Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4979 results about "Fiber layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The retinal nerve fiber layer (RNFL) or nerve fiber layer, stratum opticum, is formed by the expansion of the fibers of the optic nerve; it is thickest near the optic disc, gradually diminishing toward the ora serrata.

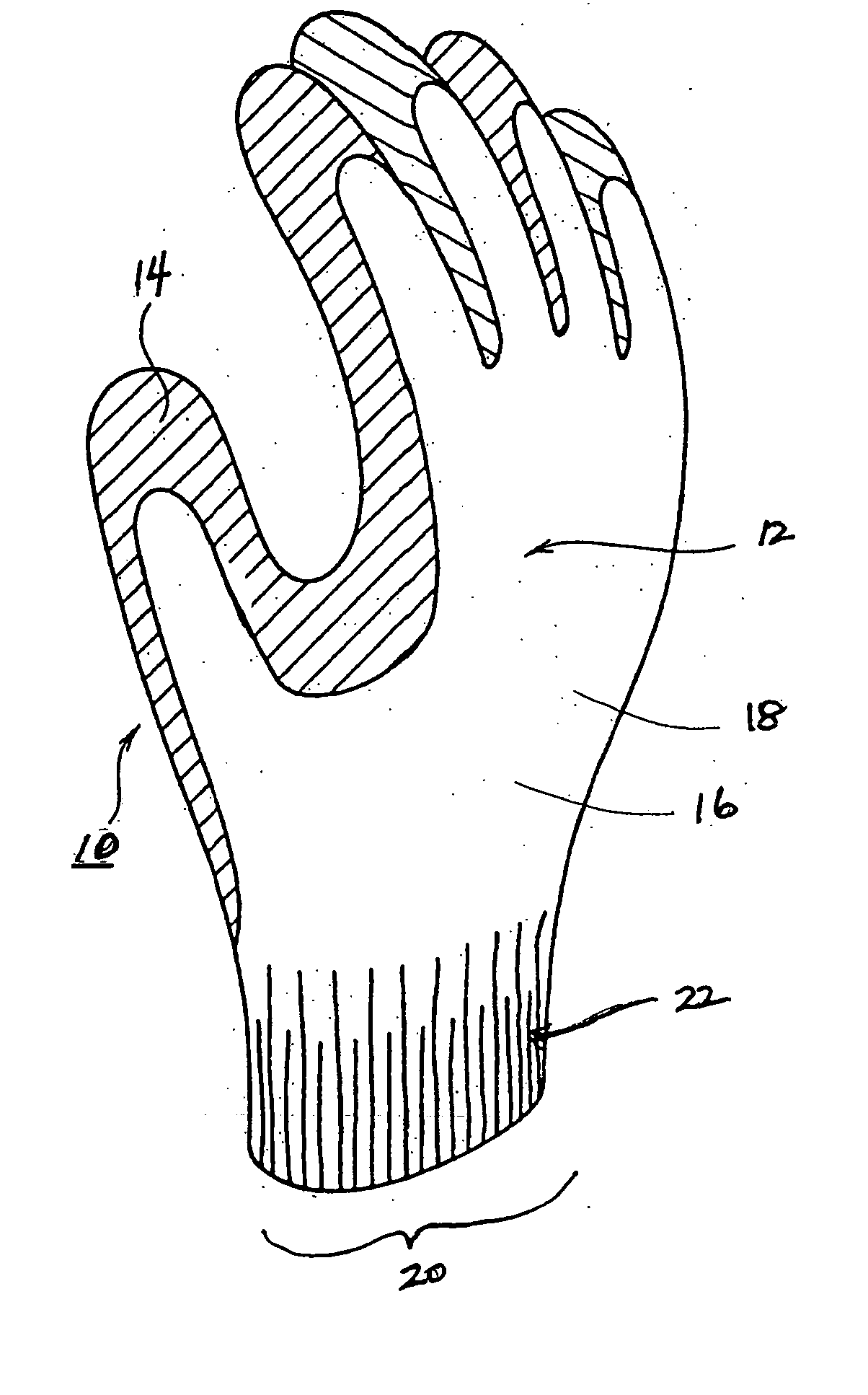

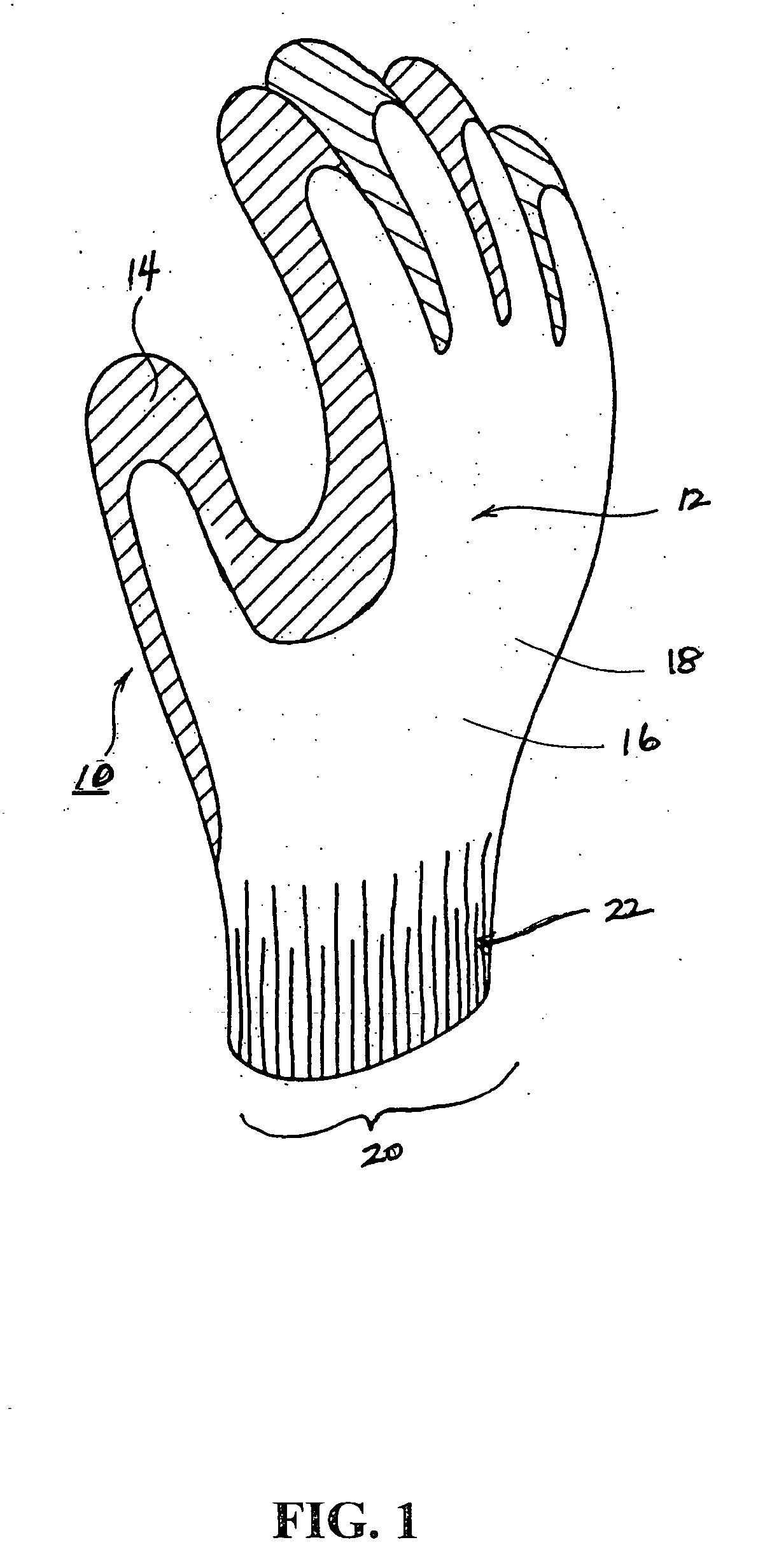

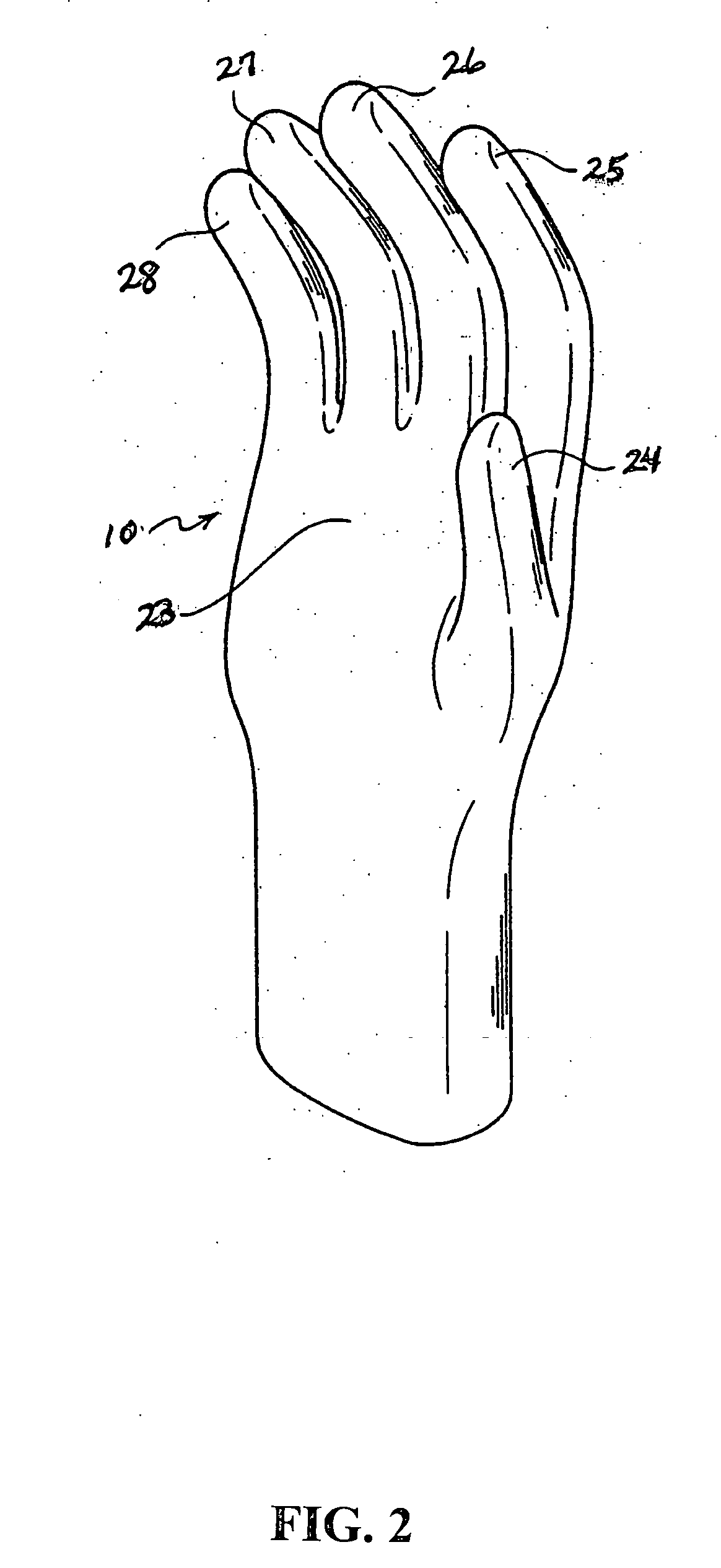

Breathable protective articles

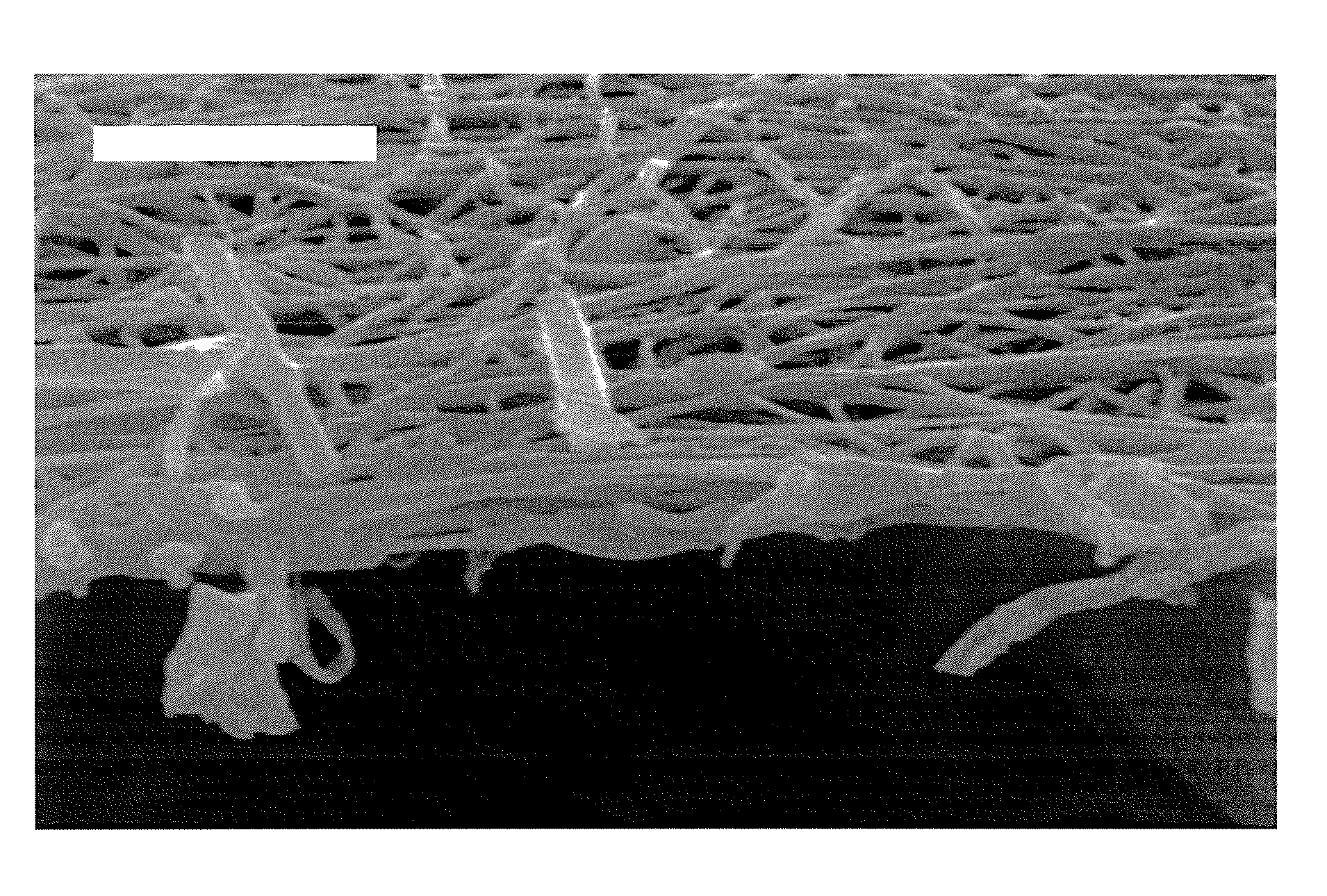

InactiveUS20060143767A1Improve gripImprove non-skidding propertyFinger bandagesNon-adhesive dressingsElastomerPliability

A protective article formed of a laminate between at least a layer of a liquid-impermeable, vapor-permeable barrier, and at least a layer of a stretchable or elastomeric, nonwoven fiber web is described. The barrier is reinforced at least on one side by the nonwoven fiber web, which remains elastic after being bonded to the barrier layer. The elasticity of both barrier and bonded fiber layers simulate the flexibility of natural or synthetic latex or other polymer films. The nonwoven fiber web includes at least about 75% of individual fibers with a length of over about 1 mm, and the fibers are substantially continuous. A second nonwoven web, a second barrier layer, or both may be attached to the exterior side of the breathable barrier. An elastomeric material coating, such as either a nature or synthetic latex or other polymers, may be applied over at least a portion of the article to provide for additional protection.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fluoropolymer fine fiber

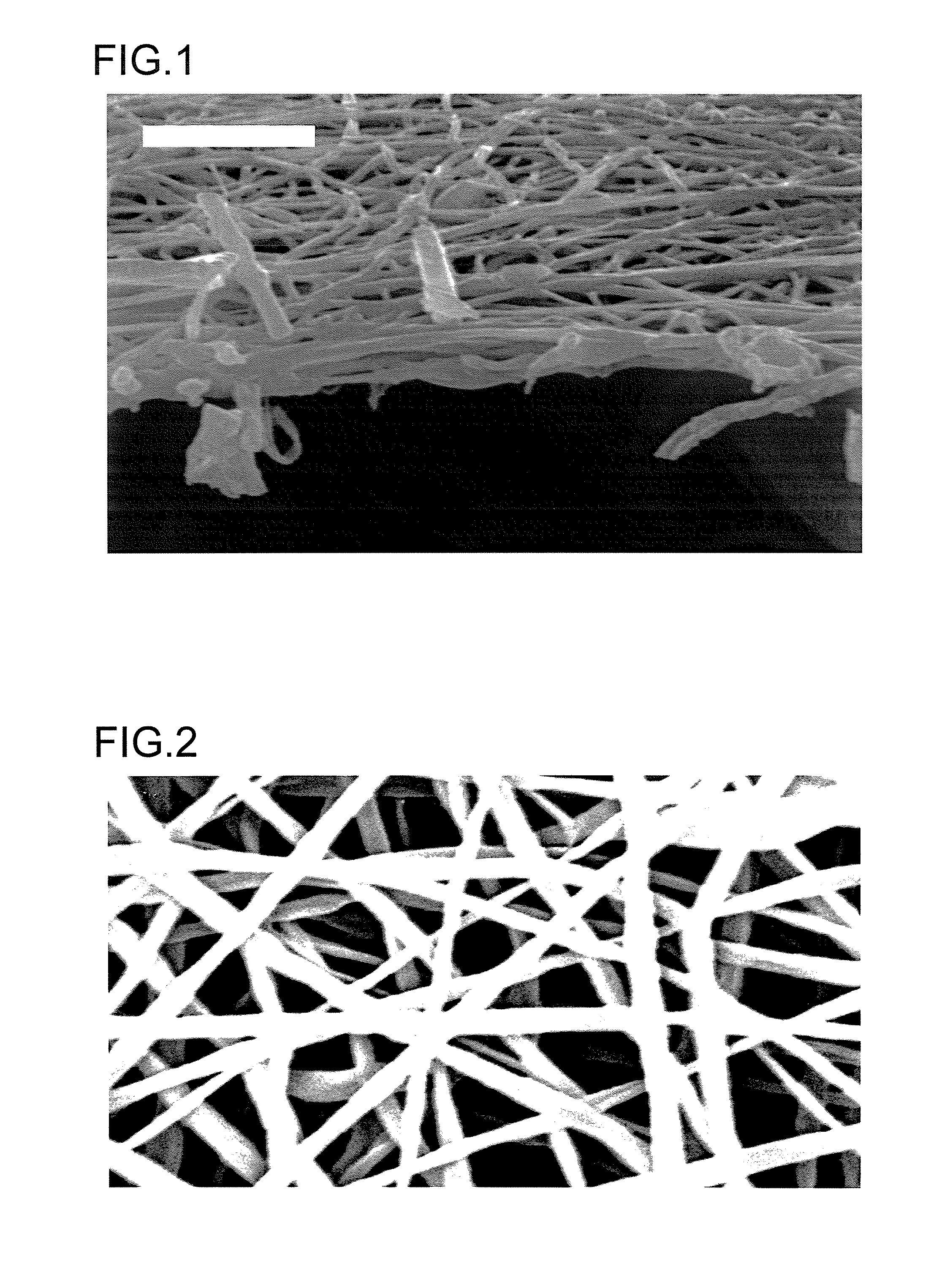

ActiveUS20090032475A1Advantageously employedHeat stableDispersed particle filtrationLiquid suspension thickening by filtrationPolymer scienceFiltration

A layer of fluoropolymer fine fiber can be made. The fine fiber can be made by electrospinning from a solvent or a solvent blend. The layers of the invention are useful in general filtration of fluid streams including gaseous and liquid streams. The fine fiber layers are also useful as hydrophobic filtration layers that can be used to separate water from a hydrocarbon stream.

Owner:DONALDSON CO INC

Web comprising fine fiber and reactive, adsorptive or absorptive particulate

ActiveUS7655070B1Increase the cross-sectional areaIncreased turbulenceMaterial nanotechnologyUsing liquid separation agentParticulatesFiltration

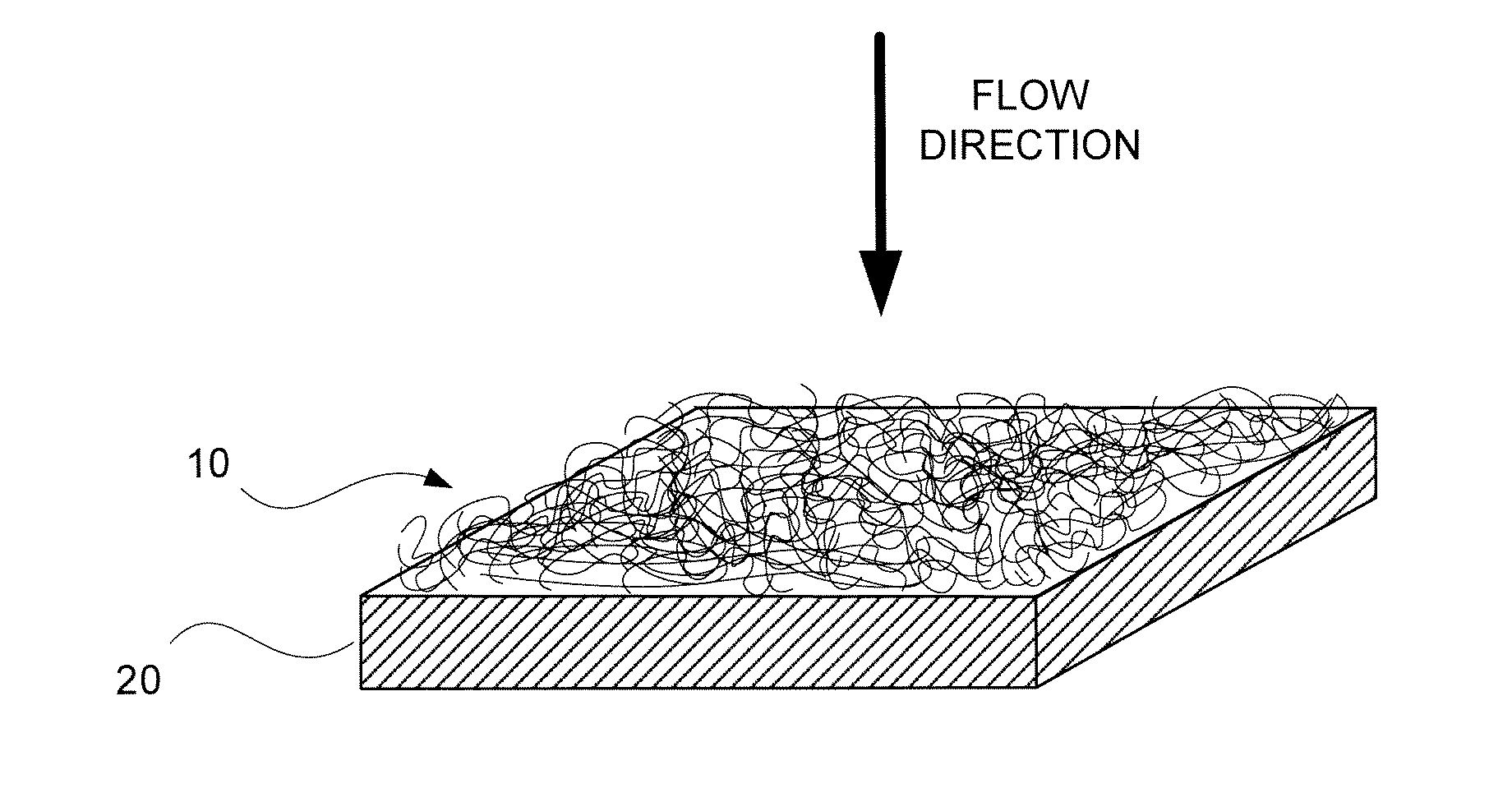

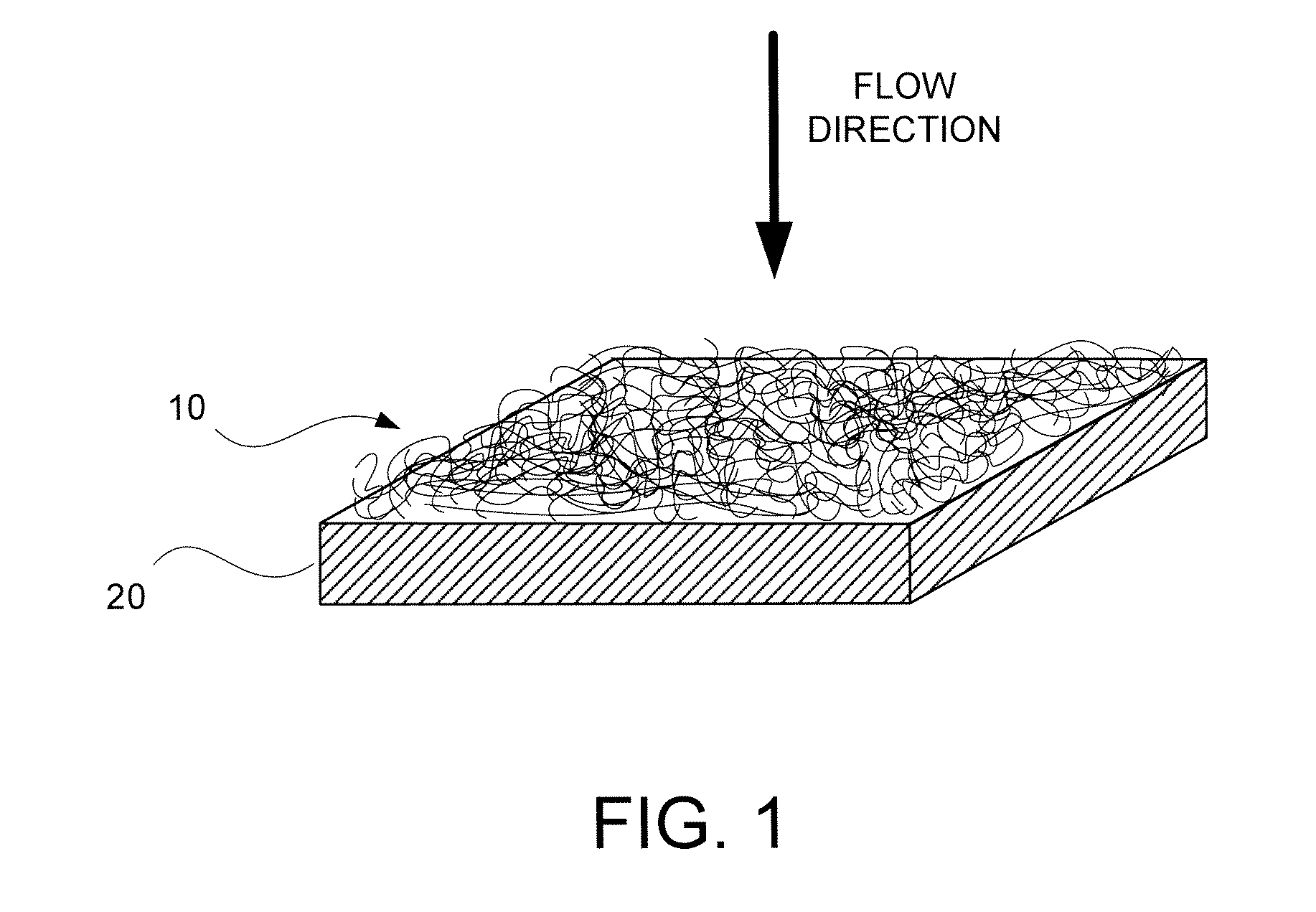

The assemblies of the invention can comprise a fine fiber layer having dispersed within the fine fiber layer an active particulate material. Fluid that flows through the assemblies of the invention can have any material dispersed or dissolved in the fluid react with, be absorbed by, or adsorbed onto, the active particulate within the nanofiber layer. The structures of the invention can act simply as reactive, absorptive, or adsorptive layers with no filtration properties, or the structures of the invention can be assembled into filters that can filter particulate from a mobile fluid while simultaneously reacting, absorbing, or adsorbing materials from the mobile fluid.

Owner:DONALDSON CO INC

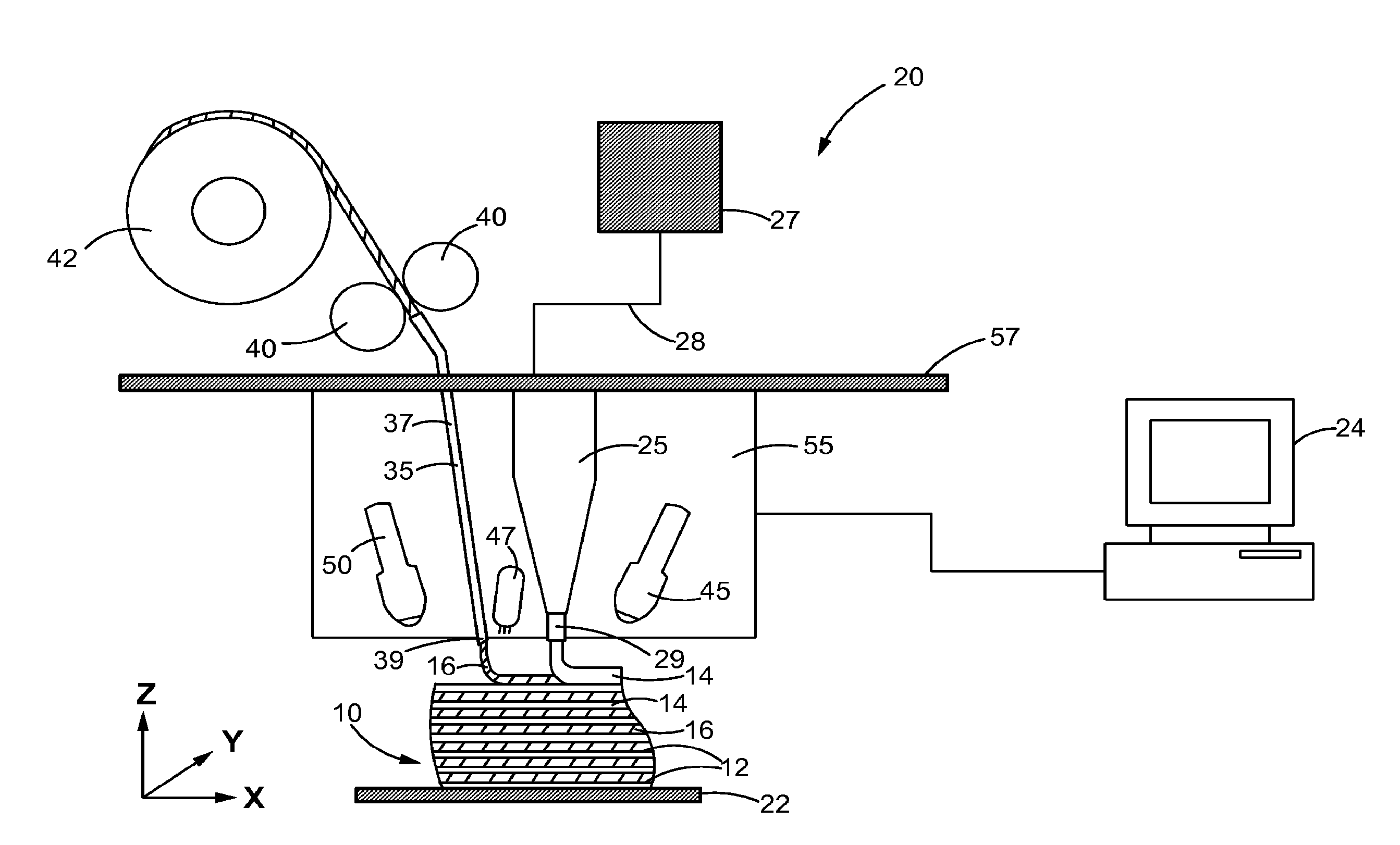

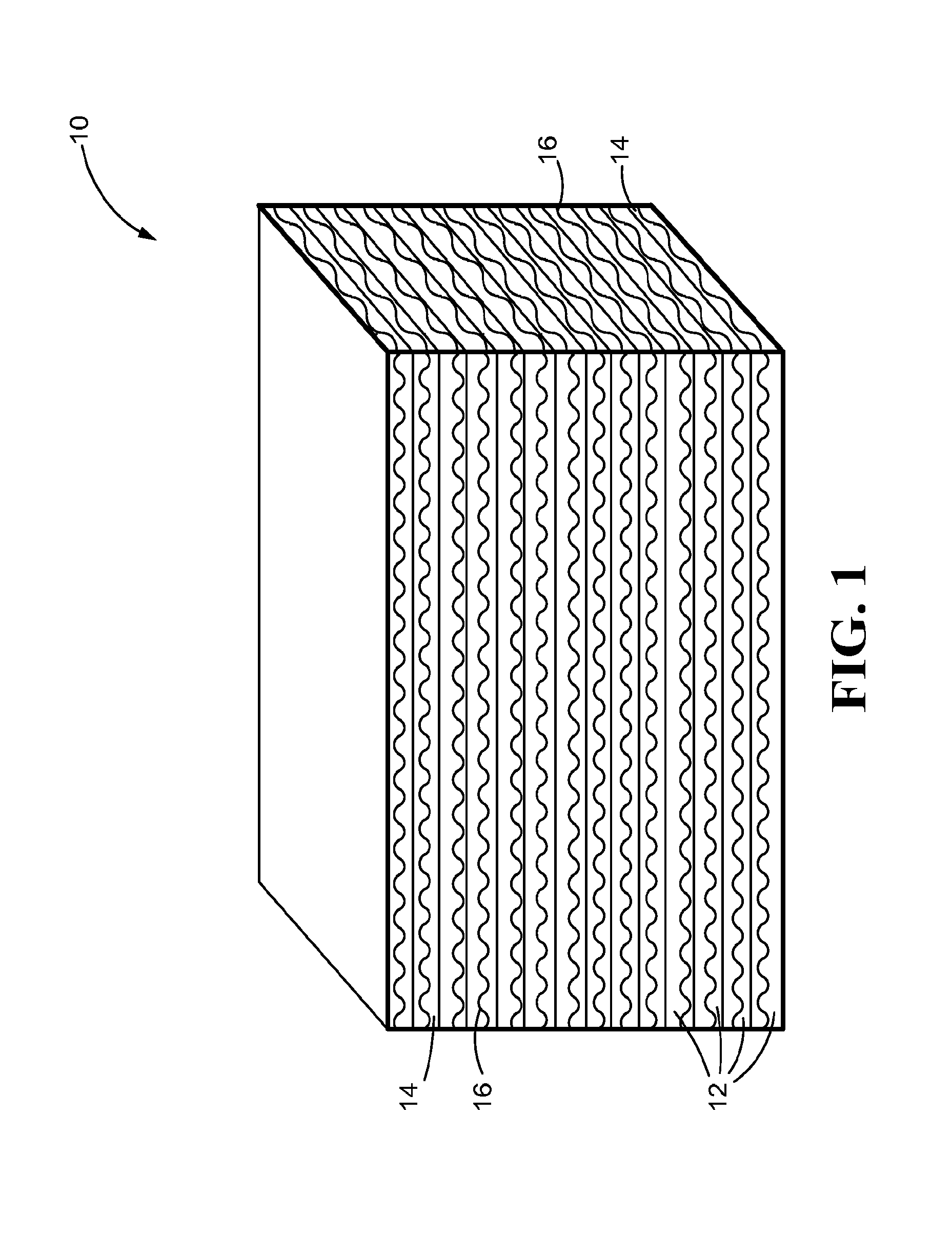

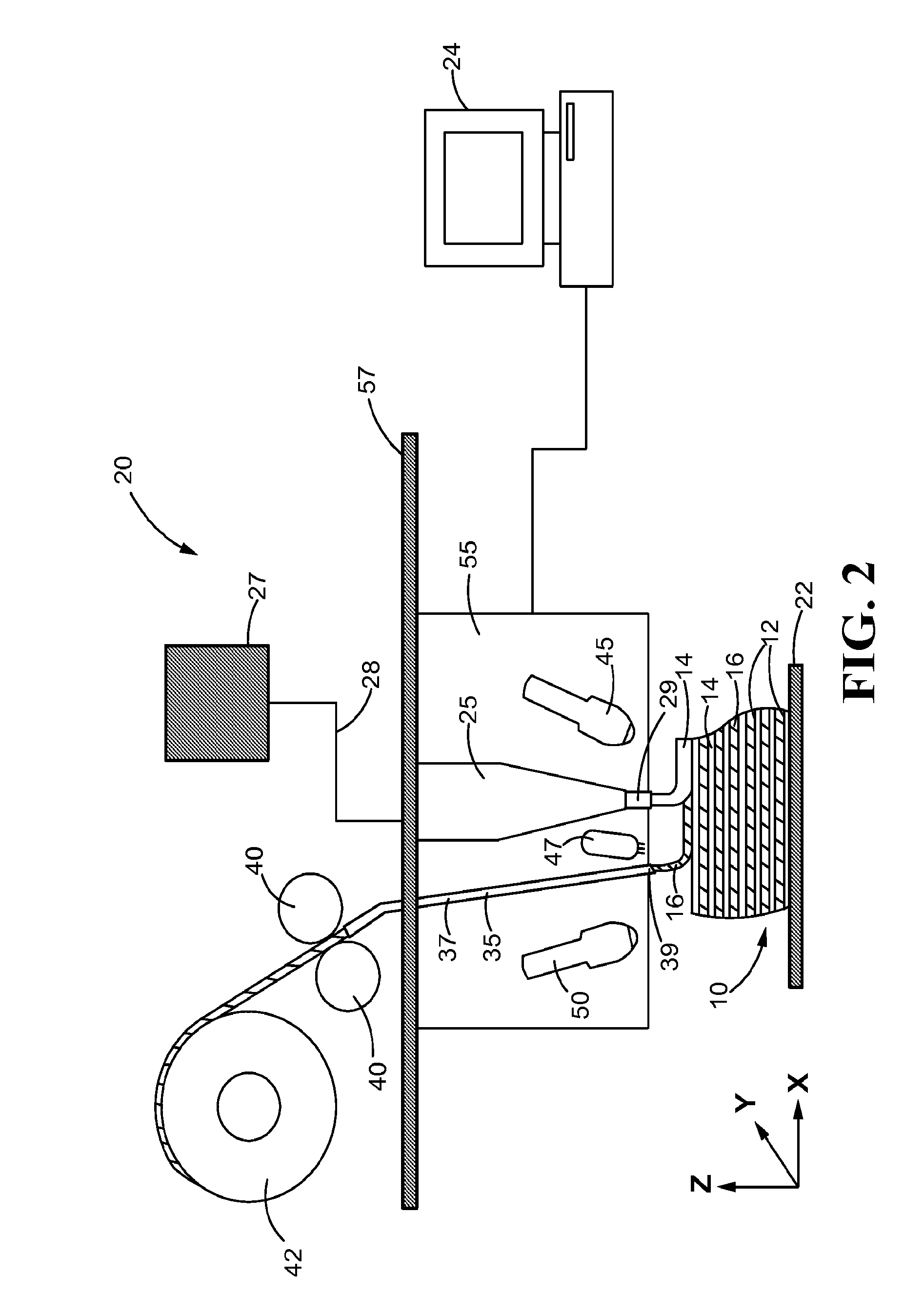

Continuous fiber-reinforced component fabrication

ActiveUS20160114532A1Additive manufacturing apparatusTailstocks/centresAdditive layer manufacturingElectrical and Electronics engineering

A machine for fabricating a fiber-reinforced component by additive manufacturing is disclosed. The machine may have a surface, a matrix feed configured to deposit a plurality of matrix layers on the surface, and a fiber feed configured to deposit a fiber layer on at least one of the plurality of matrix layers. The deposition of the plurality of matrix layers and the fiber layer may be controlled by a computer.

Owner:RTX CORP

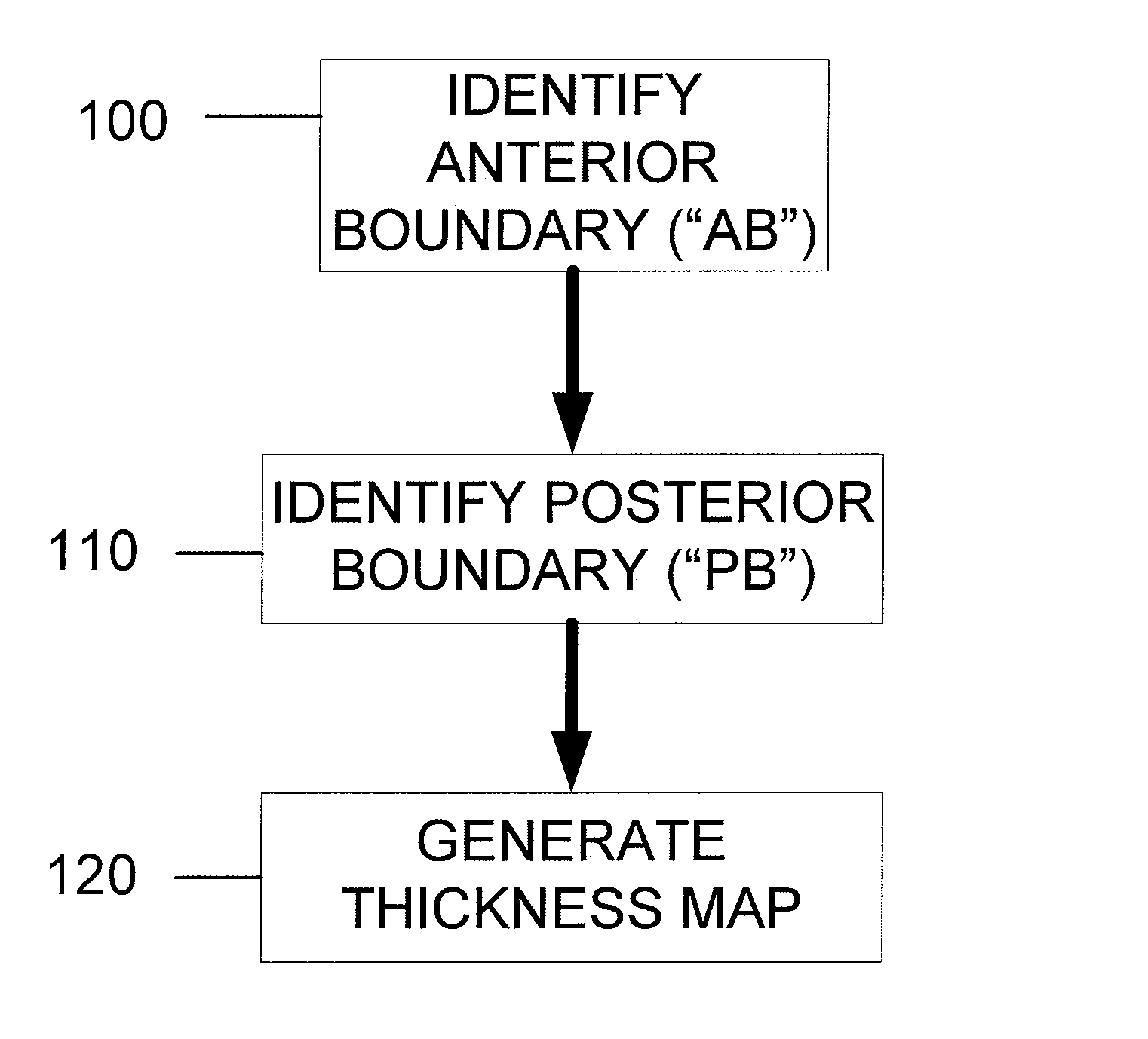

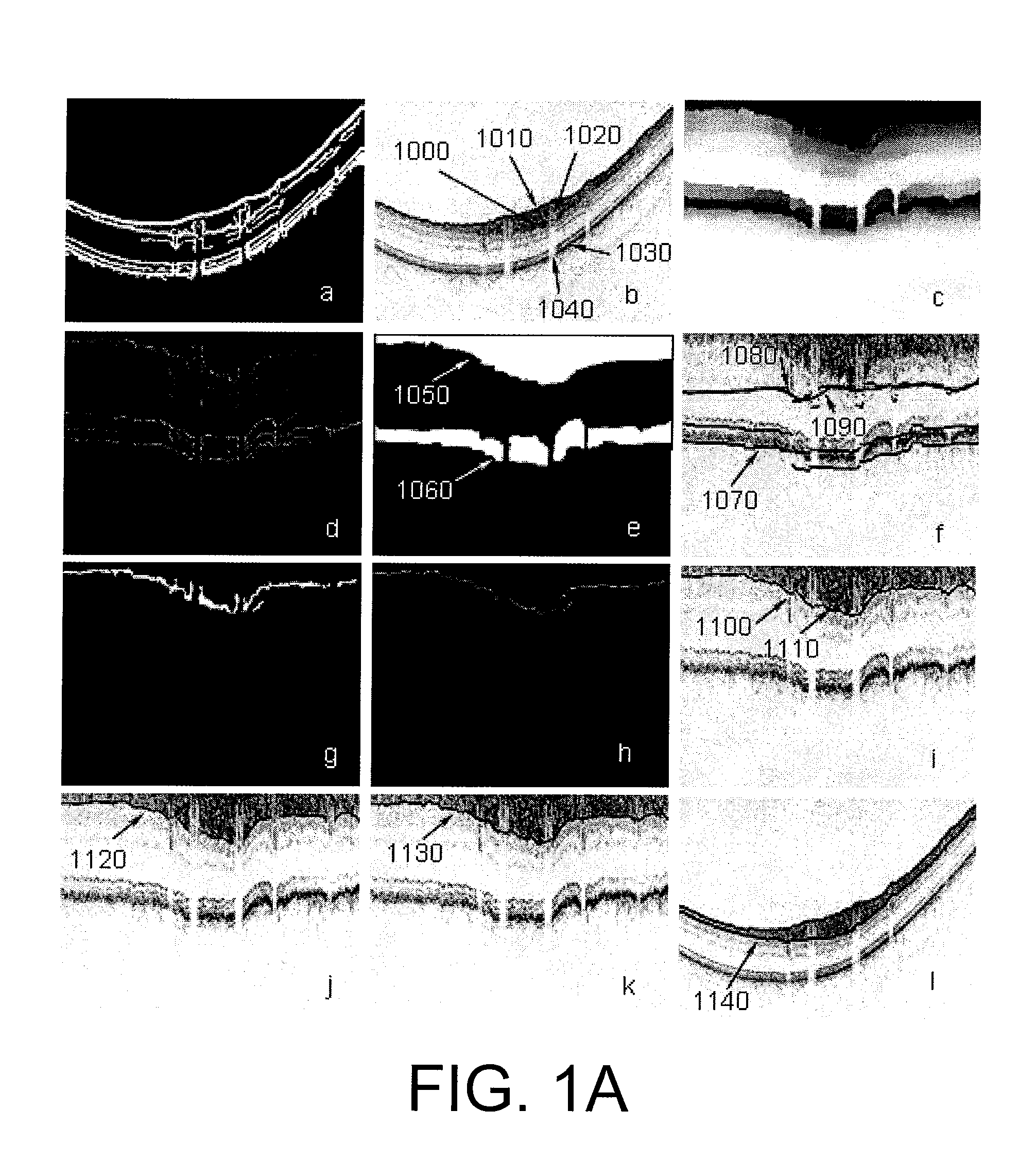

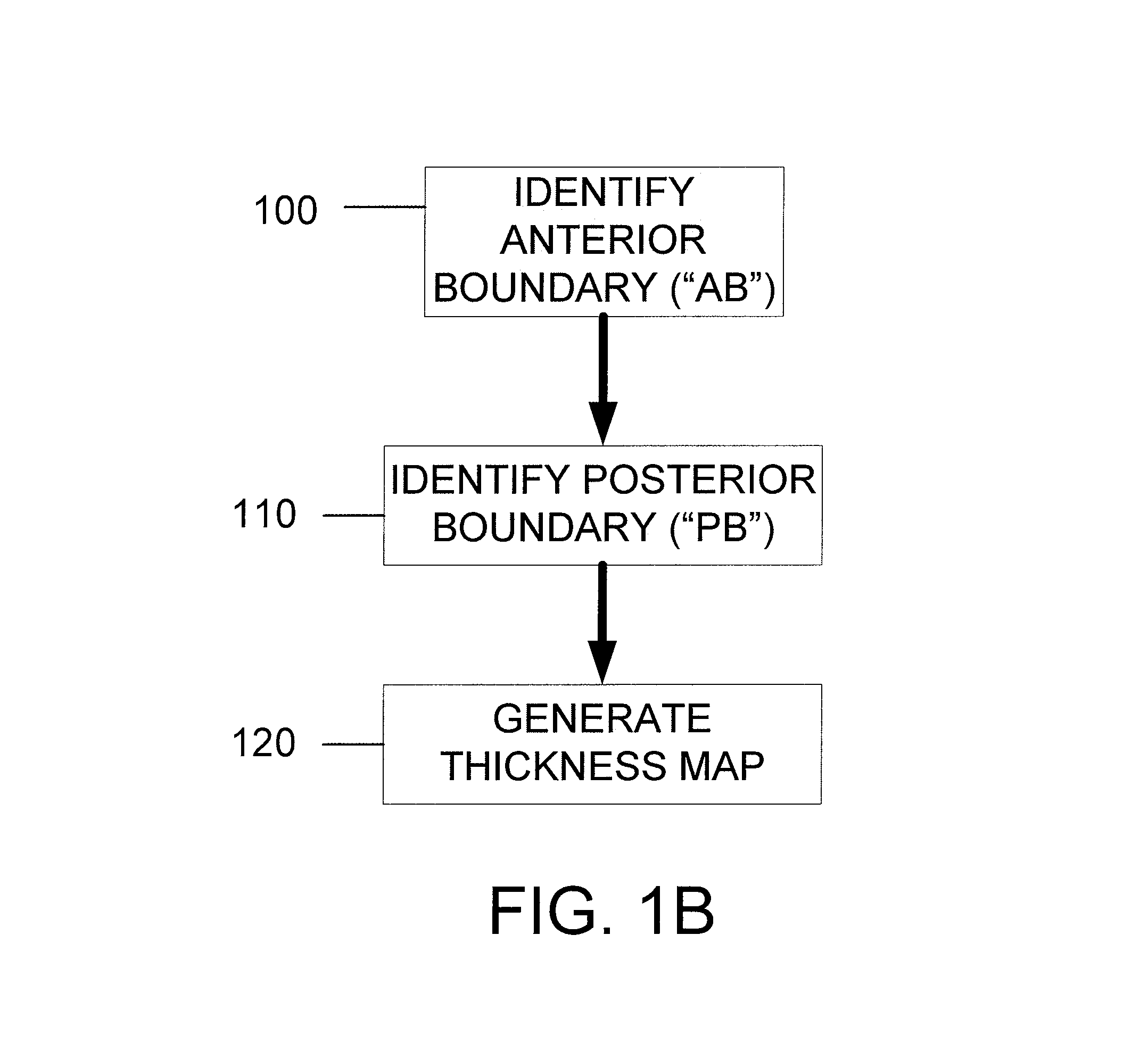

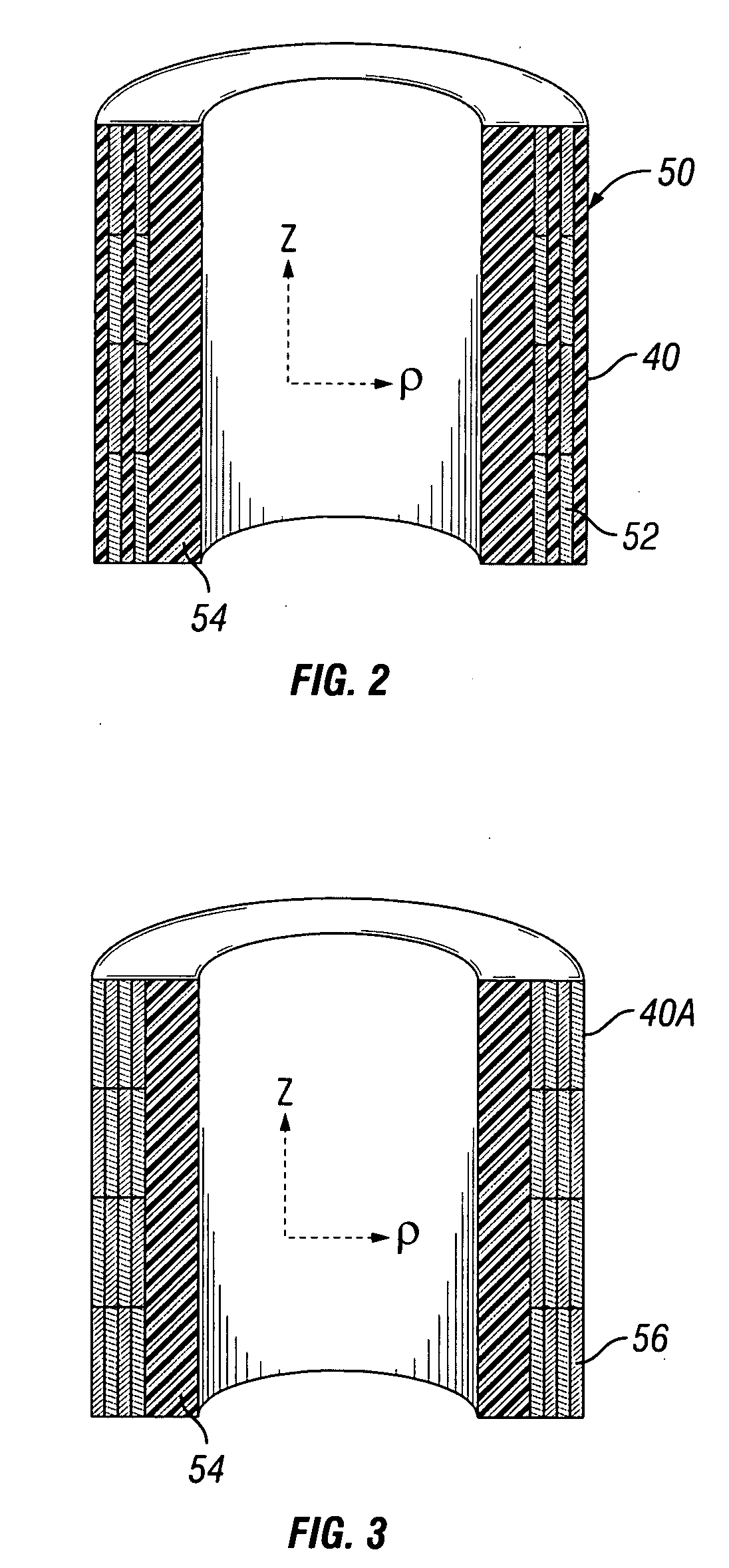

Processes, arrangements and systems for providing a fiber layer thickness map based on optical coherence tomography images

InactiveUS7782464B2Facilitating clinical interpretationImage enhancementImage analysisAnatomical structuresVolumetric data

A system, arrangement, computer-accessible medium and process are provided for determining information associated with at least one portion of an anatomical structure. For example, an interference between at least one first radiation associated with a radiation directed to the anatomical structure and at least one second radiation associated with a radiation directed to a reference can be detected. Three-dimensional volumetric data can be generated for the at least one portion as a function of the interference. Further, the information can be determined which is at least one geometrical characteristic and / or at least one intensity characteristic of the portion based on the volumetric data.

Owner:THE GENERAL HOSPITAL CORP

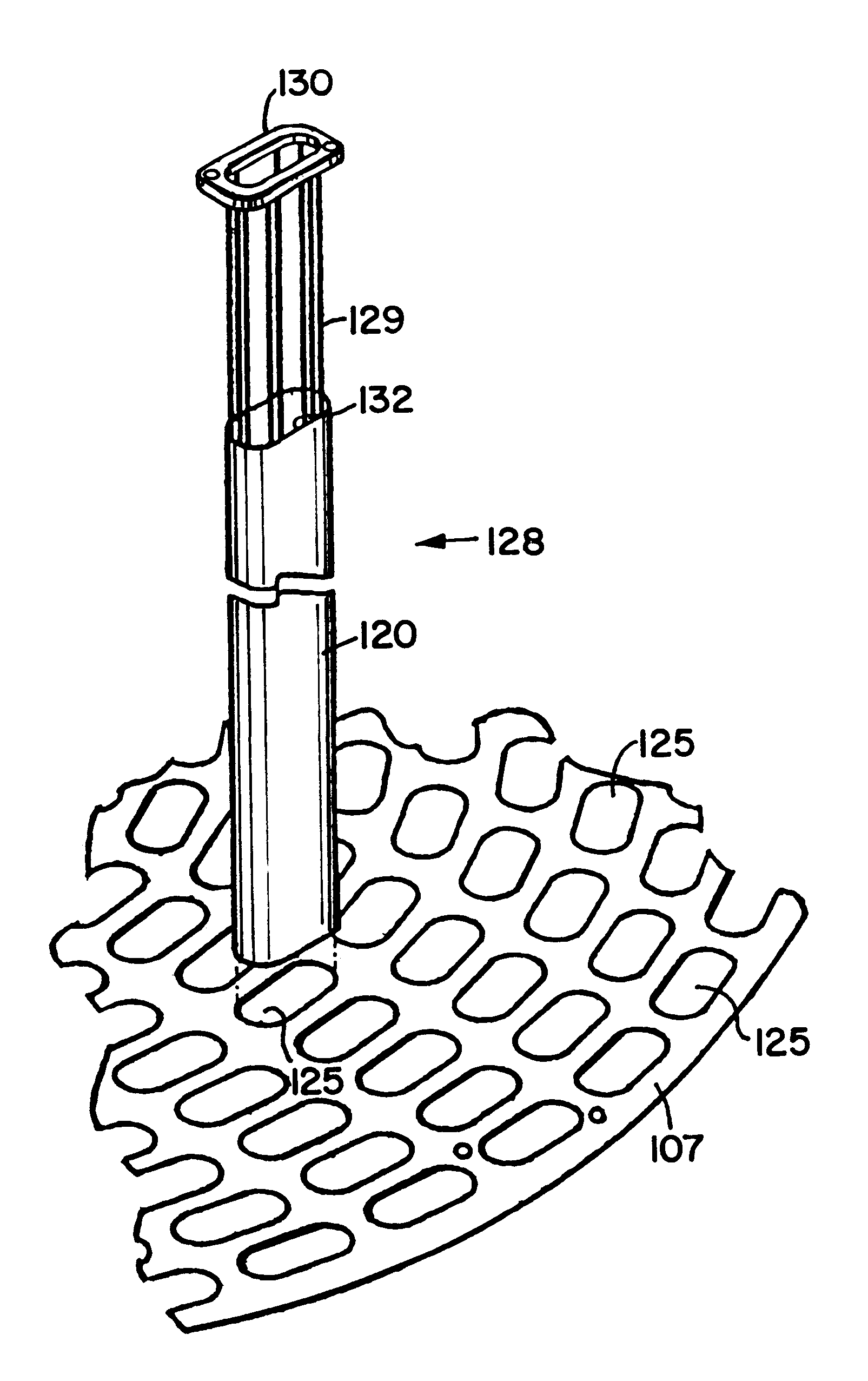

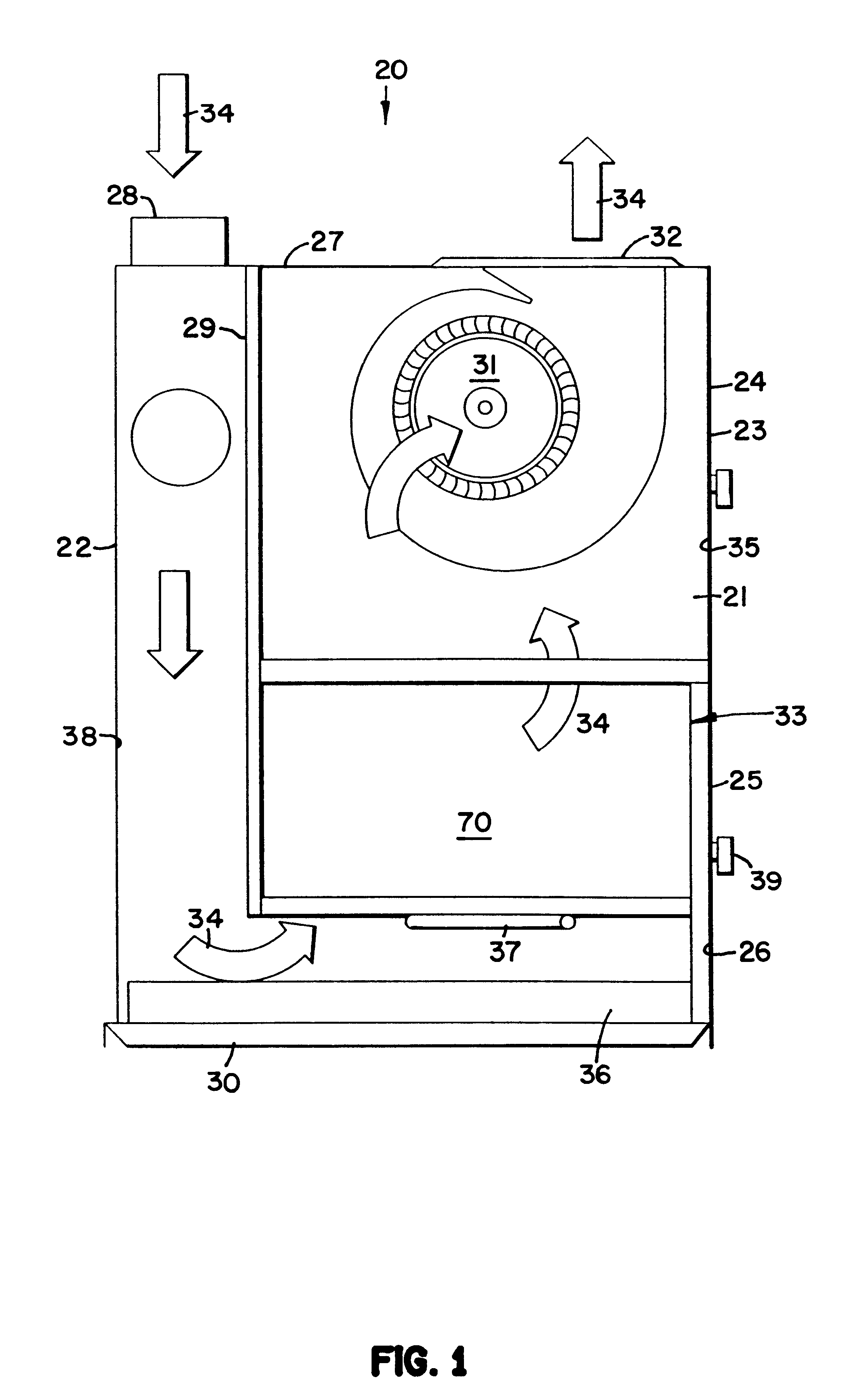

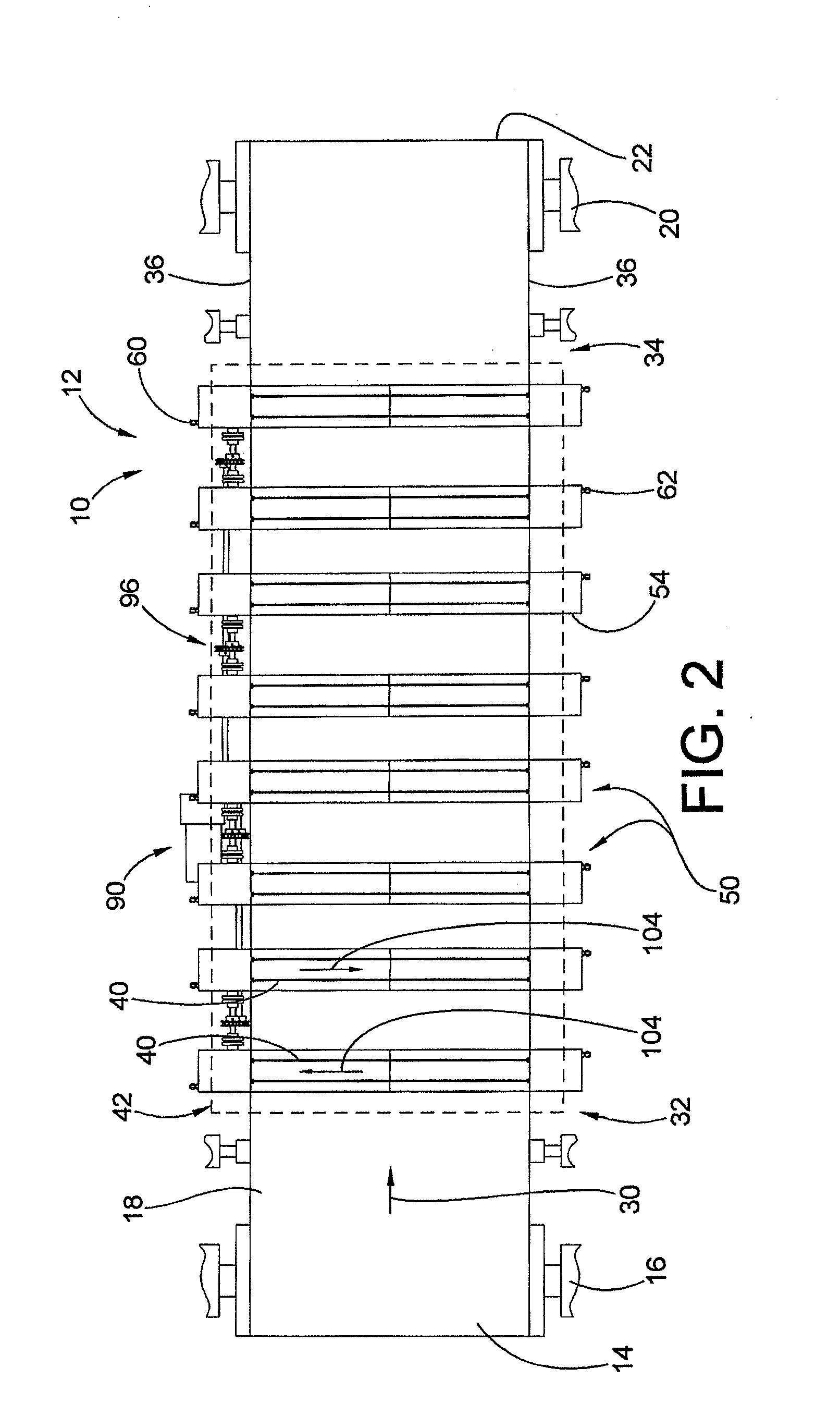

Industrial bag house elements

InactiveUS6740142B2Low efficiencyShort lifeCombination devicesMaterial nanotechnologyAir filterFilter media

The filter structures commonly known as a bag house or a filter bag or an air filter with a bag construction can be made by preparing the bag assembly, either in a tubular or a bi-fold construction by placing a layer of fine fiber on the upstream surface of the filter media structure. The filter assembly includes a filter cabinet with an interior component. The filter component is suspended within the filter cabinet interior. The filter component includes a frame or support for the filter media. The frame or support holds the filter bags such that the filter bags are suspended from the frame in the cabinet interior. The intake air enters the cabinet, passes through the filter assembly and exits the cabinet. The air must pass first into the fine fiber layer, the filter media and then the exterior of the cabinet.

Owner:DONALDSON CO INC

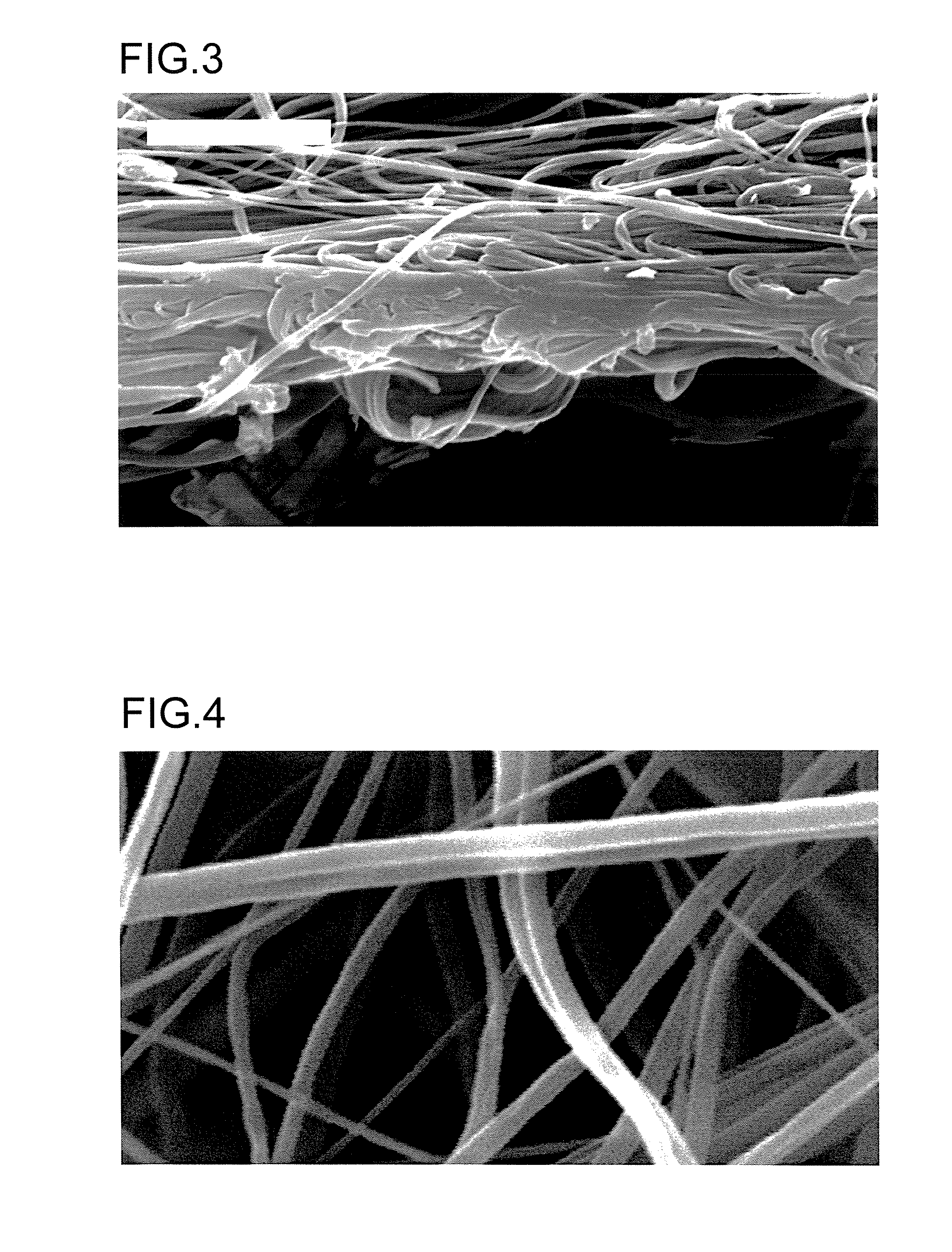

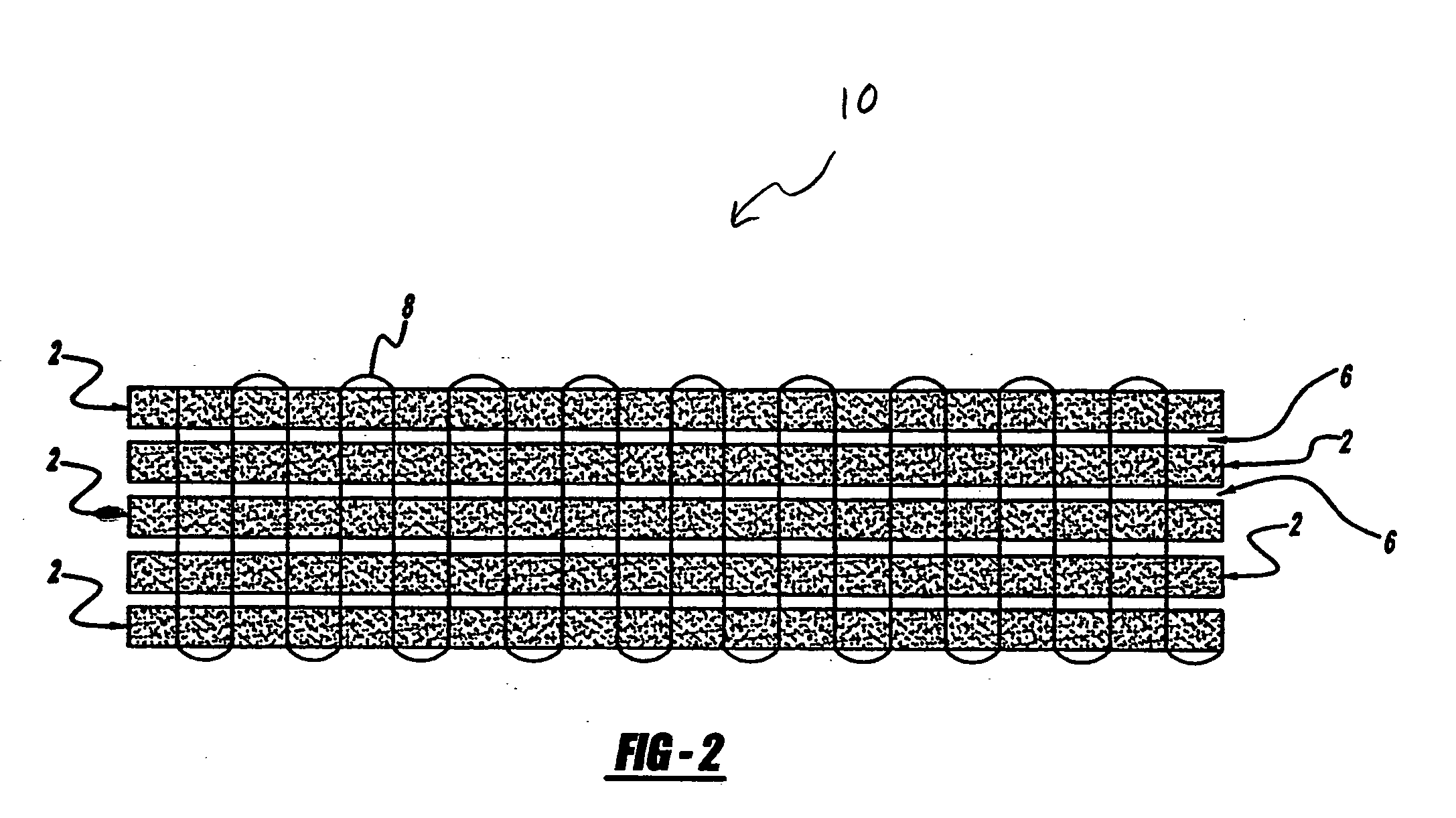

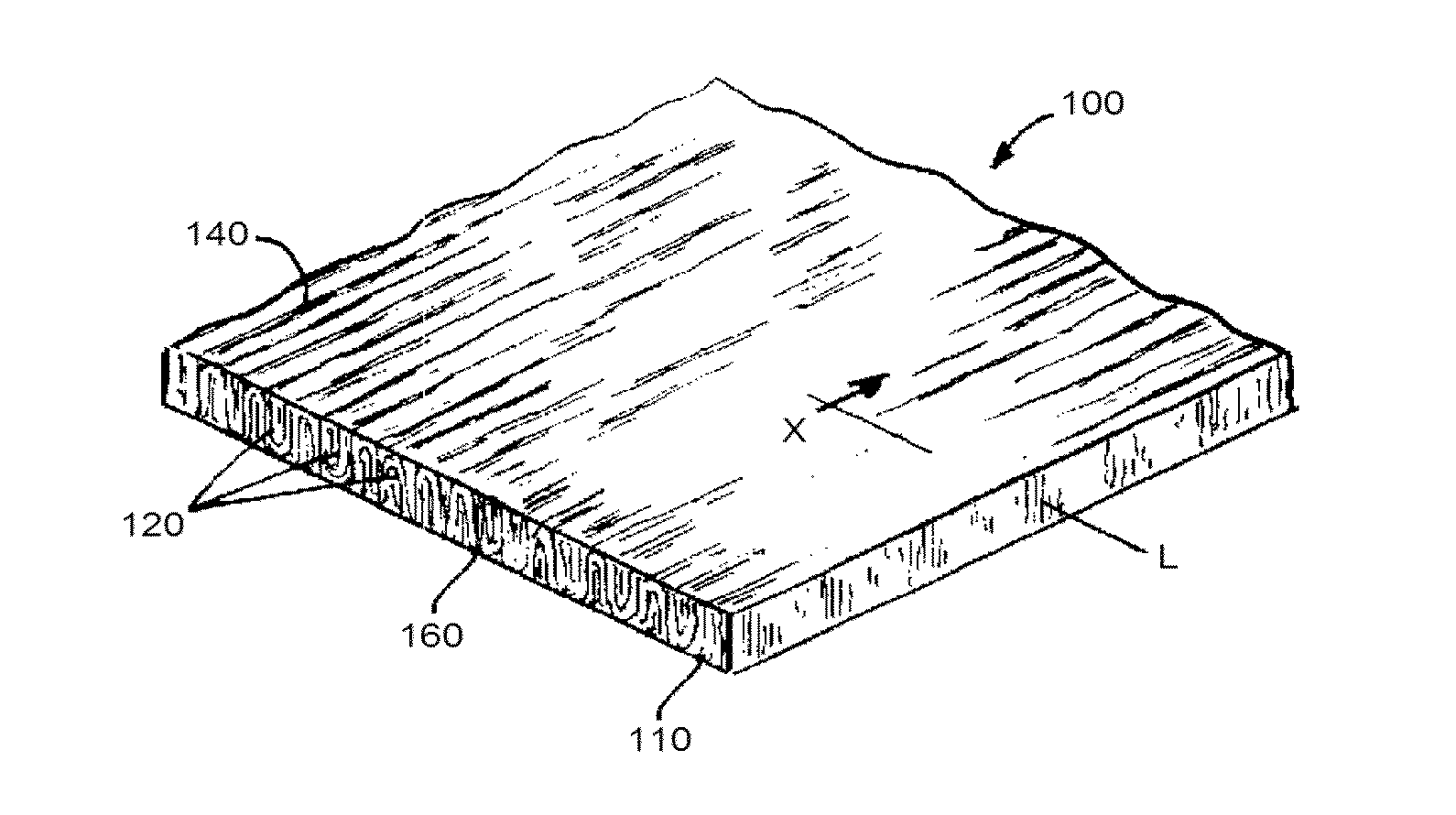

Methods and preforms for forming composite members with interlayers formed of nonwoven, continuous materials

ActiveUS20050059309A1Improve impact resistanceLayered productsWoven fabricsShell moldingMaterials science

Materials and methods are provided for producing preform materials for impact-resistant composite materials suitable for liquid molding. Interlayers formed of nonwoven, continuous fibers, such as spunbonded, spunlaced, or mesh fabric, are introduced between non-crimped layers of unidirectional reinforcing fibers to produce a preform for use in liquid-molding processes to produce a composite member. Curing of the preform provides increased impact resistance by increasing the amount of energy required to propagate localized fractures due to impact.

Owner:THE BOEING CO

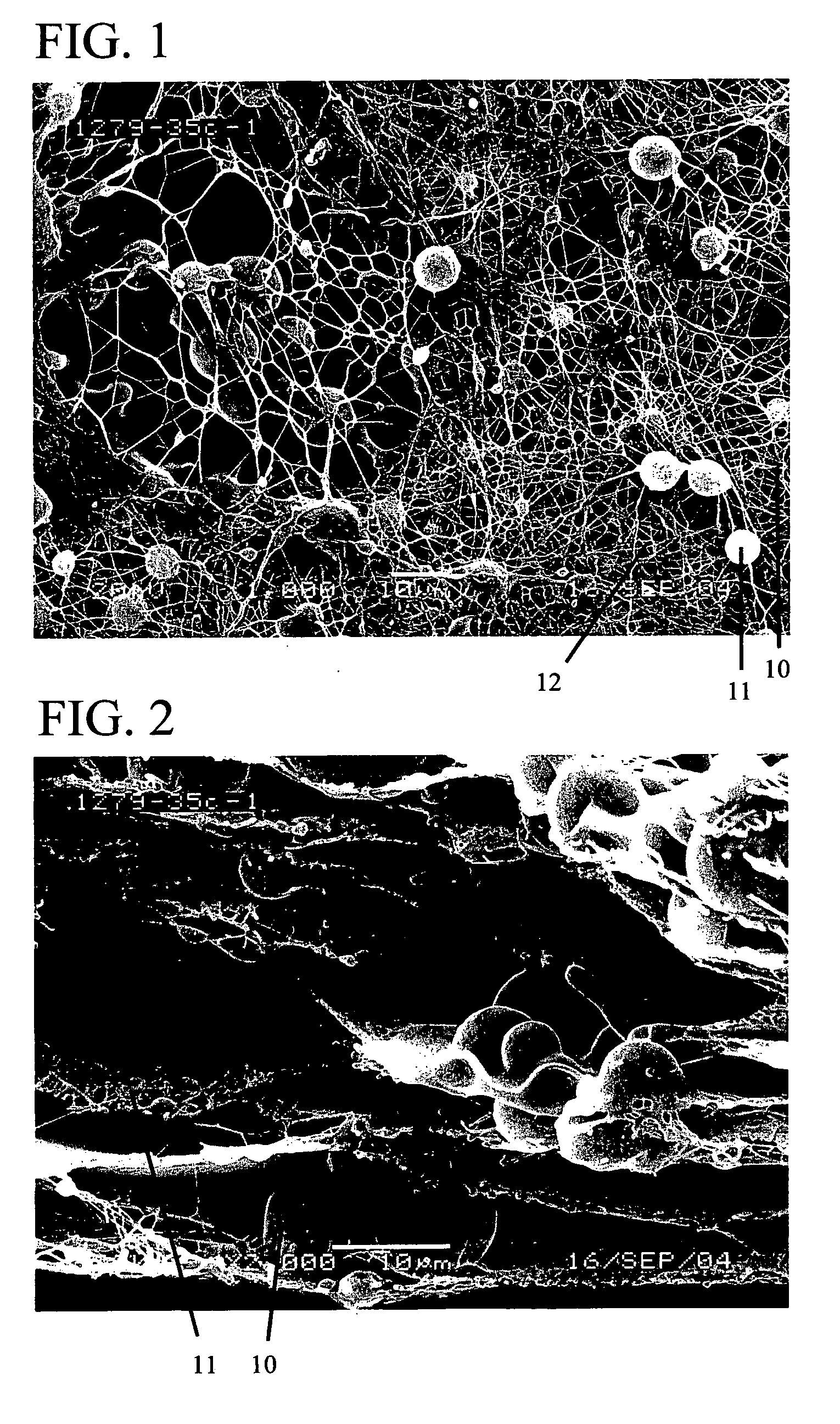

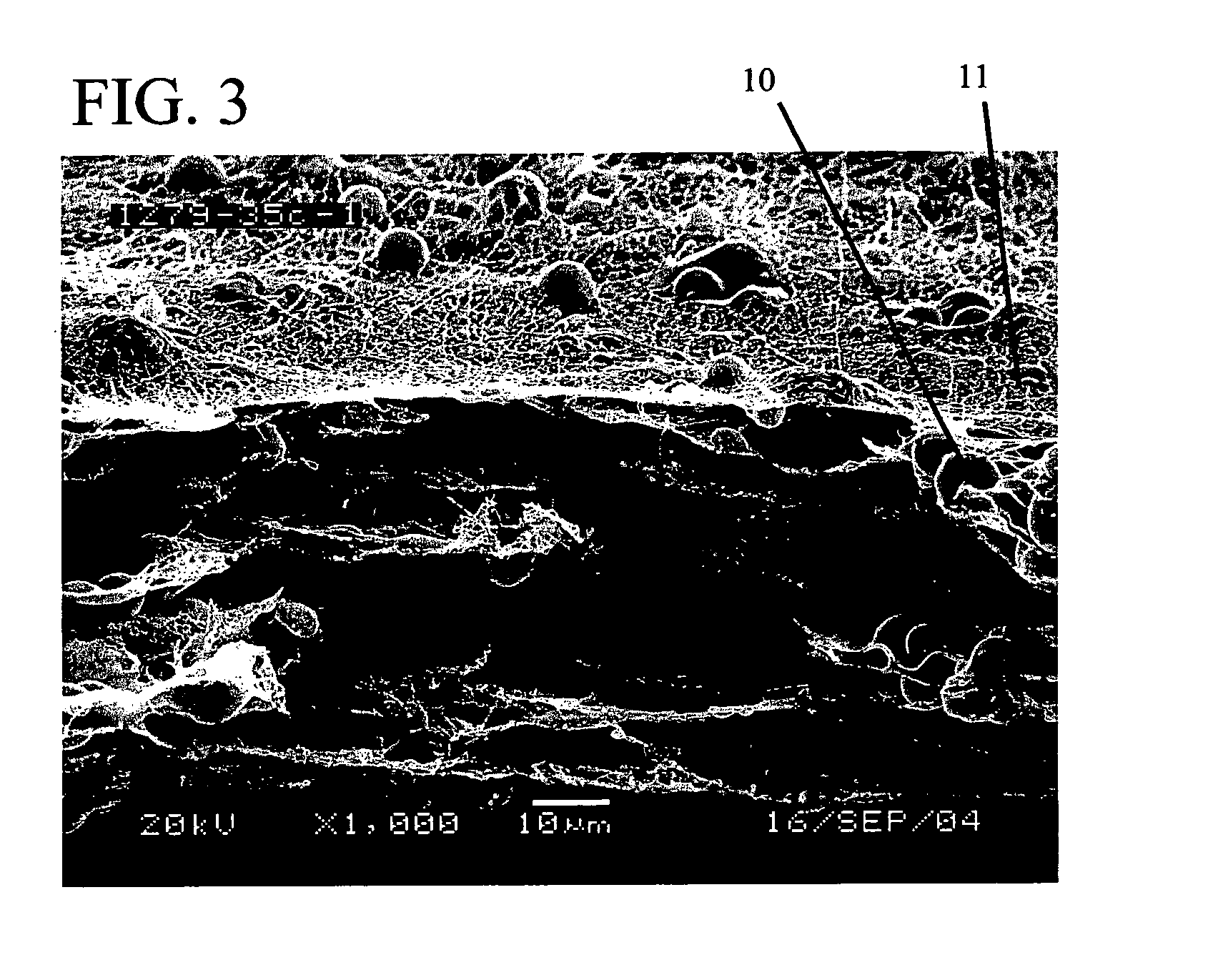

Reduced solidity web comprising fiber and fiber spacer or separation means

ActiveUS20060230731A1Improve filtering effectEnhance layeringCombination devicesOther chemical processesParticulatesFiltration

A web can comprise a substantially continuous fiber mass and a separation means dispersed into the fiber. The web having a preferred thickness resulting from forming a polymer material and a particulate into a fine fiber layer can have a variety of end uses. A filtration media can include a structure comprising such a web of fine fiber and a substantial volume of particulate embodiment of the separation means. The resulting fine fiber structure provides an improved filtration medium having substantial depth, thickness, and a layered structure. The improved properties of the web results from inclusion of the separation or spacer particulate.

Owner:DONALDSON CO INC

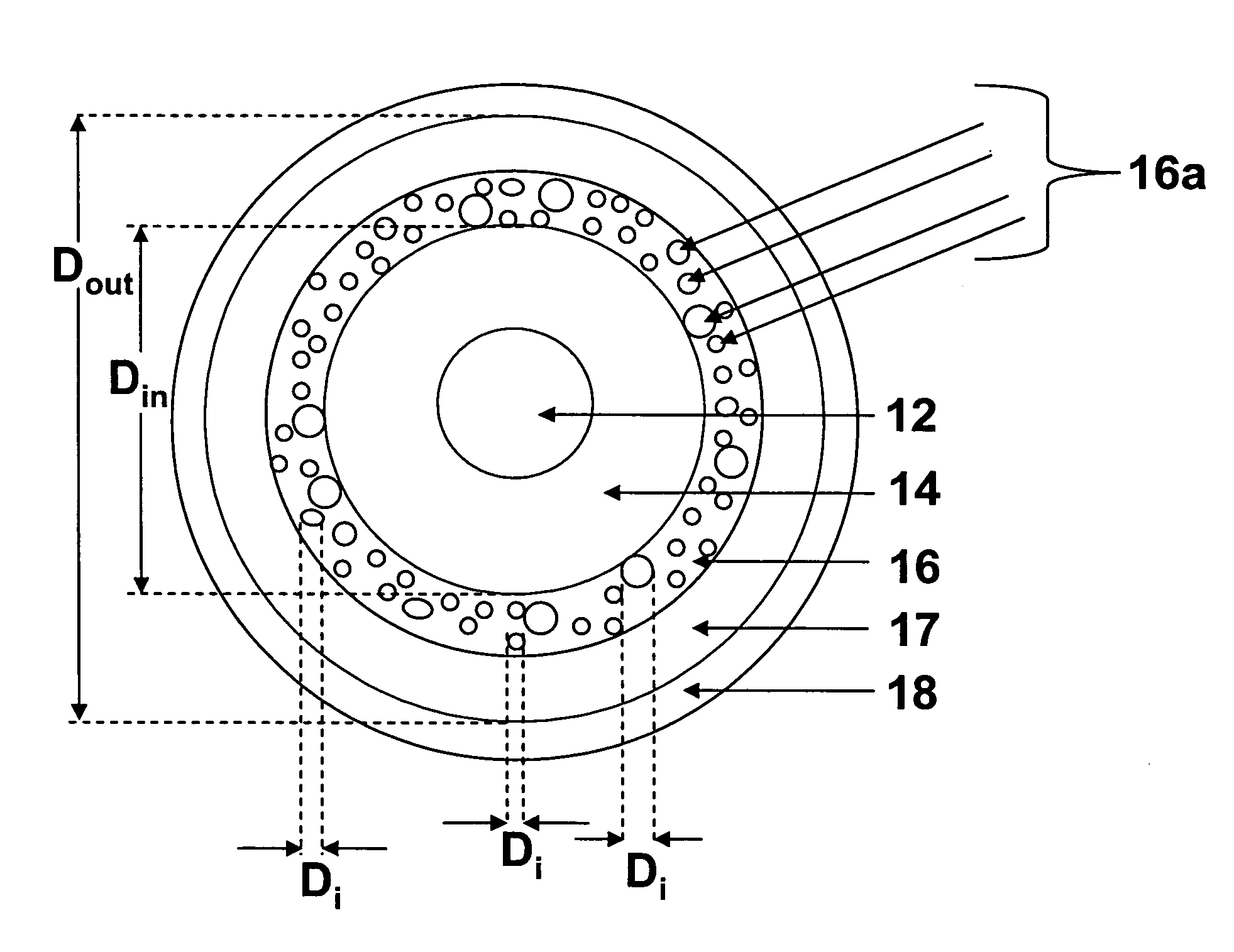

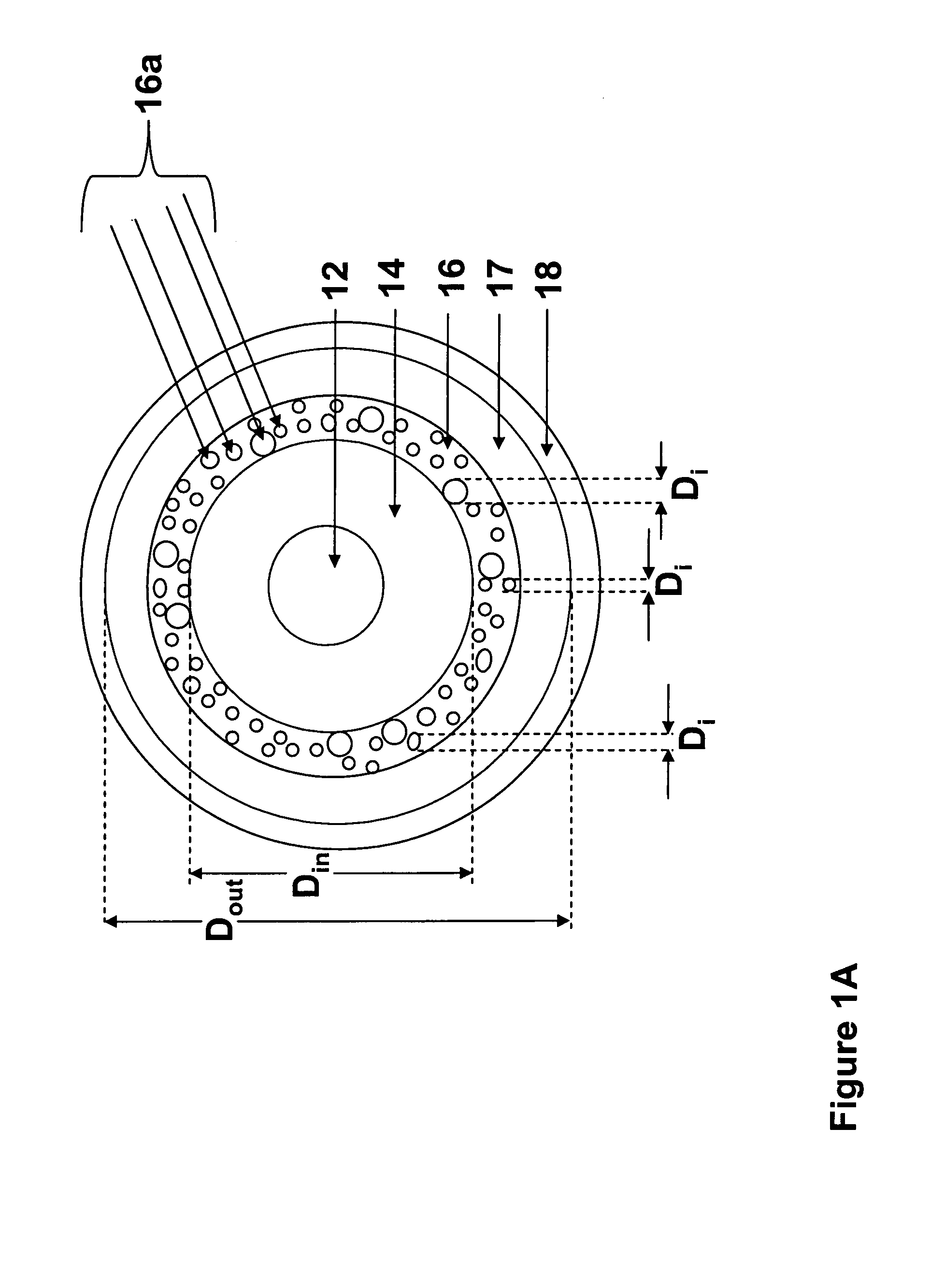

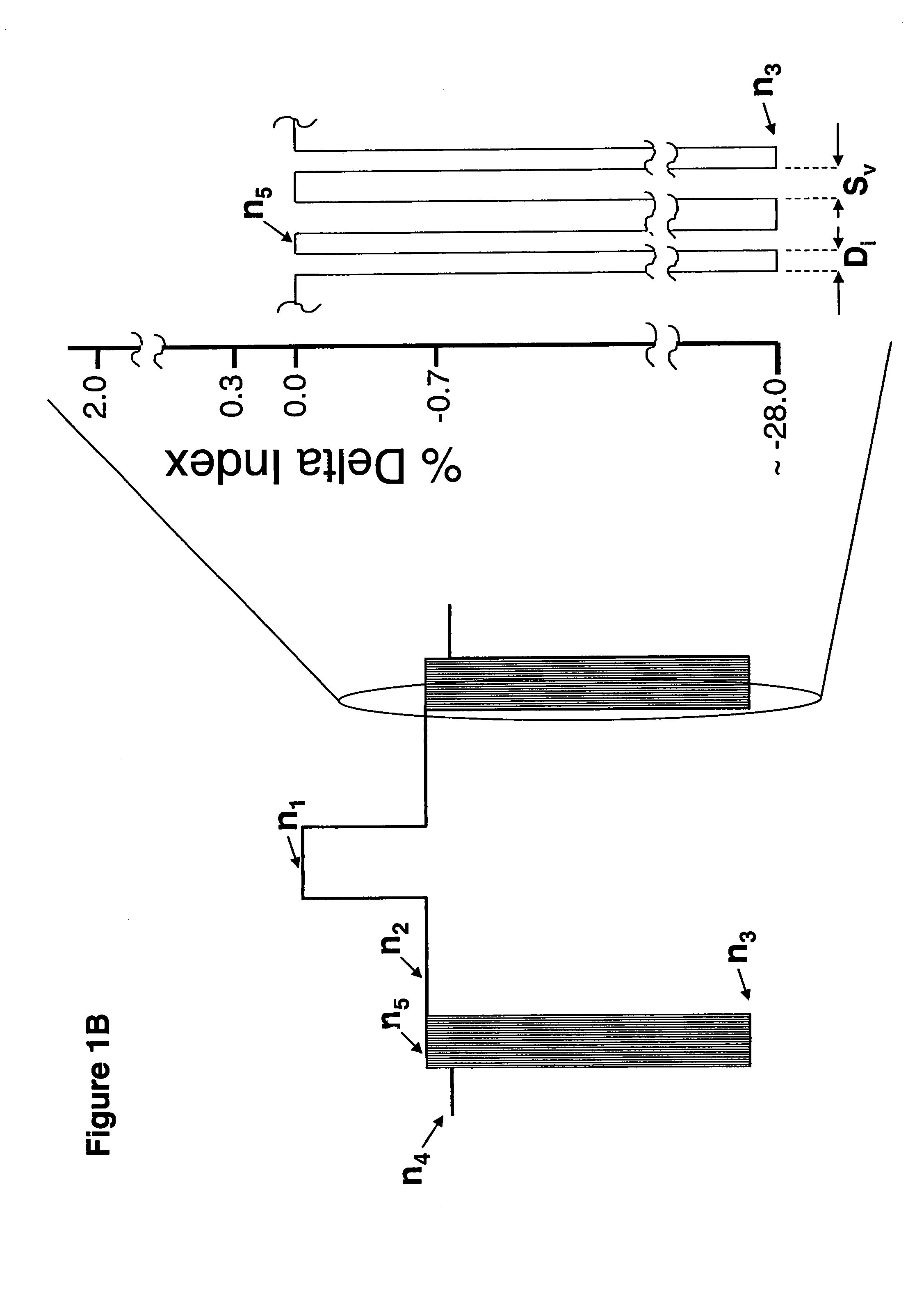

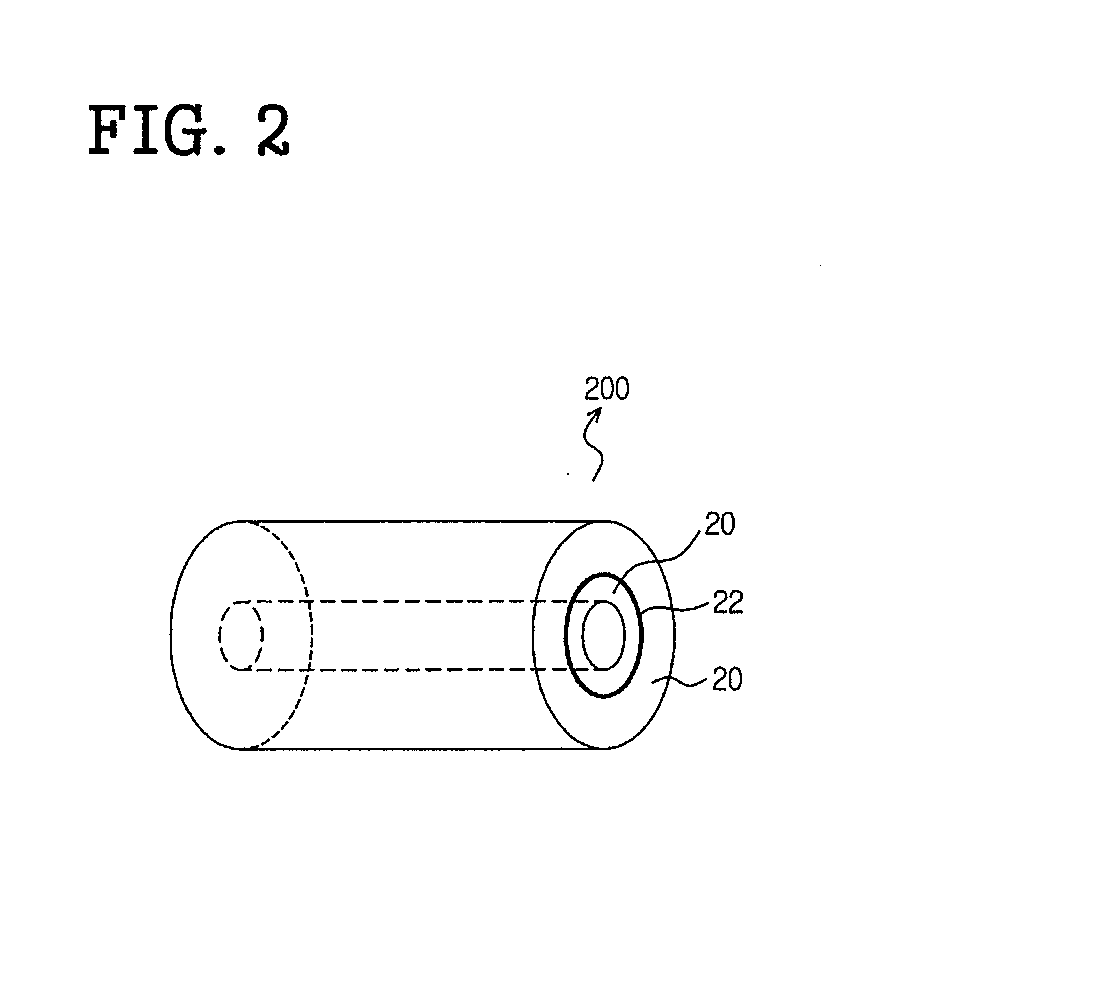

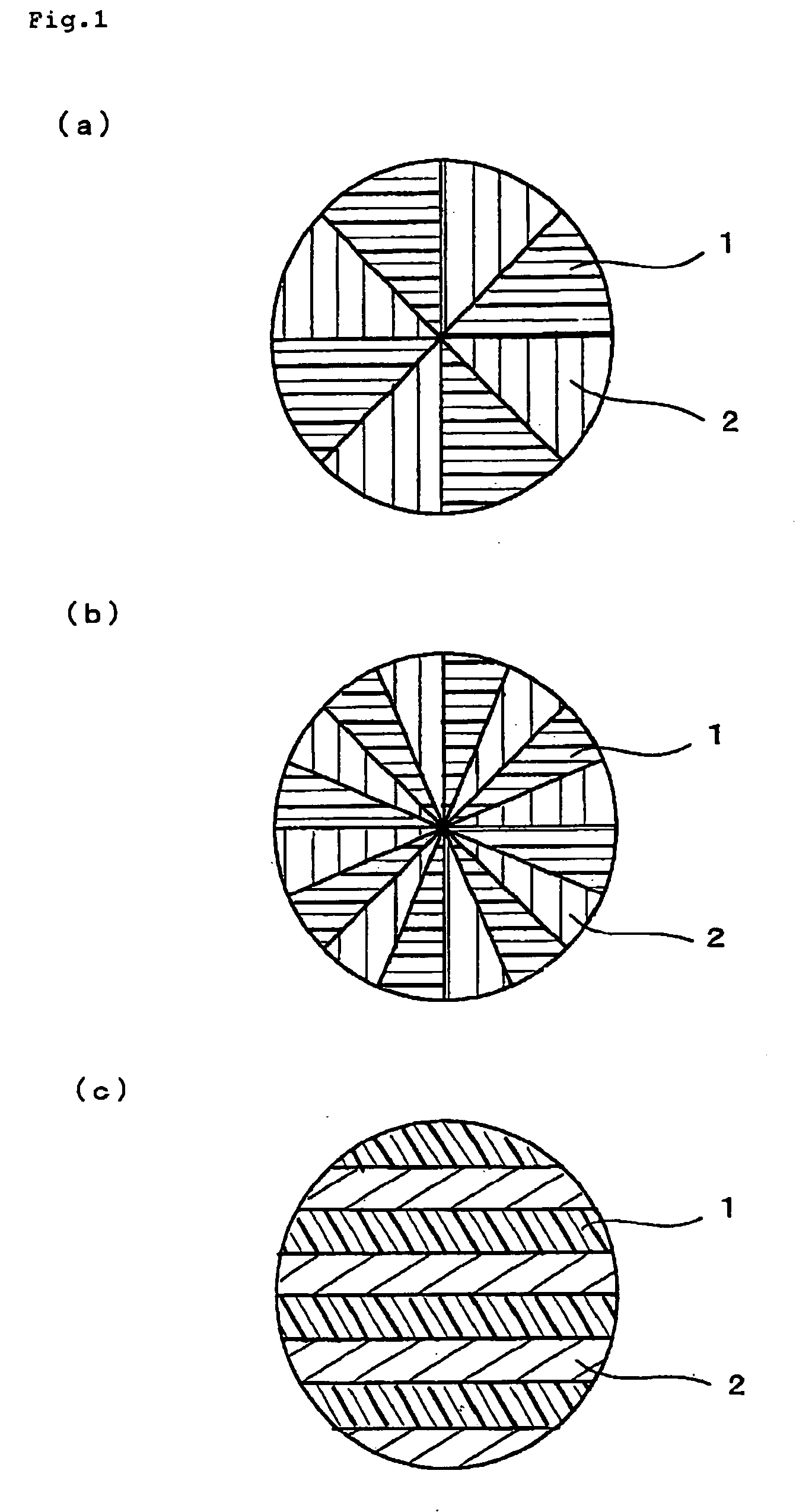

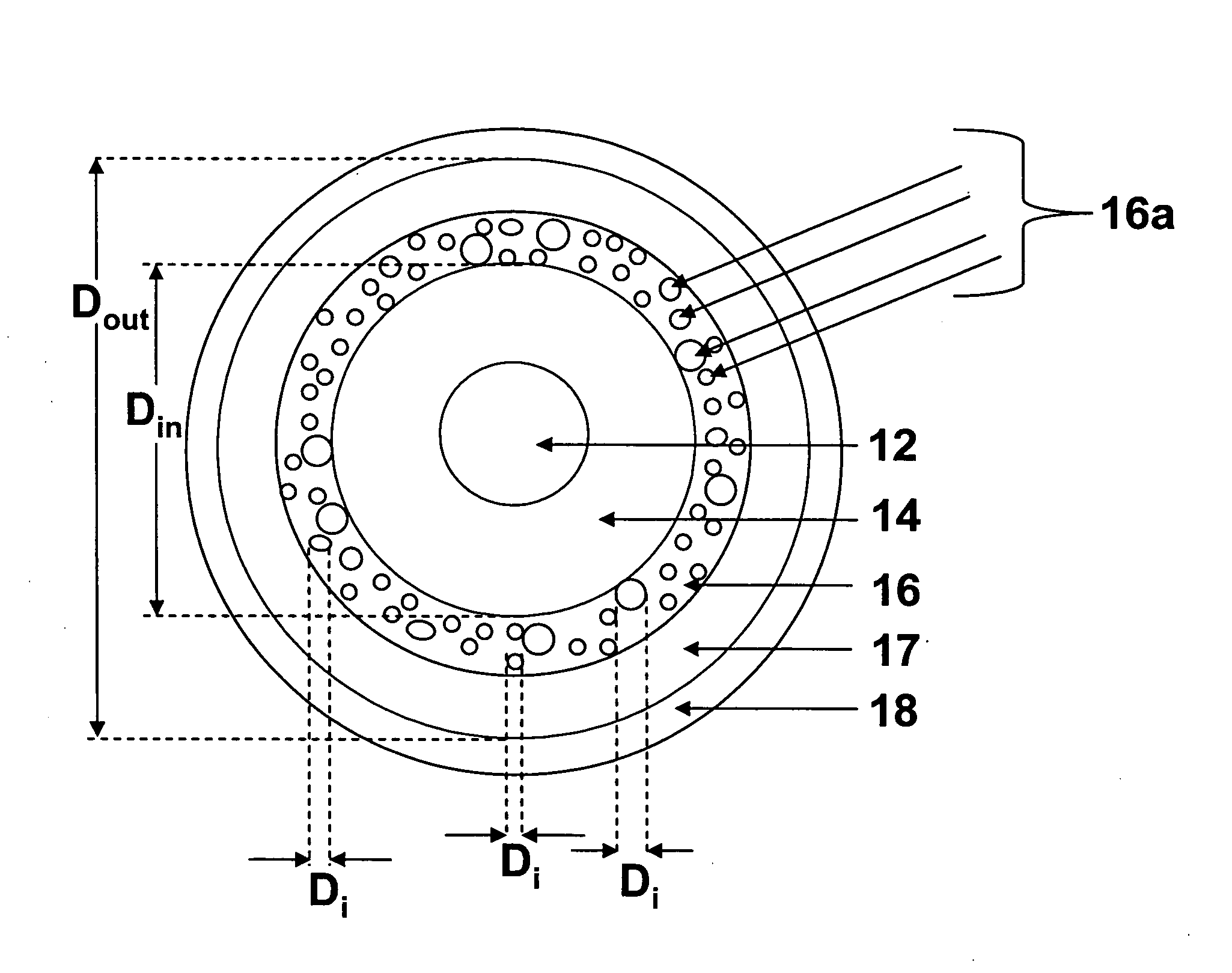

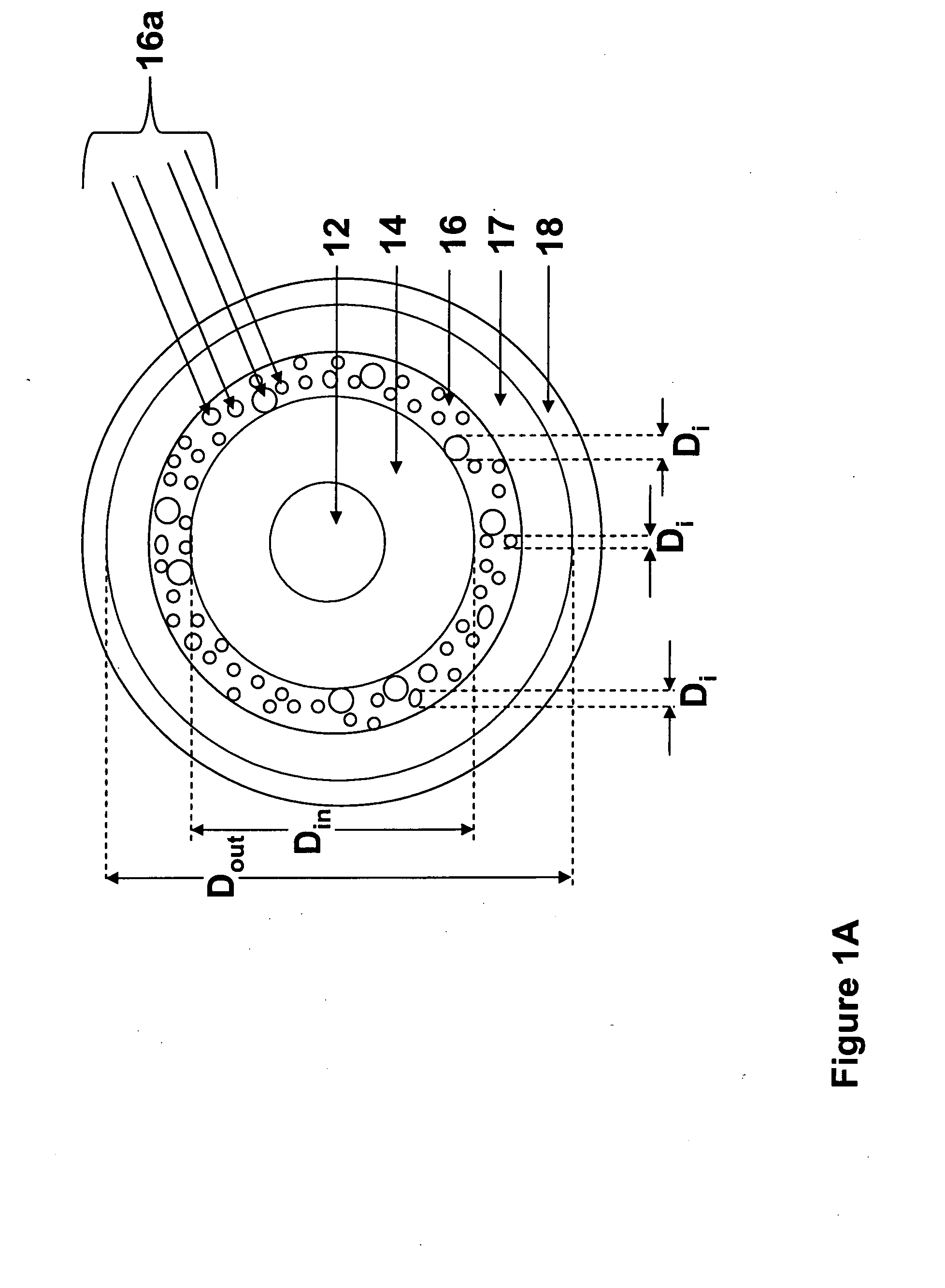

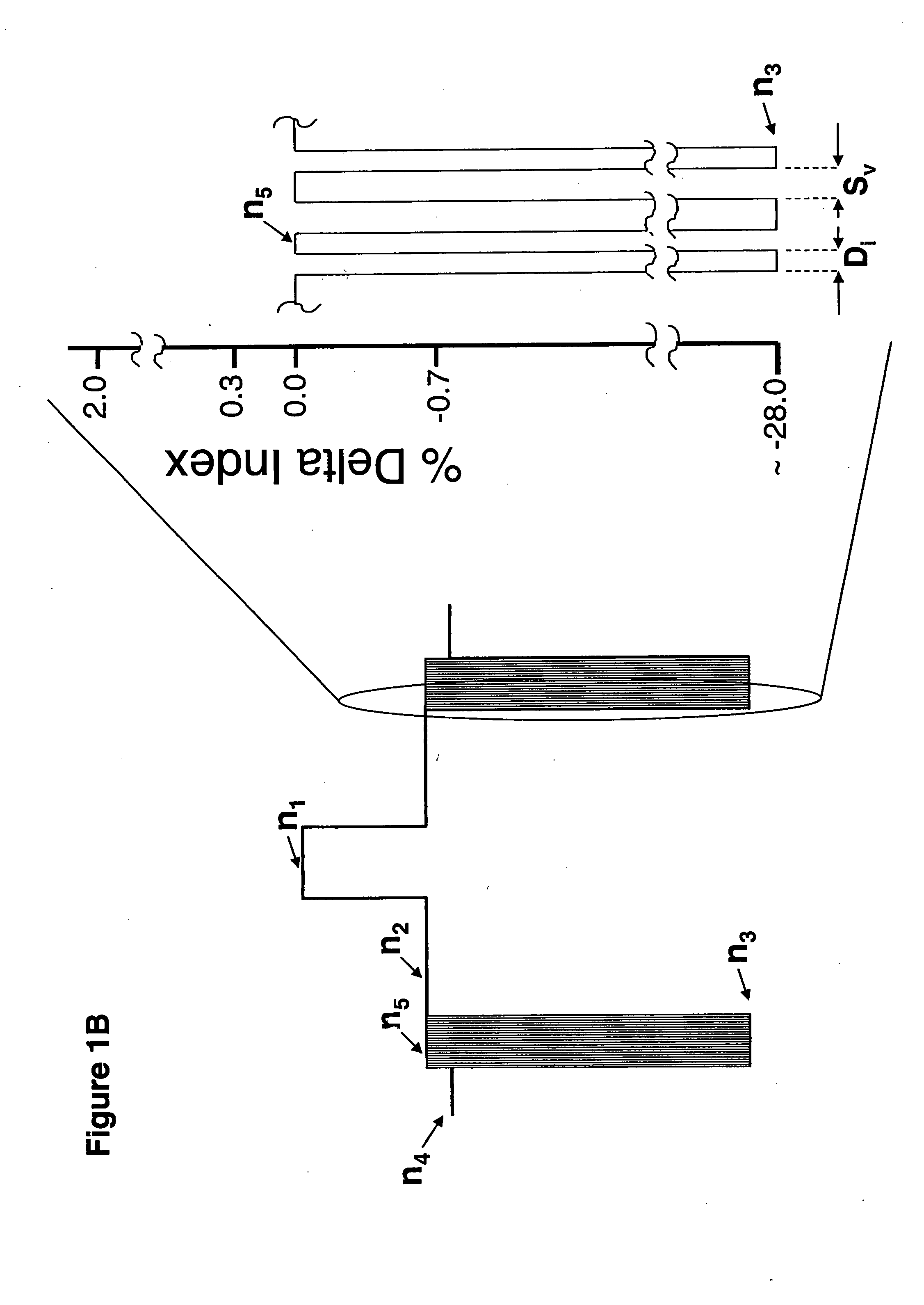

High numerical aperture fiber

InactiveUS7526166B2Optical fibre with polarisationOptical fibre with multilayer core/claddingHigh numerical apertureRefractive index

An optical fiber comprising: a silica based core having a first index of refraction n1; and at least one silica based cladding surrounding the core, the at least one silica based cladding comprising index lowering non-periodic voids containing a gas, wherein at least 80% of said voids have a maximum cross-sectional dimension of less than 2000 nm, and the NA of the fiber layer situated immediately adjacent to and inside said at least one silica based cladding is at least 0.2.

Owner:CORNING INC

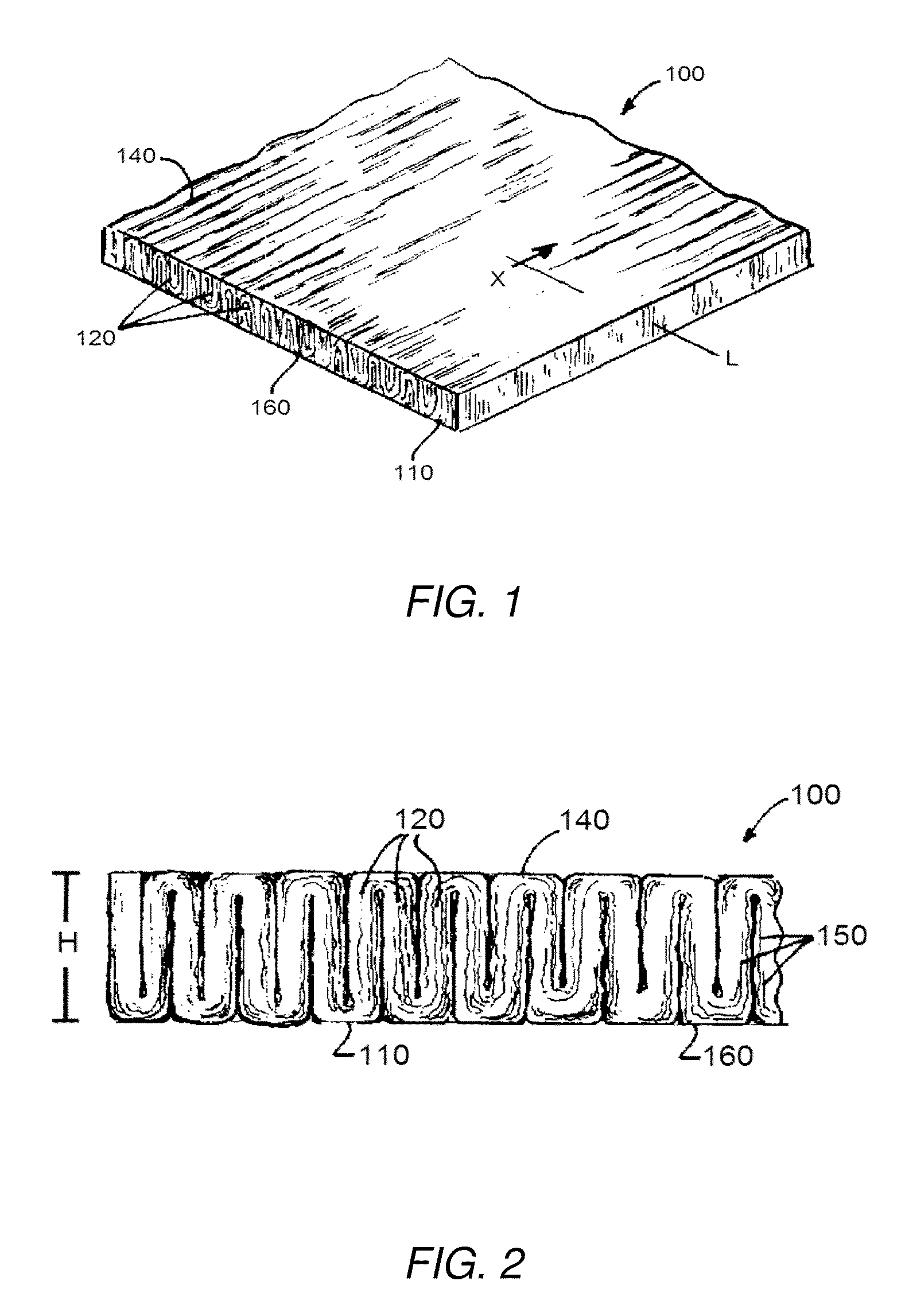

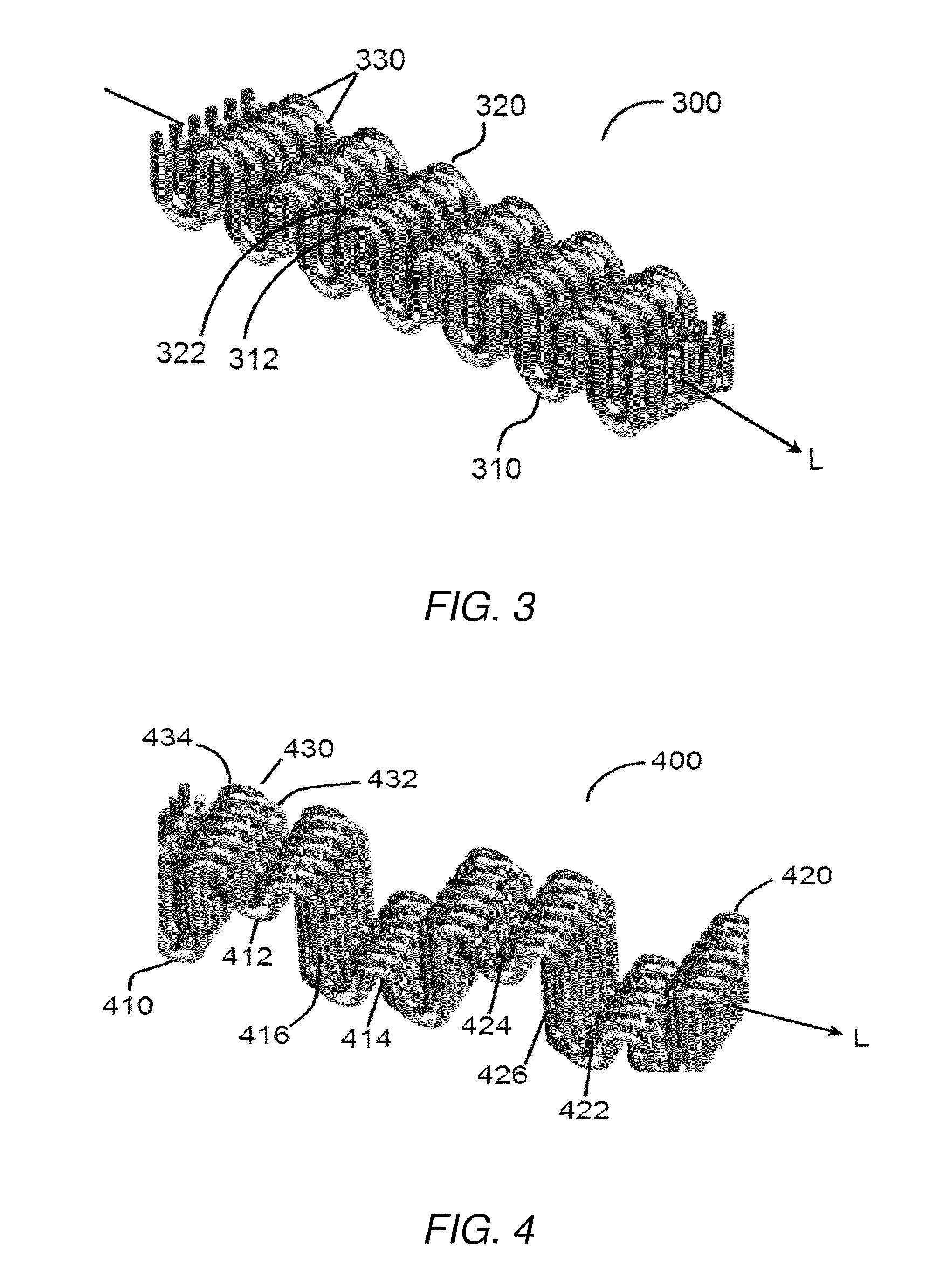

Fiber-based carpet cushion with added resilience from vertically oriented fiber construction

ActiveUS20110311758A1Increase elasticityImprove the immunityLayered productsWoven fabricsParallel fiberEngineering

A fiber pad having a core non-woven layer is disclosed. The core layer can have an upper surface and a lower surface. The core layer can comprise at least one fiber layer. The at least one fiber layer can comprise a plurality of parallel fibers. Selected groups of the parallel fibers can be folded into desired pleated configurations. Optionally, the core layer can comprise post-consumer carpet materials.

Owner:COLUMBIA INSURANCE CO

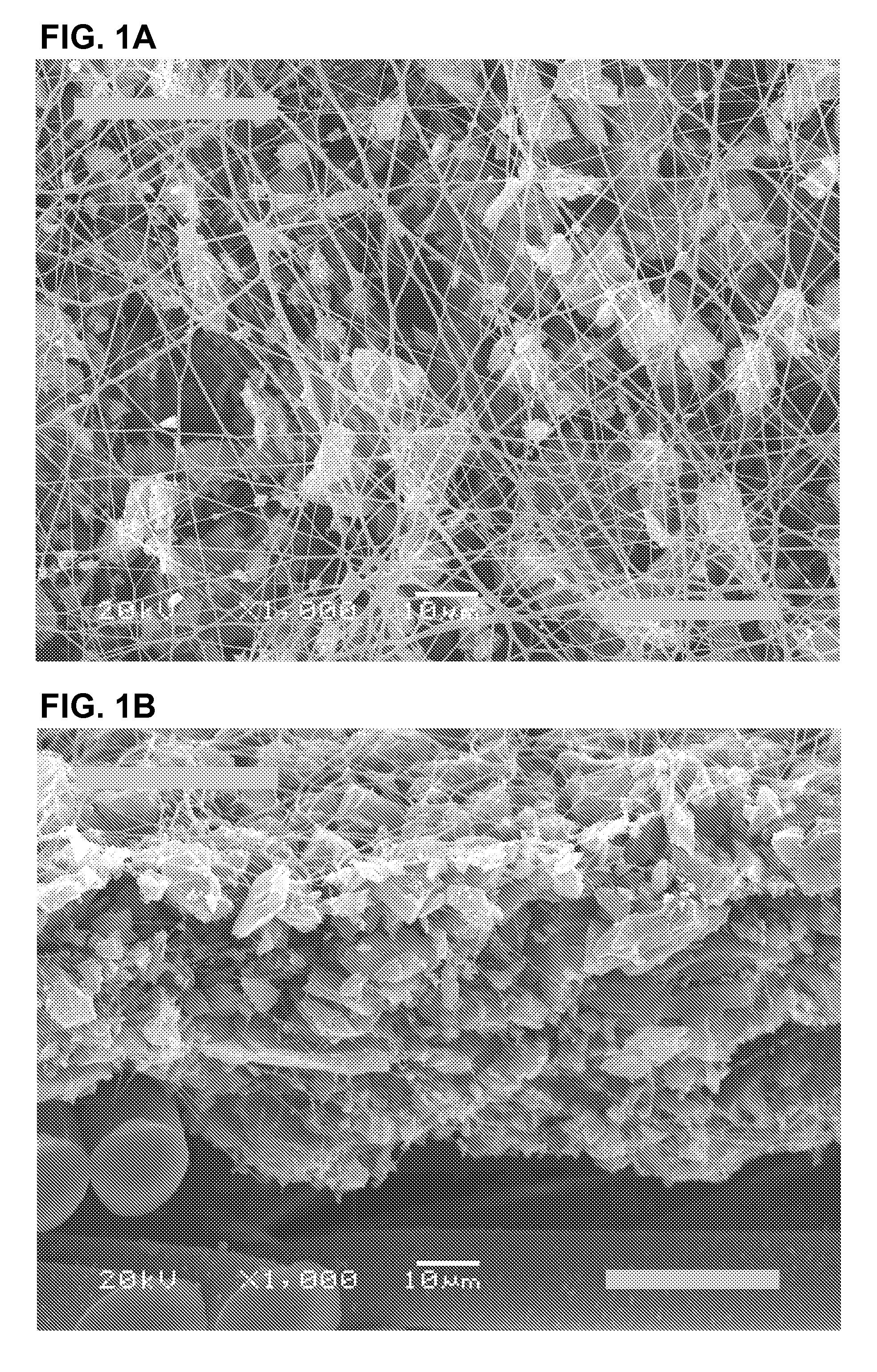

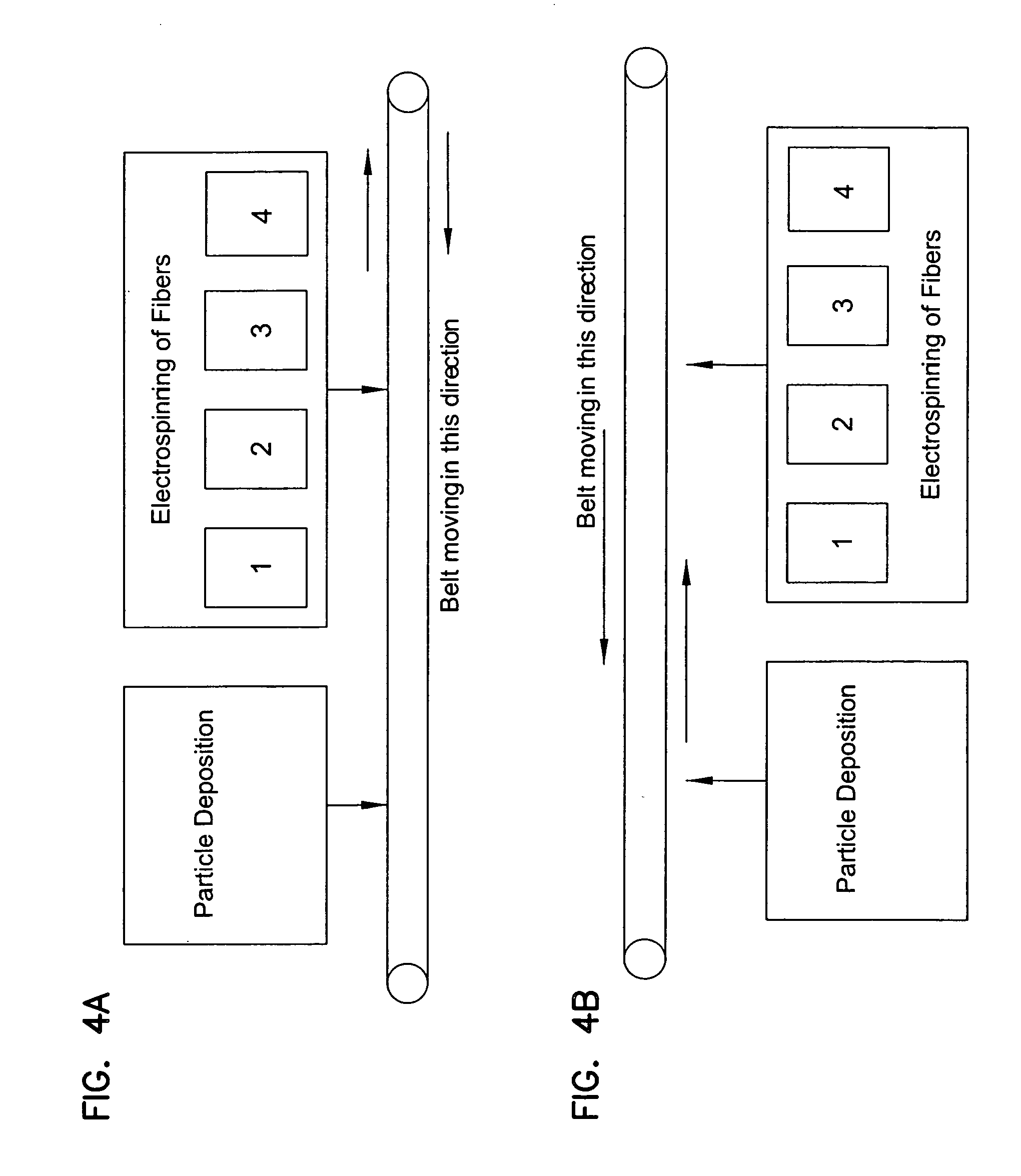

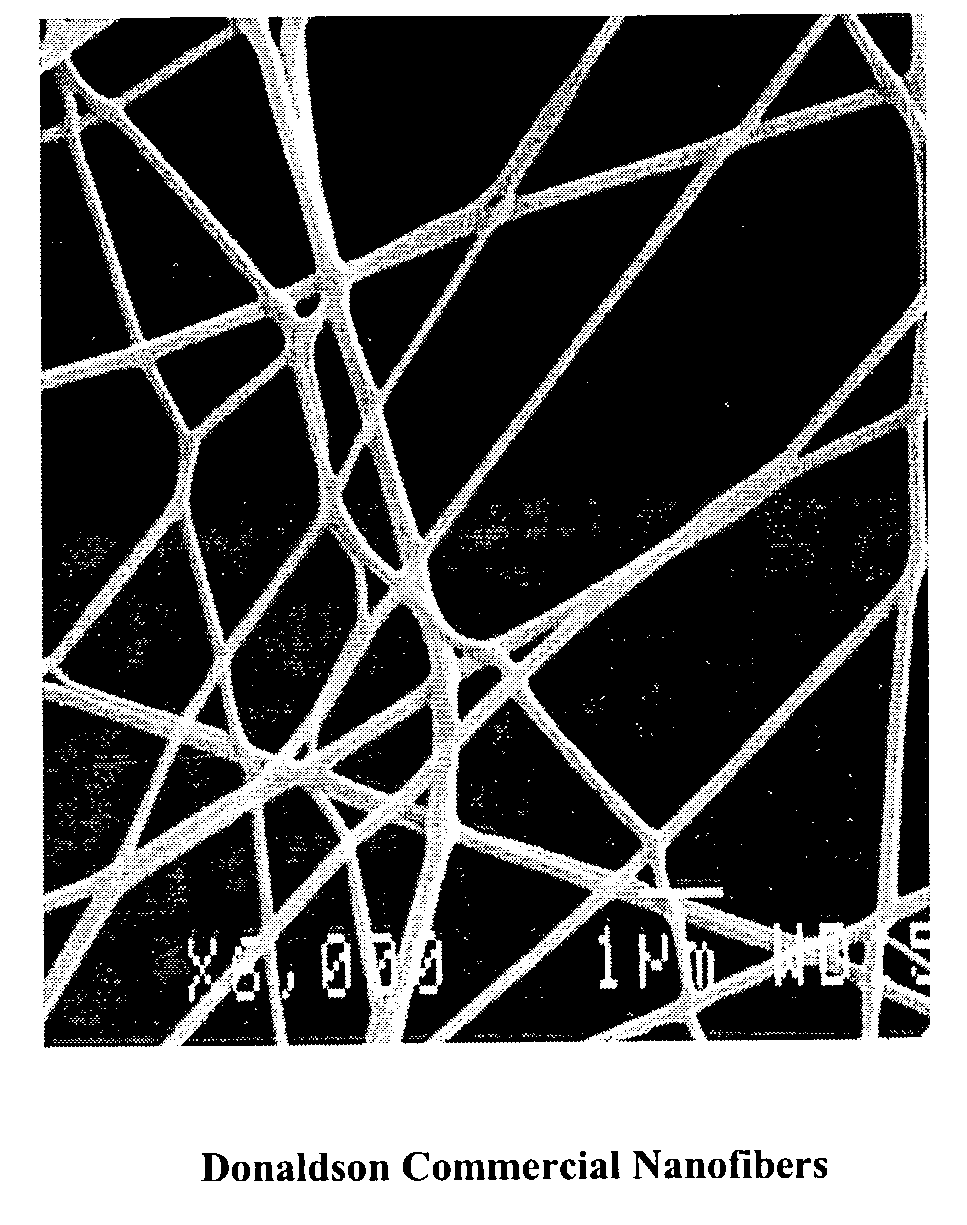

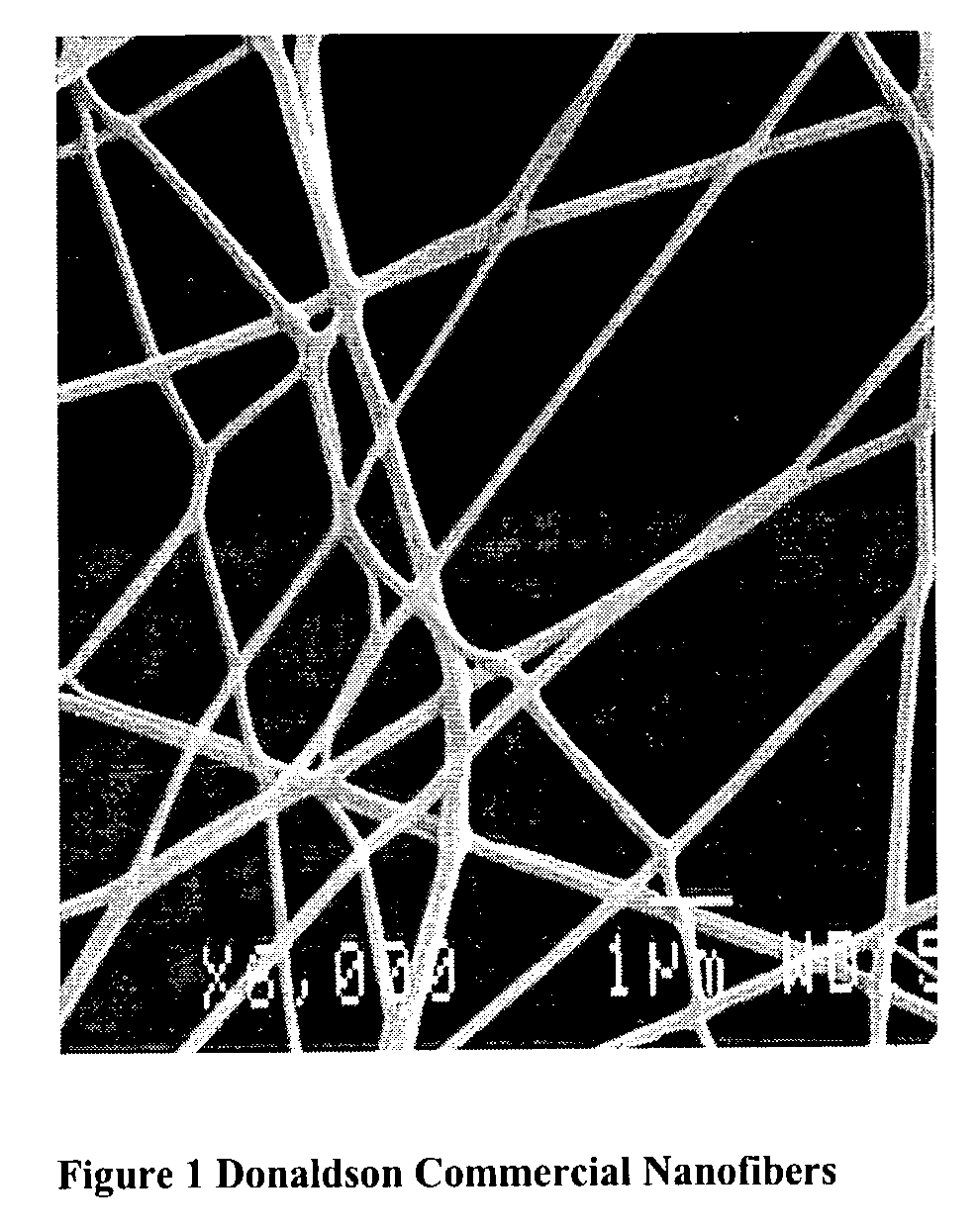

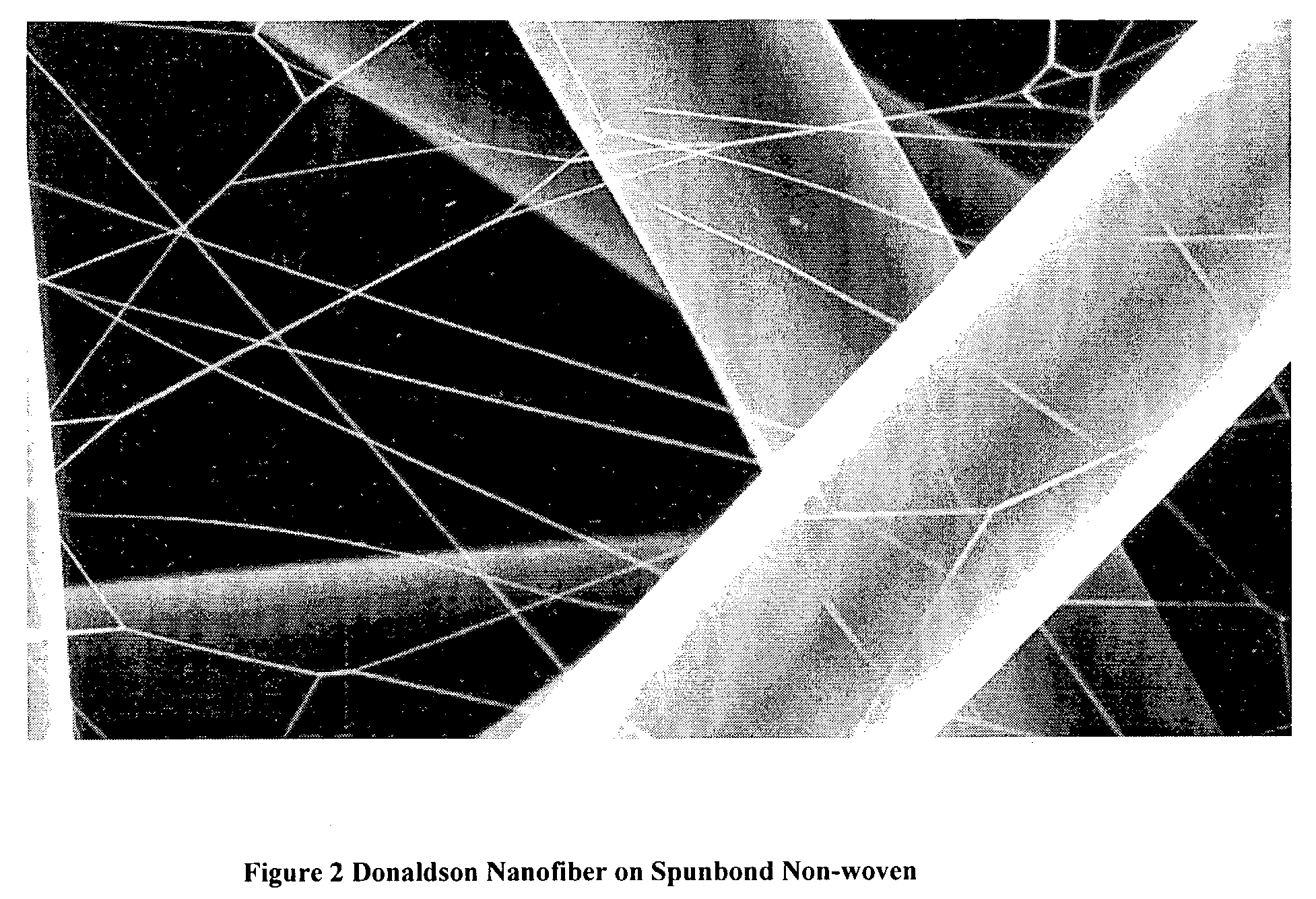

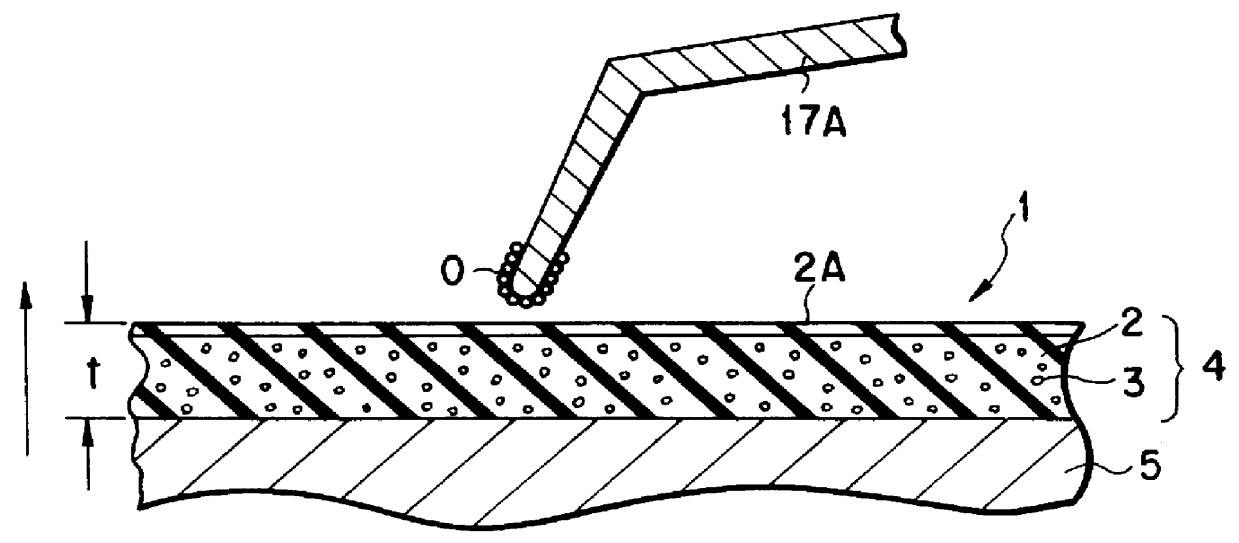

Filtration Medias, Fine Fibers Under 100 Nanometers, and Methods

InactiveUS20090199717A1Avoid layeringMaterial nanotechnologyIsotope separationAcetic acidElectrospinning

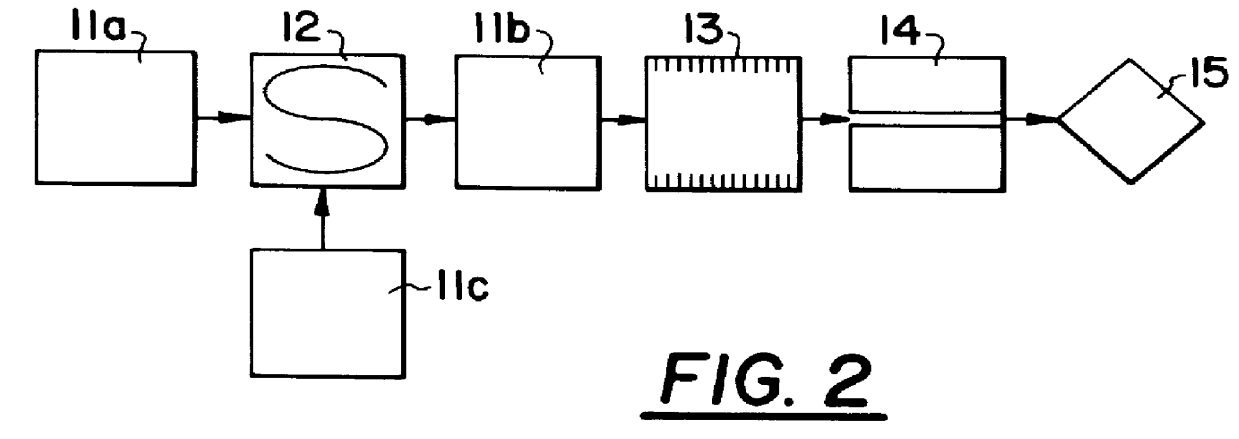

An electrospinning fine fiber production methodology for generating a significant amount of fibers with diameters of less than 100 nanometers is provided. Also, a filter media composite comprising a substrate layer and an electrospun fine fiber layer having a increased efficiency relative to pressure drop and / or a controlled pore size distribution is provided. According to some embodiments nylon is electrospun from a solvent combination of formic and acetic acids.

Owner:ELMARCO SRO

Air permeable garment and fabric with integral aerosol filtration

InactiveUS20040116025A1Maintain good propertiesProtect environmentProtective equipmentSynthetic resin layered productsGas phaseFiltration

A multilayer fabric for protection from aerosol and gas phase agents comprising a bilayer structure comprising an unfilled Fine fiber layer substantially free of materials within the pores of the Fine fiber layer secured to an outer shell, the Fine fiber layer acting as an aerosol filter, and an optional interior fabric layer having a reactive layer for the removal of gas phase agents.

Owner:DONALDSON CO INC

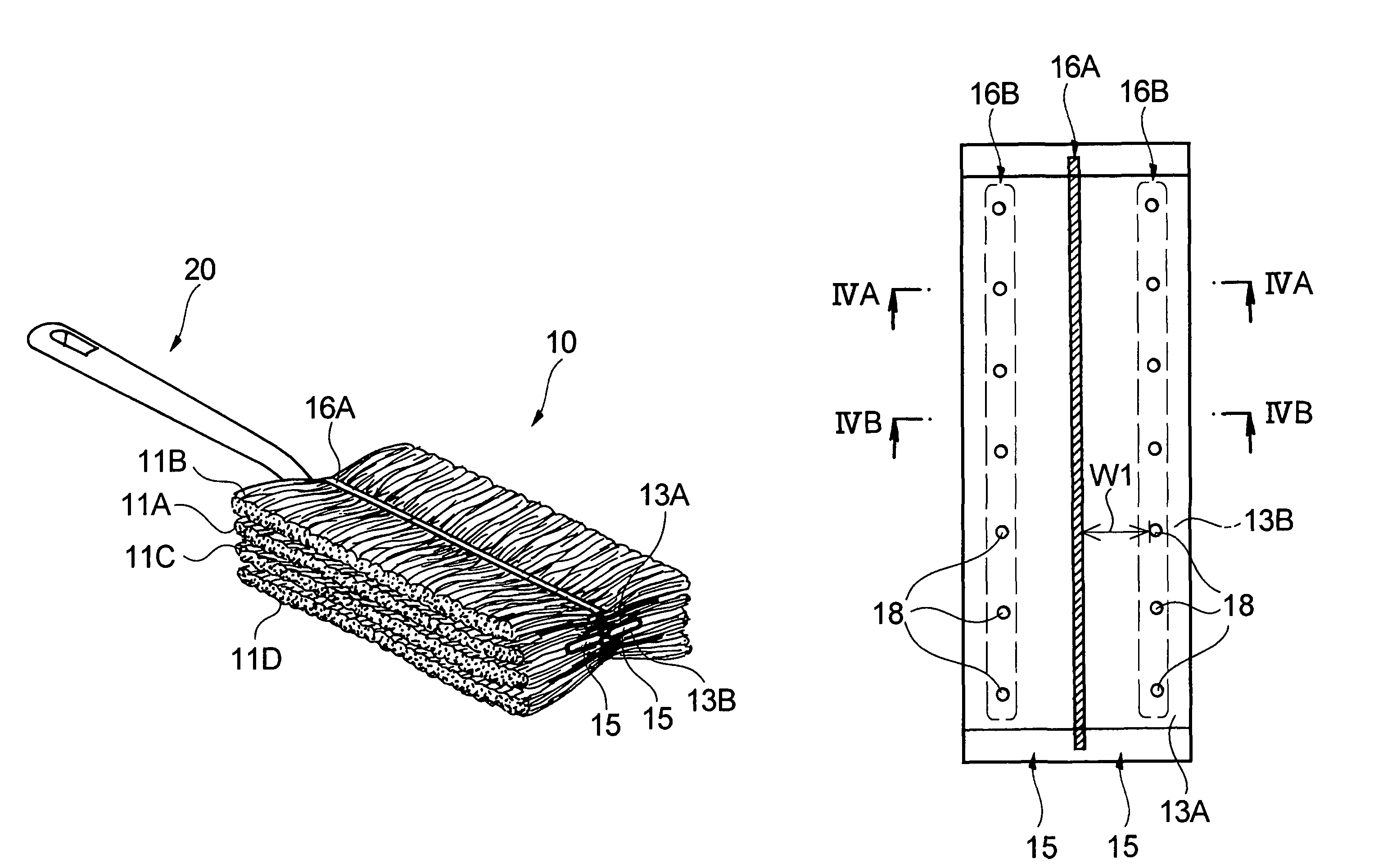

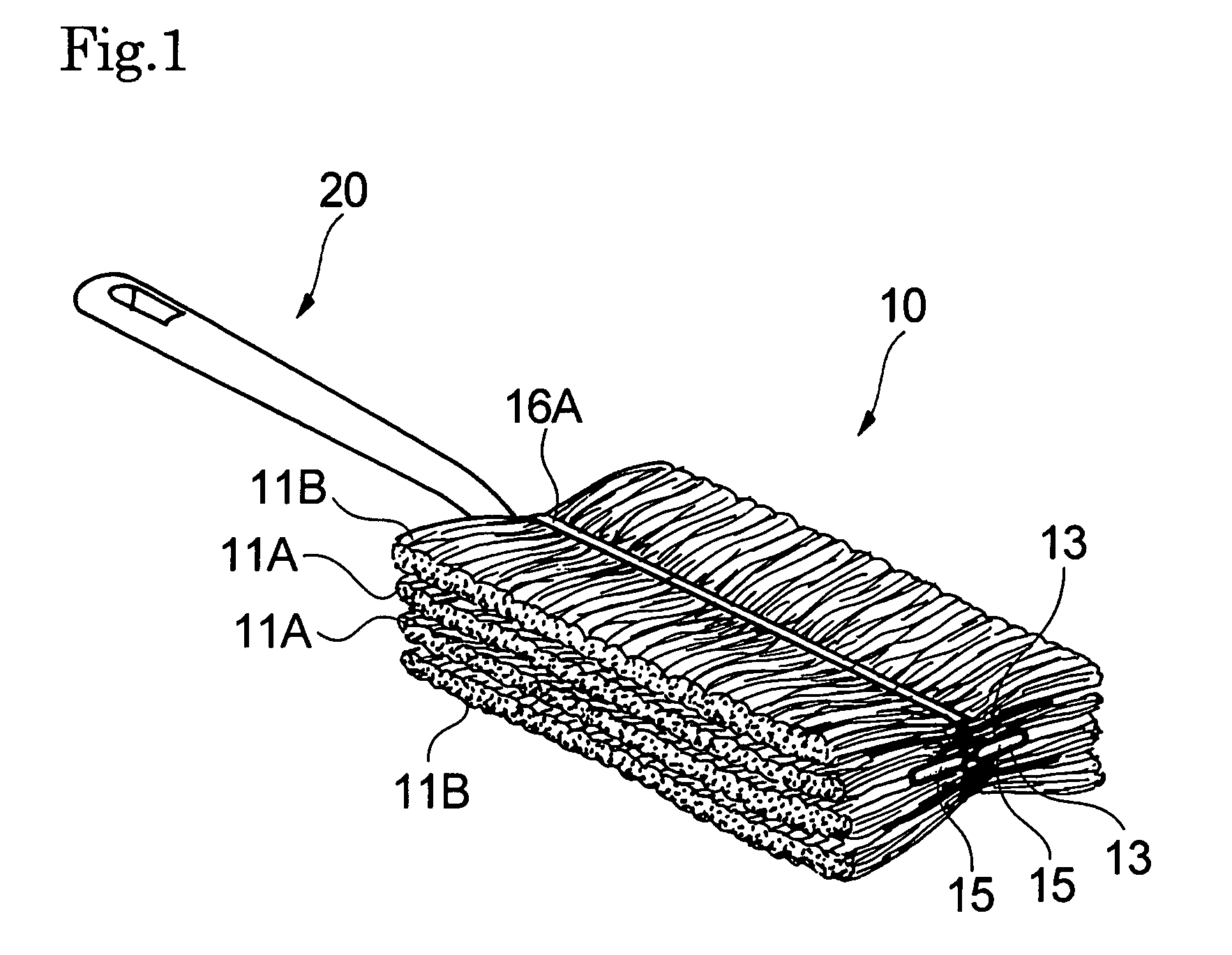

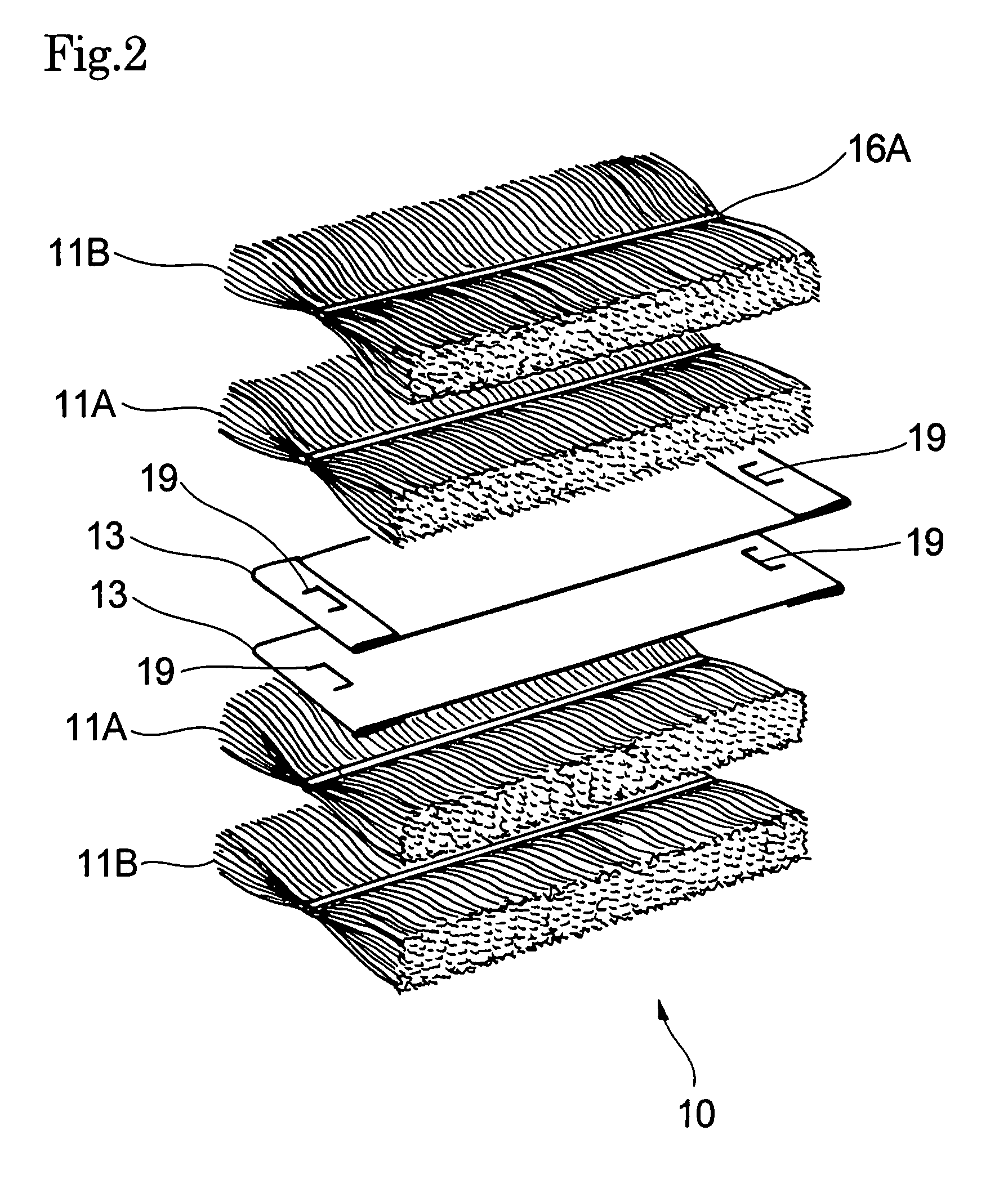

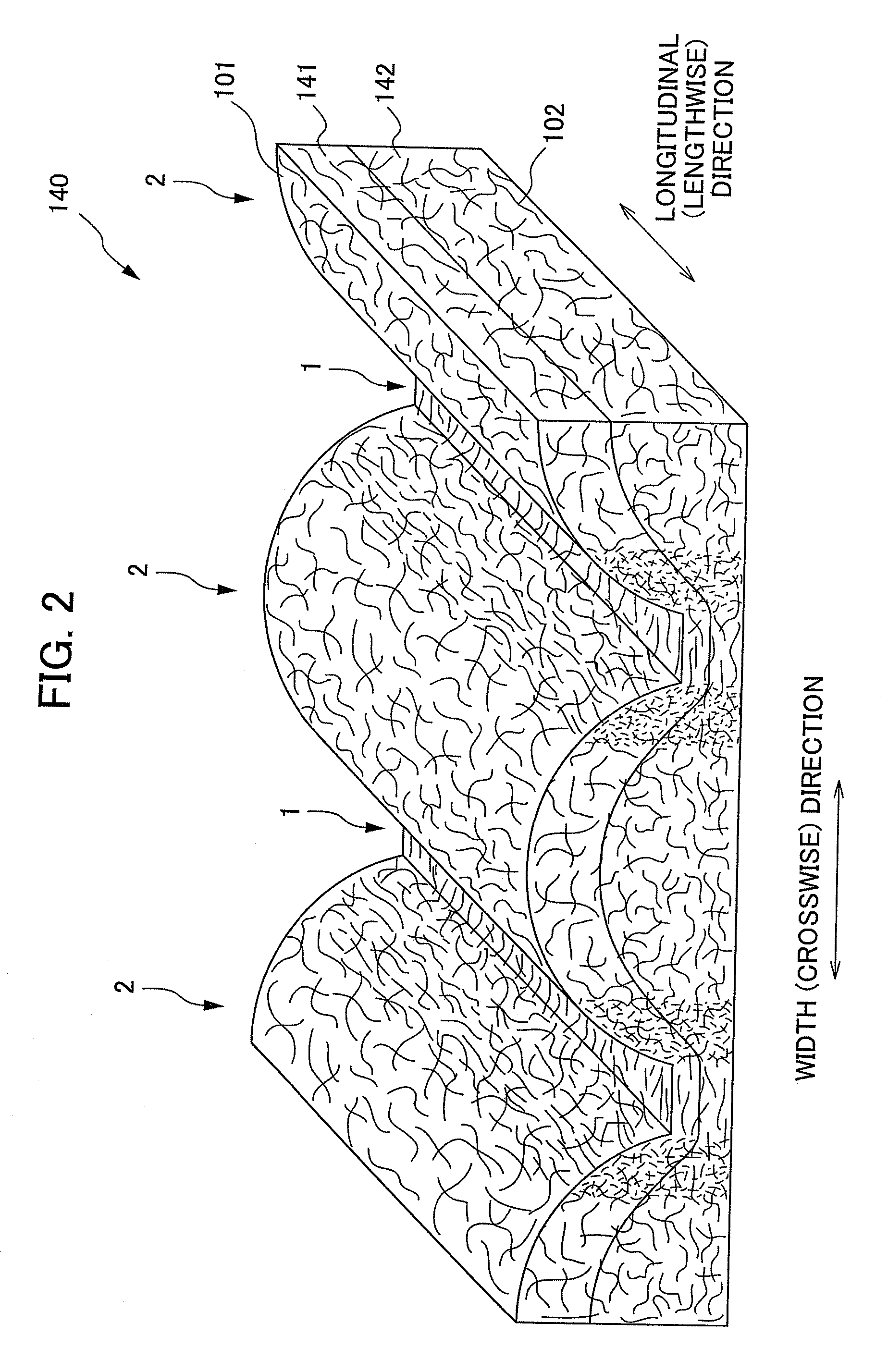

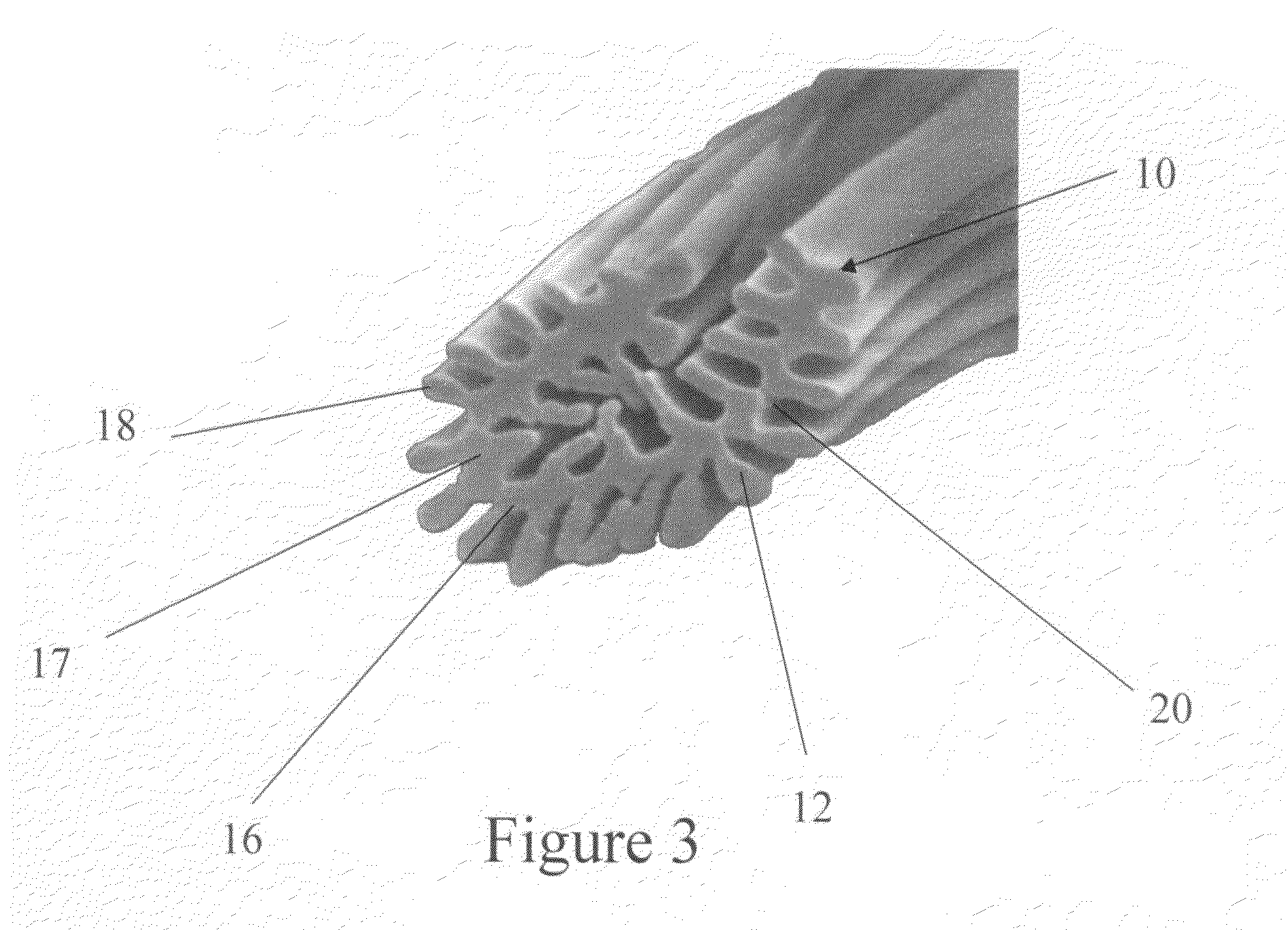

Cleaning article, method of fluffing cleaning article, and method of producing cleaning article

A cleaning article 10 having a flat tubular pocket 15 and attachable to a holder by inserting the holder into the pocket 15. The pocket 15 is formed by joining pocket-forming sheets 13 facing each other. At least one fiber layer formed of a fiber bundle, accordingly two fiber layers 11A and 11B are provided on each of the upper and lower sides of the pocket 15 of the pocket-forming sheets 13. Each of the first fiber layers 11A closest to the pocket-forming sheets 13 is joined to the respective pocket-forming sheet 13 by a continuous central linear seal 16A continuously extending in the longitudinal direction in a laterally middle portion and a discontinuous side seal 16B discontinuously extending in the longitudinal direction at a position laterally spaced away in at least one of the lateral directions from the central continuous linear seal 16A.

Owner:KAO CORP

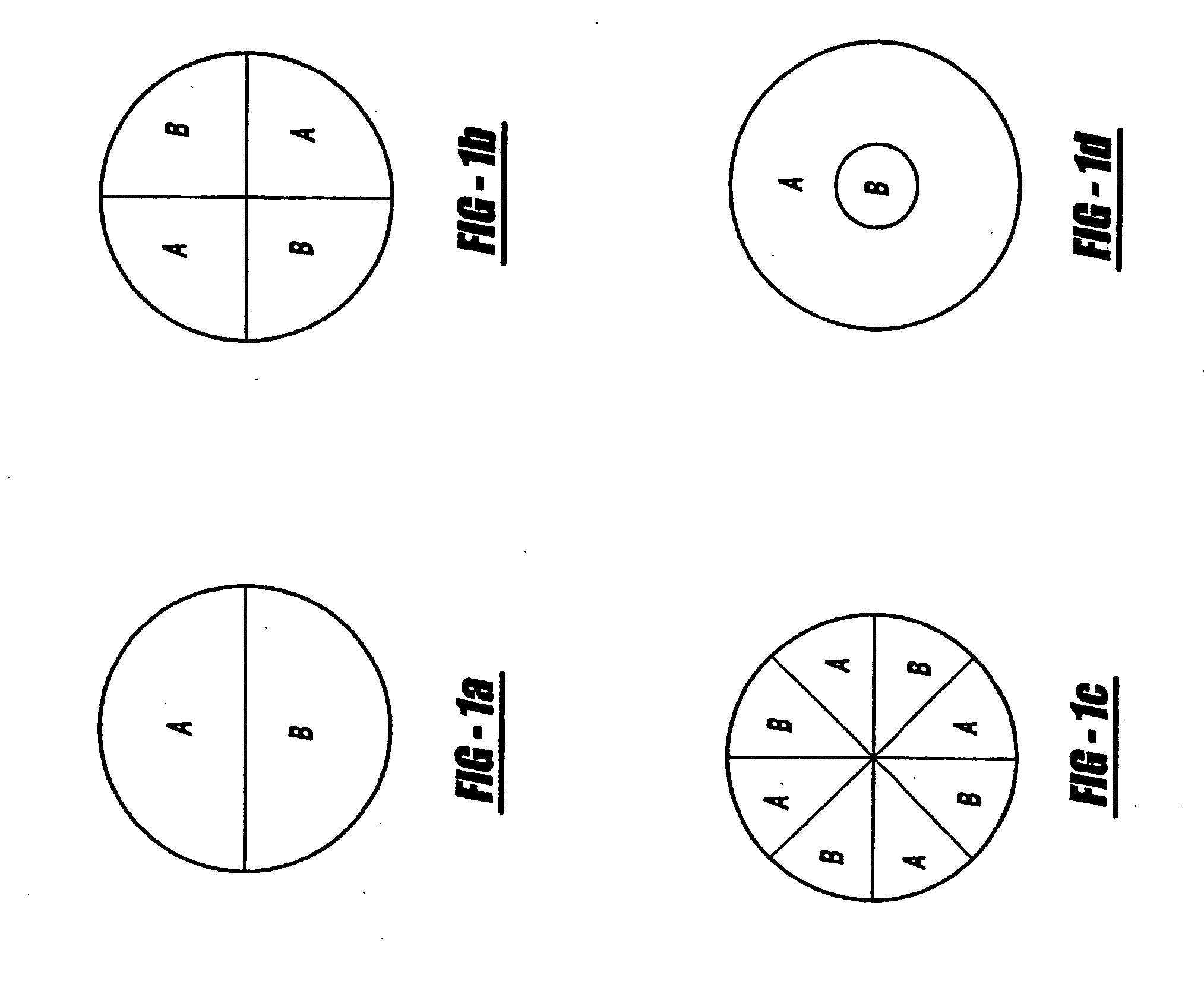

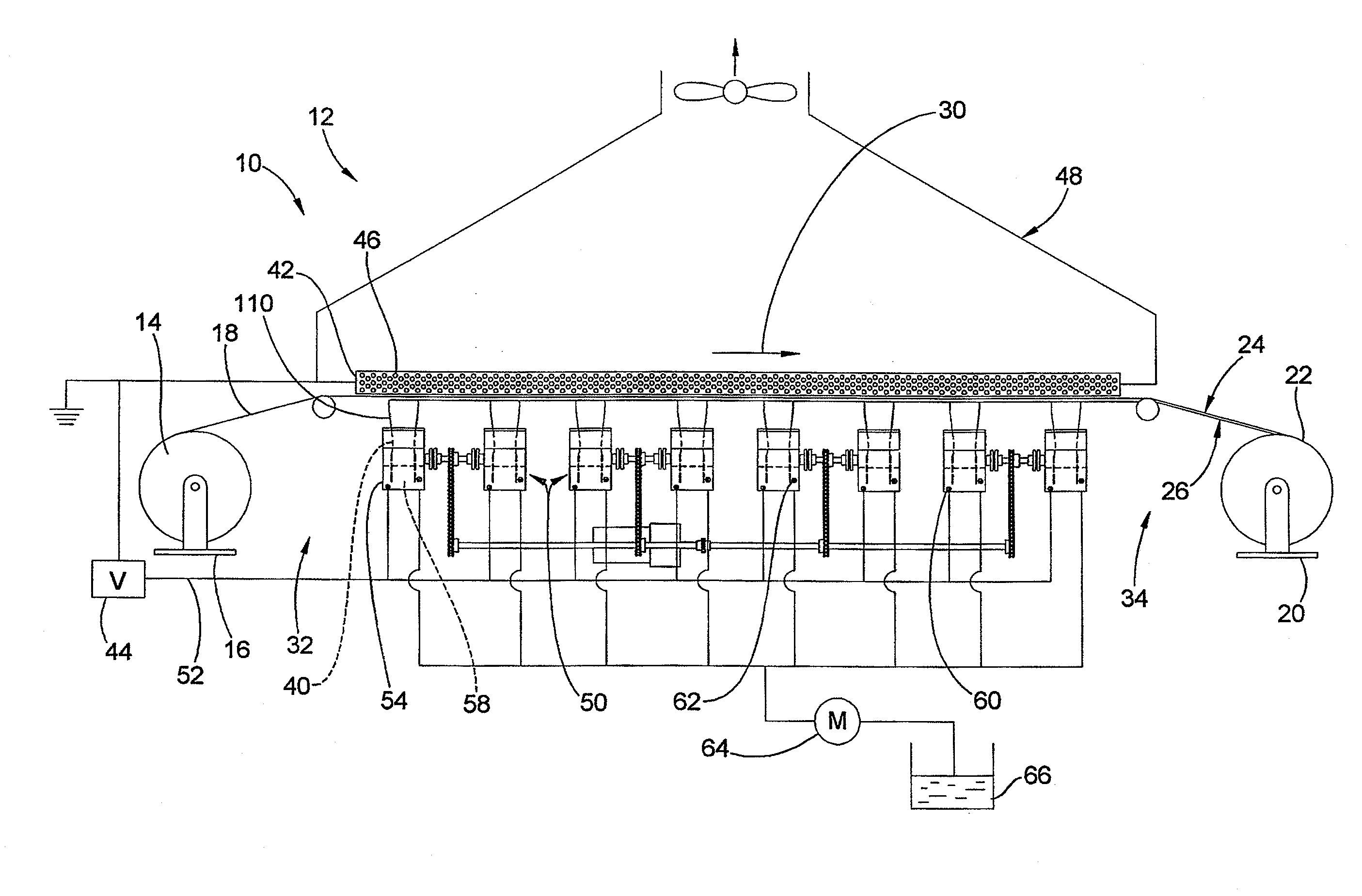

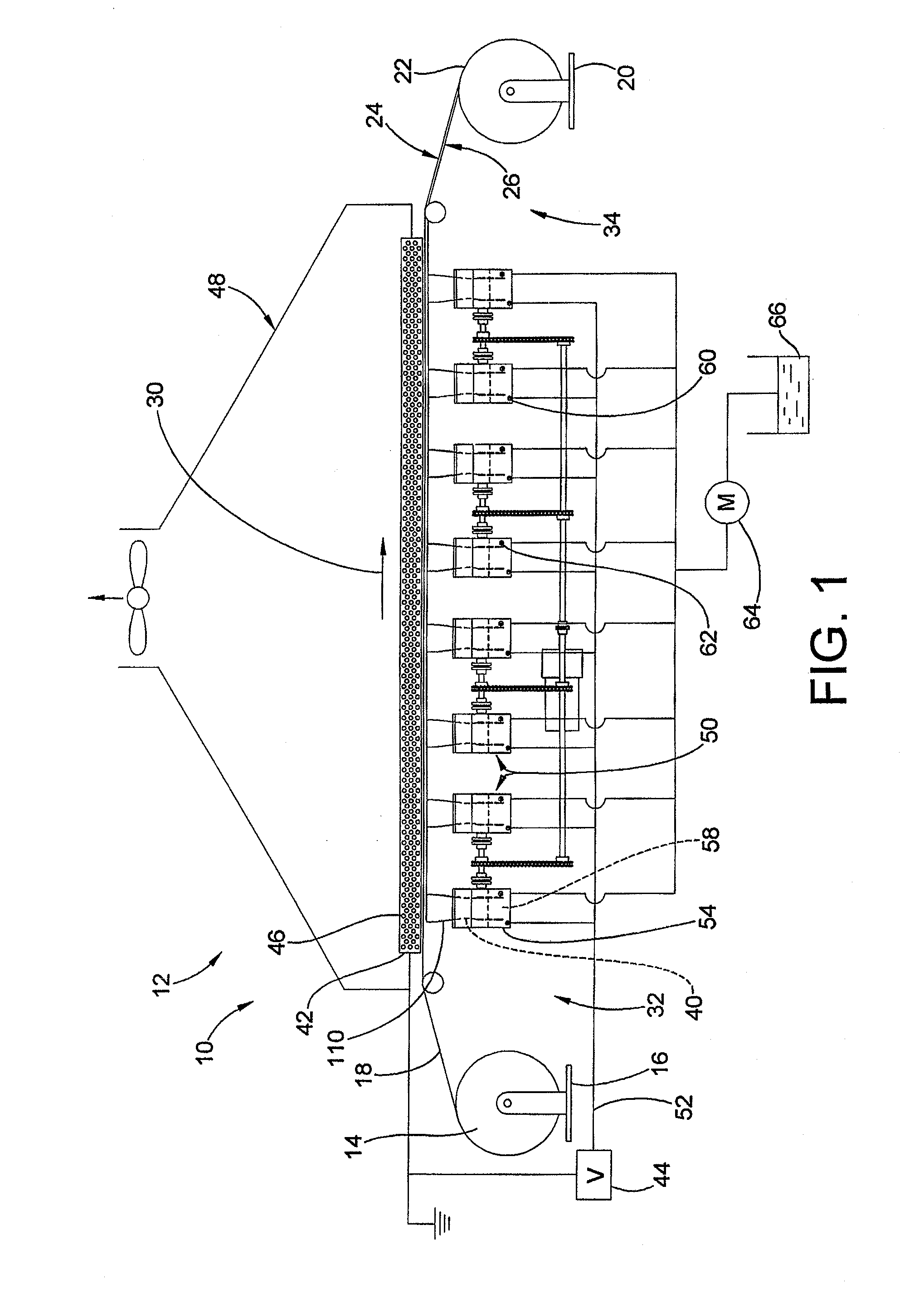

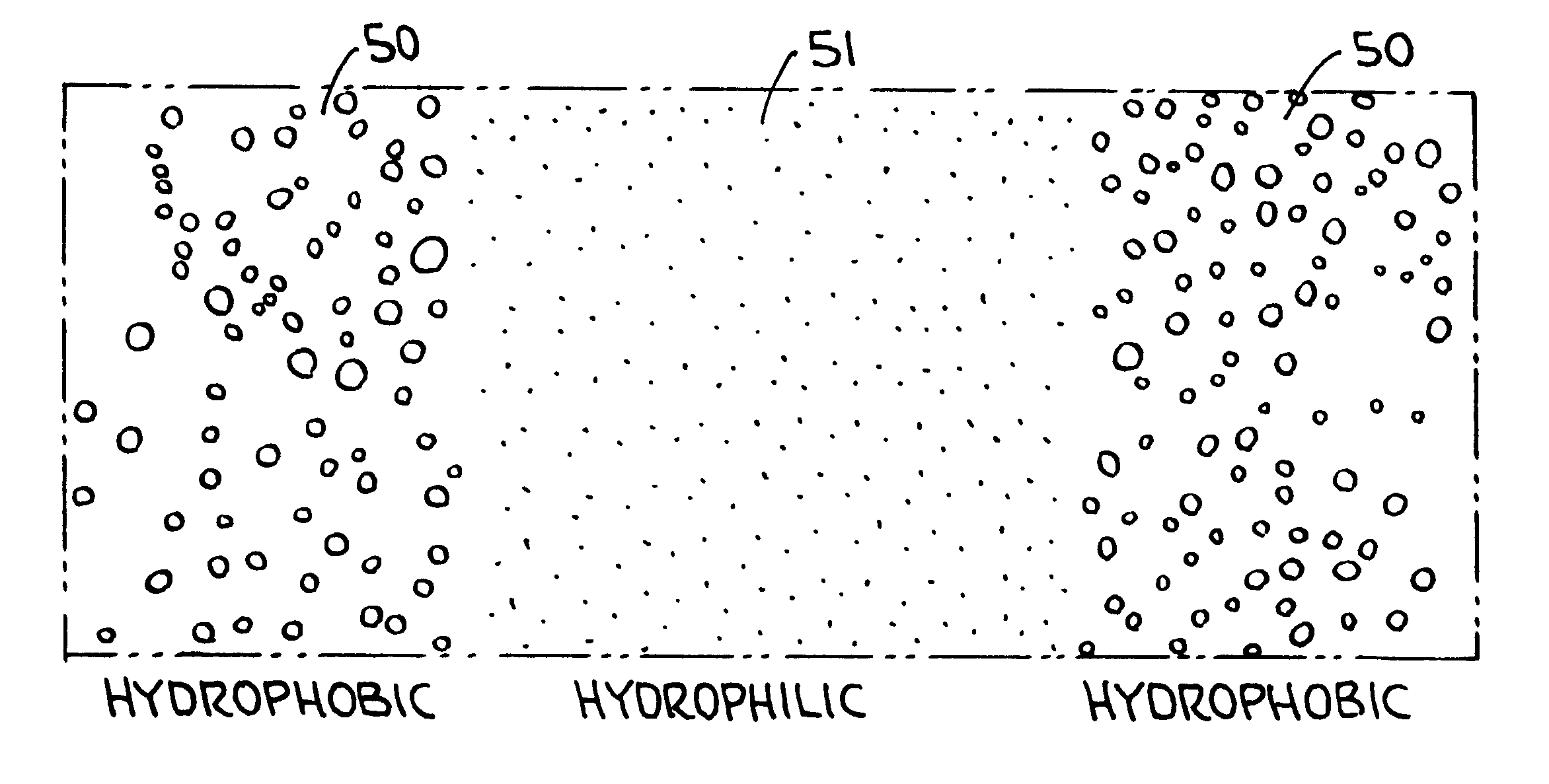

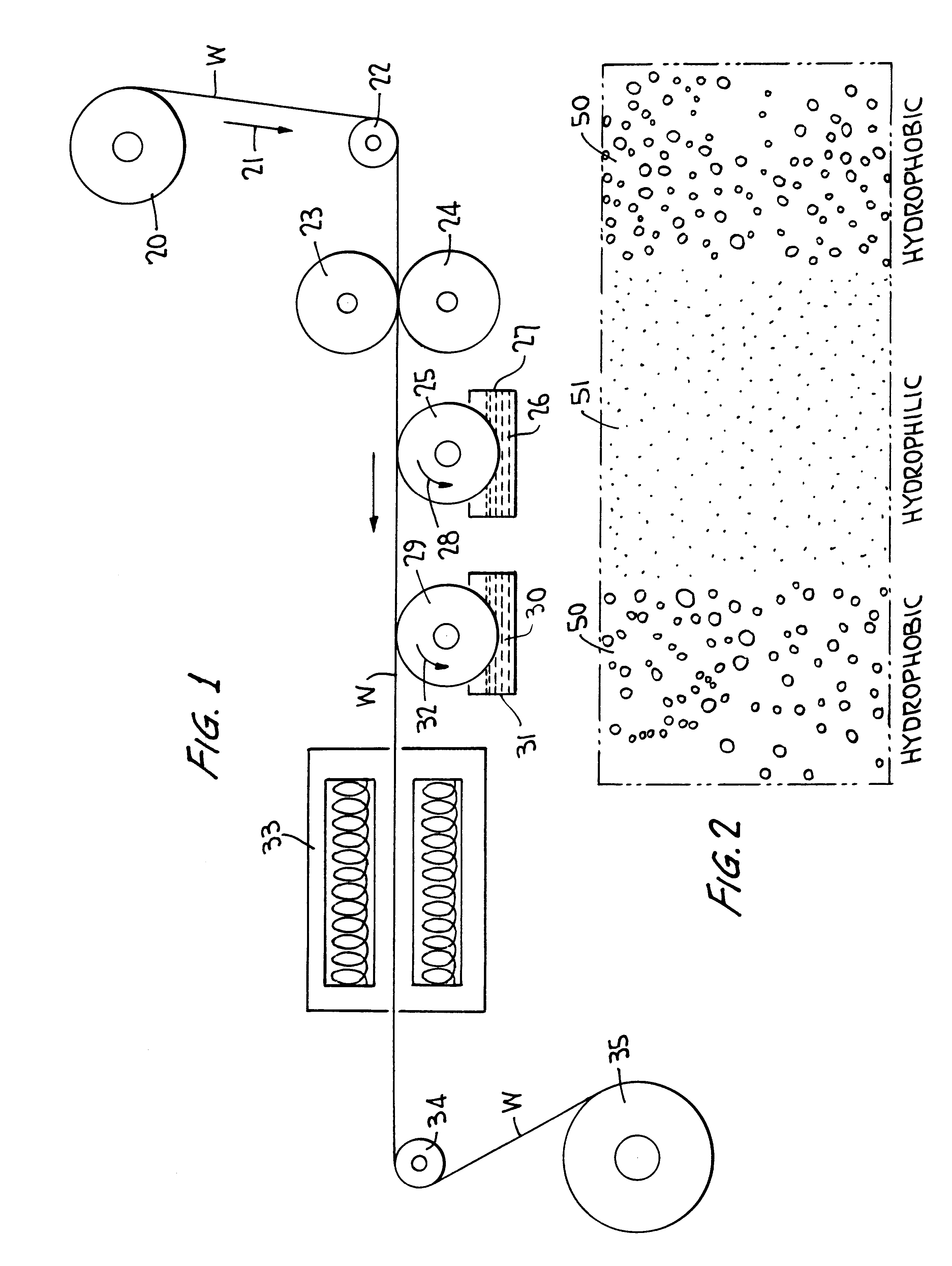

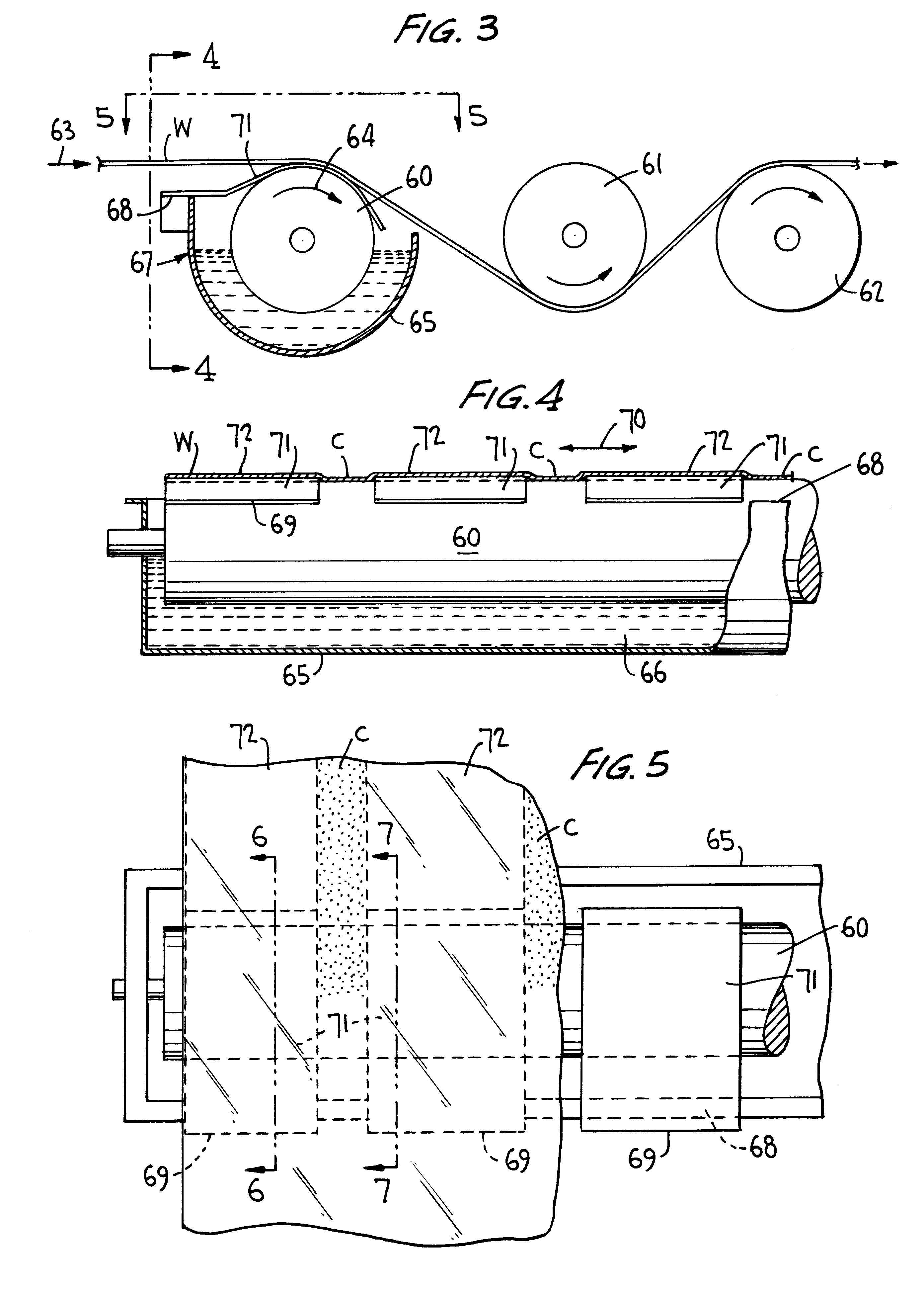

Coating selective zones of thin webs to change the pervious character thereof

InactiveUS6183847B1Easy to transportExcellent impregnationNon-adhesive dressingsDecorative surface effectsEngineeringPolypropylene

The process and apparatus of the present invention involves treating a well-integrated woven or non-woven web of hydrophobic fibers to make selected areas hydrophilic. It also can be used to make a web of hydrophilic fibers selectively hydrophobic. It uses a plurality of selectively adjustable covers on an applicator roll rotating in a bath of liquid to place the liquid material on selected areas of the web as the web moves over the roll. In a preferred embodiment the web is non-woven and the fibers are hydrophobic in nature, e.g., dry-laid or melt-blown polypropylene or polyethylene fibers or spun-bonded hydrophobic filaments. A woven web made of cotton or other hydrophilic fibers may also be used if the end result is to create partially hydrophobic areas on a hydrophilic web. The areas of liquid are positioned on the web only where desired so as to eliminate the excessive cost of unwanted and unnecessary coating material. If the web is hydrophobic, the liquid makes that area hydrophilic. If the web is hydrophilic, the liquid makes that area hydrophobic. Enhanced liquid containment and transport is obtained when at least one discontinuous fine fiber layer is utilized in the web and the fine fiber layer has a melt-blown content greater than zero but less than 1.5 gsm.

Owner:AVGOL NONWOVEN INDS

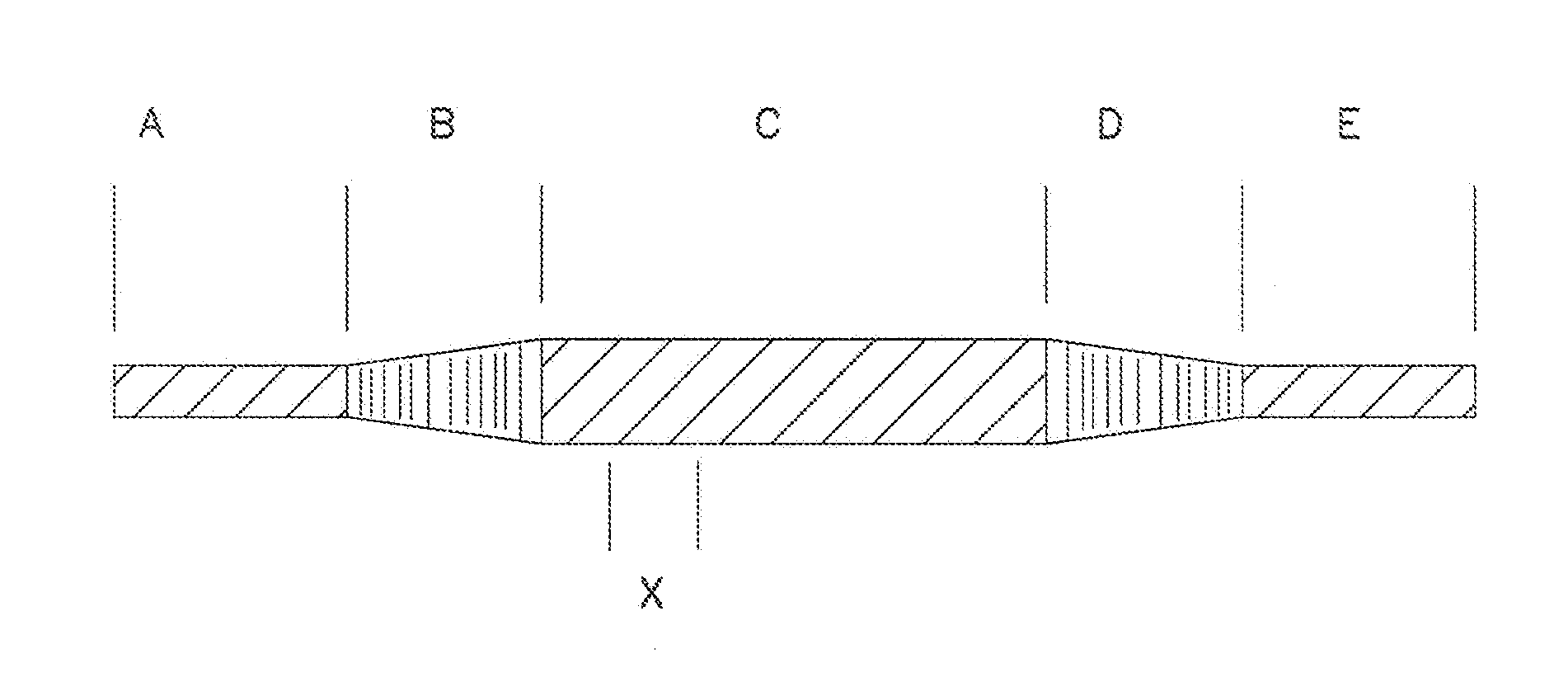

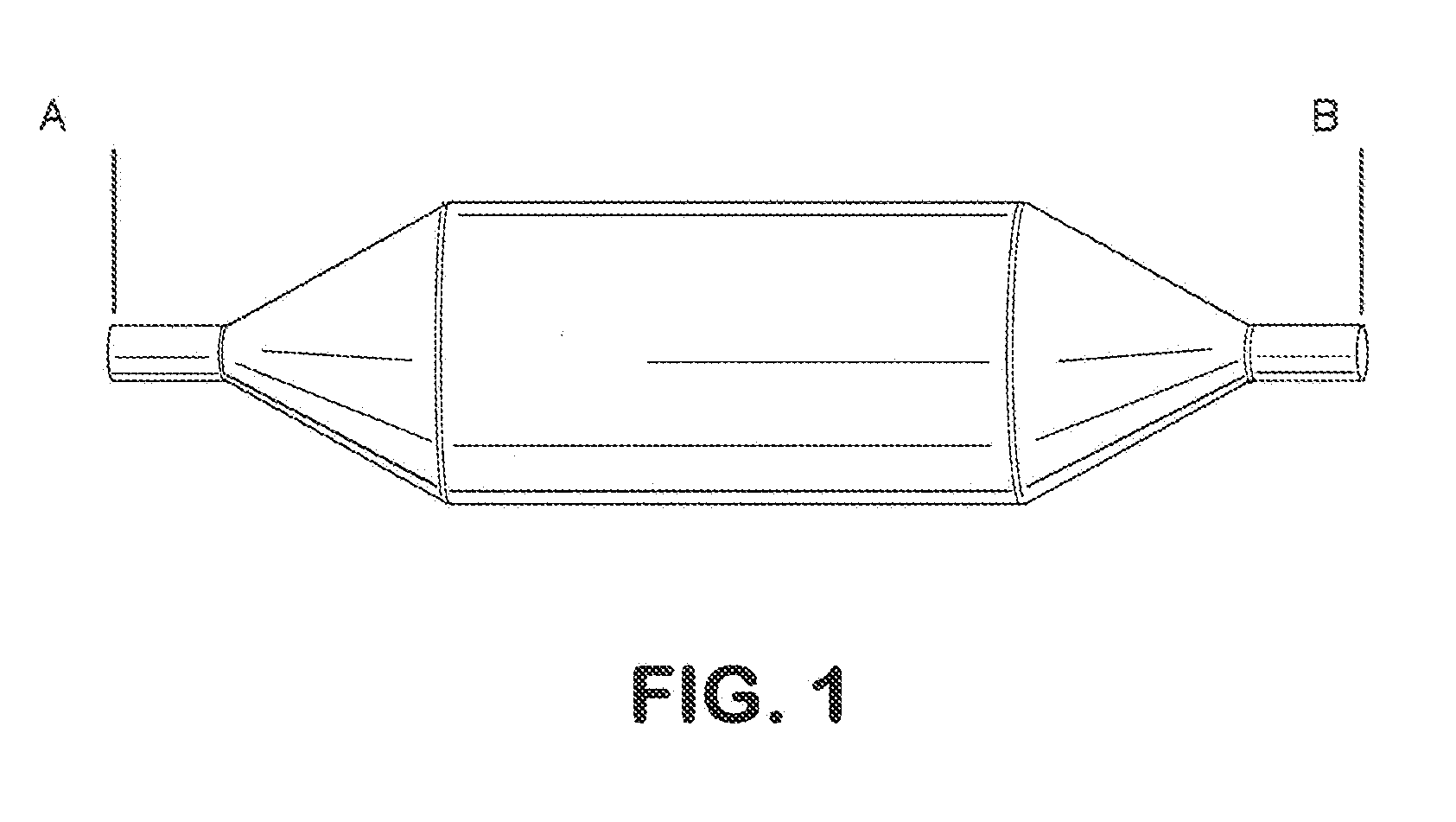

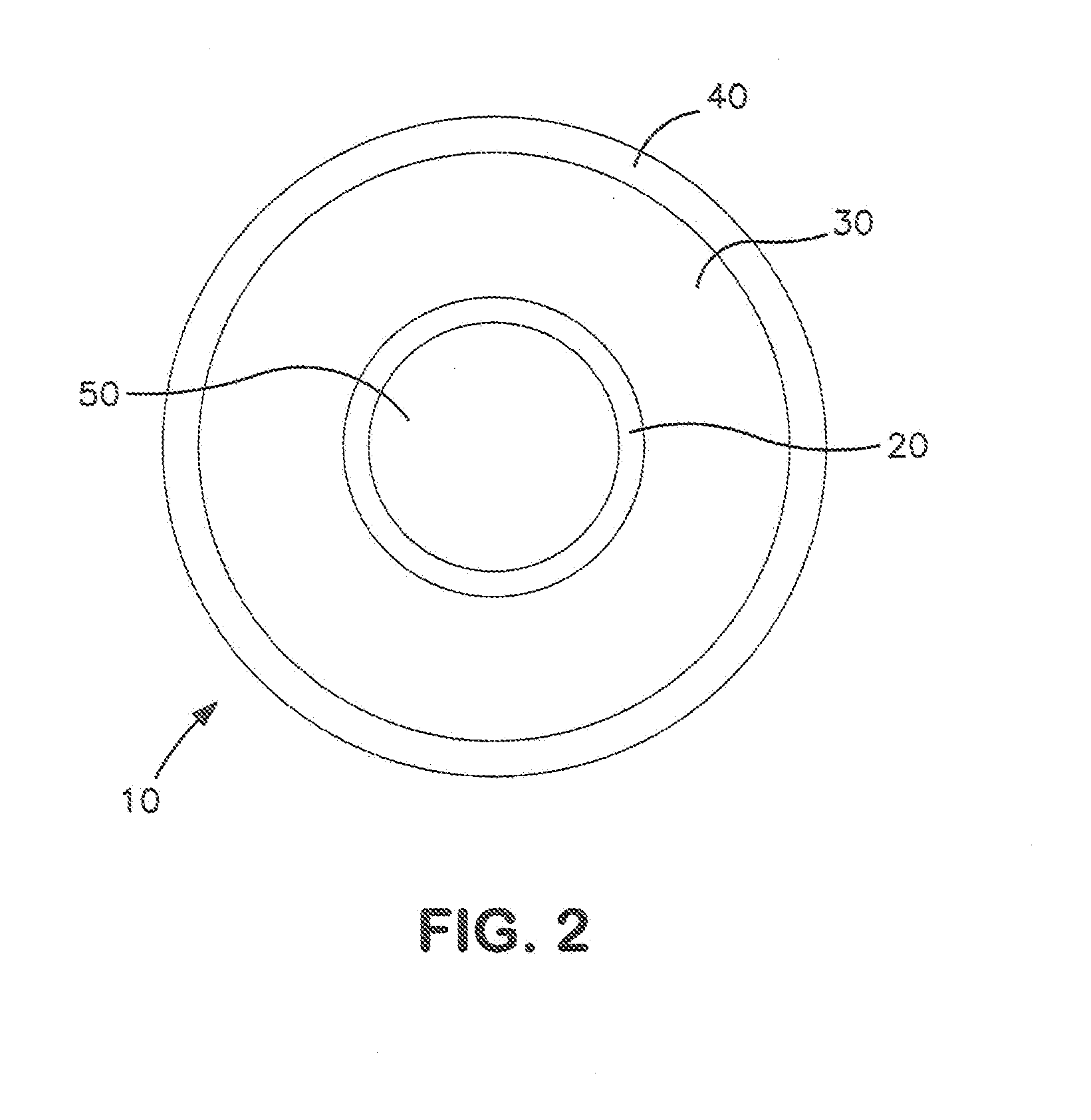

Rupture-resistant compliant radiopaque catheter balloon and methods for use of same in an intravascular surgical procedure

InactiveUS20100234875A1Extension of timeReduce usageBalloon catheterSurgeryFiber layerContrast medium

The present invention provides a compliant balloon for use with a catheter having an inner compliant inner layer defining a cylindrical lumen encased by a fiber layer including non-braided inelastic fibers imparting integrity to the balloon wall. The balloon further includes radiopaque material which may be disposed over substantially the entire length of the balloon as a coating or by incorporation within the fiber layer or an outer coating layer. The balloon is expandable from a folded deflated state to an inflated state by increasing pressure within the balloon and can be used with saline as the sole inflation medium to allow rapid deflation as compared to use of a balloon with a contrast medium.

Owner:VECTOR CORP

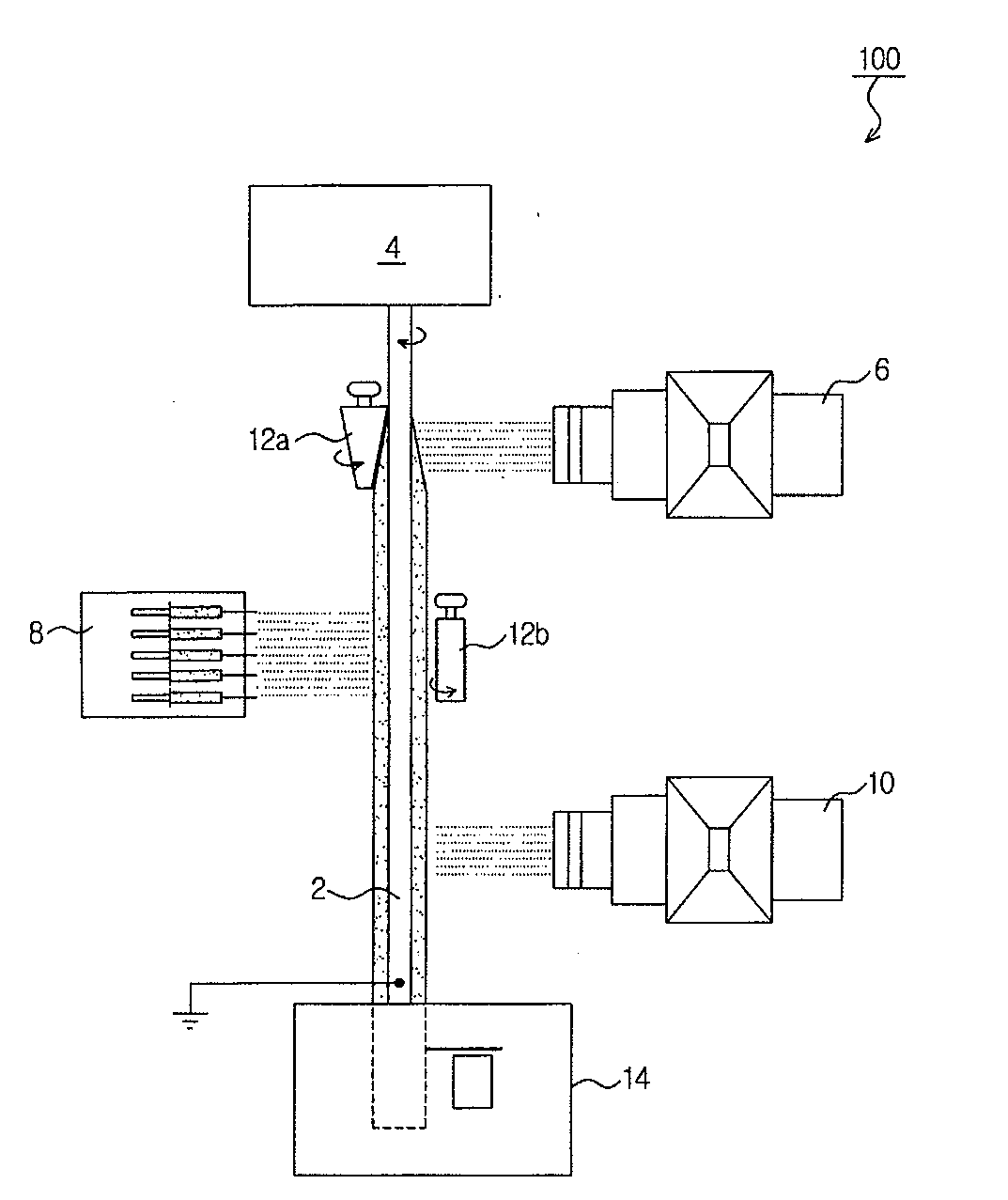

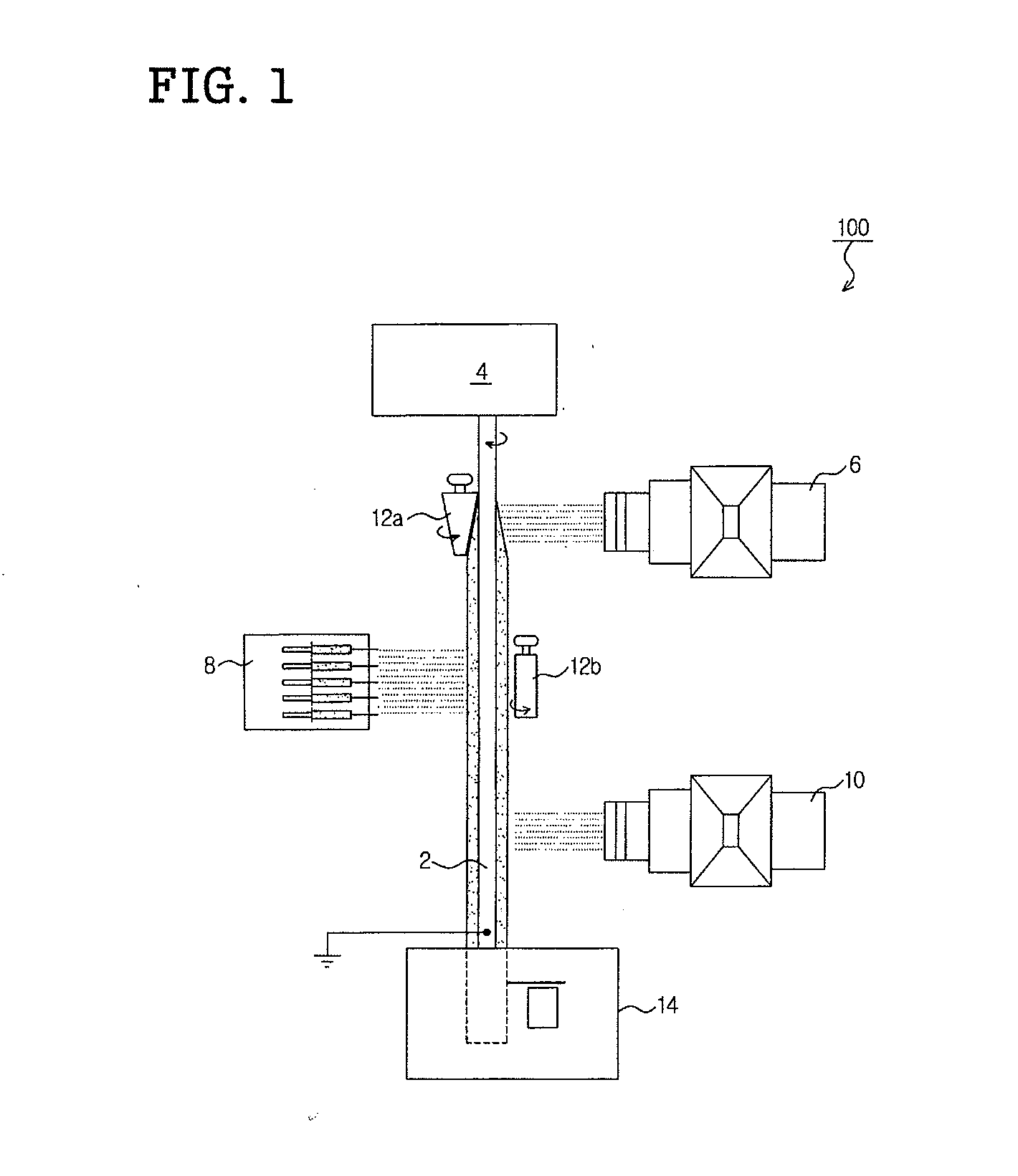

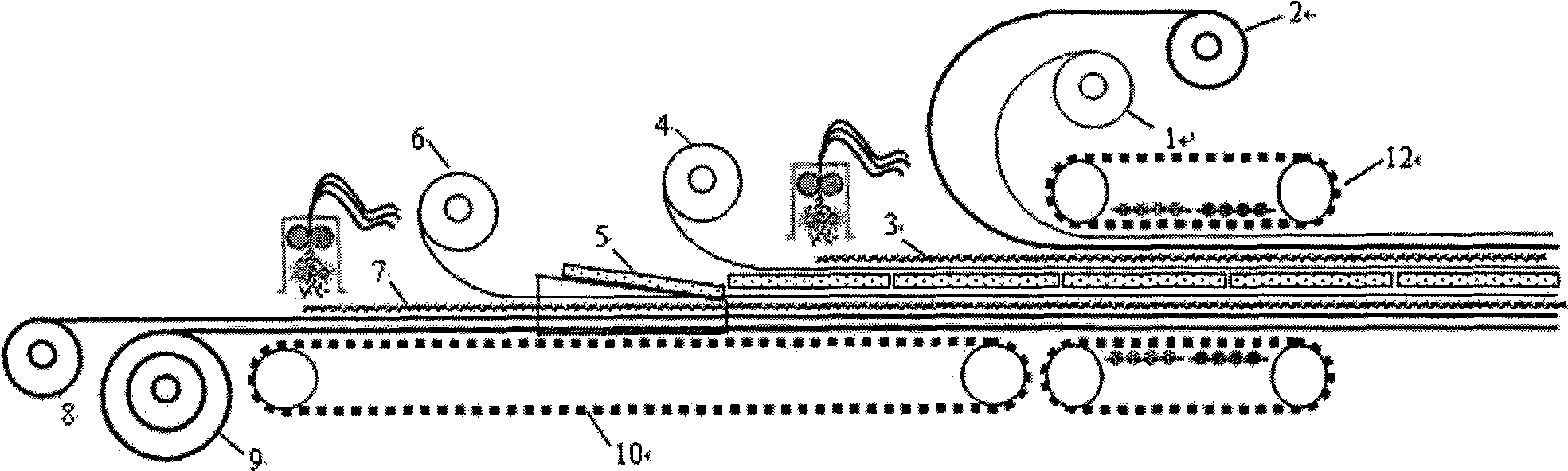

Composite fiber filter comprising nan0-materials, and manufacturing method and apparatus thereof

InactiveUS20080217807A1Improve efficiencyPronounced antibacterial activityLayered productsWood working apparatusYarnElectrospinning

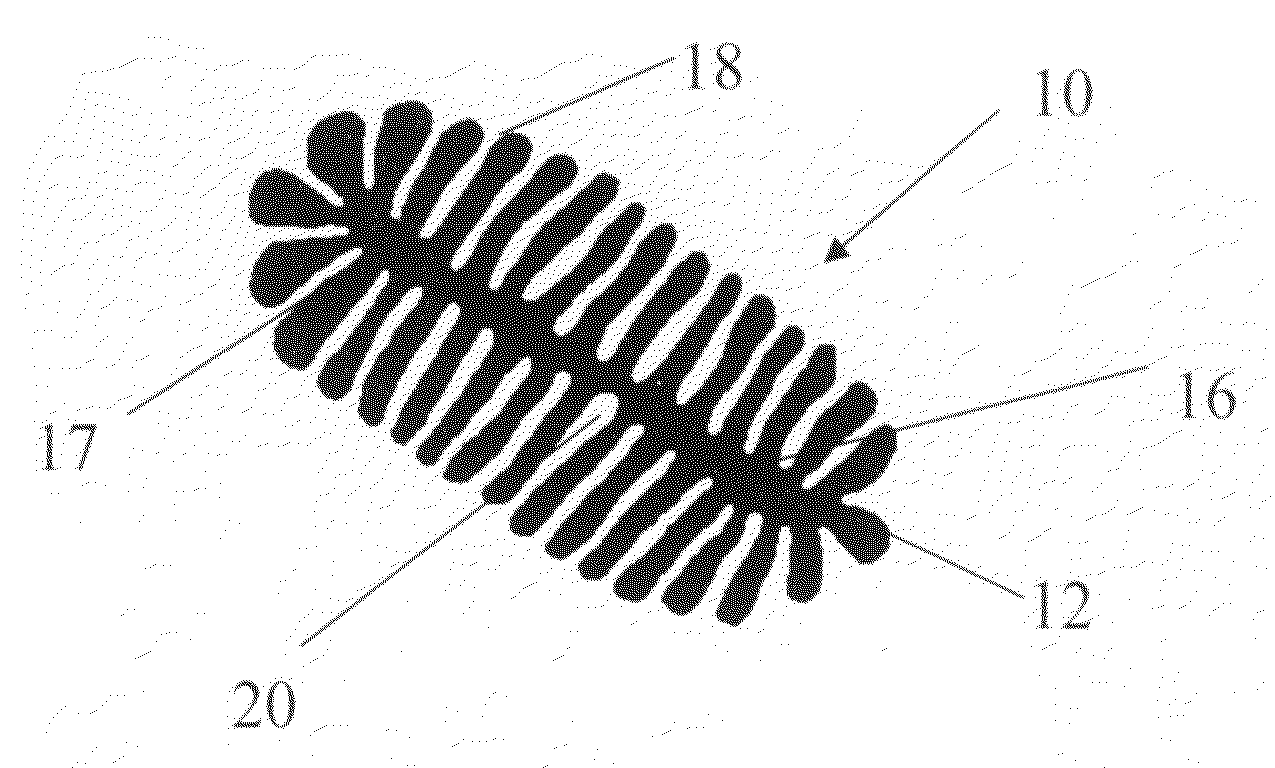

Disclosed herein is a method for manufacturing a composite fiber filter having high efficiency and high functionality, the method comprising: melt-spinning microfiber yarns on a forming rod, which is made of a conductive material, grounded at one end thereof and rotatably driven, using a melt-spinning device, to form on the forming layer a microfiber layer consisting of the microfiber yarns; and electrospinning on the microfiber layer an electrospinnable polymer solution having a given dielectric constant, using an electrospinning device, so as to form on the microfiber layer a nanofiber layers consisting of nanofiber yarns, wherein the microfiber yarns of the microfiber layer and the nanofiber yarns of the nanofiber layer contain silver nanoparticles so as to have an antibacterial function.

Owner:LEE BONG DAE +2

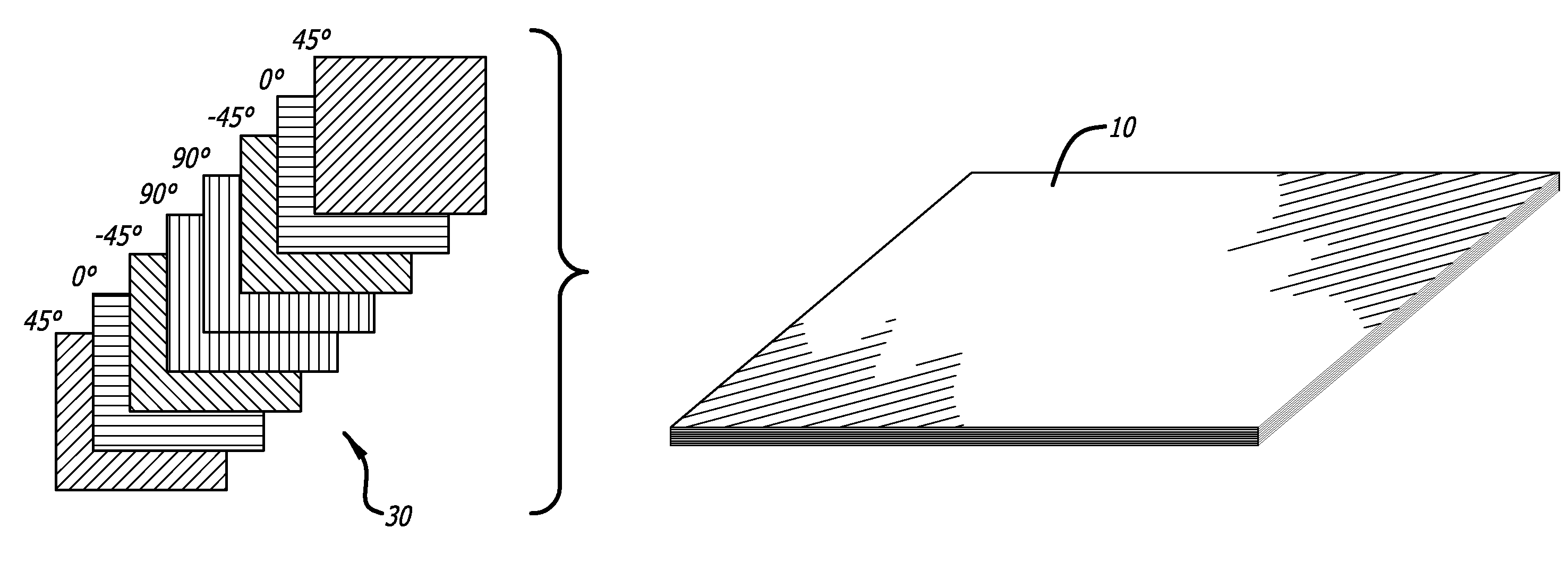

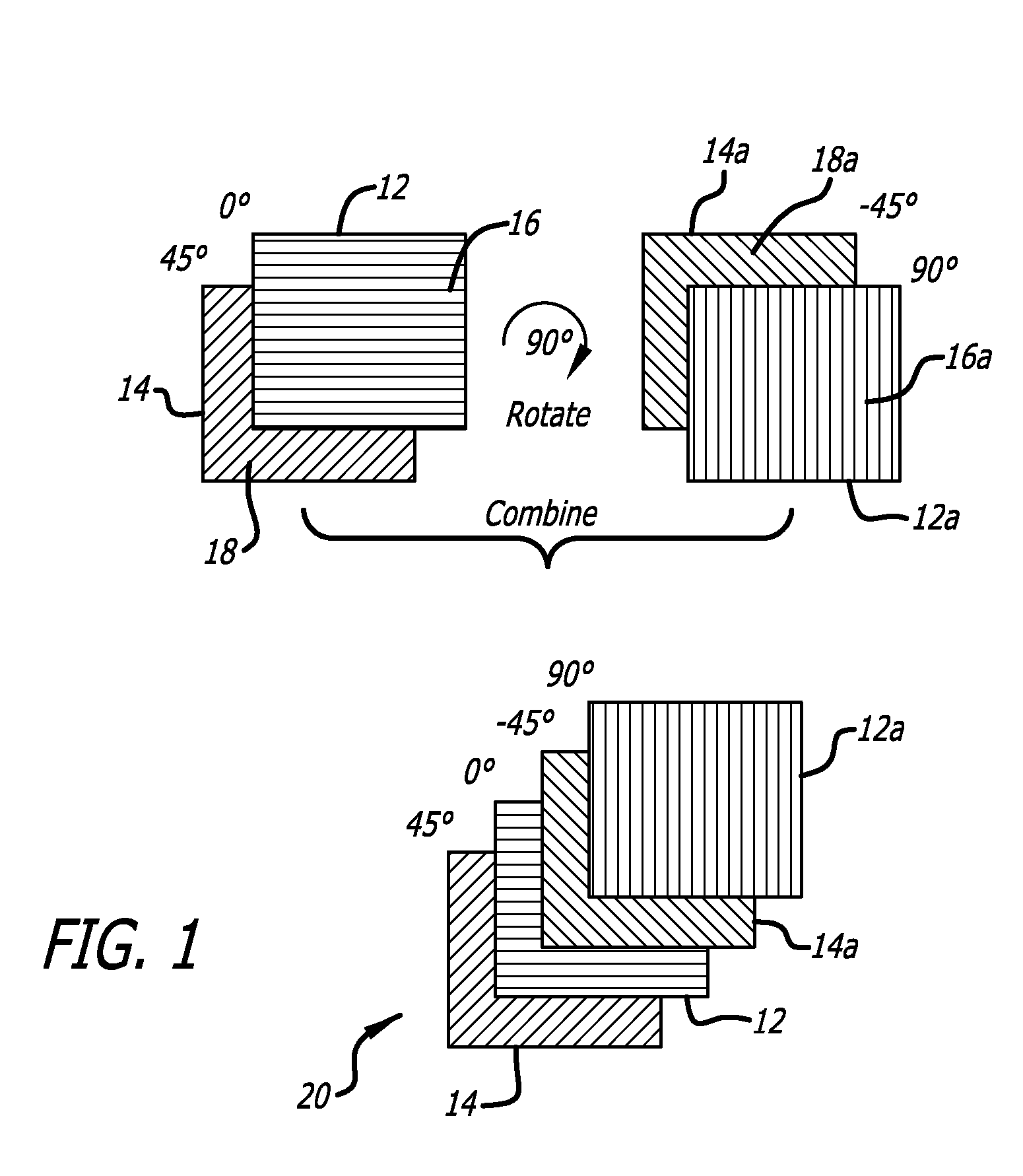

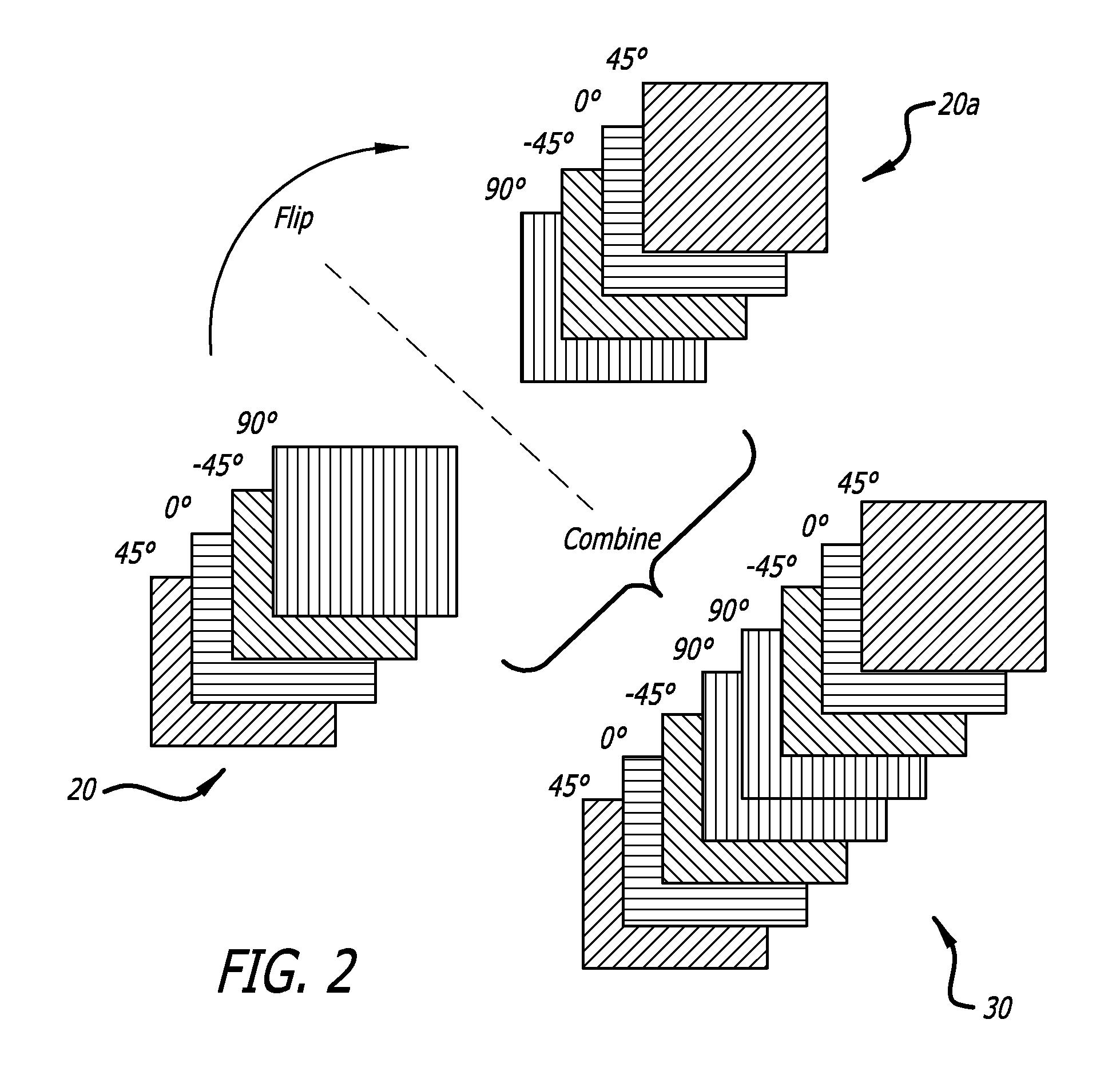

Method of molding complex composite parts using pre-plied multi-directional continuous fiber laminate

ActiveUS20110064908A1Simple processLayered productsEfficient propulsion technologiesShell moldingFiber-reinforced composite

Layers of unidirectional (UD) fiber prepreg are formed into a pre-plied, multi-directional, continuous fiber laminate that is used as a molding compound to form three dimensional structures. Cut-outs from the laminate are slotted and folded along fold lines to provide near-net-shaped preforms that may be compression molded to form fiber-reinforced composite structures having complex shapes.

Owner:HEXCEL

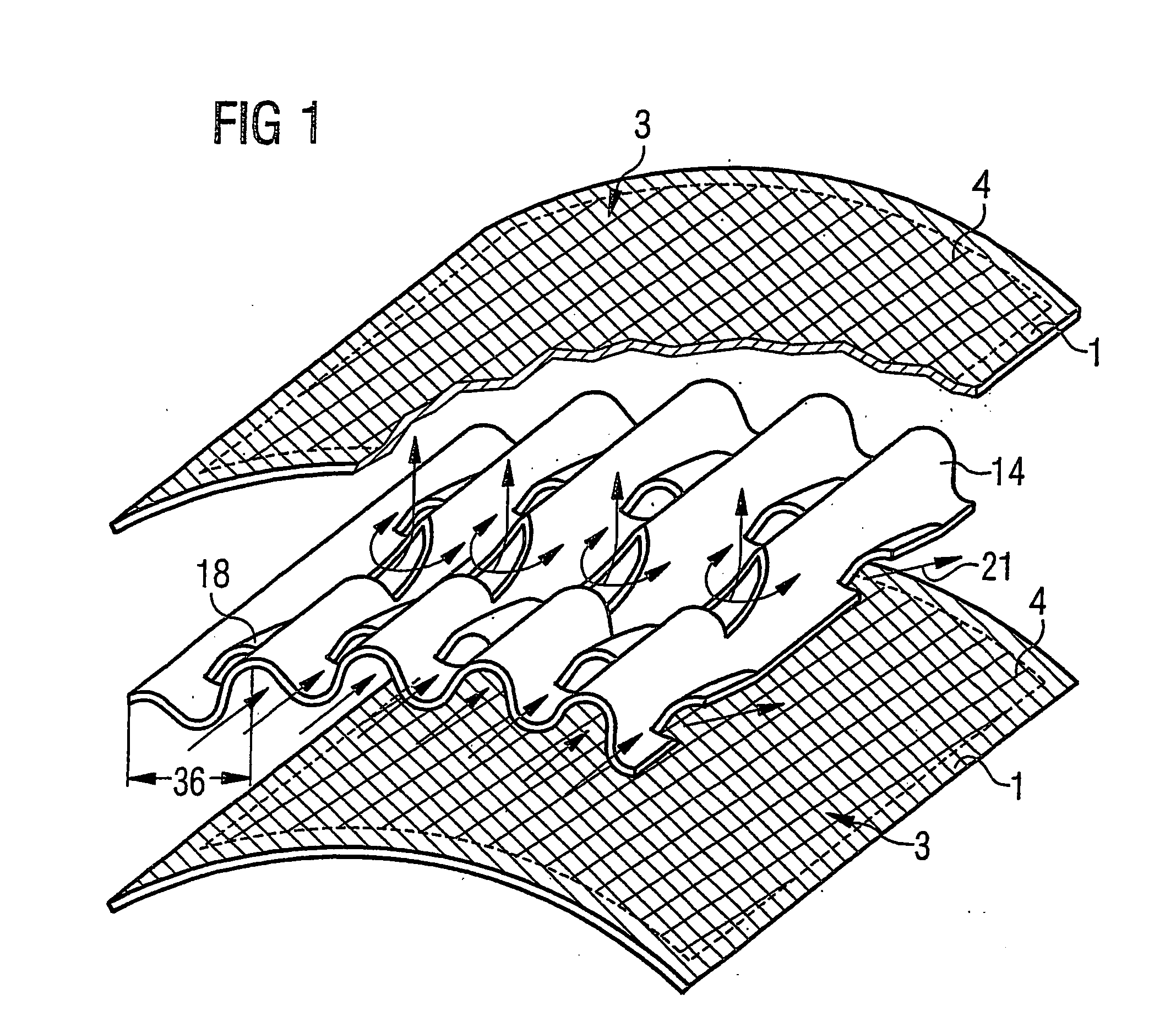

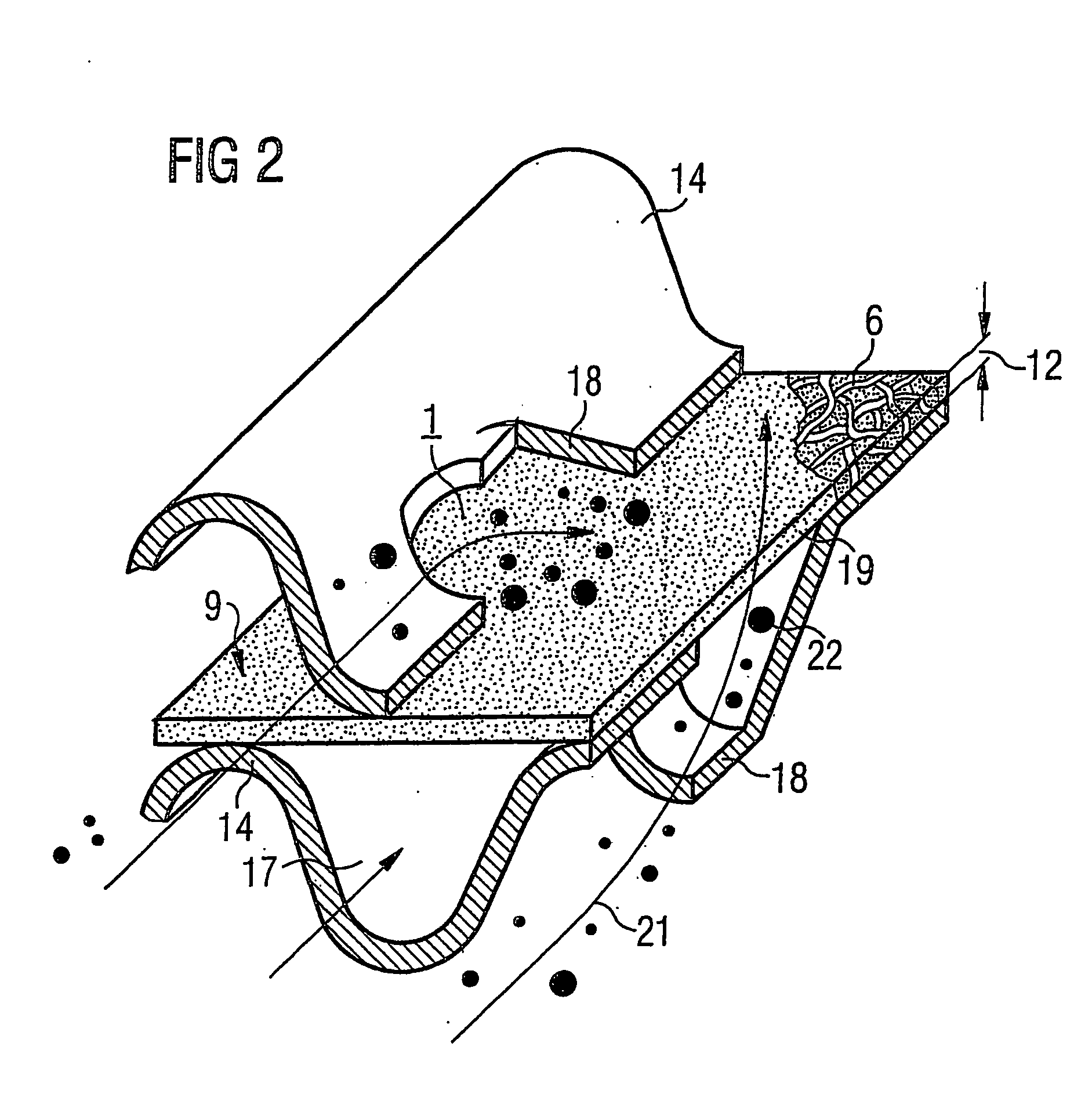

High-temperature-resistant coated fiber layer and particulate trap with the coated fiber layer

InactiveUS20050232830A1Improve efficiencySmall structureCombination devicesInternal combustion piston enginesParticulatesMetal fiber

A high-temperature-resistant fiber layer for an open particulate trap for purifying exhaust gases from mobile internal combustion engines includes metal fibers. At least a section of the fiber layer has a catalytically active and / or adsorbent coating, in particular such as that of an oxidation catalyst and / or a three-way catalyst and / or an SCR catalyst. A longitudinal section, which is substantially perpendicular to a largest outer surface, has openings formed therein with an average size of 0.01 mm to 0.5 mm, in particular 0.05 mm to 0.25 mm. A particulate trap with the coated fiber layer is also provided.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

Wiping sheet

InactiveUS20060009106A1Improve wiping effectPromote stratificationCarpet cleanersFloor cleanersNonwoven fabricFiber structure

A wiping sheet is provided, which presents excellent in handling during wiping, high wiping ability for greasy dirt, and less liquid remains on an object after wiping. A wiping sheet having a fiber structure (such as a woven fabric, a knitted fabric and a nonwoven) is obtained, which includes an ultrafine fiber layer containing ultrafine fibers having a fineness of at most 0.9 dtex which result from at least two types of ultrafine fiber-generating conjugate fibers, at least one conjugate fiber giving ultrafine fibers containing a modified vinyl alcohol resin, and the other conjugate fibers giving ultrafine fibers containing another resin(s). The ultrafine fibers can be obtained by a first splittable conjugate fiber including a component containing the modified vinyl alcohol resin and a second splittable conjugate fiber composed of components of other resins. In the ultrafine fiber layer, the fibers are preferably bonded by thermoadhesive resin-containing ultrafine fibers.

Owner:DAIWABO HLDG +1

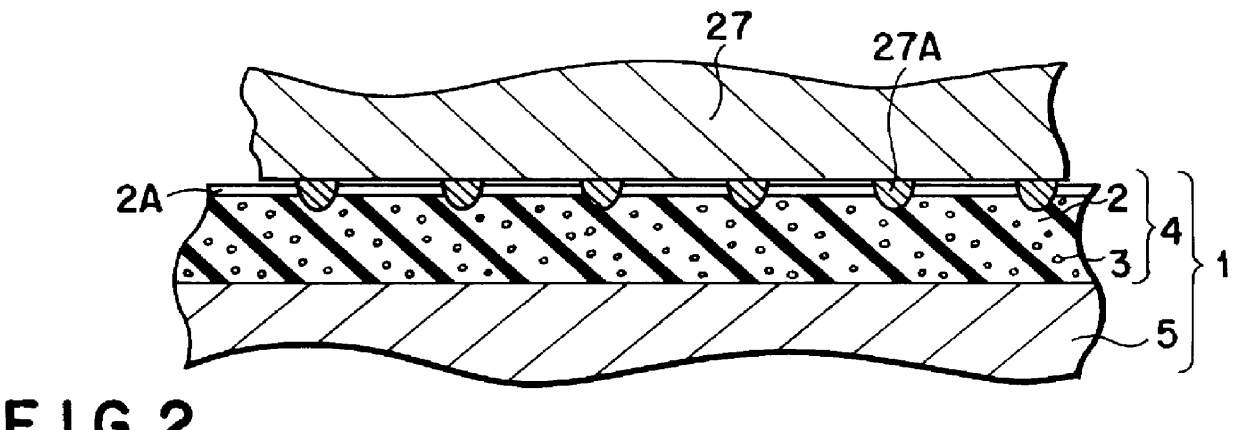

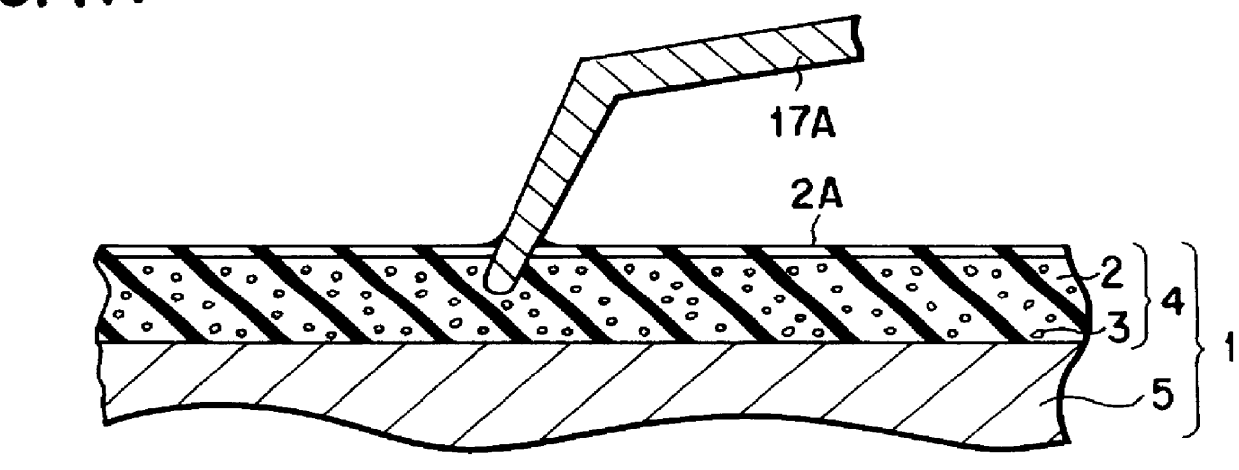

Cleaner for inspecting projections, and inspection apparatus and method for integrated circuits

InactiveUS6130104AImprove surface conditionAnalog circuit testingSemiconductor/solid-state device testing/measurementWaddingBiomedical engineering

A cleaner of this invention is a cleaner for inspecting projections and removes any substance, e.g., aluminum oxide, which attaches to needle points of probe needles, when the probe needles pierce into the cleaner. The cleaner has a cleaner layer and a substrate. The cleaner layer is constituted by an elastic material layer, and a filler having a surface state improving function of the inspecting projections and dispersed in the elastic material layer. As the filler having a surface state improving function, a powder including at least one of ceramic materials, e.g., sand, glass, alumina, Carborundum (trade name), and the like, or a fiber layer made of an inorganic fiber or organic fiber can be employed.

Owner:TOKYO ELECTRON LTD

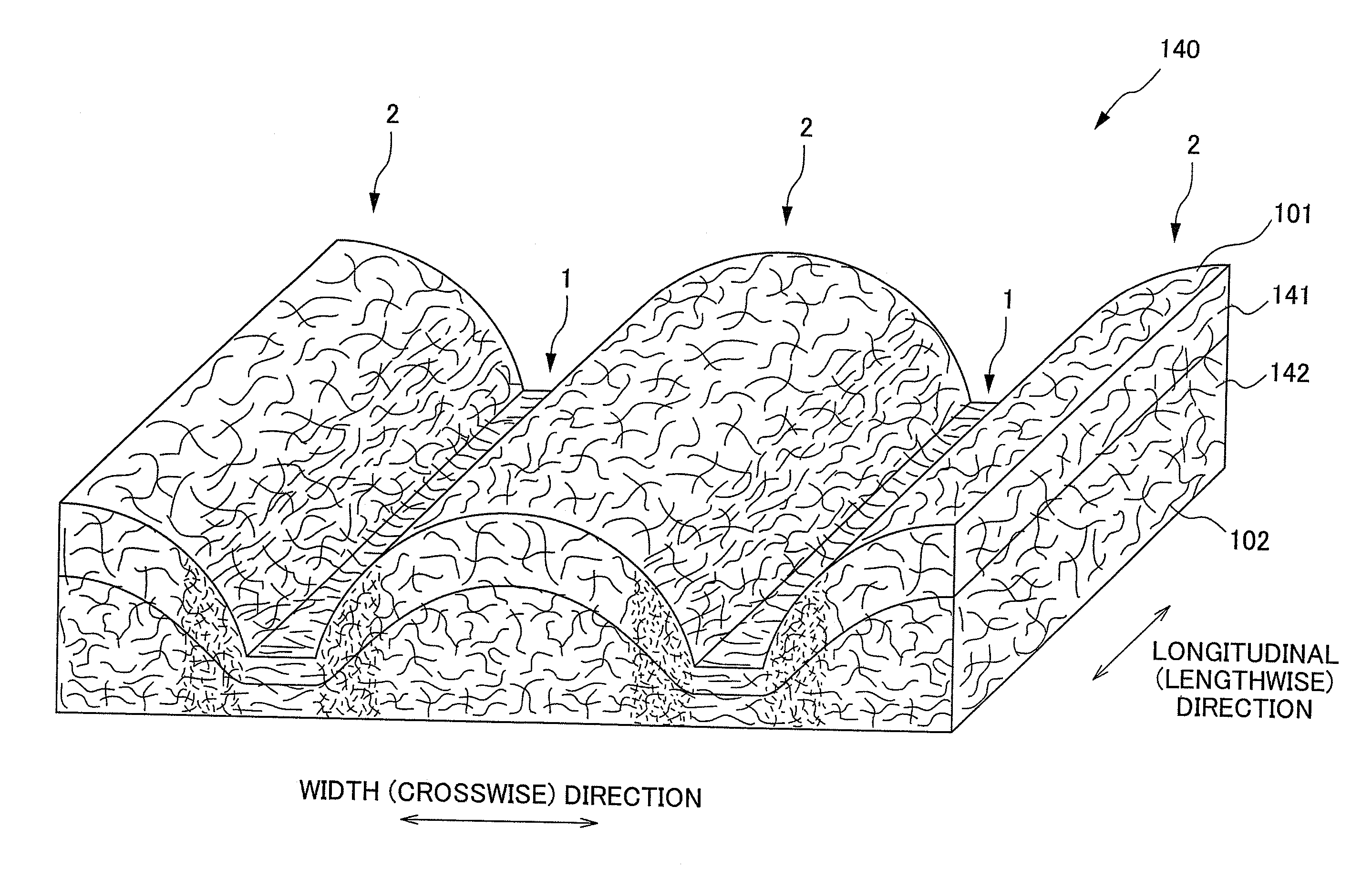

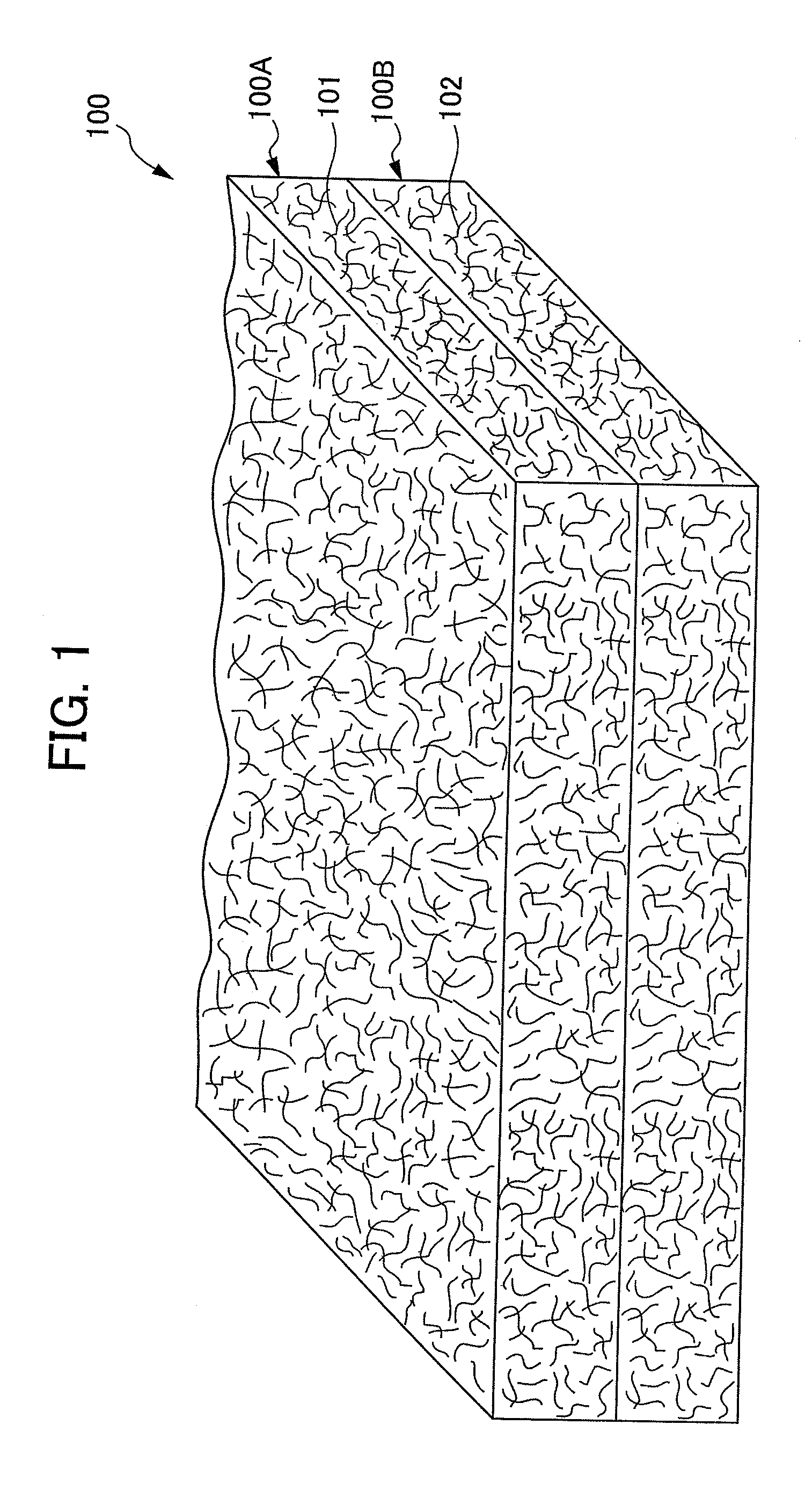

Multilayer nonwoven fabric and method of manufacturing the same

ActiveUS20080085399A1Non-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

A multilayer nonwoven fabric comprises a first fiber layer and a second fiber layer laminated and arranged on a first surface of the first fiber layer, wherein a plurality of groove portions is formed along a prescribed direction in a shape depressed in a thickness direction of the multilayer nonwoven fabric and a plurality of raised ridge portions are formed adjacent to the plurality of groove portions in a shape projected in the thickness direction and in which the basis weight is greater than the basis weight in regions A constituting the bottoms of the groove portions 1 are formed, and the second fiber layer constituting each of the plurality of raised ridge portions is in such a shape that a surface, on the side of the first fiber layer, of the second fiber layer is projected in the same direction as the direction in which the second surface of the first fiber layer is projected.

Owner:UNI CHARM CORP

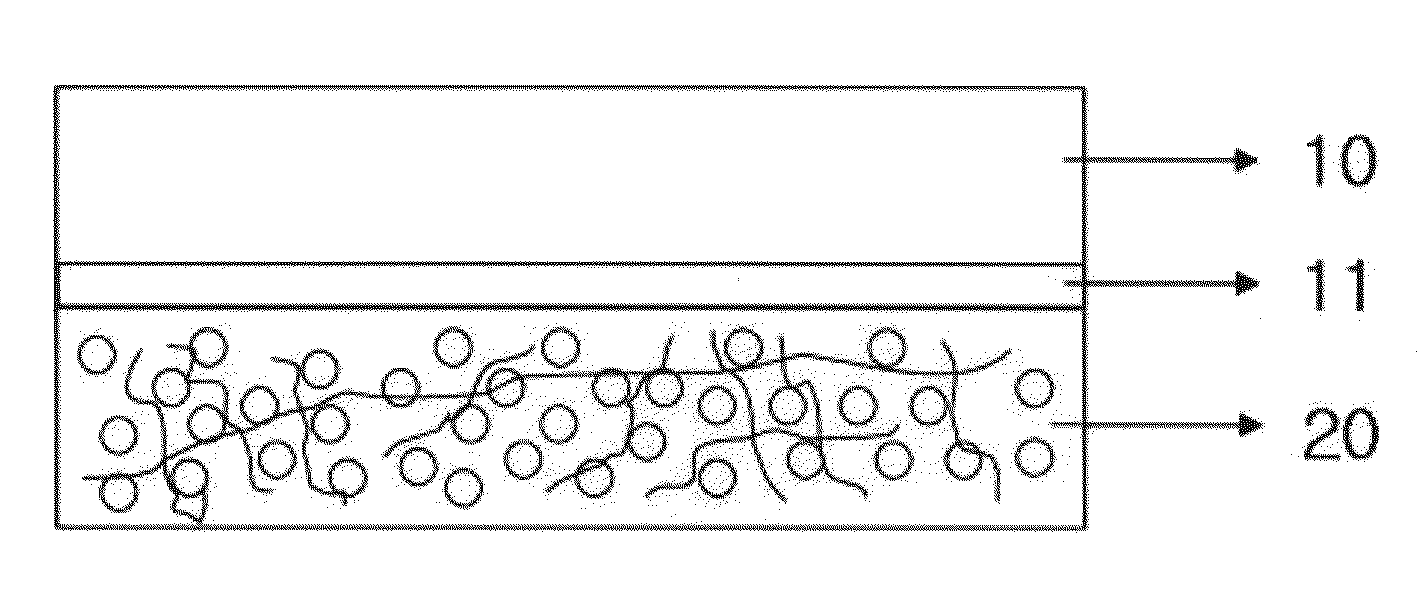

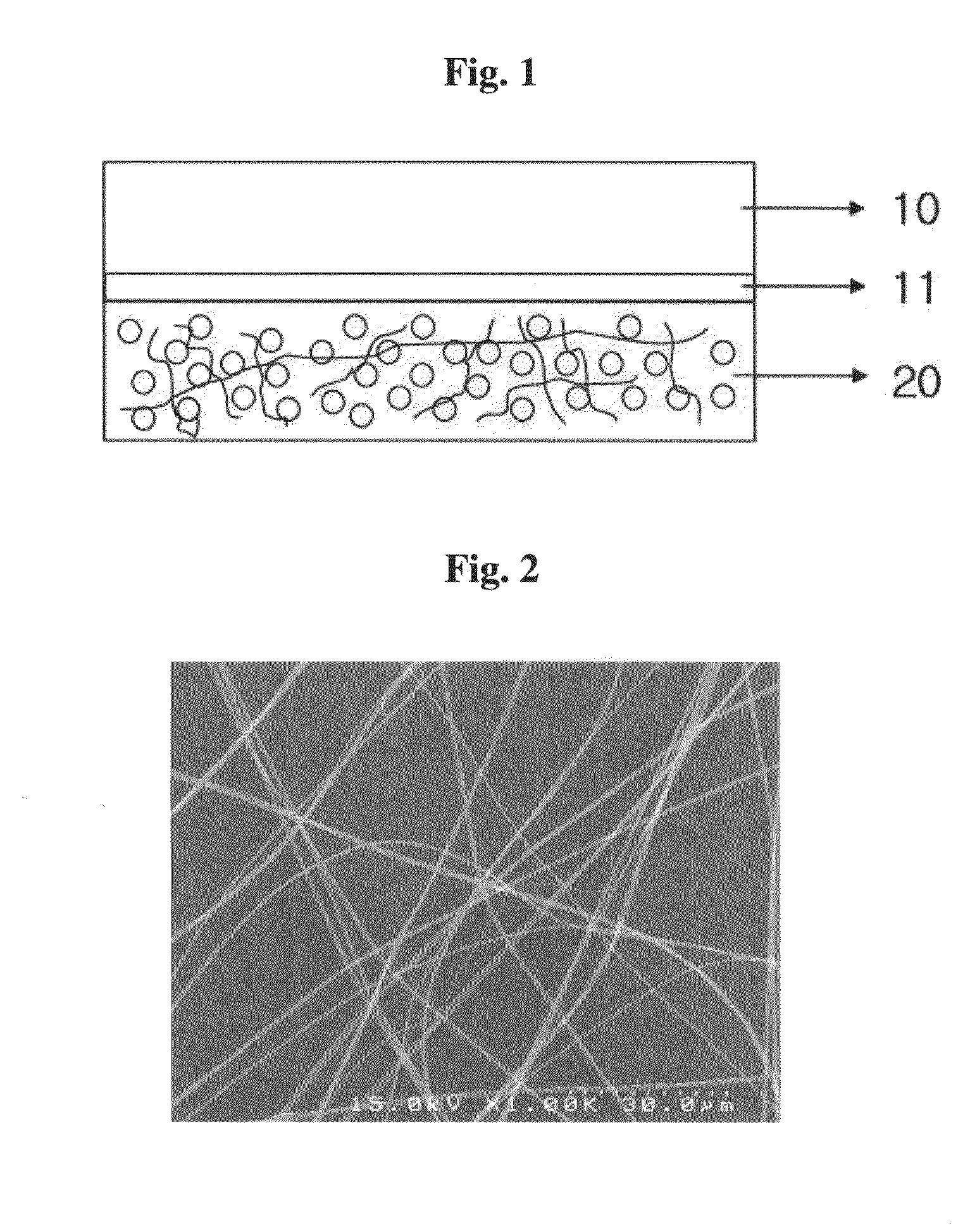

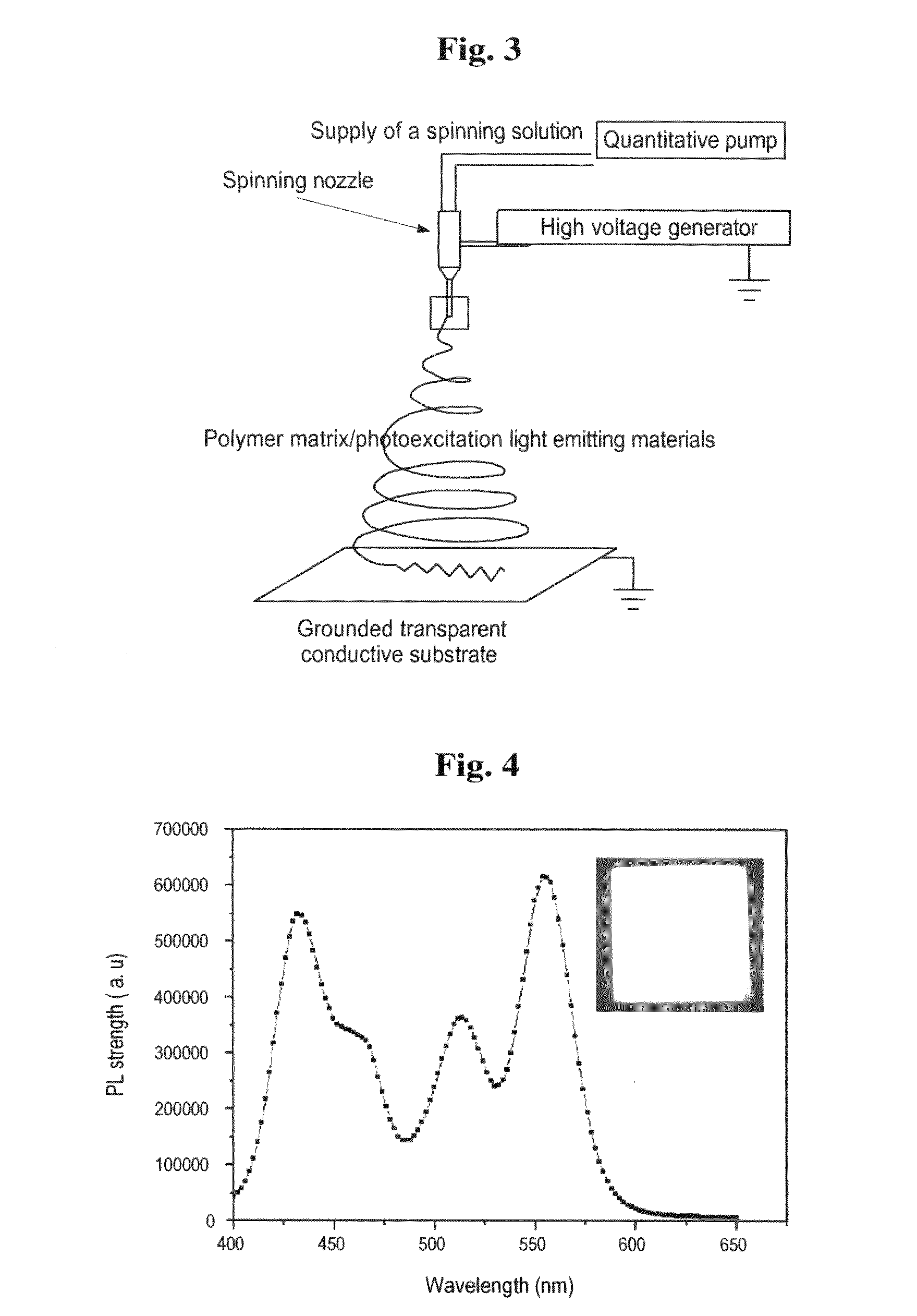

White and color photoexcitation light emitting sheet and method for the fabrication thereof

The present invention relates to a white and color photoexcitation light emitting sheet comprising a substrate, a light source formed on the substrate, and a white and color photoexcitation light emitting layer capable of converting a light emitted from the light source into a light having a different wavelength, where the white and color photoexcitation light emitting layer is fabricated by mixing a matrix polymer, white and color photoexcitation light emitting materials and a solvent, spinning the resulting mixture to prepare an ultrafine composite fiber layer of the matrix polymer / photoexcitation light emitting materials, and thermocompressing the ultrafine composite fiber layer; and a method for fabrication thereof. The white and color photoexcitation light emitting sheet according to the present invention has uniform brightness and color coordinates and exhibits high color reproducibility.

Owner:KOREA INST OF SCI & TECH

Bag house elements

InactiveUS20020073849A1Low efficiencyReduce filter lifeCombination devicesMaterial nanotechnologyAir filterFilter media

The filter structures commonly known as a bag house or a filter bag or an air filter with a bag construction can be made by preparing the bag assembly, either in a tubular or a bi-fold construction by placing a layer of fine fiber on the upstream surface of the filter media structure. The filter assembly includes a filter cabinet with an interior component. The filter component is suspended within the filter cabinet interior. The filter component includes a frame or support for the filter media. The frame or support holds the filter bags such that the filter bags are suspended from the frame in the cabinet interior. The intake air enters the cabinet, passes through the filter assembly and exits the cabinet. The air must pass first into the fine fiber layer, the filter media and then the exterior of the cabinet.

Owner:DONALDSON CO INC

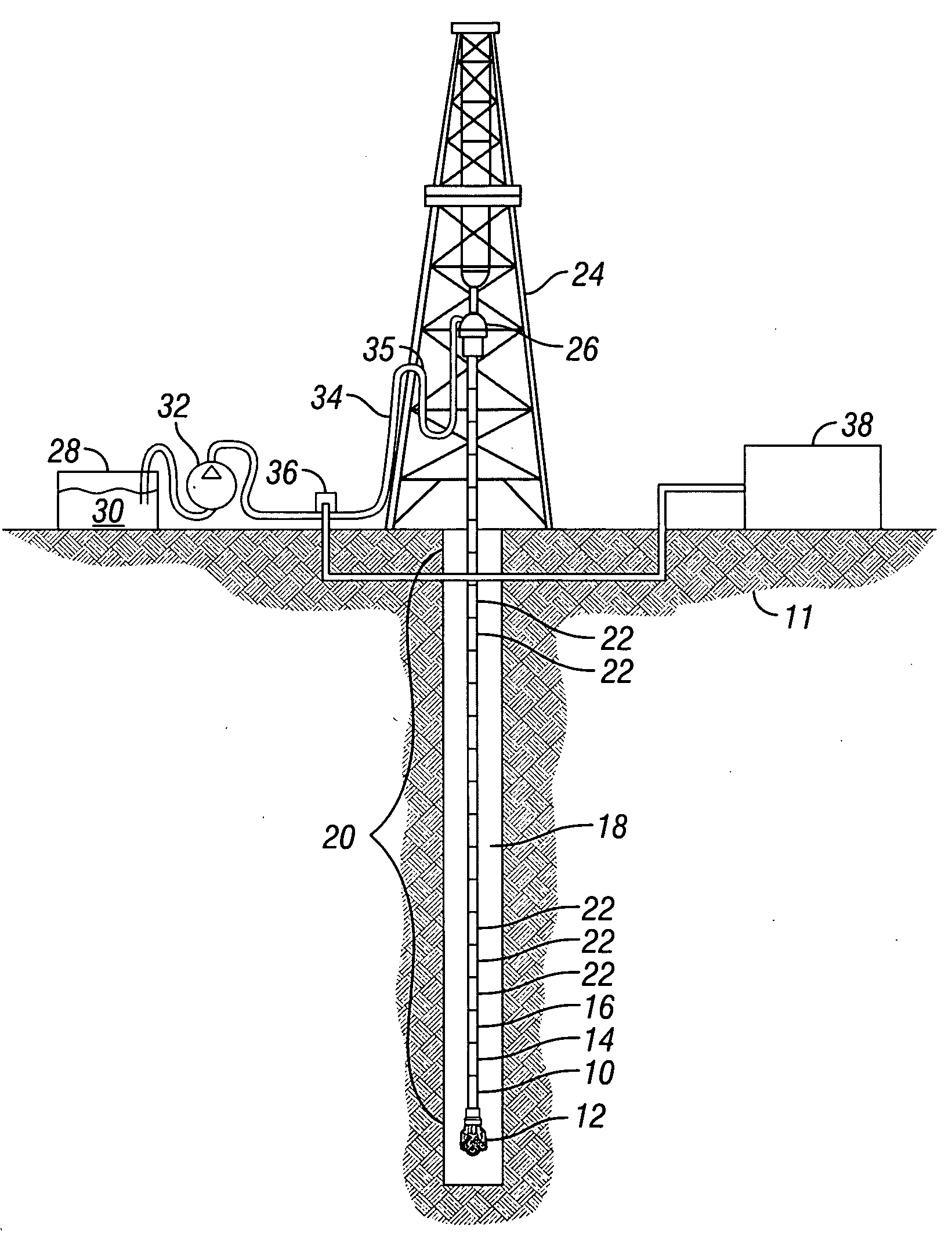

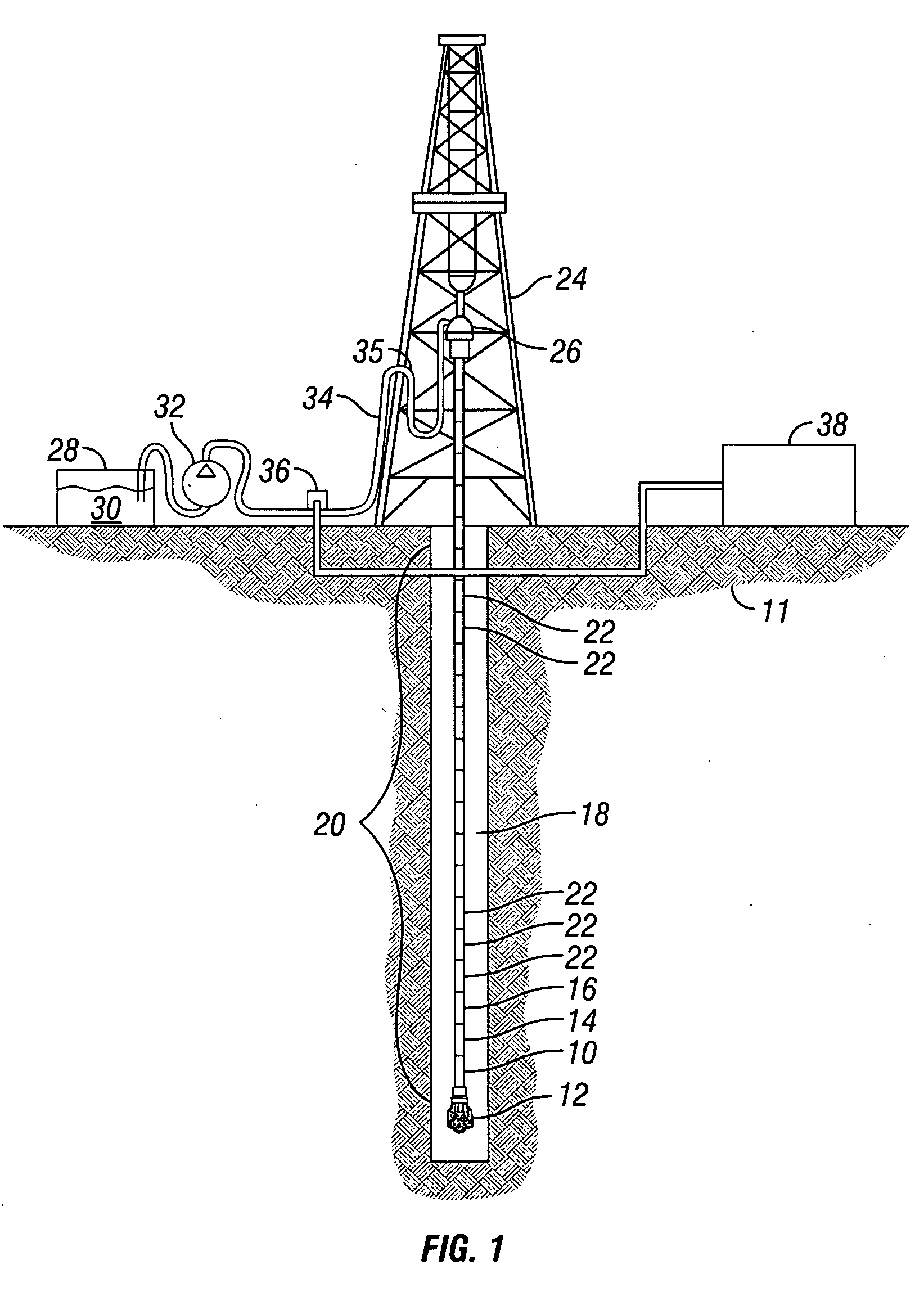

Electrically non-conductive sleeve for use in wellbore instrumentation

A well logging instrument housing includes an electrically non-conductive tube and at least one layer of fiber embedded in a matrix surrounding an exterior of the tube. The at least one fiber layer includes at least one carbon fiber. The at least one or carbon fiber is arranged to have substantially no closed loops.

Owner:SCHLUMBERGER TECH CORP

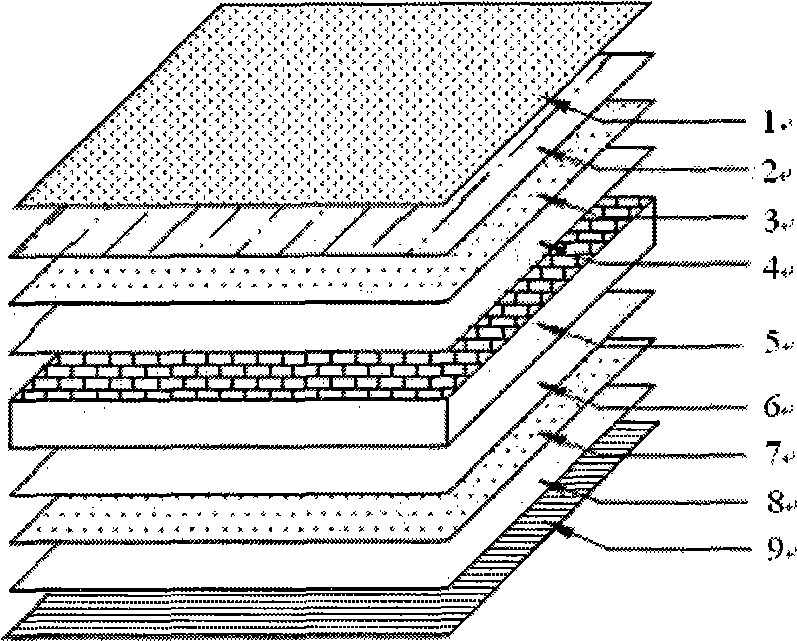

Polyurethane multilayer composite sheet for automotive headliner and processing method thereof

InactiveCN101544083ASolve pollutionAvoid product qualitySynthetic resin layered productsLaminationSurface finishGlass fiber

The invention discloses a polyurethane multilayer composite sheet for an automotive headliner, which has a non-woven fabric layer, a first reinforcing glue film layer, a first reinforcing fiber layer, a first adhesive film layer, polyurethane foam board, a second adhesive film layer, a second reinforcing fiber layer, a reinforcing glue layer and a surface finish layer from bottom to top. The production method of the polyurethane multilayer composite sheet has the characteristics that: the use of the reinforcing glue films as a substitute of hot-melt adhesive powder simplifies production process, improves production efficiency and product quality, radically solves dust pollution in a production process, and improves the working environment of workers. The polyurethane multilayer composite sheets produced by the method can be used for fiber glass-free automotive roofs, biodegradable automotive roofs, light automotive roofs, and other high-quality automotive headliners; the introduction of reinforcing fiber mats in different forms enables the method to produce breathable automobile roofs, high acoustic absorption automotive roofs, high strength automotive roofs and other functional automotive headliners; and the sheet and the method fill a gap of the automotive headliner industry in China.

Owner:陈雅君

Wound dressing

InactiveUS6077526AEffectively isolate in useGuaranteed usageNon-adhesive dressingsPlastersFiber layerBiomedical engineering

PCT No. PCT / GB96 / 01087 Sec. 371 Date Nov. 14, 1997 Sec. 102(e) Date Nov. 14, 1997 PCT Filed May 8, 1996 PCT Pub. No. WO96 / 36304 PCT Pub. Date Nov. 21, 1996A wound dressing combining a graduated density felt 1 with an absorbent fiber layer 2 in order that the aggressive absorption of the absorbent layer 2 may be regulated to acceptable rates for wound dressing usage and to ensure potentially irritative alginate absorbent fibers are isolated from the wound site. The graduated density felt 1 acts as a regulating or gate layer for the absorbent fiber layer 2 and so limits the rate that exudate from a wound can pass to the absorbent fiber layer 2. Furthermore, the regulating layer 1 effectively spreads the exudate to give a conical transmission profile enhancing wound dressing performance.

Owner:TEXON UK LTD

High numerical aperture fiber

InactiveUS20080181567A1Optical fibre with polarisationOptical fibre with multilayer core/claddingHigh numerical apertureRefractive index

An optical fiber comprising: a silica based core having a first index of refraction n1; and at least one silica based cladding surrounding the core, the at least one silica based cladding comprising index lowering non-periodic voids containing a gas, wherein at least 80% of said voids have a maximum cross-sectional dimension of less than 2000 nm, and the NA of the fiber layer situated immediately adjacent to and inside said at least one silica based cladding is at least 0.2.

Owner:CORNING INC

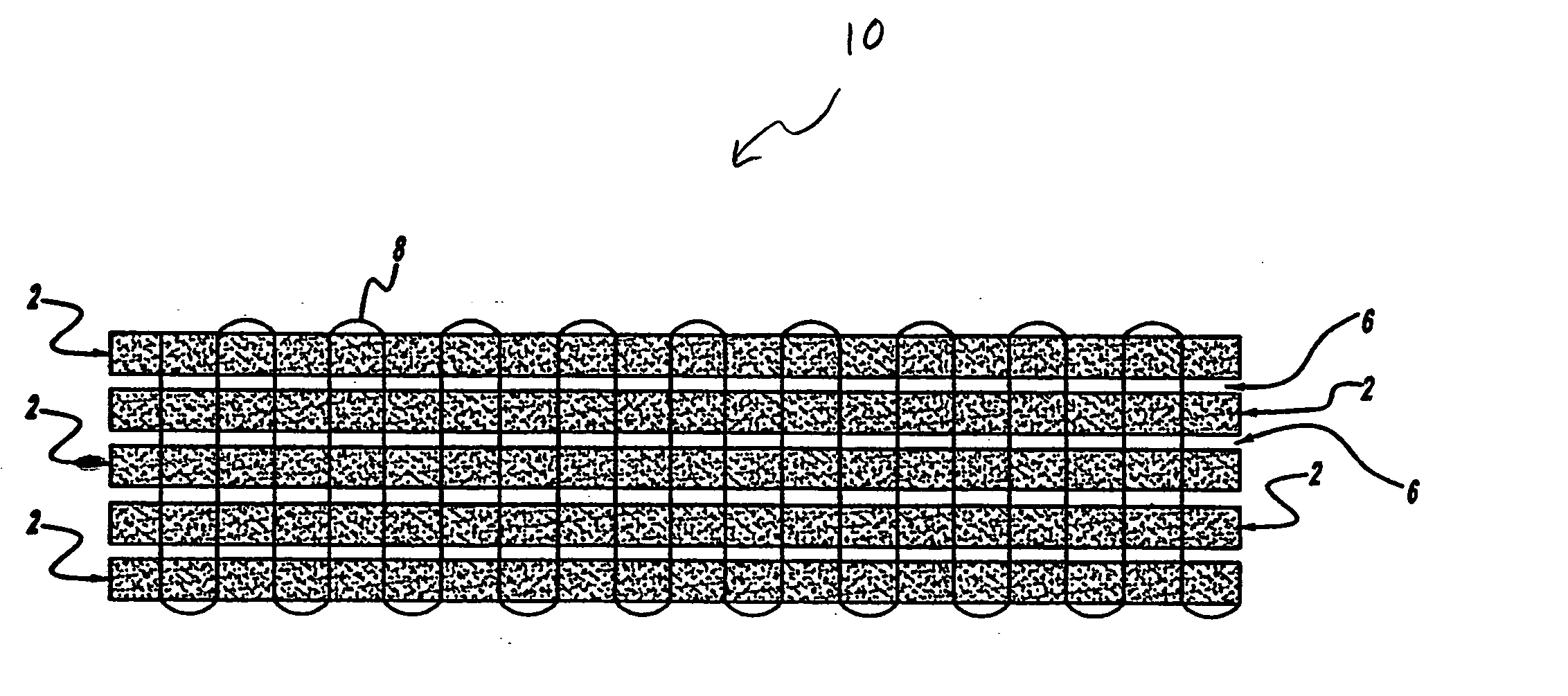

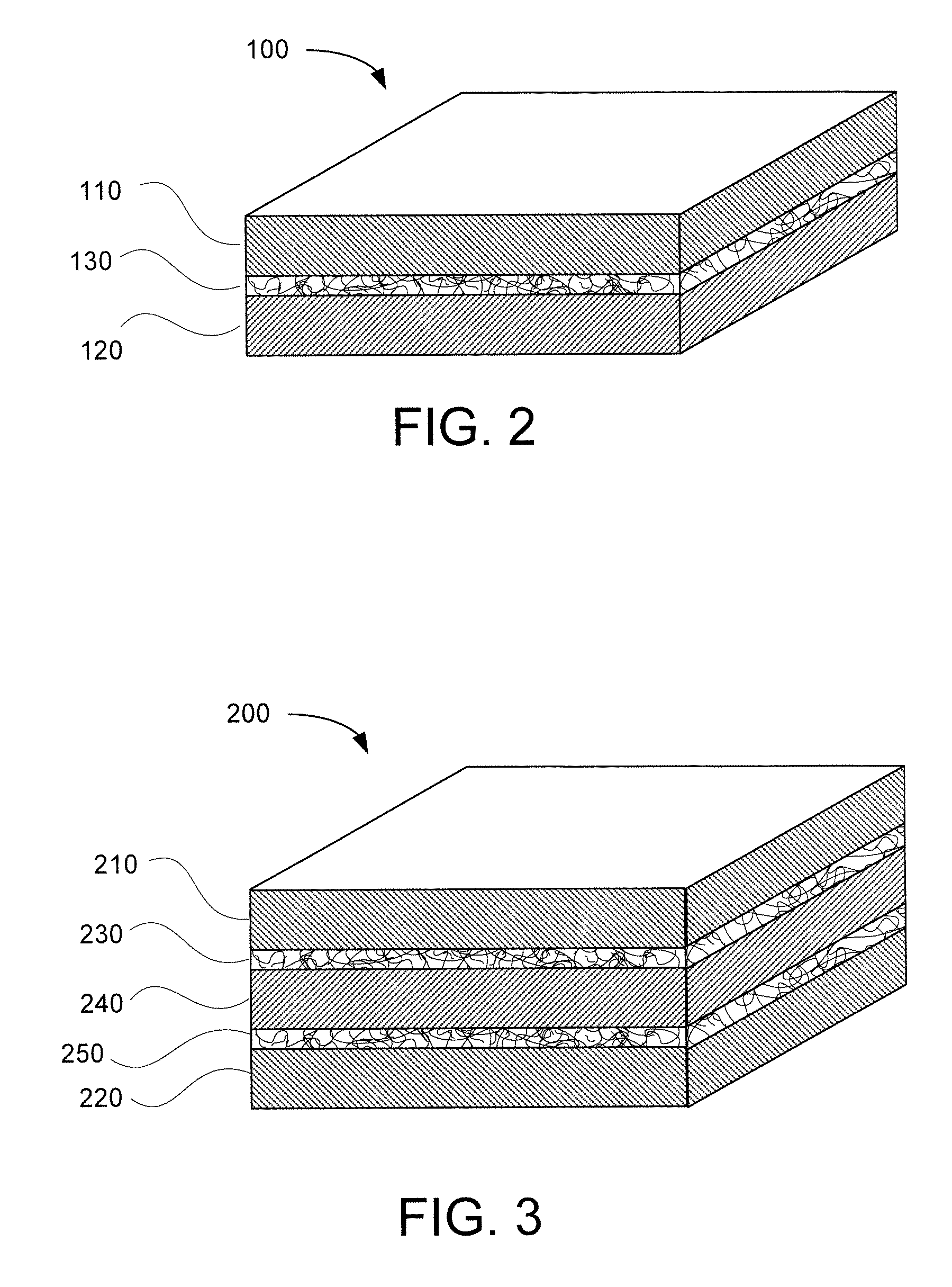

Multi-Layer, Fluid Transmissive Fiber Structures Containing Nanofibers and a Method of Manufacturing Such Structures

A multi-layer, fluid transmissive structure is provided that comprises first and second fiber layers each comprising a plurality of polymeric fibers bonded to each other at spaced apart contact points. The polymeric fibers of these fiber layers have diameters greater than one micron and collectively define interconnected interstitial spaces providing tortuous fluid flow paths through the first and second fiber layers. The structure also comprises a plurality of nanofibers disposed intermediate at least a portion of the first fiber layer and at least a portion of the second fiber layer.

Owner:POREX TECHNOLOGIES GMBH

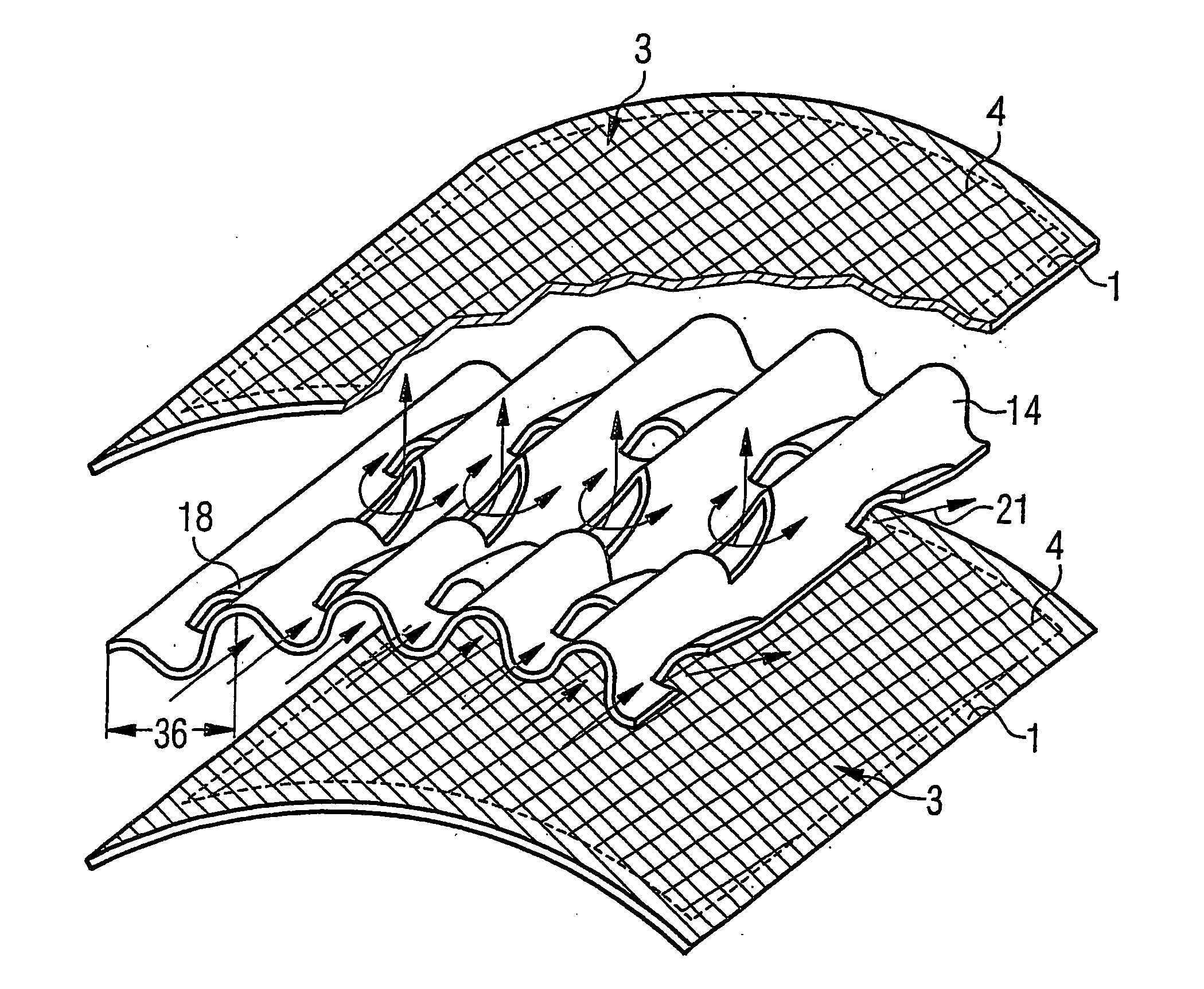

Process for the production of a nonwoven and nonwoven obtained by this process

InactiveUS6066388AThe process is simple and fastLayered productsWoven fabricsPolymer scienceLow melting point

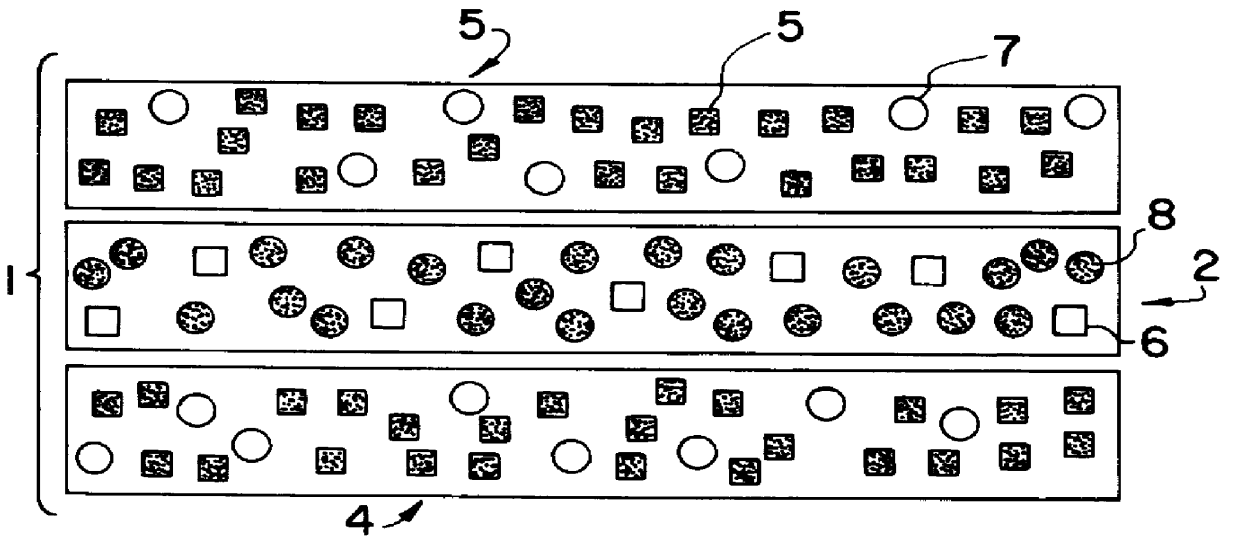

A nonwoven (1) comprising two outer fiber layers (3, 4) and at least one inner fiber layer (2) having a different composition from that of the outer layers (3, 4). The nonwoven (1) comprises structural fibers (7, 8) and binding fibers (5, 6), said binding fibers (5, 6) at least partially consisting of a polymer with a lower melting point than the structural fibers (7, 8). Said nonwoven (1) is densified by needling on both sides to a given depth while leaving an undensified central region. A method for producing the nonwoven is also disclosed.

Owner:LIBELTEX

Composite filter media with high surface area fibers

ActiveUS20080105612A1Increased durabilityPromote absorptionOrnamental textile articlesFilament/thread formingComposite mediaPolymer science

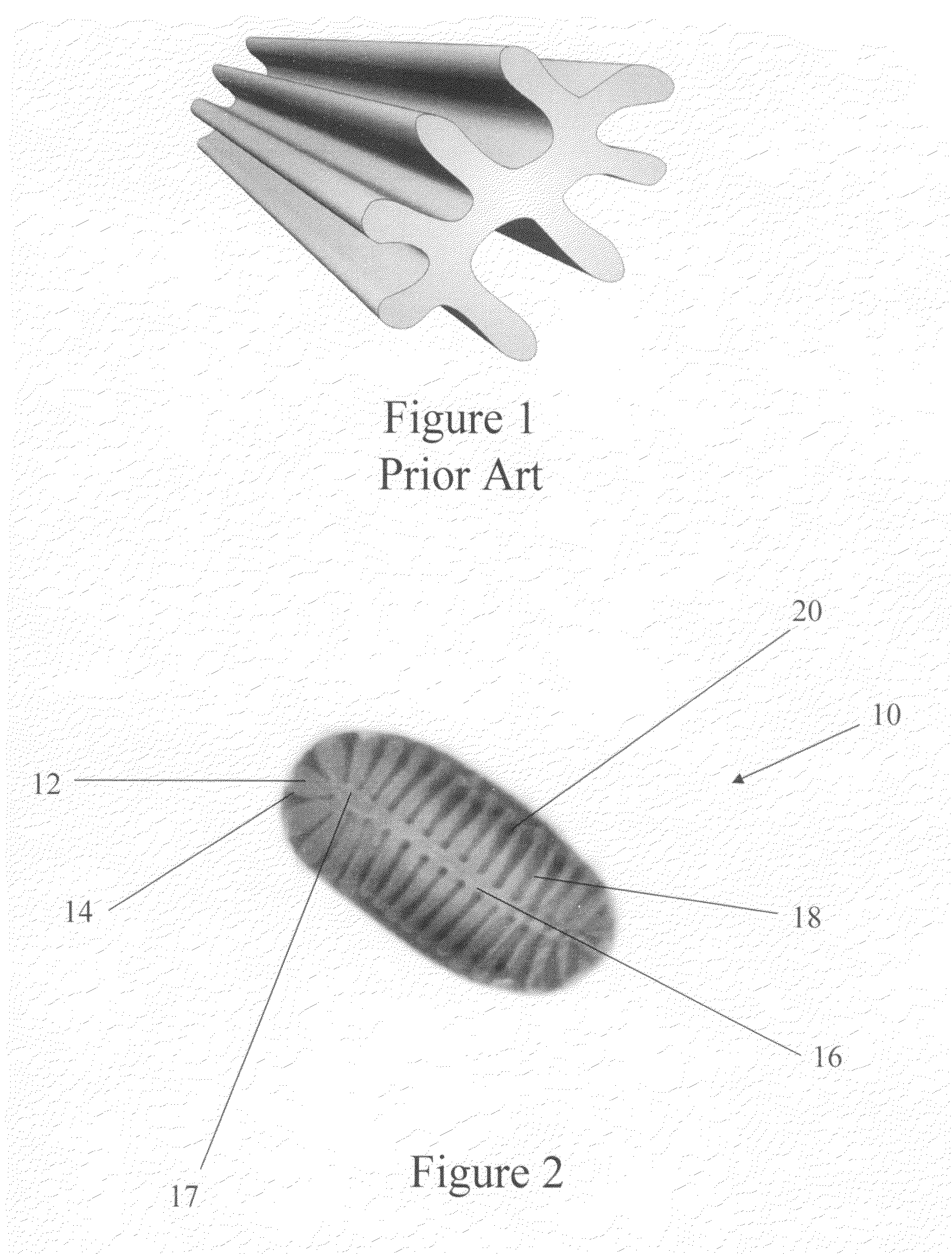

The present invention is directed to a high surface area fibers and an improved filter composite media made from the same. More specifically, the composite media preferably comprises a winged-fiber layer having high surface area fibers for increased absorption and strength and a meltblown layer for additional filtration. In one preferred embodiment the high surface area fibers have a middle region with a plurality of projections that define a plurality of channels, which increases the surface area of the fiber. In one preferred embodiment, the high surface area fiber has a specific surface area of about 140,000 cm2 / g or higher and a denier of about 1.0 to about 2.0. The high surface area fiber of the present invention is made using a bicomponent extrusion process using a thermoplastic polymer and a dissolvable sheath.

Owner:ALLASSO IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com