Steel-concrete composite beam bridge hogging moment area bridge deck structure adapting to deformation and construction method

A technology that adapts to deformation and steel-concrete. It is used in bridges, bridge parts, bridge construction, etc., and can solve problems such as increasing the burden of steel beams, adverse effects on durability, and weakening the effect of precompressive stress on concrete slabs, and achieves good stability. , good deformation ability, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

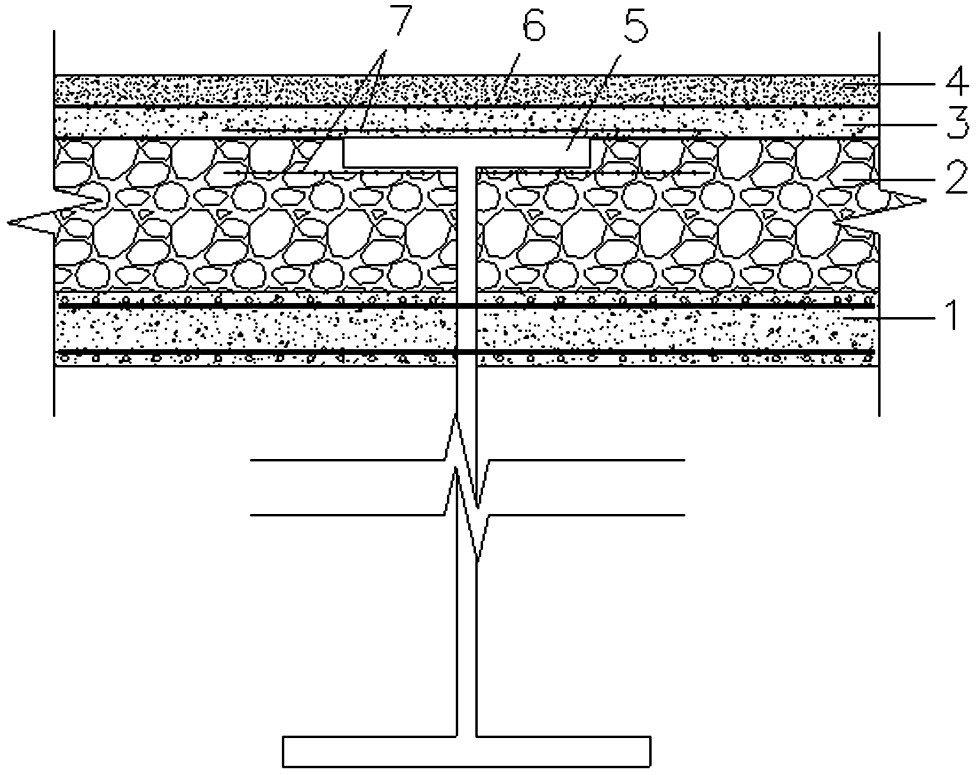

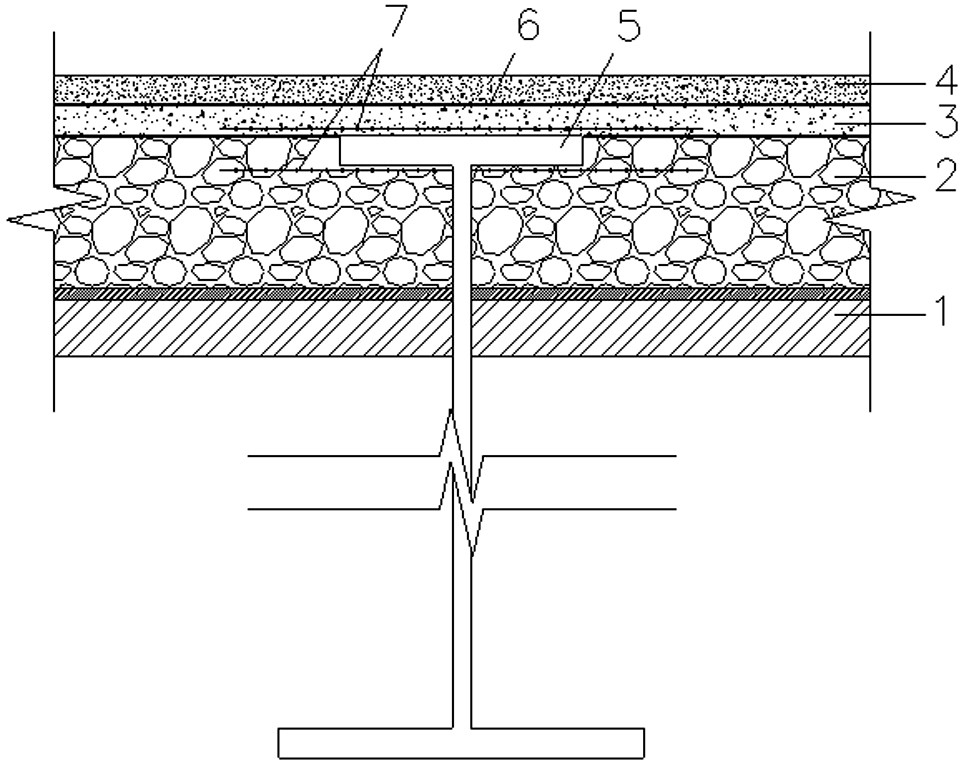

[0027] Embodiment one: if Figure 1~2 As shown, a steel-concrete composite girder bridge deck structure adaptable to deformation in the negative moment zone includes a steel girder 5, a pavement surface layer, a pavement base layer 2, and a bearing plate 1. The steel girder section is I-shaped, The girder height of the steel girder in the negative moment zone is 10 to 40 cm higher than the beam height in the positive moment zone, that is, the steel beam in the bridge deck structure in the negative moment zone is raised upwards, that is, figure 1 In the height H, the pavement base is located on the upper side of the bearing plate, the web of the steel beam passes through the bearing plate, and the upper flange of the steel beam is embedded in the pavement base or between the pavement base and the pavement surface; The surface layer, the pavement base 2 and the bearing plate 1 are arranged sequentially from top to bottom; the bridge deck structure of the present invention has a ...

Embodiment 2

[0040] Embodiment two: if image 3 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the bearing plate is different. In this embodiment, the bearing plate 1 adopts a profiled steel plate, and the profiled steel plate is connected to the web connection of the steel beam 5 by welding or bolts. superior.

[0041] The construction method of the bridge deck structure in the negative moment zone of the adaptive steel-concrete composite beam bridge described in the second embodiment includes the following steps:

[0042](1) Steel girder processing and manufacturing: During the construction of the bridge substructure, the processing and manufacturing of steel girders are carried out at the same time, and the corners of the upper wing plates of the steel girders are smoothed to reduce stress concentration; the profiled steel plates and steel girder webs used as bearing plates When the plates are connected by bolts, connecting holes correspondin...

Embodiment 3

[0047] Embodiment three: as Figure 4 As shown, the difference between the present embodiment and the second embodiment is that a layer of lower edge concrete slab 8 is paved on the upper side of the lower flange of the steel beam 5 .

[0048] The construction method of the bridge deck structure in the negative moment zone of the adaptive steel-concrete composite girder bridge described in the third embodiment includes the following steps:

[0049] (1) Steel girder processing and manufacturing: During the construction of the bridge substructure, the processing and manufacturing of steel girders are carried out at the same time, and the corners of the upper wing plates of the steel girders are smoothed to reduce stress concentration; the profiled steel plates and steel girder webs used as bearing plates When the plates are connected by bolts, connecting holes corresponding to the positions of the bolt holes on the profiled steel plate shall be opened on the web of the steel bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com