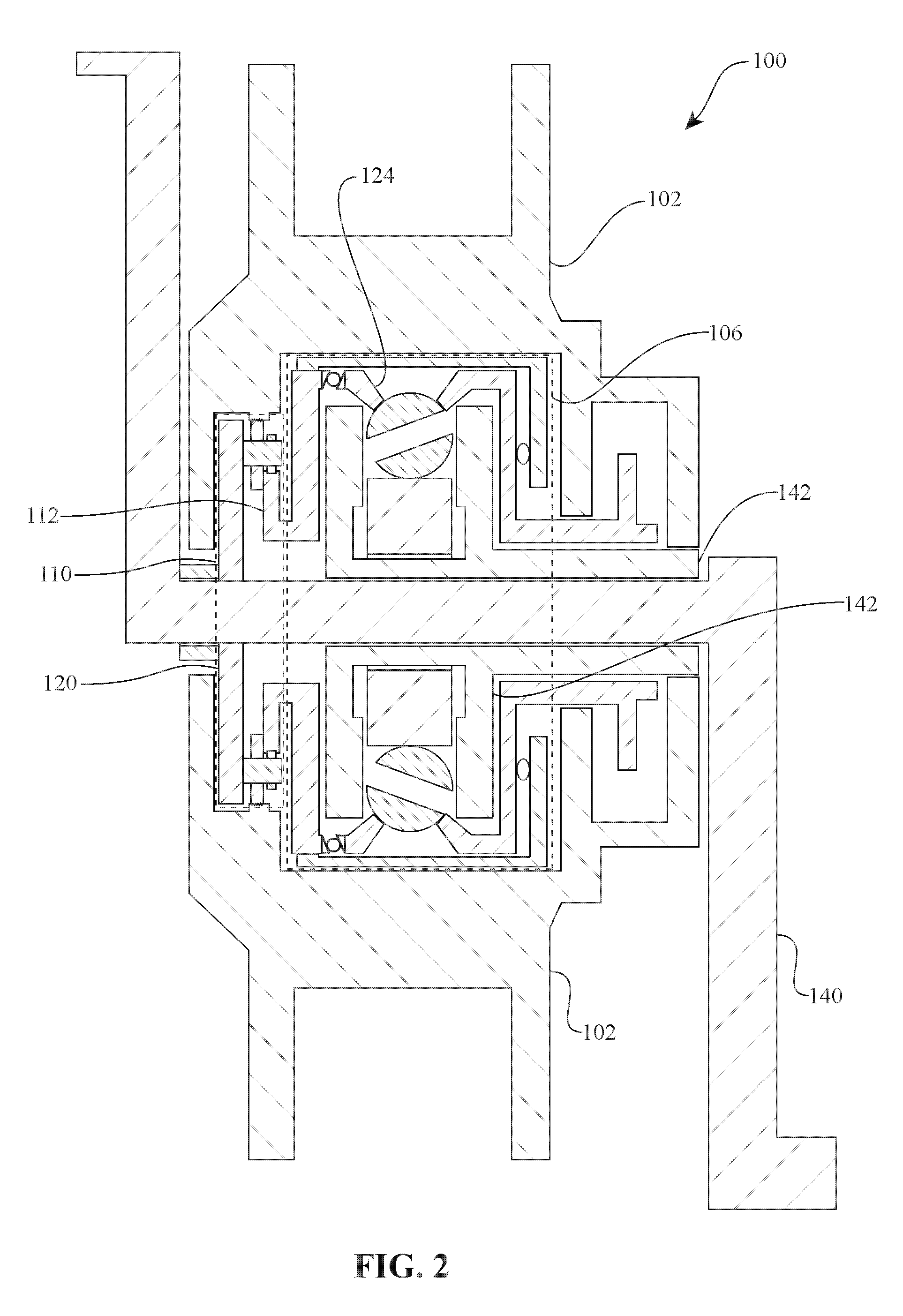

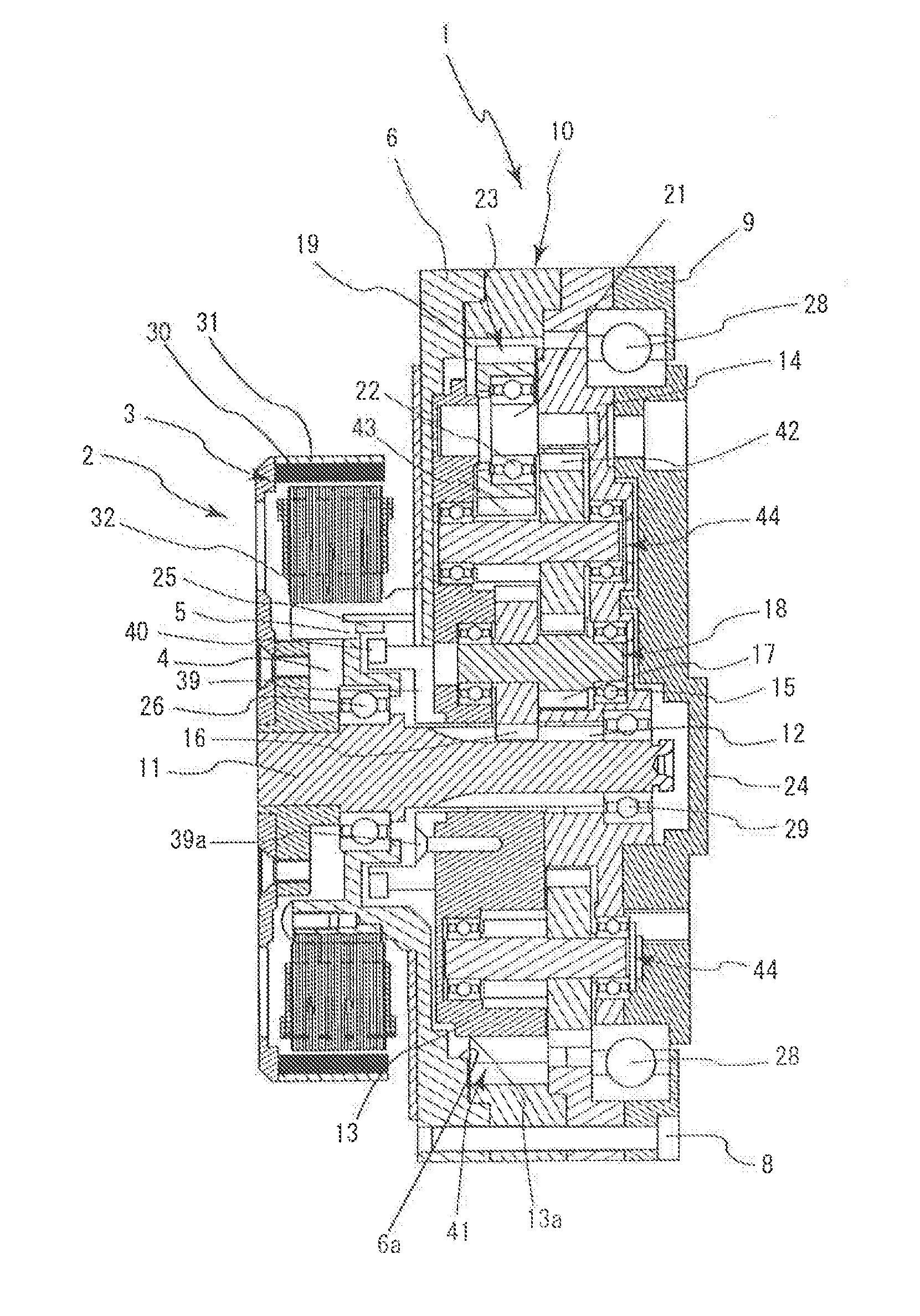

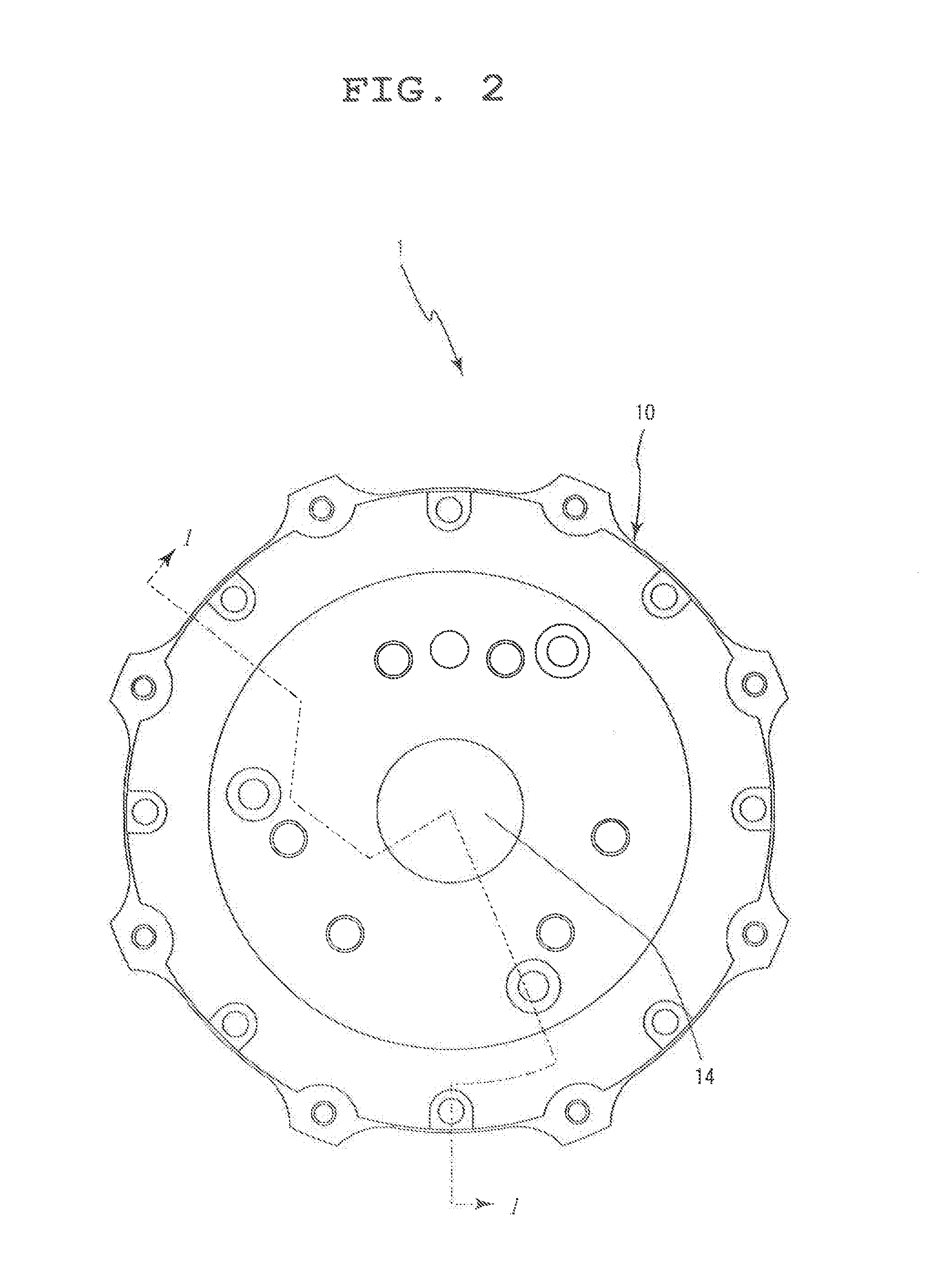

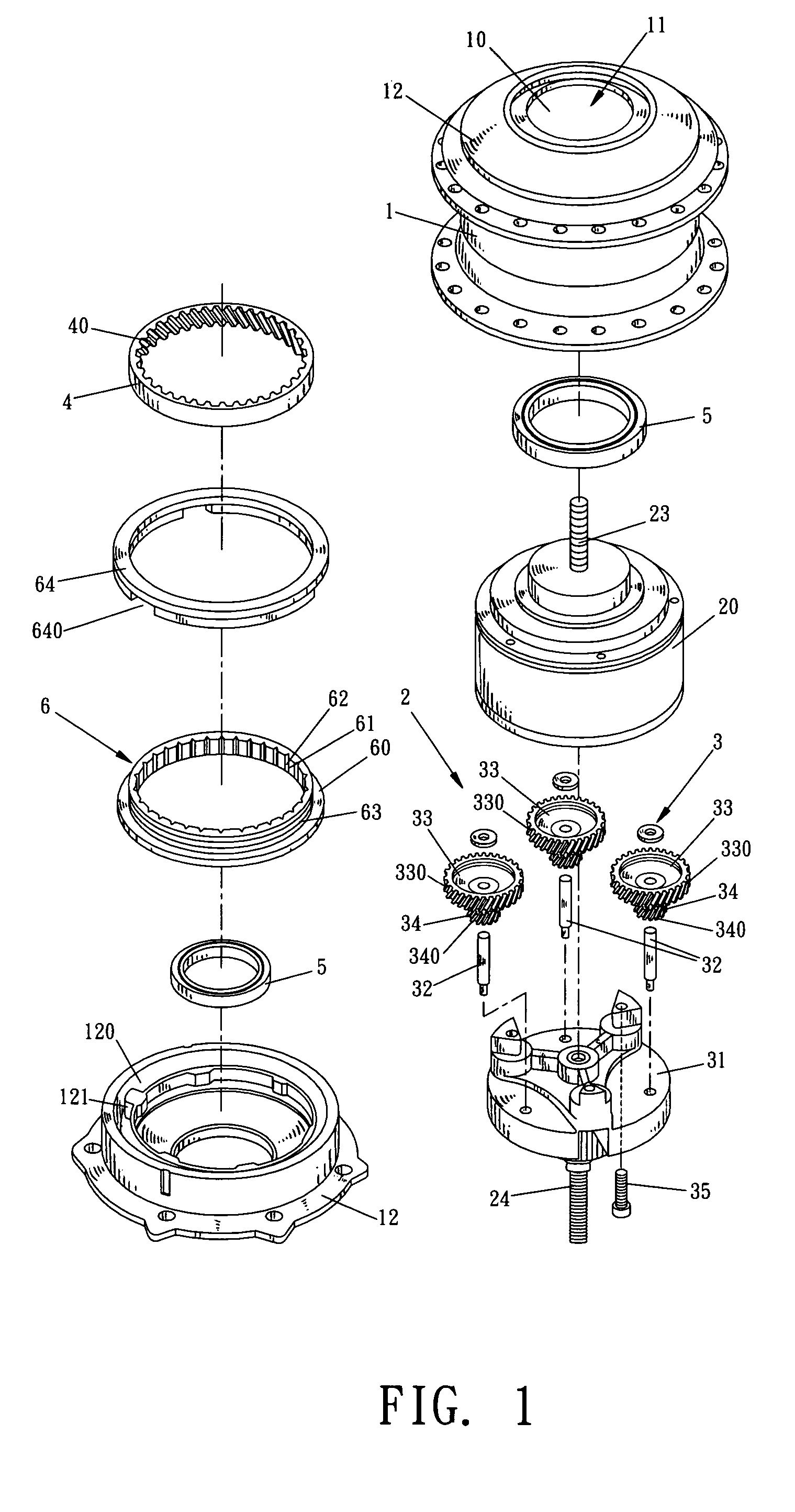

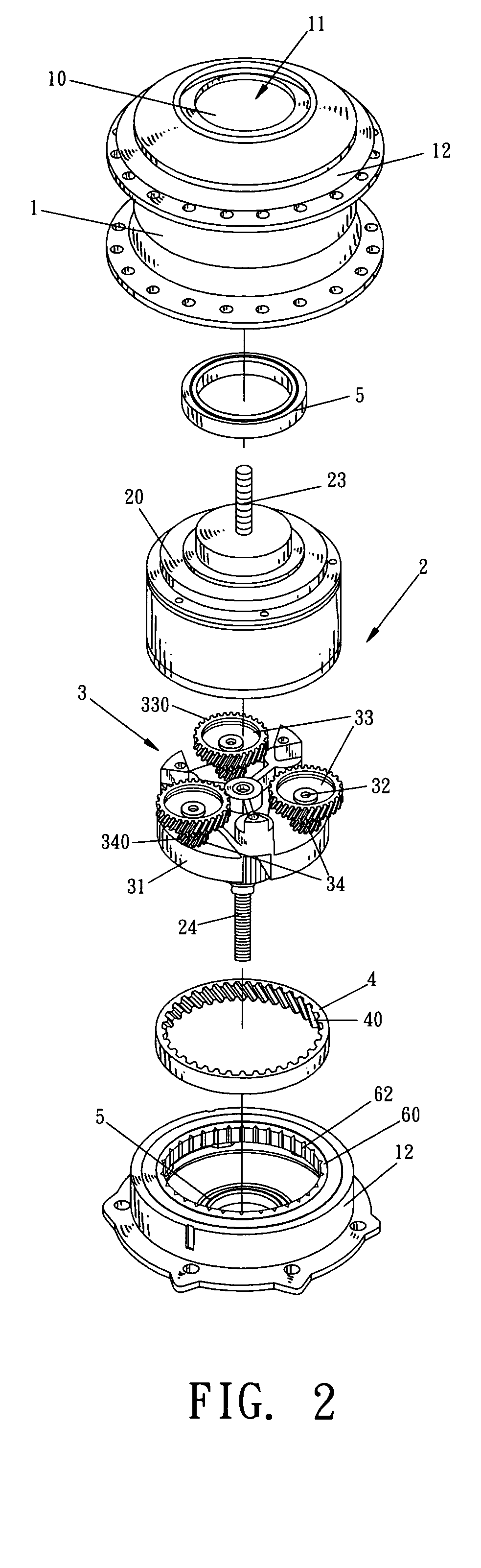

Gear motor including reduction mechanism

ActiveUS9689466B2Thinness and size and weight reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can he achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

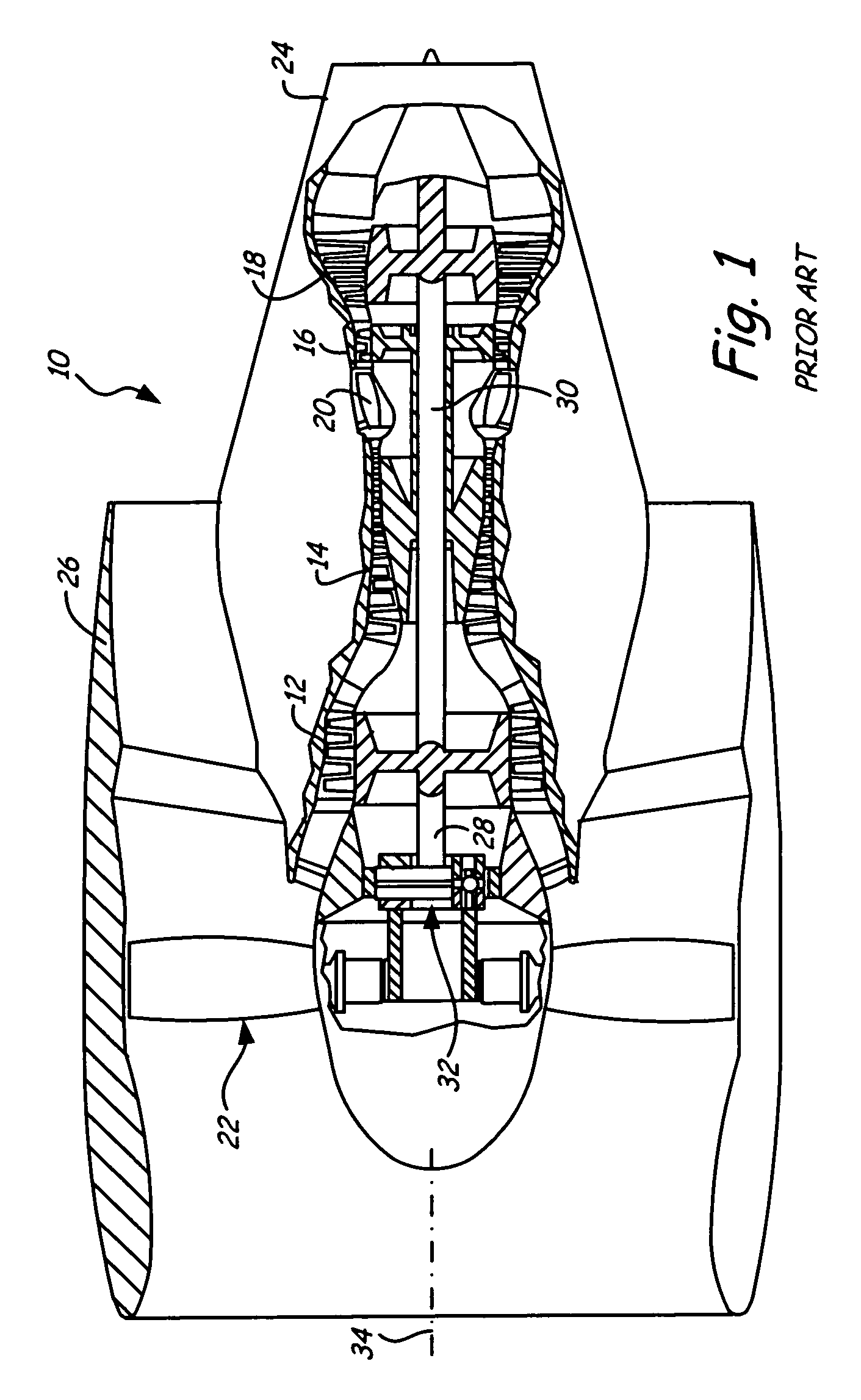

Epicyclic gear train integral sun gear coupling design

A coupling system for connecting a sun gear to a shaft within a planetary gear train, includes a sun gear coupling connecting the sun gear to the shaft. The sun gear coupling has at least one undulant flexible section joined to an inflexible spindle for accommodating misalignment between the sun gear and the shaft. The flexible section comprises a cylindrical ring having a diameter greater than the diameter of the spindle, and joined to the spindle by two longitudinally spaced apart diaphragms. The juncture between the diaphragms, the ring, and the spindle is curved in cross section on an outer side to improve flexibility and minimize stress concentrations, and the inner sides of the diaphragms are straight edges which result in a non-symmetric contour of the diaphragm walls.

Owner:RTX CORP

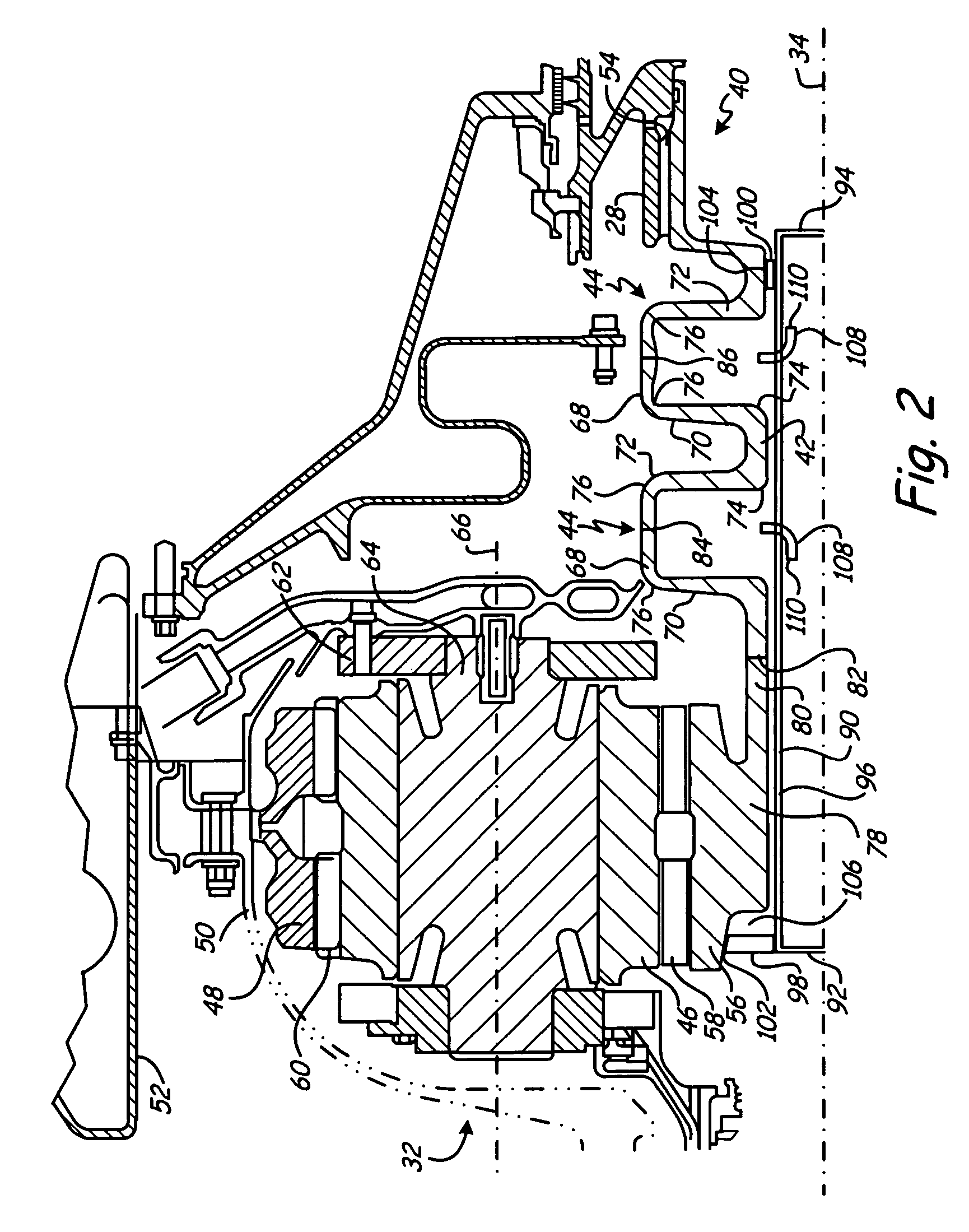

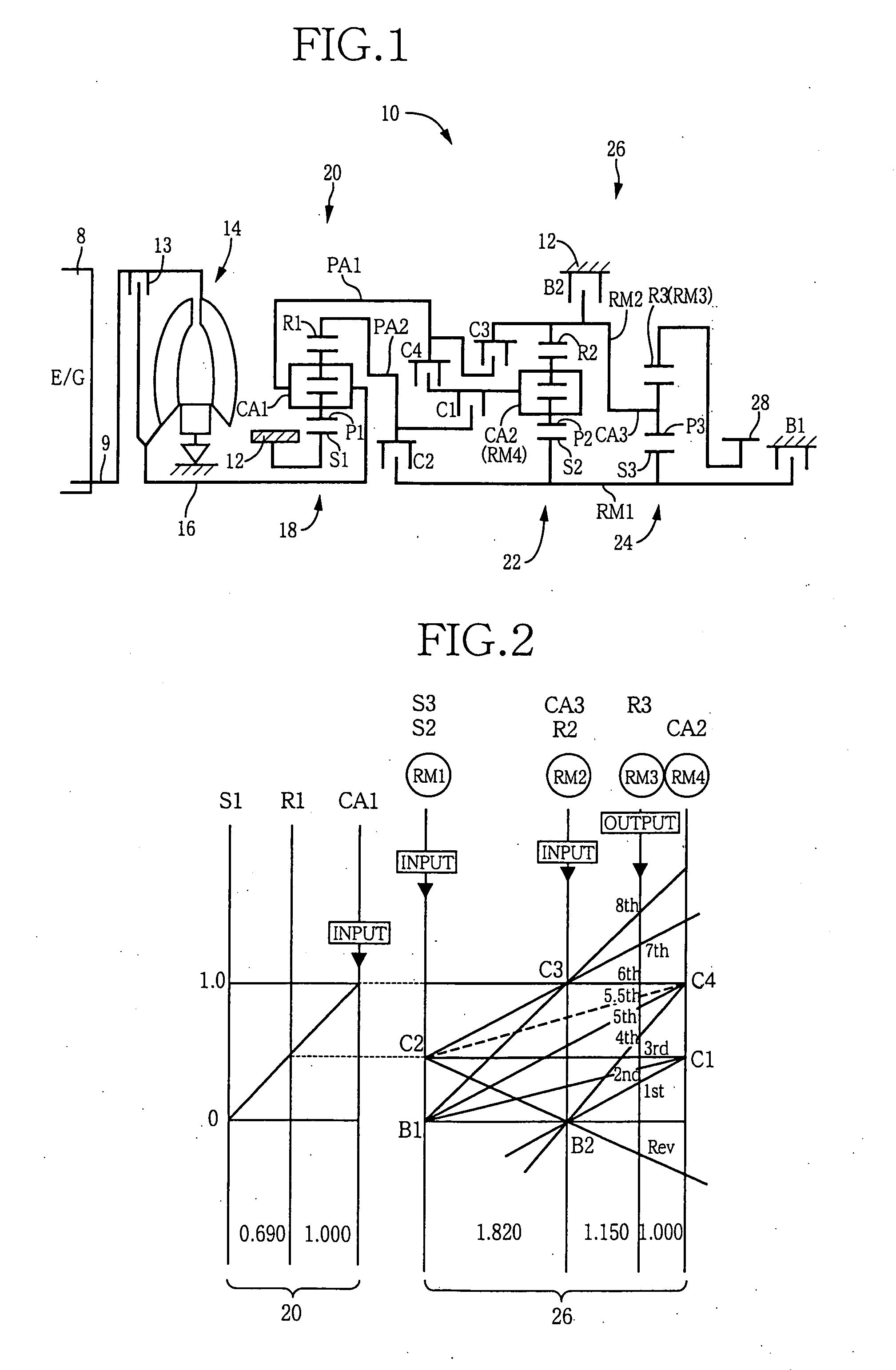

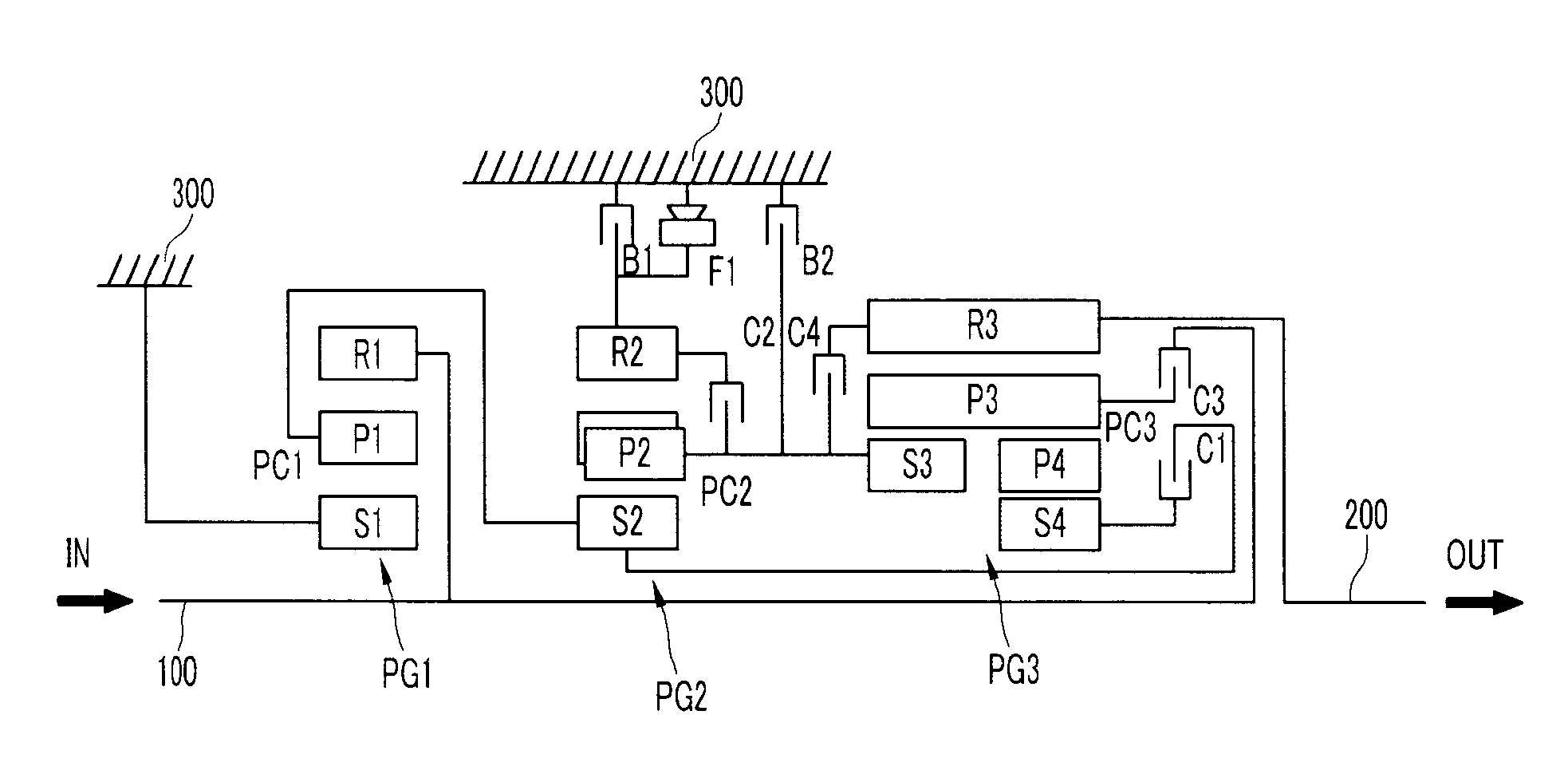

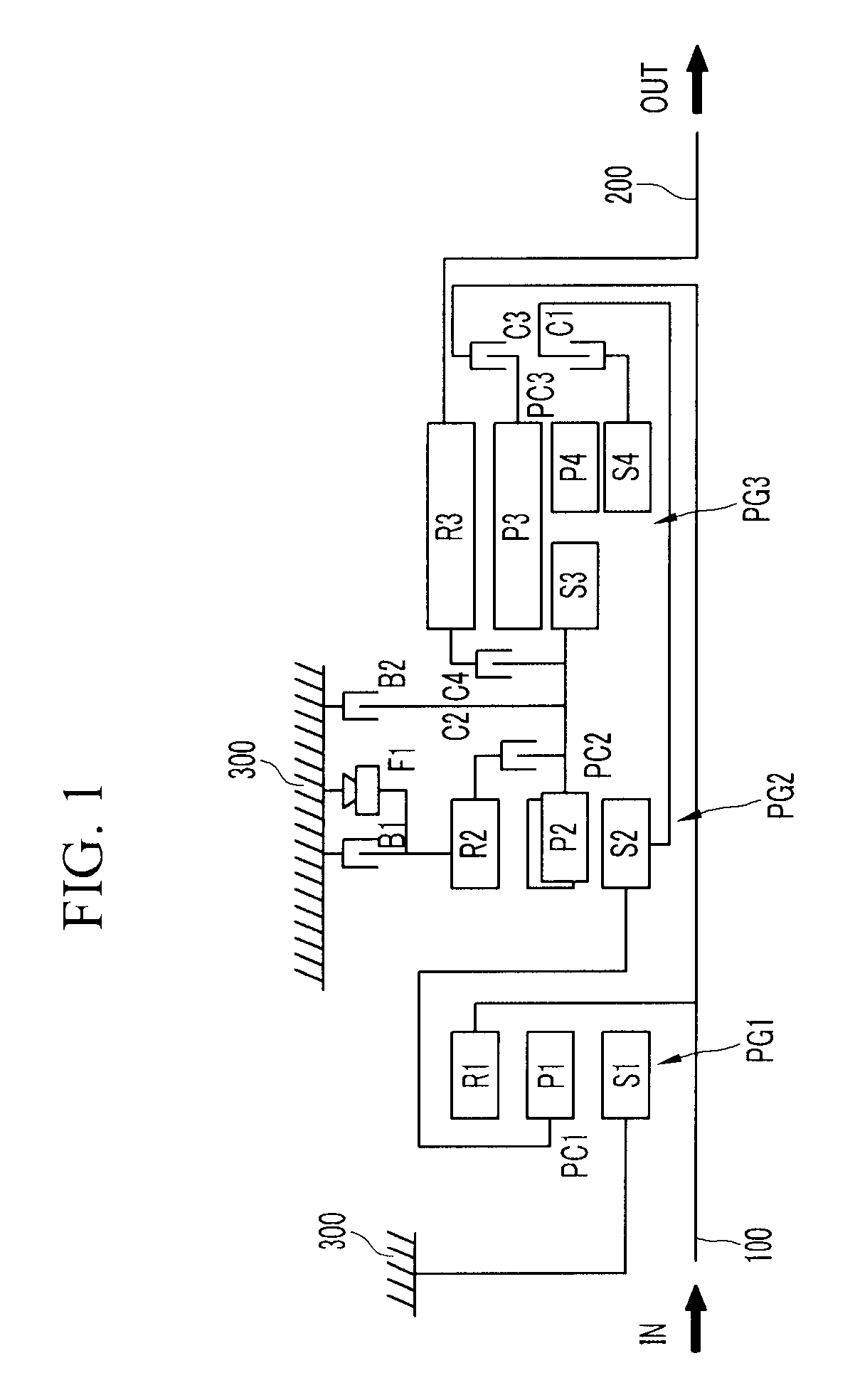

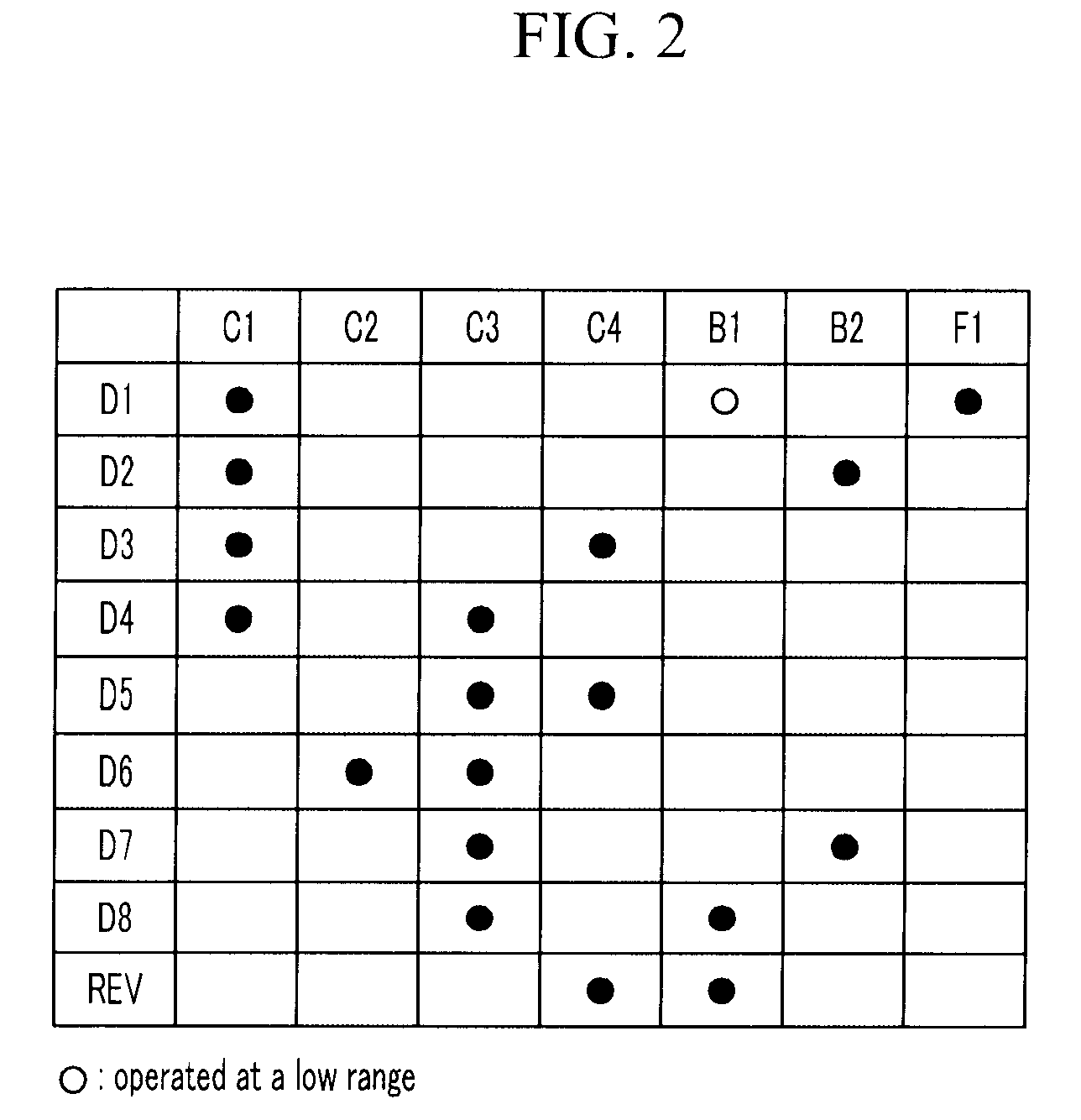

Planetary-gear-type multiple-step transmission for vehicle

InactiveUS7101305B2Small axial lengthShorten the axial lengthToothed gearingsTransmission elementsGear wheelEngineering

Owner:TOYOTA JIDOSHA KK

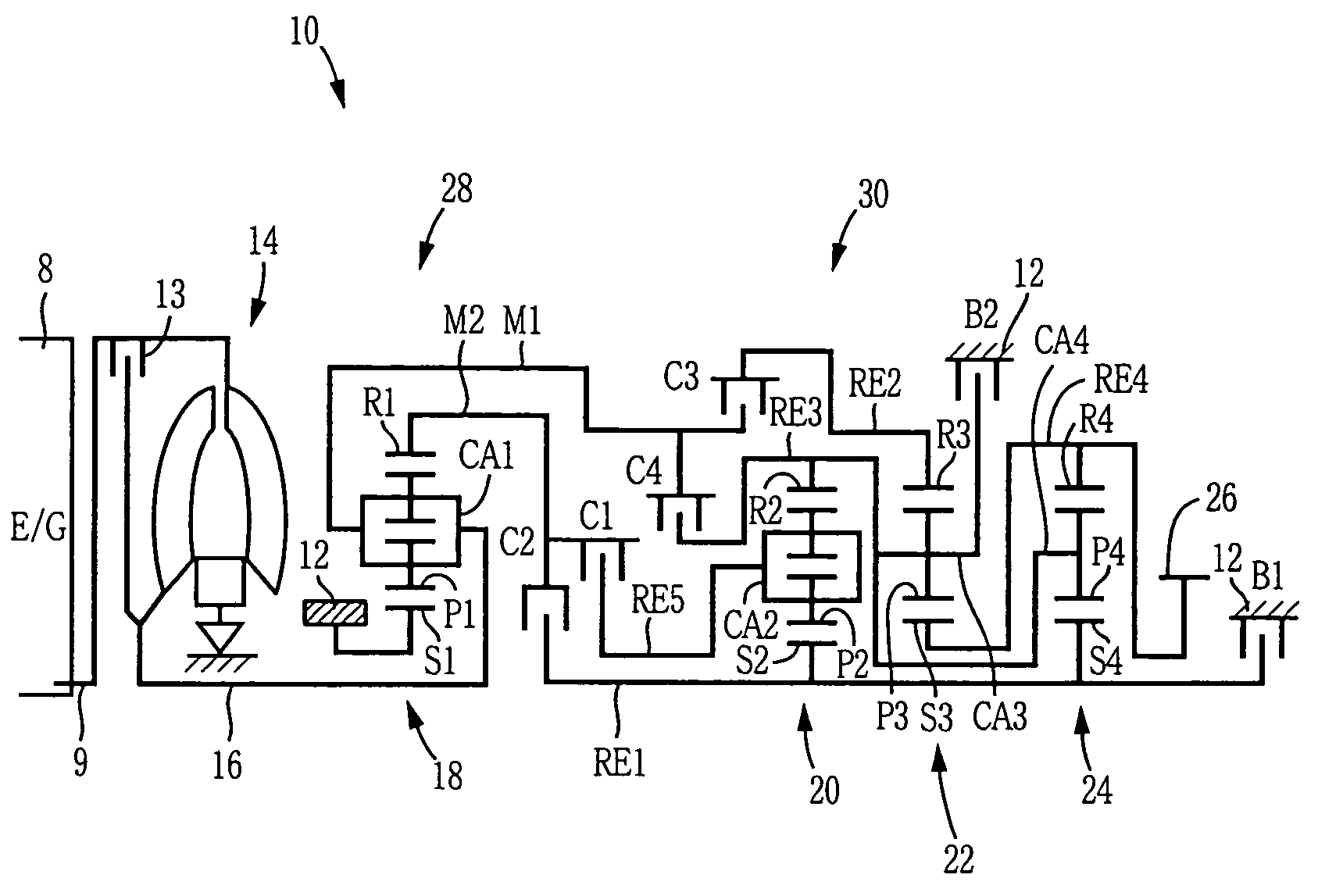

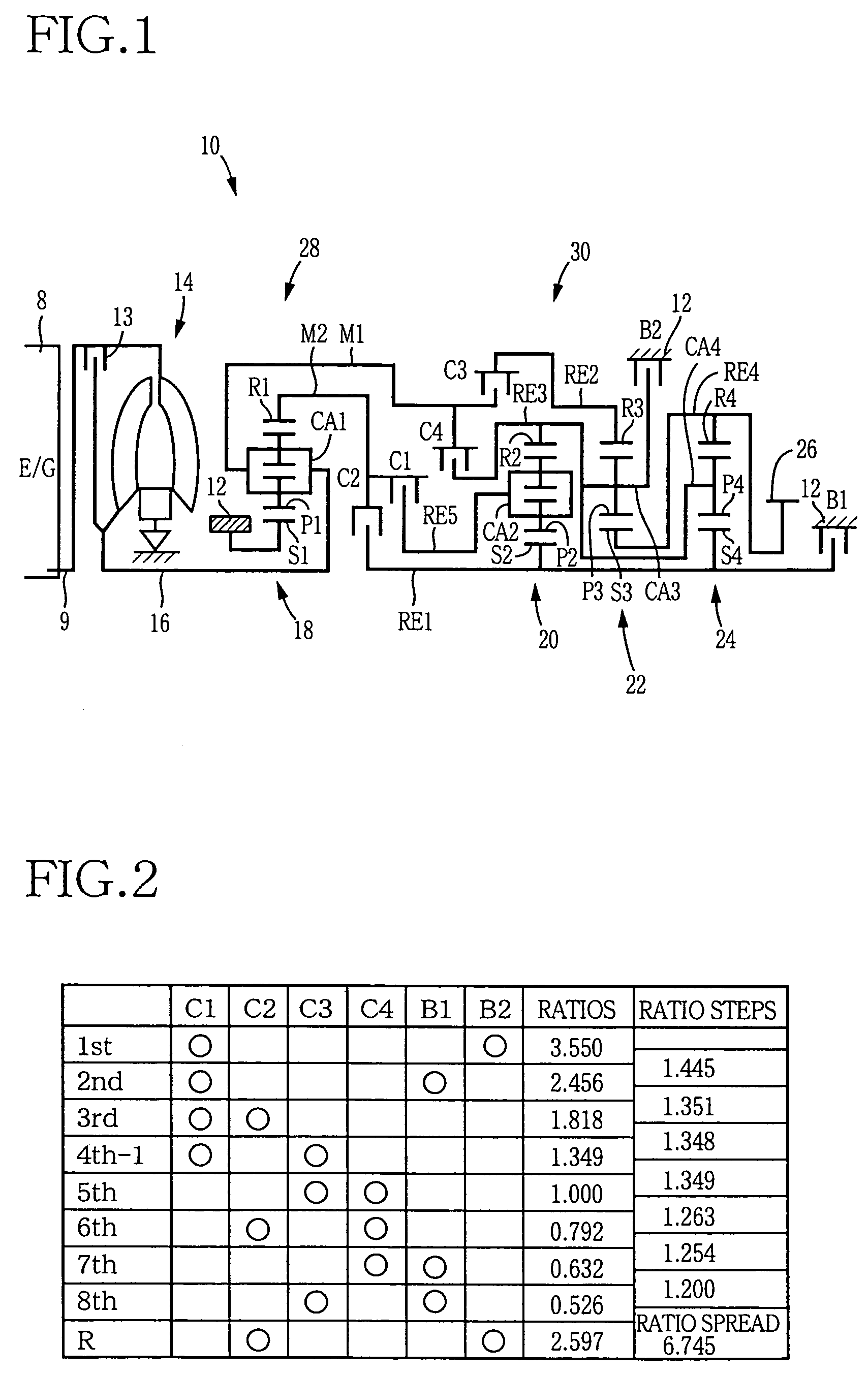

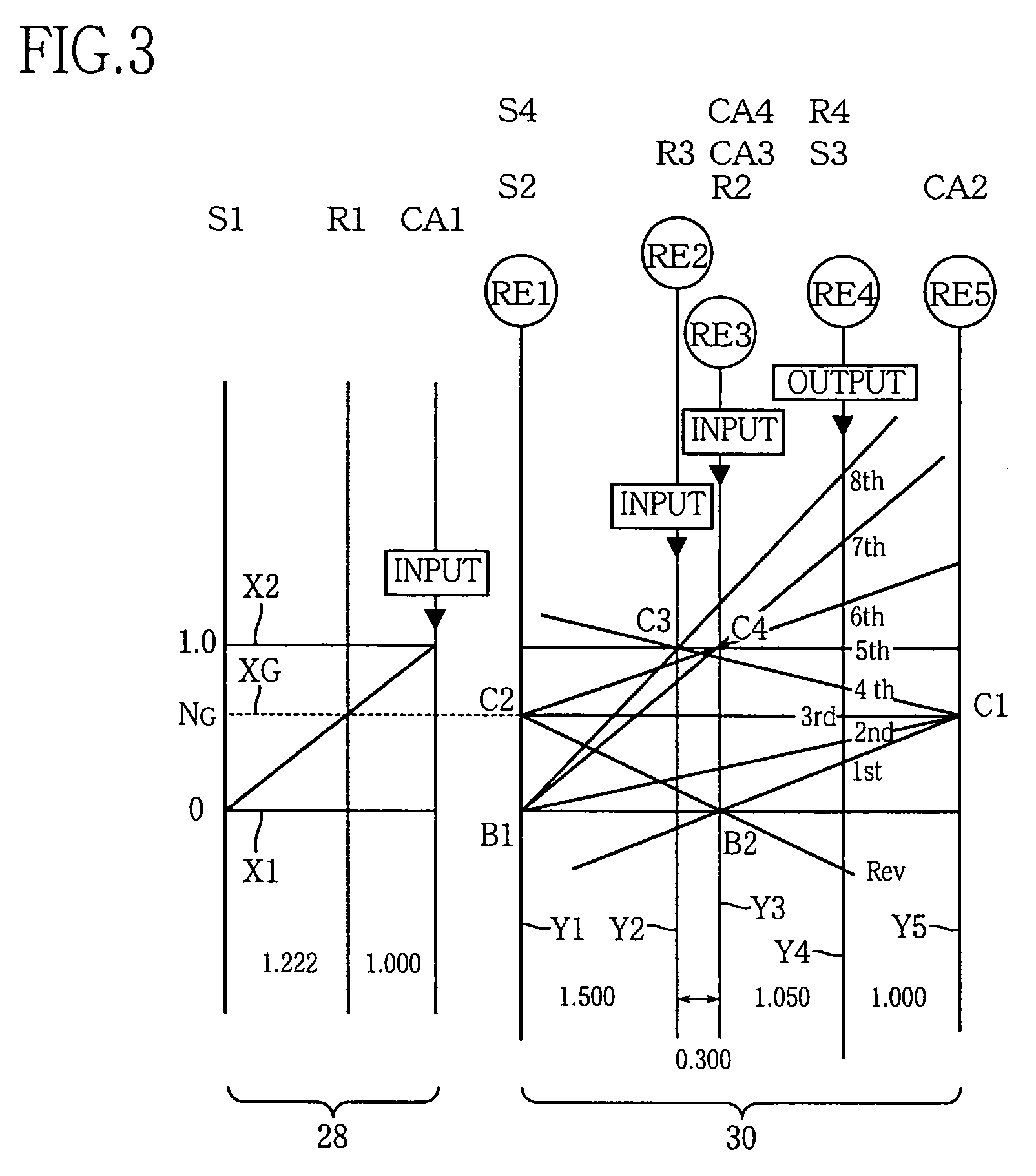

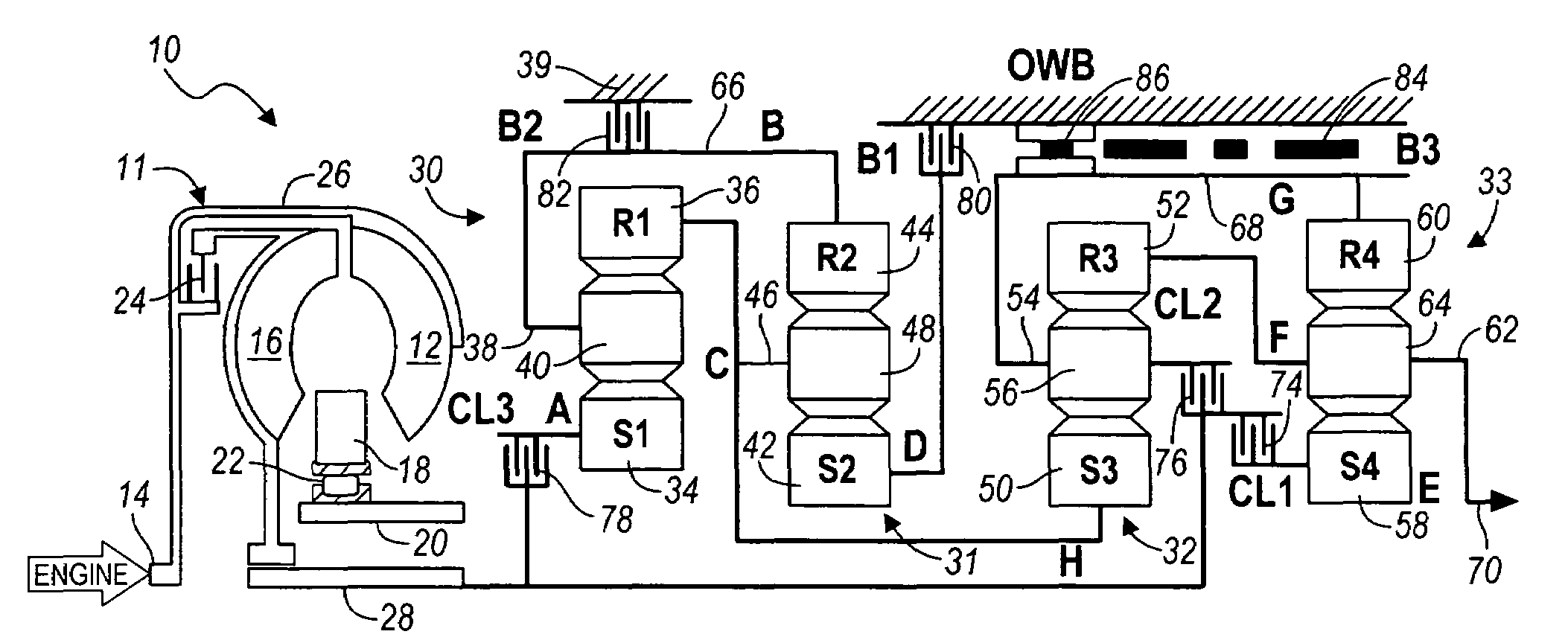

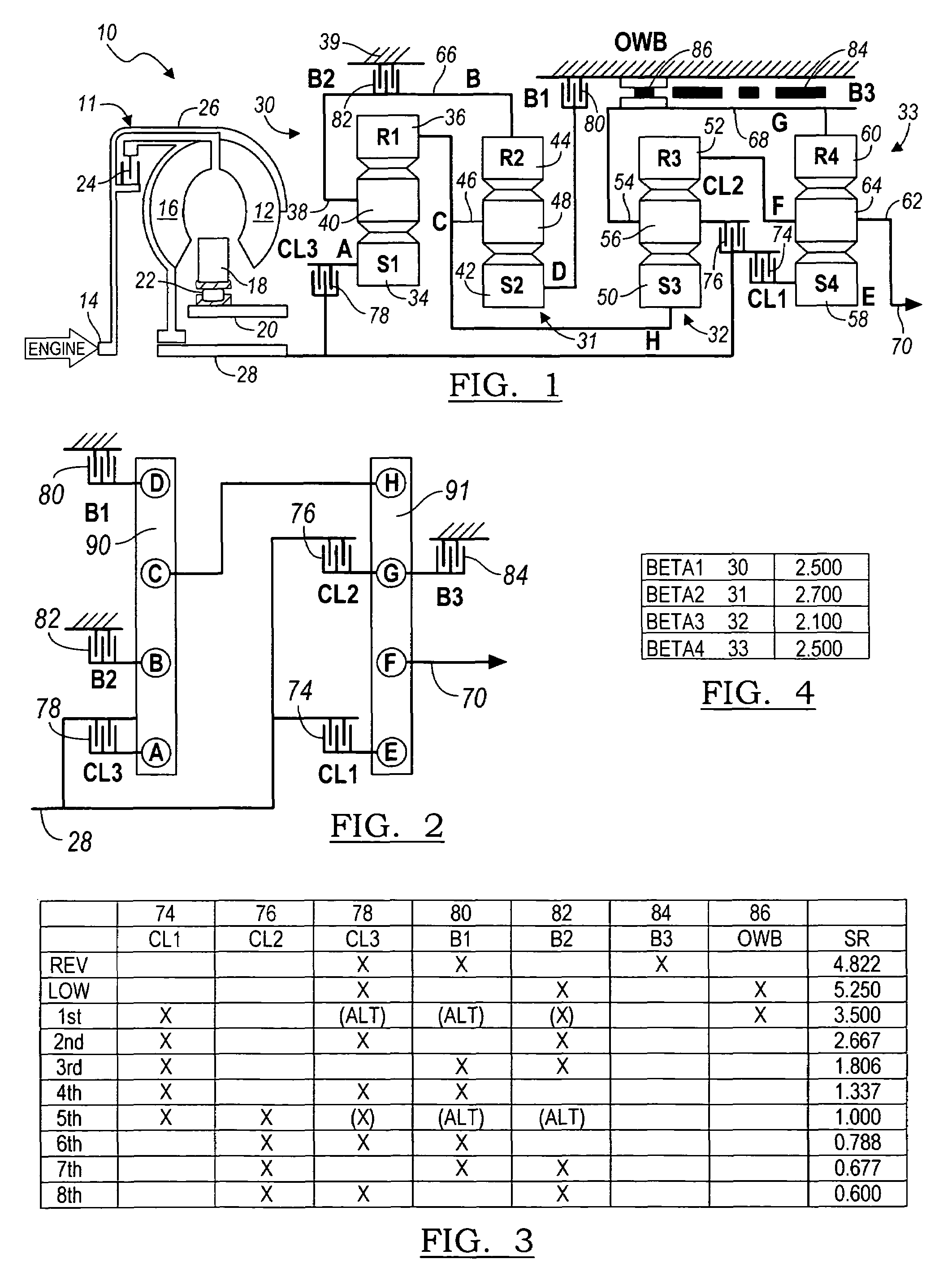

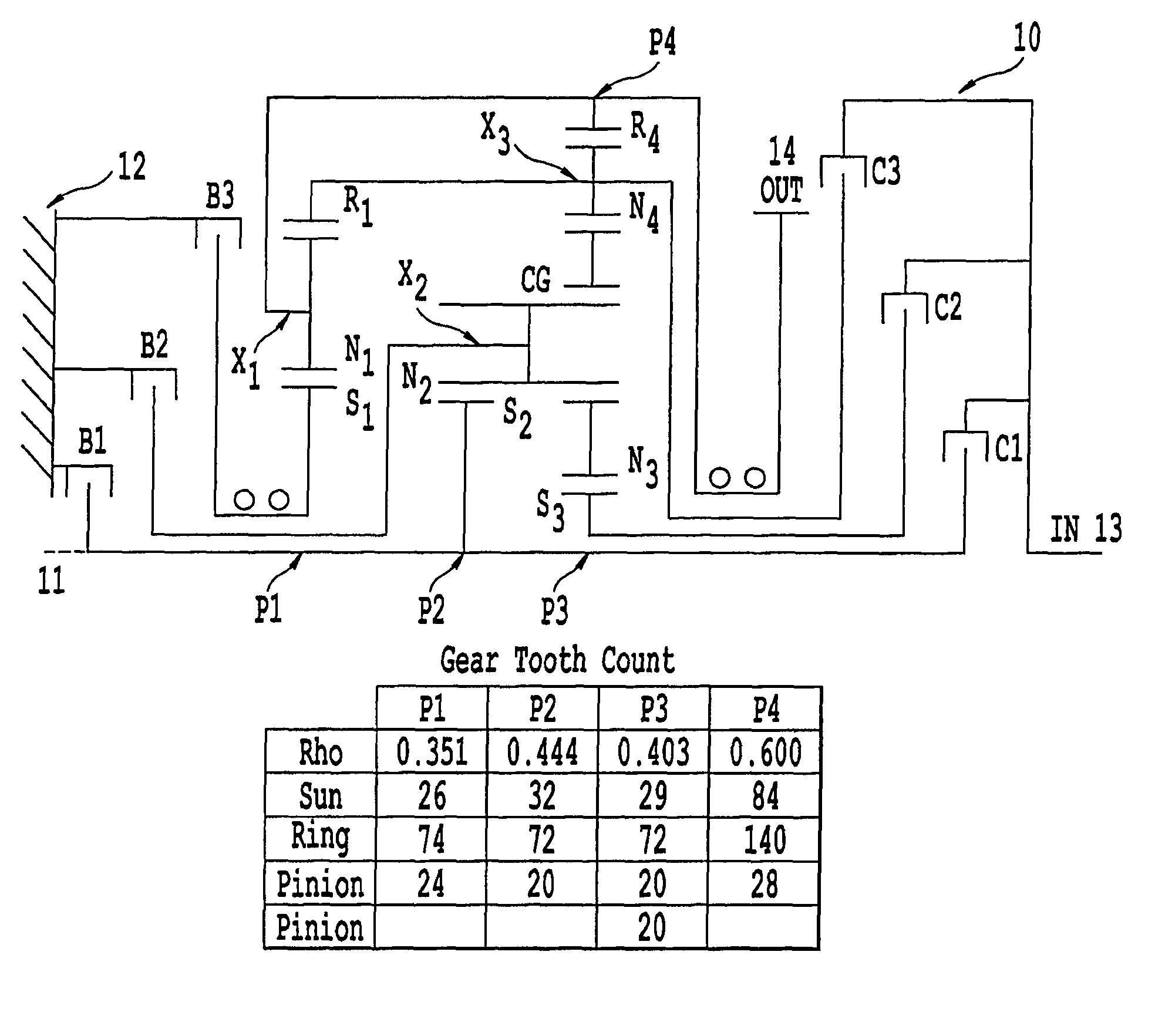

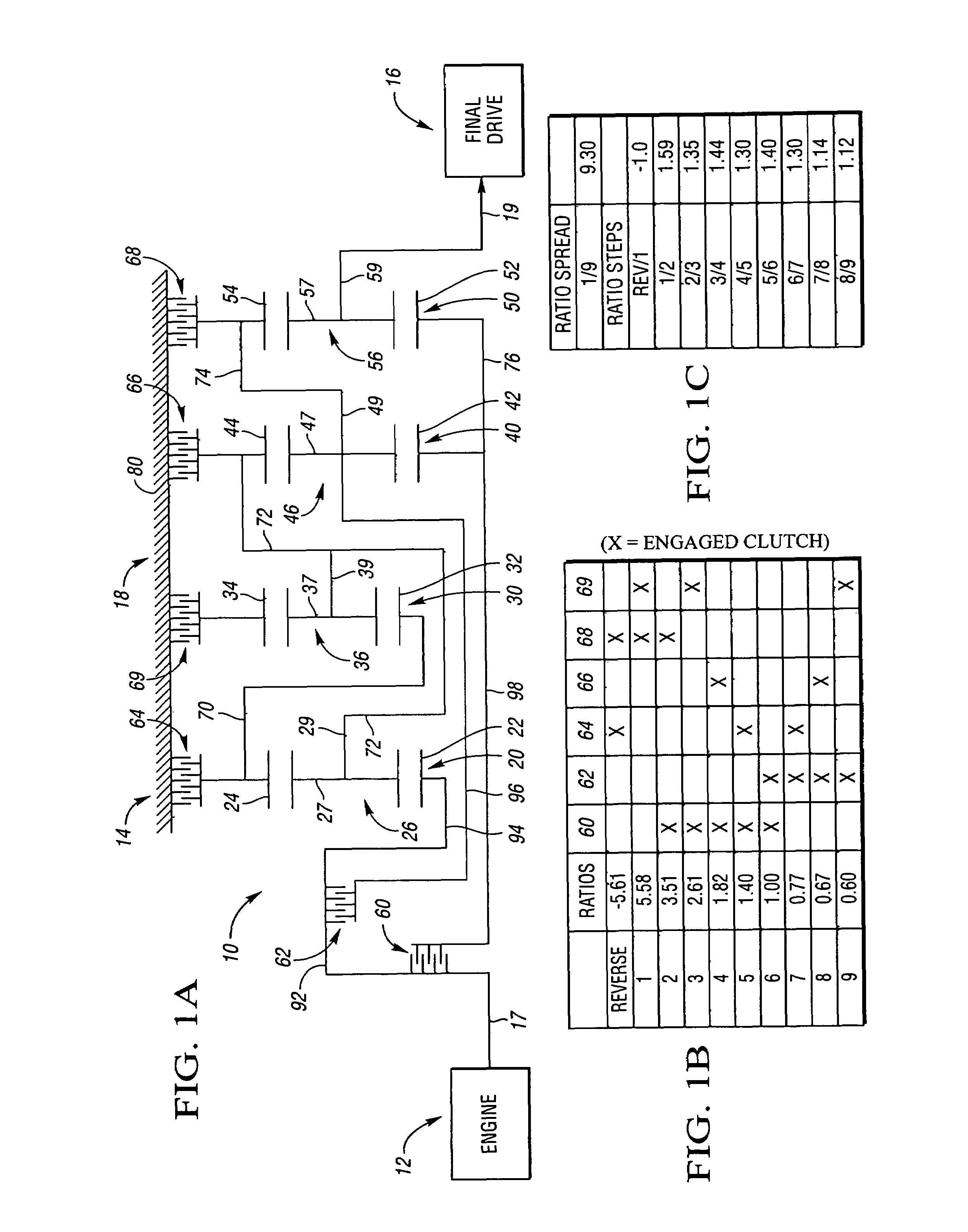

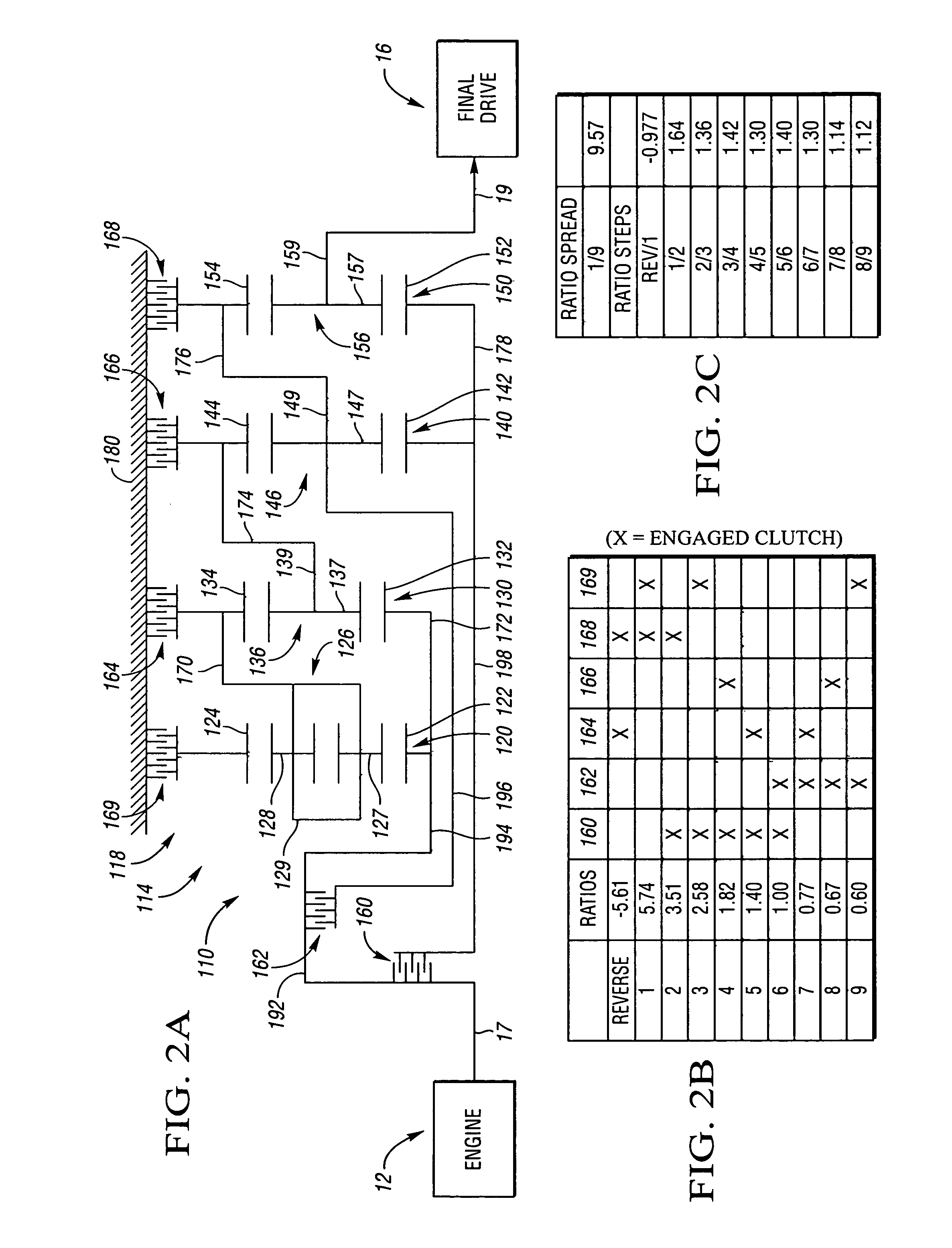

Eight-speed transmissions with four planetary gear sets

ActiveUS7163484B2Shorten speedLow sun gearToothed gearingsTransmission elementsGear wheelInterconnection

Owner:GM GLOBAL TECH OPERATIONS LLC

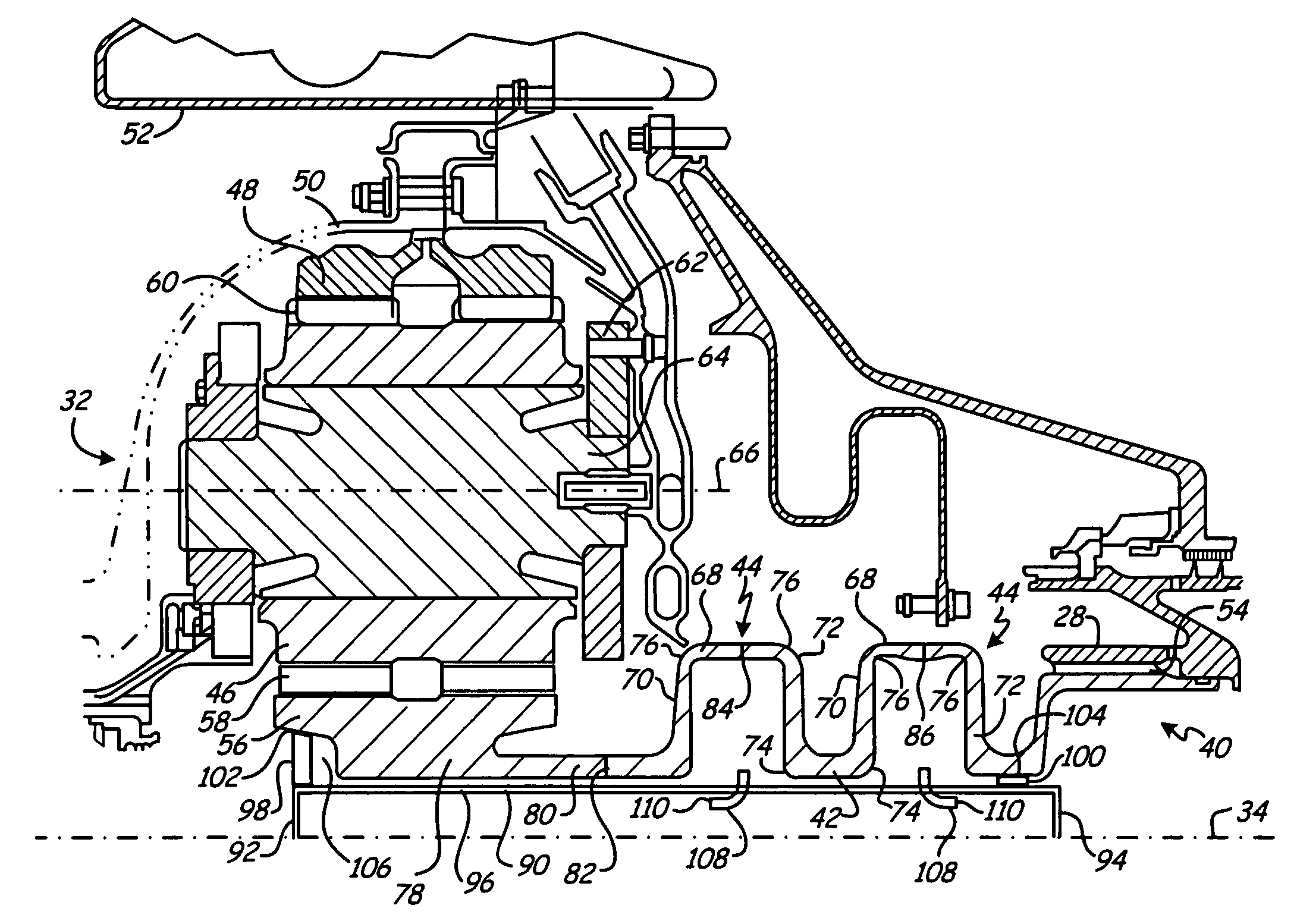

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

Planetary-gear-type multiple-step transmission for vehicle

InactiveUS20050090362A1Easy constructionSmall sizeToothed gearingsTransmission elementsGear wheelEngineering

Owner:TOYOTA JIDOSHA KK

Continuously variable transmission

InactiveUS20070155567A1Easy to adjustImprove translationWheel based transmissionChain/belt transmissionEngineeringMechanical engineering

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

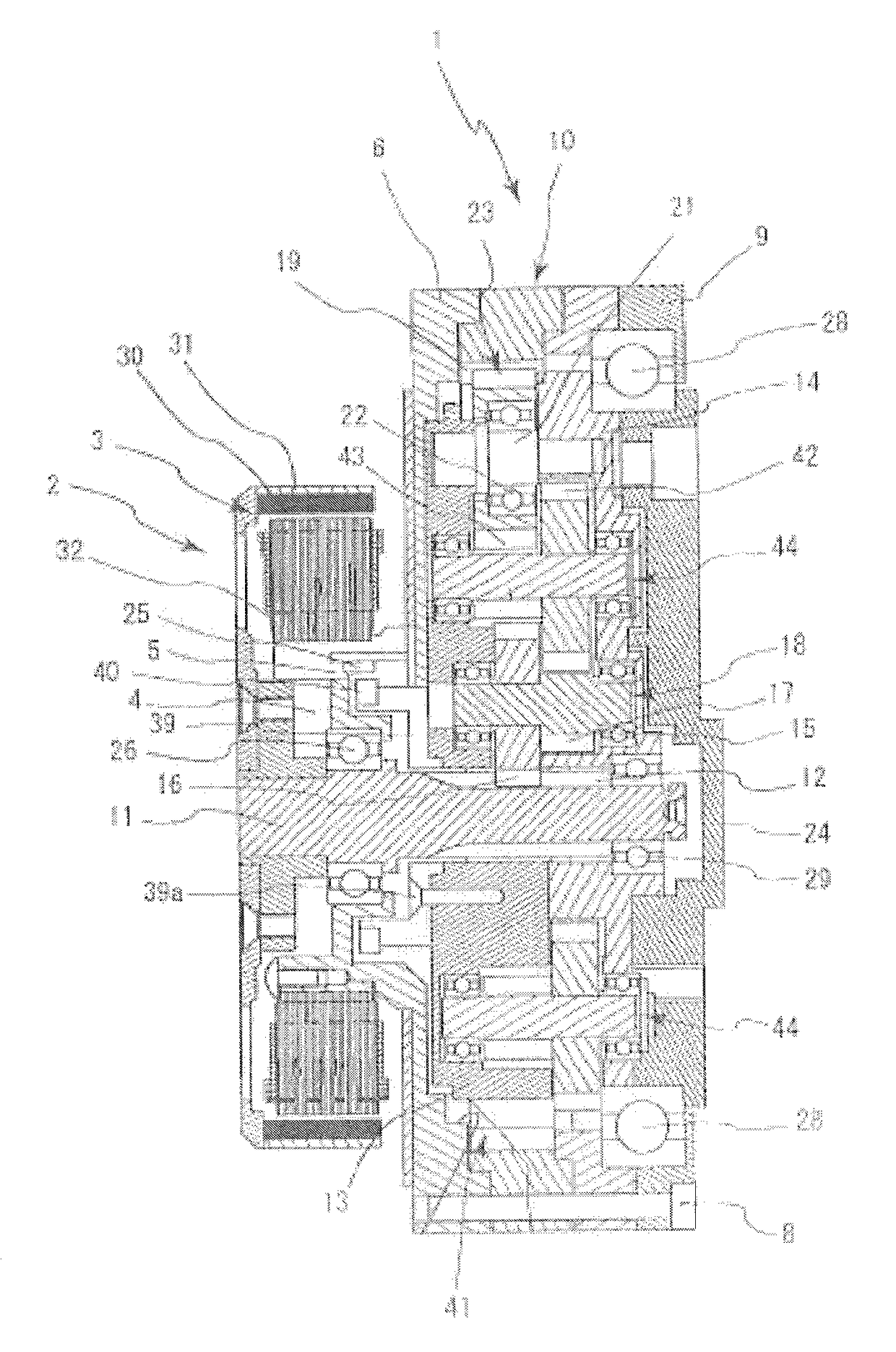

Gear motor including reduction mechanism

ActiveUS20160238108A1Thinness and size and weight reduction of reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can be achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

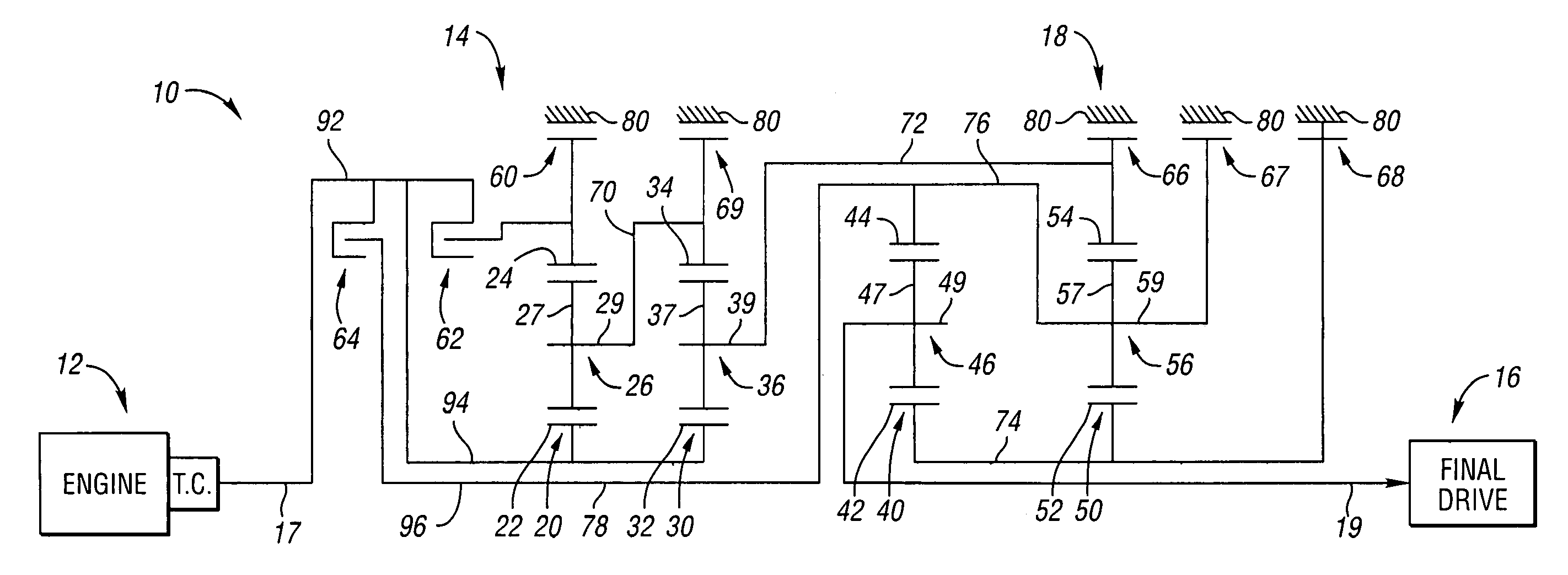

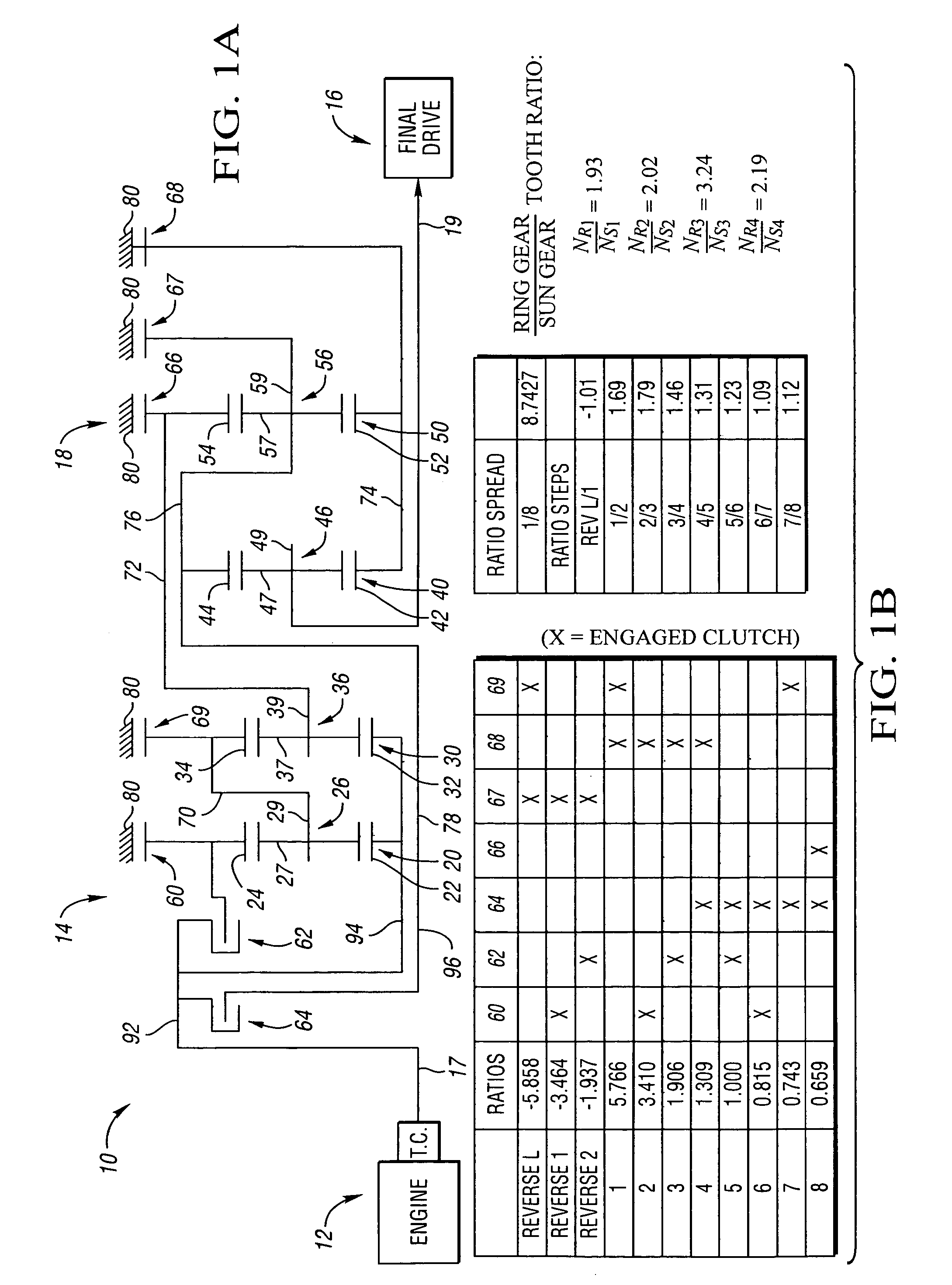

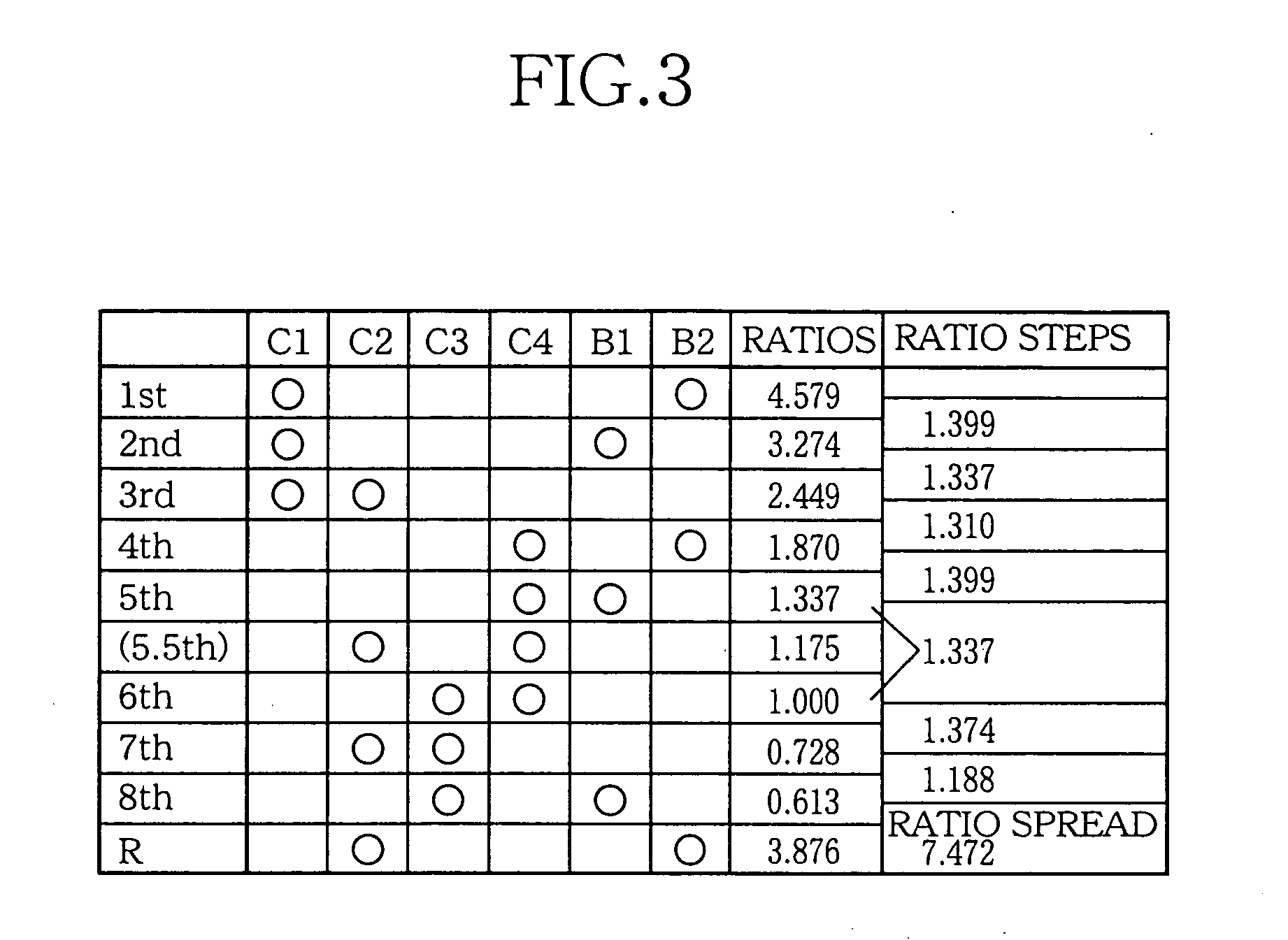

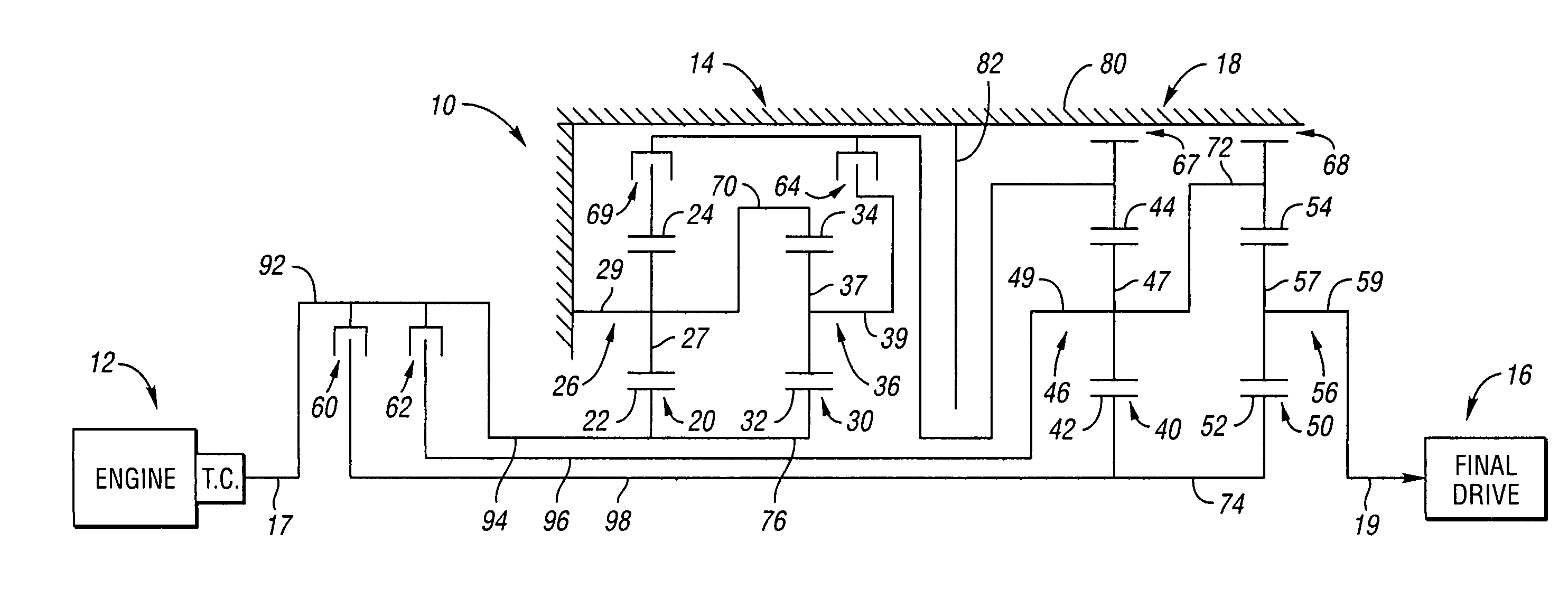

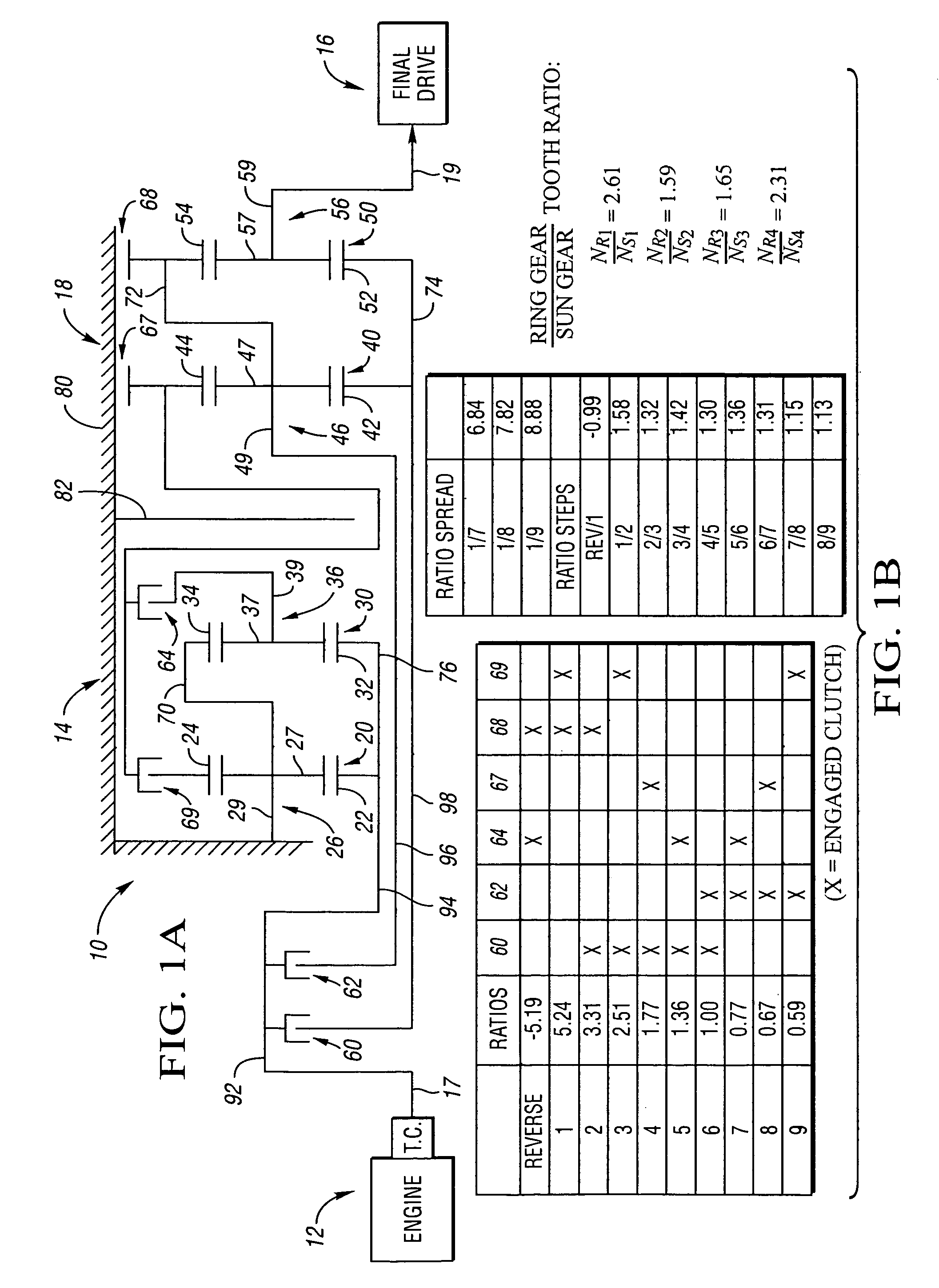

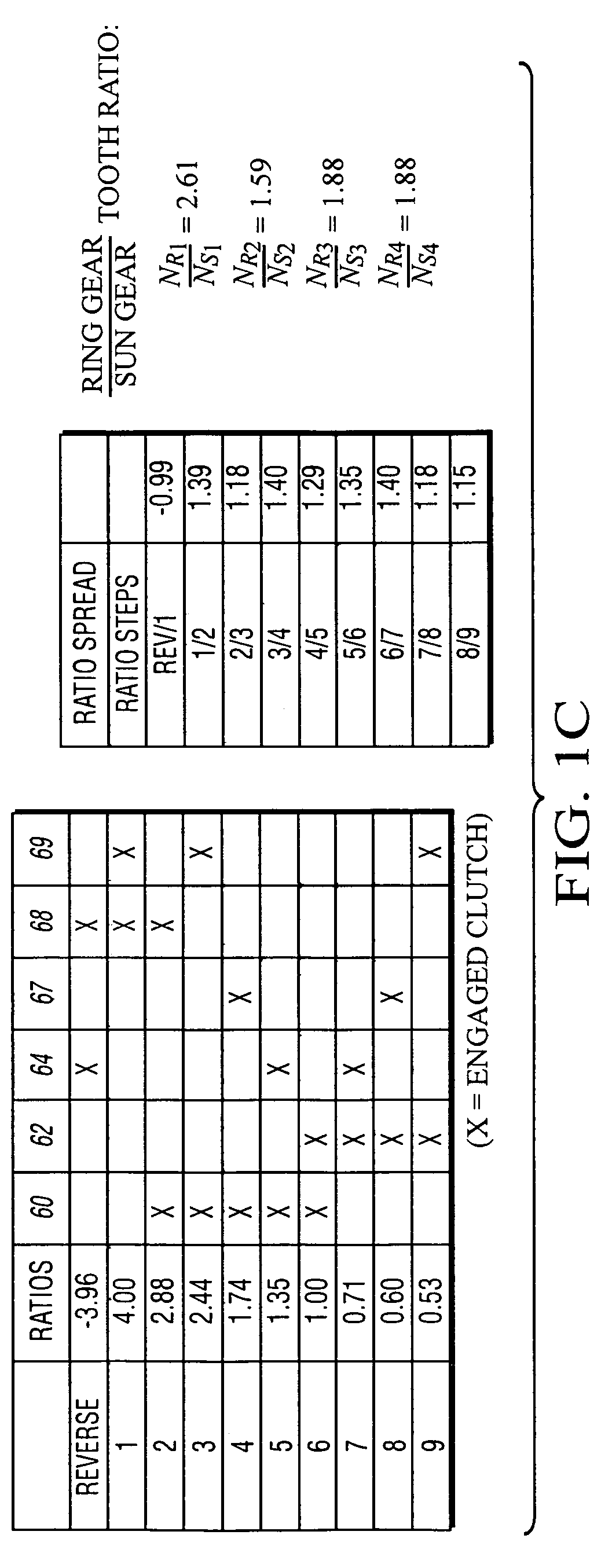

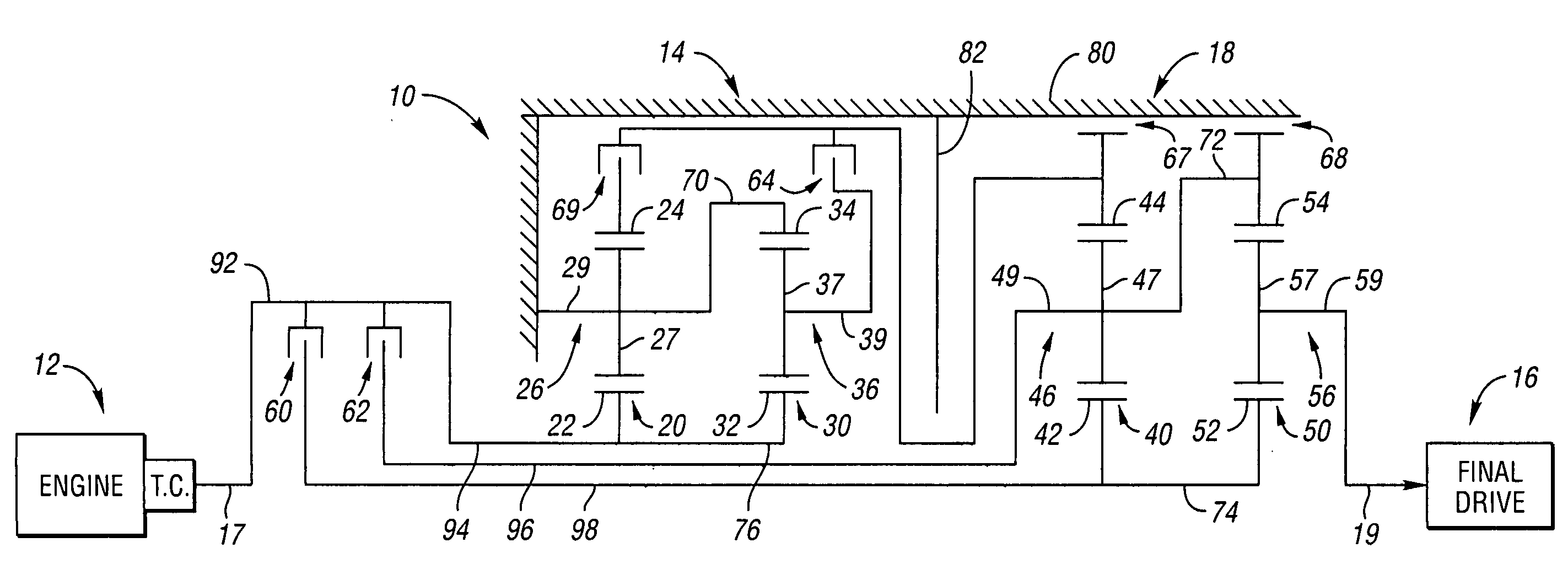

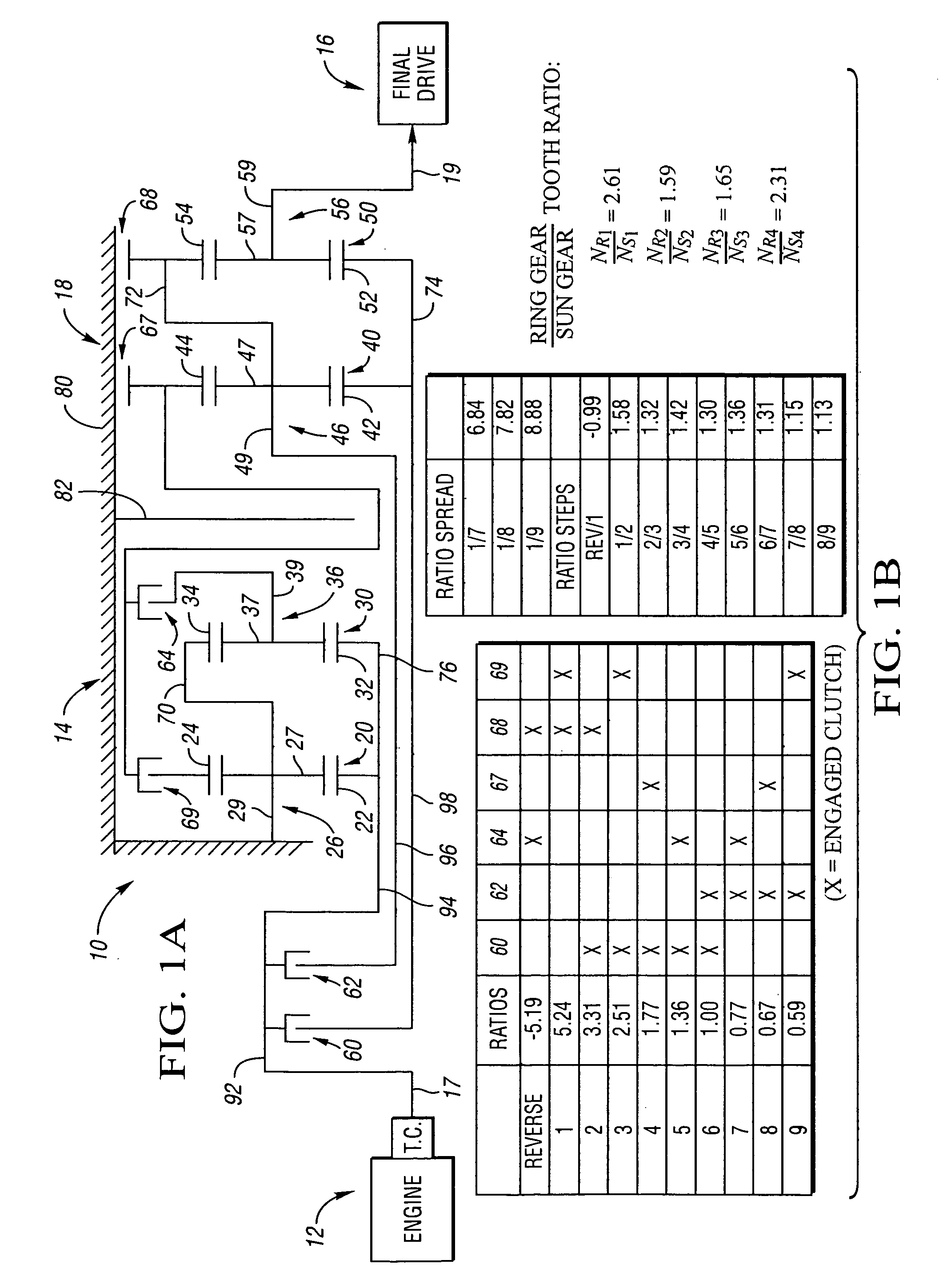

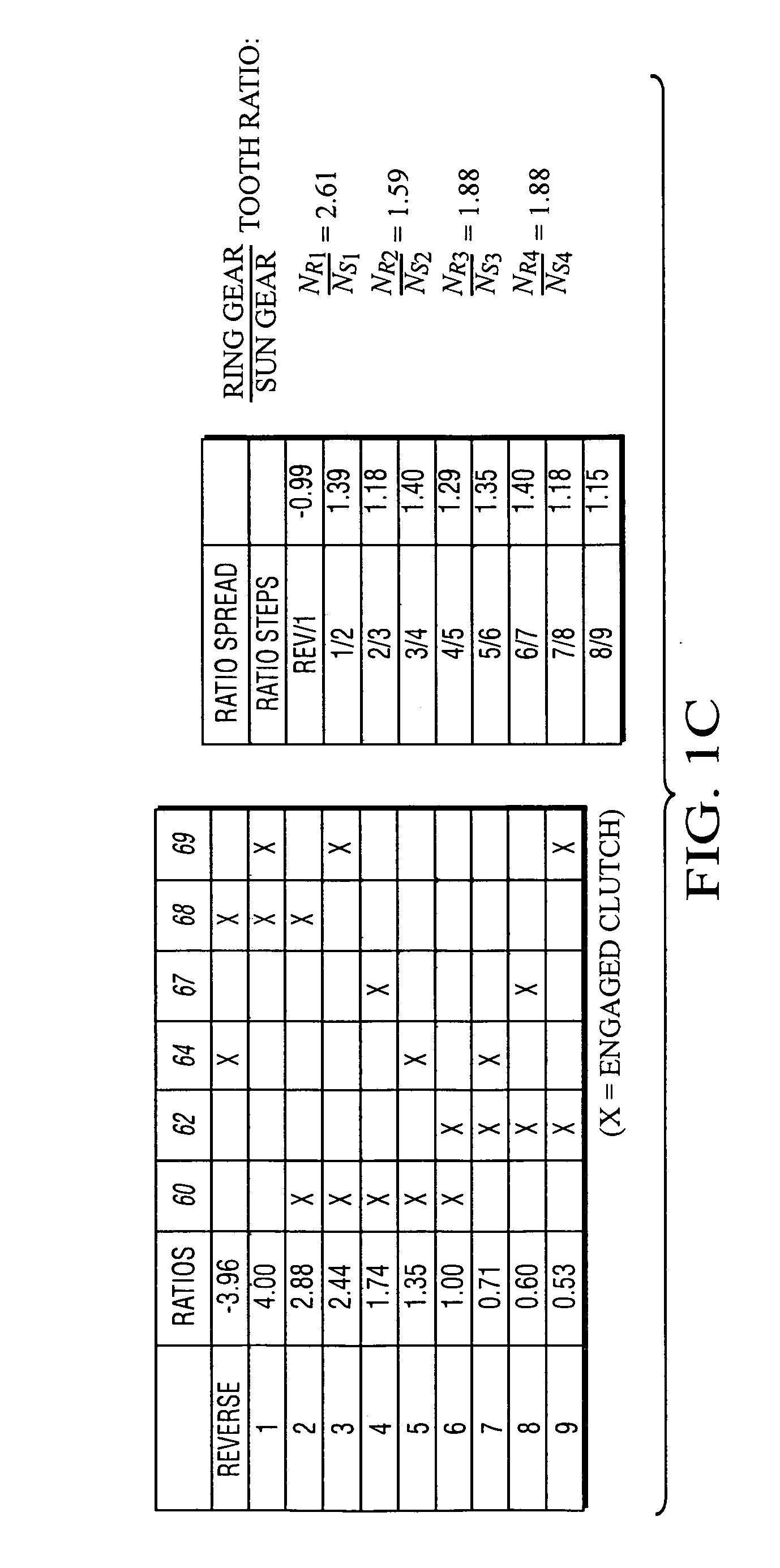

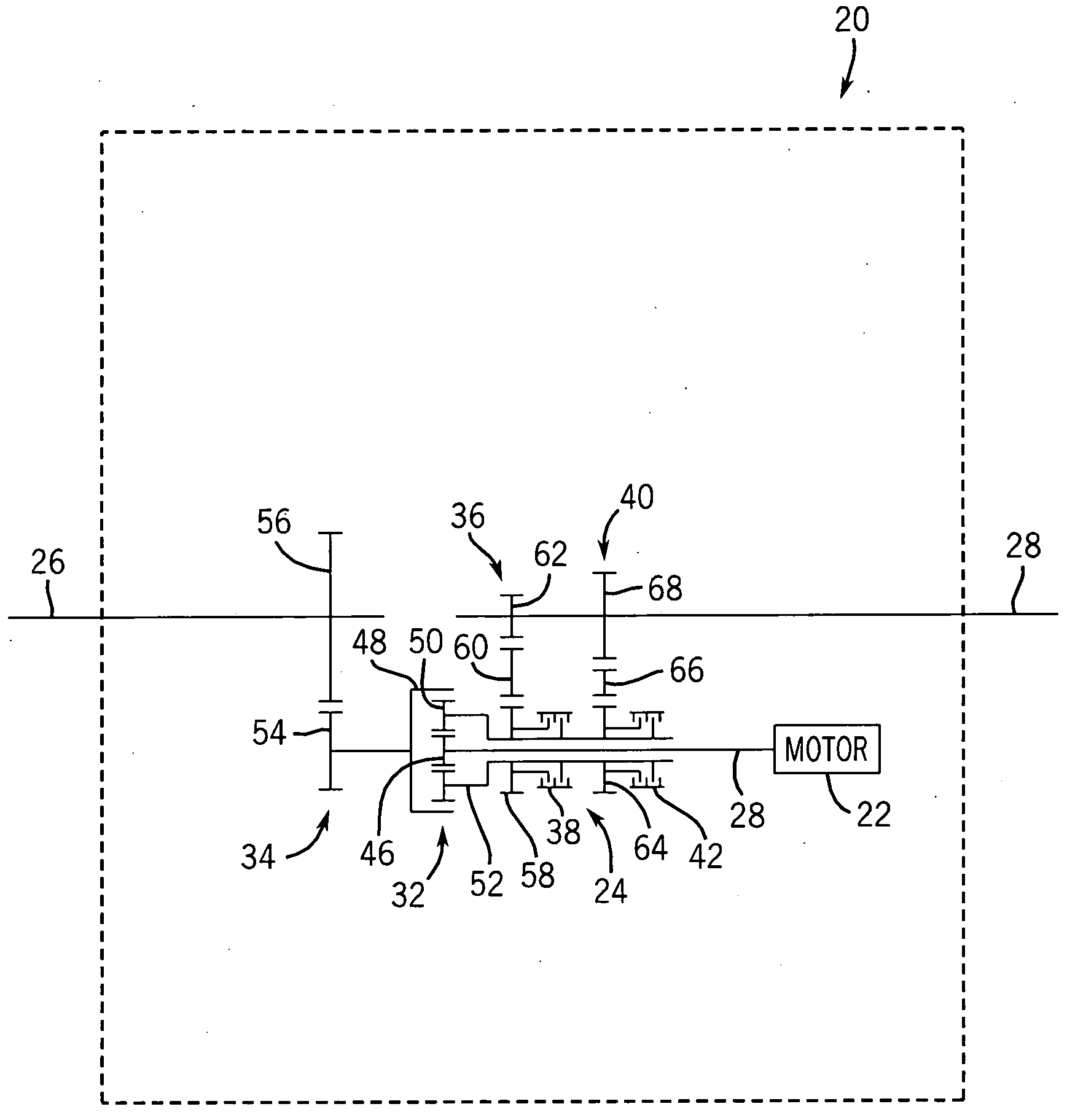

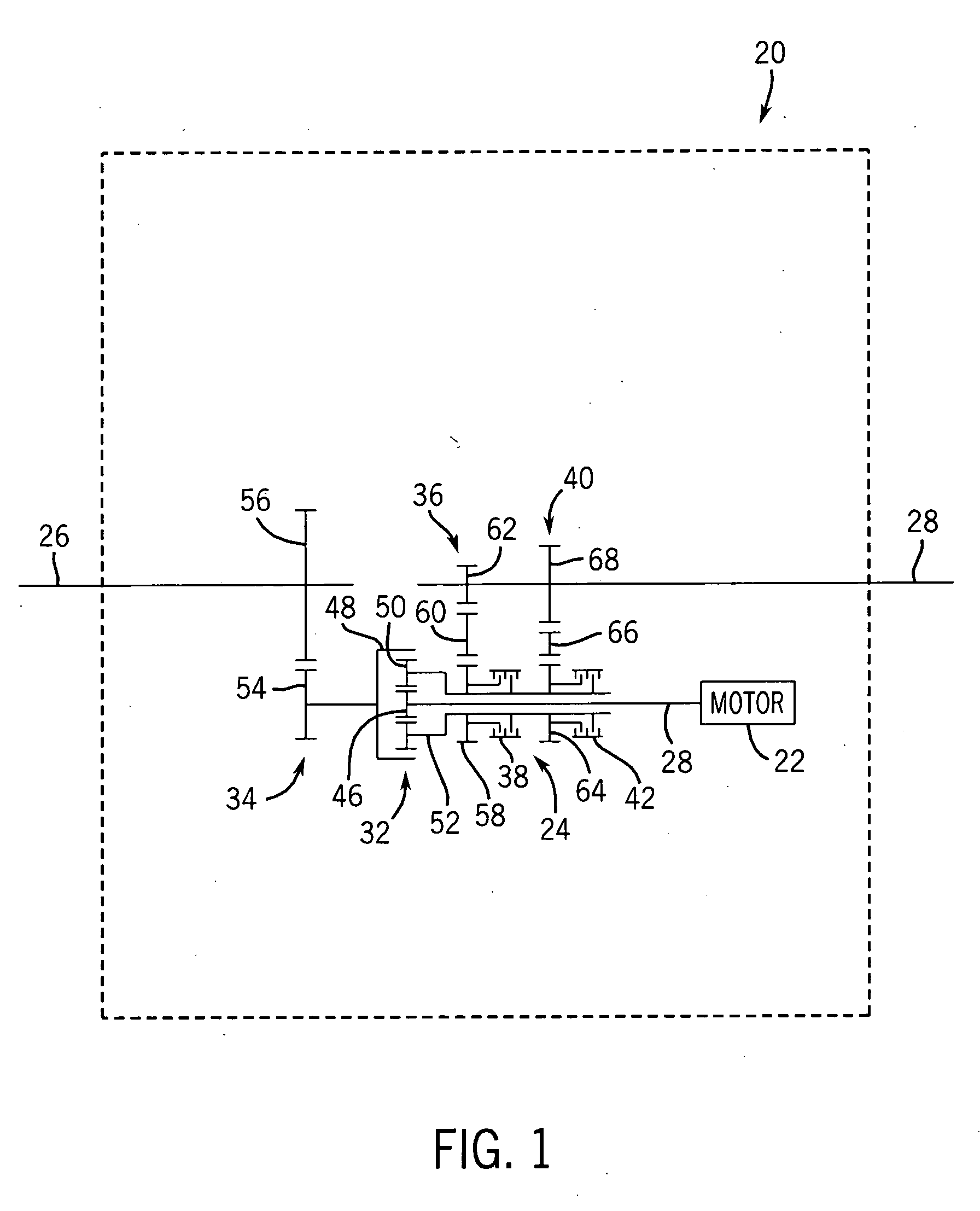

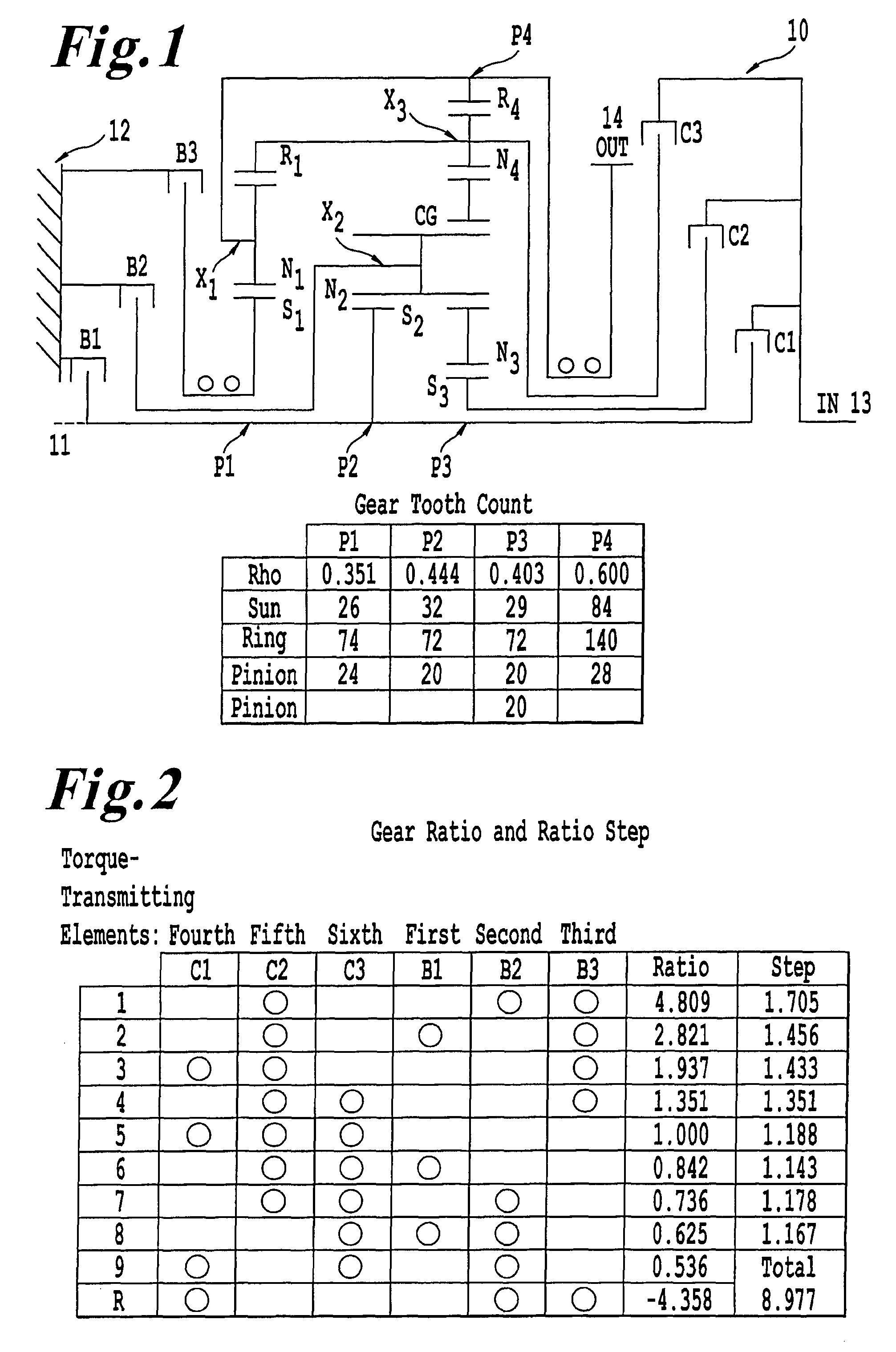

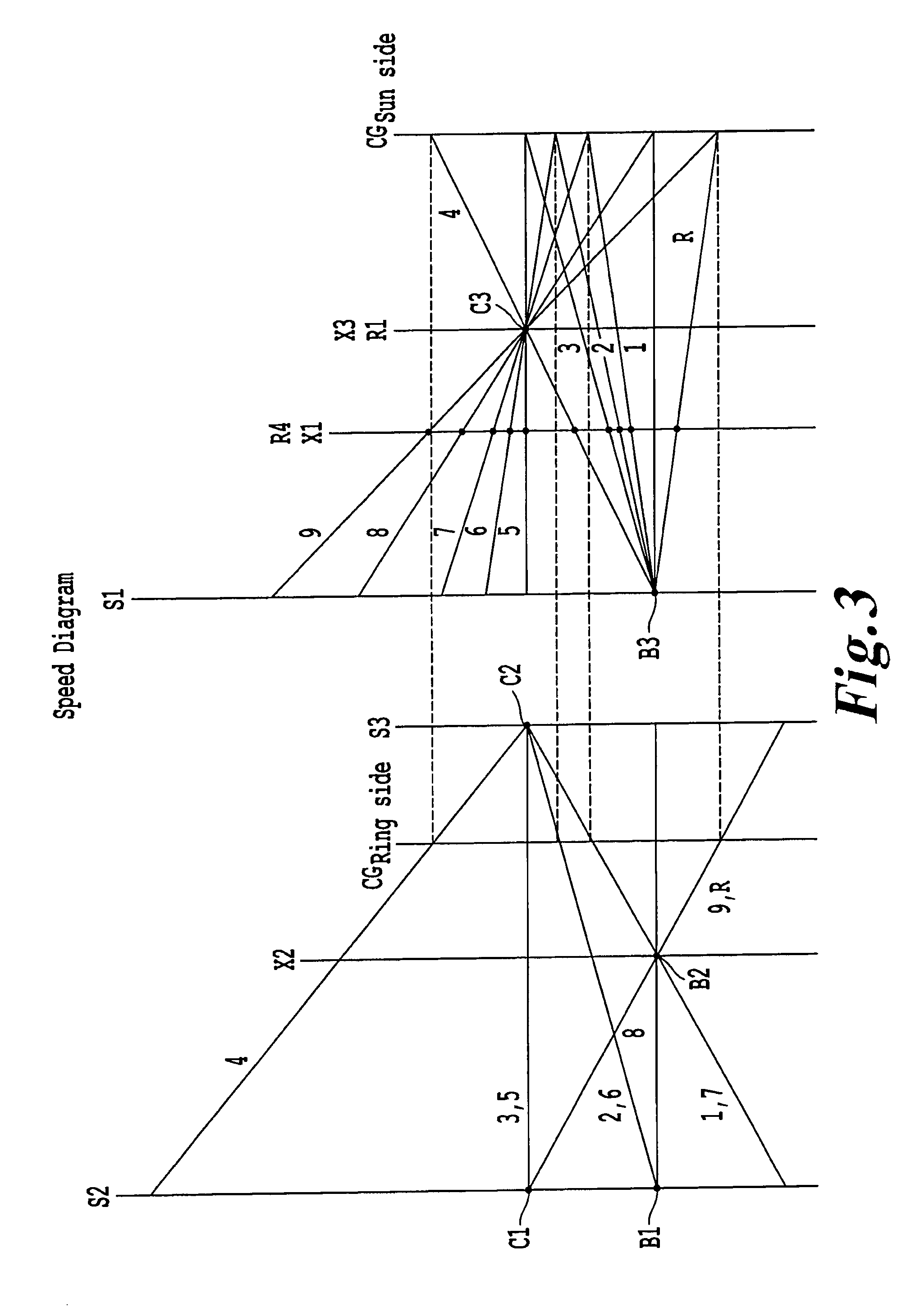

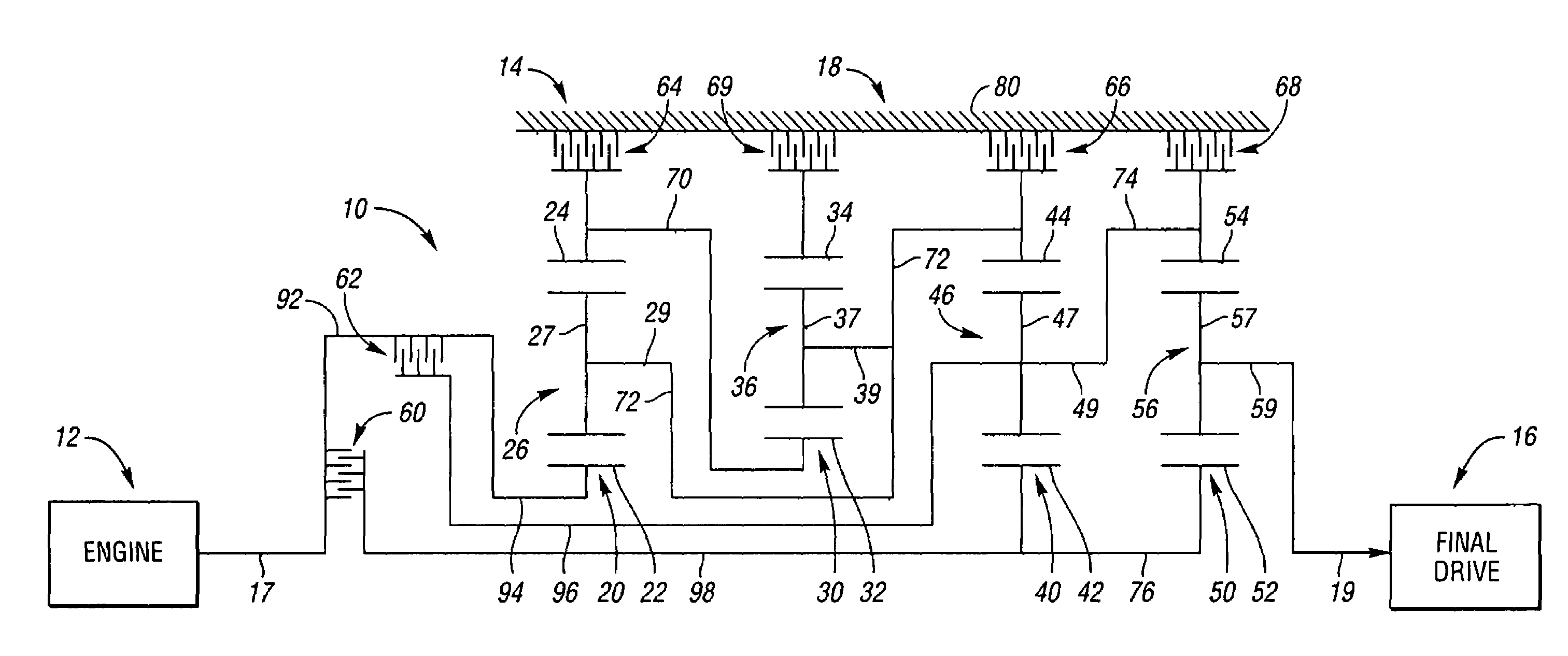

Nine-speed transmissions with four planetary gear sets

ActiveUS7226381B2Improve fuel economyImprove traction performanceToothed gearingsTransmission elementsGear wheelInterconnection

Nine-speed transmissions are provided that include four planetary gear sets having six torque-transmitting mechanisms and various fixed interconnections to provide nine forward speed ratios and a reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The six torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

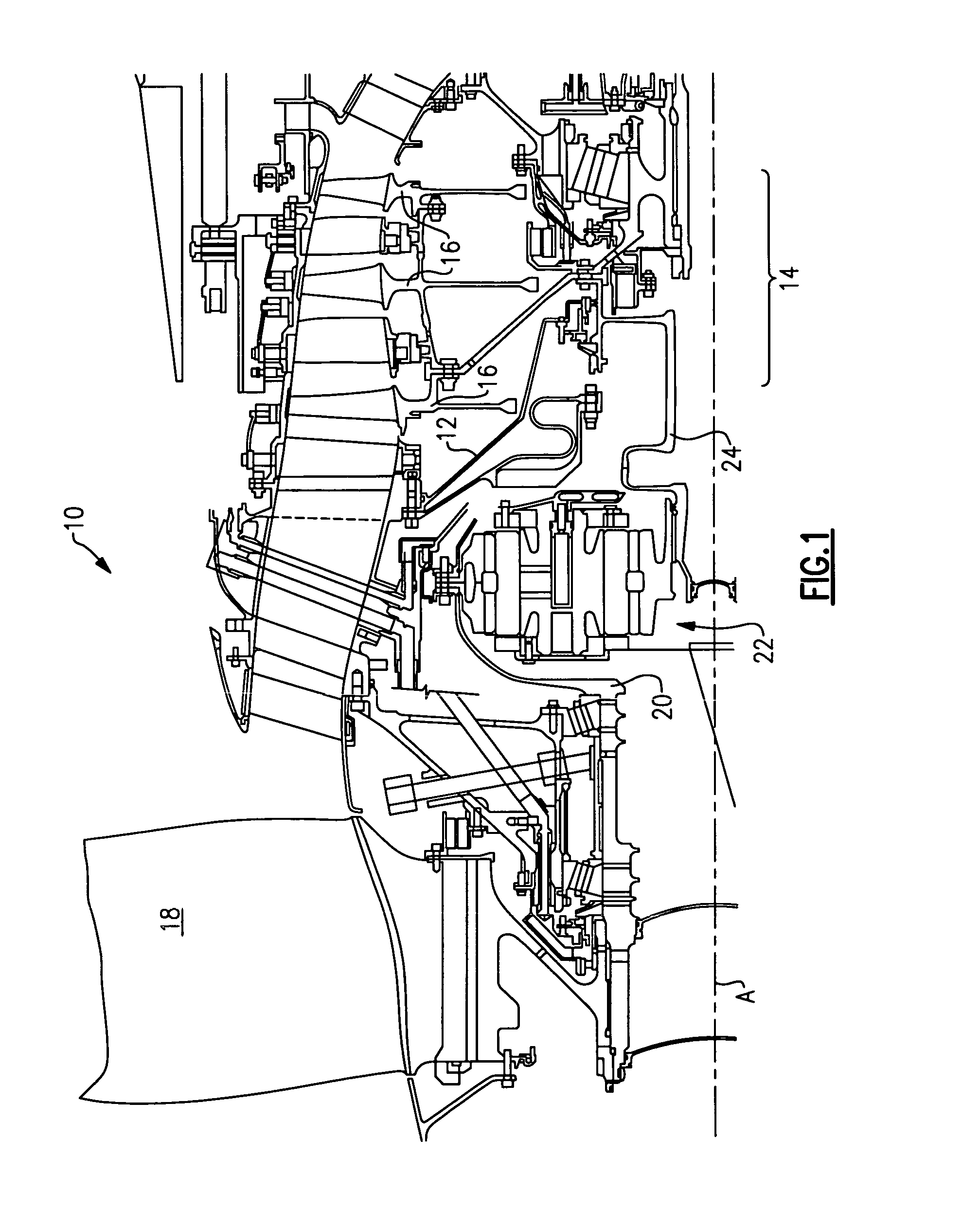

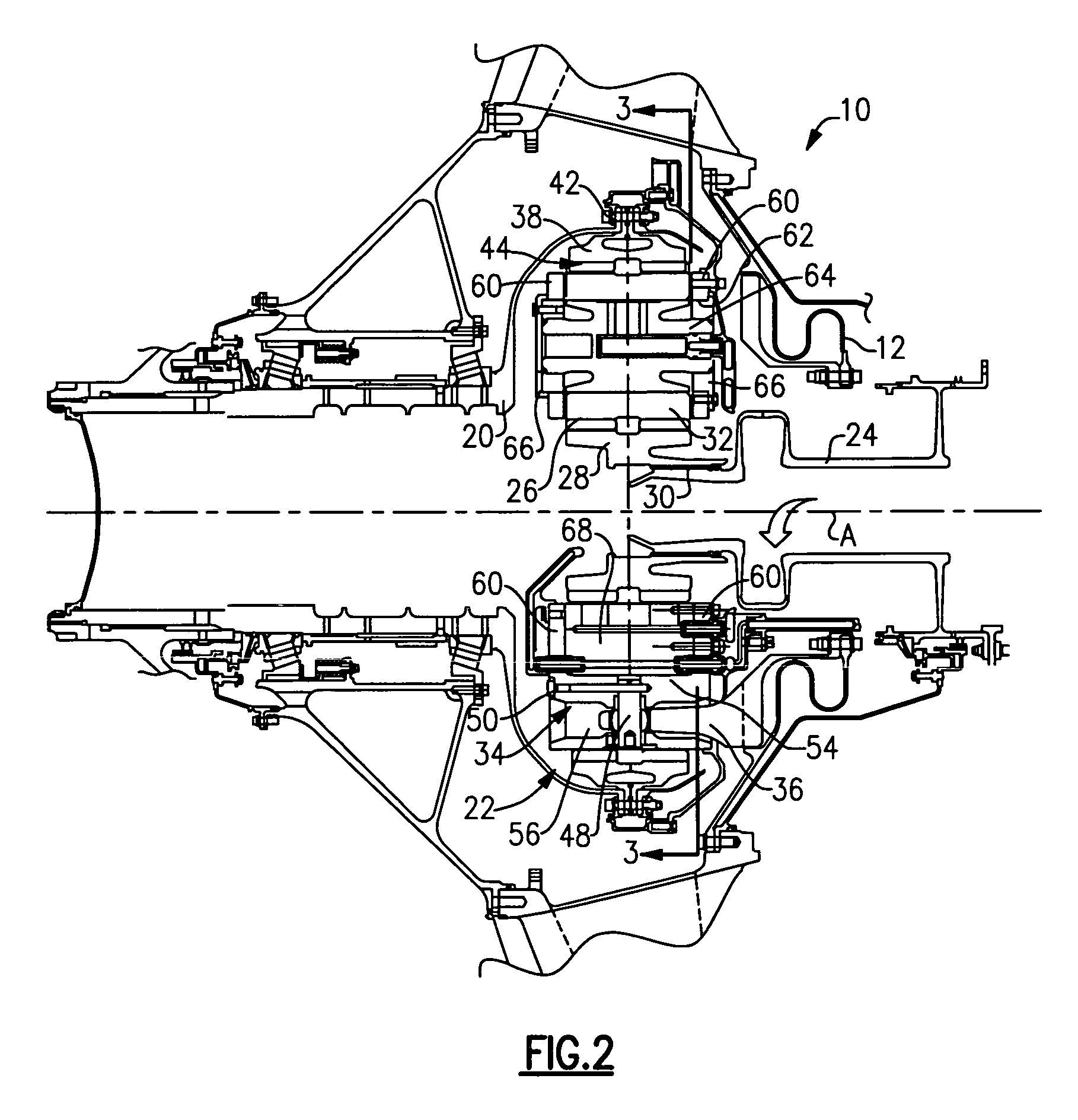

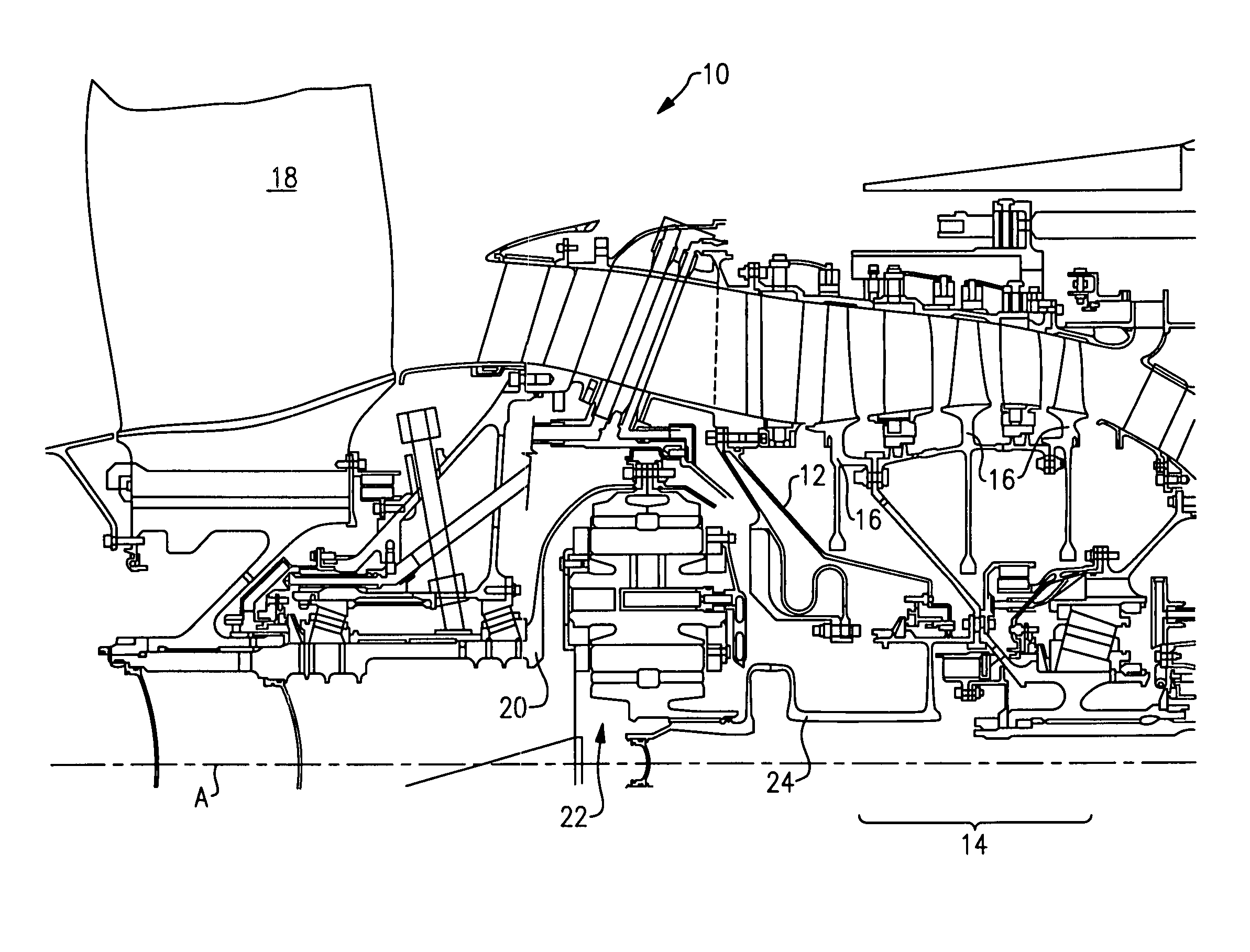

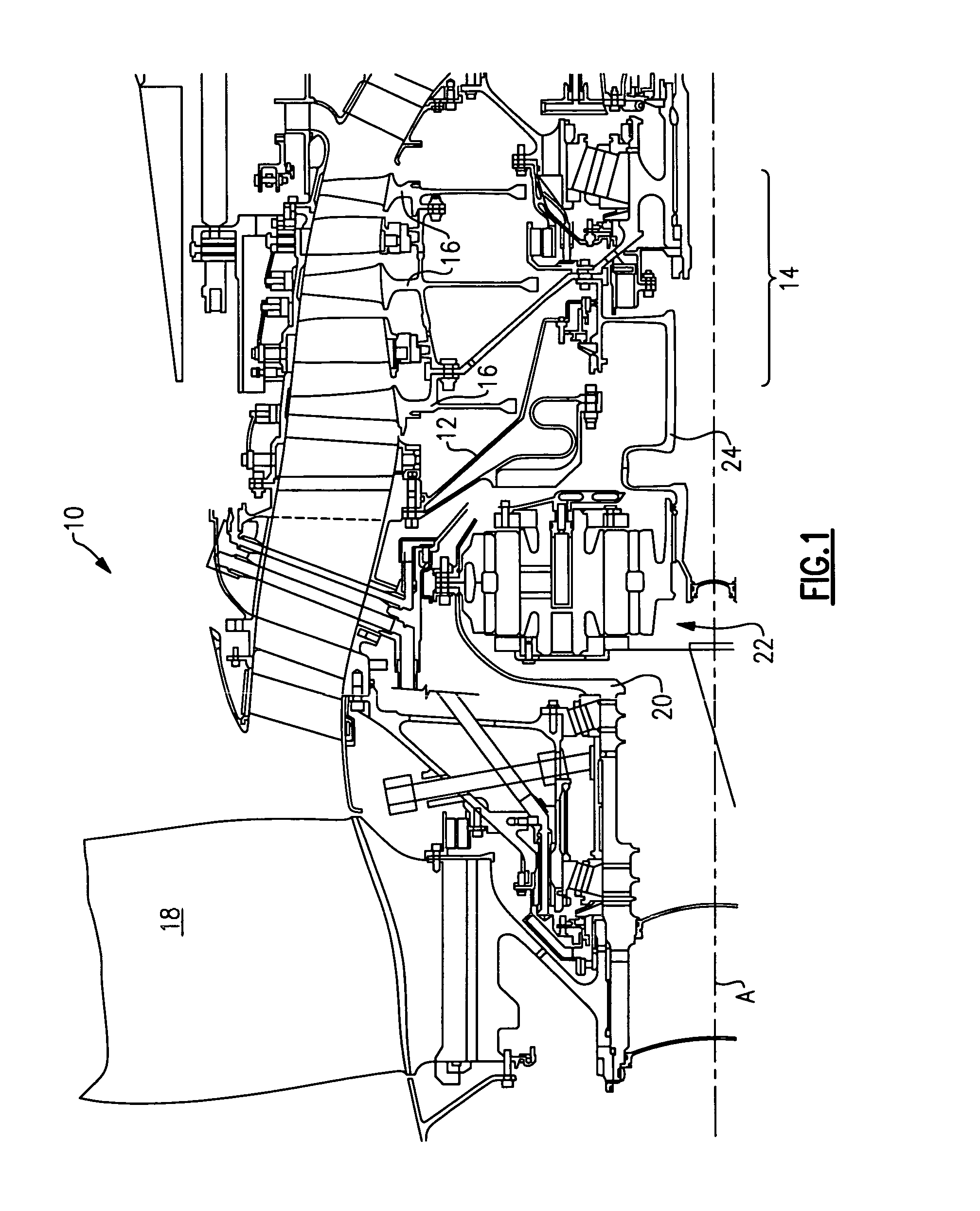

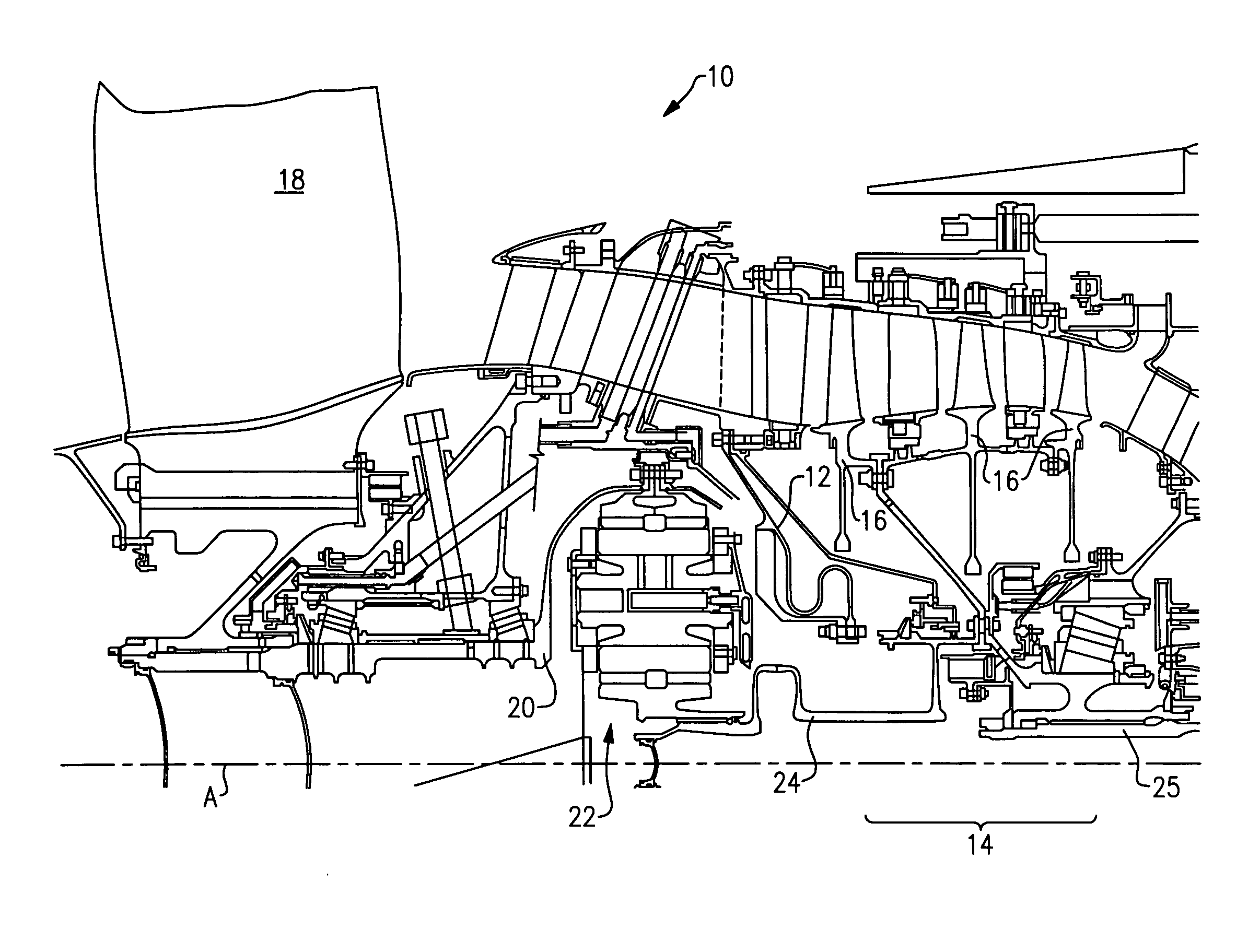

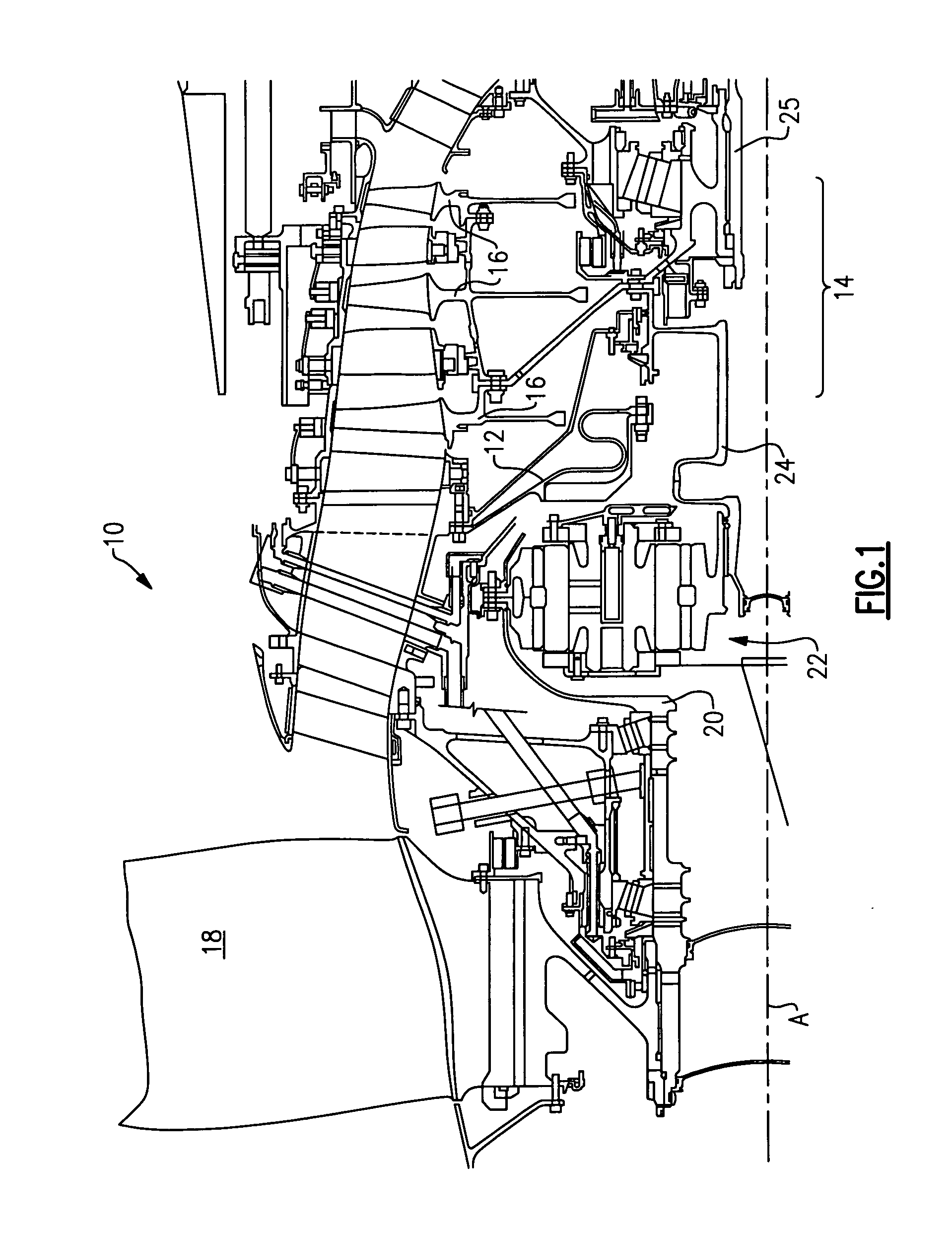

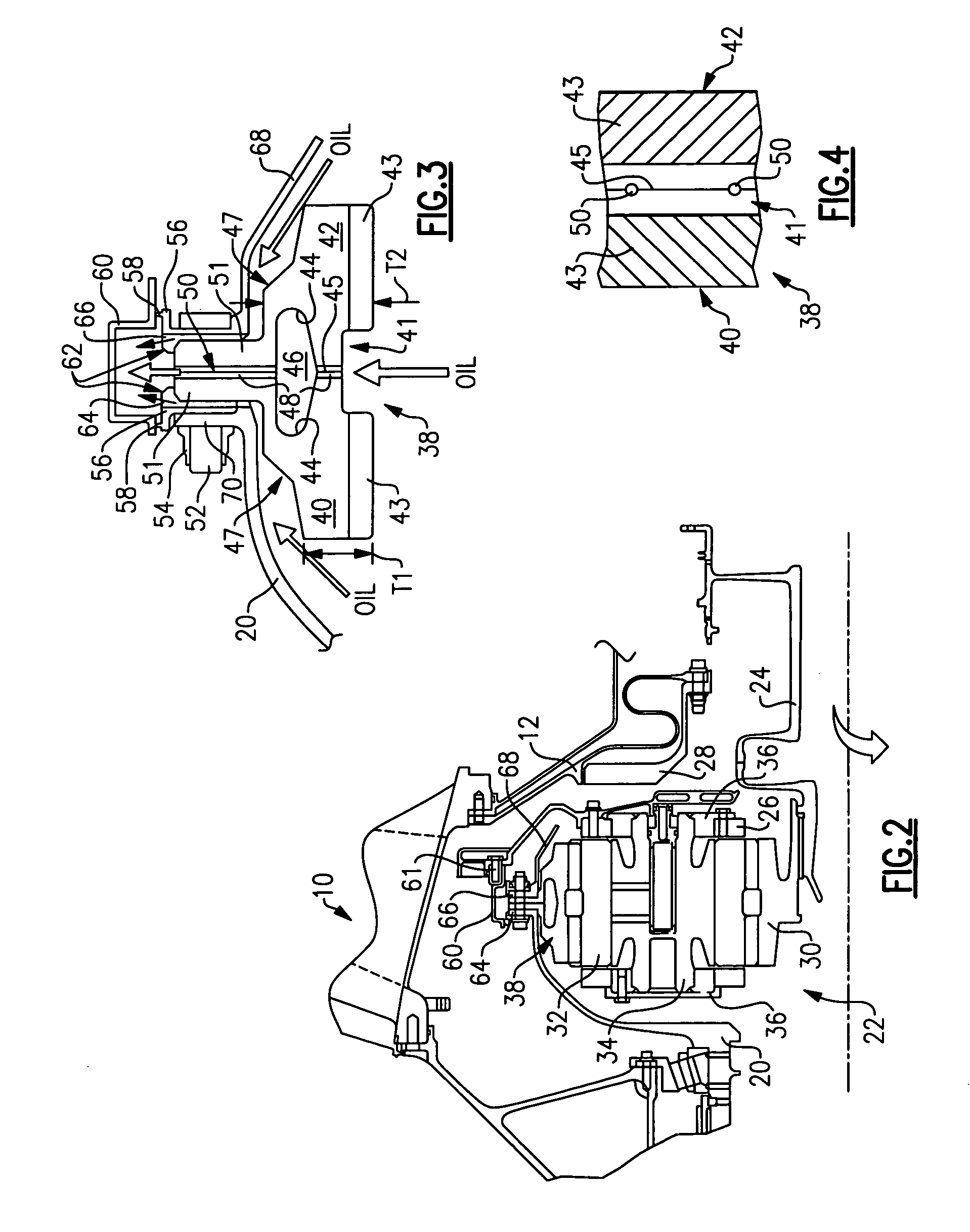

Oil baffle for gas turbine fan drive gear system

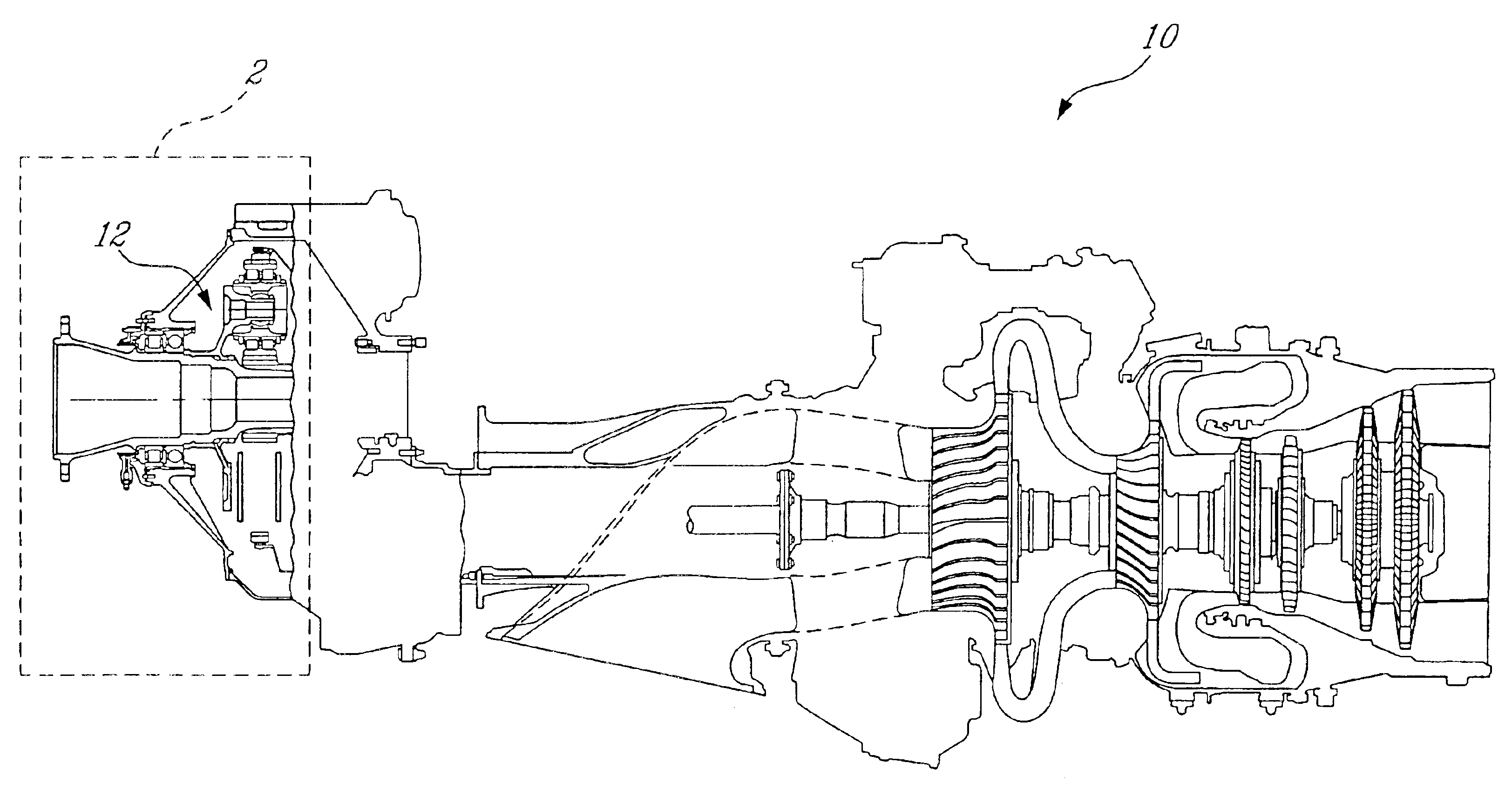

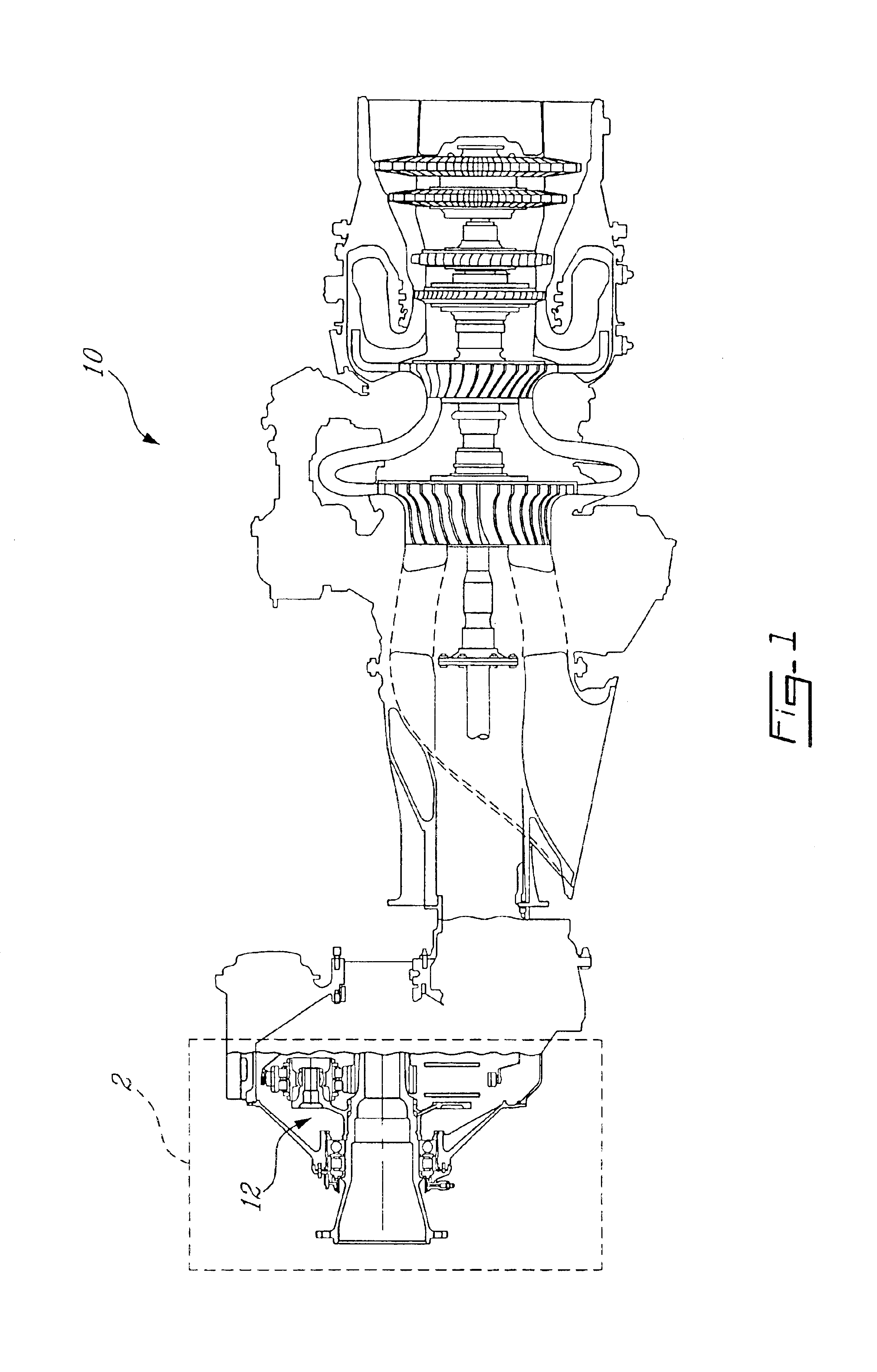

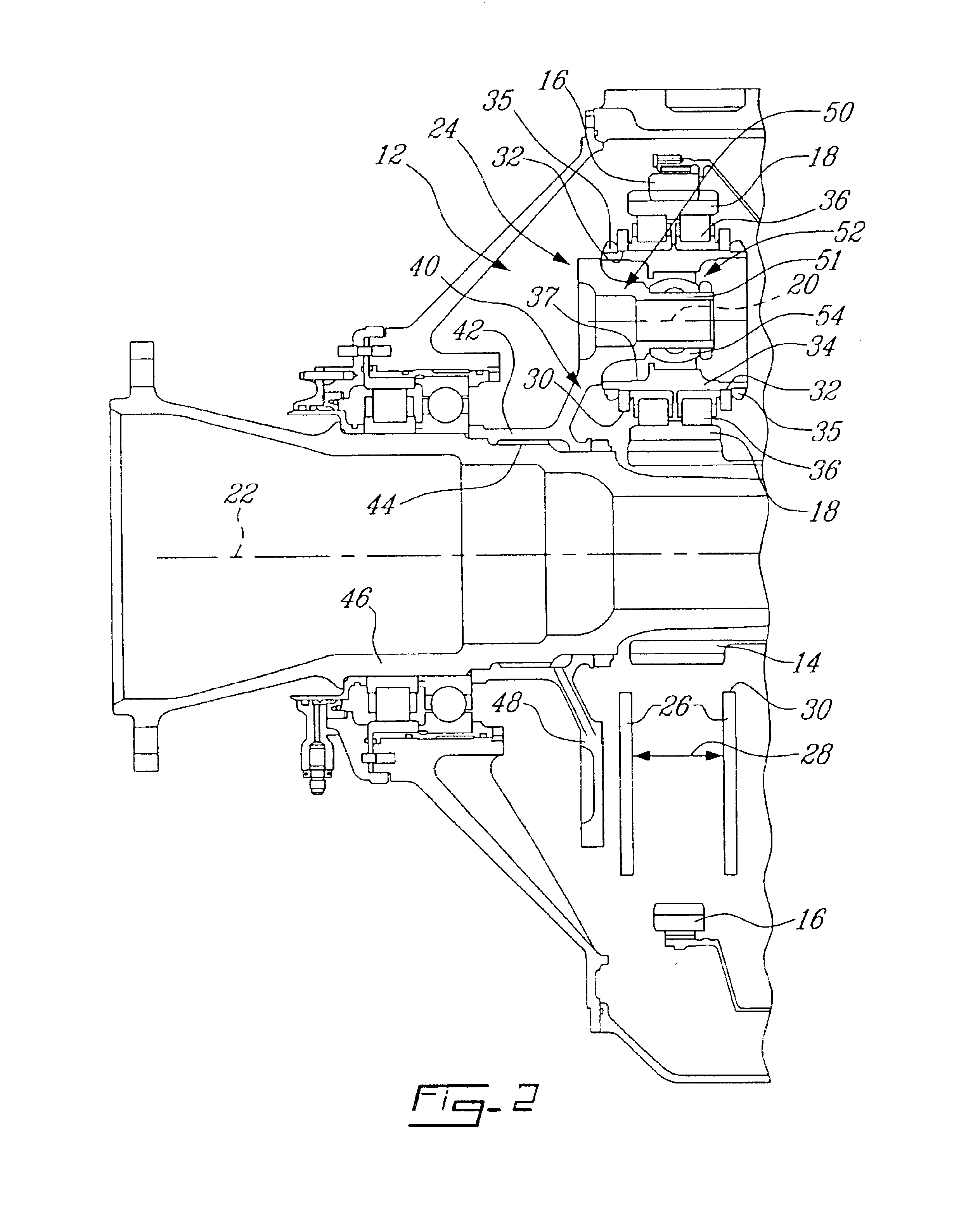

A gas turbine engine includes an epicyclic gear train that drives a turbo fan. The epicyclic gear train employs a one-piece carrier in which the spaced side walls are interconnected with circumferentially spaced apart mounts to form a unitary structure. Baffles are secured to the carrier near the mounts and provide lubrication passages that spray oil onto the sun gear and / or intermediate gears arranged between the baffles. The baffles can be constructed from a different material than the carrier since the baffles are not structural components in the gear train.

Owner:RAYTHEON TECH CORP

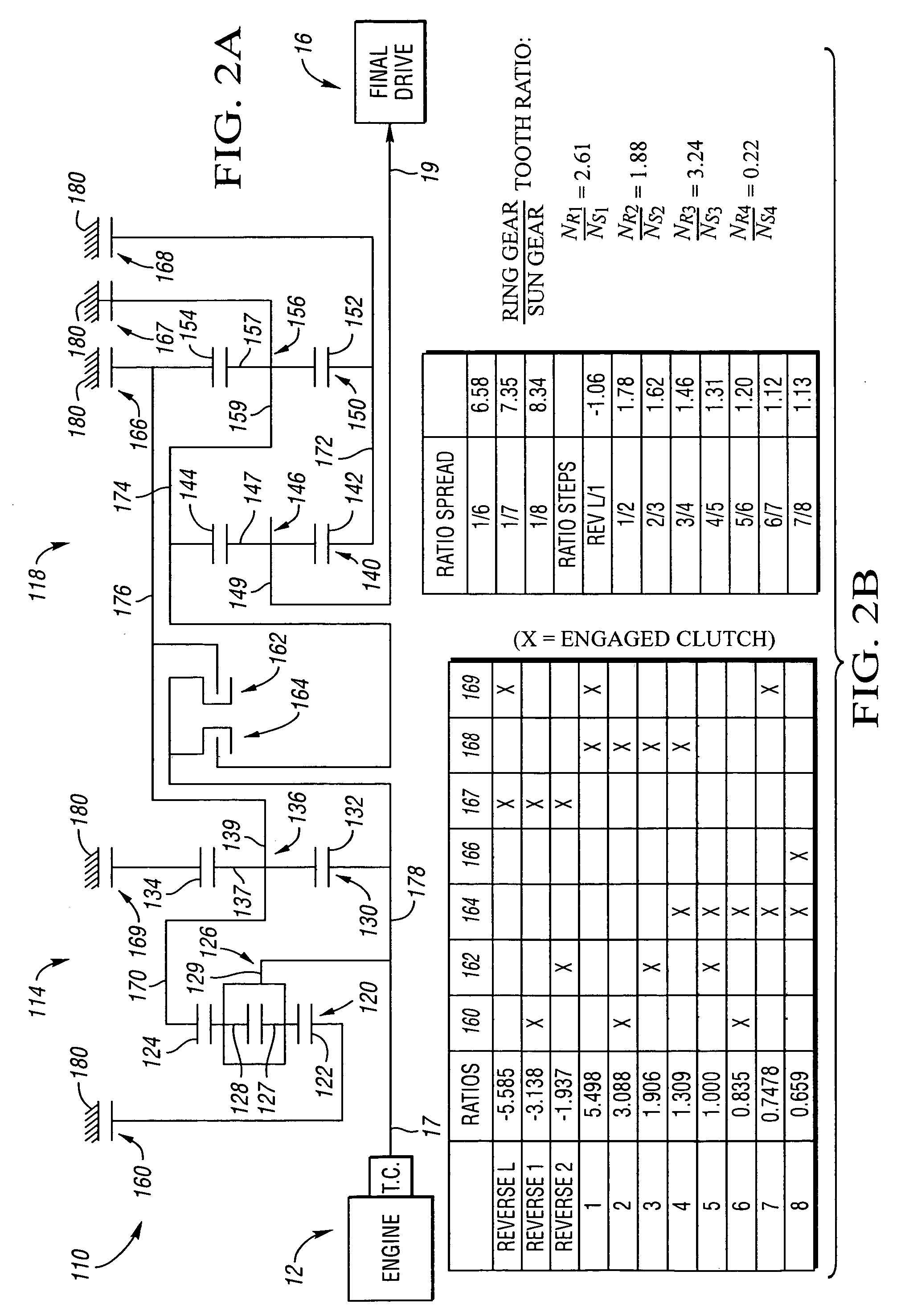

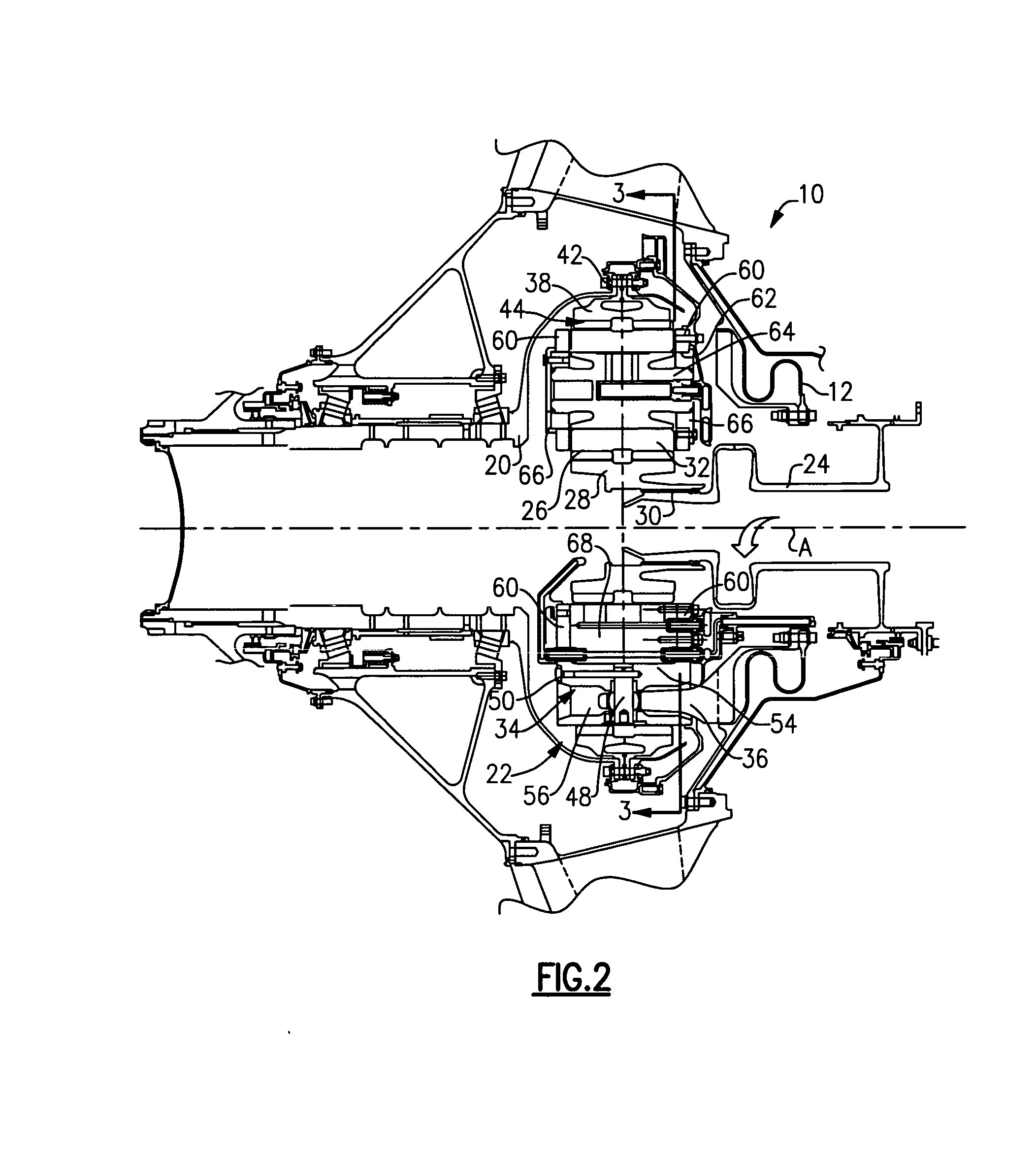

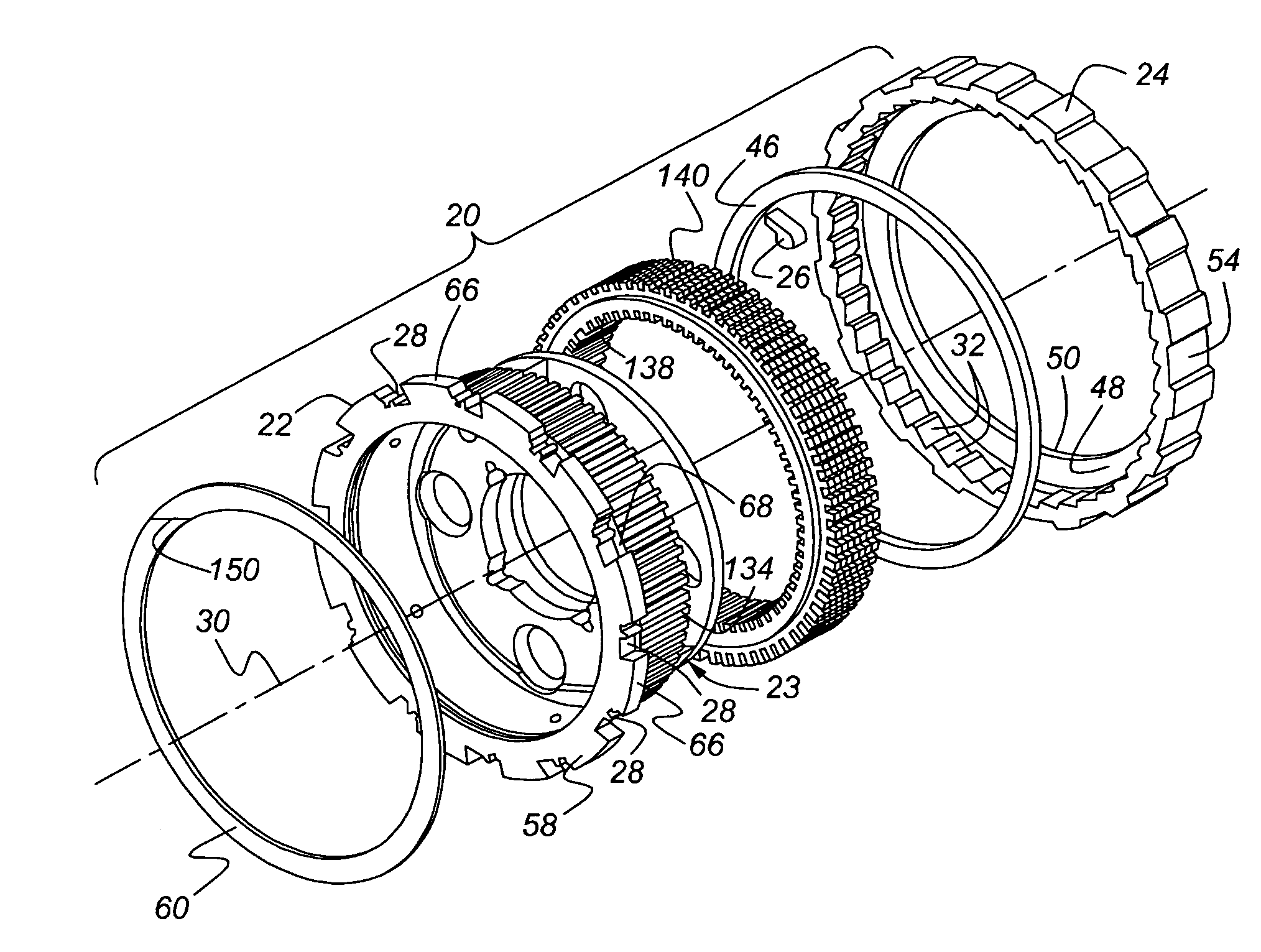

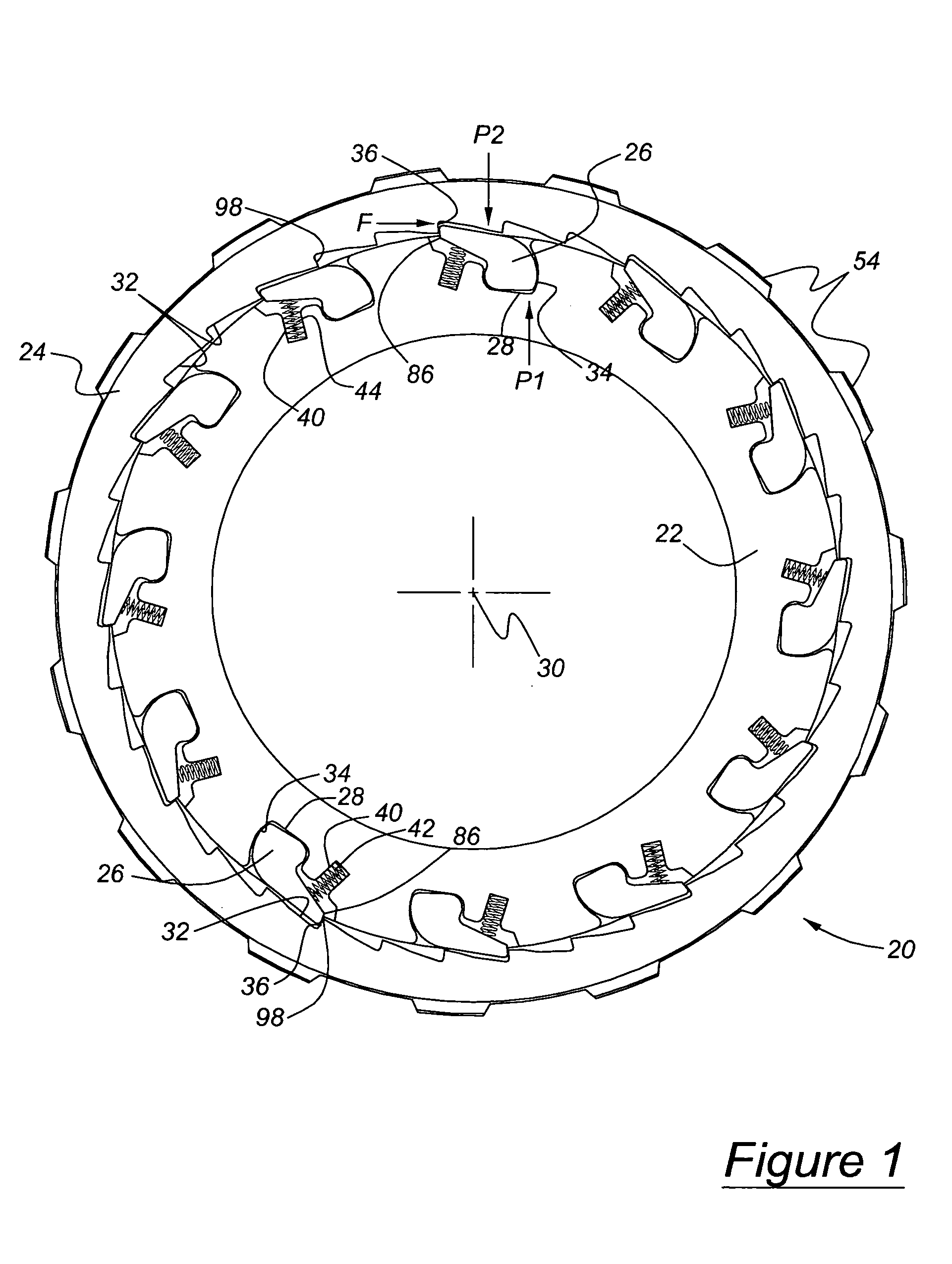

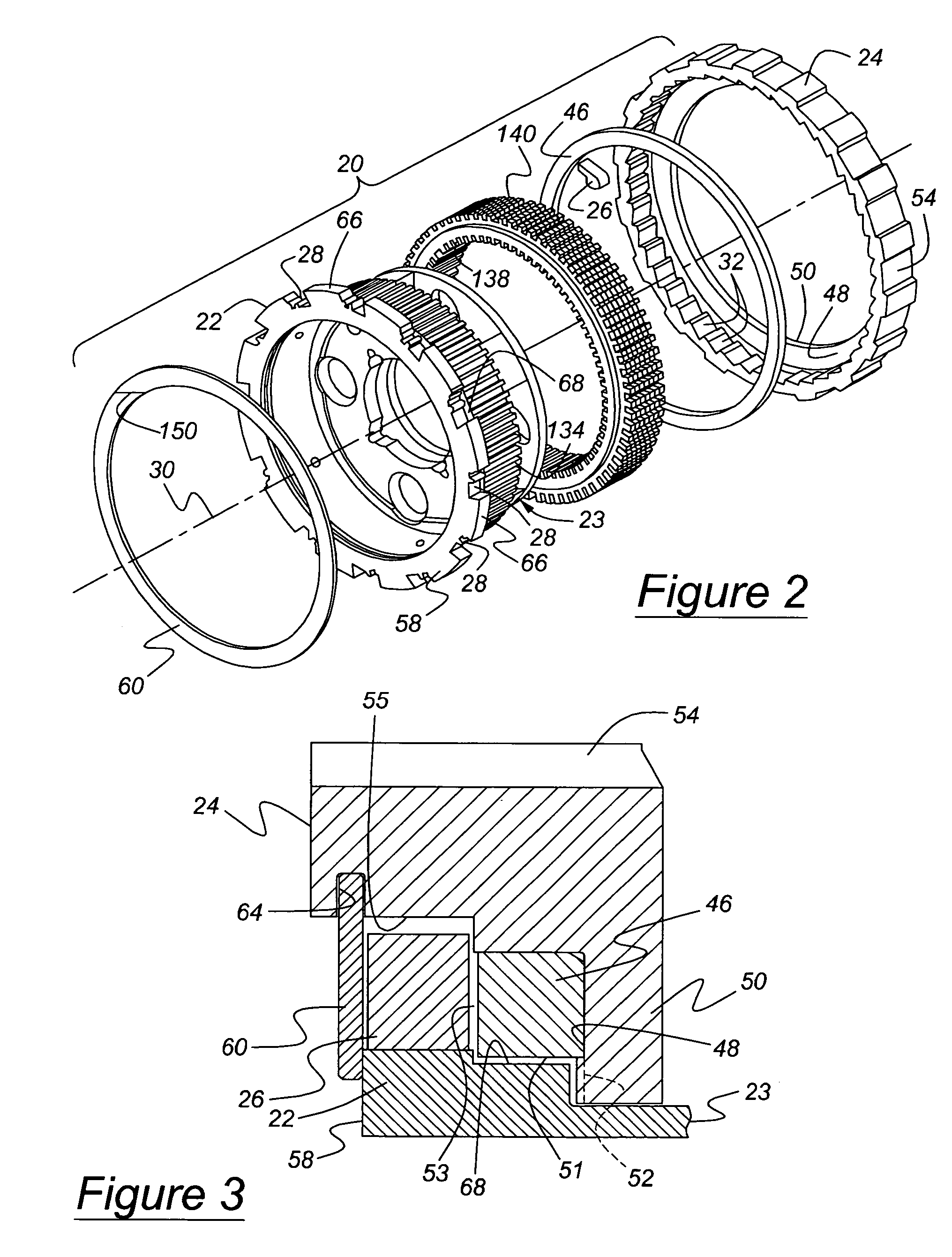

Automatic transmission carrier assembly including an overrunning brake

ActiveUS7223198B2Well formedEliminate needToothed gearingsGearing detailsAutomatic transmissionEngineering

A carrier assembly for a planetary gearset of a transmission includes a pinion carrier, a one-way brake having a rocker ring integral with the carrier and having multiple pockets mutually spaced about an axis and located on an outer radial surface of the carrier. A cam ring includes multiple notches angularly spaced about the axis and facing the rocker ring. A rocker, located in each pocket, pivots about a pivot center to engage the cam ring, and a spring urges each rocker to pivot toward engagement with the cam ring. A hydraulically actuated friction brake secured to the carrier alternately holds the carrier against rotation relative to a housing and permits the carrier to rotate.

Owner:FORD GLOBAL TECH LLC

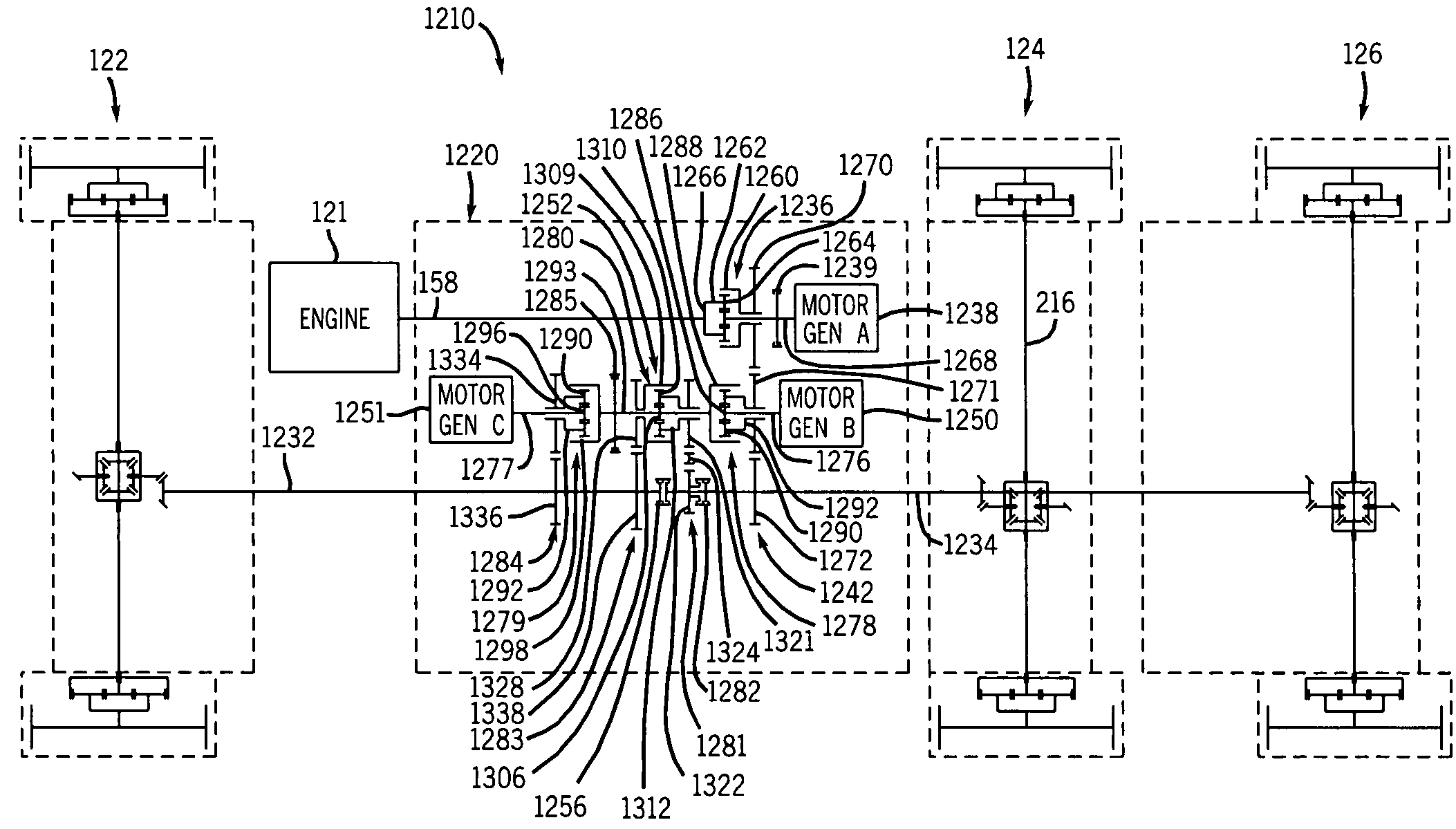

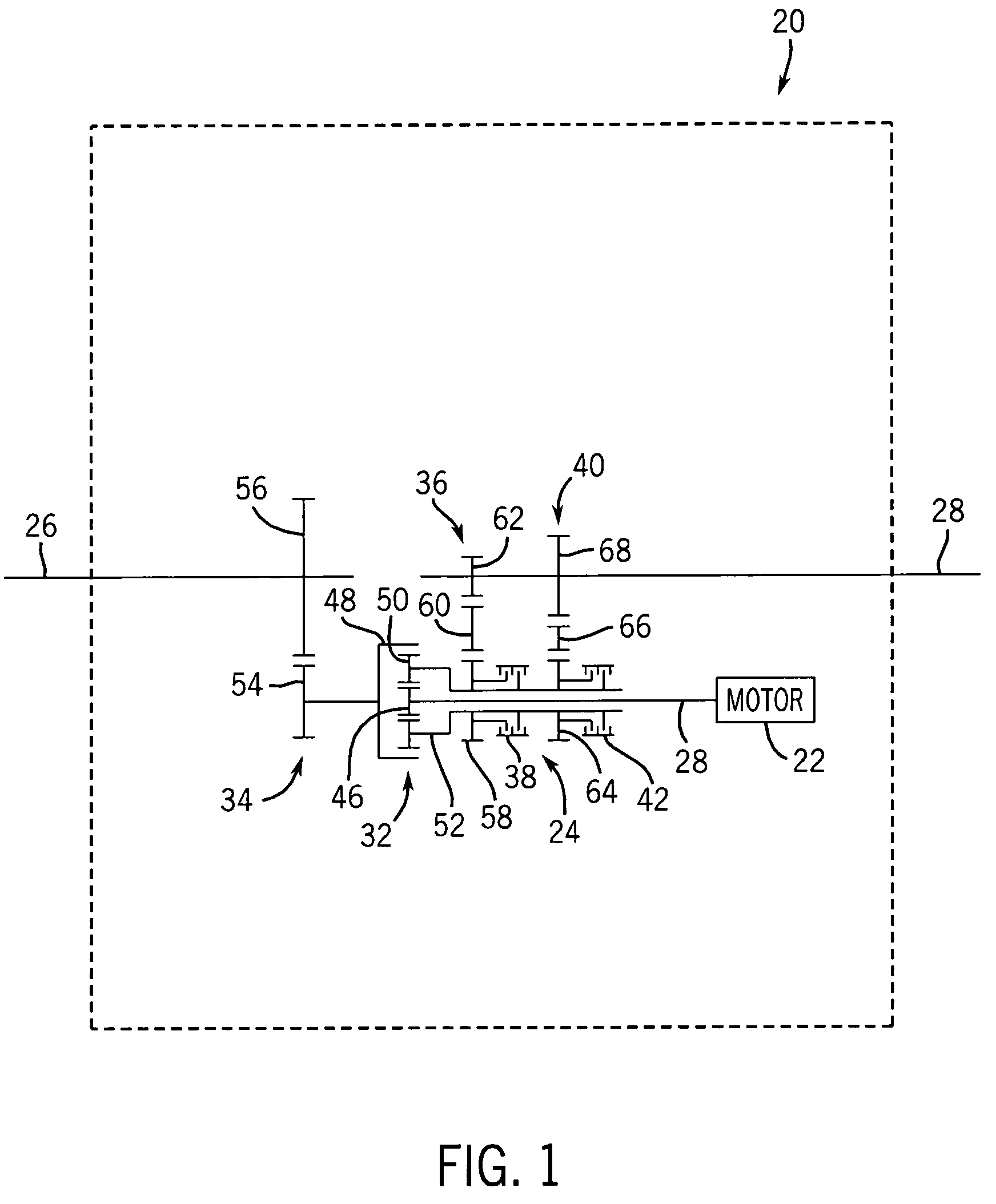

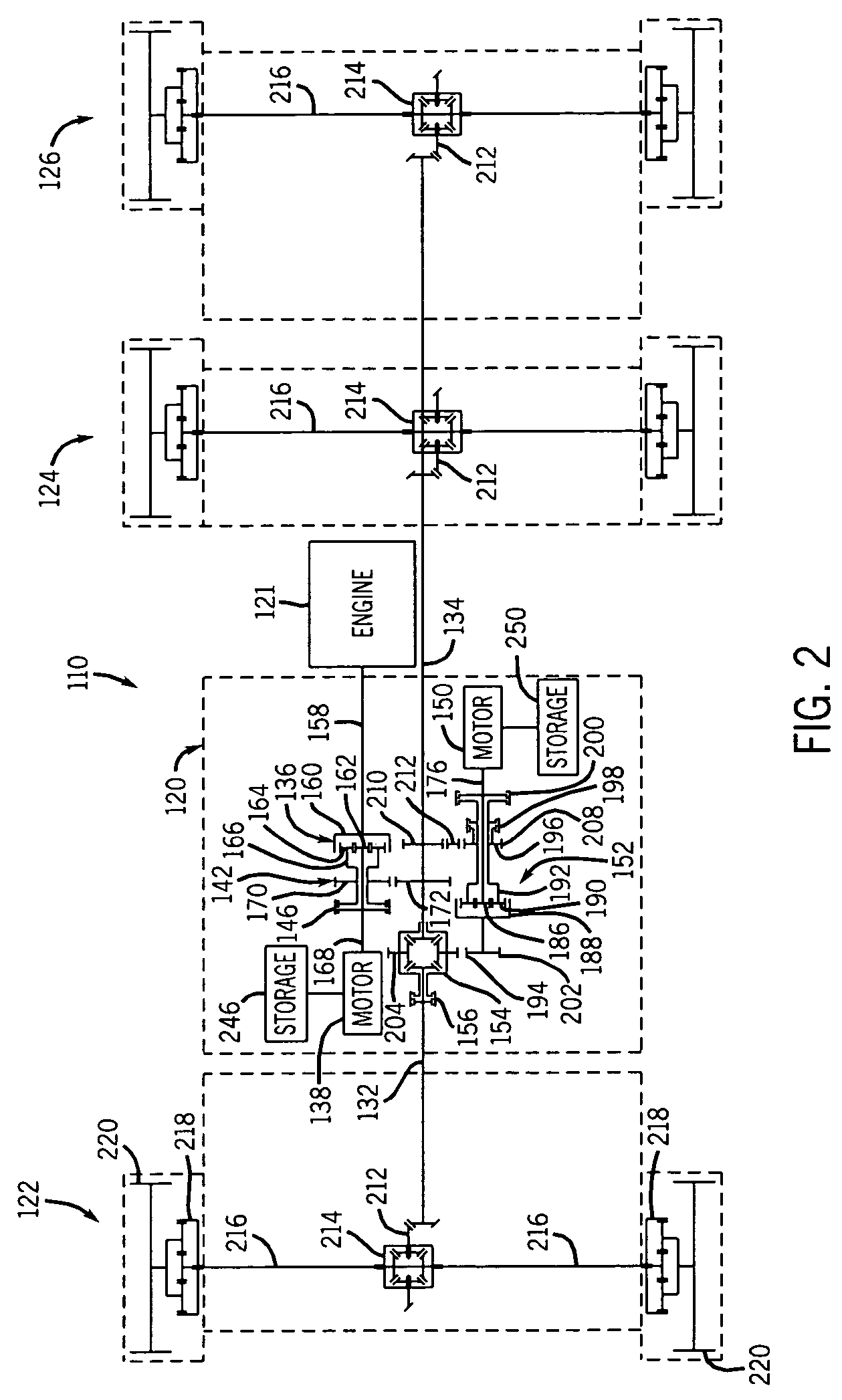

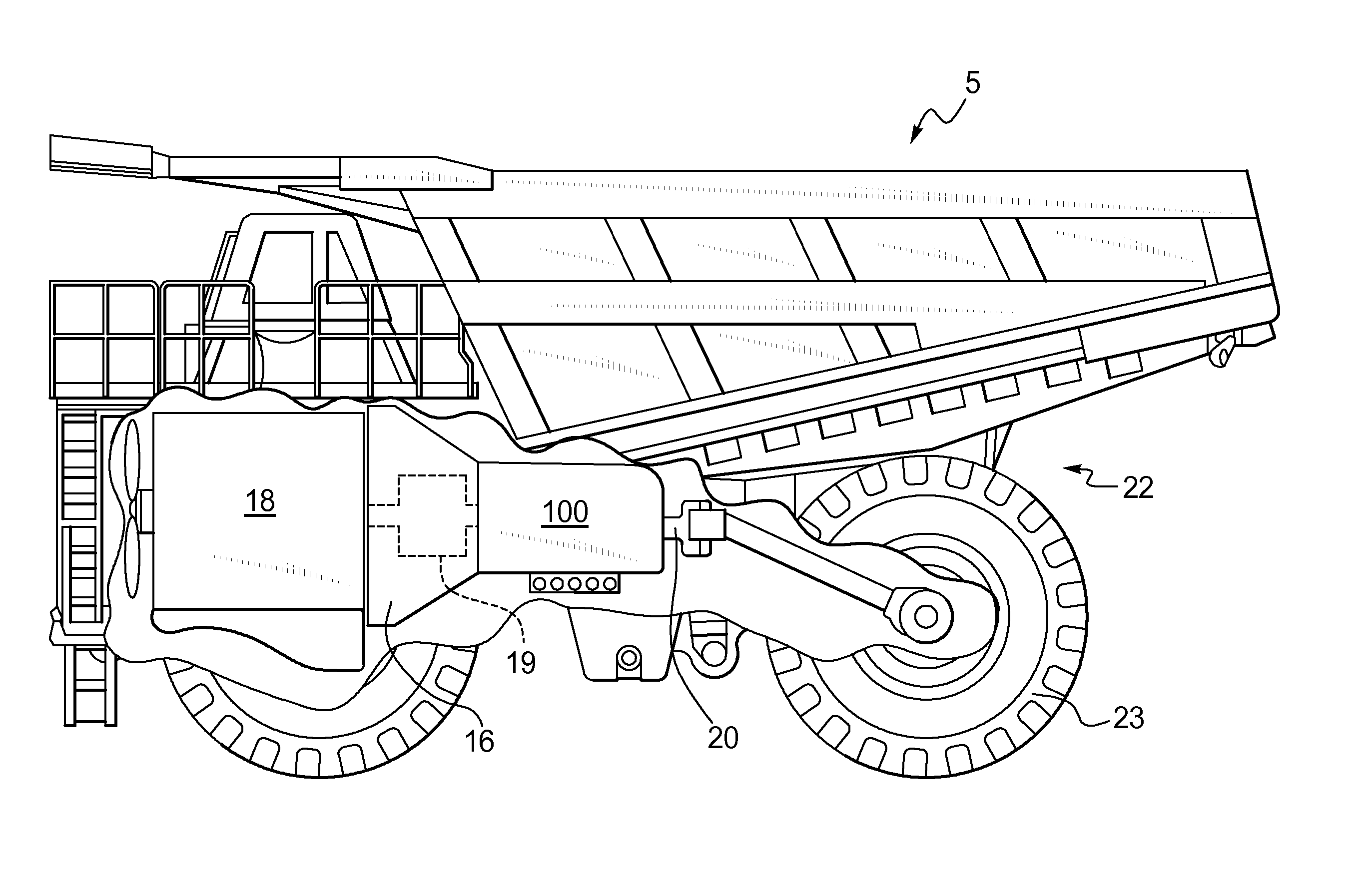

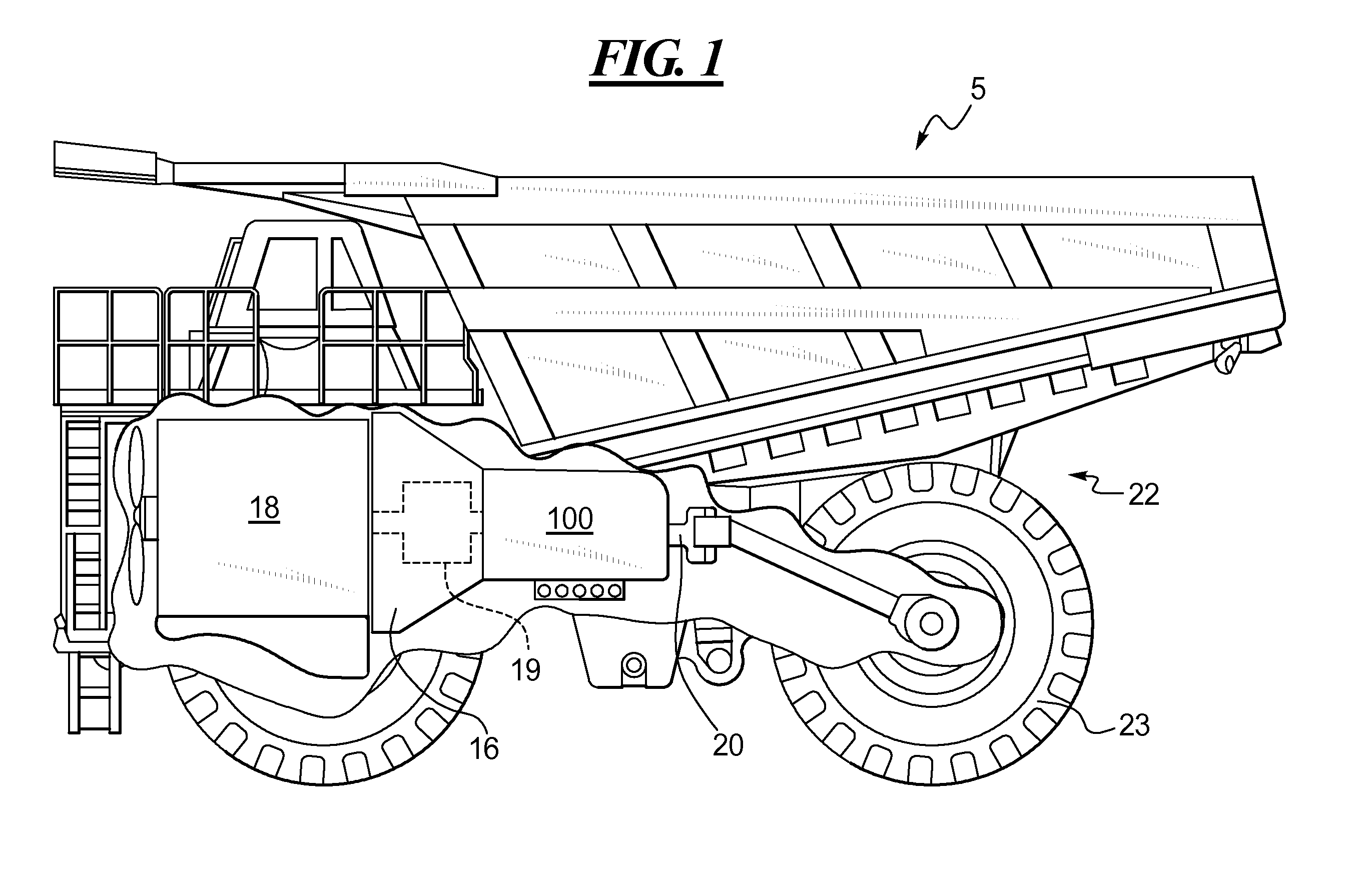

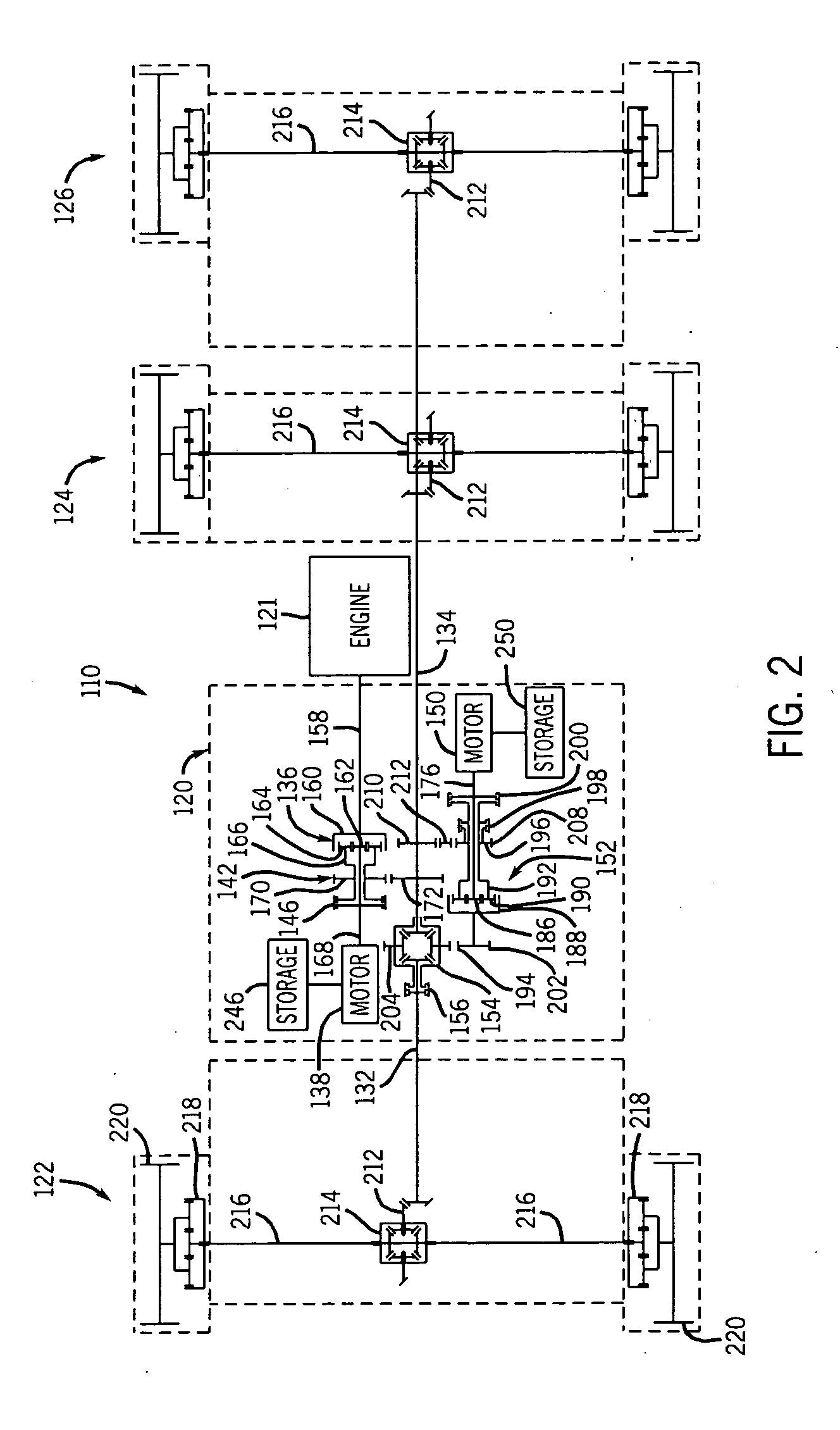

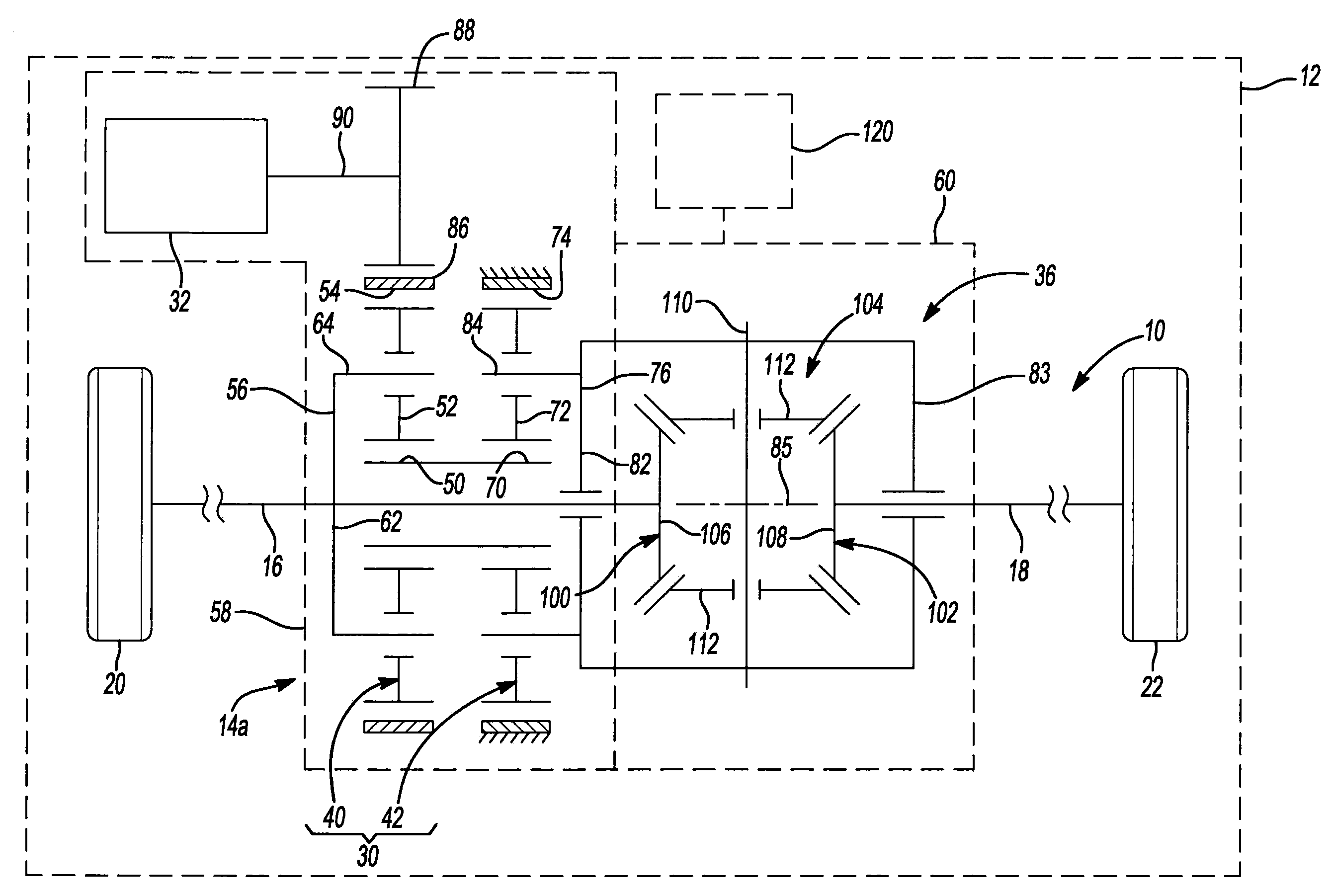

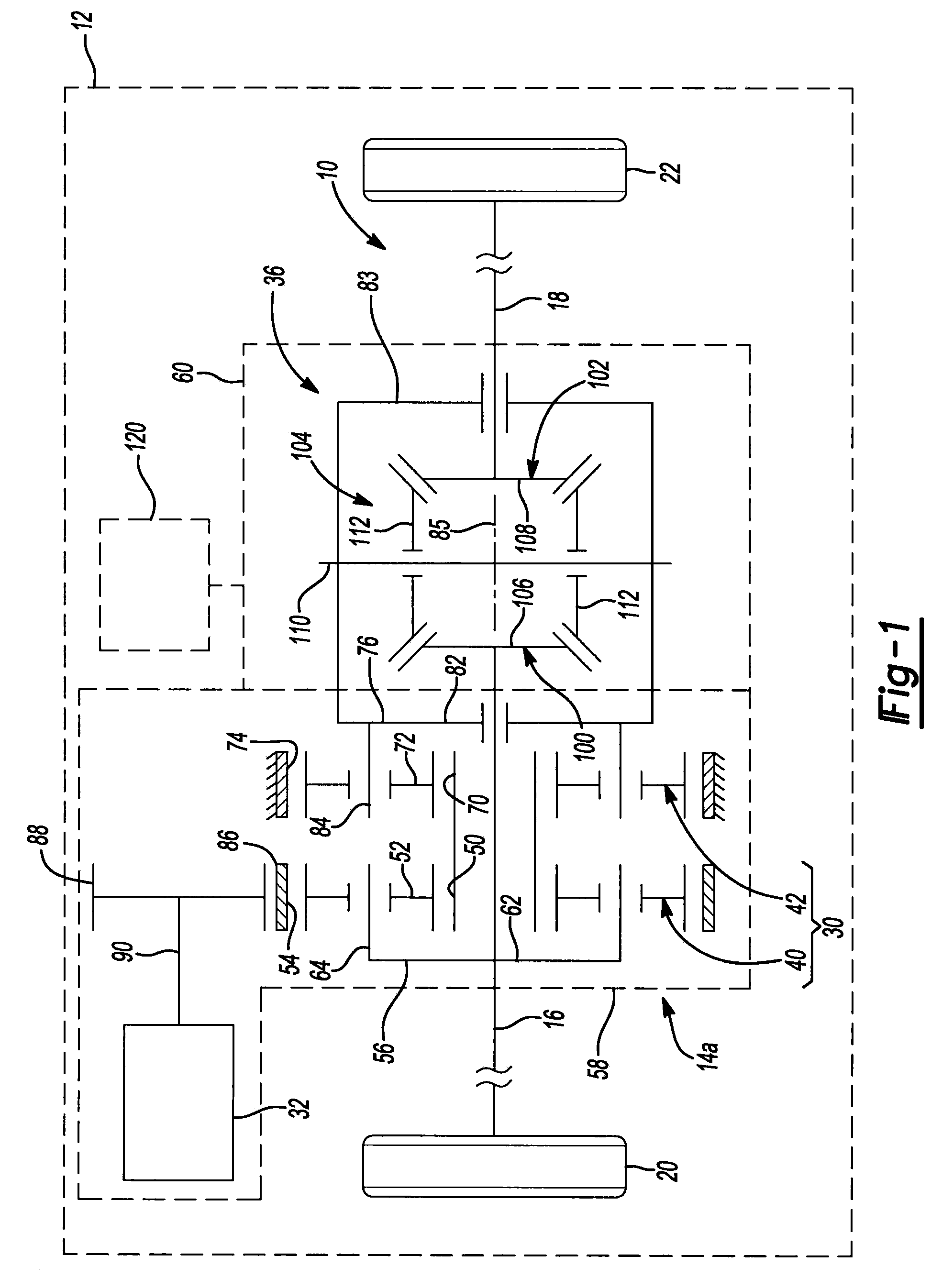

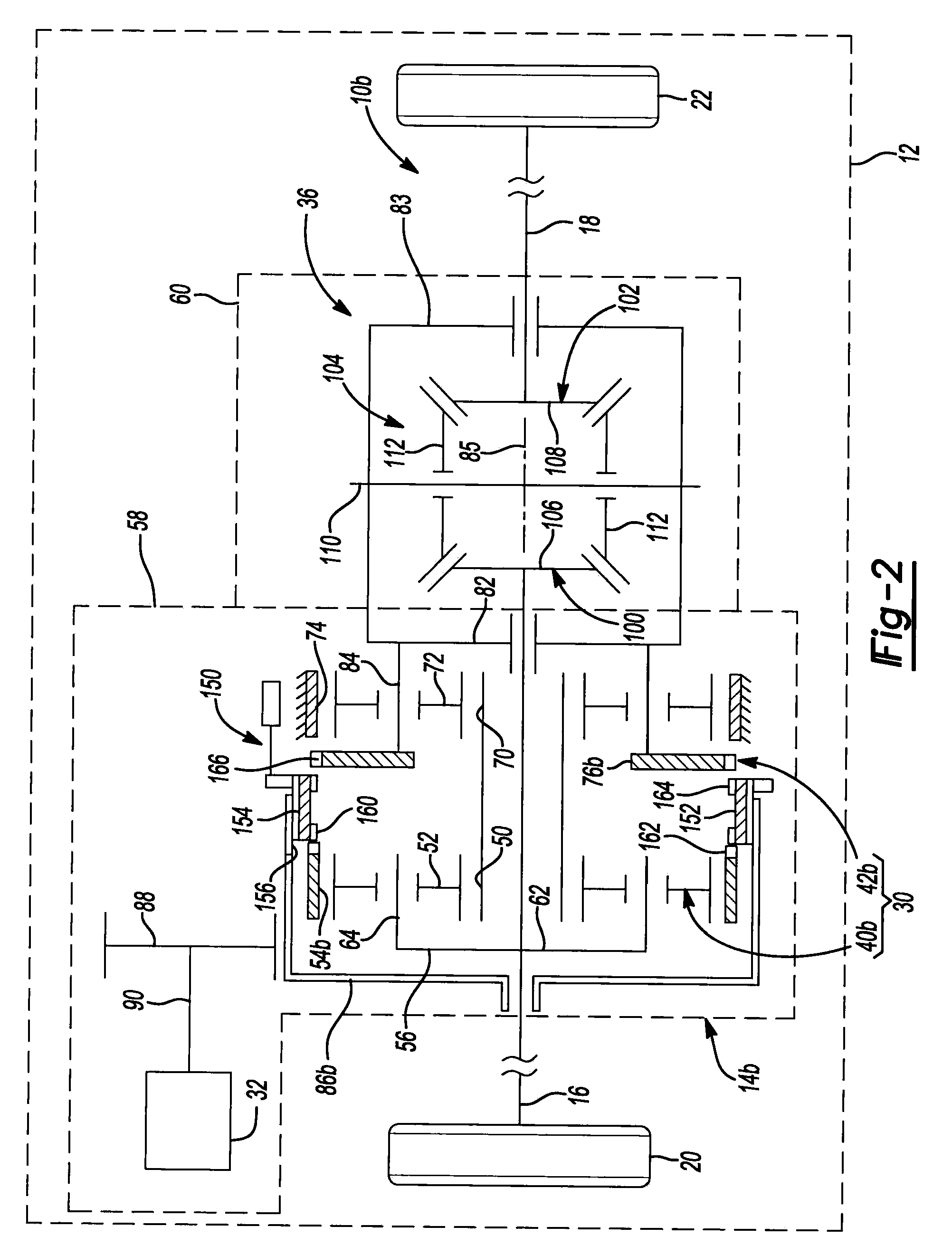

Power splitting vehicle drive system

A vehicle includes a prime mover, a first output shaft, a second output shaft and a planetary gear assembly. The planetary gear assembly includes a sun gear, a ring gear and a plurality of planetary gears supported between the ring gear and the sun gear by a carrier. One of the sun gear and the ring gear is coupled to the prime mover. The other of the ring gear and the sun gear is coupled to the first output shaft. The first carrier is coupled to the second output shaft.

Owner:OSHKOSH CORPORATION

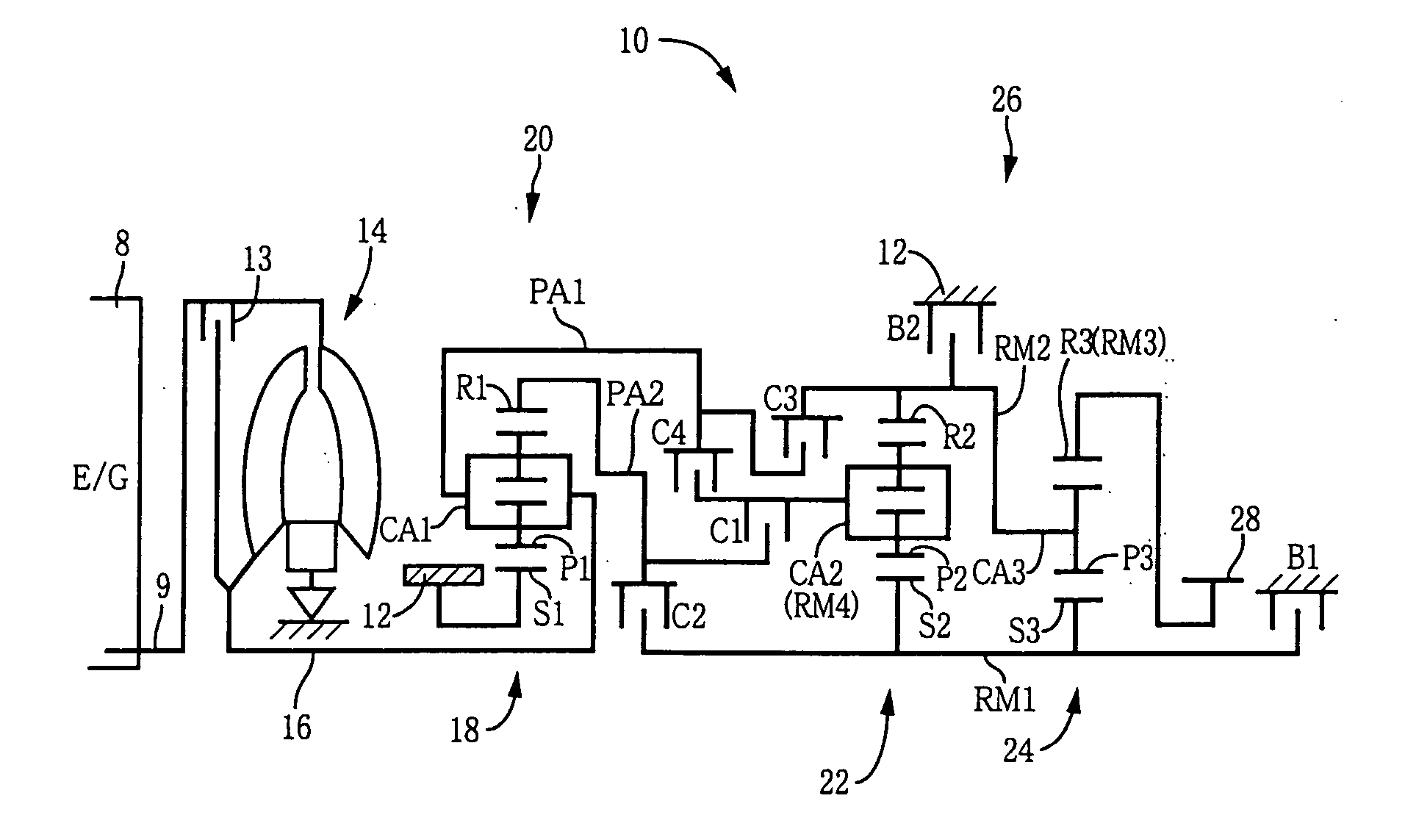

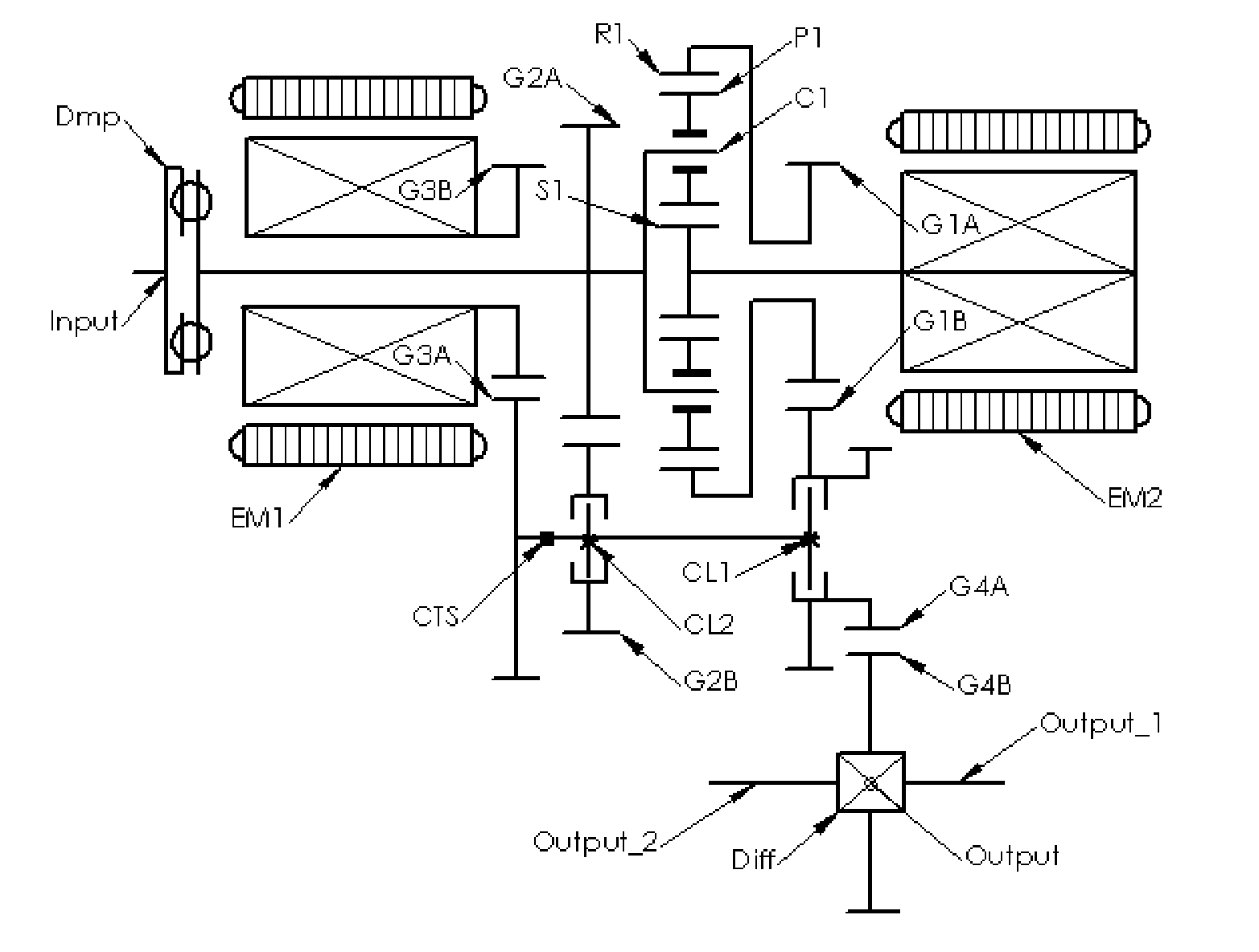

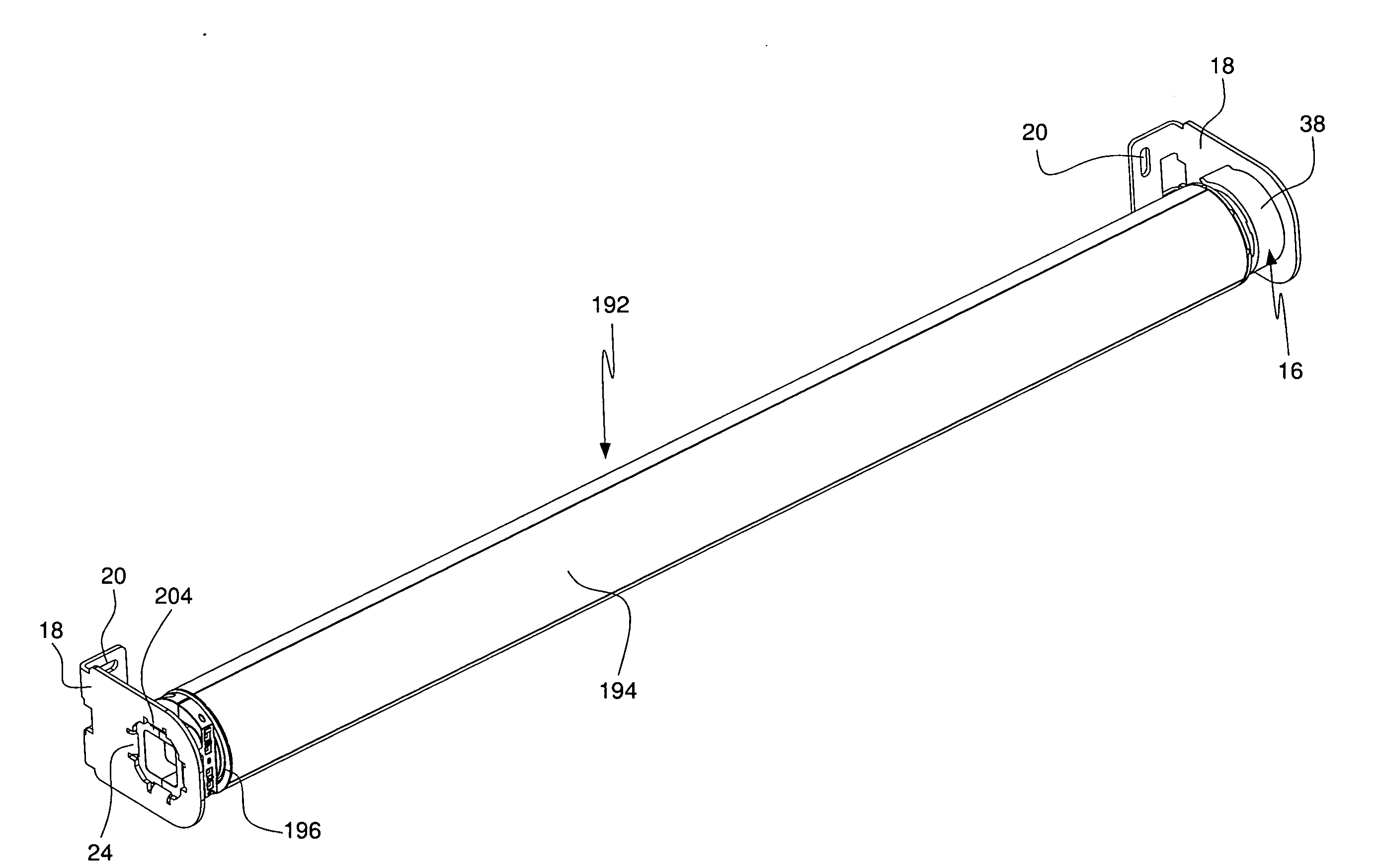

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS20100261565A1Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingDual modeElectric machine

The current invention discloses a dual-mode electro-mechanical variable speed transmission. Said transmission includes an input shaft, an output shaft system, a planetary gear system having at least three co-axial rotating members, two electric machines along with the associated controllers for the electric machines, and at least a clutch. Said planetary gear system has at least three branches; each branch corresponds to a co-axial rotating member. The first branch couples to the first electric machine with a fixed speed ratio; another branch couples to the input shaft with a fixed speed ratio; and yet anther branch couples to the output shaft system with a fixed speed ratio; the second electric machine couples selectively to two of the branches in the planetary gear system with different speed ratios. Said two branches are not the first branch and one of the said two branches is connected to the output shaft system. Said dual-mode electro-mechanical variable speed transmission is capable of providing at least two power splitting operation modes, including an output power splitting mode. Different operation modes cover different speed ratio regimes. At the mode switching point, the corresponding clutch or clutches is automatically synchronized. Thus the speeds of the rotation members of the transmission are continuous, and the transmission is free from shock loads at the operating mode switching point. In addition, said transmission is capable of providing operations with at least a fixed input-to-output speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

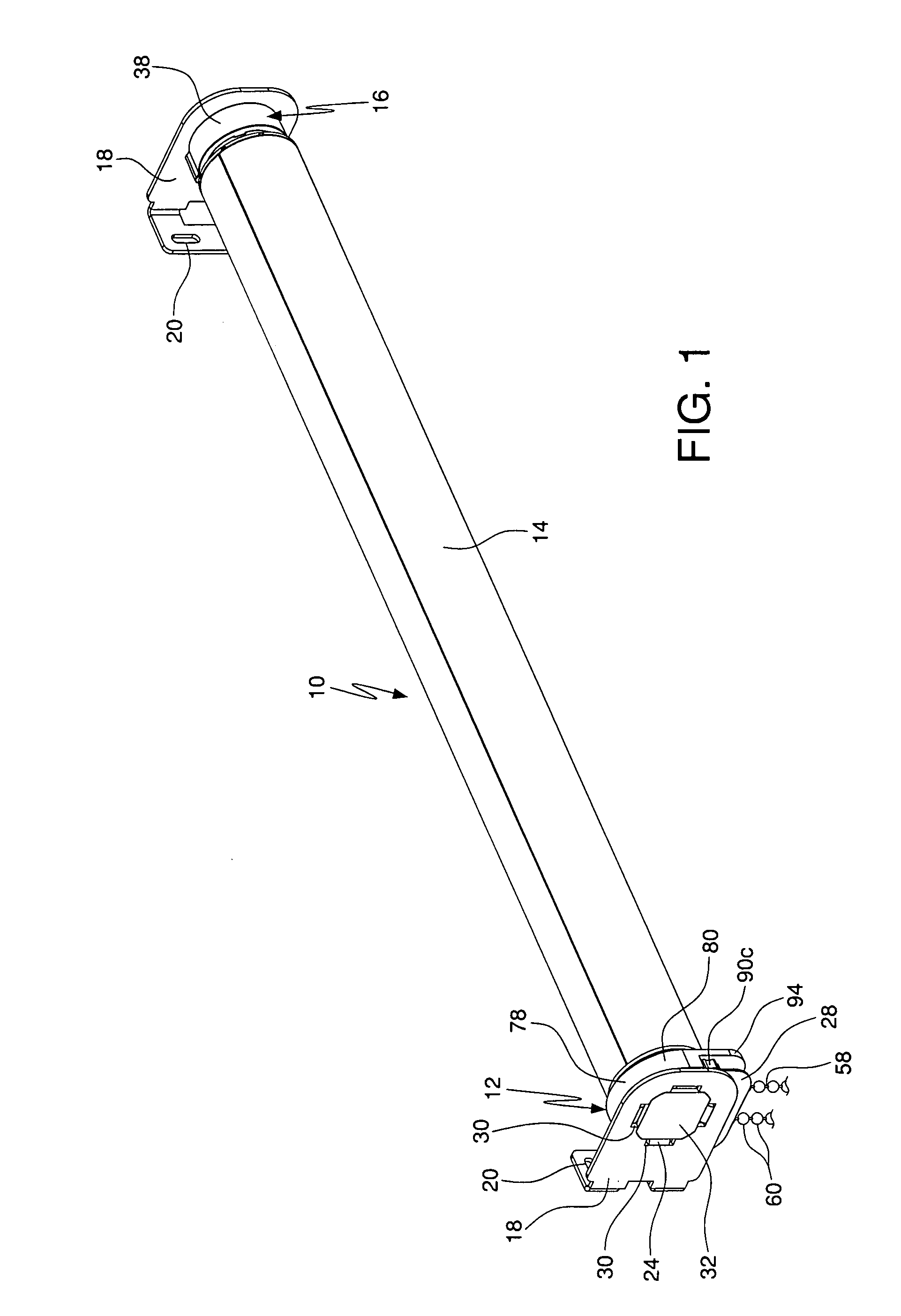

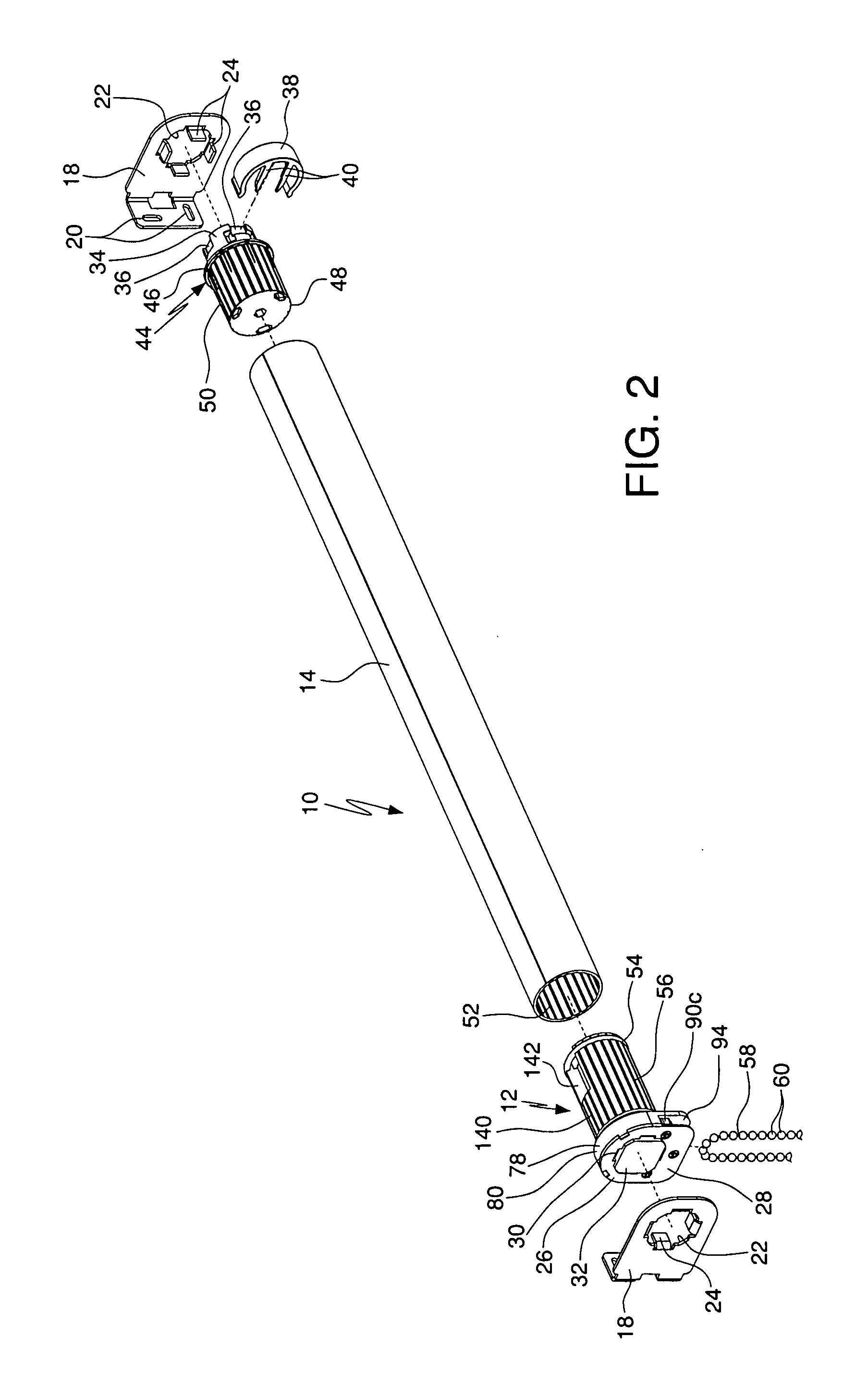

Manual roller shade having clutch mechanism, chain guide and universal mounting

A manual roller shade includes a clutch mechanism having a gear train transferring rotation of an input sprocket to rotation of an output member engaging a roller tube. The gear train includes a sun gear, planet gears supported by a carrier and engaging the sun gear, and a ring gear engaging the planet gears. According to one embodiment, the carrier does not rotate. The ratio between the diameters of the input sprocket and the roller tube is selected to offset mechanical advantage of the gear train to provide an effective gear train ratio of approximately 2:1. A drive chain guide system includes spaced guide wheels controlling where a drive chain is suspended from the manual shade. A roller shade mounting system includes a bracket receiving either an input assembly of the manual roller shade or a motor of a motorized roller shade to facilitate conversion.

Owner:LUTRON TECH CO LLC

Ring gear mounting arrangement with oil scavenge scheme

ActiveUS20080044276A1Reliably rotationally balancedDesired stiffness and resistance to overturning momentsEngine fuctionsBlade accessoriesEngineeringGear train

A turbine engine includes an epicyclic gear train that has a two-piece ring gear. Each portion of the ring gear includes radially outwardly extending flanges that are axially constrained to a turbo fan shaft by bolts secured circumferentially along the flanges. Knife edge seals are secured to the flanges to contain oil expelled through the ring gear into a gutter. The ring gear and turbo fan shaft can be rotationally balanced together.

Owner:RAYTHEON TECH CORP

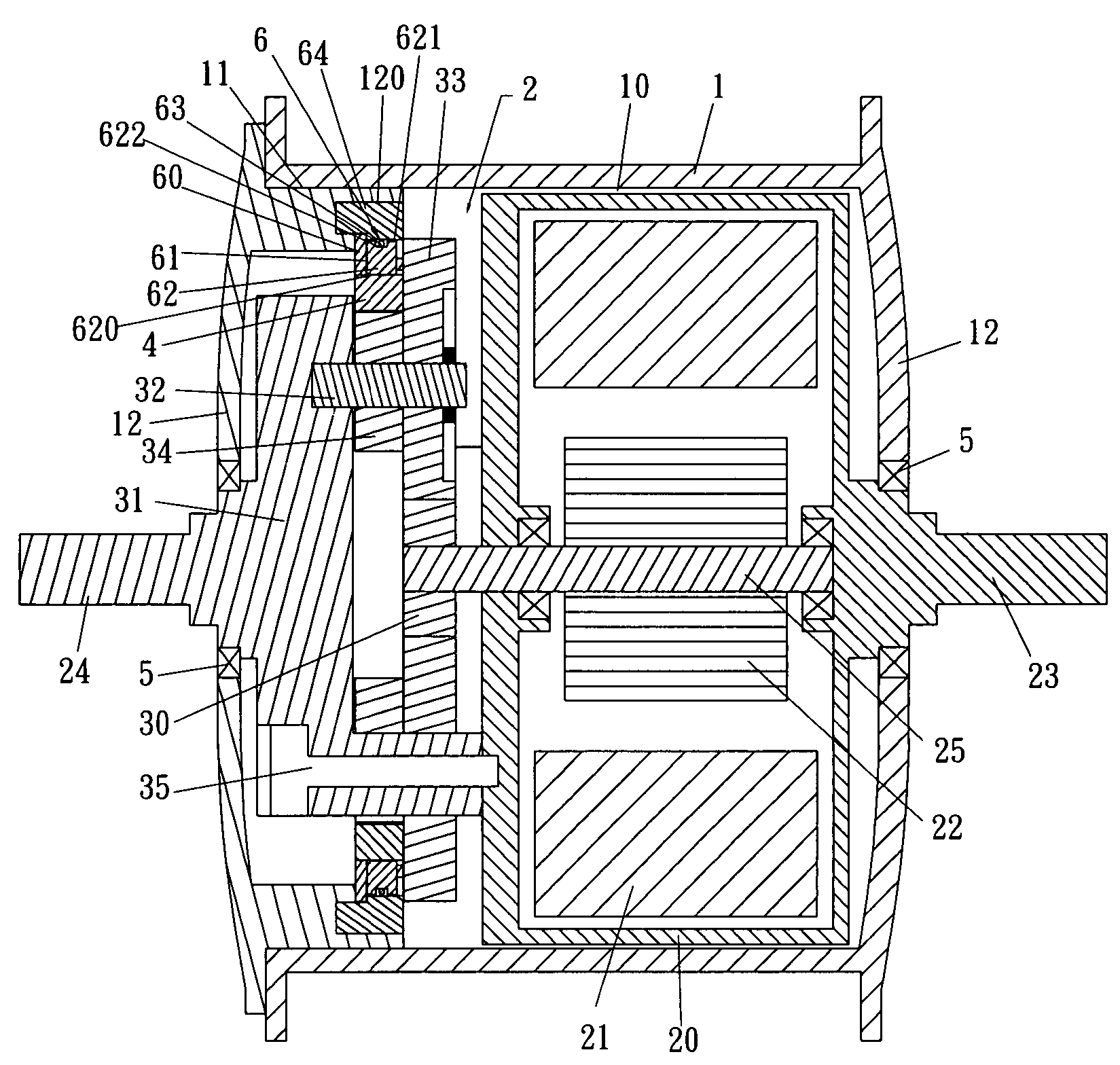

Hub motor mechanism

An electrically driven hub includes an electrical mechanism including an electrical motor and a planetary gear system connected to the electrical mechanism. A first fixed shaft is connected to the stator of the electrical motor and a second fixed shaft is connected to a second end of the stator of the electrical motor. The first and second fixed shafts are connected to the vehicle frame. A one-way clutch is connected between a cover of the hub and the planetary gear system so that the hub is rotated when the planetary gear system is activated by the motor.

Owner:LO CHIU HSIANG

Nine-speed transmissions with four planetary gear sets

ActiveUS20060205556A1Improve fuel economyImprove traction performanceToothed gearingsTransmission elementsGear wheelEngineering

Nine-speed transmissions are provided that include four planetary gear sets having six torque-transmitting mechanisms and various fixed interconnections to provide nine forward speed ratios and a reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The six torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

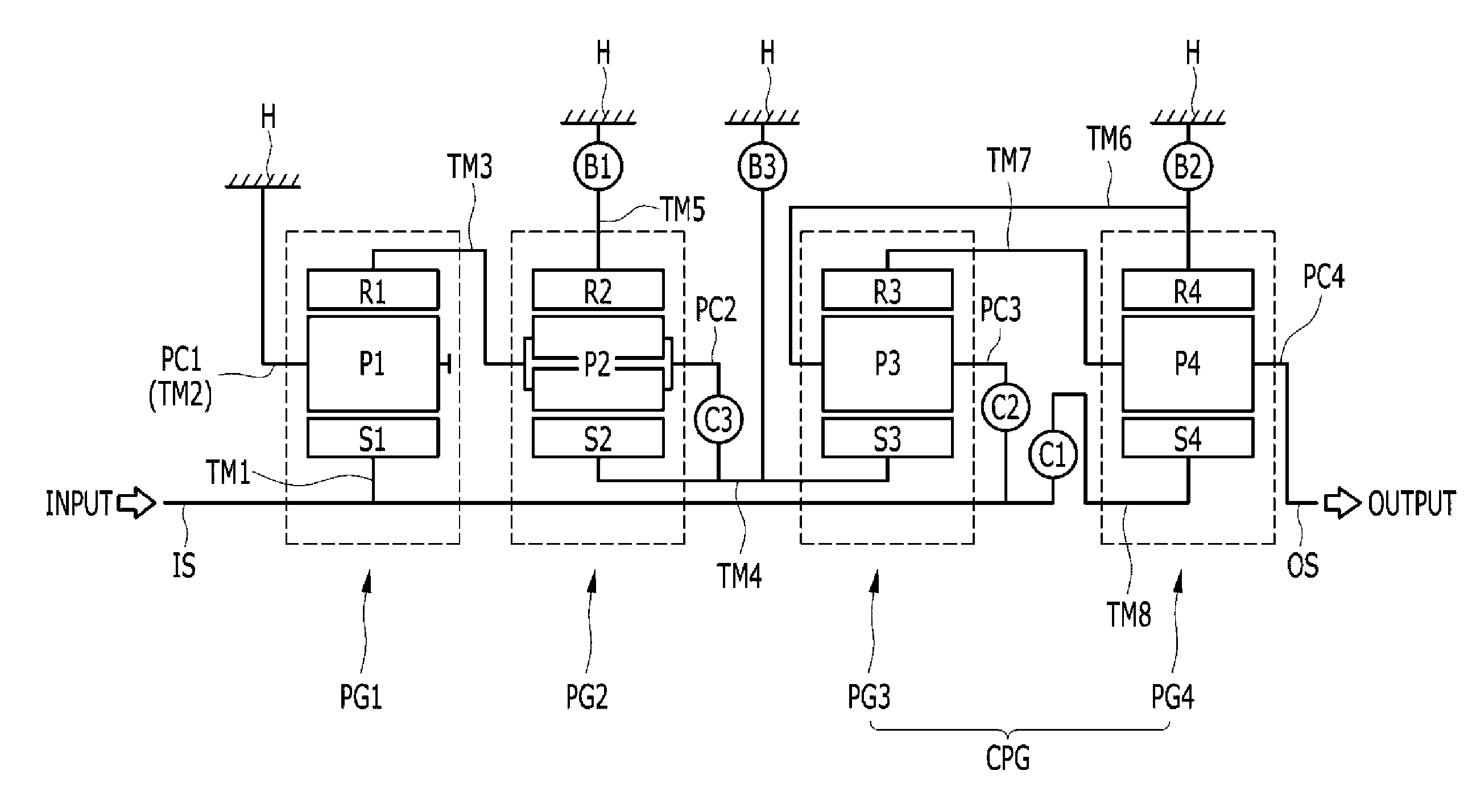

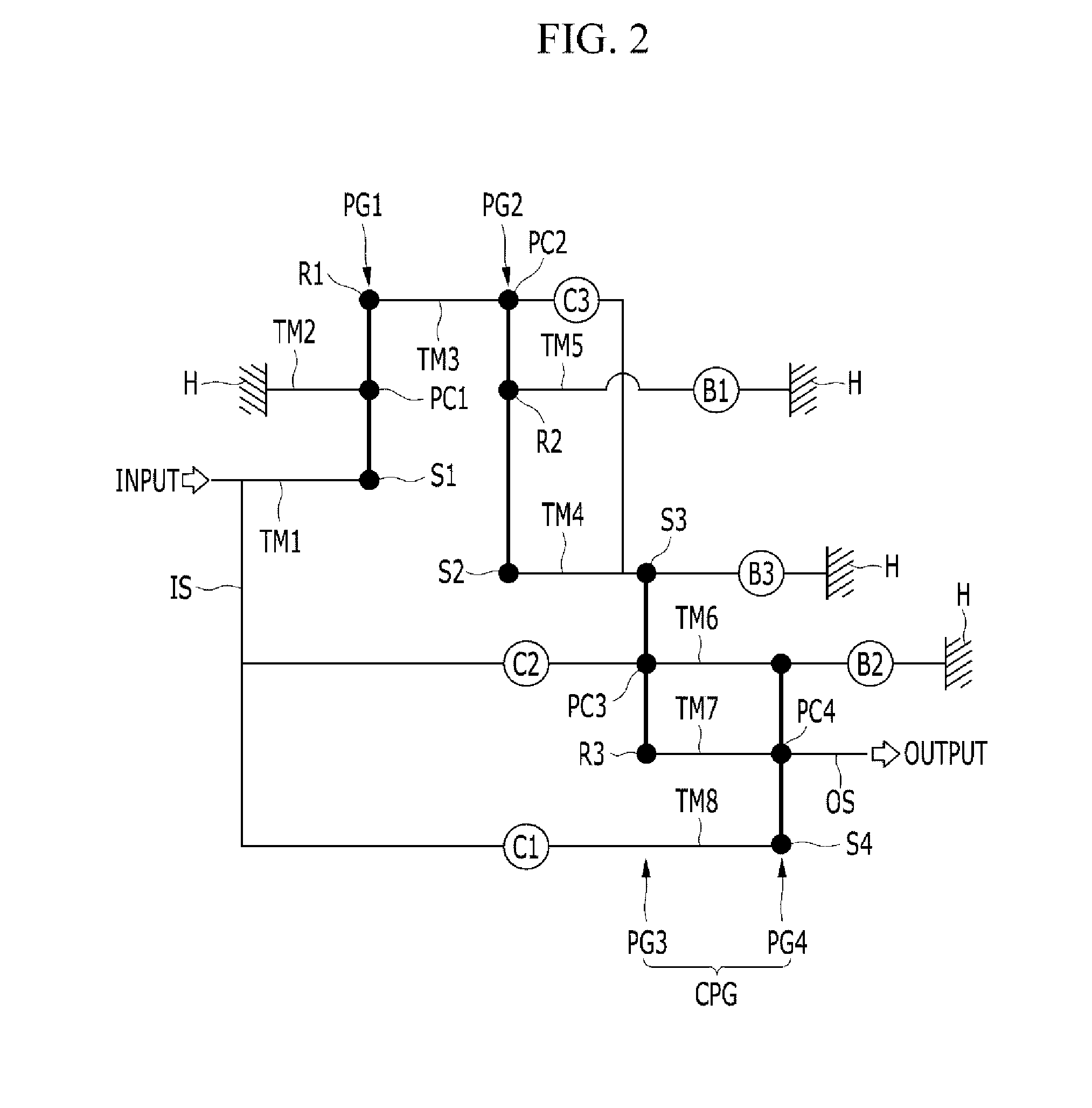

Planetary gear train of automatic transmission for vehicles

InactiveUS20130029799A1Improve controllabilitySuitable step ratioToothed gearingsTransmission elementsAutomatic transmissionForward speed

A planetary gear train of an automatic transmission may include an input shaft, an output gear, a first planetary gear set always outputting a negative rotation speed from a rotation speed input from the input shaft, a second planetary gear outputting the negative rotation speed input from the first planetary gear set or converting negative rotation speed into a positive rotation speed and outputting the positive rotation speed, a compound planetary gear set formed by third and fourth planetary gear sets and changing the rotation speed selectively through two paths and into nine forward speeds and one reverse speed, eight rotational members including two rotation elements connected to each other or one rotation element among the rotation elements of the first and second planetary gear sets and the compound planetary gear set, and a six friction members, and a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

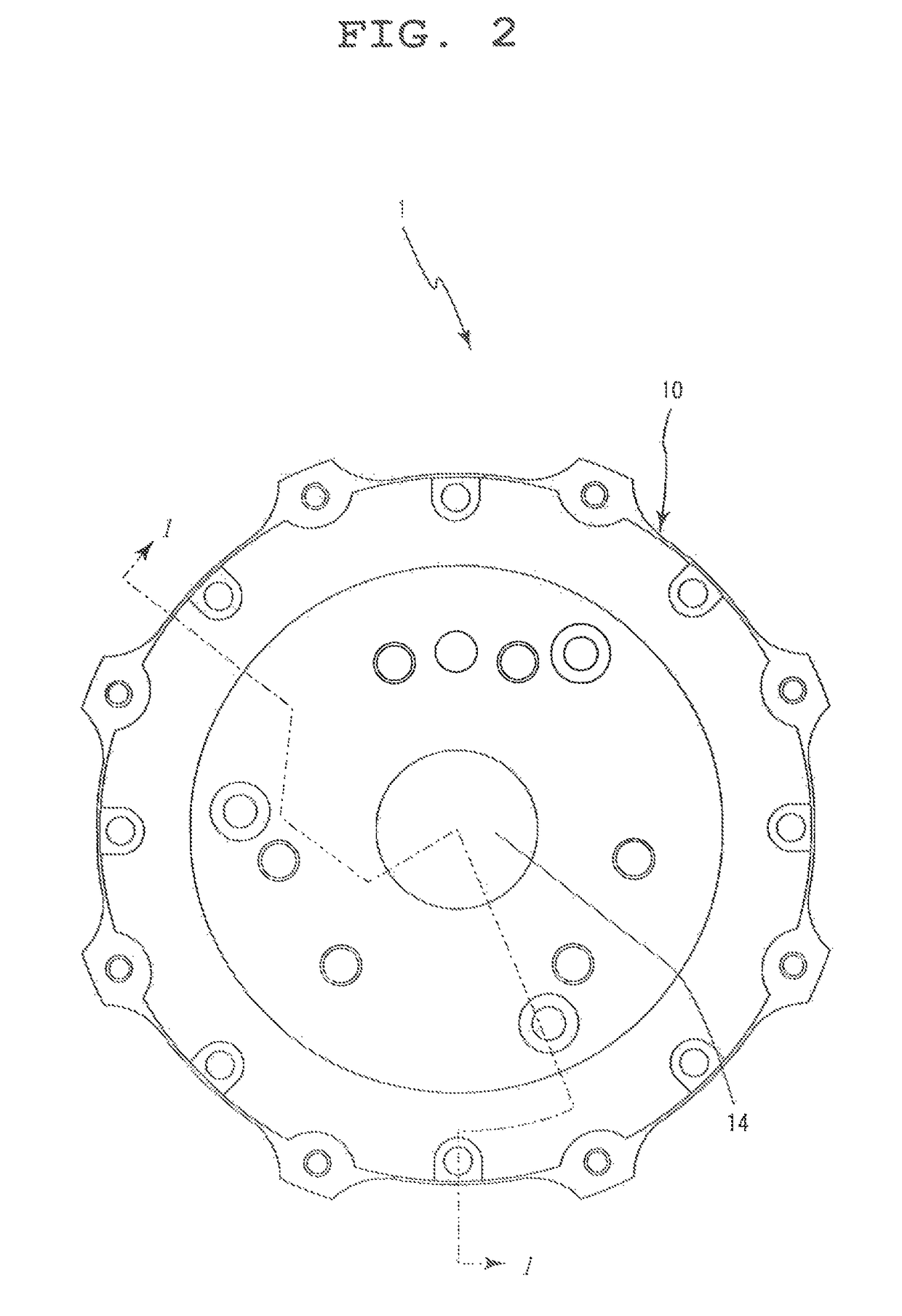

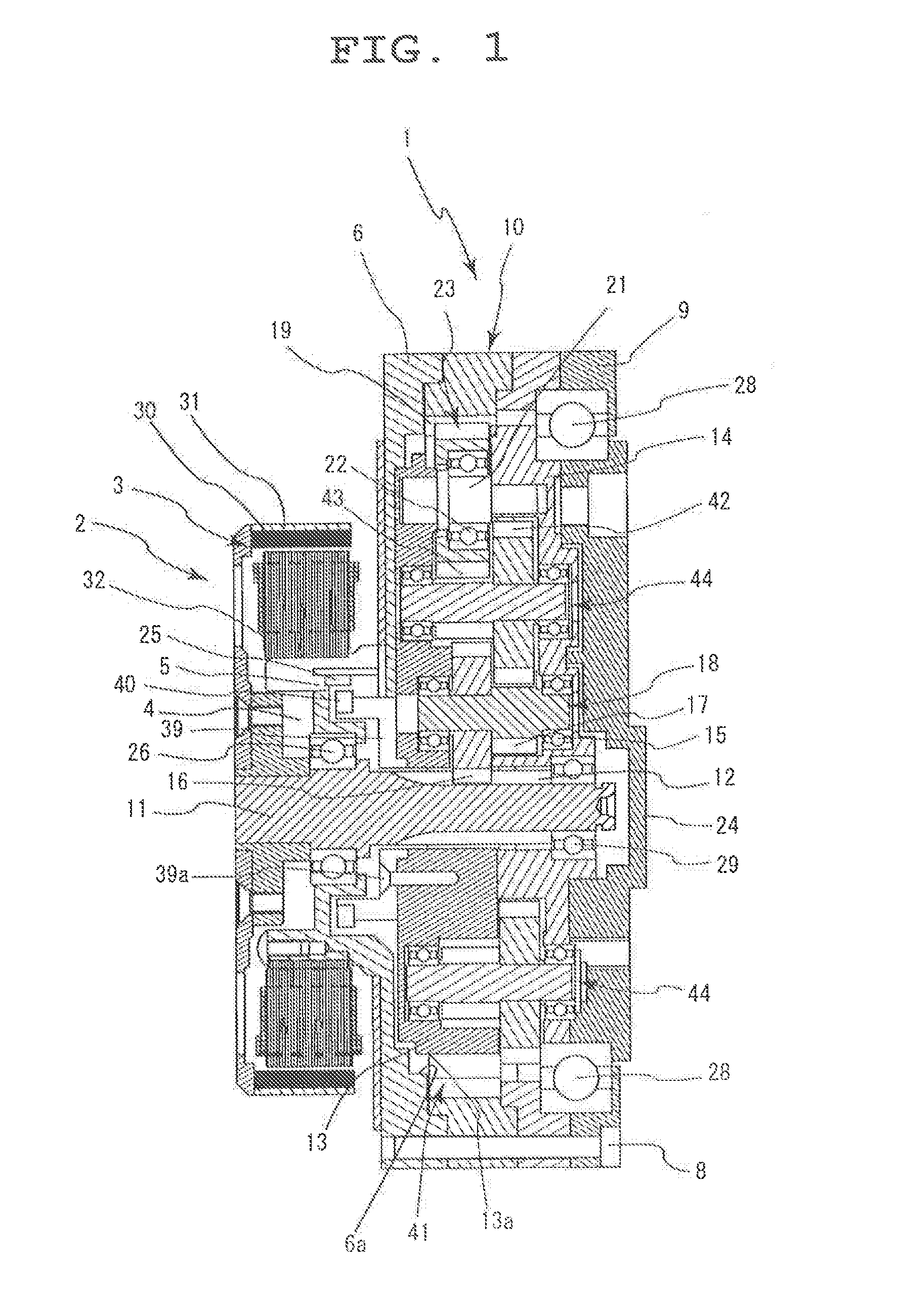

Compact epicyclic gear carrier

ActiveUS7104918B2Closely arrangedReduced torque induced twistEngine fuctionsToothed gearingsGear wheelEngineering

An epicyclic gear carrier assembly for use in an epicyclic gear train of a gas turbine engine, the epicyclic gear train having a central axis and a plurality of epicyclic gears rotatable about individual gear axes. The epicyclic gear carrier assembly comprises at least a carrier plate defining a plurality of circumferentially spaced axle bores which are disposed radially outward from the central axis and are co-axial with the individual gear axes. A plurality of corresponding gear axles are disposed within the axle bores, and the plurality of epicyclic gears are rotatably mounted to the gear axles via bearing elements. An epicyclic carrier member comprises a plurality of axle engaging elements that are co-axial with the gear axles and are engaged thereto by load transmission members such that load is transferred from the gear axles to the epicyclic carrier member.

Owner:PRATT & WHITNEY CANADA CORP

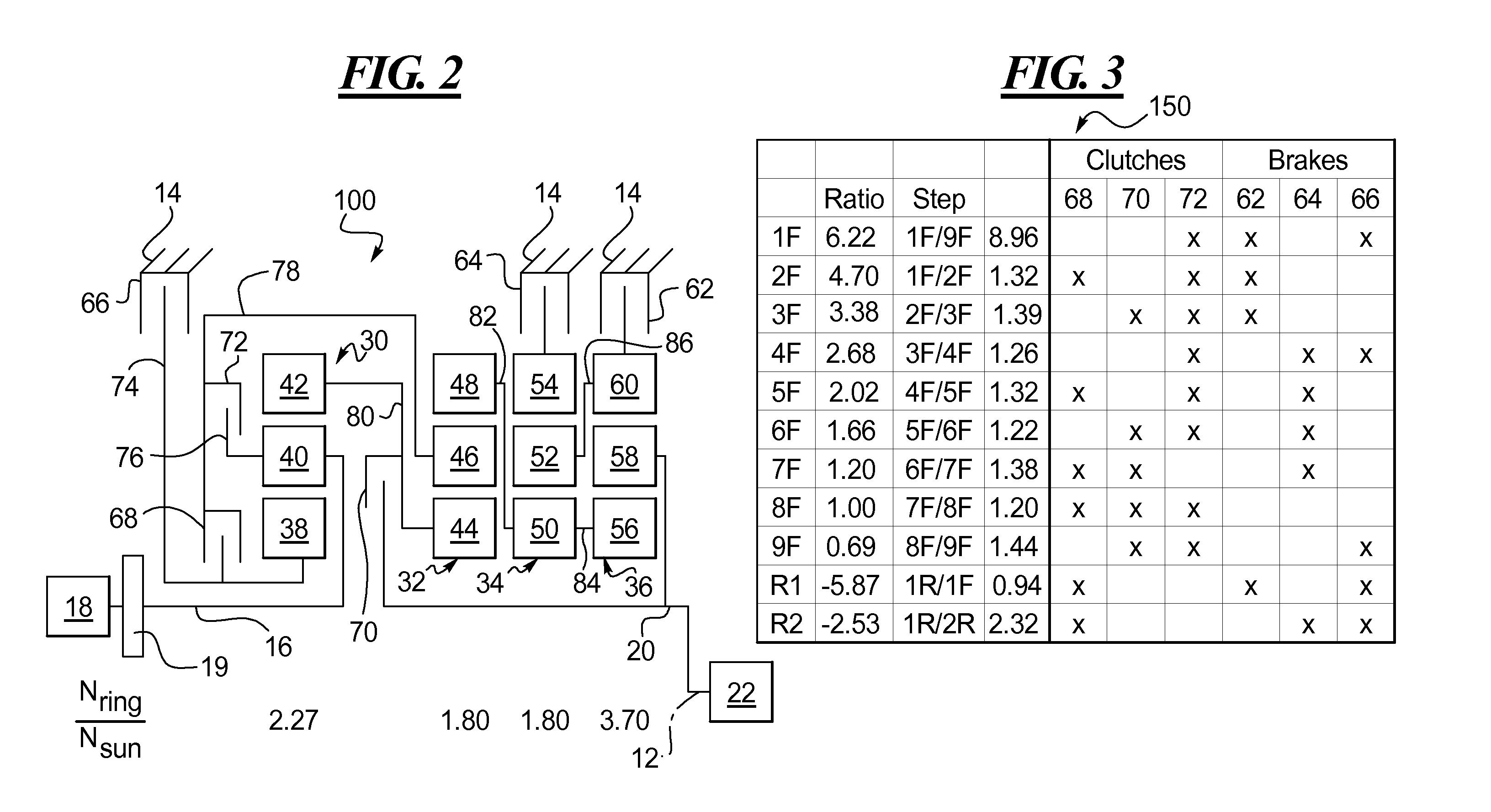

Multi-Speed Transmission

A multi-speed transmission may include an input member and an output member disposed in a housing. A first planetary gear set, a second planetary gear set, a third planetary gear set, and a fourth planetary gear set may also be disposed in the housing, each planetary gear set including a sun gear, a planet carrier, and a ring gear. Six control elements may be operably coupled to the planetary gear sets and selectively engageable to create a set of different gear ratios between the input member and the output member, the set of different gear ratios including at least nine forward gear ratios and at least two reverse gear ratios.

Owner:CATERPILLAR INC

Power splitting vehicle drive system

ActiveUS20050109549A1Electric propulsion mountingGas pressure propulsion mountingEngineeringMechanical engineering

A vehicle includes a prime mover, a first output shaft, a second output shaft and a planetary gear assembly. The planetary gear assembly includes a sun gear, a ring gear and a plurality of planetary gears supported between the ring gear and the sun gear by a carrier. One of the sun gear and the ring gear is coupled to the prime mover. The other of the ring gear and the sun gear is coupled to the first output shaft. The first carrier is coupled to the second output shaft.

Owner:OSHKOSH CORPORATION

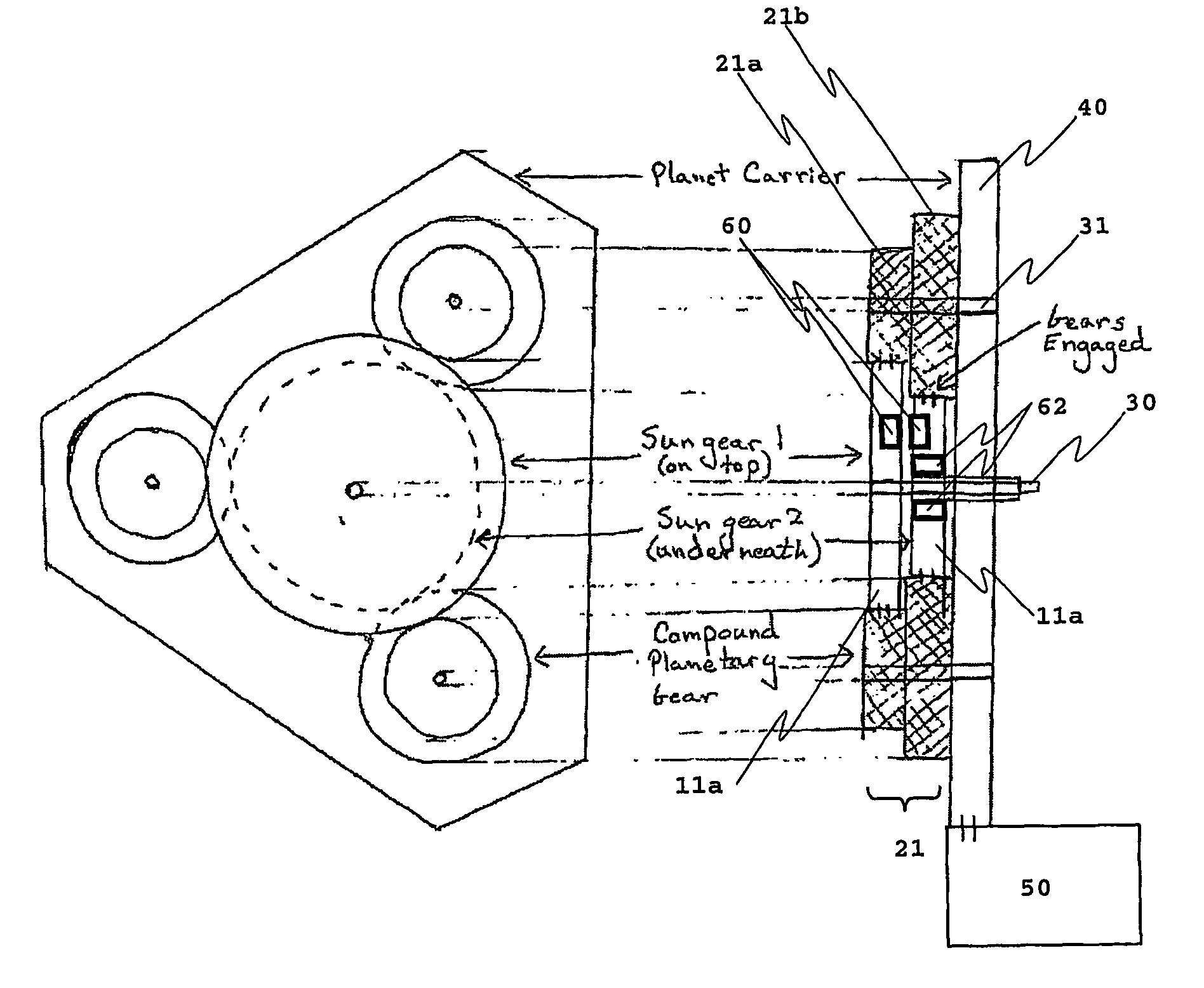

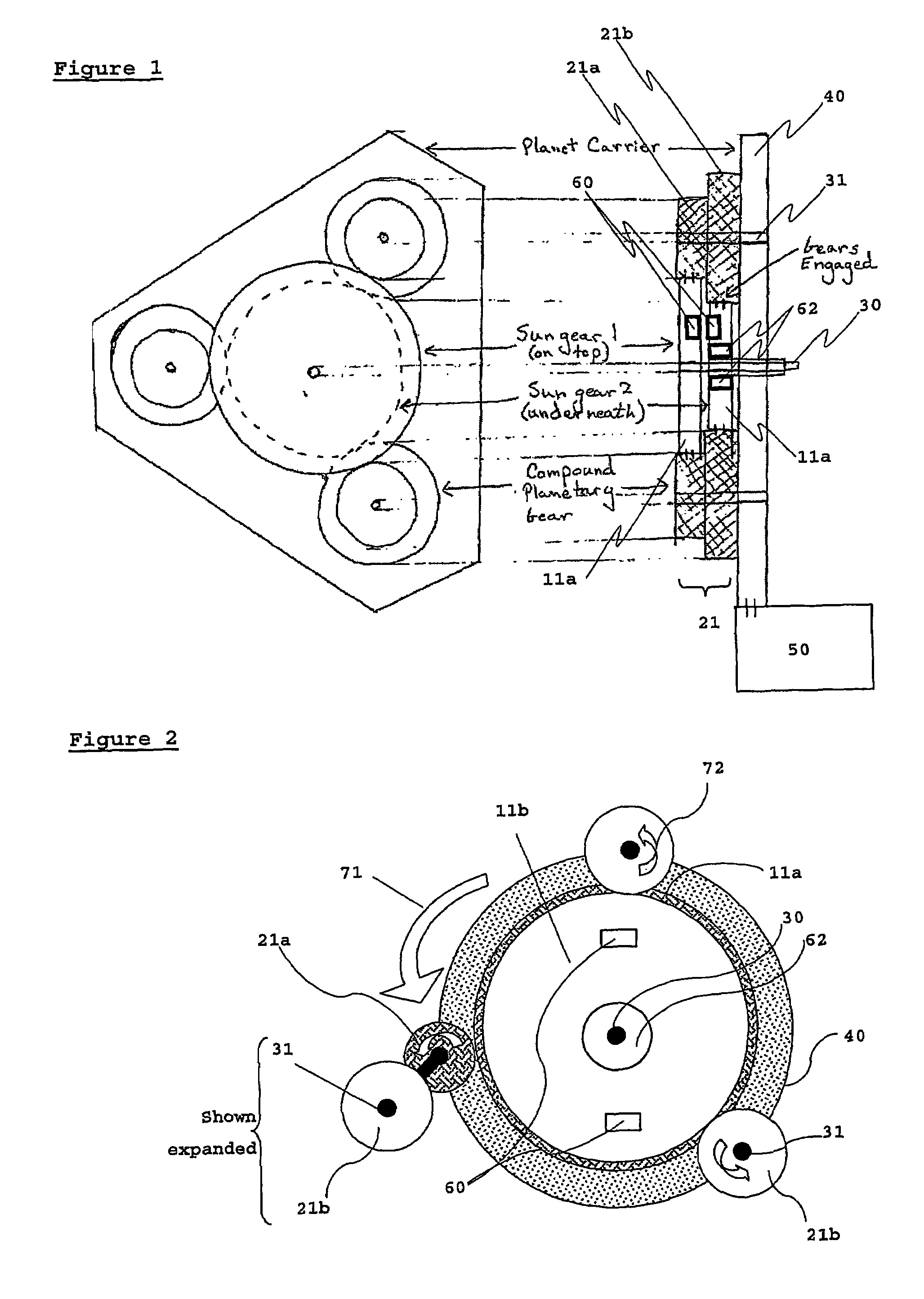

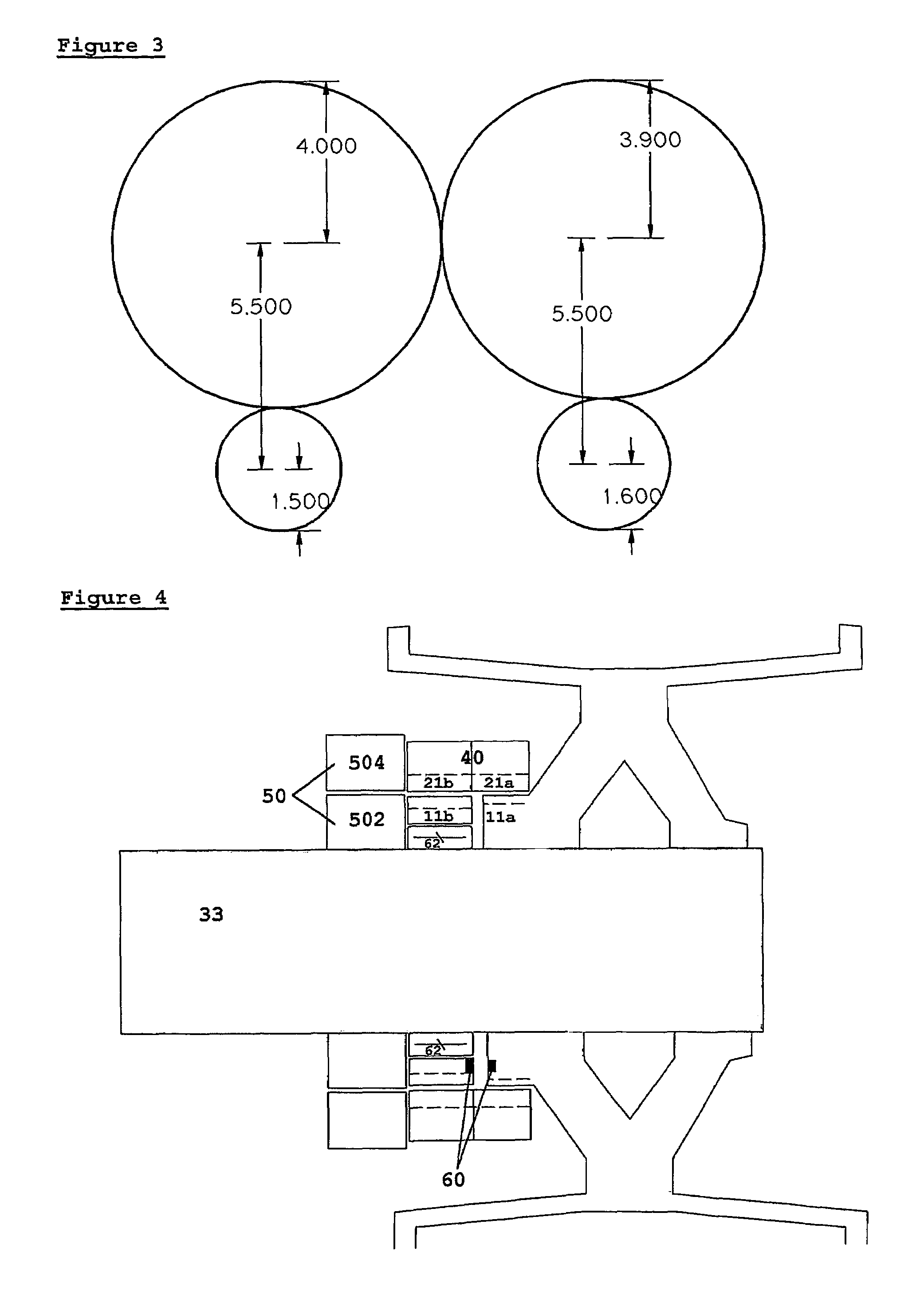

Geared wheel motor design

InactiveUS7469858B2High levelLower levelEnergy efficient operational measuresToothed gearingsGear wheelGear system

The present invention is a compound planetary gear system which has a moveable sun gear and a lockable sun gear to change the gear ratio between a high gear ratio and a pseudo 1:1 slipping ratio. The system makes use of a ratchet and pawl mechanism to provide a safety backup for when the lockable sun gear is locked. The invention may be used to move the aircraft from a stationary position, for taxiing, and for pre-rotating the wheels prior to landing.

Owner:BOREALIS TECH LTD

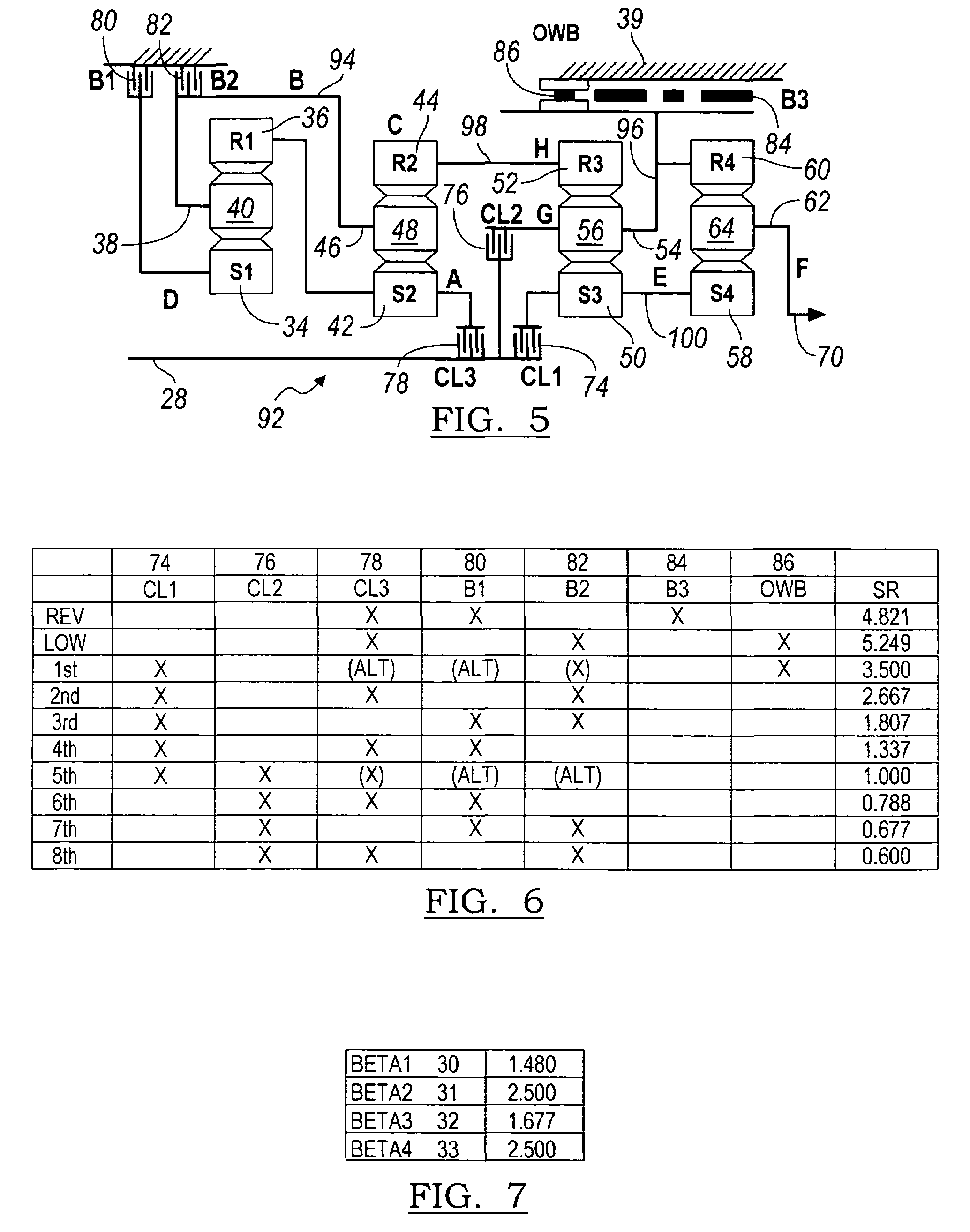

Multiple speed automatic transmission

ActiveUS7686730B2Shorten speedImprove fuel economyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A multiple speed transmission includes an input and output; a first, second, third and fourth planetary gear sets, each gear set including a sun gear, a ring gear, a carrier, and pinions supported on the carrier and meshing with the sun gear and the ring gear; a first epicyclic gearing assembly including the first gear set, the second gear set, a first clutch, a first brake, a second brake, and first, second, third and fourth rotating members, said first clutch being operable to couple said first rotating member to the input, said first brake being operable to hold said fourth rotating member against rotation, and said second brake being operable to hold said second rotating member against rotation; and a second epicyclic gearing assembly including the third gear set, the fourth gear set, a second clutch, a third clutch, a third brake, and fifth, sixth, seventh and eighth rotating members, the third rotating member being secured to the eighth rotating member, said second control clutch being operable to couple said fifth rotating member to the input, said second control clutch being operable to couple said seventh rotating member to the input, said third brake being operable to hold the seventh rotating member against rotation, and said sixth rotating member being secured for rotation to the output.

Owner:FORD MOTOR CO

Multi-speed automatic transmission

InactiveUS8617022B1Guaranteed normal transmissionReduce package sizeToothed gearingsTransmission elementsAutomatic transmissionSpur gear

An automatic transmission includes a first planetary gear set including a first sun gear, a first pinion, and a ring gear of the first planetary gear set. The transmission includes a second planetary gear set including a second sun gear, a second pinion, and a common gear. The transmission includes a third planetary gear set including a third sun gear, the second pinion, a third pinion, and the common gear. The transmission also includes a fourth planetary gear set including the common gear, a fourth pinion, and a ring gear of the fourth planetary gear set. The second planetary gear set and the third planetary gear set form a Ravigneaux gear set. The fourth planetary gear set is concentrically arranged with the second planetary gear set or the third planetary gear set, and the second and third planetary gear sets are radially inward of the fourth planetary gear set.

Owner:TOYOTA JIDOSHA KK

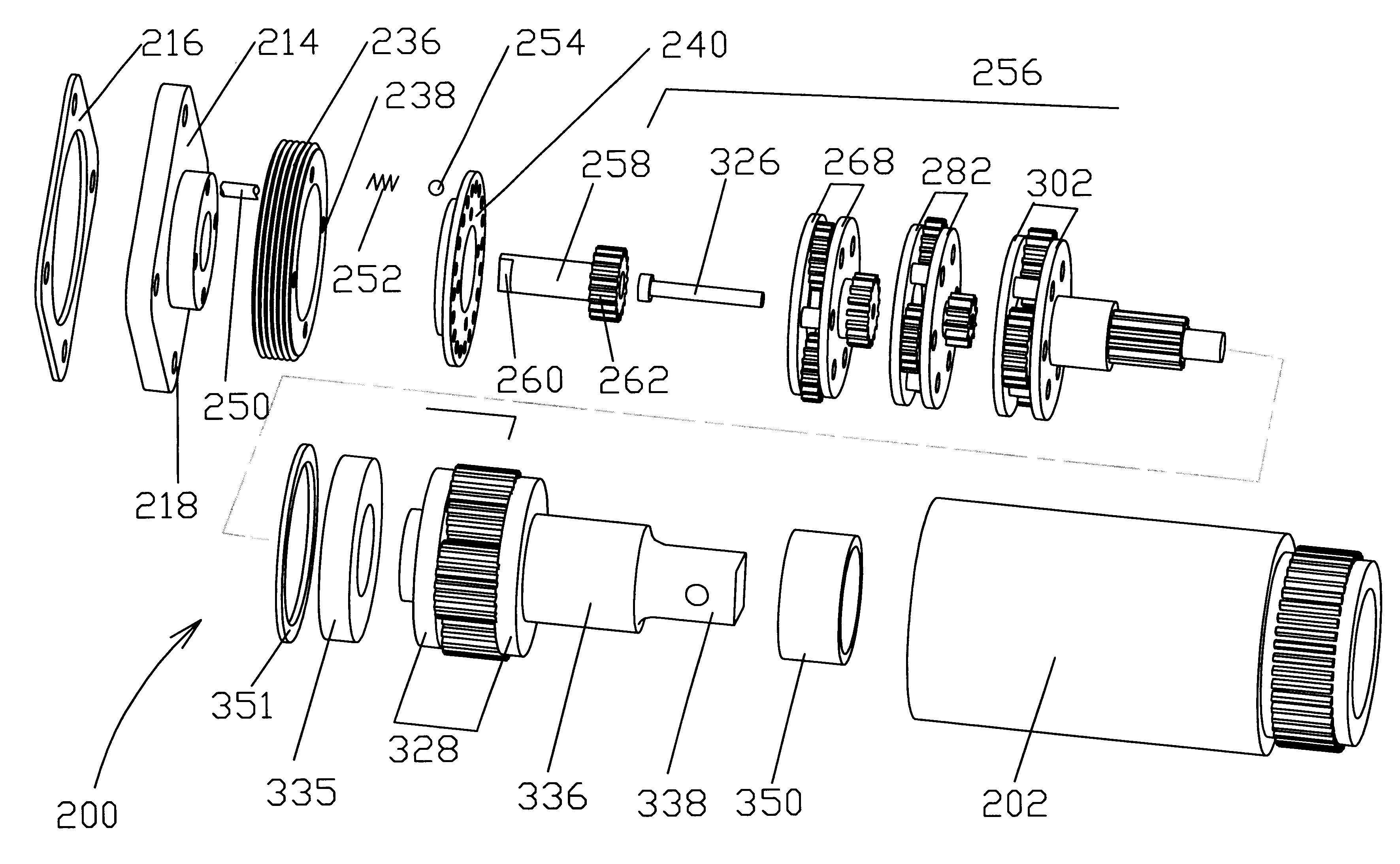

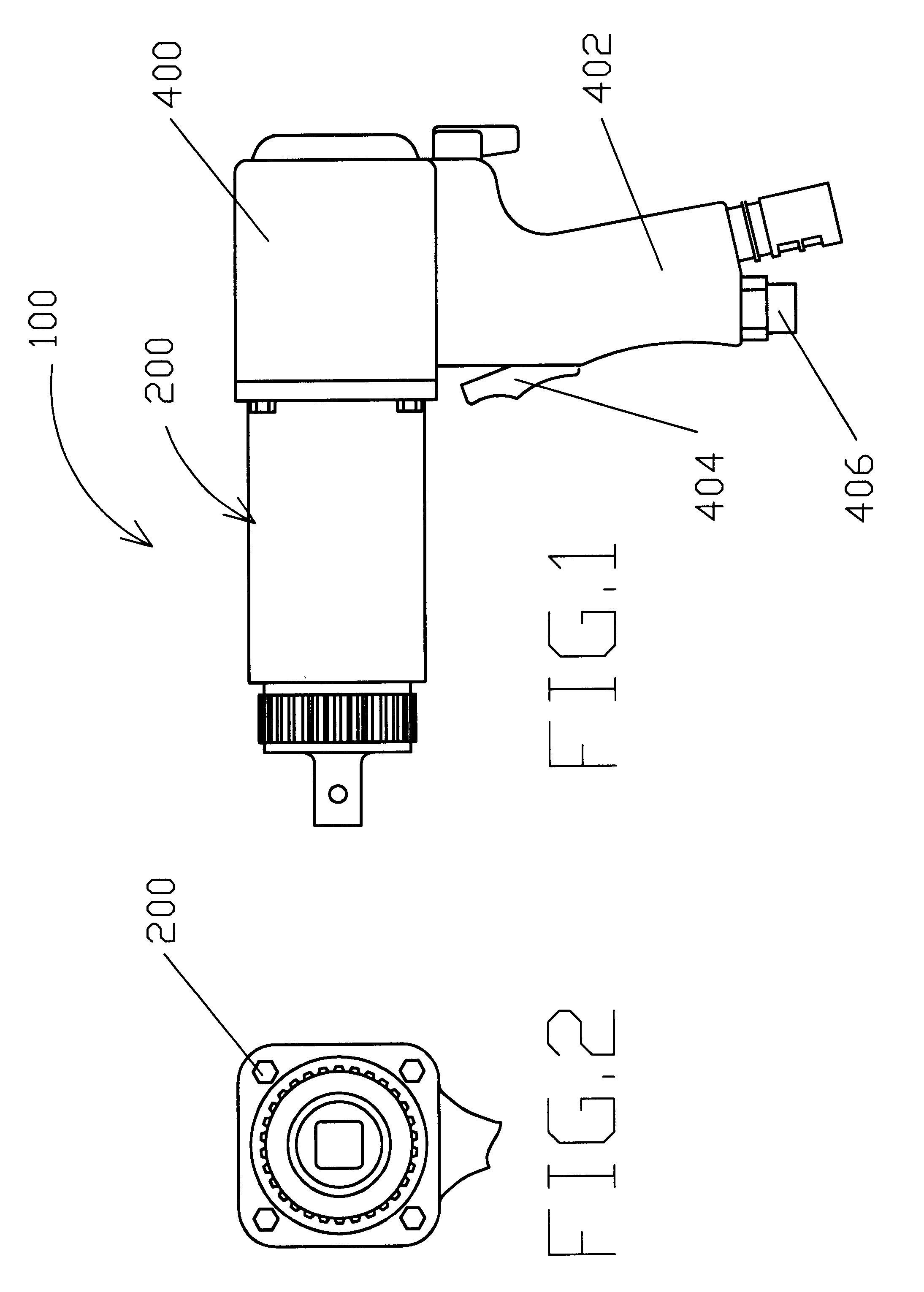

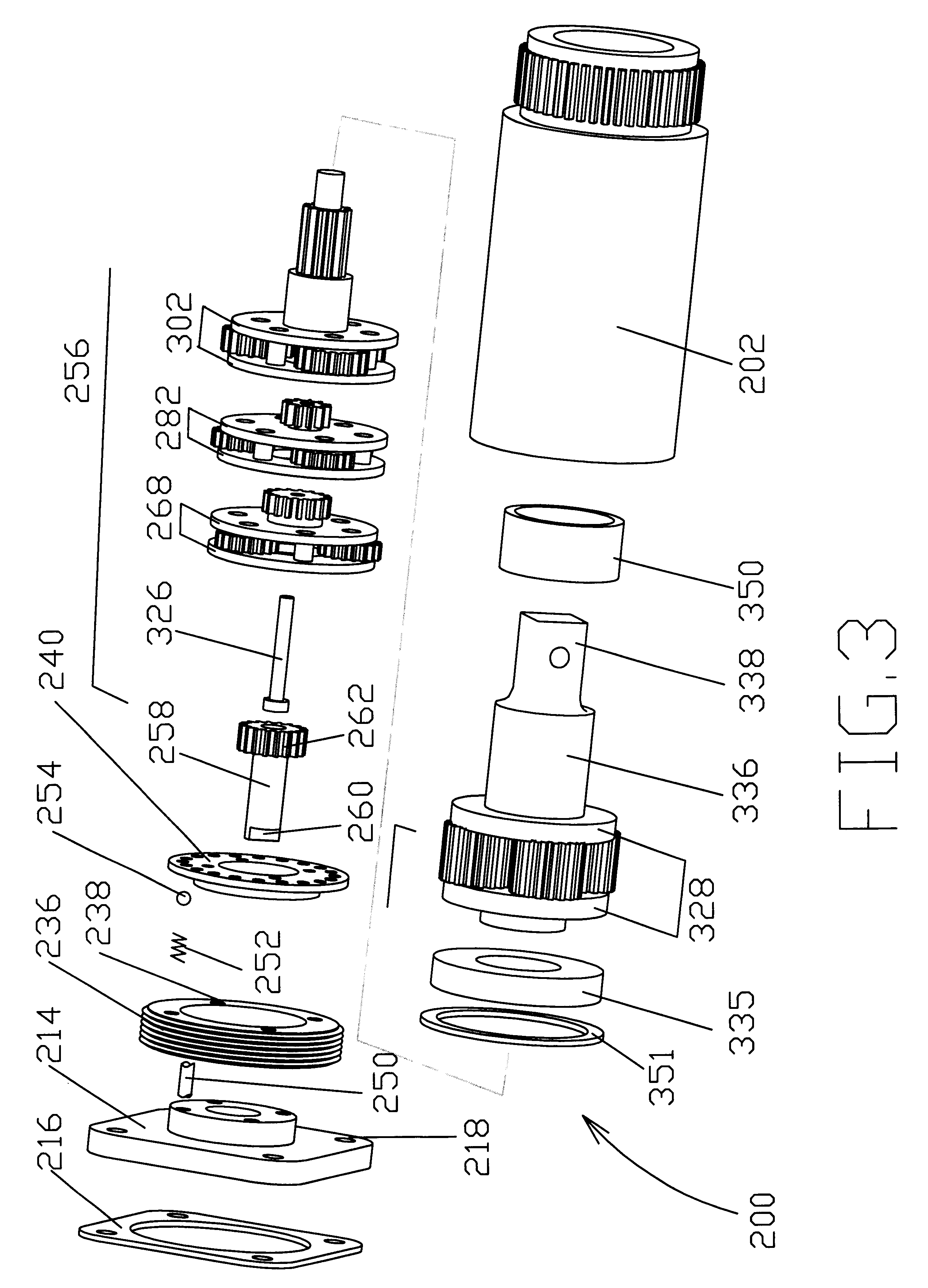

Torque tool

The torque tool comprises a torque converter including three planet carriers which encase three planetary gears. Each of the three planetary gears includes a sun gear and three planet pinions. Each of the three planet carriers has an input disc-shaped plate, directed towards an input shaft of the torque tool and an output disc-shaped plate directed towards an output shaft of the torque tool. The input and output shafts constitute the main shafts of the torque tool. Two of the three planet carriers, which are next to the input shaft, have their output disc-shaped plates extending into sun gears with which they form unitary structures. A stepped pin is centrally disposed in a needle bearing of a first sun gear adjacent the input shaft and extends through sliding bearings located in the following sun gears. A first large diameter of the stepped pin is commensurate with an interior diameter of the needle bearing and a second small diameter of the stepped pin is commensurate with interior equal diameters of the sliding bearings inserted in the following sun gears. The planet pinions of one of the three planet gears, which is adjacent to the output gear, arc each provided with a multiplicity of roll needles closely spaced together, the multiplicity of roll needles being inserted between each of the at least three planet gears and an axle for supporting.

Owner:NEW WORLD TECH

Nine speed automatic transmission with six torque-transmitting mechanisms

ActiveUS7364527B2Great tractionToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A multi-speed transmission that achieves nine forward speed ratios and a reverse speed ratio has two planetary gear sets and a plurality of intermeshing gear members which may consist of two additional planetary gear sets or gear members arranged in a countershaft design. A speed ratio of an equal value but with an opposite direction of rotation is achieved at one of the gear members connected with one of the planetary gear members in a reverse ratio as in a first forward speed ratio. Six torque-transmitting mechanisms are employed.

Owner:ALLISON TRANSMISSION INC

Power train of automatic transmission

Owner:HYUNDAI MOTOR CO LTD

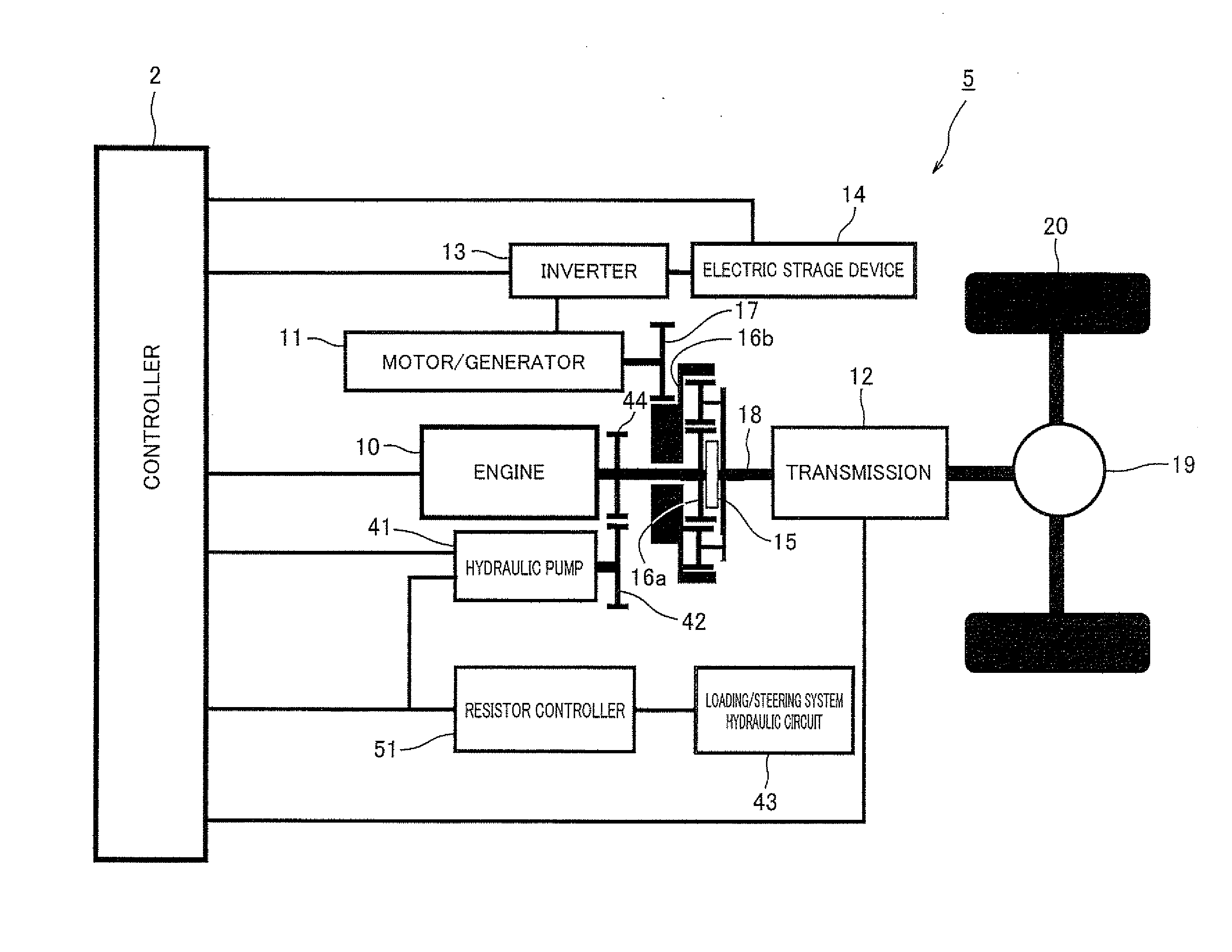

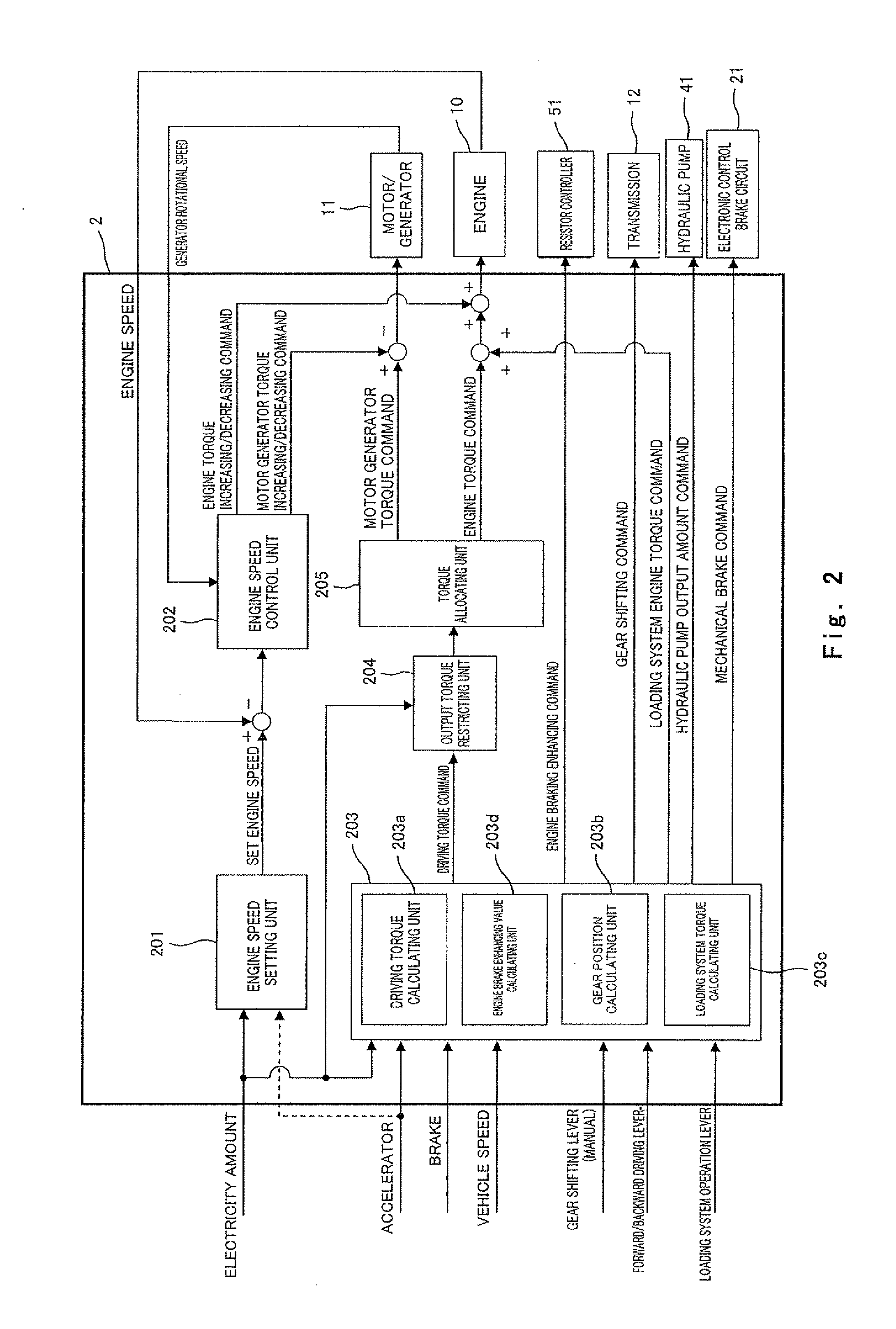

Construction machine and control method thereof

ActiveUS20120004797A1Enhance engine braking forceSuppress degreeDigital data processing detailsGearing controlDrive wheelState of charge

A construction machine comprises an electric motor / generator; an engine; an epicyclic gearing for rotating the electric motor / generator reversely when speed of a rotation output to a drive wheel is zero during running of the engine; a transmission configured to switch between a forward driving gear position and a backward driving gear position; and a controller for controlling the engine, the electric motor / generator and the transmission, based on at least an accelerator opening, and a state of charge in an electric storage device; the controller being configured to switch the forward driving gear position or the backward driving gear position to a direction opposite to a direction in which the construction machine is moving, and cause the electric motor / generator to generate reverse torque in a power running mode, when the electric storage device is in a fully charged state and the accelerator has been pressed down by a driver.

Owner:NIHON KENKI CO LTD

Axle assembly with torque distribution drive mechanism

An axle assembly with an input member, a first planetary gear set, a differential assembly, and a second planetary gear set. The first planetary gear set has a first transmission input that is driven by the input member. The differential assembly has a differential carrier and first and second differential output members received in the differential carrier. The second planetary gear set has a planet carrier coupled to the differential carrier for common rotation. A sun gear of the first planetary gear set is non-rotatably coupled to a sun gear of the second planetary gear set.

Owner:E AAM DRIVELINE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com