Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

511results about How to "Increase surface temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

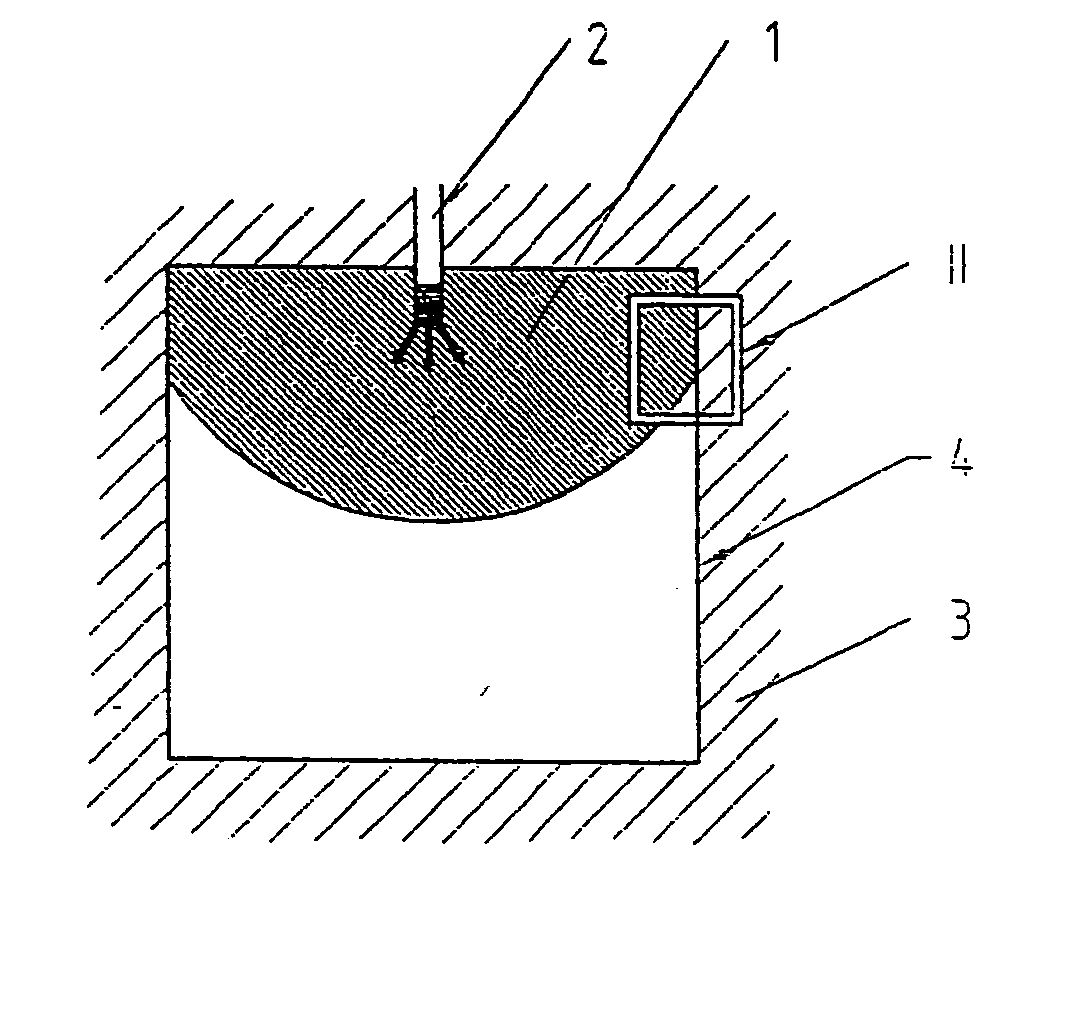

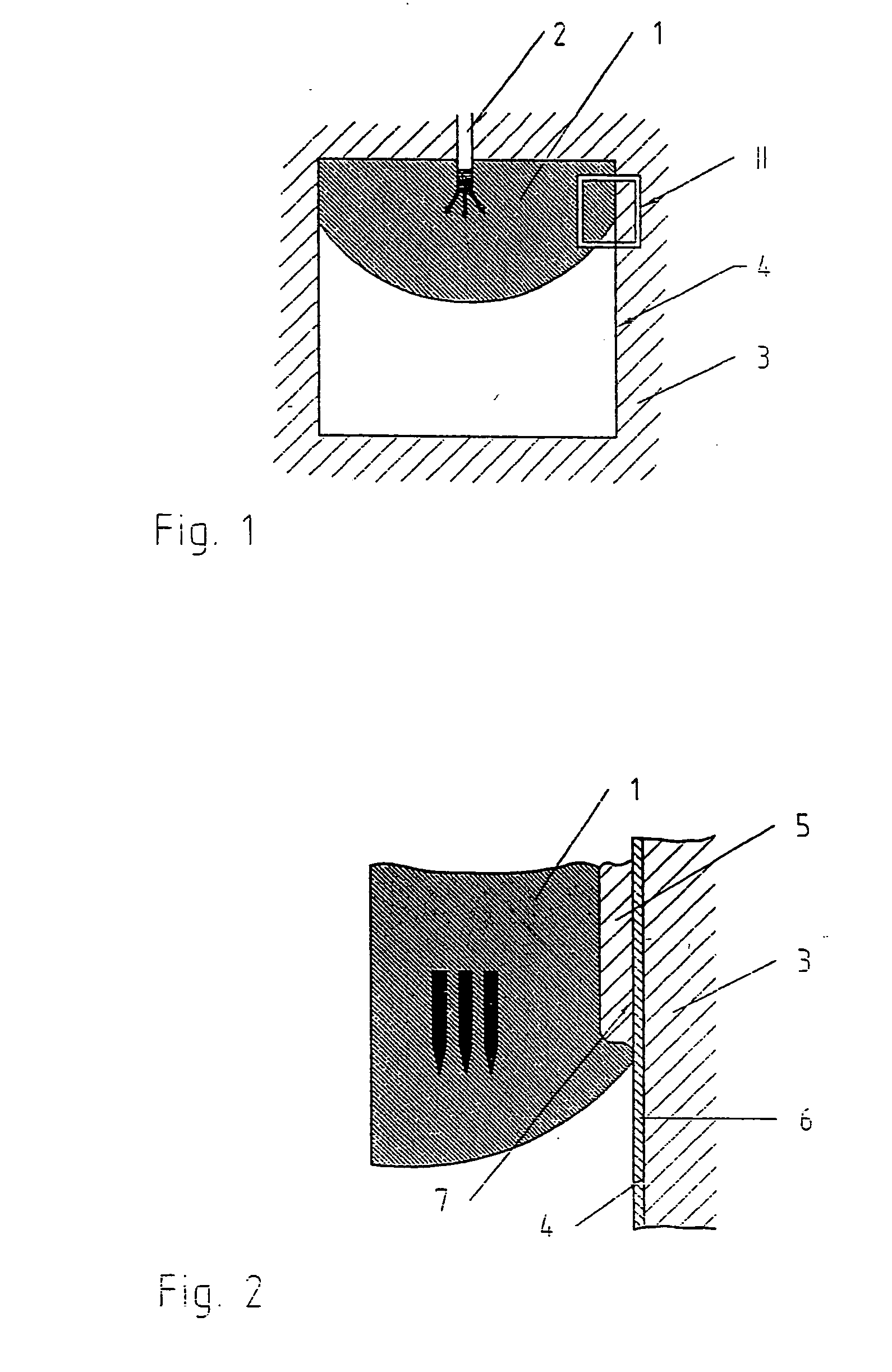

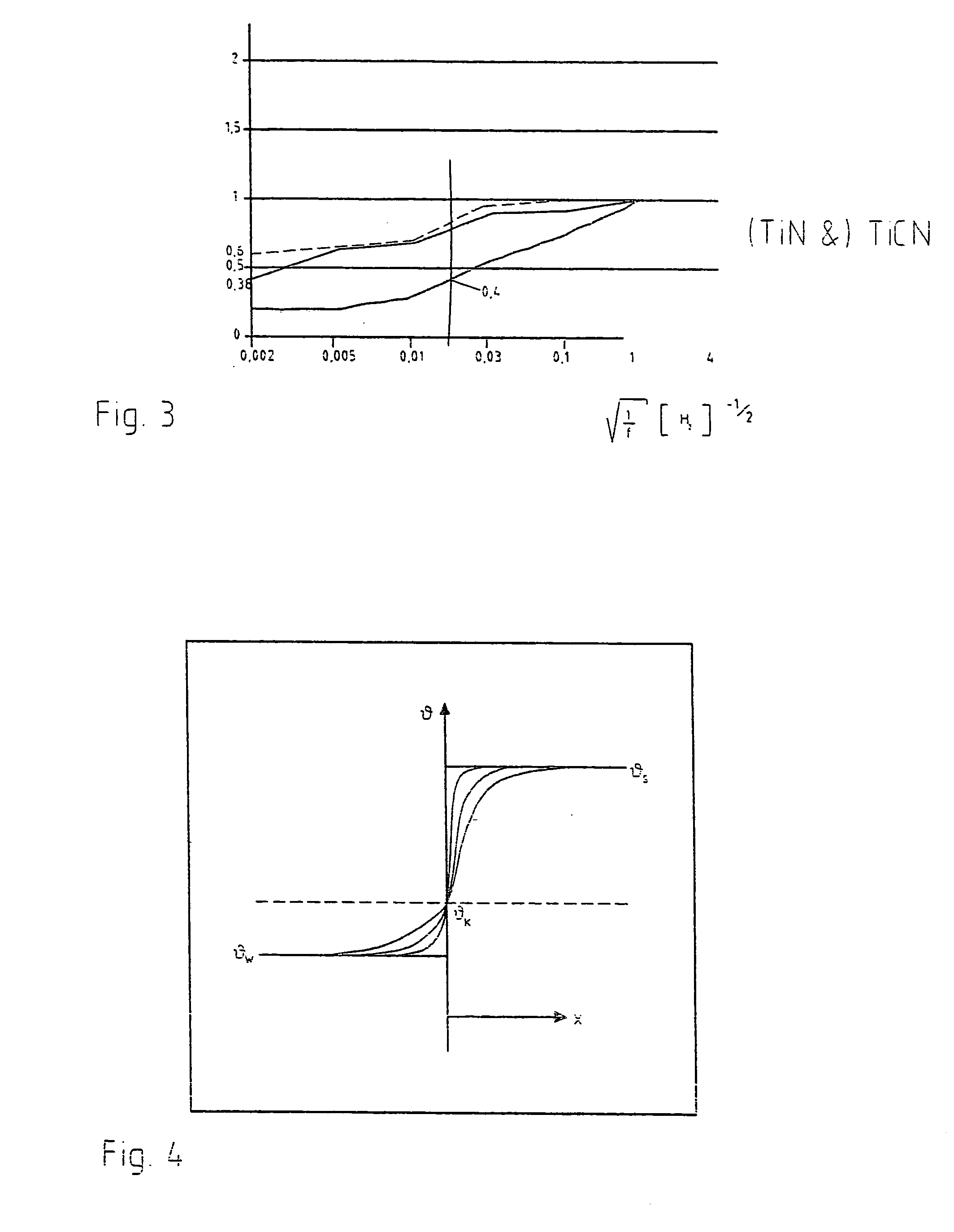

Method of producing quartz glass bodies

InactiveUS6047564AImprove the usefulnessIncrease surface temperatureBlowing machine gearingsGlass deposition burnersVitreous BodiesEngineering

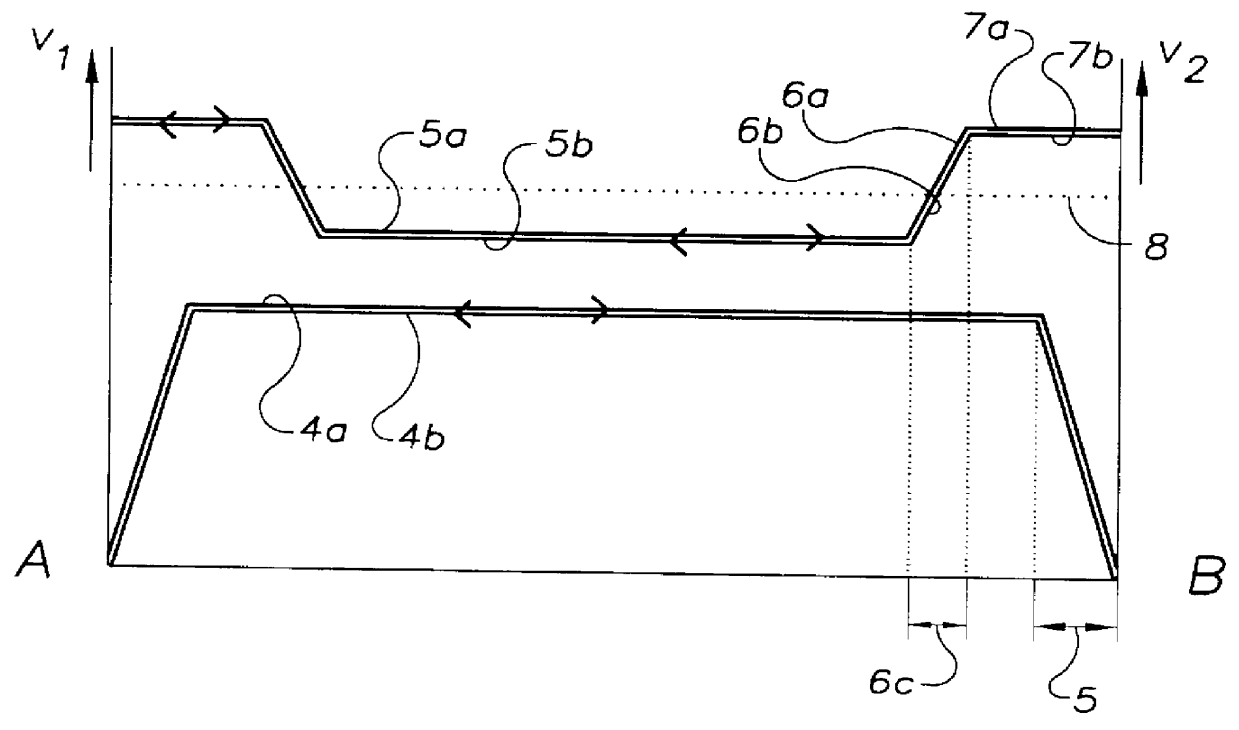

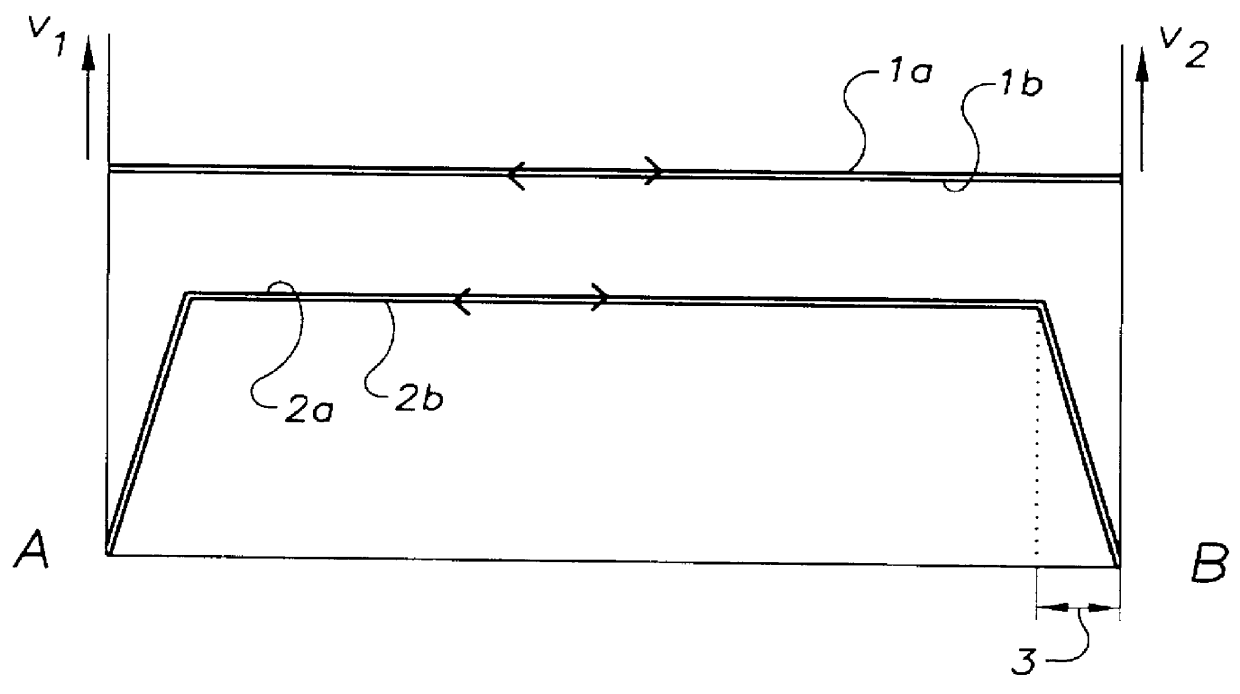

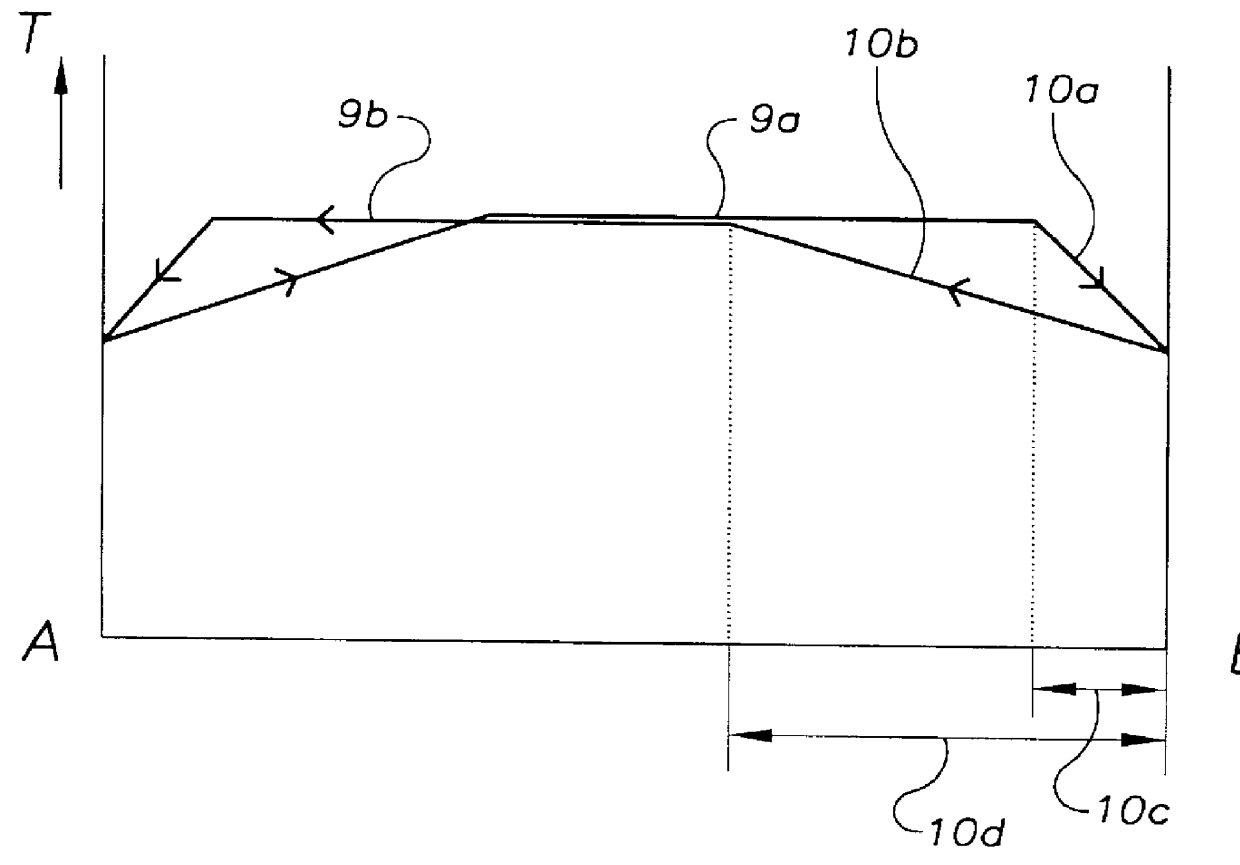

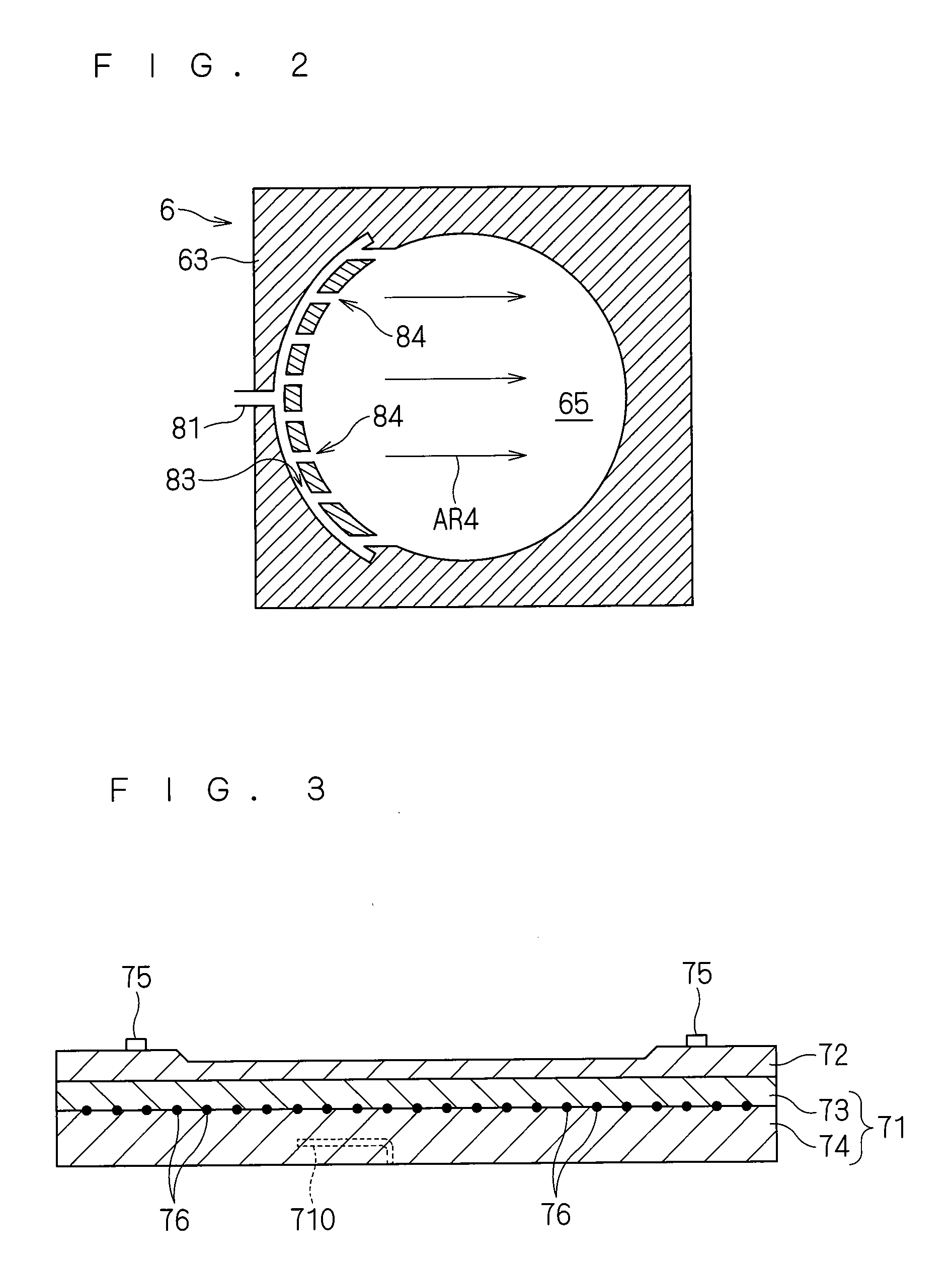

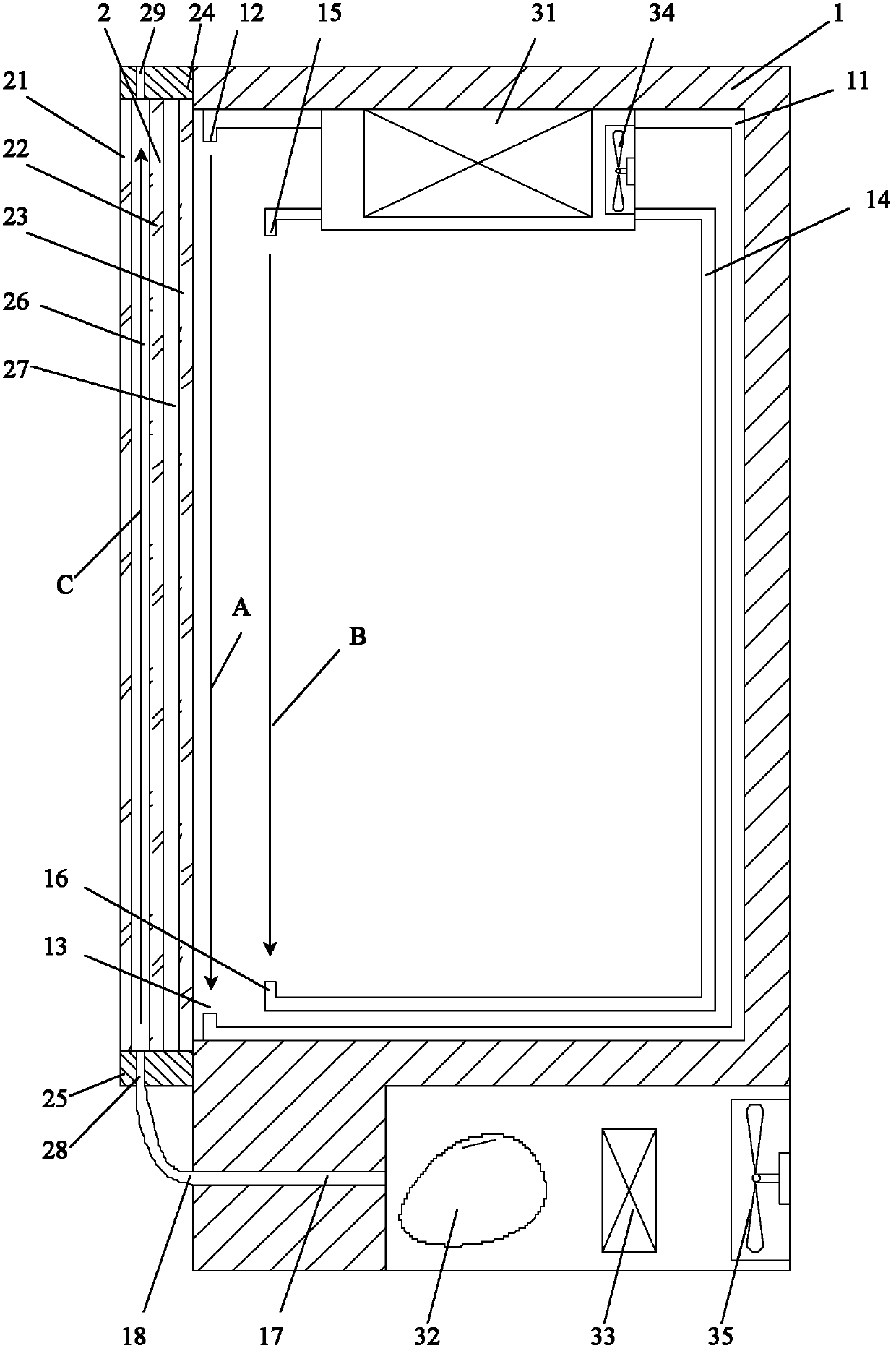

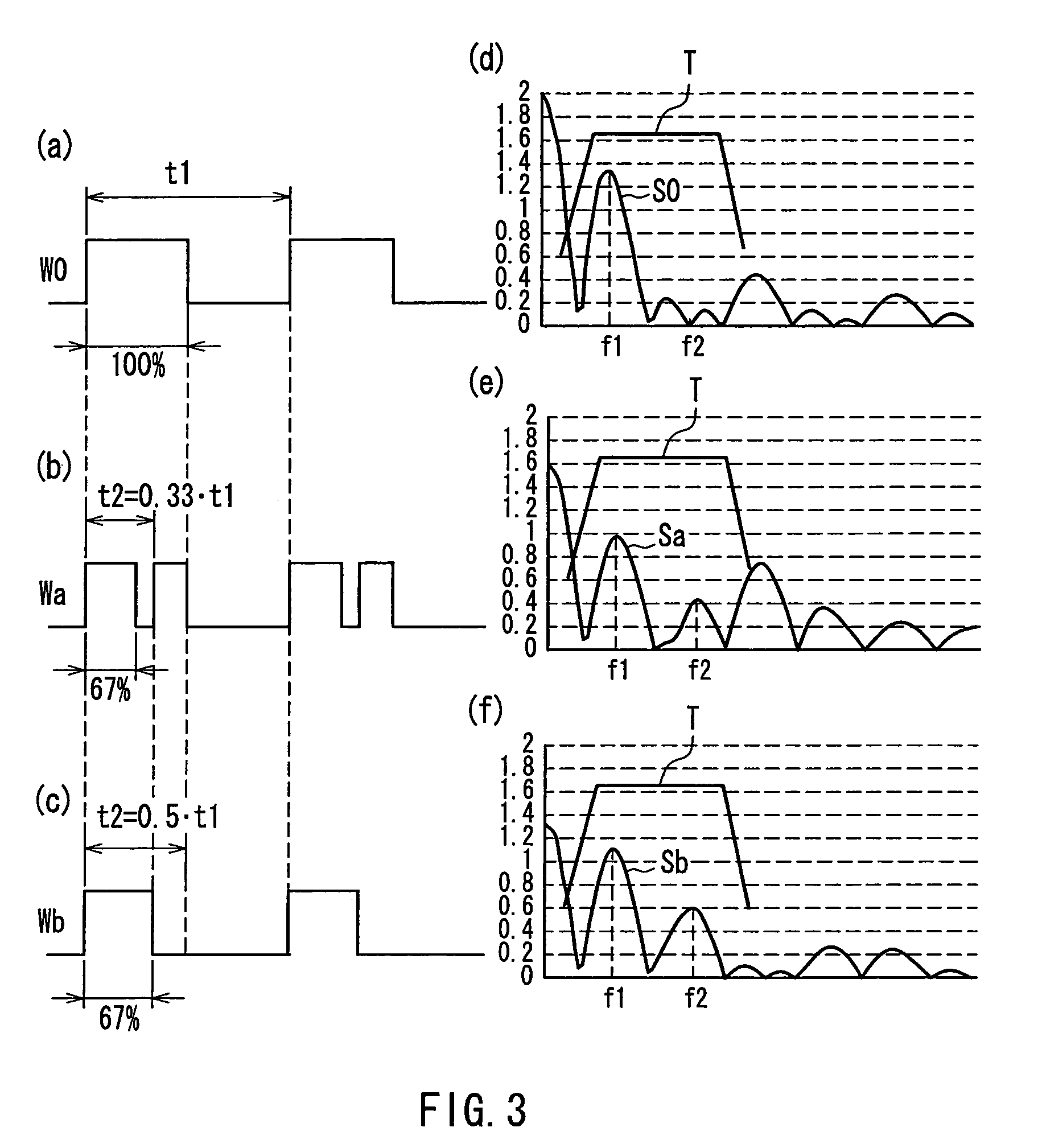

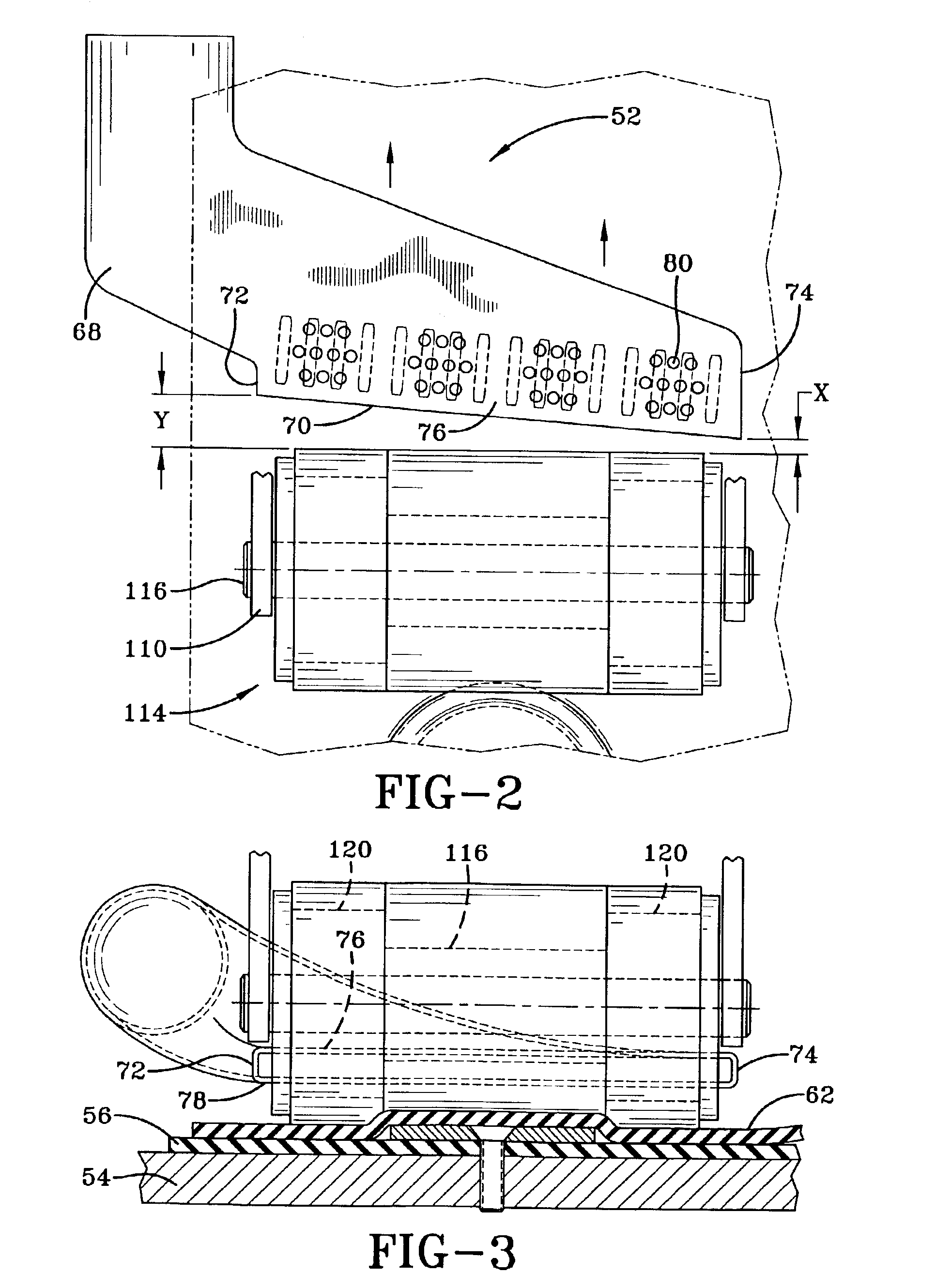

PCT No. PCT / EP97 / 03818 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 17, 1997 PCT Pub. No. WO98 / 03440 PCT Pub. Date Jan. 29, 1998In a known process for the production of quartz glass bodies, SiO2 particles are deposited of the mantle surface of a cylindrical carrier rotating about its longitudinal axis, forming an elongated, porous preform, where the SiO2 particles are formed in a plurality of flame hydrolysis burners which are arranged in at least one burner row parallel to the longitudinal axis of the carrier and are moved at a preset translational speed forward and back between turnaround points at which points their direction of movement is reversed, and in which process the preform is sintered. In order to make available on this basis an easily accomplished process that makes it possible to manufacture a preform which is largely free of localized density variations, the invention proposes on the one hand that the base value of the surface temperature of the preform being formed be kept in a range between 1,050 DEG C. and 1,350 DEG C., that the average peripheral velocity of the preform be kept in the range between 8 m / min and 15 m / min and the average translational velocity of the burner row be kept in a range between 300 mm / min and 800 mm / min. On the other hand, the object is also accomplished according to the invention and on the basis of the known process in that in the area of the turnaround points (A, B) the peripheral velocity of the preform being formed is increased and / or the flame temperature is lowered and / or the distance of the burners from the preform surface is changed.

Owner:HERAEUS QUARZGLAS

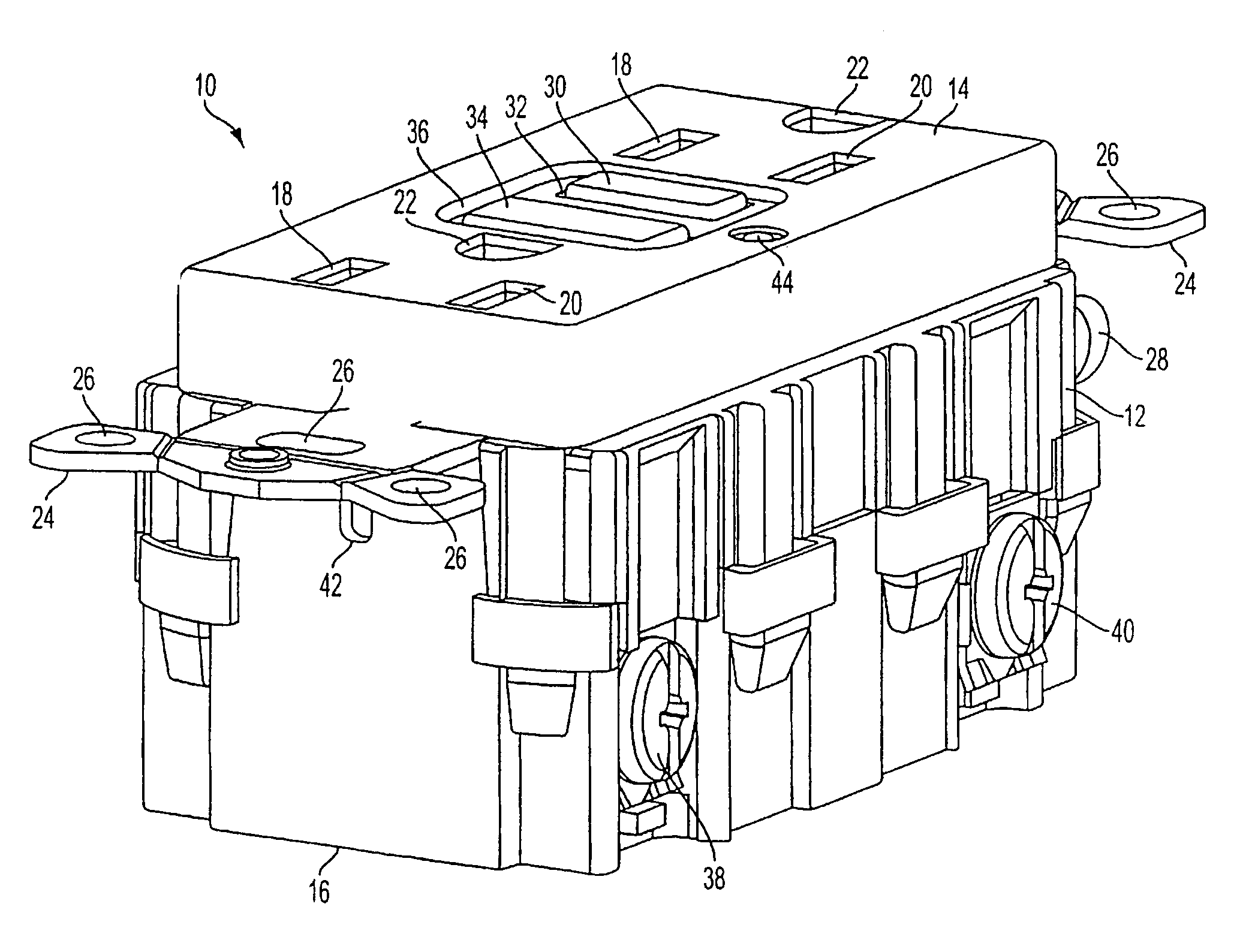

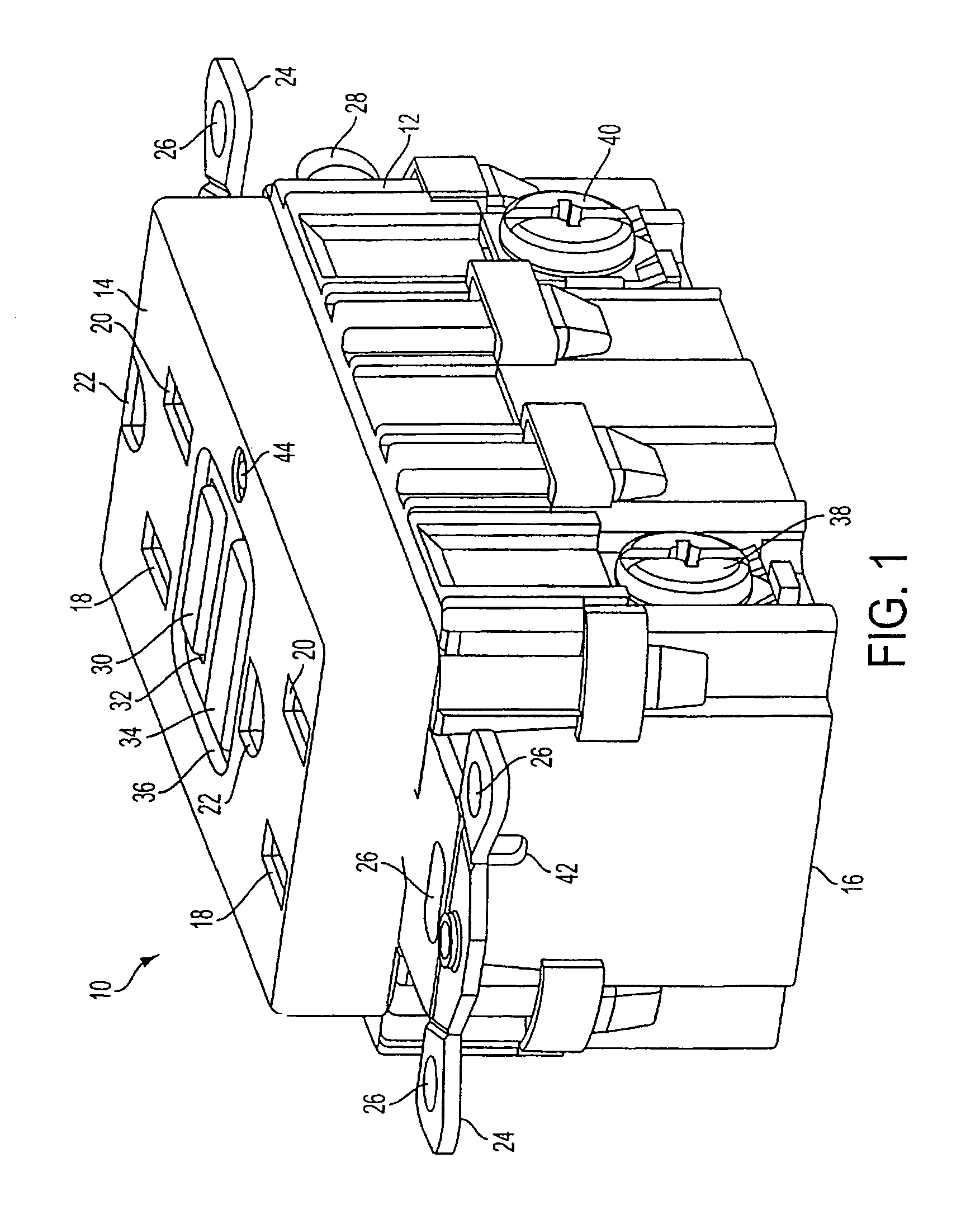

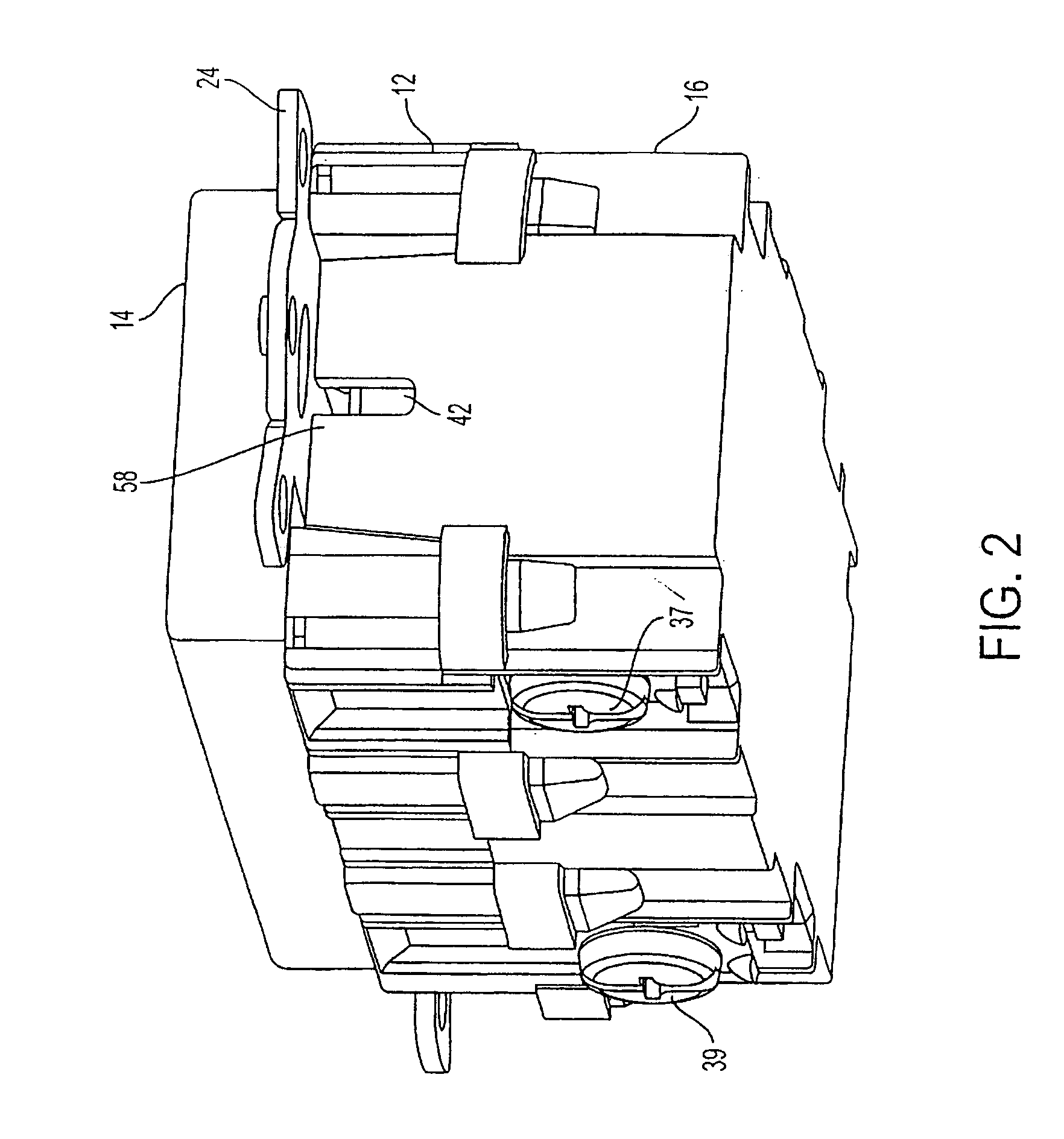

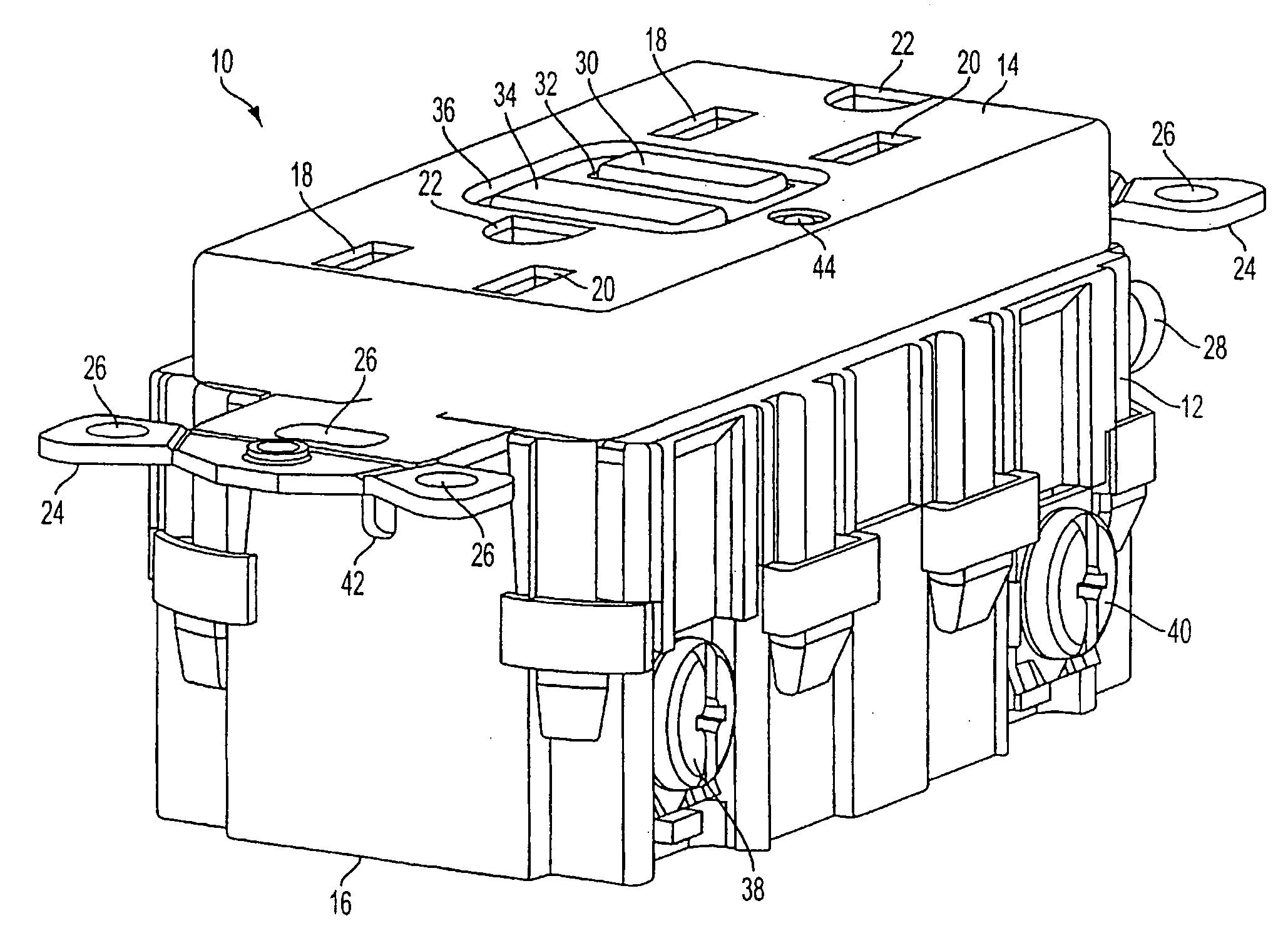

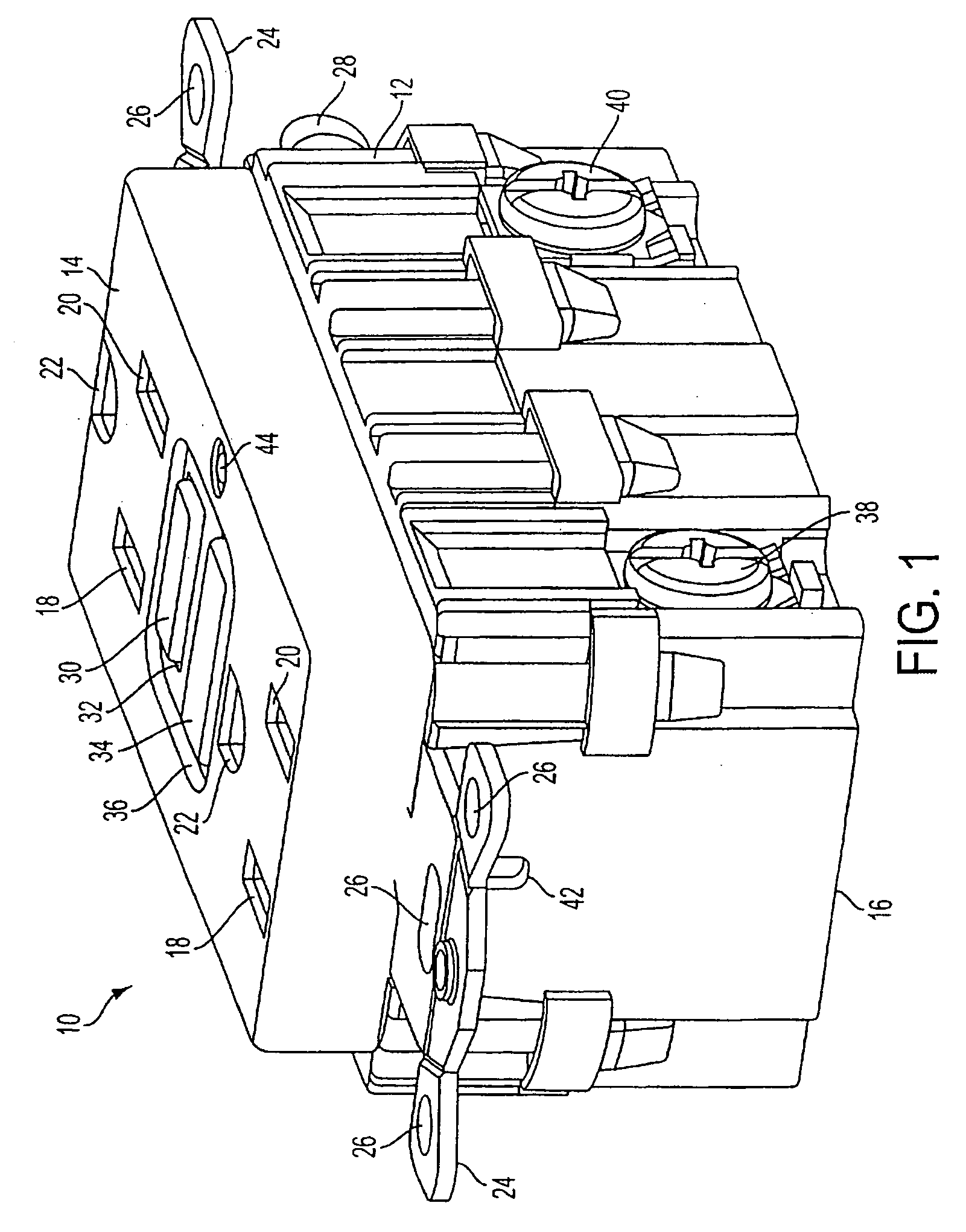

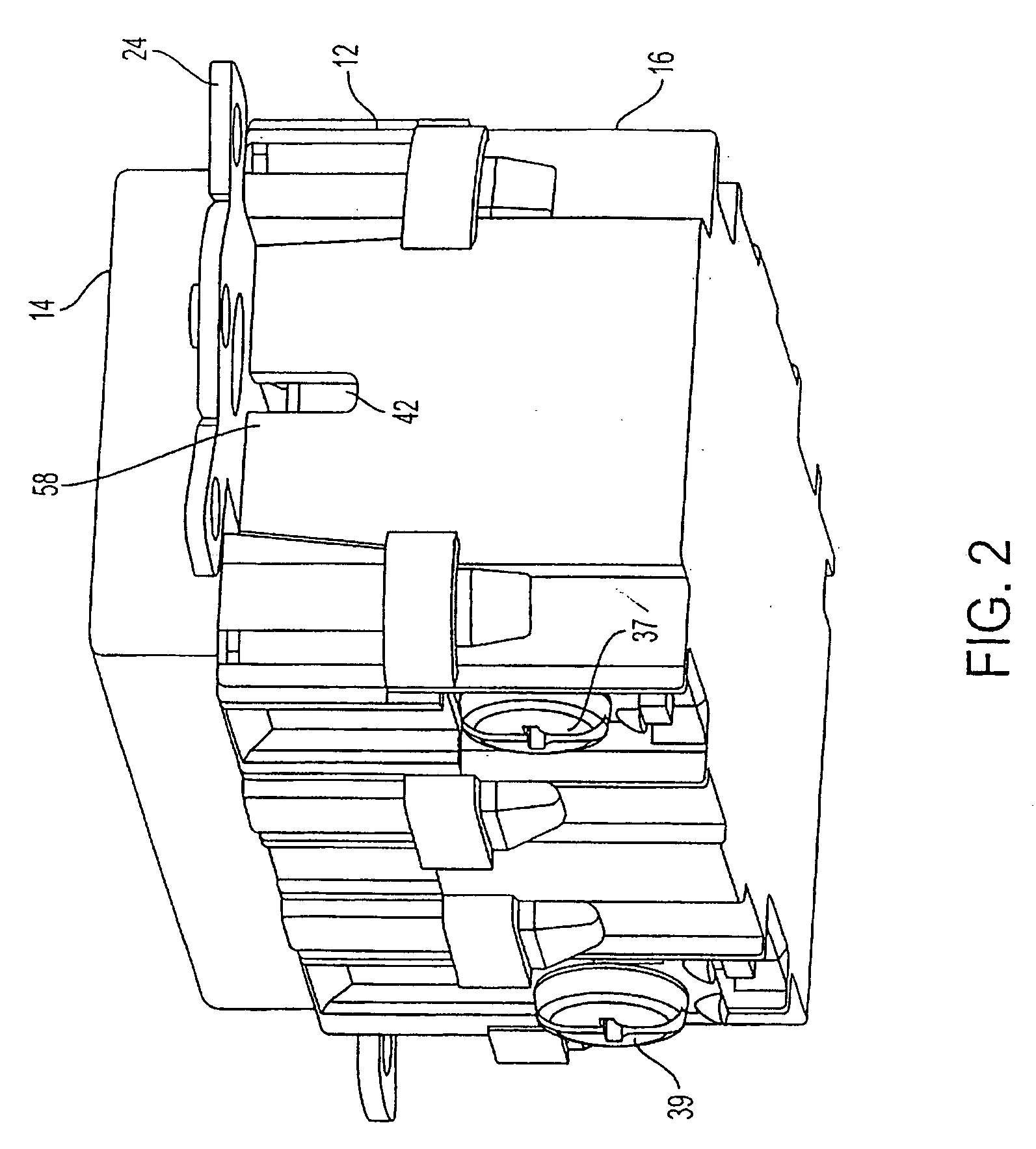

Self testing ground fault circuit interrupter (GFCI) with end of life (EOL) indicator, secondary power supply for EOL and self test circuitry, and device for opening line hot when EOL occurs

ActiveUS7315437B2Increase surface temperatureProtective switch detailsSwitch operated by earth fault currentsHeat conductingPrinted circuit board

A self test (ST) ground fault circuit interrupter (GFCI) provides a half wave rectifier for powering circuitry for determining and annunciating end of life (EOL) of the GFCI regardless of a shorted diode bridge or opening of a printed circuit board (PCB) trace. A fuse resistor is provided to open before an open PCB trace can occur. A microprocessor-controlled heat-conducting circuit is provided adjacent to a thermal fuse to controllably open the thermal fuse and remove power from face receptacle contacts and load terminals when EOL occurs.

Owner:HUBBELL INC

Self testing ground fault circuit interrupter (GFCI) with end of life (EOL) indicator, secondary power supply for EOL and self test circuitry, and device for opening line hot when EOL occurs

ActiveUS20070279814A1Increase surface temperatureProtective switch detailsSwitch operated by earth fault currentsDiode bridgePrinted circuit board

A self test (ST) ground fault circuit interrupter (GFCI) provides a half wave rectifier for powering circuitry for determining and annunciating end of life (EOL) of the GFCI regardless of a shorted diode bridge or opening of a printed circuit board (PCB) trace. A fuse resistor is provided to open before an open PCB trace can occur. A microprocessor-controlled heat-conducting circuit is provided adjacent to a thermal fuse to controllably open the thermal fuse and remove power from face receptacle contacts and load terminals when EOL occurs.

Owner:HUBBELL INC

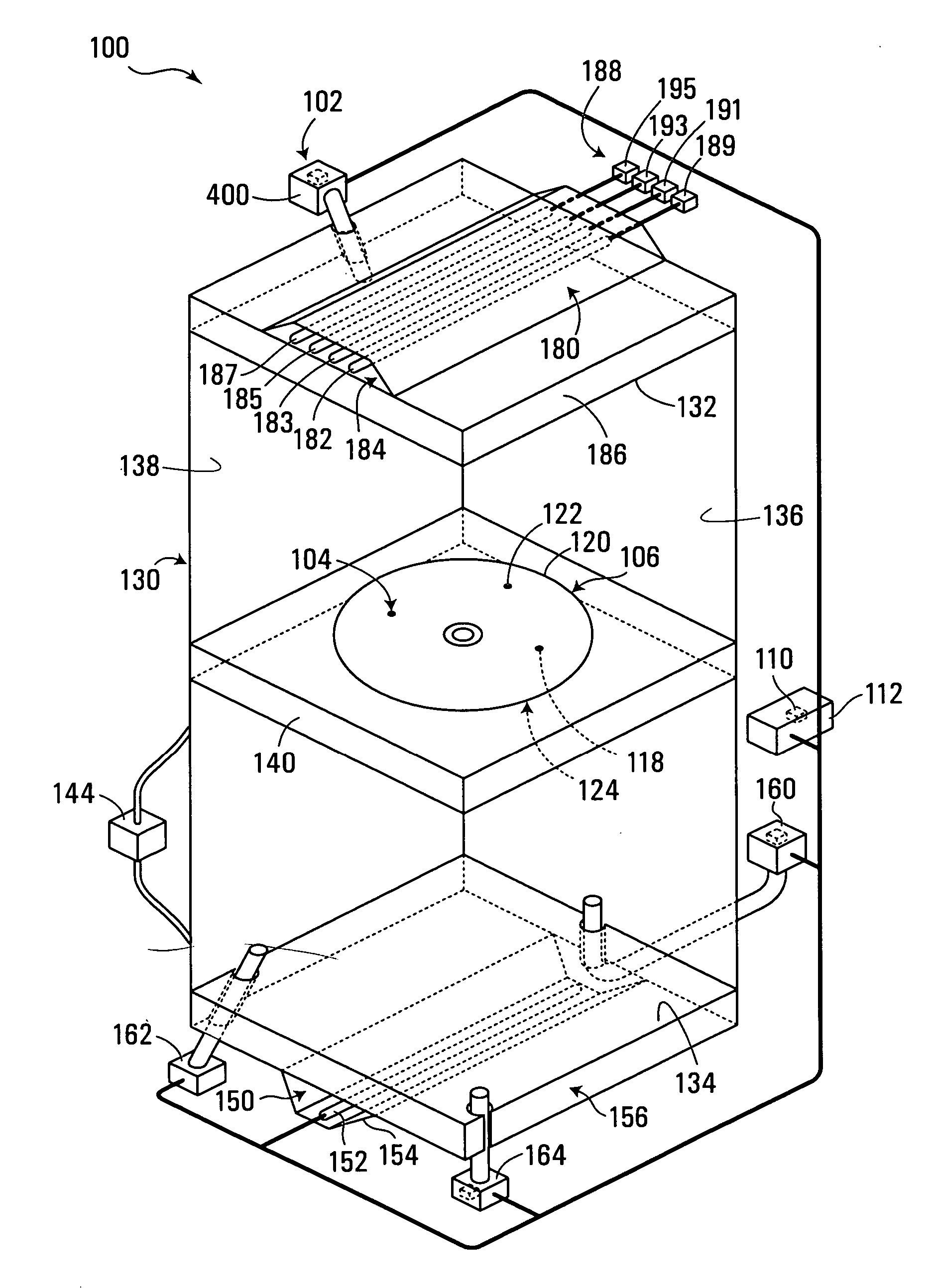

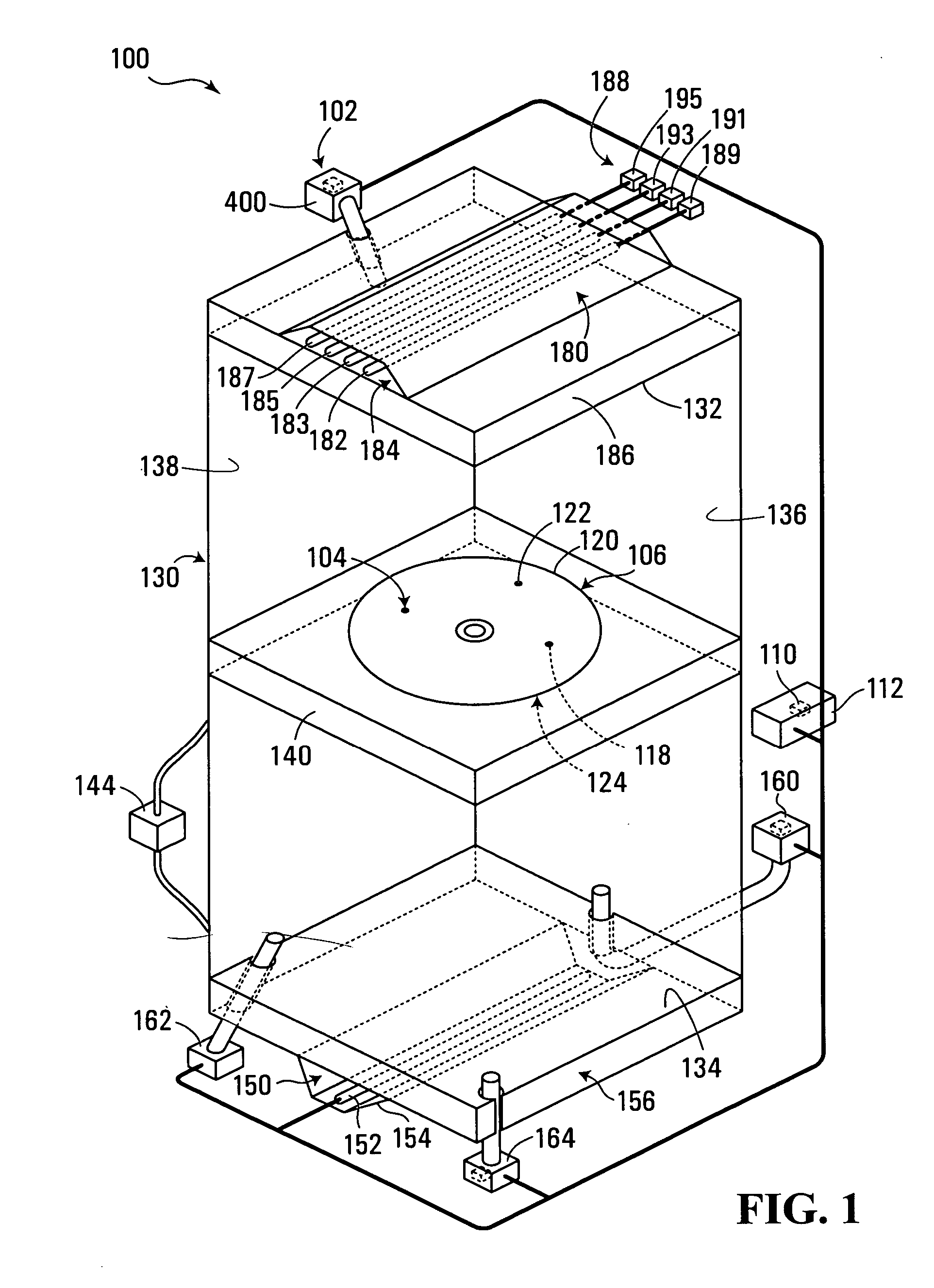

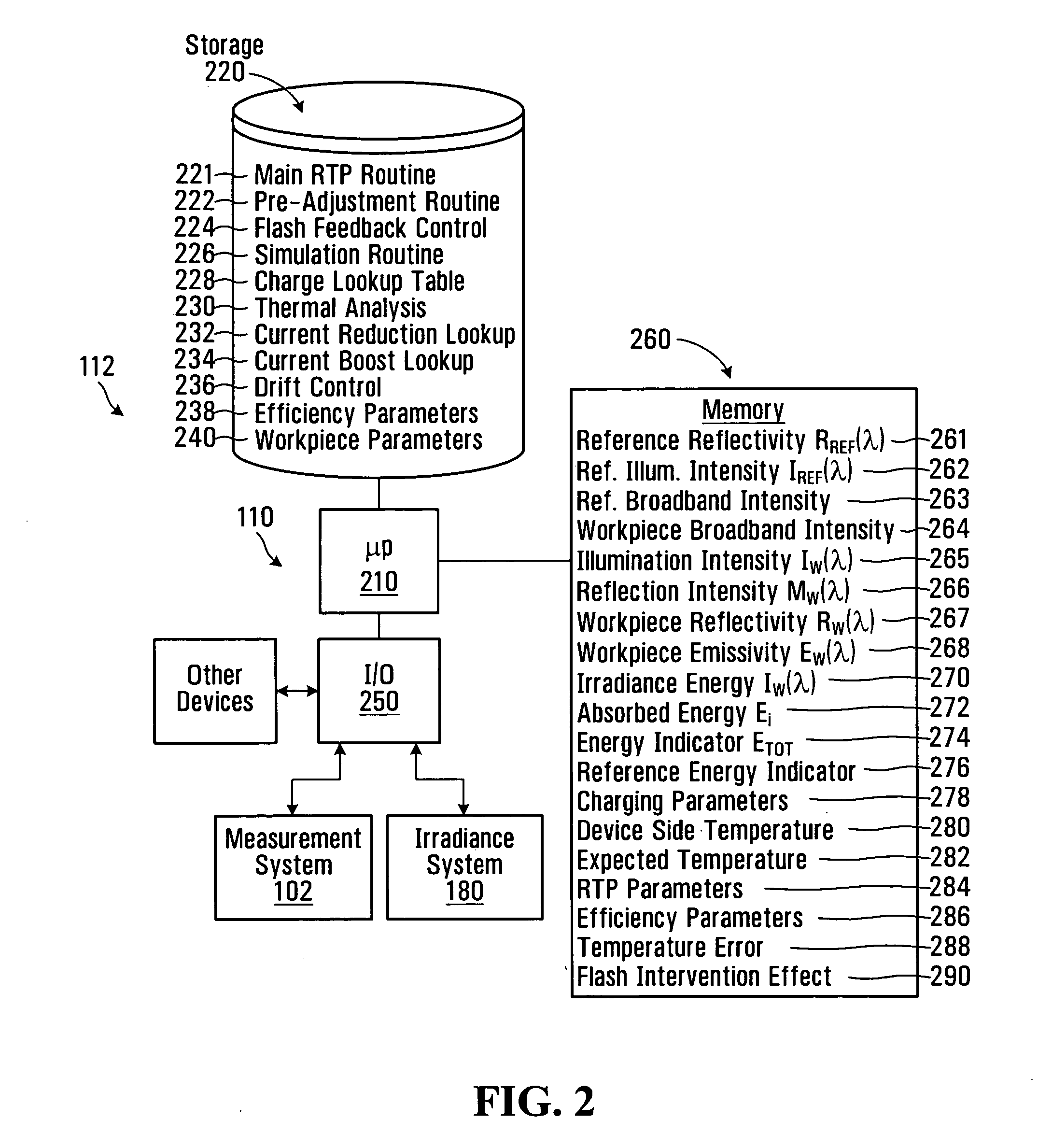

Repeatable heat-treating methods and apparatus

ActiveUS20070069161A1Weakening rangeChange efficiencyRadiation pyrometrySemiconductor/solid-state device testing/measurementTemperature controlHeating effect

A first heat-treating method involves monitoring at least one thermal efficiency parameter associated with an irradiance system configured to produce an irradiance flash incident on a surface of a workpiece, and automatically updating control information used by the irradiance system to produce the irradiance flash, in response to the monitoring of the thermal efficiency parameter. A second method involves predicting a heating effect of an irradiance flash to be incident upon a surface of a workpiece, in response to a measurement of a heating parameter of the surface, and pre-adjusting the irradiance flash, in response to the predicted heating effect. A third method involves measuring a temperature of a surface of a workpiece during an initial portion of an irradiance flash incident on the surface, and controlling a power of a remaining portion of the irradiance flash, in response to the temperature.

Owner:MATTSON TECHNOLOGY +1

Heat sink and method of making same

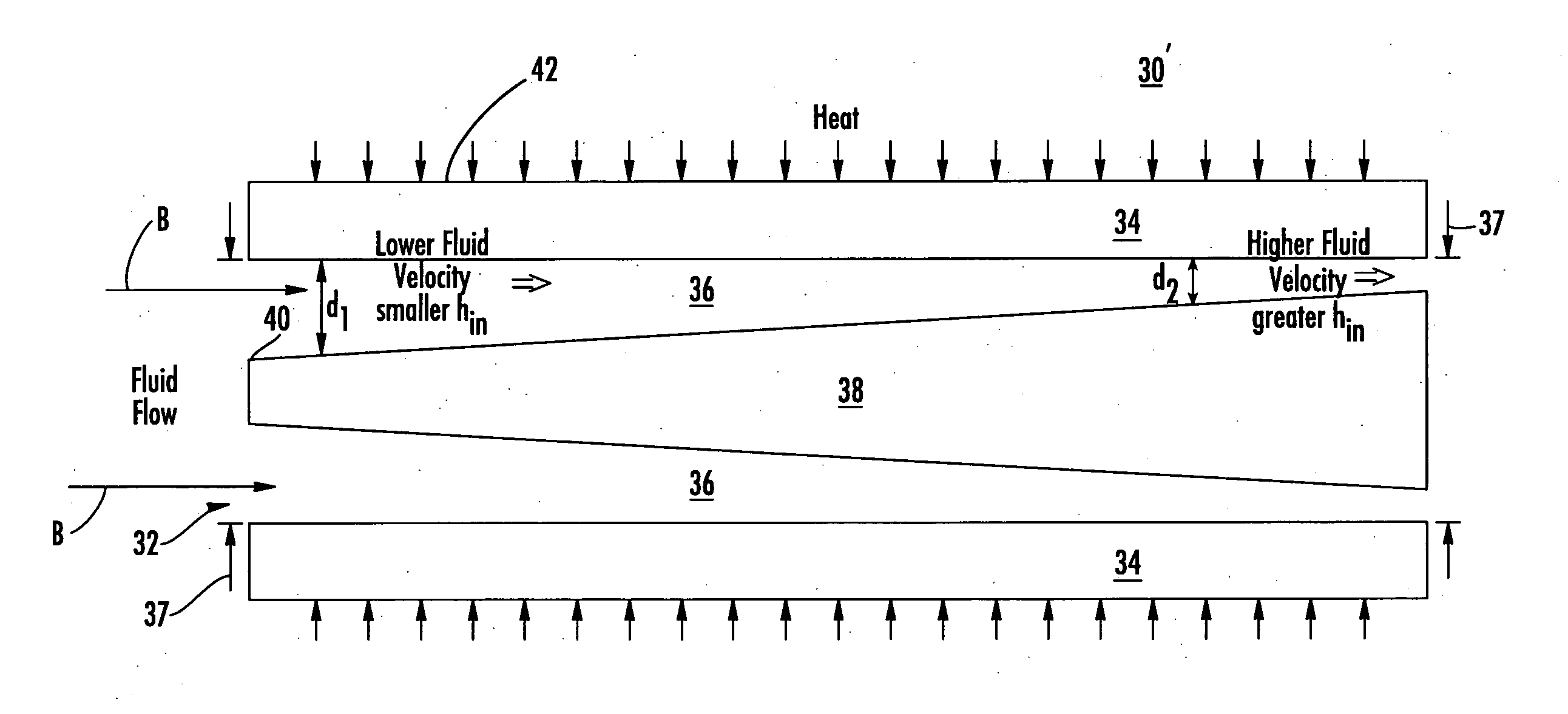

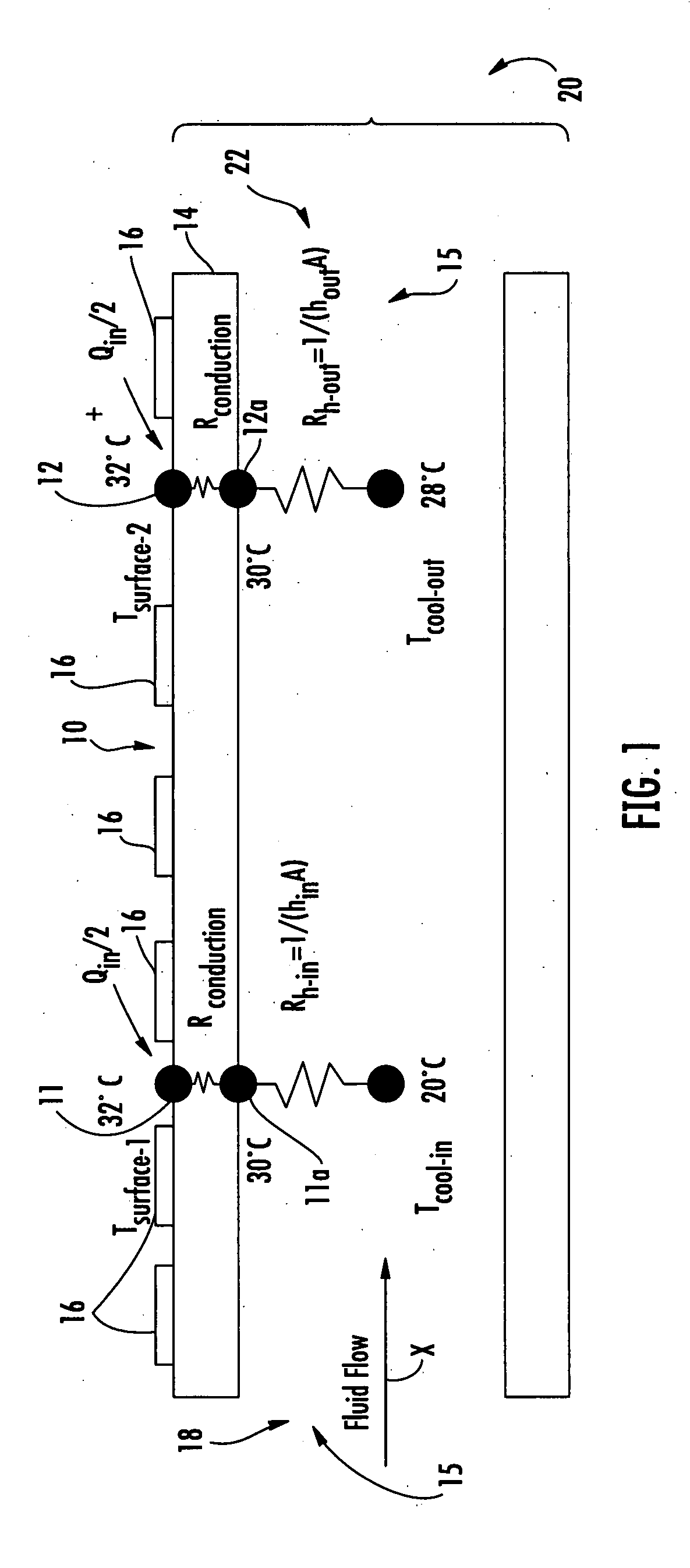

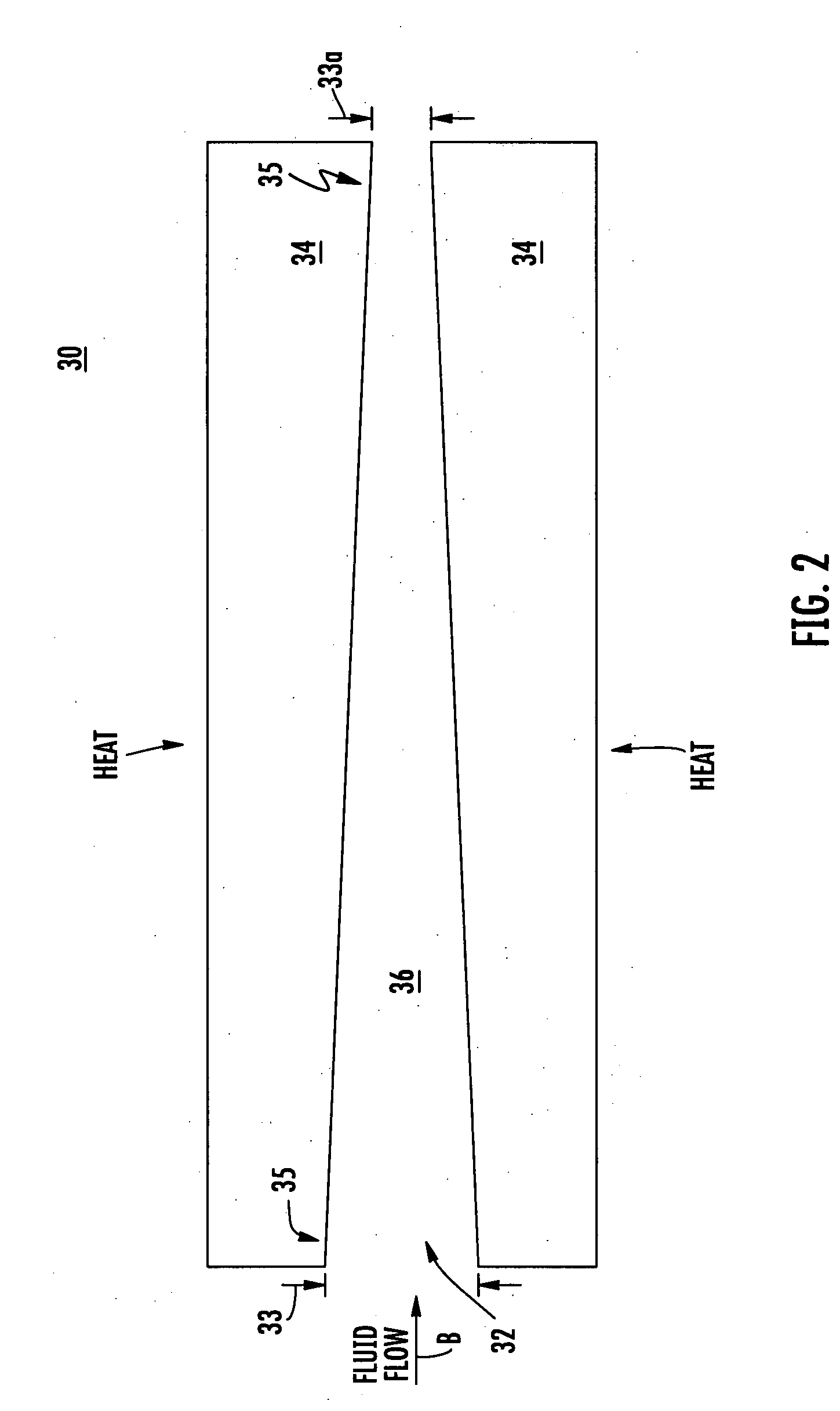

ActiveUS20070289718A1Less complexReduce riskIndirect heat exchangersHeat transfer modificationCoolant flowEngineering

A heat sink includes a fluid channel and a cooling wall in contact with coolant flowing in the fluid channel. The channel is configured to vary the velocity of coolant along the length of the fluid channel to vary the coolant's heat transfer coefficient and thereby compensate for the coolant's temperature rise along the length of the fluid channel. The result is a heat sink that is isothermal along its length.

Owner:RAYTHEON CO

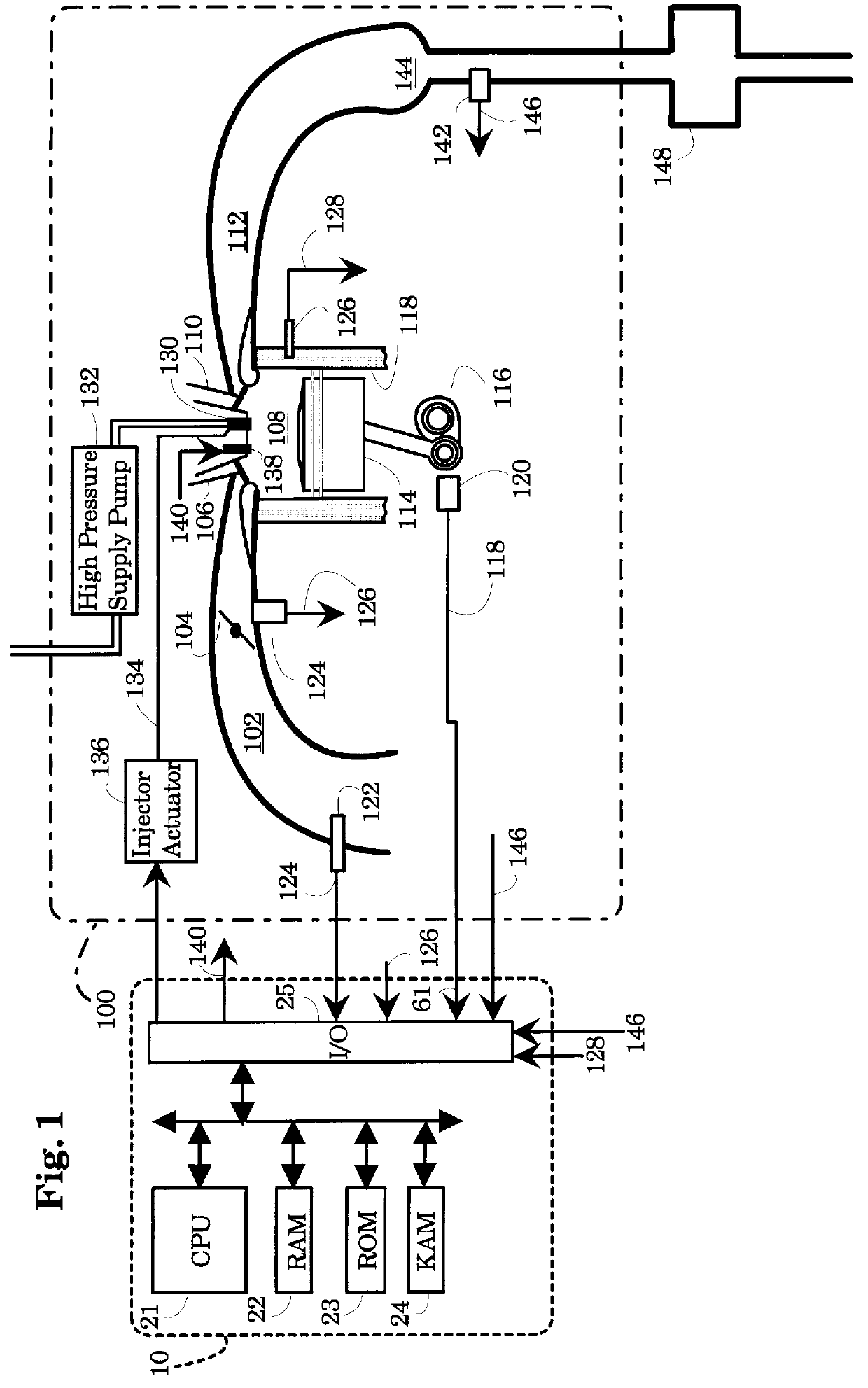

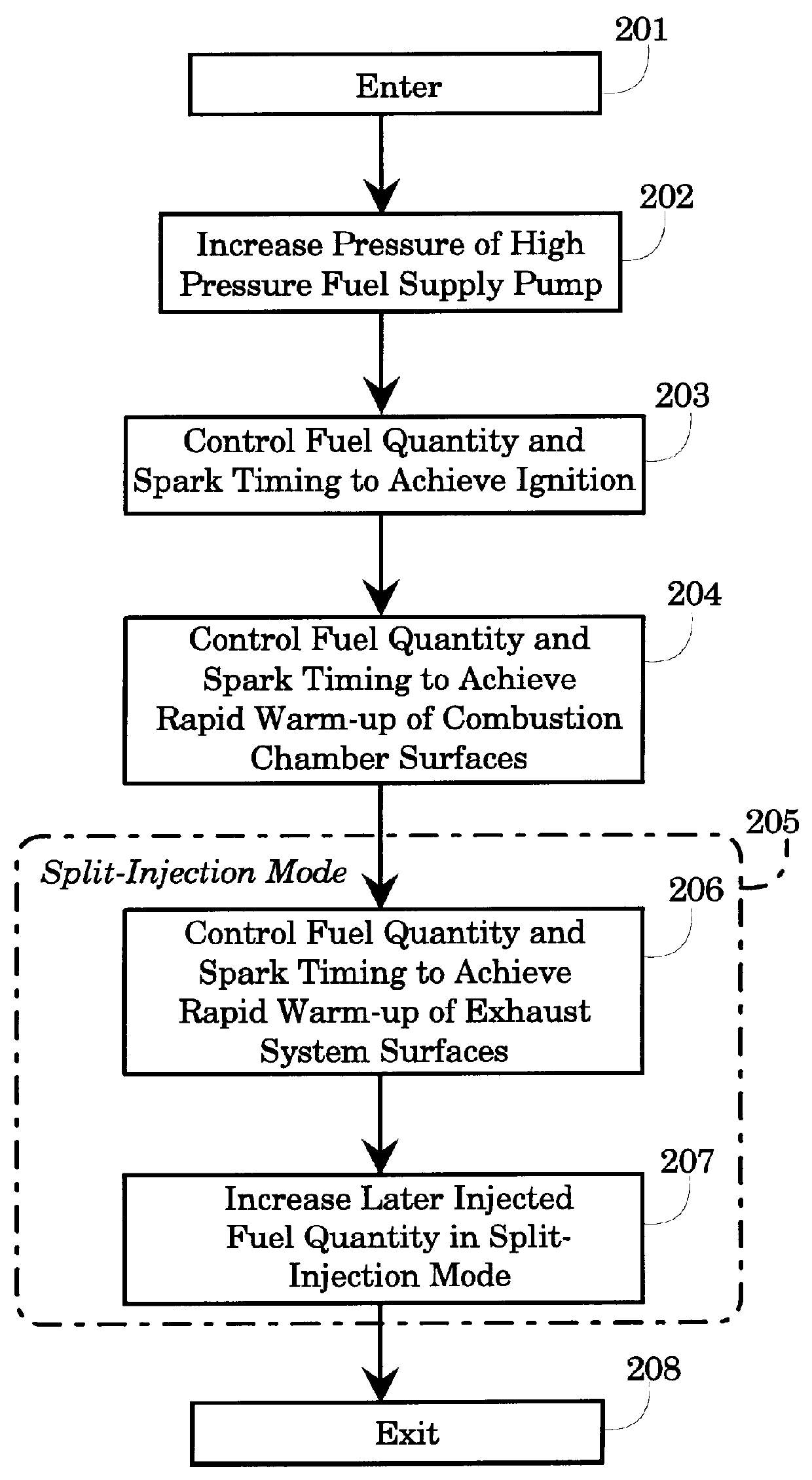

Reduction of cold-start emissions and catalyst warm-up time with direct fuel injection

InactiveUSRE36737E1Reduce decreaseReduce hydrocarbonElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

An internal combustion engine employs fuel injectors positioned to inject fuel directly into combustion chambers of the engine, and an electronic engine controller (EEC) to control operation of the engine. The EEC implements a cold start routine which controls the amount of fuel injected, the time at which the fuel is injected and spark timing to achieve a rapid increase in temperature of the engine and the exhaust system components, thereby decreasing tailpipe hydrocarbon emissions during cold start.

Owner:FORD GLOBAL TECH LLC

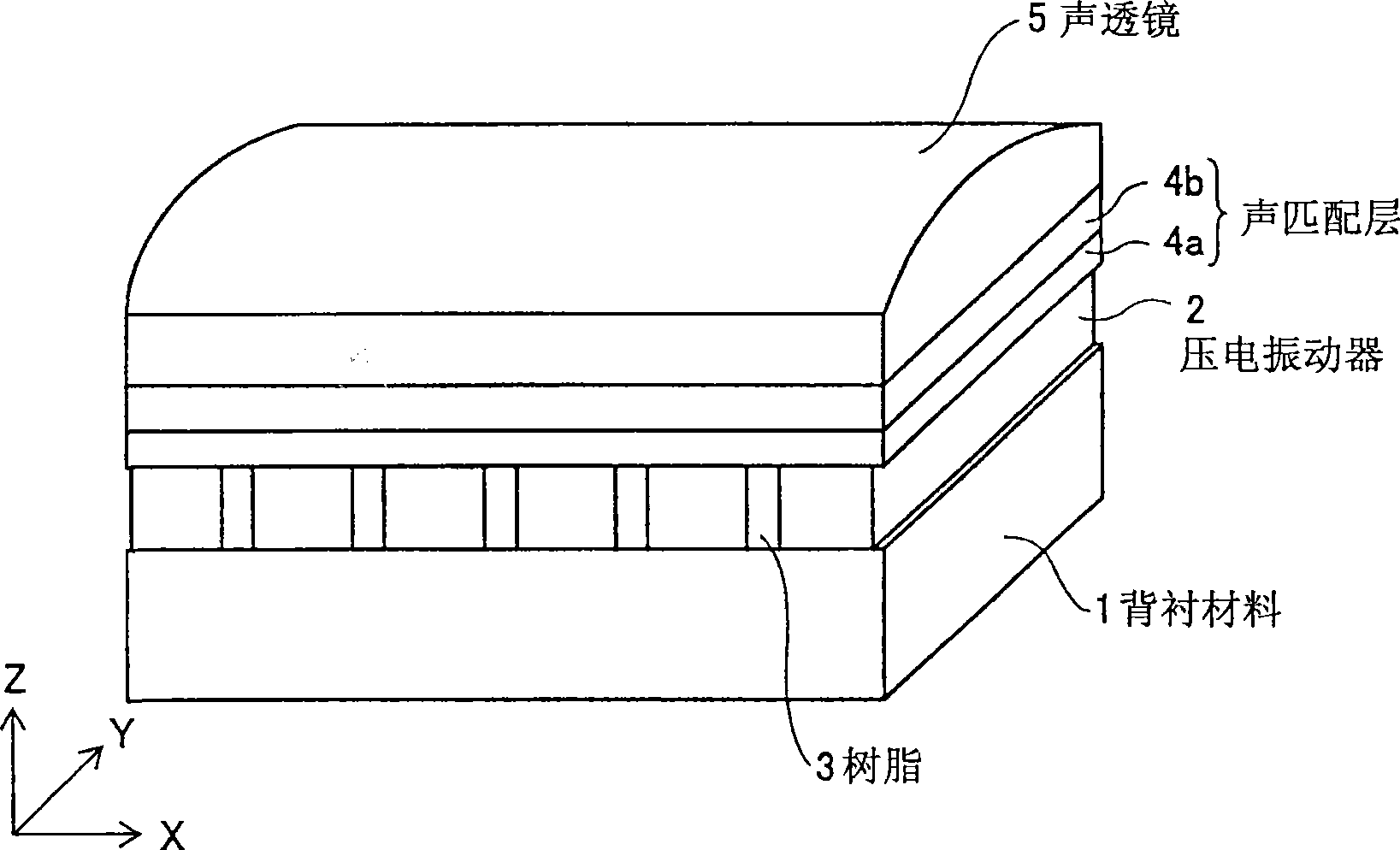

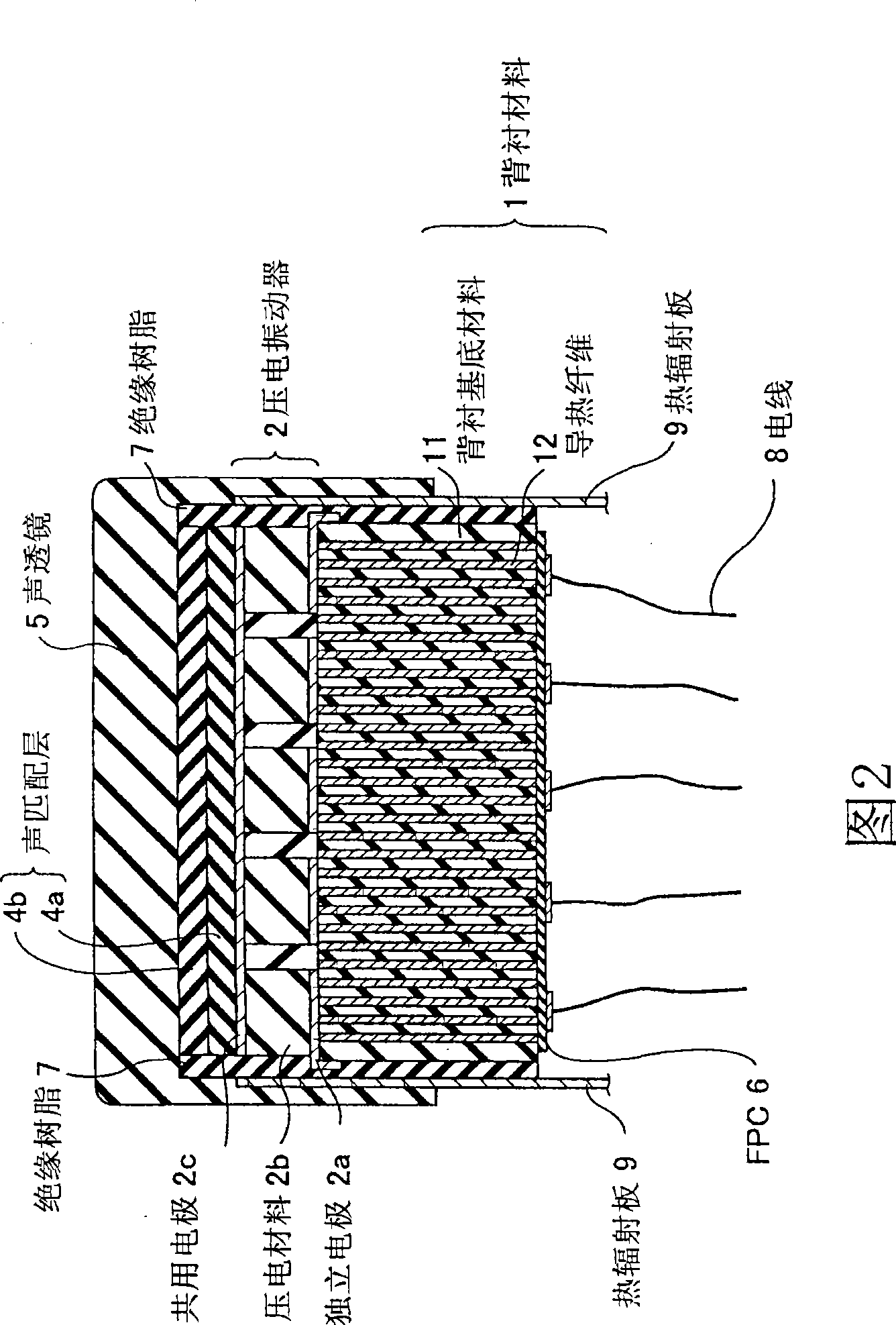

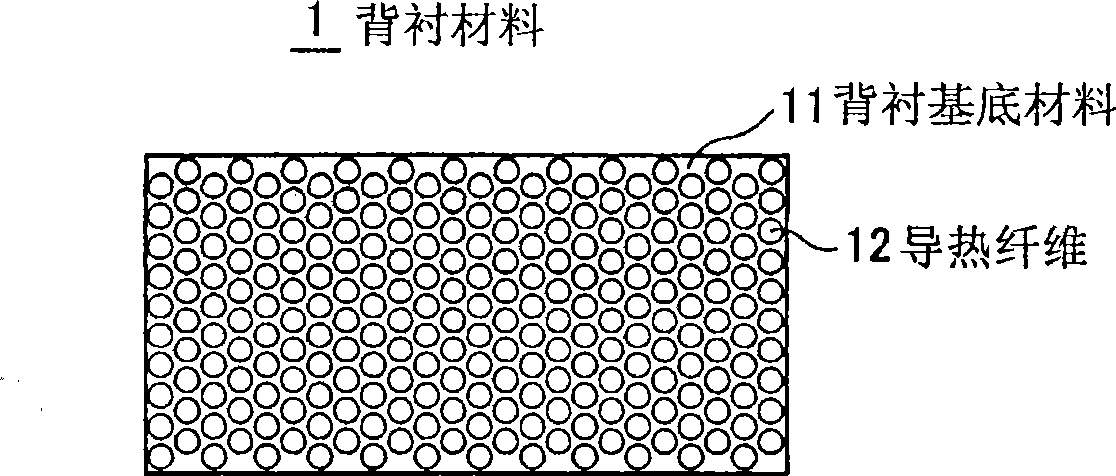

Backing material, ultrasonic probe, ultrasonic endoscope, ultrasonic diagnostic device, and ultrasonic endoscope device

InactiveCN101444430AImprove thermal conductivityIncrease surface temperatureUltrasonic/sonic/infrasonic diagnosticsSurgeryFiberHeat conducting

A backing material for suppressing the surface temperature rise of an ultrasonic probe. This backing material is provided on a back face of at least one vibrator for transmitting and / or receiving ultrasonic waves in an ultrasonic probe, and includes: a backing base material containing a polymeric material; and a heat conducting fiber provided in the backing base material, having a larger coefficient of thermal conductivity than that of the backing base material, and running through without disconnection from a first face of the backing material in contact with the at least one vibrator to a second face different from the first face.

Owner:FUJIFILM CORP

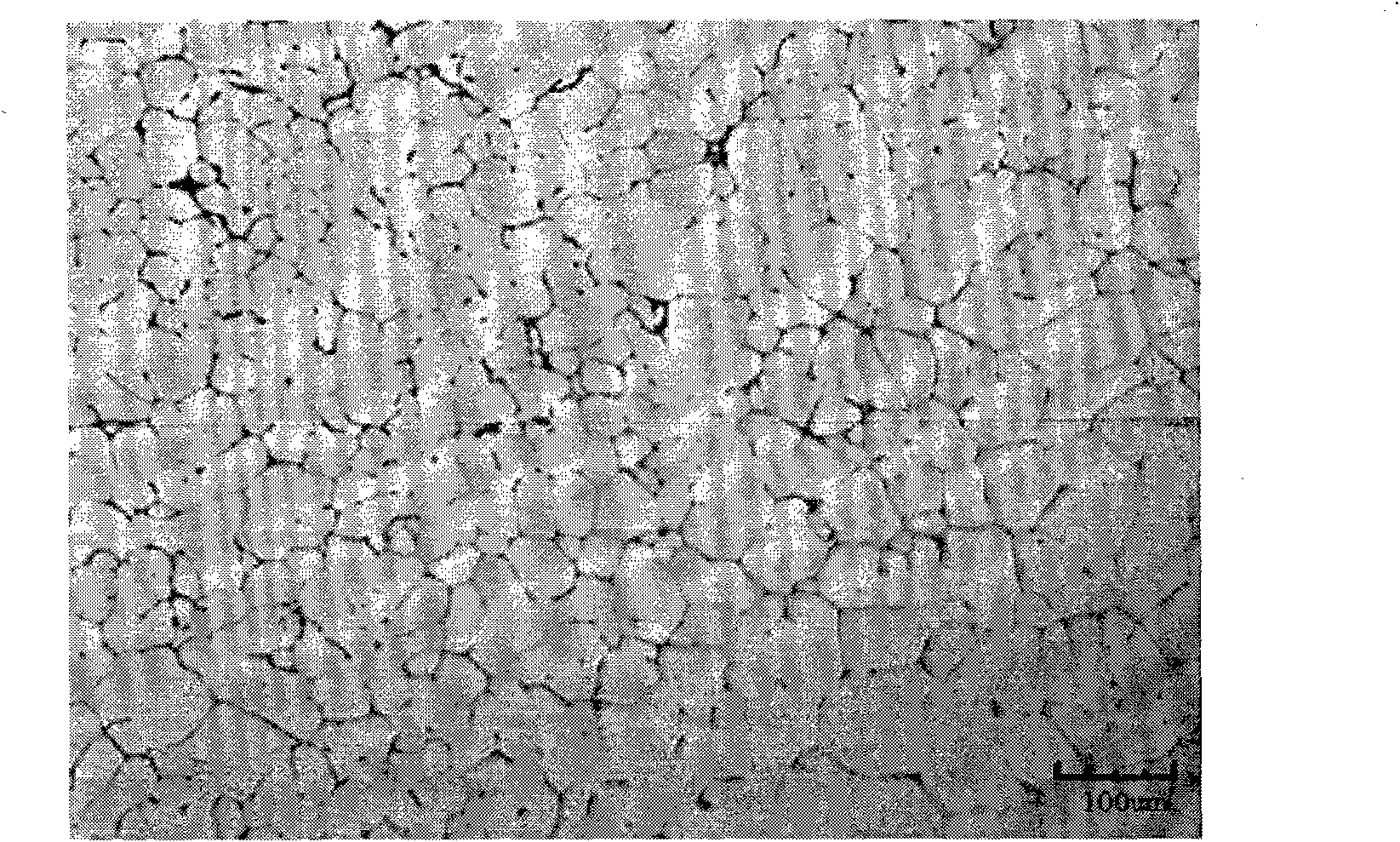

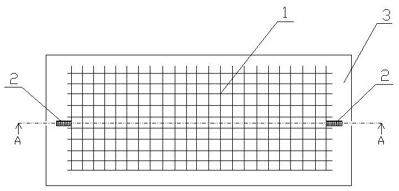

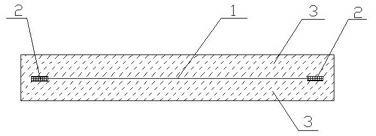

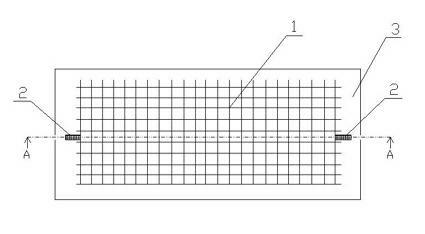

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method to Regulate temperature and Reduce Heat Island Effect

InactiveUS20070113500A1Storage moreReduce air temperatureRoof coveringIn situ pavingsRegulation temperatureEngineering

The present invention relates to a method of regulating and controlling surface temperature of concrete or asphalt structure (the structure) and the like, as well as atmospheric or air temperature around the structure by encapsulating and containing temperature (thermal) control materials (TCMs) or / and water in the structure which constructs or constitutes pavements, roofs, parking lots, walls and the like. Volume ratio of water and one or more TCMs encapsulated and contained in the structure are from 0.01% to 99.99%. Based on simulation analysis, on one hand, the present invention, in summertime, can reduce the highest temperature on surface of the structure by up to 56.5% (reduced by about 46° C.), and reduce the highest temperature of air around the structure by up to 54.4% (reduced by about 48° C.), therefore “heat island” effect in urban areas in summer can significantly be reduced, thus saving cooling energy and benefiting human health. On the other hand, in wintertime, by the invention the surface temperature of the structure can be raised by up to 5.6° C., and the temperature of air around the structure can be raised by up to 5° C., accordingly heating energy demand is reduced.

Owner:ZHAO JOE RU HE

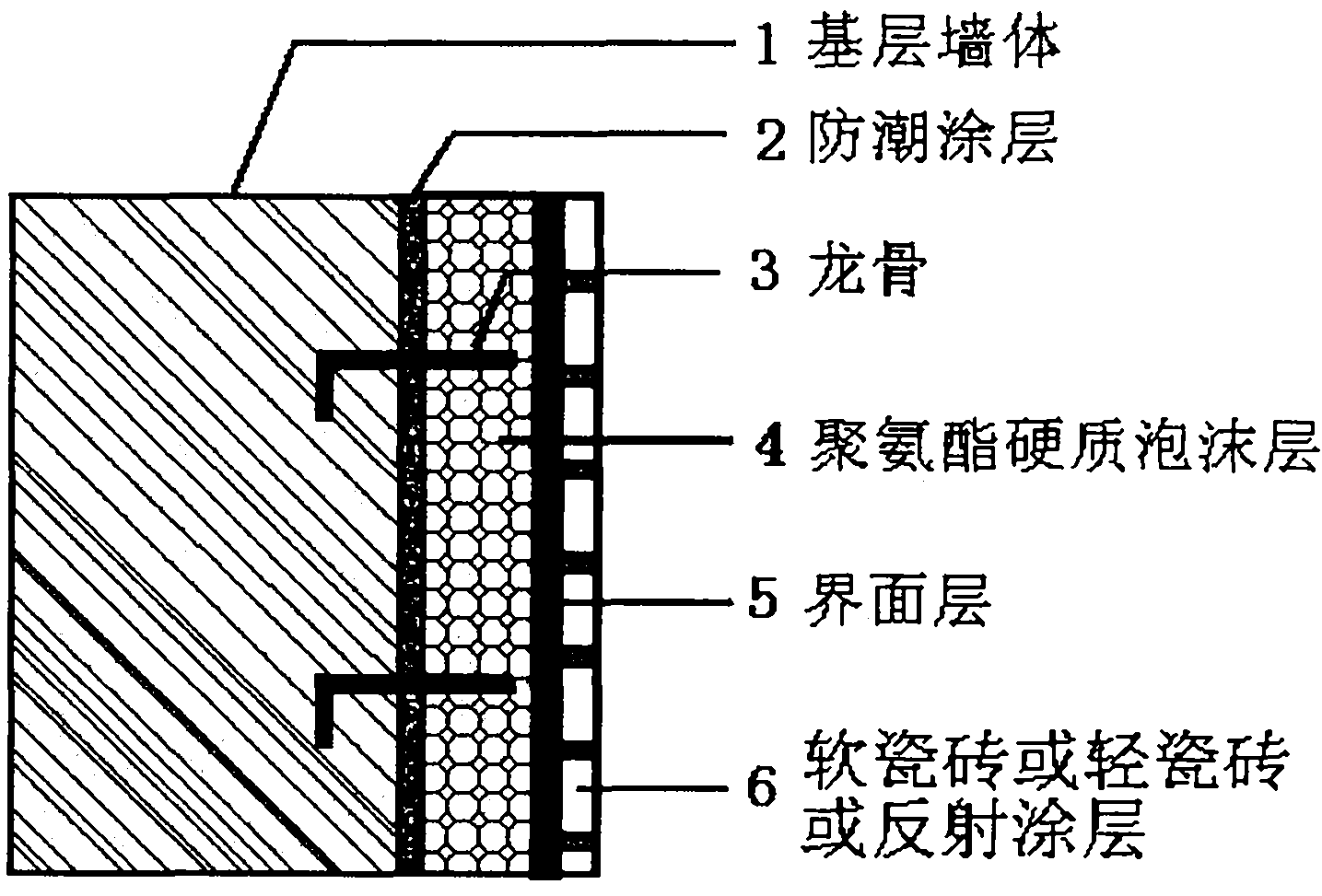

High flame retardant polyurethane rigid foam outer wall thermal insulation system

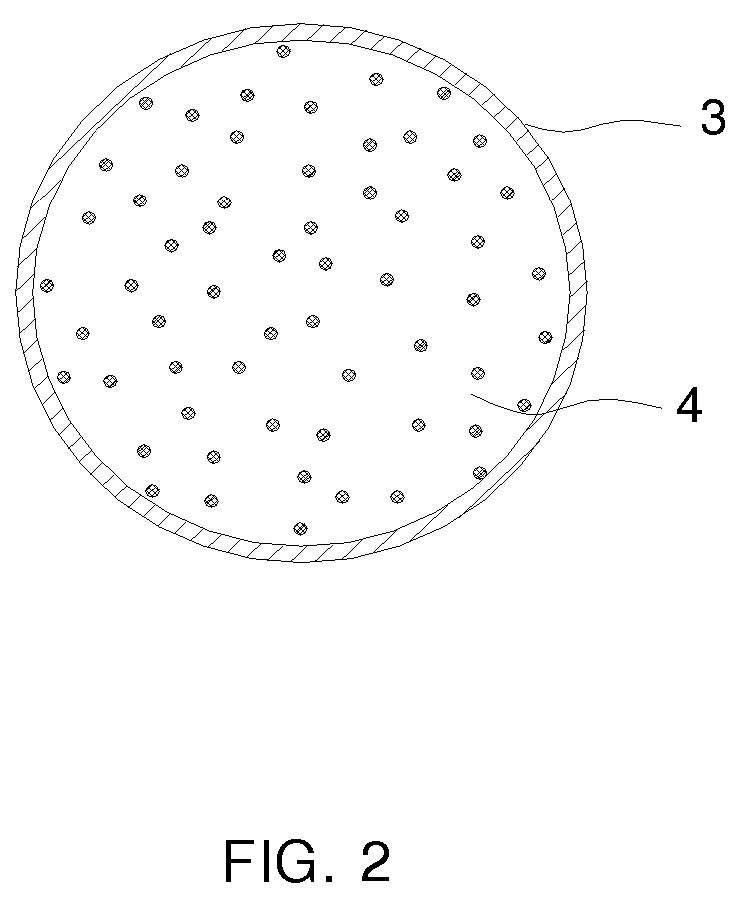

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots and solving the problems of easy cracking and difficult forming during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO.1 flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials in the smelting furnace are smelted; adding magnesium ingots and then smelting; then refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the prepared ingot is 500-600mm, the width is 600mm, and the length is 2,000-3,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 90.5 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

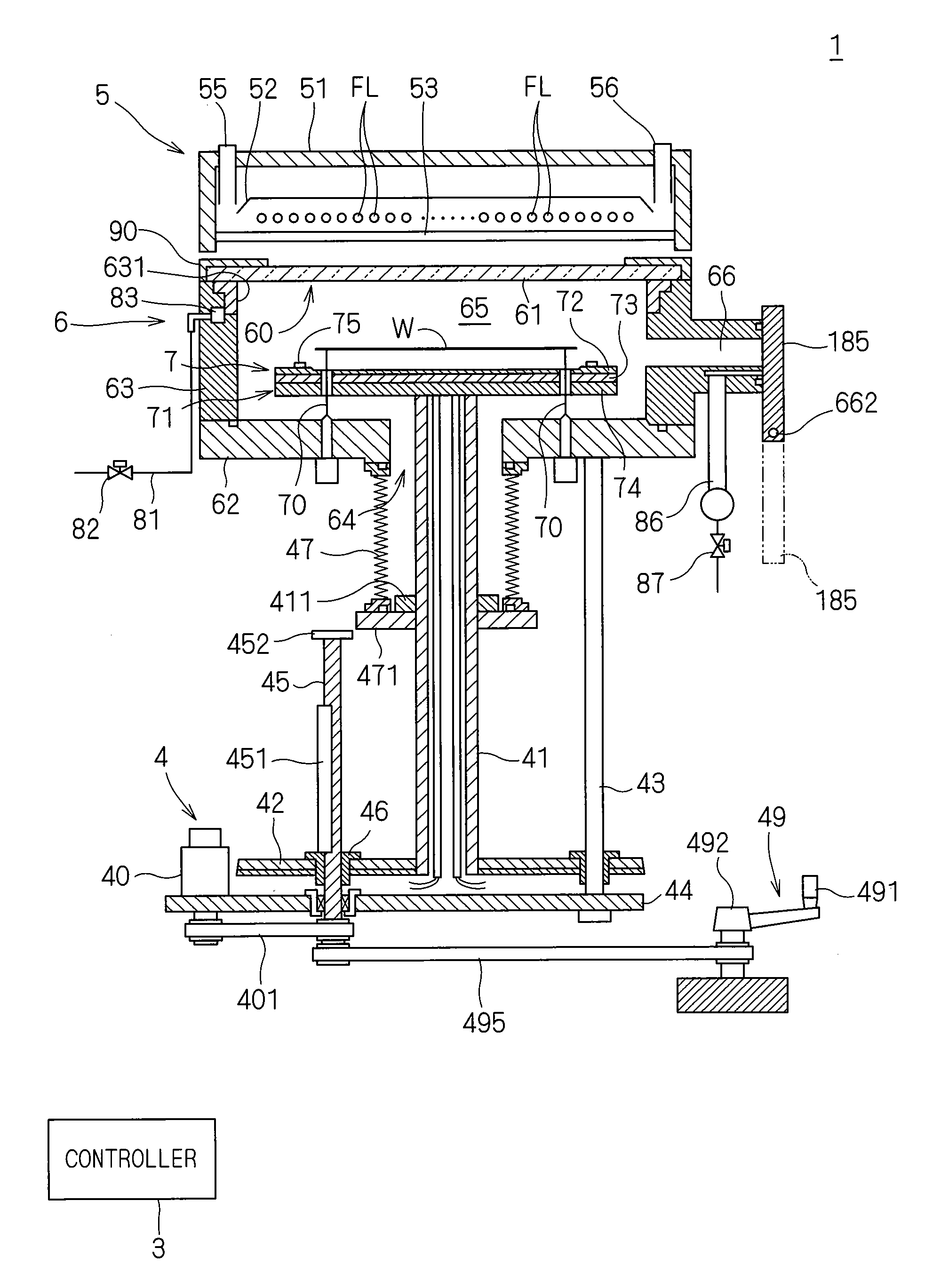

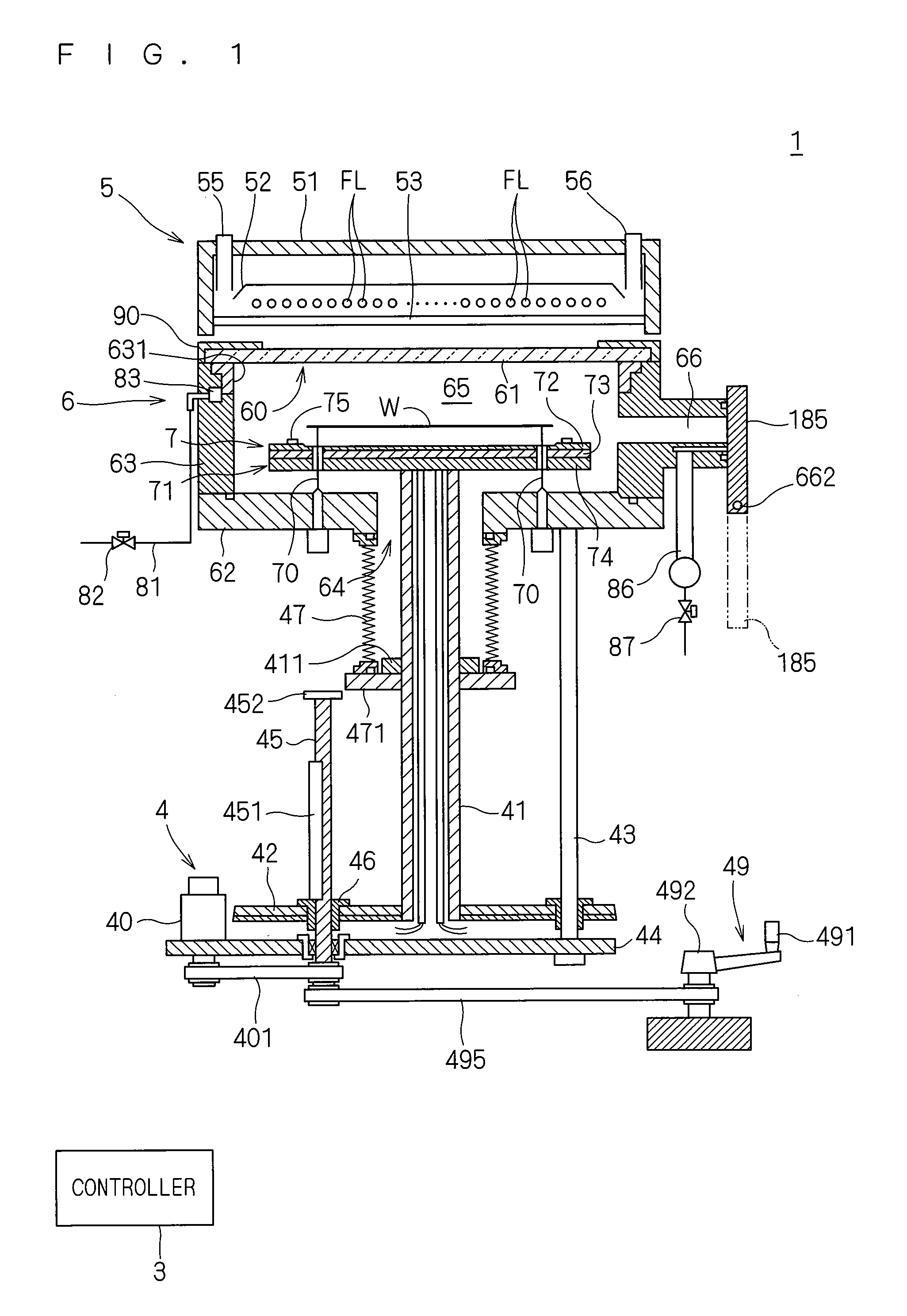

Heat treatment apparatus and method for heating substrate by photo-irradiation

ActiveUS20100111513A1Increase surface temperatureReduce thermal damageDomestic stoves or rangesDrying solid materials with heatEngineeringElectrical and Electronics engineering

Two-step photo-irradiation heat treatment is performed so that a total photo-irradiation time is not more than one second and that a first step of photo-irradiation of a semiconductor wafer is performed with a light-emission output that averages out at a first light-emission output and a second step of photo-irradiation of the semiconductor wafer is performed in accordance with an output waveform that peaks at a second light-emission output that is higher than both average and maximum light-emission outputs in the first step. Performing preliminary photo-irradiation with a relatively low light-emission output in the first step and then performing intense photo-irradiation with a higher peak in the second step enables the surface temperature of a semiconductor wafer to increase further with a smaller amount of energy than in conventional cases, while preventing the semiconductor wafer from shattering.

Owner:SCREEN HLDG CO LTD

Anti-condensing closed-type display cabinet

ActiveCN102379580AImprove cooling effectSmall temperature differenceShow cabinetsLighting and heating apparatusCold airEngineering

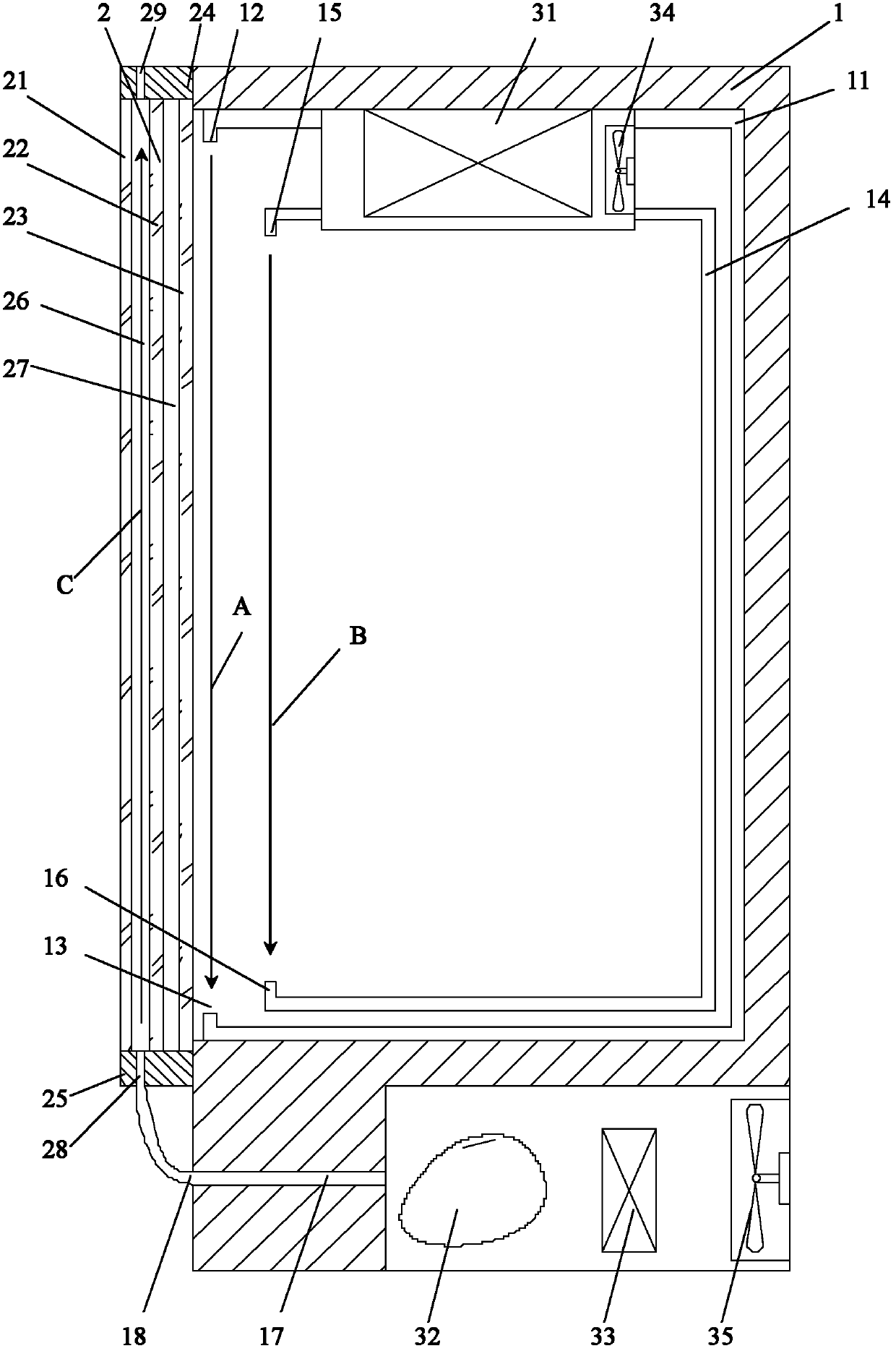

The invention relates to an anti-condensing closed-type display cabinet, which comprises a box body and a glass cabinet door. The glass cabinet door is installed on door frames. The door frames are fixedly connected with the box body. A refrigerating system is installed in the box body. An outer cold air duct and an inner cold air duct are installed in the box body. The first cold air duct outlets of the outer cold air duct are arranged in the box body at positions adjacent to the glass cabinet door, and the first cold air duct outlets and first cold air duct inlets are relatively arranged vertically to form an outer cold air curtain; and the second air duct outlets of the inner cold air duct are arranged in the box body at positions adjacent to the outer cold air curtain, and the second air duct outlets and second air duct inlets are relatively arranged vertically to form an inner cold air curtain. The invention provides the anti-condensing closed-type display cabinet which has a good refrigerating effect and can effectively prevent condensate from occurring on the external surface of the glass cabinet door at the same time.

Owner:YINDU KITCHEN EQUIP

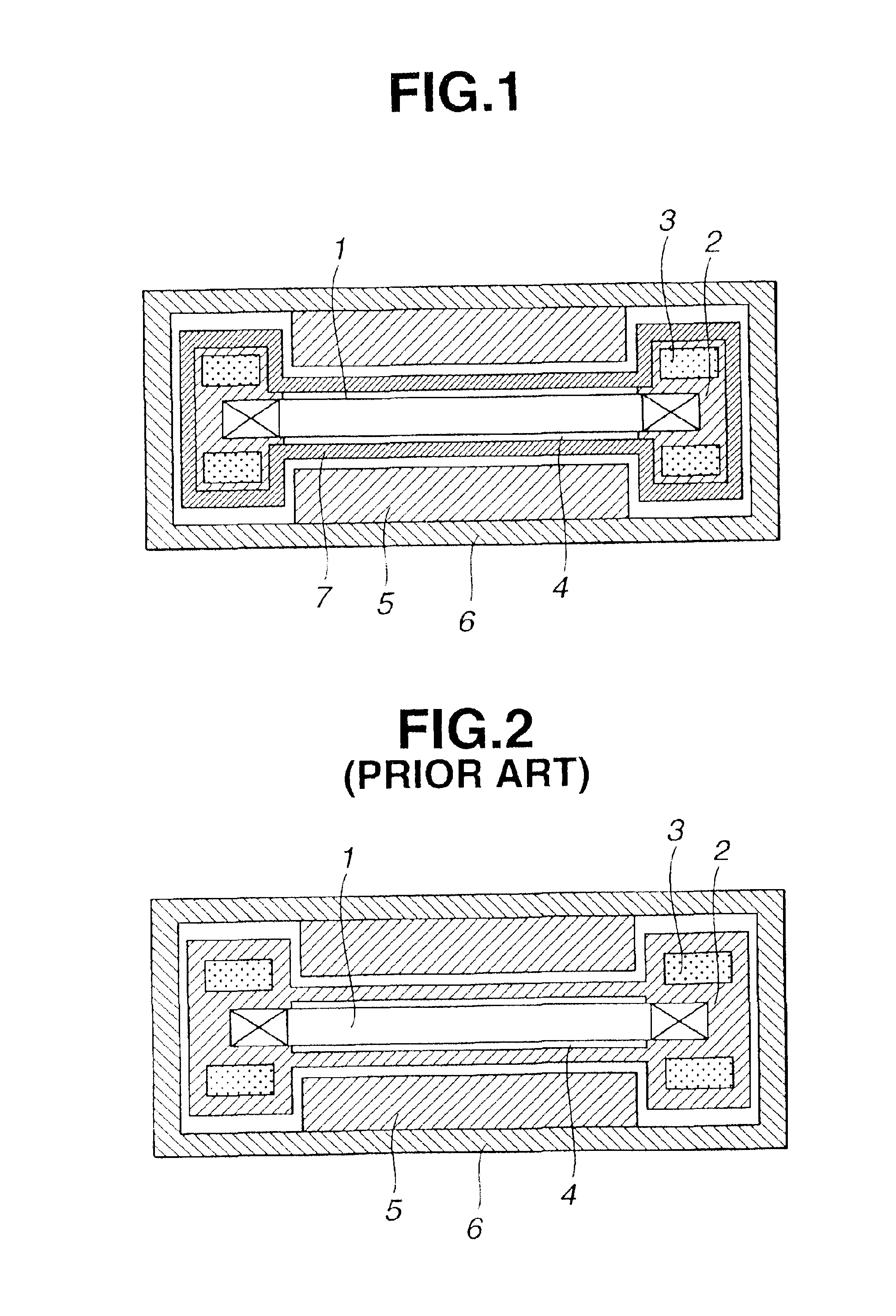

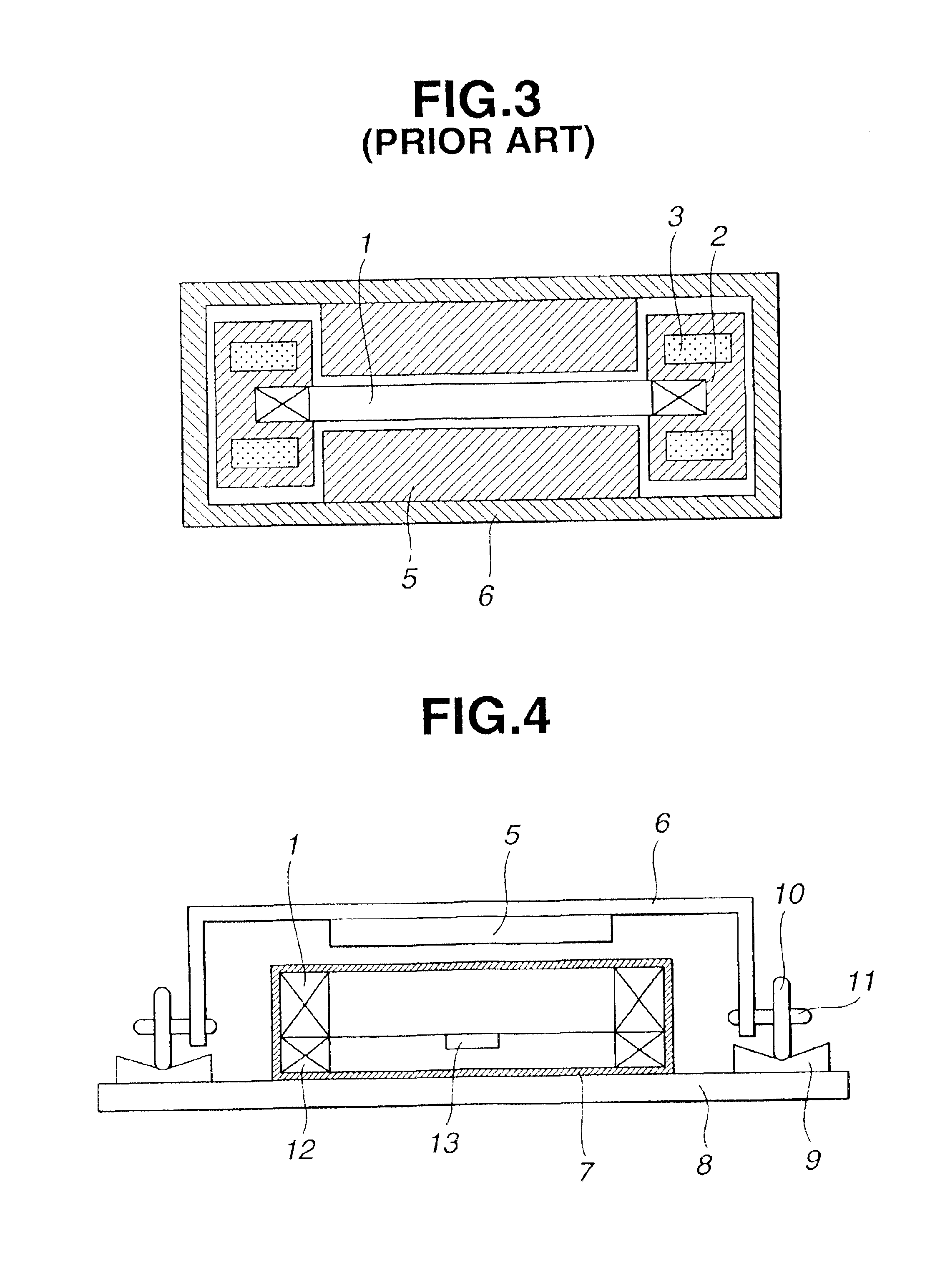

Electromagnetic actuator having an armature coil surrounded by heat-conducting anisotropy material and exposure apparatus

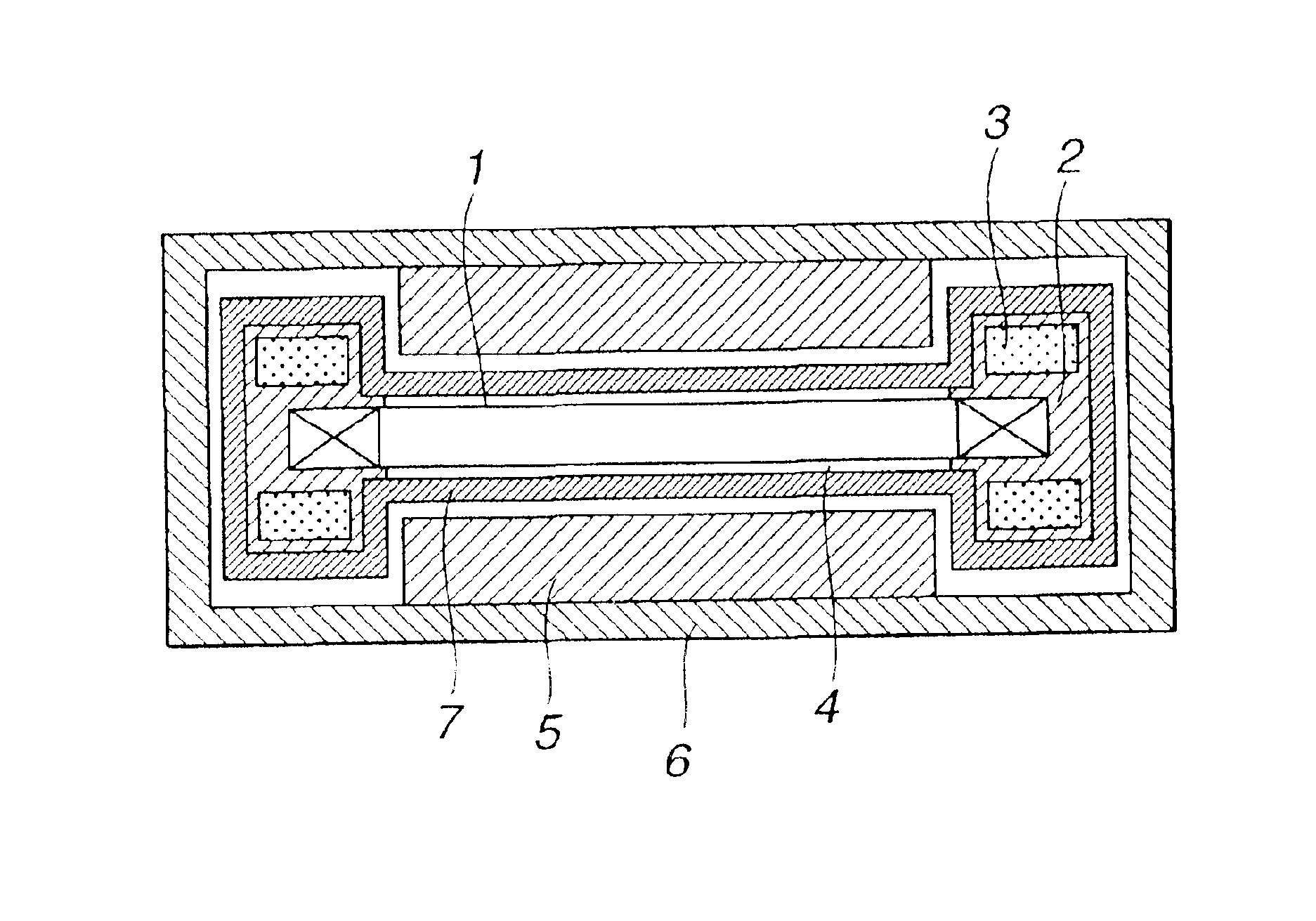

InactiveUS6847132B2Reduce surface temperatureIncrease thrustMagnetic circuit rotating partsPhotomechanical apparatusPhysicsMagnet

An electromagnetic actuator has a permanent magnet and an armature coil that performs relative movement with respect to the permanent magnet. A material having heat conduction anisotropy surrounds a surface of the armature coil and a heat radiating member radiates heat generated by the armature coil. The heat conduction anisotropic material is oriented to guide the heat generated from the armature coil to the heat radiating member. The actuator may be used in one or more groups of semiconductor substrate exposure apparatuses in a manufacturing factory that performs plural processes using the group of manufacturing apparatuses.

Owner:CANON KK

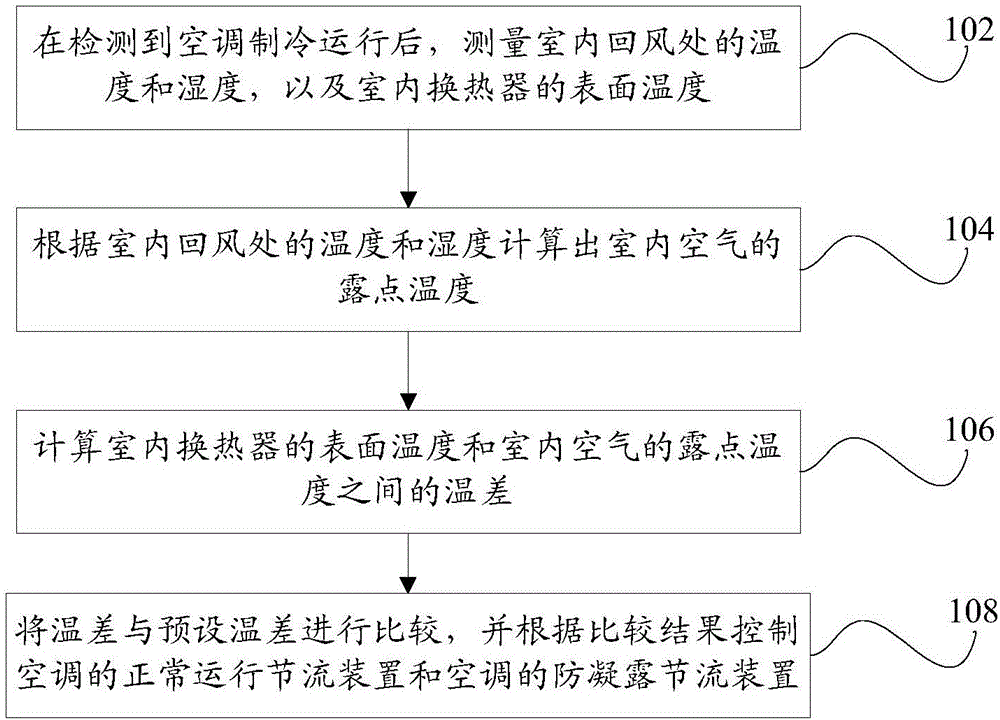

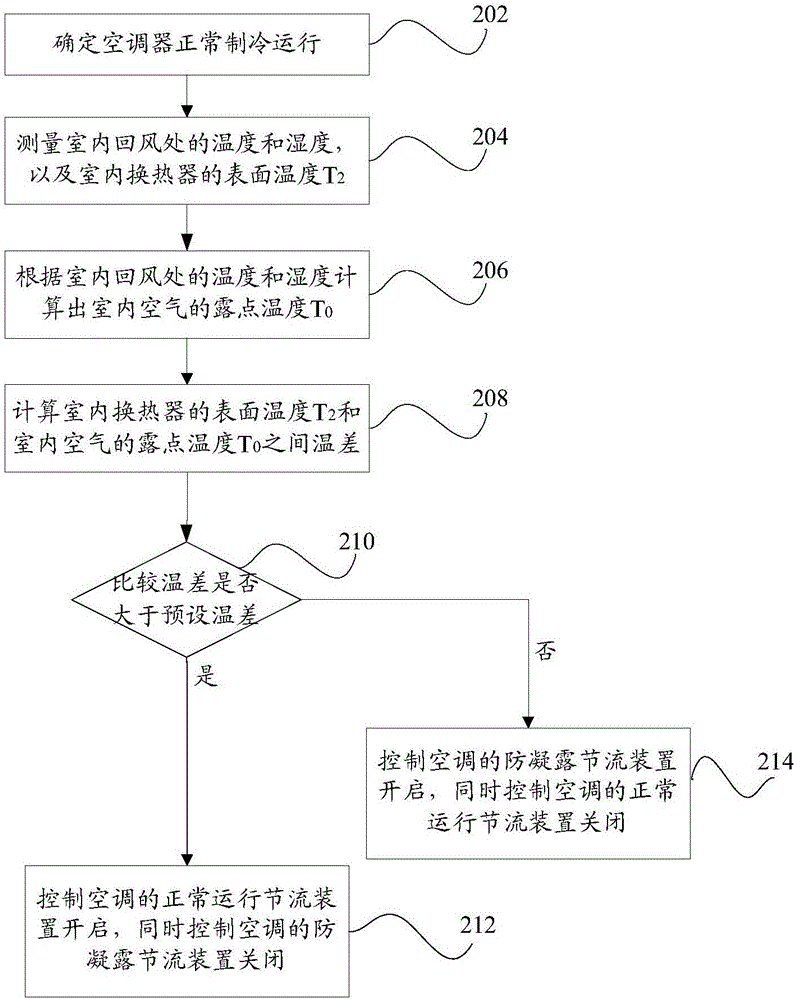

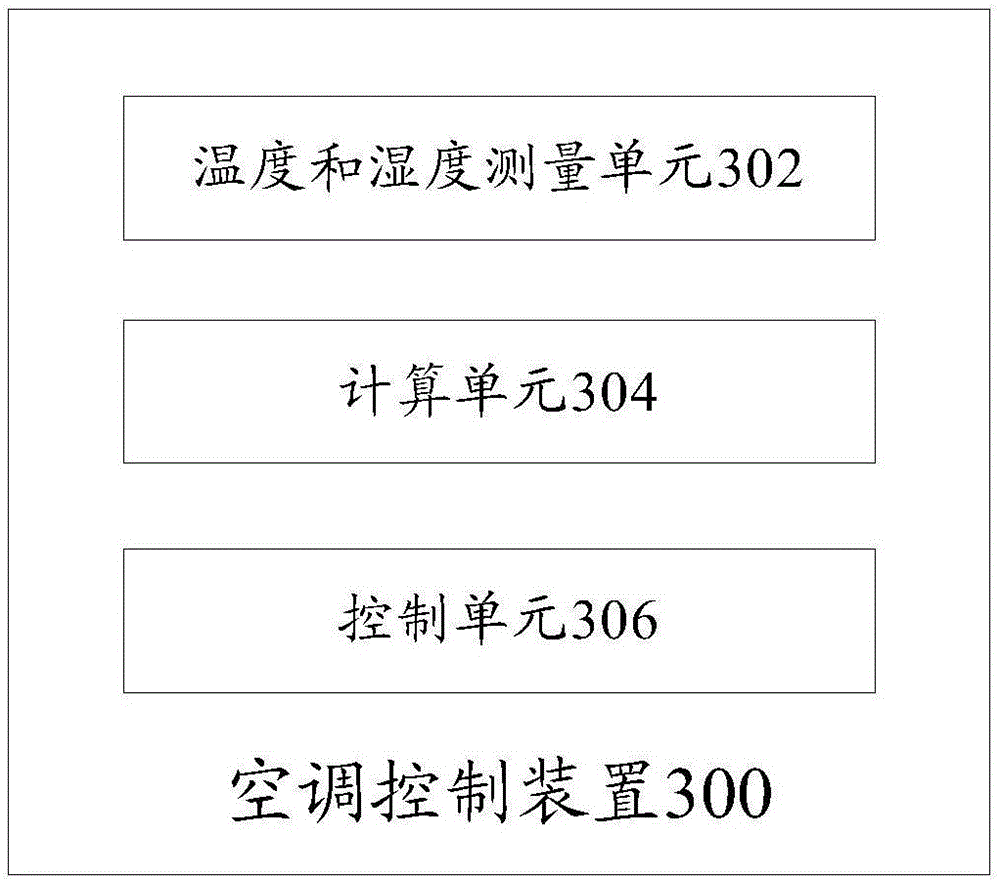

Anti-condensation air conditioner controlling method and device as well as air conditioner

PendingCN106403161AImprove user experienceGuaranteed accuracyMechanical apparatusCondensate preventionEngineeringTemperature difference

The invention provides an anti-condensation air conditioner controlling method and device as well as an air conditioner. The anti-condensation air conditioner controlling method comprises the steps of measuring the temperature and the humidity of an indoor air return position and the surface temperature of an indoor heat exchanger after refrigeration operation of the air conditioner is detected; calculating the dew point temperature of indoor air according to the temperature and the humidity of the indoor air return position; calculating the temperature difference between the surface temperature of the indoor heat exchanger and the dew point temperature of the indoor air; and comparing the temperature difference with a preset temperature difference and controlling a normal operation throttling device and an anti-condensation throttling device of the air conditioner according to a comparison result. According to the method, the flow of a refrigerant entering the indoor heat exchanger side is controlled by controlling the anti-condensation throttling device of the air conditioner, so that the surface temperature of the indoor heat exchanger is controlled to be higher than the dew point temperature of the indoor air all along, and the anti-condensation purpose is achieved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

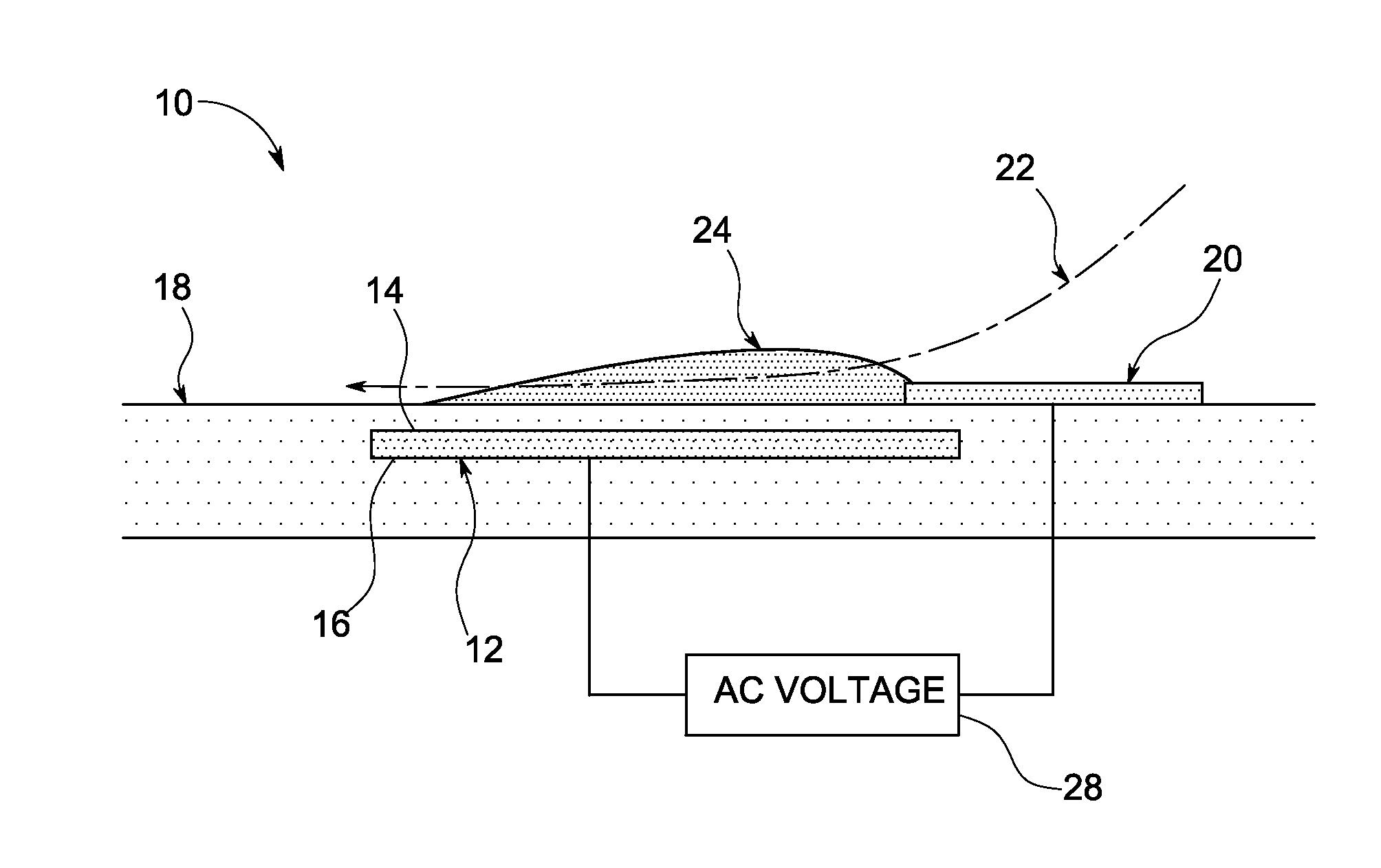

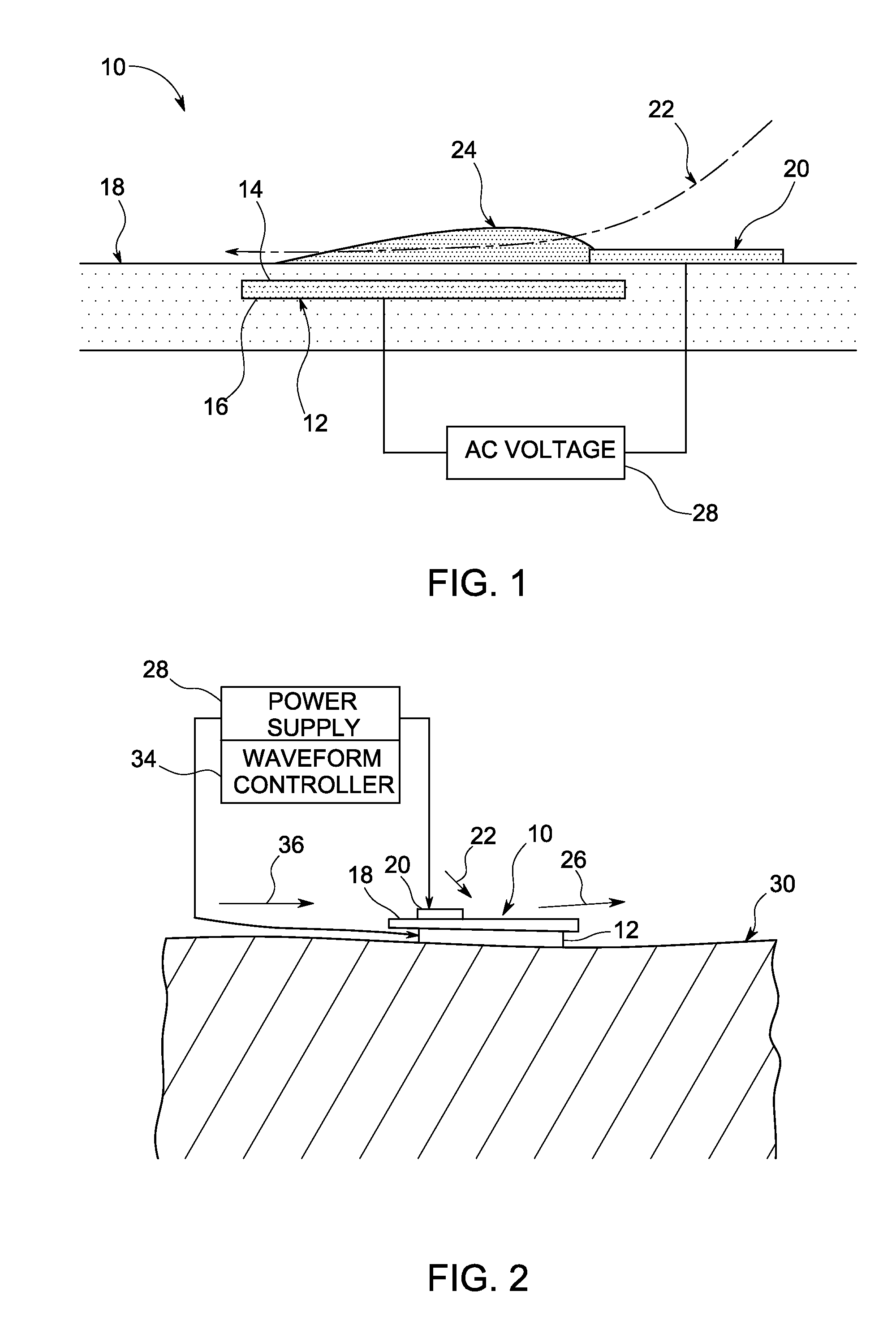

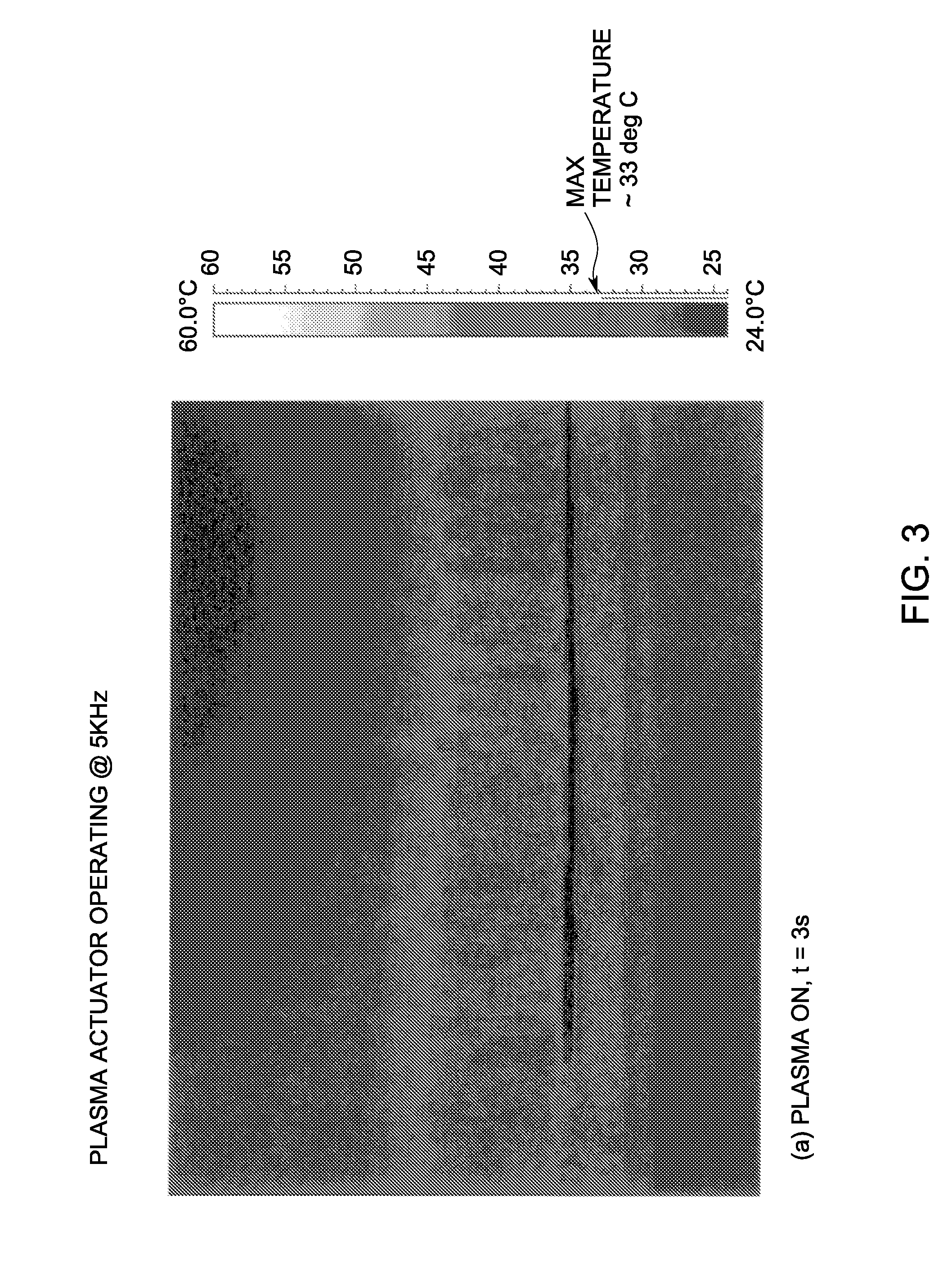

System and method of deicing and prevention or delay of flow separation over wind turbine blades

ActiveUS20110135467A1Reduce and eliminate collectionIncrease surface temperaturePropellersReaction enginesPlasma actuatorTurbine blade

A system for deicing a wind turbine blade includes an electrically powered active plasma actuator applied to a desired portion of a wind turbine blade. The activated plasma actuator energizes the air in the vicinity of the plasma actuator to increase the surface temperature of the wind turbine blade in the vicinity of the plasma actuator sufficiently to reduce or eliminate the collection of ice on a desired portion of the wind turbine blade.

Owner:GENERAL ELECTRIC CO

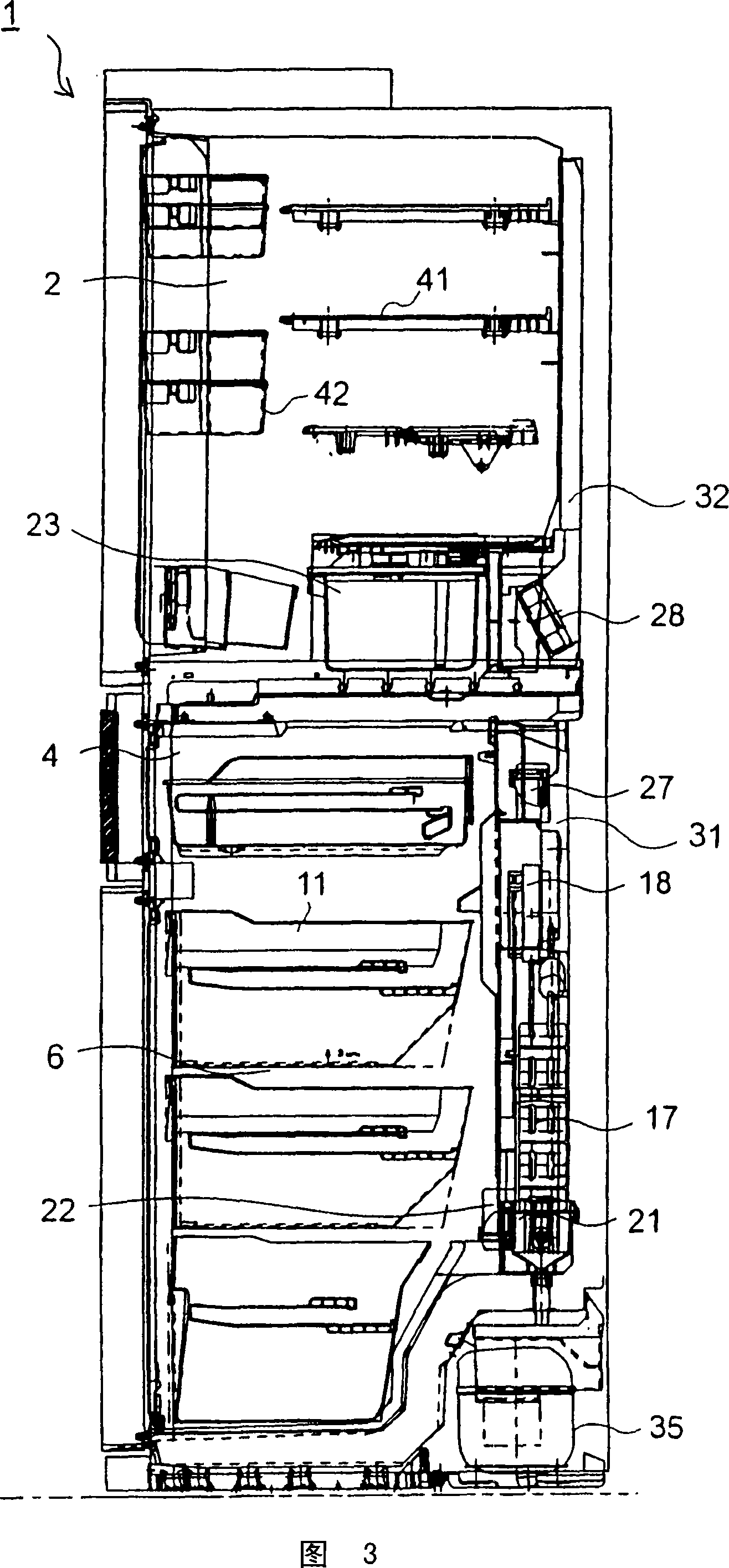

Refrigerator

InactiveCN101048633AReduce financial burdenImprove convenienceDoors for stoves/rangesLighting and heating apparatusEngineeringRefrigerated temperature

Owner:SHARP KK

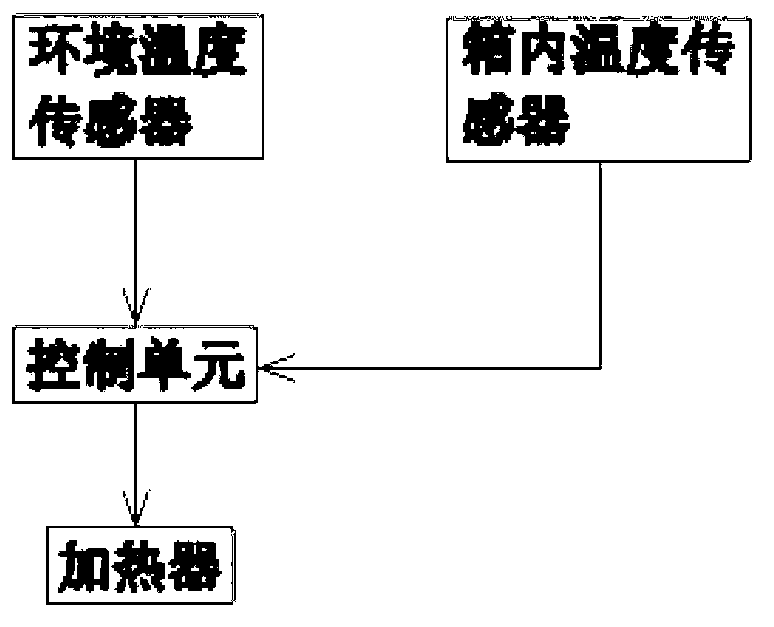

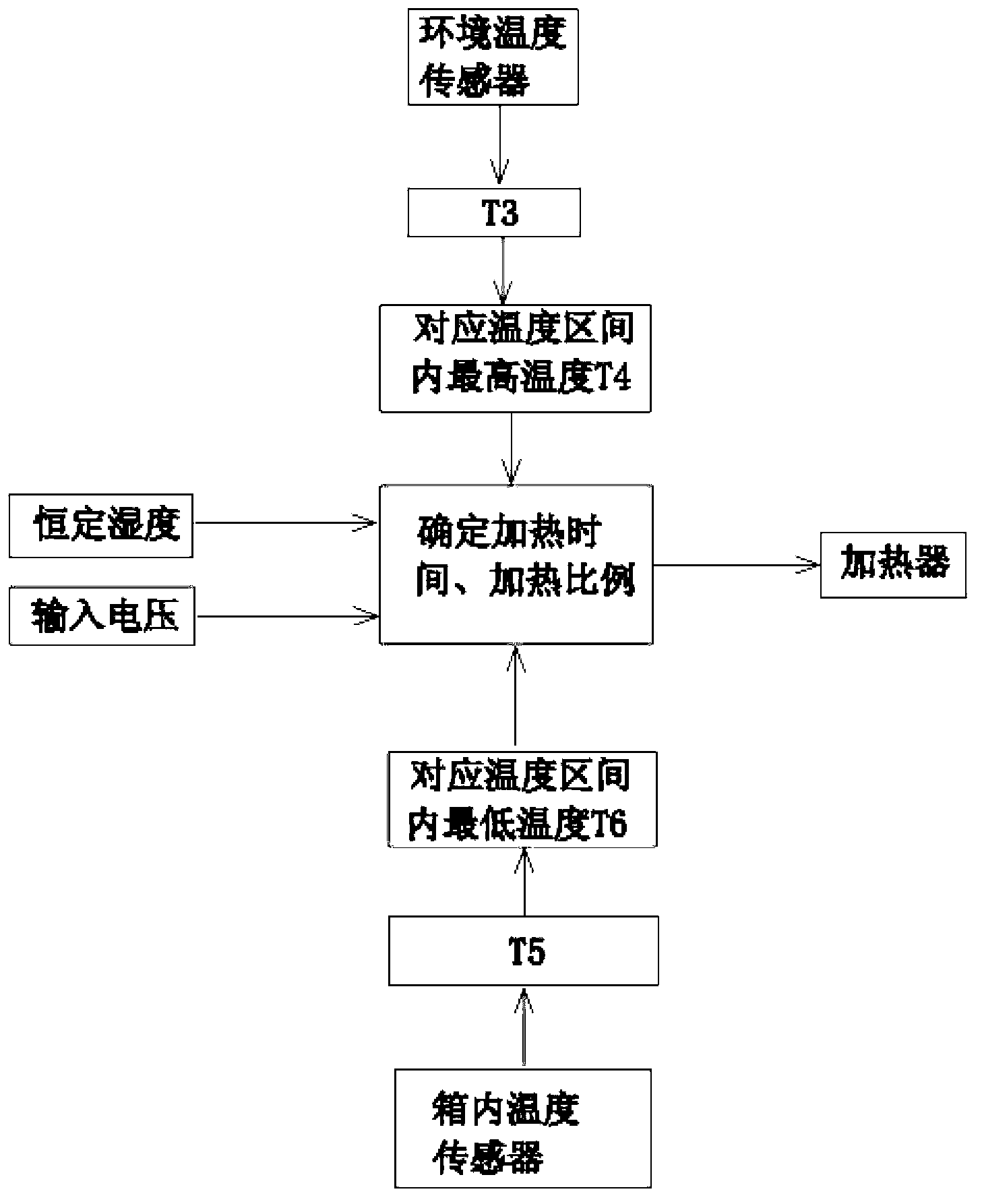

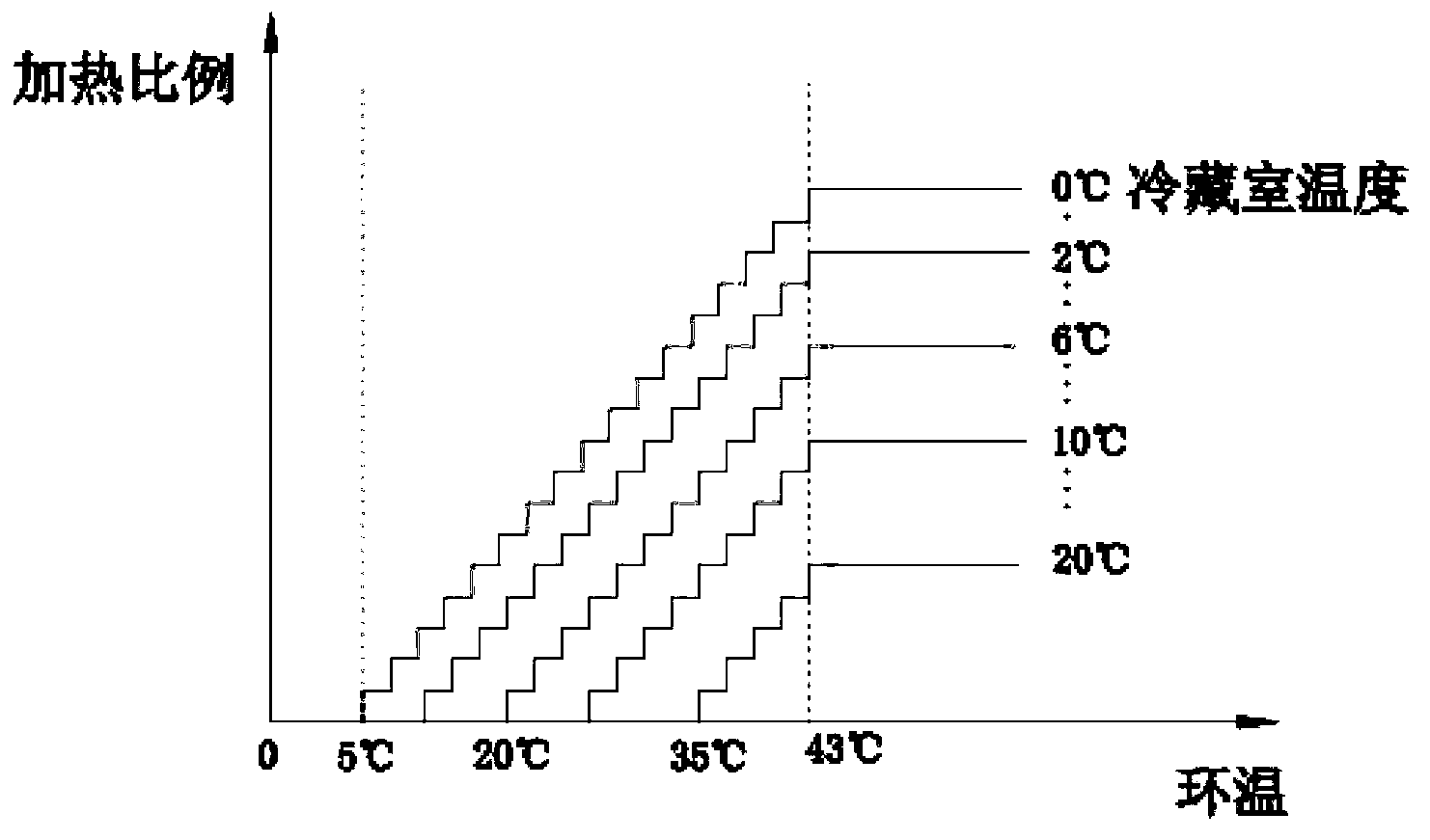

Refrigerator condensation preventing heating control device and control method

ActiveCN103062978AIncrease surface temperatureLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention discloses a refrigerator condensation preventing heating control device and a control method. The heating control device comprises an environmental temperature sensor, a box inner temperature sensor, a control unit and a heater arranged on a condensation preventing position, wherein the control unit utilizes the environmental temperature collected by the environmental temperature sensor as one parameter to control the working state of the heater, and further utilizes the box inner temperature collected by the box inner temperature sensor as an auxiliary parameter to control the the working state of the heater. The refrigerator condensation preventing heating control device disclosed by the invention adopts the environmental temperature sensor and the box inner temperature sensor to control the condensation preventing heater according to the variation of two parameters of the environmental temperature and the box inner temperature, extra cost increase is not needed, and the control program is simplified and meanwhile, the reliability and stability of the system are guaranteed.

Owner:CHANGHONG MEILING CO LTD

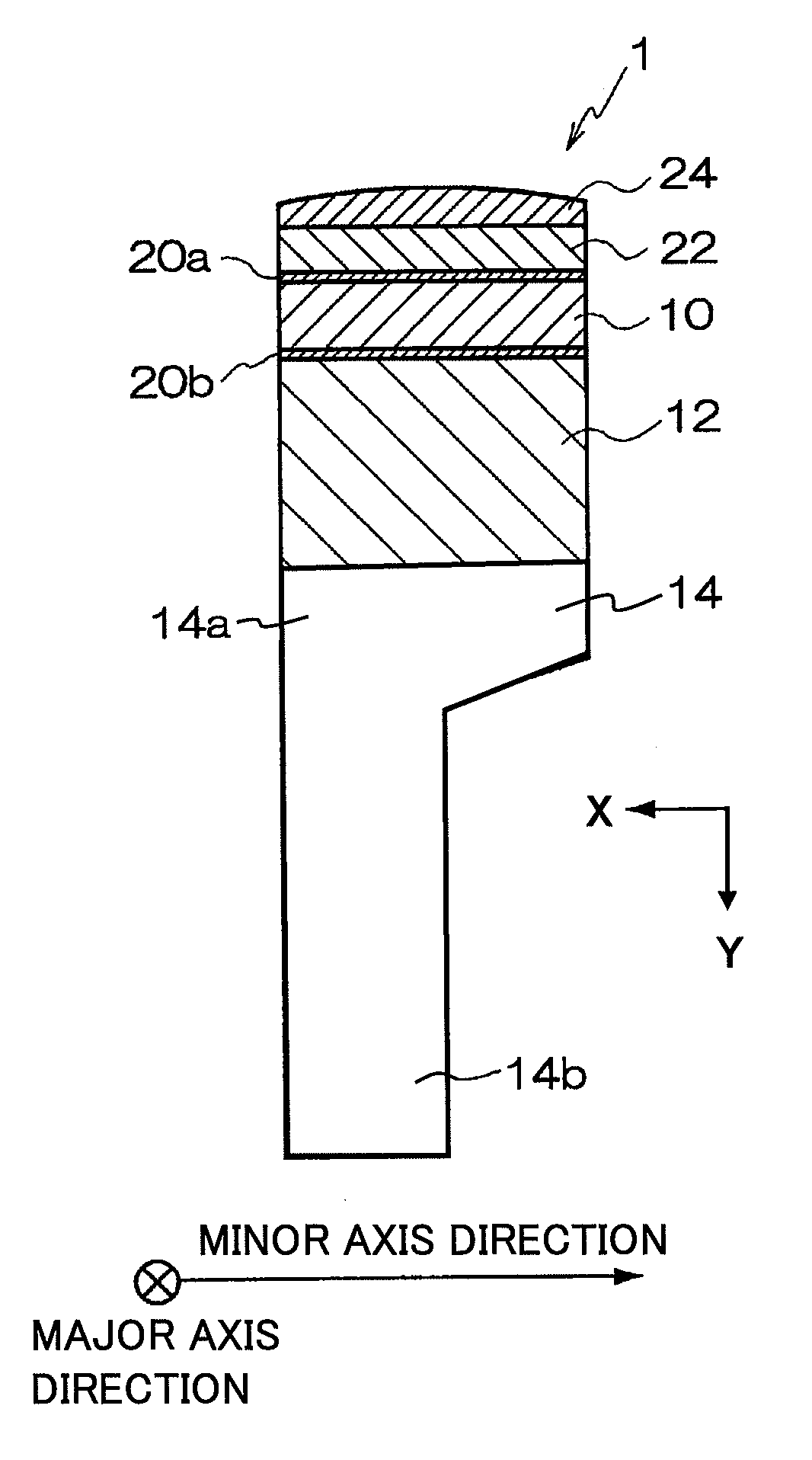

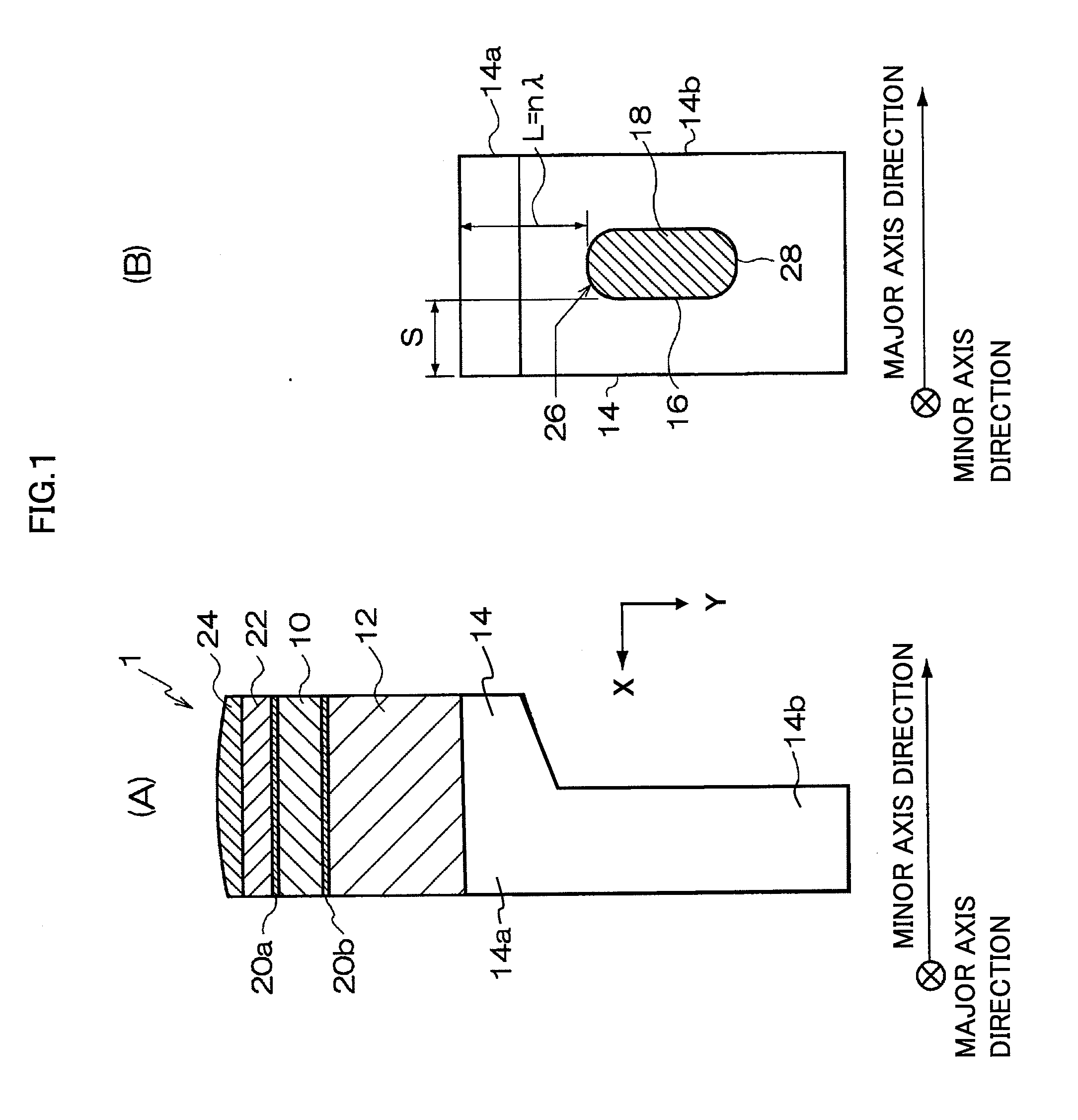

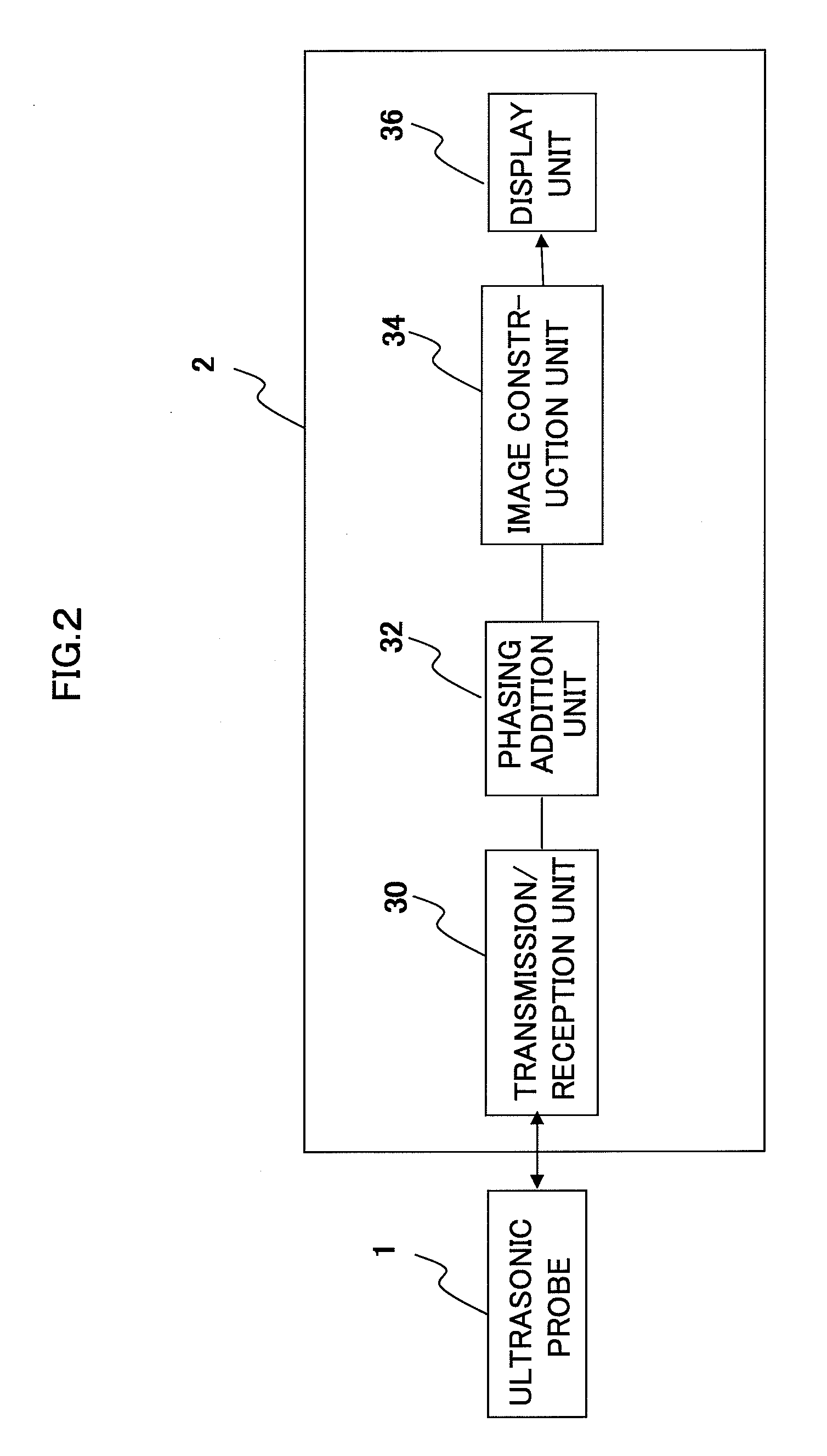

Ultrasonic Probe and Ultrasonic Diagnosis Apparatus

InactiveUS20080139945A1Good effectEasy to carryUltrasonic/sonic/infrasonic diagnosticsWave based measurement systemsTransducerReflected waves

An ultrasonic probe suitable for reducing reflected waves returning from a rear surface part to a transducer side, and an ultrasonic diagnostic apparatus. Ultrasonic probe 1 comprises transducer 10 transmitting and receiving ultrasonic waves to and from a subject, a backing material 12 disposed on the rear side of the transducer 10, and heat dissipating block 14 stacked on the backside of the backing material 12. At least one of the backing material 12 and heat-dissipating block 14 comprises void 16 therein. A sound absorbing material 18 is desirably filled in void 16.

Owner:HITACHI LTD

Fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and preparation and usage method thereof

InactiveCN104987032AThe composition of the formula is reasonableReasonable ratioCeramic coatingSpray coating

The invention relates to a fouling and slagging resistance and high temperature and corrosion resistance ceramic paint and a preparation and usage method thereof. The ceramic paint comprises, by mass, the components of 20-30% of filler, 23-29% of binders, 0.8-1.2% of addition agents and the balance water. According to the ceramic paint, the formula component and ratio are reasonable, the filler granularity is small, granularity matching among different filler components is reasonable, and the matching compatibility of the filler and a binder system is good. A ceramic coating prepared by spray coating can resist high temperature 1320 DEG C, is thinner, has the functions of resisting fouling and slagging and resisting high temperature and corrosion, and cannot be pulverized and fall off in a long-term high-temperature operating environment; the high emissivity above 0.95 can be still kept at high temperature and is close to the thermal expansion coefficients of metal, and heat transfer can be enhanced; the coating integrates chemical inertness and passivation protection into a body, and therefore a high-temperature corrosion environment is prevented from corroding the metal through the compact ceramic coating; meanwhile, due to the fact that the coating has the self-cleaning effect, the coating can be applied easily and conveniently.

Owner:HANGZHOU CHITIAN ENERGY TECH CO LTD

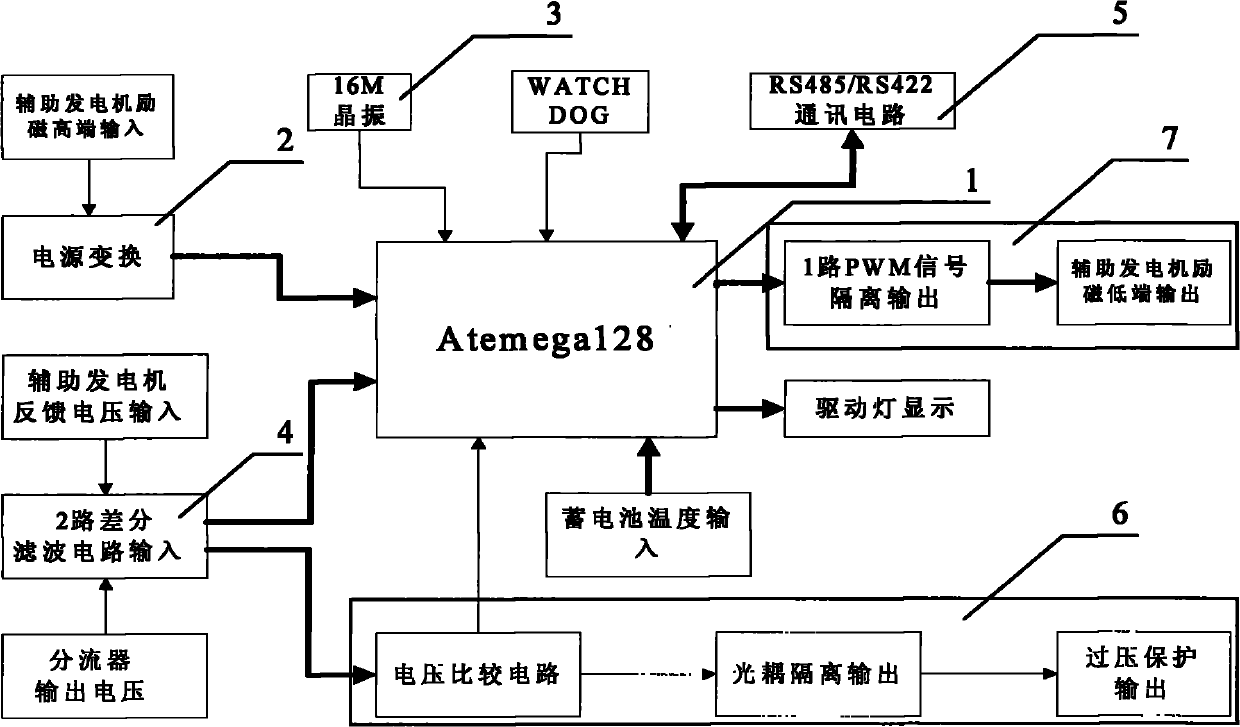

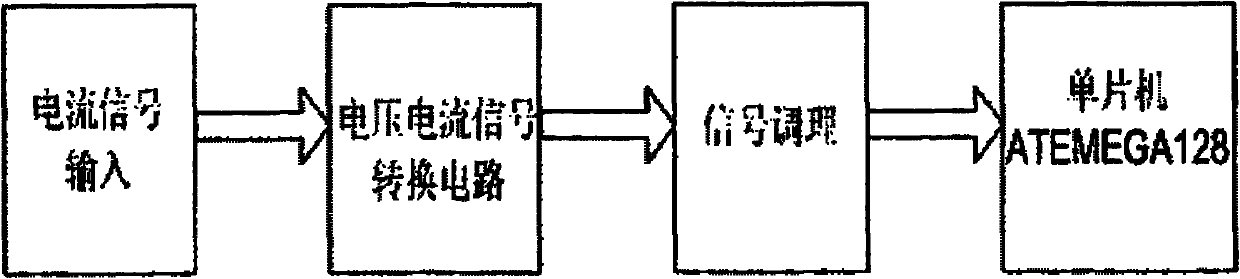

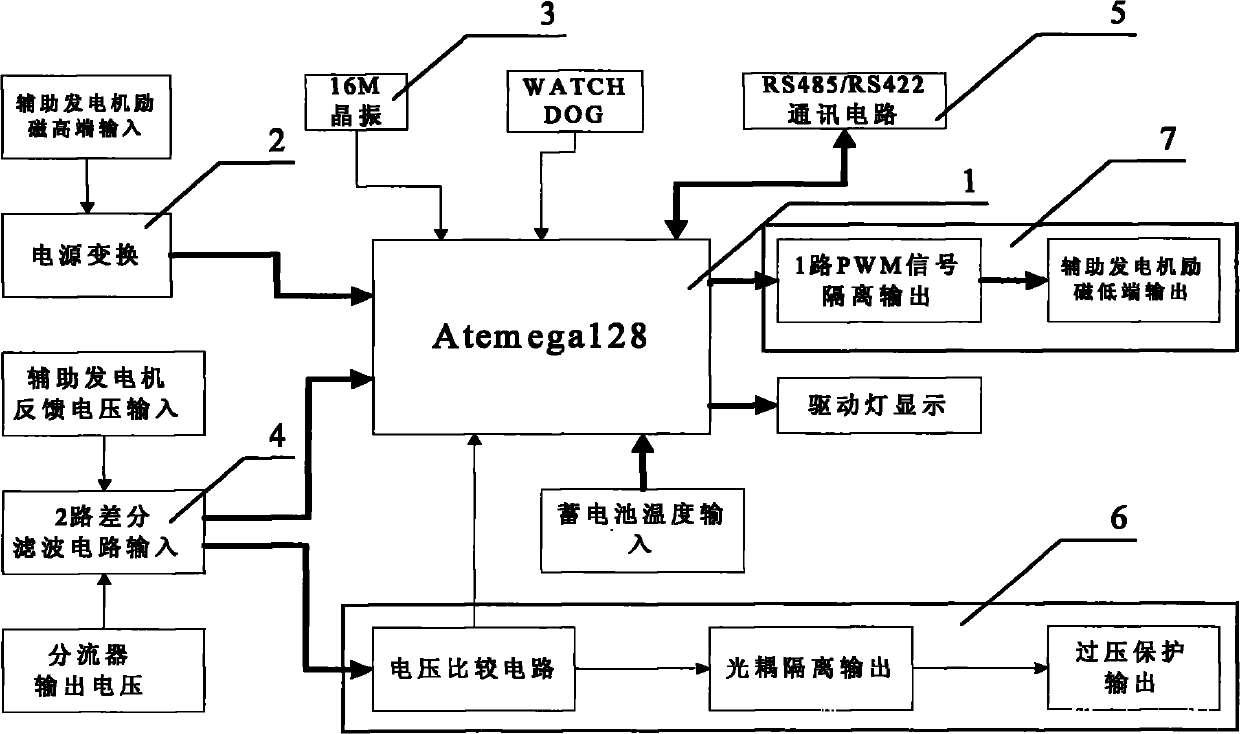

Diesel locomotive auxiliary engine control device

ActiveCN101951217ARealize temperature protectionAvoid shockEmergency protective circuit arrangementsGenerator control by field variationOvervoltageDiesel locomotive

The invention discloses a diesel locomotive auxiliary engine control device, which comprises a CPU, a power circuit, a crystal oscillator circuit, a differential filter circuit, a communication circuit, an overvoltage protection circuit and a drive circuit, wherein the power circuit provides power for the auxiliary engine control device; the crystal oscillator circuit is connected with the CPU and provides clock pulses for the CPU; the communication circuit is connected with the CPU, performs network communication with a control and display device on the locomotive through a serial port, and downloads a control program; the auxiliary engine outputs voltage feedback, the input DC voltage is converted into small-signal DC voltage through the differential filter circuit, and the feedback voltage is transmitted to an inner analog-digital converter of the CPU; the overvoltage protection circuit is connected with the CPU, and the auxiliary engine is made to output stable voltage by adjusting exciting current; and the drive circuit is connected with the CPU and drives the exciting current. The invention solves the technical problems of larger volume, installation space occupancy, larger deviation of parameters of analog devices, and susceptibility to multiple kinds of interference in the prior art.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Method for manufacturing high-hardness and high-abrasion-resistant pre-bending machine lower die

ActiveCN102581145ALarge heat treatment deformationHigh hardnessShaping toolsManufactured materialEngineering

The invention discloses a method for manufacturing a high-hardness and high-abrasion-resistant pre-bending machine lower die, which belongs to the technical field of machining methods for pre-bending machine lower dies. The method includes steps of (1), preparing raw materials of the pre-bending machine lower die; (2), annealing a forged blank; (3), primarily machining the forged blank; (4), conditioning the pre-bending machine lower die, quenching the pre-bending machine lower die by water or oil after the pre-bending machine lower die is kept at the temperature ranging from 830 DEG C to 850 DEG C for 3 hours, and then tempering the pre-bending machine lower die under the condition of the temperature ranging from 680 DEG C to 700 DEG C; (5), realizing deep processing of the pre-bending machine lower die; and (6), realizing heat treatment of the pre-bending machine lower die, dipping an arc surface R of the pre-bending machine lower die into quenching media for cooling at first during quenching, and then dipping the complete pre-bending machine lower die into the quenching media after the arc surface R is cooled in the quenching media for 4 minutes to 6 minutes. The raw materials of the forged blank include from 1.70 to 2.2% of Cr. The pre-bending machine lower die is low in final deformation, high in hardness and fine in abrasion resistance, and does not crack during the heat treatment, and the surface cannot sink even if the pre-bending machine lower die bears extremely high pressure during usage.

Owner:马鞍山博新高科产业服务有限公司

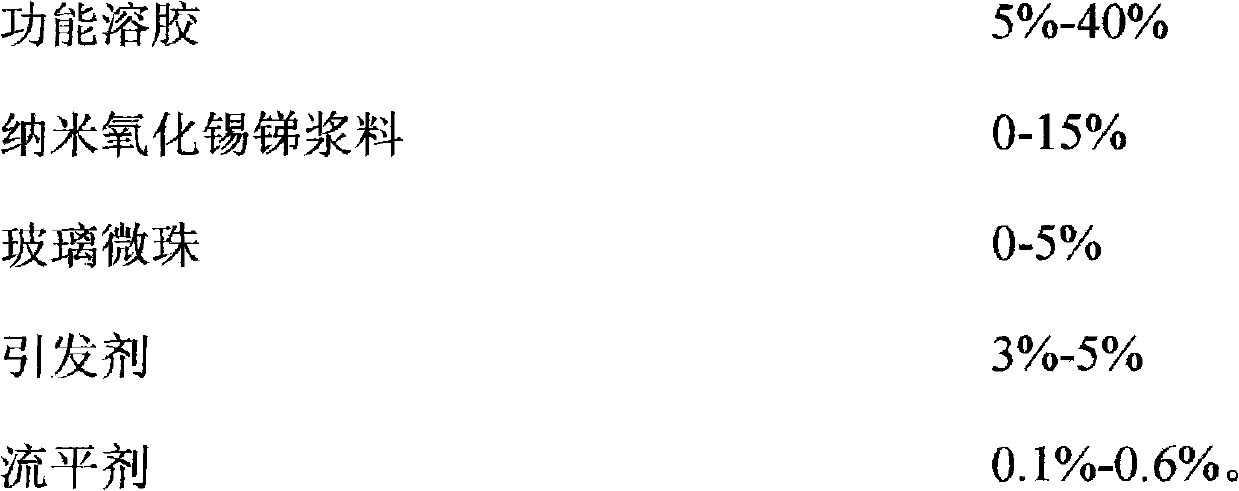

Method for preparing ultraviolet (UV) curing flame-retardant coating material and UV curing flame-retardant coating material

The invention discloses a method for preparing an ultraviolet (UV) curing flame-retardant coating material. The method comprises the following steps of: (1) preparing functional sol which is nano-sol modified by a silane coupling agent or sol generated by hydrolyzing alkoxide or the silane coupling agent; and (2) adding 20 to 70 mass percent of UV curing resin, 20 to 50 mass percent of reactive diluent, 5 to 40 mass percent of functional sol, 0 to 15 mass percent of nano antimony tin oxide slurry, 0 to 5 mass percent of glass microspheres, 3 to 5 mass percent of initiator and 0.1 to 6 mass percent of leveling agent into a dispersing kettle, and dispersing for 0.5 to 3 hours at the rotating speed of 1,000 to 2,000rpm to obtain the UV curing high-hardness wear-resistant flame-retardant coating material. The invention also discloses the UV curing flame-retardant coating material. The UV curing flame-retardant coating material can prevent heat transfer from the source, the surface temperature and internal environment temperature of the coating material are effectively reduced, and the aims of improving the working environment and reducing energy consumption are fulfilled.

Owner:上海大学浙江嘉兴新兴产业研究院

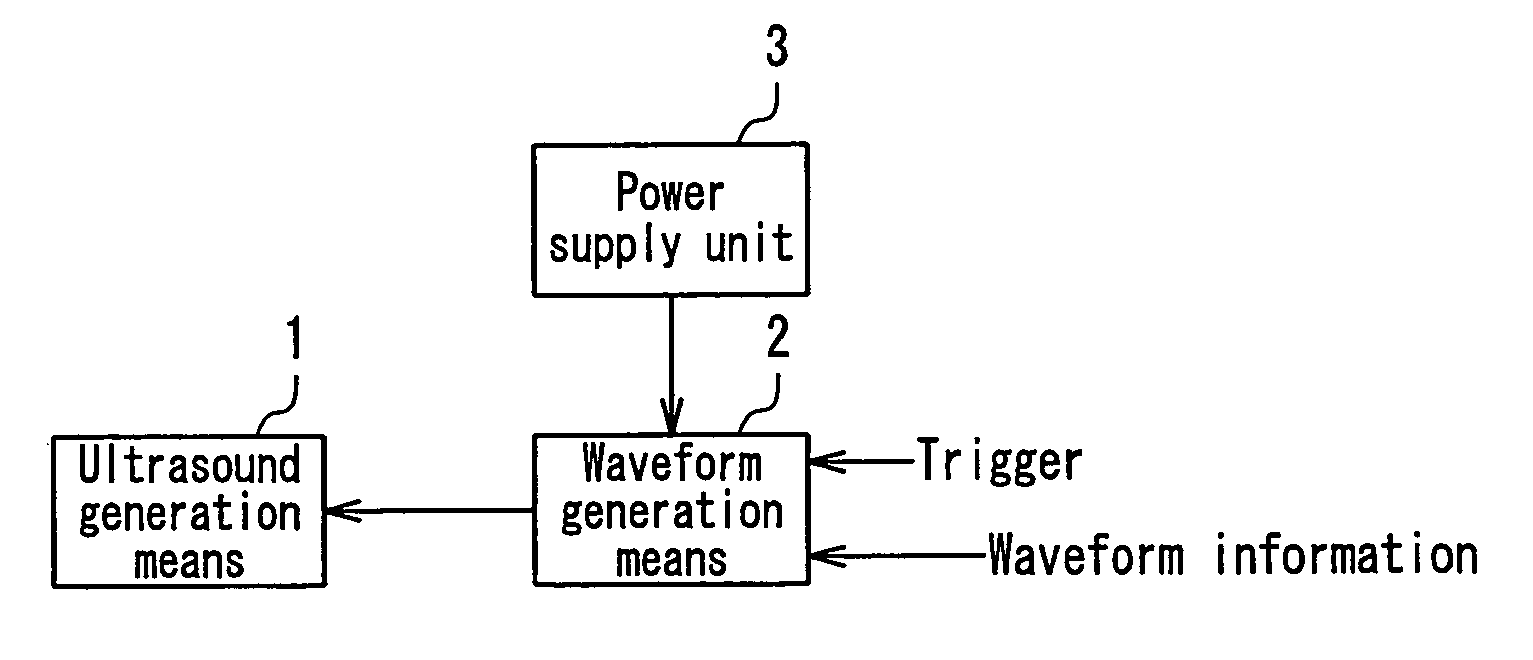

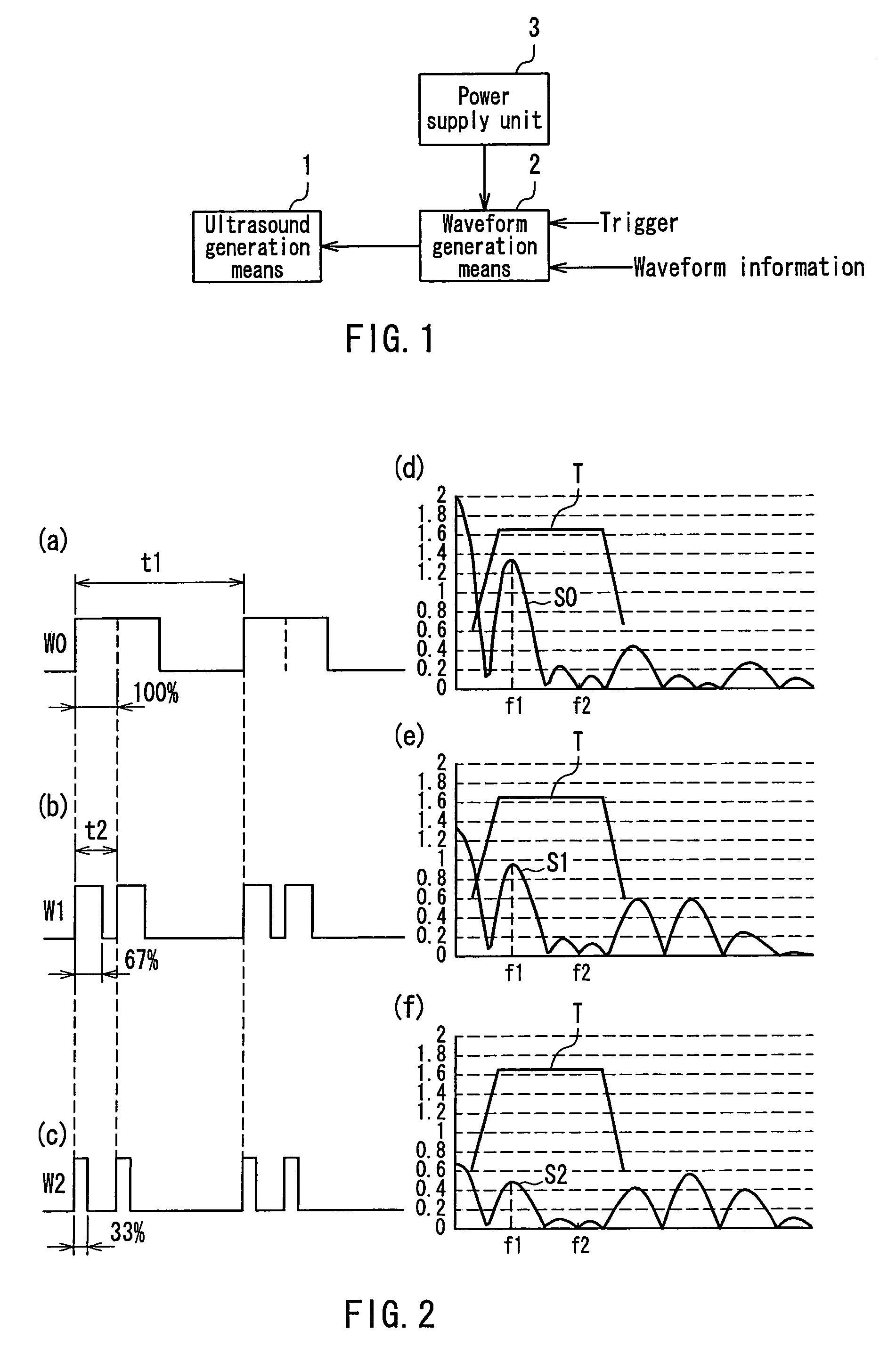

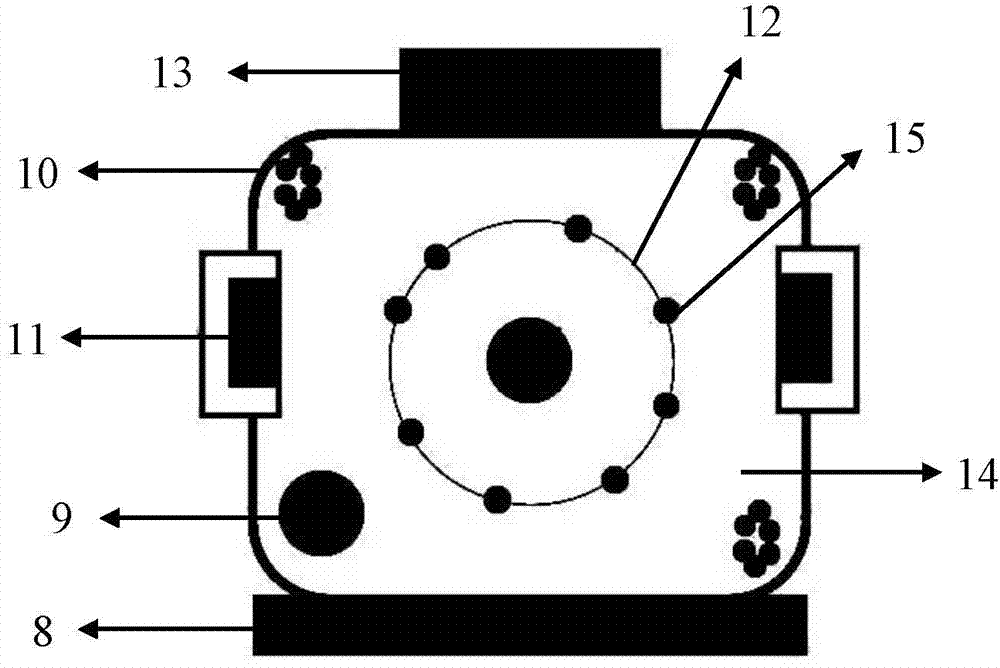

Ultrasound diagnostic device

InactiveUS7566304B2Low costEasy to controlUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationTransmission amplitudeSonification

A small ultrasound diagnostic device is provided at a low cost that enables the appropriate control by a single power supply unit so as to give a predetermined transmission power to a driving waveform different for each mode without excess or deficiency and without affecting properties of the driving waveform. The ultrasound diagnostic device includes: an ultrasound generation unit (1) that transmits ultrasound; a waveform generation unit (2) that generates a single pulse or a burst pulse whose duty factor is variable in units of a time that is a period corresponding to a frequency outside a frequency band of the ultrasound generation unit (1) so as to drive the ultrasound generation unit (1); and a single power supply unit (3) that determines an amplitude of a driving waveform generated by the waveform generation unit (2). Thereby, an acoustic power of the transmitted ultrasound can be controlled without making the transmission amplitude variable.

Owner:KONICA MINOLTA INC

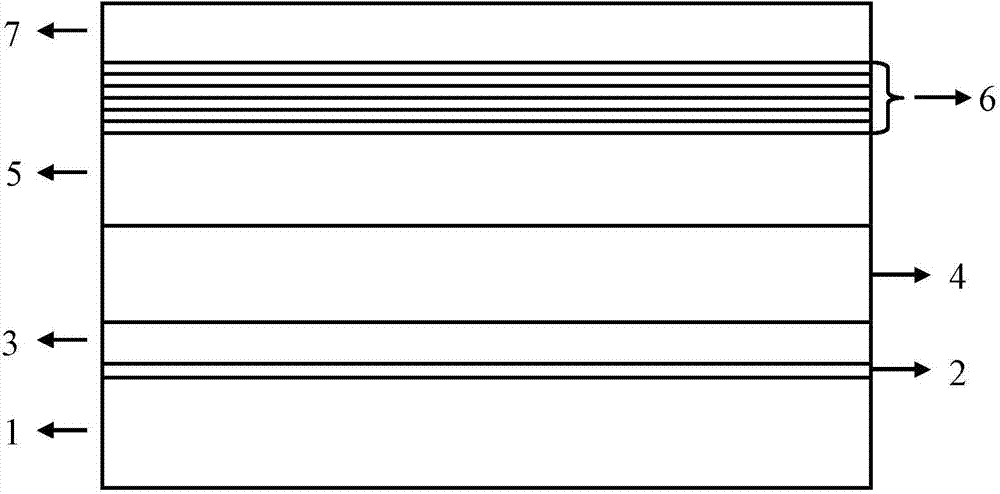

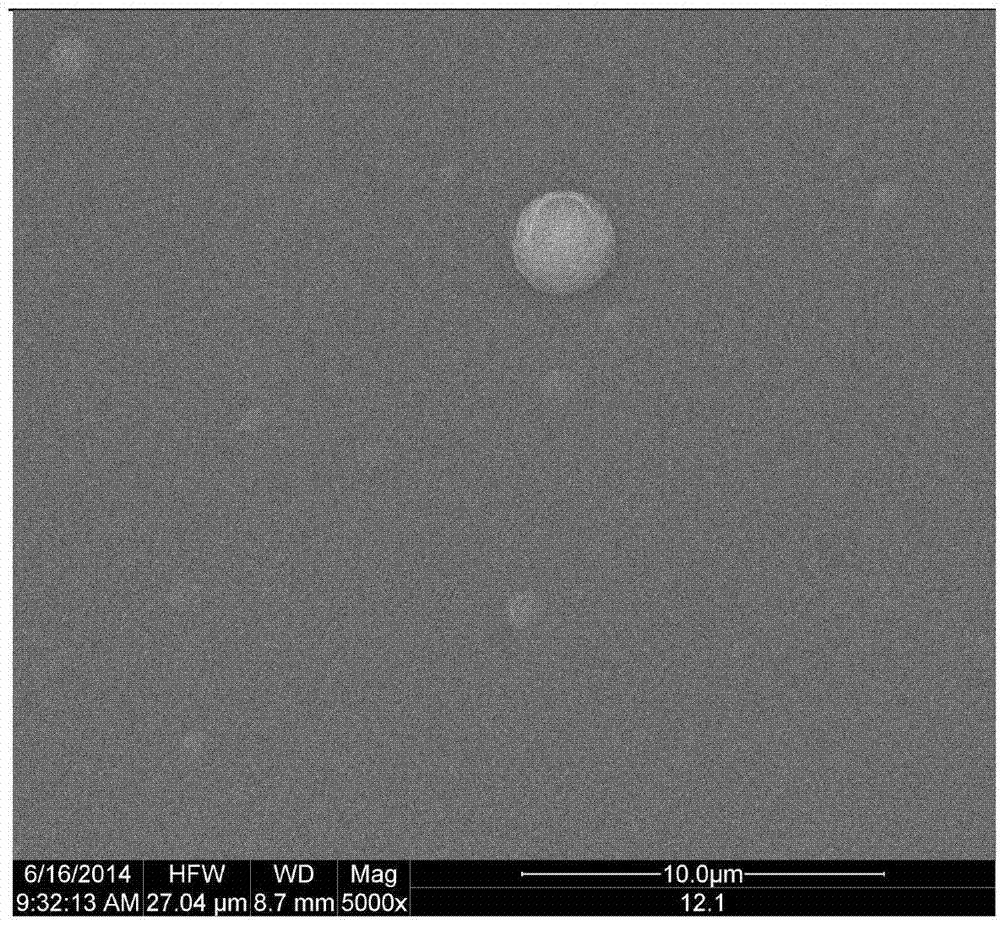

Cr-Cr nanometer composite metal ceramic coating as well as preparation method and device thereof

ActiveCN104711515AReduce coating stressGood cushioning effectVacuum evaporation coatingSputtering coatingCorrosion resistantCermet

The invention provides a Cr-Cr nanometer composite metal ceramic coating as well as a preparation method and device thereof. The coating is provided with a Cr diffusion layer, a Cr bonding layer, a Cr transition layer, a CrNx supporting layer, a Cr / CrN corrosion-resistant layer and a Cr decoration layer, wherein the CrNx supporting layer satisfies 0<=x<1; the Cr / CrN corrosion-resistant layer is an alternating layer of Cr layers and CrN layers and provided with at least one layer of Cr layer and one CrN layer. The coating provided by the invention has gradual changes of structure and composition, good interlayer bonding and excellent corrosion resistance and comprehensive properties.

Owner:AEROSPACE PRECISION PROD INC LTD

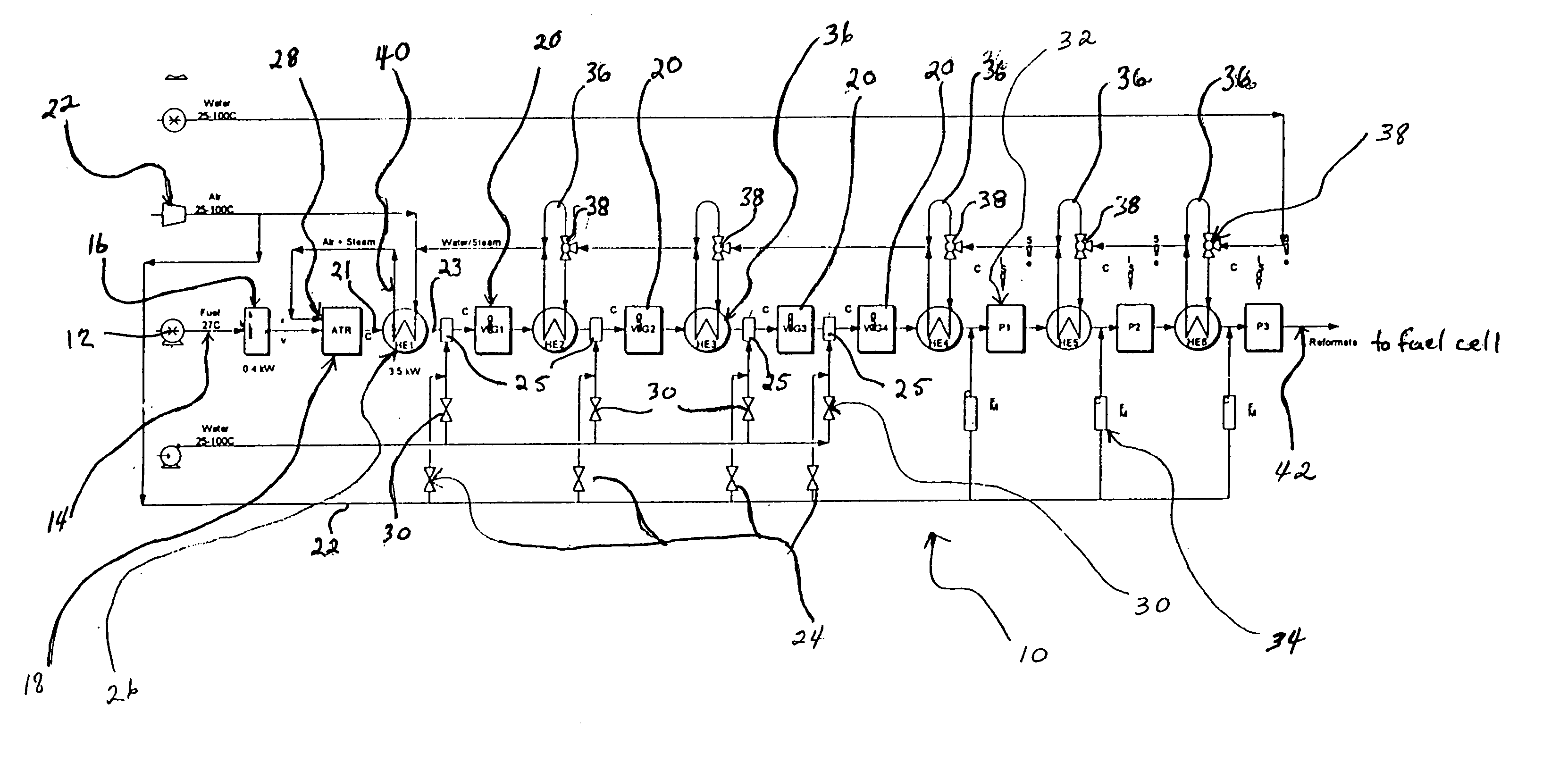

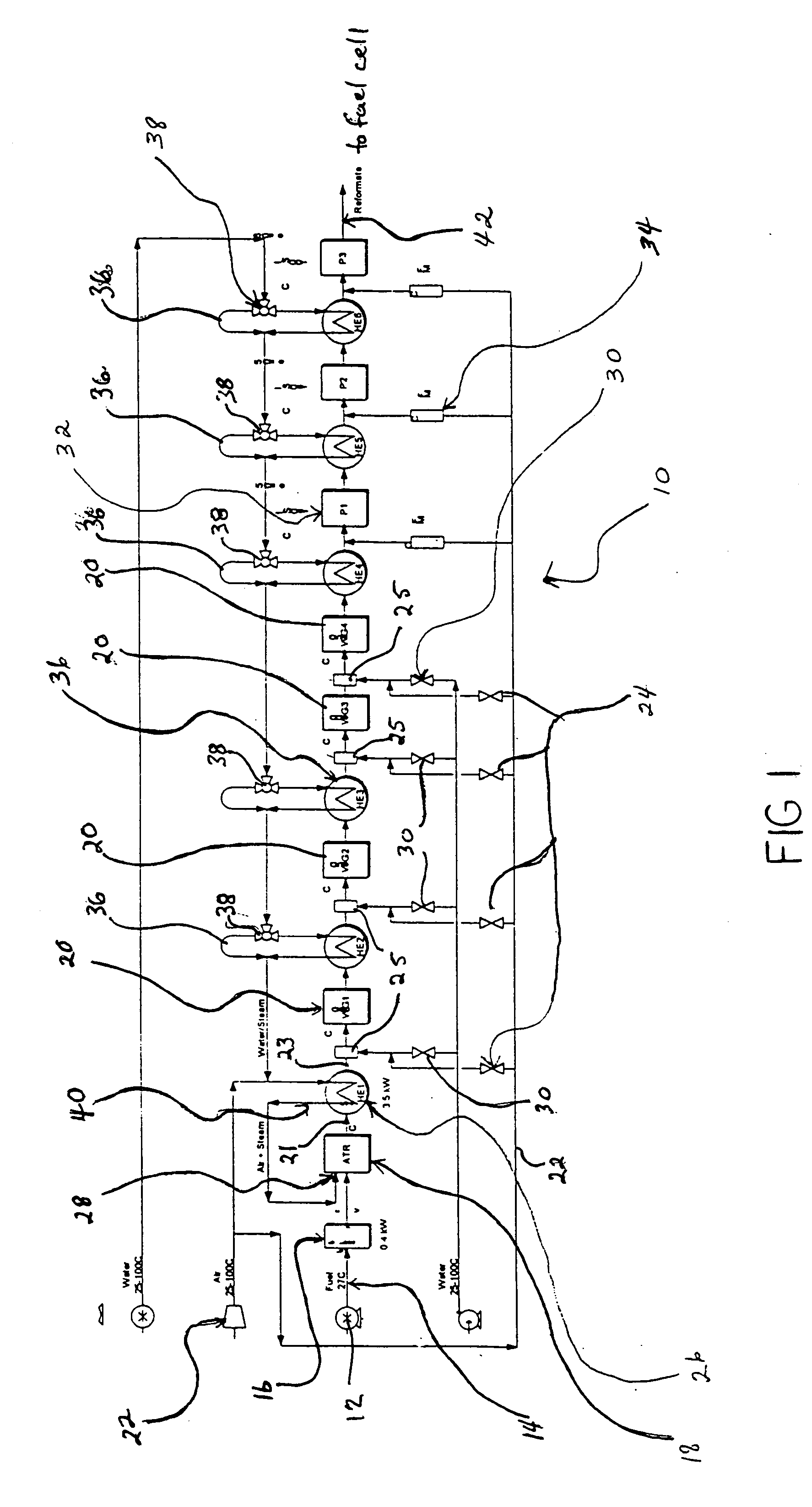

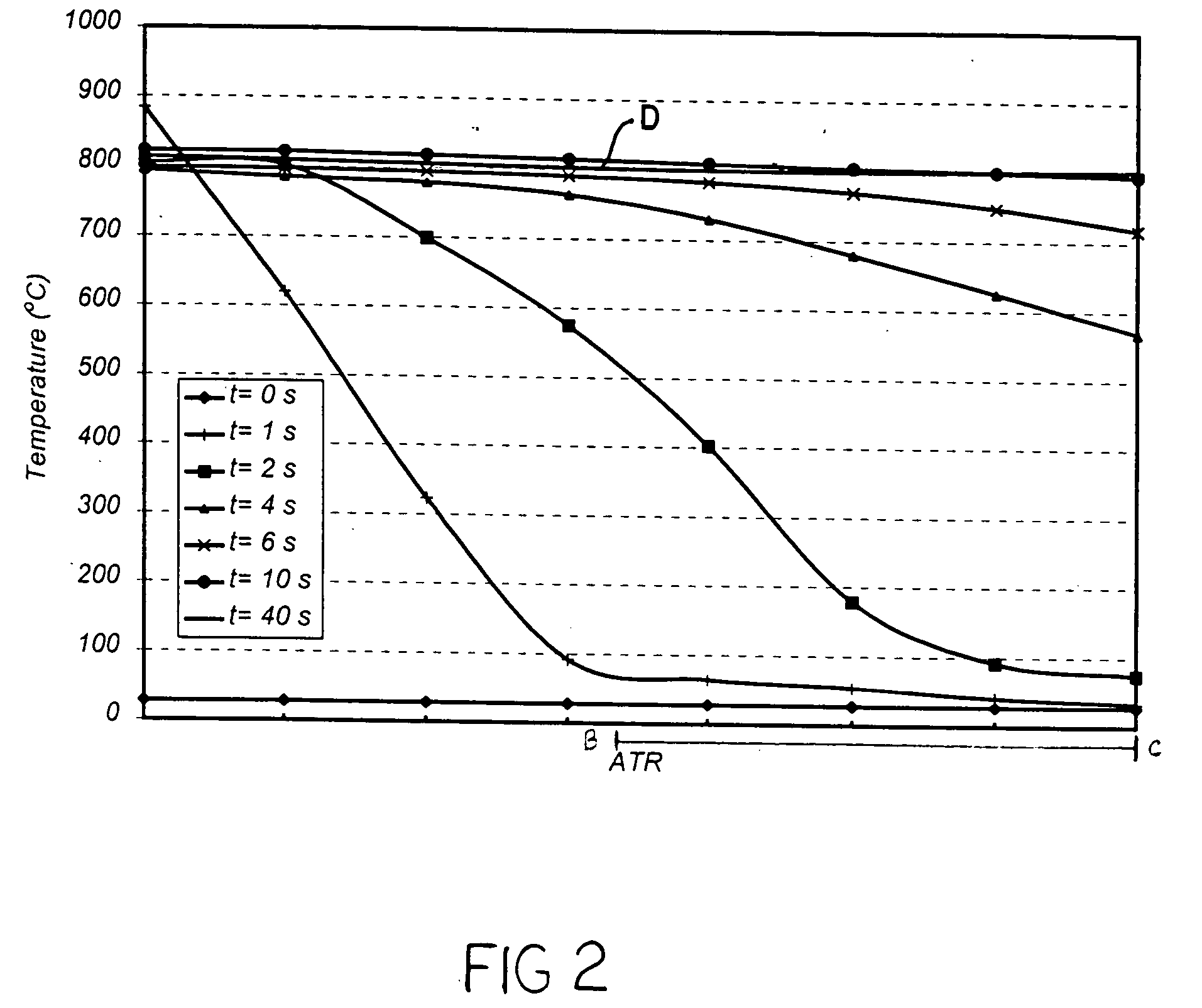

Method for fast start of a fuel processor

InactiveUS20050227130A1Little electrical powerReduce weightHydrogen separation using solid contactRegenerative fuel cellsFuel cellsCombustible gas

An improved fuel processor for fuel cells is provided whereby the startup time of the processor is less than sixty seconds and can be as low as 30 seconds, if not less. A rapid startup time is achieved by either igniting or allowing a small mixture of air and fuel to react over and warm up the catalyst of an autothermal reformer (ATR). The ATR then produces combustible gases to be subsequently oxidized on and simultaneously warm up water-gas shift zone catalysts. After normal operating temperature has been achieved, the proportion of air included with the fuel is greatly diminished.

Owner:UCHICAGO ARGONNE LLC +1

Gloss level adjustment

ActiveUS20050133962A1Highly accurate reproductionAvoid differencesDischarging arrangementMouldsTemperature controlHeat penetration

In a method for injection molding molten materials, especially plastic, in a mold that has a mold surface which comes into contact with the material, at least one coating on the mold surface and a temperature-control means for the mold surface, the mold surface is cooled by the temperature-control means so that the molten material solidifies at the interface with the coating and an injection-molded part can be removed from the form. During this process the molten material is brought into contact with the coating on the mold surface, the thickness of said coating being selected in coordination with the heat penetration coefficient of the coating material such that a specified 60° gloss level and / or color value L is obtained for the injection-molded part.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

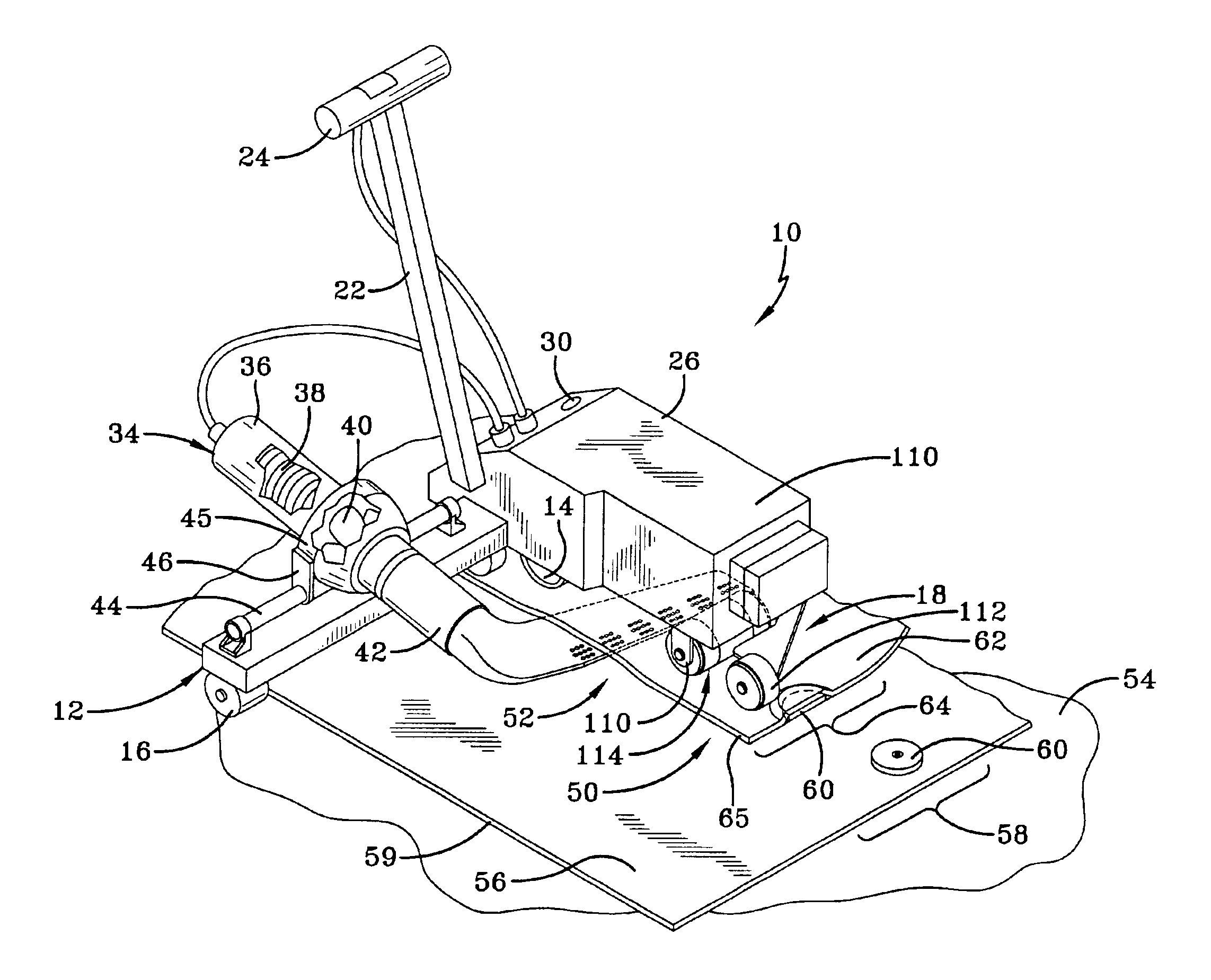

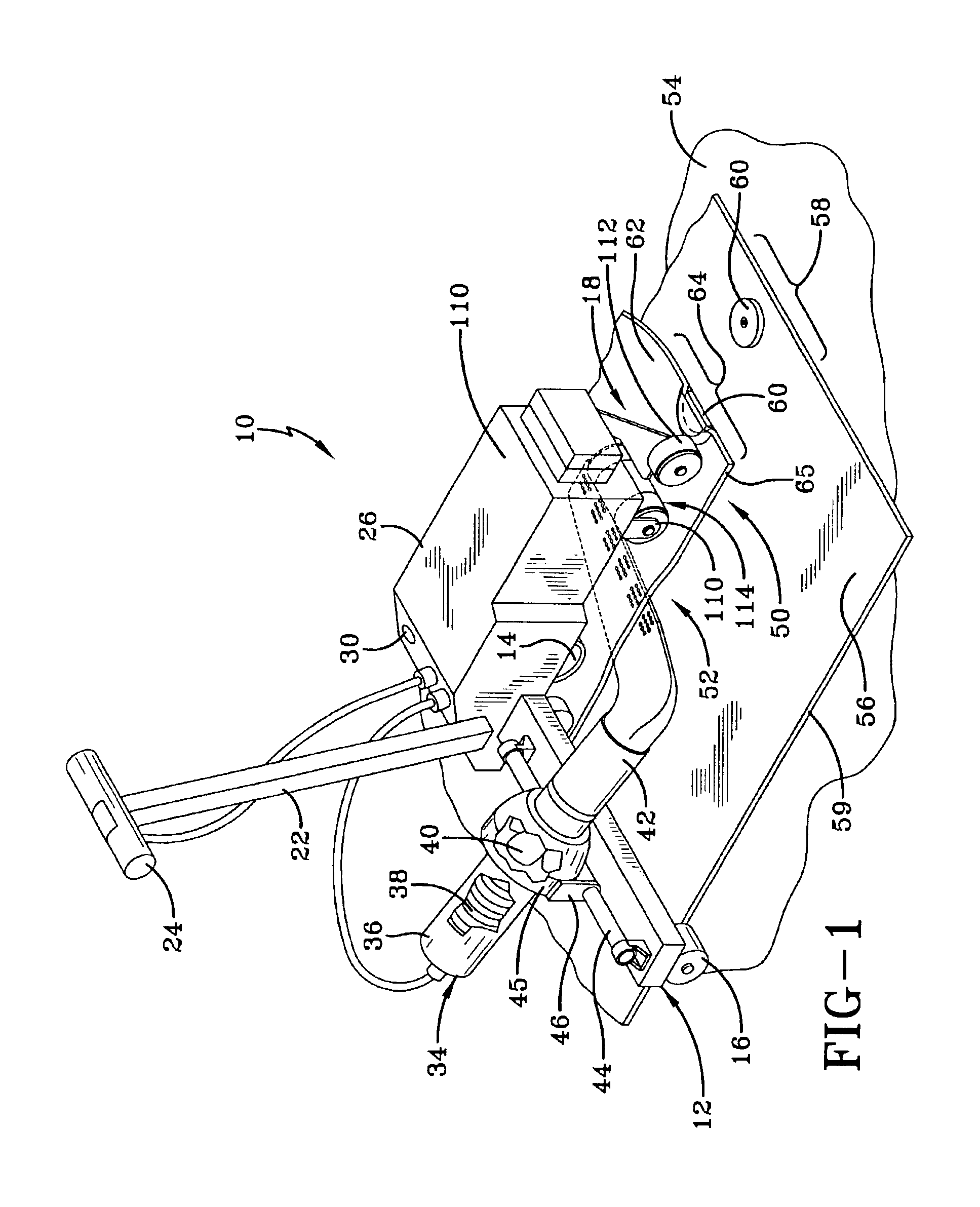

Obstruction avoidance continuous seam welding system

InactiveUS6973951B2Avoid obstructionOptimal heat gradientMechanical working/deformationFilament handlingEngineeringSeam welding

An apparatus for seaming roofing membranes to one another, wherein one of the membranes is secured to an underlying support structure by at least one protruding fastener is provided. The apparatus includes a wheeled carriage having an upwardly extending push / pull bar. A power supply propels the wheeled carriage and energizes a heating assembly that generates a heated airflow sufficient to fuse the roofing membranes to one another. A nozzle is coupled to the heating assembly for directing the heated airflow between the two membranes. A variable pressure roller assembly is coupled to the carriage and has a single durometer material carried by an axle that may have different diameter sections. The roller passes over the at least one protruding fastener while still applying a uniform pressure so as to form a substantially continuous width seam except where interrupted by the protruding fastener.

Owner:FIRESTONE BUILDING PRODS

Novel carbon fiber composite electric heating film and preparation method thereof

InactiveCN102123529AReduce energy lossImprove efficiencyHeating element materialsPlastic filmMetal electrodes

The invention discloses a novel carbon fiber composite electric heating film which comprises a conductive carbon fiber layer, wherein the conductive carbon fiber layer is of a meshy structure weaved by carbon fibers, two ends of the conductive carbon fiber layer are connected with metal electrodes, and the conductive carbon fiber layer is entirely cladded by an insulated heat conduction plastic film to form a laminated structure. The carbon fiber electric heating film provided by the invention is resistant of high temperature and not easy to oxidize; and the outer-layer heat conduction plastic of the carbon fiber electric heating film is an insulated material and can resist high temperature of 300 DEG C and high voltage; and therefore, the carbon fiber electric heating film provided by the invention has extremely high safety and can be guaranteed to be used for over 50 years. The carbon fibers supply heat to the external environment in an infrared irradiation mode, is free of dust, noise, wastes and waste gases and is basically free of electromagnetic irradiation. The invention has the advantages of concise preparation process, low cost, energy source saving and eco-environmental protection and accords with the environment protection and energy source development directions.

Owner:ANHUI UNIVERSITY +1

Laser preprocessing wire filling tungsten inert gas (TIG) welding method of titanium alloy and pure aluminum sheets

InactiveCN103084714AReduce lossesPromote homogenizationArc welding apparatusWelding/cutting media/materialsLaser processingTitanium

The invention provides a laser preprocessing wire filling tungsten inert gas (TIG) welding method of titanium alloy and pure aluminum sheets. Firstly, a titanium alloy sheet and a pure aluminum sheet are cleaned. Secondly, a to-be-welded part of the titanium alloy sheet undergoes liquid immersing processing. Thirdly, a laser is utilized to preprocess the to-be-welded surface of the lateral side of the titanium alloy sheet, wherein the surface of the lateral side of the titanium alloy sheet undergoes aluminizing so that a stable middle layer which is easy to combine is formed, and meanwhile, after laser processing, the to-be-welded surface of titanium alloy undergoes self cooling quenching. Finally, a welding wire with specific proportioning is utilized for TIG of titanium and the pure aluminum sheet, and the titanium alloy sheet and the aluminum sheet can be connected through the middle layer by welding. The laser preprocessing wire filling TIG welding method of the titanium alloy and pure aluminum sheets improves plasticity and toughness of a joint, operation is simple, cost is low, and connection effect is good.

Owner:东莞昶能镭射金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com