Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3296results about How to "Small structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

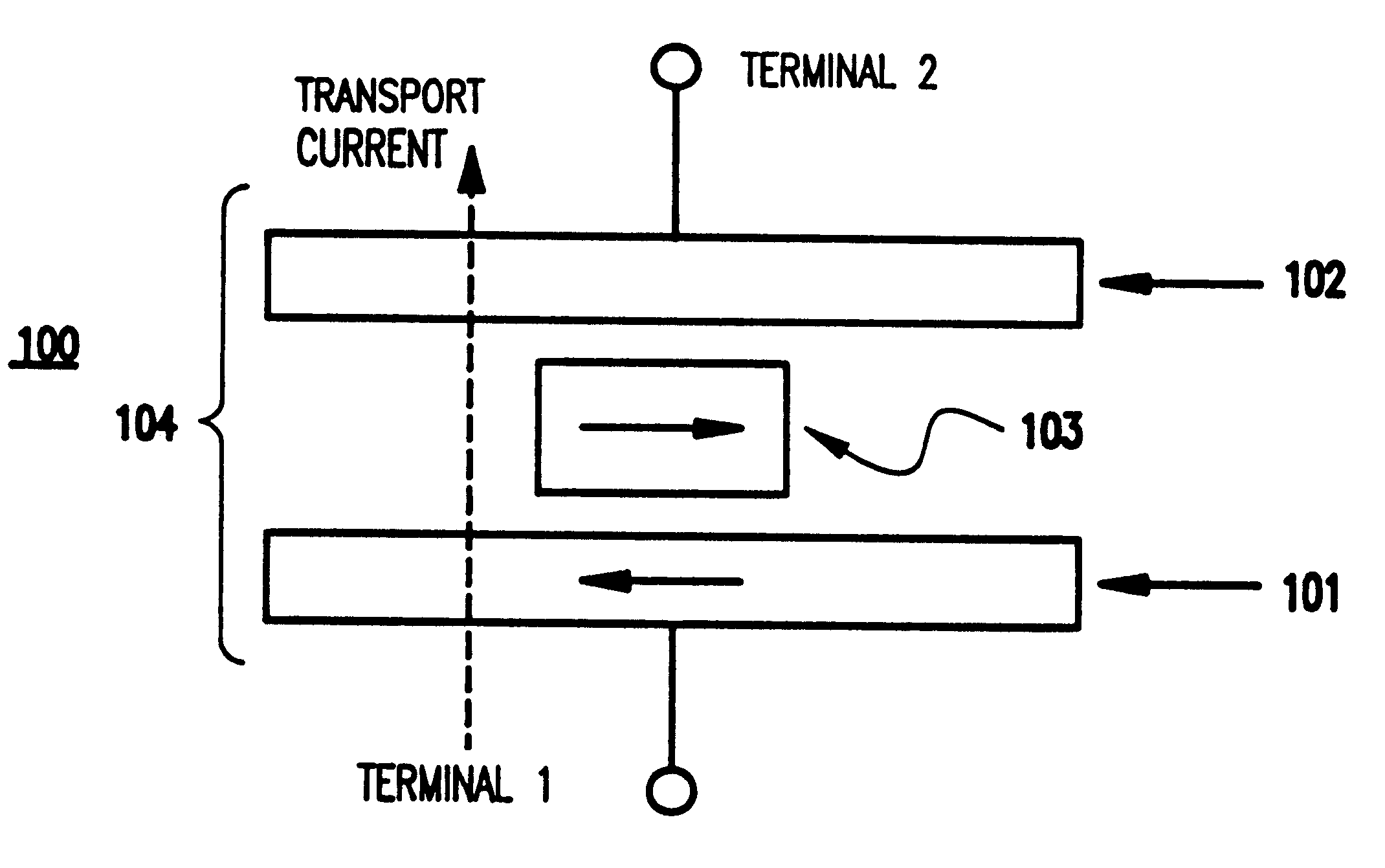

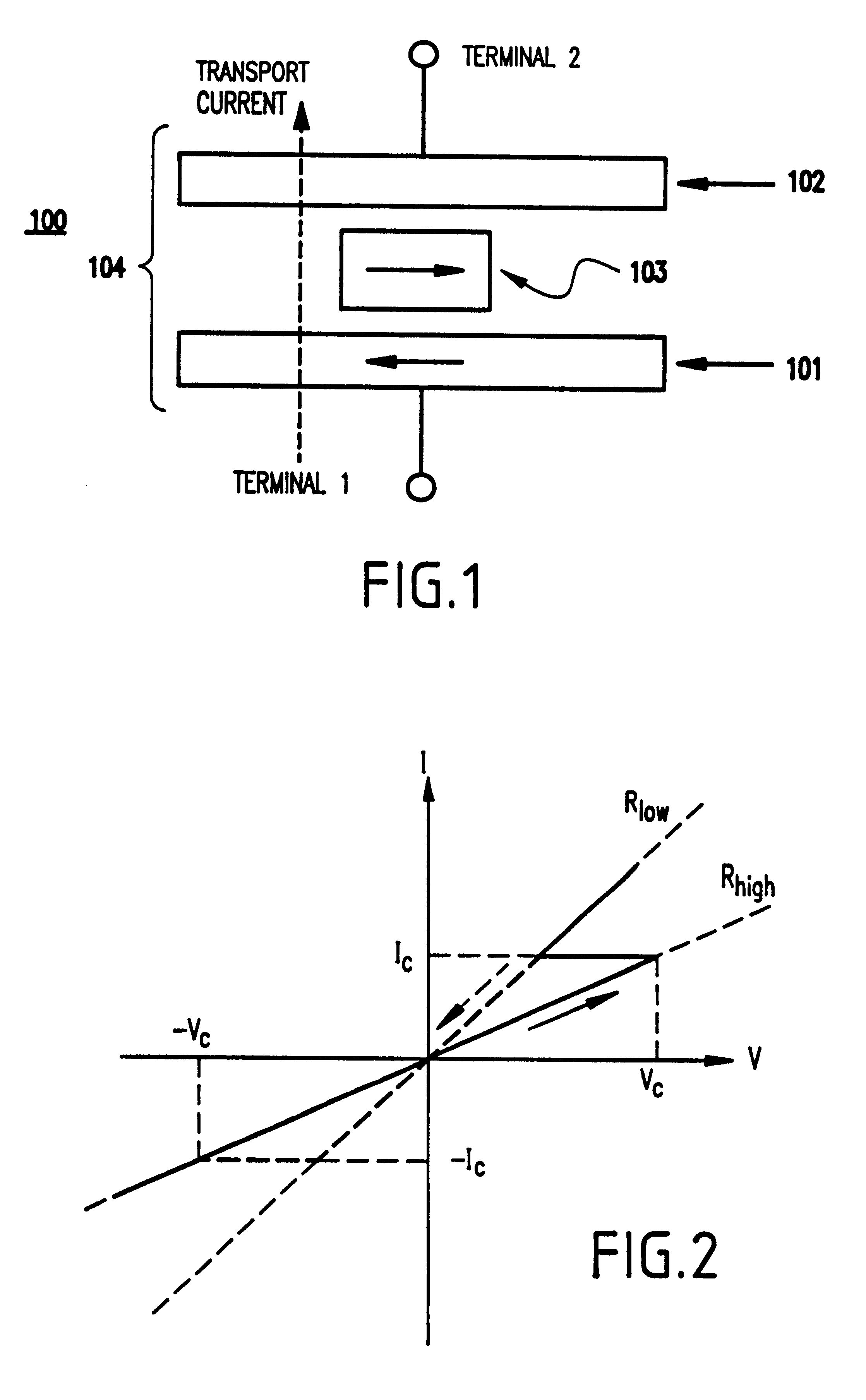

Current-induced magnetic switching device and memory including the same

InactiveUS6256223B1High bulk densitySimpler driving circuitsNanomagnetismMagnetic-field-controlled resistorsNanoparticleConduction band

A magnetic switching device, includes a first electrode, a second electrode, and a nanoparticle having a magnetic moment and being disposed between the first and second electrodes. At least one of the first electrode and the second electrode includes a magnetic material which has a net spin polarization in its conduction band for injecting, into the nanoparticle, an electrical current including a net spin polarization for overcoming the magnetic moment of the nanoparticle upon selection of a predetermined magnitude for the electrical current.

Owner:INT BUSINESS MASCH CORP

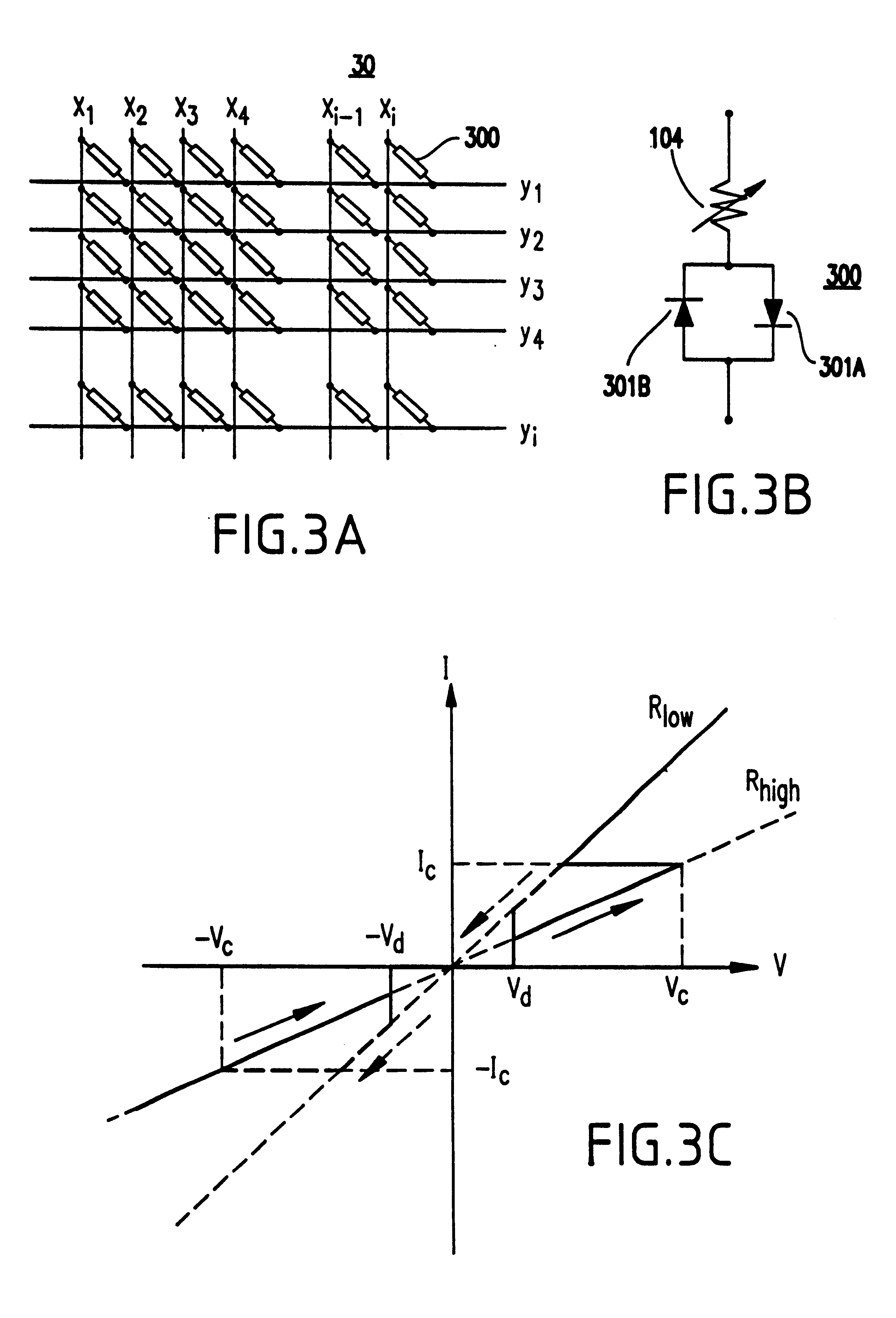

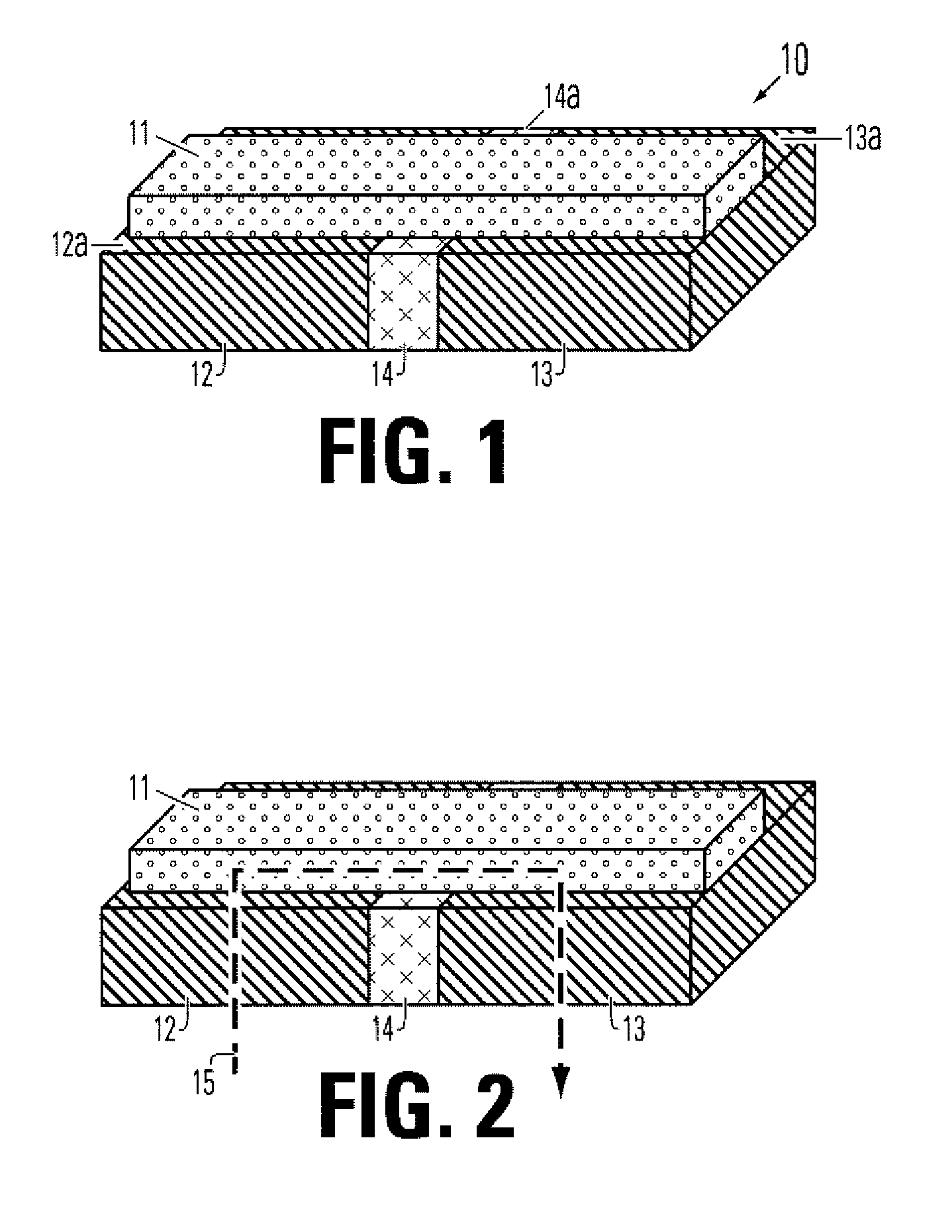

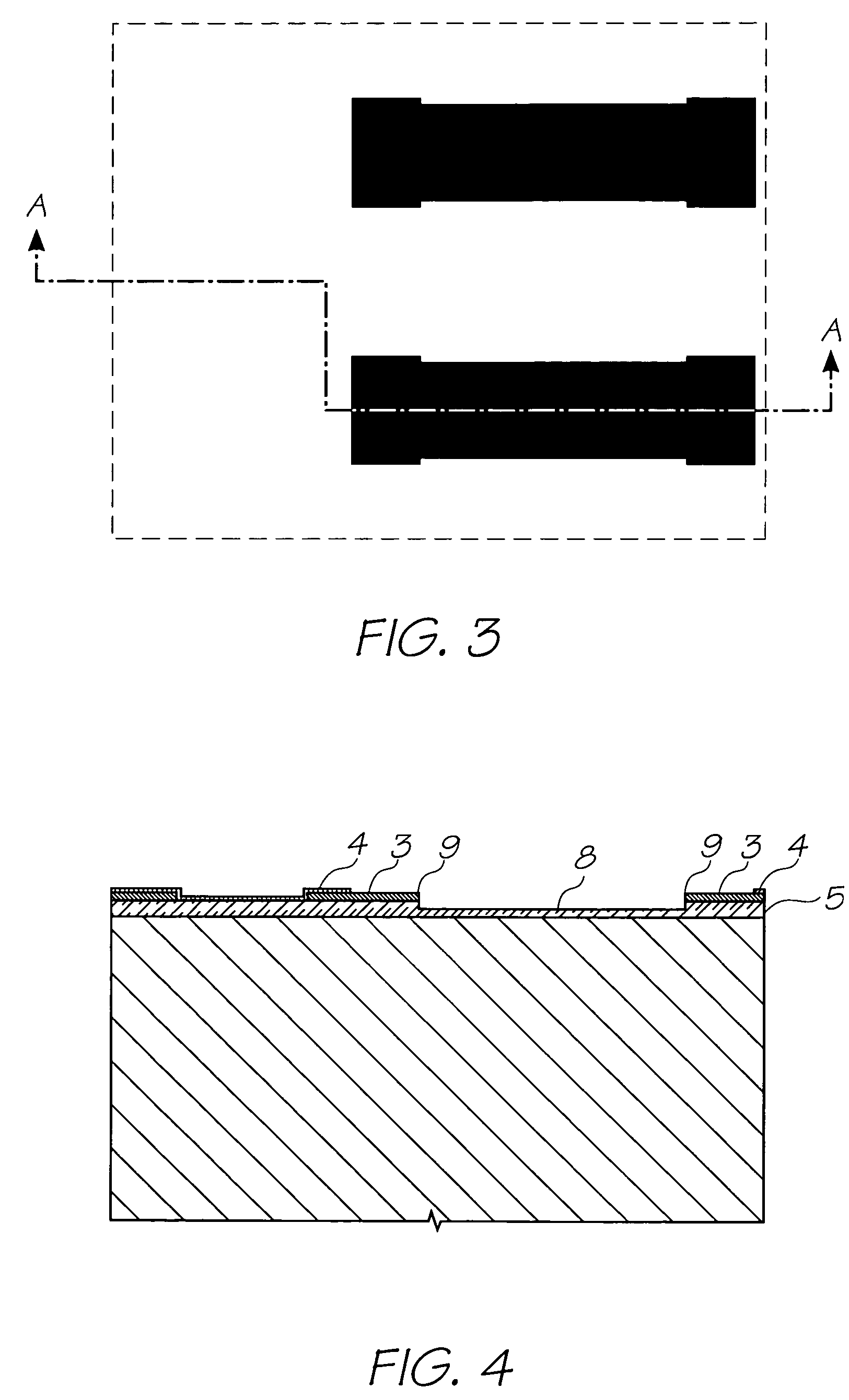

Phase Change Memory Cell and Manufacturing Method

ActiveUS20070121363A1Raise the transition temperatureLower transition temperatureSolid-state devicesDigital storageElectricityPhase-change memory

A phase change memory cell includes first and second electrodes having generally coplanar surfaces spaced apart by a gap and a phase change bridge electrically coupling the first and second electrodes. The phase change bridge may extend over the generally coplanar surfaces and across the gap. The phase change bridge has a higher transition temperature bridge portion and a lower transition temperature portion. The lower transition temperature portion comprises a phase change region which can be transitioned from generally crystalline to generally amorphous states at a lower temperature than the higher transition temperature portion. A method for making a phase change memory cell is also disclosed.

Owner:MACRONIX INT CO LTD

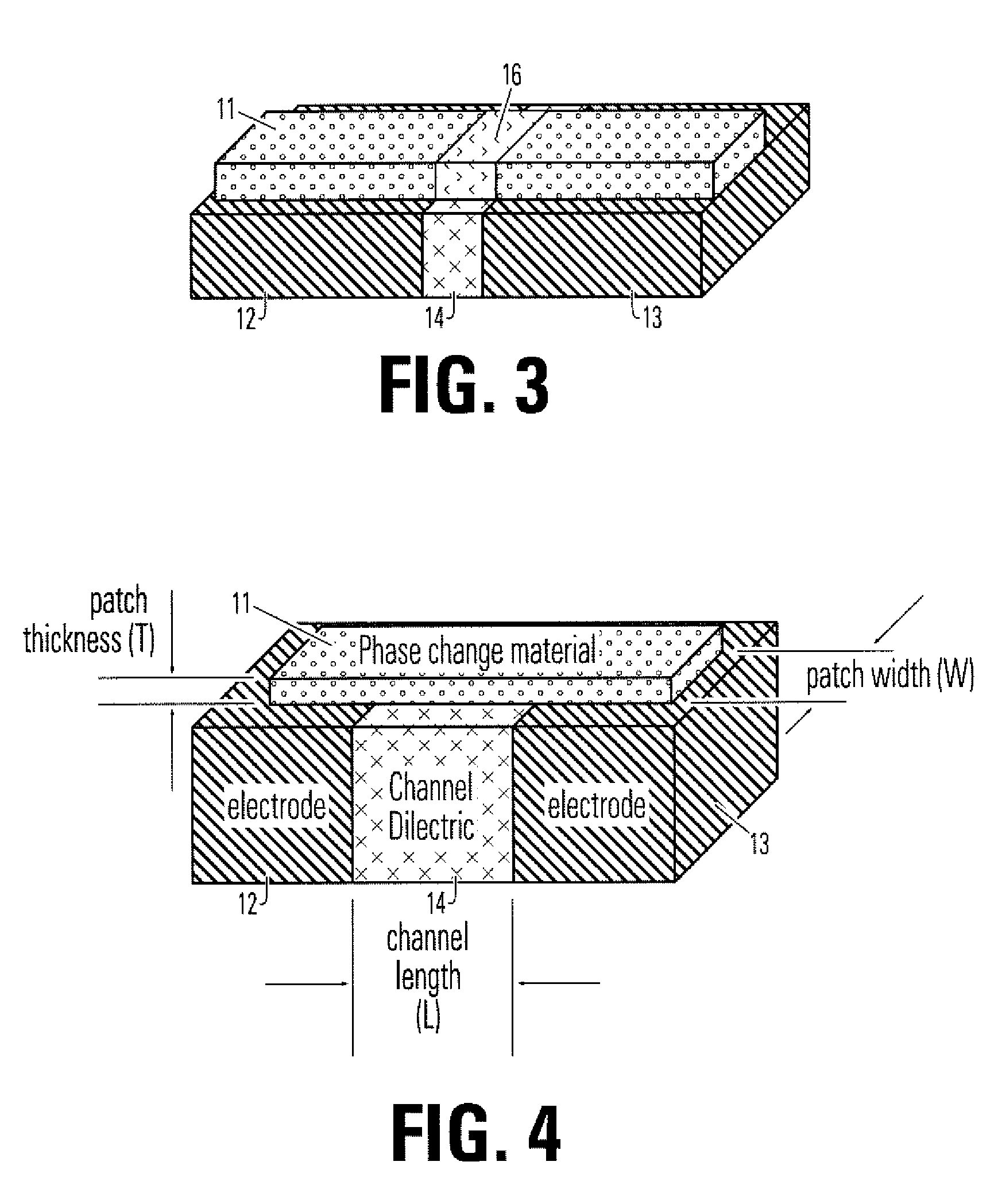

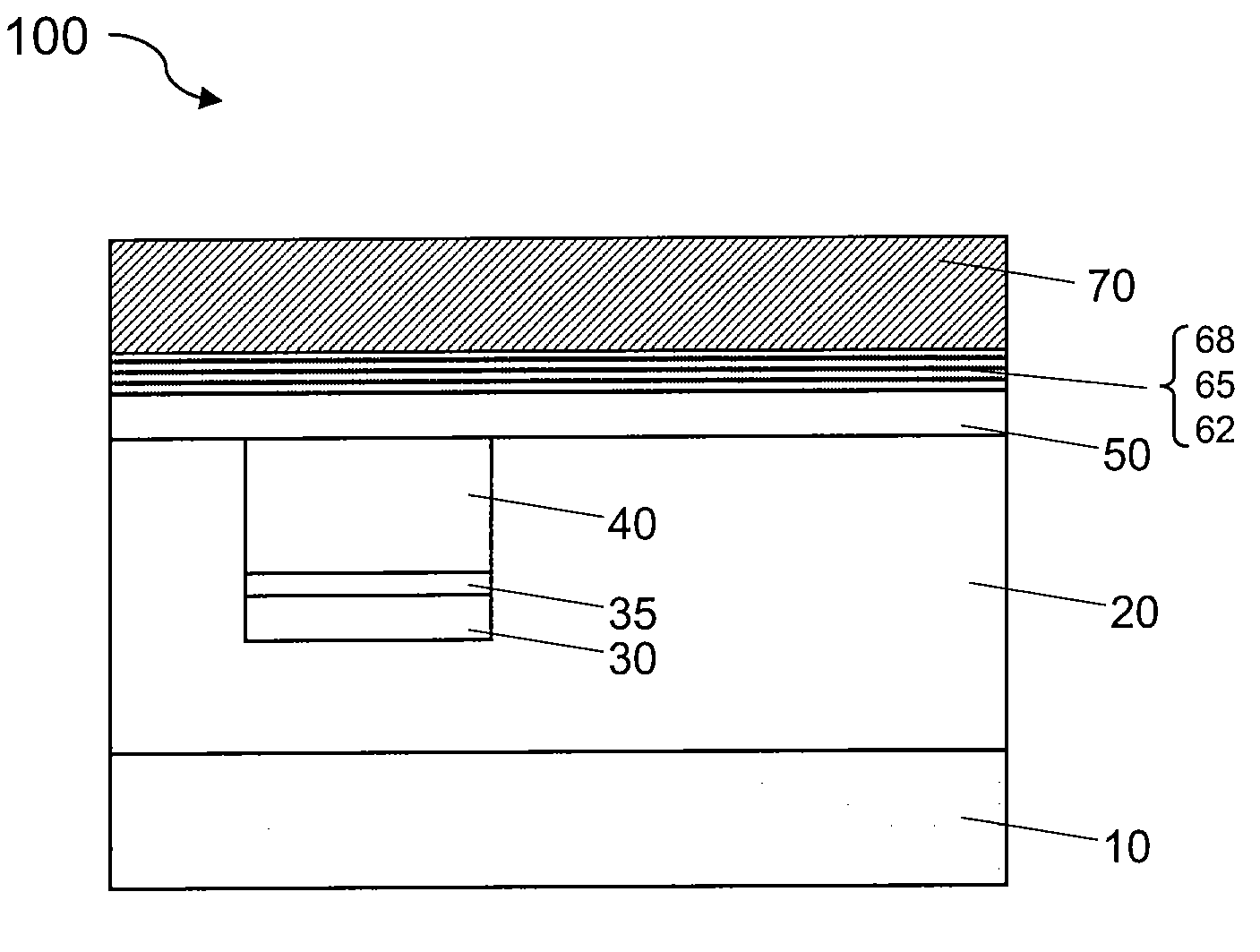

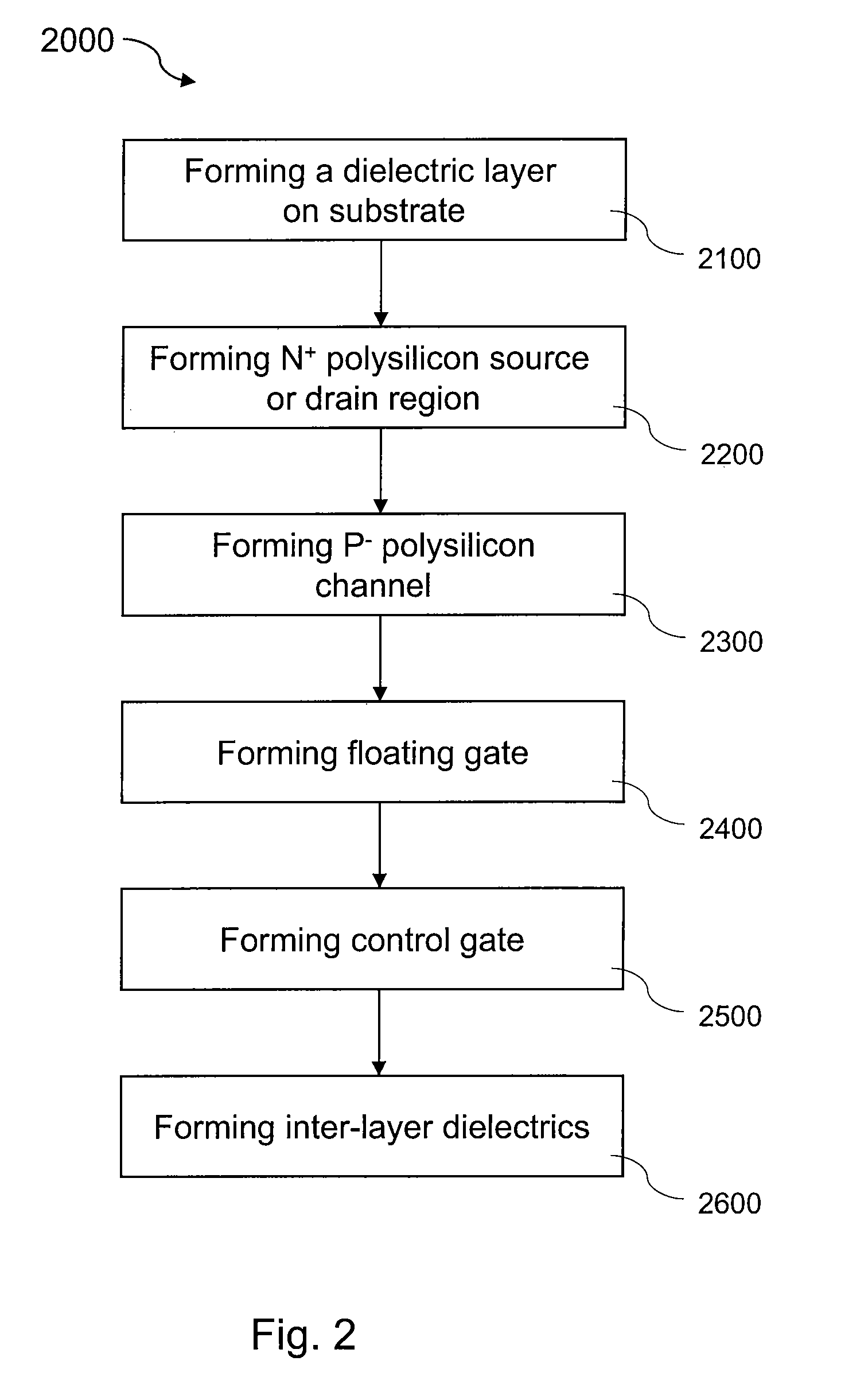

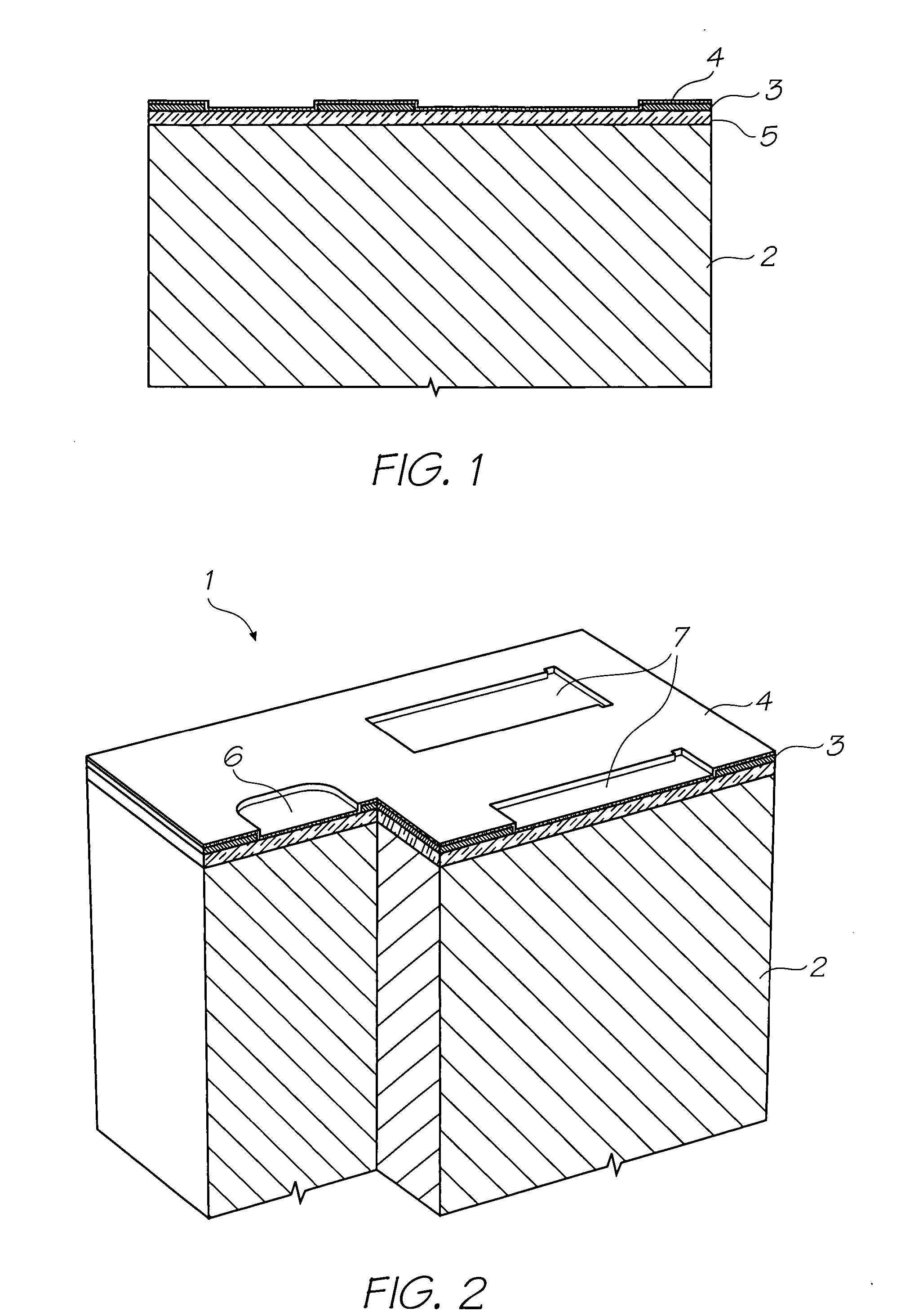

TFT floating gate memory cell structures

ActiveUS20100001282A1Improve reliabilitySmall geometric cell sizeTransistorSemiconductor/solid-state device manufacturingDiffusion barrierDielectric layer

A device having thin-film transistor (TFT) floating gate memory cell structures is provided. The device includes a substrate, a dielectric layer on the substrate, and one or more source or drain regions being embedded in the dielectric layer. the dielectric layer being associated with a first surface. Each of the one or more source or drain regions includes an N+ polysilicon layer on a diffusion barrier layer which is on a first conductive layer. The N+ polysilicon layer has a second surface substantially co-planar with the first surface. Additionally, the device includes a P− polysilicon layer overlying the co-planar surface and a floating gate on the P− polysilicon layer. The floating gate is a low-pressure CVD-deposited silicon layer sandwiched by a bottom oxide tunnel layer and an upper oxide block layer. Moreover, the device includes at least one control gate made of a P+ polysilicon layer overlying the upper oxide block layer. A method of making the same memory cell structure is provided and can be repeated to integrate the structure three-dimensionally.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

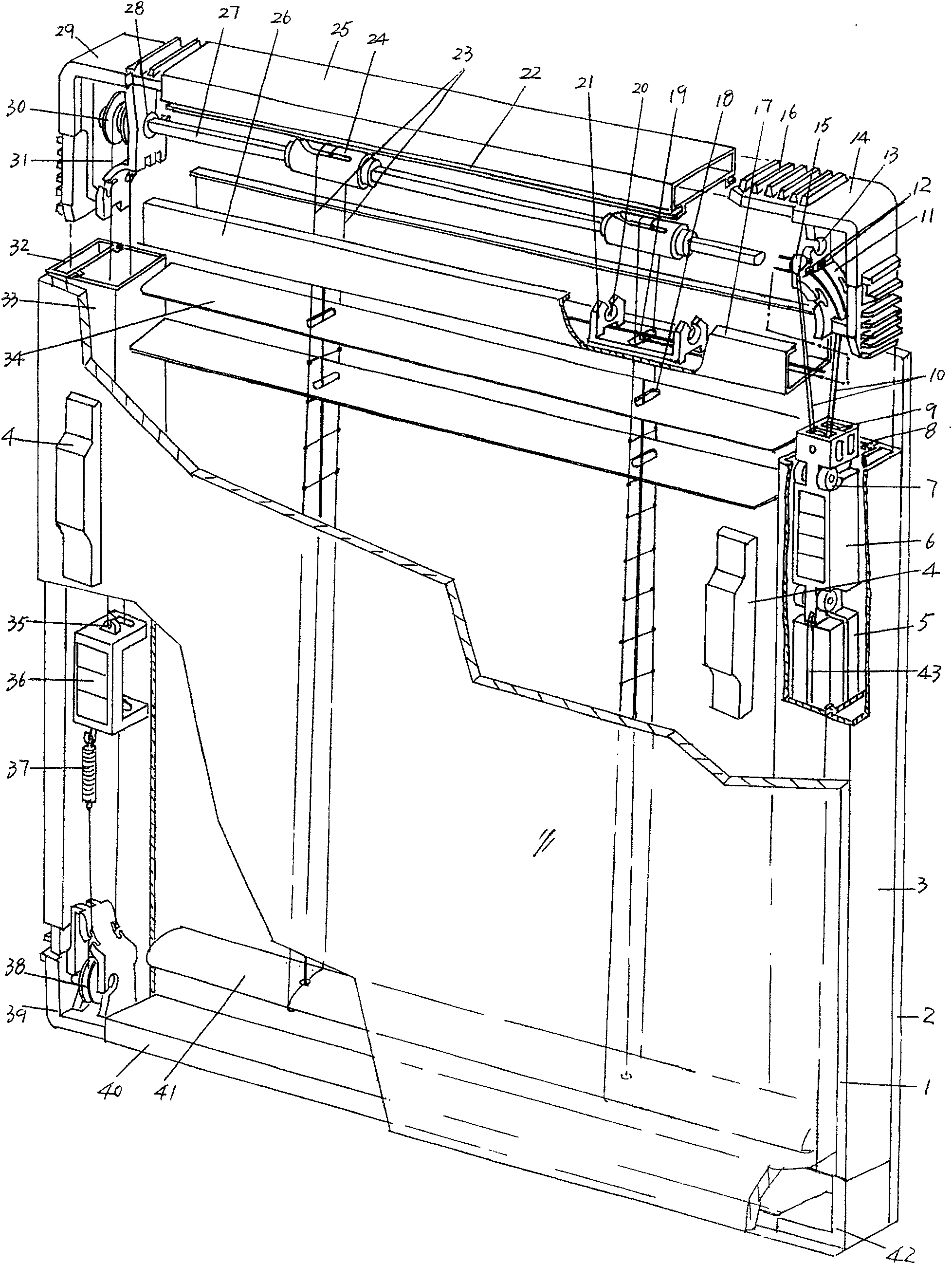

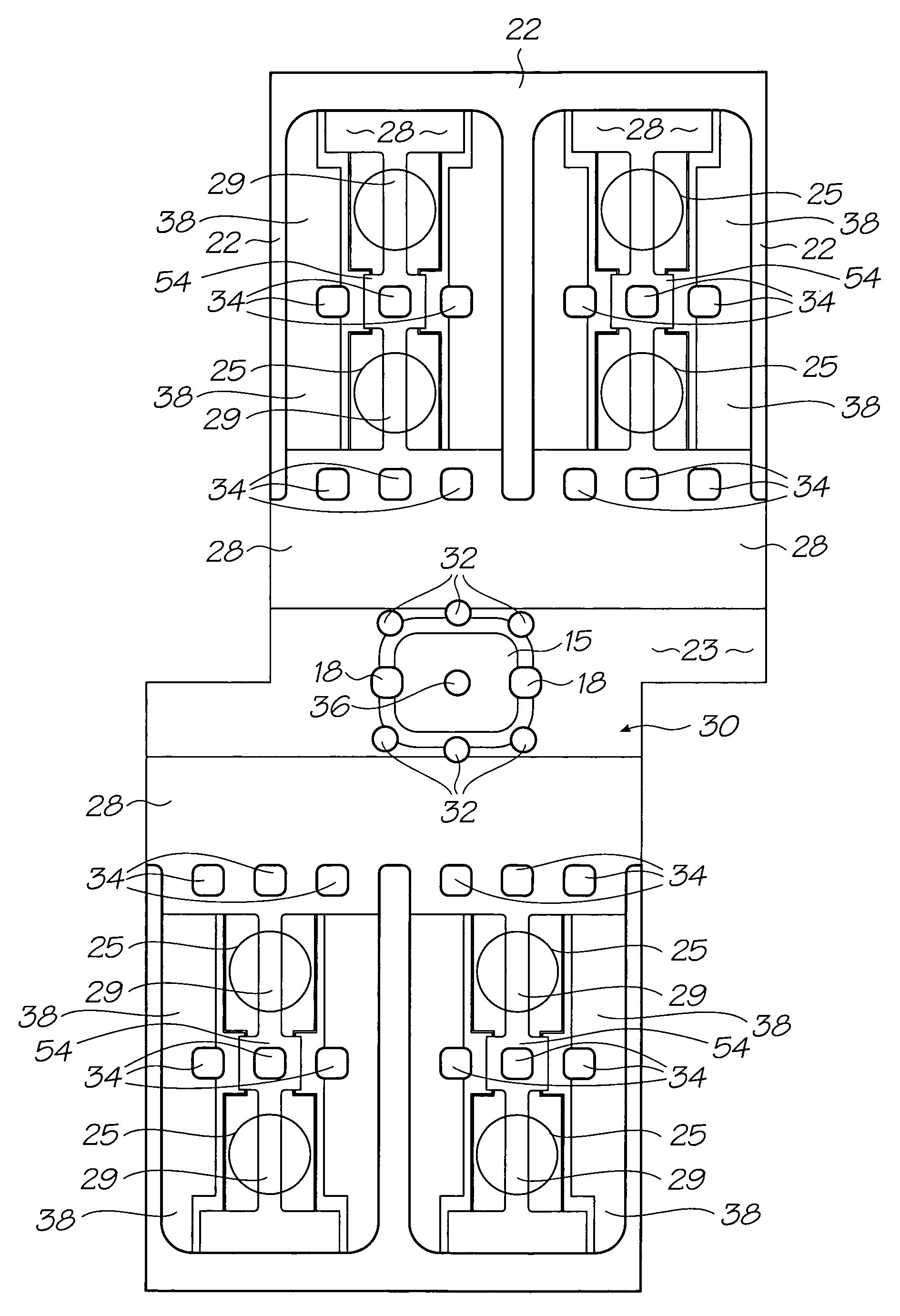

Structure-improved window shutter in hollow glass

ActiveCN100535378CImplement the flipping actionReduce manufacturing costLight protection screensWindow shutterEngineering

Owner:江苏中诚建材集团有限公司

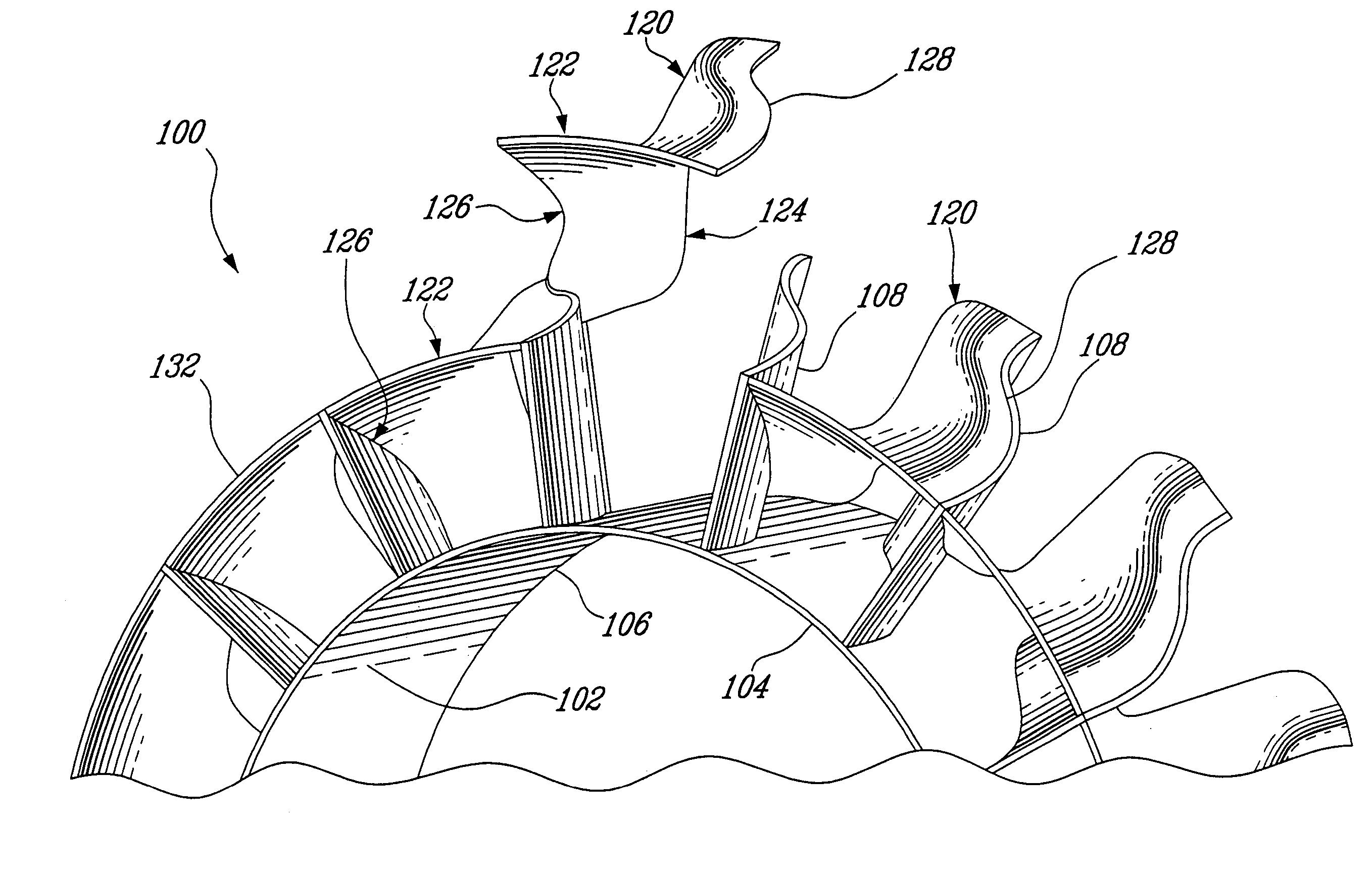

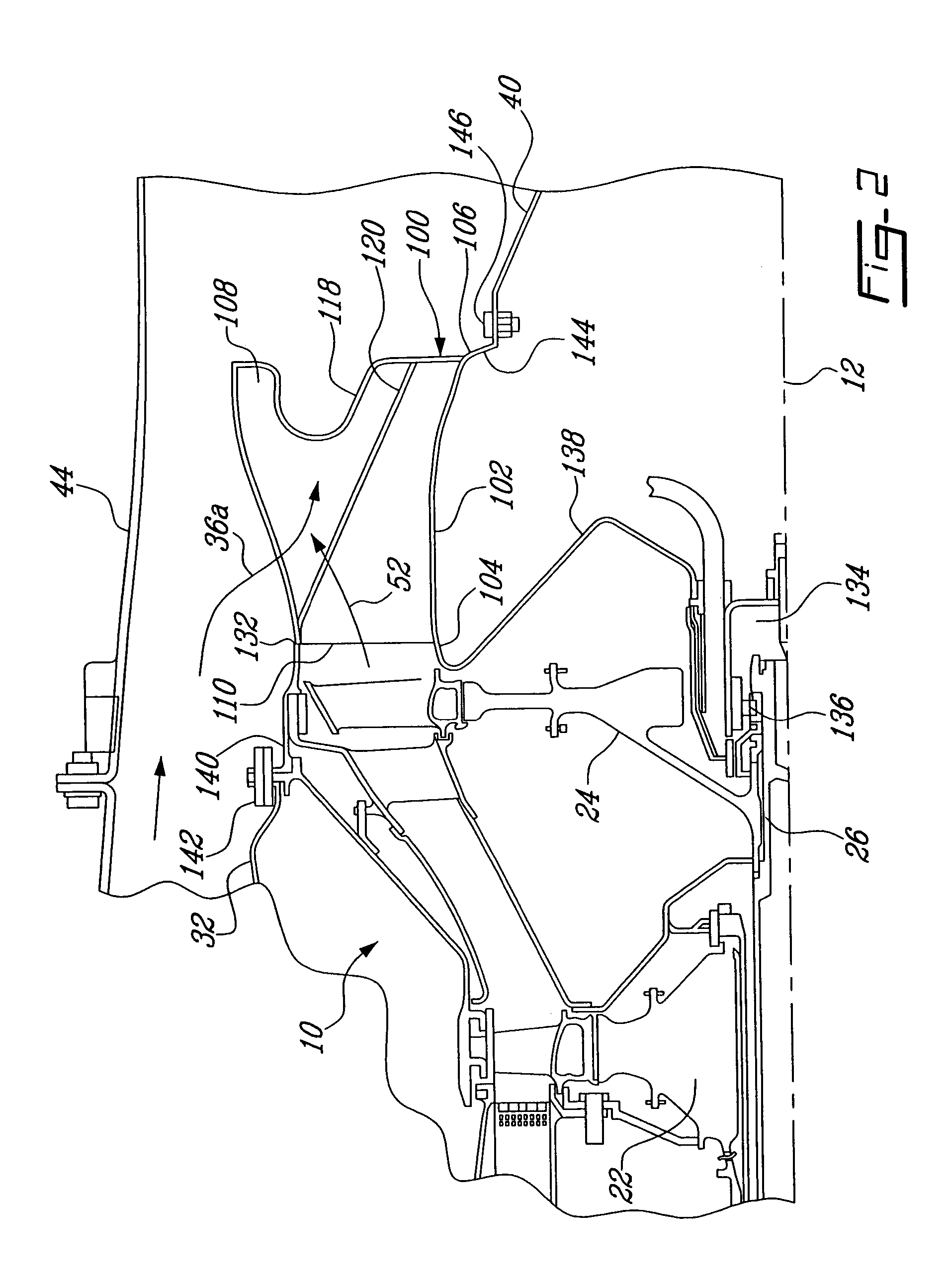

Combined exhaust duct and mixer for a gas turbine engine

ActiveUS7043898B2Low costSmall structureWriting implementsMetal-working apparatusExhaust gasGas turbines

A gas turbine engine including a gas exhaust duct assembly which comprises an annular shroud forming at least a section of an inner wall of a gas exhaust duct, a plurality of strut members radially projecting from the shroud, and a plurality of insert members. The strut members are disposed in a circumferentially, substantially equally spaced-apart relationship, and extend in a substantially axial direction. The insert members each define a circumferential section of an outer wall of the gas exhaust duct and are positioned in a space between adjacent strut members, and are secured to same. The gas exhaust duct is thereby defined between inner surfaces of the insert members and the outer surface of the shroud, and is circumferentially divided by the respective strut members, for directing exhaust gases rearwardly in an axial direction, meanwhile surrounding flow passages are defined by outer surfaces of the insert members and the strut members in combination, for directing surrounding air flows rearwardly in an axial, radial and inward direction.

Owner:PRATT & WHITNEY CANADA CORP

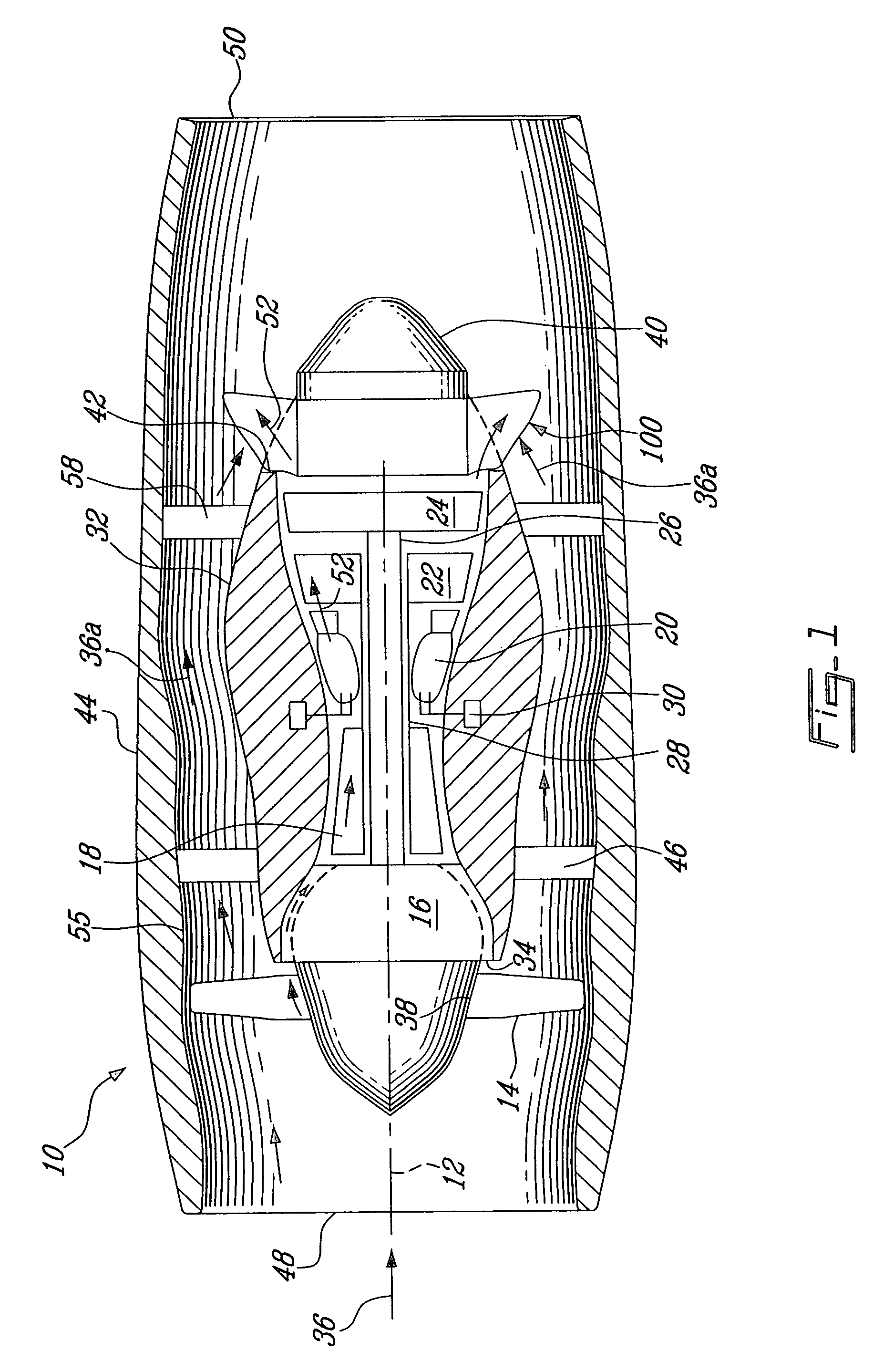

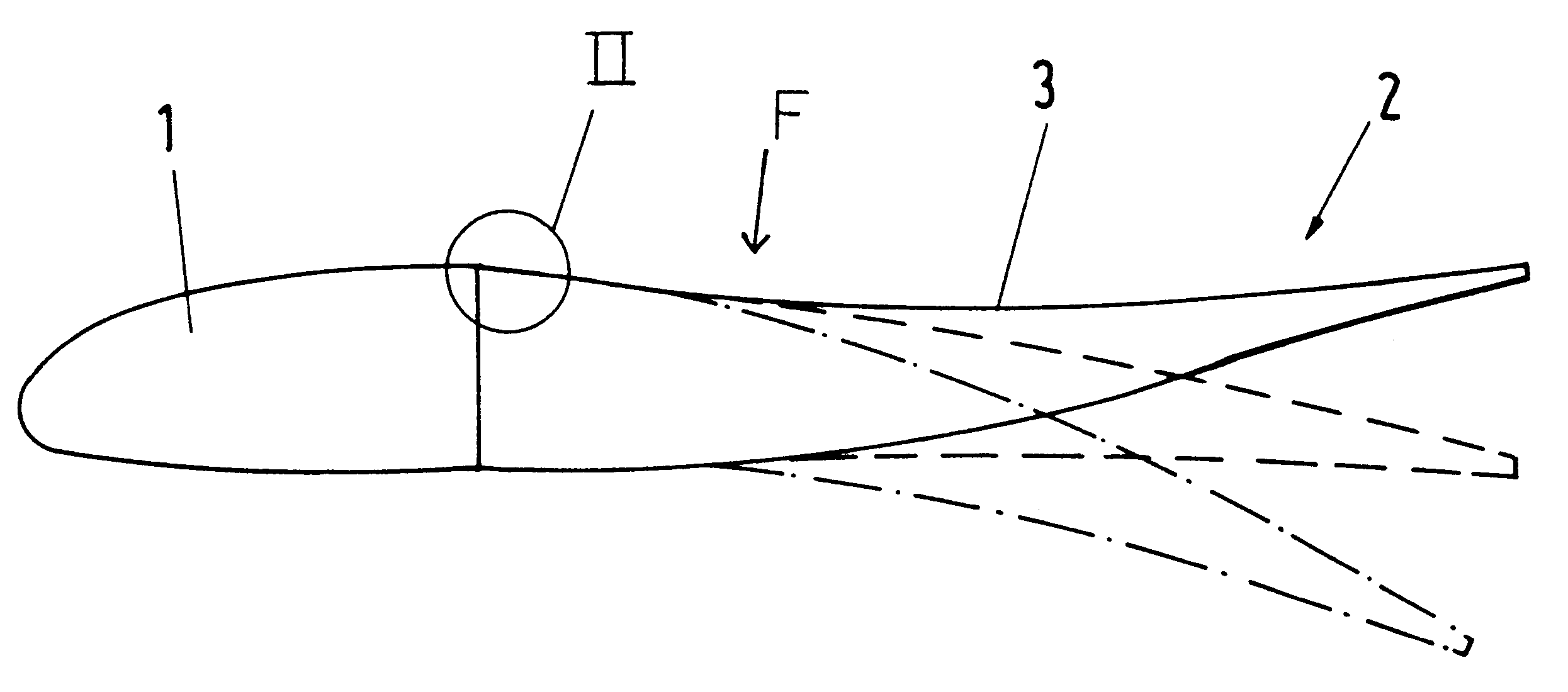

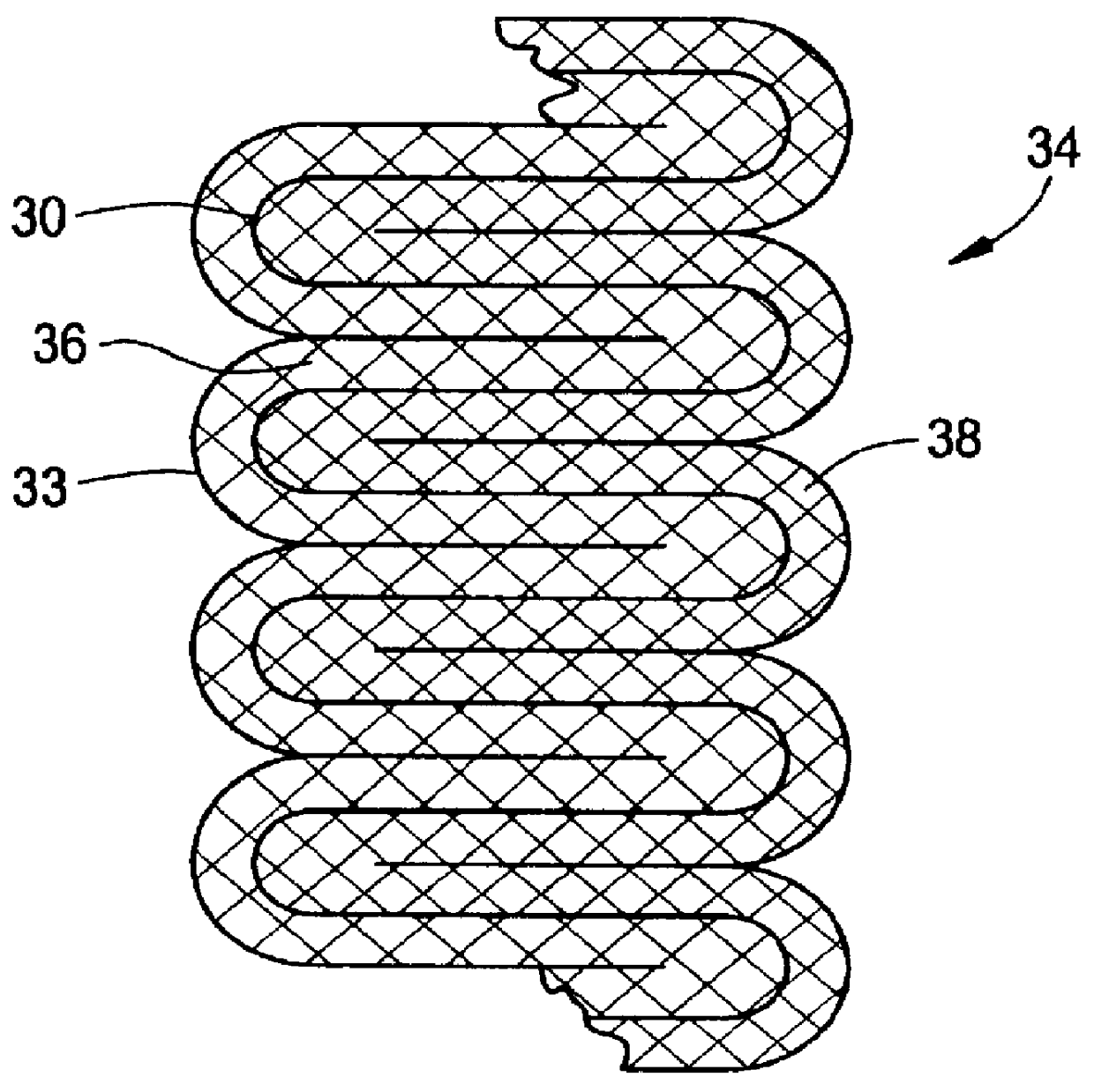

Load carrying structure having variable flexibility

InactiveUS6182929B1Simple wayReduce stiffnessPropellersPump componentsShape-memory alloyOperating temperature range

A load carrying structure having a selectively rigid or flexible characteristic includes a thermoplastic material (7) having a softening temperature above the operating temperature range of the load carrying structure, and a heating arrangement (8) provided to selectively heat the thermoplastic material to above its softening temperature. During normal operation, the thermoplastic material is in a rigid state and the overall load carrying structure is rigid to the prevailing loads. By activating the heating arrangement to heat the thermoplastic material to at least its softening temperature, the thermoplastic material and therewith the load carrying structure becomes flexible so that it may be deformed to a different configuration by applying a deforming load. Once the desired deformed configuration is achieved, the heating arrangement is deactivated, and the thermoplastic material is allowed to cool below its softening temperature so that it once again becomes rigid and rigidly fixes the new deformed configuration. The deforming force may be applied by any actuating mechanism, or for example by arranging shape memory alloys in connection with the thermoplastic material.

Owner:INST FUER VERBUNDWERKSTOFFE GMBH +1

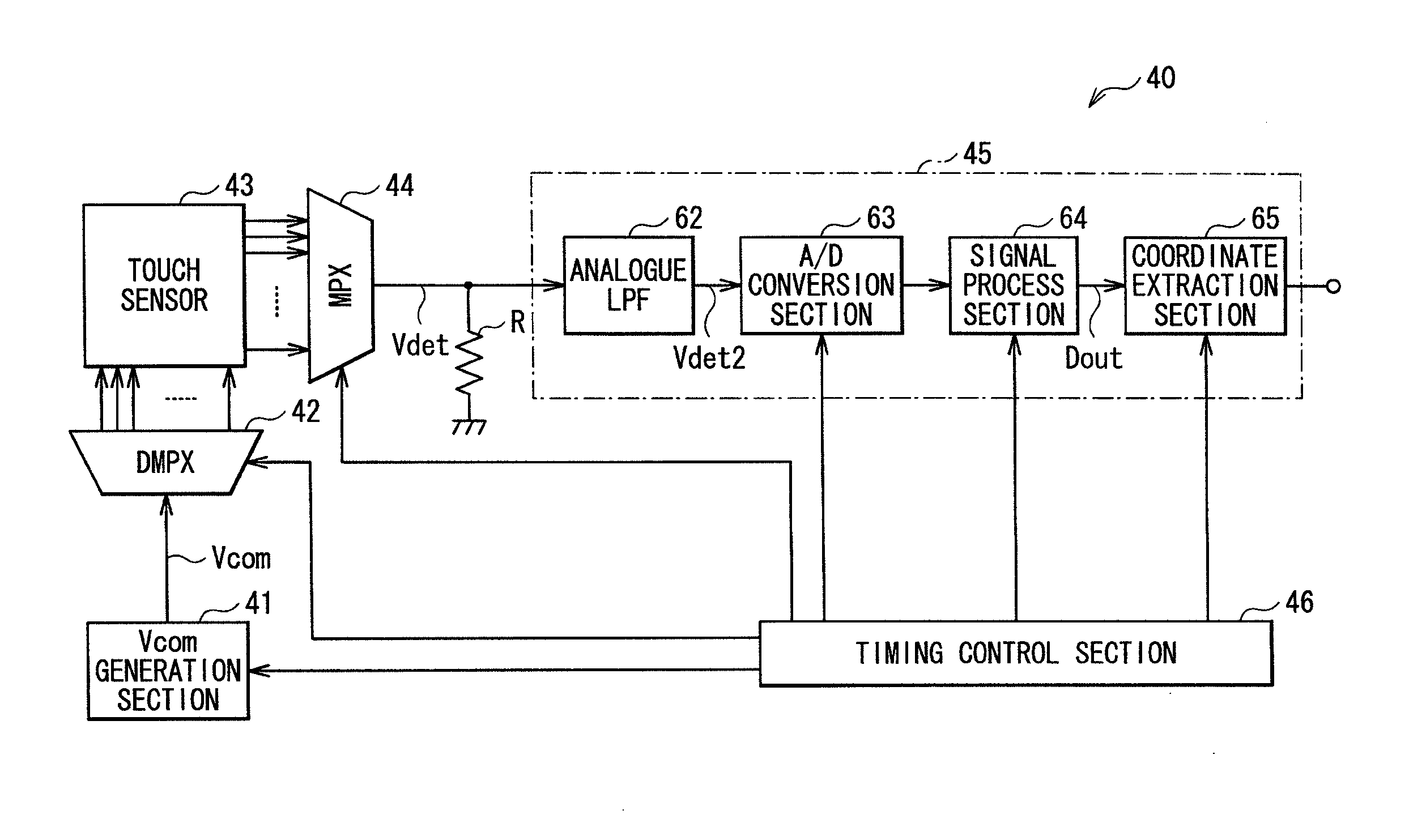

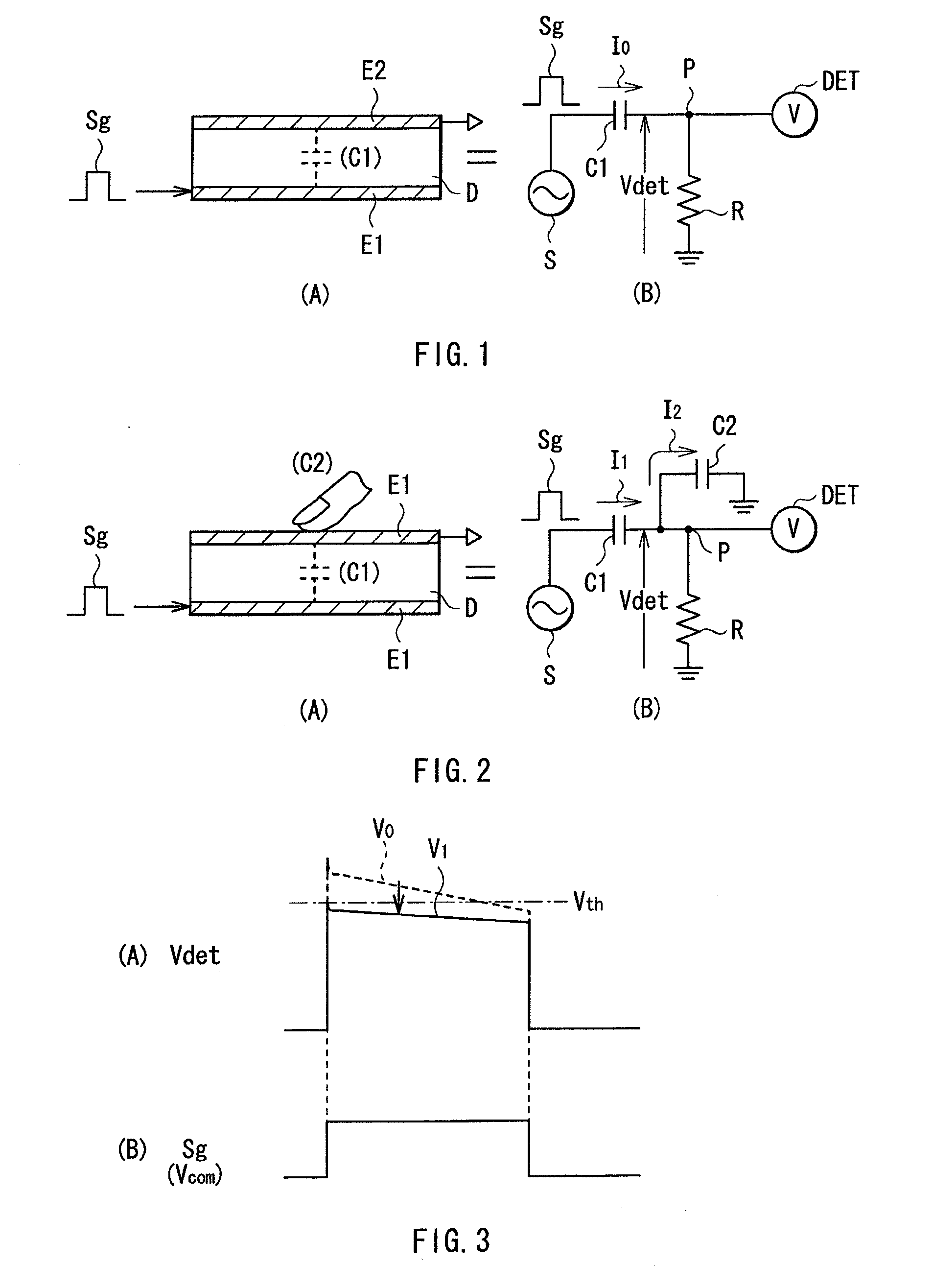

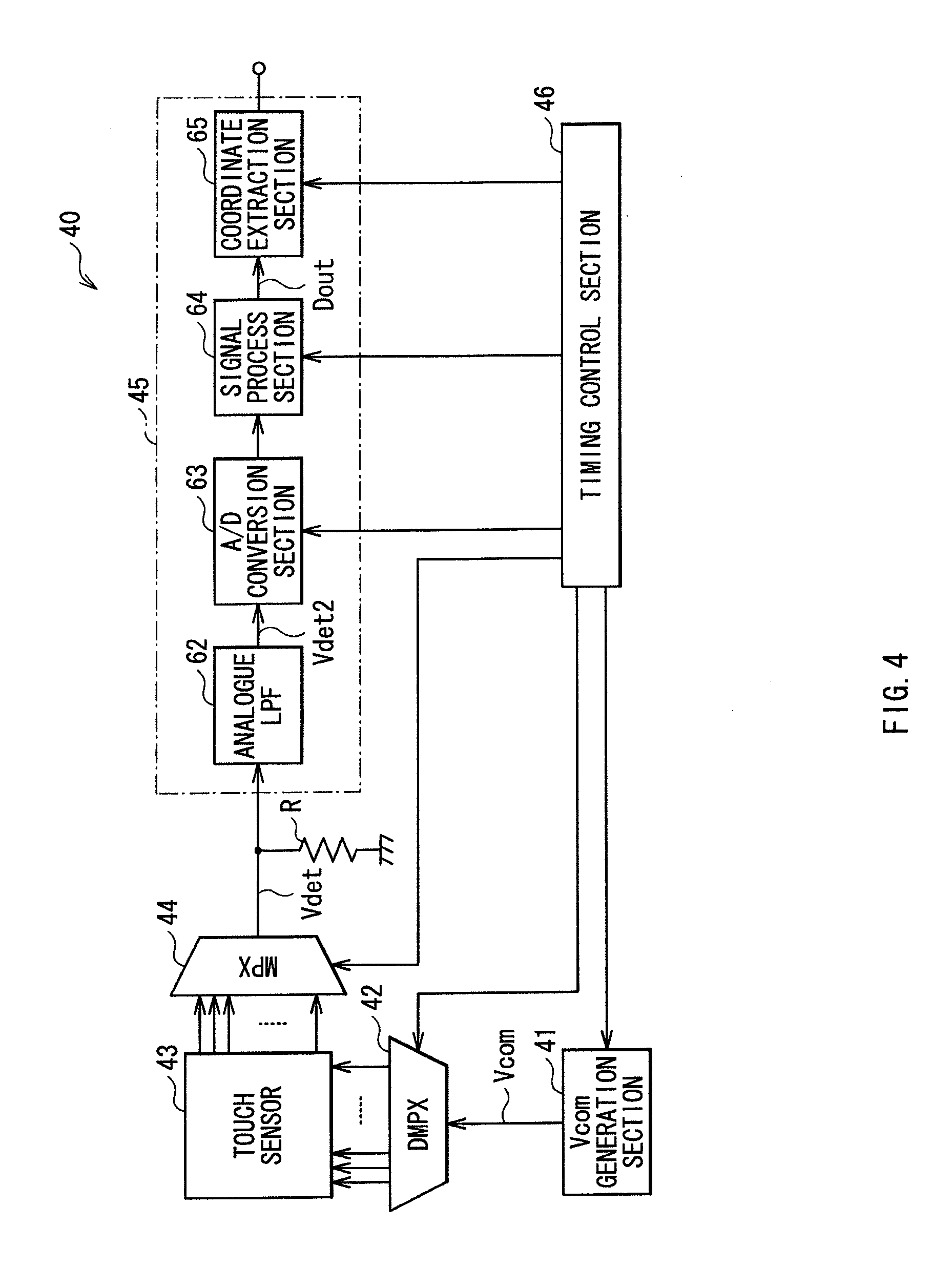

Capacitive touch panel and display device with touch detection function

InactiveUS20110134076A1Reduce the necessary timeImprove performanceInput/output processes for data processingDisplay deviceTouch panel

A capacitive touch panel capable of reducing a disturbance noise and reducing touch detection time with a simple structure is obtained. The capacitive touch panel includes: a plurality of drive electrodes each to which a drive signal for touch detection is applied; a plurality of touch detection electrodes arranged to intersect the plurality of drive electrodes, and each outputting a detection signal synchronized with the drive signal; a first sampling circuit (A / D conversion circuits 72 and 73) extracting a first series of sampling signal including a signal component with first level and a noise component, from the detection signal; a second sampling circuit (A / D conversion circuits 75 and 76) extracting a second series of sampling signal including a signal component with second level different from the first level and the noise component, from the detection signal; a filter circuit (digital LPFs 81 and 82) performing a high range cut process on the first series of sampling signal and the second series of sampling signal; and a computation circuit (a subtraction circuit 90) determining a signal for touch detection based on an output of the filter circuit.

Owner:JAPAN DISPLAY WEST

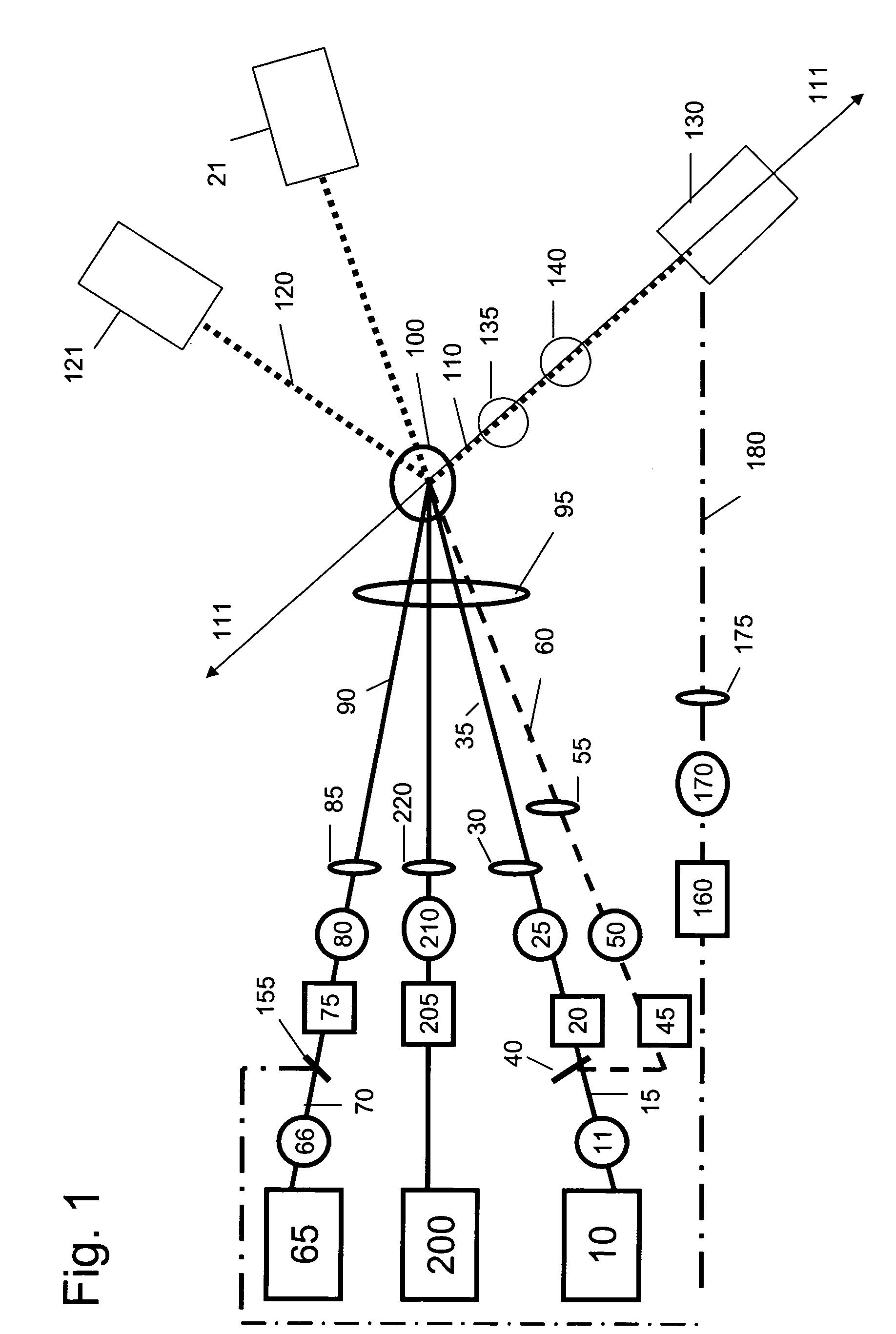

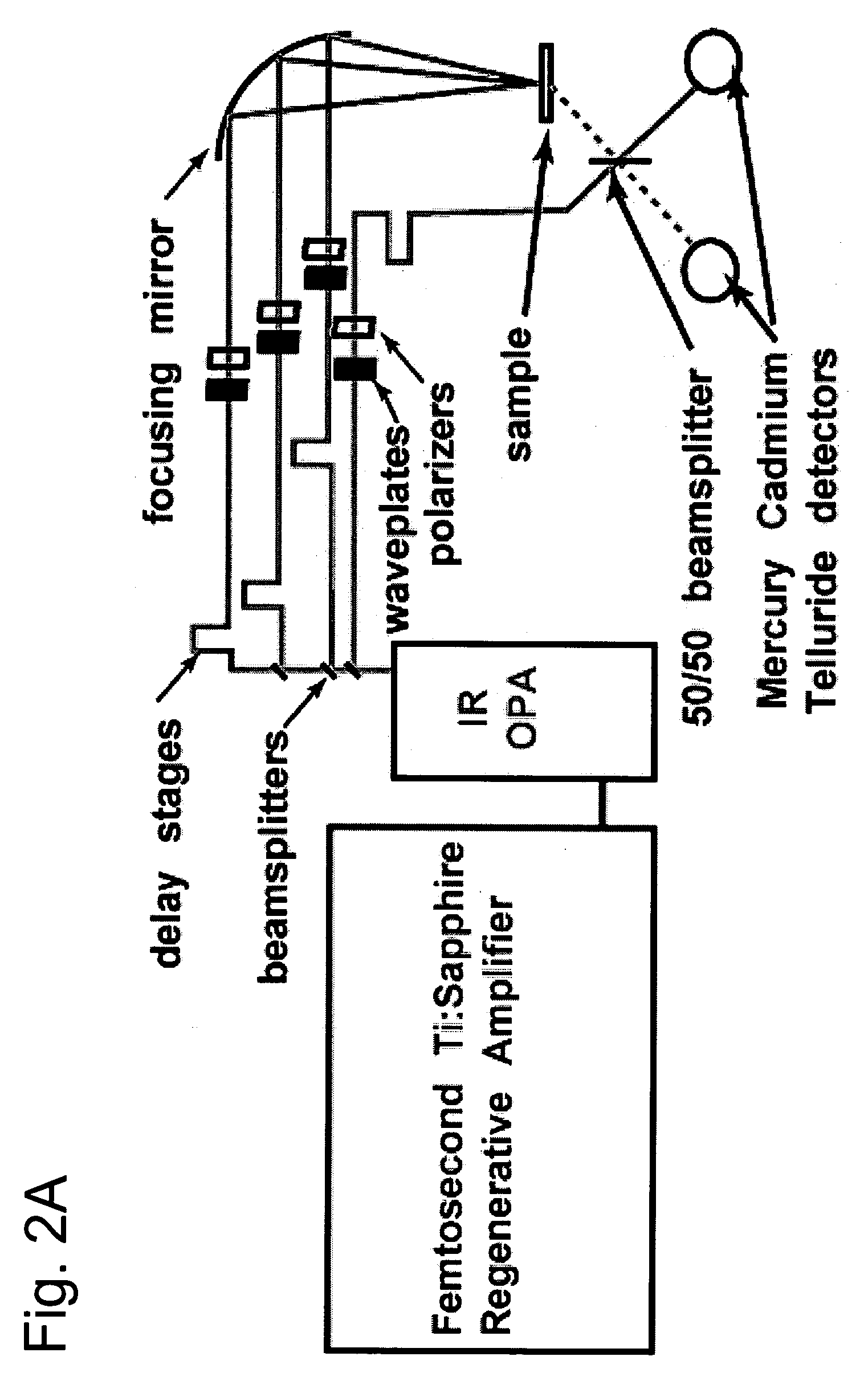

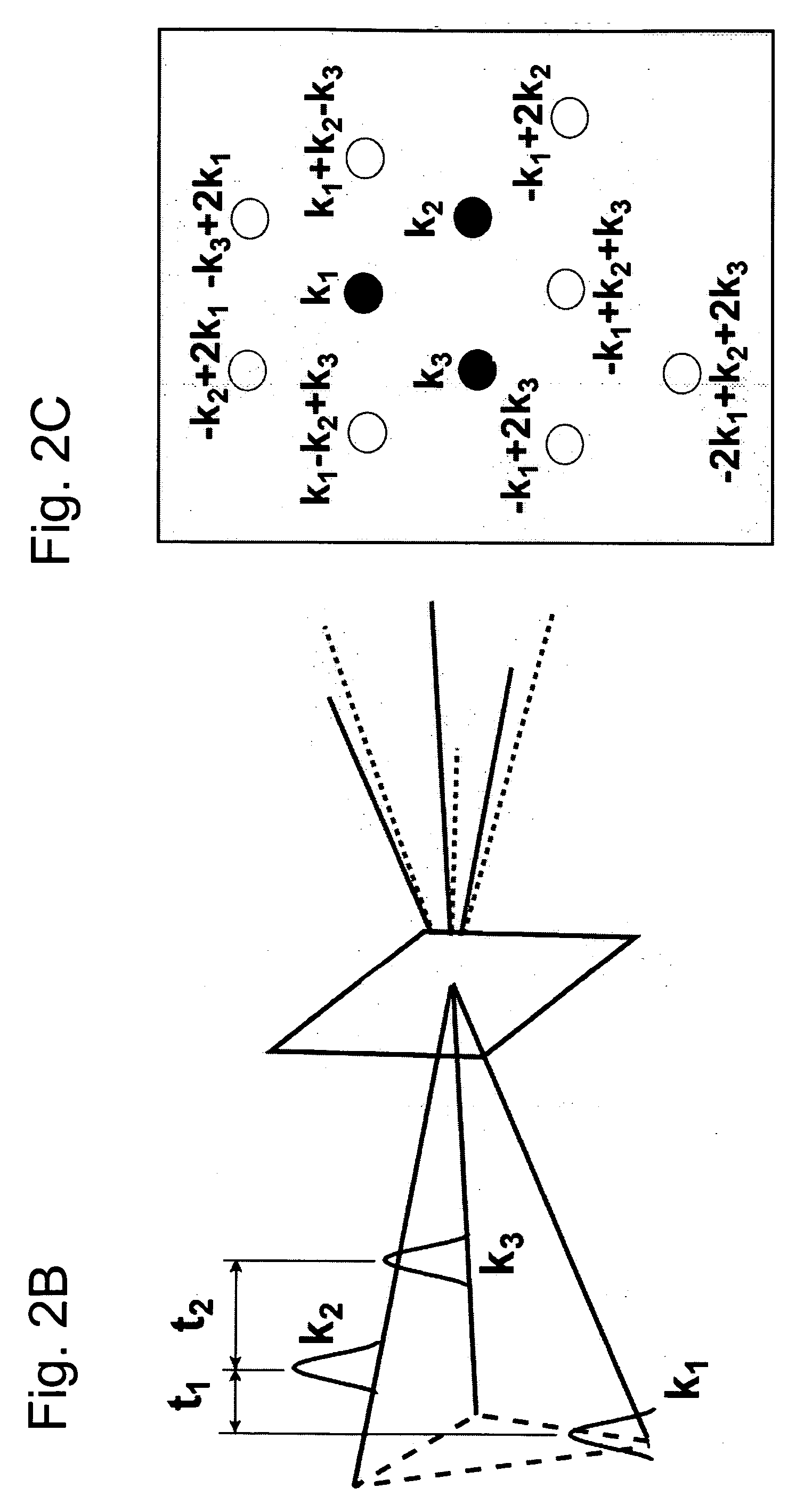

Nonlinear spectroscopic methods for identifying and characterizing molecular interactions

ActiveUS20060063188A1Remarkable effectSmall structureSugar derivativesPeptide/protein ingredientsNonlinear spectroscopyEquilibrium constant

This invention provides methods and devices for identifying and / or characterizing interactions involving molecules, including, but not limited to, identifying and / or characterizing interactions involving target molecules and candidate molecules. The present invention provides methods using multidimensional infrared spectrographic techniques, such as four wave mixing and pump-probe techniques, for identifying interactions involving biomolecules and therapeutic candidate molecules, and for characterizing such interactions in terms of their binding coefficients and / or equilibrium constants.

Owner:WISCONSIN ALUMNI RES FOUND

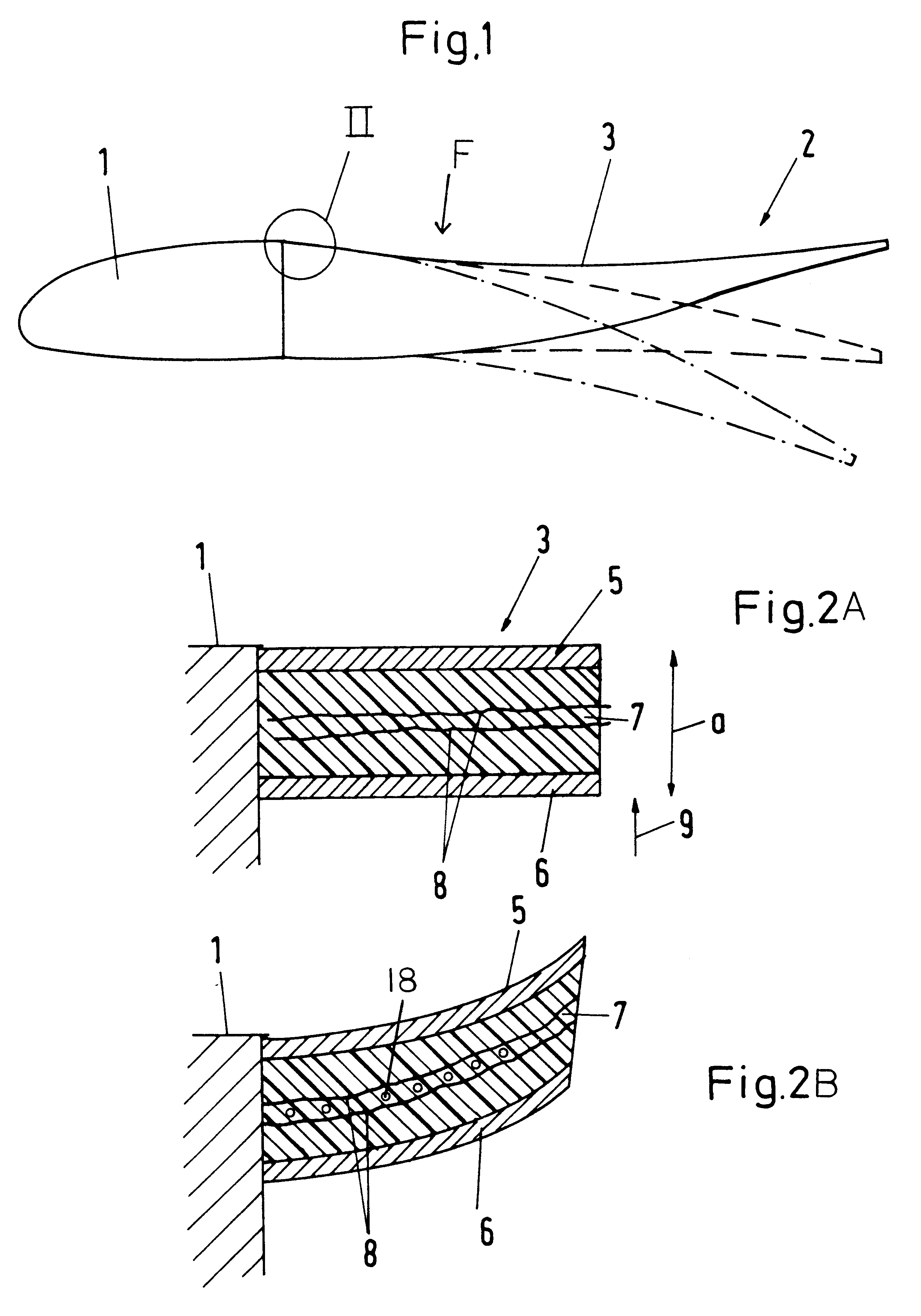

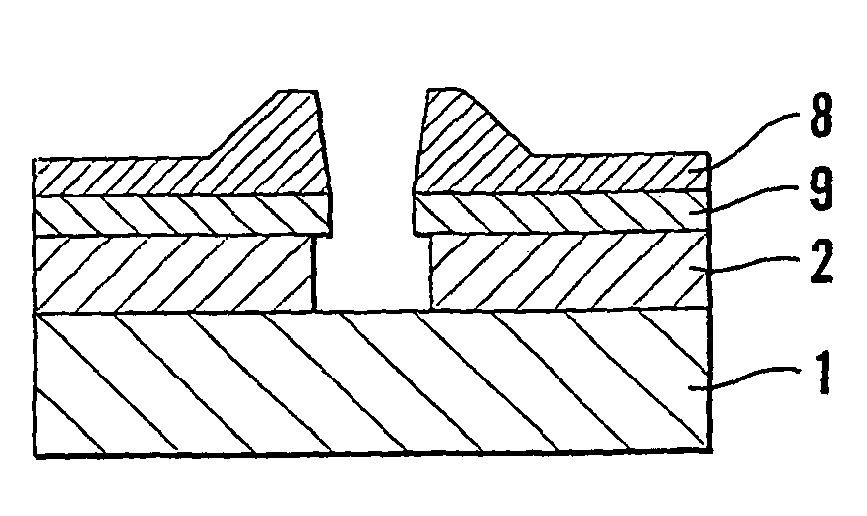

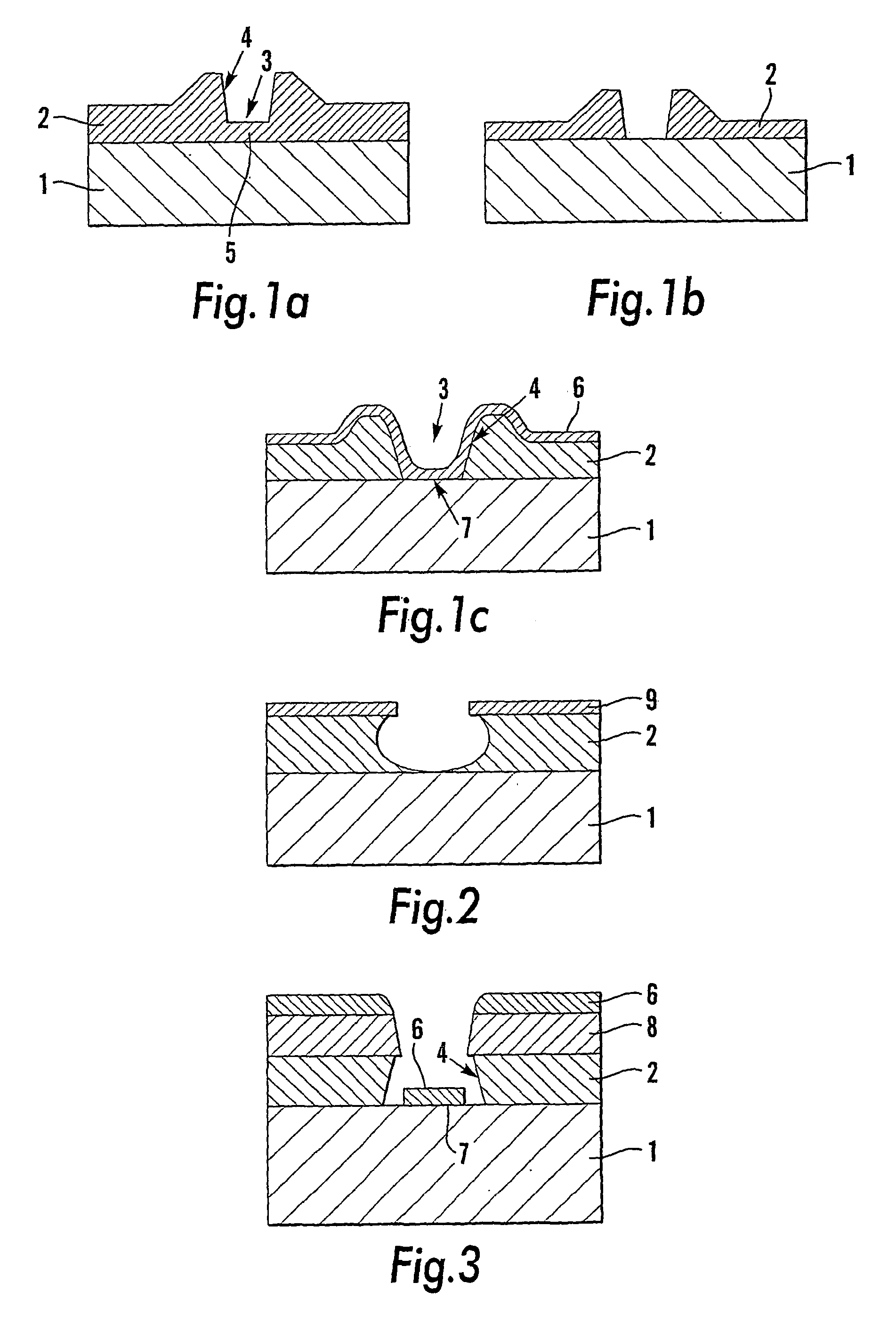

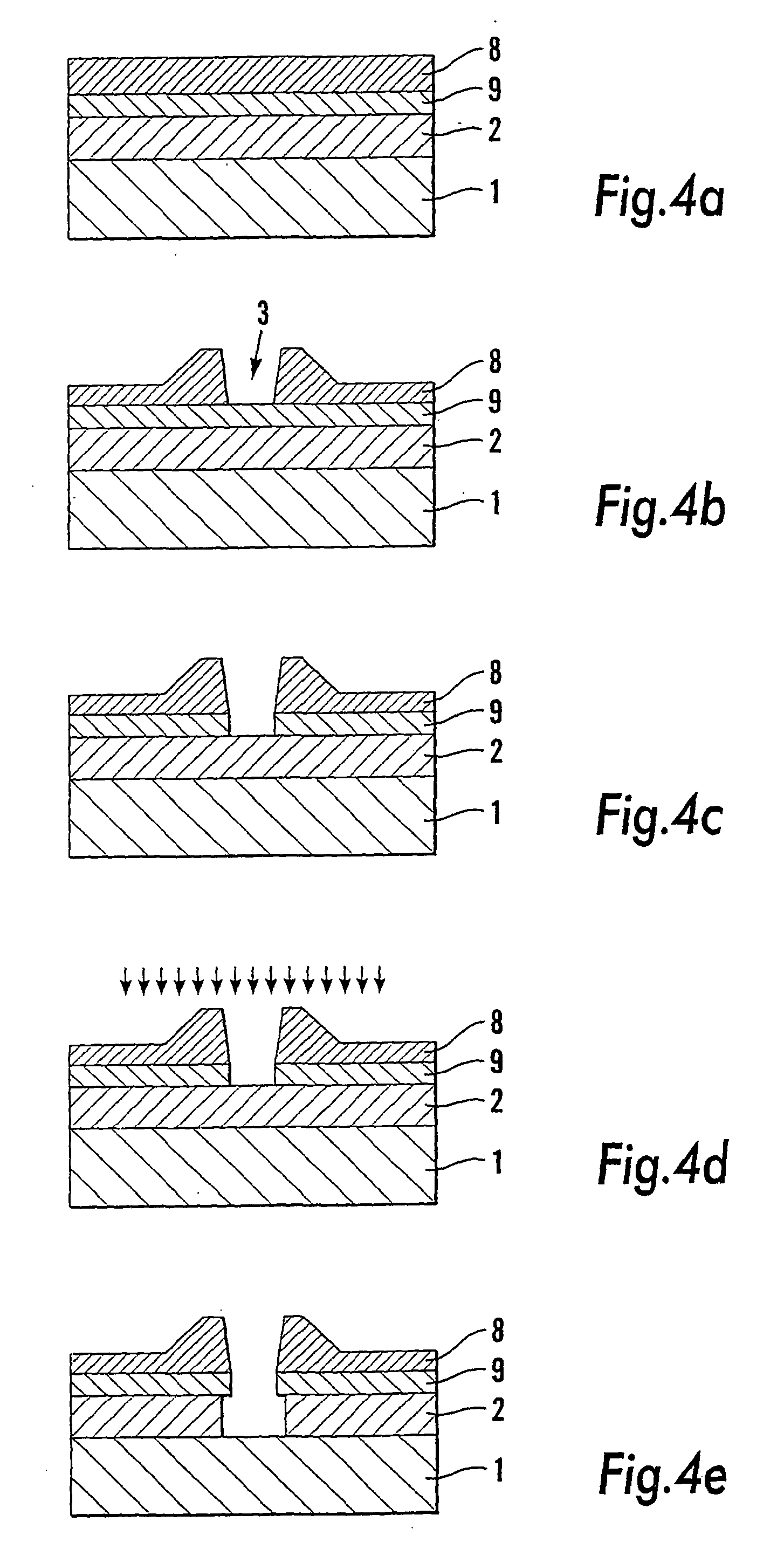

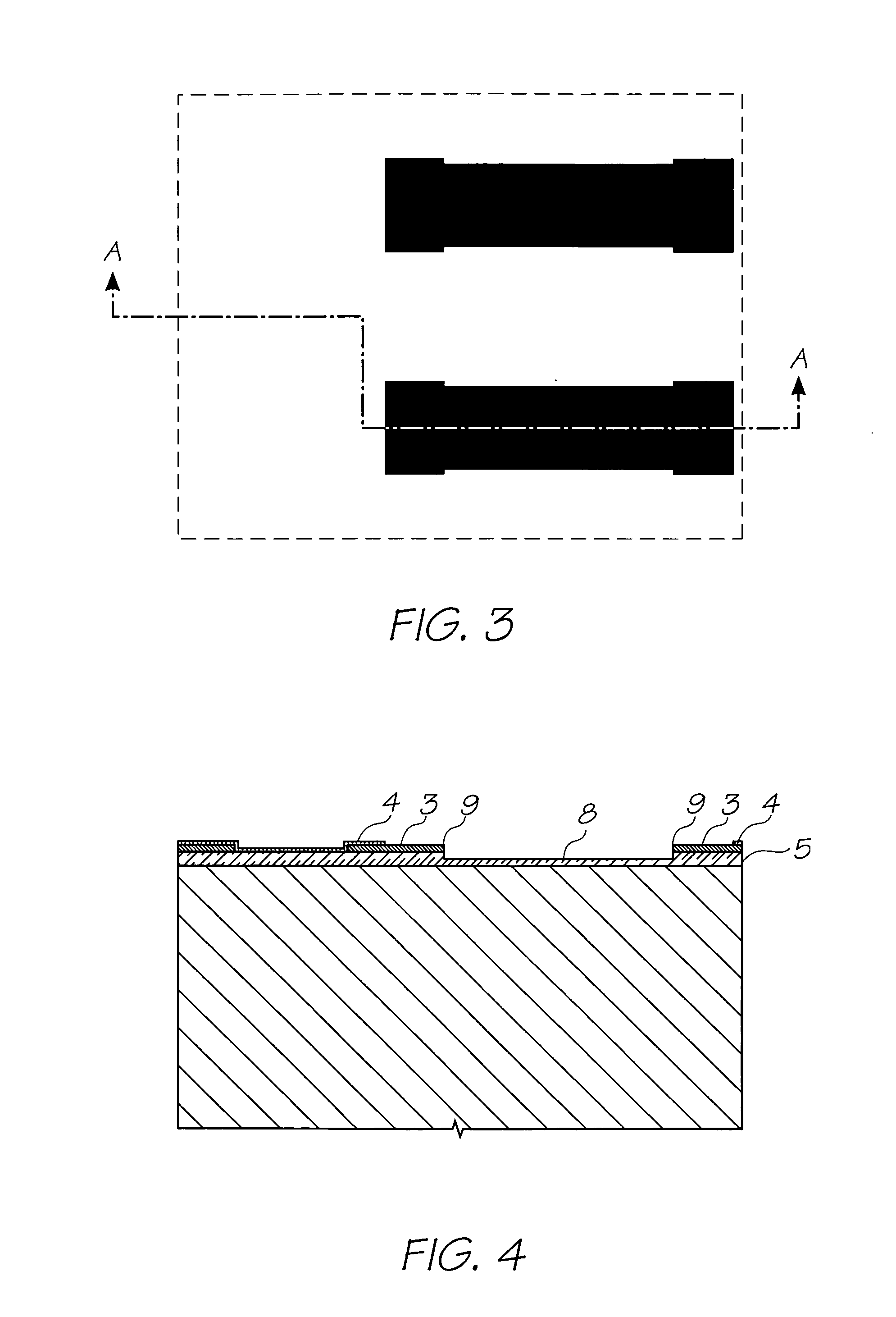

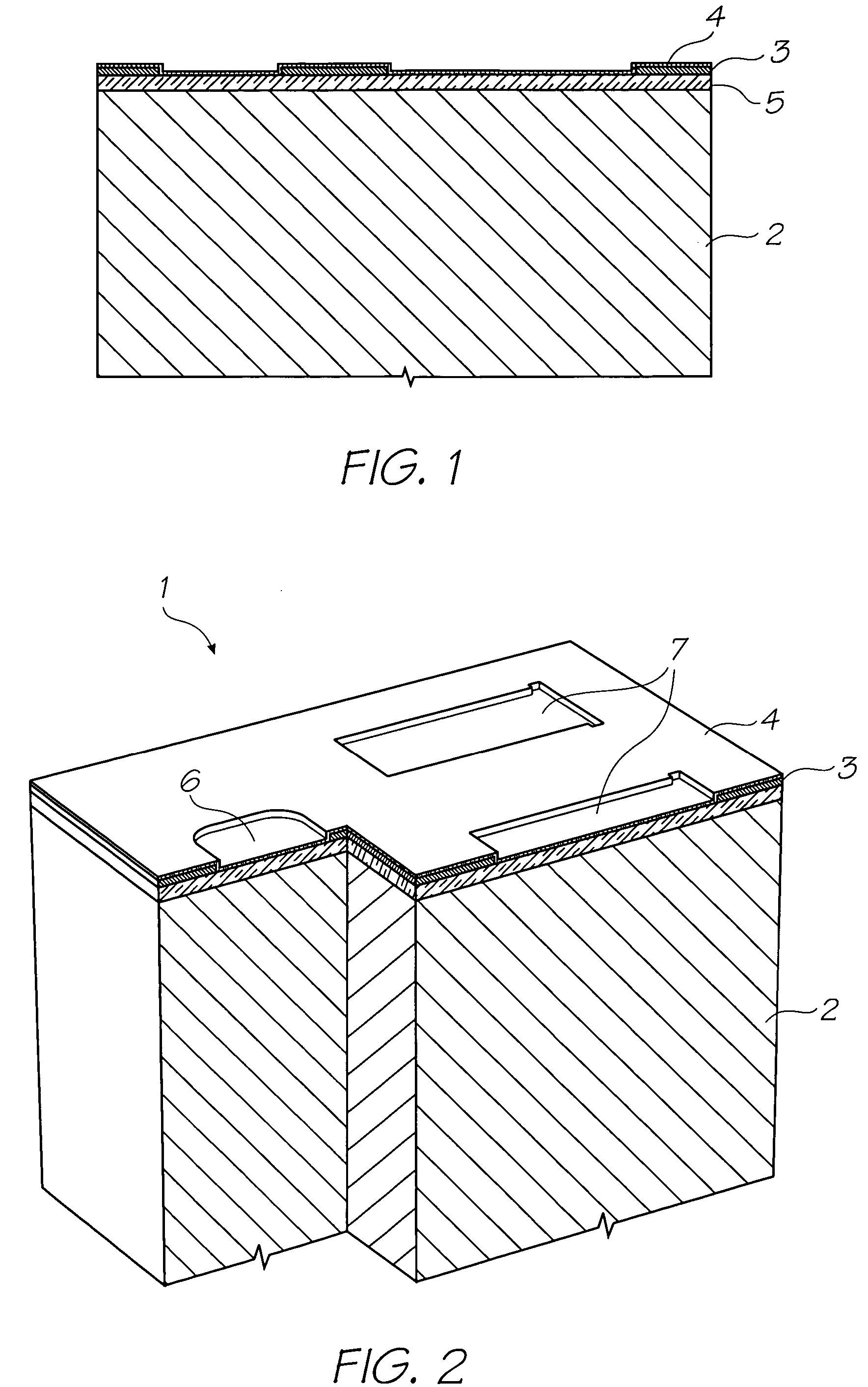

Substrate for and a process in connection with the product of structures

InactiveUS20040005444A1Easy to disassembleFacilitate NILSemi-permeable membranesFixed microstructural devicesResistMetallurgy

The invention relates to a substrate (1) comprising at least a first (2) and a second (8) coating layer on one surface of the substrate, for nanoimprint lithography, said first coating layer (2) consisting of a positive resist and said second (8) coating layer consisting of a negative resist. The invention also relates to a process in connection with nanoimprint lithography on the substrate (1), a pattern (3) of nanometre size being impressed in a first stage into the second coating layer (8) by means of a template (610), following which the first coating layer (2), in a second stage, is exposed to a chiefly isotropic developing method on surfaces thereof that have been exposed in connection with said first stage, a method for developing and material for said first and second coating layers being selected so that the first coating layer (2) is developed more quickly than the second coating layer (8), so that an undercut profile is obtained in the coating layers.

Owner:OBDUCAT AB SE

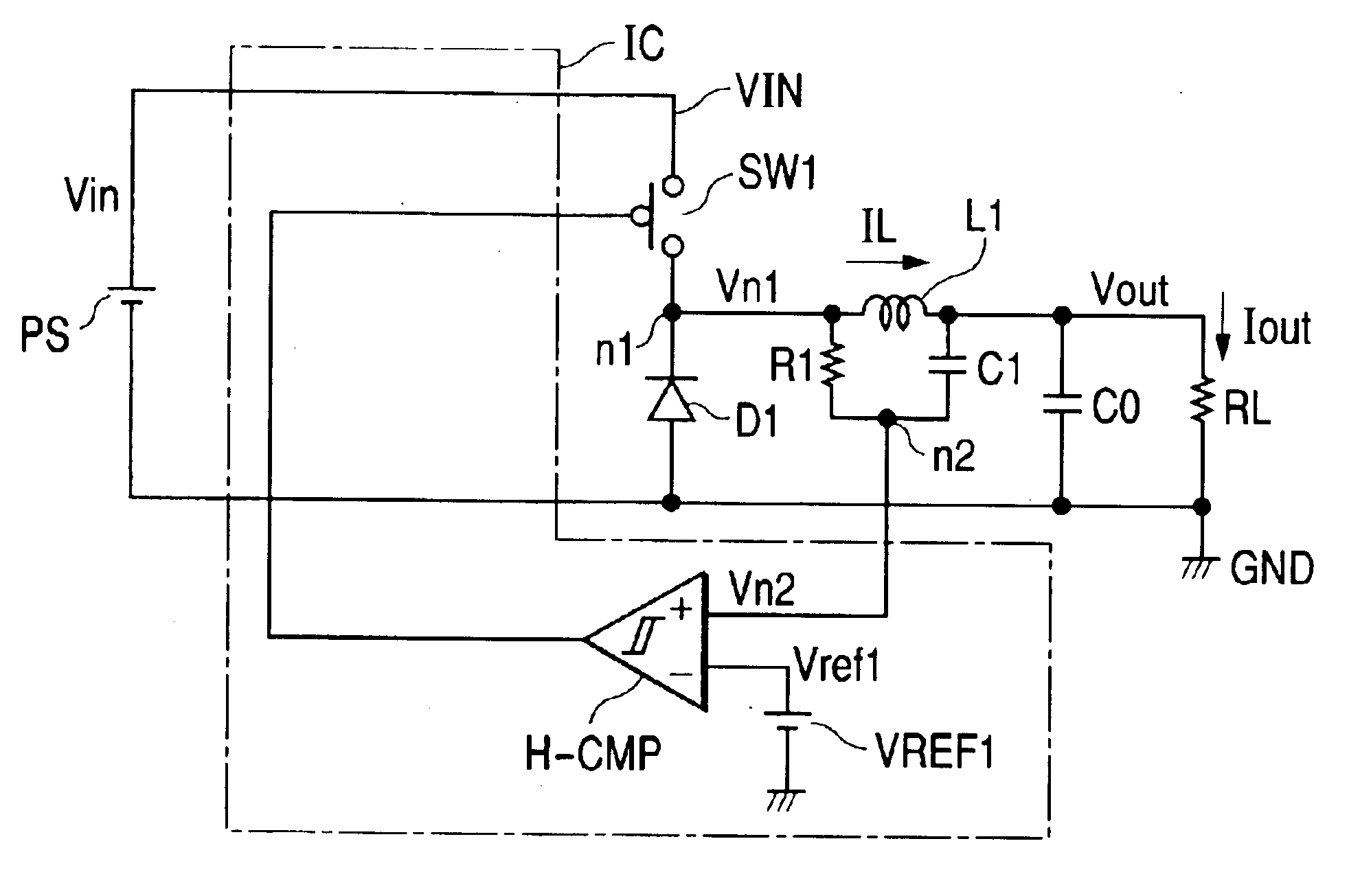

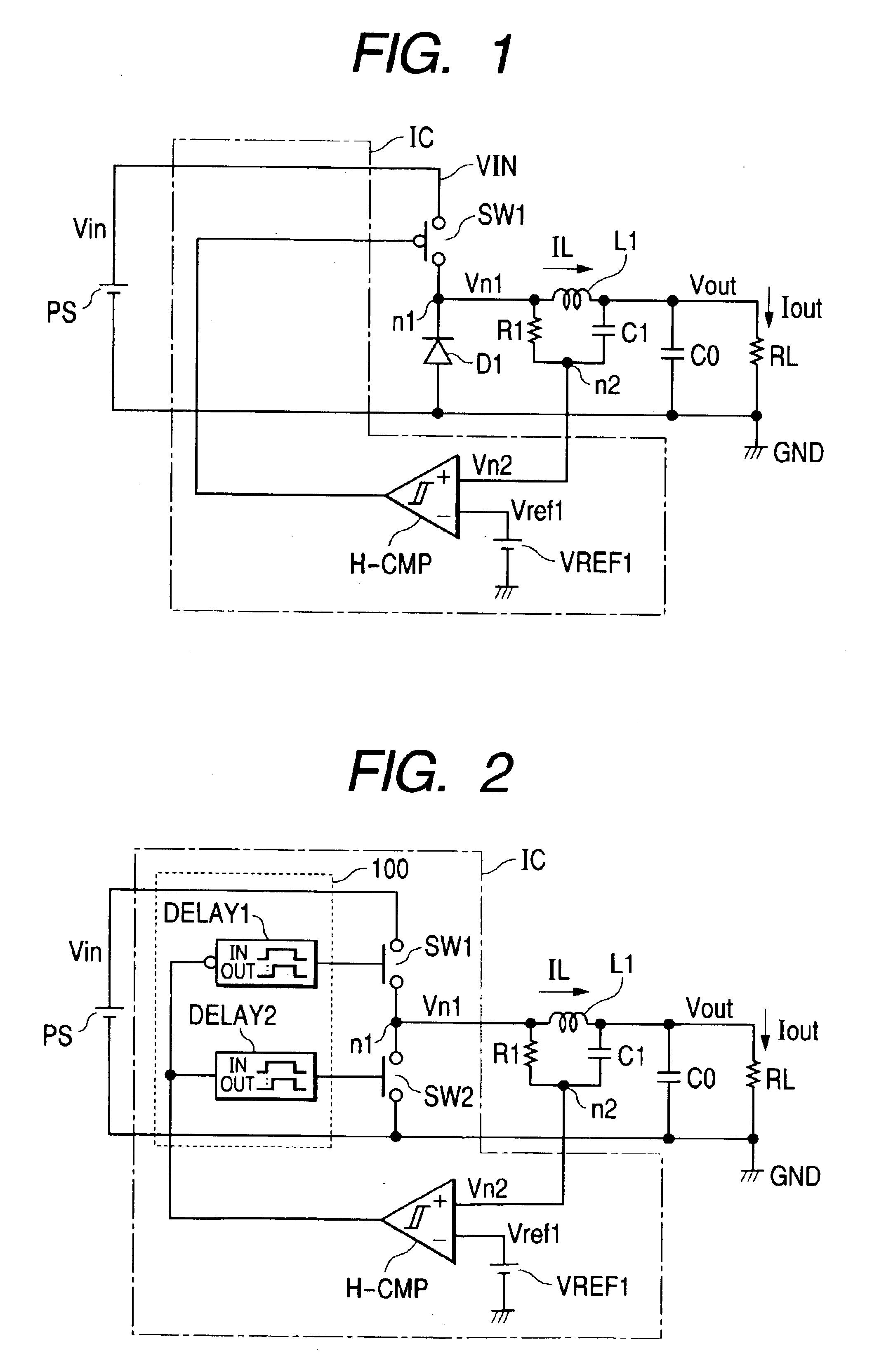

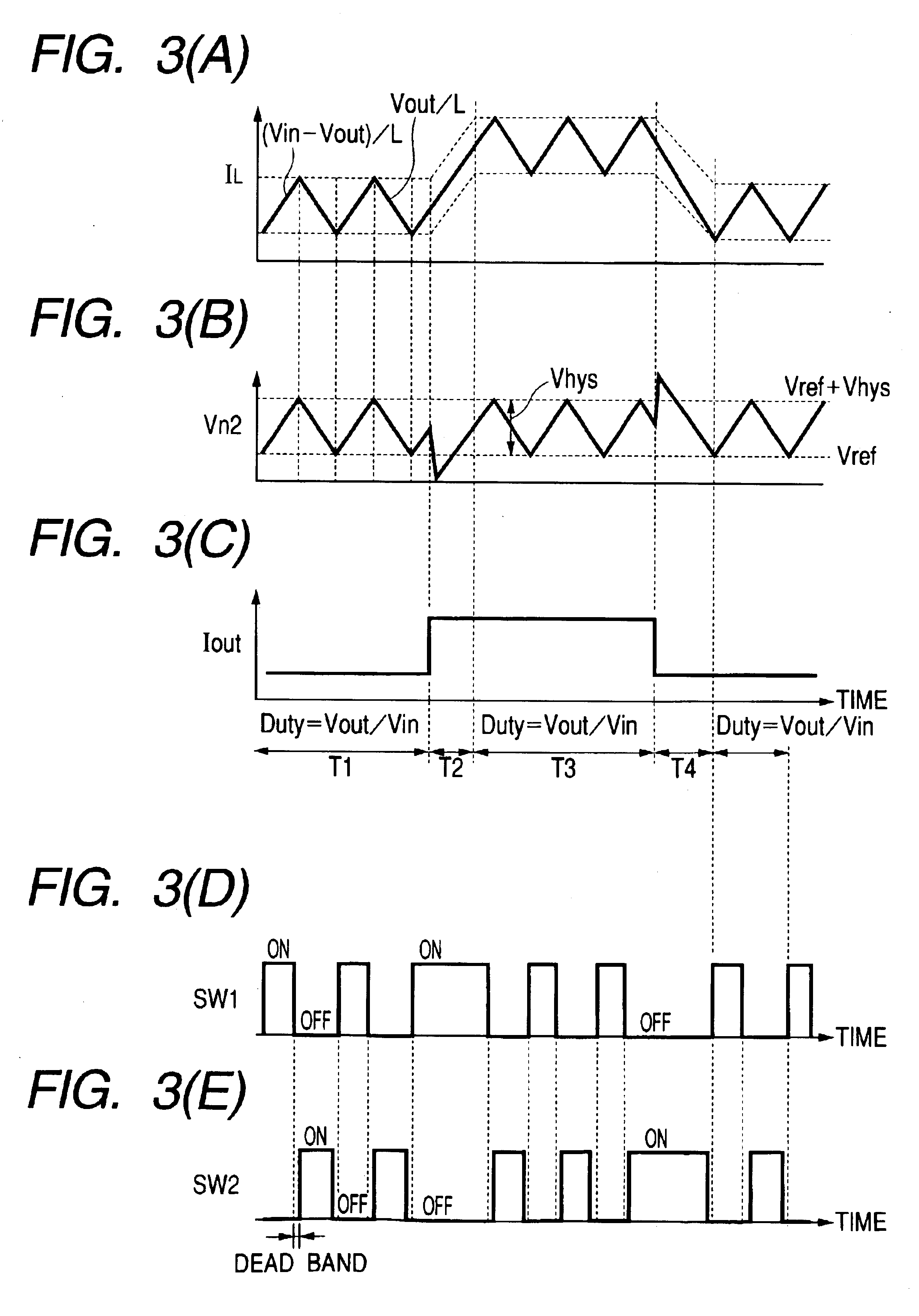

Switching power supply device and switching power supply system

InactiveUS6979985B2Reduce power consumptionReduction in circuit sizeEfficient power electronics conversionDc-dc conversionComparators circuitsVoltage reference

There is provided a switching power supply device of hysteresis current mode control system which assures excellent response characteristic for change of output current and reduction of power consumption. In a switching regulator of hysteresis current mode control system, a sense resistor connected in series to a coil is eliminated, a serially connected resistor and a capacitor are connected in parallel to a coil in place of such sense resistor. Thereby, a potential of a connection node of these resistor and capacitor is inputted to a comparator circuit having the hysteresis characteristic for comparison with the reference voltage. Accordingly, a switch may be controlled for ON and OFF states.

Owner:RENESAS ELECTRONICS CORP

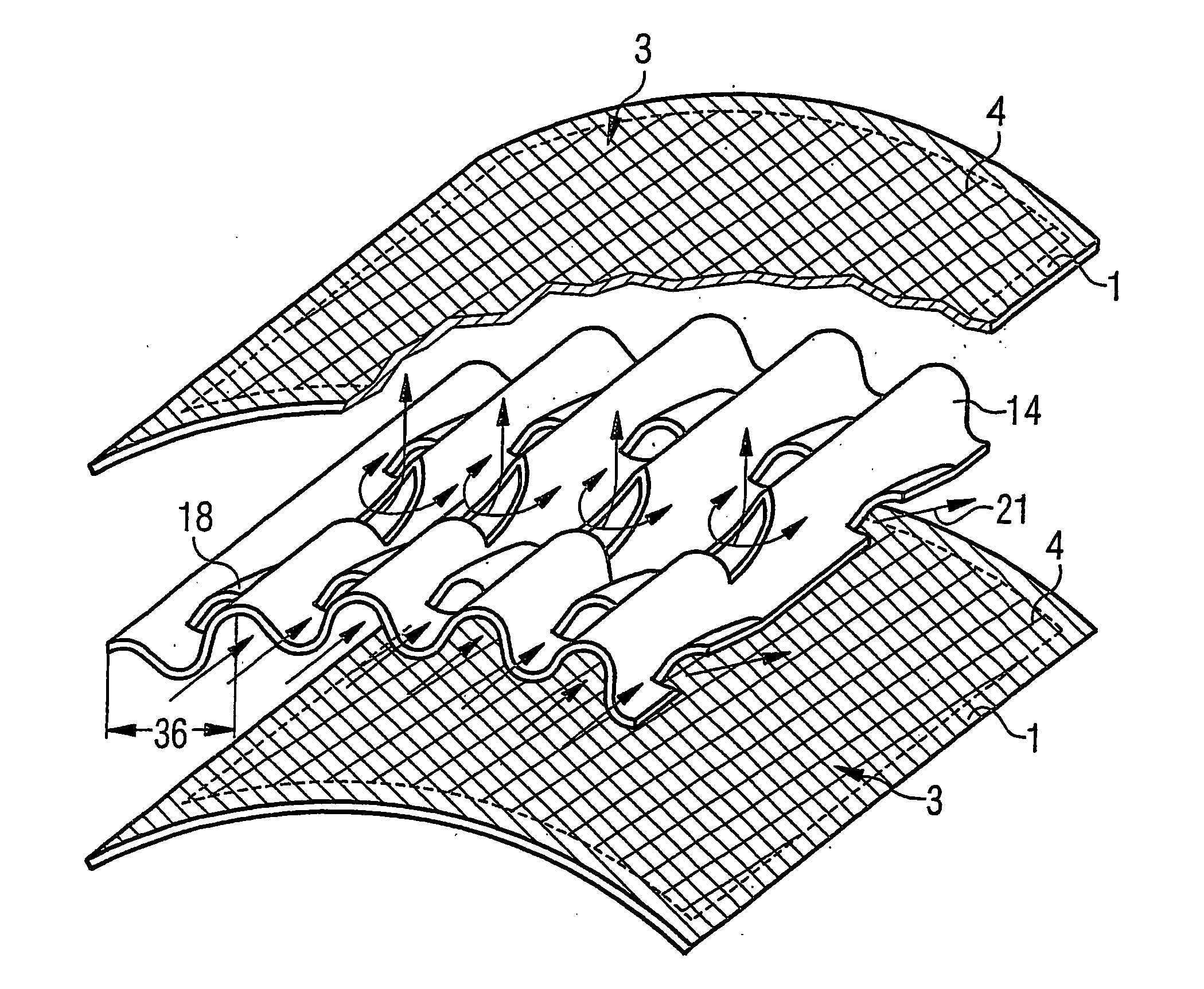

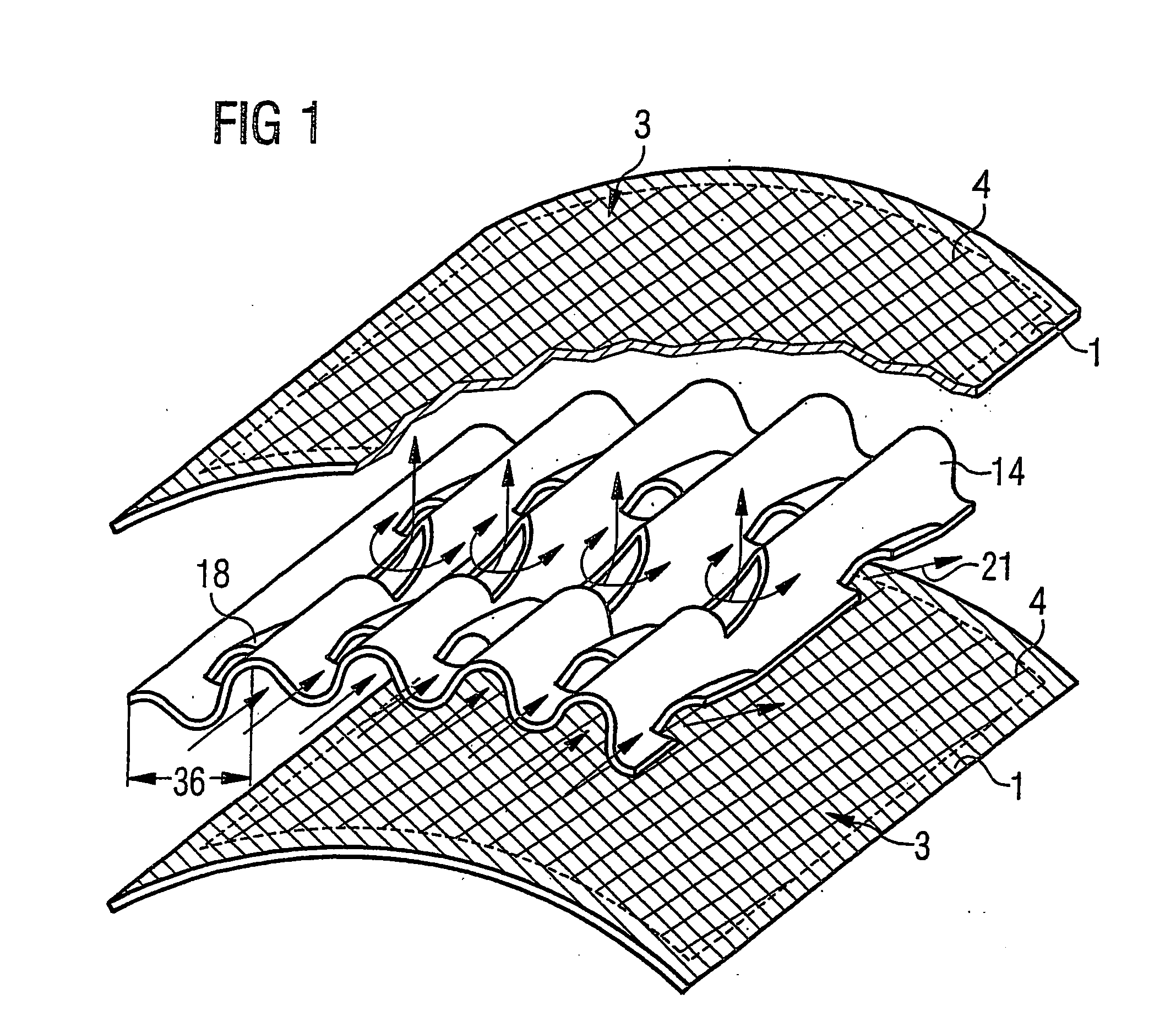

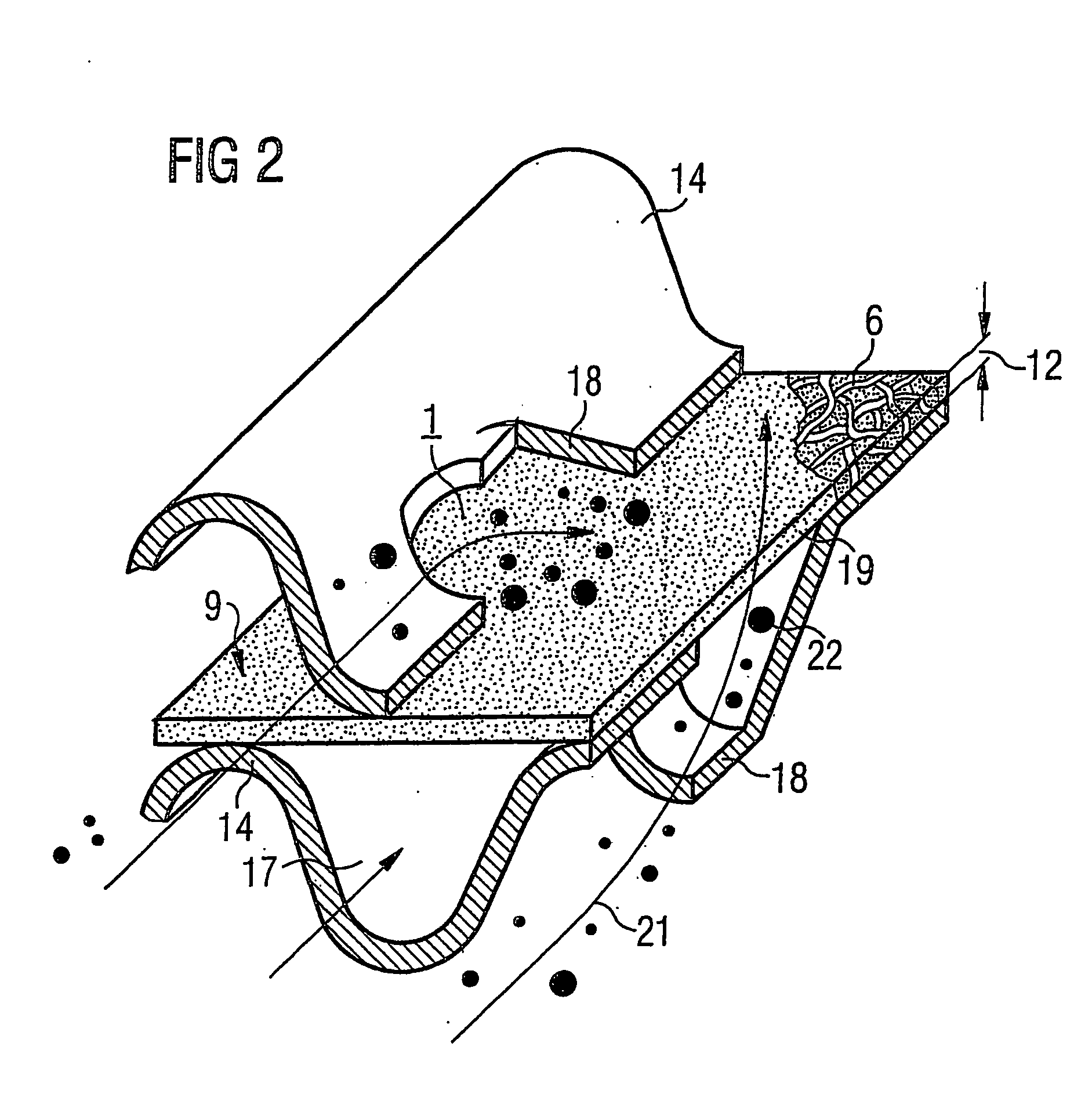

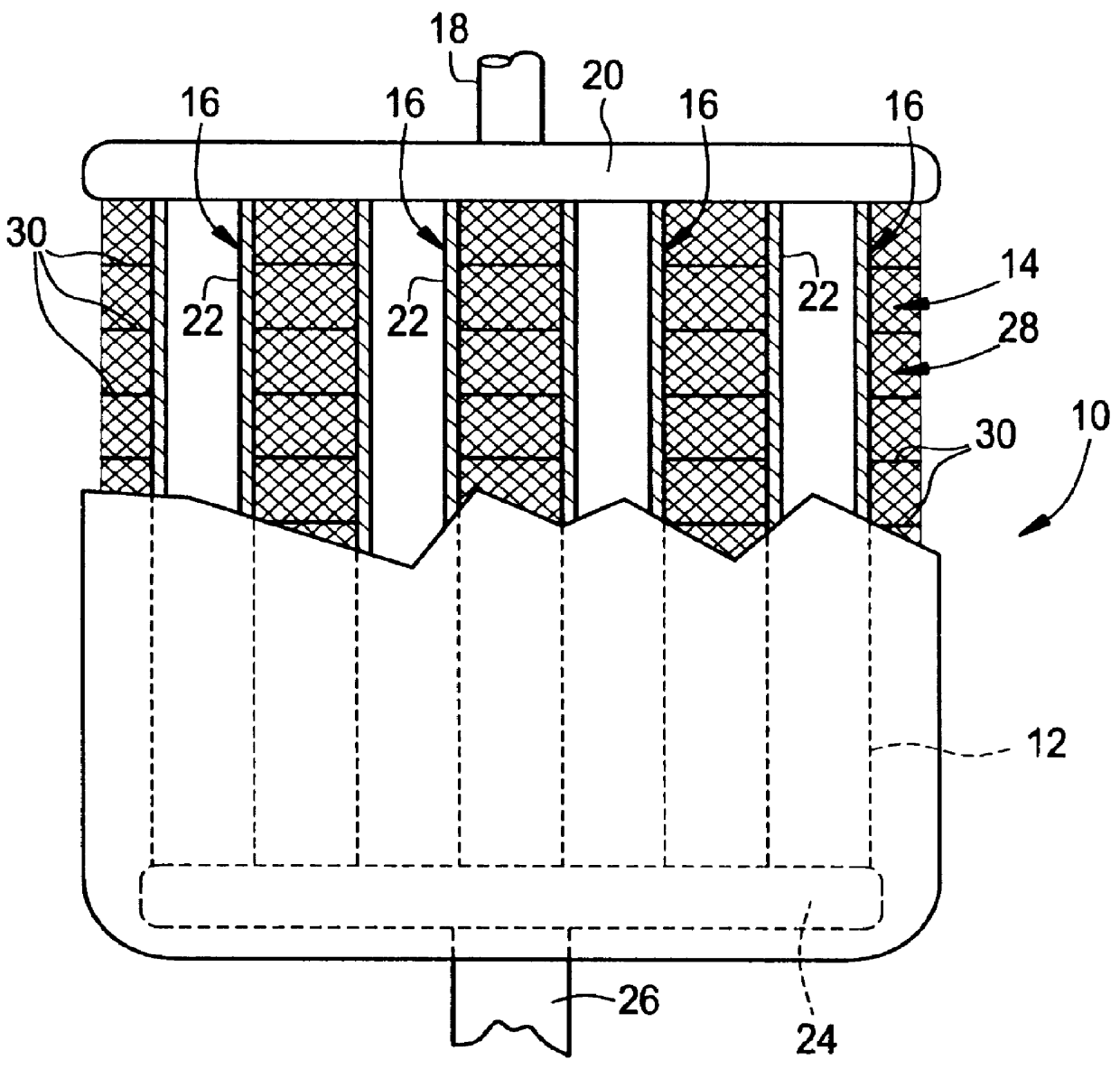

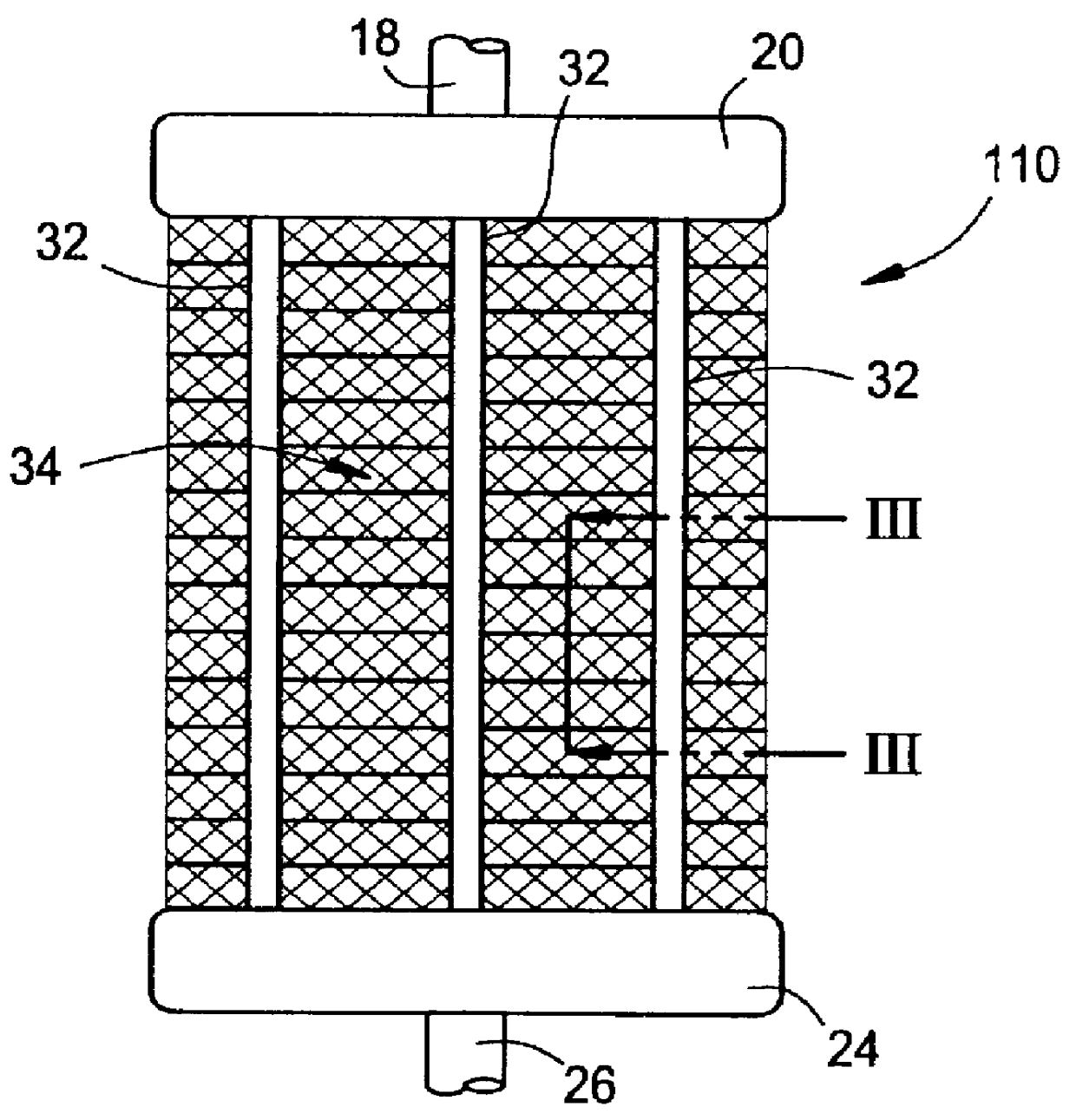

High-temperature-resistant coated fiber layer and particulate trap with the coated fiber layer

InactiveUS20050232830A1Improve efficiencySmall structureCombination devicesInternal combustion piston enginesParticulatesMetal fiber

A high-temperature-resistant fiber layer for an open particulate trap for purifying exhaust gases from mobile internal combustion engines includes metal fibers. At least a section of the fiber layer has a catalytically active and / or adsorbent coating, in particular such as that of an oxidation catalyst and / or a three-way catalyst and / or an SCR catalyst. A longitudinal section, which is substantially perpendicular to a largest outer surface, has openings formed therein with an average size of 0.01 mm to 0.5 mm, in particular 0.05 mm to 0.25 mm. A particulate trap with the coated fiber layer is also provided.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

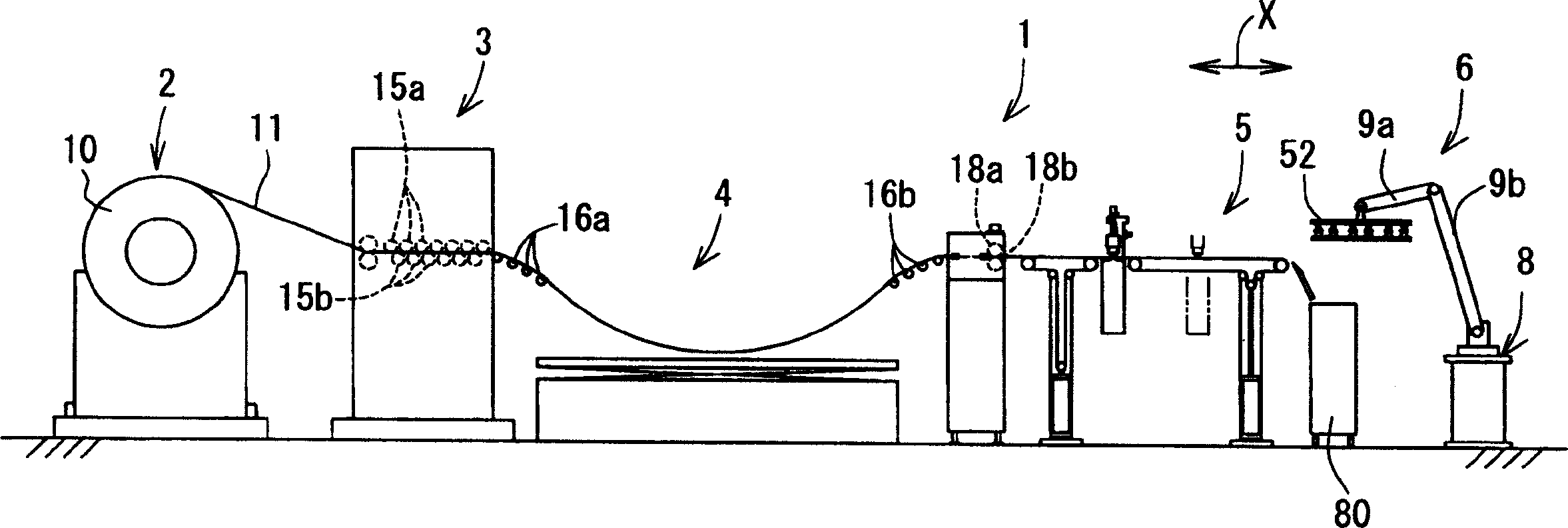

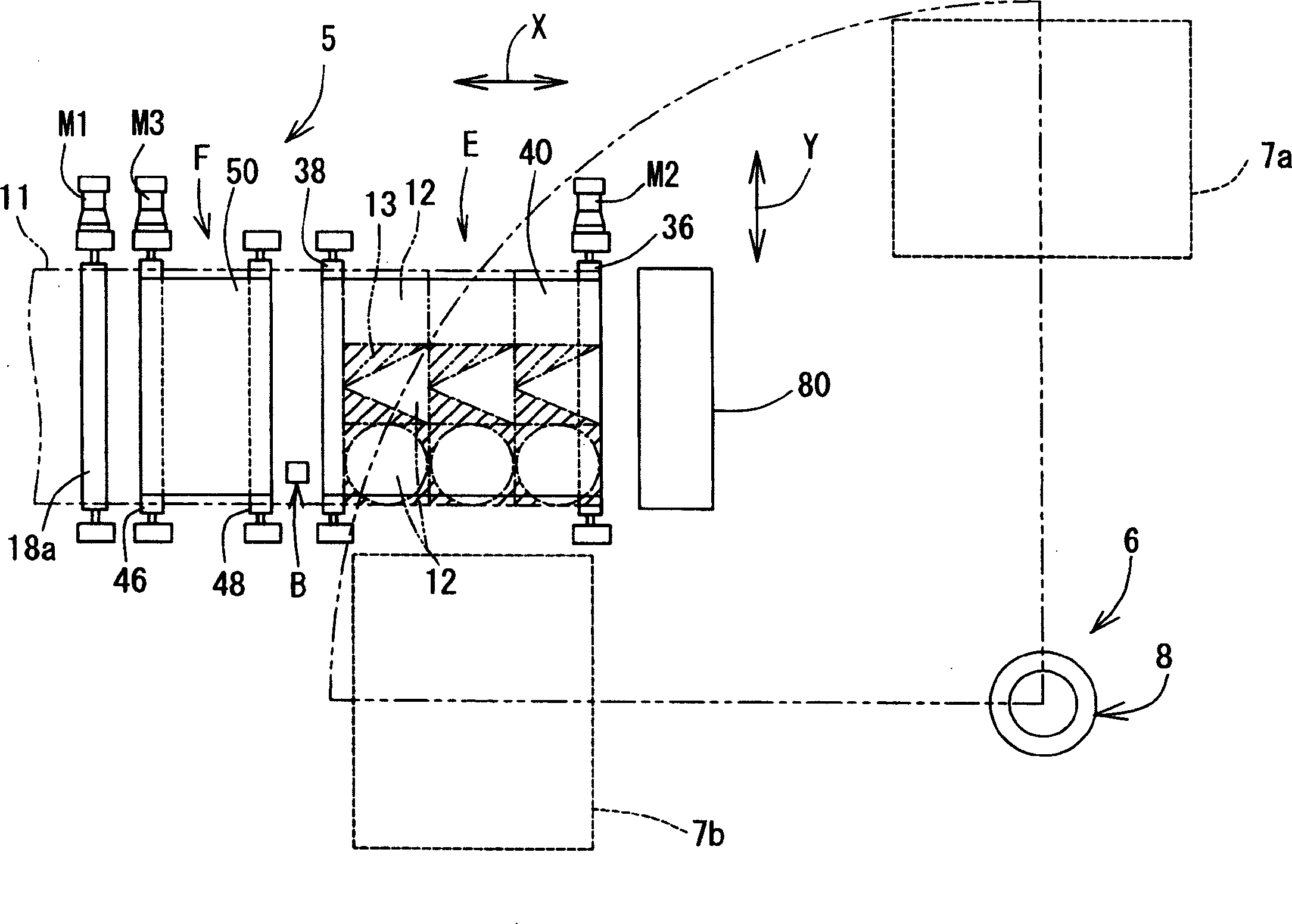

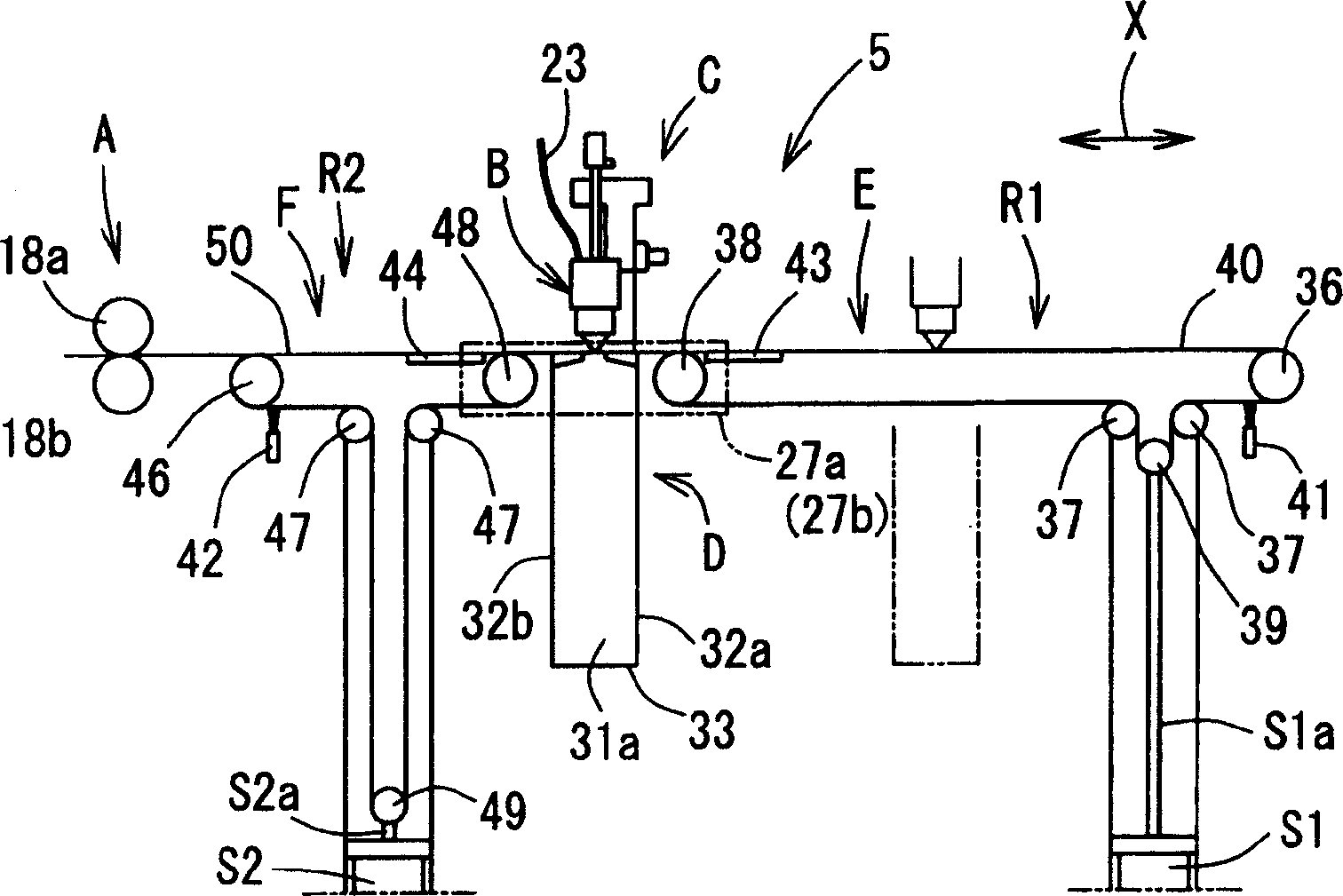

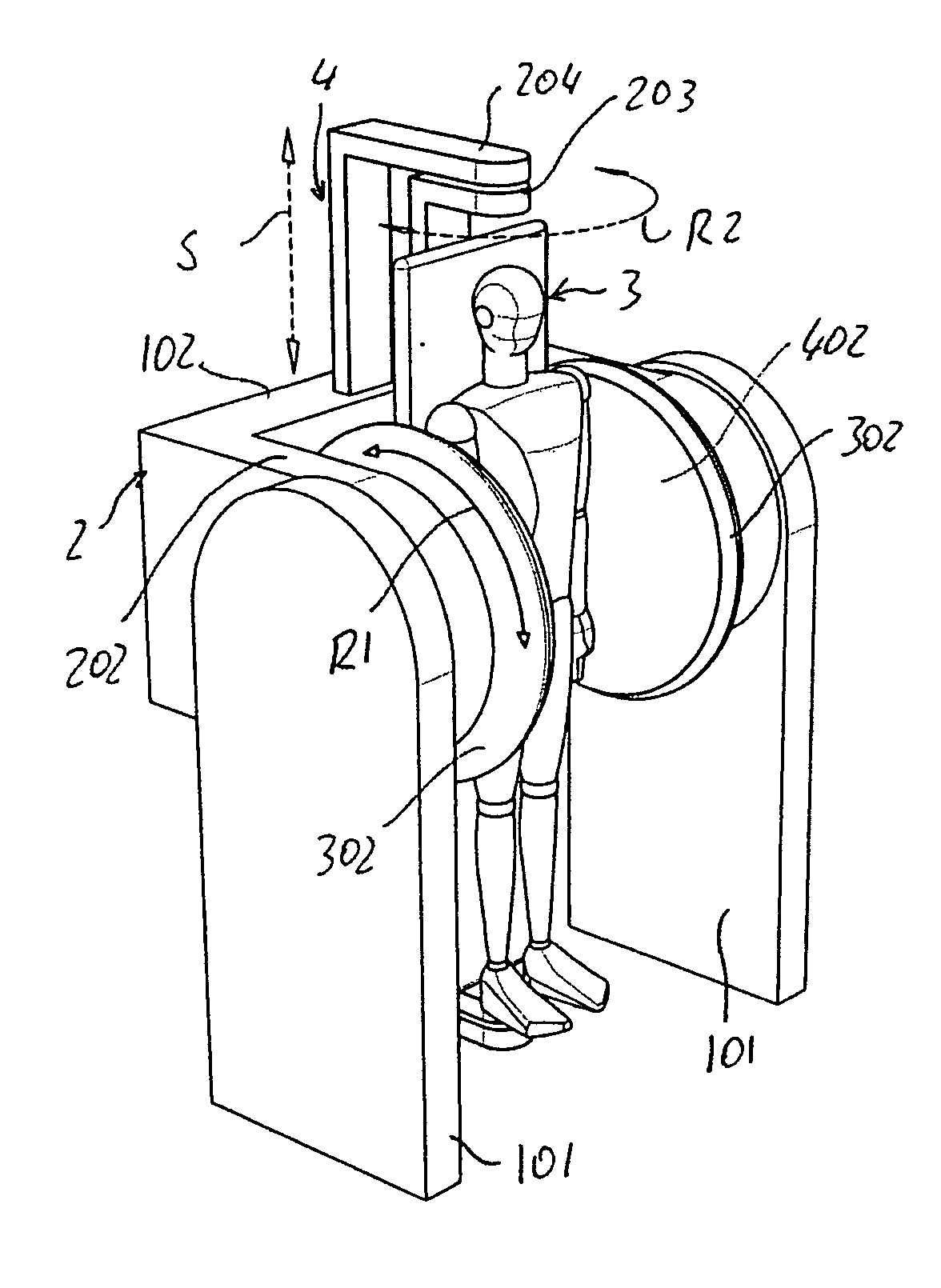

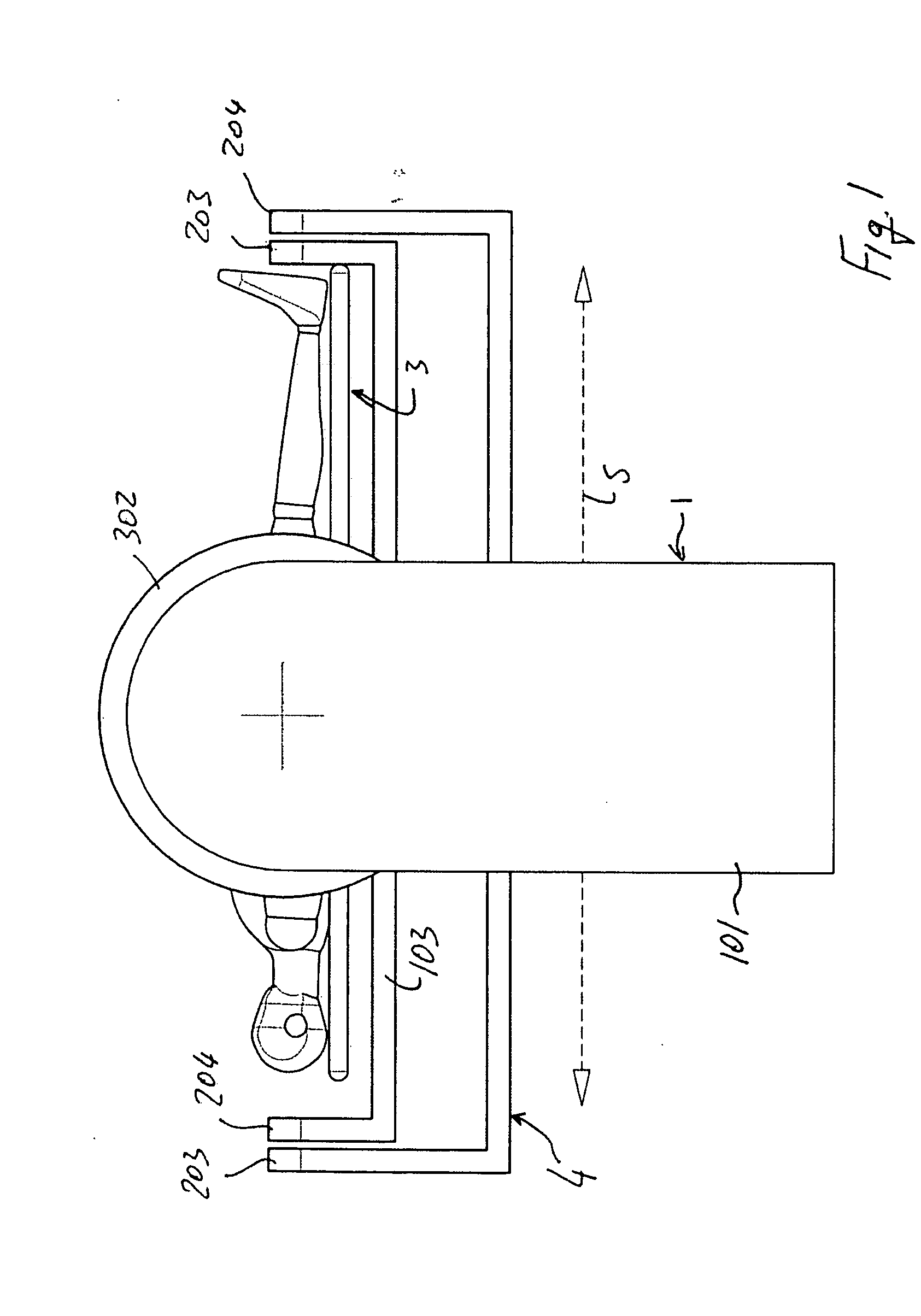

Laser cutting device, laser cutting method and laser cutting system

InactiveCN1652895APrevent adhesionReliable supportConveyorsWelding/soldering/cutting articlesEngineeringLaser cutting

A laser cutting device, comprising a material feeding means for feeding a sheet-like material in a feeding direction, a processing head capable of radiating laser beam toward the material, a head moving means for moving the processing head in a material feeding direction X and a material lateral direction Y, an upstream side support means (belt conveyor mechanism F) for supporting the material on the upstream side of the lower part of the processing head and increasing / decreasing the support area (R2) of the material in the feeding direction according to the movement of the processing head in the feeding direction, and a downstream side support means (belt conveyor mechanism E) for supporting a part cut on the processing side lower part of the processing head and increasing / decreasing the support area (R1) of the cut part in the feeding direction according to the movement of the processing head in the feeding direction.

Owner:TOYOTA STEEL CENT CO LTD

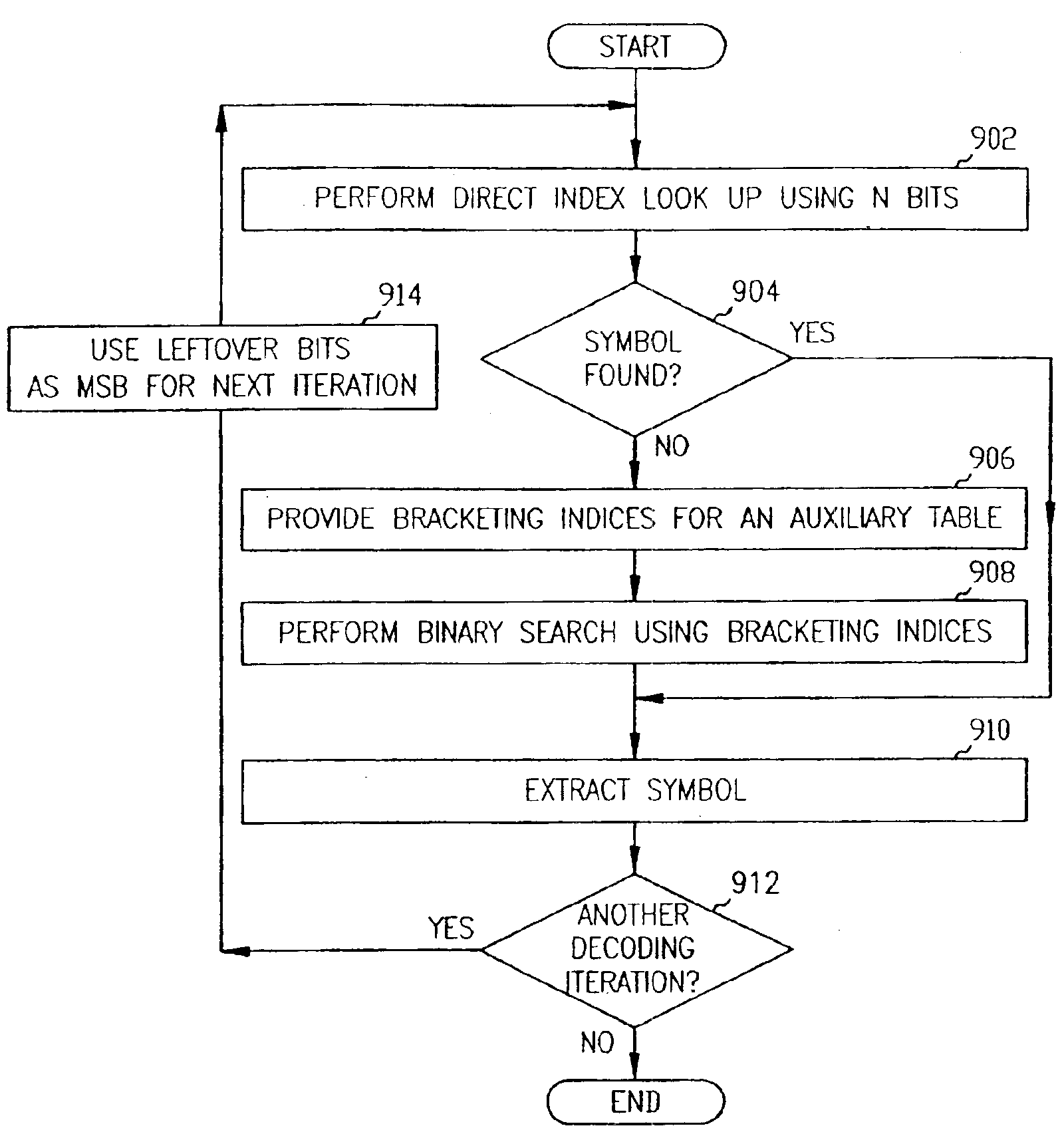

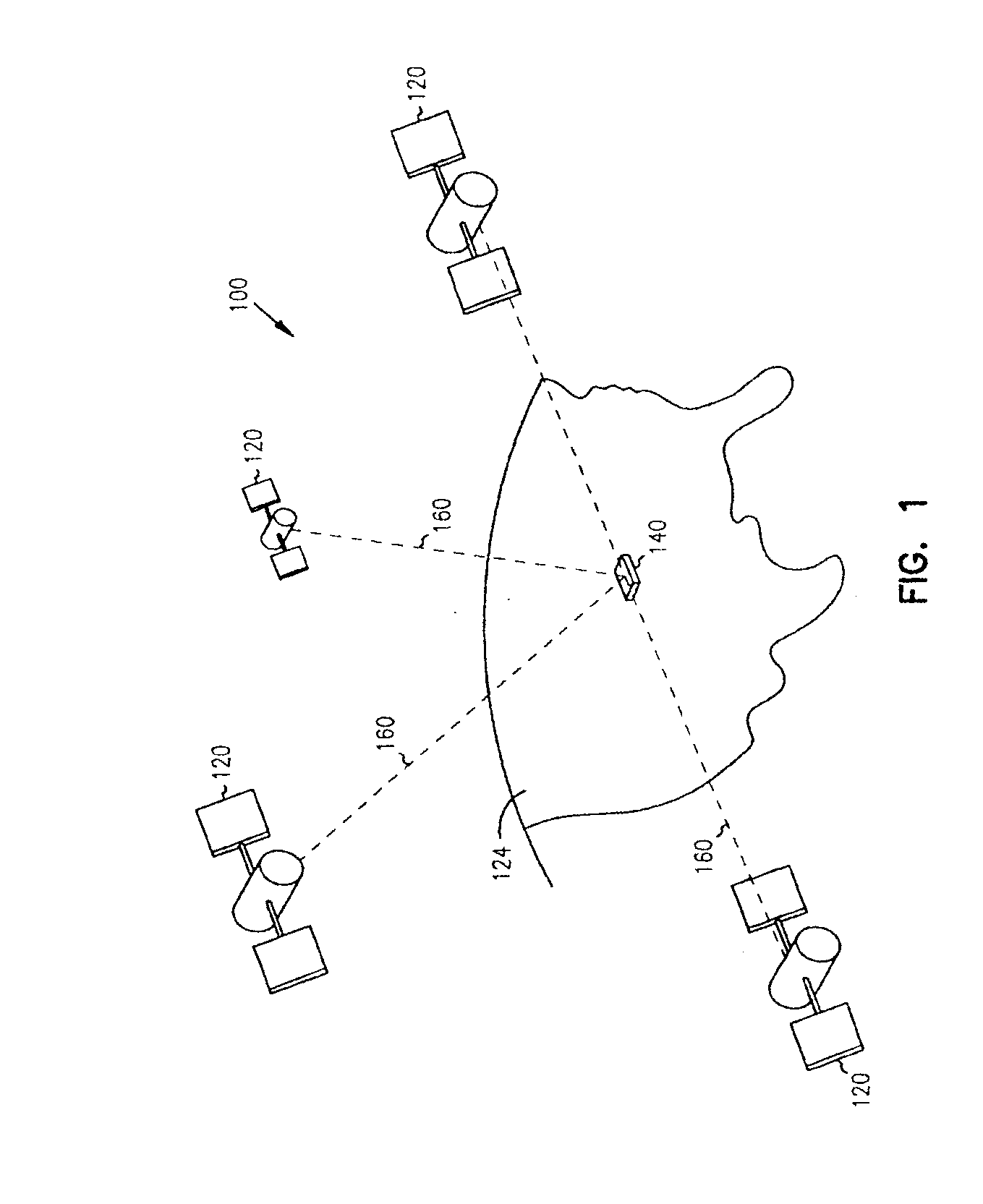

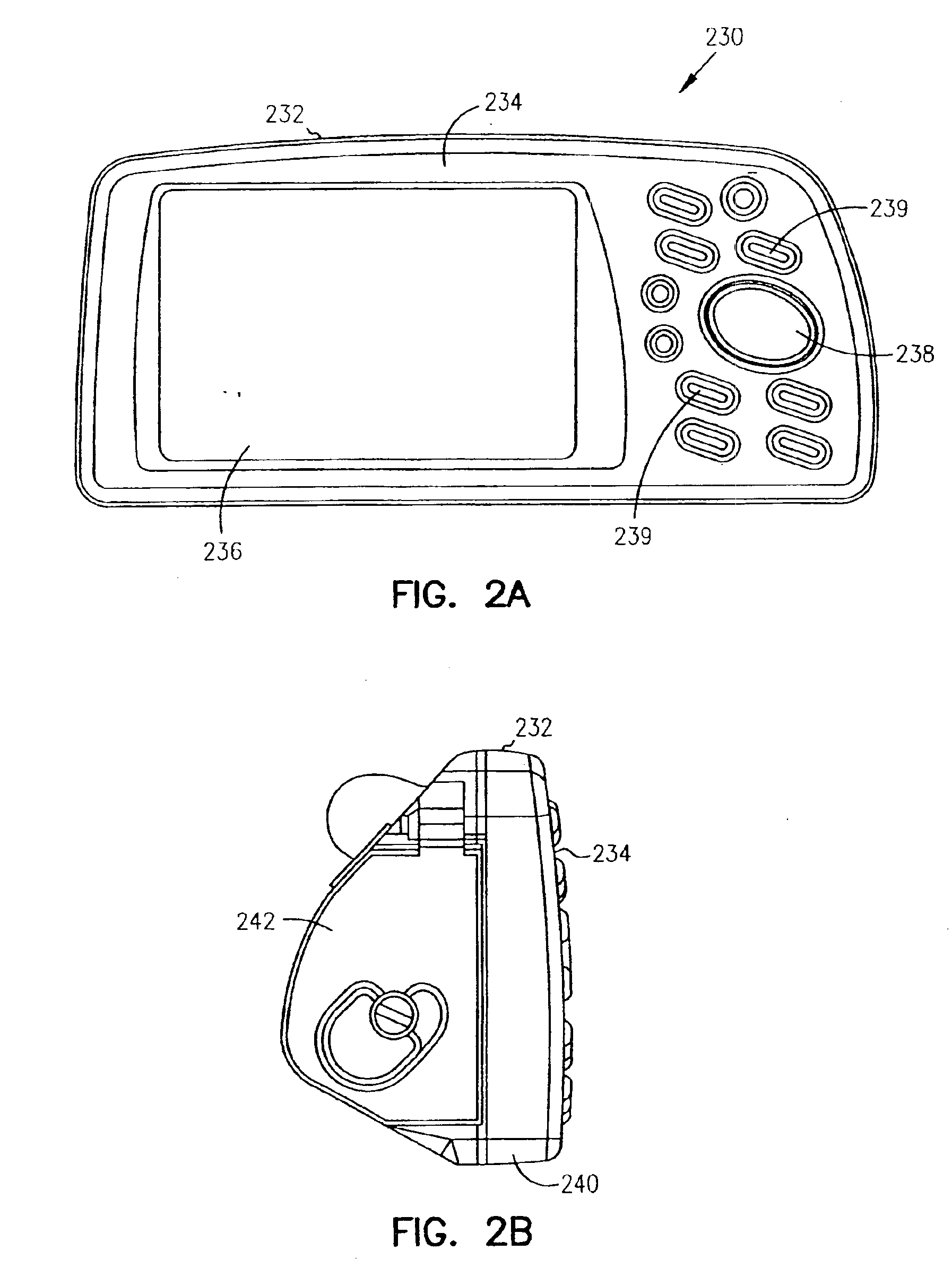

System and method for compressing data

InactiveUS6839624B1Improve decoding speedSave memory spaceNavigational calculation instrumentsPosition fixationTheoretical computer scienceSubject matter

Systems, devices and methods are provided to compress data, and in particular to code and decode data. One aspect of the present subject matter is a data structure. The data structure includes a field representing a decoding structure to decode canonical Huffman encoded data, and a field representing a symbol table. The decoding structure includes a field representing an accelerator table to provide a 2N-deep direct-index lookup to provide high-frequency symbols for high-frequency data and to provide bracketing indices for low-frequency data. The decoding structure also includes a field for a binary search table to provide a low-frequency symbol index using a binary search bounded by the bracketing indices provided by the accelerator table. The symbol table is adapted to provide a symbol associated with the low-frequency index.

Owner:GARMIN

Interface paint with high hydrophobicity, heat conductivity and adhesion

A high-hydrophobicity, heat conductivity and adhesivity pigment of interface is prepared by taking methyl chloroform and butanone as medium, liquid-phase treating ordinary carbon black by silicone oil to hydrophobic activate, forming coating into dense methyl surface by polyester modified dimethylsilicone and agitation dispersing by supersonic homogenizer. The formed coating (2) is three-dimensional cross-linking network of cured polyphenylene methyl resin, which contains nanometer carbon black and silicon dioxide, and it forms dense methyl thin layer (3) on coating surface. It can be used to treat heat exchanger surface (1) of indoor apparatus and outer tube fin of household air conditioner. It has good hardness and is non- toxic.

Owner:李跃

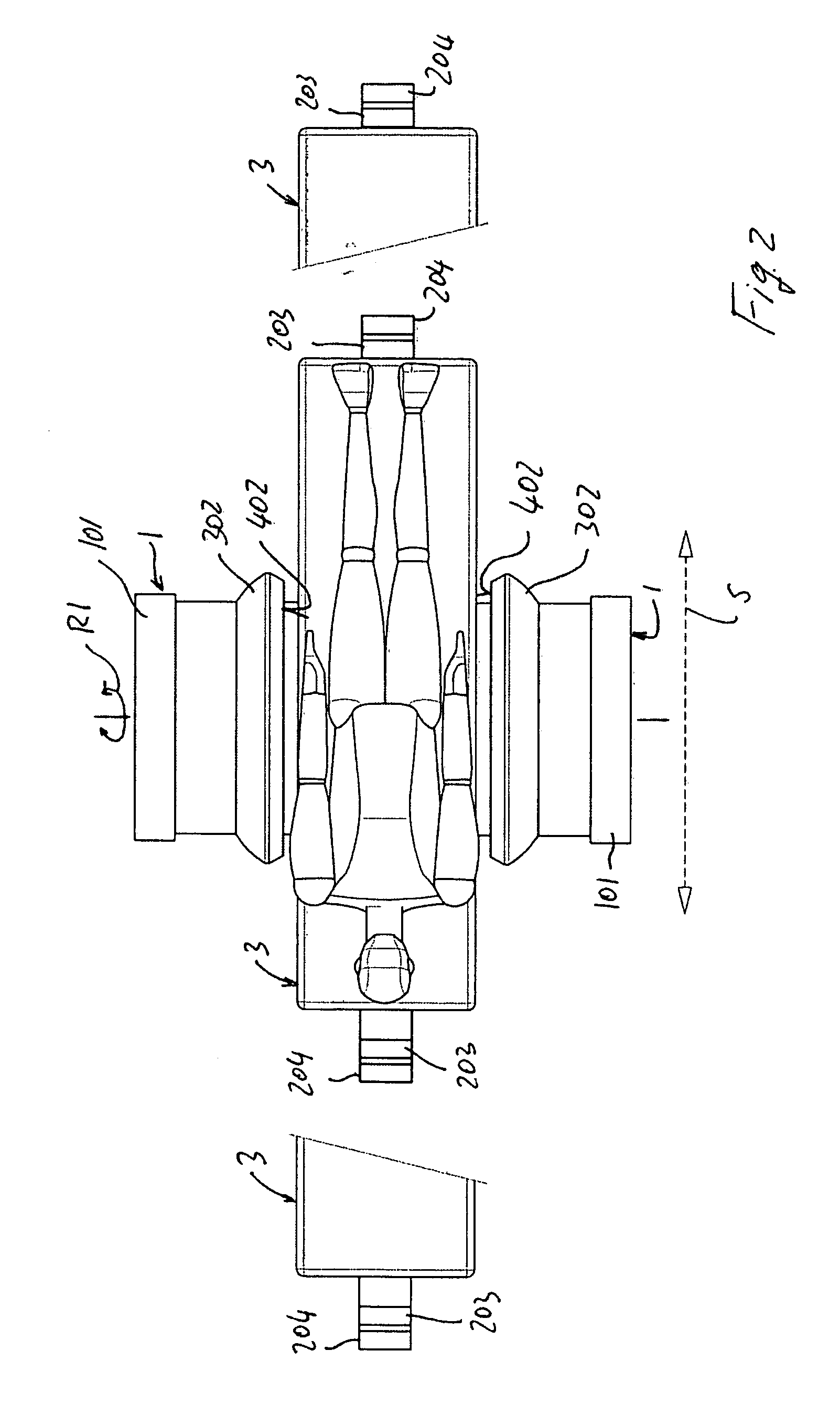

Magnetic resonance imaging apparatus

ActiveUS20050187459A1Small magnetic structureSmall structureDiagnostic recording/measuringSensorsVertical planeMR - Magnetic resonance

A magnetic resonance imaging apparatus including a magnetic structure having two opposite and spaced apart poles and a column or wall transverse to the poles and connecting the poles; the poles defining two opposite walls delimiting a patient-imaging space, the two opposite walls extending along substantially parallel planes which are substantially parallel to a vertical plane; and a patient positioning table which is slidably connected to a supporting frame between the two poles; the table being positioned with its longitudinal axis substantially parallel to the two opposite parallel walls of the poles and the table being oriented with its transverse axis perpendicular to at least one of the two opposite walls.

Owner:ESAOTE

Low loss electrode connection for inkjet printhead

InactiveUS20070081032A1Reduce the amount requiredIncreasing nozzle densityPrintingCMOSHeating element

An inkjet printhead with planar thermal actuators, with contacts directly deposited onto the CMOS electrodes and suspended heater element, which avoids hotspots caused by vertical or inclined surfaces so that the contacts can be much smaller structures without acceptable increases in resistive losses. Low resistive losses preserves the efficient operation of a suspended heater element and the small contact size is convenient for close nozzle packing on the printhead.

Owner:ZAMTEC +1

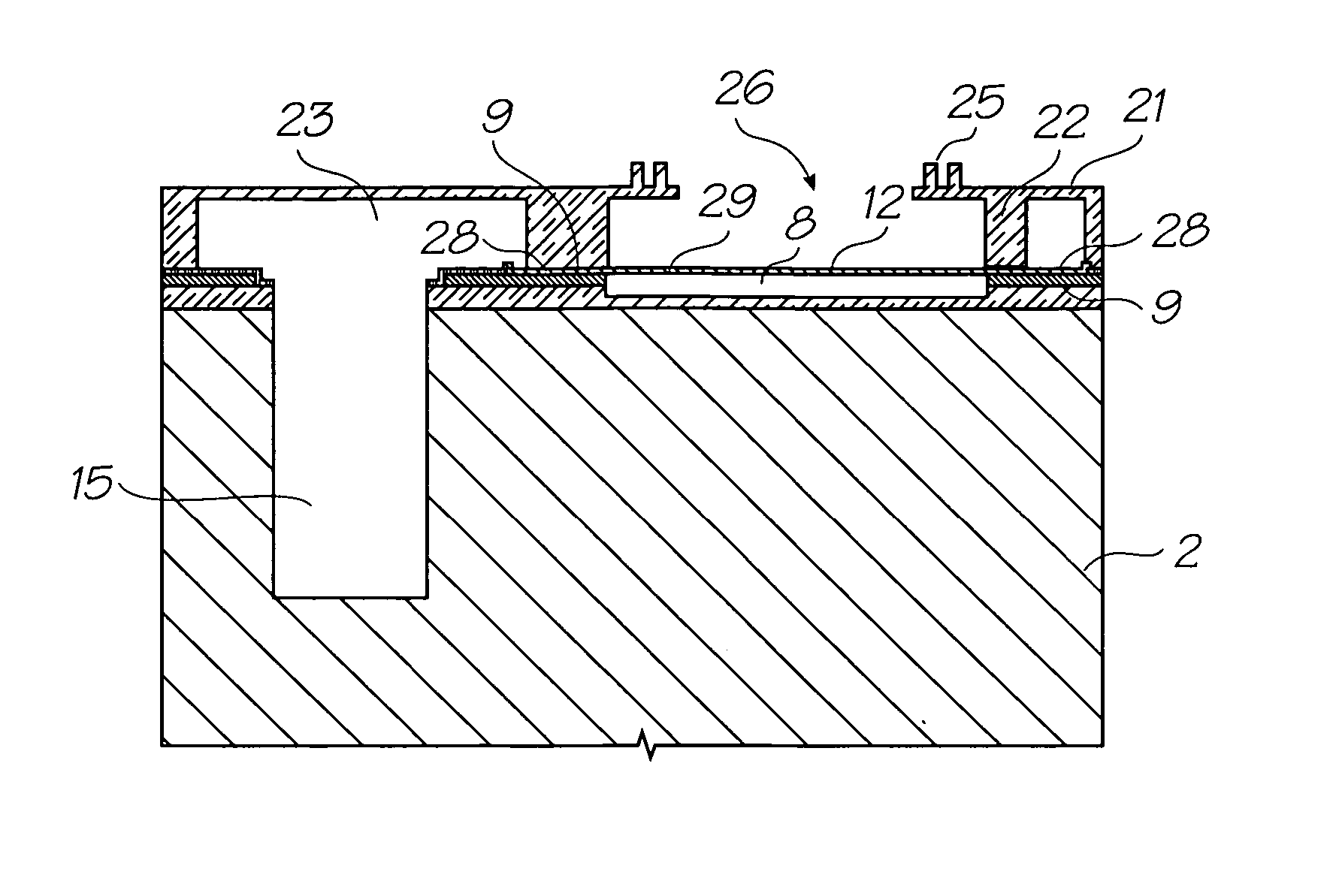

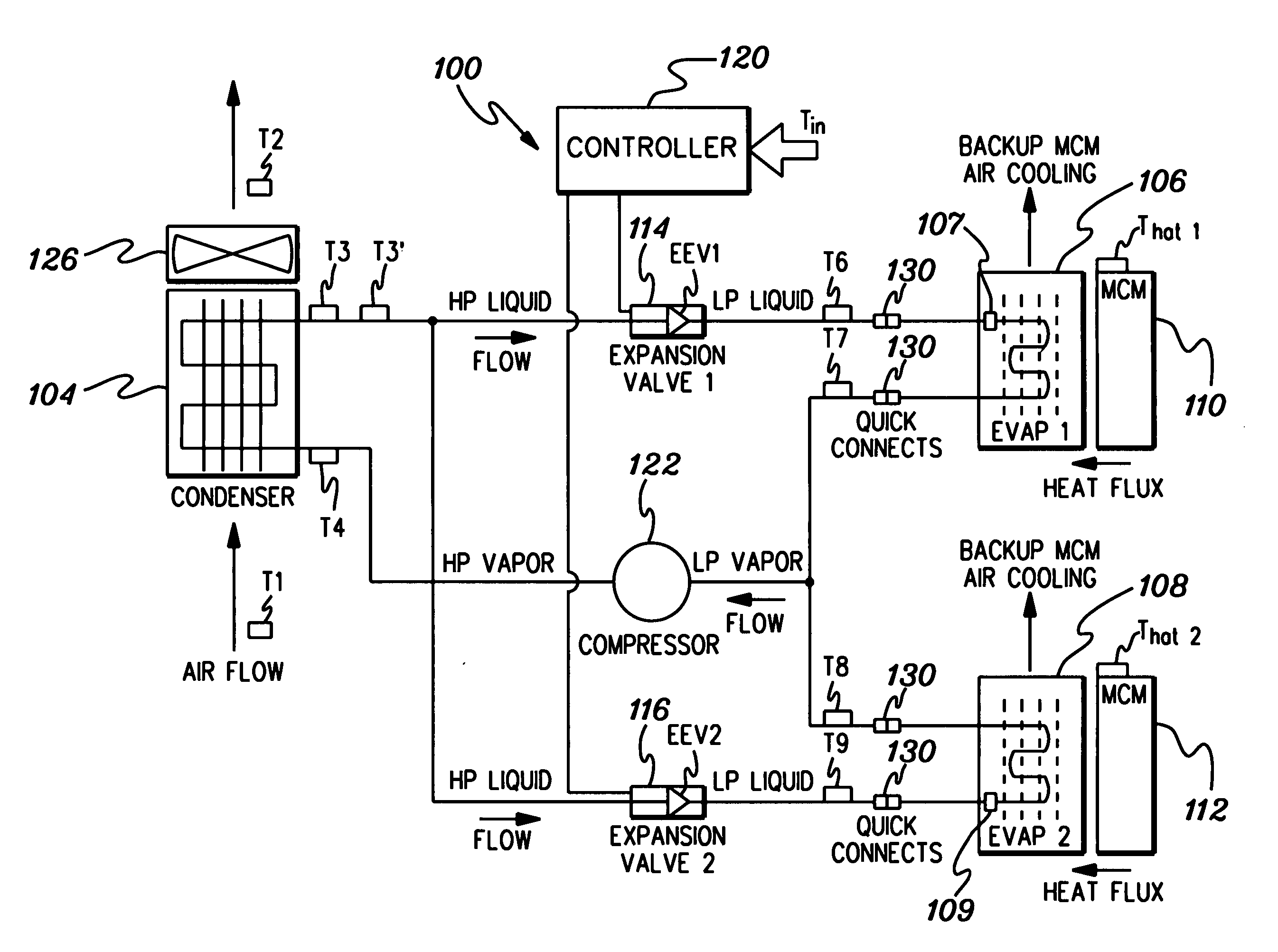

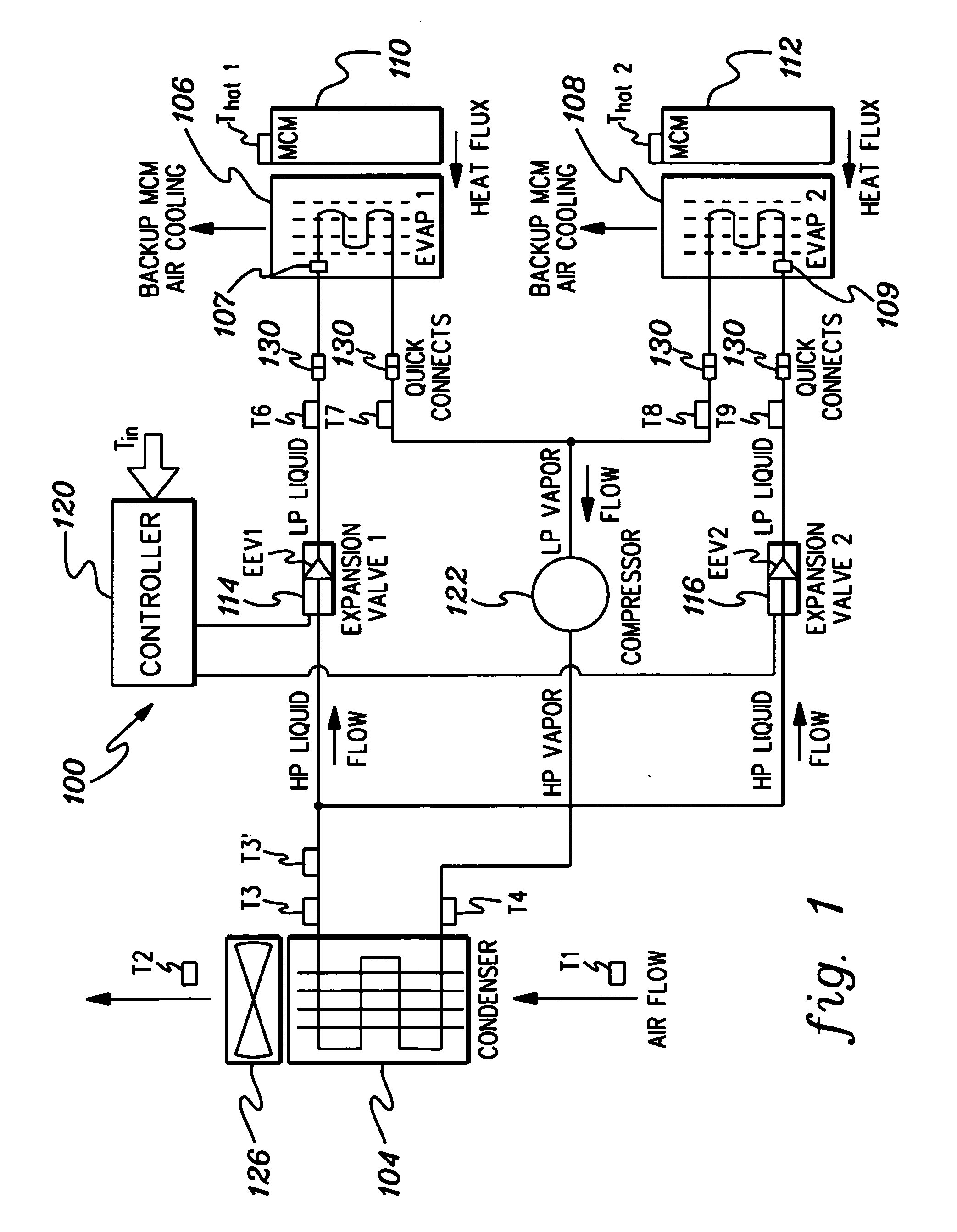

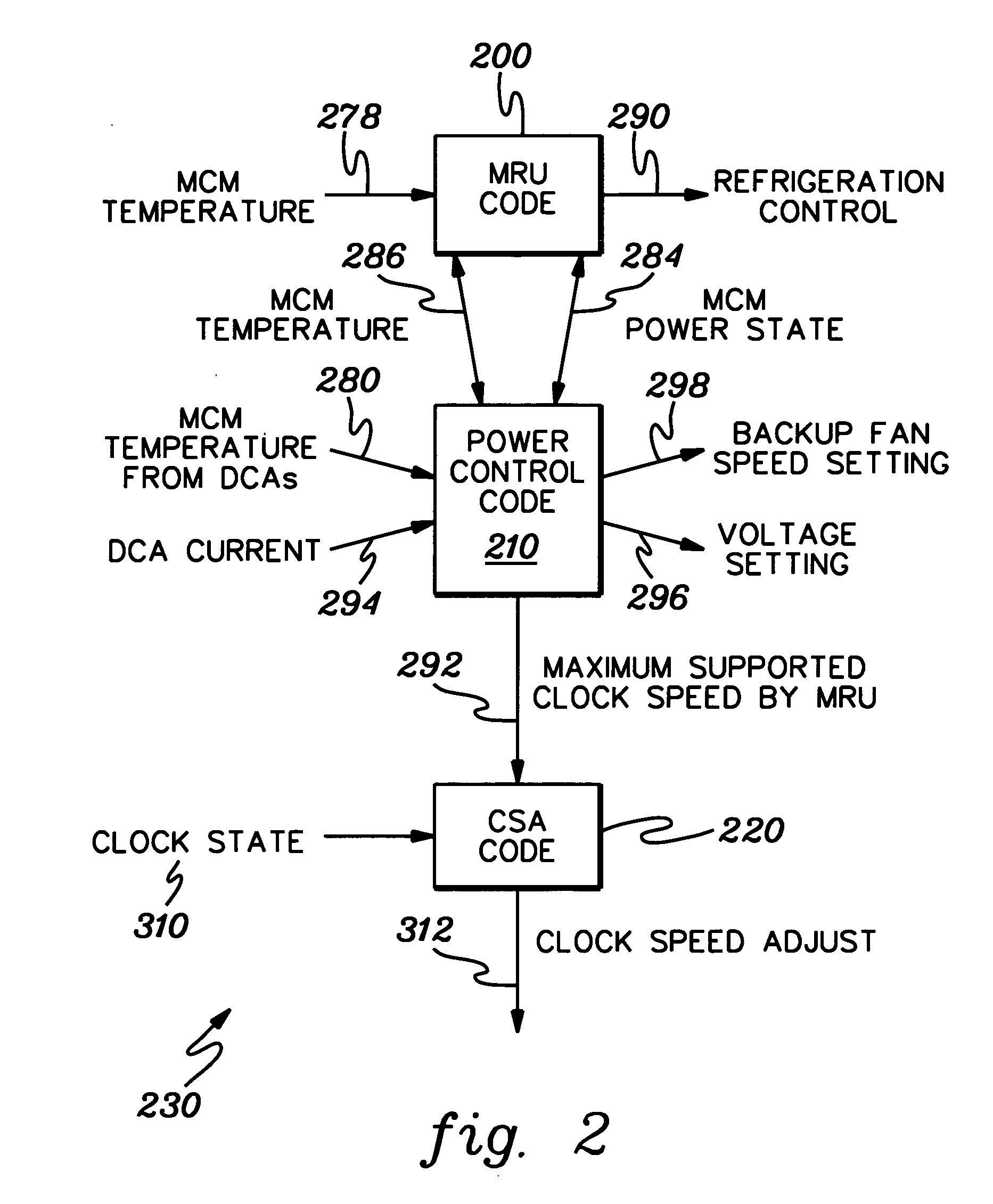

Systems and methods for cooling electronics components employing vapor compression refrigeration with selected portions of expansion structures coated with polytetrafluorethylene

InactiveUS20070044493A1Small structureImprove cooling effectTemperature control without auxillary powerMechanical apparatusEvaporatorPolytetrafluoroethylene

Systems and Methods of cooling heat generating electronics components are provided employing vapor compression refrigeration. In one embodiment, the vapor compression refrigeration system includes a condenser, at least one expansion structure, at least one evaporator, and a compressor coupled in fluid communication to define a refrigerant flow path, and allow the flow of refrigerant therethrough. The at least one evaporator is coupled to the at least one heat generating electronics component to facilitate removal of heat produced by the electronics component. At least a portion of the at least one expansion structure is coated with a polytetrafluorethylene in the refrigerant flow path for inhibiting accumulation of material thereon. The polytetrafluorethylene coating has a thickness sufficient to inhibit accumulation of material in a pressure drop area of the expansion structure without significantly changing a pressure drop characteristic of the pressure drop area.

Owner:IBM CORP

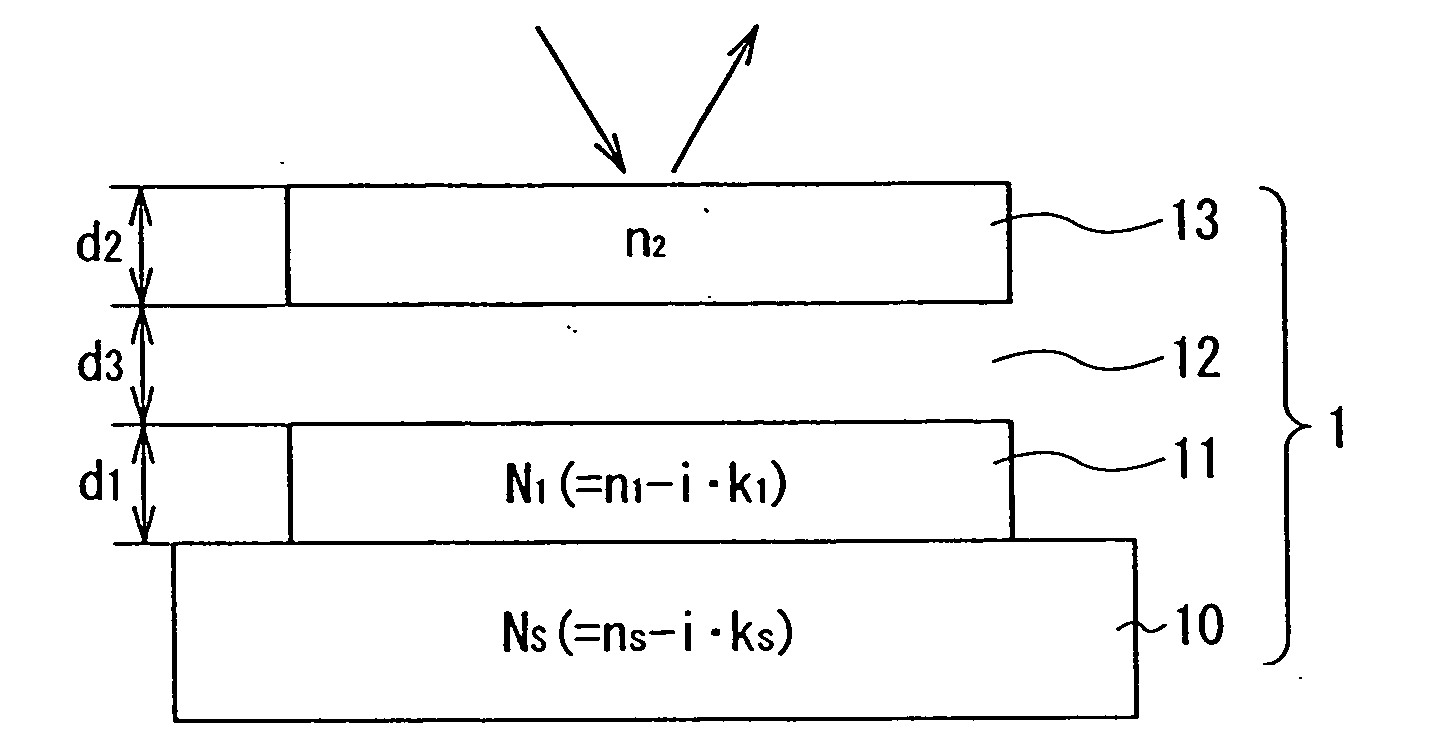

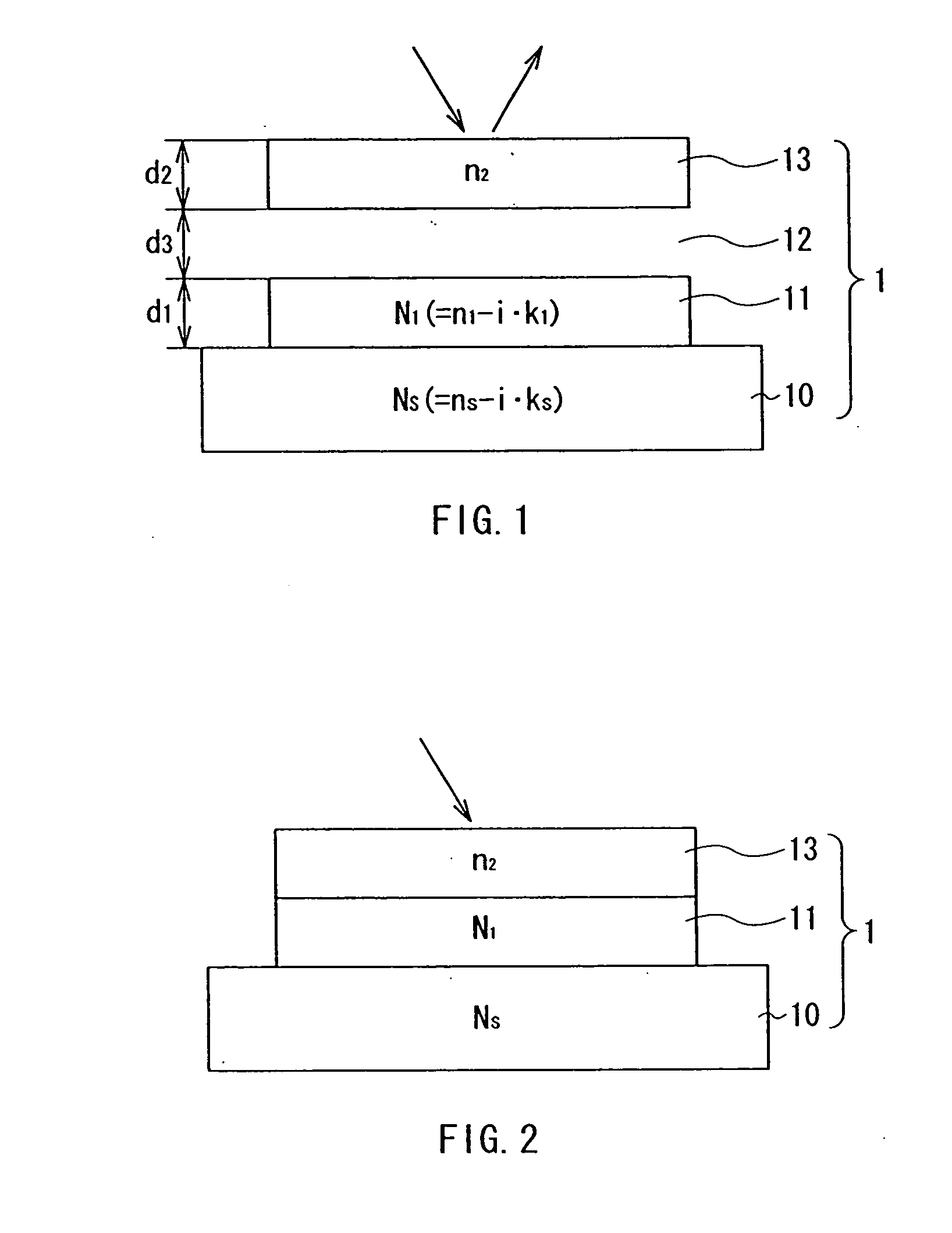

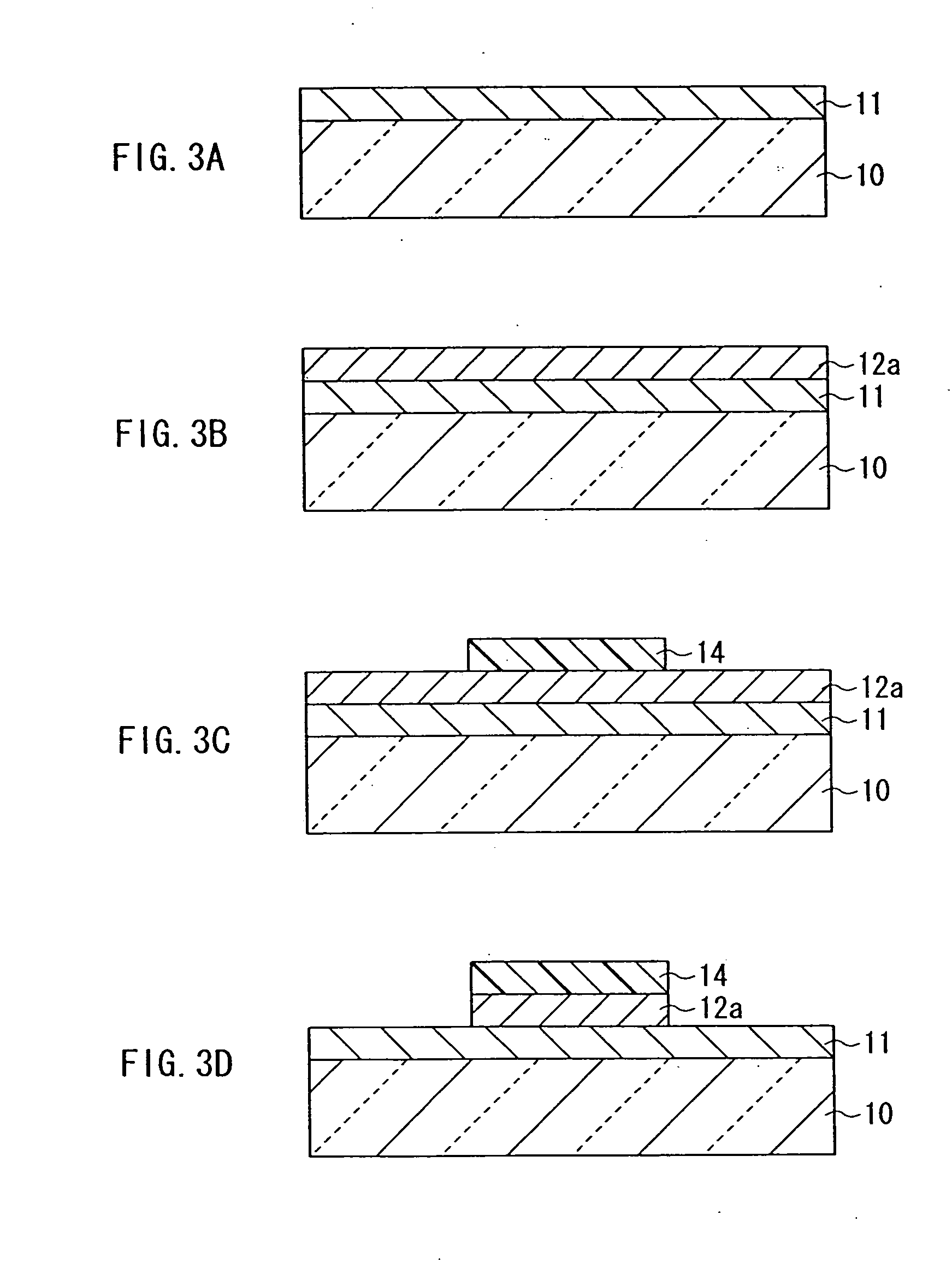

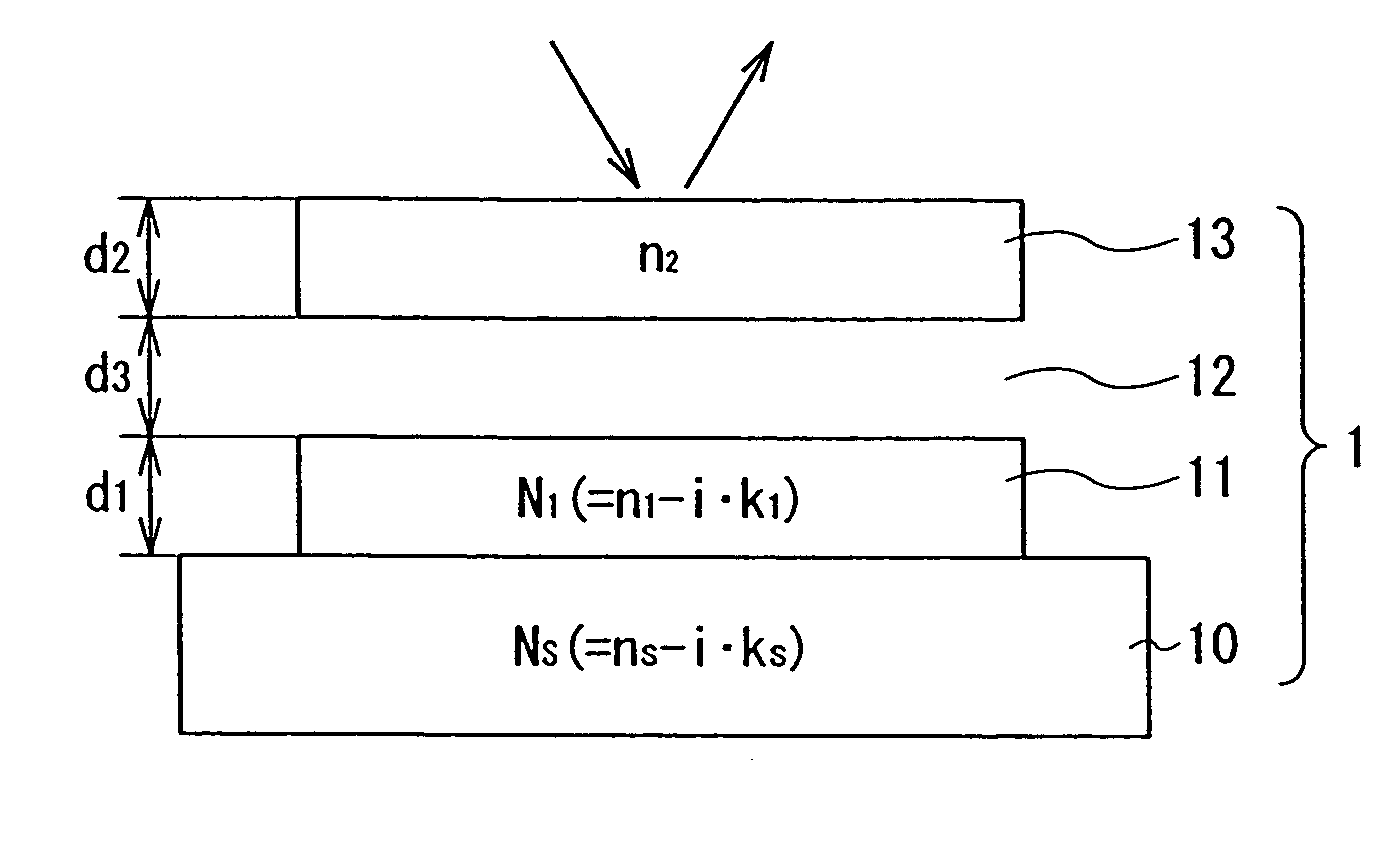

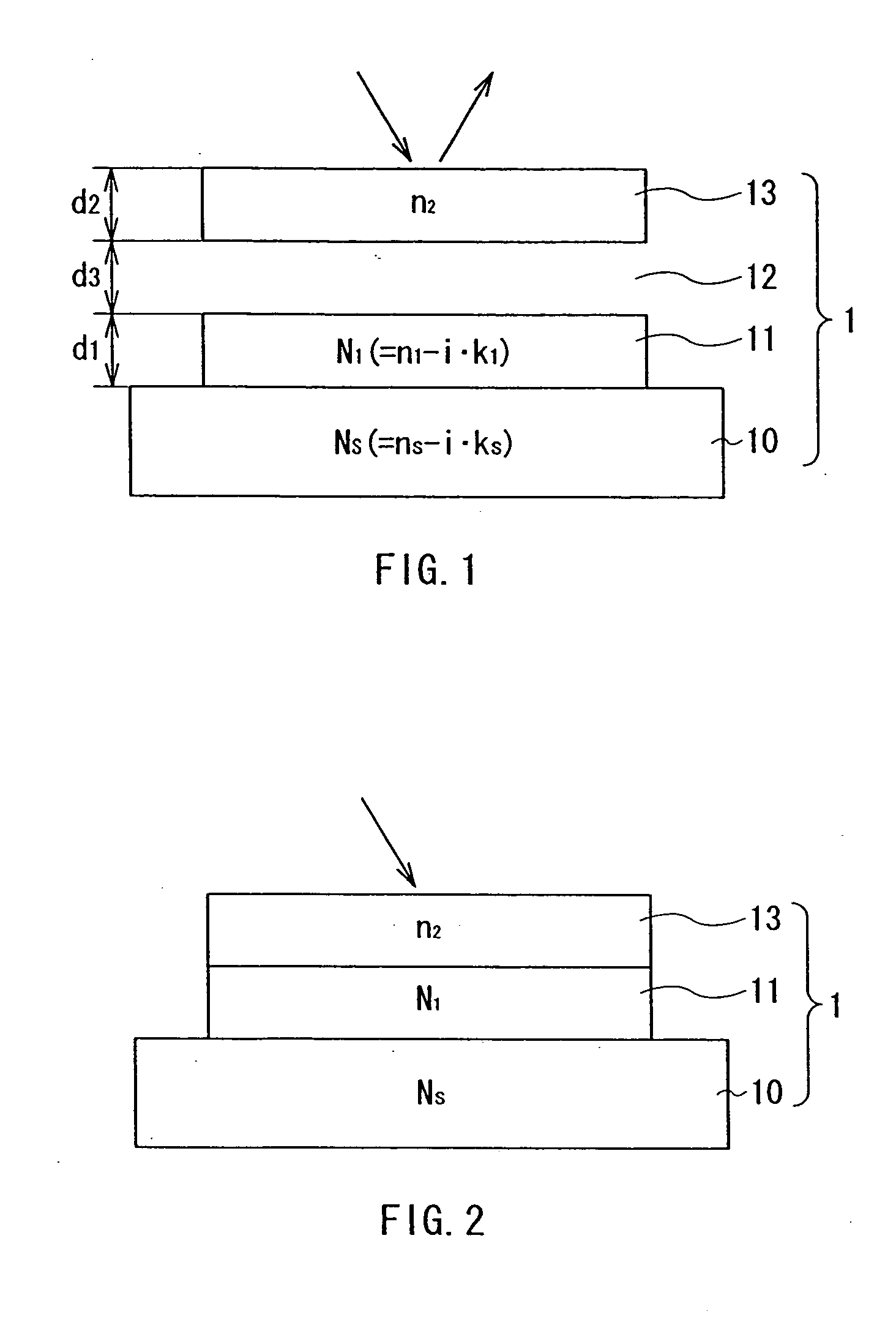

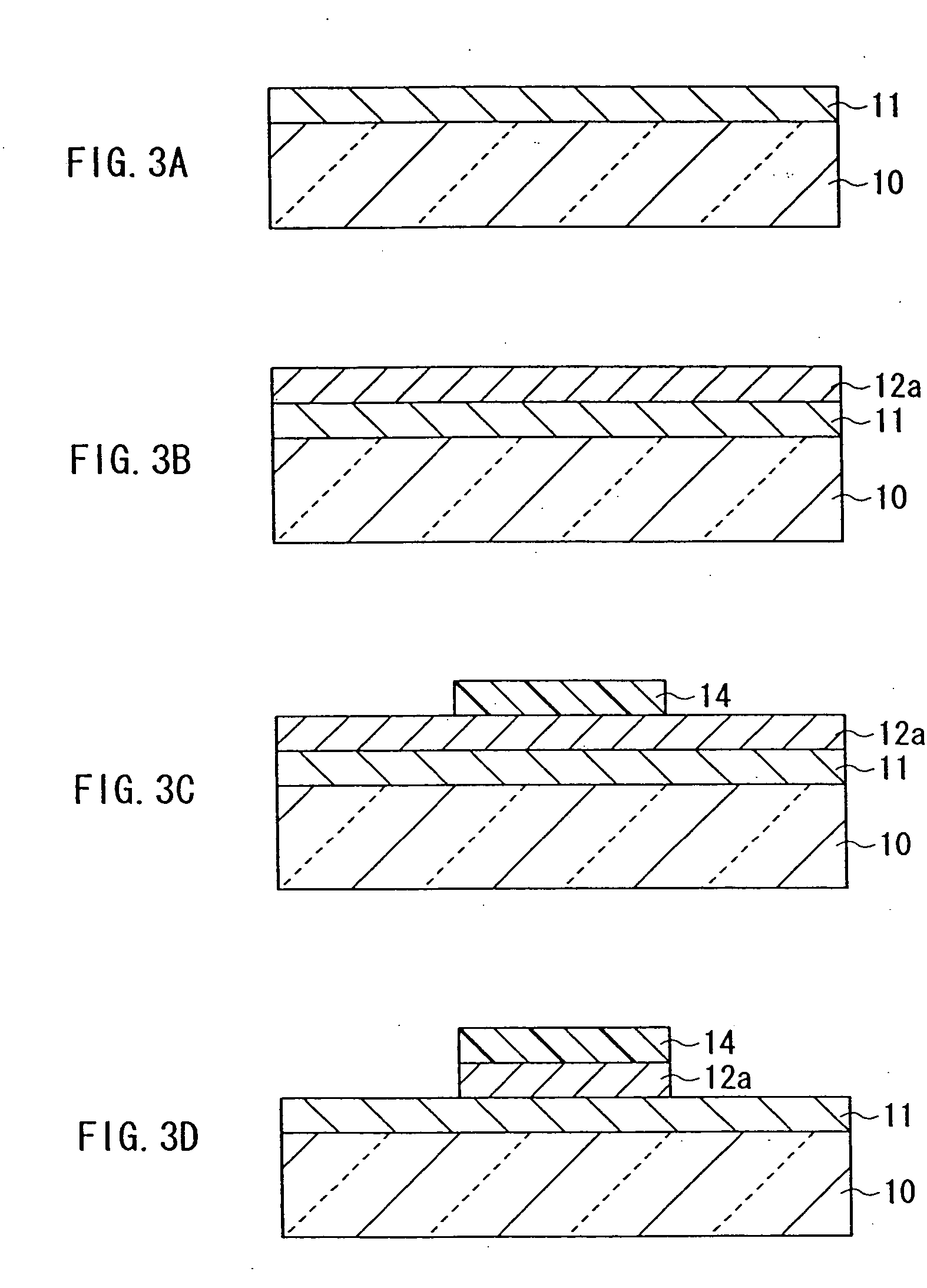

Optical multilayer structure, optical switching device, and image display

InactiveUS20050219680A1Simple configurationSmall structureCoupling light guidesNon-linear opticsInterference phenomenonRefractive index

Owner:SONY CORP

Optical multilayer structure, optical switching device, and image display

InactiveUS20050219679A1Simple configurationSmall structureCoupling light guidesBundled fibre light guideInterference phenomenonRefractive index

Owner:SONY CORP

Inkjet printhead with bubble trap

ActiveUS7401910B2Acceptable increases in resistive lossesSmall structureInking apparatusSpray nozzleEngineering

Owner:MEMJET TECH LTD +1

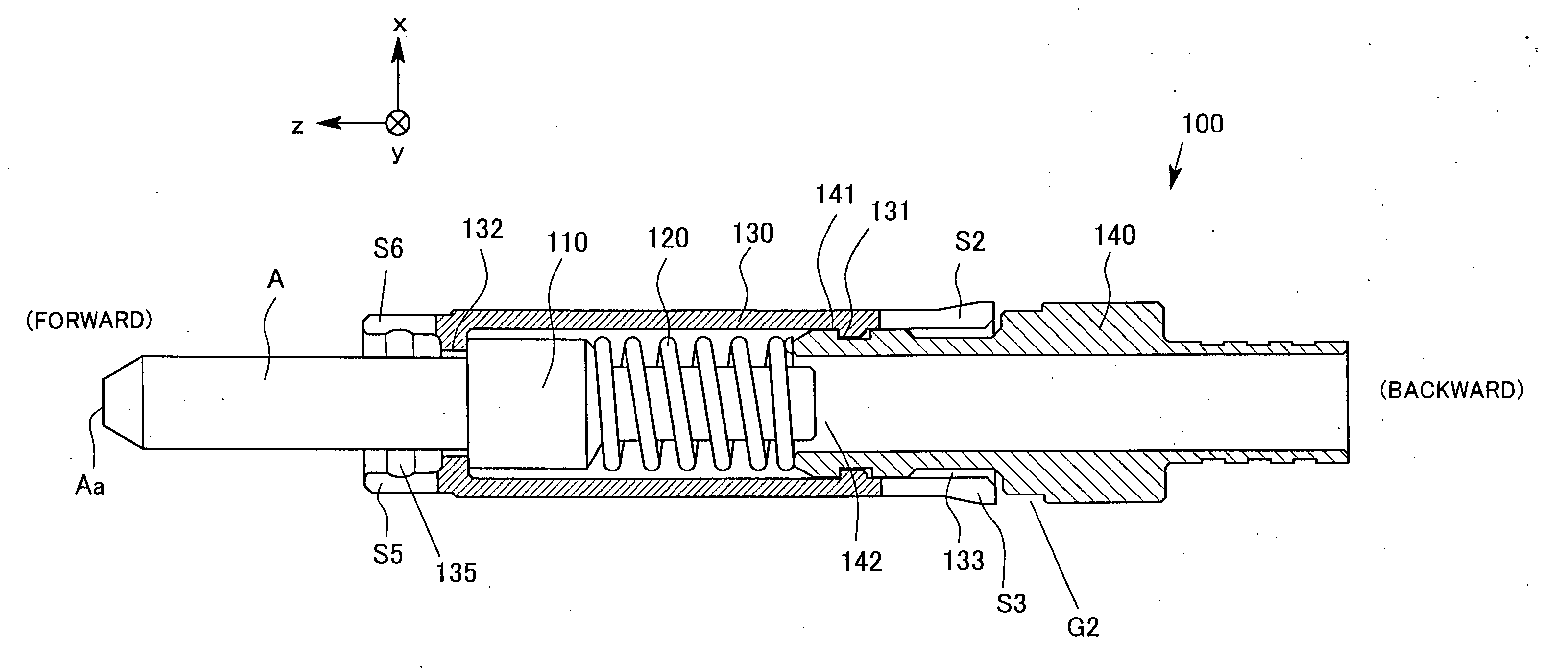

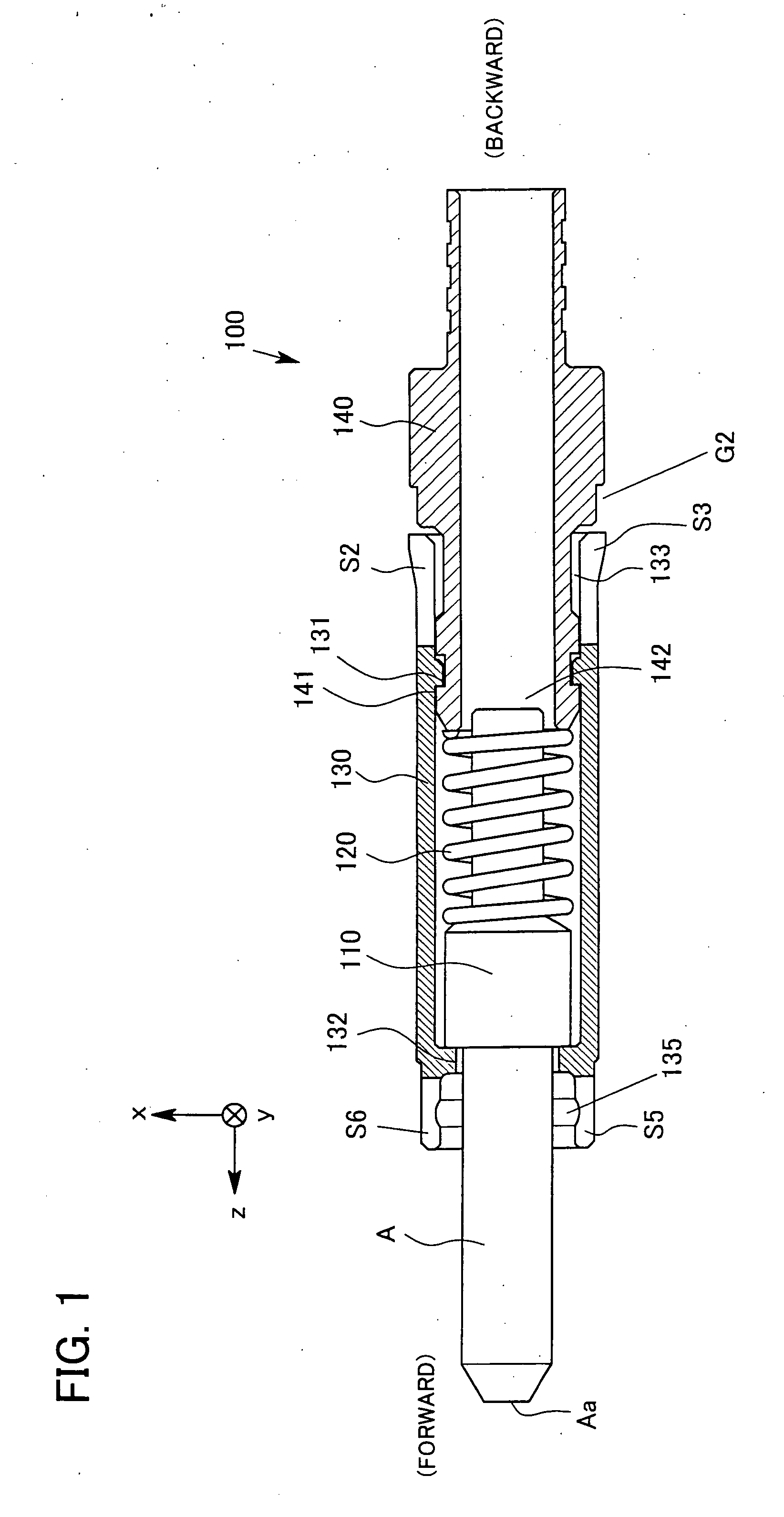

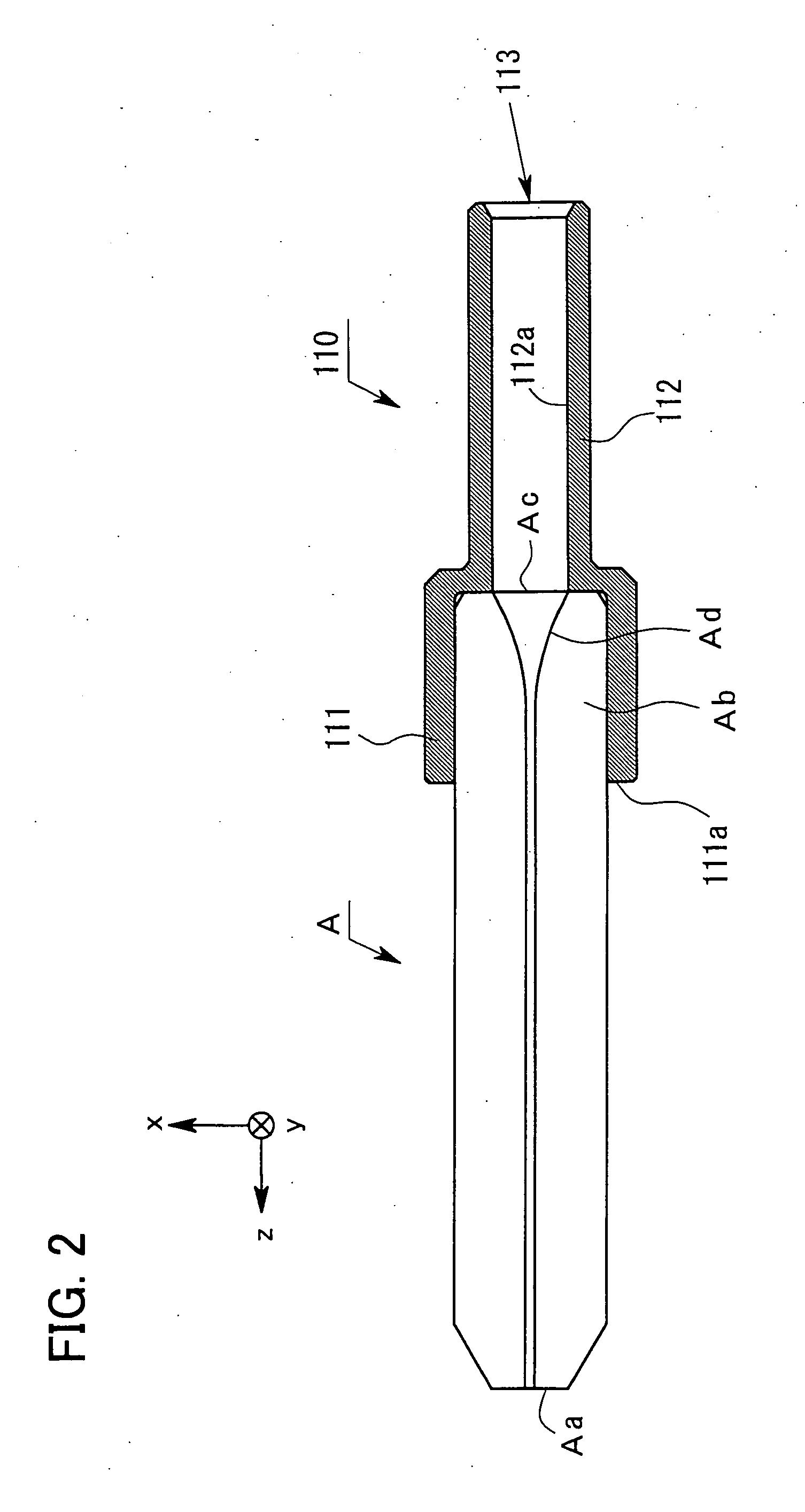

Optical contact unit and optical plug

ActiveUS20050232552A1Advanced technologySmall connection structureCoupling light guidesOptical axisCoil spring

A ferrule holder 110 and a coil spring 120 are comprised in a main body 130 formed in an approximately tube shape. A cable adaptor 140 comprising a front opening part 142 at a large diameter part 141 is inserted from a back opening part 133 into the main body 130 having slits S2 and S3. A first small diameter part 131 of the main body 130 fits with the large diameter part 141 of the cable adaptor 140 and prevents the cable adaptor 140 from translating in the z-axis direction. And the second small diameter part 132 of the main body 130 controls transfer of the ferrule holder 110 in the z-axis direction. At the forward part of the large diameter 141, a taper part which helps to insert the cable adaptor 140 is formed around the circuit of the optical axis. Each slit formed at the back opening part 133 also helps to insert the cable adaptor 140.

Owner:CANARE ELECTRIC

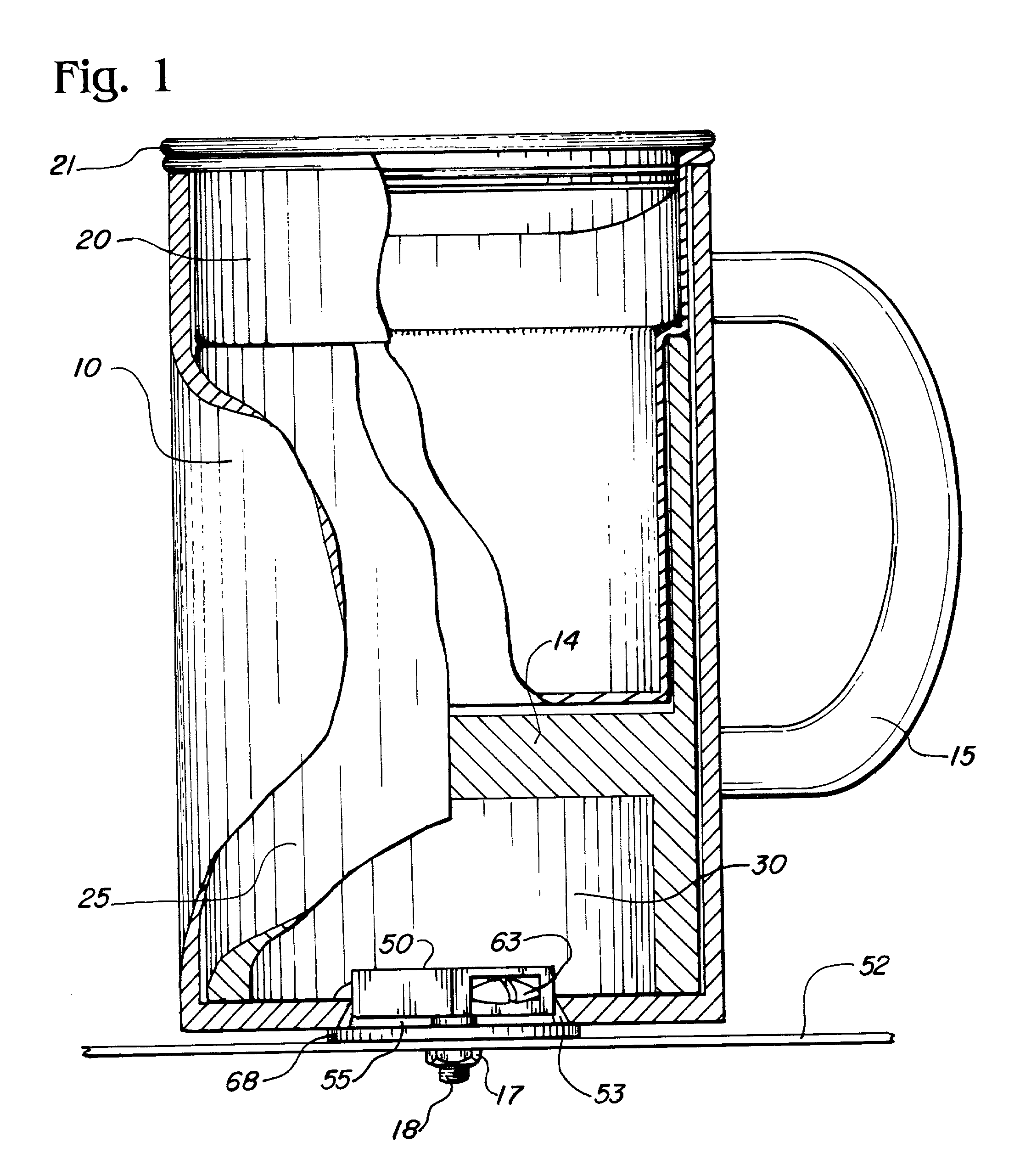

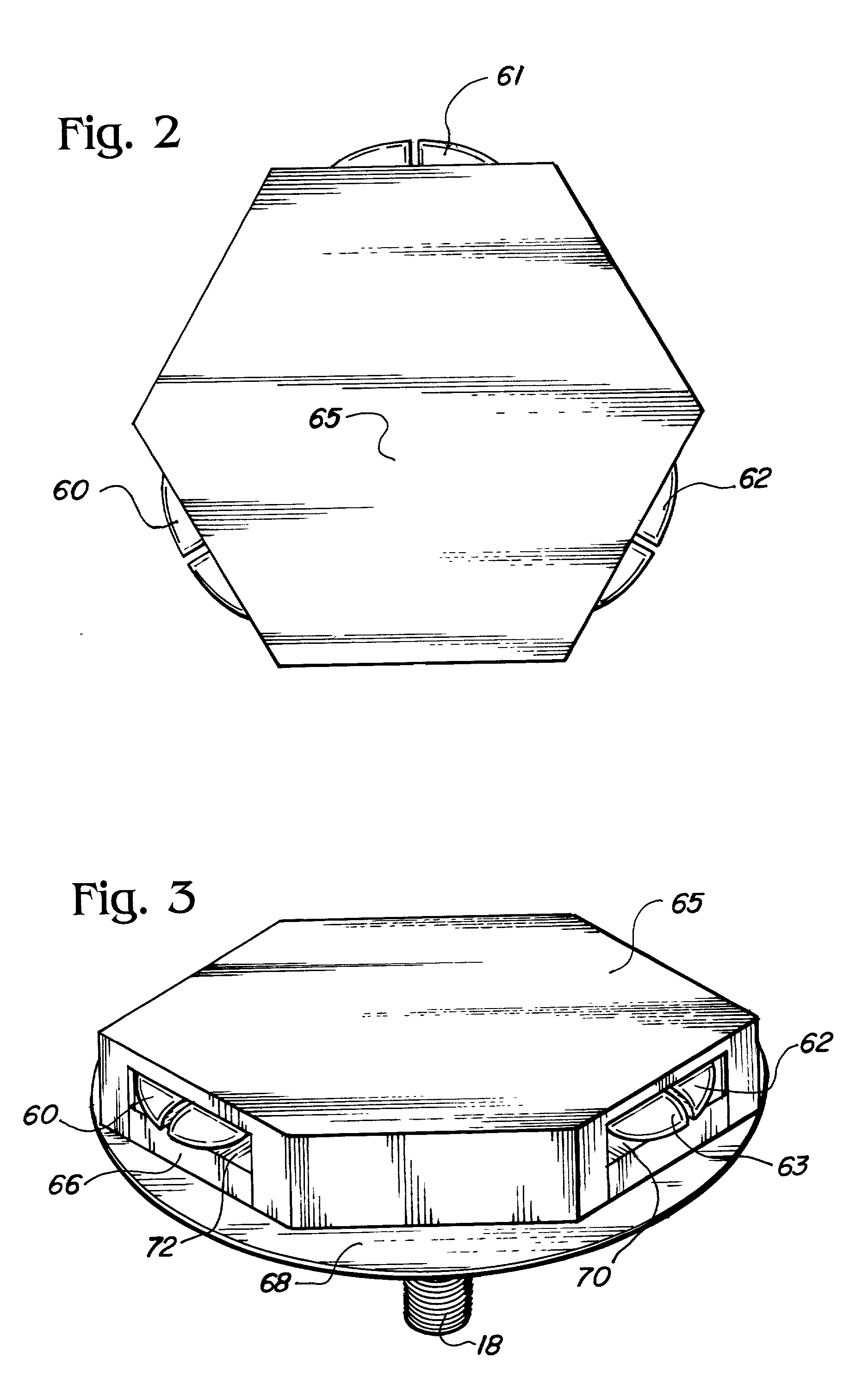

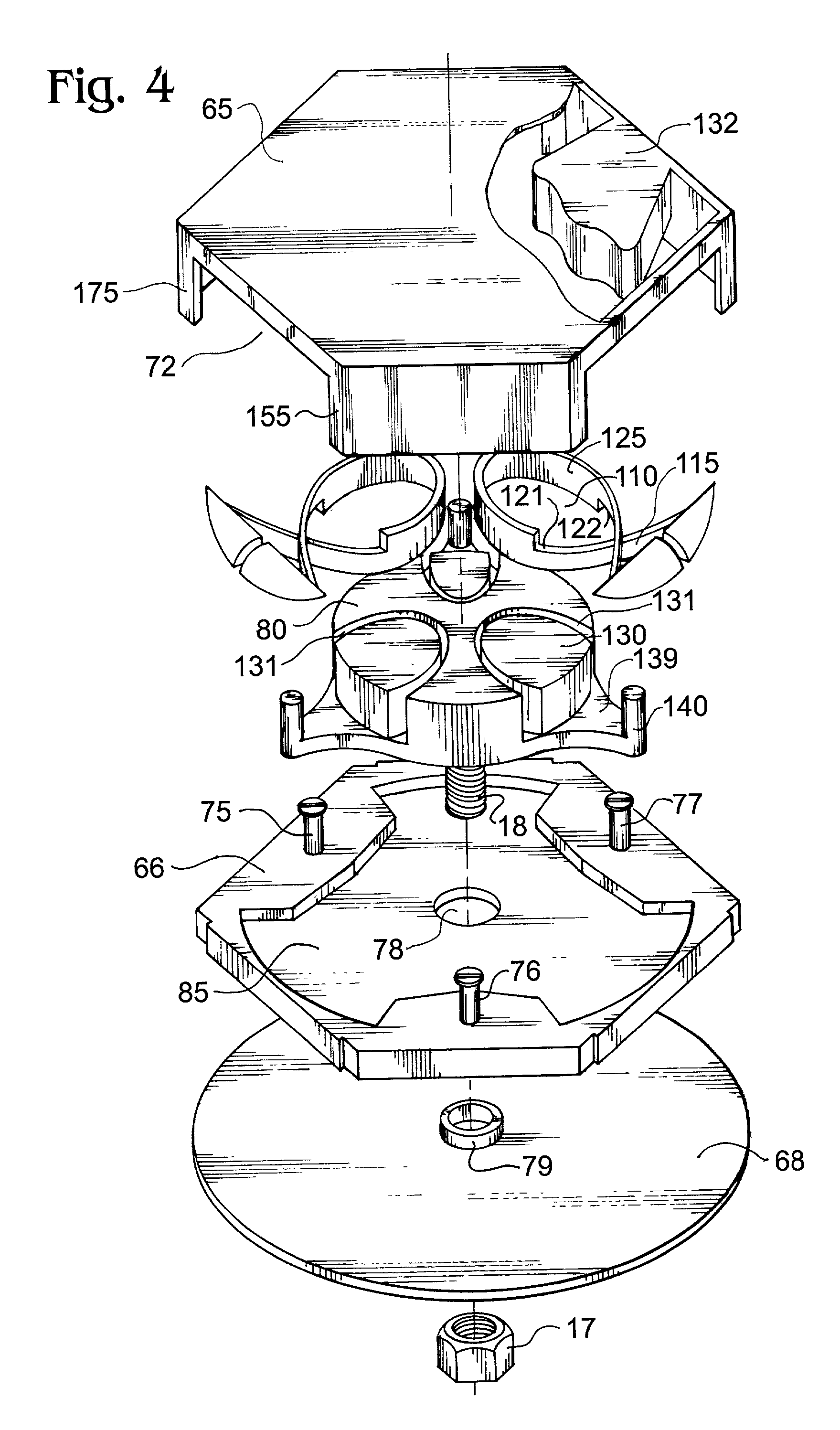

Self locking bi-directional lock/release fixture

InactiveUS20010000617A1Premature releaseImprove load resistanceVehicle arrangementsWash-standsEngineeringSelf locking

Invention provides a self latching, object-holding fixture designed to release a held object whenever the object is turned slightly in either direction. Fixture has a shaped housing and the object to be held has a mated opening of a similar matching shape. Placing an object to be held locks the object to the fixture by spring-loaded latching action. The fixture housing covers a fixed spring holding base that is anchored by any suitable means to a support surface. Covering that fixed-position base, except for exposed spring-loaded keeper latches, is a rotatable casing having a pair of spring compression cam surfaces carried by the casing. Using a cam follower action, these cam surfaces selectively cause the spring to collapse in response to the rotation of the casing holding in either direction of casing rotation. As the object / casing is turned slightly, this cam follower / spring collapse action releasably disengages the keepers from the object being held.

Owner:TRACY DAVID S

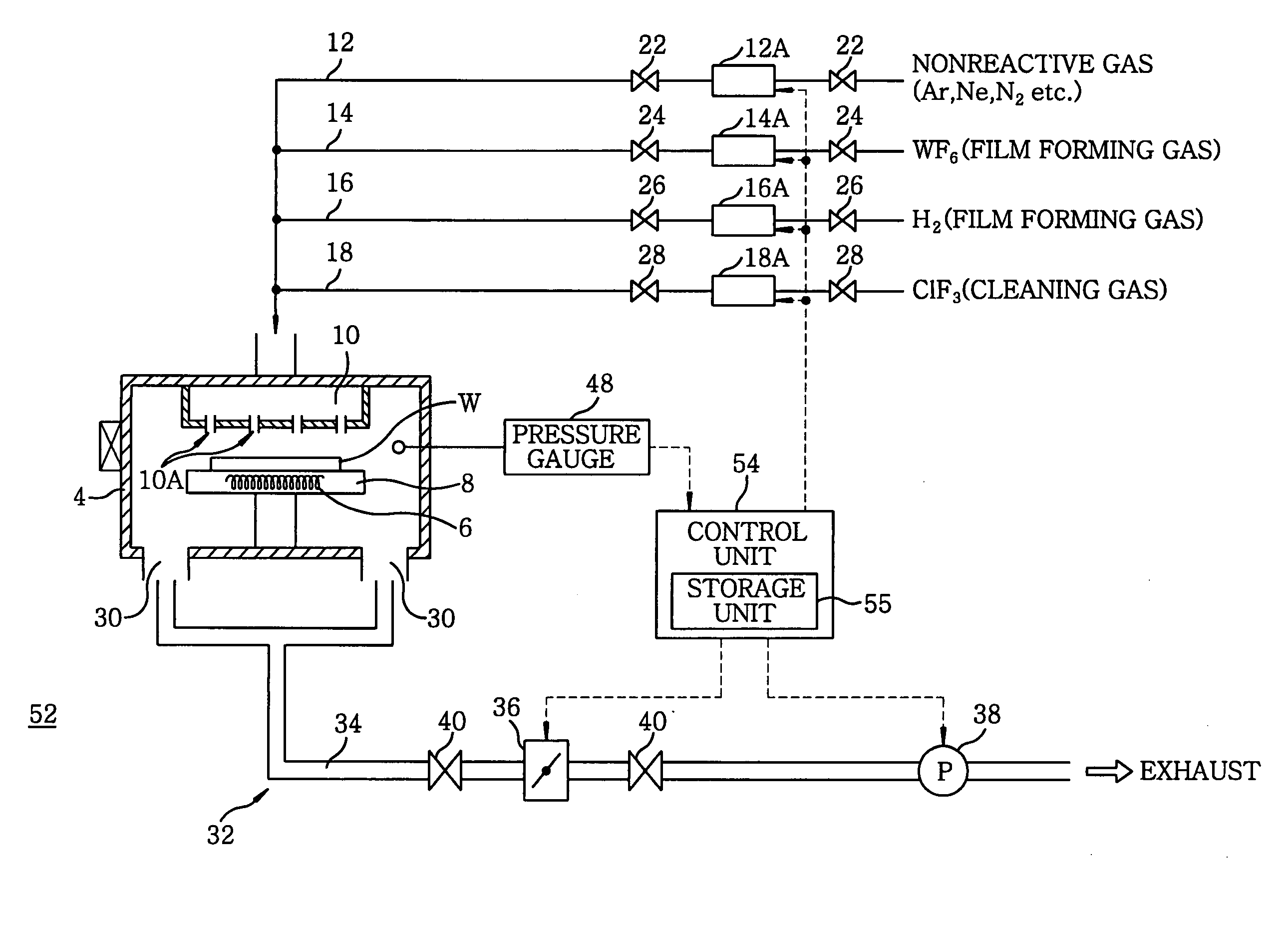

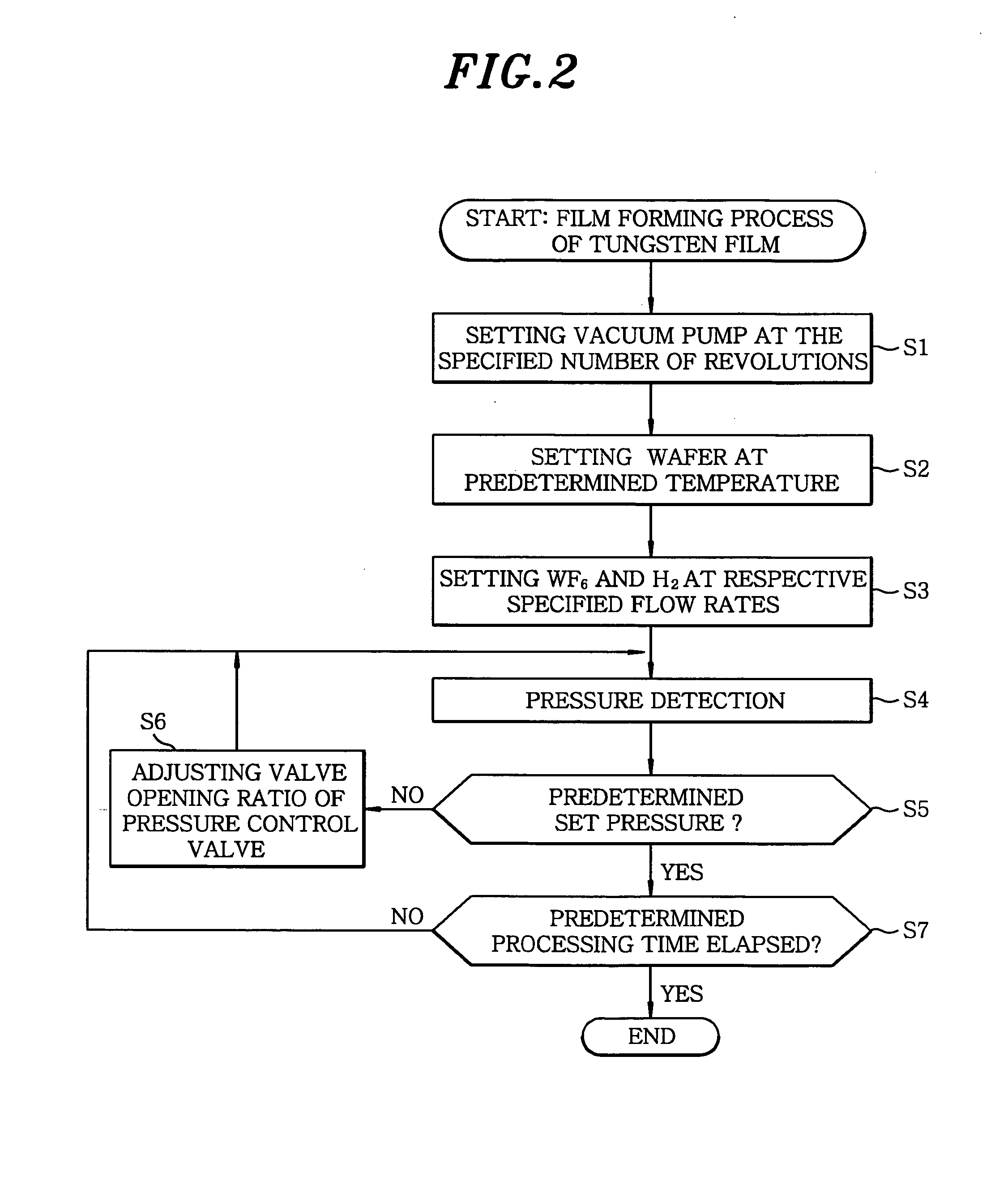

Gas processing apparatus and method and computer storage medium storing program for controlling same

InactiveUS20050189074A1Ensure correct executionWithout usingVacuum gauge using ionisation effectsElectrical testingVacuum pumpingProcess engineering

A processing apparatus includes a processing vessel, a gas introduction unit, a processing gas supply unit, a nonreactive gas supply unit, a vacuum pumping unit, a pressure gauge and a control unit. The control unit controls a valve opening ratio of a pressure control valve based on a detection value of the pressure gauge while making a processing gas flow to a flow rate controller of the processing gas supply unit at a constant flow rate when performing a process in which a partial pressure of the processing gas is important. Meanwhile, when performing a process wherein the partial pressure of the processing gas is relatively unimportant, the control unit fixes the valve opening ratio of the pressure control valve at a predetermined value, and operating a flow rate controller of the nonreactive gas supply unit to control a flow rate based on the detection value.

Owner:TOKYO ELECTRON LTD

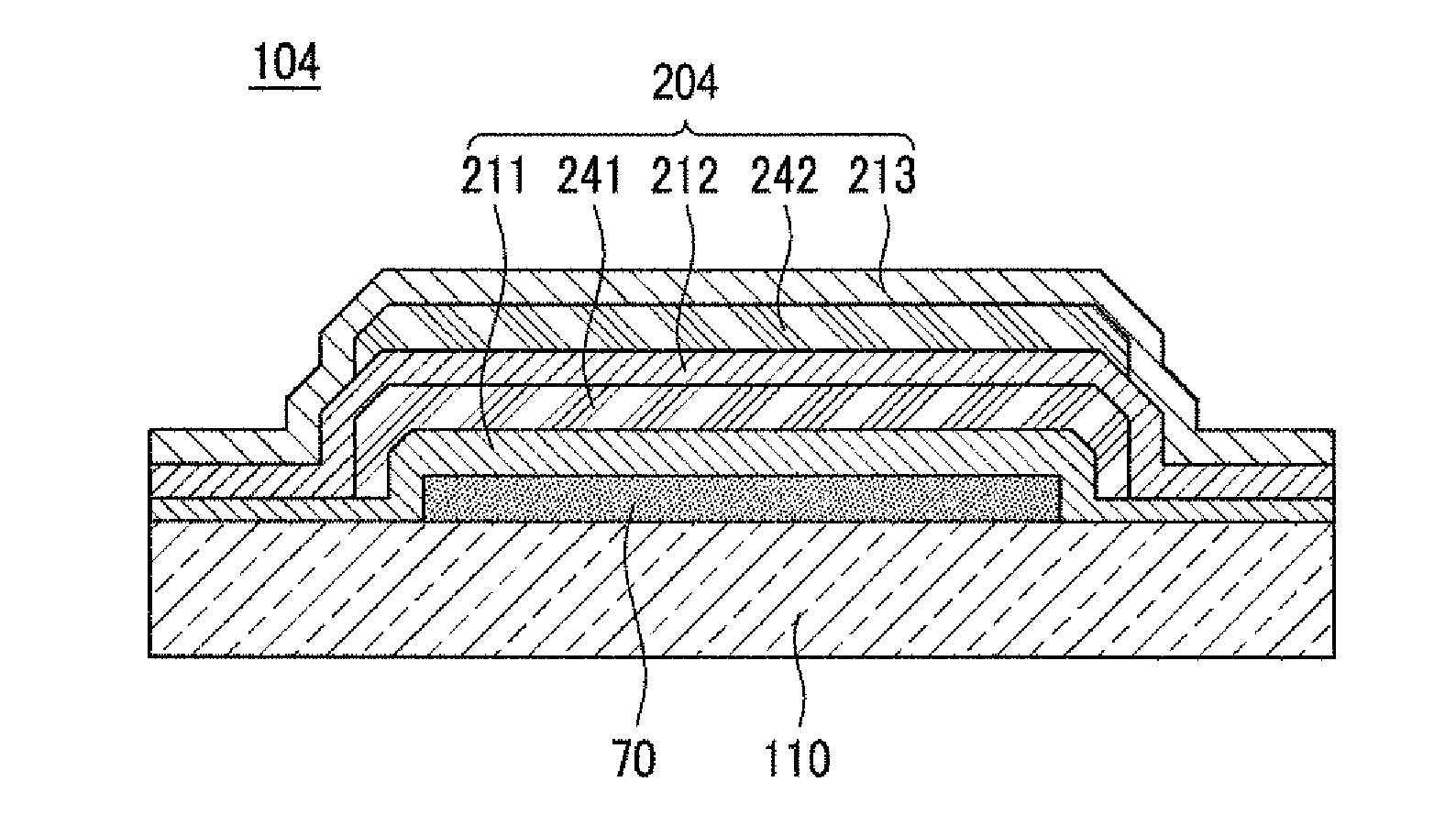

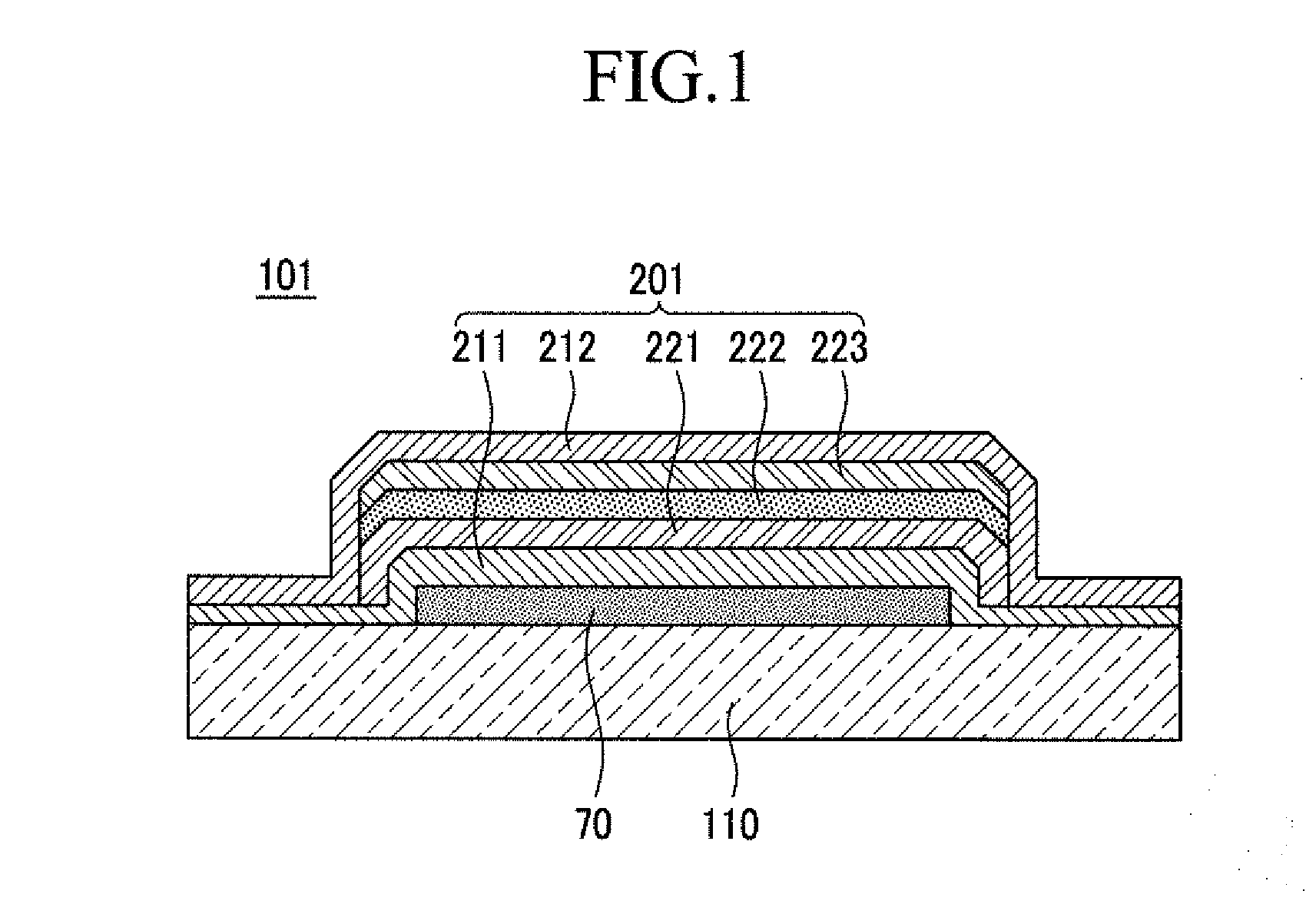

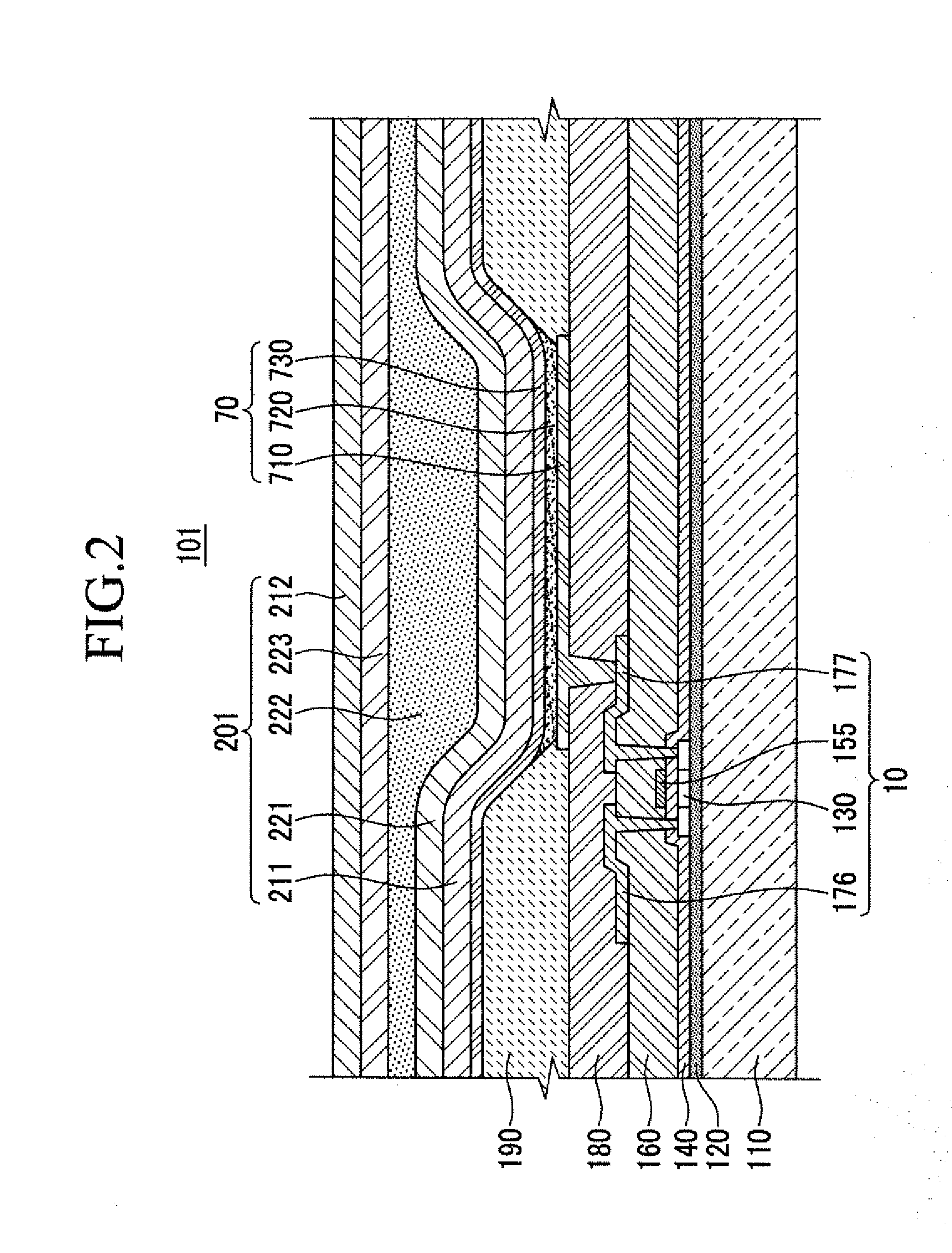

Organic Light Emitting Diode Display and Method for Manufacturing the Same

ActiveUS20130092972A1Simple structureSuppressing permeation of moistureSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceAtomic layer deposition

An organic light emitting diode (OLED) display includes: a substrate; an organic light emitting diode formed on the substrate; a first inorganic layer formed on the substrate and covering the organic light emitting diode; an intermediate layer formed on the first inorganic layer and covering an area relatively smaller than the first inorganic layer; and a second inorganic layer formed on the first inorganic layer and the intermediate layer, and contacting the first inorganic layer at an edge thereof while covering a relatively larger area than the intermediate layer. A third inorganic layer may be formed on the second inorganic layer so as to contact the second inorganic layer at an edge thereof. At least one of the first, second and third inorganic layers is formed by an atomic layer deposition (ALD) method.

Owner:SAMSUNG DISPLAY CO LTD

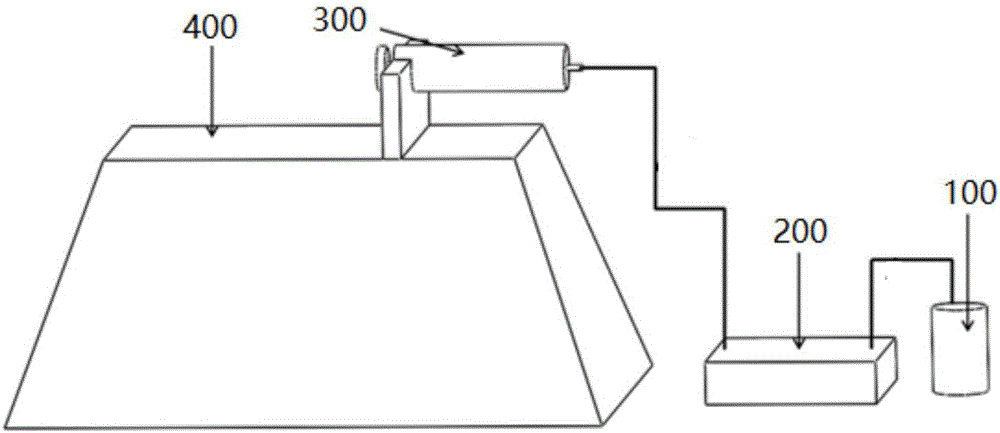

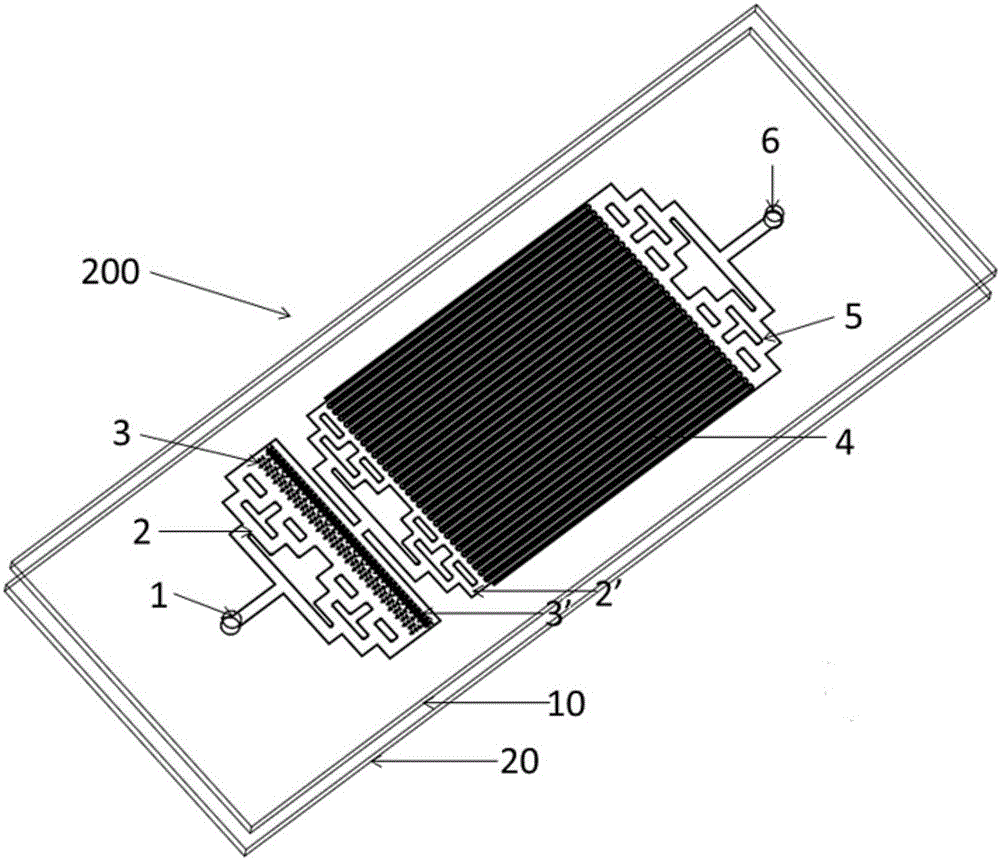

Micro-fluidic device and method for detecting circulating tumor cell on basis of dimension

ActiveCN106076441ASolve the detection speed is slowHigh detection sensitivityPreparing sample for investigationLaboratory glasswaresInjection portCirculating cancer cell

The invention provides a micro-fluidic device and a method for detecting circulating tumor cells on the basis of dimensions. The micro-fluidic device comprises a solution storage chamber, a micro-fluidic chip, a waste liquid collecting syringe and a power system which are connected in sequence, wherein the micro-fluidic chip is made of a glass substrate layer and a PDMS (Polydimethylsiloxane) chip layer in a laminated manner; the PDMS chip layer comprises an injection port, a block mass filtering area, a target sell screening area and a discharge port which are communicated in sequence; the block mass filtering area is formed by a column array; the target cell screening area comprises a plurality of main pipelines and side pipelines which are extended in a parallel manner at intervals and are communicated through filtering channels; the front ends of the main pipelines are opened; the filtering channels are formed in the rear ends of the main pipelines; the front ends of the side pipelines are sealed; the rear ends of the side pipelines are opened; the main pipelines and the side pipelines have a first height greater than the dimensions of the circulating tumor cells; the filtering channels have a second height smaller than the dimensions of the circulating tumor cells. The micro-fluidic device and the method for detecting the circulating tumor cells on the basis of the dimensions are good in sensitivity, simple to operate, low in cost, large in flux and short in time.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

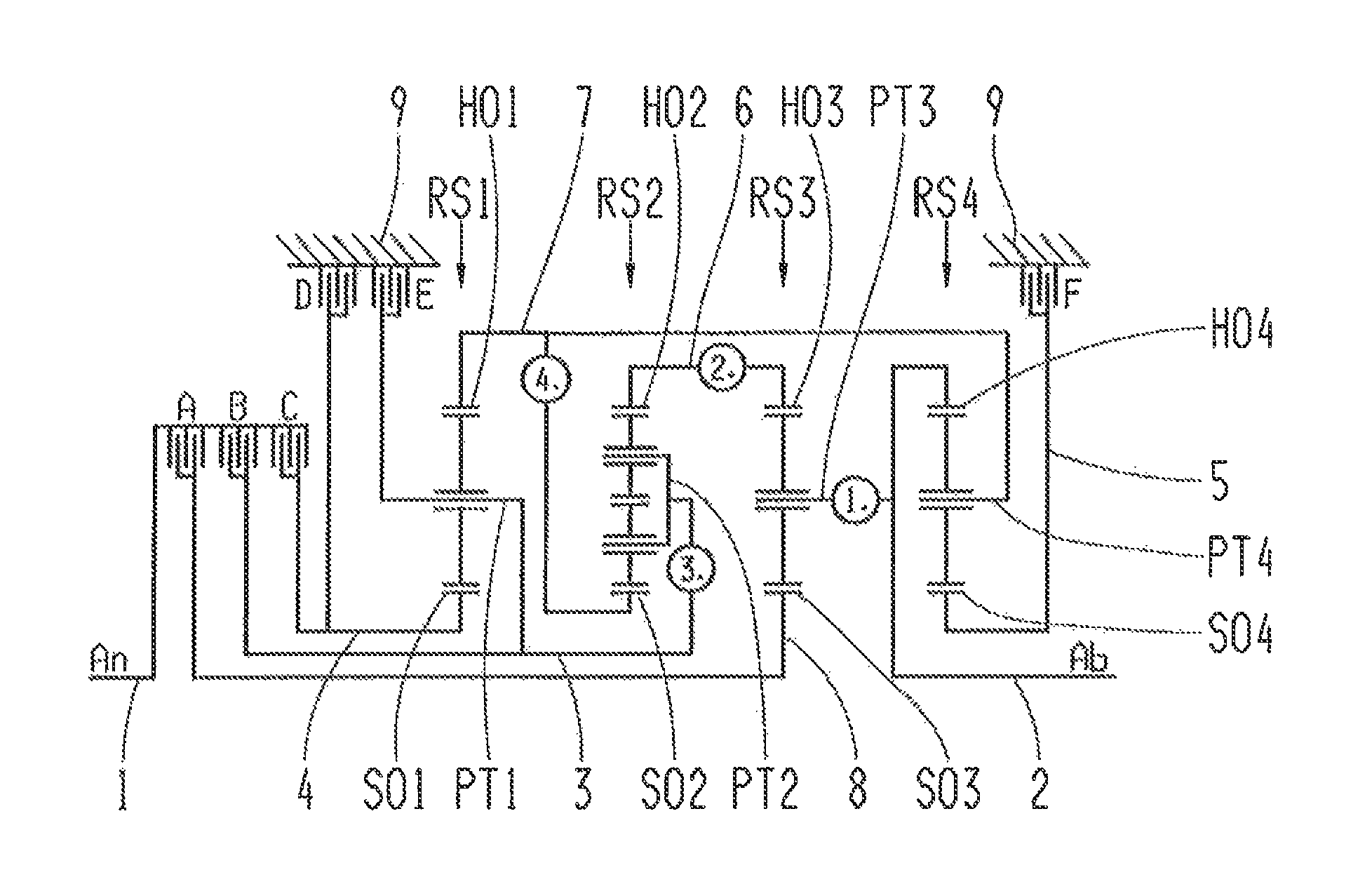

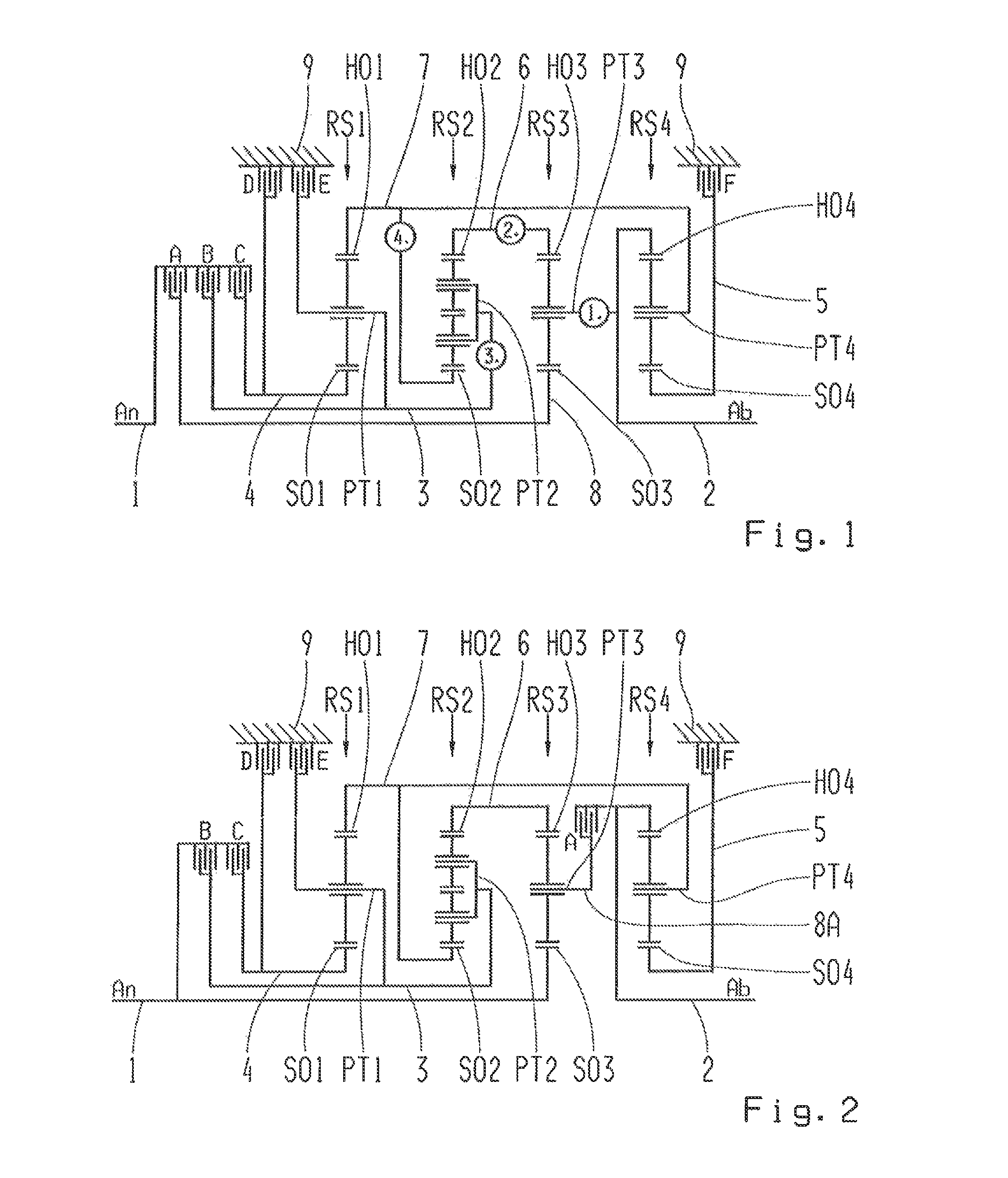

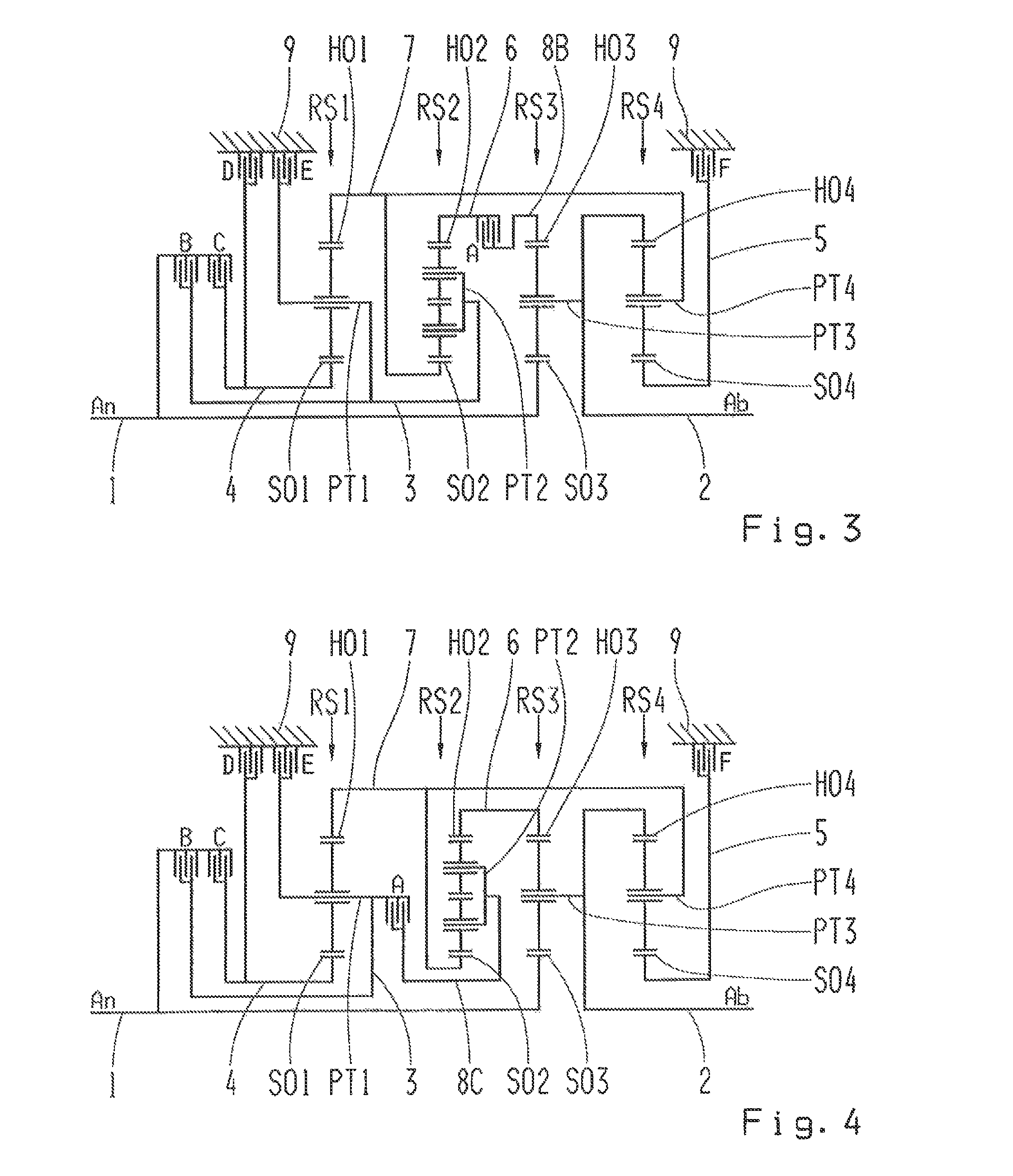

Multi-stage planetary vehicle transmission

InactiveUS8992373B2Improve efficiencyLittle structural complexityToothed gearingsTransmission elementsEngineeringGear transmission

A multi-gear transmission of a vehicle having a housing in which four planetary gearsets and a plurality of shafts and shifting elements are arranged. The drive input shaft can couple the sun gears of gearsets (RS1, RS3) and the carrier of gearset (RS1) and can be connected indirectly to the carrier of gearset (RS2). The drive output shaft couples the ring gear of gearset (RS4) and is connected directly or can be indirectly connected to the carrier of gearset (RS3), the sun gear and carrier of gearset (RS1) and the sun gear of gearset (RS4) can be connected to the housing. The ring gear of gearset (RS1) couples the carrier of gearset (RS4) and can be or is connected to the sun gear of gearset (RS2), and the ring gear of gearset (RS2) and the ring gear of gearset (RS3) are, or can be, connected to one another.

Owner:ZF FRIEDRICHSHAFEN AG

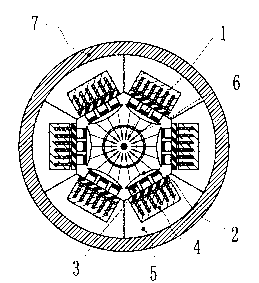

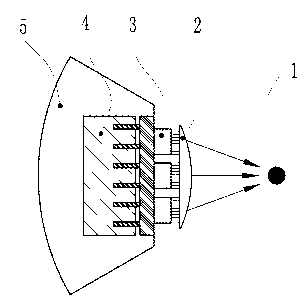

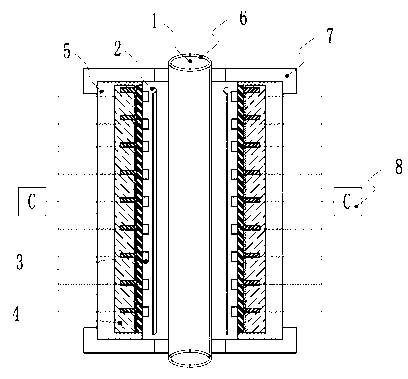

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

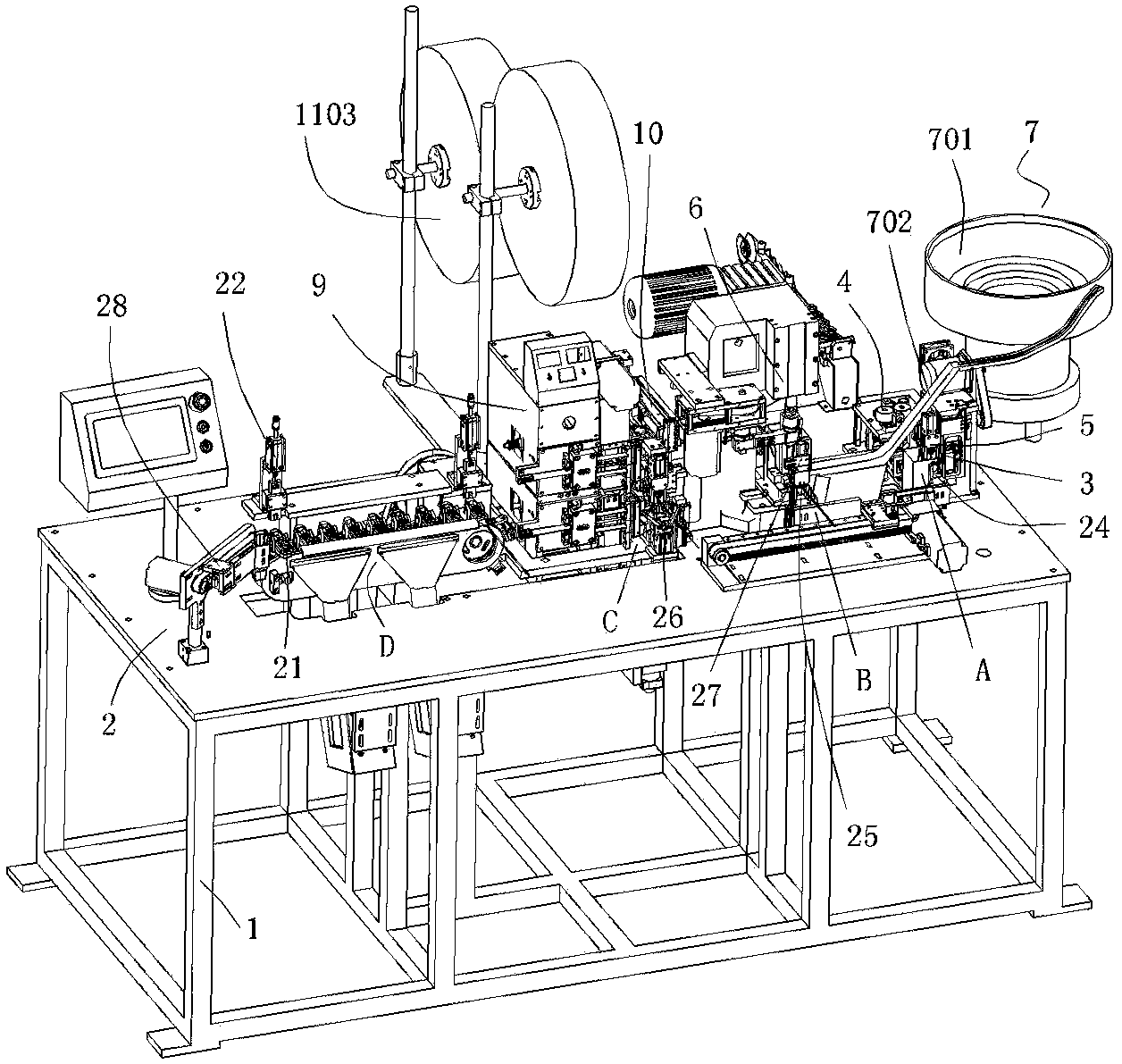

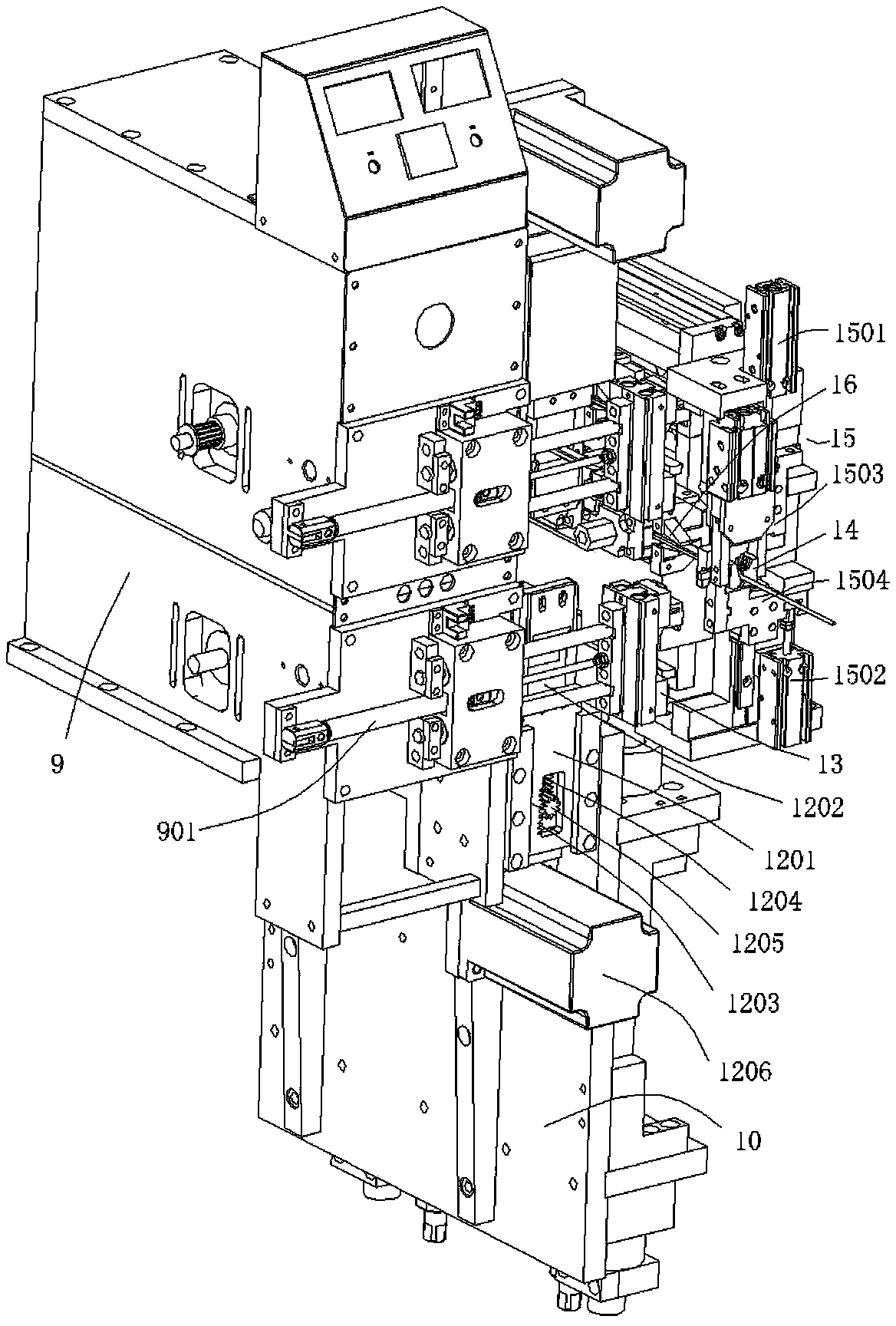

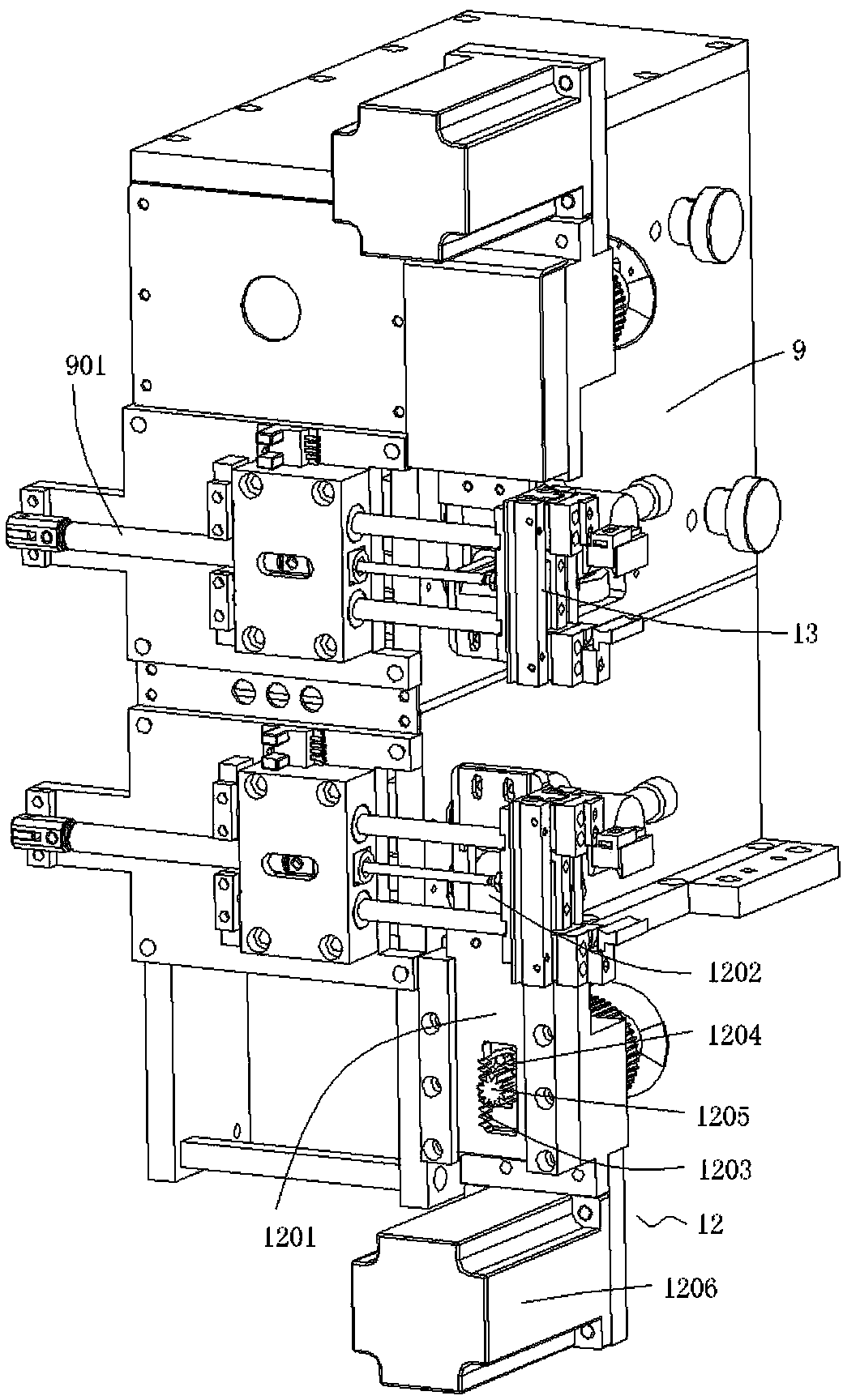

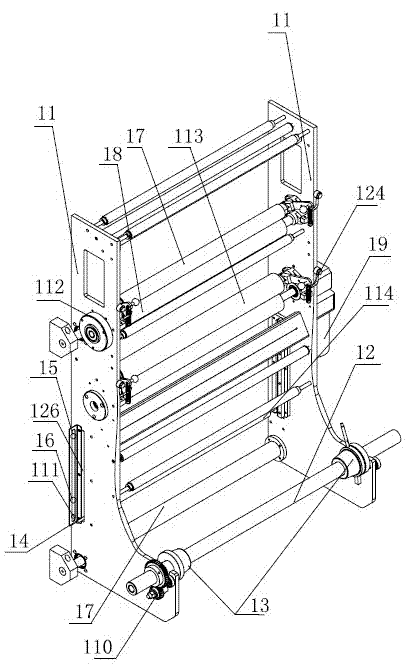

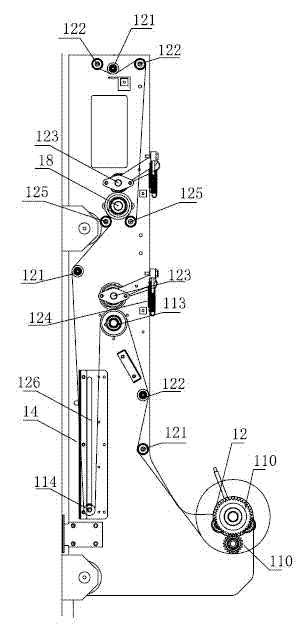

Full-automatic heat shrinkage tube penetrating pressing machine

ActiveCN104319592ACompact structureSmall structureConnection formation by deformationWire cuttingManipulator

The invention provides a full-automatic heat shrinkage tube penetrating pressing machine. The pressing machine comprises a machine frame and a workbench arranged on the machine frame. The workbench is sequentially provided with a wire cutting and peeling station, a terminal pressing station, a heat shrinkage tube penetrating station and a heat adhesion station side by side. A wire cutting and peeling mechanism, wire feeding mechanisms and wire pulling mechanical arms are arranged on the wire cutting and peeling station, a terminal pressing mechanism, terminal feeding mechanisms and pressing positioning mechanical arms are arranged on the terminal pressing station, tube feeding mechanisms, tube cutting mechanisms, tube feeding mechanical arms, wire clamping mechanical arms, a tube penetrating positioning mechanism and tube penetrating mechanical arms are arranged on the heat shrinkage tube penetrating station, and a conveying chain, a clamping mechanism, an opening mechanism and a heating mechanism are arranged on the heat adhesion station. The pressing machine further comprises a first transfer mechanical arm, a second transfer mechanical arm, a third transfer mechanical arm, a first take-up mechanism and a second take-up mechanism. By the adoption of the structure, the automation degree is high, wire harnesses of three structures can be machined, the functions are diversified, the application range is wide, production efficiency is high, production quality is good, and labor cost is low.

Owner:HONGSHENG MACHINERY EQUIP

Cold storage device, in particular for an automobile

InactiveUS6101830ASmall structureProduced cost-effectivelyAir-treating devicesDomestic cooling apparatusLiquid stateEngineering

The invention relates to a cold storage device, in particular for an automobile, having a storage medium for storing cold and a storage medium carrier that is connected in a thermally conductive manner to pipes for carrying a heat transfer medium for charging or discharging the cold storage device. To provide an improved cold storage device particularly suitable for use in an automobile, that is able to accommodate changes in volume of the storage medium while itself having a small structural volume and which can be produced cost-effectively, the storage medium carrier comprises an absorbent material, and the storage medium, in its liquid state, is preferably completely absorbed by the storage medium carrier.

Owner:BEHR GMBH & CO KG

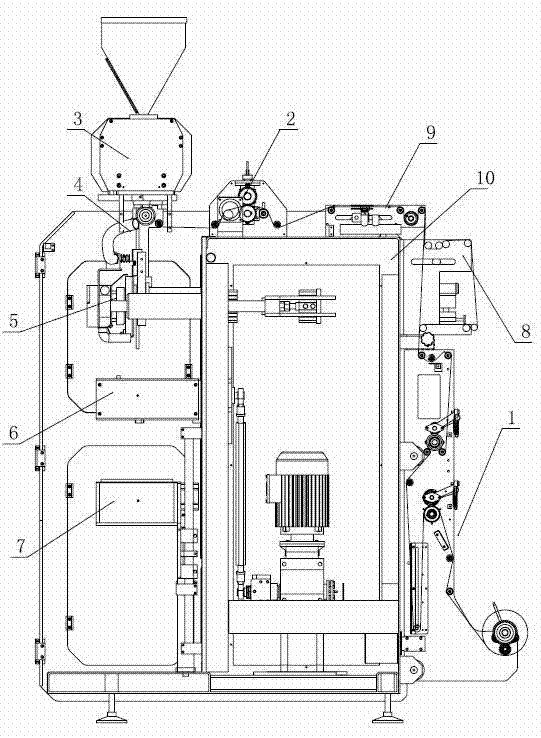

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com