Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3317results about "Interengaging clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

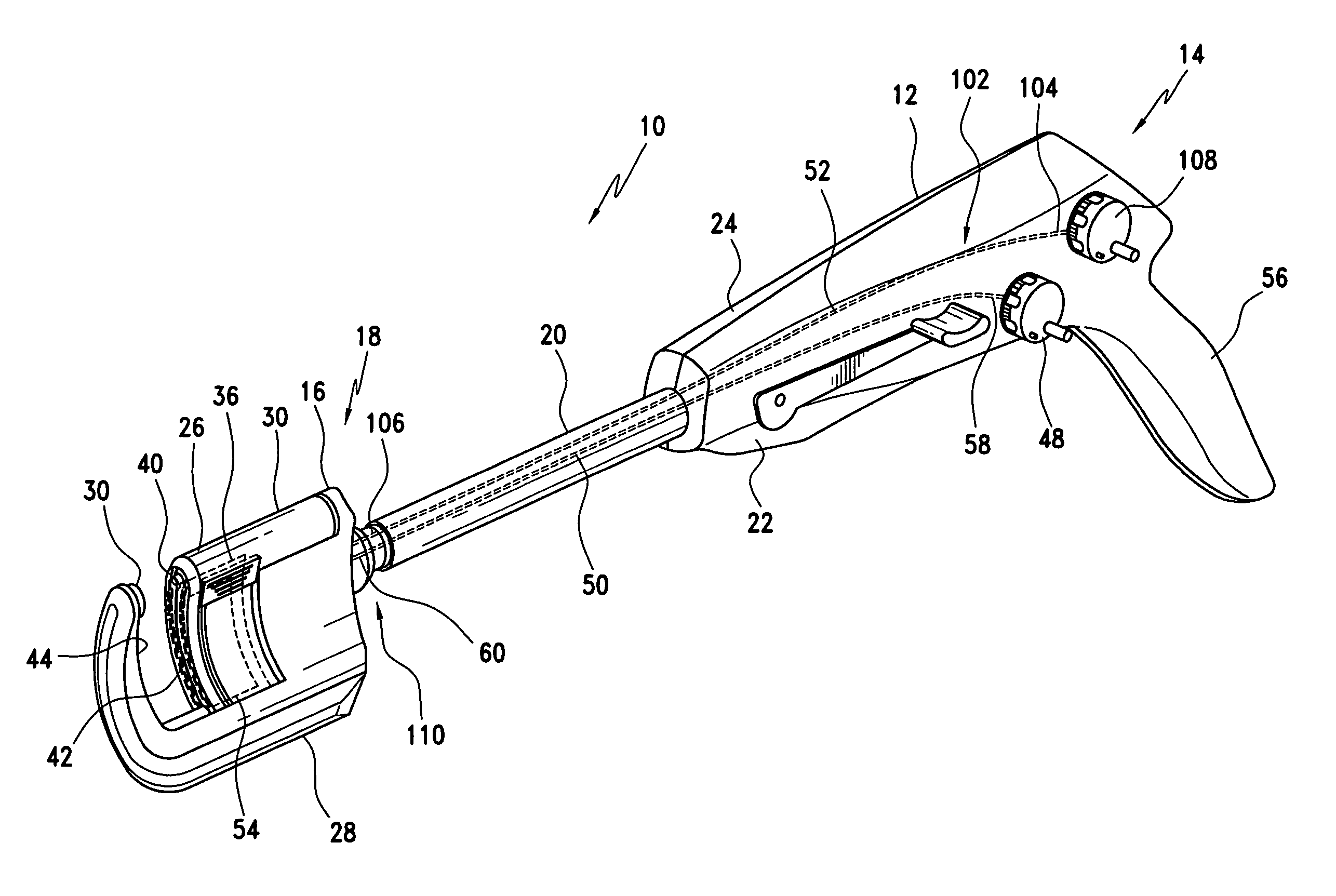

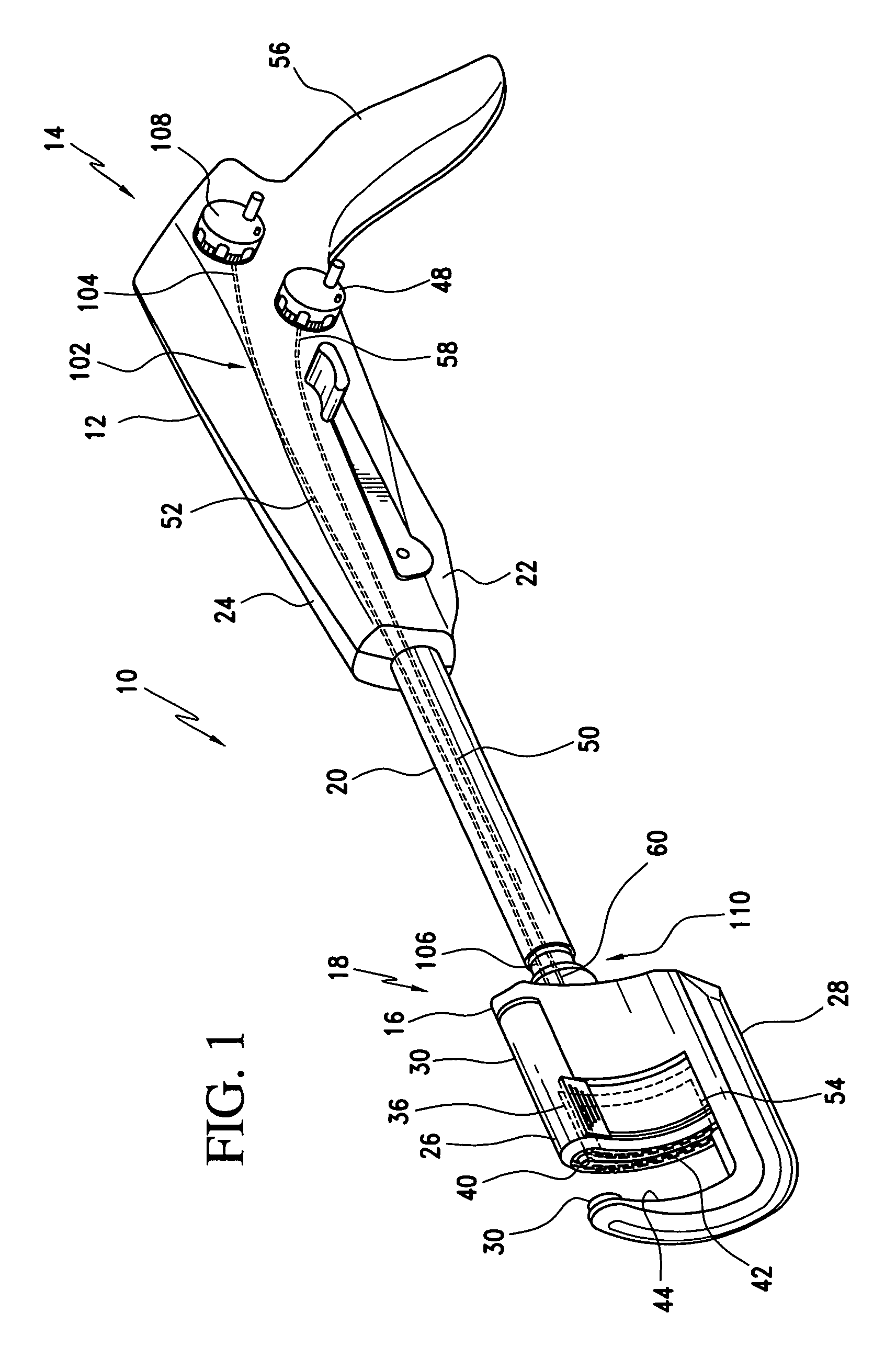

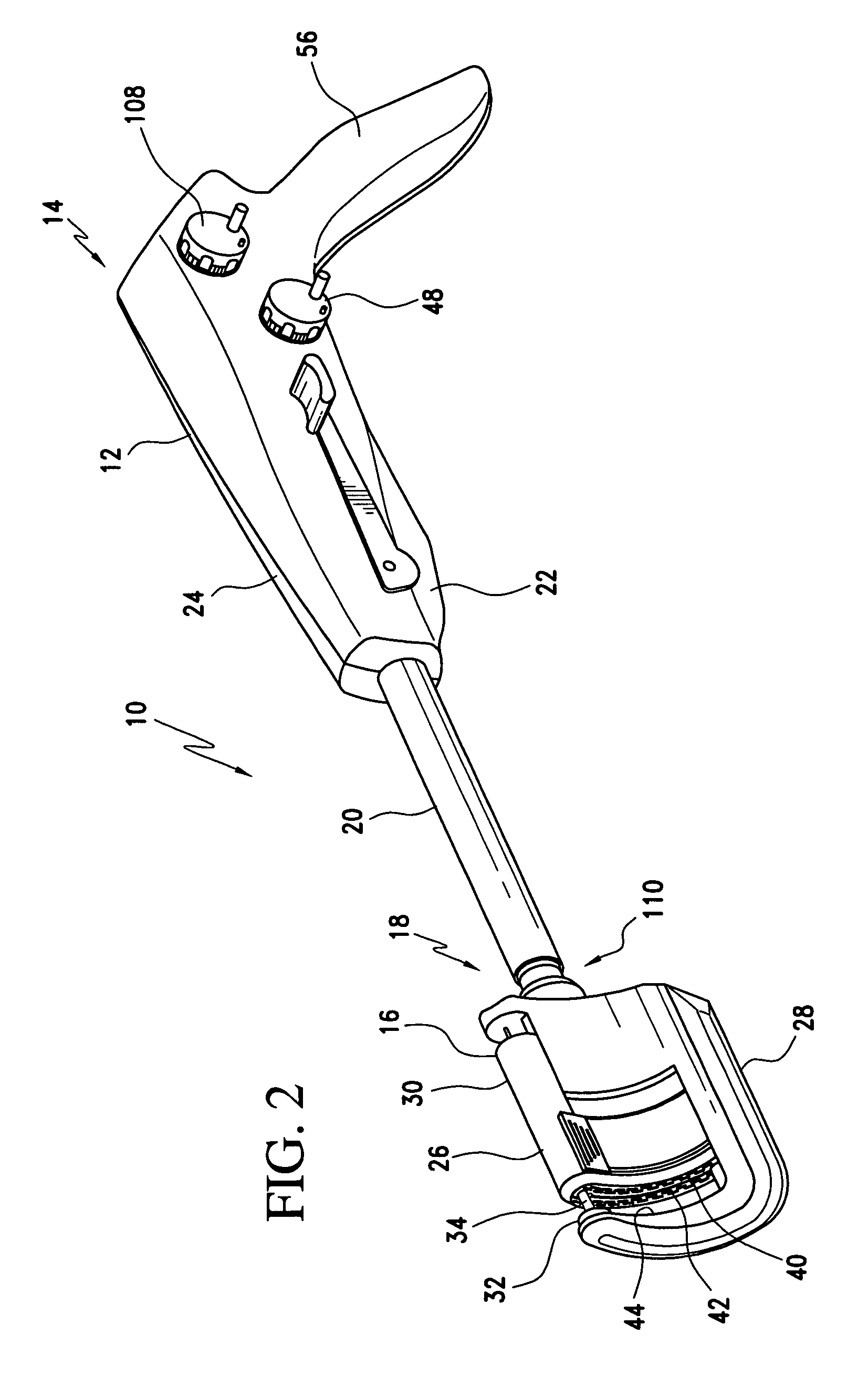

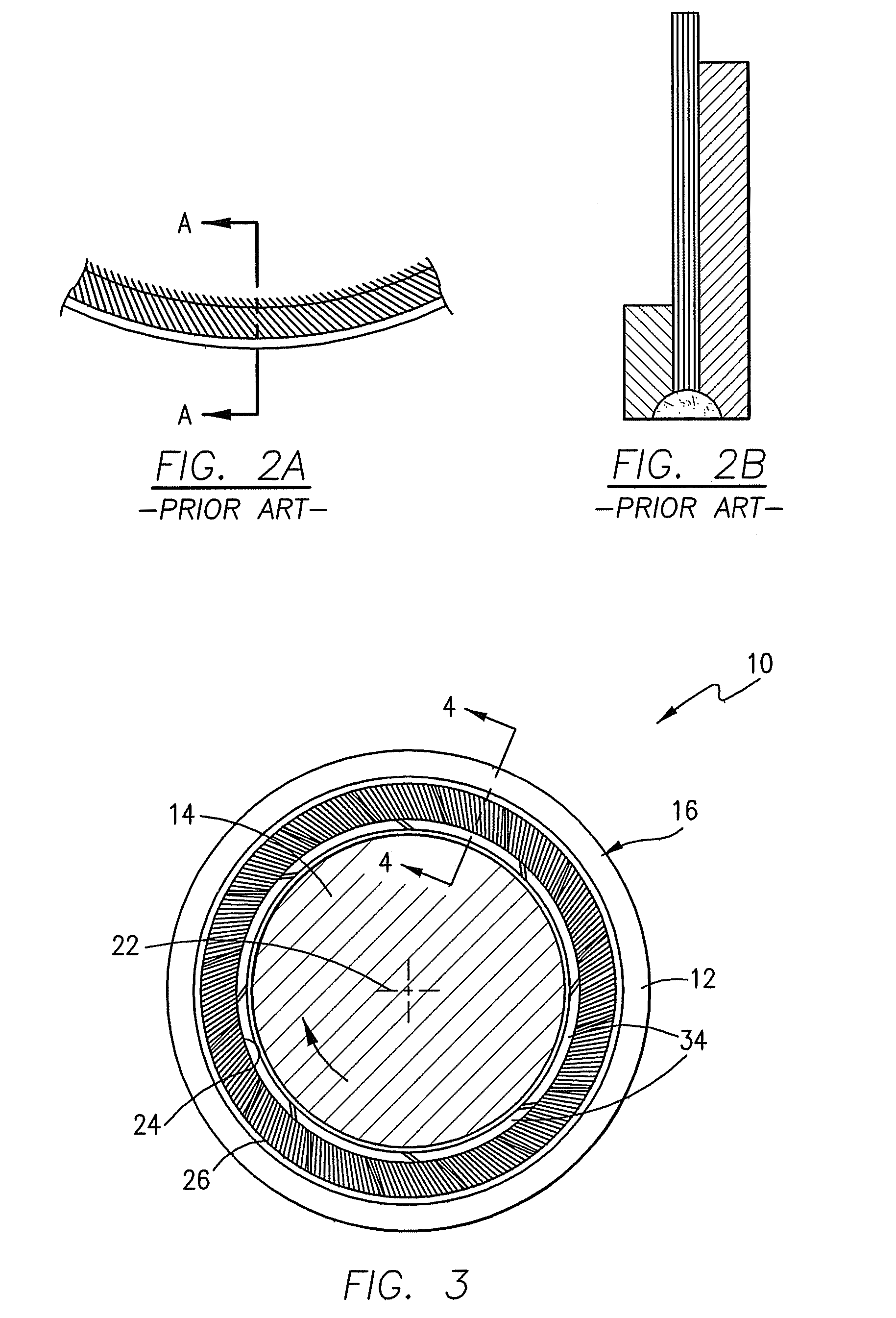

Articulating curved cutter stapler

ActiveUS7766207B2Expand accessReduce usageSuture equipmentsStapling toolsEngineeringRobot end effector

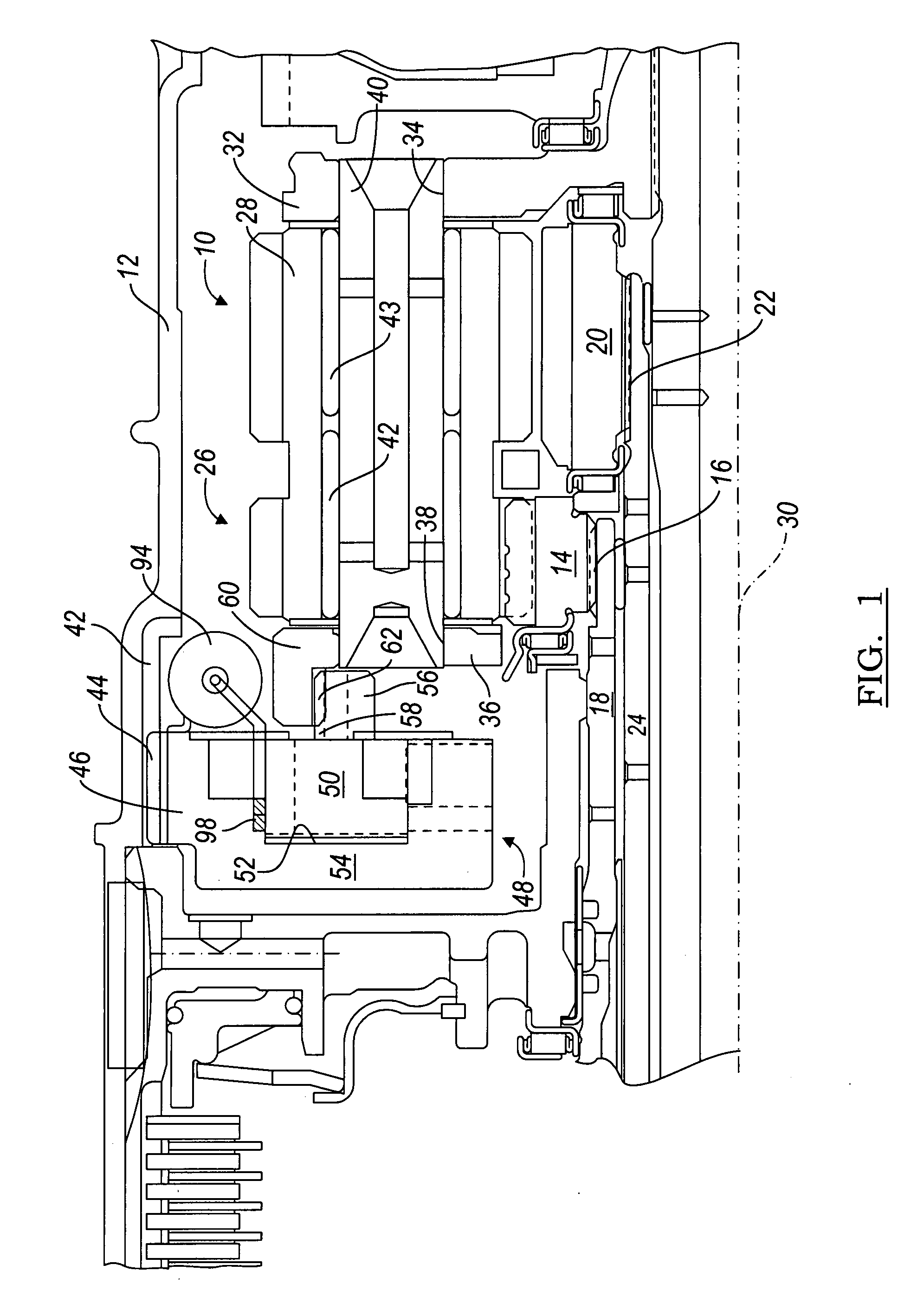

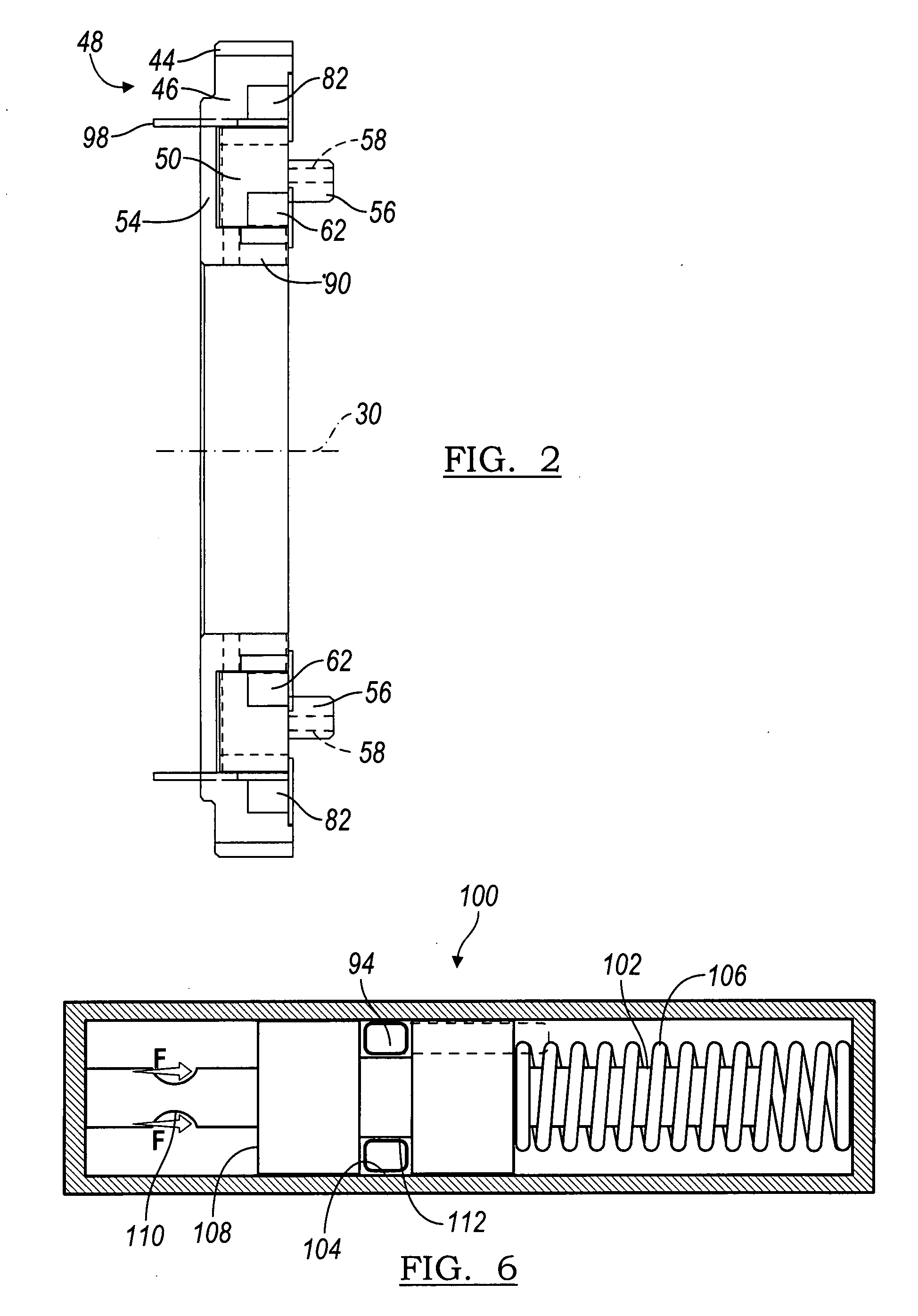

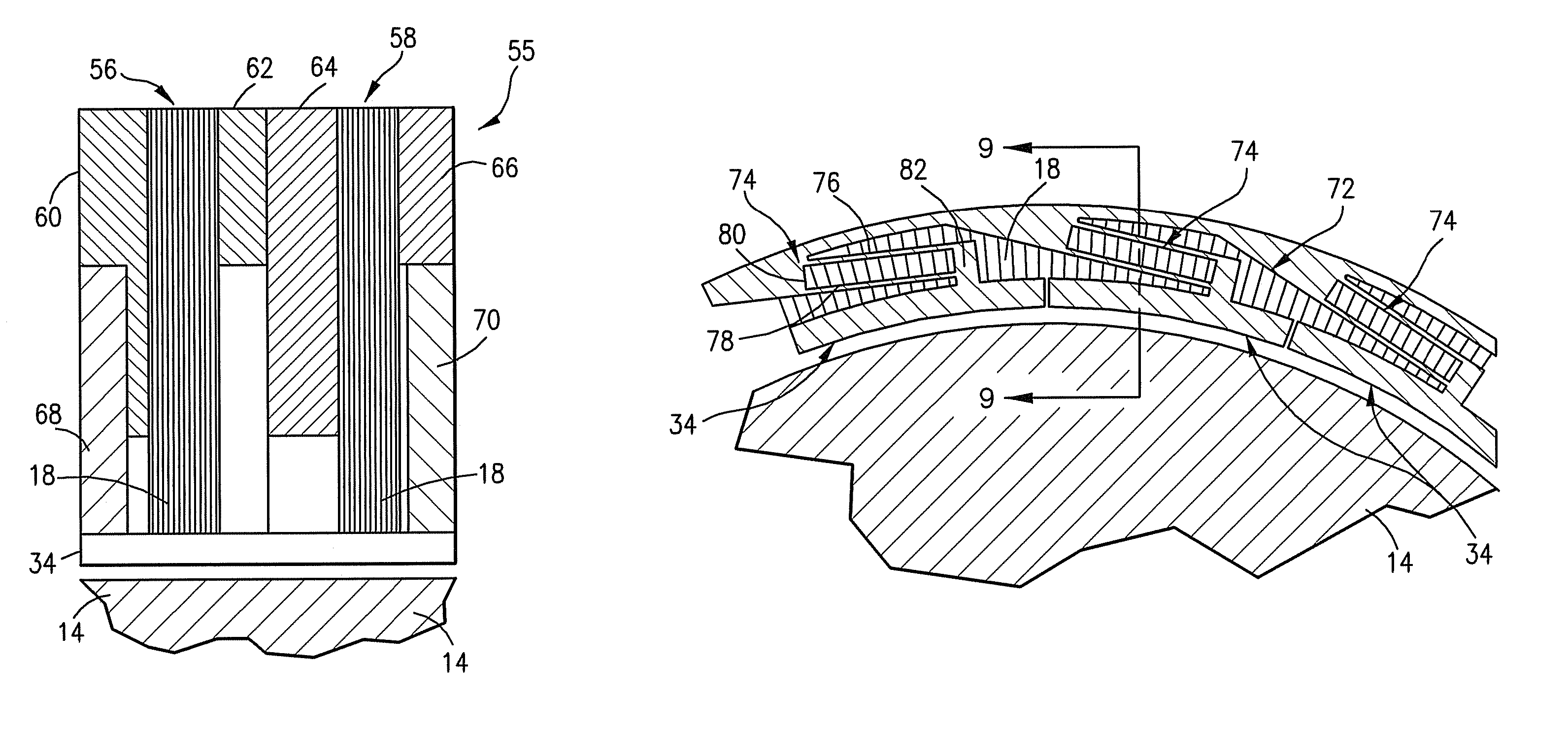

An articulating surgical stapler having a proximal end and a distal end includes a handle at the proximal end and an end effector at the distal end for selective articulation to improve access to tissue requiring treatment and ease of use of the present linear surgical stapler. A support shaft connects the handle to the end effector. An articulation mechanism is positioned between the support shaft and the end effector permitting selective movement of the end effector relative to the support shaft.

Owner:ETHICON ENDO SURGERY INC

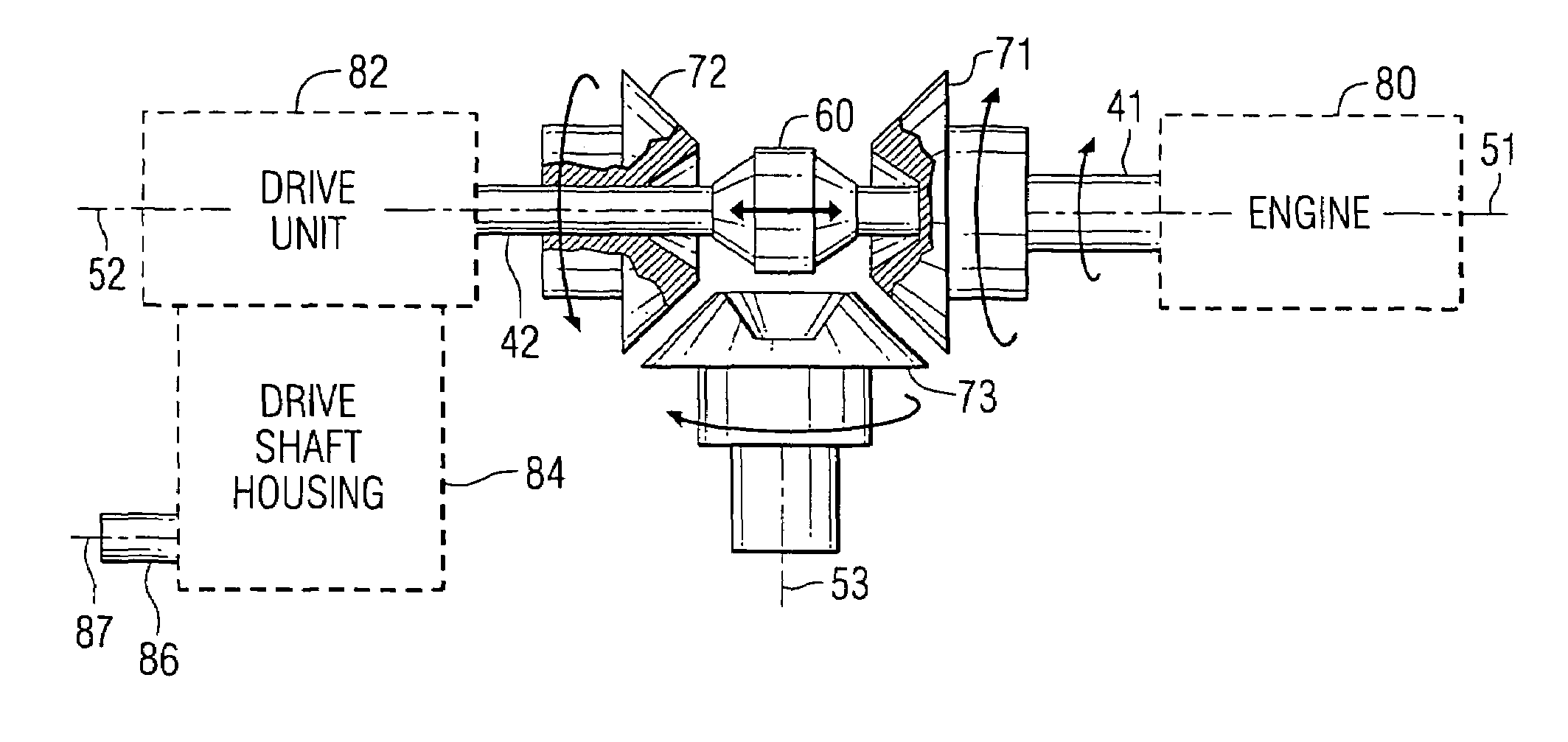

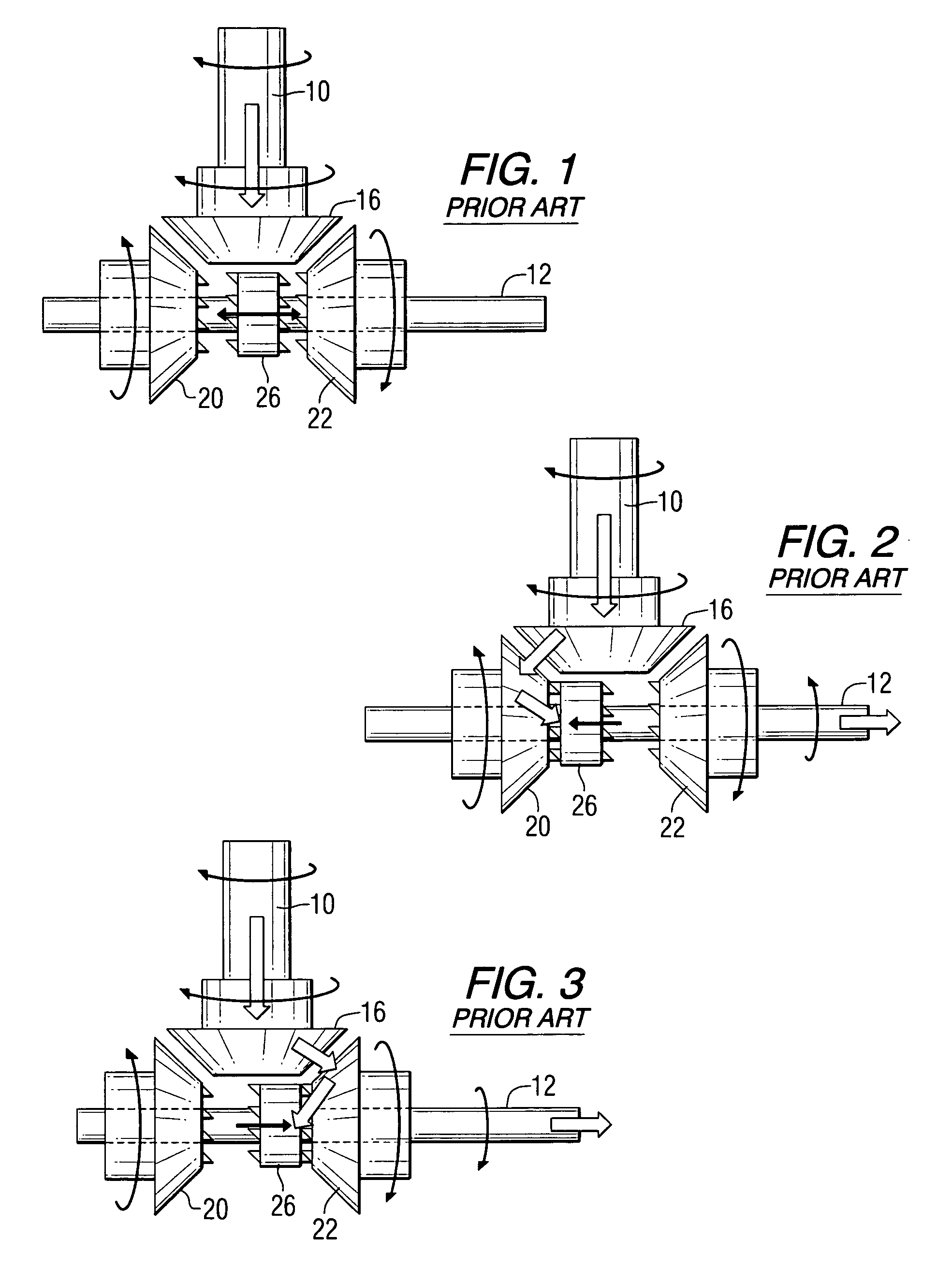

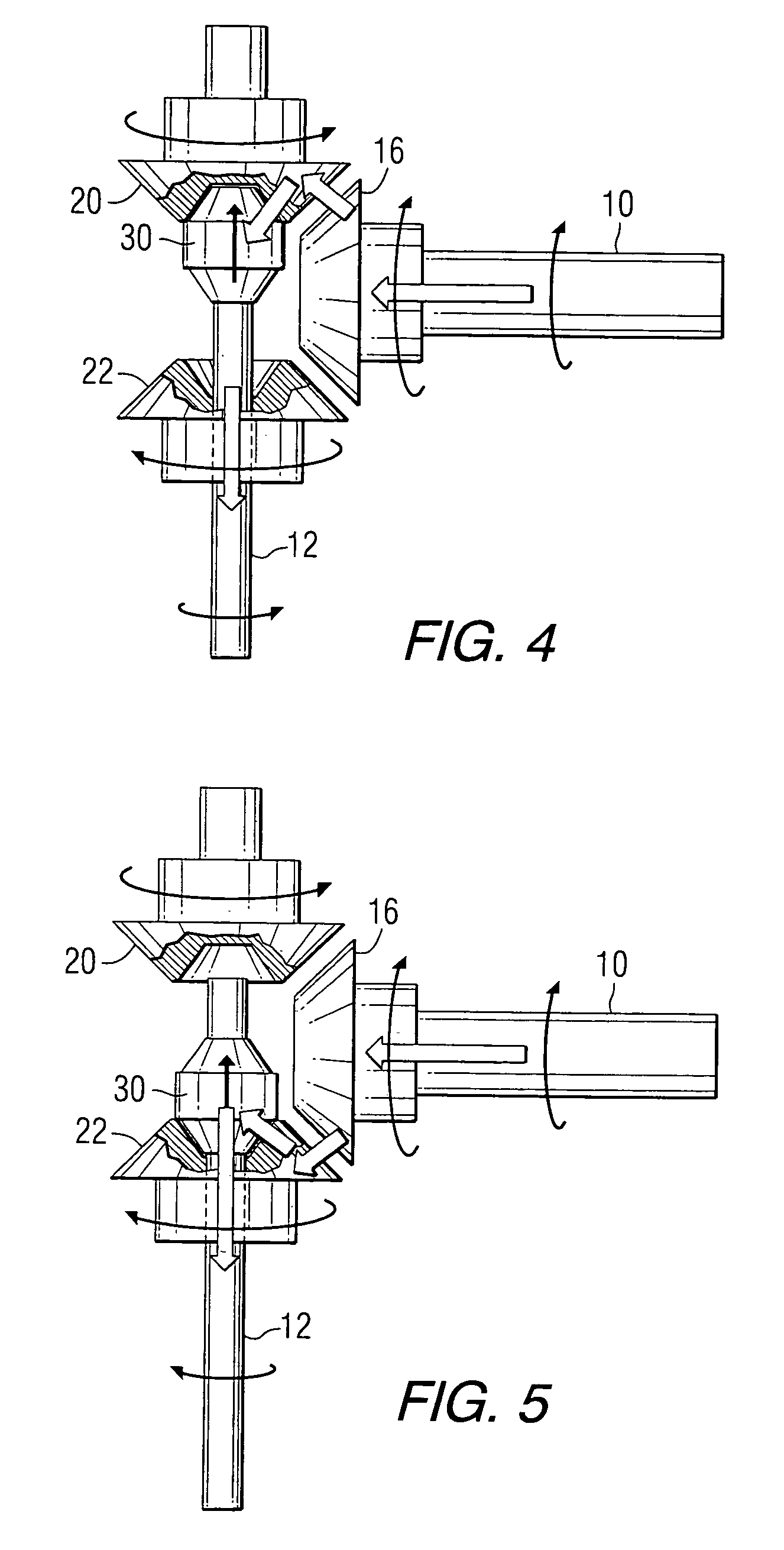

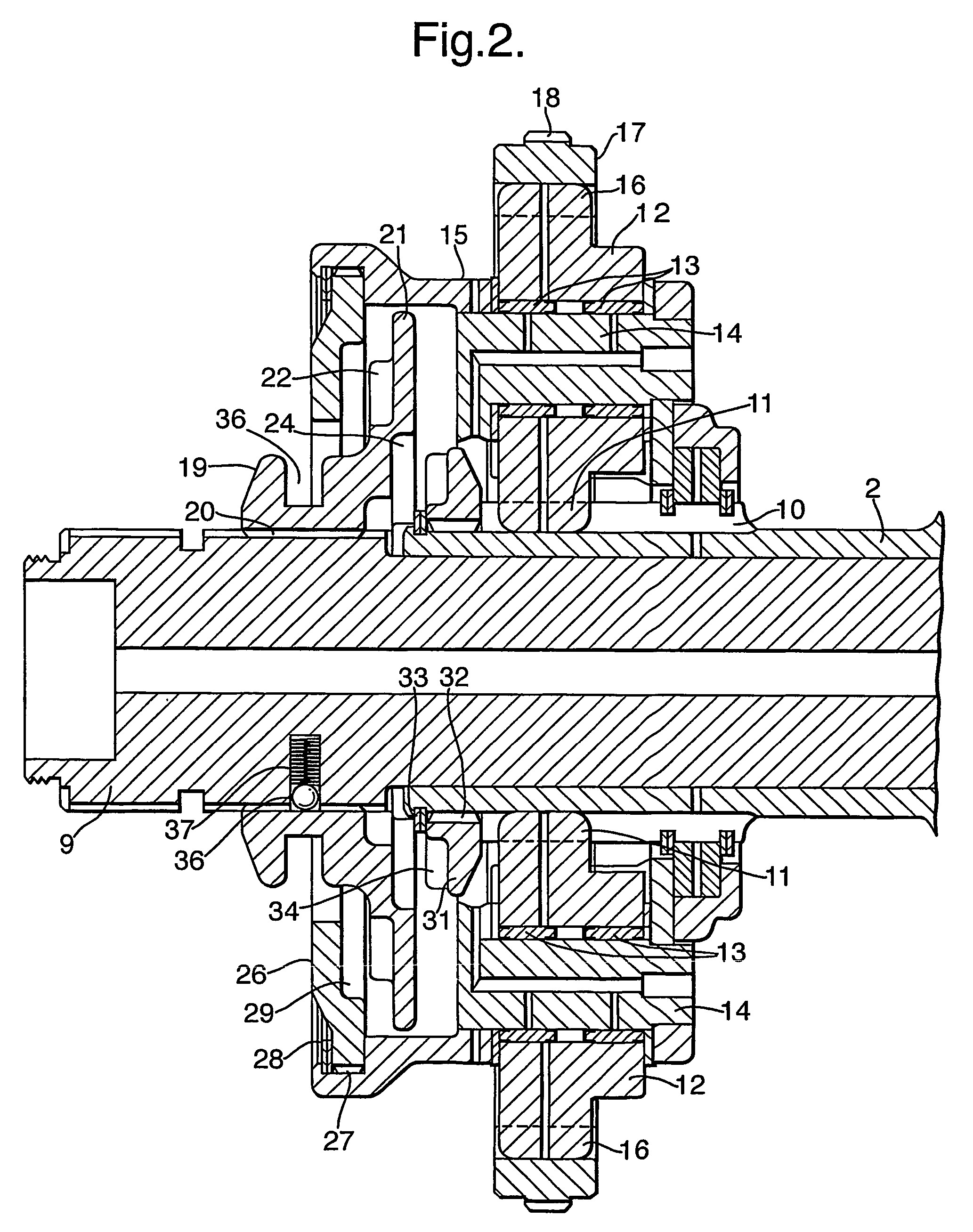

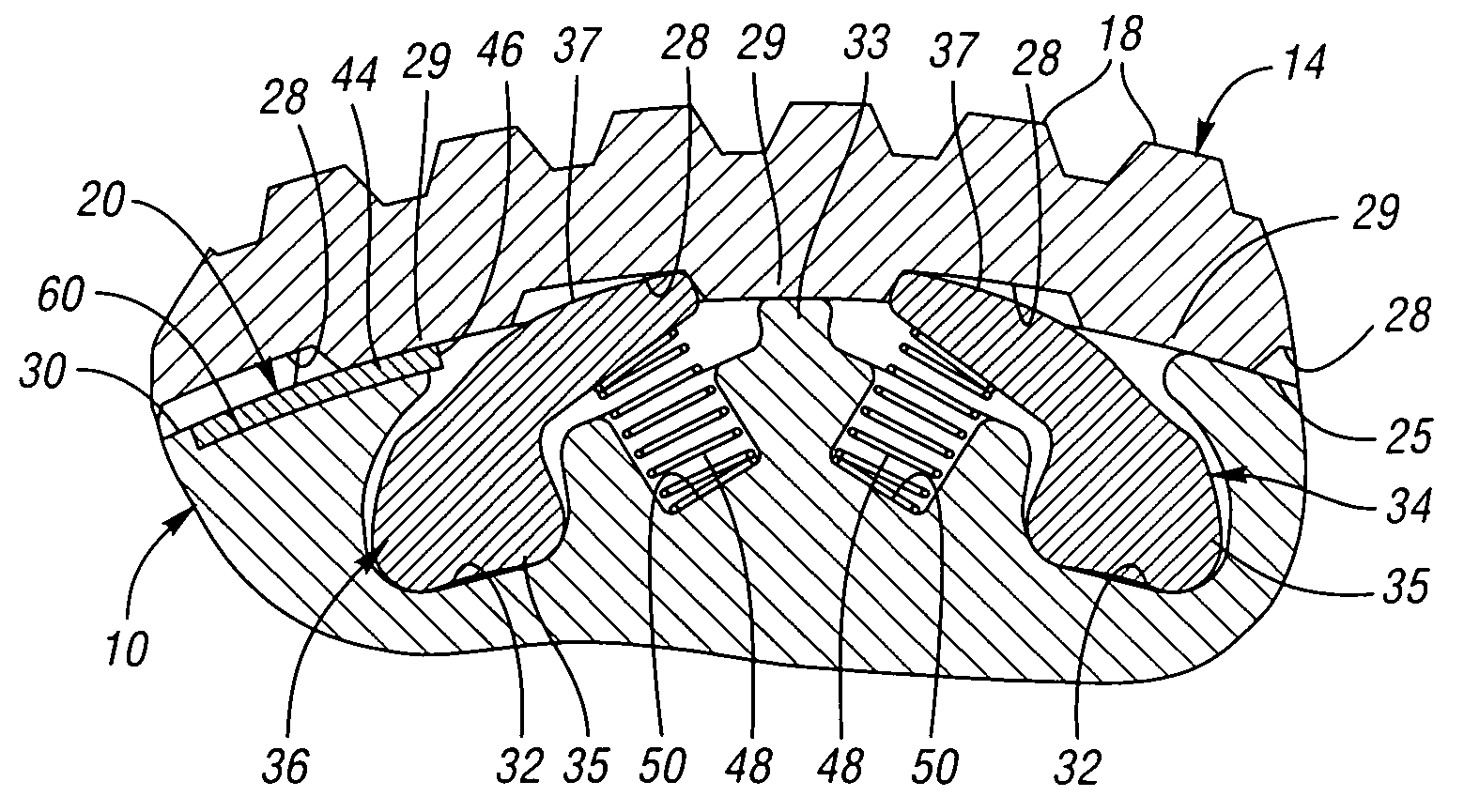

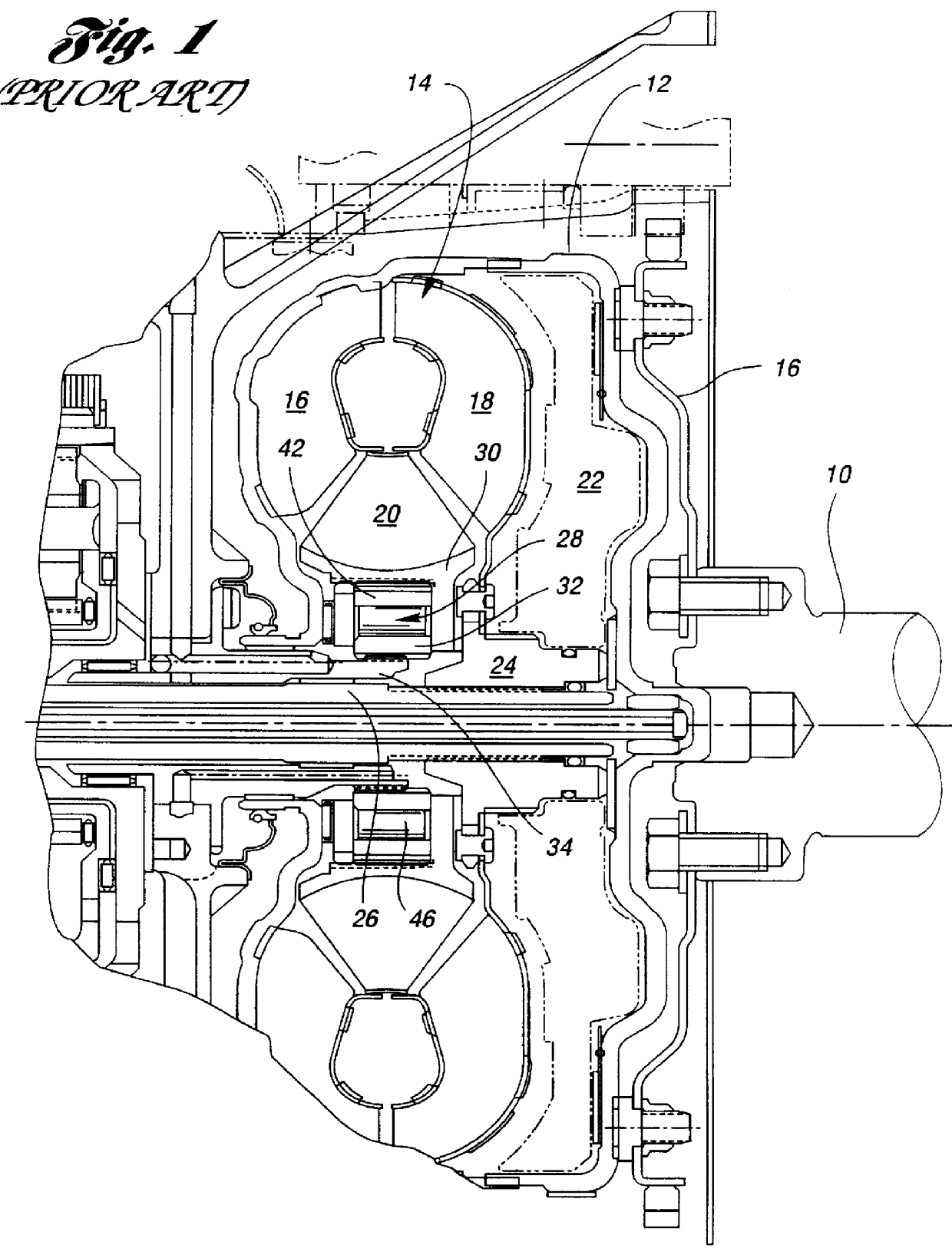

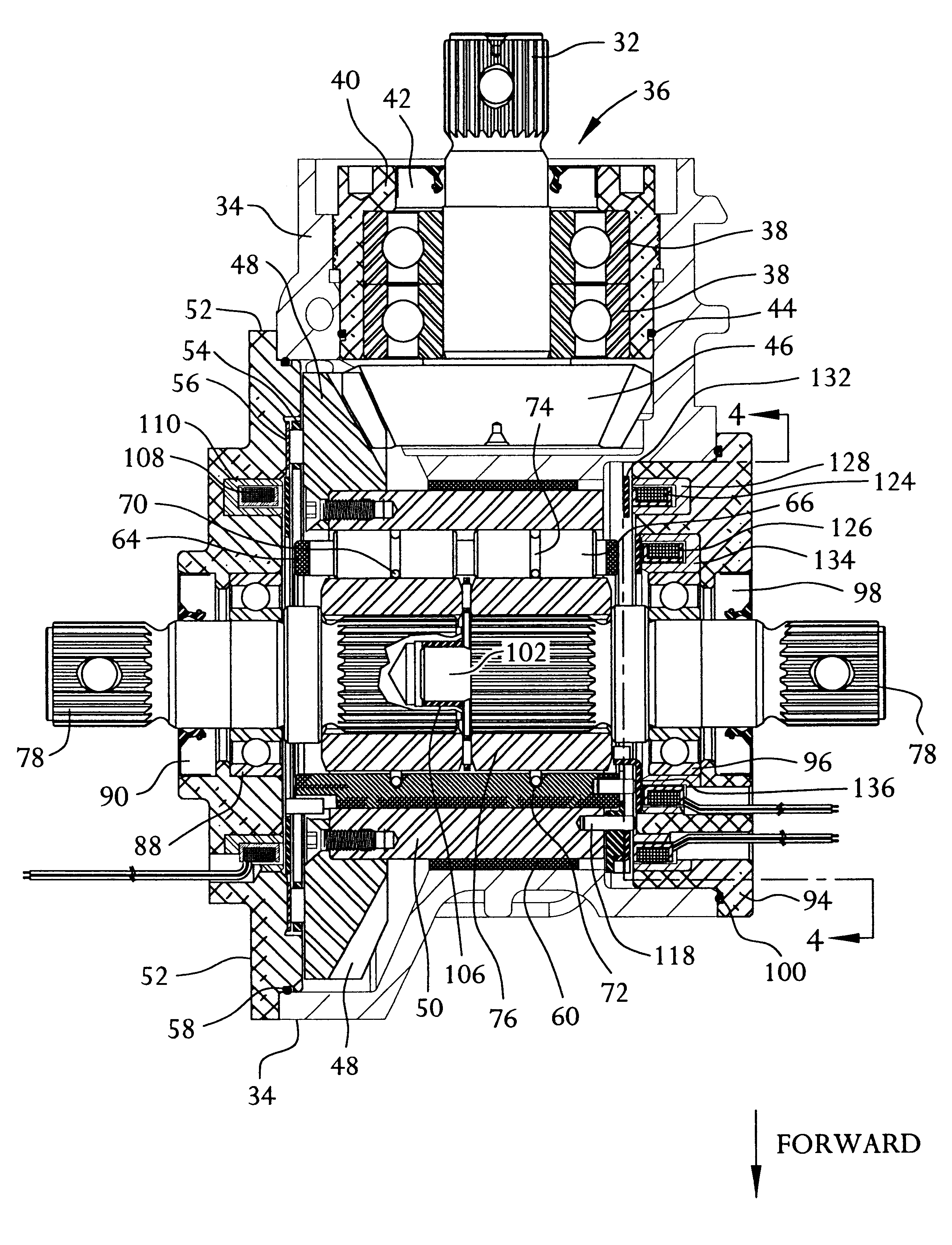

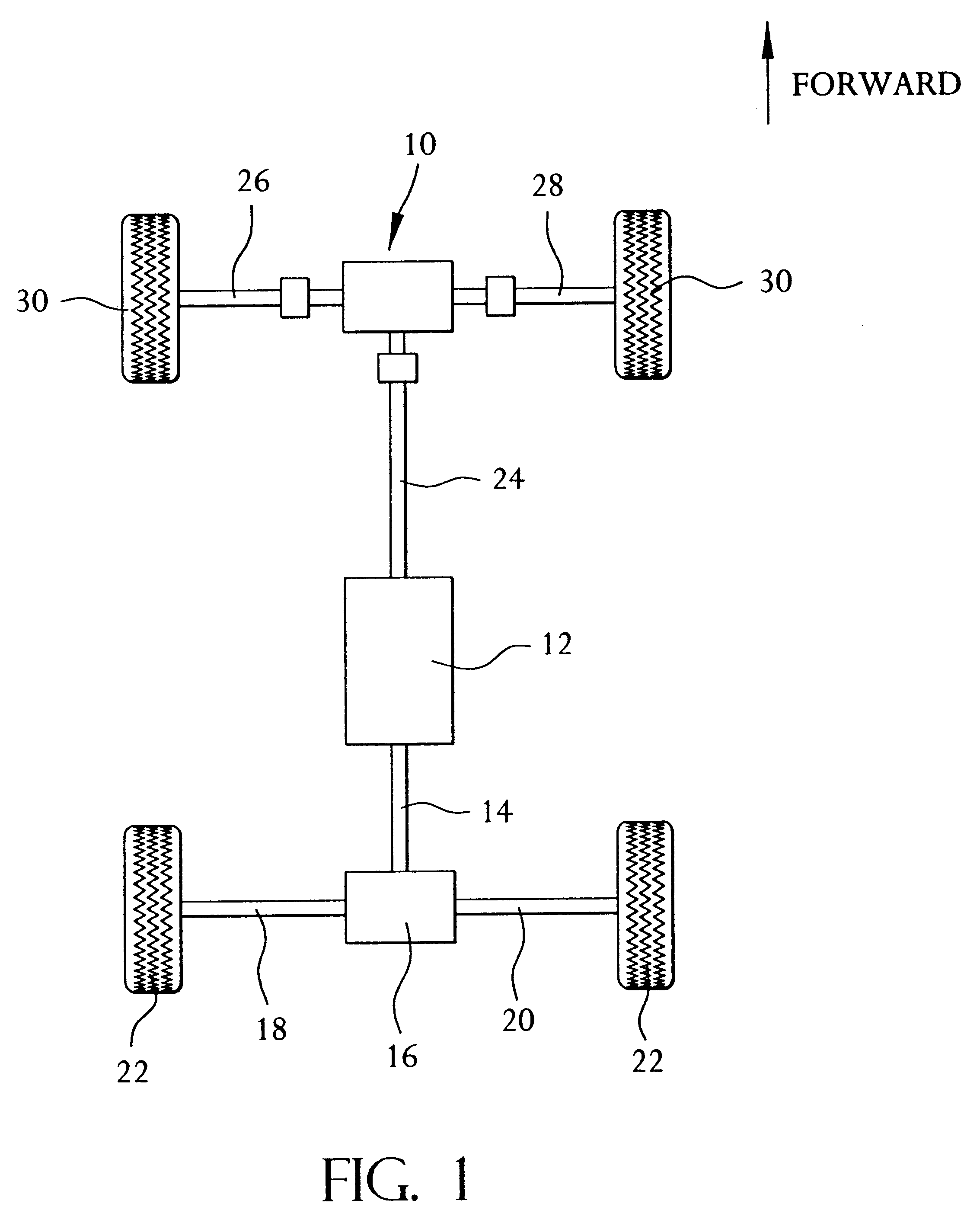

Marine transmission with a cone clutch used for direct transfer of torque

A transmission for a marine propulsion system uses a cone clutch in such a way that, when in a forward gear position, torque is transmitted from an input shaft, or driving shaft, to an output shaft, or driven shaft, solely through the cone clutch. When in forward gear position, driving torque between the driving and driven shafts is not transmitted through any gear teeth. When in reverse gear position, torque is transmitted through an assembly of the bevel gears.

Owner:BRUNSWICK CORPORATION

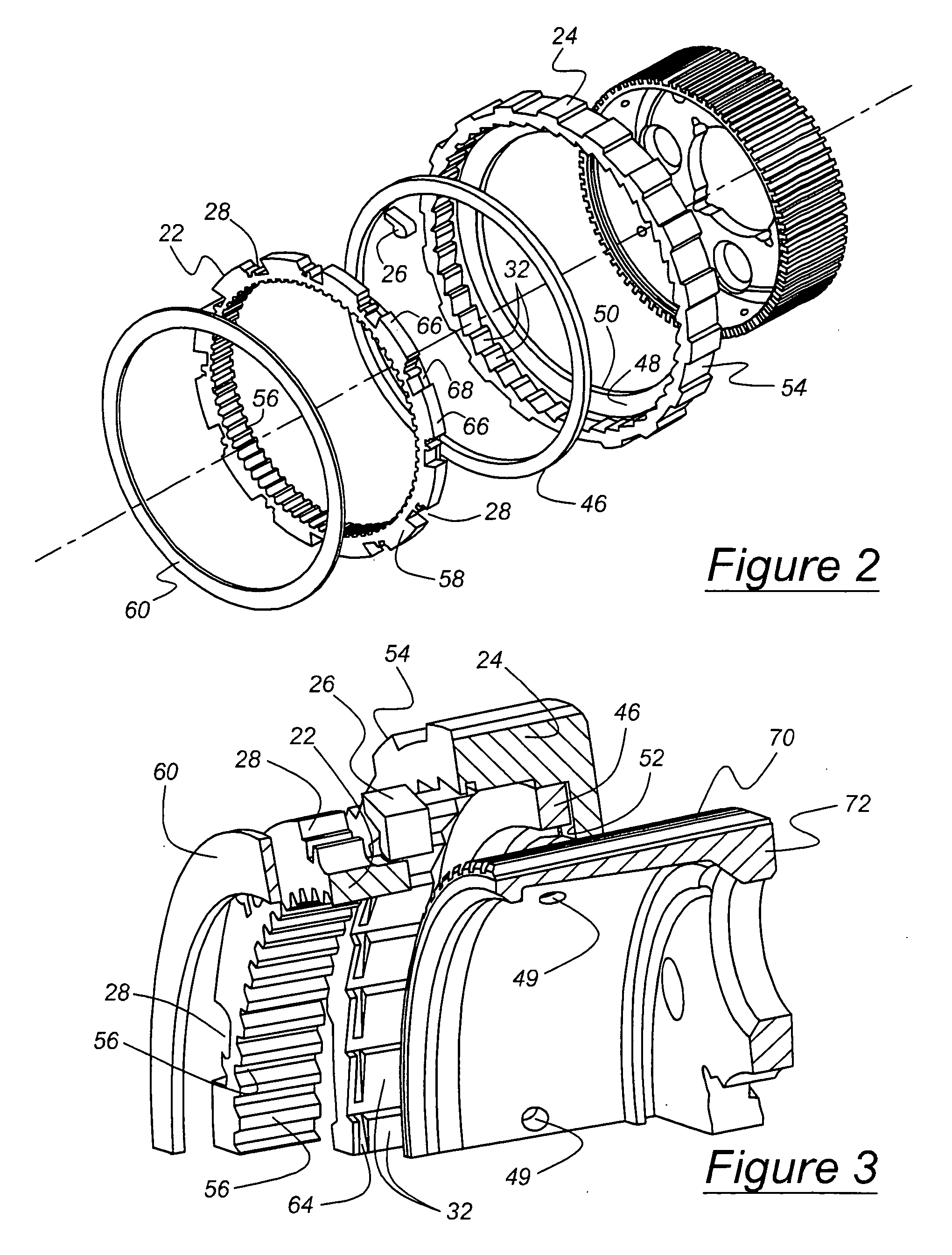

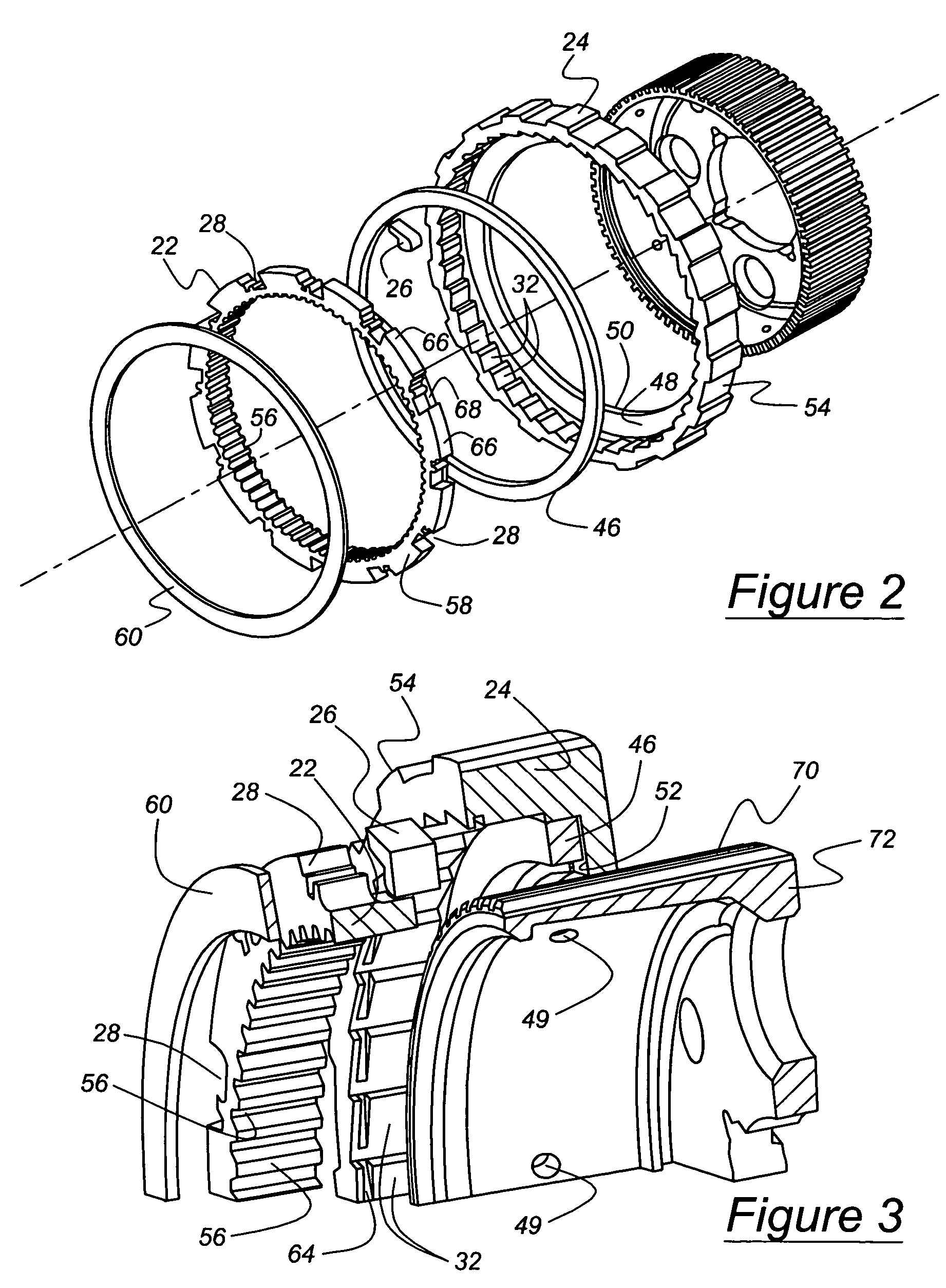

Gear change mechanism

ActiveUS7303502B2Easy to participateSpace minimizationToothed gearingsInterengaging clutchesEngineeringDog clutch

A gear change mechanism coupling a pair of shafts employs a planetary gear set comprising a sun gear fast with a first of the shafts, planet gears in a planet carrier, and an annulus or ring gear, the latter being fixed. A selector hub slidable on the other of the shafts has sets of radially spaced dogs to engage with corresponding dogs on the planet carrier and sun gear respectively, so as to couple the shafts at two different ratios depending on the axial position of the selector hub. This results in a more axially compact package than conventional dog clutch gear changers. In an alternative embodiment a reversing mechanism is provided by fixing the planet carrier and engaging the selector hub with the sun gear or annulus depending on its axial position.

Owner:QINETIQ LTD

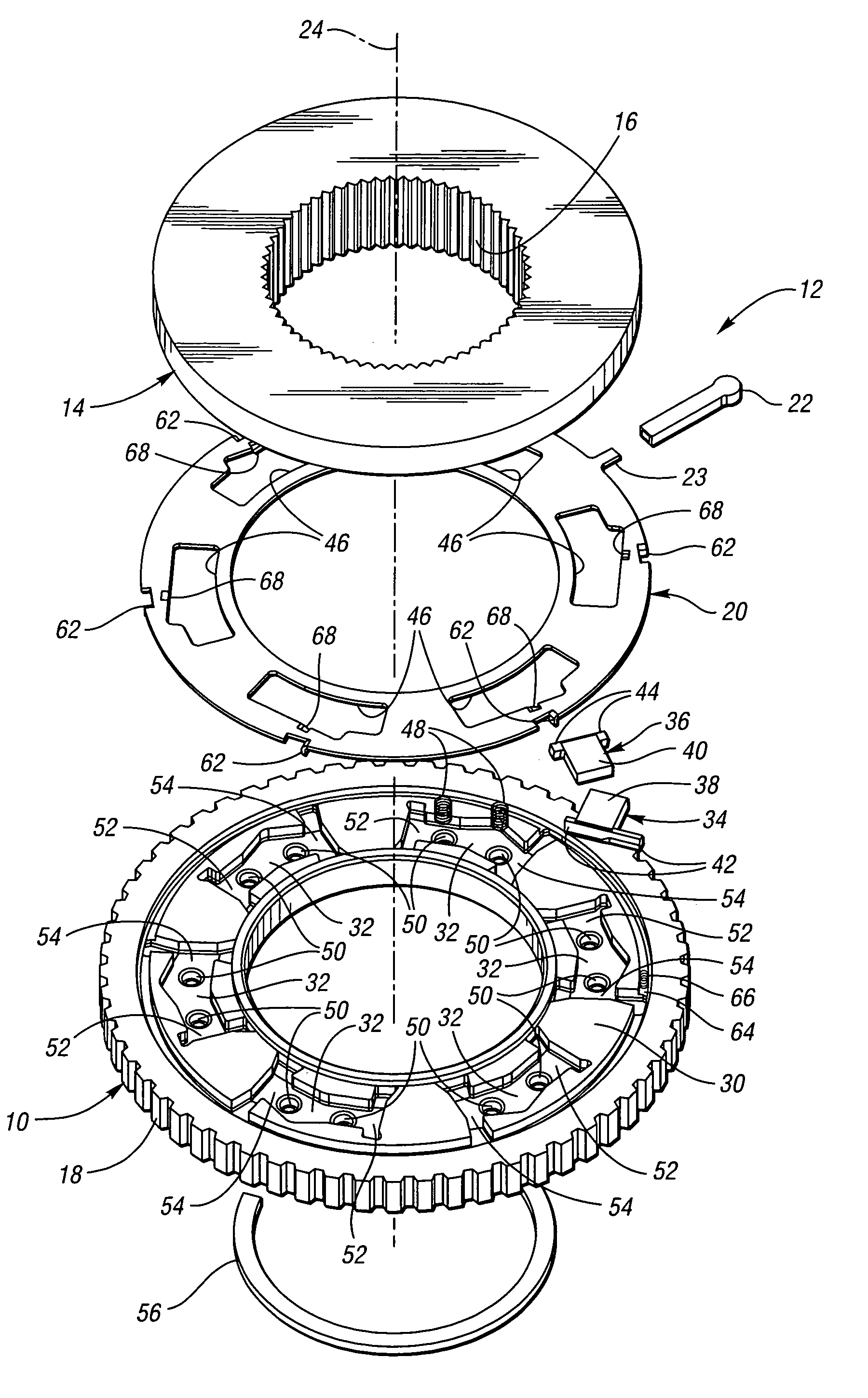

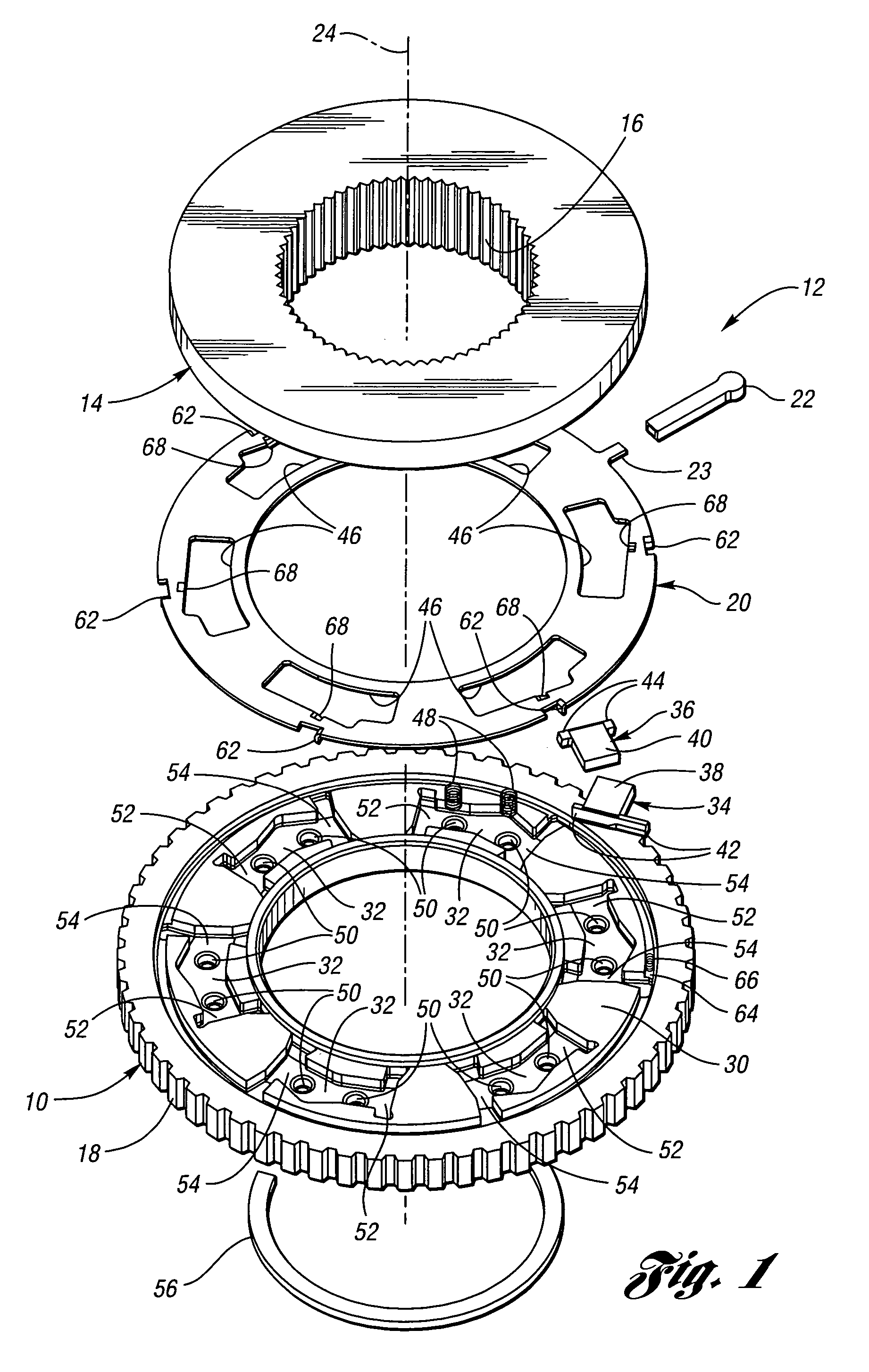

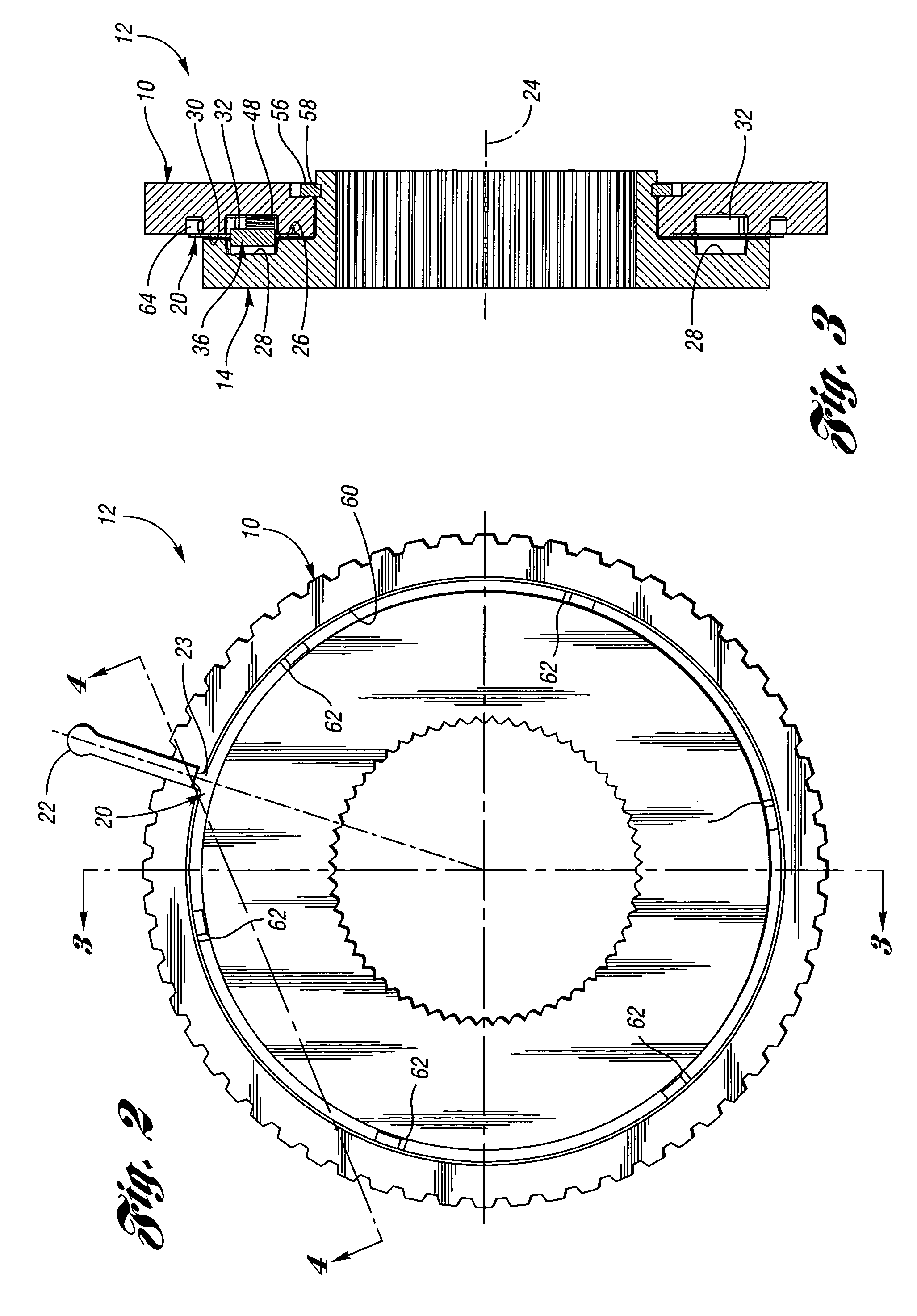

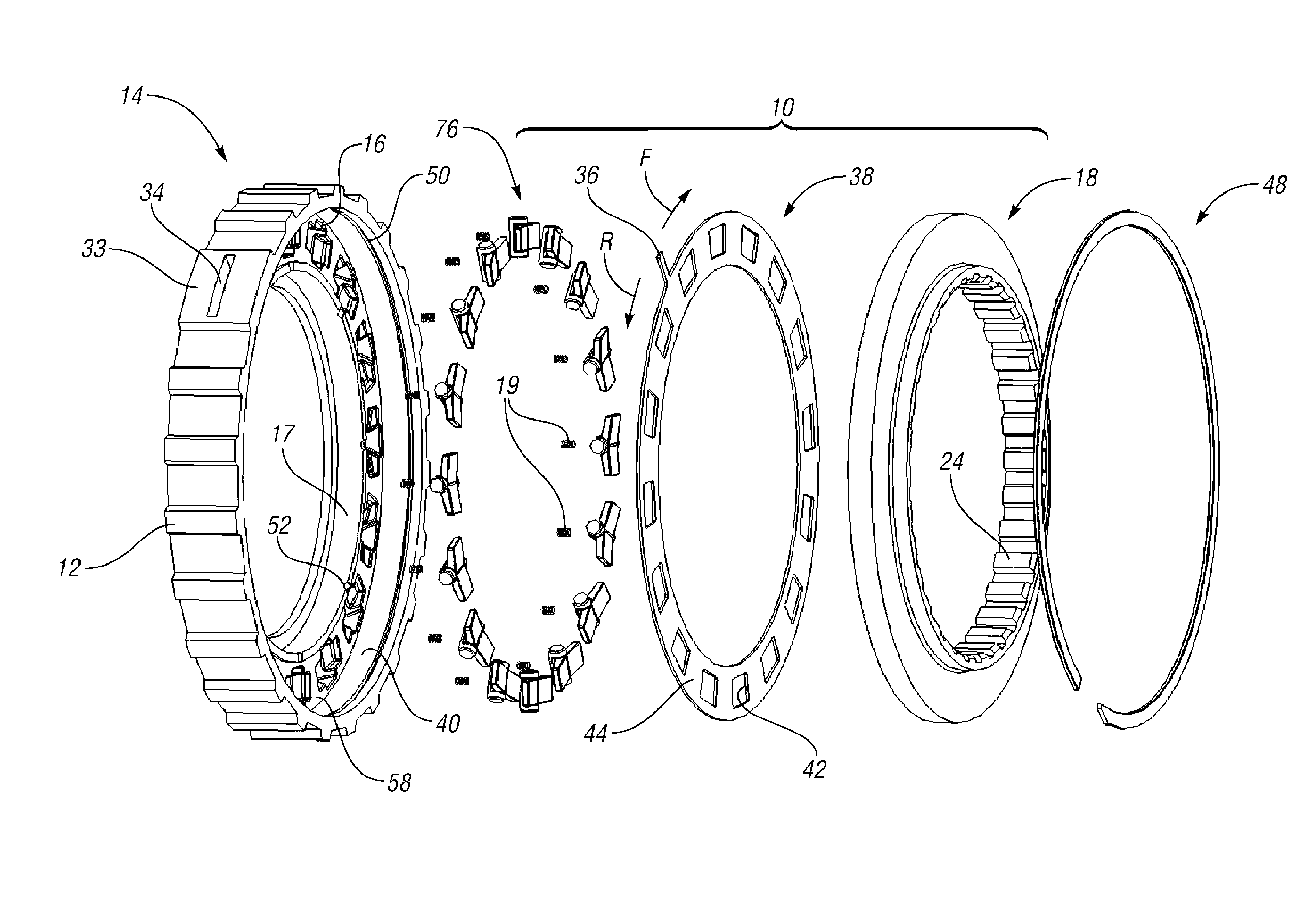

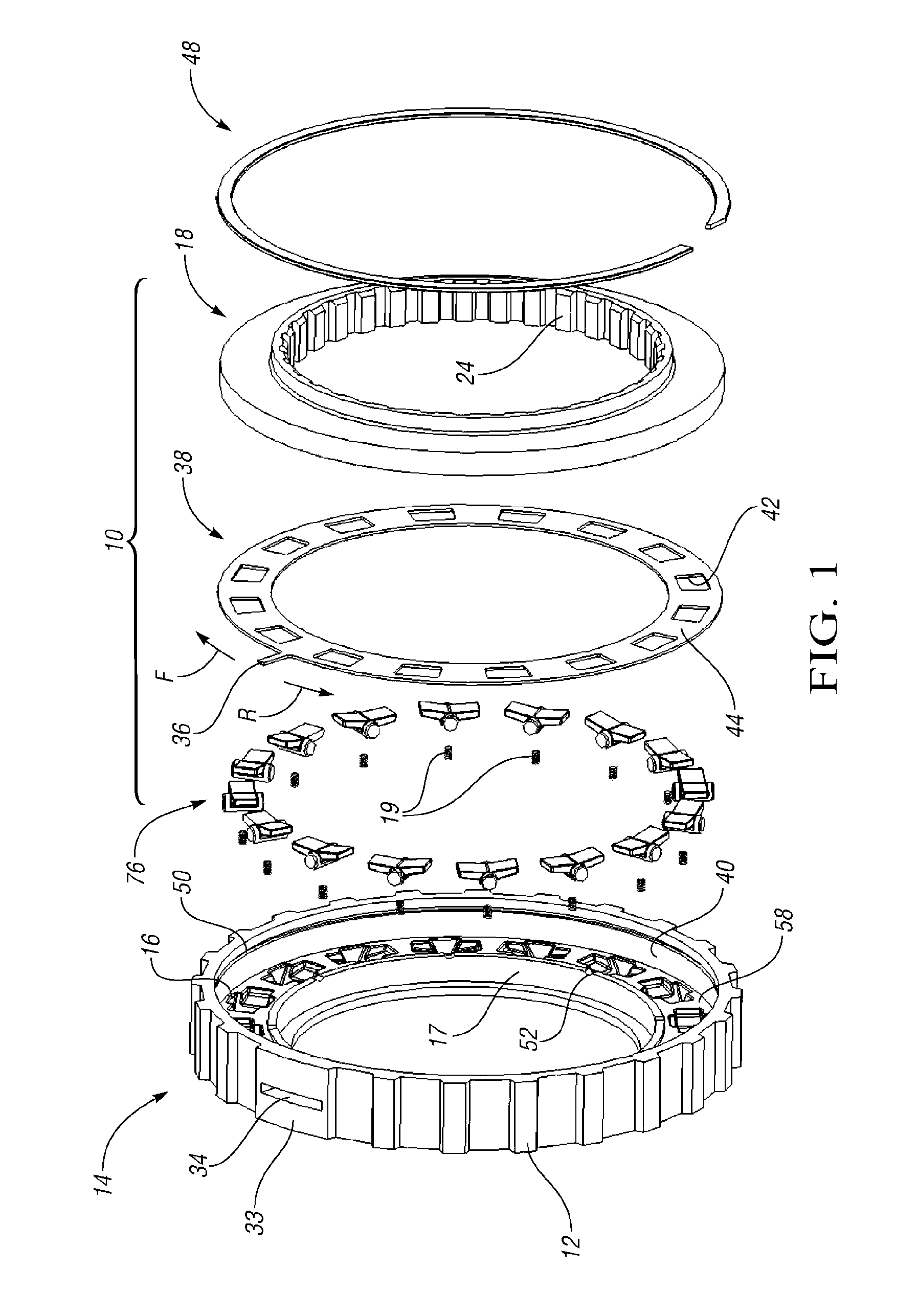

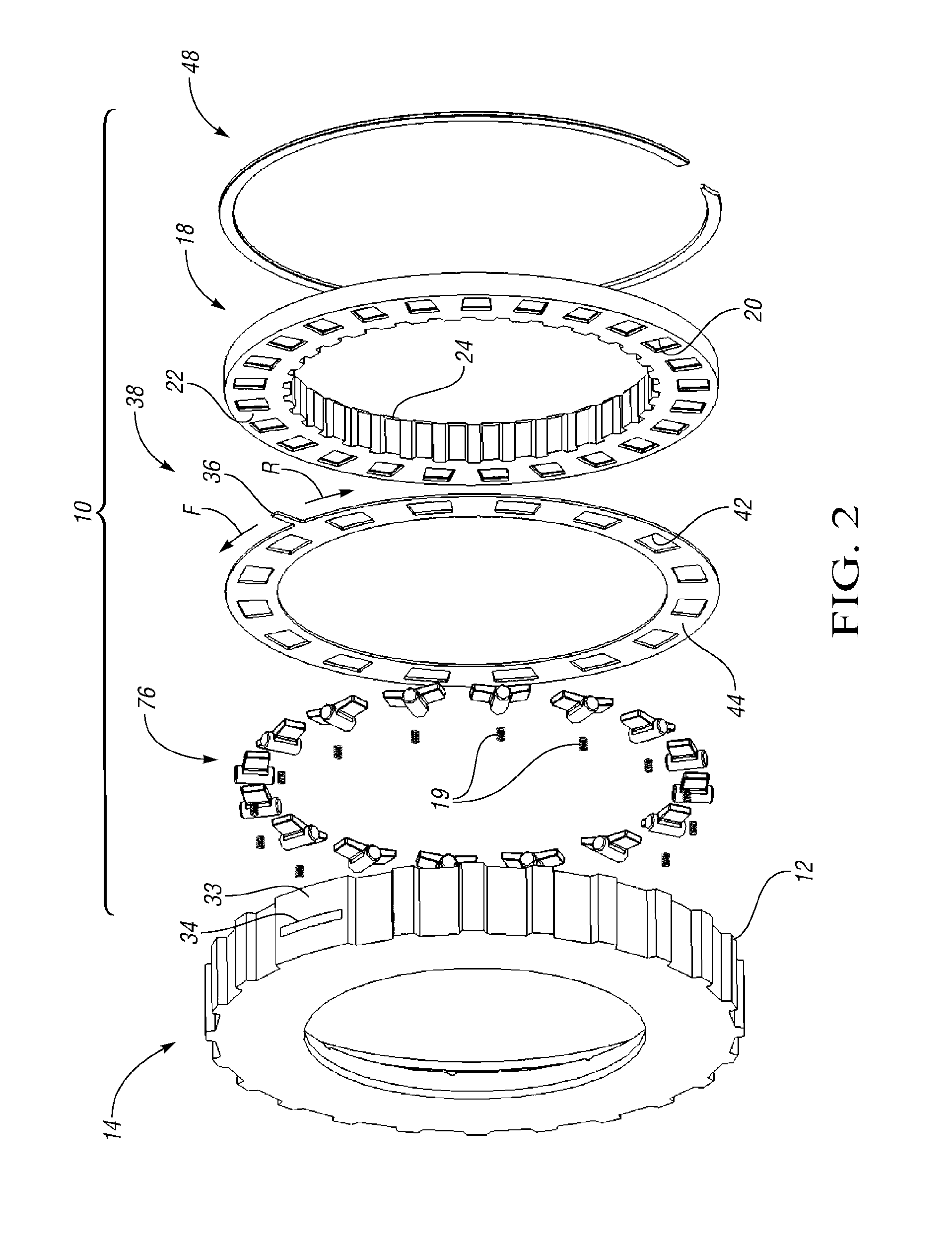

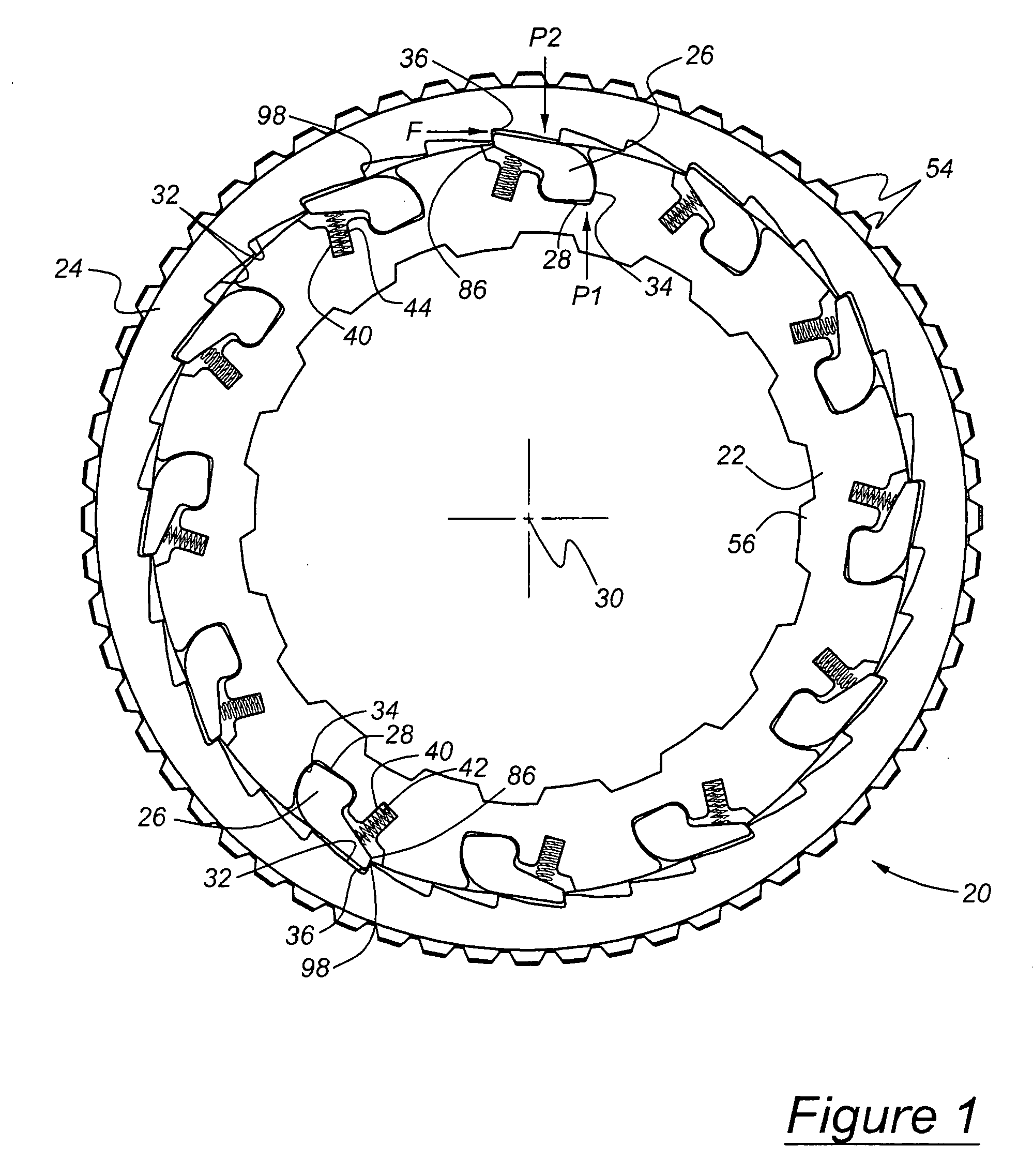

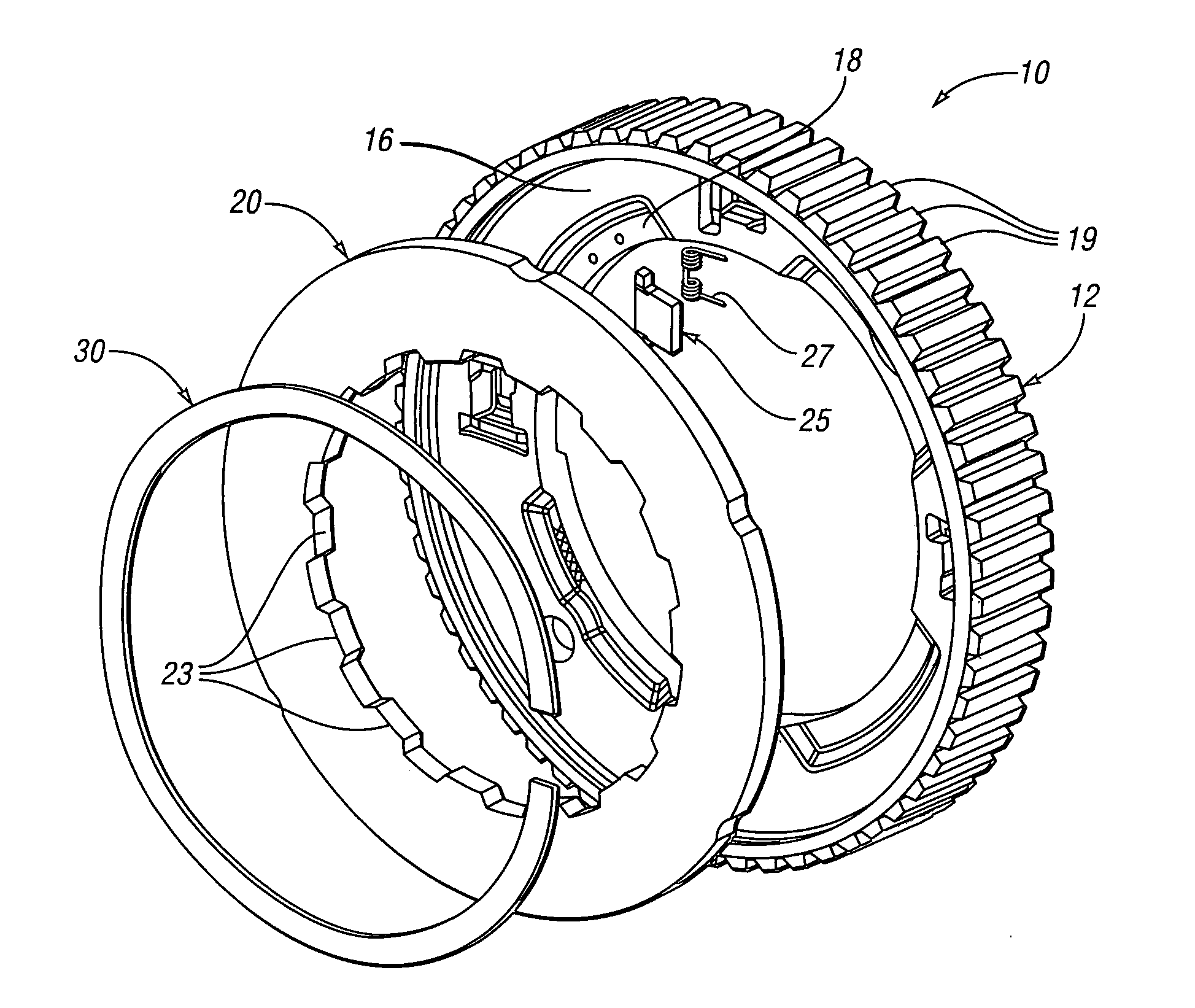

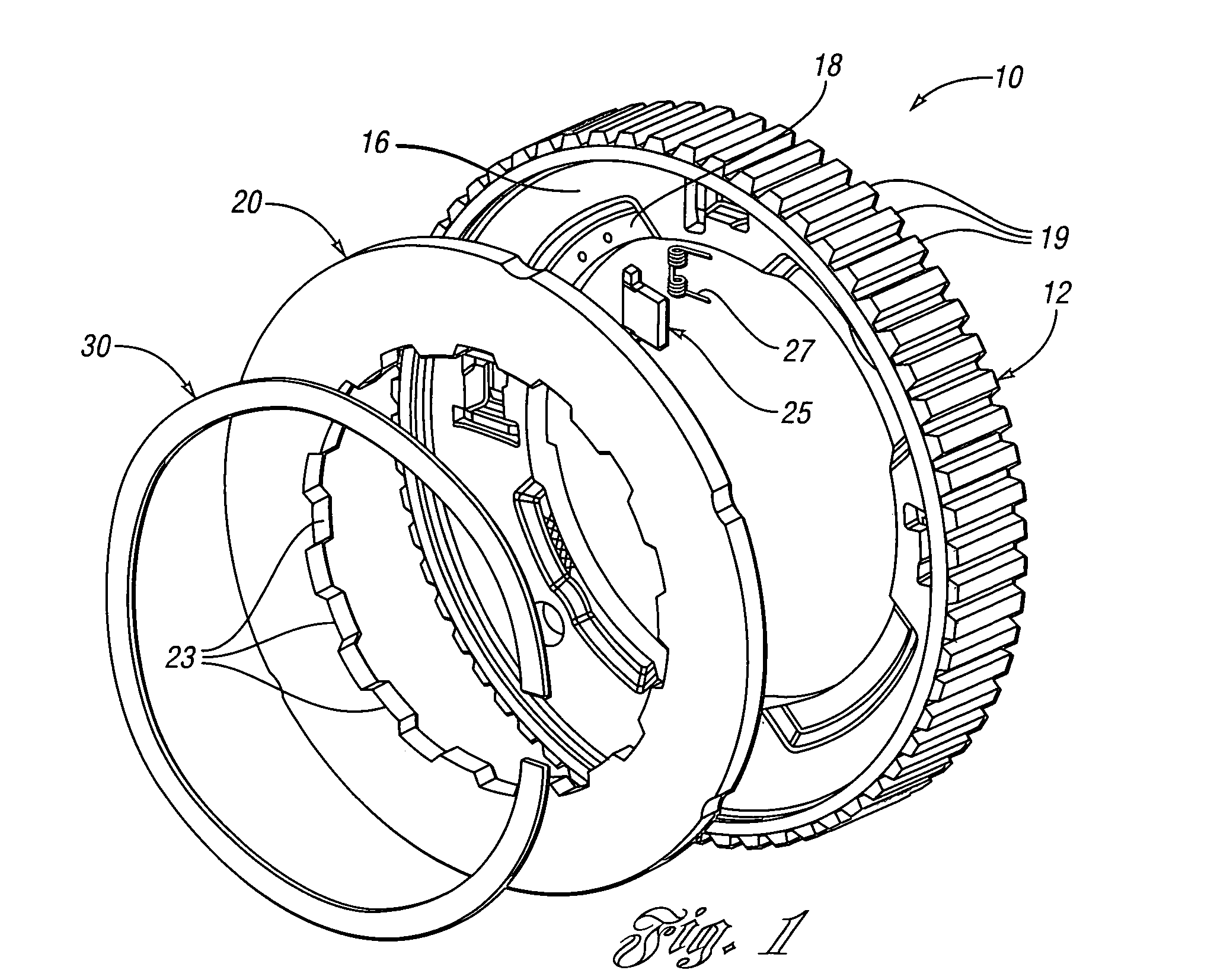

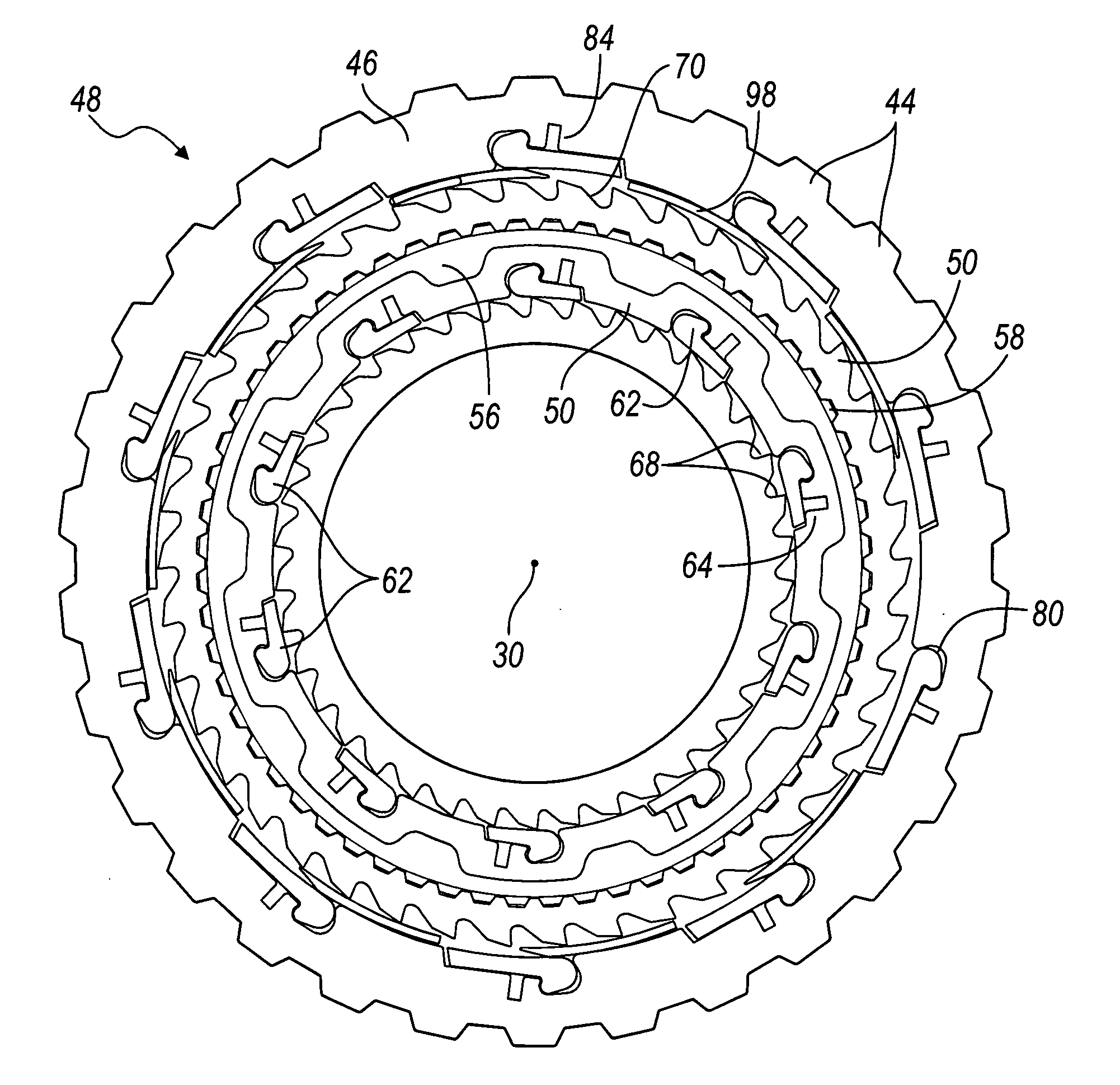

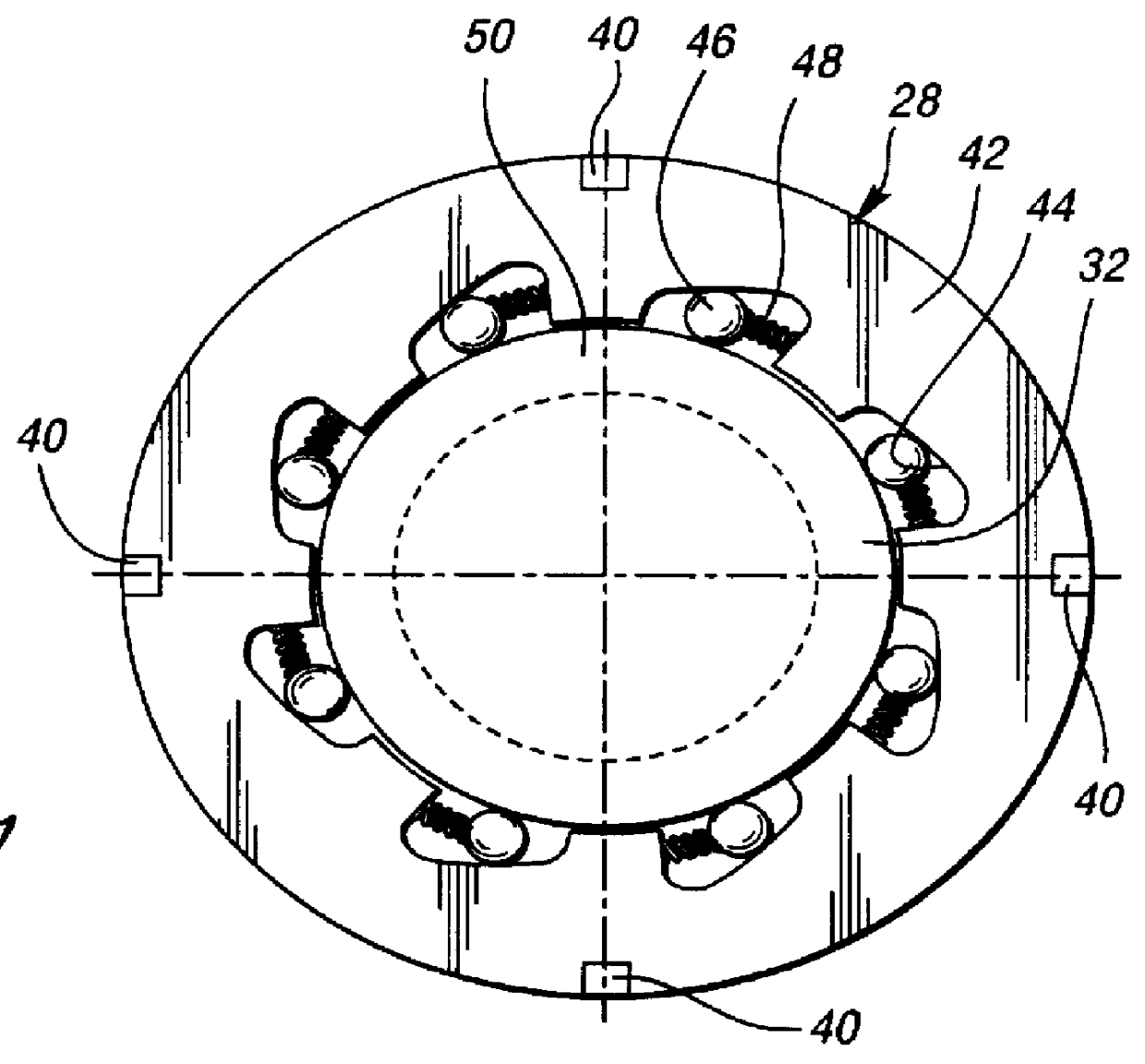

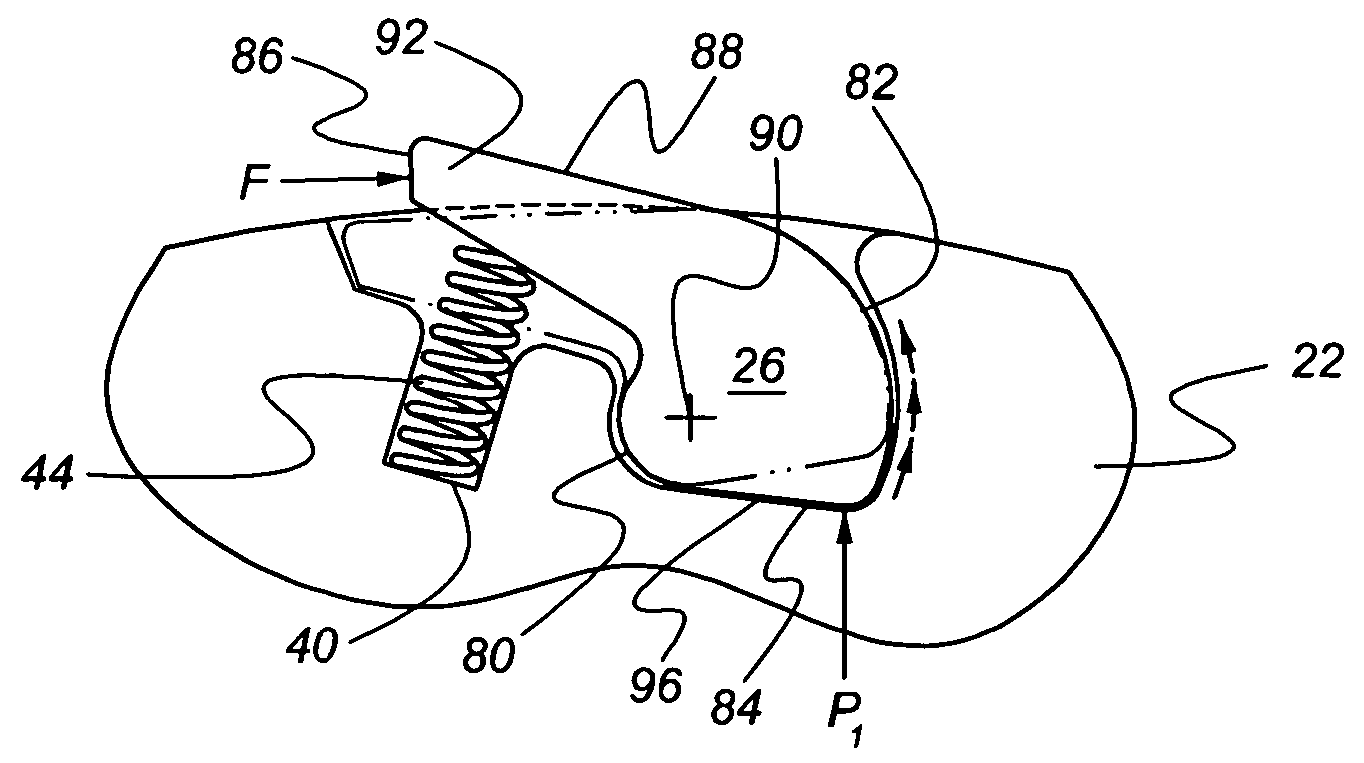

Overrunning coupling assembly and method for controlling the engagement of planar members

ActiveUS7258214B2Reduce complexityReduce controlFriction clutchesInterengaging clutchesEngineeringMechanical engineering

An overrunning coupling assembly and a method of controlling the engagement of planar first and second members are provided wherein two sets of opposed engaging struts are applied with one motion of a single control plate or member. The planar first and second members have inside surfaces extending generally normal to a first axis. The assembly includes free-floating, forward keys and free-floating, reverse keys opposed to the forward keys. The forward and reverse keys are movable between a notch-engaging, engaged position and a disengaged position in which the second member is permitted to free-wheel relative to the first member. The planar control member is disposed between the first and second surfaces and is controllably rotatable about the first axis between first and second angular positions relative to the first member.

Owner:MEANS IND INC

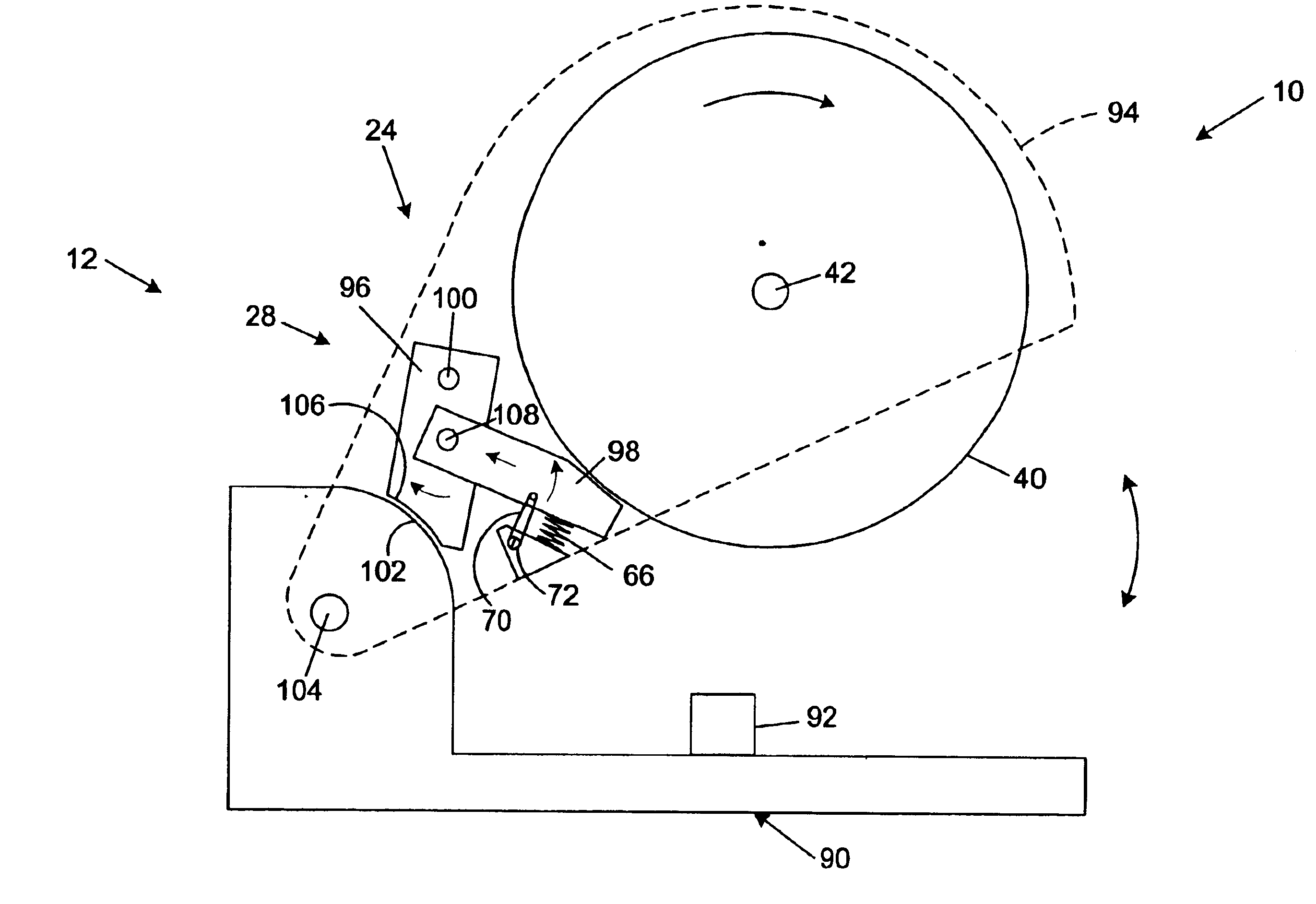

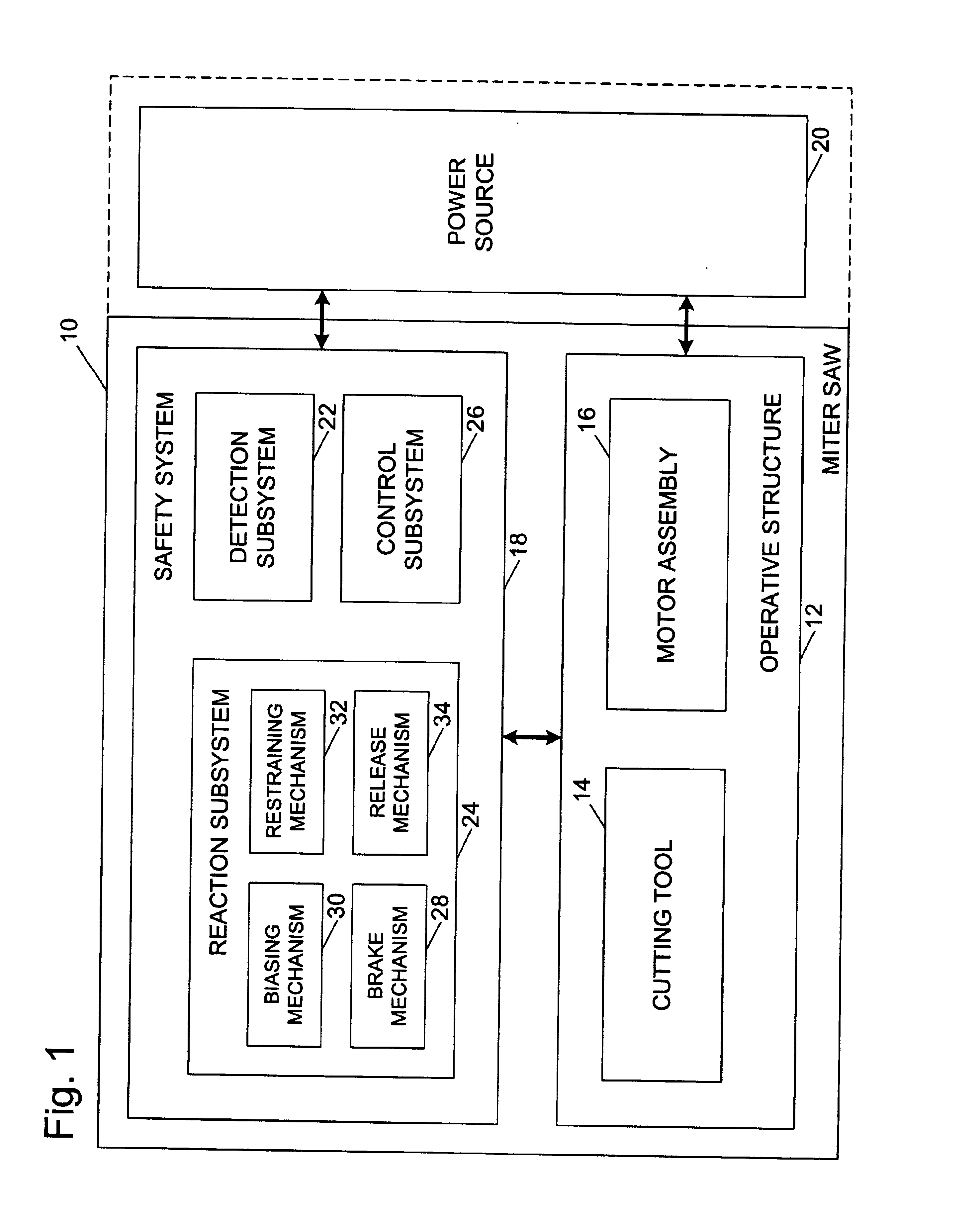

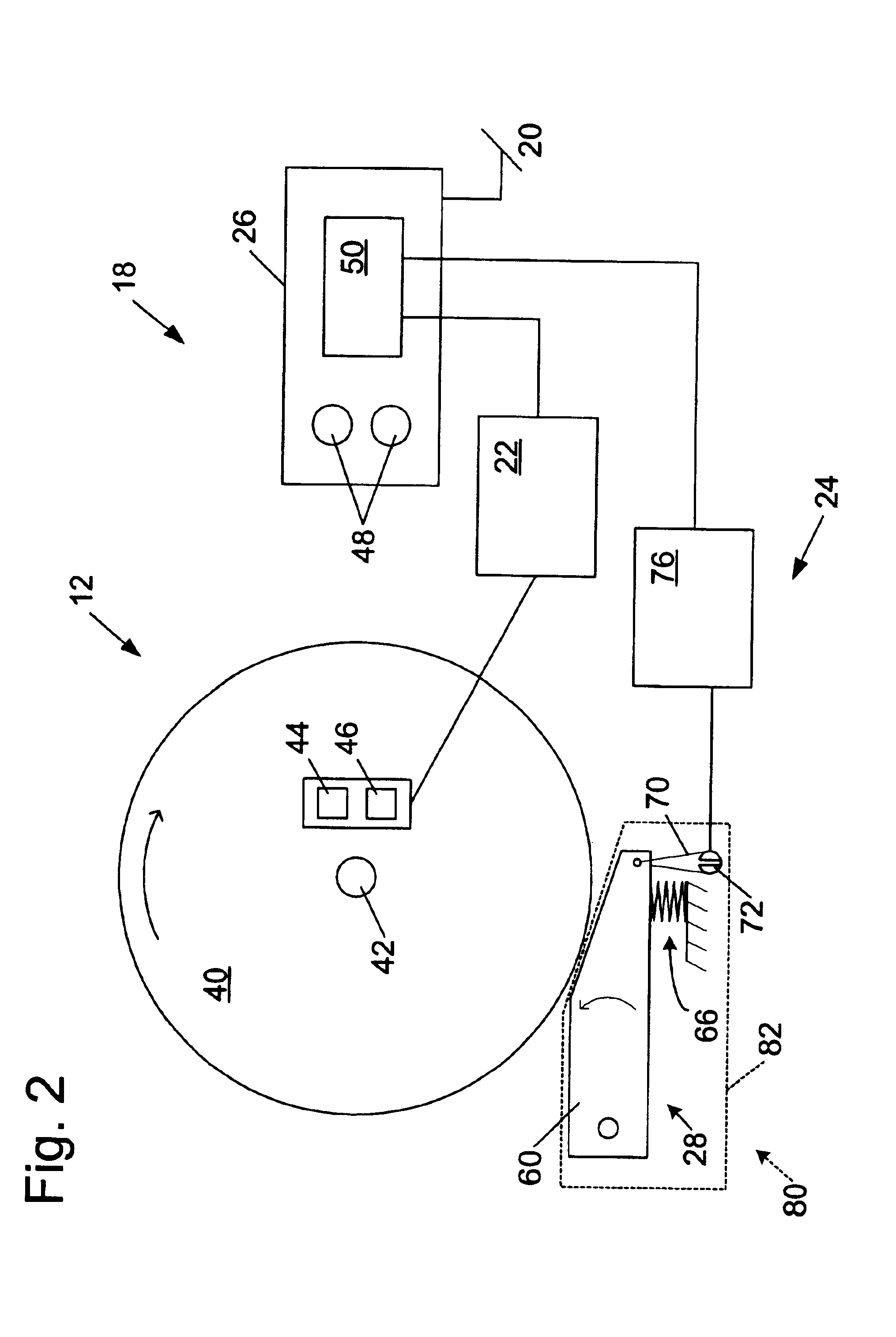

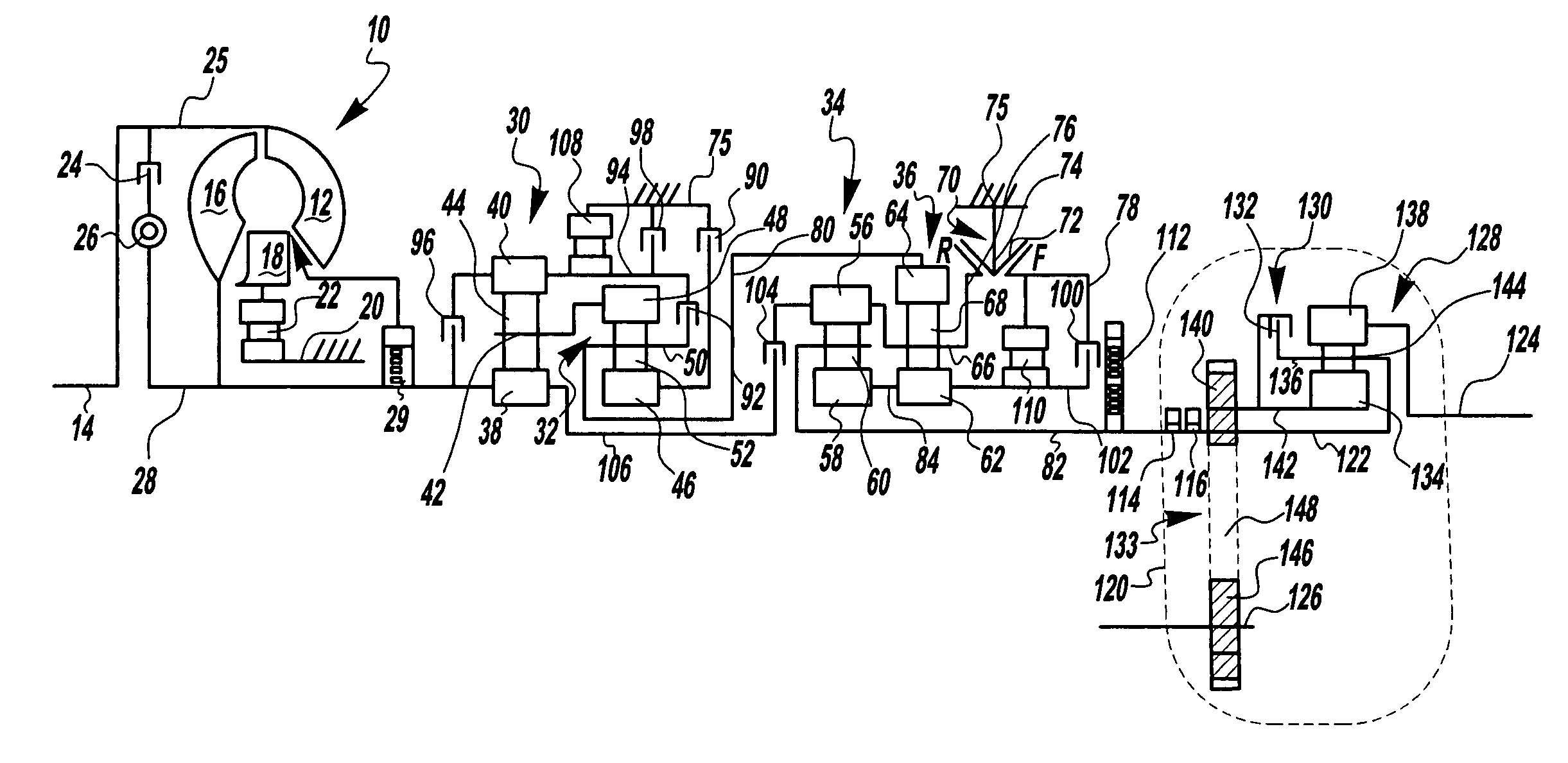

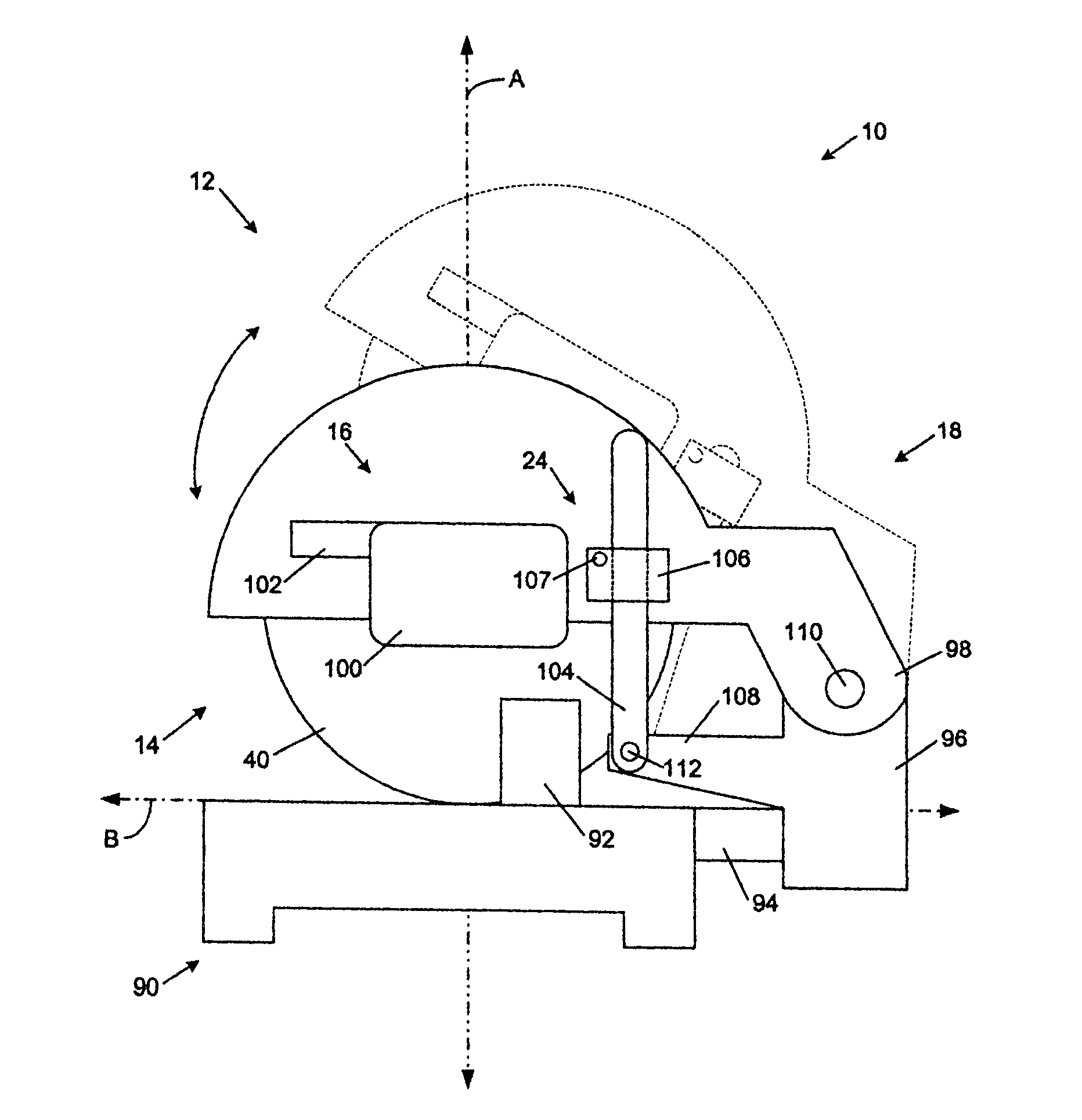

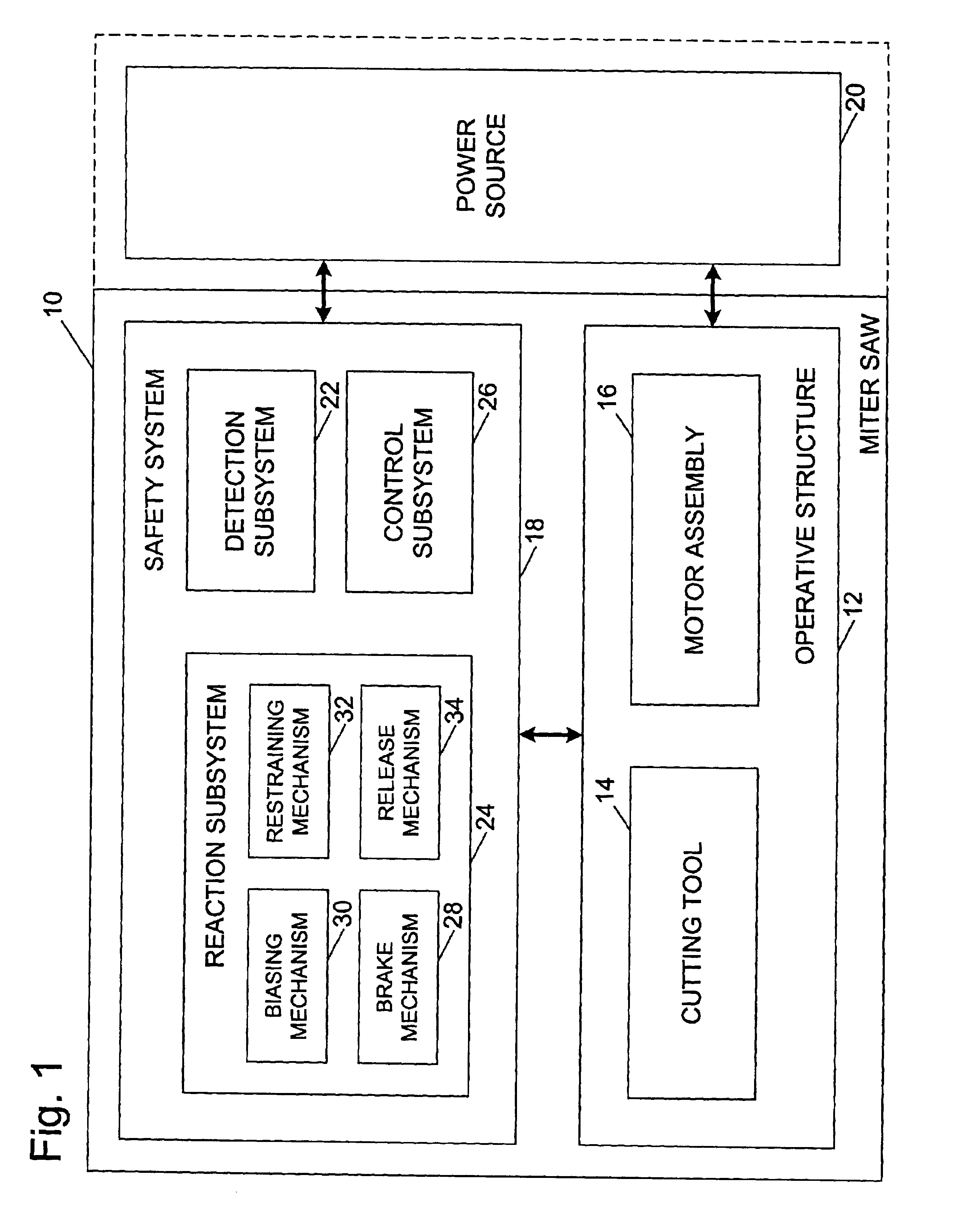

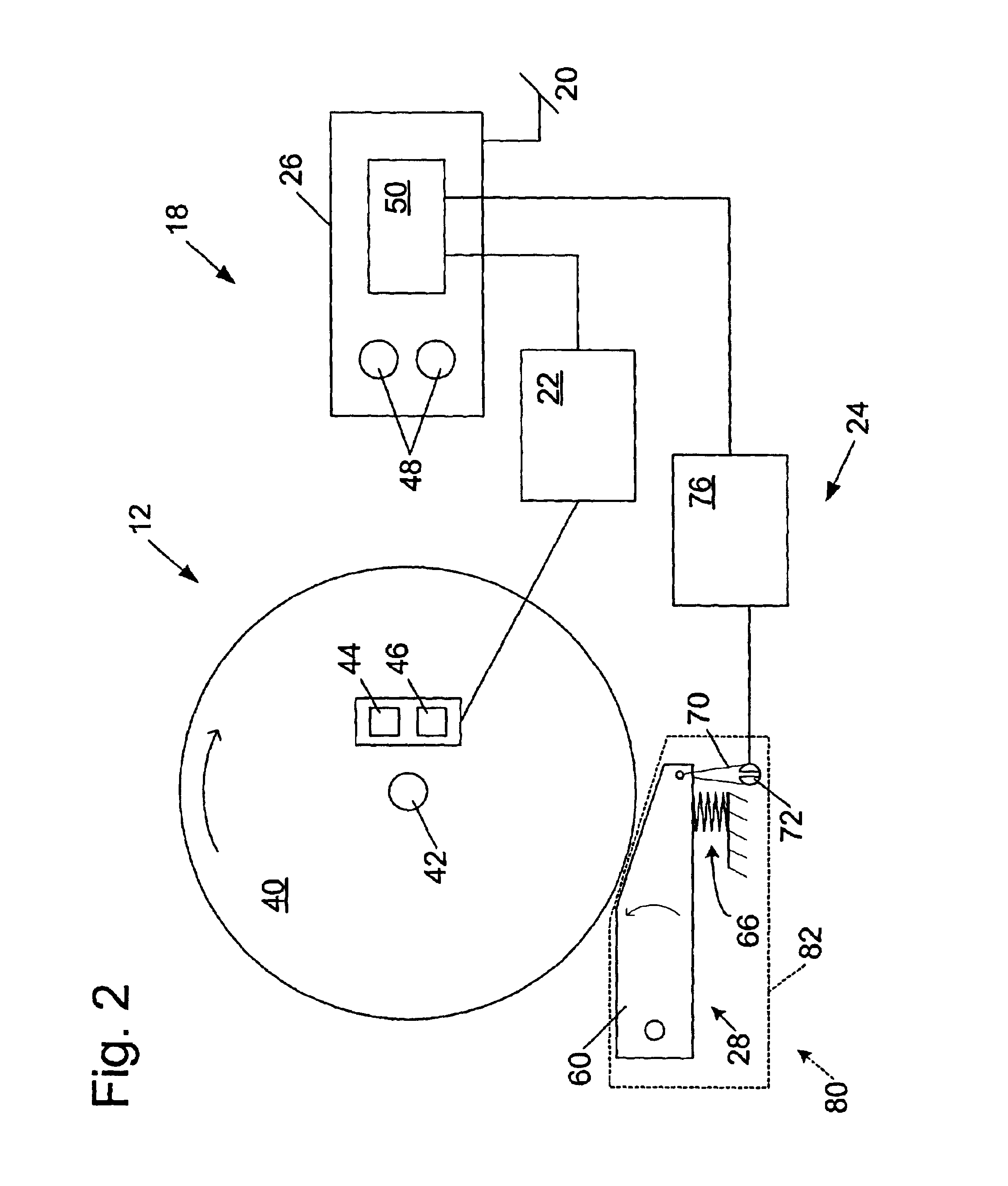

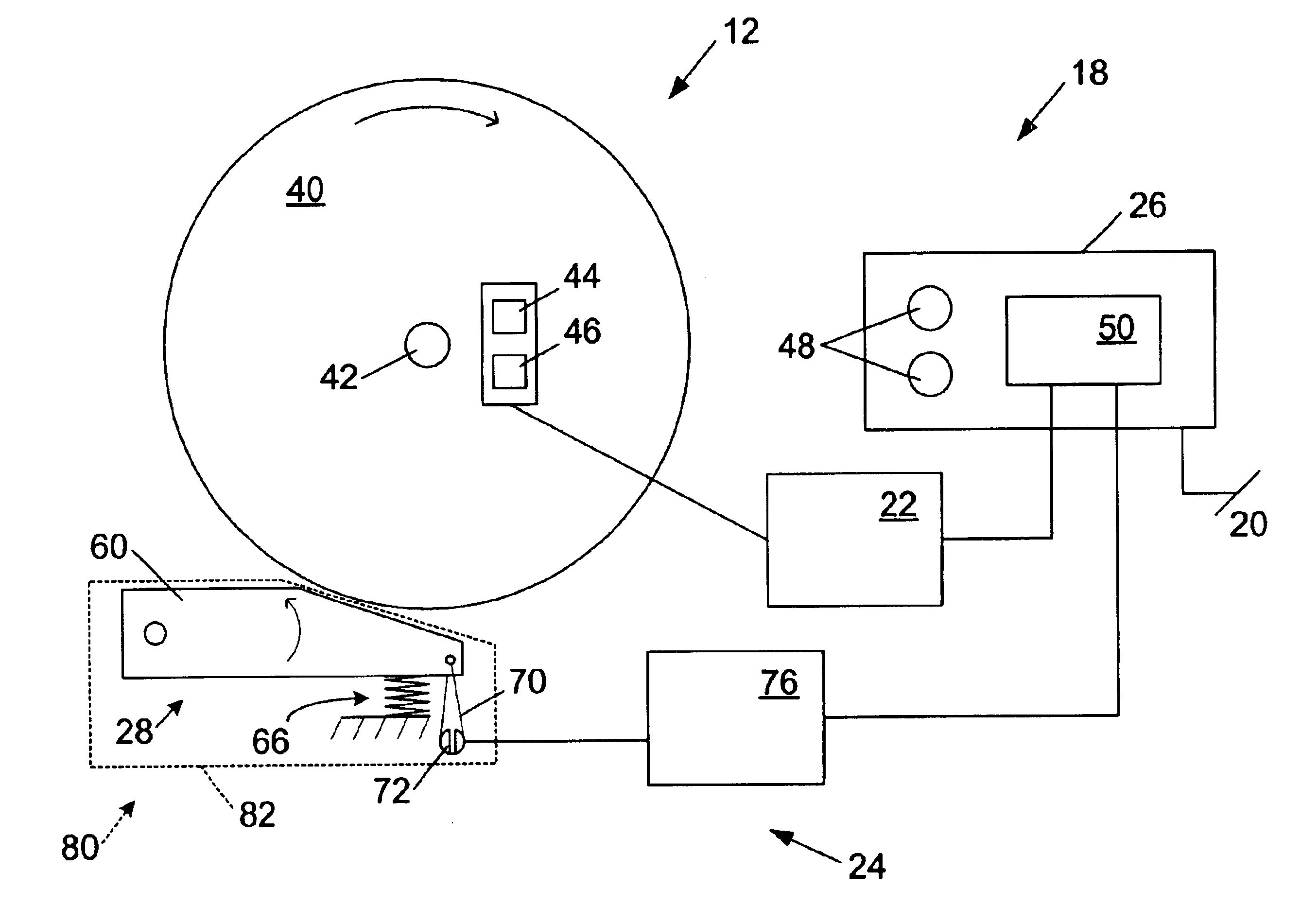

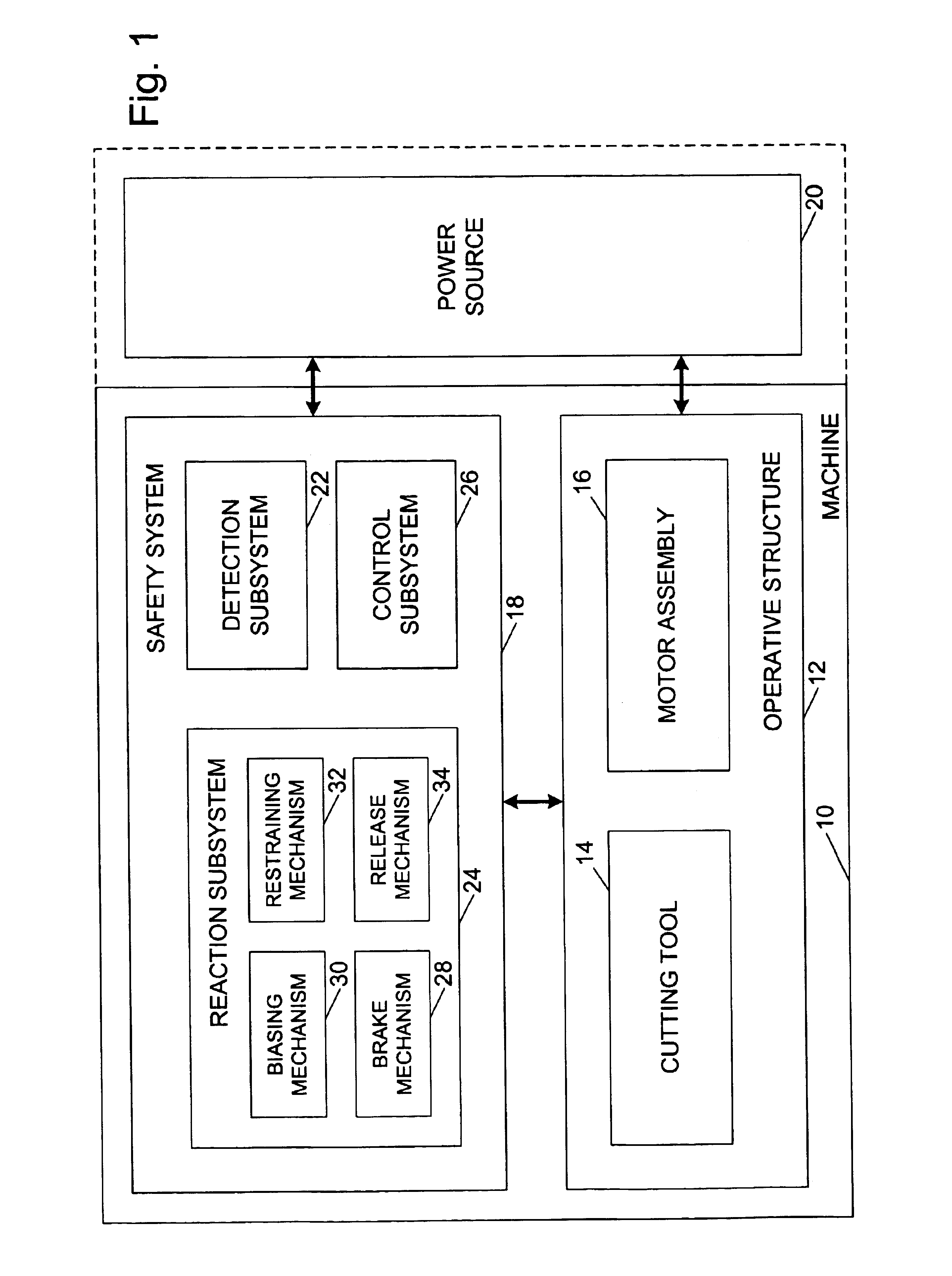

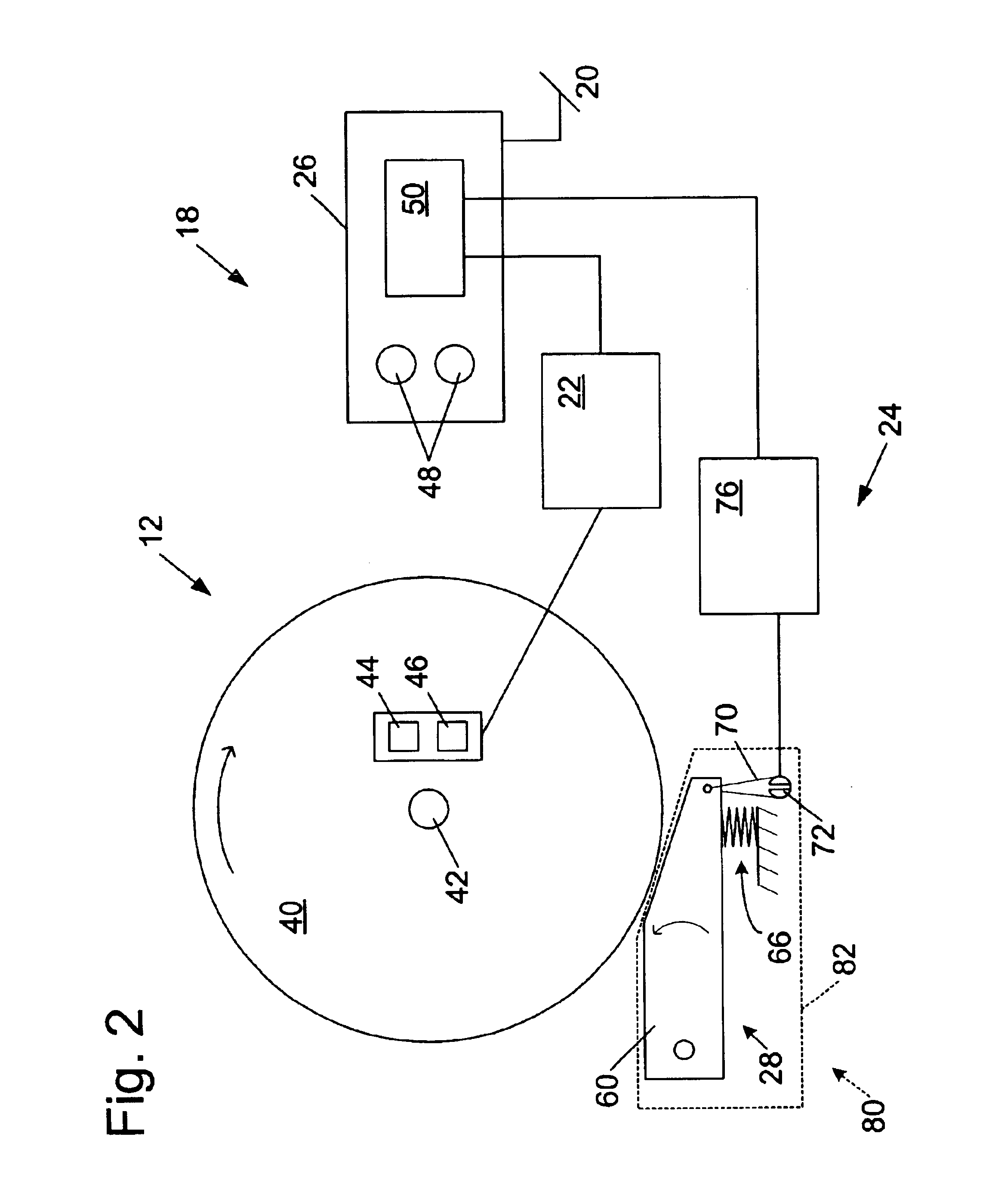

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

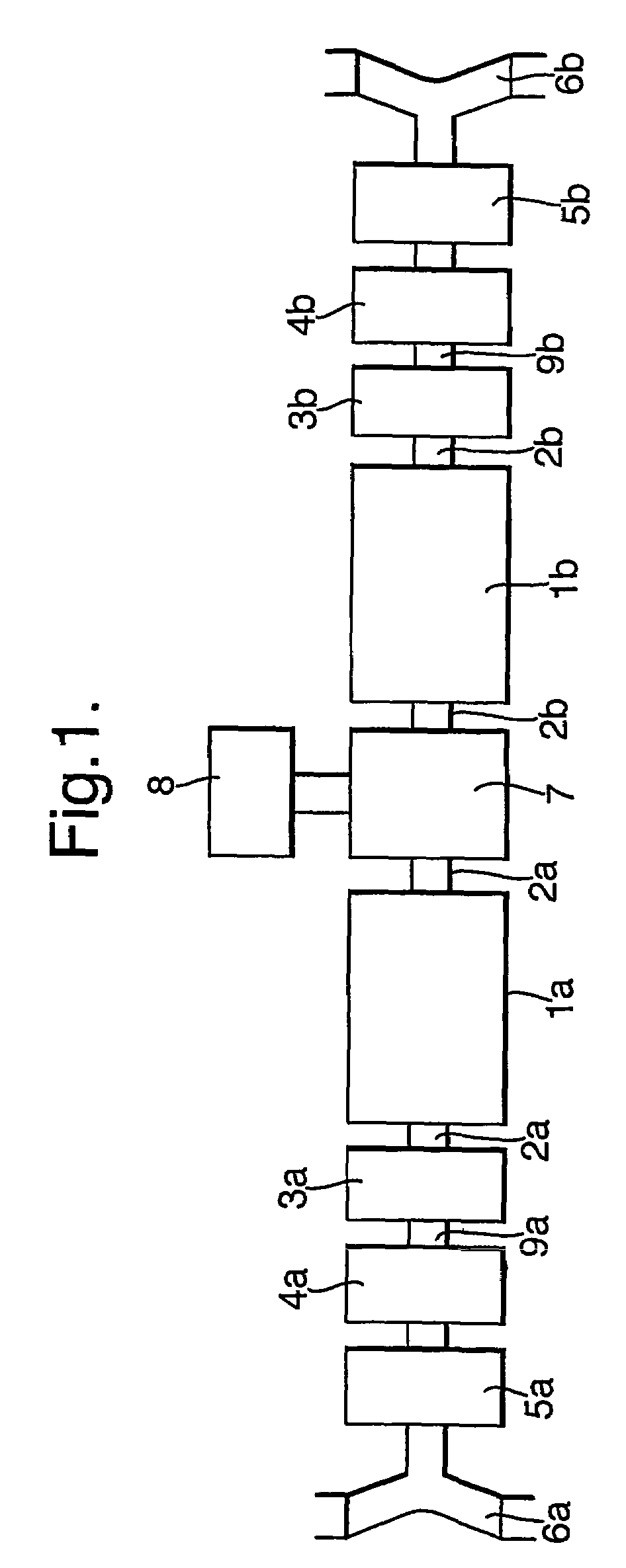

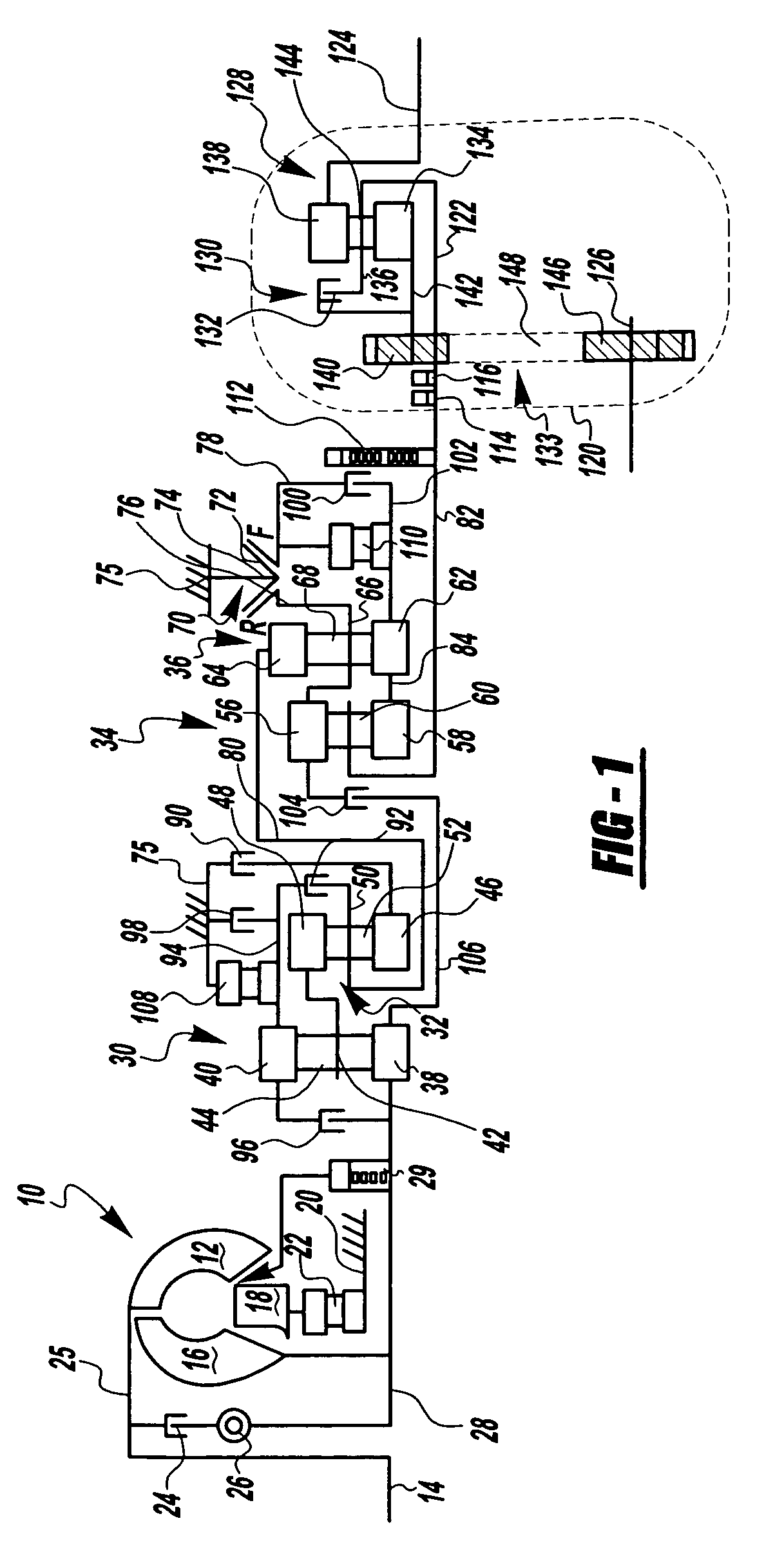

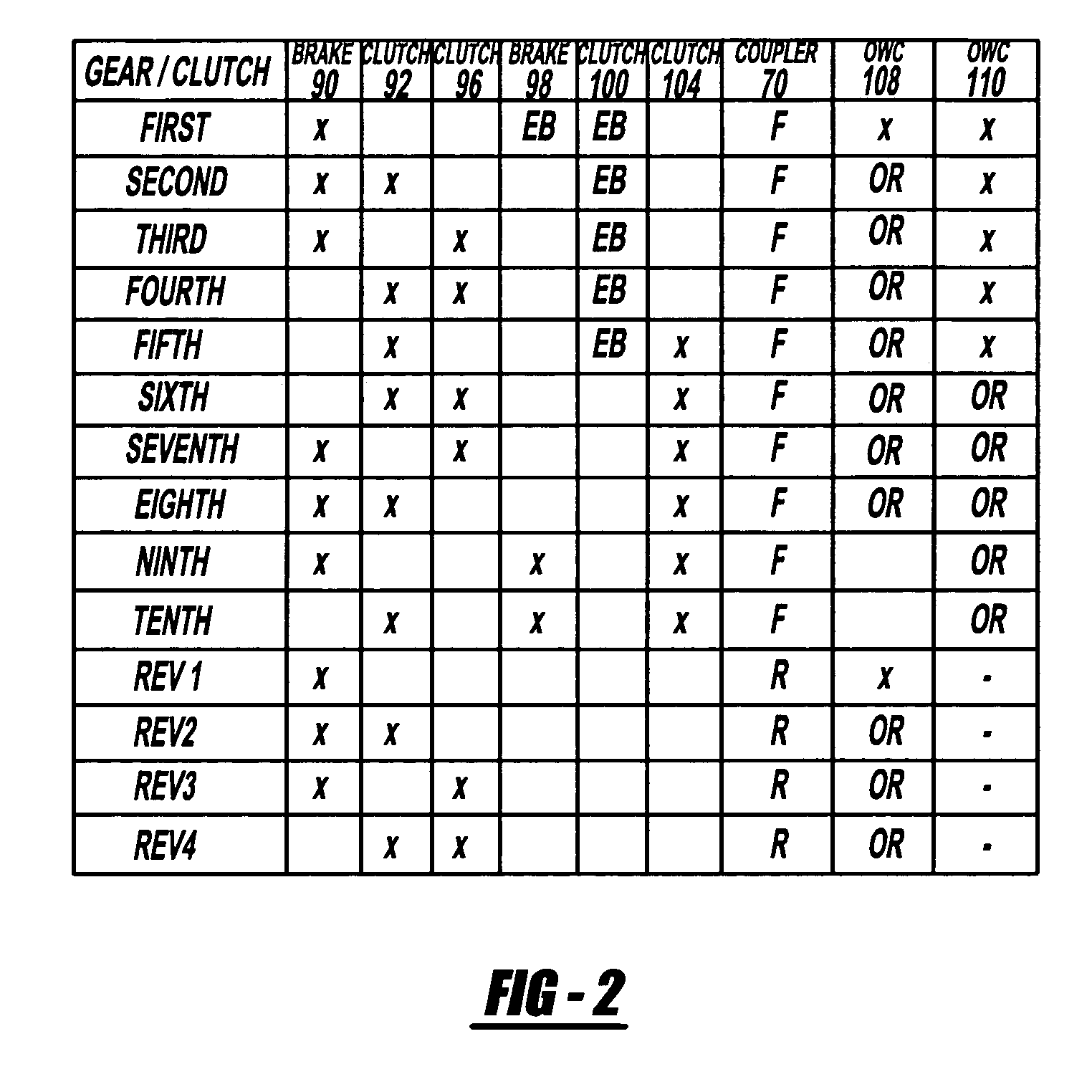

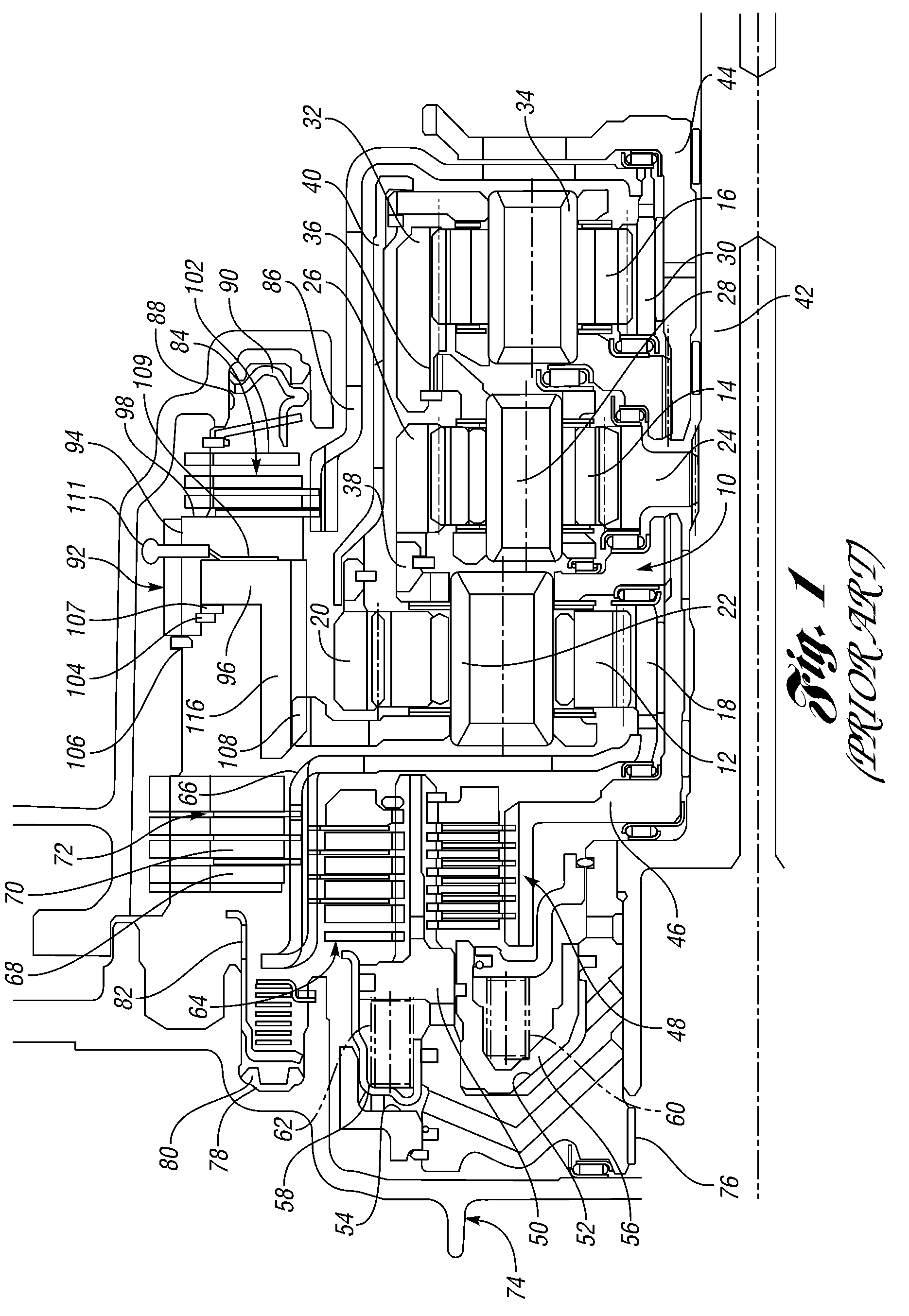

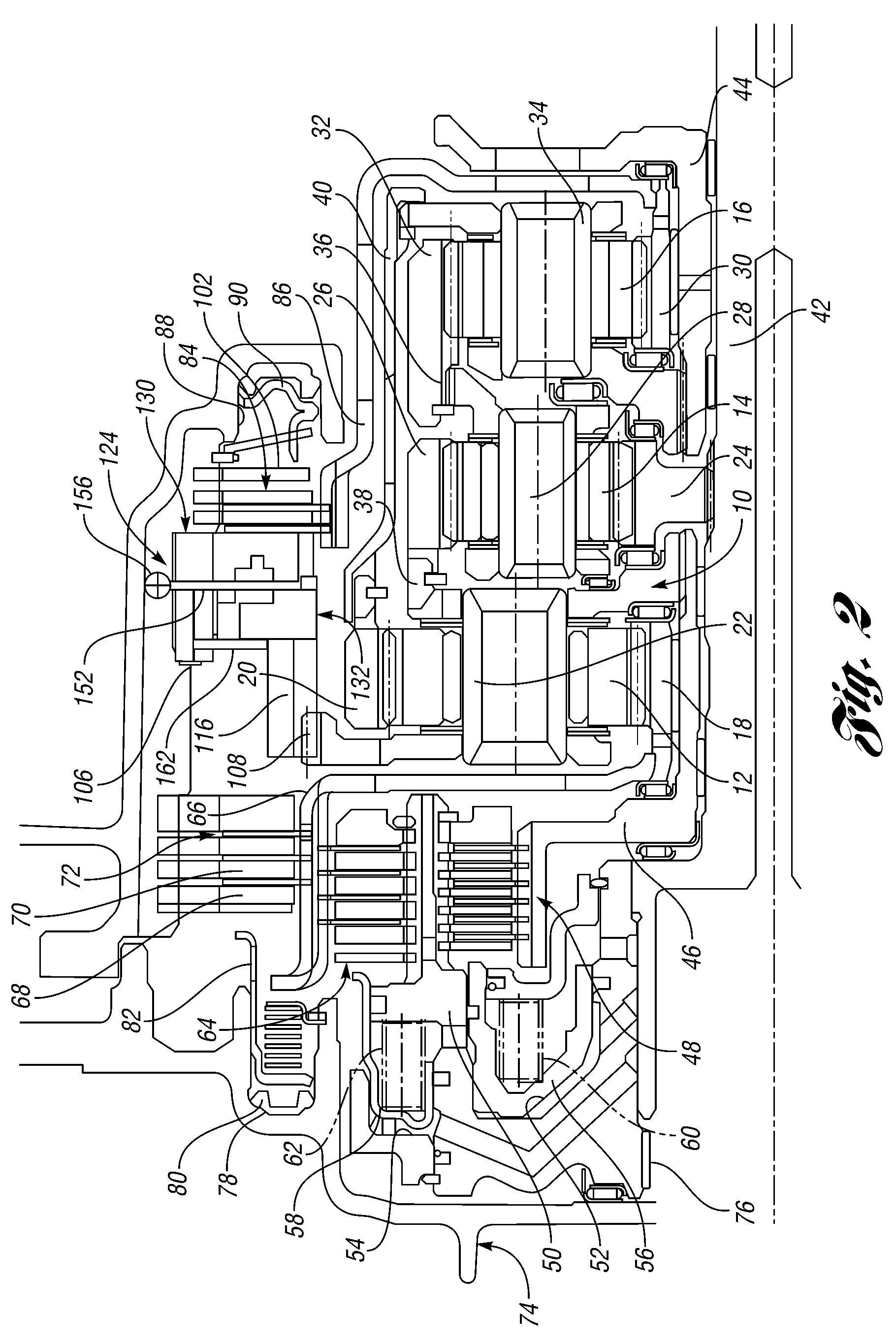

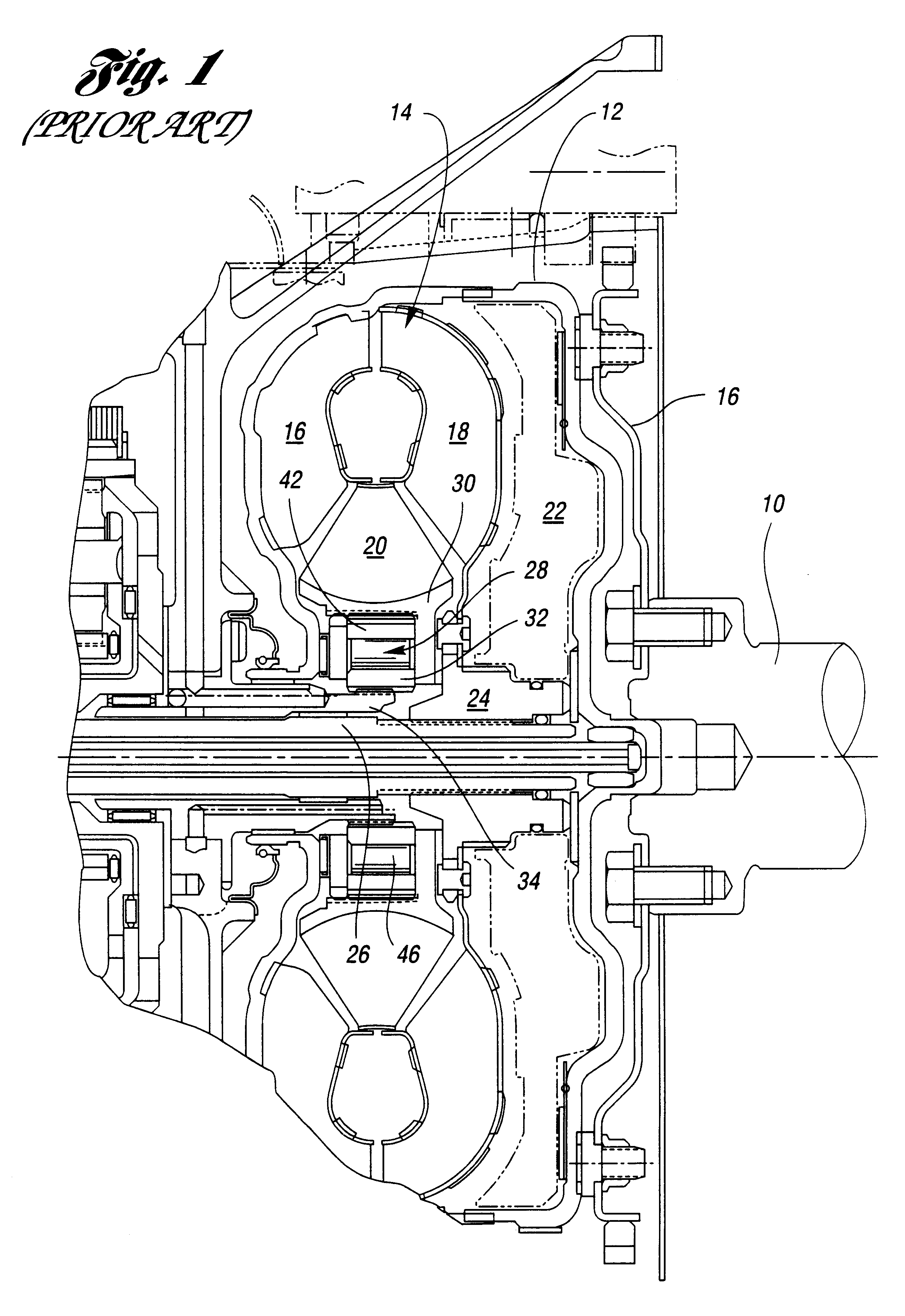

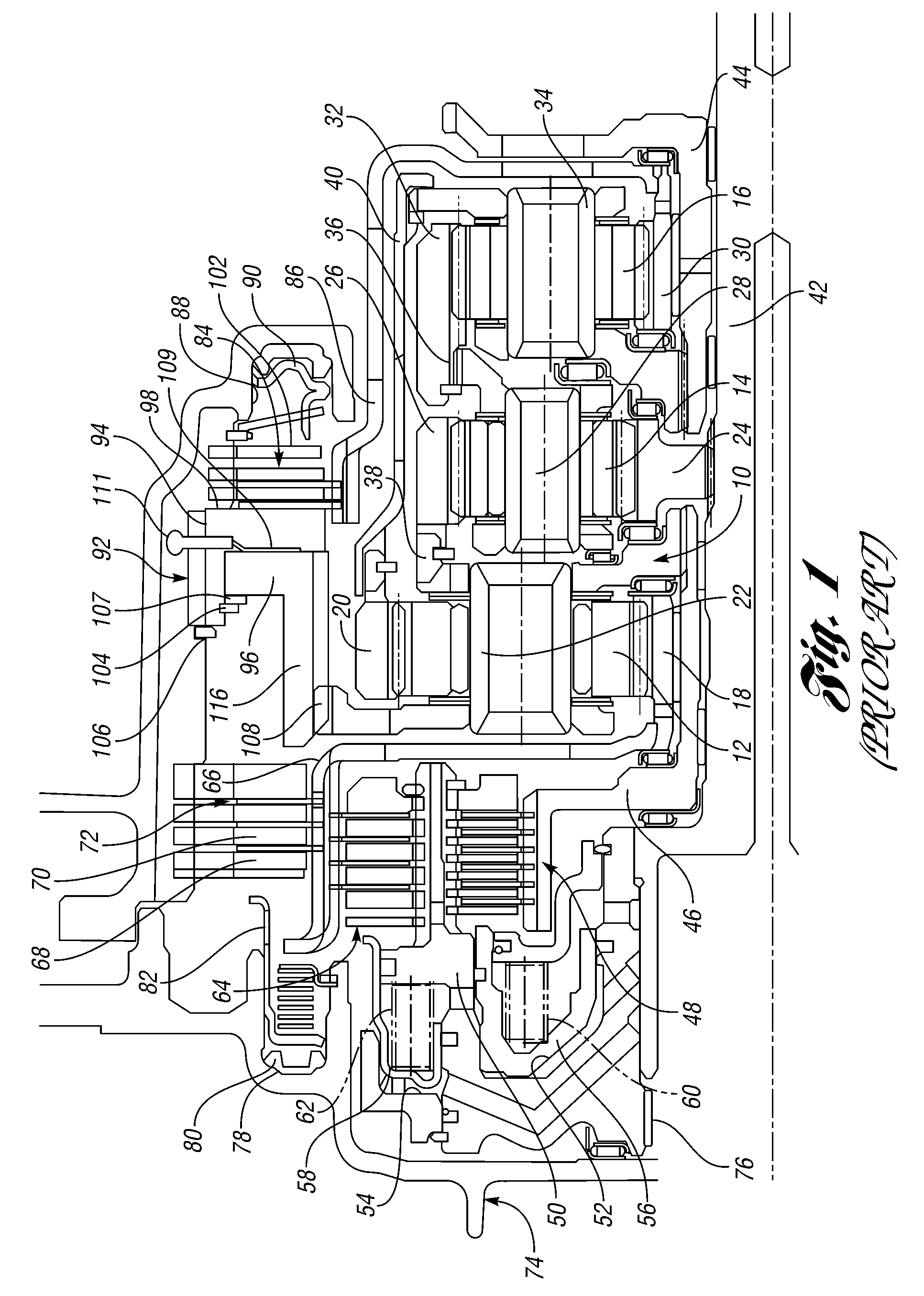

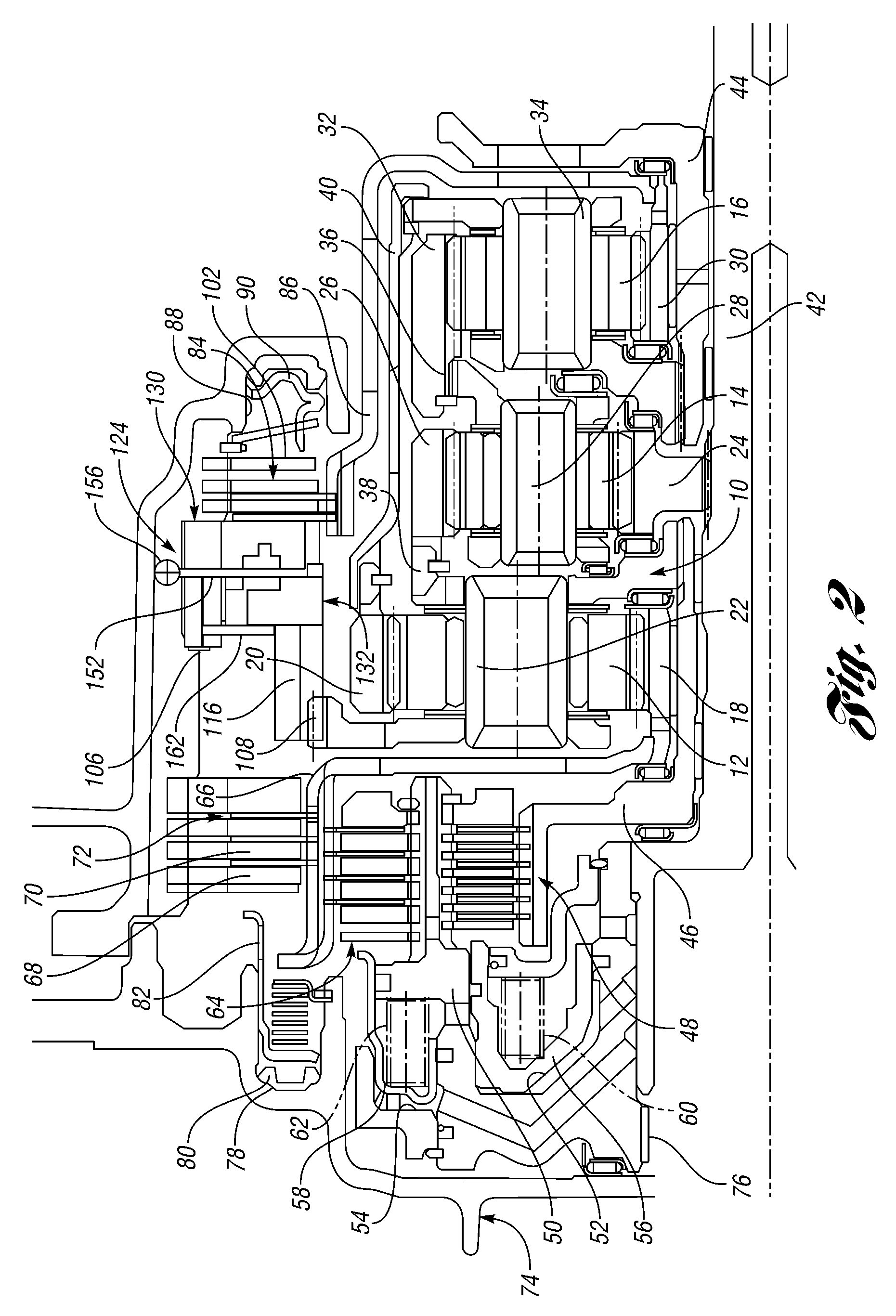

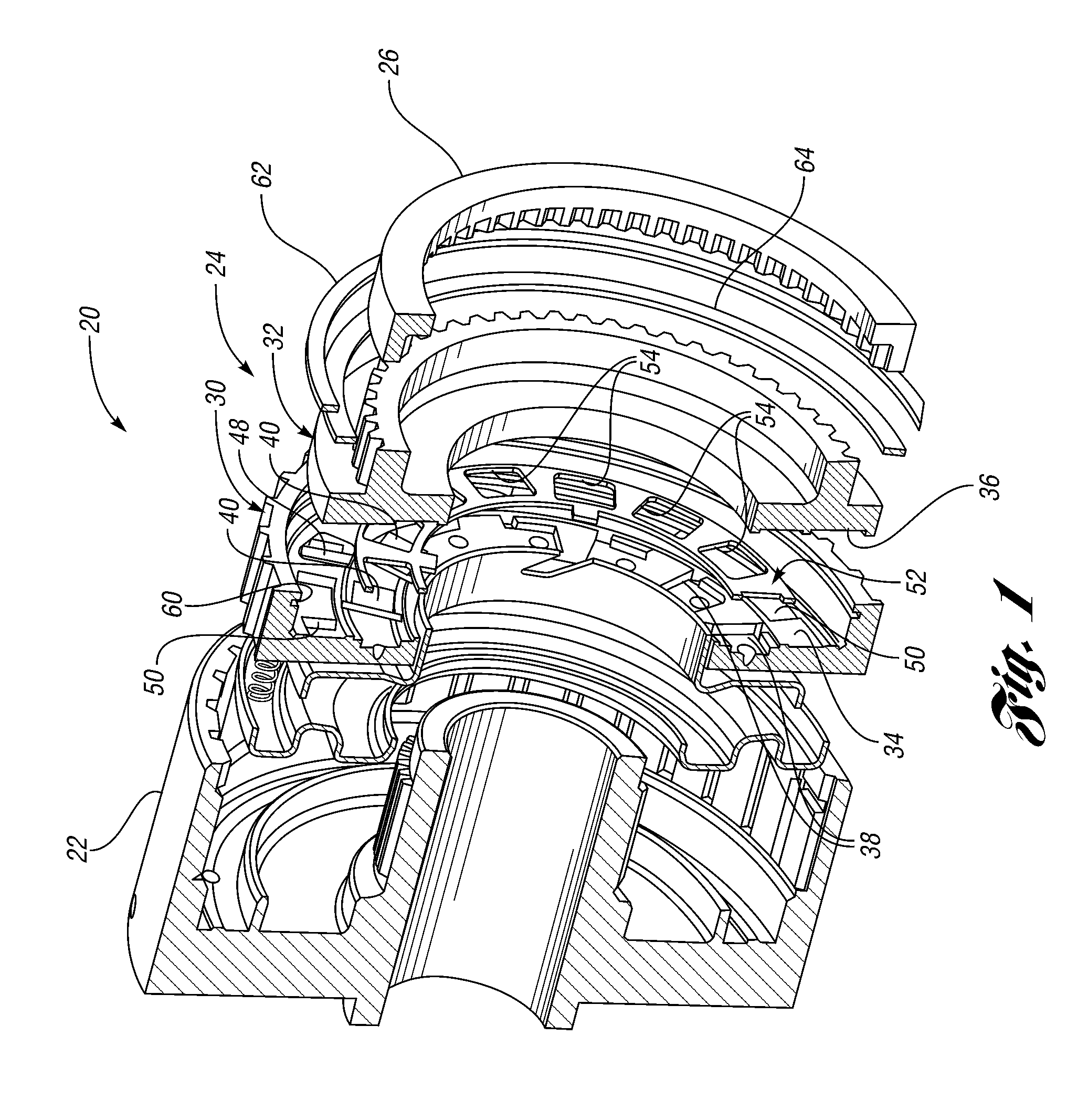

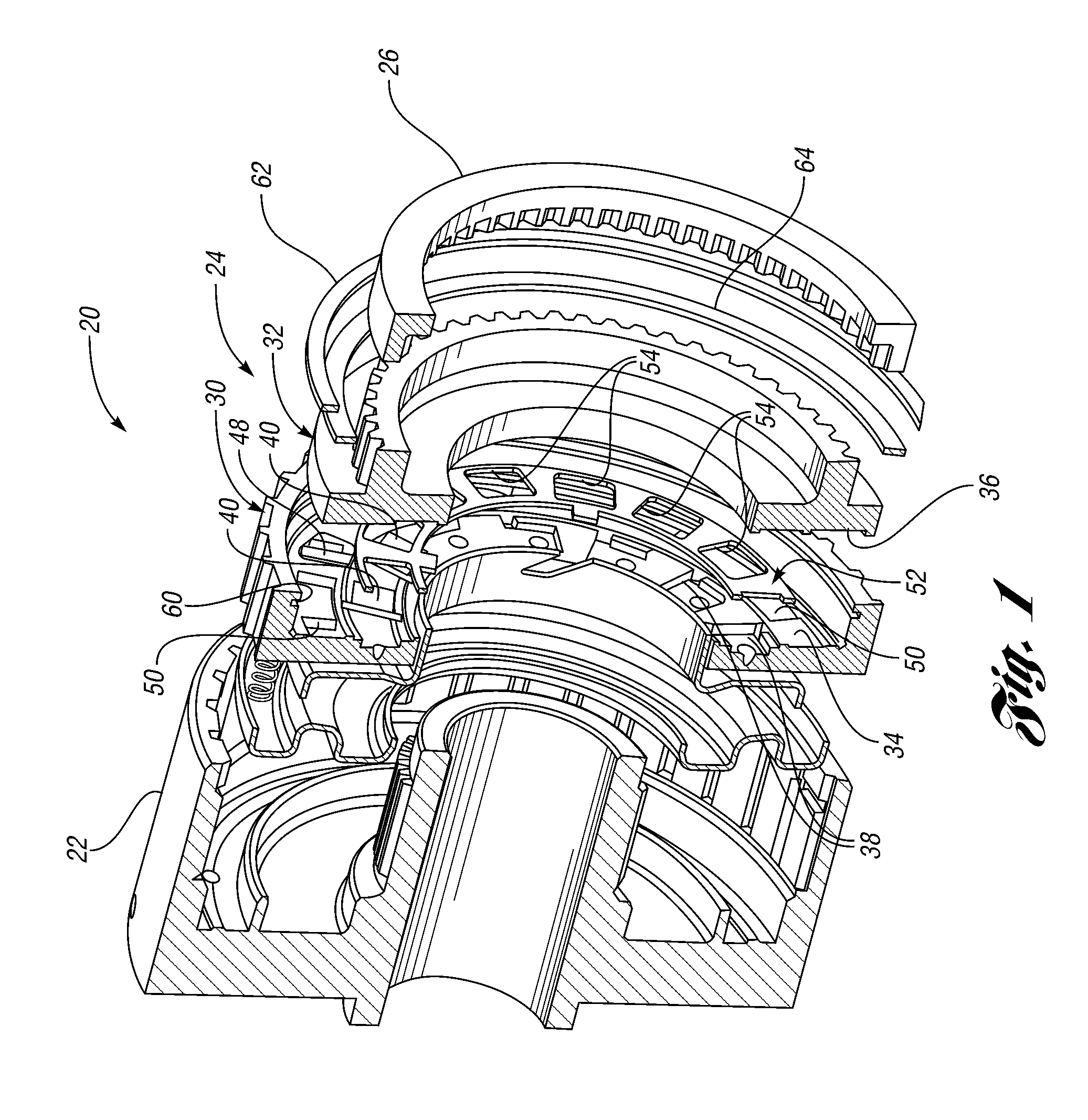

Multi-speed transmission and integrated drive transfer mechanism

InactiveUS6955627B2Improve shift qualityPowerfulToothed gearingsInterengaging clutchesTransfer caseCoupling

A multiple speed transmission capable of producing five underdrive gear ratios, one direct drive ratio, four overdrive ratios, and four reverse ratios includes four interconnected planetary gearsets, multi-plate clutches and brakes controlling the gearset elements, and a coupler that changes between forward drive and reverse drive by holding and releasing alternate gearset components against rotation on the transmission case. The transmission in combination with a single-speed transfer case having either an on-demand transfer clutch, or a full-time all-wheel drive system, are formed in an integrated package.

Owner:FORD GLOBAL TECH LLC

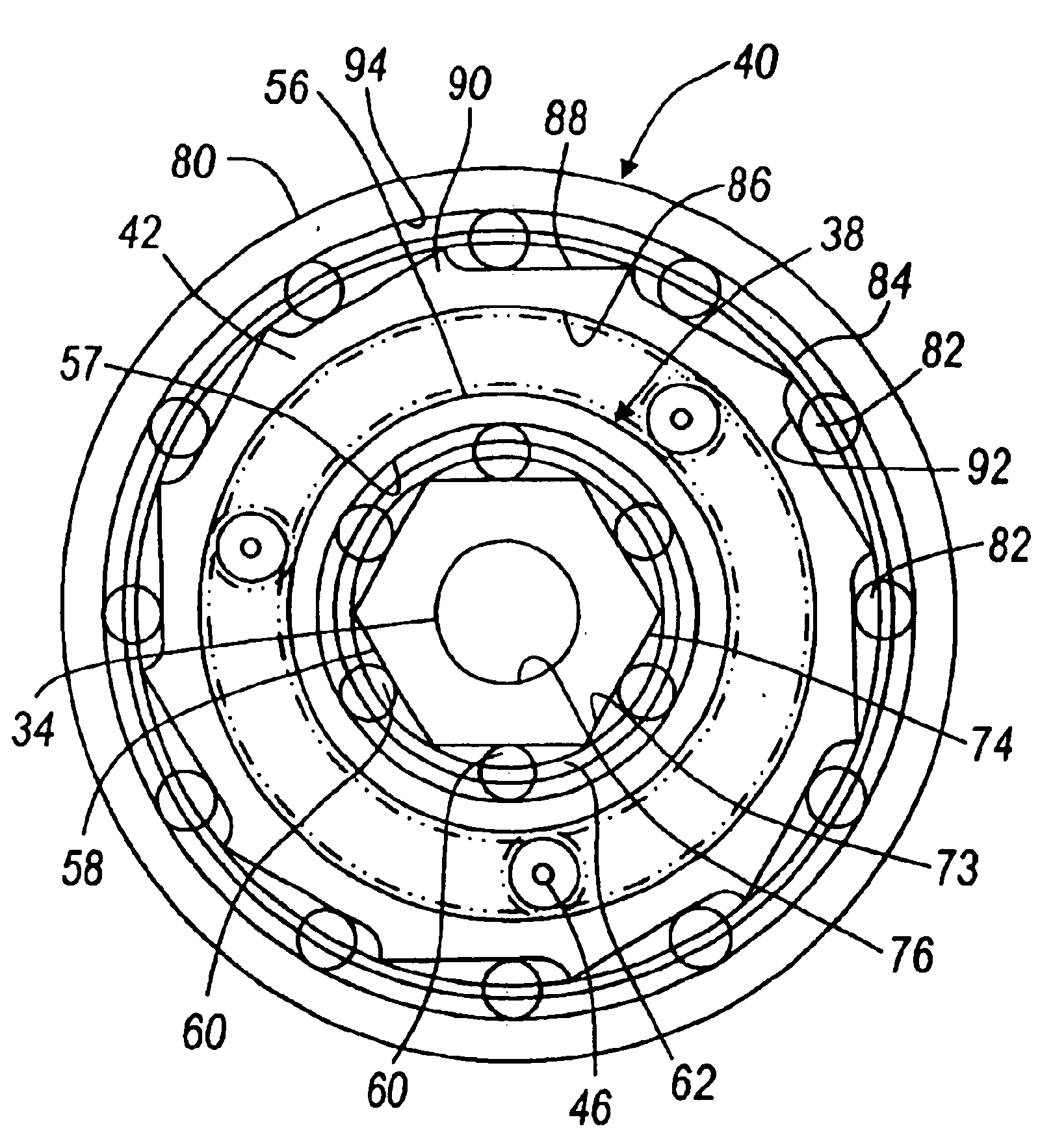

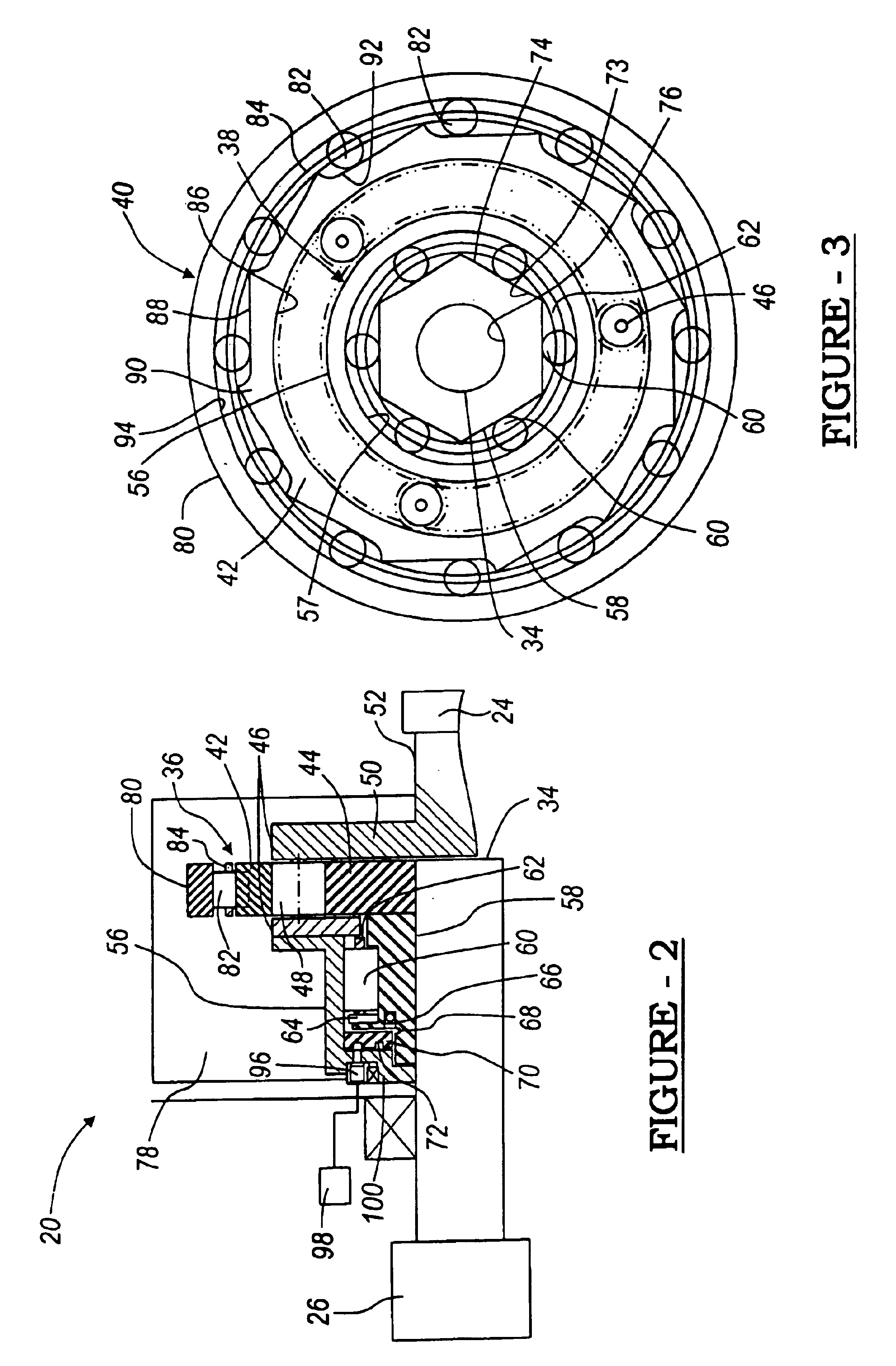

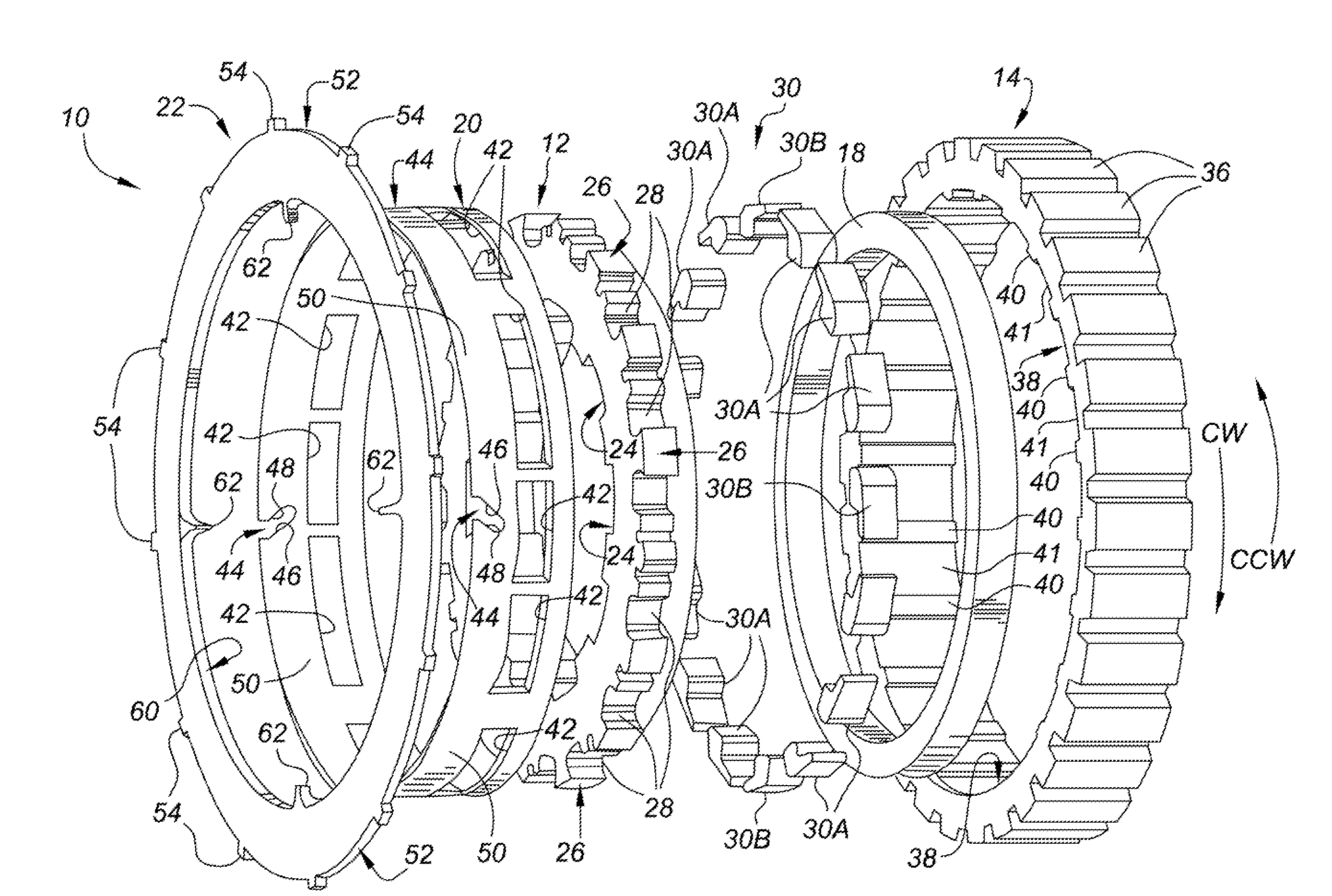

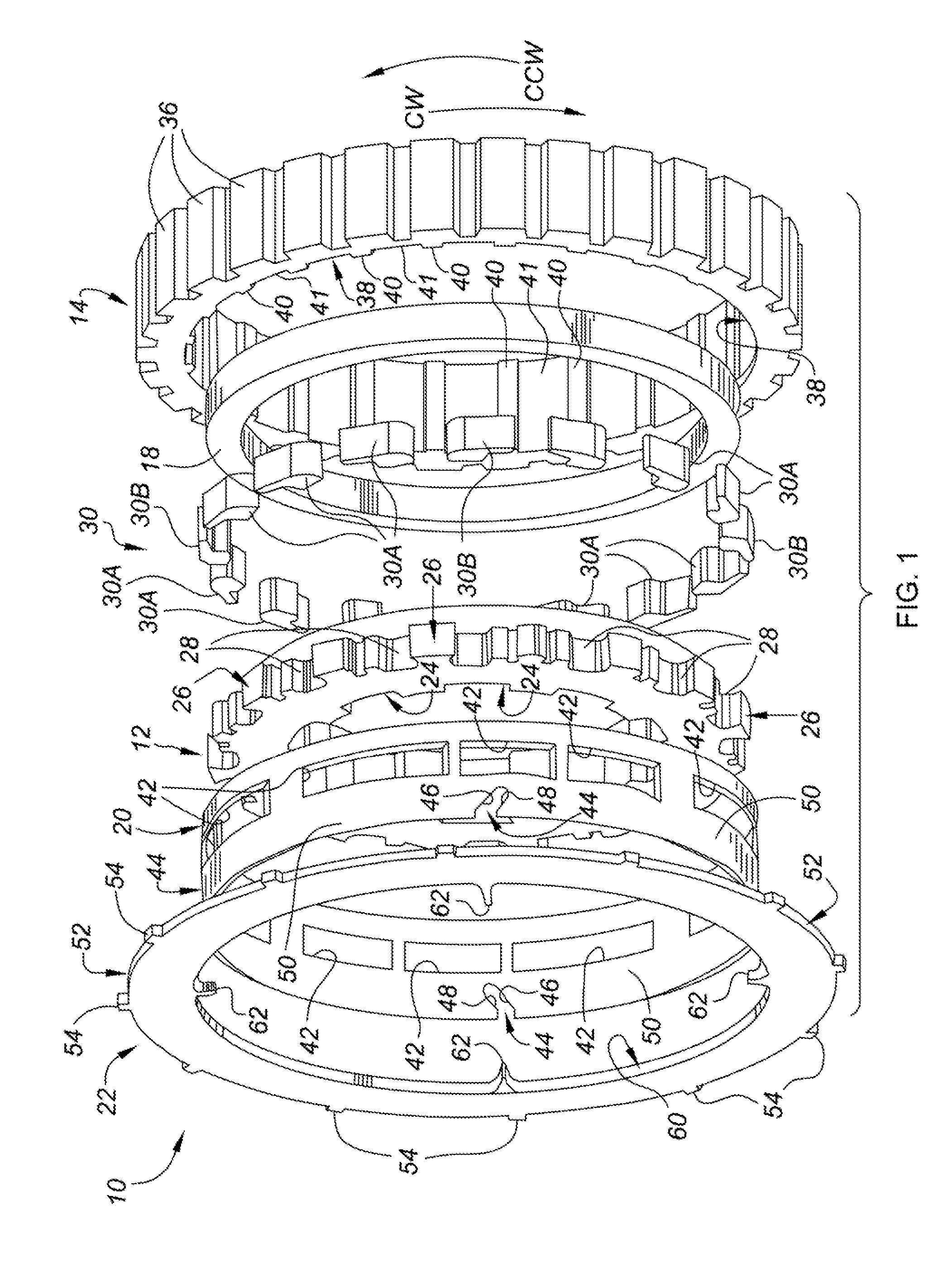

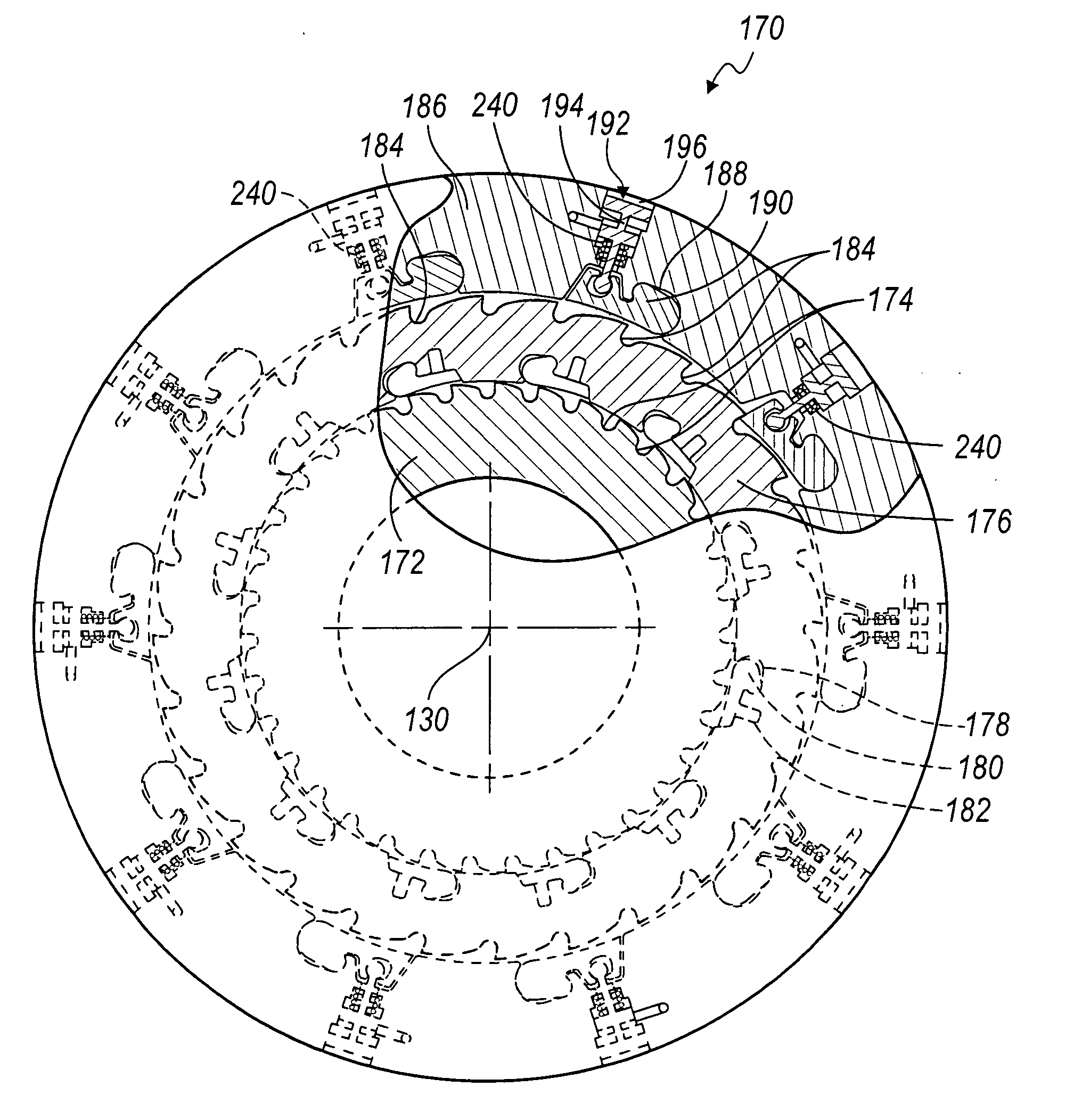

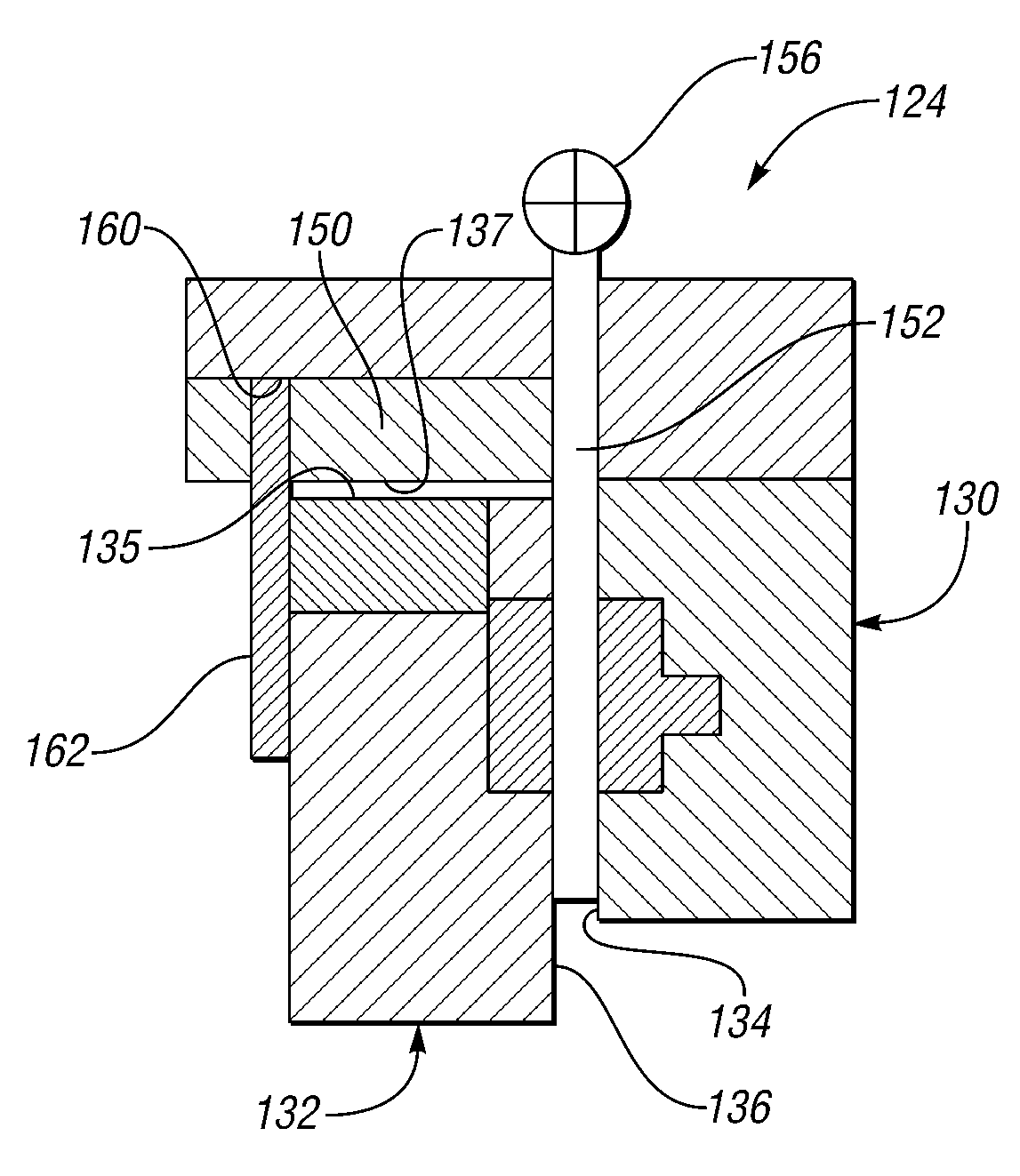

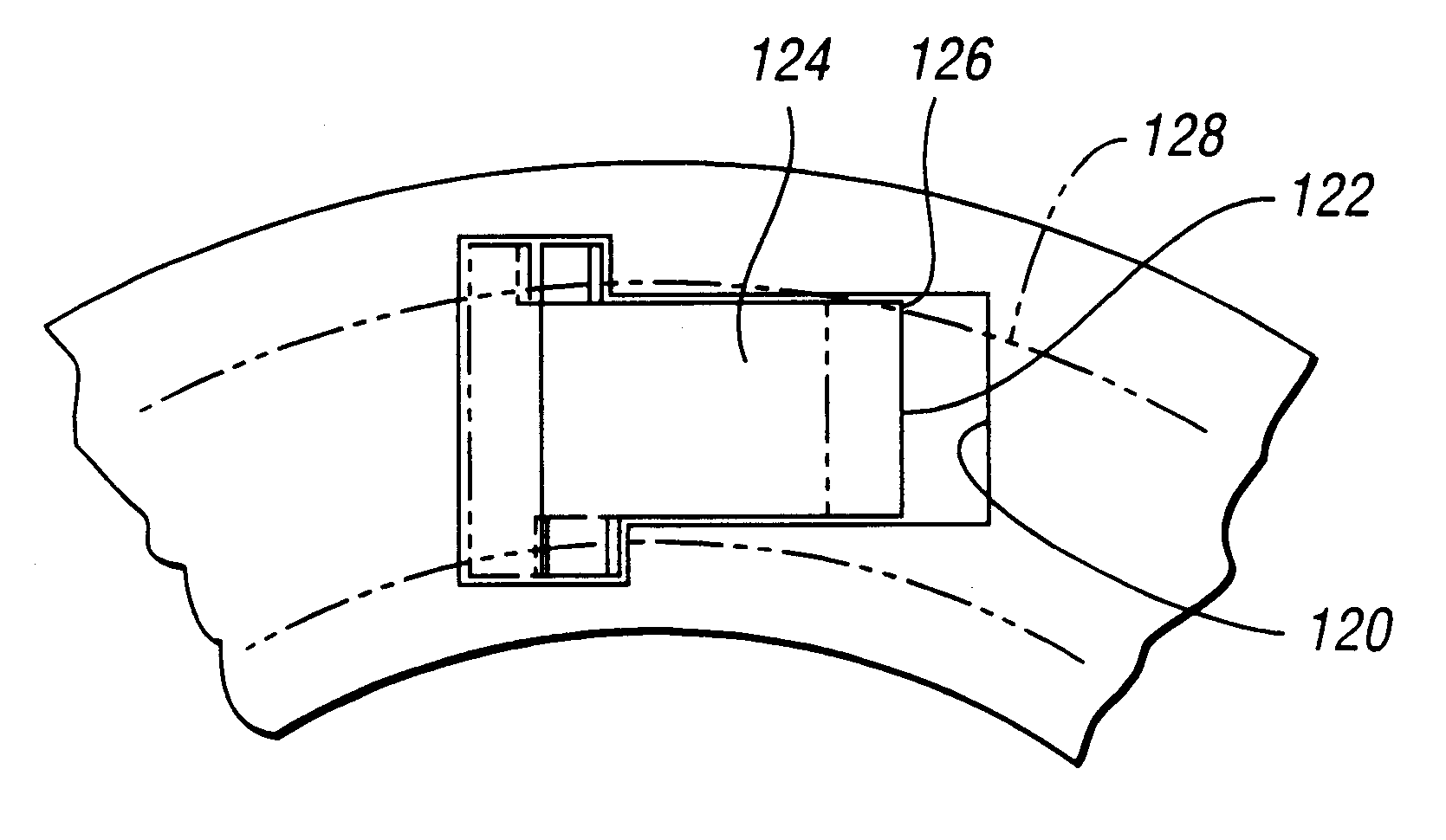

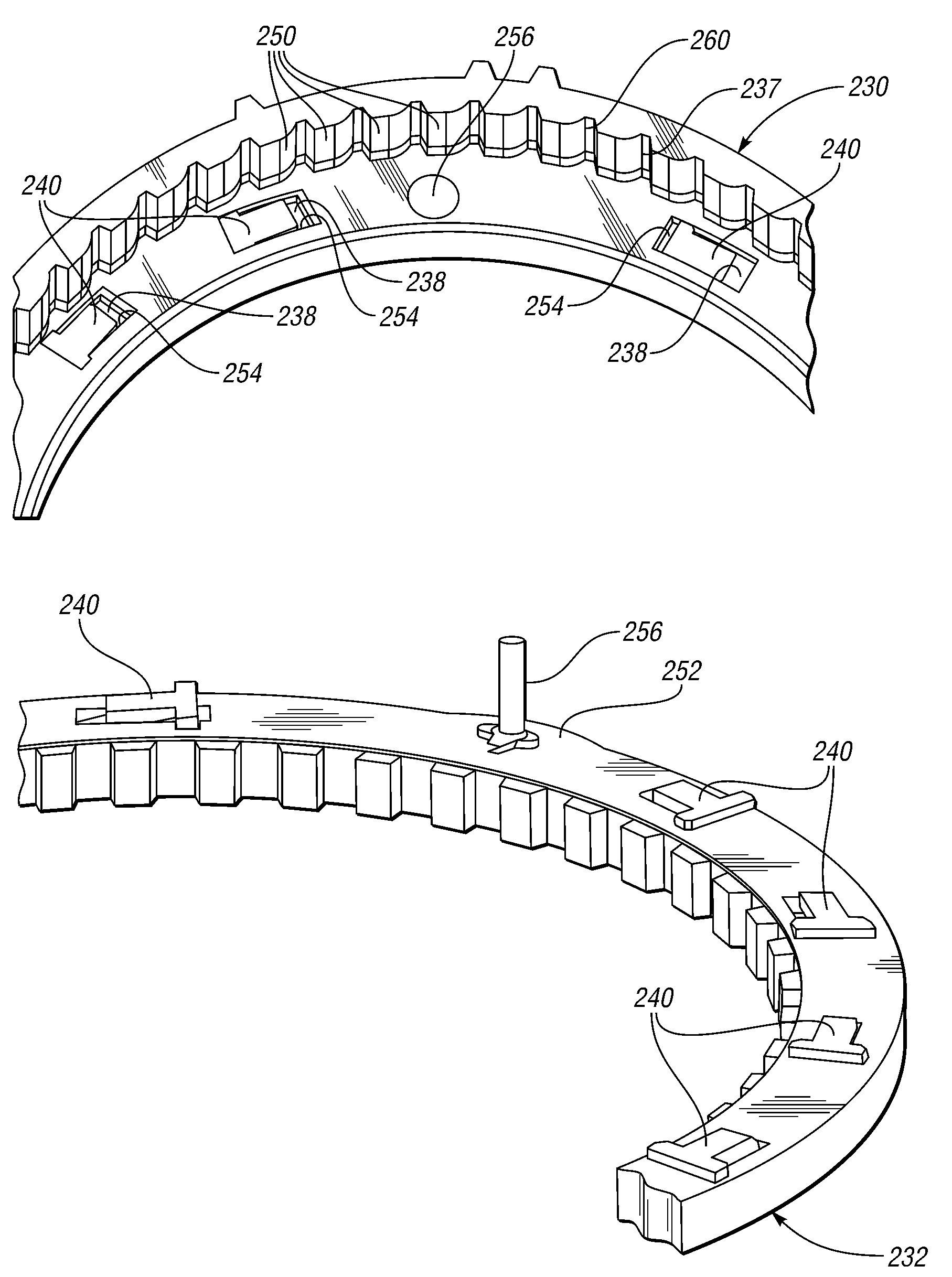

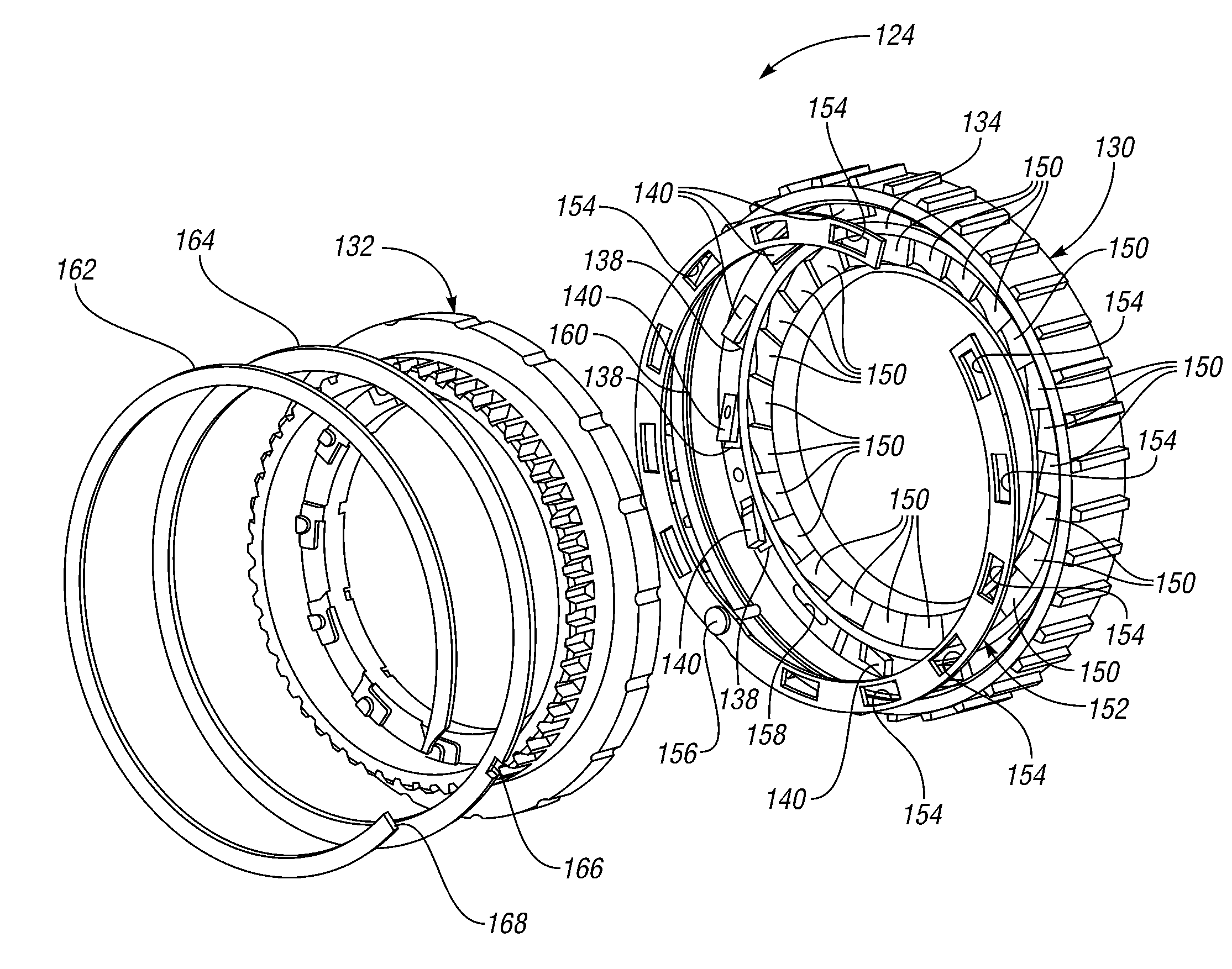

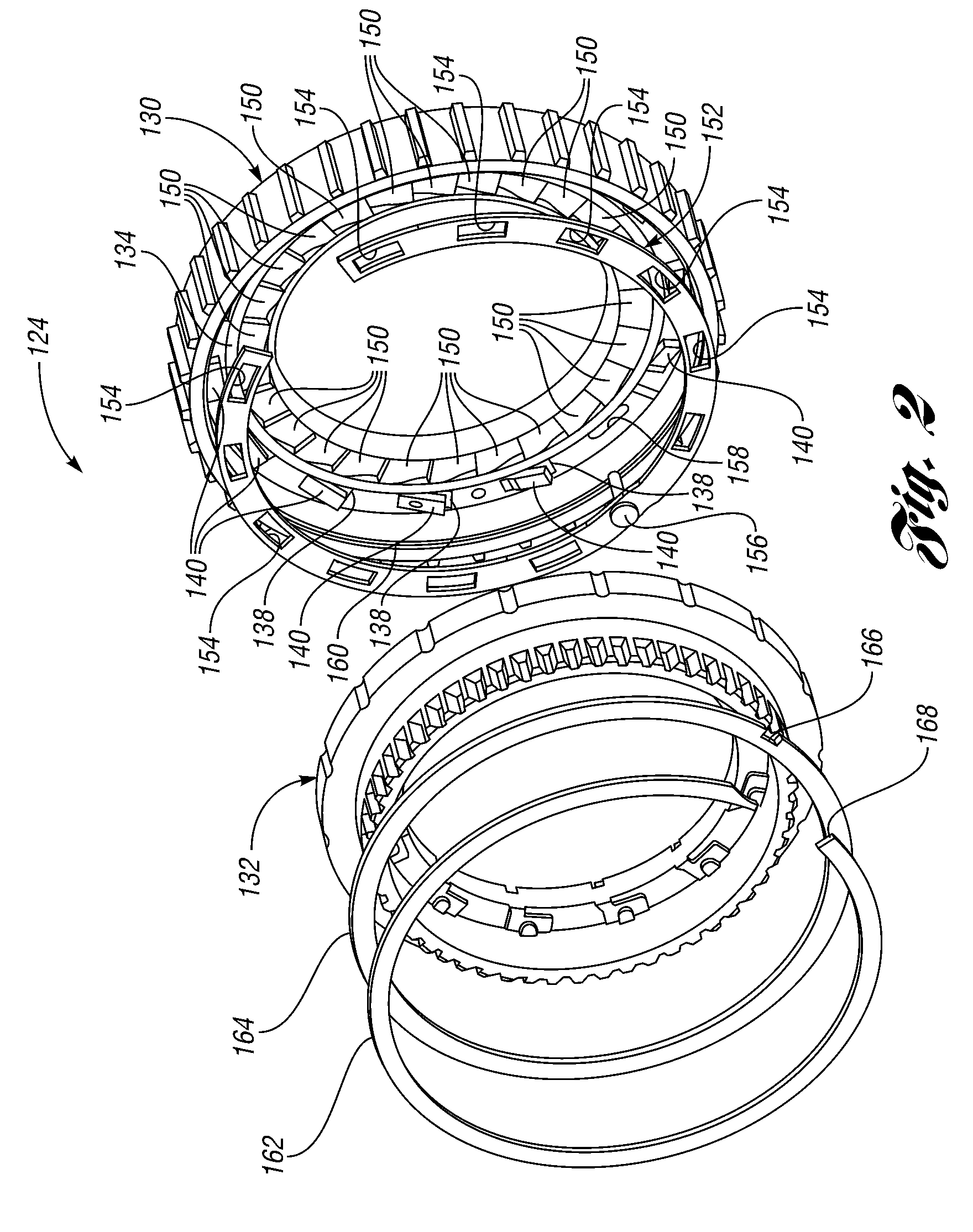

Overrunning radial coupling assembly and method for controlling the engagement of inner and outer members of the assembly

The overrunning radial coupling assembly or clutch and a method of controlling the engagement of inner and outer plates or members of the assembly are provided wherein adjacent engaging radial locking pawls are selectively controlled by a single, rotatable control plate or element to obtain full lock, one-way lock and one-way overrun conditions. The assembly includes free-floating, forward pawls and free-floating, reverse pawls adjacent to their respective forward pawls. The forward and reverse pawls are movable between a notch-engaging, engaged position (i.e., full lock condition) and a disengaged position in which the outer member is permitted to free-wheel relative to the inner member in the one-way overrun condition in one direction about a first axis and the outer member is locked to the inner member in the one-way lock condition in the opposite direction. A number of different embodiments of the assembly and method are provided.

Owner:MEANS IND INC

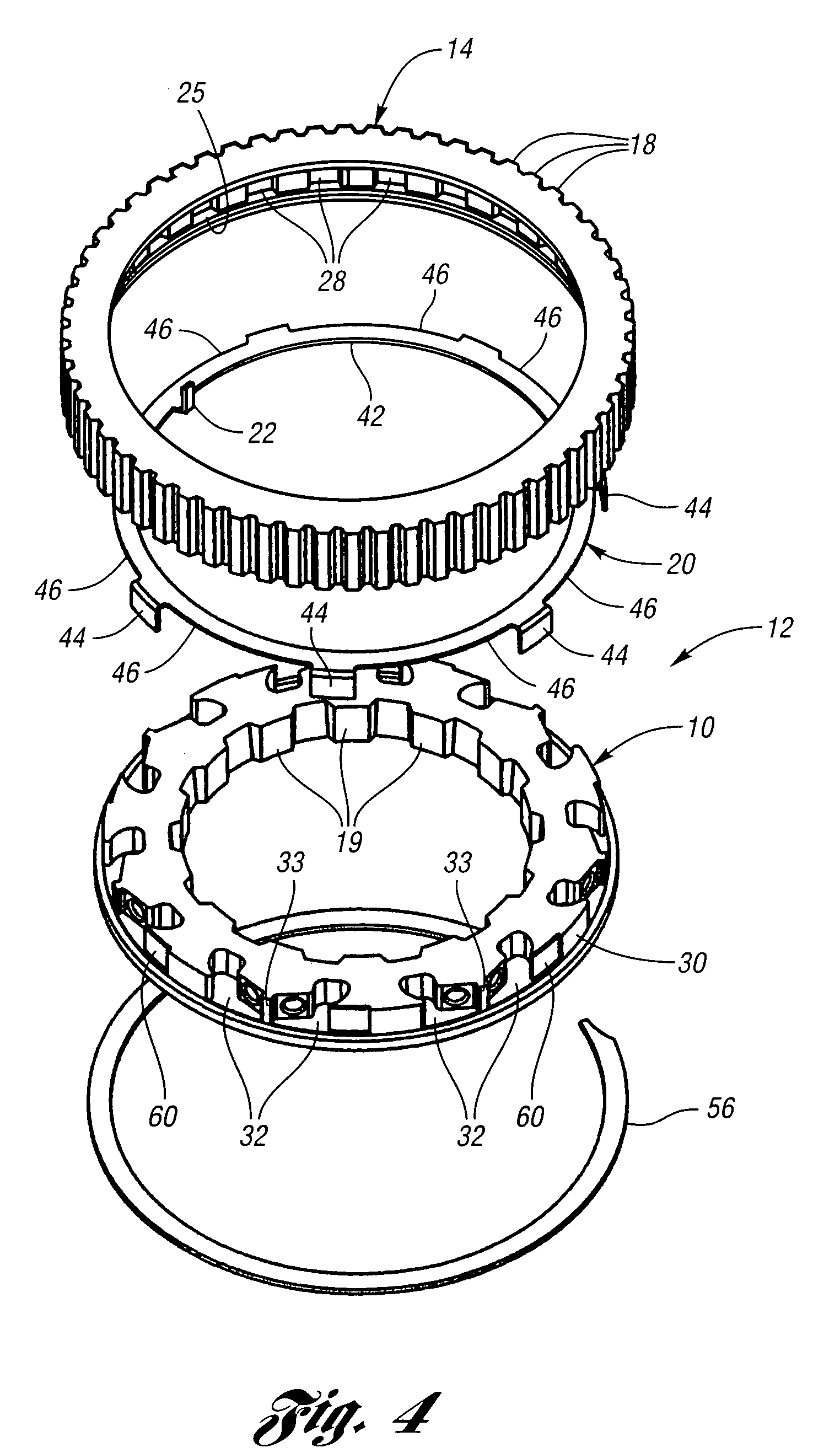

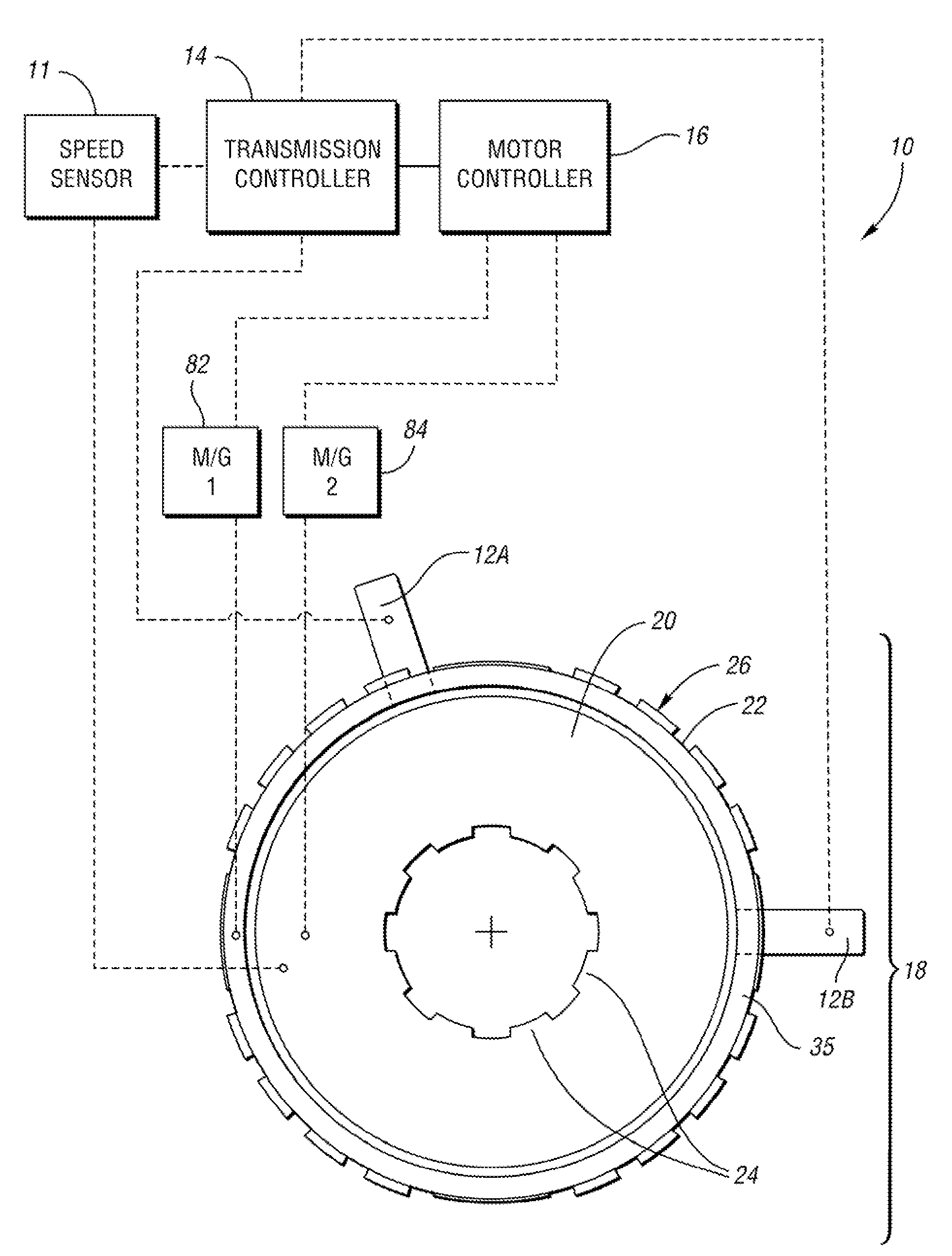

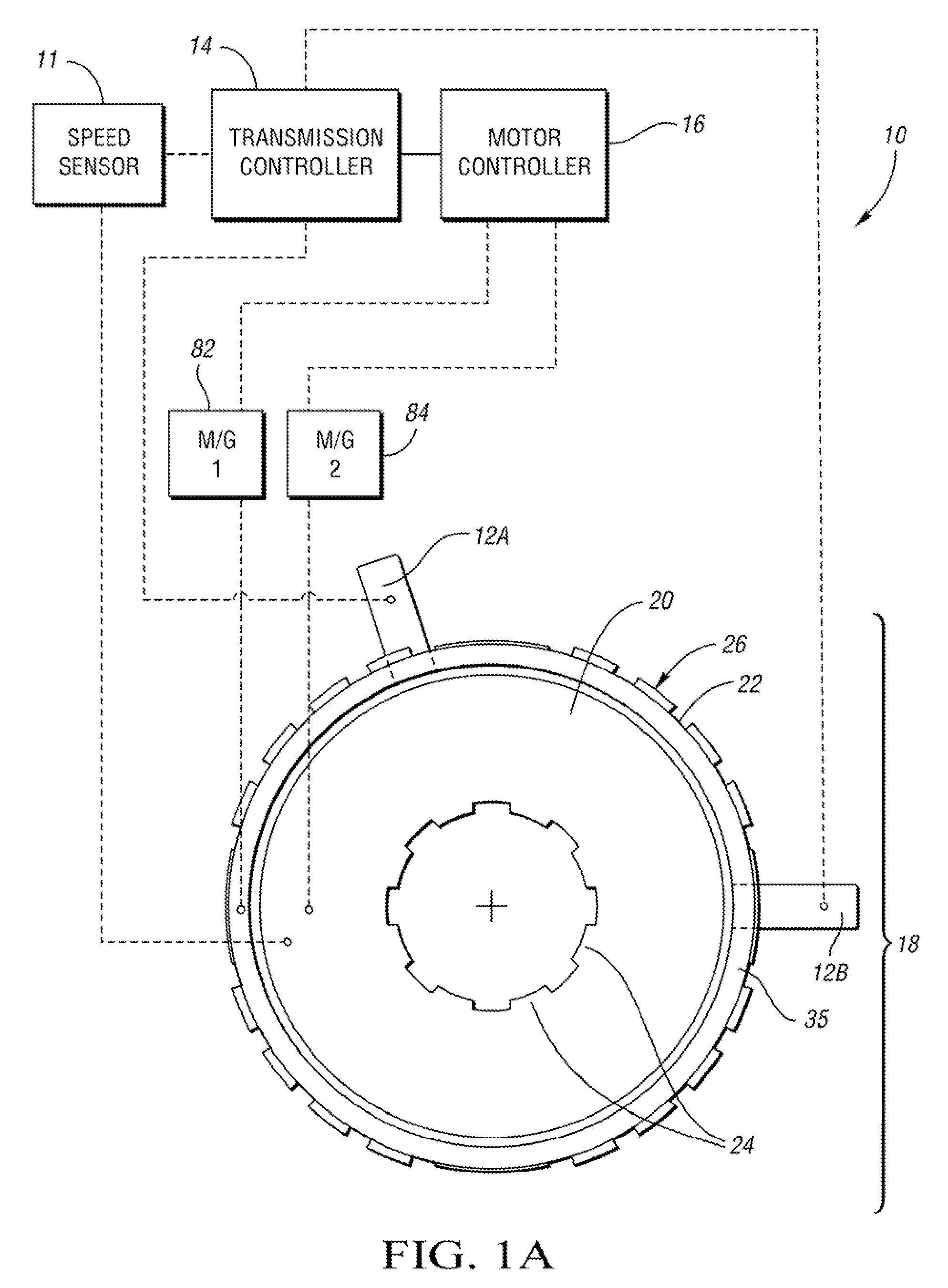

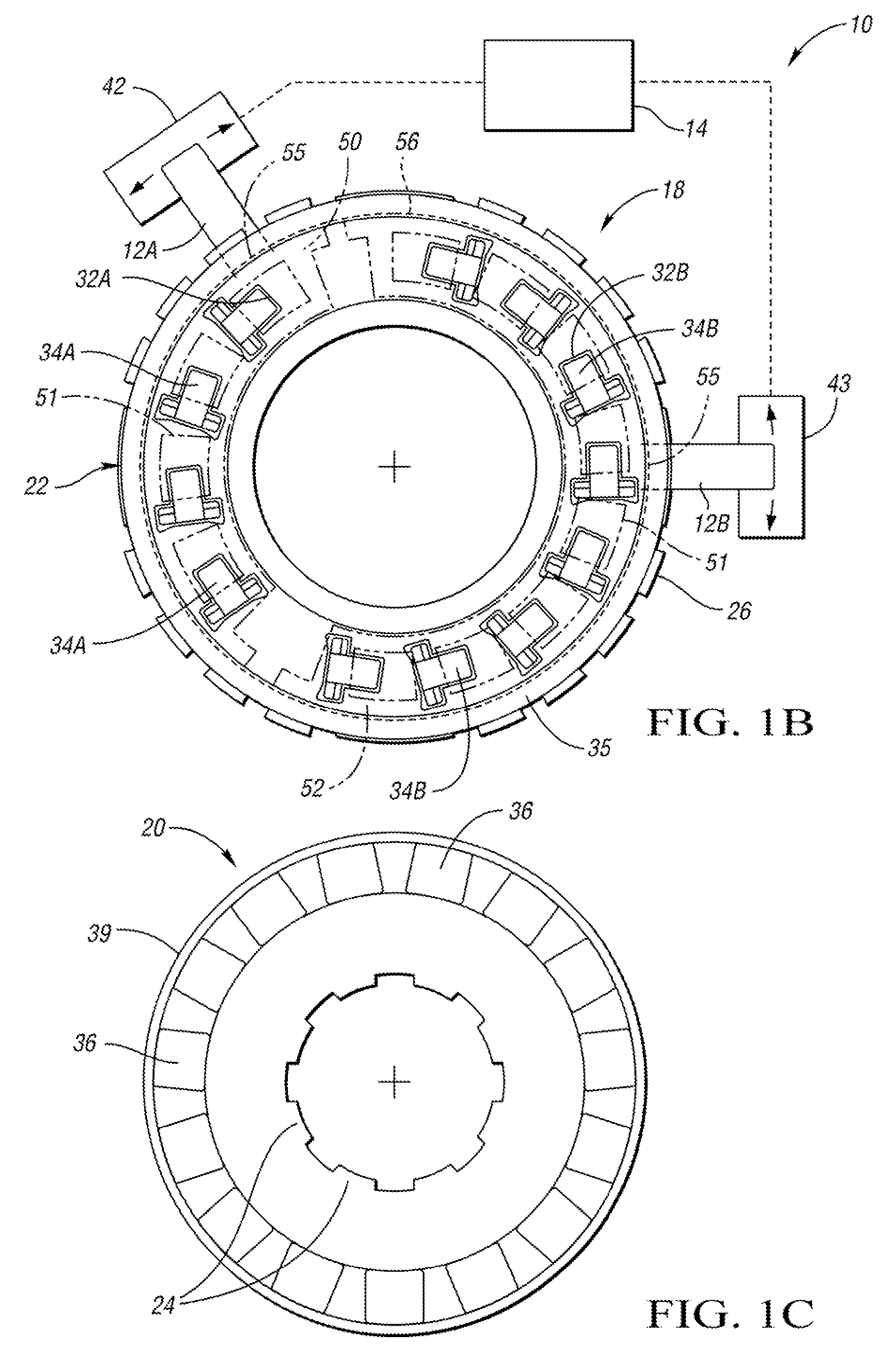

Selectable one-way clutch

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

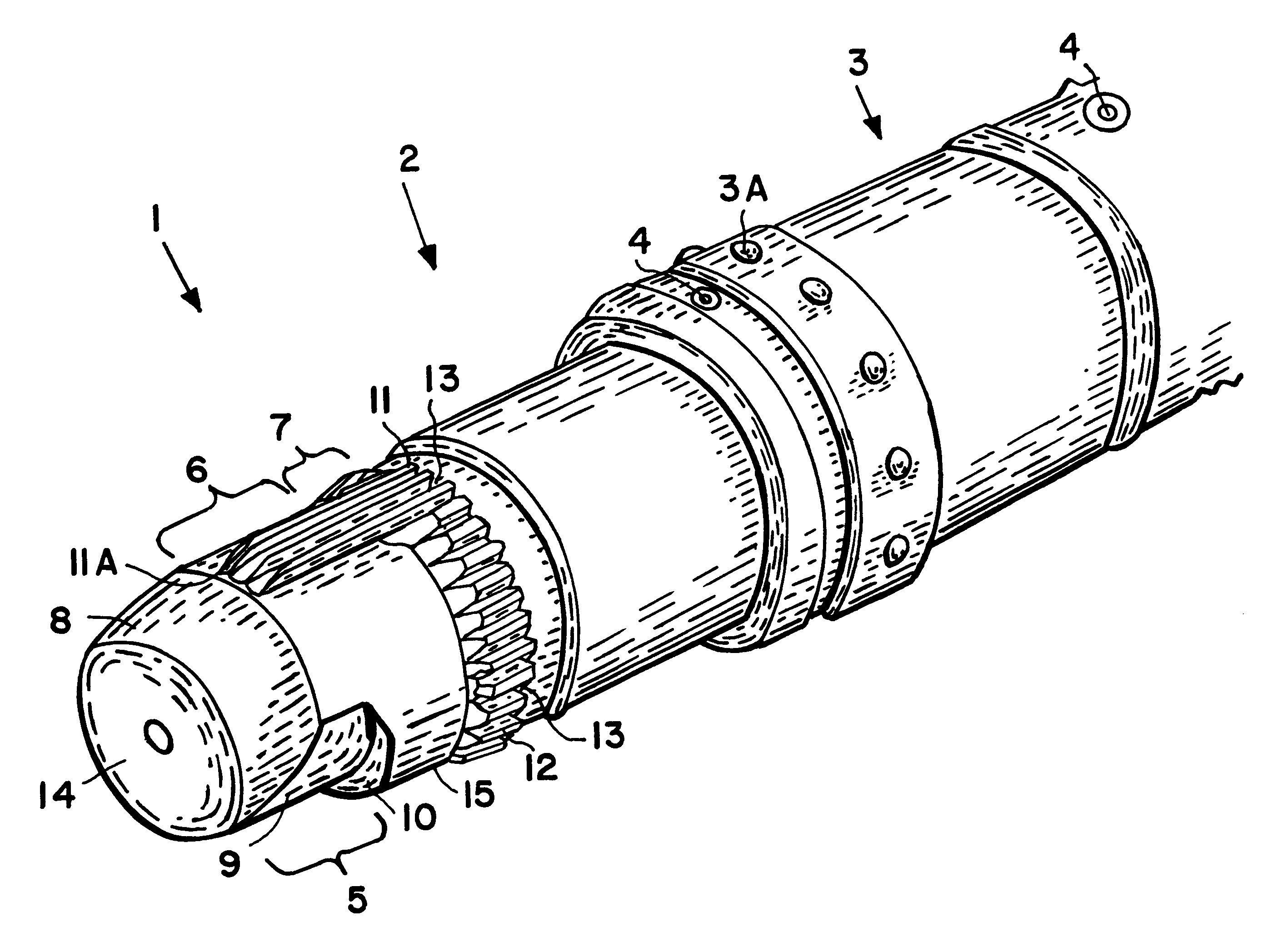

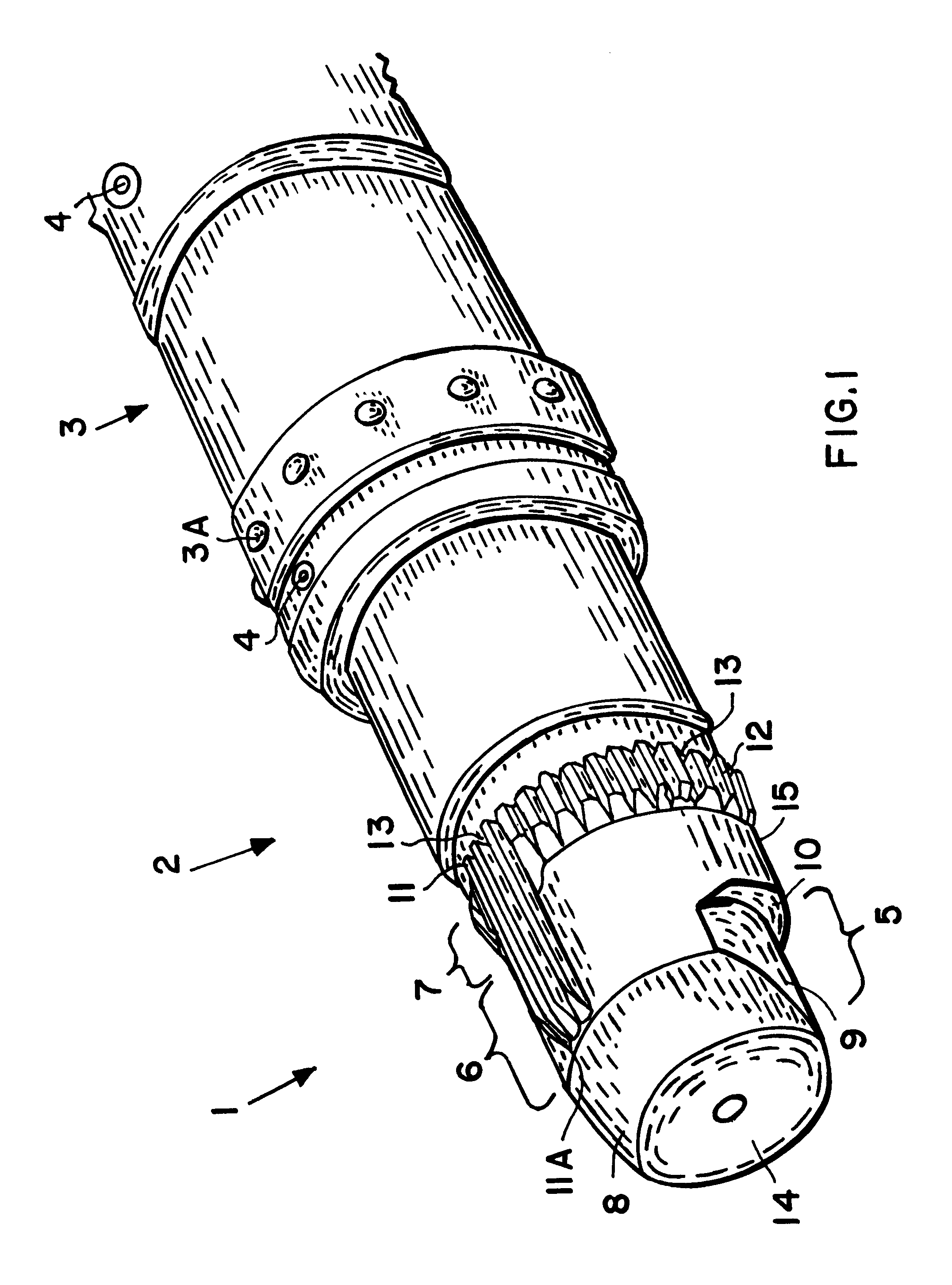

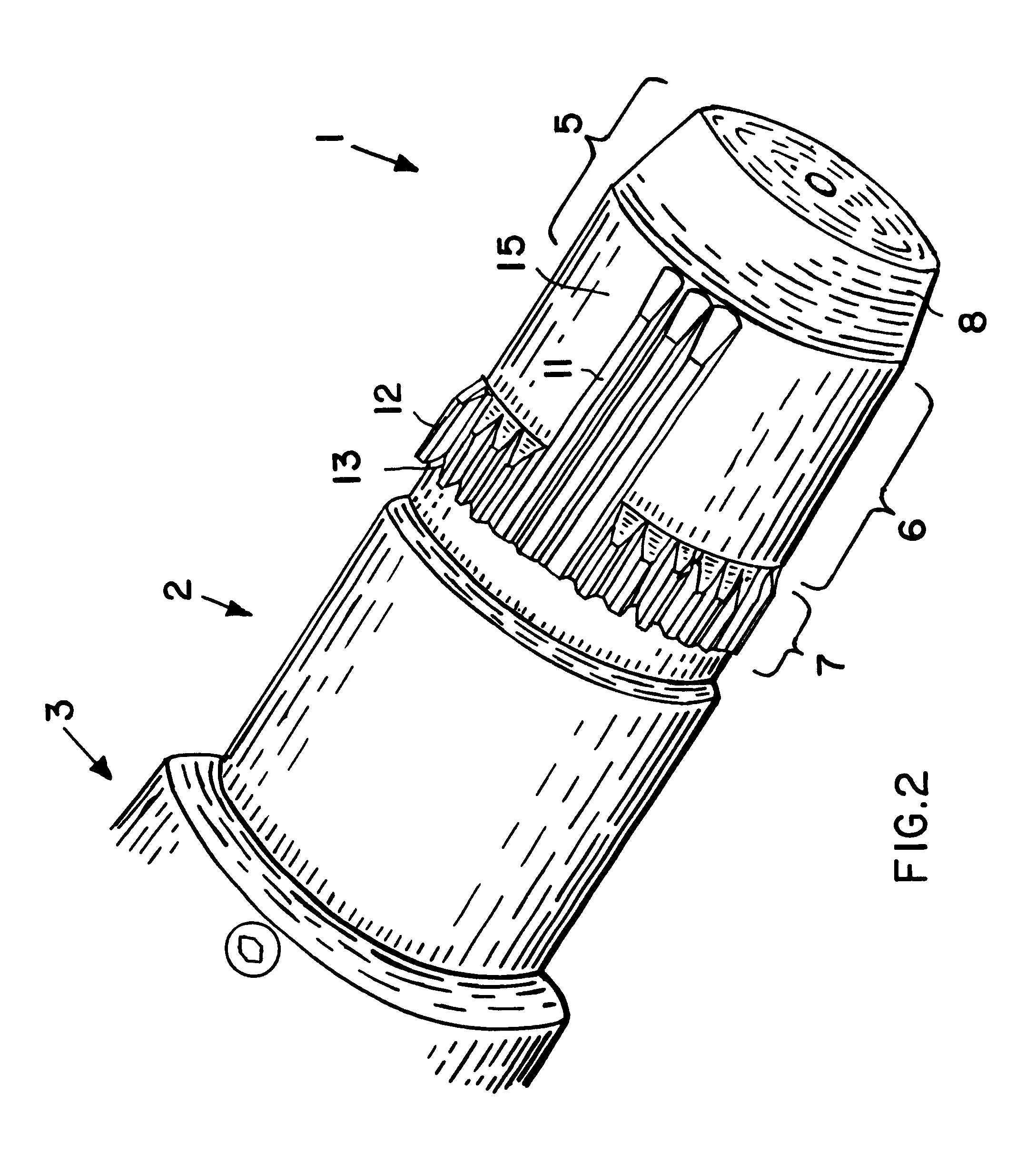

Self-aligning splined male shaft head and engagement method

InactiveUS6482094B2Simple processReduce wearShaftsInterengaging clutchesMechanical engineeringRotational alignment

A splined shaft head for engaging a splined hub includes first, second and third stages. The first stage has a conical taper on one side, and a cylindrical setback on the other side, which transitions through a tapered shoulder to the cylindrical body of the shaft head. The second stage includes lead spline teeth extending along the cylindrical body to the conical taper. The third stage includes torque-transmitting main spline teeth regularly arranged around the circumference. The shaft head is rotated while being inserted axially into the hub. The first stage allows radial free play and de-centering of the hub so the lead spline teeth find a proper rotational alignment with spline grooves of the hub. Then, the tapered shoulder at the end of the first stage positively centers the hub on the shaft axis, and finally the main spline teeth of the third stage provide full form-locking engagement.

Owner:SCHENCK ROTEC GMBH

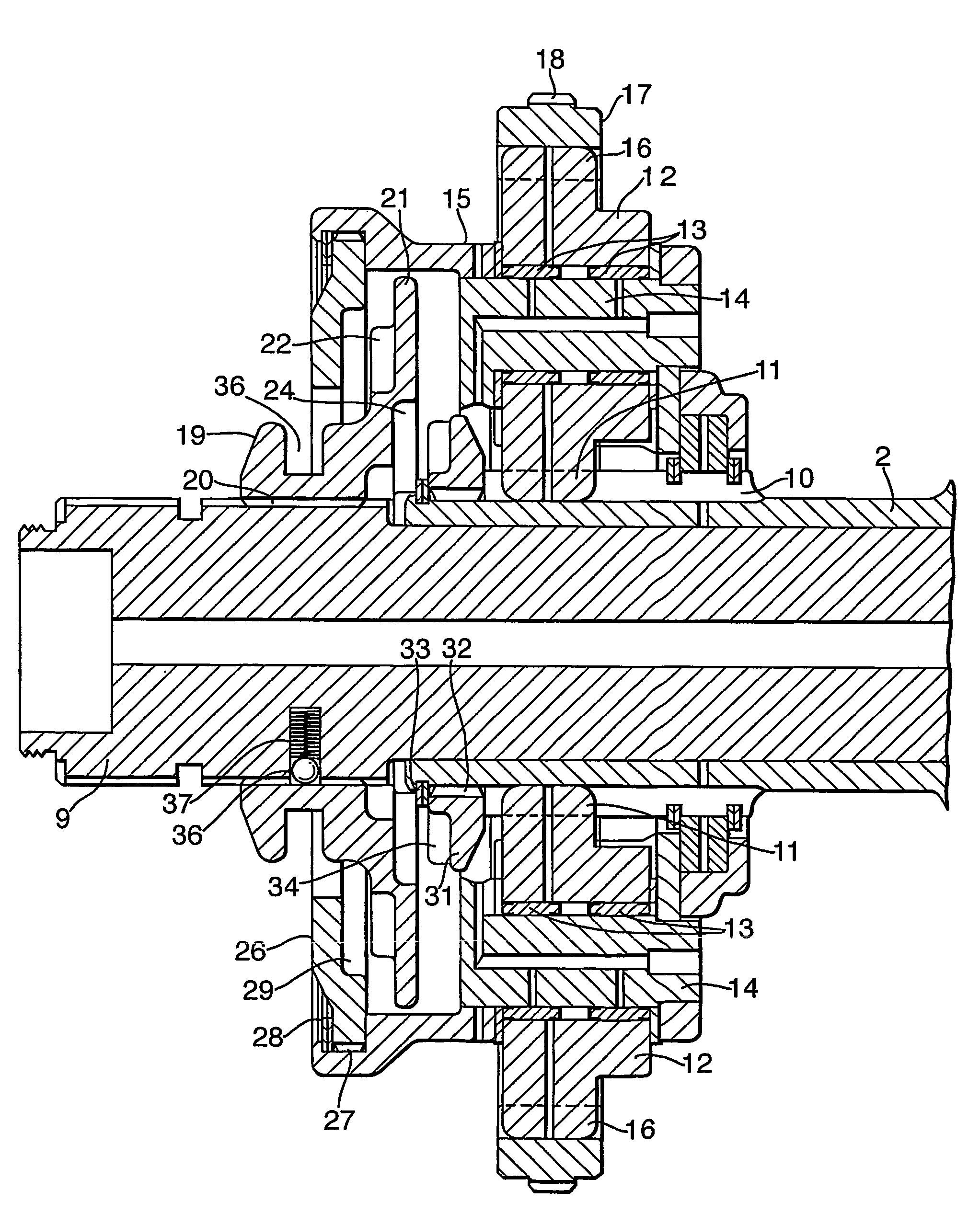

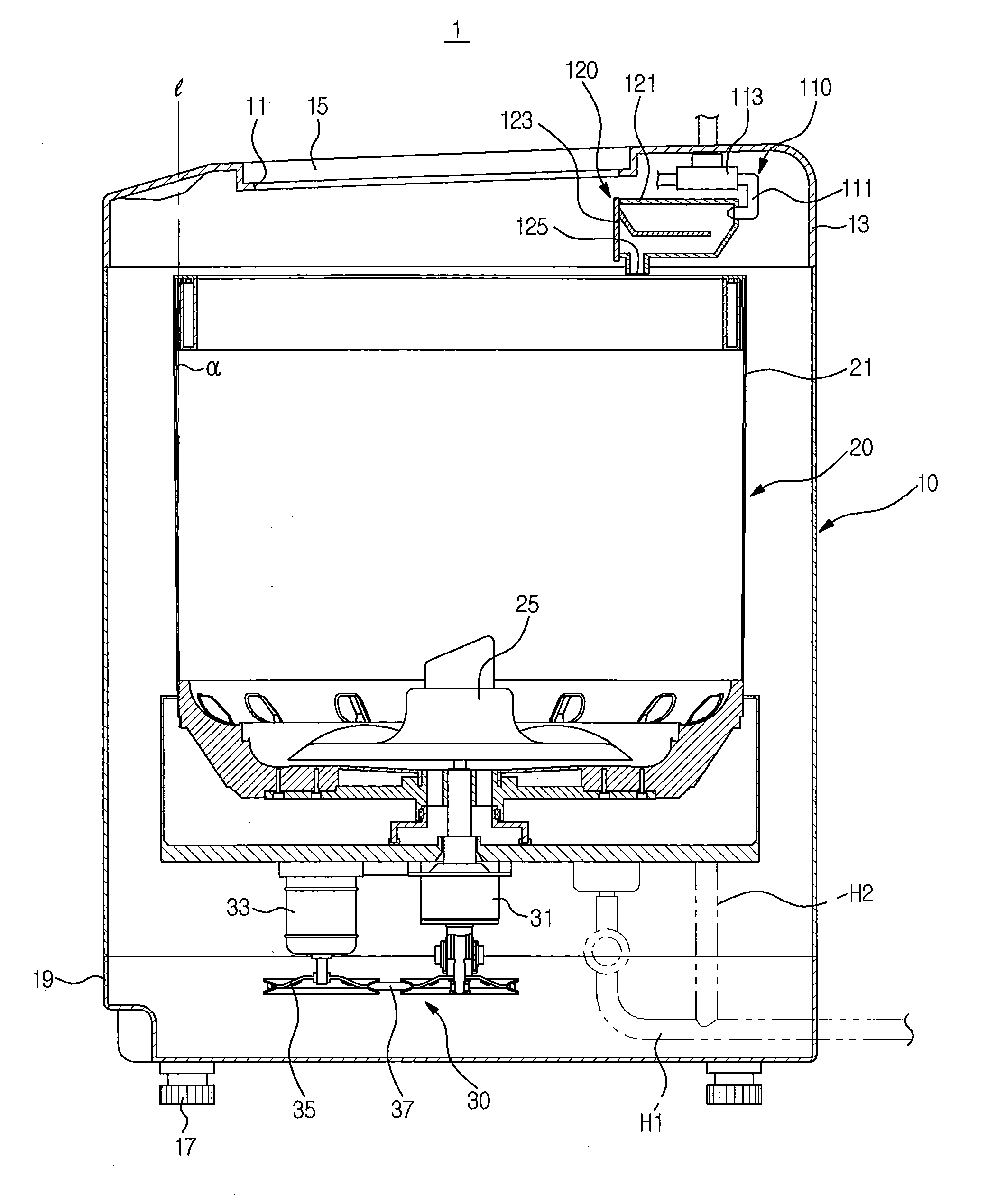

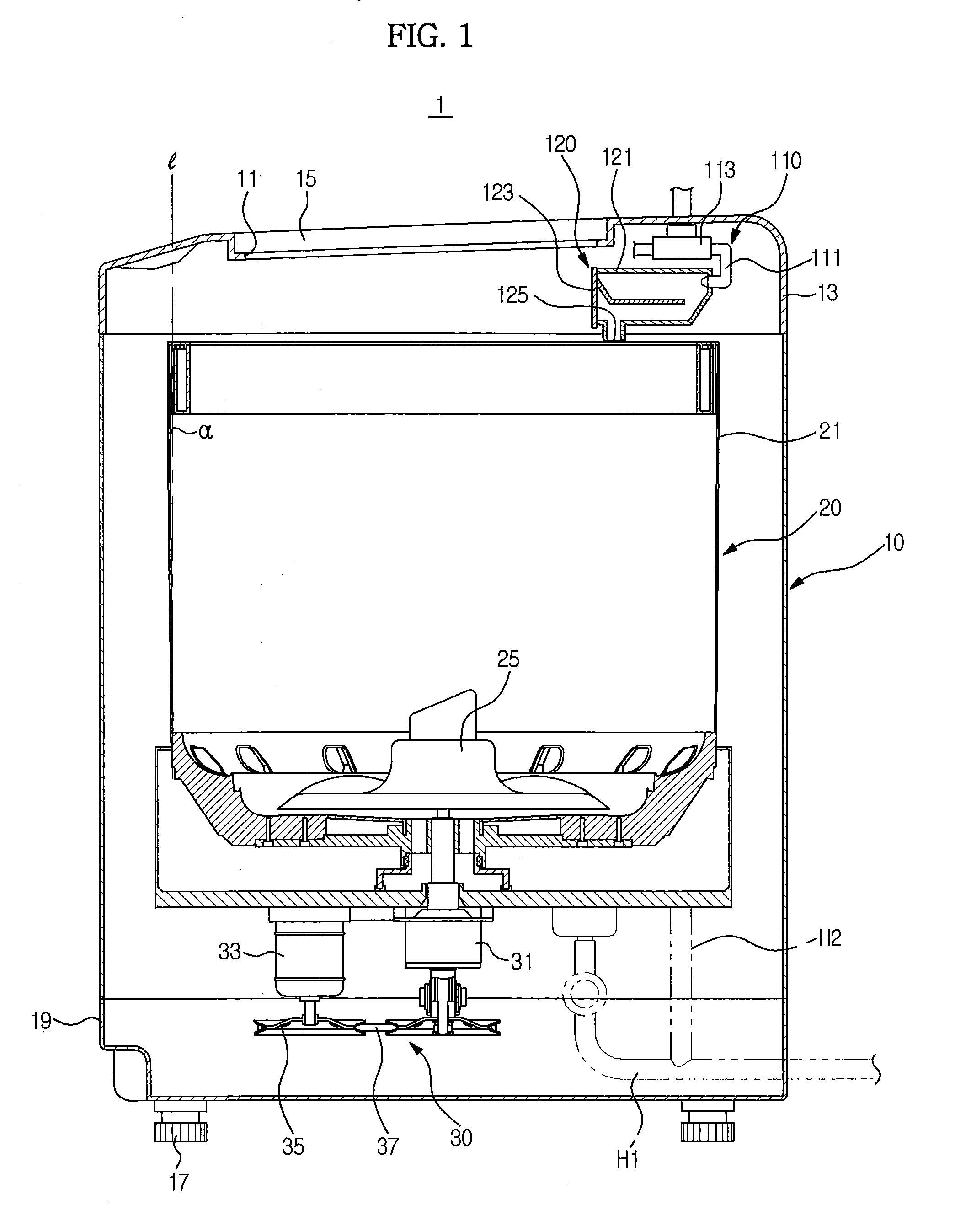

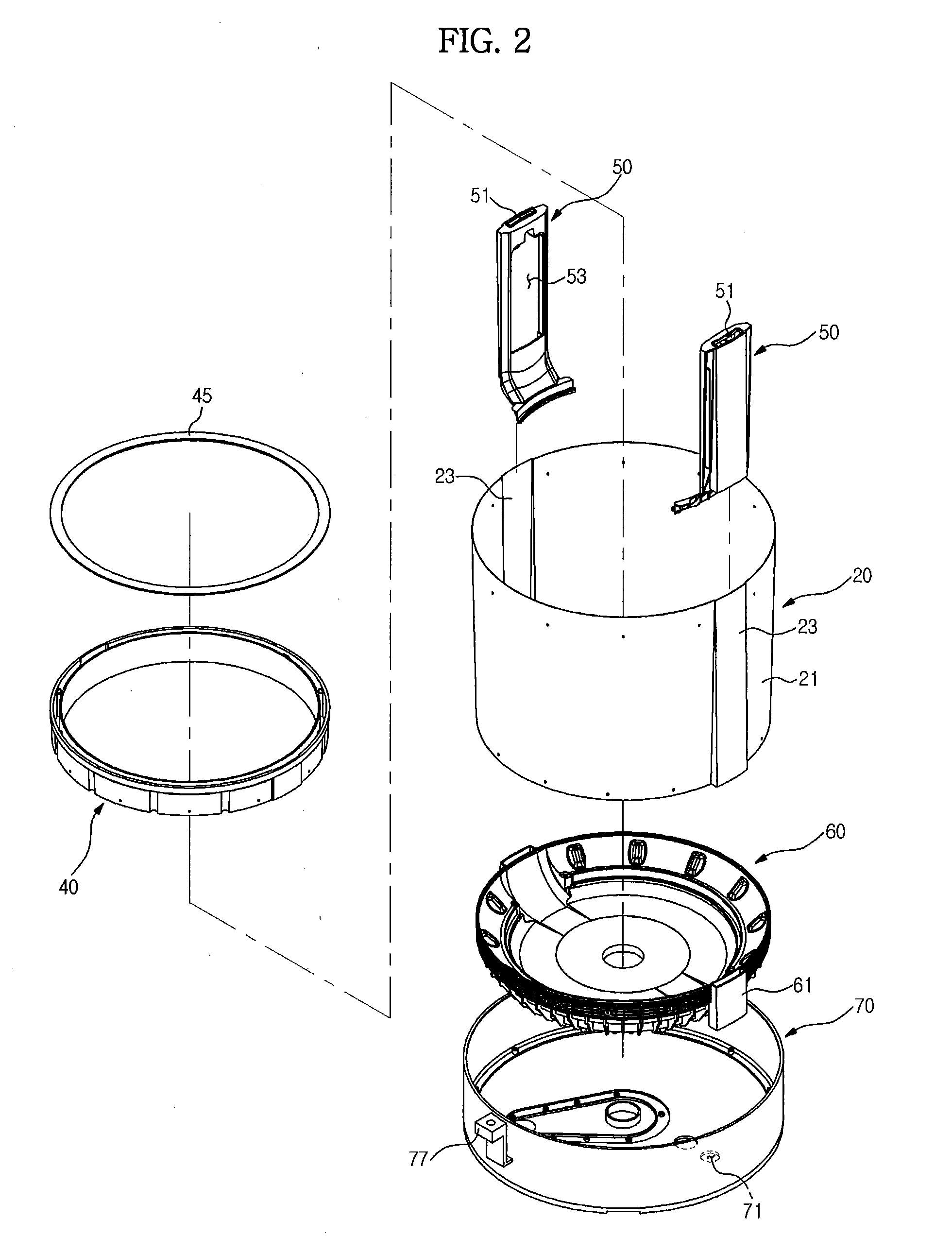

Washing machine

InactiveUS20130036776A1Reduce water consumptionImprove washing effectOther washing machinesInterengaging clutchesWater dischargeDrive shaft

A washing machine includes a cabinet forming an external appearance of the washing machine, a rotary tub disposed to rotate around a driving shaft vertically provided inside the cabinet and including a sidewall, which extends with inclination to have a diameter increasing from a lower side to an upper side of the washing machine, and at least one protrusion part, which protrudes from the sidewall with inclination to have a diameter increasing from an upper side to a lower side of the sidewall. A guide water filter is mounted on at least one protrusion part inside the rotary tub and provided at a rear surface thereof with a drain passage to discharge the washing water discharged from the balance ring to outside. A base is installed at the lower side of the rotary tub and includes a guide part and a support plate.

Owner:SAMSUNG ELECTRONICS CO LTD

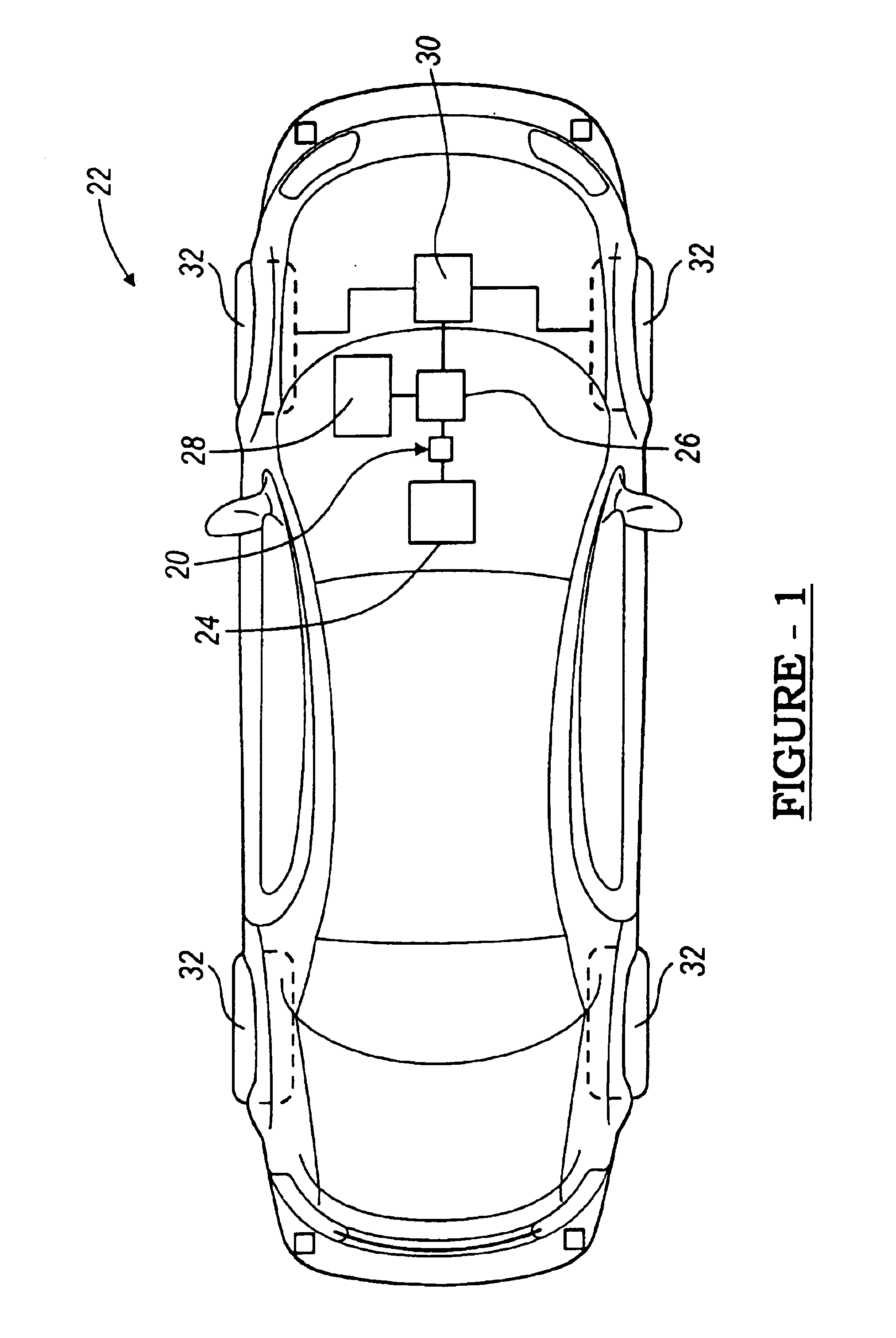

Series drive clutch

InactiveUS6846257B2Prevent rotationPlural diverse prime-mover propulsion mountingFluid clutchesCombustionEngineering

A clutch mechanism is disclosed for use with a hybrid electric vehicle wherein the electric motor-generator and engine are arranged in a series configuration. The clutch mechanism is positioned between and in communication with the electric motor-generator and engine to allow for either direct drive or a predetermined gear ratio between the electric motor-generator and engine. The electric motor-generator is preferably an integrated electric motor and generator. The engine is preferably a combustion engine.

Owner:NTN CORP

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

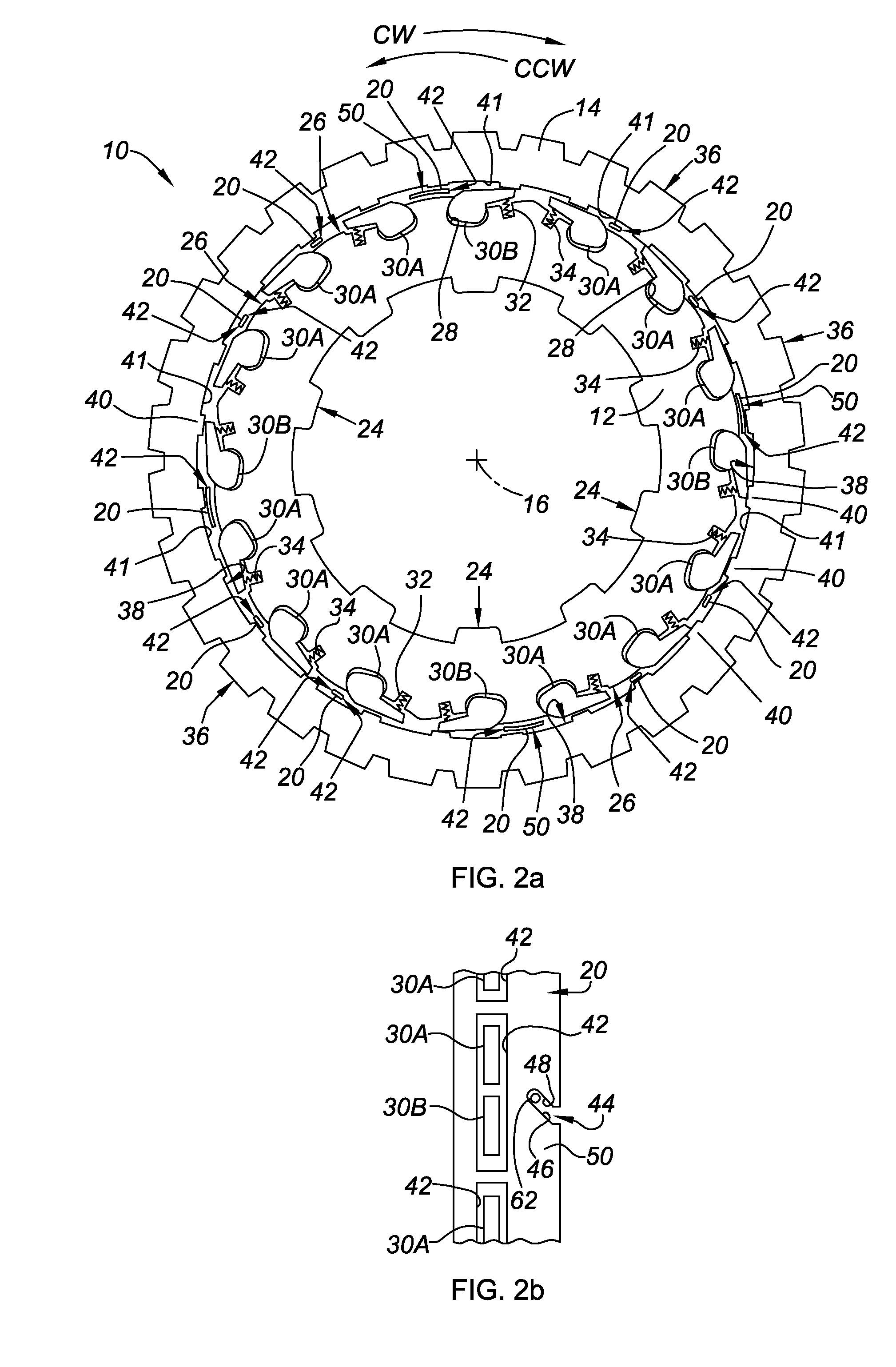

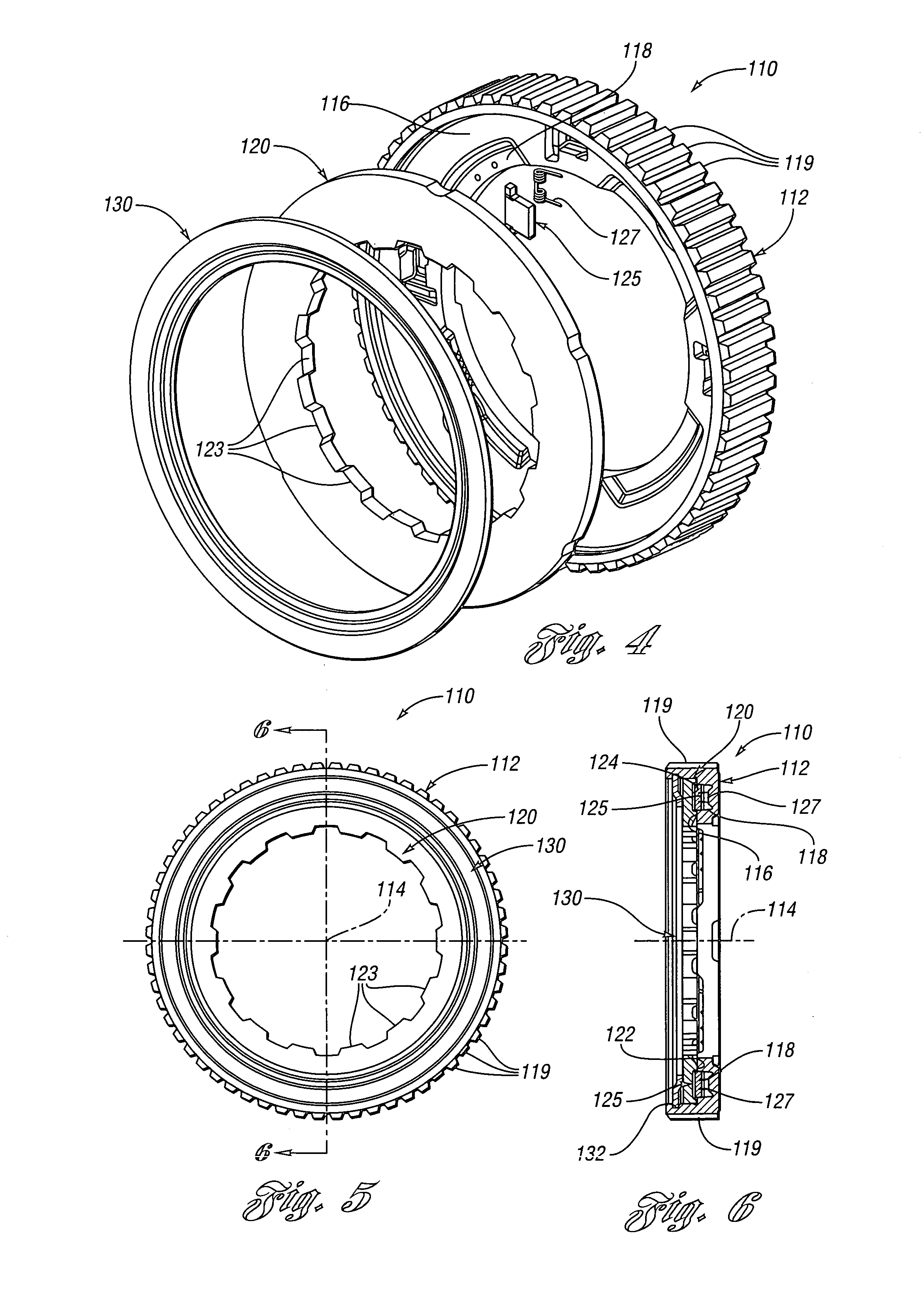

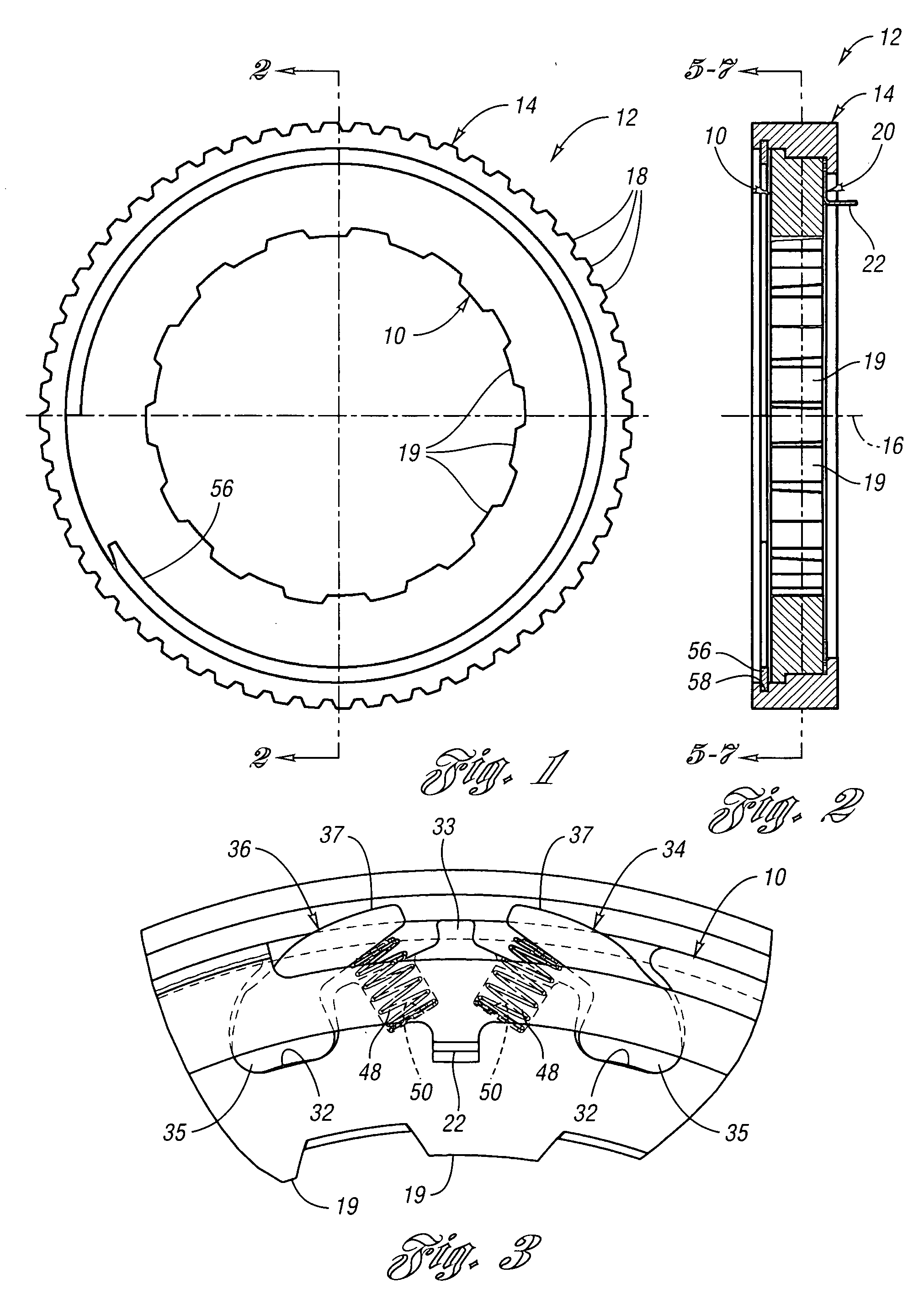

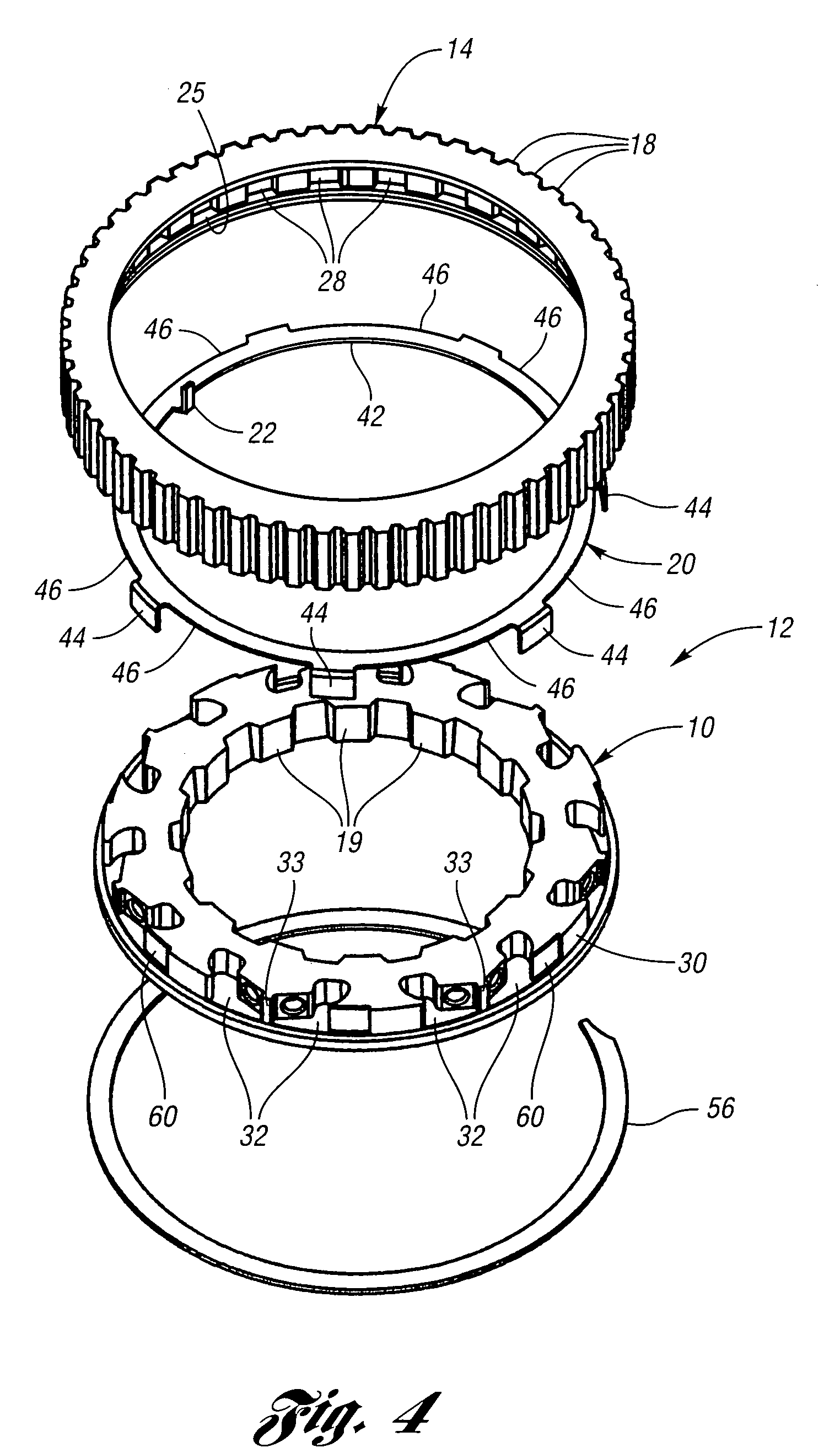

Selectable One-Way Clutch with Symmetrical Struts

ActiveUS20080169165A1Prevent rotationReduce bending stressFriction clutchesInterengaging clutchesControl theoryClutch

A selectable one-way clutch (SOWC) is provided for use with a vehicle transmission, and has a first race with a plurality of strut pockets, a moveable selector plate, symmetrical torque-holding elements or struts, and a second race that is rotatably engageable with a torque input device. The selector plate has a plurality of windows, and the struts selectively prevent rotation of the second race in either rotational direction depending on the position of the selector plate. The struts have a cylindrical portion and a pair of strut wings each having a free end. The strut wings connect to the cylindrical portion, and a different one of the free ends engages a strut pocket when an opposite strut wing is depressed in order to prevent rotation of the second race.

Owner:GM GLOBAL TECH OPERATIONS LLC

Selectable One-Way Rocker Clutch

The present invention provides a selectable one-way rocker clutch assembly having an inner race disposed radially within an outer race, first and second plurality of rockers, a selector ring and an apply plate. The inner race defines a plurality of pockets configured to operatively retain the first and second plurality of rockers. The first plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a first direction. The second plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a second direction. The selector ring is disposed radially between the inner race and outer race. The apply plate is configured to engage with the selector ring and, in so doing, rotate the selector ring to thereby selectively retract the first and / or second plurality of rockers and thus control the state of the rocker clutch assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

Dual-mode one-way torque transmitting device

InactiveUS20060185957A1Low costReduce hoop stressFluid actuated clutchesFriction clutchesDual modeEngineering

A dual mode one-way torque transmitting device includes an inner race having a first plurality of notches spaced about an axis. An intermediate race includes a second plurality of notches spaced about the axis, a first plurality of pockets spaced about the axis, and a first plurality of rockers, each rocker being located in a pocket of the intermediate race. A spring urges each rocker toward engagement with a notch on the inner race. An outer race includes a second plurality of pockets spaced about the axis, a second plurality of rockers, each rocker being located in a pocket on the outer race, and a plurality of actuators, each actuator alternately engages and disengages a rocker on the outer race and a notch on the intermediate race.

Owner:FORD GLOBAL TECH LLC

Controllable overrunning coupling assembly

A controllable overrunning coupling assembly includes a control member mounted for controlled shifting movement between a first pair of coupling faces of first and second coupling members relative to reverse pockets formed in one of the coupling faces. The first pair of coupling faces oppose each other and are oriented to face axially along a common rotational axis. The control member is operable for controlling position of only reverse struts in the reverse pockets without controlling the position of forward rockers in forward pockets formed in a coupling face of a second pair of coupling faces of the coupling members that oppose each other and are oriented to face radially with respect to the rotational axis.

Owner:MEANS IND INC

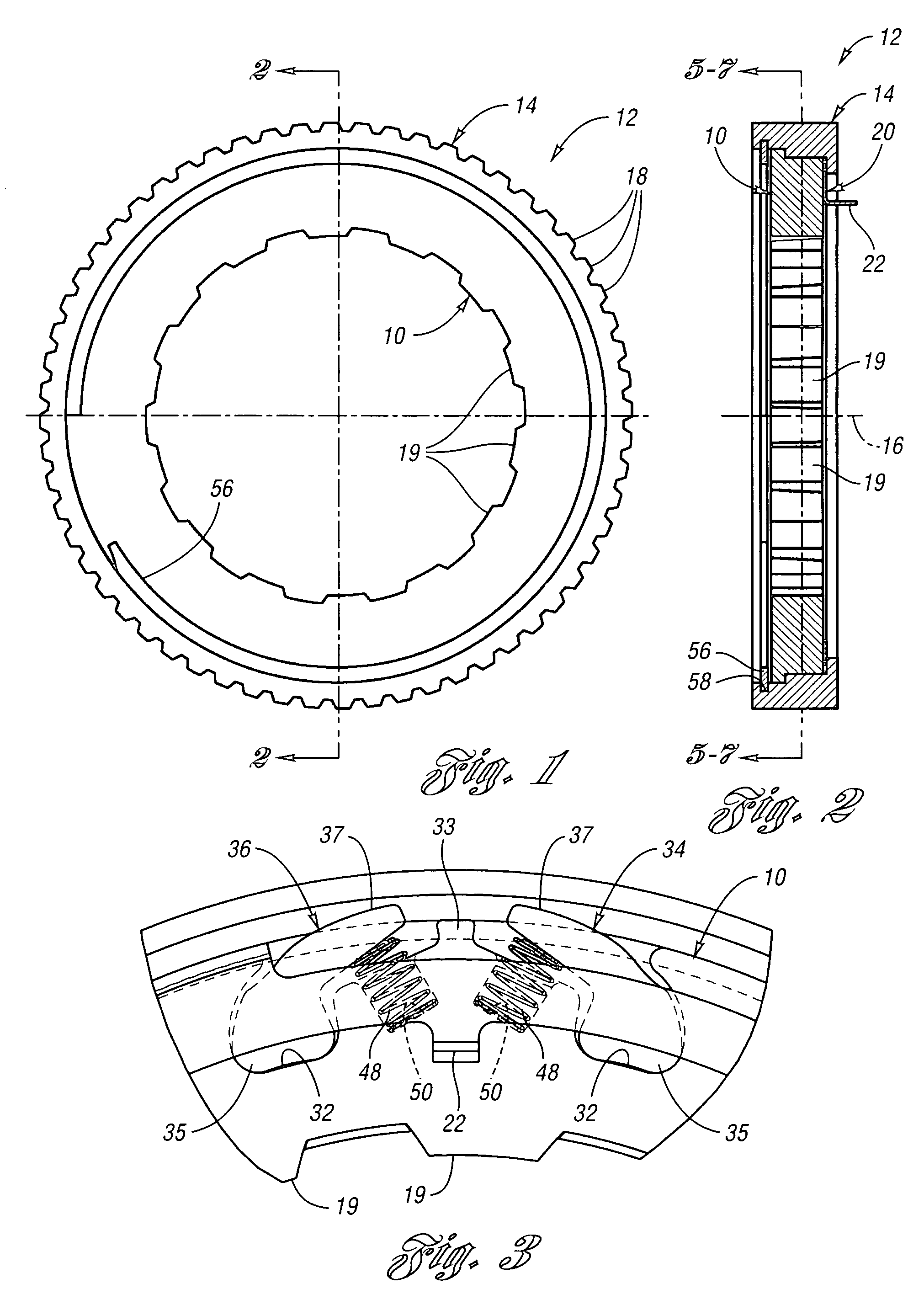

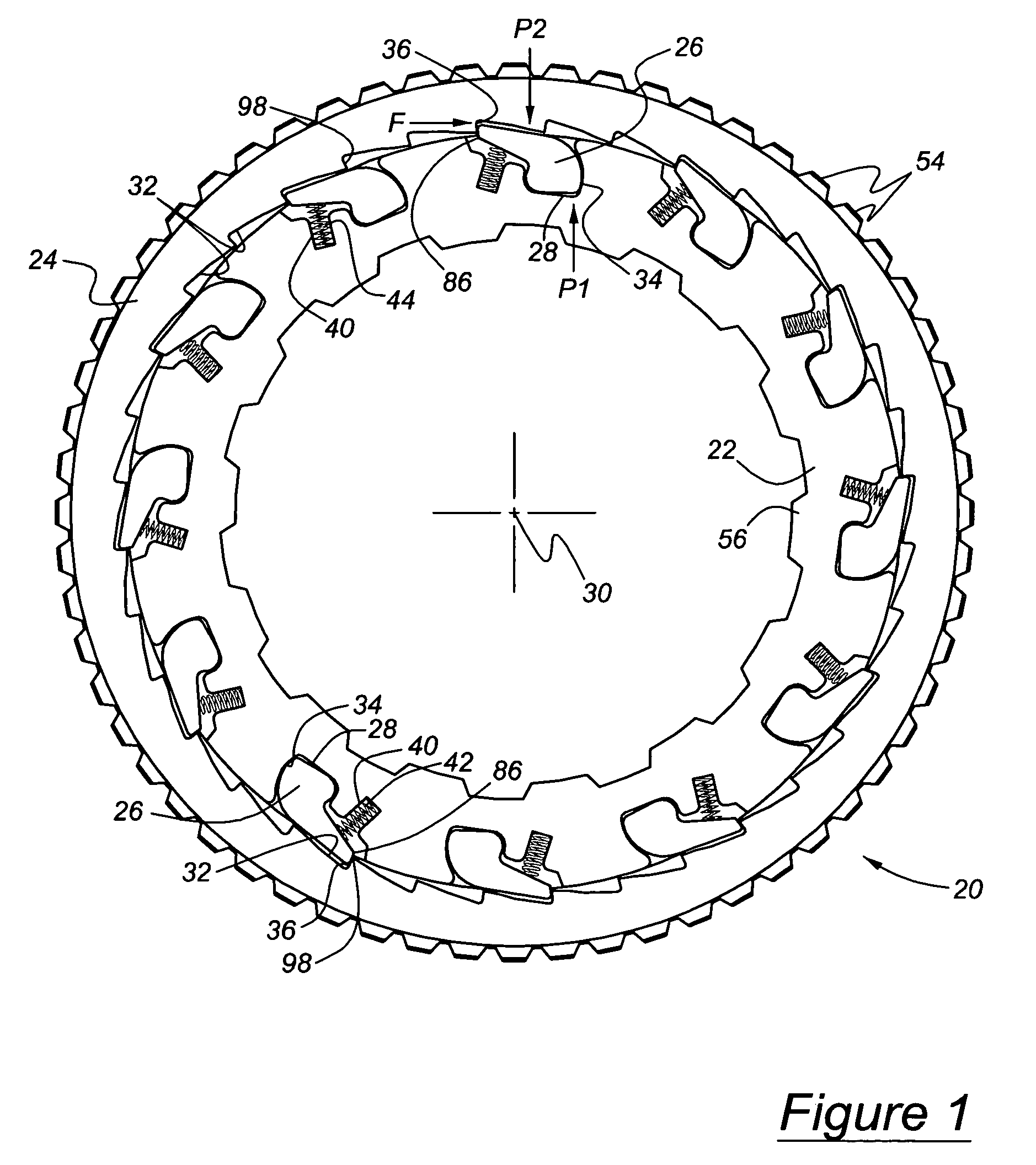

Overrunning coupling assembly

InactiveUS6186299B1Reduce wearLower requirementFriction clutchesInterengaging clutchesForward slidingCoupling

An overrunning coupling assembly includes a notch plate and an annular coupling pocket plate positioned in face-to-face relationship with respect to each other along a common axis. The pocket plate has strut pockets disposed at angularly spaced positions about the common axis. The notch plate has notch recesses at angularly spaced positions about the common axis and positioned in juxtaposed relationship with respect to the strut pockets. Torque-transmitting struts are positioned in each of the strut pockets. Each strut has first and second ears at one edge thereof for enabling pivotal motion of the struts about an ear axis intersecting the ears. The opposite edge of each strut is movable between disengaged and engaged positions with respect to one of the notch recesses whereby one-way torque transfer may occur between the plates. A lubricant flows between the notch plate and pocket plate. A spring is positioned in each strut pocket and biases the respective strut toward the notch plate. Each spring engages the respective strut intermediate the ear axis and the opposite edge. Each strut pocket provides sufficient clearance forward of the respective opposite edge of the strut to allow forward sliding movement of the respective strut during overrunning to cause the engagement of the respective spring and strut to occur nearer the ear axis, thereby reducing the length of a moment arm about which the spring acts upon the strut which enables frictional forces of the flowing lubricant to hold the strut in its disengaged position to prevent the strut from slapping against the notch recesses as the notch plate and pocket plate are respectively counterrotated.

Owner:MEANS IND INC

Overrunning coupling assembly having improved shift feel and/or noise reduction

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

Controllable Overrunning Coupling Assembly

ActiveUS20090211863A1Improved overrunningFriction clutchesInterengaging clutchesRotational axisCoupling

A controllable overrunning coupling assembly includes a control member mounted for controlled shifting movement between a first pair of coupling faces of first and second coupling members relative to reverse pockets formed in one of the coupling faces. The first pair of coupling faces oppose each other and are oriented to face axially along a common rotational axis. The control member is operable for controlling position of only reverse struts in the reverse pockets without controlling the position of forward rockers in forward pockets formed in a coupling face of a second pair of coupling faces of the coupling members that oppose each other and are oriented to face radially with respect to the rotational axis.

Owner:MEANS IND INC

Overrunning Coupling Assembly

ActiveUS20090159391A1Improved overrunningEasy to assembleFriction clutchesInterengaging clutchesCouplingControl theory

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

Selectively controlled rocker one-way clutch

ActiveUS20080185253A1Easy to assembleSignificantly reducing backlashToothed gearingsFriction clutchesEngineeringClutch

An overrunning clutch assembly includes a first ring having pockets spaced mutually about an axis, rockers each located in a pocket, springs each urging a rocker to pivot in a respective pocket, and first notches arranged around the axis. A second ring includes second pockets spaced mutually about the axis, second rockers each located in a second pocket such that at least one second rocker is engageable with a notch, second springs each urging a second rocker toward engagement with a notch, and second notches around the axis, at least one rocker being engageable with at least one second notch. A control member moves about the axis alternately to prevent the first rockers from engaging the second notches and to permit the first rockers to engage the second notches.

Owner:FORD GLOBAL TECH LLC

Hydrodynamic brush seal

A hybrid brush seal is provided for sealing a circumferential gap between two machine components that are relatively rotatable with respect to each other having seal bristles mounted in a ring shape on a first machine component with bristle ends directed at the sealing surface of the second, rotating machine component. The bristle ends are kept from direct contact with the rotating machine component via one or more shoes which create a non-contact seal with the rotating machine component which is enhanced by the imposition of one or more spring elements connected between the machine component and shoes.

Owner:SIEMENS ENERGY INC

Controllable or selectable bi-directional overrunning coupling assembly

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

Overrunning coupling assembly

InactiveUS6116394AReduce wearEliminate lubrication control requirementRotary clutchesFriction clutchesCouplingTrunnion

An overrunning coupling assembly includes a notch plate and an annular coupling pocket plate positioned in face-to-face relationship with respect to each other along a common axis. The pocket plate includes strut pockets disposed at angularly spaced positions about the axis. The notch plate includes notch recesses at angularly spaced positions about the common axis and positioned in juxtaposed relationship with respect to the strut pockets. The notch plate includes an inner circumferential rail at a radially inward side of the notch recesses and an outer circumferential rail at a radially outward side of the notch recesses. Torque-transmitting struts are positioned in the strut pockets. Each strut has first and second ears at one edge thereof for enabling pivotal motion of the struts about an ear axis intersecting the ears. The opposite edge of each strut is engageable with one of the notch recesses whereby one-way torque transfer may occur between the plates. Each opposite edge has first and second corners. Each strut pocket is sufficiently enlarged to allow pivotal movement of each strut about a strut axis which is parallel with the common axis, thereby enabling one of the first and second corners to be selectively supported by one of the inner and outer circumferential rails to prevent the struts from slapping against the notch recesses as the notch plate and pocket plate are respectively counterrotated.

Owner:MEANS IND INC

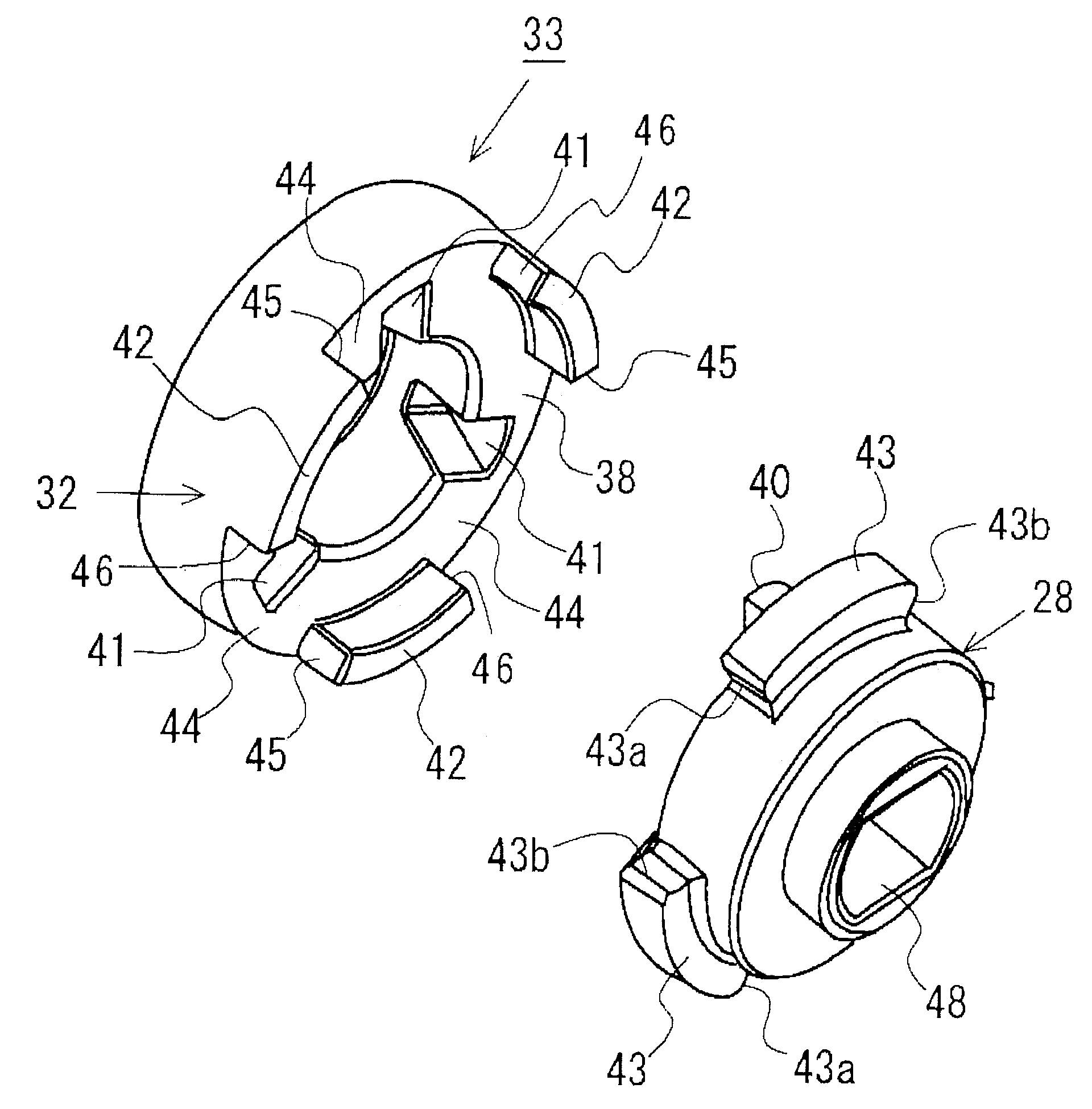

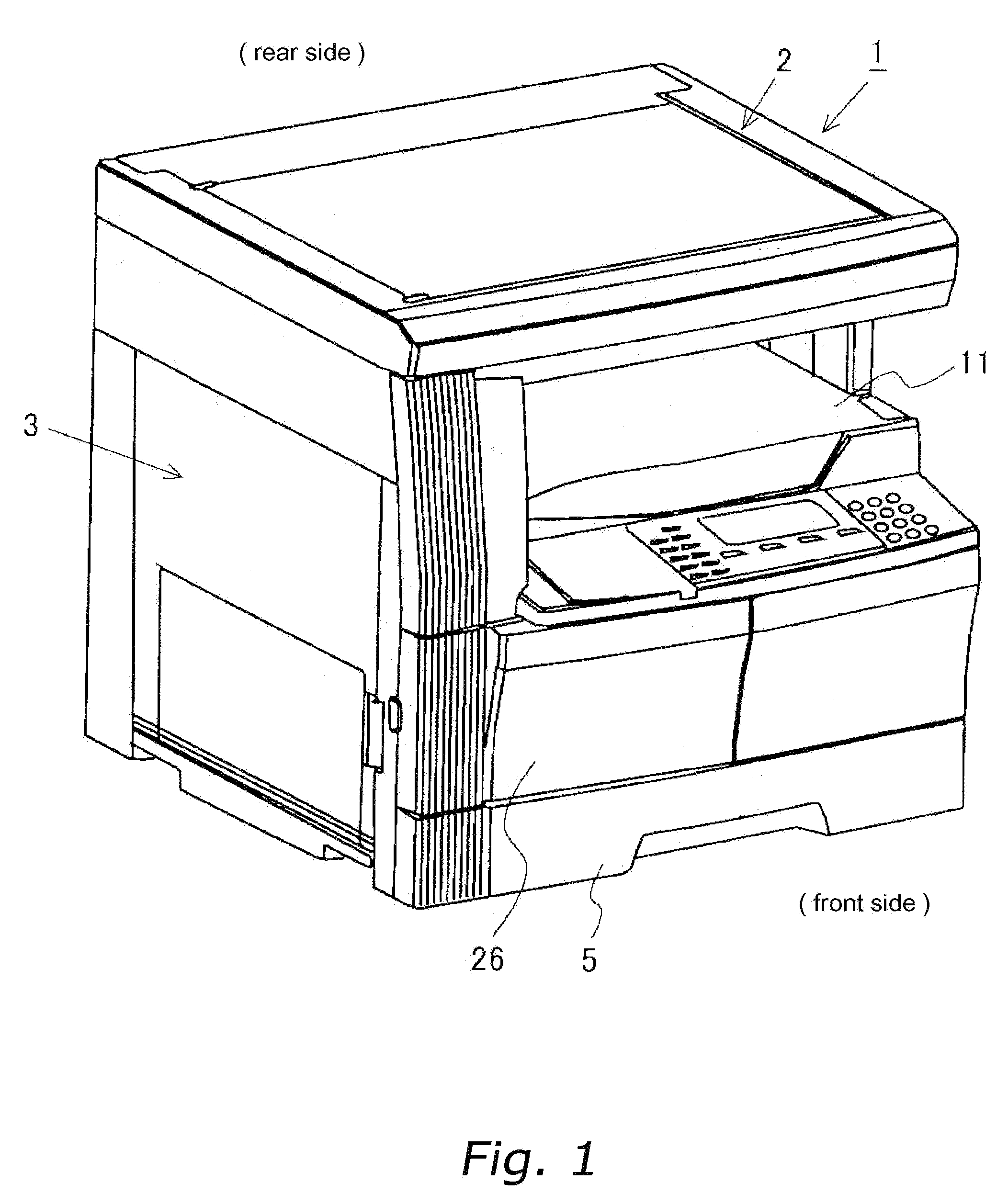

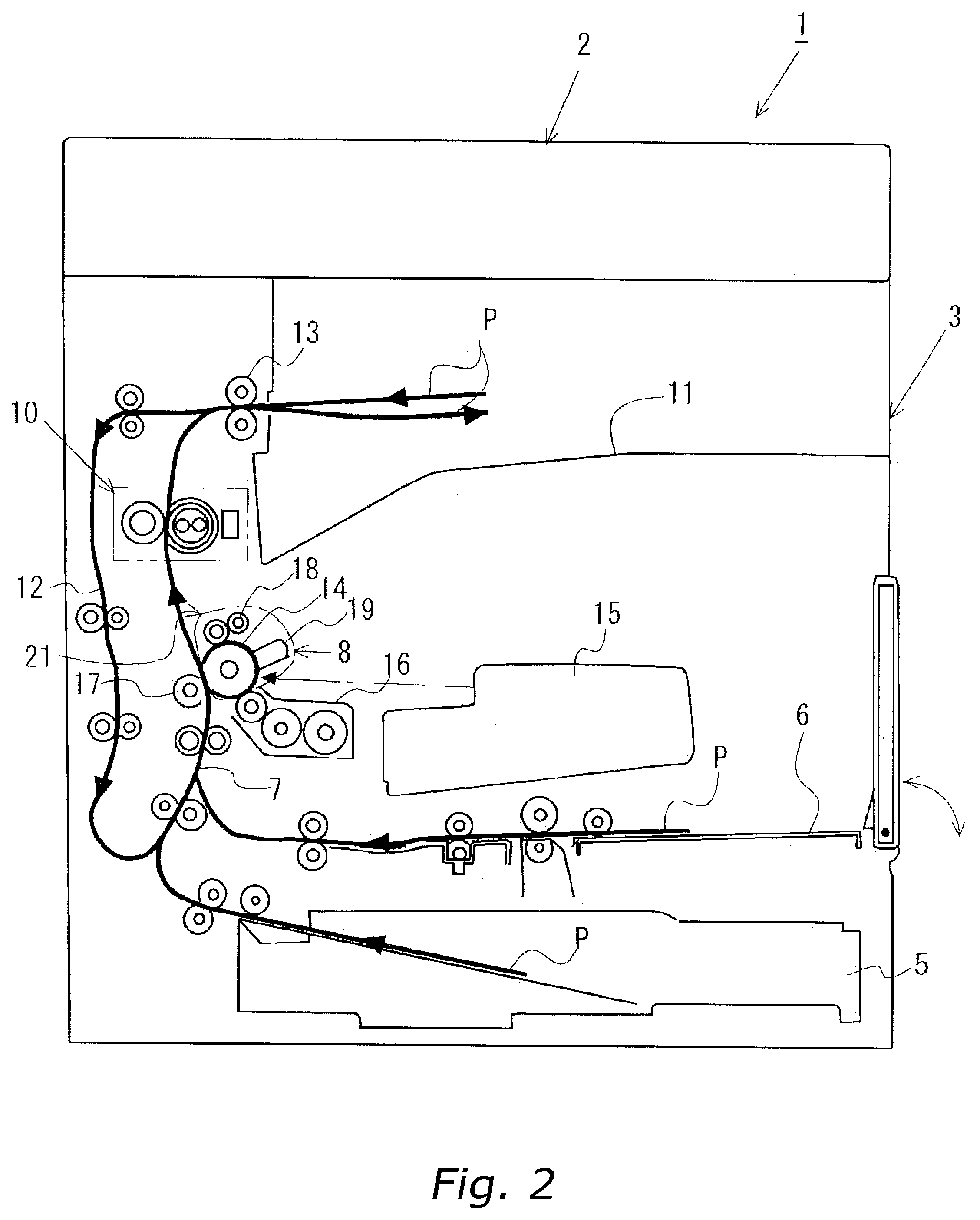

Shaft coupling, and function unit drive device for an image forming device comprising the same

InactiveUS7603059B2Suppress couplingReliable transmissionFriction grip releasable fasteningsCorona dischargeCouplingImage formation

Inner circumference projections of a driven coupling are engaged with inner circumference recesses of a drive coupling. Outer circumference projections of the driven coupling are engaged with outer circumference recesses of the drive coupling. A chamfered portion formed at each tip of the rotational leading-side side surface of the inner circumference projections is capable of contact with the leading-side side surface of each inner circumference recess. A rotational trailing-side circumferential end face of each outer circumference projection and a rotational trailing-side circumferential end face of each outer circumference recess are in surface-to-surface contact with each other. As a result, the drive coupling and the driven coupling can rotate integrally without rattling in the rotational direction.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Bi-directional overrunning clutch

InactiveUSRE38012E1Prevent rotationYielding couplingFluid couplingsElectronic control systemDrive shaft

A bi-directional overrunning clutch is disclosed for controlling torque transmission between a secondary drive shaft and secondary driven shafts. The overrunning clutch includes a pinion input shaft in a differential housing that engages with a clutch housing rotatably disposed within the differential housing. At least one race is located adjacent to the clutch housing and is engaged with an output shaft. A cage is located between the race and the clutch housing. The cage is movable with respect to the clutch housing. A <DEL-S DATE="20030304" ID="DEL-S-00001" / >first<DEL-E ID="DEL-S-00001" / > coil is mounted within the differential housing adjacent to the cage and is adapted to produce an electromagnetic field when energized which causes the cage to drag with respect to the clutch housing. The dragging of the cage with respect to the clutch housing positions <INS-S DATE="20030304" ID="INS-S-00001" / >rolls within <INS-E ID="INS-S-00001" / >the cage to engage the clutch housing with the race when wheels on a primary drive shaft lose traction. <DEL-S DATE="20030304" ID="DEL-S-00002" / >A<DEL-E ID="DEL-S-00002" / > <INS-S DATE="20030304" ID="INS-S-00002" / >If desired a <INS-E ID="INS-S-00002" / >second coil <DEL-S DATE="20030304" ID="DEL-S-00003" / >is<DEL-E ID="DEL-S-00003" / > <INS-S DATE="20030304" ID="INS-S-00003" / >may be <INS-E ID="INS-S-00003" / >mounted within the differential housing adjacent <DEL-S DATE="20030304" ID="DEL-S-00004" / >adjacent<DEL-E ID="DEL-S-00004" / > to the cage. The second coil is adapted to produce an electromagnetic field when energized which advances cage with respect to the clutch housing causing the clutch housing to engage with the races. When the second coil is activated, the output shaft drives the pinion input shaft producing engine braking. An electronic control system is utilized to control the energizing of the coils.

Owner:HILLIARD

Overrunning clutch

ActiveUS7100756B2Significantly reducing backlashEasy to assembleFriction clutchesInterengaging clutchesEngineeringClutch

A one-way clutch includes a first race having a plurality of pockets, each pocket defining a pivot center, a second race including a plurality of notches, a plurality of rockers, each rocker being supported on a respective pocket for pivoting movement about a pivot center relative to the second race, and a spring for urging a rocker toward engagement with a notch.

Owner:FORD GLOBAL TECH LLC

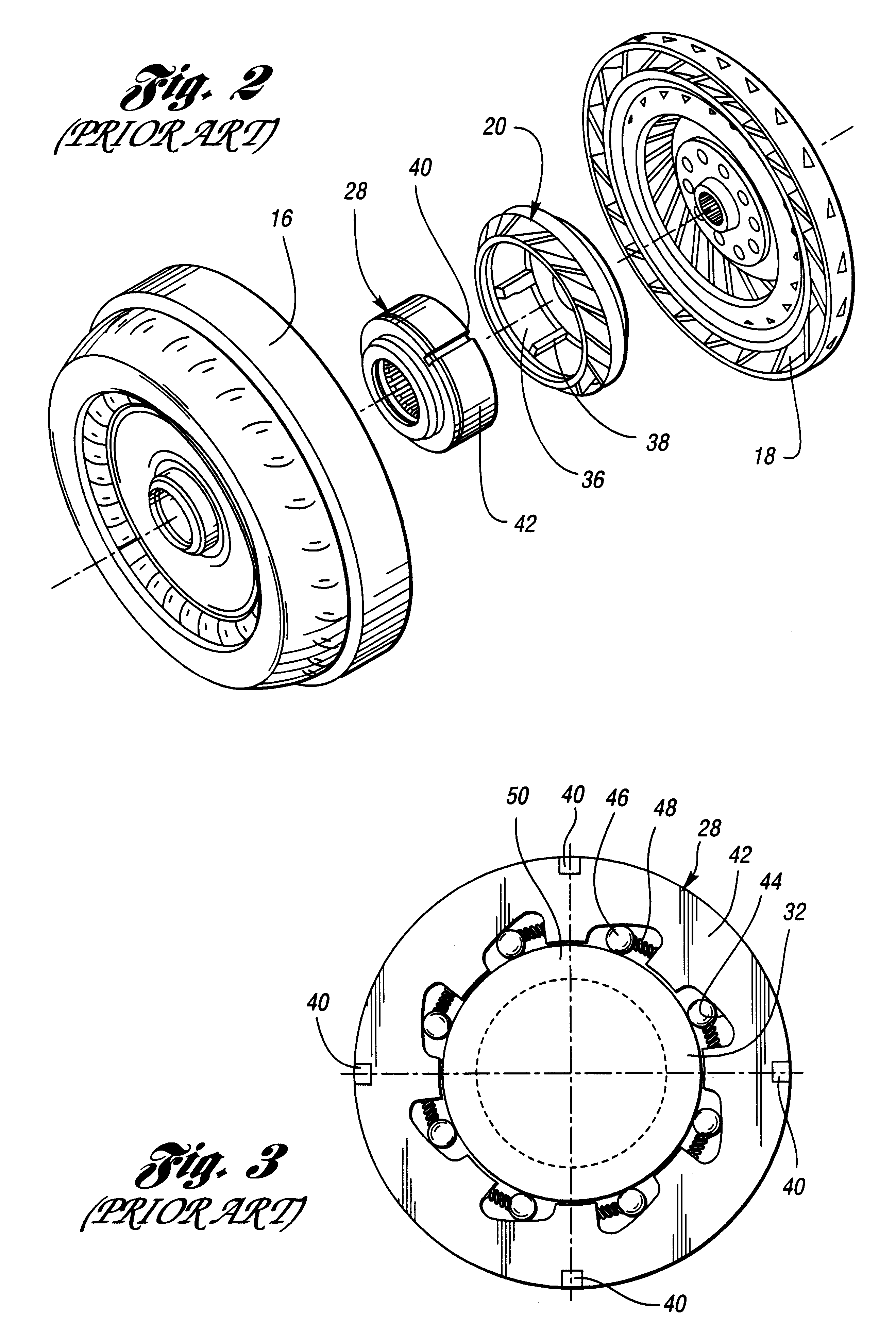

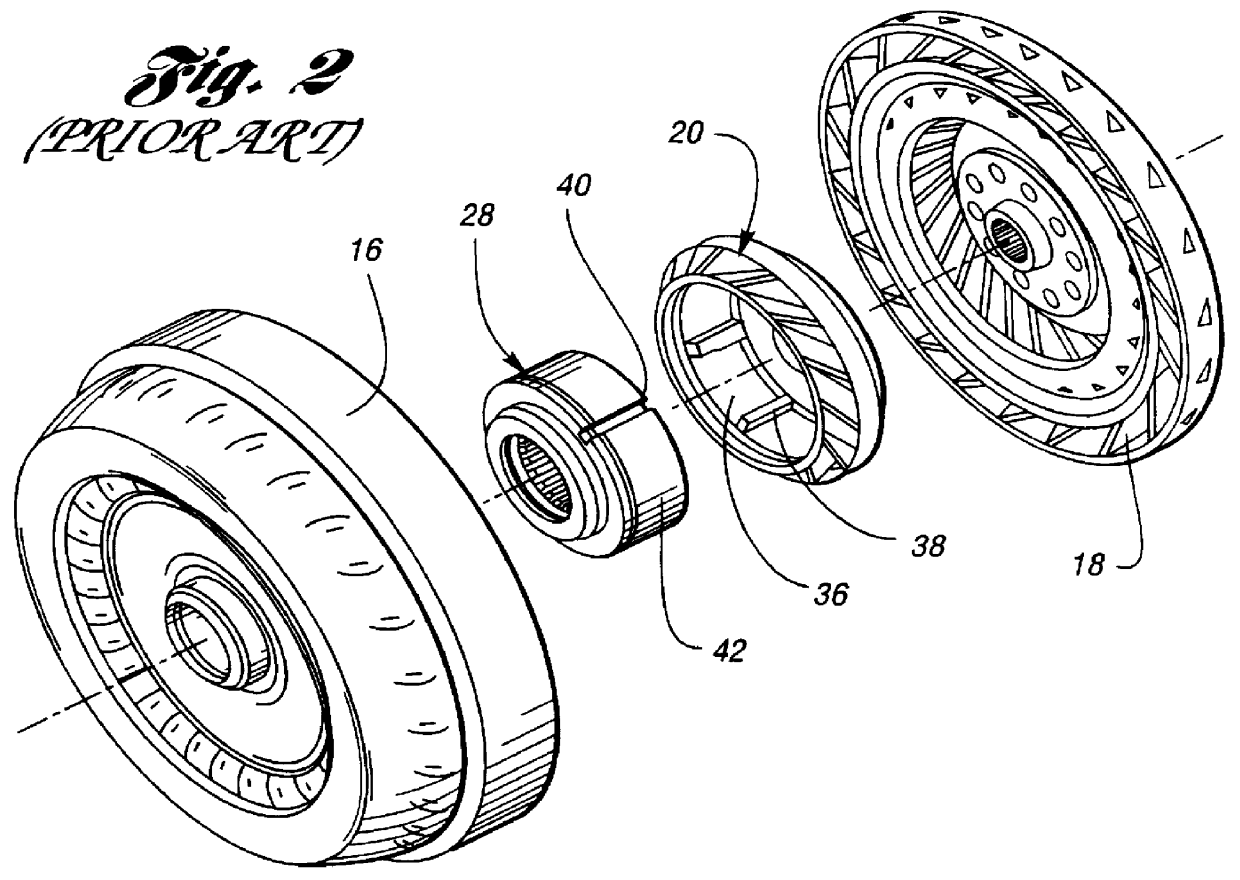

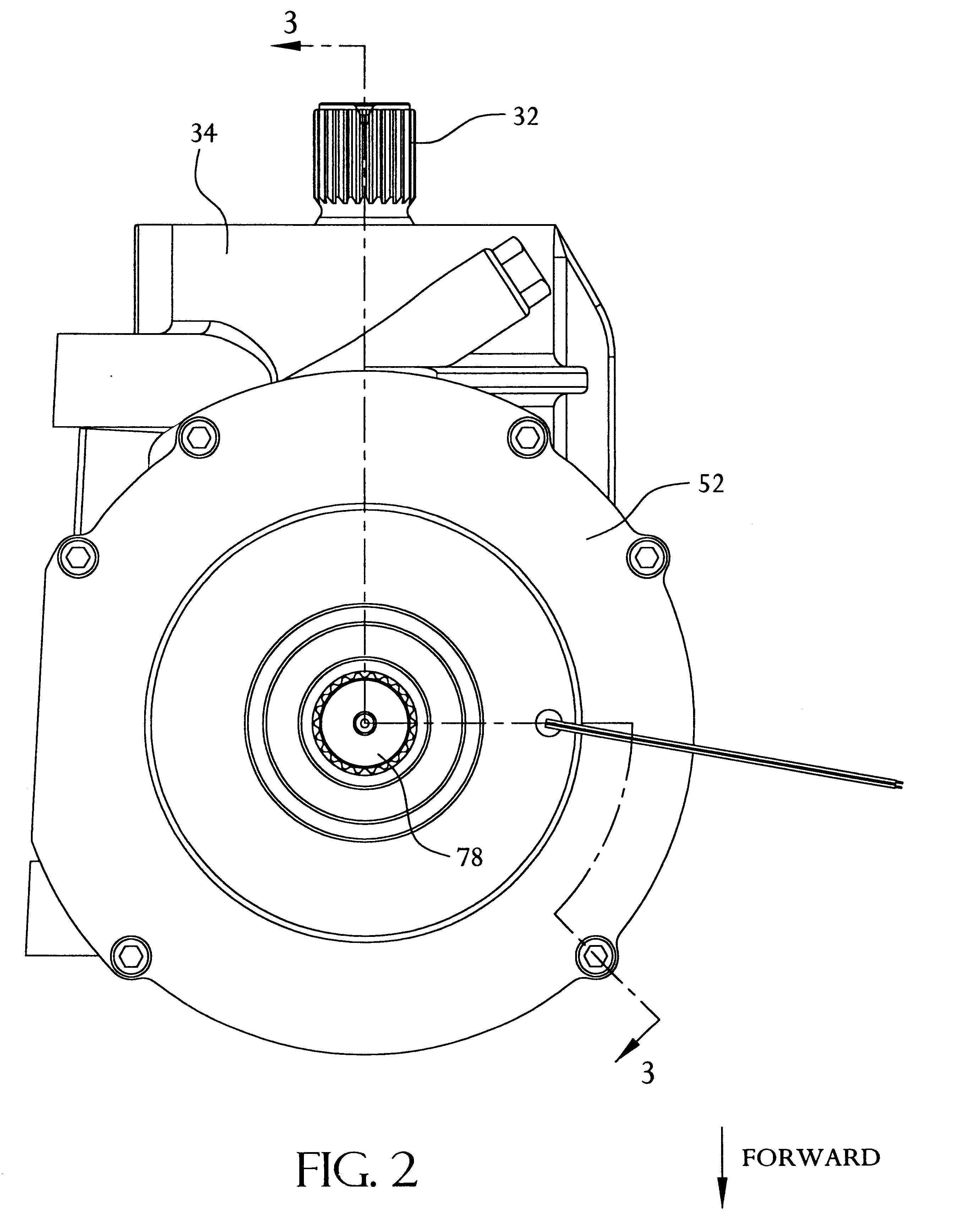

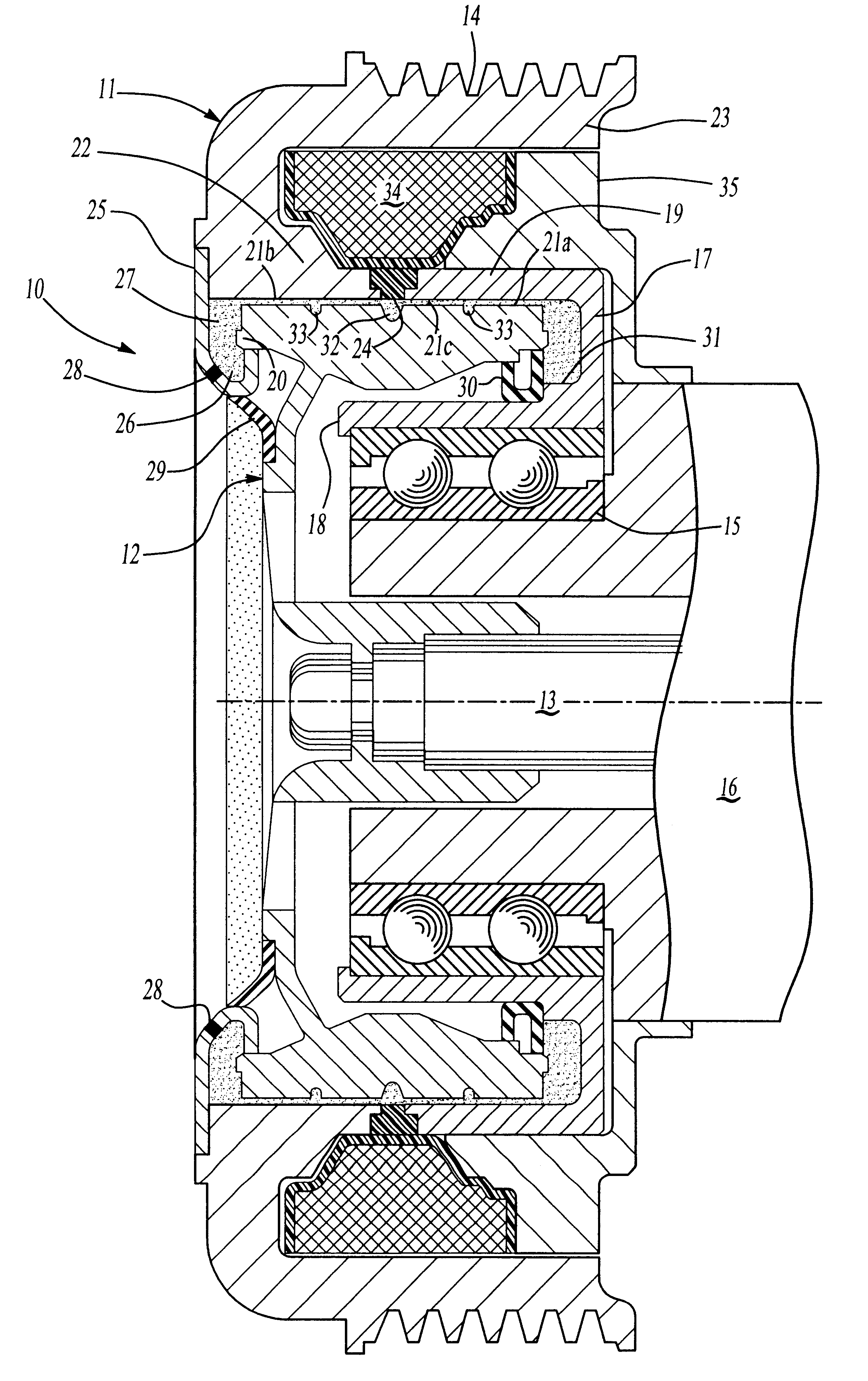

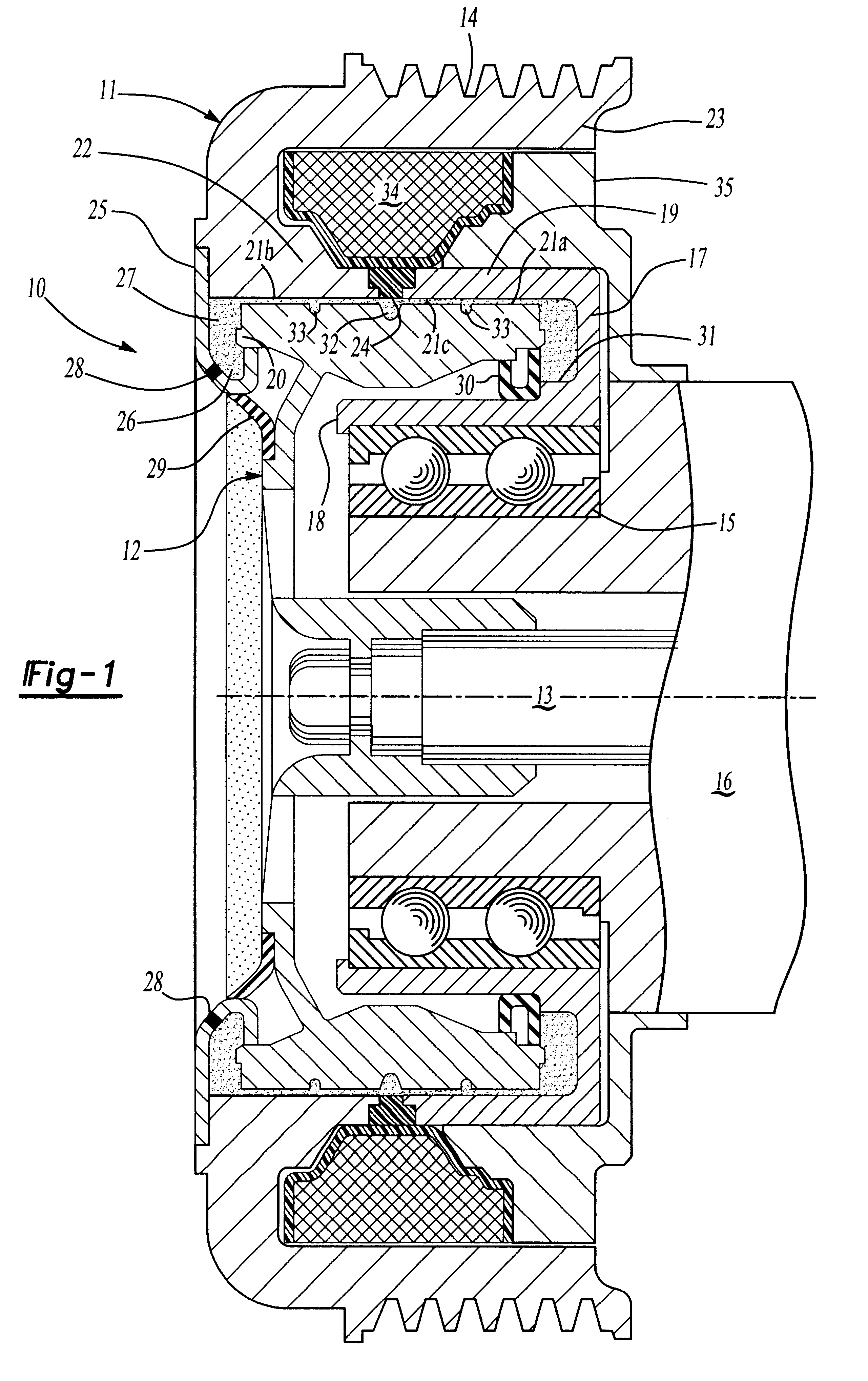

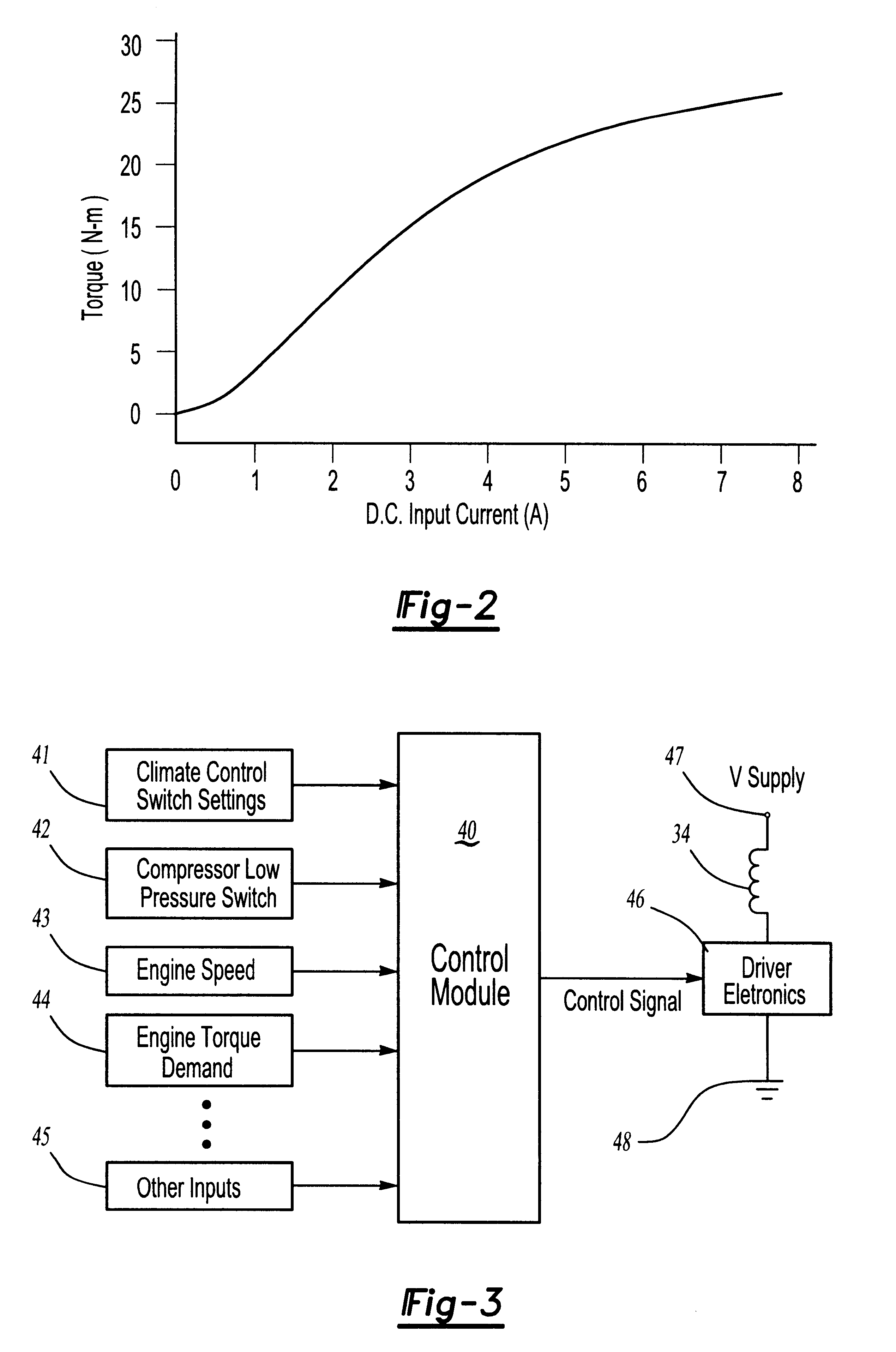

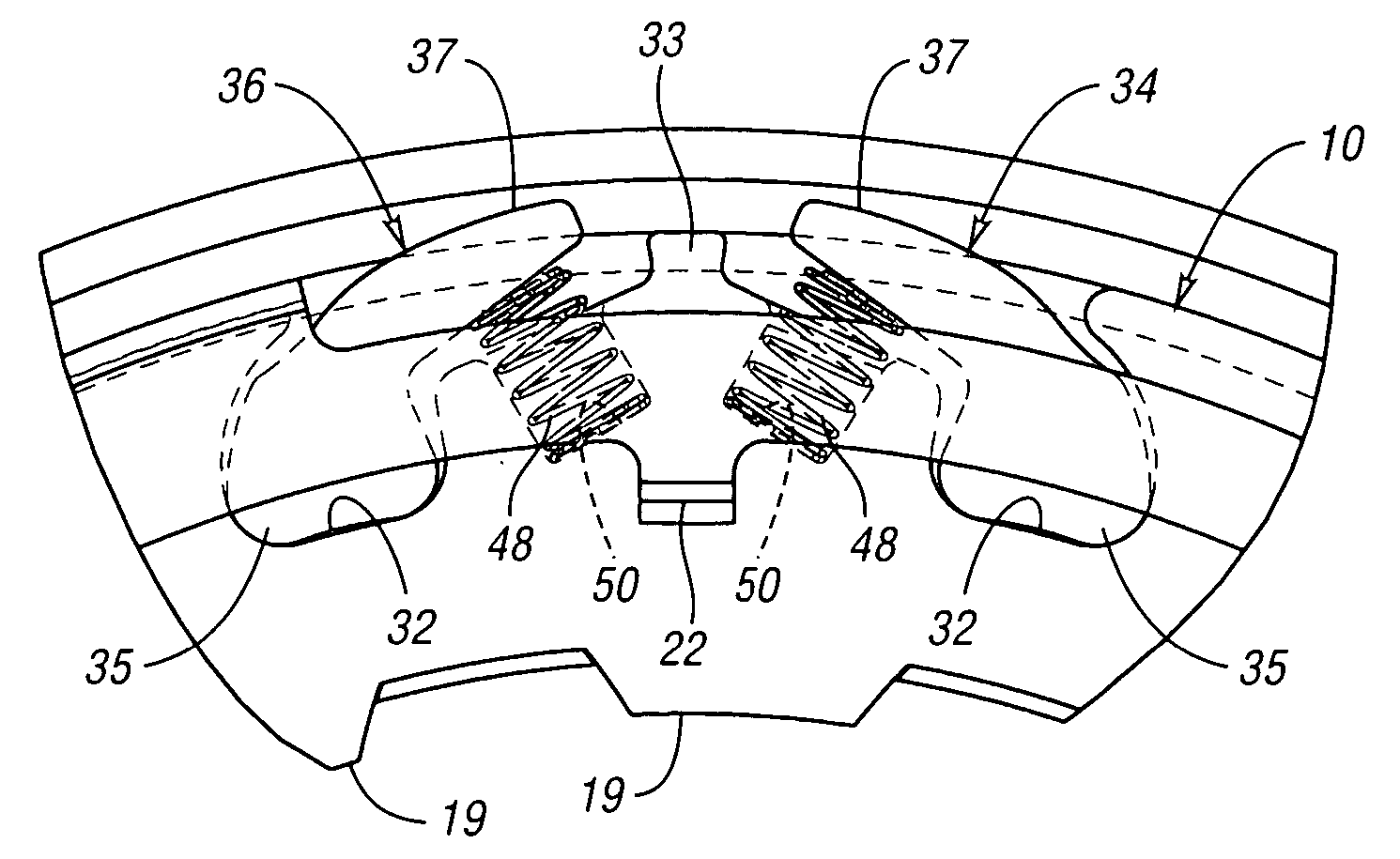

Soft start compressor clutch

InactiveUS6290043B1Start softLess objectionable noiseMagnetically actuated clutchesInterengaging clutchesElectromagnetic clutchEngineering

An electromagnetic clutch (10) for an air conditioning compressor includes a generally cylindrical pulley (11) rotatably mounted on a compressor housing (16) and having an annular friction surface (21b), a driven member (12) mounted on a compressor shaft (13) and having an annular friction surface (21a) positioned radially adjacent the first friction surface to form an annular space (21c) therebetween. A quantity of flowable magnetic material (27) is provided in the annular space (21c) and a magnetic coil (34) is fixed on the housing adjacent thereto. A control (40,46,46') connected to the magnetic coil (34) supplies electrical power from a power supply (47) to energize the magnetic coil and create magnetic flux in the annular space (21c) polarizing the magnetic material and frictionally coupling the first and second friction surfaces (21a,21b) to cause the pulley (11) to rotate the driven member (12). The control (40,46,46') can pulse width modulate or ramp the supplied power for "soft" starting and / or stopping of the compressor.

Owner:VISTEON GLOBAL TECH INC +1

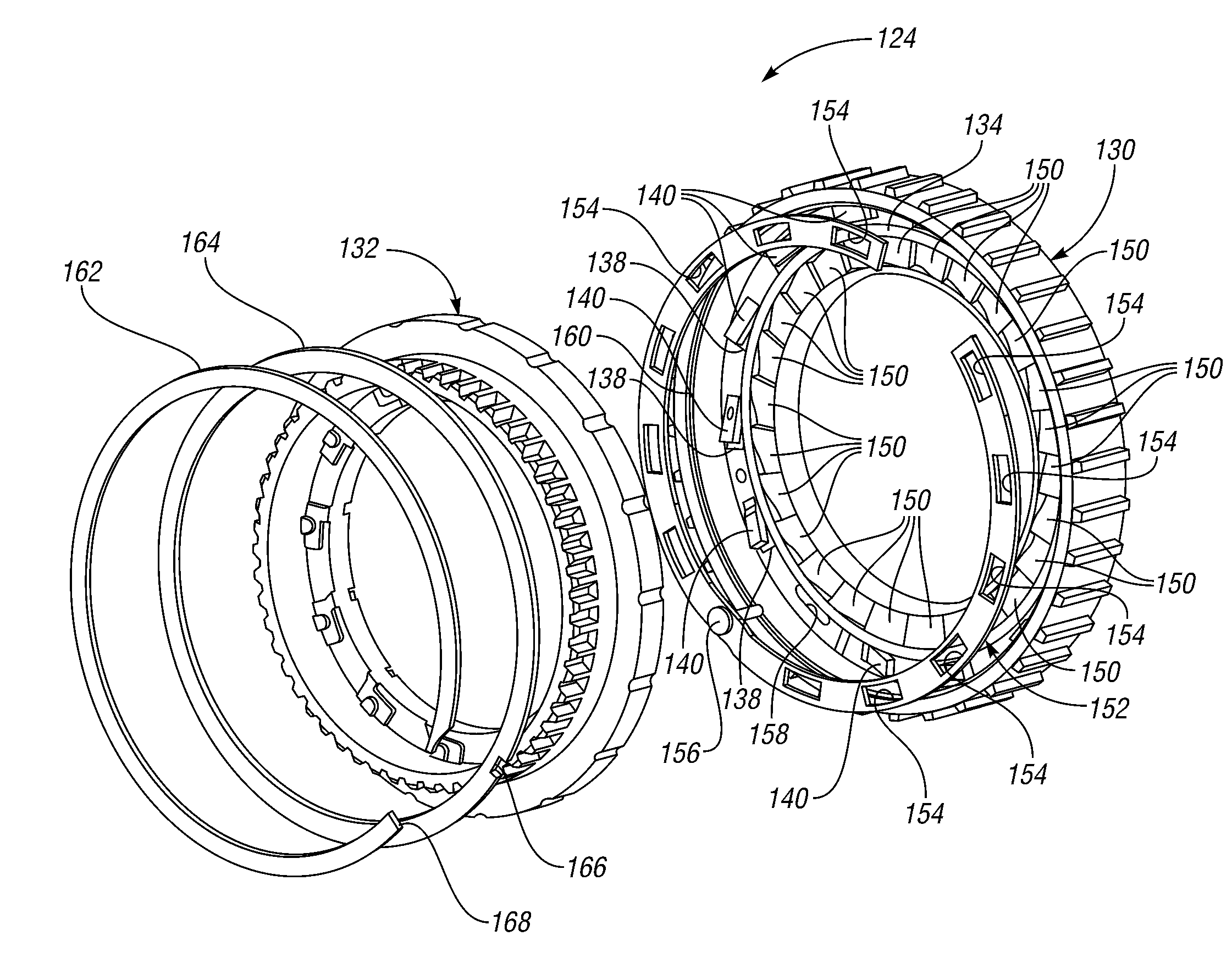

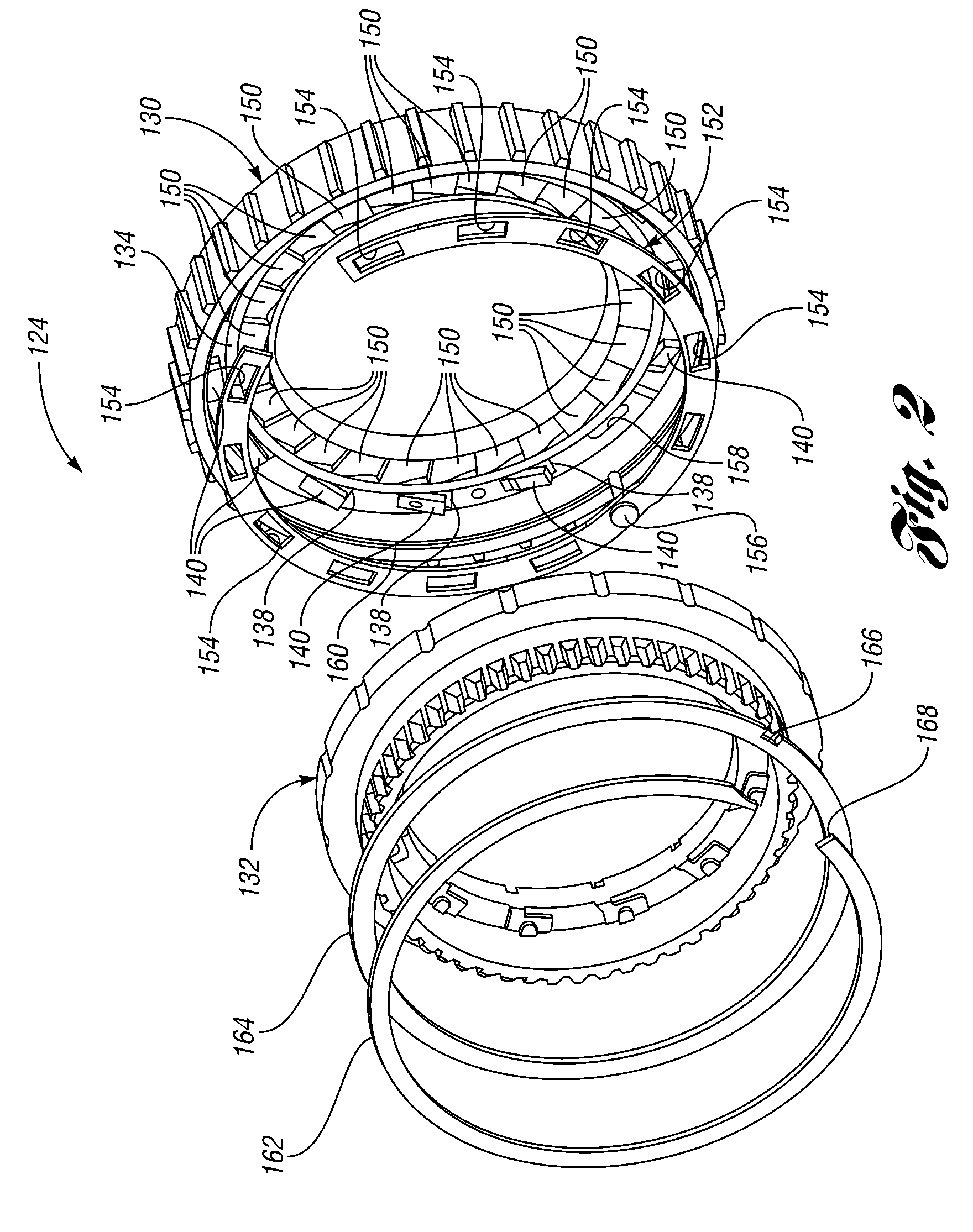

Overrunning radial coupling assembly and method for controlling the engagement of inner and outer members of the assembly

ActiveUS20060278487A1Prevent rotationFriction clutchesInterengaging clutchesCouplingRotation control

The overrunning radial coupling assembly or clutch and a method of controlling the engagement of inner and outer plates or members of the assembly are provided wherein adjacent engaging radial locking pawls are selectively controlled by a single, rotatable control plate or element to obtain full lock, one-way lock and one-way overrun conditions. The assembly includes free-floating, forward pawls and free-floating, reverse pawls adjacent to their respective forward pawls. The forward and reverse pawls are movable between a notch-engaging, engaged position (i.e., full lock condition) and a disengaged position in which the outer member is permitted to free-wheel relative to the inner member in the one-way overrun condition in one direction about a first axis and the outer member is locked to the inner member in the one-way lock condition in the opposite direction. A number of different embodiments of the assembly and method are provided.

Owner:MEANS IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com