Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3671results about "Limiting/preventing/returning movement of parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

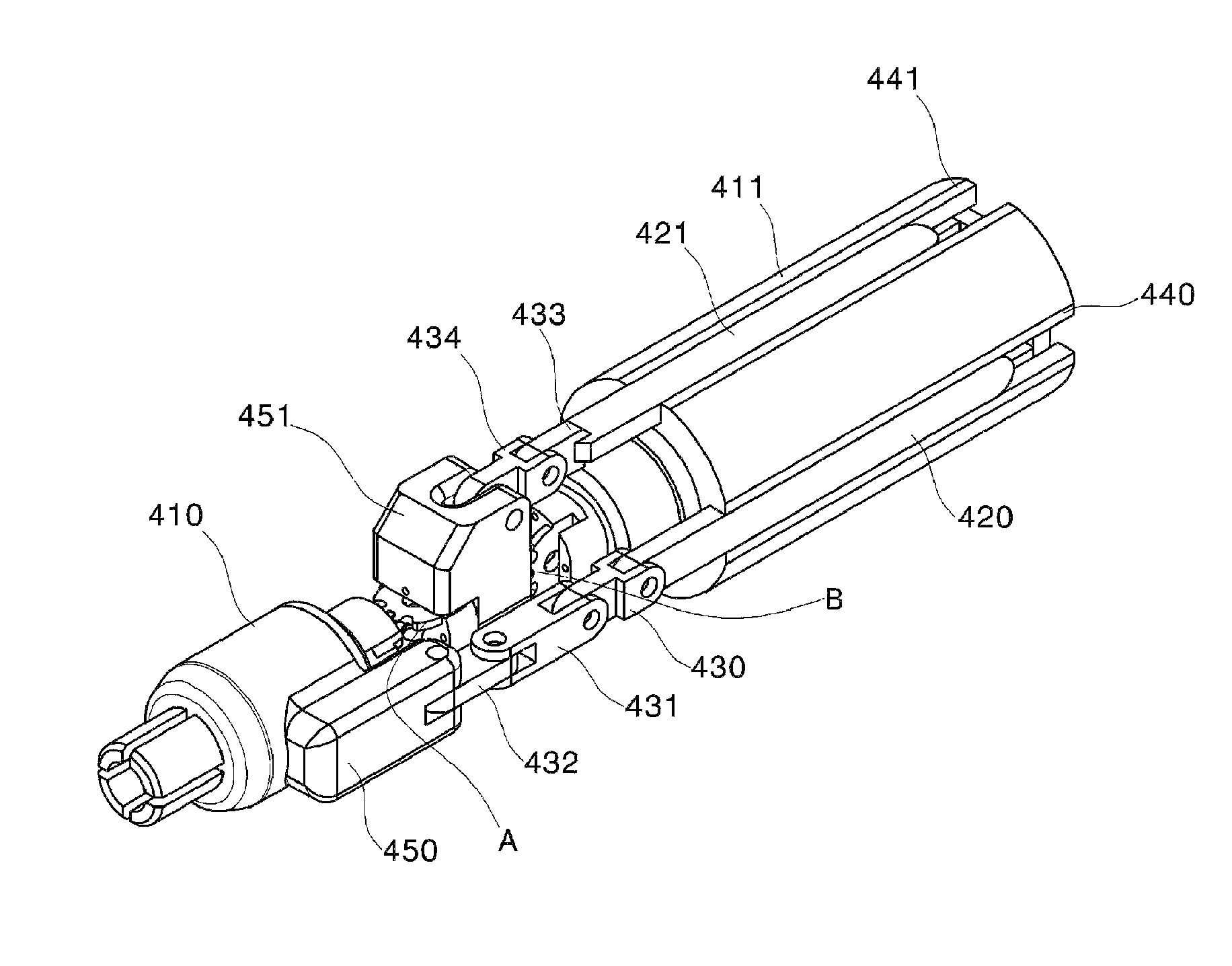

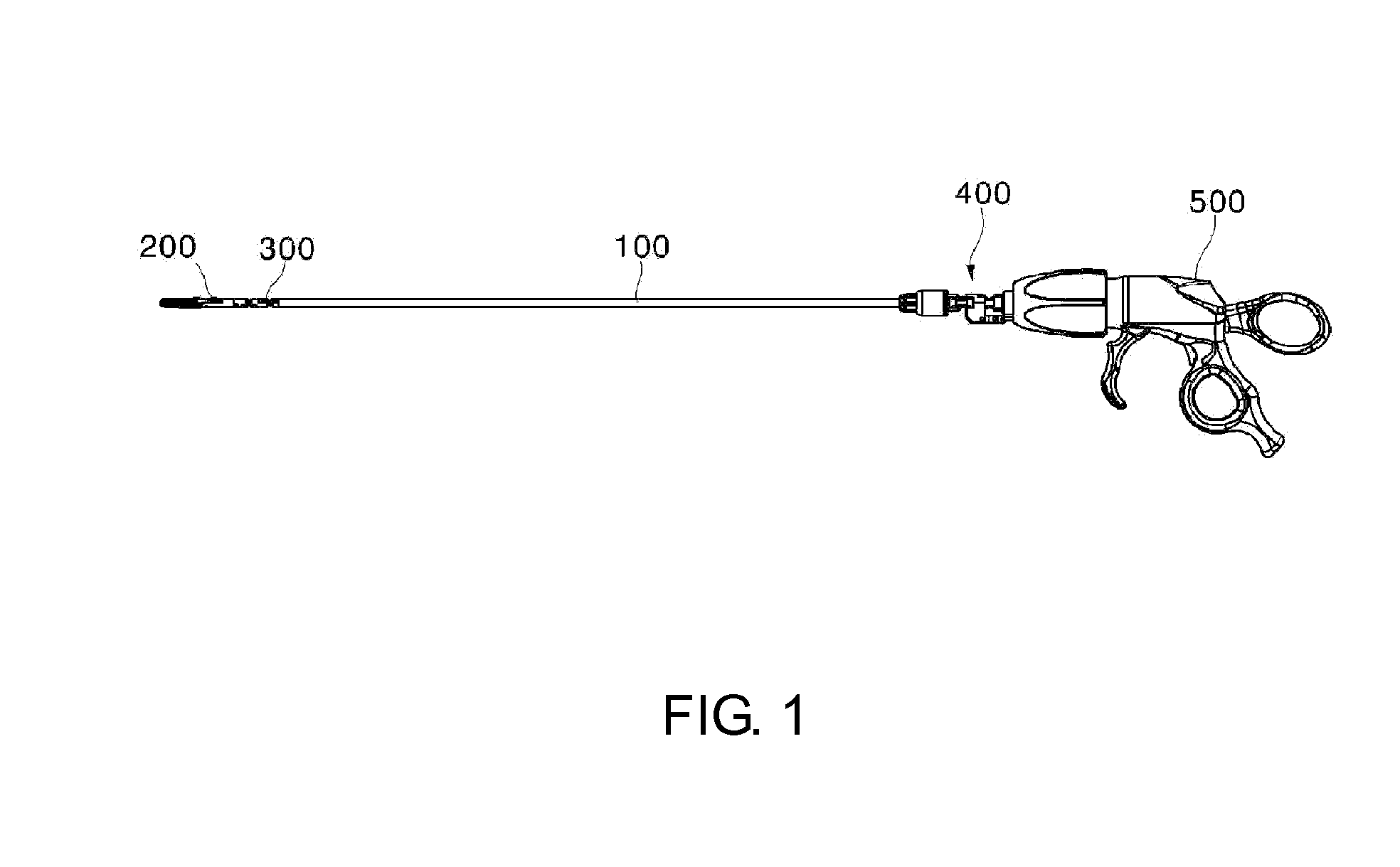

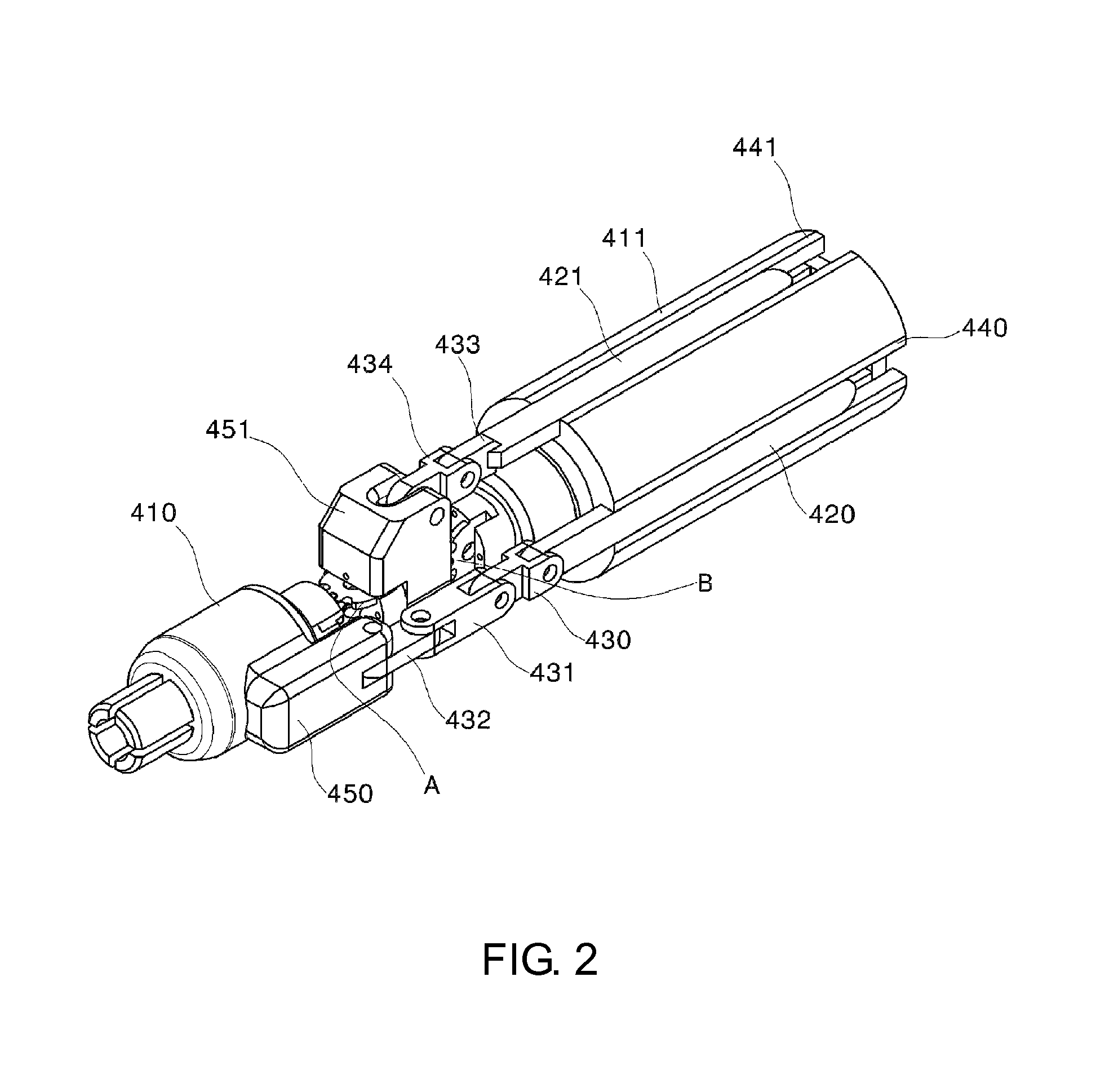

Device for fixing joint structure

Owner:MOVASU

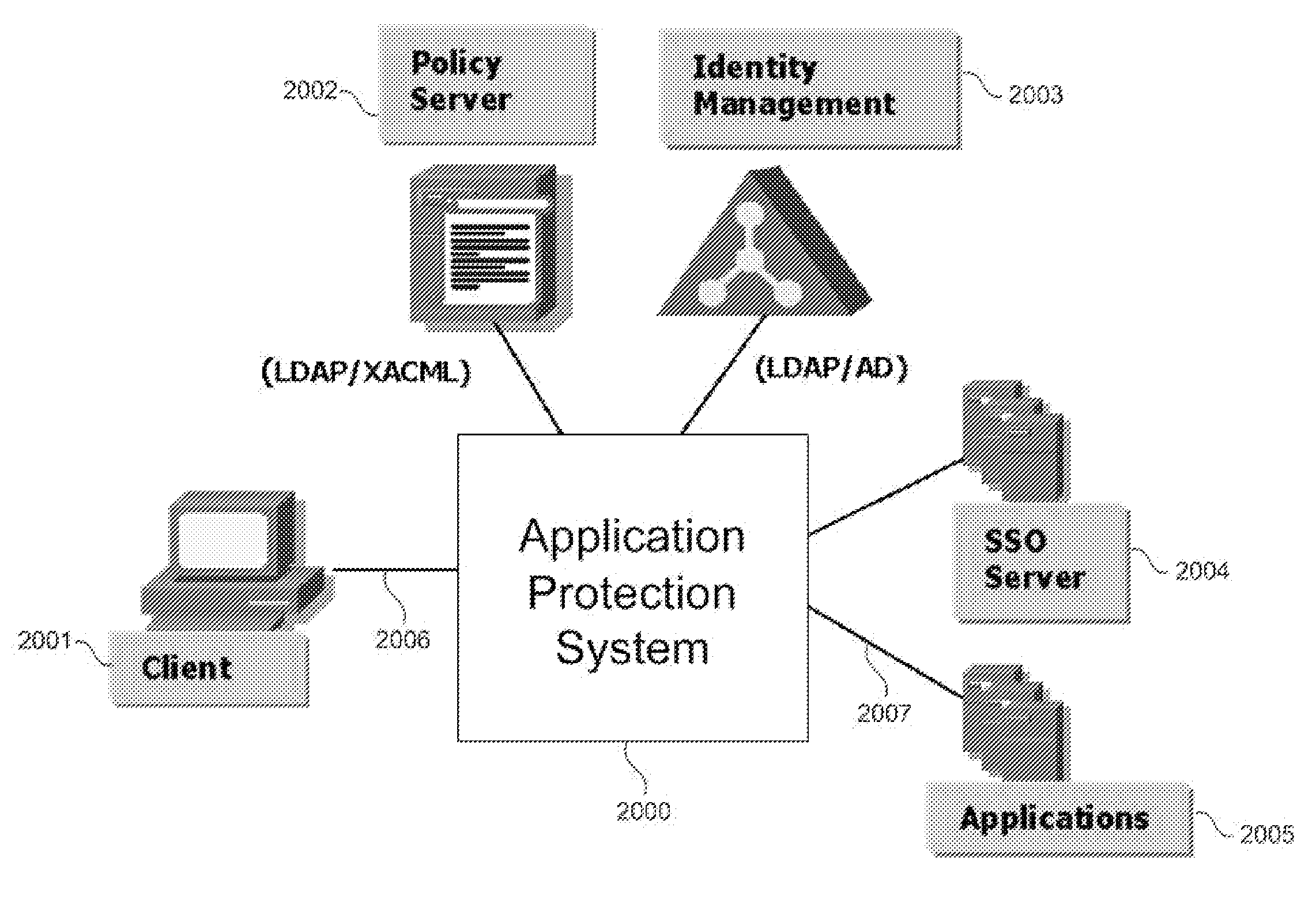

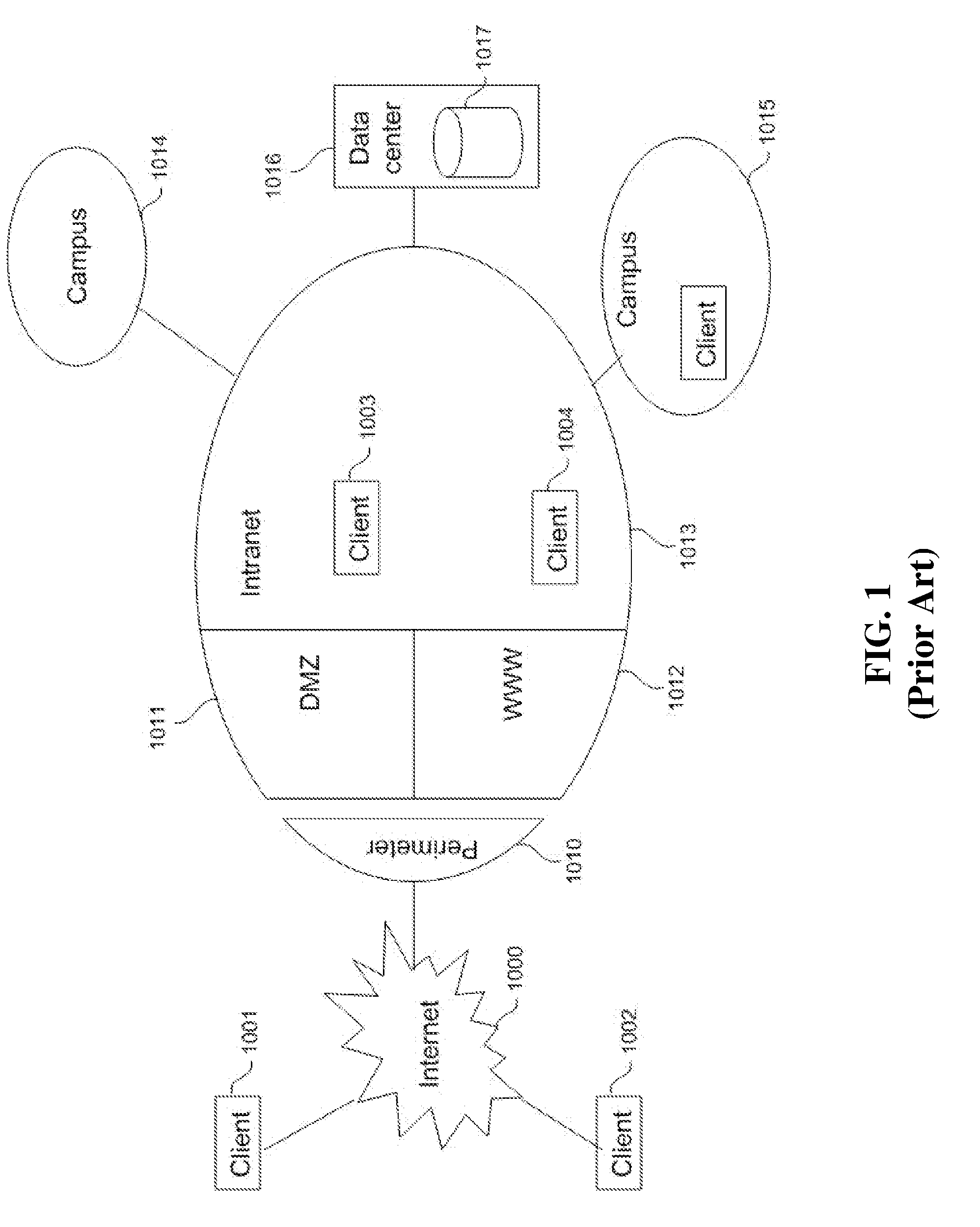

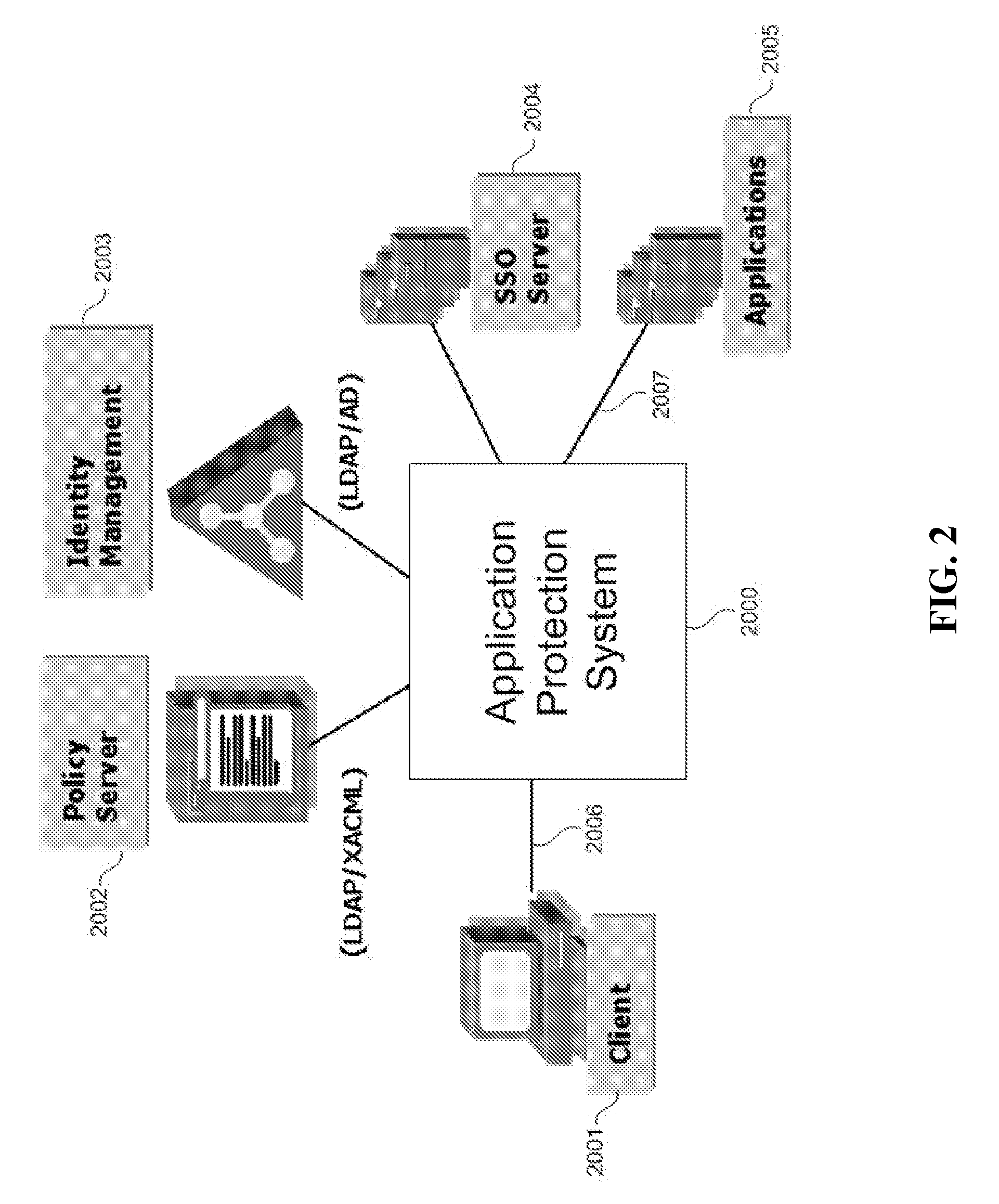

Highly scalable architecture for application network appliances

A highly scalable application network appliance is described herein. According to one embodiment, a network element includes a switch fabric, a first service module coupled to the switch fabric, and a second service module coupled to the first service module over the switch fabric. In response to packets of a network transaction received from a client over a first network to access a server of a data center having multiple servers over a second network, the first service module is configured to perform a first portion of OSI (open system interconnection) compatible layers of network processes on the packets while the second service module is configured to perform a second portion of the OSI compatible layers of network processes on the packets. The first portion includes at least one OSI compatible layer that is not included in the second portion. Other methods and apparatuses are also described.

Owner:CISCO TECH INC

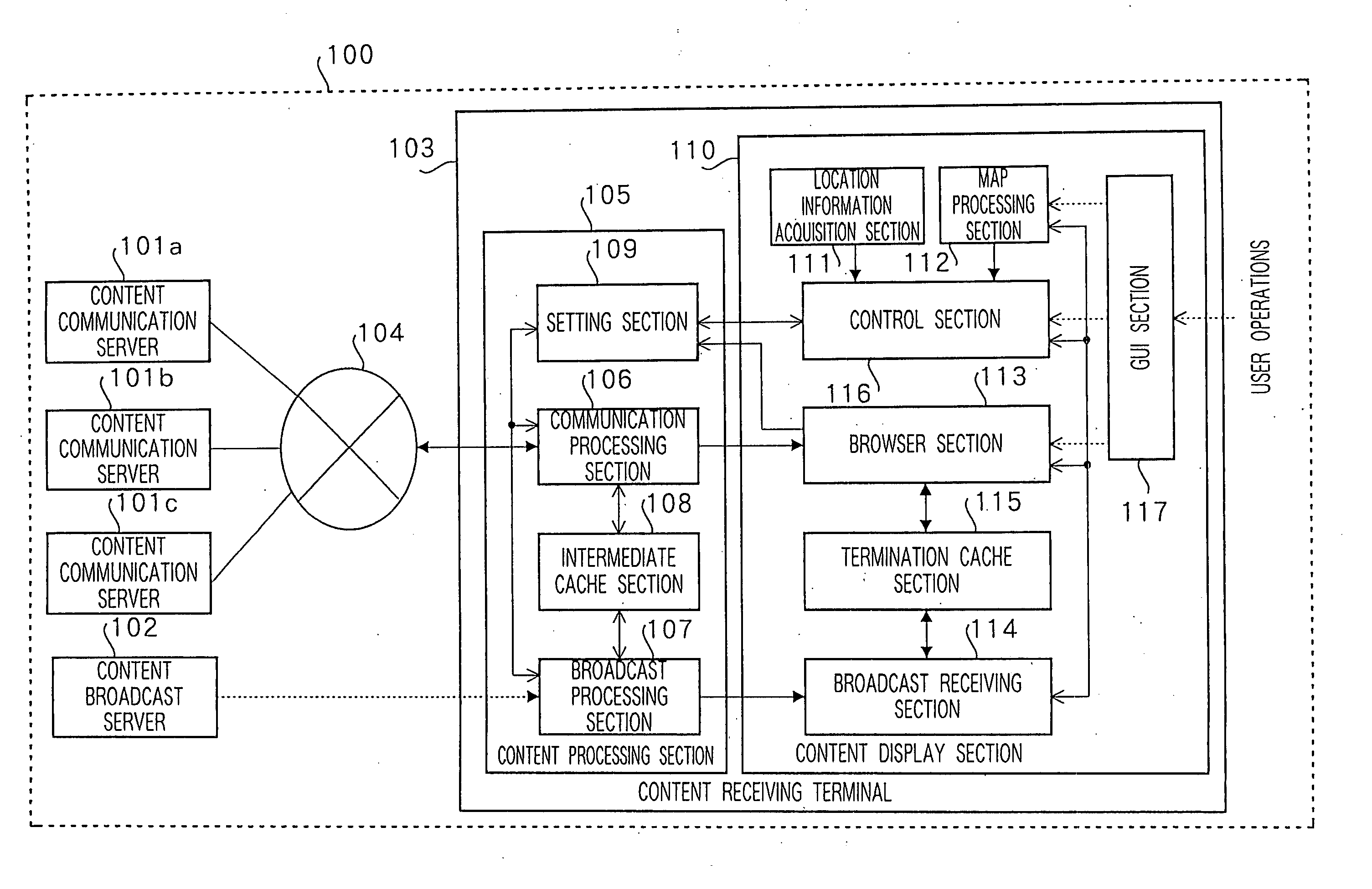

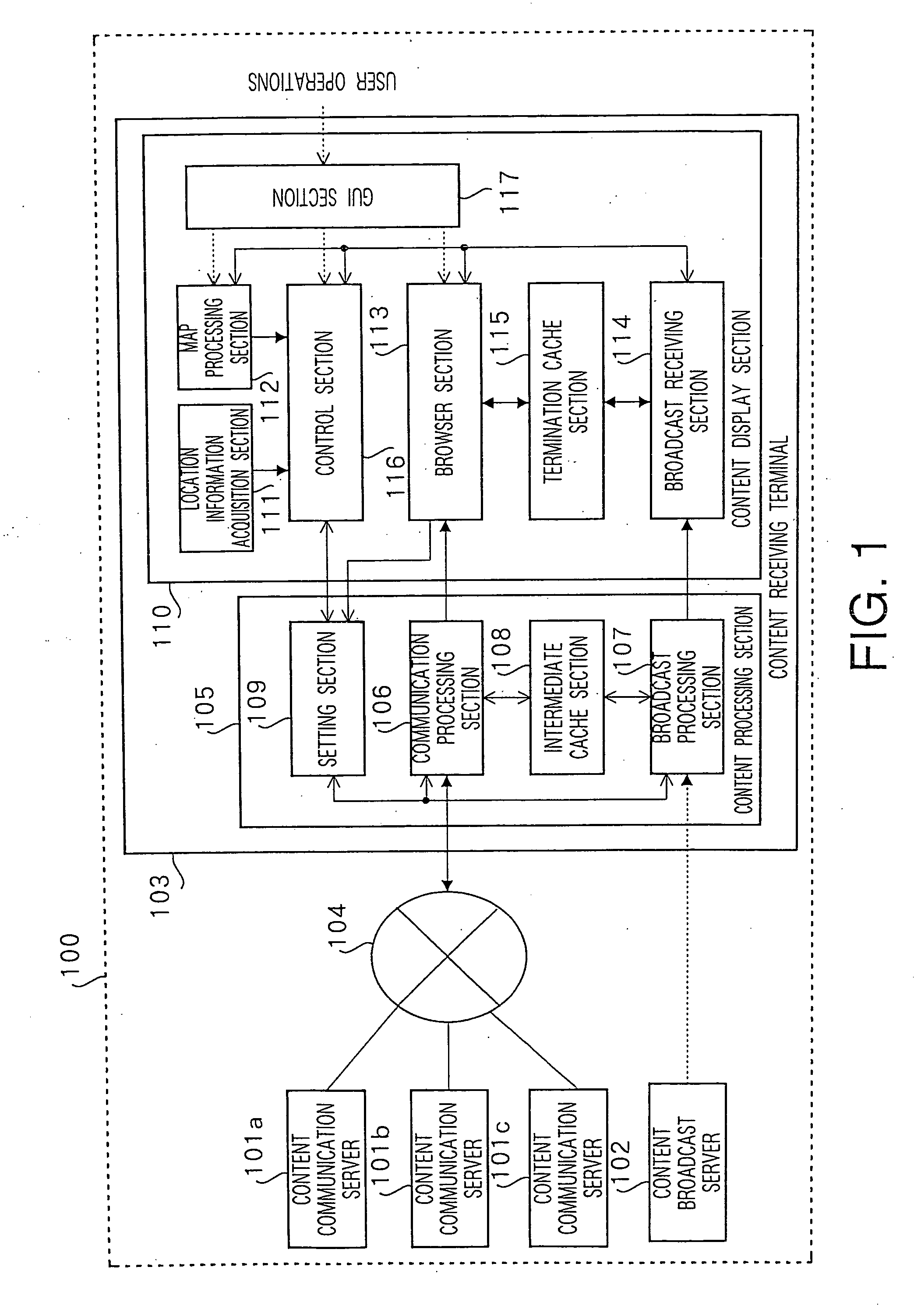

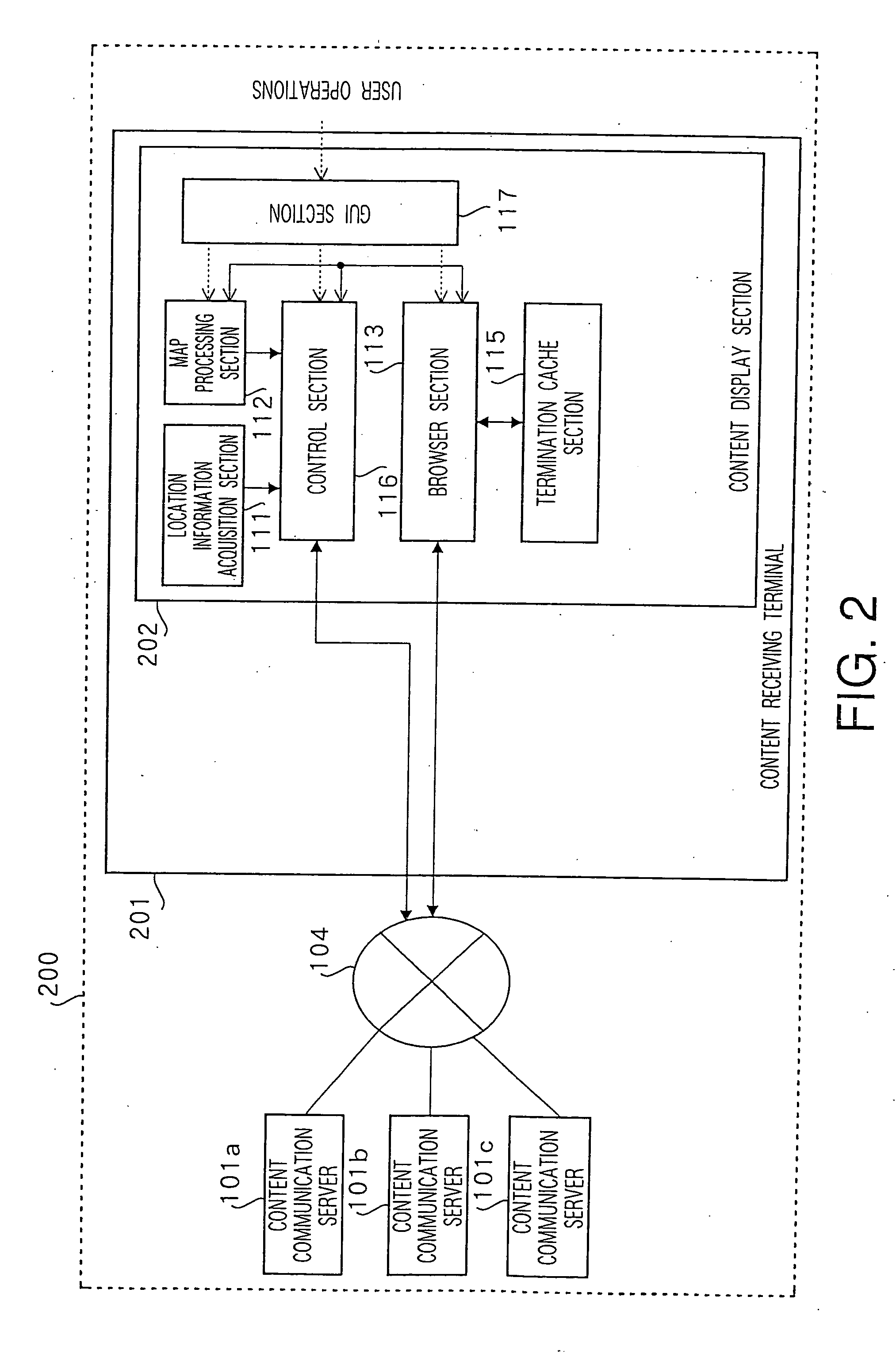

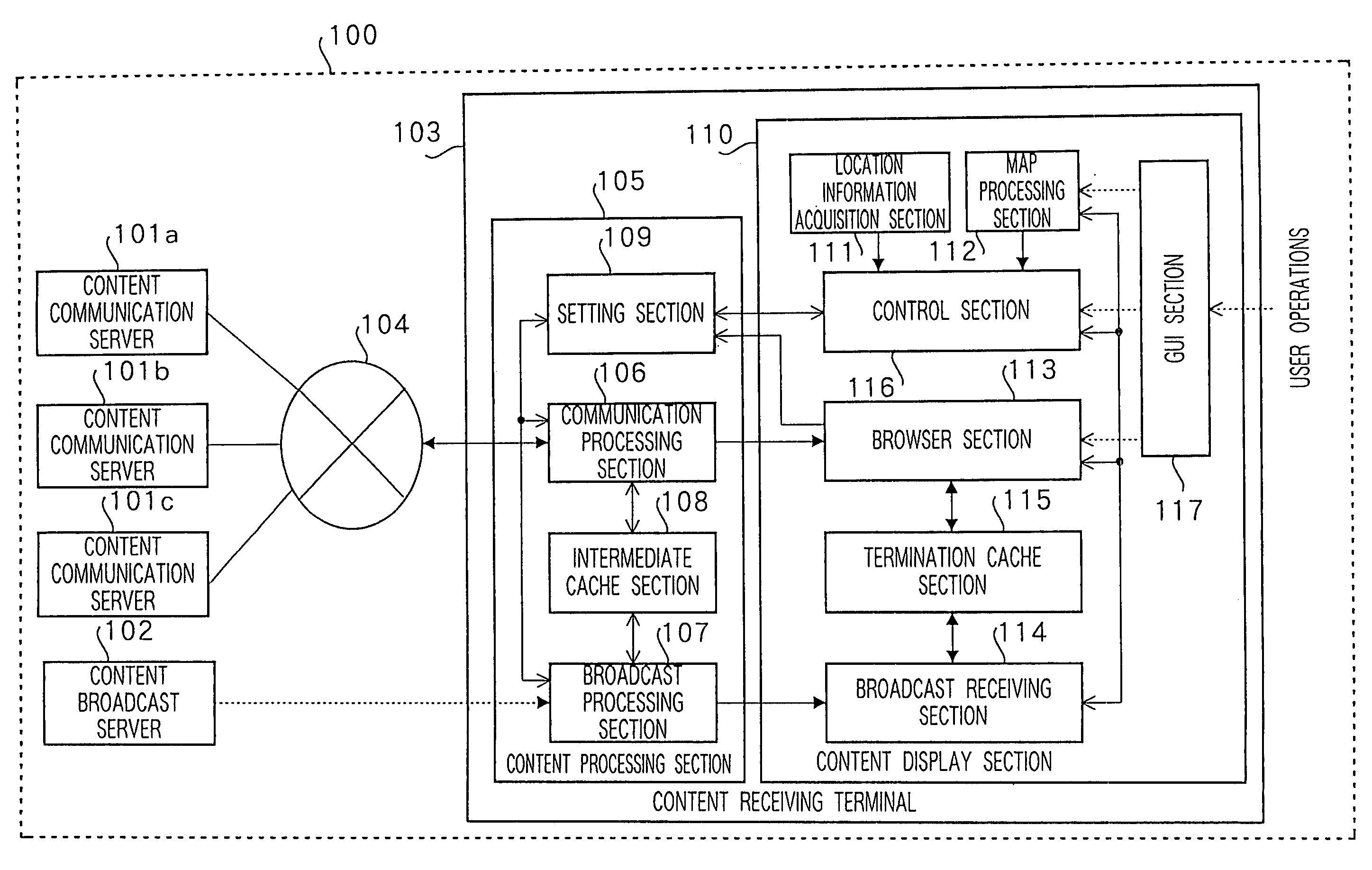

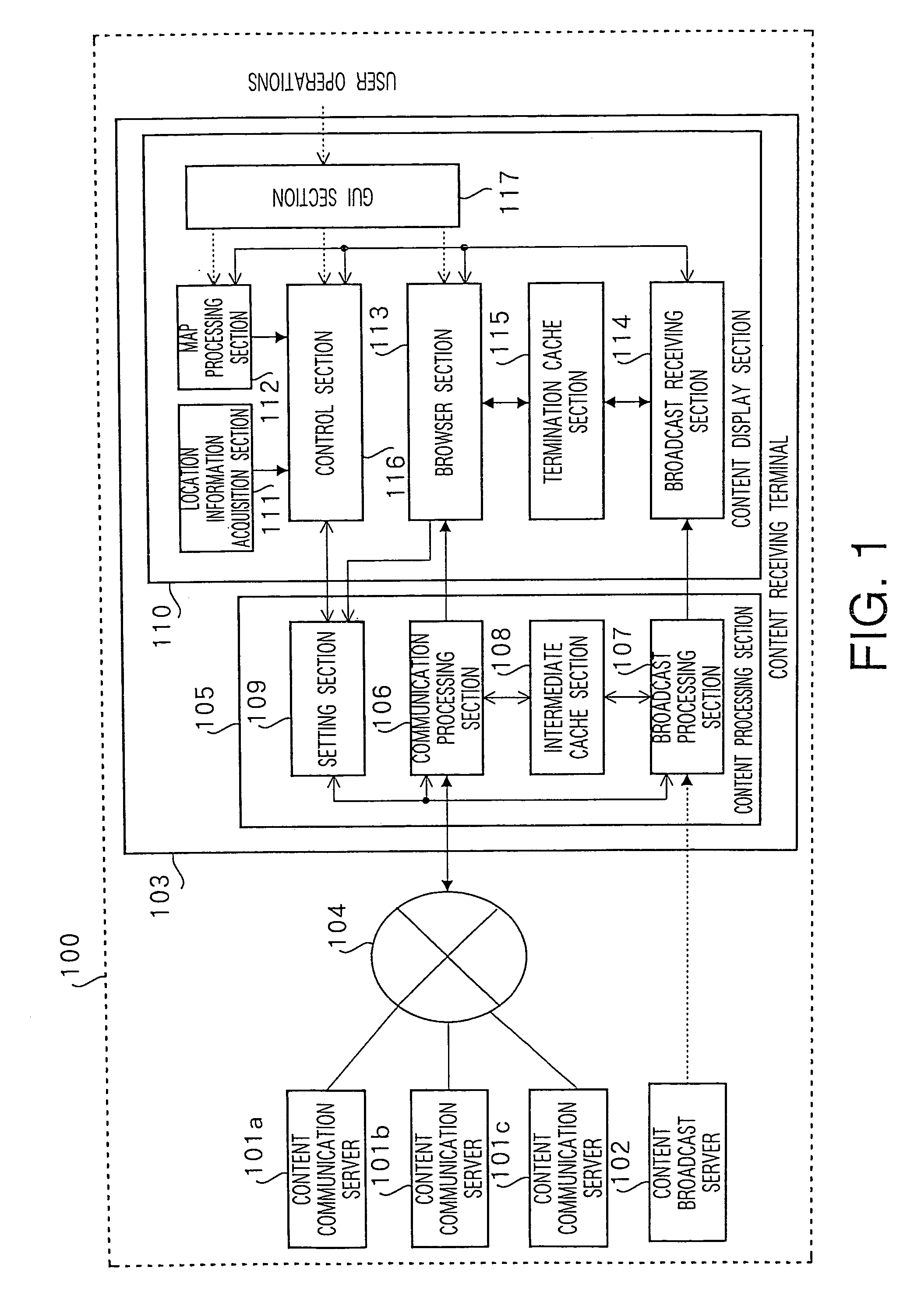

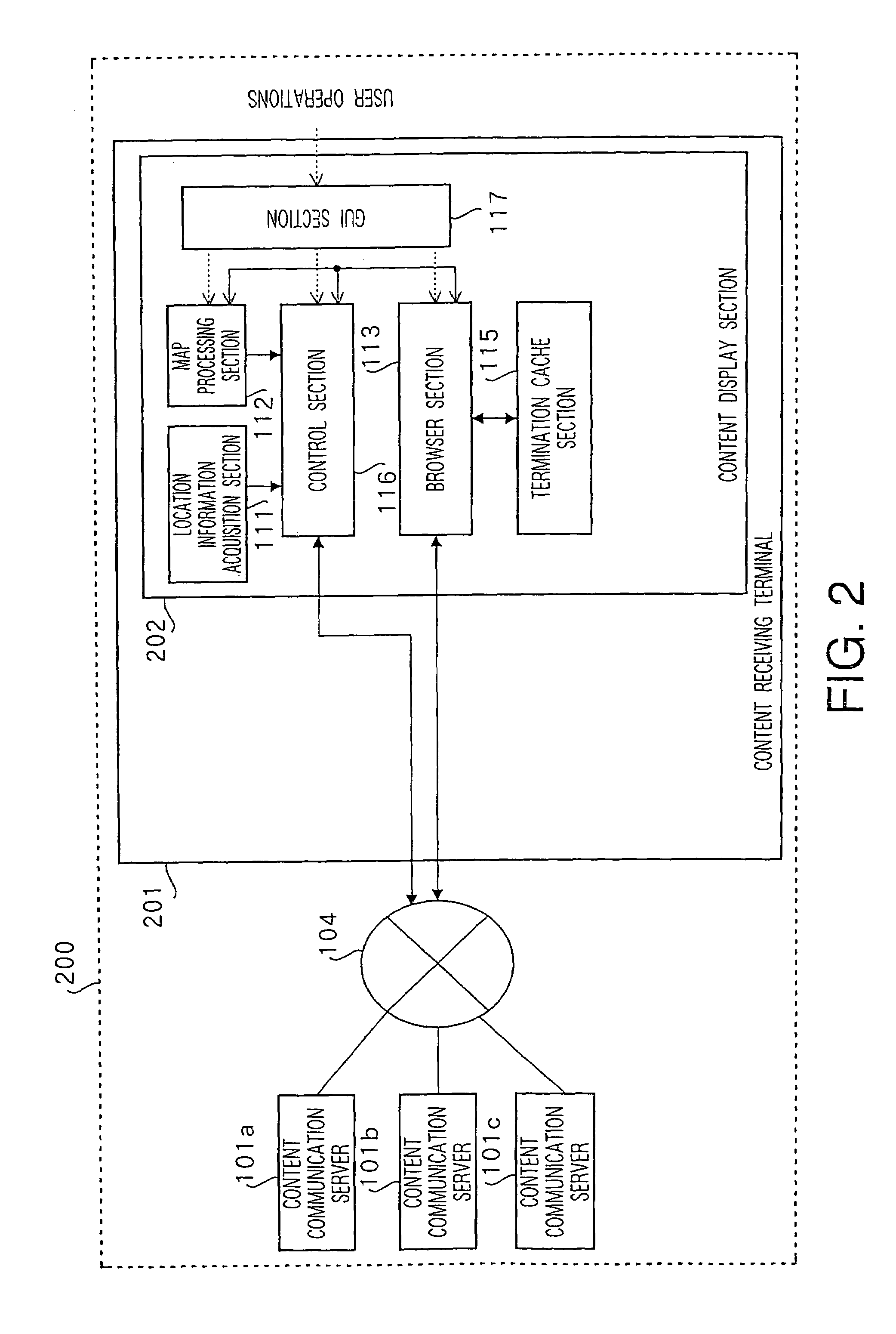

Content processing apparatus and content display apparatus based on location information

ActiveUS20060041556A1Effective distributionInstruments for road network navigationDigital data information retrievalPosition dependentGeolocation

The present invention receives list content providing location conditions in a list organized by location conditions in which a reference destination of location-dependent content, being content assigned correspondence to geographical location information, is compiled for each location condition, sent from a content communication server; receives the sent location information; generates area-specific list content comprising information on location-dependent content corresponding to location information, by extracting a list organized by location conditions, in which location conditions matching location information are provided, from the list content; and outputs the area-specific list content.

Owner:PANASONIC CORP

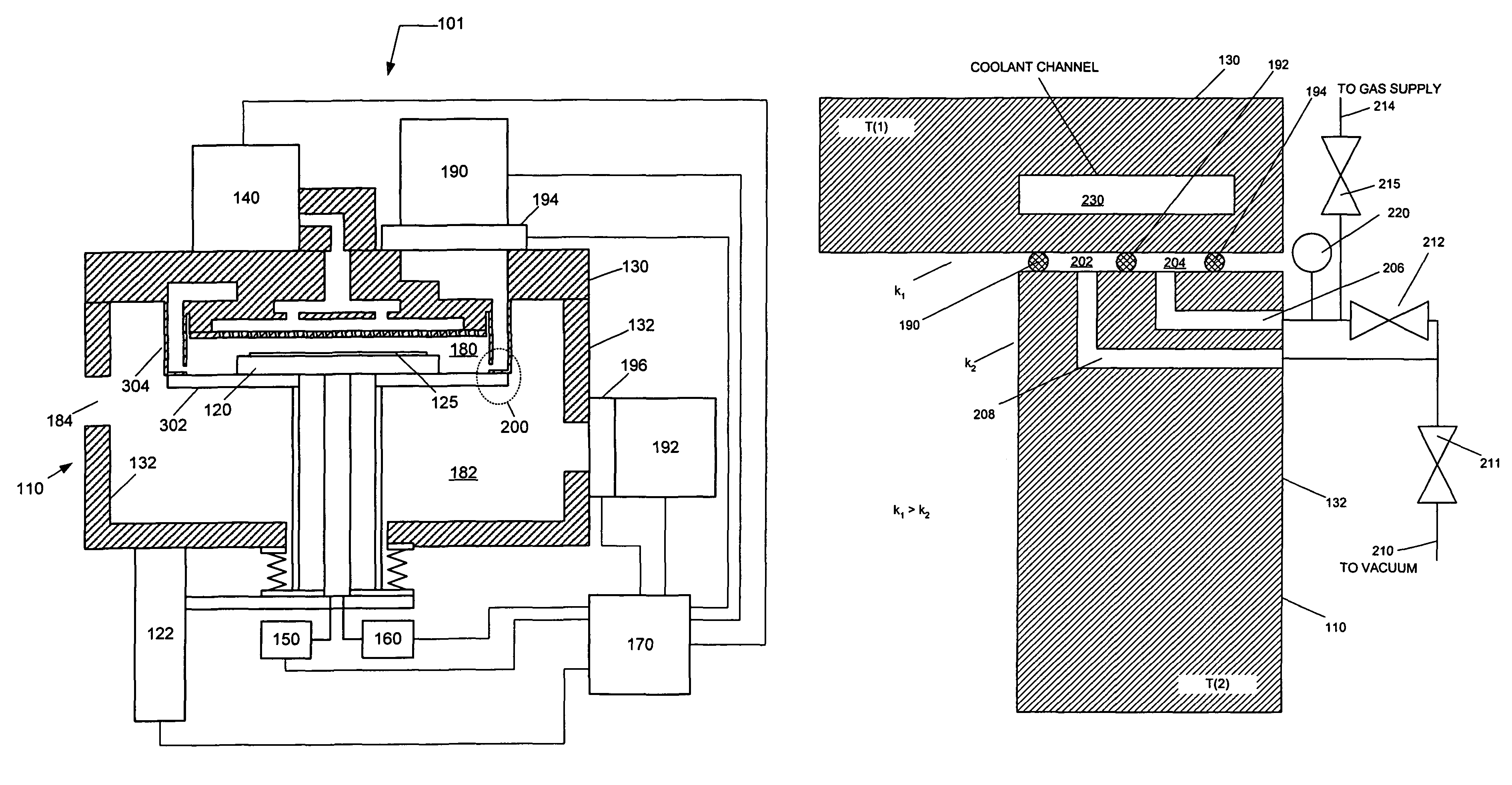

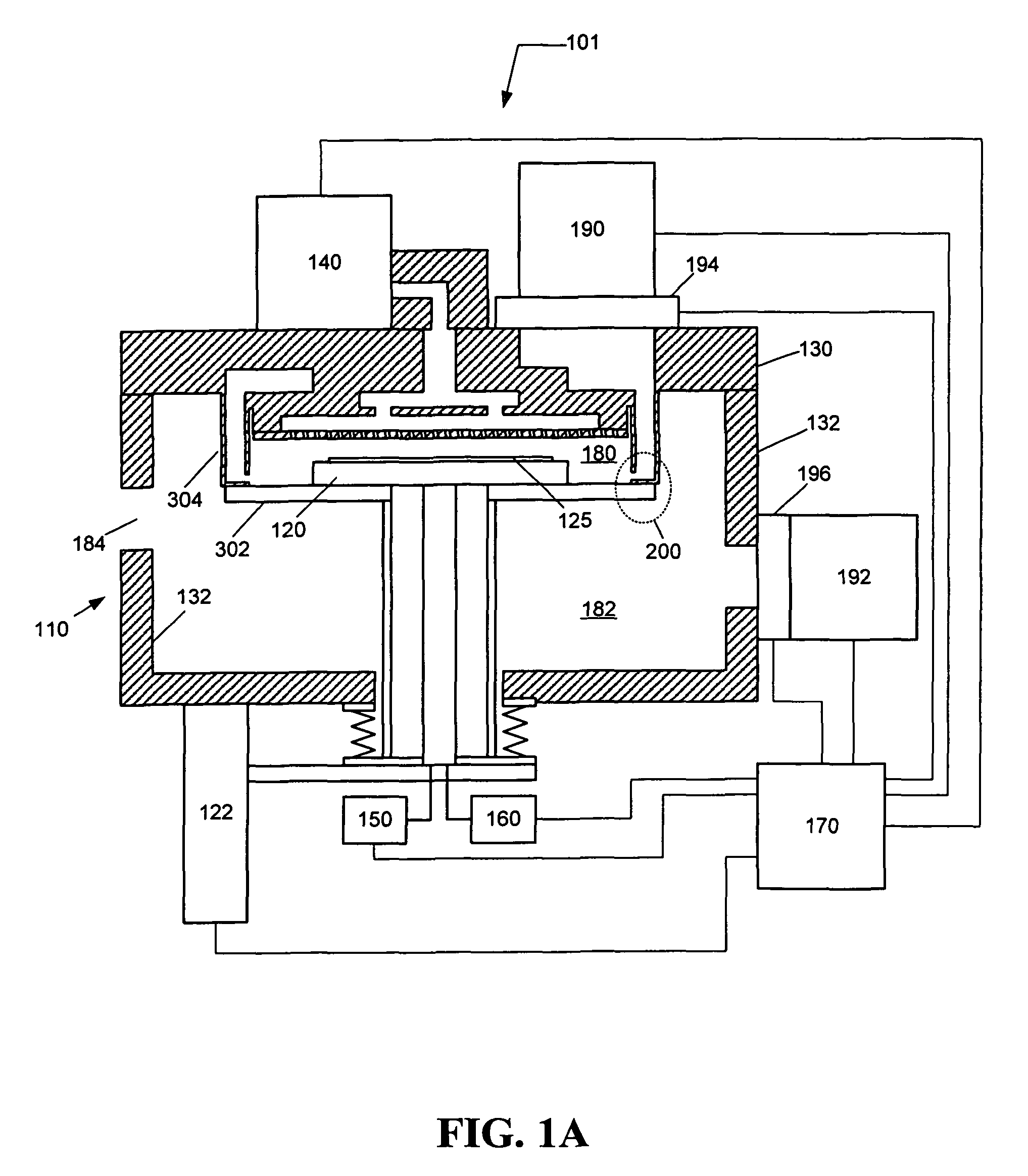

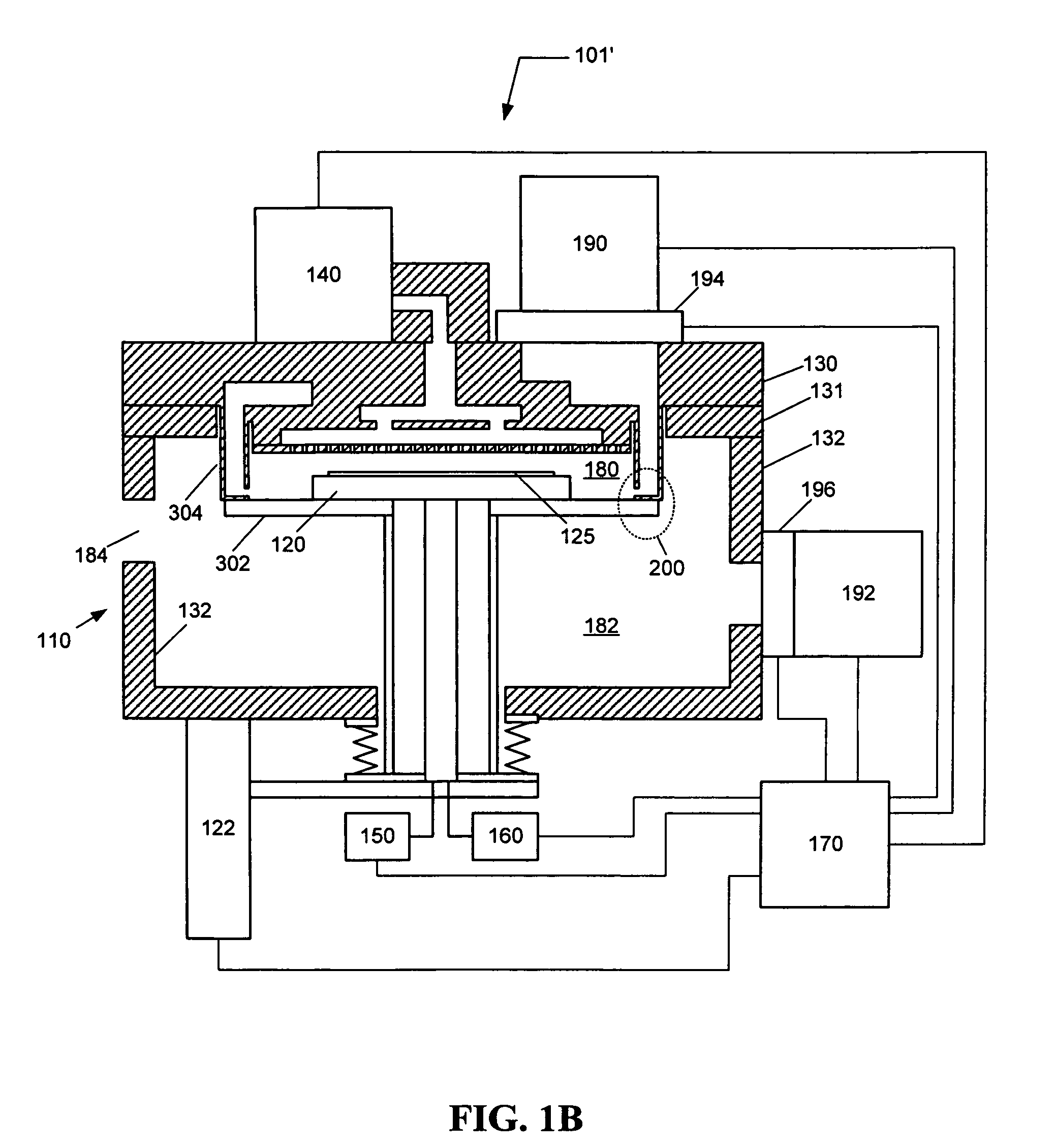

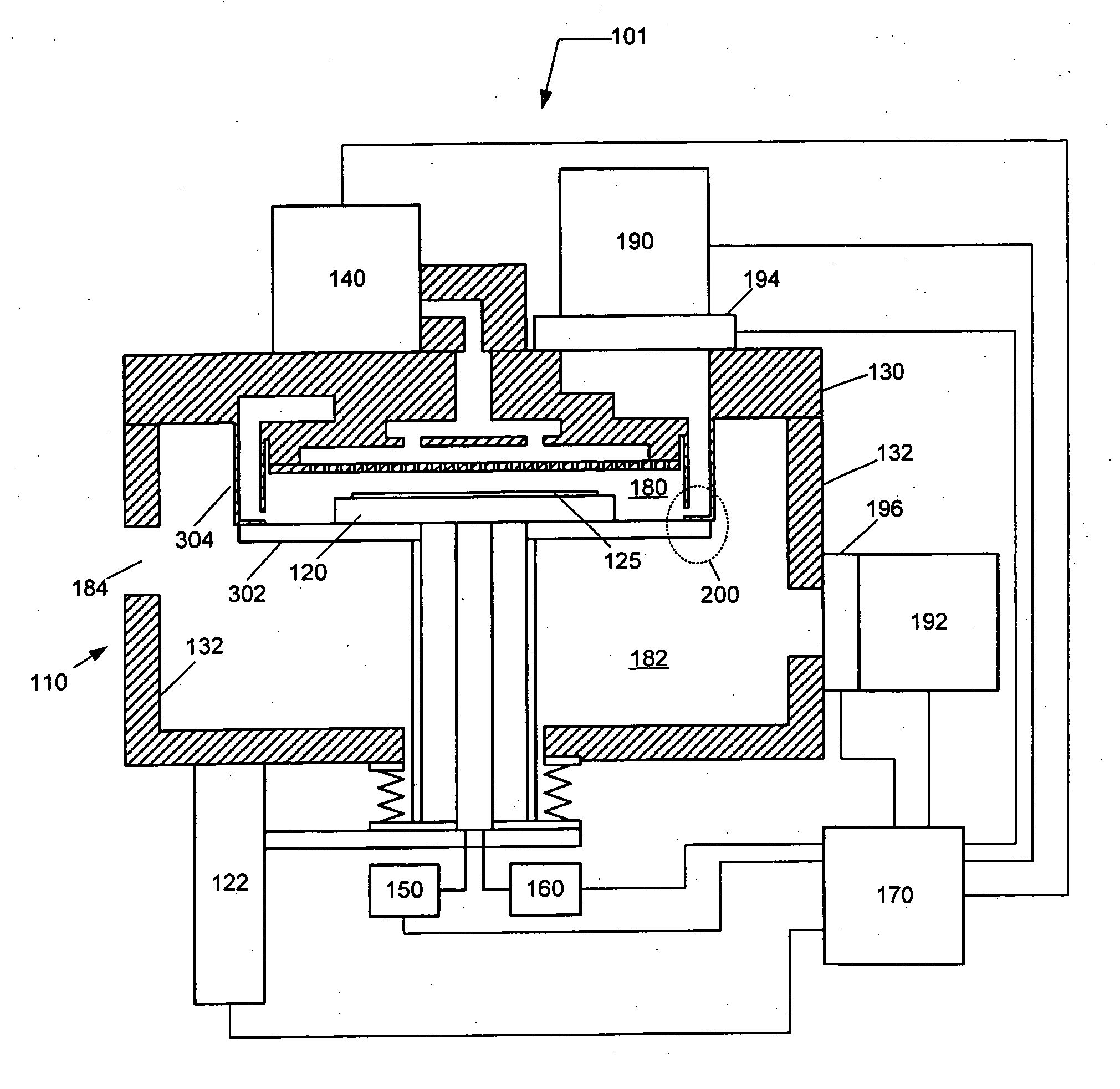

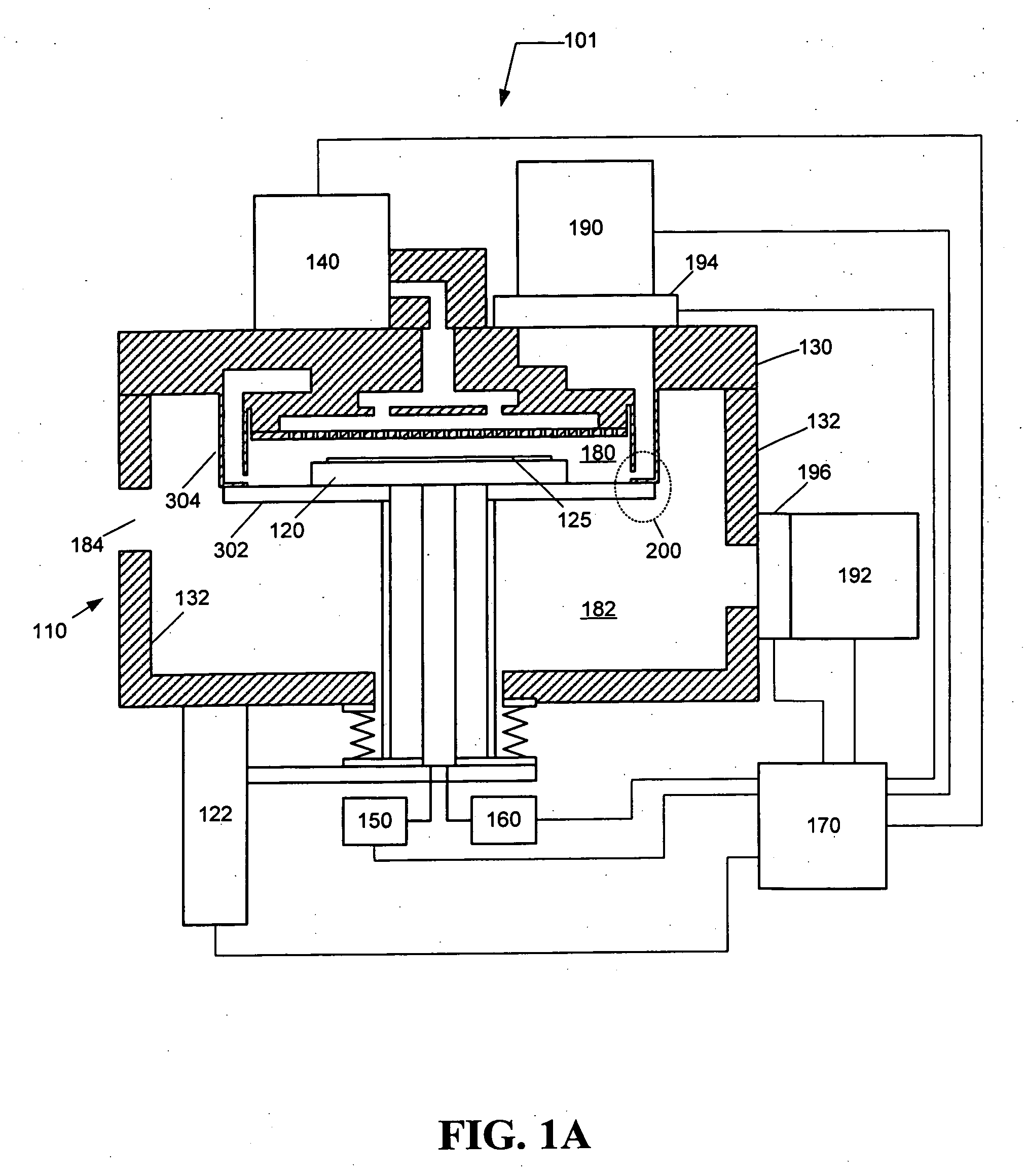

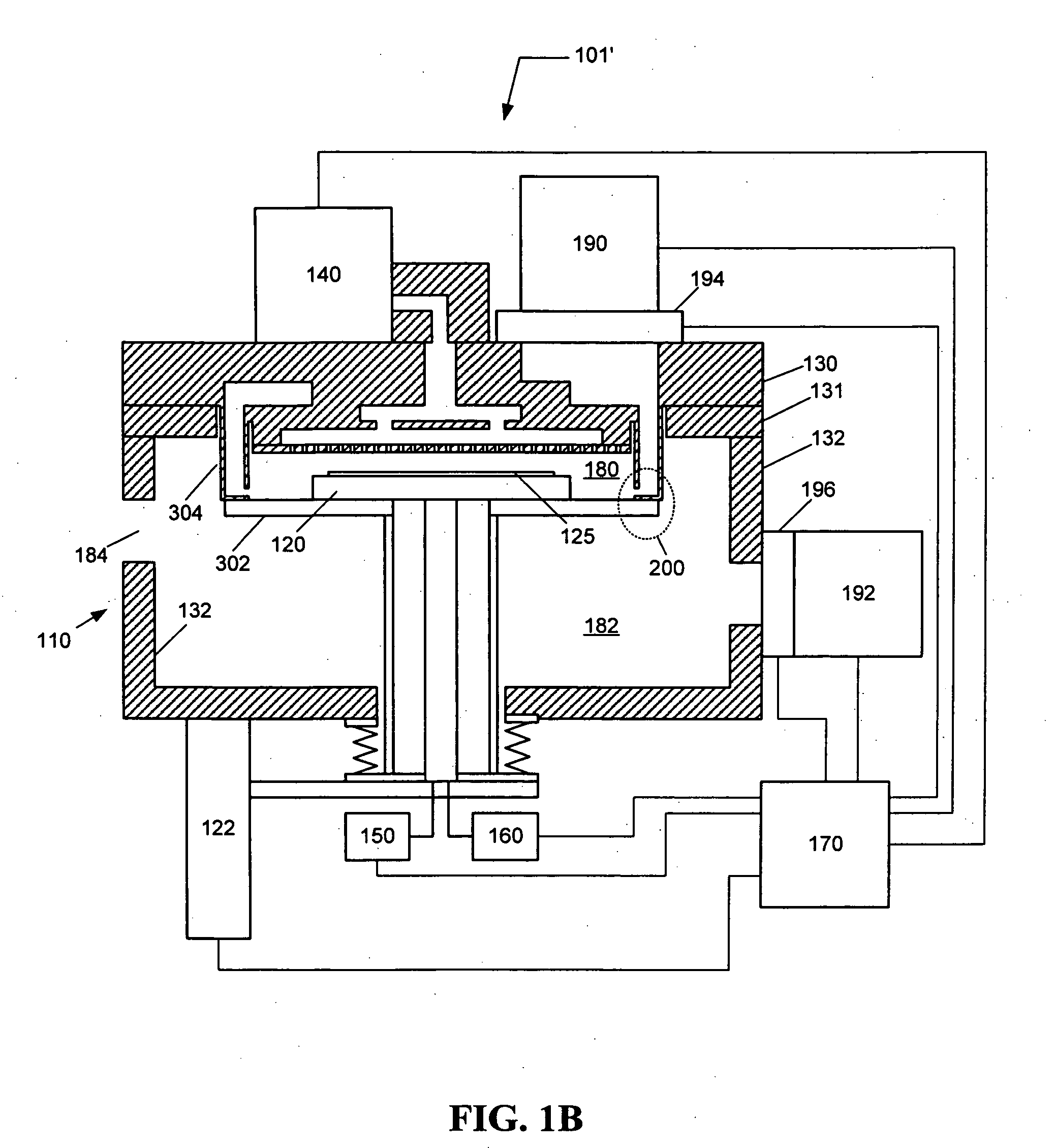

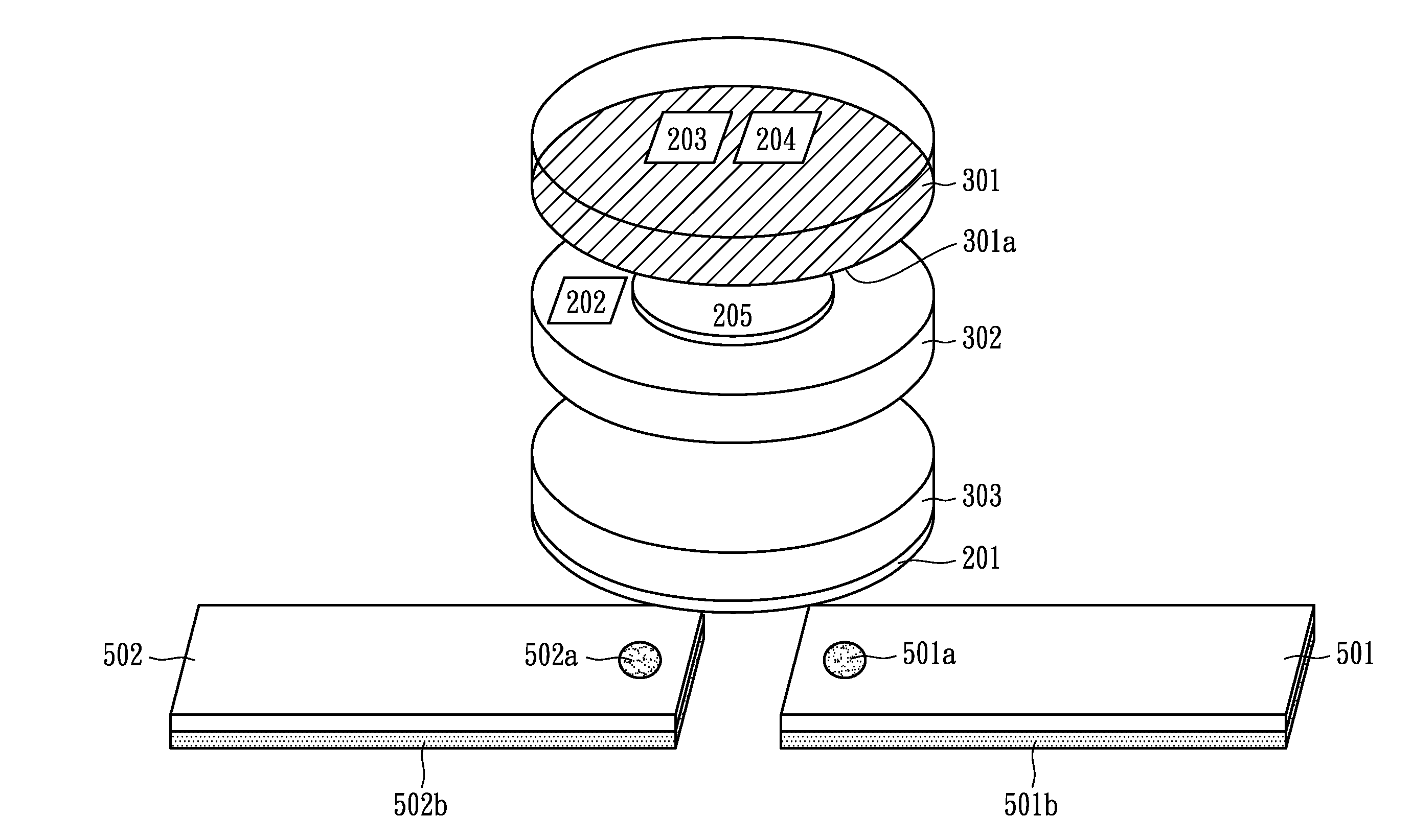

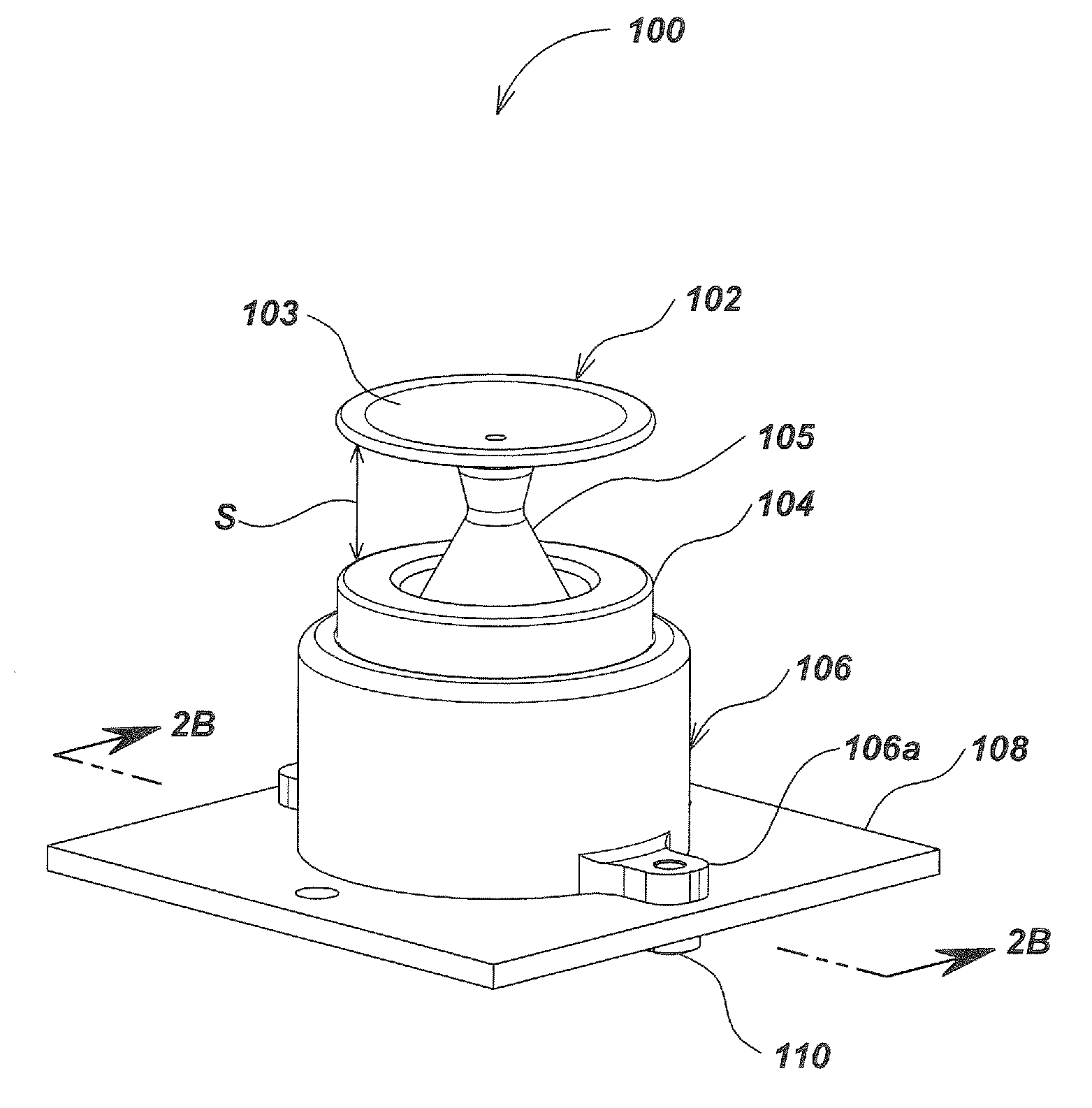

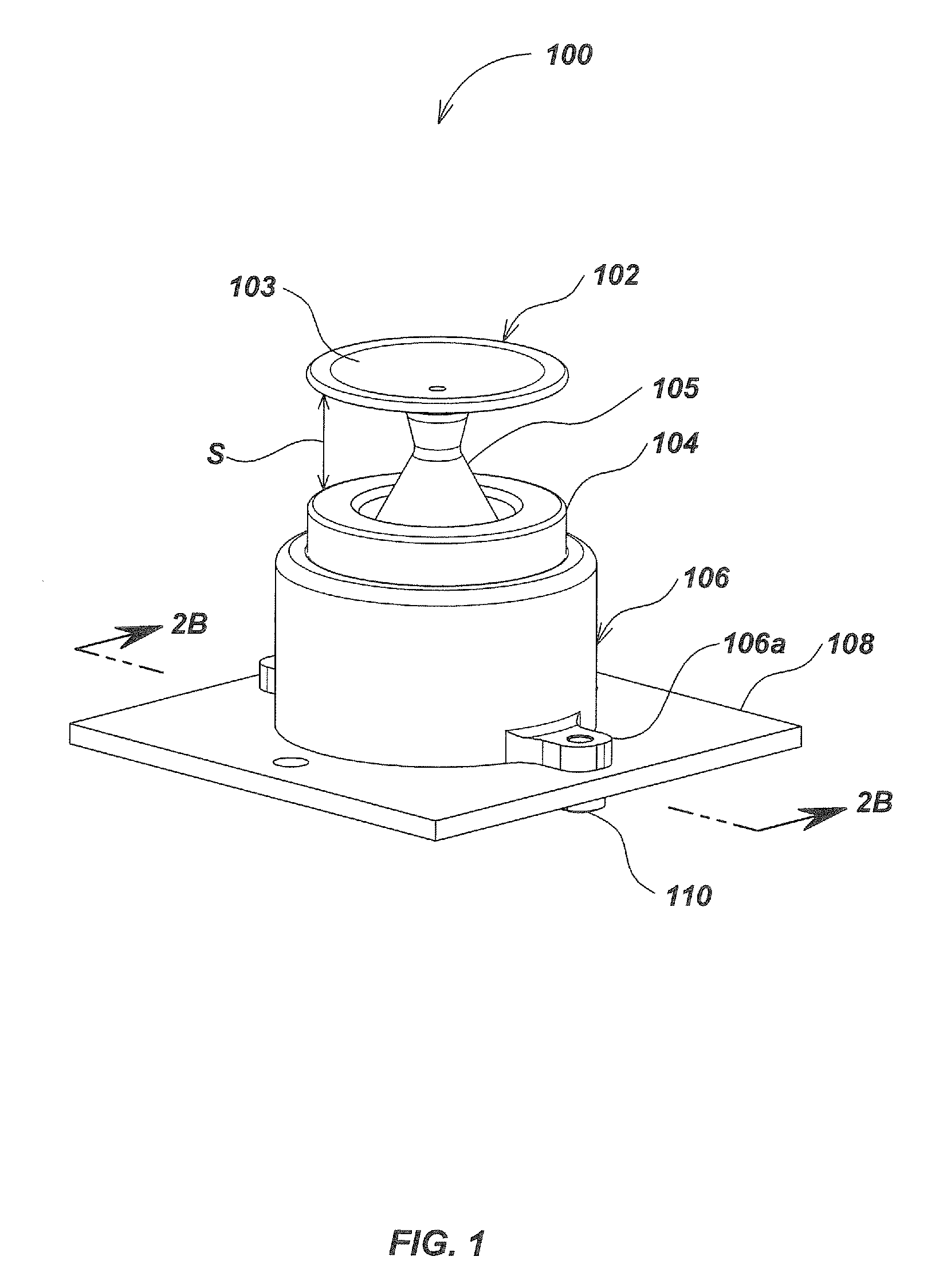

Method and system for sealing a first assembly to a second assembly of a processing system

ActiveUS8454749B2Reduce pollutionAnti-theft cycle devicesElectric discharge tubesEngineeringMechanical engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

Method and system for sealing a first assembly to a second assembly of a processing system

ActiveUS20070157683A1Reduce pollutionAnti-theft cycle devicesElectric discharge tubesGas phaseMechanical engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

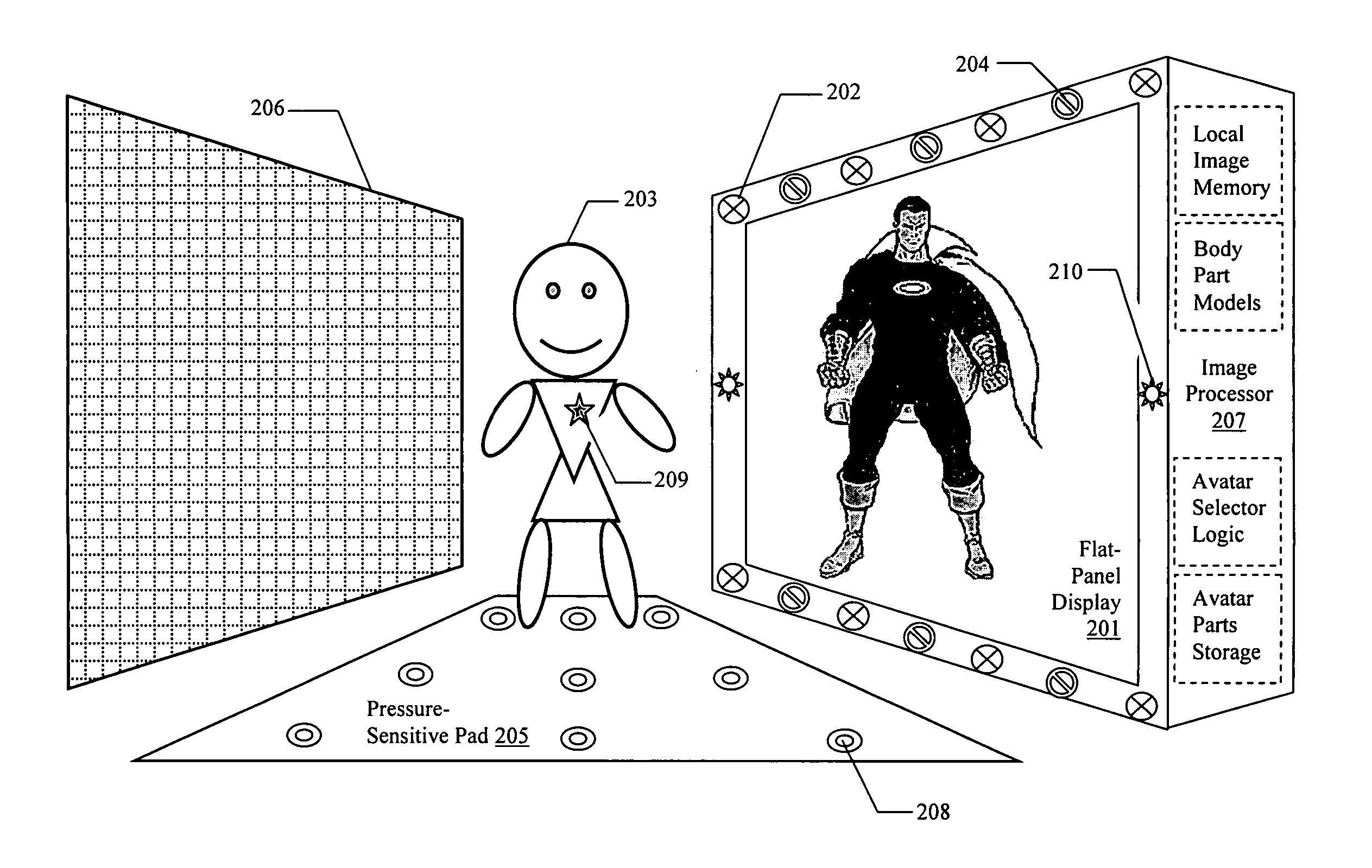

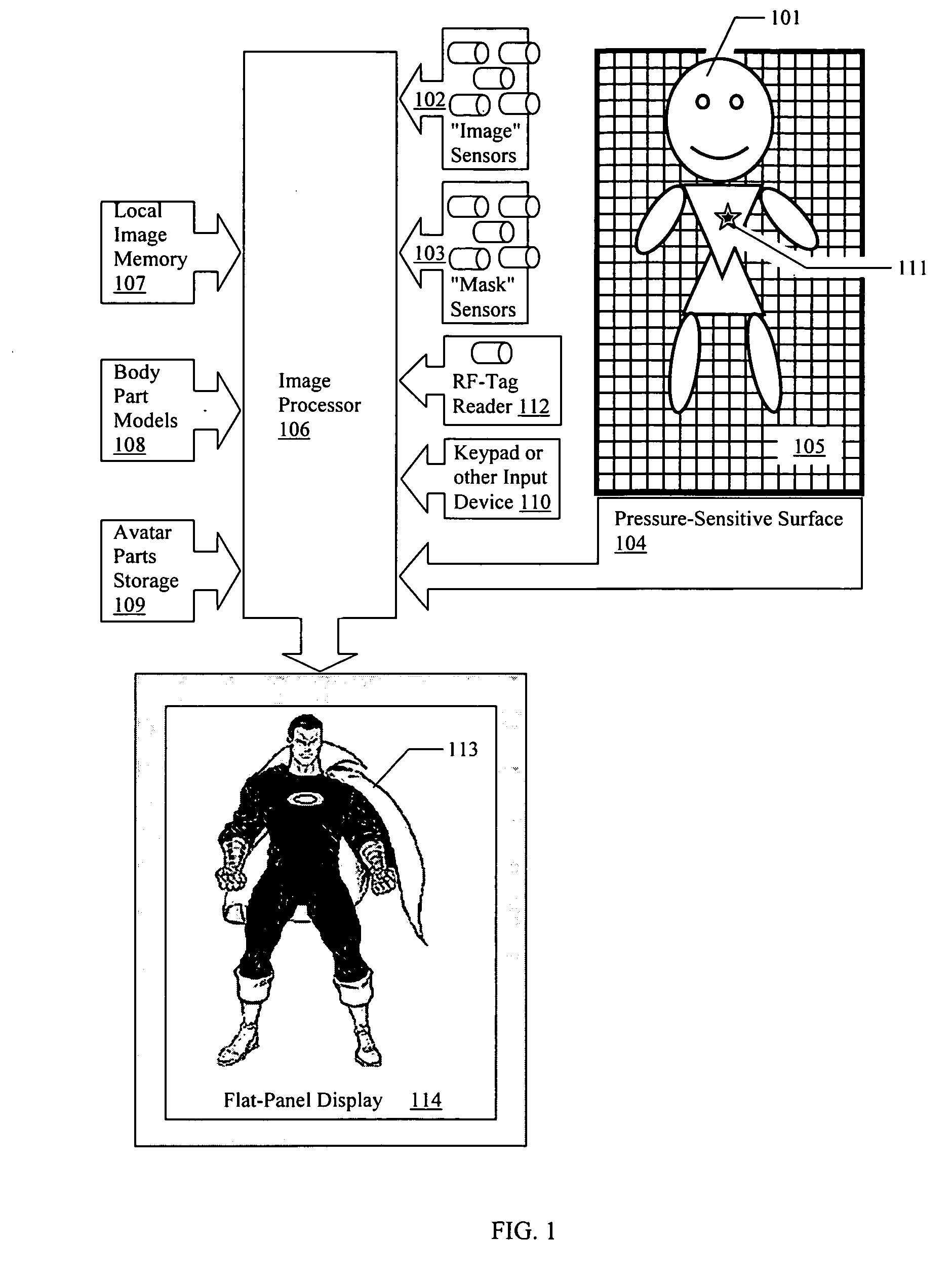

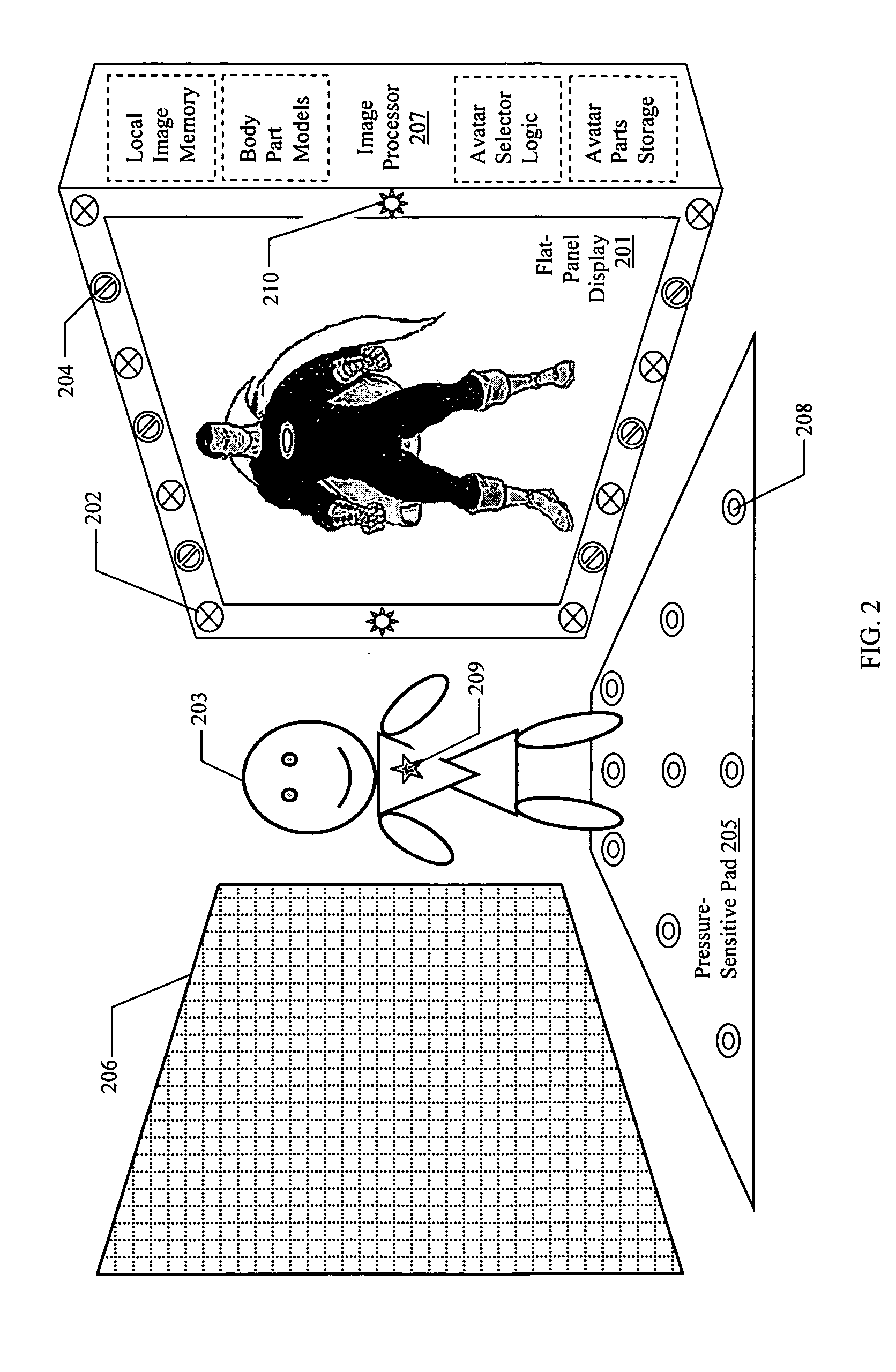

Computer-"reflected" (avatar) mirror

InactiveUS20050206610A1Avoid physical contactFaithfully reproducedLimiting/preventing/returning movement of partsCathode-ray tube indicatorsFlat panel displayComputer science

The mirror of the present invention provides a new device and method for generating a “reflection” of an object that may be processed before display. The invention comprises an image-capture system, an image-processor and a flat-panel display. By this combination, the invention is capable of acquiring the image of a subject in front of the display by passive means not requiring transmitters or reflectors on the subject (such means including optical, ultra-sonic, and electromagnetic sensors), processing the image in programmable ways to create an altered image of the subject and displaying the new image, which appears to mimic the movement and orientation of the original subject.

Owner:CORDELLI GARY GERARD

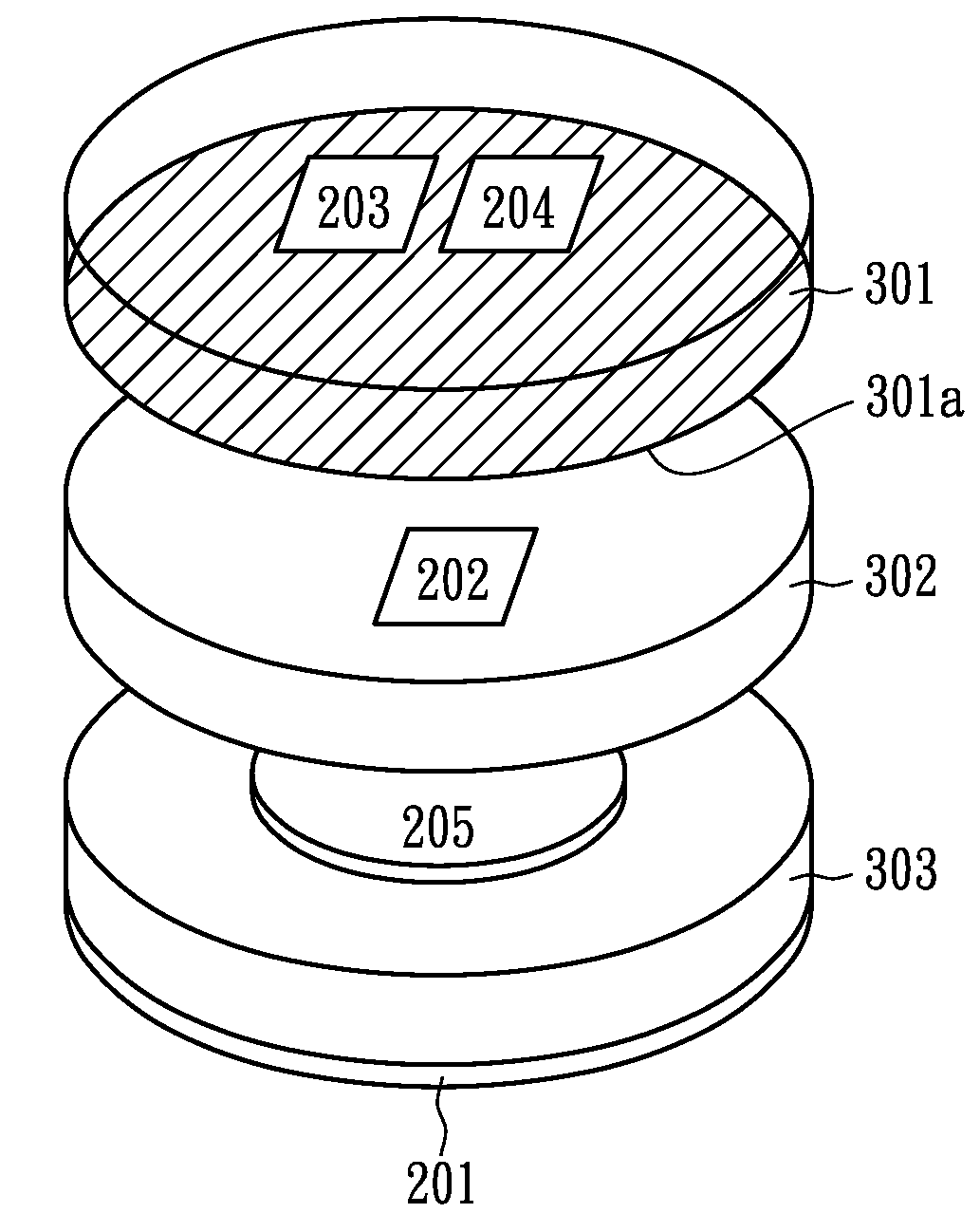

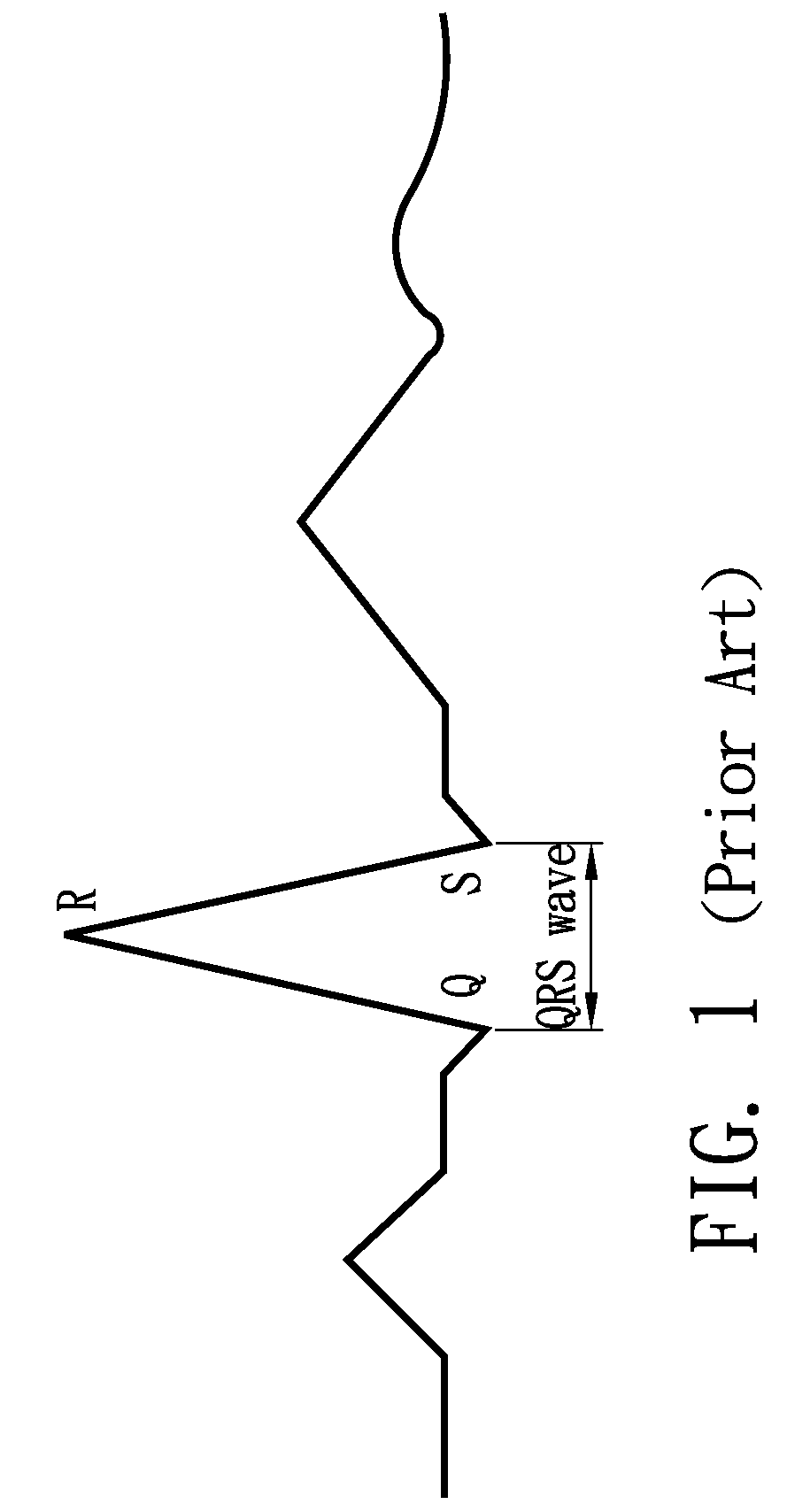

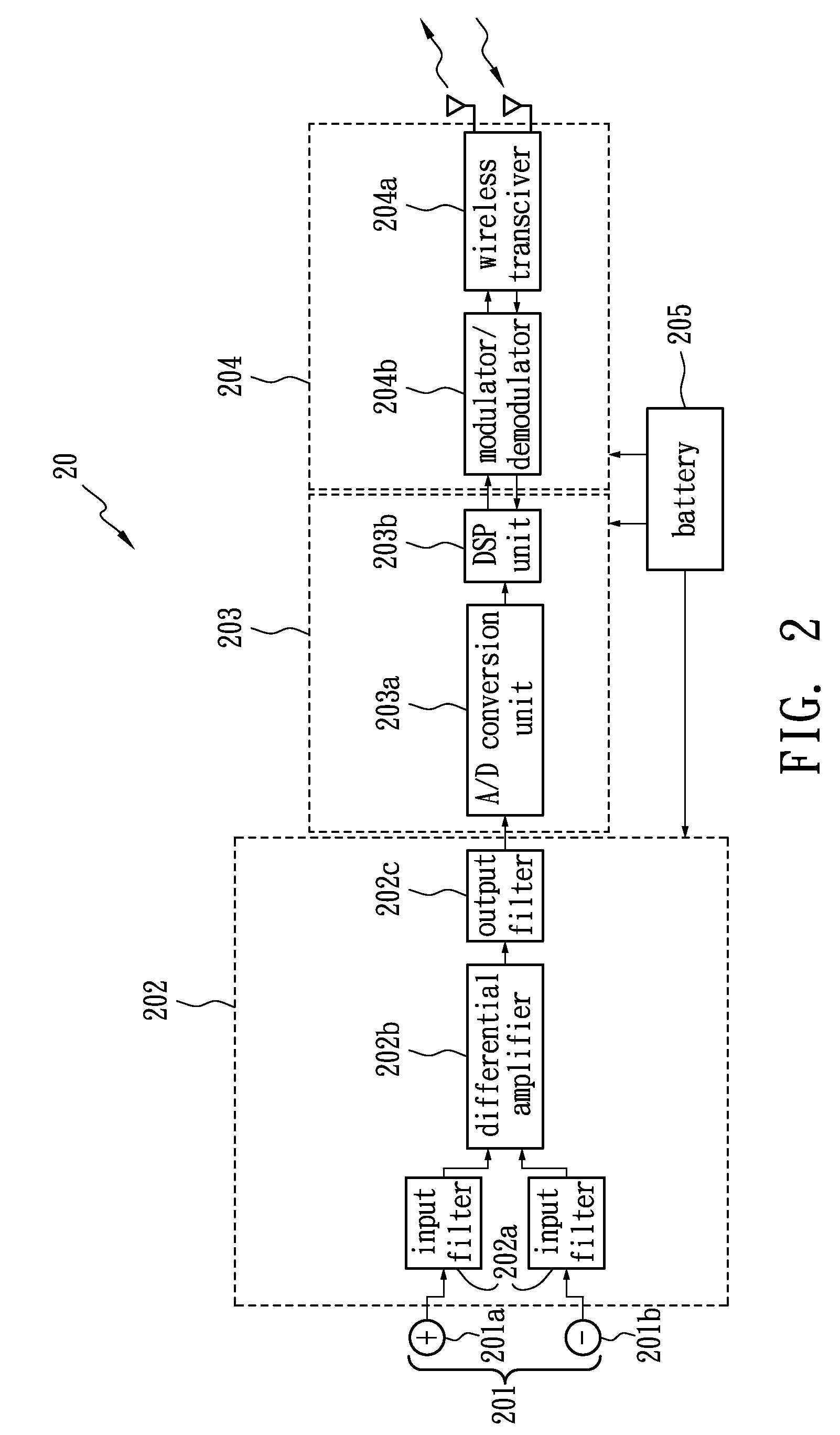

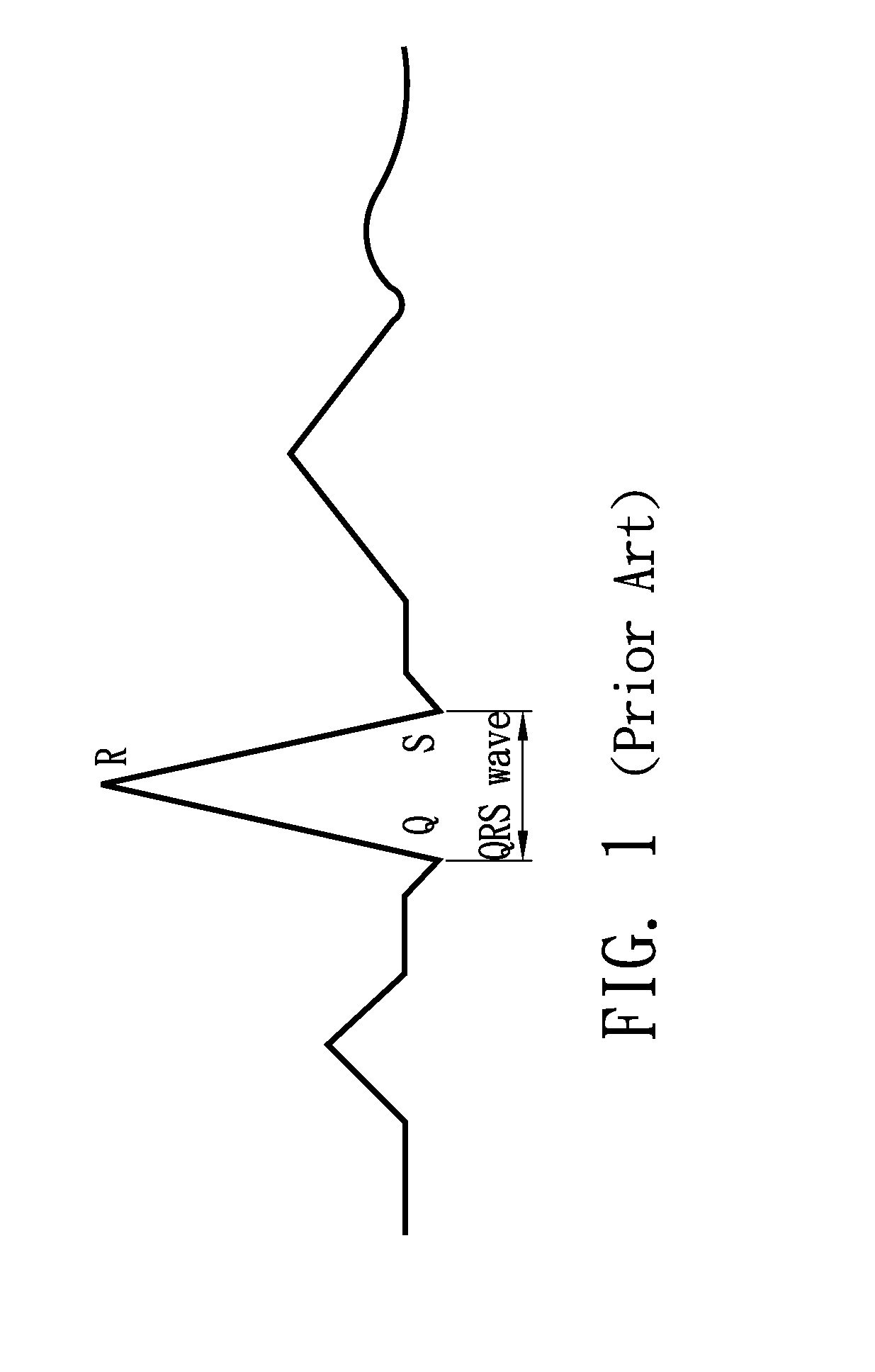

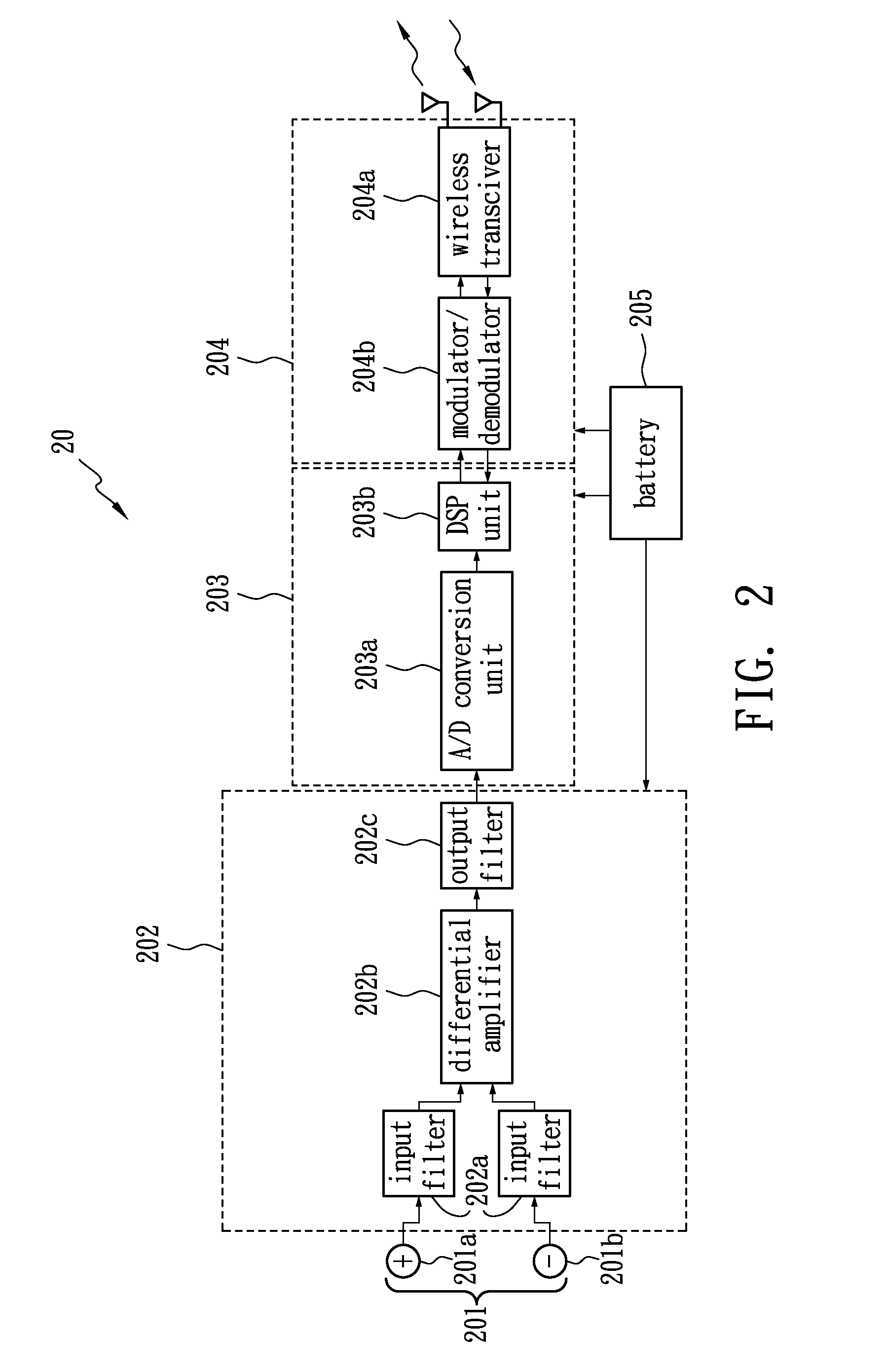

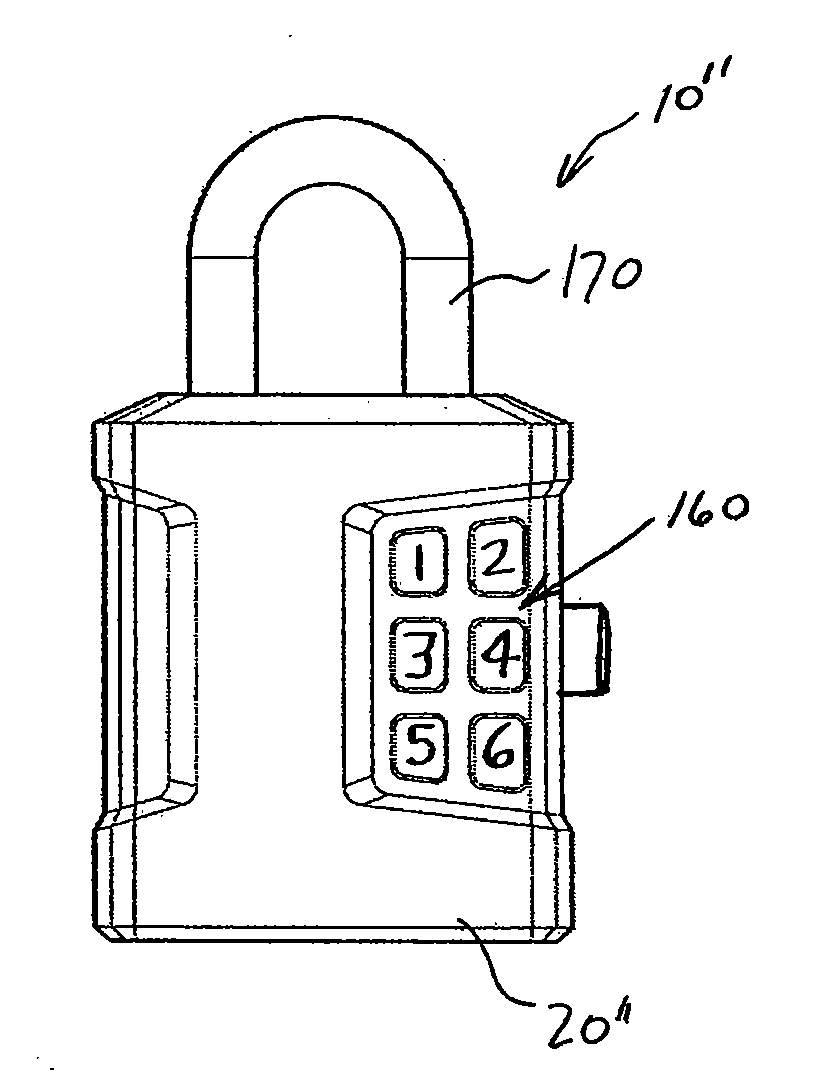

Miniature wireless apparatus for collecting physiological signals

InactiveUS7672714B2Simple materialLow costControlling membersElectrocardiographyMicrocontrollerData compression

Owner:KUO TERRY B J +2

Content processing apparatus and content display apparatus based on location information

ActiveUS7461528B2Effective distributionInstruments for road network navigationDigital data information retrievalPosition dependentGeolocation

Owner:PANASONIC CORP

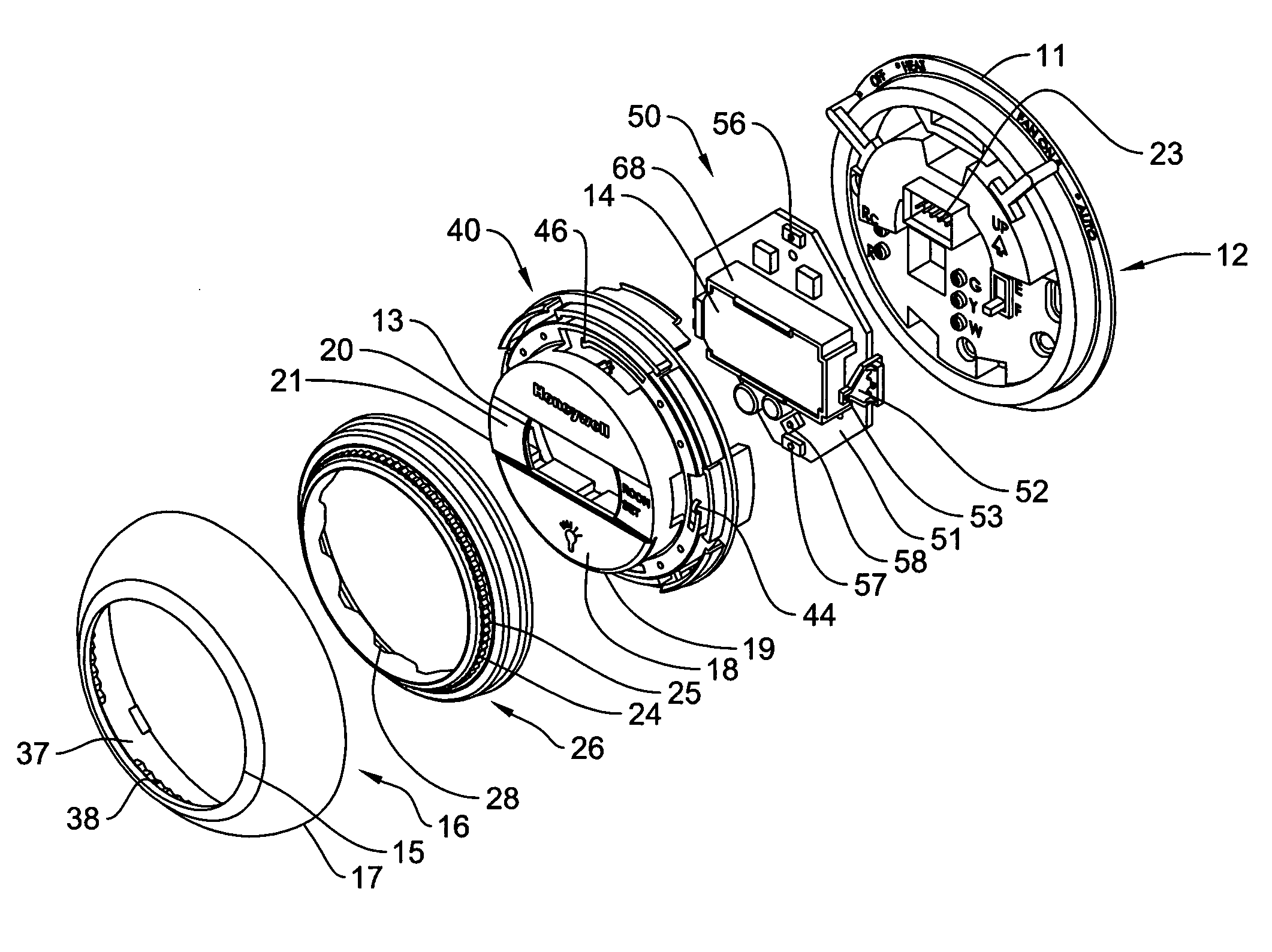

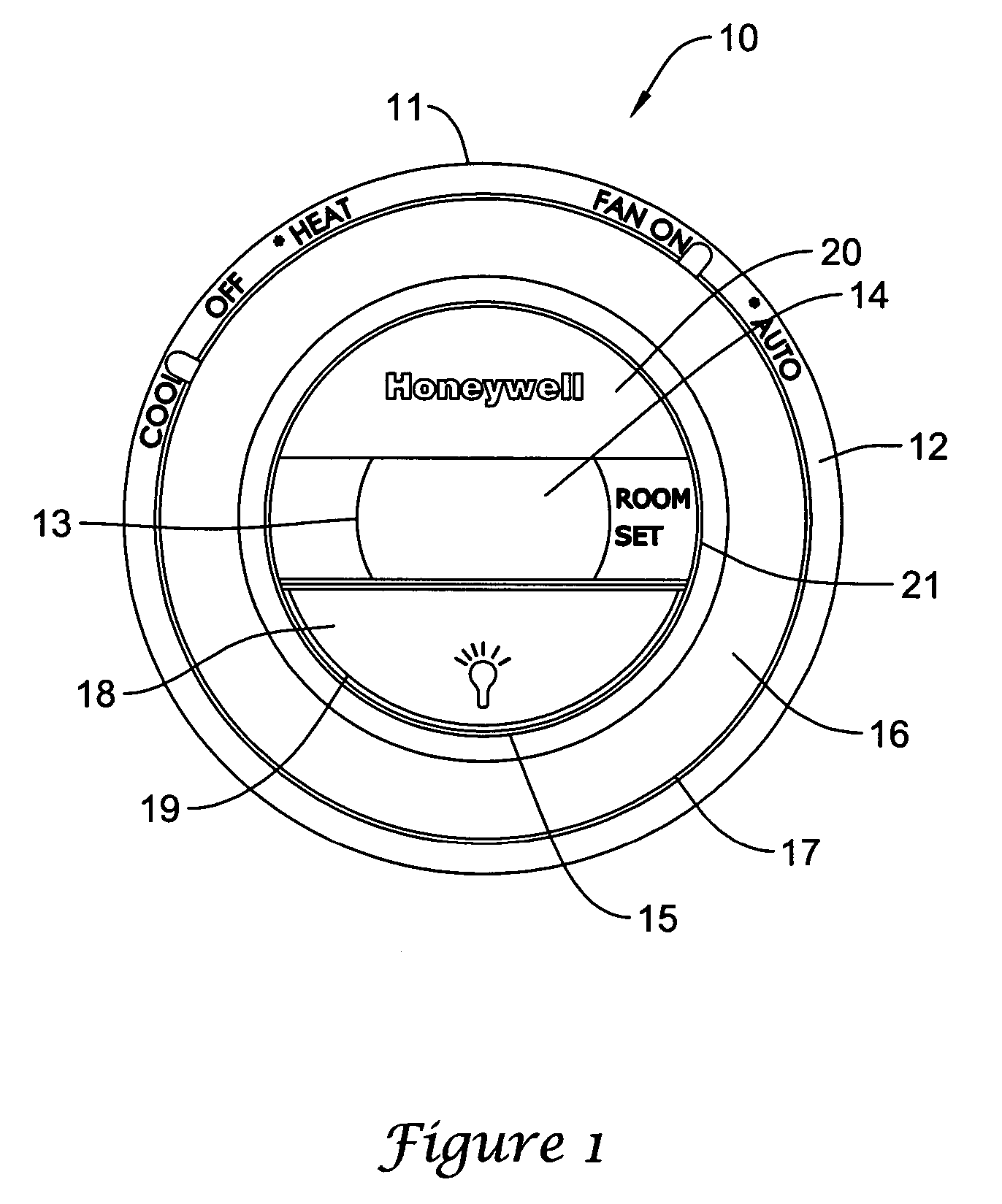

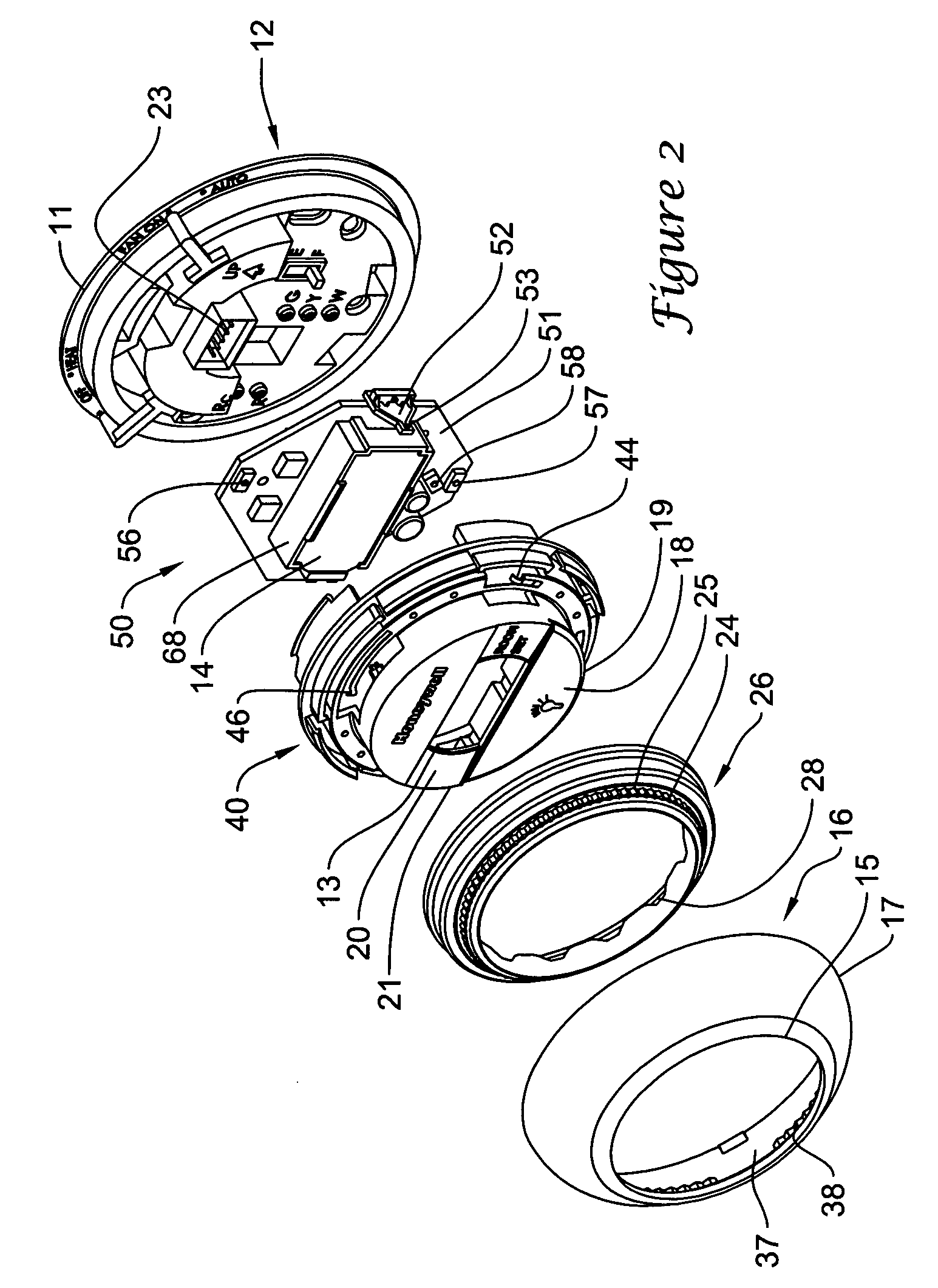

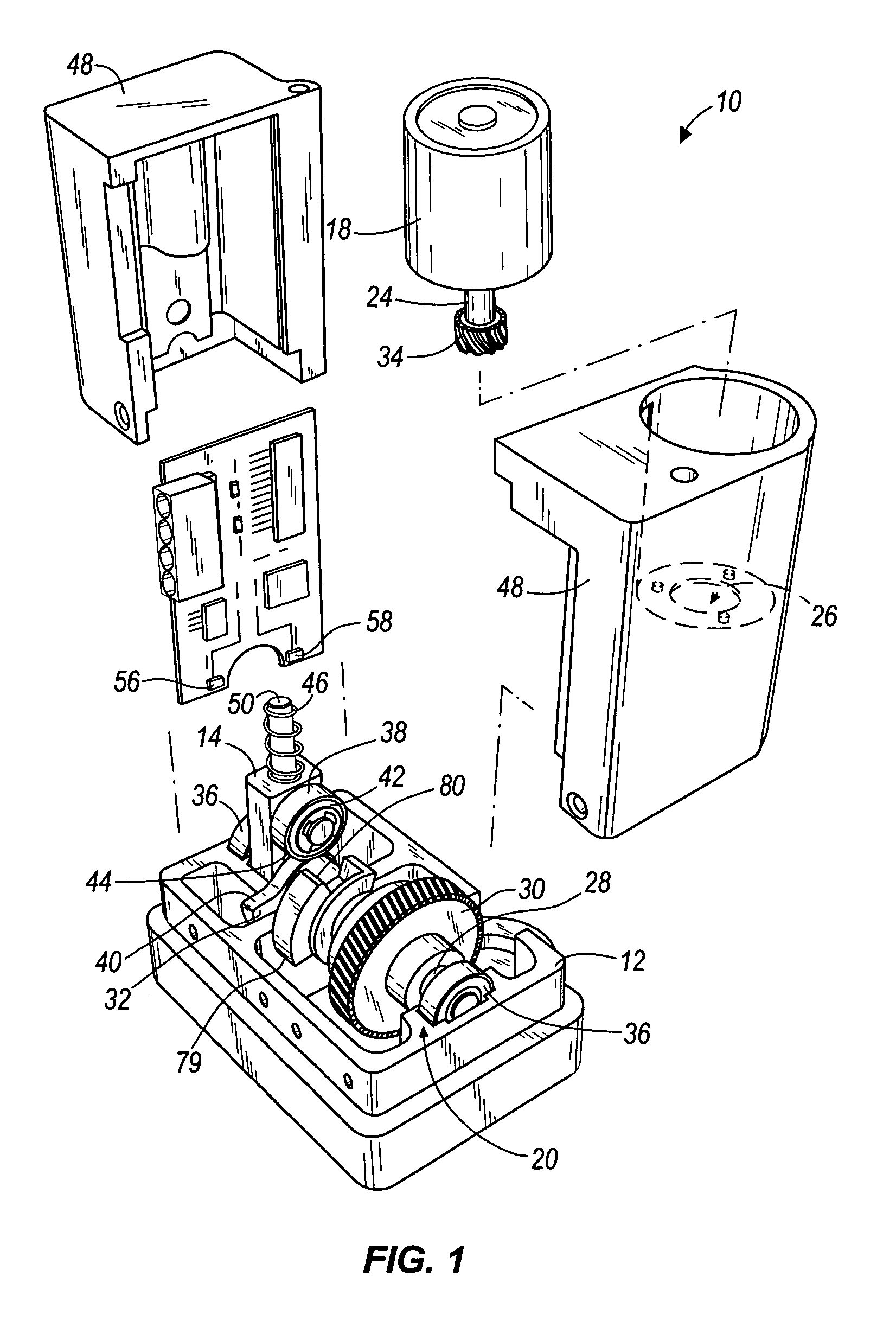

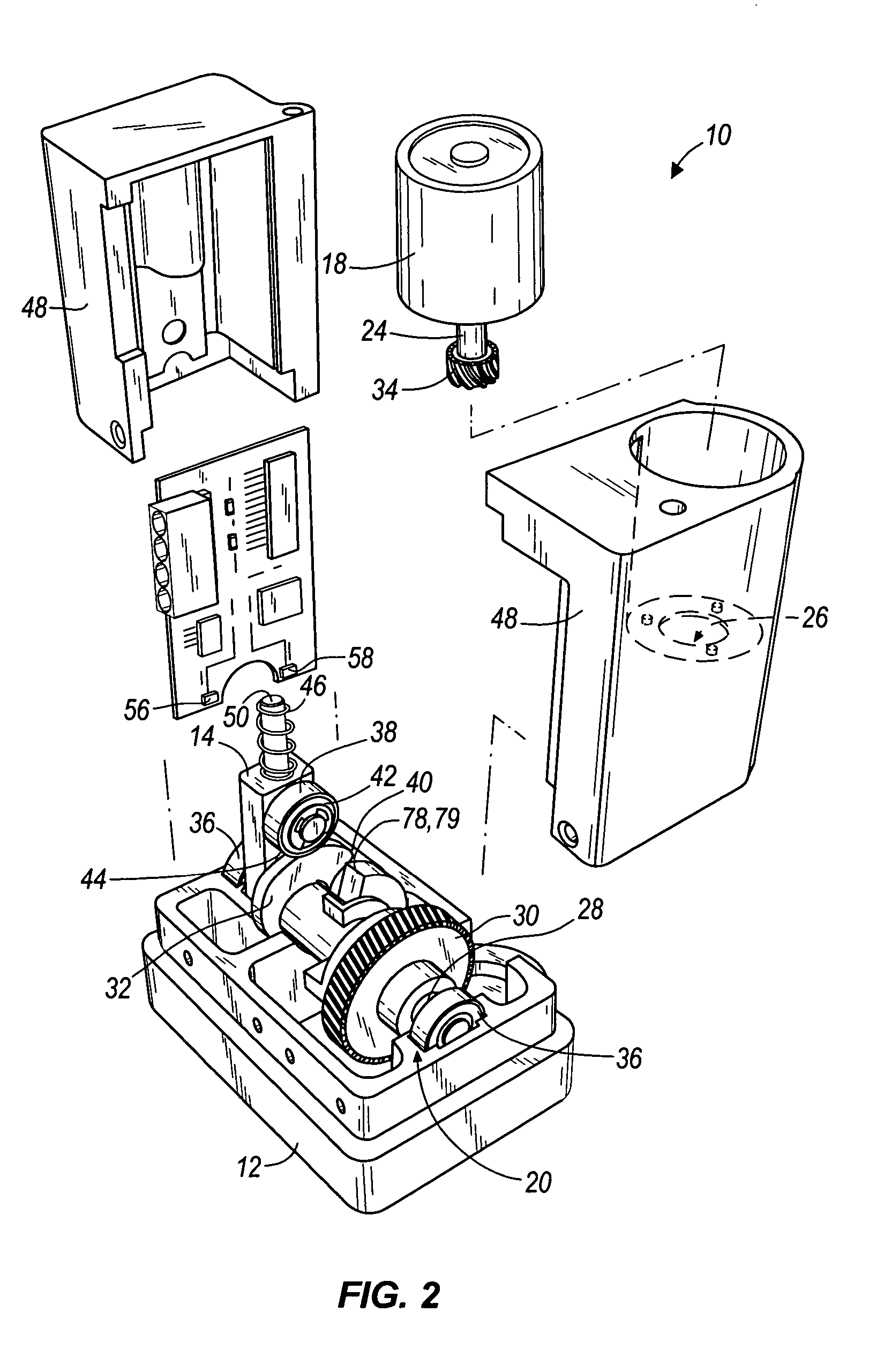

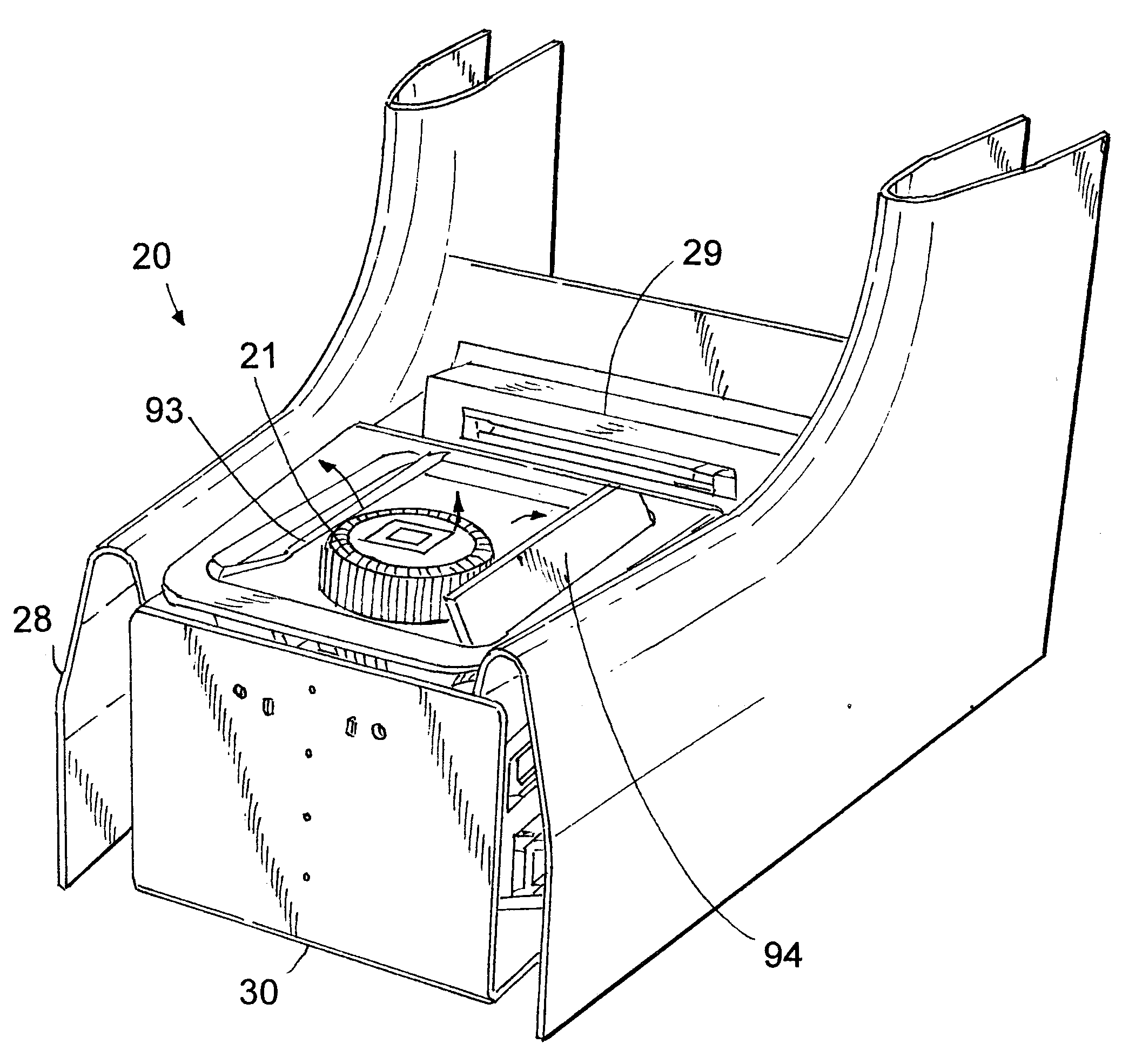

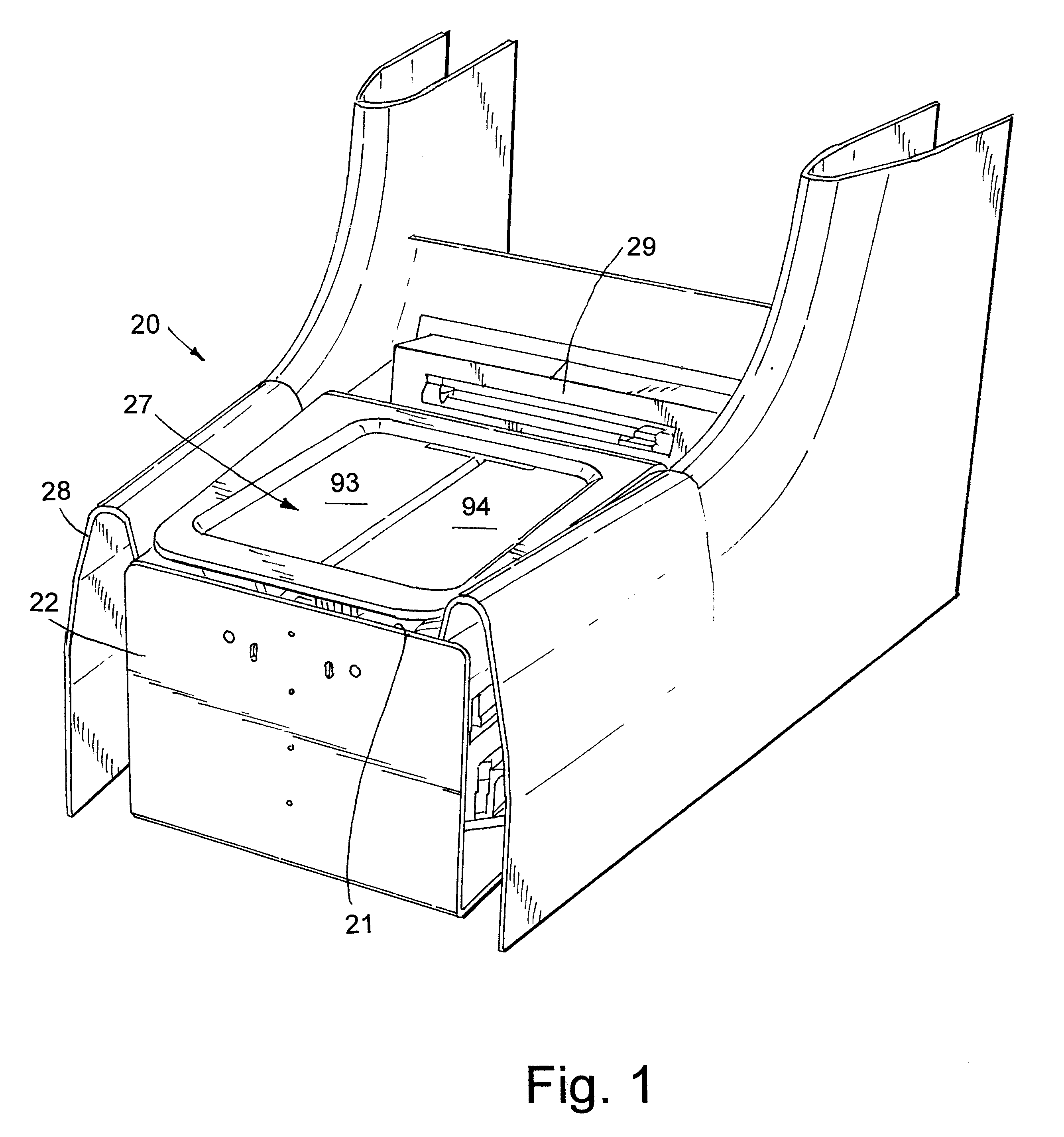

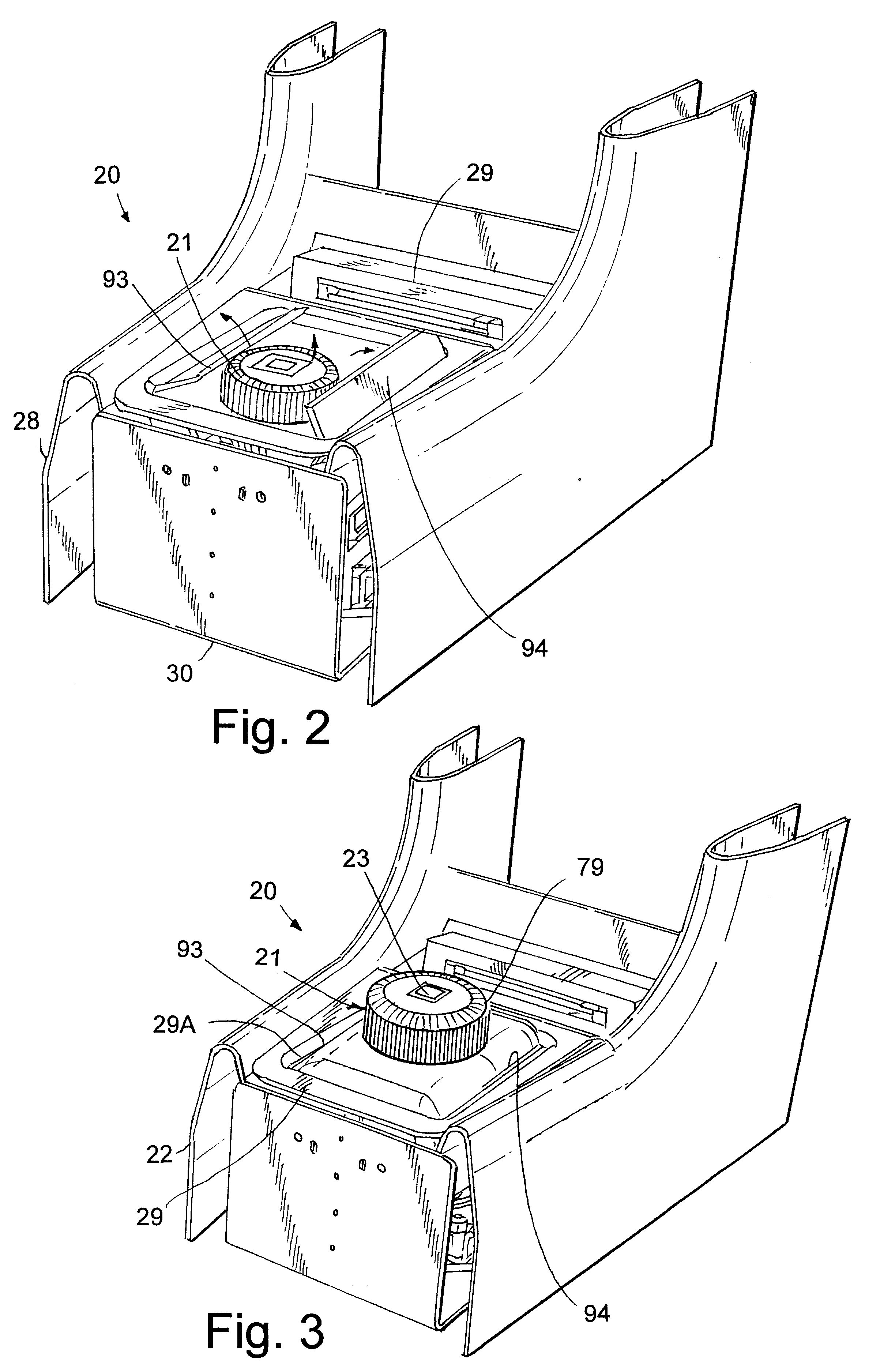

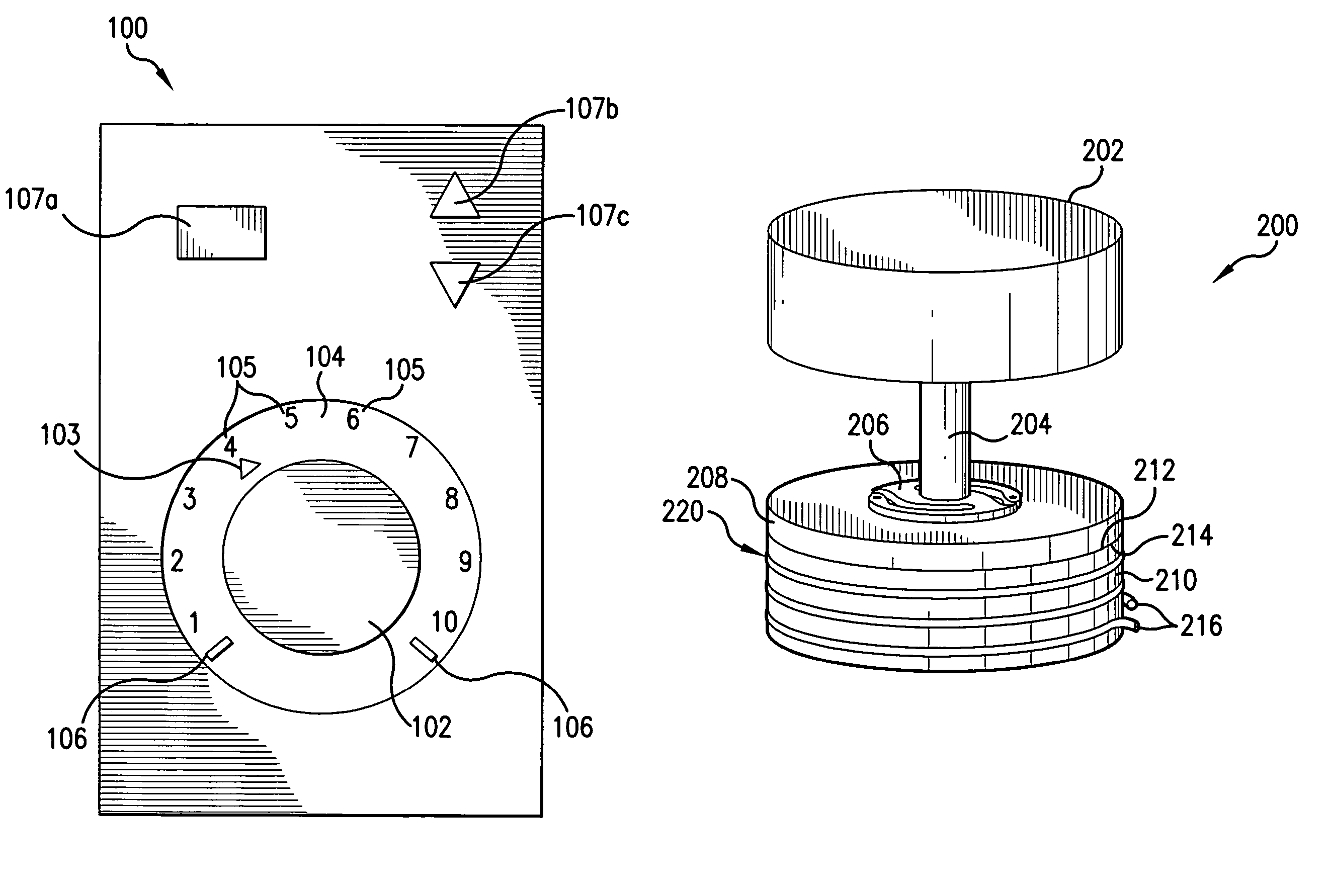

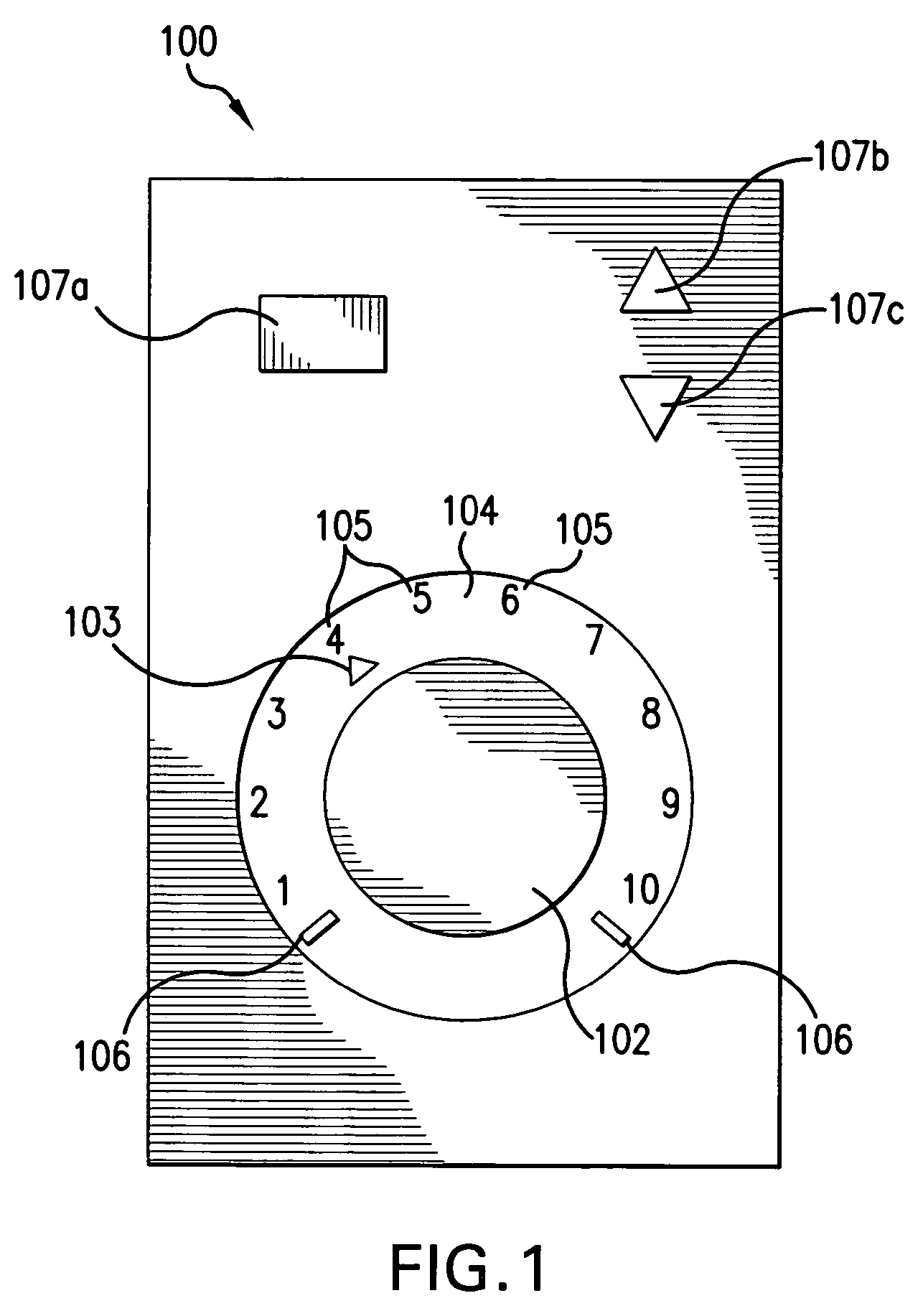

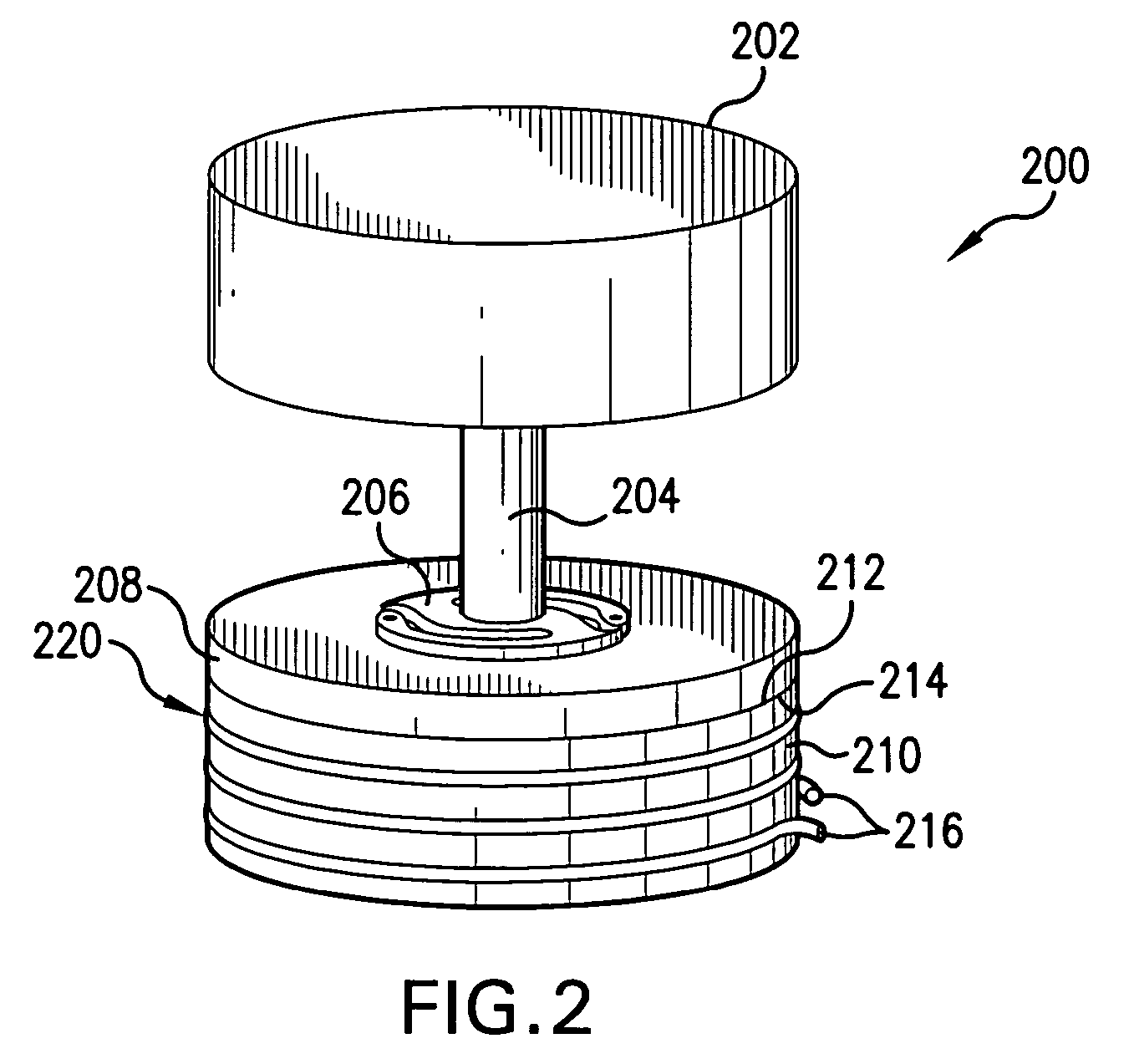

HVAC controller

ActiveUS7140551B2Space heating and ventilation safety systemsLighting and heating apparatusDetentControl theory

An HVAC controller with a simplified and / or lower cost user interface. In one illustrative embodiment, the HVAC controller includes two switches, a movable member, and a plurality of detents. The detents are configured to cause the two switches to be switched in a sequence when the movable member is moved. In some cases, a controller is coupled to the two switches, and may change an HVAC control parameter based on the switch sequence.

Owner:ADEMCO INC

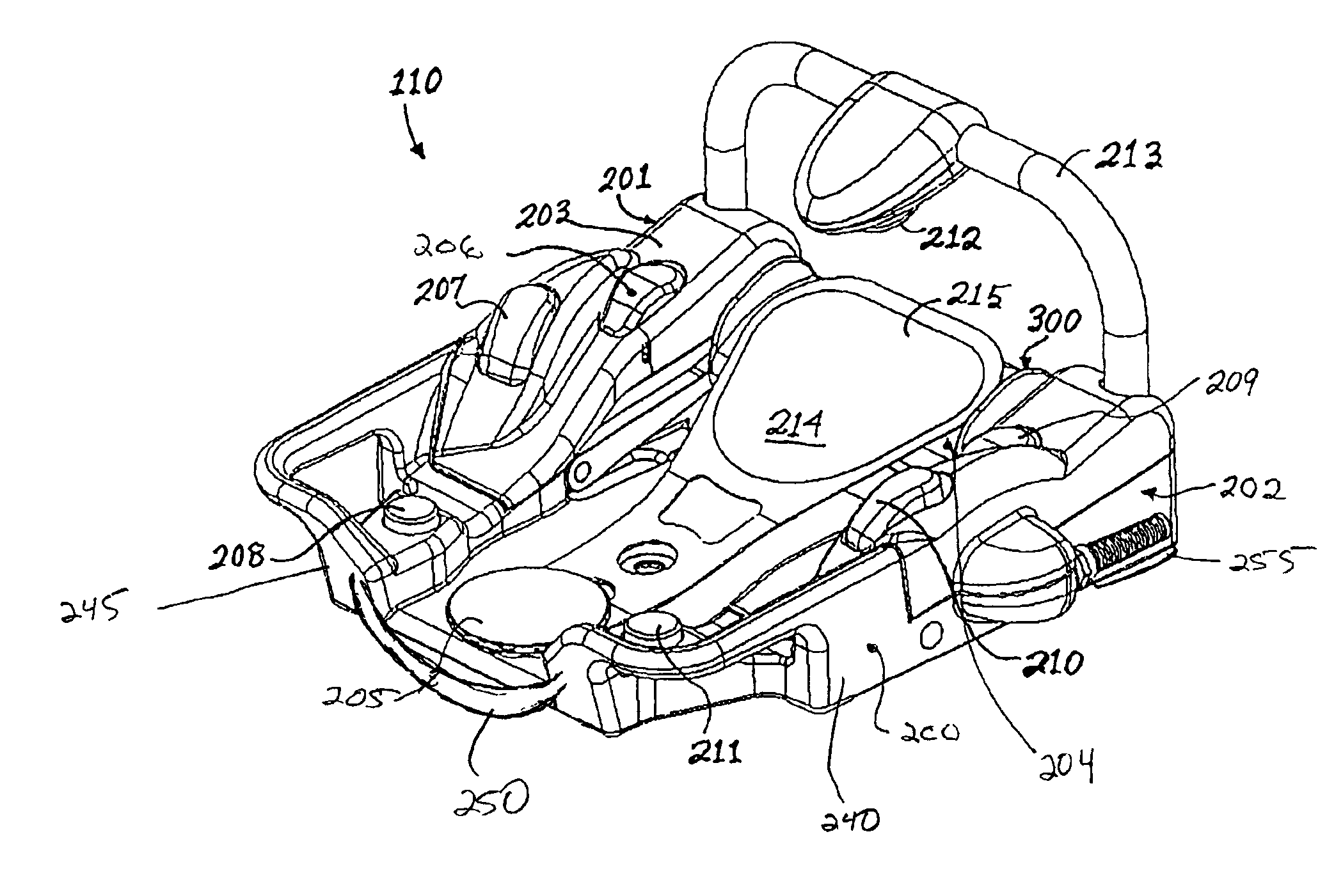

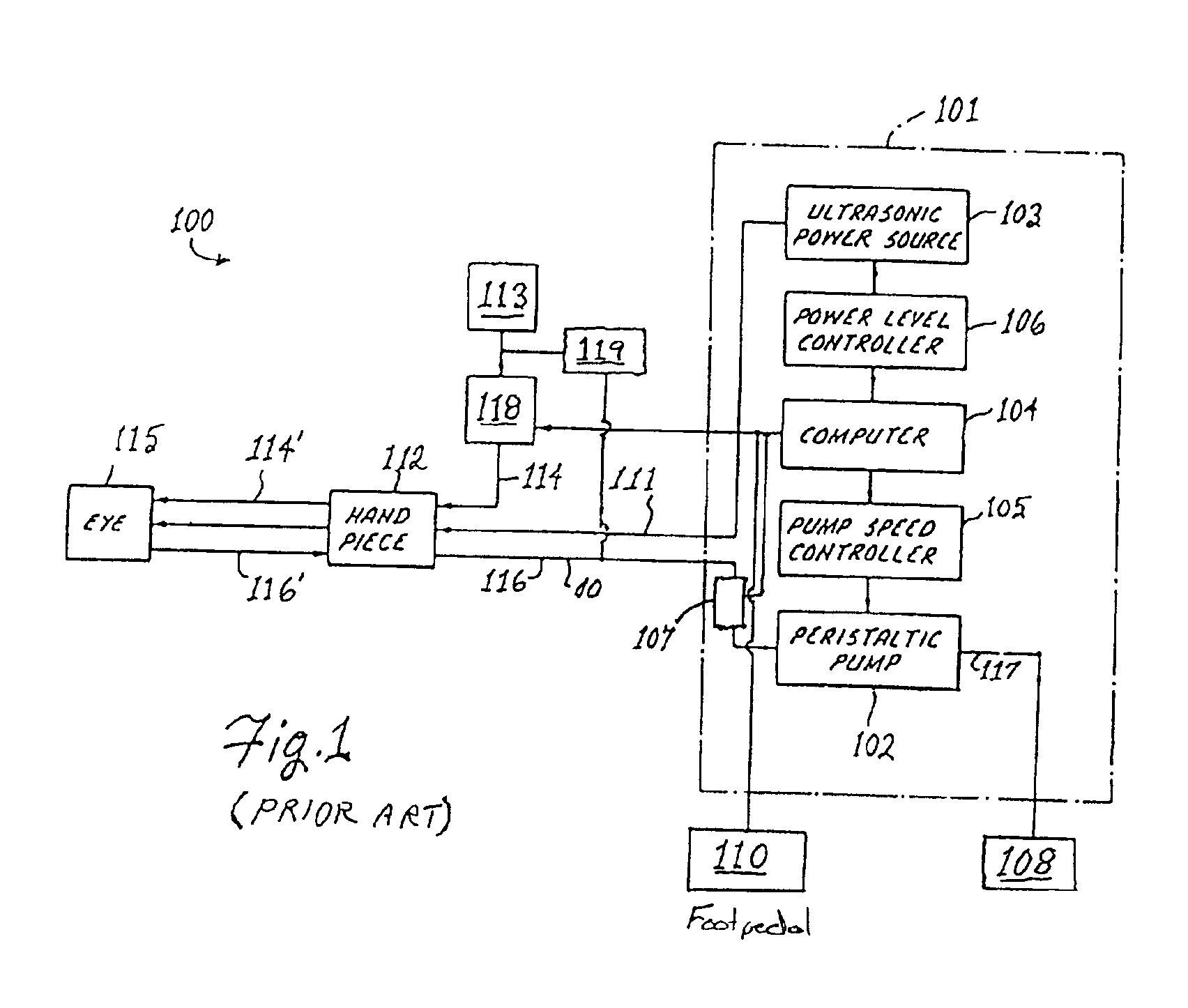

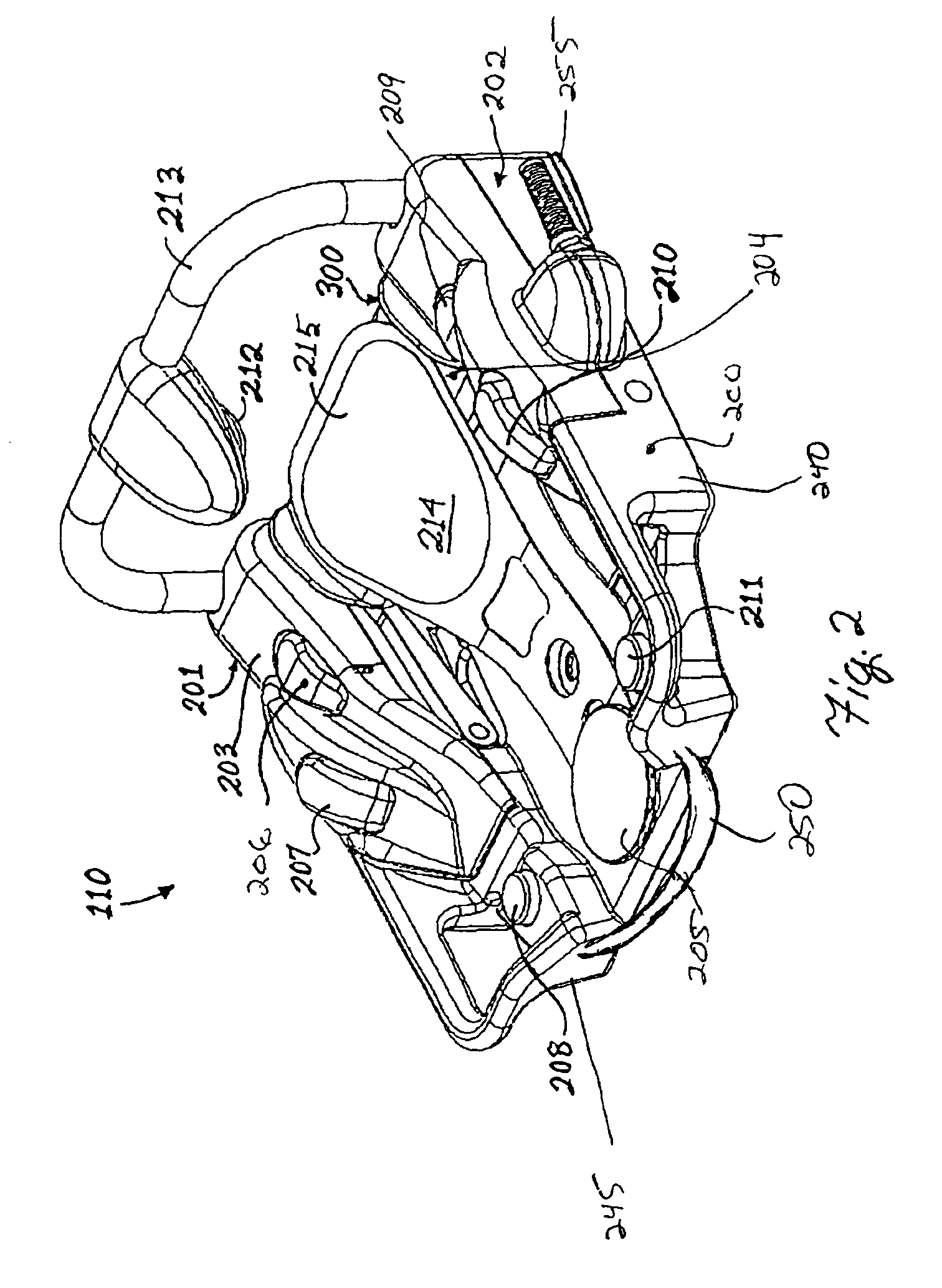

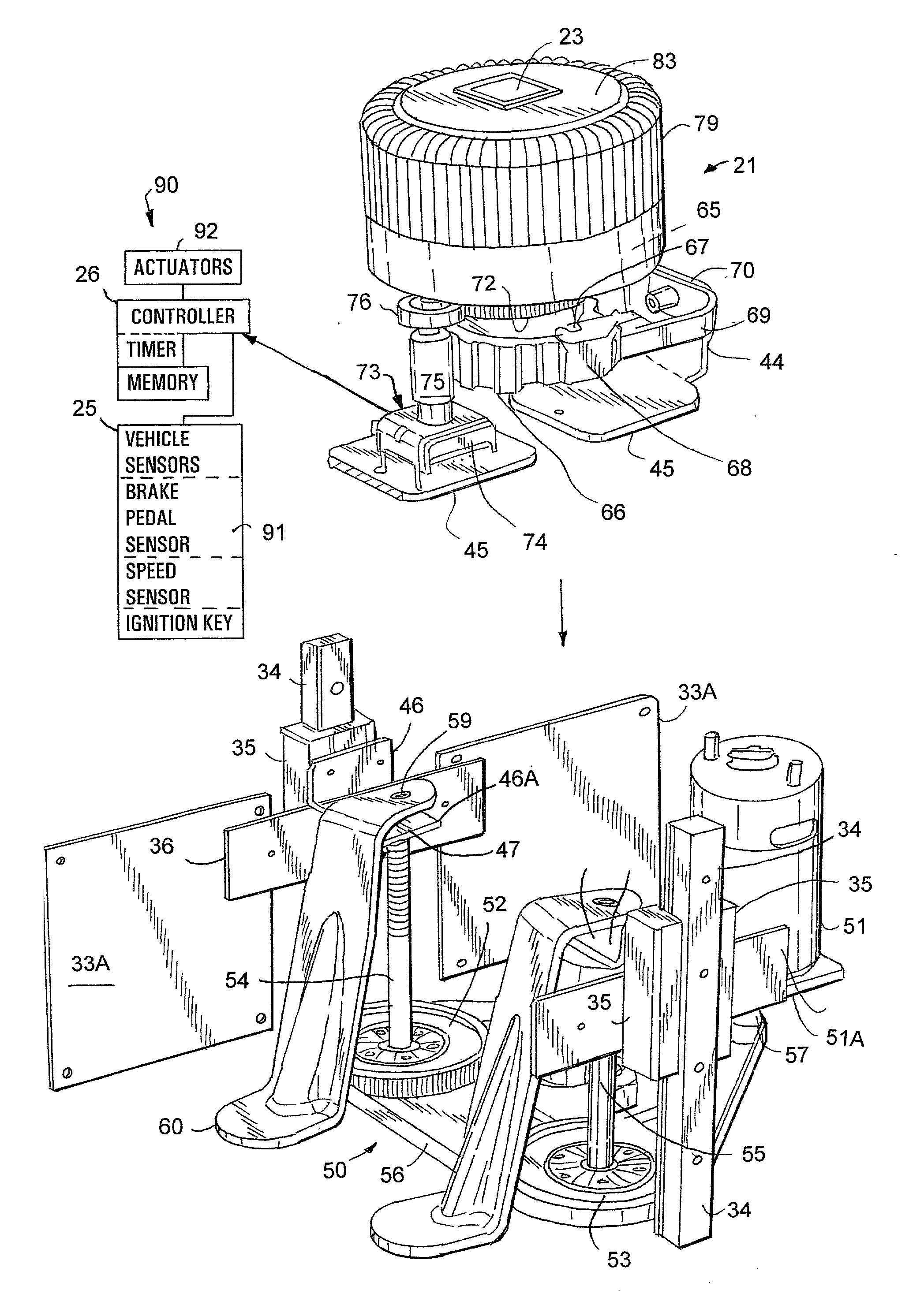

Foot switch pedal controller for a surgical instrument

InactiveUS7012203B2Inhibition of activationControlling membersMechanical apparatusLinear controlEngineering

A foot operable controller for a surgical instrument having a main foot pedal assembly providing either proportional or linear control signals when moved laterally and in a vertical direction. Friction between an operator's foot and the foot pedal is minimized by a foot pad having a rotating heel plate. A neutral zone between left and right control positions of the foot pedal enables the operator to move his foot freely without changing control settings. Vertical displacement of the foot pedal is indicated by a plurality of mechanical detents during both upward and downward travel. Changing detent resistance alerts the operator to the vertical position of the foot pedal, indicating that further vertical displacement will change an instrument control signal corresponding to the new foot pedal position, thus providing sensory feedback to the operator indicating a change in the functional mode when the foot pedal is moved.

Owner:PHACOR +1

Miniature wireless apparatus for collecting physiological signals

InactiveUS20070167848A1Simple materialLow costControlling membersElectrocardiographyMicrocontrollerData compression

Owner:KUO TERRY B J +2

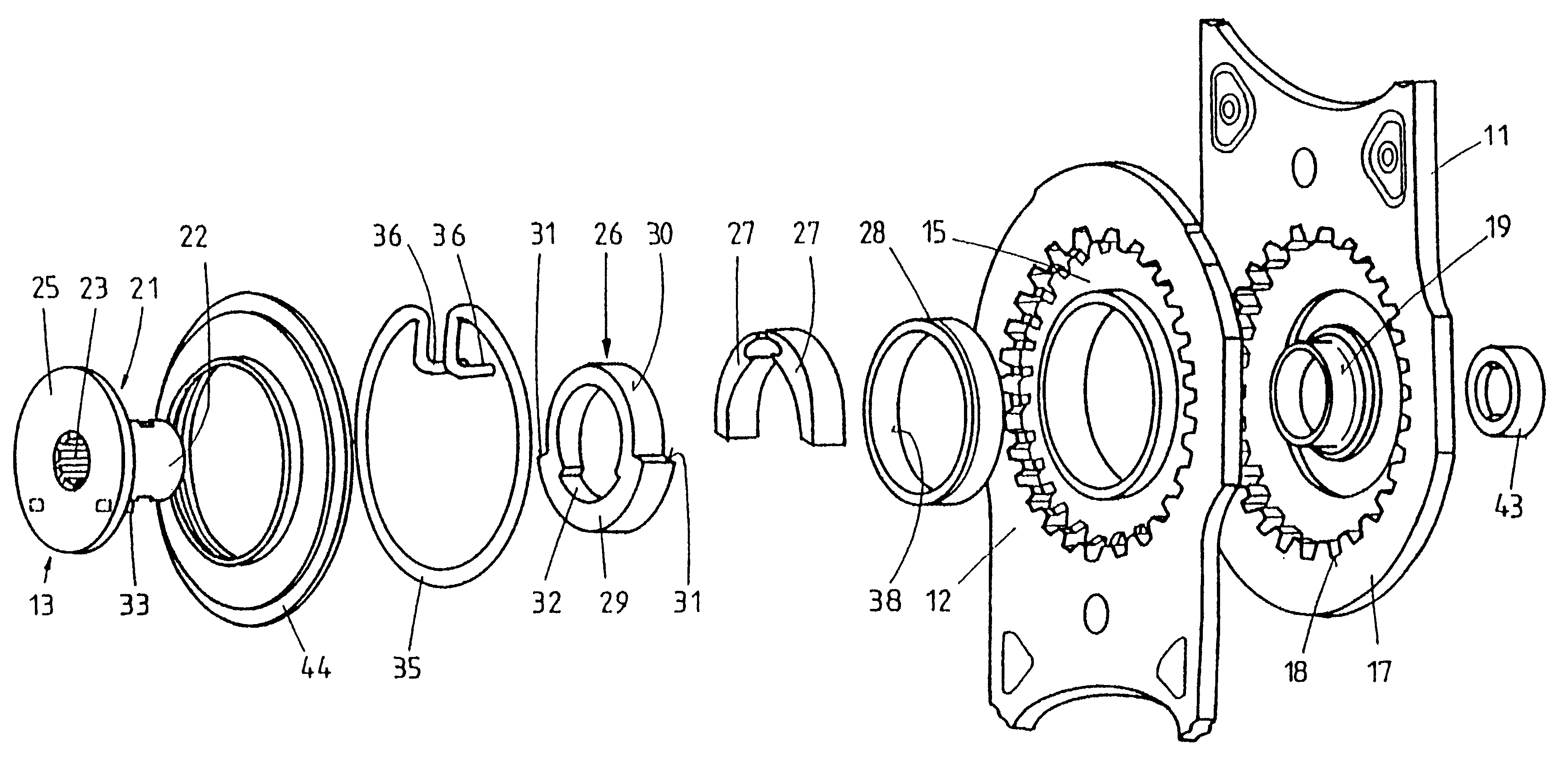

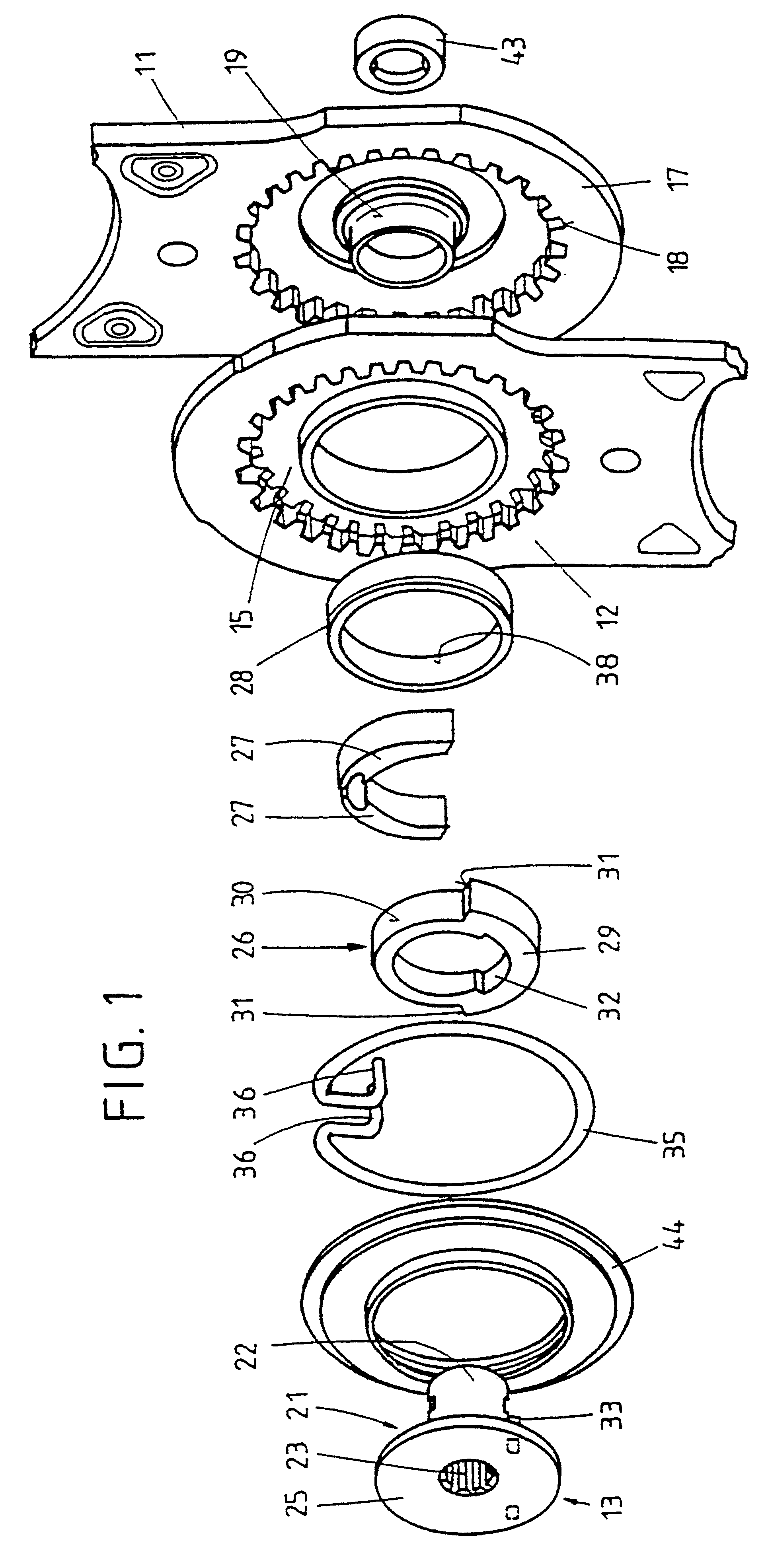

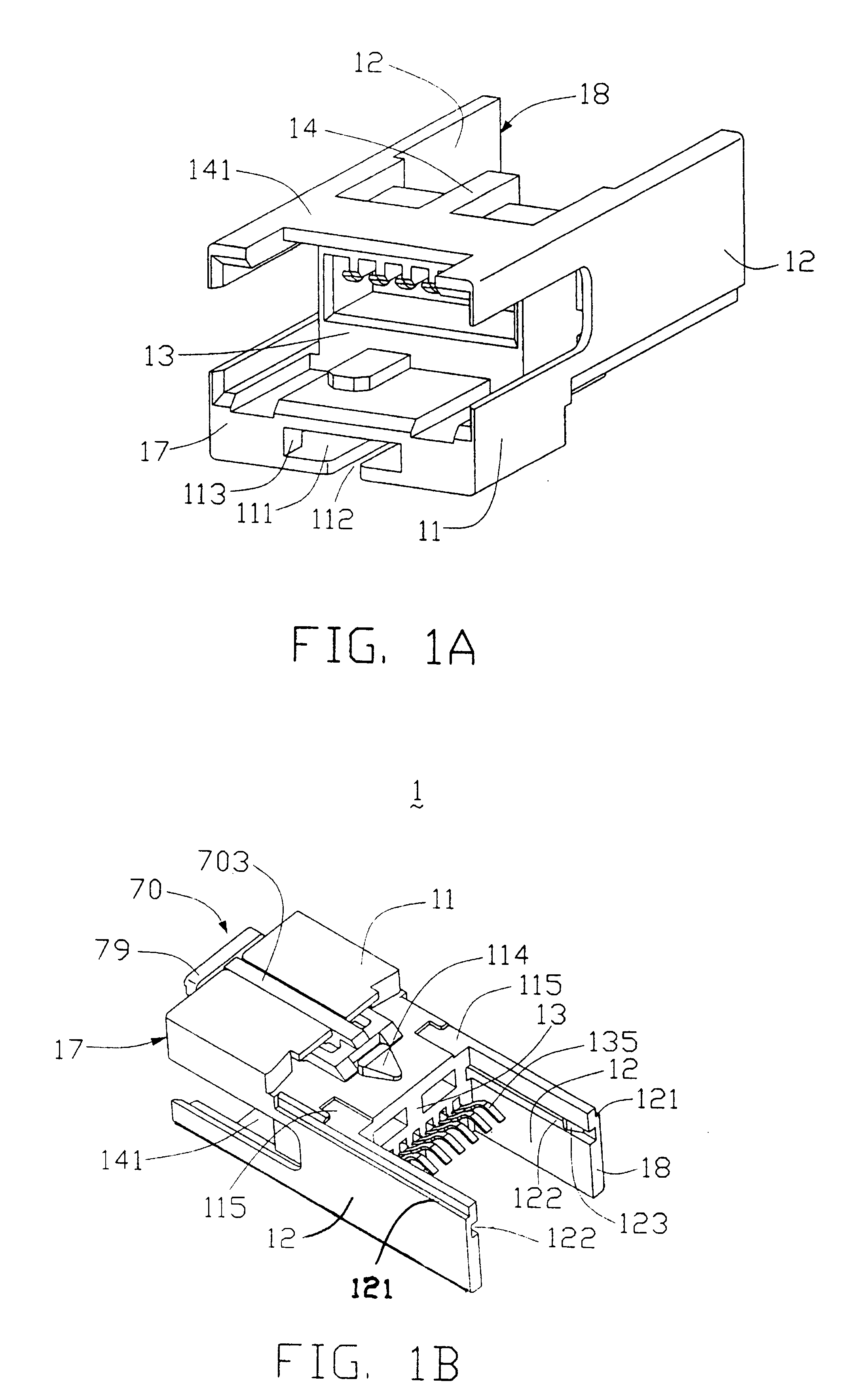

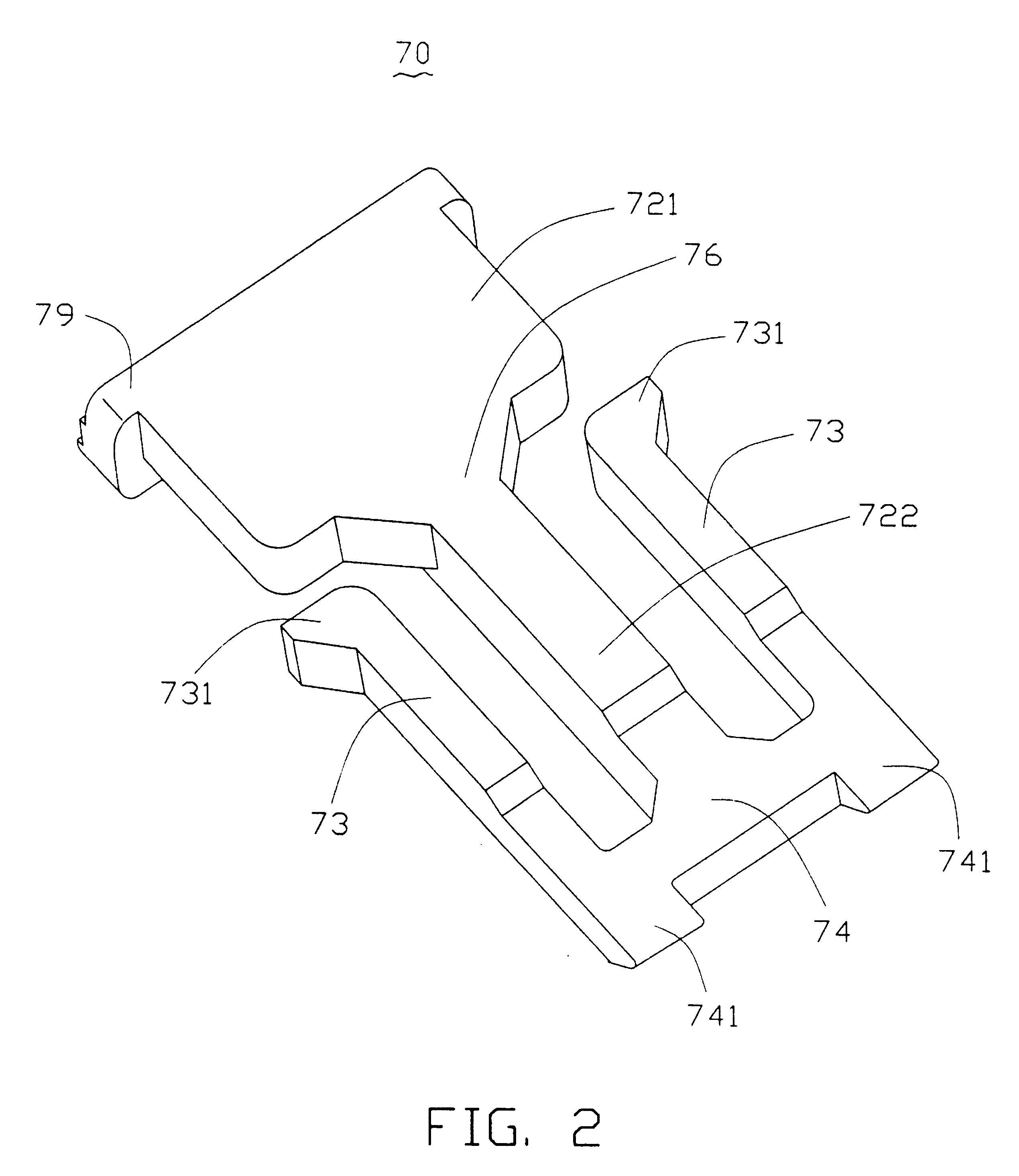

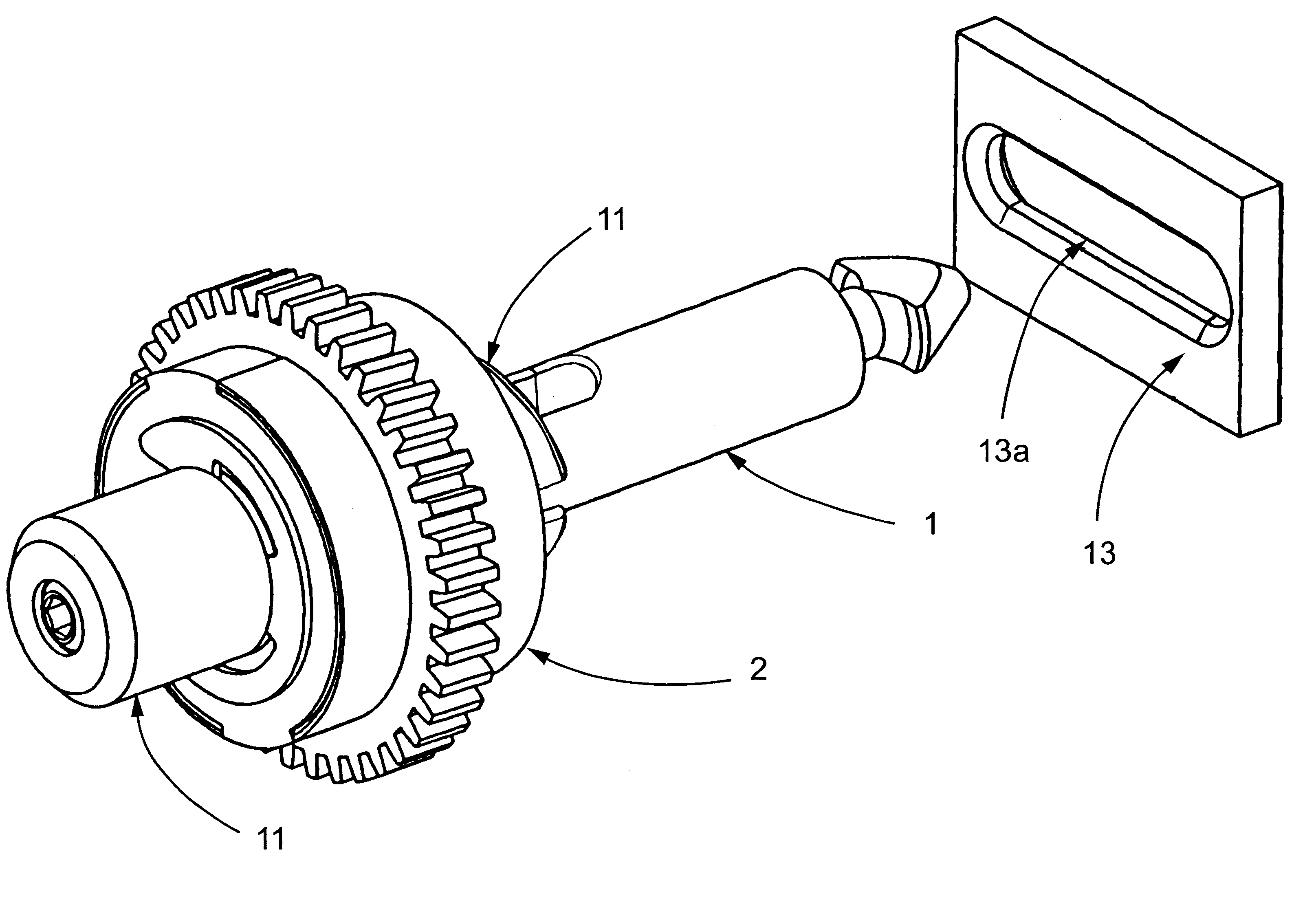

Adjustment armature for seats, especially motor vehicle seats, with an adjustable inclinable backrest

InactiveUS6619743B1Optimizing frictional connectionIdle time of the adjustment is significantly reducedMechanical apparatusLimiting/preventing/returning movement of partsEngineeringMechanical engineering

The invention relates to an adjustment armature comprising a fixed component (11) which is associated with part the seat and an adjustable component (12) which is connected to the backrest. The components of the armatures (11, 12) are joined to each other by means of an actuating member (13). An adjusting and locking device, having the form of a gear, is provided in order to adjust the relative positions of the two armature components (11,12). The adjusting member (13) comprises an eccentric segment (14), whereby one of the armature components (12) is mounted thereon. The other armature component (11) acts as a bearing for the eccentric segment (14). The eccentric segment (14) is comprised of wedge segments (27), which rest against each other and partially overlap a catch (20). Said eccentric segment is also provided with a catch segment (29) between the narrow sides thereof and an energy accumulator which moves the wide ends of, the wedge segments (27) apart. The actuating member (13) optionally comprises a central receiving section for a rotationally fixed connection to the transmission rod. The catch (20) is made up of a bushing (21), and a ring (26), which is rotationally fixed to said bushing and consists of a catch segment (29), whereby no free movement can be felt when the armature (10) is initially displaced for adjustment purposes. The catch ring (26) is mounted on the armature component (11) and acts as a bearing for the wedges (27) in a peripheral region of said ring, which does not contain said catch segment (29).

Owner:ADIENT LUXEMBOURG HLDG SARL

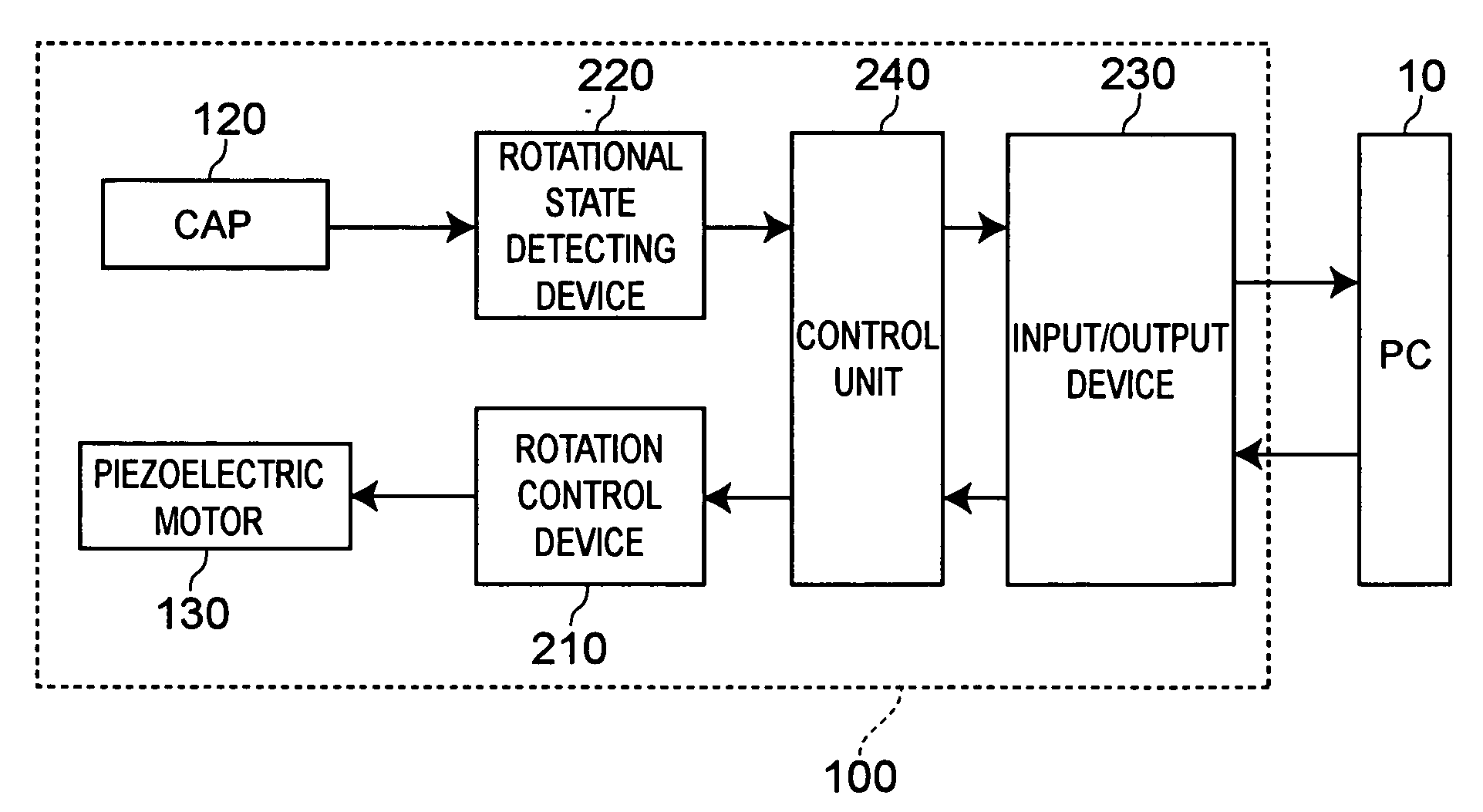

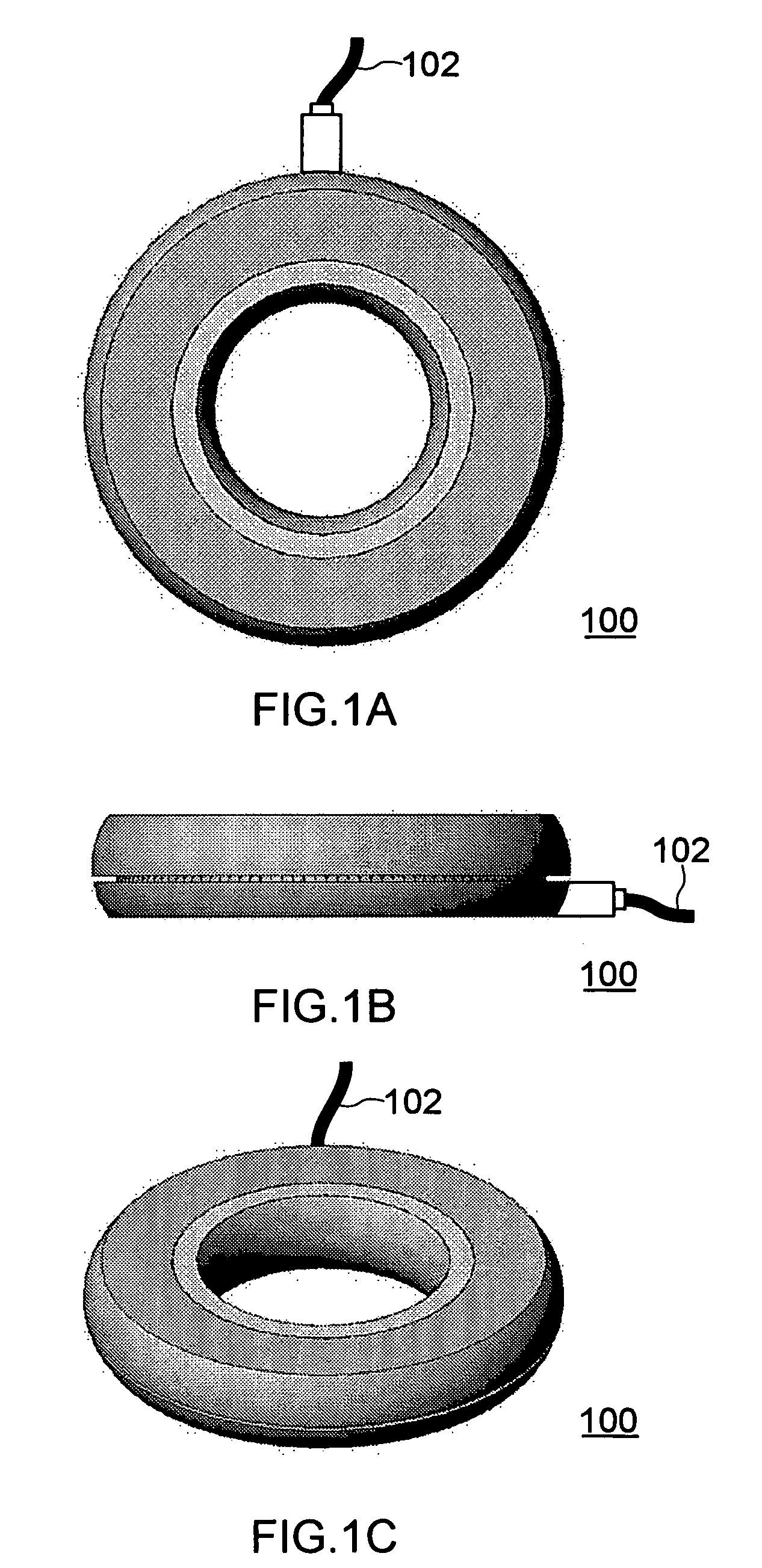

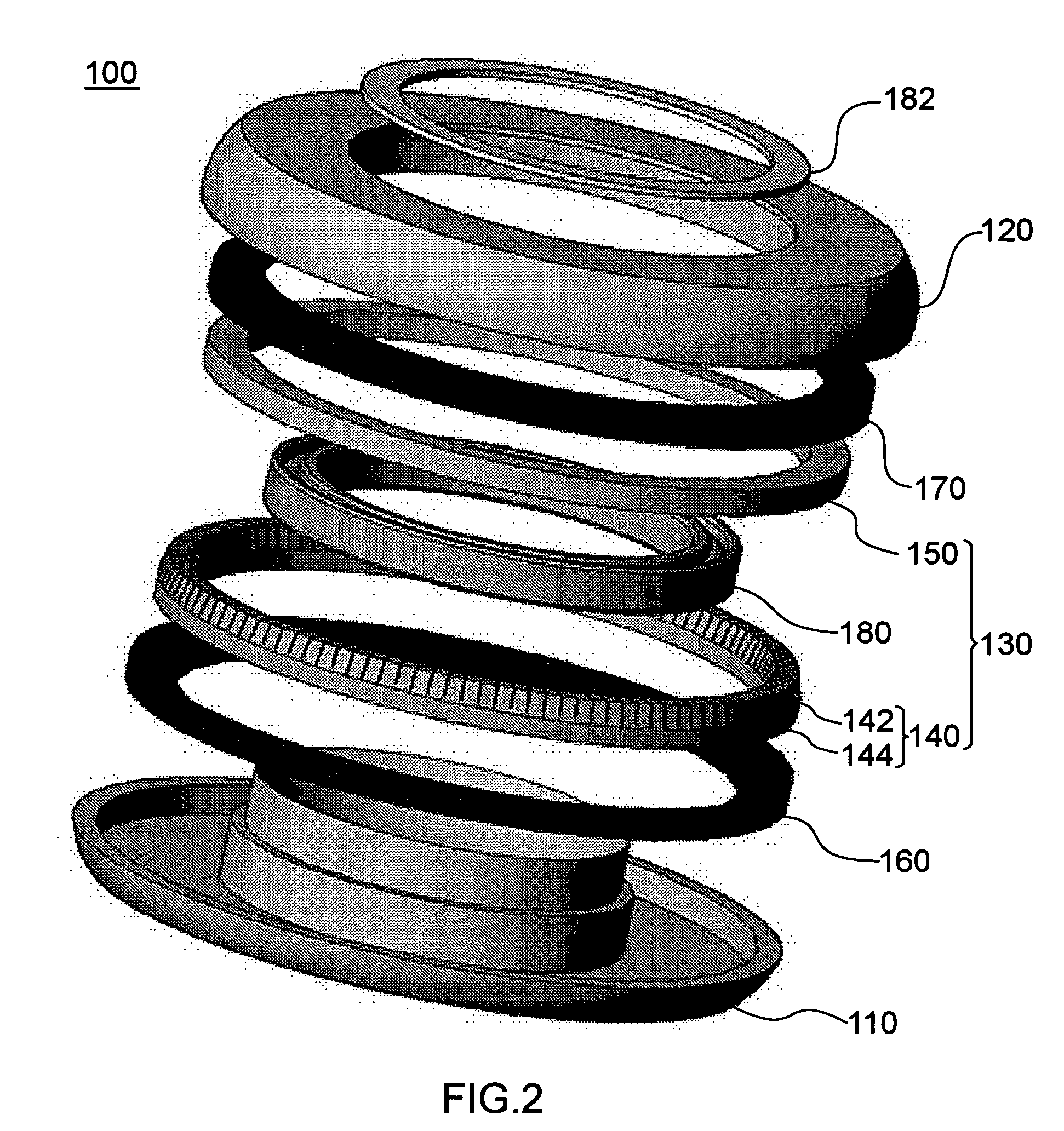

Haptic feedback controller, method of controlling the same, and method of transmitting messages that uses a haptic feedback controller

InactiveUS20060255683A1More feedbackFun to playControlling membersPiezoelectric/electrostriction/magnetostriction machinesLow speedFeedback controller

A haptic feedback controller 100 according to the present invention is a haptic feedback controller that controls a controlled appliance and includes a base 110, a cap 120, a piezoelectric motor 130, a rotation control device, and a rotational state detecting device. According to haptic feedback controller 100 of the present invention, the piezoelectric motor 130 that can produce a large torque even when rotating at low speed is used, so that even when the cap 120 is rotated at low speed, sufficiently large haptic feedback can be applied to the cap 120. Also, since the base 110 and the cap 120 are respectively fixed to the stator 140 and the rotor 150 of the piezoelectric motor 130, there is no backlash. As a result, according to the present invention it is possible to provide a haptic feedback controller for which there is no loss in the ability to express haptic feedback, so that a wide variety of haptic feedback can be expressed.

Owner:FUKOKU CO LTD

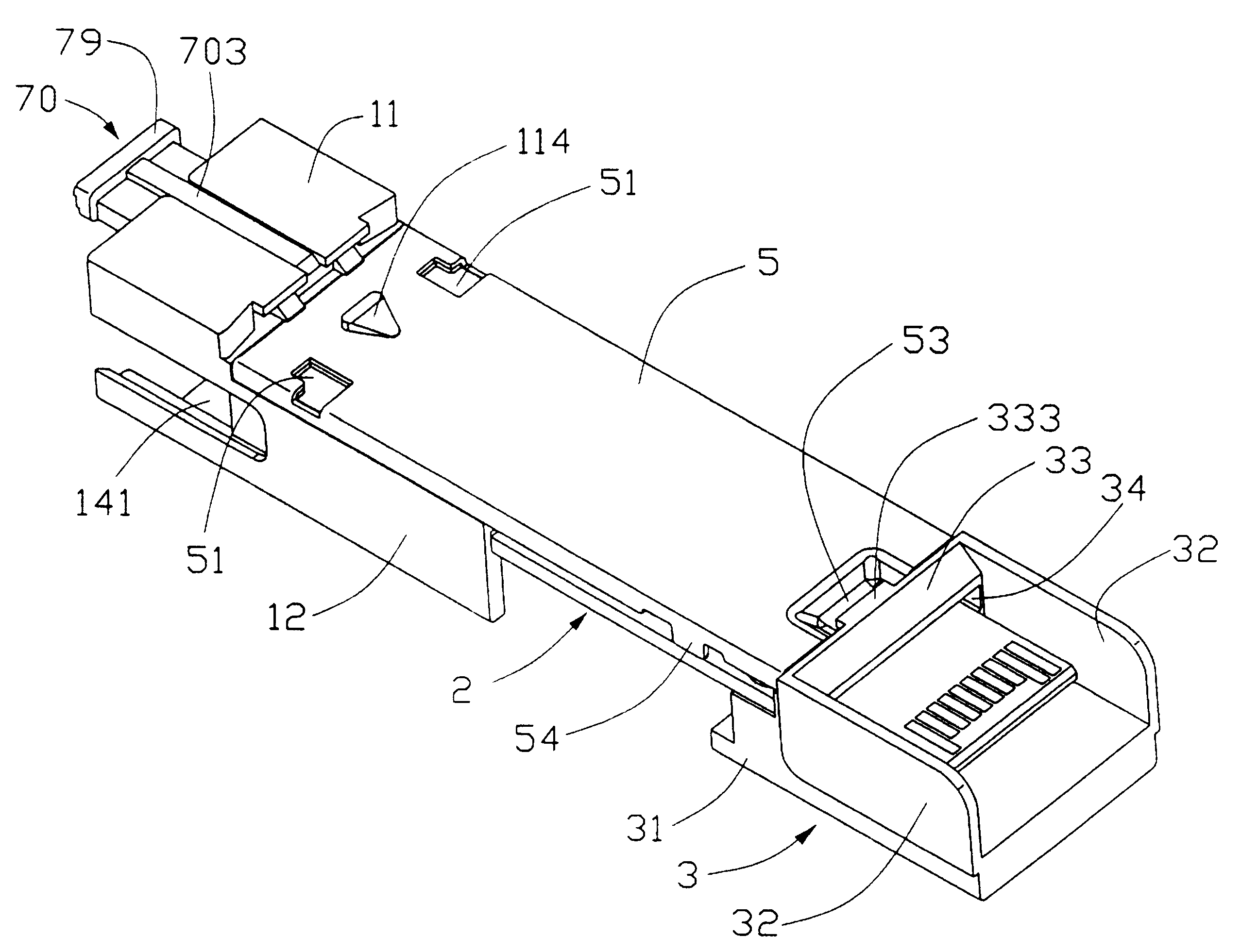

Small form-factor pluggable module having release device

InactiveUS6434015B1Engagement/disengagement of coupling partsAnti-theft cycle devicesSmall form factorComputer module

Owner:HON HAI PRECISION IND CO LTD

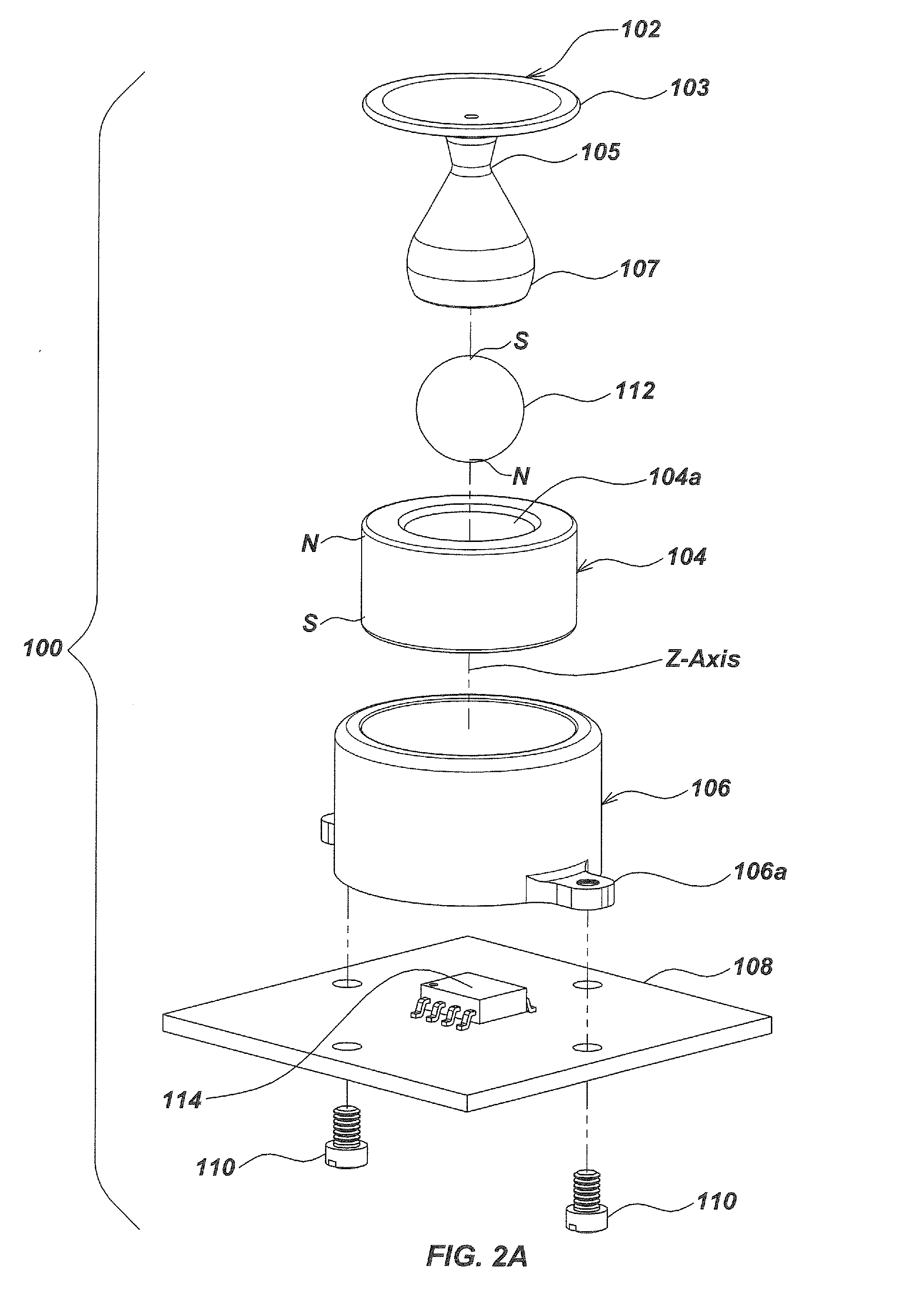

Magnetic Manual User Interface Devices

InactiveUS20100265176A1Manual control with multiple controlled membersLimiting/preventing/returning movement of partsElectrical polarityPersonal computer

Various finger tip controlled manual interface devices that can be used as inputs to personal computers, electromechanical systems and video game consoles utilize concentrically arranged magnets. The polarities of the magnets are oriented to provide restoration forces on a one of the magnets to bias it toward a neutral position. A magnetic sensor including a plurality of sensing elements such as Hall effect devices generates output signals representative of direction and amount of movement of the magnet that is biased to the neutral position.

Owner:SEEKTECH

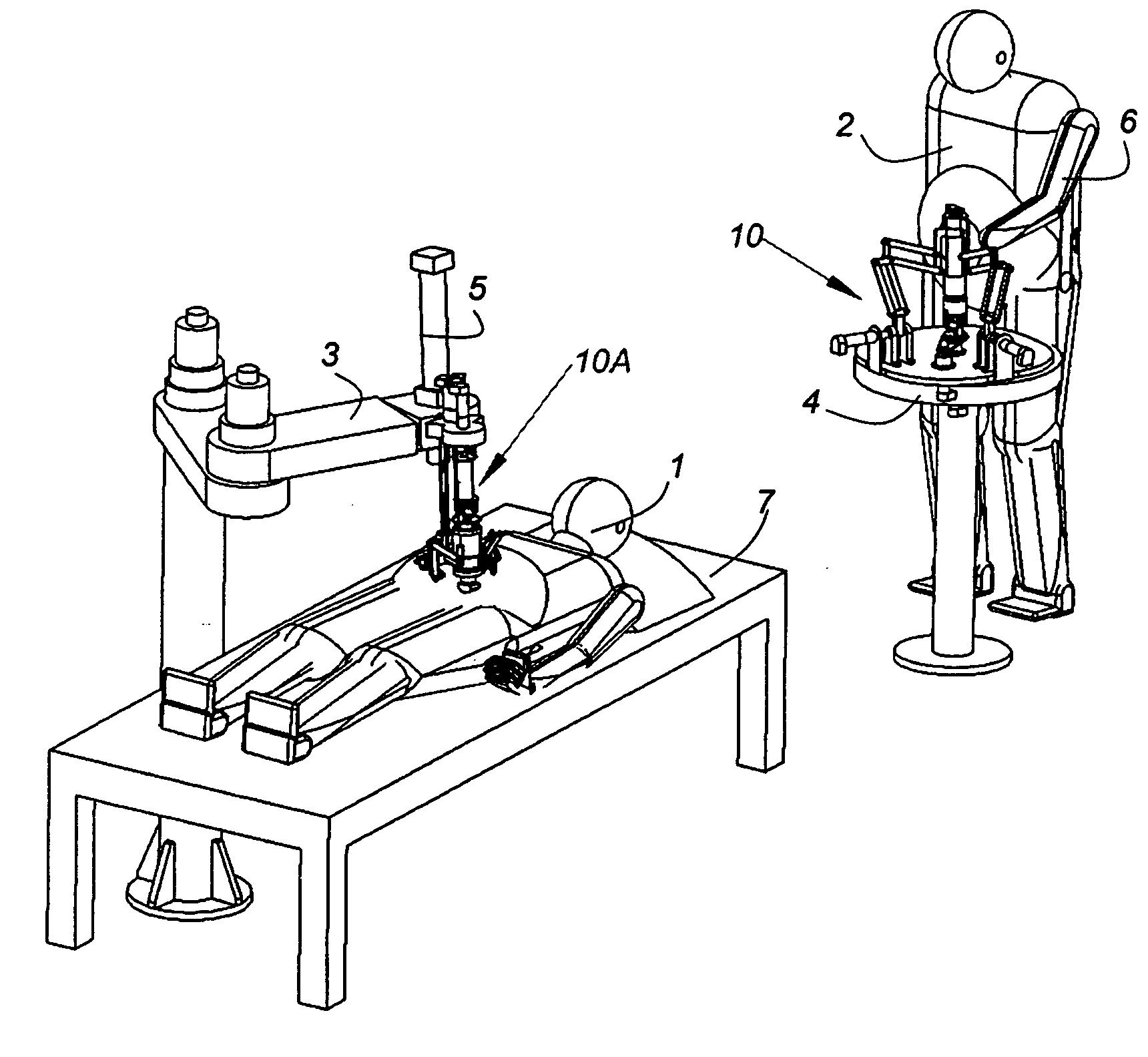

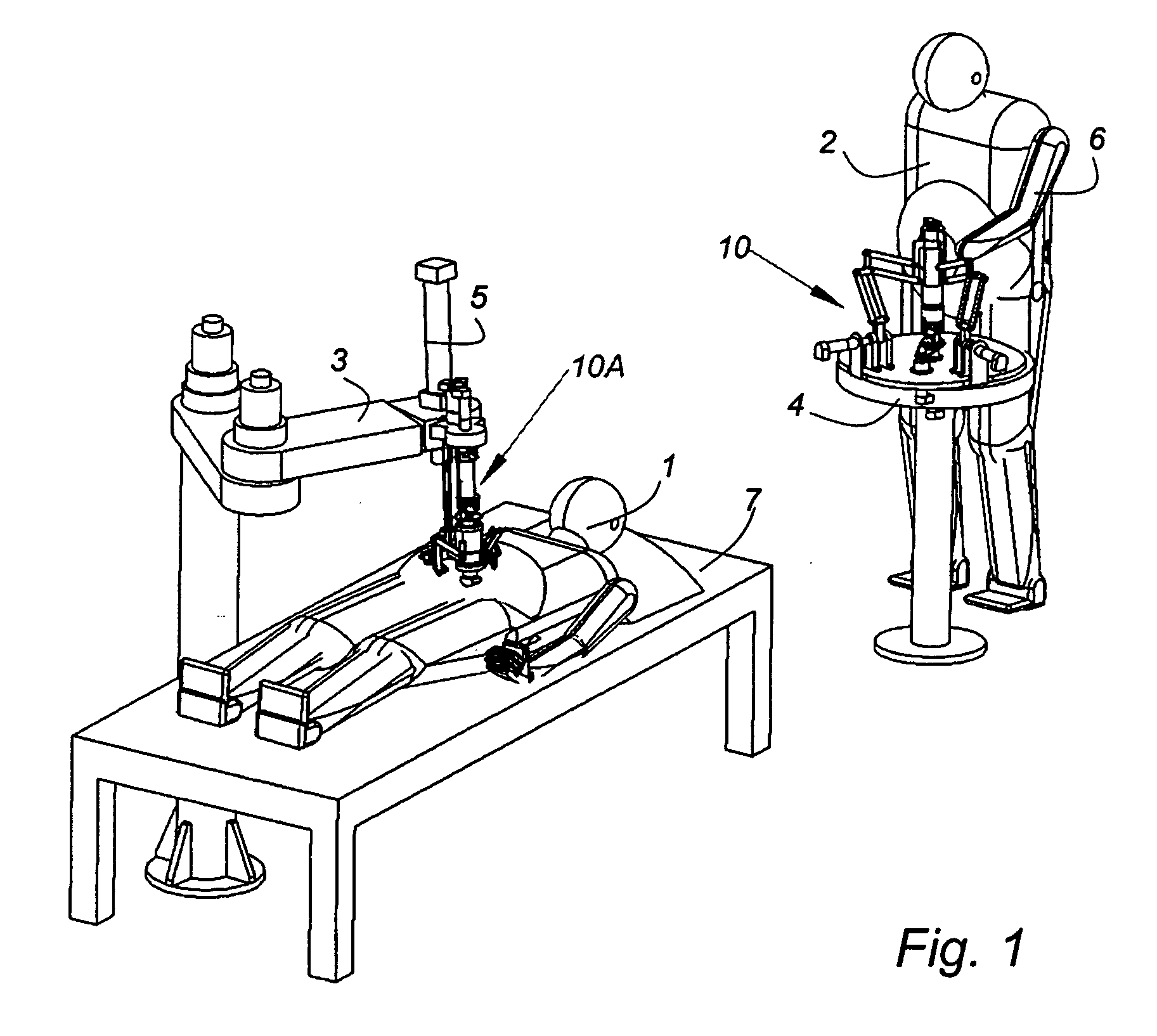

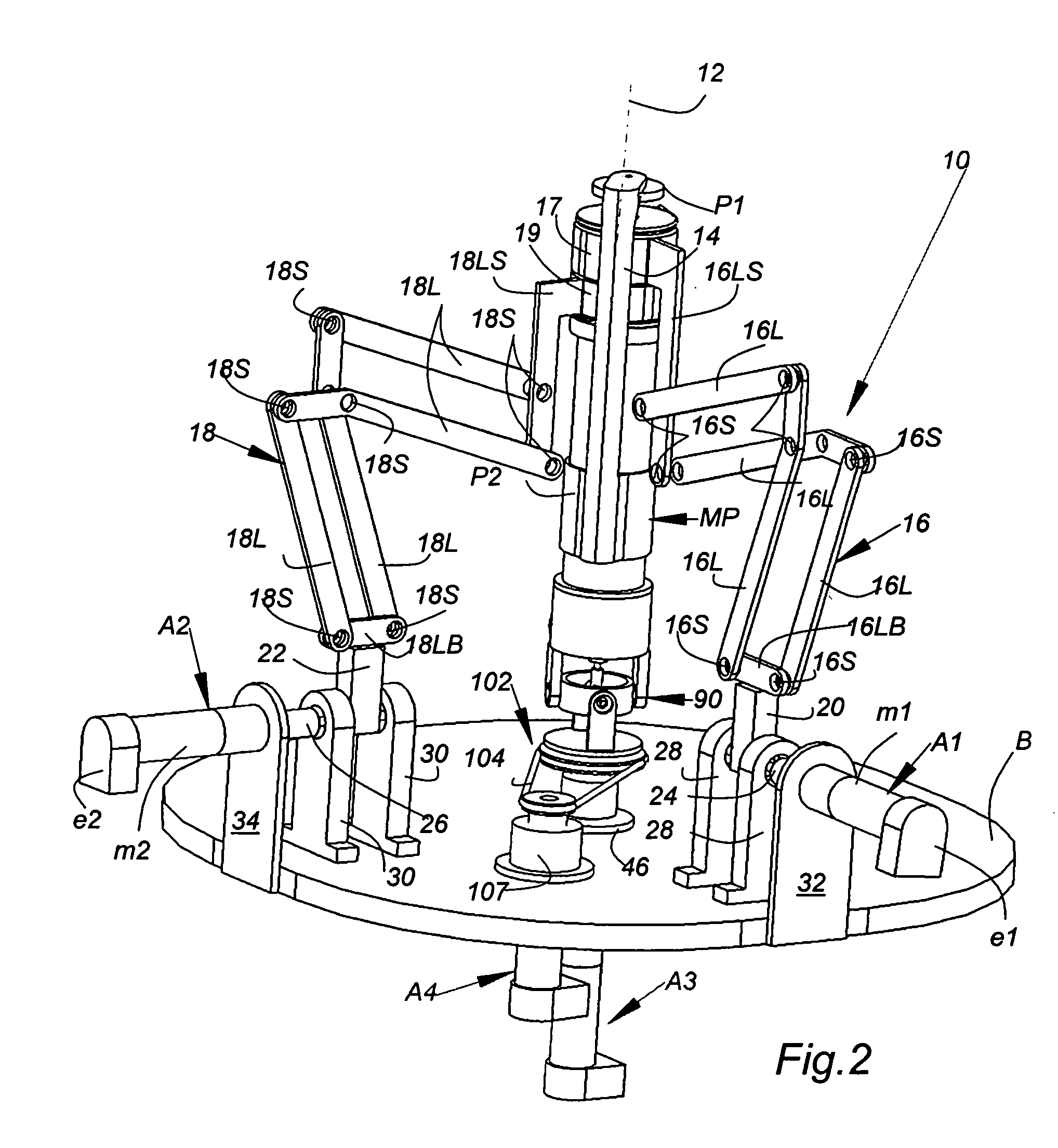

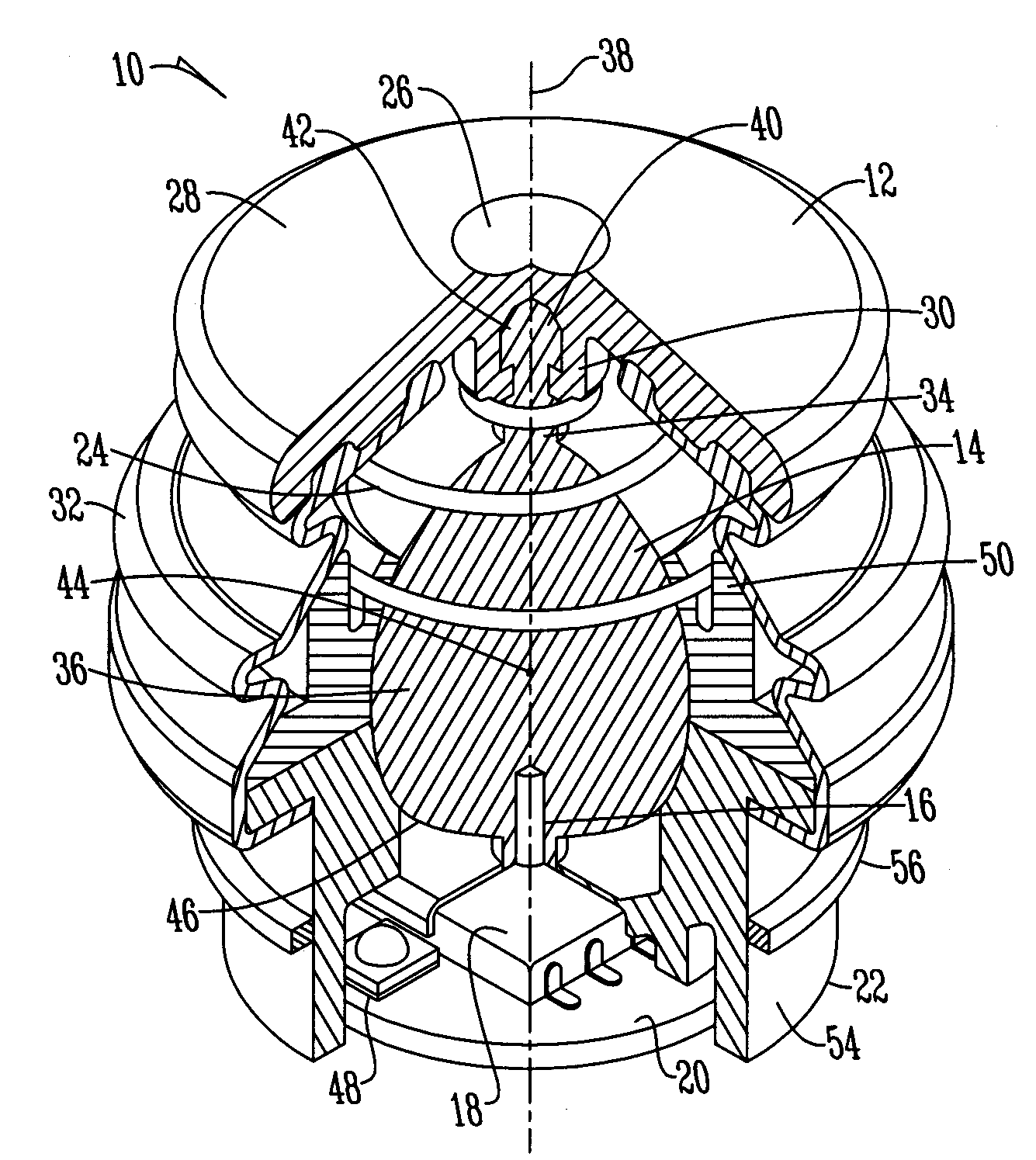

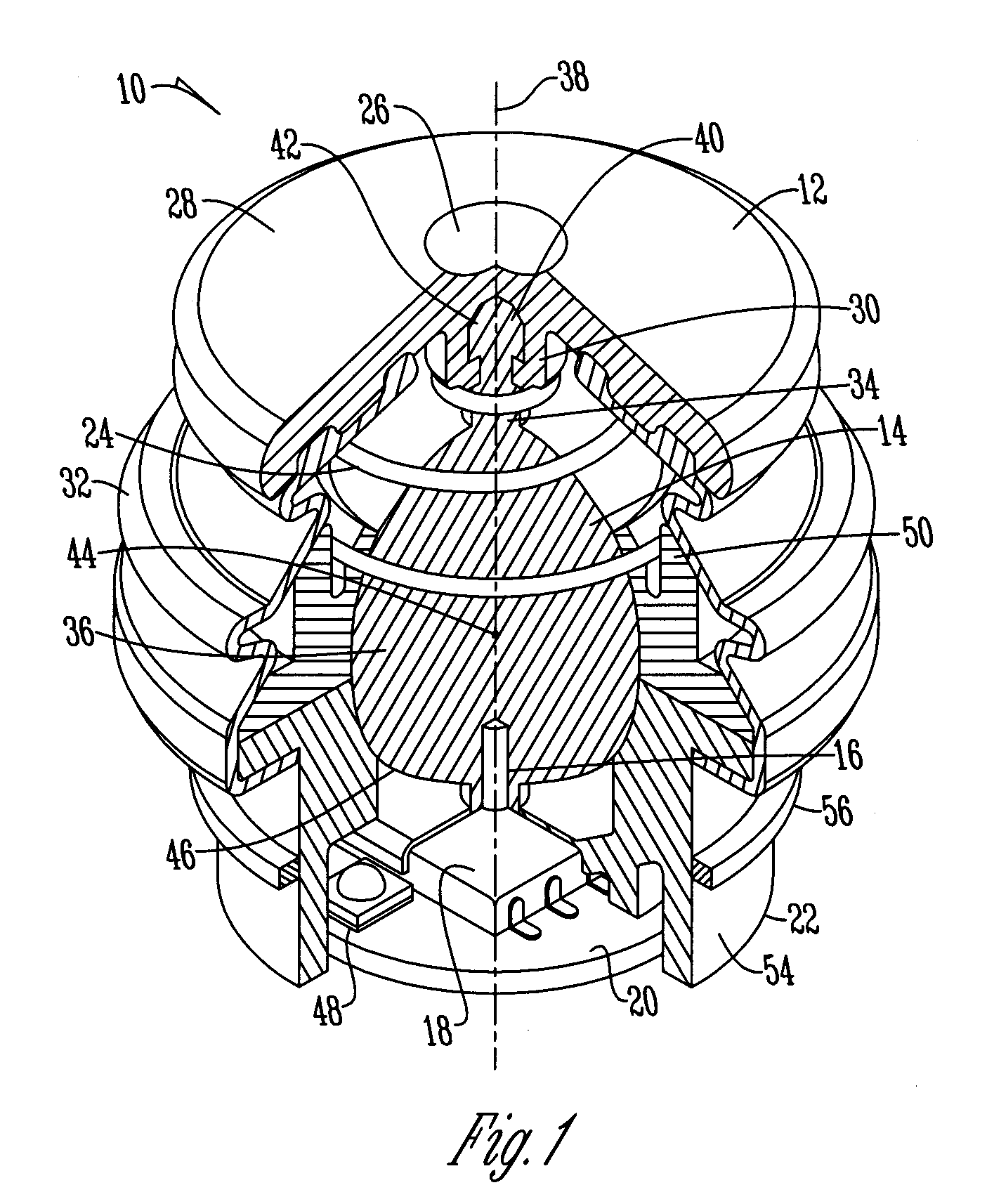

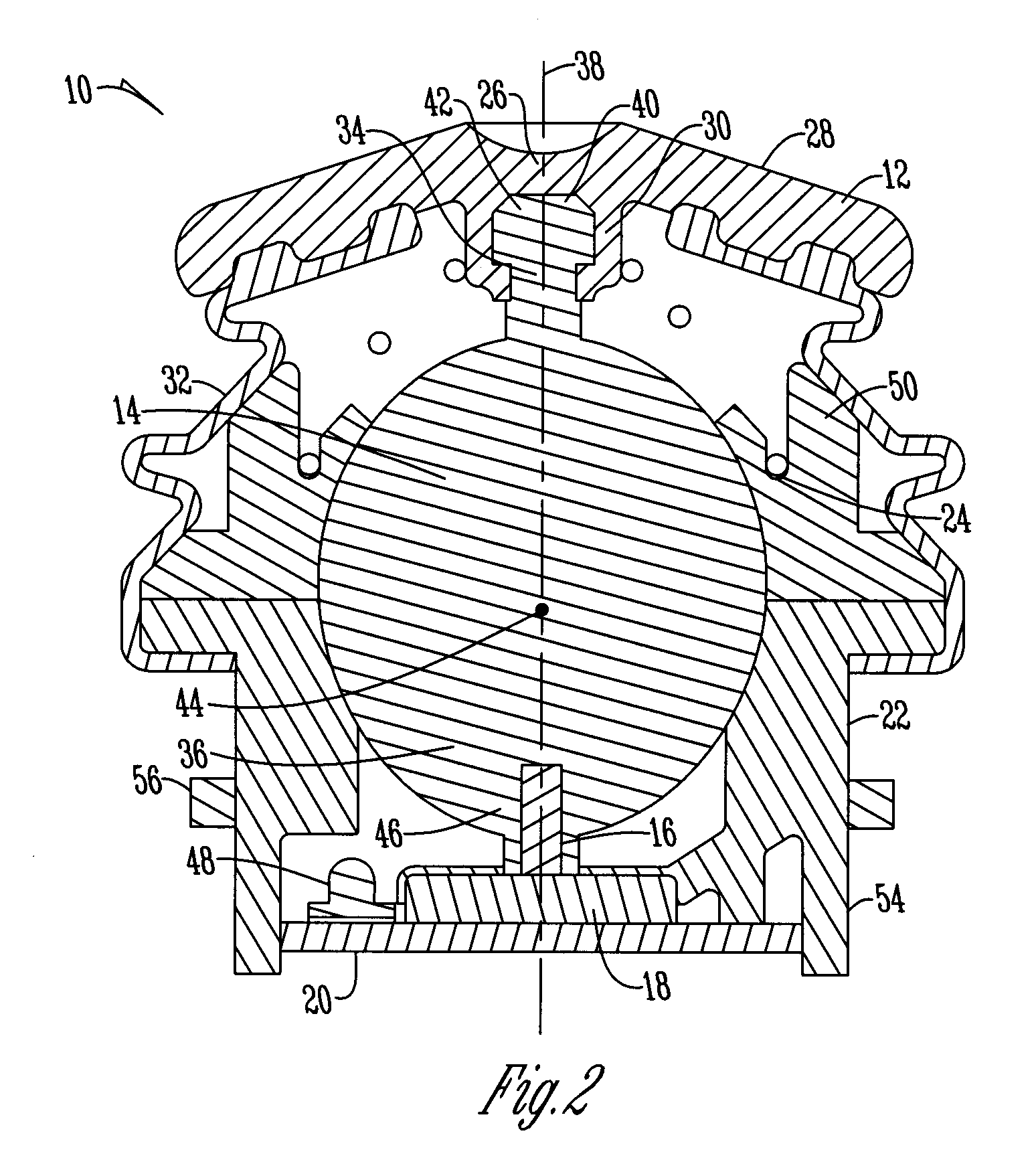

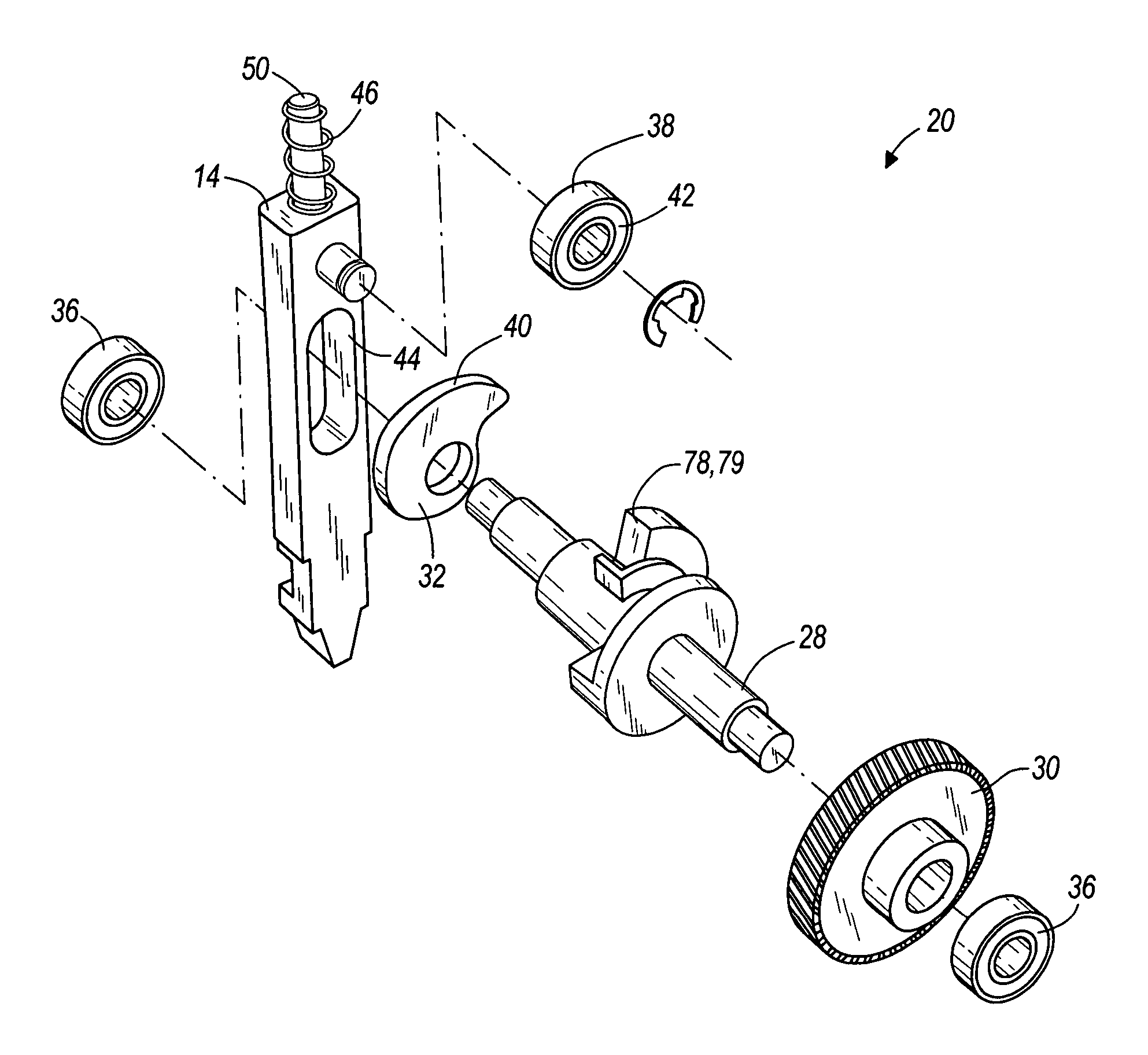

Hand controller and wrist device

InactiveUS20050183532A1Zero backlashEasy to measureMechanical apparatusJointsWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

Joystick and method of manufacturing the same

ActiveUS20090212766A1Manual control with multiple controlled membersControlling membersJoystickEngineering

A joystick having a movable member that includes a shaft portion and a spherical portion wherein the shaft portion has a diameter less than the spherical portion. An actuating member is secured to the shaft portion of the movable member to provide actuation of the movable member. A magnet is disposed within the spherical portion of the movable member and positioned adjacent a three axis sensor such that the magnet moves in a hemispherical pattern along the three axis sensor to operate a device.

Owner:DANFOSS POWER SOLUTIONS INC

Steering column lock apparatus and method

A lock bolt extendible and retractable by movement of a power transmission assembly driven by an actuator and having a cam thereon which cams against the lock bolt to retract the lock bolt and unlock the steering column. In some embodiments, the cam has a curved surface with varying distance from the axis of rotation of the cam or pivot to improved lock bolt motion. The cam can have a gradual ramp surface to extract a lock bolt even in binding conditions of the lock bolt.

Owner:STRATTEC SECURITY

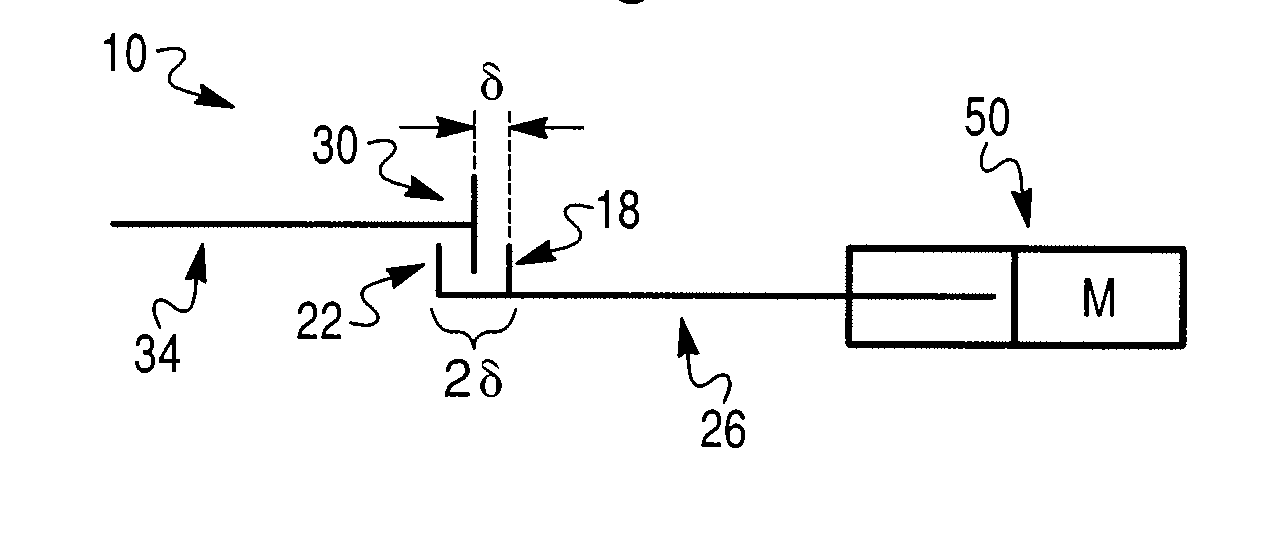

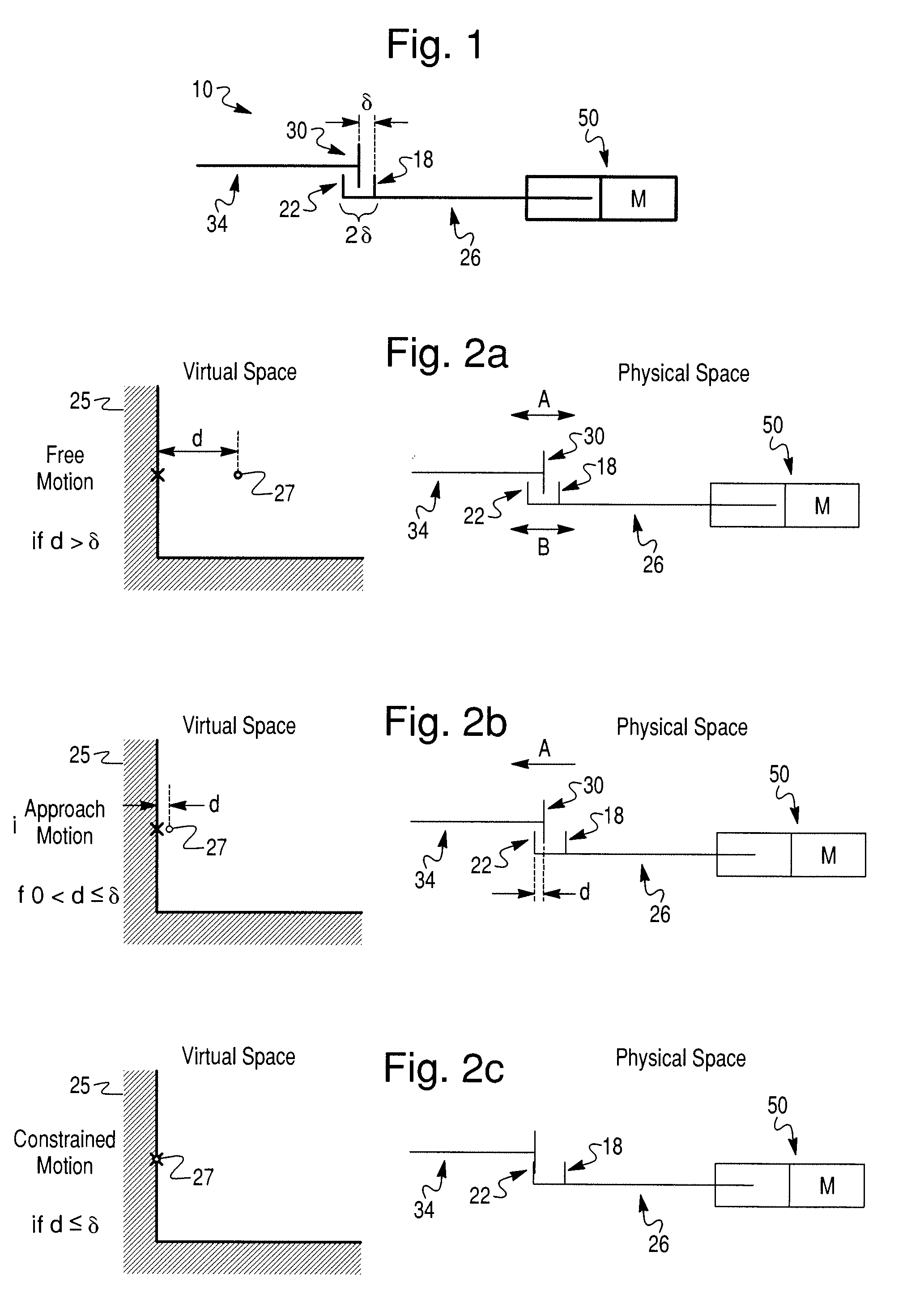

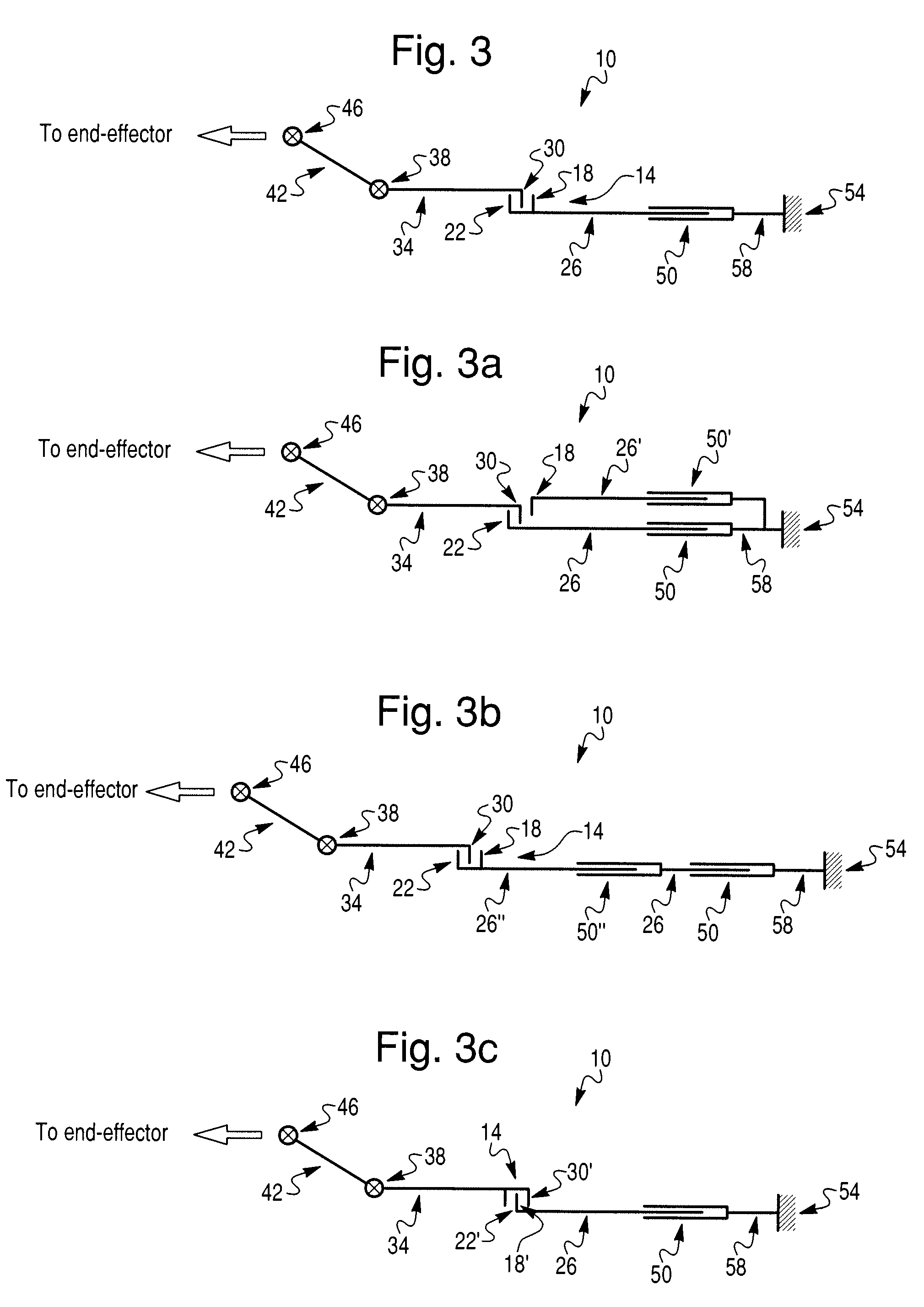

Apparatus and method for providing an adjustable positive stop in space

A method and apparatus for constraining motion of an end-effector in space. In one embodiment, the apparatus comprises a mechanical positioner and first and second stops. The first and second stops are controllable by a drive mechanism to constrain movement of the mechanical positioner and thereby to constrain the ability of a user to manipulate an end-effector outside a predetermined range of motion. The first and second stops are further controllable by the drive mechanism to permit movement of the end-effector within the predetermined range of motion.

Owner:MAKO SURGICAL CORP

Storable shifter with electronic gear shift reset

Owner:GRAND HAVEN STAMPED PRODS DIV OF JSJ

Systems and methods for providing a haptic device

ActiveUS8002089B2Degree of rotationControlling membersDynamo-electric brakes/clutchesEngineeringActuator

Systems and methods for providing a haptic device are described. In one described system, a first brake surface of a first element contacts a second brake surface of a second element. At least one actuator is configured to exert a force on at least one of the first and second elements. A flexure is coupled to at least one of the first element, the second element, a housing, a manipulandum, and a shaft coupled to the manipulandum. The flexure provides a degree of rotational flexibility to the manipulandum when the at least one actuator exerts the force. The described system may include a processor in communication with the at least one actuator for providing the haptic effects.

Owner:IMMERSION CORPORATION

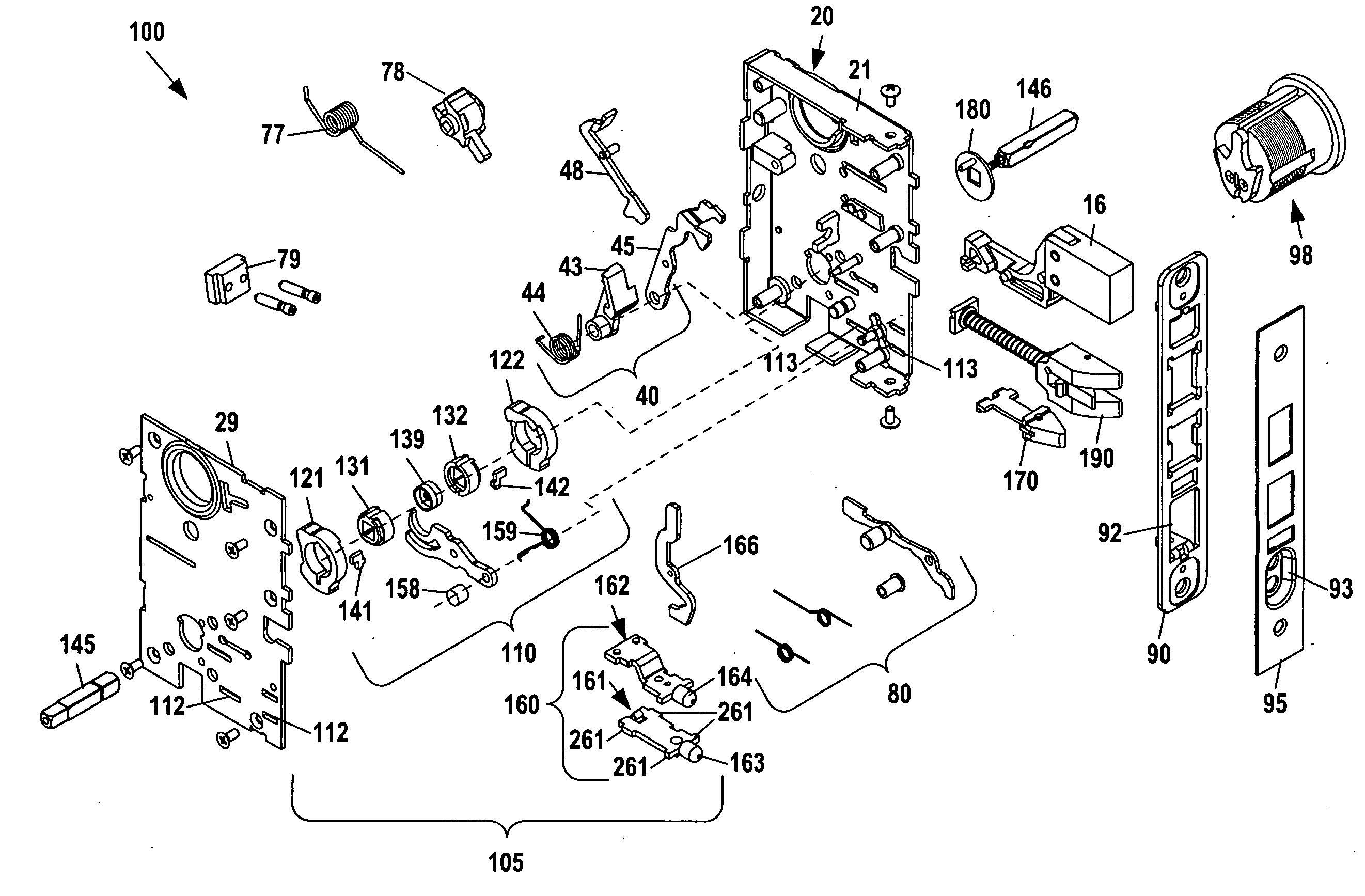

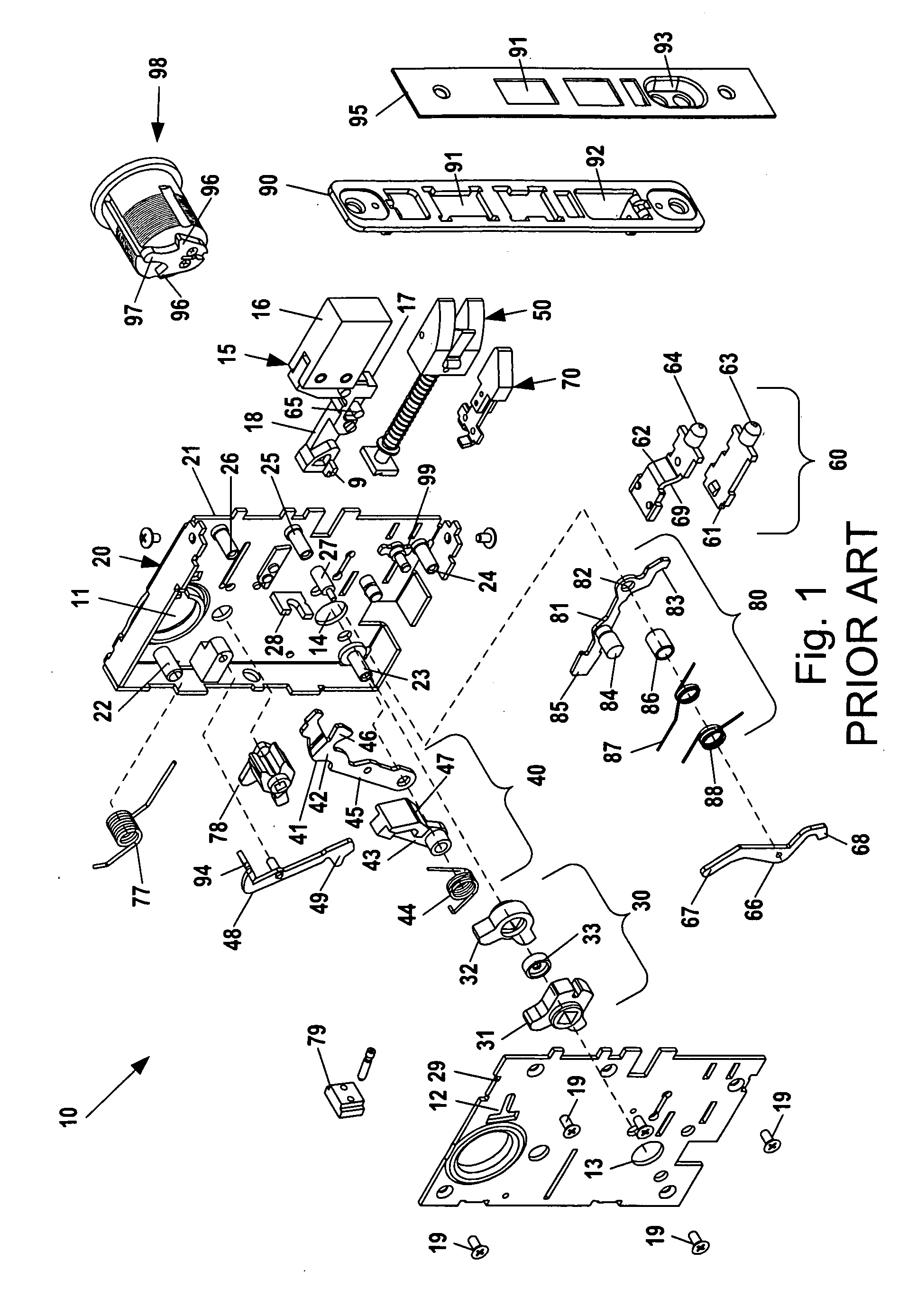

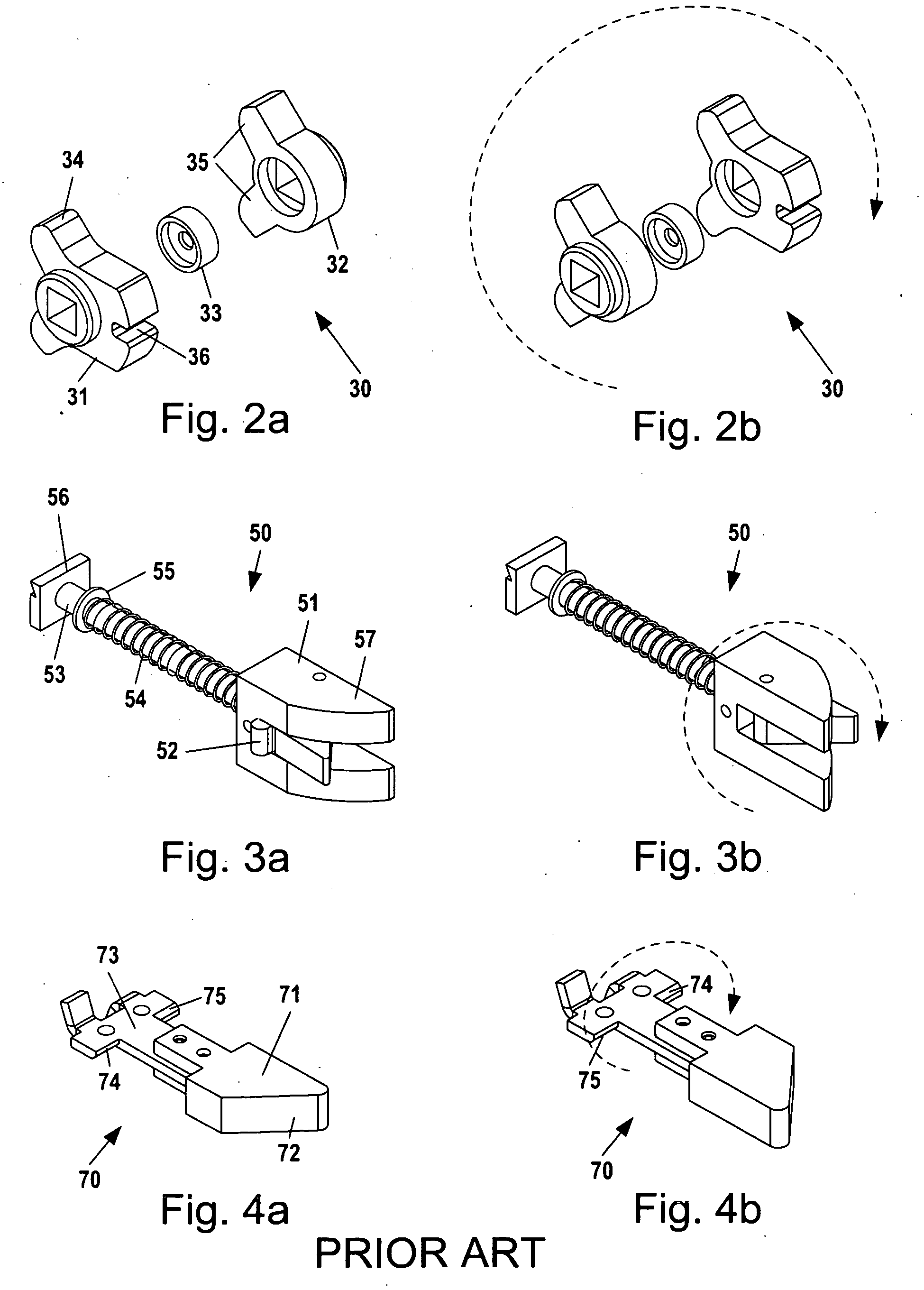

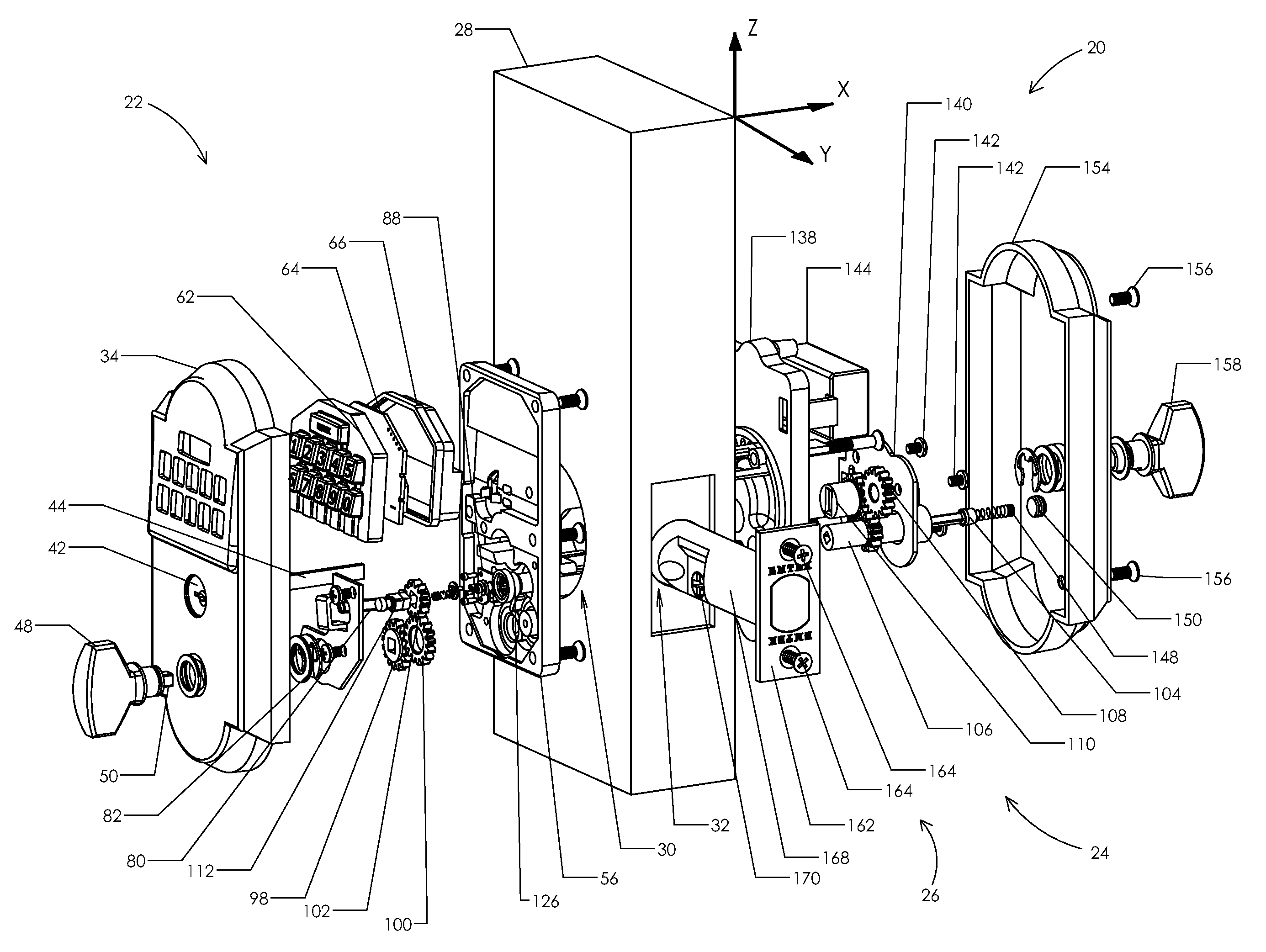

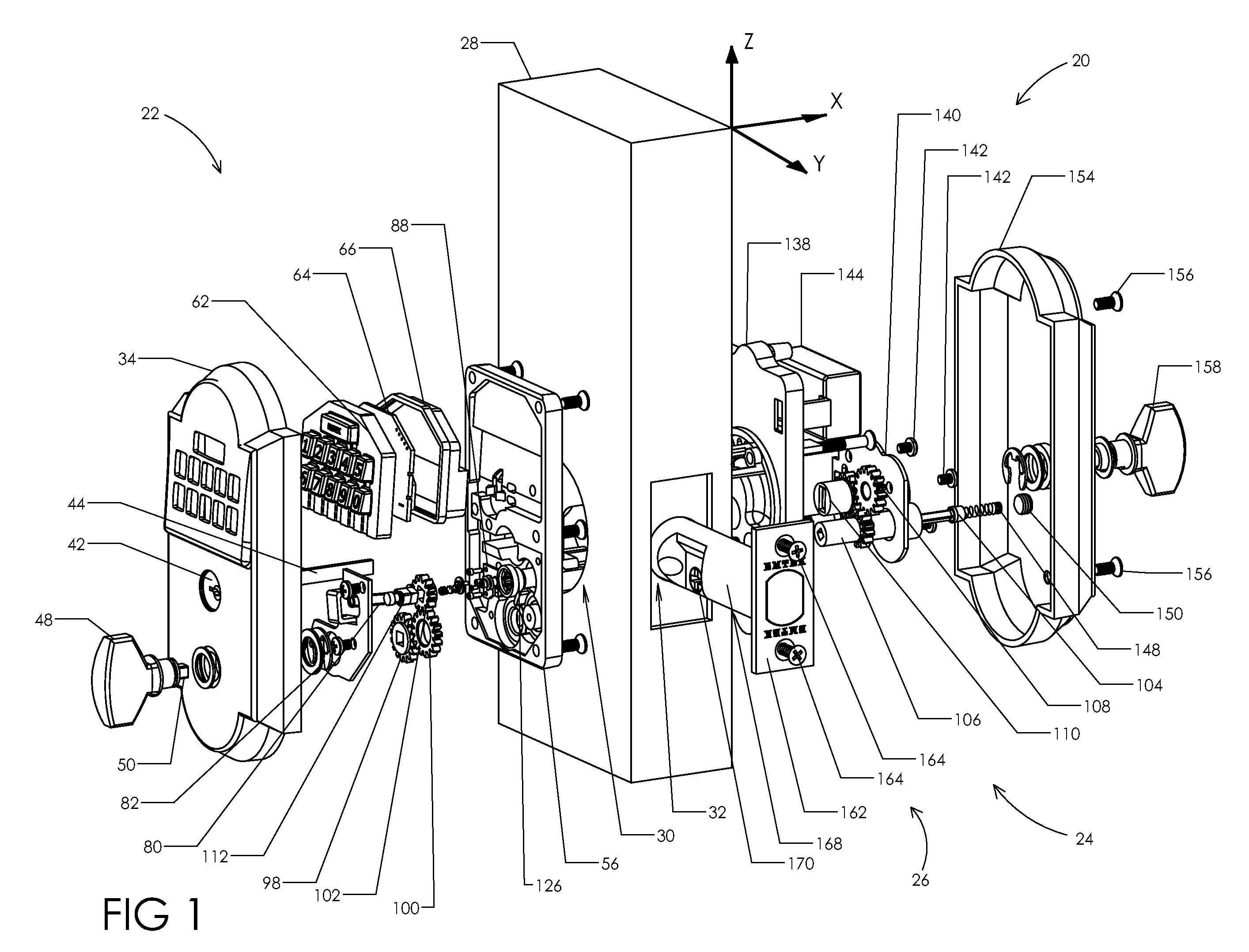

Mortise Lock Assembly

Several new components are provided for a mortise lock. First, a non-handed clutching assembly, including a pair of spindle hubs rotatable within a pair of outer hubs, is provided for a mortise lock. Second, a spindle-mounted lock-handing selector—which can be removed from one side of the lockset body while the lockset body is installed in the mortise of a door—is provided to set the handing of the clutching assembly. Third, an escapement mechanism is provided for a reciprocating-slide-based clutch-actuator assembly, enabling the slides to move into a position biasing a locker-carrying lever toward a hub-coupling position, even if the outer and spindle hubs are misaligned. Fourth, a guardbolt-actuated blocking assembly for a lockset is provided to block movement of the stop works or clutch works when the door is closed and the outside door handle is disabled.

Owner:TOWNSTEEL

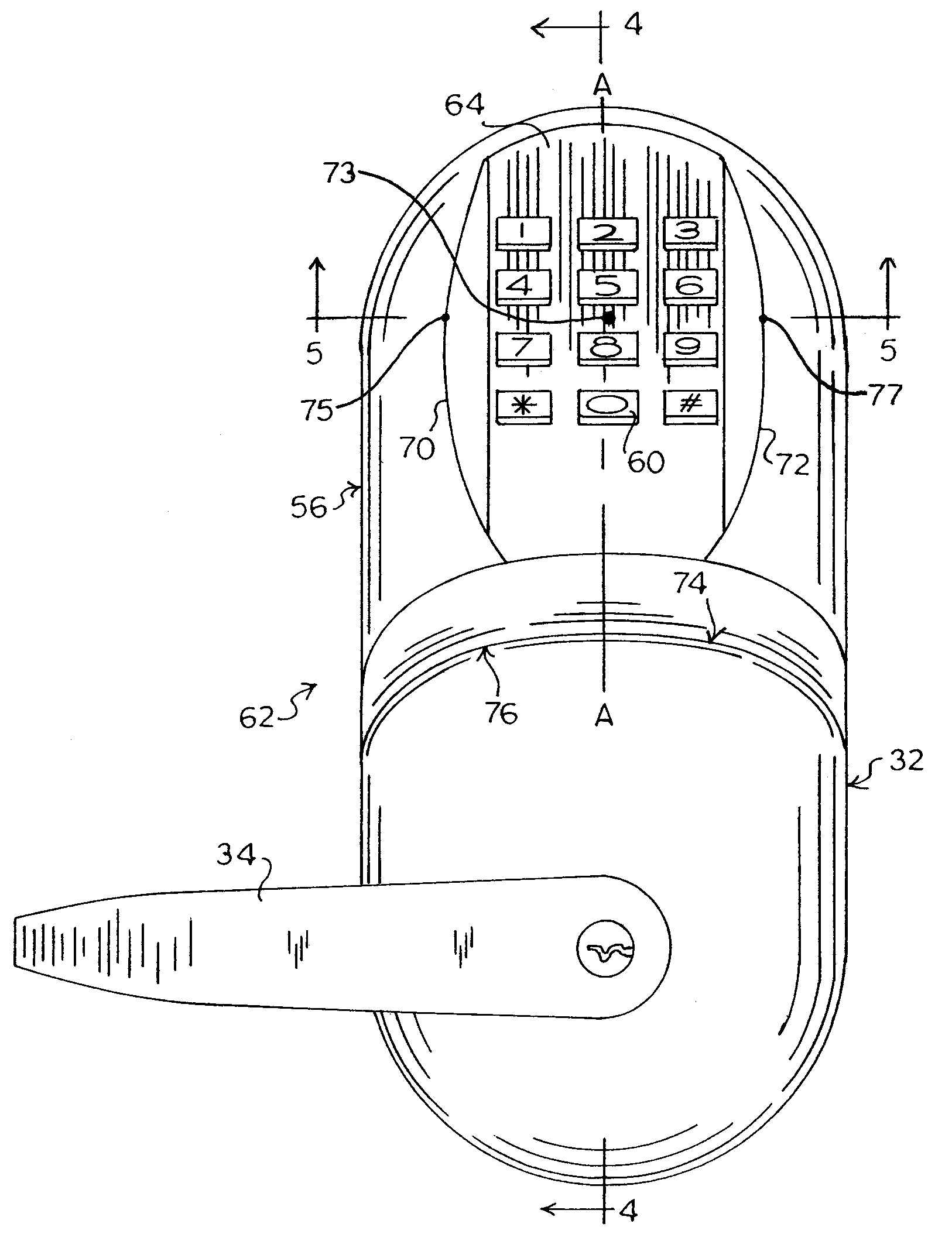

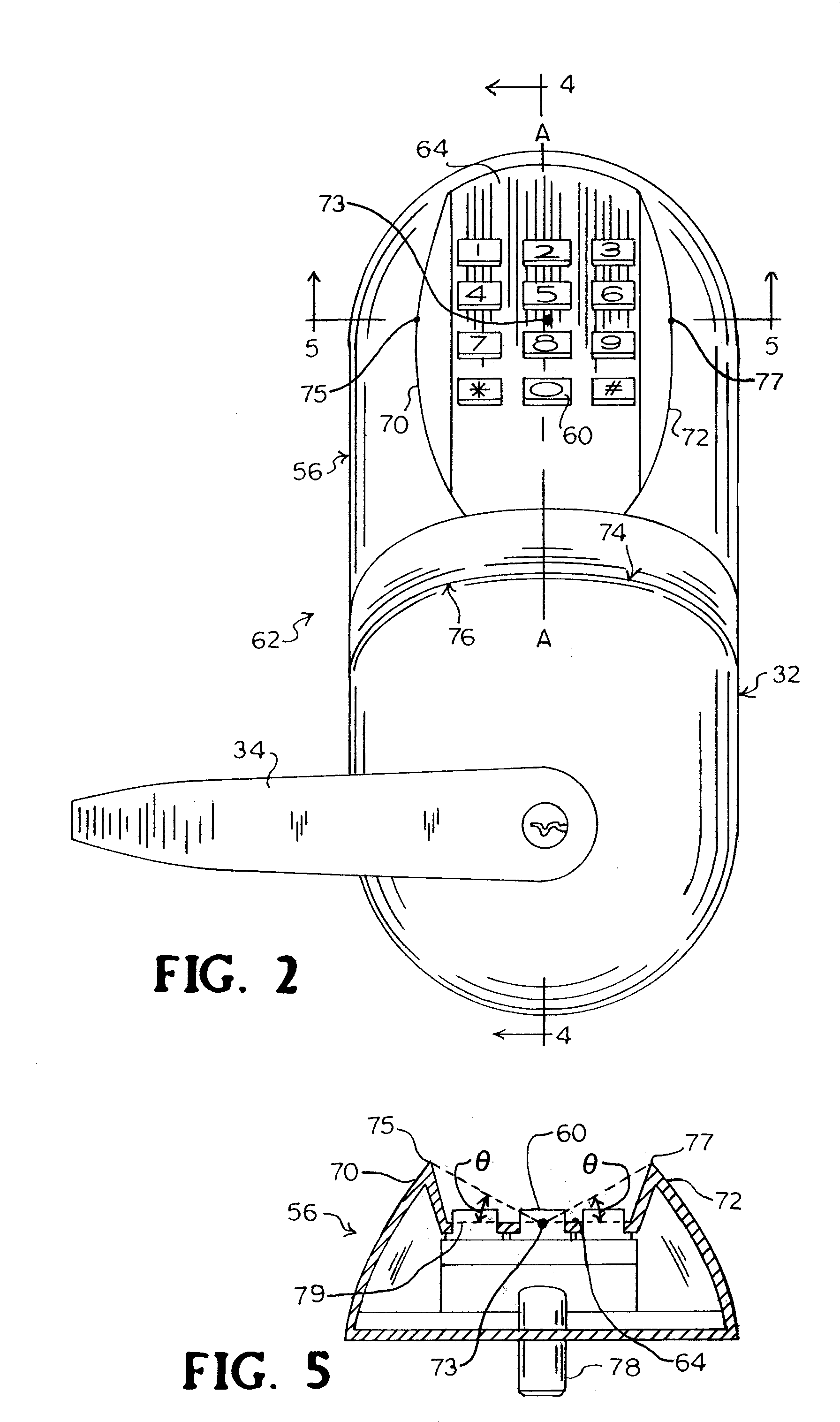

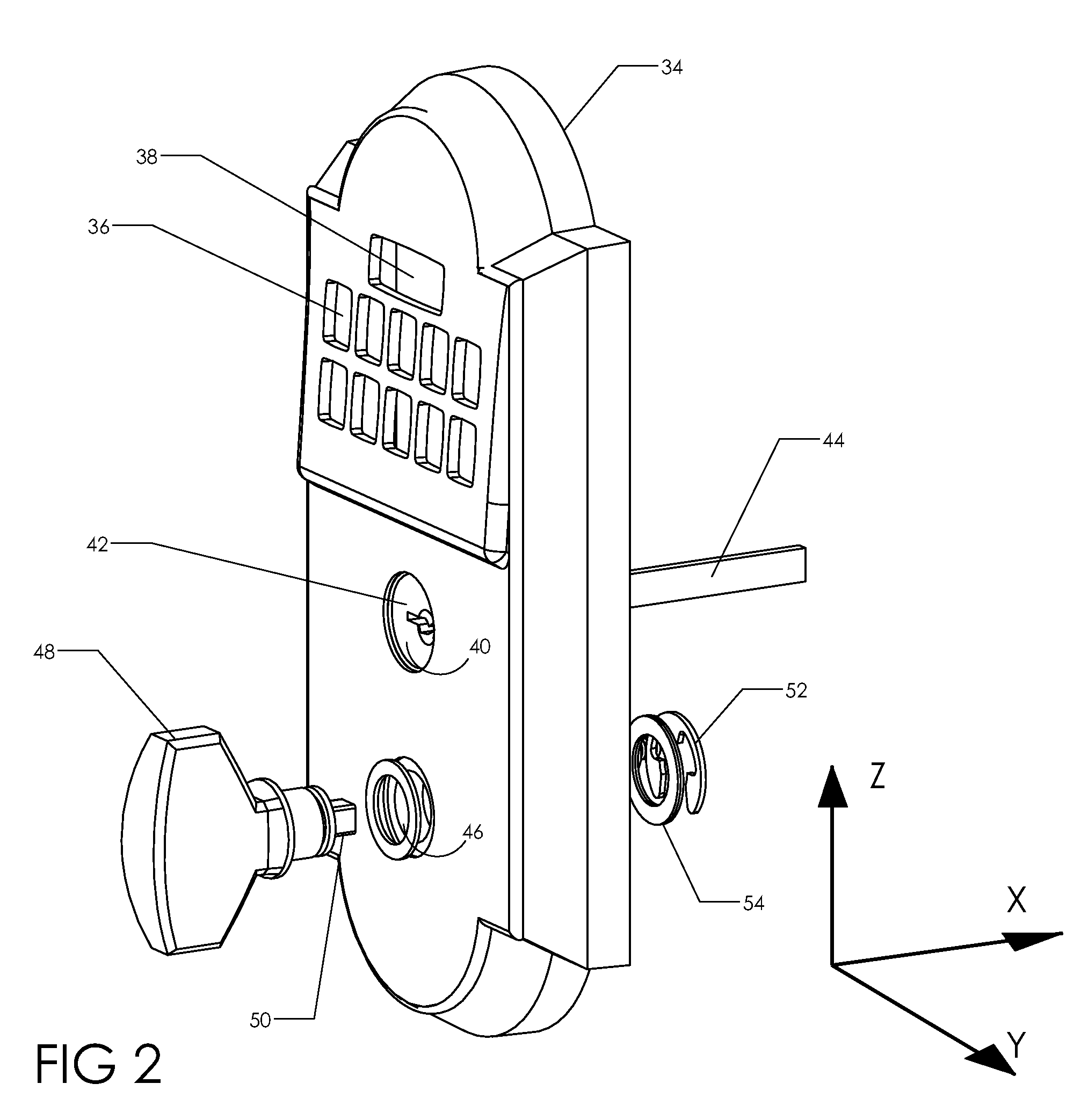

Privacy keypad

A privacy keypad providing privacy for keypad character entry and concealment of a joint in an escutcheon. A privacy keypad may include a faceplate, a keypad disposed on the faceplate, and at least one protrusion integral with the faceplate. An escutcheon for a door lock may include a housing, a keypad disposed on the housing for unlocking the door lock, and at least one protrusion integral with the housing. The protrusion may obstruct at least partially a line of sight to the keypad. An escutcheon may include top and bottom covers with the top cover projecting outward from the surface of a door more than the lower cover, resulting in an at least partially hidden joint between covers. Top and bottom covers may be interchangeable with covers having similar edges.

Owner:YALE SECURITY

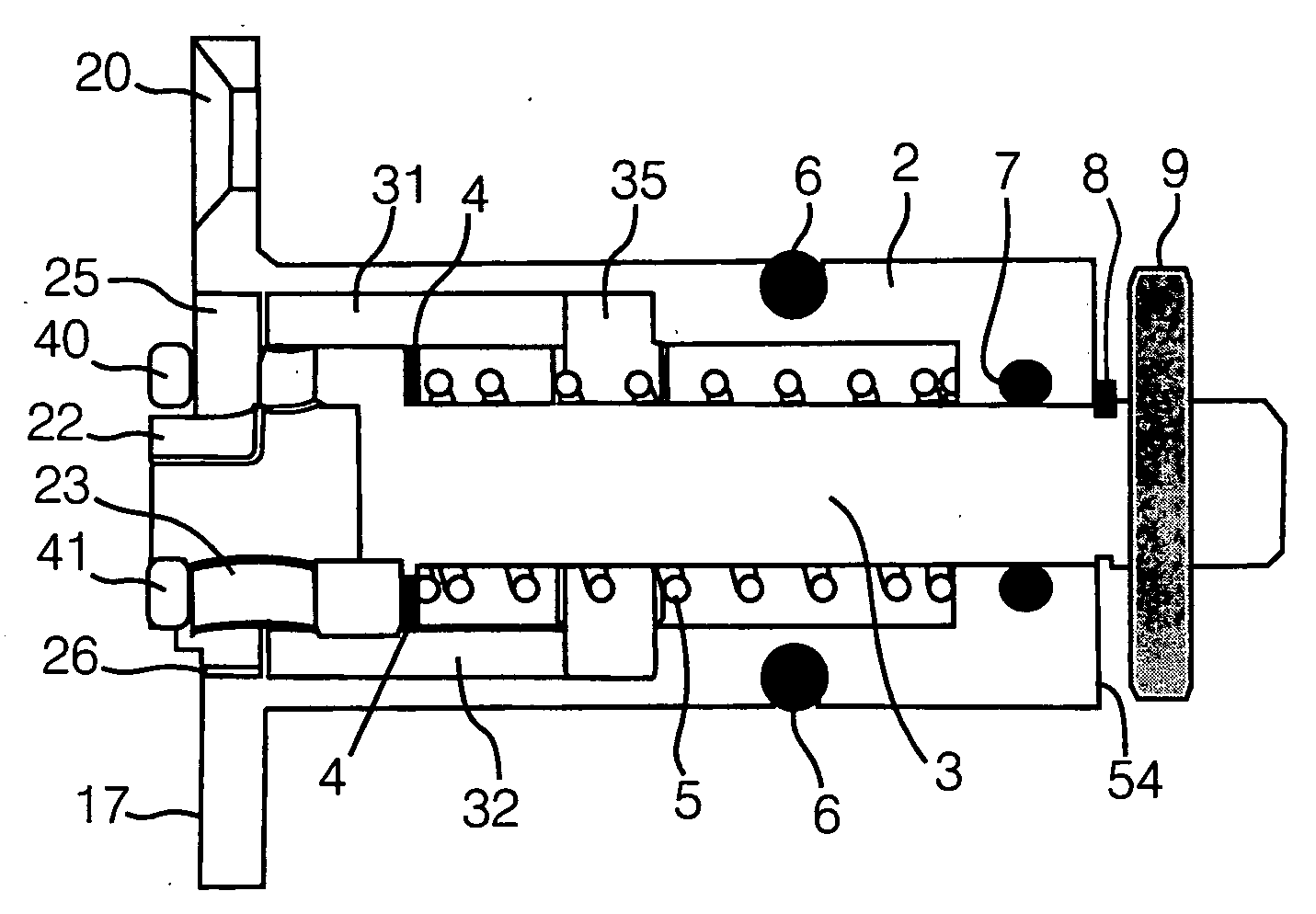

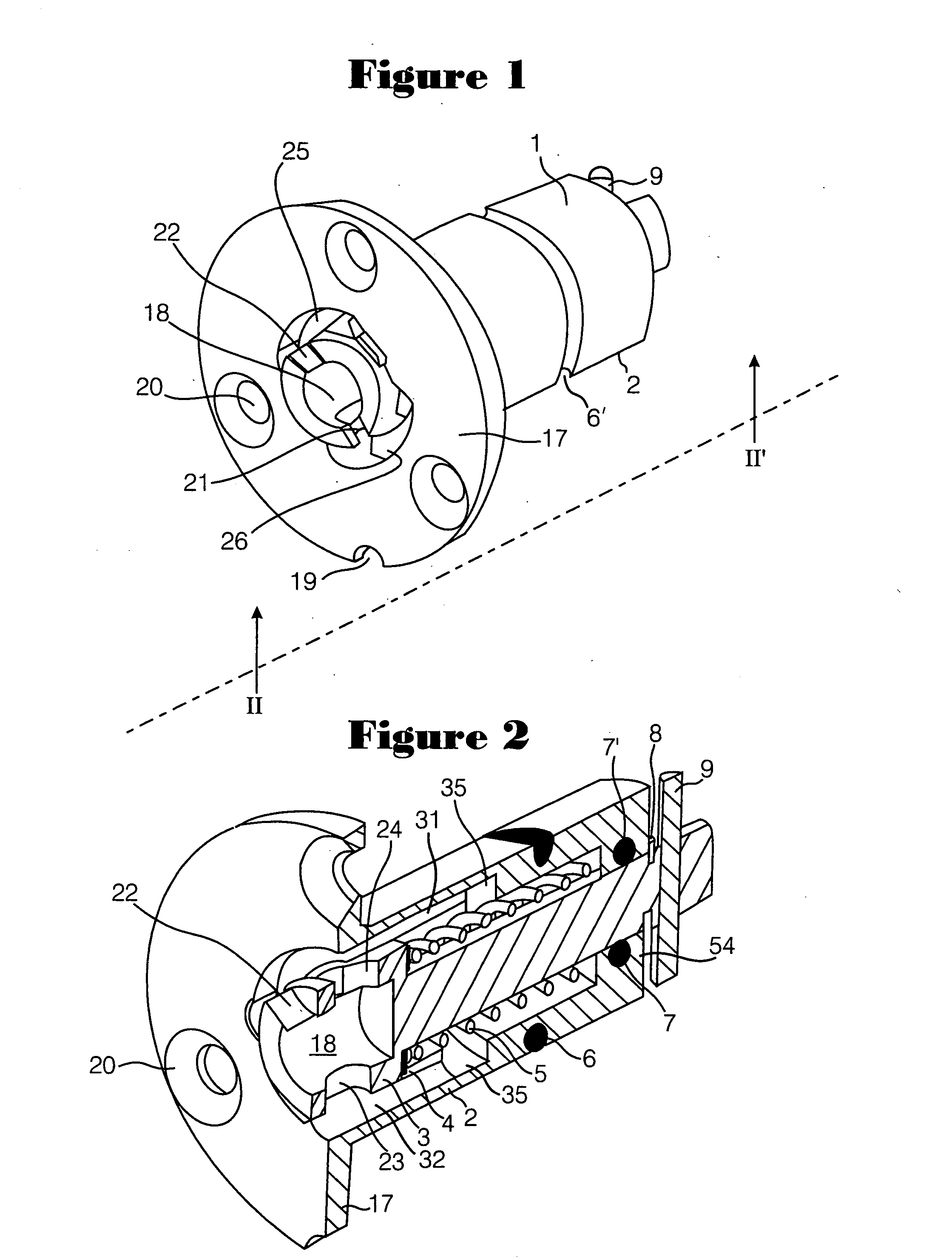

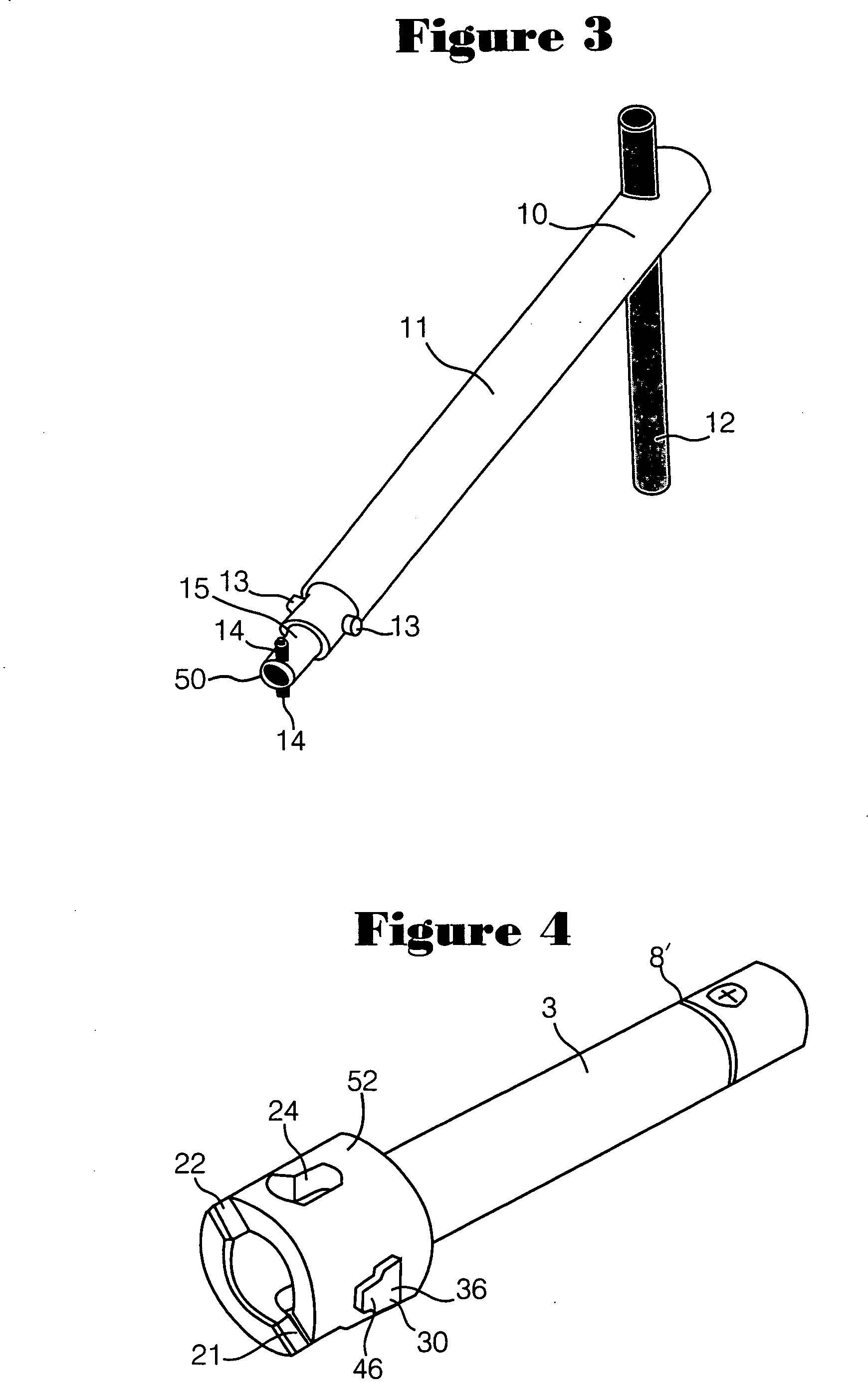

Safing lock mechanism

A locking mechanism for a pyrotechnic safe and arm interrupter 98 may be constructed with an external lock casing 2, longitudinally extending bolt 3, washer 4, spring 5, retaining ring 8 and interlocking element 9 that may be configured in various shapes and features corresponding with a safety release component. A key 10 may be constructed with key stem 11, handle 12 and two pairs of teeth 13, 14 of different diameters radially protruding from successively reduced diameters along a distal portion of key stem 11. Lock 1 may be installed with notch 19 in alignment with a corresponding feature of the safe and arm interrupter mechanism and fastened in place with mounting holes 20 so that only mounting flange 17 and the key access 18 are external to the interrupter device, panel or door.

Owner:SCOT

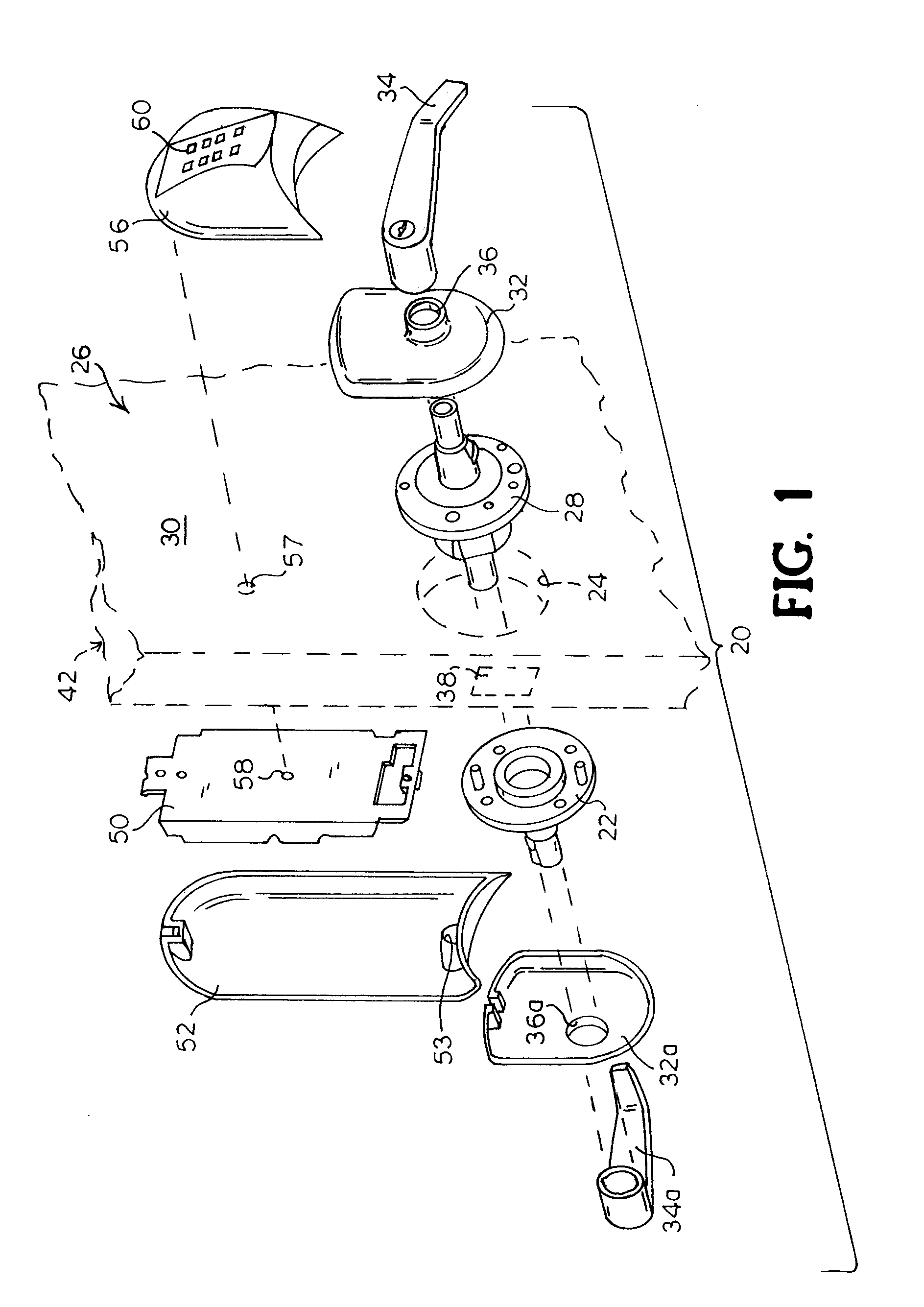

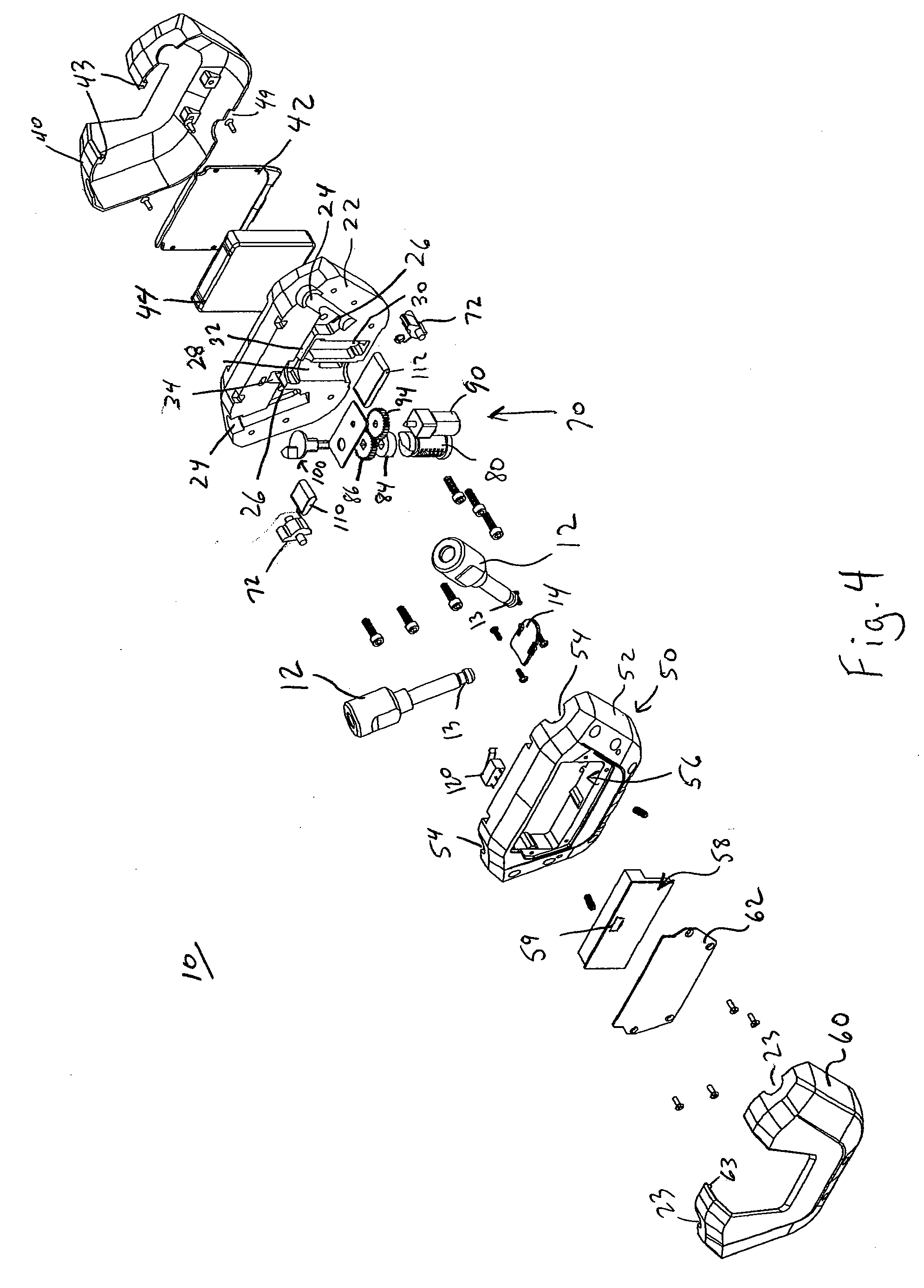

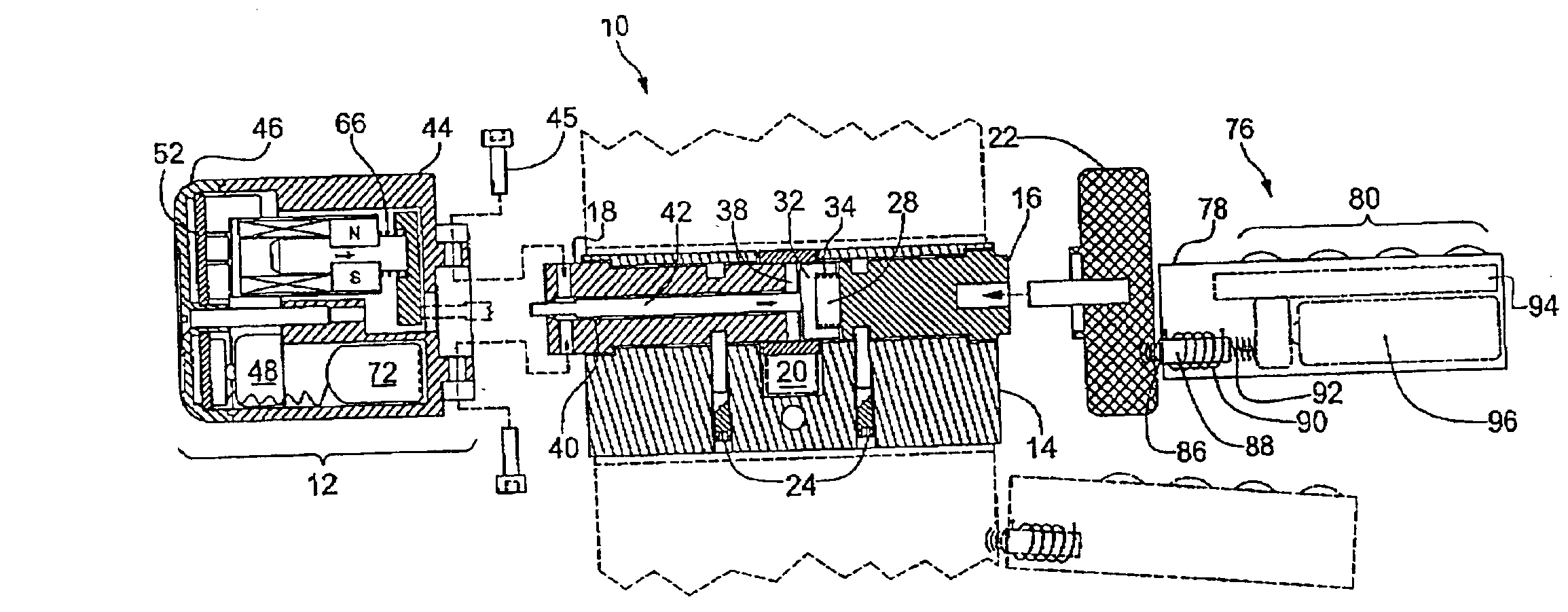

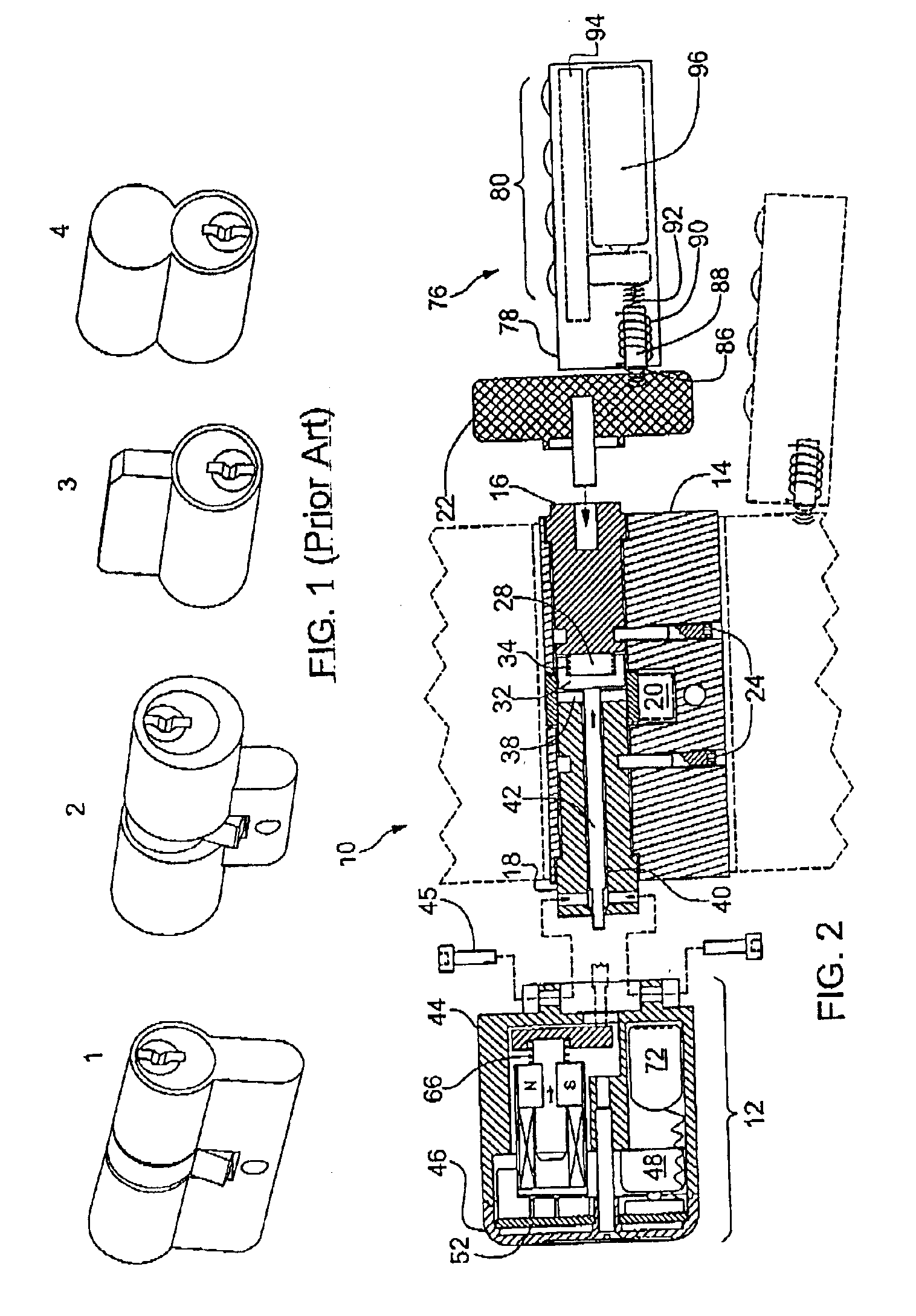

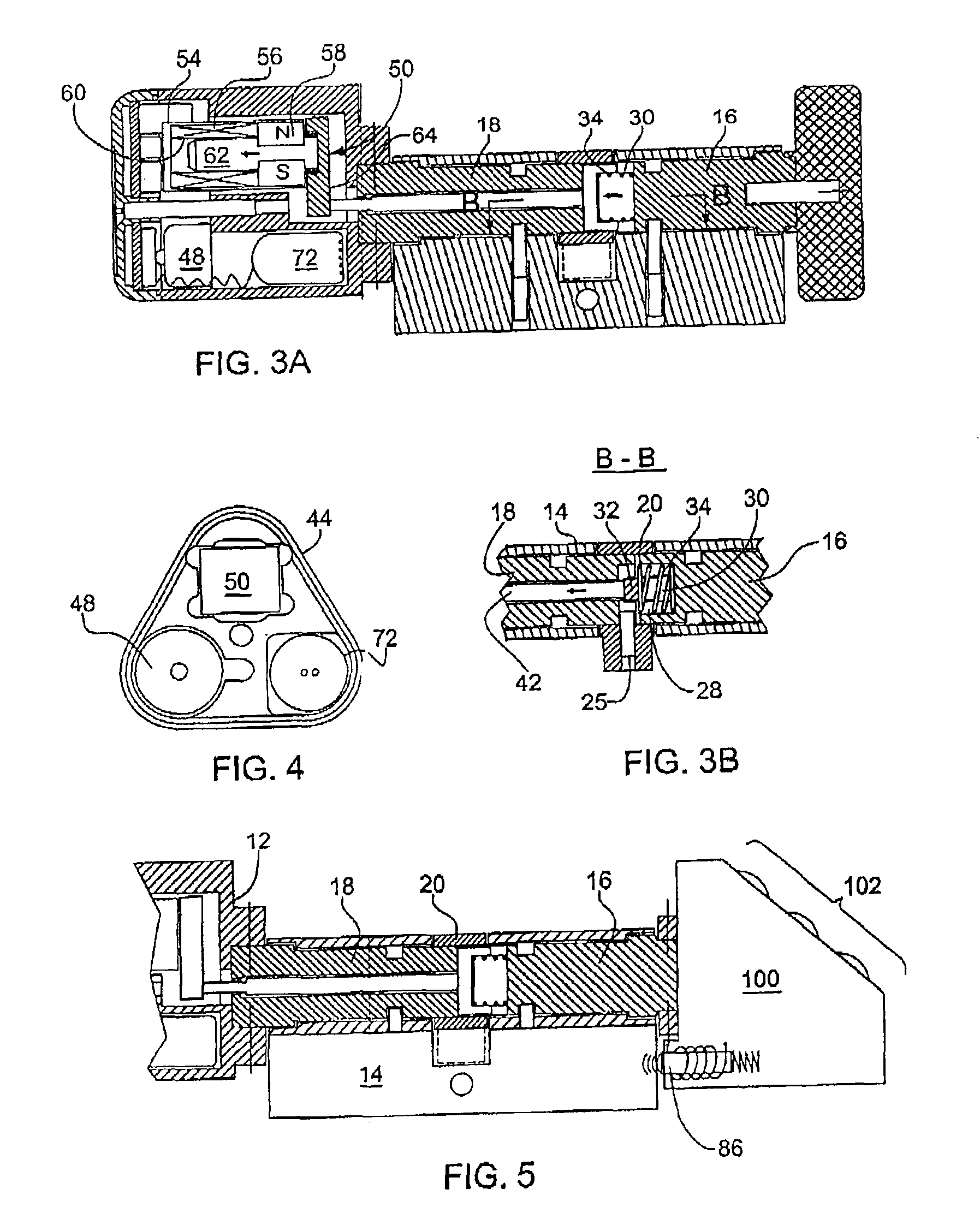

Keypad lockset

ActiveUS20100257906A1Accurate and reliable engagementSmooth engagementLock applicationsDigital data processing detailsElectrical FailureEngineering

A keypad lockset adapted for deadbolt as well as lever locks, and having as a first embodiment an exterior gear train, an interior gear train, and an electronically controlled clutch for coupling the gear trains when engaged and for uncoupling the gear trains when the clutch is disengaged, so that when the clutch is engaged rotation of an external thumb turn will permit the door latch to be withdrawn and thus to permit opening of the door, and a mechanical override mechanism that can be operated in case of electrical failure, and in which clutch mechanism and the override mechanism both operate through the single, standard 2⅛ inch door preparation hole, or alternatively as a second embodiment, a keypad lockset in which two four-bar mechanical linkages are used in place of gears as means to actuate the clutch, and alternatively to provide for a pass-through override function.

Owner:ASSA ABLOY RESIDENTIAL GRP INC +1

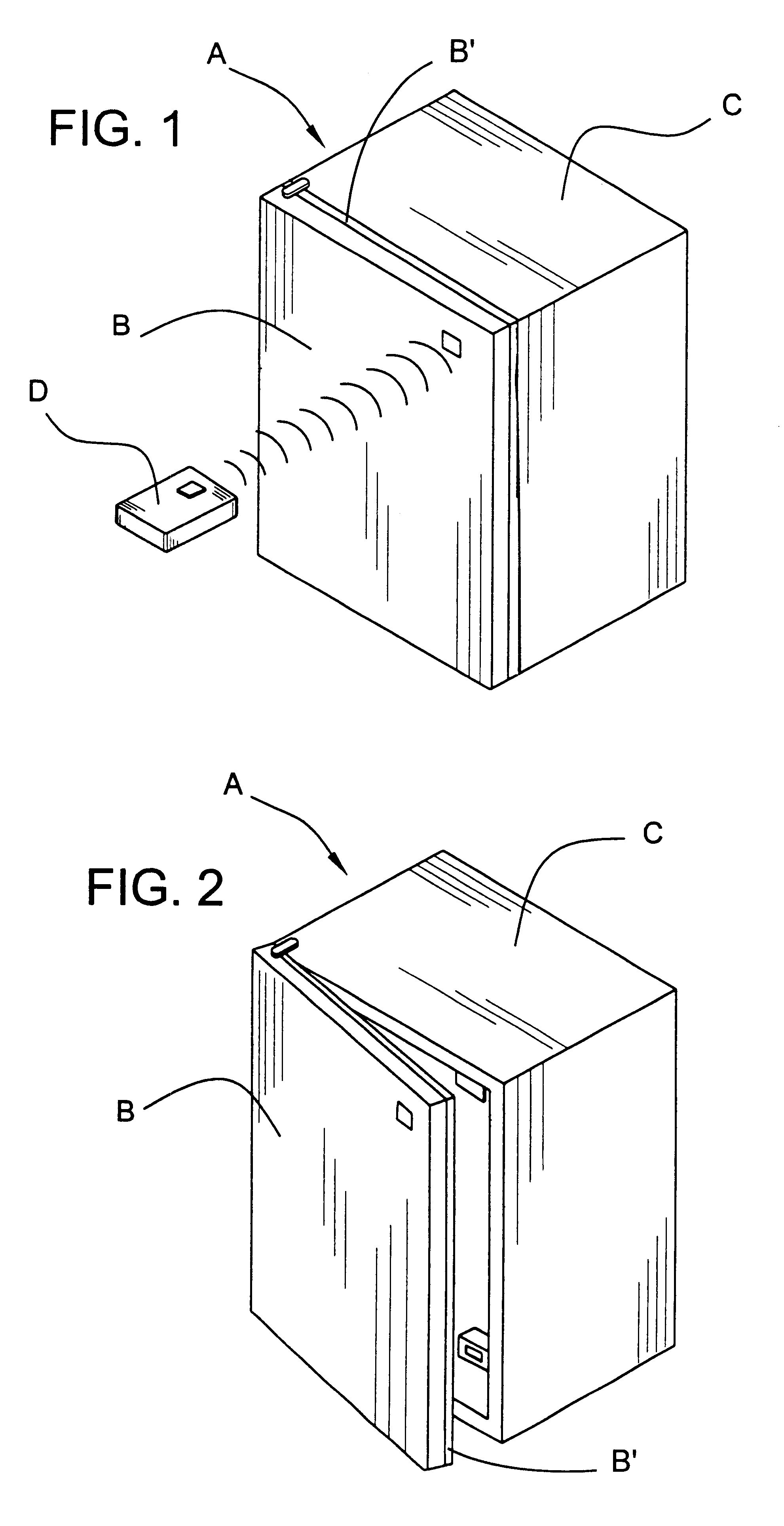

Bayonet locking system and method for vending machines and the like

InactiveUS6581986B2Avoid plastic deformationAnti-theft cycle devicesAnti-theft devicesMotor driveEngineering

A bayonet locking system for vending machines is provided to lock and unlock the machine preferably with a remotely controlled electronic operating unit. It includes at least one motor driven axially and rotationally movable bayonet with an enlarged shaped head being mounted preferably on a gasketed door and at least one receptacle receiving device disposed within the machine interior positioned for engagement by the bayonet when the door is moved to an intermediate position. The bayonet advances into the receptacle and rotates to capture it in the receptacle and then axially retracts to pull the door into the closed position wherein a gasket disposed between the door and the machine is substantially uniformly compressed and sealed around its periphery. An axially rotatable pin with fins may be used with a bracket on either the door or machine to prevent prying of the door at opposite corners.

Owner:TRITEQ LOCK & SECURITY L L C

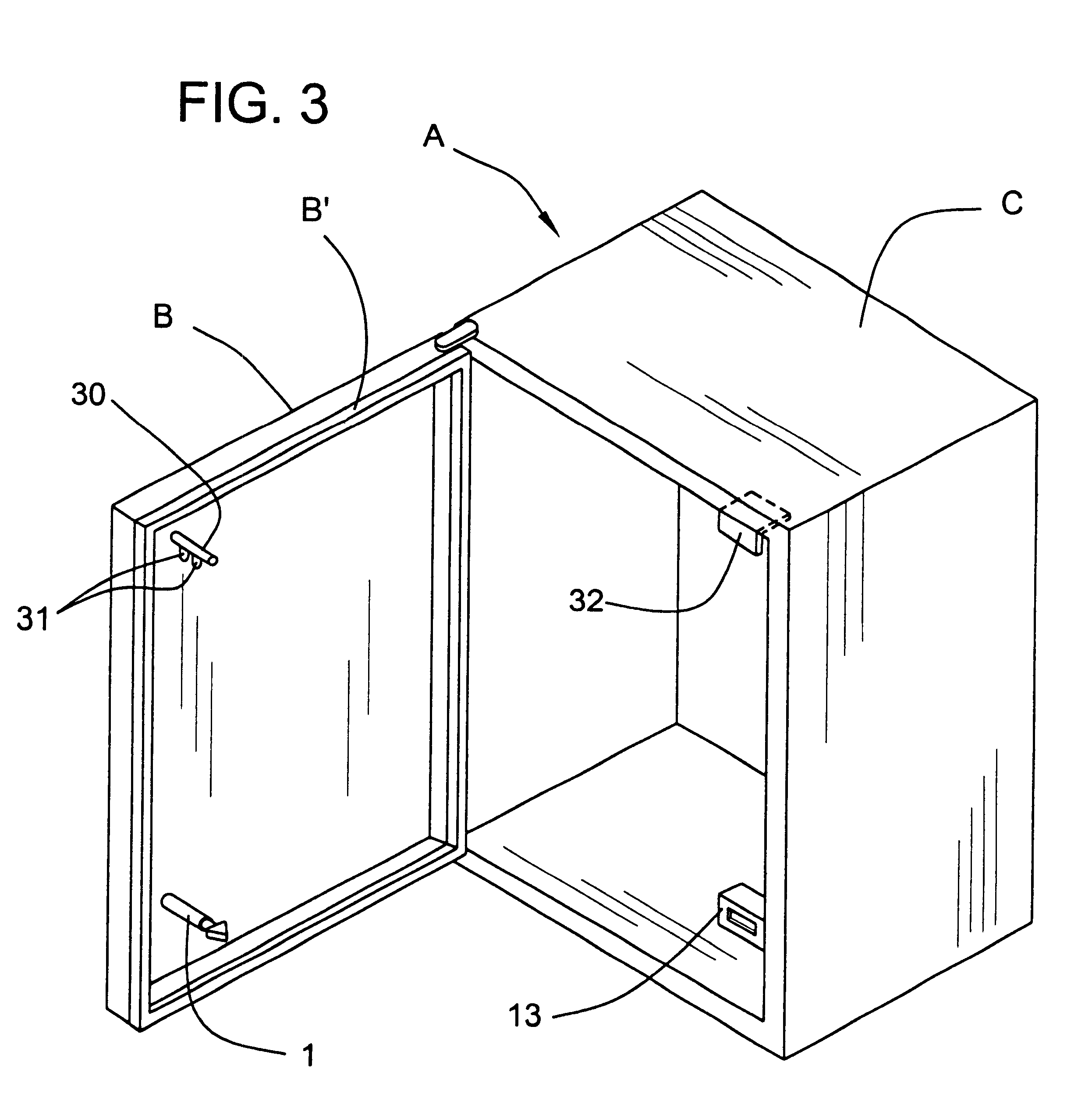

Portable lock with electronic lock actuator

ActiveUS20090282876A1Prevent movementLock applicationsDigital data processing detailsEngineeringActuator

A lock assembly including a body and at least one locking member. An actuator mechanism within the body is moveable between locked and unlocked positions. The actuator mechanism may be actuated by either a key lock cylinder or an electronic actuator. The lock assembly may also include a memory configured to store user identification information.

Owner:SCHLAGE LOCK

Door cylinder lock

InactiveUS6865916B2Good flexibilityConsiderable convenienceAnti-theft cycle devicesAnti-theft devicesCamLight signal

A cylinder lock for use in a door lock, comprising an outer plug, an inner plug, a rotary cam adapted to move a deadbolt of the door lock, and a clutch adapted to engage for rotation the outer plug to the rotary cam. The cylinder lock further comprises an electronic blocking device (EBD) and a drive adapted to actuate the clutch upon an unblocking command from the EBD generated upon receiving therein an unblocking signal emitted from the outer side of the door, thereby enabling moving the deadbolt by rotation of the outer plug. The cylinder lock comprises an inner handle attached thereto at the inner side of the door, the EBD and the drive being entirely accommodated within the inner handle. The signal is emitted by an electronic key or panel and may be a mechanical vibration signal, a light signal, or a radio signal.

Owner:GOLDMAN & CO INC

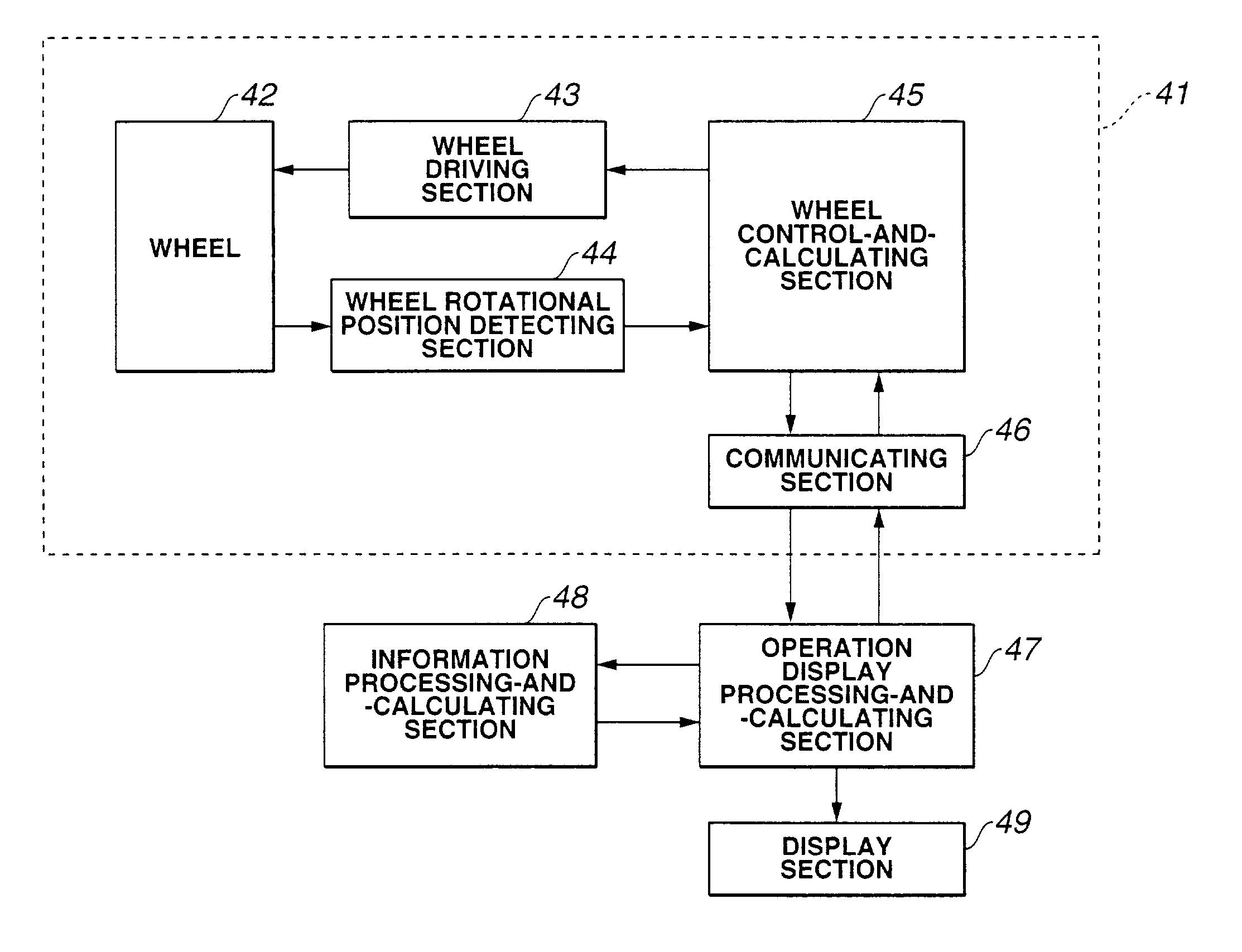

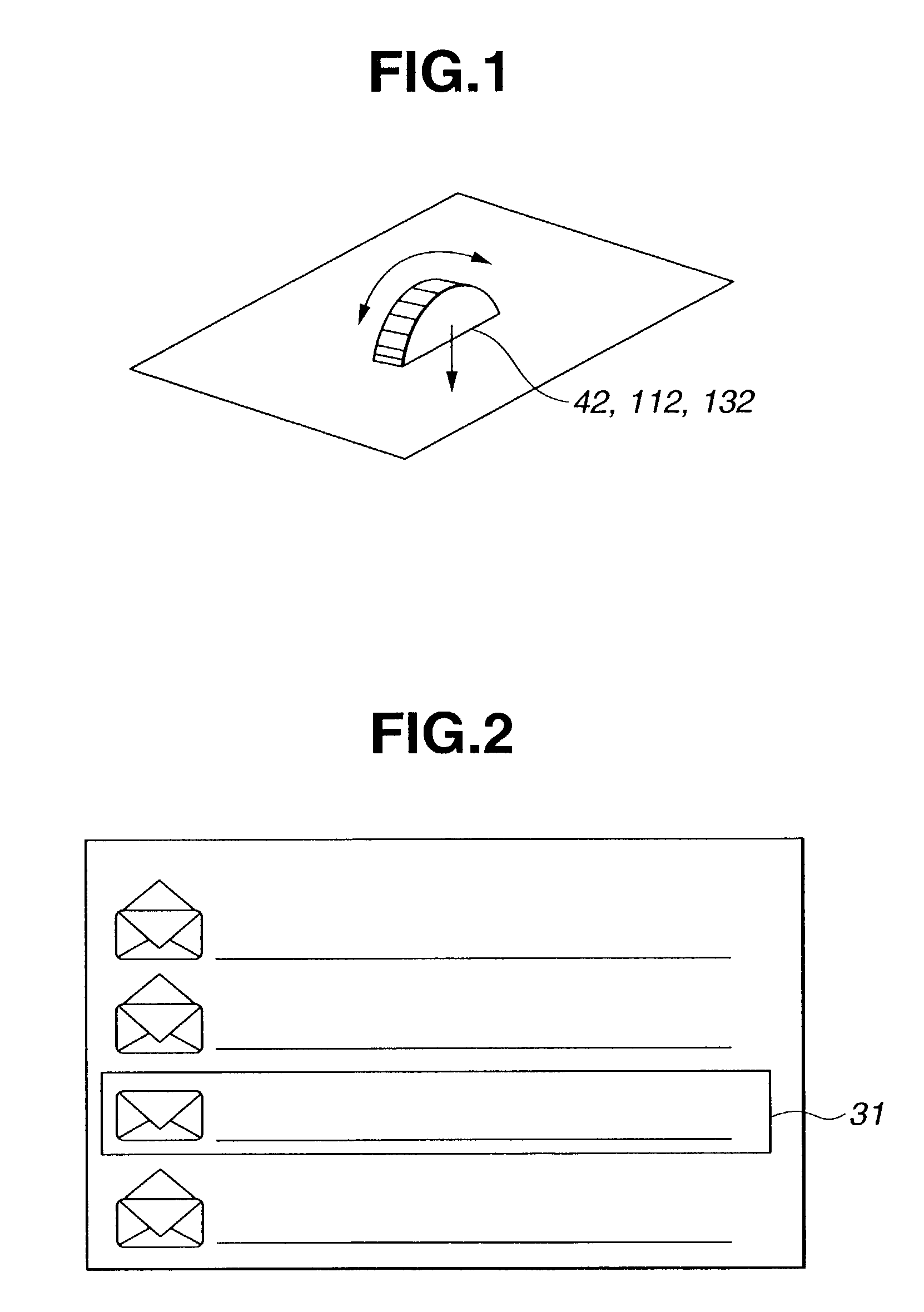

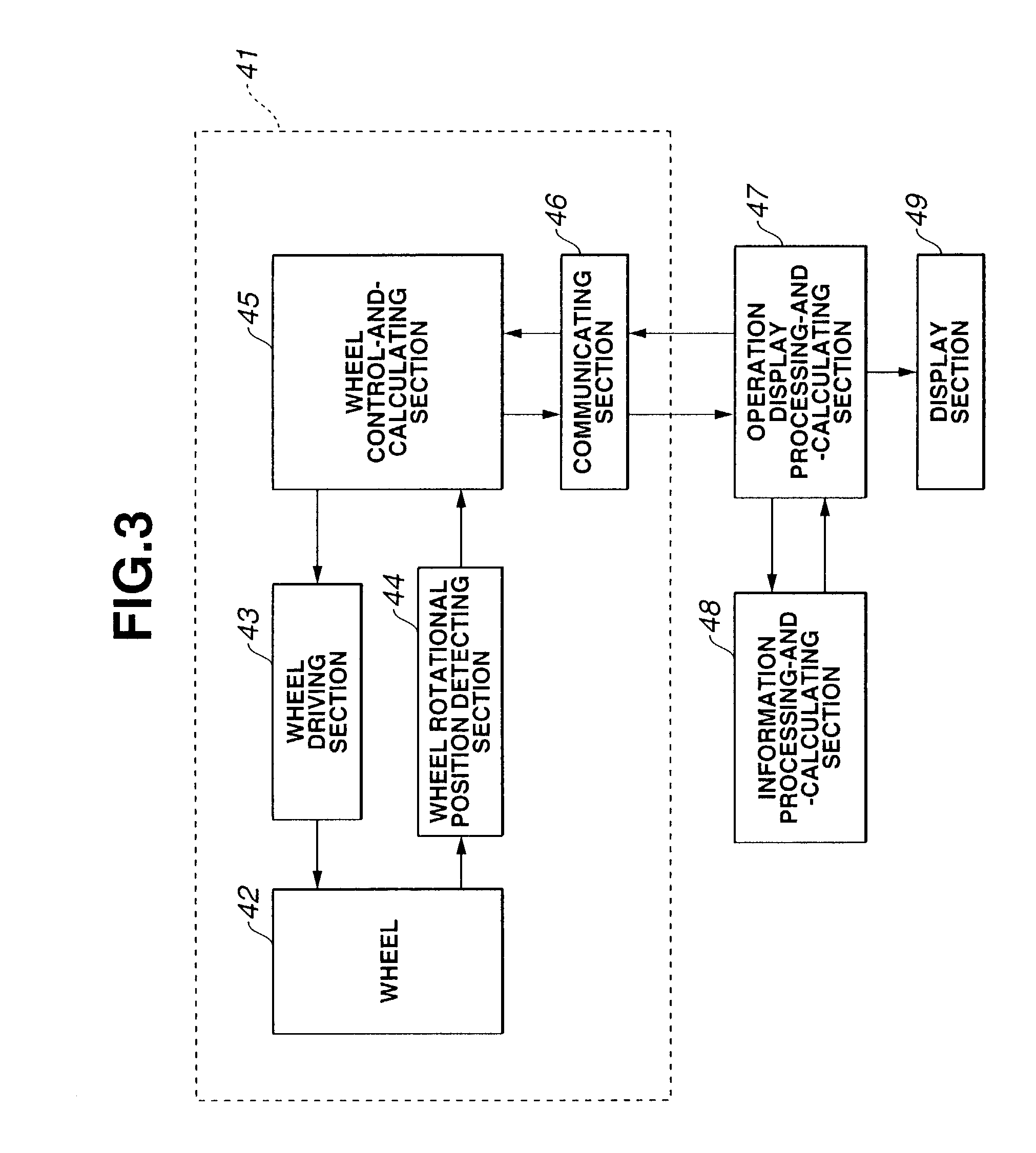

Rotary input apparatus

InactiveUS7545367B2Operation of switchingInput/output for user-computer interactionLimiting/preventing/returning movement of partsDisplay deviceEngineering

In a rotary input apparatus, an operational end enabled to be rotationally operated is provided, an operational input device detects a rotational displacement of the operational end to move a pointer displayed on a display thereof to perform a selection operation of any one of various kinds of selection items displayed on the display and a driving force generating section generates and transmits a driving force to the operational end in accordance with a reaction force pattern when the operational end is rotationally operated, the operational input device setting the reaction force pattern against the rotational displacement of the operational end and varying the reaction force pattern on the basis of an input signal from at least one of an internal of and an external to the operational input device when the operational end is rotationally operated.

Owner:NISSAN MOTOR CO LTD

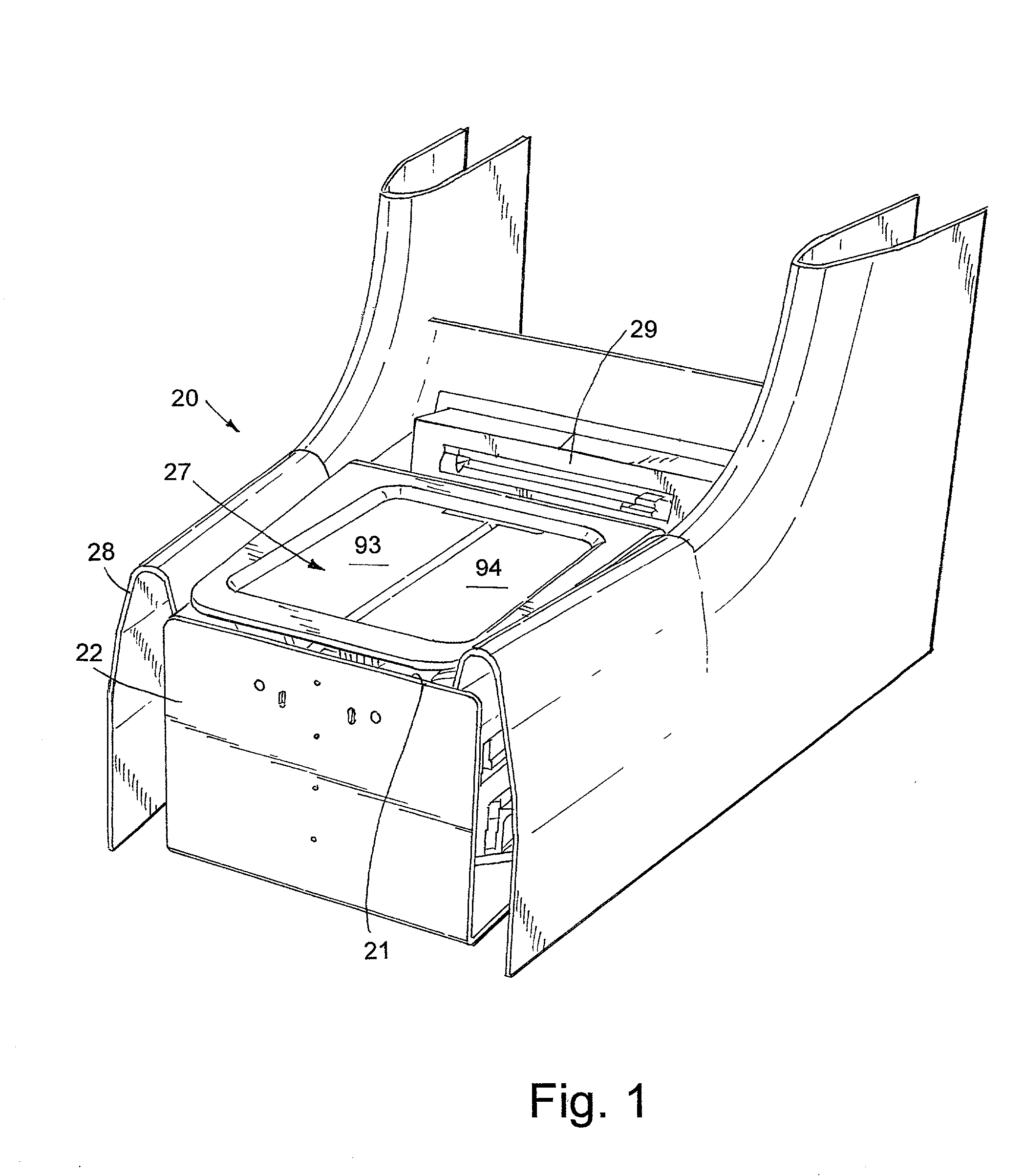

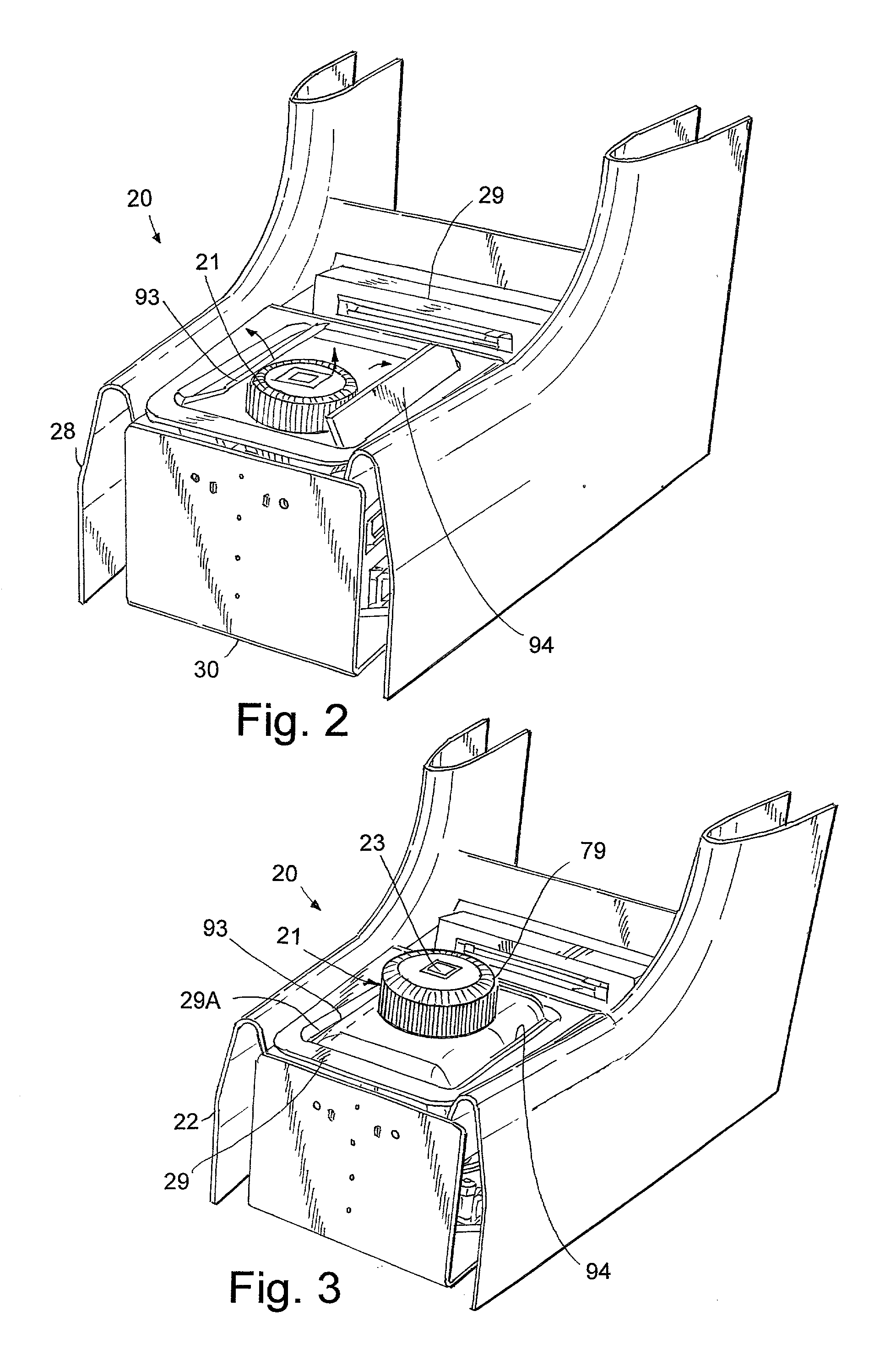

Storable shifter with electronic gear shift reset

InactiveUS20030029261A1Controlling membersDashboard fitting arrangementsDisplay deviceEmbedded system

Owner:GRAND HAVEN STAMPED PRODS DIV OF JSJ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com