Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

663results about How to "Raise the natural frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

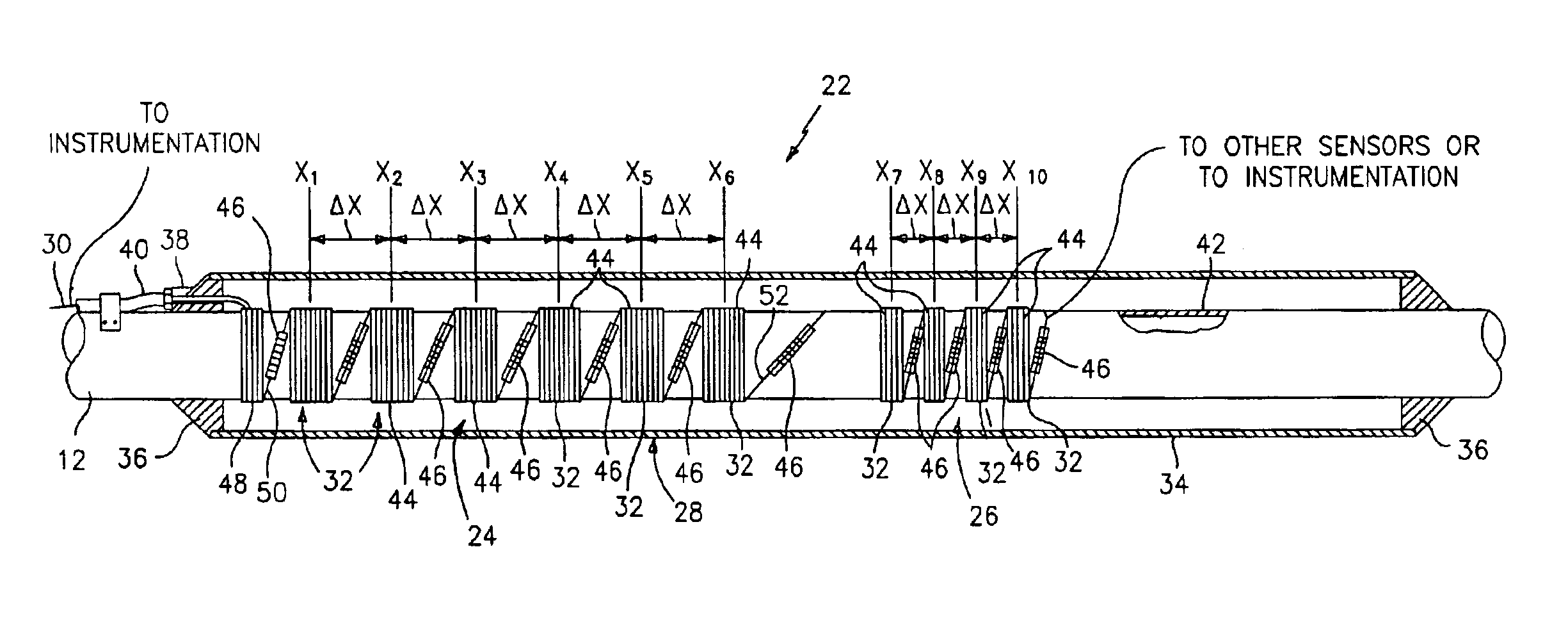

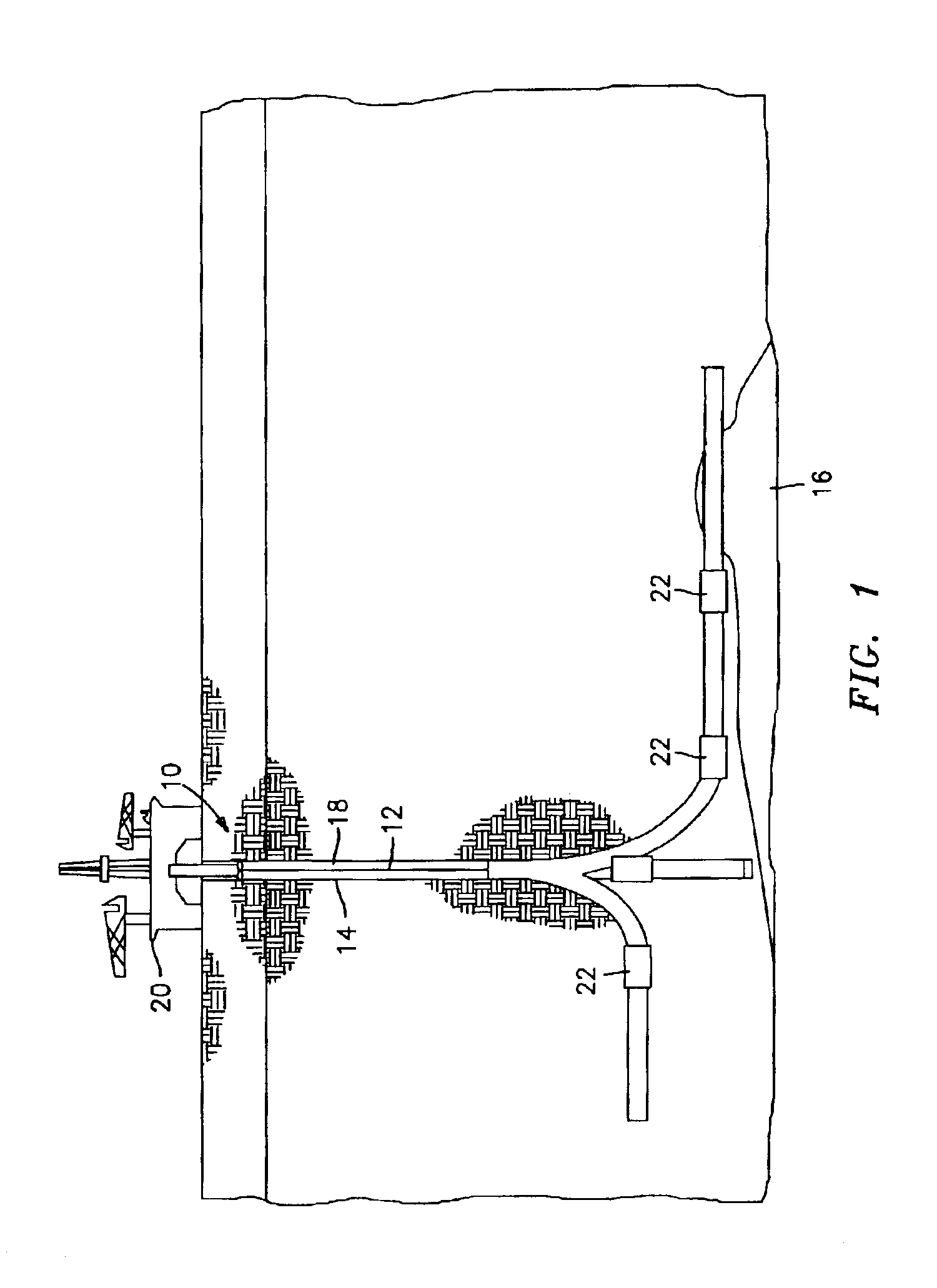

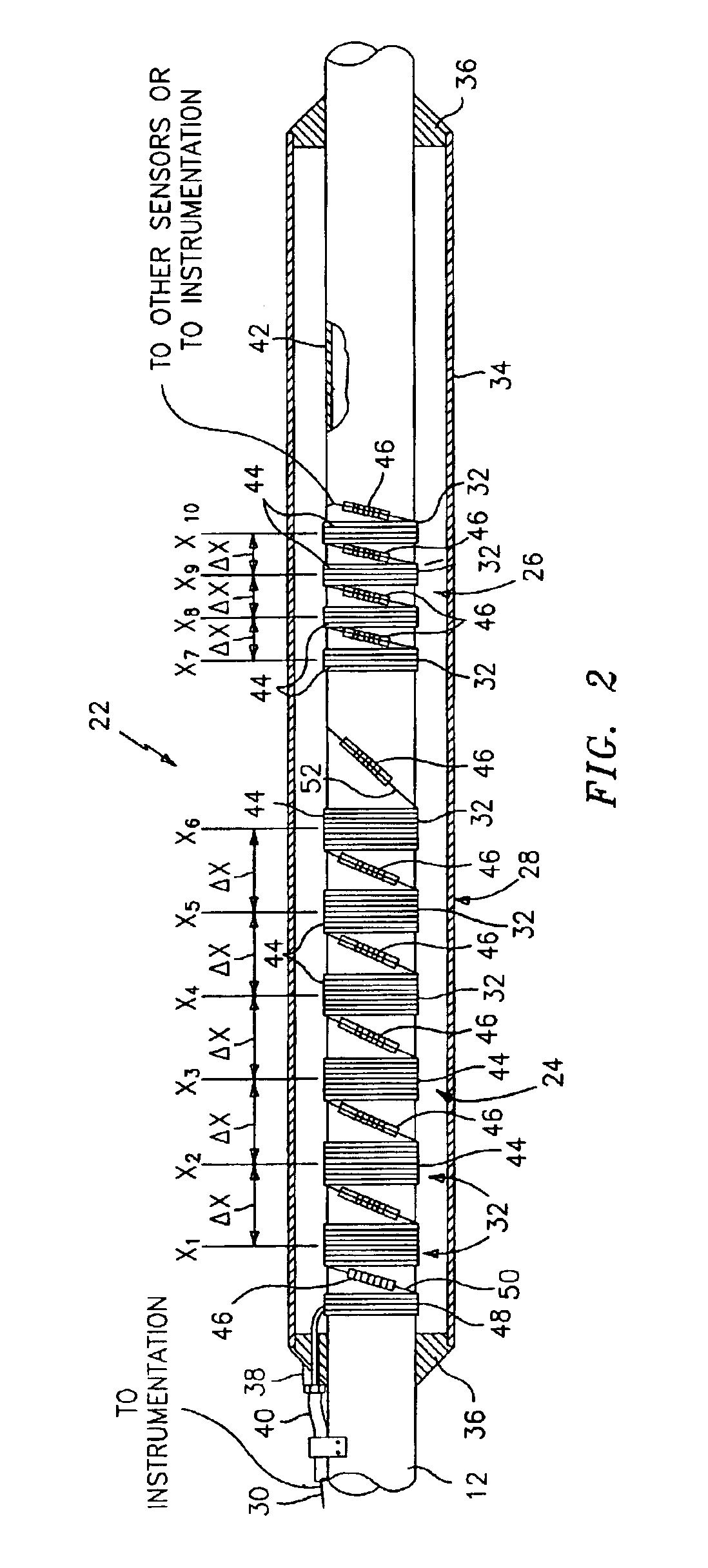

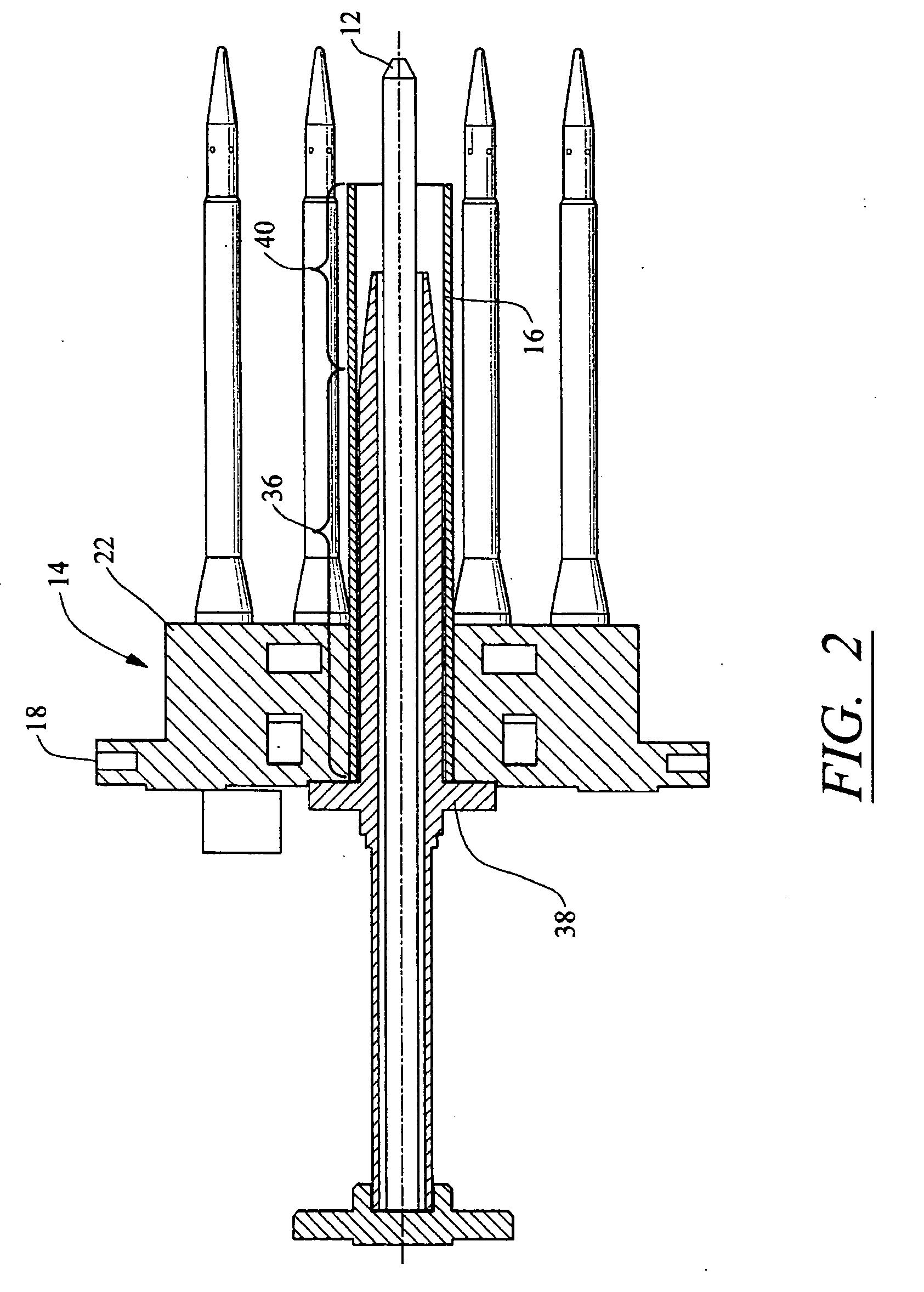

Circumferential strain attenuator

InactiveUS6868737B2Reduce gainWide rangeSubsonic/sonic/ultrasonic wave measurementForce measurement by measuring optical property variationCircumferential strainEngineering

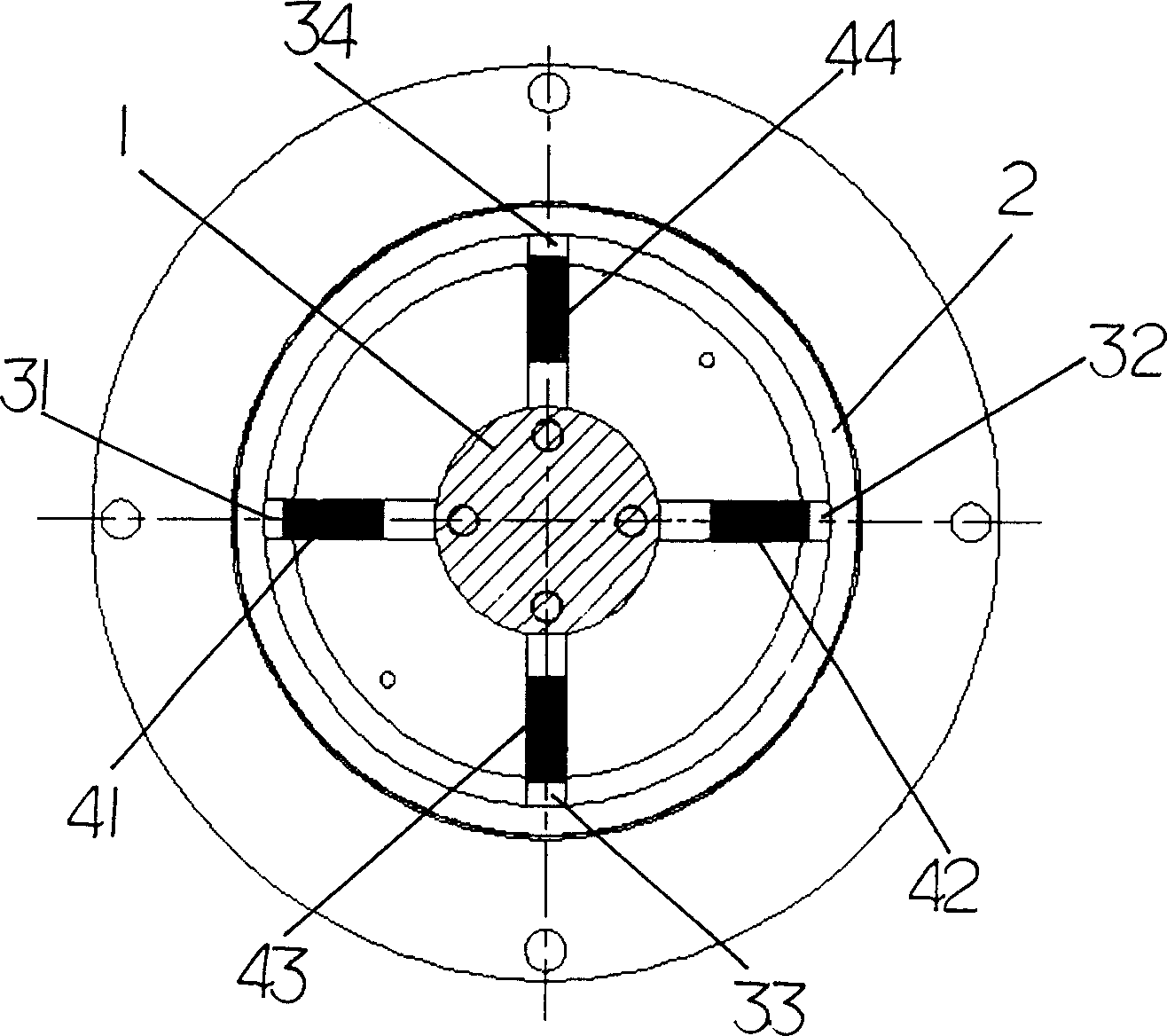

An apparatus for varying the gain of a fiber optic sensor that non-intrusively senses the strain response of a pipe is provided. The apparatus includes a circumferential strain attenuator that has an annular land portion that mechanically couples the attenuator to the pipe. An annular web extends coaxially from the land portion and has a reduced cross sectional area relative to the land, and an annular mandrel portion extends coaxially from the web portion and forms a gap between the pipe and the mandrel. The fiber optic sensor is wound on the circumferential strain attenuator. The web and mandrel cooperate to reduce the strain response of the fiber optic sensor relative to the strain response of the pipe.

Owner:WEATHERFORD TECH HLDG LLC

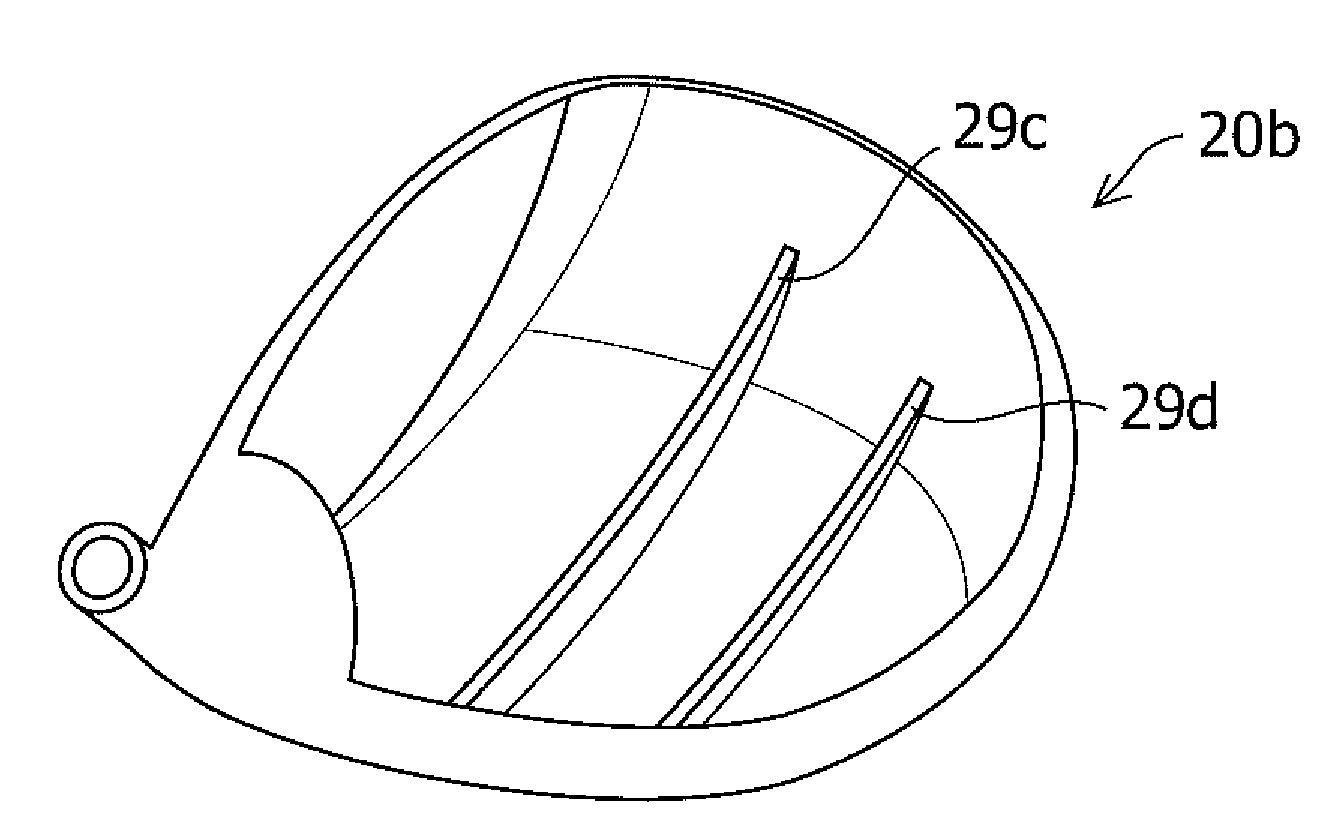

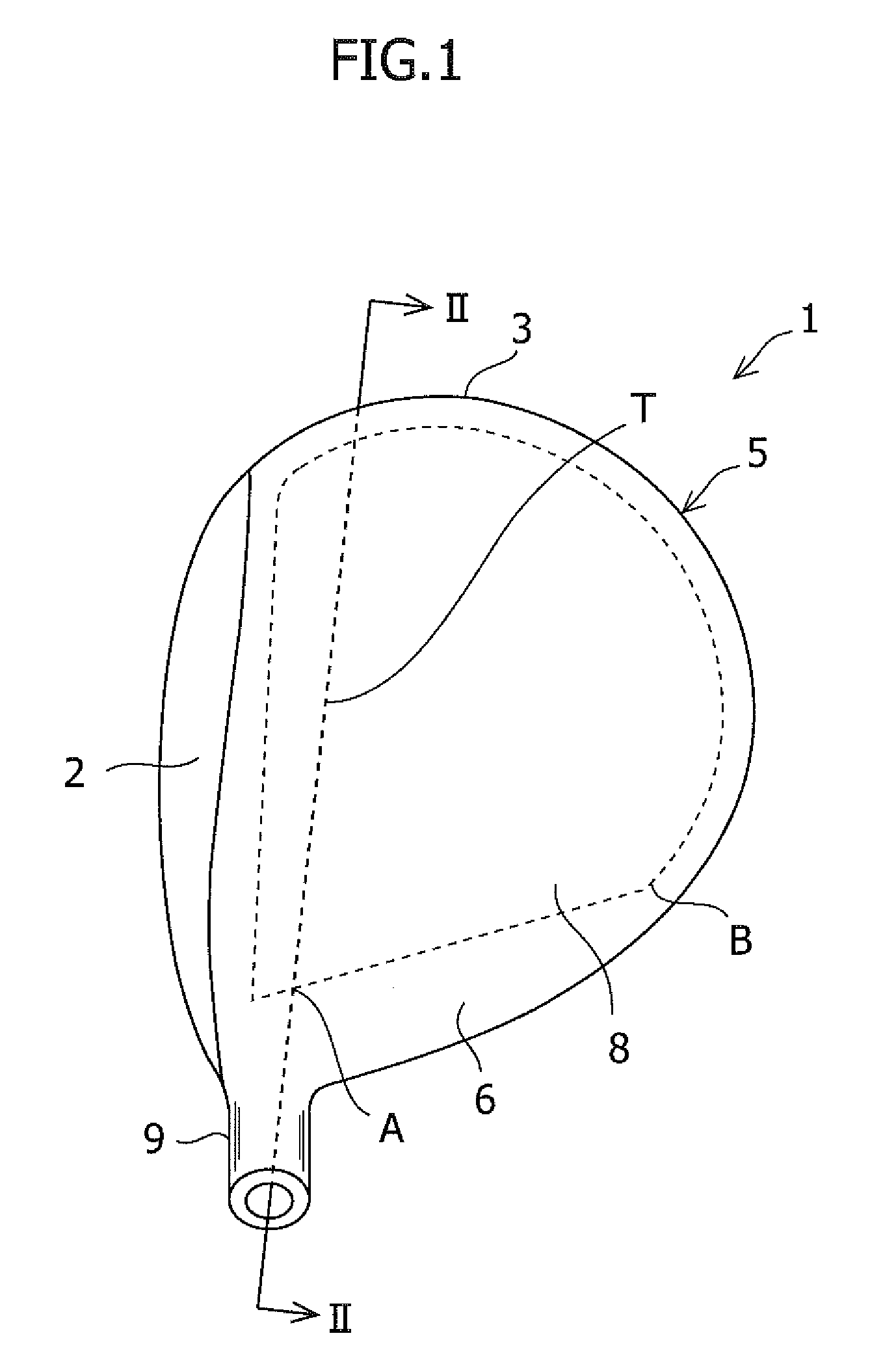

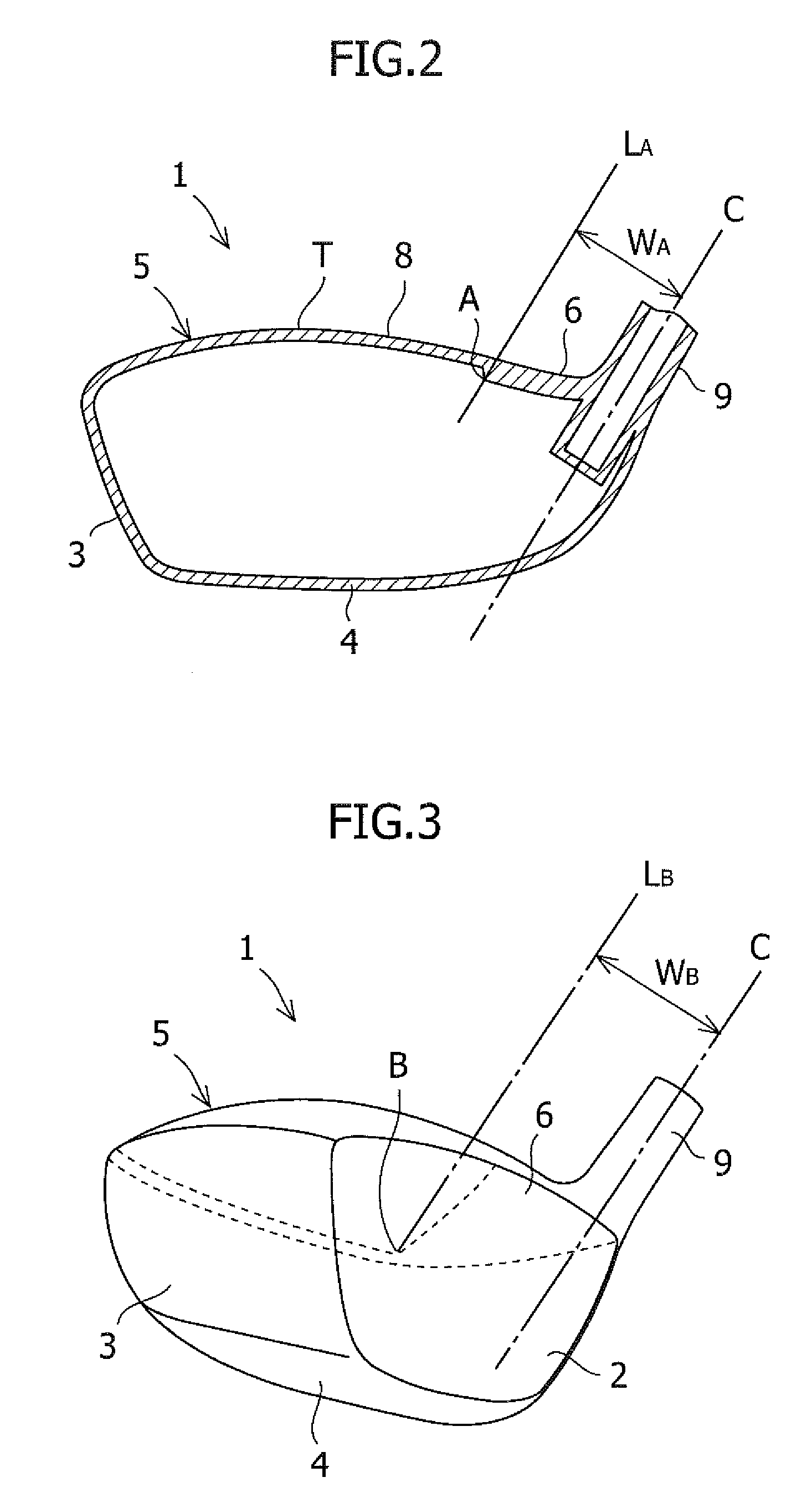

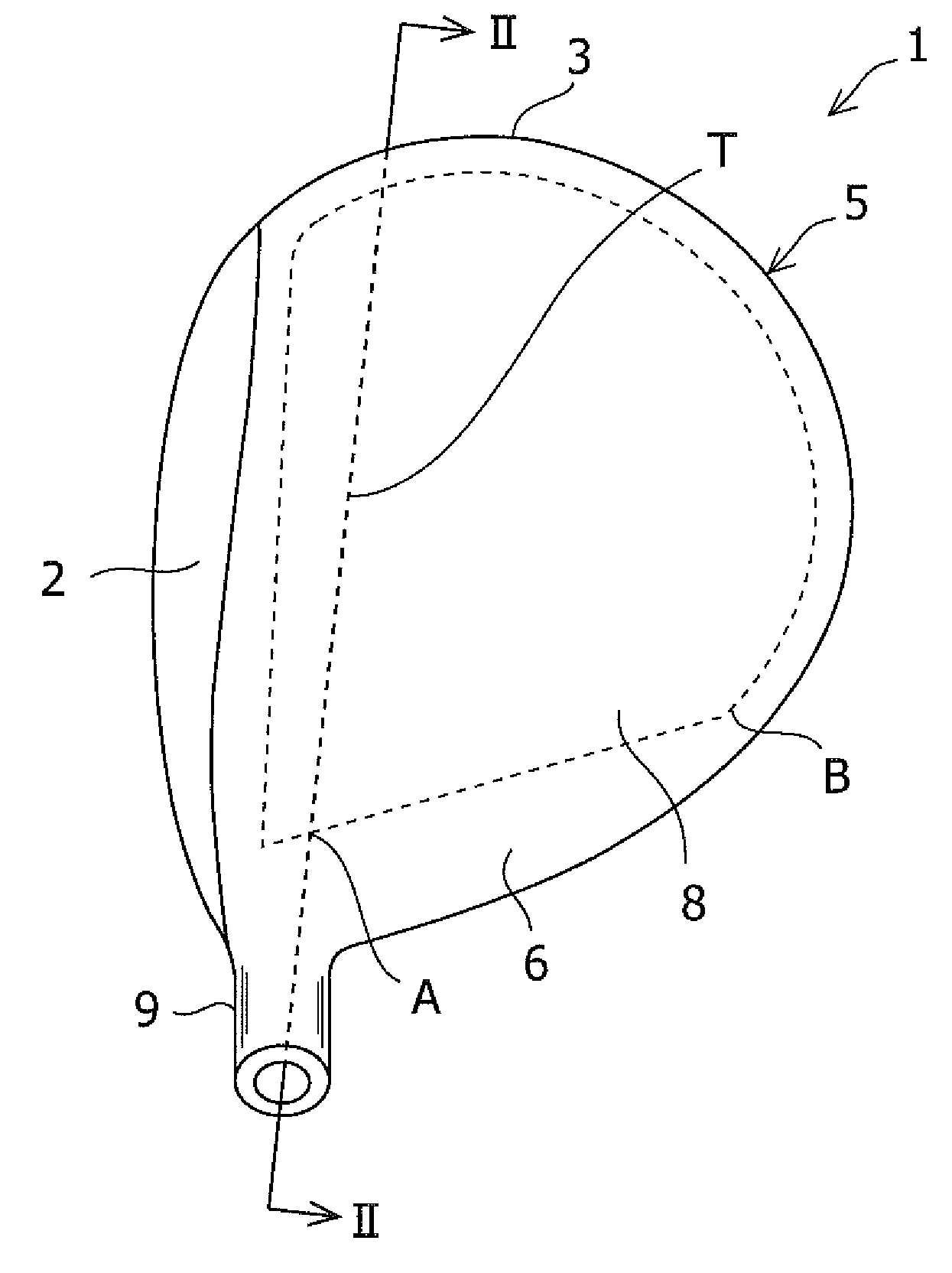

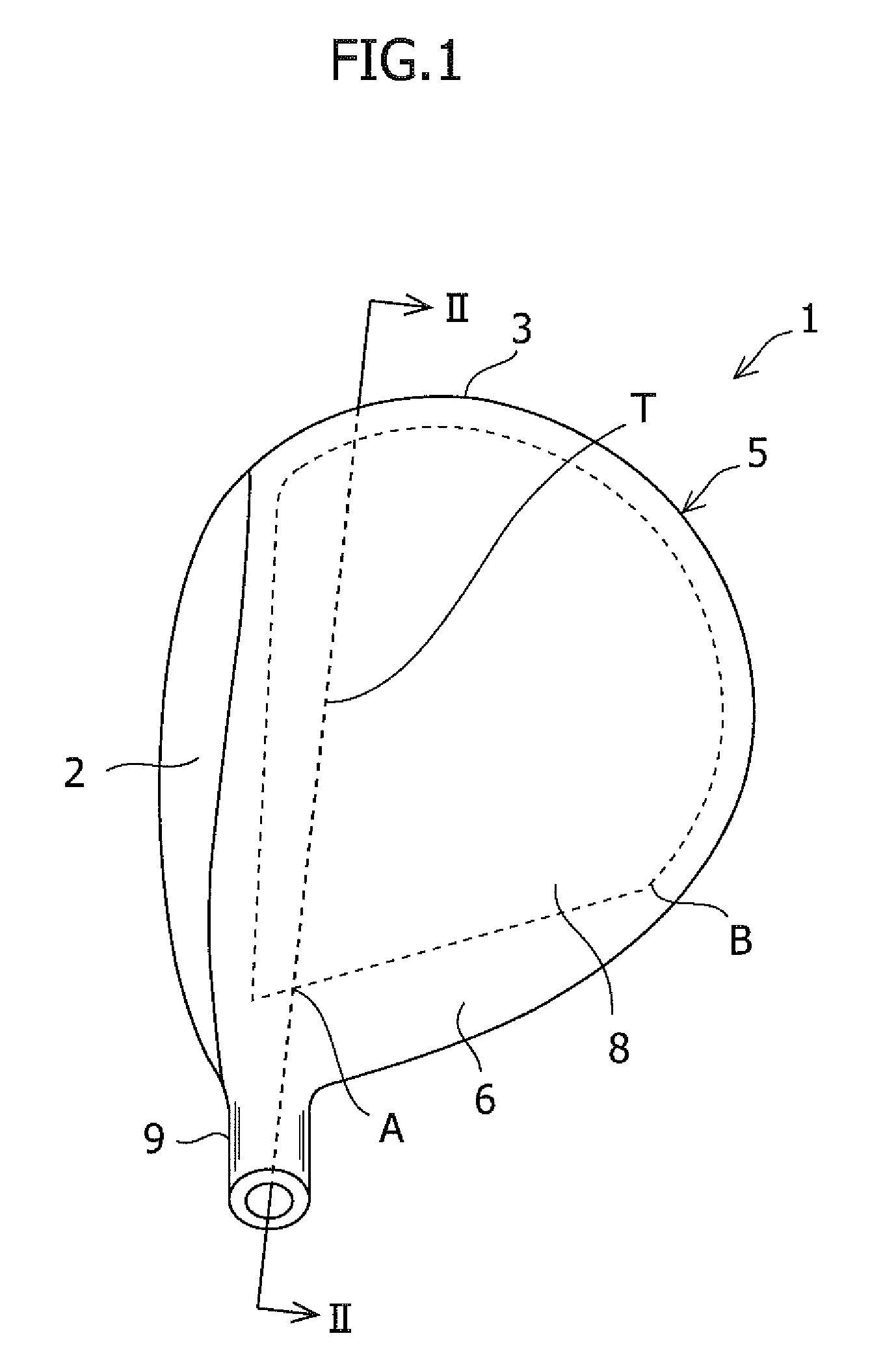

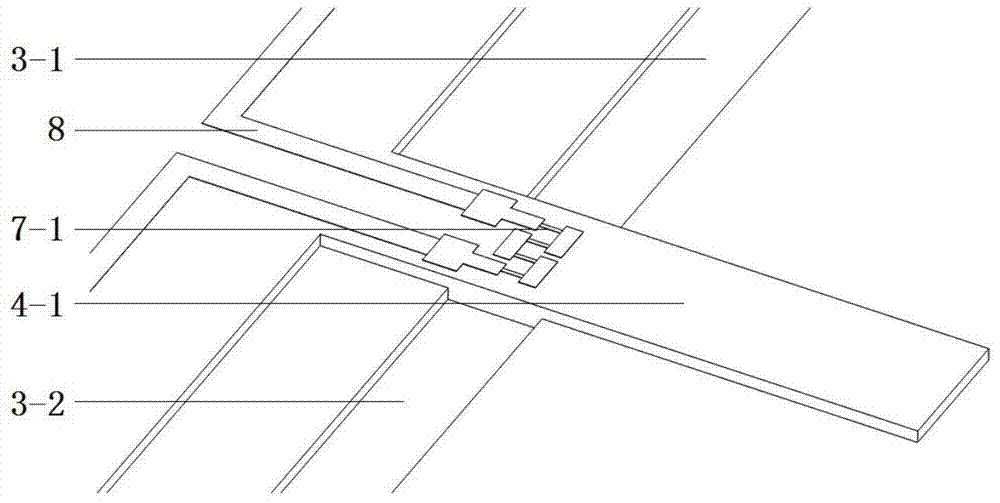

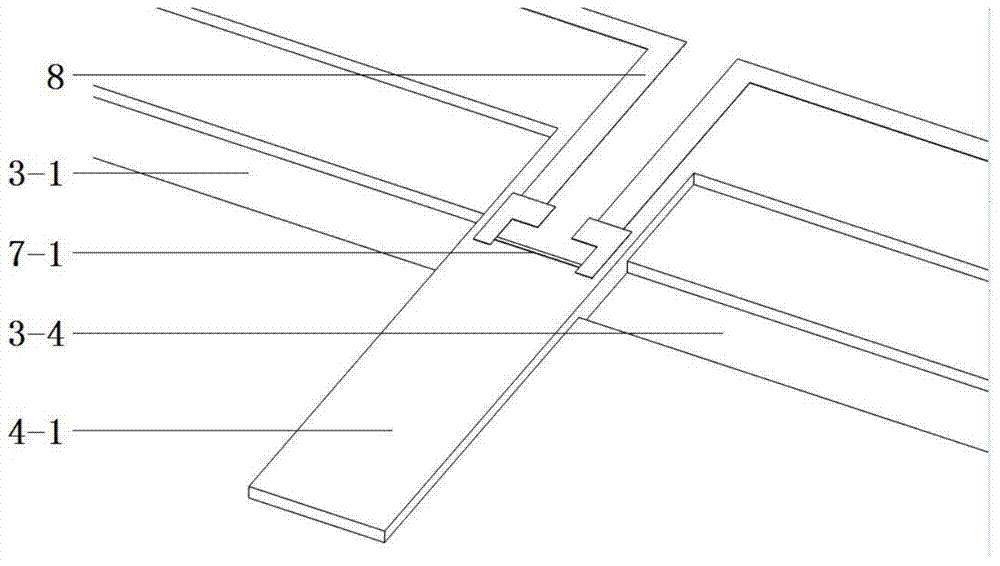

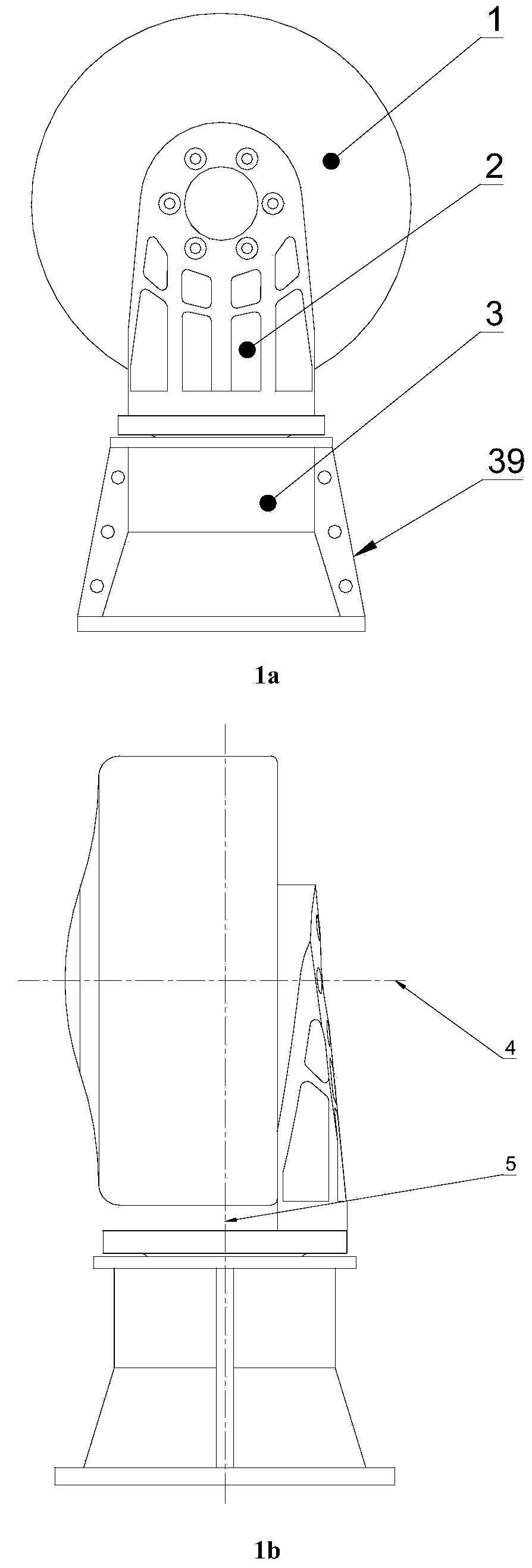

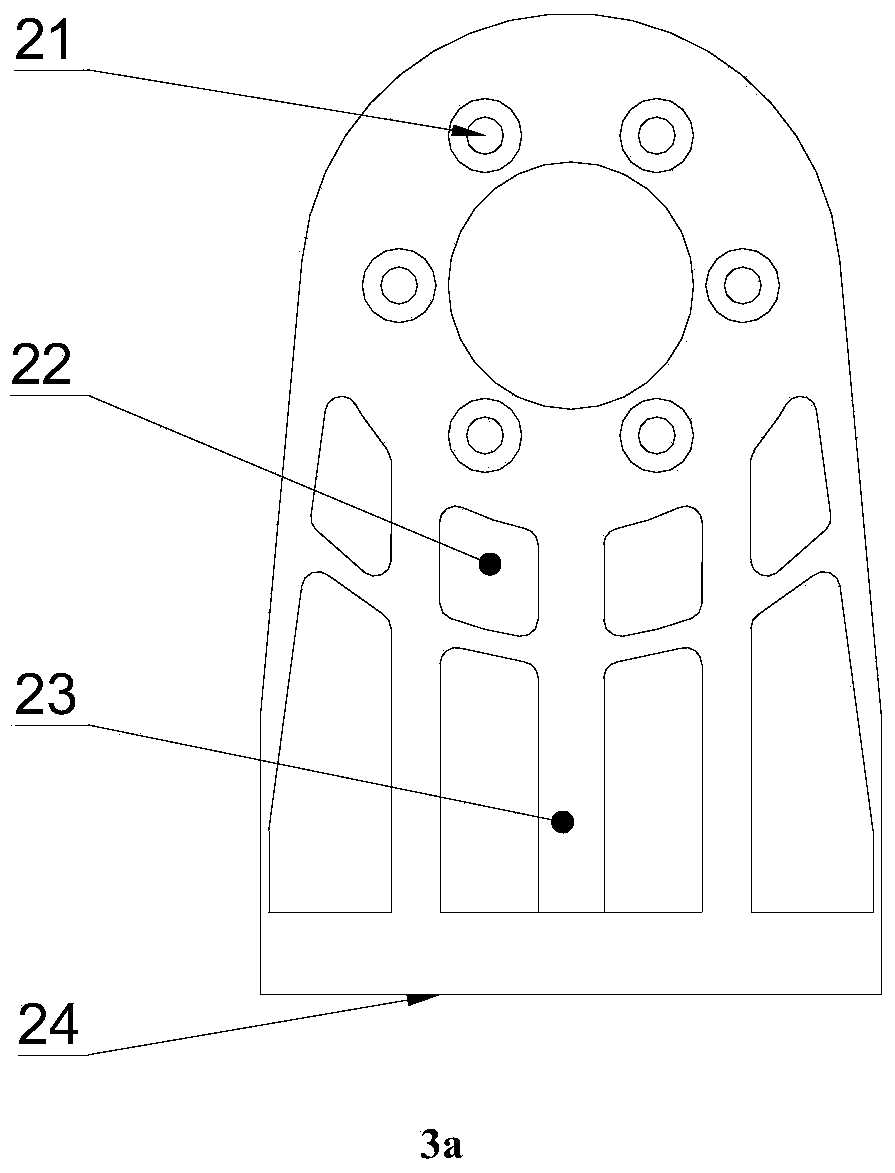

Golf club head

There is provided a golf club head that produces a loud hitting sound satisfying the golfer even if the volume of the golf club head having a hollow structure is increased to at least about 400 cc. A golf club head 1 having a hollow structure comprises a face part 2, a side part 3 comprising a back side, a sole part 4, a crown part 5, and a hosel part 9 having a shaft insertion hole, and the crown part 5. The crown part comprises a thick region 6 and a thin region 8. The thick region 6 extends through a distance WA of at least about 20 mm from the center axis line C of the shaft insertion hole toward the highest point T of the crown part 5 and extends through a distance WB of at least about 30 mm from the center axis line C of the shaft insertion hole toward the back side so that the crown part 5 has the first-order natural frequency of at least about 3000 Hz.

Owner:BRIDGESTONE SPORTS

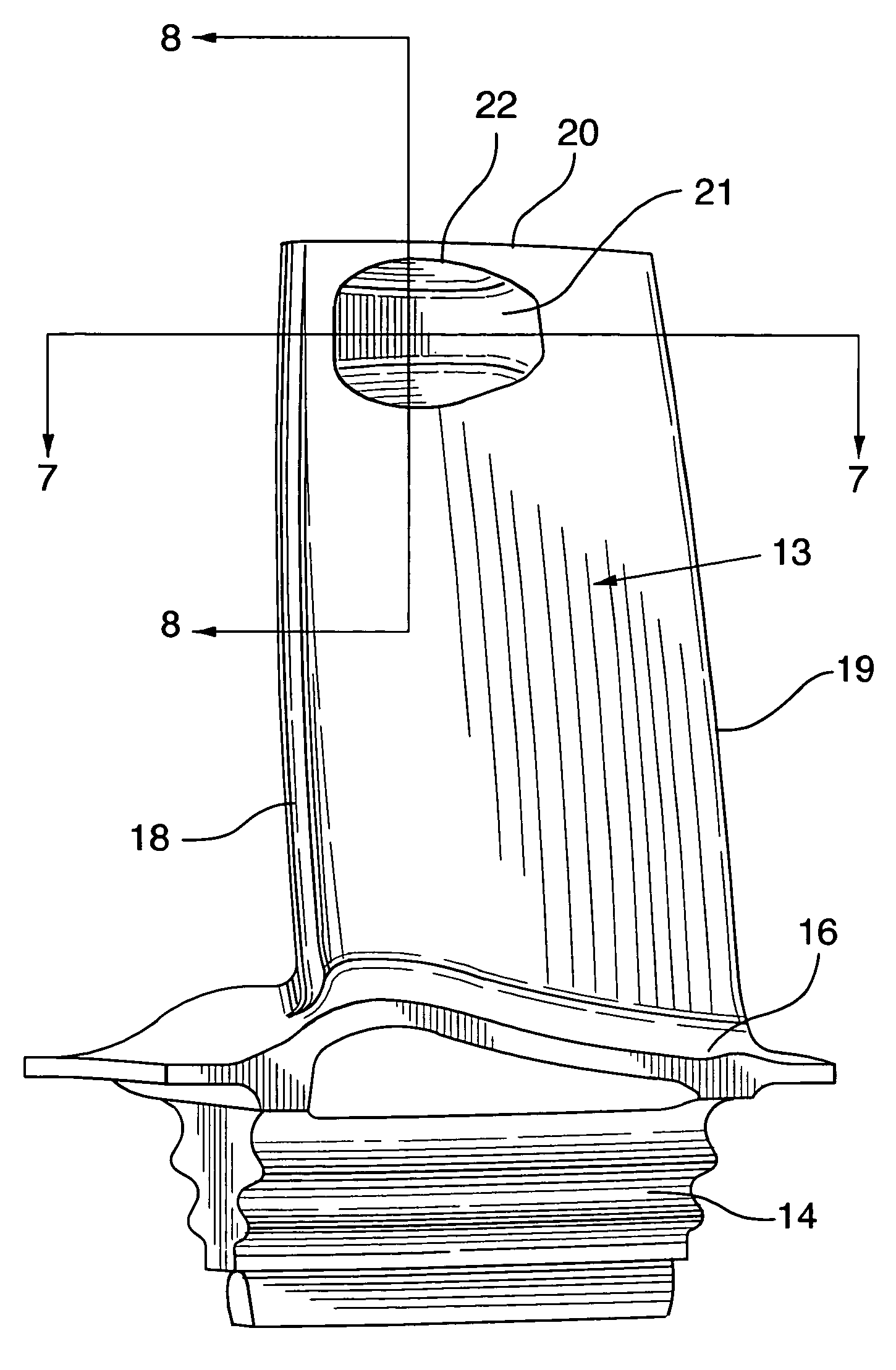

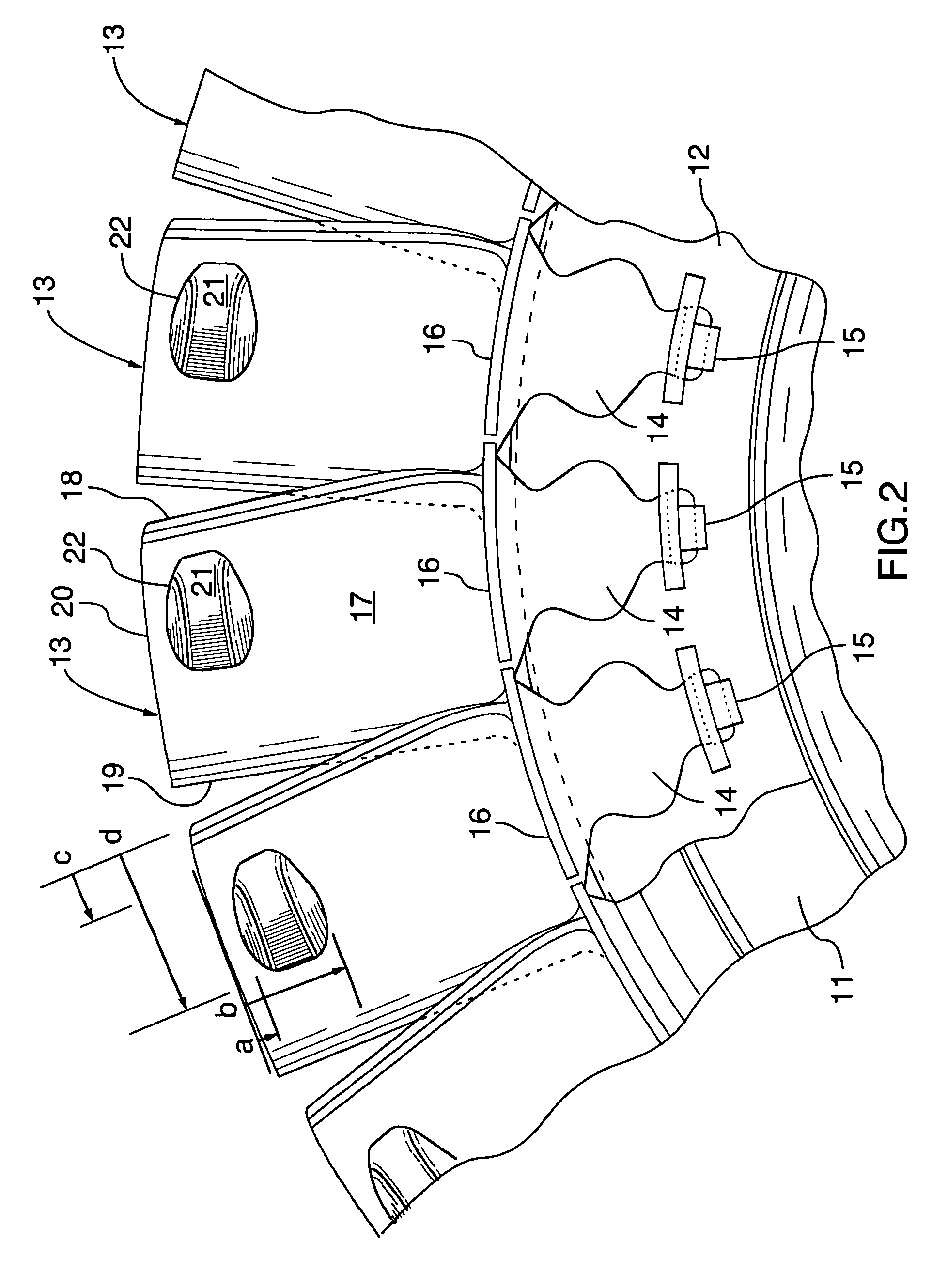

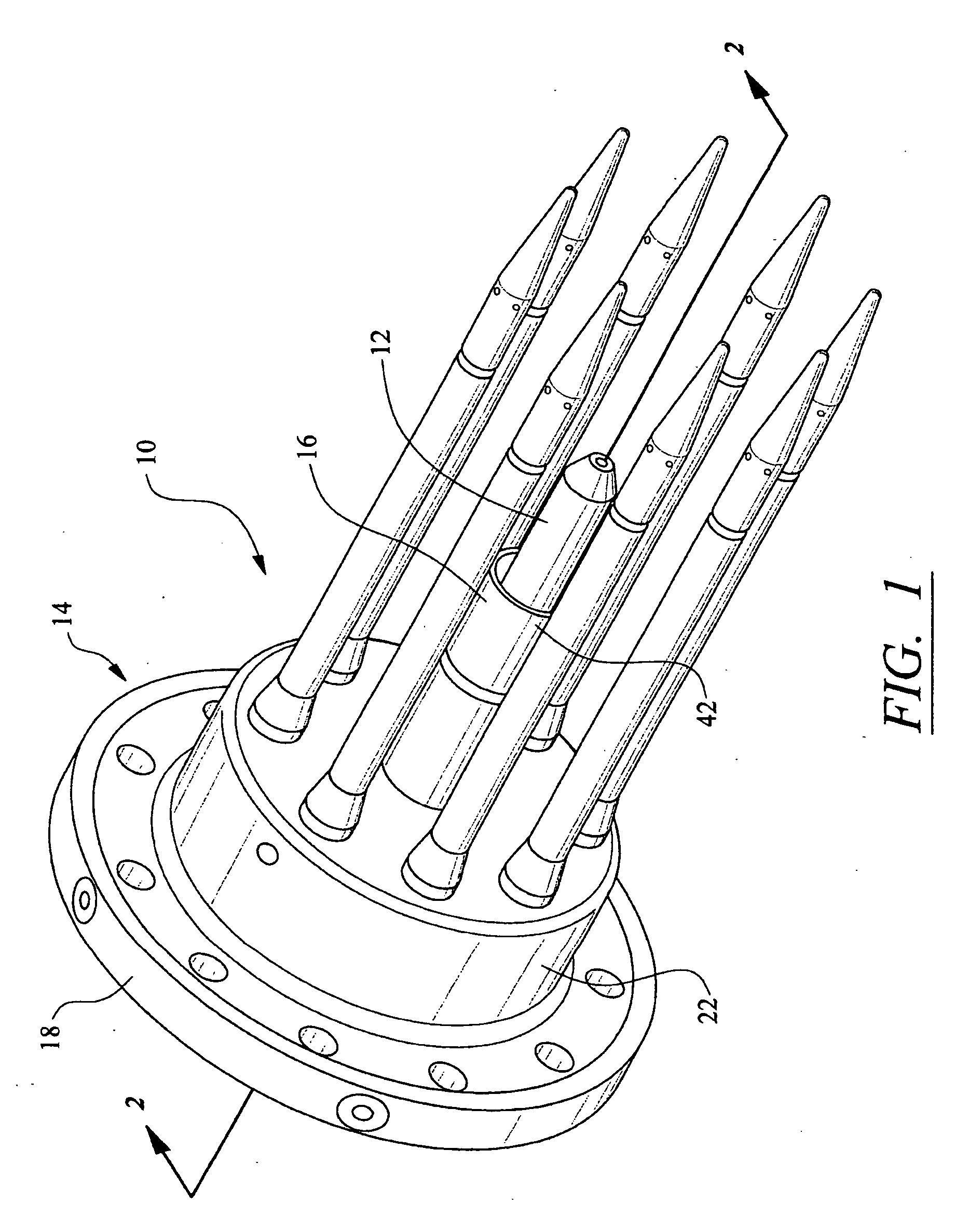

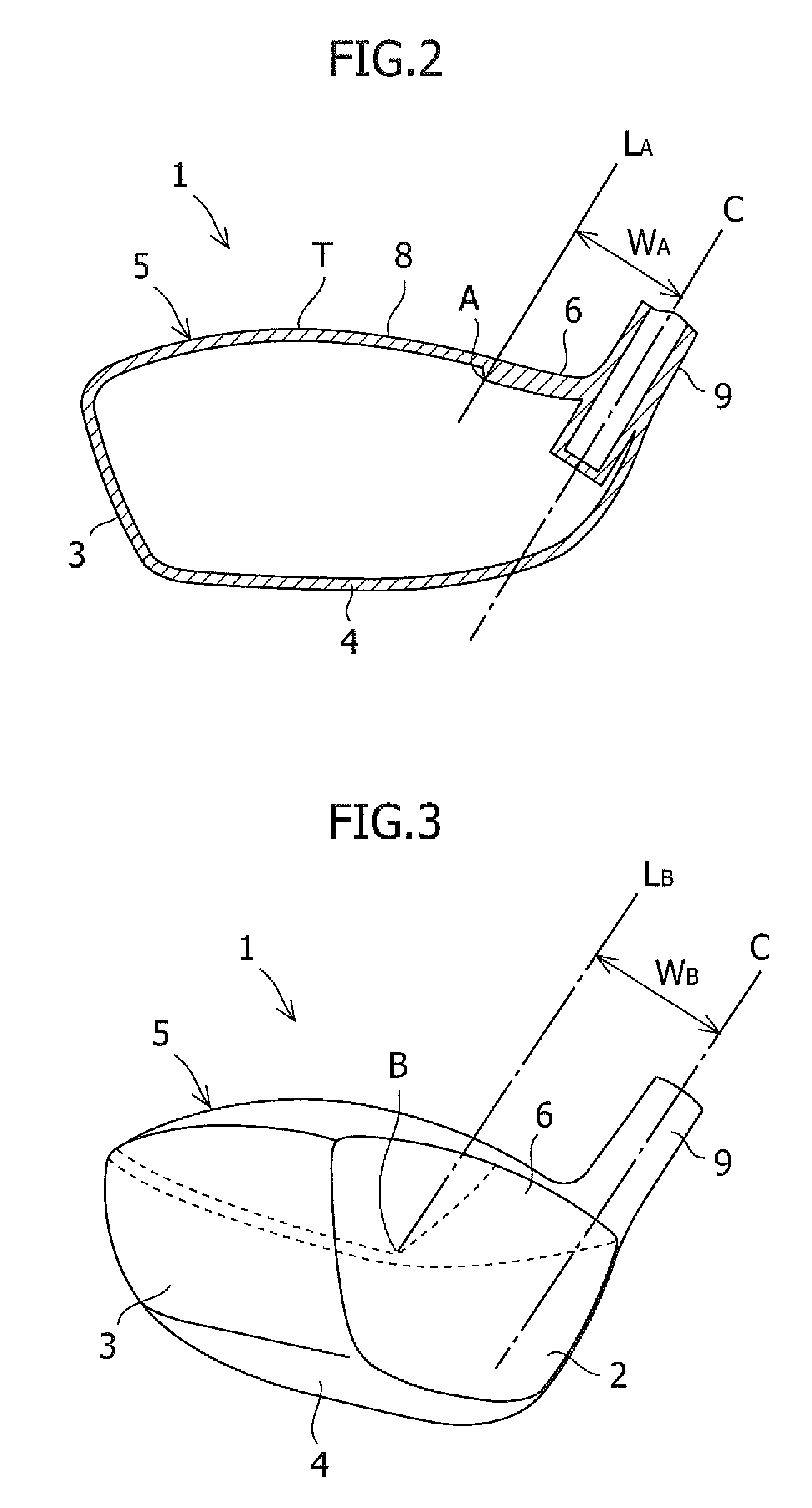

Turbine blade dimple

InactiveUS6976826B2Raise the natural frequencyReduce blade weightPropellersRotary propellersLeading edgeTurbine blade

A blade for mounting in an annular array about a rotary hub, the blade having: a blade root; an airfoil profile with a concave pressure side surface; a chord line extending between a leading edge and a trailing edge; and a blade tip, where the blade has a recess in the pressure side surface with an outer periphery disposed radially inwardly from the blade tip, and inwardly along the chord line from the leading edge and from the trailing edge.

Owner:PRATT & WHITNEY CANADA CORP

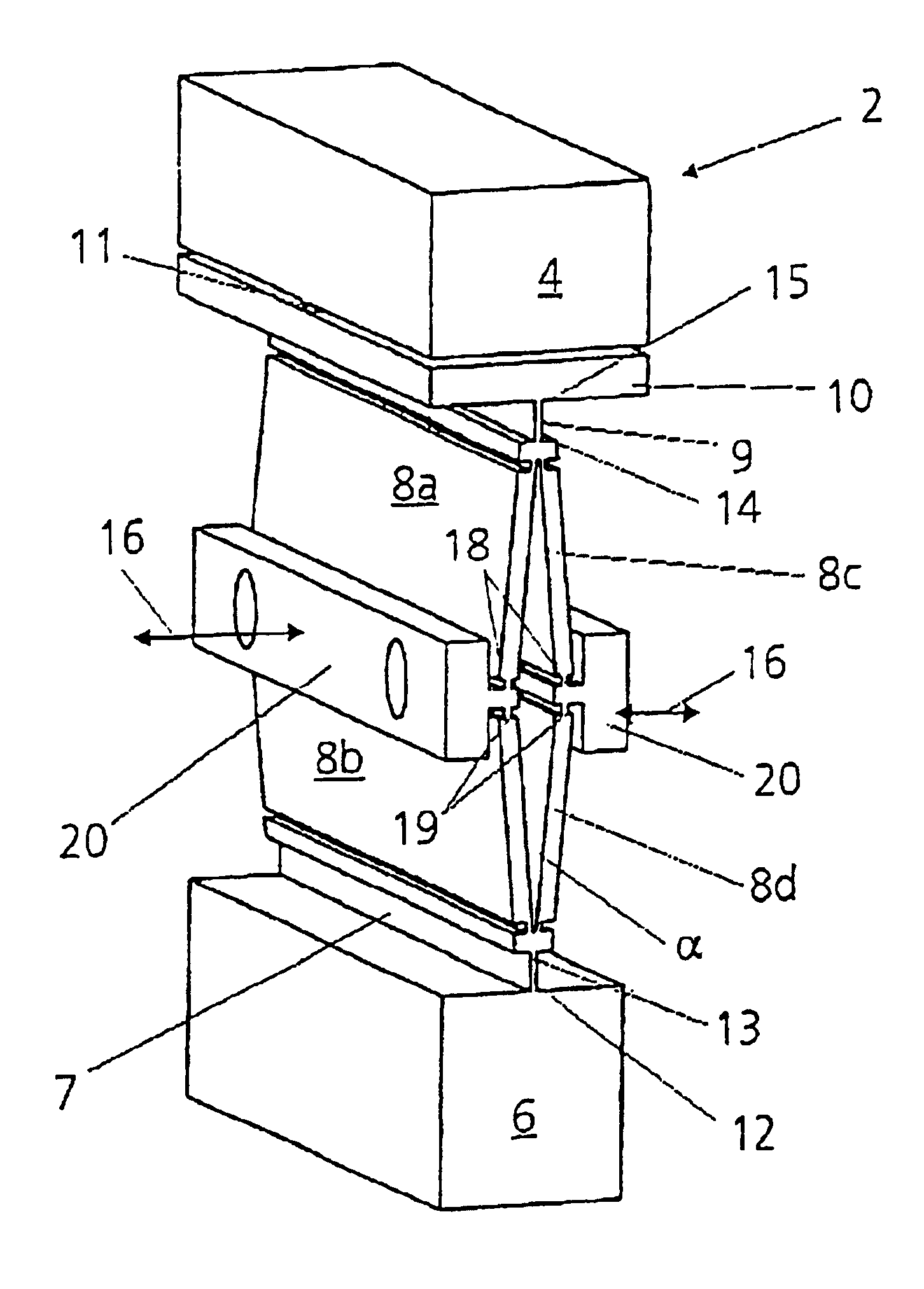

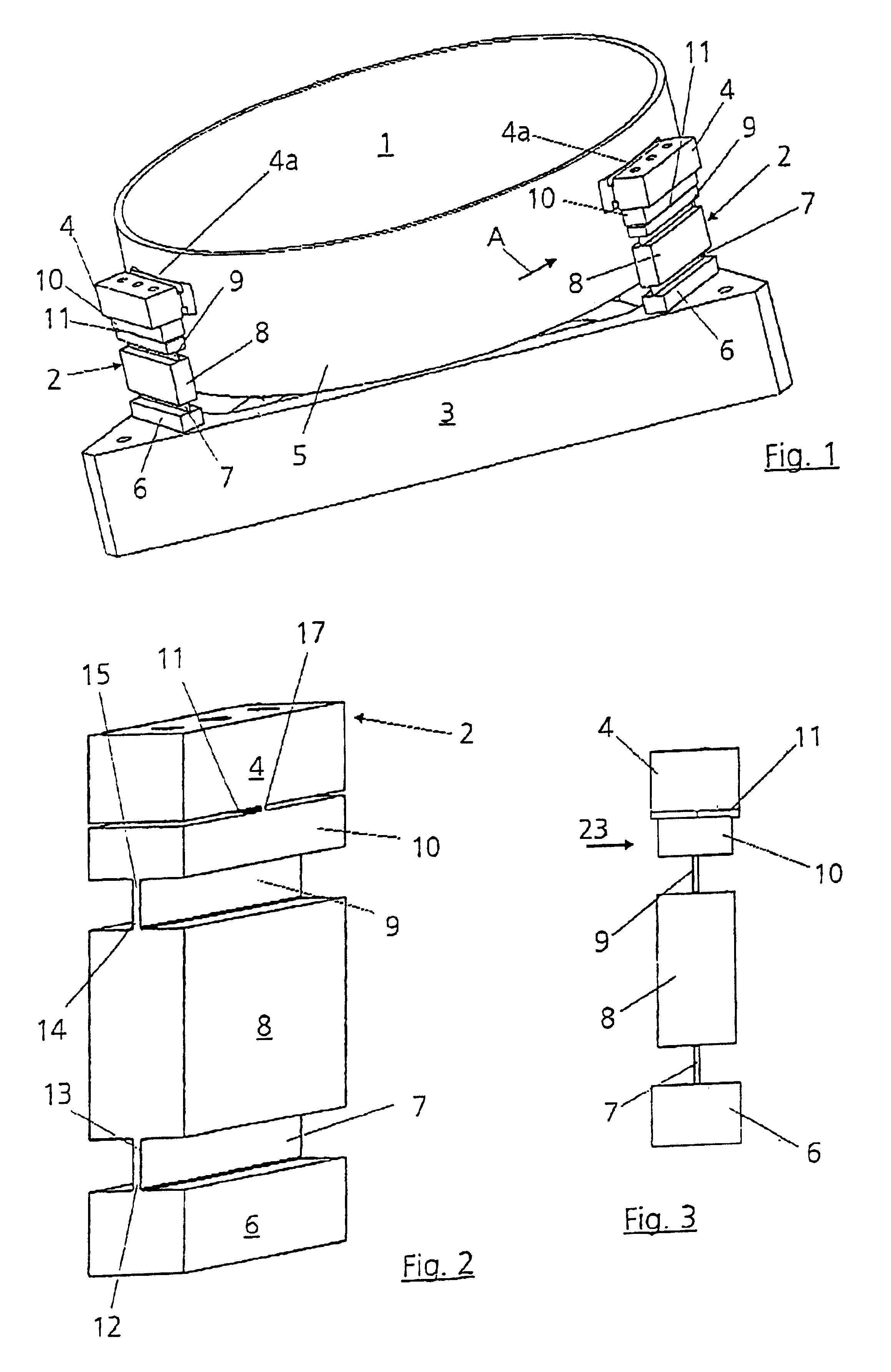

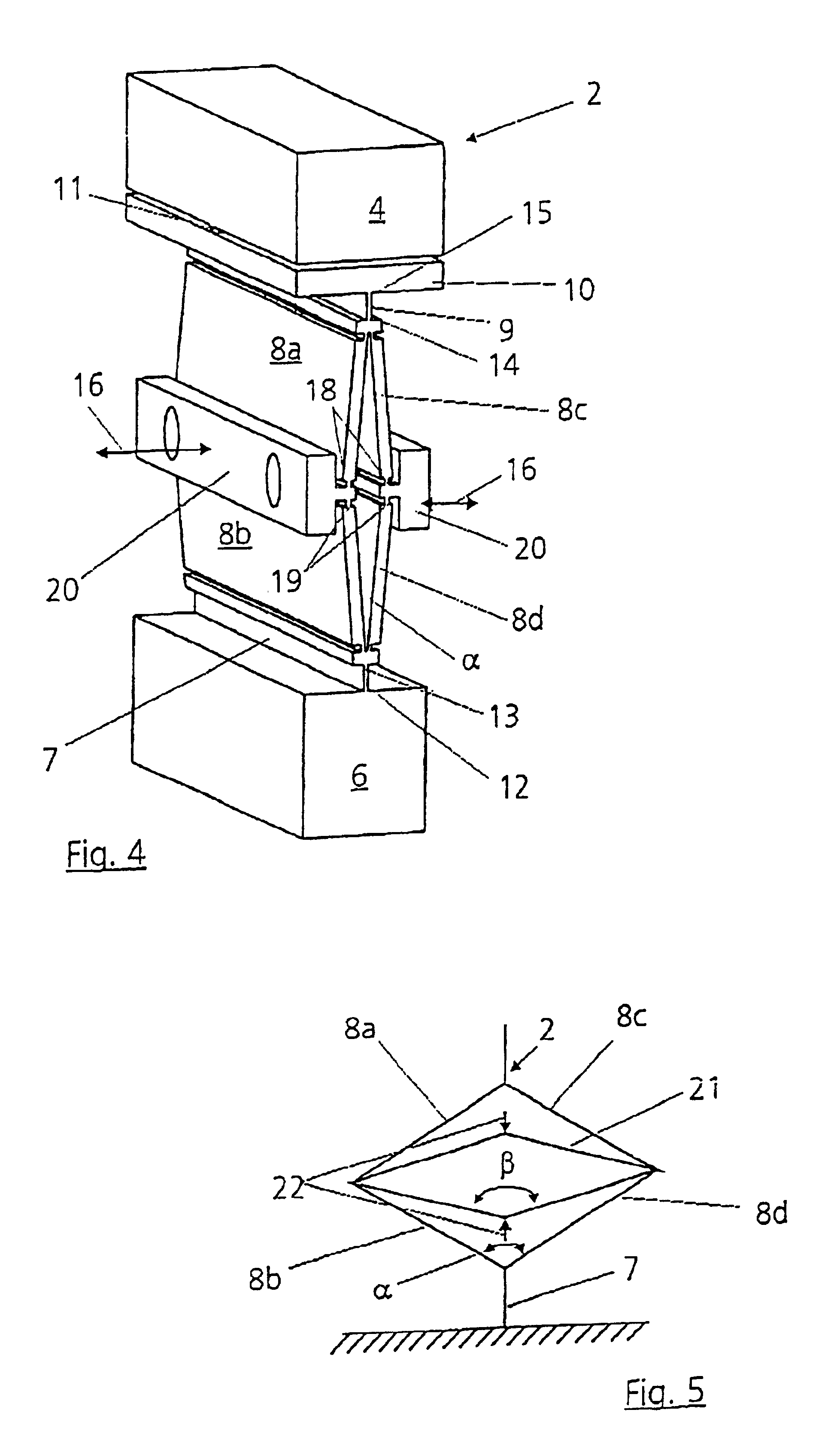

Apparatus for mounting an optical element in an optical system

InactiveUS6870632B2Raise the natural frequencyEasy to decoupleSemiconductor/solid-state device manufacturingUsing electrical meansPhotolithographyEngineering

An apparatus or mounting an optical element in an optical system, in particular a mirror or a lens, in a projection exposure machine, in particular a projection lens in semiconductor lithography, is connected to an external base structure with the aid of at least three articulation sites that are arranged on the circumference of the optical element and at which a bearing device acts in each case, wherein the bearing device has at least one bending element, resembling a leaf spring, arranged tangentially to the optical element, and at least one bending element, resembling a leaf spring, arranged in the radial direction relative to the optical element.

Owner:CARL ZEISS SMT GMBH

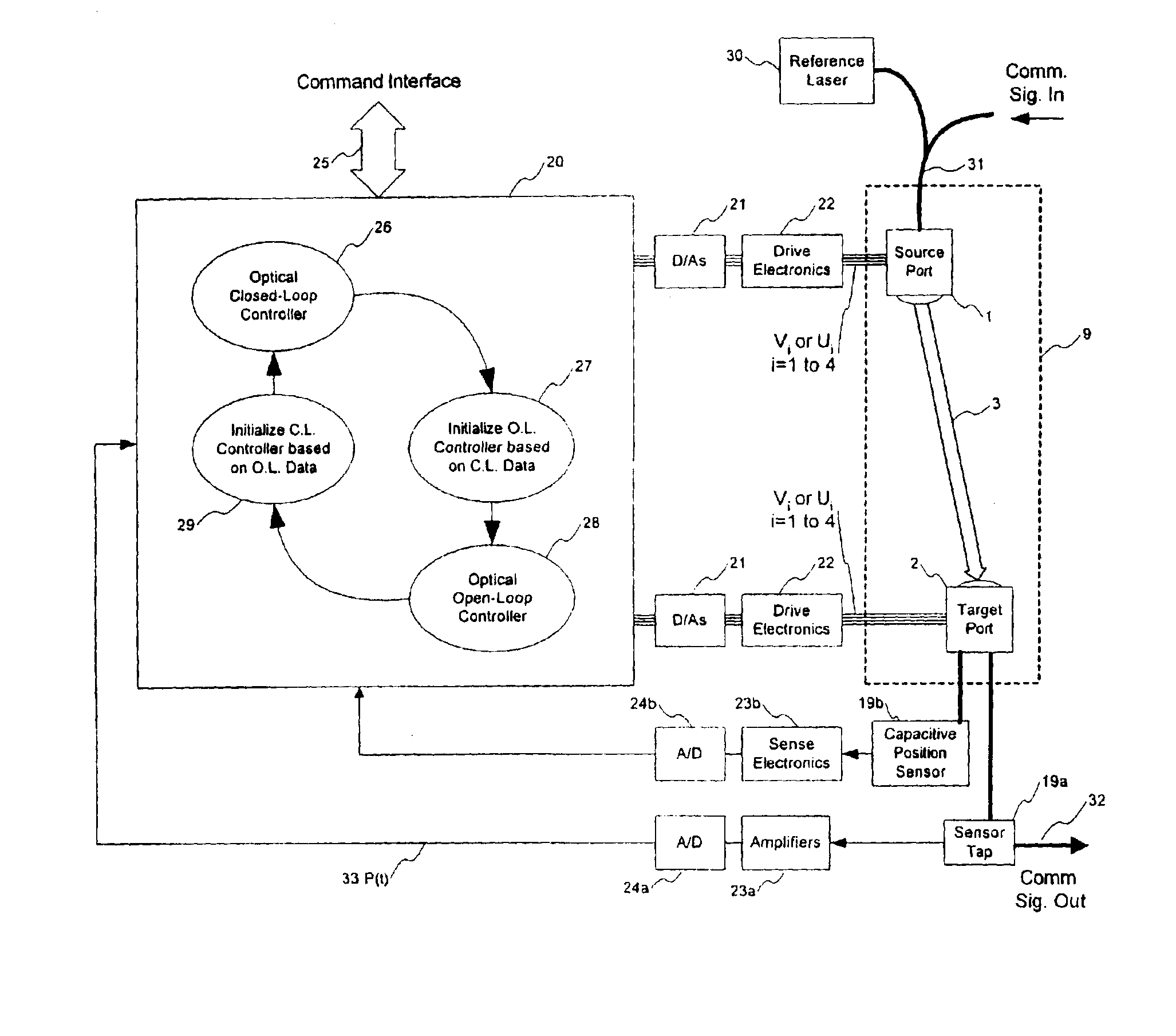

Multiple-axis control system for an optical switch

ActiveUS6975785B2Move fastRapidly tiltMultiplex system selection arrangementsCoupling light guidesFir systemLoop control

A free space optical switch that uses both an open loop control mode and a closed loop control mode. The open loop control mode is used to transition to a state where at least some light is sensed at a destination port. A closed loop control mode is then used, whereby a series of controlled dither signals are adjusted for system dynamics. Modifying the dither signals in this matter allows moving actuators at a rate that is much closer to the natural frequency of the underlying system, and hence speeds up the system convergence process. Variable modulation amplitudes may be employed on the dither signals to maximize convergence speed. In particular, changes in the dither signal can be made in accordance with the change in amplitude as a function of a gradient along a parabola that models the optical system response. According to still further aspects, the dither signals may be compensated for a desired and selectable attenuation level of output optical power.

Owner:POLATIS PHOTONICS INC

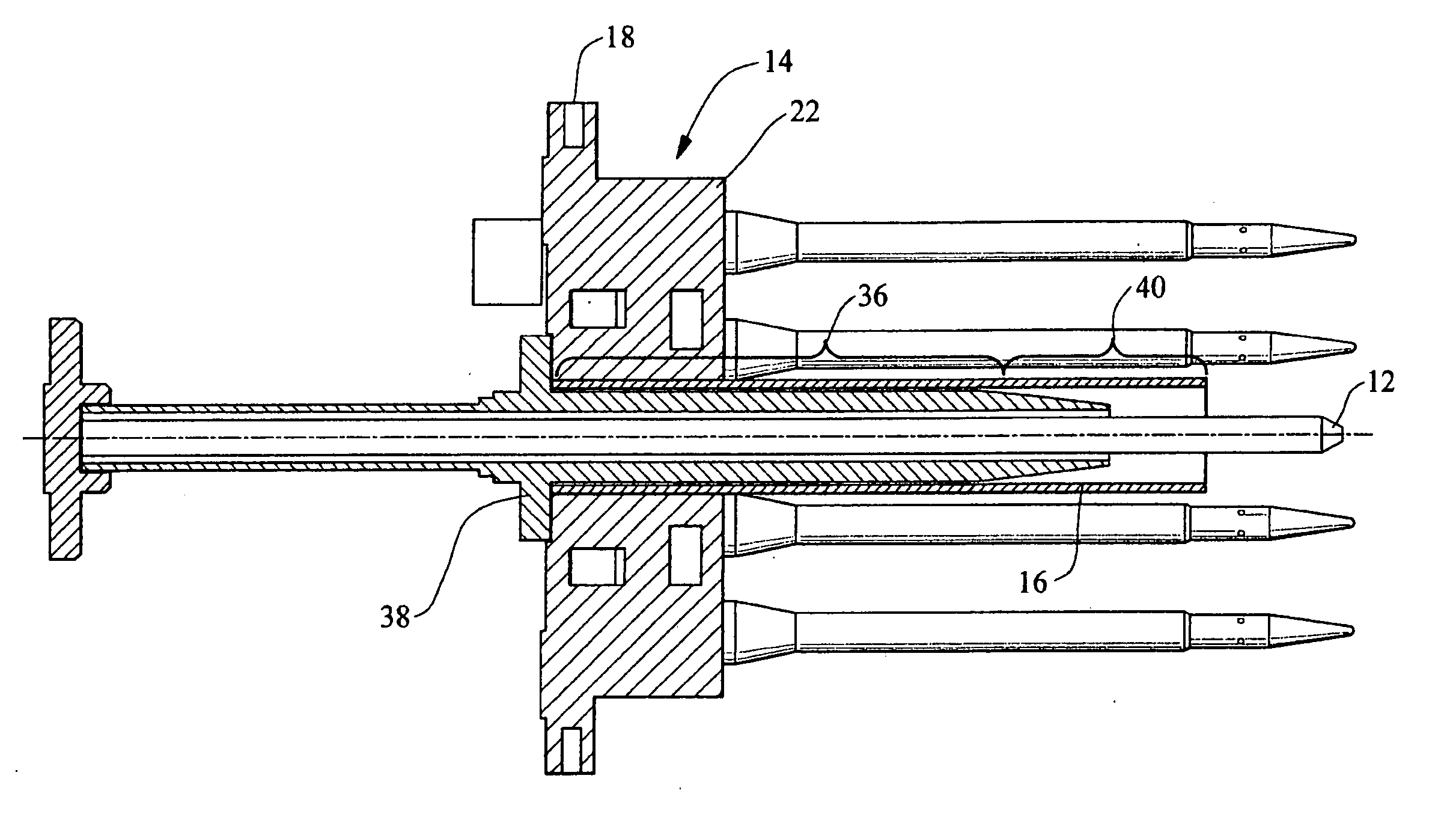

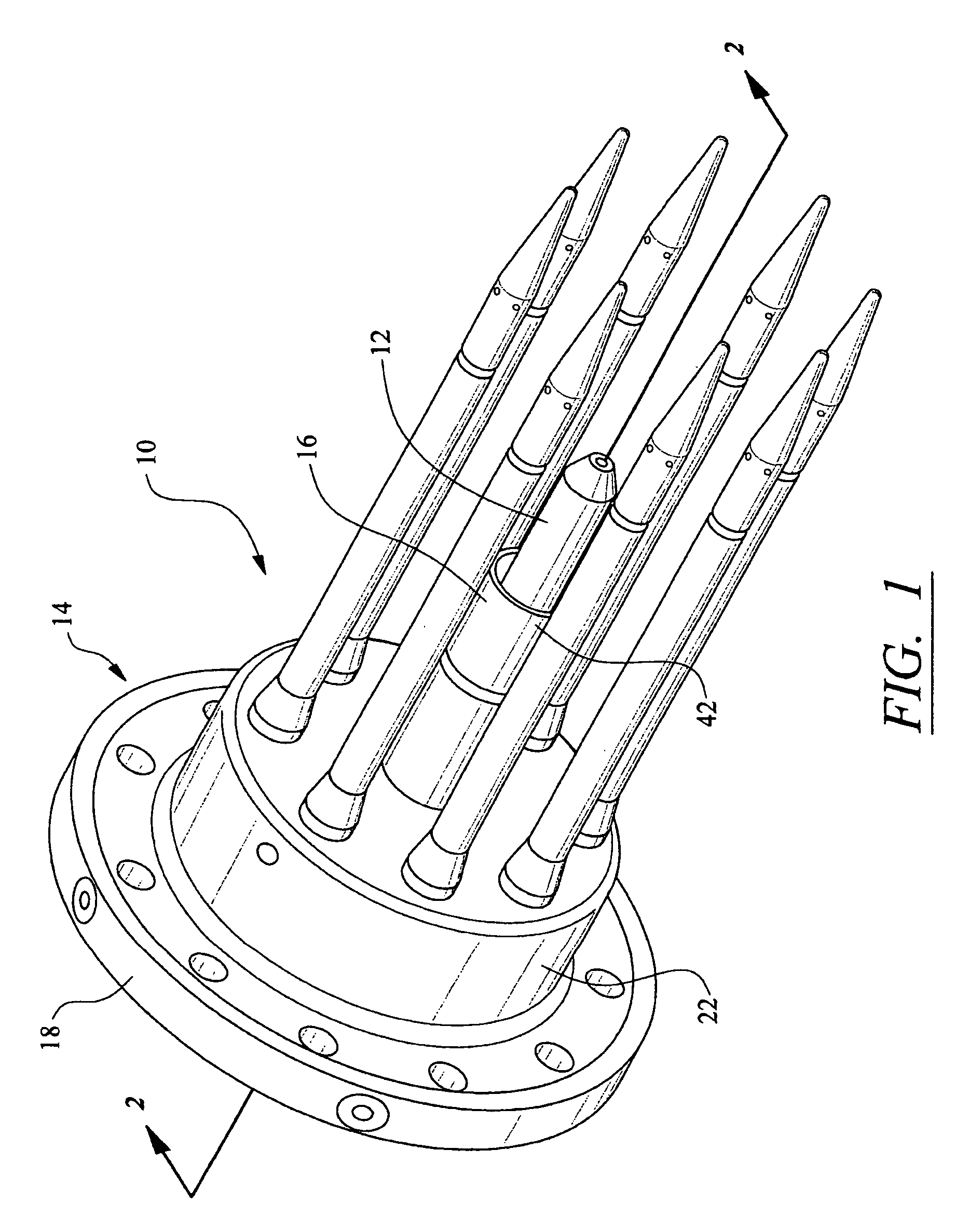

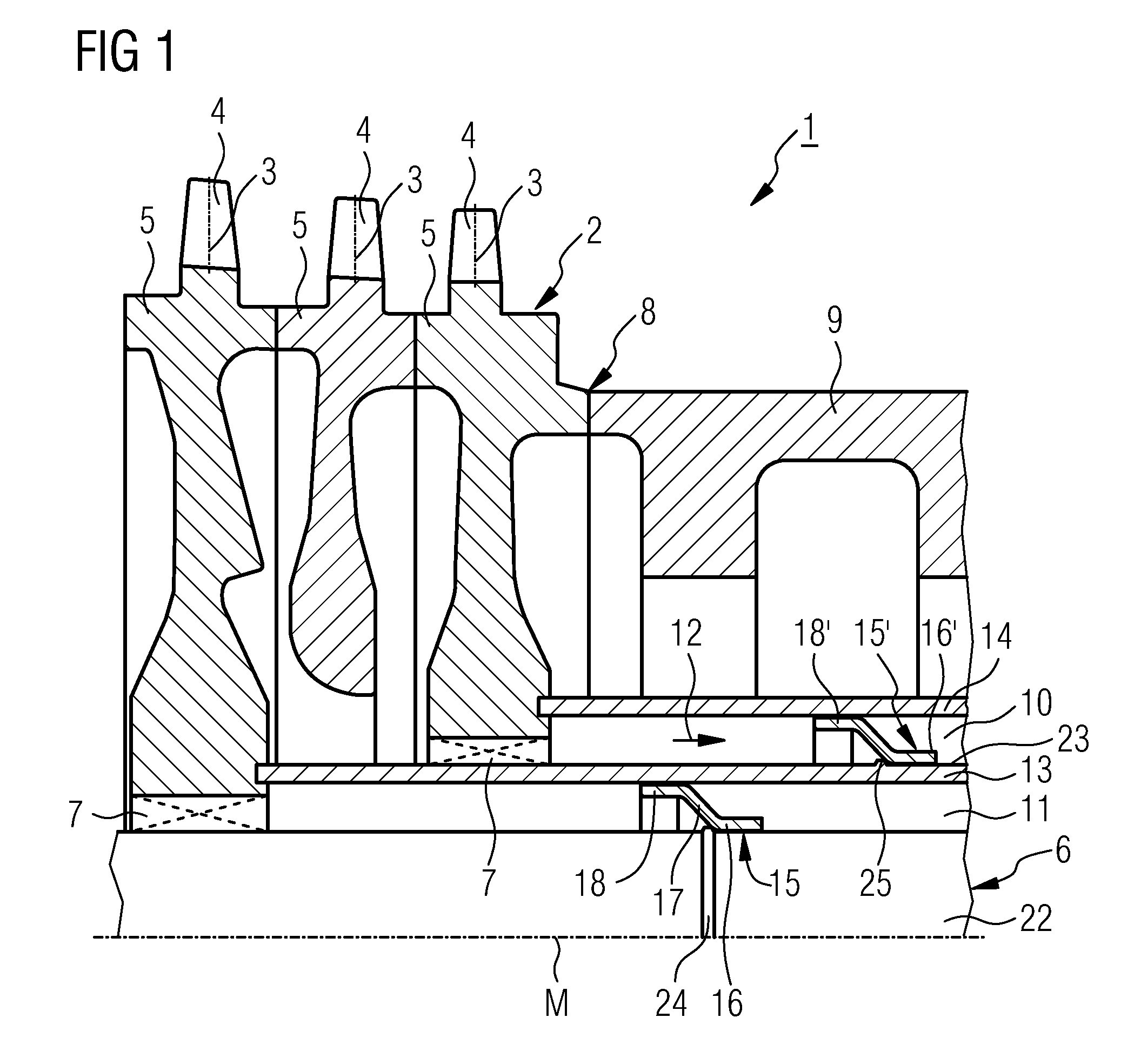

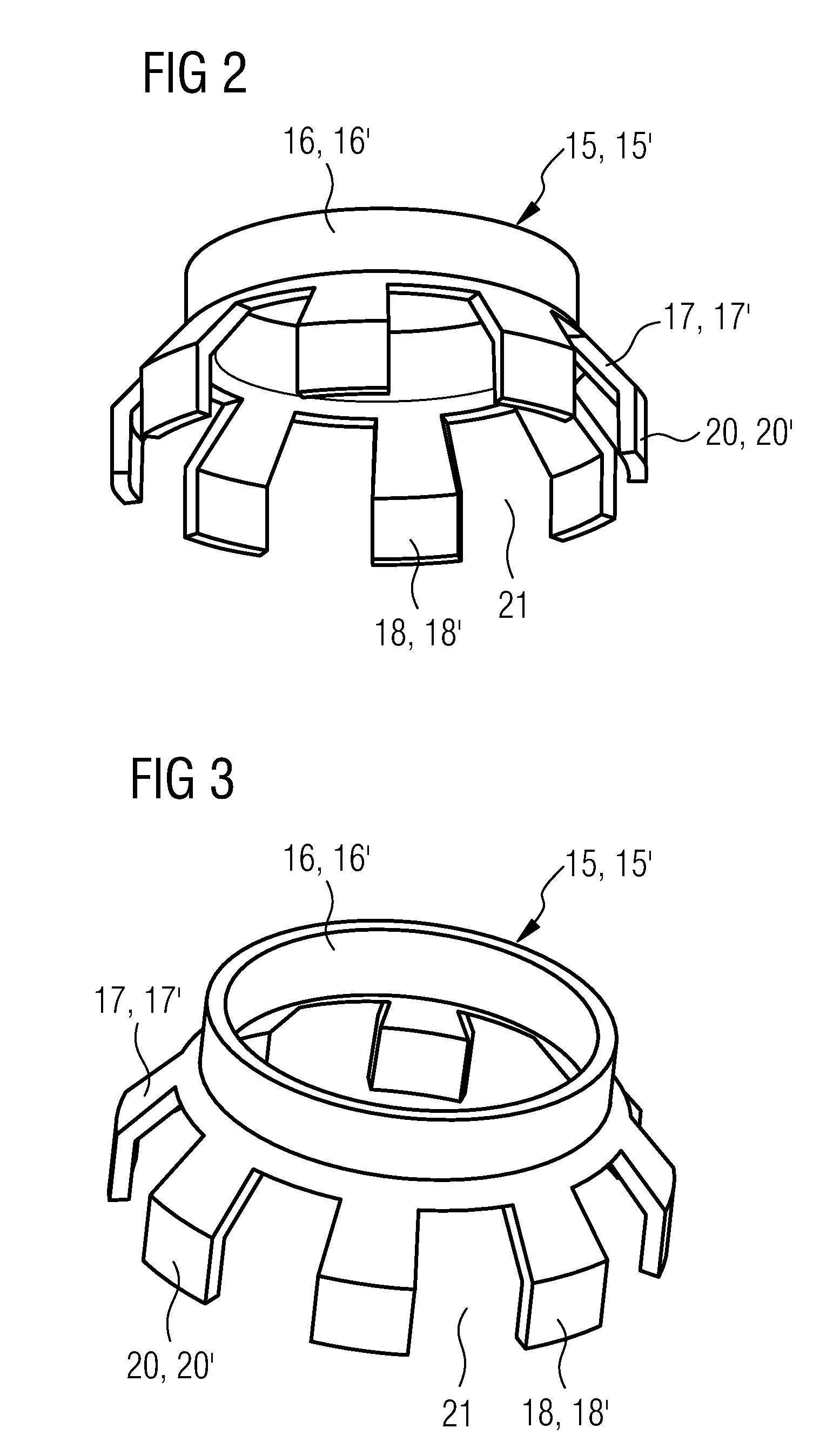

Support system for a pilot nozzle of a turbine engine

ActiveUS20060026966A1Raise the natural frequencyPrevent insertionContinuous combustion chamberTurbine/propulsion fuel supply systemsInterference fitSupporting system

An automatic recovery pilot nozzle support system for supporting a pilot nozzle in a fuel injection system of a turbine engine. The support system includes a sleeve extending from an orifice in a support housing, wherein the sleeve has a hollow opening for containing a pilot nozzle. The sleeve may increase the natural frequency of the pilot nozzle above an excitation zone, thereby limiting destructive vibrations. The sleeve may be attached to the support housing with an interference fit. The automatic recovery aspect of the support system enables the sleeve to maintain an interference fit with the support housing such that anytime the sleeve looses contact with the support housing, an insulative film of air forms between the sleeve and the support housing. The insulative film of air causes the temperature of the sleeve to increase, and the sleeve to expand and reform the interference fit with the support housing.

Owner:SIEMENS ENERGY INC

Golf club head

Owner:BRIDGESTONE SPORTS

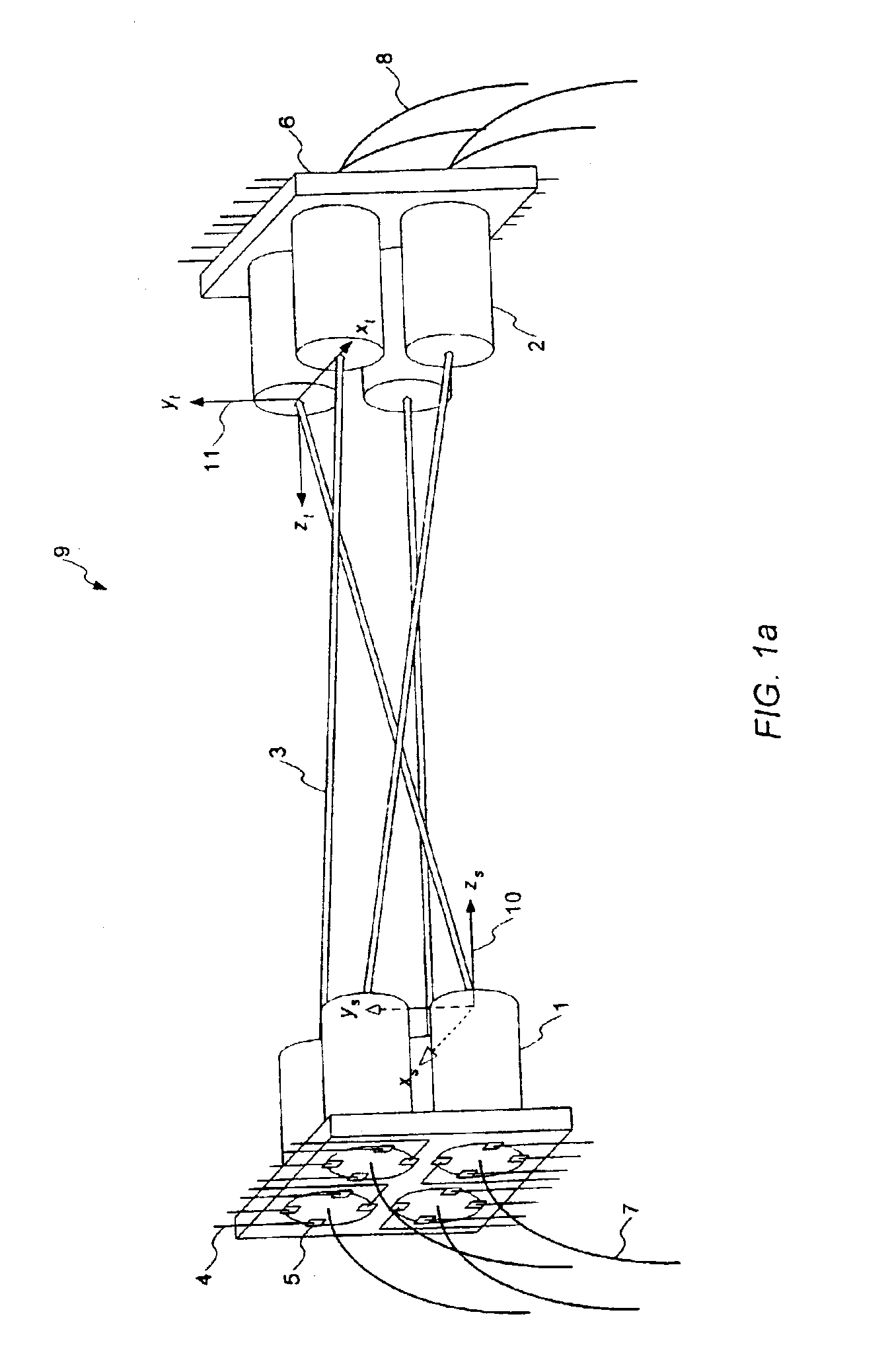

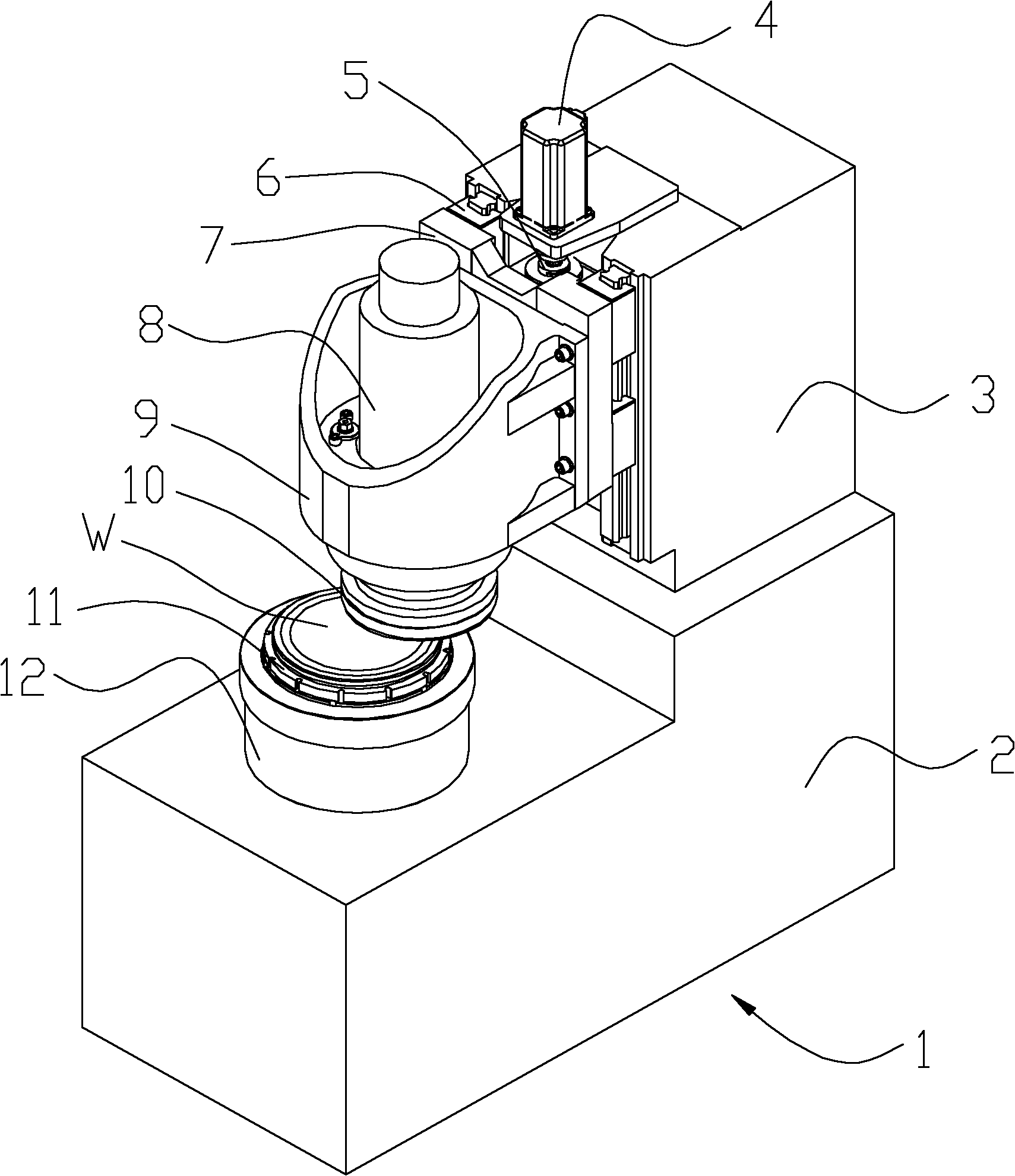

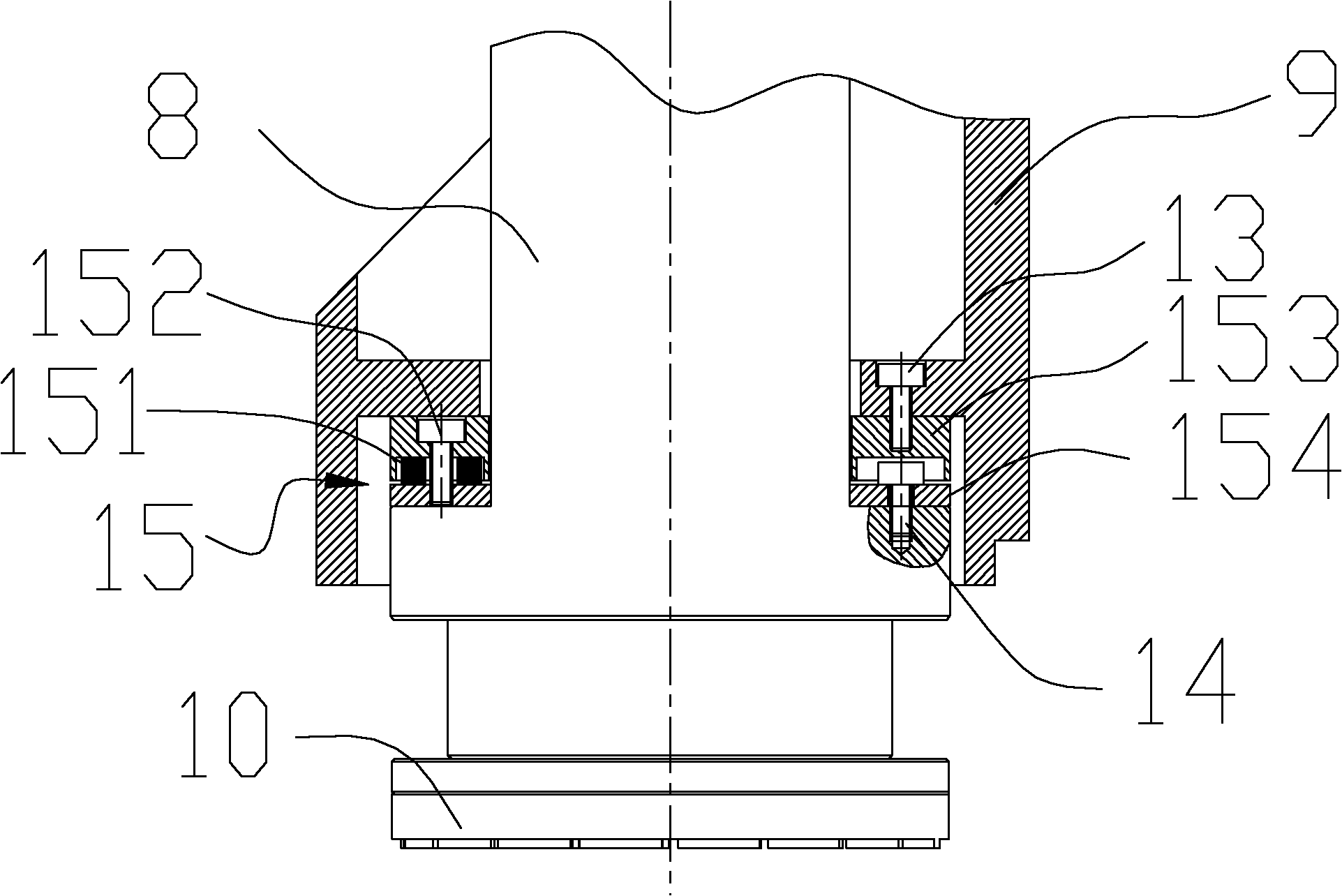

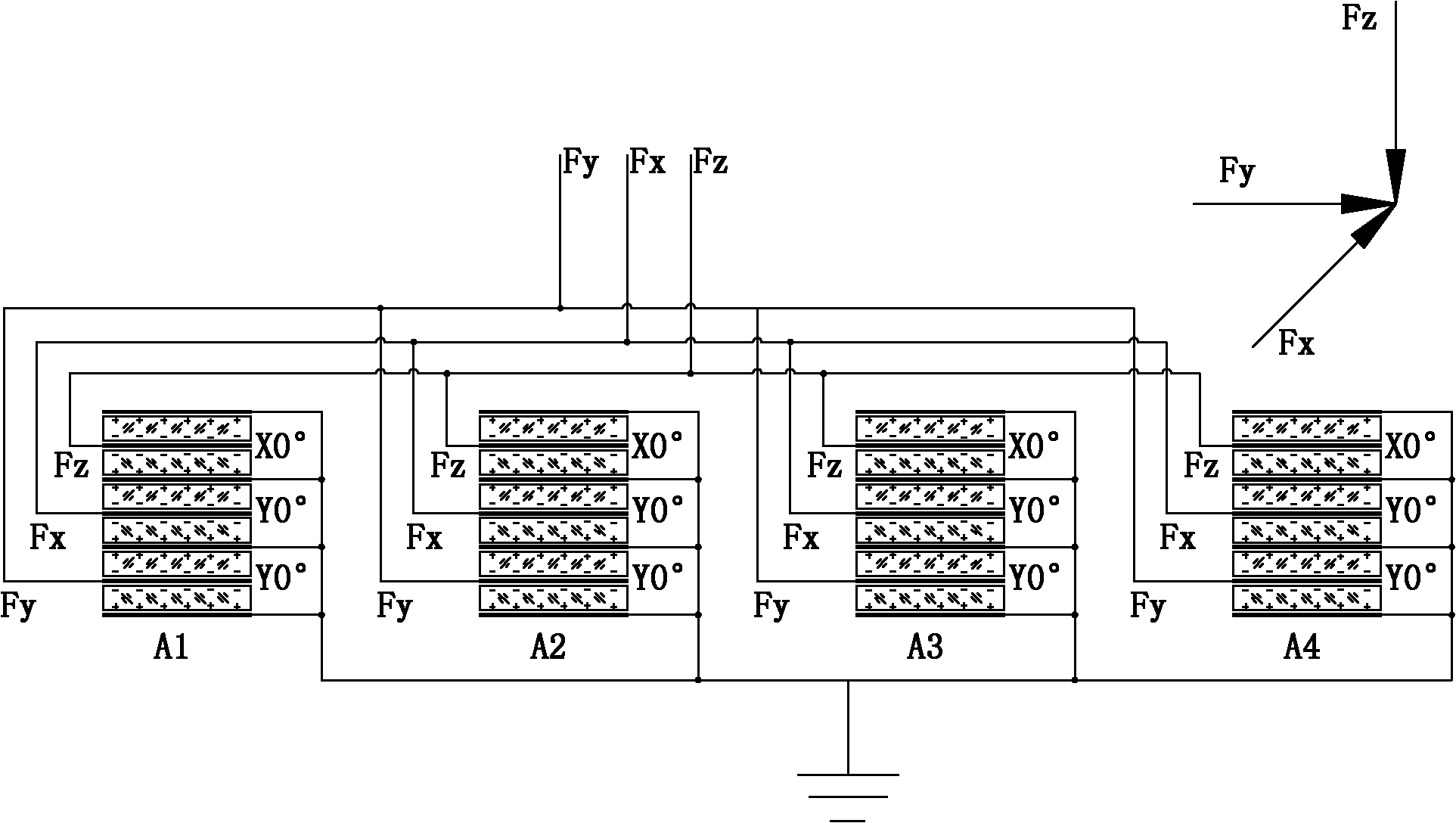

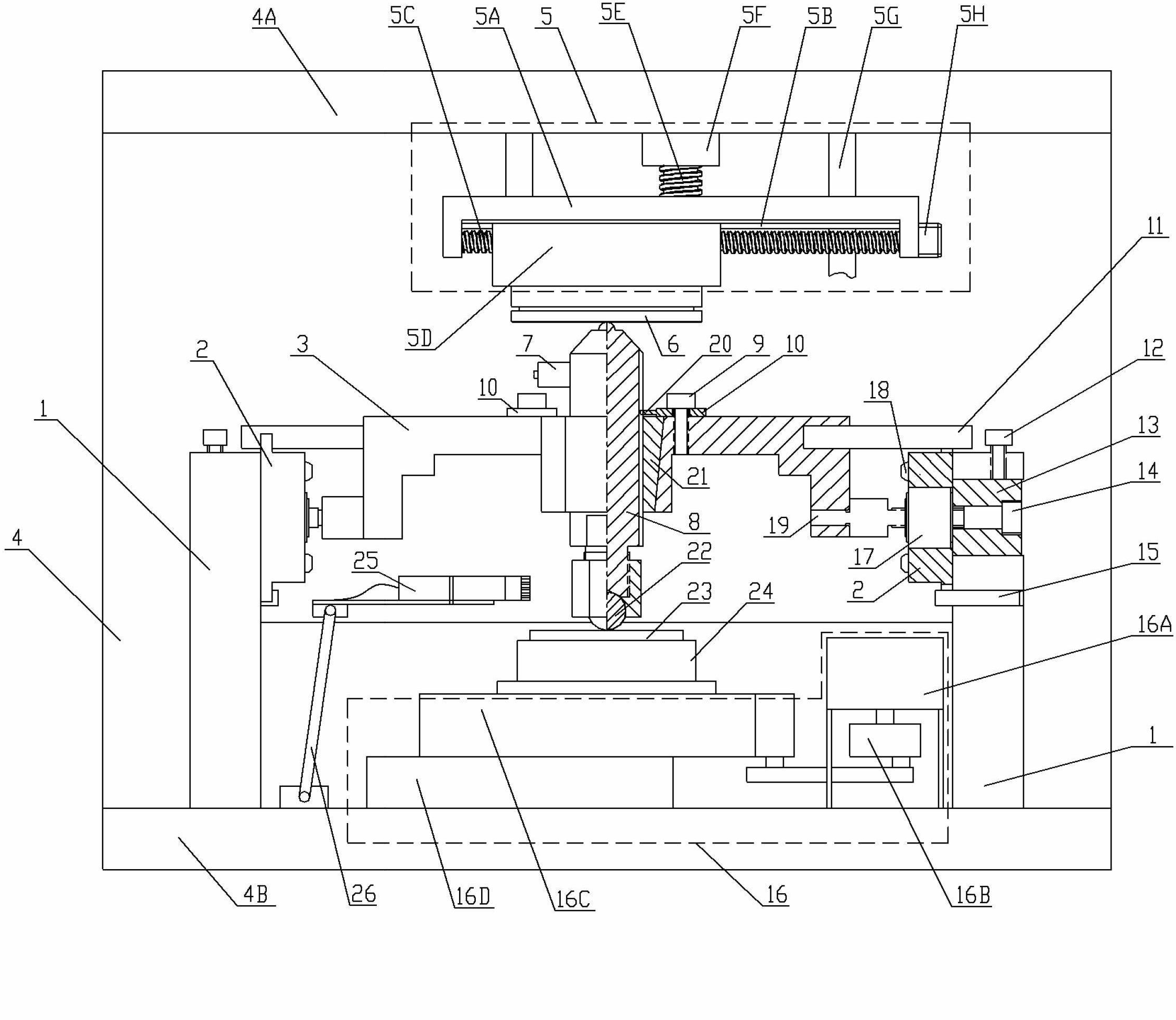

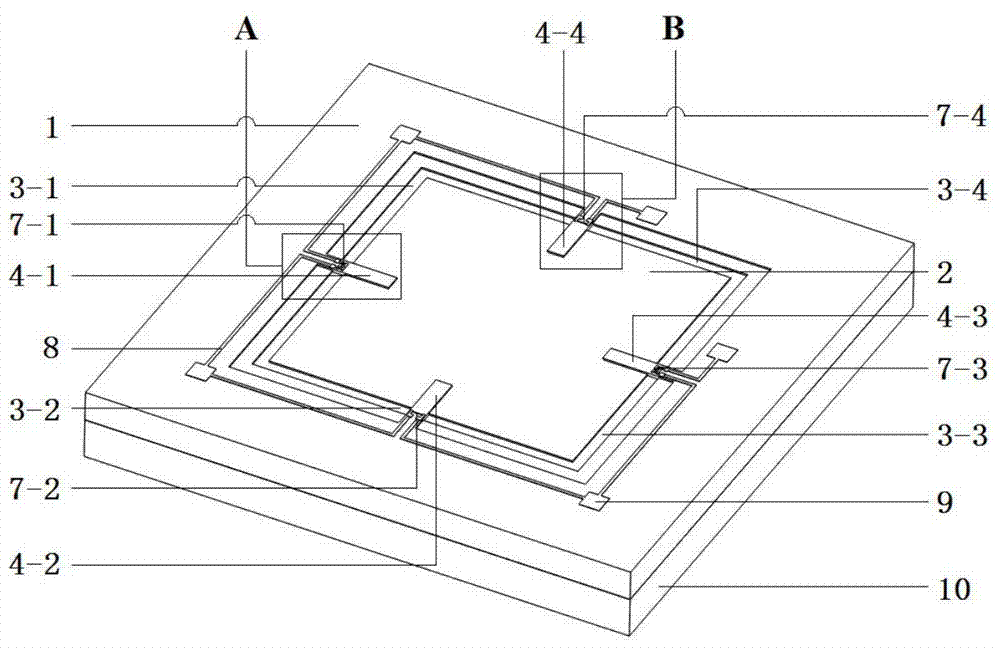

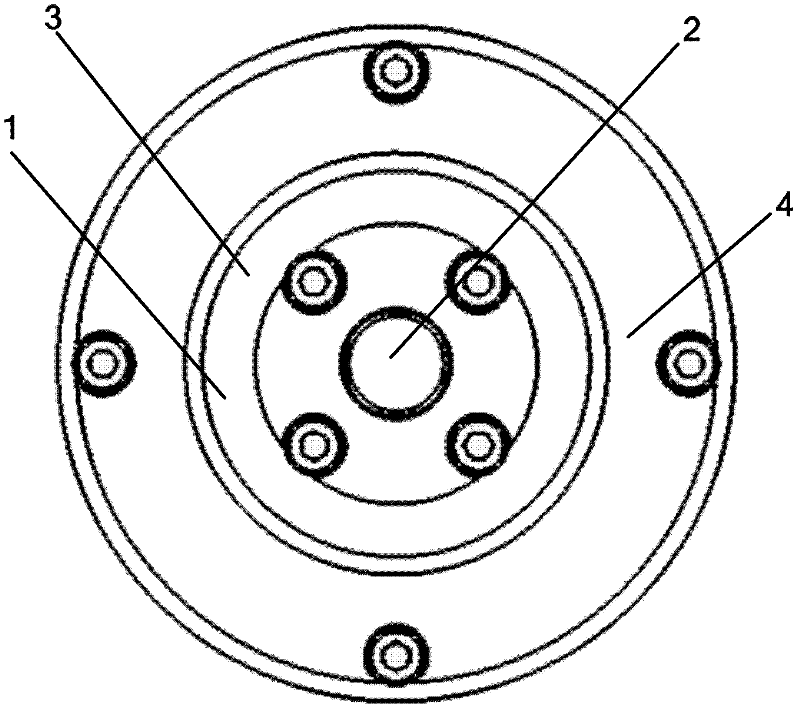

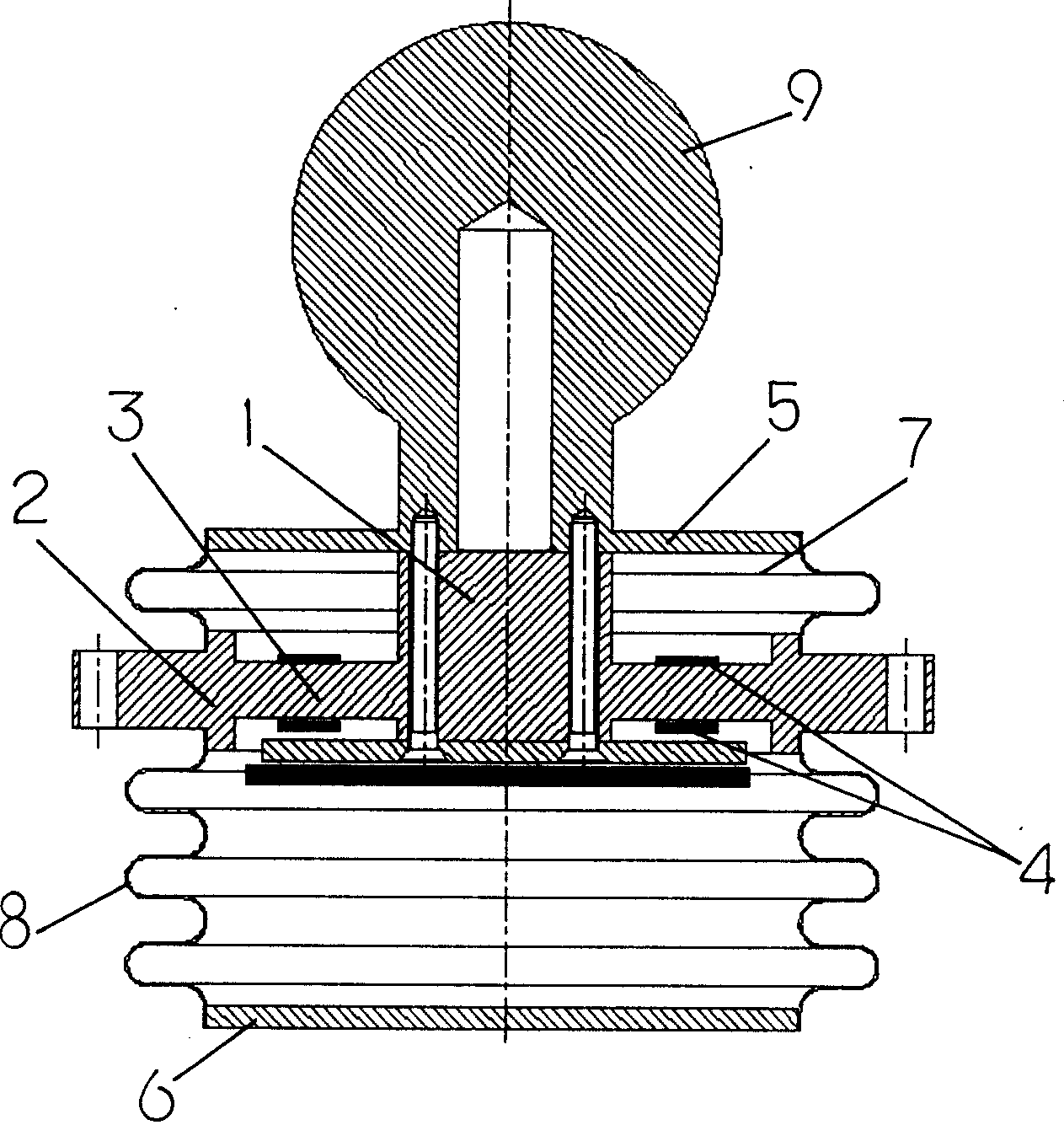

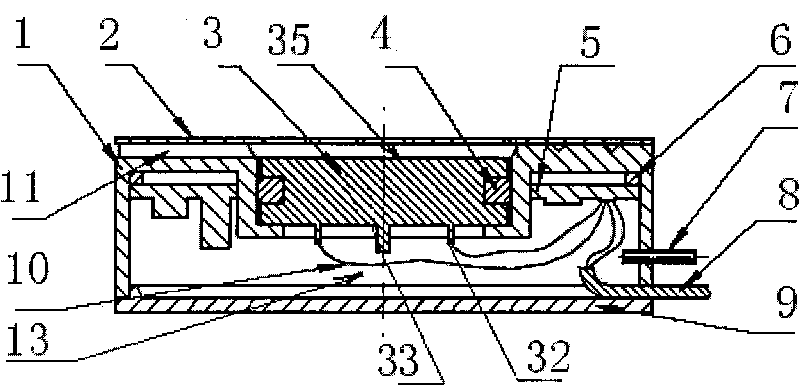

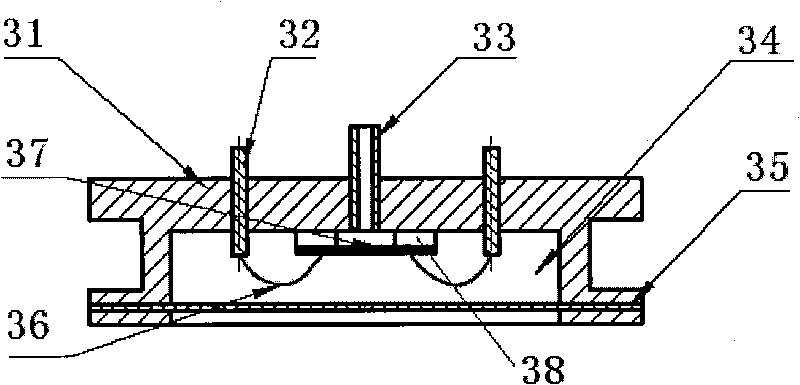

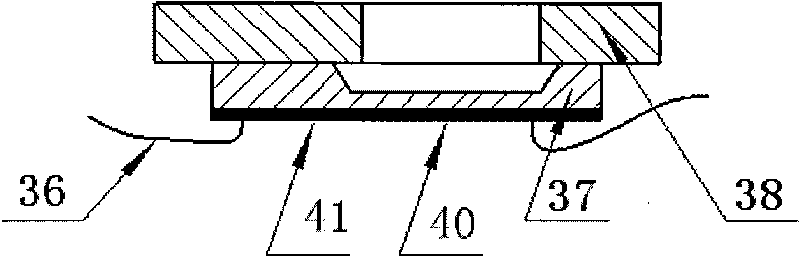

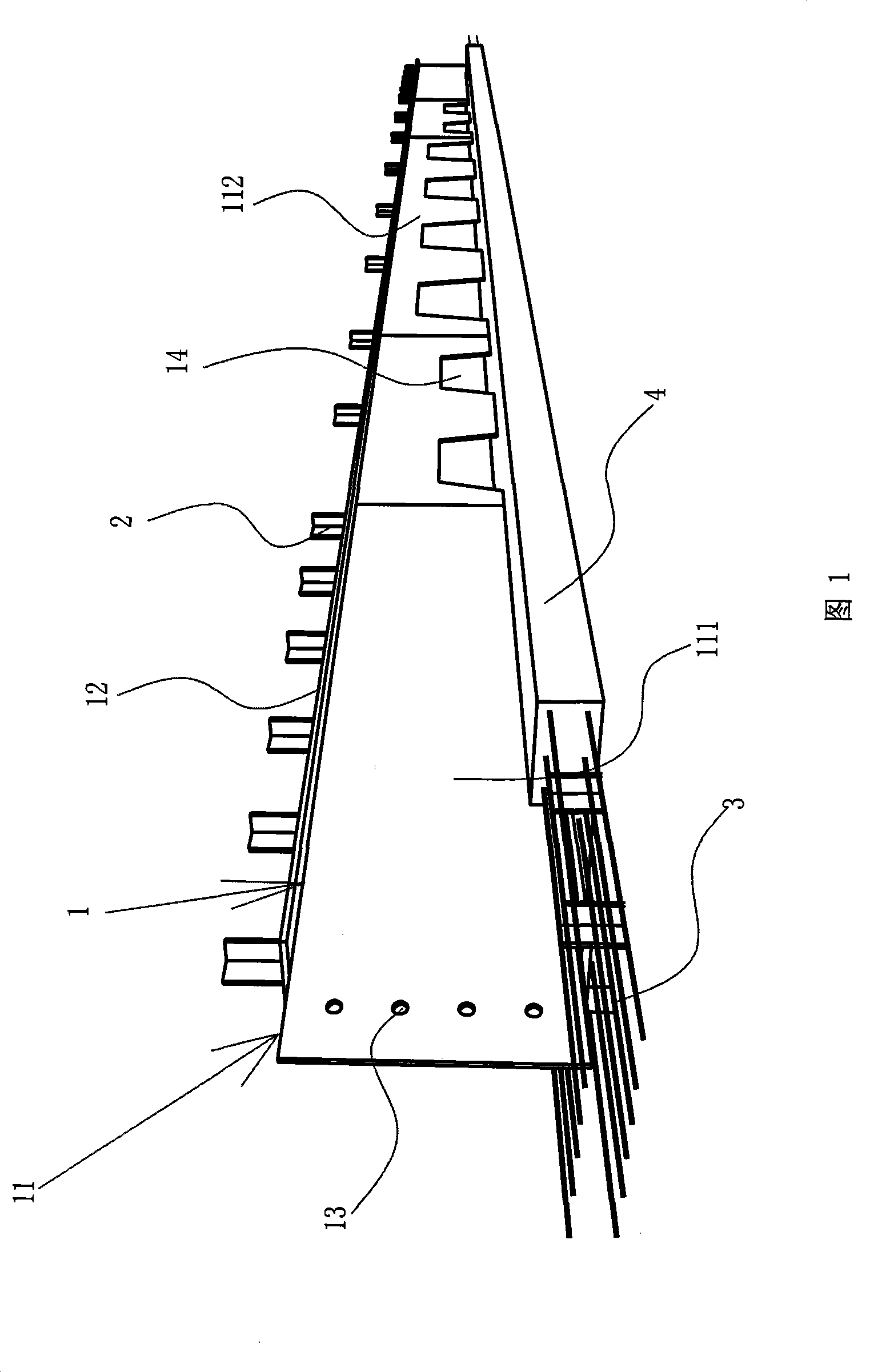

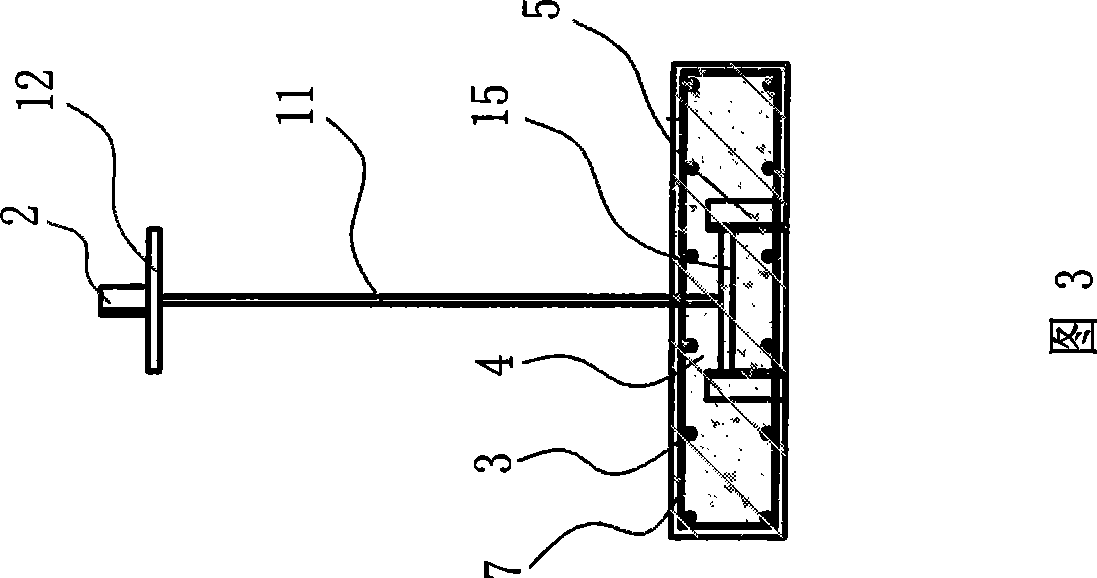

Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

ActiveCN102009387AImprove machining accuracyImprove processing qualityGrinding feed controlMeasurement deviceTangential force

The invention belongs to the ultraprecision machining field of the hard and brittle semiconductor crystalline materials and relates to a grinding force on-line measurement device used in the grinding process of the semiconductor wafer and a force-controlling grinding method. The invention discloses a semiconductor wafer grinding force on-line measurement device which is used as the feedback element of a grinding force adaptive control system. The grinding force measurement device adopts the piezoelectric measuring principle and contains a sensor part and a data processing unit, wherein the sensor part is used for the on-line measurement of the radial force Fr, the tangential force Ft and the axial force Fz; and the data processing unit is used to collect and analyze the grinding force data and perform feedback control to the feed speed and feed amount of the grinding wheel, thus the aim of on-line measurement can be achieved. The invention has the following advantages: the grinding force on-line measurement device has simple structure, and the modifications to the original equipment are less; the grinding force on-line measurement links are fewer, the response speed is fast, and the precision is high; and the grinding efficiency of the semiconductor wafer can be increased and the thickness of the damaged layer is reduced.

Owner:宁波知行半导体有限公司

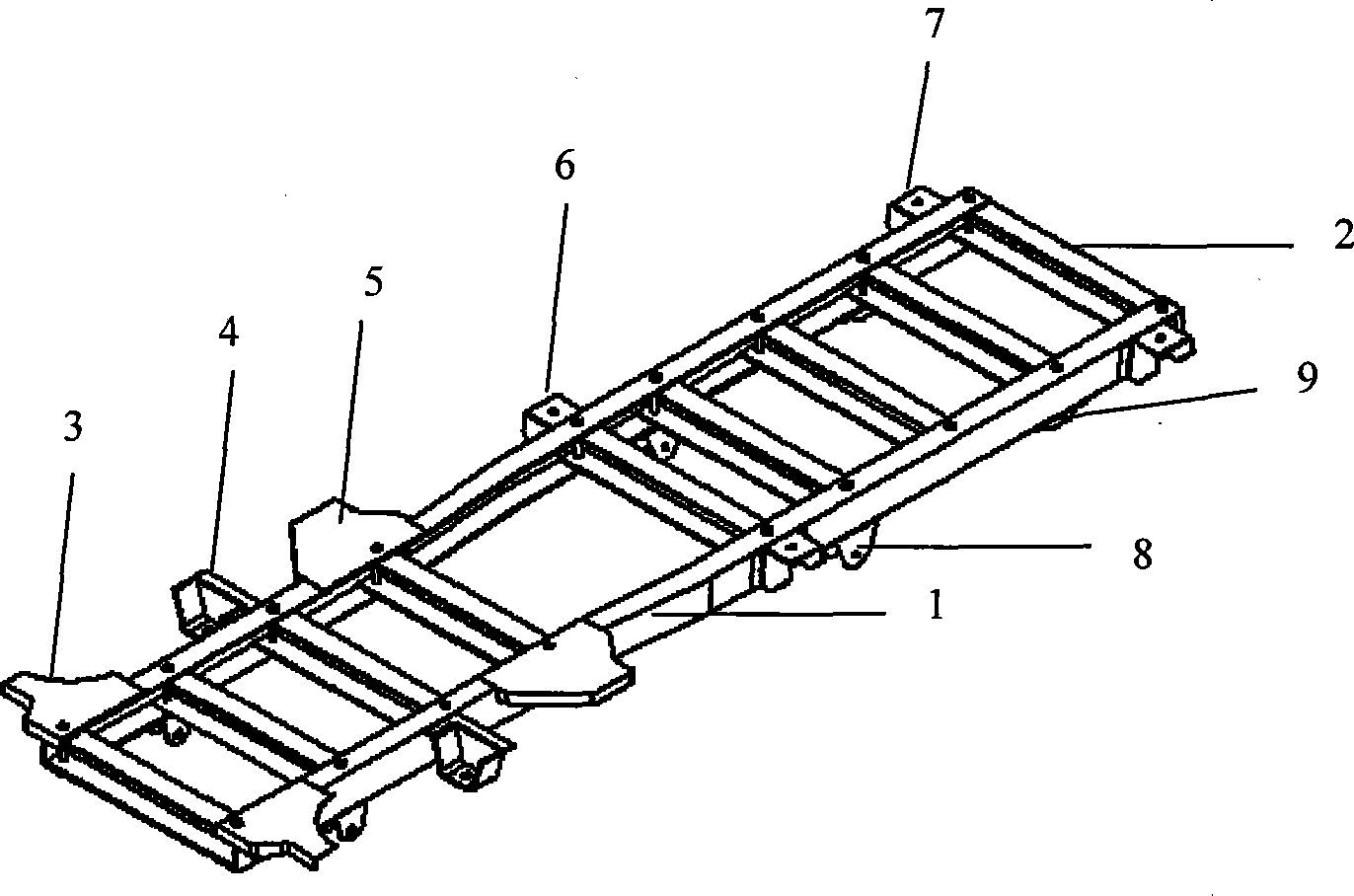

Optimum design method of non-bearing frame structure of light vehicle

InactiveCN104112050AIncreased bending stiffnessIncrease stiffnessSpecial data processing applicationsVehicle frameData file

The invention provides an optimum design method of a non-bearing frame structure of a light vehicle. The optimum design method comprises the steps of establishing a three-dimensional geometrical model of the original frame structure of the light vehicle by use of SolidWorks software and outputting the model in the IGES (Initial Graphics Exchange Specification) data file format, thereby obtaining the IGES model of the frame structure, next, reading the IGES model of the frame structure in Hypermesh software, performing geometrical processing and dividing finite element meshes by use of the Hypermesh software, and performing topological optimization on the cross beam structure of the frame by use of the structure optimization function of the Hypermesh software without changing the structural forms of the longitudinal beam and the attached seats of the frame, thereby realizing the optimum design of the arrangement position and the structural form of the cross beam structure. The optimum design method of the non-bearing frame structure of the light vehicle is capable of improving the bending rigidity and torsional rigidity of the frame of the light vehicle and the inherent frequency of the frame structure without increasing the weight of the frame structure, thereby ensuring that the frame has relatively high overall rigidity and improving the reliability, security, operation stability and vibration property of the vehicle.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

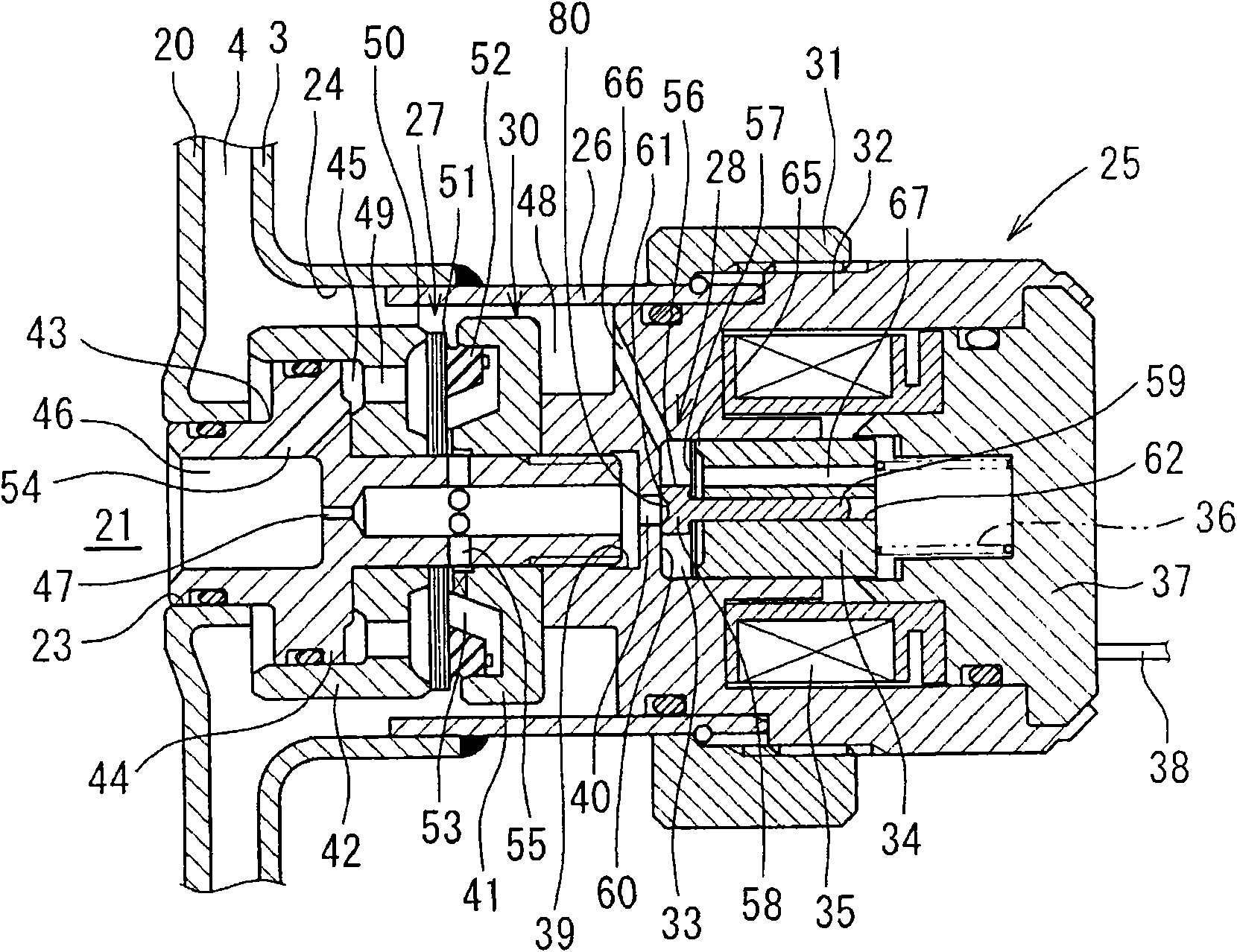

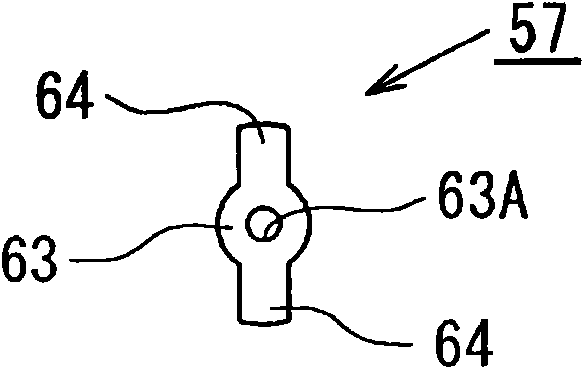

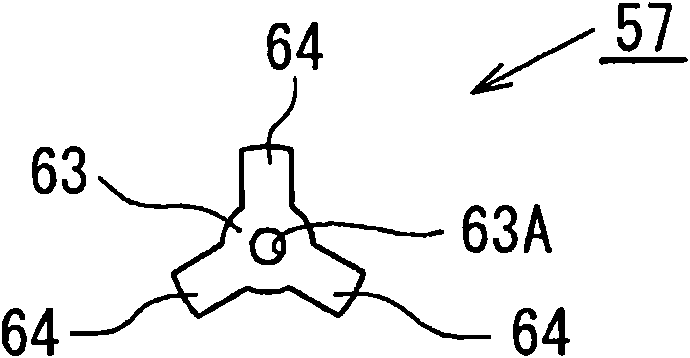

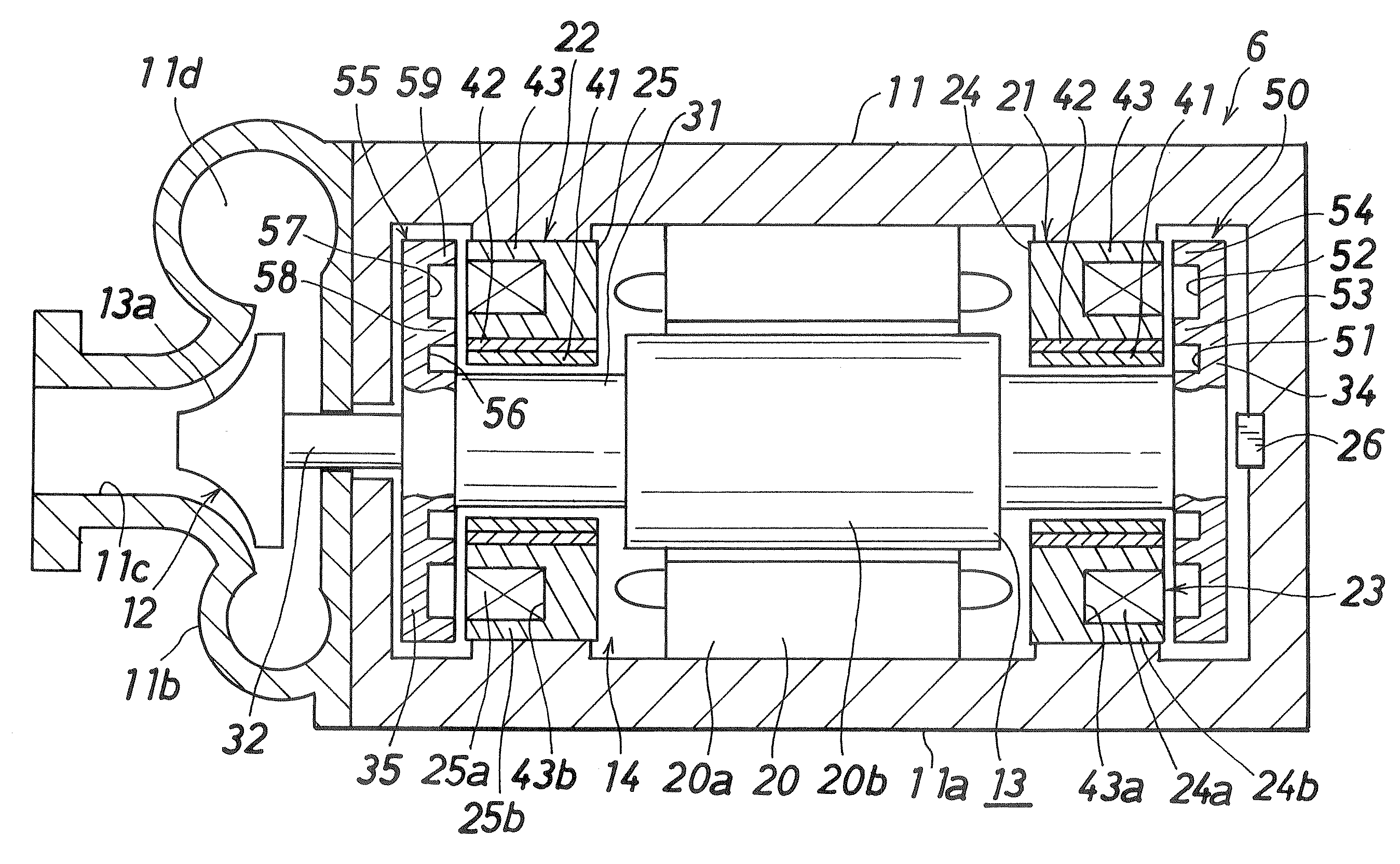

Damping force adjustment type buffer

InactiveCN101550981AImprove responsivenessRaise the natural frequencySpringsLiquid based dampersSelf excitedEngineering

The invention relates to a damping force adjustment type buffer, capable of preventing the response delay of a pressure control valve and the self-excited vibration of the valve. The buffer controls the flow of the oil liquor between a ring oil line (21) and an oil storage chamber (4) generated by the slide of an inner piston of a hydraulic cylinder by a back pressure main valve (27) and a pressure control valve (28) to generate damping force. The direct damping force is generated by the pressure control valve (28) and the inner pressure of a back pressure chamber (53) is adjusted to control the valve opening pressure of the main valve 927). A valve spring (57) is mounted between a valve (56) and a plunger (34) in the pressure control valve (28) and the weight of the valve (56) is fully less than the weight of the plunger (34) and the spring rigid of the valve spring (57) is higher than the spring rigid of the plunger spring (36). Thus the response of the valve (56) is increased and the response delay of the damping force control is prevented. In addition, the natural frequency of the valve (56) is increased therefore the generation of the self-excited vibration is prevented.

Owner:HITACHI LTD

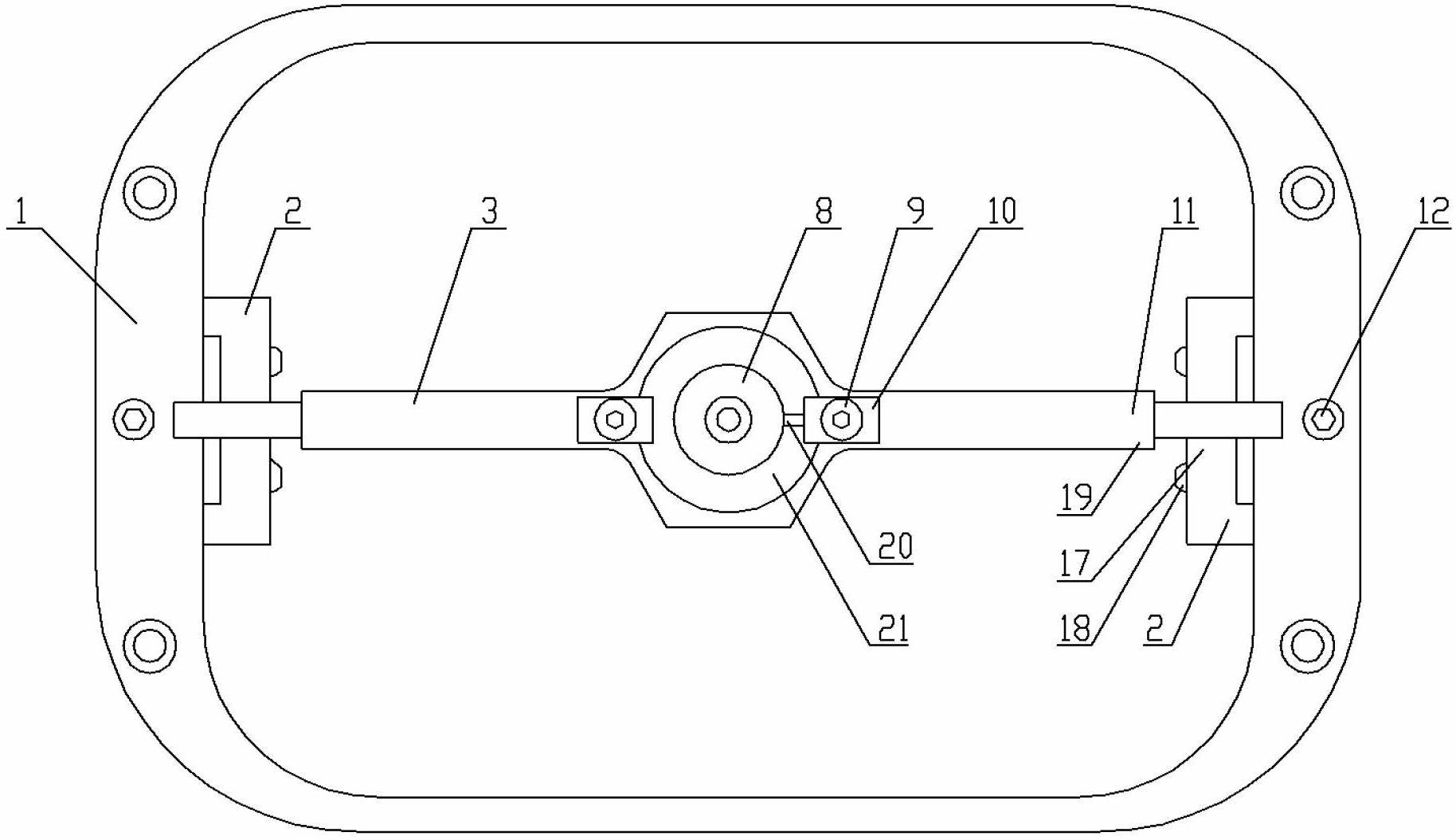

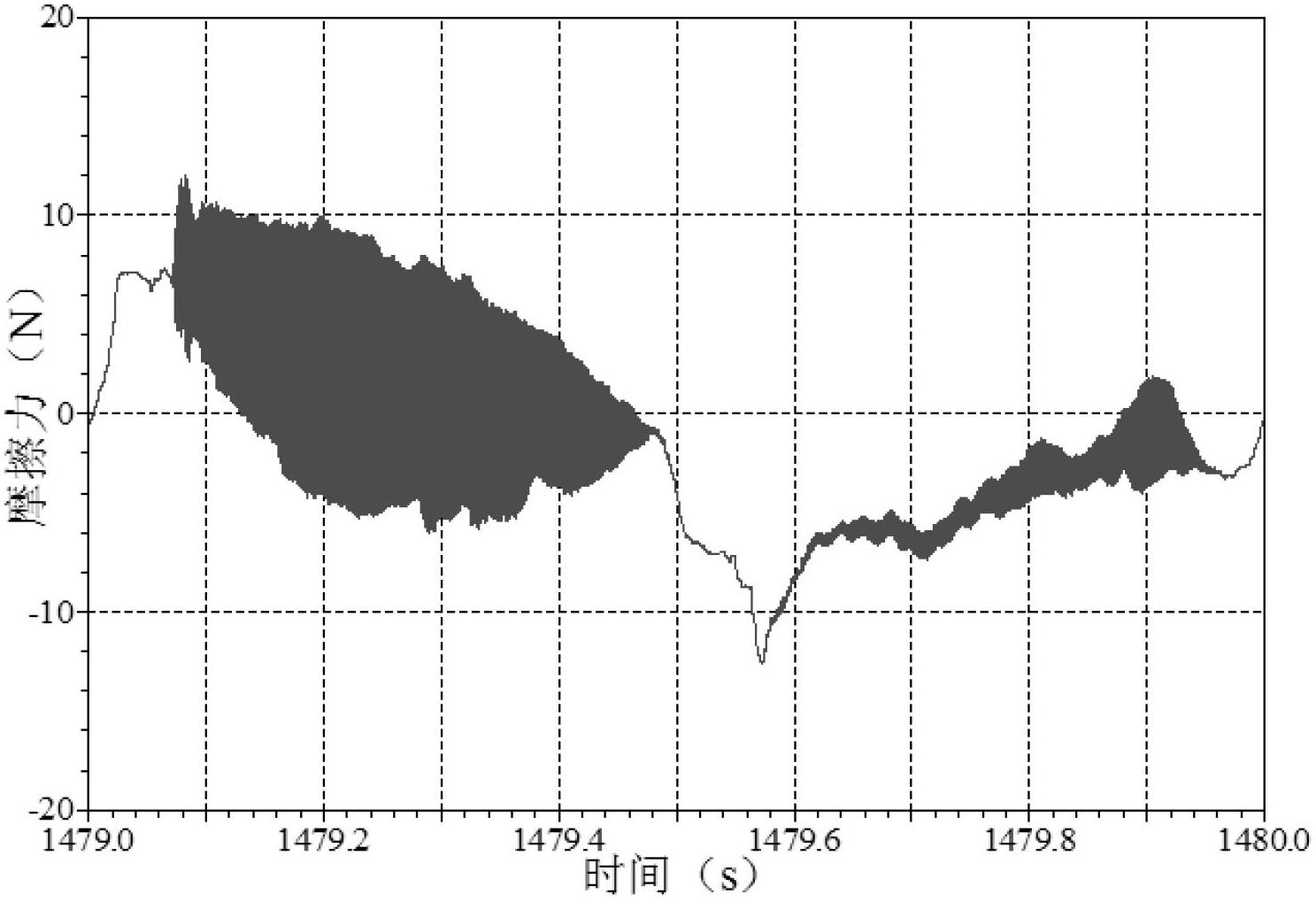

Method for testing and analyzing frictional noise and test device for method

InactiveCN102680083ASimple designEasy to useAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementVibration accelerationEngineering

The invention discloses a method for testing and analyzing frictional noise and a test device for the method. The method comprises that: a lower fixture clamping a lower friction part is fixed onto a reciprocating device; an upper fixture clamping an upper friction part penetrates through a horizontal support to contact with the bottom of a strain force sensor; a three-dimensional acceleration sensor is mounted on the upper fixture; two ends of the horizontal support are fixed onto support bases by piezoelectric force sensors; and the strain force sensor is fixed to the bottom of a two-dimensional moving table. A sensing end of an acoustic sensor is close to a contact interface of the upper friction part and the lower friction part, and the two-dimensional moving table is controlled so that the upper friction part and the lower friction part are controlled to do reciprocating friction motion, and the three sensors accurately, synchronously and dynamically acquire the frictional noise,vibration acceleration and frictional force and analyze the frictional noise, the vibration acceleration and the frictional force in real time. Therefore, mutual relation and influencing law of the frictional noise, the interface and characteristics of a system are accurately analyzed, a mechanism of production of the frictional noise is disclosed, and a more accurate and reliable test basis is provided for realizing noise-reduction design for mechanical equipment, improving performance of the mechanical equipment and prolonging the service life of the mechanical equipment.

Owner:SOUTHWEST JIAOTONG UNIV

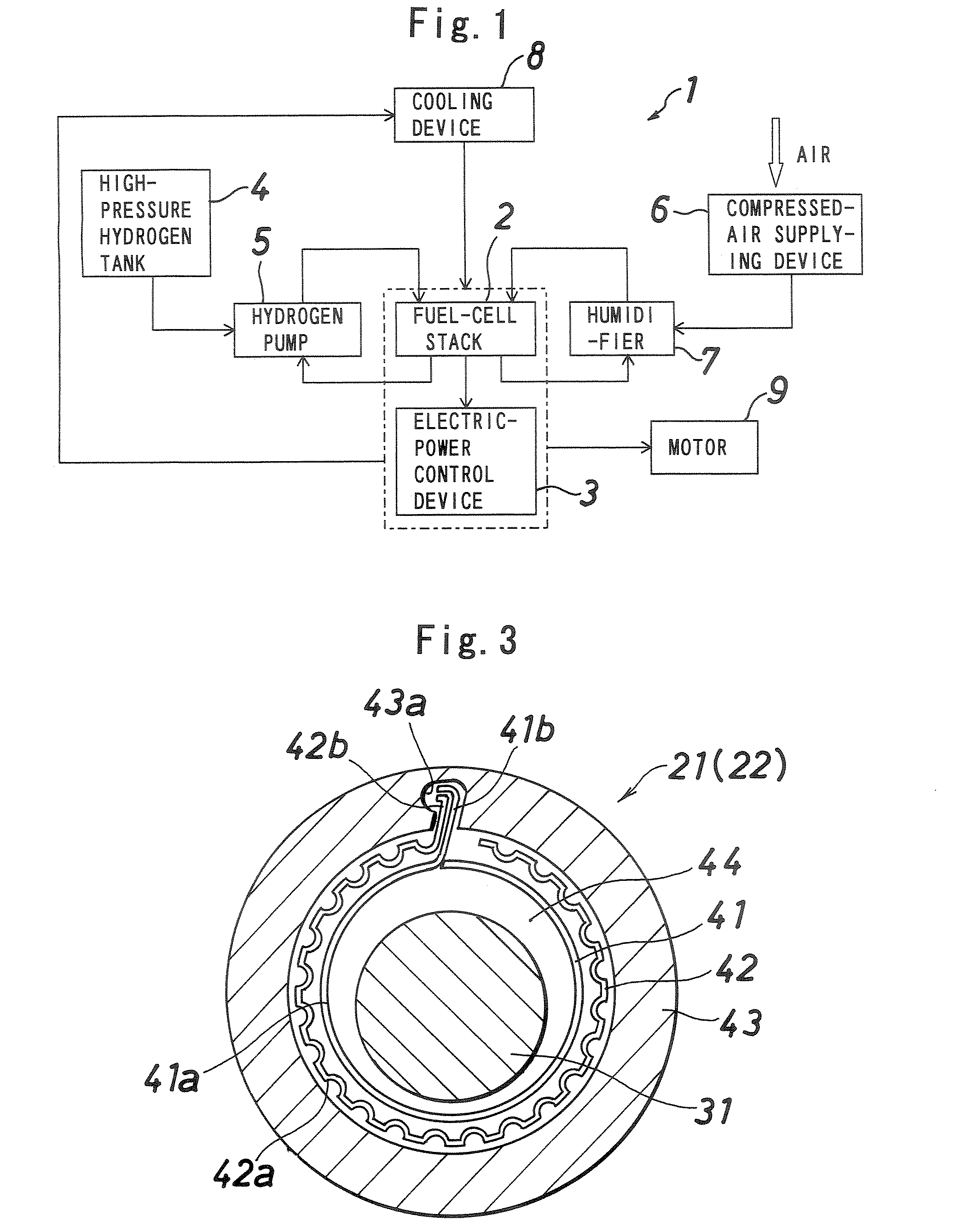

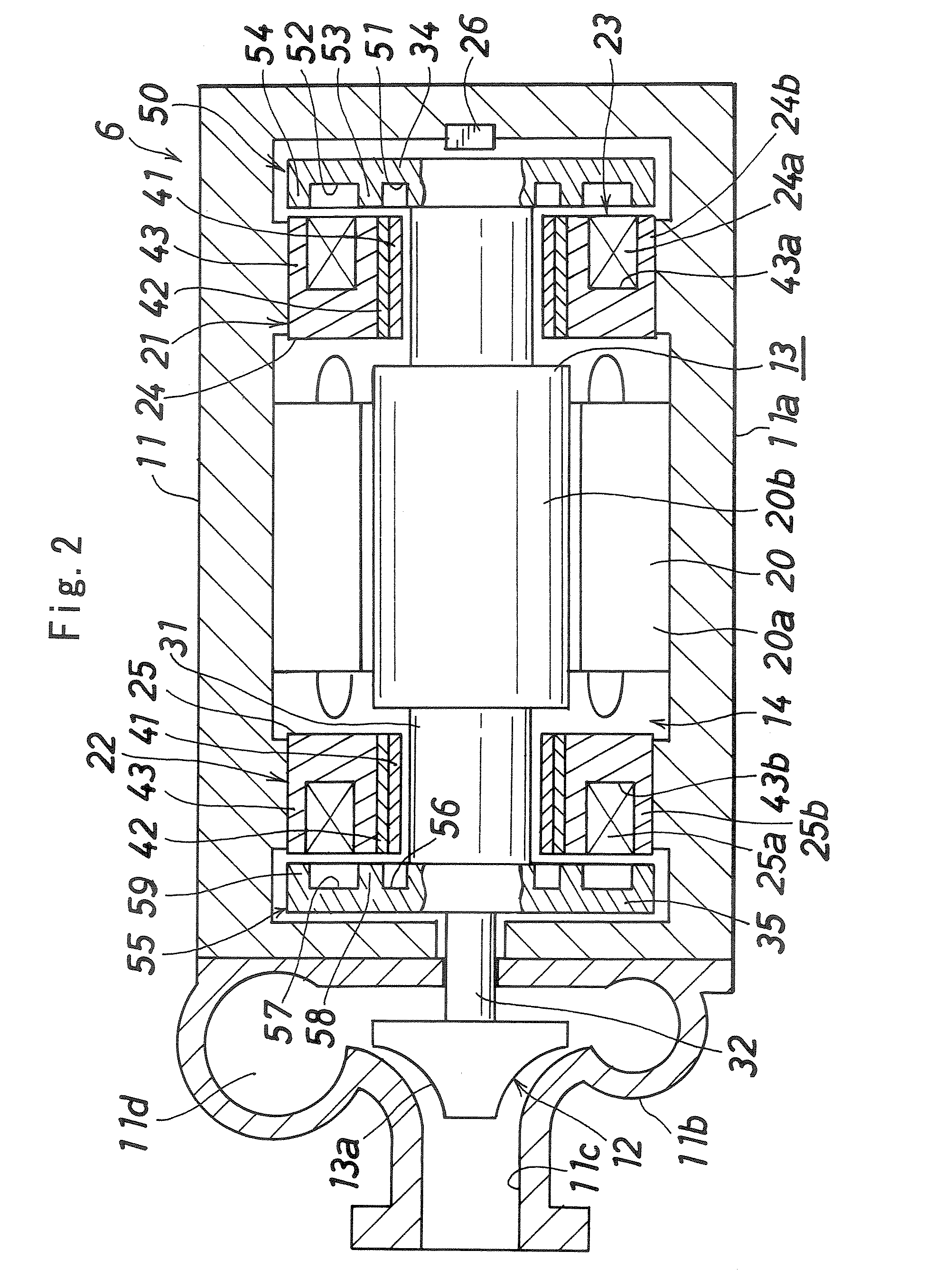

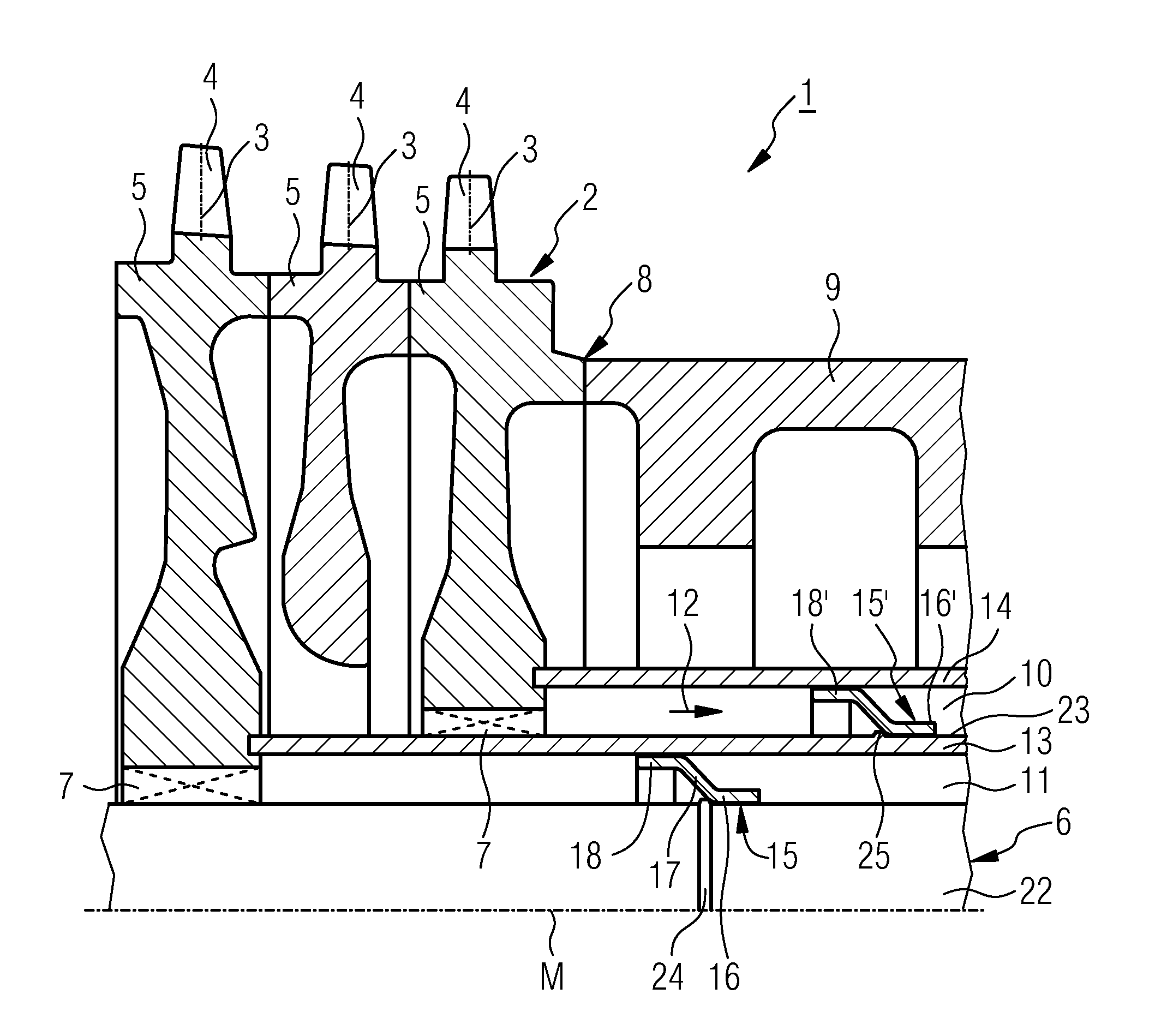

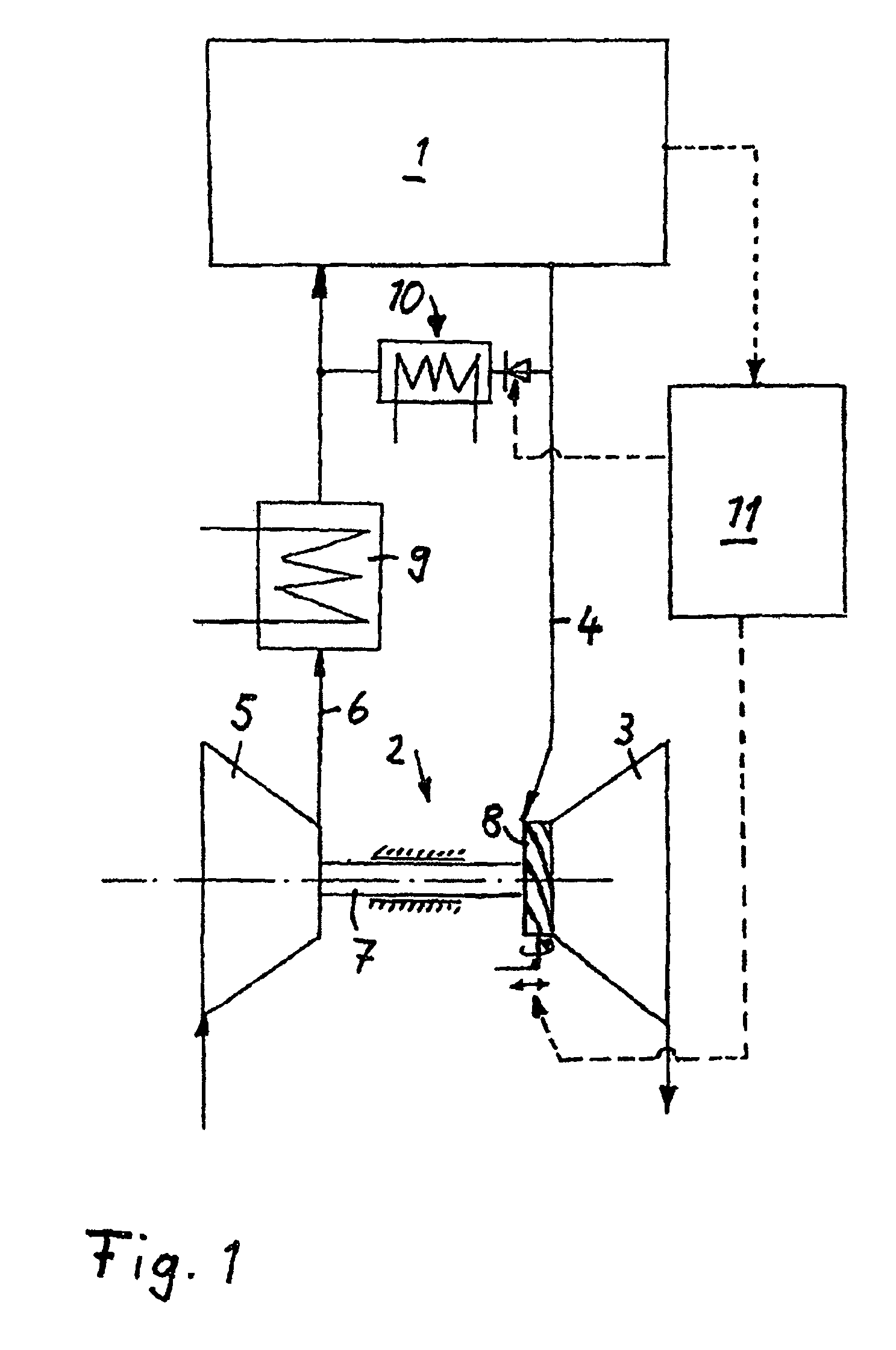

Fuel-cell compressed-air supplying device

A fuel-cell compressed-air supplying device 6 includes a centrifugal compressor 12 provided in a casing 11, and a bearing device 14 for supporting a rotation shaft 13 of the compressor 12. The bearing device 14 includes a pair of radial foil bearings 21 and 22 provided coaxially with the rotation shaft 13 for supporting the rotation shaft 13 in the radial direction, and an axial magnetic bearing 23 facing to the rotation shaft 13 in the axial direction for supporting the rotation shaft 13 in the axial direction. Axial electromagnets 24 and 25 of the axial magnetic bearing 23 are integrated with the radial foil bearings 21 and 22, respectively.

Owner:JTEKT CORP

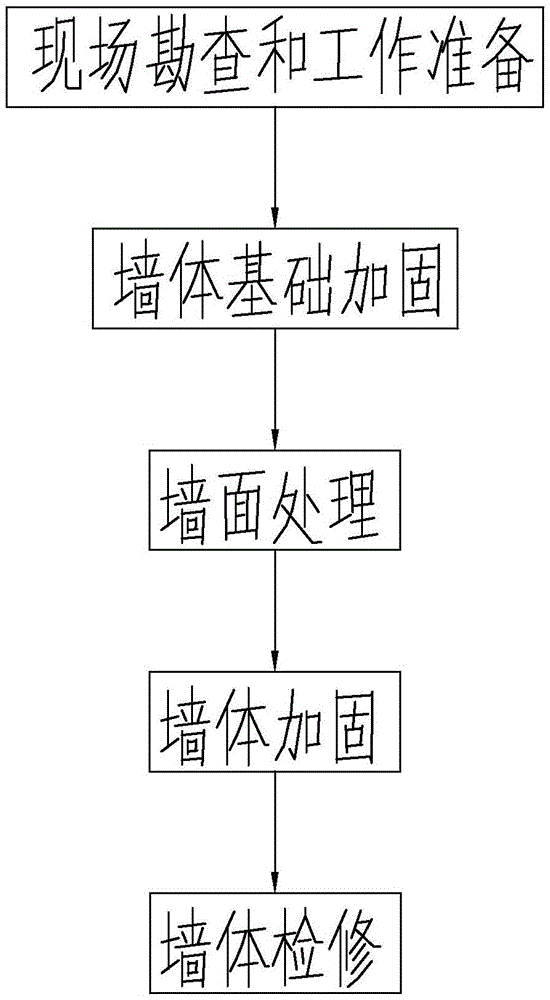

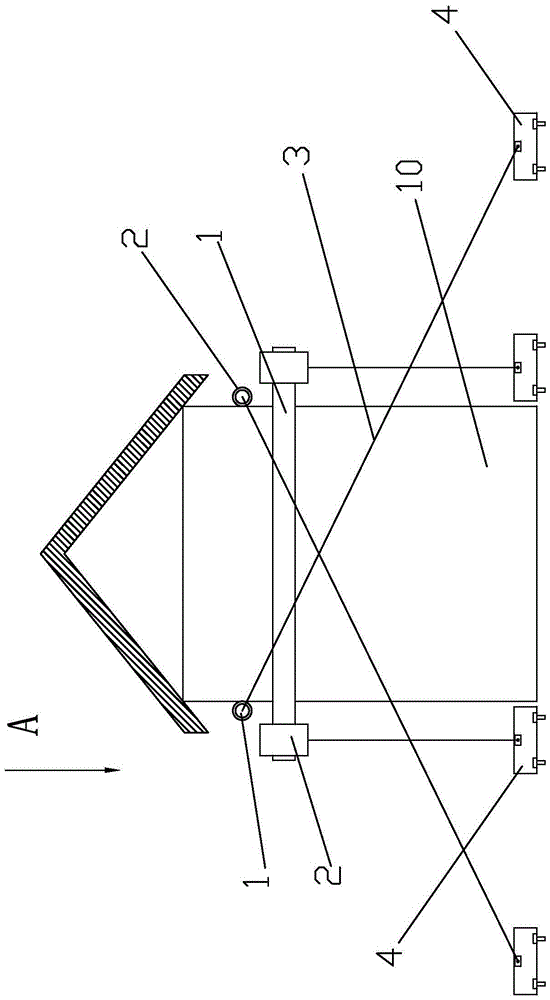

Construction method for reinforcing and repairing integral wall of ancient architecture

InactiveCN105604343ASimple construction methodEasy to implementBuilding repairsBearing capacityBuilding construction

The invention discloses a construction method for reinforcing and repairing an integral wall of ancient architecture. The construction method comprises the steps of site survey and work preparation, wall foundation reinforcement, wall surface treatment, wall reinforcement and wall maintenance. The construction method is simple and easy to implement, scientific and convenient, and has the advantages of fast construction progress, low construction cost, high working efficiency and wide application range. According to the principle of 'repairing the old as the old', the cultural relic value of ancient architectural elements is kept, only damaged parts are repaired and reinforced, and the whole wall does not need to be replaced. The ancient architecture wall is priceless in cultural relic value. By using the method, original parts can be kept when the ancient architecture wall is damaged and loses bearing capacity, and a bearing function is recovered; the method conforms to the principle of 'repairing the old as the old', and is of great significance to the protection of the national cultural relics.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Differential wideband vibration sensor

InactiveUS6220096B1Eliminates costly precision tuningIncrease capacitanceVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringField-effect transistor

This invention relates to an apparatus for making highly sensitive differential measurements of acceleration. The vibration sensor includes the use of moveable gate field effect transistors to sense the motion of a cantilever beam relative to the motion sensed by a reference structure, it also includes an actuator element formed by a pair of electrodes actuating electrostatically on the beam. A feedback control loop is also included for force balance operation resulting in a very wide dynamic range for the sensor.

Owner:INTERSCI

Integrated actuator meniscus mirror

An integrated actuator meniscus mirror includes an optical substrate having a mirror surface on one side and a support structure on the other and a plurality of actuators embedded in the support structure, spaced from and generally parallel to the mirror surface for applying bending moments to the mirror surface for controllably altering the shape of the mirror surface.

Owner:NORTHROP GRUMMAN SYST CORP

Beam and groove combined stepped island film micropressure sensor chip and manufacturing method thereof

ActiveCN104729784AHigh sensitivityGuaranteed nonlinear indexFluid pressure measurement using ohmic-resistance variationSemi openOhmic contact

The invention relates to a beam and groove combined stepped island film micropressure sensor chip and a manufacturing method thereof. The chip comprises a thin film in the middle of a substrate, four shallow grooves are formed along the edges of the upper portion of the thin film, four embossment beams are arranged between the ends of the adjacent shallow grooves and connected with the substrate, and the upper surfaces of the embossment beams, the upper surface of the thin film and the bottom faces of the shallow grooves form a beam and groove combined stepped thin film structure; four piezoresistor strips are arranged on the four embossment beams and connected through metal leads into semi-open-loop Wheatstone bridges, and the output ends of the bridges are connected with bonding pads; four bumps are evenly distributed along the edges of the lower portion of the thin film and connected with the substrate; four mass blocks are spaced from the bumps, and the bumps are connected to the thin film. The manufacturing method includes the steps that the piezoresistor strips are made of SOI silicon wafers in an oxidized mode at high temperature, and an Ohmic contact region is obtained to manufacture the metal leads and the bonding pads; then the four embossment beams and the shallow grooves are manufactured, and the back face of the substrate and anti-overload glass are bonded. The beam and groove combined stepped island film micropressure sensor chip has the advantages of being high in sensitivity and linearity and the like.

Owner:XI AN JIAOTONG UNIV

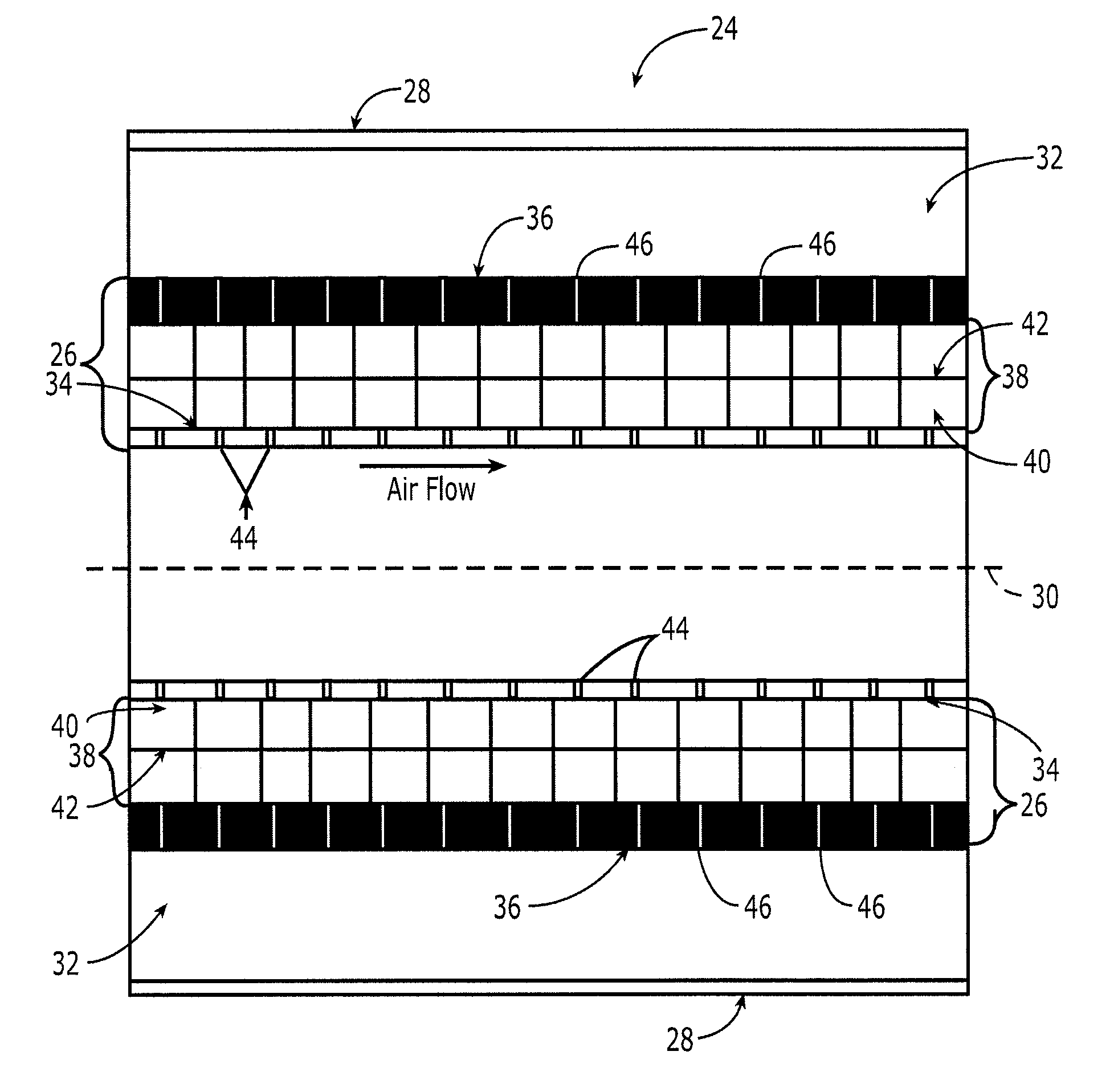

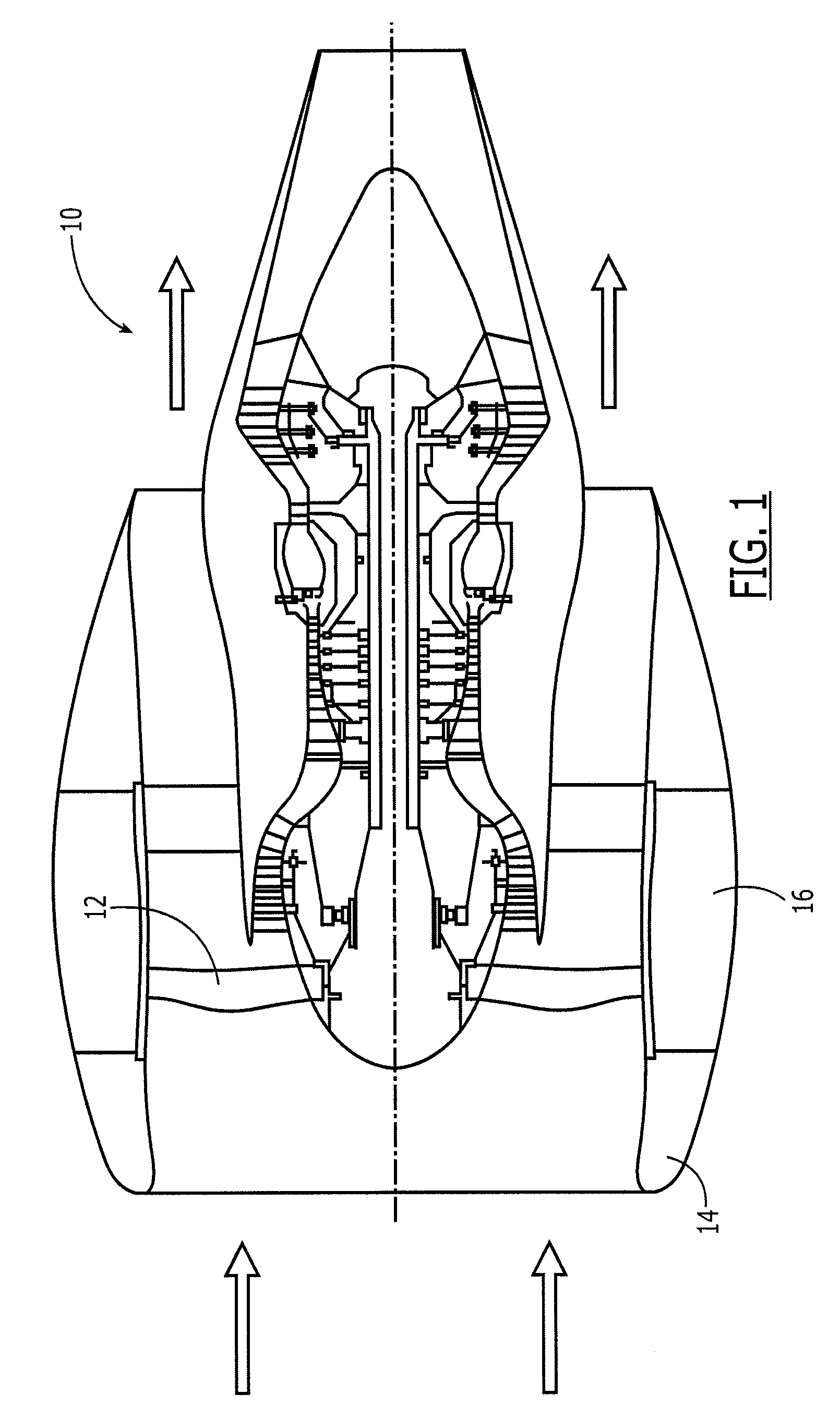

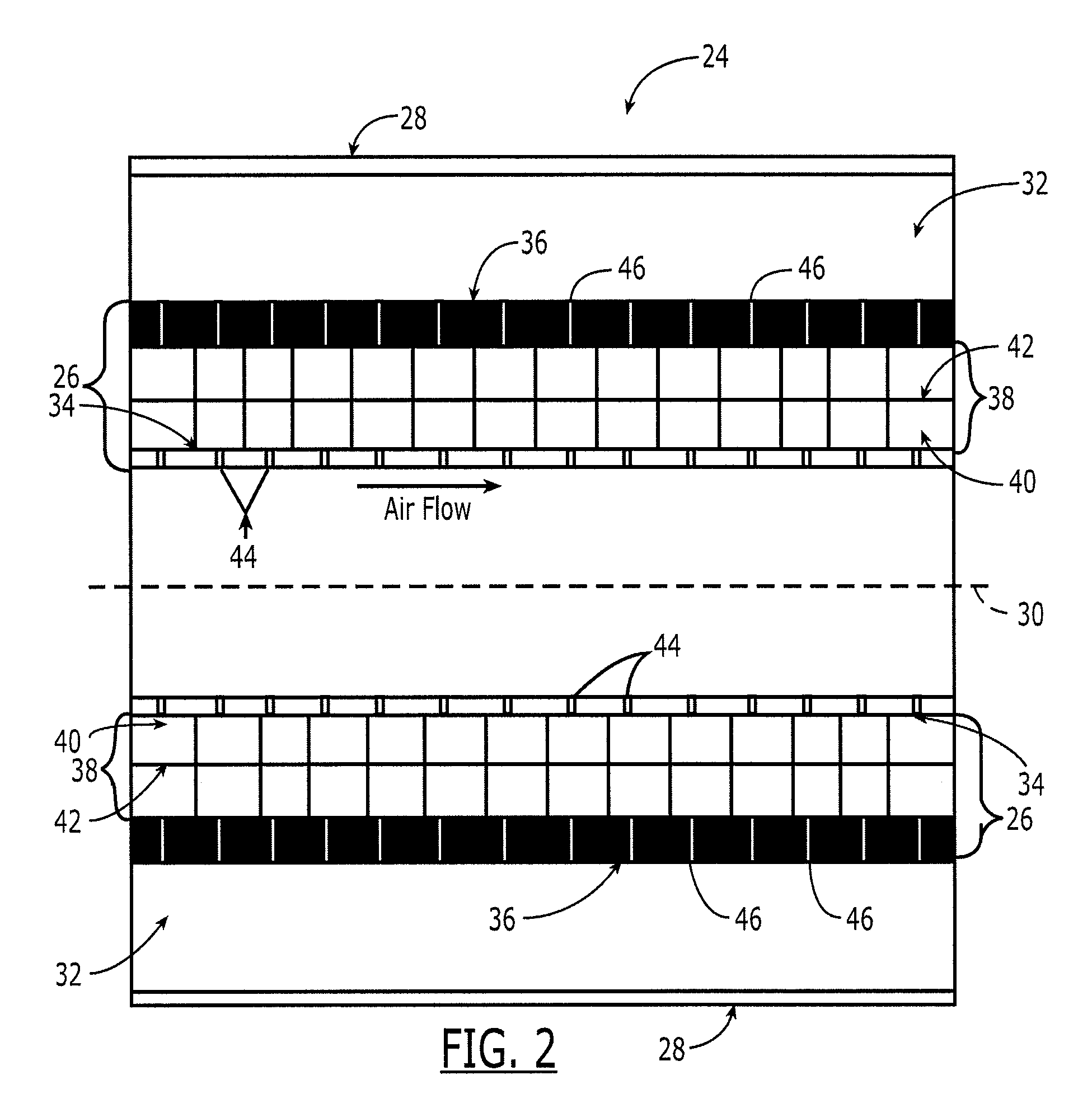

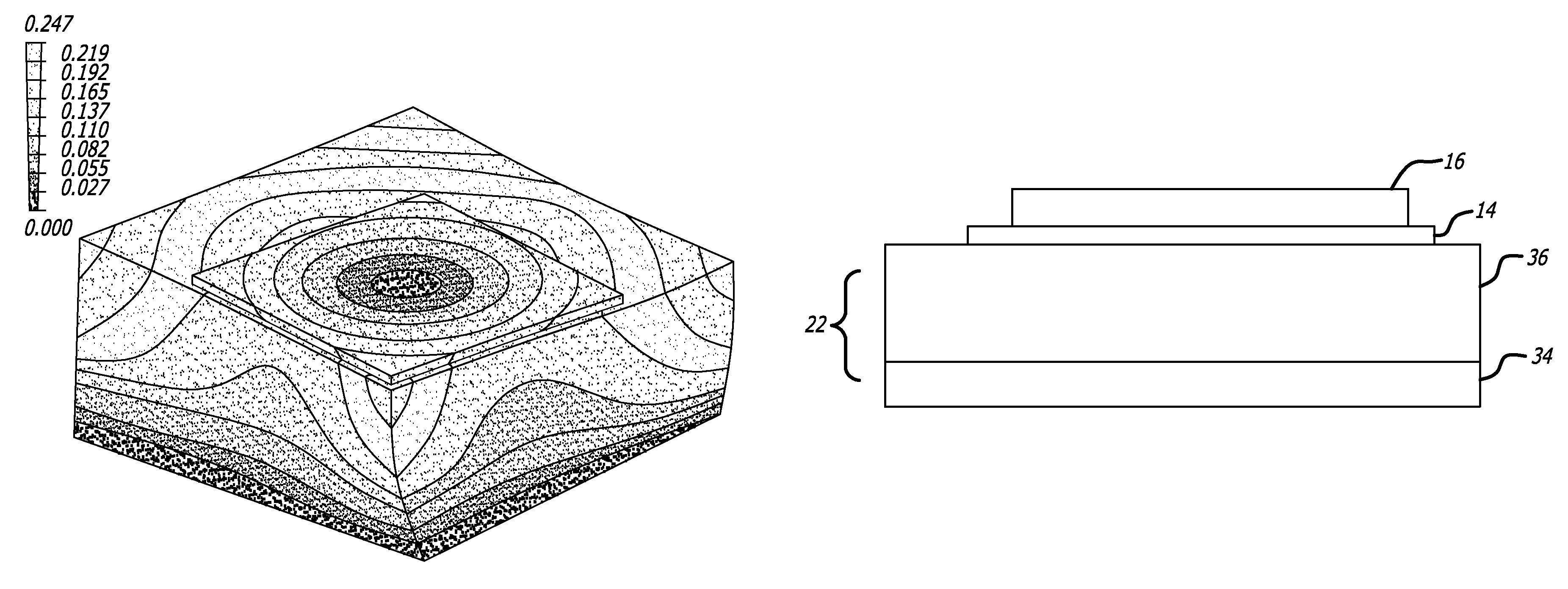

Engine assembly, acoustical liner and associated method of fabrication

ActiveUS7870929B2Weight increaseAvoid discontinuitiesRecord carriersPower plant arrangements/mountingNoise controlEngineering

An engine assembly, an acoustical liner and an associated fabrication method are provided to address fan blade flutter and fan noise control simultaneously within the same liner area. Fan blade flutter is therefore controlled without necessarily increasing the weight of the engine, impairing the structural integrity of the engine, or increasing the noise generated by the engine. The acoustical liner may have additional acoustical degrees of freedom which permit these seemingly competing concerns to be addressed in a complementary manner. The acoustical liner may include inner and outer barrels with the inner barrel having a perforated face sheet, a perforated back skin and a core disposed between the perforated face sheet and the back skin. The fluid communication between the core and the space between the inner and outer barrels provides additional acoustical degrees of freedom which may be utilized to reduce fan blade flutter while concurrently limiting fan blade noise.

Owner:THE BOEING CO

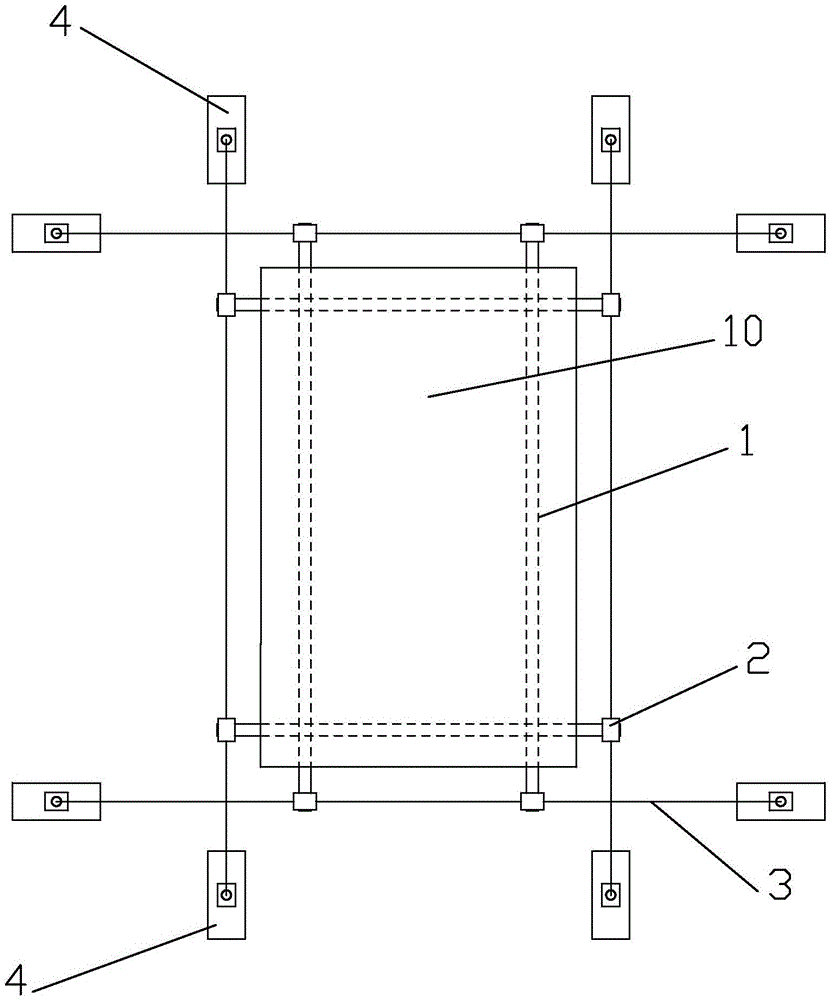

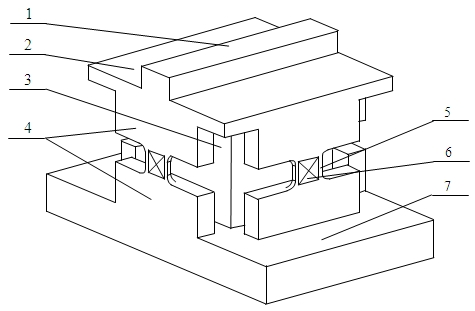

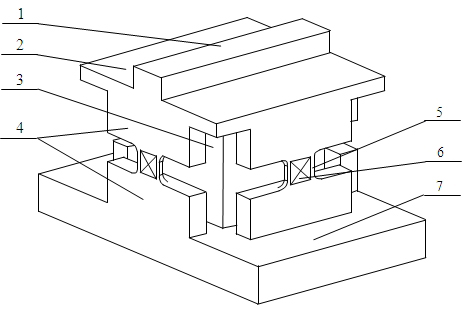

Ultra-high speed cutting three-dimensional dynamic force test platform

InactiveCN102267069ARaise the natural frequencyLower natural frequencyMeasurement/indication equipmentsClassical mechanicsEngineering

The invention discloses a three-dimensional dynamic force test platform for ultra-high-speed cutting, which includes a structure to be cut, four resistance strain gauge groups, an integrally formed upper surface platform, an elastic cylinder, eight elastic thick slices, four elastic thin slices, a support The base; the elastic cylinder is located on the supporting base; 8 elastic slabs are in pairs, 4 elastic sheets correspond to 4 groups of elastic slabs one by one, and the two ends of the elastic sheets are respectively connected to two elastic slabs in each group. One end of the sheet constitutes 4 elastic groups, and the 4 elastic groups are respectively located around the elastic cylinder, and the other ends of the two elastic slabs in each elastic group are respectively connected to the support base and the upper surface platform; the upper surface platform is located on The upper part of the elastic cylinder and the elastic group is connected with the elastic cylinder; the structure to be cut is arranged on the upper surface platform; the resistance strain gauge group is respectively fixed at the middle position of the four elastic sheets. This kind of test platform can meet the requirements of ultra-high speed cutting force signal measurement, and realize the accurate measurement of three-dimensional dynamic force.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

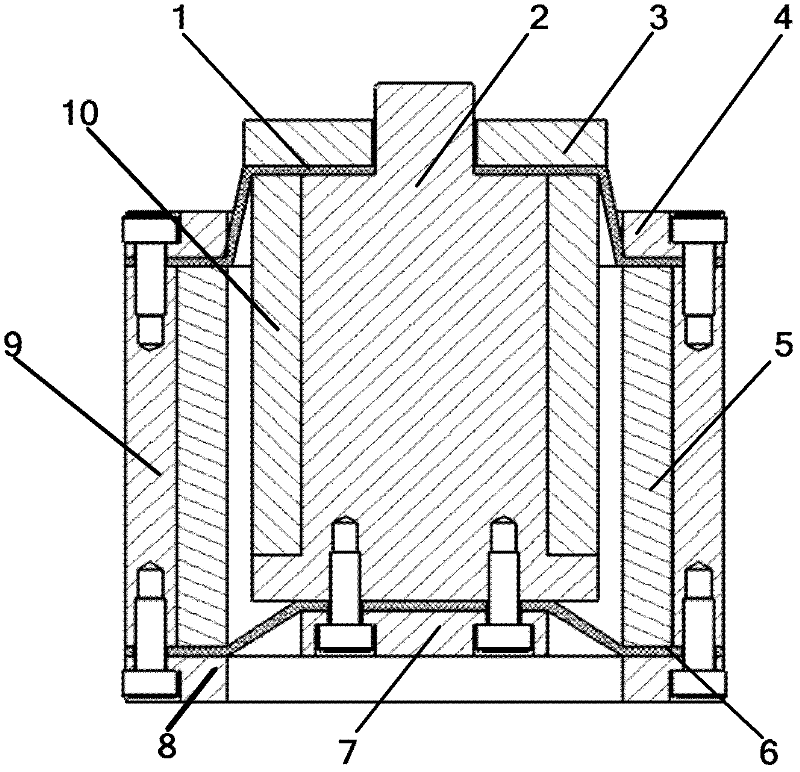

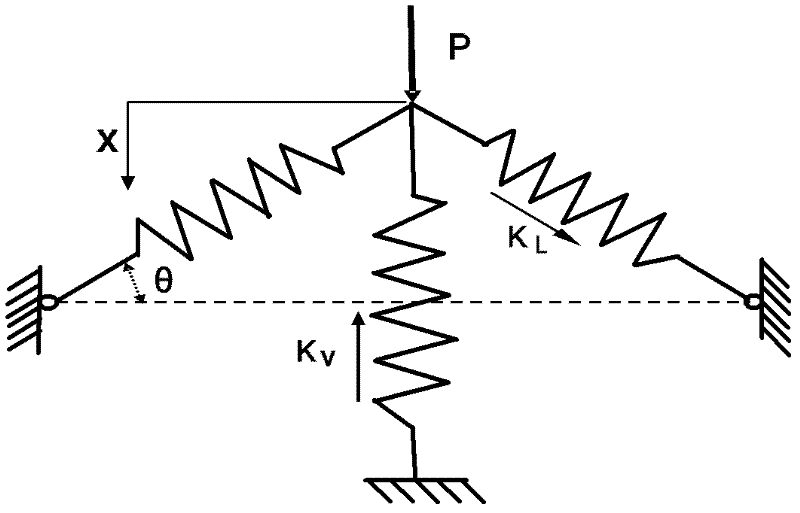

Permanent magnet low frequency single-degree-of-freedom vibration isolation mechanism based on negative stiffness theory

ActiveCN102506110AGood vibration isolationSimple structureSprings/dampers functional characteristicsMagnetic springsThree degrees of freedomSingle degree of freedom

The invention discloses an annular permanent magnet low frequency vibration isolation mechanism based on a negative stiffness theory. The mechanism comprises an upper rubber sheet, an inner annular permanent magnet fixing mandrel, an upper rubber sheet upper pressing ring, an upper rubber sheet outer pressing ring, an outer annular permanent magnet, a lower rubber sheet, a lower rubber sheet inner pressing sheet, a lower rubber sheet outer pressing ring, an outer annular permanent magnet fixing sleeve and an inner annular permanent magnet, wherein the inner annular permanent magnet is magnetized axially; the outer annular permanent magnet is radially magnetized; a positive stiffness system consists of the inner annular permanent magnet and the outer annular permanent magnet; a negative stiffness system consists of the upper rubber sheet and the lower rubber sheet; and the positive stiffness system and the negative stiffness system are used in parallel to form the low frequency vibration isolation mechanism. Three or four single-degree-of-freedom vibration isolation mechanisms are used in parallel to realize three-degree-of-freedom low frequency vibration isolation. When the vibration isolation mechanism has the largest magnetic force, the stiffness of the vibration isolation mechanism approximates to zero. Without an outside air source, the vibration isolation mechanism has a prospect of being used in vacuum, has the characteristics of simple structure and low cost, is easy to process, and can be applied to the fields of optics, acoustics, biologics, semiconductor manufacturing, precise measurement and the like.

Owner:TSINGHUA UNIV +1

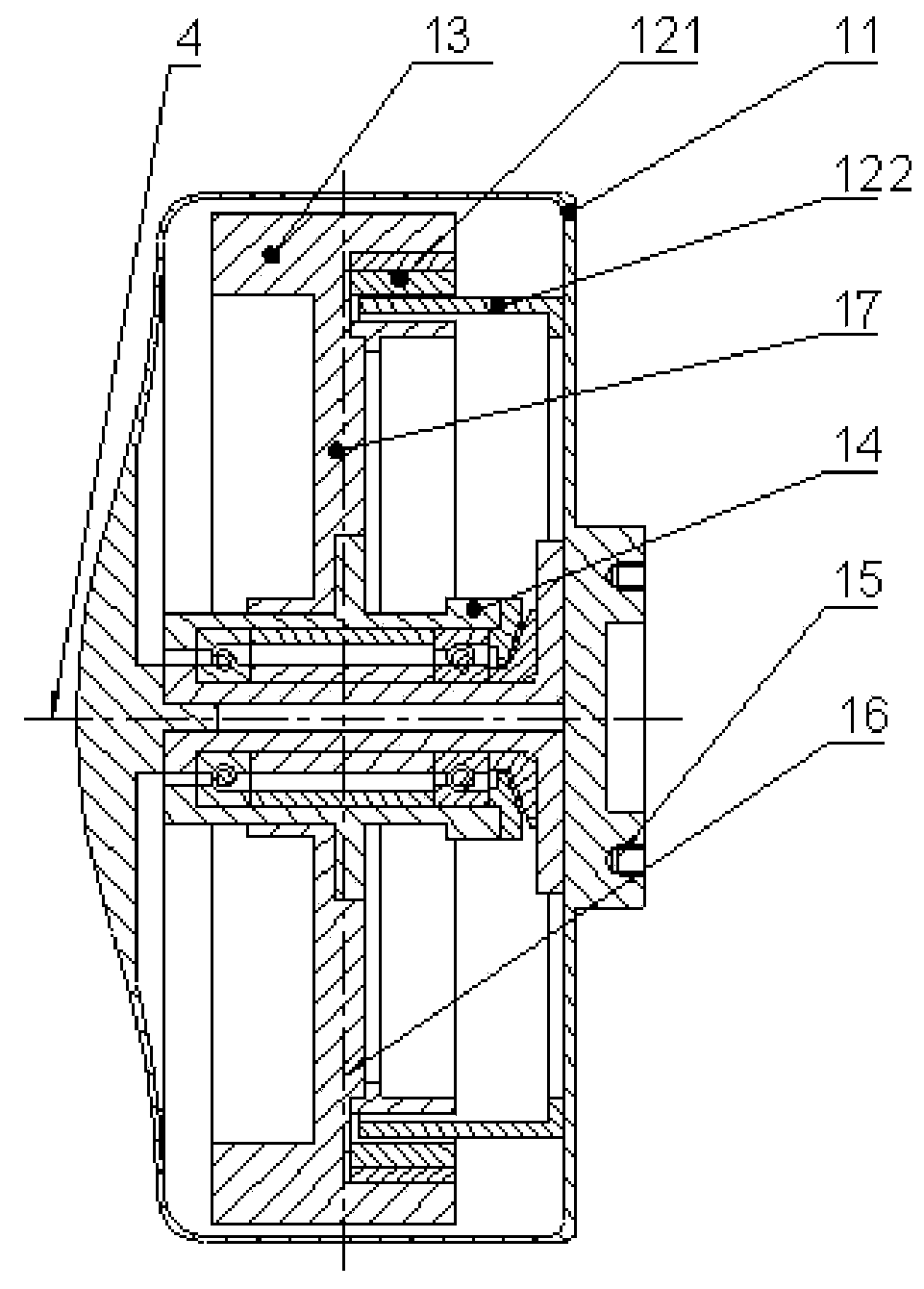

Small-size speed change control moment gyroscope

InactiveCN104075700AIncrease moment of inertia/mass ratioFirmly connectedRotary gyroscopesGyroscopeLow speed

The invention discloses a small-size speed change control moment gyroscope, and belongs to the technical field of control moment gyroscopes. The small-size speed change control moment gyroscope comprises a high-speed component, a connection bracket and a low-speed component, wherein the high-speed component supplies constant angular momentum in a control moment gyroscope mode and outputs fine moment required by whole satellite attitude control in a flywheel mode; the connection bracket is connected with the high-speed component and the low-speed component and guarantees the orthogonal perpendicularity between the angular momentum direction and the axial direction of a framework; the low-speed component supports the high-speed component and the connection bracket and supplies a mounting interface for a whole satellite; in the control moment gyroscope mode, large moment which is required by fastmoving of the whole satellite and is also orthogonal to the angular momentum direction and the axial direction of the framework is generated; in the flywheel mode, the fine moment output by the high-speed component is transmitted to the whole satellite for the attitude control. The speed change control moment gyroscope disclosed by the invention realizes the high-precision framework locking, the minimization, the light weight and the high rigidity, and is suitable for the application to small quick satellites.

Owner:BEIJING INST OF CONTROL ENG

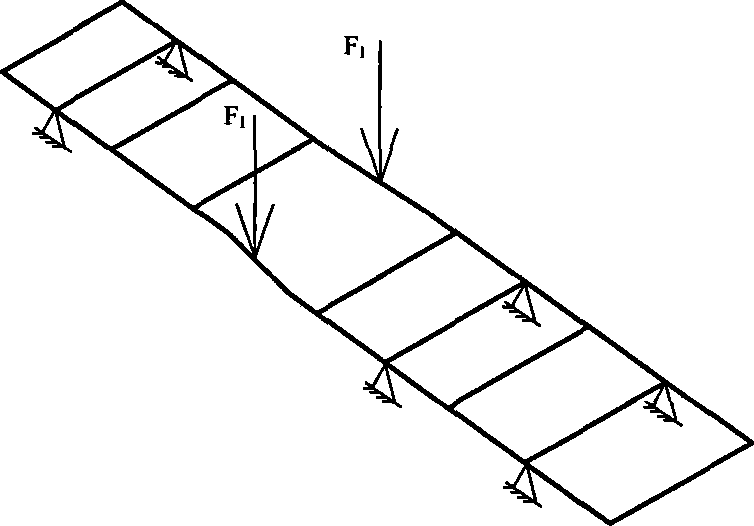

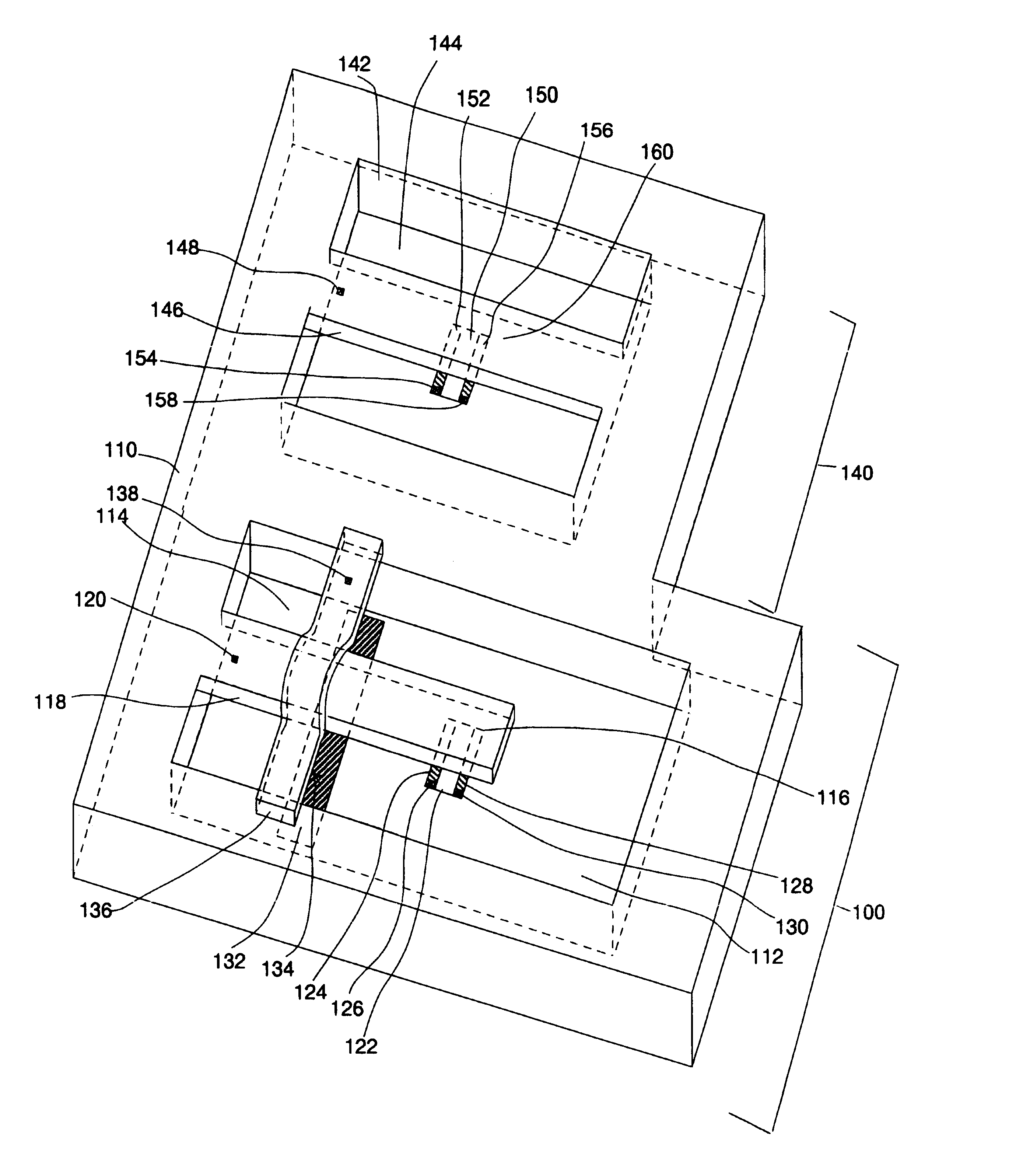

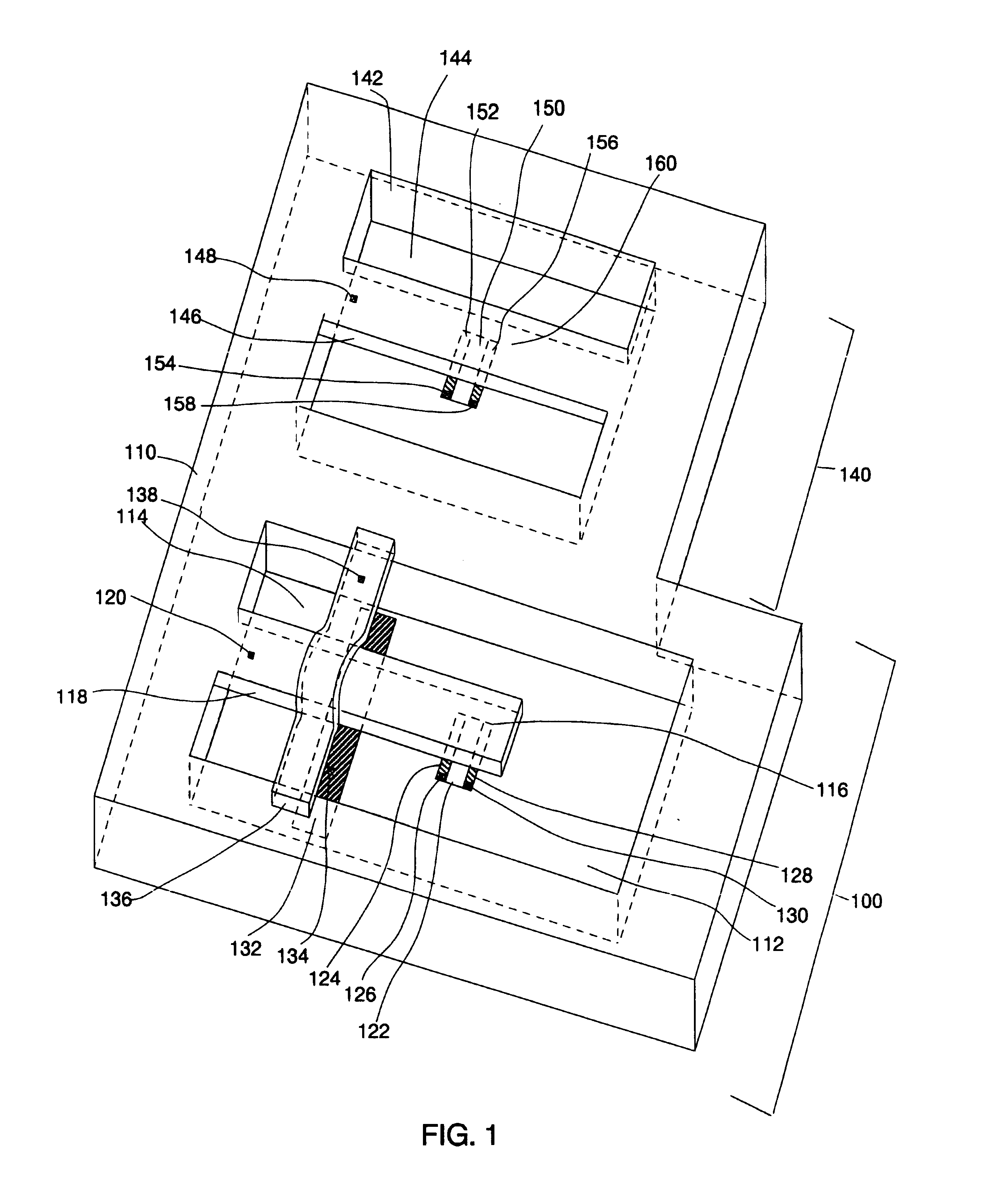

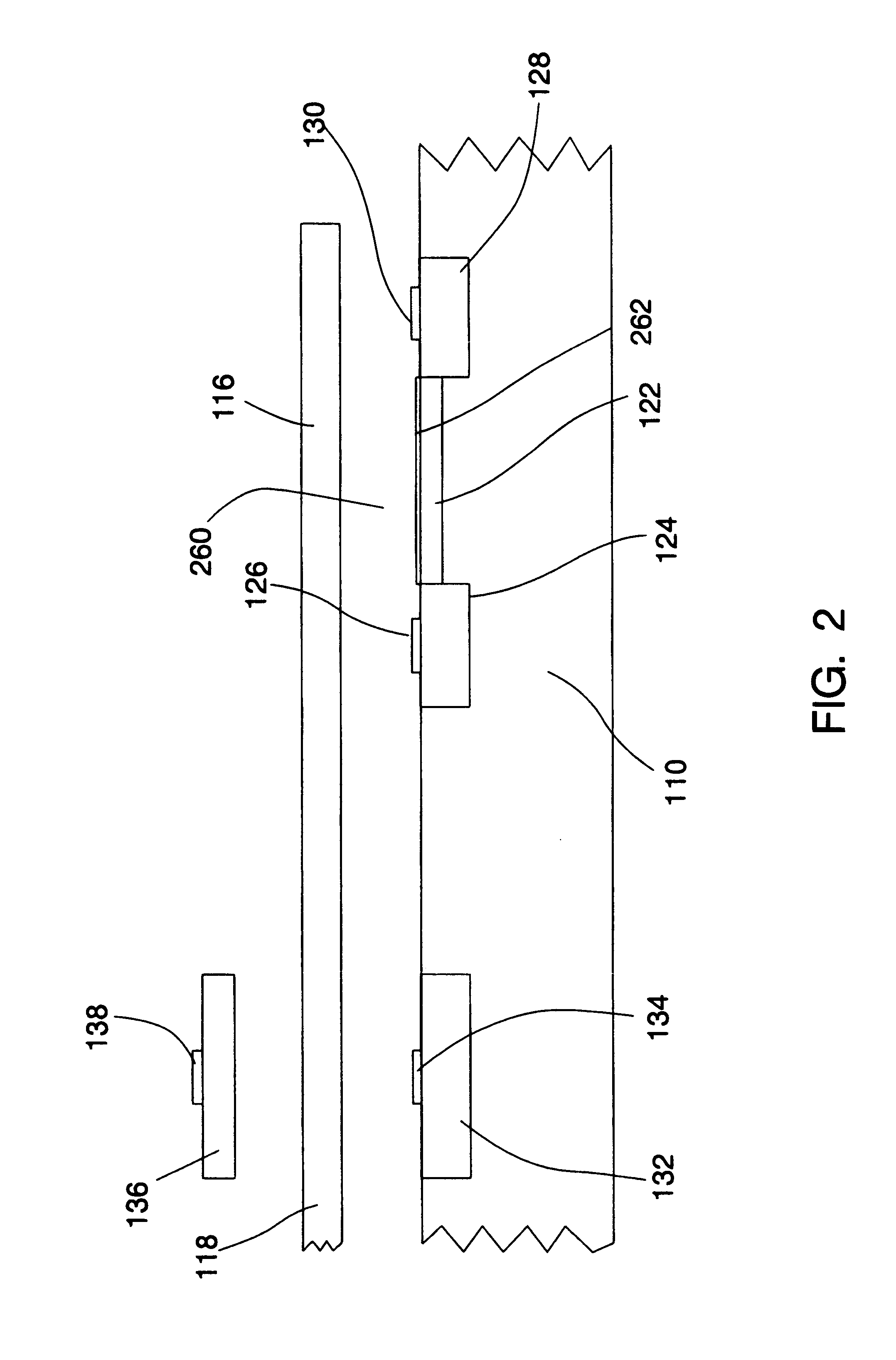

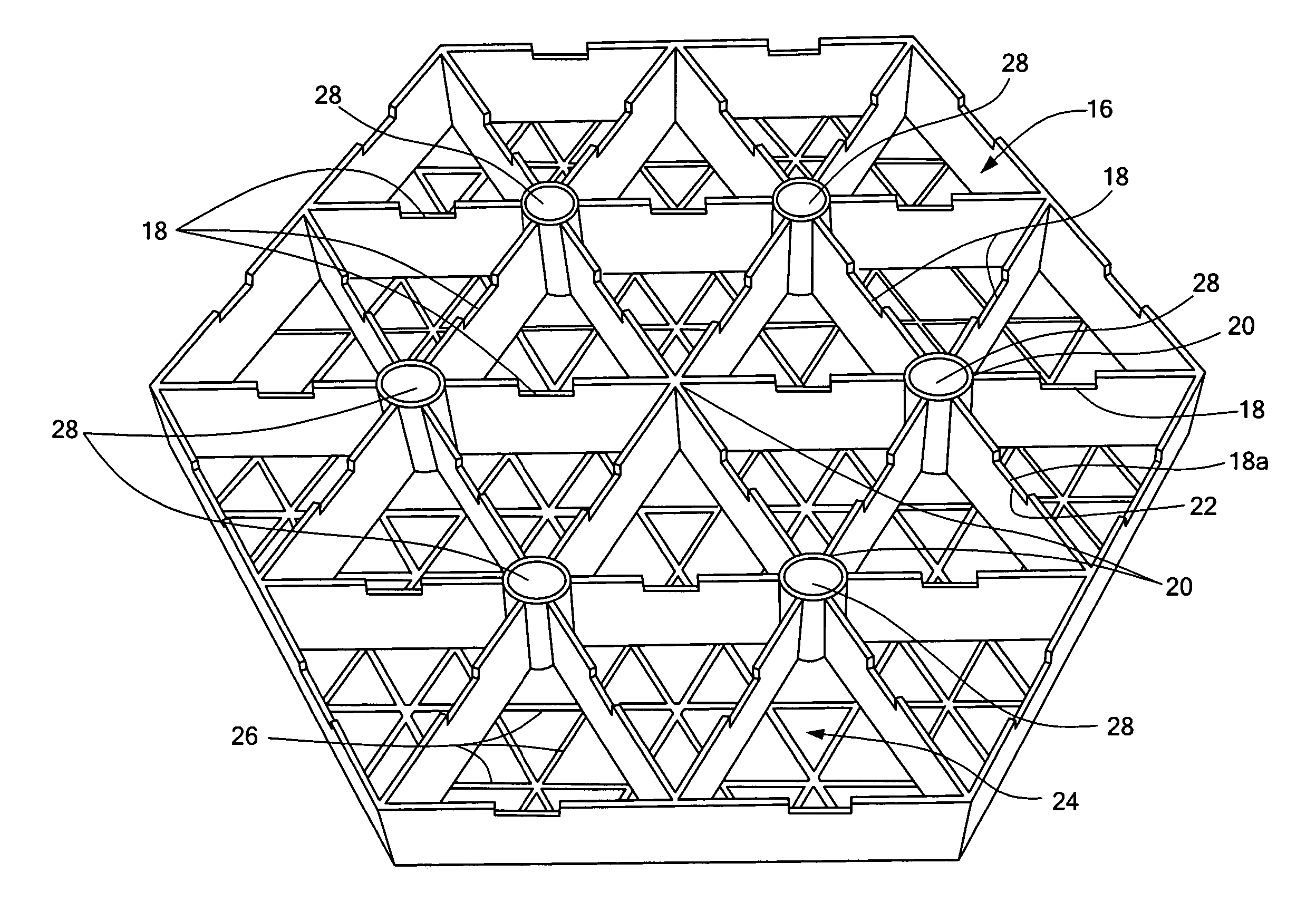

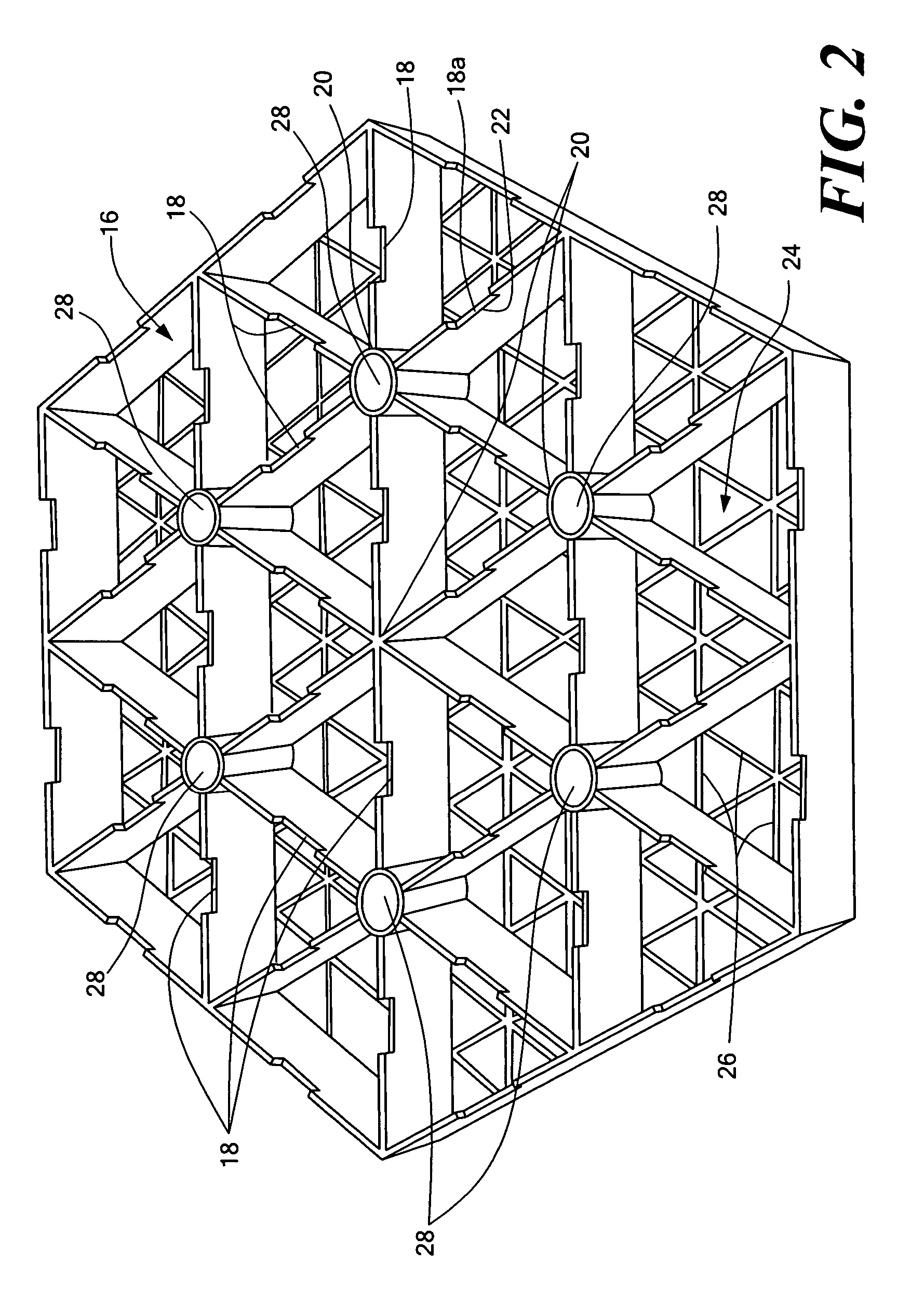

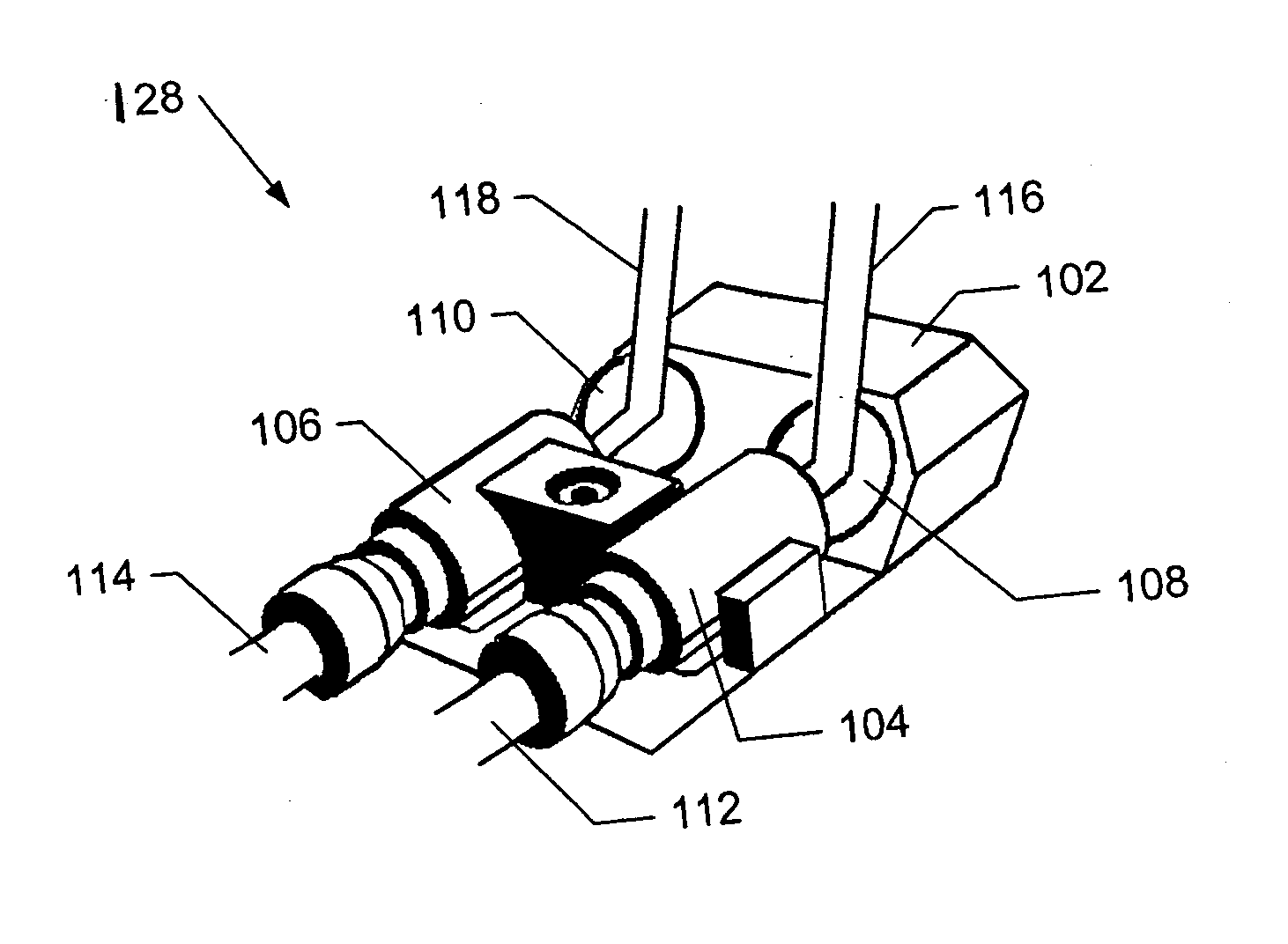

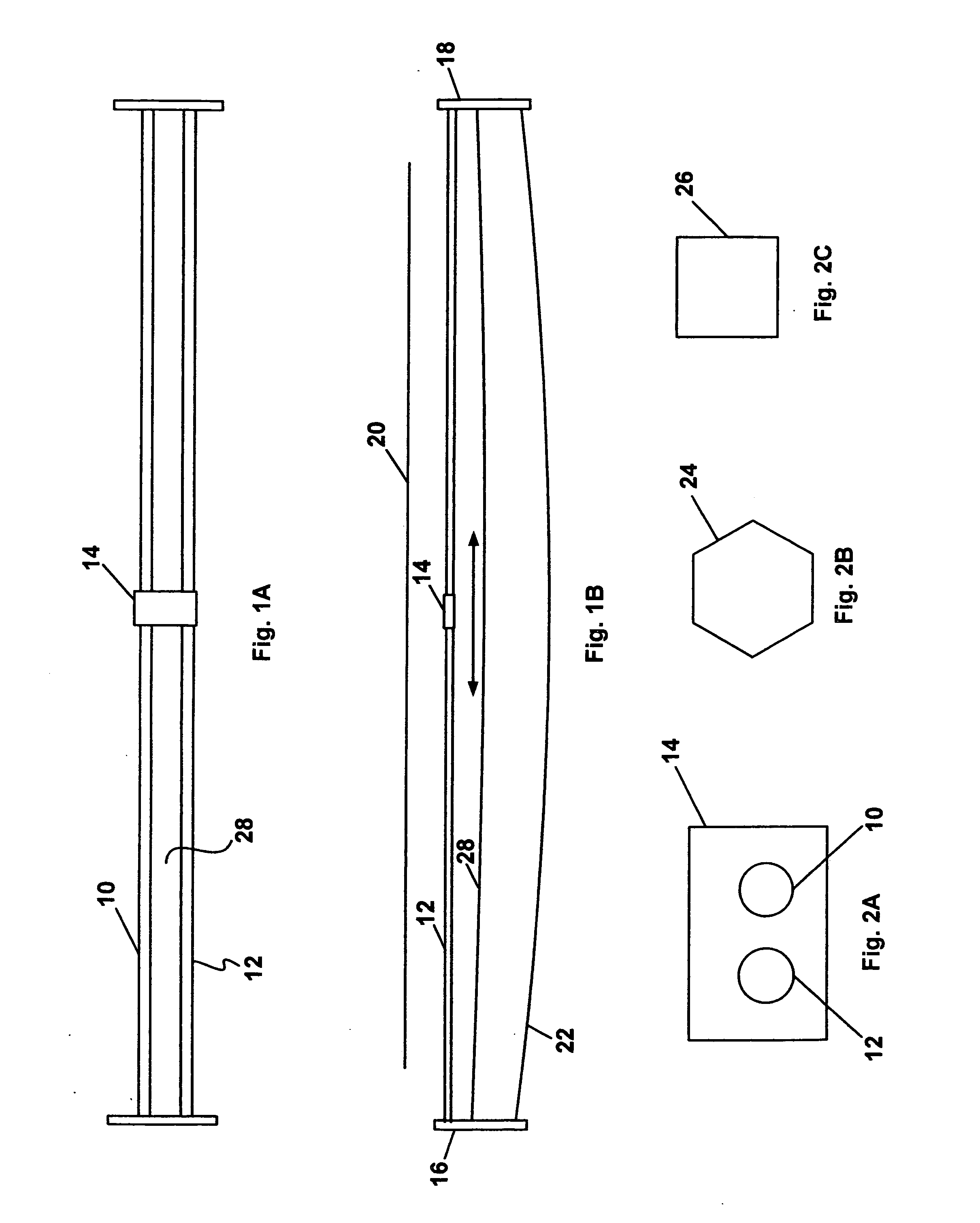

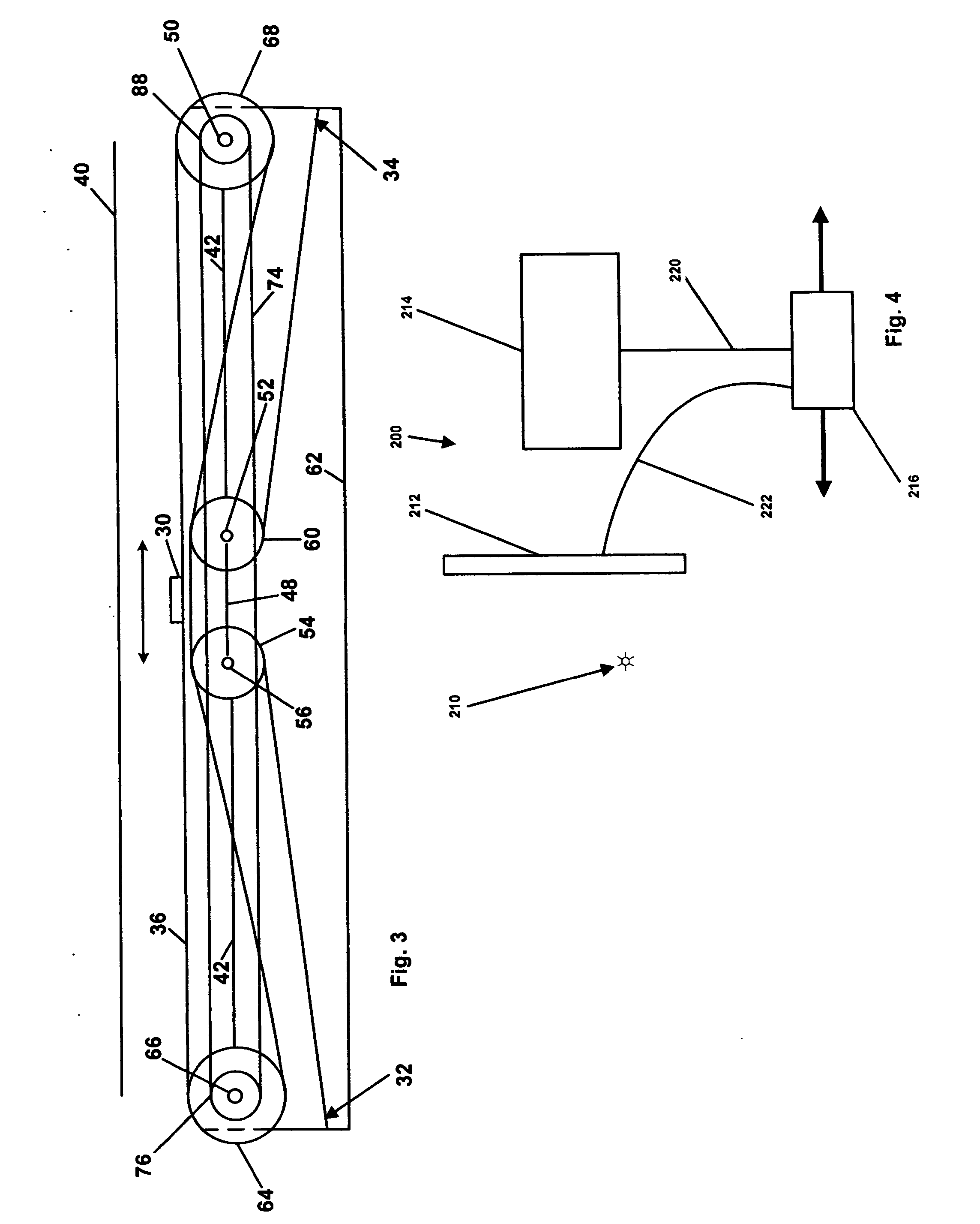

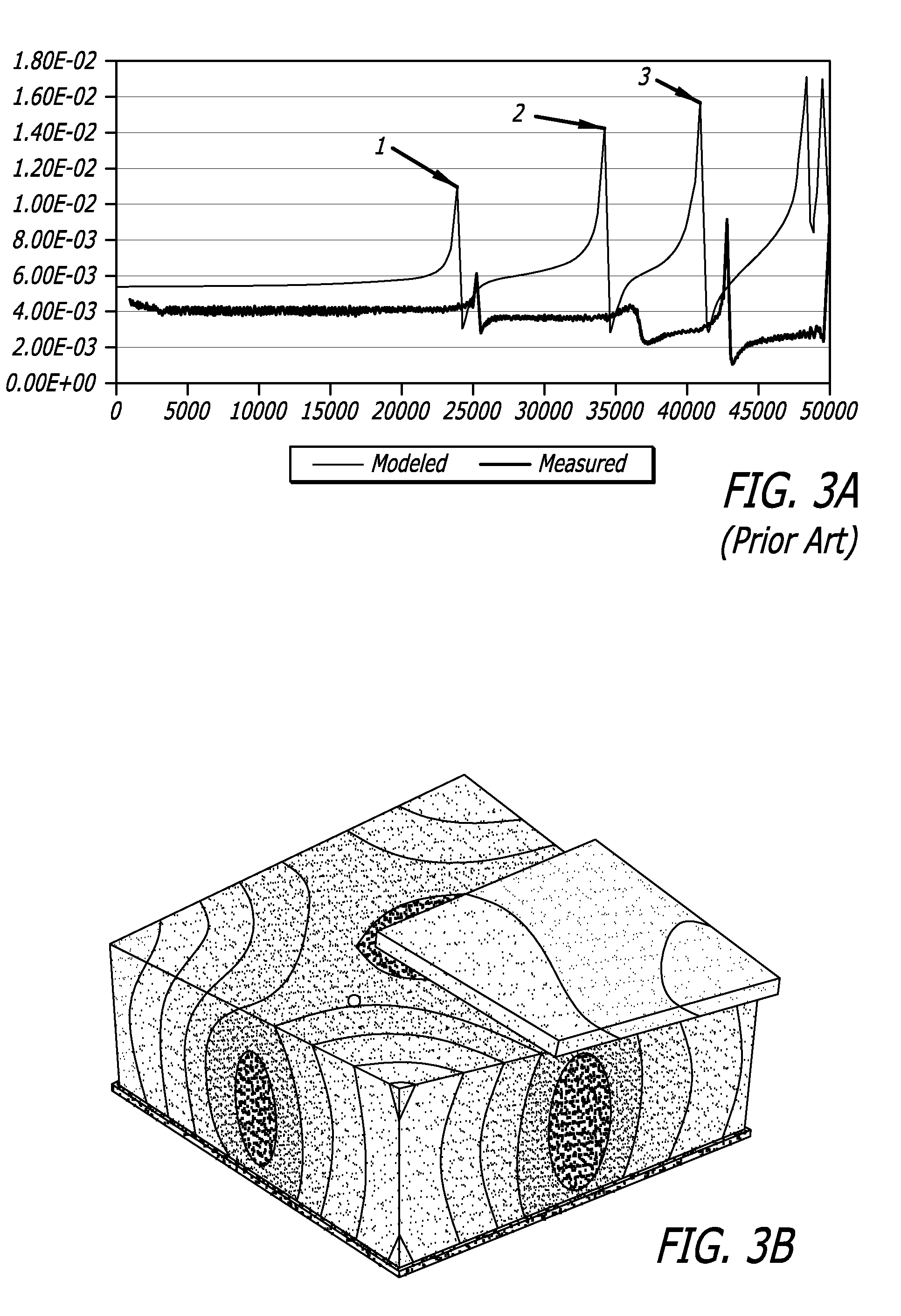

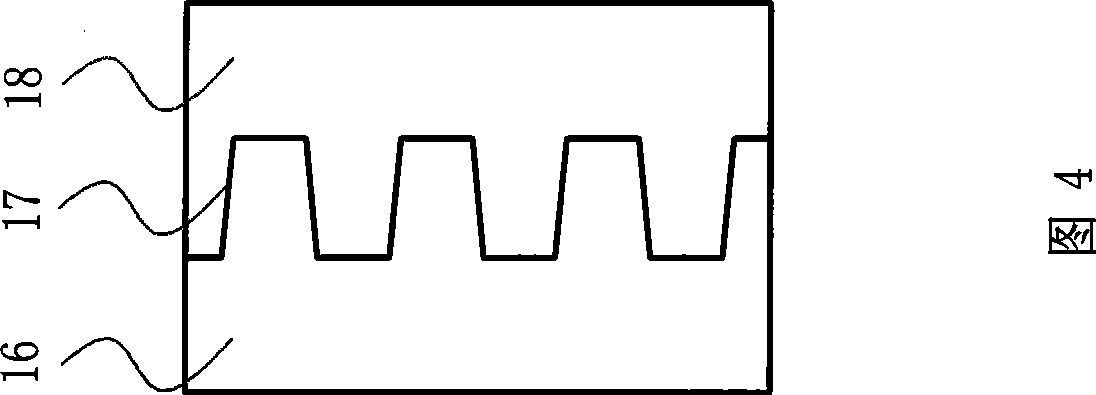

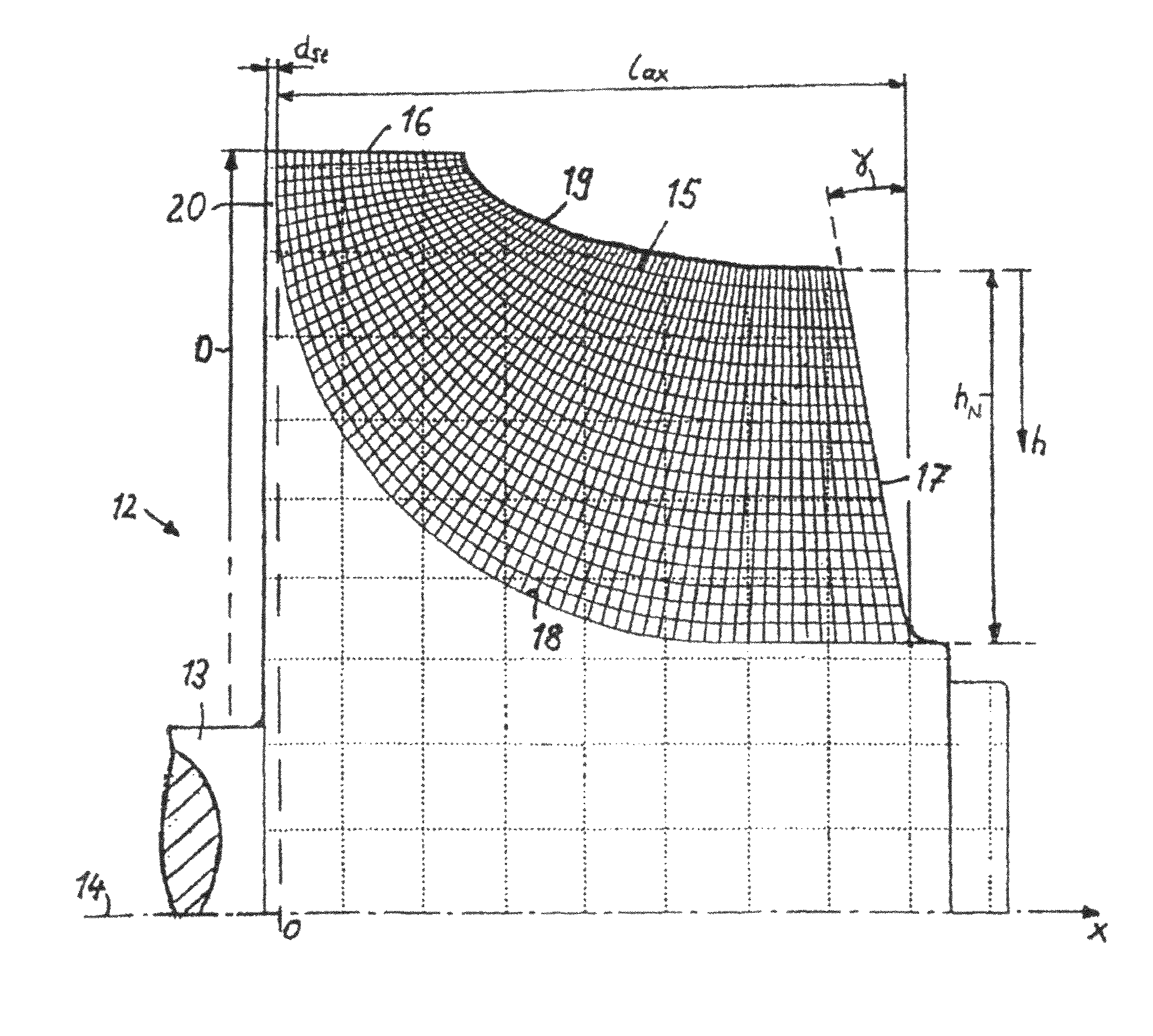

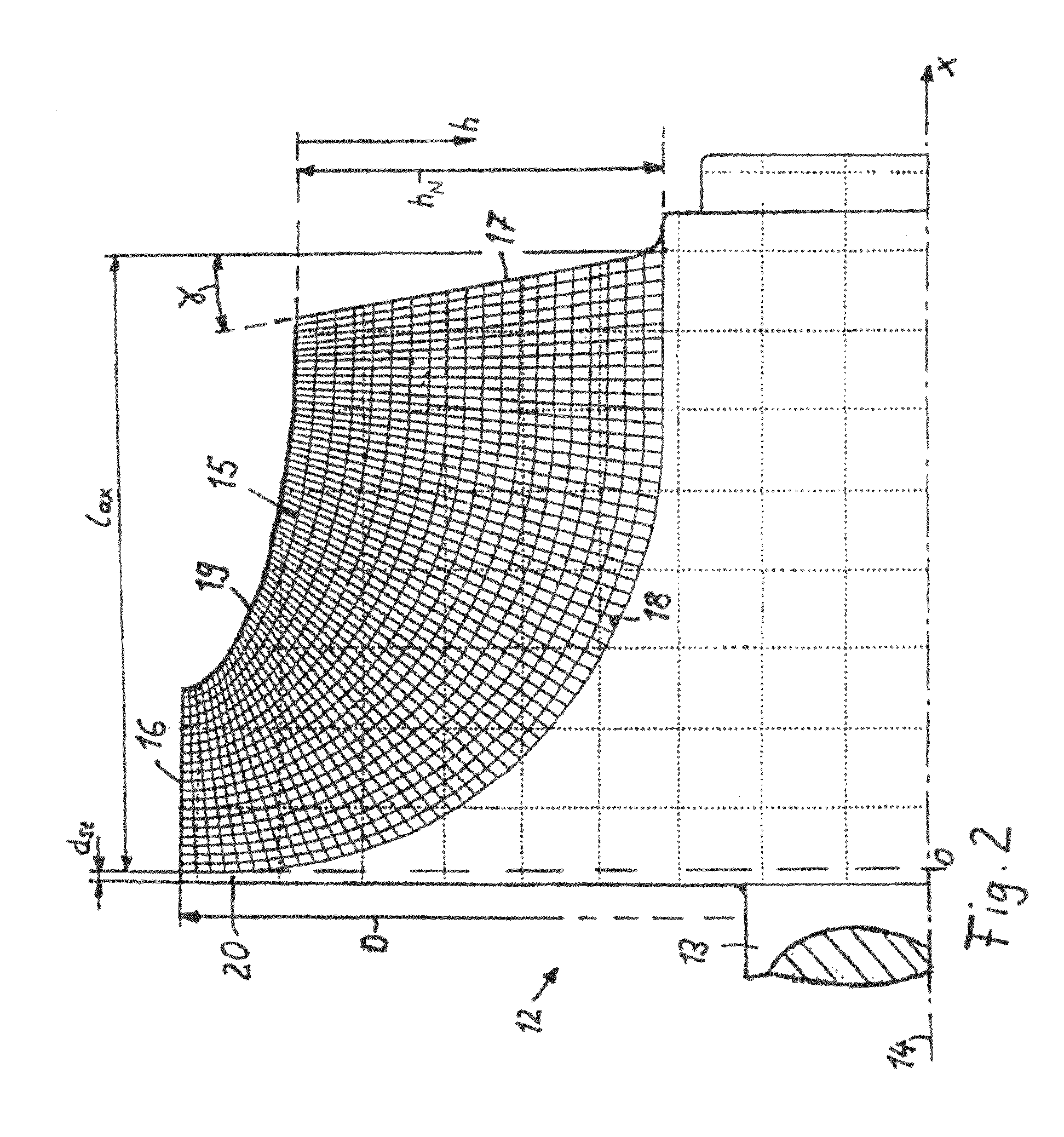

Tensioned scanner rails

ActiveUS20070058212A1Inherent insensitivity to thermal distortionRaise the natural frequencyPictoral communicationEngineeringMobile device

A rail system made of one or more flexible guide rods, each consisting of a tension rod, is used to support lightweight, mobile devices such as carriages, scanning heads or optical sensors. The rail is configured to permit movement of the mobile device, when driven by an external drive mechanism, along a main scanning direction but prohibits rotational movement of the mobile device. In this fashion, the mobile device remains substantially at the same measured distance from the flat surface of an object, e.g., moving sheet or web, being analyzed.

Owner:HONEYWELL INT INC

Deep sea pressure, flow speed and direction sensor and use thereof

InactiveCN1710394AImprove sealingGuaranteed to workFluid pressure measurement using elastically-deformable gaugesMarine engineeringTransducer

A transducer of pressure , flow speed and flow direction at deep sea features having column formed seat and its ring shell , setting elastic beam support used as strain plate carrier between seat and shell , setting four said beams on one plane vertical to seat axis and arranging them two by two symmetrically in cross based on seat axis , using top and bottom end covers as well as bellows to form closed oil cavity , using strain plate to output collected signal and solid connecting gyro-rotor with seat axis as rotation centre at centre of top end cover.

Owner:HEFEI UNIV OF TECH

Head gimbal assembly apparatus having an actuator mounted on a mounting plate comprising a ceramic sub-plate formed on a stainless steel mounting plate

ActiveUS8148791B1Accurate resonance testingExtends usable test frequency rangeDriving/moving recording headsArm with actuatorsDensity ratioResonance

A test assembly for a disk drive suspension head gimbal assembly includes a steel mount plate and a mount sub-plate of a material such as silicon carbide having a modulus of elasticity to density ratio that is significantly higher than the ratio for stainless steel. Preferably the mount plate and the mount sub-plate taken together have a first resonant shear frequency of greater than 50 KHz, which is generally greater than the frequency range of interest for testing head gimbal assemblies. The high modulus of elasticity to density ratio helps to ensure that any shear mode resonances of the test assembly occur at frequencies that are higher than the frequencies of interesting for head gimbal assembly shear resonance testing purposes.

Owner:MAGNECOMP

Improved wind load pressure sensor

ActiveCN101738281AThe result is accurateSimple designFluid pressure measurement using ohmic-resistance variationAmbient pressureEngineering

The invention discloses an improved wind load pressure sensor, comprising a sensor shell, an oil charge sensitive body and a signal conditioning circuit, wherein, the oil charge sensitive body is composed of a sensitivity body shell in the form of a groove, a silicon integrated sensitive chip and an elastic separation film fixed on the opening of the groove, the ring circumambience of the back pressure face of the silicon integrated sensitive chip is fixed at the bottom of the groove through a fixed supporting ring in a sealing manner, the back pressure face of the silicon integrated sensitive chip is communicated with ambient pressure through a back pressure airway tube, the pressure surface of the silicon integrated sensitive chip is provided with a Wheatstone bridge on which a strain resistor is led to the signal conditioning circuit through an internal lead and a lead column and then is output, the non-pressure surface of the silicon integrated sensitive chip is provided with a temperature sensor, a heating resistor and a constant temperature control circuit controlling the heating resistor according to the temperature sensor, and silicon oil is filled among the elastic separation film, a groove internal ring surface and the pressure surface of the silicon integrated sensitive chip. The invention can control the temperature of the oil charge sensitive body, and eliminate the problem that an oil charge micro-pressure sensor is in fault due to the influence of ambient temperature, thereby realizing high-accuracy survey of wind loads.

Owner:KUNSHAN SHUANGQIAO SENSOR MEASUREMENT CONTROLLING

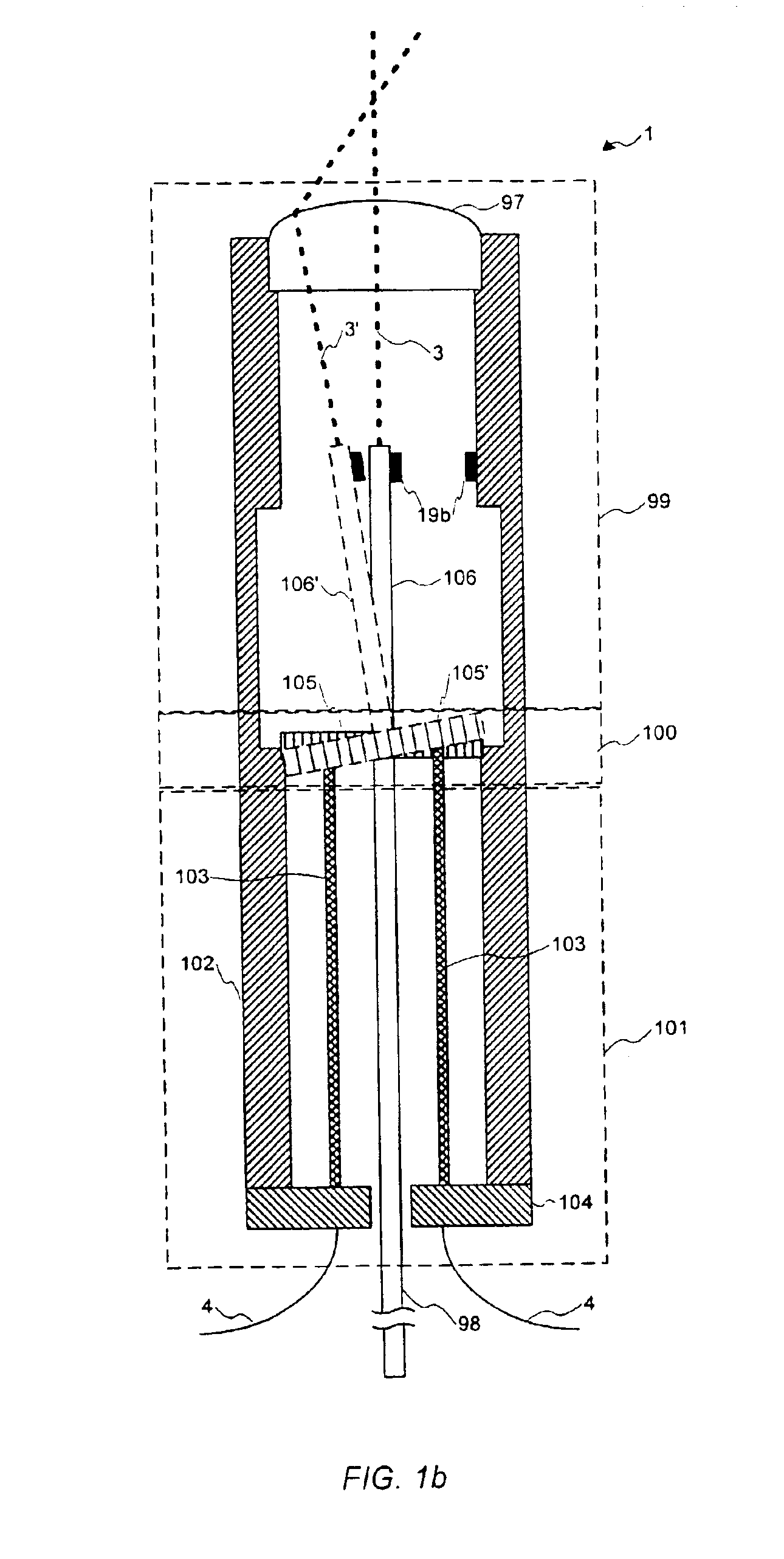

Support system for a pilot nozzle of a turbine engine

ActiveUS7197877B2Raise the natural frequencyPrevent insertionTurbine/propulsion fuel supply systemsContinuous combustion chamberInterference fitSupporting system

An automatic recovery pilot nozzle support system for supporting a pilot nozzle in a fuel injection system of a turbine engine. The support system includes a sleeve extending from an orifice in a support housing, wherein the sleeve has a hollow opening for containing a pilot nozzle. The sleeve may increase the natural frequency of the pilot nozzle above an excitation zone, thereby limiting destructive vibrations. The sleeve may be attached to the support housing with an interference fit. The automatic recovery aspect of the support system enables the sleeve to maintain an interference fit with the support housing such that anytime the sleeve looses contact with the support housing, an insulative film of air forms between the sleeve and the support housing. The insulative film of air causes the temperature of the sleeve to increase, and the sleeve to expand and reform the interference fit with the support housing.

Owner:SIEMENS ENERGY INC

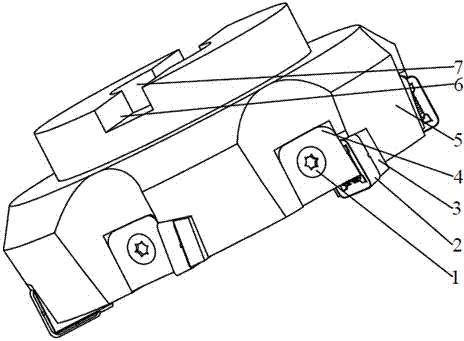

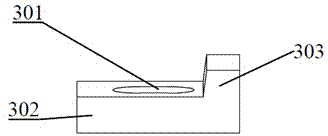

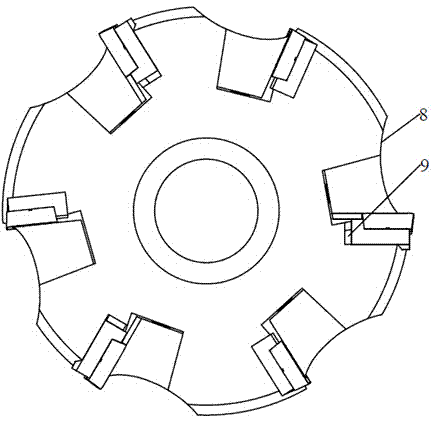

Radially-adjustable heavy-duty cutting layer milling cutter

InactiveCN104841994ARaise the natural frequencyChange milling forceTransportation and packagingMilling cuttersMilling cutterEngineering

The invention discloses a radially-adjustable heavy-duty cutting layer milling cutter applicable to the field of heavy-type milling processing, and aims to solve the problems that during heavy-duty milling water chamber end enclosing, surfaces of workblanks are uneven, multi-defective and poor in machinability; cutting blades are prone to being damaged by impacts during rough machining or hogging machining; during milling, cutting depth changes frequently, which results in that not all cutter teeth are involved in cutting, utilization rate of the milling cutter is low, the cutting layer milling cutter of a fixed radial stepped structure is short in service life, machining efficiency is influenced and the like. Cutter teeth of the cutting layer milling cutter are designed in a stepped distribution, by means of increasing cutting depth, metal removal rate is increased, and machining efficiency is improved; by the aid of a radial adjusting mechanism, the cutting blades in an upper layer are enabled to move radially, a proper overhang amount can be selected, and strength of the cutting blades is enhanced. A radially-adjustable cutter pad is positioned by a pad block, auxiliary time including cutter amounting time, cutter adjusting time and the like is saved; up-warp chip holding grooves are formed in a cutter body in design, the depths of the positions, close to the cutting blades, of the chip holding grooves are far larger than that of the positions, distant from the cutting blades, of the chip holding grooves, up-warp slopes are formed in the chip holding grooves, and when cutting chips flow in the chip holding grooves, the chips can be separated from the cutter body quickly, friction between the chips and the cutter body is reduced, and service life of the cutter body is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

Turbine with at least one rotor which comprises rotor disks and a tie-bolt

InactiveUS8506239B2Increases damping and rigidityEasy to installEngine sealsEngine manufactureRadial planeTurbine

A gas turbine is provided. The gas turbine includes at least one rotor, having rotor blades arranged on the periphery of rotor disks in a plurality of radial planes, and a tie-bolt extending along slots in the rotor disks and holding the rotor disks together as a unit. At least one annular spacer for fixing the position of the tie-bolt in relation to the center line of the rotor disks is also provided. The spacer includes through-openings that are arranged radially in relation to the tie-bolt or to its center line and that extend coaxially.

Owner:SIEMENS AG

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

Turbine wheel in an exhaust gas turbine of an exhaust gas turbocharger

InactiveUS7798770B2Improve efficiencyReduce quality problemsPropellersWind motor controlImpellerTurbine wheel

In a turbine wheel of an exhaust gas turbine comprising a turbine wheel with a hub and a plurality of turbine wheel blades which are arranged on the turbine wheel hub and which extend axially between a turbine wheel inlet and a turbine wheel outlet, the turbine wheel blades are constructed in such a way that the ratio of the hub contour thickness to the external contour thickness of each turbine wheel blade follows a defined function.

Owner:DAIMLER AG

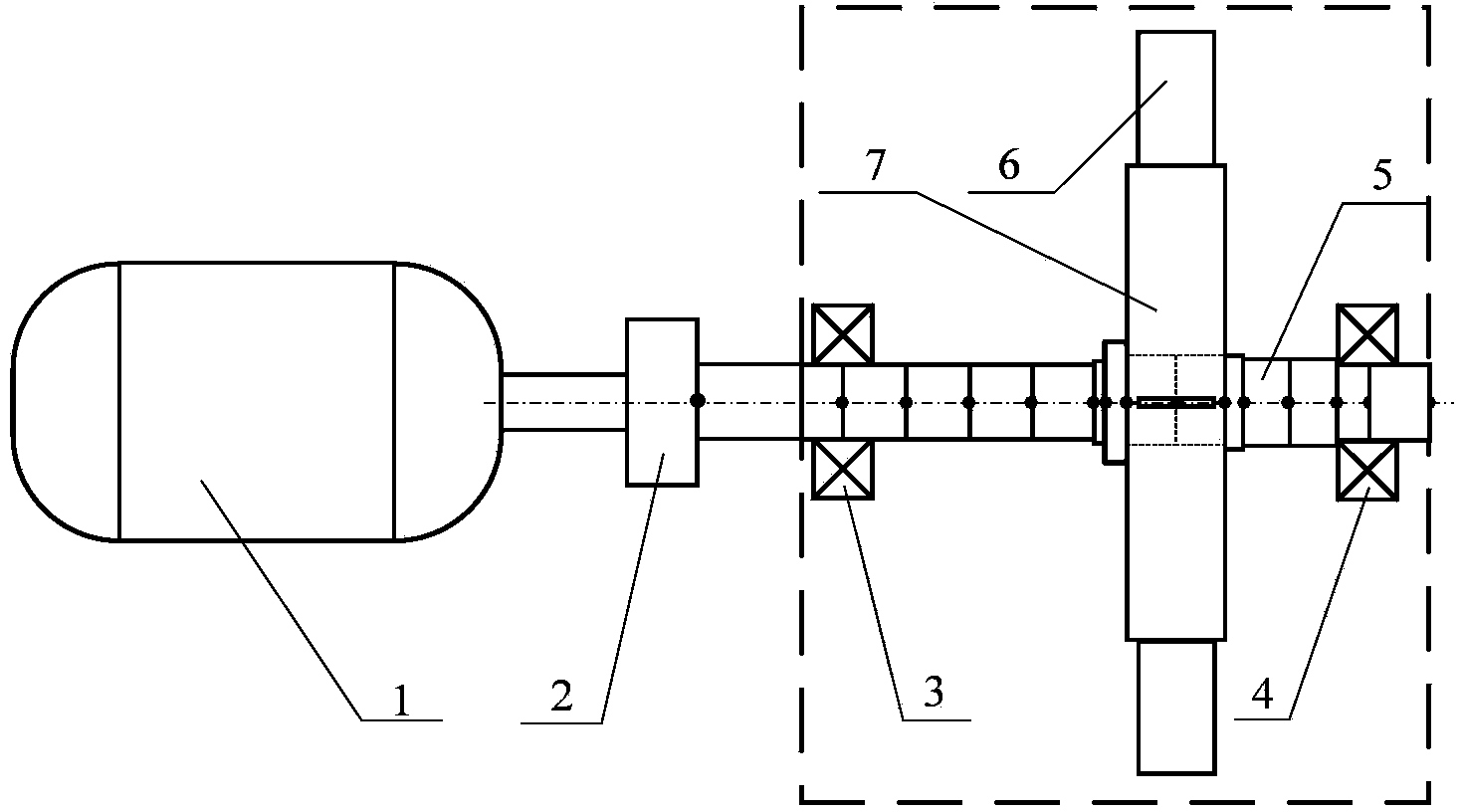

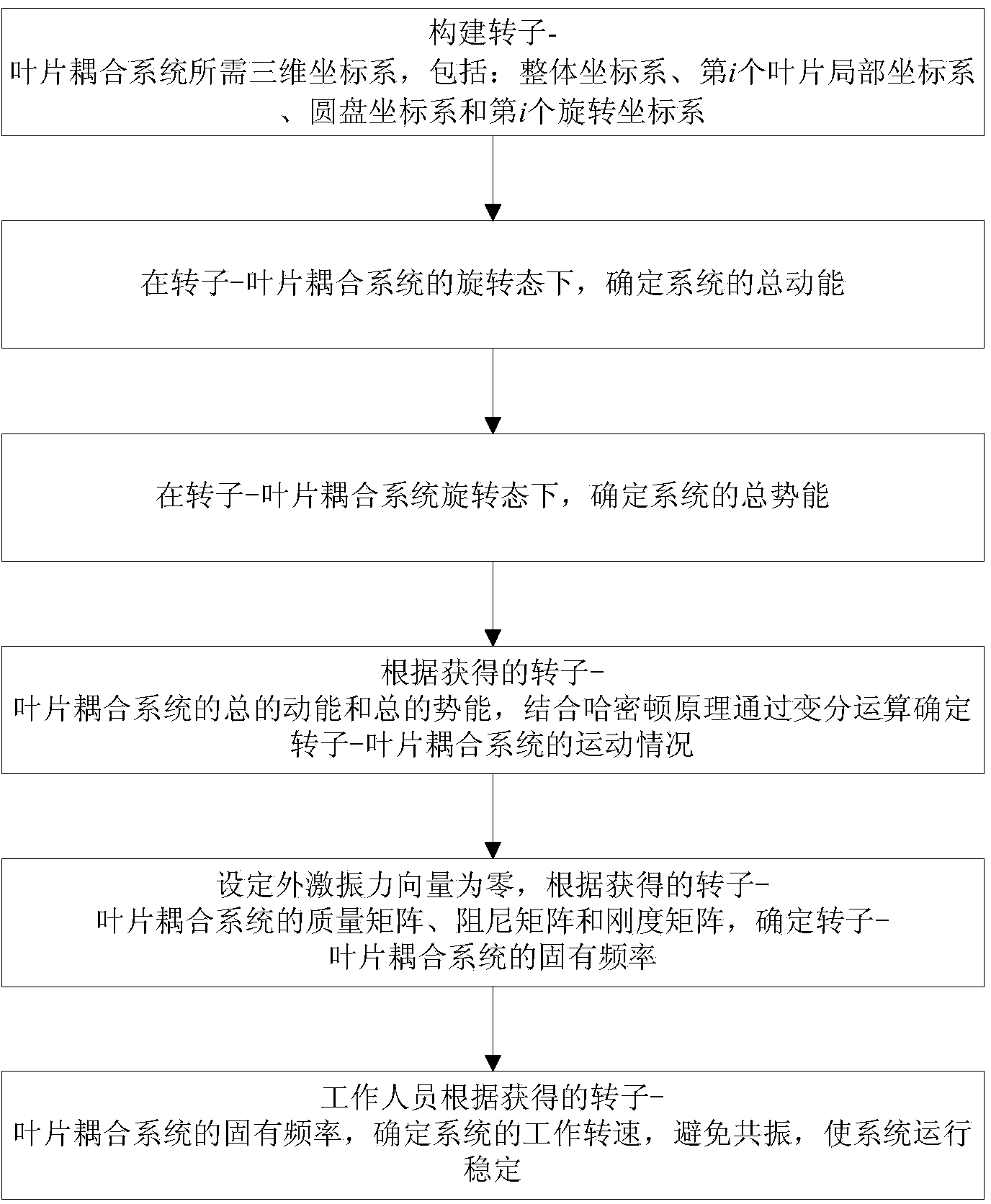

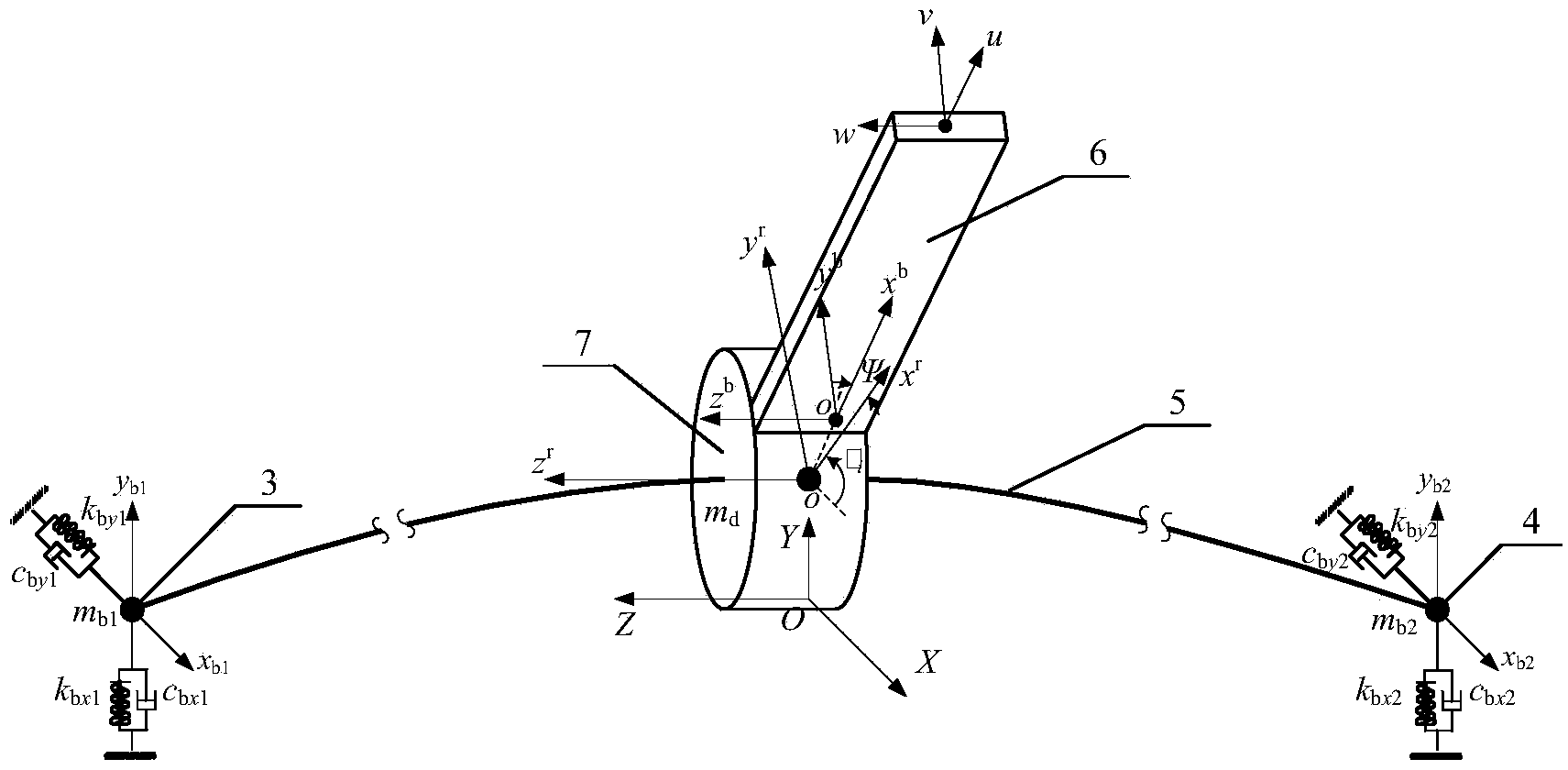

Determination method for inherent frequency of rotor-blade coupled system

ActiveCN104166758ALow costRaise the natural frequencySpecial data processing applicationsAudio power amplifierCoupling system

The invention belongs to the technical field of mechanical dynamics, and relates to a determination method for the inherent frequency of a rotor-blade coupled system. The determination method saves the cost of a sensor, an amplifier and a display or record instrument needed by experimental tests and can obtain the higher-order inherent frequency and the inherent frequency in a rotating state. The inherent frequency of the rotor-blade coupled system can be obtained just by modifying the structural size of the system without repeated modeling, the bending and torsion influence on a complex stepped rotating shaft of the coupled system, the gyroscopic effect of a shaft and a disc, centrifugal rigidifying, rotary softening and the Coriolis force influence on blades are considered so that a more accurate result can be obtained; in addition, imbalance responses, blade tip rub-impact and other faults of the rotor-blade coupled system can be analyzed, so that the system structure is optimized.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com