Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

333results about "Blowing machine gearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

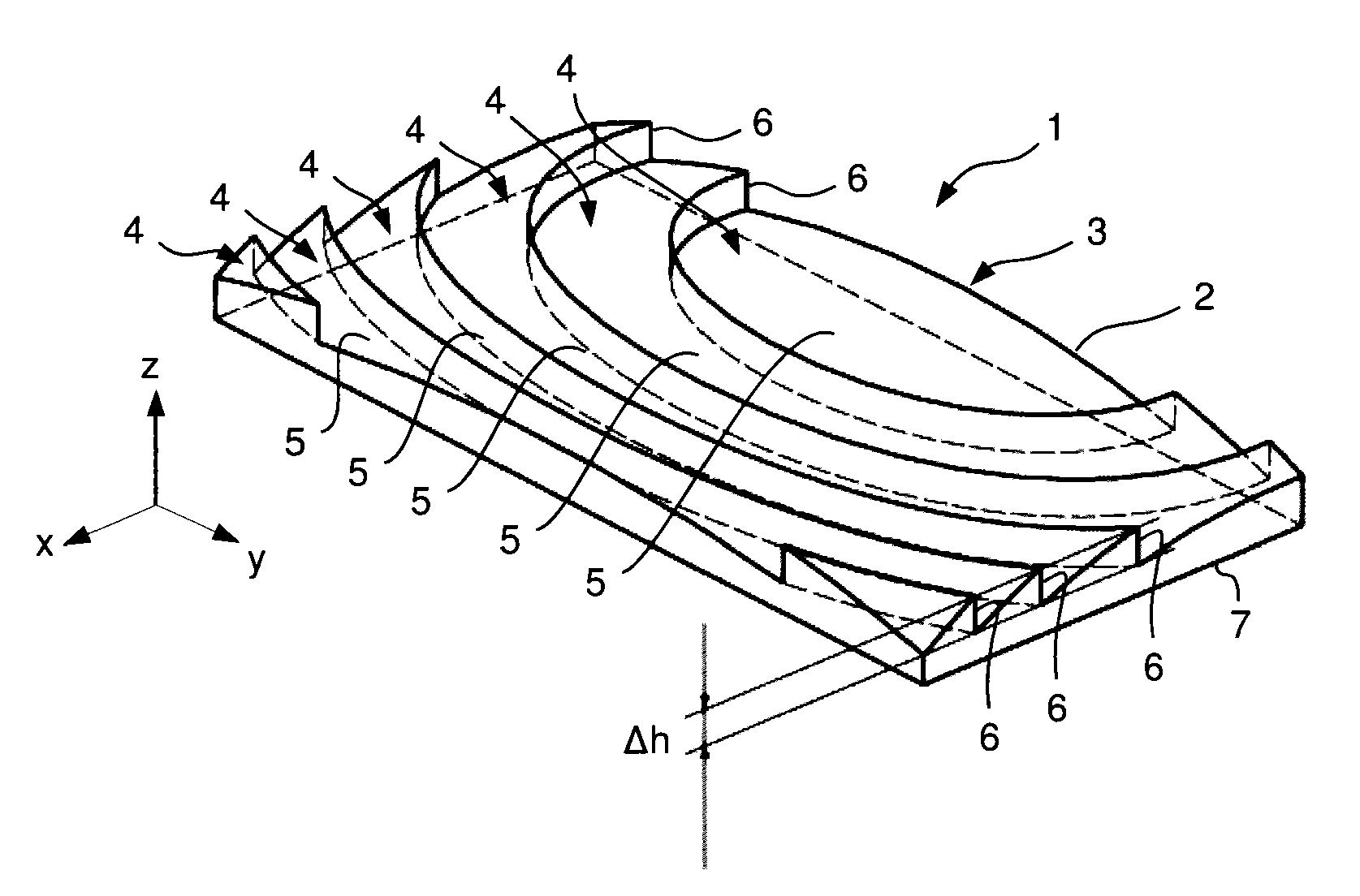

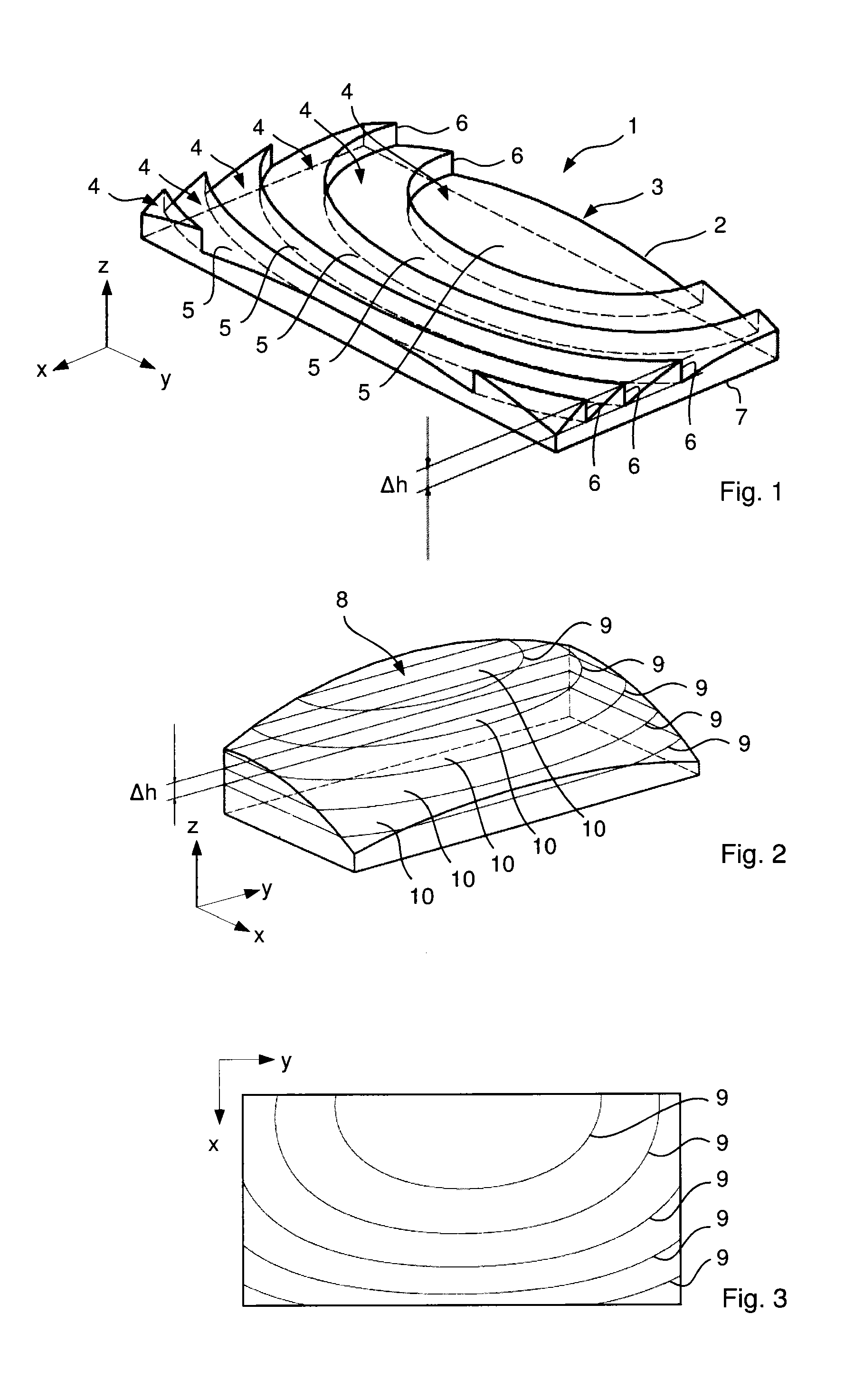

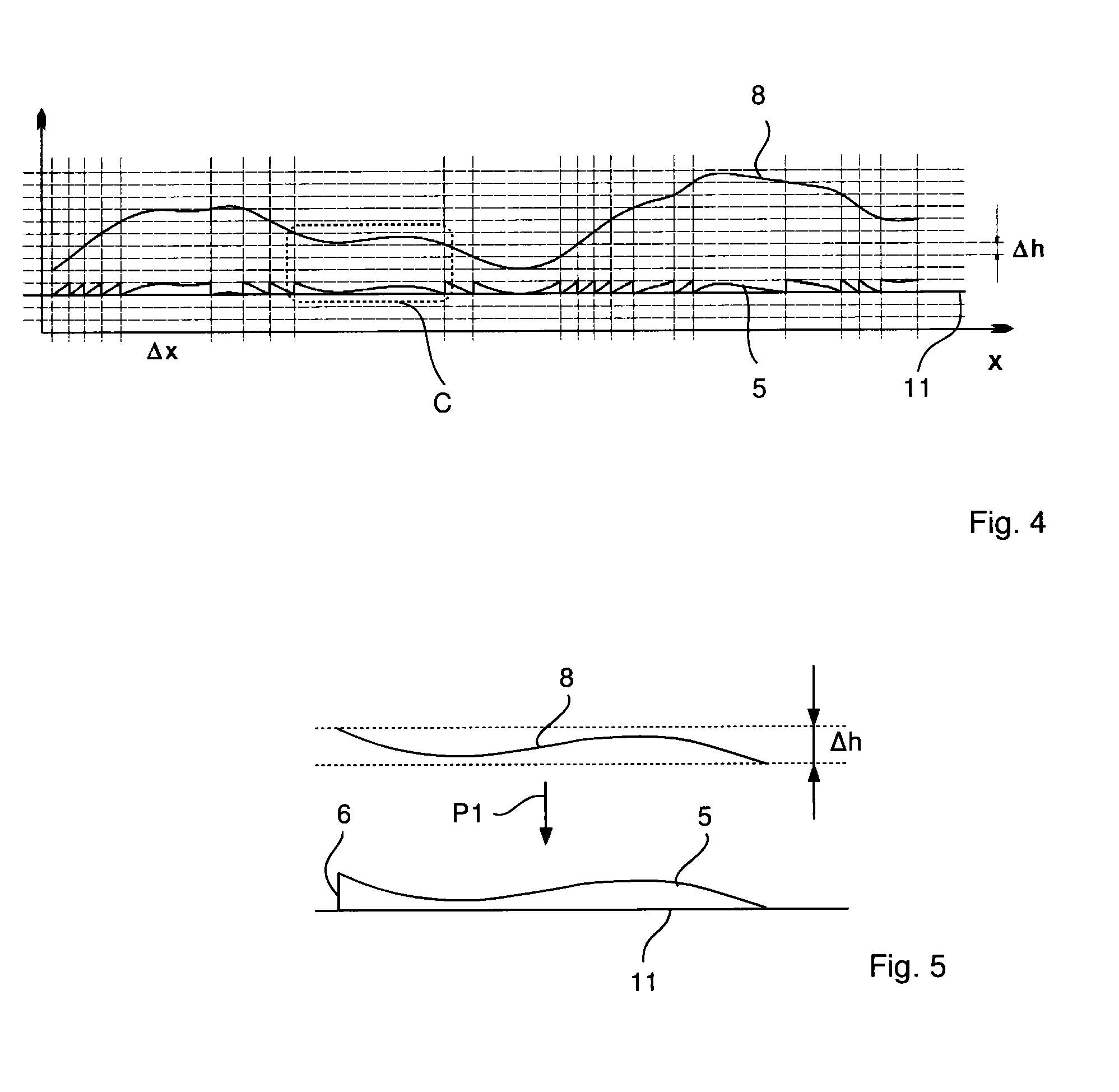

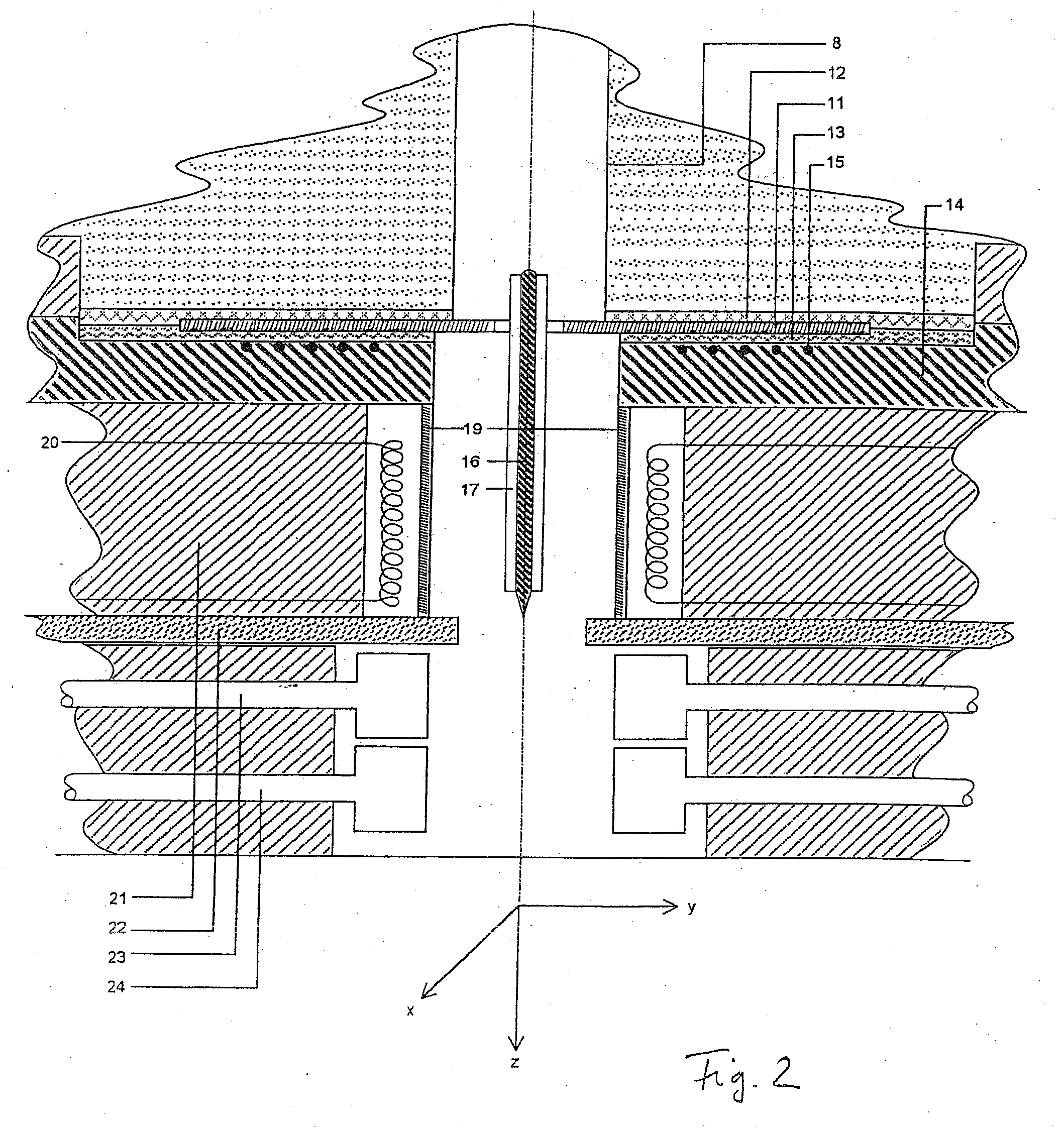

Display device comprising multifunction glass, production method, and optical element having a fresnel structure

ActiveUS20120002295A1Improve the display effectAvoid imaging errorsBlowing machine gearingsProjectorsEngineeringMultiple function

A display device including a holding device that can be placed on the head of a user, an image generating module fixed to the holding device and generating an image, and a multifunction glass that is fixed to the holding device and has a coupling in area and a coupling out area. The image produced is coupled into the multifunction glass via the coupling in area, guided in the multifunction glass to the coupling in area, and extracted via the coupling out area, in such a way that the user can perceive the coupled out image superimposed on the surroundings when the holding device is placed on the head of the user. The coupling in area has a Fresnel structure causing a folding of the beam path when the image is injected into the multifunction glass, said structure having an imaging property.

Owner:TOOZ TECH GMBH

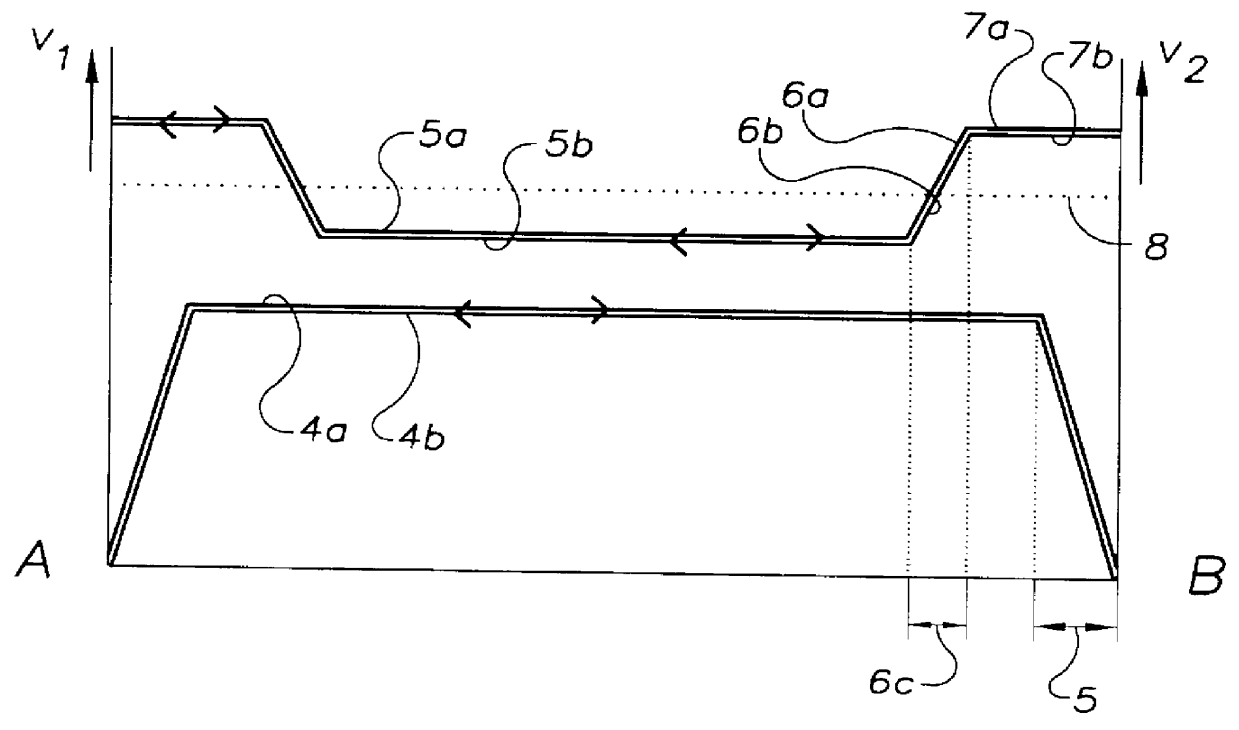

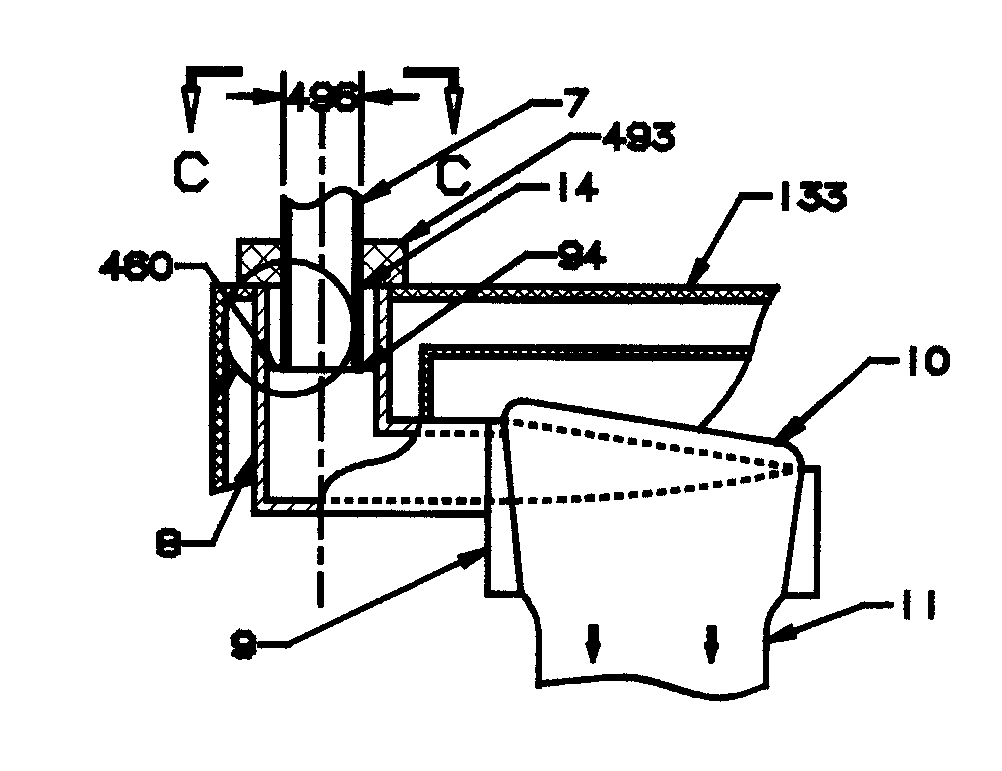

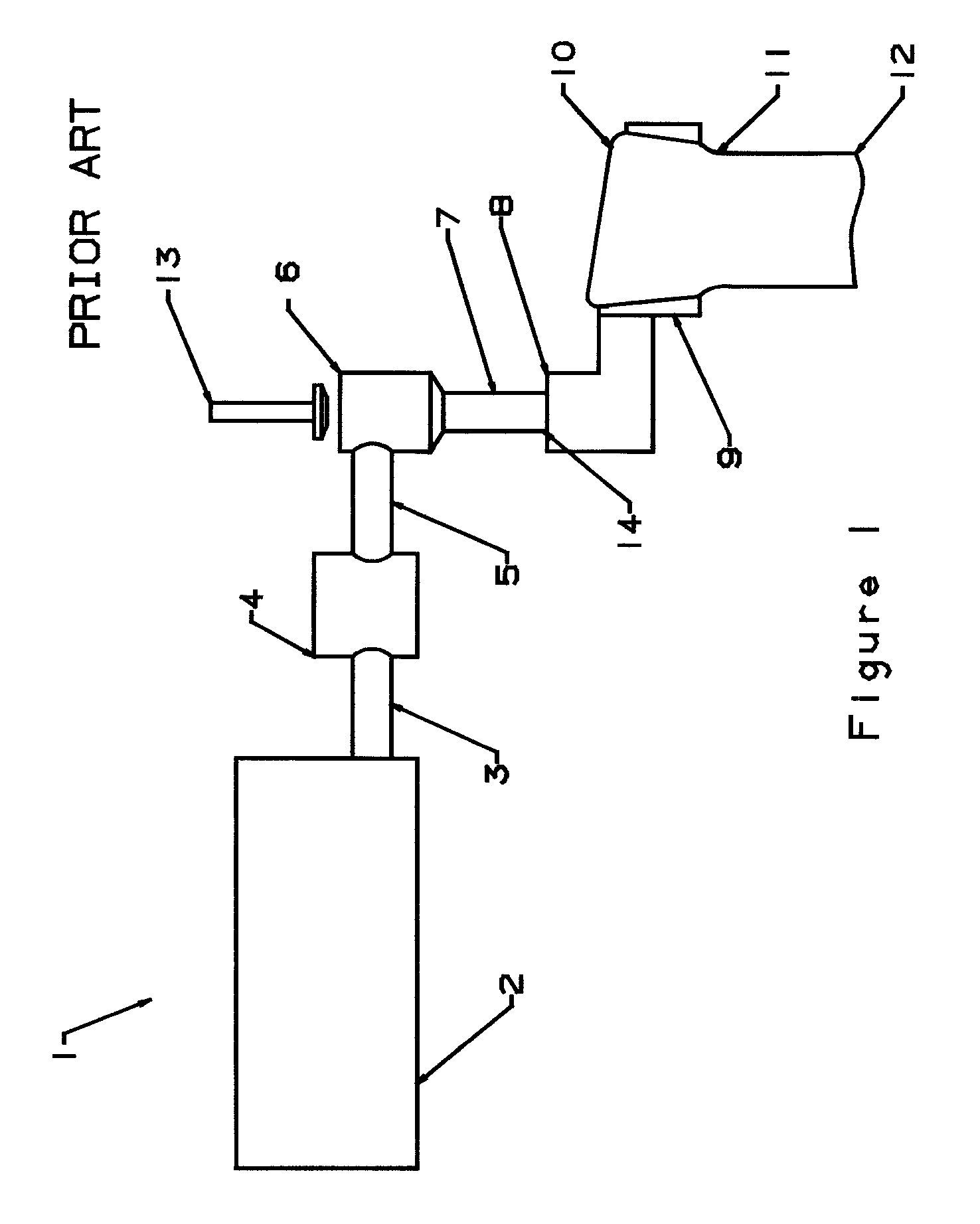

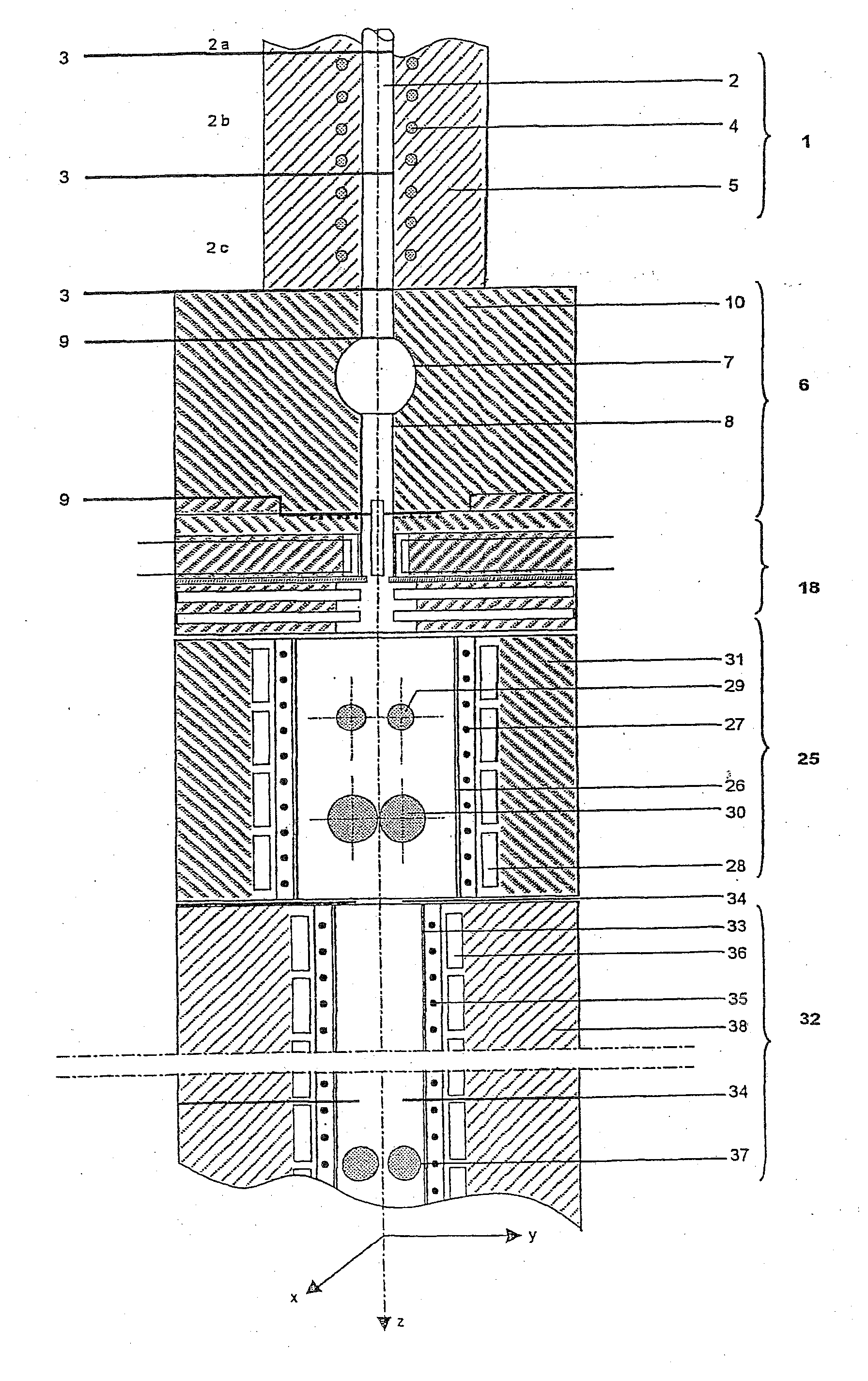

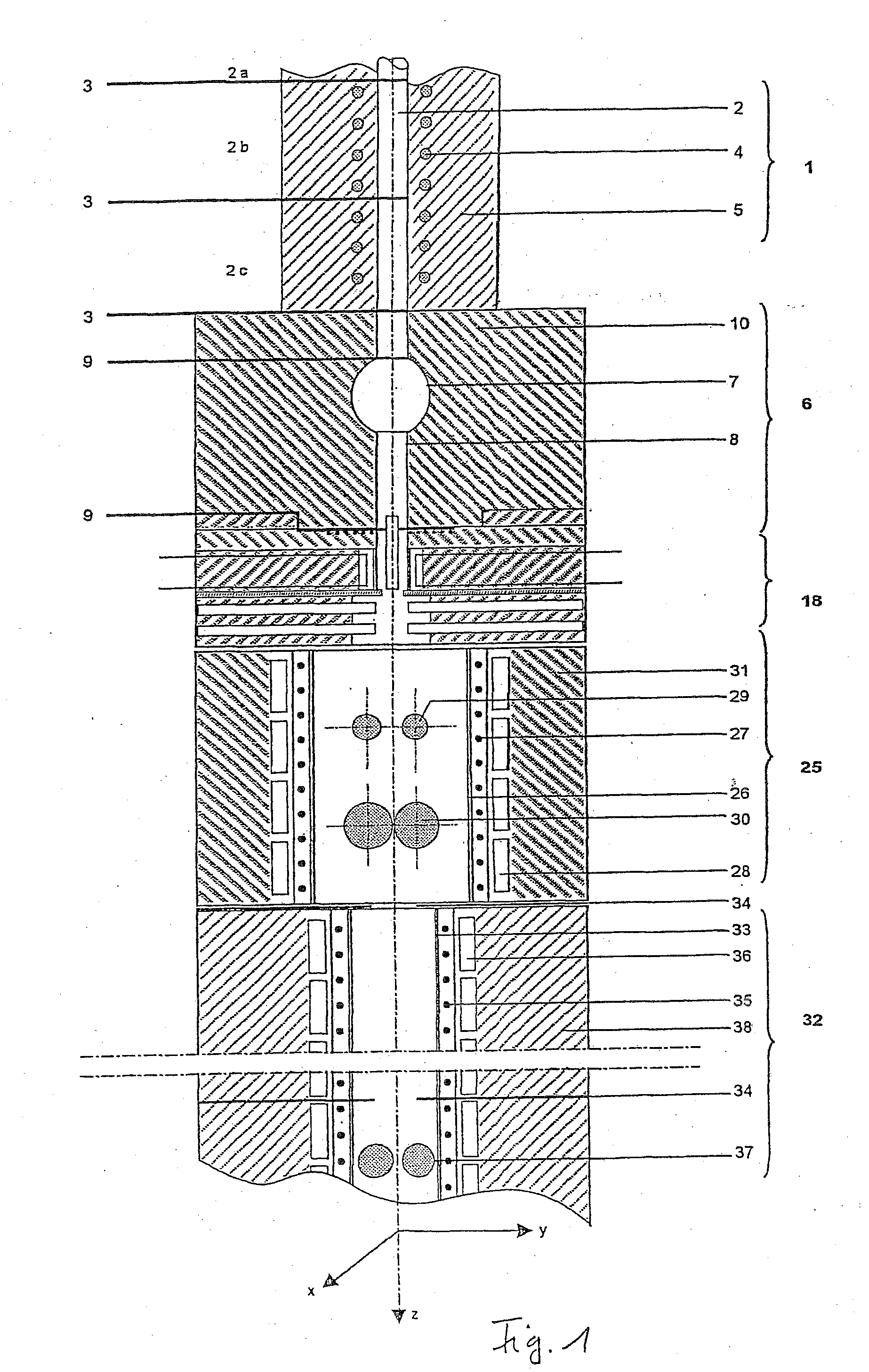

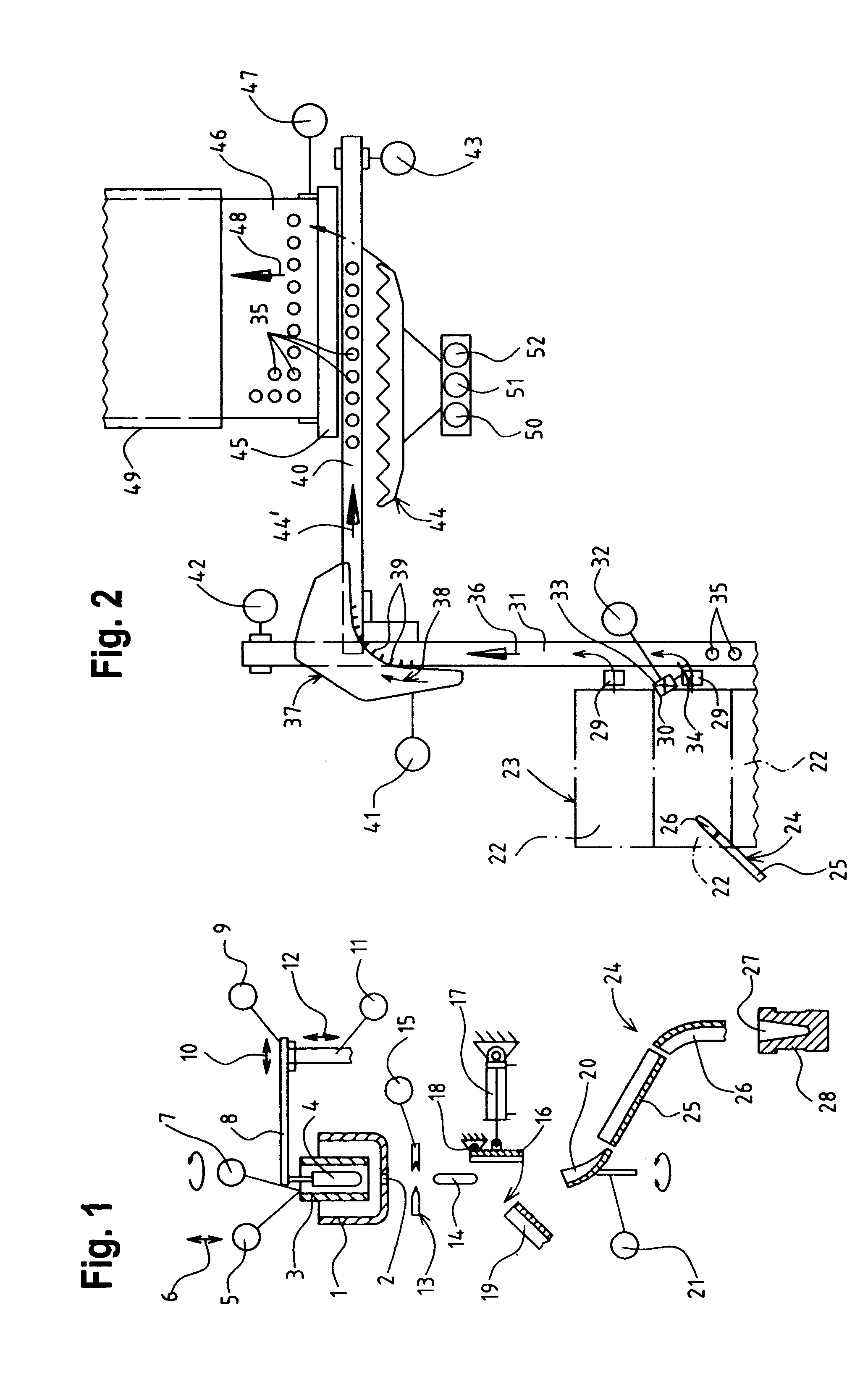

Method of producing quartz glass bodies

InactiveUS6047564AImprove the usefulnessIncrease surface temperatureBlowing machine gearingsGlass deposition burnersVitreous BodiesEngineering

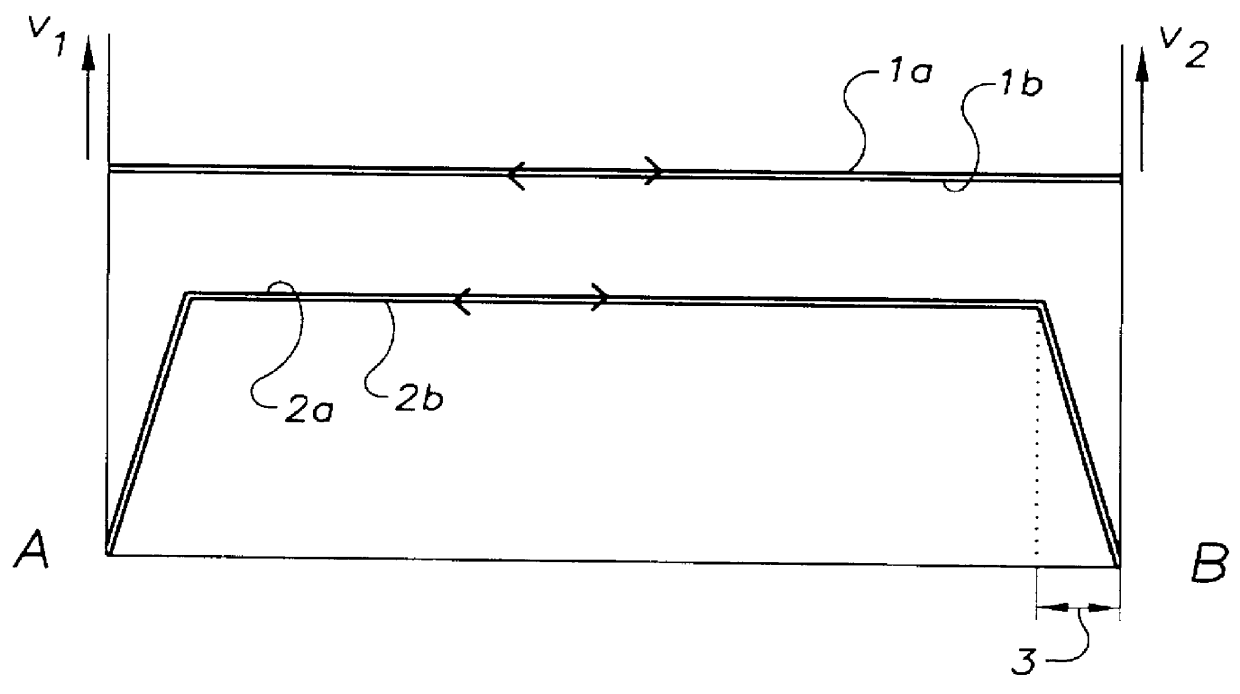

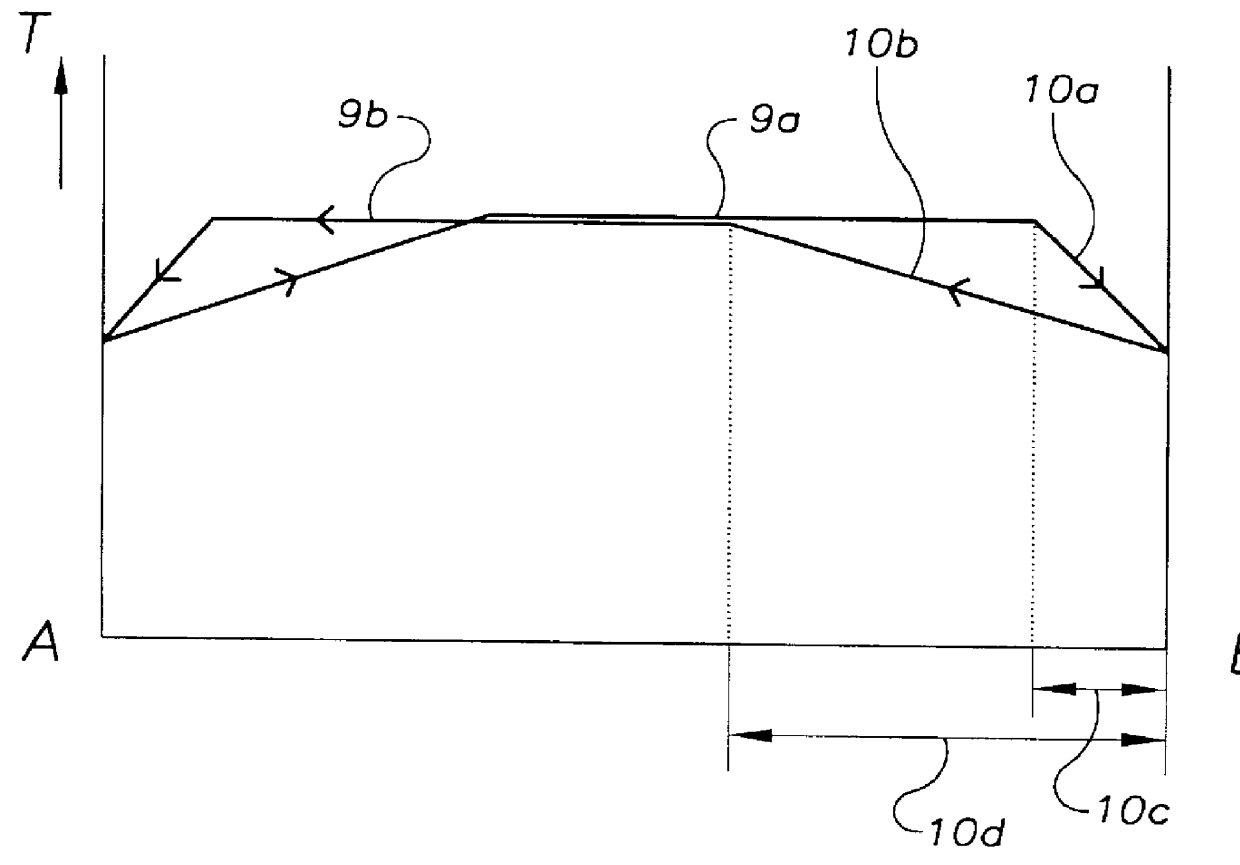

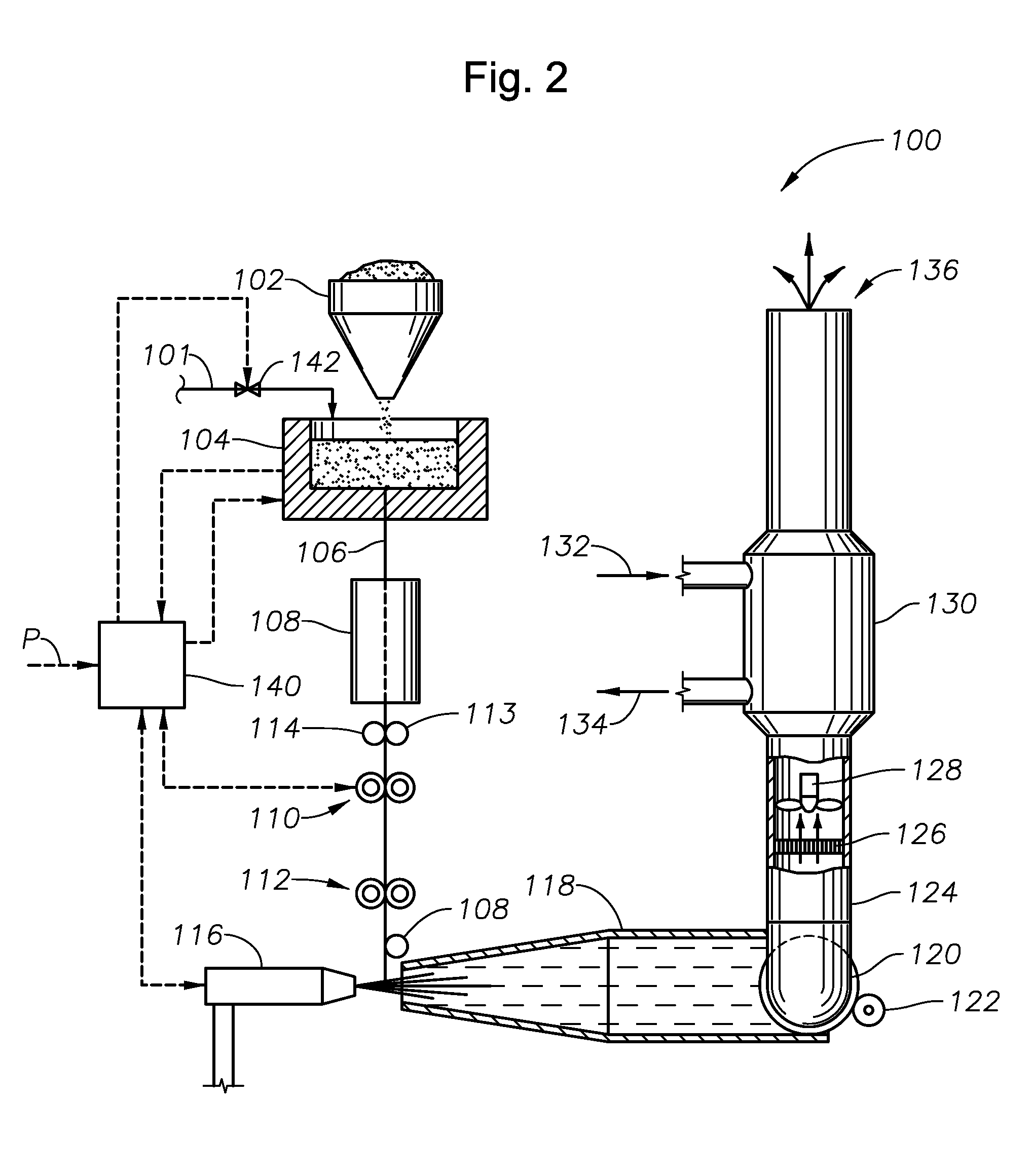

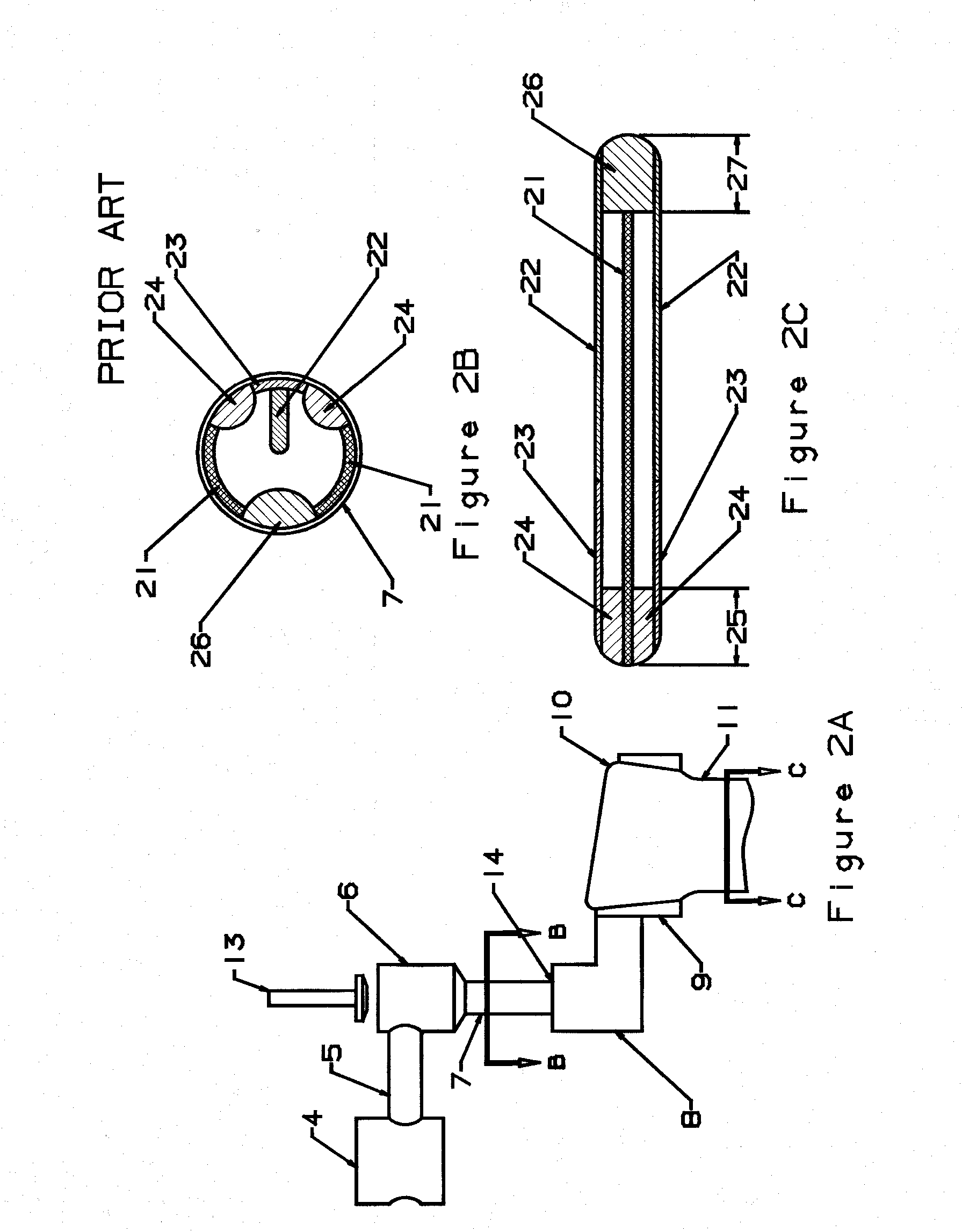

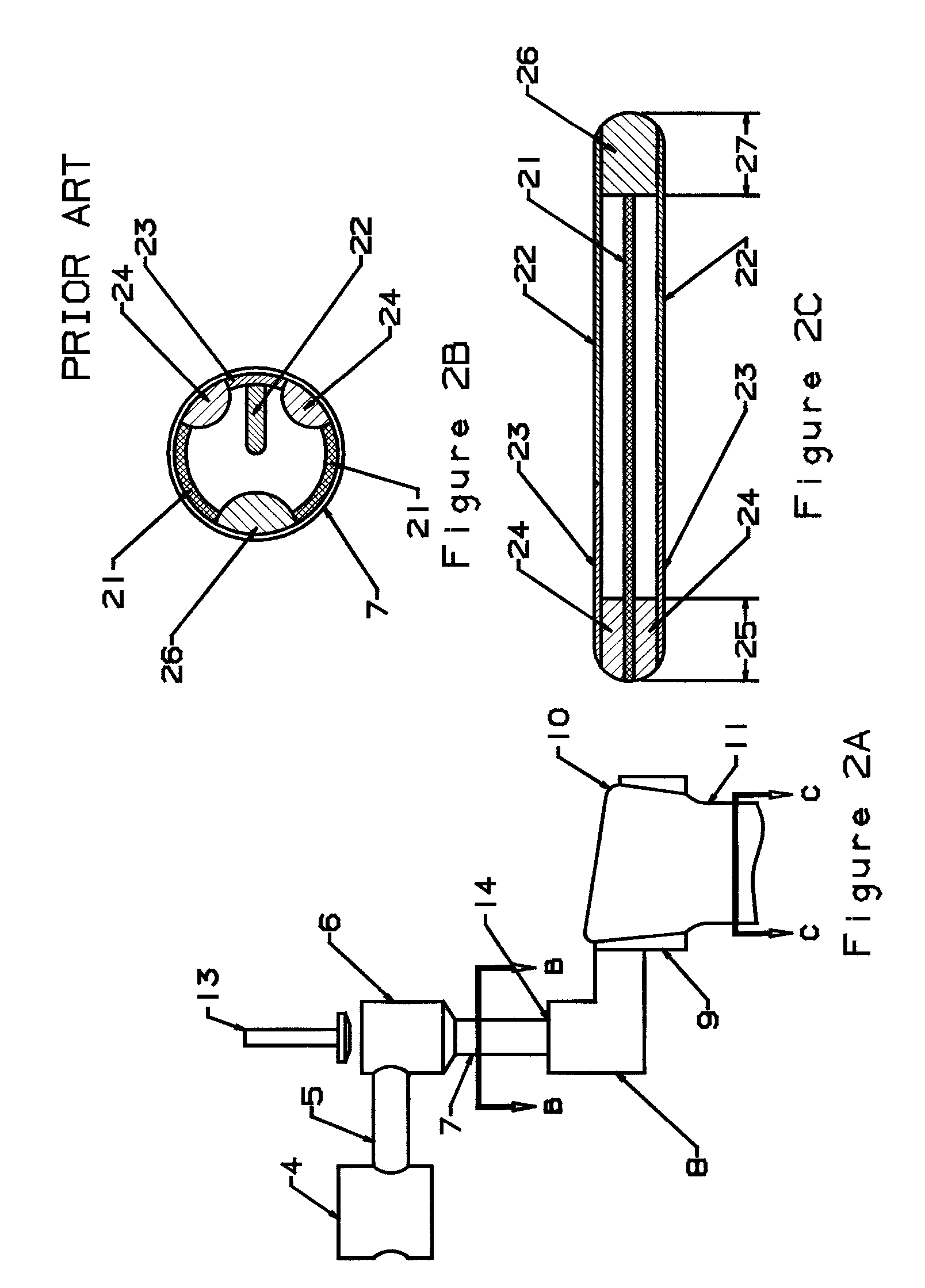

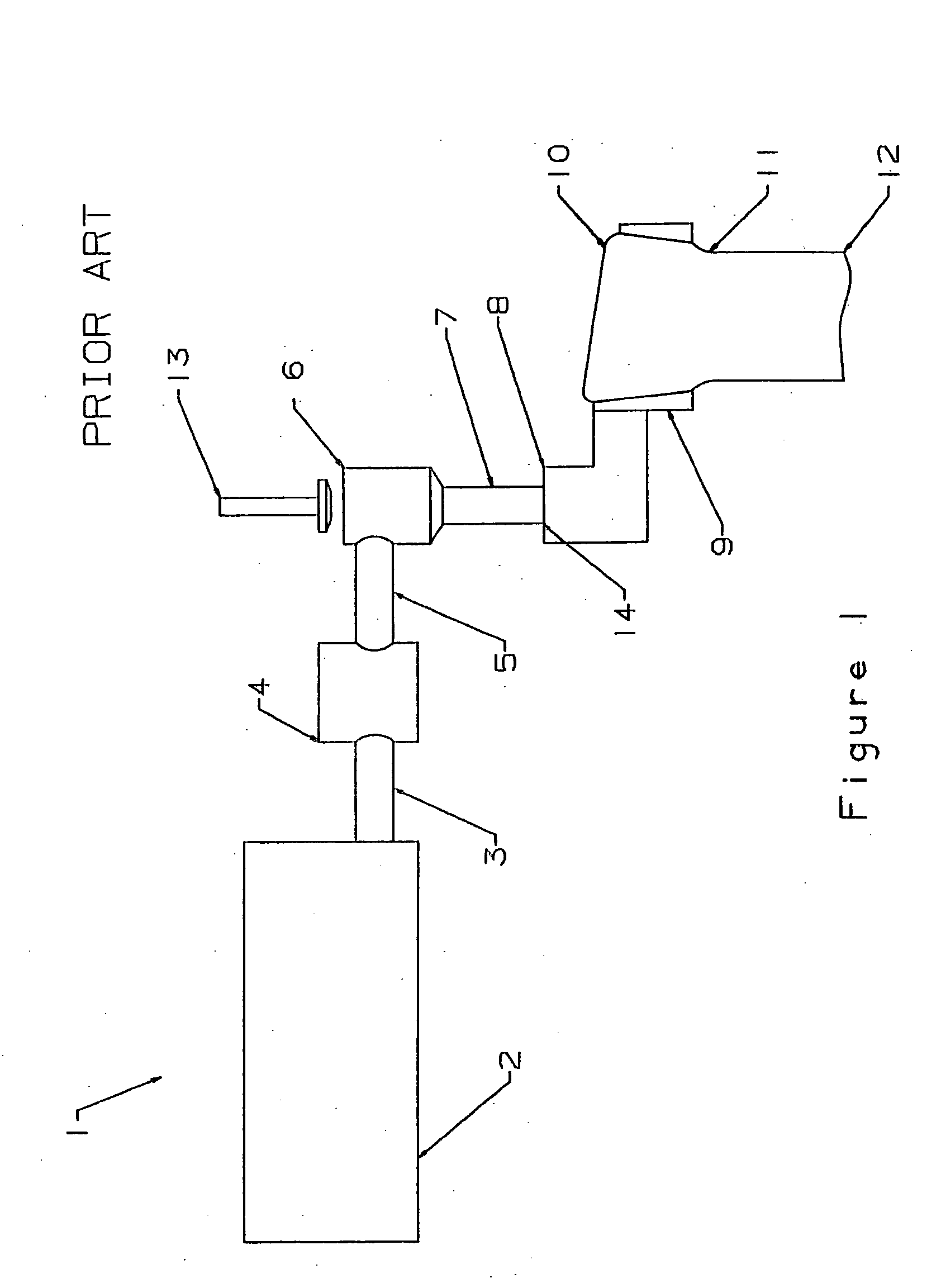

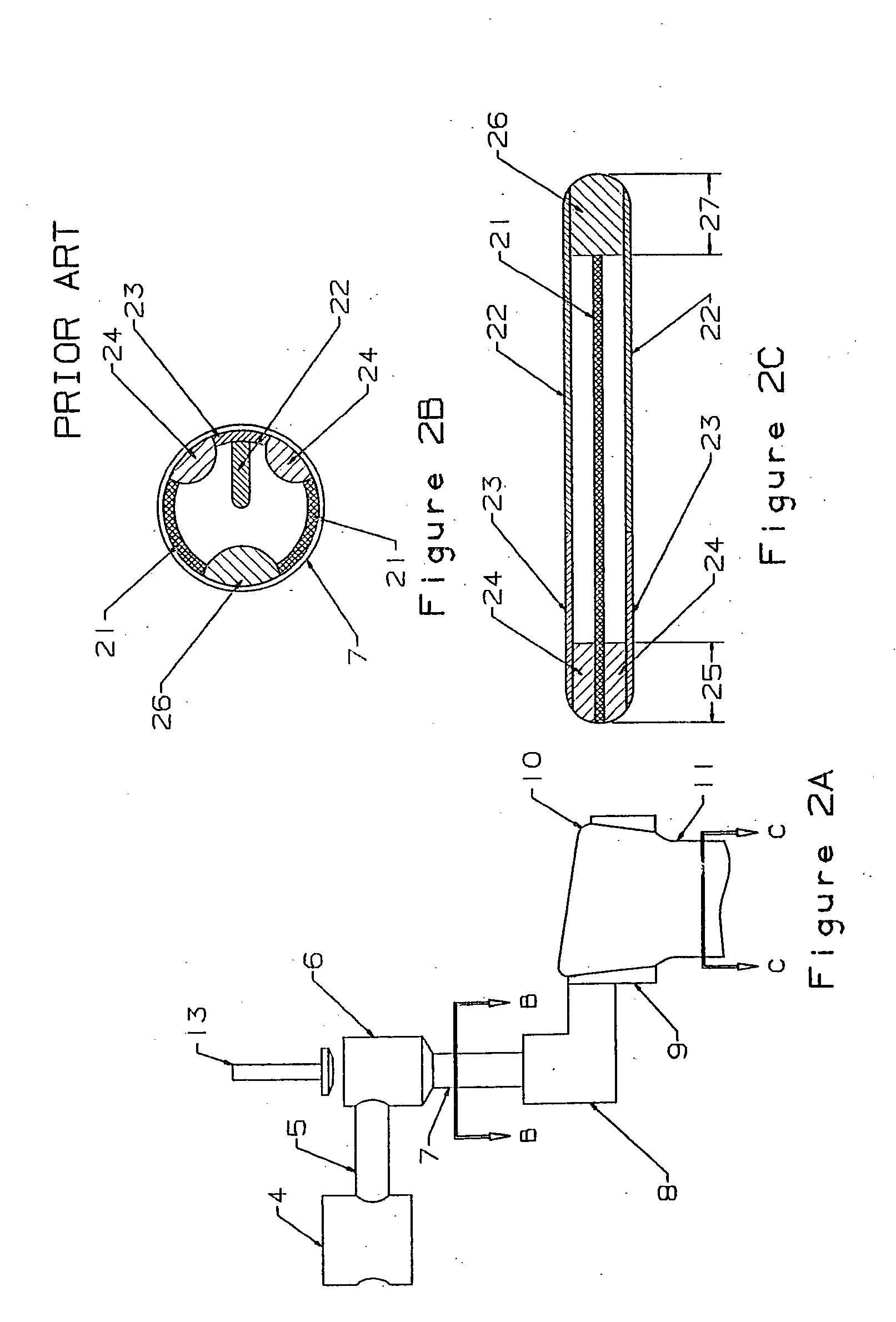

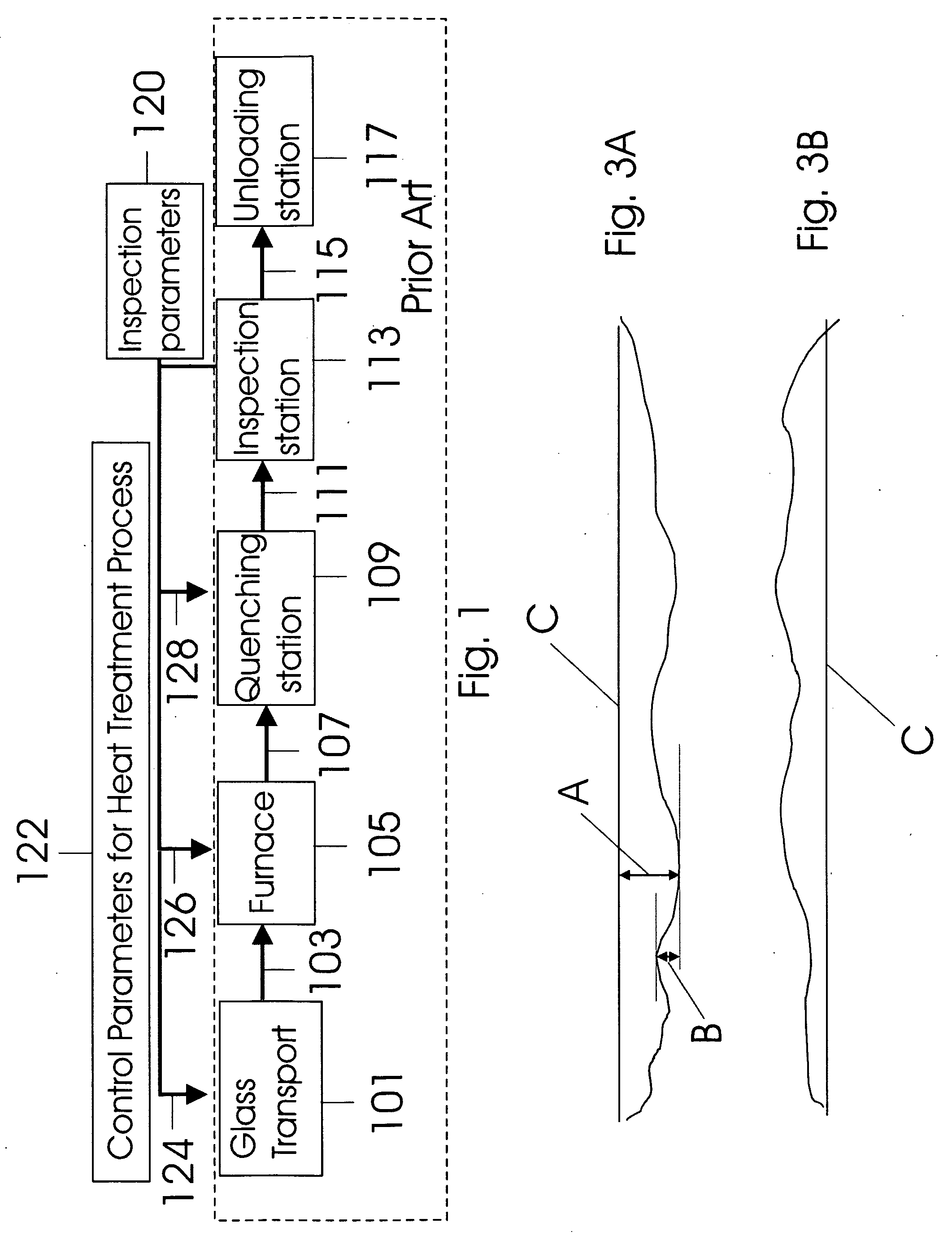

PCT No. PCT / EP97 / 03818 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 17, 1997 PCT Pub. No. WO98 / 03440 PCT Pub. Date Jan. 29, 1998In a known process for the production of quartz glass bodies, SiO2 particles are deposited of the mantle surface of a cylindrical carrier rotating about its longitudinal axis, forming an elongated, porous preform, where the SiO2 particles are formed in a plurality of flame hydrolysis burners which are arranged in at least one burner row parallel to the longitudinal axis of the carrier and are moved at a preset translational speed forward and back between turnaround points at which points their direction of movement is reversed, and in which process the preform is sintered. In order to make available on this basis an easily accomplished process that makes it possible to manufacture a preform which is largely free of localized density variations, the invention proposes on the one hand that the base value of the surface temperature of the preform being formed be kept in a range between 1,050 DEG C. and 1,350 DEG C., that the average peripheral velocity of the preform be kept in the range between 8 m / min and 15 m / min and the average translational velocity of the burner row be kept in a range between 300 mm / min and 800 mm / min. On the other hand, the object is also accomplished according to the invention and on the basis of the known process in that in the area of the turnaround points (A, B) the peripheral velocity of the preform being formed is increased and / or the flame temperature is lowered and / or the distance of the burners from the preform surface is changed.

Owner:HERAEUS QUARZGLAS

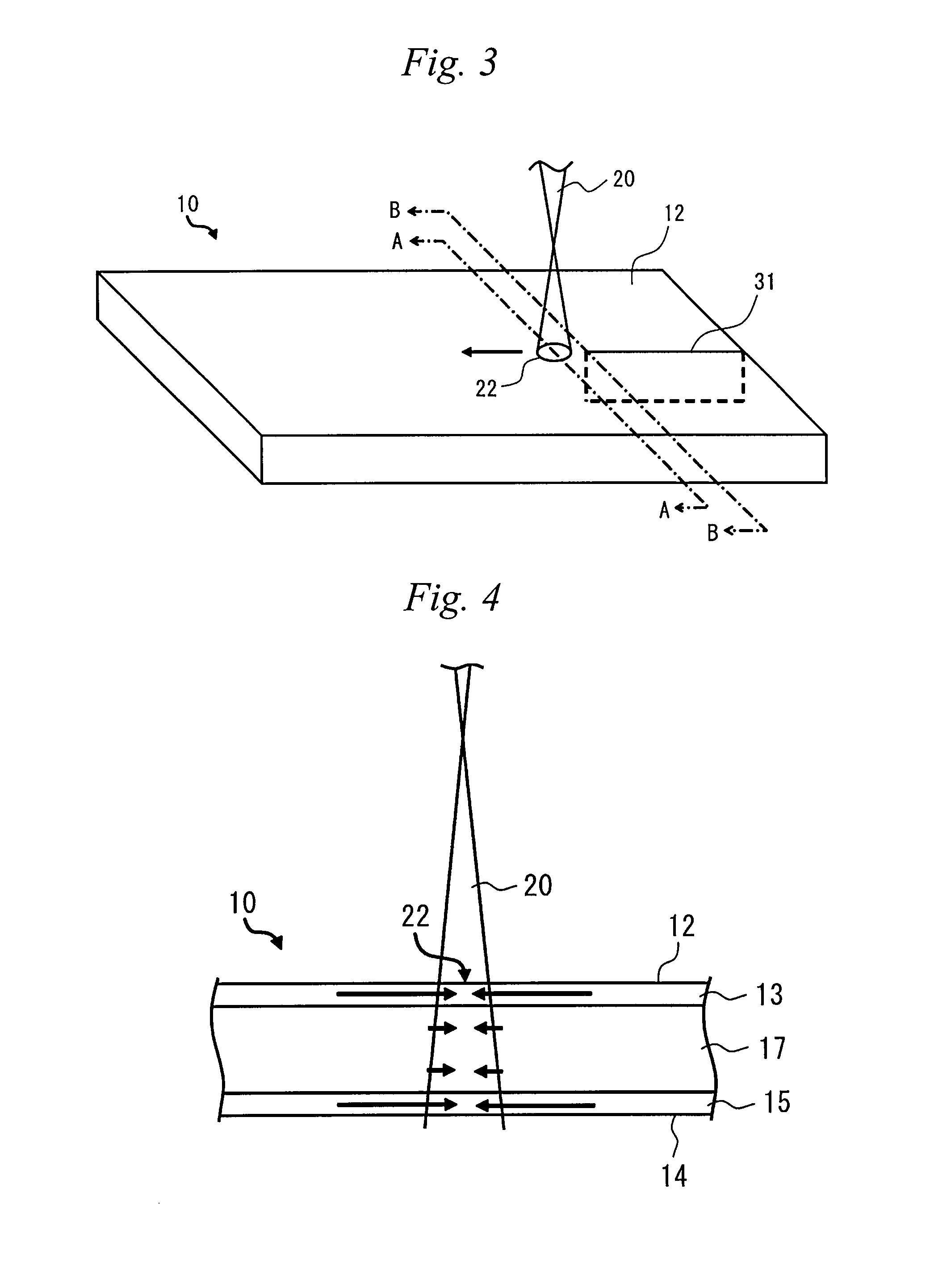

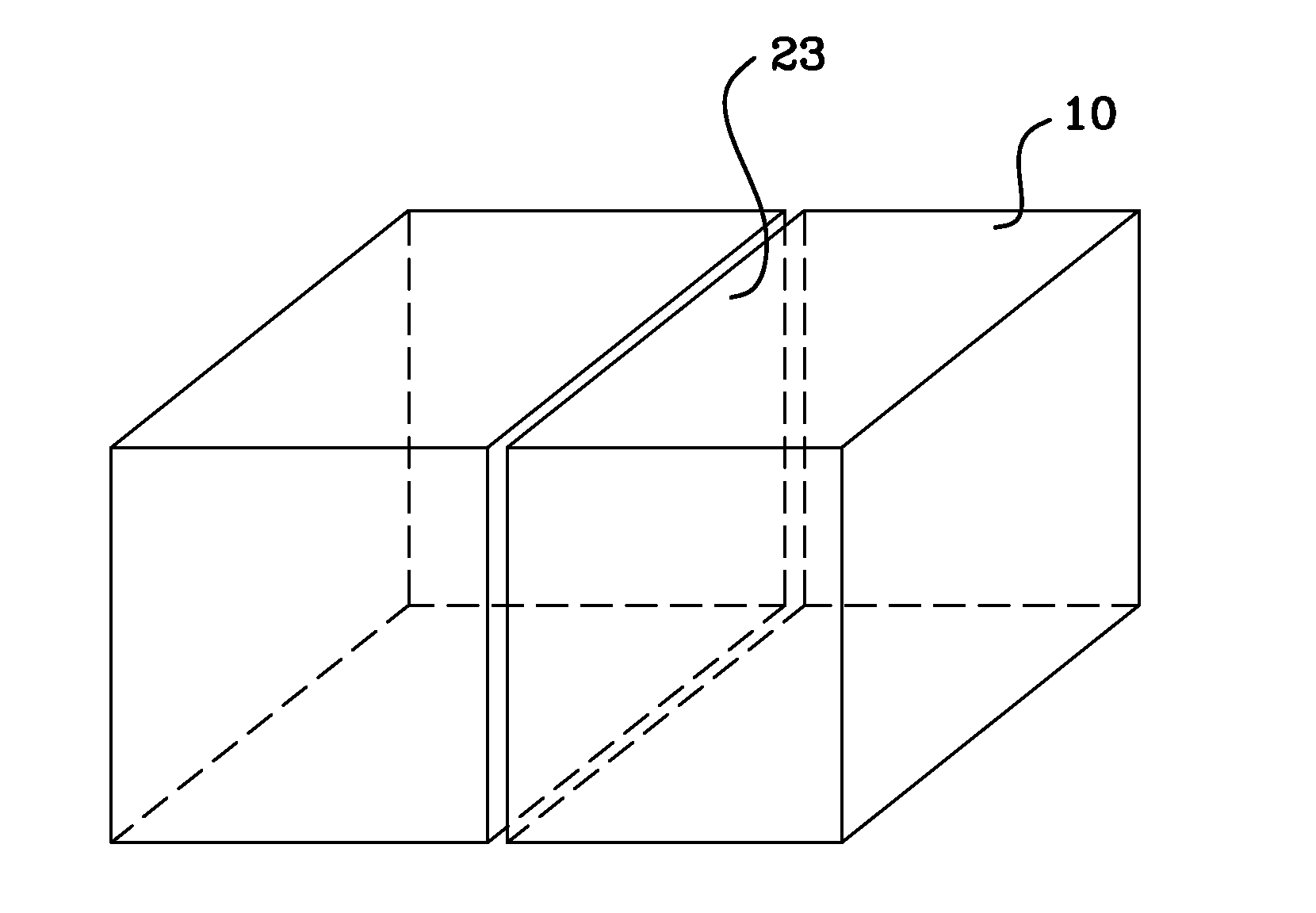

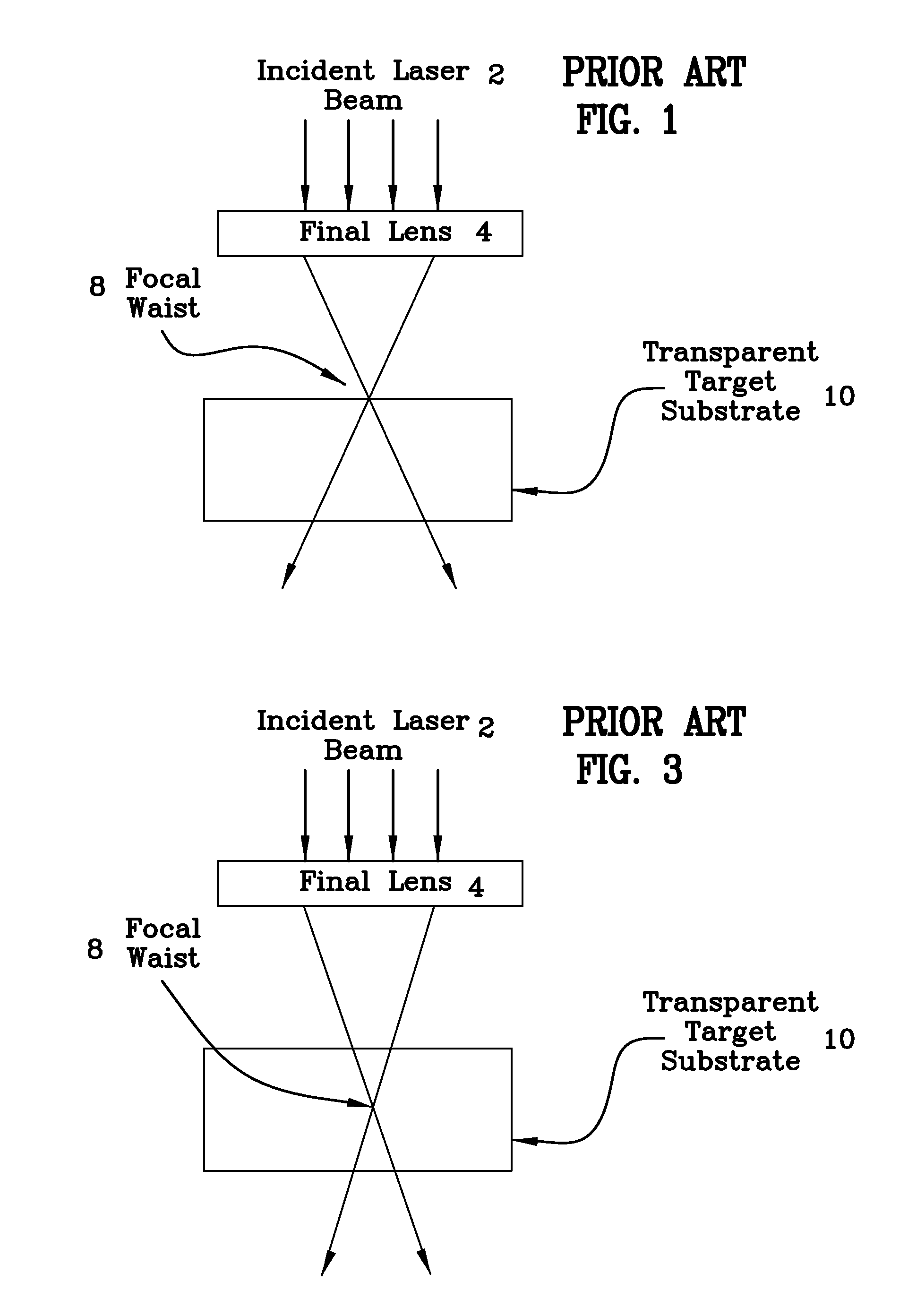

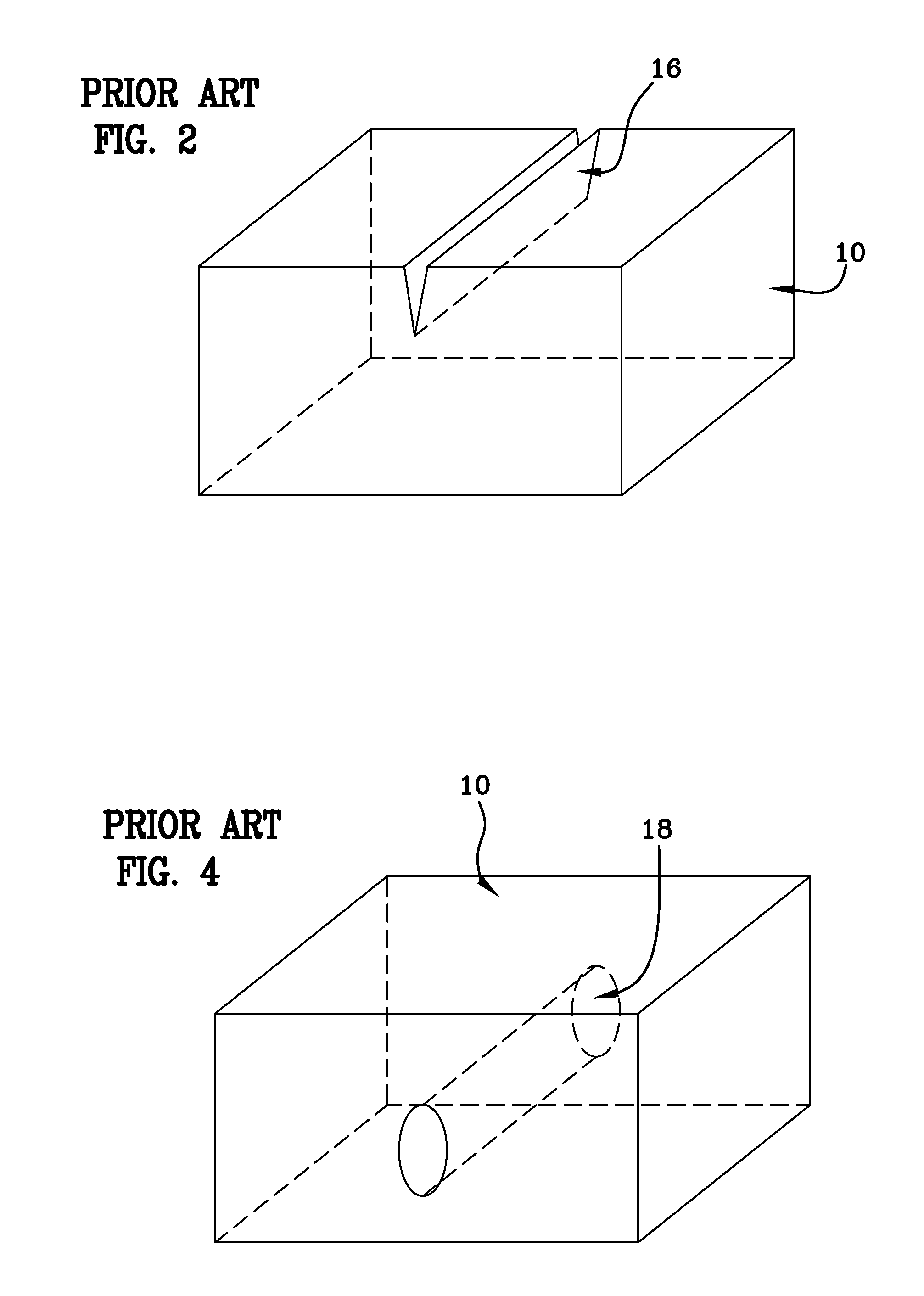

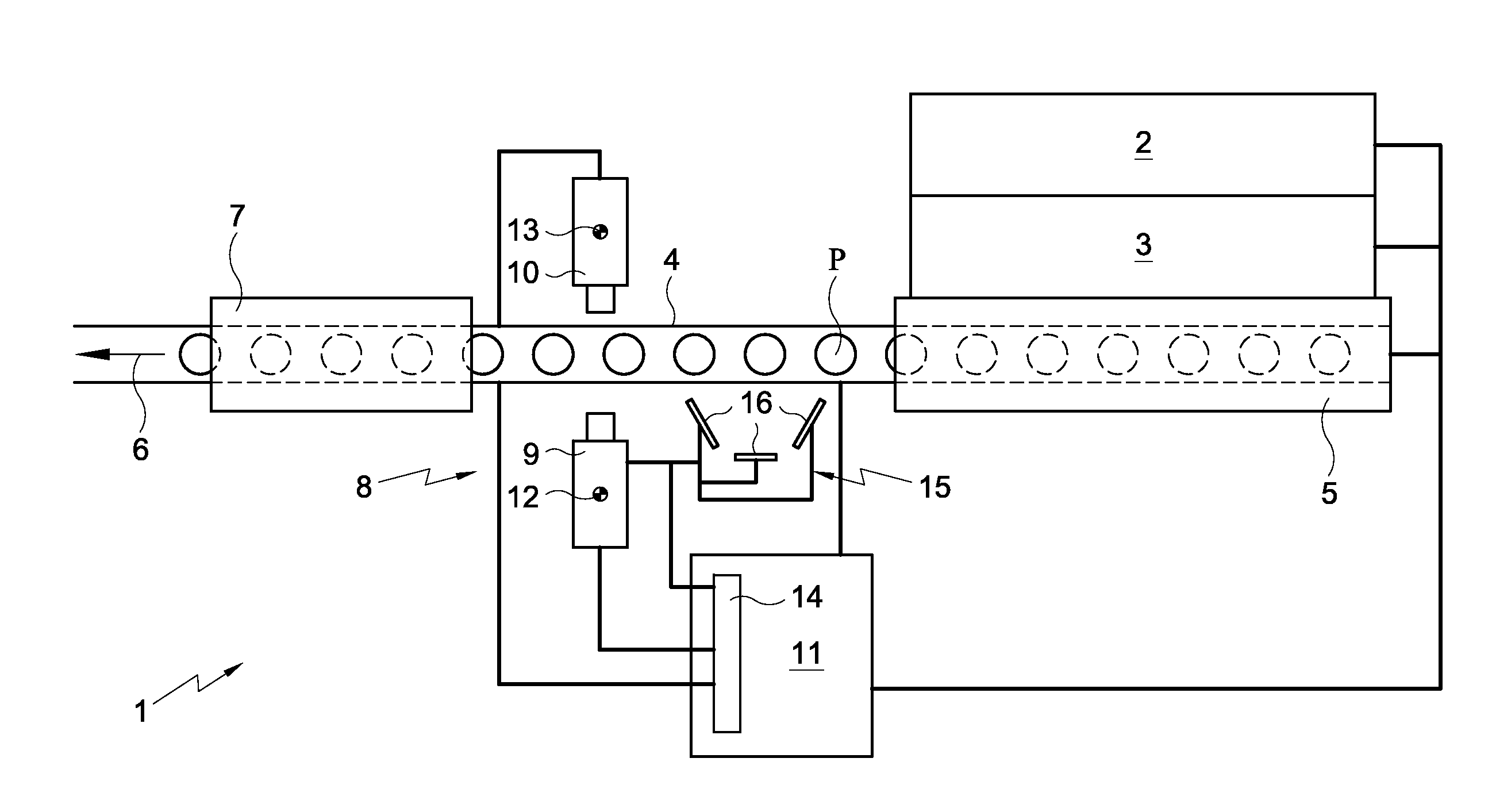

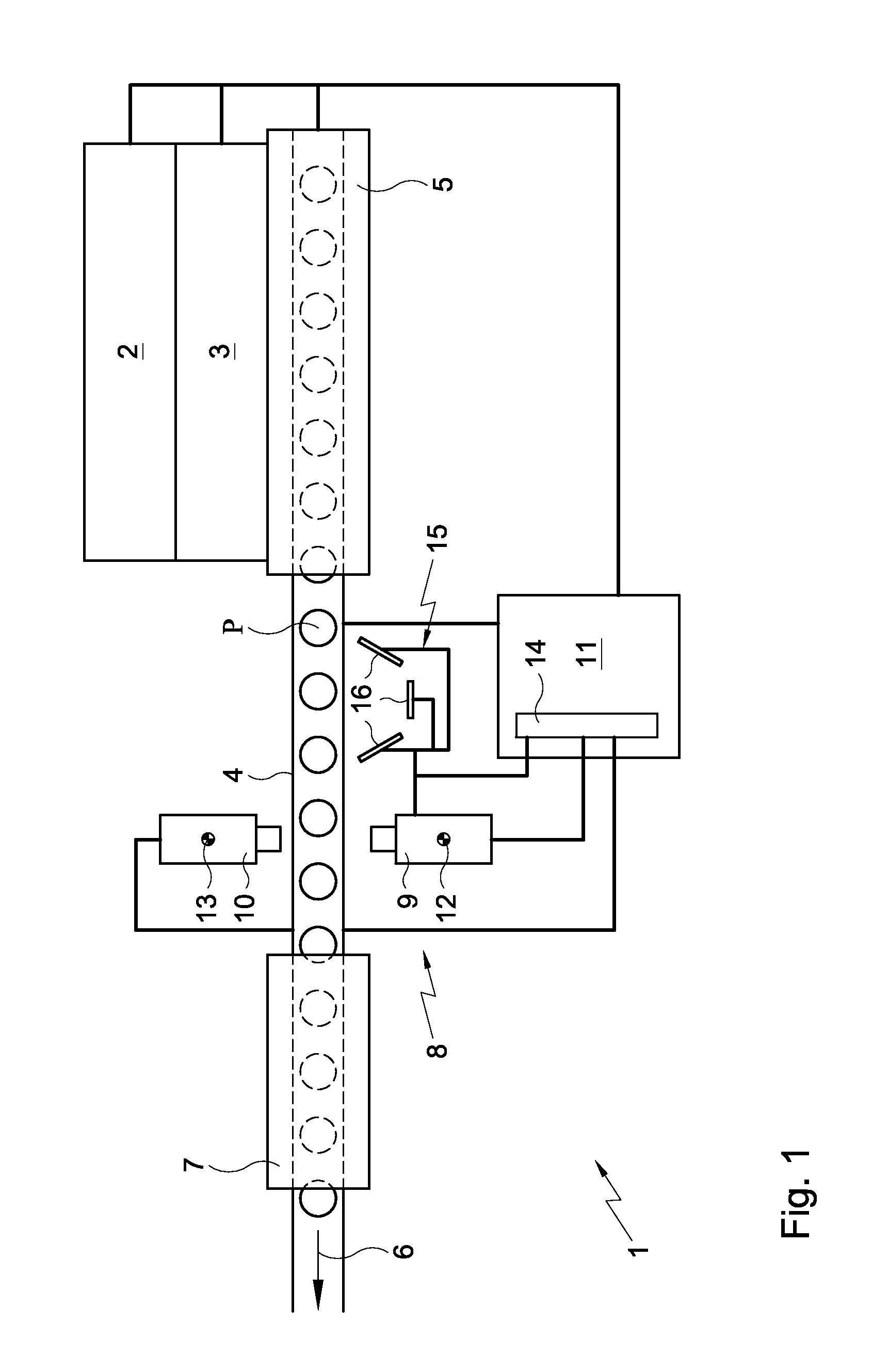

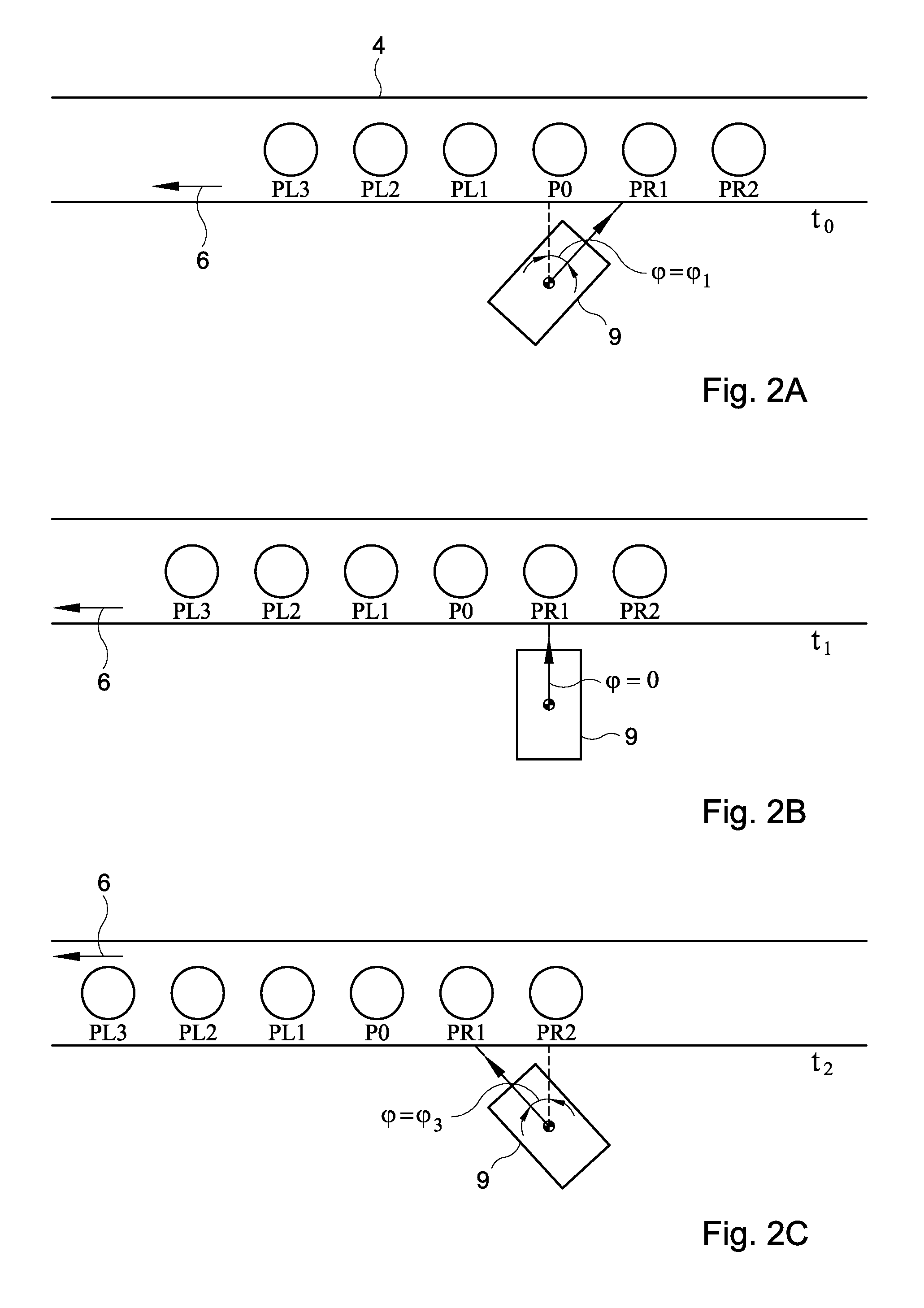

High Speed Laser Processing of Transparent Materials

ActiveUS20150299018A1Avoid focusHigh precision laserBlowing machine gearingsGlass furnace apparatusLaser processingAtomic physics

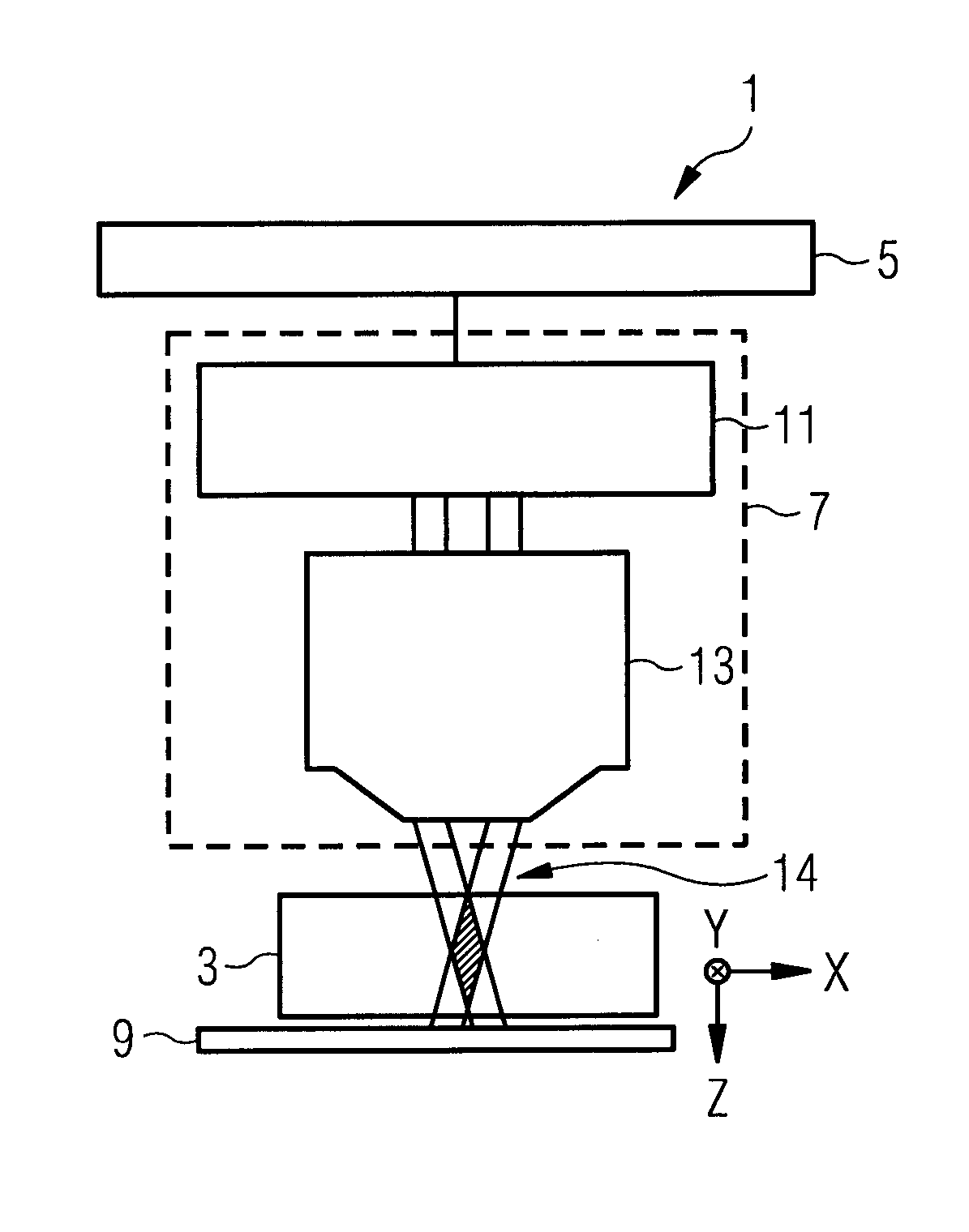

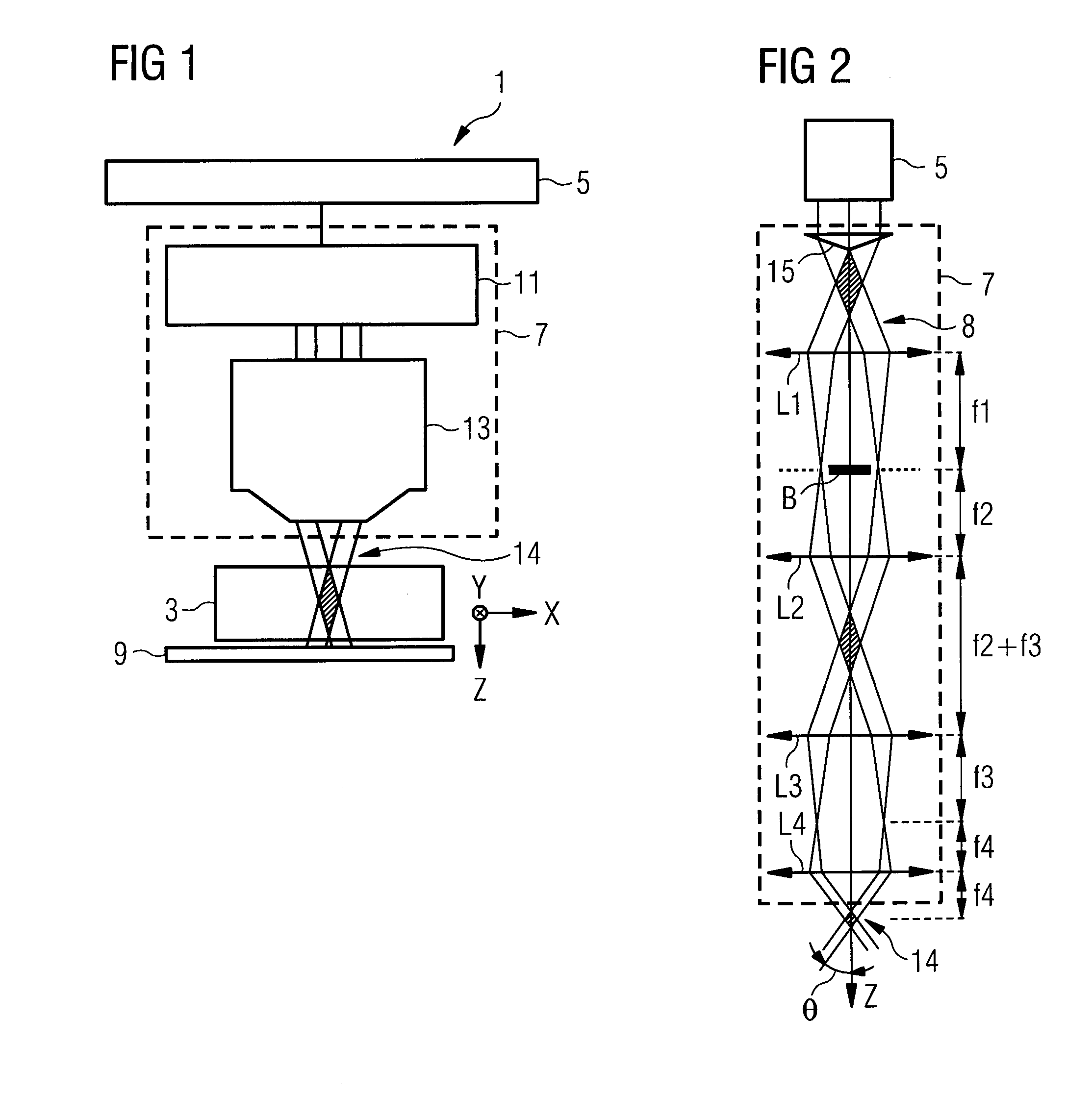

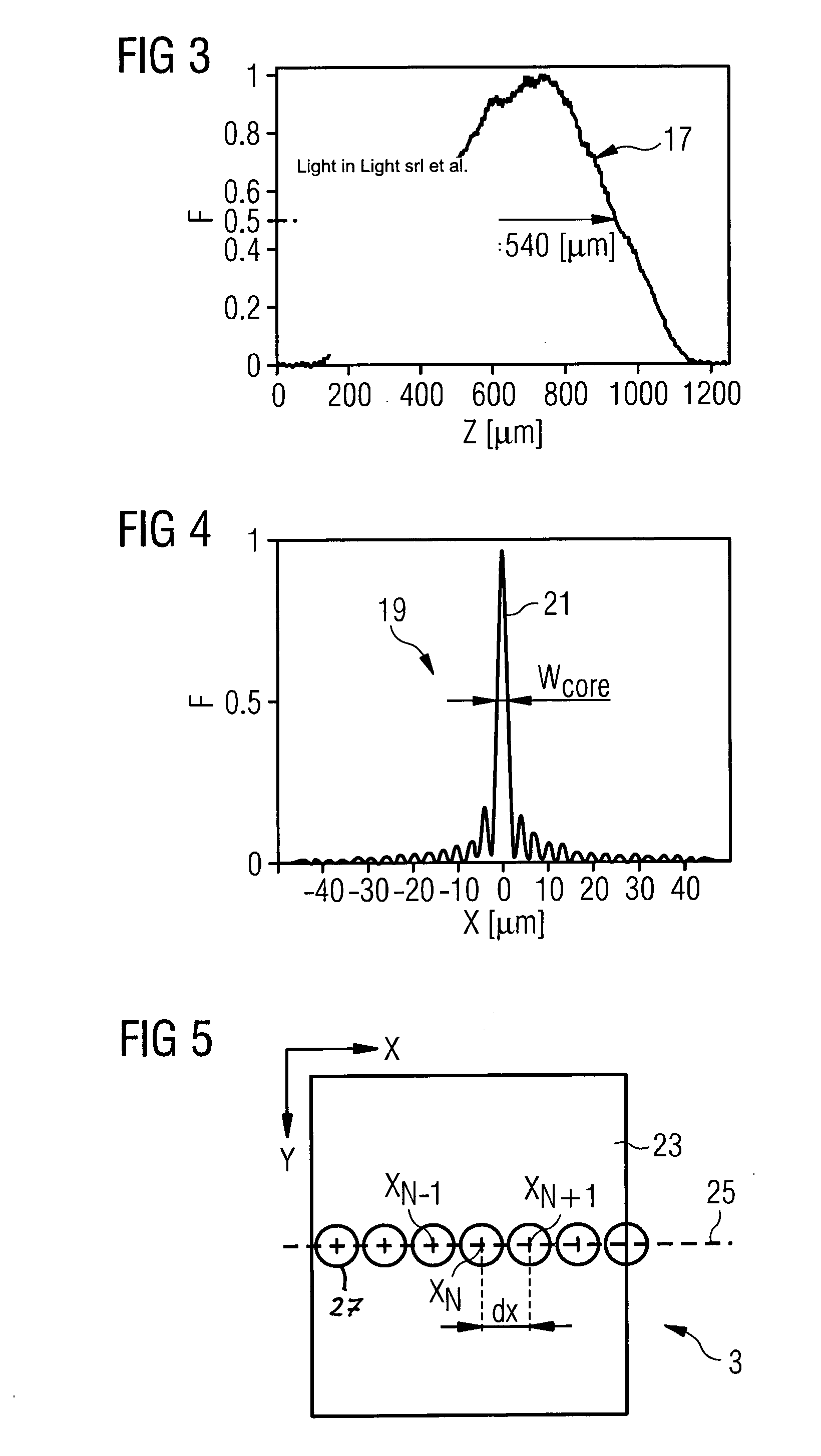

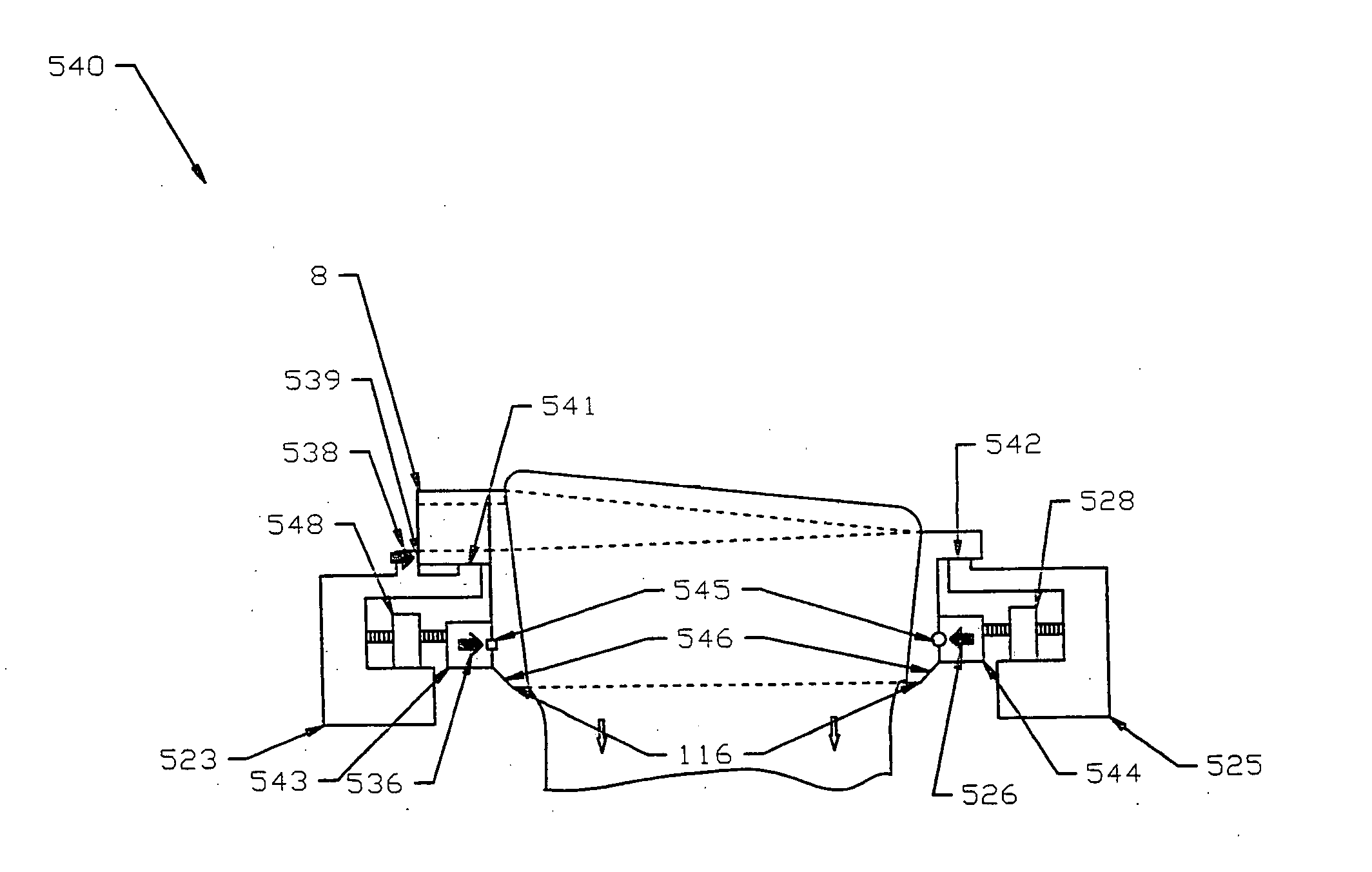

A method and system for laser pre-cutting a layered material (31) with a laser beam (14) is disclosed. The layered material (31) comprises at least one tensile stress layer (TSL), at least one compression stress layer (CSL1, CSL2), and at least one interface region (IR1, IR2) between the at least one tensile stress layer (TSL) and the at least one compression stress layer (CSL1, CSL2) and is transparent to allow propagation of the laser beam (14) through the layered material (31). The method may comprise setting an optical beam path (8) and a laser characteristic of the laser beam (14) such that an interaction of the laser beam (14) with the layered material (31) generates an elongate damage region (57) in the layered material (31), and, for each of a series of pre-cut positions (XN−1, XN, XN+1) of the layered material (31), pre-cutting the layered material (31) by positioning the layered material (31) and the laser beam (14) with respect to each other and irradiating the laser beam (14) such that the respective elongate damage regions (57) extend across the at least one interface region (IR1, IR2).

Owner:UAB ALTECHNA R&D

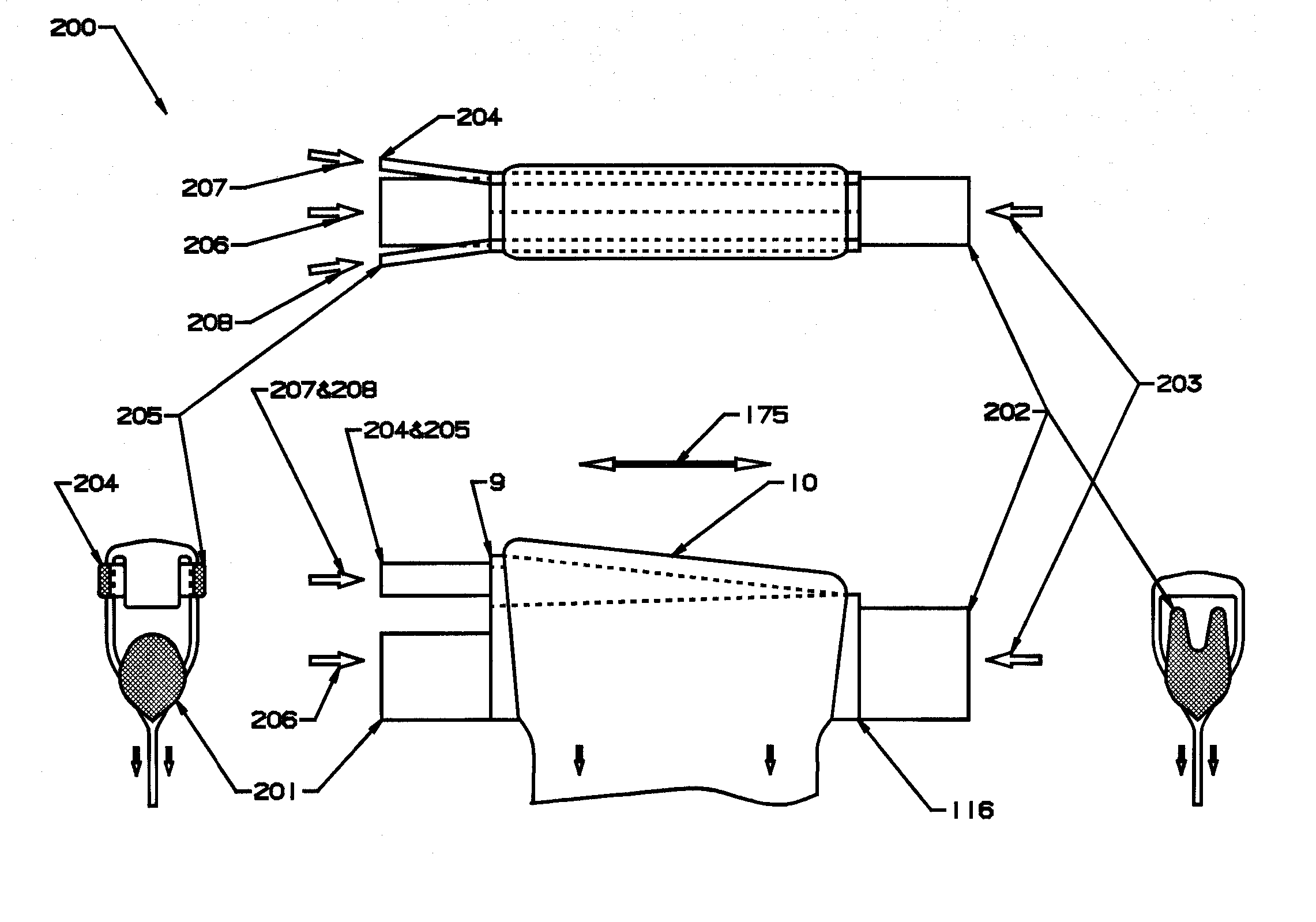

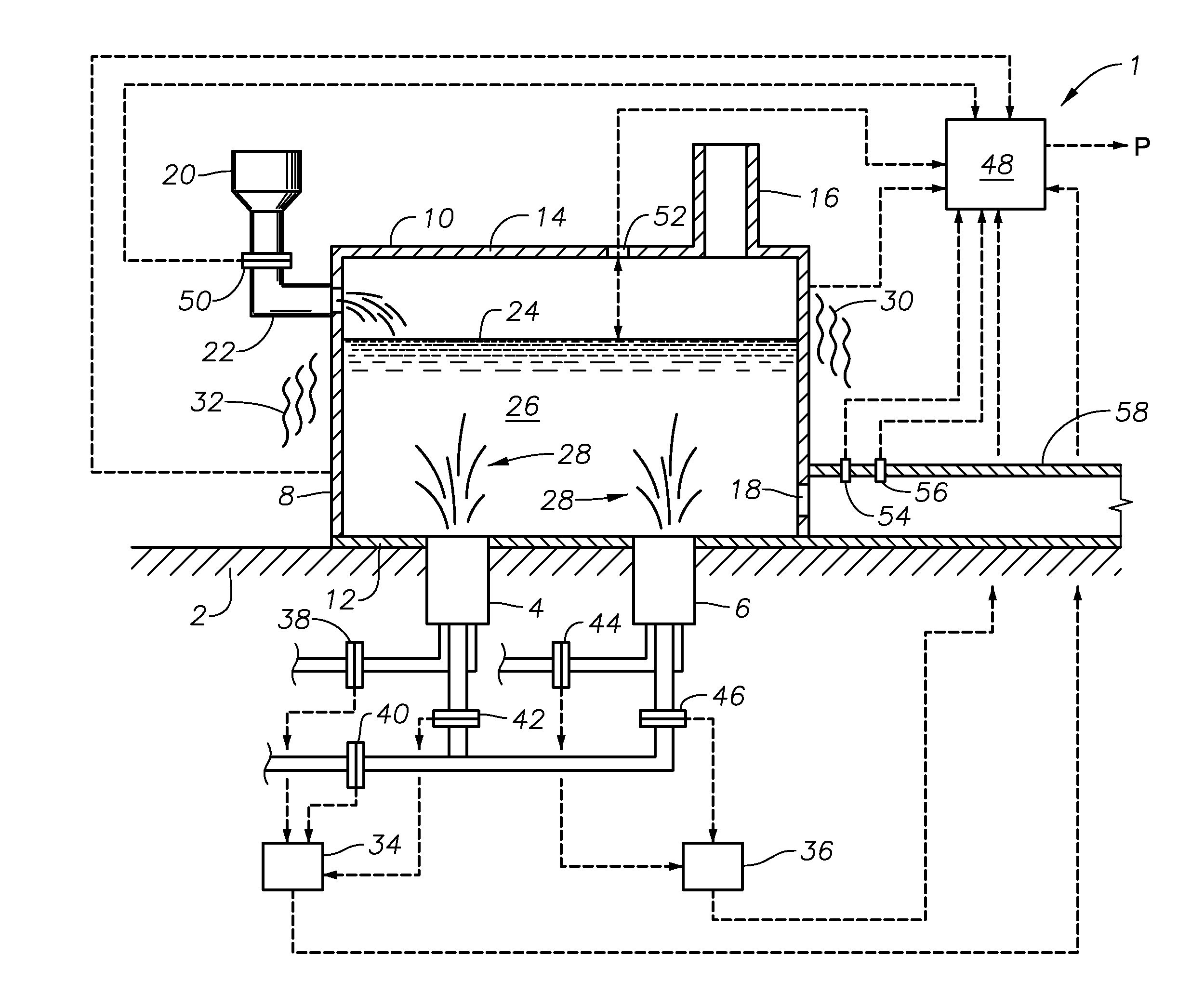

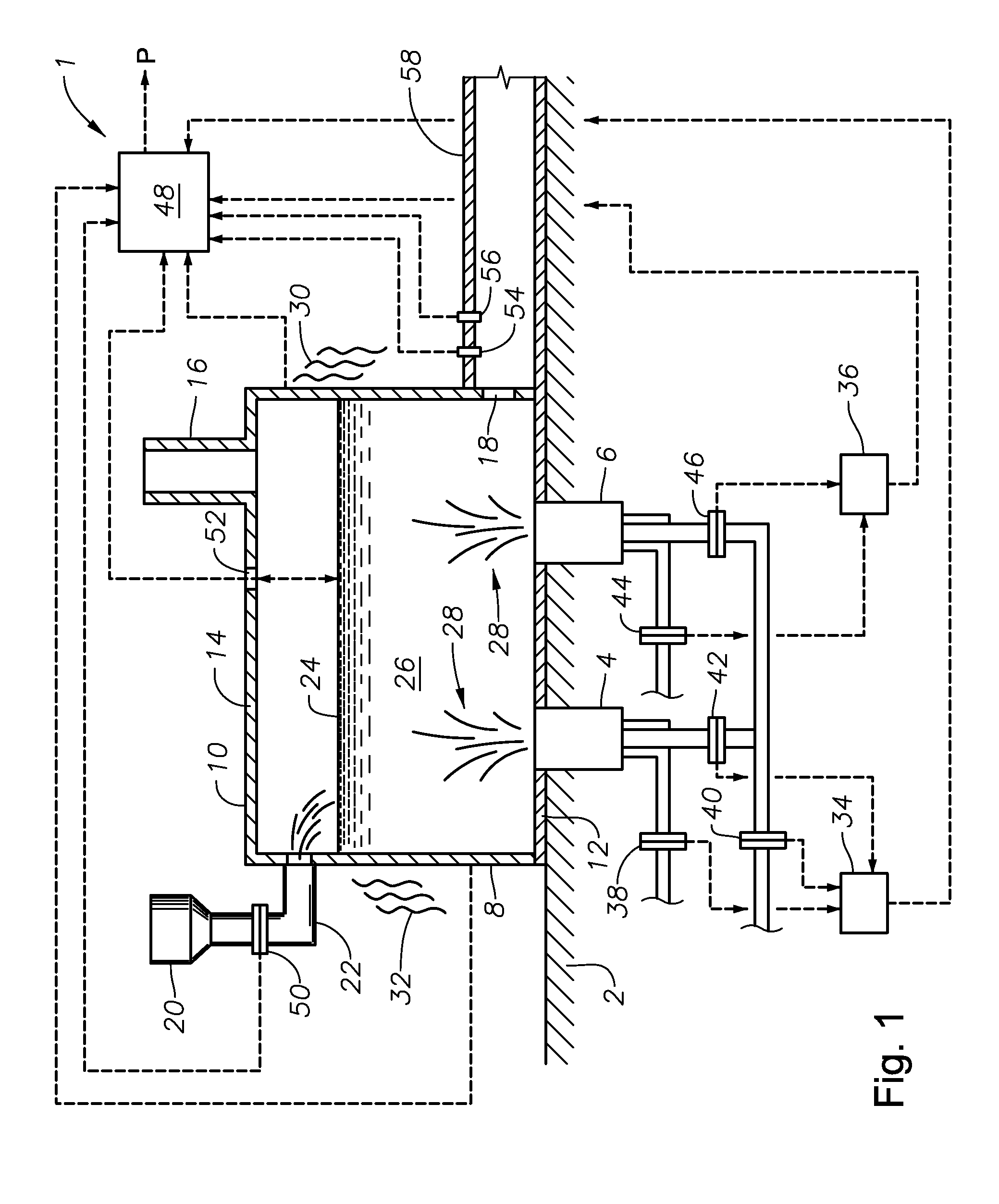

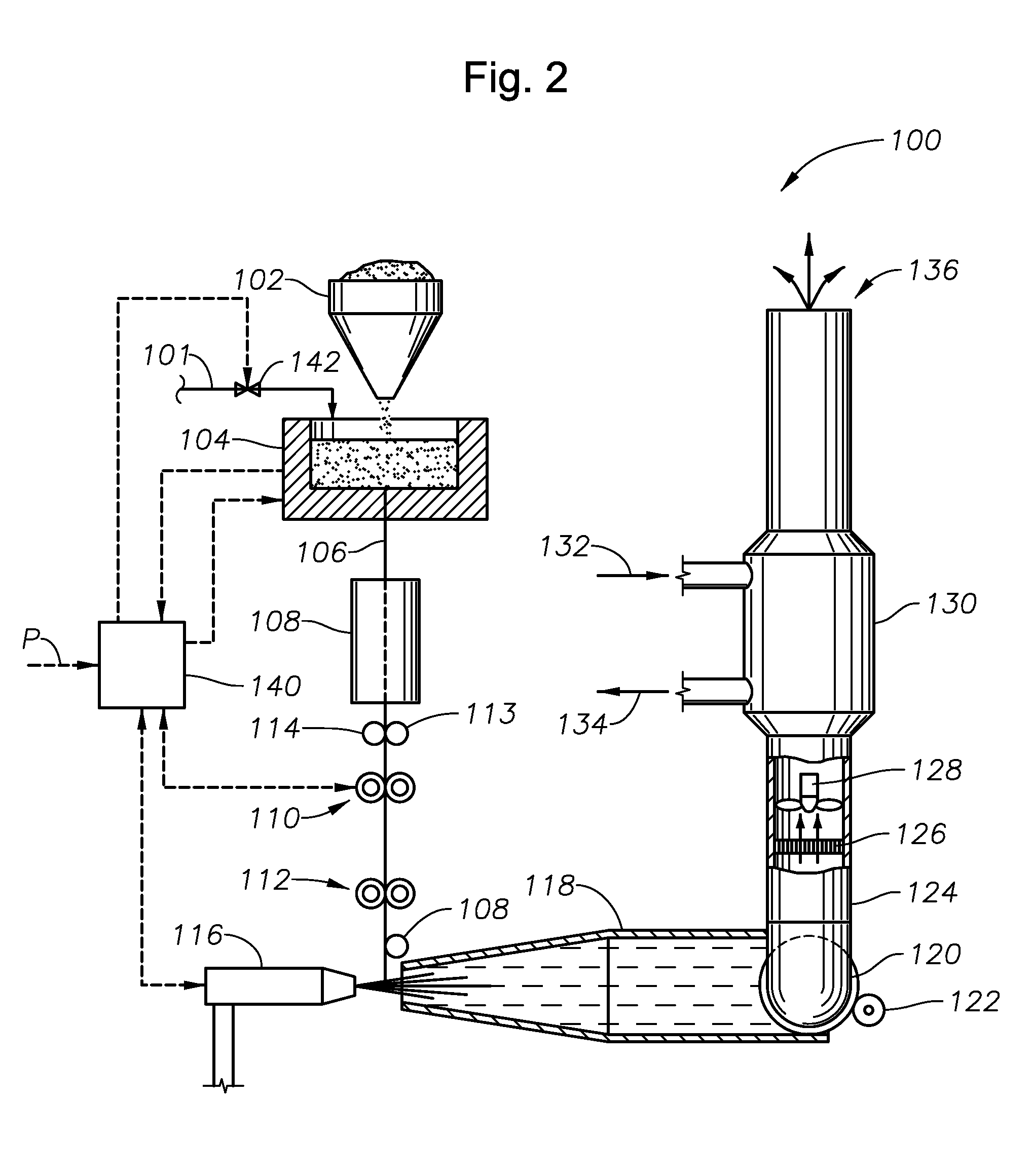

Methods of using a submerged combustion melter to produce glass products

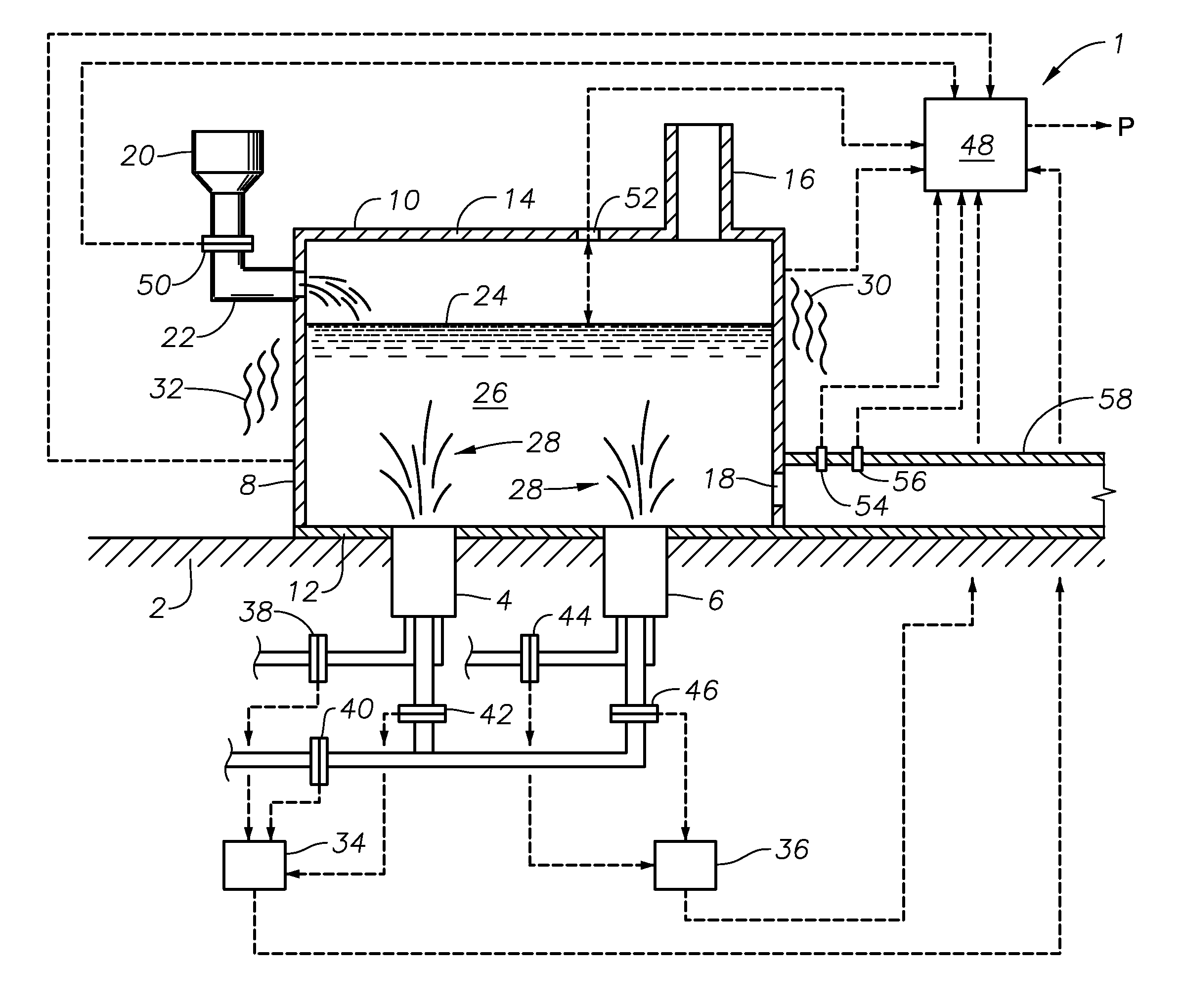

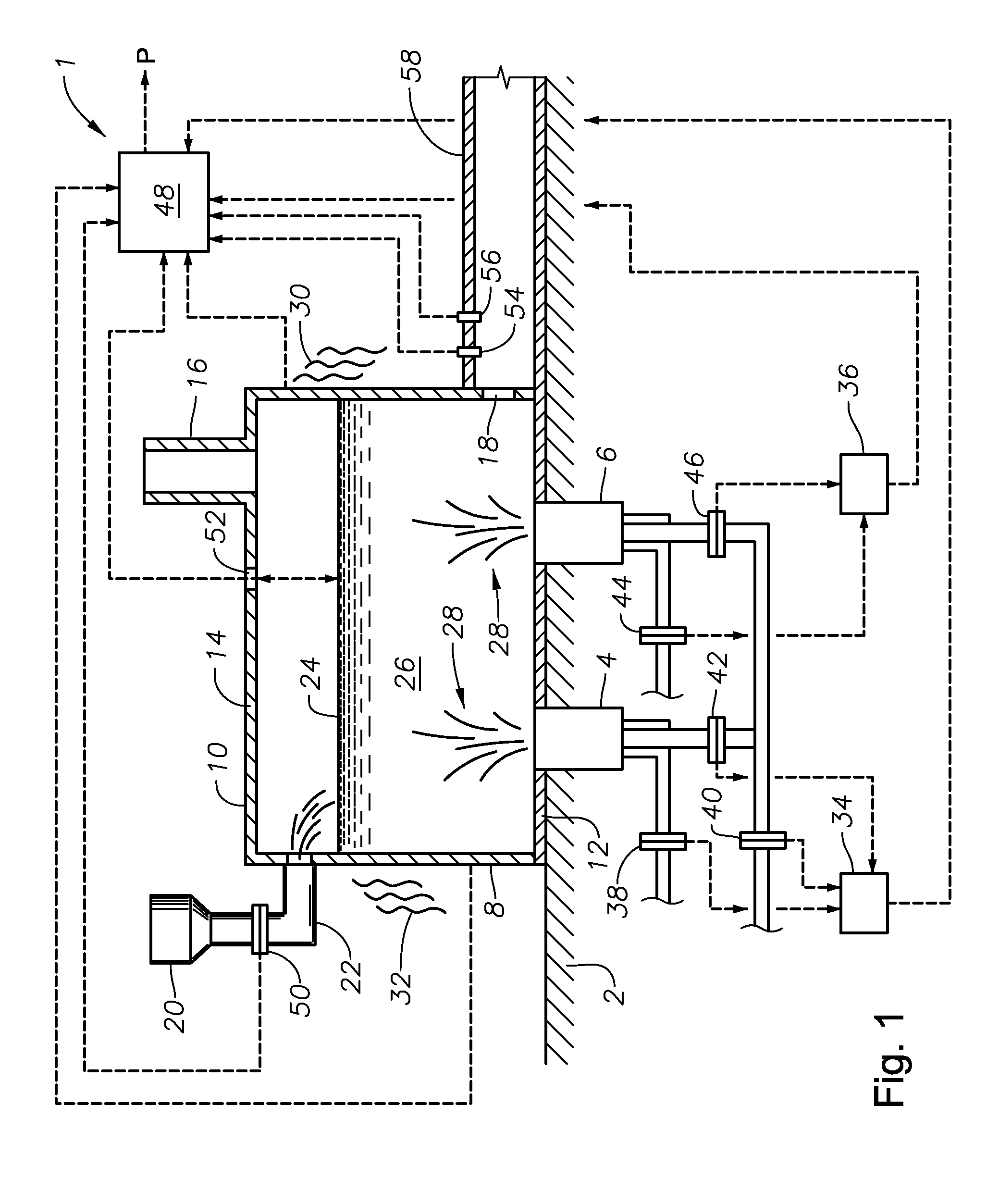

A method comprises flowing an oxidant and a fuel into a submerged combustion burner in a glass tank furnace, the glass tank furnace receiving a feed of glass forming material and producing molten glass, the burner and furnace comprising a melting system. The melting system has a variable system vibration and / or oscillation due to the nature of submerged combustion. One method includes predicting a value of at least one property, such as viscosity, of the molten glass using the variable system vibration and / or oscillation.

Owner:JOHNS MANVILLE CORP

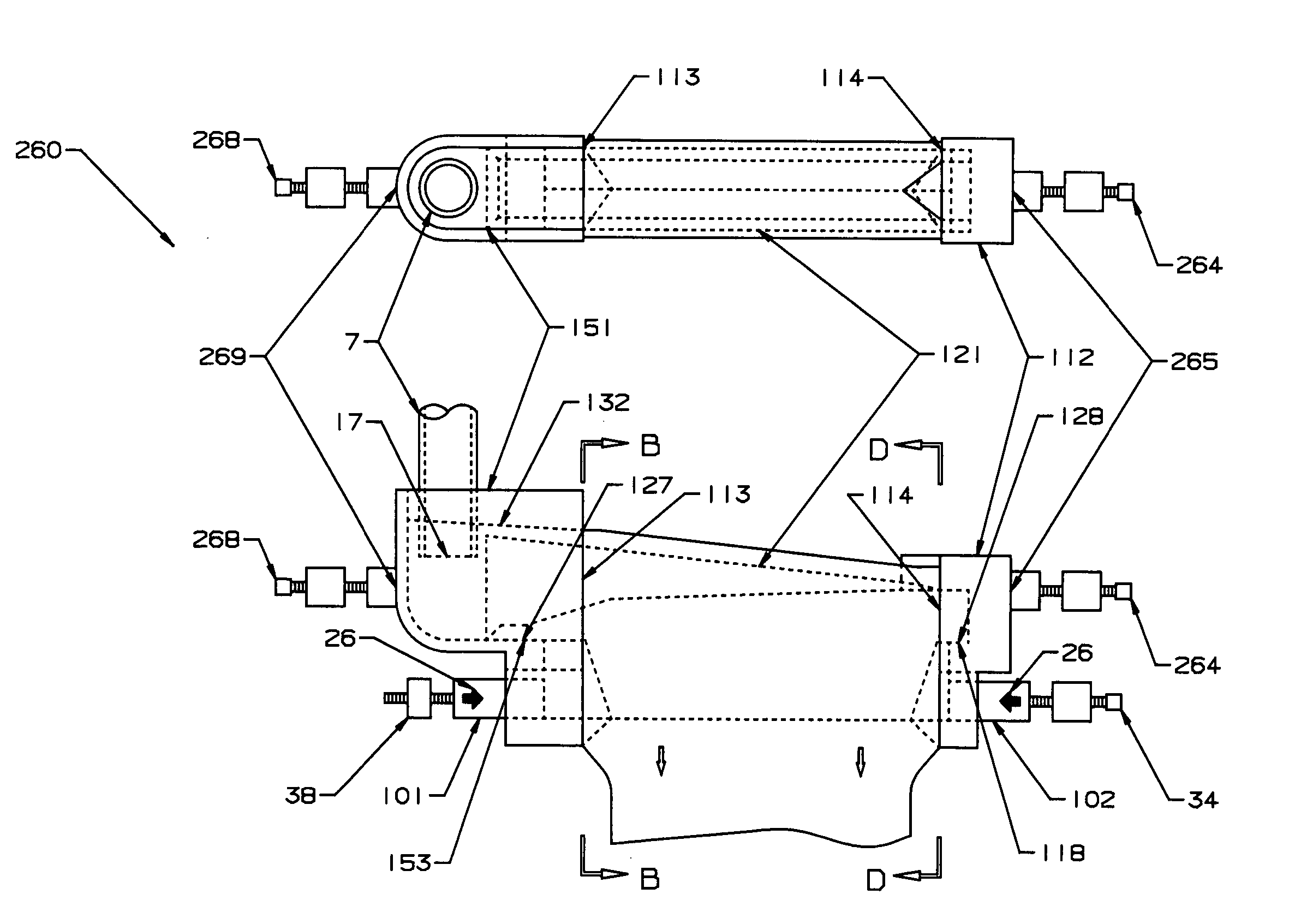

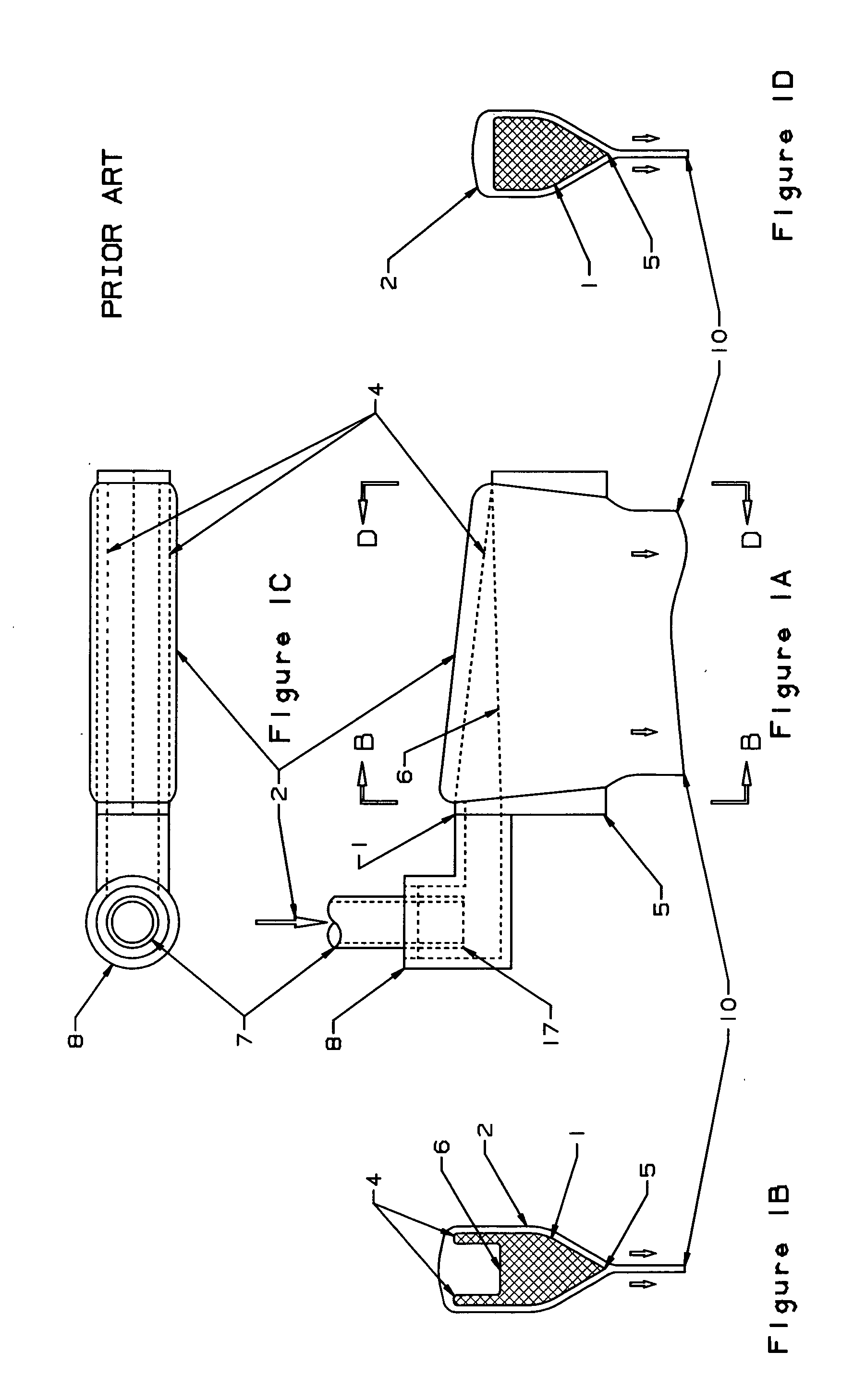

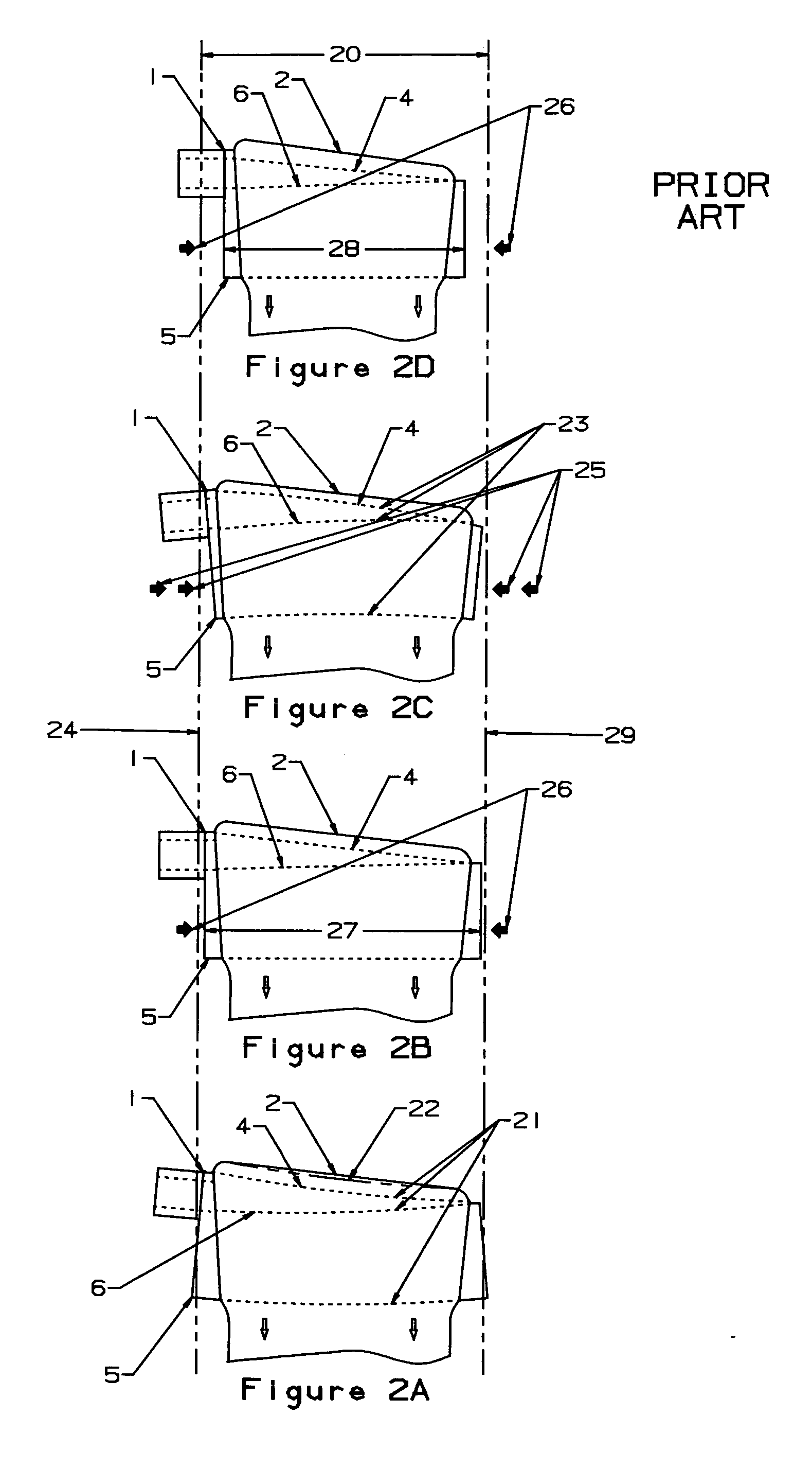

Sheet width control for overflow downdraw sheet glass forming apparatus

InactiveUS20050183455A1Minimize distortionKeep widthBlowing machine gearingsGlass furnace apparatusFlat glassManufactured apparatus

Owner:CORNING INC

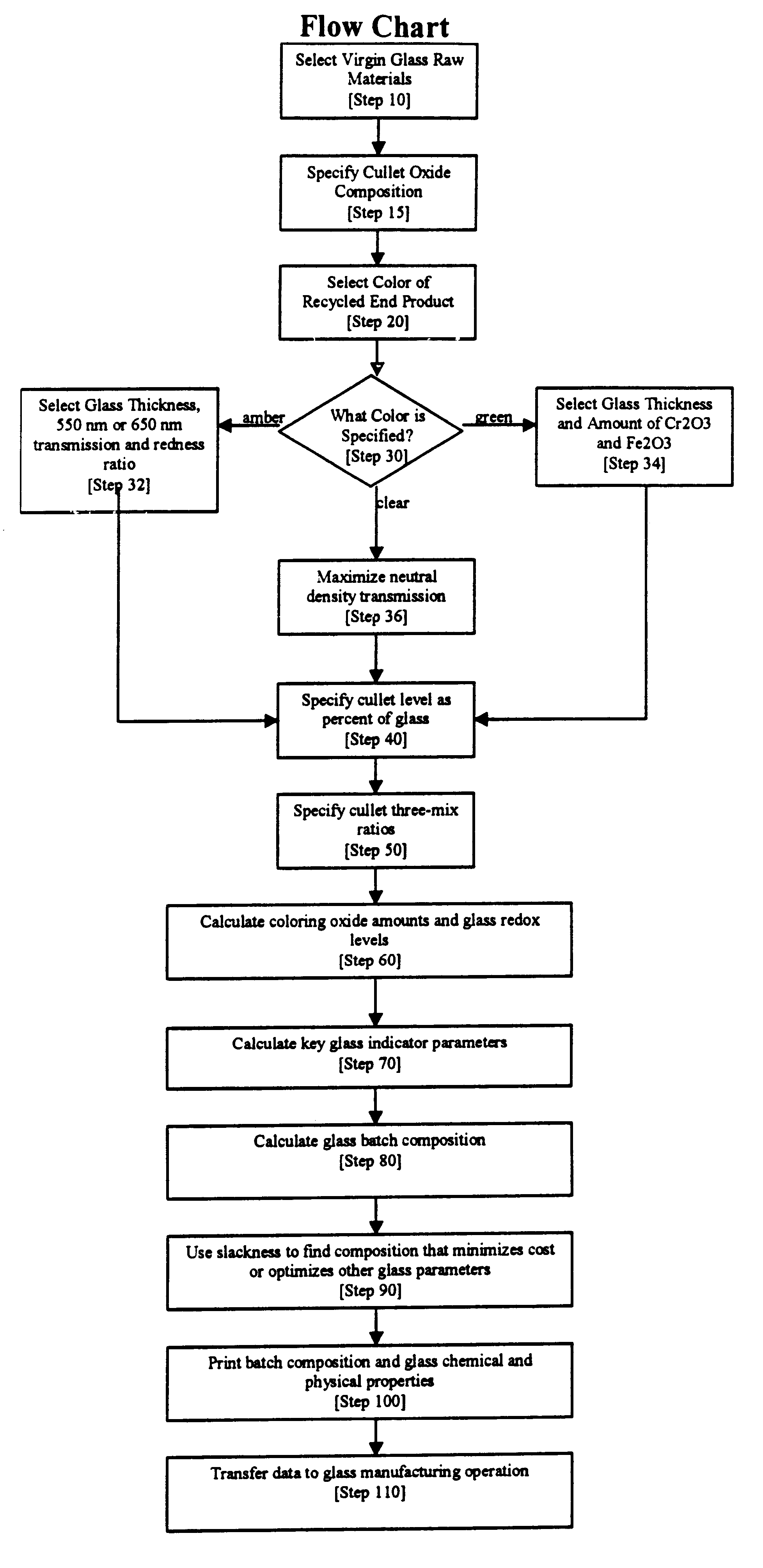

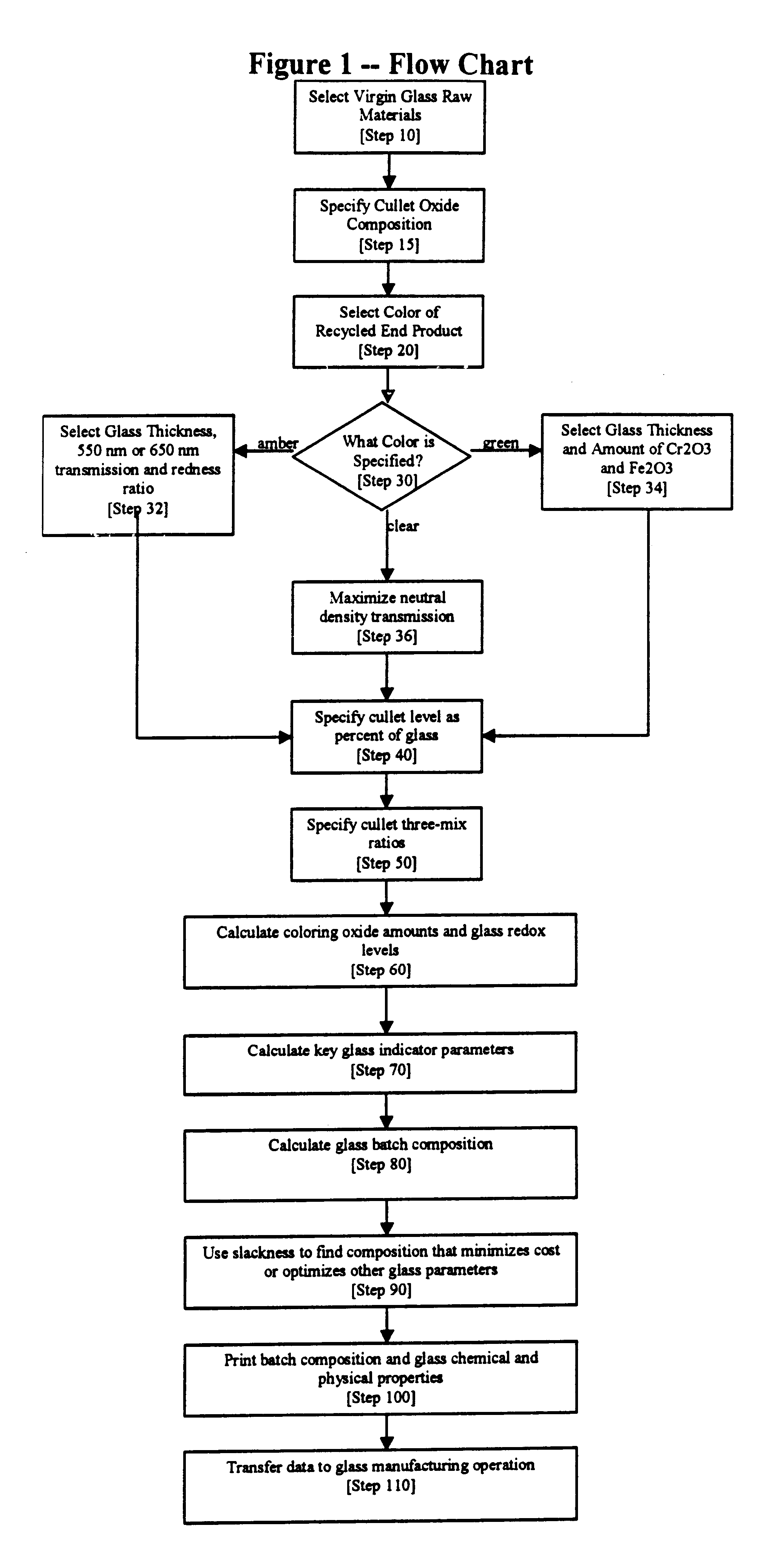

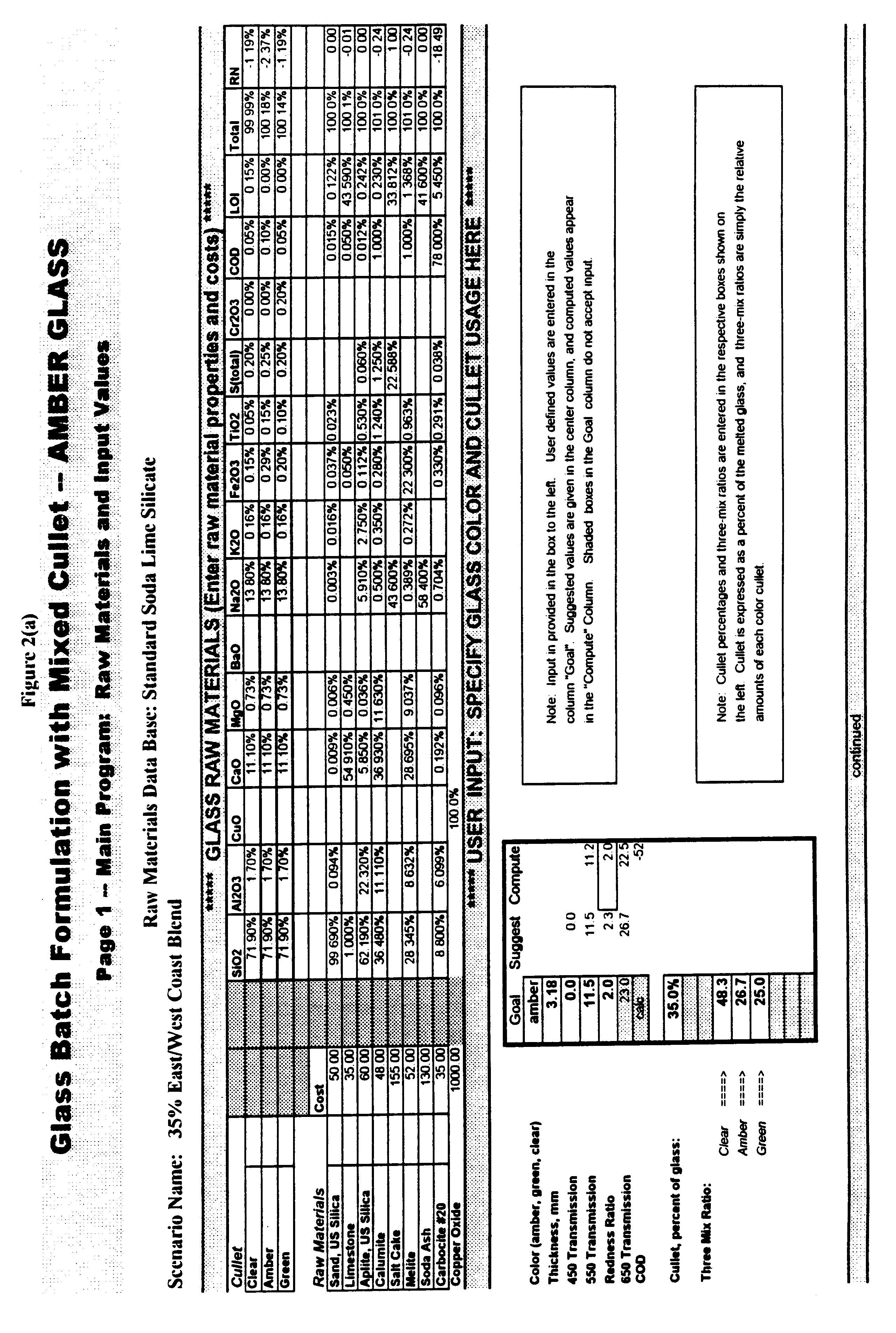

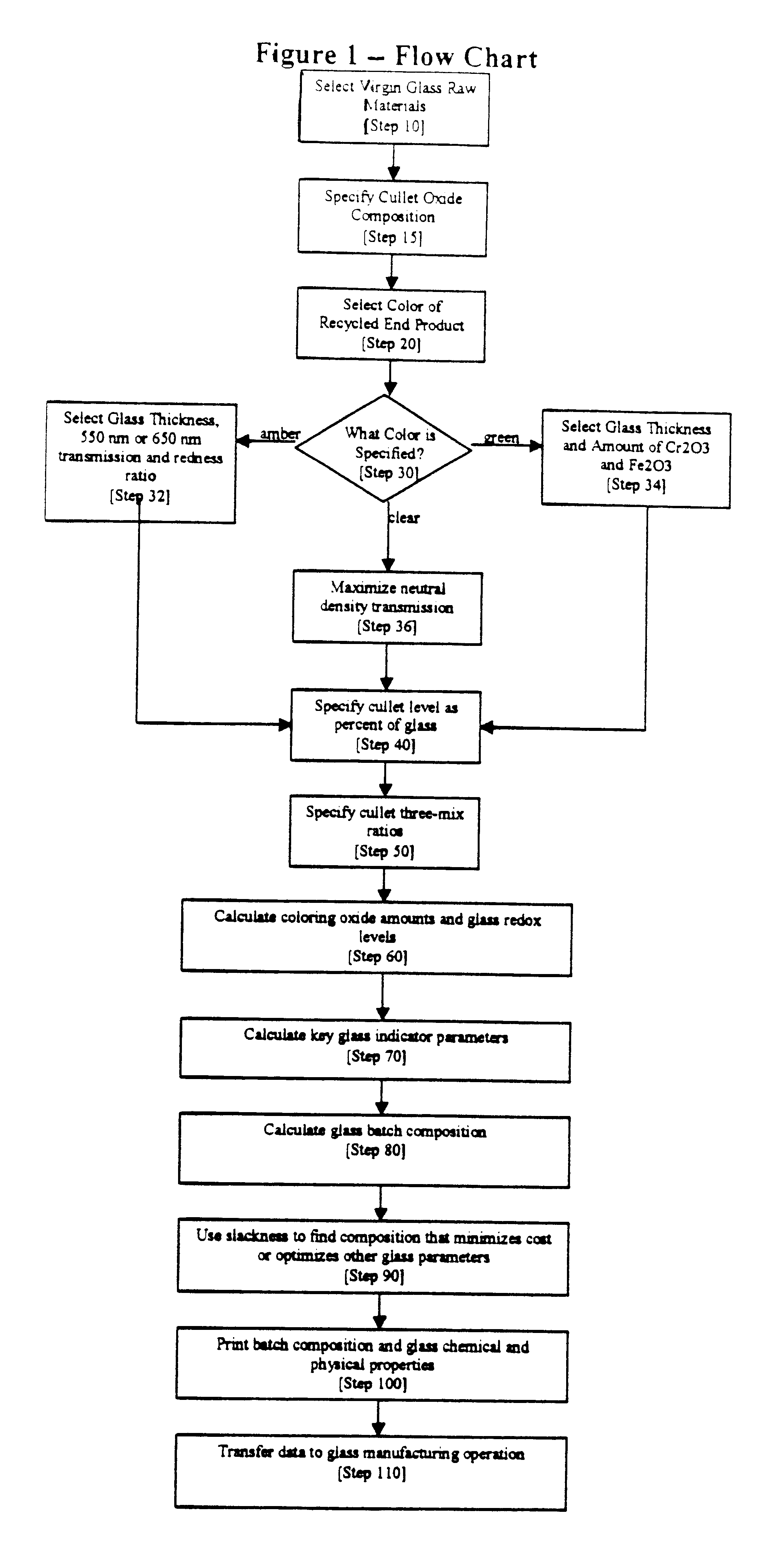

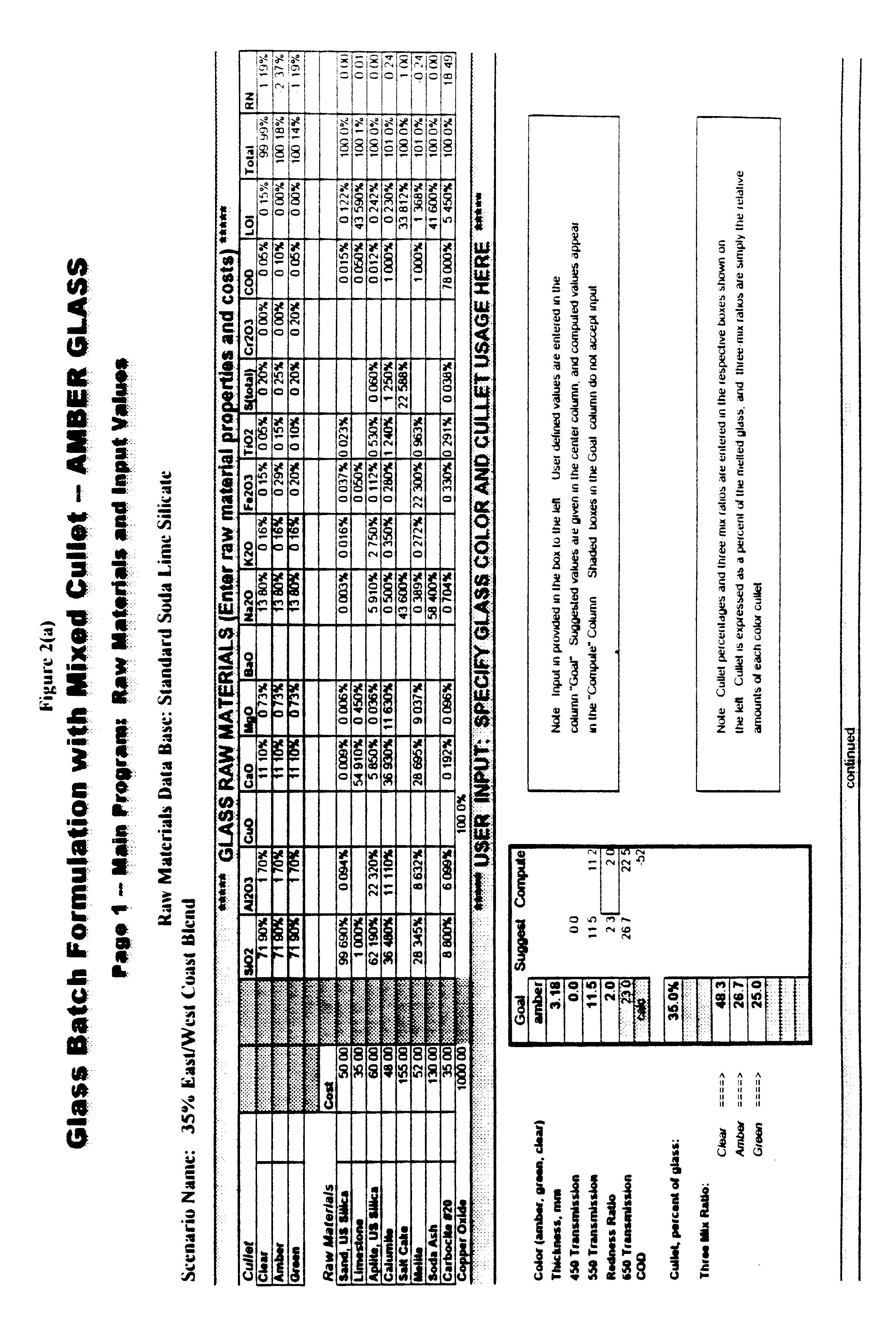

Method of recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6230521B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsOxidation-Reduction AgentBottle

An automated method for recycling mixed colored cutlet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

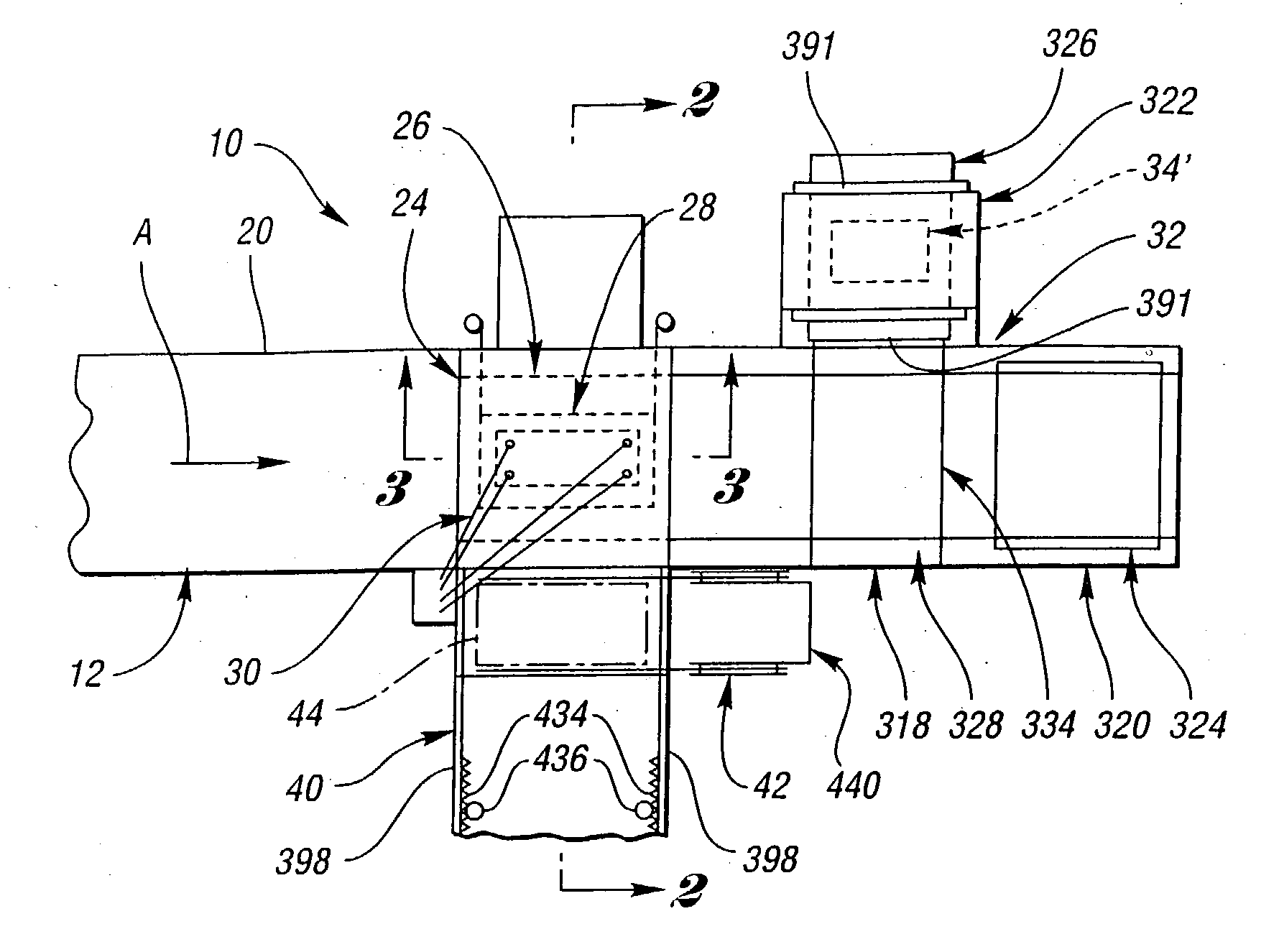

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070068197A1Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Lithium silicate amorphous or crystalline glass overlaying top surface of zirconia and preparation methods thereof

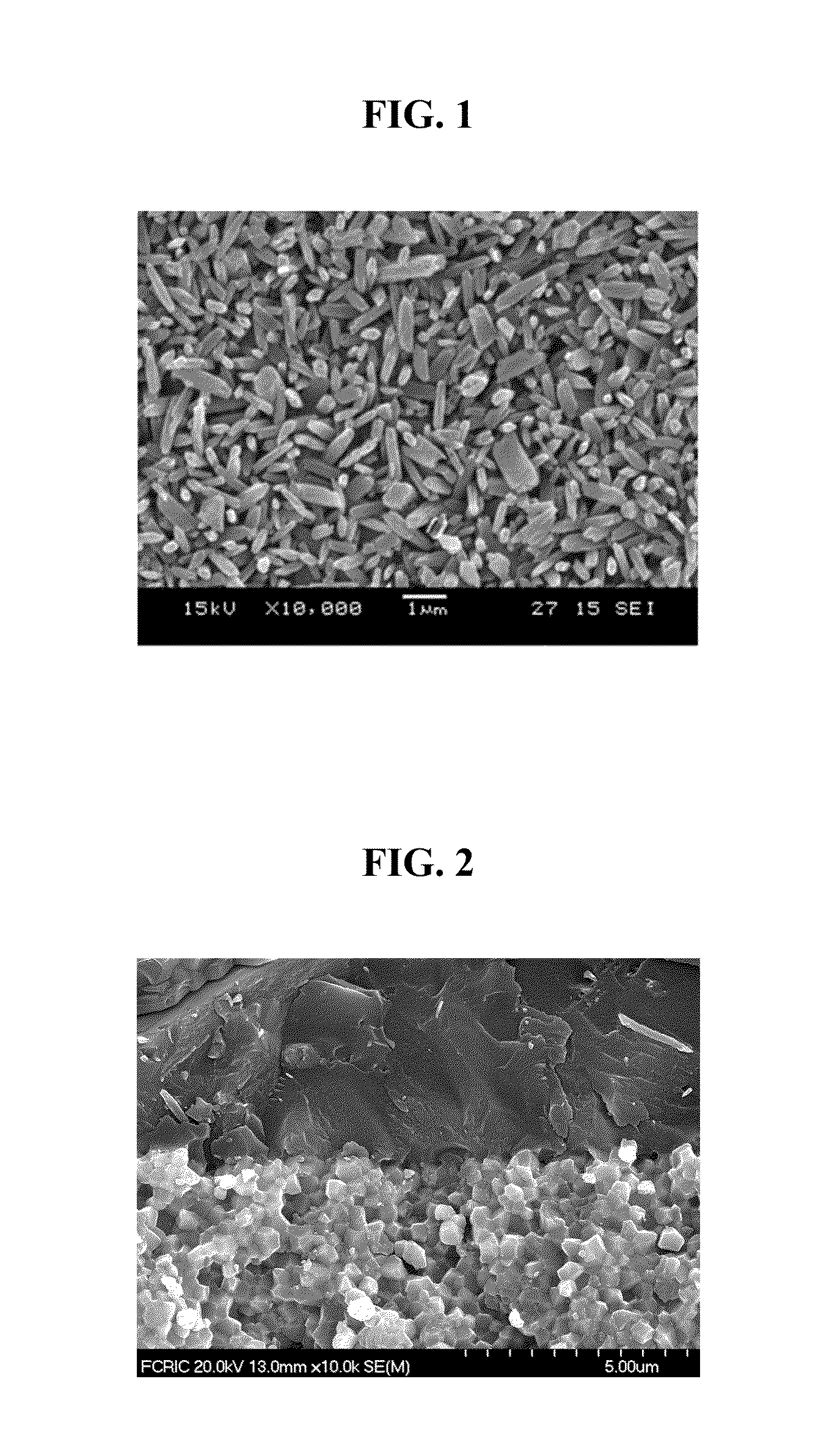

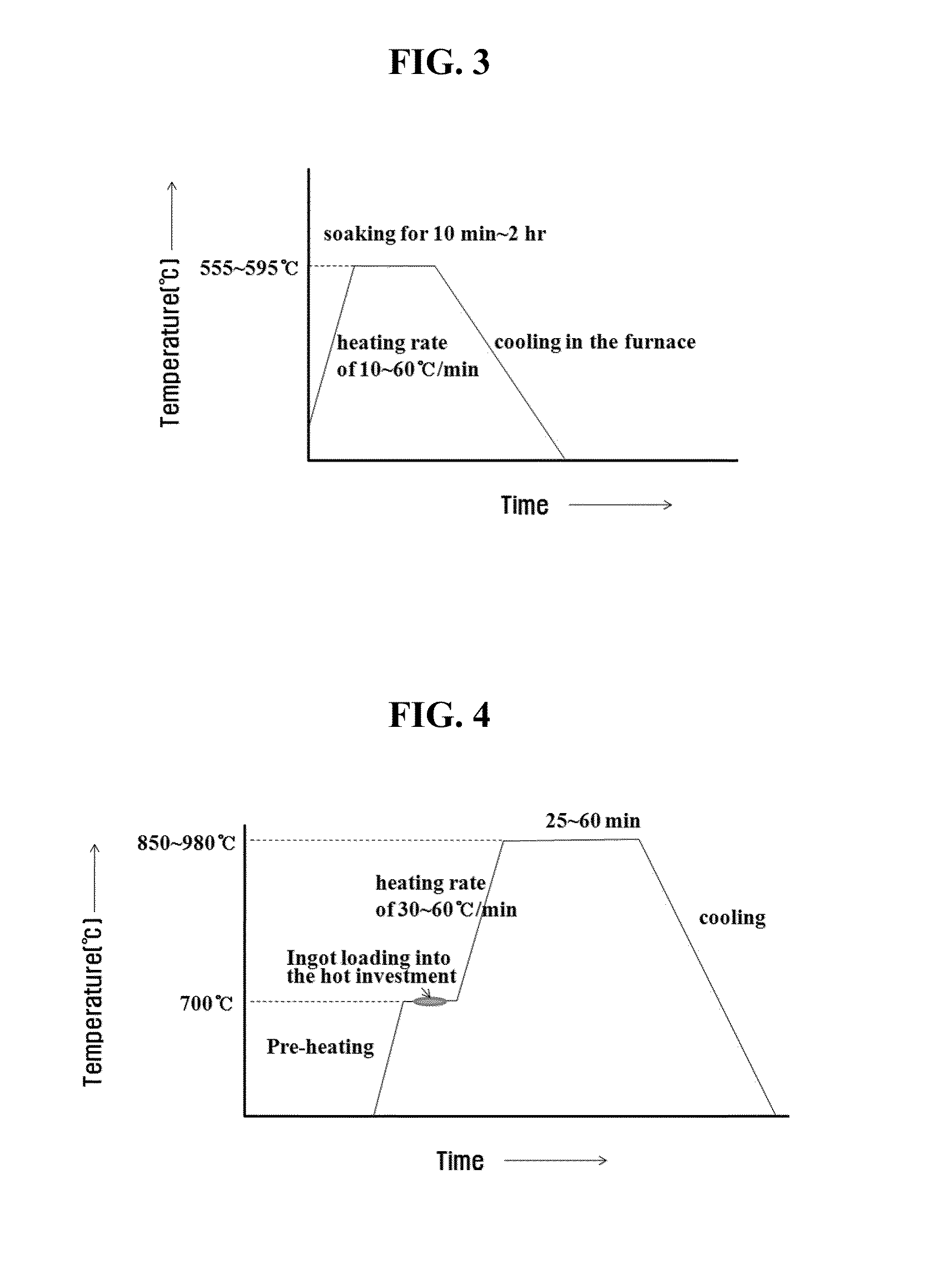

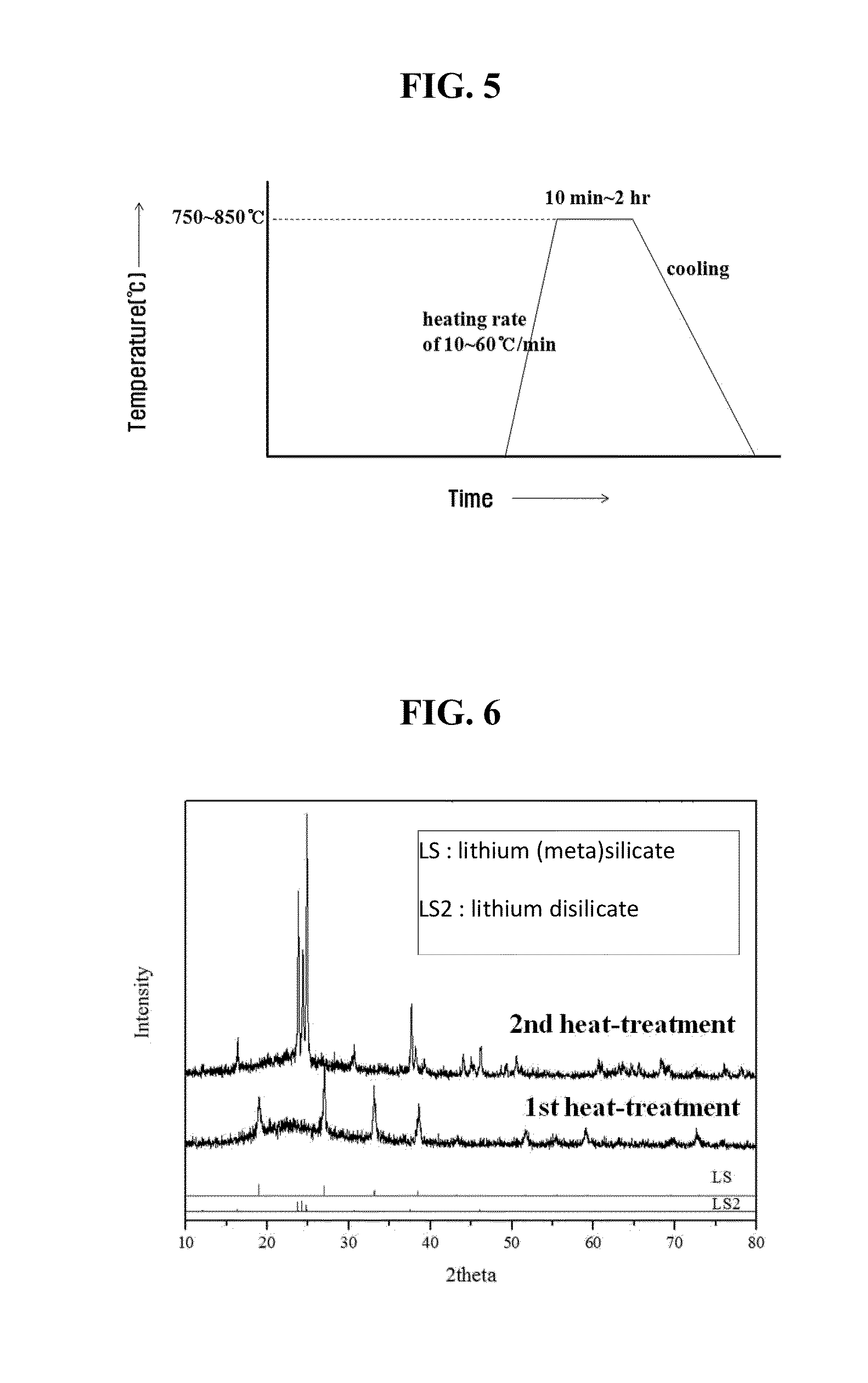

ActiveUS20150104655A1High bonding strengthMore flexural strengthBlowing machine gearingsGlass furnace apparatusLithiumVitrification

Exemplary embodiments of the present disclosure provide a lithium silicate crystalline or amorphous glass overlaying the top surfaces of zirconia and the manufacturing process thereof. More specifically, exemplary embodiments of the present disclosure provide a lithium silicate glass or lithium silicate crystalline glass with high light transmittance and good coloring characteristics and the manufacturing process thereof, which overlays the top surface of zirconia with high mechanical strength, frameworks, or copings.The lithium silicate crystalline or amorphous glass may include 10-15 wt % Li2O, 71.1-85.0 wt % SiO2, 2-5 wt % P2O5 working as nuclear formation agent, 1-5 wt % Al2O3 to increase glass transition temperature and softening temperature, as well as chemical durability of the glass, and 0.01-1.0 wt % ZrO2 which increases the binding strength of the zirconia substructure.

Owner:HAAS & CO GMBH

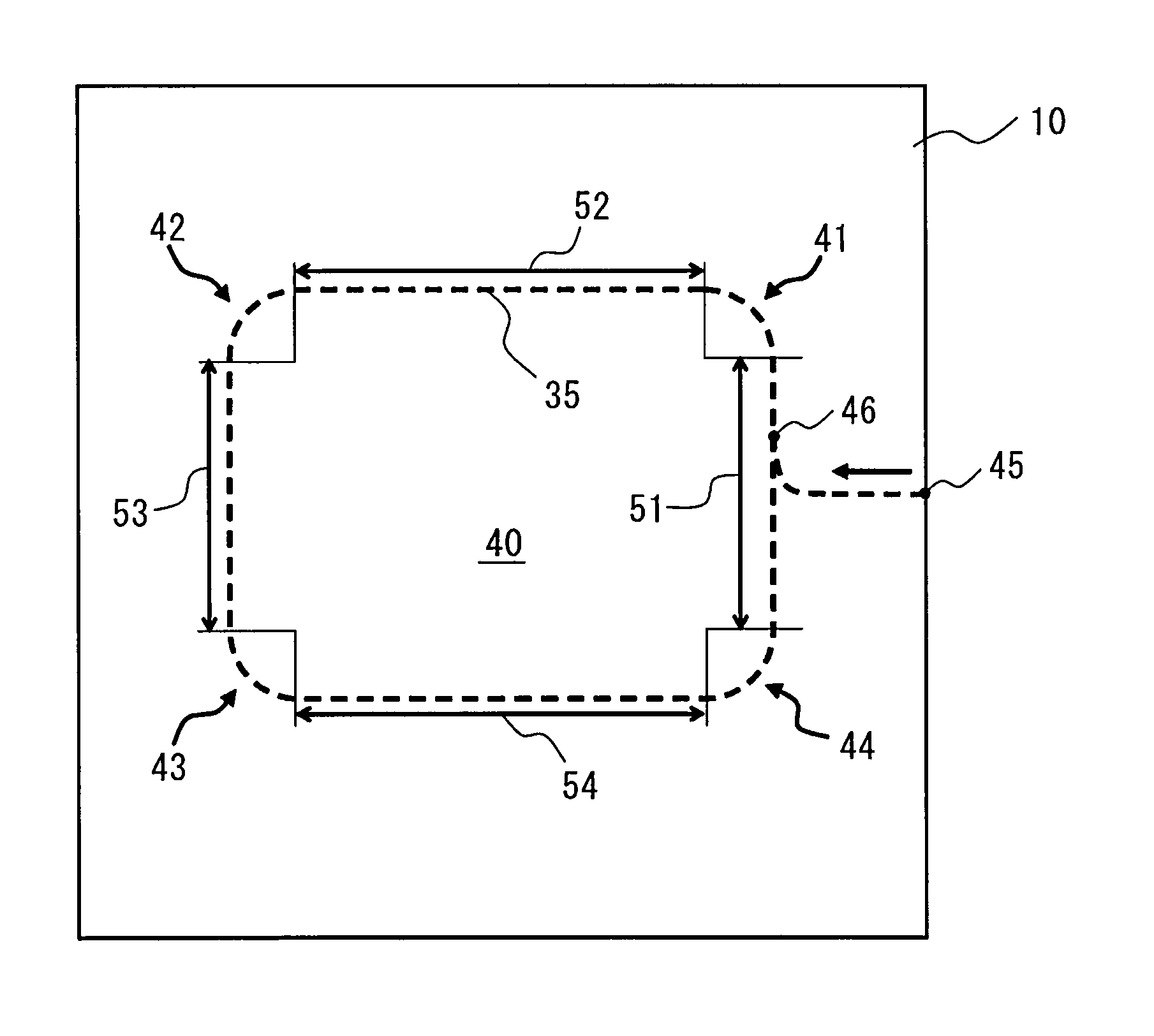

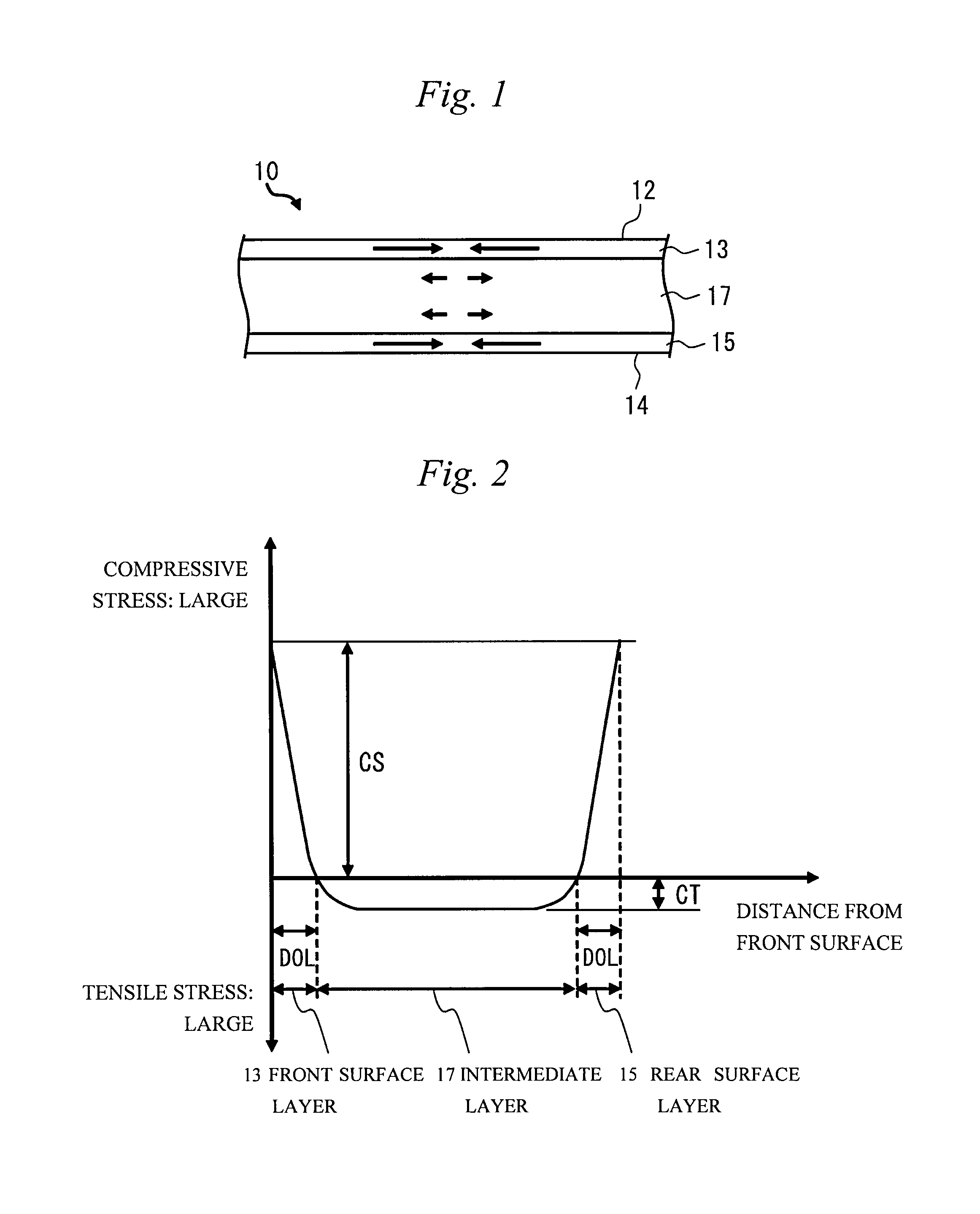

Cutting method for reinforced glass plate and reinforced glass plate cutting device

InactiveUS20140165652A1Quality improvementBlowing machine gearingsGlass reforming apparatusSurface layerOptoelectronics

The invention relates to a method for cutting a strengthened glass sheet in which, when a strengthened glass sheet 10 including a front surface layer 13 and a rear surface layer 15 which have a residual compressive stress, and an intermediate layer 17 which has an inside residual tensile stress, is cut by moving an irradiation region 22 of a laser beam so as to have a predetermined curvature radius, an irradiation energy per unit irradiation area of a laser beam 20 to be irradiated on the strengthened glass sheet 10 is increased as a curvature radius decreases. Thereby, it is possible to cut a strengthened glass sheet using a laser beam without causing a deterioration of quality.

Owner:ASAHI GLASS CO LTD

Method and apparatus for machining diamonds and gemstones using filamentation by burst ultrafast laser pulses

InactiveUS20150121960A1Efficient cuttingLess-waste is producedBlowing machine gearingsFine working devicesNon ablativeFilamentation

A non-ablative laser machining method and apparatus for cutting facets of a diamond, using a material machining technique involving filamentation by burst ultrafast laser pulses well suited to mass production. Coupled with 3D modeling and the computerized laser machining system, complex geometric surfaces can be created on the diamond. The facets of the diamond need not be planar in configuration, and may incorporate acute as well as oblique angles. This method minimizes the need for diamond polishing, speeds up production, and realizes great reductions in the quantity of lost material from the cutting process.

Owner:ROFIN SINAR TECH

Overflow downdraw glass forming method and apparatus

InactiveUS7681414B2Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

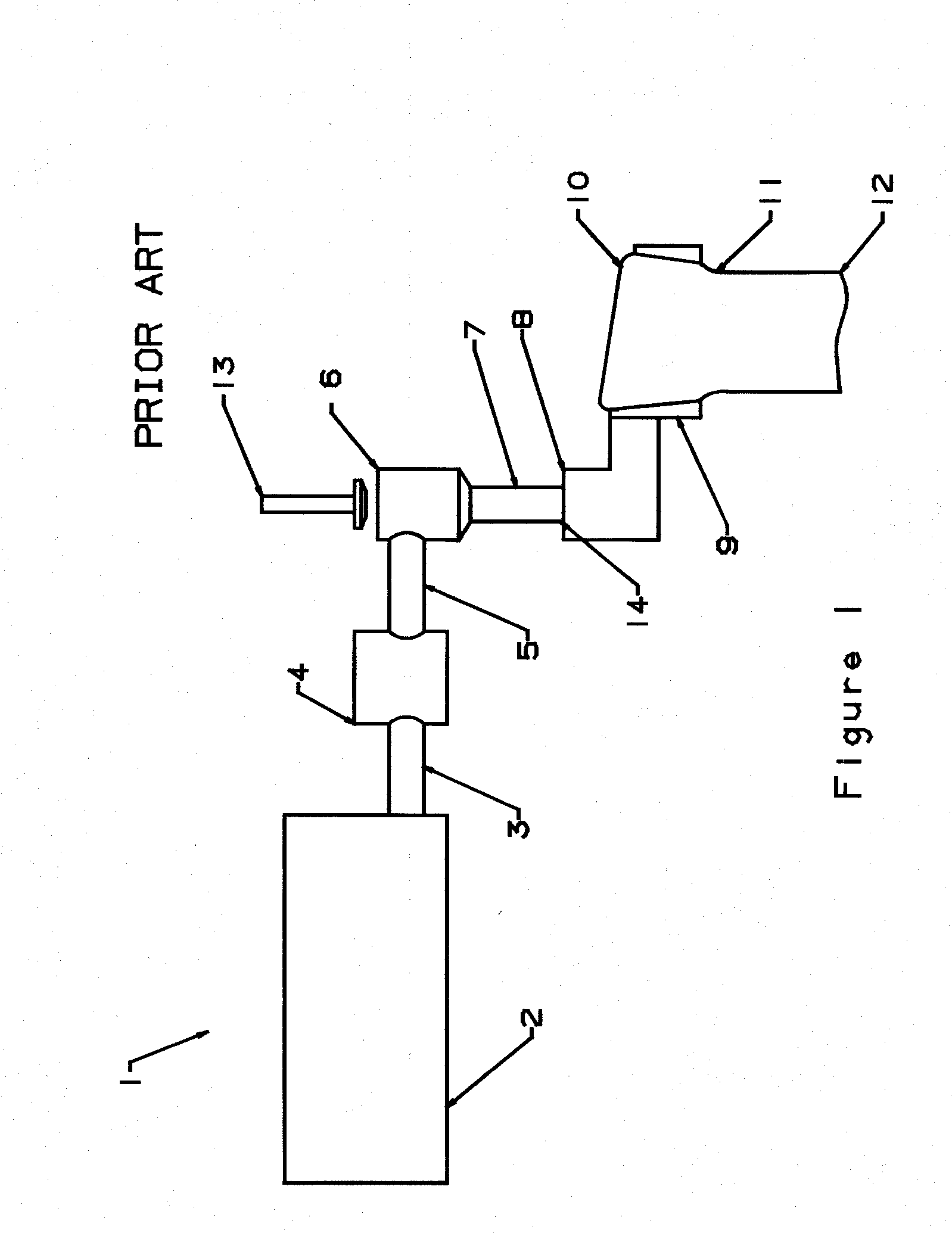

Method and apparatus for preparation of molded glass

Owner:HOYA CORP

Method for forming heated glass sheets

Owner:GLASSTECH

Automated process for recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6763280B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsManufactured materialRedox

An automated method for recycling mixed colored cullet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

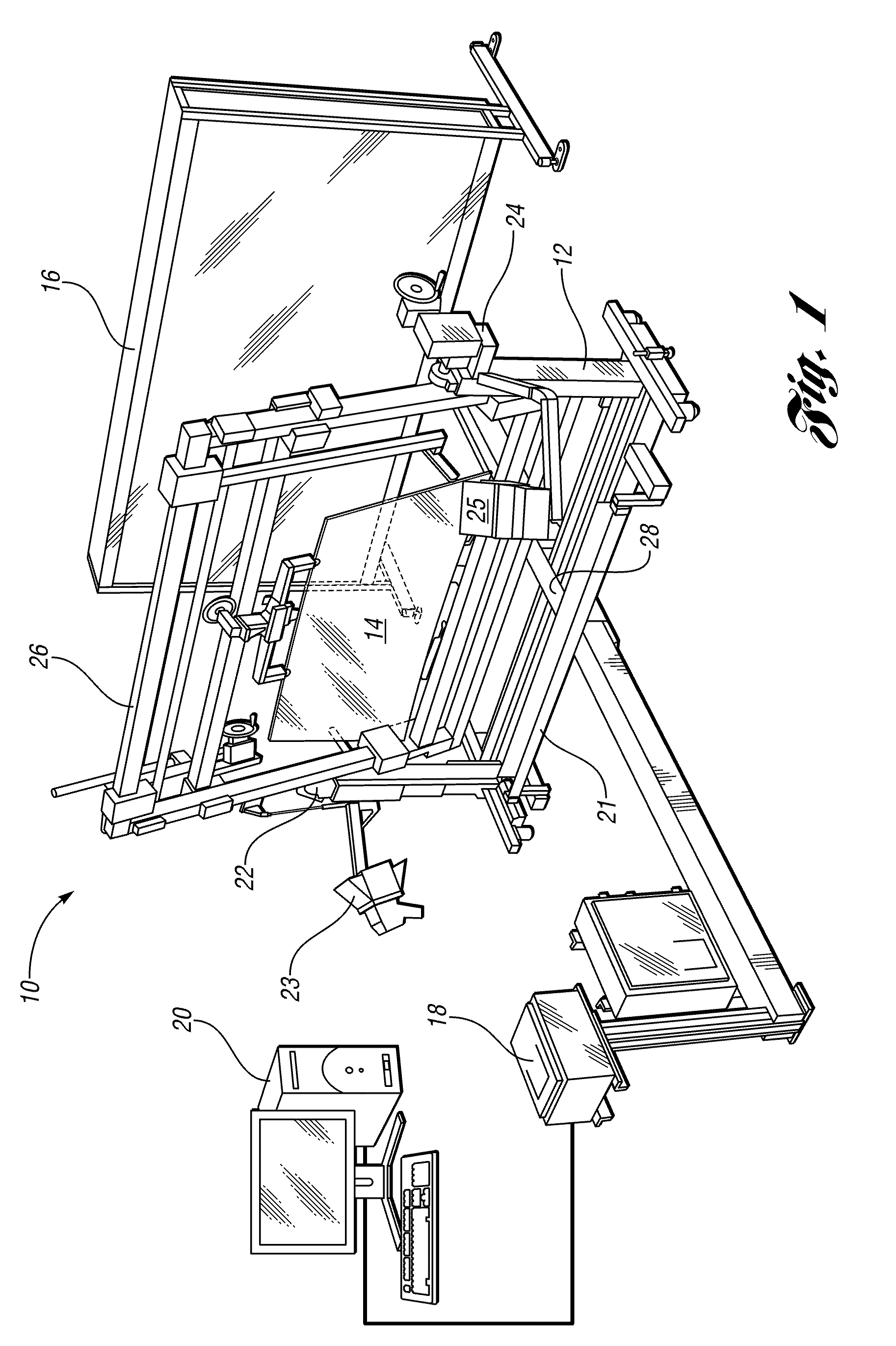

Method and apparatus for measuring transmitted optical distortion in glass sheets

ActiveUS20090282871A1Blowing machine gearingsMaterial analysis by optical meansSurface markerDot matrix

An apparatus and associated method for measuring transmitted optical distortion in a glass sheet includes a glass stand which receives a glass sheet for mounting between a background screen which includes a matrix of spaced apart dots, and a digital camera which captures (1) an image of the glass sheet surface, and (2) an image of the dot matrix transmitted through the glass sheet. The captured images are downloaded to a computer that is suitably programmed to analyze the image data to (1) determine the presence of any markings or elements on the surface of the glass sheet that should be isolated from the dot matrix image, (2) modify the background image to eliminate the image data corresponding to any such surface markings or elements from the image, and (3) determine characteristics indicative of optical distortion in the modified image of the dot matrix background transmitted through the glass sheet.

Owner:GLASSTECH

Methods of using a submerged combustion melter to produce glass products

A method comprises flowing an oxidant and a fuel into a submerged combustion burner in a glass tank furnace, the glass tank furnace receiving a feed of glass forming material and producing molten glass, the burner and furnace comprising a melting system. The melting system has a variable system vibration and / or oscillation due to the nature of submerged combustion. One method includes predicting a value of at least one property, such as viscosity, of the molten glass using the variable system vibration and / or oscillation.

Owner:JOHNS MANVILLE CORP

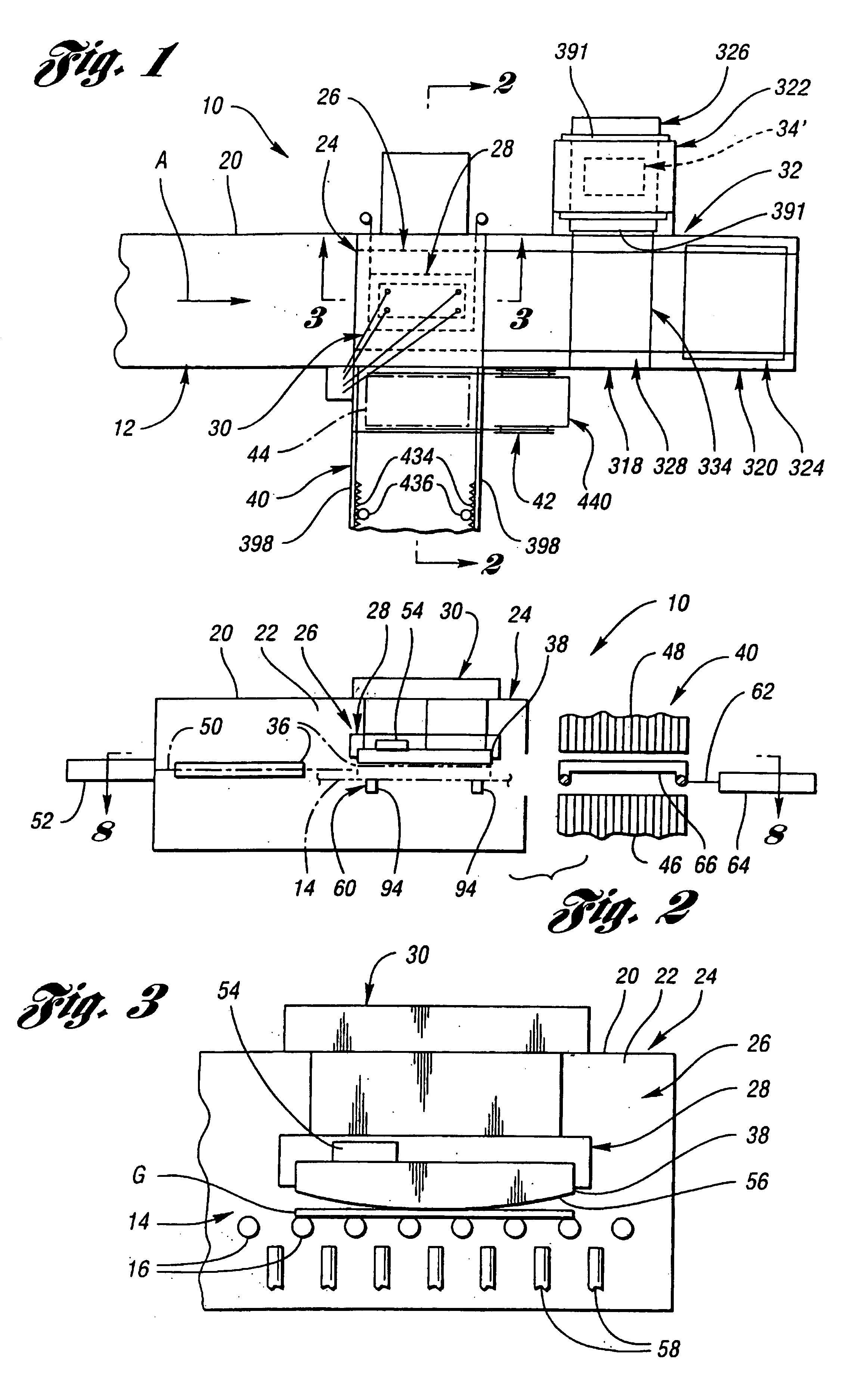

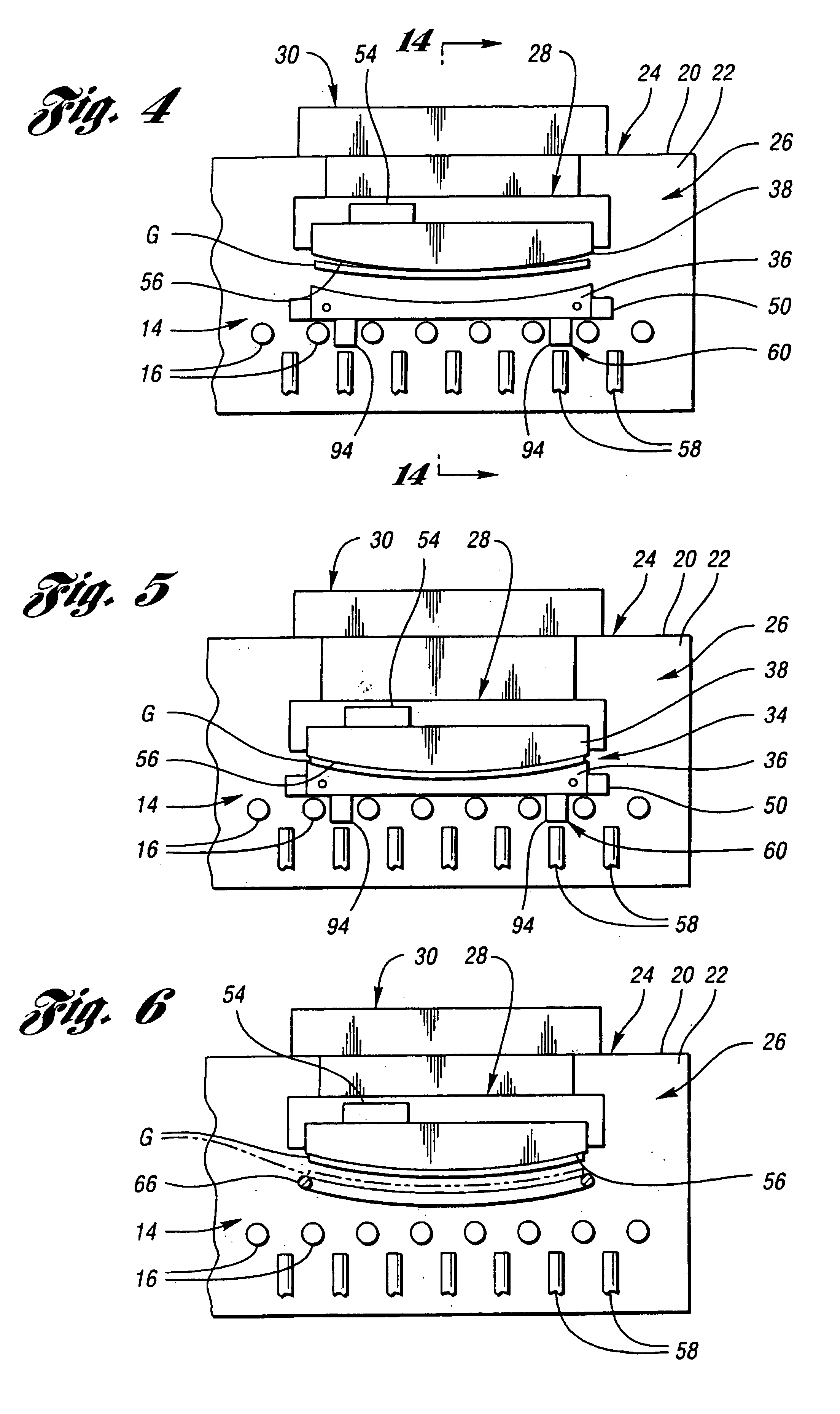

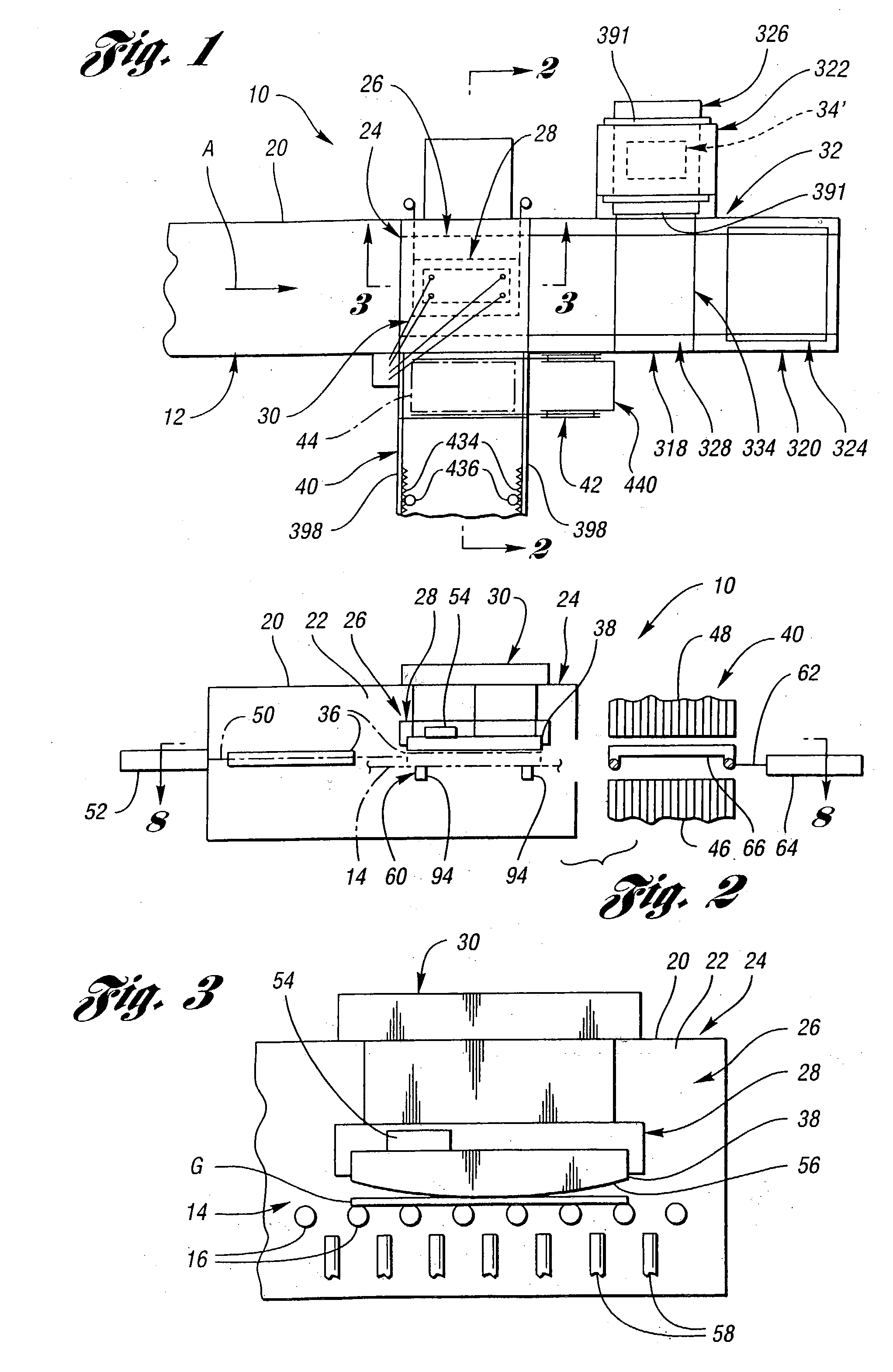

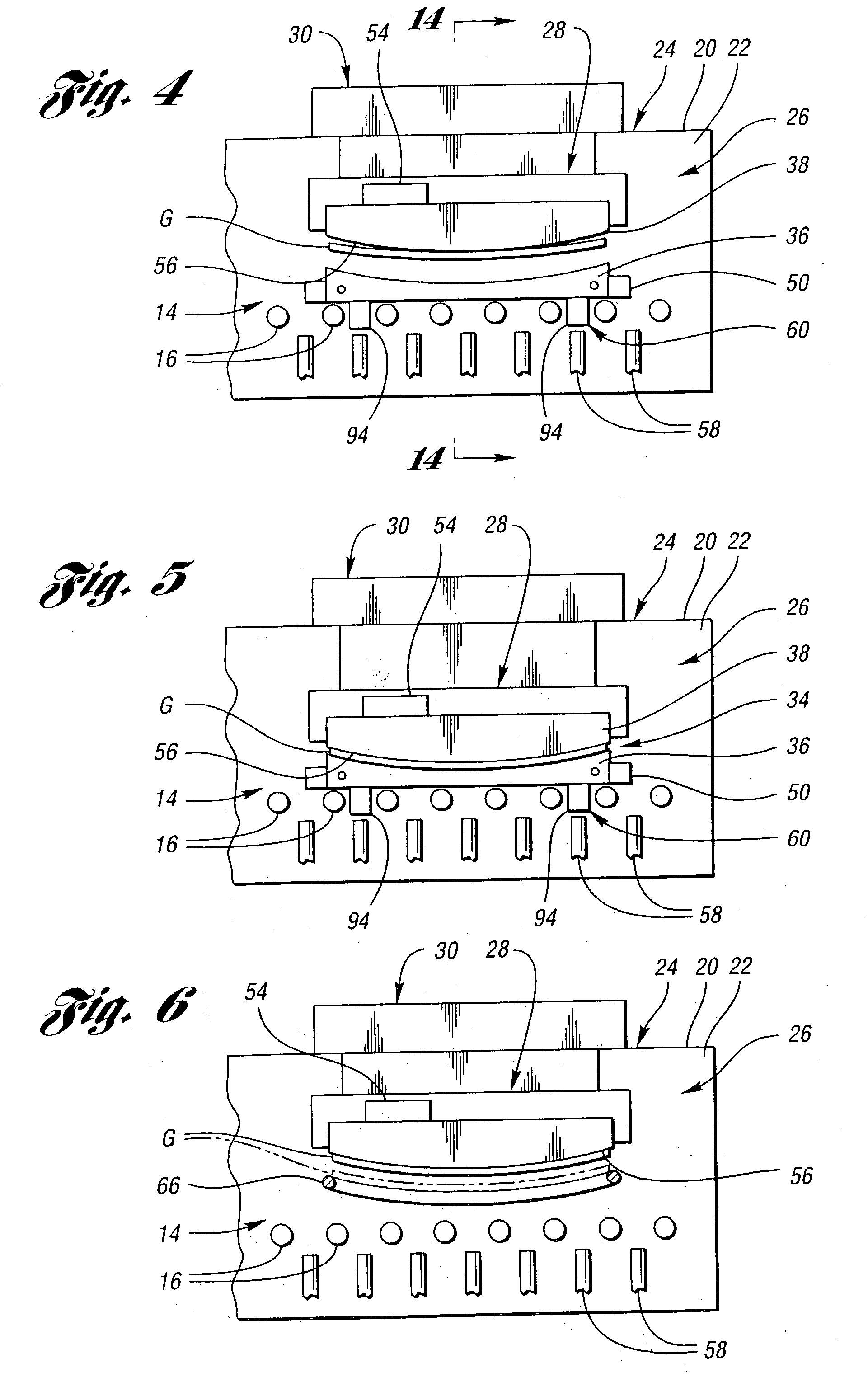

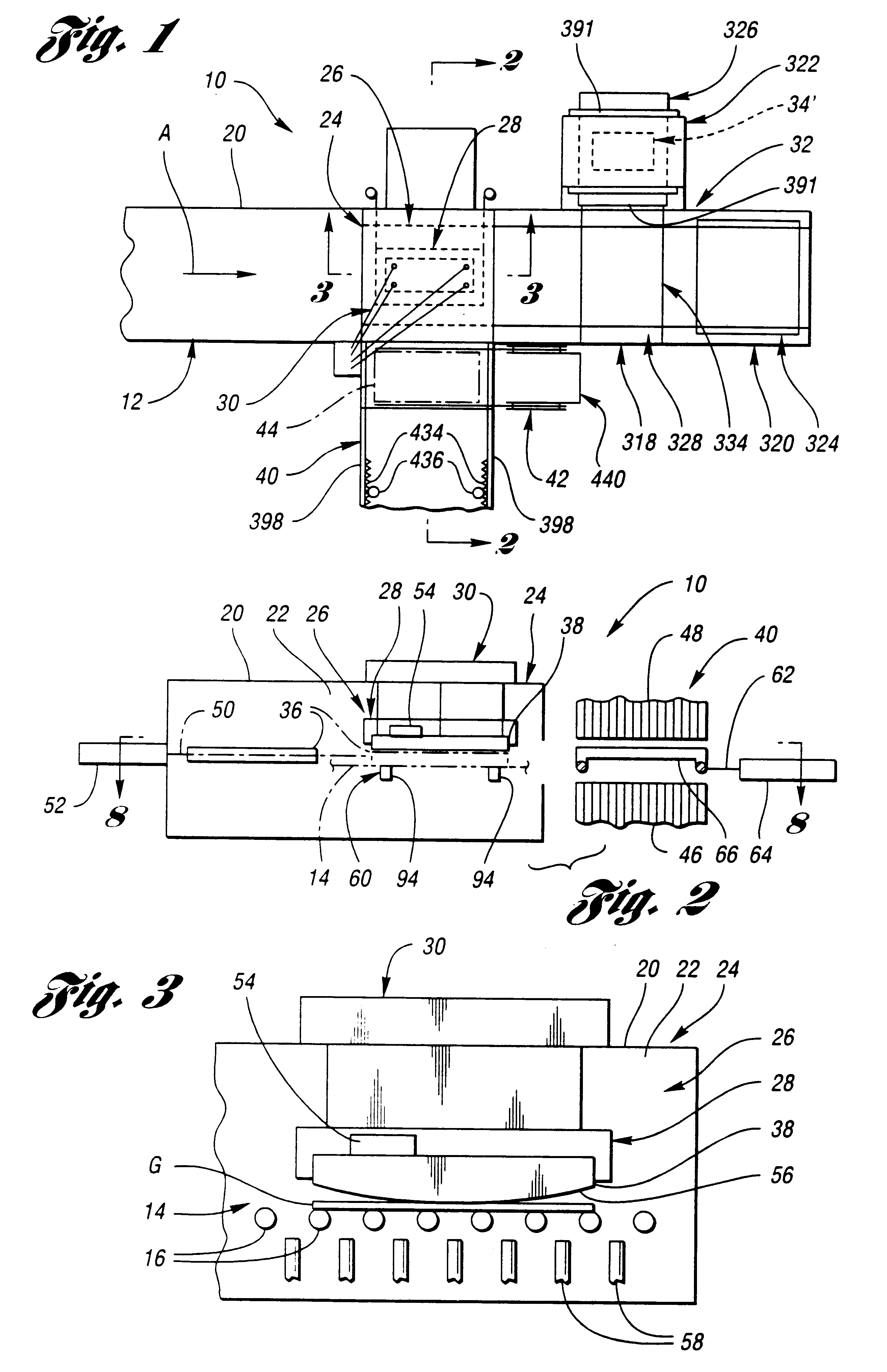

Method for forming heated glass sheets

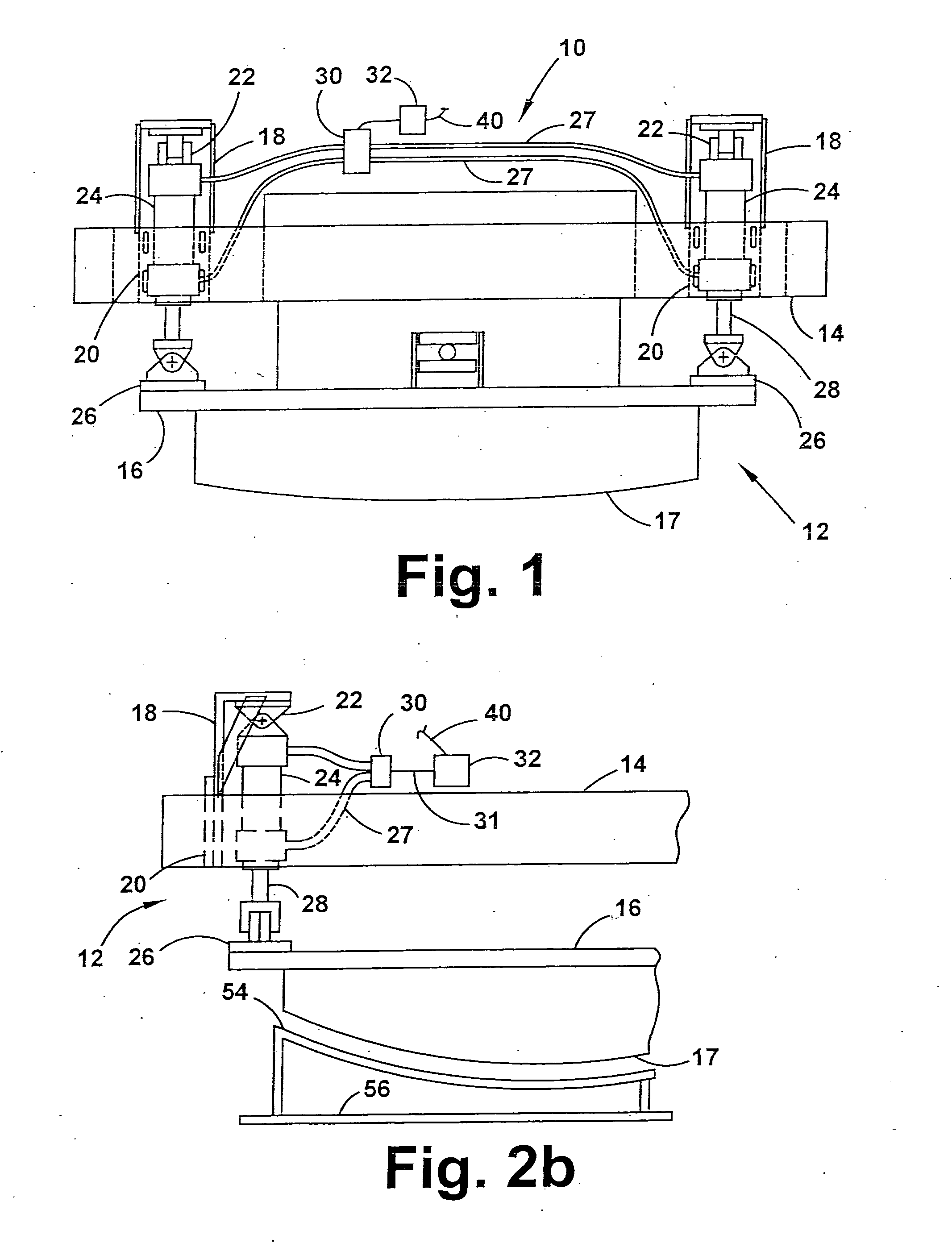

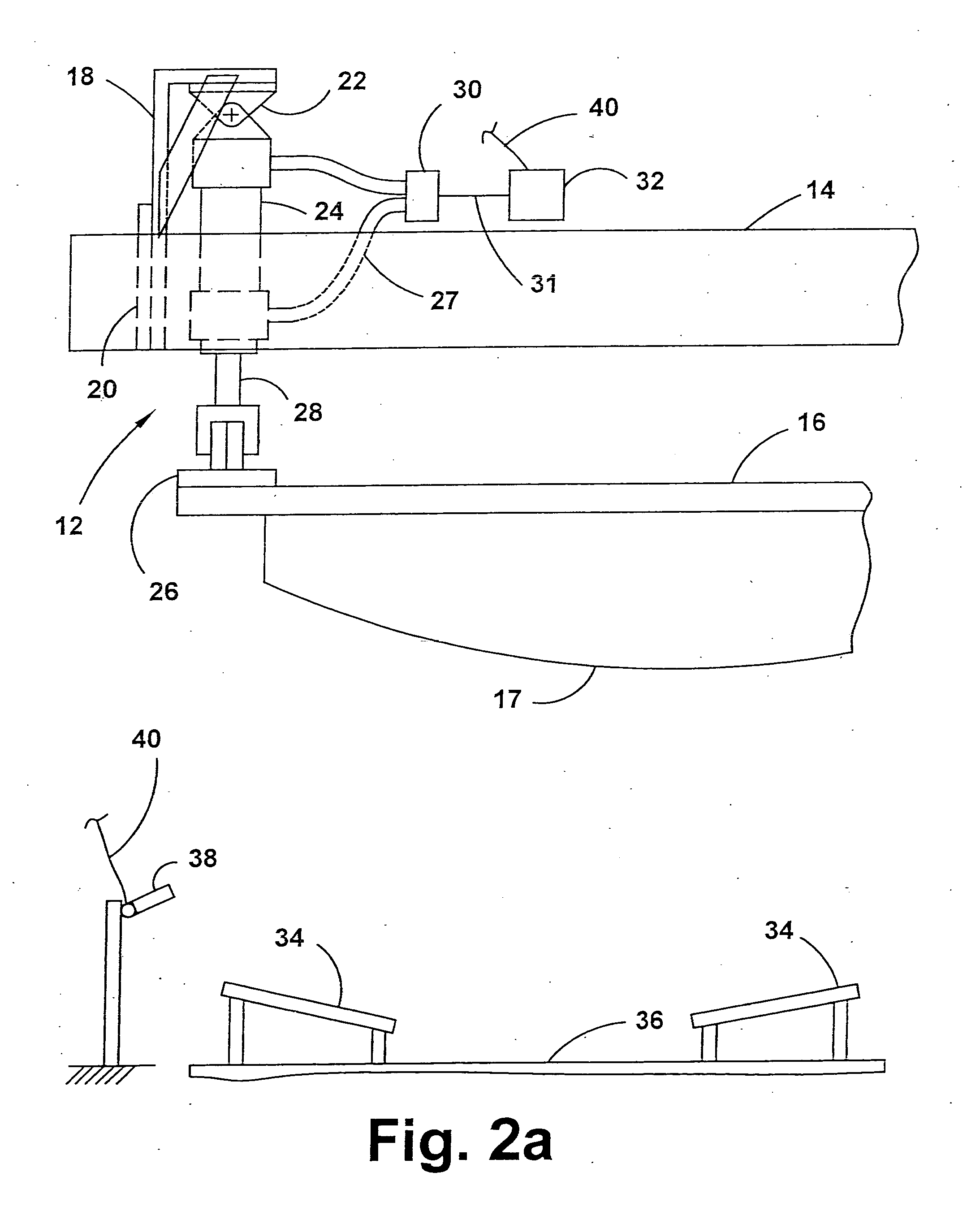

InactiveUS20030106340A1Blowing machine gearingsGlass drawing apparatusMechanical engineeringGlass sheet

Apparatus (26) and a method for forming heated glass sheets in a heated chamber (22) of a housing (20) includes an upper mold support assembly (28) for supporting an upper mold (38) within the heated chamber for cyclical vertical movement between upper and lower positions. A lower mold shuttle (50) supports a lower mold (36) for movement between an idle position horizontally spaced from the upper mold and a use position below the lower mold. The apparatus also includes a lower mold support assembly (60) to which the lower mold is transferred from the lower mold shuttle (50) to provide support thereof while permitting horizontal alignment with the upper mold upon each cycle of downward movement to form a heated glass sheet between the molds. The lower mold shuttle (50) is supported by vertically movable rollers (70) to provide the transfer between the lower mold shuttle and the lower mold support assembly (60). A quench station (40) includes a quench shuttle (62) that moves a quench ring (66) to receive the formed glass sheet from the upper mold (38) and to then move the formed glass sheet between lower and upper quench modules (46,48) of the quench station for quenching.

Owner:GLASSTECH

Sheet glass forming apparatus

InactiveUS20050138966A1Reduce unevennessBlowing machine gearingsGlass furnace apparatusFlat glassThumb opposition

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

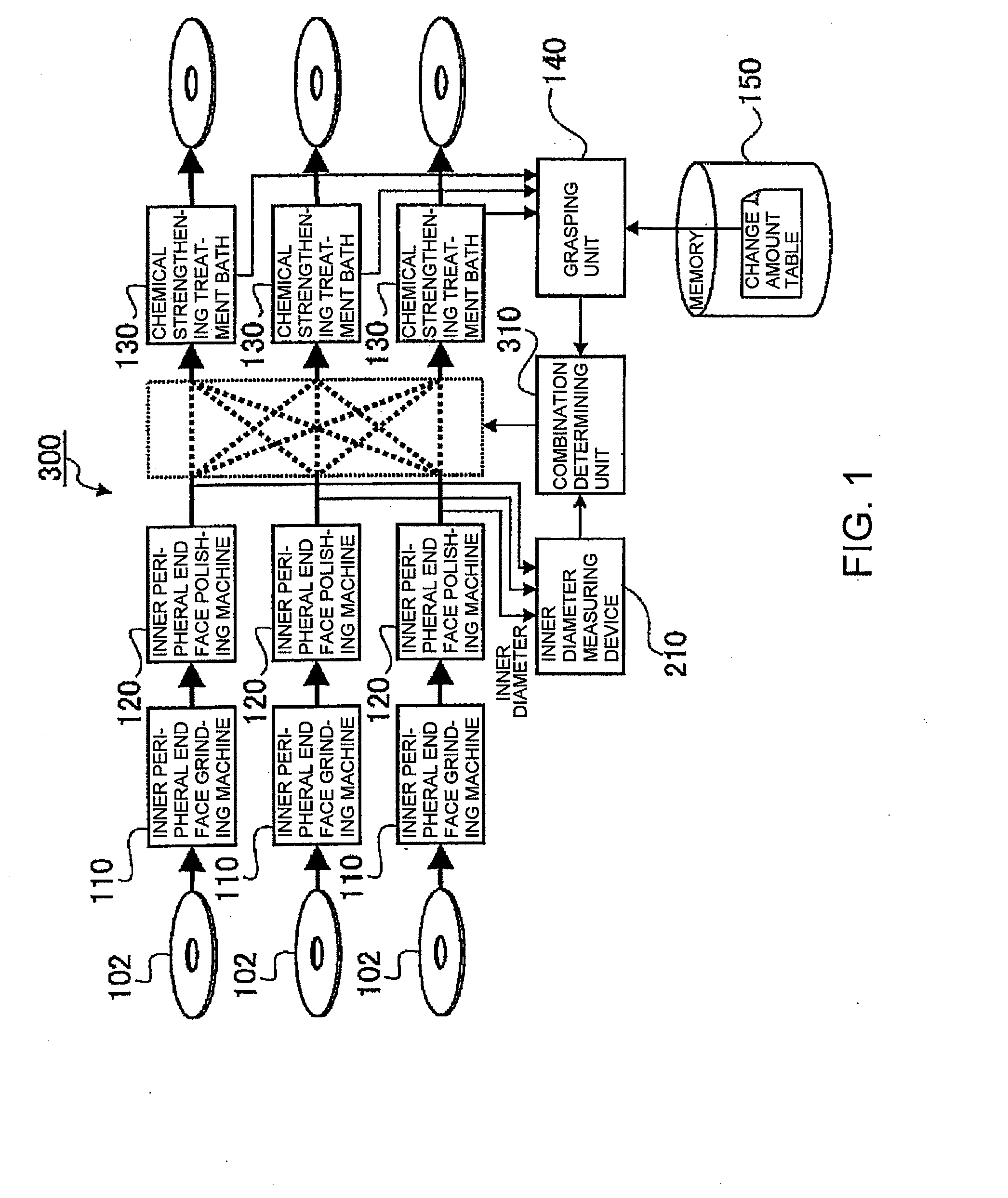

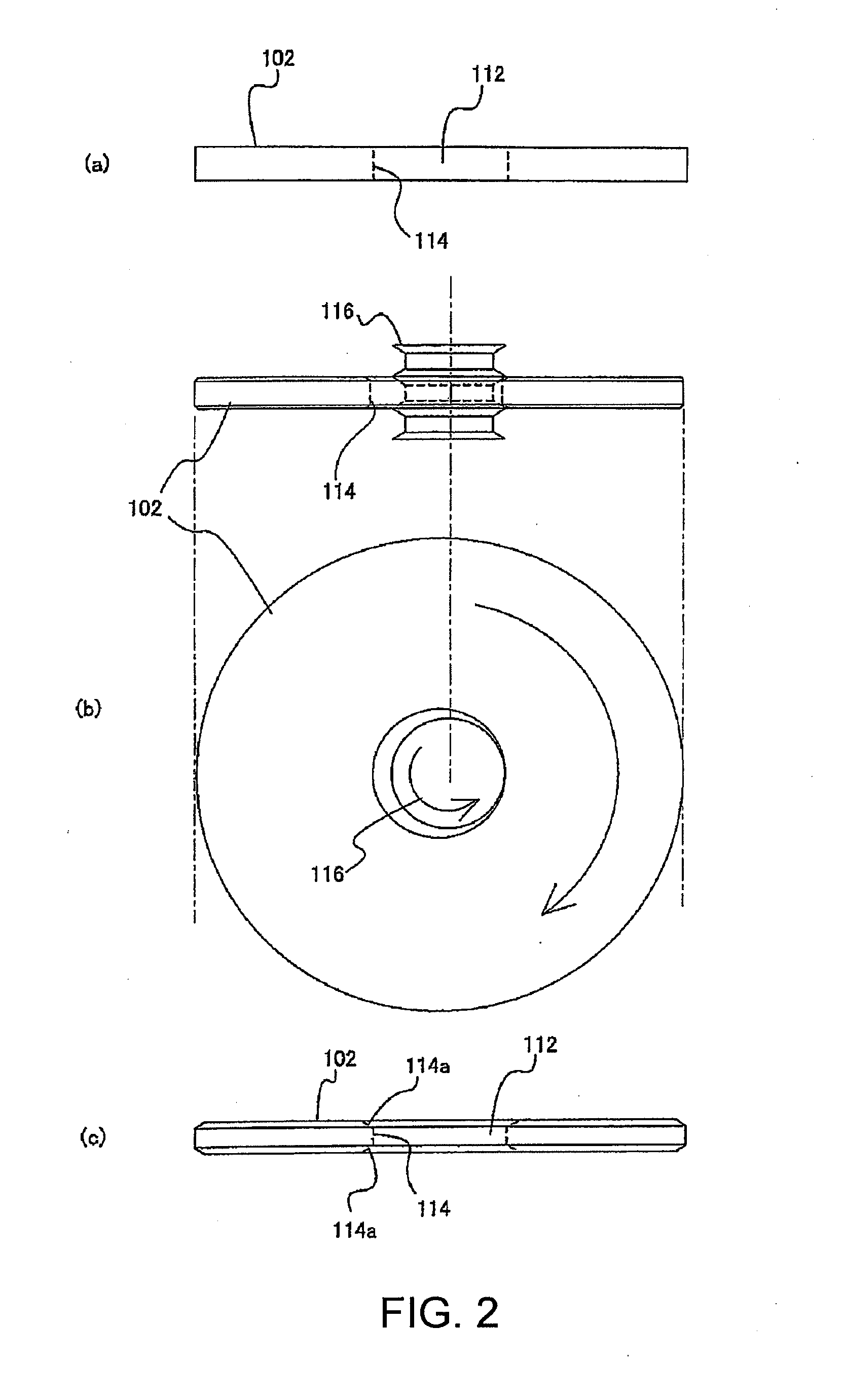

Method of manufacturing glass substrate for magnetic disk and system for manufacturing glass substrate for magnetic disk

ActiveUS20100024484A1Reduce the inner diameter dimensional error of a magnetic-disk glass substrateEdge grinding machinesBlowing machine gearingsMetallurgyMagnetic disks

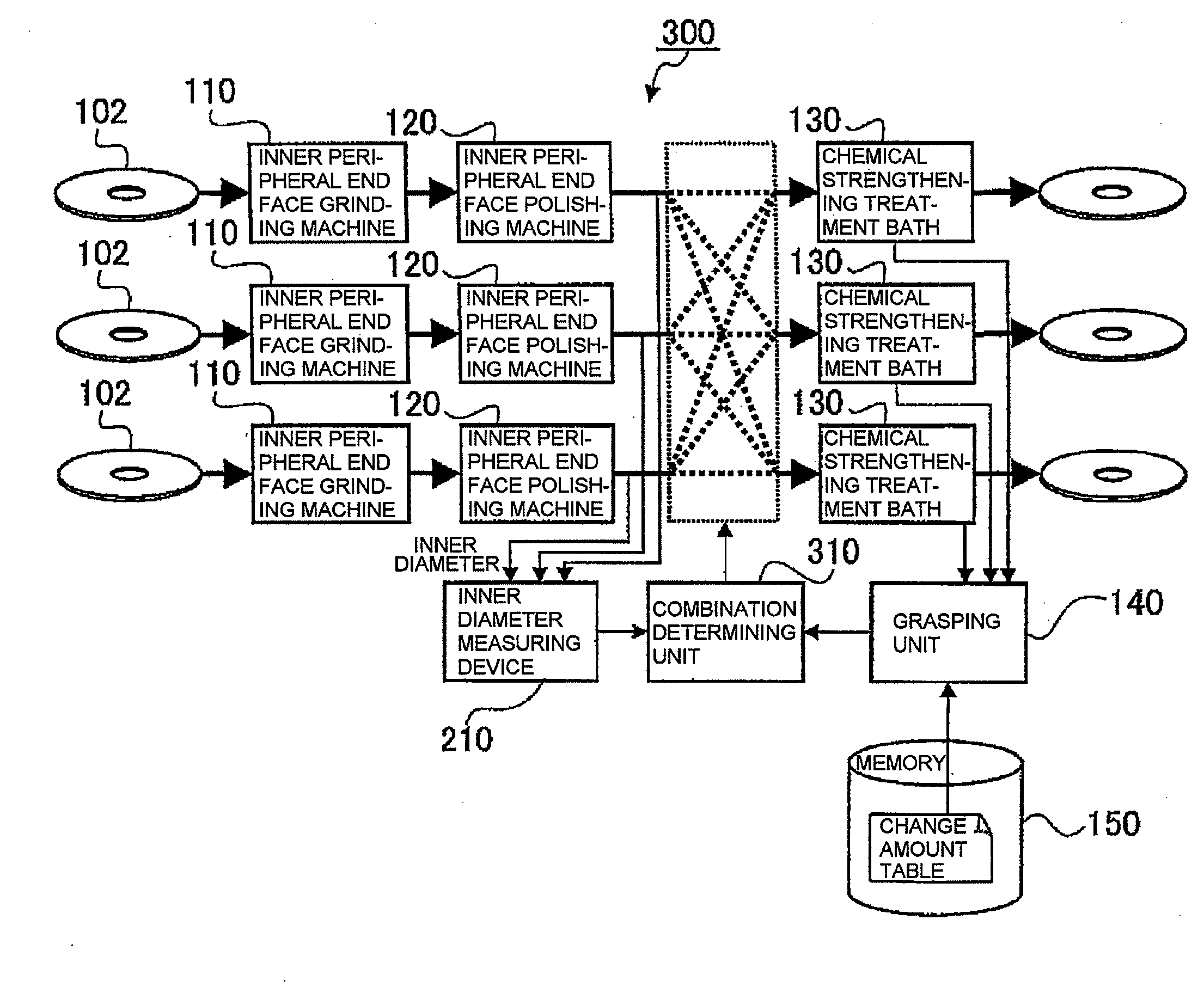

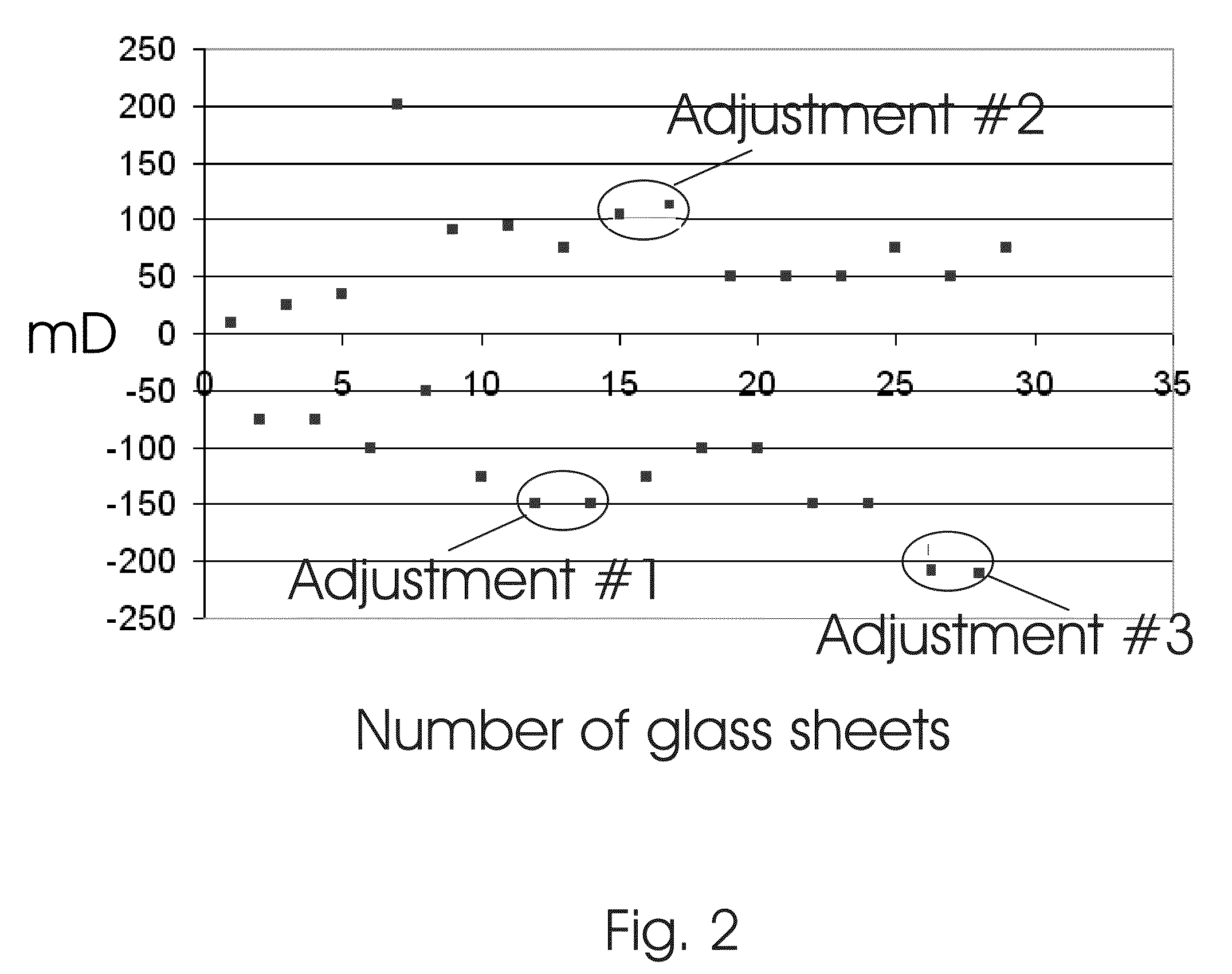

To provide a magnetic-disk glass substrate manufacturing method that can reduce the inner diameter dimensional error.A magnetic-disk glass substrate manufacturing method of this invention including a chemical strengthening step of bringing a plurality of glass substrates 102 into contact with chemical strengthening treatment solutions of a plurality of chemical strengthening treatment baths 130, respectively, to chemically strengthen the glass substrates further includes an inner diameter measuring step of measuring the inner diameter of each of the glass substrates 102 before the chemical strengthening step, a grasping step of grasping a variation of the inner diameter of the glass substrate 102 to be generated by the chemical strengthening step for each of the chemical strengthening treatment baths 130, and a combination determining step of determining the chemical strengthening treatment baths 130, that perform chemical strengthening, based on the variations so that the inner diameters of the glass substrates, whose inner diameters are measured, after the chemical strengthening step become a desired value. In the chemical strengthening step, the glass substrates 102 are chemically strengthened in the determined chemical strengthening treatment baths 130, respectively.

Owner:HOYA LAMPHUN LTD +1

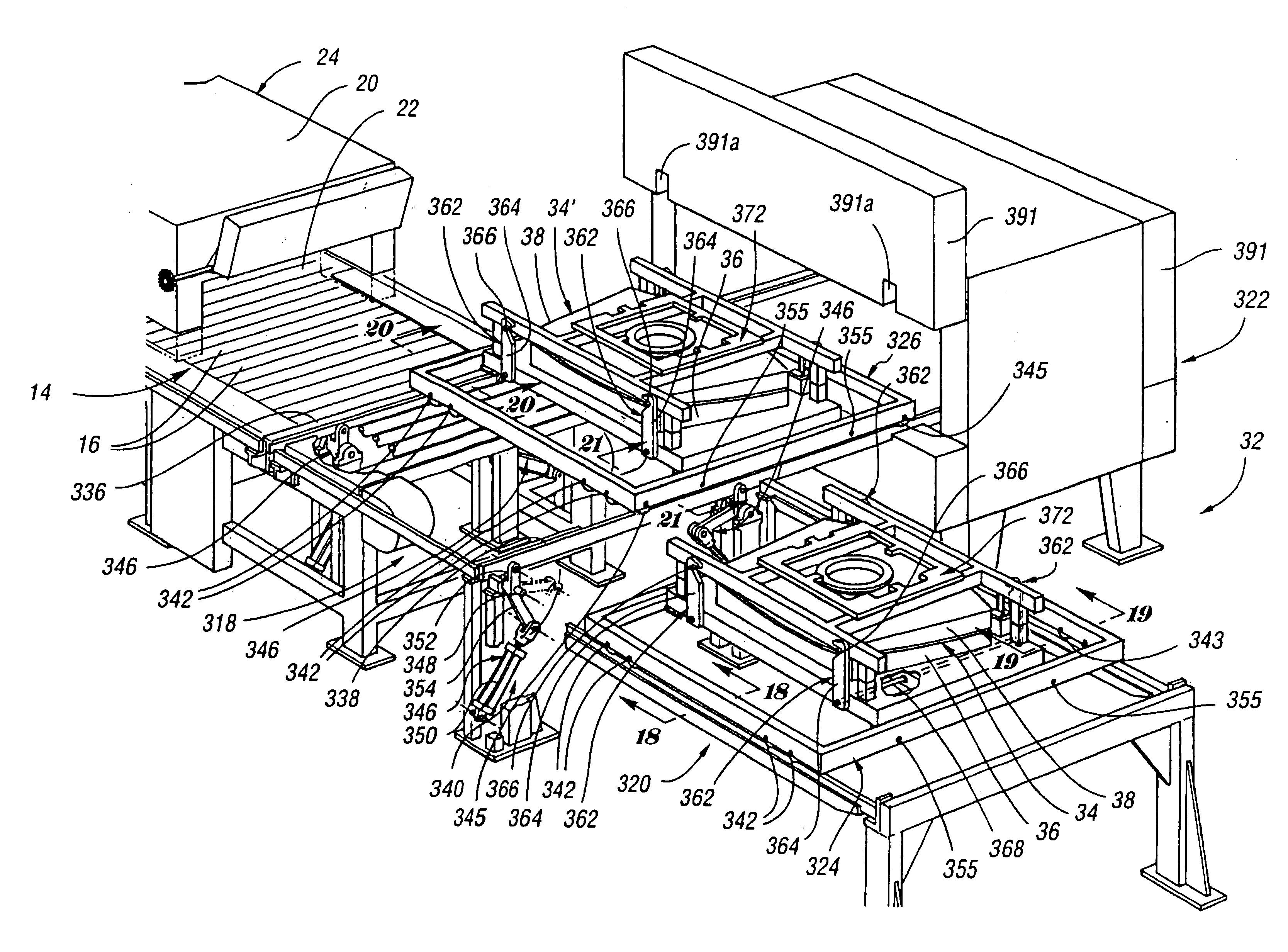

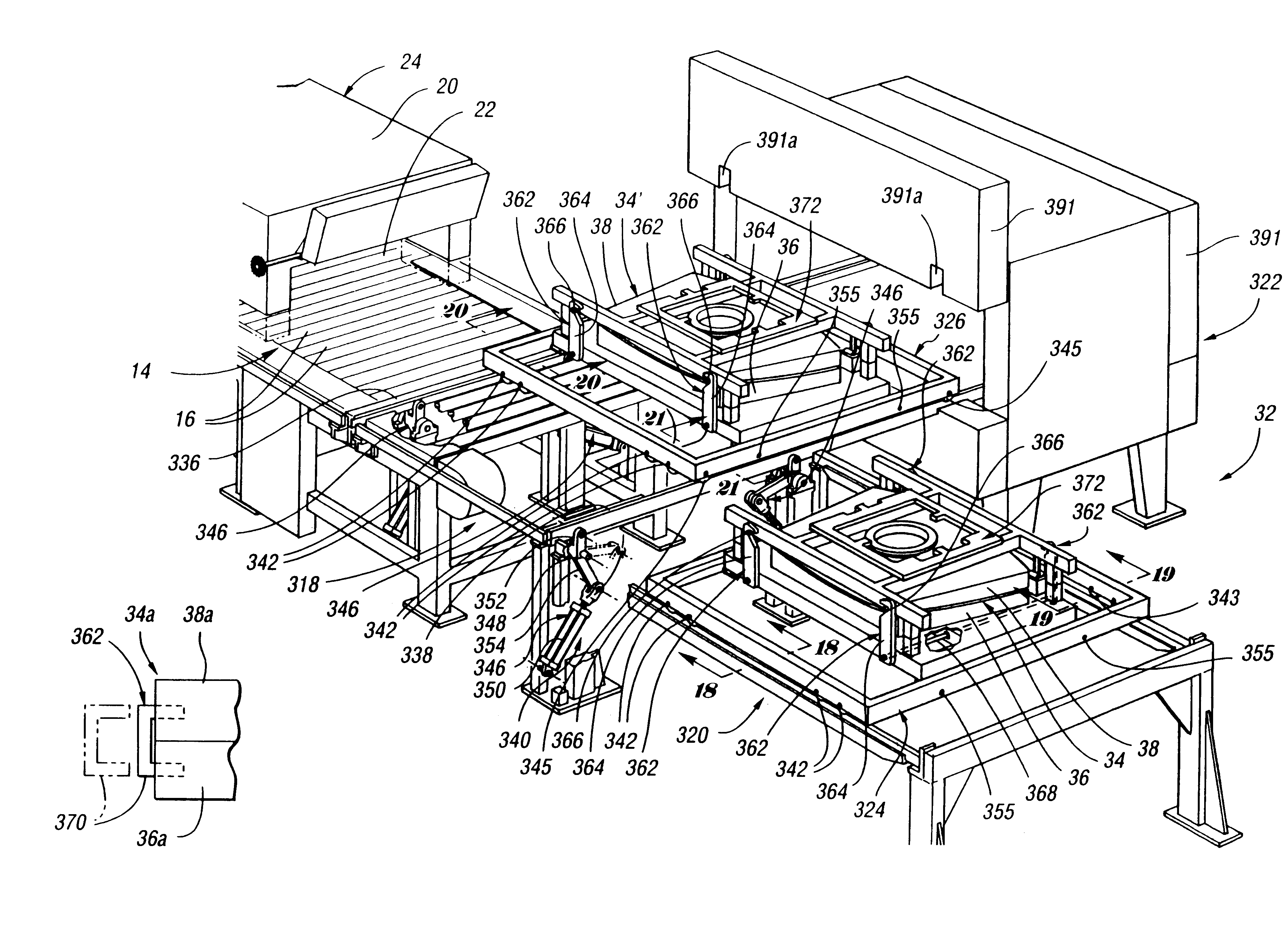

Method for installing mold assembly

InactiveUS6173587B1Simple methodBlowing machine gearingsGlass transportation apparatusGlass sheetMaterials science

A mold assembly (34) for cyclically forming heated glass sheets includes a lower mold (36) having an upwardly oriented mold face (356) and an upper mold face having a downwardly oriented mold face (56) that opposes the upwardly oriented mold face of the lower mold to form a heated glass sheet during movement of the molds toward each other. Alignment guides (122,124) align the molds (36,38) with each other as necessary during movement of the molds toward each other. Detachable connectors (362) detachably connect the molds to each other for installation and are disconnectable to permit the molds to be used for glass sheet forming. In one embodiment, the detachable connectors (362) are latches that include a latch member (364) and a keeper (366), and in another embodiment the detachable connectors are retainers (370) engageable and disengageable from the molds to provide their detachable securement. The upper mold (38) includes a support plate (372) having mounting portions (374,376) and mounting guide portions (378,380,382) for providing alignment during mounting.

Owner:GLASSTECH

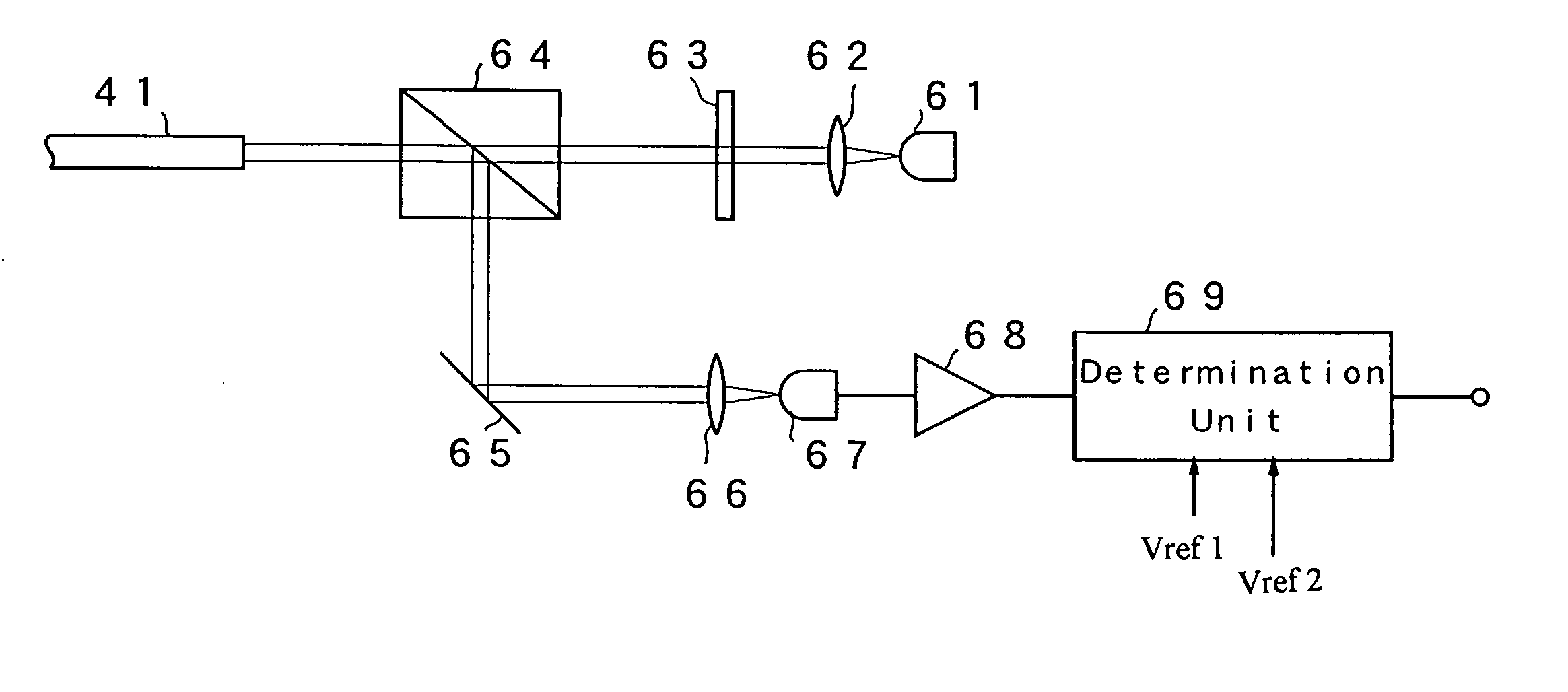

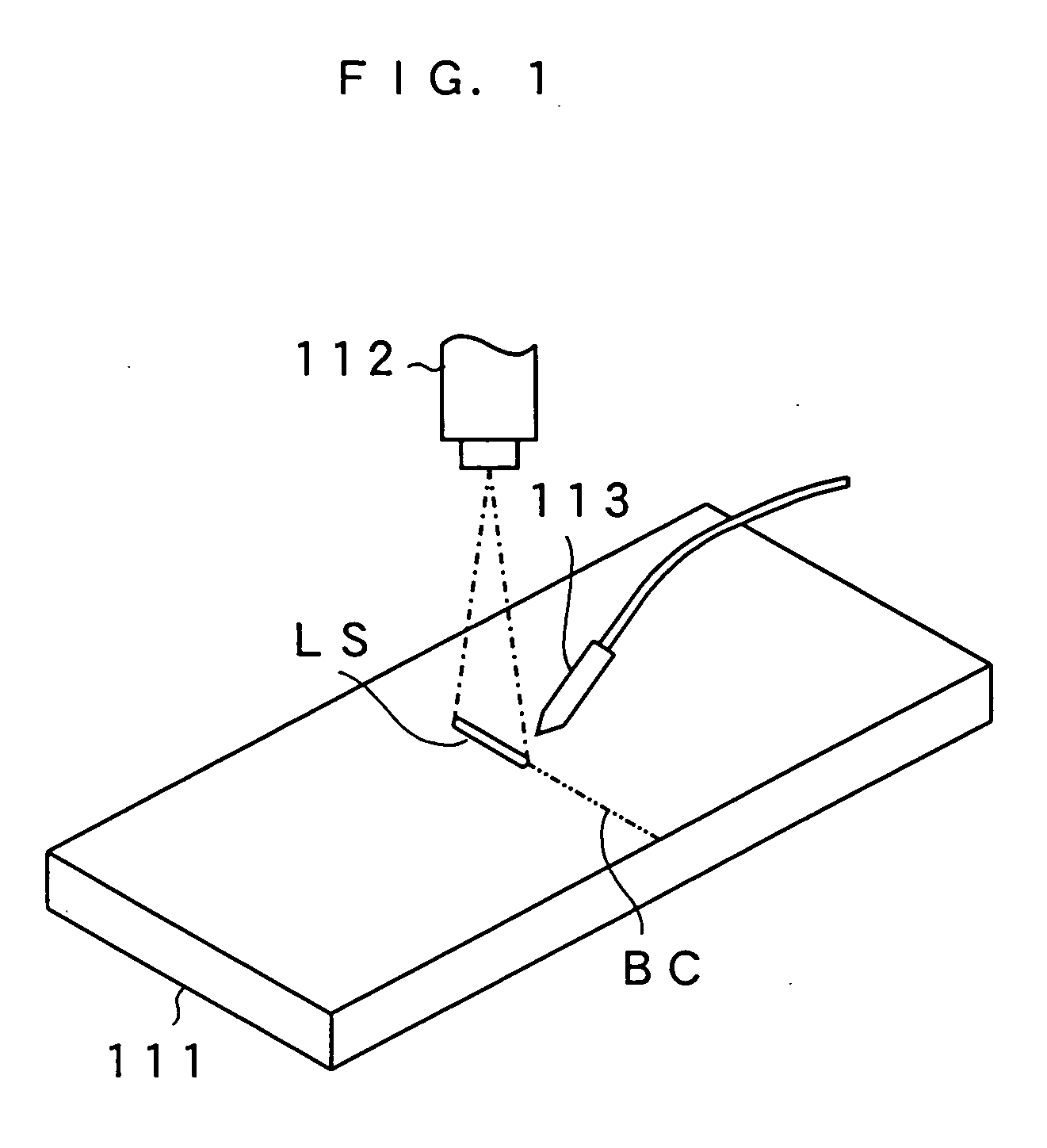

Brittle material substrate scribing device and scribing method, and automatic analysis line

Along a region where a scribe line is formed on a surface of a glass substrate 50, a laser spot is continuously applied for heating at a temperature lower than a softening point of the glass substrate 50, and a region in the vicinity of the heated region is cooled. In this manner, a blind crack is formed along a line to be scribed. A detection unit 40 applies light to the blind crack, immediately after formed in the vicinity of to a cooling spot, through an optical fiber 41. When the blind crack has been formed, part of the light is obtained in the optical fiber 41 because of diffuse reflection. Therefore, detection of the level of this reflected light allows checking as to whether the blind crack has been normally formed or not.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Method and device for producing thin glass panes

InactiveUS20080184741A1Quality improvementImprove productivityBlowing machine gearingsRibbon machinesUnit of lengthGlass sheet

The method of making thin glass panes includes conveying a glass melt through a vertical inlet to a drawing tank with a slit nozzle; drawing a glass ribbon downward from the slit nozzle; setting a total throughput by setting length and cross section of the inlet and by heating and cooling the inlet to control glass melt viscosity so that pressure in the inlet decreases; and setting a throughput per unit of length in a lateral direction along the glass ribbon via nozzle system geometry and by heating and cooling of the drawing tank and slit nozzle to control melt viscosity, so that glass does not wet an underside of the slit nozzle near a breaking edge. The setting of the total throughput and the throughput per unit length are largely decoupled to simplify process control. An inventive apparatus for performing the method is also disclosed.

Owner:SCHOTT AG

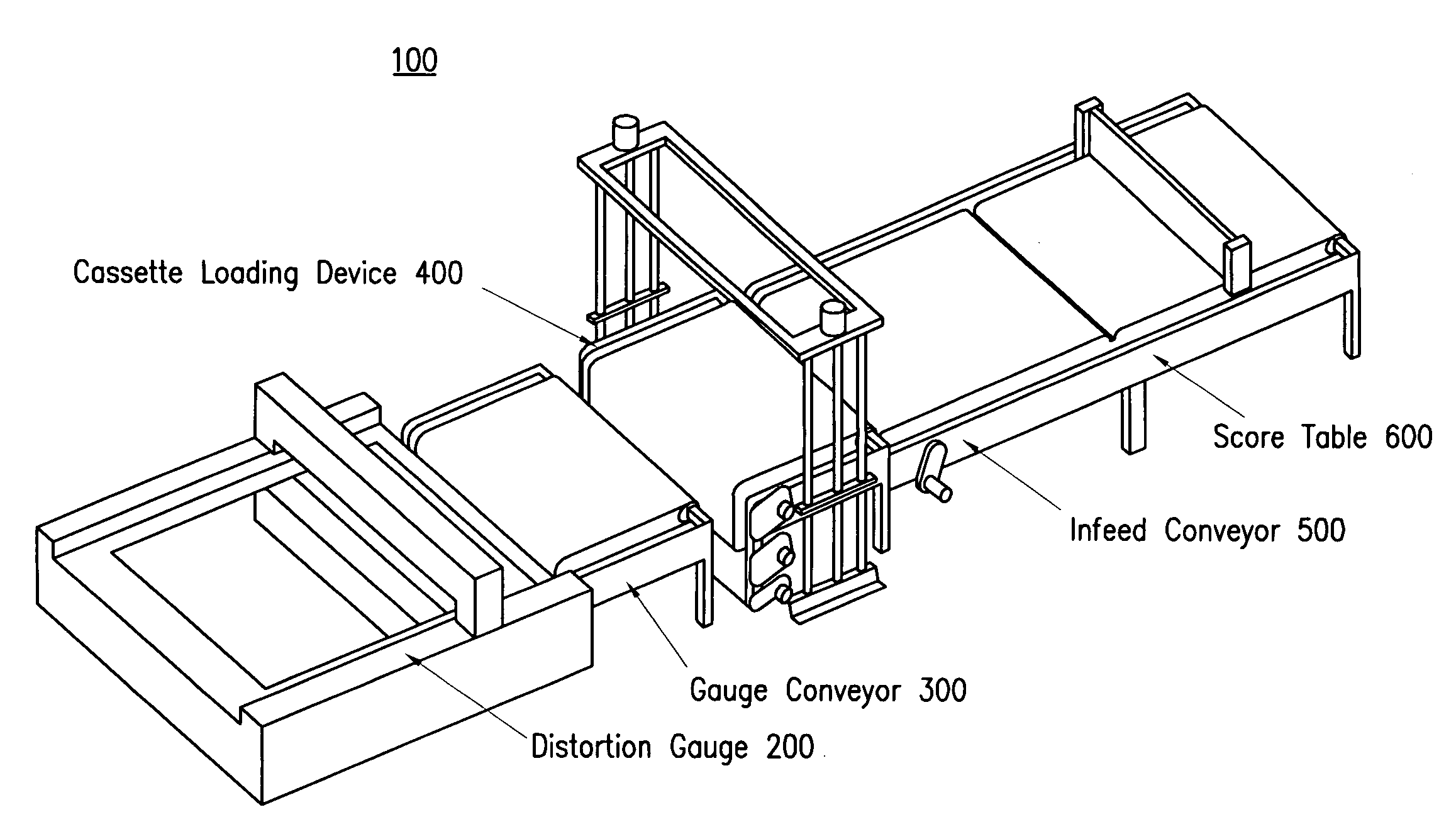

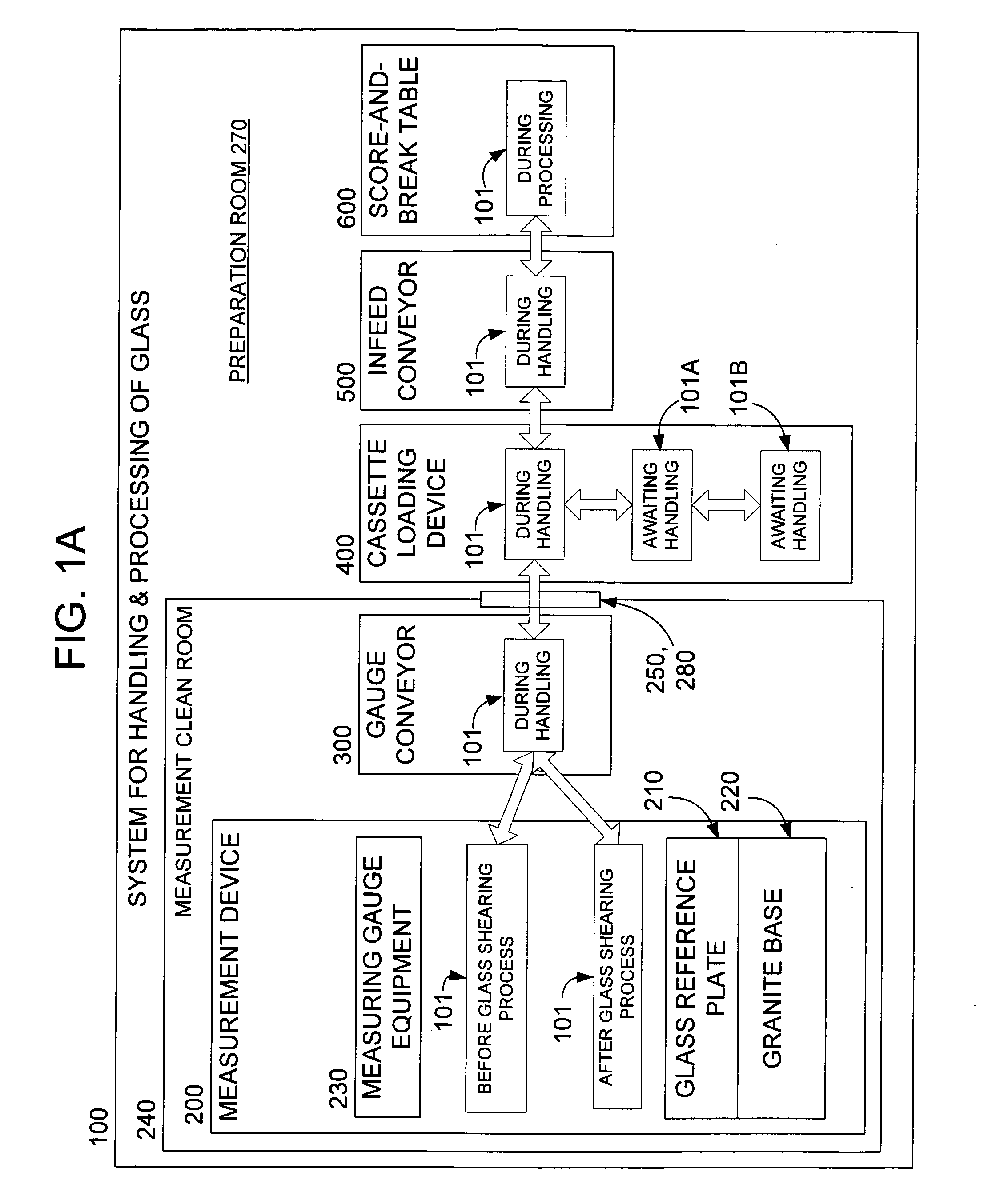

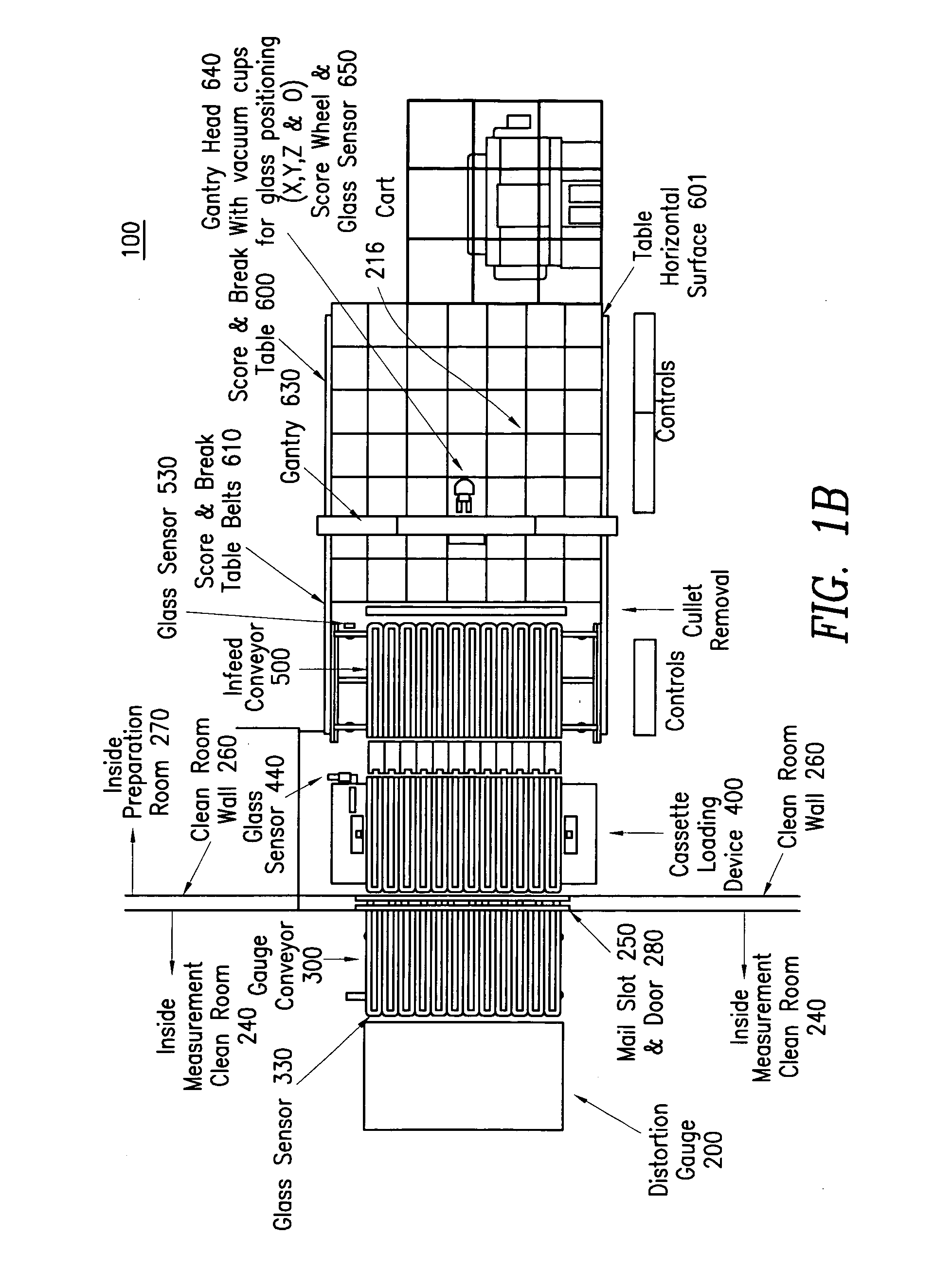

Glass handling and processing system

InactiveUS20080110205A1Extend product lifeScalabilityBlowing machine gearingsGlass furnace apparatusLiquid-crystal displayMeasurement device

Systems, methods and apparatus relate to handling and processing glass, such as glass for use in liquid crystal displays, involving a measurement device, such as a distortion gauge, residing in an environmentally controlled measurement room, and a cassette loading device for storage and conveyance of glass between the measurement device and other components of a glass handling and processing system residing with the cassette loading device in a preparation room. A mail-slot opening may be present in a wall separating the measurement room from the preparation room. A gauge conveyor may convey glass between the cassette loading device and the measurement device. A distortion gauge may measure a reference value of the product glass with respect to reference marks on a glass reference plate of the distortion gauge. Other examples of a measurement device include a warp gauge, a stress gauge, a thickness gauge, and a compaction gauge.

Owner:CORNING INC

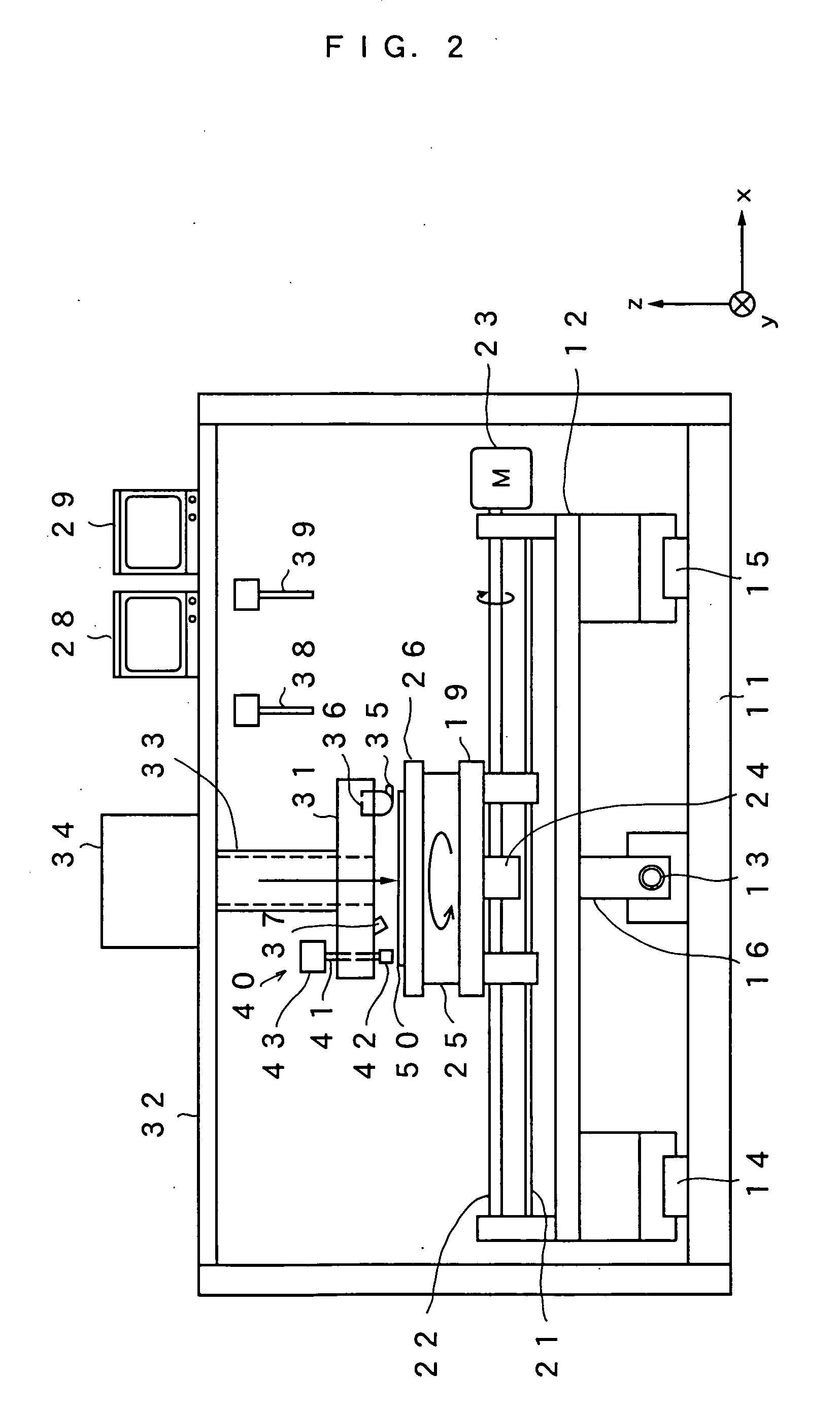

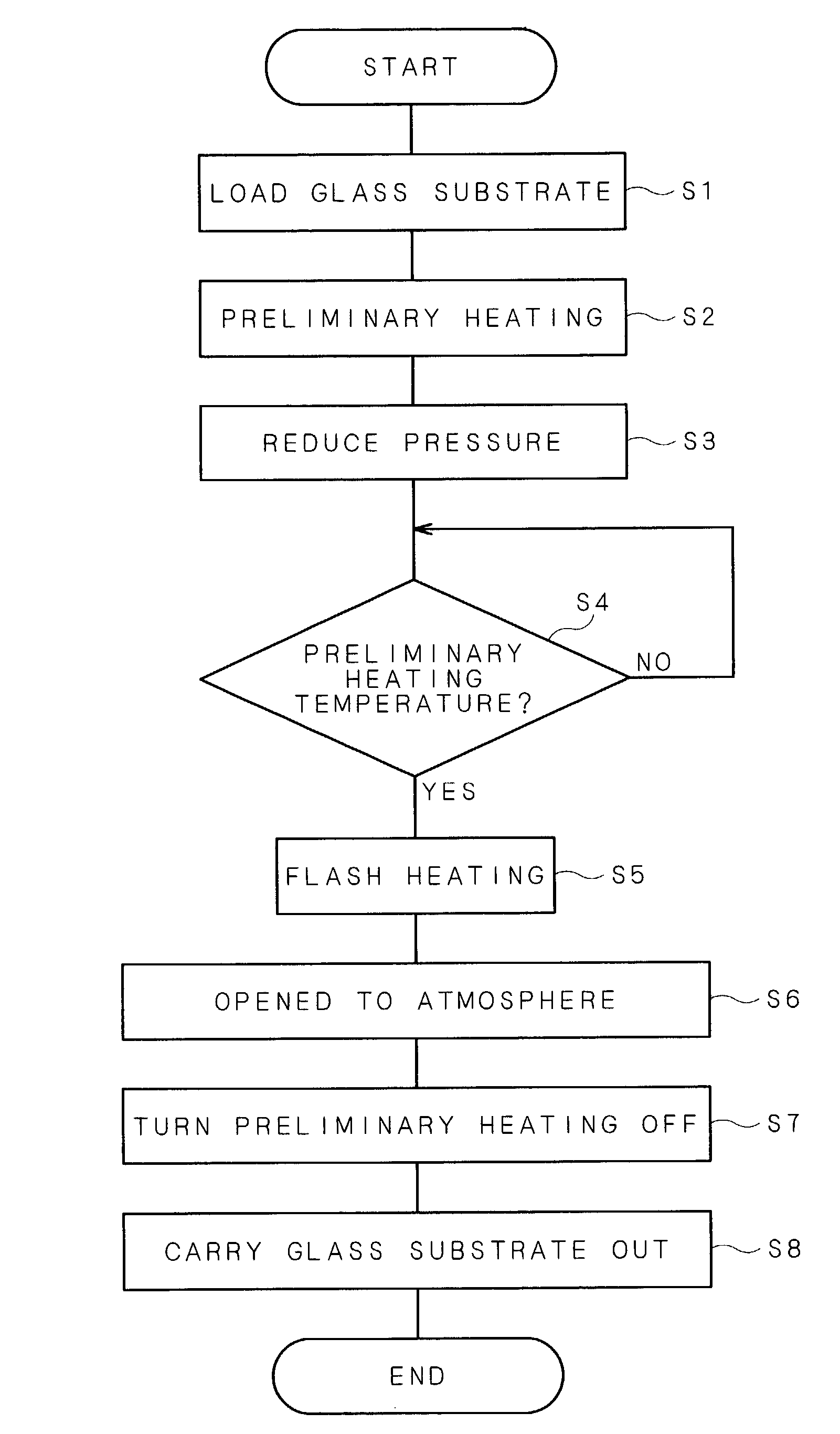

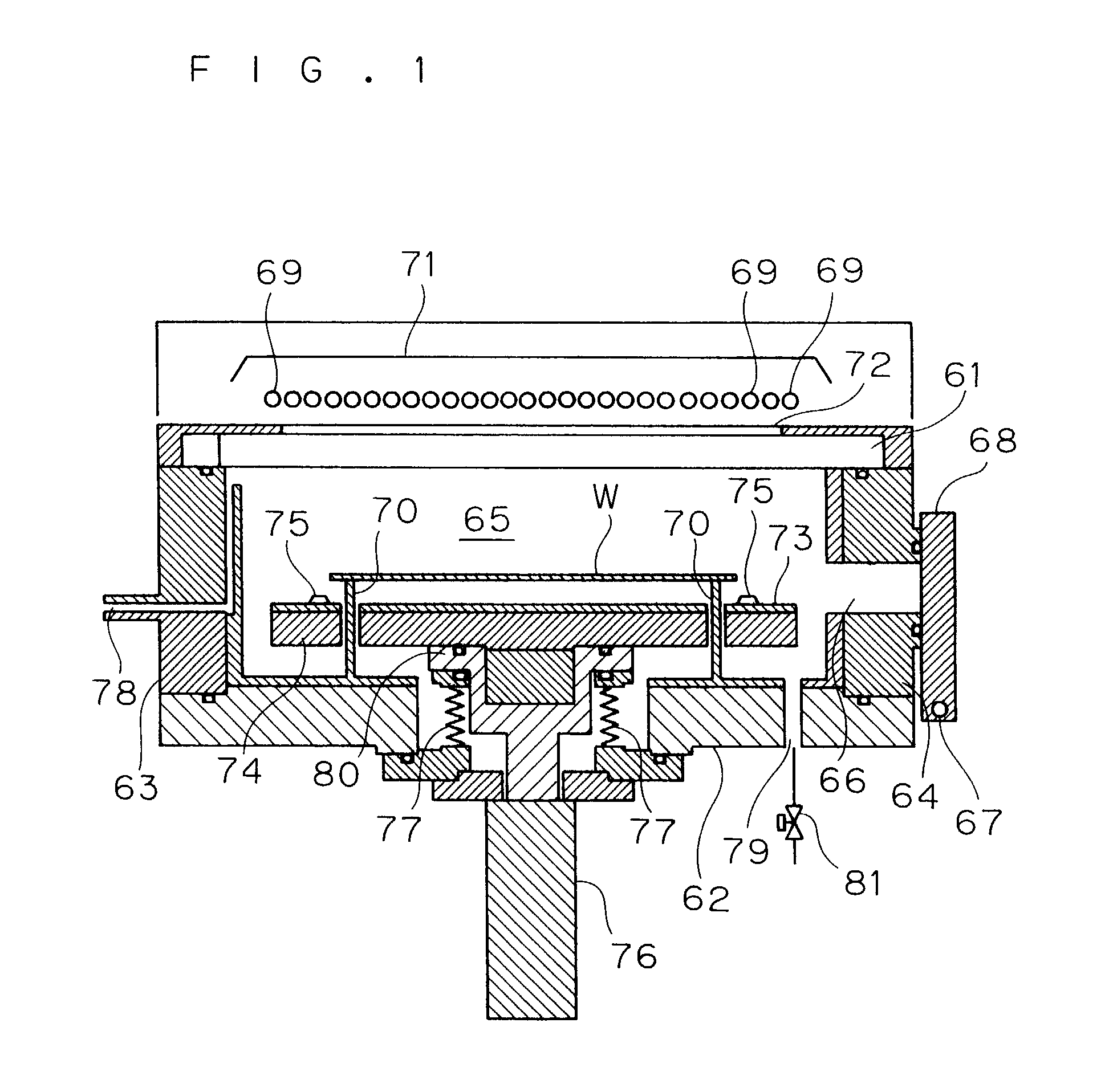

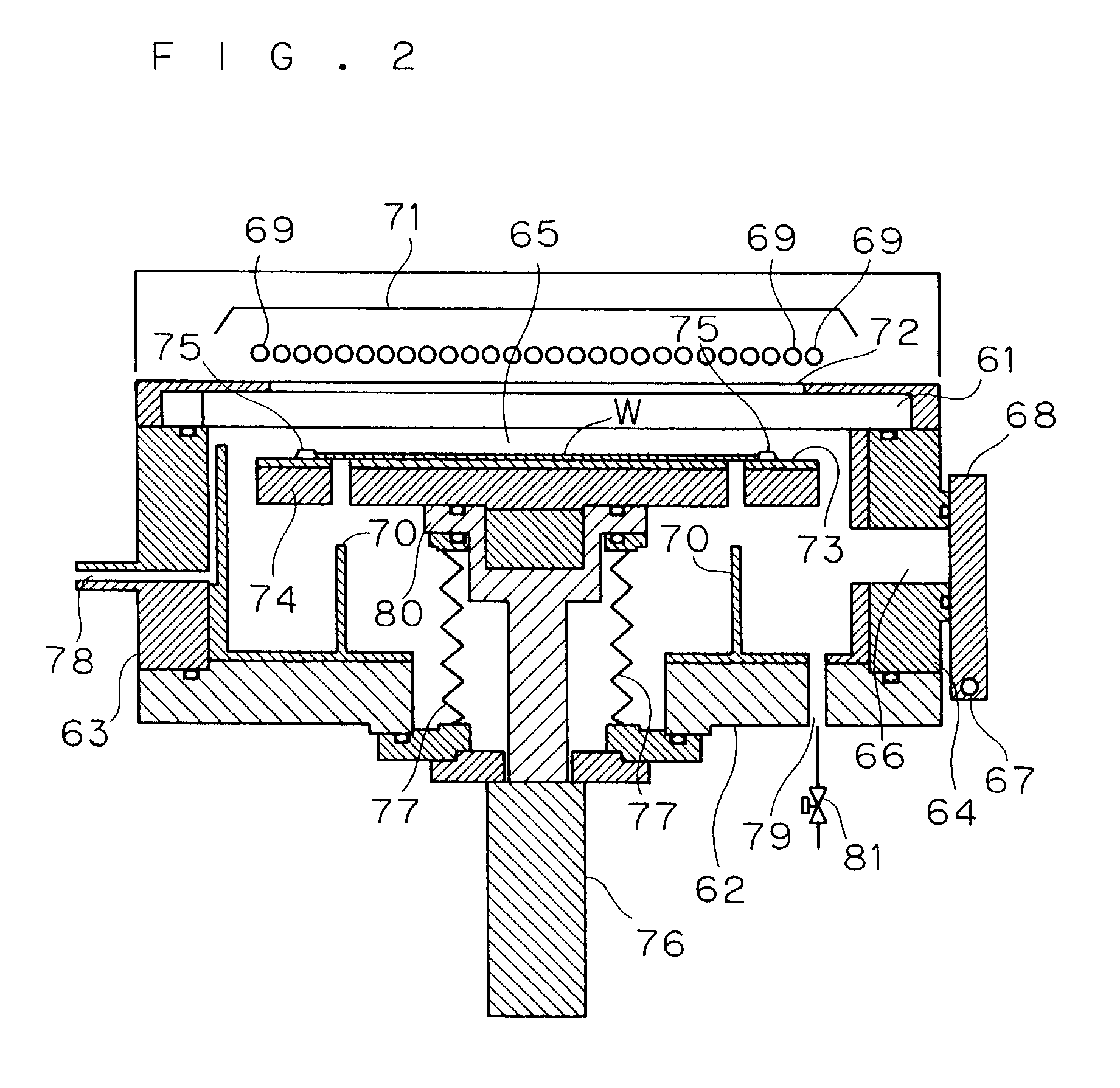

Heat treatment apparatus and heat treatment method of substrate

ActiveUS7255899B2Well formedExcellent characteristicsBlowing machine gearingsGlass furnace apparatusAmorphous siliconIrradiation

A heat diffusion plate and a heating plate are placed in a heat treatment chamber in this order. The heating plate is used for preliminarily heating a glass substrate to a temperature in a range from 200° C. to 400° C. The glass substrate thus preliminarily heated is subjected to a heat treatment by flash light irradiation by a xenon flash lamp. The flash light irradiation makes it possible to uniformly heat an amorphous silicon film on the glass substrate, and consequently to be poly-crystallized. Thus, it becomes possible to provide a heat treatment technique capable of carrying out a uniform heat treatment on the silicon film on the glass substrate sufficiently.

Owner:DAINIPPON SCREEN MTG CO LTD

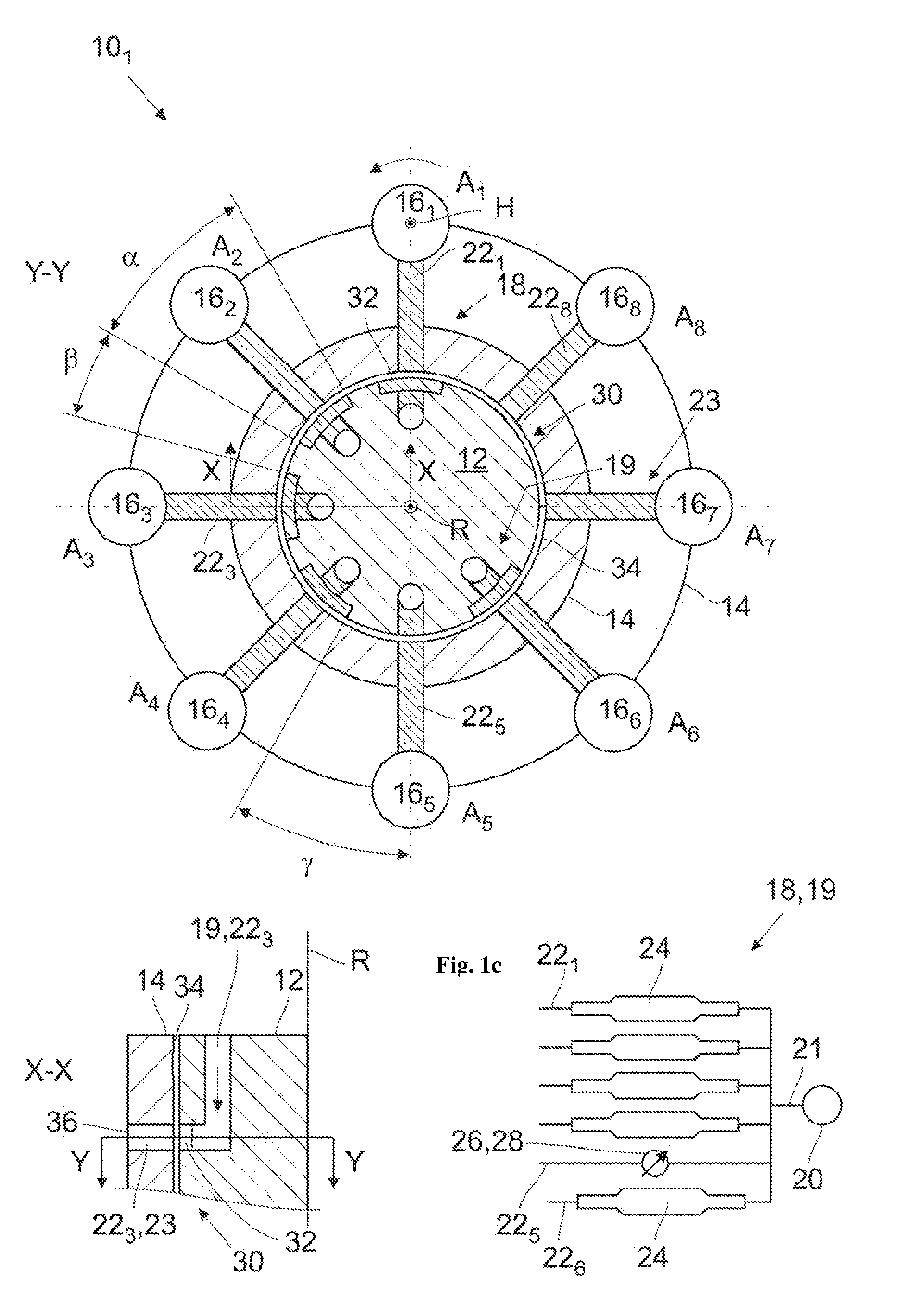

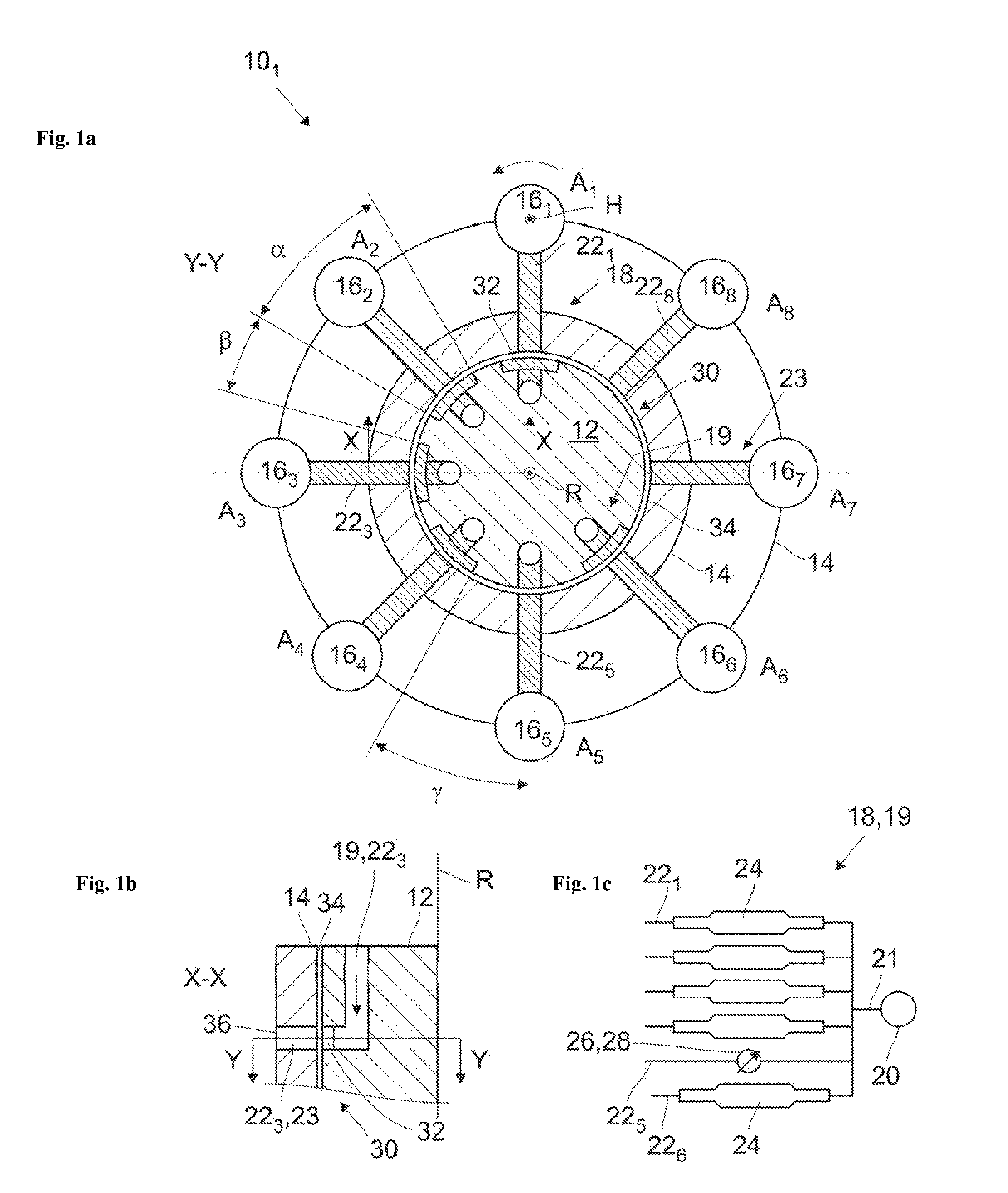

Method of producing glass products from glass product material and an assembly for performing said method

ActiveUS20140174127A1Eliminate the effects ofBlowing machine gearingsGlass furnace apparatusMaterials scienceRadiation

The invention is related to a method of producing glass products from glass product material. Said method comprises the steps of heating the glass product material, shaping the heated glass product material into a glass product, cooling the shaped glass product, and inspecting the shaped glass products by means of at least one sensor sensitive to infrared radiation In said inspecting step a first image of the glass product is taken under a first viewing angle. In addition a second image of said glass product is taken under a second viewing angle which is different from the first viewing angle. The first image is compared with the second image for eliminating parasite reflections. The first and second images are analyzed for detecting whether said glass product is defective or not. An assembly is described for performing said method of producing glass products from glass product material.

Owner:CENT VOOR TECHN INFORMATICA

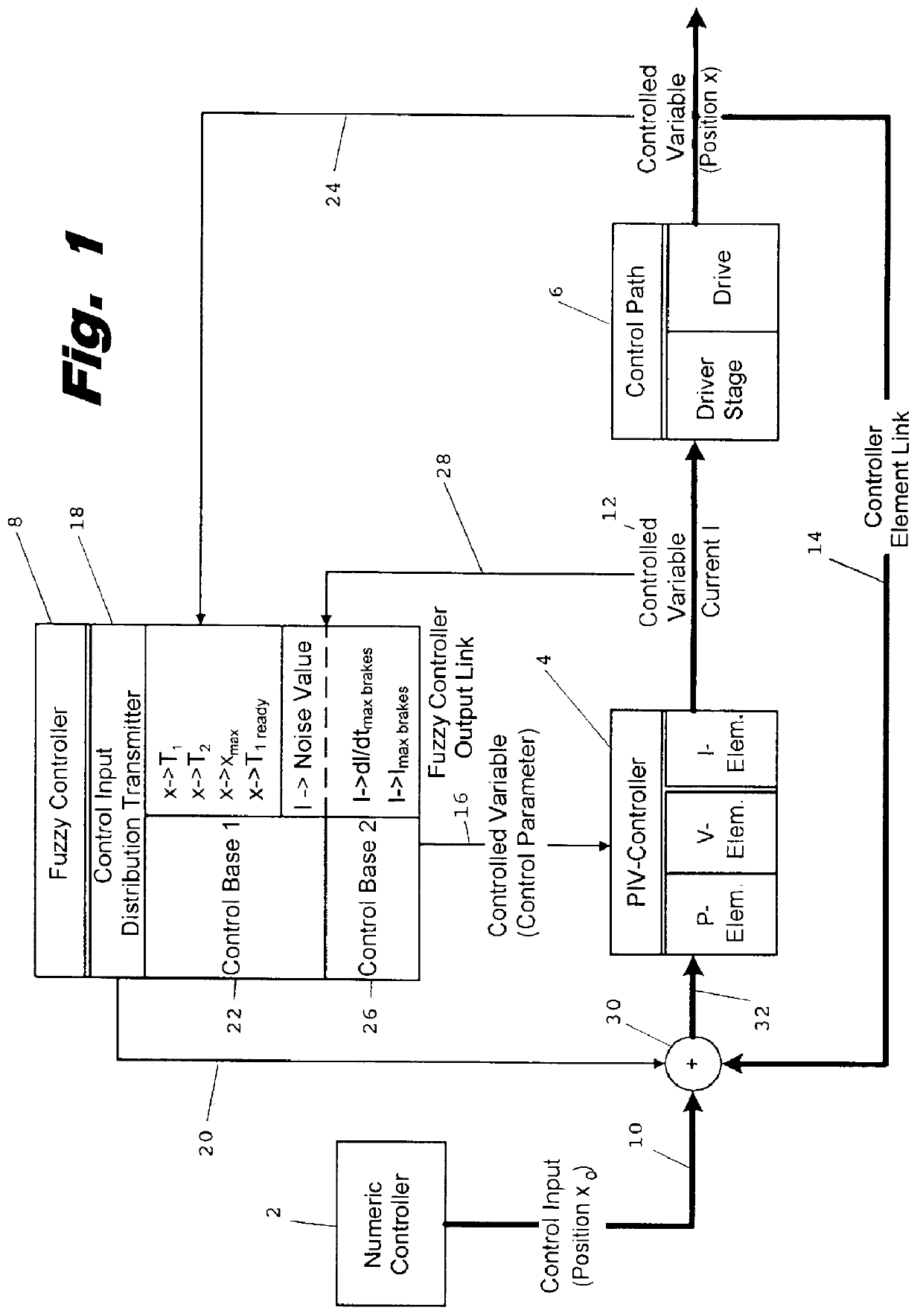

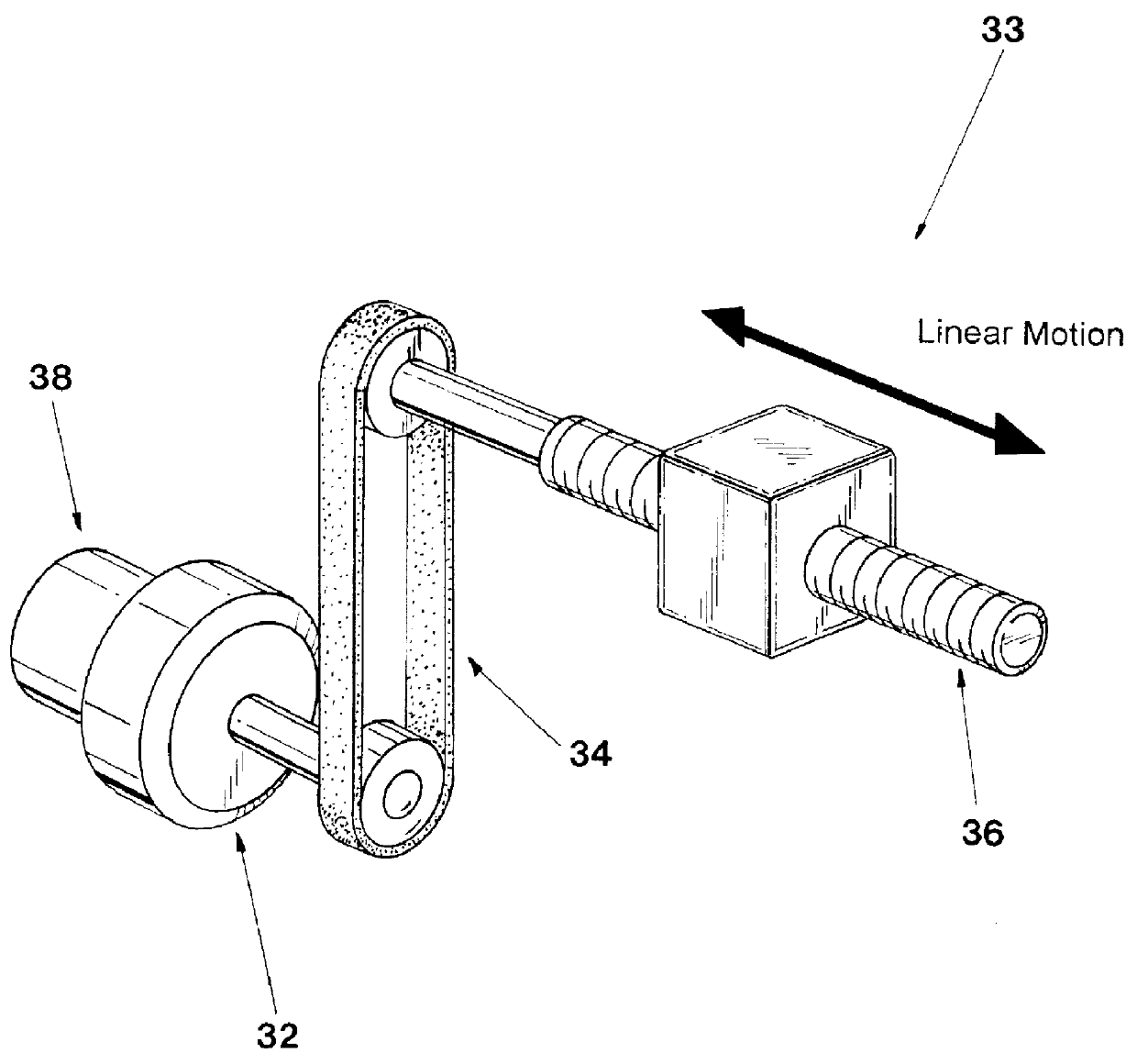

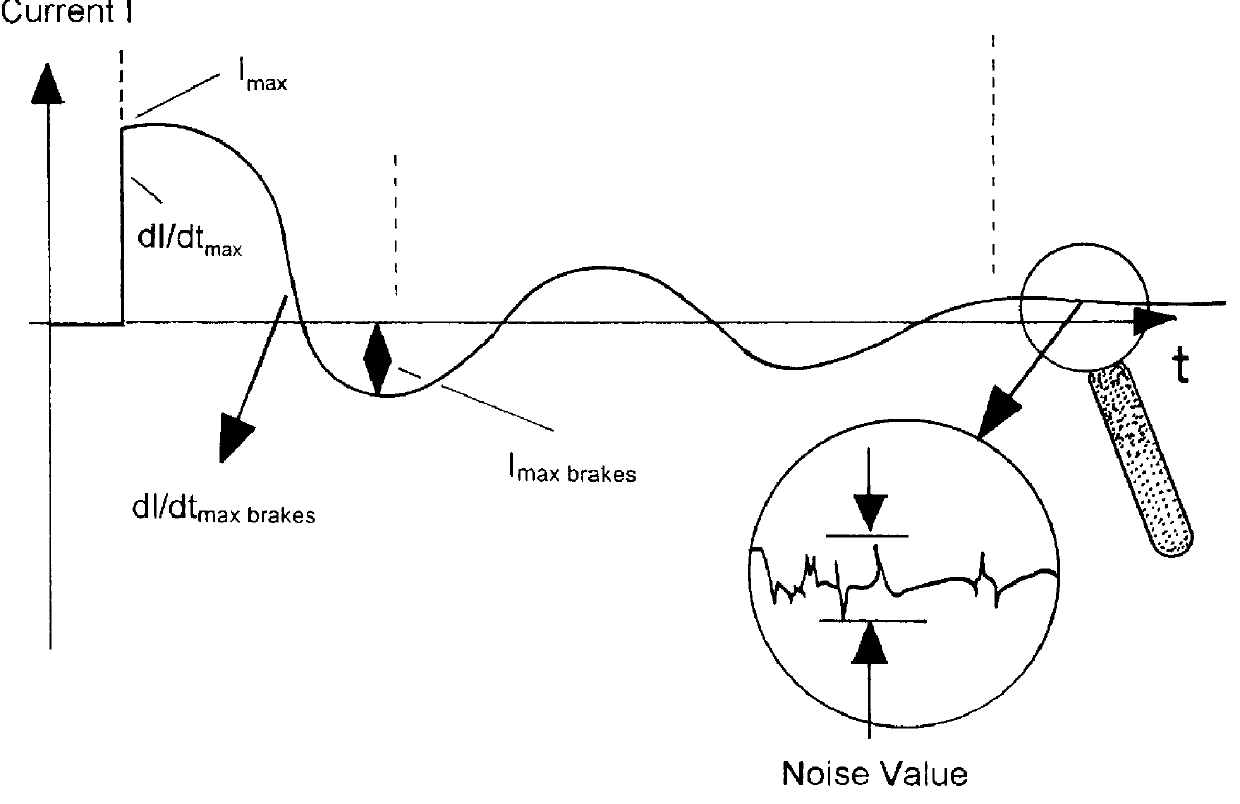

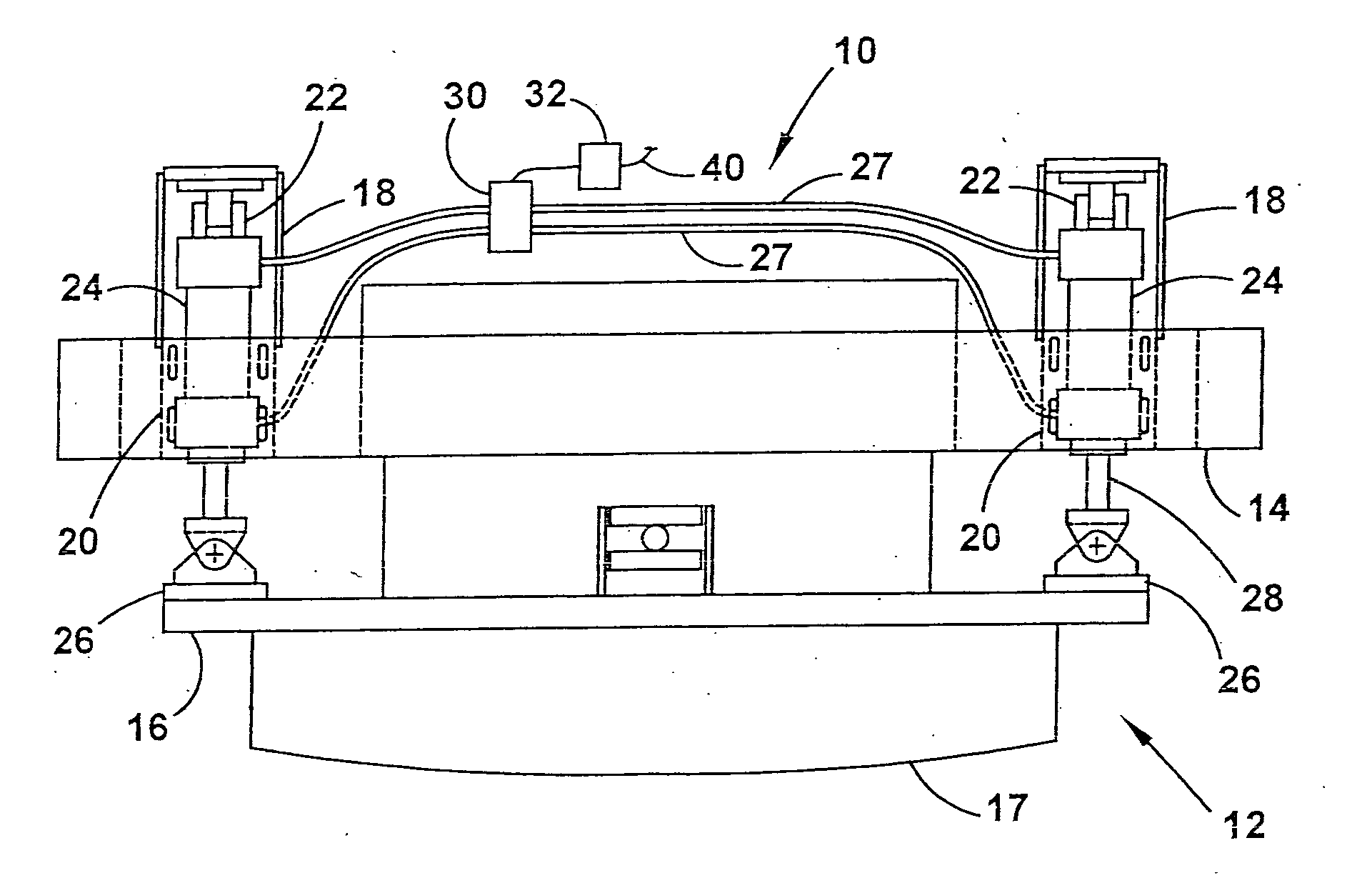

Electroerosion apparatus drive control system employing fuzzy logic

InactiveUS6064920AEmployabilityMinimize convergence problems in tuning the controller parametersBlowing machine gearingsControllers with particular characteristicsControl systemFuzzy control system

An apparatus and method is provided for tuning a controller parameter of a PIV controller with a position, velocity and / or integral controller element for a control path of a drive in an electroerosion apparatus, with the help of a fuzzy controller, wherein for the purpose of tuning, a preset control input distribution, such as a time-dependent distribution of the position of the drive, is provided to the PIV controller as input variable and wherein an input variable of the fuzzy controller is derived from the control variable of the controller. Additional input variables of the fuzzy controller are derived from a controller output of the PIV controller.

Owner:FUR IND ELEKTRONIK AGIE LOSONE B LOCARNO

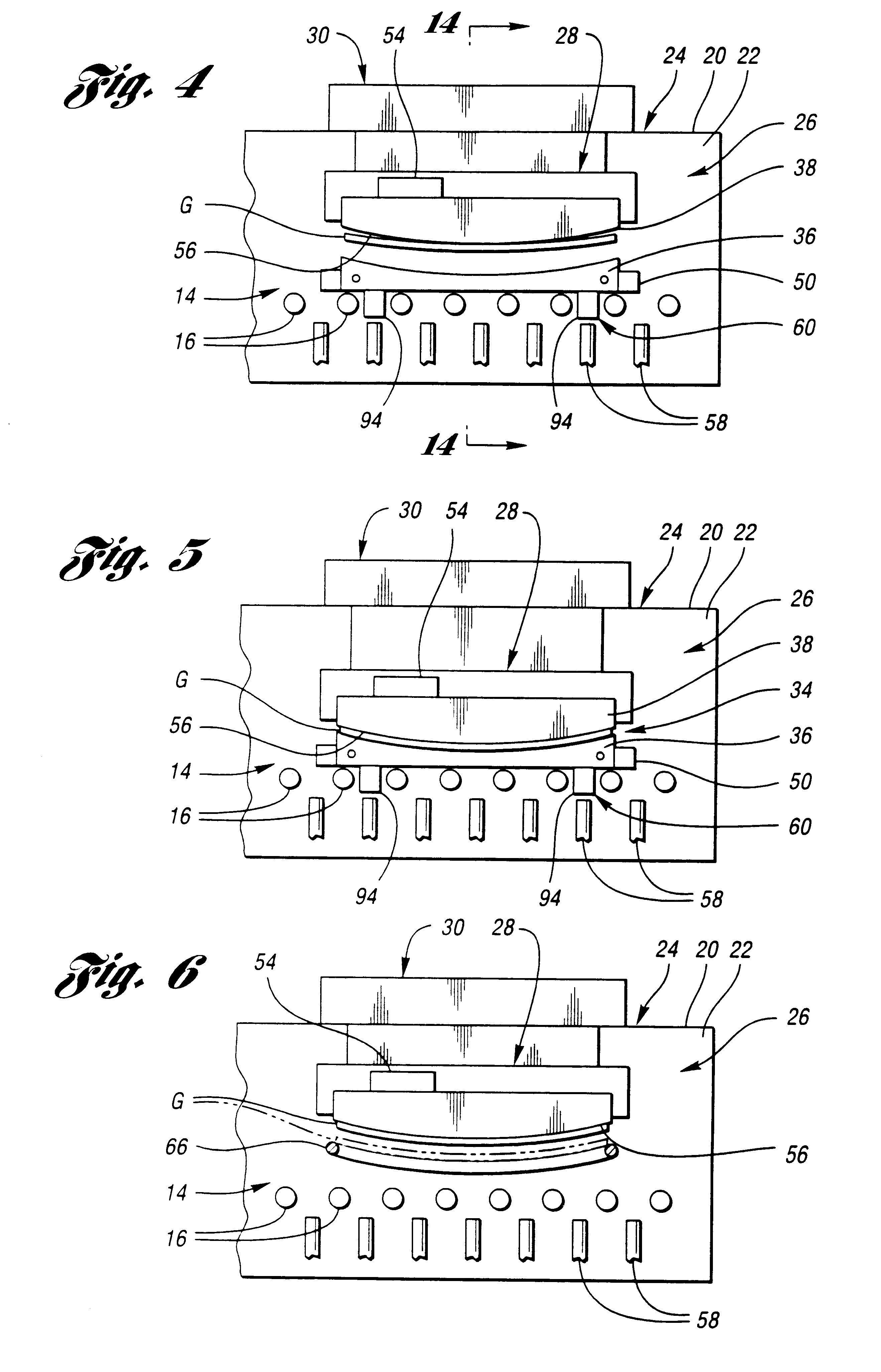

Hood tilt mechanism for curved glass processing

InactiveUS20050178158A1Shorten the timePrecise positioningBlowing machine gearingsGlass transportation apparatusHOOD assemblyEngineering

A glass forming assembly for forming complex shaped glass, with the glass forming assembly having a hood assembly including a hood lift superstructure movable horizontally back and forth over a cold ring and a cooling shuttle and movable vertically relative to the cold ring and the cooling shuttle, and a hood frame supported by the hood lift superstructure by a hood tilt mechanism. The hood tilt mechanism includes an air cylinder assembly actuable to tilt the hood frame relative to the hood lift superstructure, which allows for proper orientation of the glass prior to dropping it on the cooling shuttle, thus allowing for reduced glass chipping and cracking.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

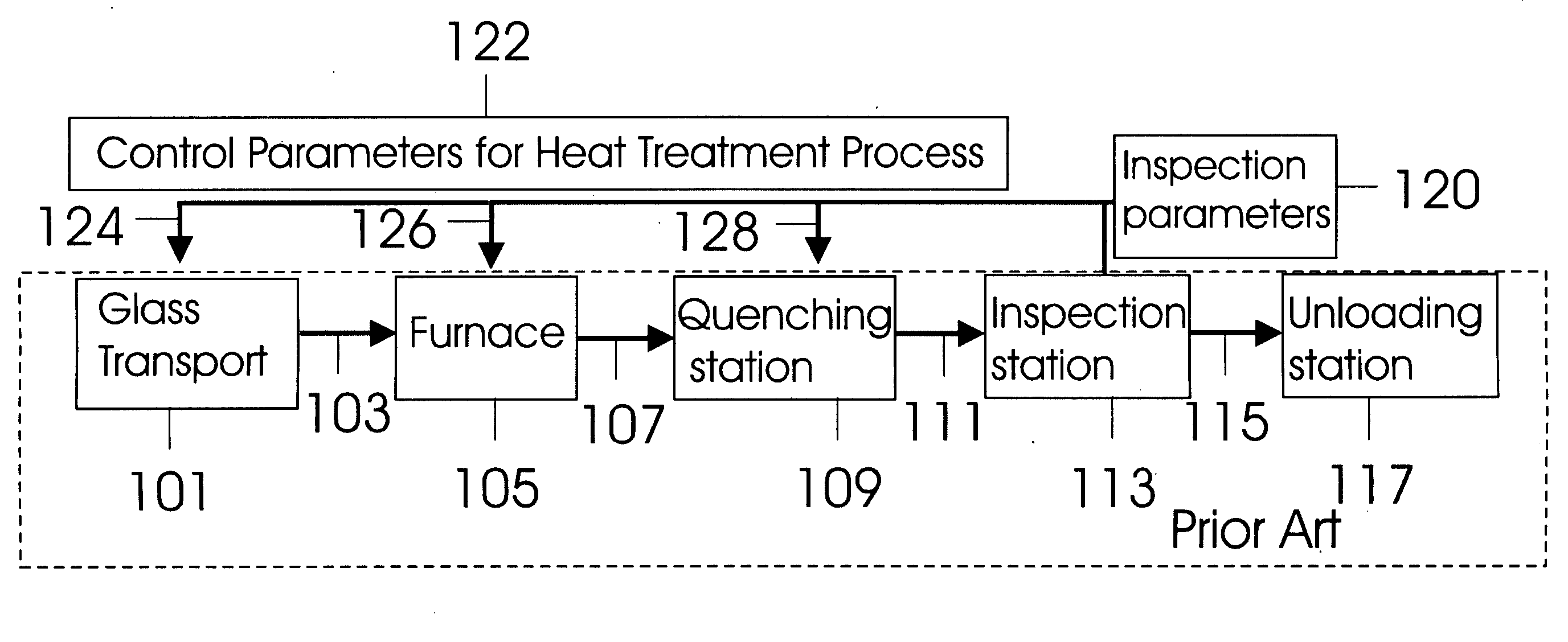

Closed loop control system for the heat-treatment of glass

InactiveUS20090199594A1Reduce laborWeaken energyBlowing machine gearingsGlass furnace apparatusControl systemClosed loop

A method and apparatus for controlling the process used in the heat treatment of glass measures the quality of the glass following the heat treatment process. Inputs to the control system for the heat treatment process derive from the automated inspection of glass following heat treatment. Outputs from the control system for the heat treatment process may adjust one or more parameters in the heat treatment process including a furnace or heating setting, a transport setting, and a quench or cooling setting.

Owner:LITESENTRY CORP

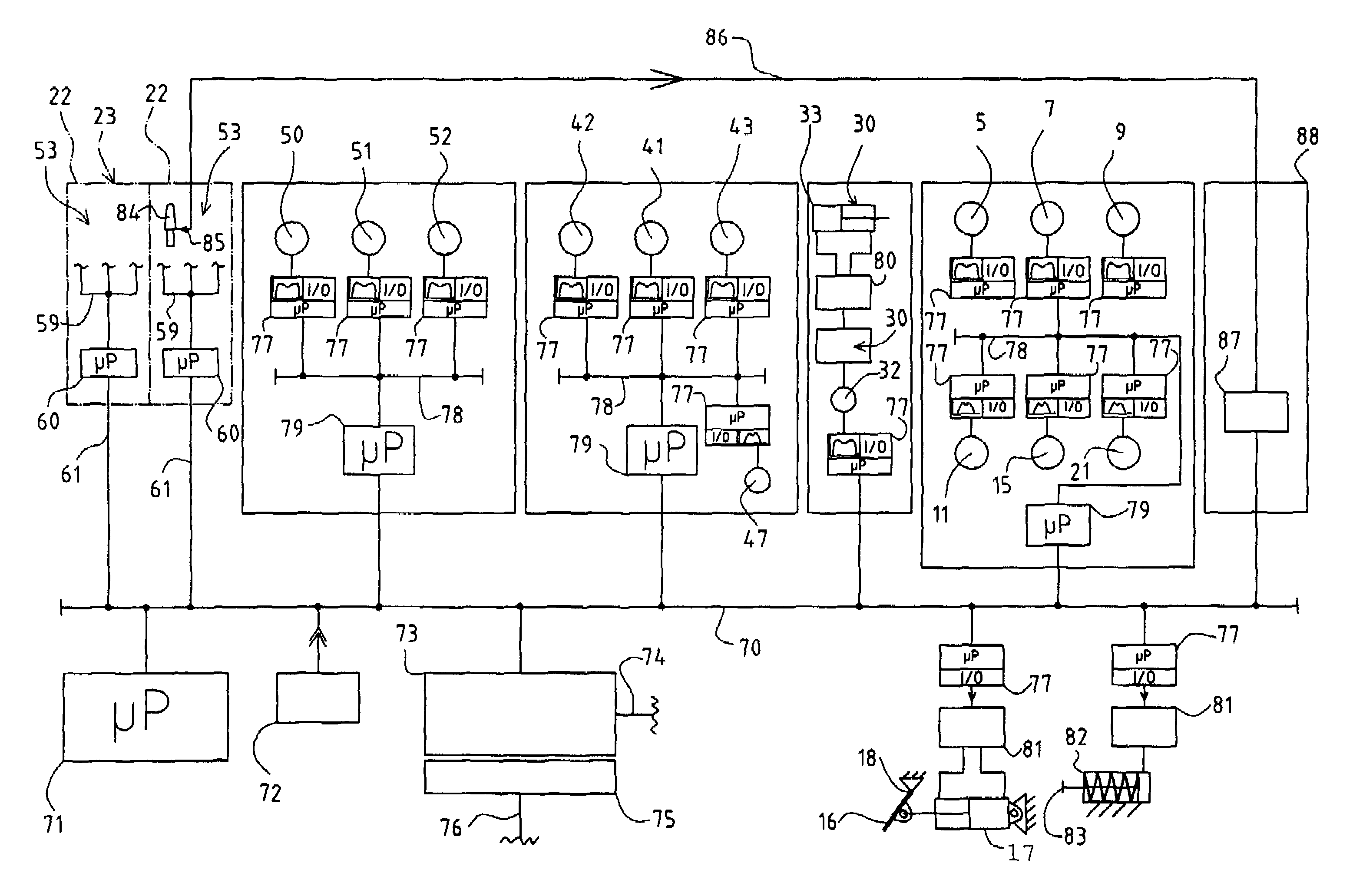

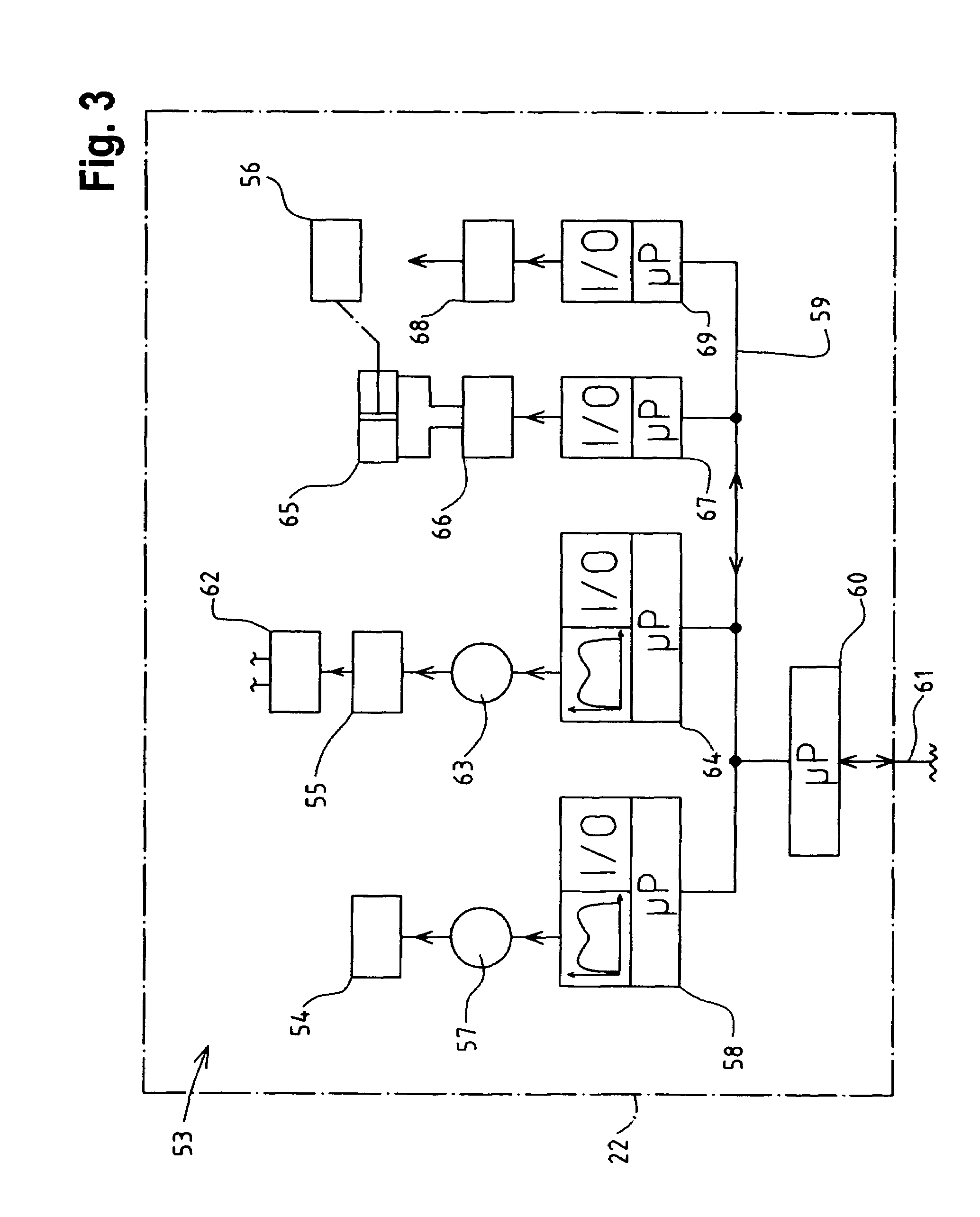

Electronic control for glass moulding machines

InactiveUS7054710B2Fast inputEasy accessBlowing machine gearingsSensitive elementsModem deviceEngineering

Sections (22) of an I.S. glass forming machine (23) have a plurality of mechanisms which can be respectively driven by a first drive. Each first drive is allocated a controller which is connected to a first sequencer (60) via a first bus (59). All first sequencers (60) are connected to a second bus (70) to which a second sequencer (71), a manually-operated device (72), a PC (73) with an Internet connection (74) and a modem (75) are connected. Peripheral devices of the I.S. glass forming machine (23) each have at least one third drive (5, 7, 9, 11, 15, 21, 32, 41, 42, 43, 50, 51, 52, 17, 82). Each third drive is connected to a first control device (77). In the case of the third drives (17, 82) associated first control devices (77) are directly connected to the second bus (70), whereas in the other cases a plurality of first control devices (77) are connected to a third bus (78) which is connected to the second bus (70) via a second control device (79).

Owner:HEYE INT

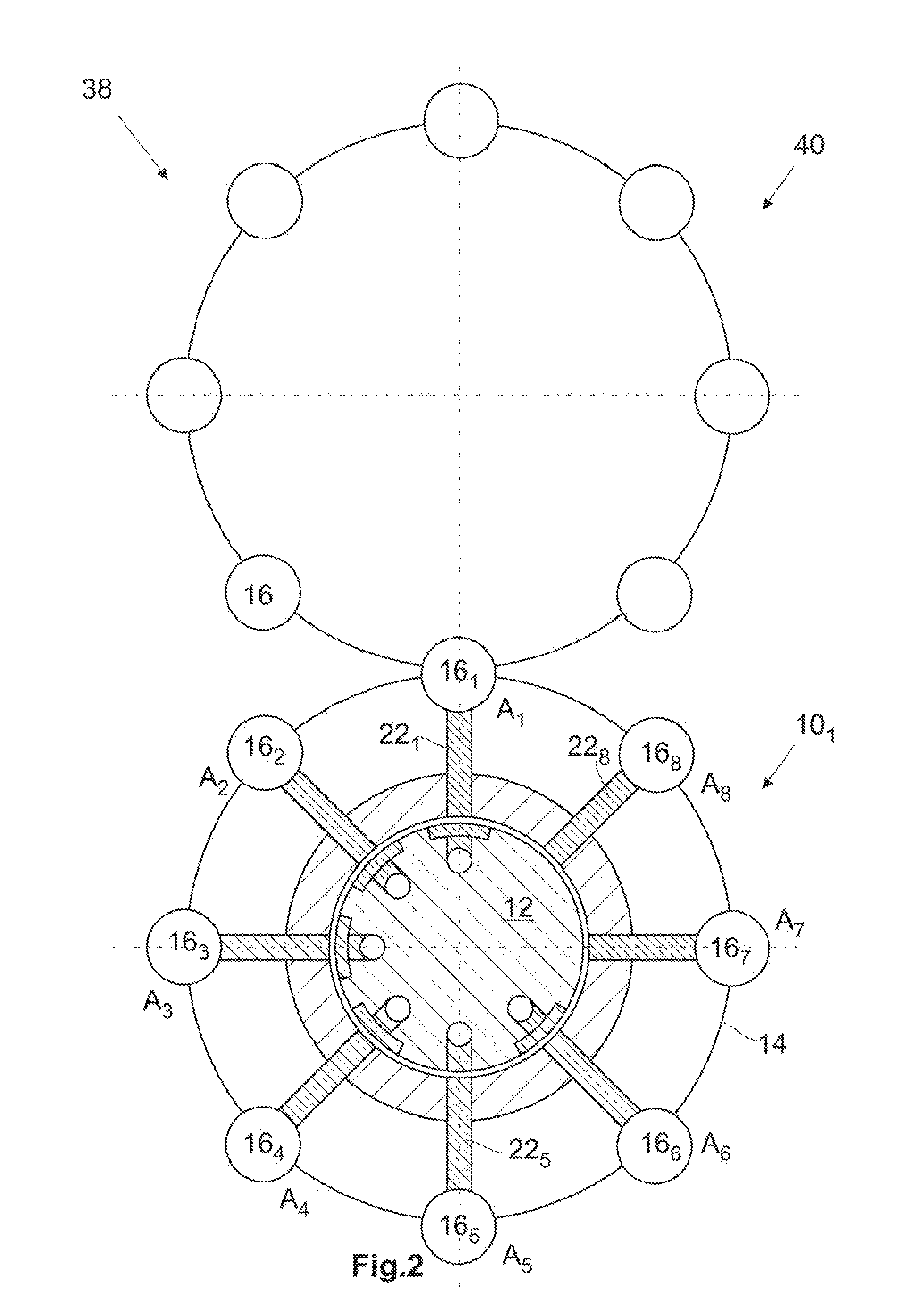

Glass processing device and bottom machine therefor for manufacturing glass containers

ActiveUS20140373574A1Delamination tendency is not reducedReduced tendency of delaminationBlowing machine gearingsGlass reforming apparatusEngineeringGlass container

A bottom machine is provided for a glass processing device to manufacture glass containers from glass tubes. The bottom machine includes one or a plurality of holding units for holding the glass container or glass tube, with the holding units being mounted so as to rotate around an axis of rotation of the bottom machine in order to convey the glass container or glass tube to various processing positions, a pressure source for supplying a gas flow, a duct system communicating with the pressure source for directing the gas flow to the holding units and for feeding the gas flow into the glass tube or into the glass container, with the duct system being designed to be free of gaps.

Owner:SCHOTT PHARMA AG & CO KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com