Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5054 results about "Brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. It is also known as a bending machine or bending brake or in Britain as a sheet metal folder or just a folder.

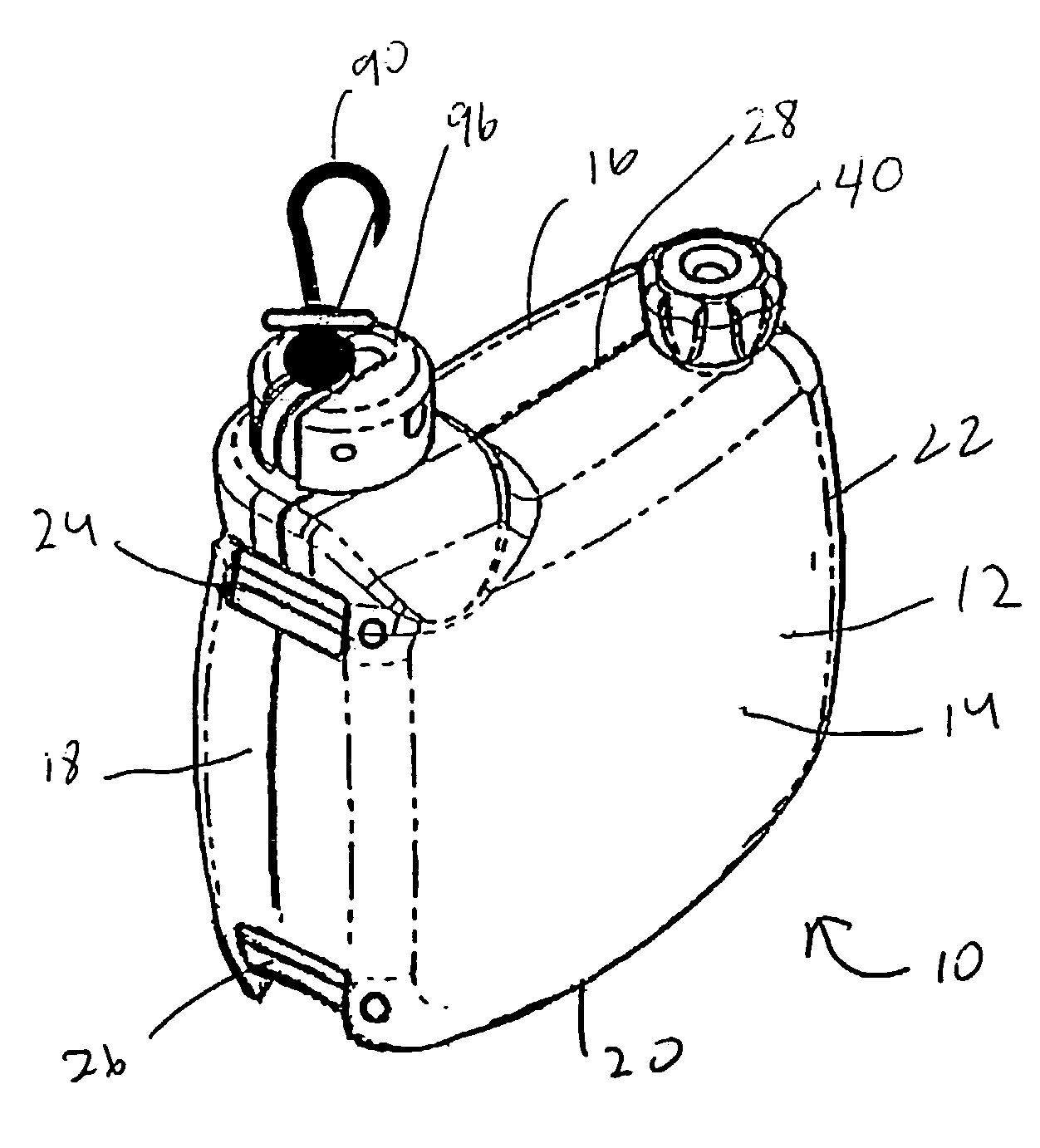

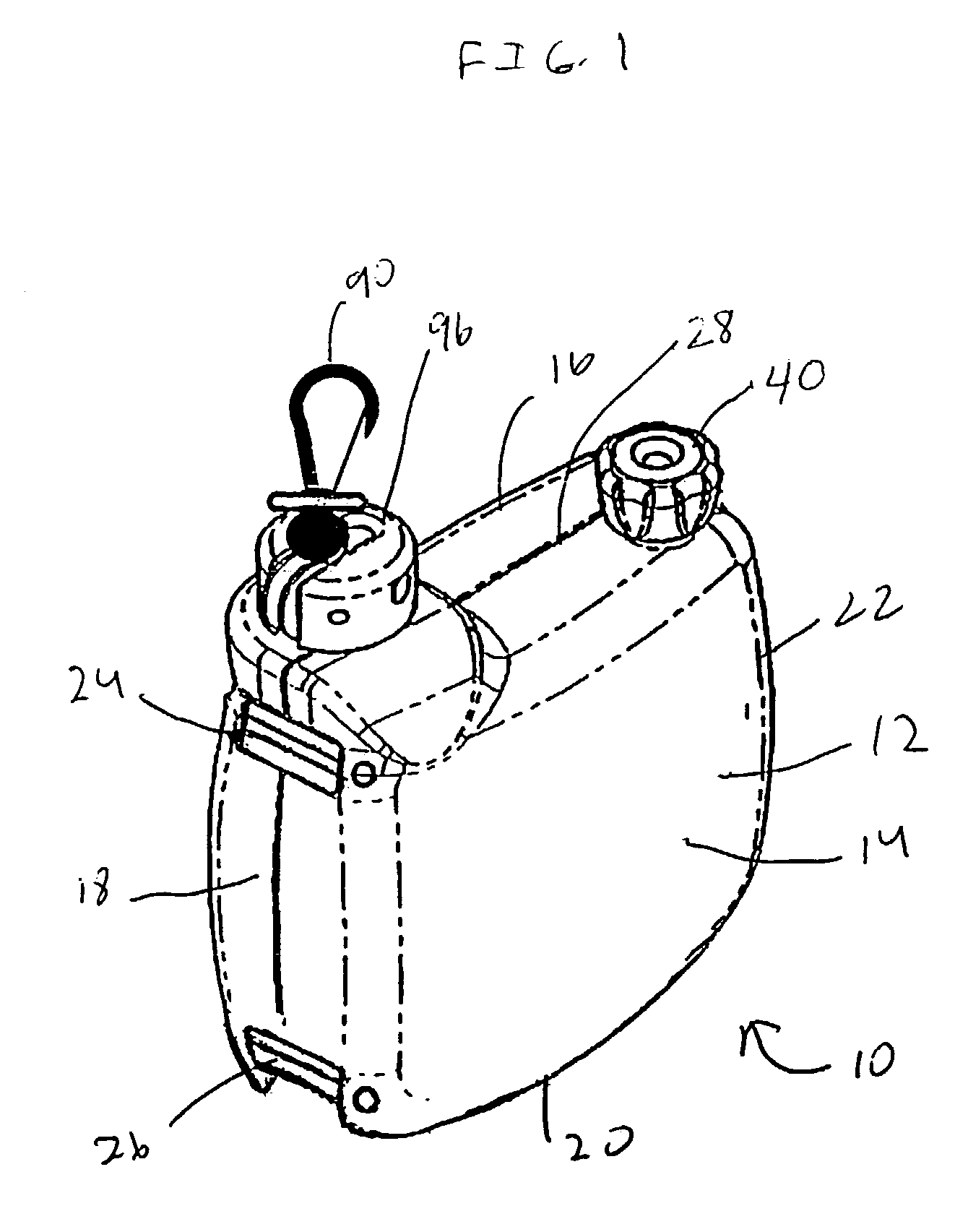

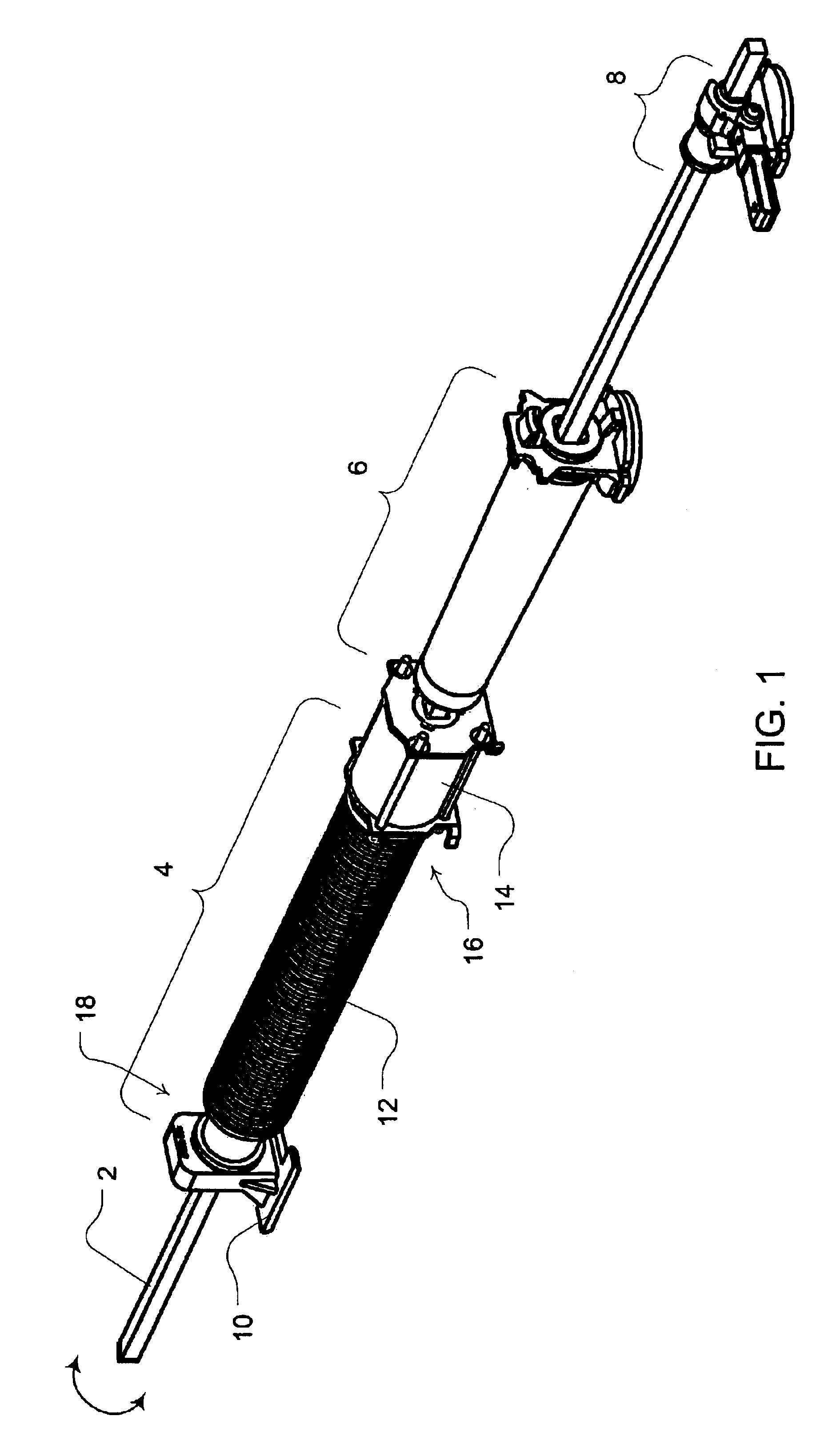

Portable handheld exercise apparatus which can be attached to a multiplicity of body parts

InactiveUS7087001B1Full rangeHigh variationTaming and training devicesFrictional force resistorsBall bearingHand held

The present invention is directed to a portable personal training and exercise device with a cable and pulley mechanism which also is a mobile personal training and exercise device having an ergonomic plastic external housing that with the use of straps fits in the hand as well as against different parts of the body. The present invention has a cable and pulley mechanism inside a housing which has a pulley rotatably mounted on a shaft that spins in only one direction. The pulley spins in both directions so that it is spring biased for rewinding a cord onto the pulley. Next to the pulley is a brake wheel or brake bushing that is attached to the shaft. The brake wheel or brake bushing and a pulley spinning on a single shaft inserts into a sealed ball bearing on both ends. A spring is connected to the bottom of the pulley. In the center of the pulley is a combination ball bearing / one-way clutch that turns the shaft only in one direction. The shaft is attached to the brake wheel or brake bushing. Secured around the outer edge of the brake wheel is a brake band. Secured around the outer edge of the brake bushing is a brake clamp. The brake band or brake bushing can be tightened for variable resistance through a tension adjustment assembly including a tension bolt. There is also a multi-directional guide unit mounted on the housing for allowing the pulley cords to be pulled in multiple directions with variable amounts of friction. The cord, which is wrapped around the pulley, emerges through a multi-directional bearing that rotates 360 degrees, thus allowing full range of three dimensional motion. Therefore, a user may pull the cords of the pulley for exercising various muscles of the user and adjust the resistance force of the cord at an appropriate level from the user. Different attachments can be connected to the snap at the end of the cord or cable such as a grip handle, wrist strap, waistband, ankle strap and foot strap.

Owner:IHLI STEPHEN P

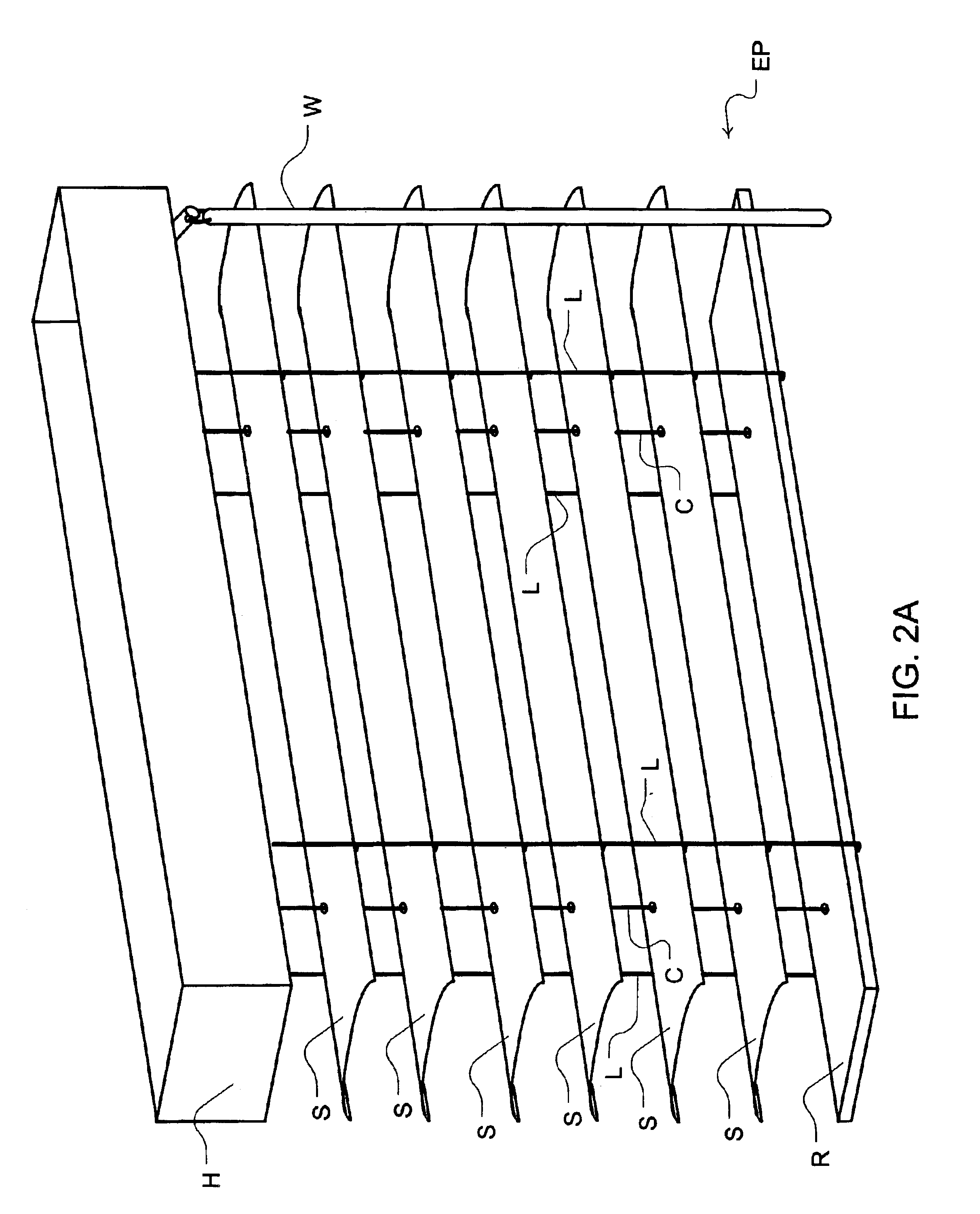

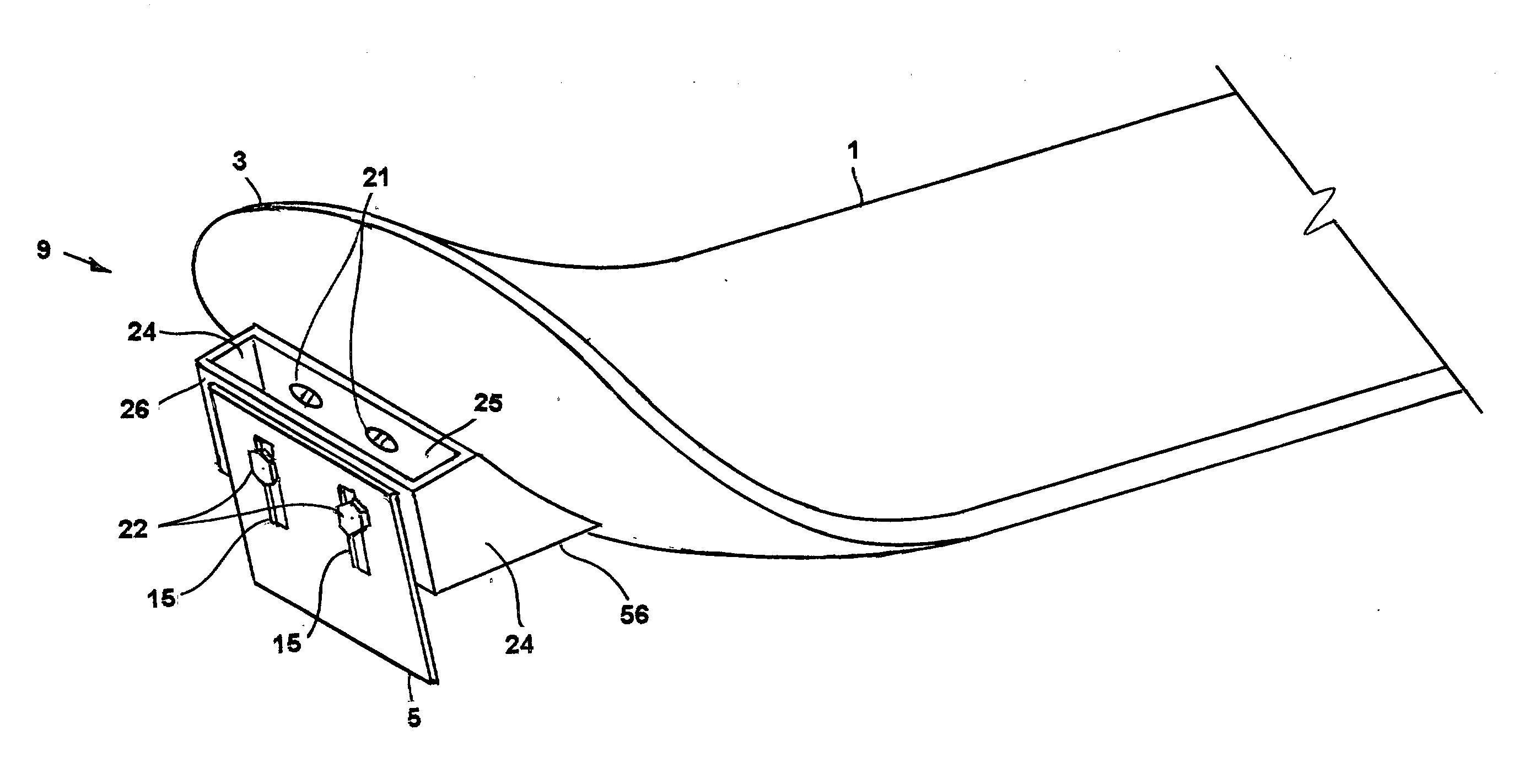

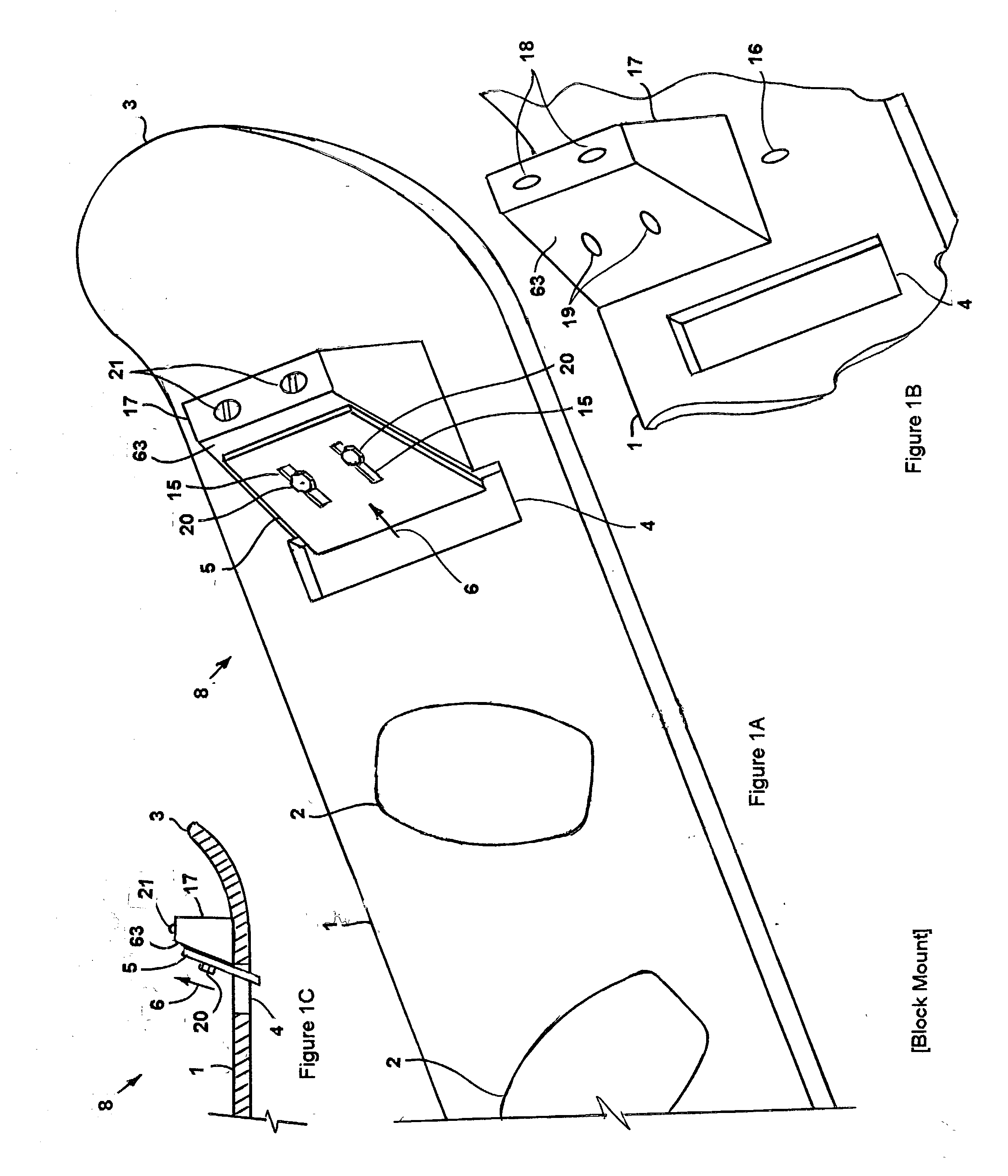

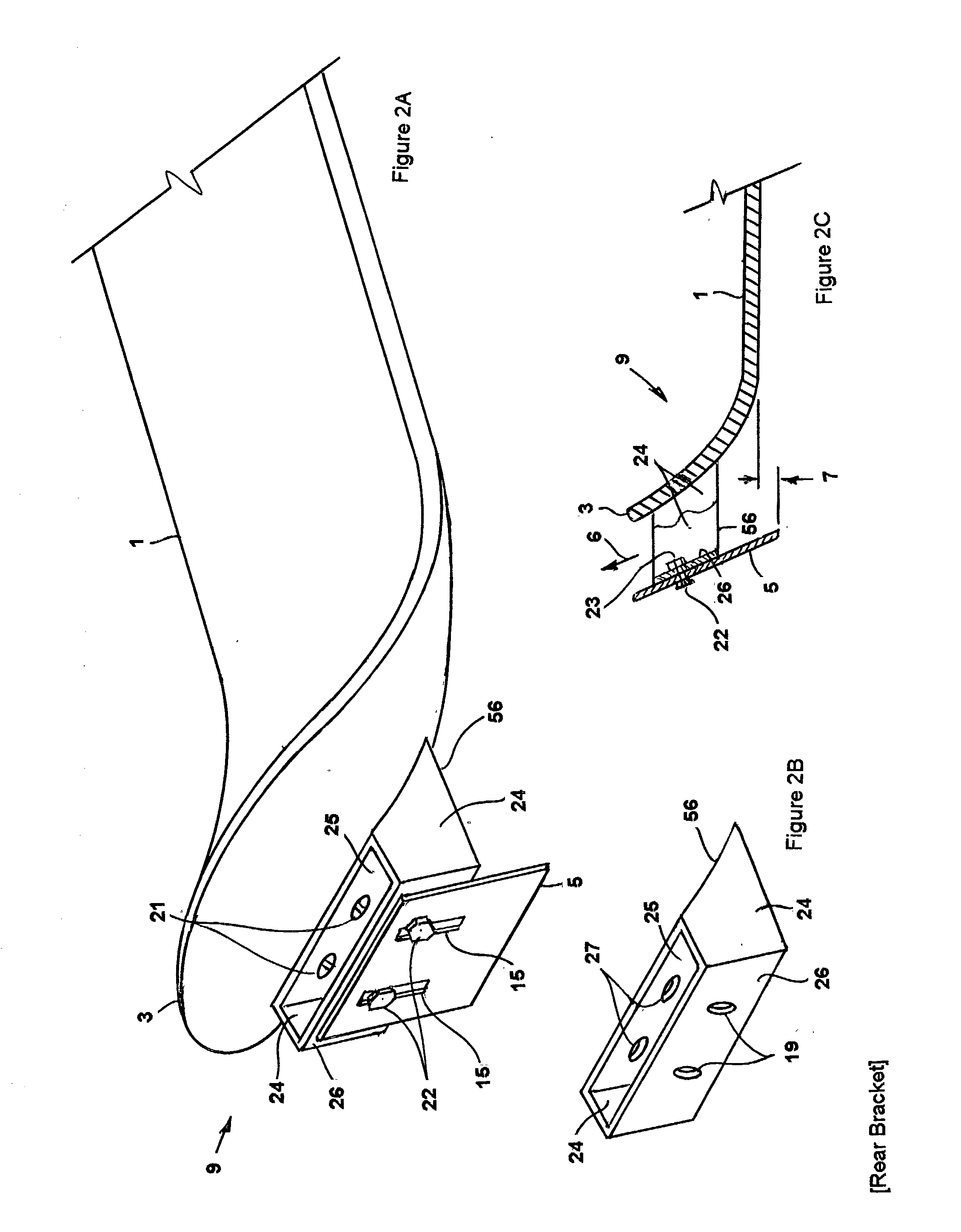

Semi-cordless unbalanced spring driven blind system and methods for adjusting and making same

InactiveUS6854503B2Reduce the possibilityLight protection screensCounterweightsEngineeringMechanical engineering

The invention includes an unbalanced horizontal blind with a spring means to provide a lifting or retraction force for the slats of the blinds. A brake means prevents undesired movement of the slats that would otherwise result from the continuous retraction force of the spring means when the slats are set in a desired position. Controls for the release of the brake means and tilting are also provided in an embodiment of a blind of the invention. An embodiment of the invention permits the blind to be operated by a single wand that can be used to either raise the slats or tilt the slats. This eliminates the need for a loose cord or bead chain that would traditionally be used as the user interface for controlling the movement of the slats of the blind.

Owner:ROLLERASE INC

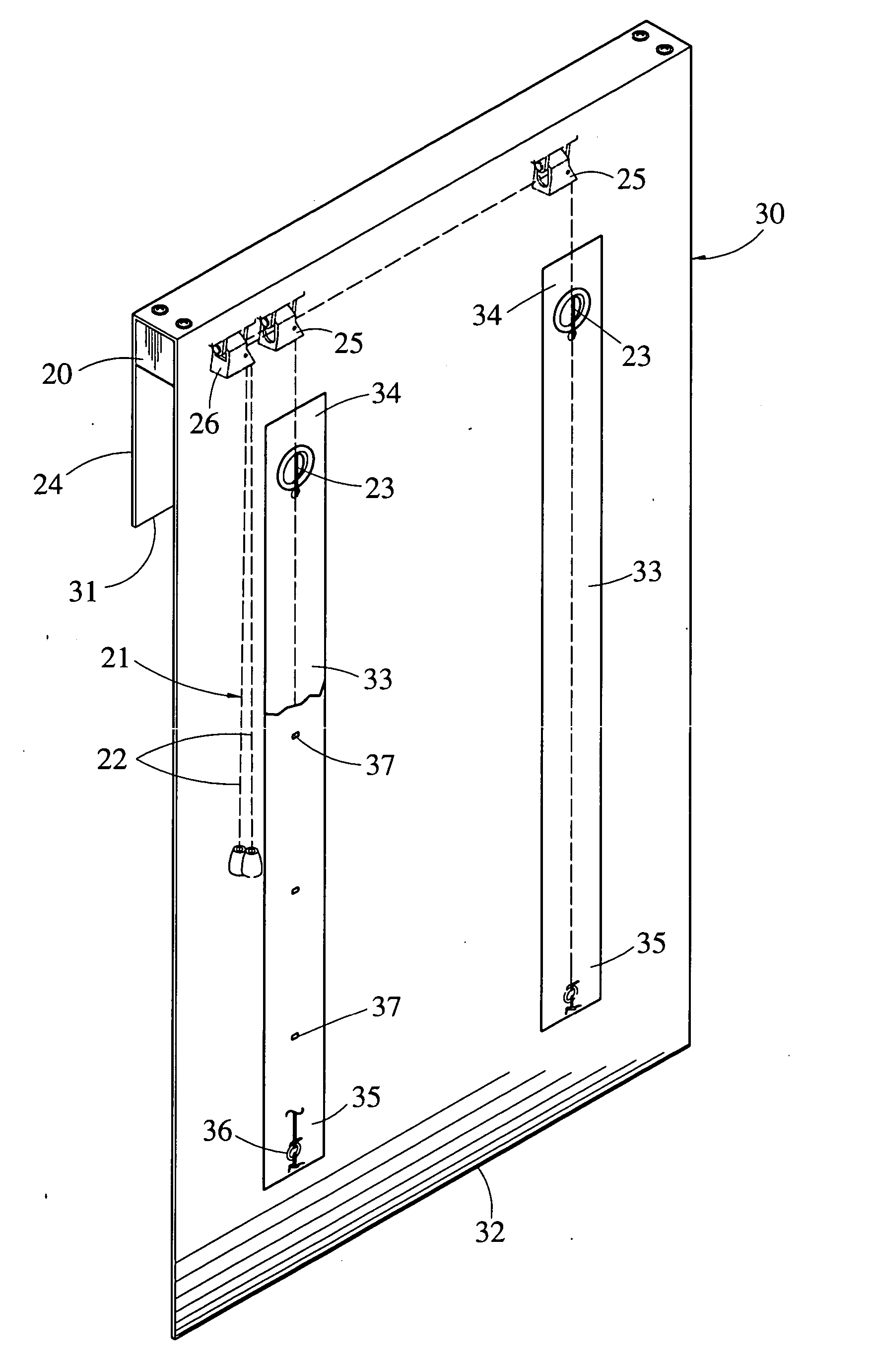

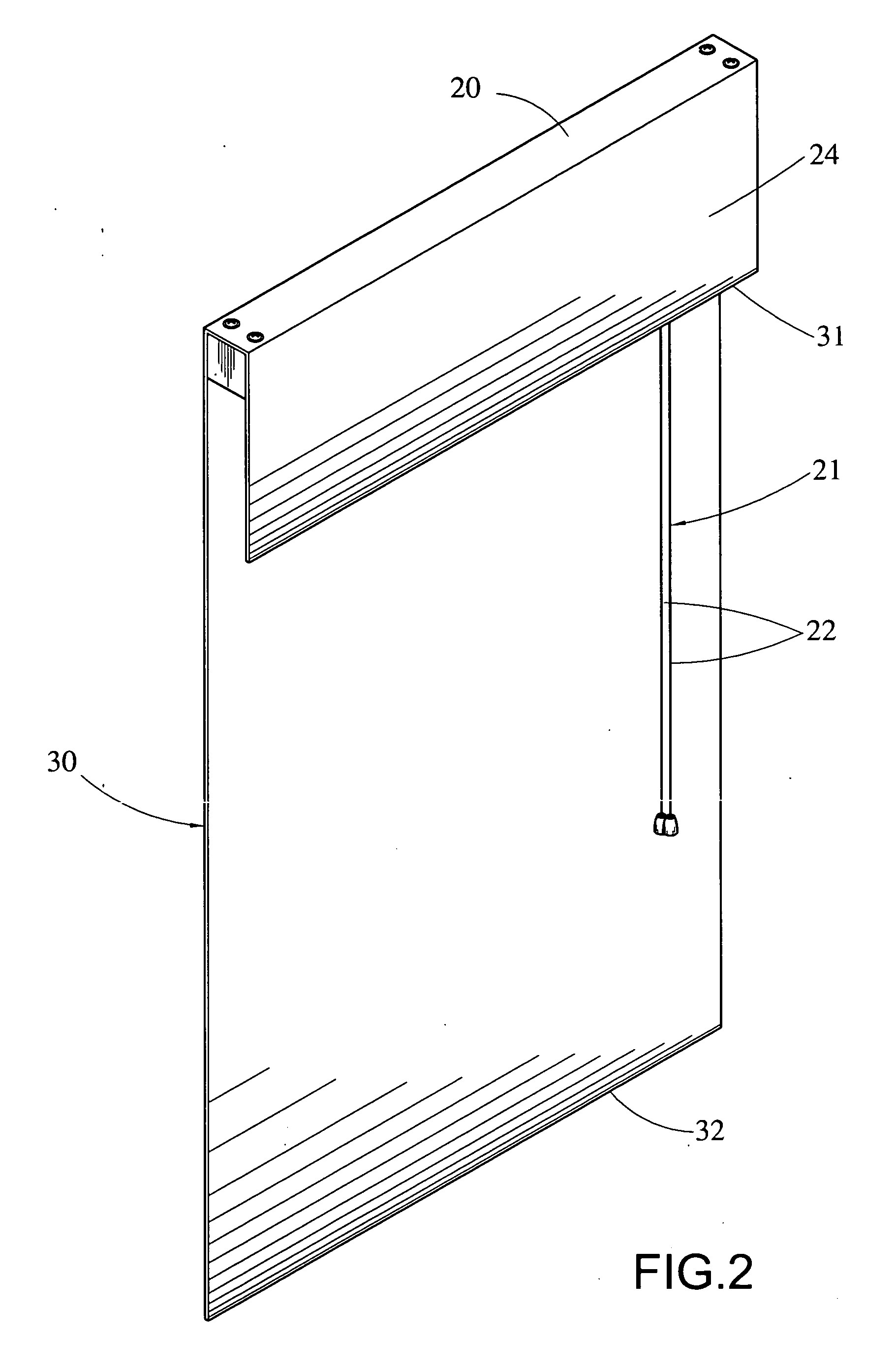

Roll-up blind with safety cord cover

Disclosed is a roll-up blind with safety arrangement. The blind comprises a headrail, a brake mechanism proximate the headrail, a cord having one end passed the brake mechanism to form an operable portion, a shade cloth coupled to the headrail, the shade cloth having a lower end coupled to the other end of the cord, and a plurality of cord covers formed on the shade cloth to cover the other end of the cord. Whereby pulling the operable portion of the cord will cause the shade cloth to wrinkle upwardly and the cord covers to contract together. Most importantly, a dangerous ring will not be formed by the cord and the cord covers in operation. Also, the shade cloth is wrinkled upwardly and the cord covers are contracted together to form aesthetic members in response to drawing up.

Owner:LIN HENRY

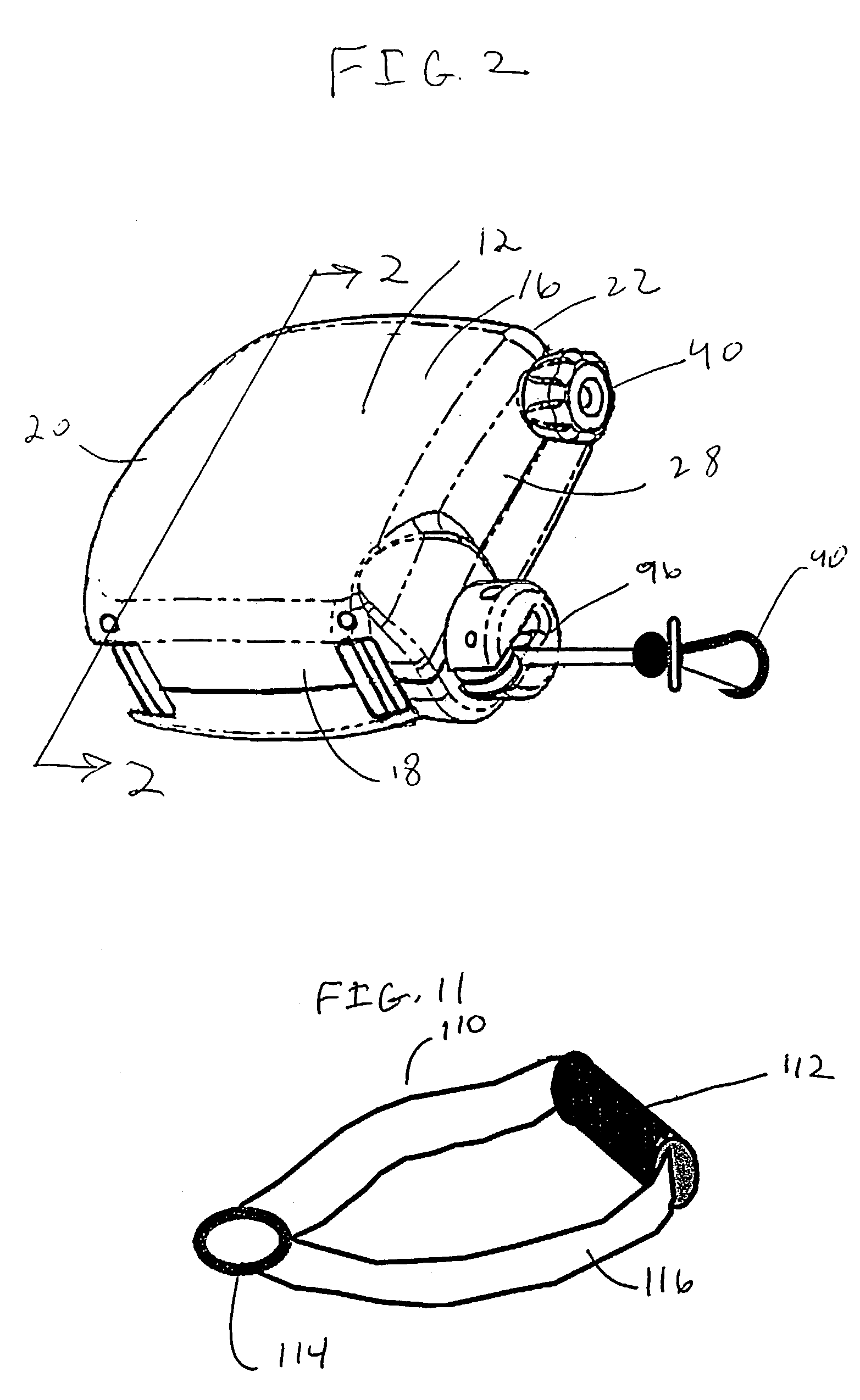

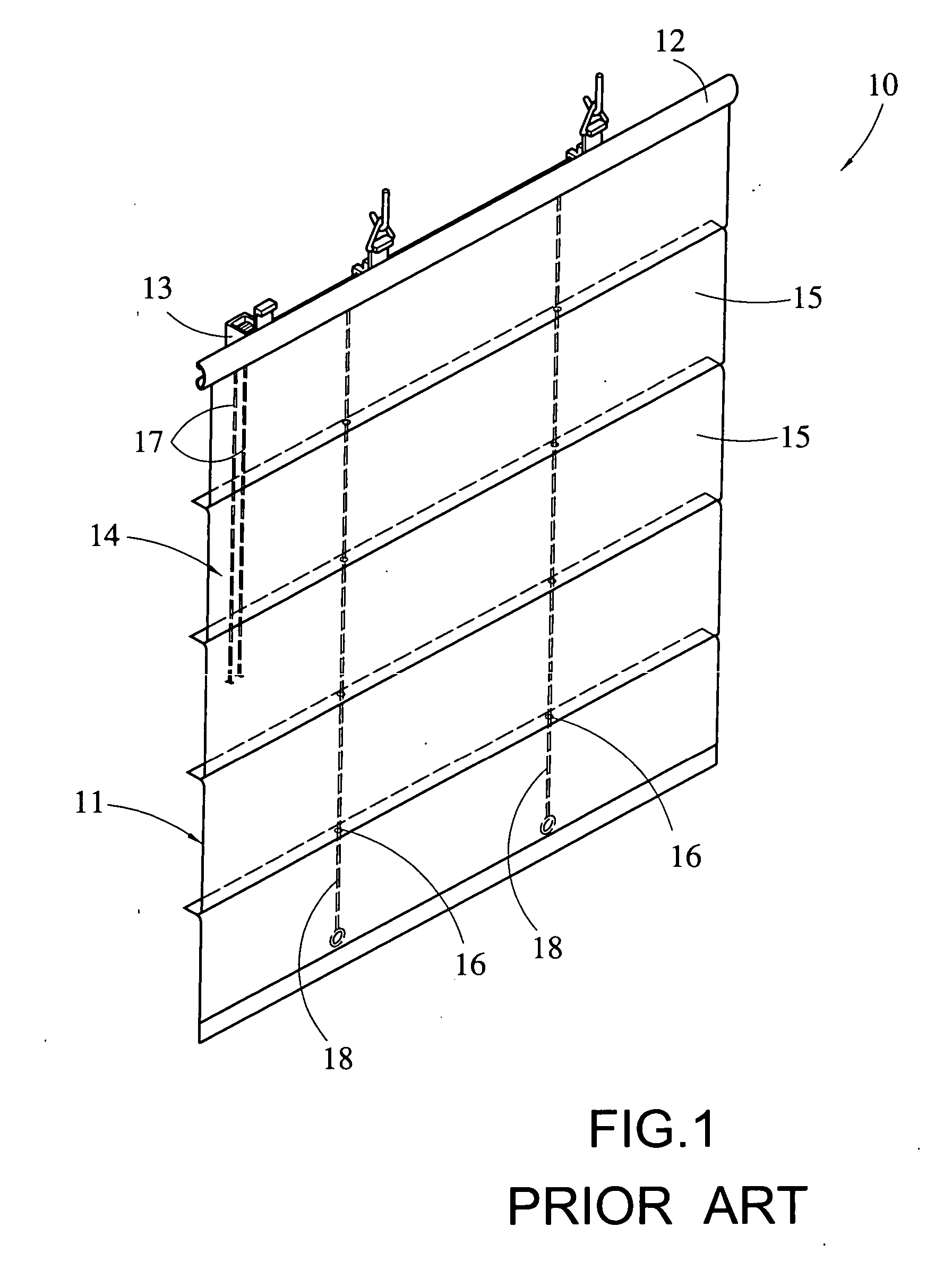

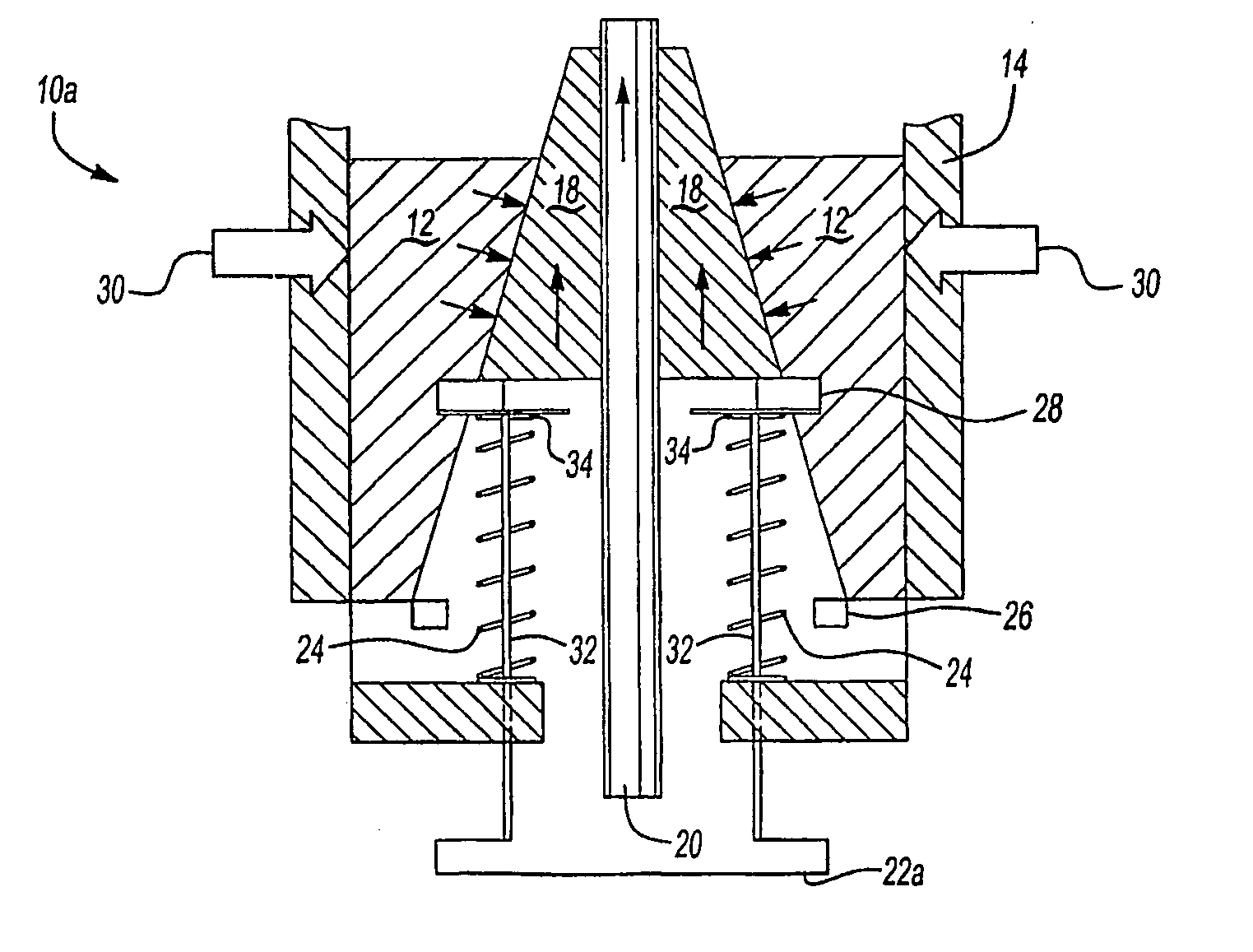

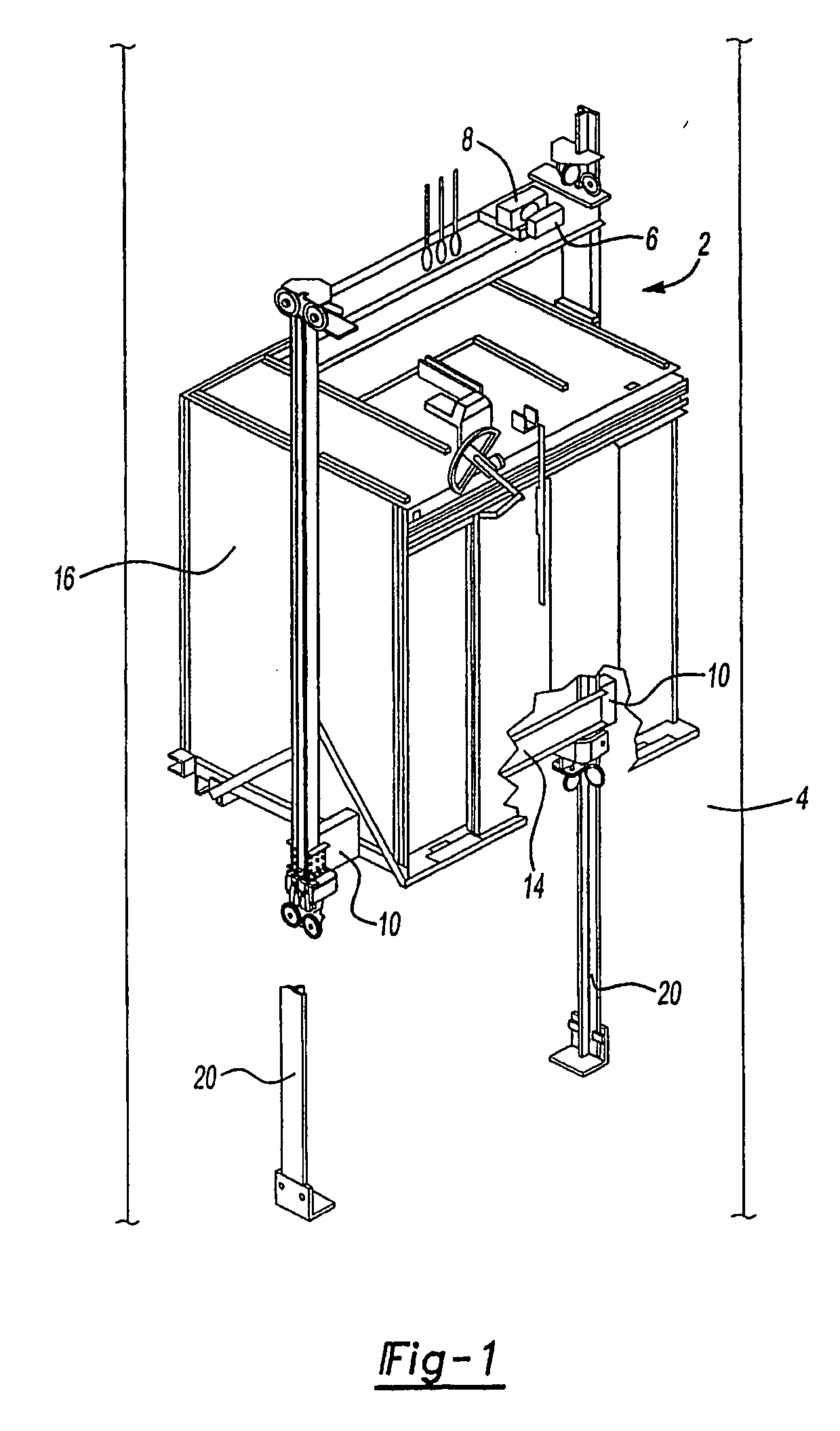

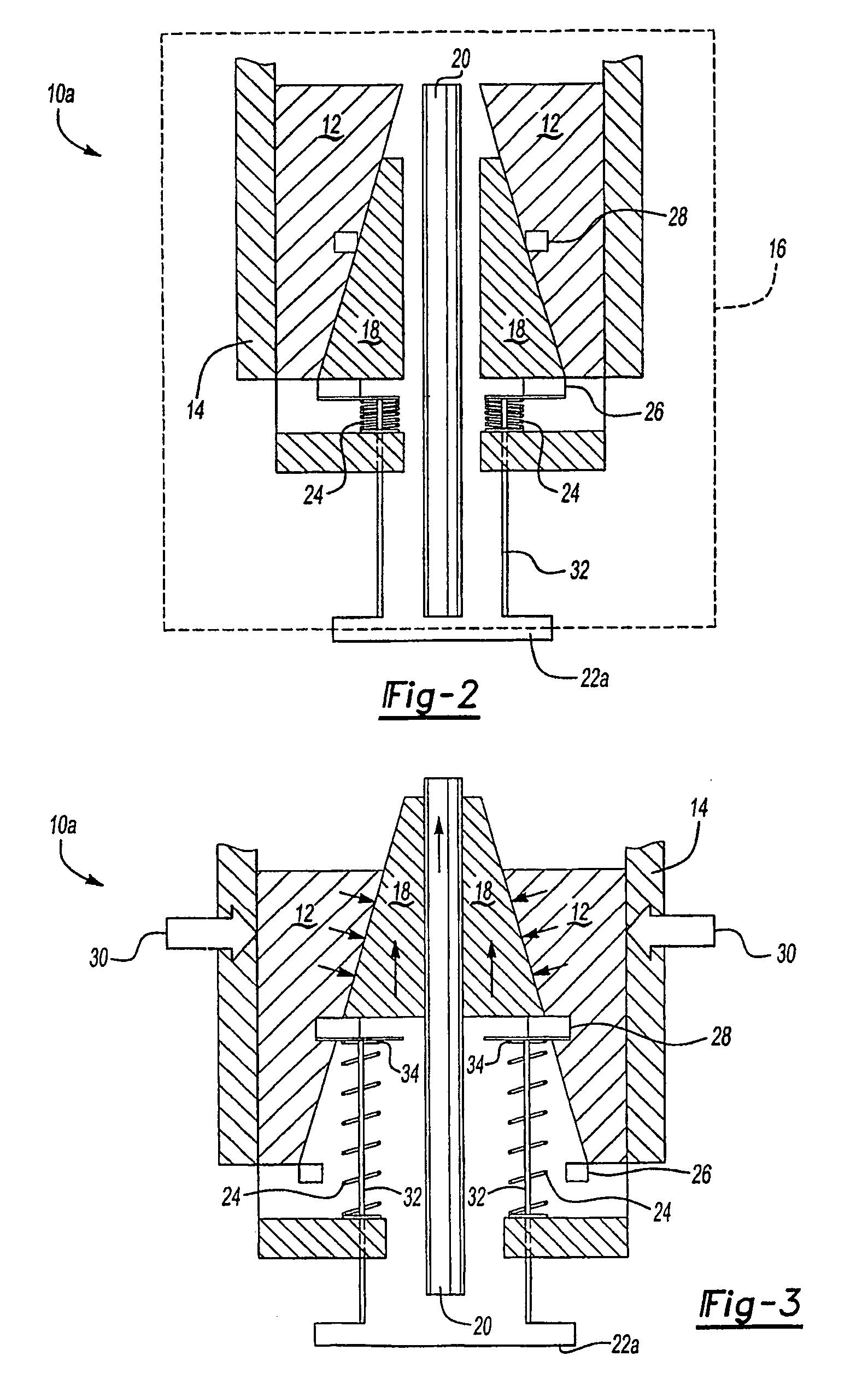

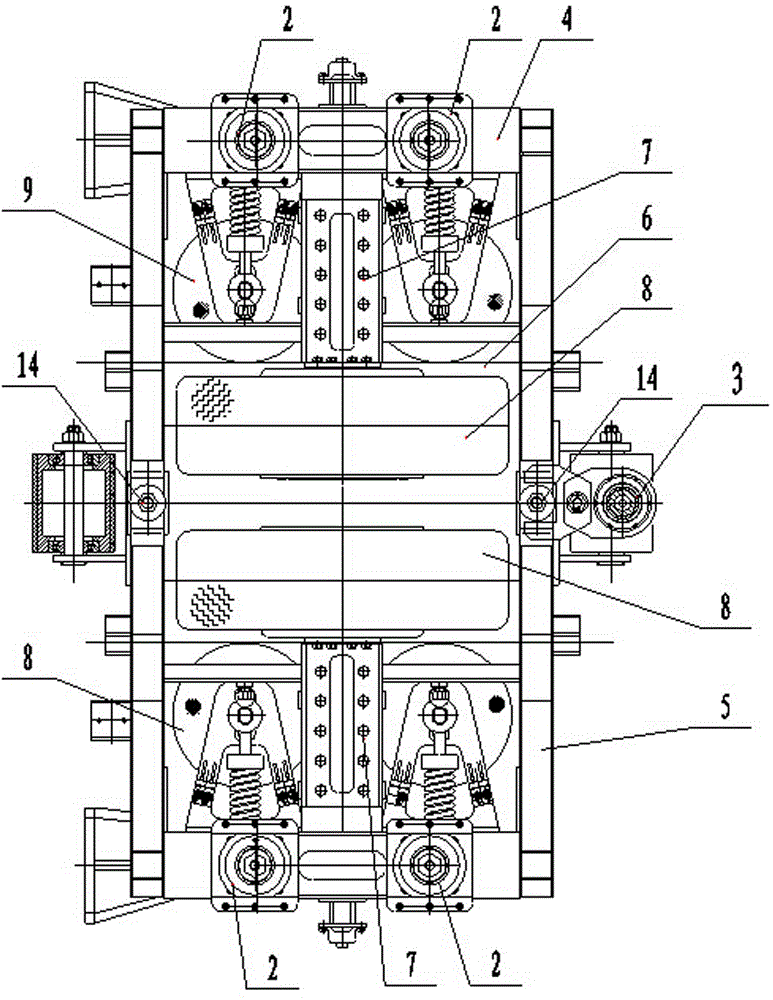

Remotely resettable ropeless emergency stopping device for an elevator

ActiveUS20070051563A1Decreases equipment cost and installation timeReduce maintenanceComputer controlElevatorsControl signalSolenoid valve

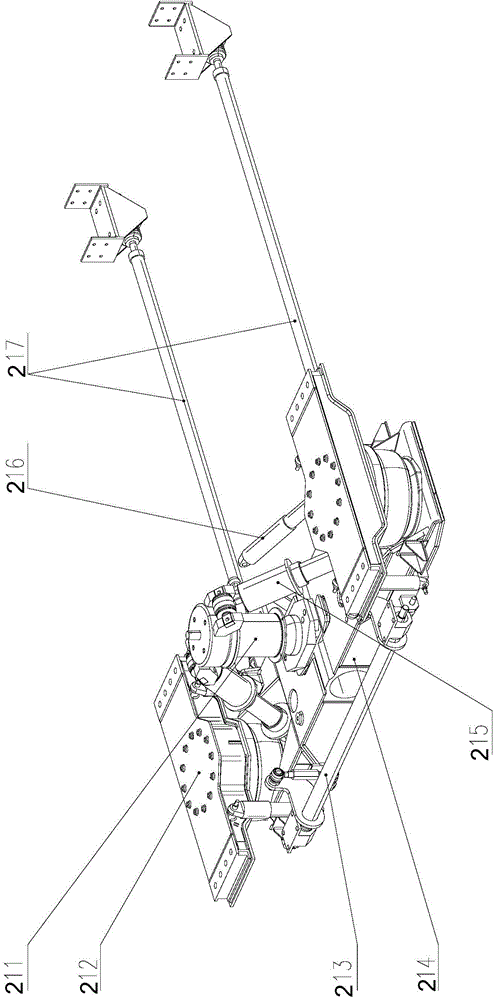

A brake mechanism (10) for an elevator (2) is activated in response to an electronic control signal to prevent movement of an elevator car (16) under predetermined conditions. The brake mechanism is preferably a safety mechanism (10) and does not require a governor sheave, a governor rope, or a tension sheave. The safety mechanism in one disclosed example utilizes a solenoid actuator (22b) and an electric motor (40) and gear box assembly (42) to move safety wedges (18) into engagement with a guide rail (20) to stop the elevator car (16). The safety wedges (18) are held in a non-deployed position during normal elevator operation. If there is a power loss or if elevator car speed exceeds a predetermined threshold, an electronic control signal activates the safety mechanism (10) causing the solenoid to release, which causes the safety wedges (18) move in a direction opposite to that of a safety housing (12) mounted for movement with the elevator car (16). Angled surfaces of the safety housing (12) force the safety wedges (18) into engagement with the guide rail (20). The safety mechanism (10) can be selectively reset from a remote location.

Owner:OTIS ELEVATOR CO

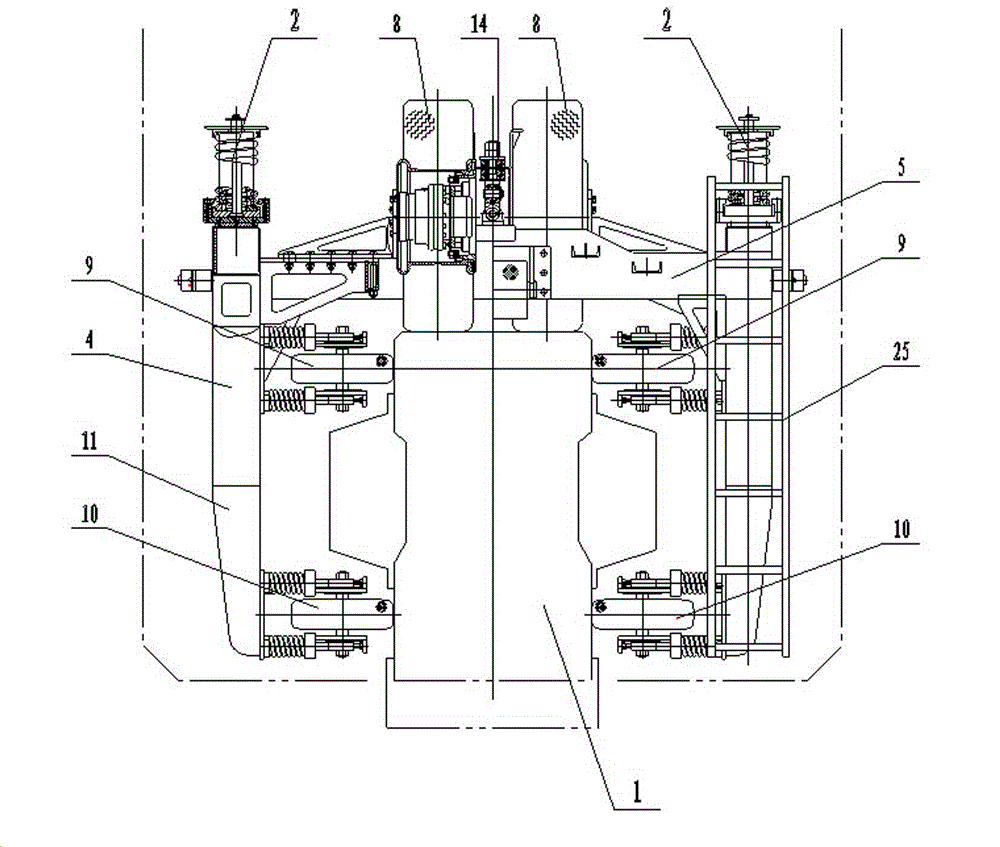

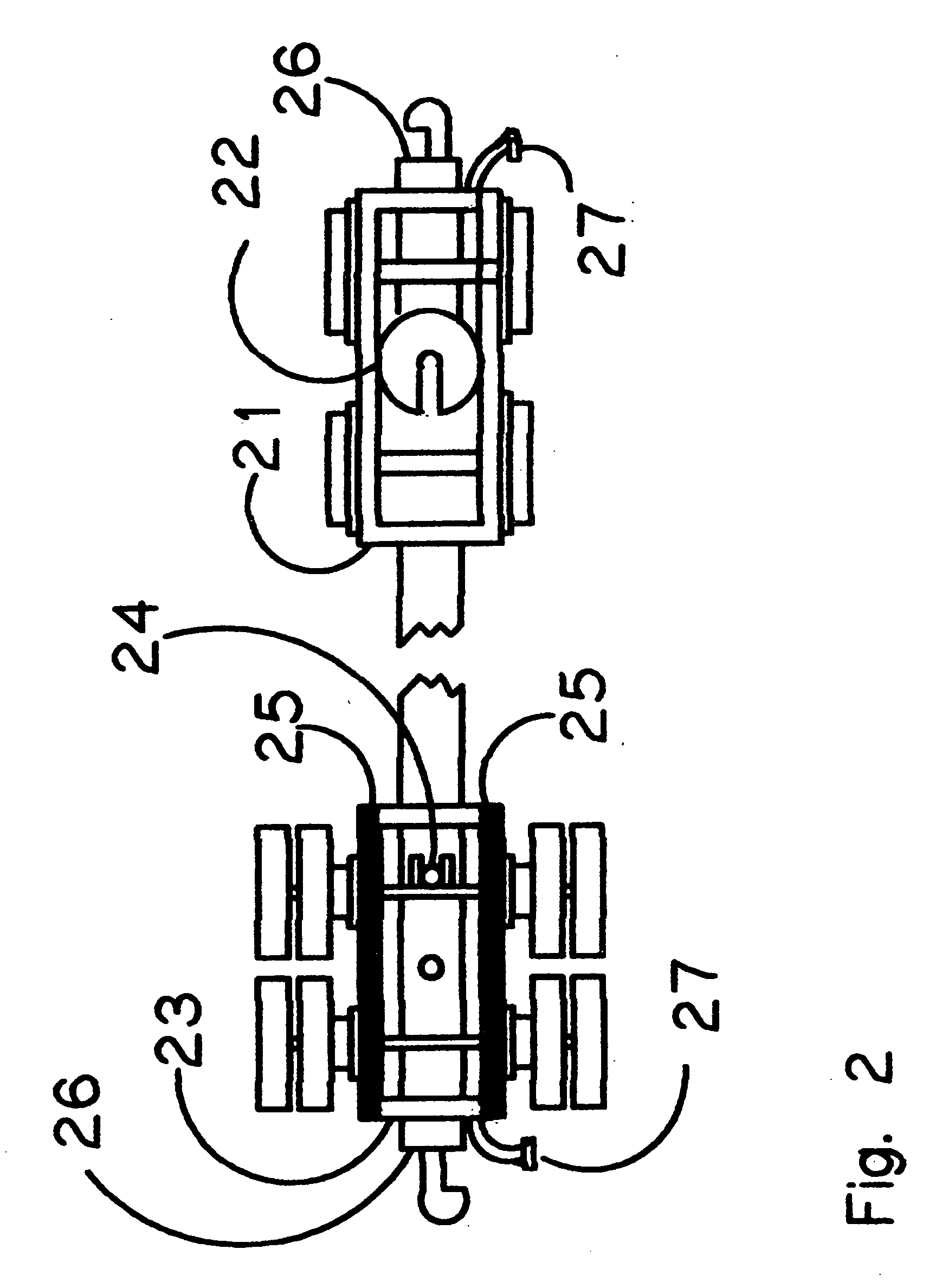

Straddle type monorail operation vehicle with structure comprising two pairs of wheels

ActiveCN104554323AEnsure stabilityFree up spaceRail-engaging wheelsIC reciprocating piston engine transmissionBogieTransfer case

The invention relates to an urban rail operation vehicle and in particular relates to a straddle type monorail operation vehicle with a structure comprising two pairs of wheels. The straddle type monorail operation vehicle comprises a carriage, a steering frame, an engine, a transfer case and a walking pump, wherein the steering frame is connected with an underframe of the carriage through a central pin dragging device; the steering frame comprises a framework, a secondary suspension device and a dragging device; the overall framework is of an II-shaped full-steel installed and welded plate type box structure and comprises a side beam, end beams connected to two ends of the upper part of the side beam and two vertical beams which are connected between the end beams; a motor bracket is fixed between the upper part of the side beam and the corresponding vertical beam; two independently-driven walking wheel assemblies are mounted on two motor brackets; four guide wheel assemblies are mounted on two sides of the middle part of the side beam; two stabilizing wheel assemblies are mounted on two sides of the lower part; the secondary suspension device adopts a secondary steel coil spring assembly. The straddle type monorail operation vehicle can reasonably meet the circuit requirements of monorail PC beams and is high in safety coefficient, excellent in dragging performance, simple and compact in structure, easy to maintain, stable in running and excellent in brake performance.

Owner:太原中车时代轨道工程机械有限公司

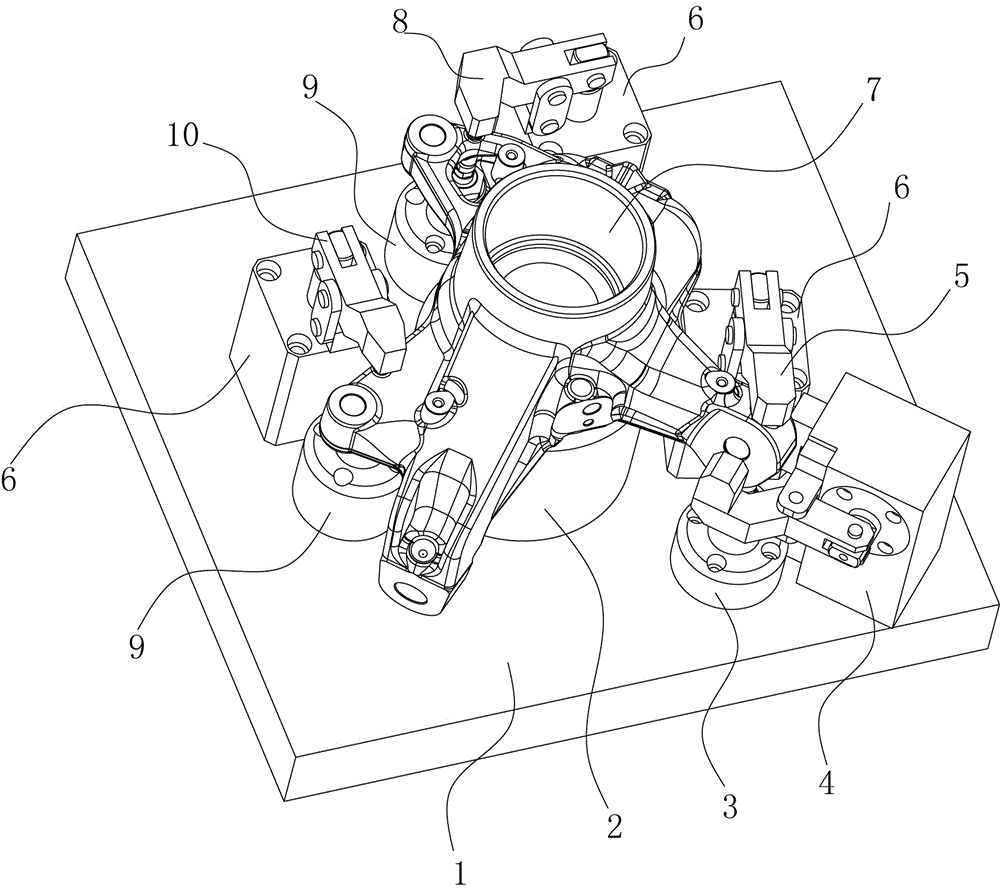

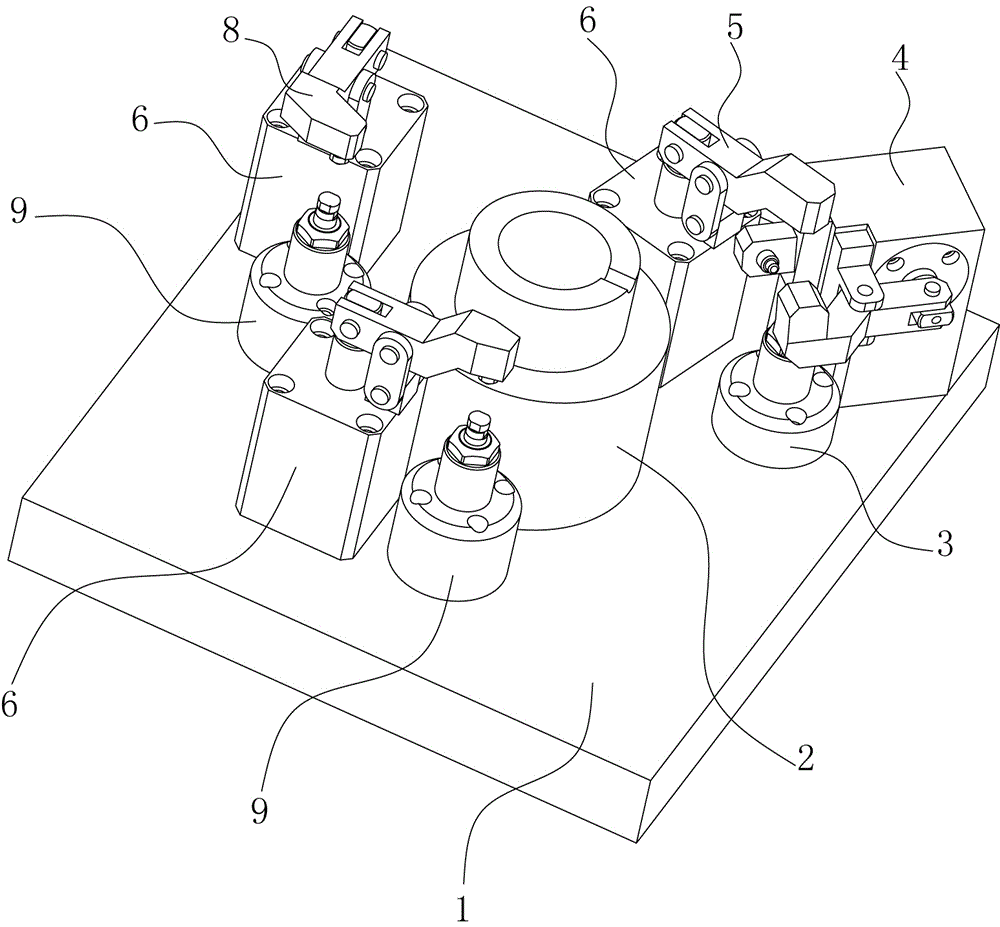

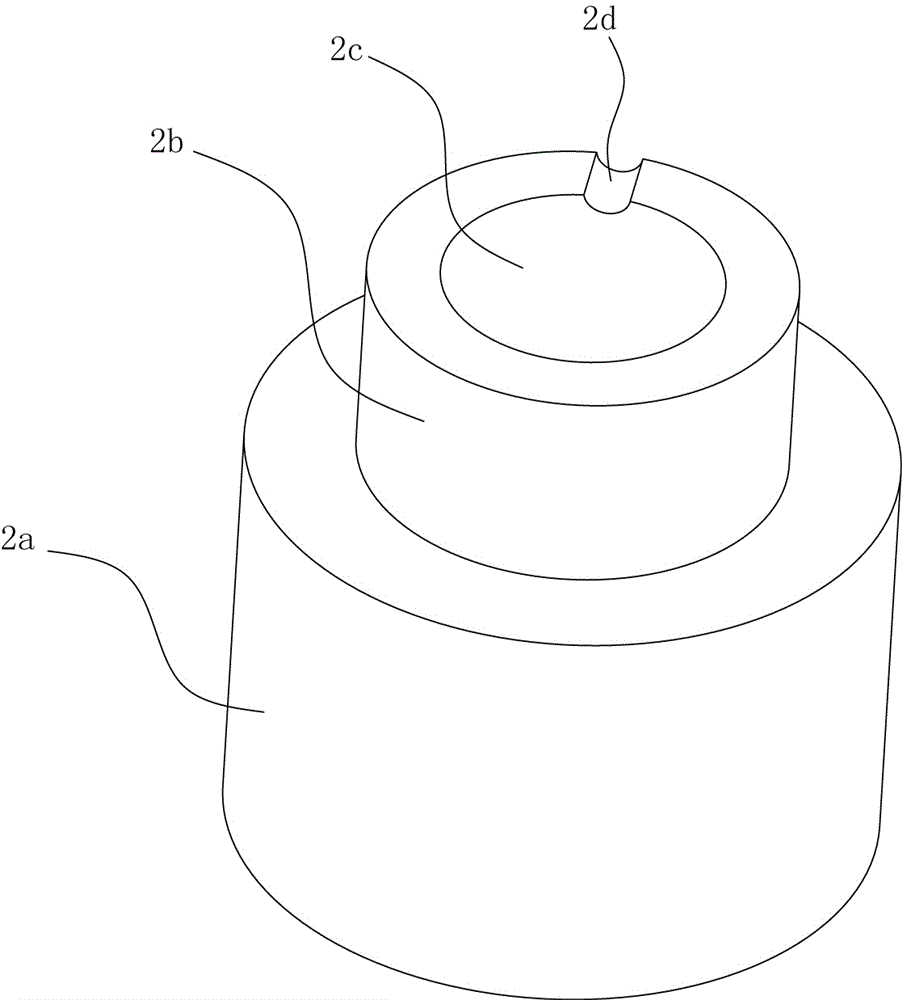

Machining tool and machining method of steering knuckle bearing hole

ActiveCN105945616AHigh precisionImprove efficiencyVehicle componentsPositioning apparatusBrakeStructural engineering

The invention discloses a machining tool and a machining method of a steering knuckle bearing hole. The tool comprises a fixture; the fixture includes a baseplate, a positioning shaft, a support part, a peripheral positioning clamping device, an auxiliary pressing device and a pressing device; the auxiliary pressing device is arranged in a tool magazine of a machining center; and a cutter clamping device on a main shaft of the machining center is used for automatically clamping to press on a steering knuckle to be machined in the fixture. The invention further designs the machining method corresponding to the tool. The tool and the method realize high-precision and high-efficiency machining of the steering knuckle bearing hole, integrate machining of a fender fixed hole end surface, a brake mounting hole end surface, an ABS mounting surface and a hole, reduce the clamping times, save the time, and improve the efficiency.

Owner:NINGBO HUIZHONG AUTOMOTIVE CHASSIS MFG

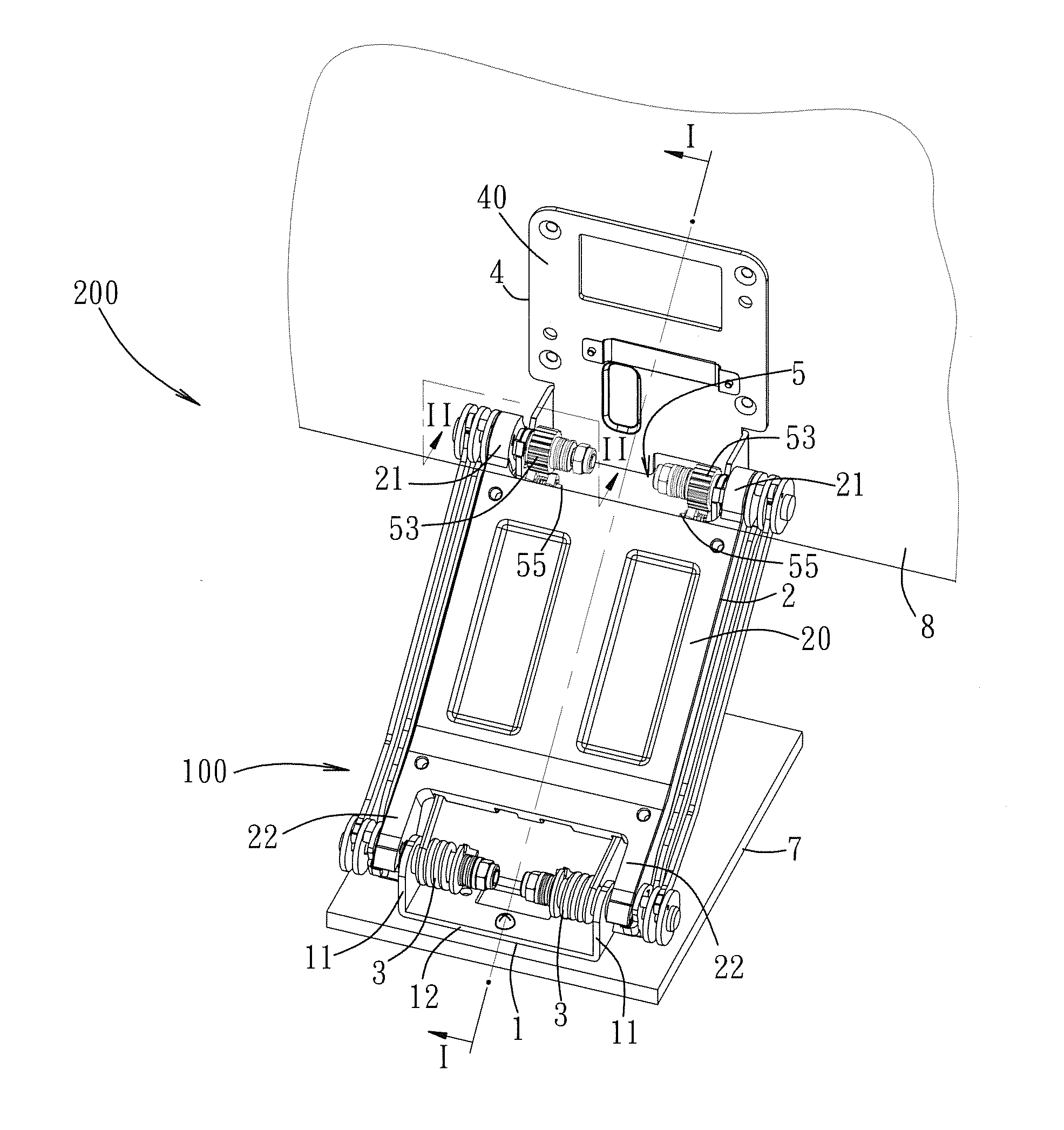

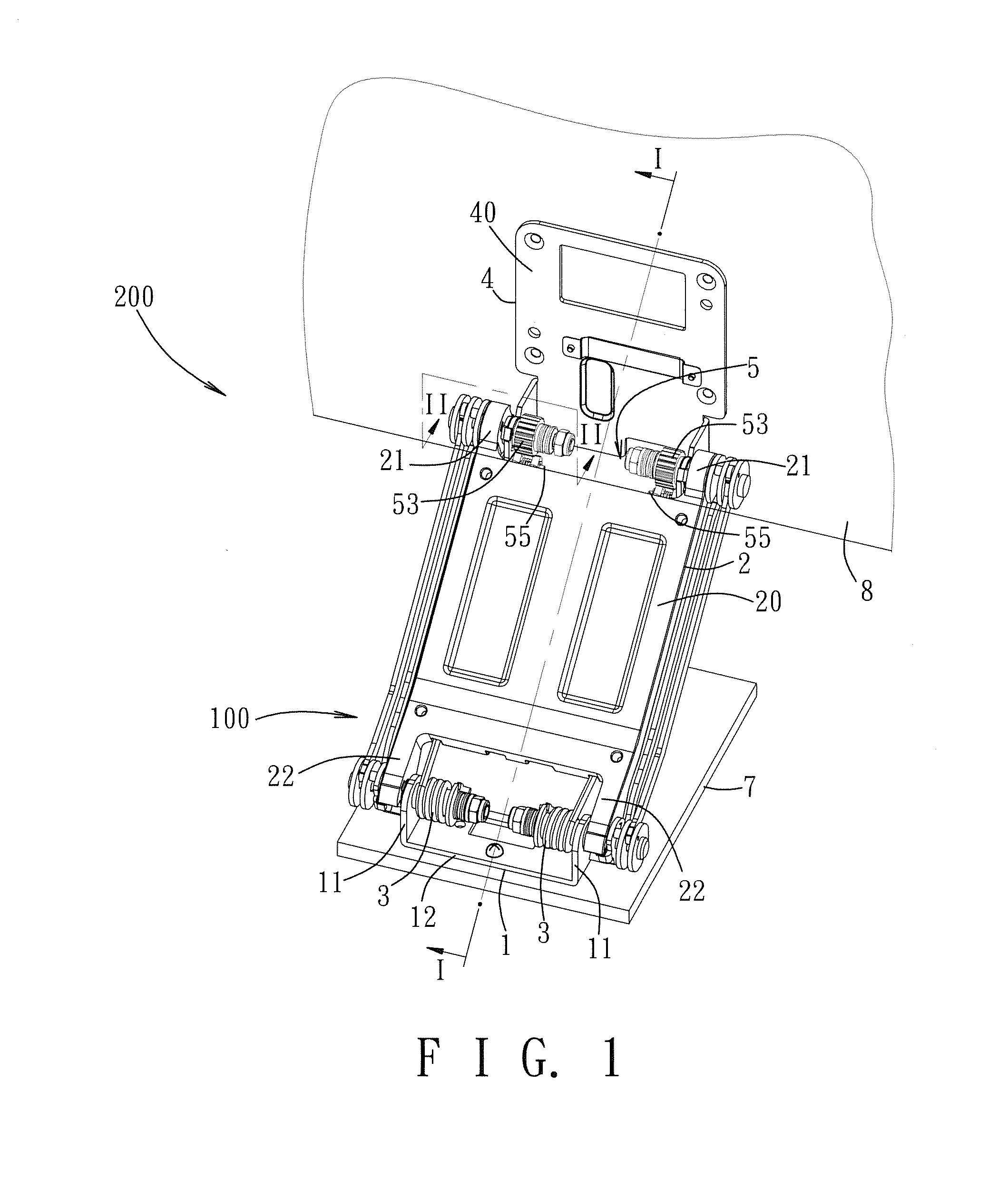

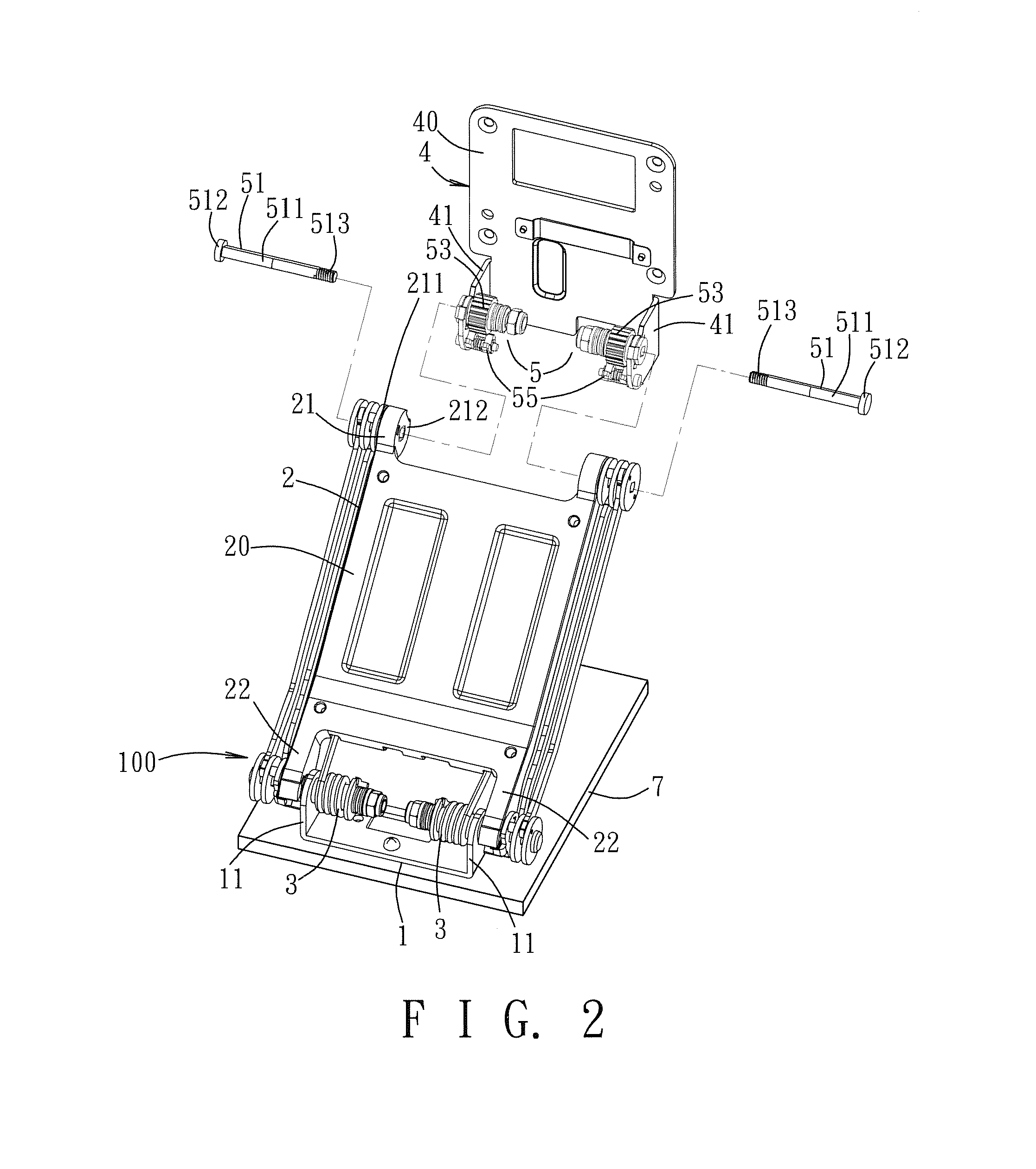

Hinge, supporting module having the hinge, and display device having the supporting module

ActiveUS20140063750A1Different frictional force and rotational torqueDifferent friction forceDigital data processing detailsWing fastenersRatchetBrake

A hinge for pivotally interconnecting first and second brackets includes a shaft having a shaft body extending through the first and second brackets and formed with an engaging end portion proximate to the second bracket, a fixing member connected to the engaging end portion, a ratchet sleeved rotatably on the shaft body between the fixing member and the second bracket, a friction mechanism having an urging unit sleeved on the shaft body between the ratchet and the fixing member and pressing the ratchet toward the second bracket, and a brake mechanism disposed on the second bracket and having a pawl member releasably engaged to the ratchet.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Vitreous carbon composite and method of making and using same

A reinforced vitreous carbon composite suitable for use in the formation of wear-resistant assemblies, such as joint prosthetic devices, bearings, current collectors, sealing components, brake linings, electrical motor brushes, and other tribological products. The reinforced composite is formed by impregnating a metal reinforcement structure with a furfuryl alcohol resin, and polymerizing the resin while thermally managing the polymerization process, to produce a poly(furfuryl) alcohol continuous phase that is isotropic, homogeneous and essentially completely void-free, e.g., in a bulk composite form having dimensions greater than 25 millimeters in each of the x, y and z directions thereof.

Owner:CARBON CERAMICS CO LLC

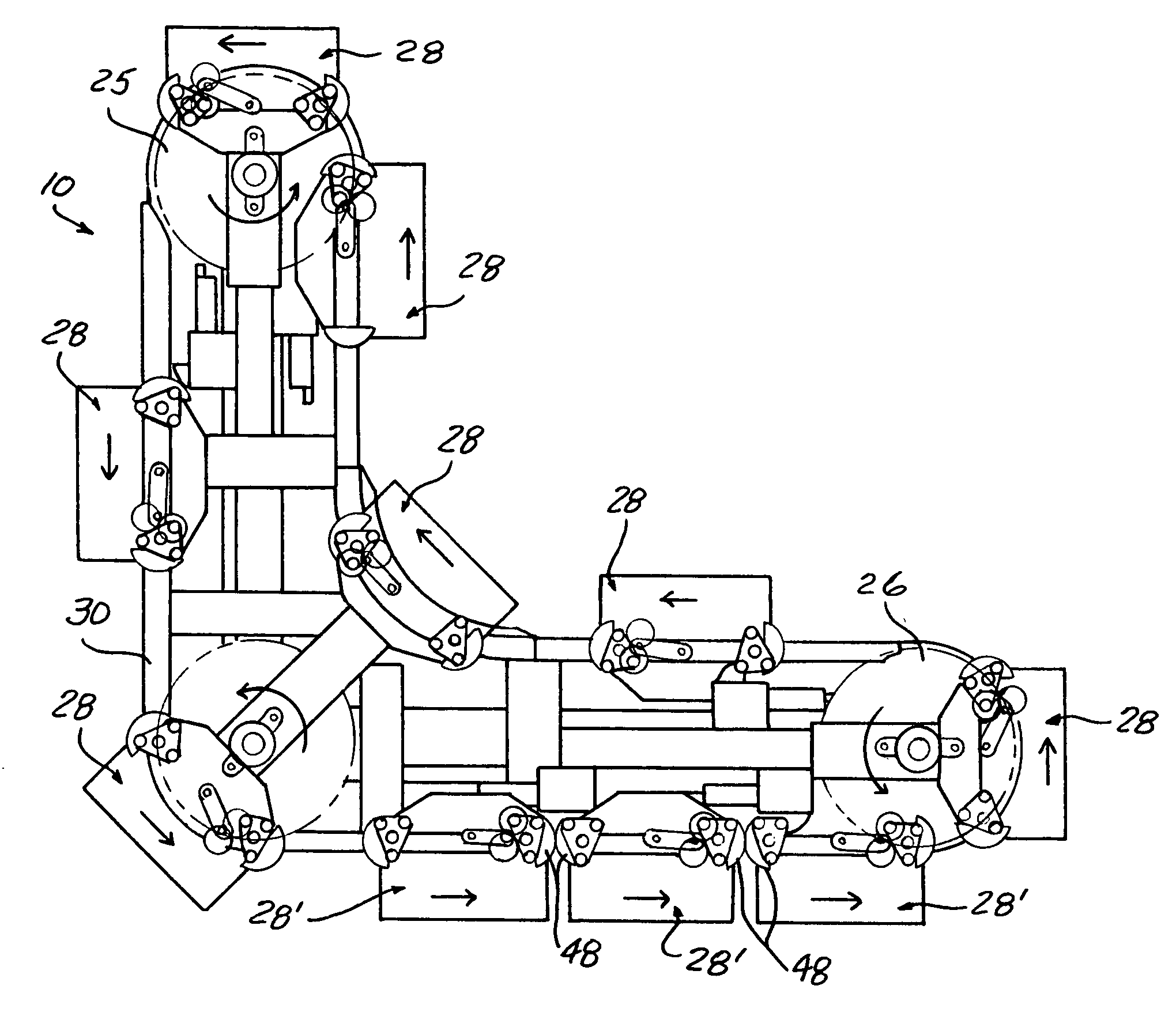

Pallet conveyor with chain drive recirculating in a horizontal plane

ActiveUS20050247546A1Simplified and reliableEliminate spaceMetal working apparatusConveyor partsClosed loopEngineering

A conveyor using a drive chain to drive pallets along a closed loop path on a track lying in a horizontal plane through inside and outside turns so that the conveyor may transport parts along non aligned stations. An advance and a return run extend parallel to each other and are closely spaced to minimize the floor space required. The drive chain is engaged by two spaced apart sprockets engaging a respective side of the drive chain, the sprockets mounted to the pallet on a pivoted bar spring biased to urge the sprocket teeth into engagement with the chain. The sprocket bar is pivotally mounted to one end of the swing bar which has an opposite end connected to the pallet to allow the chain and pallet to move together along the track and negotiate inside and outside turns. The chain is guided in a chain guide channel through inside turns, and on sprockets around the outside turns. A pair of friction brake rollers are included, each attached to one of the sprockets and are normally in firm contact with each other to brake the sprockets and carry the pallet along with the chain, which friction brake rollers slip when the pallet is arrested by a stop mechanism to be allowed to accumulate, the sprockets then able to rotate and the chain allowed to continue to circulate past the stopped pallet. The pallets extend alongside the chain and track to allow vertical mounting of parts on a side plate of the pallet or alternatively on a horizontal top plate. Alternatively, the swing bars can each be connected to the chain by one of a series of pins connected to the drive chain and pivotally received in the swing bar end in a synchronous nonaccumulating conveyor.

Owner:ROBERTS SINTO A MICHIGAN

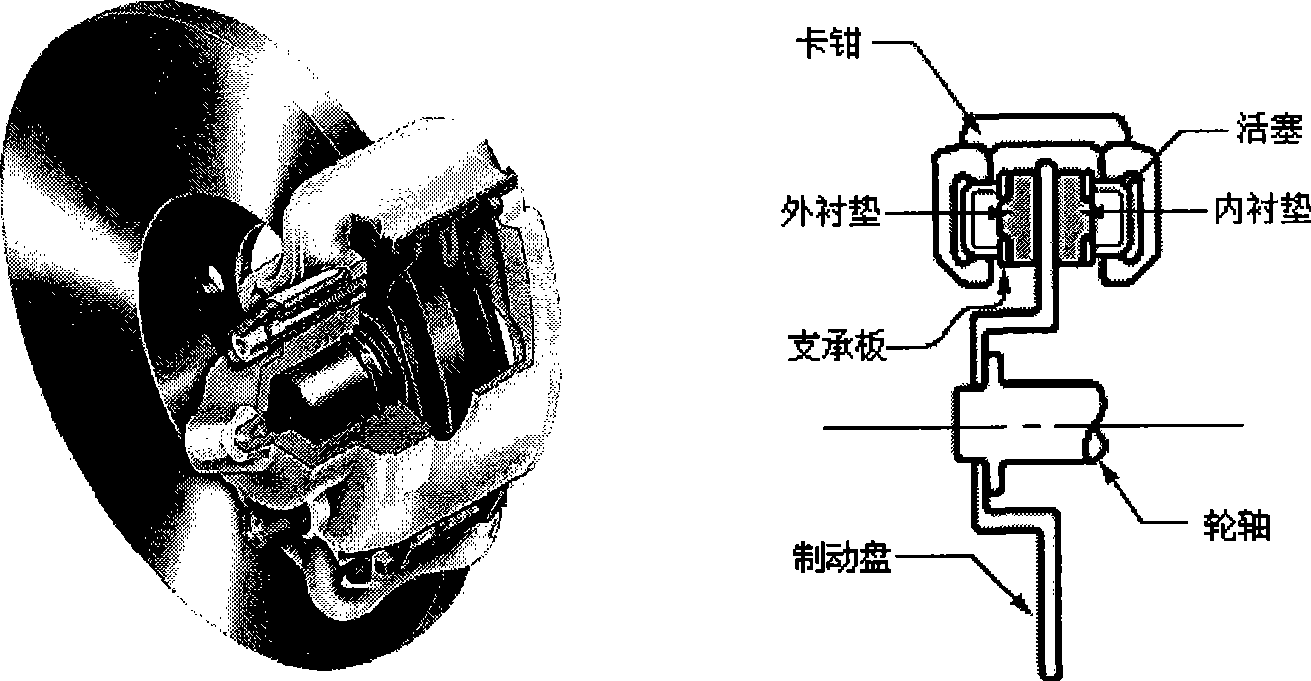

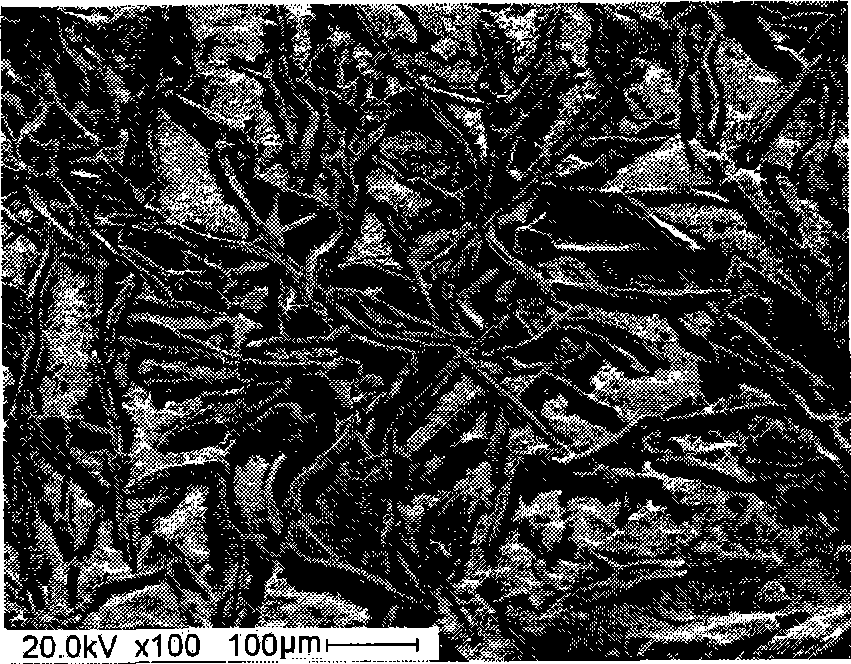

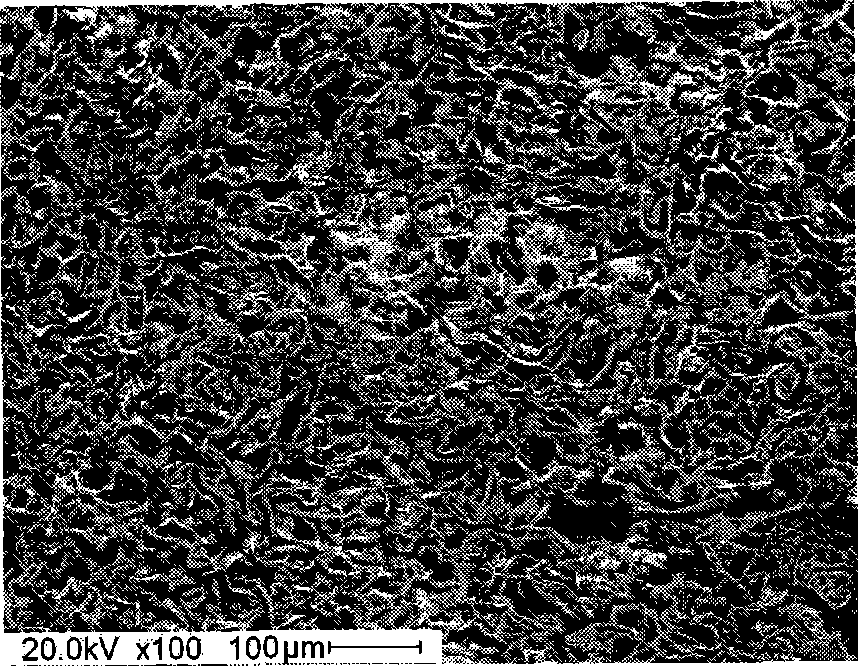

Niobium alloy cast iron brake disk material and technique for producing the same

The invention relates to a material for a niobium alloy cast iron braking disc and a production technology thereof, and belongs to the field of production technology of high-carbon equivalent hypereutectic gray cast iron. The material for the niobium alloy cast iron braking disc comprises the following chemical compositions in weight percentage: 3.7 to 3.9 percent of carbon, 1.8 to 2.2 percent of silicon, 0.5 to 0.8 percent of manganese, less than or equal to 0.08 percent of sulfur, less than or equal to 0.60 percent of copper, less than or equal to 0.20 percent of nickel, less than or equal to 0.05 percent of vanadium, less than or equal to 0.05 percent of stannum, less than or equal to 0.05 percent of titanium, less than or equal to 0.25 percent of chrome molybdenum, 0.08 to 0.3 percent of niobium, and the balance being iron, wherein the iron is melted by an intermediate frequency furnace. The structure of the material is characterized by comprising pearlite, graphite (A3-5), and a small amount of ferrite The performance characteristics of the material are as follows: the hardness HB is more than or equal to 150 and the tensile strength is more than or equal to 170 N / mm<2>. The material is suitable for braking discs for medium-to-high grade sedans made of gray cast iron, and has the advantages of stable performance, low cost, longer service life, and convenient processing.

Owner:SHANGHAI UNIV +1

Elevator brake

A brake (26) for an elevator system (10) and method of using the brake (26) is disclosed. The brake (26) may comprise first and second brake linings (38) configured to be frictionally engageable with a rail (14) of the elevator system (10), a first biasing member (34) configured to urge the first brake lining (38) to engage the rail (14), and a first actuator (30) configured to move the first brake lining (38) to disengage the rail (14) when the first actuator (30) is energized. The brake (26) may be configured to be mounted on an elevator car (16) of the elevator system (10).

Owner:OTIS ELEVATOR CO

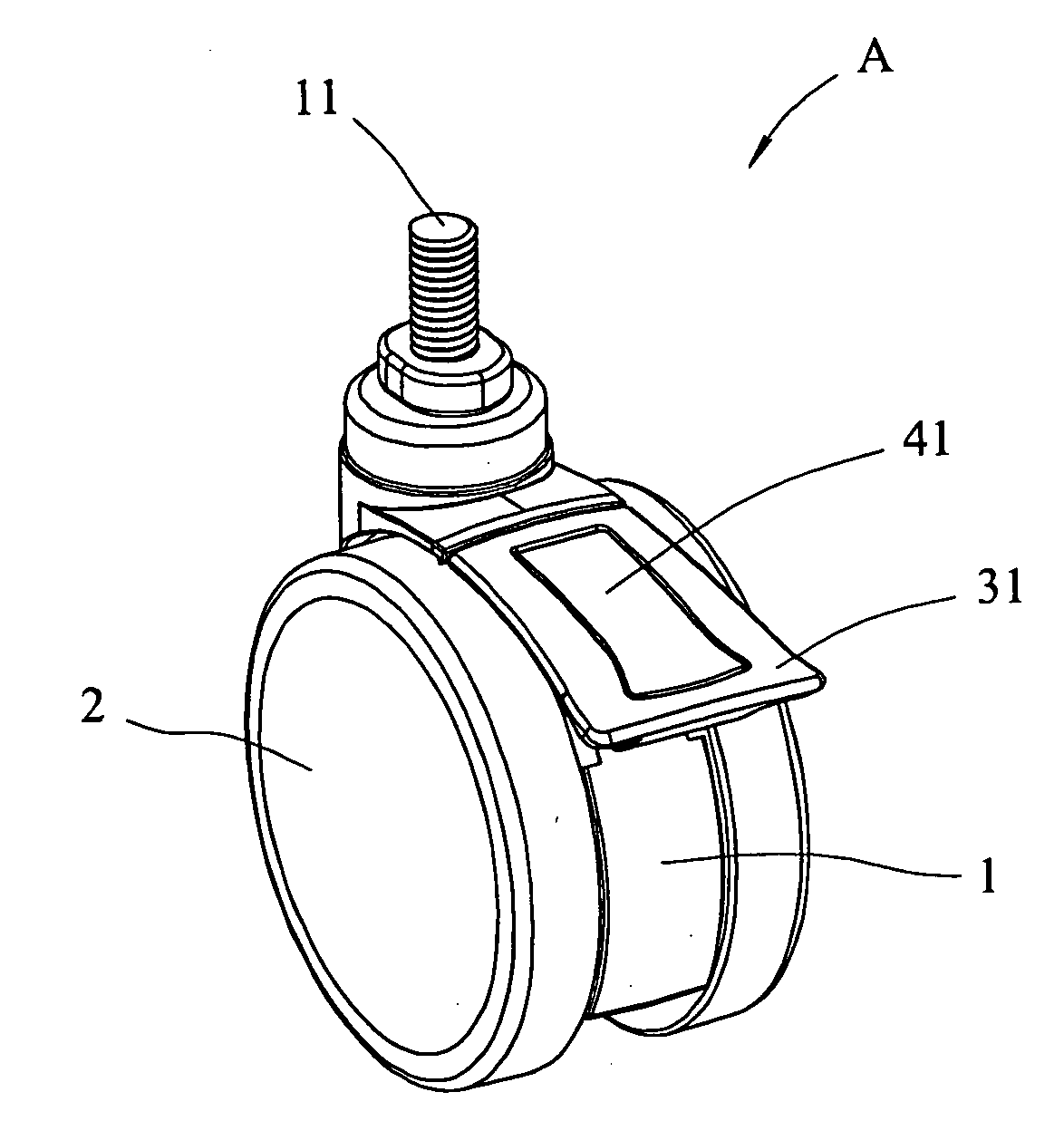

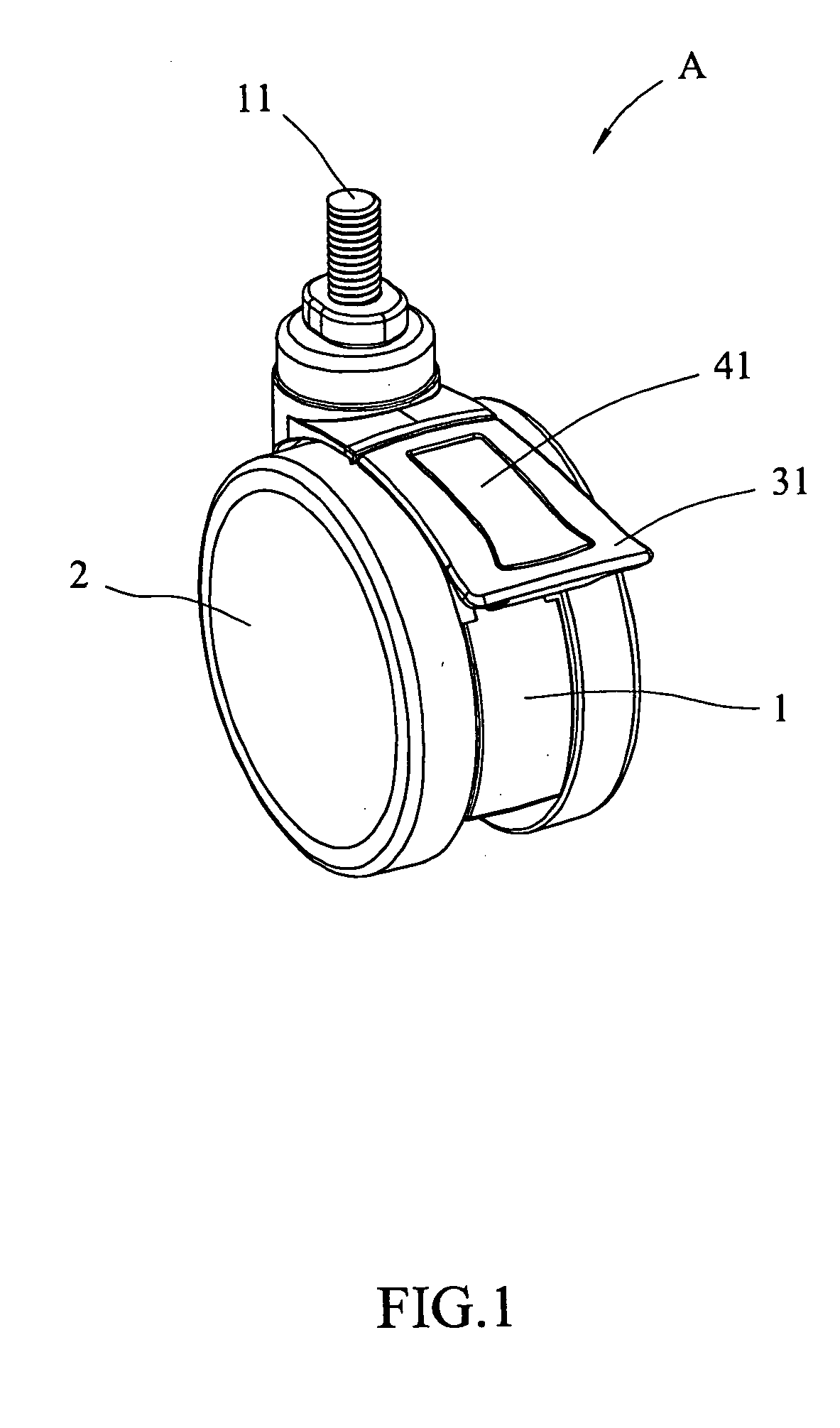

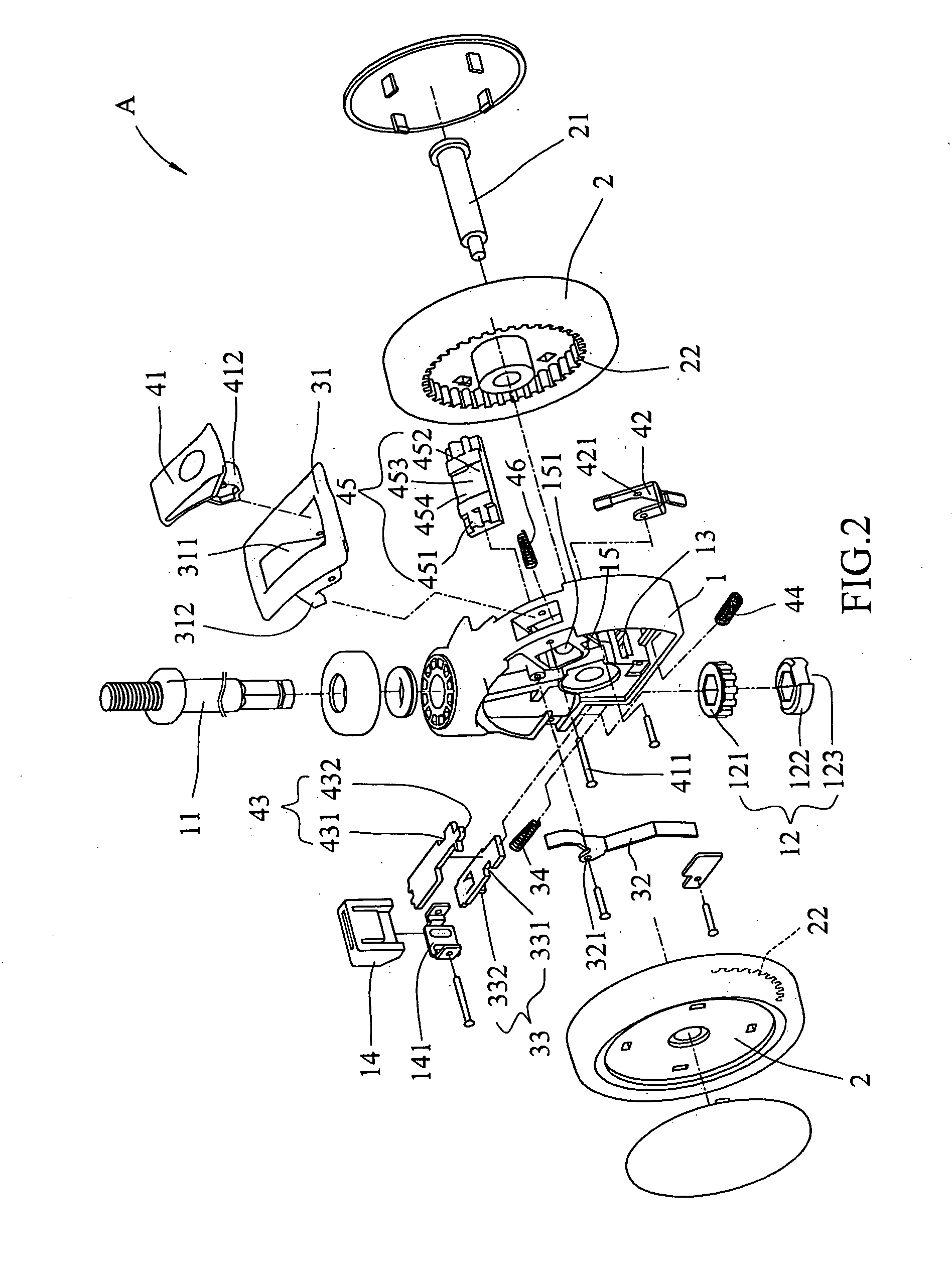

Caster with brake unit and direction unit

A caster includes a casing having a shank and a locking unit is located at a lower end of the shank. Two wheels are connected to two sides of the casing by a shaft and an inner gear is connected to each of the two wheels. A direction unit is located in the casing and includes a first lever and an opening, the first lever connects the direction unit to the locking unit. A brake unit is located in the casing and includes a second lever. The second lever connects the brake unit to the locking unit and the inner gears. The second lever is engaged with the opening of the first lever and shares a common pivot with the first lever so as to respectively brake the caster and control direction of the caster.

Owner:CHU KEIO

Snow board brake

InactiveUS20040036257A1Simple adjustmentEasily understoodSki bindingsSki-brakesEngineeringKnife blades

A braking device for slowing a snow board which is to be used by novice or inexperienced users. The invention is comprised of a blade which is affixed either between the rear boot attachment means and the rear of the snow board or on the bottom upturned portion of the rear end of the snow board. The blade is adjustably angled forward against the snow in the direction of travel. When the blade is in the lowered position it cuts snow and directs the cut snow upward over the blade. A slot in the snow board just ahead of the blade allows the snow to pass upward through the snow board. Alternately for another embodiment, the blade is held in a bracket which is affixed to the rear upturned surface of the snow board. For this embodiment of the invention, the cut snow is directed upward between the blade and its supporting structure. The preferred embodiment of the invention is to employ a broad straight bottom edge for the blade about 4 inches wide with a maximum depth of cut of about 1 / 2 inch. An acceptable angle of cut of the angled blade can range from a vertical position to about 45 degrees downward and forward. When the snow board is not being used, the blade is repositioned by loosening the blade and sliding or rotating it relative to its support with tightening of the blade fixing means for its final securement. In another embodiment, a fixed blade in the form of a angle is attached directly to the bottom of the snow board perpendicular to the length of the snow board. Such blades can extend downward different distances to provide different amounts of drag.

Owner:LILLE GREGORY L +3

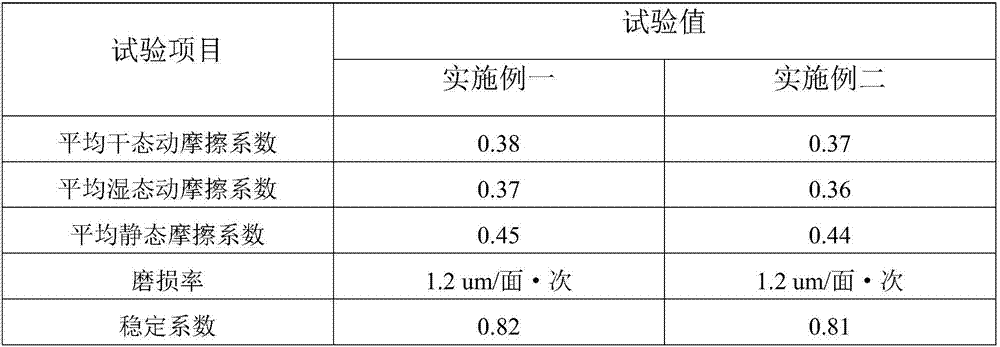

High performance and low cost C/C-SiC composite brake disc, preparation method and application thereof

ActiveCN106966751ALow priceLow cost of preparationBraking discsActuatorsMolten siliconThermal conductivity

The invention relates to a high performance and low cost C / C-SiC composite brake disc, a preparation method and application thereof. The preparation method includes: carbonizing a brake disc prefab, and densifying the carbonized brake disc prefab by chemical vapor infiltration method to obtain a C / C composite material; then performing heat treatment in an inert atmosphere to improve the graphitization degree of the composite material; then conducting machining to obtain a C / C composite blank; treating the C / C composite blank by molten silicon infiltration method to obtain a C / C-SiC composite brake disc; then treating the C / C-SiC composite brake disc by means of chemical vapor infiltration or precursor infiltration pyrolysis; and machining the obtained product into a final design size, thus obtaining a composite brake disc finished product. The C / C-SiC composite brake disc and the preparation method thereof provided by the invention can reduce the preparation cost and improve the mechanical performance, thermal conductivity and friction and wear performance of the brake disc.

Owner:BEIHANG UNIV

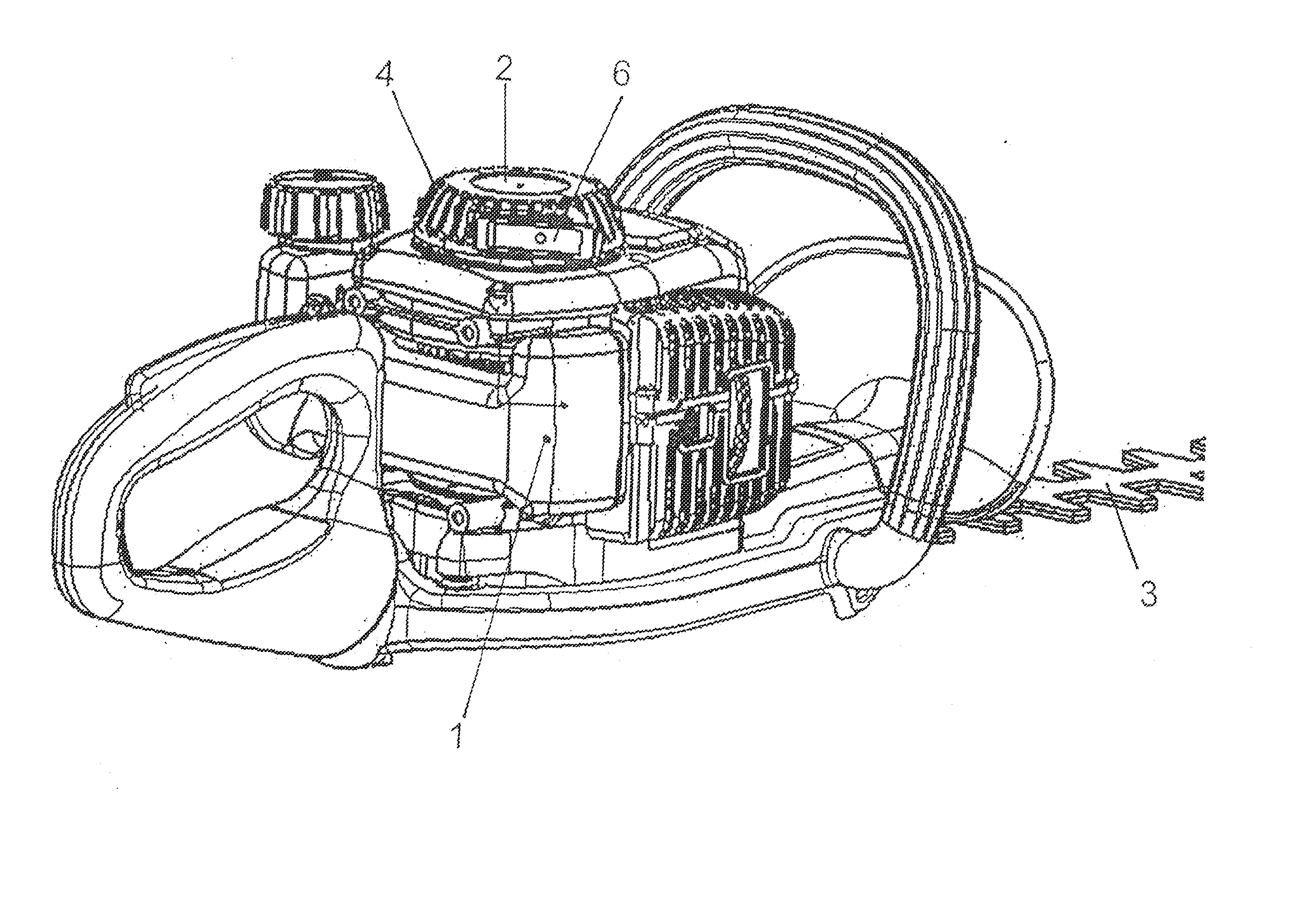

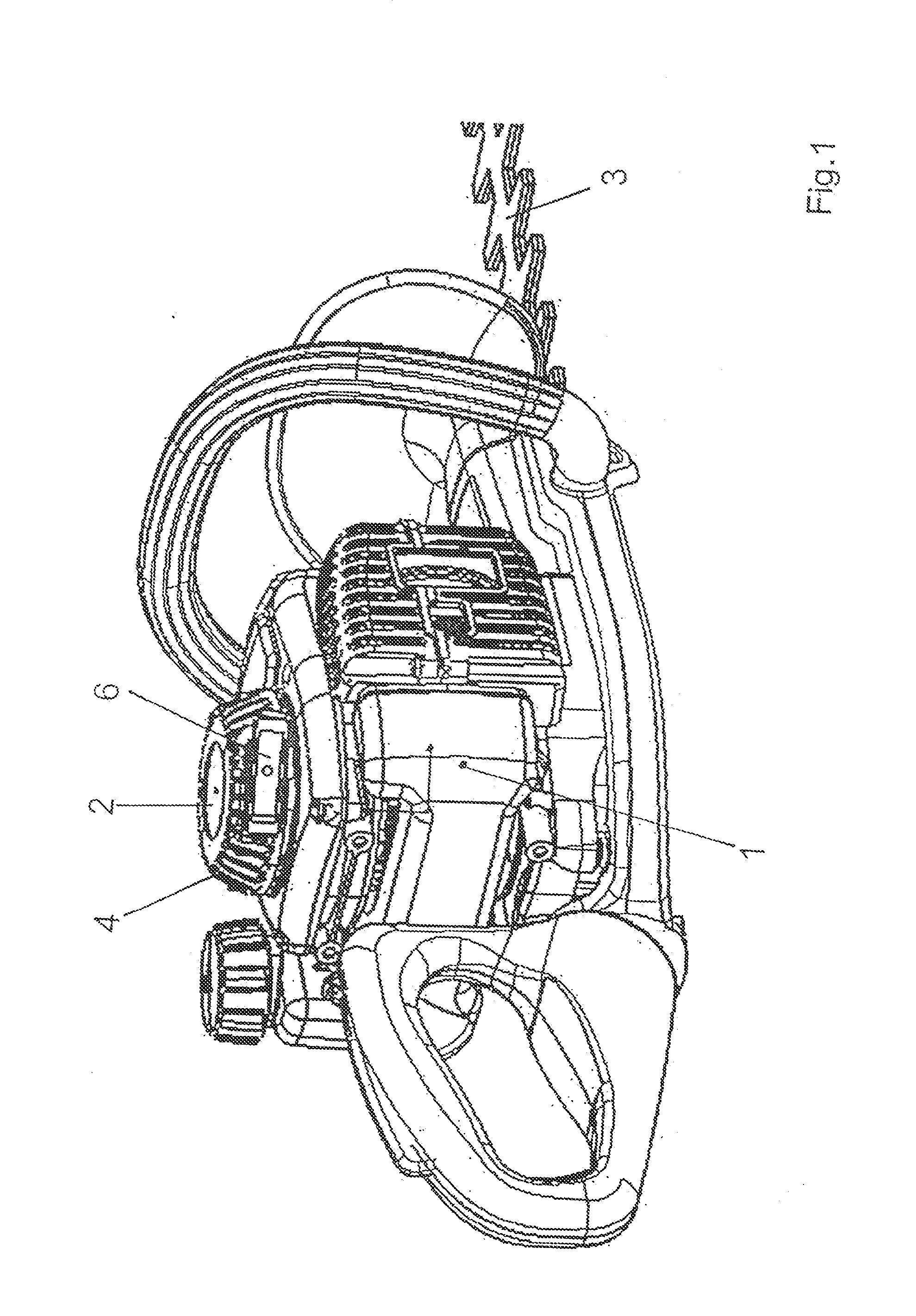

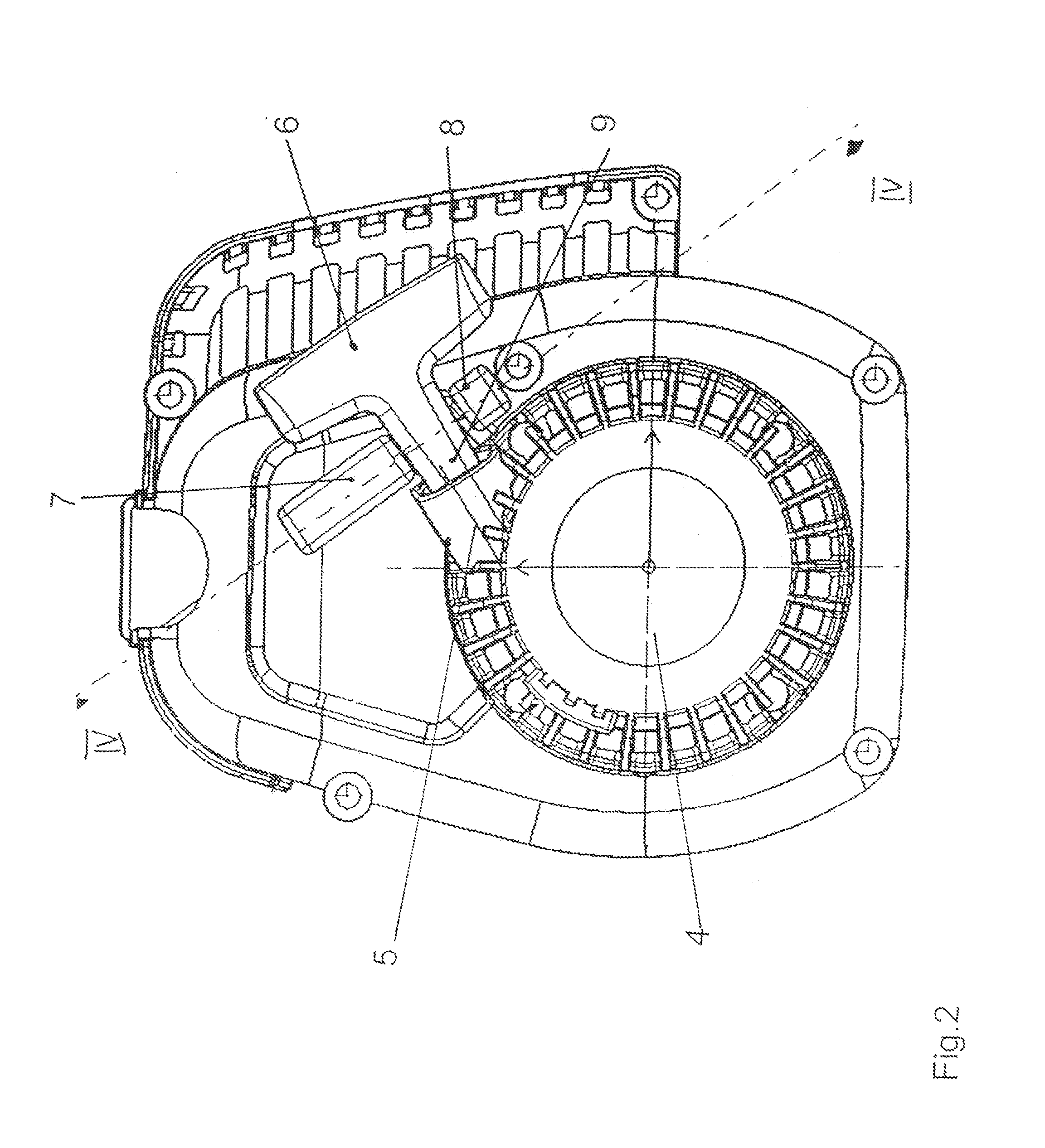

Starting Brake for a Hedge Clipper

InactiveUS20070295298A1Easy to handleAutomatic controlMuscle operated startersCuttersRest positionEngineering

The invention relates to a work implement including a drive which can be started by a cable pull starter, wherein the cable pull starter has a starter handle which is located in a holder in a rest position and which can be removed from the holder by a user for starting the drive. The work implement also includes a starting brake for a tool which prevents tool movements hazardous to the user directly after starting the drive, wherein a tripping mechanism disposed on the holder is provided for the starting brake, which by removing the starter handle from the holder automatically tightens the starting brake.

Owner:DOLMAR

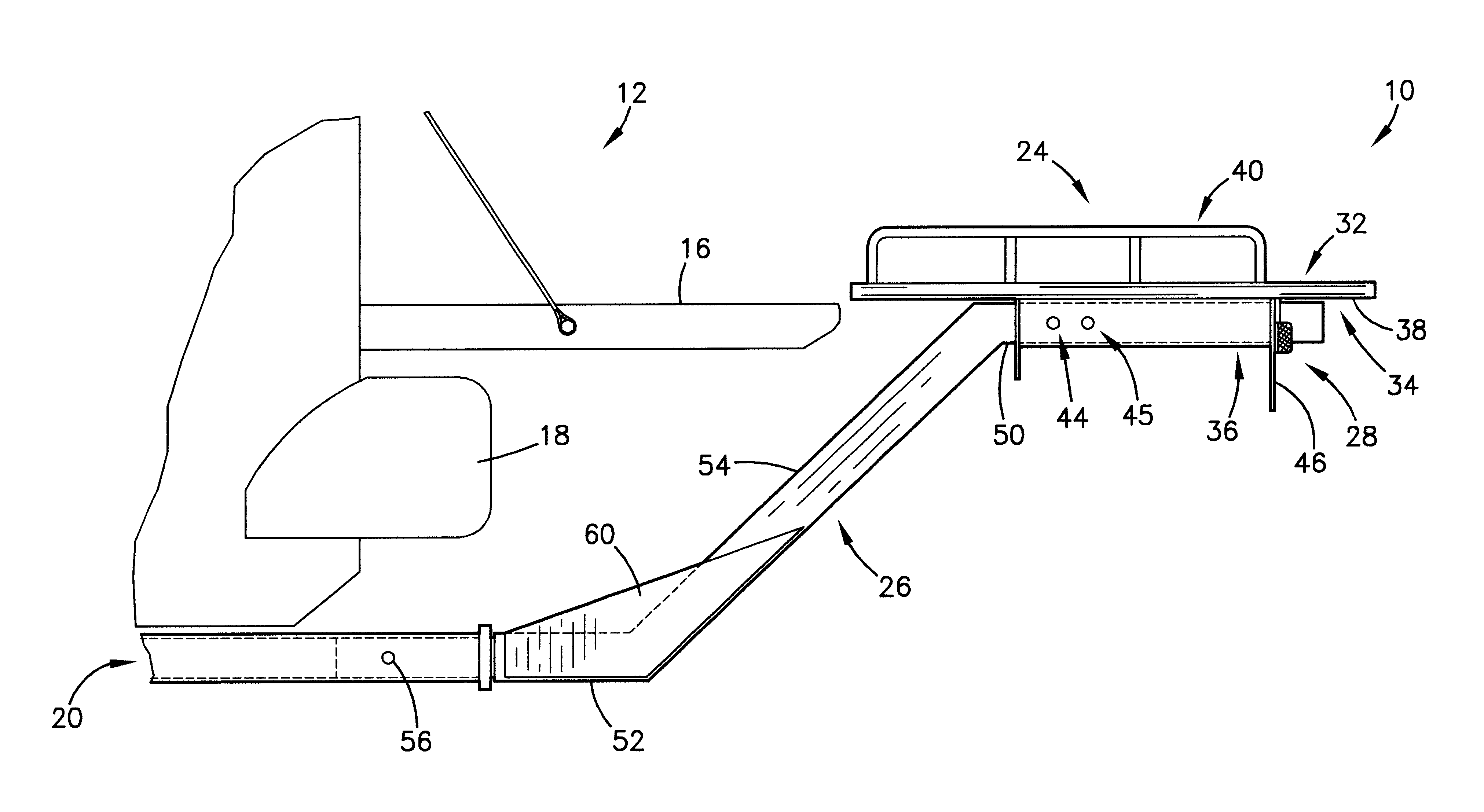

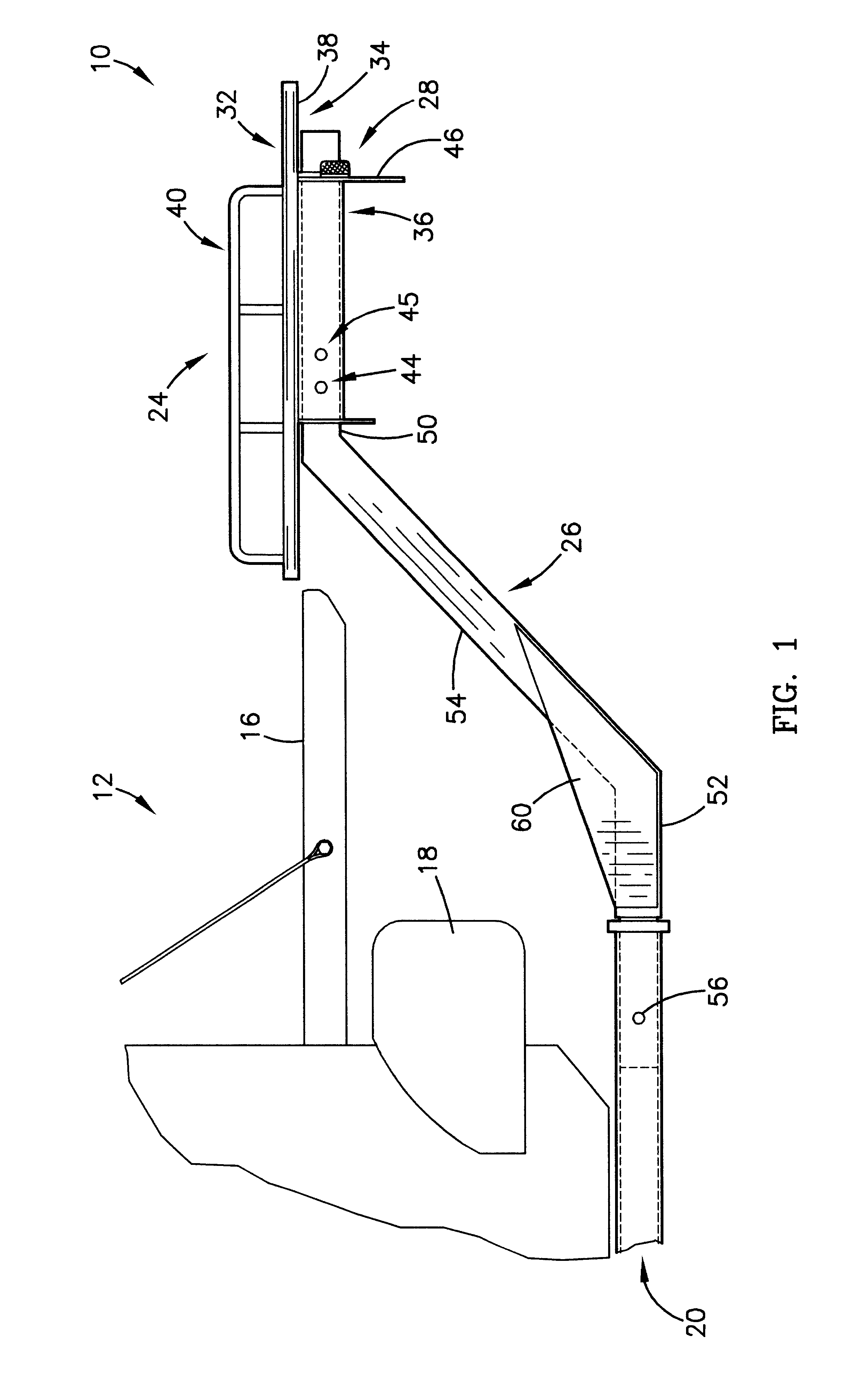

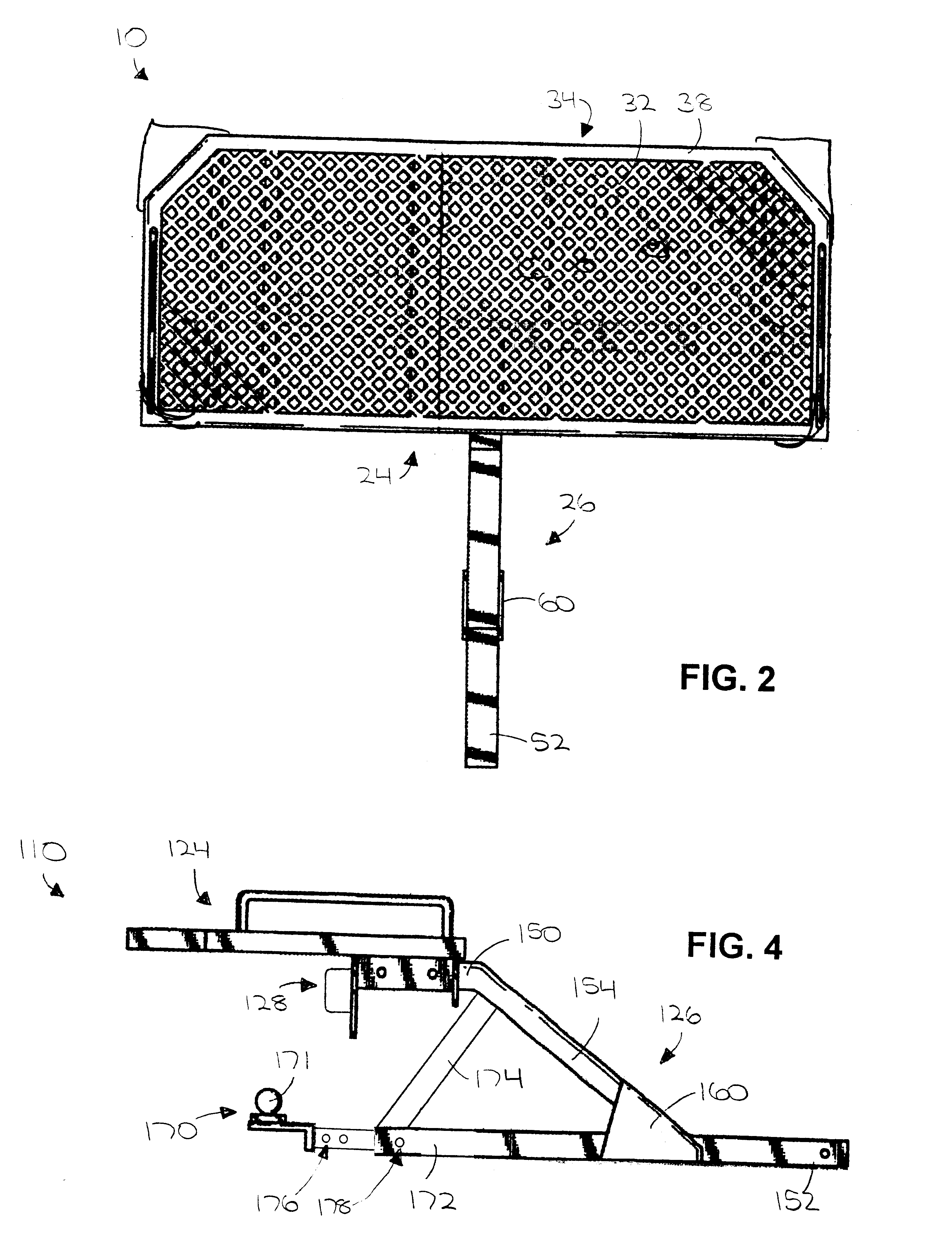

Truck bed extension device

InactiveUS6648391B1Vehicle to carry long loadsVehicle with living accommodationEngineeringSignaling system

A truck bed extension device (10) for use with a truck (12) having a cargo bed structure, wherein the device (10) allows for carrying items which extend beyond or overhang the bed structure. The device (10) comprises a deck (24); a support structure (26); and a signaling system (28). The deck (24) is horizontally adjustable relative to the bed structure so as to allow for achieving a desired spacing therebetween. The deck (24) is also vertically offset when unloaded so as to be substantially flush when loaded. Because the device (10) or the load carried thereon may obstruct viewing of the truck's existing brake and turn signals, the signaling system (28) repeats these signals where they are more visible. A second embodiment of the device (110) provides a hitch structure (170) for coupling the truck with a trailer via the device (110).

Owner:WHITEFORD BARRY +1

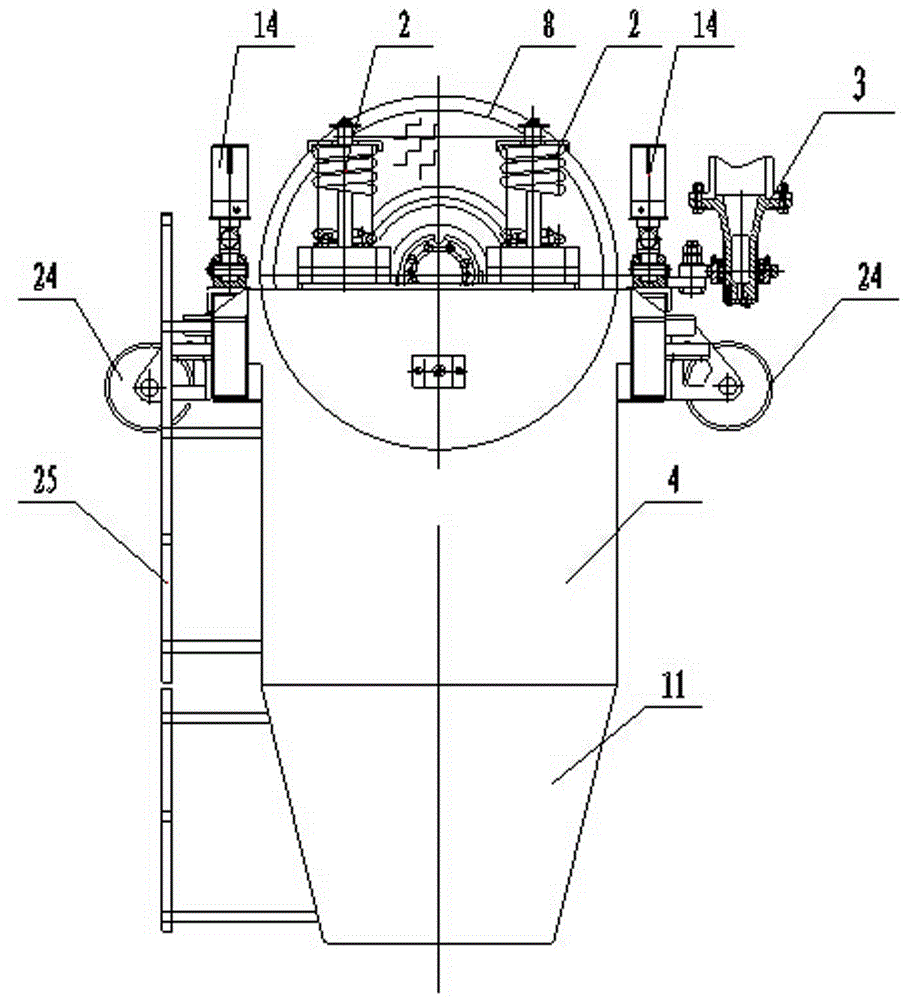

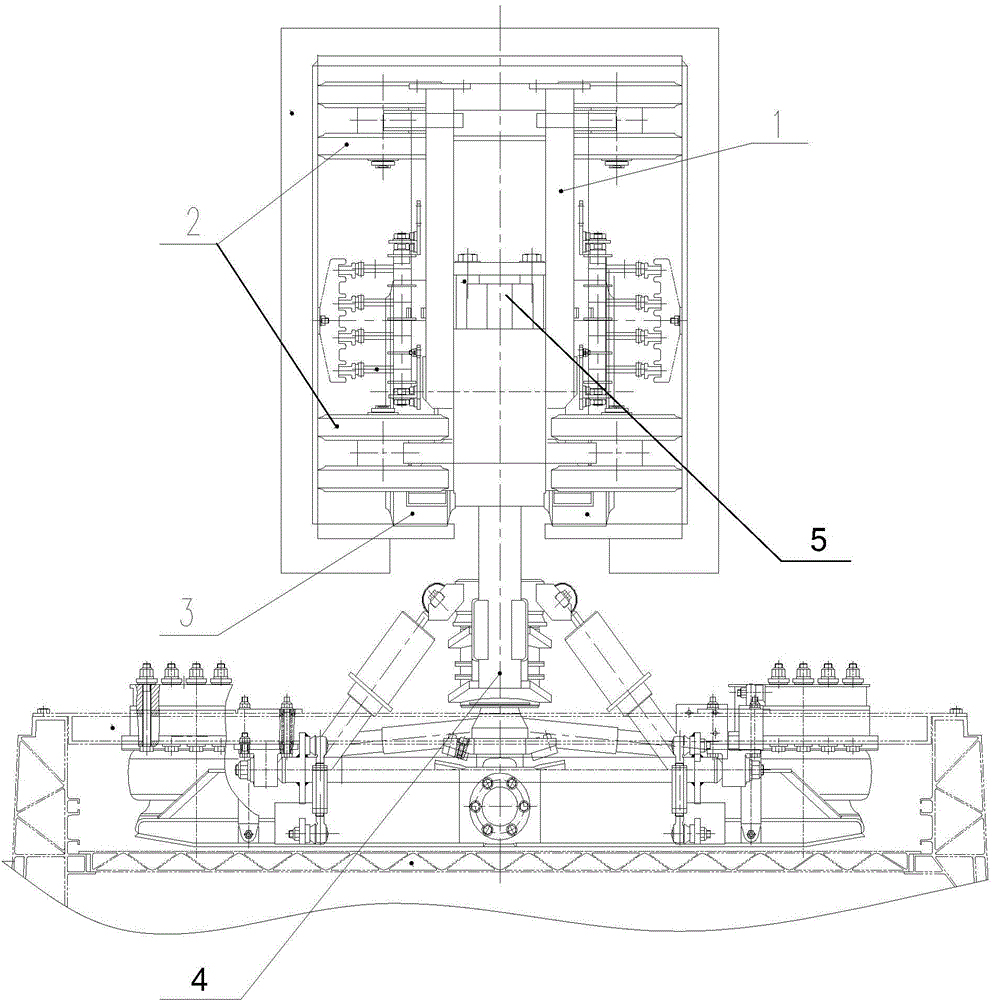

Suspension type monorail train bogie

ActiveCN104442880AGuaranteed uptimeExcellent ride comfortElectric motor propulsion transmissionBogiesBogieBrake

The invention discloses a suspension type monorail train bogie. The suspension type monorail train bogie comprises a framework, a traction suspension device, guide wheels, walking wheels, a driving device, a brake device and a collector shoe. The at least eight guide wheels are arranged at the four end corners of the upper portion of the framework and the four end corners of the lower portion of the framework respectively, the driving device comprises a gearbox, the four walking wheels are arranged on four output shafts of the gearbox respectively, the guide wheels are solid rubber wheels, and the walking wheels are inflated rubber wheels. The eight solid rubber wheels are used as the guide wheels, the self-guide function of the bogie is achieved, the four inflated rubber tires are used as the walking wheels, longitudinal force between a train and a rail is transmitted, and the weight of the train is borne. The suspension type monorail train bogie is compact in structure, excellent in train running stability and riding comfort, and capable of being driven on lines with the big gradient (100 parts per thousand) and the small radius (the minimum curve radius of the plane is 30 m) and has the good adaptability to the complex terrain (up and down terrain, mountain cities and rivers).

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

High-toughness low-alloy constructional steel and producing method thereof

ActiveCN1920080AMeet the technical requirements of steelGood mechanical propertiesAluminiumHeat processing

The invention relates the low-alloy high-tensile structural steel and preparing method. The components are as follows: C:0.05%-0.60%, Si: 0.05%-0.70%, Mn: 0.5%-2.5%, P: <= 0.04%, S: <=0.04%, Cr: 0-0.70%, Ni: 0-0.70%, molybdenum: 0-0.60%, Cu: 0-0.20%, vanadium: 0.01%-0.30%, Al 0-0.1%, niobium: 0.001%-0.10%, N: 0.004%-0.02%, and the left is Fe. The method comprises the following steps: using revolving furnace to smelt, and using LF furnace to refine. The yield strength as is above 460Mpa, the dynamic ductility Akv is above 27J at low temperature (-40Deg.C), endurance life is above 2 million times, and the finished steel can be used for train brake beam, engineering machinery and hydraulic support without heat treatment. After quenching and high tempering modified heat treatment, the strength for extension of the steel is above 750Mpa, the dynamic ductility Akv is above 150J at low temperature (-40Deg.C). After carbonization, the steel can be used for abrasion-proof driving mechanism elements and parts.

Owner:SHOUGANG CORPORATION

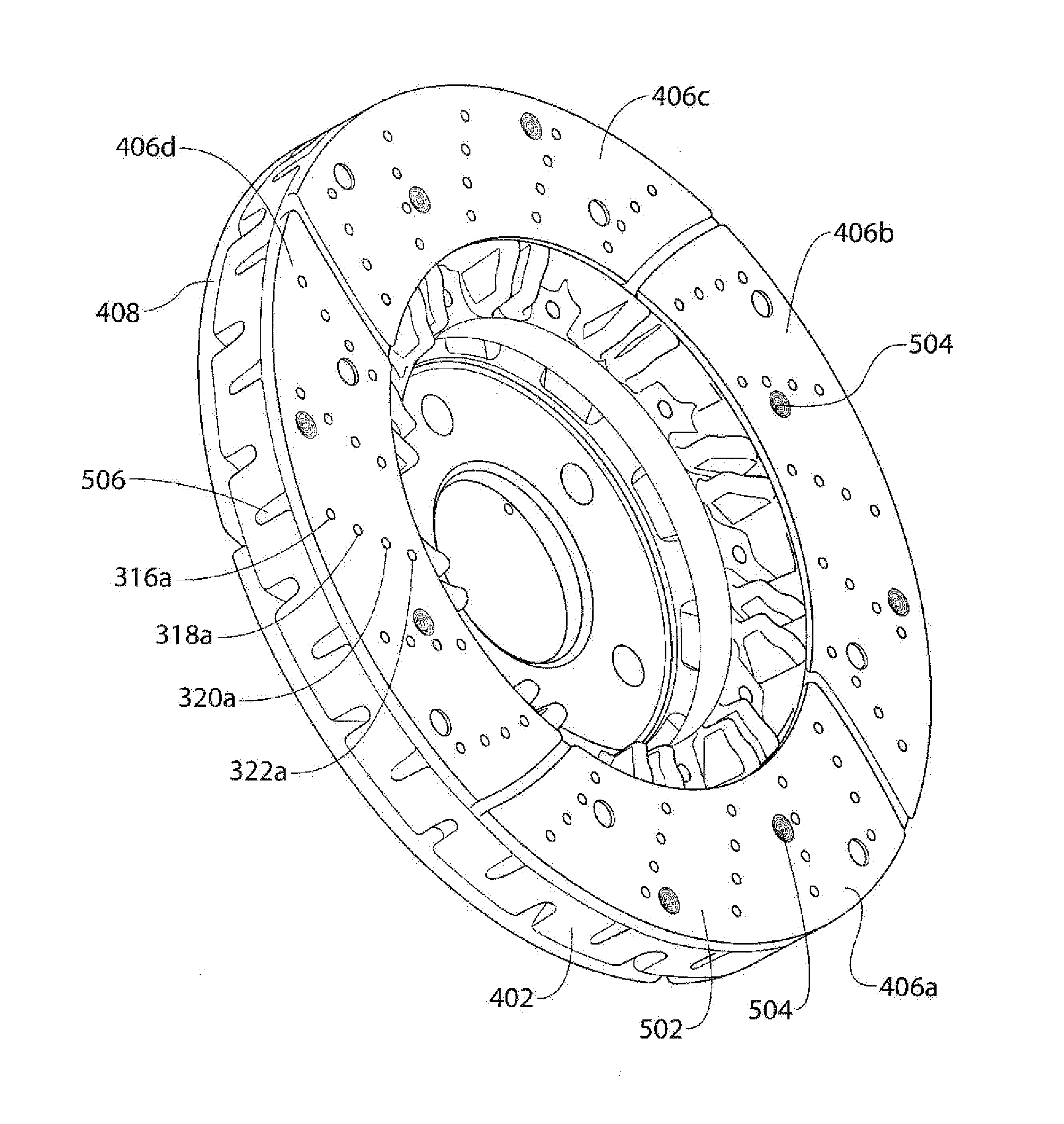

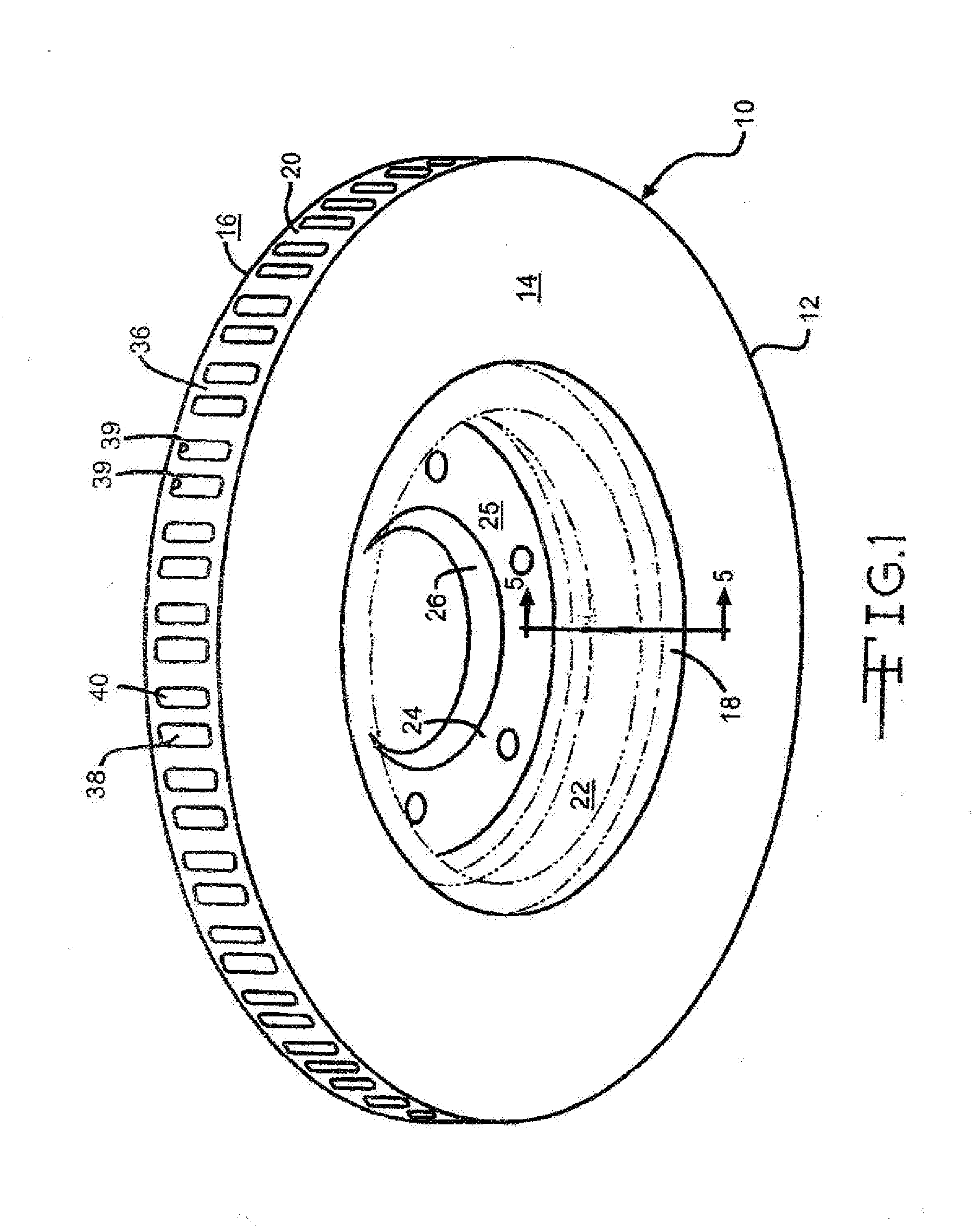

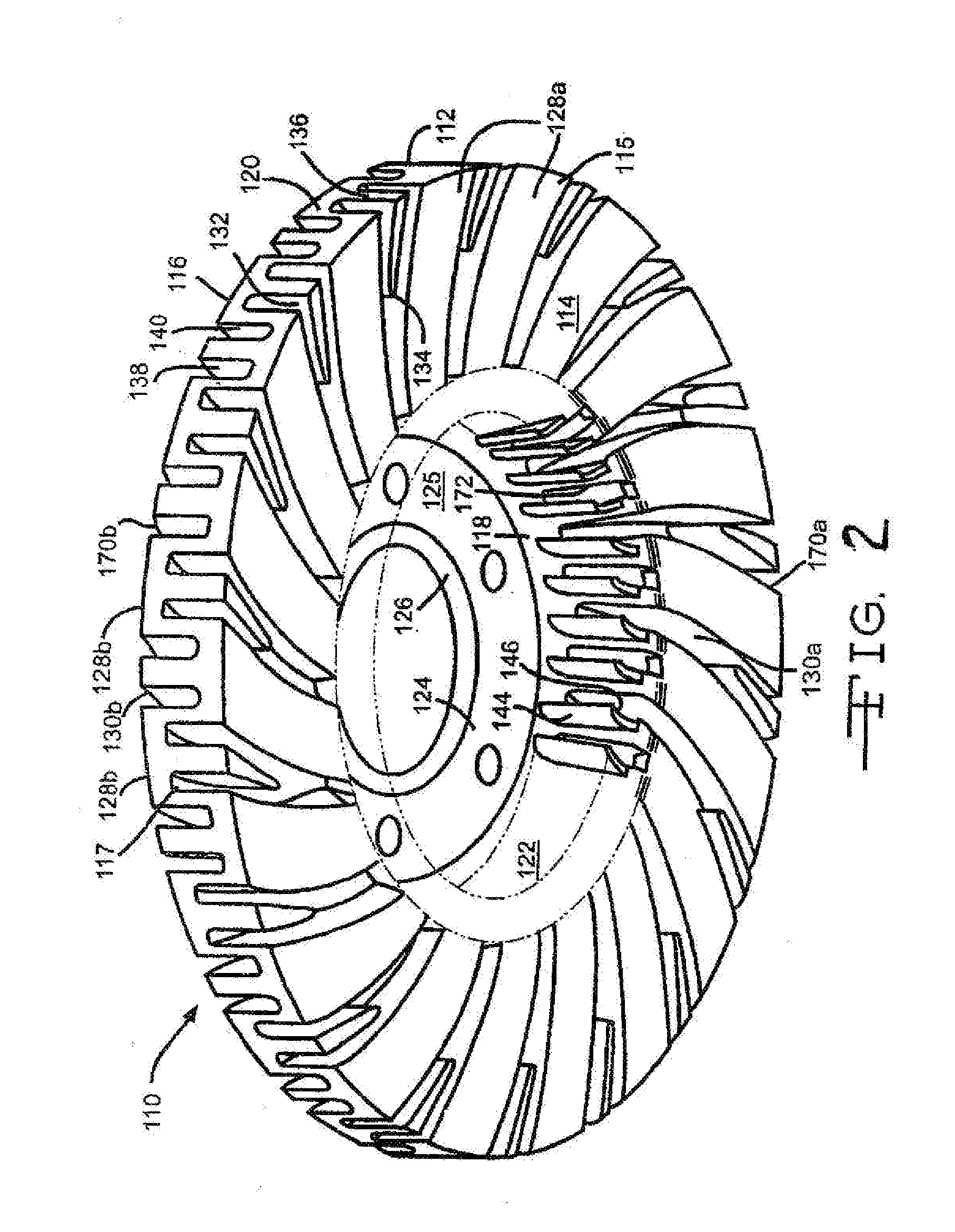

Segmented brake rotor with externally vented carrier

InactiveUS20120255820A1Improve effectivenessFunction increaseBraking discsFriction liningBrakeThermal force

An externally vented brake rotor (EVR) core design, such as exemplified by U.S. Pat. No. 6,536,564, is being used to improve the function and effectiveness of a segmented brake rotor (SBR) through more efficient management of the thermal forces created in the segmented rotor. Specifically, segmented friction plates are attached to the EVR core to form friction surfaces. Air flow through the vents contacts the back side of the friction plates. At least one segmented friction plate may be provided with a tab or protrusion that engages a corresponding receiving recess in the carrier surface of the EVR core, thereby relieving lateral stress forces.

Owner:MCCORD GEOFFREY K +1

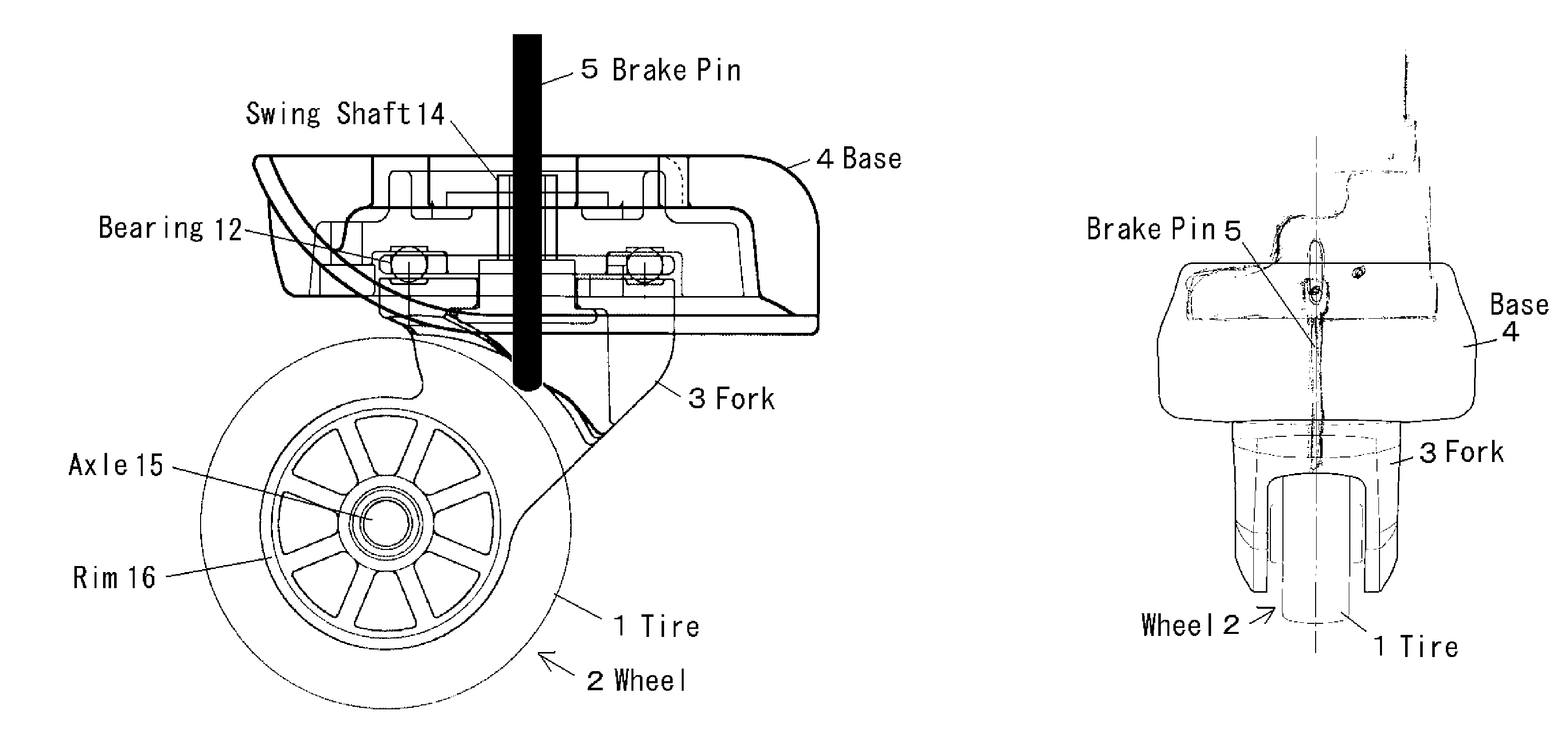

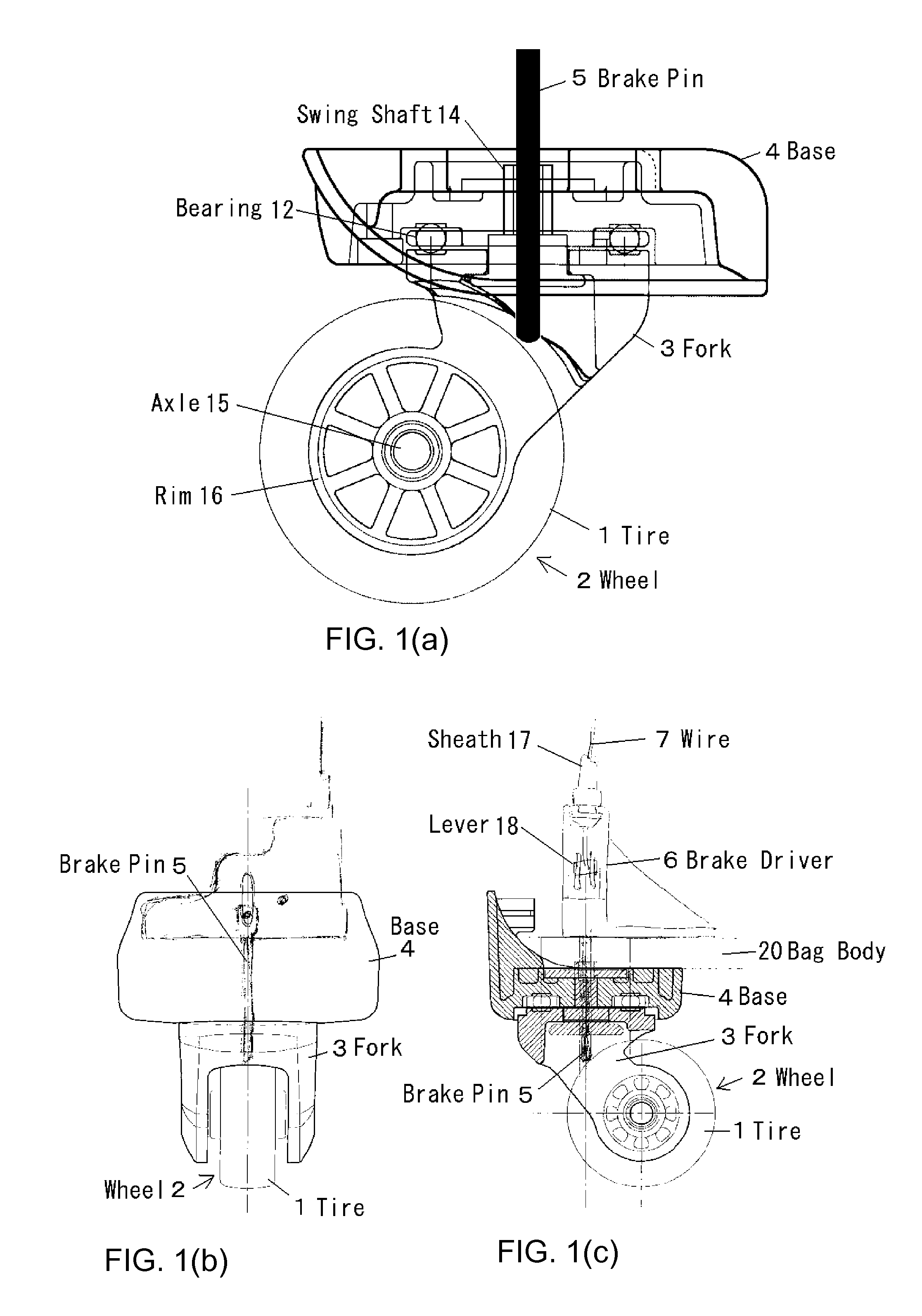

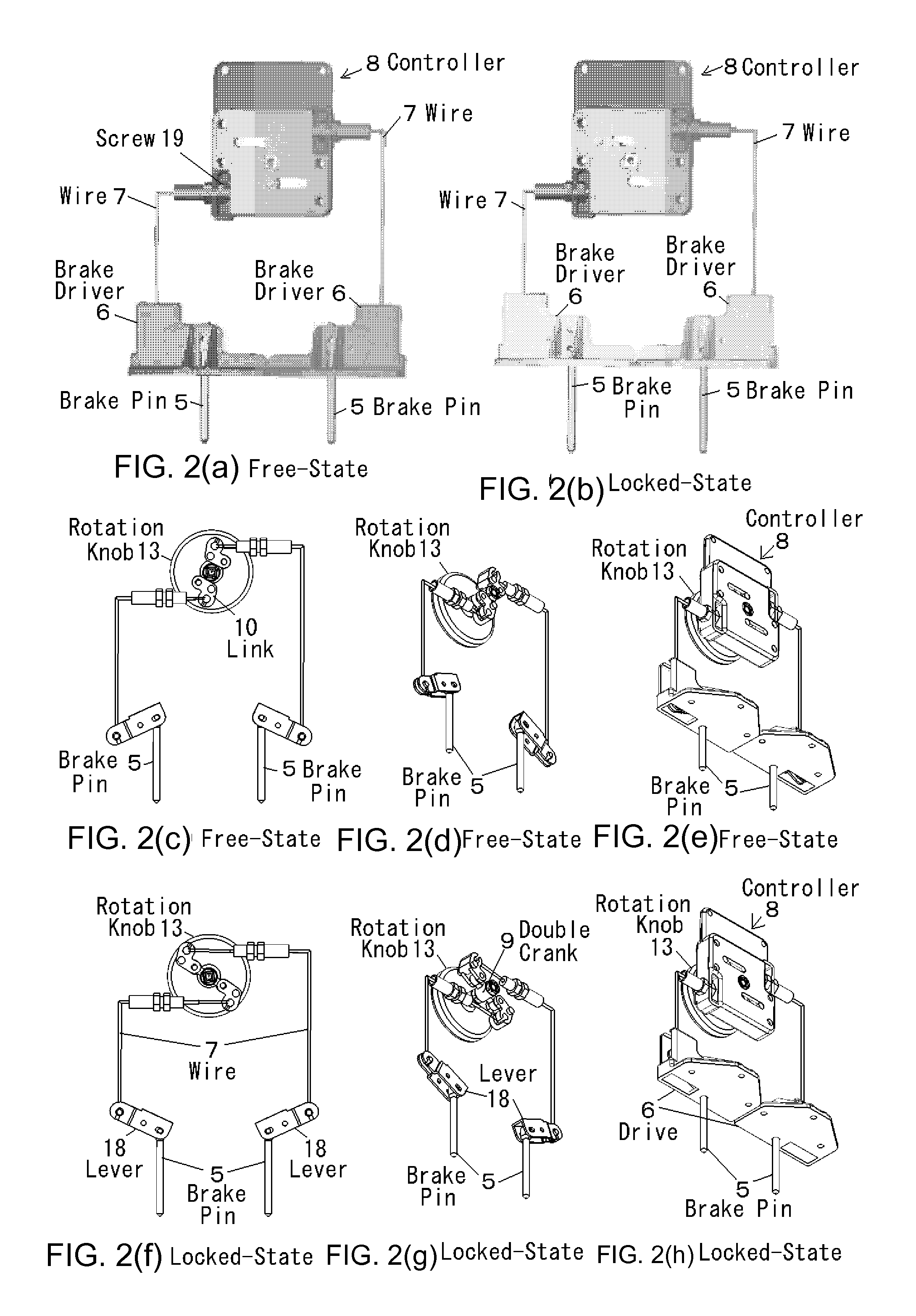

Caster system equipped with hand-operated brakes

ActiveUS20120311821A1Convenient to useSmall-sized, light-weightedSledge wheelsCastorsEngineeringFrictional resistance

Hand-operated brakes caster system is easy to use, compact, lightweight, low-cost. A fork supports a rotating wheel via an axle. A bag mounted base supports the swinging fork. A hollow swing shaft mounts on a base bearing. A force transmitting wire is pulled by a rotation knob in a controller away from the wheel. Opening direction force is applied by a spring to the wire in the opening direction. Therefore, if the knob is rotated by an angle not smaller than a predetermined value, reverse rotational moment is applied, locking the rotation knob. Force transmitted to a lever via the wire is magnified by the action of the lever, and the resulting force pushes a brake pin located inside the fork swing shaft. The brake pin abuts the tire resulting in frictional resistance preventing rotation of the wheel.

Owner:HINOMOTO JOMAE

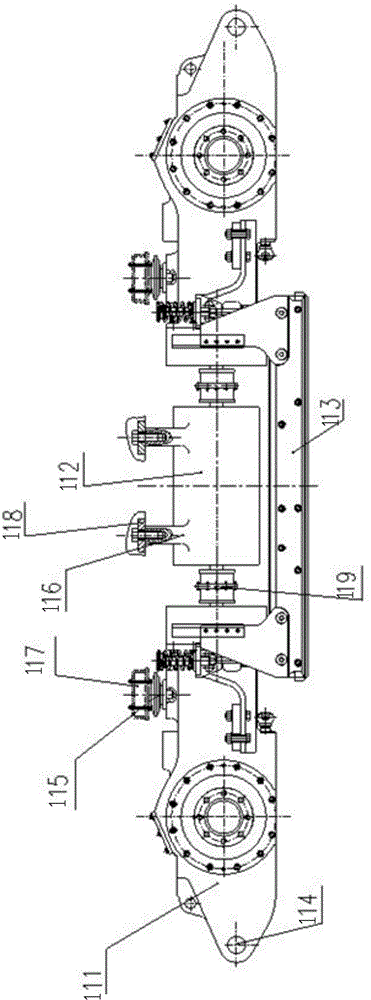

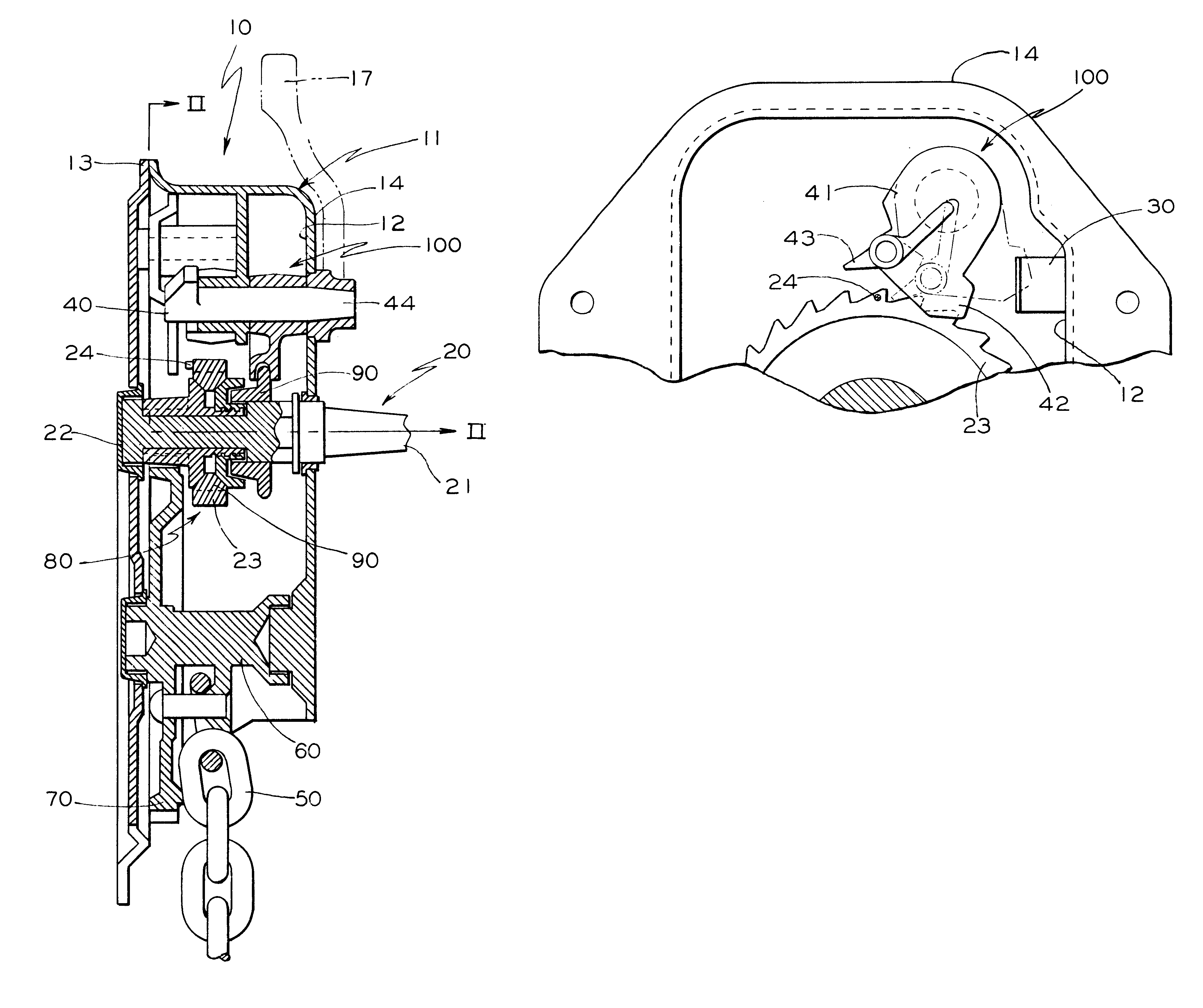

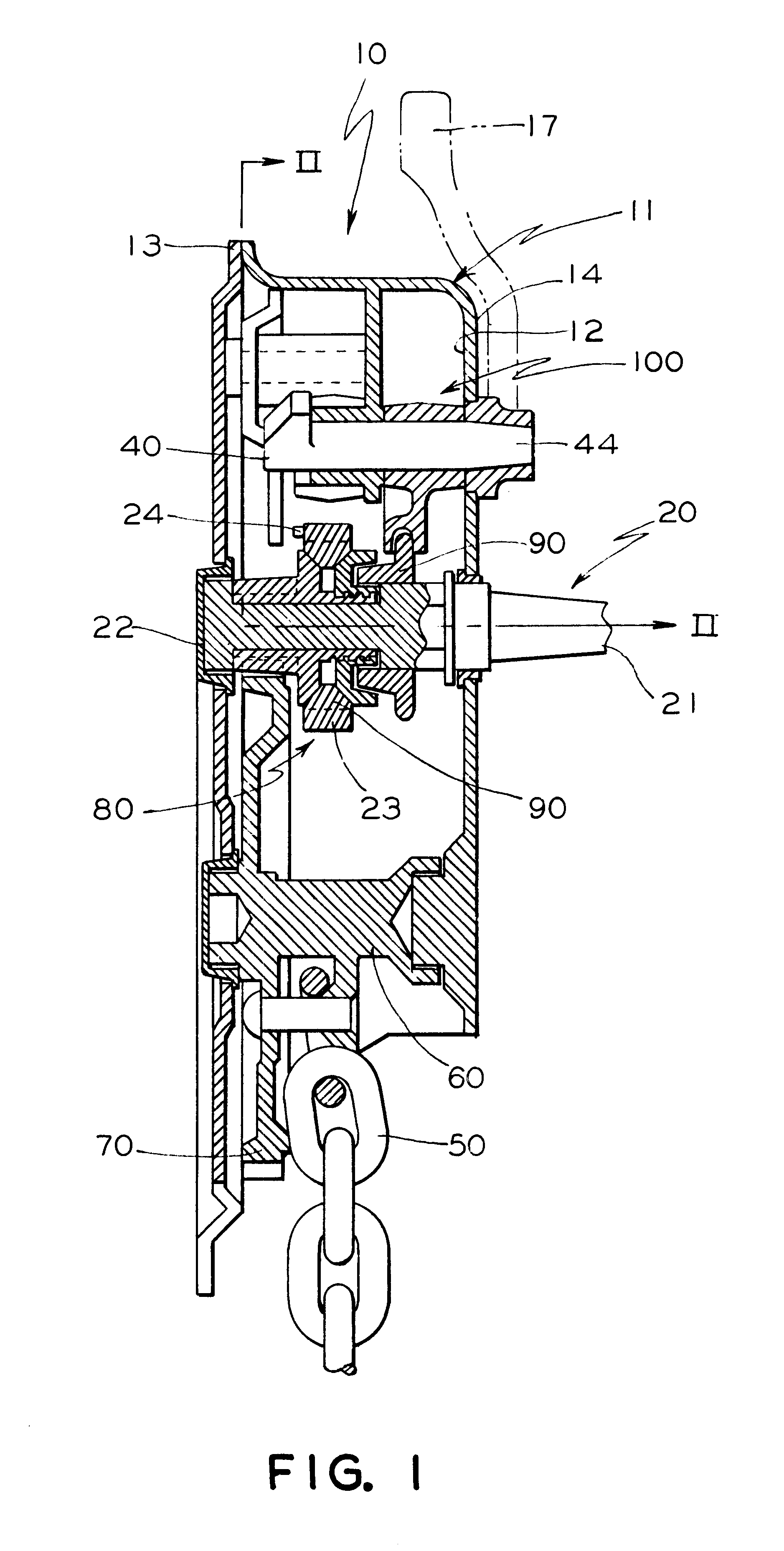

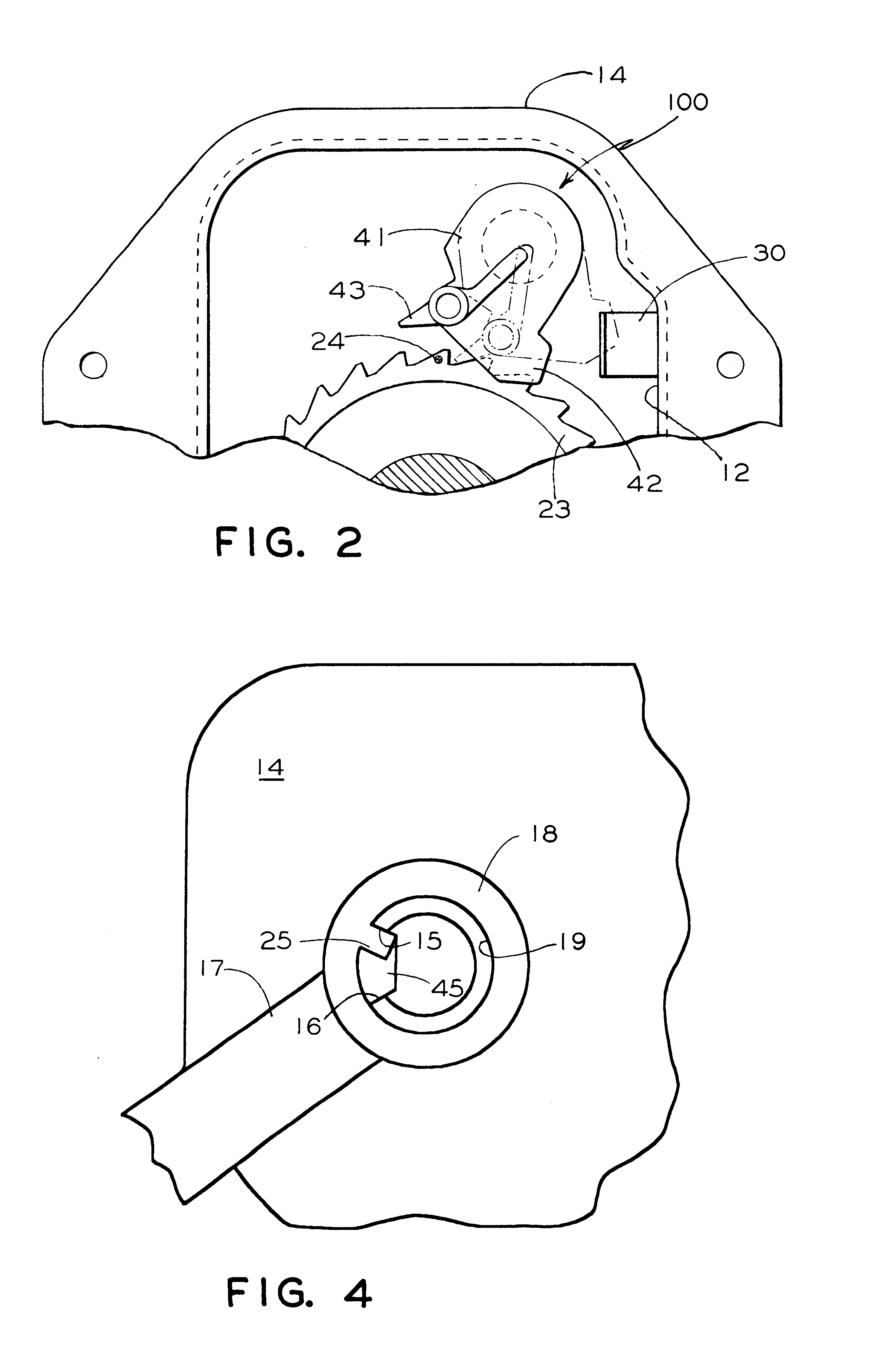

Apparatus for a quick release mechanism in a railcar hand brake

InactiveUS6364428B1Increase railcar wheel lifeSlow down premature wearControlling membersLimiting/preventing/returning movement of partsMechanical engineeringEngineering

An apparatus for a quick release mechanism in a railcar hand brake. The hand brake has a housing having a front casing with an inside wall of a predetermined size and shape, and a back plate. An operating shaft is rotatably mounted in the housing. The operating shaft includes a first end and a second end. The operating shaft further includes a ratchet wheel rotatable with the operating shaft intermediate the first and second ends thereof, and a release shaft rotatably mounted in the housing. The apparatus comprises a projection of a predetermined size and shape disposed substantially perpendicular to the ratchet wheel, and a flexible clamp of a predetermined size and shape mounted inside the housing. A member is disposed substantially perpendicular to, and about the circumference of the release shaft, having a first element disposed on the member wherein the first element interposes with the flexible clamp when the release shaft is rotated to achieve and maintain full brake release, and a second element disposed on the member and engageable with the projection when the operating shaft is rotated to disengage the first element from the flexible clamp to allow for brake application.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

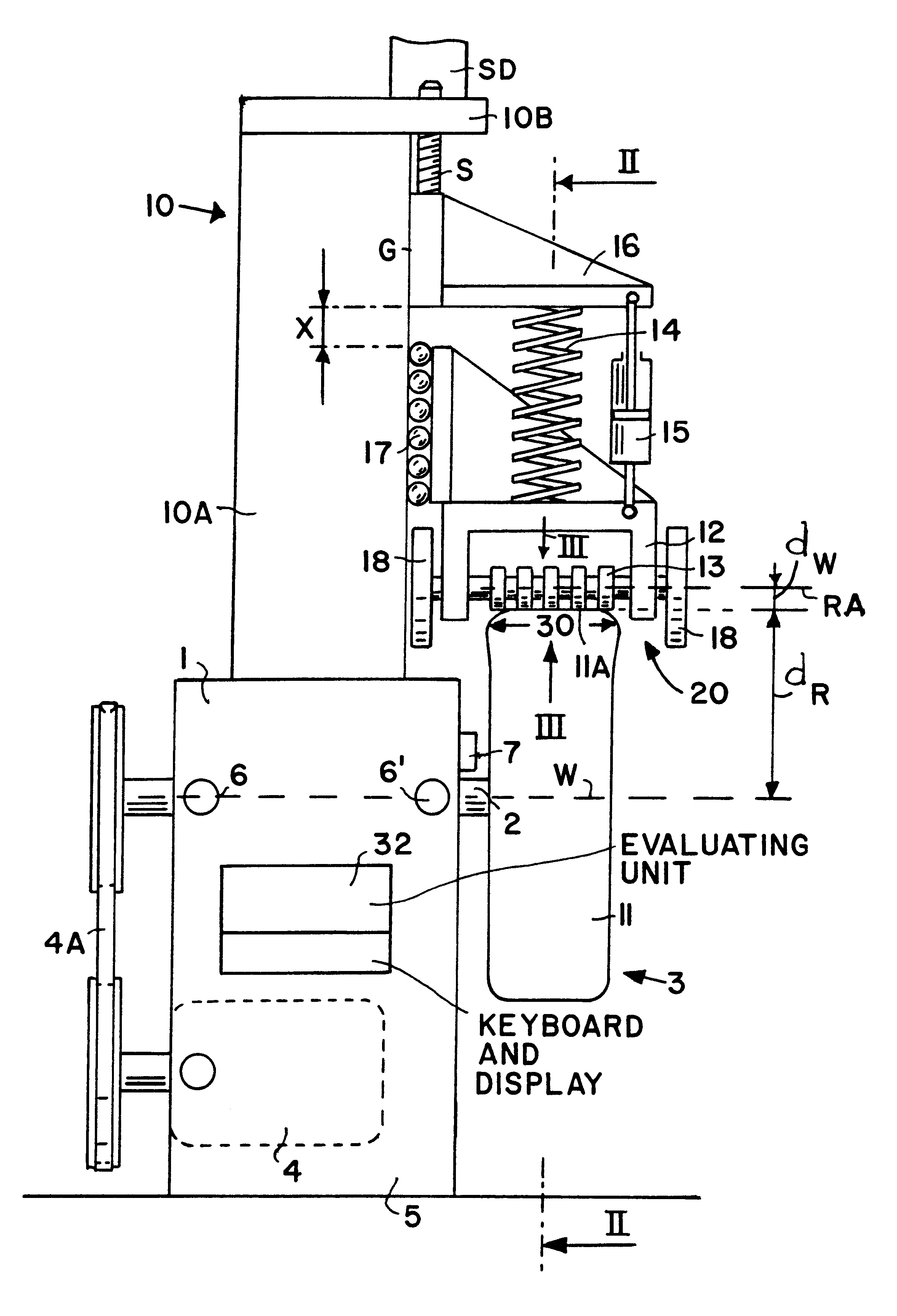

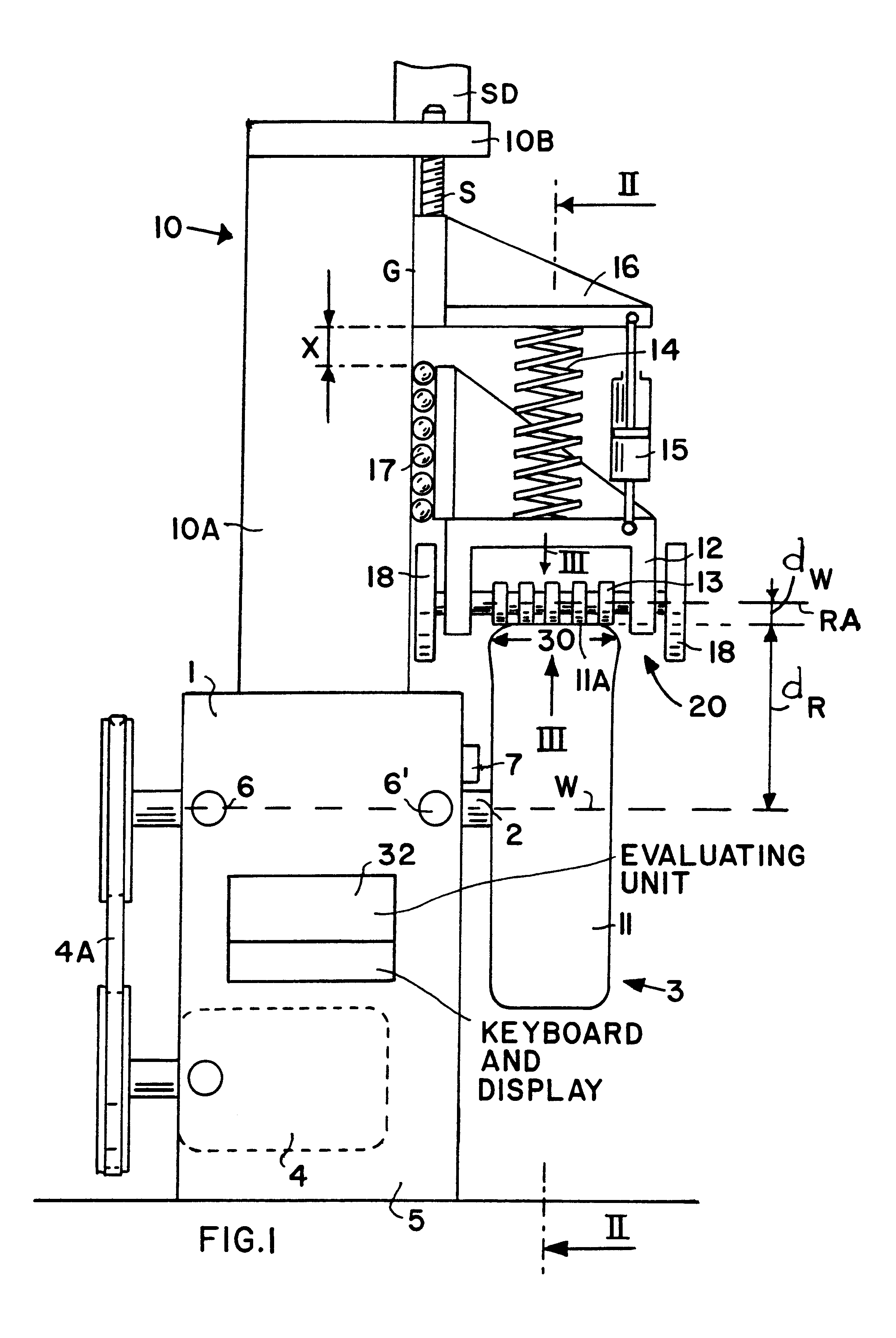

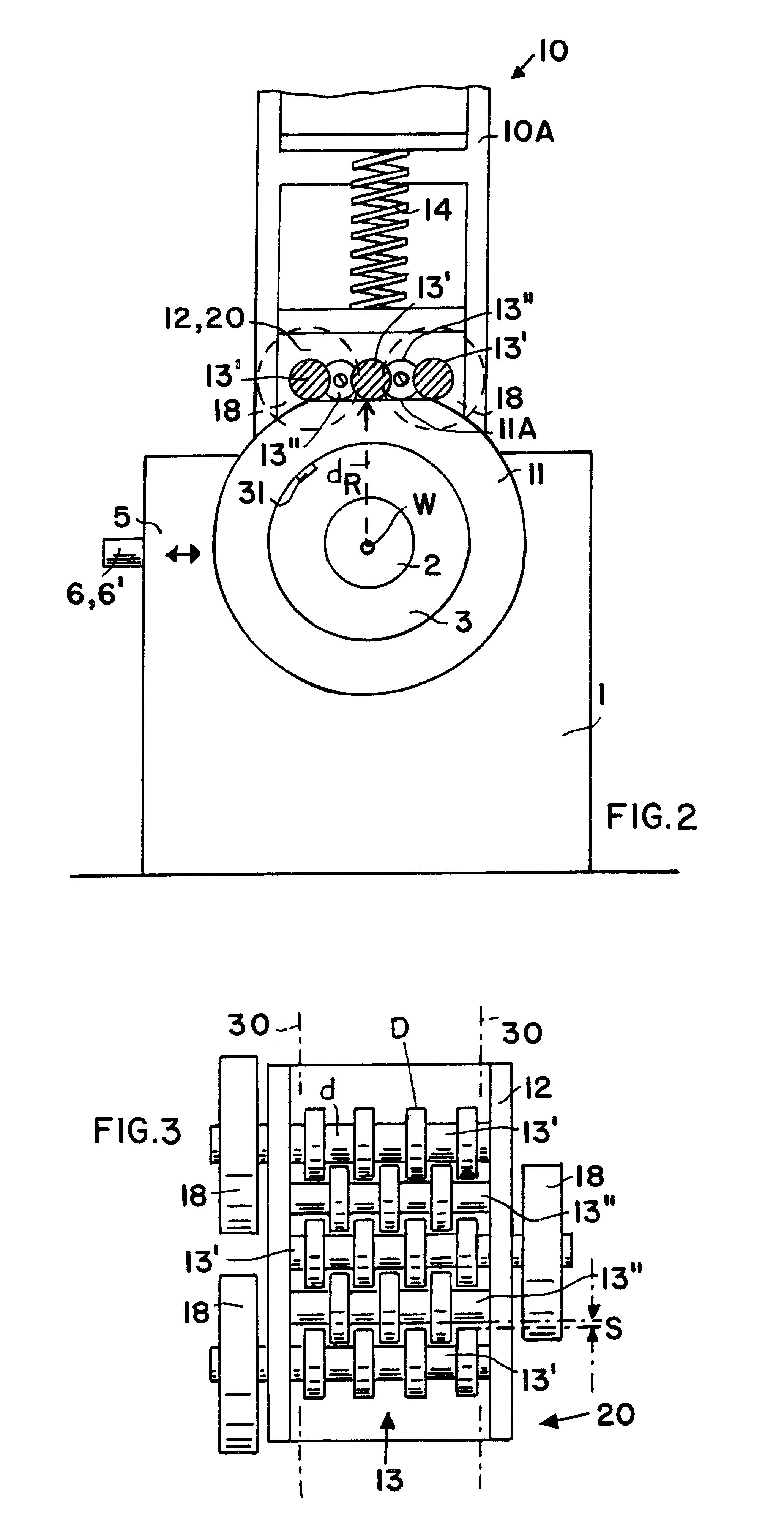

Method and apparatus for reducing vibrations transmitted to a vehicle from a wheel unit

InactiveUS6360593B1High simulationSimpler to precisely determineStatic/dynamic balance measurementUsing mechanical meansBrakeDynamic balance

Vibrations generated by the wheel units of a vehicle are reduced by a low pulsating operation that optimally simulates actual vehicle operating conditions. For this purpose the mass moment of inertia of the wheel unit and of rotating components such as the hub and the brake disc are taken into account. The wheel unit is rotatably mounted on a balancing spindle (2) in a measuring apparatus to determine the mass and angular location of balancing weights (31). The vibrations are measured at a speed that corresponds to a typical travel speed of a vehicle. A loading mechanism including a roller shoe (20) applies a force to the tire tread surface through a spring damping (14, 15) to optimally simulate the conditions of a roadway. The roller shoe (20) has rollers (13) with sections of larger and smaller diameters so that neighboring rollers intermesh. The combined masses of the rollers, as reduced to the roller radius dw, corresponds to the rotational mass of the vehicle wheel as reduced to the tread radius (dR). It is also possible to disengage the contact force from the tread surface for dynamically balancing the wheel unit under load-free conditions. Thus, wheel-balancing steps under loaded and load free conditions can be done on one machine.

Owner:SCHENCK ROTEC GMBH

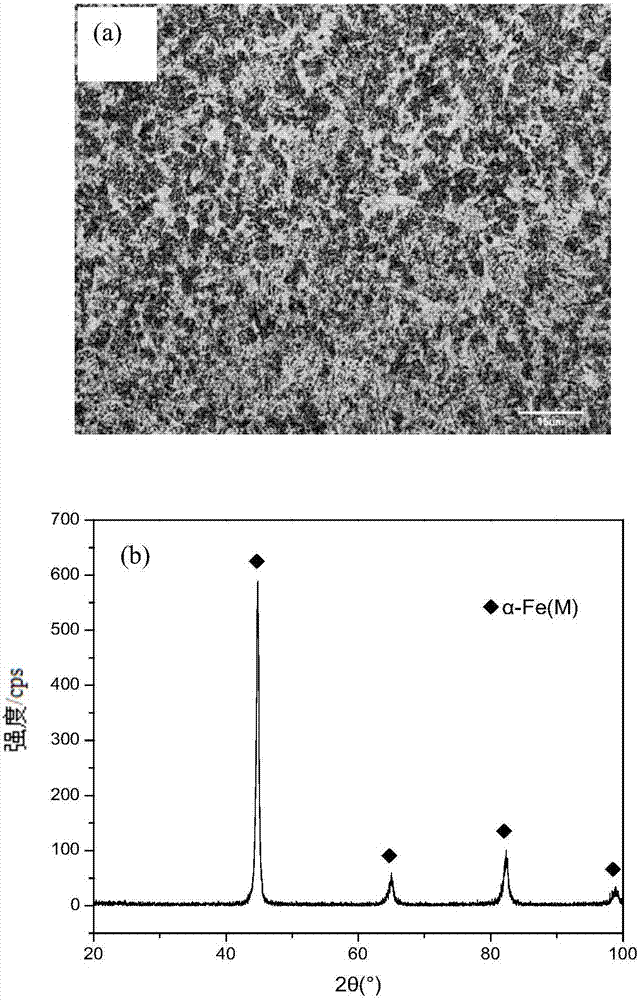

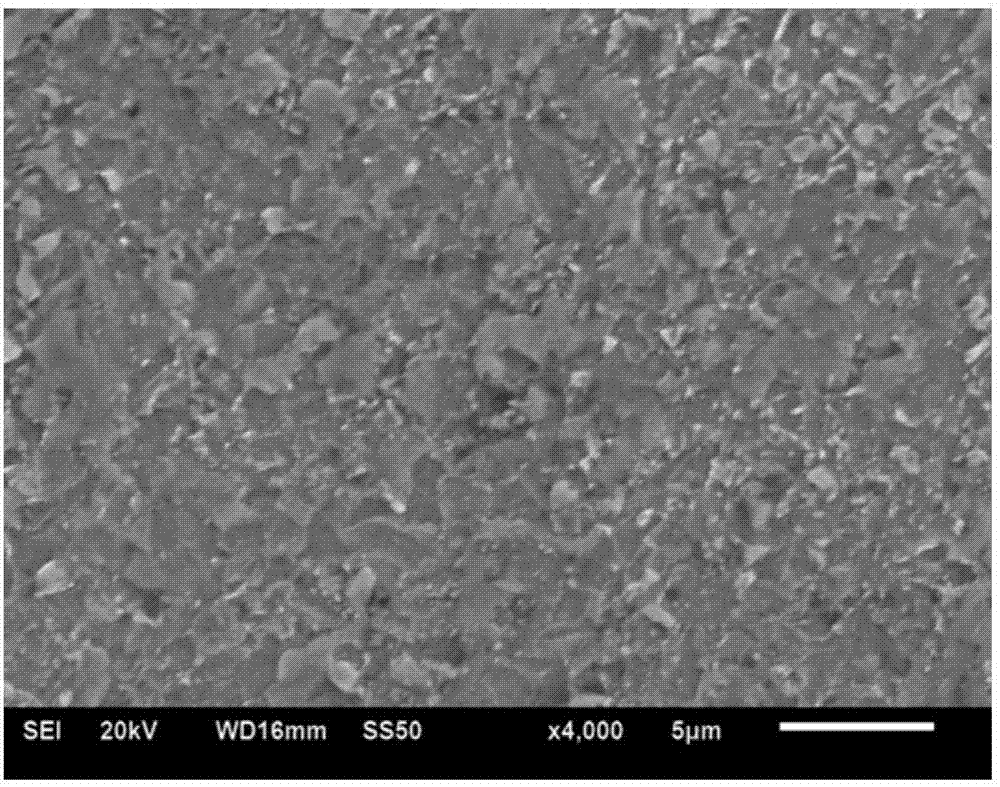

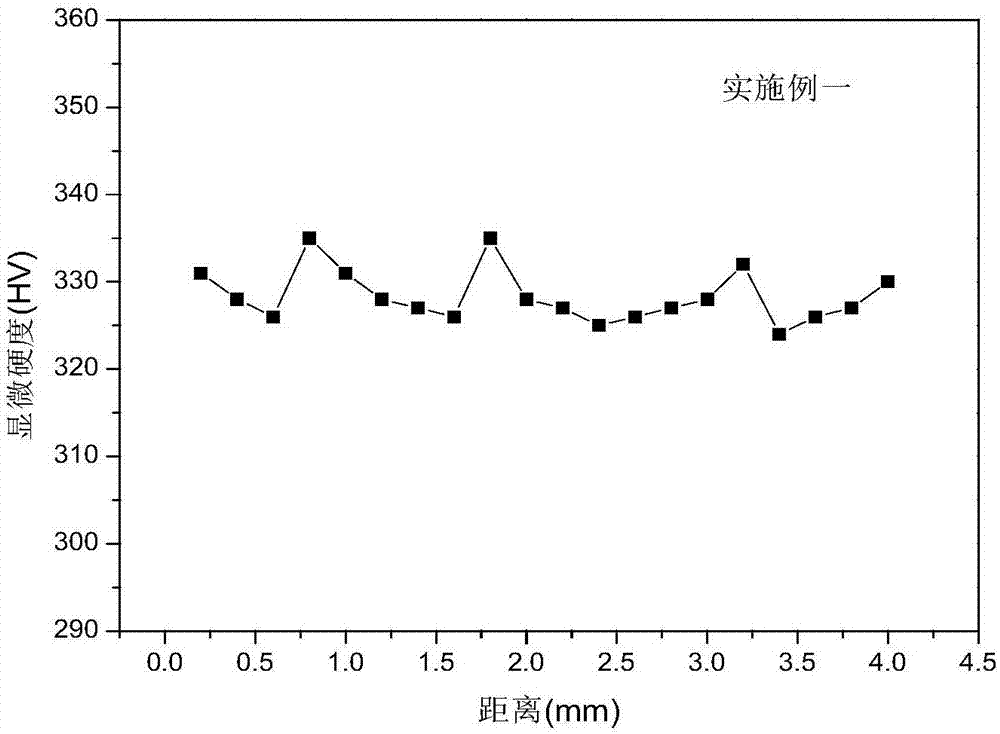

Method for preparing 24CrNiMo bainite alloy steel by using selective laser melting technology

ActiveCN107214336ARemarkable effect of fine grain strengtheningImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHardness

The invention provides a method for preparing 24CrNiMo bainite alloy steel by using a selective laser melting technology. The method includes the steps that a laser device is used for conducting scanning on 24CrNiMo alloy steel power which is spread out on a base plate according to a preset selective laser melt scanning route till the power melts. According to the method, by optimizing technology parameters, taking use of the effects of alloy elements such as C, Cr, Ni, Mo, the bainite alloy steel which is uniform in microstructure is obtained at a high selective laser melting cooling speed, the average micro-hardness of the obtained bainite microstructure reaches 330-346 HV, the tensile strength is 962-978 Mpa, the elongation ratio is 16.4-17.6%, the product of tensile strength and elongation reaches 16.1-16.9 Gpa%, and the microstructure has excellent matched strength and toughness. The method and the technology are mainly applied to selective laser melting manufacture of 24CrNiMo alloy steel high speed rail brake discs.

Owner:NORTHEASTERN UNIV

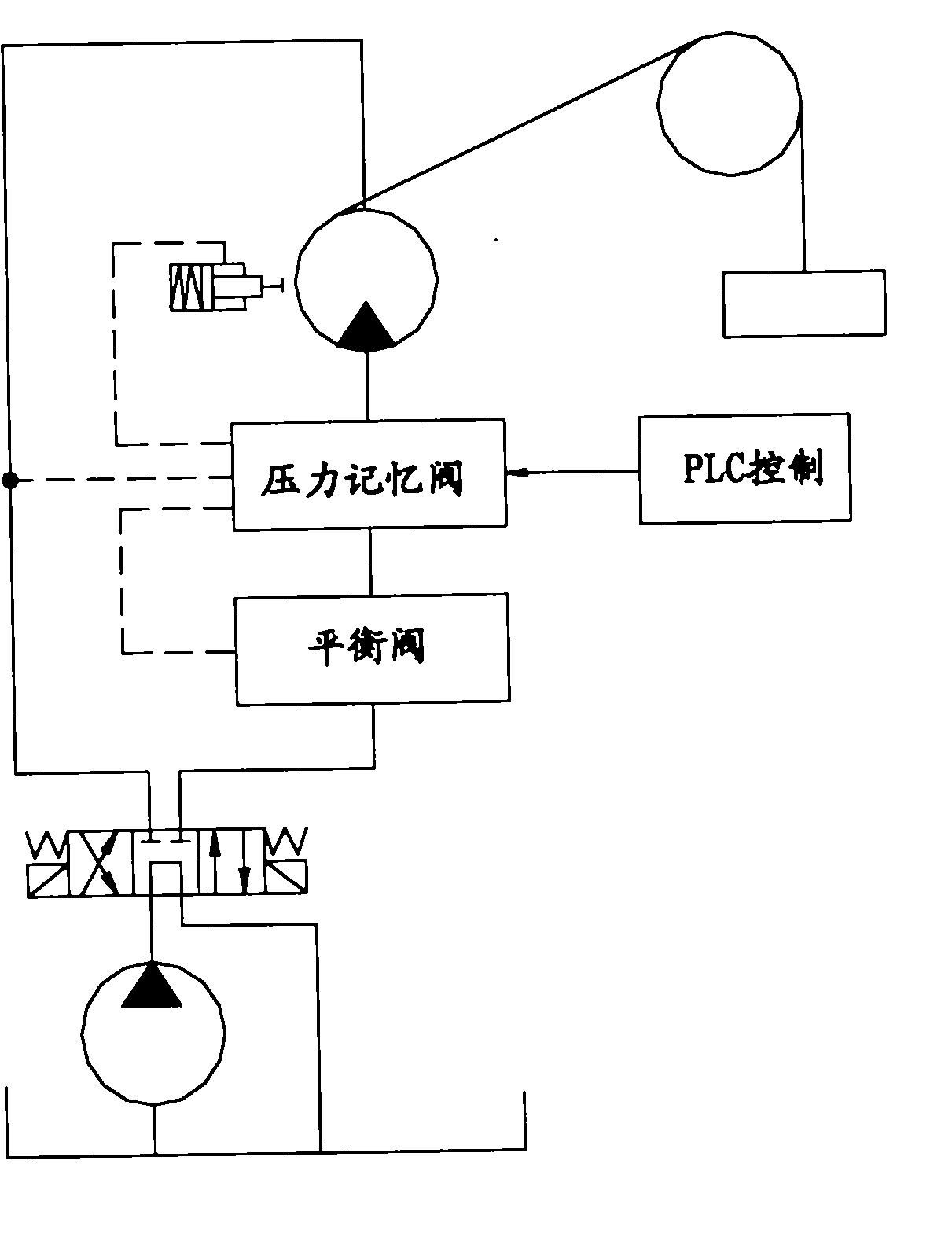

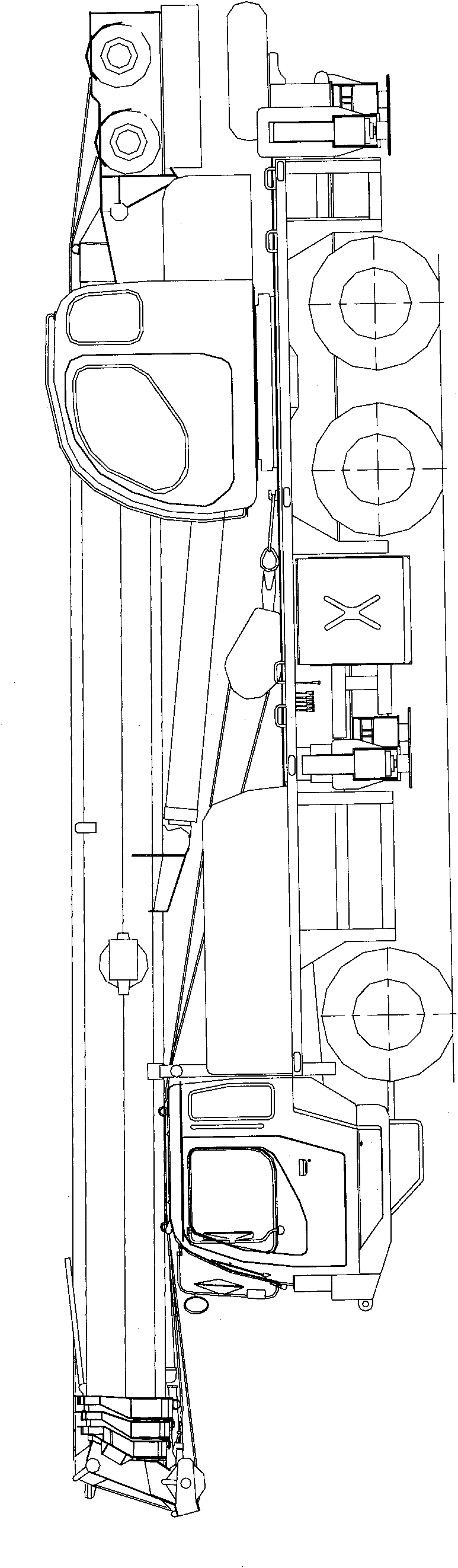

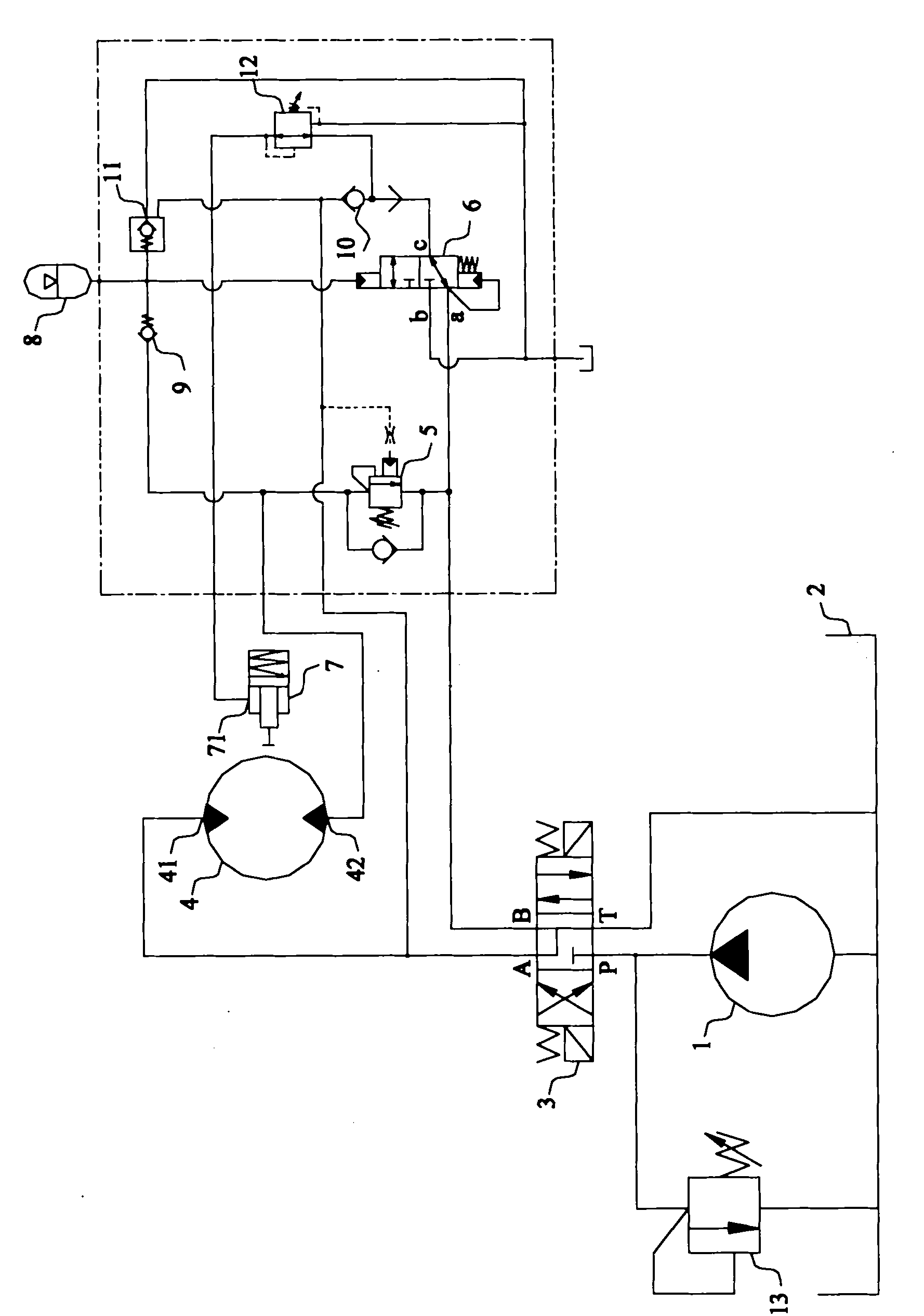

Hydraulic control system of crane and winch device of crane

InactiveCN102336372AAvoid the phenomenon of secondary declineReduce manufacturing costWinding mechanismsBrakeControl system

The invention discloses a hydraulic control system of a winch system. The hydraulic control system comprises a motor for a driving roller and an oil cylinder of a brake roller. The hydraulic control system further comprises a hydraulically operated direction control valve with two work positions and an energy accumulator, wherein the hydraulically operated direction control valve is arranged between an oil port of the direction control valve, which is communicated with a winch rope folding and liquid feeding port of the motor and a brake removing liquid inlet of the oil cylinder; at the first work position, the oil port of the direction control valve, which is communicated with the winch rope folding and liquid feeding port of the motor, is conducted with an oil return path; the winch rope folding and liquid feeding port of the motor is unidirectionally conducted with an oil port of the energy accumulator; the winch rope folding and liquid feeding port of the motor in the direction control valve is communicated with a chamber where one end of a valve core is arranged and is used for pushing the valve core to generate the trend of sliding towards the first work position; and the oil port of the energy accumulator is communicated with a chamber where the other end of the valve core is arranged and is used for pushing the valve core to generate the trend of sliding towards the second position. The invention further provides a crane adopting the hydraulic control system.

Owner:XUZHOU HEAVY MASCH CO LTD

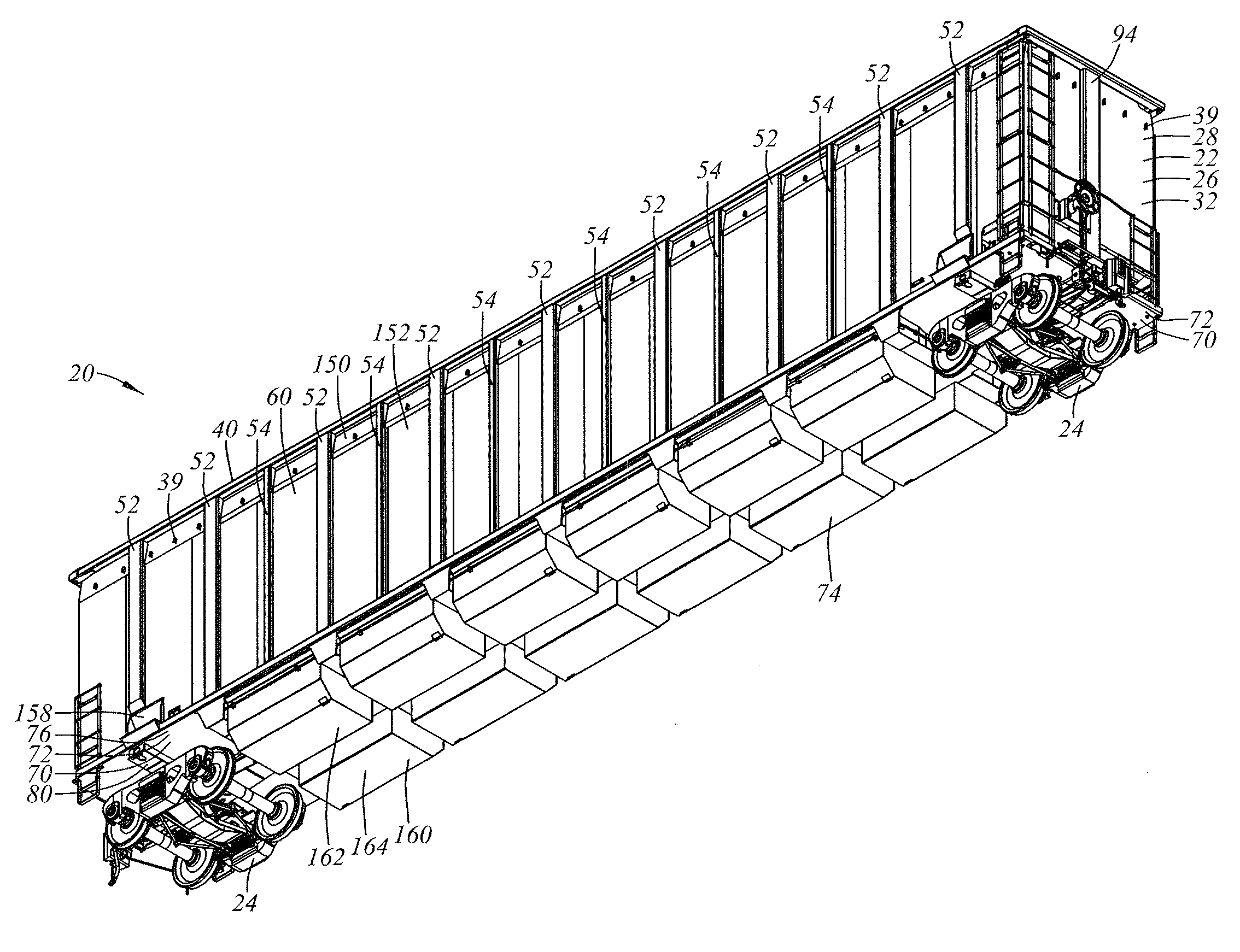

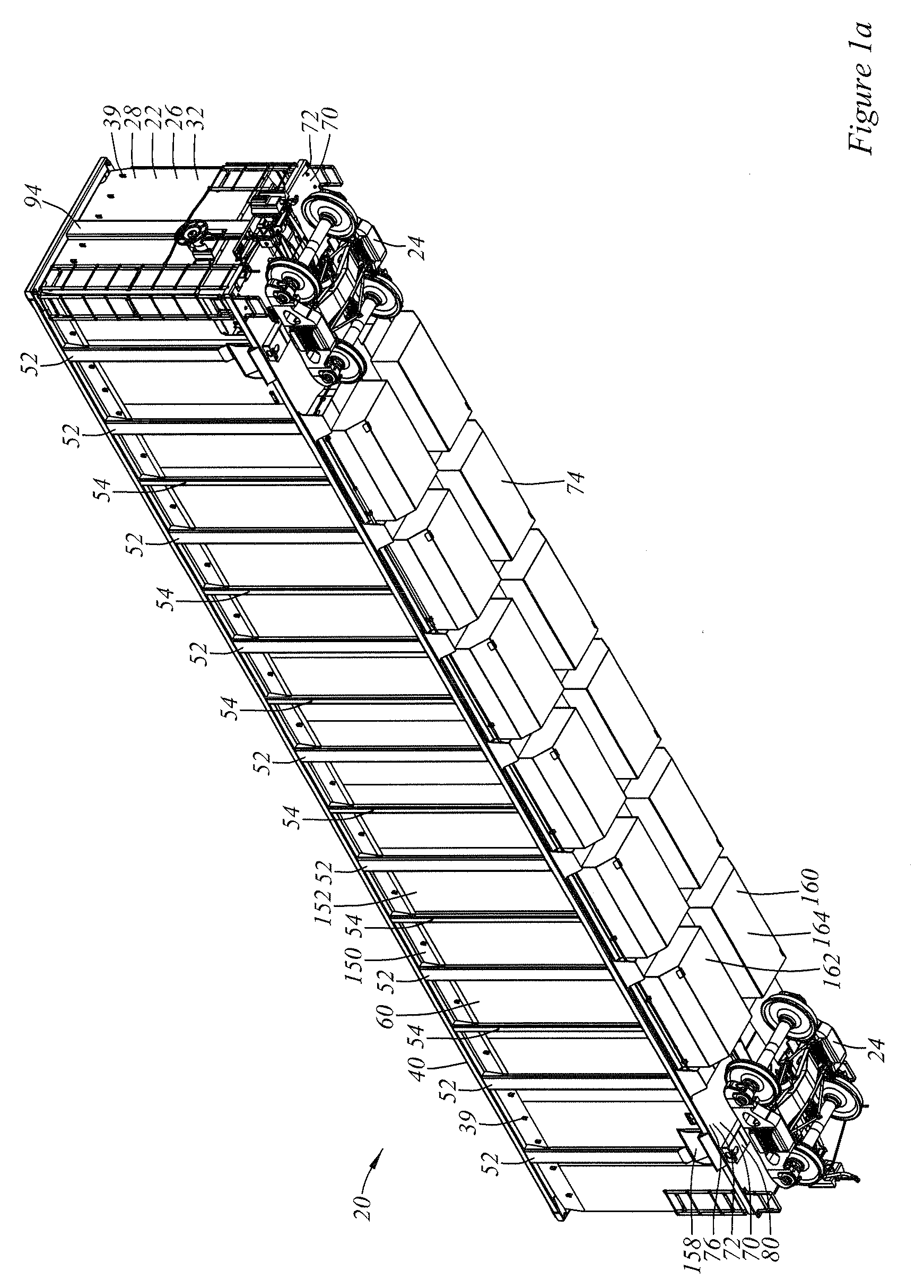

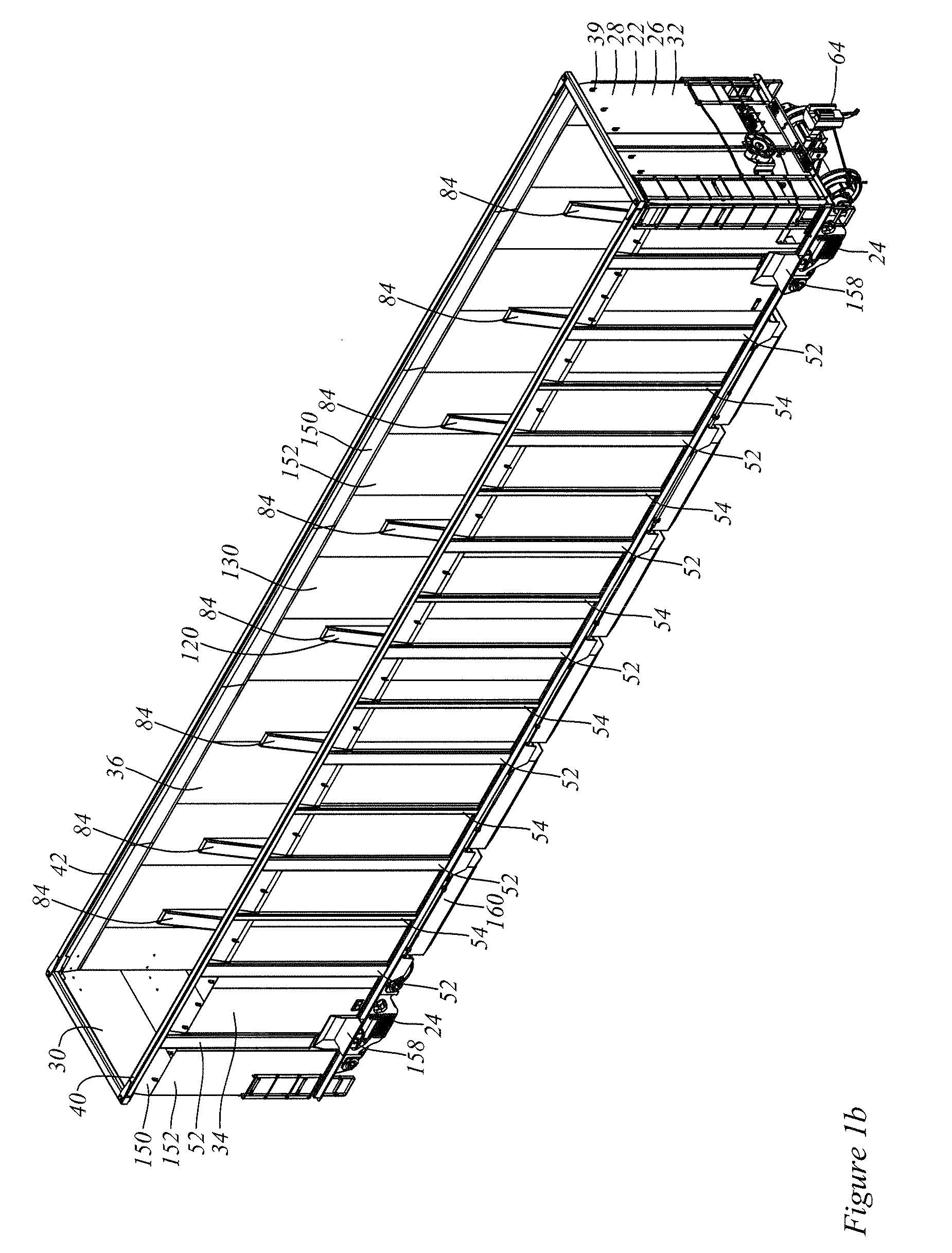

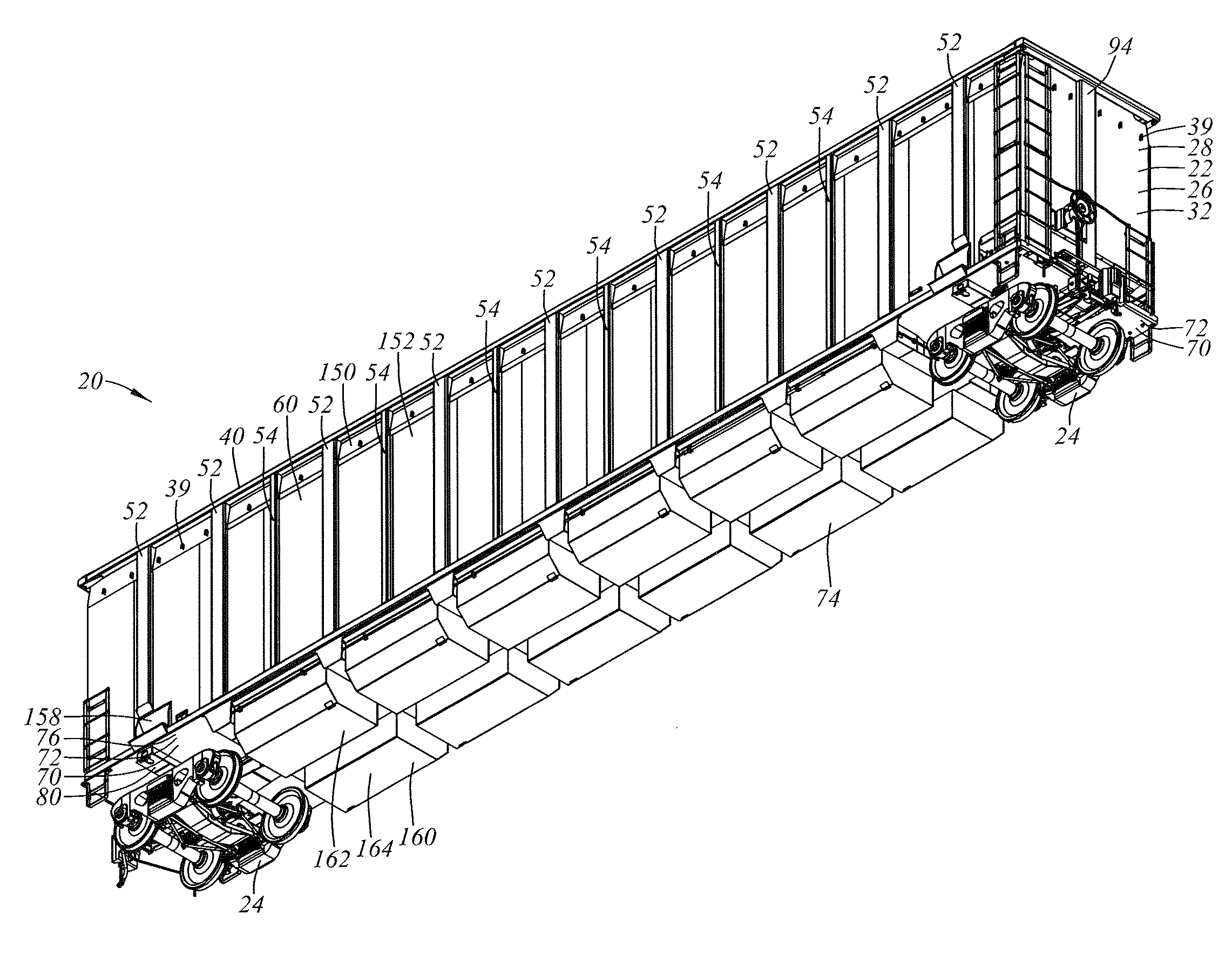

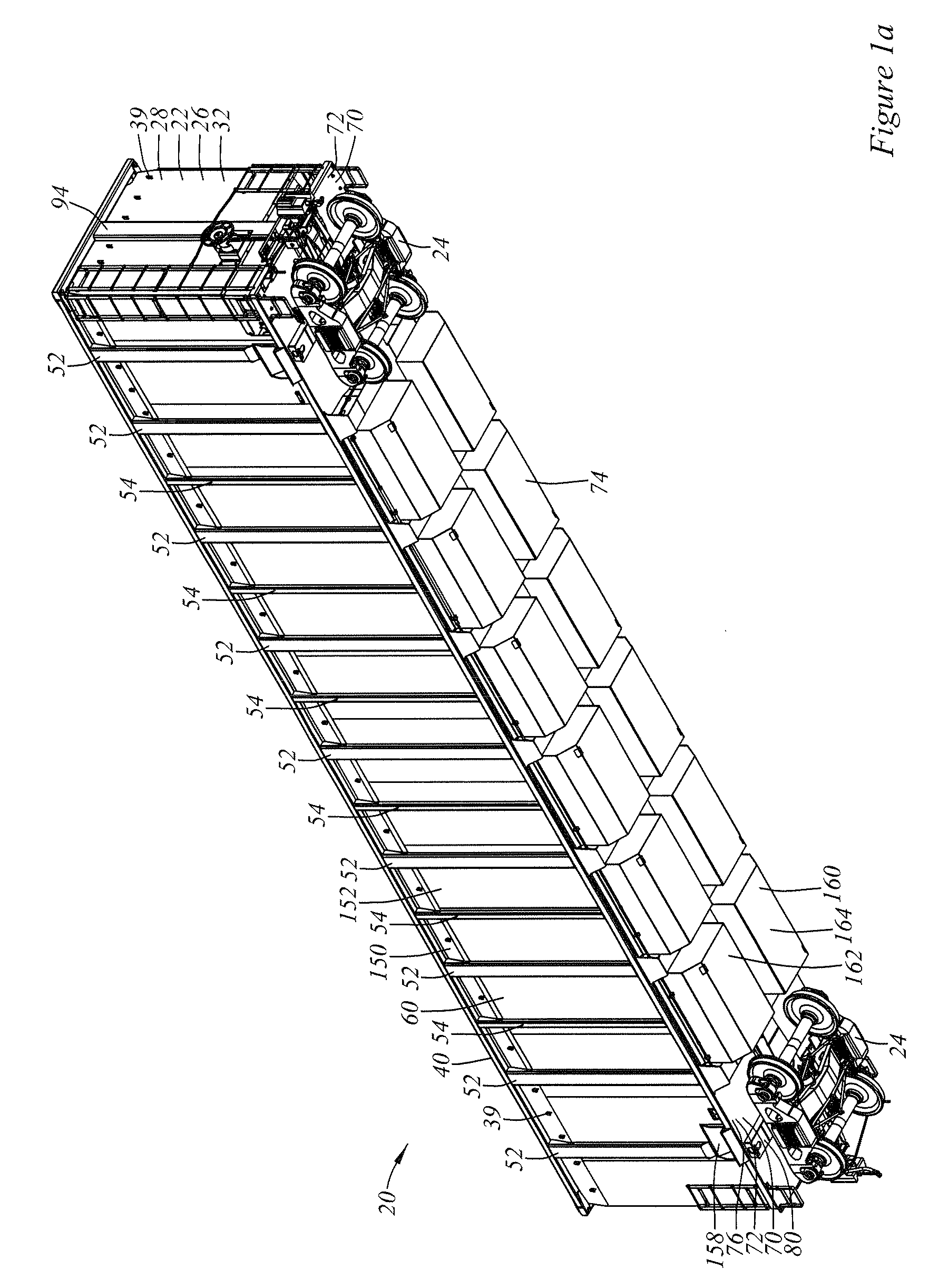

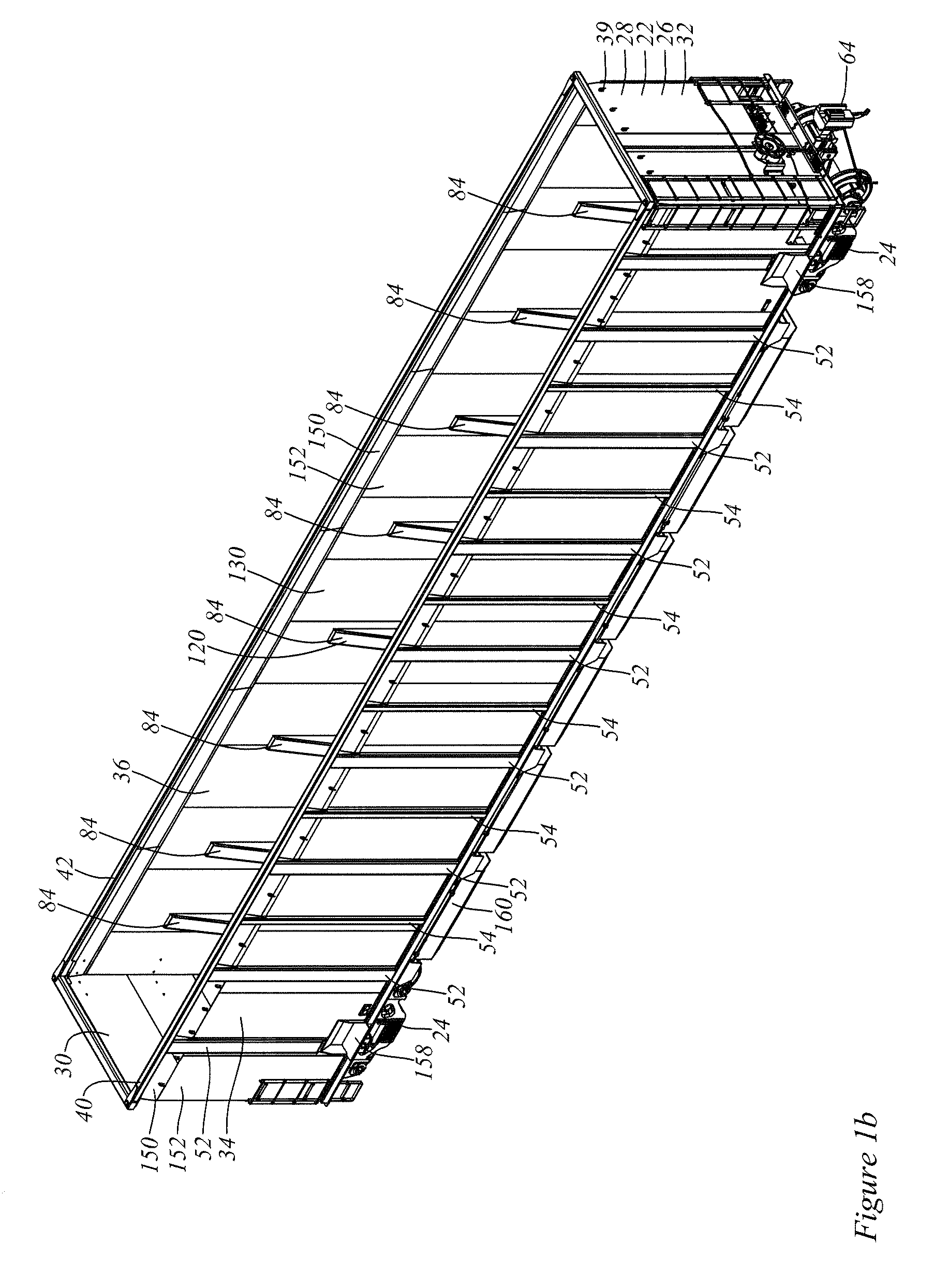

Railroad gondola car structure

A gondola car has a body for lading carried on an underframe. The underframe includes a center sill and cross-bearers. The car has deep side beams having top chords, side sills, and side sheets. The lower portion of the car includes tubs that seat between the cross-bearers. The car may have an internal volume of more than 8000 cu. ft. The car may have rotary dump claw sockets. The car has opposed internal and external stiffeners aligned at the longitudinal stations of the cross-bearers. The internal stiffeners may be triangular cantilevers extending upwardly inside the side sheets. The side sheet lies intermediate the stiffeners and their flanges. The top chords may be wider in cross-section than the side sills. The side sills may define torque tubes that co-operate with the sidewall stiffeners and the top chords to resist lateral deflection. The car may include a false deck, or dog-house at one end to accommodate the brake reservoir and brake valve, such that the car is longitudinally asymmetric.

Owner:NATIONAL STEEL CAR

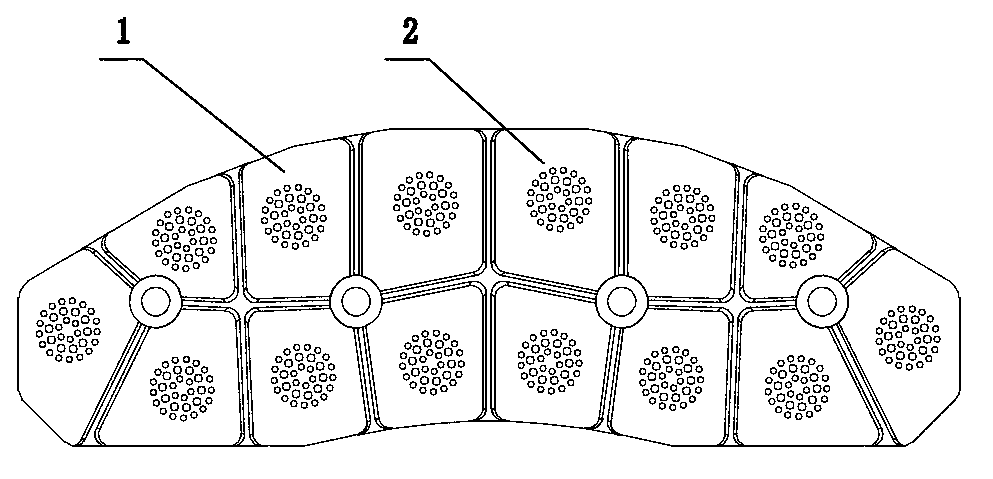

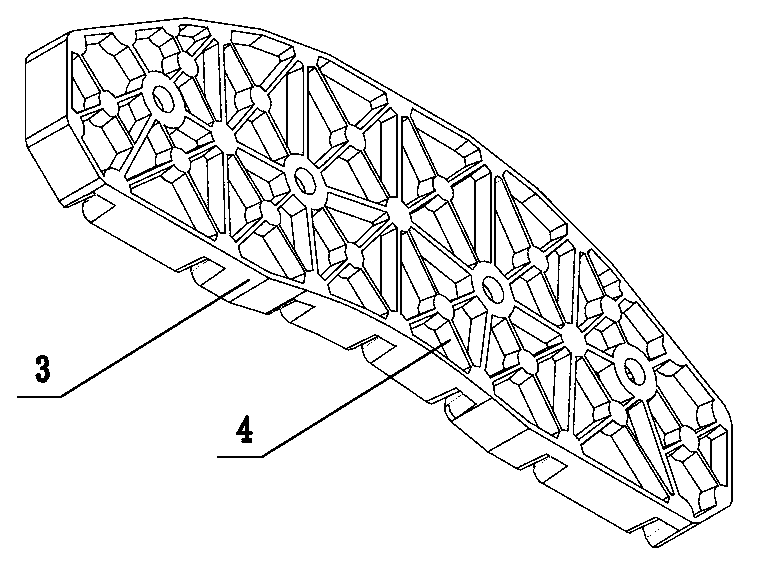

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

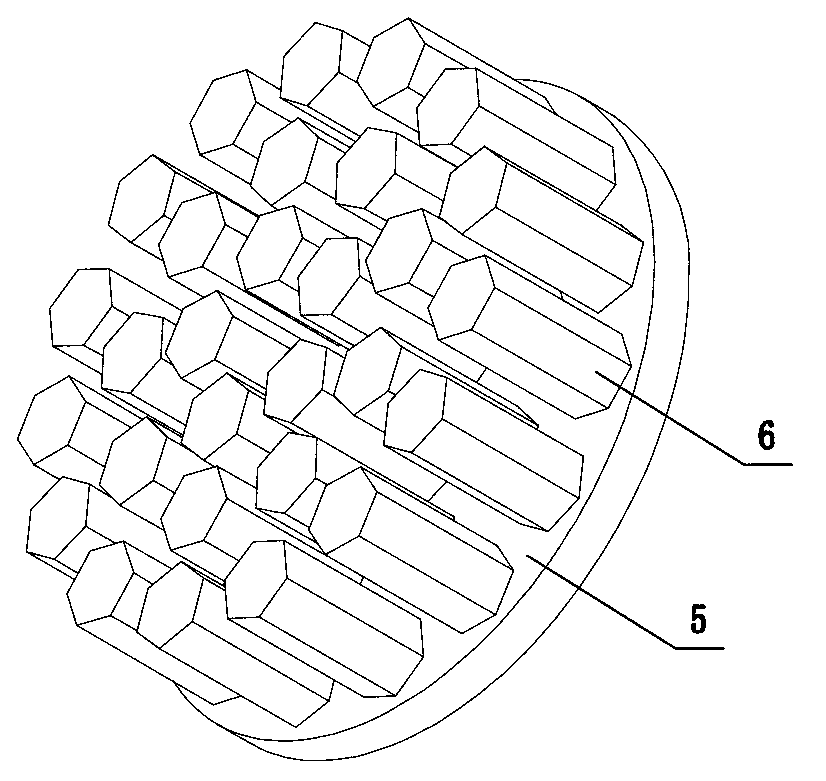

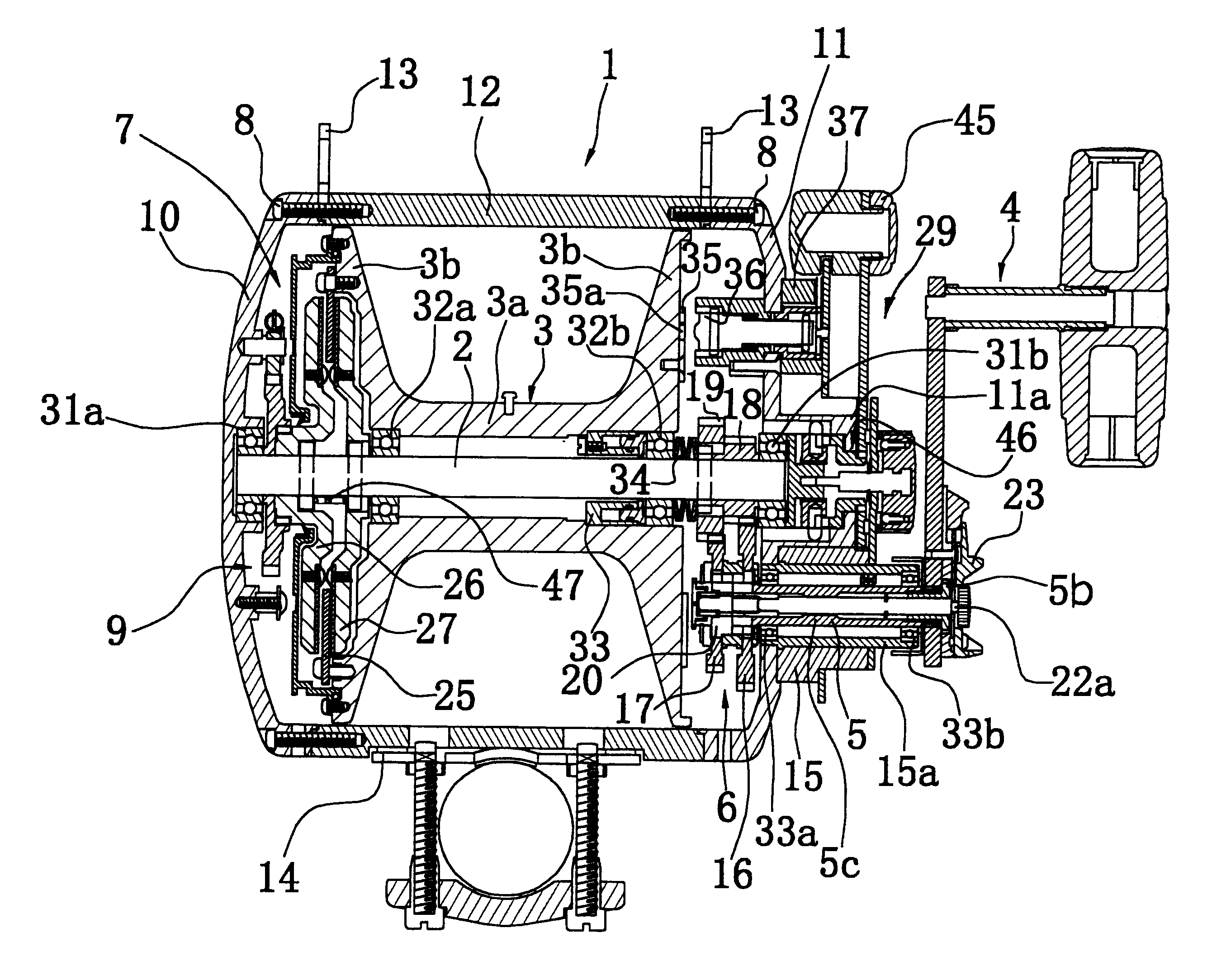

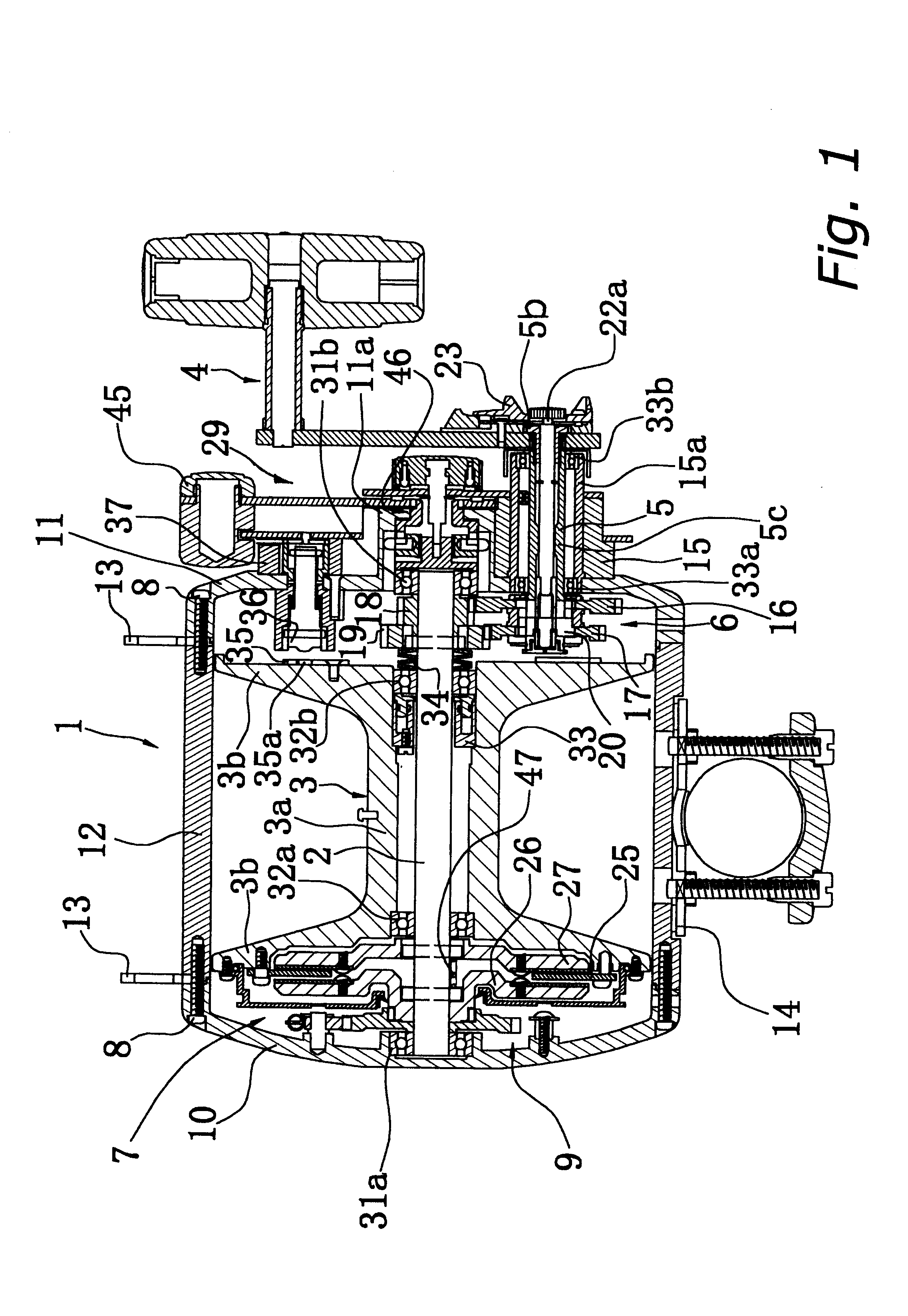

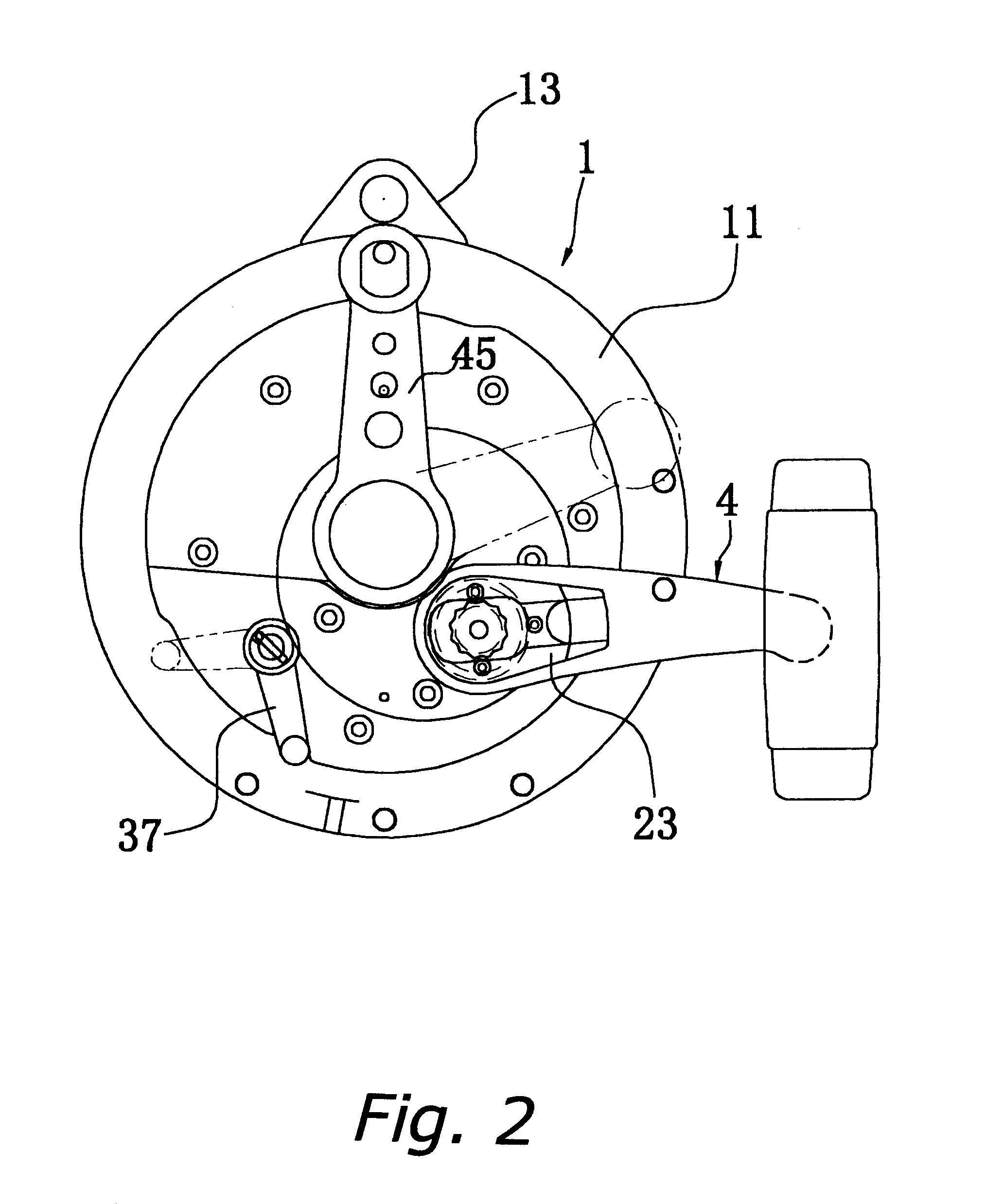

Dual-bearing reel brake device and drag cover attachment structured therefor

A double-drag type lever-drag mechanism for a double-bearing trolling reel. The drag mechanism is configured to improve overall reel braking and drag performance by securing the brake release state reliably and by a design that curbs increase in spool inertia and provides for ease of operation and precision in attaching the drag cover. The lever drag mechanism 7 brakes the spool 3 rotation in the line spool-out direction, and is equipped with a brake disk 25 non-rotatably fitted to one end of the spool such to be axially shiftable a predetermined distance. Sandwiching the brake disk 25 between friction disk 26, immobilized against axially outward movement, and axially shiftable friction disk 27 rotates the drag / brake disks 25-27 unitarily with the spool 3. Against the spool 3 a coil spring 28 urges the brake disk 25 away from the spool 3. A shifting mechanism 29 reciprocates the spool 3 and drag / brake disks 25-27 axially. The mounting configuration for the drag cover includes a circular groove 3c radially beyond which is a plurality of circumferentially spaced threaded holes 3d in the end face of the spool 3; a tubular centering portion 41c that snugly fits into the circular groove 3c, radially extending from which is a ring-shaped mounting portion 41b; an O-ring 42 in the circular groove 3c making sealing contact circumferentially with the tubular centering portion 41c; and a plurality of machine screws 44 passing through-holes in the mounting portion 41b and screwed into the threaded holes 3d.

Owner:SHIMANO INC

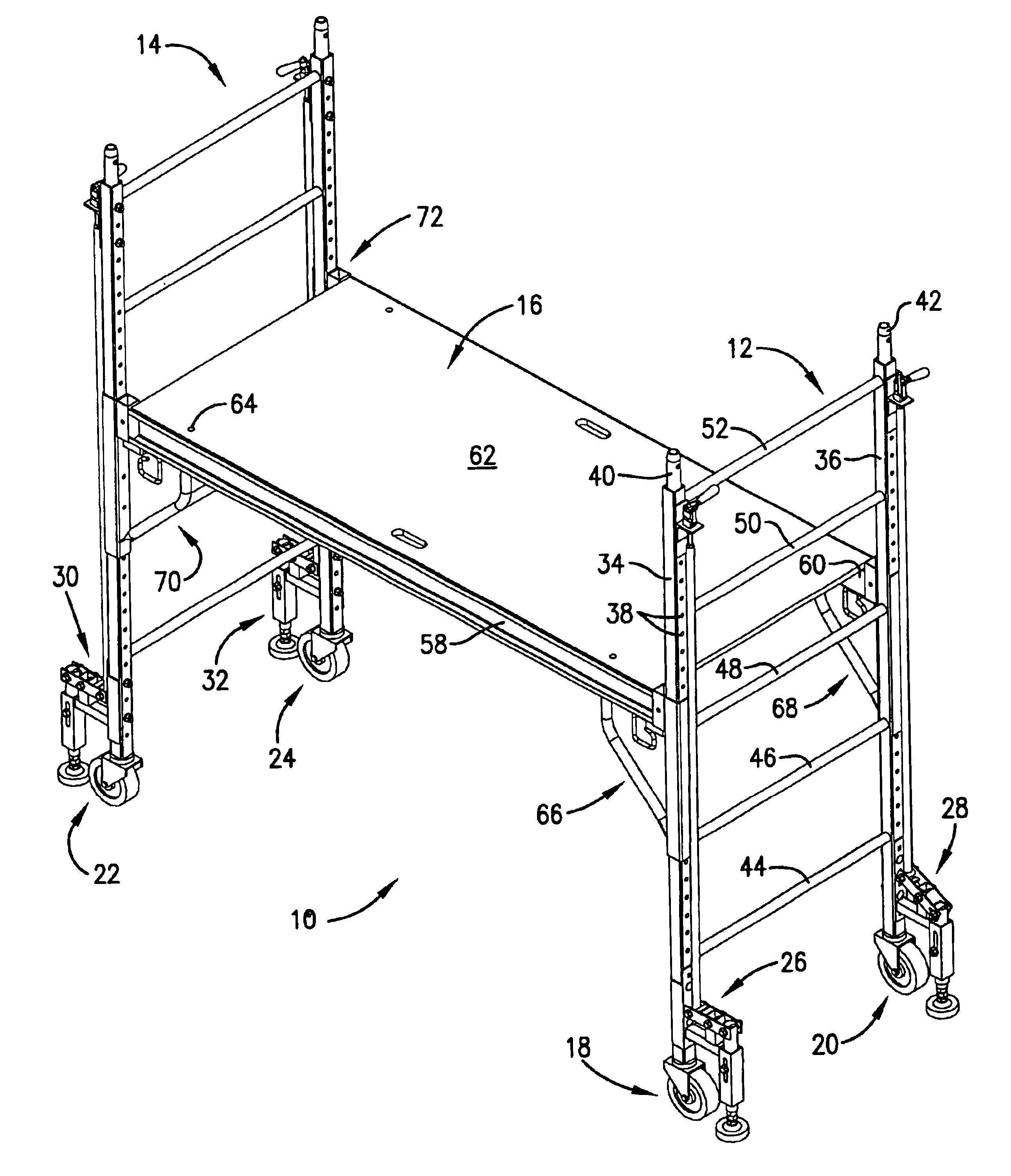

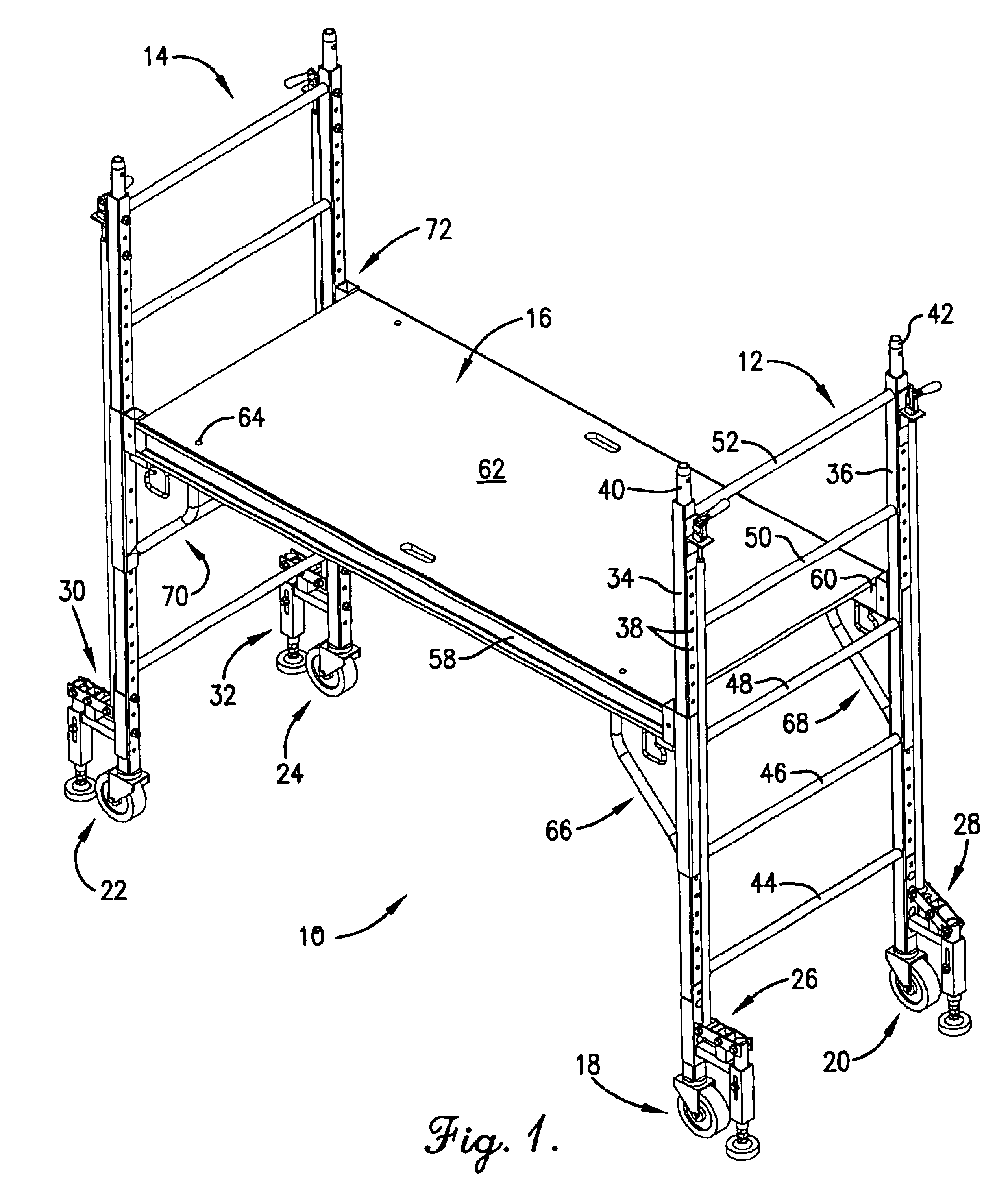

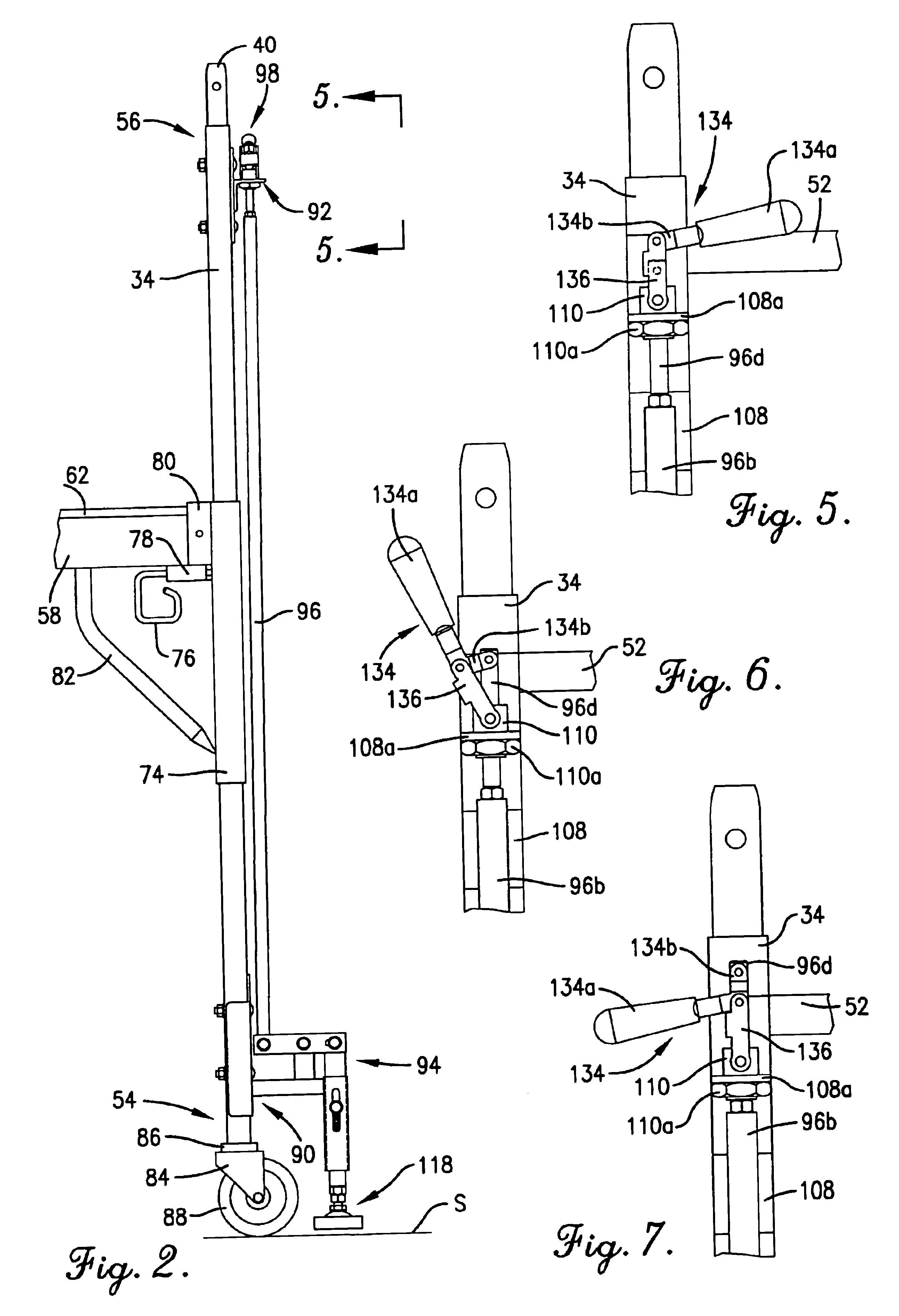

Mobile scaffolding brake

InactiveUS6863155B2Avoid relative motionMotion can be unsafeBuilding support scaffoldsLaddersEngineeringCaster

A mobile scaffolding (10) for elevating a worker (not shown) above a floor or ground surface (S) is disclosed. The scaffolding (10) broadly includes a pair of frames (12) and (14), a platform (16) supported by the frames (12,14), a pair of casters (18, 20) and (22,24) rollably supporting a respective one of the frames (12,14), and a brake assembly (26, 28,30, and 32) associated with a corresponding one of the casters (18,20,22,24), respectively. The inventive brake assemblies (26,28,30,32) enable the worker supported on the platform (16) to selectively activate and deactivate the respective brake assemblies (26,28,30,32) from the platform (16). This enables the worker supported on the platform (16) to deactivate the brake assemblies (26,28,30,32), reposition the scaffolding (10), and then reactivate the brake assemblies (26,28,30,32) without requiring the worker to dismount from the platform (16).

Owner:GRANITE IND

Railroad gondola car structure

Owner:NATIONAL STEEL CAR

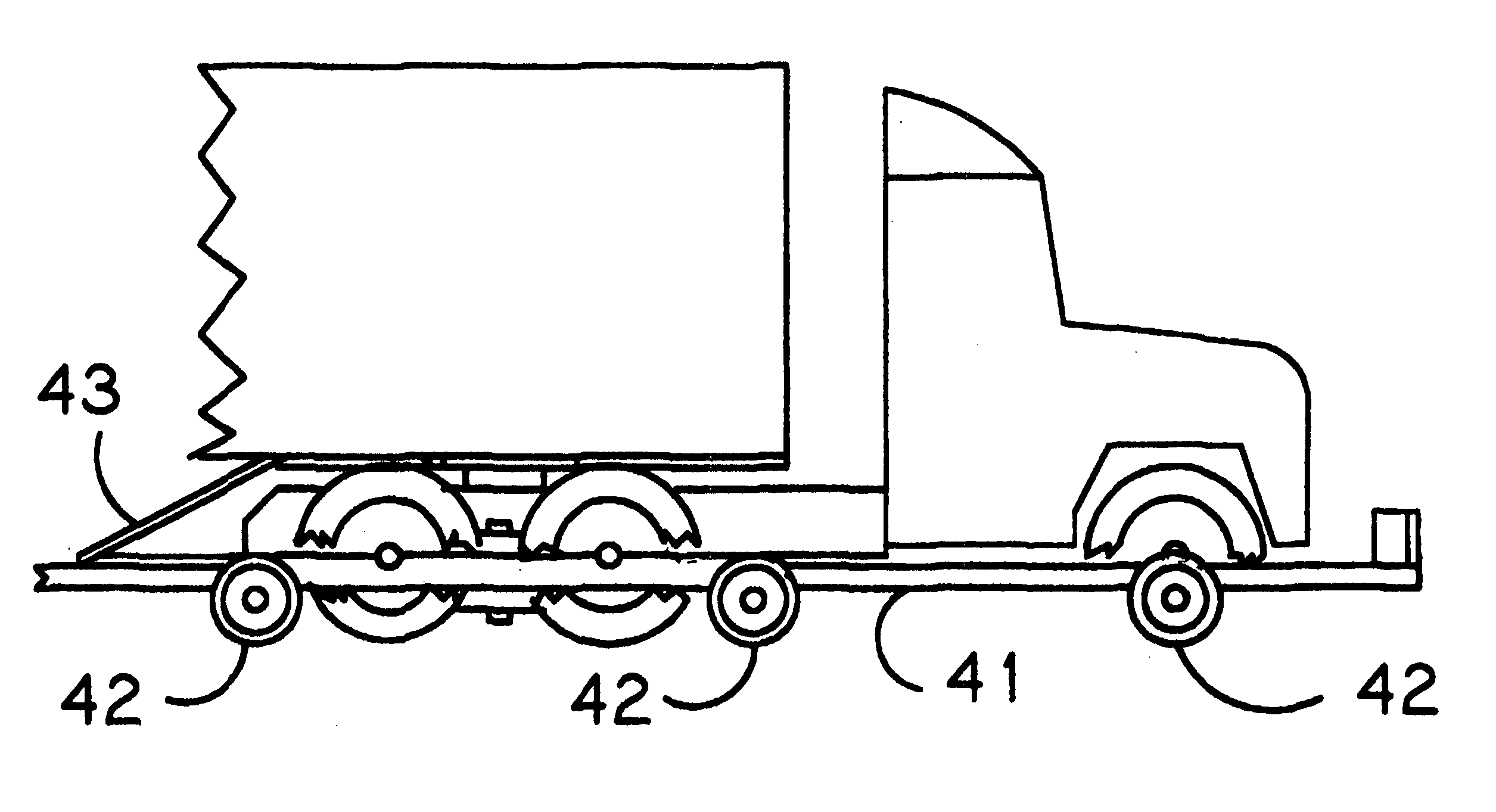

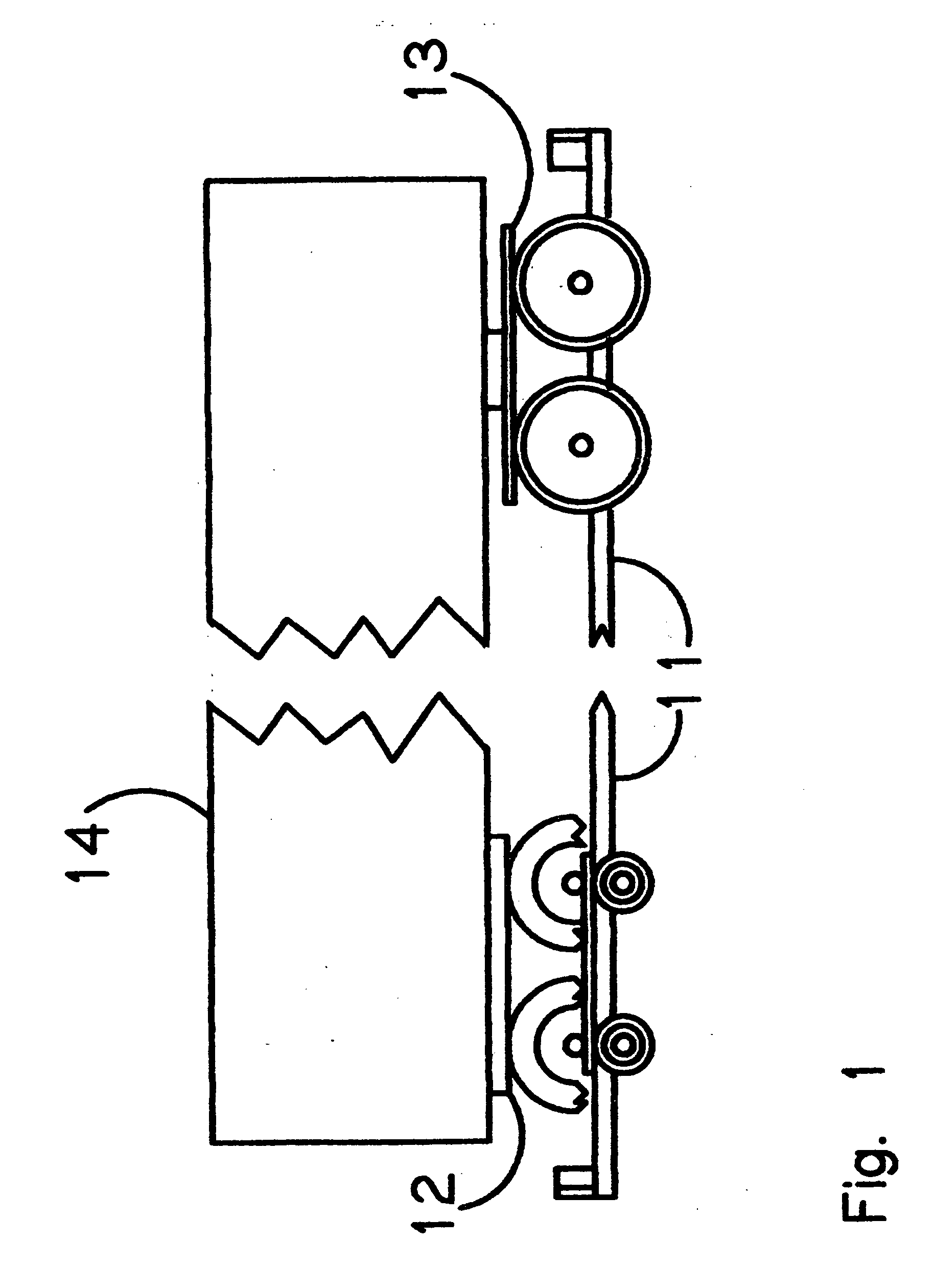

Apparatus and method for intermodal conversion of transport vehicles; rail-to-highway and highway-to-rail

InactiveUS20070089637A1Reduce fuel consumptionExtend delivery timeRail and road vehiclesWagons/vansBogieActuator

This invention is an apparatus and method for reversible intermodal conversion of transport tractors and trailers, highway-to-rail. Trailer add-ons are wheel mount shims and an axle housing draft sill pin receptacle. No add-ons are required for tractors. Highway-to-rail conversion involves securing a rail interface apparatus, consisting of rail carriage assemblies, bogies, and end coupler draft sills beneath each vehicle to align and bear loads-to-rails, and to provide draft load transfer. Staging is on paved grade slightly above rail level. Vehicle conversion is made without loading / unloading mechanized infrastructure, add-on weight, wheel removal, or powered actuators. Full use of inherent vehicle suspension and anti-roll devices is afforded. Draft sills, pneumatic brake lines, and knuckle couplers are employed for train configurations. Draft may be afforded by either a locomotive or a rail converted highway tractor.

Owner:SPROAT WILLIAM HARVEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com