Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

854 results about "Compression stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

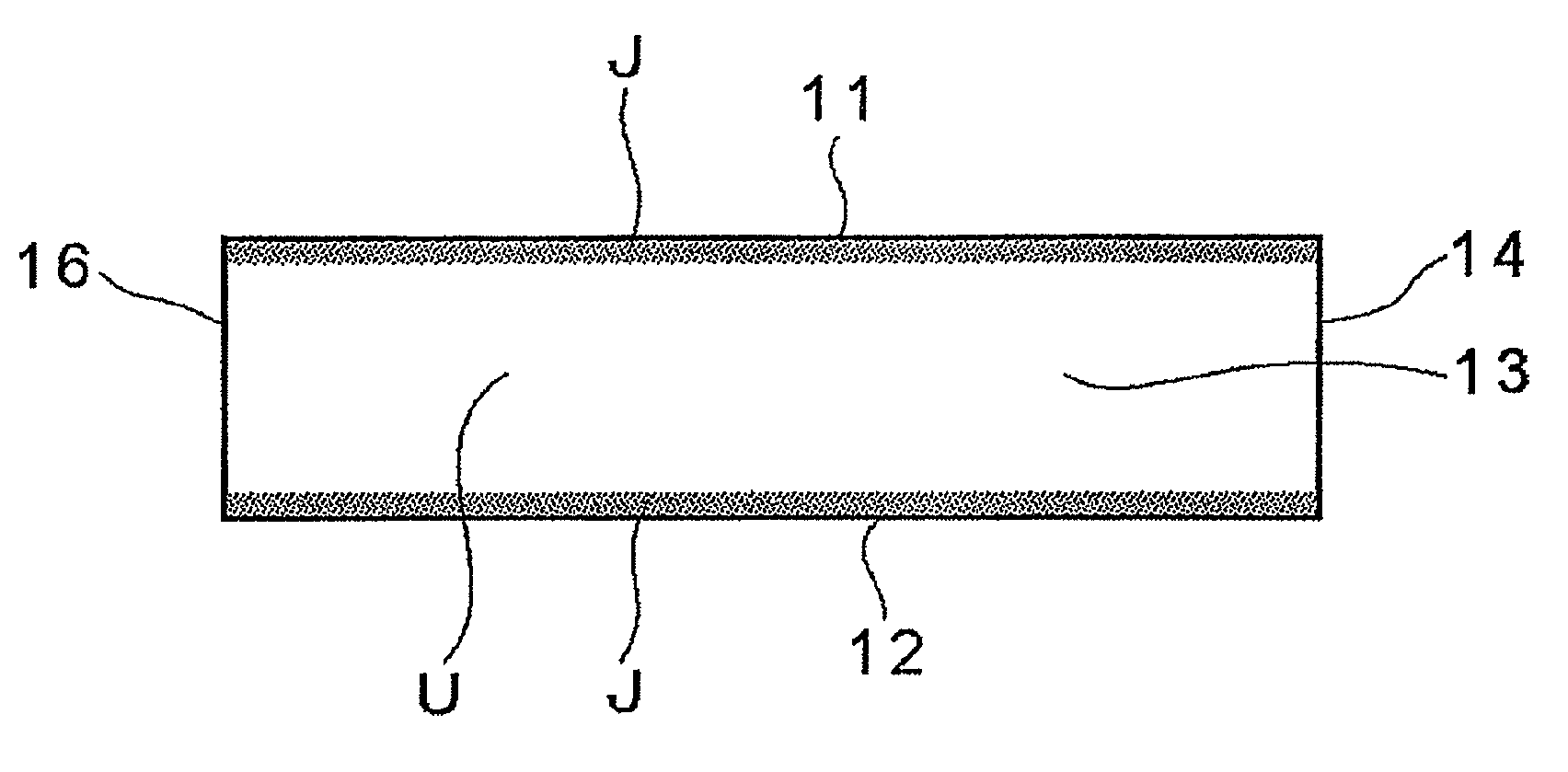

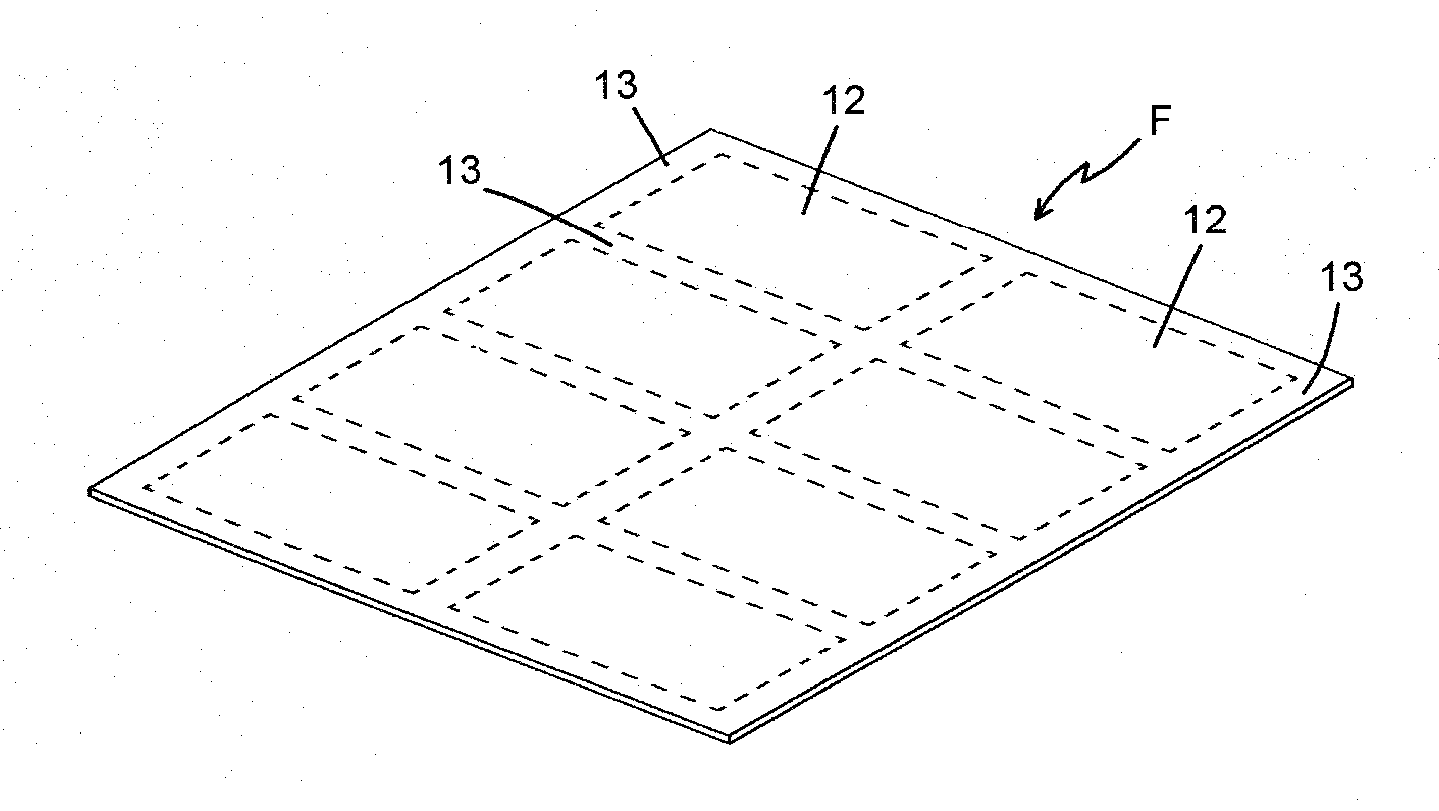

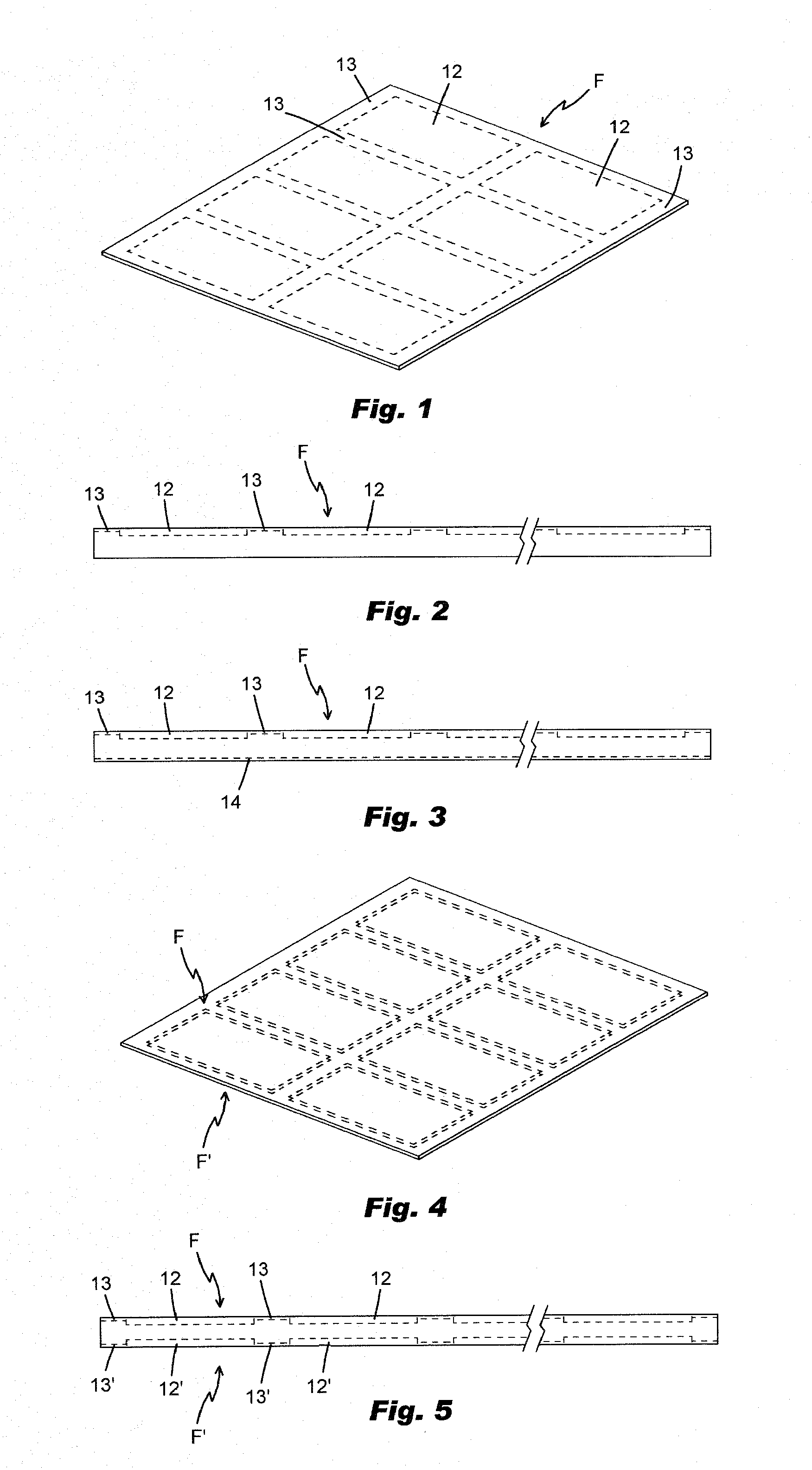

Reinforced plate glass and method for manufacturing the same

InactiveUS20100119846A1Quality improvementStrength of plate glass surfaces opposed to each otherGlass/slag layered productsGlass severing apparatusFlat glassUltimate tensile strength

[Object] To provide a method of manufacturing a reinforced plate glass by which glass surface strength can be sufficiently increased, and a stable quality reinforced plate glass is manufactured at high production efficiency, and to provide a reinforced plate glass manufactured by the manufacturing method.[Solving Means] A reinforced plate glass (10) is formed of an inorganic oxide glass, and is provided with a compression stress layer by chemical reinforcement on plate surfaces (11, 12) opposed to each other in a plate thickness direction. Plate end faces (13, 14, 15, 16) have regions where a compression stress is formed and regions where no compression stress is formed.

Owner:NIPPON ELECTRIC GLASS CO LTD

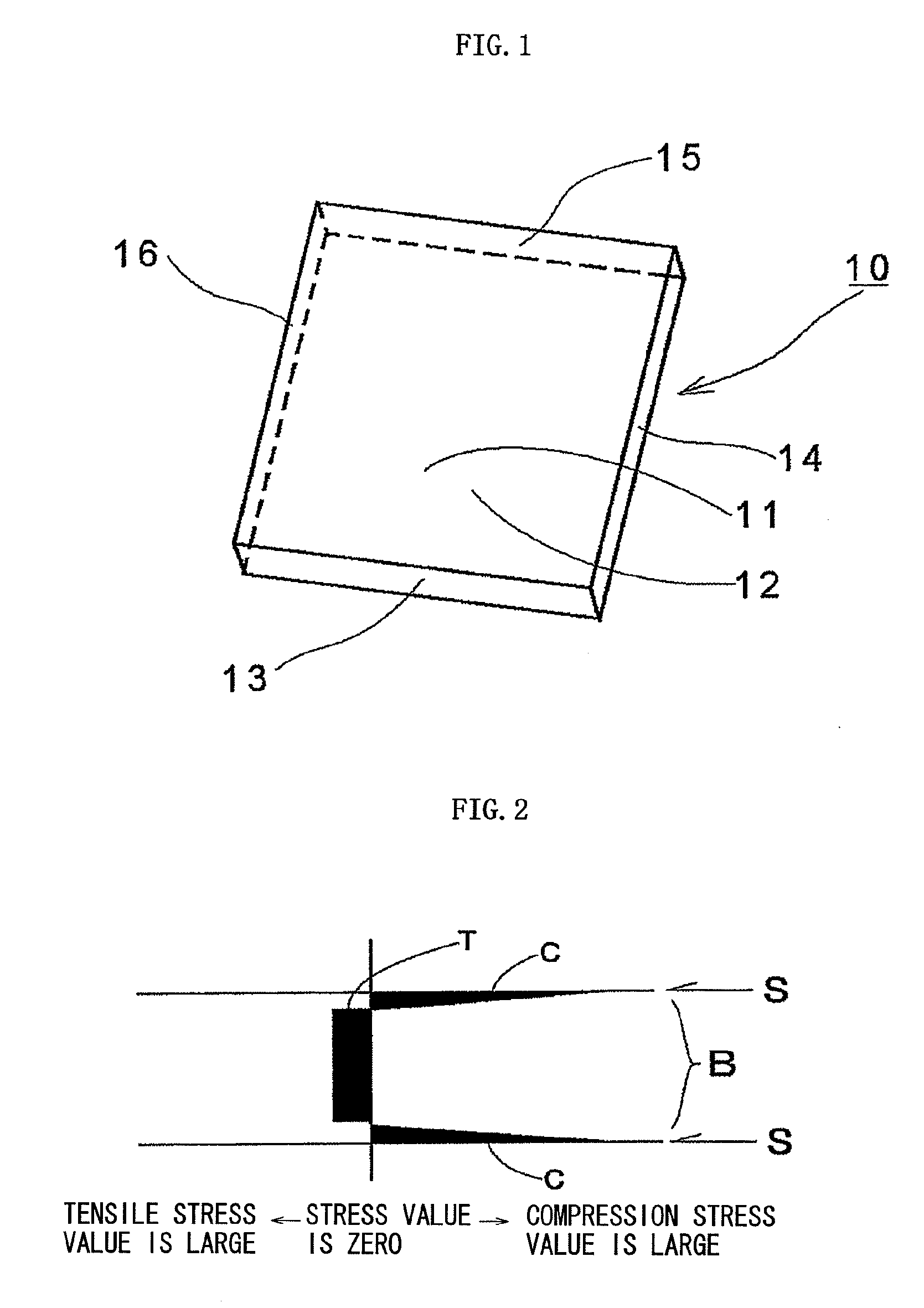

Strengthened glass substrate and process for producing the same

ActiveUS20100087307A1Excellent devitrification proofHigh mechanical strengthGlass/slag layered productsThin material handlingDevitrificationMetallurgy

An object of the invention is to obtain a glass substrate having high mechanical strength by reconciling suitability for ion exchange and devitrification proof in a glass. The strengthened glass substrate of the invention is a strengthened glass substrate having a compression stress layer in the surface thereof, the glass substrate having a glass composition including, in terms of % by mass, 40-70% of SiO2, 12-25% of Al2O3, 0-10% of B2O3, 0-8% of Li2O, 6-15% of Na2O, 0-10% of K2O, 13-20% of Li2O+Na2O+K2O, 0-3.9% of MgO, 0-5% of CaO, 0-5% of ZnO, 0-6% of ZrO2, and 0-5% of SrO+BaO, the value of (MgO+ZrO2+ZnO) / (MgO+ZrO2+ZnO+Al2O3) in terms of mass proportion being from 0.25 to 0.45. The above-mentioned strengthened glass can be produced by melting raw glass materials mixed together so as to result in the given glass composition, forming the melt into a sheet by an overflow downdraw process, and then conducting an ion exchange treatment to form a compression stress layer in the glass sheet surface.

Owner:NIPPON ELECTRIC GLASS CO LTD

Glass plate for display devices

ActiveUS20090298669A1Low environmental loadQuality improvementGas discharge vessels/containersThin material handlingDisplay deviceGlass sheet

To provide a glass plate for display devices wherein without carrying out a post treatment, the depth of a compression stress layer is increased, while the surface compression stress is prevented from being excess only by chemical tempering.A glass plate for display devices, which is obtained by chemically tempering a glass plate comprising, as represented by mol % based on the following oxides, from 50 to 74% of SiO2, from 1 to 10% of Al2O3, from 6 to 14% of Na2O, from 3 to 15% of K2O, from 2 to 15% of MgO, from 0 to 10% of CaO and from 0 to 5% of ZrO2, wherein the total content of SiO2 and Al2O3 is at most 75%, the total content of Na2O and K2O, i.e. Na2O+K2O, is from 12 to 25%, and the total content of MgO and CaO, i.e. MgO+CaO, is from 7 to 15%.

Owner:ASAHI GLASS CO LTD

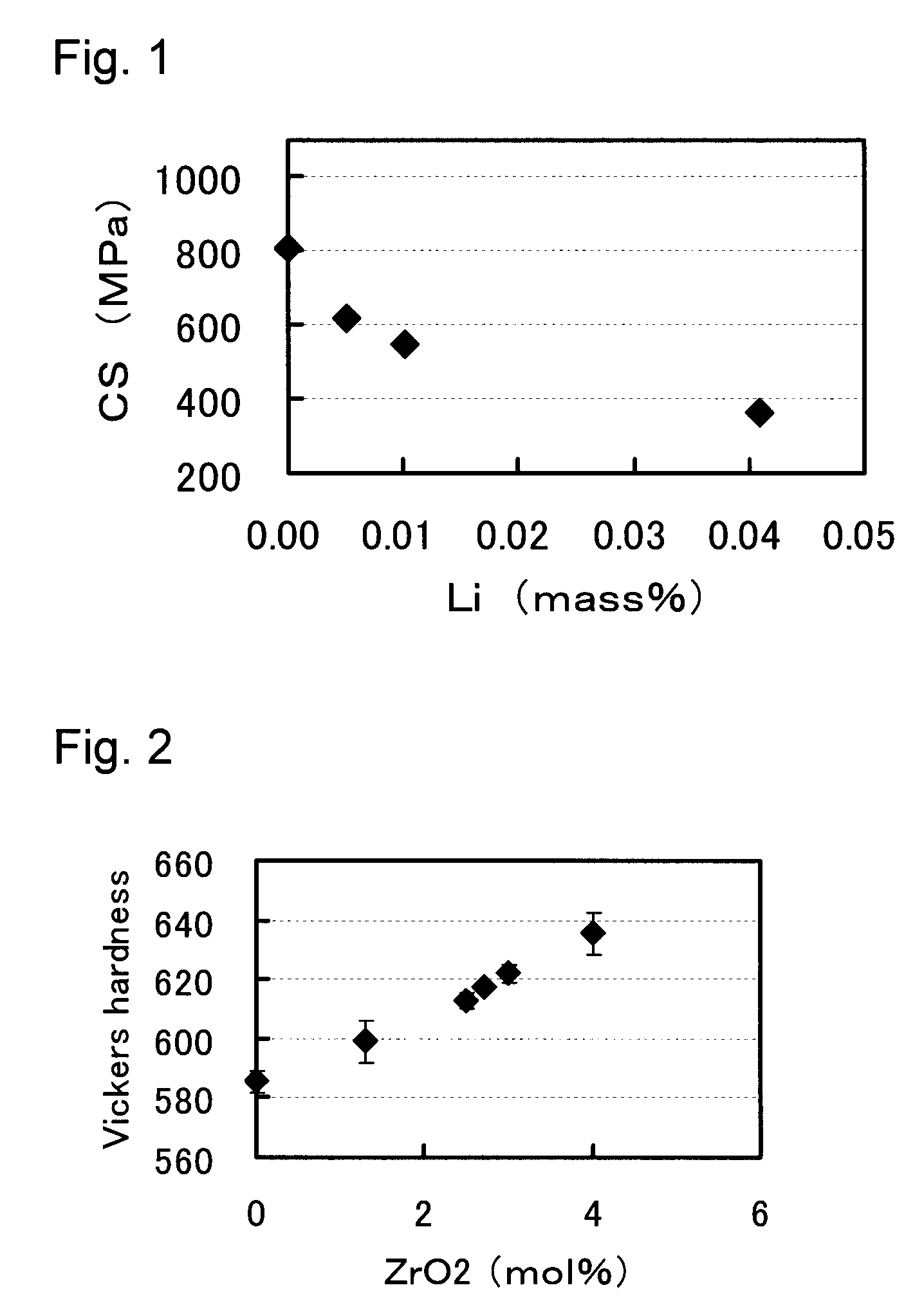

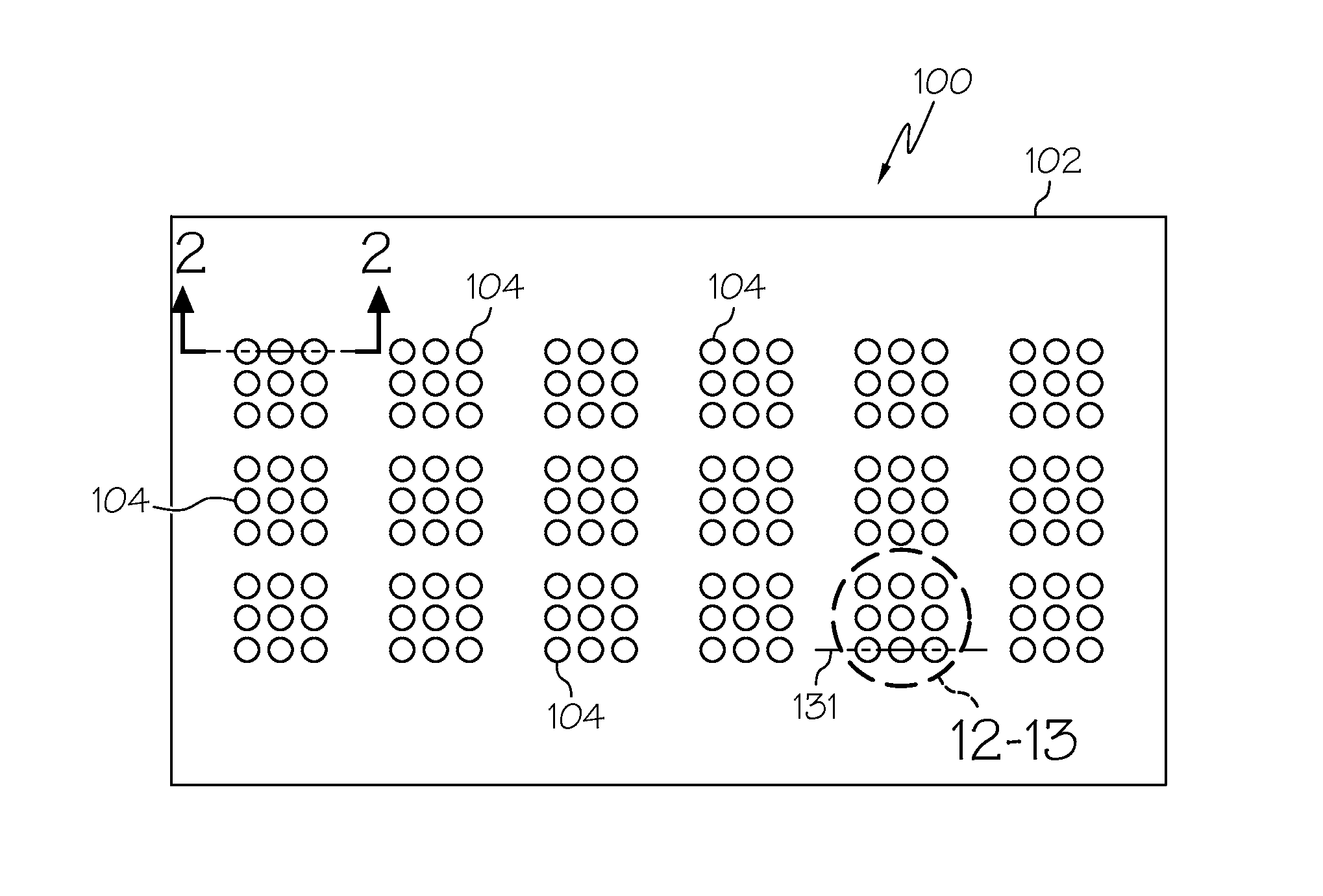

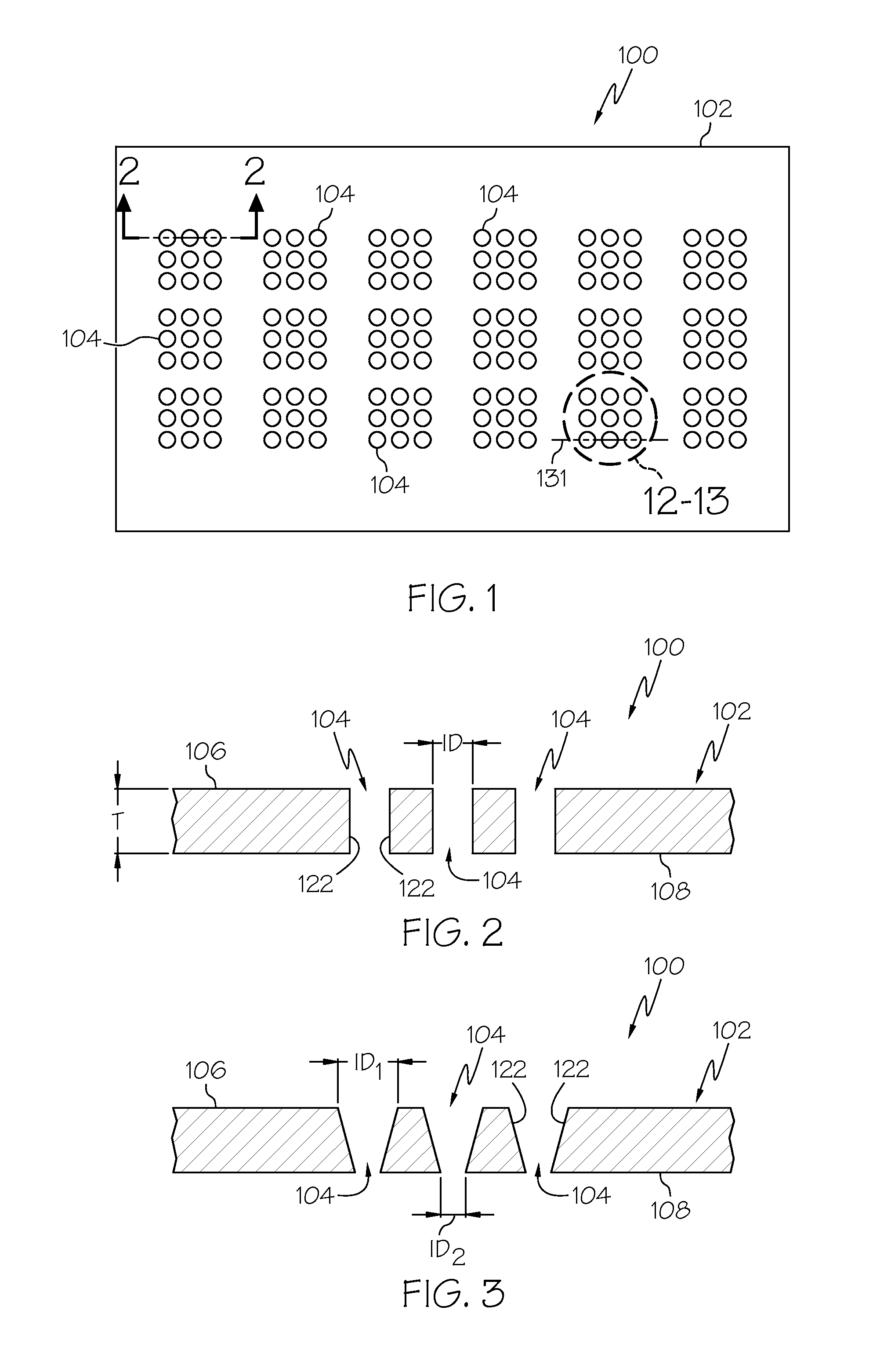

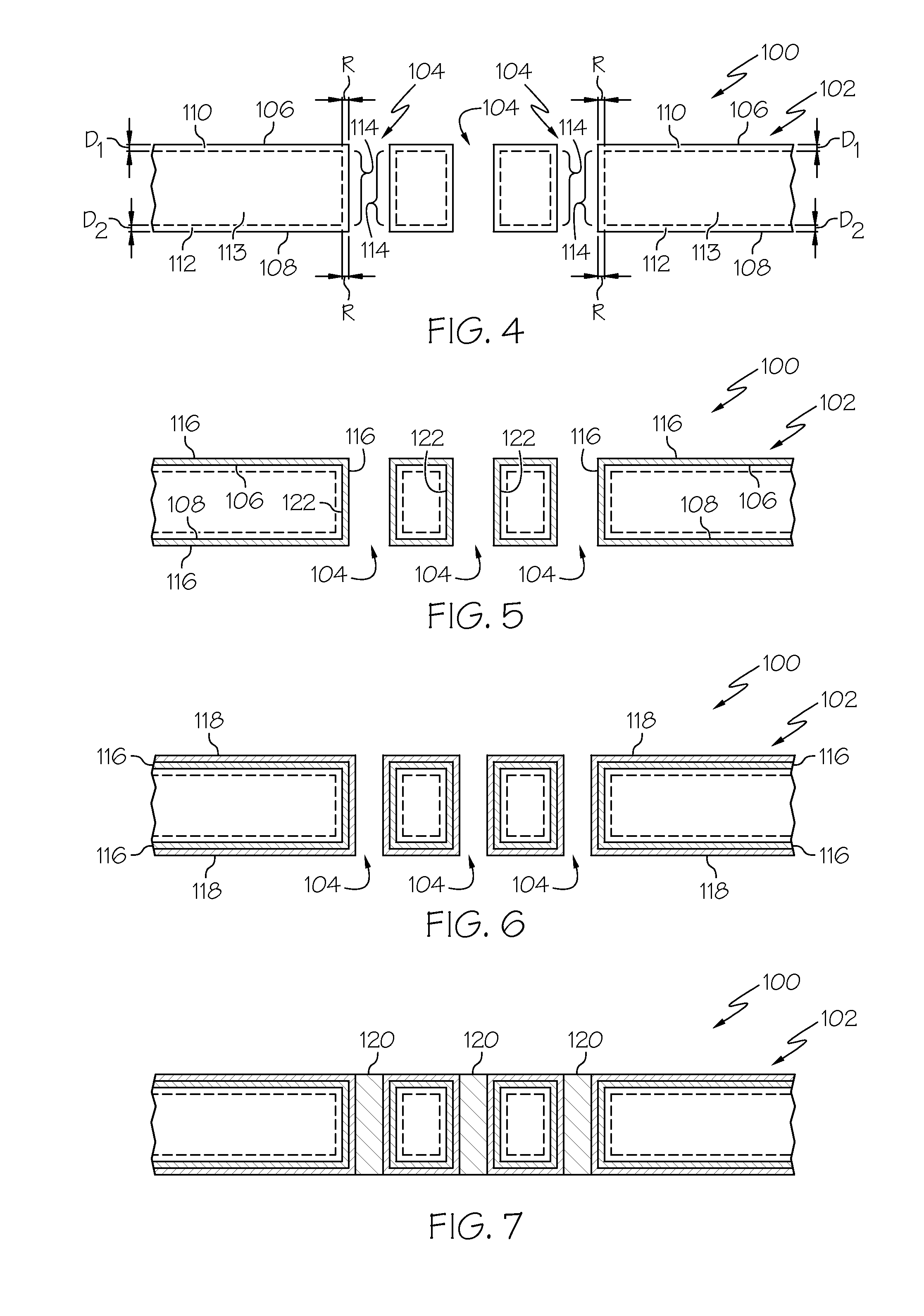

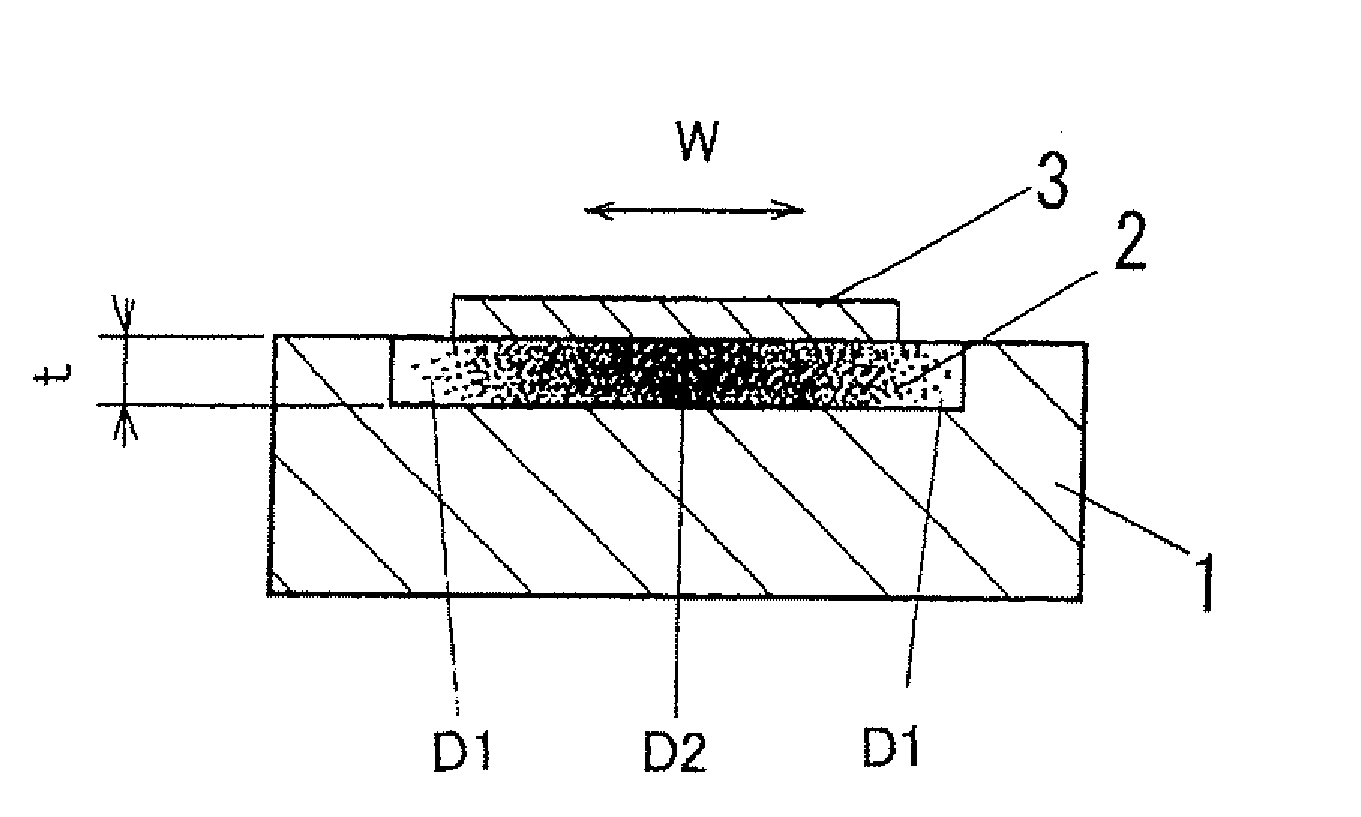

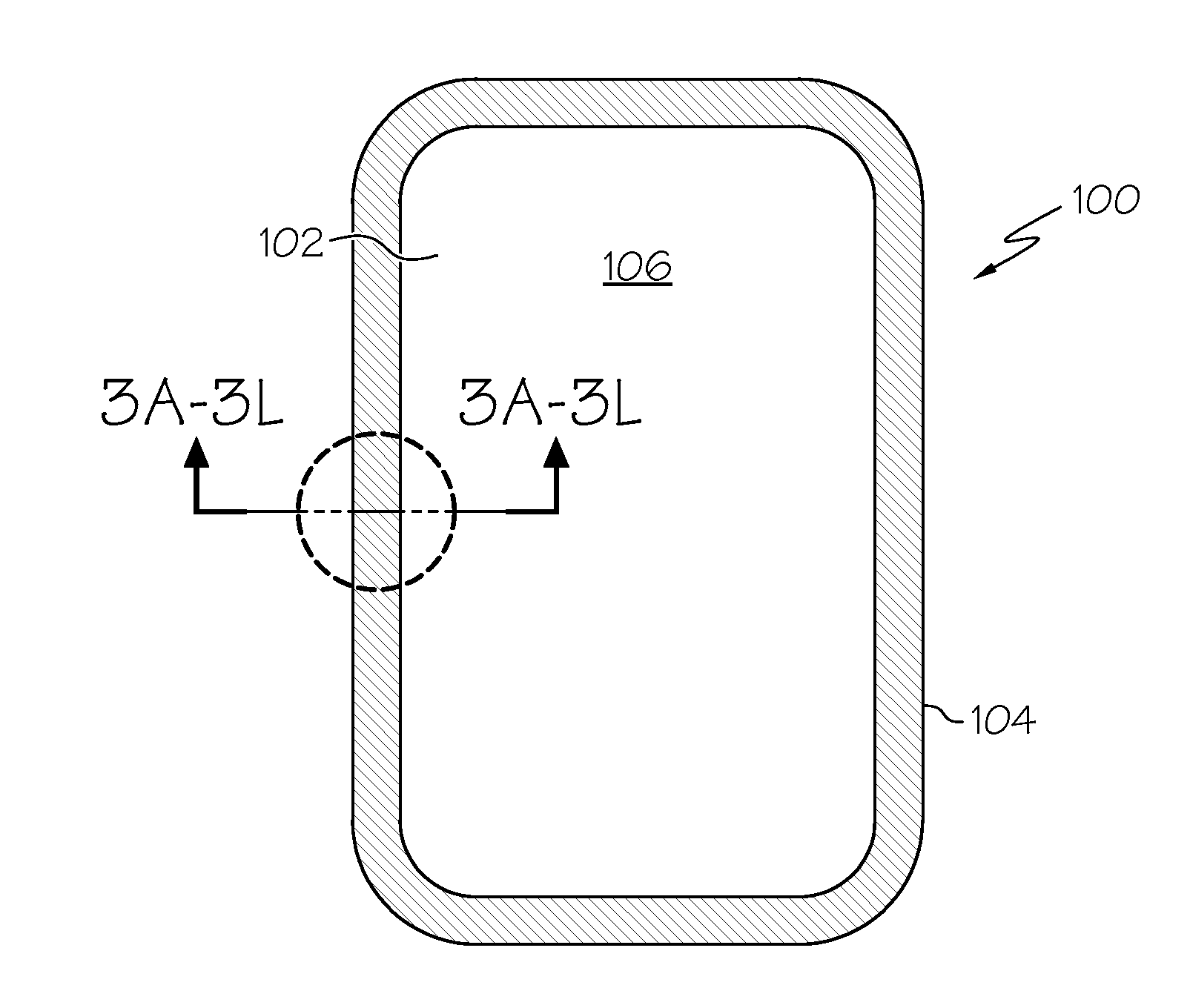

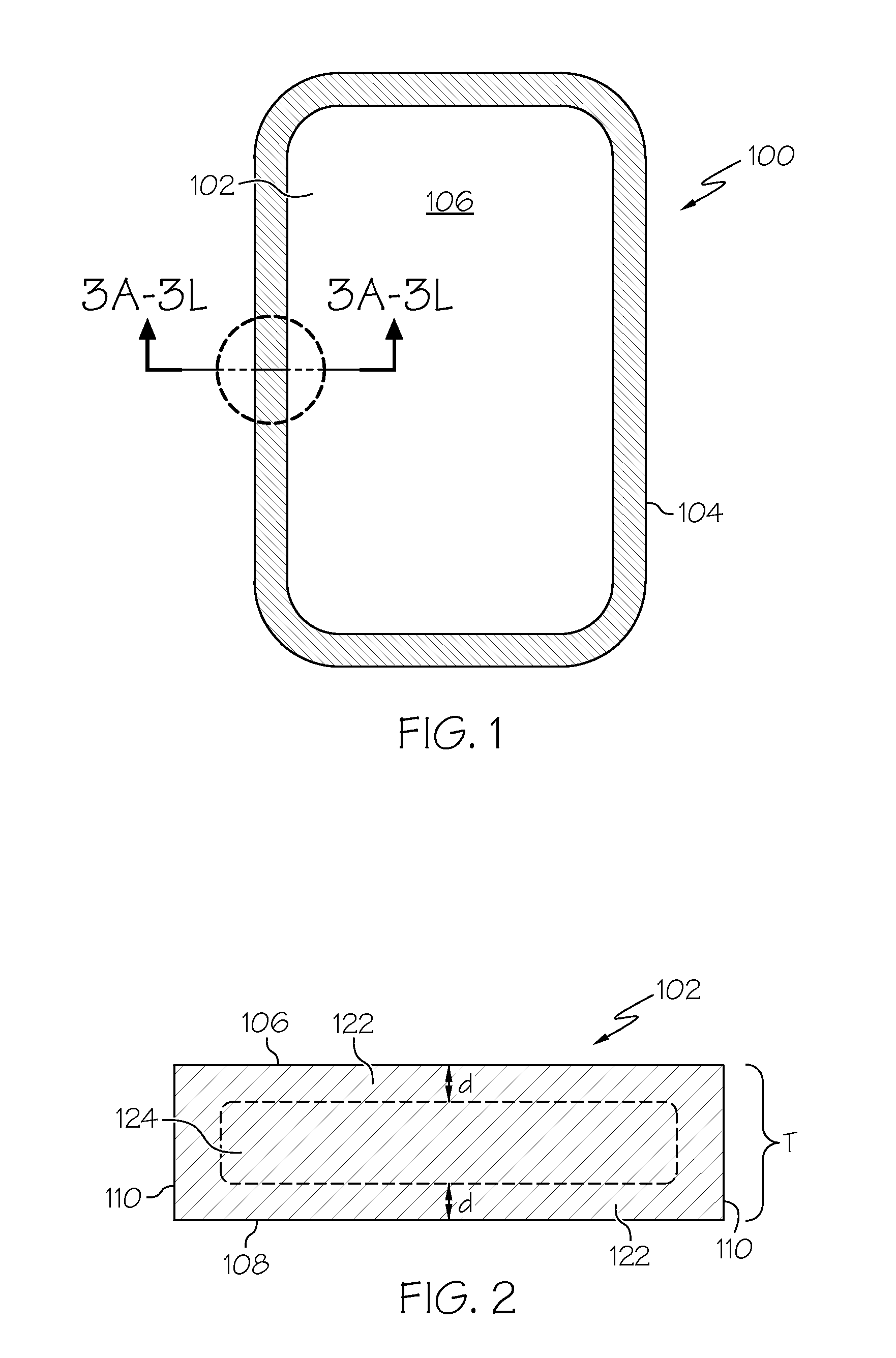

Glass Interposer Panels And Methods For Making The Same

InactiveUS20120048604A1Line/current collector detailsPrinted circuit detailsInterposerSecondary layer

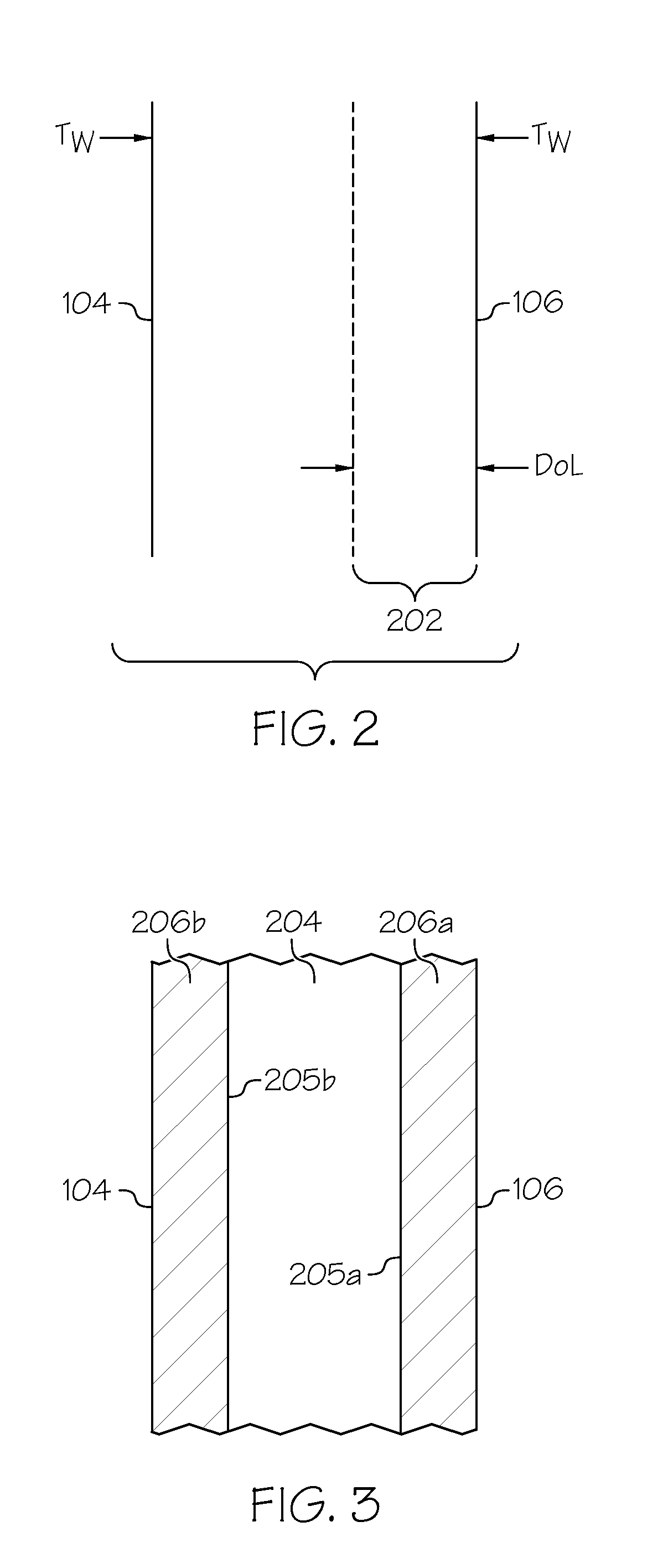

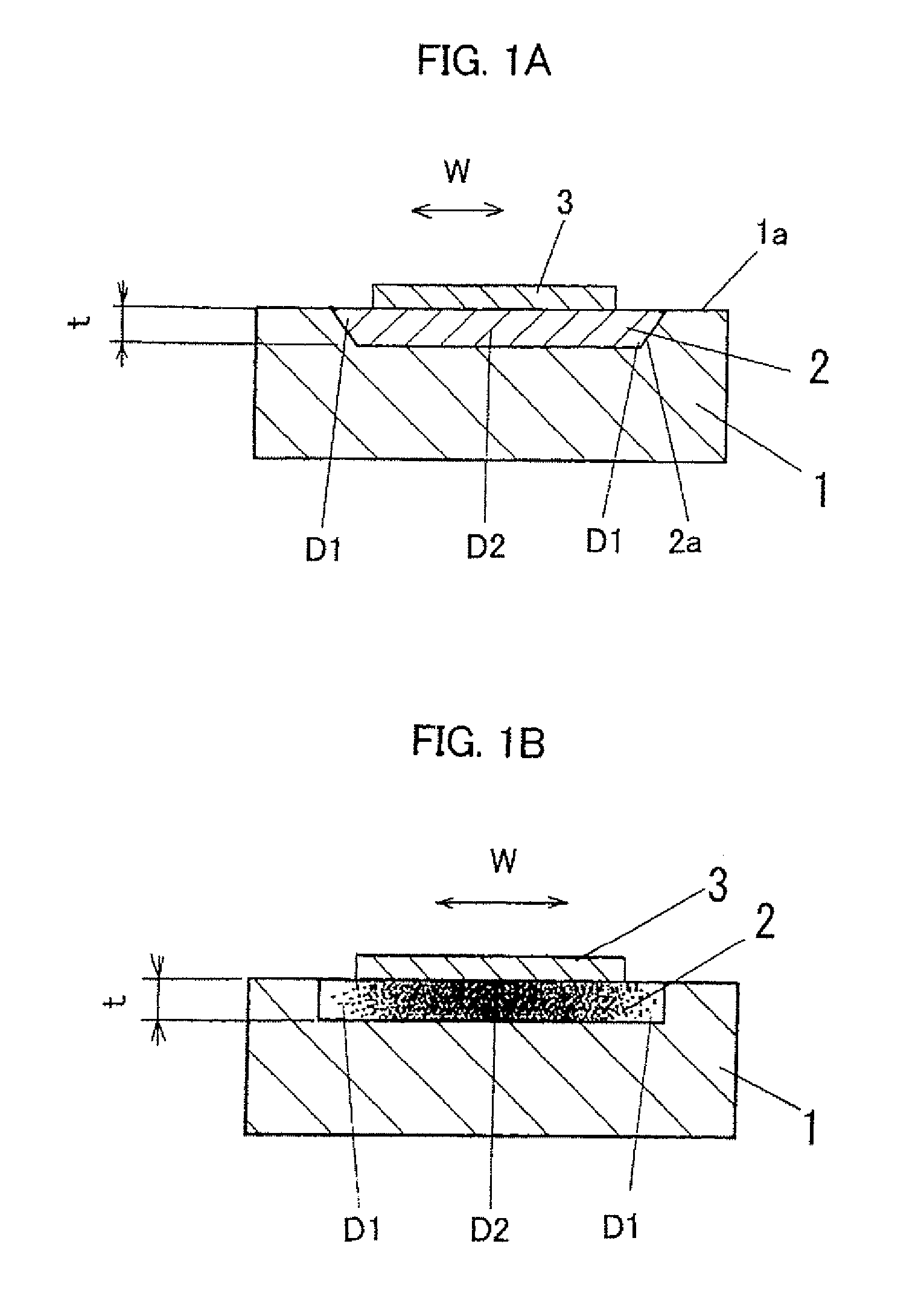

Glass interposer panels and methods for forming the same are described herein. The interposer panels include a glass substrate core formed from an ion-exchangeable glass. A first layer of compressive stress may extend from a first surface of the glass substrate into the thickness T of the glass substrate core to a first depth of layer D1. A second layer of compressive stress may be spaced apart from the first layer of compressive stress and extending from a second surface of the glass substrate core into the thickness T of the glass substrate core to a second depth of layer D2. A plurality of through-vias may extend through the thickness T of the glass substrate core. Each through-via is surrounded by an intermediate zone of compressive stress that extends from the first layer of compressive stress to the second layer of compressive stress adjacent to a sidewall of each through-via.

Owner:CORNING INC

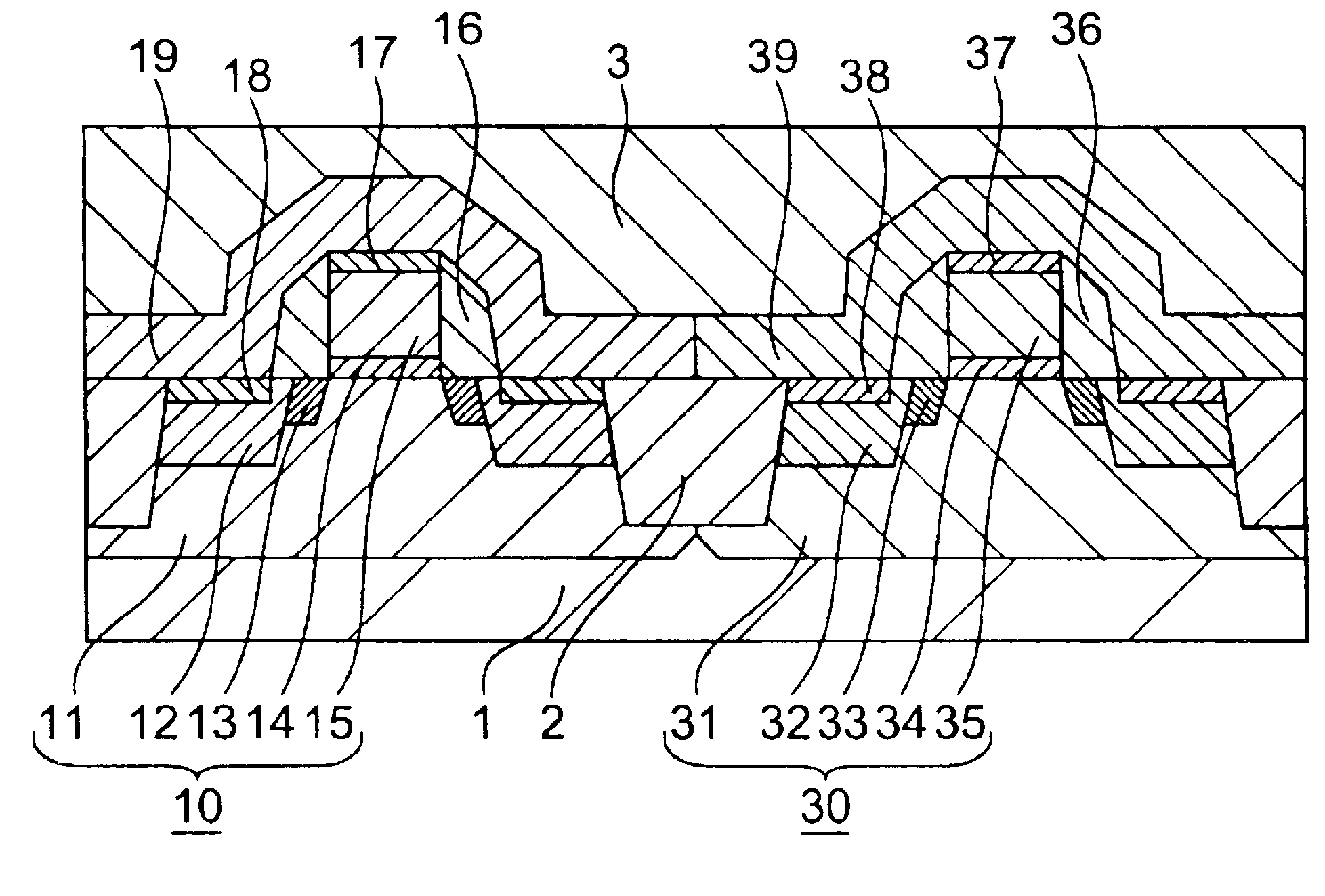

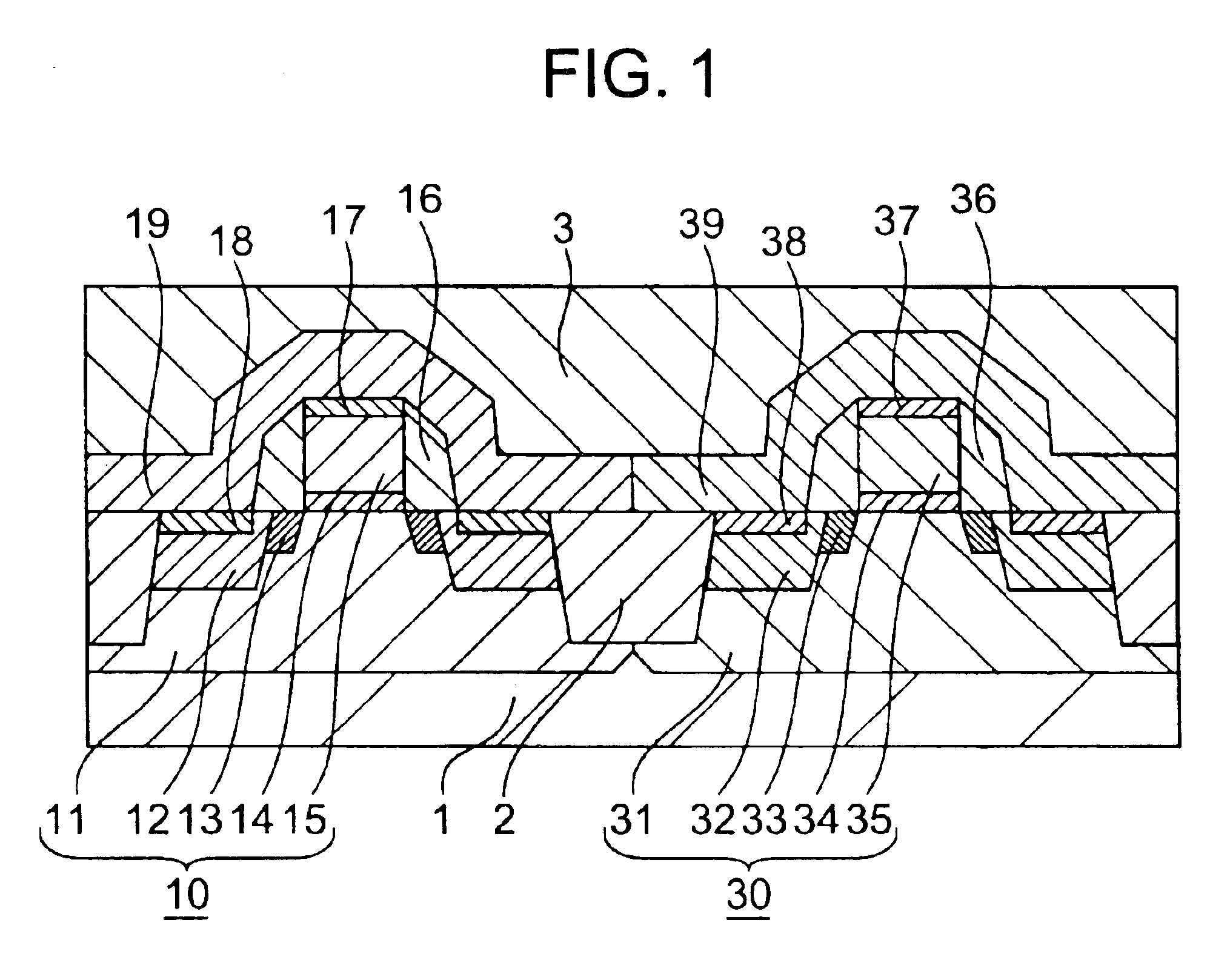

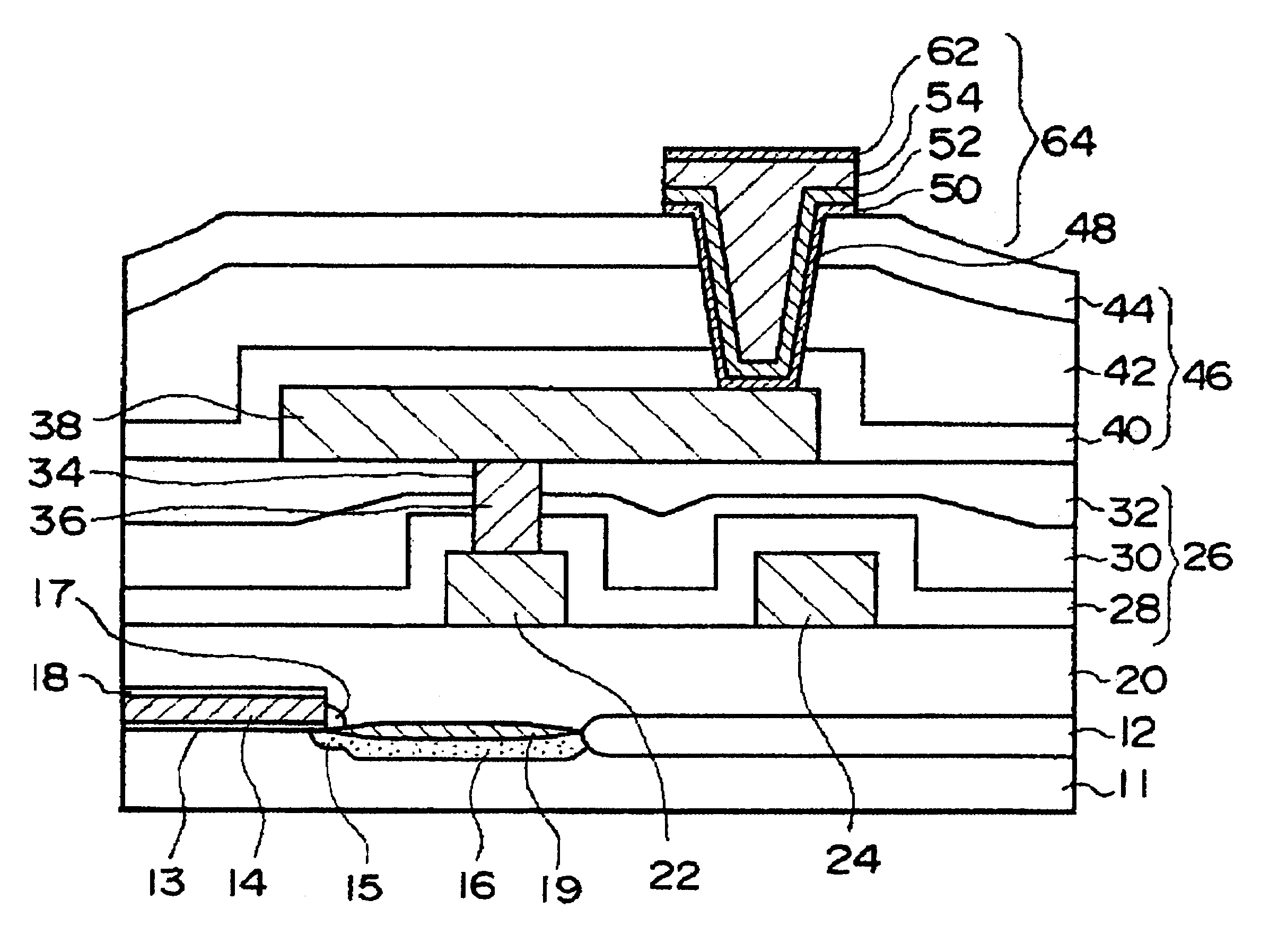

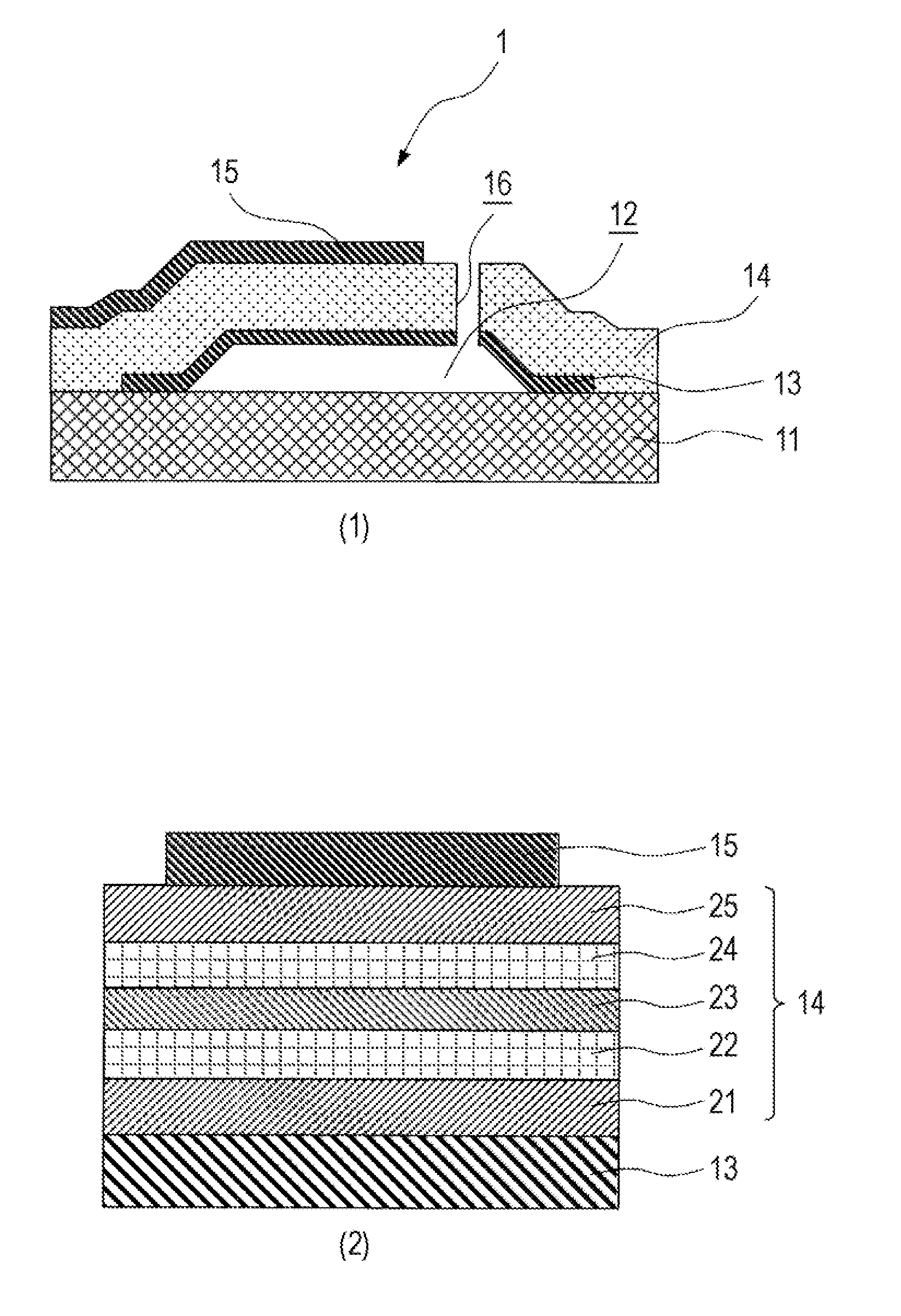

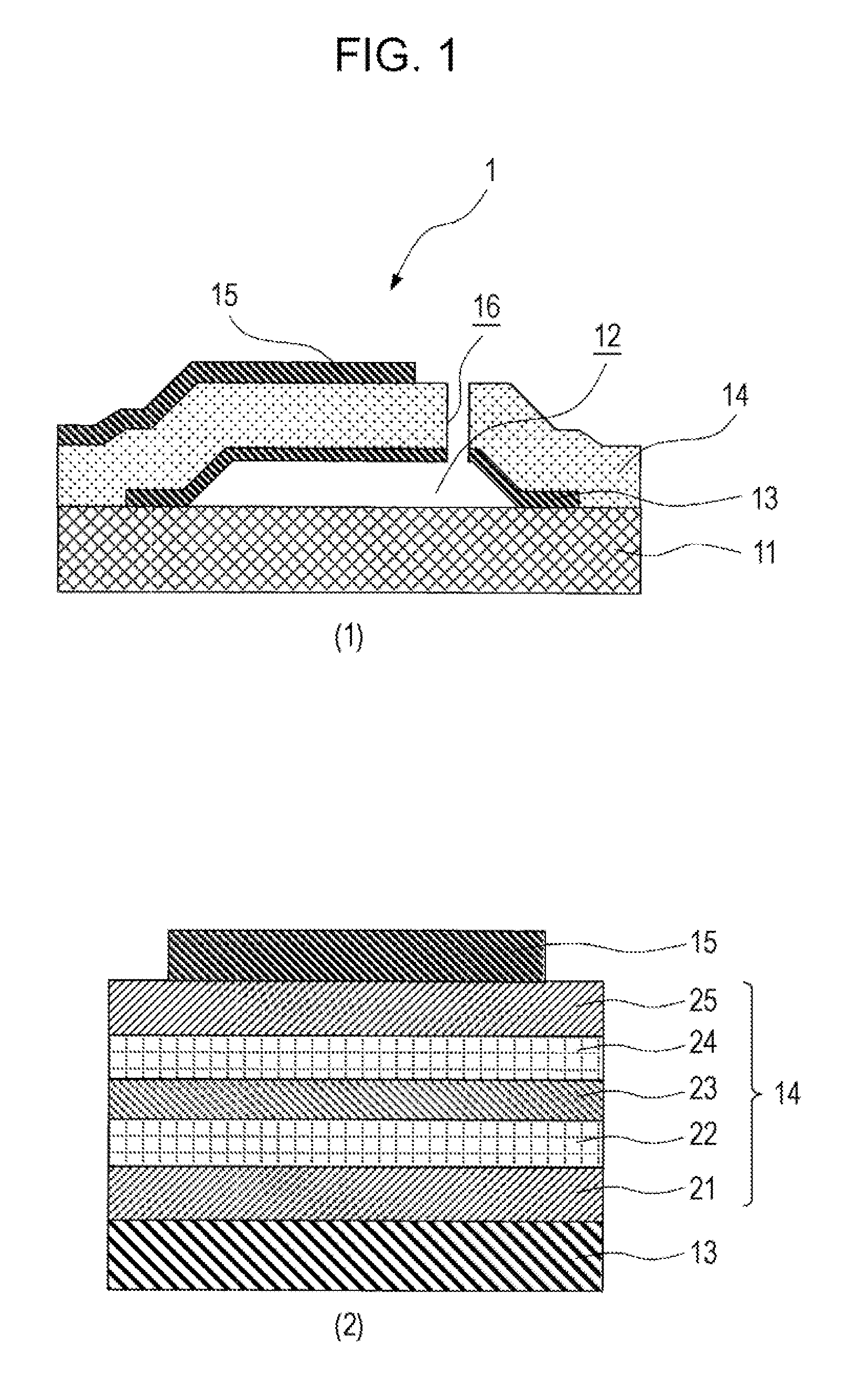

Semiconductor device with CMOS-field-effect transistors having improved drain current characteristics

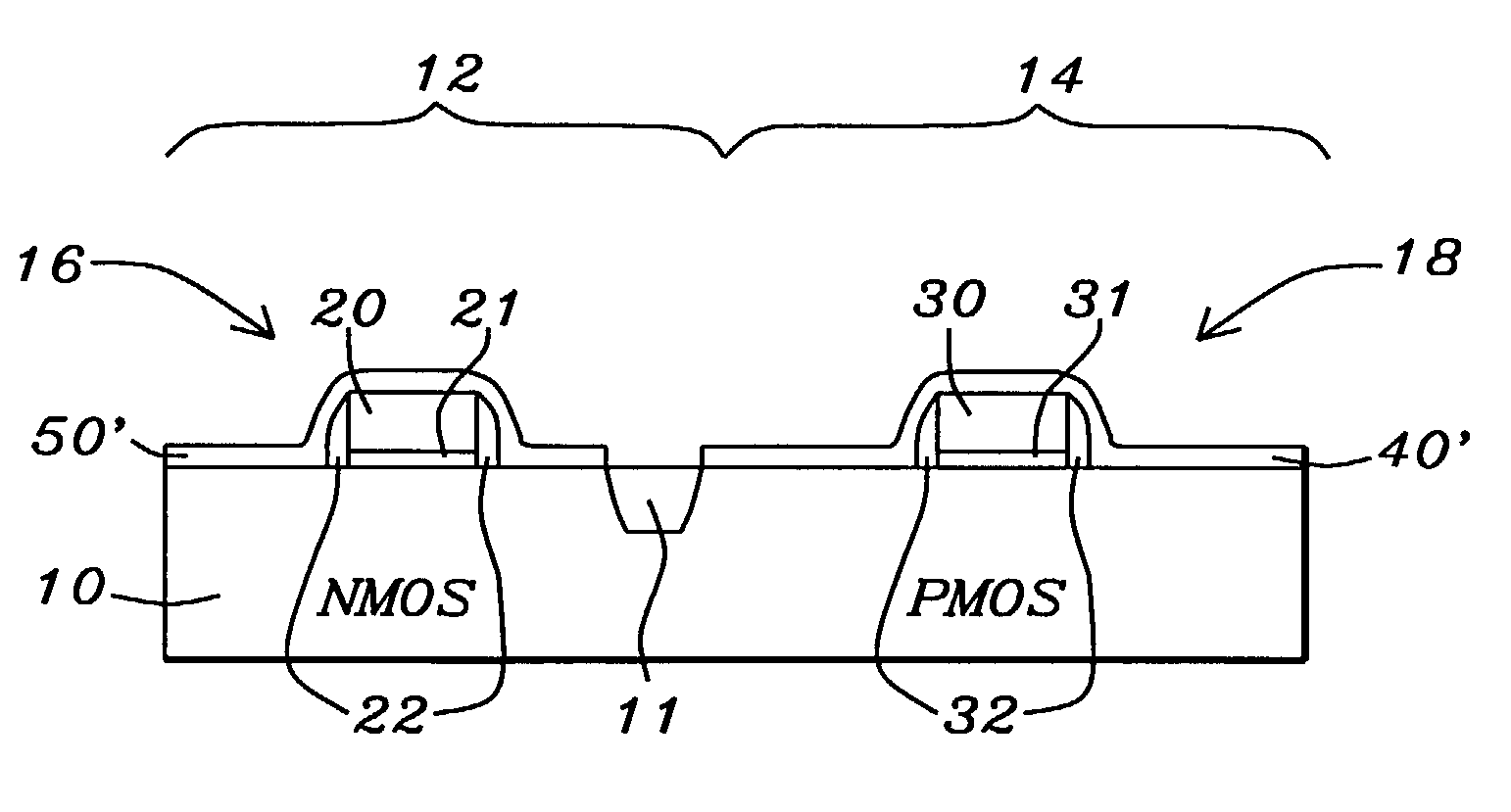

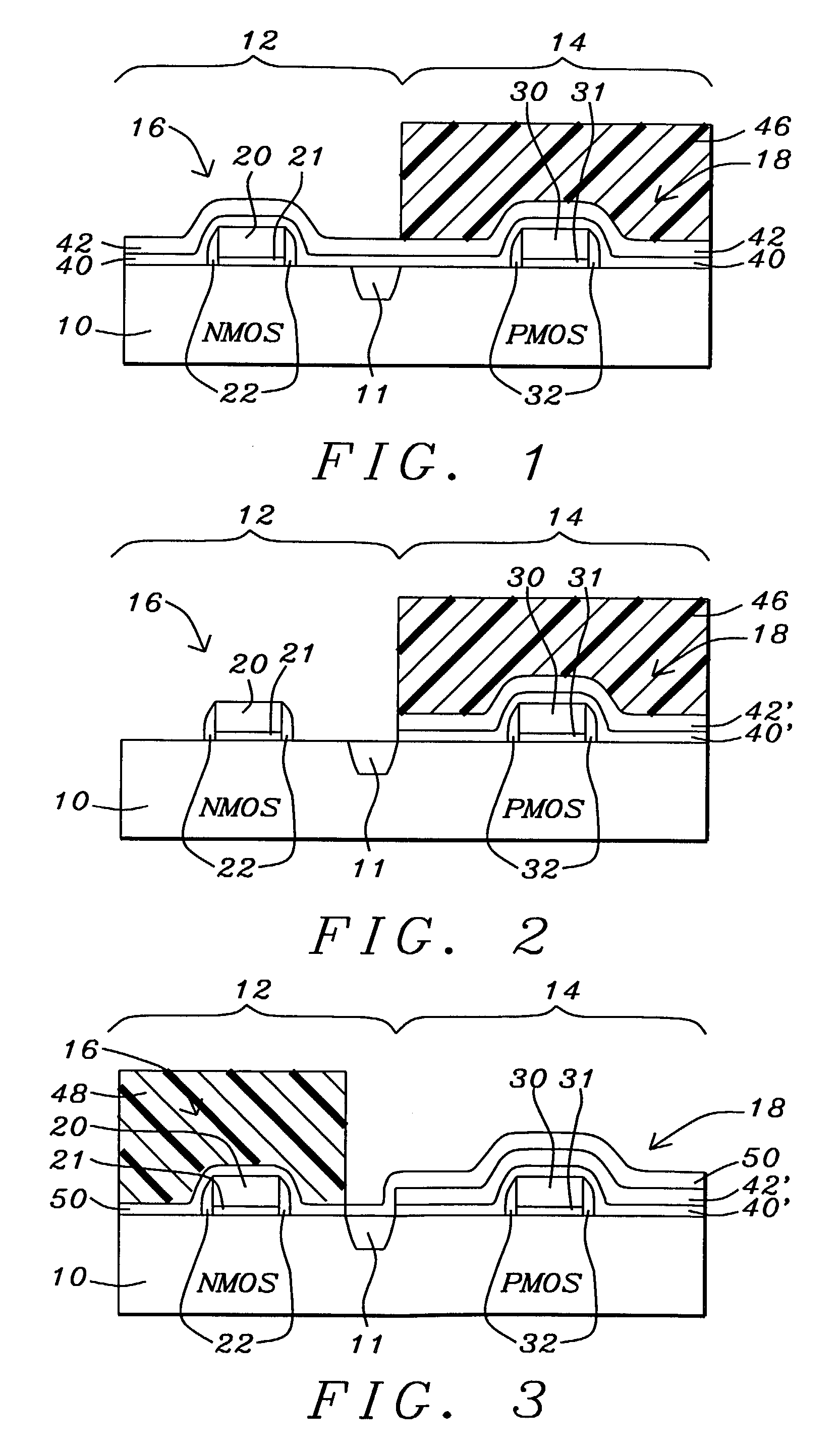

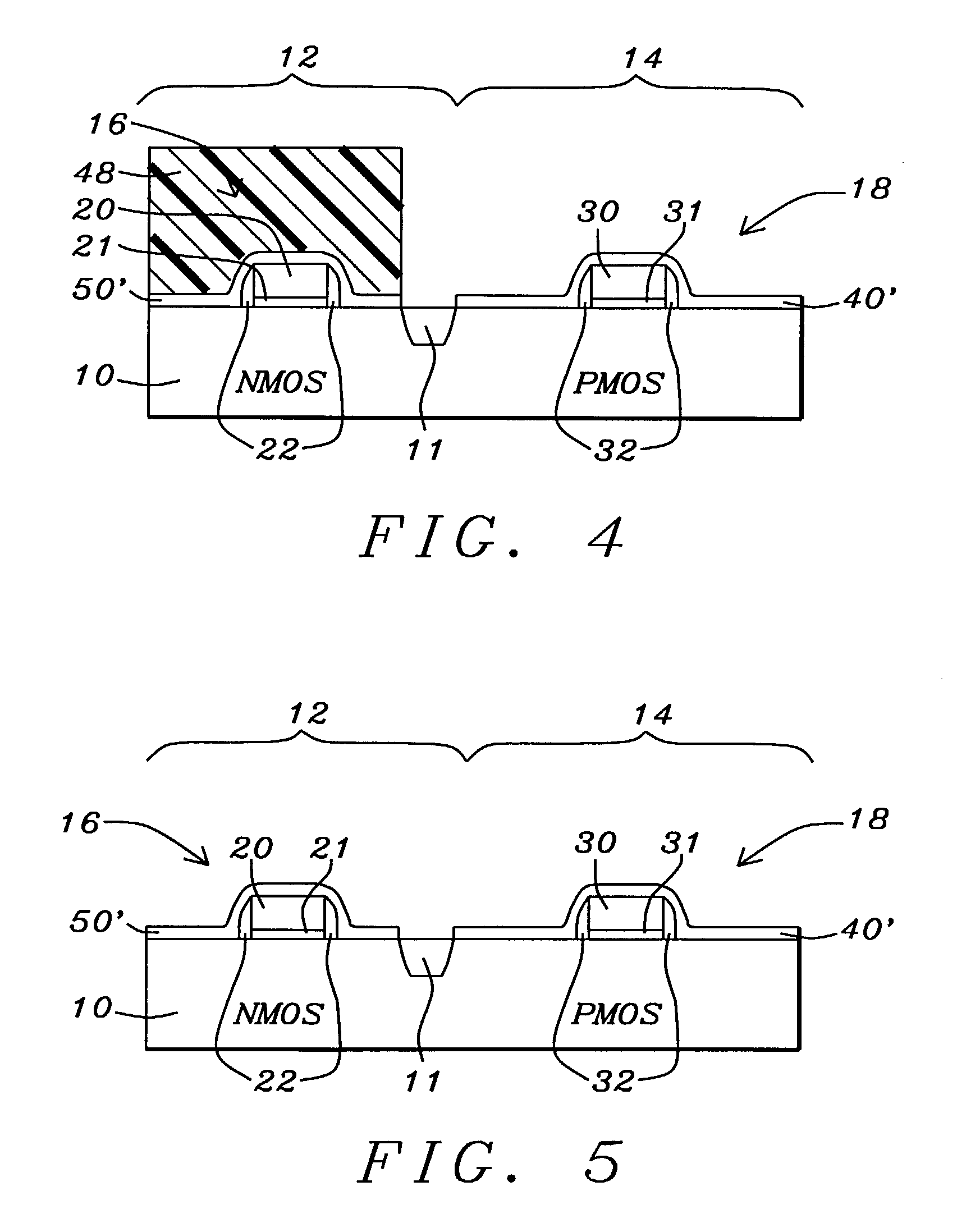

InactiveUS6982465B2High speedImprove mobilityTransistorSemiconductor/solid-state device detailsCMOSField-effect transistor

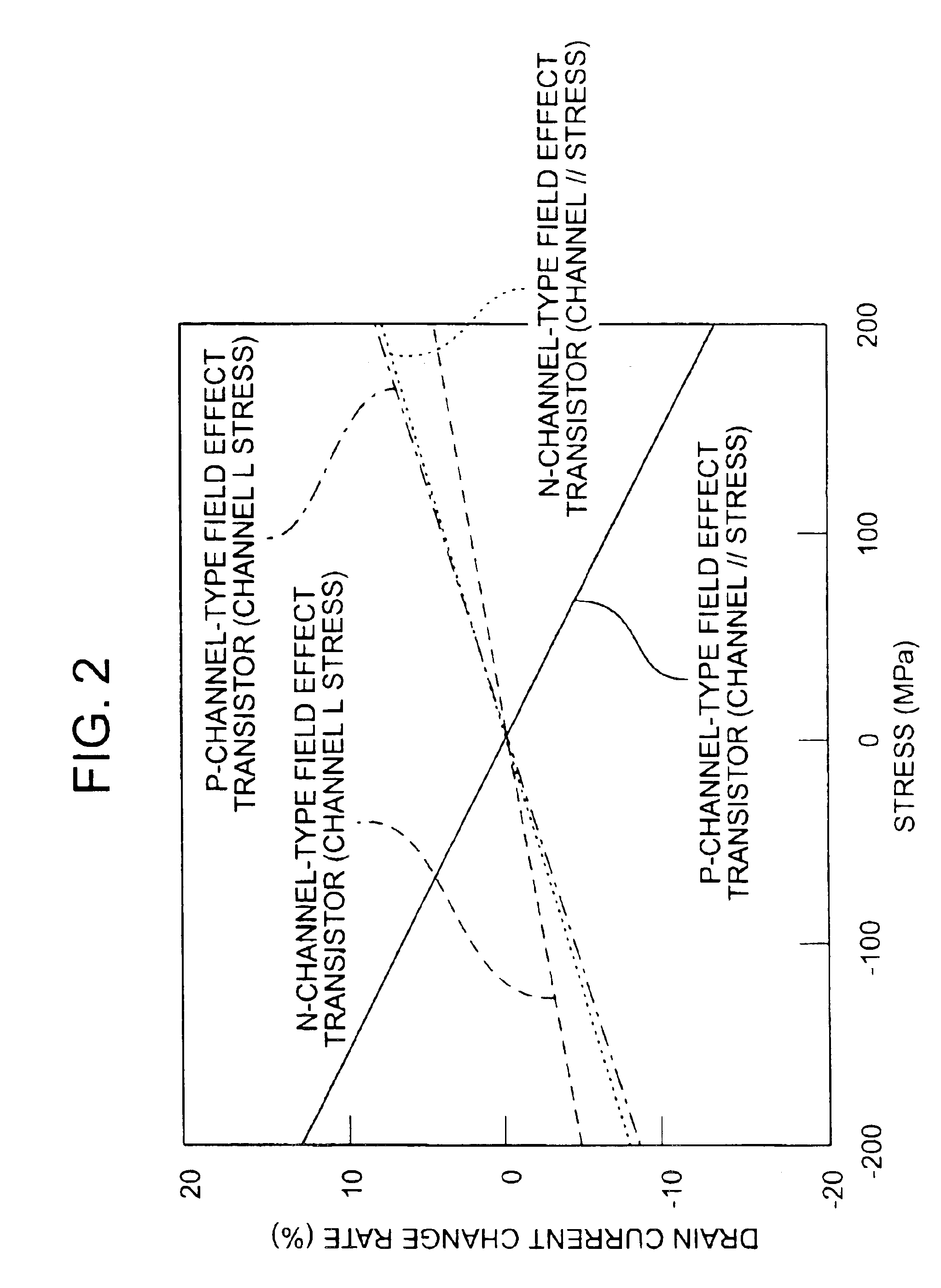

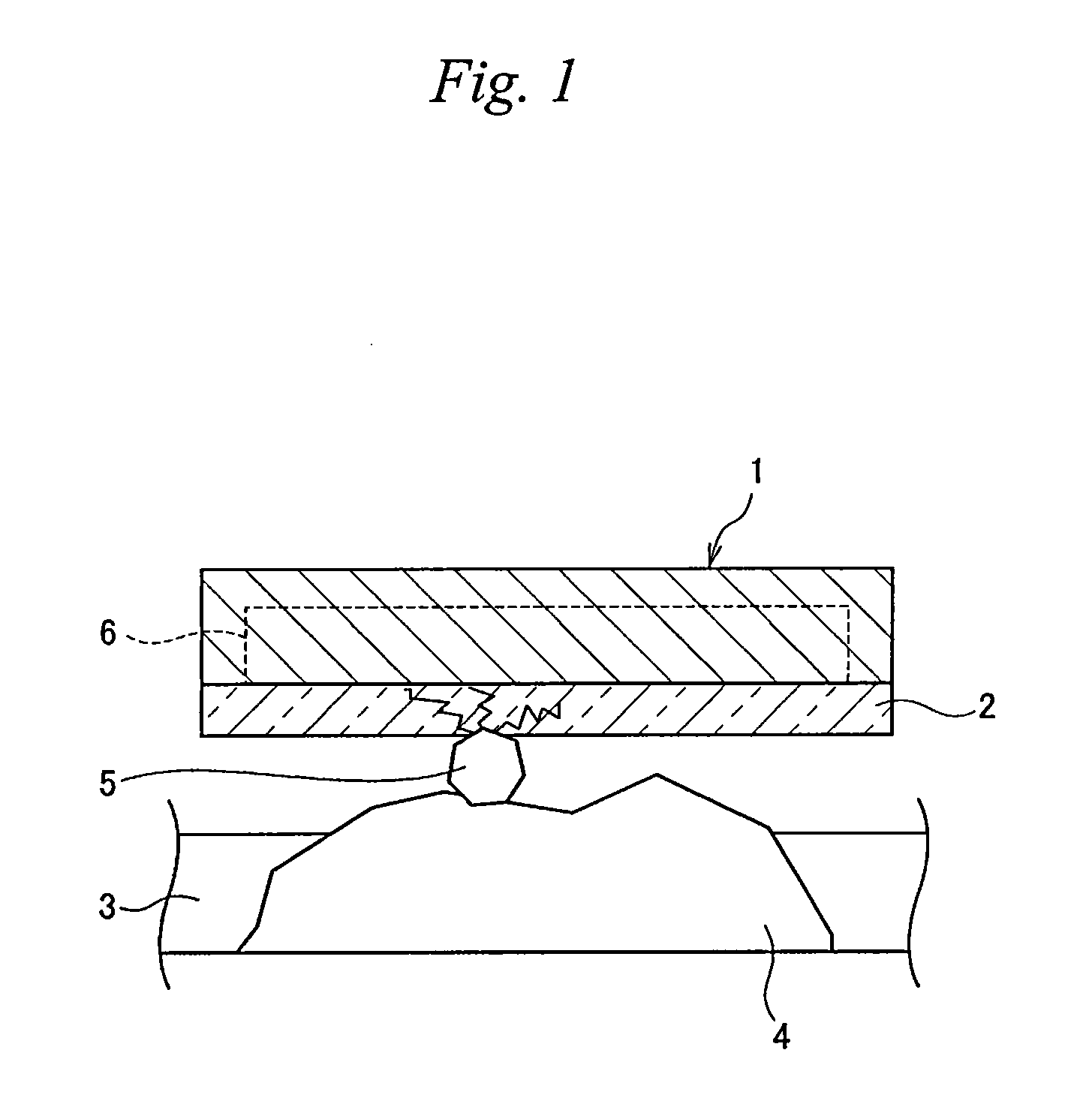

The present invention provides a semiconductor device including n-channel field effect transistors and p-channel field effect transistors all of which have excellent drain current characteristics.In a semiconductor device including an n-channel field effect transistor 10 and a p-channel field effect transistor 30, a stress control film 19 covering a gate electrode 15 of the n-channel field effect transistor 10 undergoes film stress mainly composed of tensile stress. A stress control film 39 covering a gate electrode 15 of the p-channel field effect transistor 30 undergoes film stress mainly caused by compression stress compared to the film 19 of the n-channel field effect transistor 10. Accordingly, drain current is expected to be improved in both the n-channel field effect transistor and the p-channel field effect transistor. Consequently, the characteristics can be generally improved.

Owner:RENESAS ELECTRONICS CORP

Strengthened glass containers resistant to delamination and damage

ActiveUS20140151370A1Pharmaceutical containersLarge containersUltimate tensile strengthMaterials science

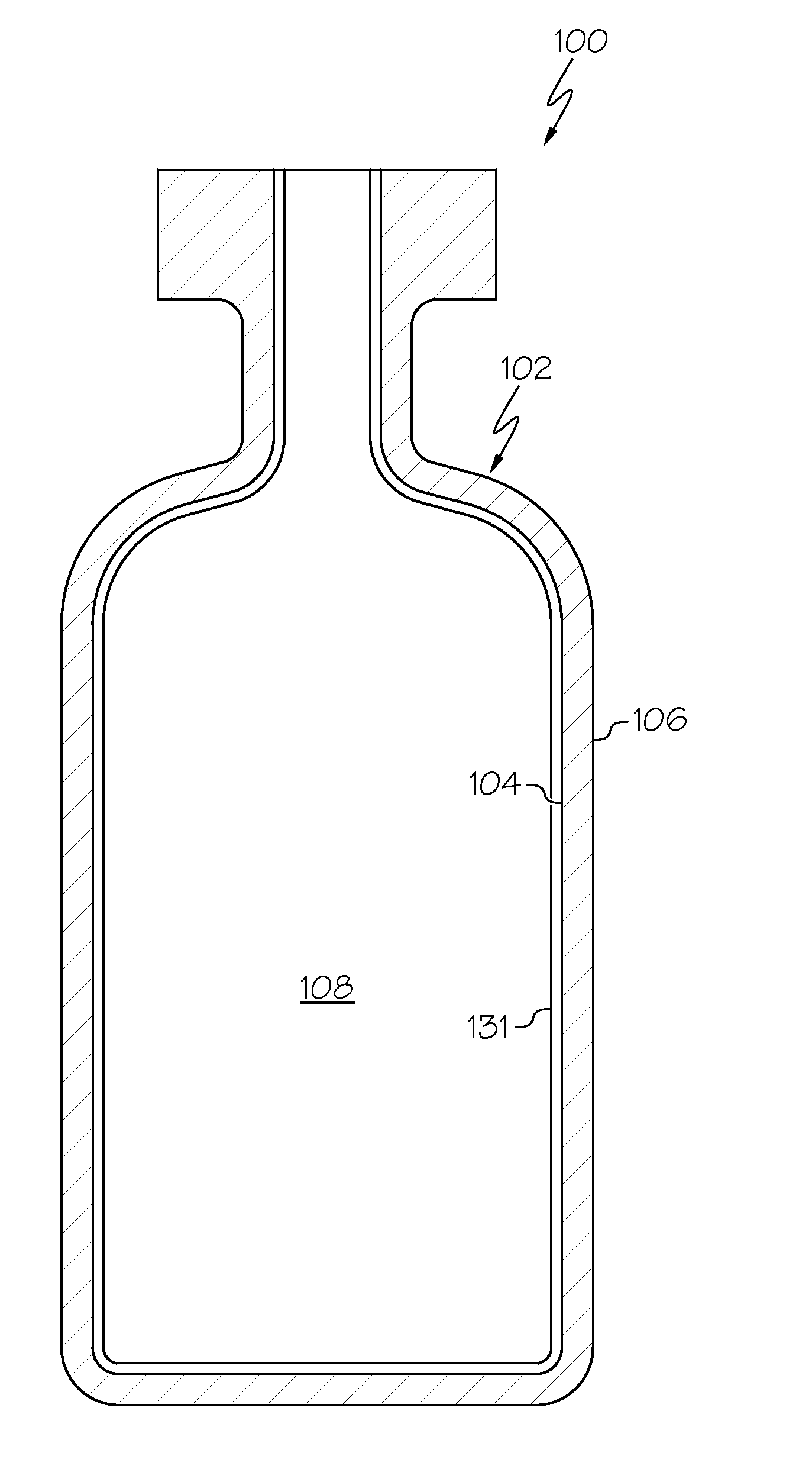

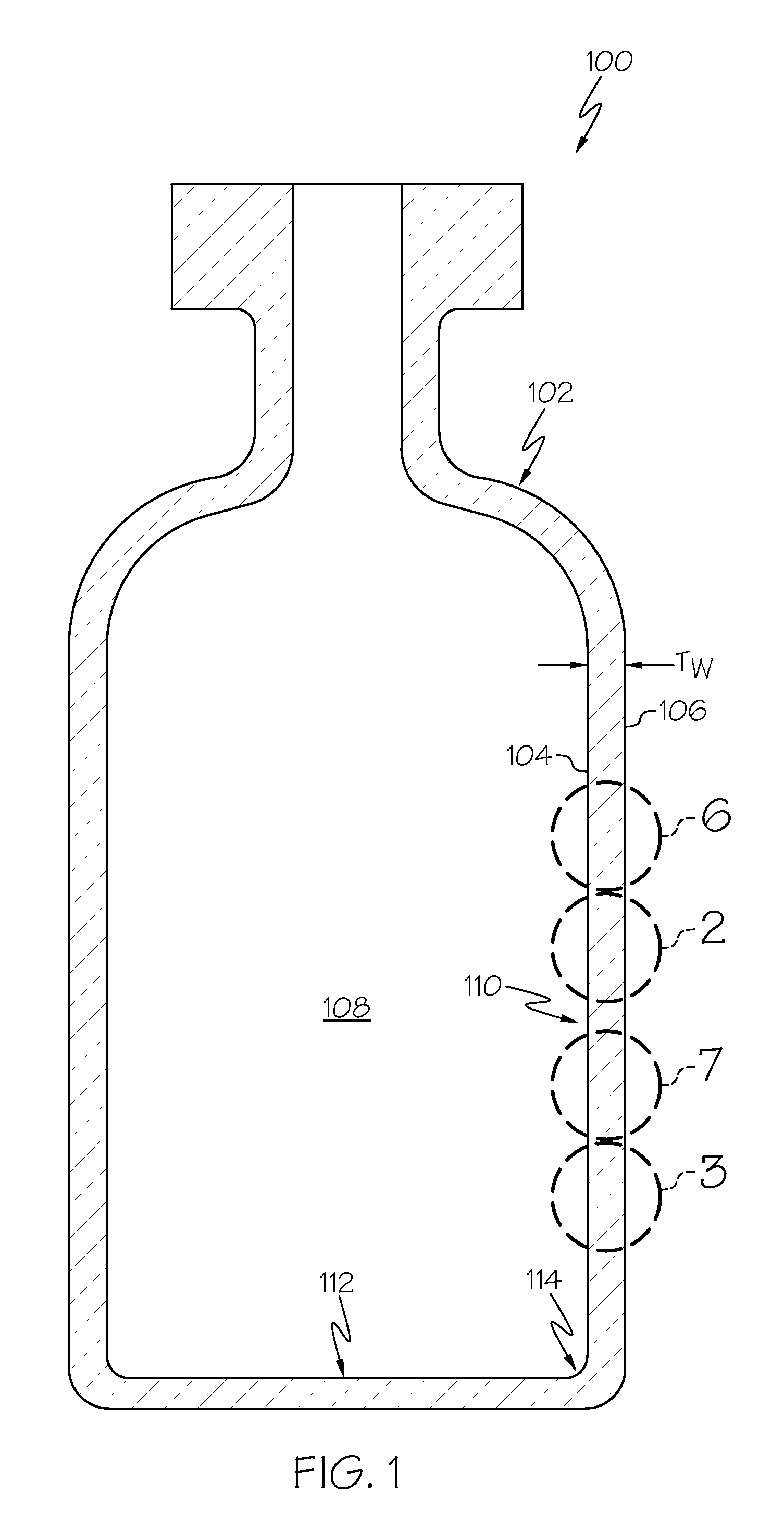

The glass containers described herein are resistant to delamination, have improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The body may also have a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa. A lubricous coating may be positioned around at least a portion of the outer surface of the body, such that the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

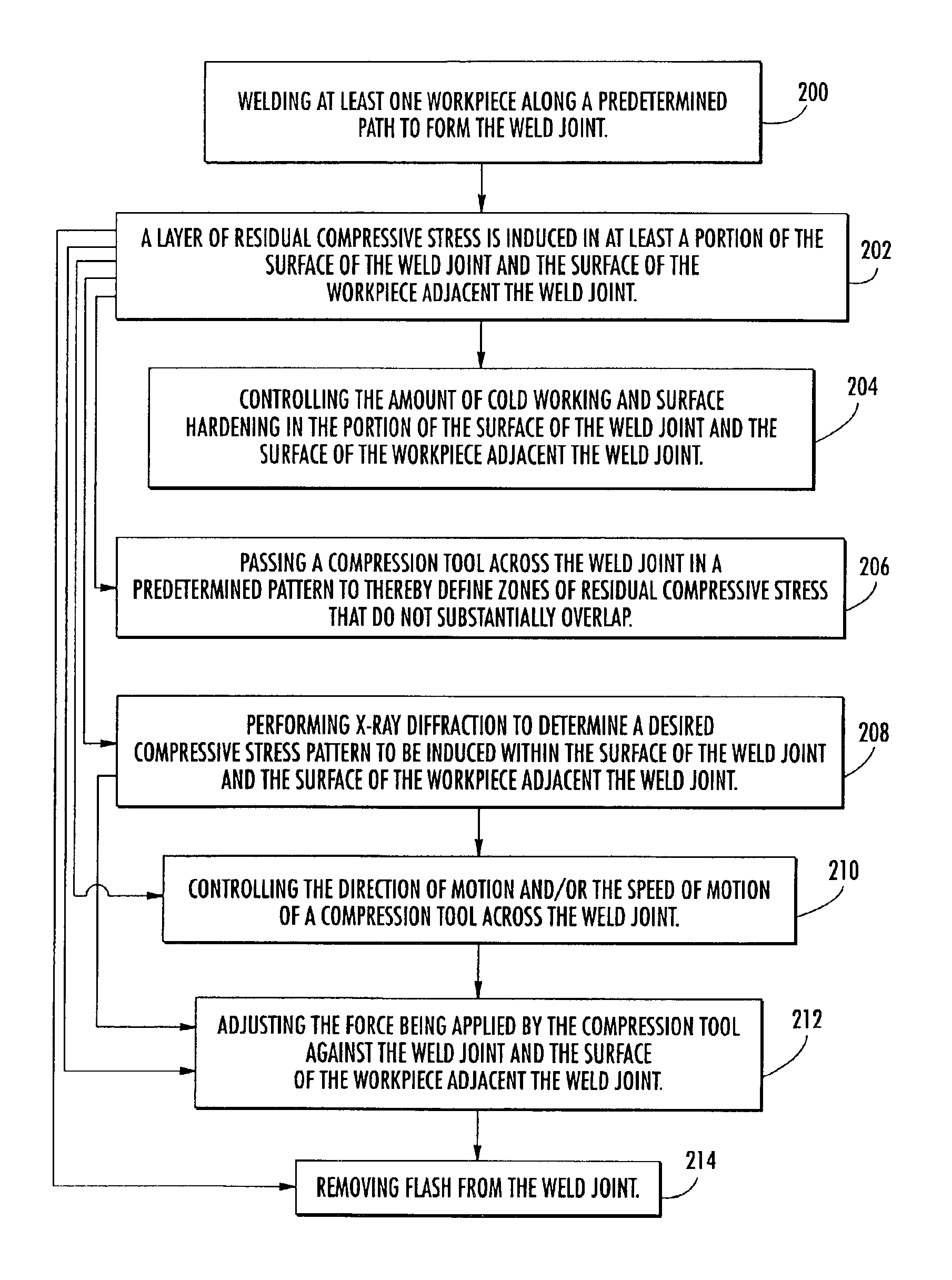

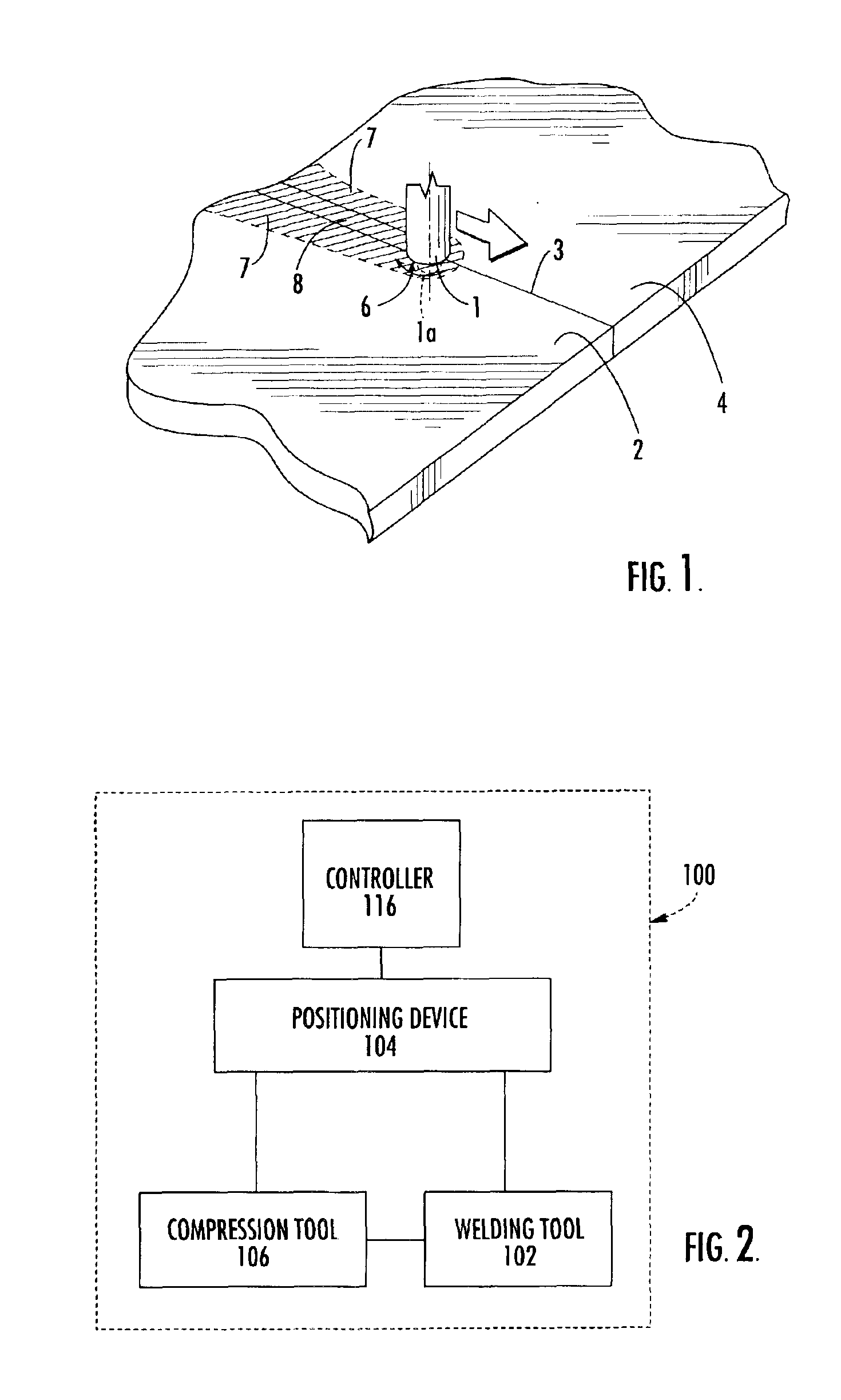

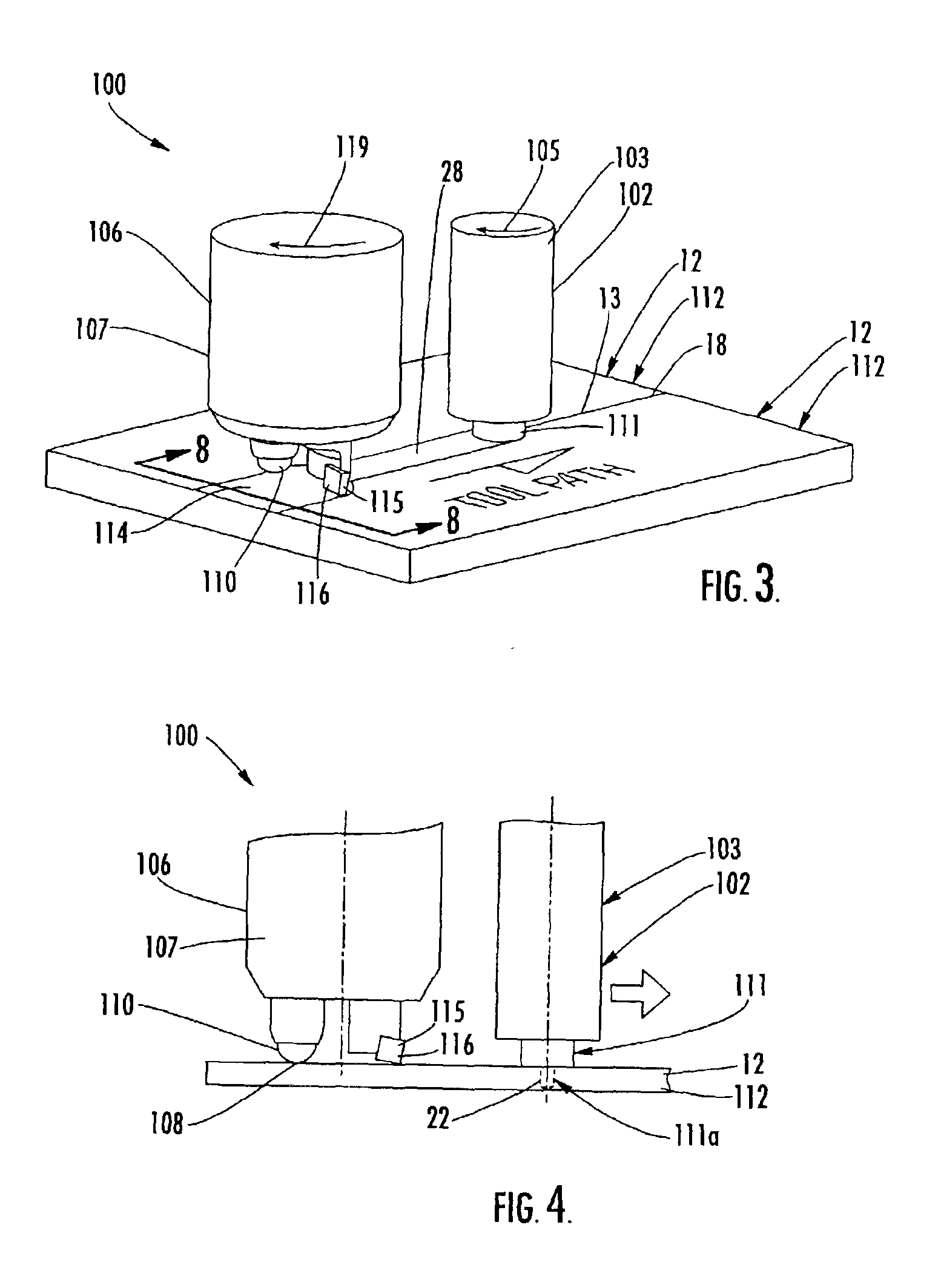

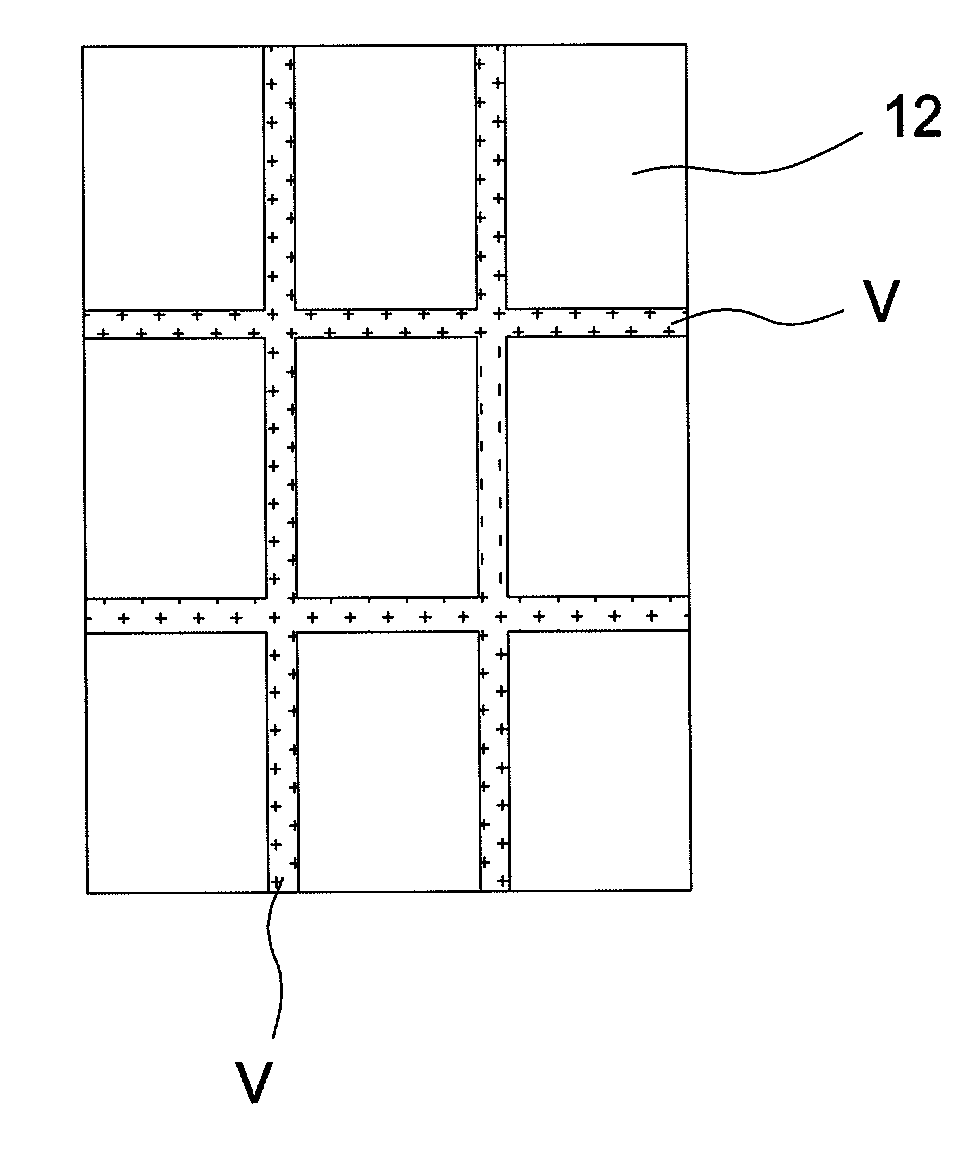

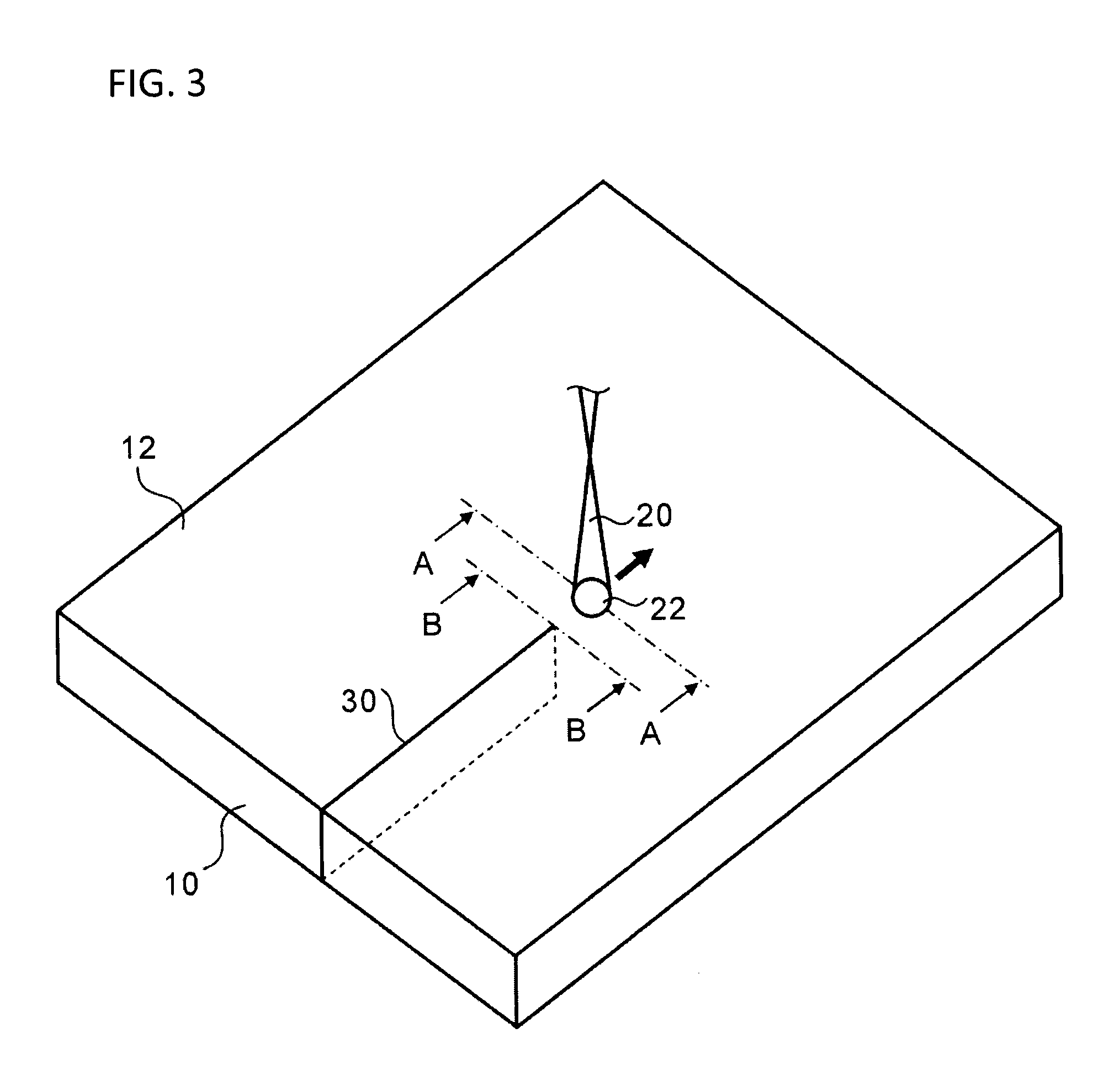

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

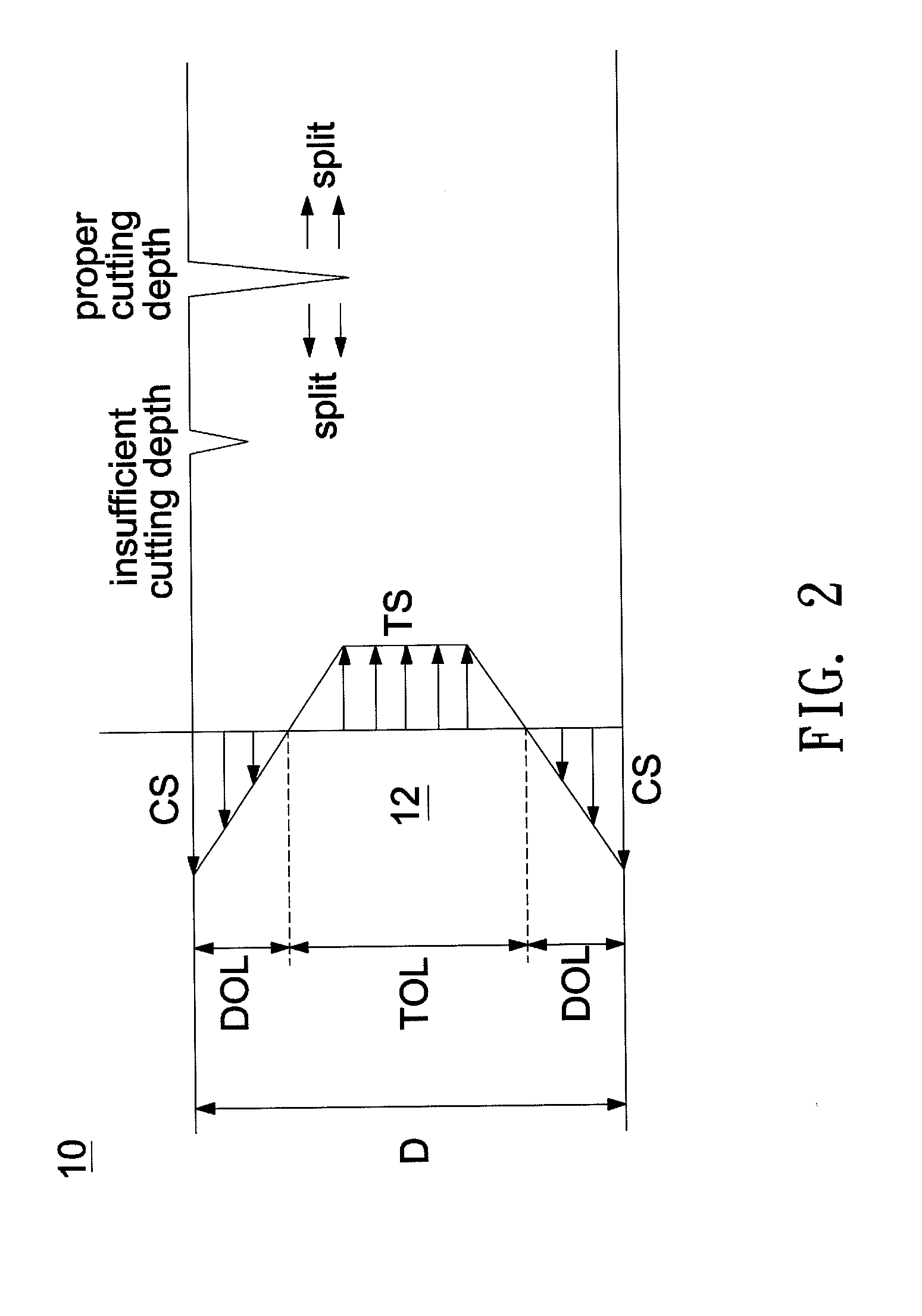

Method for cutting tempered glass and preparatory tempered glass structure

InactiveUS20110183116A1Improve production yieldReduce tensile stressGlass/slag layered productsGlass reforming apparatusToughened glassGlass structure

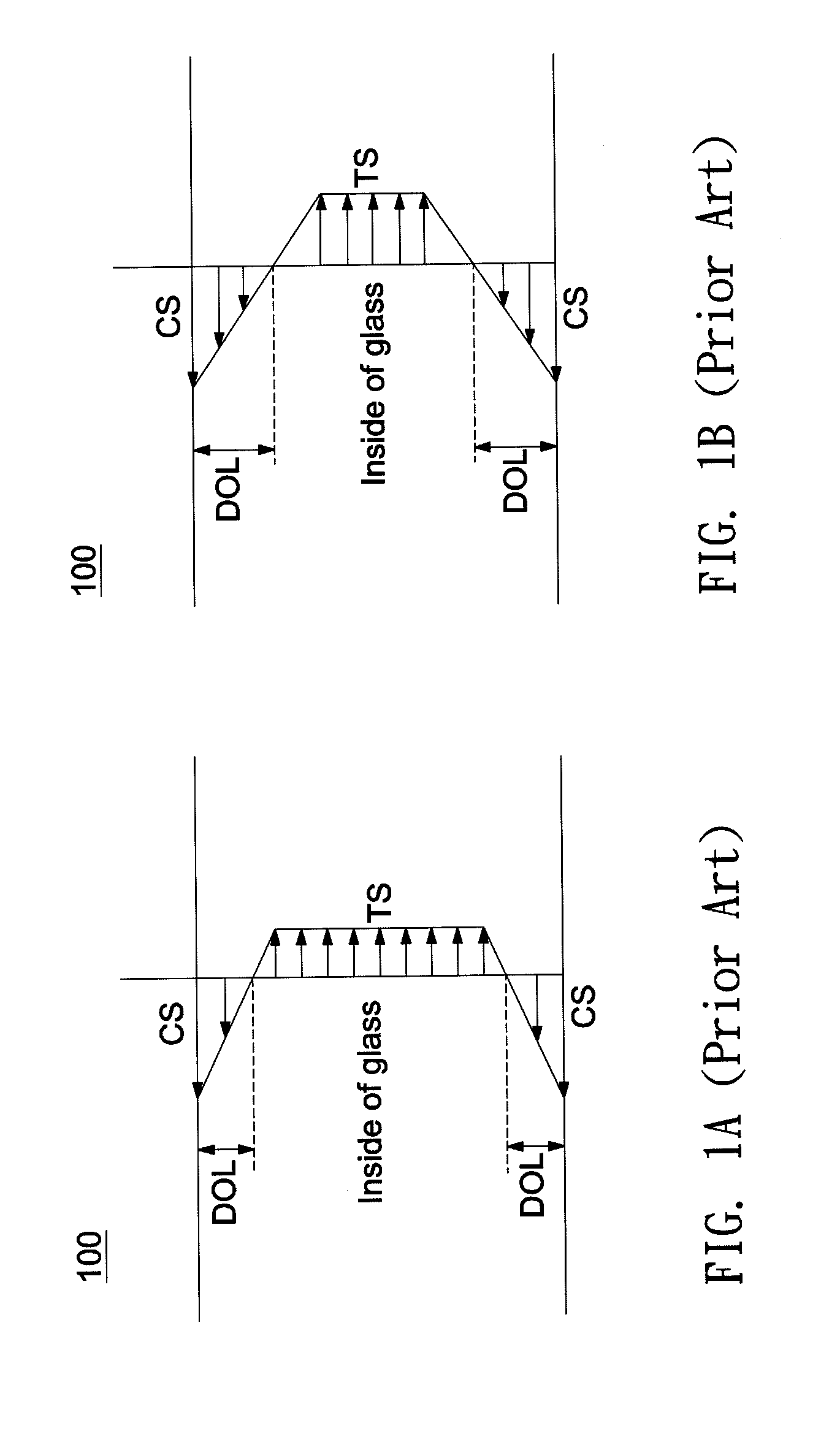

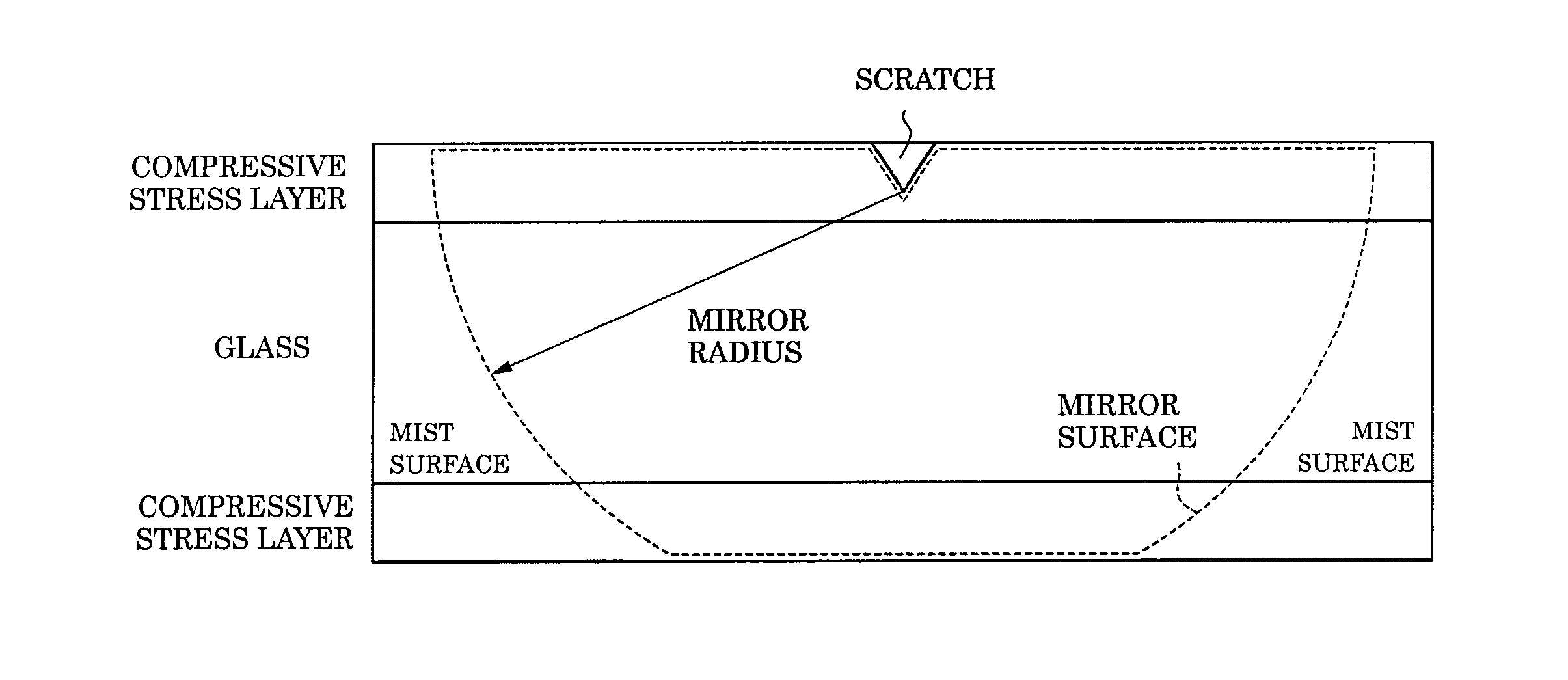

A preparatory tempered glass structure for a cutting treatment includes a glass substrate and at least one trench. The glass substrate is given a strengthening treatment to form, from a surface to the inside of the glass substrate, at least one compression stress layer and a tensile stress layer corresponding to the compression stress layer. The trench is formed in the compression stress layer of the glass substrate and overlaps a predetermined cutting path for the cutting treatment.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

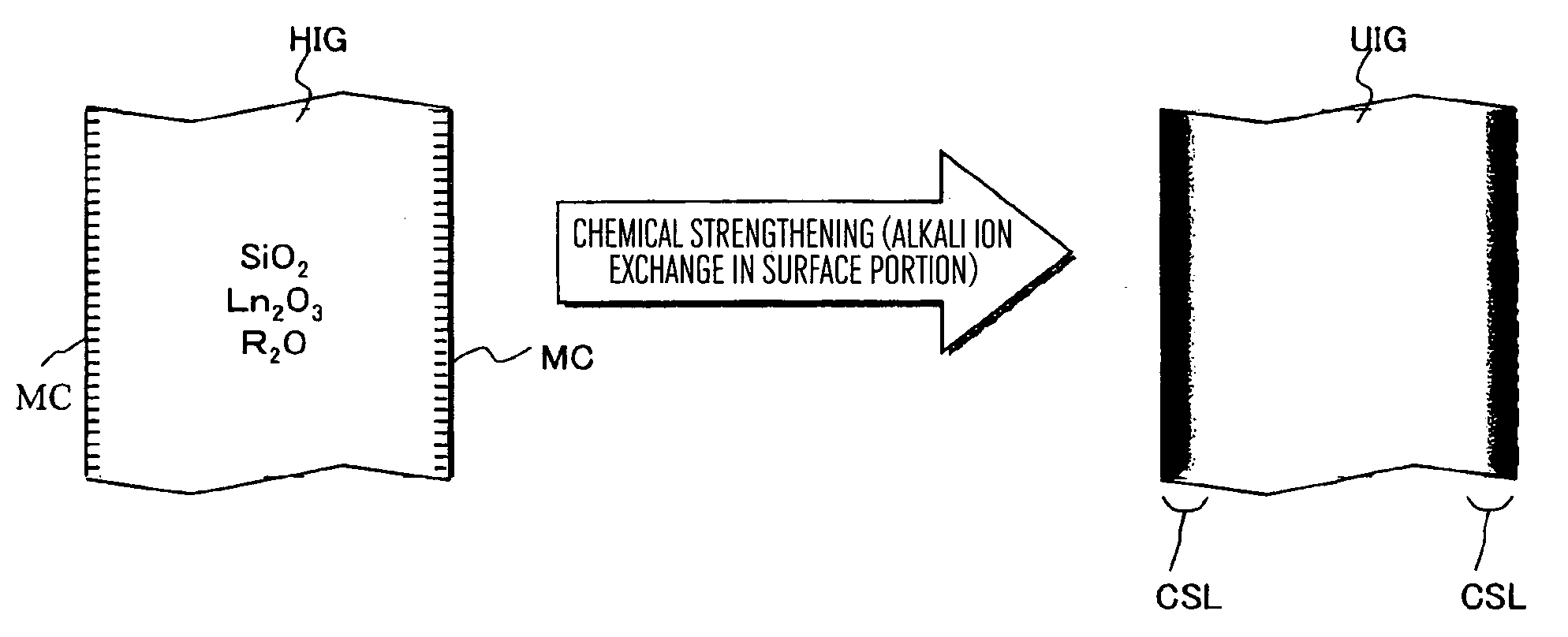

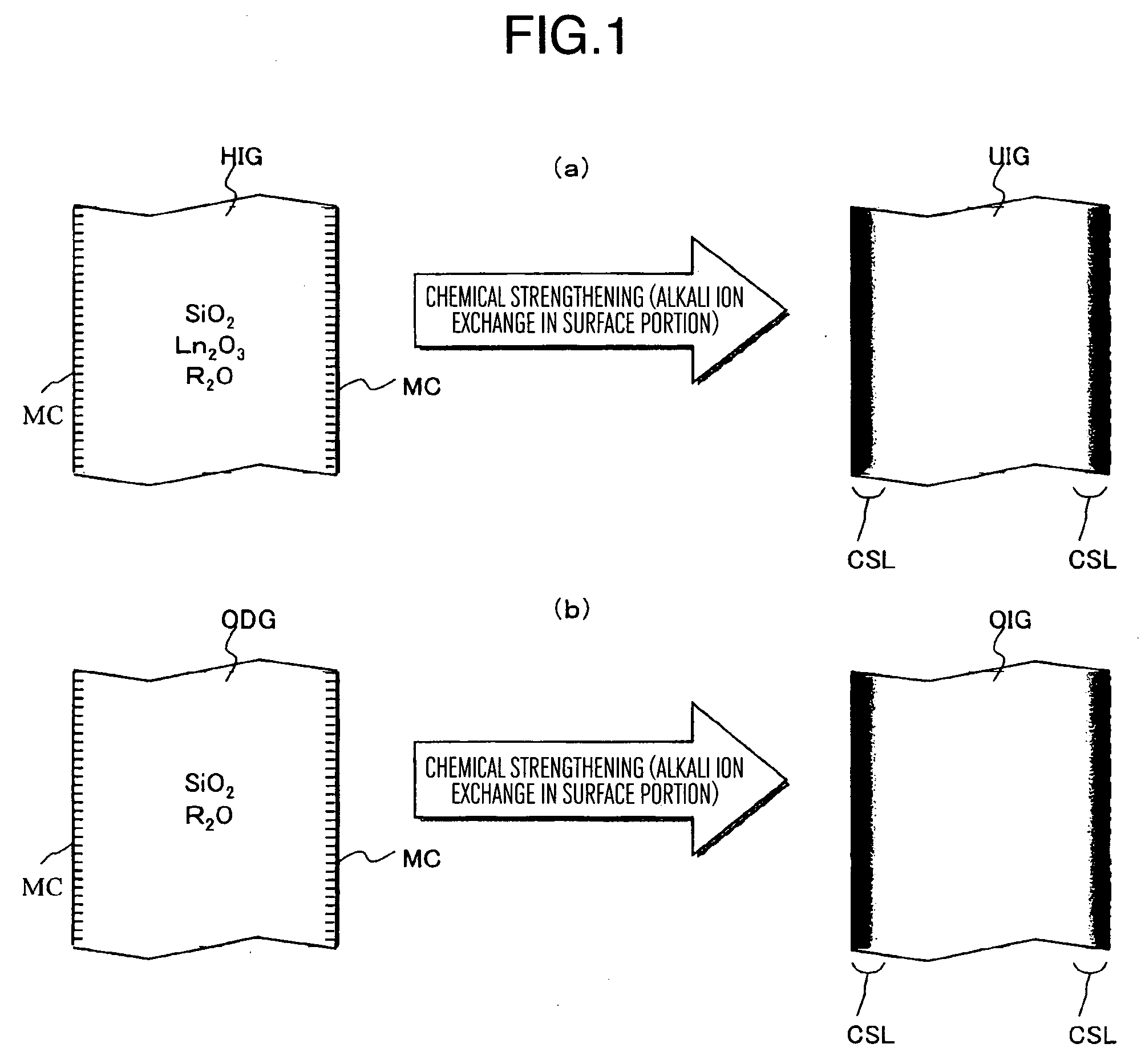

Glass member

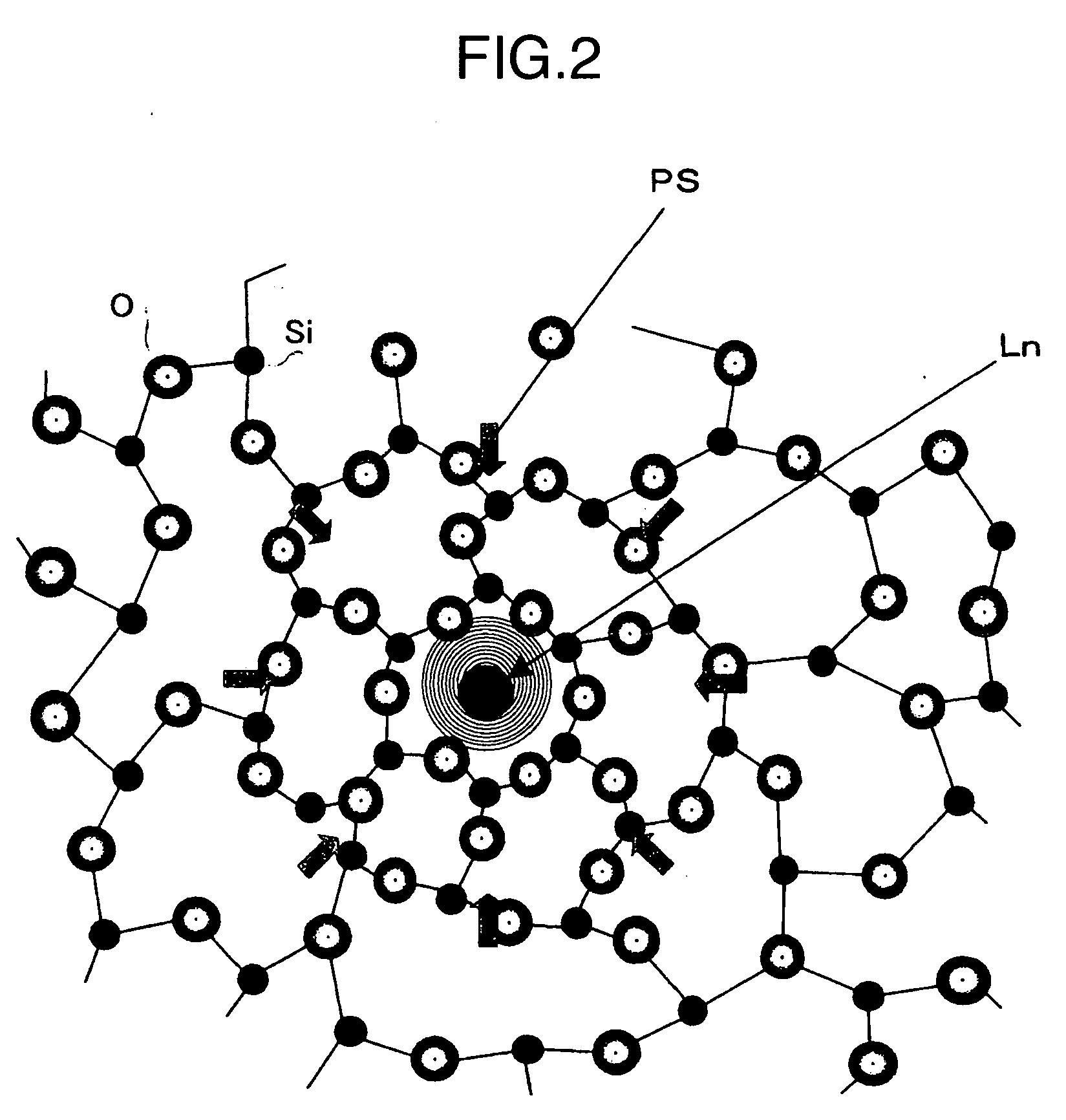

InactiveUS20060063009A1Low heat resistanceHigh strengthCathode ray tubes/electron beam tubesGlass/slag layered productsRare-earth elementHigh intensity

The present invention is envisioned to provide a high-strength glass which is applicable to the objective of size and weight reduction. A compression stress layer is formed in a surface portion of an oxide-based glass containing at least one rare earth element selected from the group consisting of Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu and further containing at least Si element and an alkali metal element.

Owner:HITACHI LTD

CMOS device

InactiveUS7022561B2High electron mobilityHigh hole mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesCMOSCompression stress

Owner:TAIWAN SEMICON MFG CO LTD

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

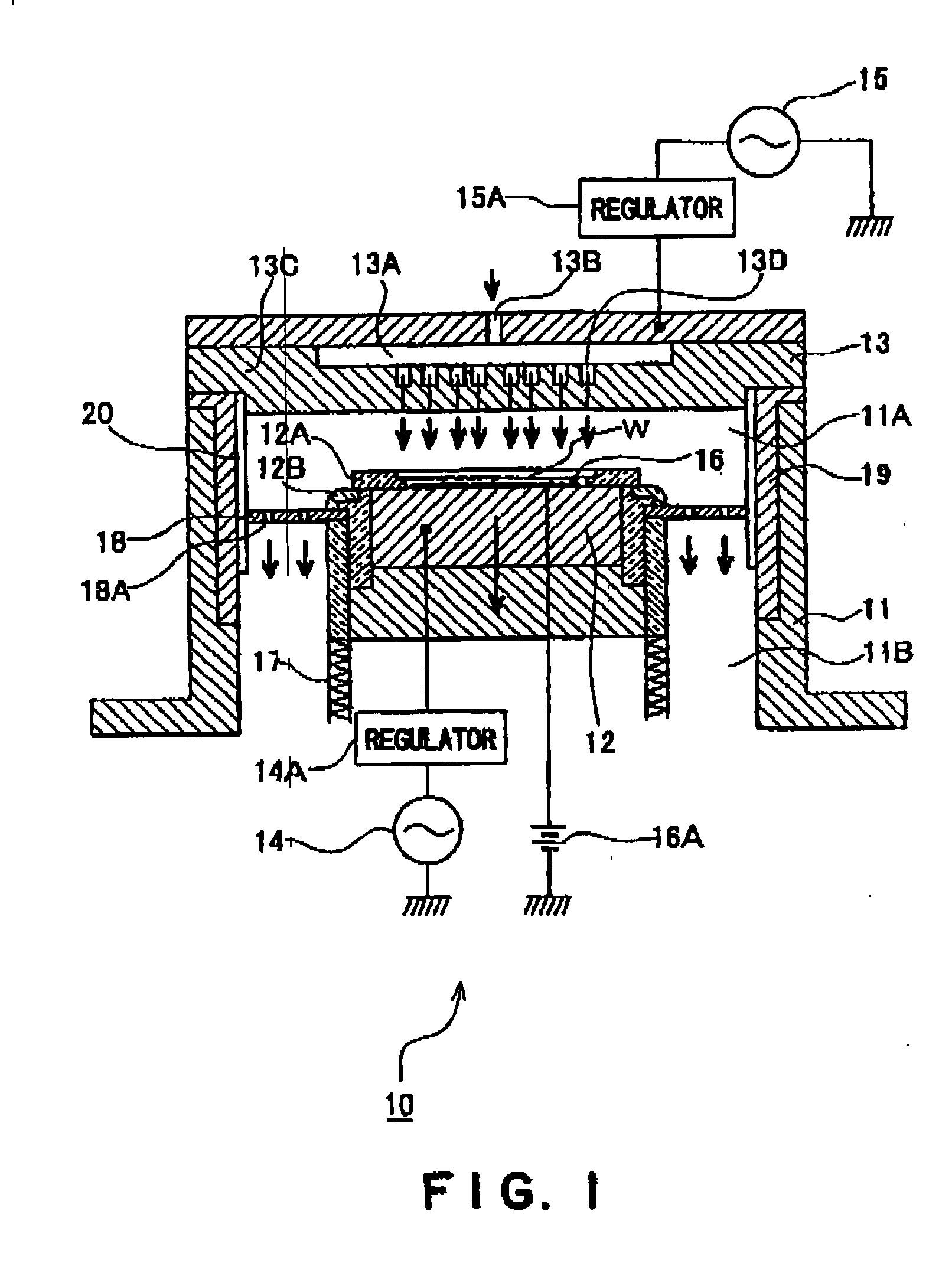

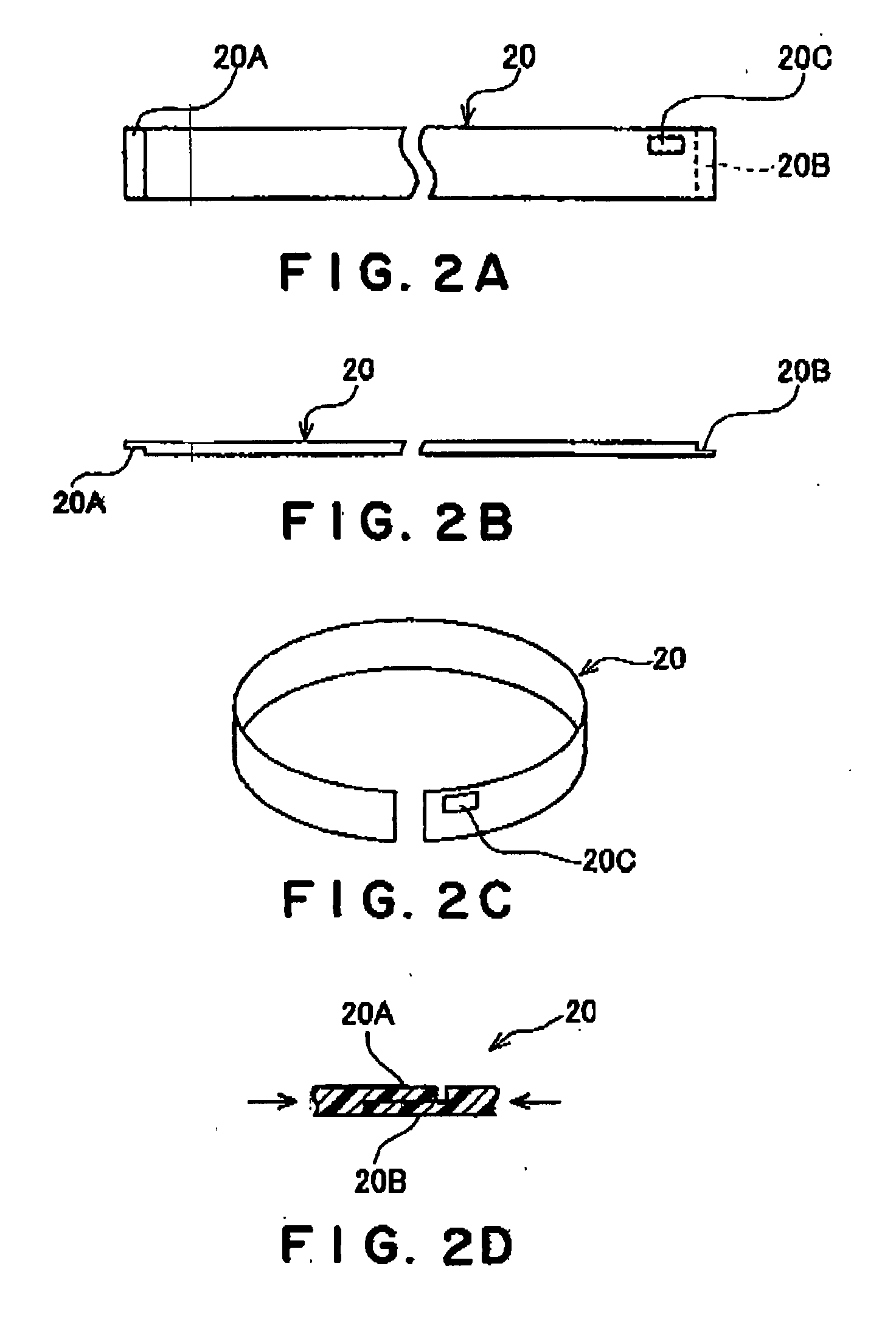

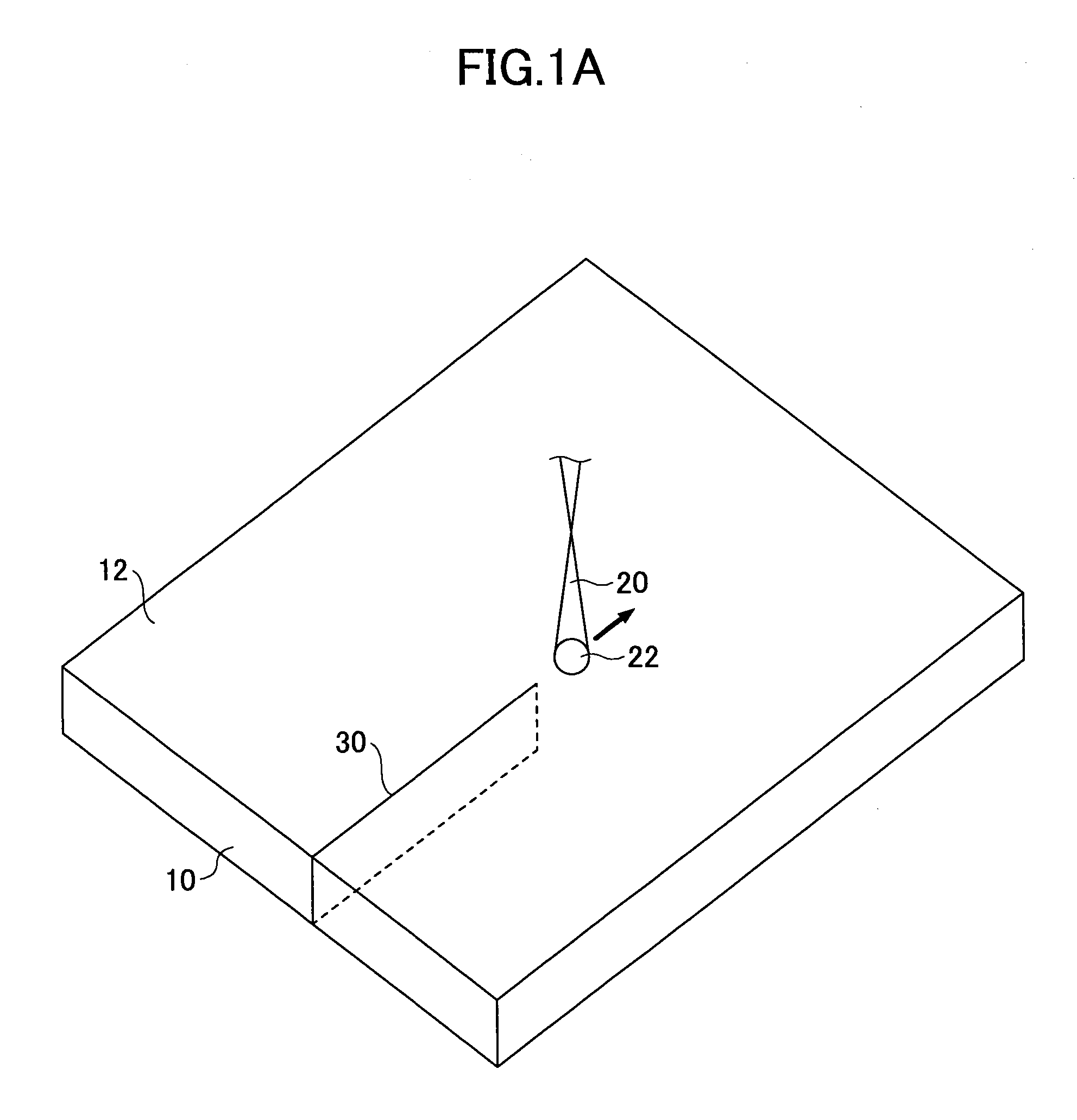

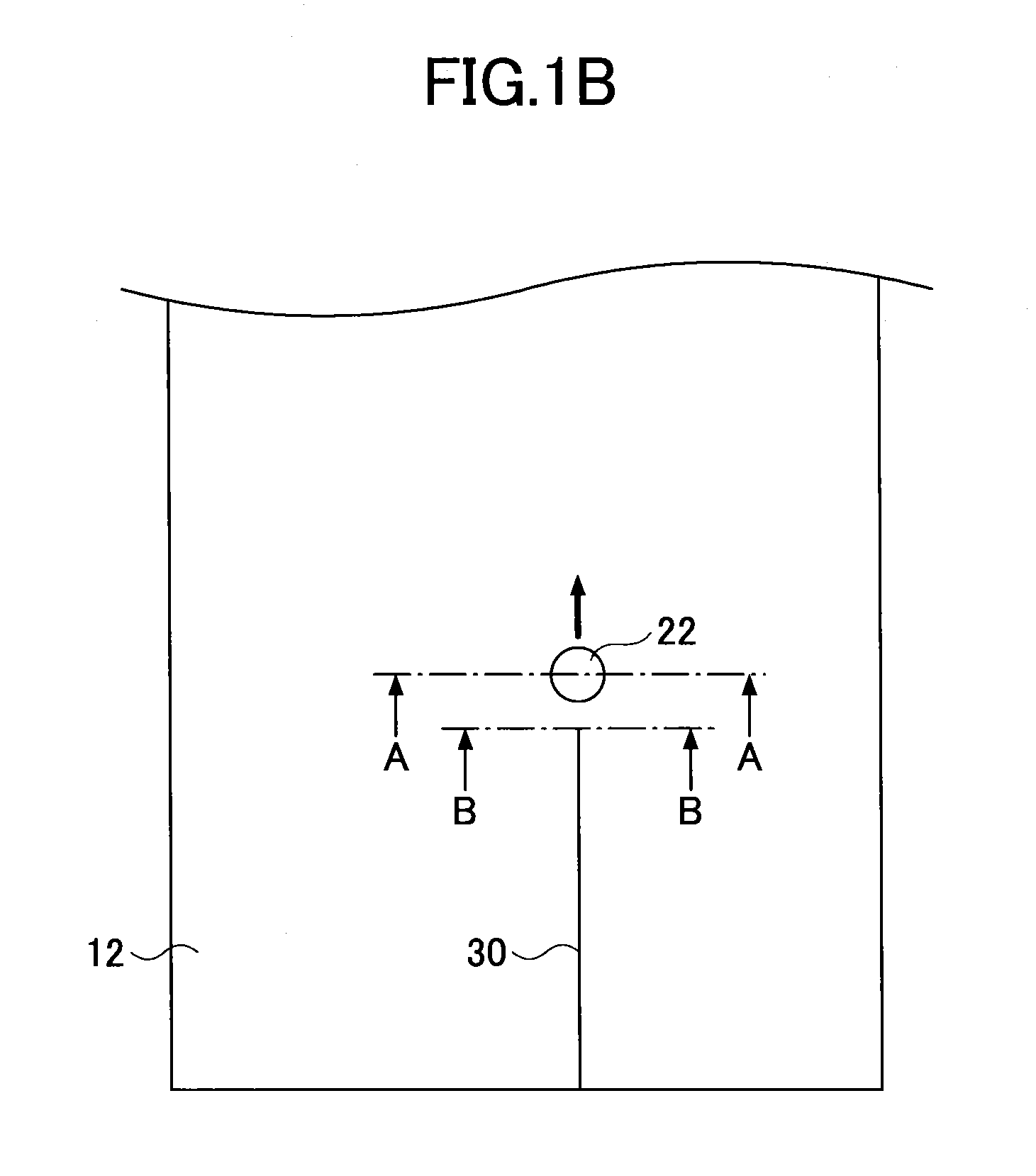

Plasma processing apparatus and method for asssembling the plasma processing apparatus

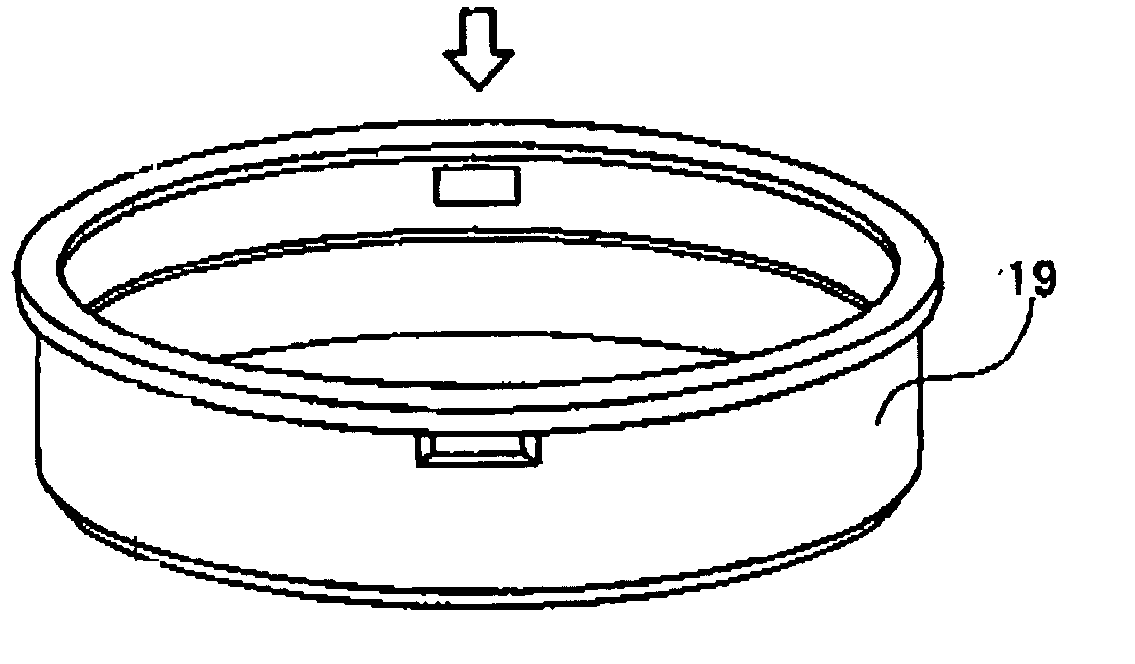

InactiveUS20040035364A1Compressive stress generatedAvoid it happening againElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

The plasma processing apparatus according to the present invention comprises a lower electrode 12 for supporting a wafer W in a chamber 11, shield member 19 for shielding an inside circumferential surface of the chamber 11 from a plasma for processing the wafer W, and a baffle plate 18 disposed in a gap between the shield member 19 and the lower electrode 12, and scattering and exhausting a gas in the chamber 11, a resin plate 20 being removably mounted on an inside circumferential surface of the shield member 19, and a circumferential compression stress being generated in the resin plate 20.

Owner:TOKYO ELECTRON LTD

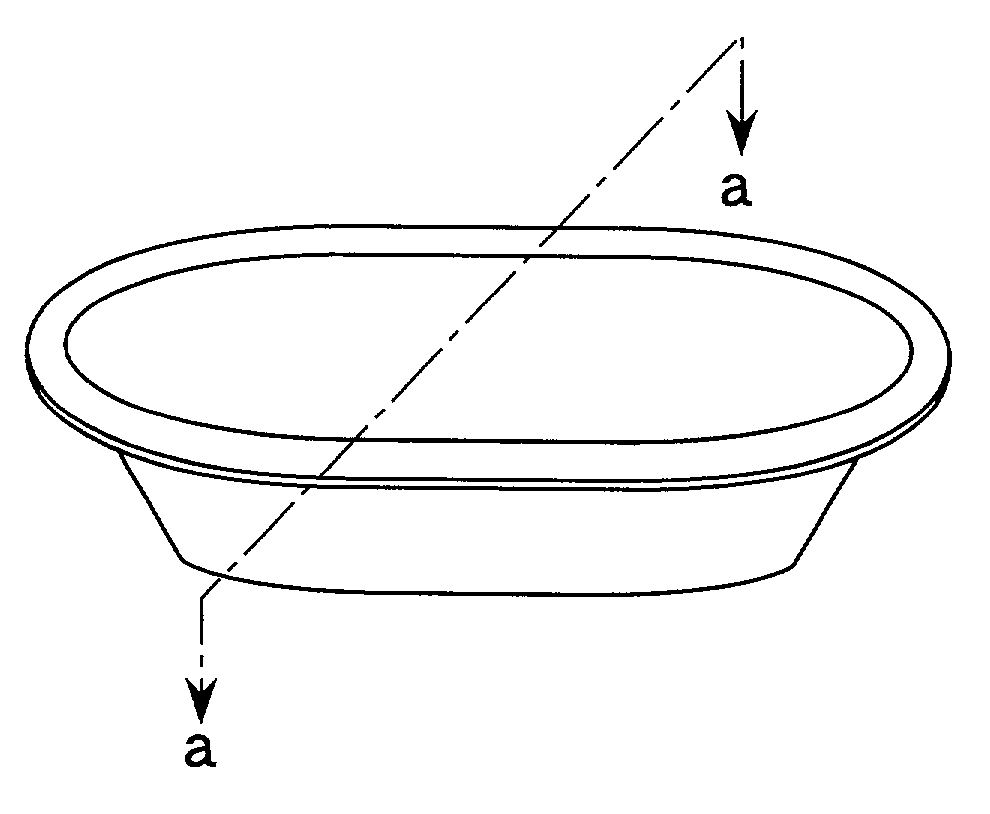

Molding base paper and molded paper vessel produced from it

InactiveUS20020012759A1Mechanical working/deformationSpecial paperCompressive strengthUltimate tensile strength

A molding base paper used for forming paper vessels such as a cup or tray for foods and various industrial products is disclosed which satisfies the following conditions (1) to (4): (1) a tensile strength (JIS-P 8113) of at least 2.0 kN / m, (2) an elongation at break (JIS-P 8113) of at least 1.5%, (3) a critical compression stress, defined by the following formula, in the range of 1 to 10 MPa: <paragraph lvl="0"><in-line-formula>critical compression stress=A / B < / in-line-formula>wherein A represents the compression strength determined by JIS-P 8126, and B represents the area of loaded part of the test piece in the determination of the compression strength, and (4) an amount of the compression deformation, caused by applying compression stress of 20 kgf / cm2in thickness direction, of at least 10 %. The paper vessels are prepared by controlling the water content of the molding base paper at 10 to 20% and then drawing the molding base paper at 100 to 150° C.

Owner:OJI PAPER CO LTD

High Speed Laser Processing of Transparent Materials

ActiveUS20150299018A1Avoid focusHigh precision laserBlowing machine gearingsGlass furnace apparatusLaser processingAtomic physics

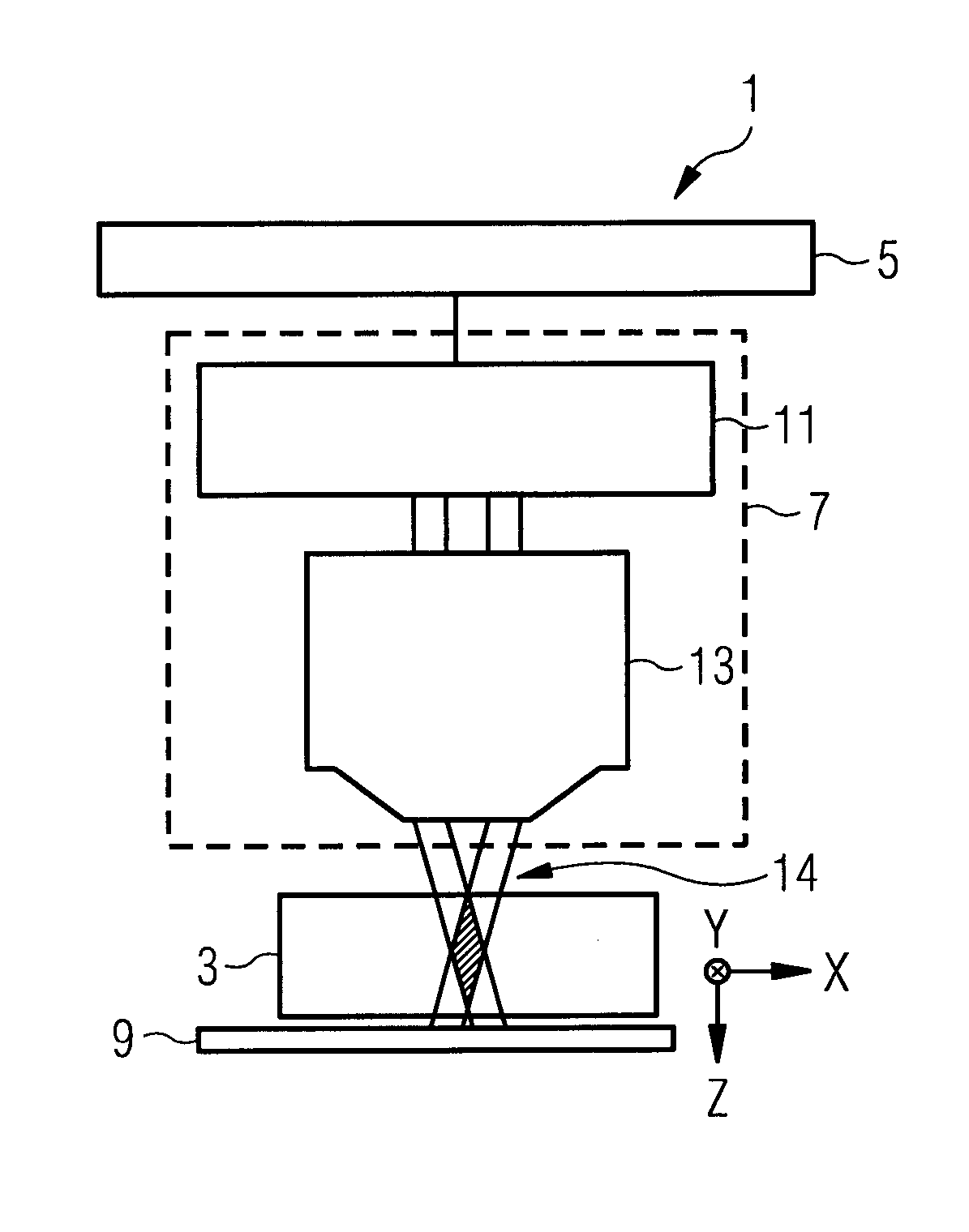

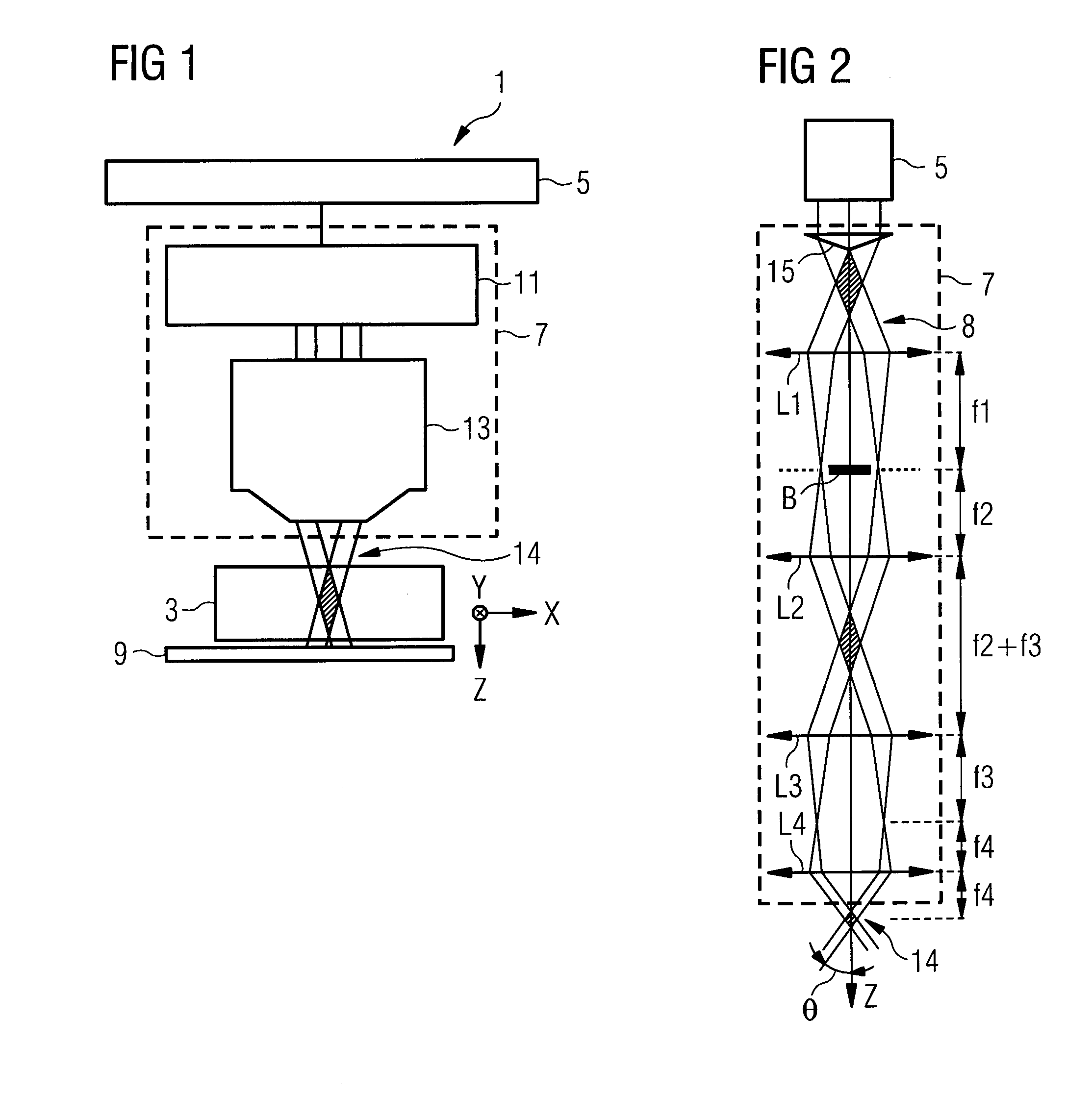

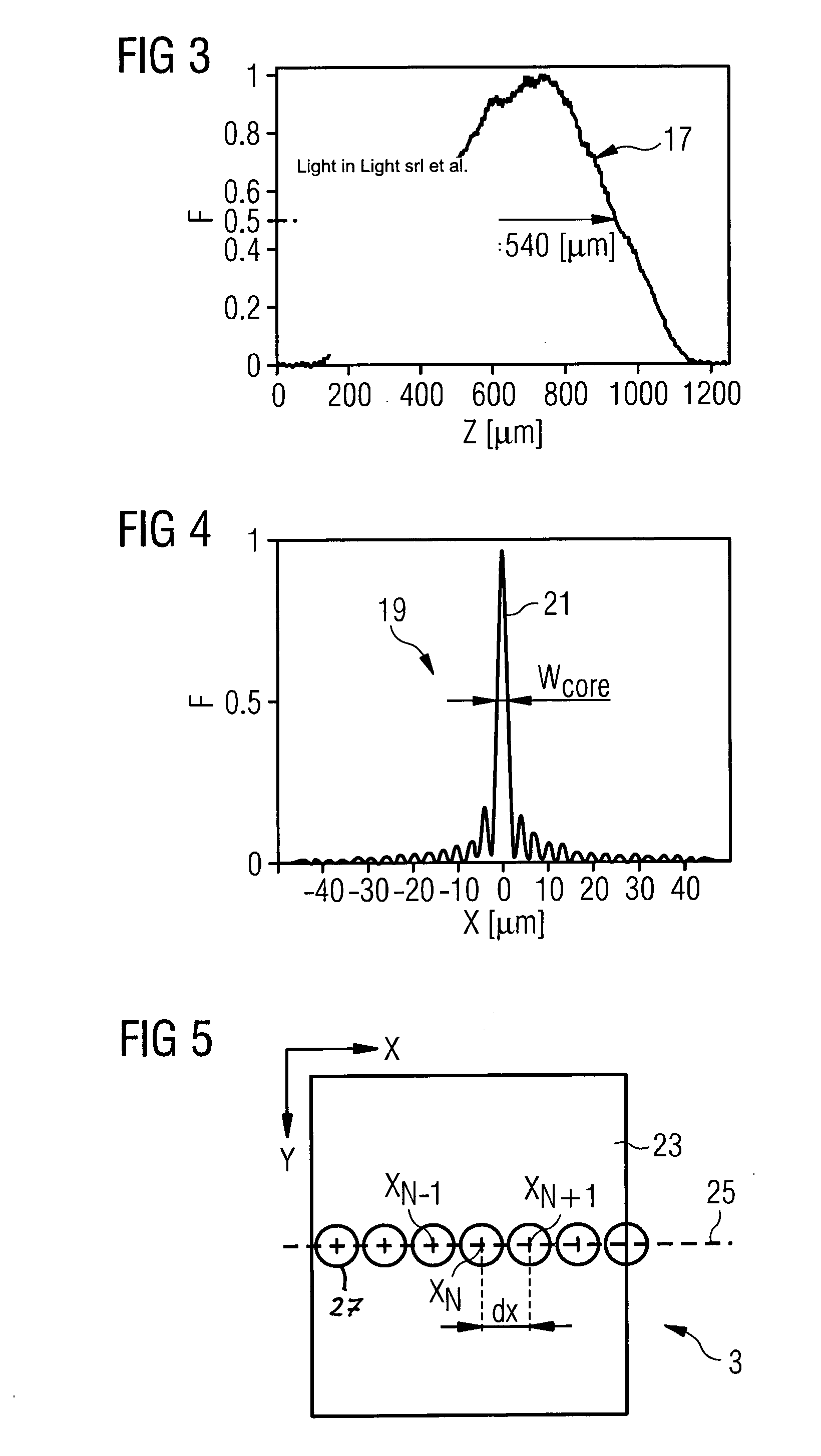

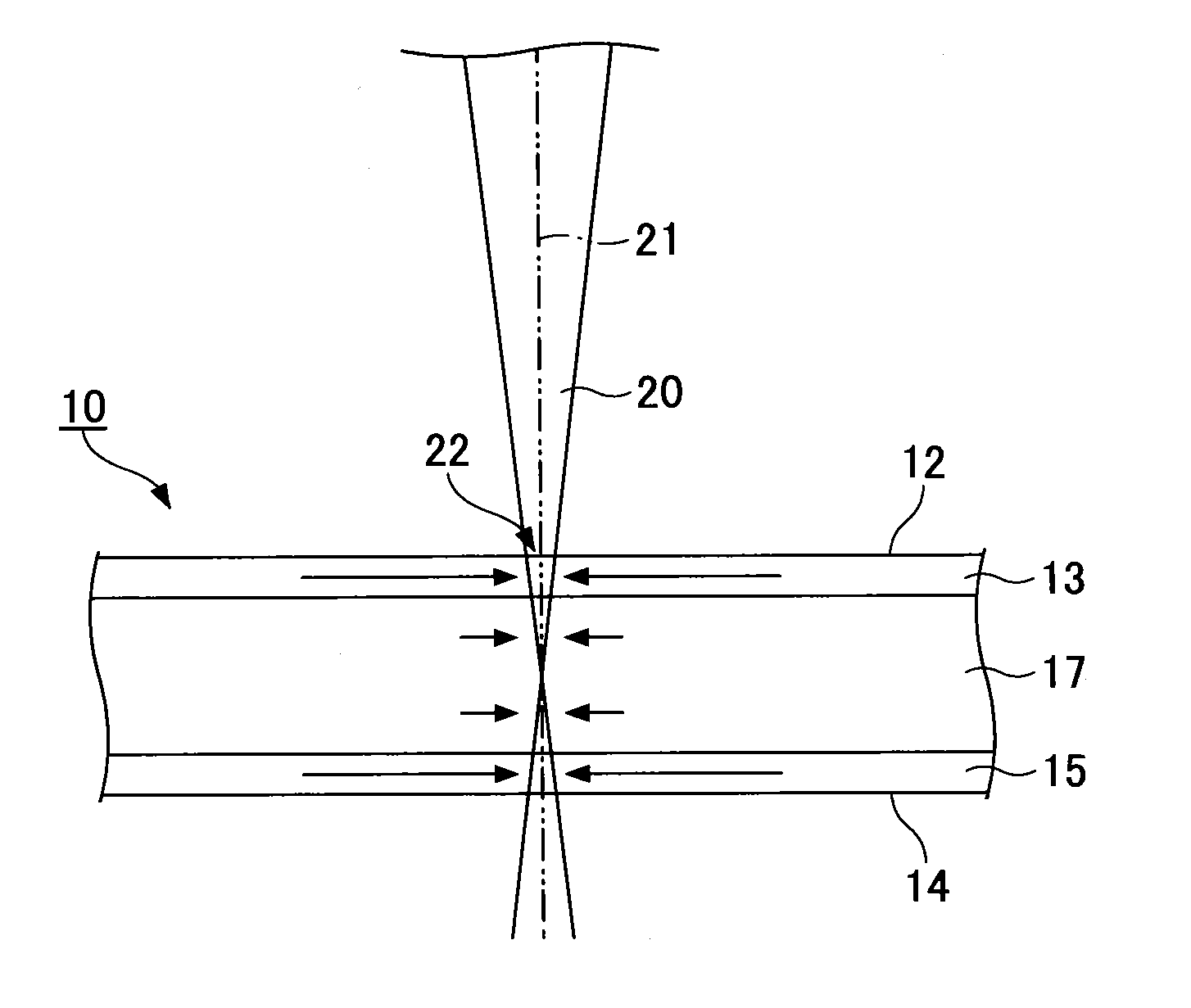

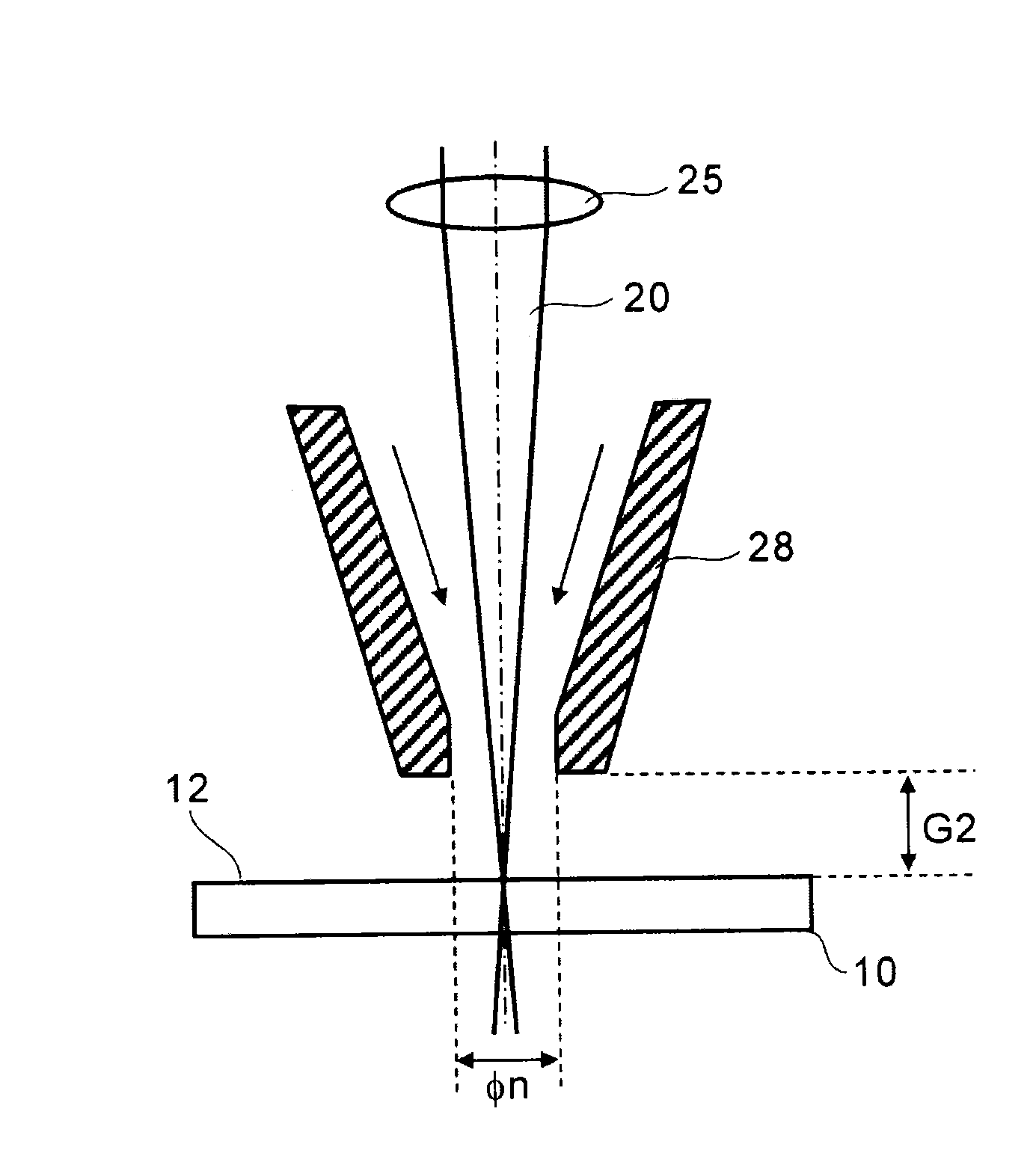

A method and system for laser pre-cutting a layered material (31) with a laser beam (14) is disclosed. The layered material (31) comprises at least one tensile stress layer (TSL), at least one compression stress layer (CSL1, CSL2), and at least one interface region (IR1, IR2) between the at least one tensile stress layer (TSL) and the at least one compression stress layer (CSL1, CSL2) and is transparent to allow propagation of the laser beam (14) through the layered material (31). The method may comprise setting an optical beam path (8) and a laser characteristic of the laser beam (14) such that an interaction of the laser beam (14) with the layered material (31) generates an elongate damage region (57) in the layered material (31), and, for each of a series of pre-cut positions (XN−1, XN, XN+1) of the layered material (31), pre-cutting the layered material (31) by positioning the layered material (31) and the laser beam (14) with respect to each other and irradiating the laser beam (14) such that the respective elongate damage regions (57) extend across the at least one interface region (IR1, IR2).

Owner:UAB ALTECHNA R&D

Method for increasing compression stress or reducing internal tension stress of a CVD, PCVD or PVD layer and cutting insert for machining

InactiveUS6884496B2Prolong lifeIncrease resistance to crack formation and corrosion resistance and wear resistanceVacuum evaporation coatingSputtering coatingMaximum diameterTension stress

A method of increasing the compressive stress or of reducing the tensile residual stress of a CVD layer, a PCVD layer or PVD layer and a cutting insert for machining.The invention relates to a method of increasing the compressive residual stress or of reducing the tensile residual stress of a hard material outer layer or a hard material outermost layer in which the coated substrate after coating is subjected to a dry blast treatment using a granular blast agent that, according to the invention, has a maximum diameter of 150 μm.

Owner:WIDIA

Method of cutting strengthened glass plate

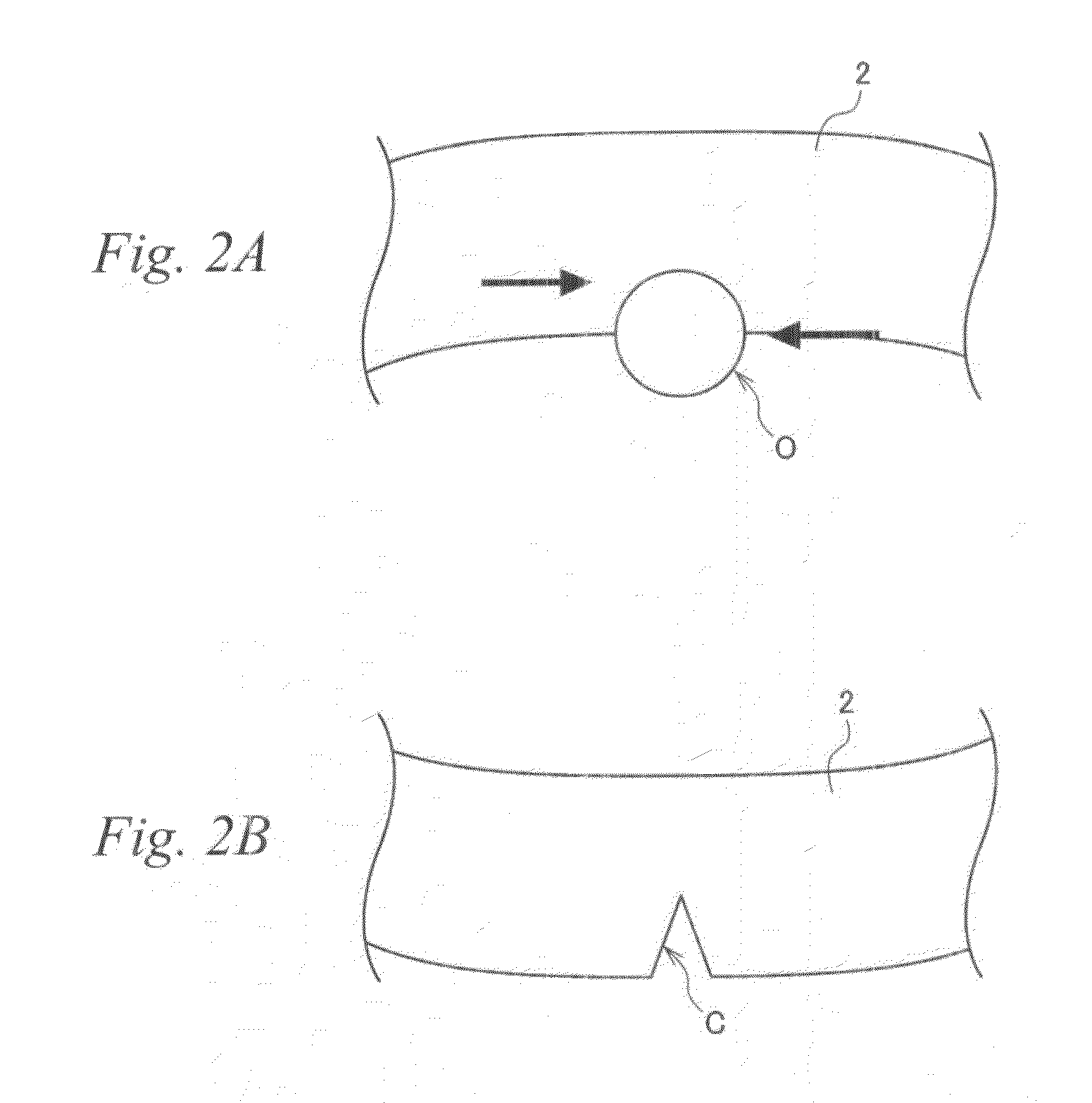

InactiveUS20130291598A1Improve accuracyEasy to trackFine working devicesVehicle componentsSurface layerTension stress

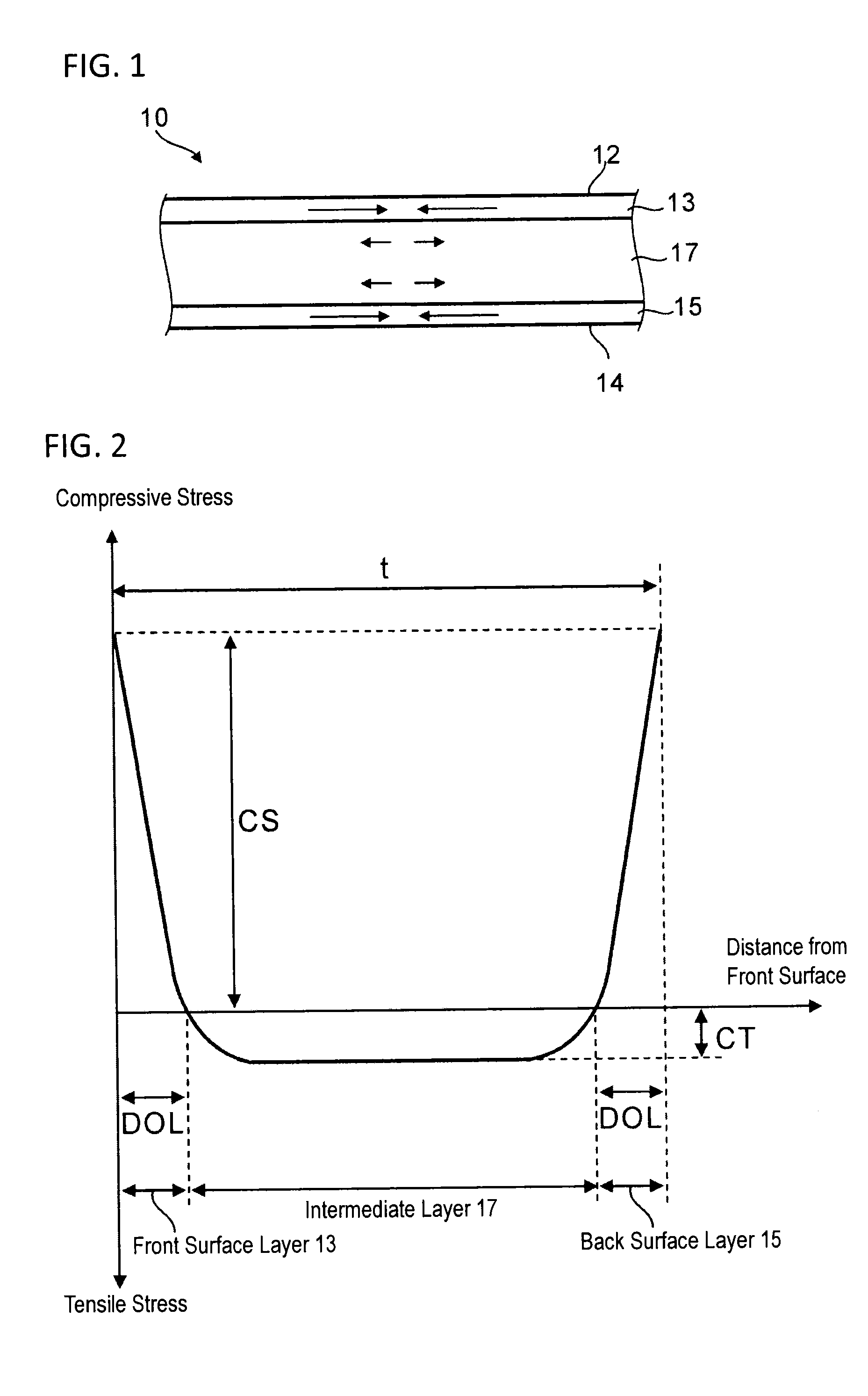

A method of cutting a strengthened glass including, a front surface layer and a back surface layer each having a remaining compression stress, respectively, and an intermediate layer formed between the front surface layer and the back surface layer, having an internal remaining tensile stress, the method includes heating the intermediate layer at an irradiation area of a laser beam at a temperature less than or equal to an annealing point to generate a tensile stress less than a value of the internal remaining tensile stress of the intermediate layer or a compression stress at the center of the irradiation area for suppressing the propagation of the crack.

Owner:ASAHI GLASS CO LTD

Tempered glass and method for producing same

InactiveUS20140170380A1Efficiently provideImprove surface qualityRecord information storageMagnetic recordingMetallurgyCompression stress

A tempered glass of the present invention is a tempered glass having a compression stress layer in a surface thereof, the tempered glass comprising, as a glass composition in terms of mol %, 45 to 75% of SiO2, 3 to 15% of Al2O3, 0 to 12% of Li2O, 0.3 to 20% of Na2O, 0 to 10% of K2O, and 1 to 15% of MgO+CaO, and having a molar ratio (Al2O3+Na2O+P2O5) / SiO2 of 0.1 to 1, a molar ratio (B2O3+Na2O) / SiO2 of 0.1 to 1, a molar ratio P2O5 / SiO2 of 0 to 1, a molar ratio Al2O3 / SiO2 of 0.01 to 1, and a molar ratio Na2O / Al2O3 of 0.1 to 5, characterized in that the surface or an end surface of the tempered glass is etched after tempering treatment.

Owner:NIPPON ELECTRIC GLASS CO LTD

Pressure wave generator and process for manufacturing the same

InactiveUS7474590B2Reduce the likelihood of occurrenceMade smallMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Method for cutting tempered glass plate

InactiveUS20150183679A1Precise cuttingGlass reforming apparatusGlass severing apparatusStrain energyToughened glass

A method for cutting a strengthened glass sheet through laser irradiation. The sheet includes a front surface layer and back surface layer each having a residual compressive stress and an intermediate layer which is formed therebetween and has an internal residual tensile stress CT (MPa). A strain energy UCT (J / m2) expressed by UCT={CT2×(t1−2×DOL)} / (2×Y) is 2.5 J / m2 or more. A cutting index K (N / mm) expressed by K=Pe / v×exp(−α×t2)×(Y×αL) / (t2×ρ×c) is 150 N / mm or less.

Owner:ASAHI GLASS CO LTD

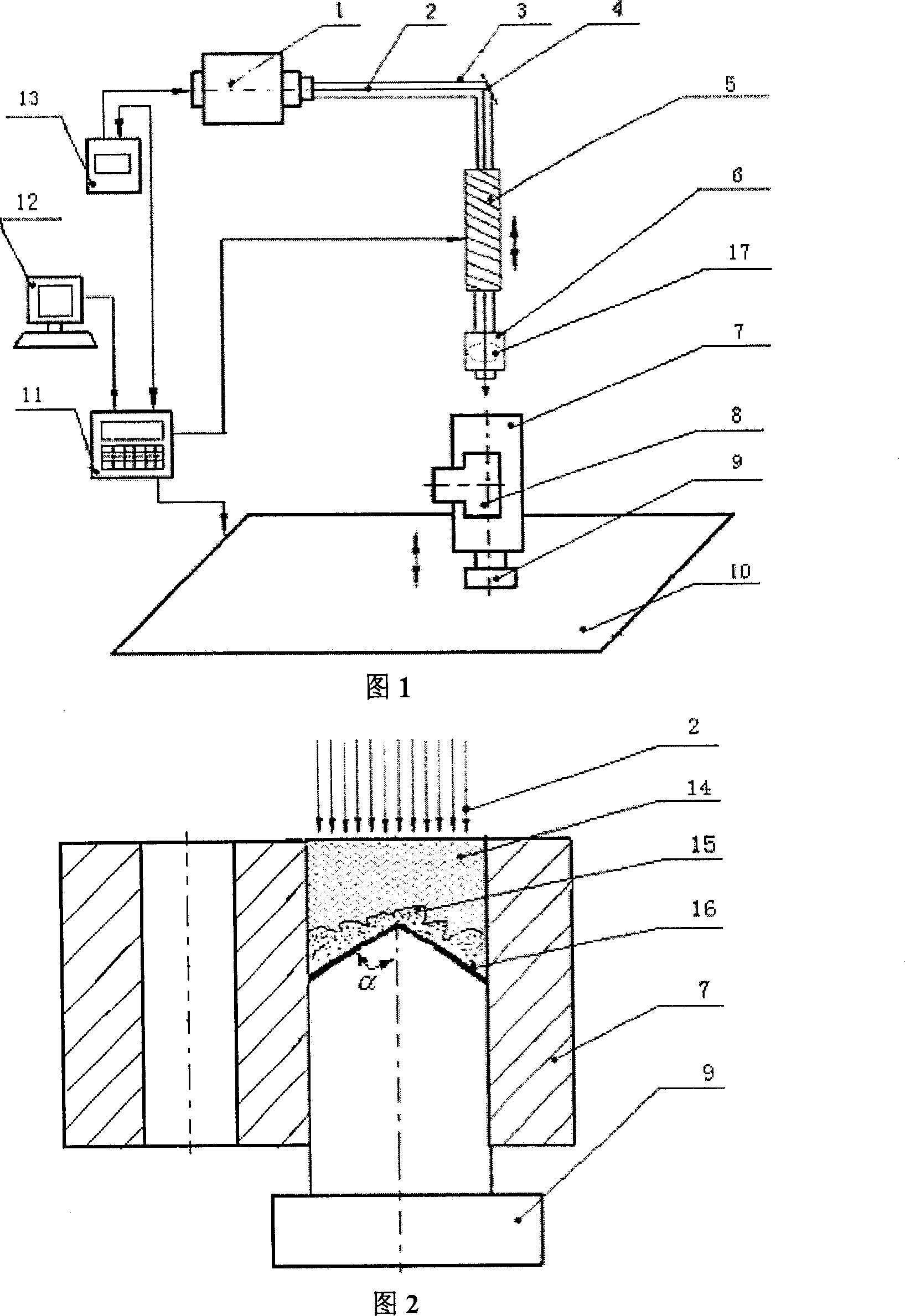

Technical hole wall intensifying method based on laser impaction wave and apparatus

The invention is a hole wall strengthening method and device based on laser shock wave technique, relating to the laser machining field. And the invention firstly determines the corresponding reflecting cone diameter according to the principle of cooperation of hole size and hole shaft of a to-be-machined workpiece, coating energy absorbing layer material on the concial surface of the reflecting cone and then inserting the reflecting cone in the workpiece, installing the workpiece on a clamp, injecting constraint layer in the to-be-machined hole; a laser generates a laser pulse which irradiates the energy absorbing layer through light guiding system and constraint layer, and the energy absorbing layer absorbs the laser energy to vaporize, ionize, form plasma explosion, generate high amplitude shock wave, and strengthen the hole wall. And the invention can strengthen the walls of holes with larger diameters and strengthen the walls of micropores. And the strength and hardness of the strengthened hole wall are remarkably improved, and the surface layer has helpful remaining compression stress and it can obtain higher size accuracy and lower surface roughness and directly act as the final procedure of hole machining.

Owner:JIANGSU UNIV

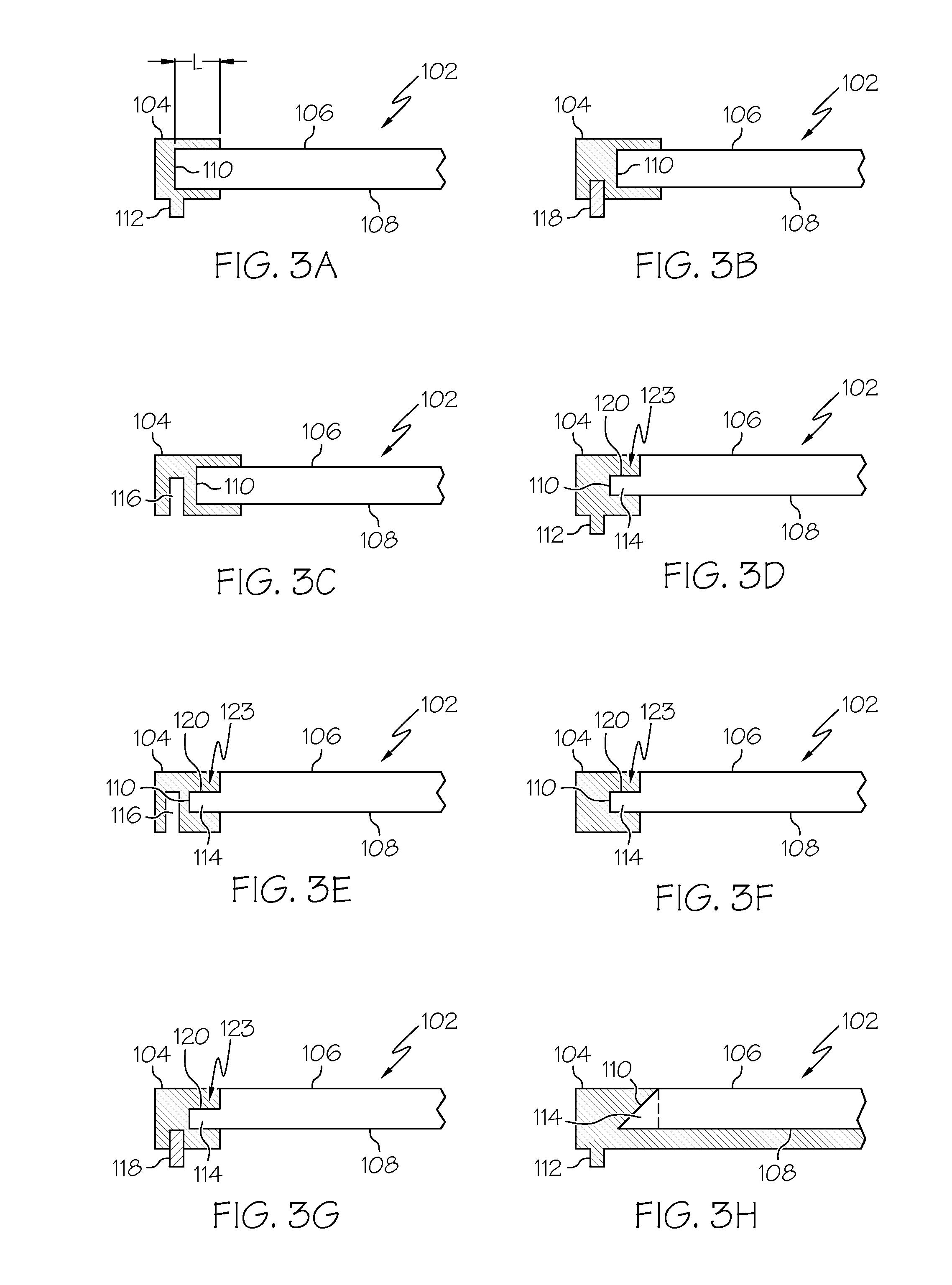

Polymer over molding of strengthened glass

Glass articles for use as covers in electronic devices and methods for forming the same are described herein. The glass articles generally include a shaped glass substrate comprising a first face, a second face and a perimeter edge. The shaped glass substrate may be formed from strengthened glass such that the shaped glass substrate has a compressive stress layer which improves the ability of the glass article to withstand surface damage without cracking. A polymer overmold is coupled to the attachment feature of the perimeter edge of the shaped glass substrate thereby protecting the perimeter edge of the shaped glass substrate from damage. In one embodiment, at least a portion of the perimeter edge of the shaped glass substrate comprises an attachment feature offset from the first face. In another embodiment the polymer overmold is integrally formed with at least one connector.

Owner:CORNING INC

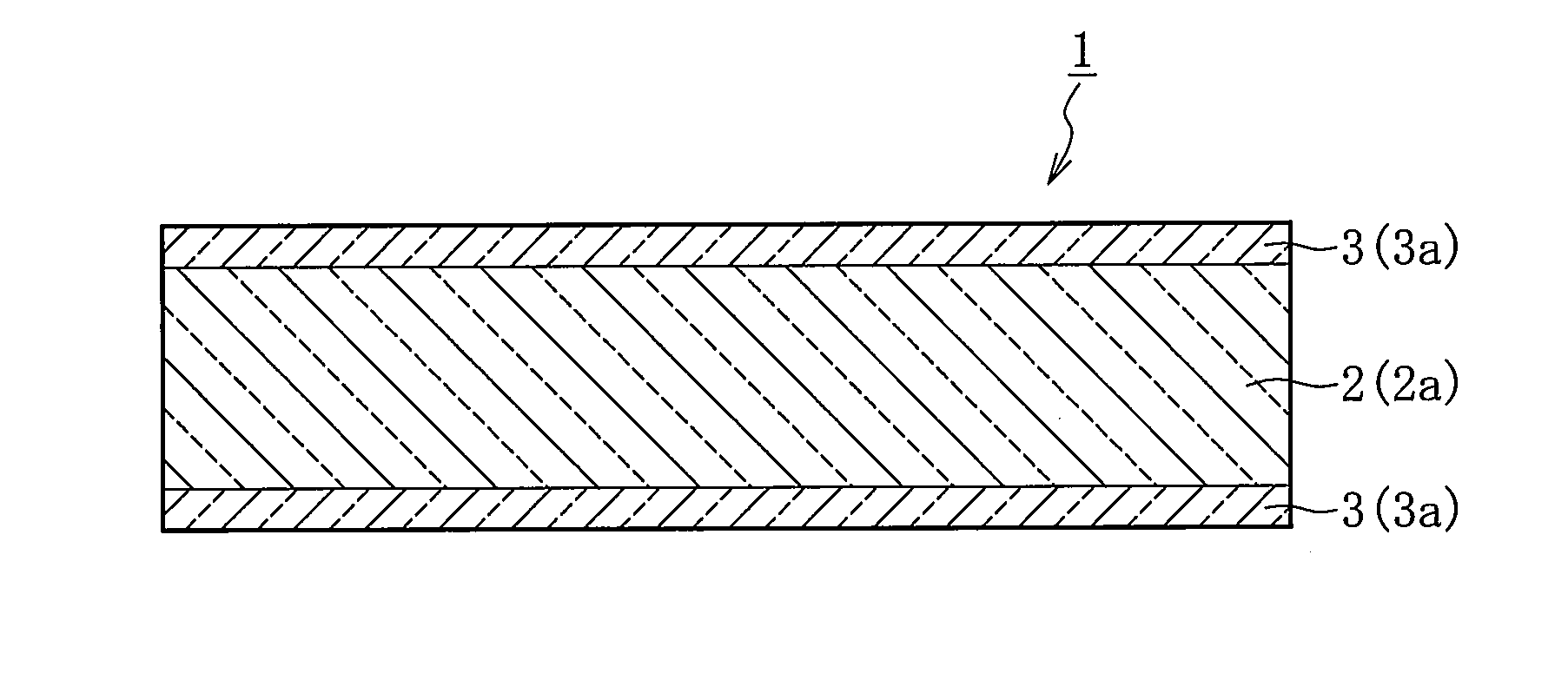

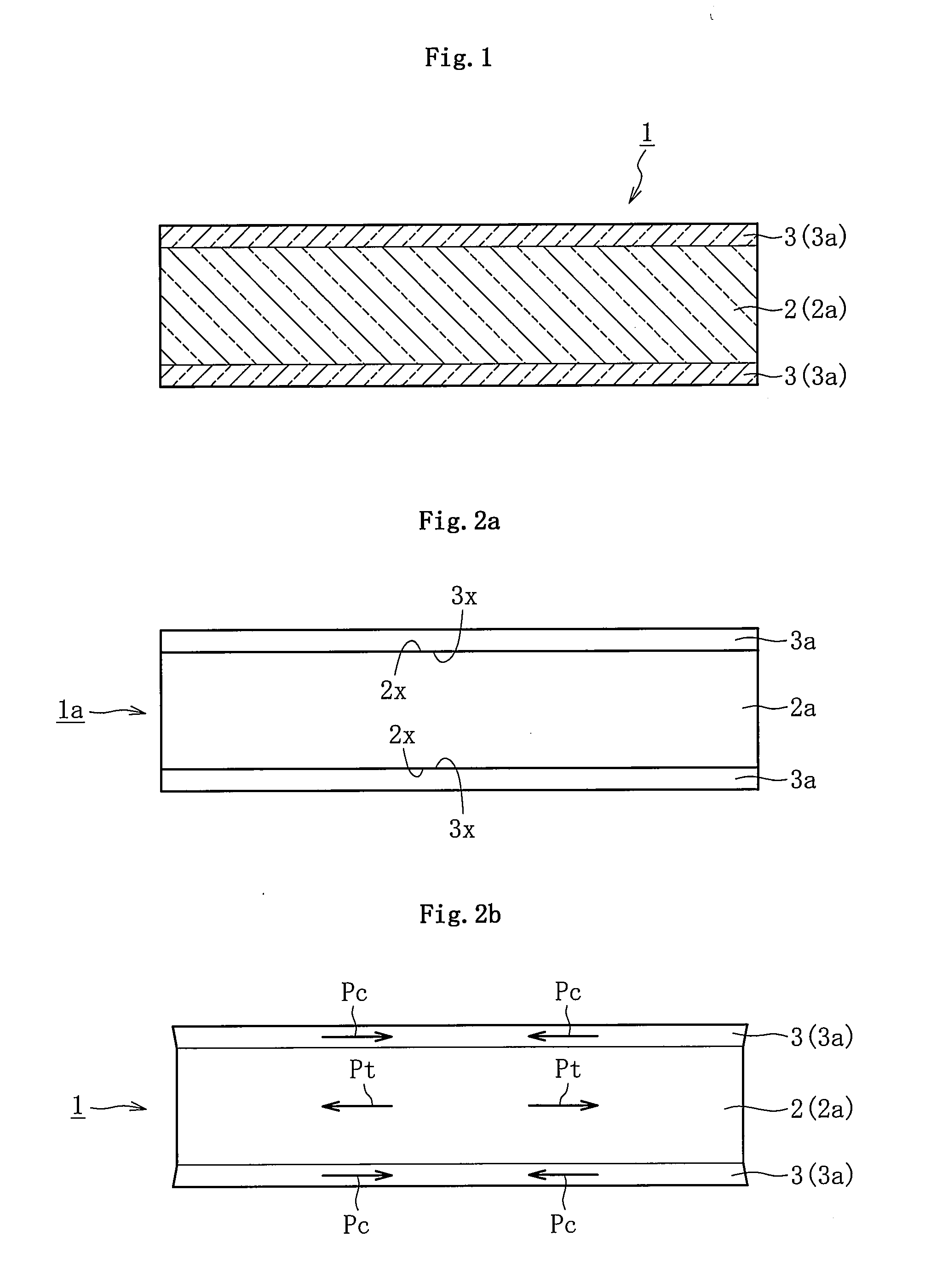

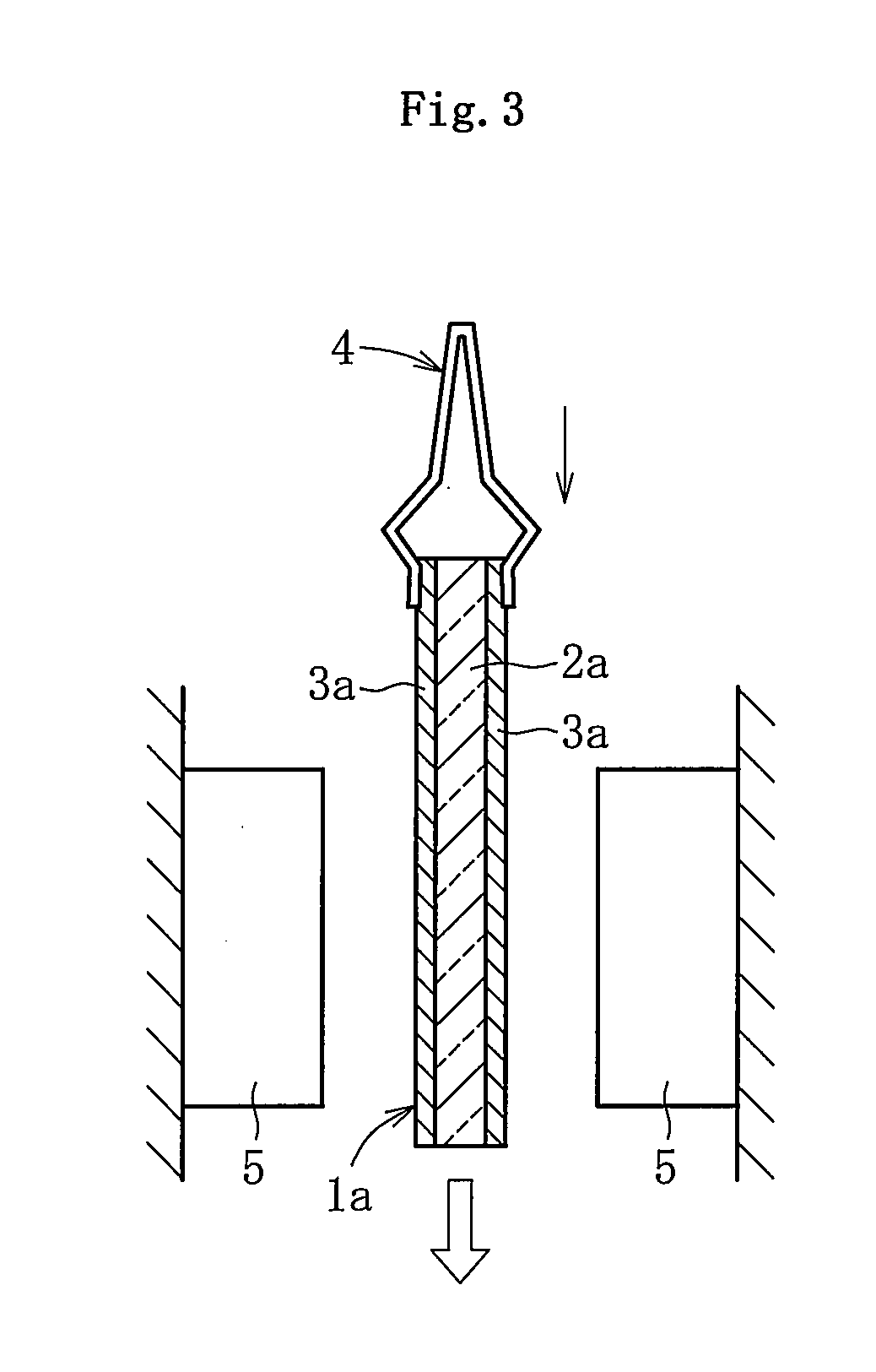

Reinforced plate glass and method for manufacturing the same

InactiveUS20110200805A1Simple processReduce work costsGlass/slag layered productsGlass reforming apparatusFlat glassSurface layer

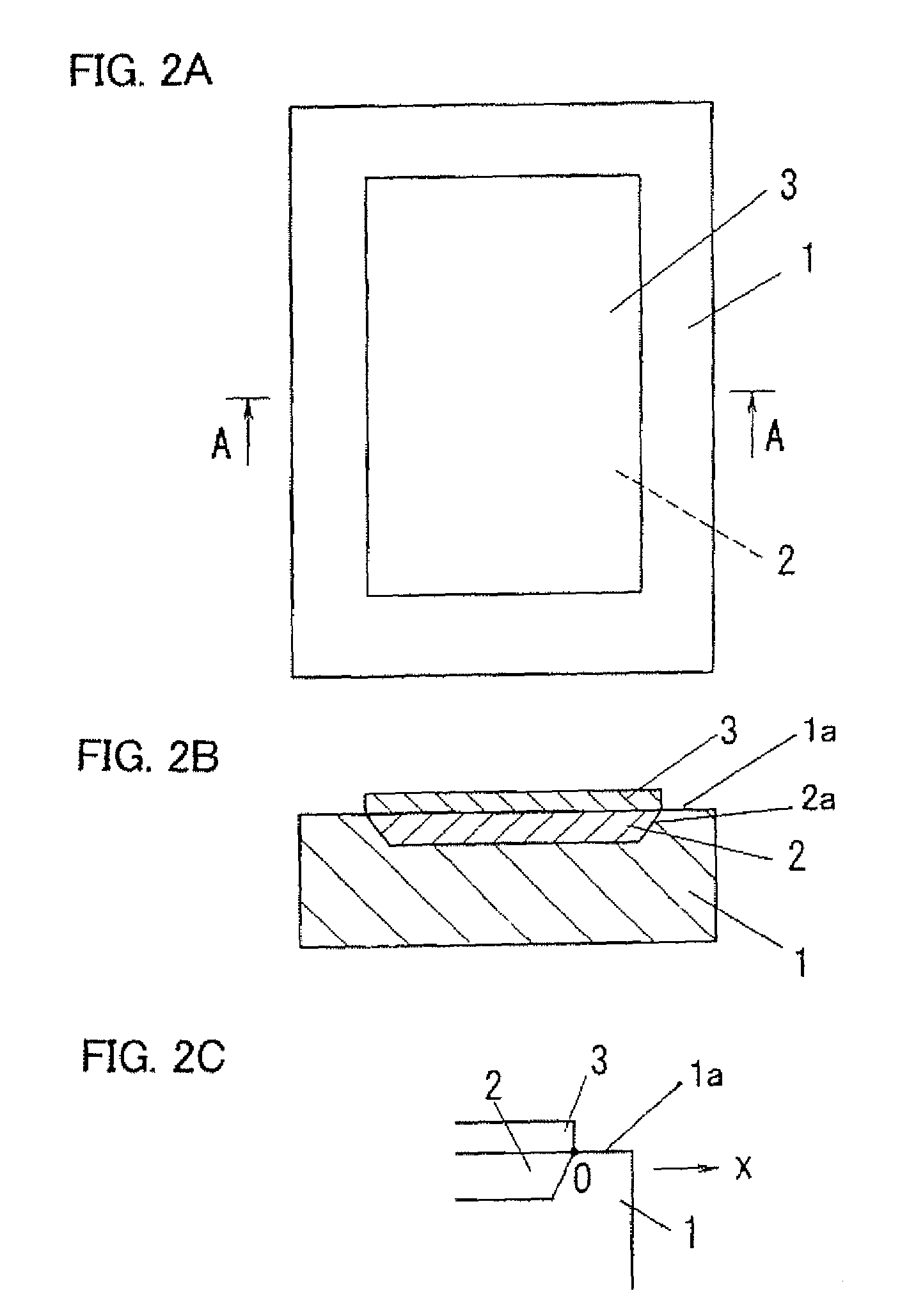

Provided is a method, including: performing heat treatment, under a state in which a thick core plate glass (2a) having a higher thermal expansion coefficient and a thin surface-layer plate glass (3a) having a lower thermal expansion coefficient are laminated together, so that the laminated portion has a temperature equal to or higher than the lower softening point out of the softening points of the core plate glass (2a) and the surface-layer plate glass (3a), thereby melt-bonding the core plate glass (2a) and the surface-layer plate glass (3a); and then performing cooling so as to attain a temperature less than the lower strain point out of strain points of the core plate glass (2a) and the surface-layer plate glass (3a), to thereby form a compression stress in a surface layer portion (3) corresponding to the surface-layer plate glass (3a) and form a tensile stress in a core portion (2) corresponding to the core plate glass (2a).

Owner:NIPPON ELECTRIC GLASS CO LTD

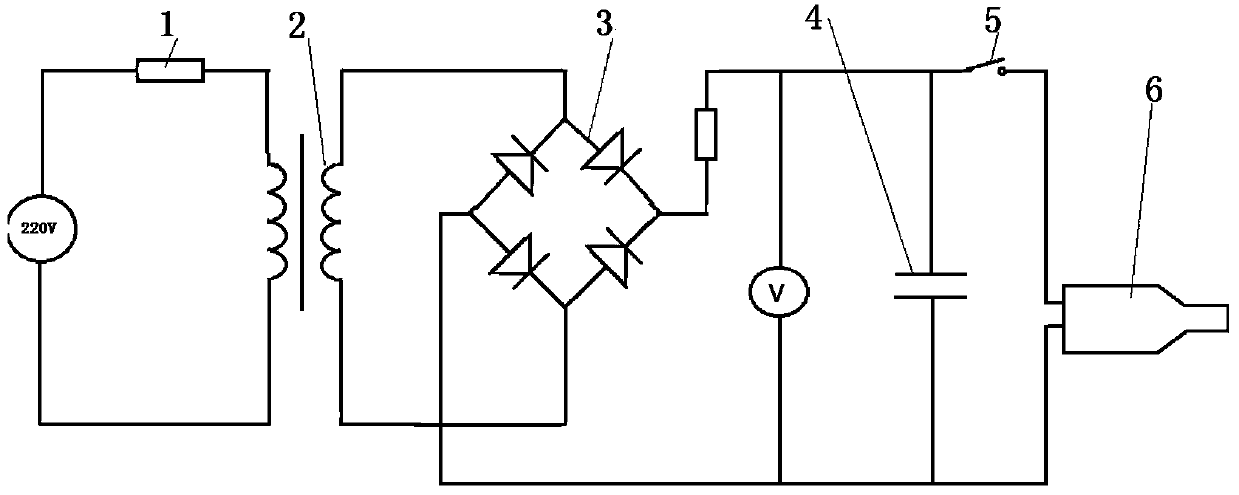

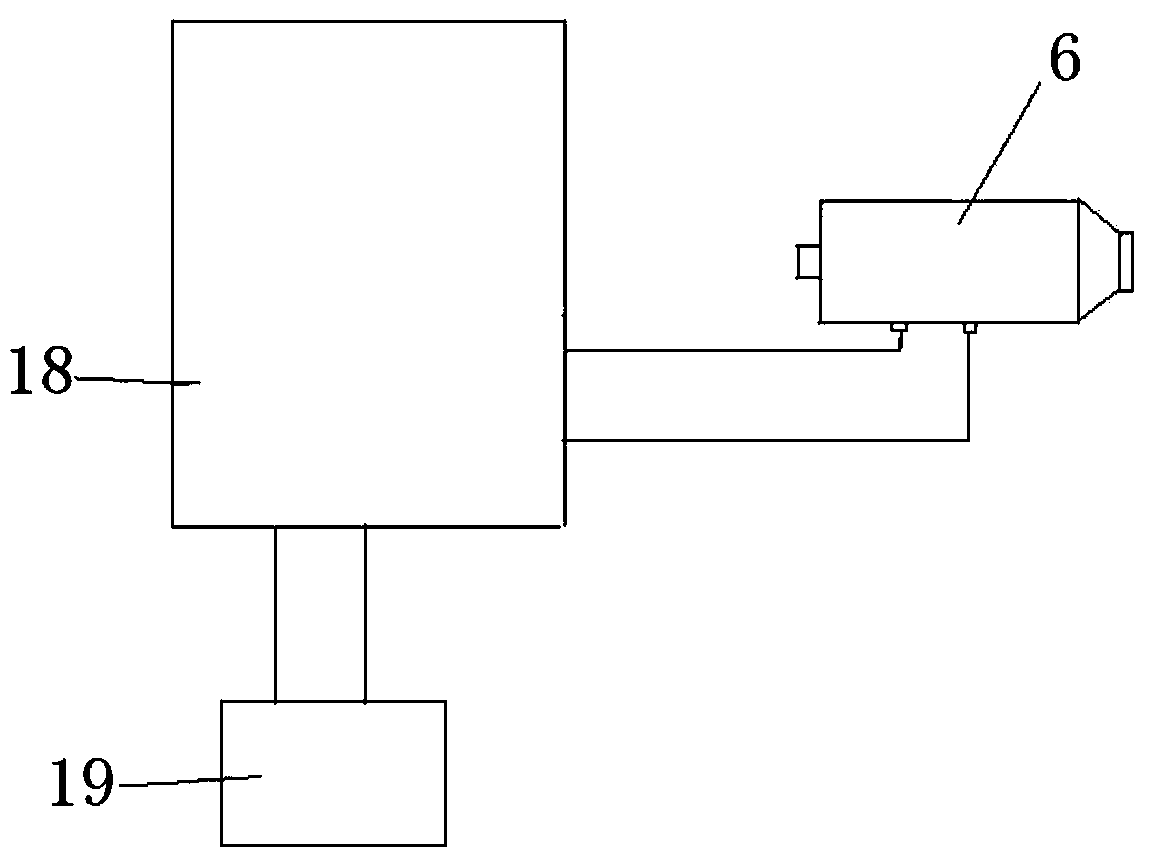

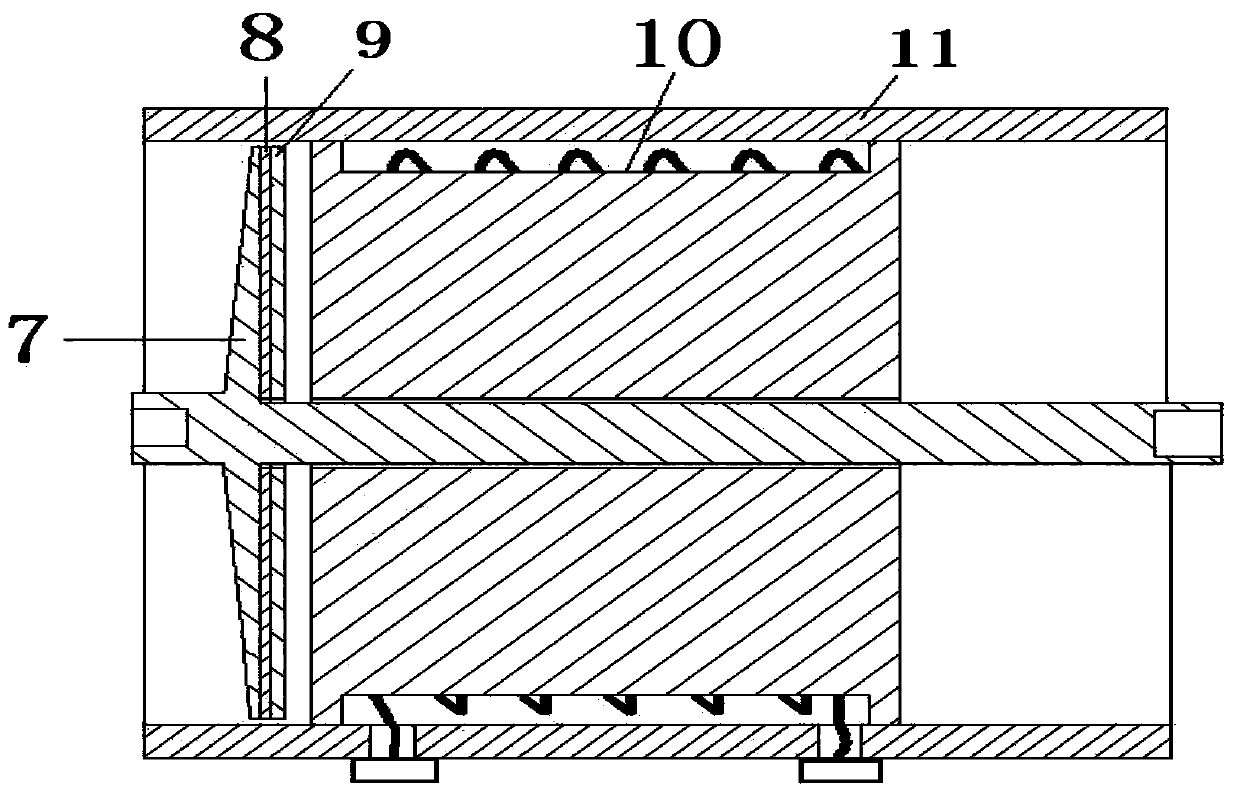

Stretching and compression stress wave generator based on electromagnetic force and experimental method

ActiveCN103994922AEasy to controlGood repeatabilityMaterial strength using tensile/compressive forcesAudio power amplifierExperimental methods

The invention provides a stretching and compression stress wave generator based on electromagnetic force and an experimental method. The stress wave generator is such structured that a capacitor charger is connected with a loading gun. A main coil, an insulating layer and a secondary coil all sleeve the locating shaft of a tapered amplifier. A power supply system is employed to provide the main coil of the loading gun with instant strong current, so strong eletromagnetic repulsion is generated between the main coil and the secondary coil; and the eletromagnetic repulsion is converted into stress waves which are amplified by the tapered amplifier and then output to a Hopkinson bar. The stretching and compression stress wave generator has a simple structure and strong controllability, can realize a strain rate and a strain scope which cannot be reached by a traditional disconnect-type Hopkinson bar, allows Hopkinson bar experimental techniques to be standardized, realizes integration of experimental apparatuses of a pull bar and a pressure bar and reduces complexity and occupied space of equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

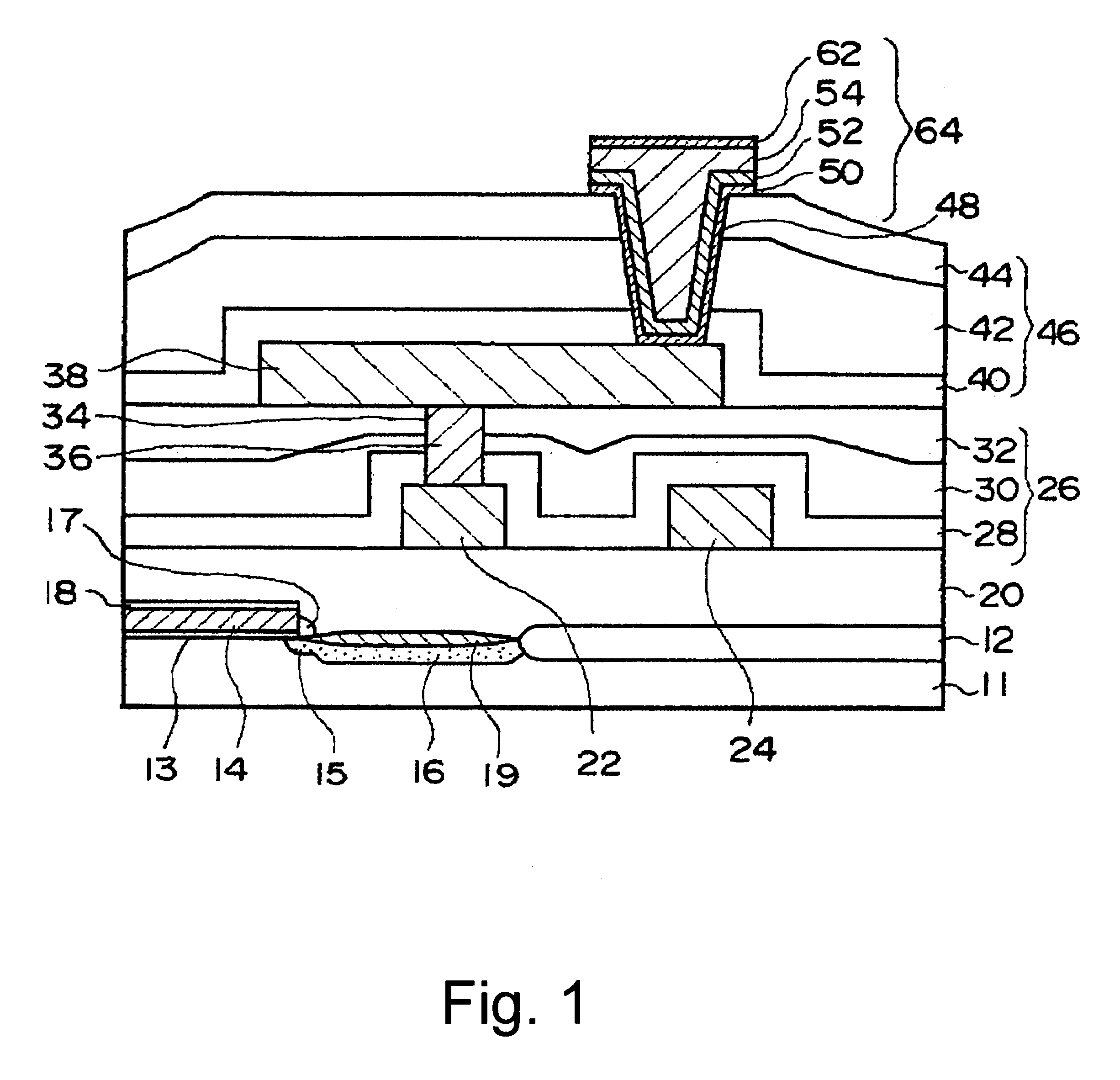

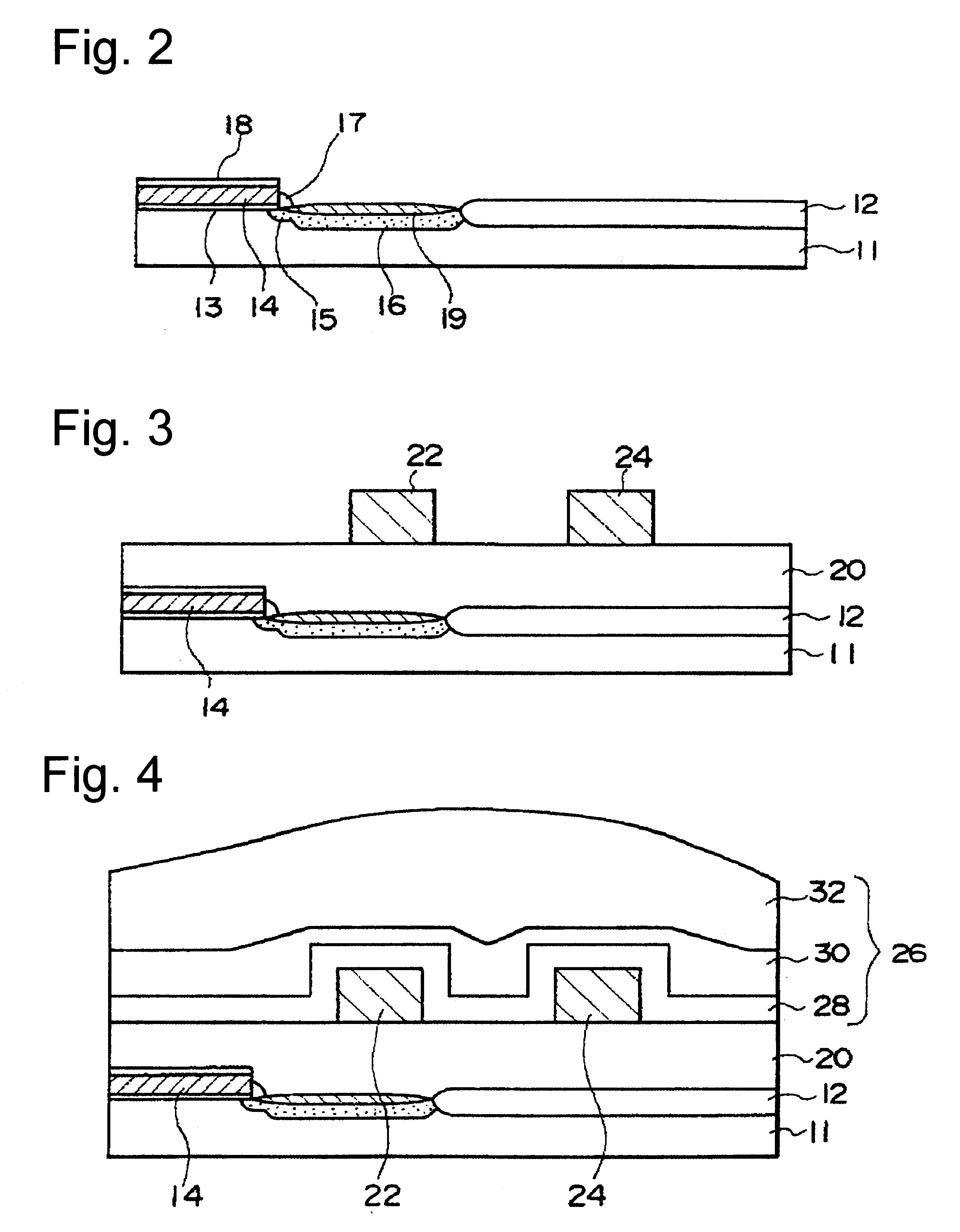

Semiconductor device and method for manufacturing the same

InactiveUS6432845B1Excellent planarization characteristicImprove liquiditySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor device has a structure that is capable of reducing warping of a semiconductor wafer when the semiconductor device is manufactured. The semiconductor device is manufactured by a method including the steps for forming an interlayer dielectric film having an internal compression stress and an interlayer dielectric film having an internal tensile stress. As a result, when semiconductor devices are manufactured, the tensile stress and the compression stress act on the semiconductor wafer. As a consequence, the overall stress that acts on the semiconductor wafer are reduced to a small level or to zero, and thus warping of the semiconductor wafer is reduced or eliminated when semiconductor devices are manufactured.

Owner:SEIKO EPSON CORP

Acoustic resonator and its fabricating method

InactiveUS20100148637A1Improve the overall coefficientSignificant occurrencePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientUltimate tensile strength

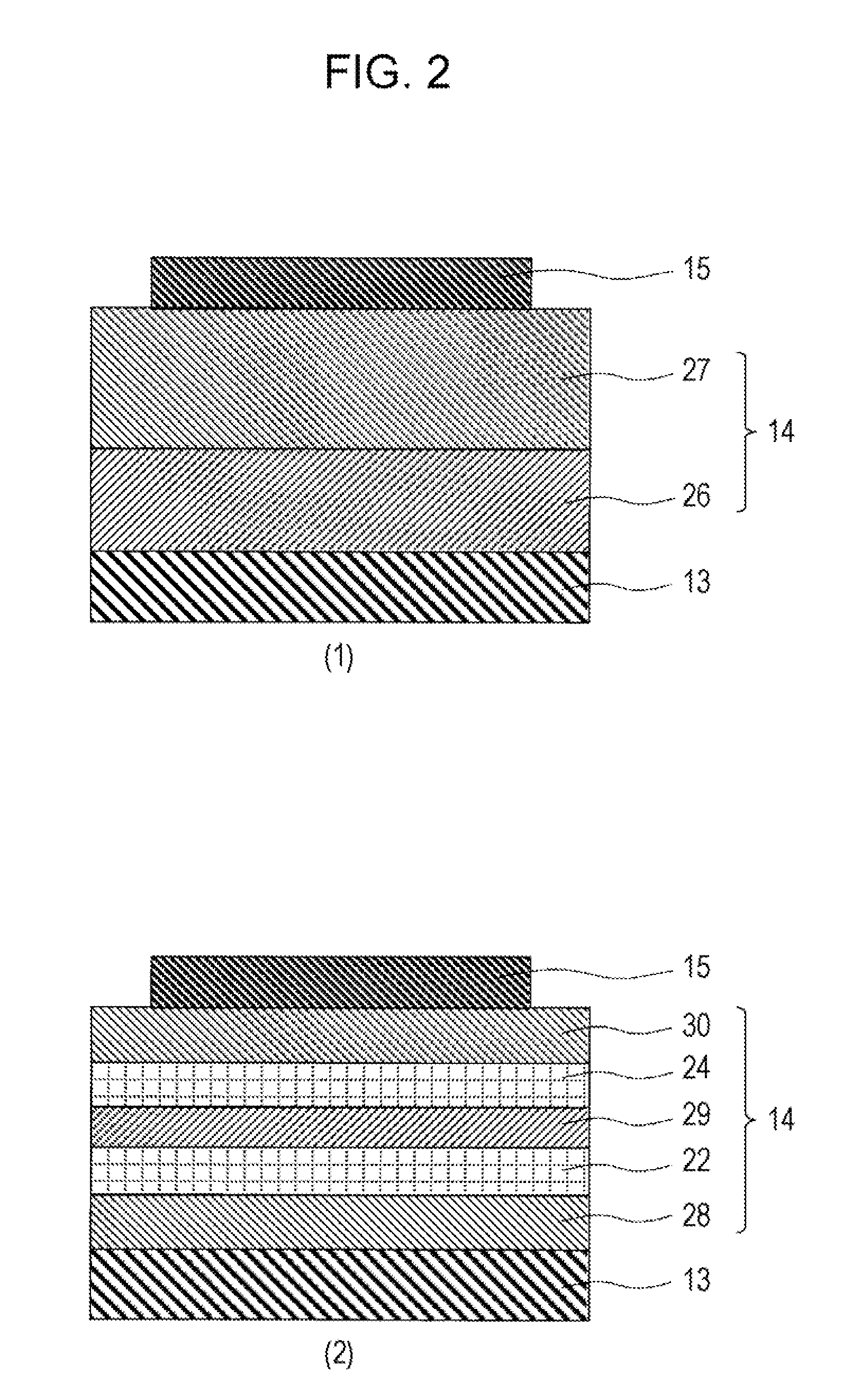

A piezoelectric layer has a multilayer structure including a tensile stress layer and a compression stress layer. The mechanical strength of the piezoelectric layer is increased to prevent the occurrence of cracks and to realize a high electromechanical coupling coefficient. An acoustic resonator 1 includes a first electrode 13 including at least one conductive layer, a piezoelectric layer 14 including a plurality of layers, the piezoelectric layer 14 being formed adjacent to the top face of the first electrode 13, and a second electrode 15 including at least one conductive layer, the second electrode 15 being formed adjacent to the top face of the piezoelectric layer 14. The piezoelectric layer 14 includes a tensile compression layer 23 in which tensile stress is present and compression stress layers 21 and 25 in which compression stress is present. The tensile stress in the tensile stress layer 23 and the compression stress in the compression stress layers 22 and 25 are adjusted to cancel each other.

Owner:SONY CORP

Abutted exchange bias design for sensor stabilization

InactiveUS7283337B2Hard structureSuppresses side-lobesRecord information storageManufacture of flux-sensitive headsIn planeSelf-stabilization

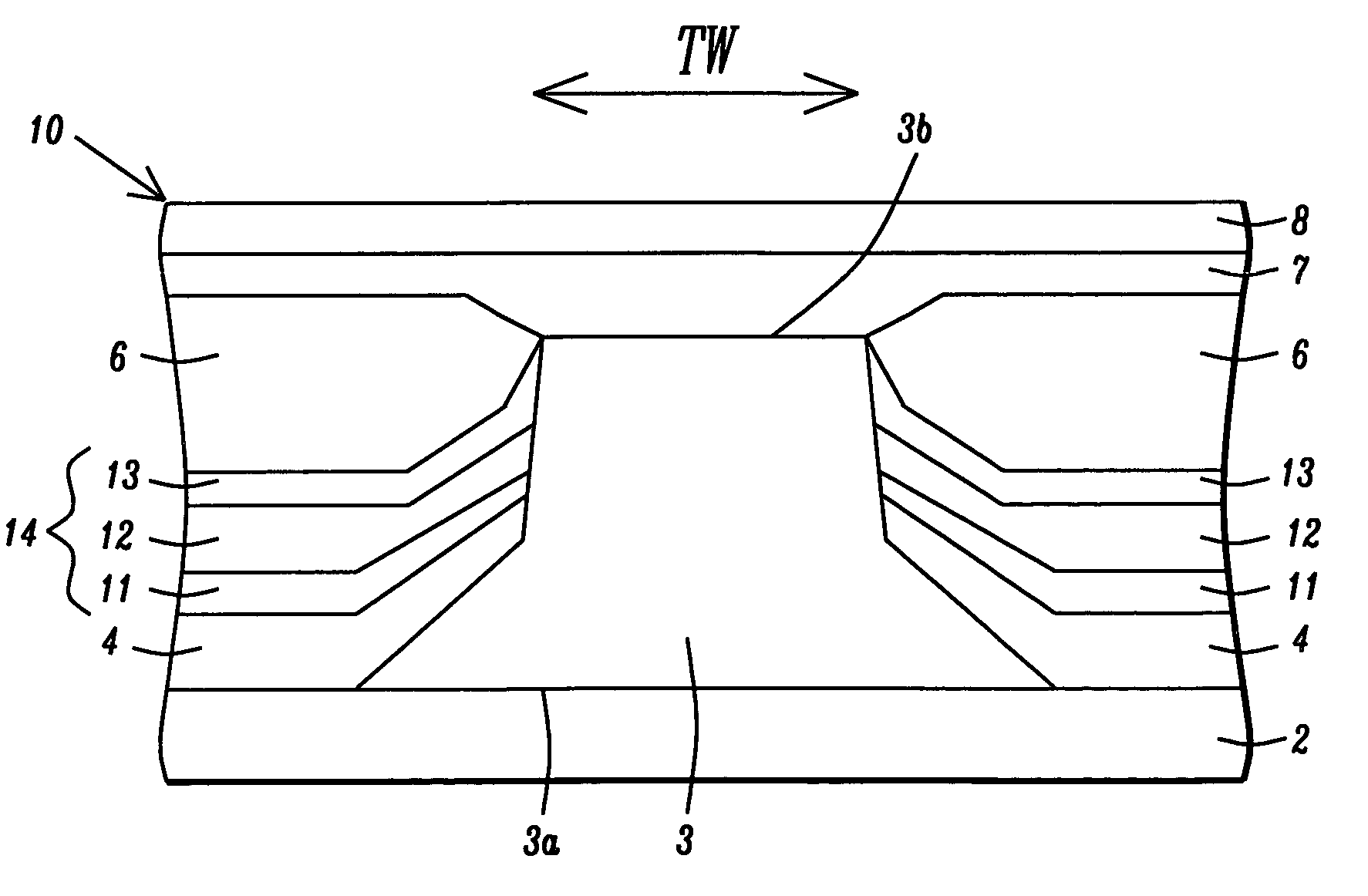

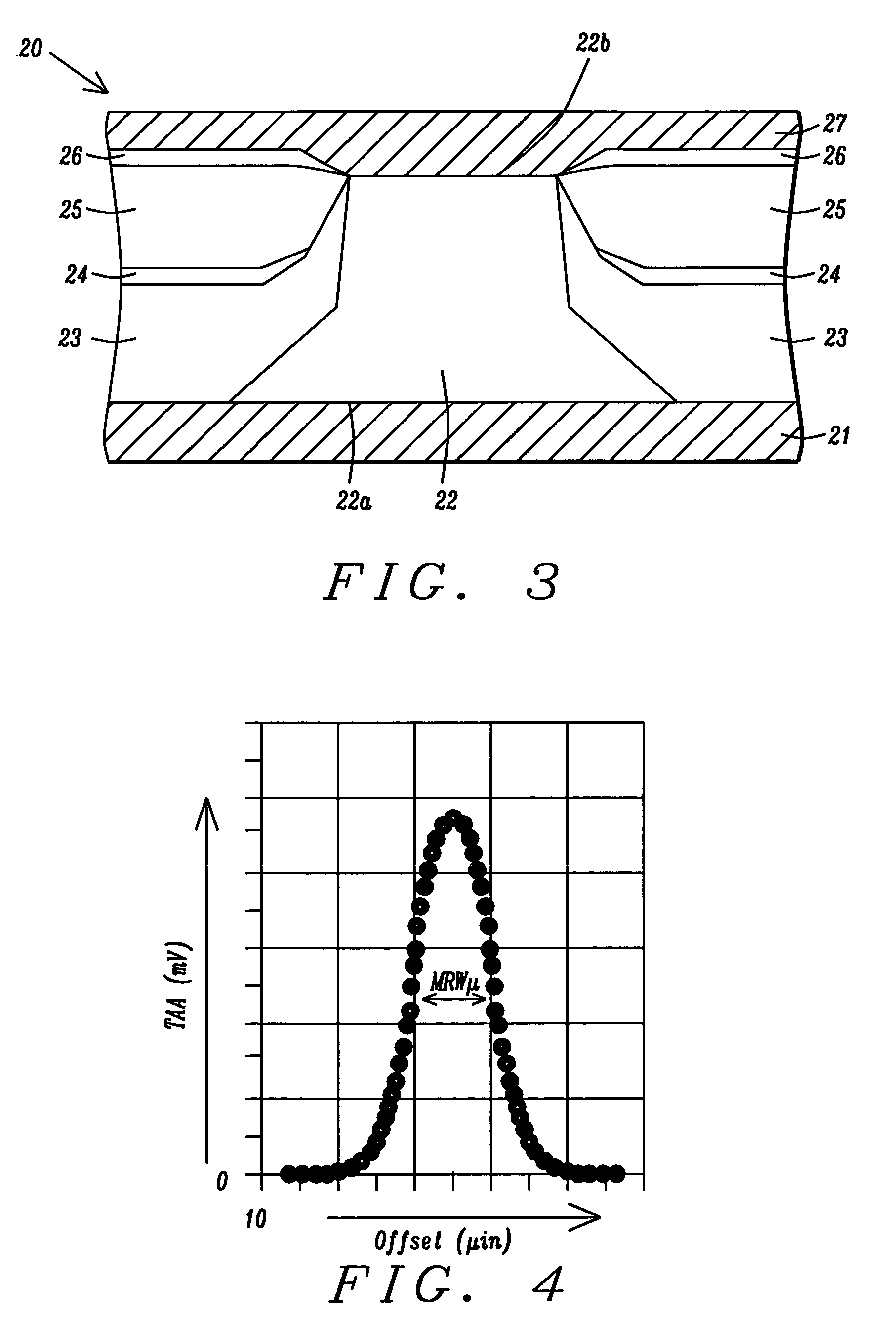

A hard bias (HB) structure for biasing a free layer in a MR sensor within a magnetic read head is comprised of a main biasing layer with a large negative magnetostriction (λS) value. Compressive stress in the device after lapping induces a strong in-plane anisotropy that effectively provides a longitudinal bias to stabilize the sensor. The main biasing layer is formed between two FM layers, and at least one AFM layer is disposed above the upper FM layer or below the lower FM layer. Additionally, there may be a Ta / Ni or Ta / NiFe seed layer as the bottom layer in the HB structure. Compared with a conventional abutted junction exchange bias design, the HB structure described herein results in higher output amplitude under similar asymmetry sigma and significantly decreases sidelobe occurrence. Furthermore, smaller MRWu with a similar track width is achieved since the main biasing layer acts as a side shield.

Owner:HEADWAY TECH INC

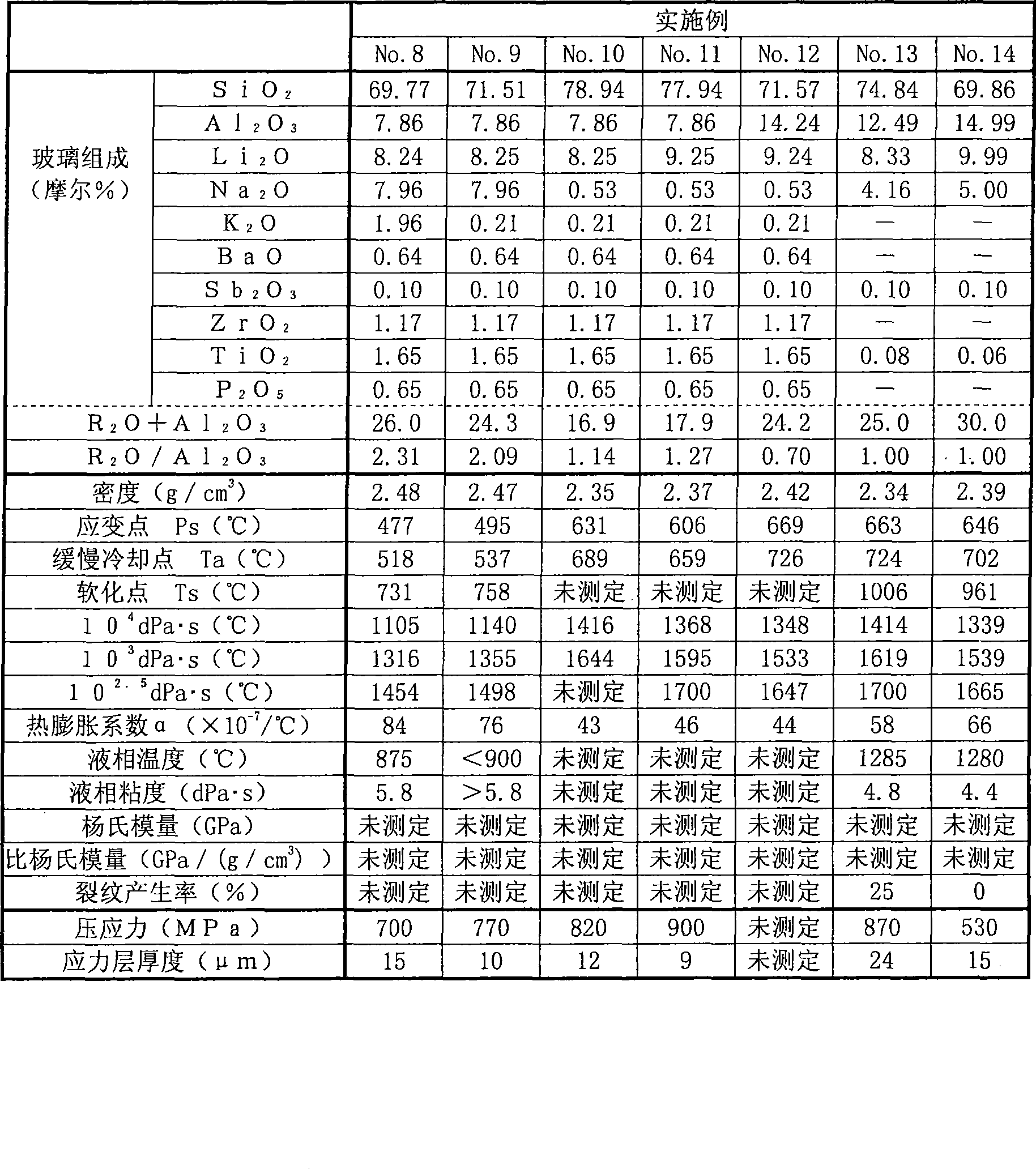

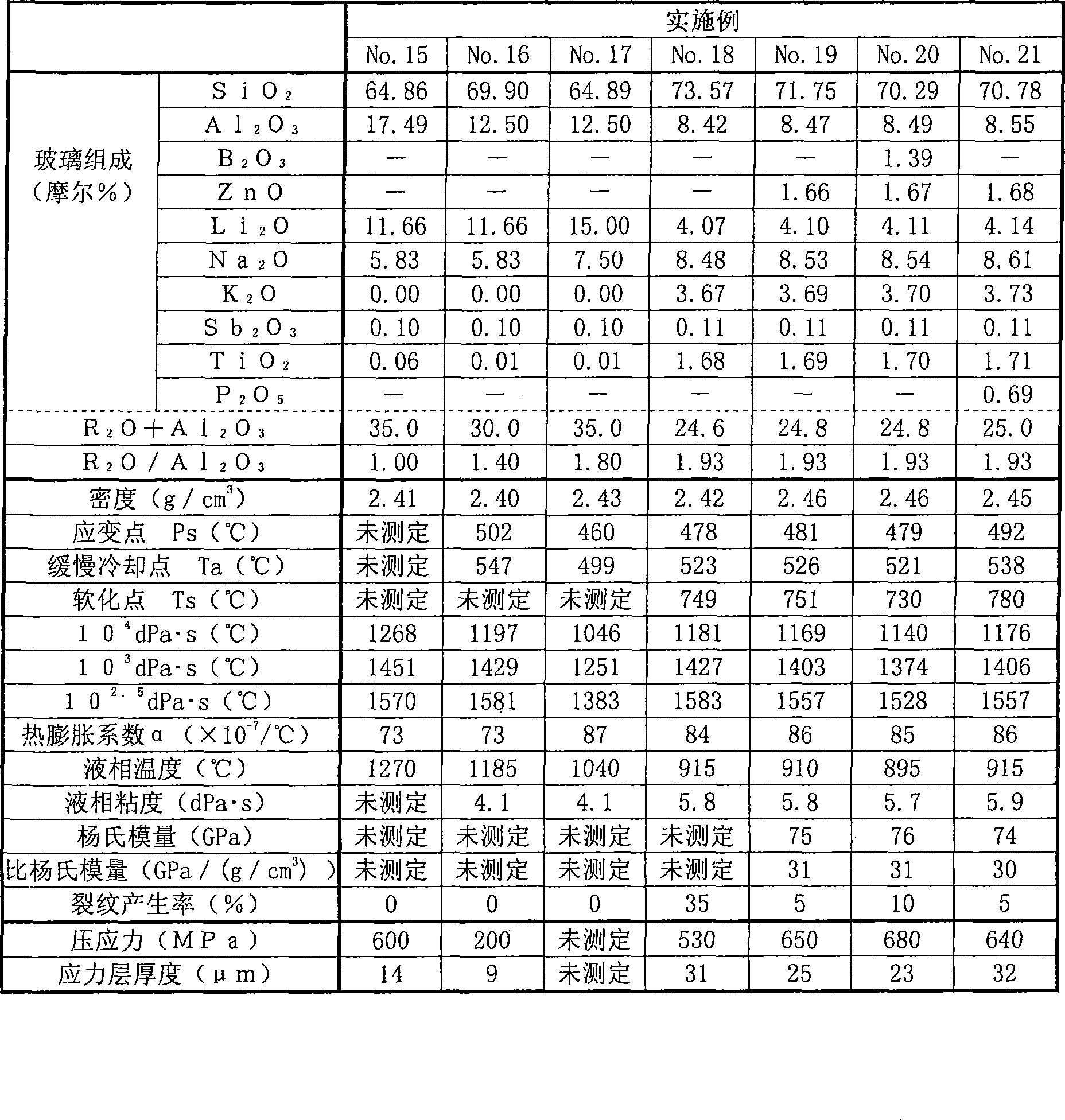

Reinforced glass substrate

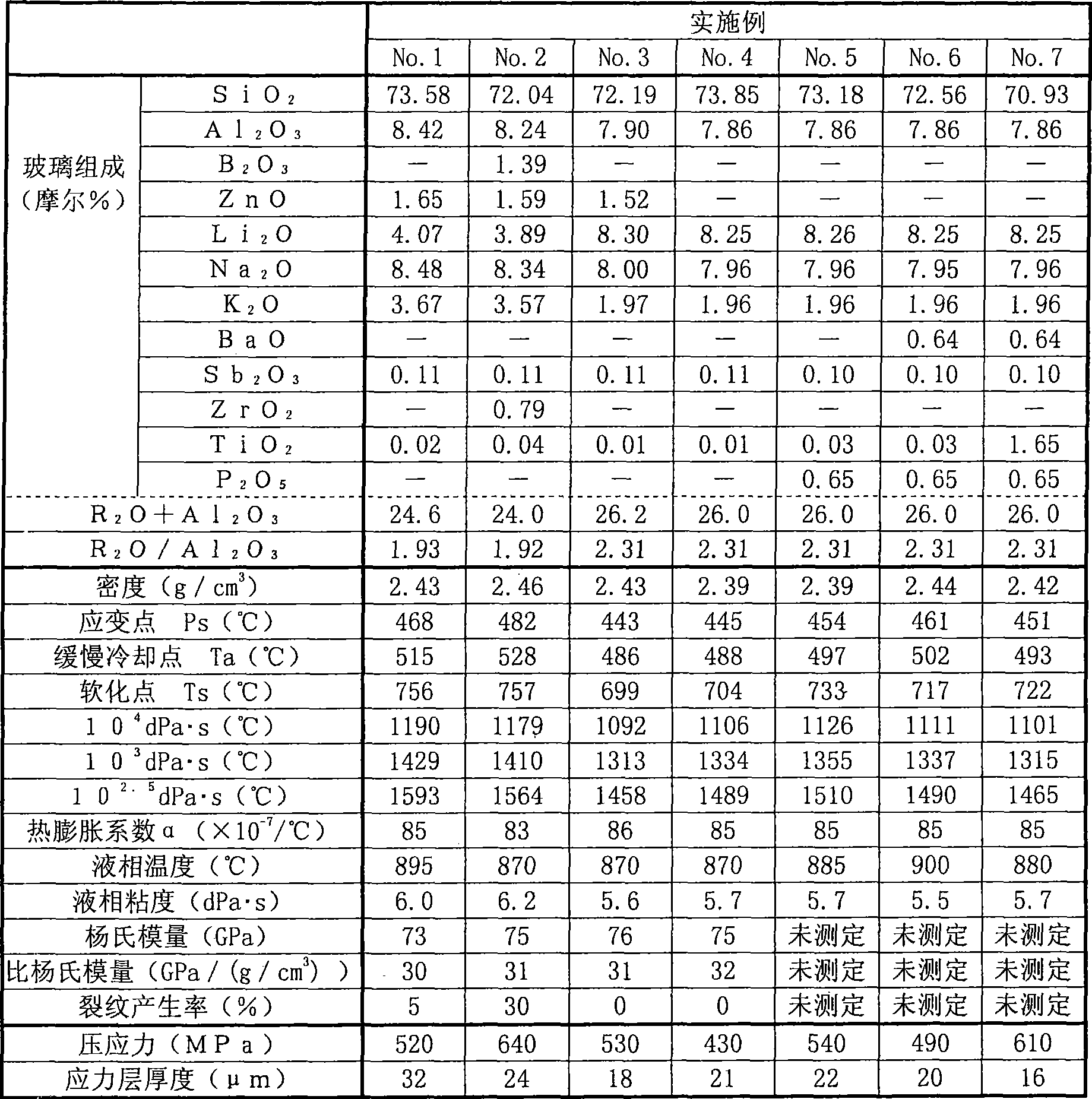

The objective of the invention is to obtain a glass substrate satisfying ion exchange performance and devitrification resistance of a glass simultaneously and having higher mechanical strength compared to a conventional glass substrate. The tempered glass substrate which has a compression stress layer on a surface thereof, comprises a glass composition including, in terms of mole%, 50-85% of SiO2 , 5- 30% of Al2O3, 0-20% of Li2O, 0-20% of Na2O, 0-20% of K2O, 0.001-10% of TiO2, and 15-35% of Li2O+Na2O+K2O+Al2O3. The tempered glass substrate has a (Li2O+Na2O+K2O) / Al2O3 value of 0.7-3 in terms of mole fraction, and is substantially free of As2O3 and F.3 in terms of mole fraction, and is substantially free of As2O3 and F.

Owner:NIPPON ELECTRIC GLASS CO LTD

Glass substrate having a patterned layer of compressive stress on a surface thereof

InactiveUS20130122260A1Improve glass strengthDecorative surface effectsLayered productsHigh stressCompressive strength

A glass substrate having a patterned layer of compressive stress on a surface thereof includes a patterned layer of compressive stress on at least one surface thereof. The patterned layer has a plurality of area of different surface compressive stress. The patterned layer includes high stress areas separated by a low stress area. The surface compressive stress difference between the areas is larger than 100 MPa, or the depth difference of the areas is larger than 5 μm. The depth of compressive stressed layer is less than 20 μm, and the compressive stress is lower than 400 MPa. The depth of compressive stressed layer is between 5 μm to 90 μm, and the compressive stress is between 100 MPa to 800 MPa. The strength of glass substrate in the high stress area will be improved, and the low stress area of the glass substrate still remains well capability for performing cutting, splitting, or grinding.

Owner:LIANG NAI YUE

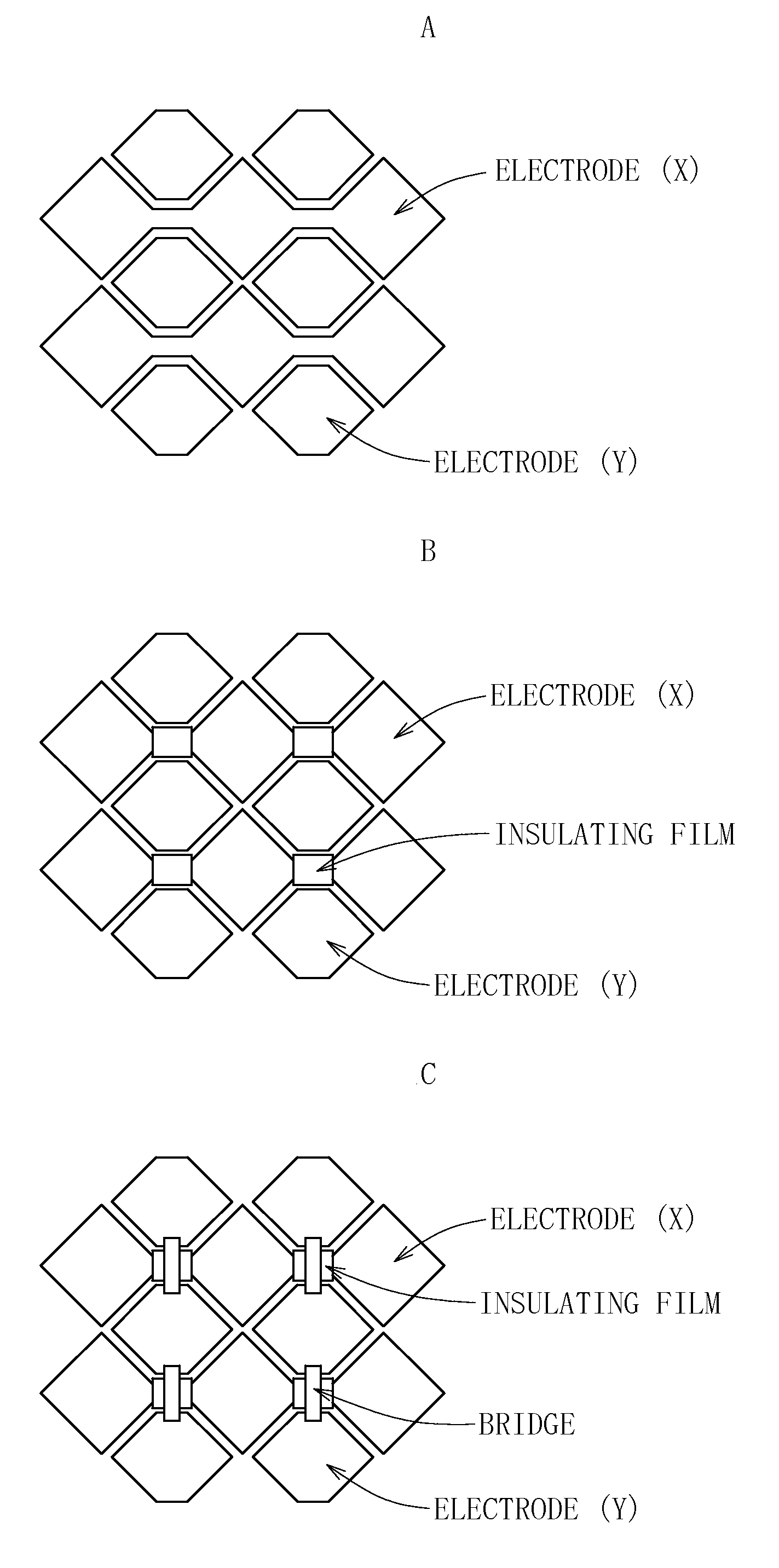

Substrate, liquid crystal display device, and method of manufacturing the same

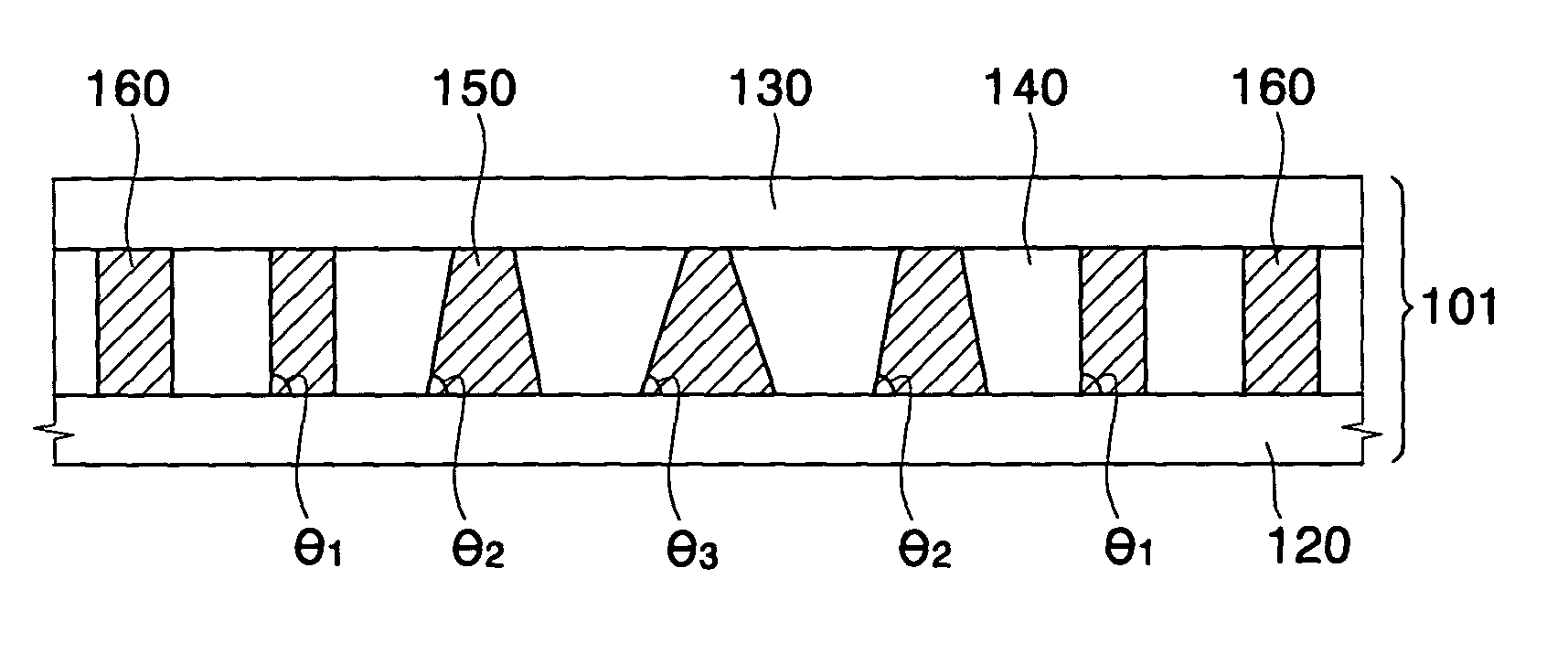

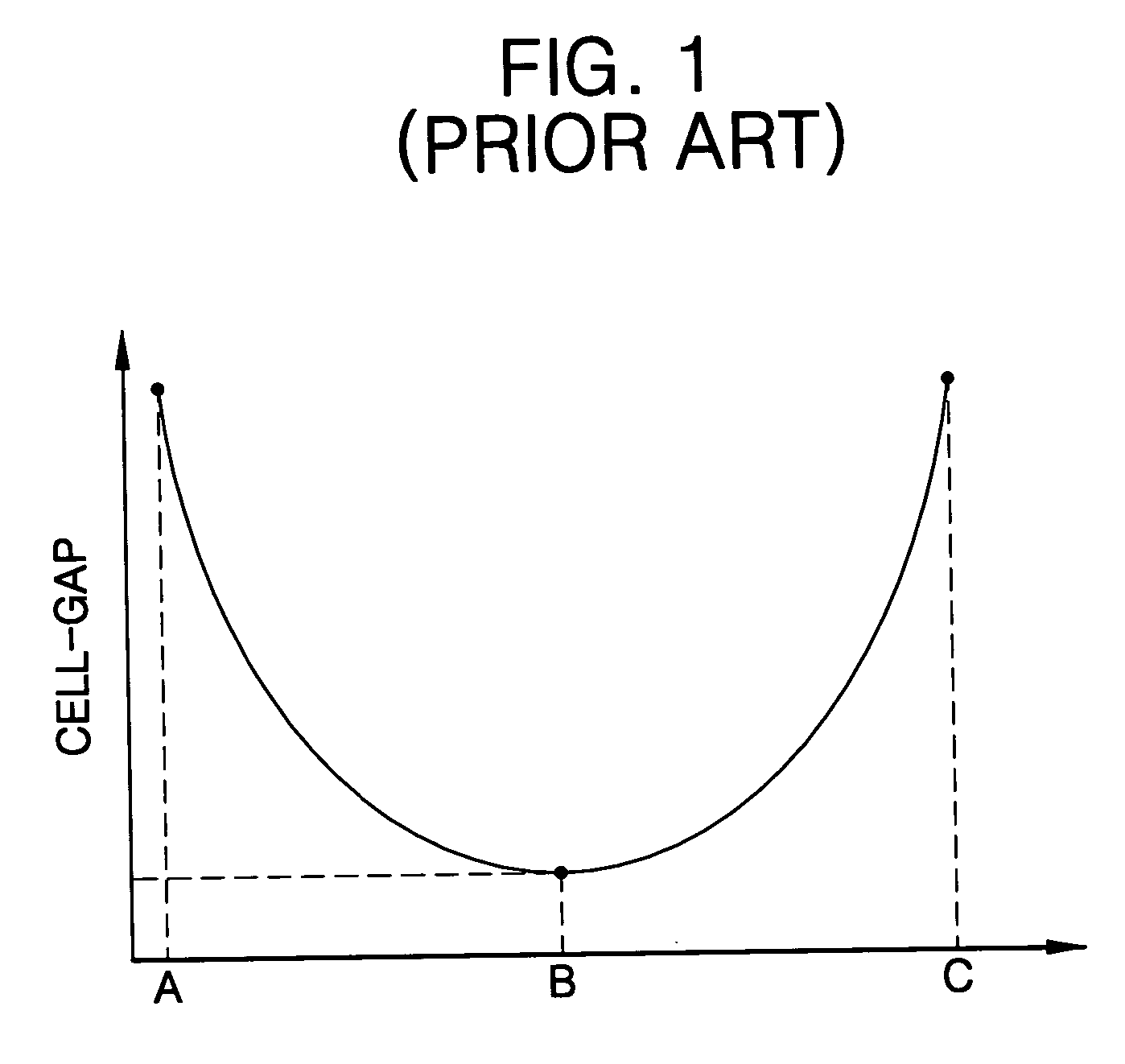

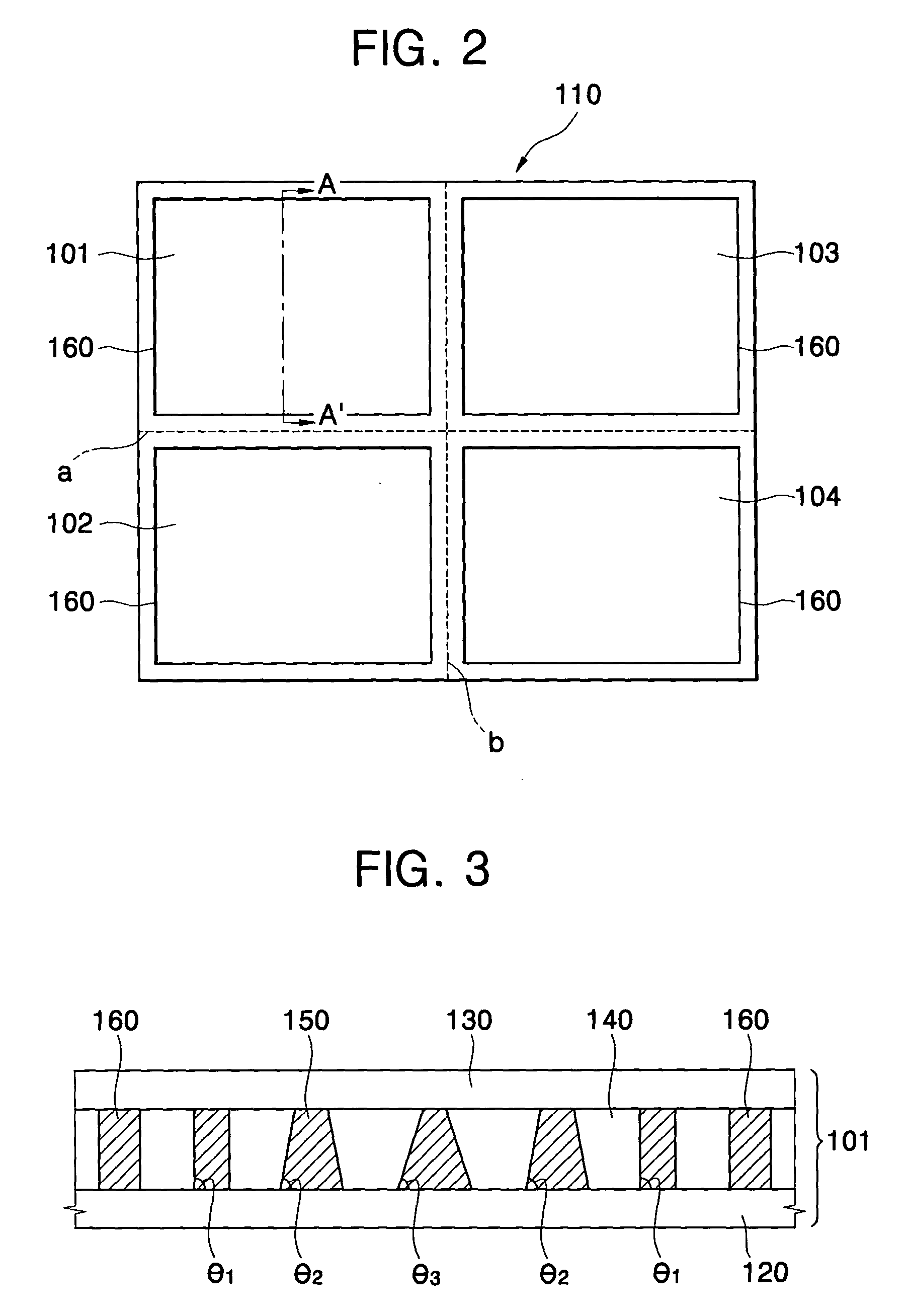

ActiveUS20050099577A1Uniform cell gapImprove display qualityNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display apparatus includes first and second substrates, a fence, a liquid crystal layer and a plurality of spacers. The first substrate includes a display region for displaying an image. The second substrate faces the first substrate. The fence is disposed between the first substrate and the second substrate. The fence surrounds the display. The spacers maintain the distance between the first and second substrates. The spacers have a gradually increasing compression ratio in a direction from a center of the display region to an edge of the display region. The liquid crystal display apparatus maintains a uniform cell gap, even though a compressive stress of a center portion of the liquid crystal display apparatus is different with a compressive stress of an edge portion of the liquid crystal display apparatus. Therefore, display quality is enhanced.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com