Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Hogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hogging or sweat hogging refers to the practice of groups of men who target overweight or obese women, typically for sexual encounters. Unlike fat fetishists, men who participate in hogging are not necessarily sexually attracted to obese women's bodies; they aim to take advantage of a female's stereotypical low self-esteem or to derive amusement for themselves and their friends by engaging in sexual activities with women who are overweight.

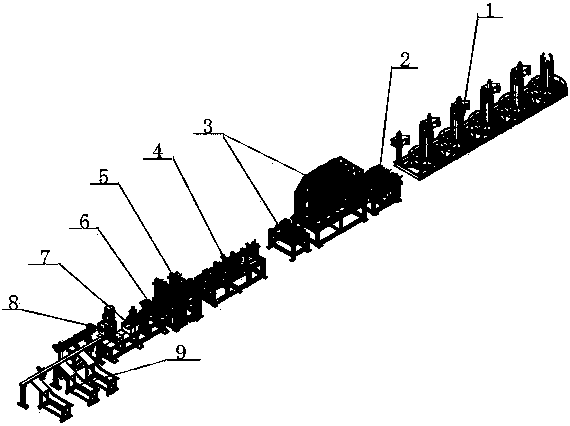

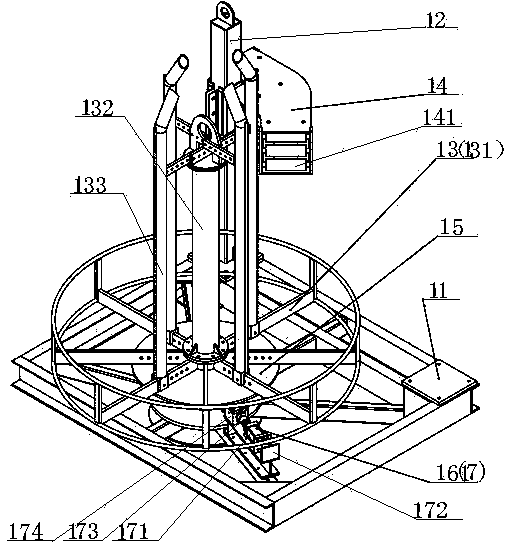

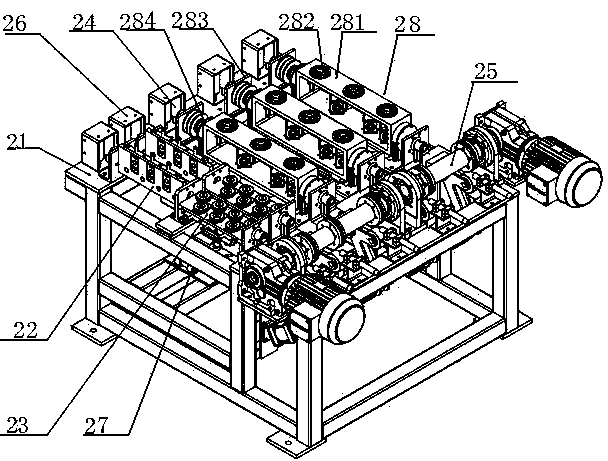

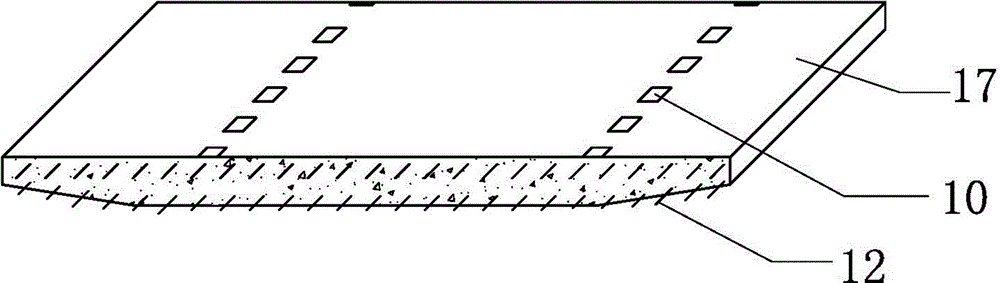

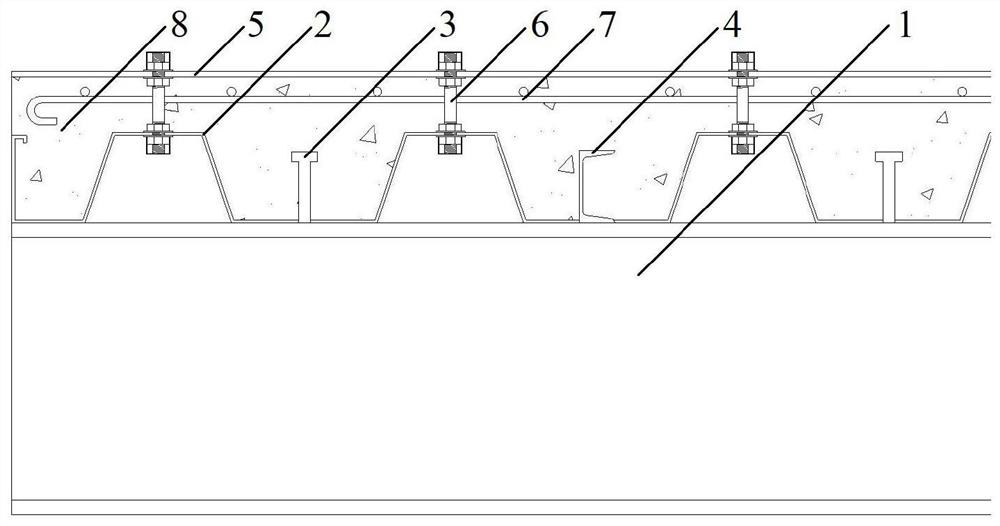

Full-automatic production line for steel bar truss

InactiveCN103465033AControl fully automated productionControl production speedOther manufacturing equipments/toolsProgrammable logic controllerRebar

The invention discloses a full-automatic production line for a steel bar truss. The production line comprises a pay-off device (1), a straightening device (2), a line-storing and terminal straightening device (3), a hogging device (4), a welding device (5), a foot bending device (6), a stepping dragging device (7), a shearing device (8) and an automatic collecting device (9) in turn, wherein all the devices are controlled by a PLC (Programmable Logic Controller). The full-automatic production line for the steel bar truss solves the problems of low production efficiency, high labor intensity, seriously restricted throughput of the steel bar truss and degree of automation caused by the production in manual and mechanical combined mode adopted by the present enterprises during the process of producing the steel bar truss.

Owner:淮安恒来达工贸有限公司

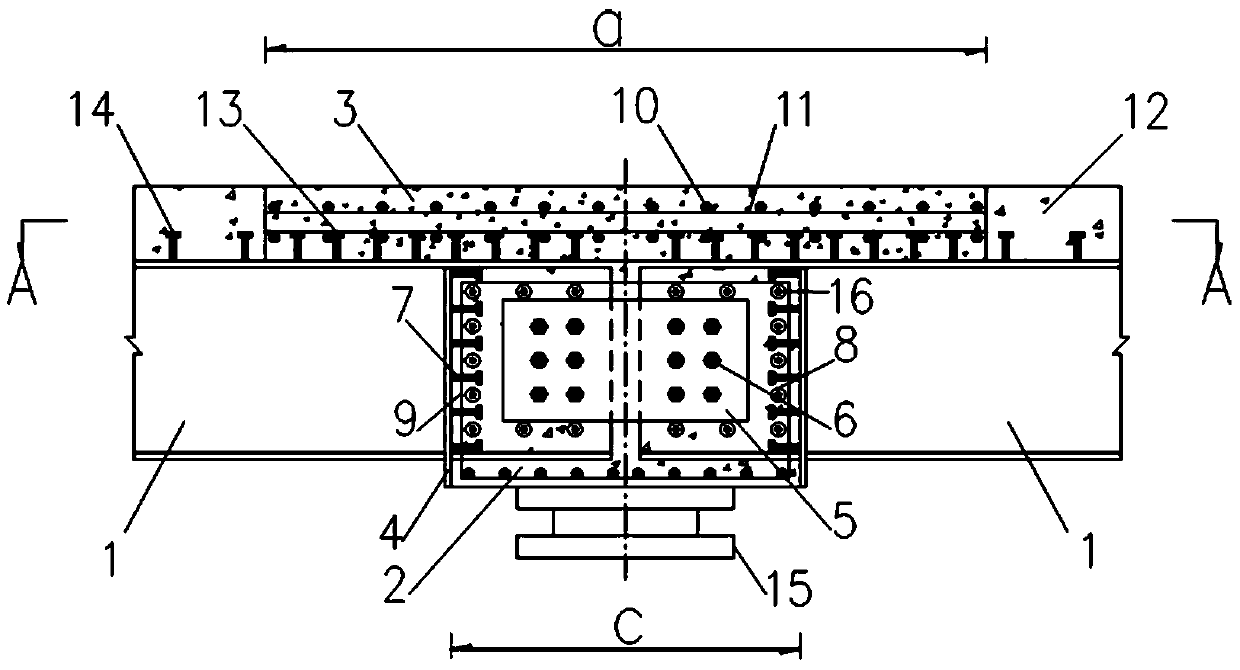

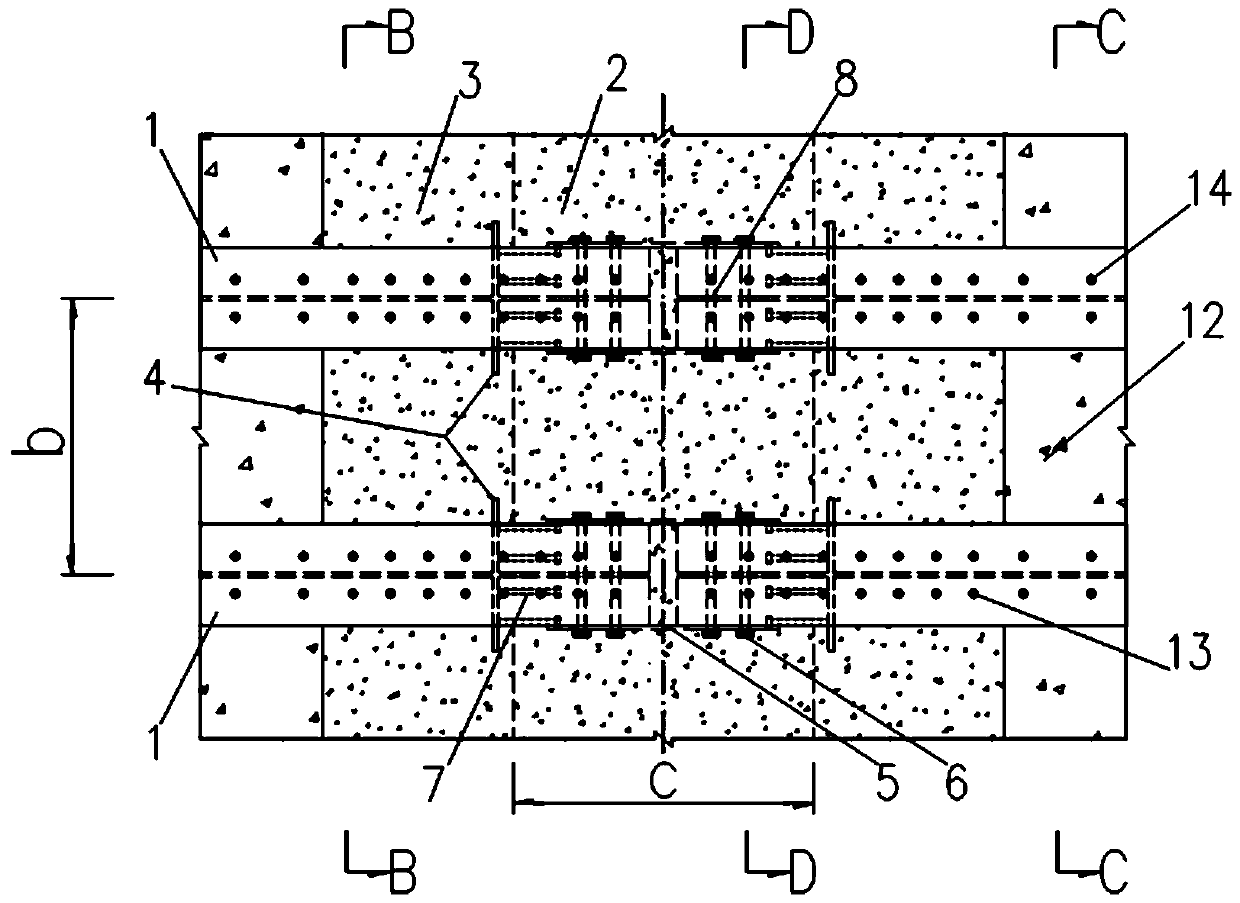

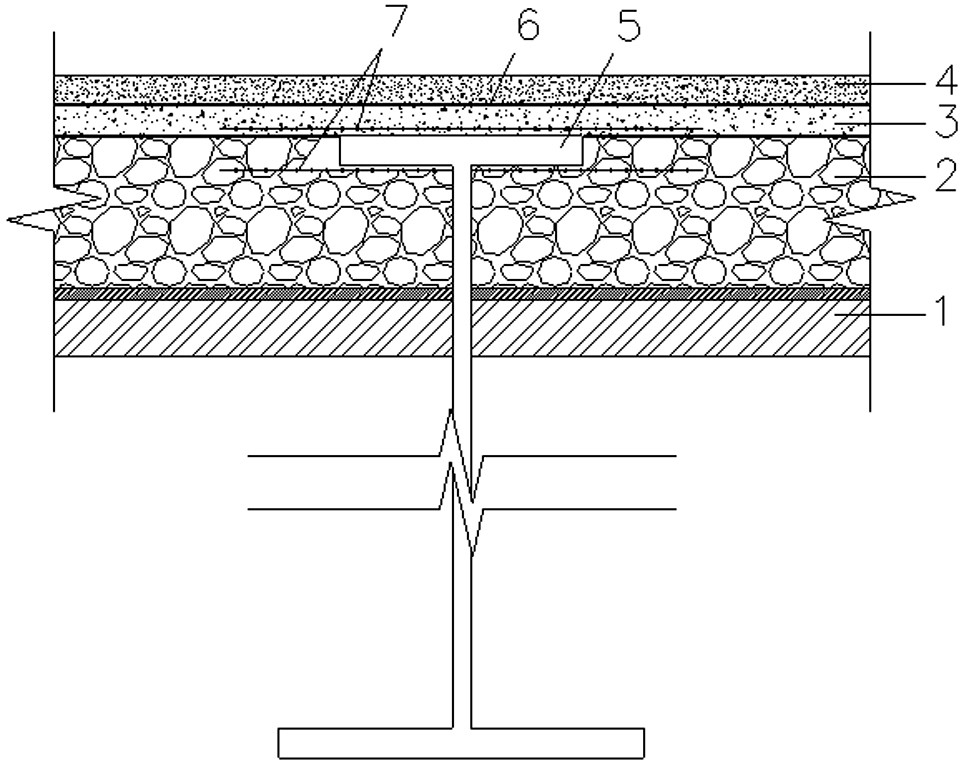

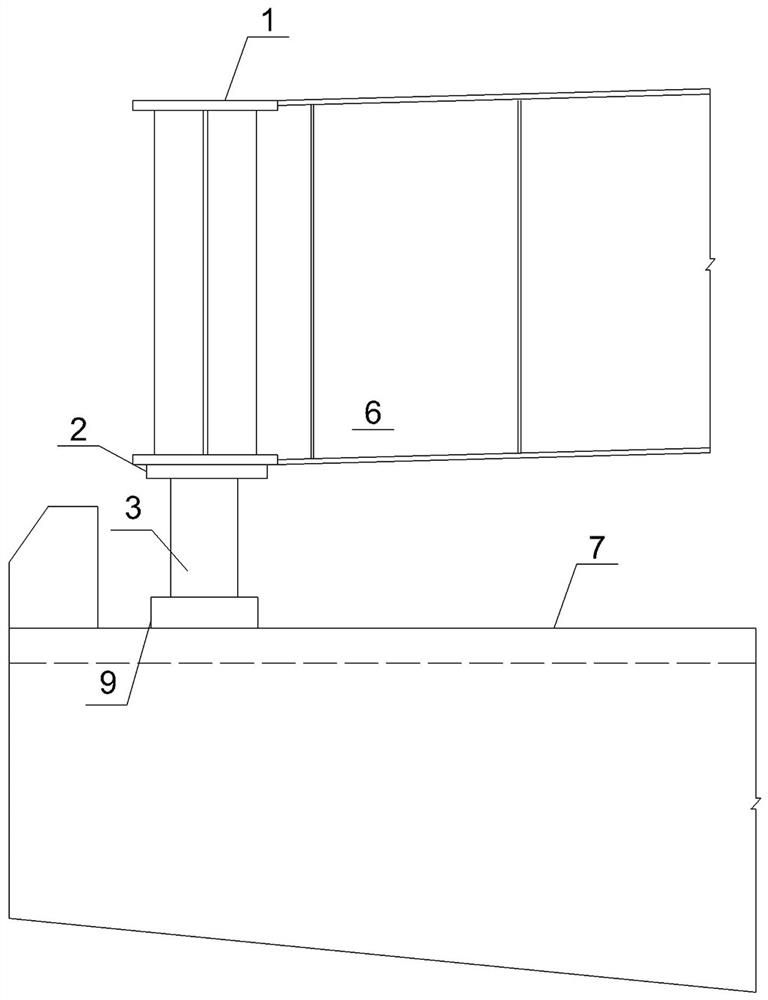

Steel-concrete combined continuous beam bridge deck as well as manufacturing method and application thereof

InactiveCN105926440AAvoid early crackingIncreased durabilityBridge structural detailsBridge erection/assemblyCrack resistancePre stress

The invention discloses an assembly type steel-concrete combined continuous beam bridge deck formed by exerting prestress to a concrete bridge deck in a hogging moment region. The deck comprises a hogging moment region concrete segmental plate, a hogging moment region concrete end plate and a sagging moment region segmental plate. The manufacturing method comprises the following steps of erecting of shuttering, pouring and curing; the deck is applied to the construction of a steel-concrete combined continuous beam bridge. Prestress is exerted to the inner part of the concrete bridge deck of the hogging moment region, but a tendon beam is not used, so that material consumption is reduced, the crack resistance and the bending resistance bearing capacity in the hogging moment region are effectively improved, and the condition that prestress beams rust is avoided; during construction of the steel-concrete combined continuous beam bridge, an assembled type prefabricated prestressed concrete deck is adopted, so that the factory degree is high, the quality of structural members is guaranteed, and the durability of a concrete bridge deck is improved. The assembly type steel-concrete combined continuous beam bridge deck disclosed by the invention is simple in method, convenient to construct, and high in quality, the construction period is greatly shortened, and the comprehensive economic benefits are improved.

Owner:HUNAN CITY UNIV

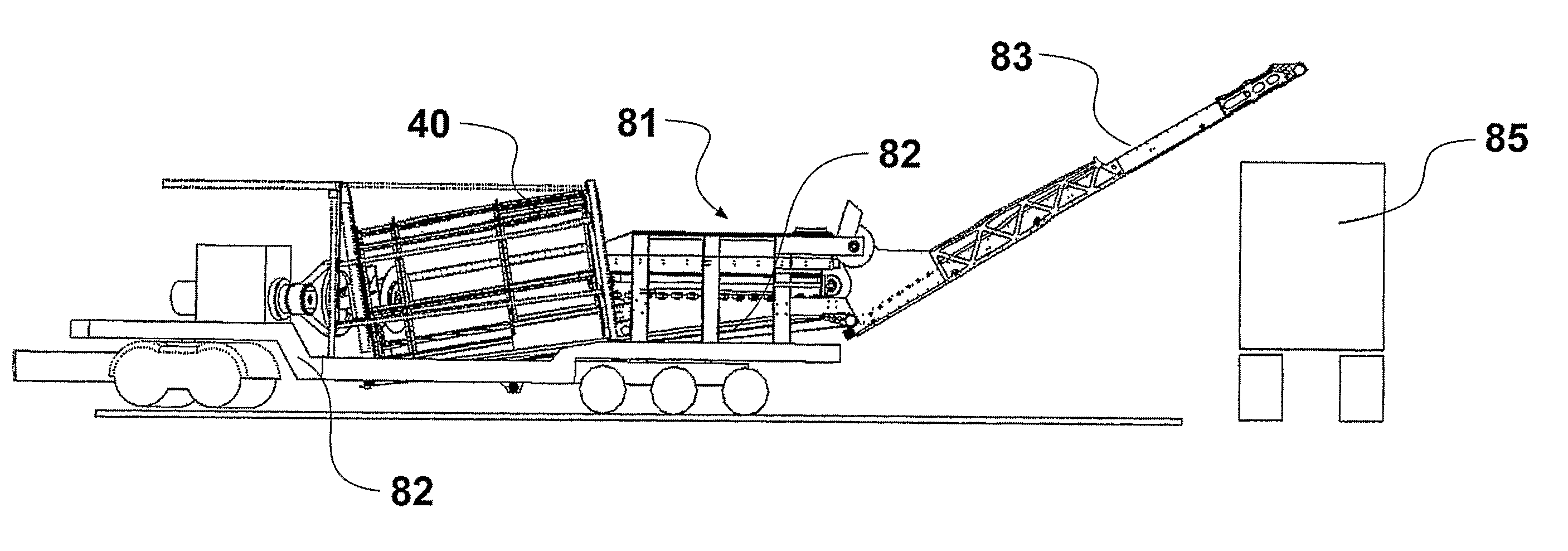

Wood Hogging Apparatus

InactiveUS20080099592A1Increase the sectionSmall sizeWood working apparatusCocoaForeign matterAsphalt

A hogging, sometimes known as reducing, apparatus for reducing wood waste into hog fuel, though some embodiments may also be used for reducing other materials including demolition timber, demolition masonry, mild steel scrap (thin sections), soft metal scrap, recycled cans, recycled glass, recycled plastic, soft rocks, occasionally hard rocks, recycled roading and asphalt, old tyres, and certain green garden waste. The apparatus includes a drum (40) inclined to the horizontal and into which raw material can be fed at its upper end. Rotation of the drum (40) assists driving raw material towards reducing elements (45) positioned at an angle near its (40) lower end. Screening apertures (41) allow sufficiently comminuted material to pass therethrough for removal. Optional features include internal agitators (60) for improving processing and screening, assisted drying of raw material by motor exhaust (71), and initial pre-screening of foreign material.

Owner:SHARP RODNEY WARWICK

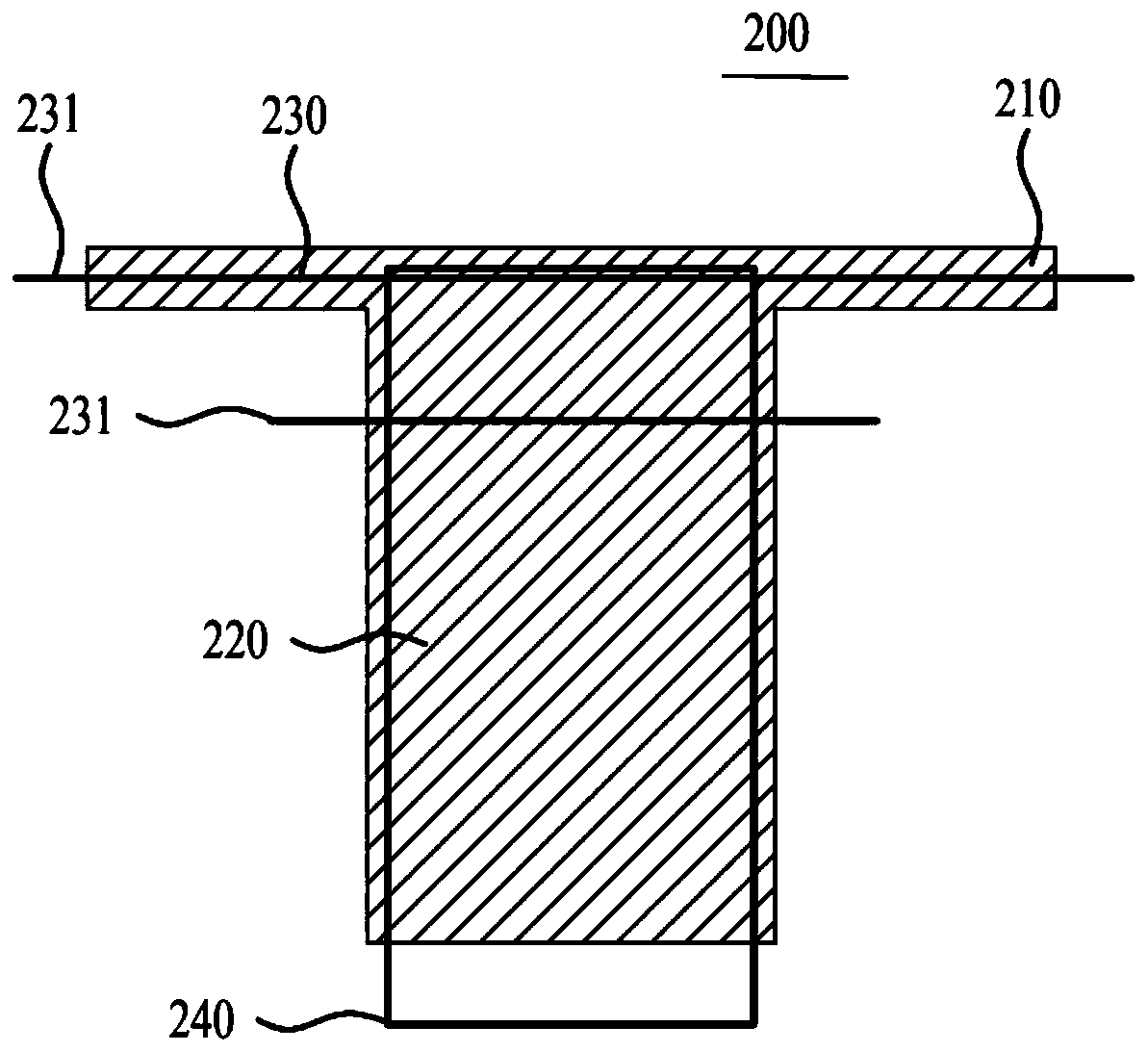

Profile steel-concrete composite beam hogging moment area structure based on high-performance material

PendingCN110847007AImprove applicabilityIncreased durabilityBridge structural detailsBridge materialsBridge deckRebar

The invention discloses a profile steel-concrete composite beam hogging moment area structure based on a high-performance material. The structure comprises steel beams, and reinforced concrete cross beams, wherein the two adjacent butt joint positions of the end parts of the steel beams are connected by adopting connecting steel plates and bolts, and the butt joint positions are referred to as hogging moment areas; and the reinforced concrete cross beams are fixed outside the hogging moment areas in a wrapping mode, the structure further comprises high-performance concrete bridge deck slabs; the high-performance concrete bridge deck slabs are laid directly above the hogging moment areas, specially, the high-performance concrete bridge deck slabs are laid on the top surfaces of the steel beams located in the hogging moment areas and are laid on the top surfaces of the reinforced concrete cross beams located in the hogging moment areas, and the high-performance concrete bridge deck slabsensure that the hogging moment areas are completely covered. The structure has the advantages of reducing the bearing bending moment of a main beam span, reducing the requirements of the structure onthe profile steel specification, saving the material consumption, widening the span diameter range of a bridge, improving the structural rigidity and being good in integrity, high in overload capacity, high in safety and the like.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST

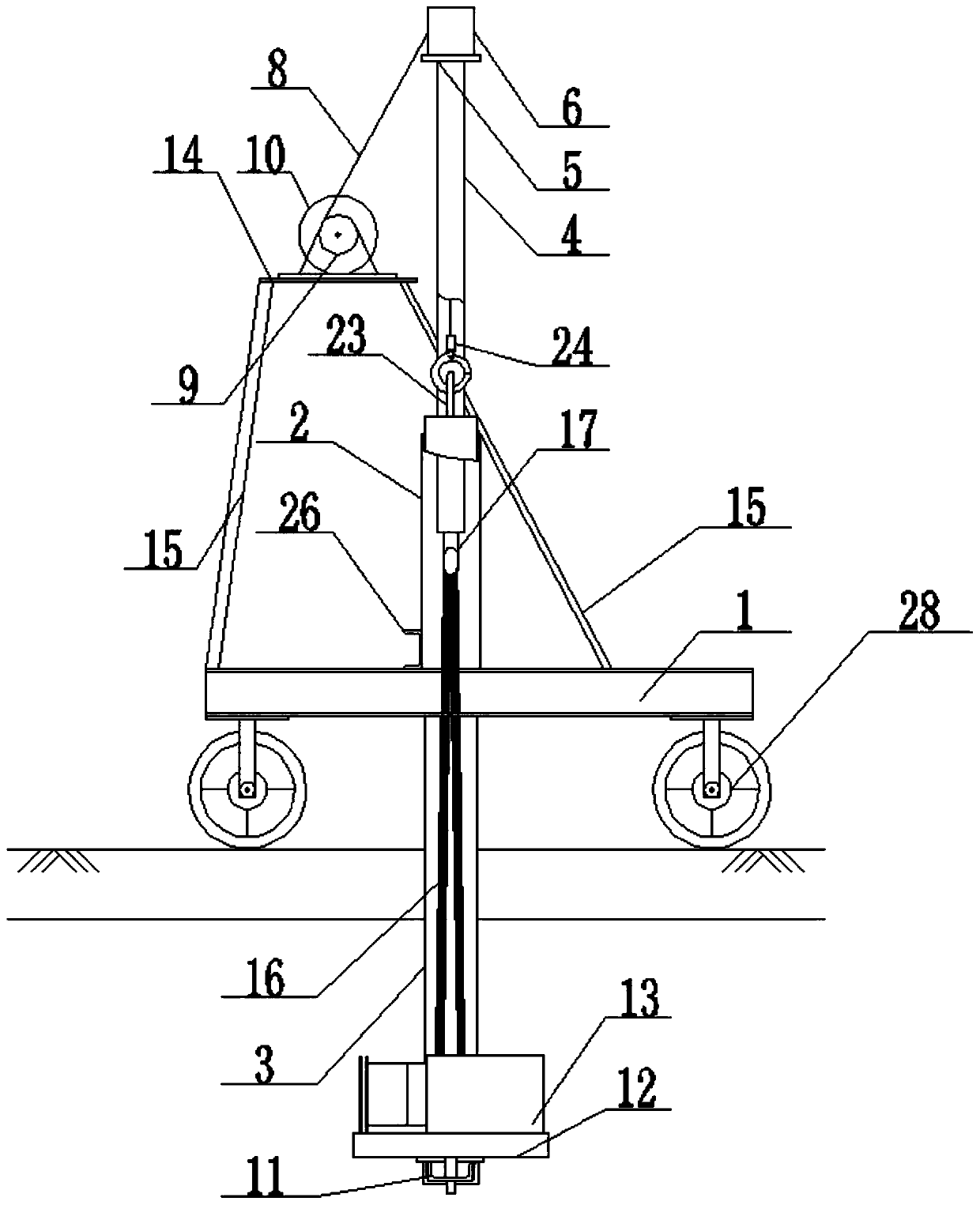

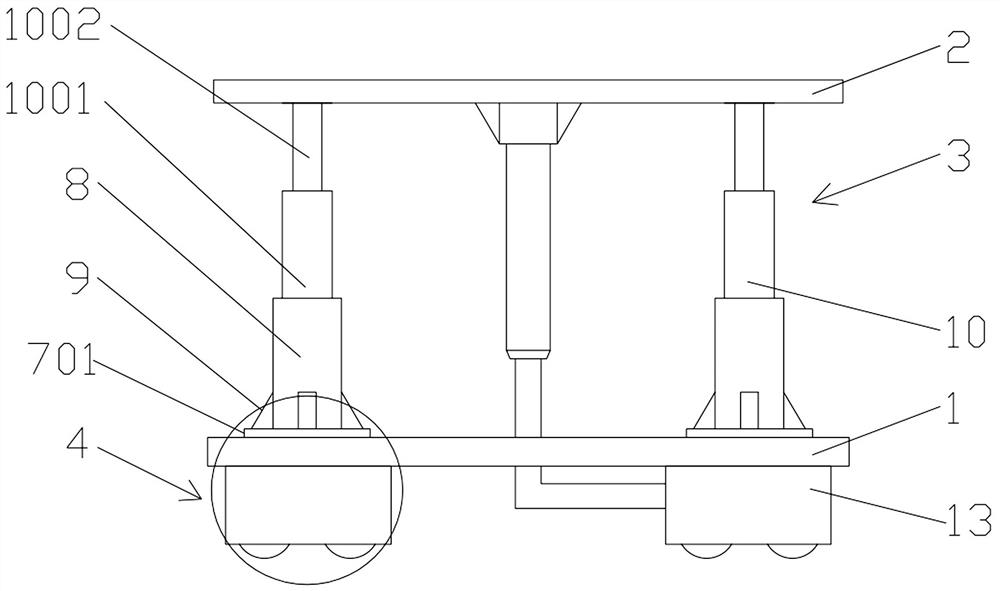

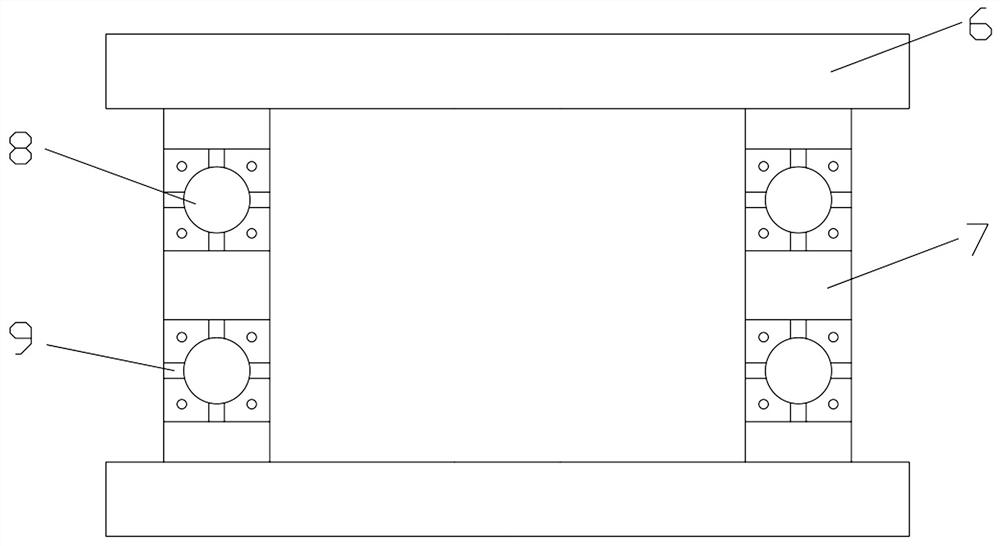

Bridge simply supported-continuous hogging moment tensioning trolley

PendingCN111576243ASolve lifting problemsSolve the positioning problemBridge erection/assemblyNumerical controlJackscrew

The invention discloses a bridge simply supported-continuous hogging moment tensioning trolley, which comprises a bottom support; an outer steel pipe is vertically and upwards arranged in the middle of the bottom support; an inner steel pipe penetrates into the outer steel pipe; two vertically upward angle steels are symmetrically arranged on the outer wall of the outer steel pipe; the top ends ofthe two angle steels are connected with the bottom of the supporting steel plate; two mounting steel plates are fixed on the surface of the supporting steel plate; a pulley is arranged between the mounting steel plates; a penetrating hole is formed in the supporting steel plate below the pulley; the steel wire rope is connected with the top of the inner steel pipe after passing through the pulleyand the penetrating hole; the other end of the steel wire rope is connected with a winch; the winch is connected with a motor; the bottom of the inner steel pipe is connected with a sliding rail; andone end of the sliding rail is rotationally connected with a jack mounting plate which is provided with a jack. According to the trolley, the jack is lifted through a rotating and telescopic structure, one-time numerical control tensioning of a whole bundle of steel strands can be achieved, the working intensity is greatly reduced, the stress of the same bundle of steel strands is uniform, and the purpose of numerical control tensioning is achieved.

Owner:GUIZHOU BRIDGE CONSTR GROUP

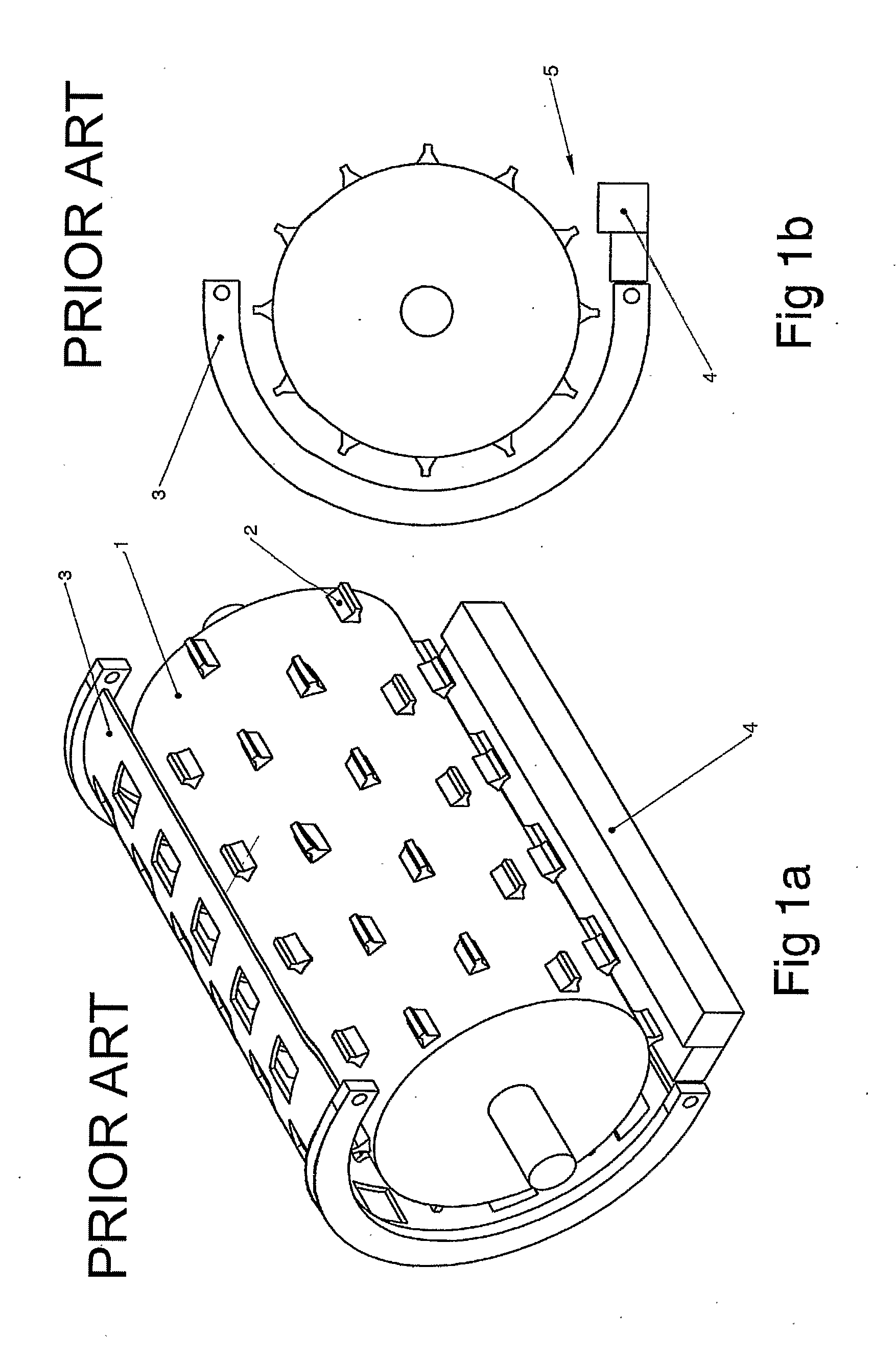

Load transference in grinding disks

InactiveUS7469852B2Firmly connectedQuick assemblyWood working apparatusCocoaCircular discWood shavings

Owner:PROGRESSIVE IP

Method for constructing continuous U-shaped beams

InactiveCN102086630AReduce dosageReduce mid-span bending momentBridge erection/assemblySocial benefitsShaped beam

The invention discloses a method for constructing continuous U-shaped beams, which comprises the following steps: pouring simply-supported U-shaped beams required for maintenance, reserving plain-bar and prestressed-tendon pipes at the ends of the simply-supported beams, and meeting the stress requirements of the simply-supported beams in the processes of simple supporting and hoisting, after the simply-supported beams meet the installation requirements, transporting the simply-supported beams to the construction site, then hoisting the integral simply-supported beams to the right places by adopting a temporary pedestal, and reserving an operating joint between each two U-shaped beams; stretching a capping hogging-moment prestressed tendon in the operating joint between each two simply-supported U-shaped beams, and connecting a wet joint with the operating seam; and after the wet joint reaches a required strength, removing the temporary pedestal and setting up a permanent pedestal, so that the original simply-supported beams are changed into stressed continuous beams. Compared with the prior art, compared with a simply-supported beam bridge with a same span, a simply-supported beam bridge adopted firstly and a continuous U-shaped beam bridge adopted sequentially in the invention can reduce the span moment, thereby saving the application amounts of steel and concrete, and obtaining the application performance as same as that of the continuous beam bridge under the condition that the technical difficulty is not high and the construction period is short, therefore, the economic benefits and social benefits of the method disclosed by the invention are extremely considerable.

Owner:SOUTHEAST UNIV +1

T-shaped hogging moment tensioning and clamping hanging cage of personnel safety protection mechanism for bridge construction

ActiveCN112049022APrevent fallingImprove the protective effectBridge erection/assemblyBuilding material handlingArchitectural engineeringWinch

A T-shaped hogging moment tensioning and clamping hanging cage of a personnel safety protection mechanism for bridge construction comprises a safety mechanism, a trolley, a hanging cage body, a pushing block and a hydraulic rod. The safety mechanism comprises the trolley, a support is arranged at the left end of the trolley, a winch is arranged at the bottom end of the support, and a positioning frame is fixedly connected to the bottom end of the winch. The hanging cage body is hung on one side of the side wall of a bridge, the top end of the hanging cage body is fixedly connected with a hook,the bottom end of the hanging cage body is fixedly connected with a storage bin, and the interior of the hanging cage body is connected with an ascending plate. The T-shaped hogging moment tensioningand clamping hanging cage is more convenient and faster to use and high in safety coefficient, mounting is carried out through combination, the space occupancy rate is reduced through dismounting after use, and the working efficiency is improved; in addition, during ascending and descending, the risk of accidental sliding is avoided through clamping of locking blocks and clamping teeth, and the guarantee for personal safety of personnel is improved.

Owner:THE THIRD ENG CO LTD OF THE CCCC THIRDHIGHWAY ENG CO LTD

Hogging moment area low-shrinkage bridge structure and construction method thereof

PendingCN111254801AEnsure force resistanceQuality assuranceBridge structural detailsBridge erection/assemblyShrinkage crackingArchitectural engineering

The invention discloses a hogging moment area low-shrinkage bridge structure and a construction method thereof. Basic filling of joints can be completed through prefabricated core blocks, so that cast-in-place of concrete is reduced. As core blocks are of a prefabricated structure, the shrinkage effect of concrete is basically eliminated, and the cracking risk of the concrete due to self reasons is reduced. And the joints and the core blocks are cast in place through the ultra-high performance concrete, so that the quality of the joints can be guaranteed only through a small amount of the ultra-high performance concrete, and economical efficiency and reliability are achieved. Besides, at least one layer of first reinforcing steel bars are embedded in the core blocks in the length directionof a bridge, multiple layers of second reinforcing steel bars are embedded at corresponding positions in a composite beam in the length direction of the composite beam, and when the core blocks are placed into joints, the second reinforcing steel bars can be mechanically connected or welded to the first reinforcing steel bars, so that the stress performance of the core blocks and the safety of the whole bridge structure are ensured. The invention aims to solve the technical problem that an existing hogging moment area joint structure is prone to shrinkage cracking.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

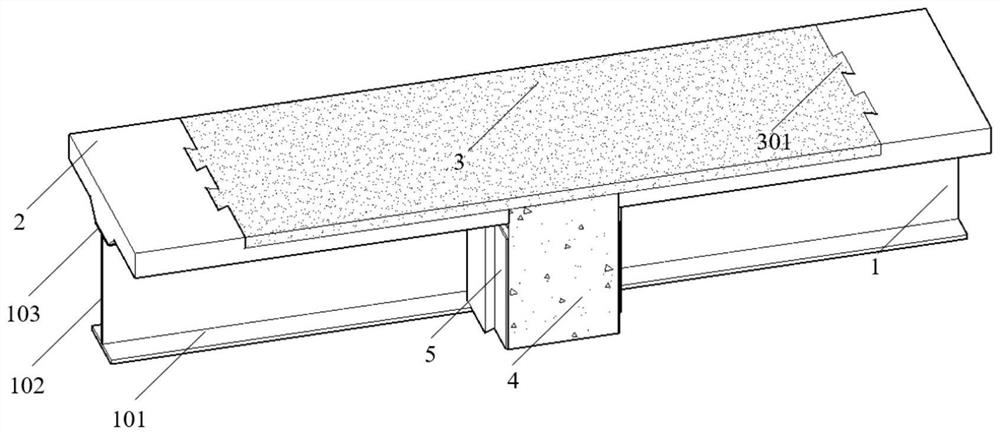

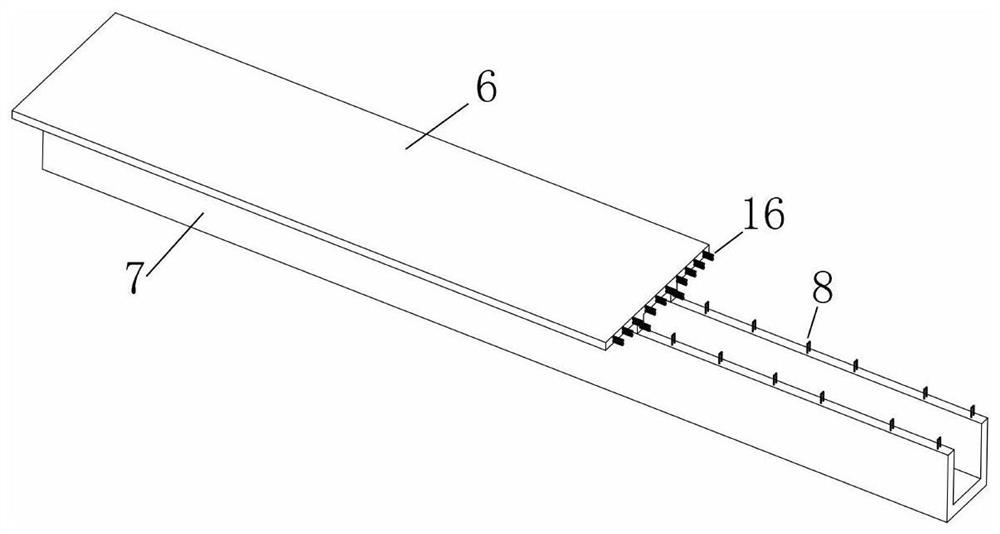

Structure for hogging moment area of steel-concrete composite continuous beam bridge

PendingCN112211089AImprove mechanical performanceImprove tensile propertiesBridge structural detailsBridge deckContinuous beam

The invention belongs to the technical field of bridges. The invention discloses a structure for a hogging moment area of a steel-concrete composite continuous beam bridge. The structure comprises a first prefabricated main beam and a second prefabricated main beam, notches are formed in opposite end parts of the first prefabricated body main beam and the second prefabricated body main beam, so that the notches of the first prefabricated body main beam and the second prefabricated body main beam are spliced to form a T-shaped joint of a vertical groove body of which the upper part is a zigzagedge and the middle lower part is a zigzag edge; the first prefabricated main beam and the second prefabricated main beam are each composed of a beam body formed by welding steel plates, the beam plates comprise I-shaped steel, bridge decks and end partition plates, the tops of the I-shaped steel are connected with the bridge decks, the bridge decks are in a step shape, and the end partition plates are welded to the junctions of the I-shaped steel and cast-in-place wet joints. The hogging moment area structure is novel in structure, convenient to construct and high in applicability, so that the cracking of concrete joints of the bridge decks in the hogging moment area is prevented, and the structural durability is improved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

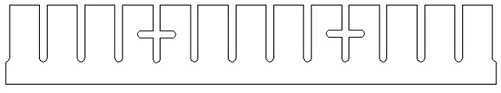

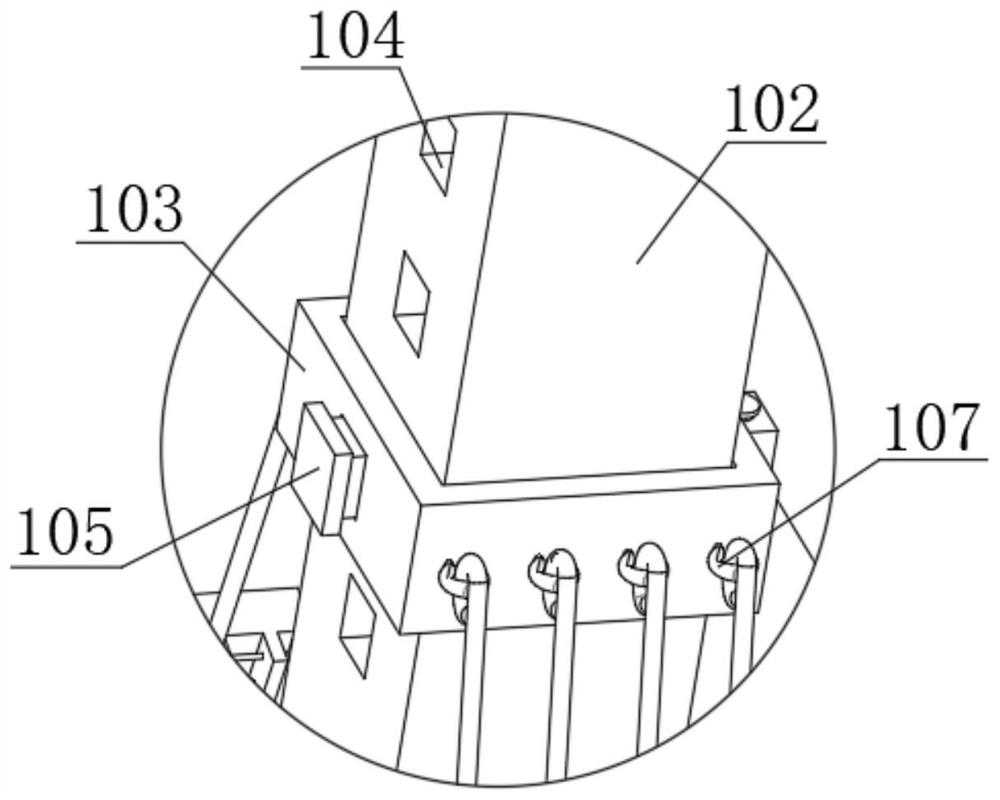

Box girder hogging moment tensioning notch formwork and construction process thereof

PendingCN111941604AReduced bite depthReduce the opening areaMould auxillary partsMould panelsArchitectural engineeringRebar

The invention discloses a box girder hogging moment tensioning notch formwork and a construction process thereof. The box girder hogging moment tensioning notch formwork comprises an upper toothed plate, a middle toothed plate and a lower toothed plate. The upper toothed plate, the middle toothed plate and the lower toothed plate are sequentially connected into a whole, the upper toothed plate andthe middle toothed plate are matched to form a plurality of steel bar preformed holes, the middle toothed plate and the lower toothed plate are matched to form a plurality of steel bar preformed holes, and a plurality of tensioning preformed holes are formed in the middle toothed plate; and the upper toothed plate and the lower toothed plate are of the same structures. According to the box girderhogging moment tensioning notch formwork, optimization design is conducted on the basis of an original formwork, the whole formwork is disassembled into three pieces, the meshing depth of the formwork and steel bars is reduced, the opening area of the formwork is reduced, formwork losses are effectively reduced, formwork turnover is increased, and the hogging moment notch concrete construction quality assurance rate is increased.

Owner:NO 5 ENG CO LTD OF CCCC FIRST HARBOR ENG

Steel-recycled concrete composite beam component with composite structure

PendingCN113152785AImprove the bending capacityImprove connectivityLoad-supporting elementsAggregate (composite)Public place

The invention provides a steel-recycled concrete composite beam component with a composite structure. The steel-recycled concrete composite beam component is mainly applied to residential buildings, public places and other civil buildings; a tensile steel plate of the component is positioned on the upper surface of concrete in a hogging moment area; the lower surface of the steel plate is a rough surface, and pouring holes are formed to ensure that the concrete is poured compactly; stud connecting pieces and channel steel connecting pieces are welded on the upper surface of a steel beam and reliably welded with the bottoms of profiled steel plates; the upper parts of tie bolts are bolted with the tensile steel plate, and the lower parts are bolted with the convex parts of the corresponding profiled steel plates; and the recycled concrete is densely filled between the profiled steel plates and the tensile steel plate, and is concrete which is completely or partially made of recycled coarse aggregate, recycled fine aggregate, recycled micro powder or doped with other waste materials. By arranging the composite structure in the composite beam, the bending resistance of the hogging moment area can be greatly improved, the problem that the width of a hogging moment crack of recycled concrete is too large is solved, the connection degree of all parts is remarkably increased, and the material performance of the concrete is fully played.

Owner:HARBIN INST OF TECH

UHPC + NC composite bridge deck in hogging moment area of steel-concrete composite beam

A steel-concrete composite beam hogging moment area UHPC + NC composite bridge deck comprises a UHPC ultra-high performance concrete layer and an NC common concrete layer, the NC common concrete layer is laid on a steel beam, and the UHPC ultra-high performance concrete layer is laid on the NC common concrete layer. The NC common concrete layer and the UHPC layer are both fixedly connected with the steel beam, the thickness of the UHPC layer and the thickness of the NC common concrete layer are the largest than tau at the middle supporting point, and tau is gradually reduced in the longitudinal direction of the bridge at the middle supporting point. According to the hogging moment area UHPC layer and NC common concrete layer laminated bridge deck based on the steel-concrete composite beam stress behavior and the steel-concrete interface behavior, the requirement for the bearing capacity and durability of the hogging moment area is met, meanwhile, the using amount of UHPC materials is reduced, and therefore the purpose of being more economical is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

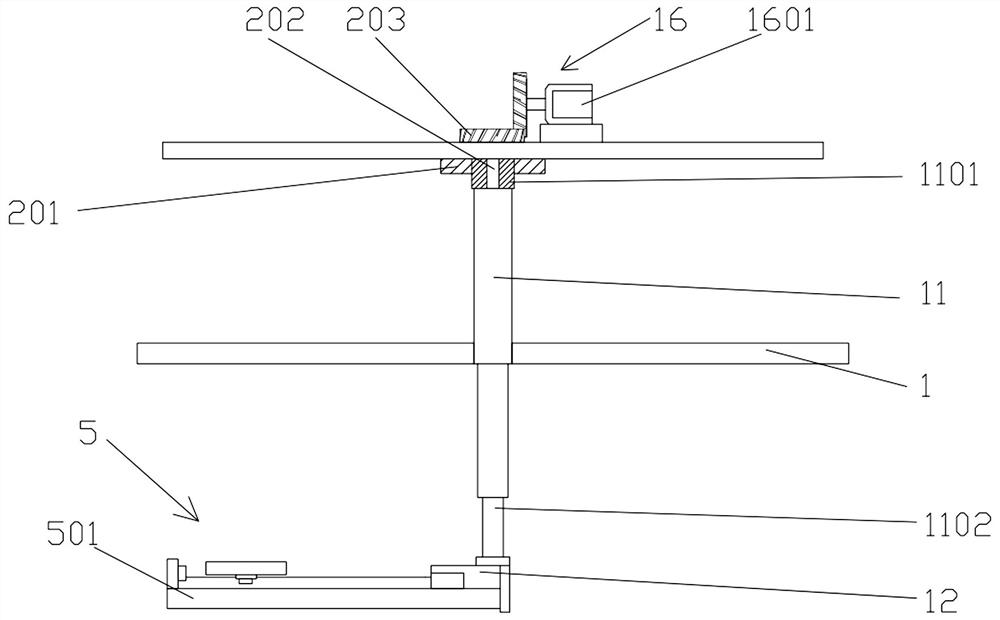

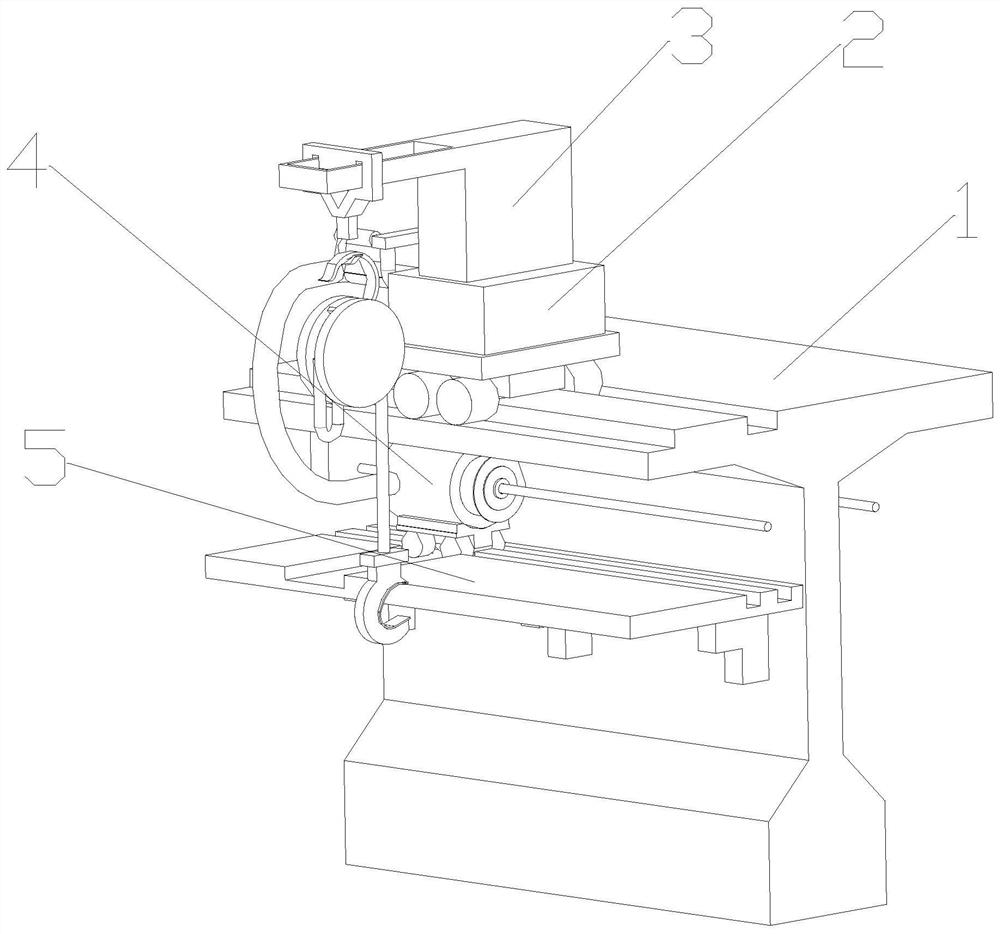

Hogging moment tensioning tool device

The invention provides a hogging moment tensioning tool device which comprises a base, an upper fixing plate, a supporting mechanism, a moving mechanism, a workbench and a rotating mechanism, the supporting mechanism is arranged between the base and the upper fixing plate, the moving mechanism is fixedly connected with the base, the workbench is connected with the supporting mechanism, and the rotating mechanism is fixedly connected with the workbench. The rotating mechanism is arranged above the upper fixing plate, a controller is further arranged, the controller comprises an operating handle, and the operating handle is used for controlling the supporting mechanism, the moving mechanism, the workbench and the rotating mechanism to work. The hogging moment tensioning device can meet the hogging moment tensioning requirements of different scenes, the labor load of operators is reduced, operation is easy and convenient, the structure is stable, running is stable, and the production efficiency is high.

Owner:CCCC SECOND HARBOR ENG

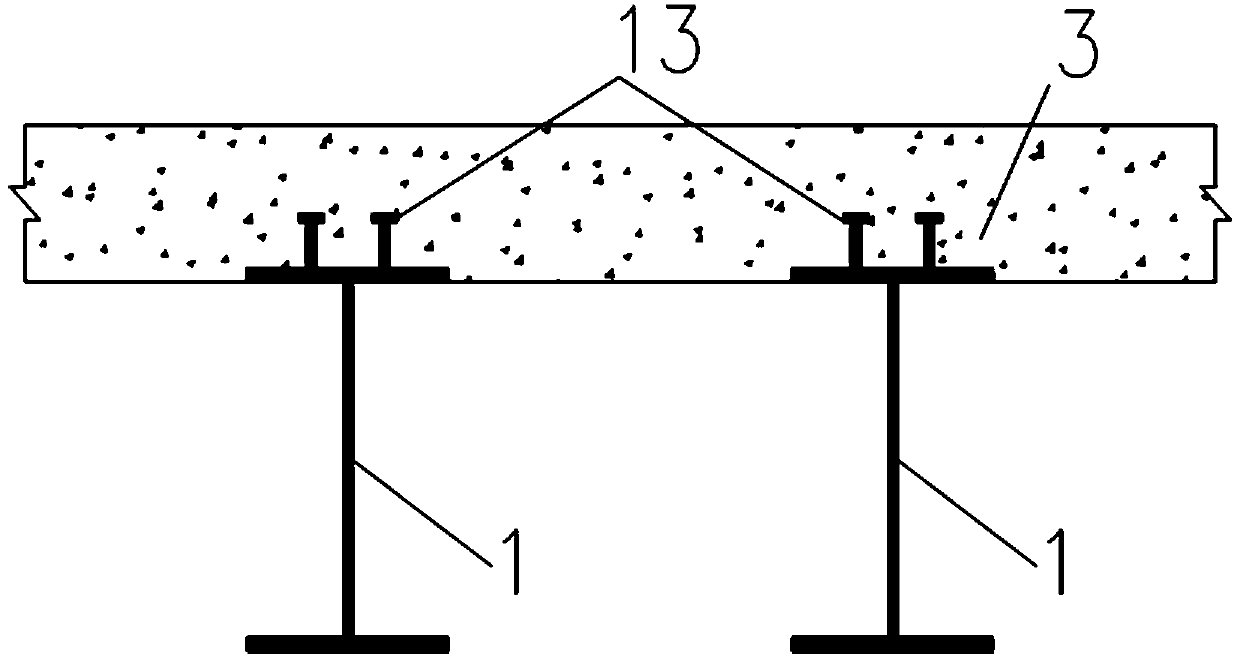

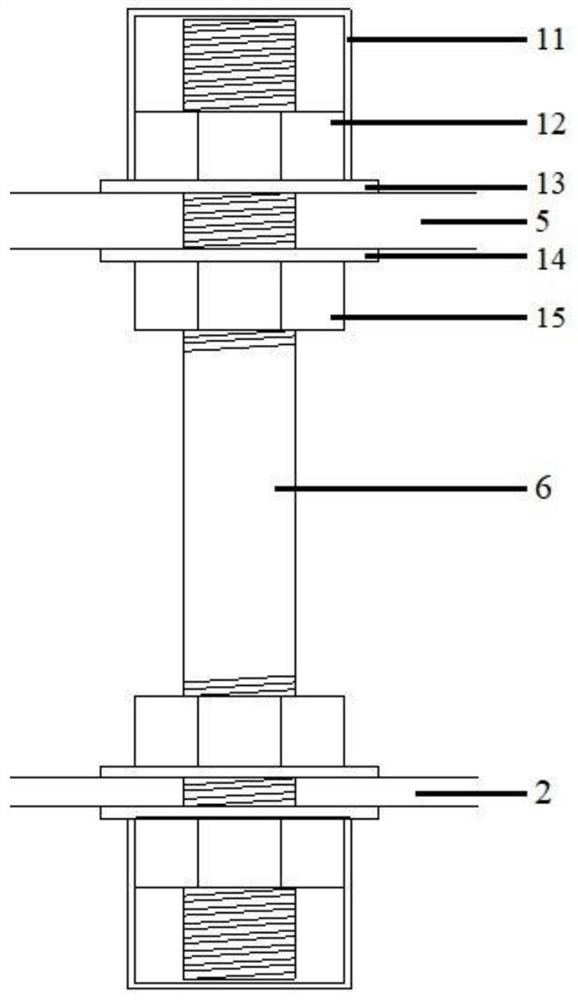

Reinforced concrete cast-in-place slab hogging-moment rebar protection structure

PendingCN111485723AImprove pass rateLow costBuilding material handlingReinforced concreteArchitectural engineering

The invention provides a reinforced concrete cast-in-place slab hogging-moment rebar protection structure. The structure comprises a framework. Sagging-moment rebars and hogging-moment rebars are arranged in the framework. The sagging-moment rebars and the hogging-moment rebars are located on the upper side and the lower side of the framework respectively and are distributed in a staggered manner.Protectors are arranged on the framework. Each protector comprises a galvanized steel pipe, a handle and a notch groove, wherein the handle is arranged on the top of the galvanized steel pipe, the notch groove is formed in the middle segment of the galvanized steel pipe, and the notch groove is located beside the corresponding hogging-moment rebar. The hogging-moment rebars are protected with theprotectors. According to the reinforced concrete cast-in-place slab hogging-moment rebar protection structure, because the hogging-moment rebars can be firmly locked by the notch grooves and do not move with vibration, the project quality is improved, seven days after initial set of concrete, an infrared detector is used to carry out detection, a deviation qualification rate of a hogging-moment rebar protective layer reaches 90% or more, and the using effect is quite good; construction is convenient to carry out, and operation is easy to carry out; and because the protection structure is returnable in using, the project cost is reduced, and the protection structure is worthy of promotion and application.

Owner:JIANGSU SUZHONG CONSTR GROUP

Simplified structure of hogging moment area of concrete continuous beam

PendingCN111424534ASimple designEasy constructionBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a simplified structure of a hogging moment area of a concrete continuous beam. The simplified structure comprises a steel bar structure and a concrete pouring structure. The steel bar structure comprises constructional steel bars arranged on a hogging moment area cast-in-place section and anti-bending steel bars arranged on a hogging moment area bridge deck slab section. The constructional steel bars are fixedly connected with beam end steel bars; the constructional steel bars are fixedly connected with the anti-bending steel bars; wherein the hogging moment area cast-in-place section is located between two adjacent beam ends, the hogging moment area bridge deck slab section is located above the two adjacent beam ends and above the hogging moment area cast-in-placesection, and an integral T-shaped structure formed by simultaneously pouring concrete on the hogging moment area bridge deck slab section and the hogging moment area cast-in-place section is a concrete pouring structure. Compared with the prior art, the simplified structure has advantages that hogging moment is resisted by arranging common steel bars and pouring high-performance concrete, the construction process is simple, and the cost is low.

Owner:JIANGXI PROVINCIAL EXPRESSWAY INVESTMENT GRP CO LTD

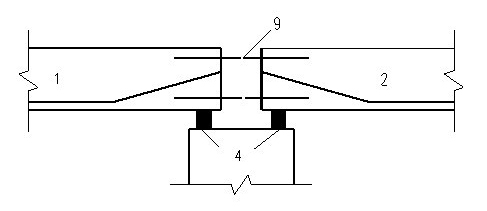

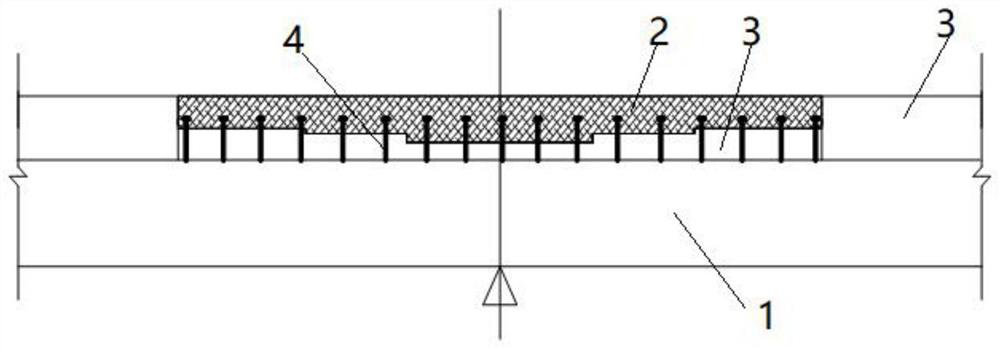

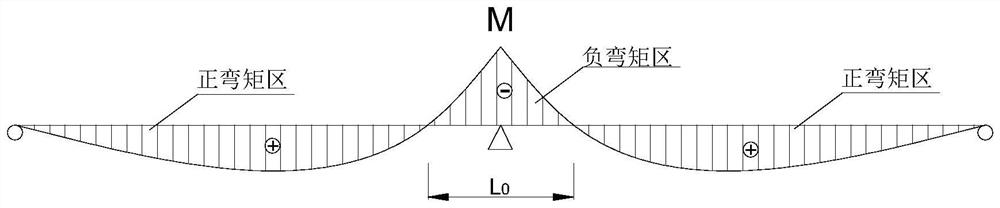

A Method of Prestressing the Concrete Slab of the Upper Flange of the Composite Beam

ActiveCN108914778BLow costSolve the problem of difficult application of prestressBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a method for applying pre-pressure to concrete boards of a composite beam top flange. The method includes the steps that the concrete boards in a sagging moment area and a hogging moment area of a composite beam are constructed, then, reserved concrete board connecting sections are arranged in the position near the junction of the sagging moment area and the hogging momentarea, jacks are arranged at intervals in the reserved concrete board connecting sections, so that the pre-pressure is applied to the concrete boards in the hogging moment area, the concrete boards areconstructed in the areas, without the jacks, of the reserved concrete board connecting sections, and then after the jacks are detached, the concrete boards are constructed in remaining parts in the reserved concrete board connecting sections. The method in the scheme has the advantages that the building cost of a project is reduced, construction is convenient, pre-pressure losses are few, efficiency is high, and the popularization prospects are good.

Owner:FUZHOU UNIV

Box girder hogging moment prestress tension protection device

ActiveCN113605237AShorten the range of bouncingAvoid harmClimate change adaptationBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a box girder hogging moment prestress tension protection device, and relates to the field of building safety protection. The box girder hogging moment prestress tensioning protection device comprises a hogging moment tensioning piece, a prestress adjusting piece and a section type tensioning falling protection piece, the upper surface of the hogging moment tensioning piece is provided with the prestress adjusting piece, and the section type tensioning falling protection piece is arranged between the hogging moment tensioning piece and the prestress adjusting piece in a sliding mode. According to the box girder hogging moment prestress tensioning protection device, a tensioning steel cable is arranged through the hogging moment tensioning piece, tensioning is carried out by controlling a tensioning trolley to move in a tensioning guide rail, personnel cannot be exposed in the tensioning range in the whole tensioning process, the personnel can be effectively prevented from being hurt by tensioning rebound, the section type tensioning falling protection part is arranged on the tensioning steel cable, the counter weight of the tensioning steel cable is increased by arranging the section type tensioning falling protection part on the tensioning steel cable in a section mode, and the springing range of the tensioning steel cable is shortened when the steel cable falls off and rebounds.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

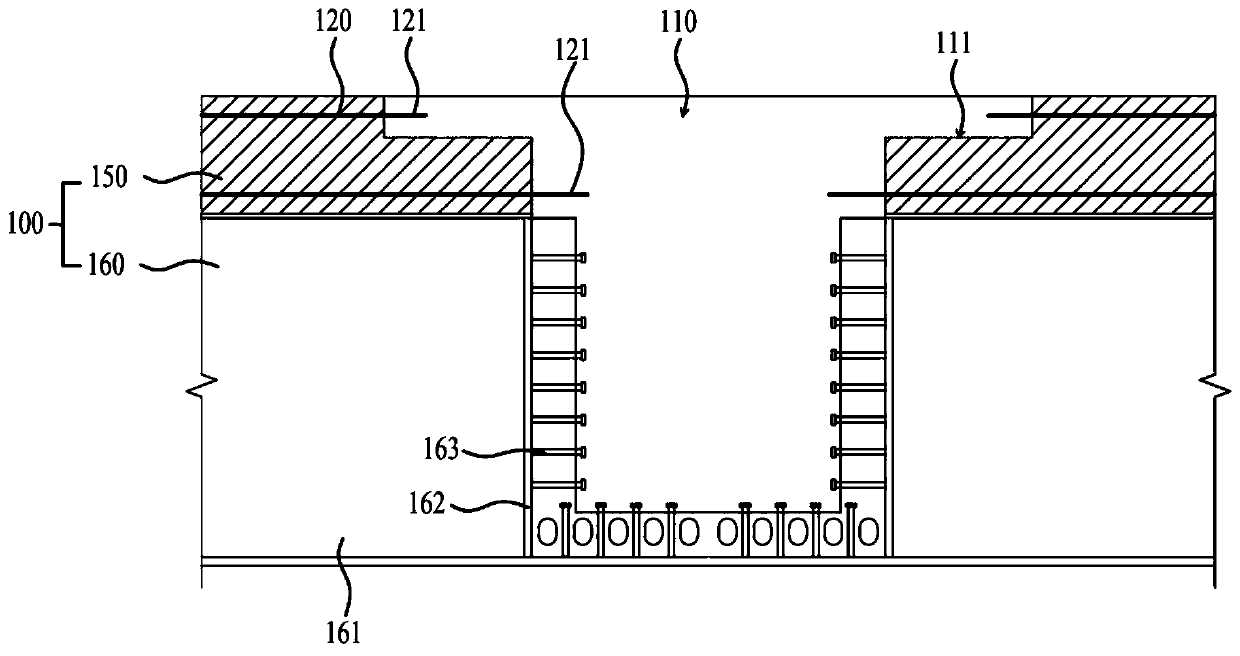

Continuous beam hogging moment zone chlorine salt environment load holding experiment device and experiment method

PendingCN114354341AEasy to useEasy to operateWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTest beamContinuous beam

The invention discloses a continuous beam hogging moment zone load holding experiment device and experiment method in a chlorine salt environment, and relates to the technical field of engineering experiments. Comprising a high-rigidity main frame, a load system, an erosion system and a test beam, and the test beam is detachably arranged on the high-rigidity main frame; the load system is arranged on the high-rigidity main frame, is positioned below the test beam and is used for applying a load to the test beam; the erosion system is arranged on the test beam, and a chlorine salt solution is arranged in the erosion system; the test beam is a continuous beam meeting design requirements. According to the experimental device, the test beam can be fixed to the load system, reverse balance force is provided for the test beam by adjusting the adjustable counter-force support, the load system provides force needed by load holding, and the load holding state is simulated; the erosion system and the dry-wet circulation system provide dry-wet circulation conditions in a chlorine salt environment; the experimental device provided by the invention is stable and reliable, is convenient to use, and can provide test conditions for the dry-wet cycle and loading coupling effect in the chlorine salt environment.

Owner:INNER MONGOLIA UNIV OF TECH

Precast box girder hogging moment reinforcing rib and construction technology

ActiveCN112554030APrecise positioningAvoid mutual interferenceBridgesBuilding reinforcementsBridge engineeringPre stress

The invention discloses a precast box girder hogging moment reinforcing rib and a construction technology, and belongs to the technical field of precast box girder construction. The precast box girderhogging moment reinforcing rib and the construction technology comprise a precast box girder and further comprise a corrugated pipe and a square reinforcement cage, and the square reinforcement cageis composed of a plurality of reinforcing main ribs, reinforcing stirrups and dense stirrups; the plurality of reinforcing main ribs are transversely arranged, the plurality of reinforcing stirrups and the plurality of dense stirrups are longitudinally arranged, the plurality of dense stirrups are symmetrically arranged on the two sides of the square reinforcement cage, and the plurality of reinforcing stirrups are arranged between the dense stirrups on the two sides. According to the precast box girder hogging moment reinforcing rib and the construction technology, the problems that when thereinforcing ribs in the hogging moment area of the prefabricated box girder and concrete are not compact and are tensioned, prestress loss, anchor bearing plate tension fracture and sinking occur, deformation is too large, and safety accidents are caused are solved, and smooth construction of bridge engineering which is simply supported first and then is continuous is guaranteed.

Owner:江西省地质工程集团有限公司

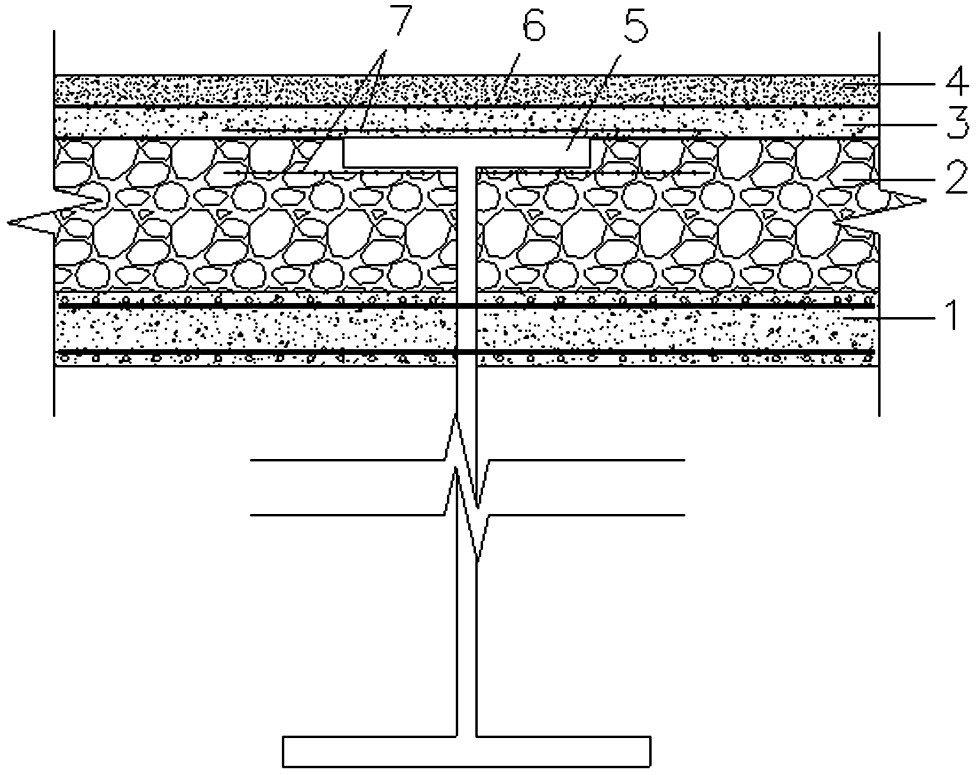

Steel-concrete composite beam bridge hogging moment area bridge deck structure adapting to deformation and construction method

PendingCN112663495AReduce stiffnessGood deformabilityBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a steel-concrete composite beam bridge hogging moment area bridge deck structure adapting to deformation and a construction method, the steel-concrete composite beam bridge hogging moment area bridge deck structure adapting to deformation comprises a steel beam, a pavement surface layer, a pavement base layer and a bearing plate, the beam height of the steel beam in a hogging moment area is 10-40 cm higher than the beam height in a positive bending moment area, and the pavement base layer is located above the bearing plate; wherein an upper wing plate of the steel beam is embedded in the paving base layer or between the paving base layer and the paving surface layer, a local reinforcing net is arranged on the upper side of the upper wing plate of the steel beam or on the upper side and the lower side of the upper wing plate of the steel beam, and the local reinforcing net is combined with the paving surface layer or the paving base layer. The bridge deck structure is small in rigidity, the deformation capacity of the bridge deck structure is better under the action of loads, meanwhile, the connection between the bridge deck structure and the upper wing plate of the steel beam is weakened, the bridge deck structure bears smaller negative bending area tensile stress, and therefore the bridge deck structure can well adapt to the characteristic of large deformation of a negative bending moment area of a composite beam bridge.

Owner:FUZHOU UNIV

Circulating water-cooled anti-fog swimming goggles

The invention belongs to the field of sports equipment, and in particular relates to a circulating water-cooled anti-fog swimming goggle, which includes a frame and a lens installed in the frame. Both sides of the frame are fixed with circulating water tanks, and both sides of the circulating water tank A one-way water inlet pipe and a one-way water outlet pipe are fixedly connected respectively. The inner bottom surface of the picture frame is provided with a condensation pipe, and the condensation pipe is made of a transparent heat-conducting material. It communicates with the condensing pipe, and the other end of the condensing pipe runs through the picture frame and extends to the outside of the picture frame. The inner wall of the circulating water tank is rotatably connected with a rotating shaft, and one end of the rotating shaft runs through the circulating water tank and is coaxially fixedly connected with an impeller. A ring magnet is arranged in the circulating water tank. In the present invention, the water vapor in the mirror frame is more likely to condense at the condensation pipe. Since the water vapor in the mirror frame will be preferentially condensed into water droplets on the surface of the condensation pipe, it effectively solves the problem of fogging and condensation water droplets on the inside of the lens, ensuring swimmers vision.

Owner:GUANGZHOU SHUAIPU SPORT GOODS CO LTD

Reinforcement method of anti-arch structure based on reduction of negative bending moment at arch foot of arch bridge

ActiveCN106836022BIncrease stiffnessReduce internal forceBridge erection/assemblyBridge strengtheningSupporting systemEngineering

The invention provides an inverted-arc structure reinforcing method based on decrement of the hogging moment of arch feet of an arch bridge. According to the inverted-arc structure reinforcing method based on decrement of the hogging moment of the arch feet of the arch bridge, an inverted arch is arranged below an arch rib of a main arch ring, and the inverted arch and the arch rib are connected through a vertical rod; then the arch feet of the inverted arch and the arch rib are connected through anti-bending embedded parts and anti-shear anchor bolts, so that the inverted arch structure used for reinforcing and the original main arch ring form a rigid restrained supporting system; and the decrement degrees of the hogging moment of the arch feet of the arch bridge in the rigid restrained supporting system have a close relation with seven parameters of a to-be-reinforced arch and the inverted arch. By setting different variable values of the seven parameters, the ratio of the hogging moment of the arch feet of the original arch to the hogging moment of the arch feet after reinforcement is used as the change characterization of the bending moment, and a relational expression between the seven parameters and the change characterization of the bending moment is obtained based on a finite element parameter analysis fitting method. By adoption of the inverted-arc structure reinforcing method based on decrement of the hogging moment of the arch feet of the arch bridge, the structural characteristic internal force value can be solved based on the relational expression, and thus the optimal scheme is selected for inverted-arch reinforcement.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Segmented prestressed concrete-filled steel tube truss continuous combined bridge and construction method thereof

PendingCN111676798AHigh strengthIncrease stiffnessTruss-type bridgeBridge structural detailsPre stressArchitectural engineering

The invention provides a segmented prestressed concrete-filled steel tube truss continuous combined bridge and a construction method thereof. The bridge comprises a segmented prestressed concrete-filled steel tube truss and concrete bridge deck slabs. The concrete-filled steel tube truss comprises a concrete-filled steel tube upper chord member, a concrete-filled steel tube lower chord member anda steel tube web member. Prestress is applied to the interiors of a bridge hogging moment area concrete-filled steel tube upper chord member and a hogging moment area concrete-filled steel tube lowerchord member, and the concrete-filled steel tube upper chord member and the upper concrete bridge deck slab are connected through shear connectors to form integration to work together. The characteristics that the concrete-filled steel tube tension chord member is suitable for applying prestress, and the concrete-filled steel tube compression chord member is high in bearing capacity and good in stability are comprehensively utilized; prestress is applied to the tensioned chord members in the hogging moment area, and prestress is applied to the tensioned chord members in the hogging moment area, so that the cracking risk of the concrete slab is reduced, the strength and rigidity of the section are improved, and thus ideal stress performance, construction performance and comprehensive economic indexes are obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

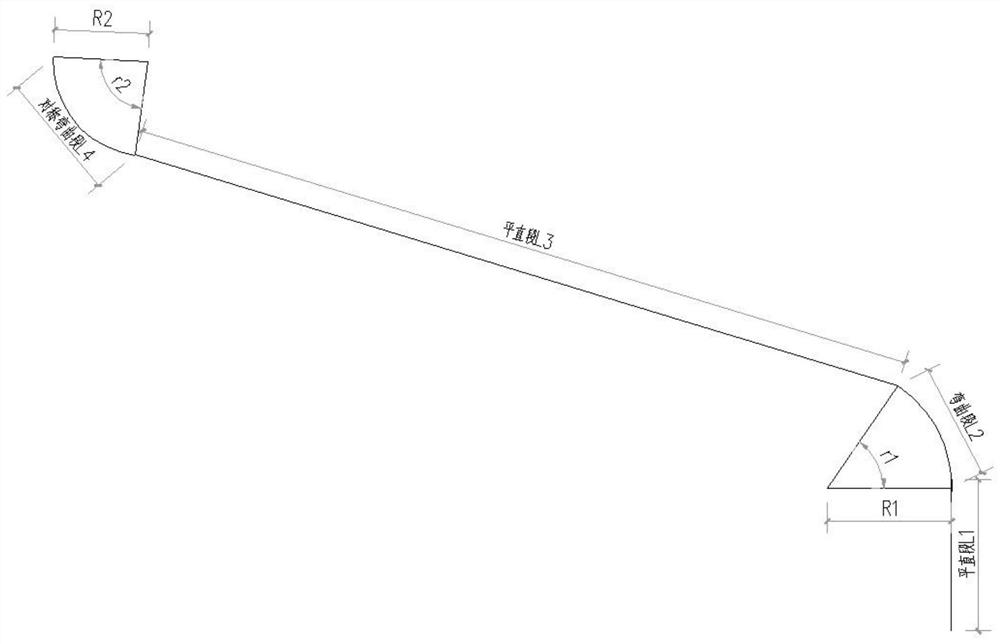

Floor slab hogging moment steel bar protection layer control device and using method thereof

PendingCN112523433ASufficient stress conditionsAvoid deformationBuilding reinforcementsBuilding material handlingFloor slabRebar

The invention discloses a floor slab hogging moment steel bar protective layer control device and a using method thereof. The protective layer control device is formed by bending deformed steel bars and comprises a supporting arc, two horizontal supporting legs, two vertical supporting legs and two front supporting points, wherein the two horizontal supporting legs, the two vertical supporting legs and the two front supporting points are symmetrically arranged, the top ends of the two horizontal supporting legs are connected to the two ends of the supporting arc correspondingly, the bottom ends of the horizontal supporting legs are connected to one ends of the vertical supporting legs, furthermore, the horizontal supporting legs symmetrically arranged in the protective layer control deviceare composed of straight sections L3, the horizontal supporting legs are perpendicular to the vertical supporting legs in the horizontal direction, and the smooth upward bending length of the connecting ends of the horizontal supporting legs and a supporting arc section is D. According to the floor slab hogging moment steel bar protection layer control device and the using method thereof, the design stress position of the floor slab reinforcing steel bar can be guaranteed, the steel bar deformation and shifting caused by treading board ribs is prevented, the device is not prone to topple, thethickness of a floor slab and the thickness of a reinforcing steel bar protection layer can be controlled at the same time, construction is convenient, and the construction quality is improved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

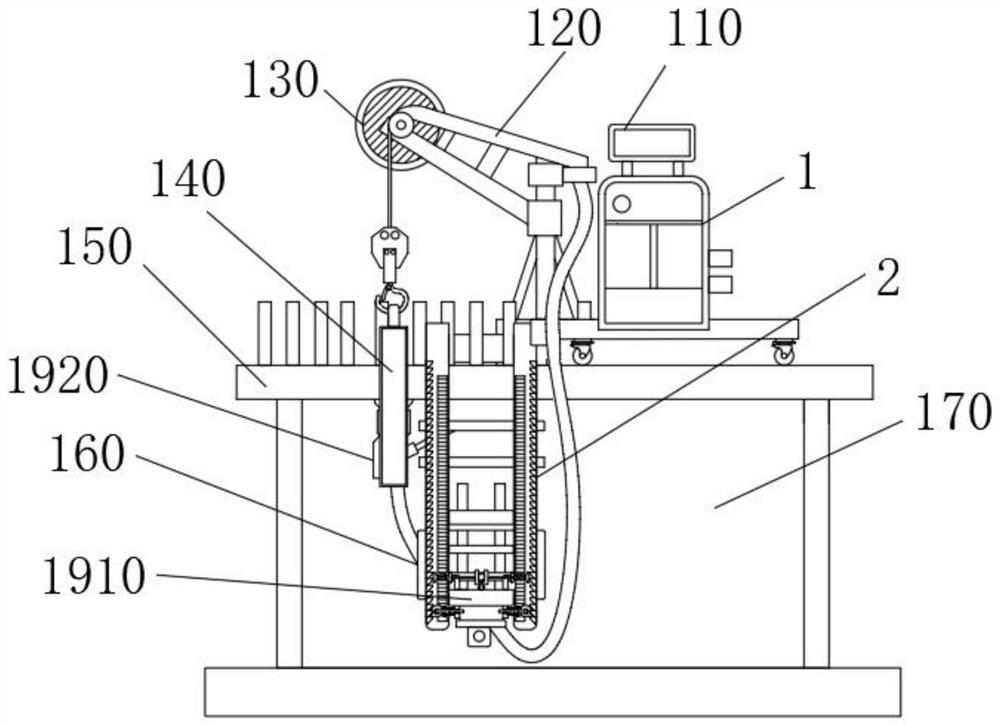

Movable and convenient hogging moment tensioning equipment

PendingCN113668396AOmit liftingSave calibration timeBridge erection/assemblyConstruction engineeringJackscrew

The invention discloses movable and convenient hogging moment tensioning equipment, and relates to the field of engineering construction. The movable and convenient hogging moment tensioning equipment comprises a supporting mechanism, the top end of the supporting mechanism is movably connected with a moving mechanism, the end, away from the supporting mechanism, of the moving mechanism is fixedly connected with a hanging mechanism, the bottom end of the supporting mechanism is provided with a fixed supporting mechanism, the fixed supporting mechanism is fixedly connected with the side wall of the bottom end of the supporting mechanism, the top end of the fixed supporting mechanism is movably connected with a tensioning mechanism, the supporting mechanism comprises a base table, a moving groove is formed in the top end of the base table, an embedded plate is arranged at the bottom end of the base table, a tensioning rib is fixedly connected with the front end of the embedded plate, and the bottom end of the moving mechanism is fixedly connected with a movable connecting bracket. When the equipment is used, a heavy jack can be hoisted to the position needing to be tensioned in a more labor-saving mode to conduct hogging moment tensioning by arranging a position-adjustable suspension type suspension mechanism, the wasted lifting and calibration time is saved, and the working efficiency is improved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

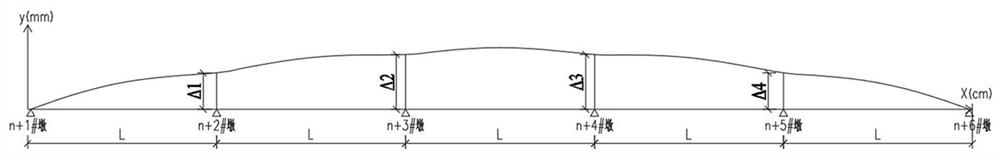

Method for improving cracking resistance of hogging moment area of steel-concrete composite beam bridge

ActiveCN112523098APrecise Collaborative Beam DropImprove ergonomicsBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention relates to a method for improving the crack resistance of the hogging moment area of a steel-concrete composite beam bridge. When the steel beam is manufactured, fulcrum settlement pre-lifting is considered, after the concrete bridge deck slab is combined with the steel beam, multi-fulcrum cooperative precise settlement is achieved through a PLC system, and pre-pressure is applied tothe bridge deck slab; and settlement pre-elevation of each supporting point is determined according to the anti-cracking requirement of the bridge deck, and the conventional pre-camber is superposedto serve as the designed pre-camber of the steel beam. After the concrete bridge deck slab is combined with the steel beam, the PLC multi-point hydraulic control system is used for controlling the jacks at all pier positions, multi-support cooperative beam falling is achieved, and it is guaranteed that the bridge deck slab is in a pressed state all the time in the beam falling process. Compared with a conventional fulcrum settlement method for applying bridge deck slab prestress, pier-by-pier jacking, concrete pouring, settlement and other operations are not needed, synchronous concrete pouring at multiple fulcrums can be achieved, accurate and cooperative beam falling of the multiple supports at all the fulcrums can be achieved, the work efficiency can be improved, and the construction period can be shortened.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +1

Oriented fiber UHPC (Ultra High Performance Concrete) bridge deck slab for hogging moment area of steel-concrete composite beam and preparation and construction method

PendingCN114808691AReduce dosageImprove economyCeramic shaping apparatusBridge structural detailsFiberBridge engineering

The invention relates to the technical field of bridge engineering, in particular to an oriented fiber UHPC bridge deck of a steel-concrete composite beam hogging moment area and a preparation and construction method. The concrete slabs are connected with the head end and the tail end of the hogging moment area oriented fiber UHPC bridge deck slab through U-shaped connecting steel bars correspondingly, and the bottom of the hogging moment area oriented fiber UHPC bridge deck slab is of a step structure which is symmetrically and gradually decreased upwards from the center of the slab to the two longitudinal sides. Concave grooves with downward openings are formed in the tail ends of the stepped structures at the two ends; the concrete slab is of a structure shaped like a Chinese character'ji 'formed by combining a transverse slab body and a vertical slab body. A concave groove with a downward opening is formed in the bottom end surface of the transverse plate body of the concrete plate; a concrete layer is poured in a bottom cavity formed after the hogging moment area oriented fiber UHPC bridge deck slab and the concrete slab are spliced to form a wet joint asymmetric stepped concrete layer. According to the invention, the utilization efficiency of fibers is fully improved, the consumption of fiber materials is reduced, the anti-cracking performance is improved, and meanwhile, UHPC is only adopted in a local structure, so that the economical efficiency is guaranteed.

Owner:SOUTHEAST UNIV

UHPC-NC superimposed bridge deck steel-concrete composite beam hogging moment area section checking calculation method

The invention discloses a UHPC-NC superimposed bridge floor steel-concrete composite beam hogging moment region section checking calculation method. The method comprises the following steps: inputting the section structure size of each part of a steel-concrete composite beam; vertically layering the section of each part to form a fiber strip; determining the width of a fiber strip; determining a nonlinear stress-strain relationship of each component material; analyzing the stress state of each part in the bridge forming stage as a primary stress state, and assigning the state to the determined fiber section; taking the NC concrete layer out of work, redistributing the internal force to the remaining section part, and obtaining the stress of each fiber strip by adopting a strip stacking method; gradually loading the bending moment of secondary stress, wherein the strain increased in each loading step linearly changes in the height direction of the cross section; judging whether the stress on the cross section meets the stress requirement or not; and obtaining the stress and strain states of each fiber, and calculating the crack width of the bridge deck UHPC and NC concrete layers in the normal use limit state according to the obtained steel bar stress and the UHPC concrete material fiber strain in combination with a related specification formula.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Continuous small box girder structure with combined section in hogging moment area and construction method thereof

PendingCN112900230AImprove cracking momentReduce dosageBridge erection/assemblyShrinkage crackingArchitectural engineering

The invention discloses a continuous small box girder structure adopting a combined section in a hogging moment area and a construction method thereof. The continuous small box girder structure comprises a prefabricated NC small box girder, a middle fulcrum connecting section and a prefabricated UHPC groove-shaped plate. The prefabricated UHPC groove-shaped plate is located in a negative bending moment area of the continuous beam, an empty groove is formed in the groove-shaped plate, and a concave connecting piece and a convex connecting piece are arranged at a web plate. According to the method, the cracking bending moment and durability of concrete in the hogging moment area are remarkably improved, the problem of shrinkage cracking of cast-in-place UHPC in the hogging moment area is solved, the method can adapt to the situation that the thicknesses of the NC plate and the UHPC plate are inconsistent, formwork erection during pouring of joints between UHPC webs is omitted, the method can adapt to prefabricated small box girders of various lengths, and industrial production is facilitated.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com