Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Zero backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

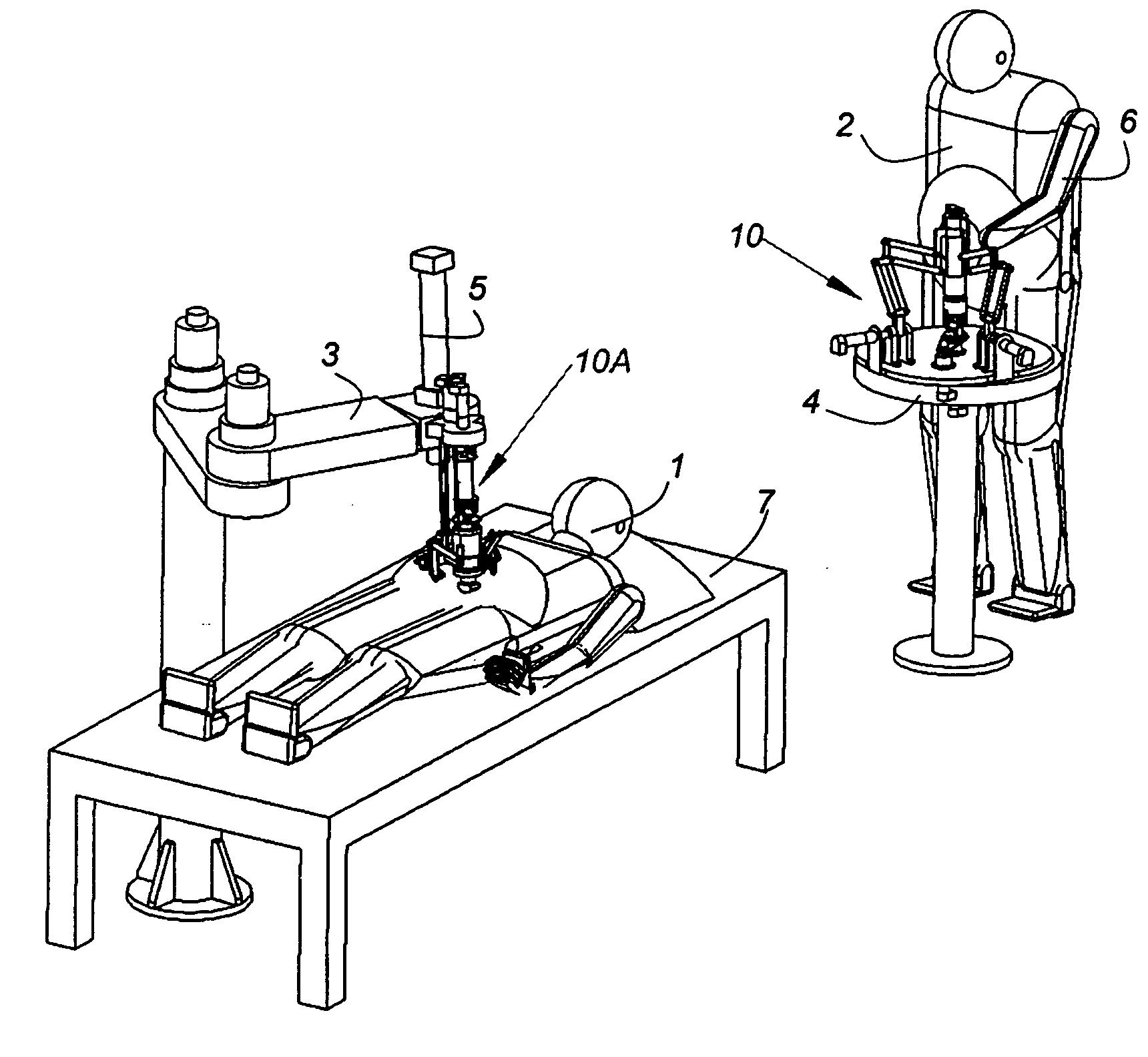

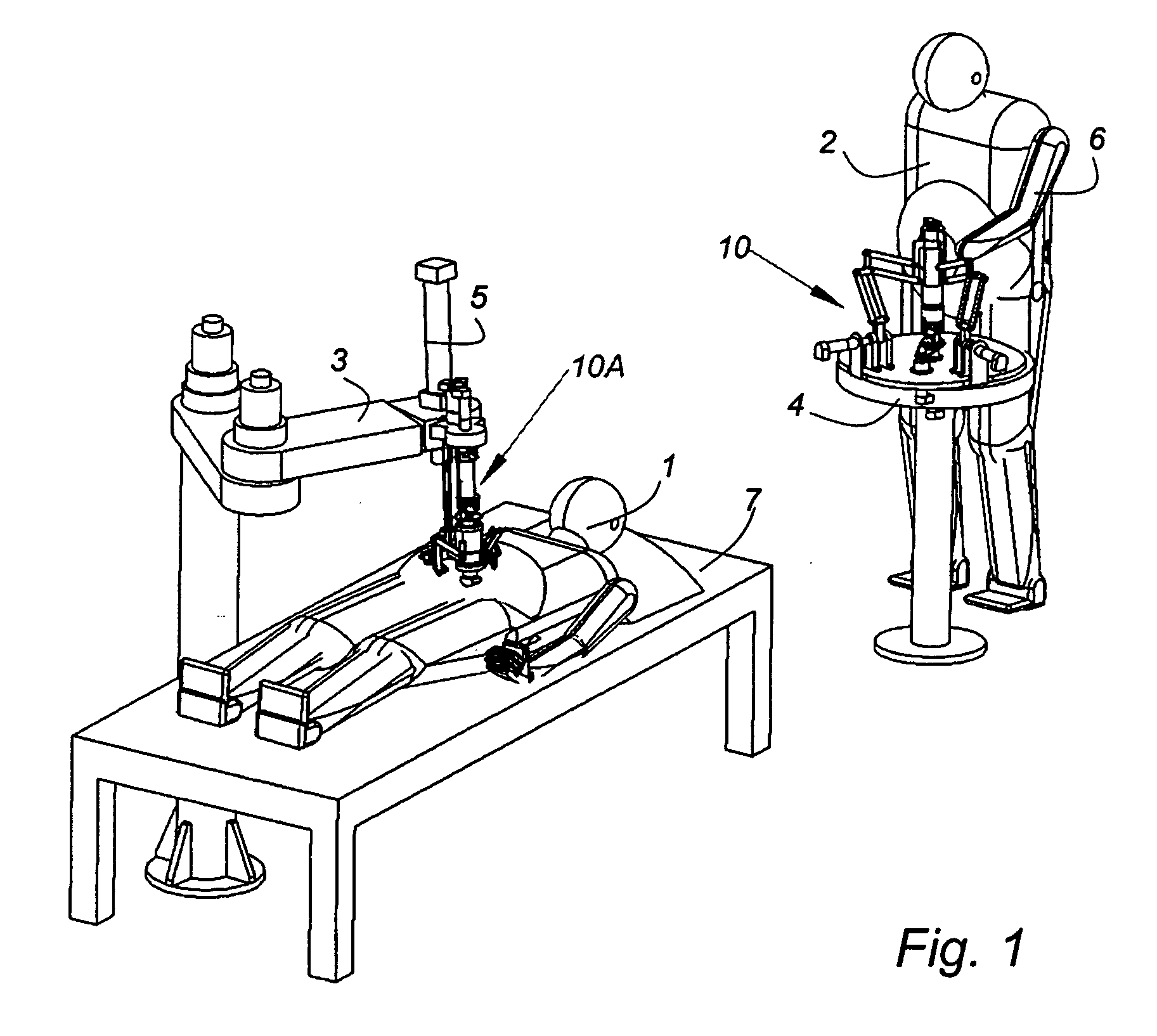

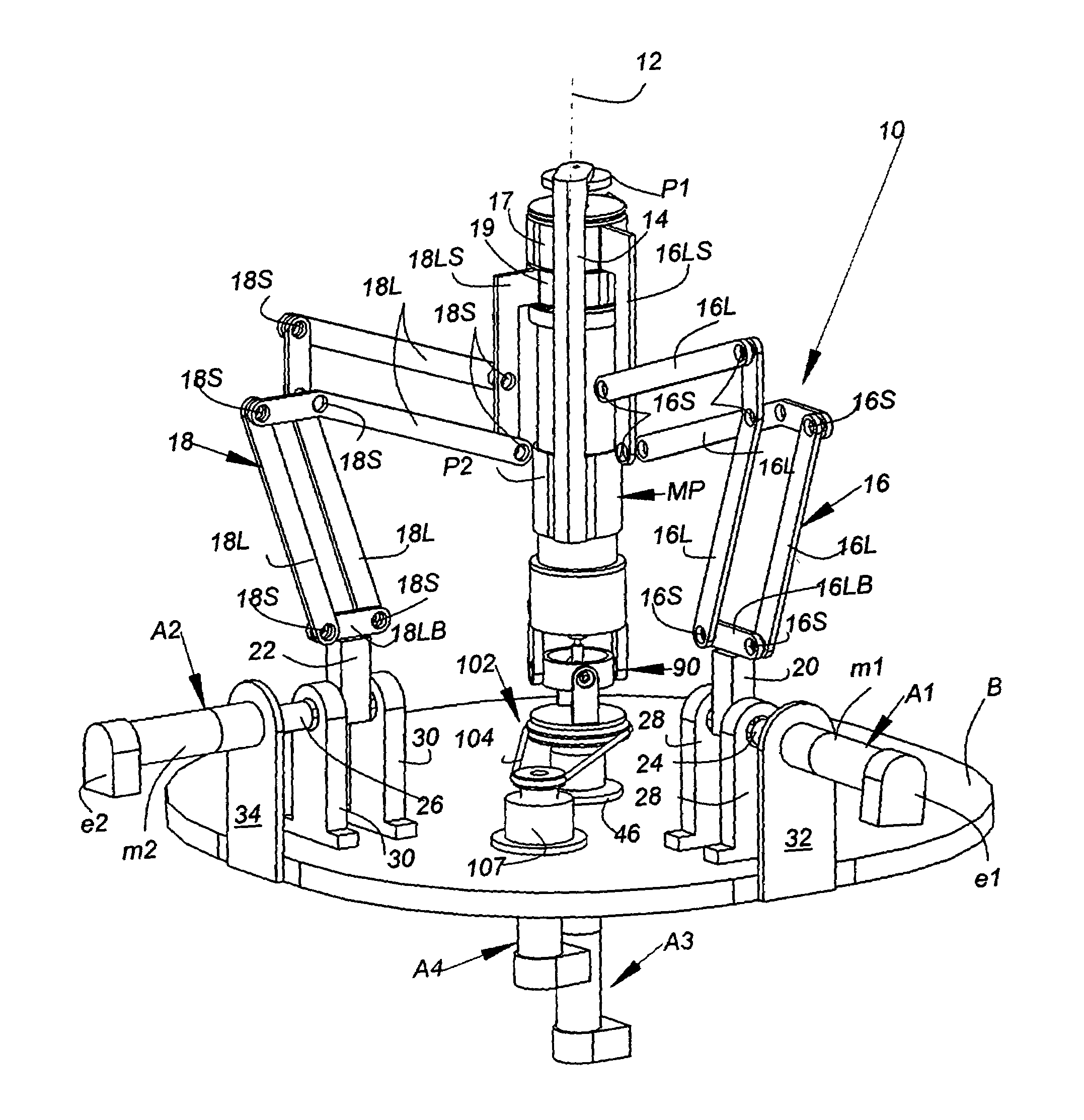

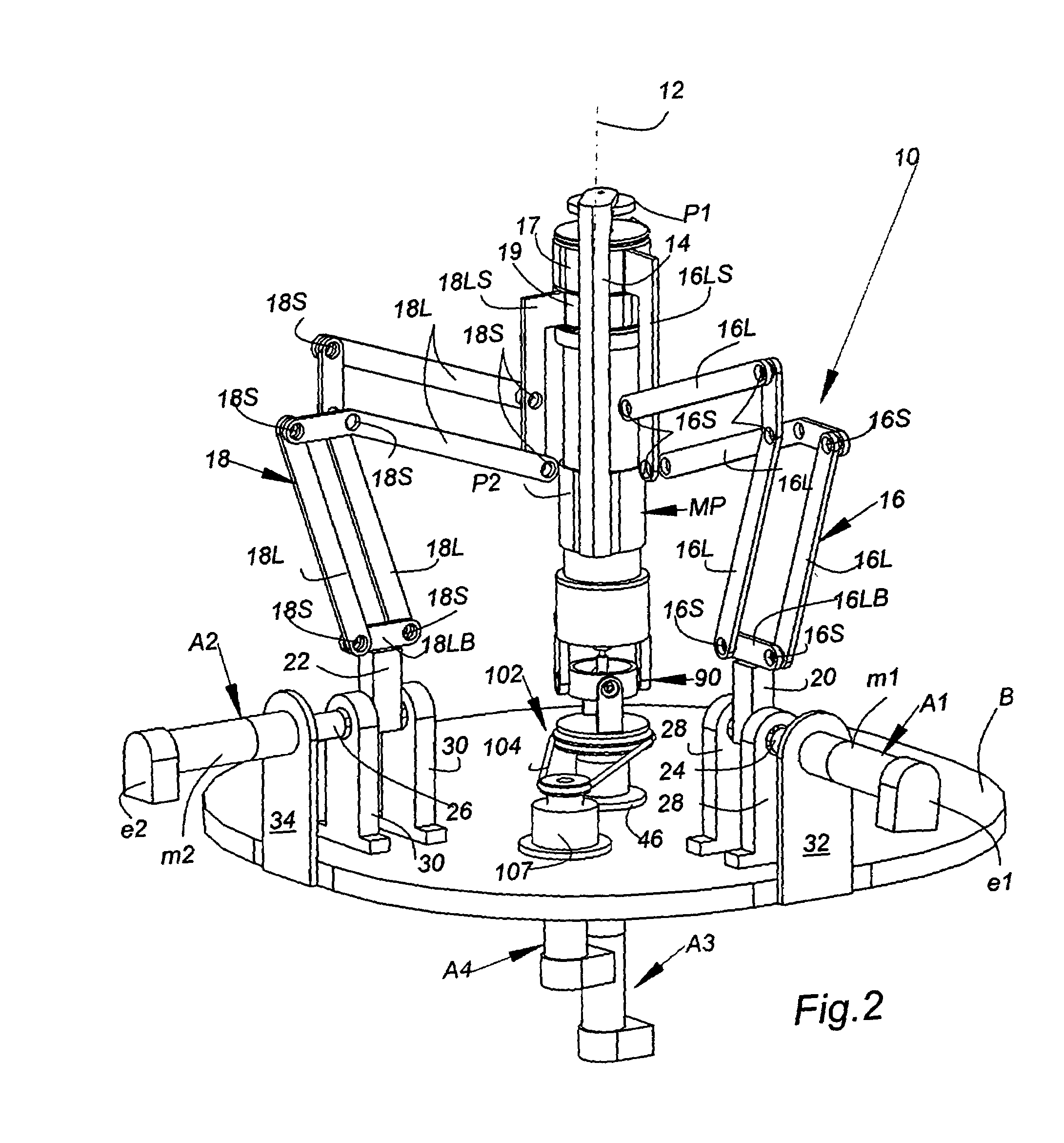

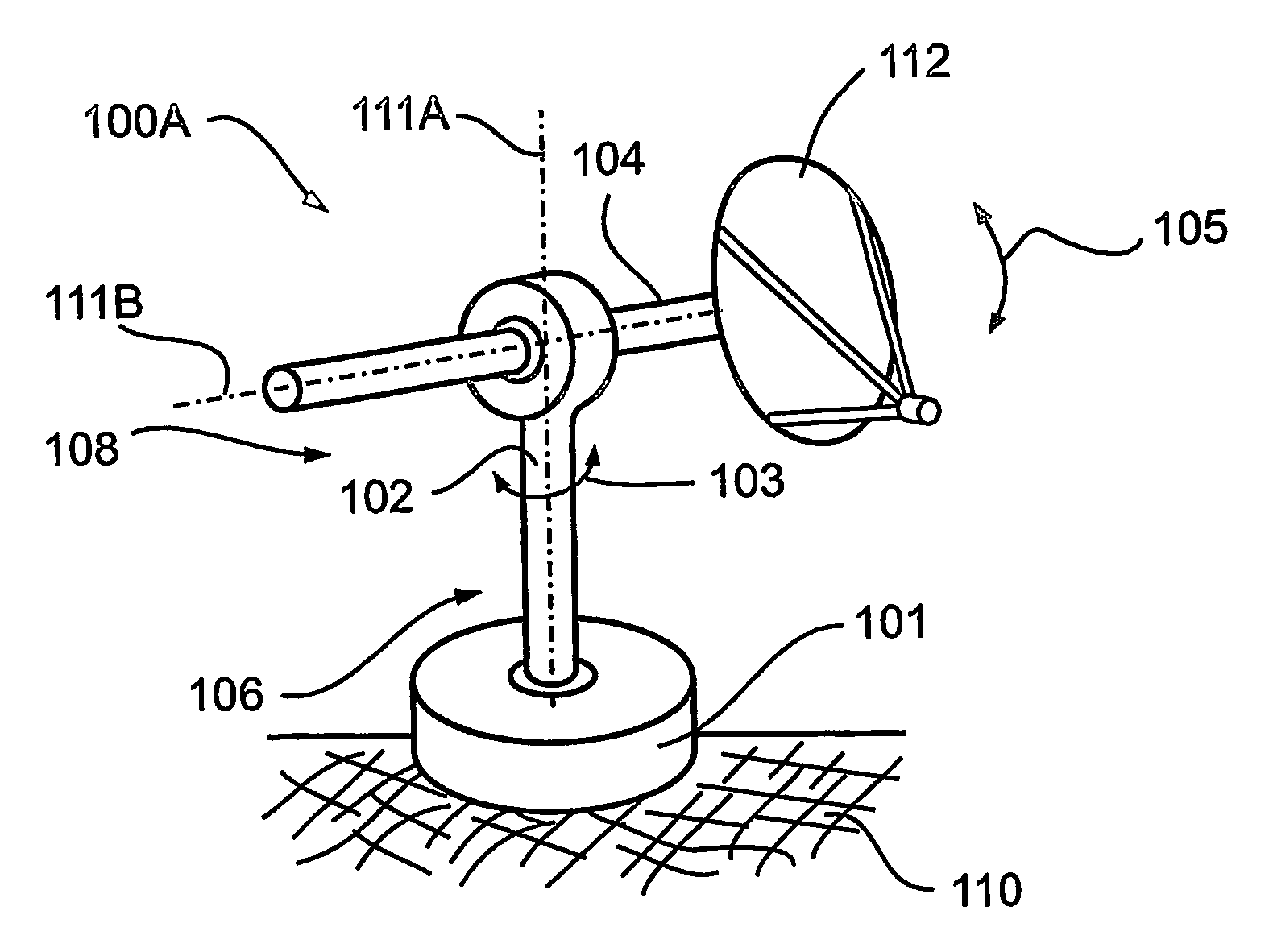

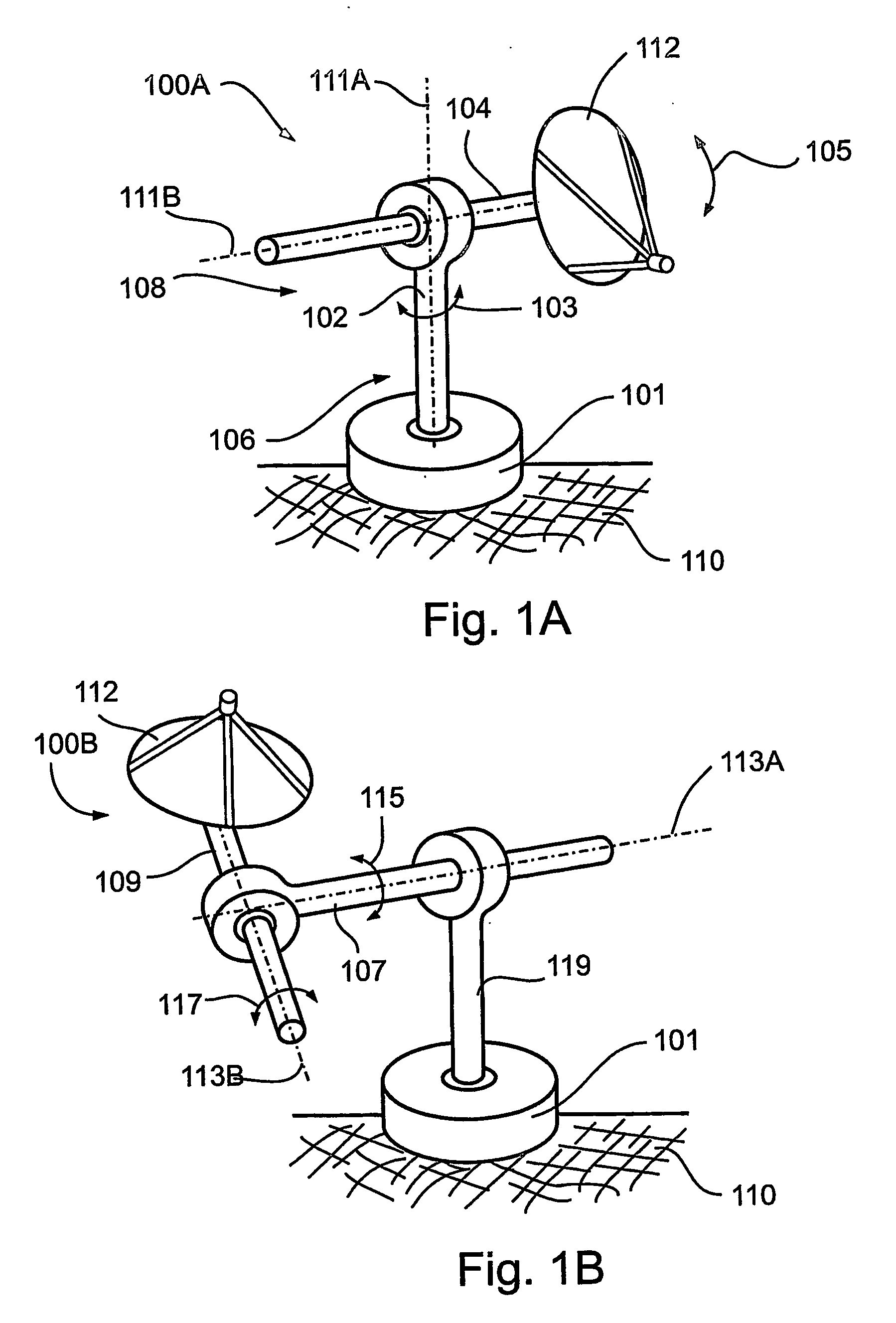

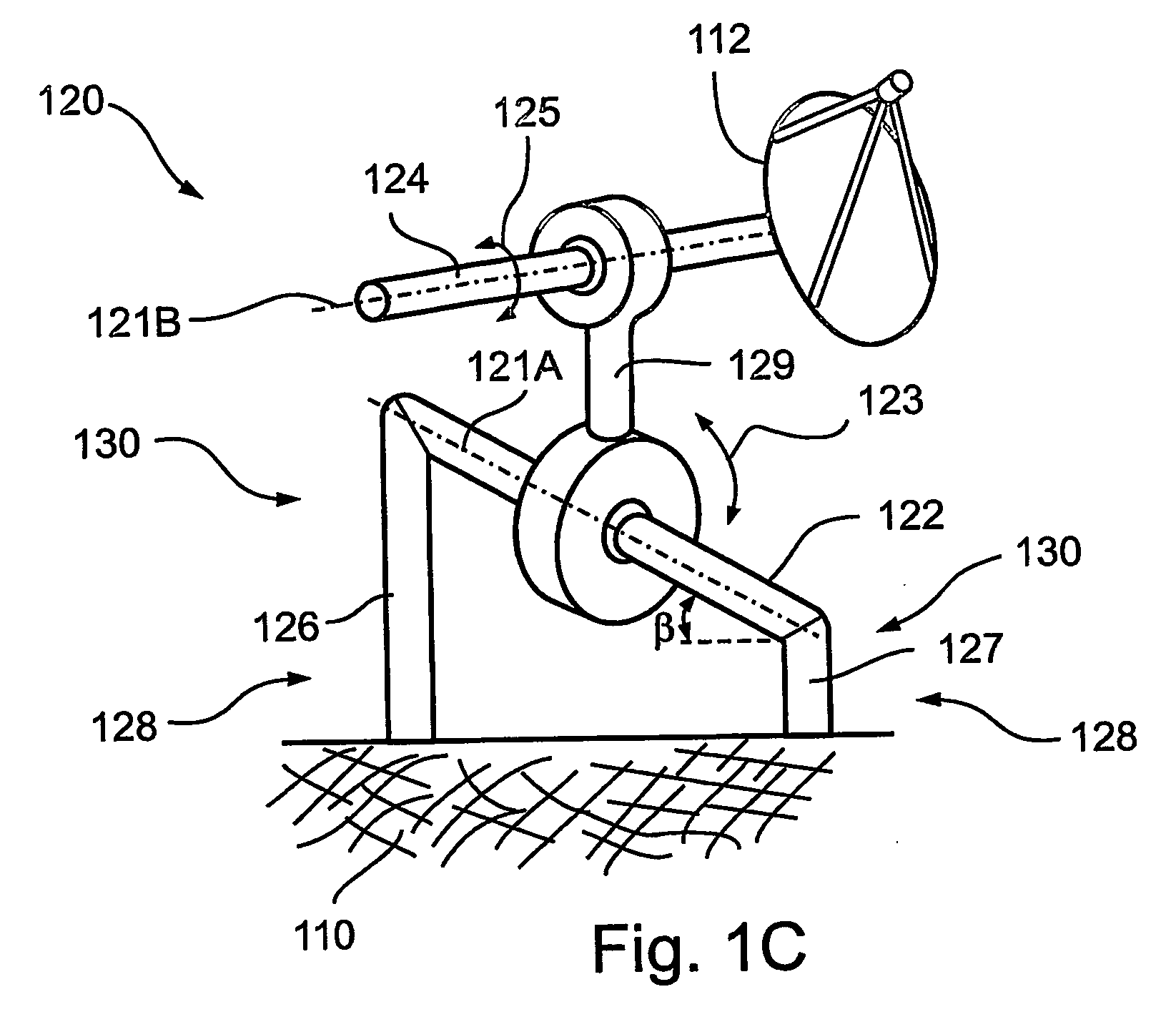

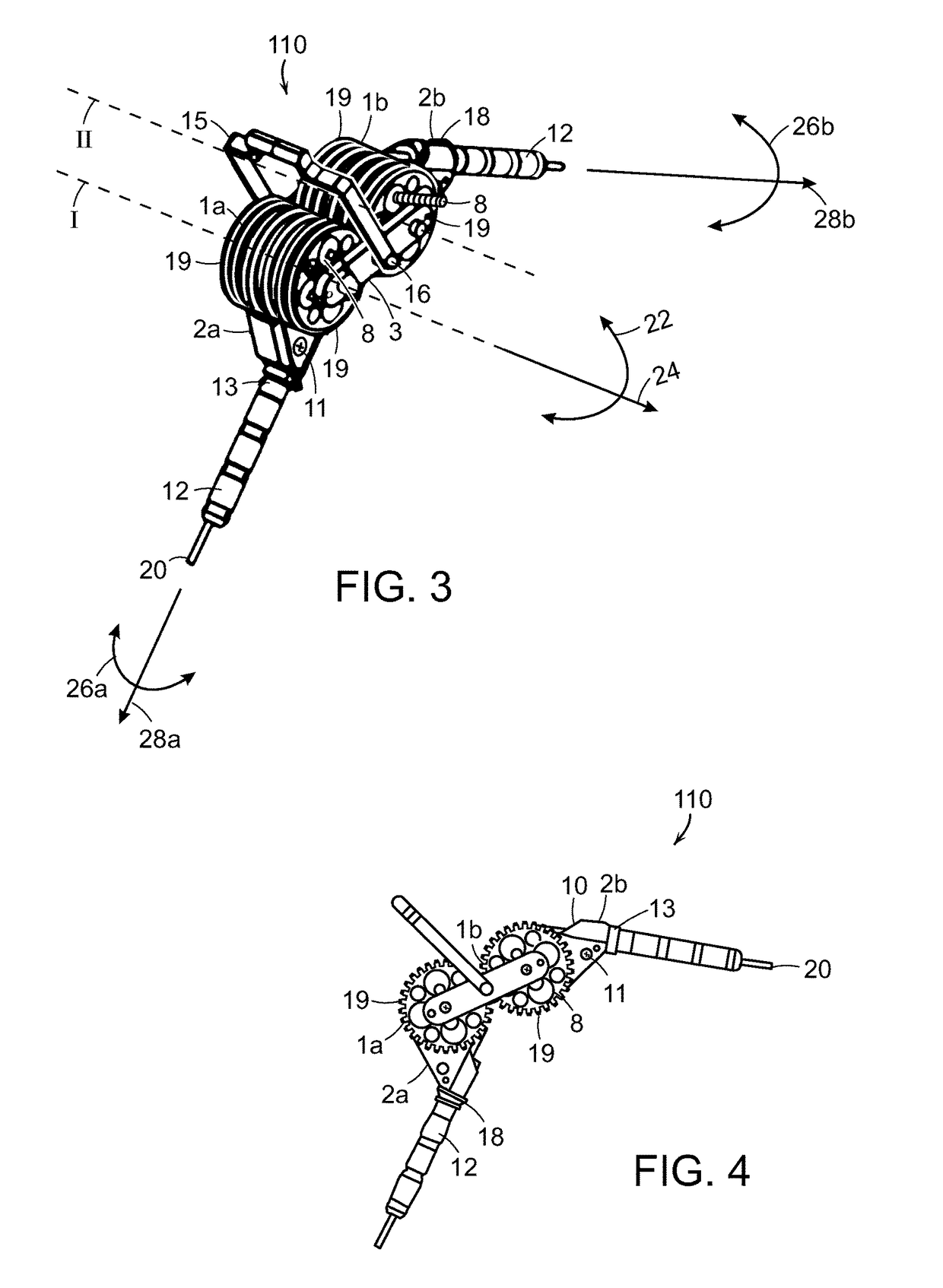

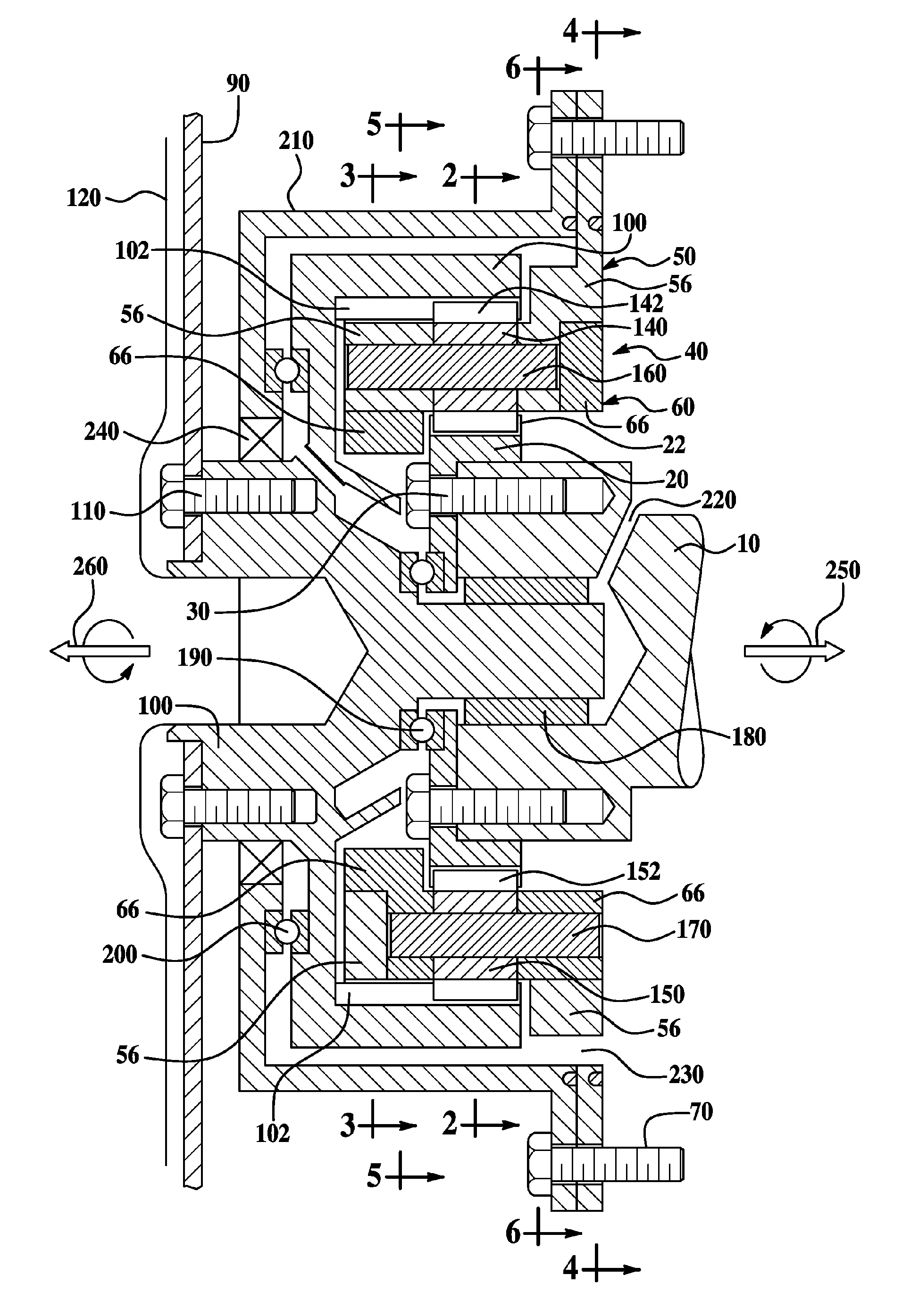

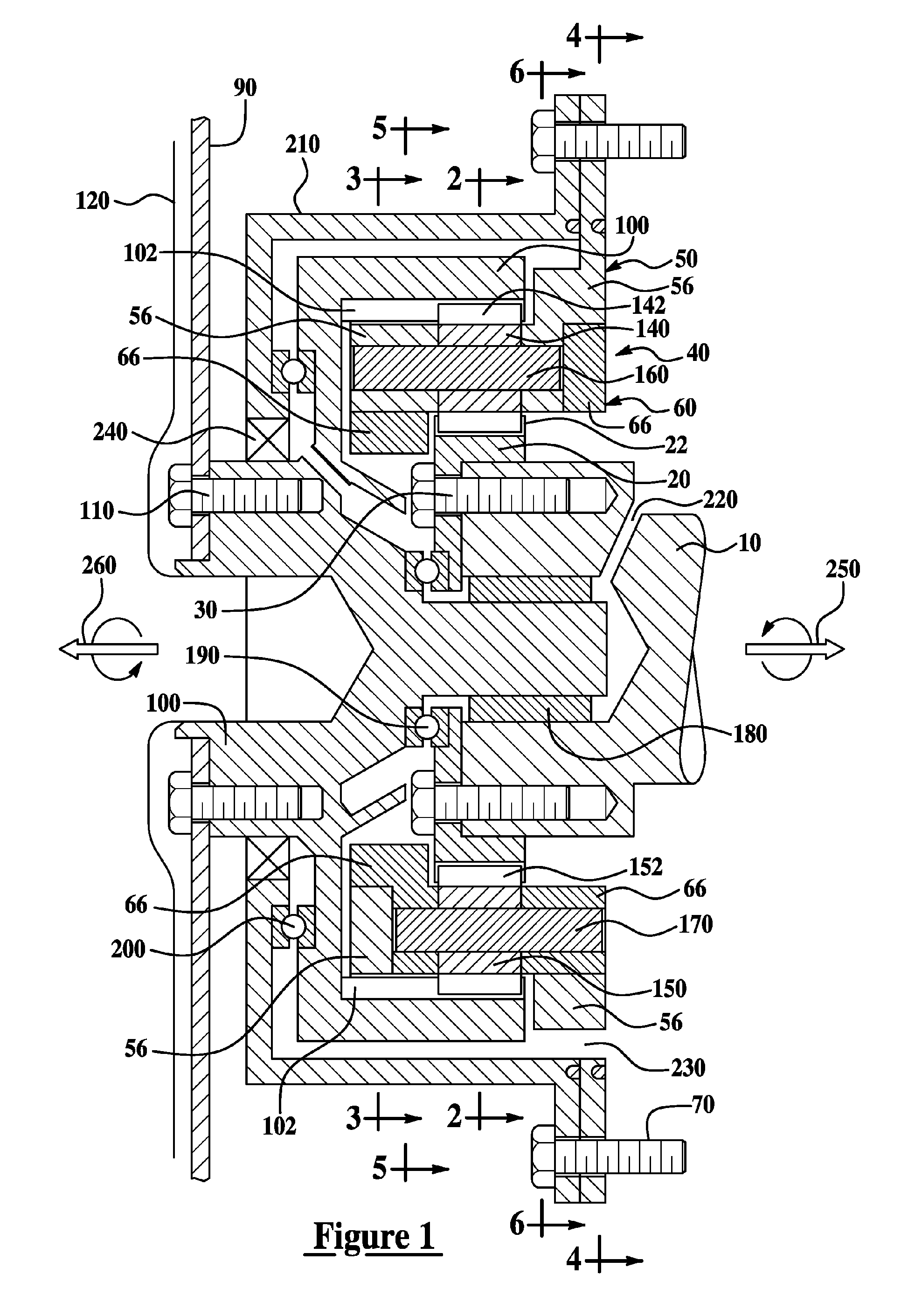

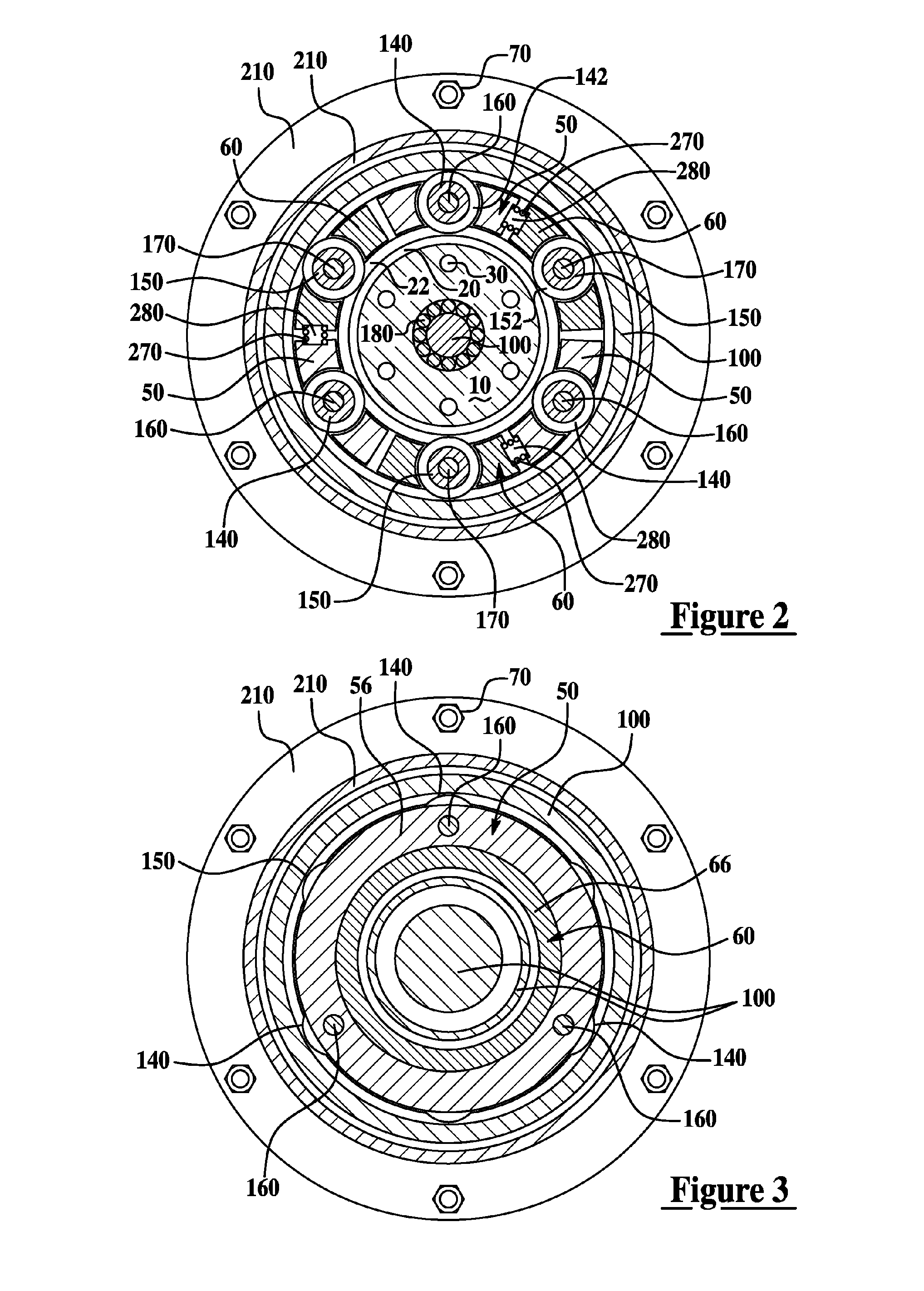

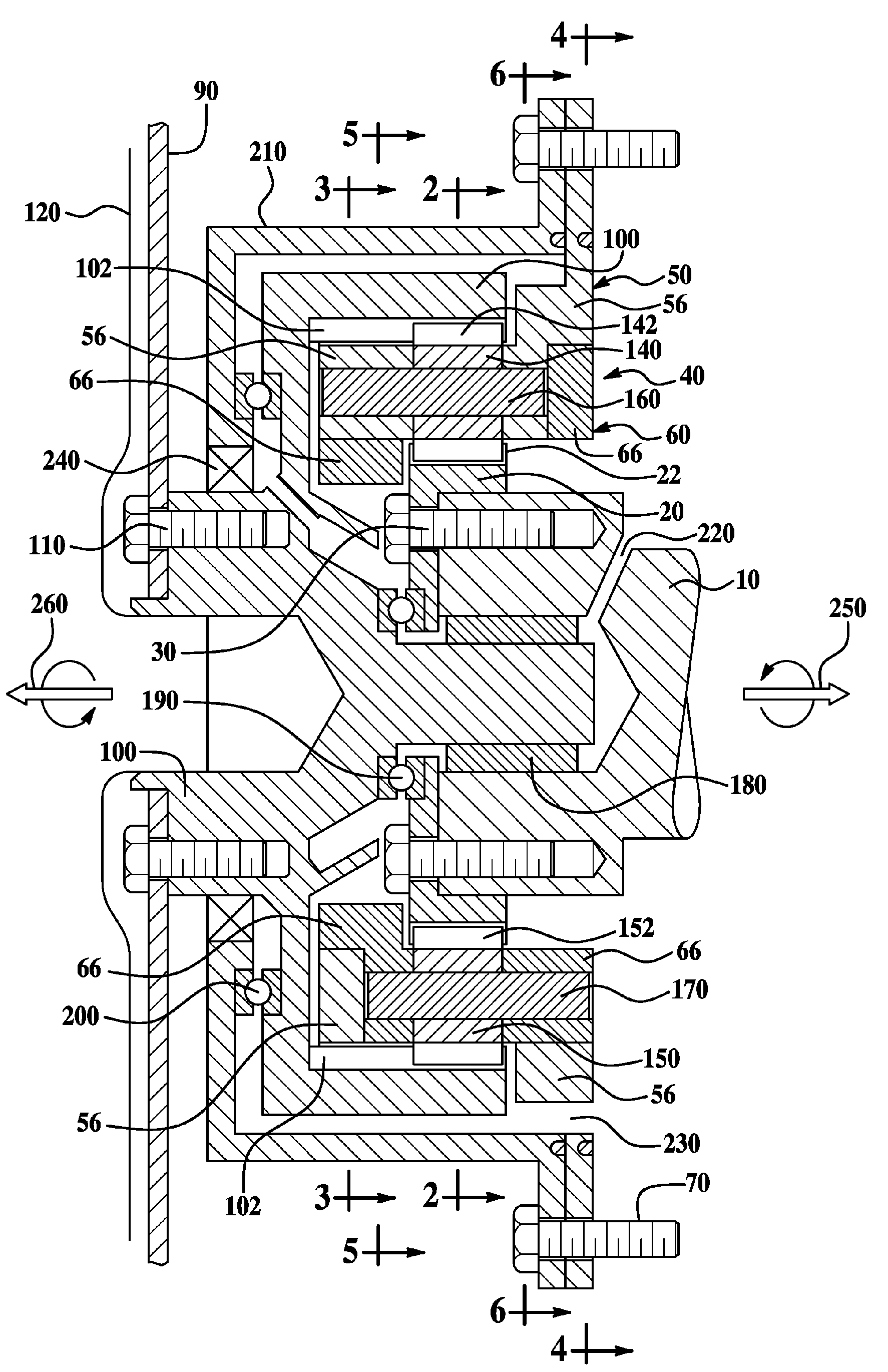

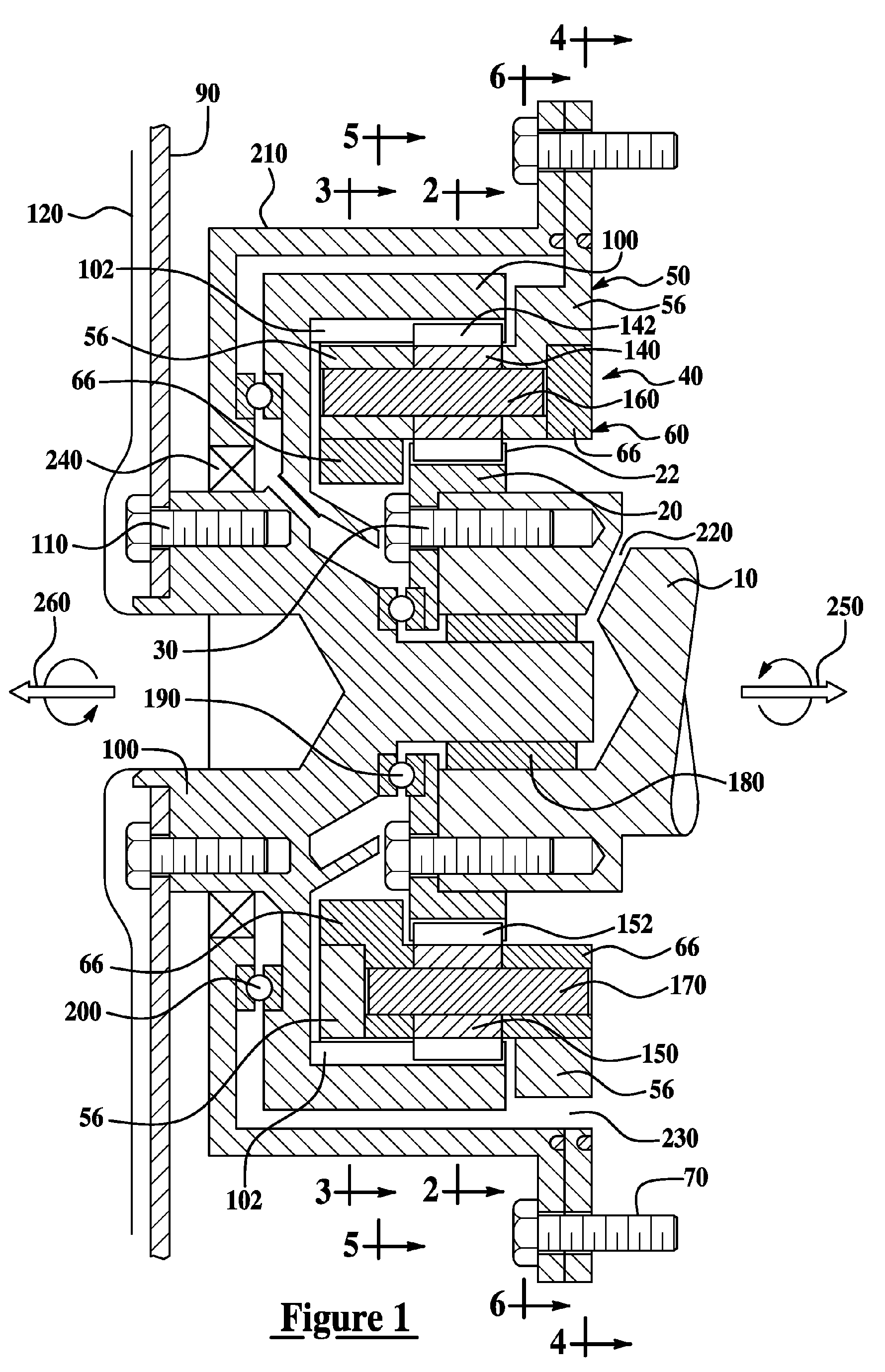

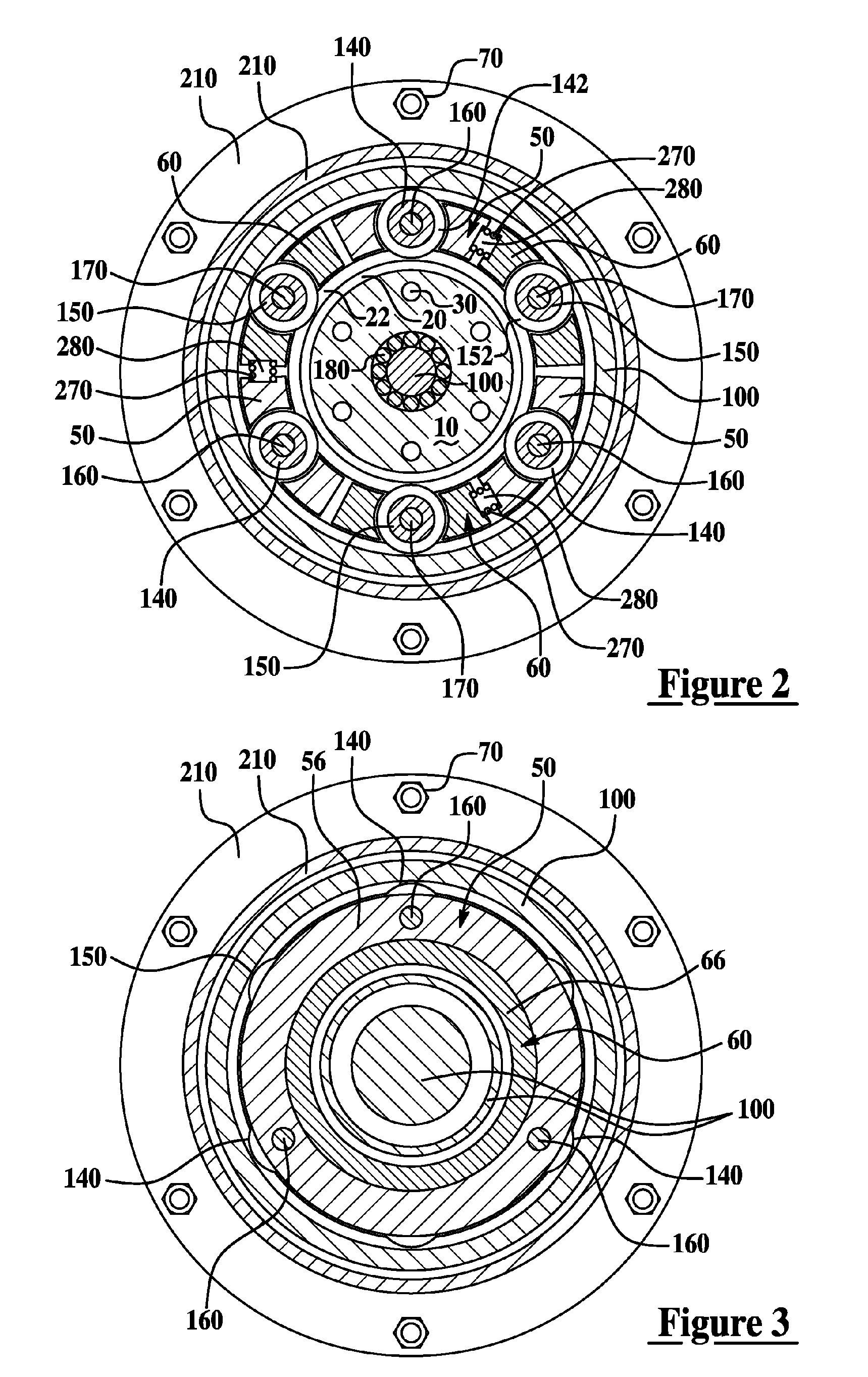

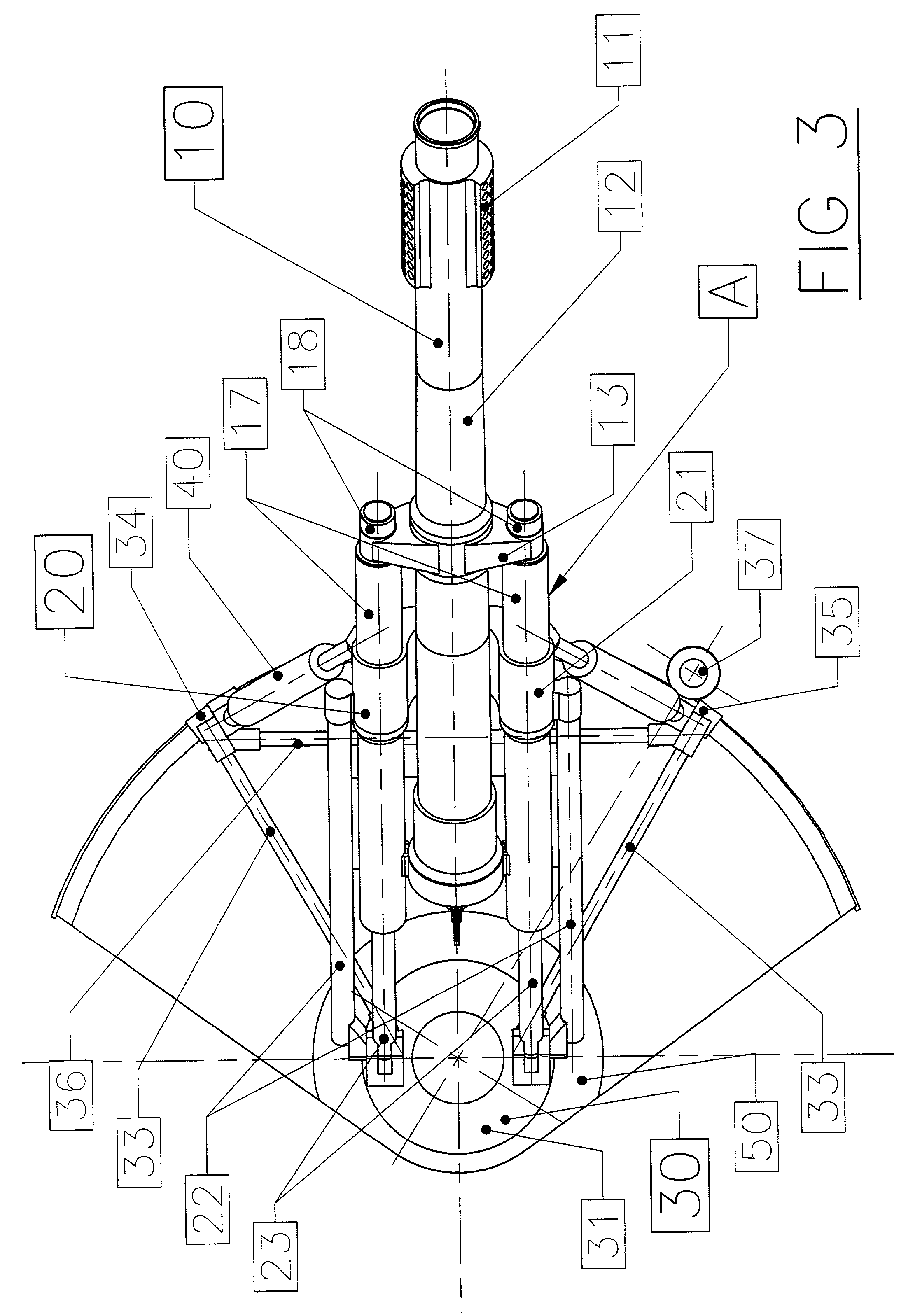

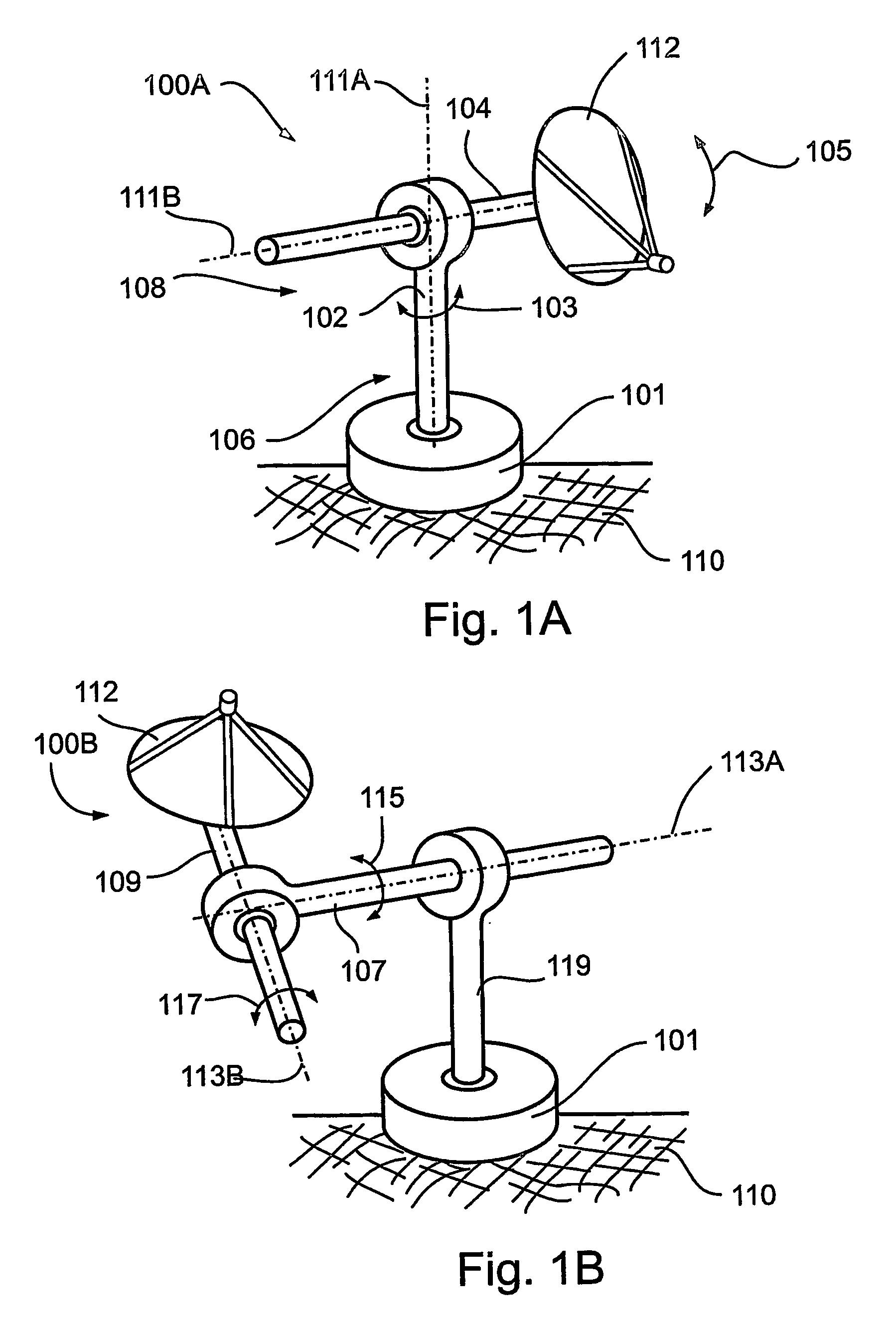

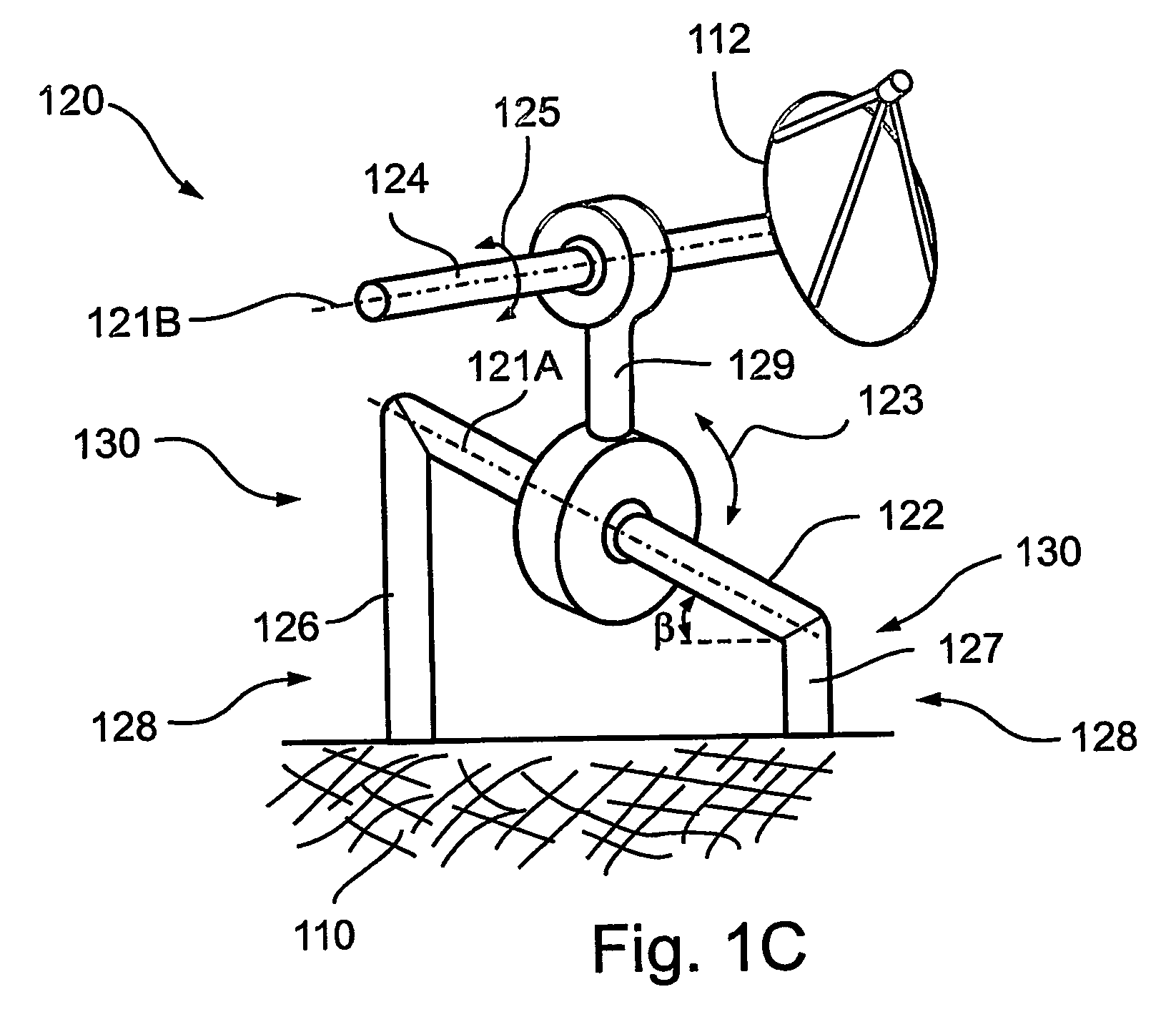

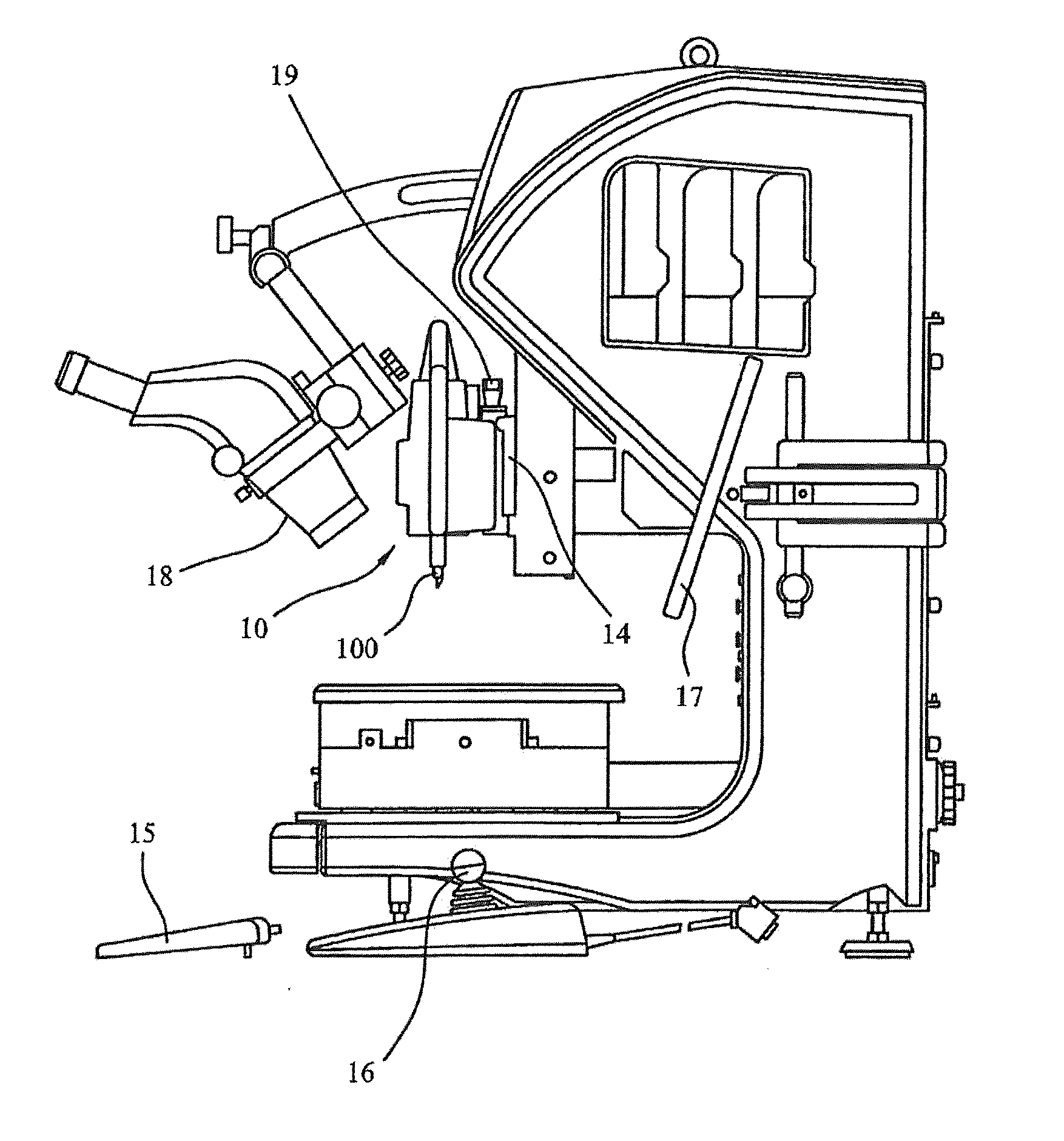

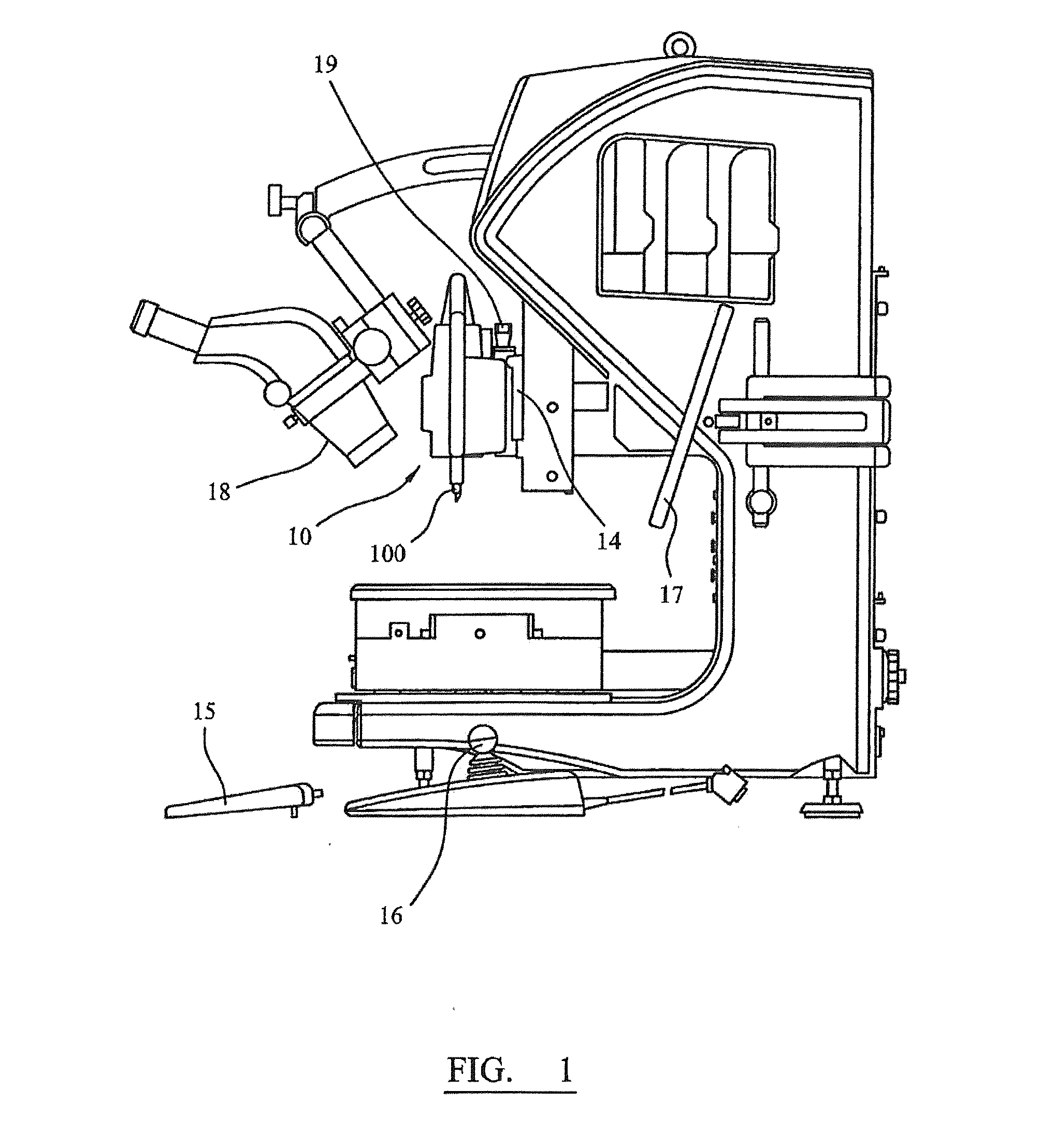

Hand controller and wrist device

InactiveUS20050183532A1Zero backlashEasy to measureMechanical apparatusJointsWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

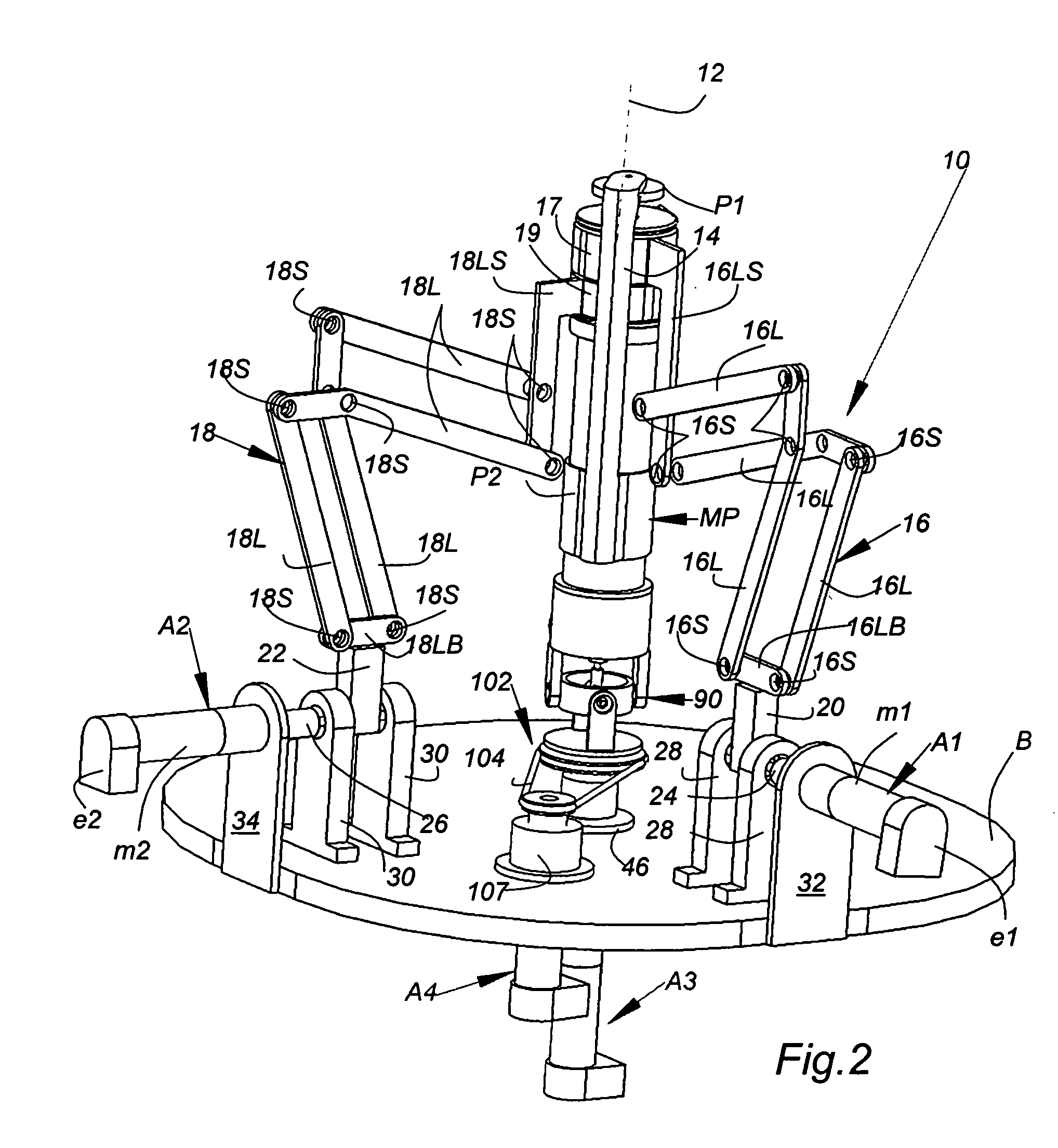

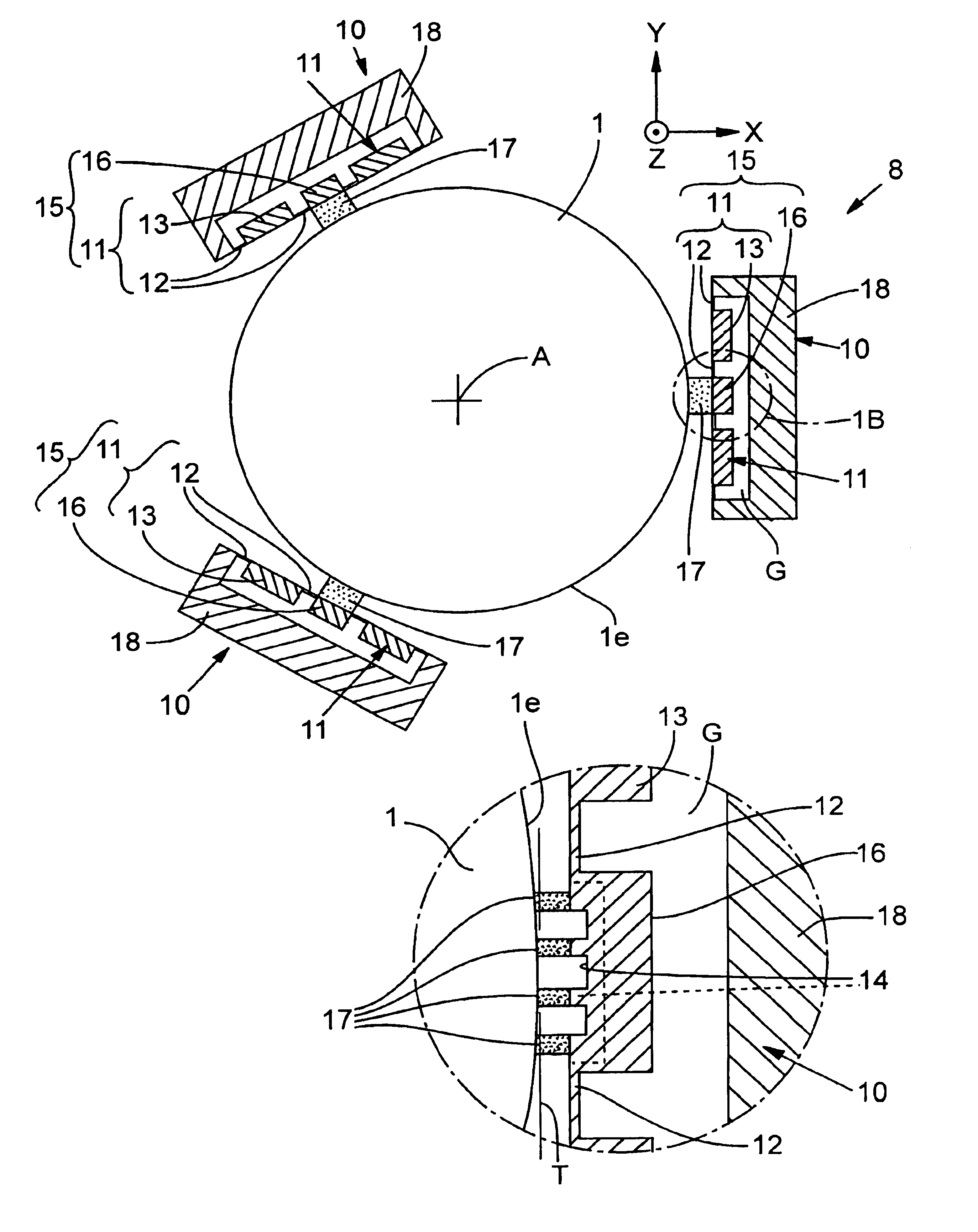

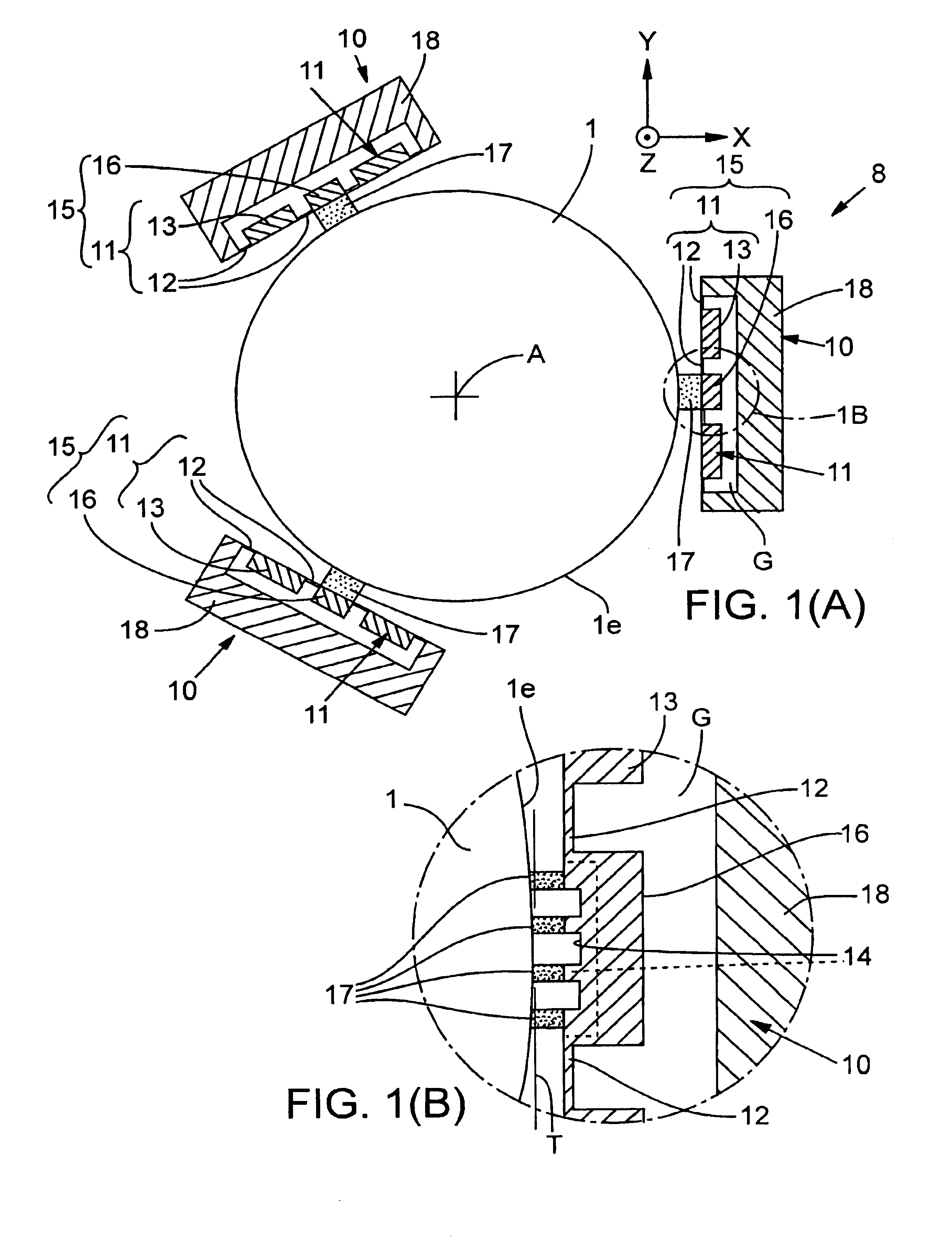

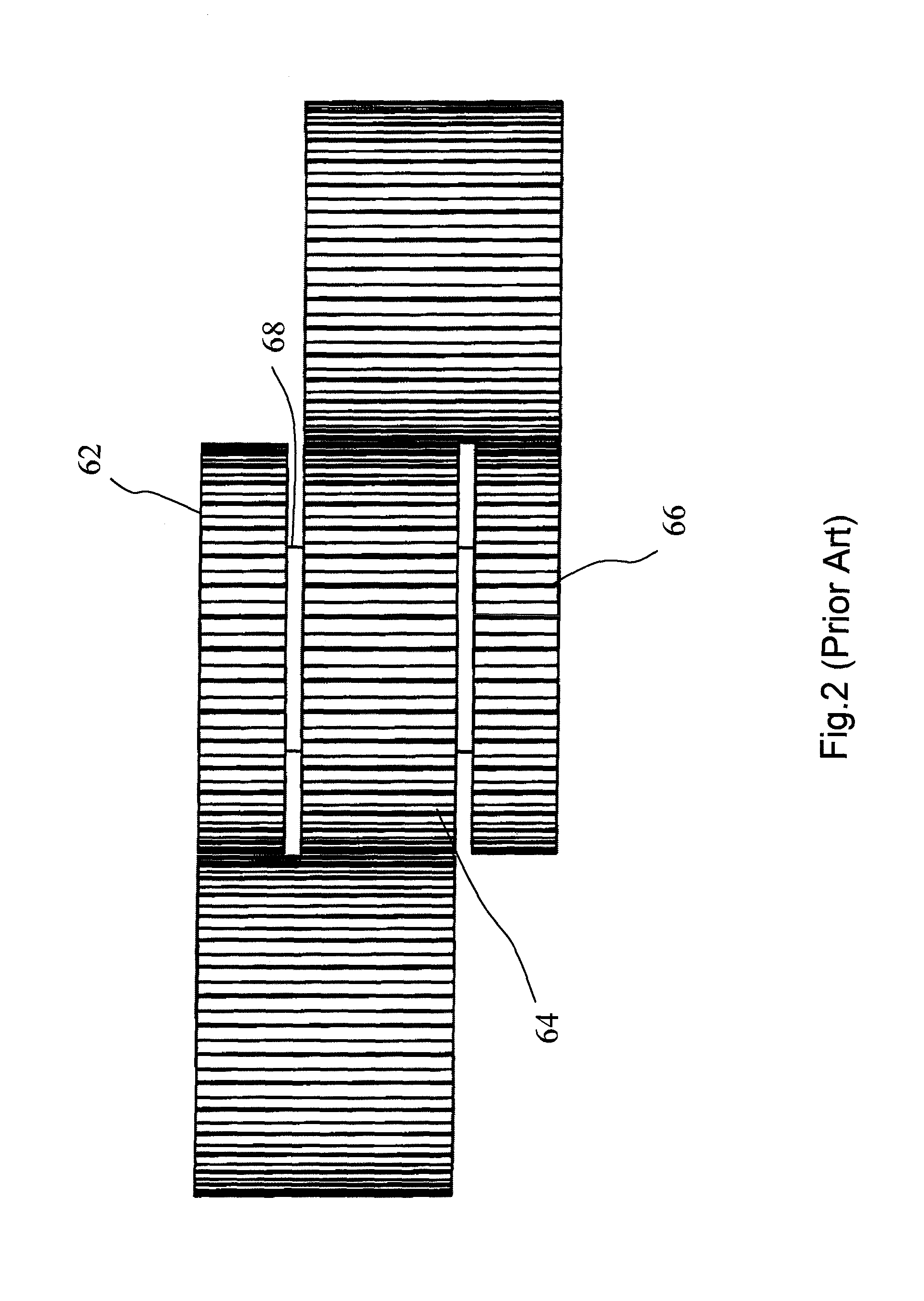

Optical-element mountings exhibiting reduced deformation of optical elements held thereby

InactiveUS6859337B2Improve performanceAvoid changeMirrorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Optical-element mountings are disclosed for holding an optical element relative to an optical column of an optical system. The optical element can have mounting protrusions extending therefrom or lack such features. An exemplary embodiment of a mounting has a respective holding device mounted to each mounting protrusion. Each holding device has a first spring-loaded support member providing rigid support of the element in a gravity direction and flexible support in tangential, radial, and tilt directions. Each holding device also can include a second spring-loaded support member providing rigid support of the element in tangential directions and flexible support in the gravity and radial directions. Another embodiment includes multiple holding devices at respective locations relative to a mounting surface of the element. Each holding device includes a respective linking unit extending from the optical column to a respective bonding member attached to a bonding location on the mounting surface. Each bonding member has a bonding pad bonded to the respective bonding location and at least first and second spring members extending from the bonding pad in respective directions to the linking unit.

Owner:NIKON CORP +1

Hand controller and wrist device

InactiveUS7204168B2Zero backlashEasy to measureManual control with multiple controlled membersMechanical apparatusWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

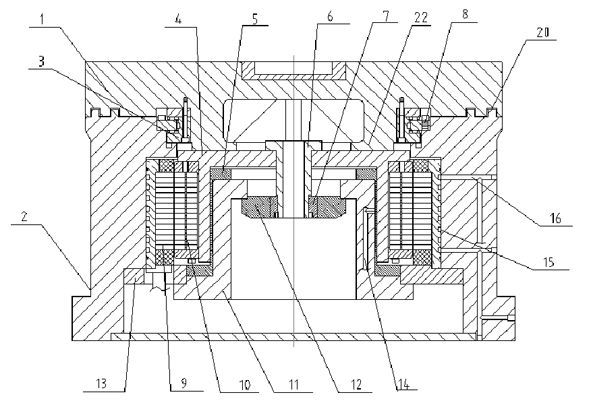

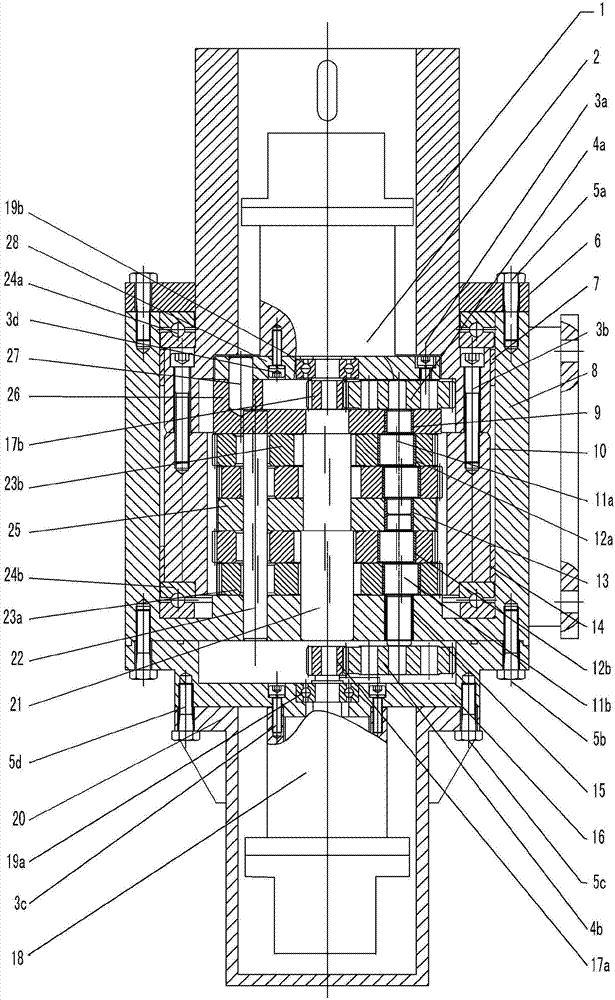

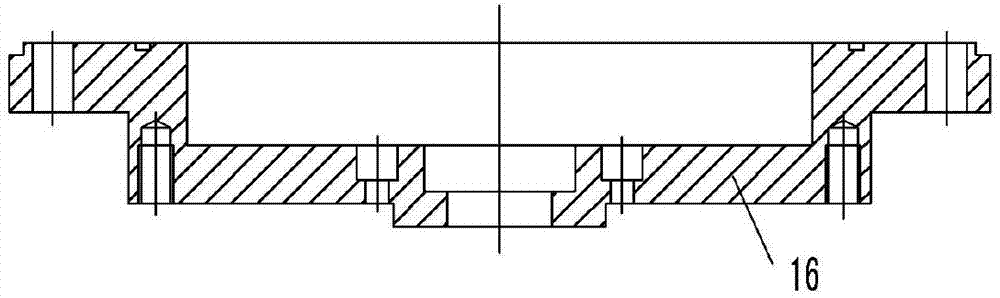

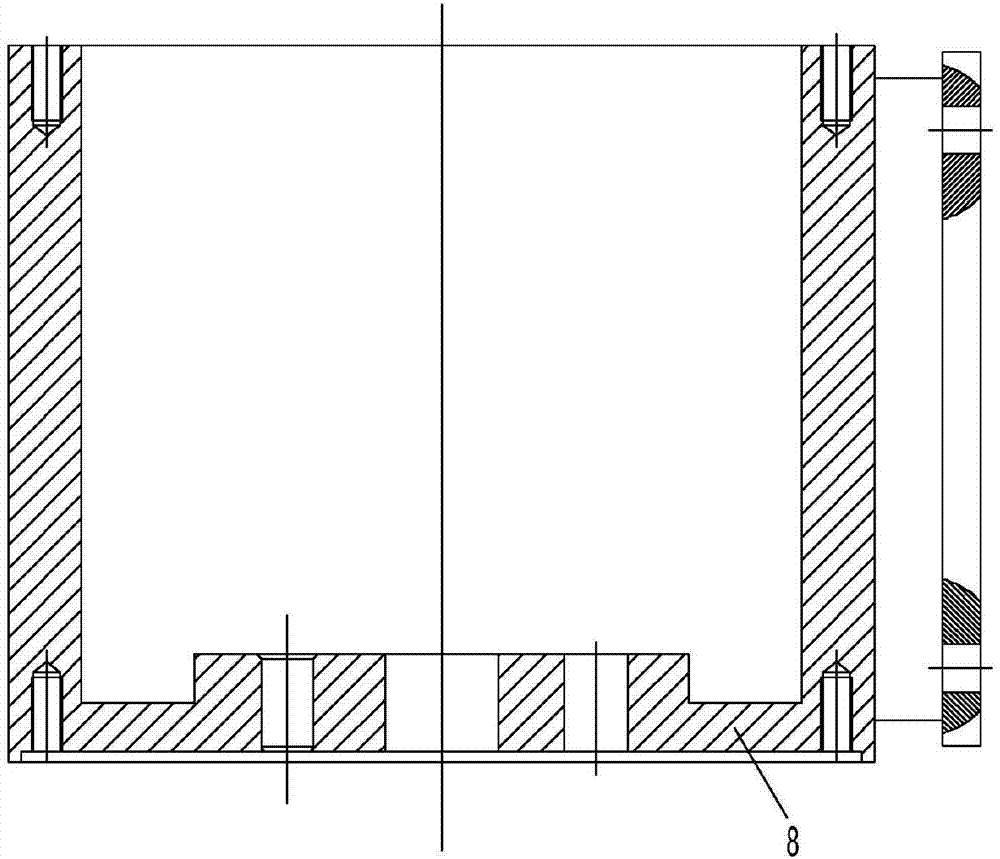

Numerical-control direct-drive turning-milling composite rotary working table

InactiveCN101954596AImprove dynamic performanceHigh precisionLarge fixed membersNumerical controlLocking mechanism

The invention discloses a numerical-control direct-drive turning-milling composite rotary working table, which comprises a disc-shaped working rotary table, a hollow rotary table base and a bearing, wherein an outer ring of the bearing is fixedly connected with an inner wall of a cavity of the rotary table base; a rotating shaft of the working rotary table extends into an inner ring of the bearing; the working rotary table is fixedly connected with the inner ring; a motor stator, a motor rotor and a cylindrical hollow connecting sleeve which is used for fixing the motor rotor are also arranged in the cavity of the rotary table base; the motor stator is fixed on an inner wall of a cavity at the lower end of the rotating shaft along the axial direction of the rotating shaft; the upper end face of the connecting sleeve is fixedly connected with the lower end face of the rotating shaft; the motor rotor is fixed on an outer wall of the connecting sleeve; and a hollow part of the connecting sleeve is provided with an angle positioning device and a locking mechanism. The numerical-control direct-drive turning-milling composite rotary working table has the advantages of high efficiency, simple transmission structure and high radiating and sealing properties.

Owner:烟台环球机床附件集团有限公司

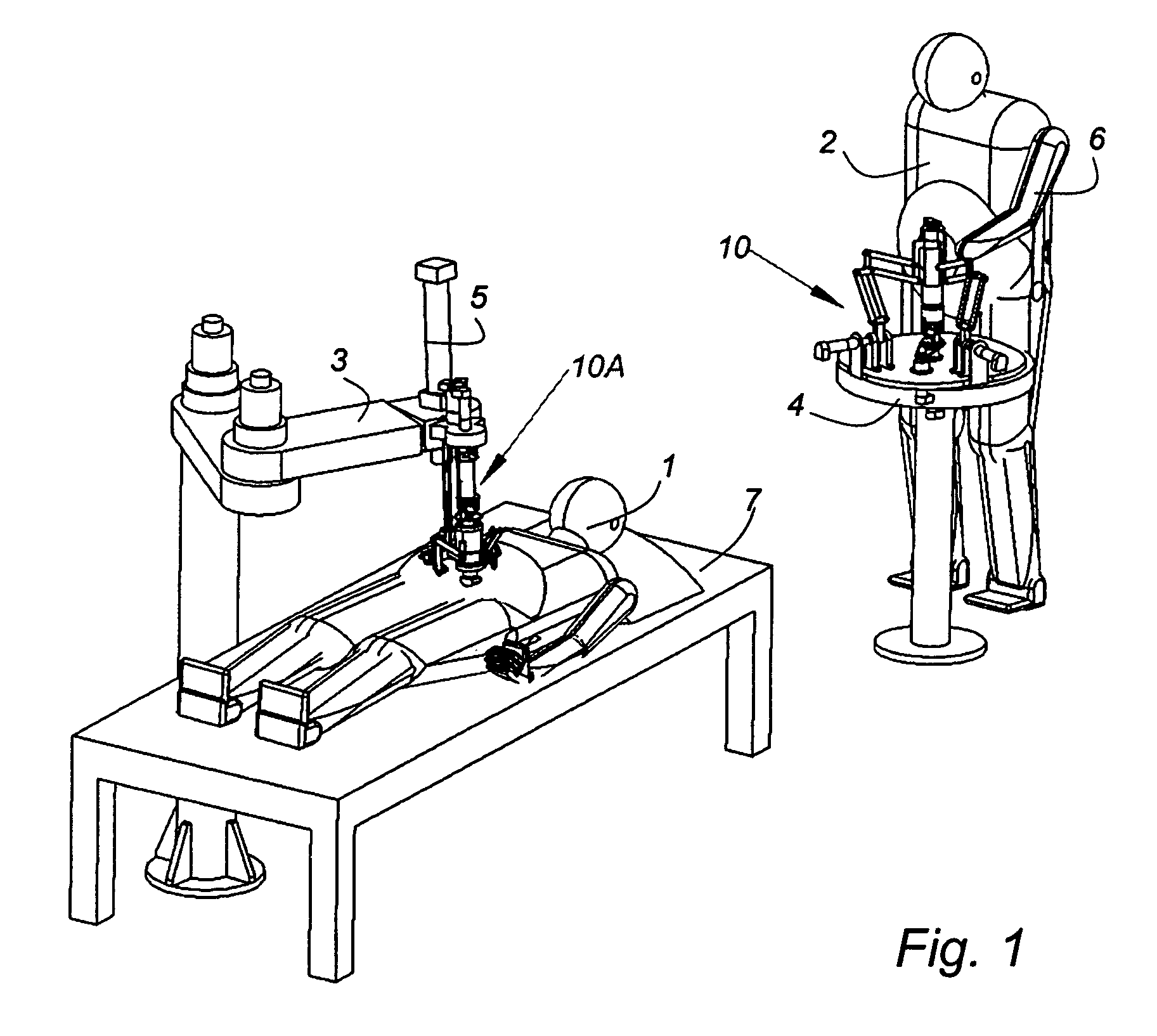

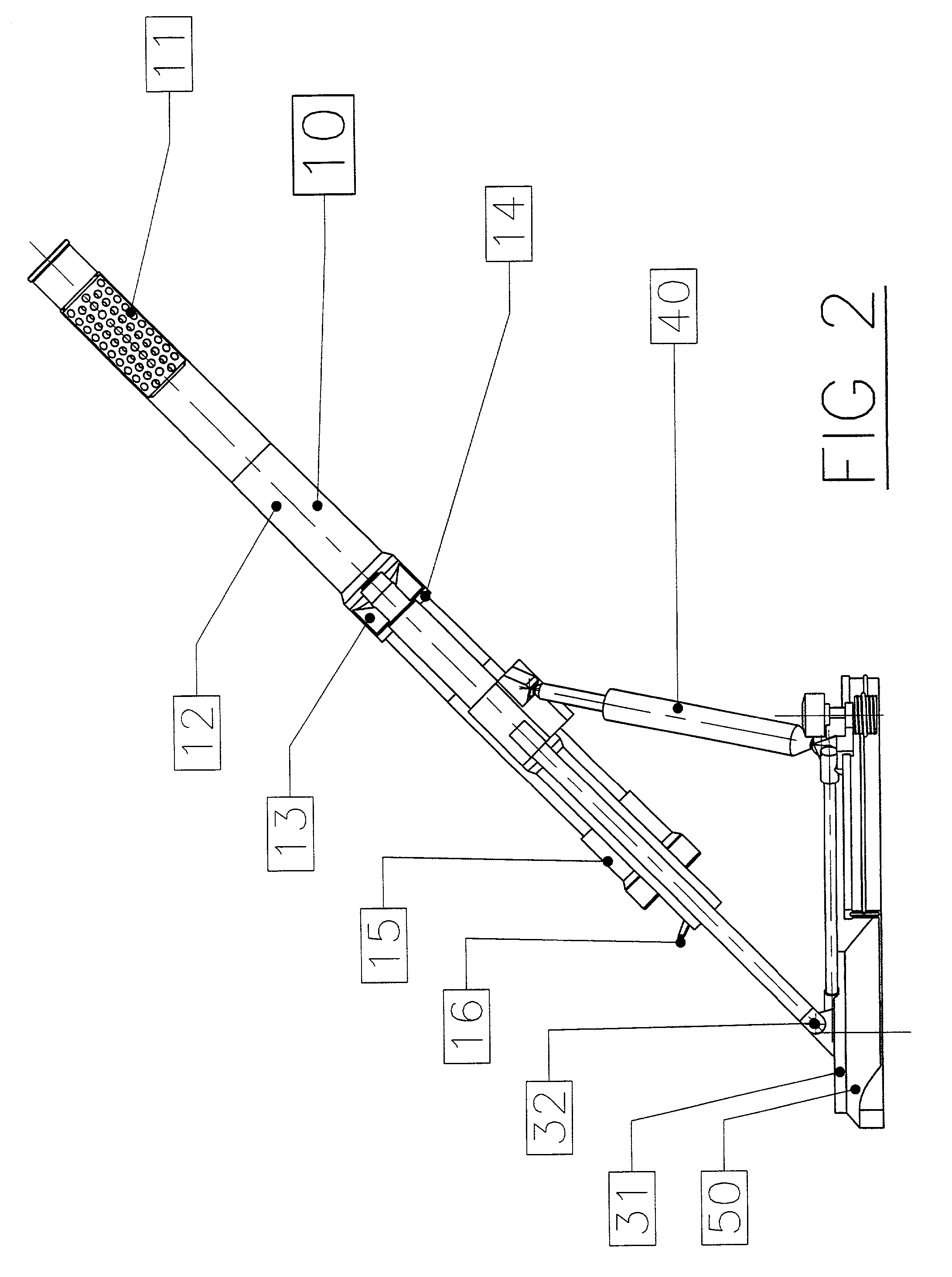

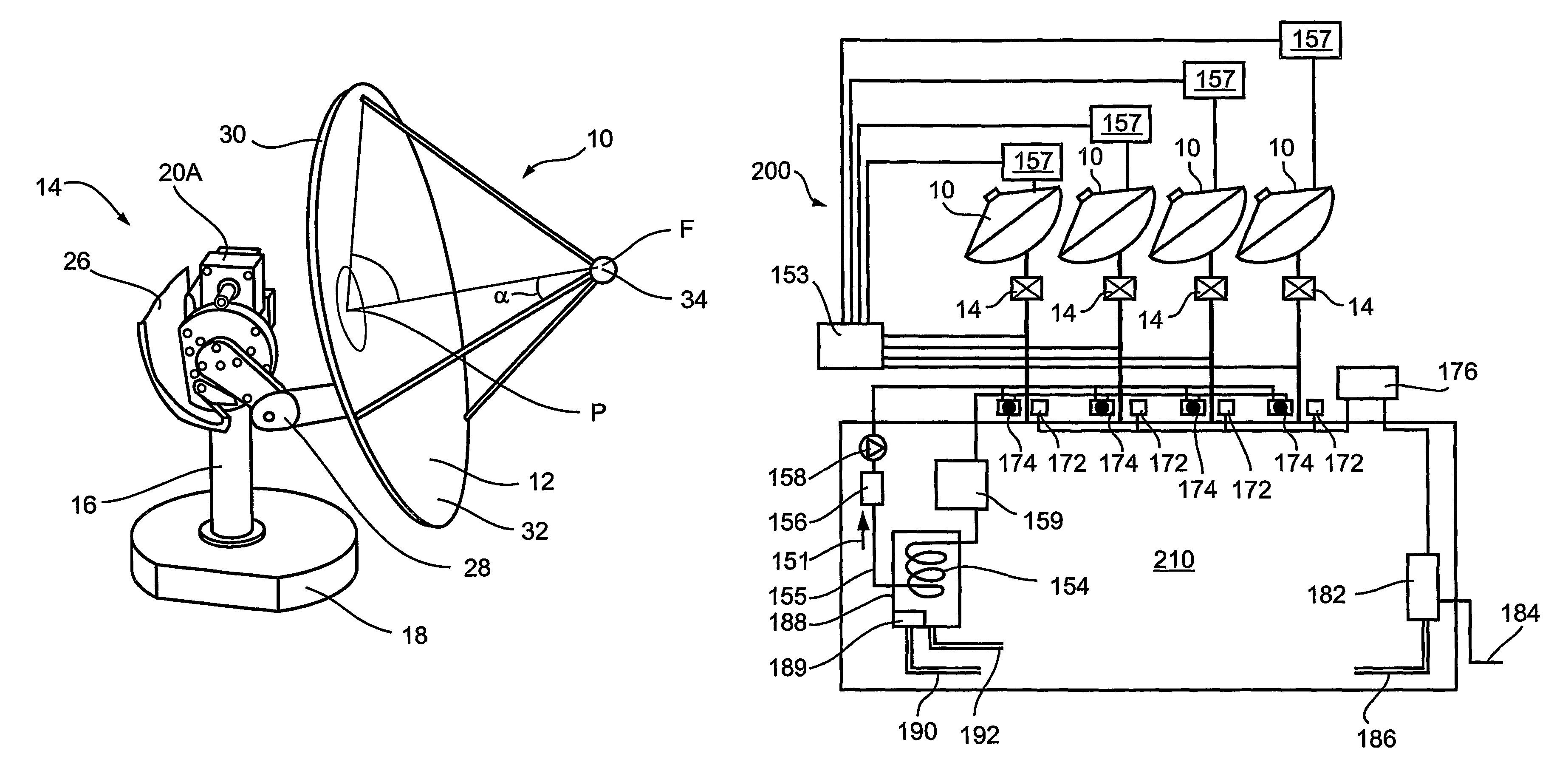

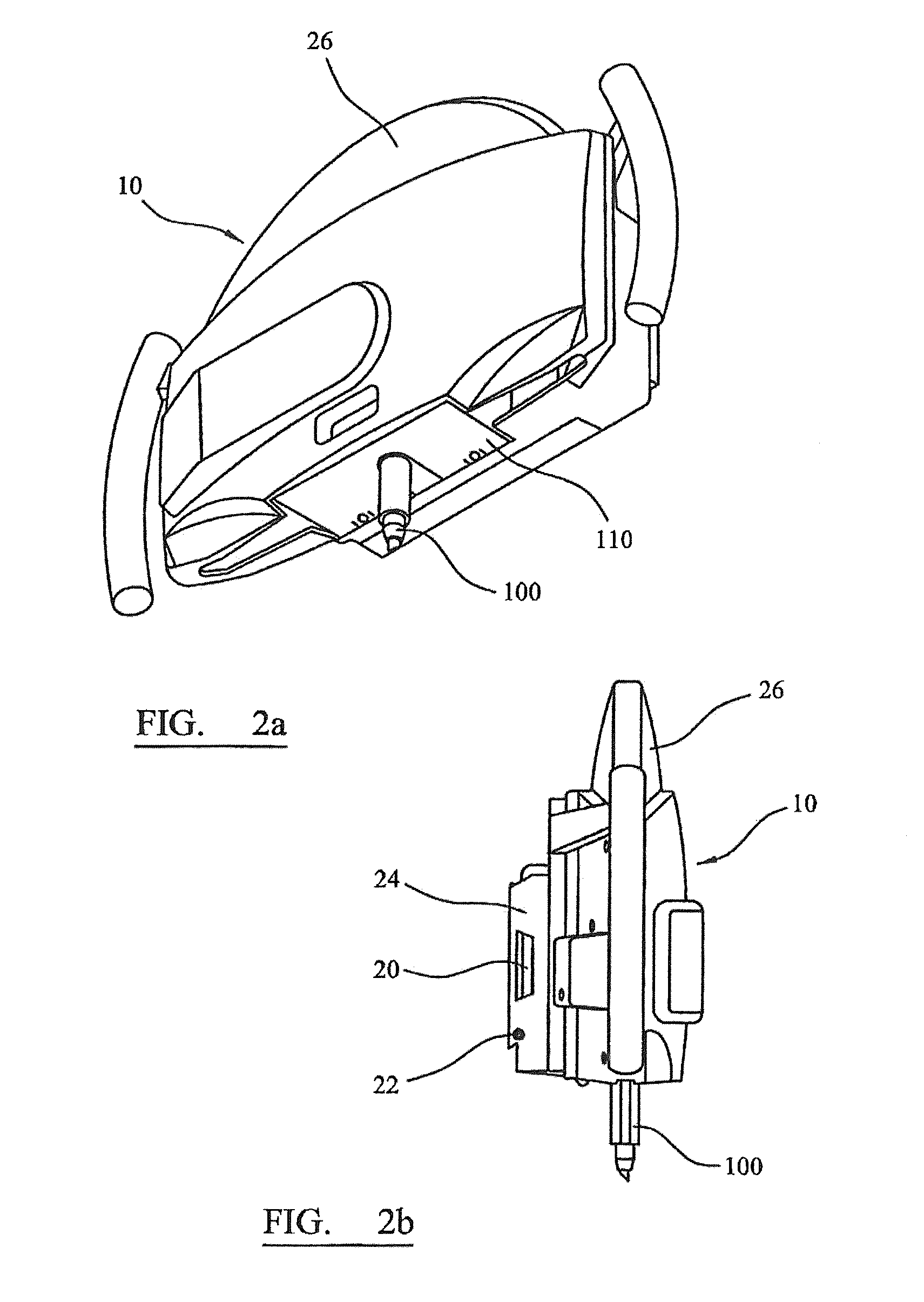

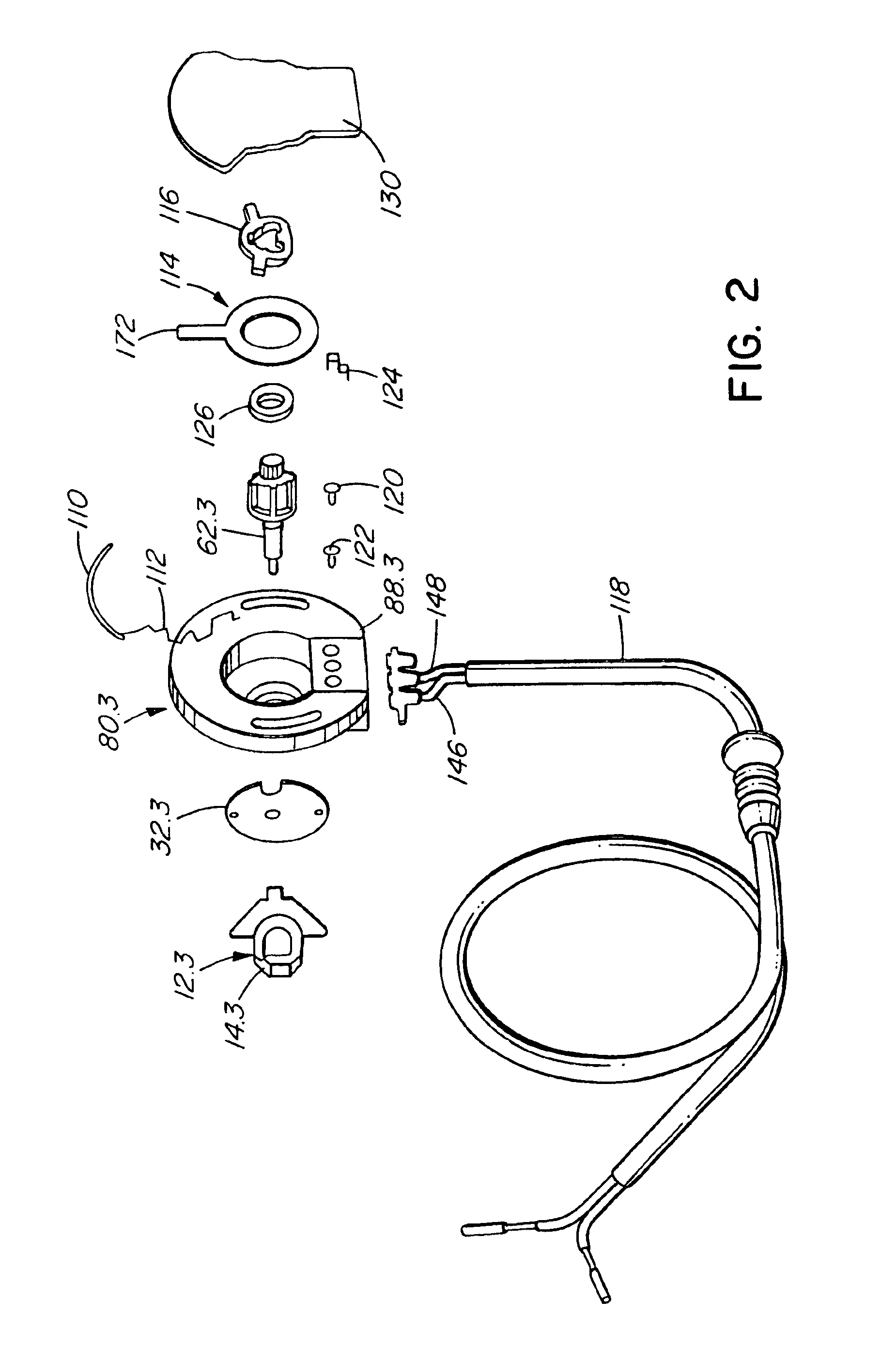

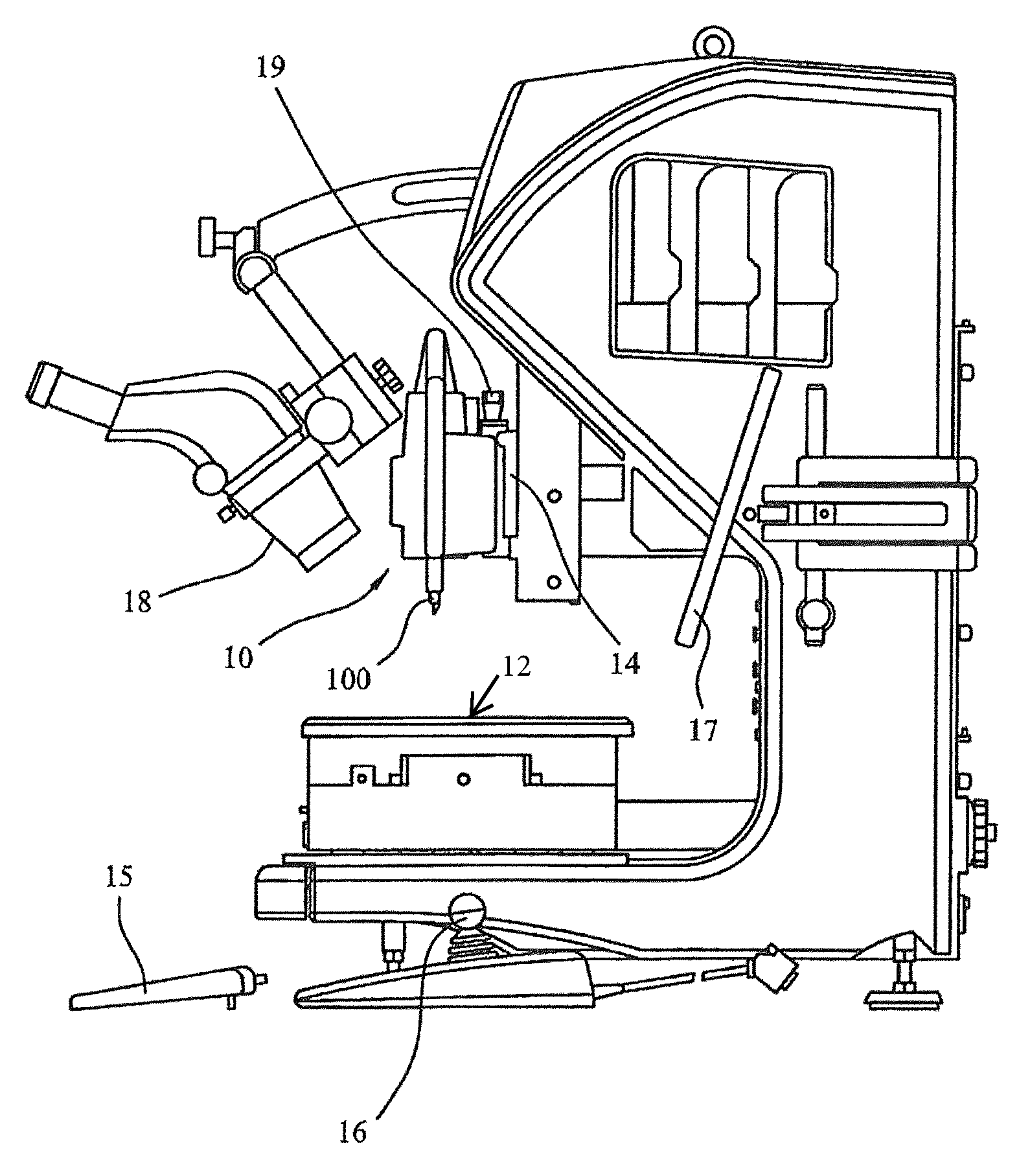

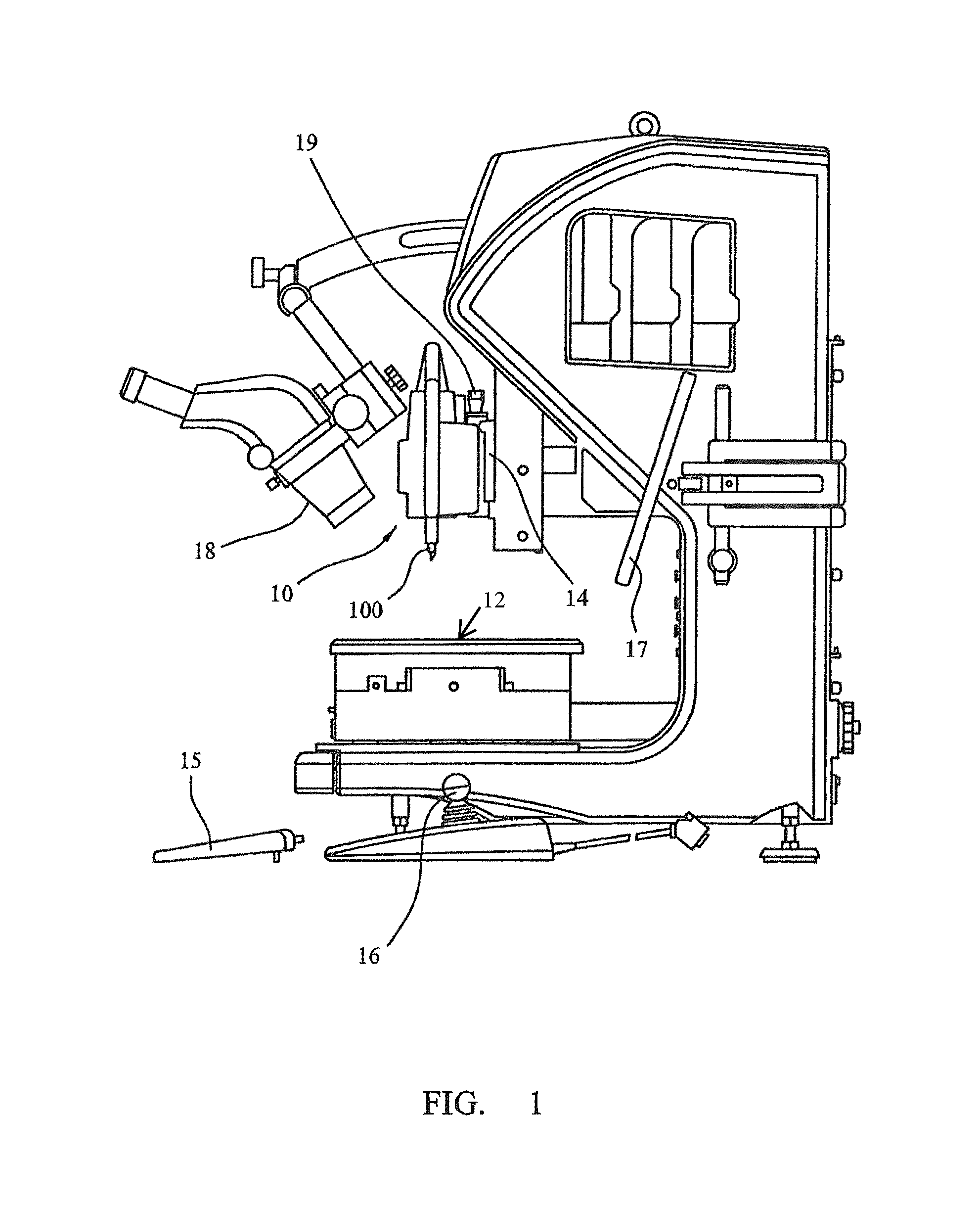

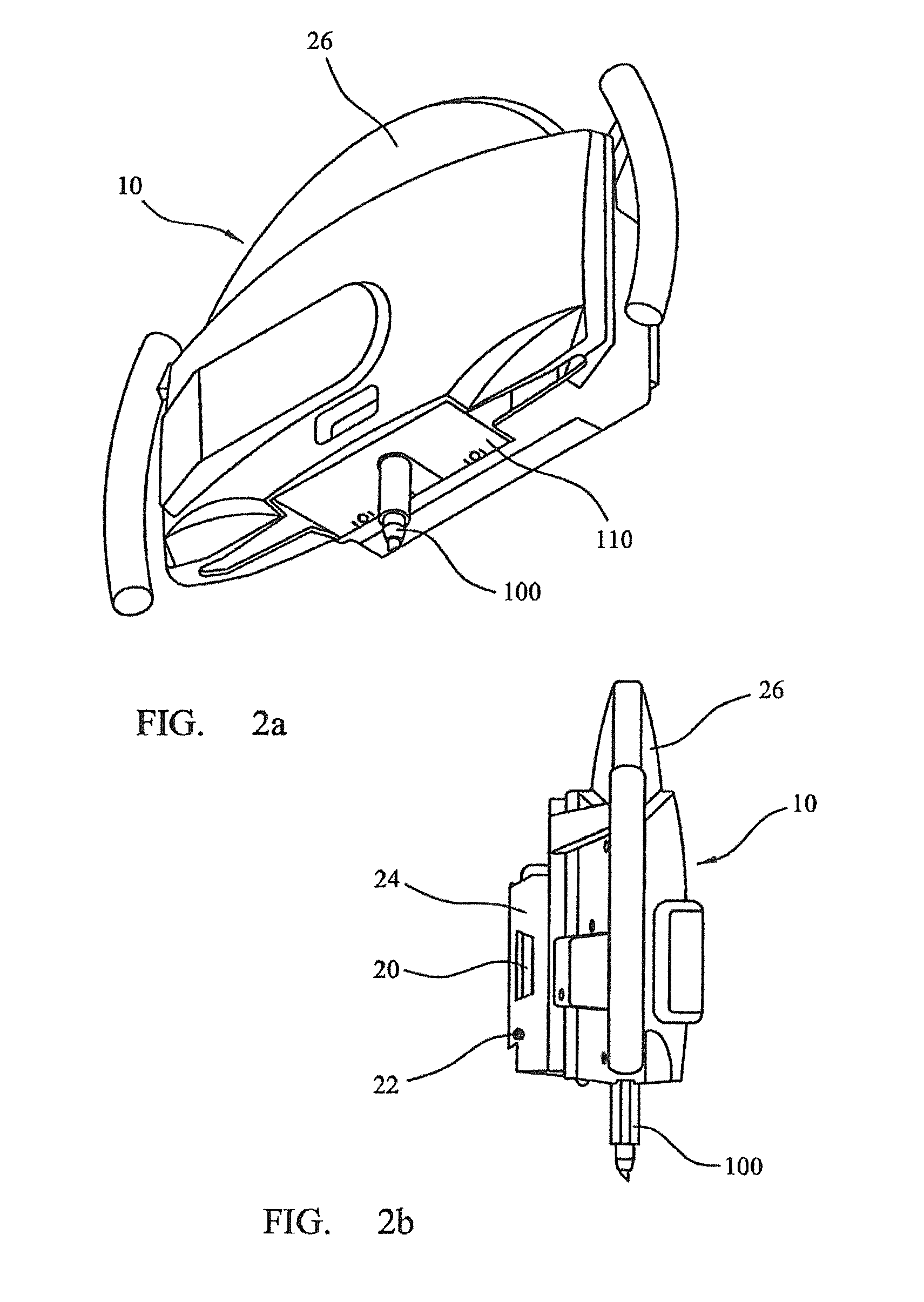

Small-scale, concentrating, solar chp system

InactiveUS20090194145A1Minimal investmentLow production costSolar heating energyPhotometry using reference valueHigh concentrationPower application

A high-efficiency, small-scale, combined heat and power, concentrating solar energy system (200), designed specifically for residential and other relatively low-power applications, rendering it cost-effective and economically viable. Two-axis tracking of a dish-like reflector (10) of between 1 and 2 meters in aperture ensures very high concentrating ratios of between 200 and 8-suns or even higher. In consequence very high coolant outlet temperatures, of 120-180° C. may be reached at the outlet of the collector coolant, which may be oil, gas, or pressurized water. The high coolant temperatures are advantageous because they may be used for air-conditioning. The high concentration is advantageous because the efficiency of the photo_voltaic cells is improved with higher concentration. The overall efficiency is greater than 60%. Additionally, a simple but accurate drive, designed as a radio-dial drive (14), with substantially zero backlash, and substantially zero drive, is provided for driving the concentrating solar energy system. Preferably, two radio-dial drives are employed and tracking is performed along two axes, of an azimuth-elevation mount, a polar mount, or a cross mount.

Owner:RAMOT AT TEL AVIV UNIV LTD

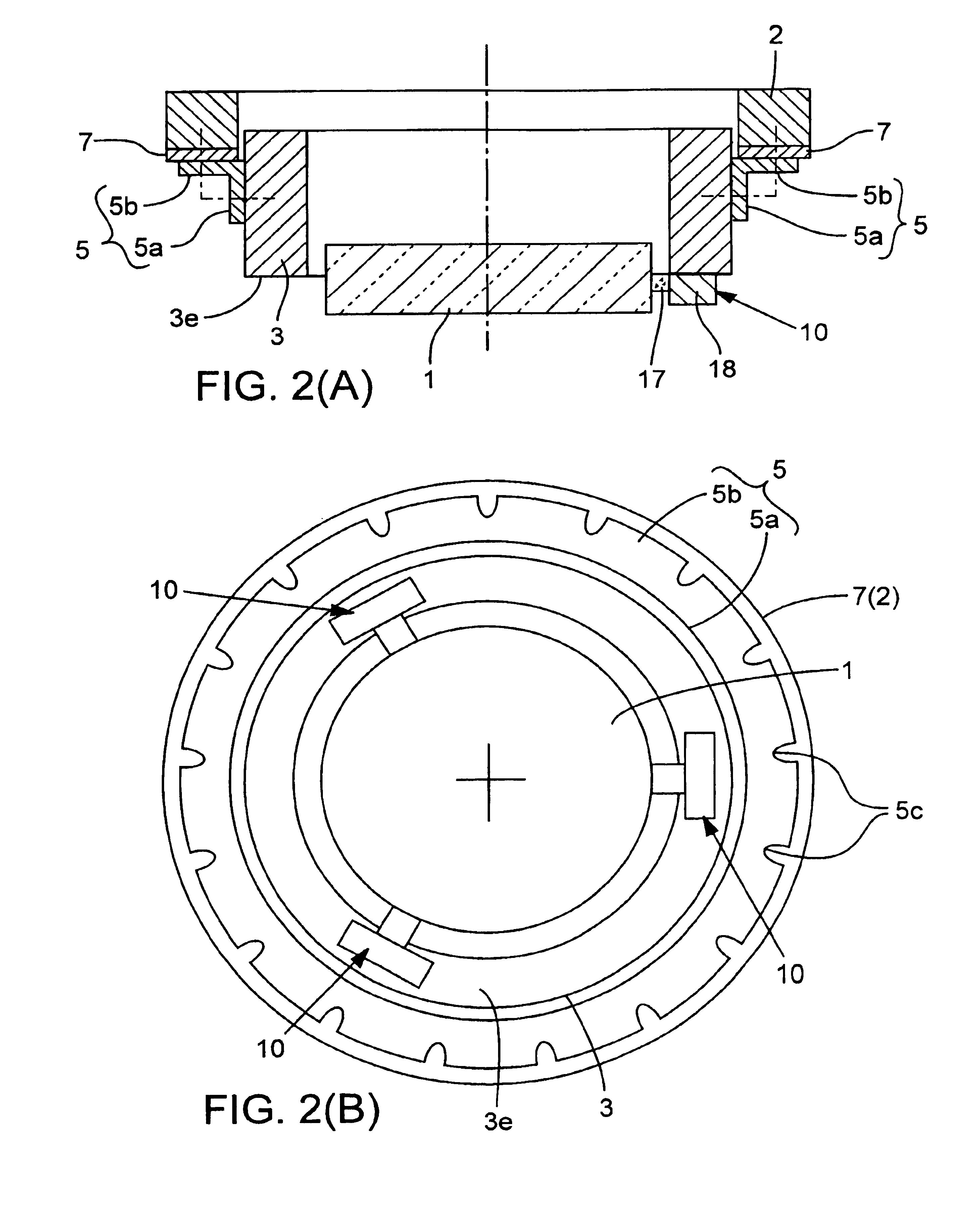

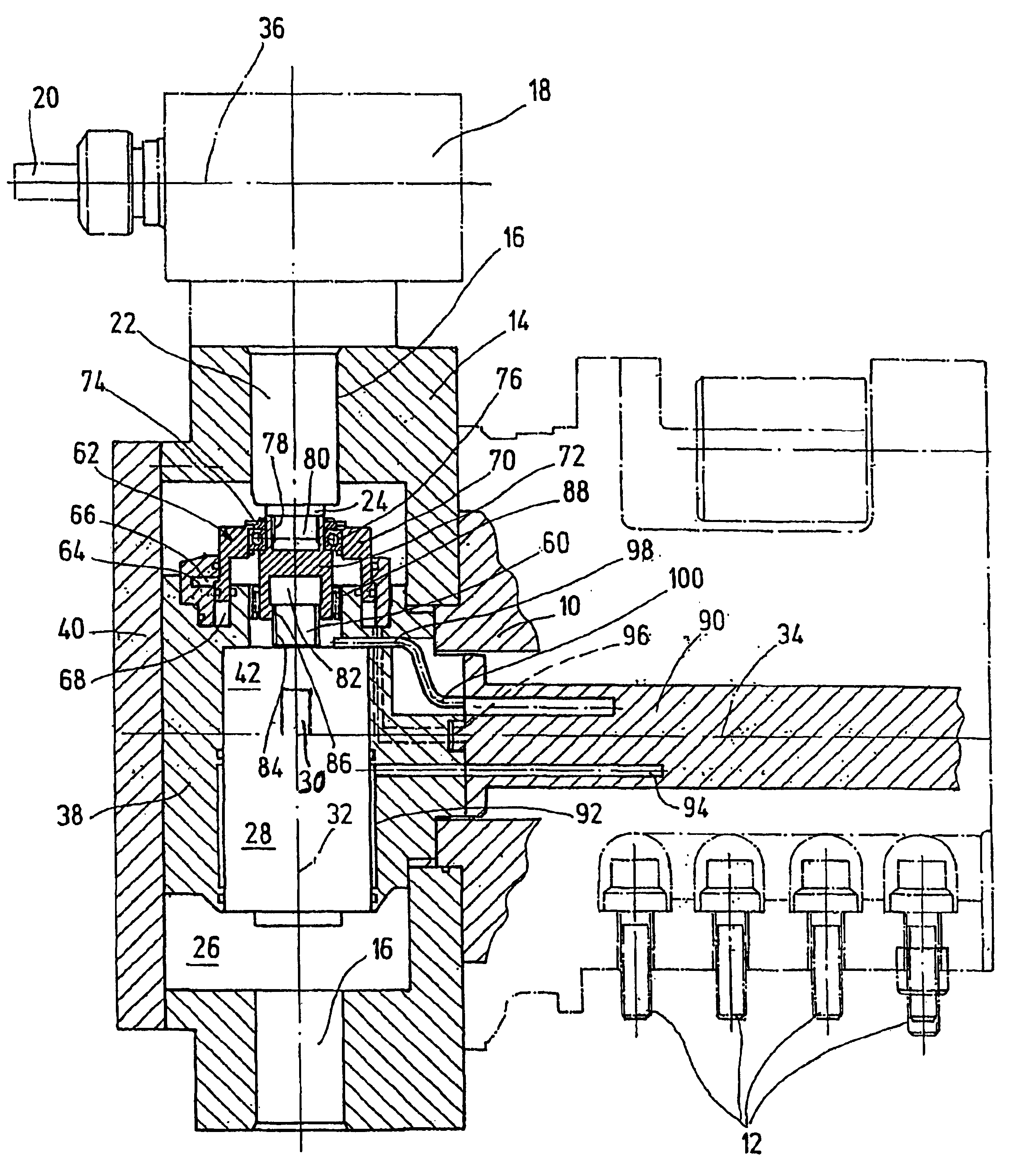

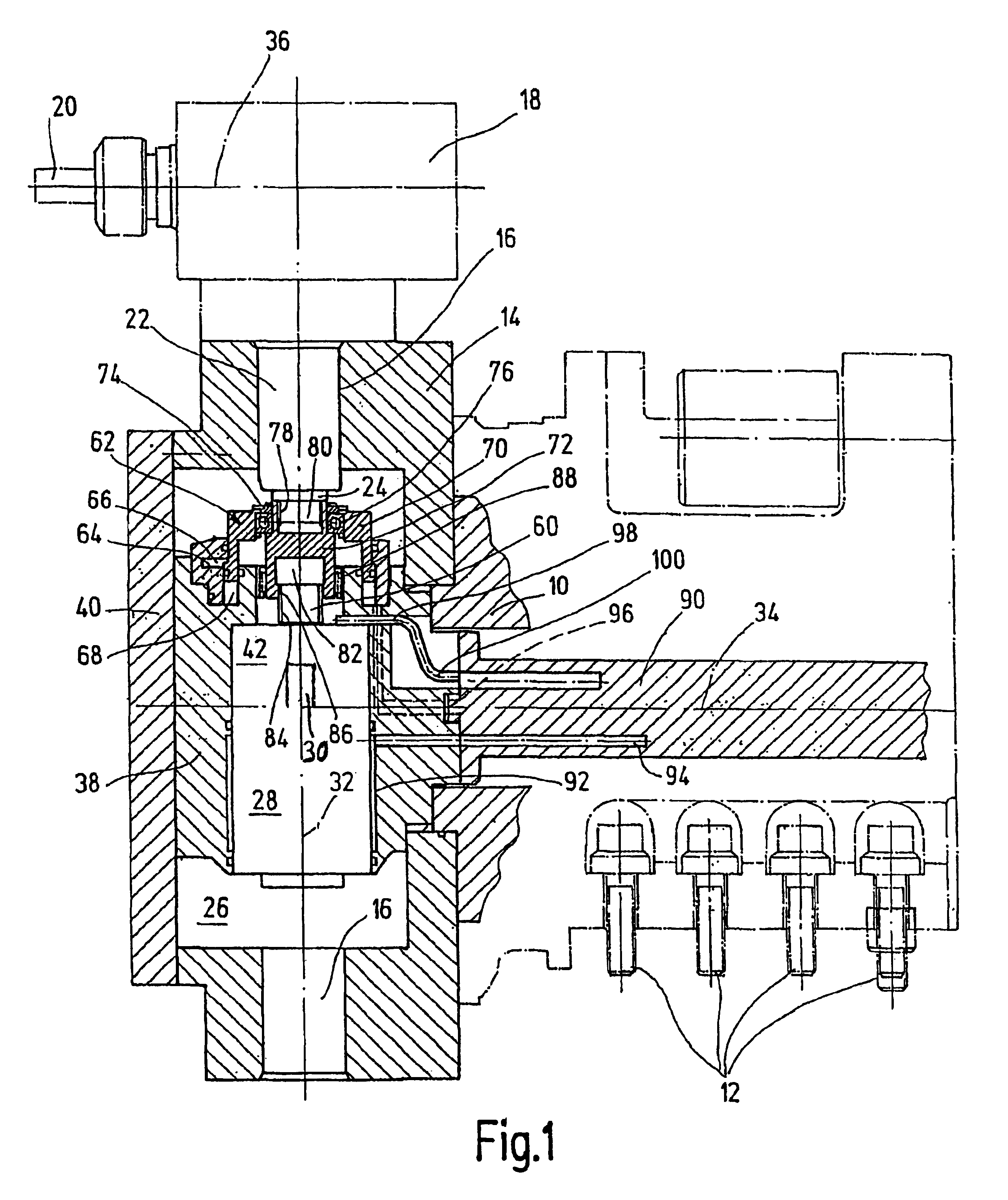

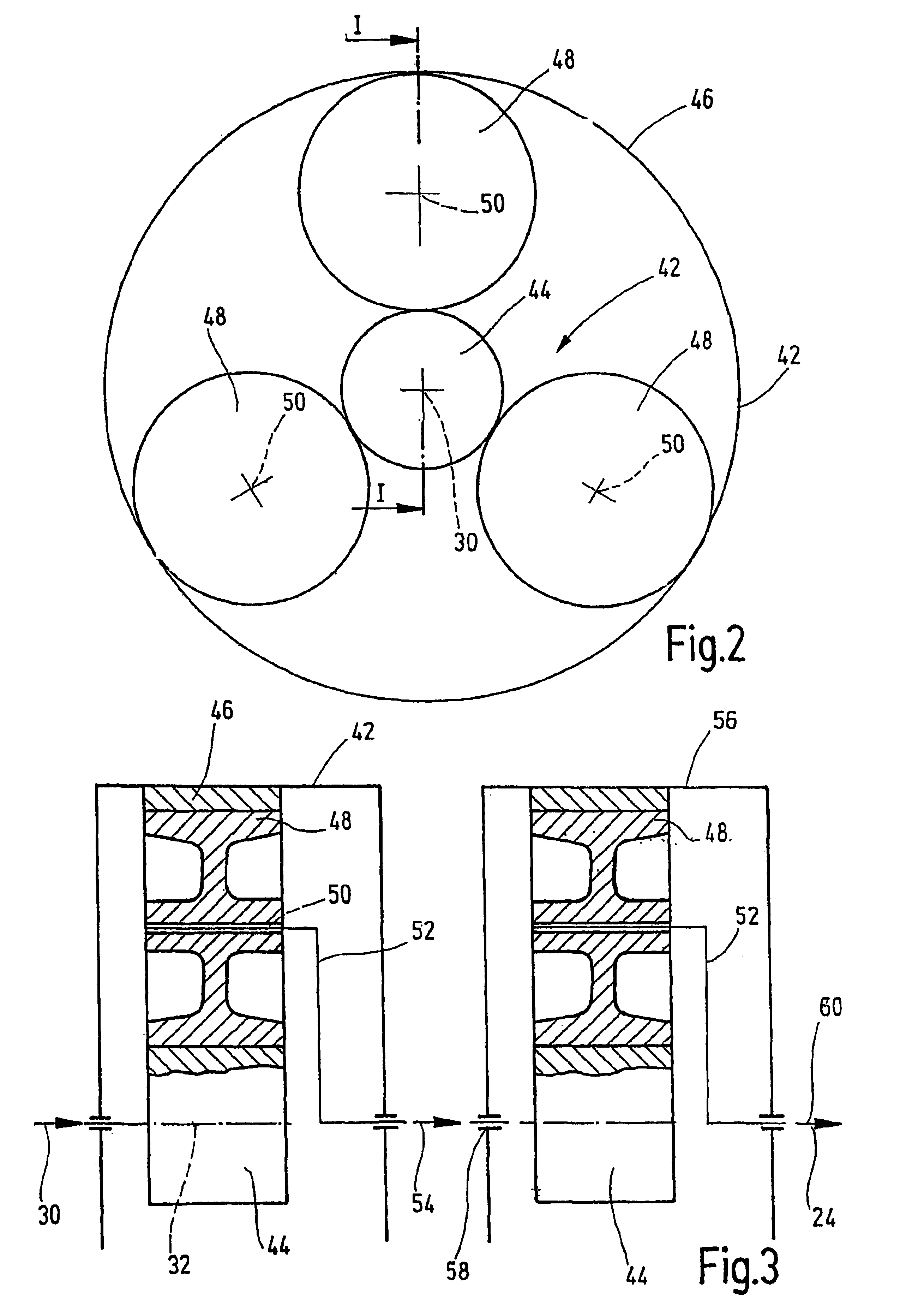

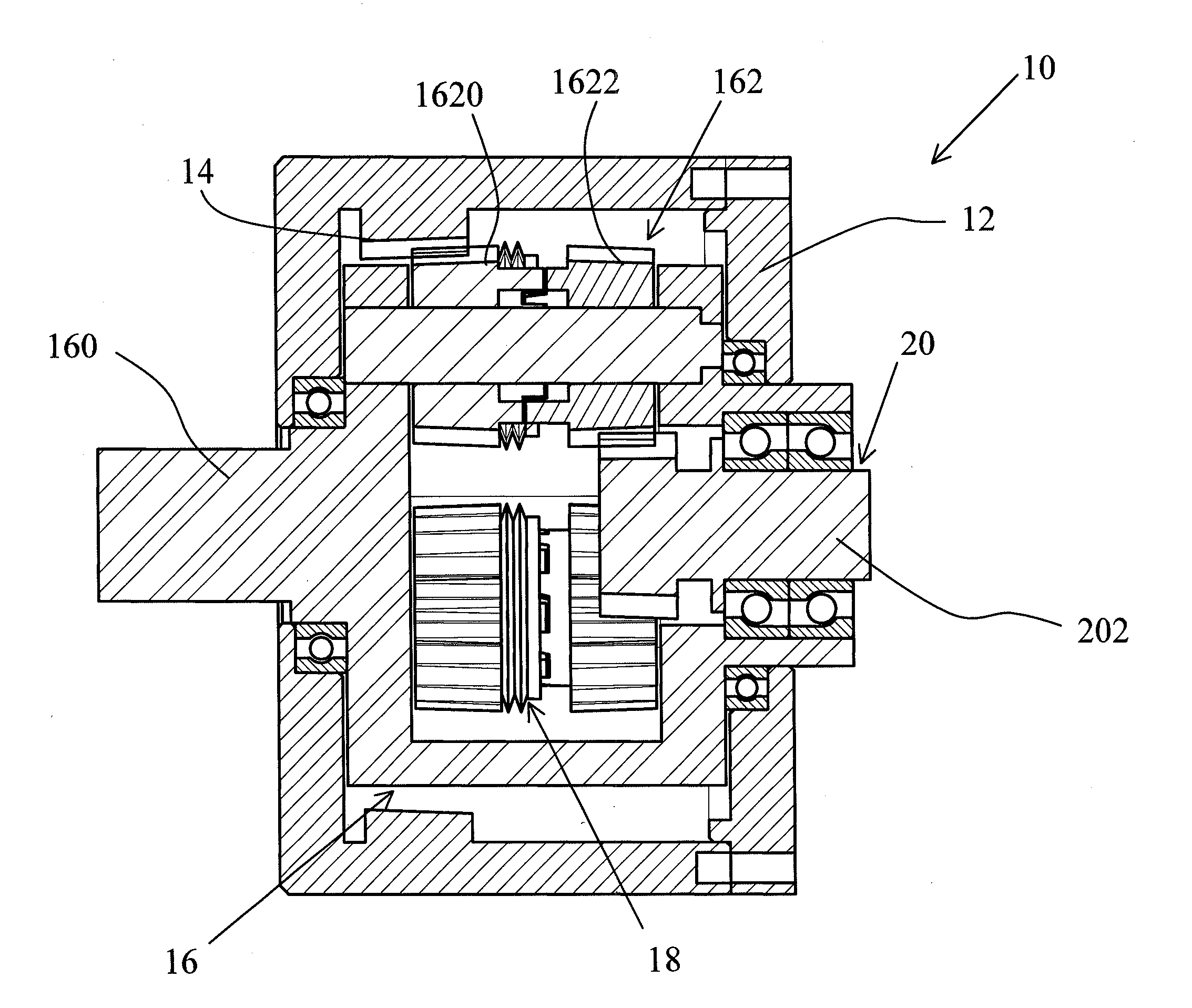

Tool turret

InactiveUS6925694B2Less structural spaceReduce maintenance costsMechanical apparatusThread cutting machinesElectric driveDrive motor

A tool turret includes a housing (10) for connection to a machine tool, and an electric drive motor (28). A tool disk (14), is mounted to rotate relative to the housing (10) about a longitudinal axis (34), may be fixed in selected angular positions, and has recesses (16) for machining tools (18). At least one rotating machining tool (18) may be driven by the drive motor (28) using shafts (24, 30), extending perpendicular to the longitudinal axis forming the swiveling axis of the tool disk (14). The electric drive motor (28) is arranged within the tool disk (14). The driveshaft (30) from the electric drive (28) is aligned with the driveshaft (24) for the machining tool (18), and is aligned with the driveshaft (24) for the machining tool (18) or extends parallel to it. An economical drive design for machining tools on a tool turret is achieved, with a small installation volume.

Owner:ZEITFRACHT GMBH & CO KGAA

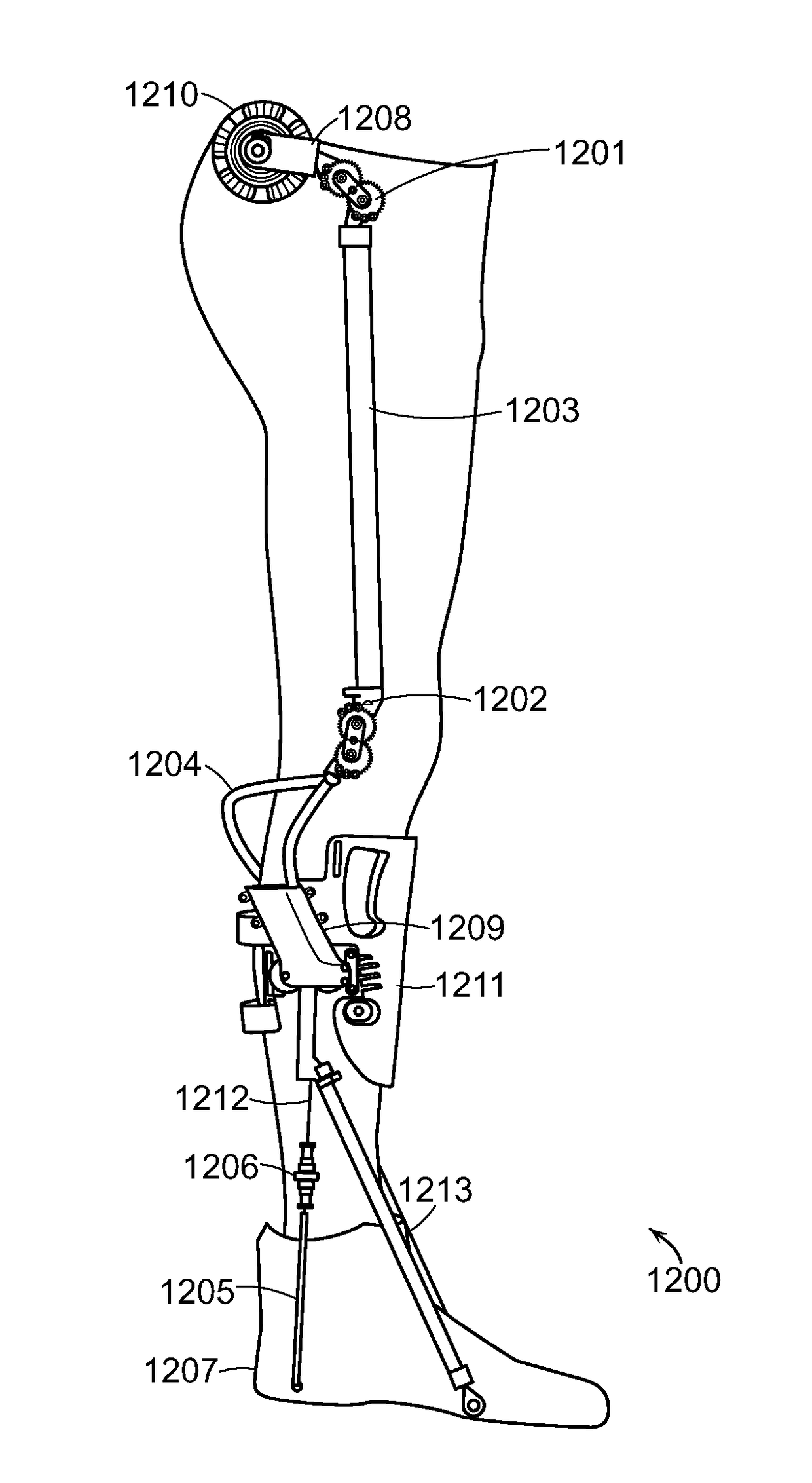

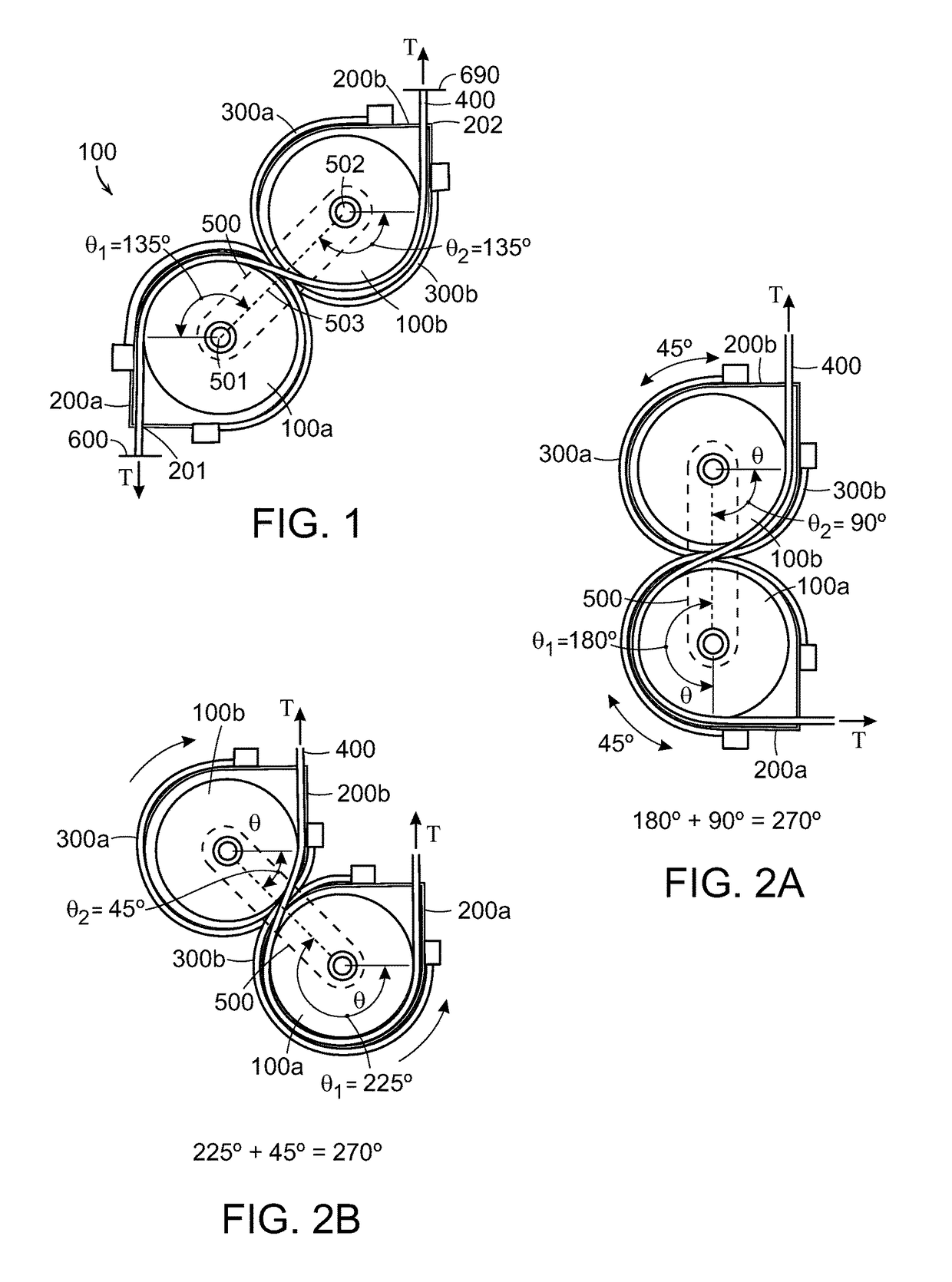

High Performance Free Rolling Cable Transmission

InactiveUS20170348176A1Efficiently mechanical powerEfficiently transmit motionProgramme-controlled manipulatorChiropractic devicesCable transmissionAngular velocity

A mechanical transmission, tethered actuation system, an autonomous ankle exoskeleton design and method of their use employing a cable, pulleys and associated pulley housings to change angular transmission of linear force on the cable. The pulleys are linked by a ground link and the cable is threaded across and between the pulleys, whereby rotation of either of the pulleys in one direction causes rotation of the other pulley in the opposite direction. Independently of the pulleys, the pulley housings can freely rotate about associated pulleys, and a link between the pulley housings is provided, whereby rotation of one of the pulley housings in one direction causes rotation of the other pulley housing at an equivalent angle in the opposite direction, thereby enabling a change in transmission angle of linear force on the cable threaded across and between the pulleys and the associated pulley housing essentially without resistance. When pulleys have the same angular velocity ratio as that of the associated pulley housings, there is no cable slack since the net changes in length of the cable wrapping around two pulleys is zero.

Owner:MASSACHUSETTS INST OF TECH

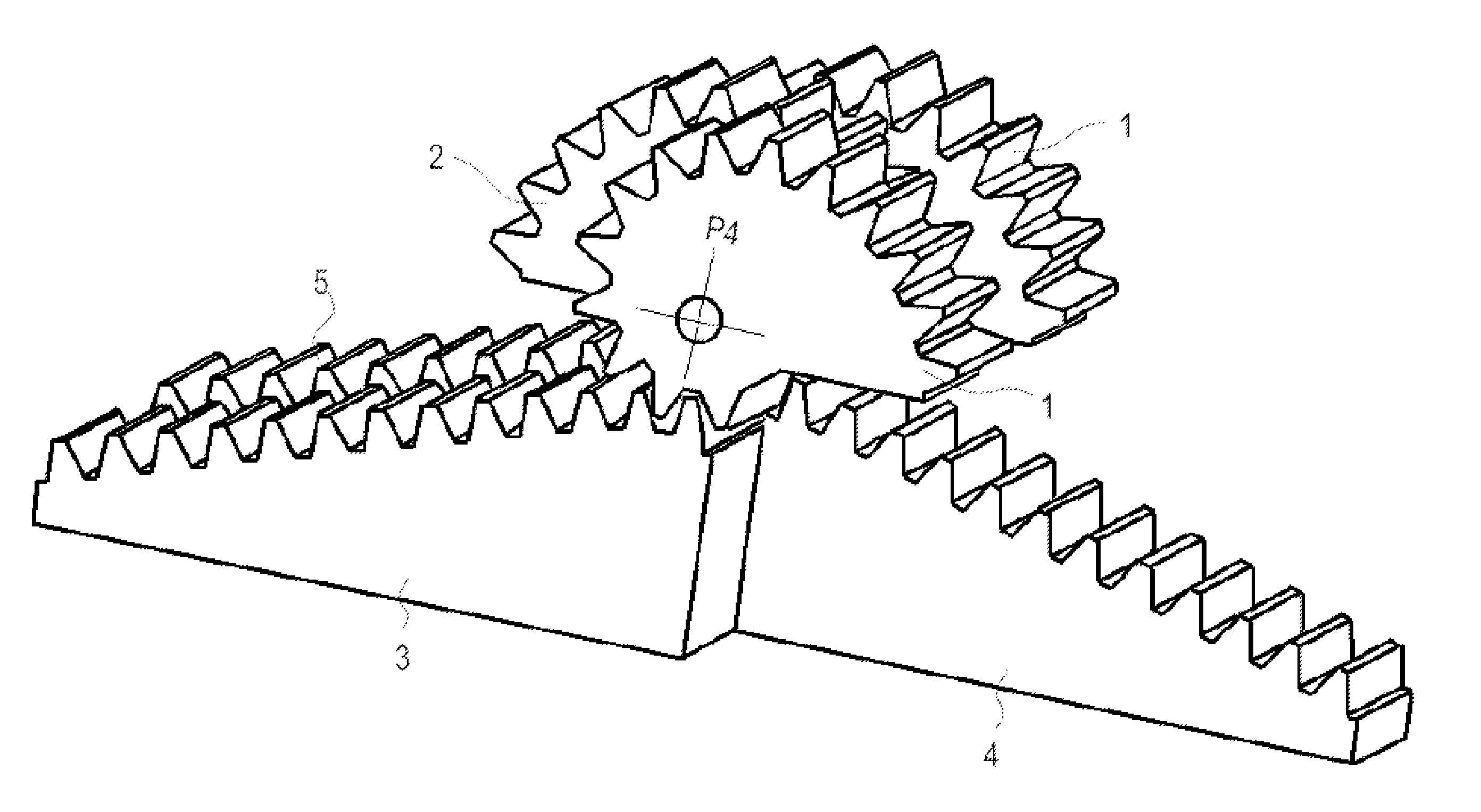

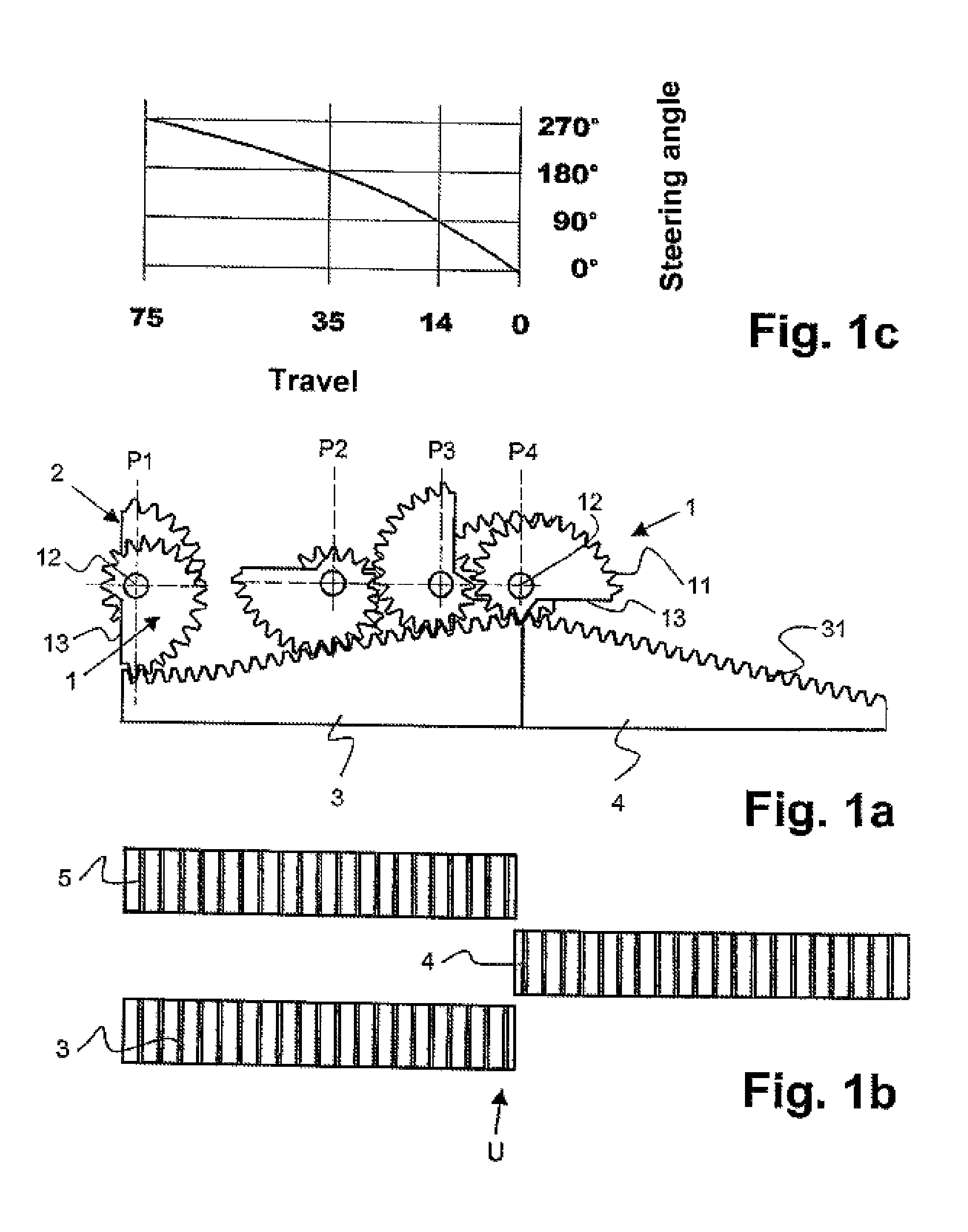

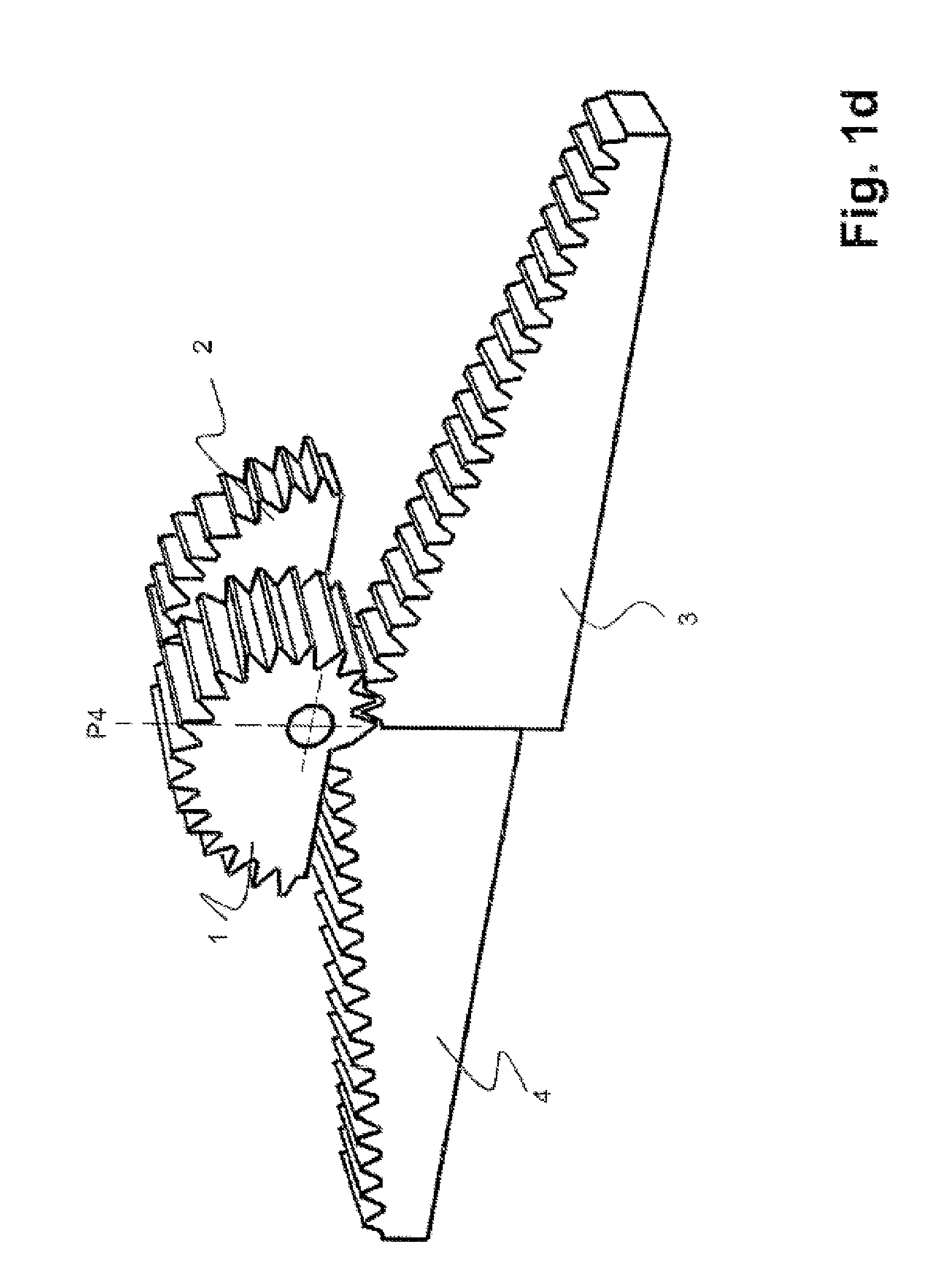

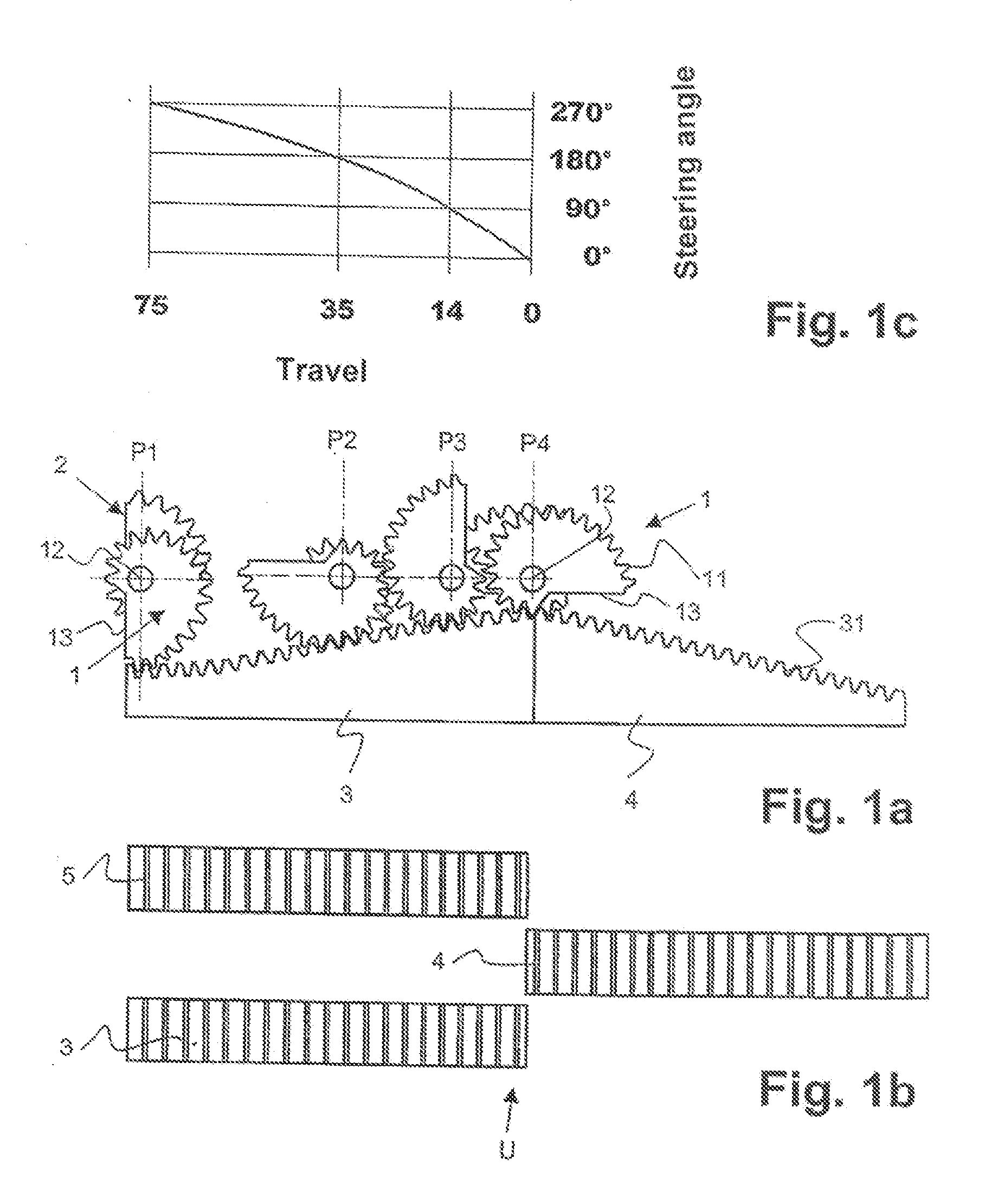

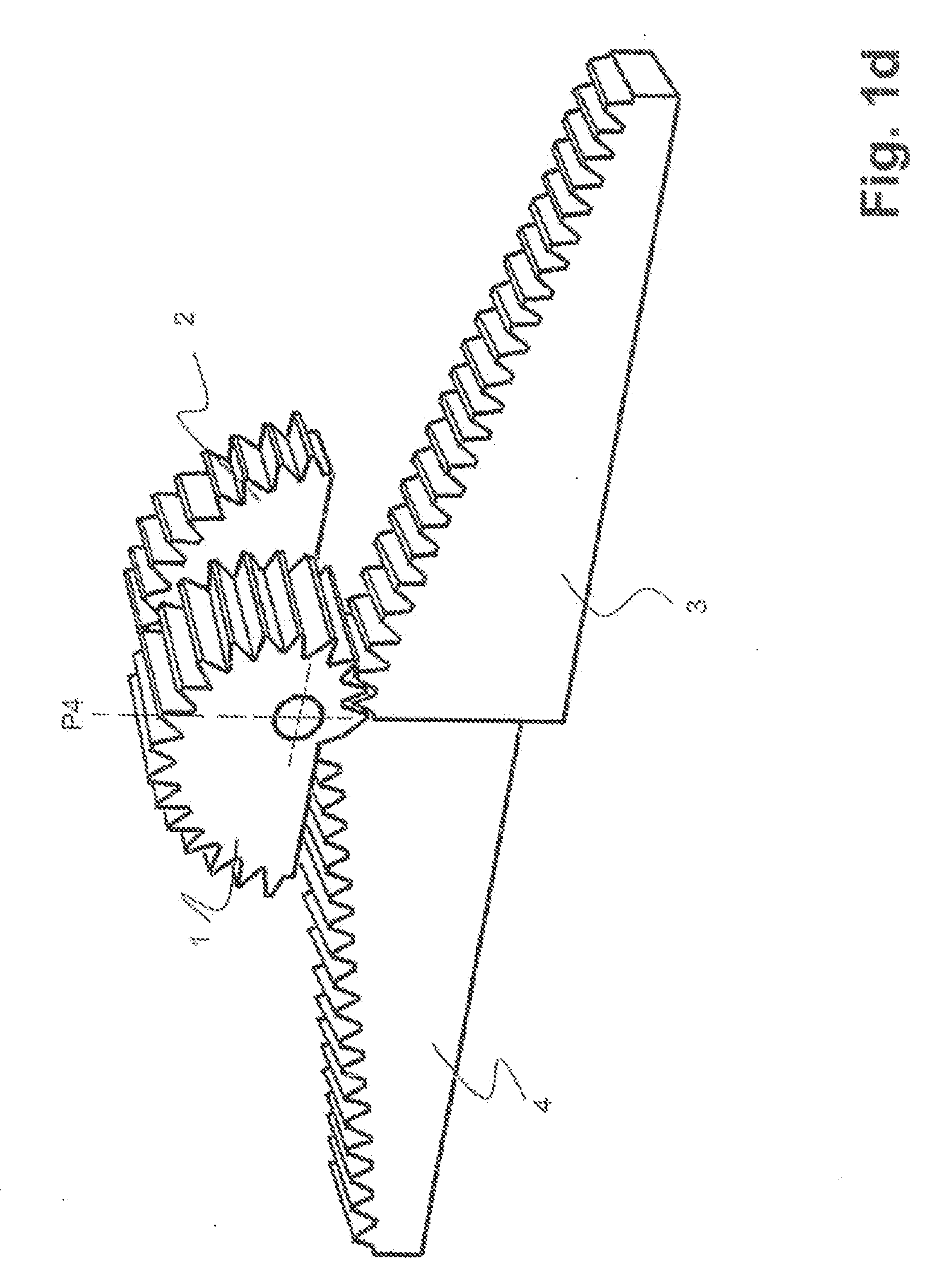

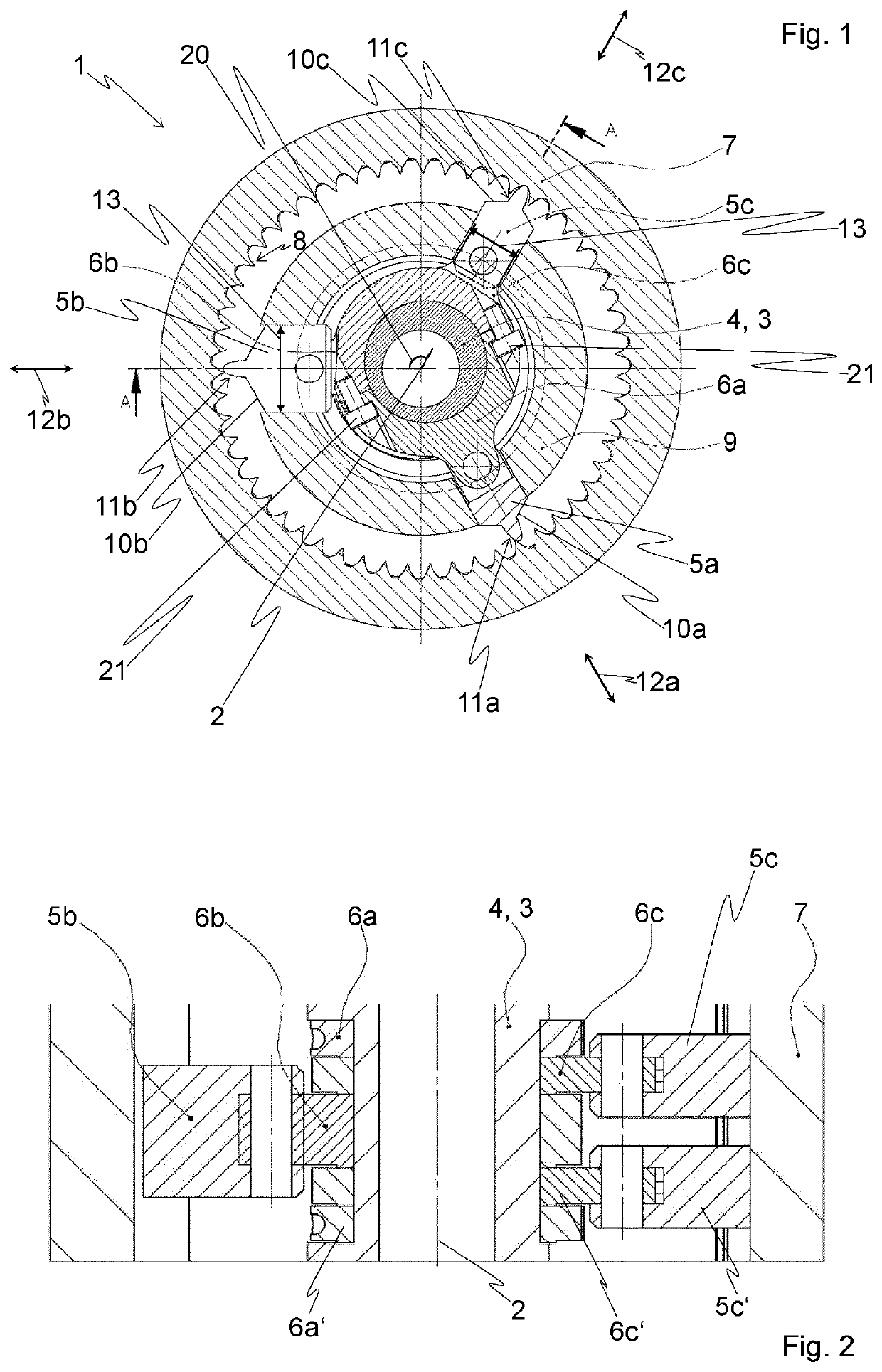

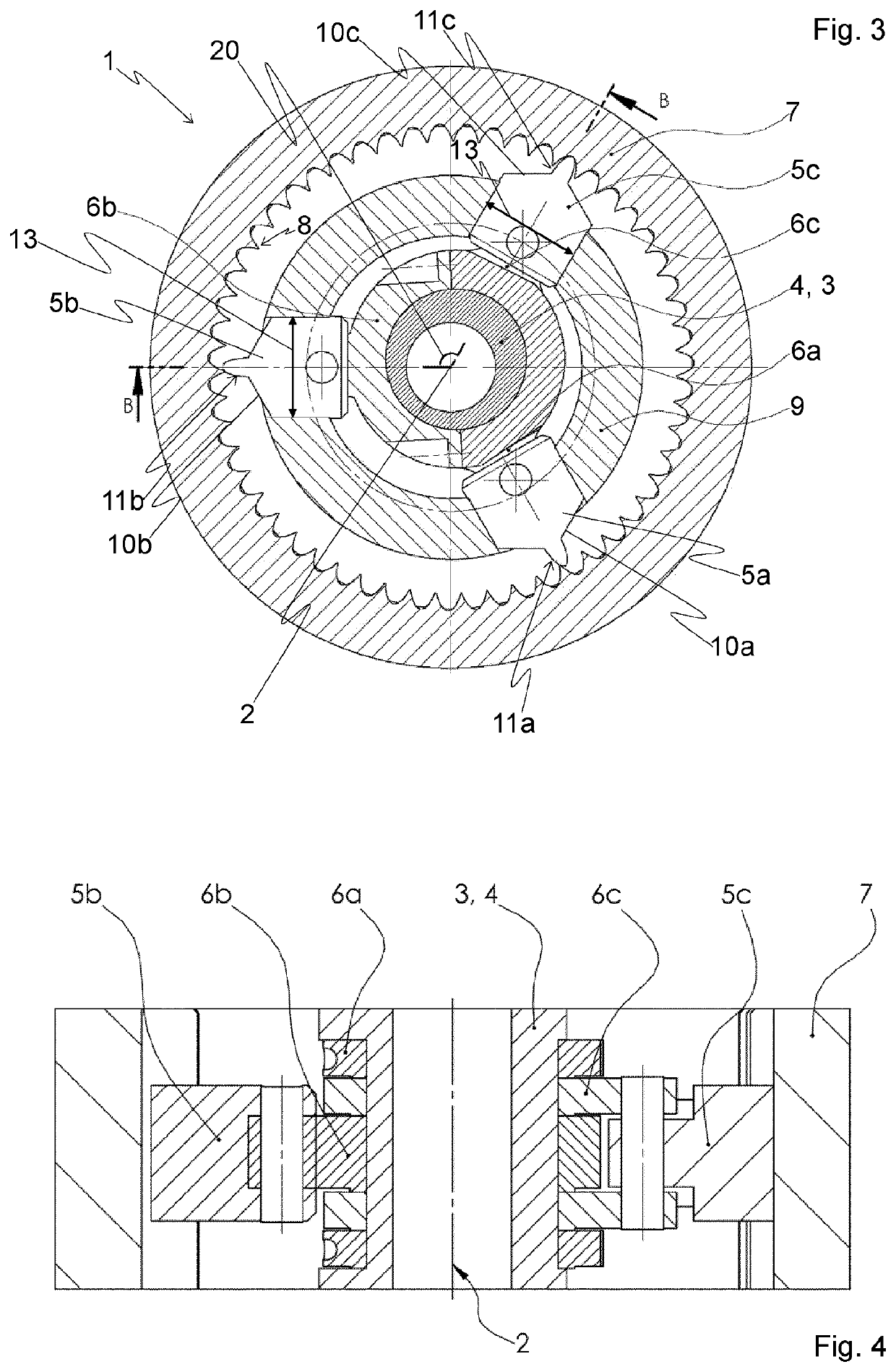

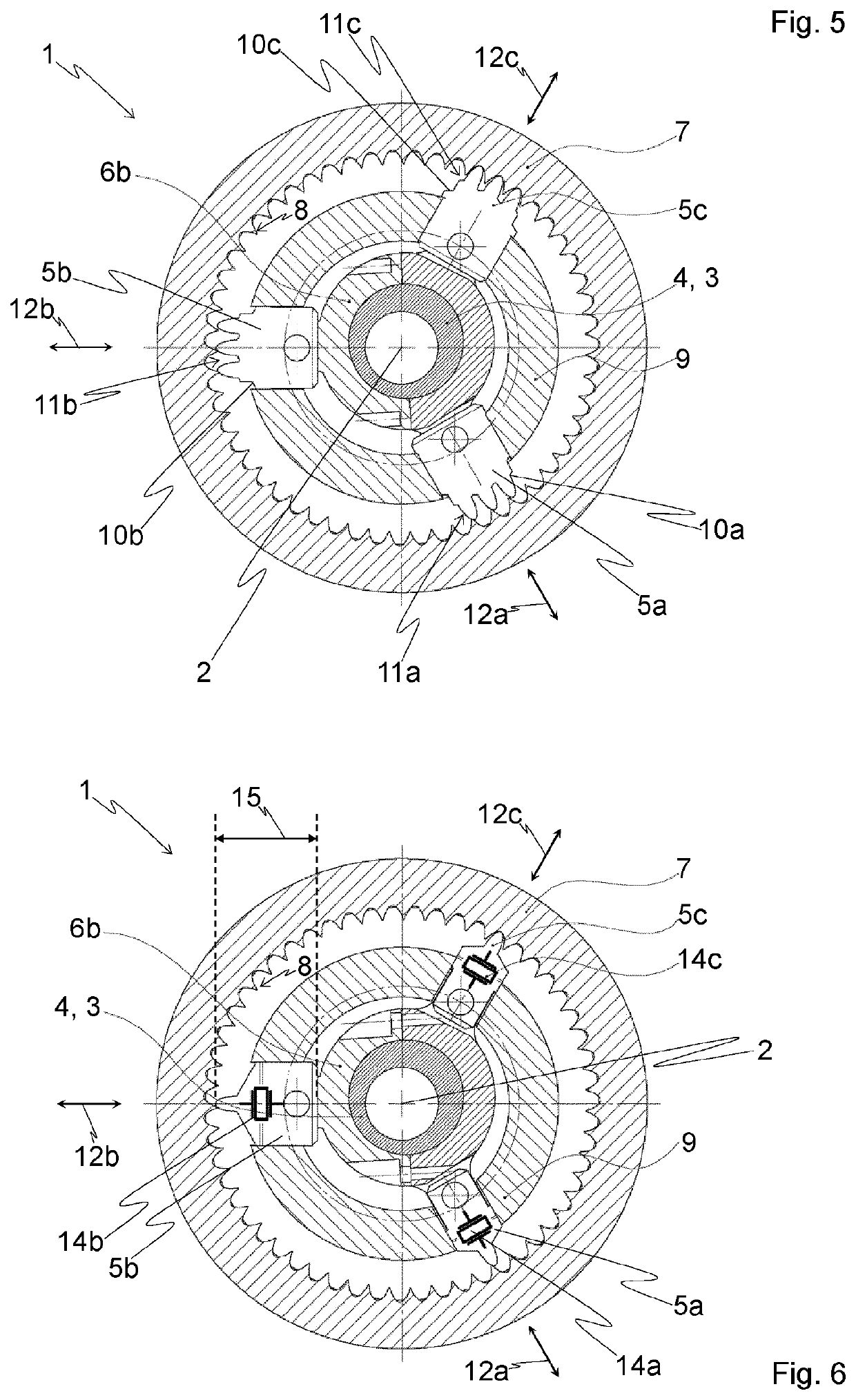

Progressive gearing

ActiveUS8196487B2No fluctuation in torqueZero backlashPortable liftingToothed gearingsEngineeringSpur gear

Owner:BLESS WERNER M

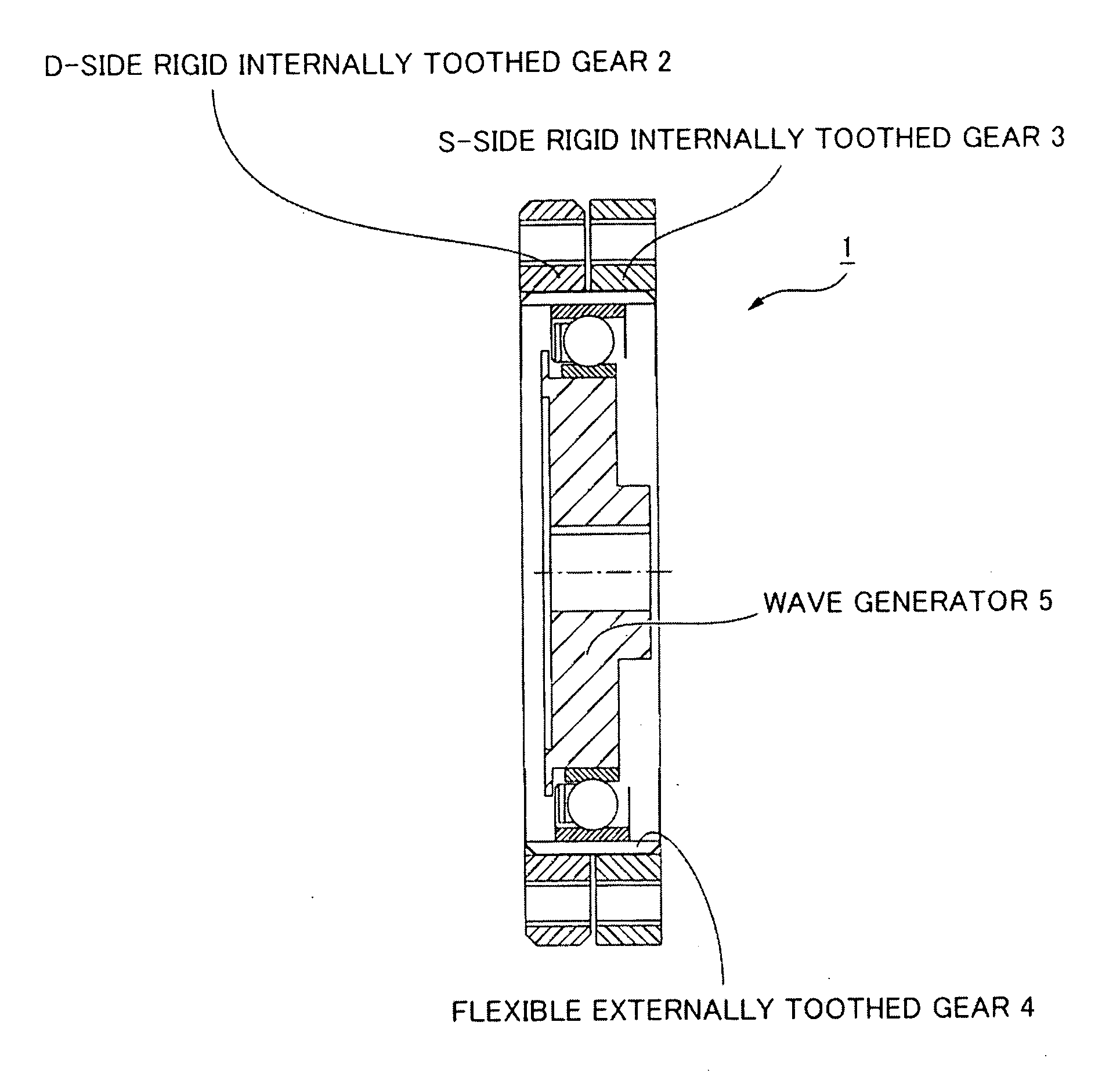

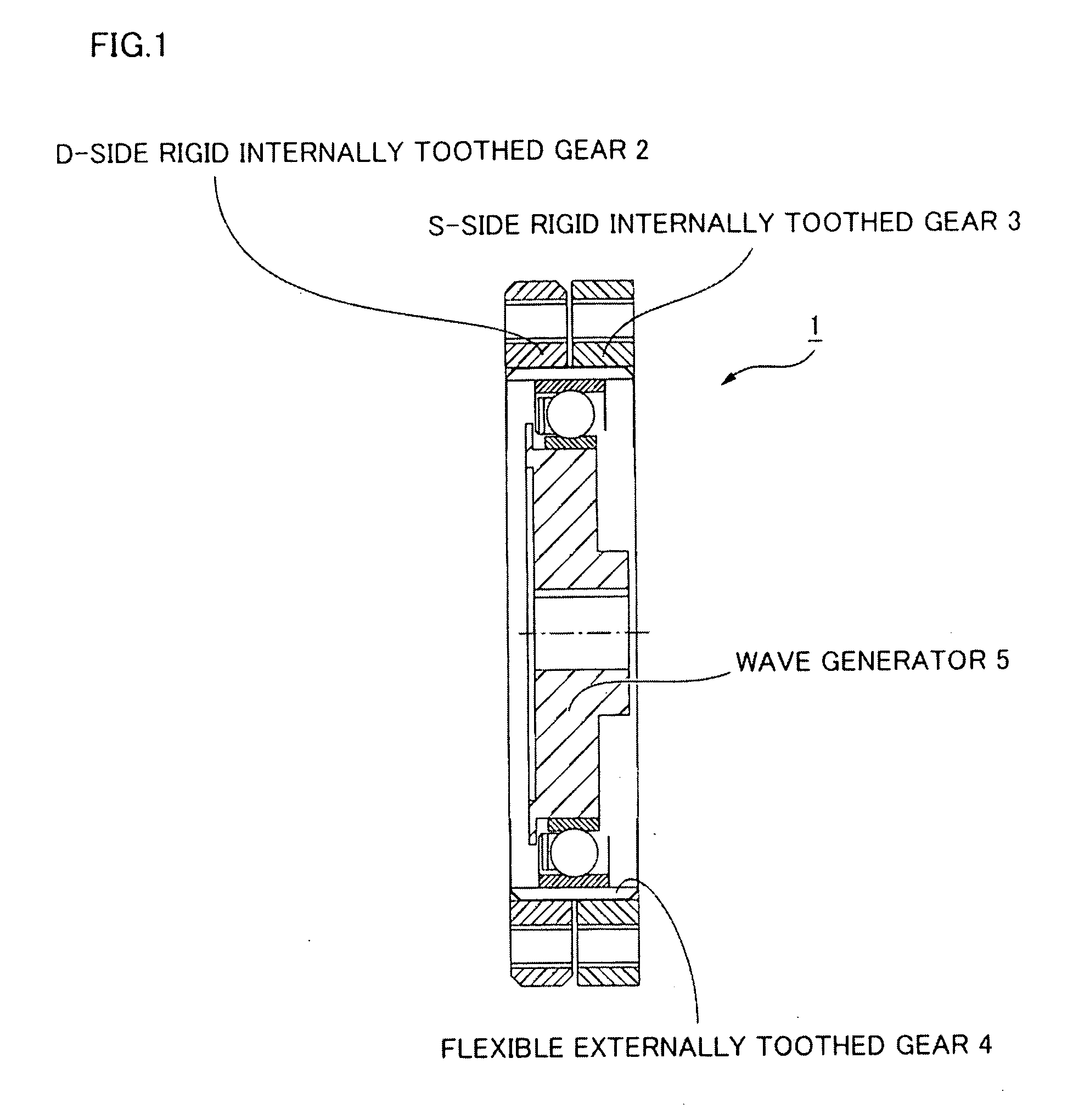

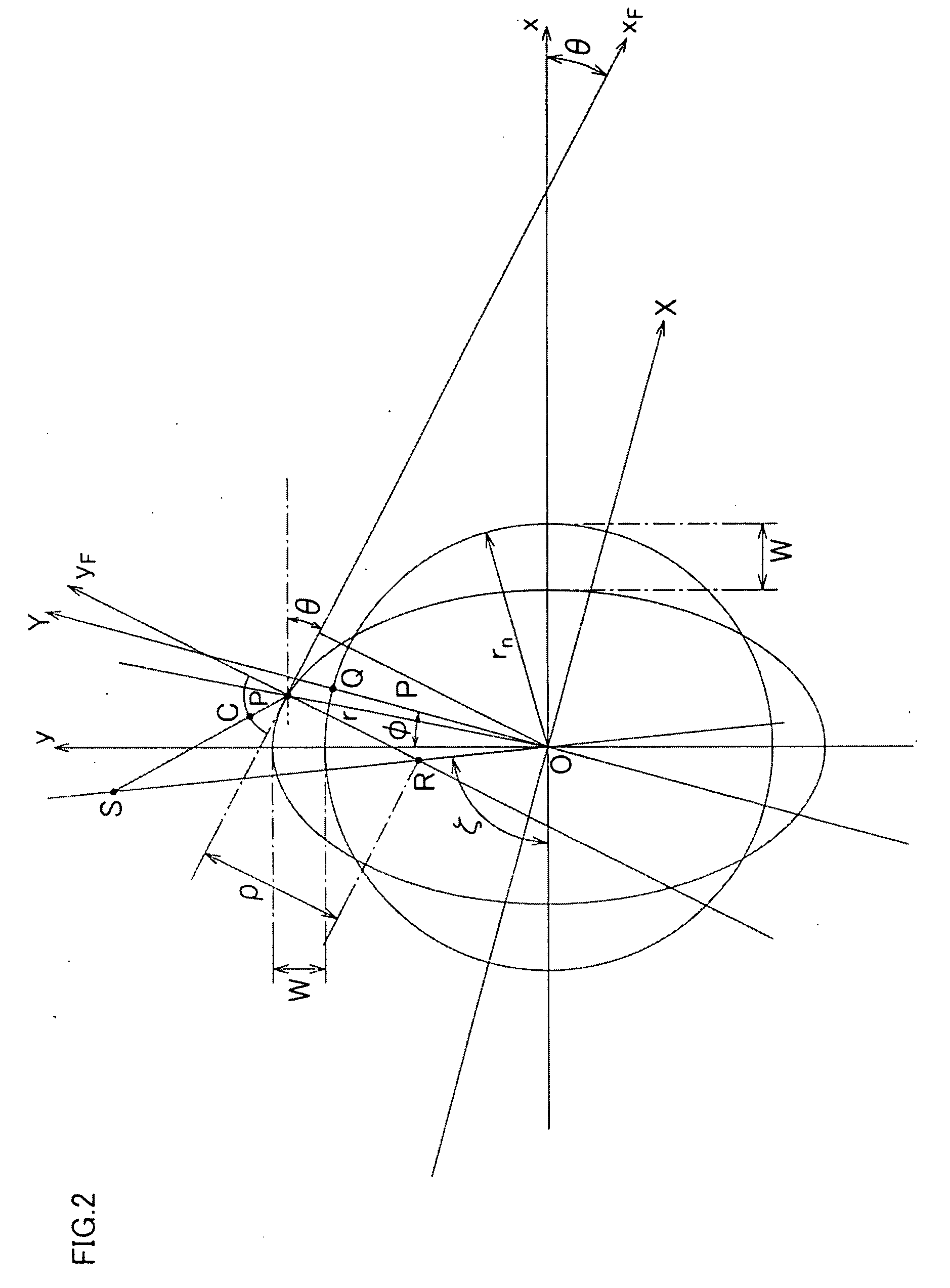

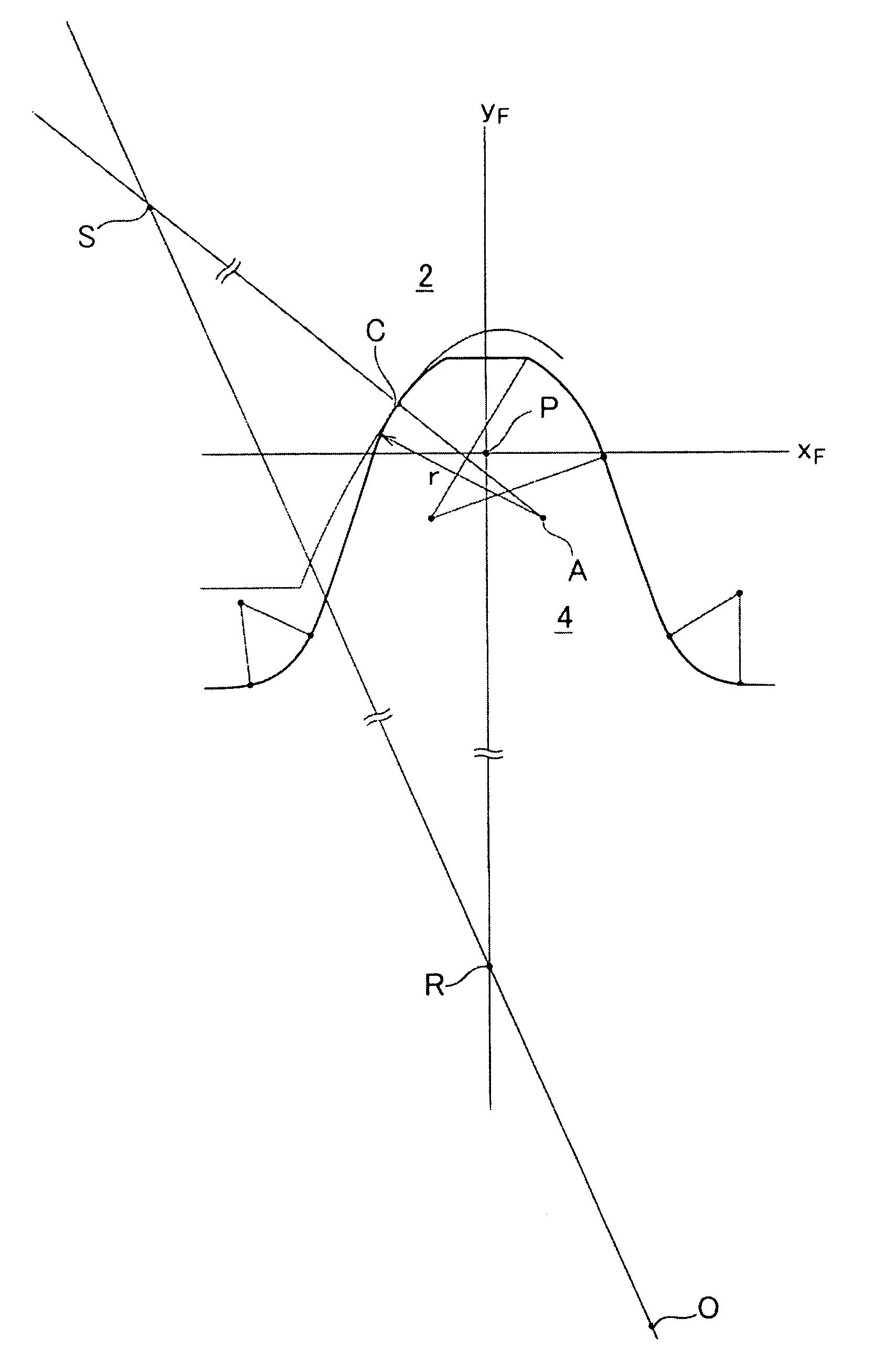

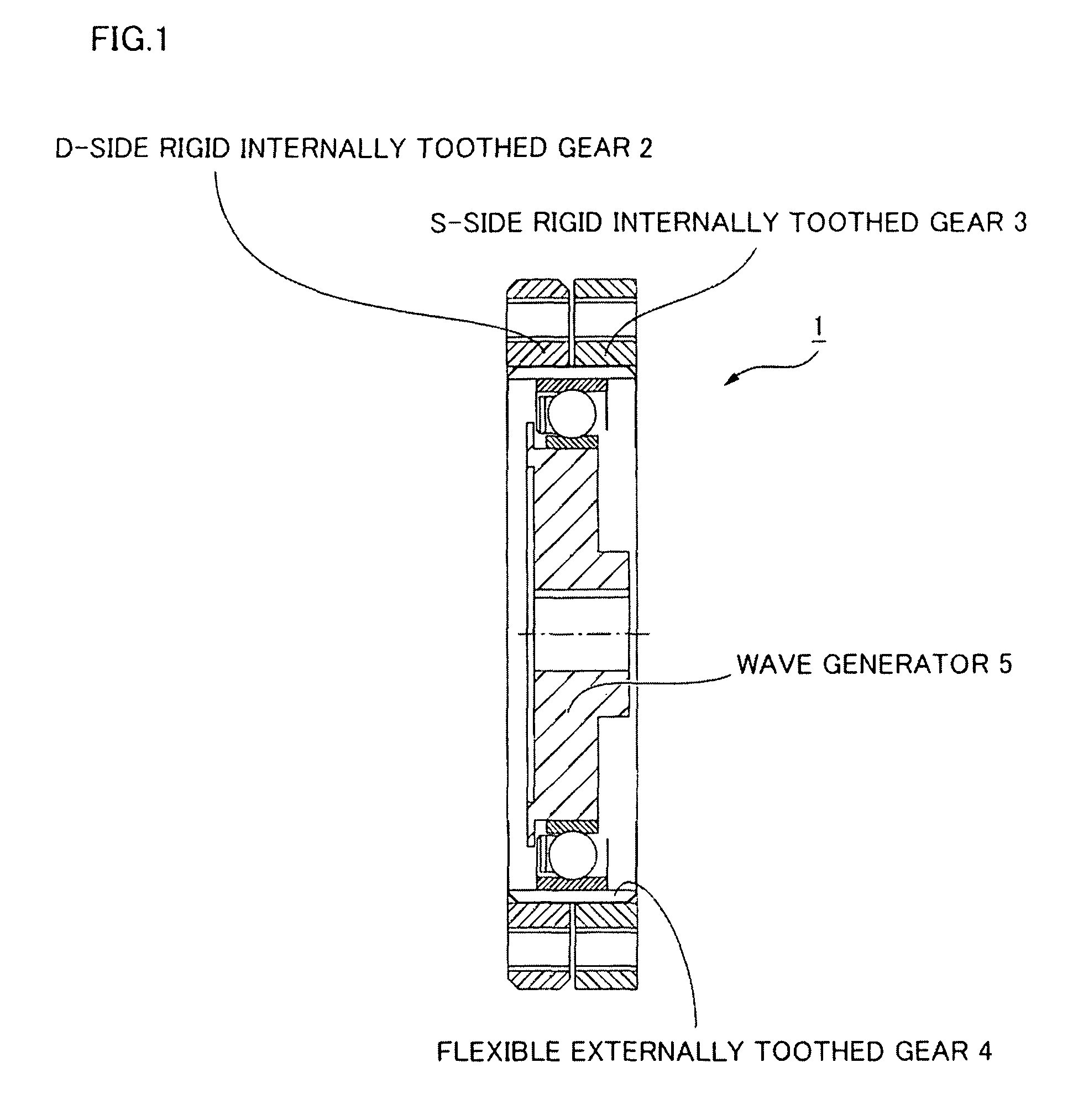

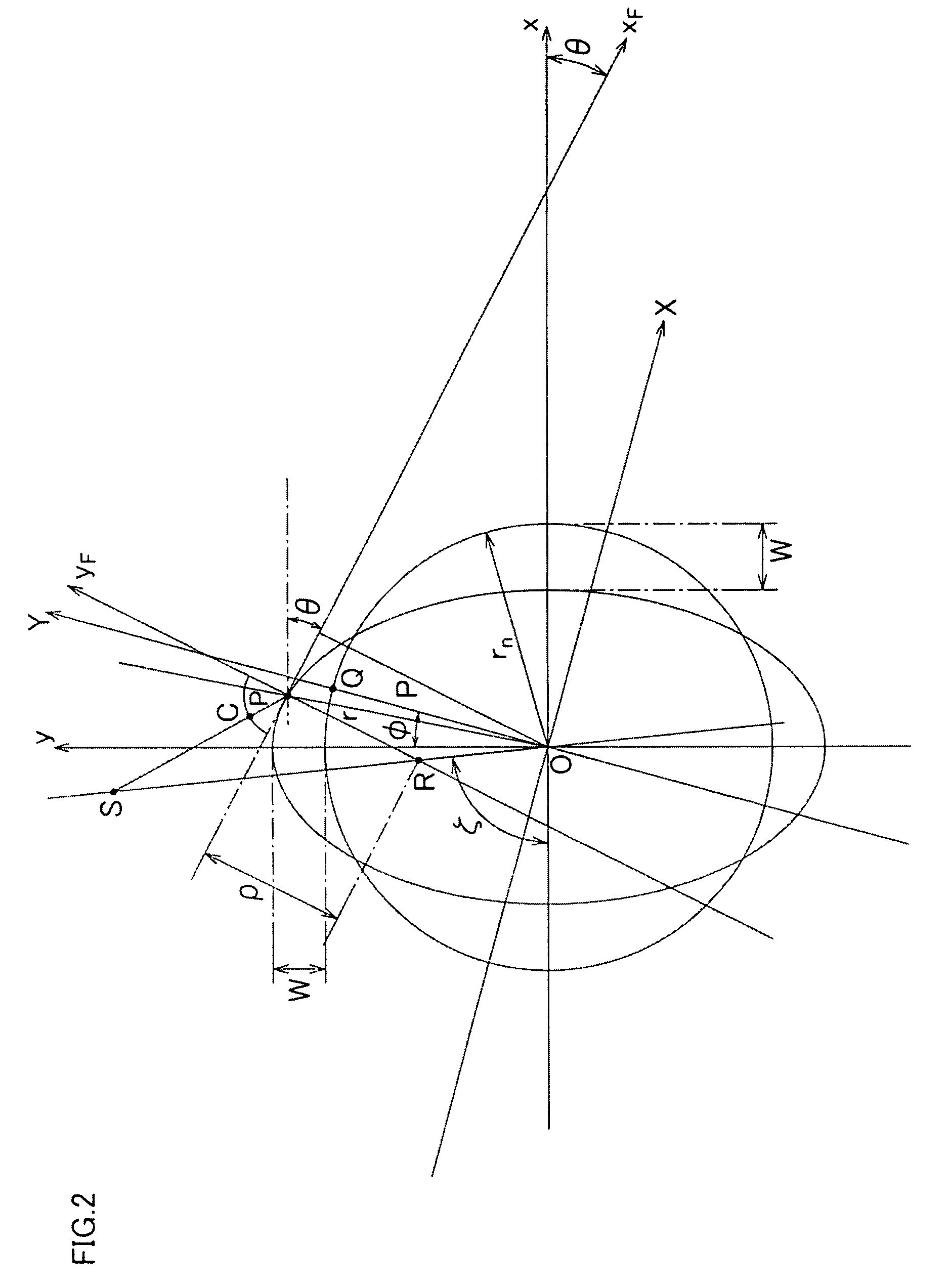

Method For Setting Gear Tooth Profile In Flat Wave Gear Device On Side Where Gears Have Same Number Of teeth

ActiveUS20090139358A1Precise designZero backlashToothed gearingsPortable liftingGear wheelTooth number

Owner:HARMONIC DRIVE SYST IND CO LTD

Method for setting gear tooth profile in flat wave gear device on side where gears have same number of teeth

Owner:HARMONIC DRIVE SYST IND CO LTD

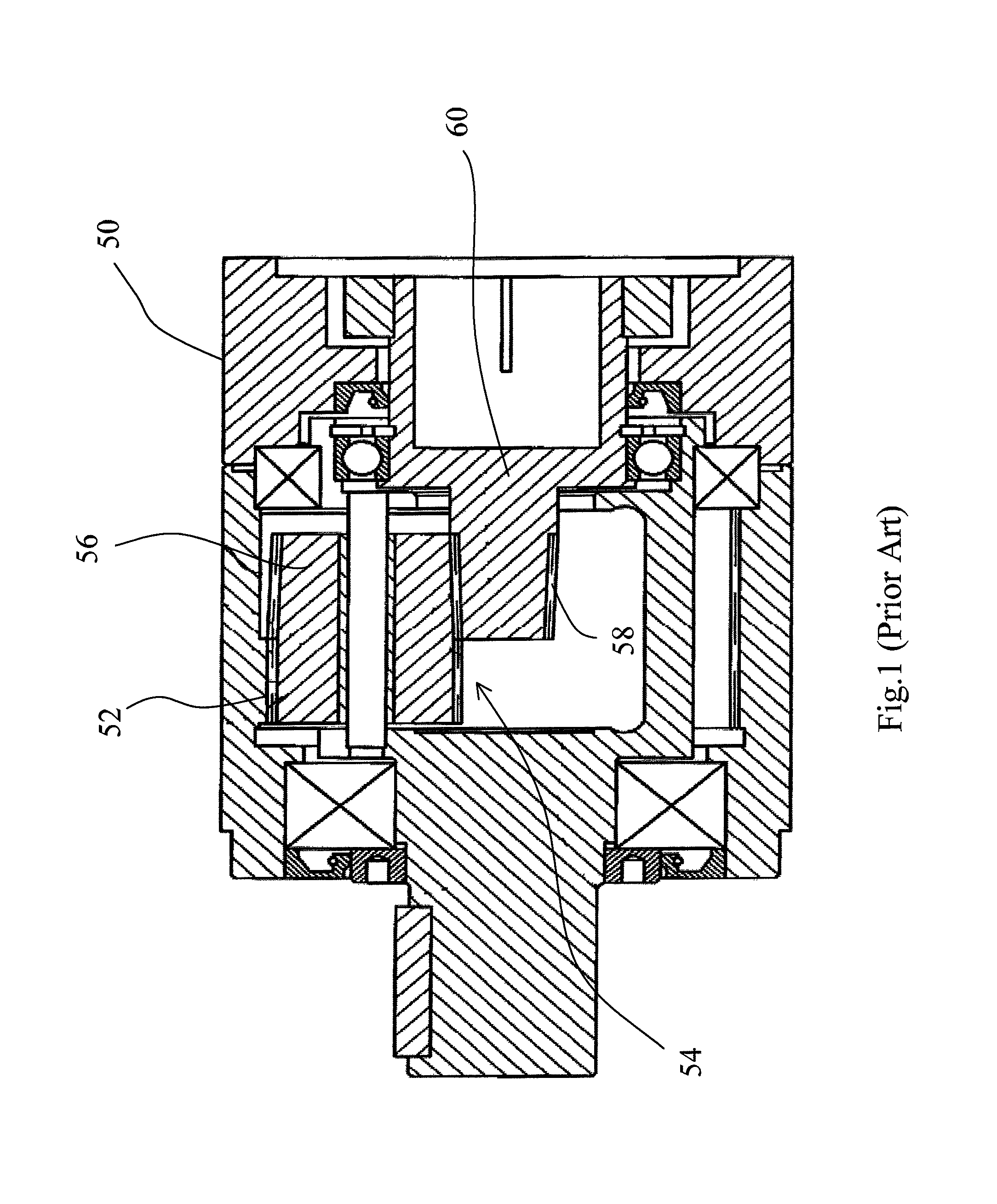

System And Method For Reducing Backlash In A Planetary Gear Set

InactiveUS20070093354A1Reduce controlPreclude creationToothed gearingsGearing detailsGear wheelGear tooth

Systems and methods for reducing or eliminating backlash to control gear rattle include a planetary gear set with a planet carrier including a first part that supports at least one forward-torque carrying planet gear that has at least one tooth contacting a drive side of gear teeth of an associated sun gear and ring gear and a second part that supports at least one reverse-torque carrying gear that has at least one tooth contacting a coast side of gear teeth of the associated sun gear and ring gear, the second part of the carrier being rotationally biased relative to the first part to reduce or eliminate effective backlash of the gear set.

Owner:FORD GLOBAL TECH LLC

System and method for reducing backlash in a planetary gear set

InactiveUS7261667B2Reduce controlPreclude creationToothed gearingsGearing detailsGear wheelEngineering

Systems and methods for reducing or eliminating backlash to control gear rattle include a planetary gear set with a planet carrier including a first part that supports at least one forward-torque carrying planet gear that has at least one tooth contacting a drive side of gear teeth of an associated sun gear and ring gear and a second part that supports at least one reverse-torque carrying gear that has at least one tooth contacting a coast side of gear teeth of the associated sun gear and ring gear, the second part of the carrier being rotationally biased relative to the first part to reduce or eliminate effective backlash of the gear set.

Owner:FORD GLOBAL TECH LLC

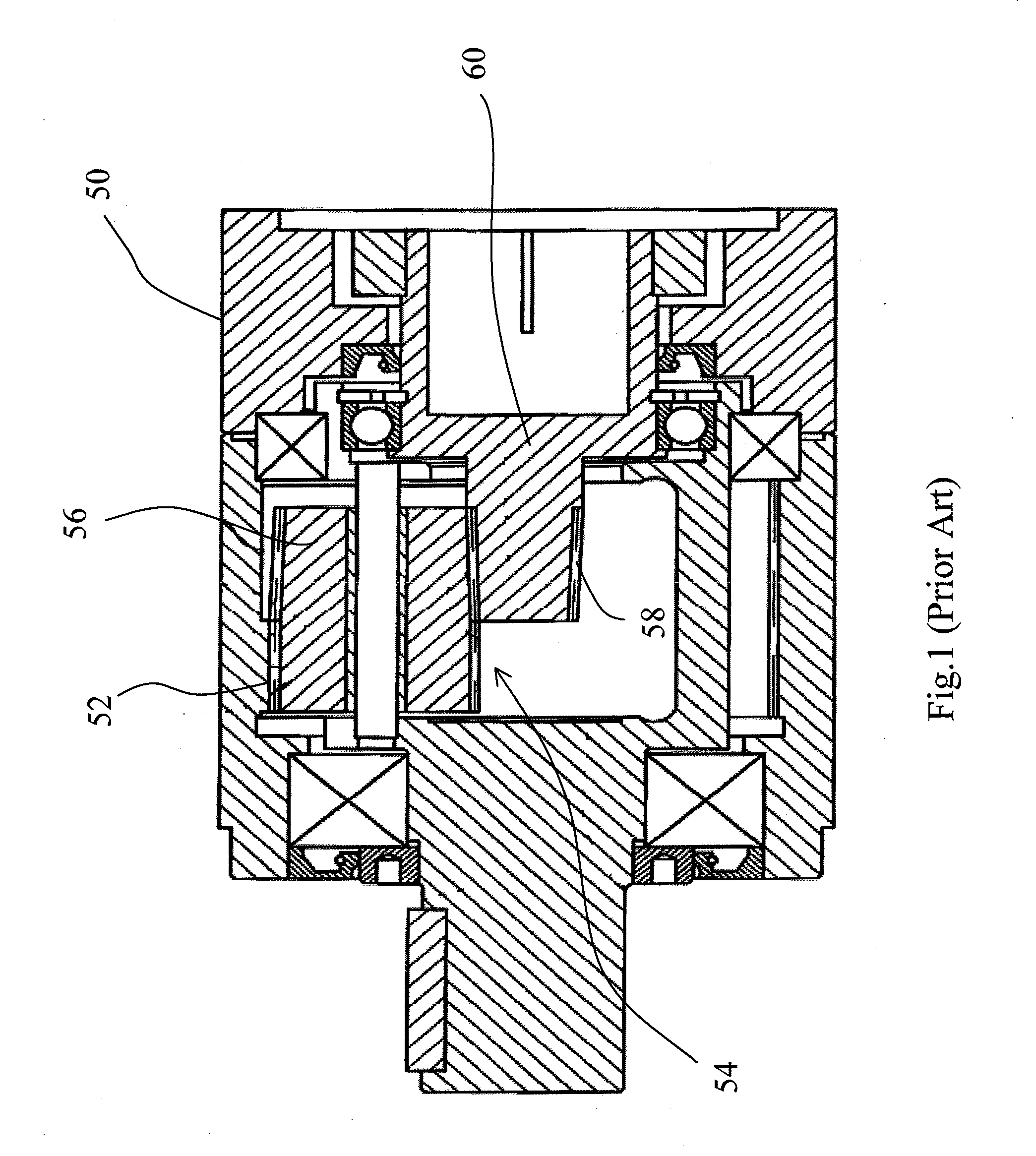

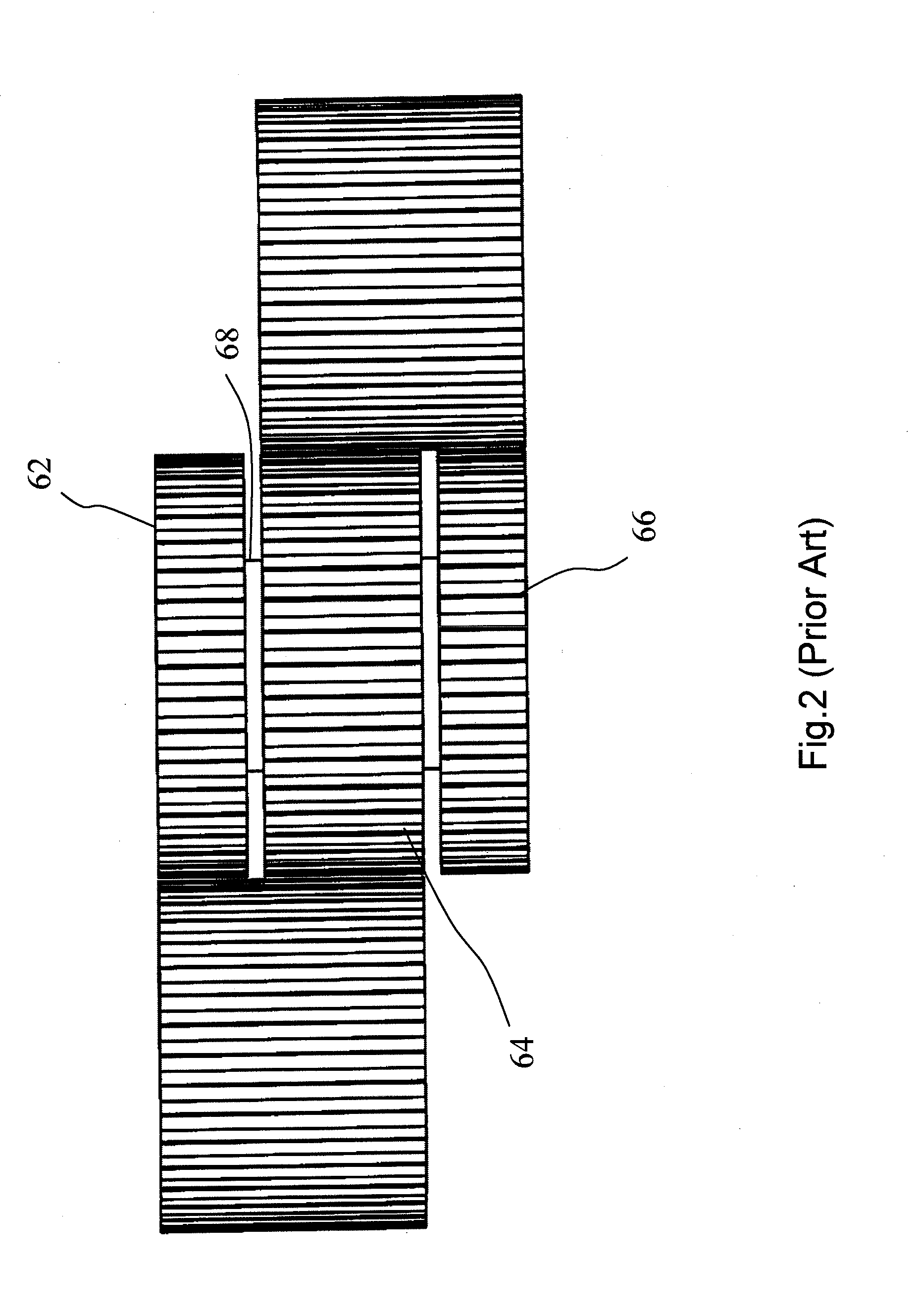

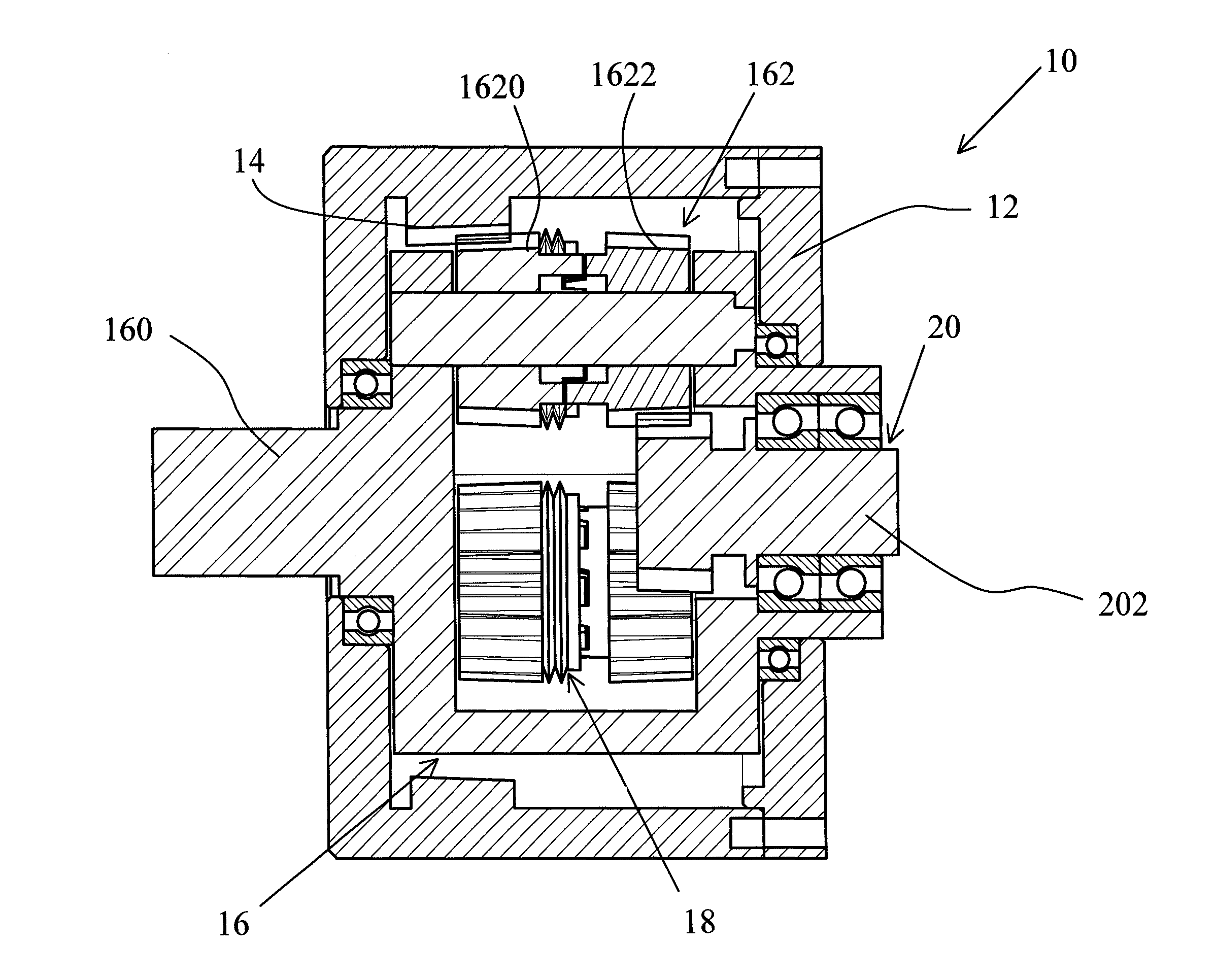

Zero backlash planetary gear train

ActiveUS20130203553A1Eliminate backlashIncrease stiffnessToothed gearingsPortable liftingEngineeringDrive motor

A zero backlash planetary gear train, comprising: a shell, a planetary gear set, and at least a sun gear set. Planetary gear set is disposed in said shell, and includes a planetary arm rack having output axis, such that planetary arm rack in said shell is provided with a plurality of double-layer planetary gears. The planetary gear set includes a first planetary gear and a second planetary gear. A buffer mechanism is provided between first planetary gear and second planetary gear. Said first planetary gear is engaged with at least an internal gear on an inner rim of shell, and second planetary gear is engaged with at least a sun gear set. Sun gear set is provided with a sun gear connected to a driving motor. Said zero backlash planetary gear train is capable of eliminating backlash between gears.

Owner:NATIONAL CHUNG CHENG UNIV

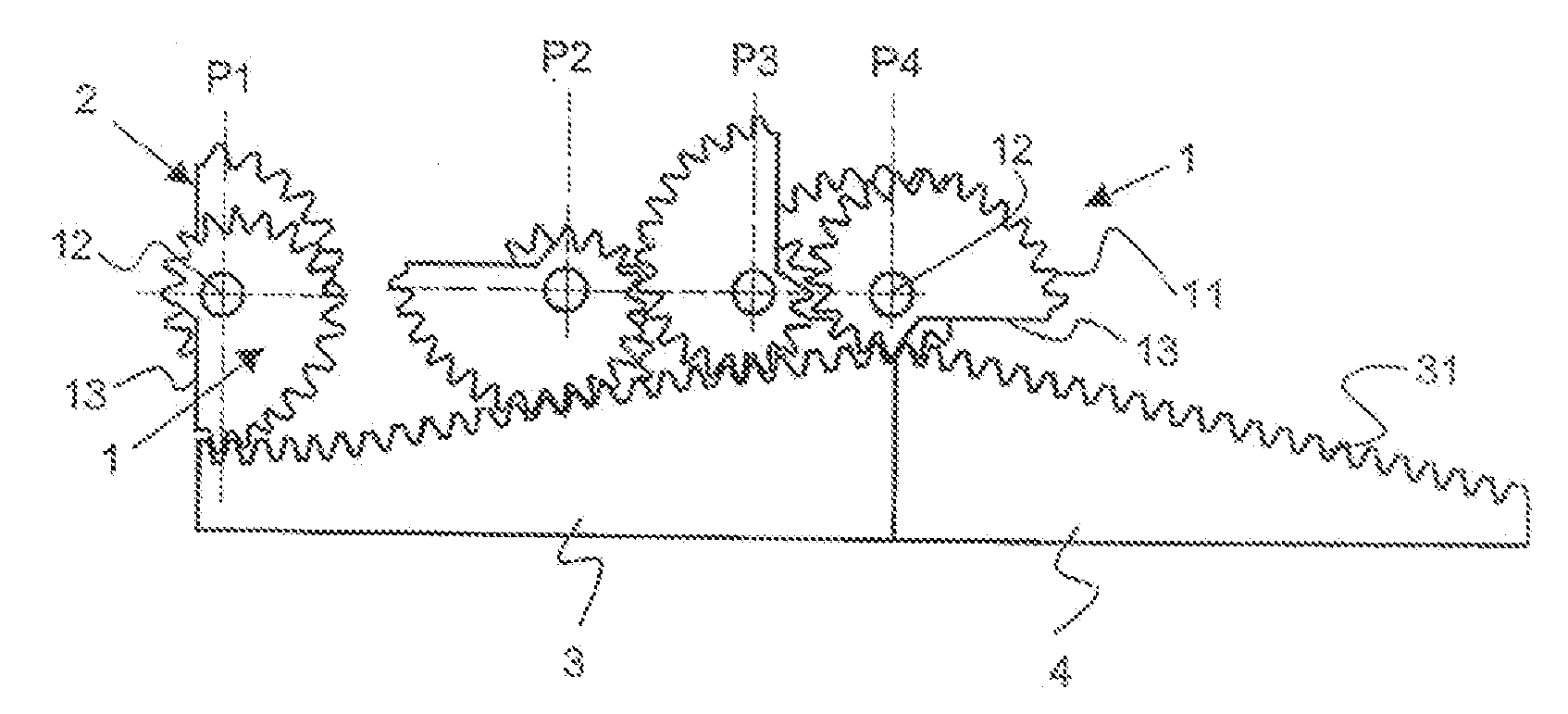

Progressive Gearing

ActiveUS20080257085A1Slowly changeNo fluctuation in torquePortable liftingToothed gearingsAngular rangeLogarithmic spiral

A progressive gear assembly comprises at least one spur gear (1, 2) and a toothed structure (3, 4, 5, 7, 8) with which the spur gear (1, 2) meshes. The spur gear (1, 2) has teeth (11) arranged along a curve (10), the curve (10) comprising a radius of curvature (r) which monotonically rises over an angular range of more than 90° of the curve (10). Preferably the curve is a spiral, particularly a logarithmic spiral. This gear assembly is configured compact and simple, features smooth running and achieves a late end point.

Owner:BLESS WERNER M

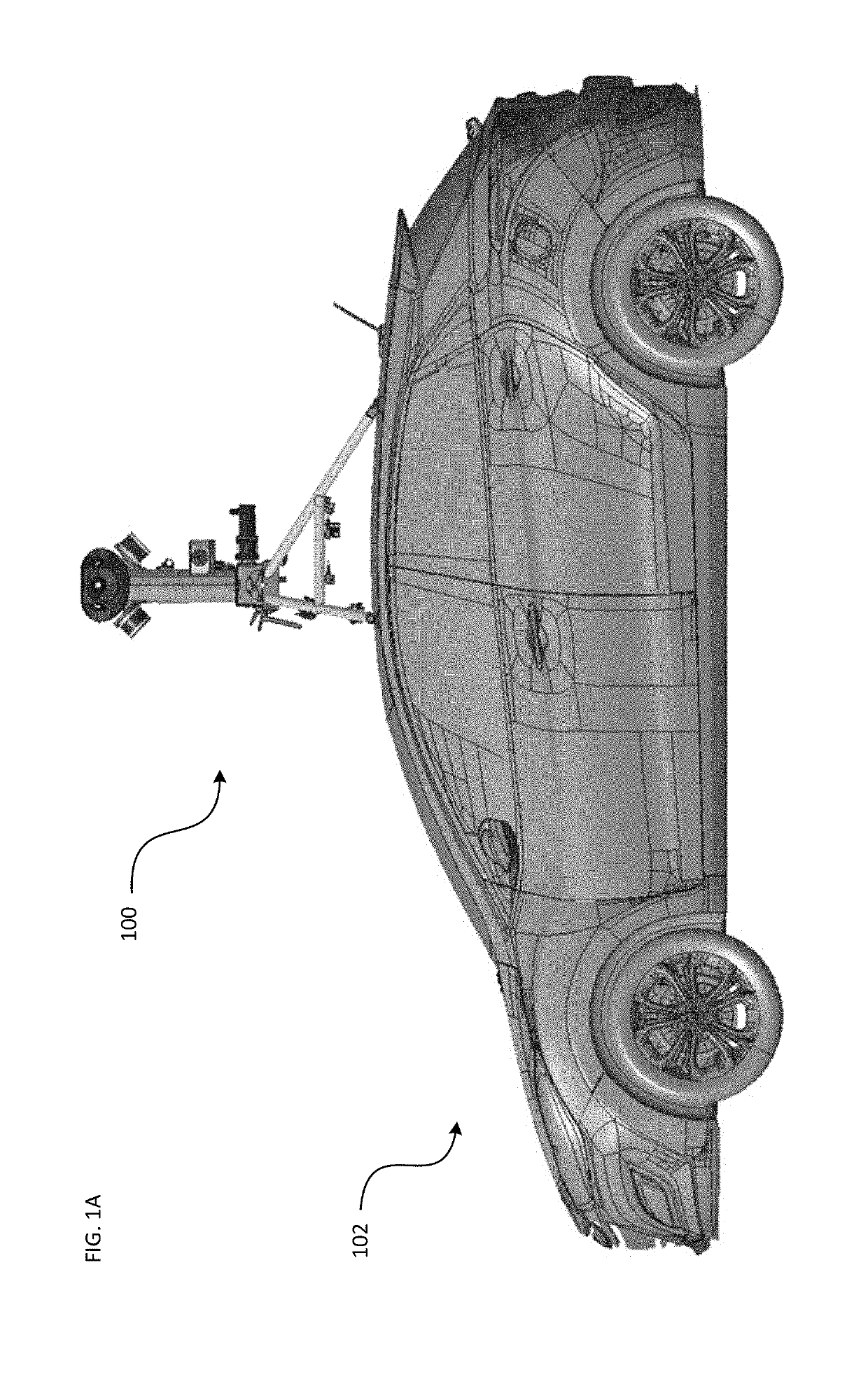

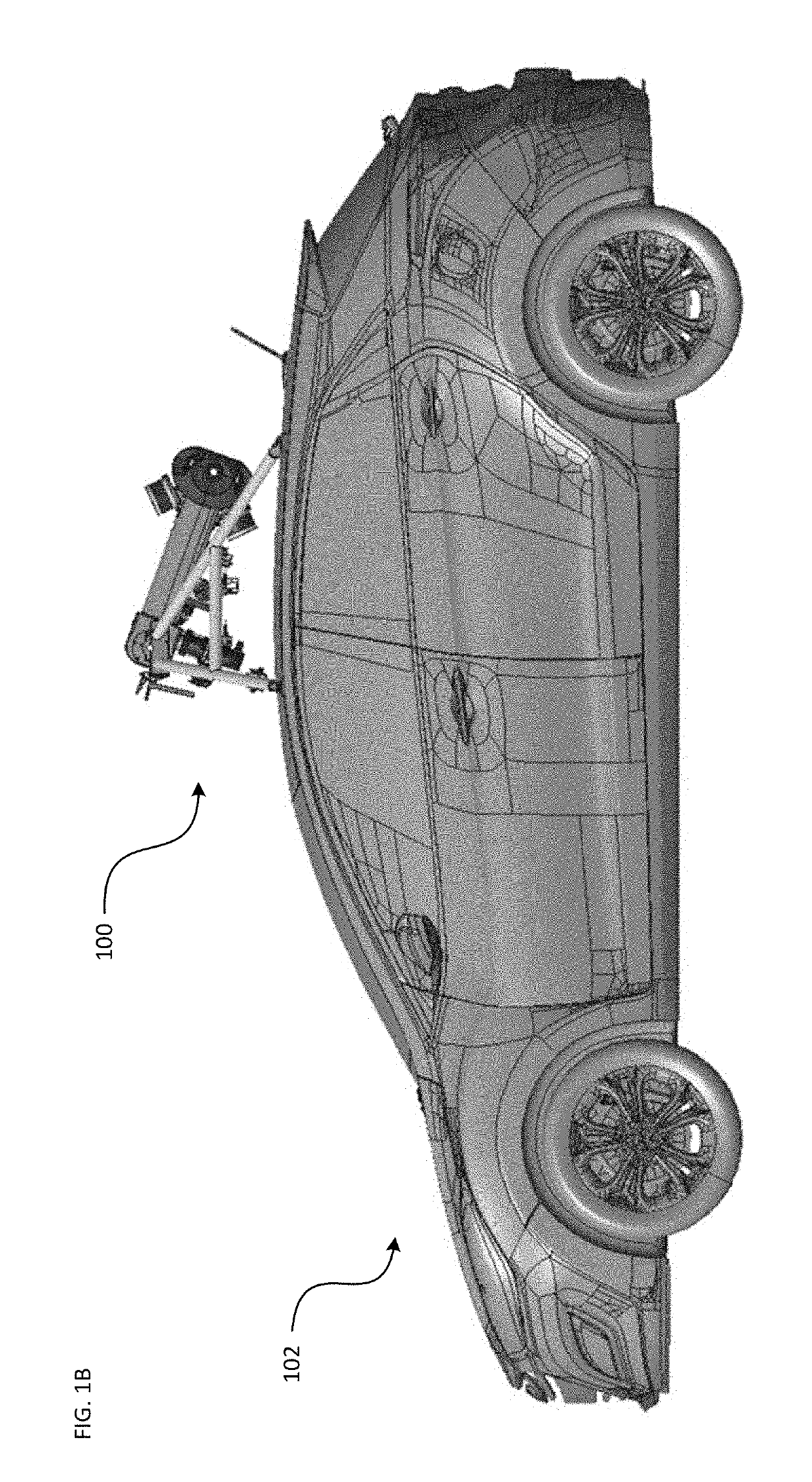

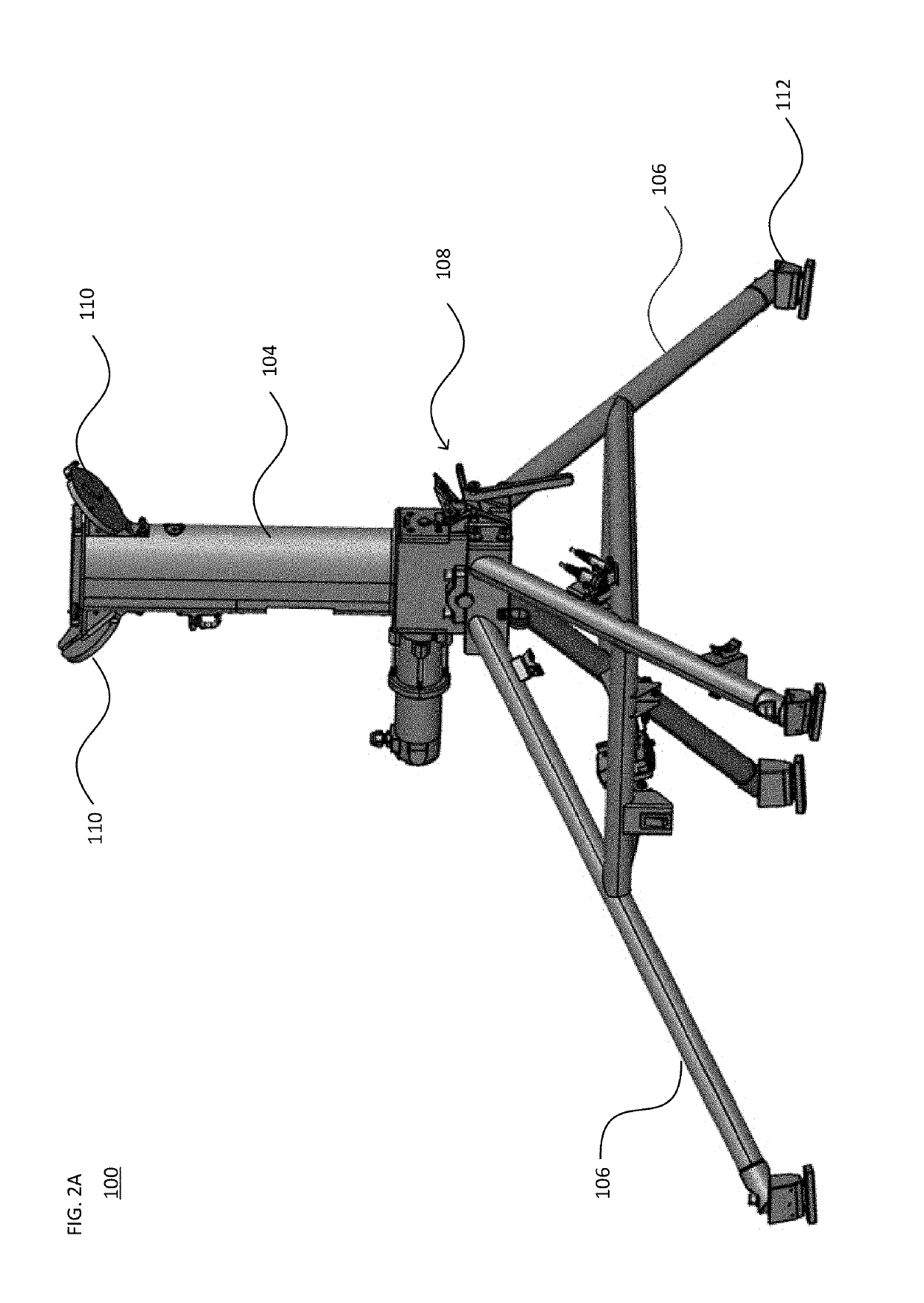

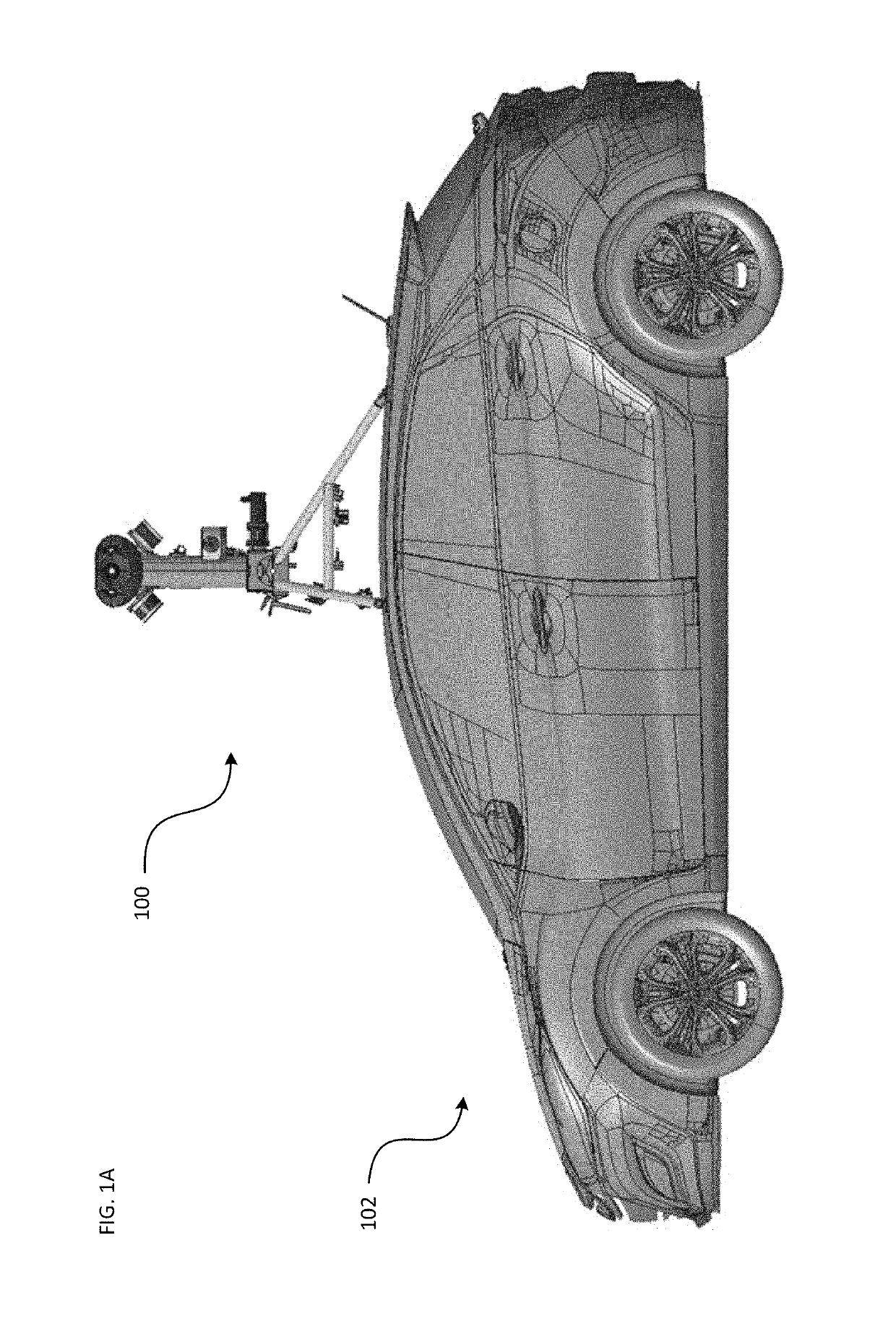

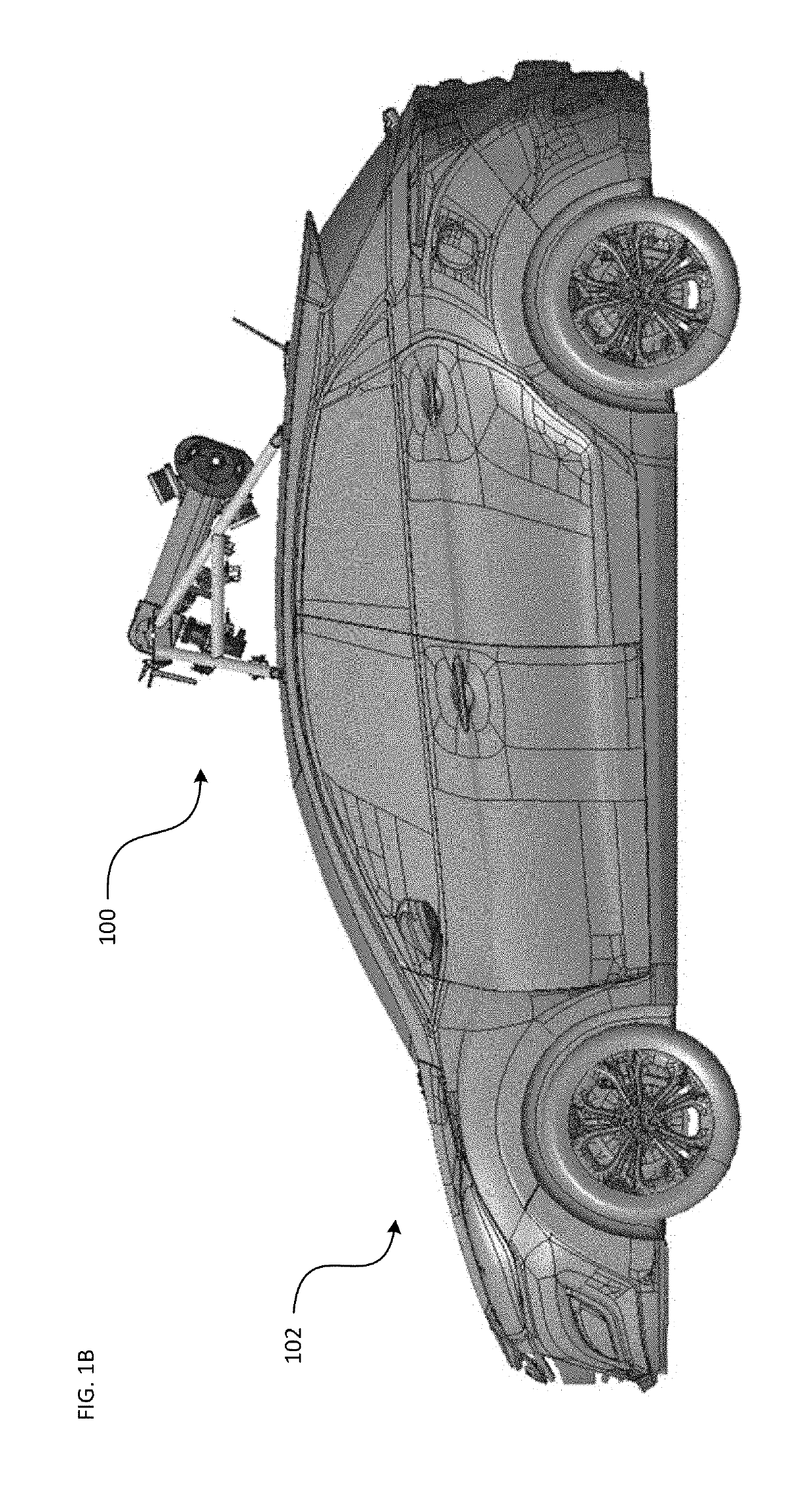

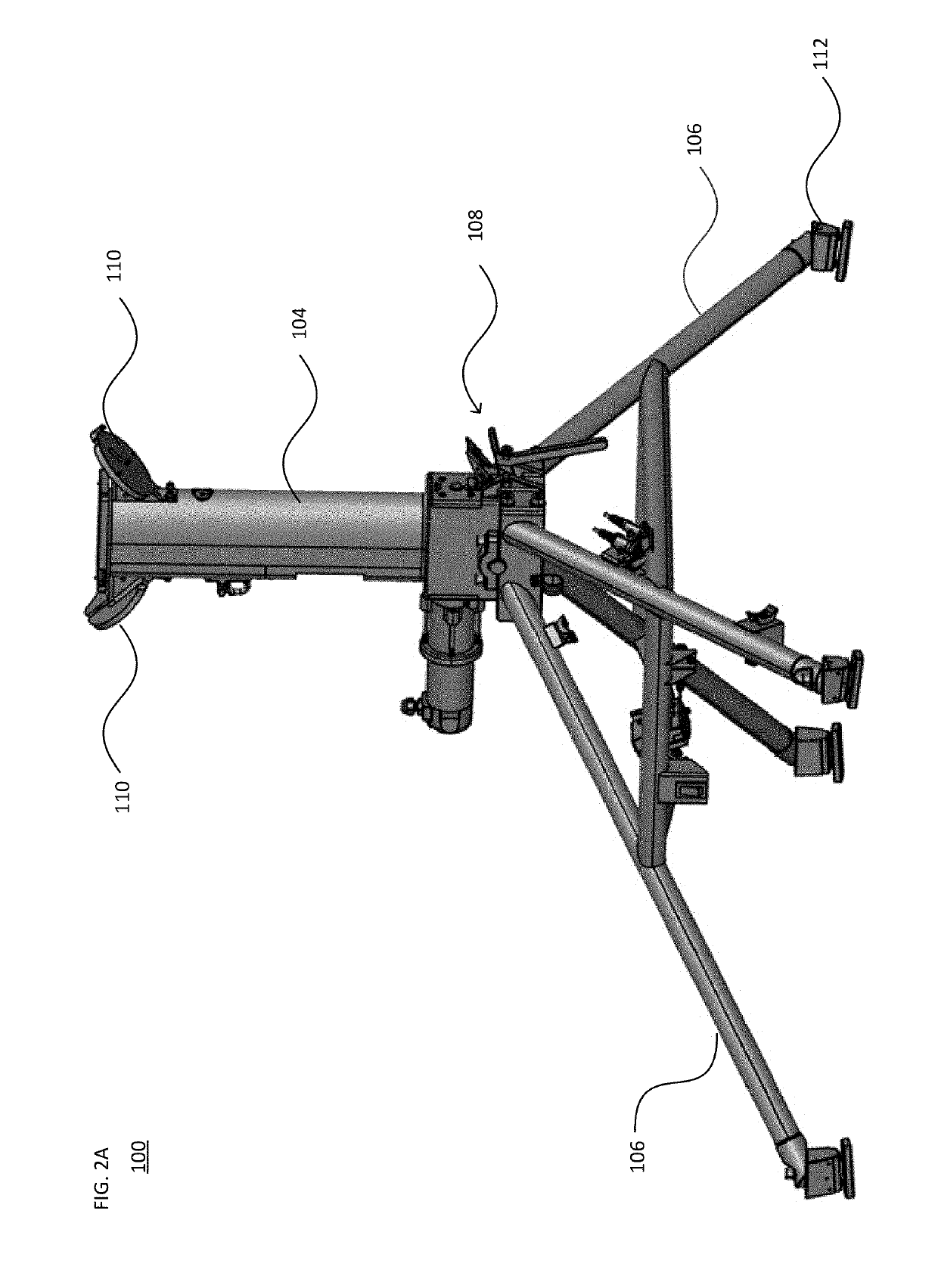

Releasable zero backlash passive locking mechanism for a vehicle mounted rotary camera mast

ActiveUS20190126846A1Easy to disengageRaise the natural frequencyRod connectionsStands/trestlesLocking mechanismEngineering

A rotary locking joint that has zero backlash is provided to secure a camera mast mounted on a vehicle in a deployed position. The joint is passive to lock while being easily releasable. The joint prevents rotation of the mast in one direction, with a hard stop element that prevents further rotation of the mast in the opposite direction. The locking joint includes a pawl member configured to rotate about a pawl rotation axis. The pawl member is maintained in place in the locked position via a torsion spring to ensure contact with a base portion of the mast. To release the joint, the pawl member is rotated in the opposite direction to remove a geometry interference condition. A sensor is arranged to detect whether the pawl member is in an unlocked position relative to the mast.

Owner:GOOGLE LLC

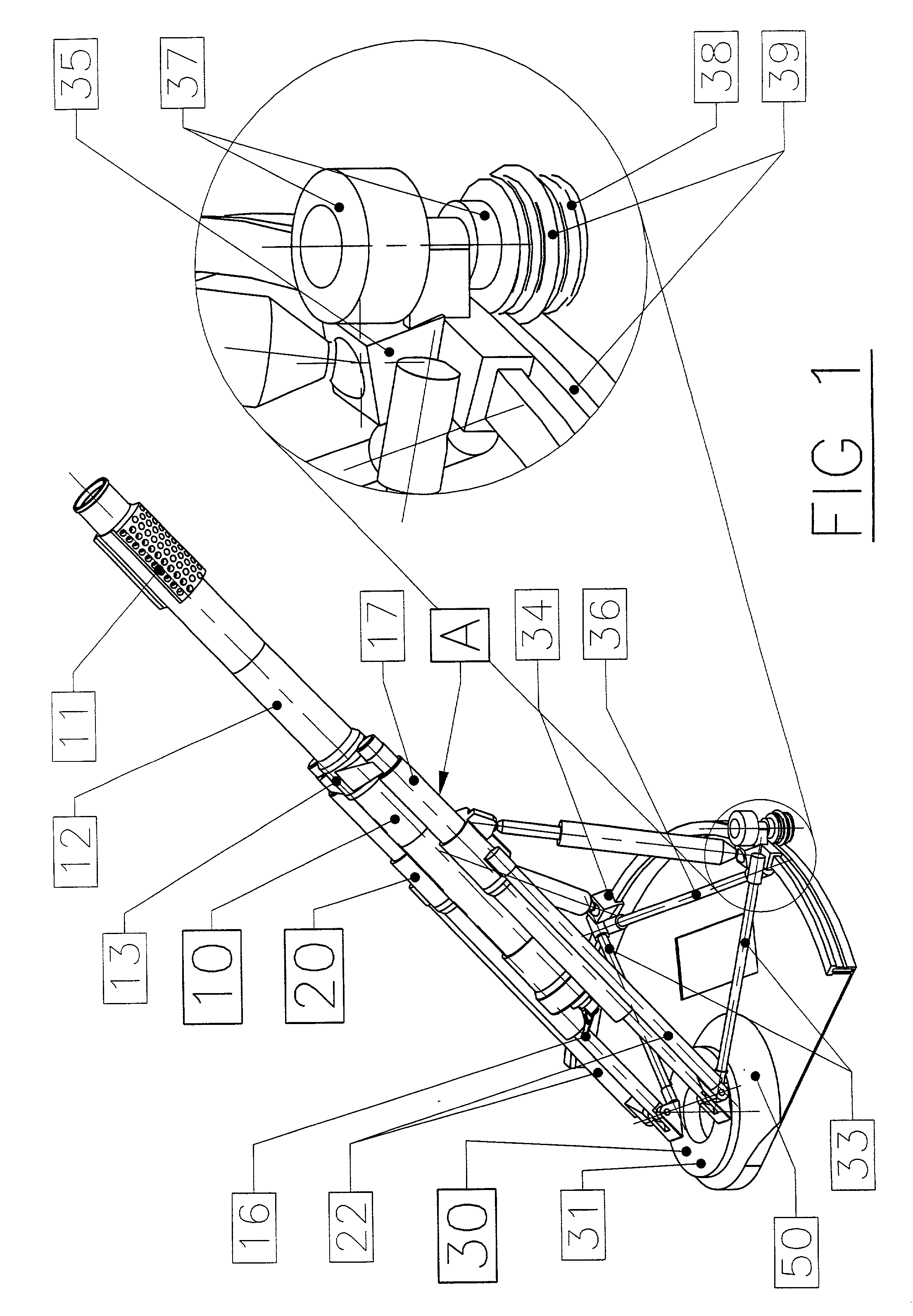

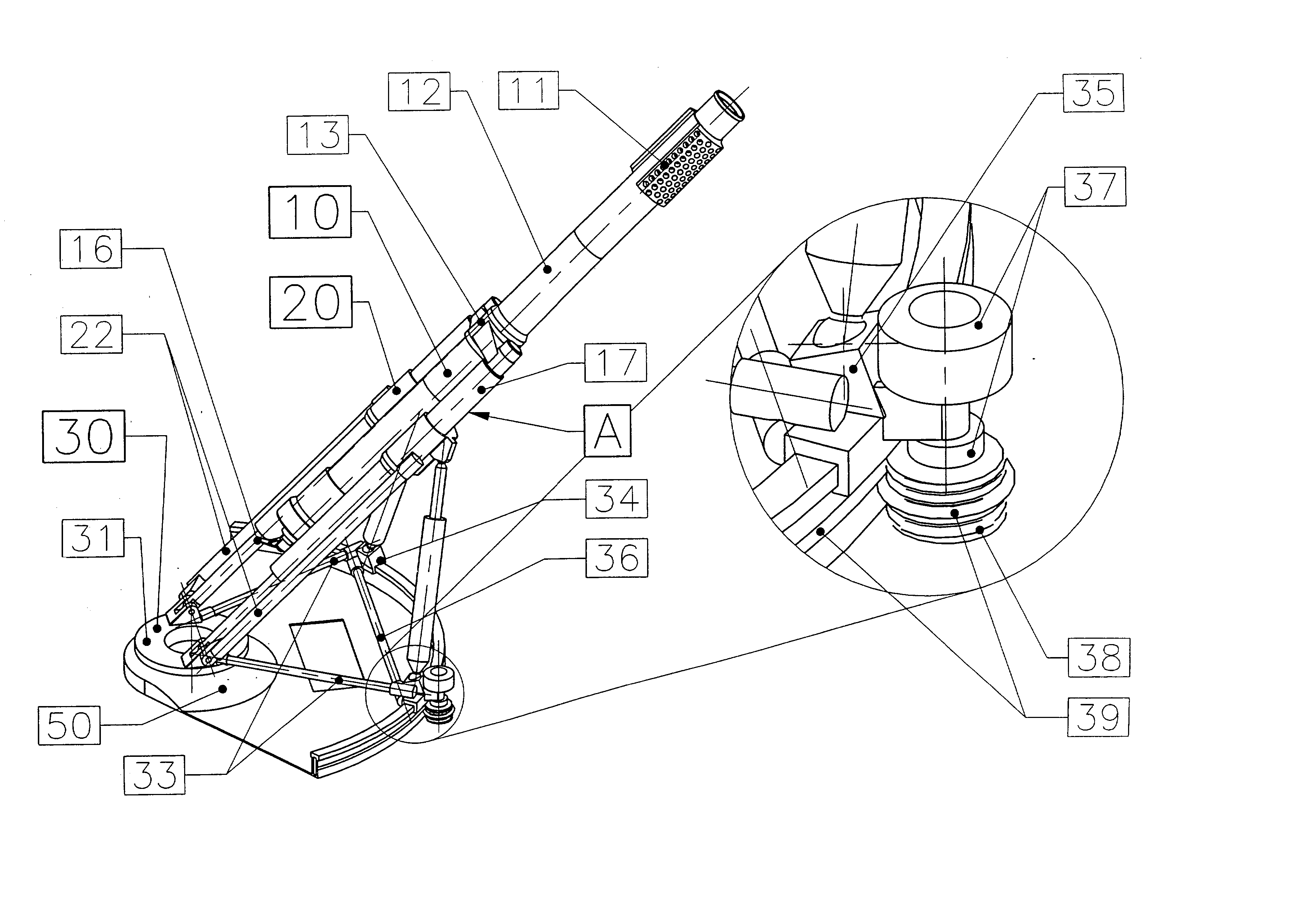

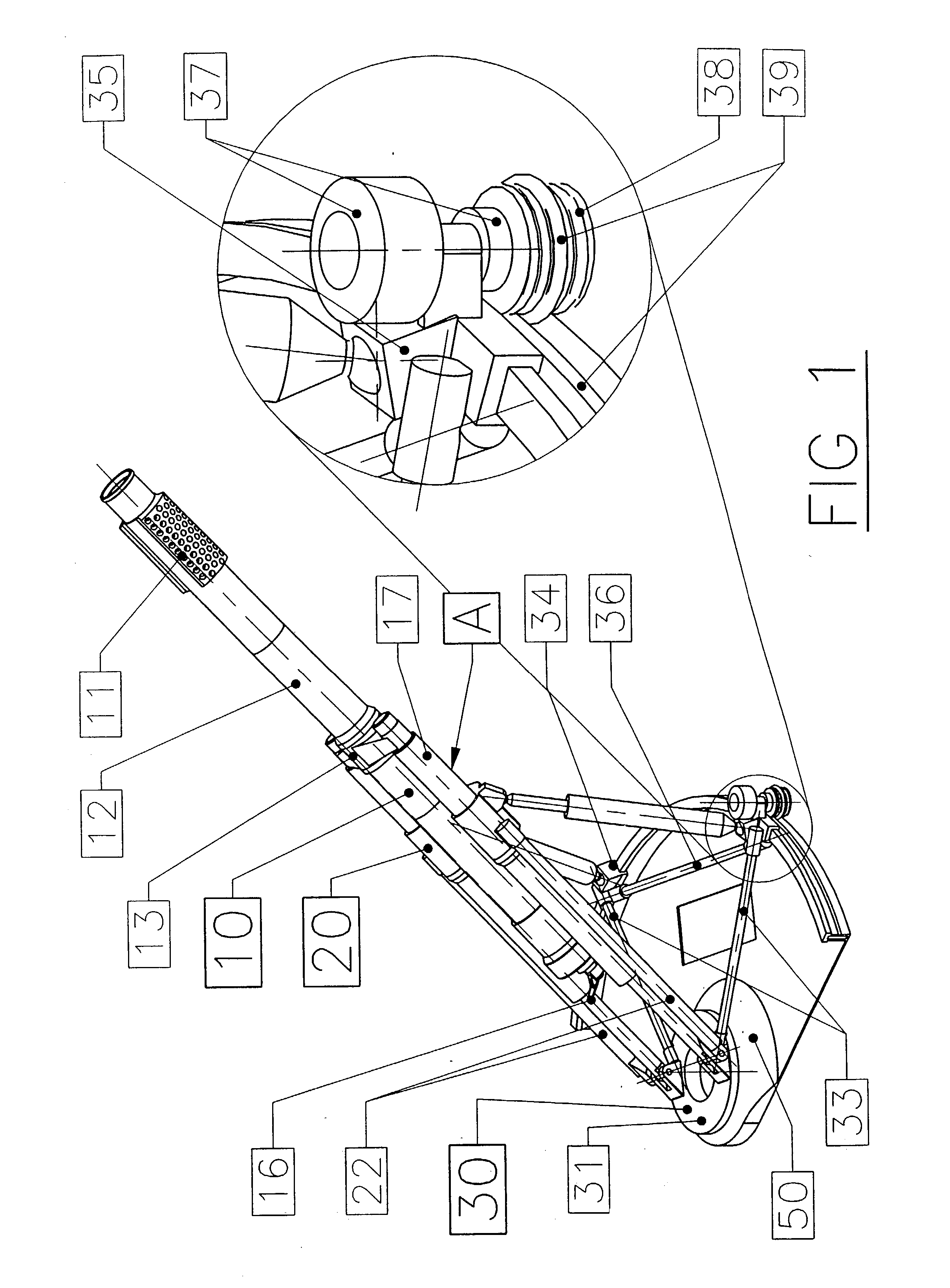

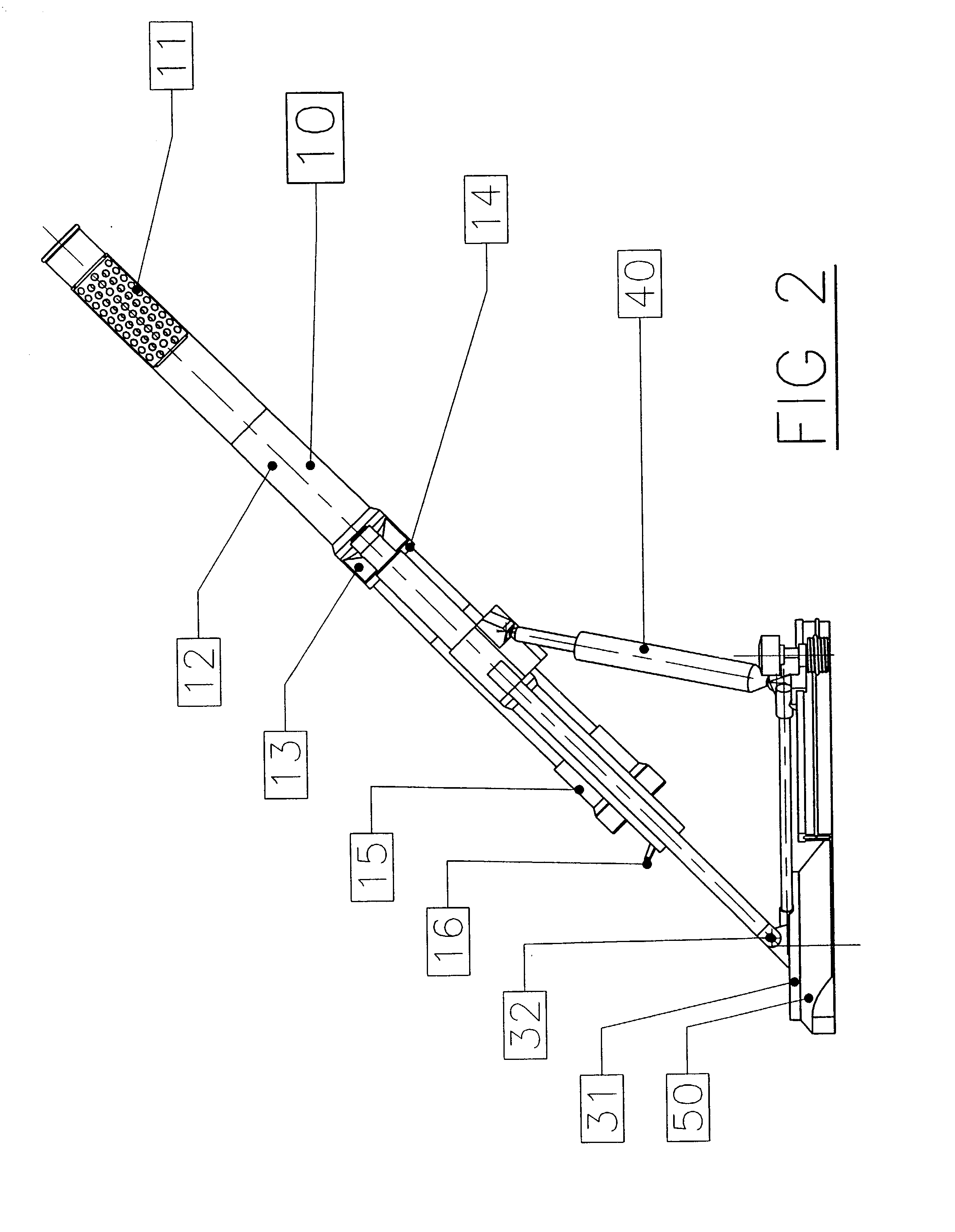

Artillery firing system

InactiveUS20010006018A1Simple designImprove efficiencyFiring/trigger mechanismsGun mountingsMuzzleEngineering

A recoil buffering apparatus for use with an artillery gun of the type comprising a breech assembly (15) connected to a barrel (12), the breech assembly (15) having a firing mechanism for firing a projectile through an open end of the barrel (12). The recoil buffering apparatus comprises a recoil buffering means adapted to be fixed to the barrel (12) and movable therewith during recoil action of the barrel (12) caused by firing of the projectile, and a support means associated with the recoil buffering means for supporting the recoil buffering means and thereby supporting the barrel (12) and breech assembly (15) through the recoil buffering means. An elevating apparatus and a traversing apparatus for an artillery gun are also described. The artillery gun can also be provided with a muzzle brake (11).

Owner:SINGAPORE TECH KINETICS

Small-scale, concentrating, solar CHP system

InactiveUS8104465B2Minimal investmentHeated withSolar heating energyPhotometry using reference valueHigh concentrationPower application

Owner:RAMOT AT TEL AVIV UNIV LTD

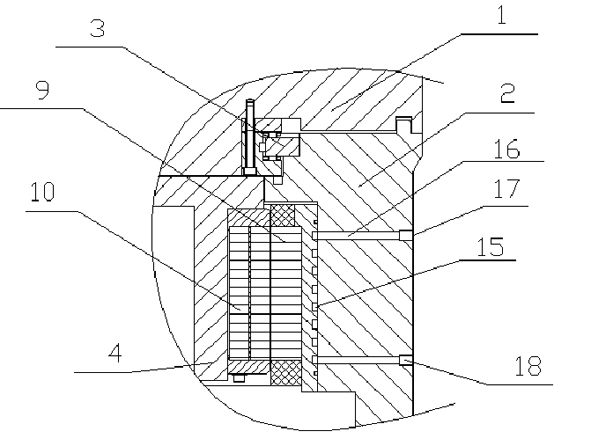

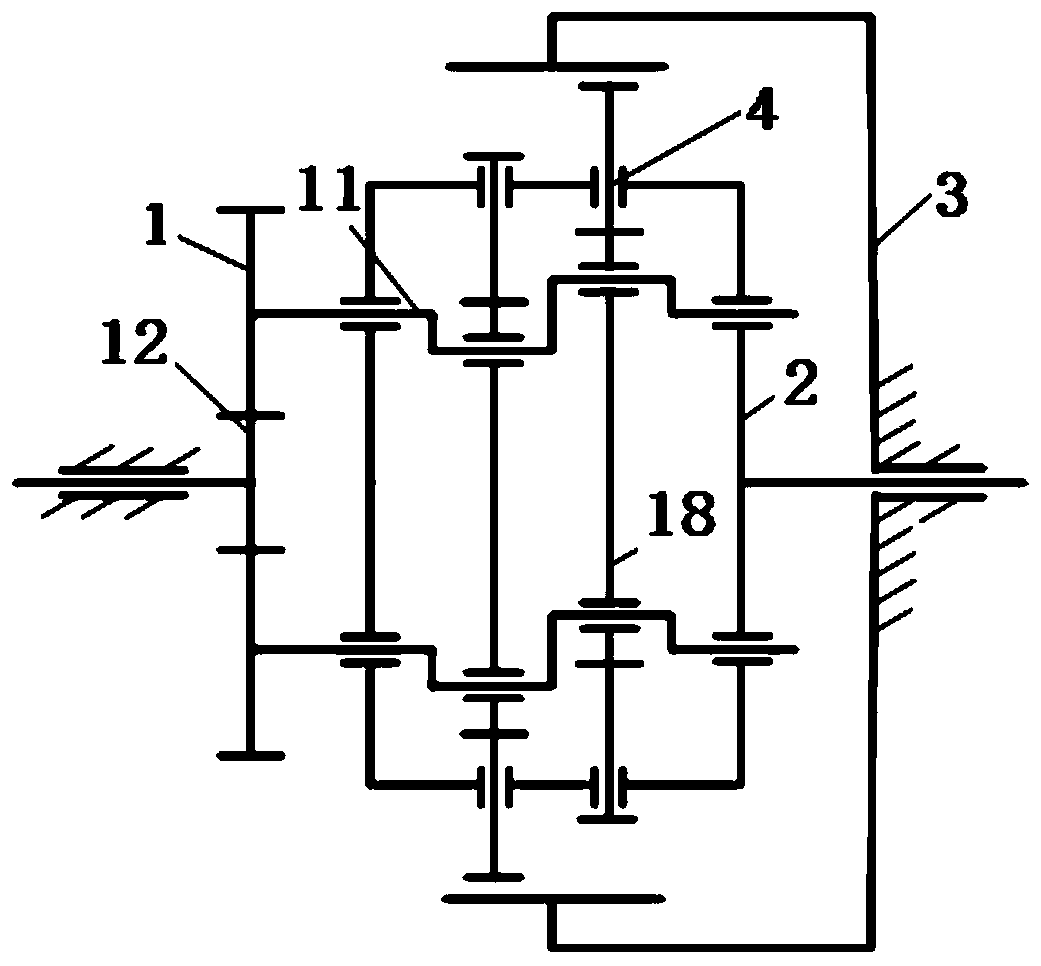

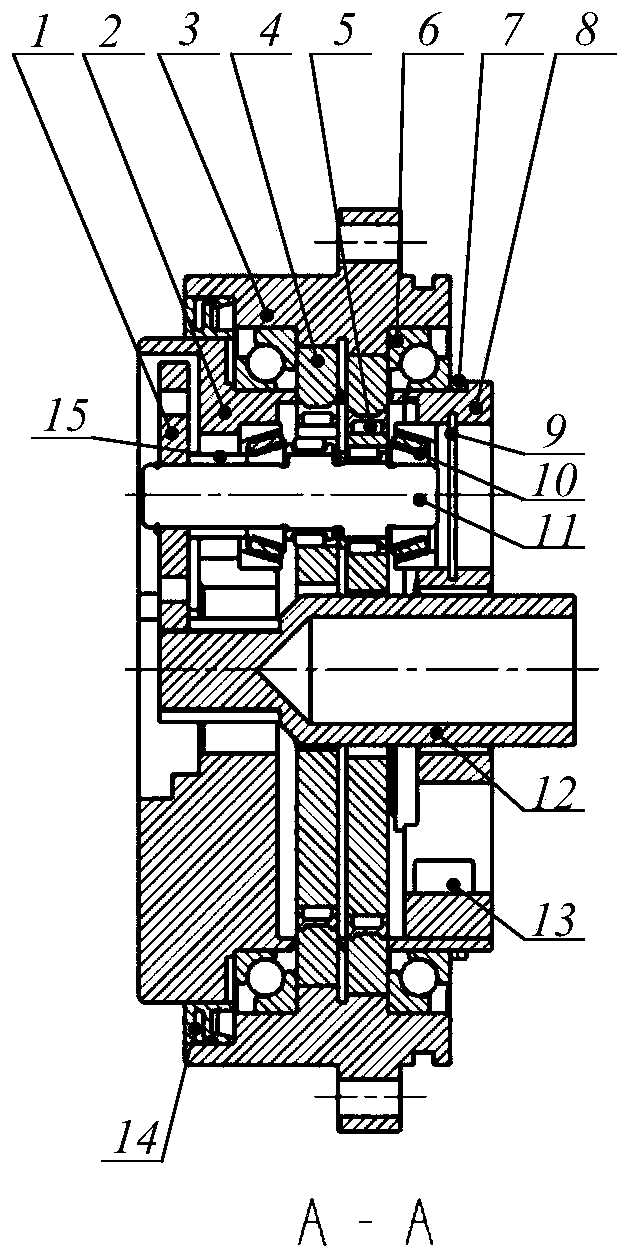

Zero back clearance planetary transmission speed reducing device

ActiveCN102927207AEliminate backlashZero backlashToothed gearingsGearing detailsClockwiseElectric signal

The invention discloses a zero back clearance planetary transmission speed reducing device which is characterized in that two speed reducing mechanisms driven by two motors are arranged in one transmission device. Electric signals are utilized to control and compensate the operating mode of pulses to completely remove the meshing clearance. The two motors start and stop simultaneously and operate synchronously. Zero back clearance transmission is achieved due to the fact that no back clearance exists in clockwise or anticlockwise directions. Simultaneously, when operating parts are abraded in long-term operation and large meshing clearance occurs, electric signal control compensation pulse value is increased to completely remove the meshing clearance to achieve the zero back clearance transmission of the whole device. The zero back clearance planetary transmission speed reducing device enables one motor to be in clearance-free mesh with the clockwise direction of the device, enables the other motor to be in clearance-free mesh with the anticlockwise direction of the device, and ensures zero back clearance transmission.

Owner:合肥波林新材料股份有限公司

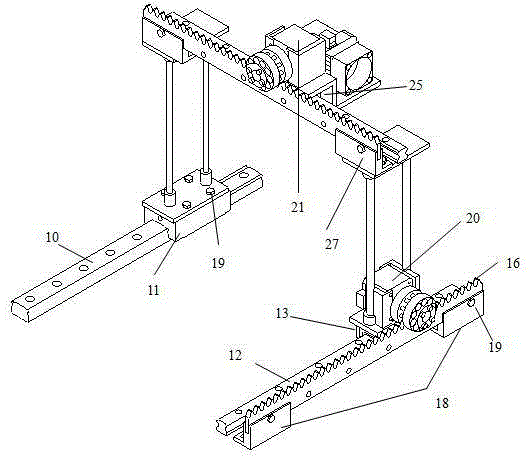

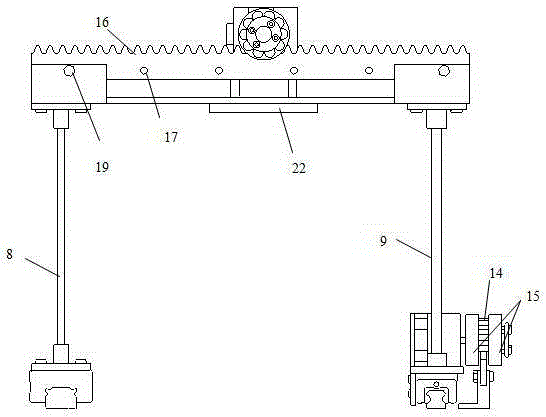

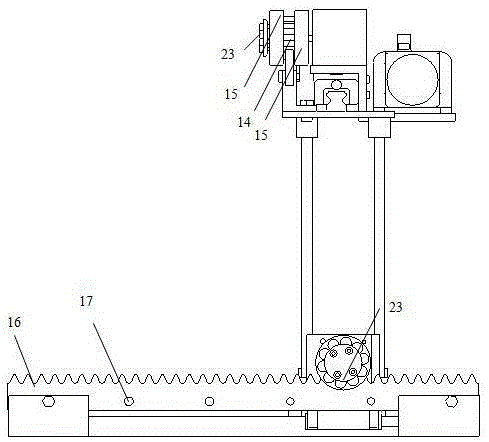

Gantry type 3D printing device based on high-precision arc rack

InactiveCN105269818ASmooth transmissionFast transmissionAdditive manufacturing apparatusMotor drive3D printing

Owner:WUHAN GUOMAO LIANDONG SCI & TECH CO LTD

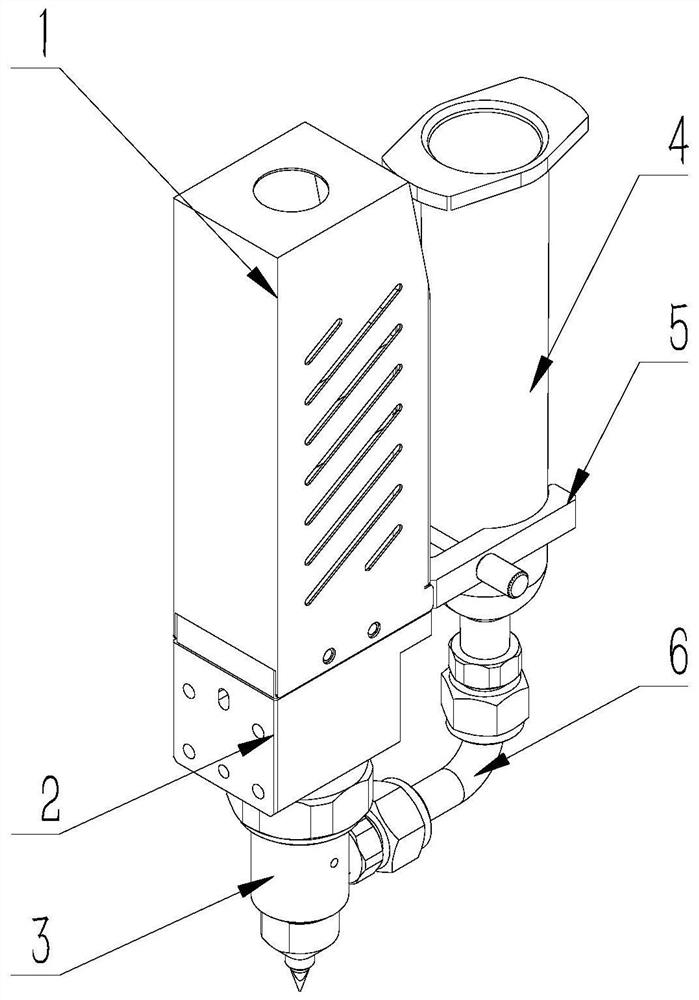

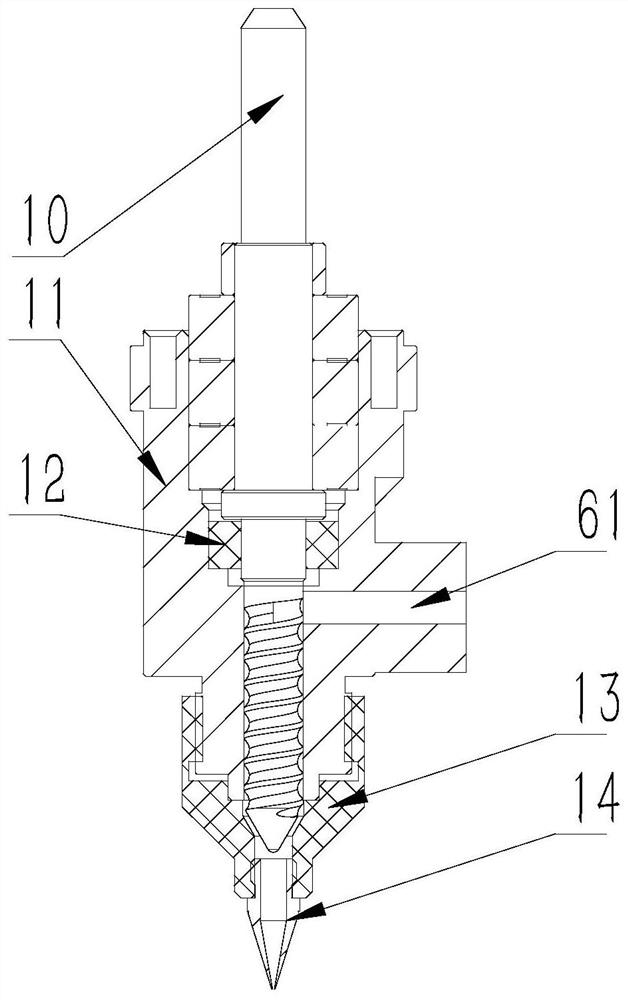

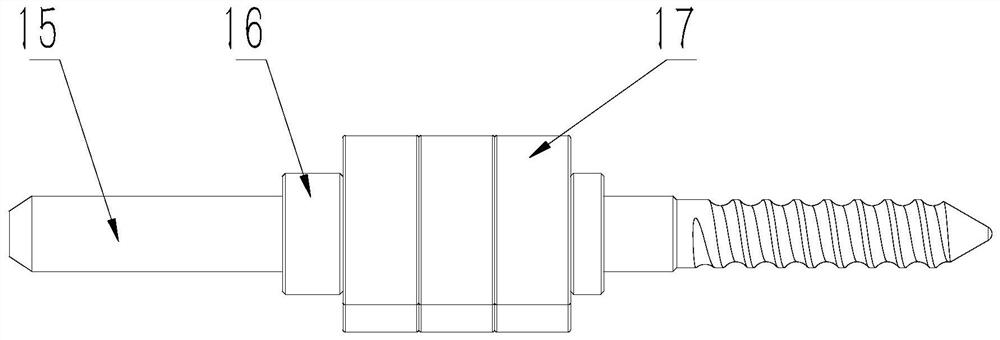

Single-liquid screw valve

ActiveCN112403834AHigh ergonomicsZero BacklashPretreated surfacesCleaning using gasesPhysicsEngineering

The invention discloses a single-liquid screw valve. The single-liquid screw valve comprises a shell, a valve body upper assembly, a valve body assembly, a glue barrel, a fixing piece and a glue conveying assembly. The shell is arranged on the valve body upper assembly, the bottom of the valve body upper assembly is connected with the valve body assembly, and the glue barrel is fixed to one side of the shell through the fixing piece. By the adoption of the structure, the number of parts is minimized when the screw valve is disassembled, assembled and cleaned, disassembly and assembly are convenient and rapid, and the man-machine efficiency is high.

Owner:SHENZHEN TENSUN IND EQUIP

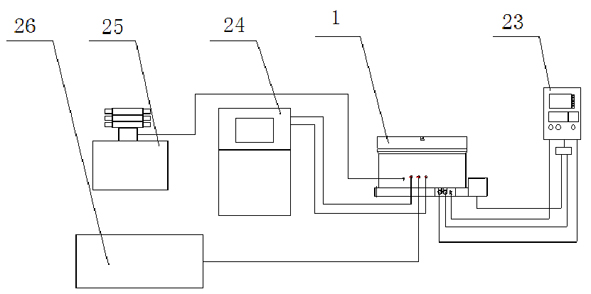

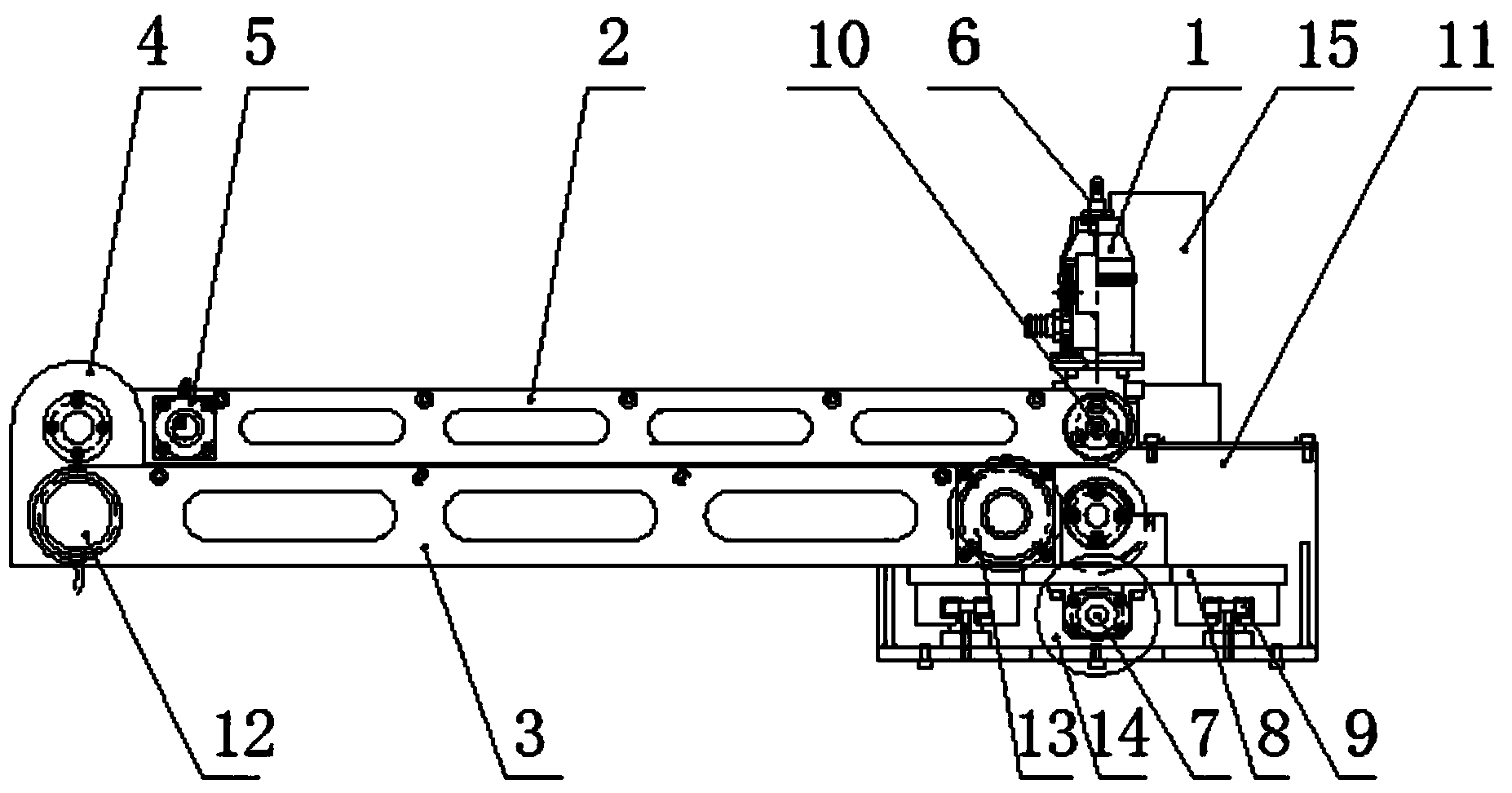

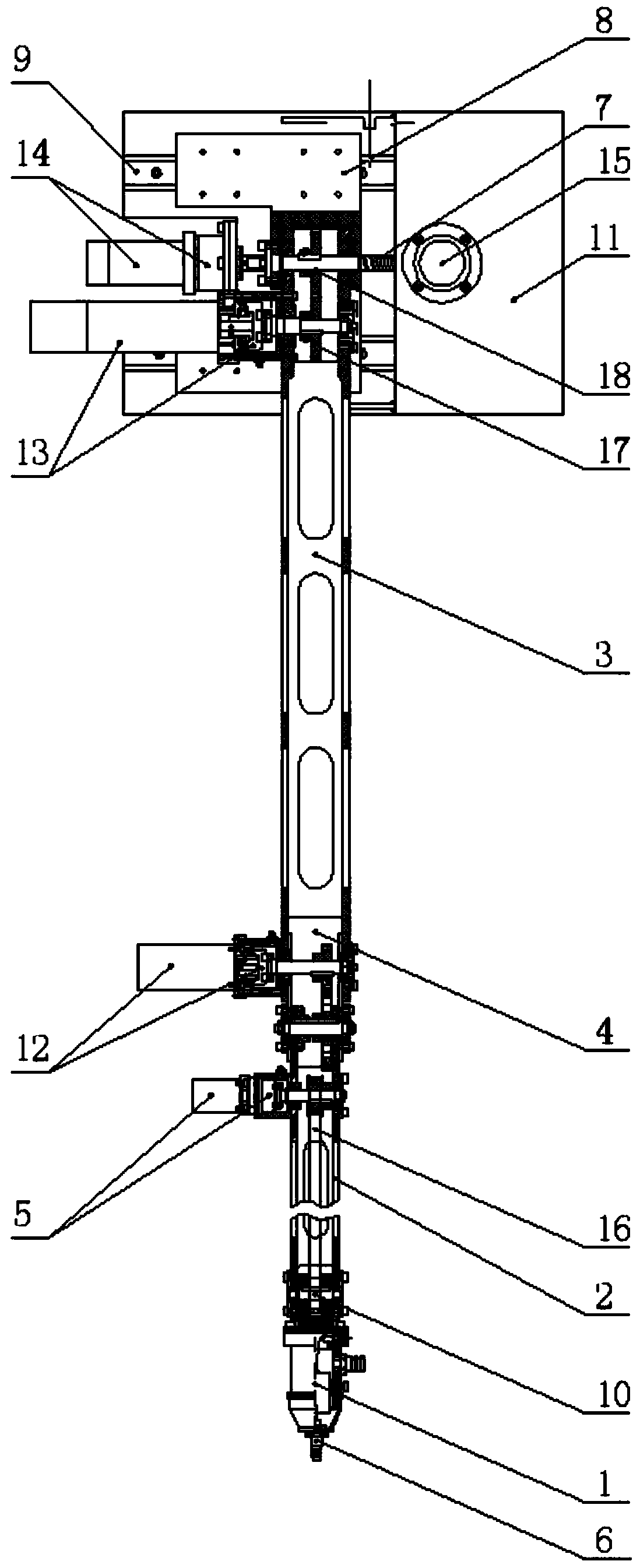

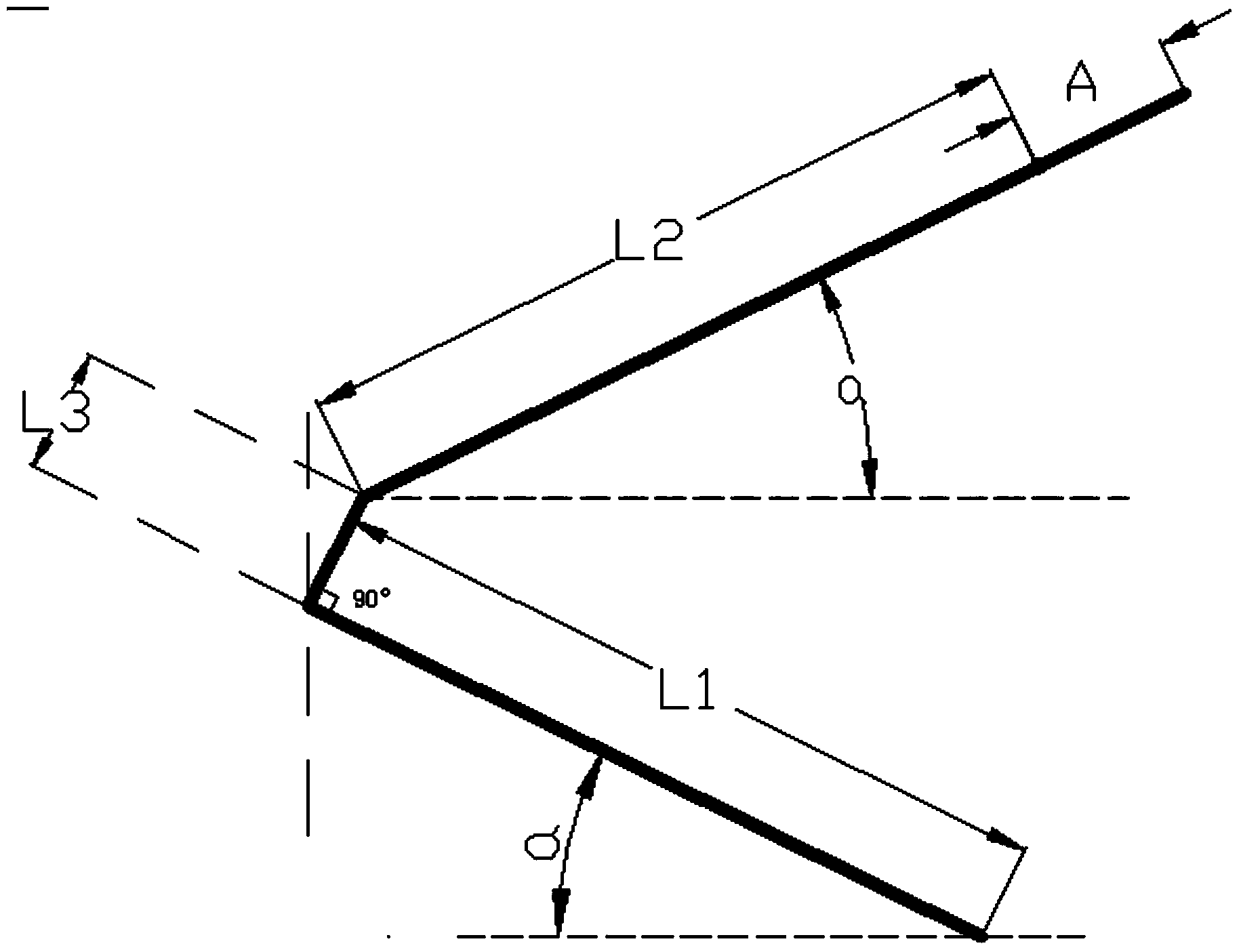

Manipulator and composite material large-scale shell automatic profile modeling system

ActiveCN103934819ARun accuratelyGuaranteed running accuracyProgramme-controlled manipulatorSimulationMotion controller

The invention relates to a manipulator and a composite material large-scale shell automatic profile modeling system. The system is formed by the manipulator, a motion controller, a sensor and an industrial computer. The sensor is mounted at the top end of a probe of the manipulator, the industrial computer is connected with the motion controller, the motion controller respectively controls five servo motors of the manipulator, and the sensor is connected with the motion controller. When the sensor on the manipulator is in contact with a shell, the motion controller records positional information of the five servo motors of the manipulator and transmits the positional information to the industrial computer, fitting is carried out on the corresponding positional information through the industrial computer so that corresponding curves can be formed, and the appearance contour of the composite material large-scale shell is formed. The system can automatically conduct profile modeling of the contour curve of the shell, fitting is carried out on all collected point coordinates to form the corresponding curves, motion trails are generated, and the manipulator can operate along the surface of the shell.

Owner:WUHAN ZHONGKE INNOVATION TECH

Closed type hypocycloid movable teeth speed reducer

The invention discloses a closed type movable teeth speed reducer. A high speed stage is a K-H type planetary gear train composed of an involute center wheel, three involute planetary gears uniformlydistributed in the circumferential direction, three crank shafts and a planet carrier; a low-speed stage is a movable teeth transmission mechanism composed of the three crank shafts, an movable teeth,the planet carrier, an hypocycloid machine shell and an eccentric disc shock wave generator; the crank shafts are fixedly connected with the planetary gears, the crank shafts and corresponding pin holes on the shock wave generator form a revolute pair, the spinning motion of the shock wave generator is realized by the revolution motion of the planetary gear, so that radial shock waves are generated; a sliding pair is arranged between the movable teeth and the planet carrier, the sliding pair transmits the revolution speed of the movable teeth to the planet carrier and the revolution speed isoutput through the planet carrier, so that a closed type large-speed-ratio transmission mechanism is formed. The closed type movable teeth speed reducer has the advantages of large speed ratio, zero back clearance, low error sensitivity, easy processing and the like, compared with the speed reducer for a general robot, the closed type movable teeth speed reducer is convenient to manufacture and compact in structure, and can meet the requirements of the speed reducer for the general robot.

Owner:TIANJIN UNIV

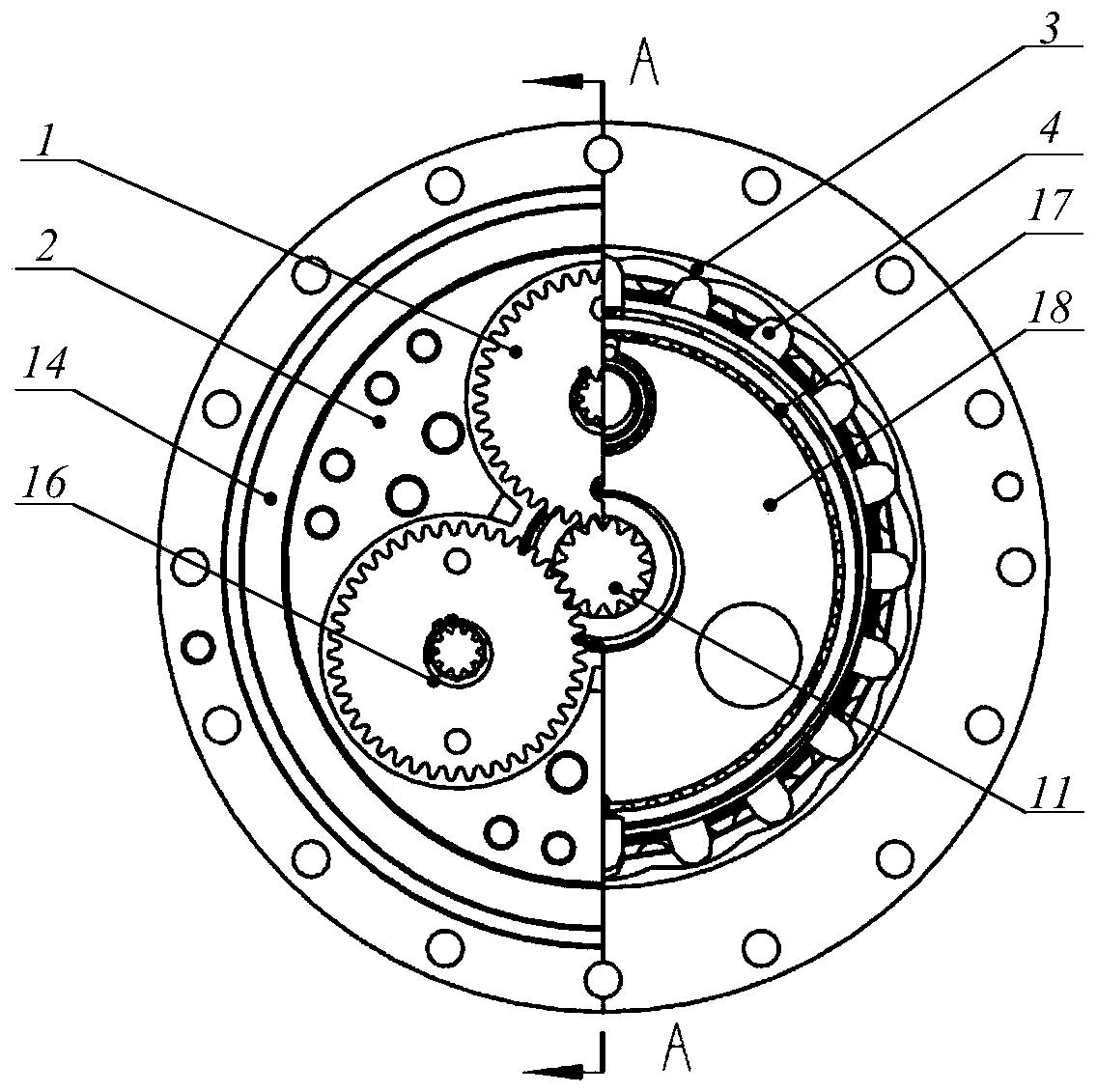

Zero backlash planetary gear train

ActiveUS8535198B2Zero backlashIncrease stiffnessToothed gearingsPortable liftingEngineeringDrive motor

A zero backlash planetary gear train, comprising: a shell, a planetary gear set, and at least a sun gear set. Planetary gear set is disposed in said shell, and includes a planetary arm rack having output axis, such that planetary arm rack in said shell is provided with a plurality of double-layer planetary gears. The planetary gear set includes a first planetary gear and a second planetary gear. A buffer mechanism is provided between first planetary gear and second planetary gear. Said first planetary gear is engaged with at least an internal gear on an inner rim of shell, and second planetary gear is engaged with at least a sun gear set. Sun gear set is provided with a sun gear connected to a driving motor. Said zero backlash planetary gear train is capable of eliminating backlash between gears.

Owner:NATIONAL CHUNG CHENG UNIV

Artillery firing system

InactiveUS20030024379A1Improve efficiencySimple designFiring/trigger mechanismsGun mountingsEngineeringGun barrel

A recoil buffering apparatus for use with an artillery gun of the type comprising a breech assembly (15) connected to a barrel (12), the breech assembly (15) having a firing mechanism for firing a projectile through an open end of the barrel (12). The recoil buffering apparatus comprises a recoil buffering means adapted to be fixed to the barrel (12) and movable therewith during recoil action of the barrel (12) caused by firing of the projectile, and a support means associated with the recoil buffering means for supporting the recoil buffering means and thereby supporting the barrel (12) and breech assembly (15) through the recoil buffering means. An elevating apparatus and a traversing apparatus for an artillery gun are also described. The artillery gun can also be provided with a muzzle brake (11).

Owner:SINGAPORE TECH KINETICS

Bond testing machine and cartridge for a bond testing machine comprising a plurality of test tools

InactiveUS20150007668A1Easy to optimizeRule out the possibilitySolid-state devicesUsing mechanical meansAir interfaceEngineering

A cartridge suitable for use in a bond testing machine includes a plurality of a different test tools. A rotary mechanism is provided and each of the plurality of different test tools is mounted to the rotary mechanism angularly spaced from one another. A drive unit is coupled to the rotary mechanism and is configured to rotate the rotary mechanism to move each of the plurality of different test tools to and from a use position. An air interface receives compressed air from a corresponding air interface on a positioning assembly of the bond testing machine.

Owner:NORDSON CORP

Releasable zero backlash passive locking mechanism for a vehicle mounted rotary camera mast

ActiveUS10377321B2Easy to disengageRaise the natural frequencyRod connectionsStands/trestlesLocking mechanismTorsion spring

A rotary locking joint that has zero backlash is provided to secure a camera mast mounted on a vehicle in a deployed position. The joint is passive to lock while being easily releasable. The joint prevents rotation of the mast in one direction, with a hard stop element that prevents further rotation of the mast in the opposite direction. The locking joint includes a pawl member configured to rotate about a pawl rotation axis. The pawl member is maintained in place in the locked position via a torsion spring to ensure contact with a base portion of the mast. To release the joint, the pawl member is rotated in the opposite direction to remove a geometry interference condition. A sensor is arranged to detect whether the pawl member is in an unlocked position relative to the mast.

Owner:GOOGLE LLC

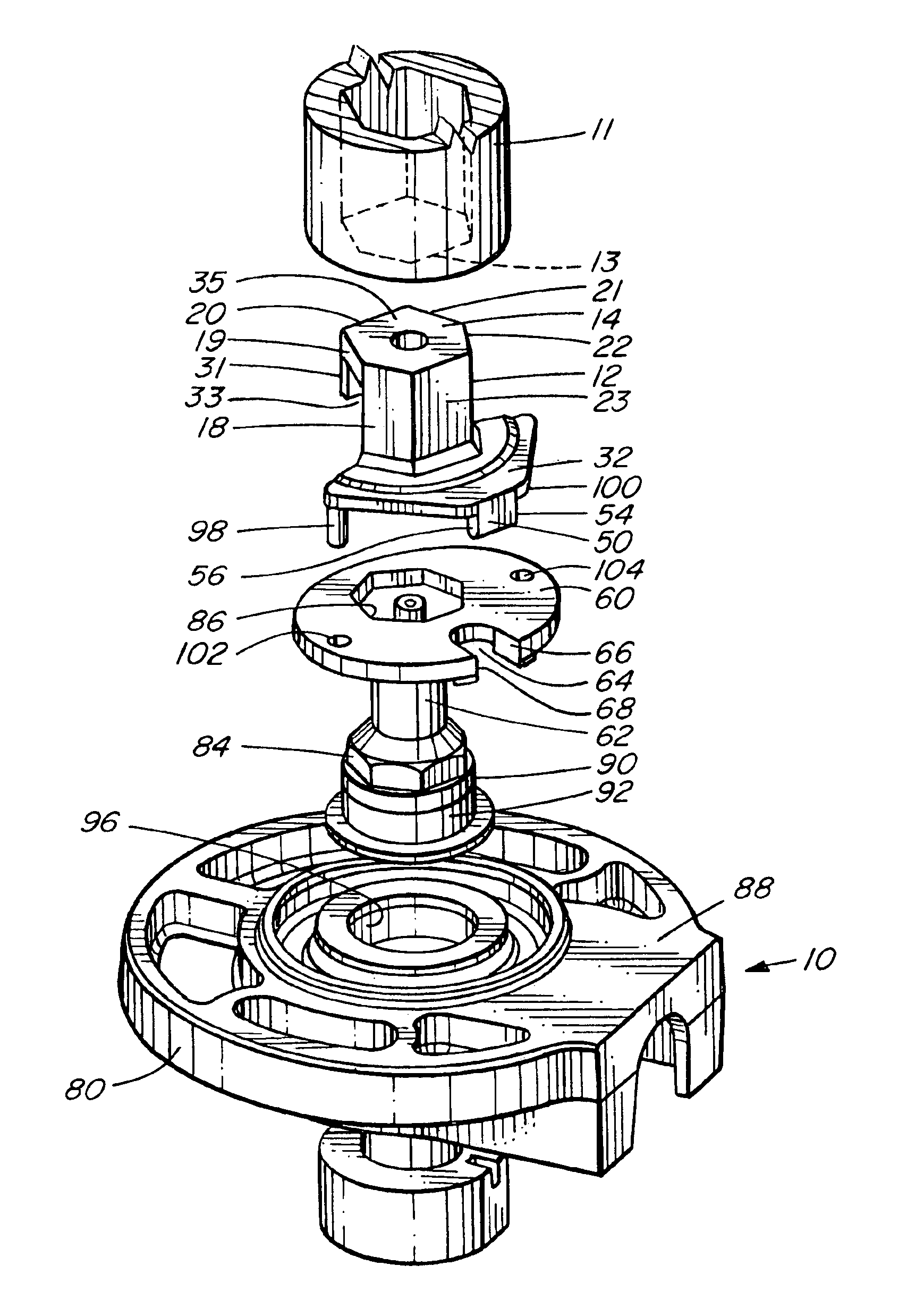

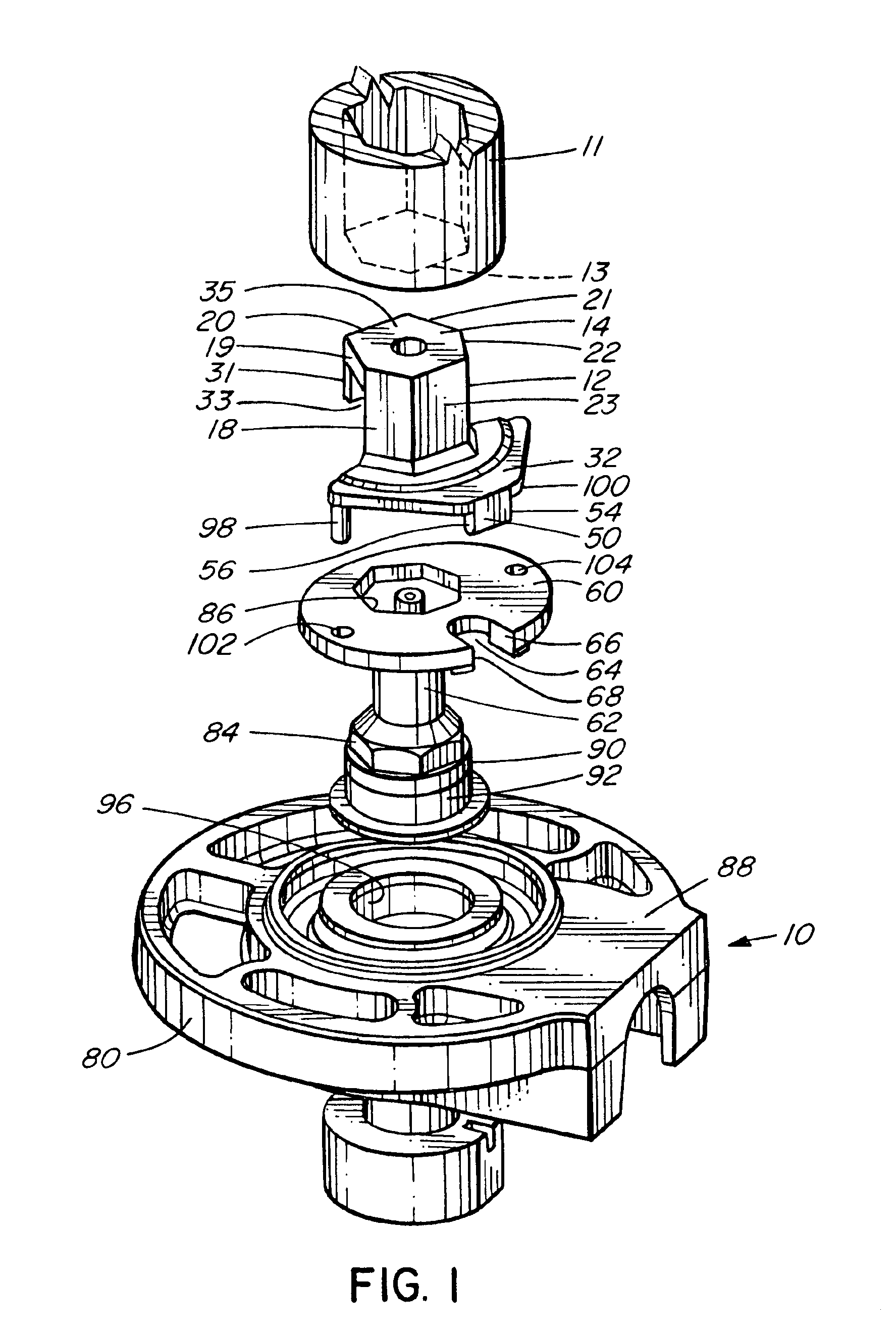

Device for rotating with a multisided socket

InactiveUS6855015B2Zero backlashThe method is simple and reliableElectrically conductive connectionsPropulsion power plantsCouplingElectrical connector

A device for rotating with a rotatable first member includes a second member having a portion engageable with the first member. The portion has a first part and a second part which is resiliently biased away from the first part. The second member tightly engages the first member. There may be a device for measuring rotation of the shaft such as a potentiometer. The rotation measuring device may include an electrical connector for the potentiometer including a socket and a post which is pressable into the socket. The device may also include a rotationally adjustable connector. There may be a coupling connected to the second member which includes a third member with a portion having n sides and a fourth member with a portion having n sides which receives the portion of the third member in a mating relationship, thereby allowing the device to be adjusted to a total of at least m.n rotational positions. The second member preferably has a projection which slidably engages a slot in the third member allowing for non-coaxial rotation, and minimal backlash, of the device for measuring rotation relative to the first member.

Owner:TELEFLEX CANADA

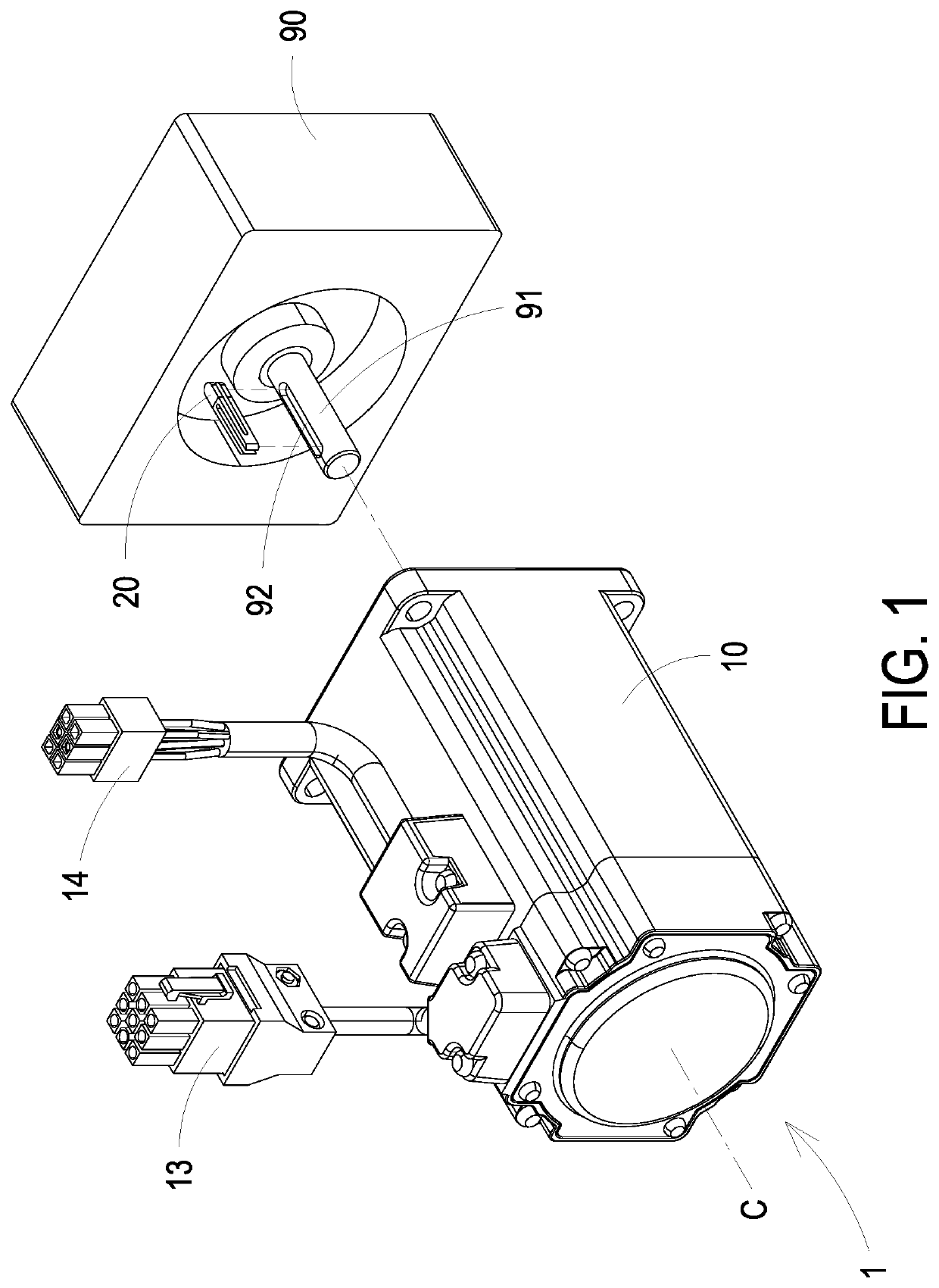

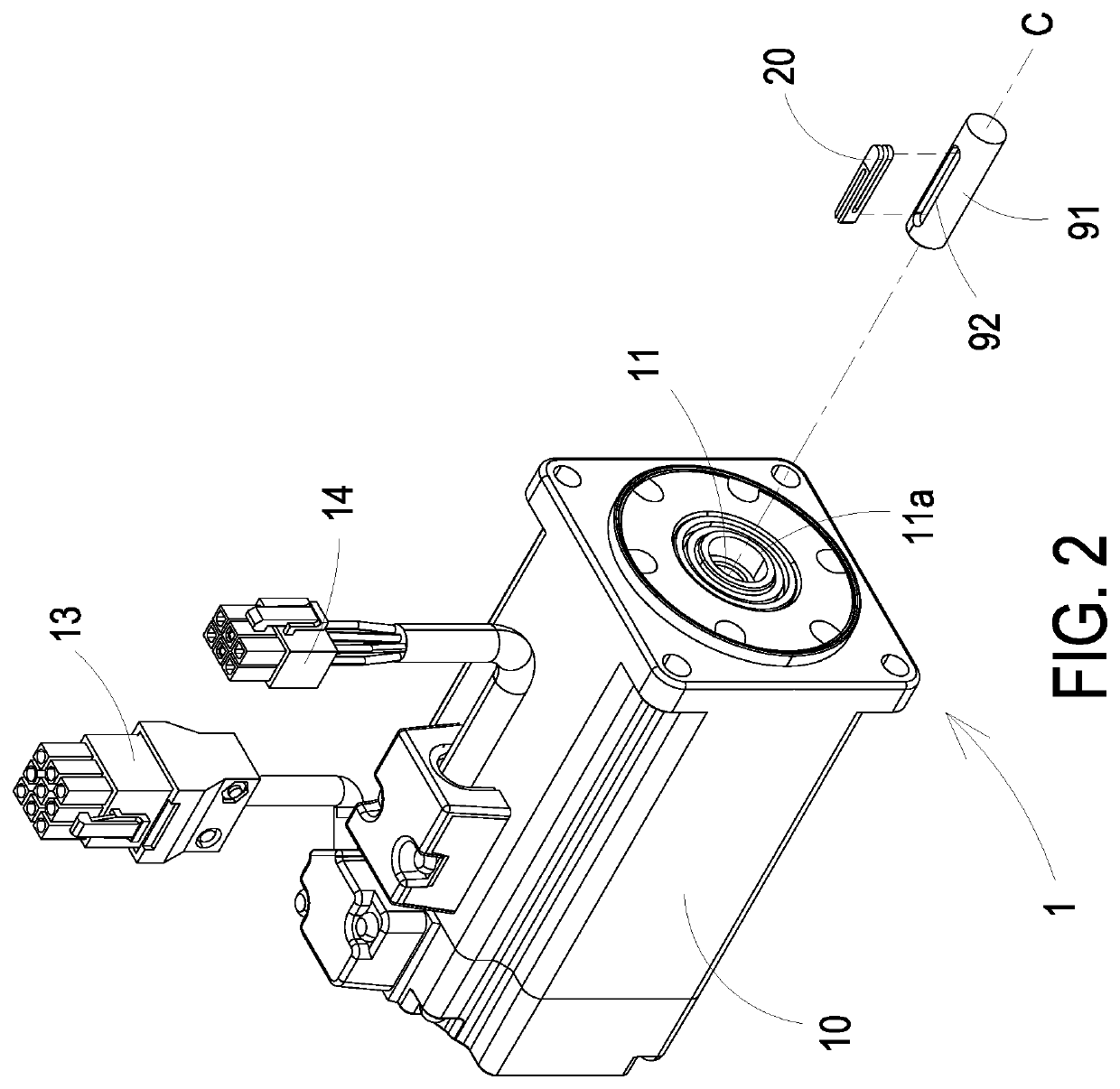

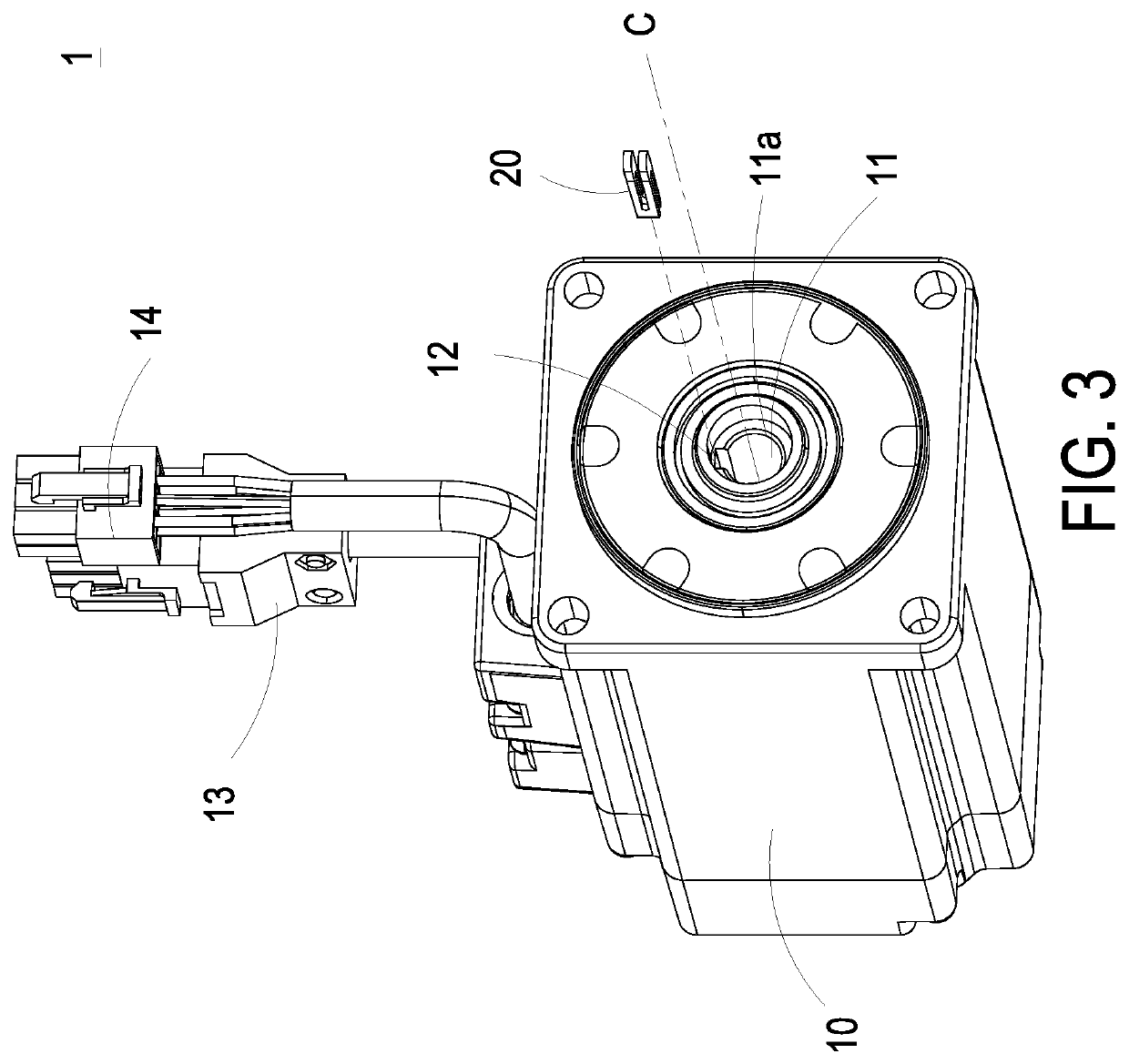

Modular motor assembly structure

ActiveUS20200224726A1Shorten the lengthSimplify the assembly processShaftsCouplings for rigid shaftsDrive shaftControl engineering

A modular motor assembly structure is disclosed and configured to couple with a drive shaft of an application device. The drive shaft includes a receiving slot. The modular motor assembly includes a main body and a combination key. The main body includes a shaft hole and a key groove. The shaft hole includes an opening and a central axis. The key groove is disposed on a side wall around the shaft hole and parallel to a central axis of the shaft hole. The combination key has a front end and a rear end. When one end of the drive shaft is inserted into the shaft hole along the central axis of the shaft hole, the combination key is at least partially accommodated in the receiving slot, and the front end faces the key groove. The combination key has a continuously increasing thickness from the front end to the rear end.

Owner:DELTA ELECTRONICS INC

Coaxial gear set

A coaxial gear set comprising: a crankshaft which can be rotated about an axis of rotation and has at least one connecting rod bearing; and multiple, preferably at least three, pistons, each connected to the crankshaft by means of a connecting rod and which each have a toothing with at least one tooth on a first end face facing away from the axis of rotation. The coaxial gear set also comprises: a hollow shaft having internal toothing, wherein the pistons are located inside the hollow shaft when viewed in a plane normal to the axis of rotation; and a guide unit, wherein the pistons are each linearly guided in the guide unit and can be moved back and forth parallel to a radial direction normal to the axis of rotation, as a result of which the toothings of the first end faces of the pistons can be successively brought into meshing engagement with the internal toothing and out of meshing engagement with said internal toothing.

Owner:KRAKEN INNOVATIONS GMBH

Bond testing machine and cartridge for a bond testing machine comprising a plurality of test tools

InactiveUS9482605B2Easy to operateShorten the timeSolid-state devicesUsing mechanical meansAir interfaceEngineering

A cartridge suitable for use in a bond testing machine includes a plurality of a different test tools. A rotary mechanism is provided and each of the plurality of different test tools is mounted to the rotary mechanism angularly spaced from one another. A drive unit is coupled to the rotary mechanism and is configured to rotate the rotary mechanism to move each of the plurality of different test tools to and from a use position. An air interface receives compressed air from a corresponding air interface on a positioning assembly of the bond testing machine.

Owner:NORDSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com