Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1977 results about "Head moving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

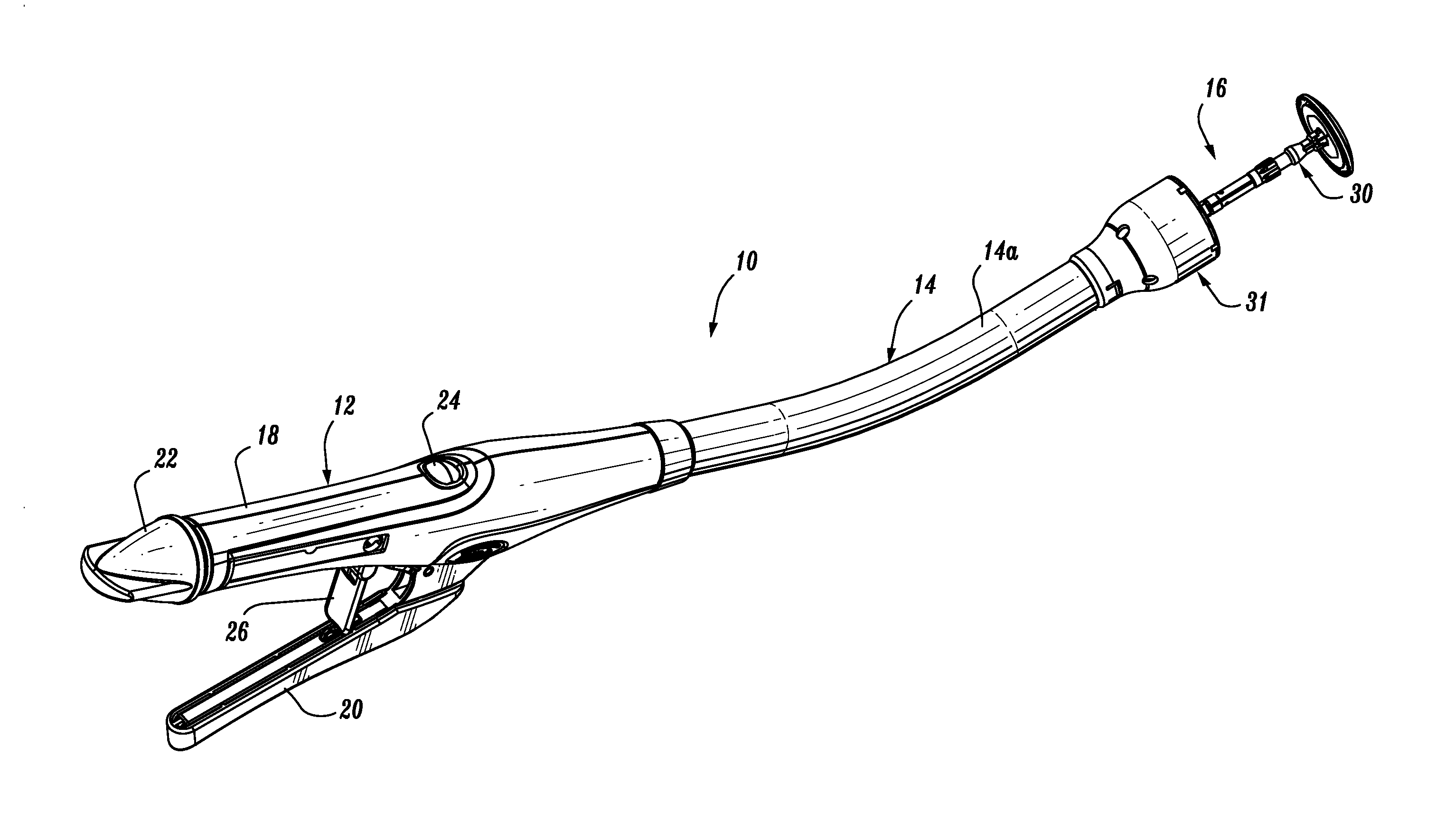

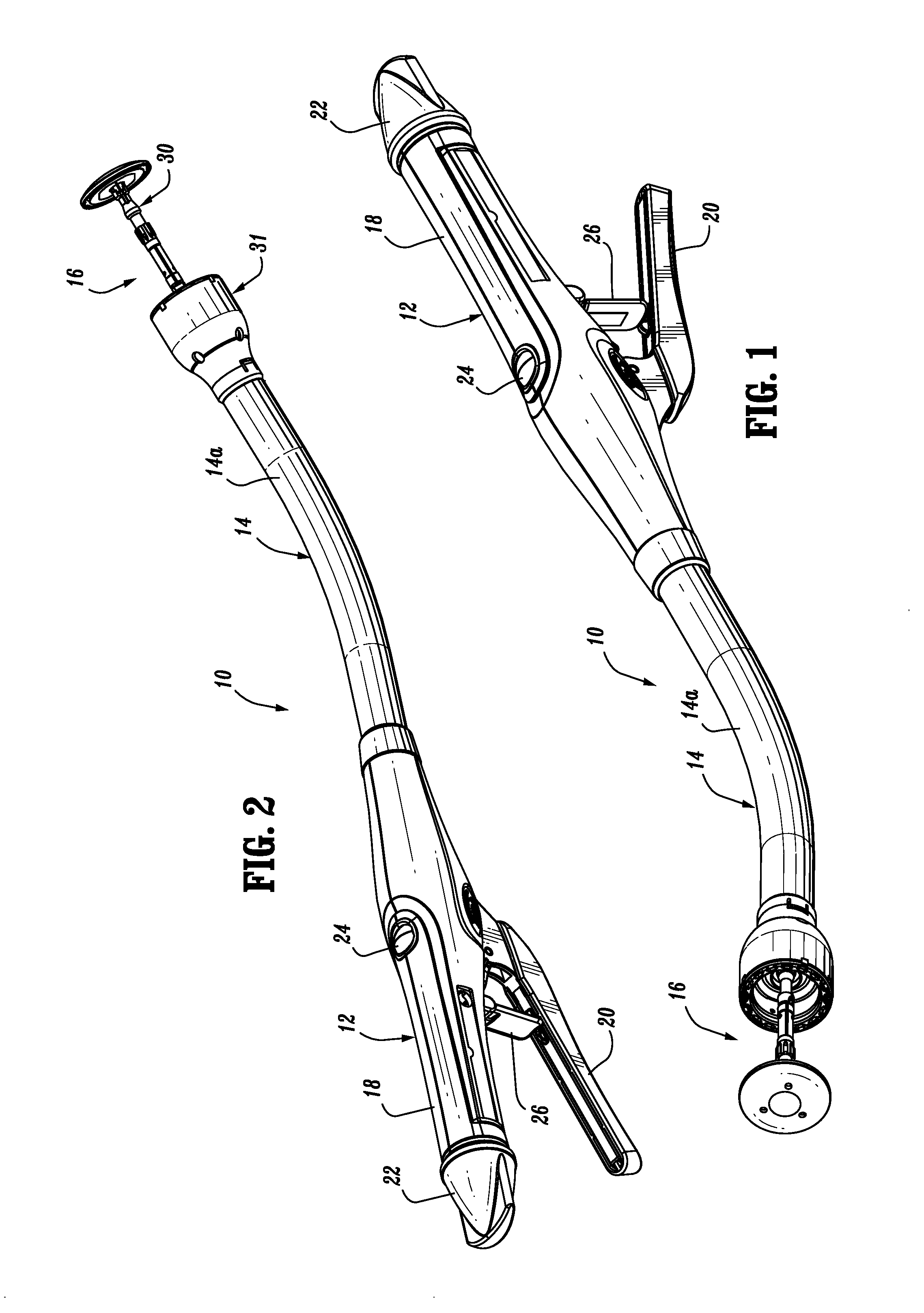

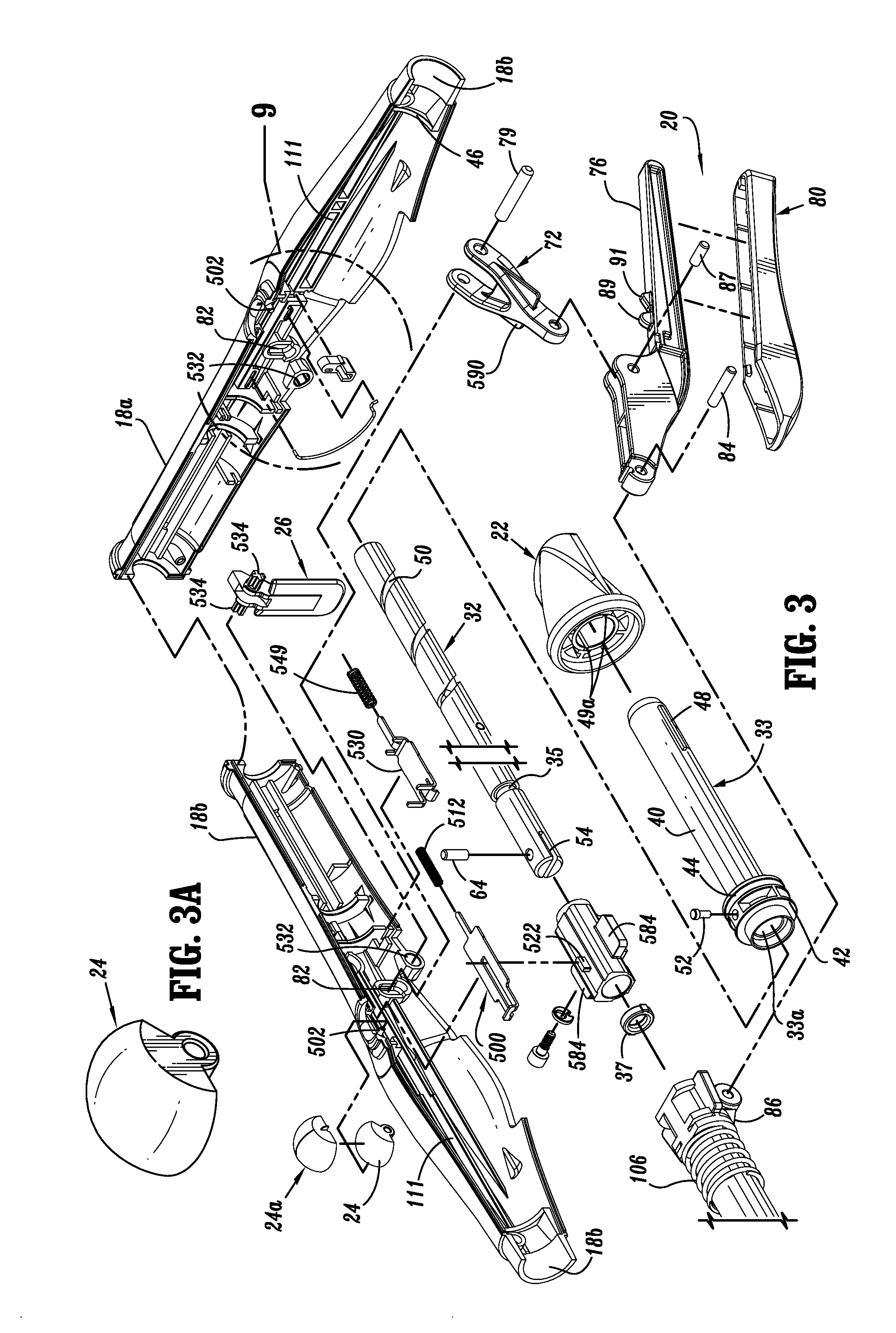

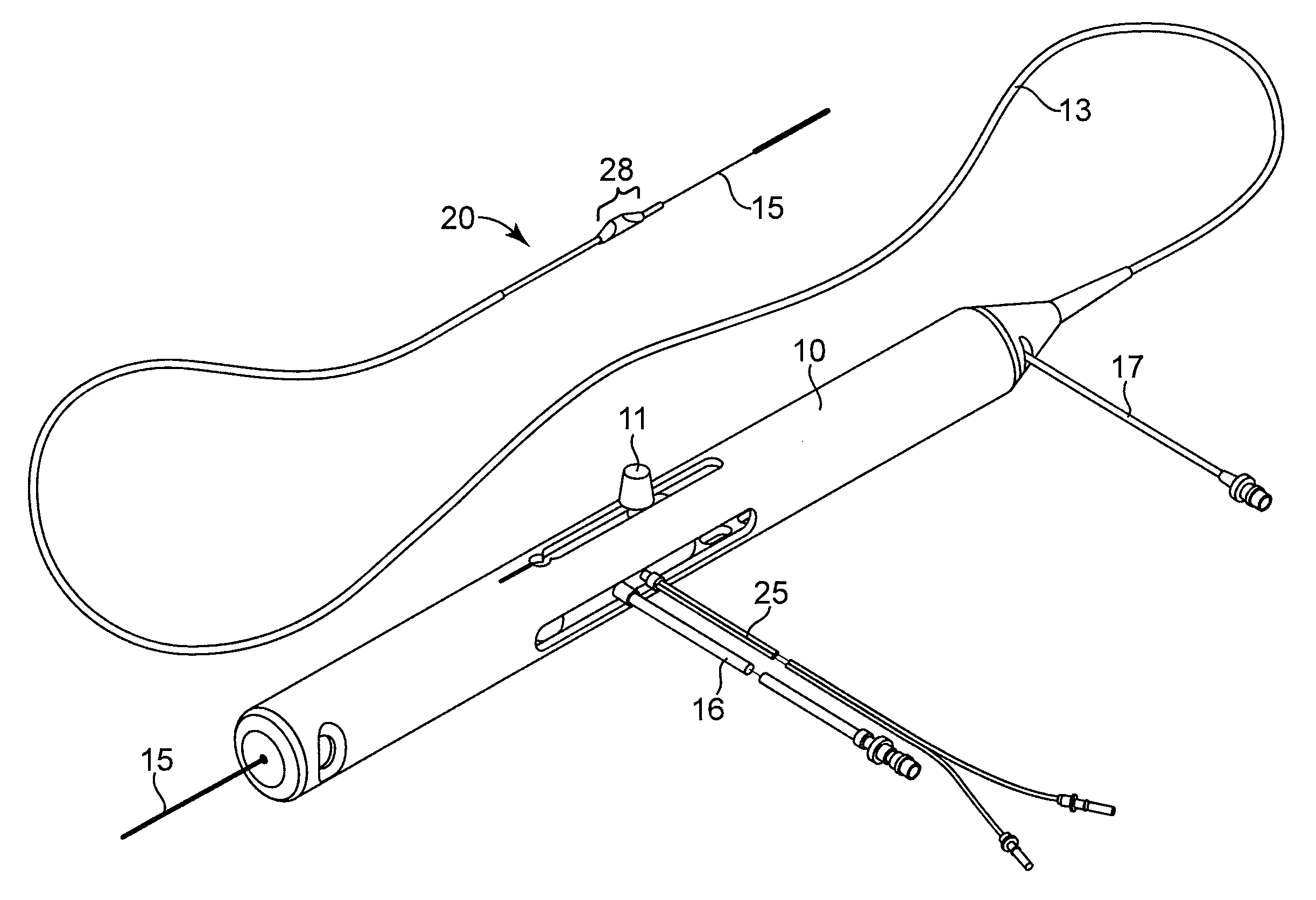

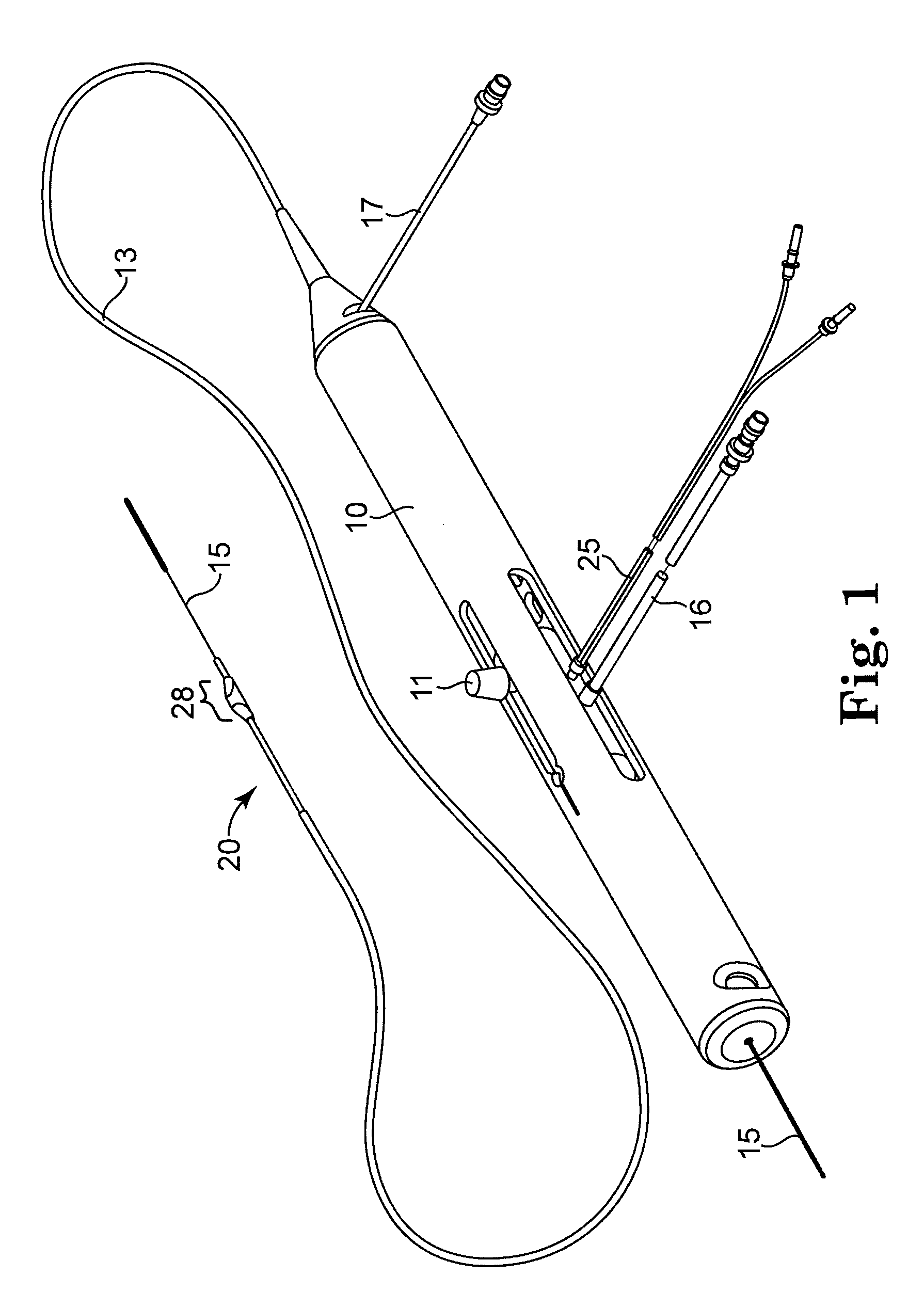

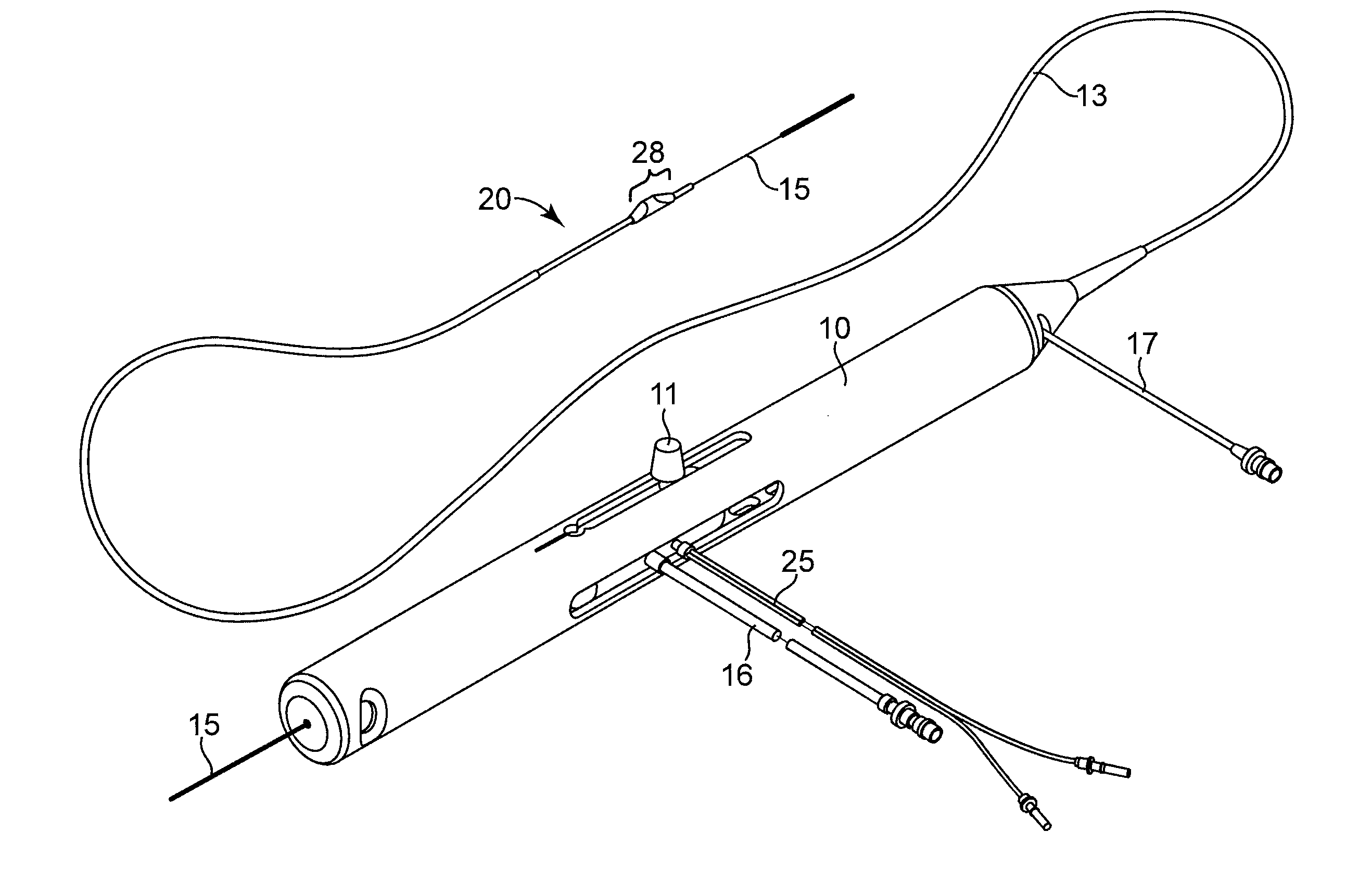

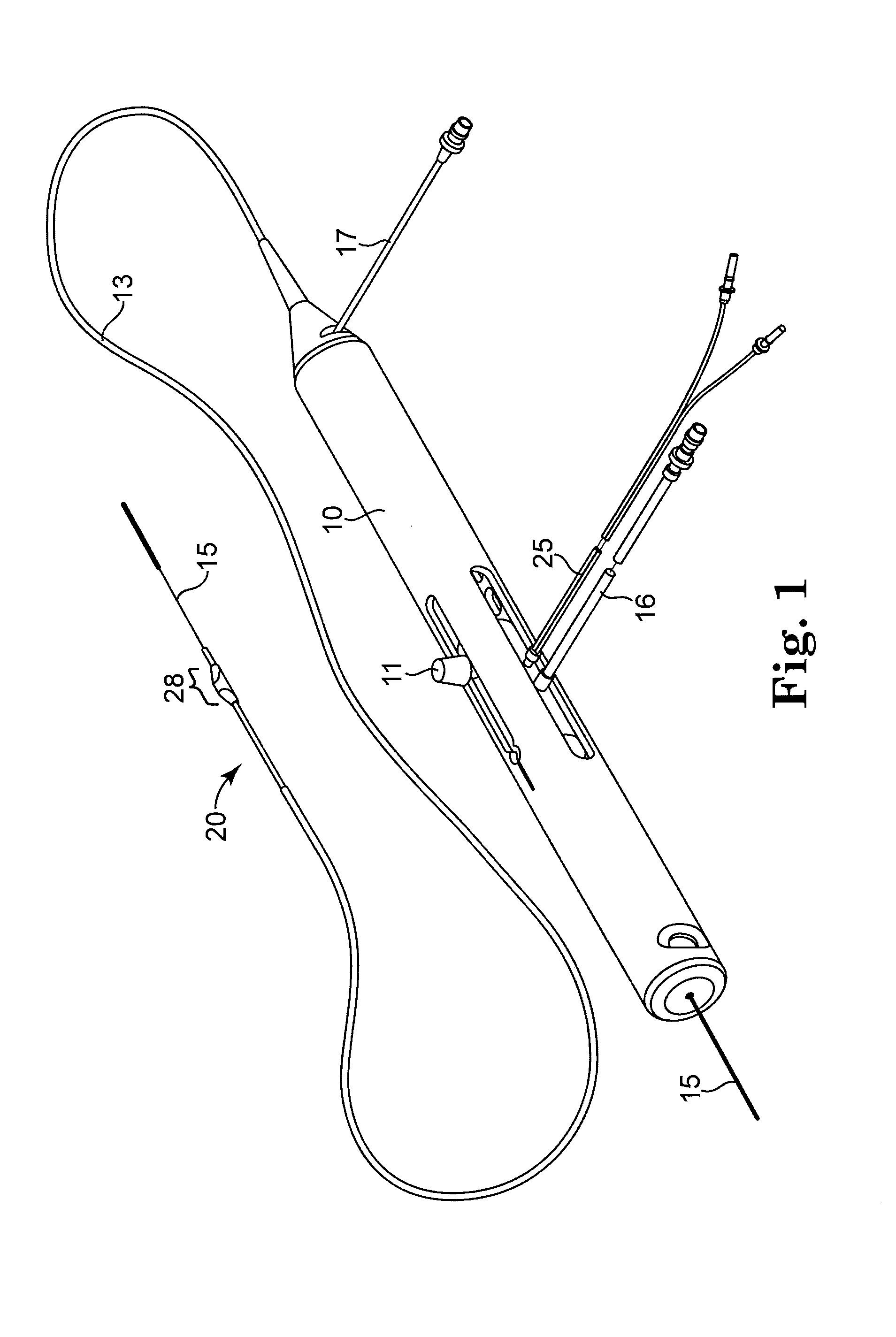

Surgical Stapling Device Including A Camera

InactiveUS20130284792A1Low profileReduce removalSuture equipmentsStapling toolsEngineeringSurgical department

A surgical stapling apparatus including a handle assembly, an elongated shaft extending distally from the handle assembly, a shell assembly containing a plurality of staples arranged in an annular array, and a firing mechanism for advancing staples from the shell assembly. An anvil assembly including a tiltable anvil head movable from an aligned operative position to a tilted position. A camera assembly is operatively coupled to a distal surface of the tiltable anvil head such that an orientation of the camera assembly changes as the anvil head moves from the operative to the tilted position.

Owner:TYCO HEALTHCARE GRP LP

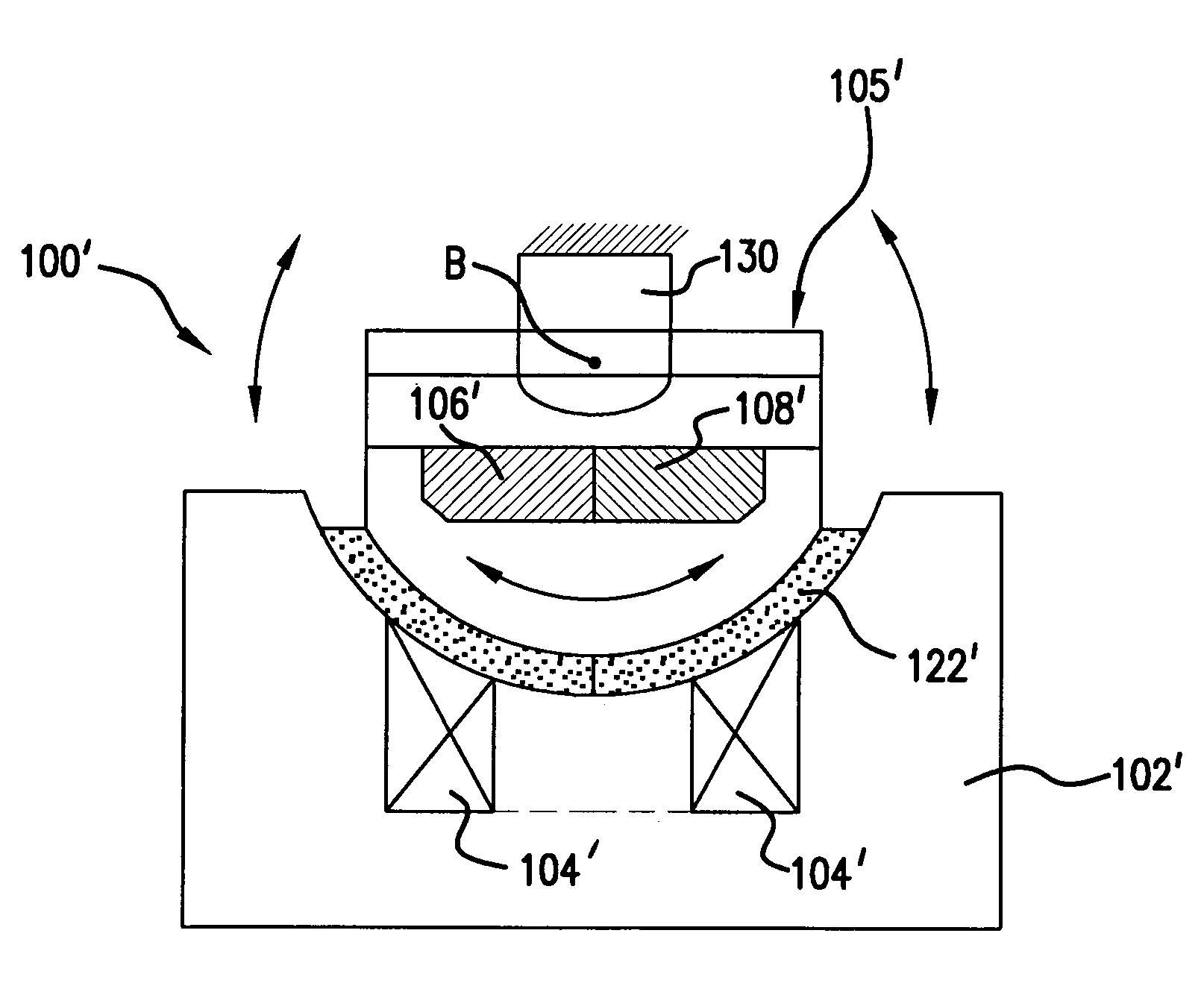

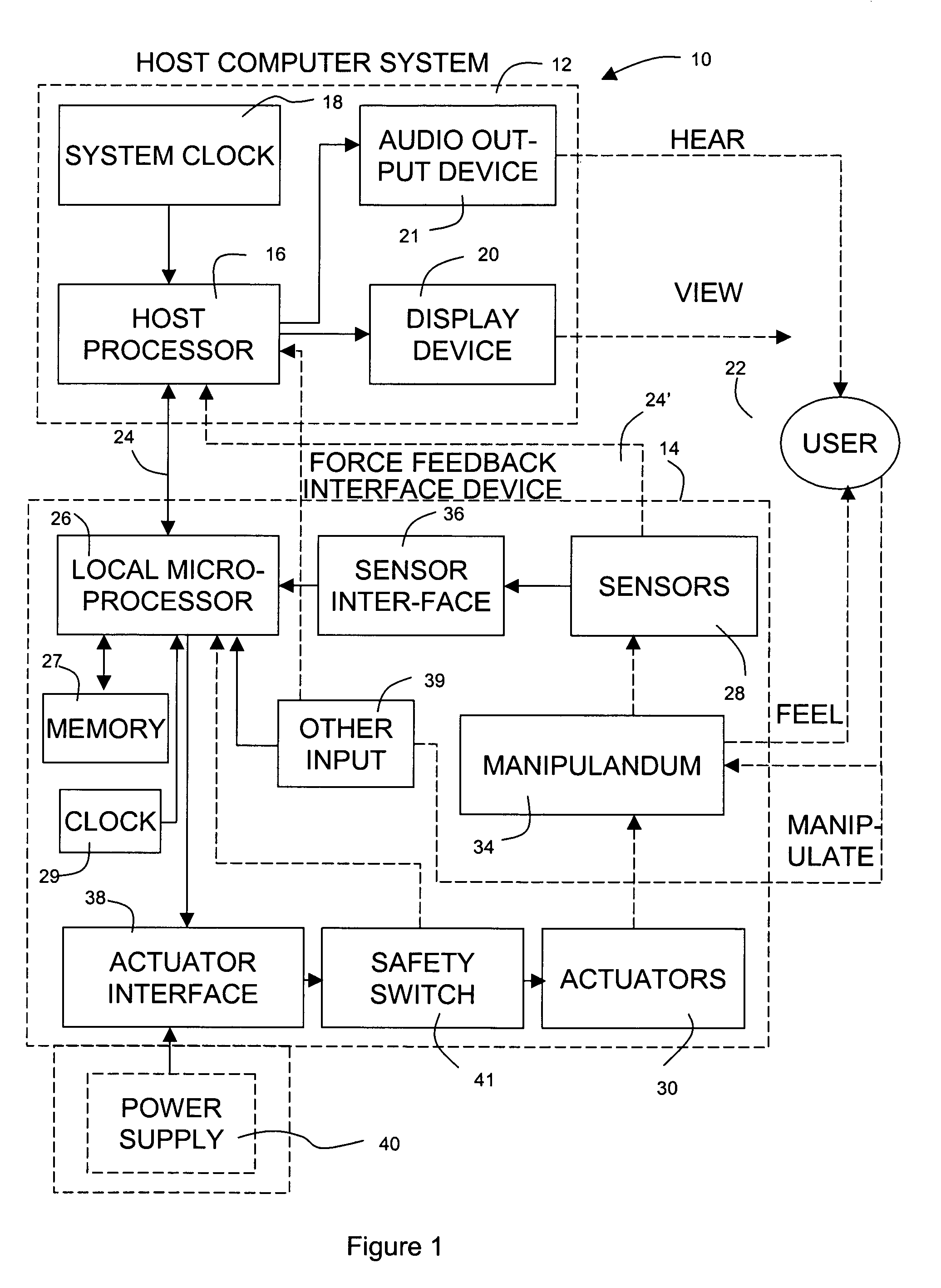

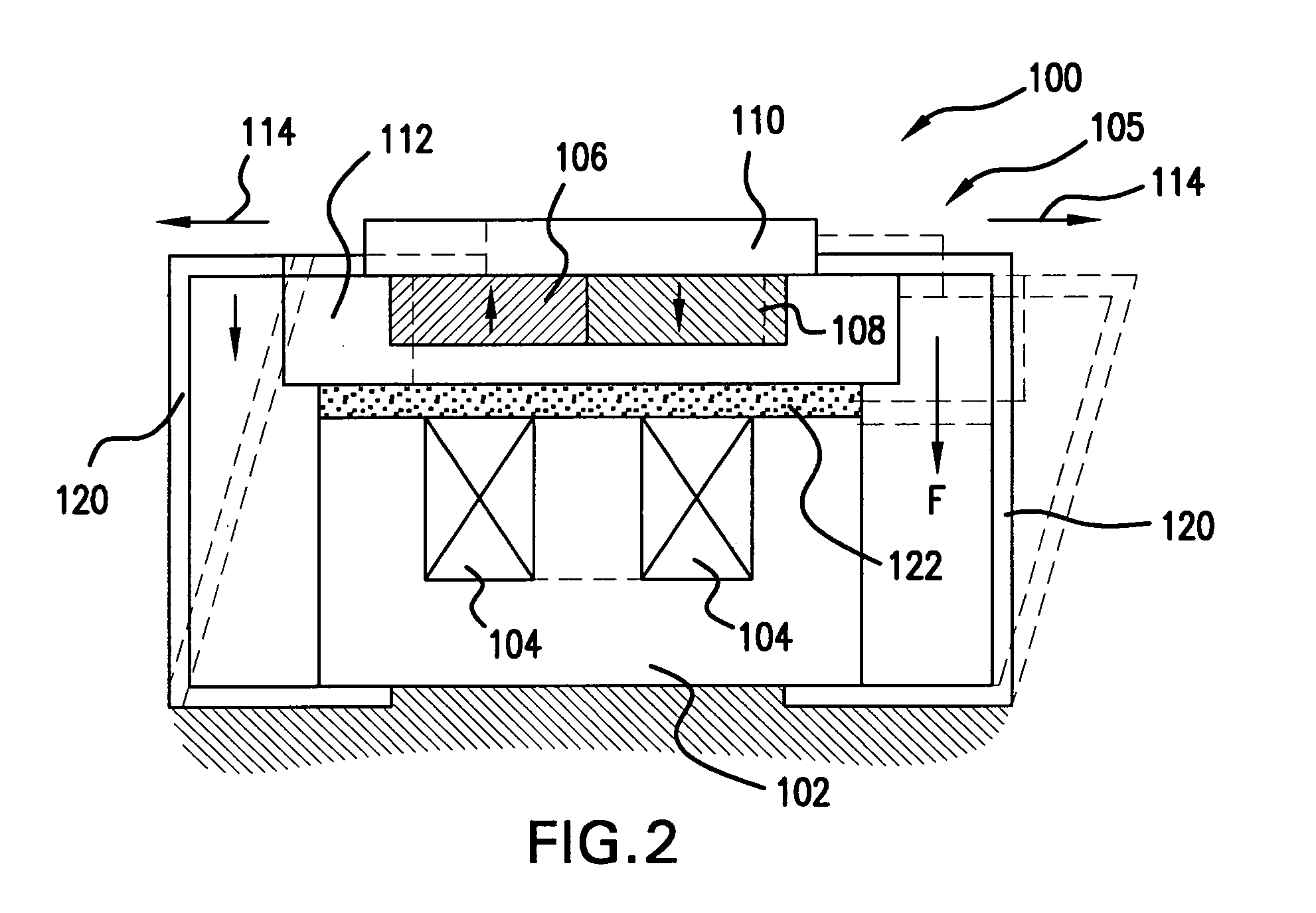

Moving magnet actuator for providing haptic feedback

InactiveUS6982696B1High magnitudeHigh bandwidthInput/output for user-computer interactionManual control with multiple controlled membersCentral projectionSpring force

A moving magnet actuator for providing haptic feedback. The actuator includes a grounded core member, a coil is wrapped around a central projection of the core member, and a magnet head positioned so as to provide a gap between the core member and the magnet head. The magnet head is moved in a degree of freedom based on an electromagnetic force caused by a current flowed through the coil. An elastic material, such as foam, is positioned in the gap between the magnet head and the core member, where the elastic material is compressed and sheared when the magnet head moves and substantially prevents movement of the magnet head past a range limit that is based on the compressibility and shear factor of the material. Flexible members can also be provided between the magnet head and the ground member, where the flexible members flex to allow the magnet head to move, provide a centering spring force to the magnet head, and limit the motion of the magnet head.

Owner:IMMERSION CORPORATION

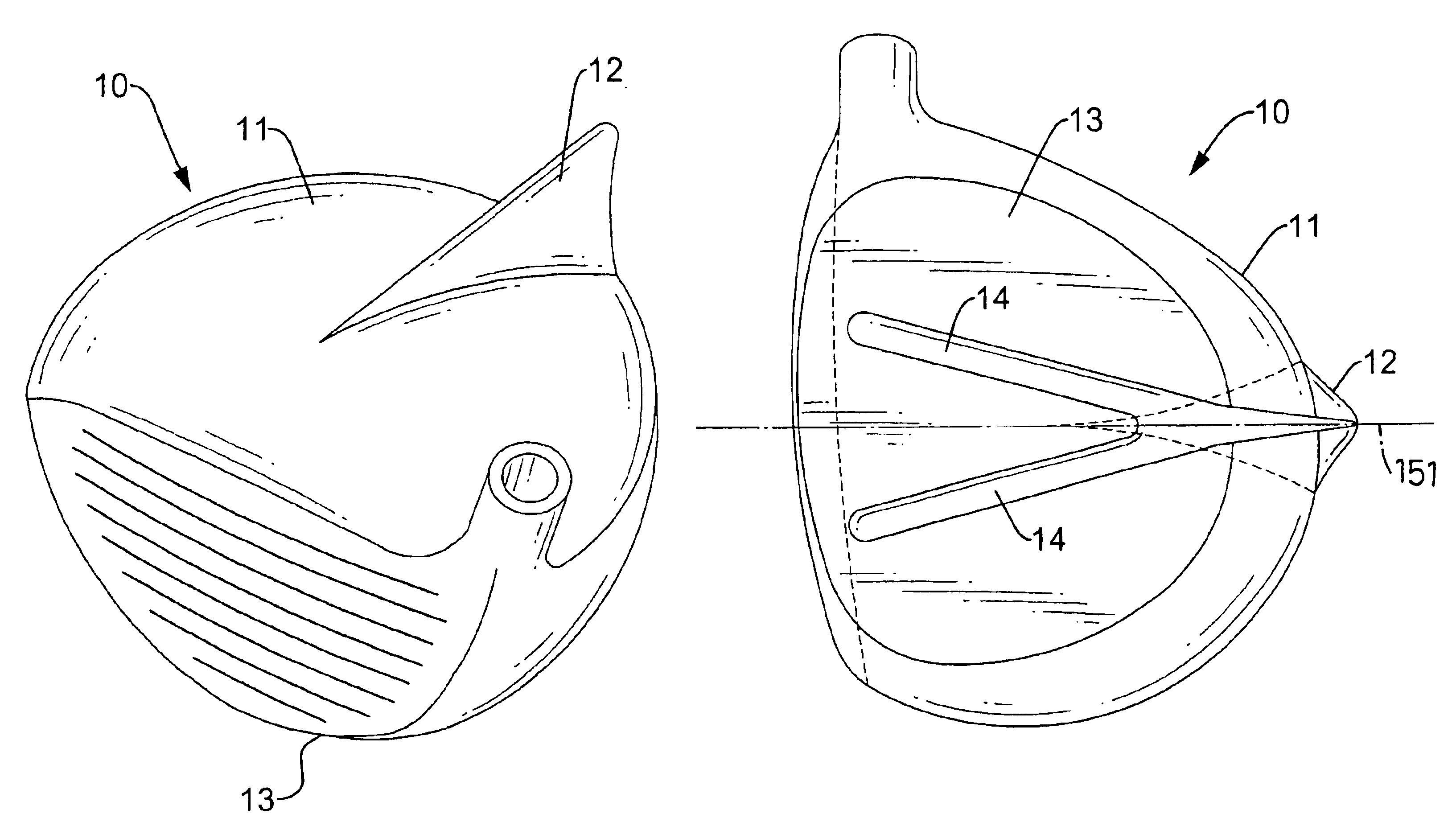

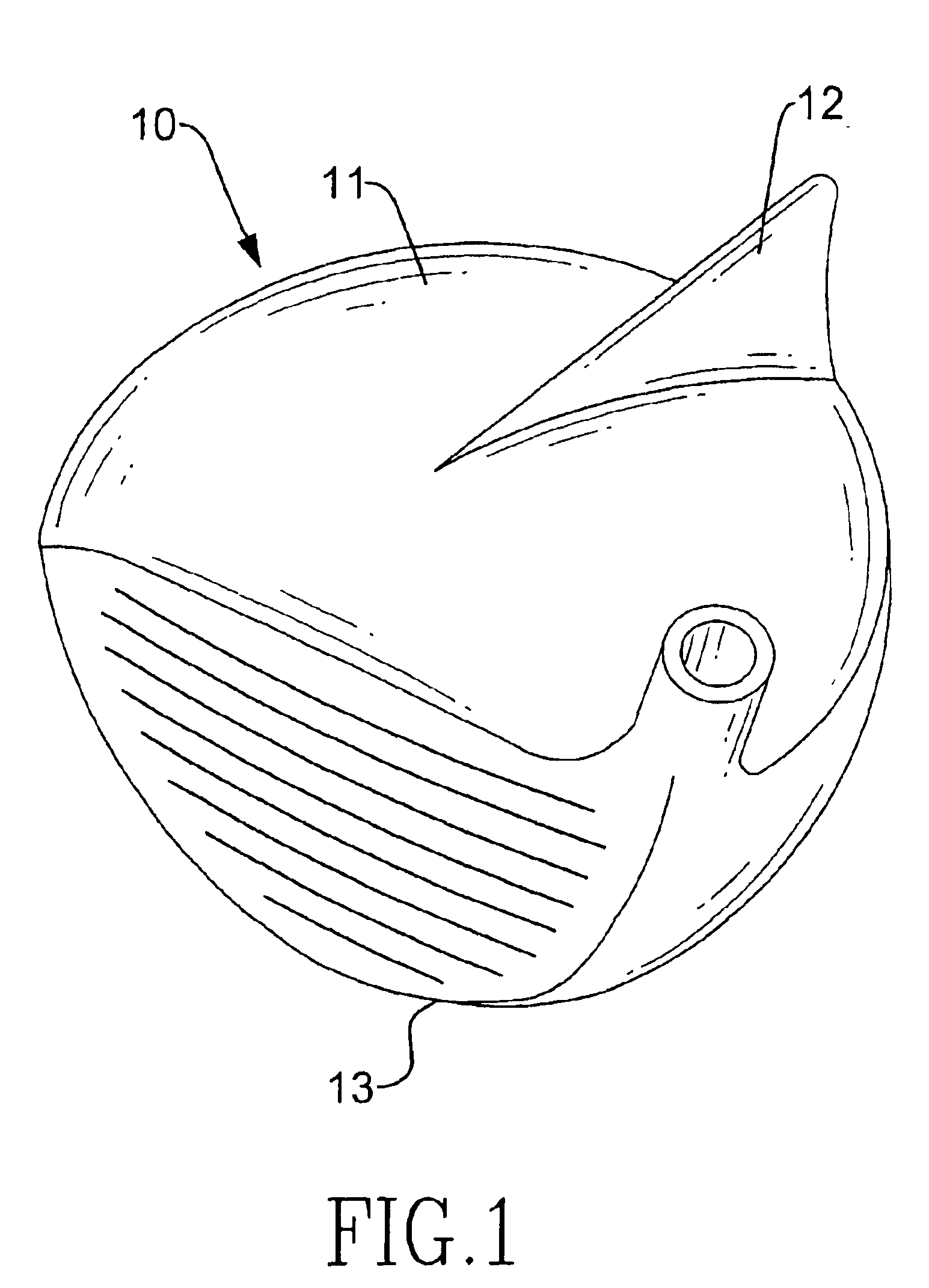

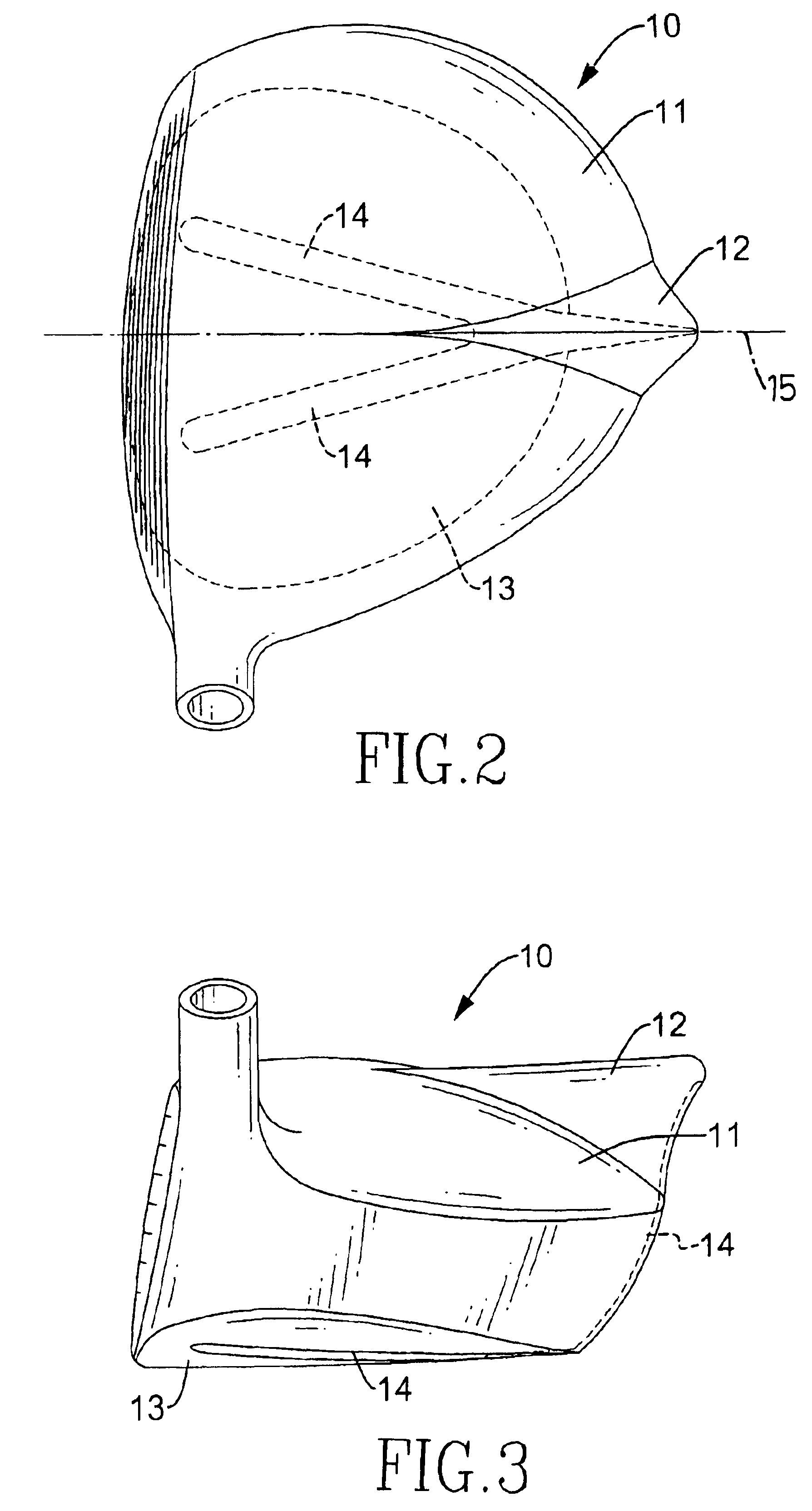

Wood type golf club head

A wood type golf club head has a hollow body, an air fin and air guides. The hollow body has a front, a rear, a crown and a sole. The crown has a top convex surface with a symmetric central line. The air fin is formed perpendicularly from the convex top surface of the crown from the front to the rear of the hollow body along the symmetric central line of the convex top surface. The air guides are defined on the sole with a forked configuration and are extended to the air fin. The air fin and the air guides will reduce external airflow effects during the golf club head moving. Consequently, the motion and direction of the motion of the golf club head will be stable such that a golfer will swing successfully to hit a golf ball.

Owner:O TA PRECISION IND

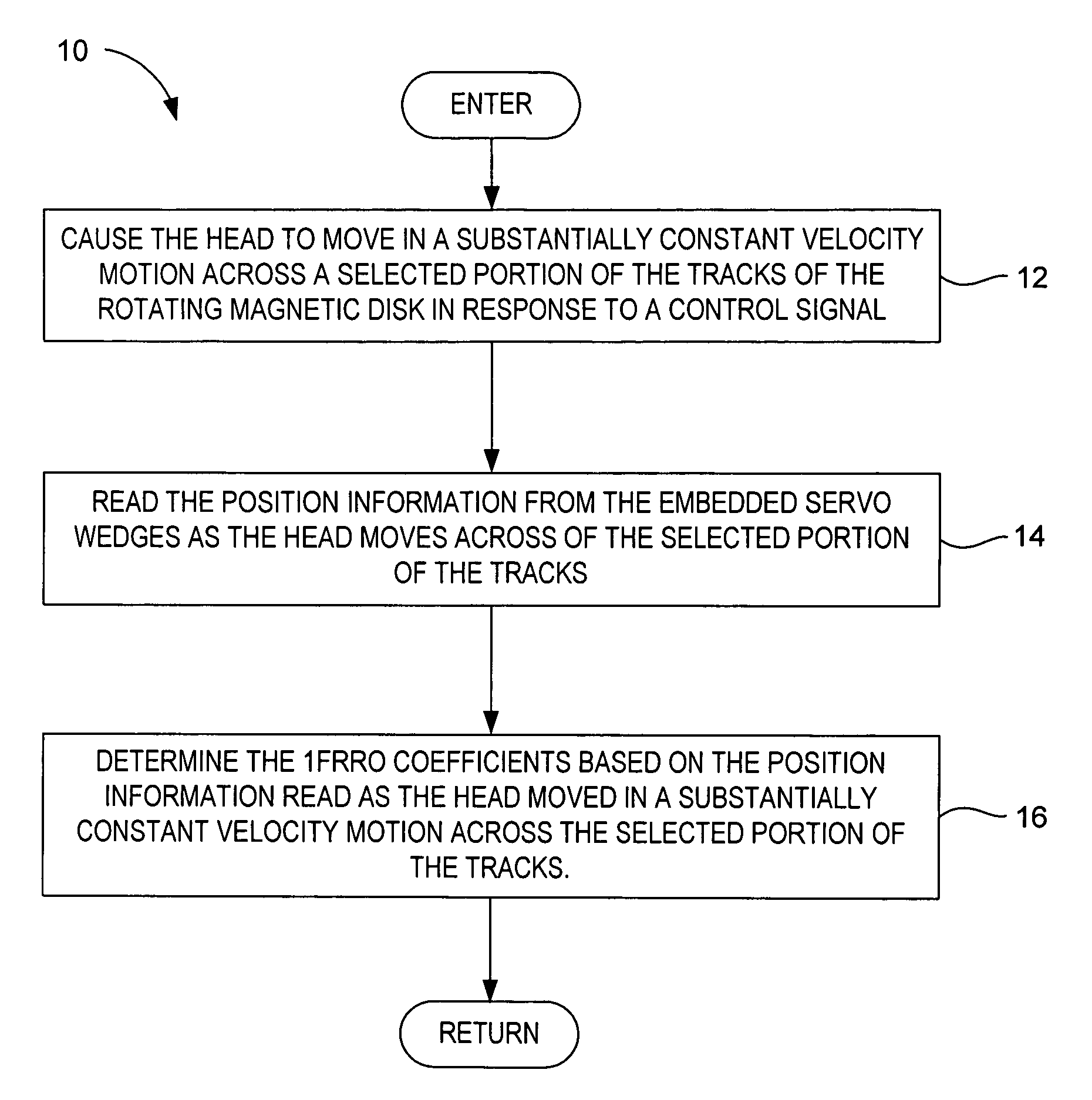

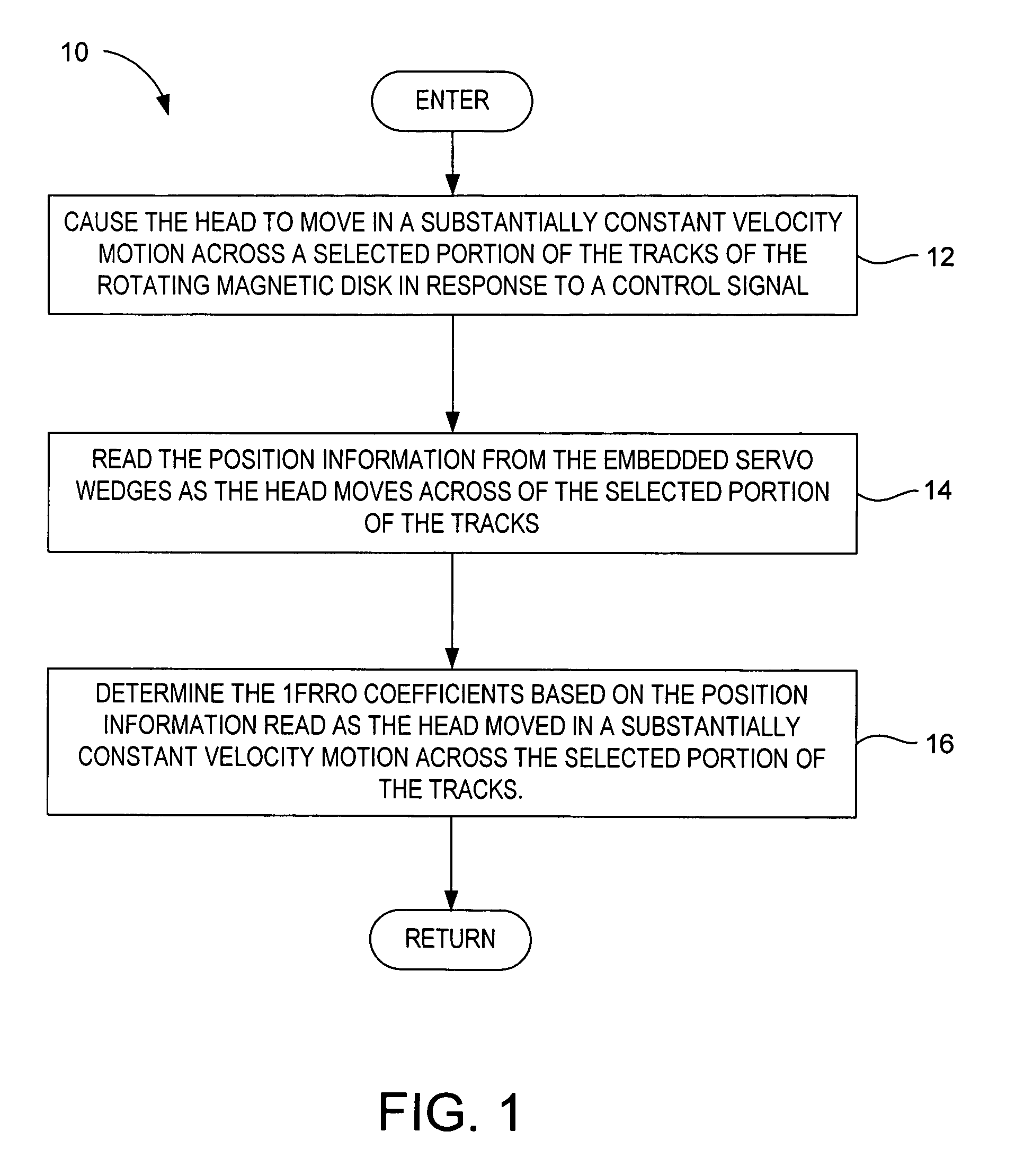

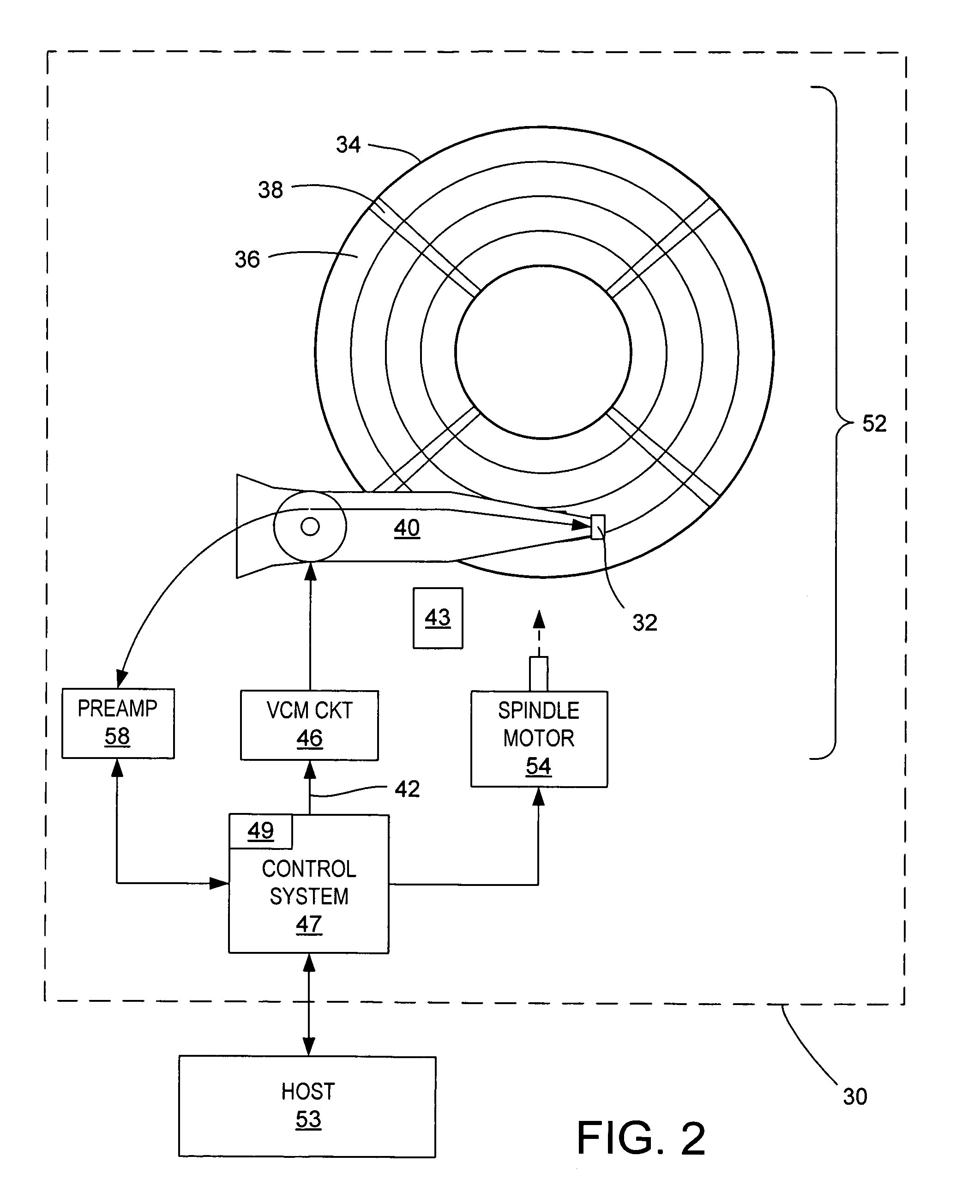

Method for improved repeatable run out learning in a disk drive

InactiveUS7450336B1Driving/moving recording headsRecord information storageControl signalFundamental frequency

A method is disclosed for determining fundamental-frequency repeatable runout (1FRRO) coefficients in a disk drive. The disk drive includes a transducer head, a rotating magnetic disk having a plurality of concentric data tracks defined by embedded servo wedges that provide position information, and an actuator coupled to the head. In the method, the head is caused to move in a substantially constant velocity motion across a selected portion of the tracks of the rotating magnetic disk in response to a control signal. The position information is read from the embedded servo wedges as the head moves across of the selected portion of the tracks. The 1FRRO coefficients are determined based on the position information read as the head moved in a substantially constant velocity motion across the selected portion of the tracks.

Owner:WESTERN DIGITAL TECH INC

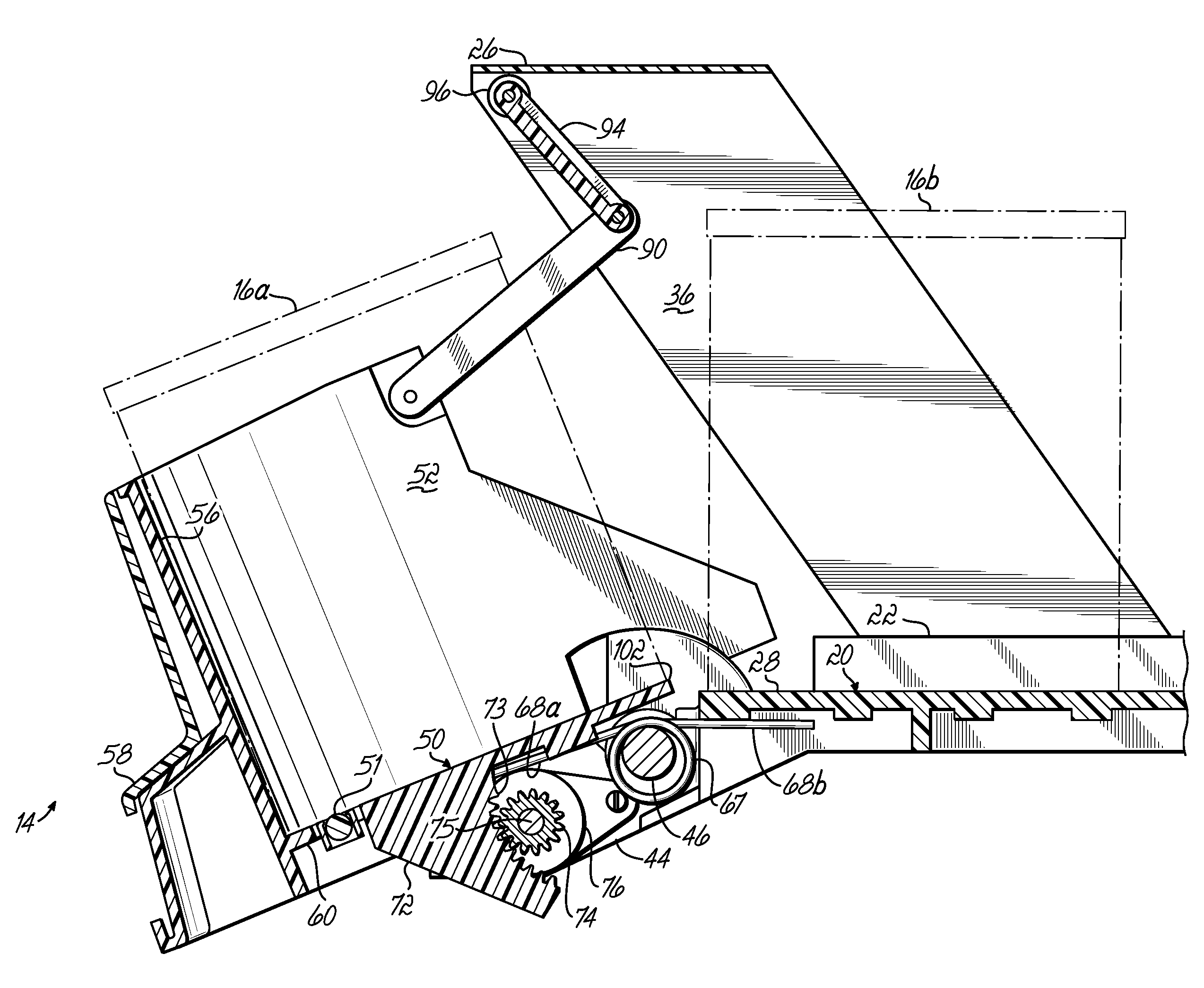

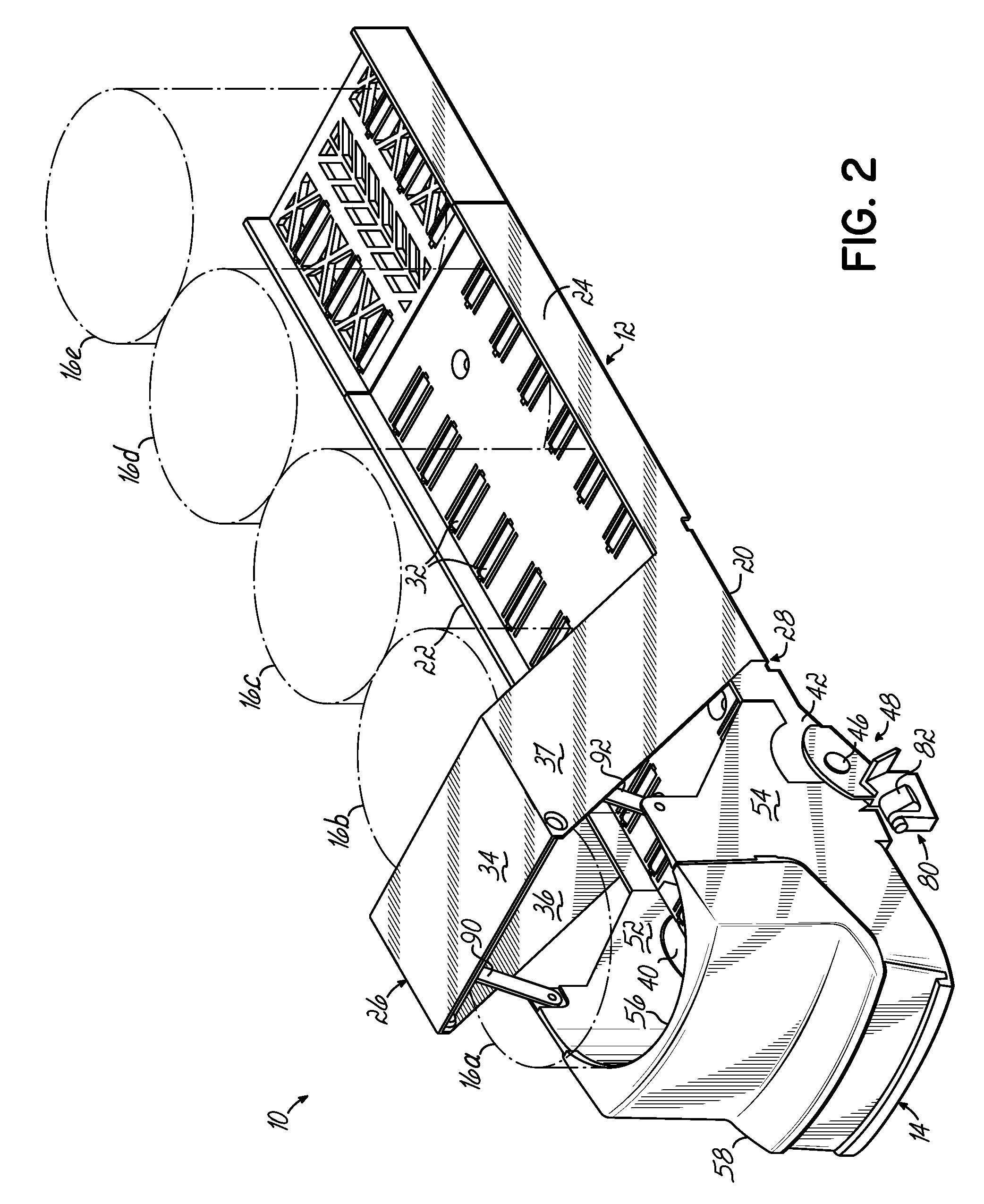

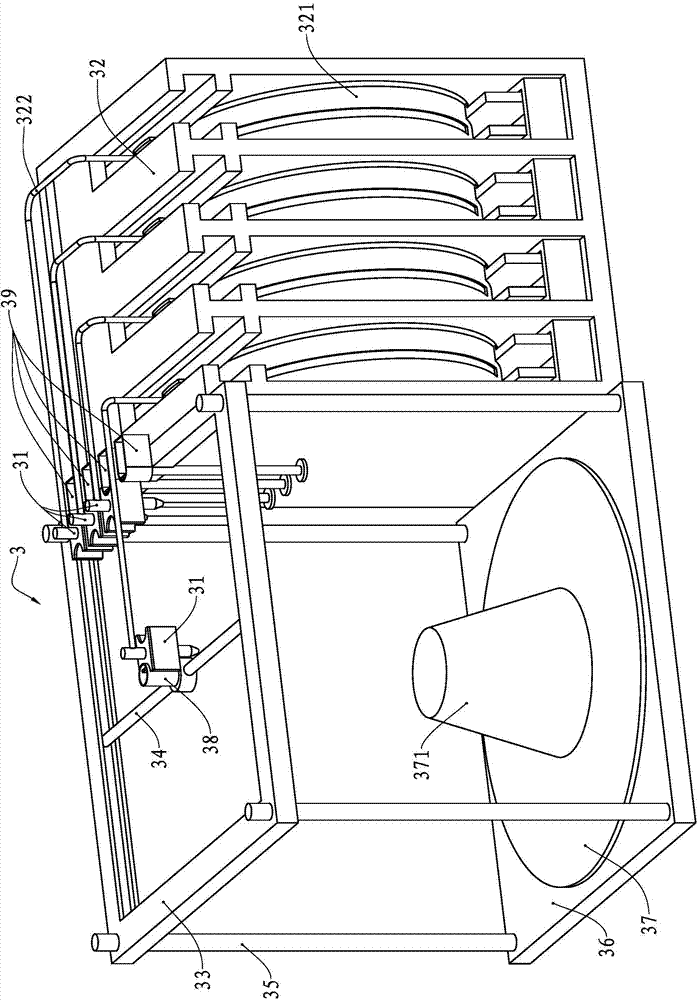

Theft deterrent can dispenser

A theft deterrent dispensing unit particularly for use with cans includes a conveyor section that leads to a dispensing head. A shroud extends over the forward edge of the conveying section. The dispensing head pivots downwardly allowing the leading can to be grasped without interference of the shroud. The rear edge of the dispensing head pivots upwardly, preventing the next adjacent can from moving immediately into the dispensing head until the dispensing head rotates back to a closed position. Likewise, when the dispensing head is rotated to an open position, a barrier is pulled down from the top of the shroud, again preventing an individual from reaching in and grabbing the next adjacent can. A locking mechanism is positioned on the side of the dispensing units to prevent two adjacent dispensing units from being opened at the same time. Finally, the speed at which the dispensing heads move from an open to a closed position is regulated to prevent rapid removal of cans from a single dispensing unit.

Owner:FASTENERS FOR RETAIL

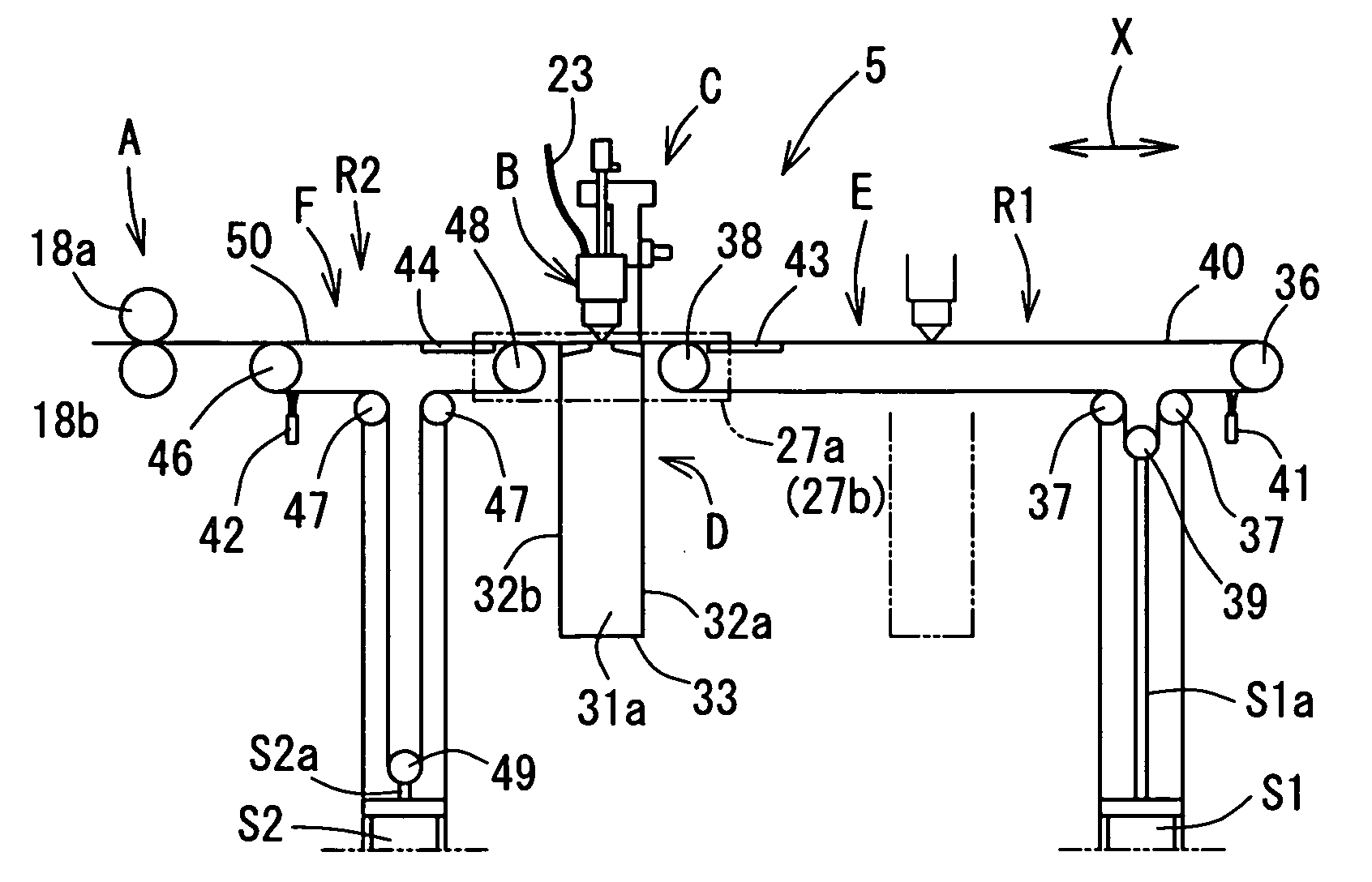

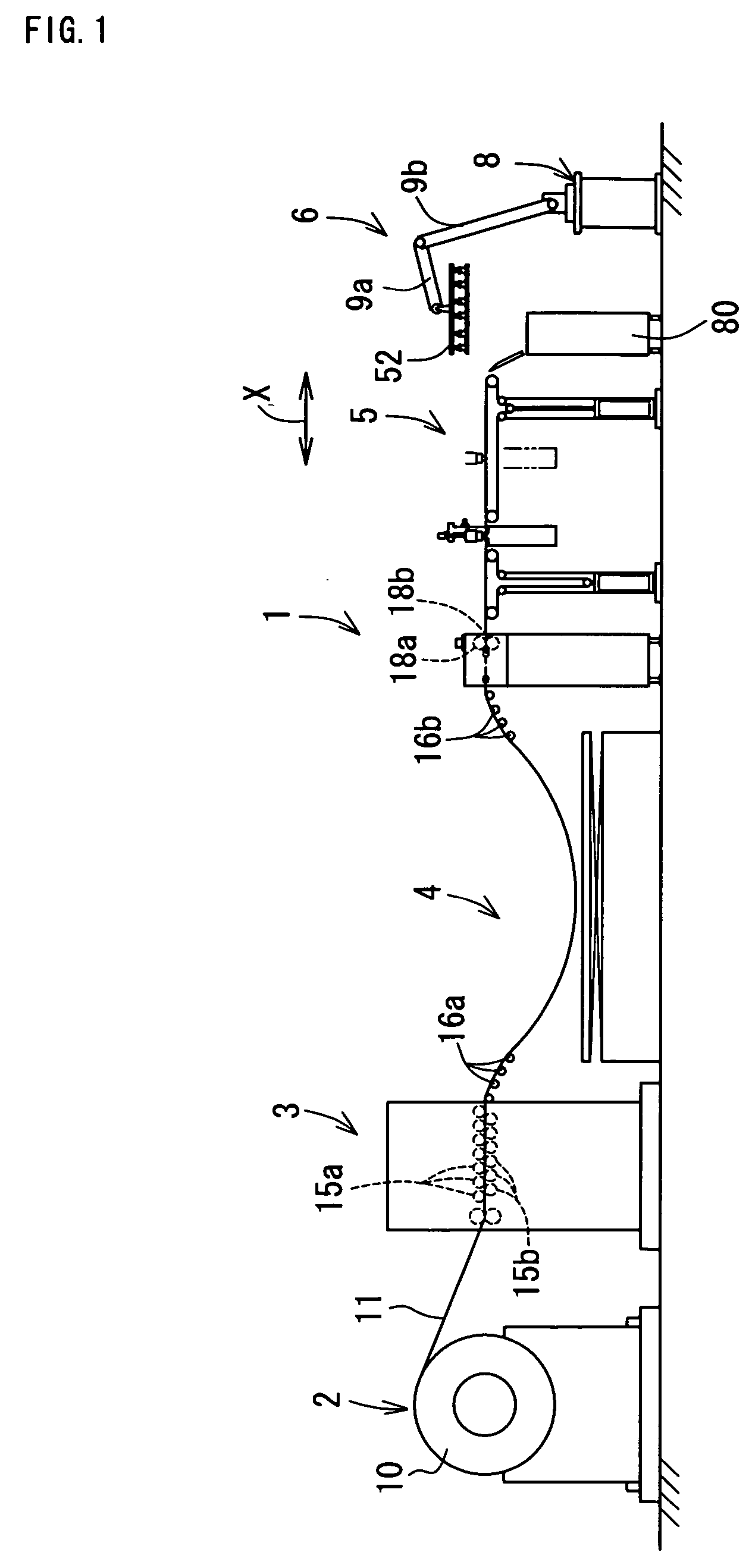

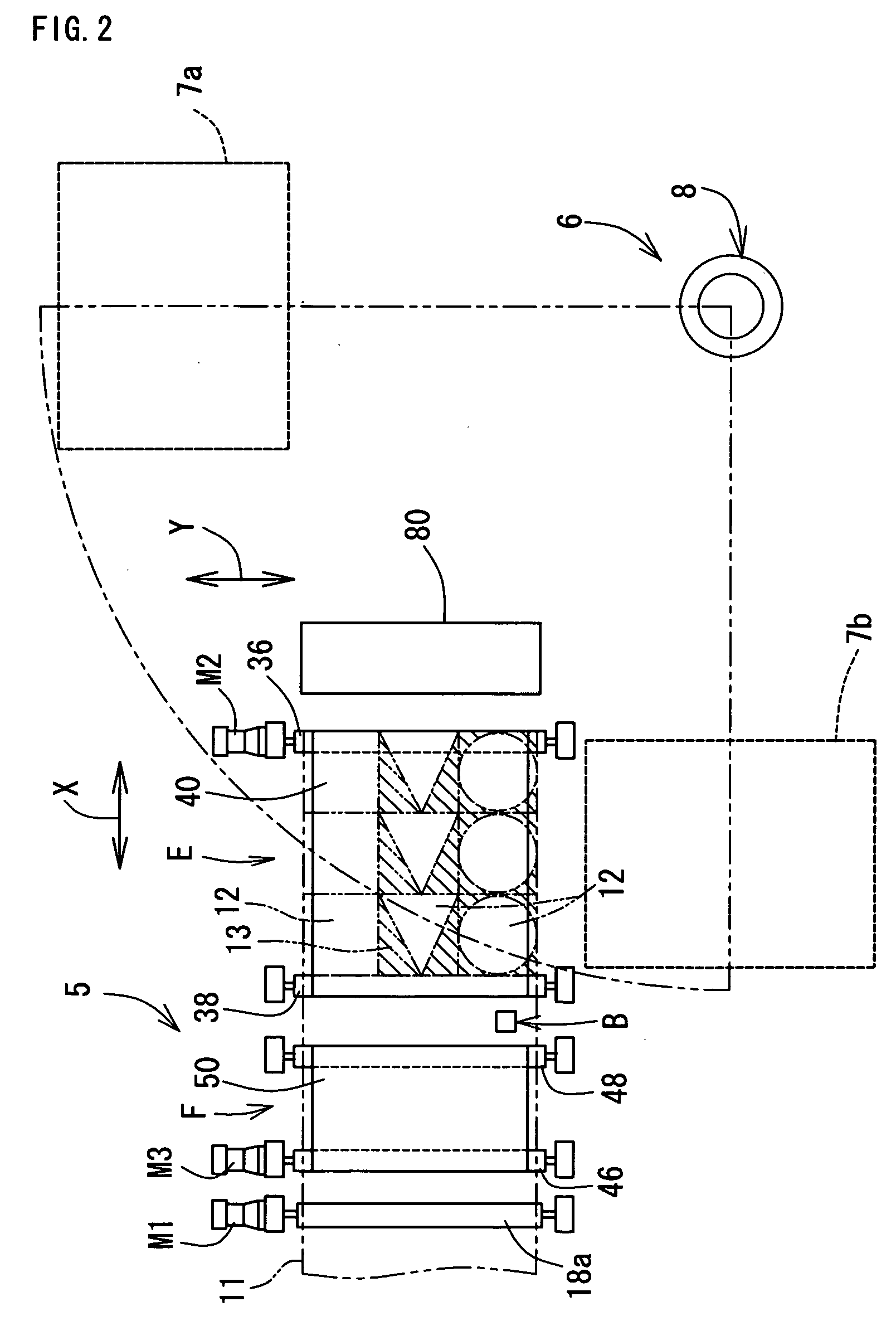

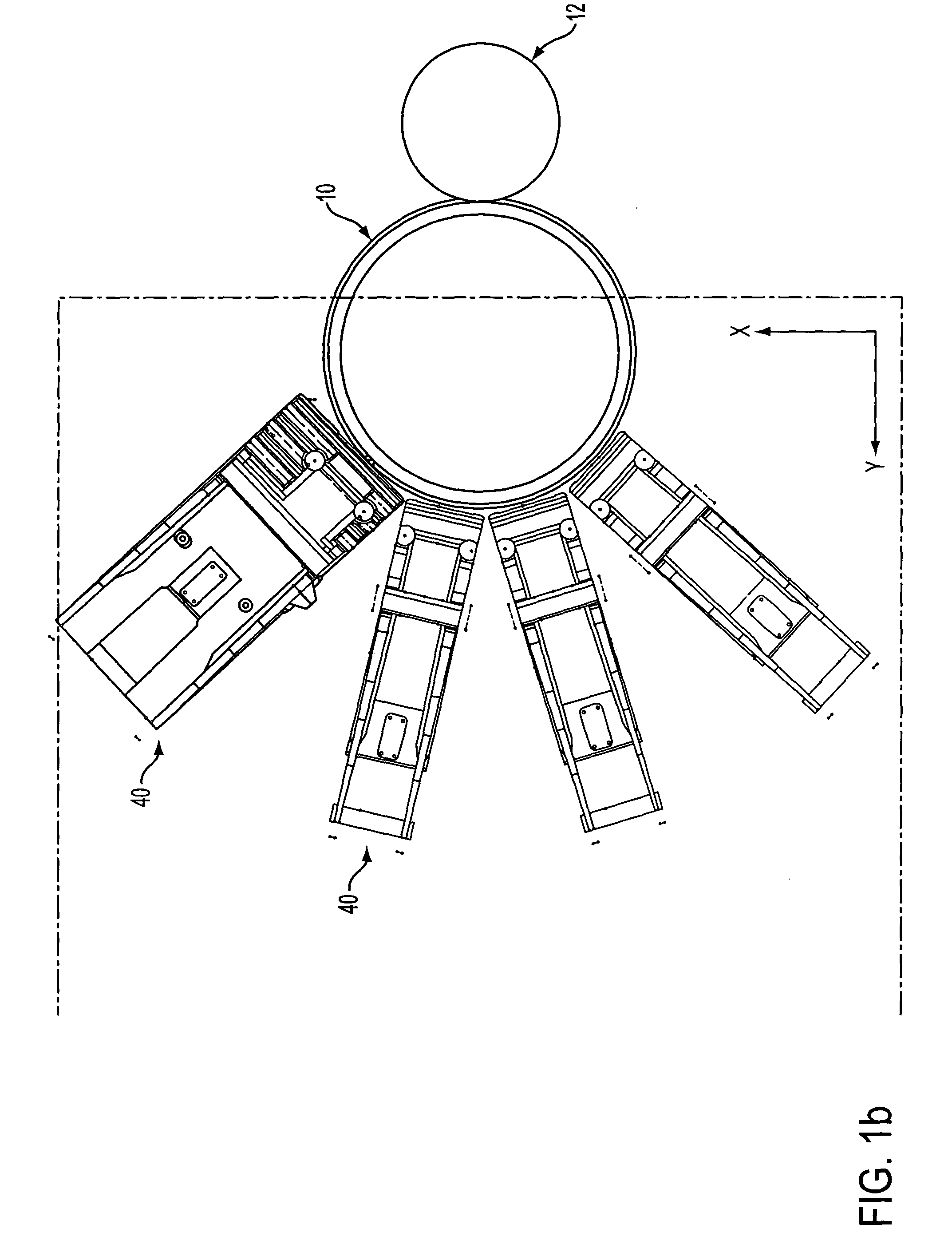

Laser cutting device, laser cutting method, and laser cutting system

InactiveUS20060118529A1Avoid dust adhesionEasy to controlConveyorsWelding/soldering/cutting articlesLaser cuttingLaser light

It is an object of the present invention to provide a laser cutting device, a method for laser cutting and a laser cutting system with which it is possible to perform laser cutting of parts of various shapes through easy control, to prevent adhesion of dust or similar and scratches being formed in cut parts, and to send out such parts while reliably supporting the same. The present laser cutting device 5 is comprised with a material transferring means A that transfers a sheet-like material 11 in a feeding direction, a processing head B that is capable of irradiating laser light towards the material, a head moving means C that makes the processing head move in the feeding direction X and a width direction Y of the material, an upstream-sided supporting means (belt conveyer mechanism F) that supports the material on an upstream side of a downward portion of the processing head and that expands and contracts a supporting region R2 for the material accompanying movements of the processing head in the feeding direction, and a downstream-sided supporting means (belt conveyer mechanism E) that supports cut parts on a downstream side of a downward portion of the processing head and that expands and contracts a supporting region R1 for the cut parts accompanying movements of the processing head in the feeding direction.

Owner:TOYOTA STEEL CENT CO LTD

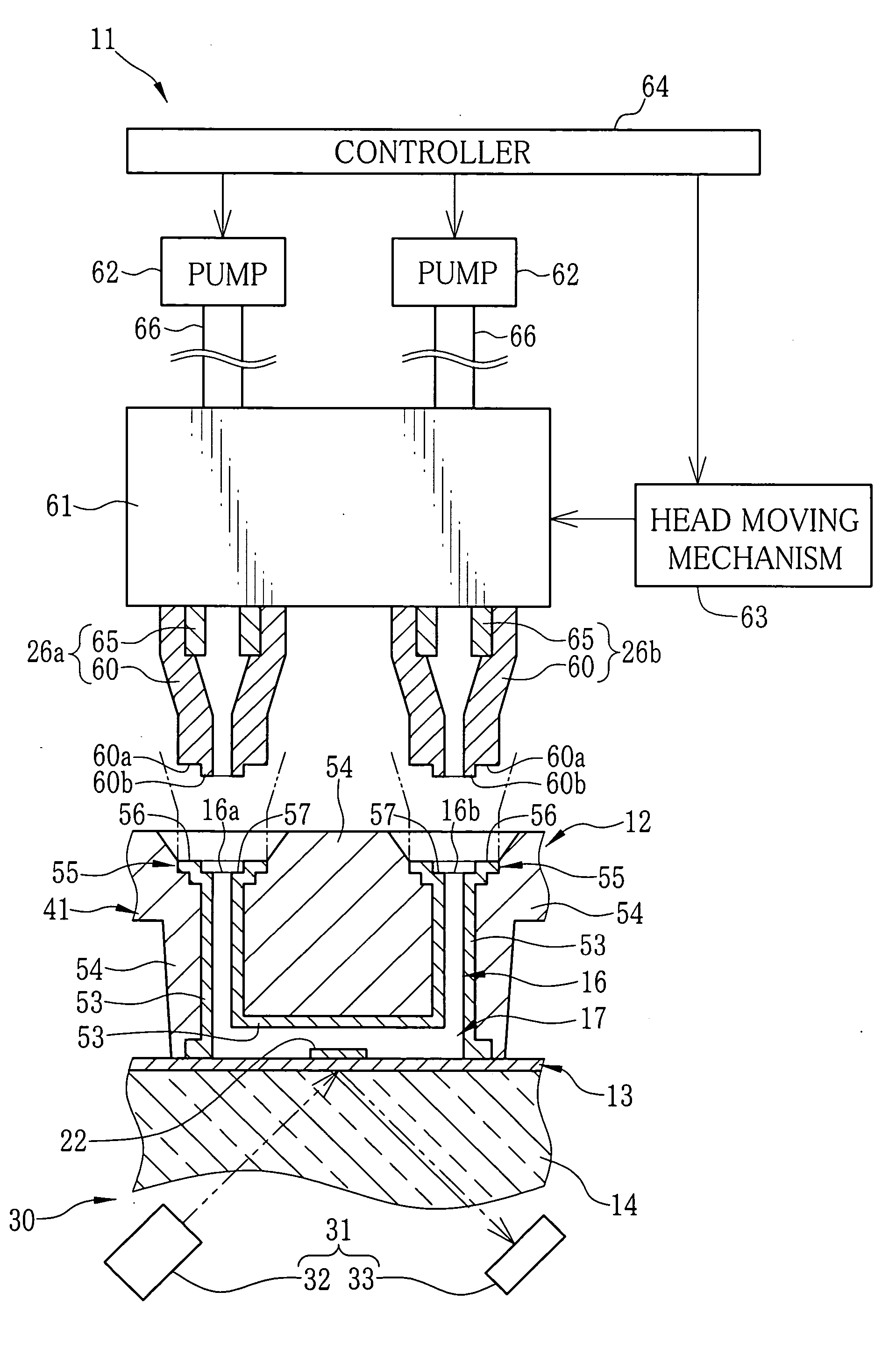

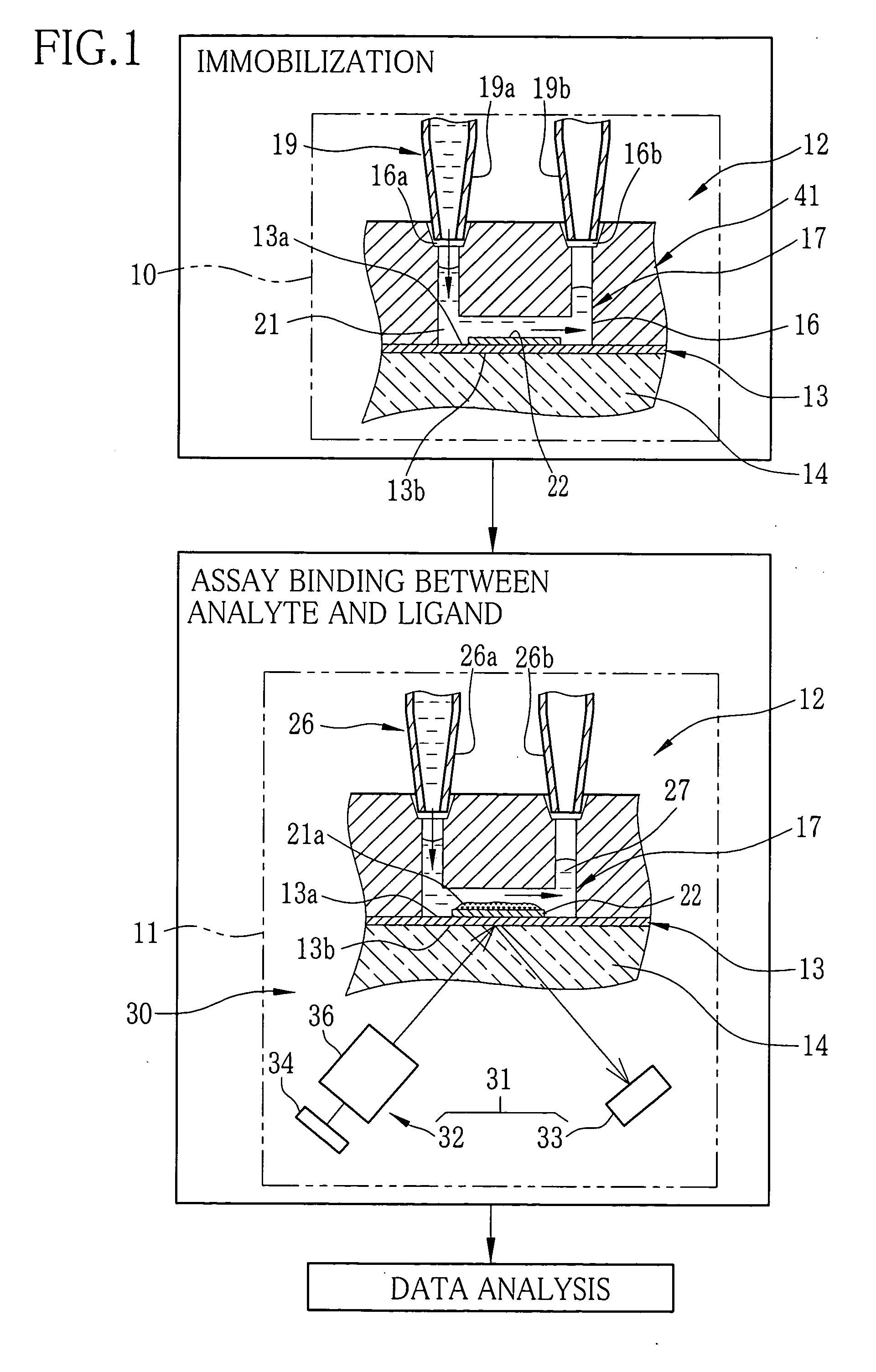

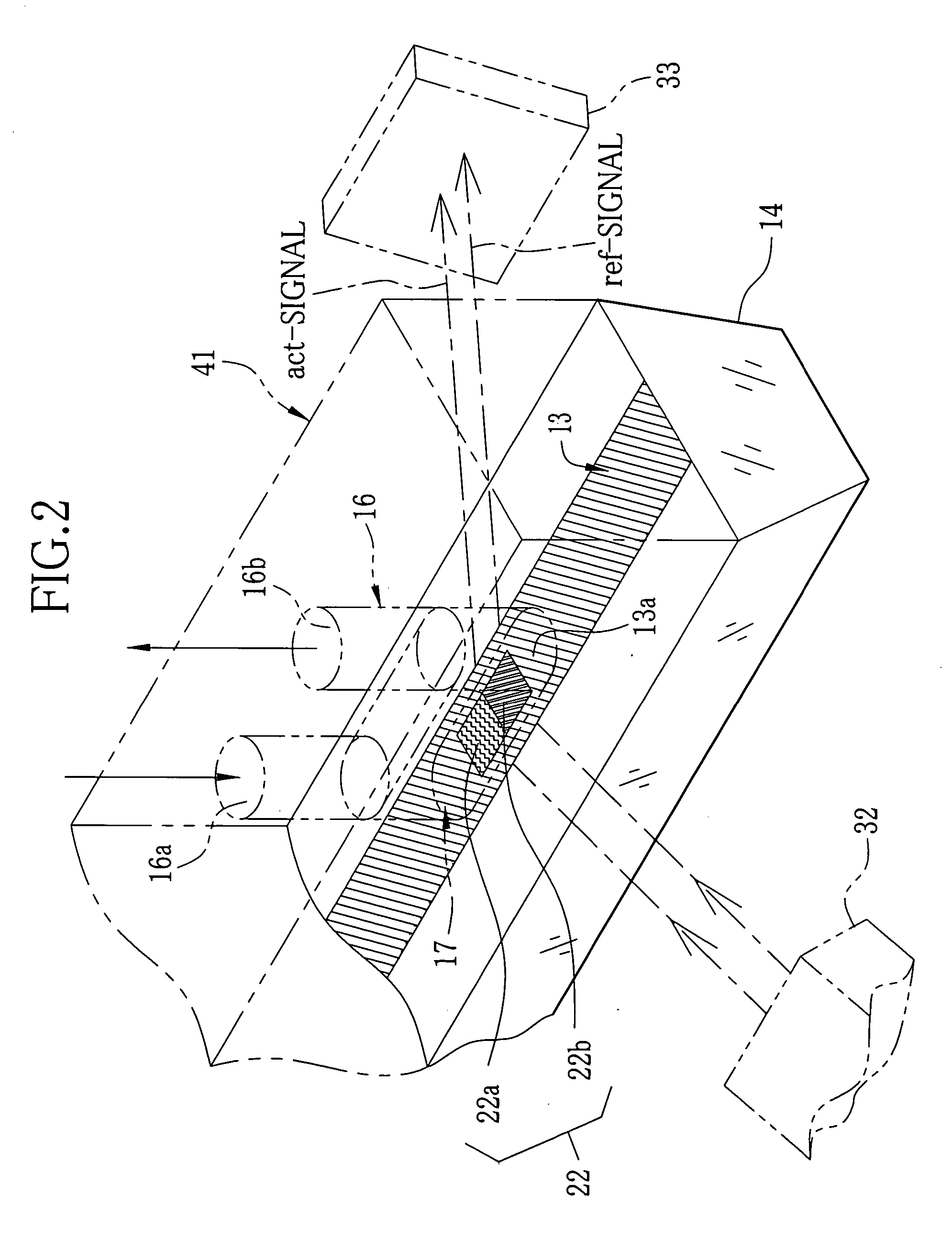

Fluid feeding system, fluid feeding method and flow channel unit

InactiveUS20060263263A1Sufficient stability in performance and accuracyPrevent rotPhase-affecting property measurementsColor/spectral properties measurementsPipetteEngineering

A fluid feeding system consists of a flow channel member and a fluid feeding apparatus. The flow channel member has at least a flow channel for feeding a fluid to a sensor surface. Pipette catchers are formed at inlet and outlet openings of the flow channel. The fluid feeding apparatus comprises a movable pipette head having a couple of pipettes, a head moving mechanism and pumps for sucking and ejecting the fluid through the pipettes. To inject the fluid into the flow channel, ends of the pipettes are pressed onto the pipette catchers. The pipette catchers are formed from a soft material, so that they are deformed resiliently when the ends of the pipettes are pressed onto the pipette catchers, thereby ensuring water-tightness between the pipettes and the flow channel, without the need for fitting the pipettes in the inlet and outlet openings.

Owner:FUJIFILM HLDG CORP +1

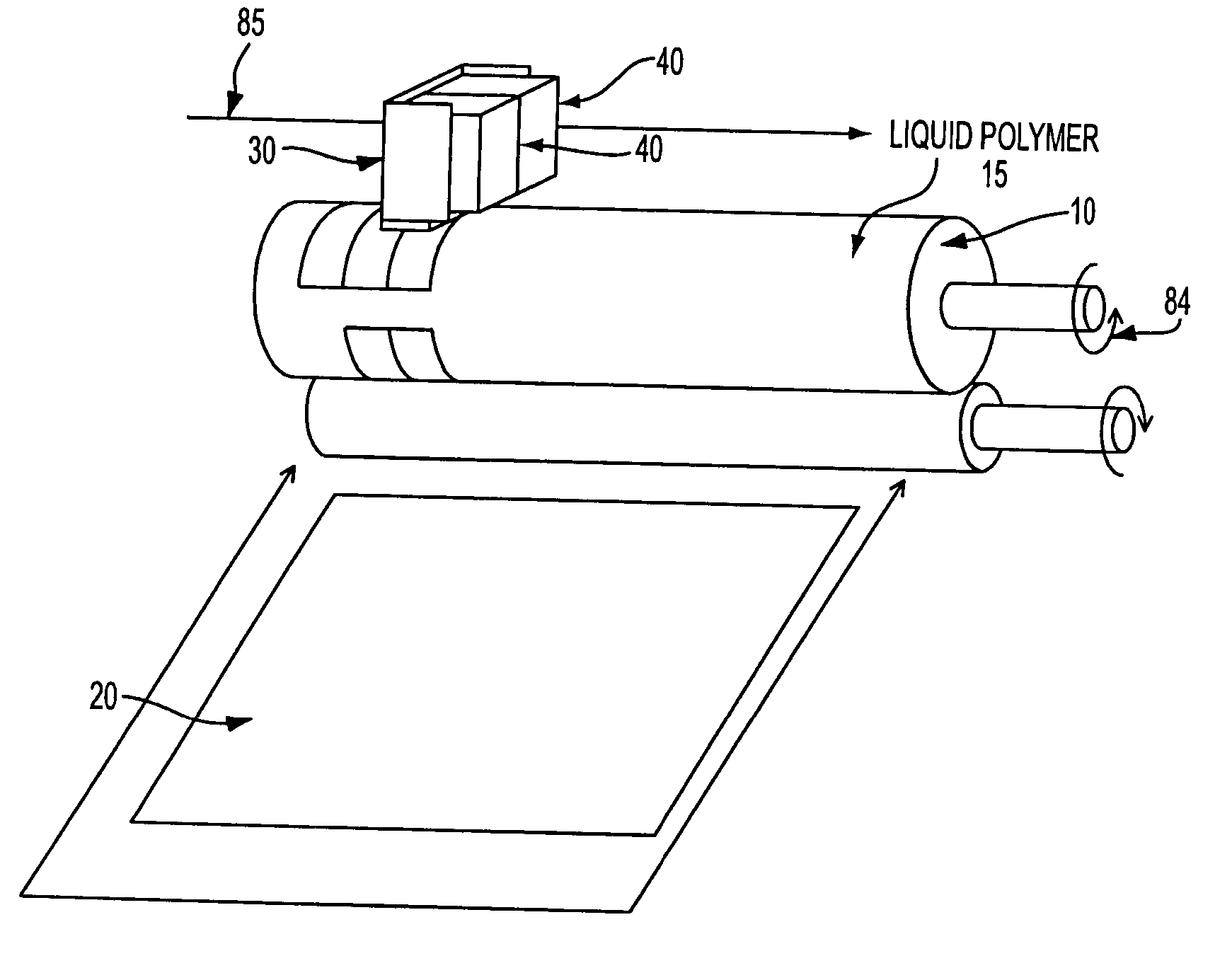

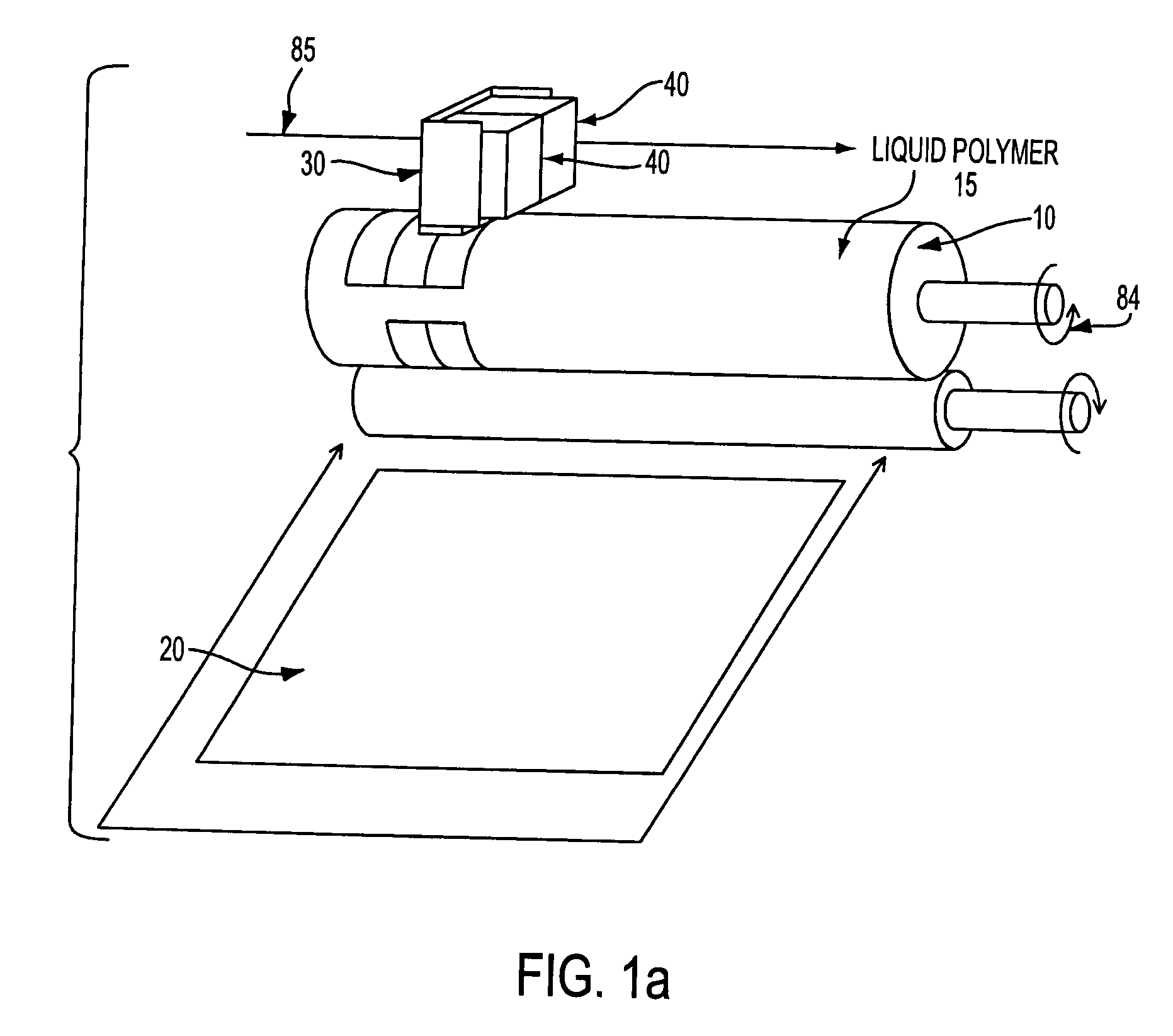

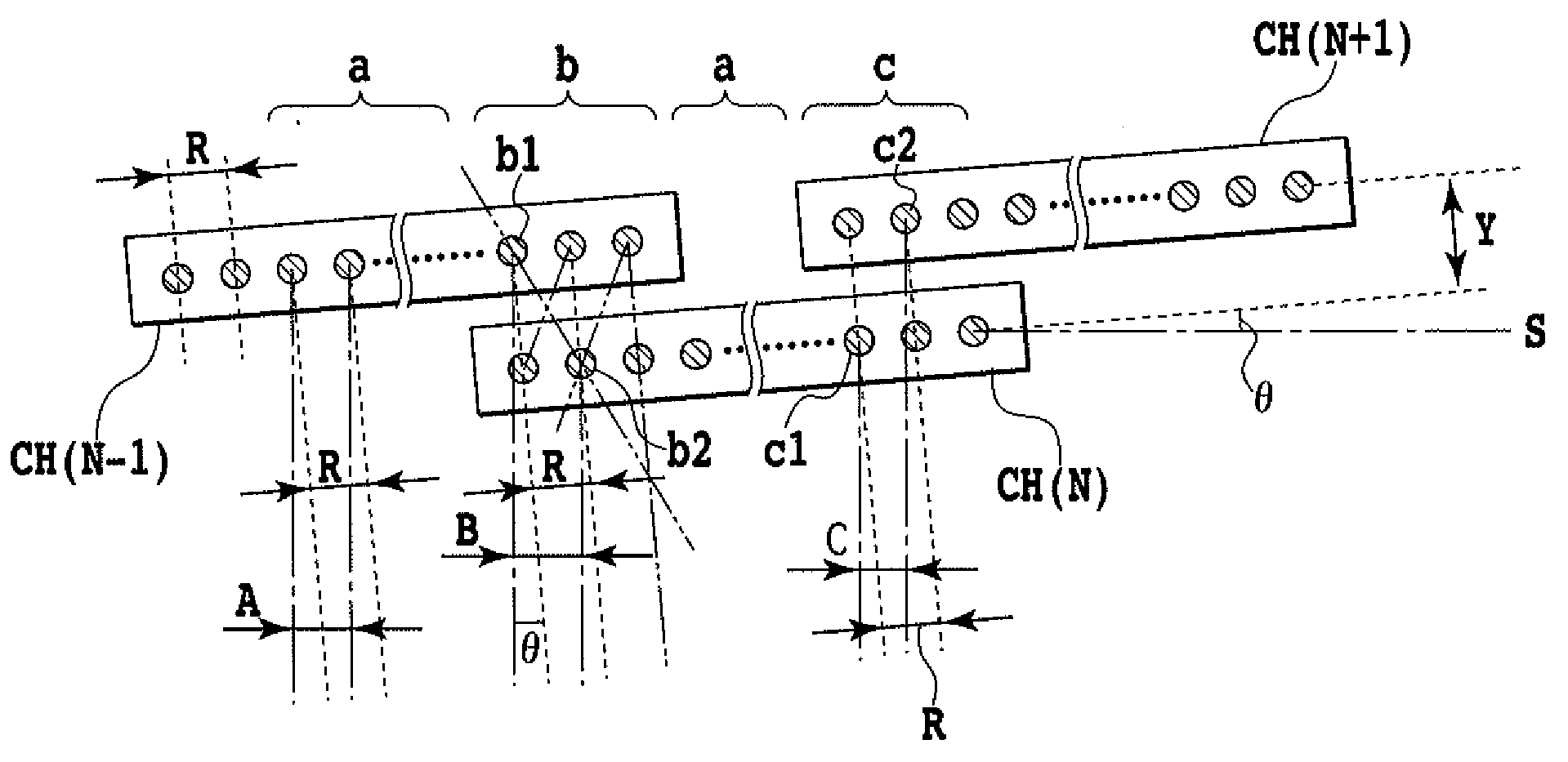

Apparatus and method for ink-jet printing onto an intermediate drum in a helical pattern

InactiveUS20050046651A1Improve printing qualityImprove throughputSpacing mechanismsOther printing apparatusImage transferImage manipulation

An apparatus and method for ink-jet printing onto an intermediate drum in a helical pattern while correcting for image skew and aliasing. A plurality of ink-jet print heads place an image on an intermediate drum, impervious to ink, in a helical patter. To compensate for helical printing, the image is altered by nozzle placement and image manipulation to correct for skewing errors, and thereafter, the nozzle timing is adjusted to correct for aliasing. The plurality of print heads move parallel to the axis of rotation of the drum while the drum is simultaneously rotating, causing the image to be placed in a helical pattern. Once the entire image is placed on the drum, paper is rolled against the drum under pressure and the image is transferred thereto.

Owner:FUNAI ELECTRIC CO LTD

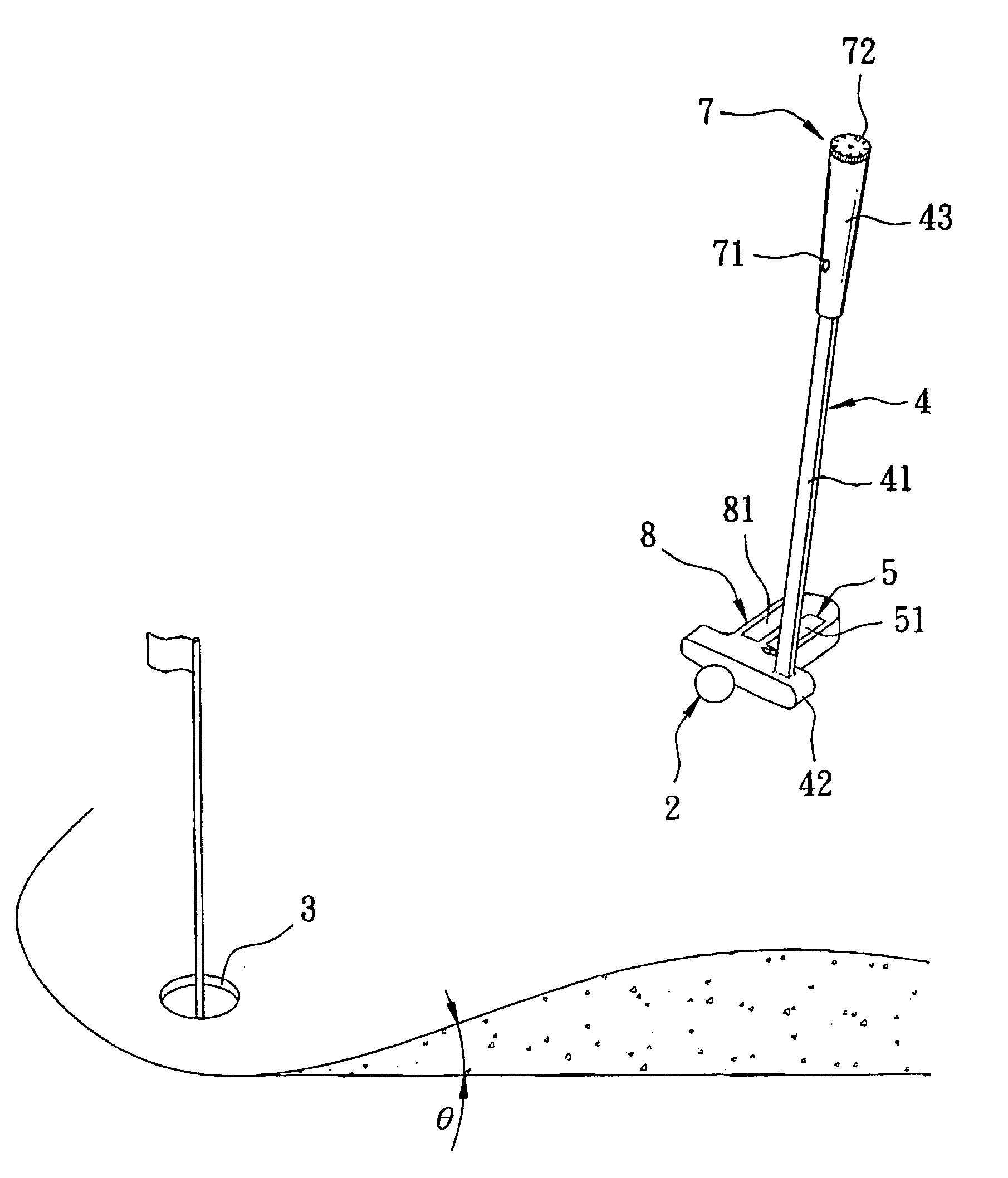

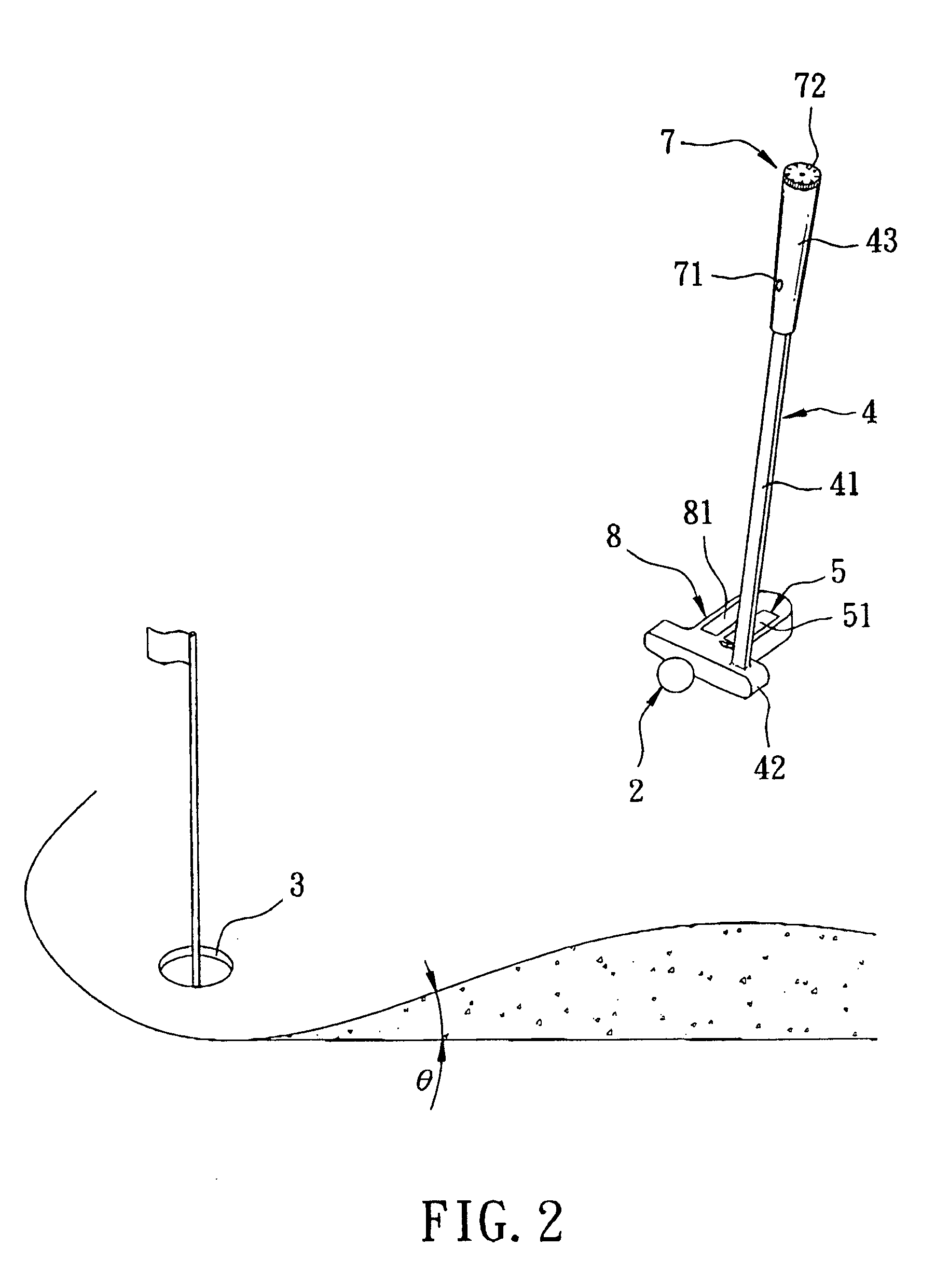

Golf putter assembly

A golf putter assembly includes a putter including a head, a display unit disposed in the putter, and a detecting unit disposed in the putter and electrically coupled to the display unit. The detecting unit is operable to detect and record a stationary starting position of a golf ball. The detecting unit is further operable to detect, during a practice swing, an instantaneous speed of the head as the head moves past the starting position, and to calculate what would be an initial speed of the golf ball if the golf ball was actually hit by the head with reference to the instantaneous speed of the head detected thereby. The detecting unit further performs control such that the initial speed of the golf ball as calculated is displayed on the display unit.

Owner:LIN CHIH CHIEN +1

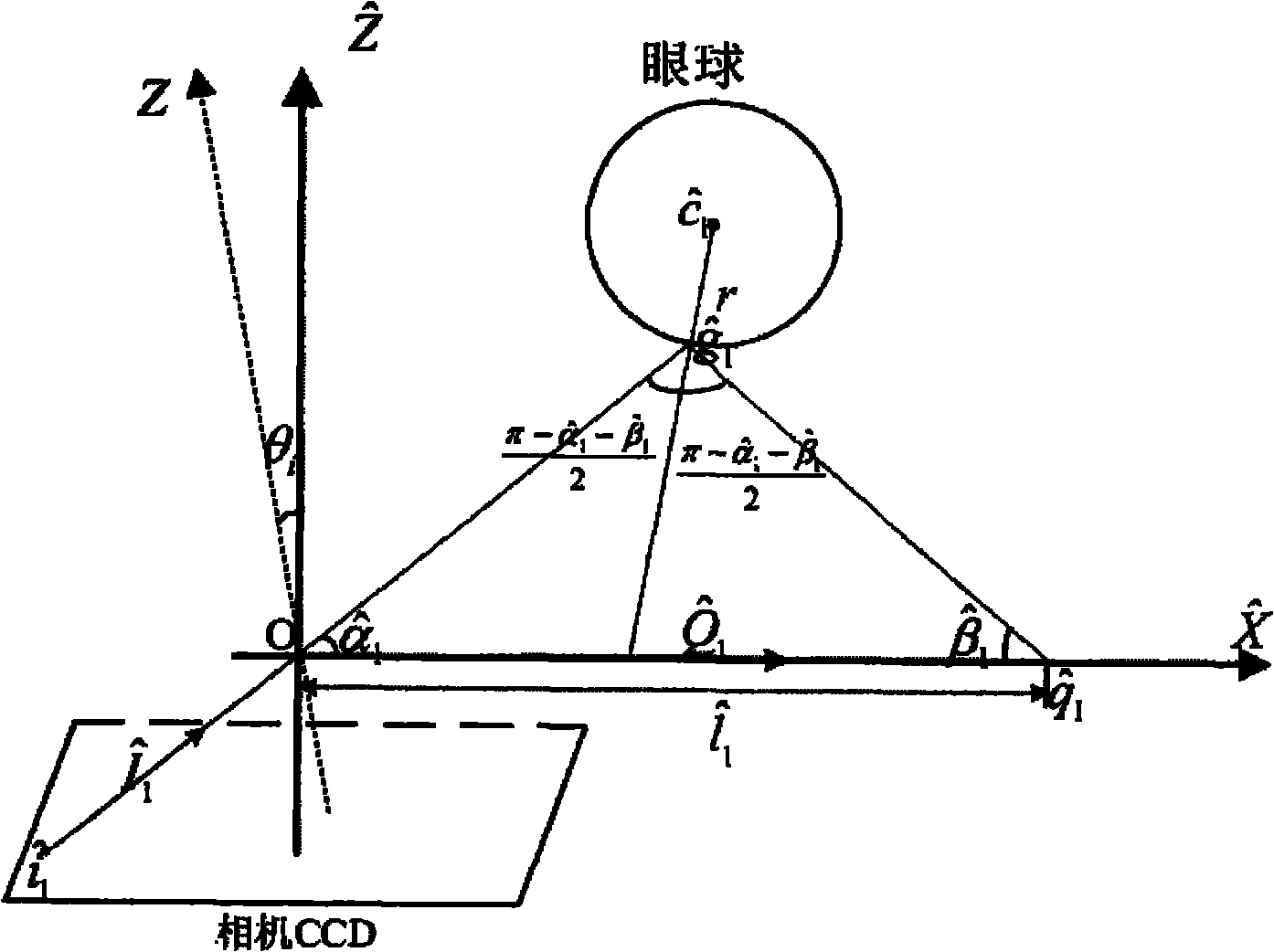

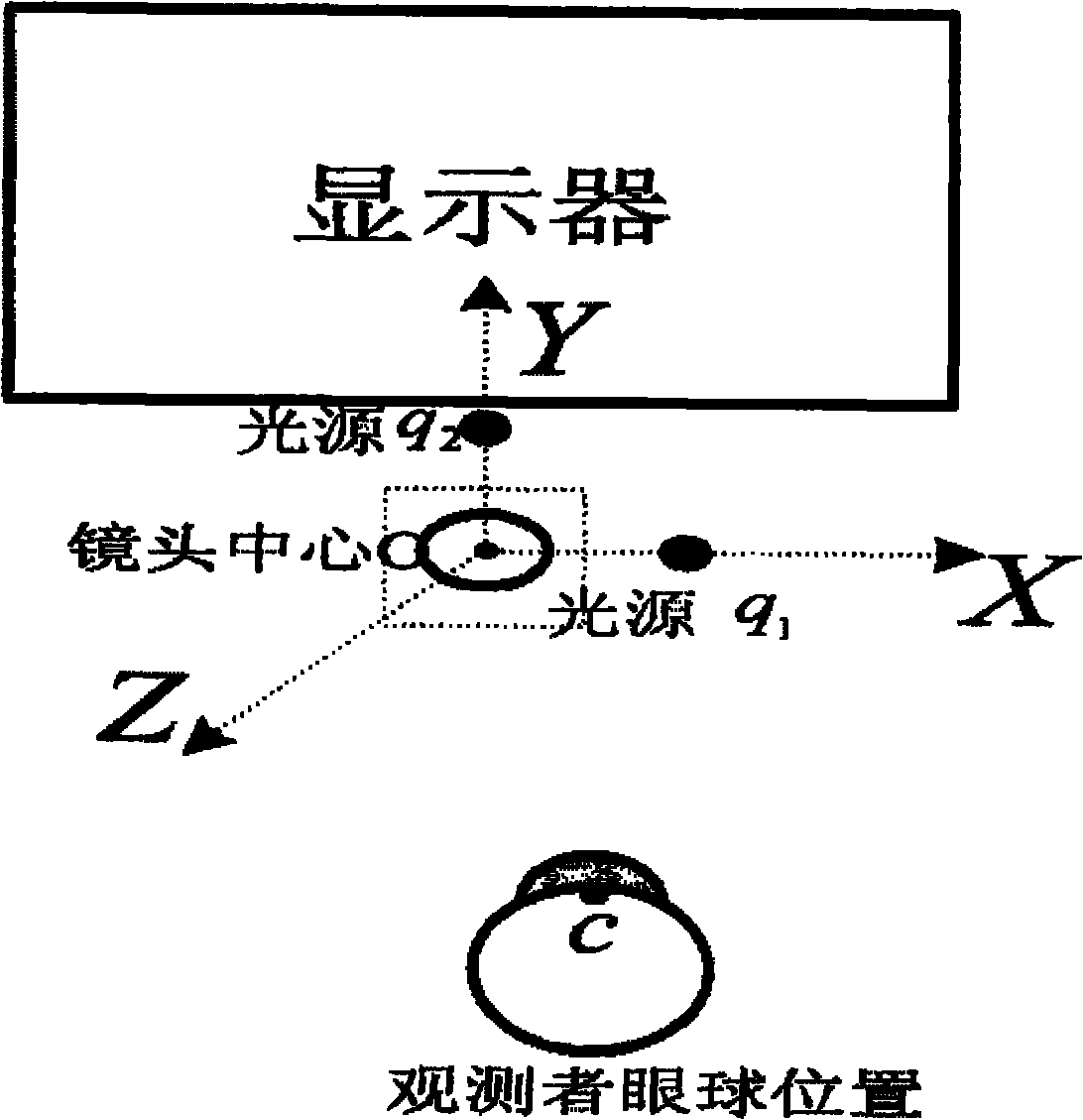

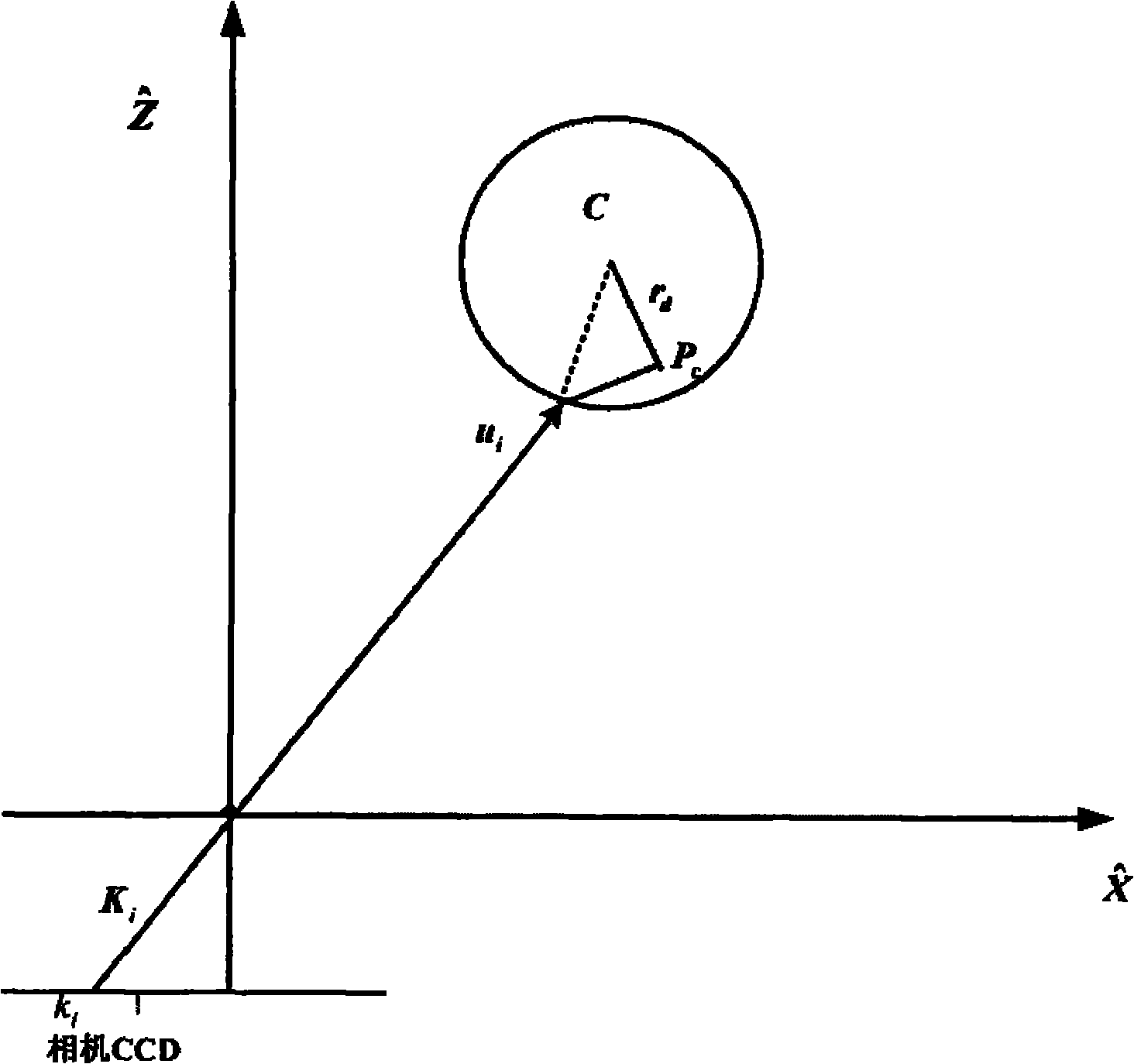

3D free head moving type gaze tracking system

The invention discloses a 3D free head moving type gaze tracking system belonging to the technical field of image processing and pattern recognition. The 3D free head moving type gaze tracking system is realized by using the method comprising the steps of: calibration of camera internal parameters, the establishment of a hardware system, the extraction of the center calibrates of pupils in images and a flare point, the determination of the three-dimensional calibrate of a cornea center, the determination of the three-dimensional of the pupil center, the reconstruction of a visual axis and the final error correction treatment. A camera and two LED light sources are adopted in the gaze tracking system which overcomes the restriction that a head part of a traditional 2 D gaze tracking system need be strictly fixed and the disadvantage that a plurality of cameras or auxiliary devices are required to position the three-dimensional calibrate information of human eyes for 3D gaze tracking, and the invention further provides a gaze tracking method with convenient use, low cost and high accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

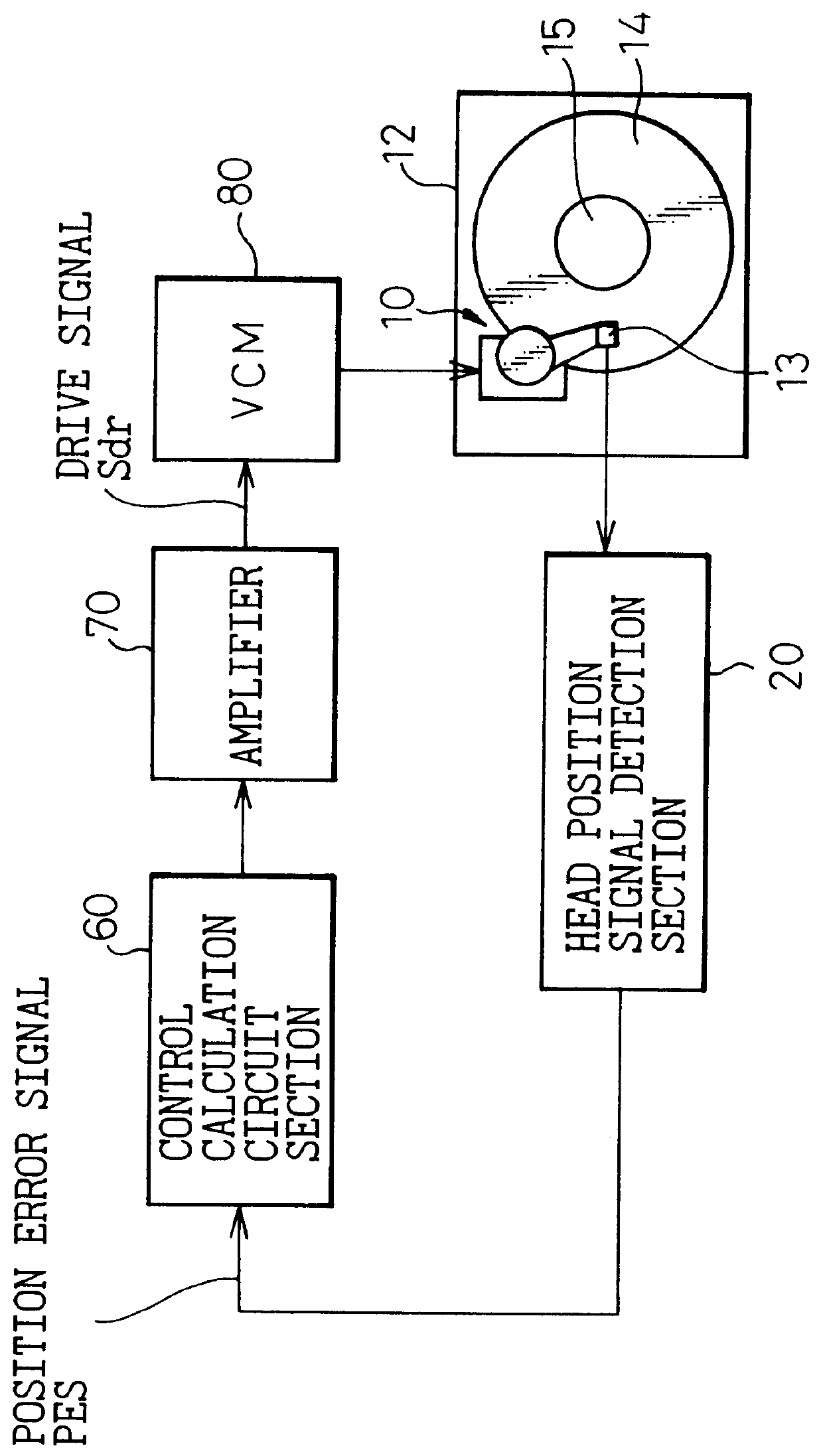

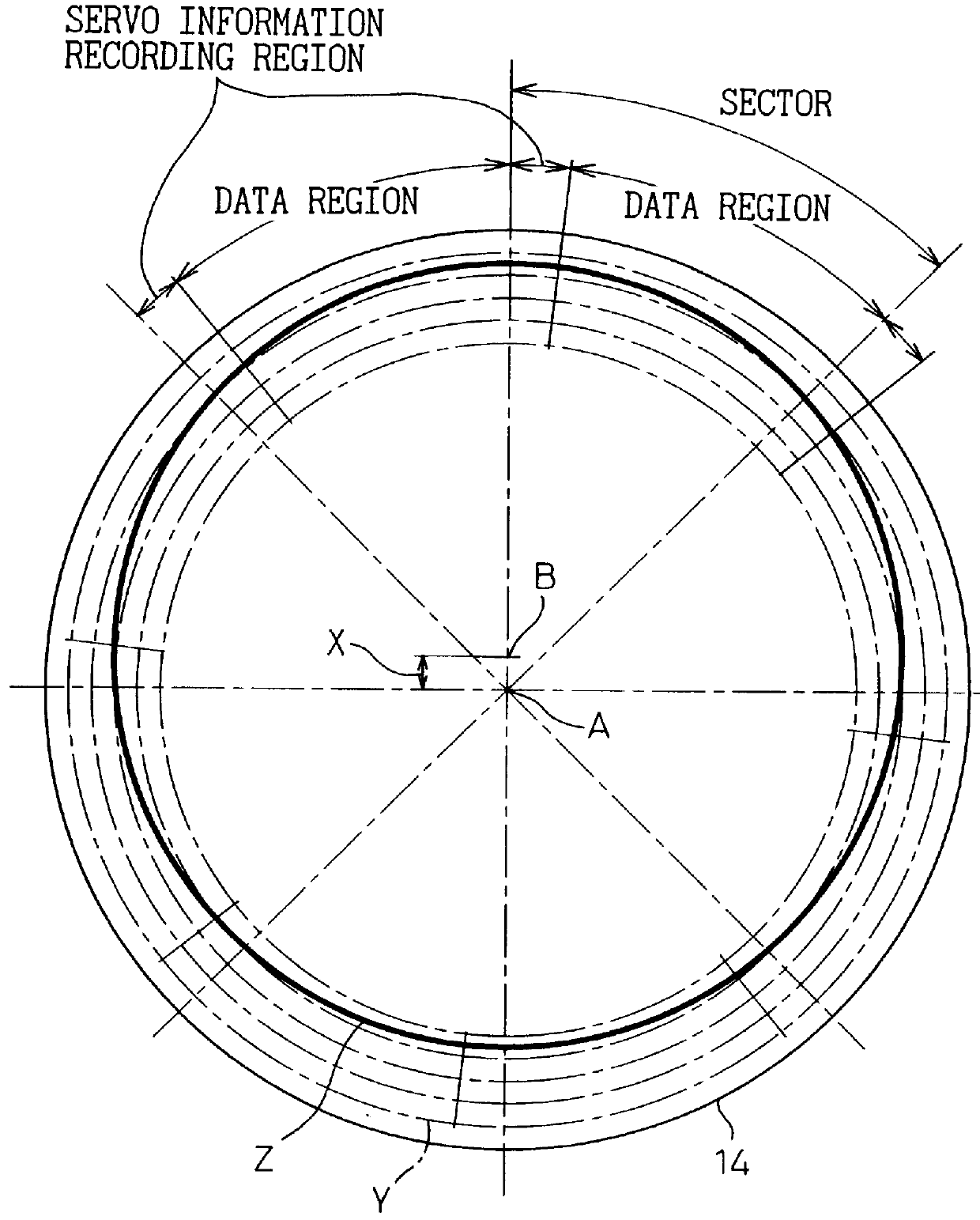

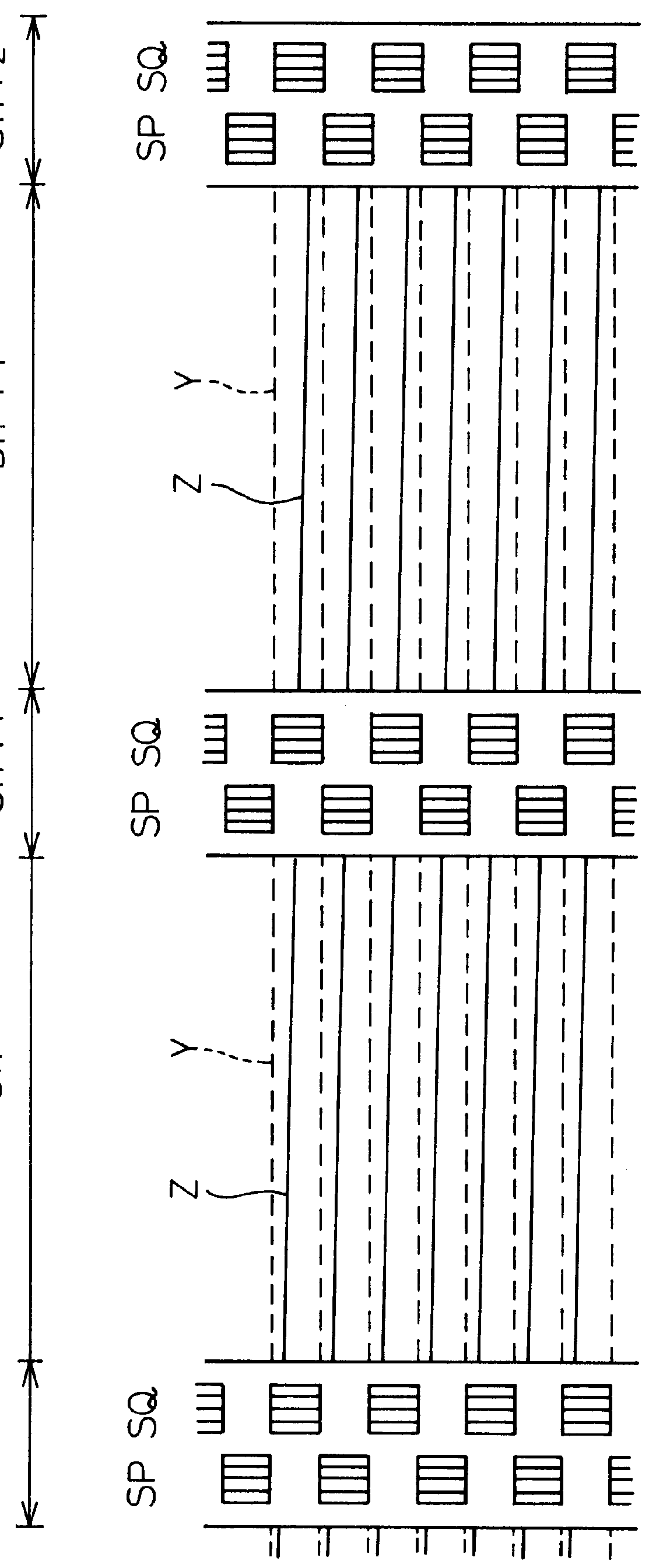

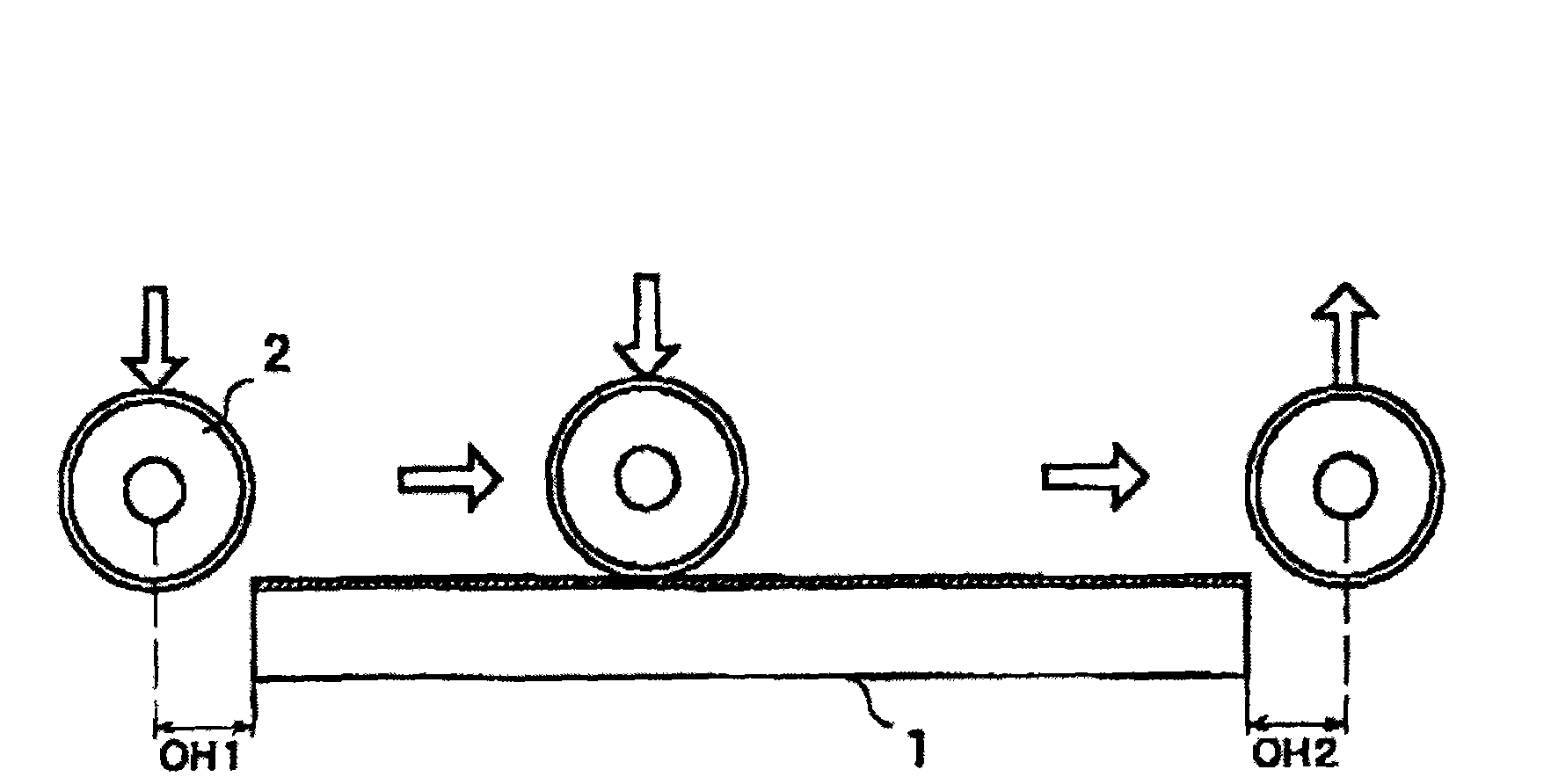

Head position control for a disk drive which performs recording about the rotational center even if the recorded servo information is eccentric

InactiveUS6128153AAverage power consumptionReduce power consumptionTrack finding/aligningRecord information storageCentre of rotationPosition control

Head position control is implemented in a disk drive for the case in which a disk is assembled into the disk drive after a precise track is recorded onto it using an external apparatus, which is capable of high-speed access even if there is eccentricity between a track defined by servo information and the center of rotation of the track. Two phase servo bursts consisting of servo information are recorded onto each of the servo information regions of a disk surface, in mutual alternation, the strength ratio between signals detected from these two phase servo bursts being used to determine to which side the head is displaced. By performing control so that this strength ratio is a prescribed value at each angular position, control is achieved so that the head moves along a circular path of rotation, even if there is eccentricity in the servo circular path defined by the recorded servo information with respect to the center of rotation.

Owner:KK TOSHIBA

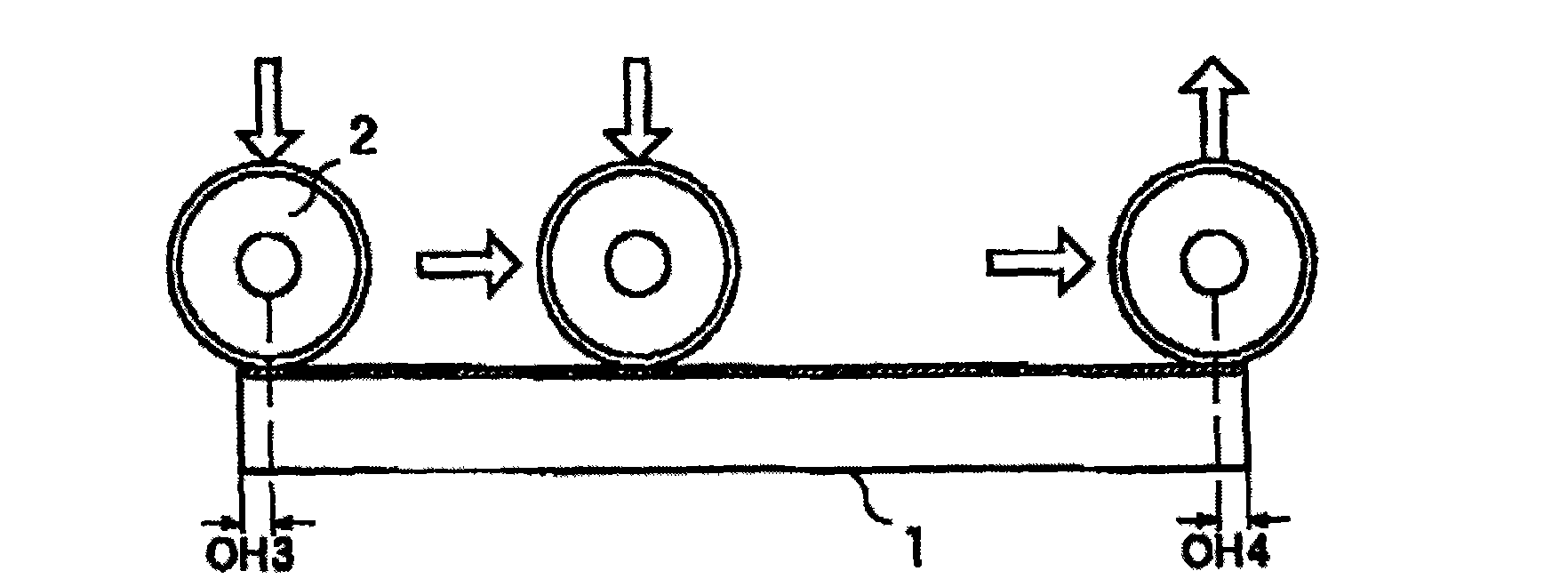

Scribing device and scribing method

InactiveCN101579854AIncrease freedomReduce deteriorationGlass severing apparatusOther workshop equipmentEngineeringPrescription data

The present invention provides a scribing device and a scribing method, for fragile material, capable of setting interior contact and exterior contact etc. A fragile material substrate is configured on a bench, such that the bench moves in Y axis direction freely and rotates freely by means of a motor. Further, the scribing head moves freely in X axis direction. Prescription data table of set interior contact and exterior contact is stored. Therefore, it can be carried out to scribe the interior contact and exterior contact according to the prescription data table.

Owner:MITSUBOSHI DIAMOND IND CO LTD

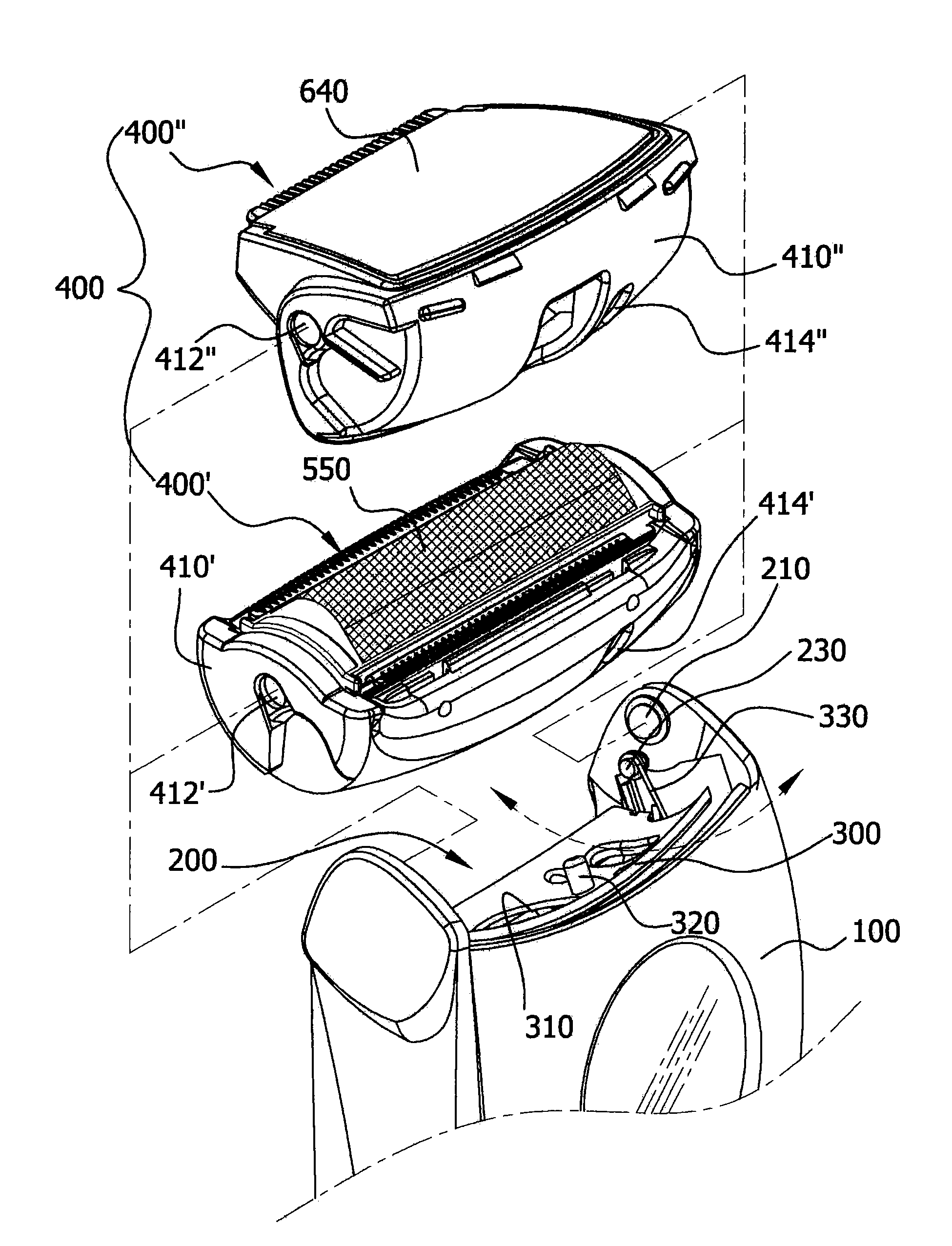

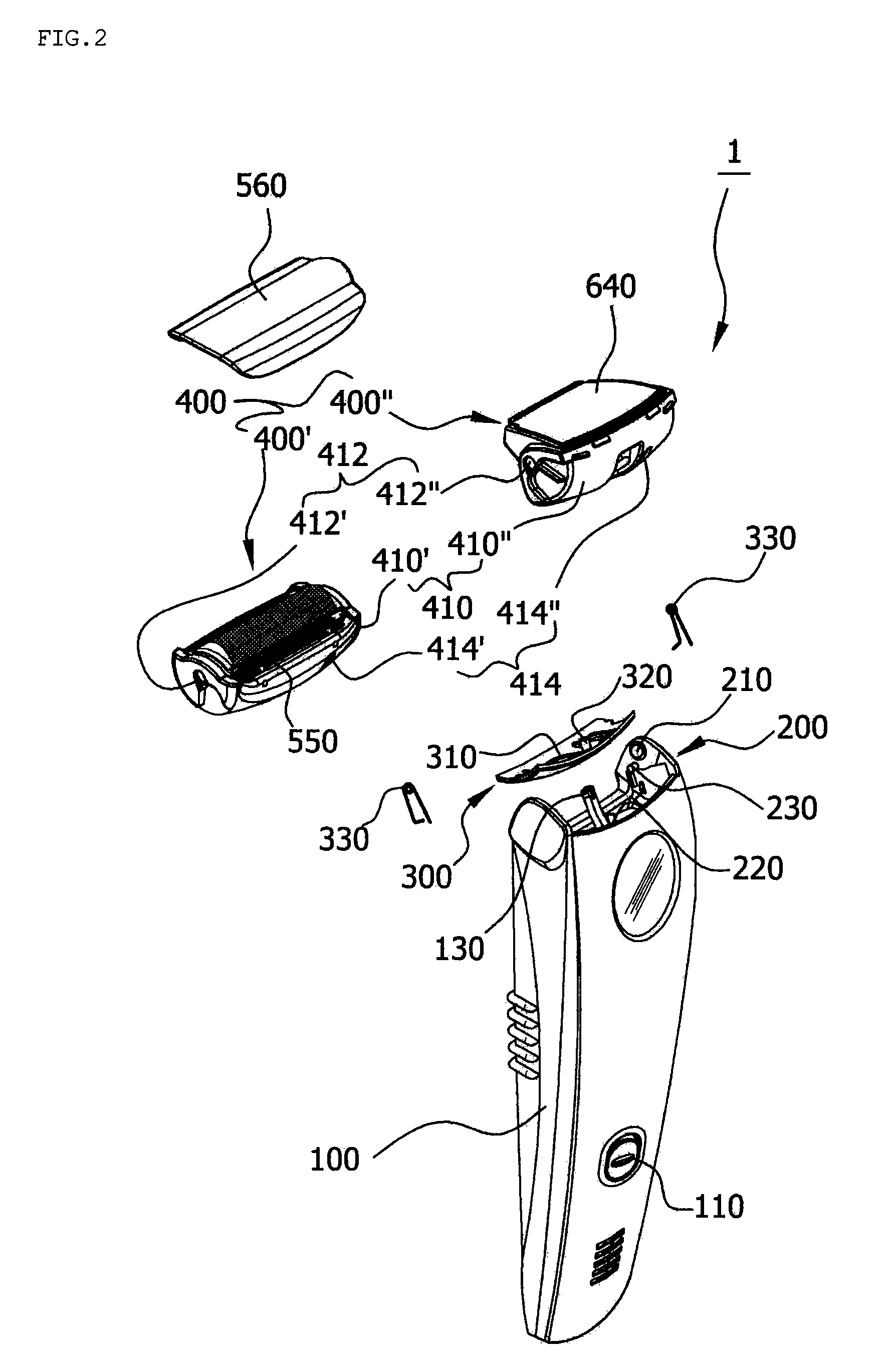

Multi type head moving shaver

InactiveUS7426785B2Simple structureCompact manufacturingMetal working apparatusDrive motorEngineering

Owner:HO TAE JUN

Electrostatic cloth attachment for vacuum head

A vacuum head assembly is disclosed which includes a vacuum head detachably connected to a secondary head, which is designed to carry an electrostatic cloth. The secondary head assumes a horizontal position behind the vacuum head so that the scoop of the vacuum head moves across the surface to be cleaned first followed by the secondary head, equipped with the electrostatic cloth. The cloth thus engages the floor after the scoop of the vacuum head. The secondary head carrying the electrostatic cloth may be easily connected to and disconnected from the vacuum head thereby rendering the vacuum head suitable for both hard and soft (i.e., carpeted) surfaces.

Owner:SHOP VAC

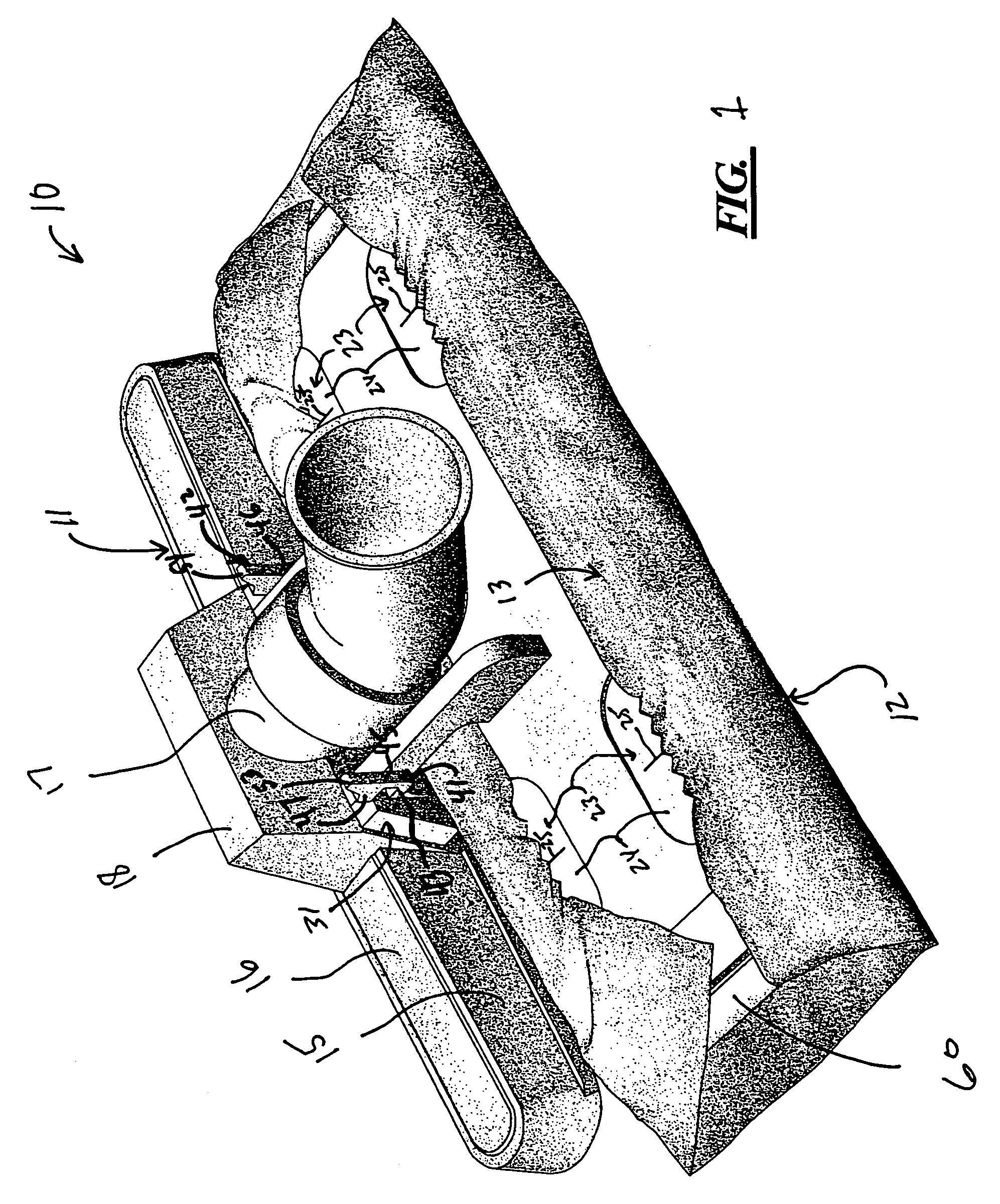

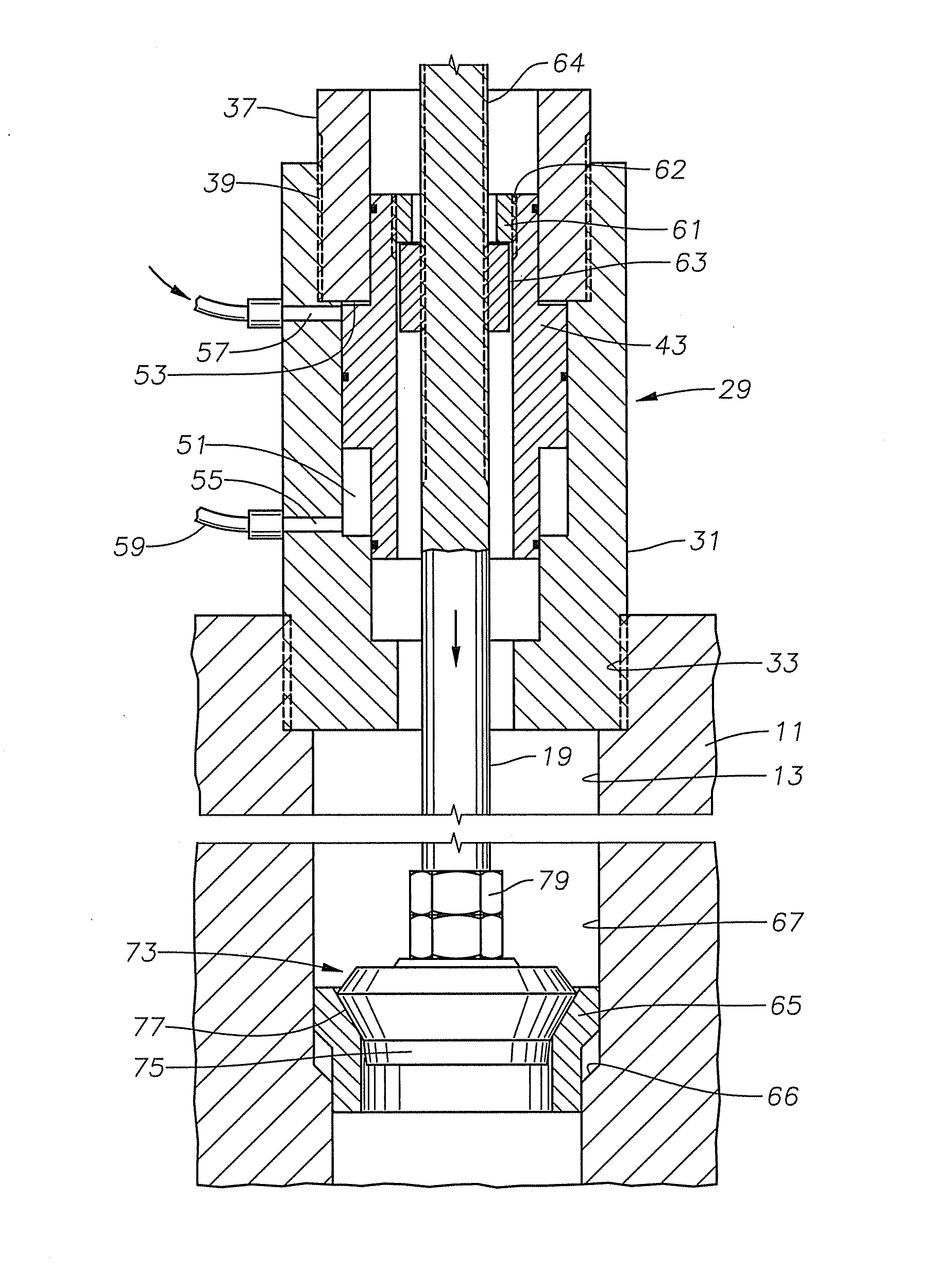

Valve Seat Installation and Retrieval Tool

InactiveUS20110173814A1Positive displacement pump componentsMetal working apparatusHydraulic cylinderEngineering

A tool for replacing a valve seat of a reciprocating pump has a puller shaft connected to a puller head having at least two spring-biased dogs. An operator inserts the puller head into a valve bore and through a valve seat, the dogs retracting as the puller head moves through the valve seat, then snapping back outward. A hydraulic cylinder engages the puller shaft to exert a force on the puller shaft causing the dogs to dislodge the seat. The operator then places a replacement valve seat on a shoulder in the valve bore. The operator attaches an installing head to an installing shaft and inserts the installing head into the valve bore into contact with the replacement valve seat. The hydraulic cylinder applies a force in an opposite direction on the installing shaft to push the replacement valve seat into installed engagement.

Owner:WEIR SPM

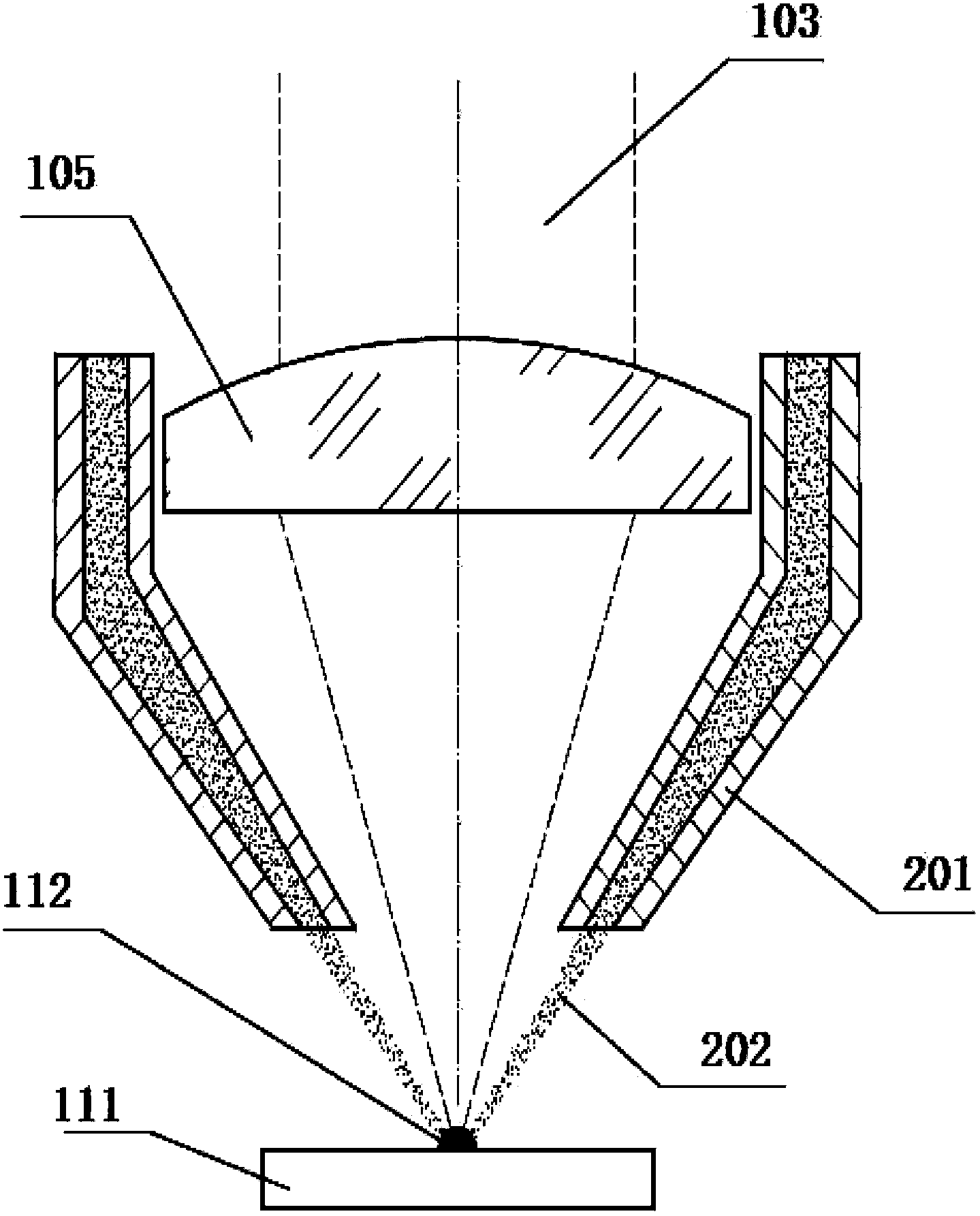

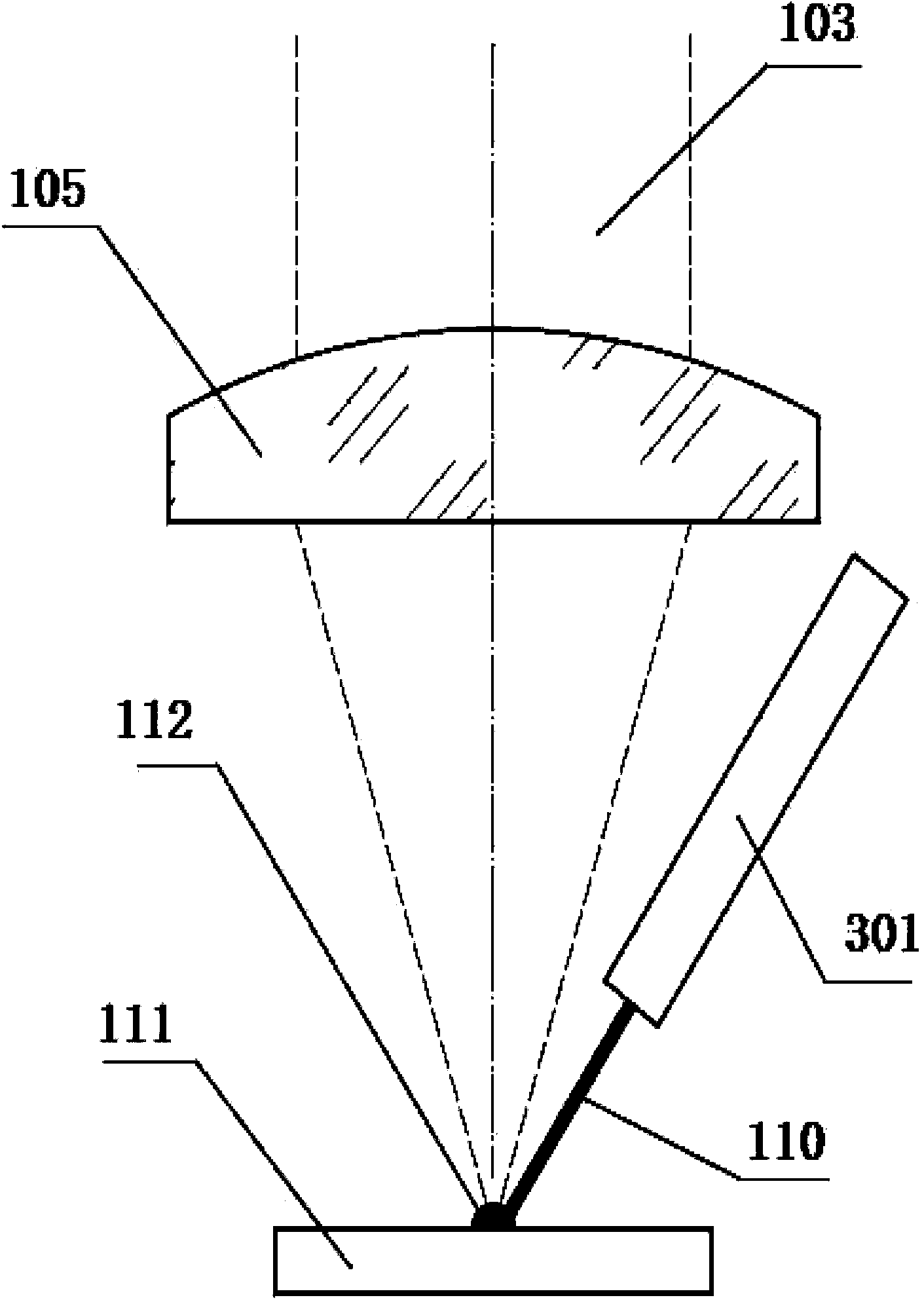

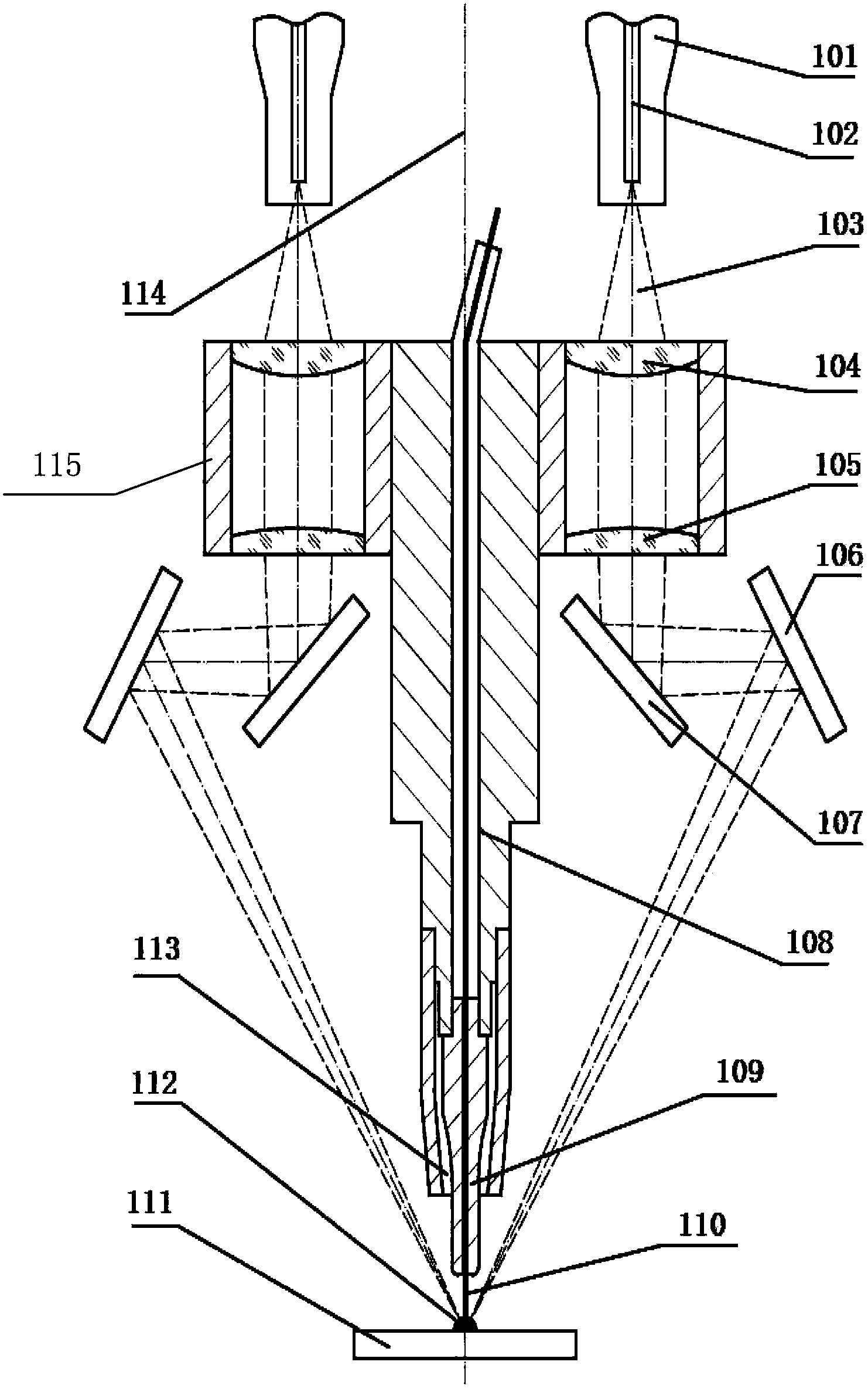

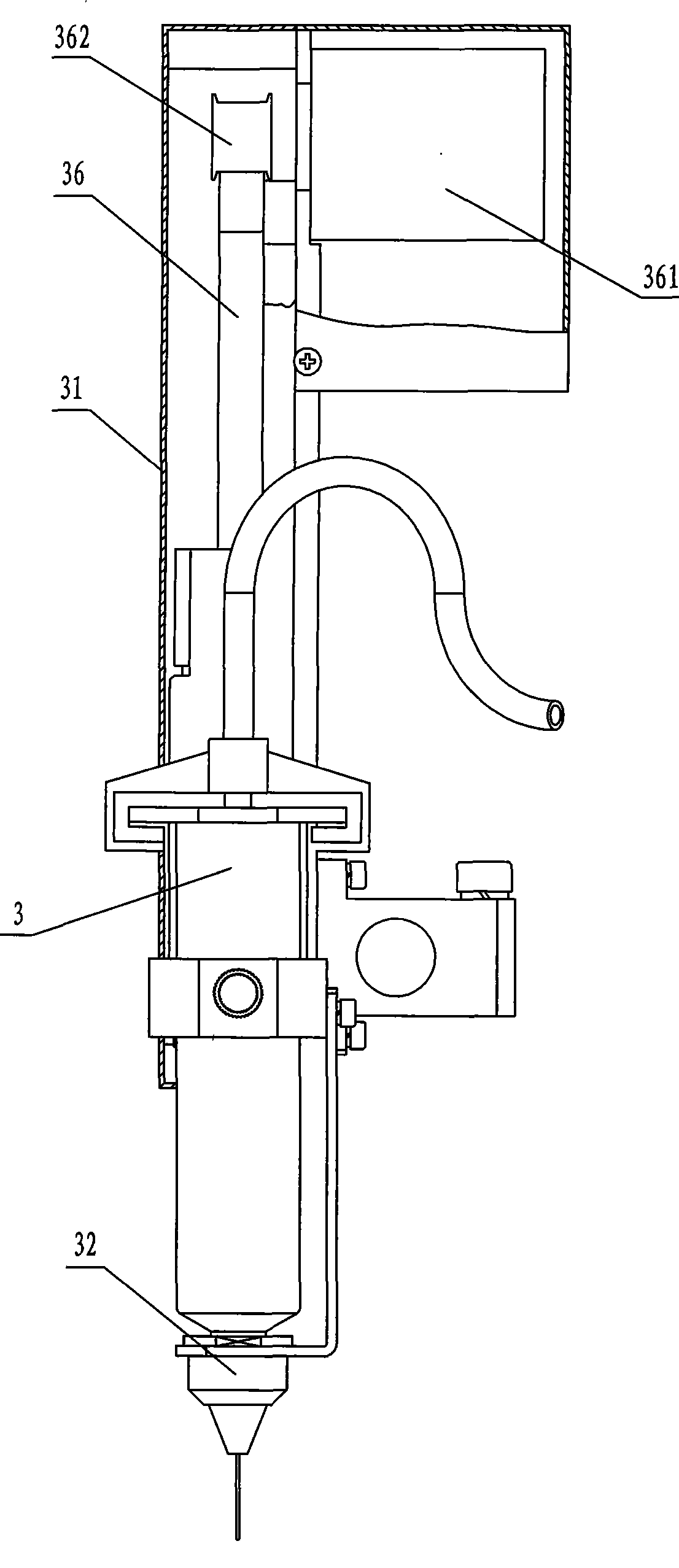

Multi-beam center wire feeding laser processing head and processing method thereof

InactiveCN104289811AEnsure consistencyEvenly heatedLaser beam welding apparatusOptical ModuleLaser processing

The invention belongs to the field of laser processing, in particular to a multi-beam center wire feeding laser processing head and a processing method of the multi-beam center wire feeding laser processing head. The laser processing head comprises a wire feeding tube, a wire feeding nozzle and a plurality of identical optical modules, wherein the wire feeding tube and the wire feeding nozzle are located on the center axis of the laser processing head, the optical modules are rotationally and symmetrically distributed around the center axis, each optical module comprises a collimating lens set, a focusing lens set and a reflecting mirror set, lasers are transmitted to the processing head through a plurality of paths of optical fibers, a plurality of laser beams are focused on one point of the surface of a workpiece to form a molten pool after being collimated, focused and reflected by the optical modules, a metal wire is perpendicularly fed into the molten pool on the surface of the workpiece through the fire feeding nozzle, and the laser processing head moves on the surface of the workpiece according to a certain track so that the center wire feeding laser processing process can be achieved. Through the multi-beam center wire feeding laser processing head, center wire feeding in laser focusing light spots in circular symmetry distribution is achieved, and the processing quality consistency is guaranteed when the laser processing head moves in different directions.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

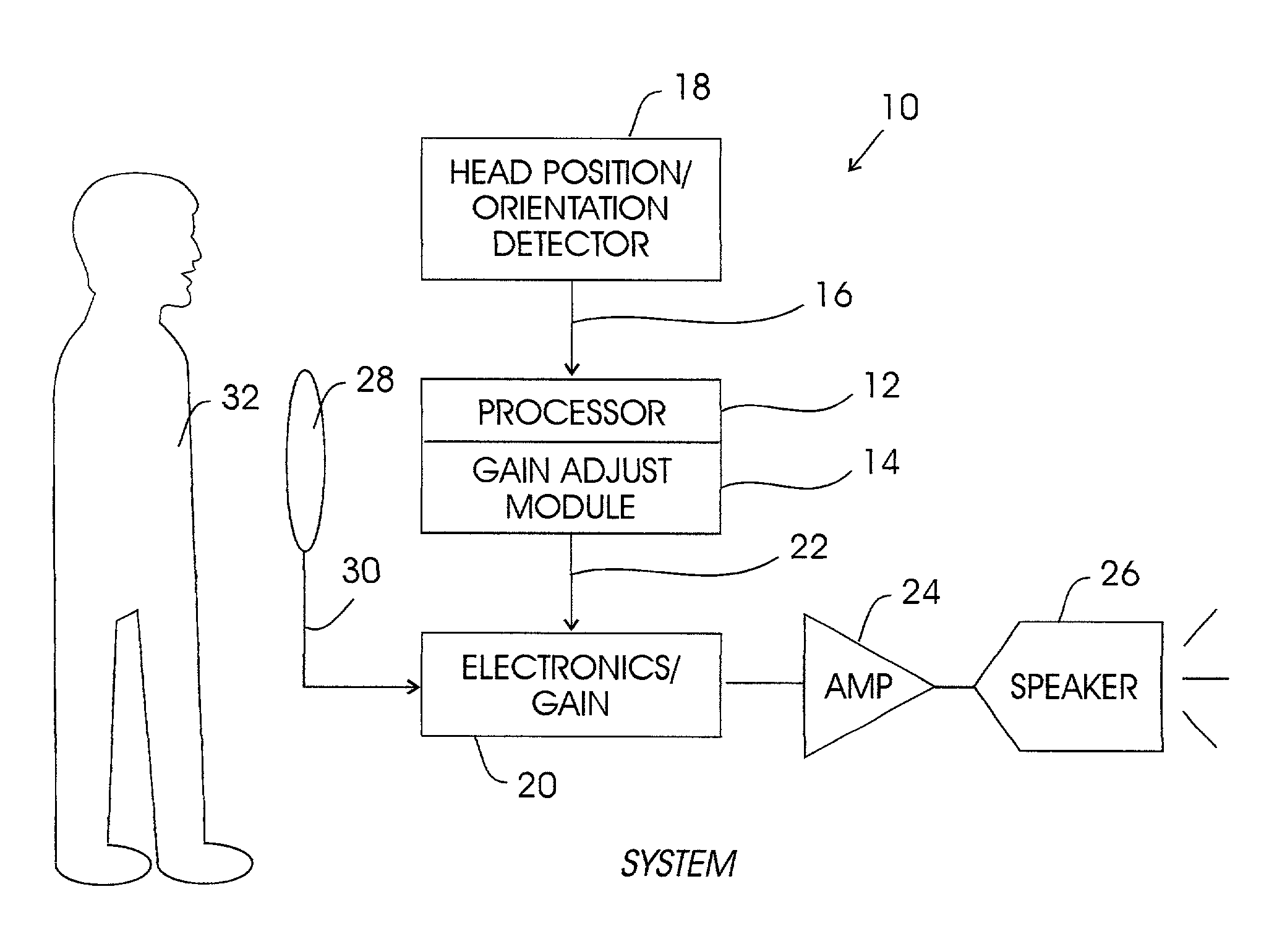

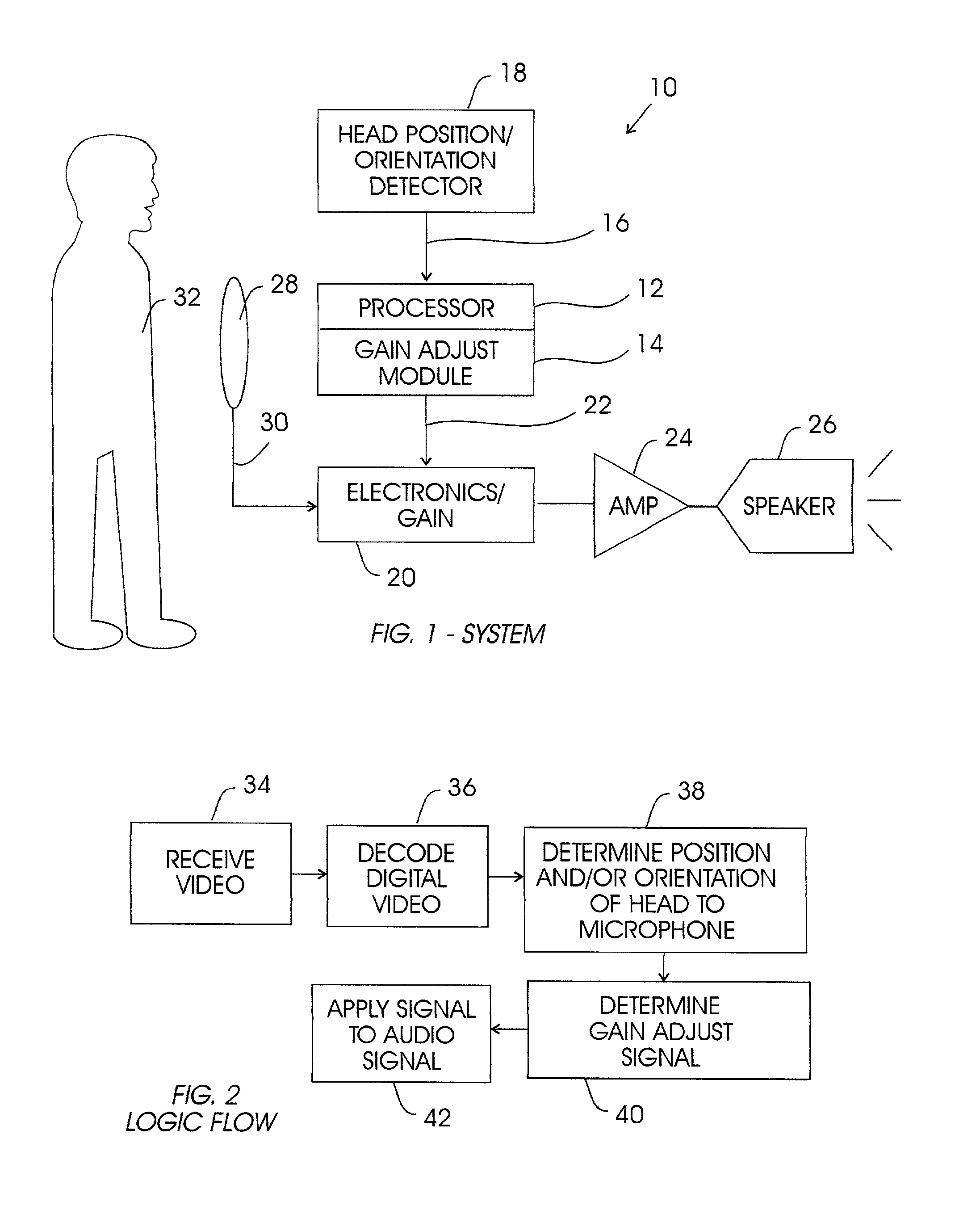

System and method for microphone gain adjust based on speaker orientation

A system and method for automatically adjusting the gain of an audio system as a speaker's head moves relative to a microphone includes using a video of the speaker to determine an orientation of the speaker's head relative to the microphone and, hence, a gain adjust signal. The gain adjust signal is then applied to the audio system that is associated with the microphone to dynamically and continuously adjust the gain the audio system.

Owner:LINKEDIN

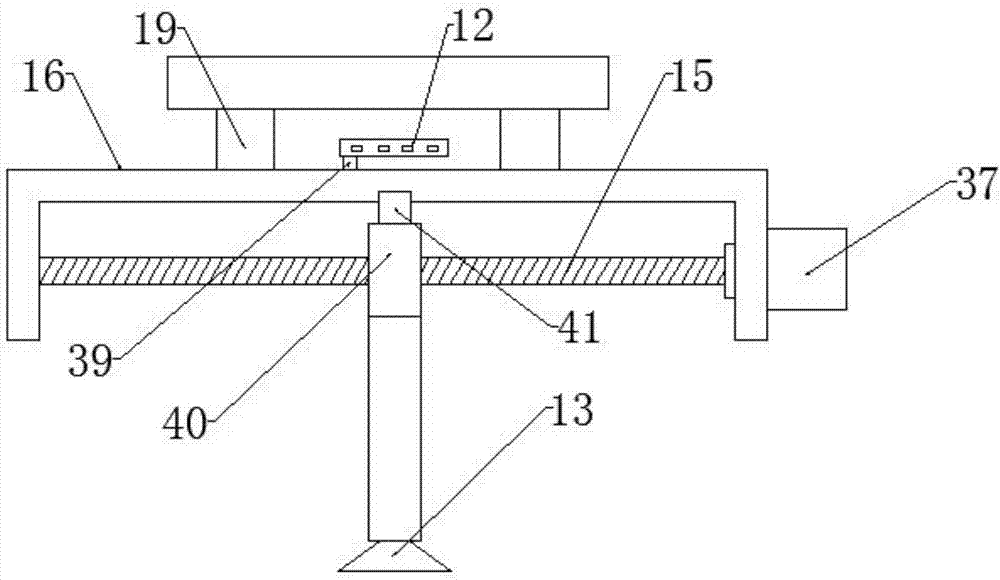

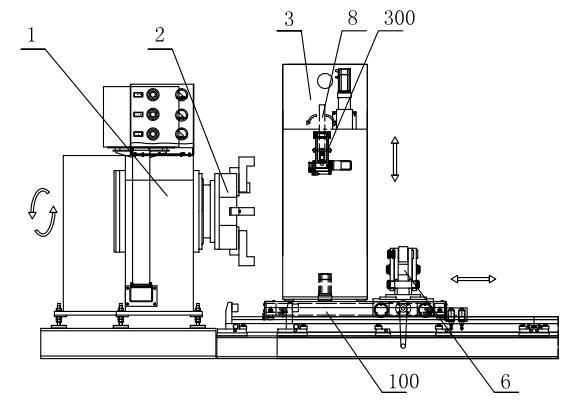

Full-automatic glue-dropping machine

ActiveCN101502825AEasy to operateRealize fully automatic operationLiquid surface applicatorsElectrical transducersLoudspeakerFully automatic

The invention discloses a fully automatic glue dispenser used for spreading glue on the bracket of a magnetic-induction circular loudspeaker, comprising a machine frame. The machine frame thereon is provided with a feeding device, a glue dispensing device and a locating device for locating a work piece. The glue dispensing device thereon is provided with a glue spreading head. The locating device thereon is provided with a material receiving channel, a fixed work piece and a rotating fixture capable of driving the work piece to rotate. The material receiving channel receives the work piece sent from a material sending device, the work piece is located on the rotating fixture and then the glue spread surface of the work piece is aligned with the glue spreading head on the glue dispensing device. In the glue spreading process, the rotating fixture drives the work piece to rotate for a set number of turns, and the glue spreading head moves downwards to a specified position and then spreads glue on the glue spread surface of the work piece. By using above structure, the invention can realize fully automatic operations of feeding and locating the work piece, spreading glue and blanking the work piece. The invention feeds material stably, accurately locates the work piece, and can be synchronously applied to the glue spreading requirement of work pieces of different specifications. The whole machine runs reliably, is in favor of improving production efficiency and ensuring product quality, and reduces influence of personal factor on the product quality.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

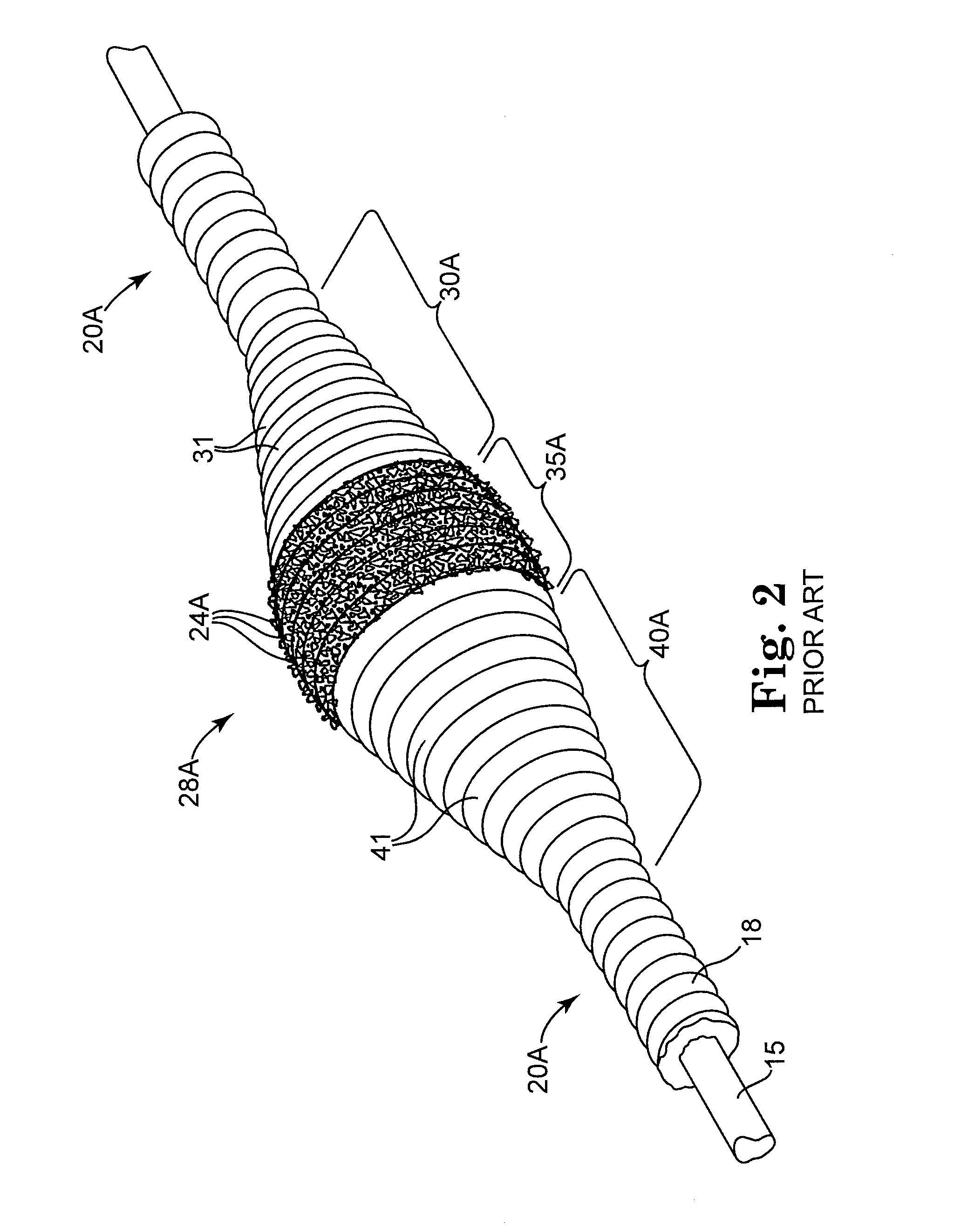

Eccentric abrading and cutting head for high-speed rotational atherectomy devices

ActiveUS20090299391A1Easy to cutMinimize traumaCannulasExcision instrumentsRotational axisHigh speed rotational atherectomy

The invention provides a rotational atherectomy device having, in various embodiments, a flexible, elongated, rotatable drive shaft with at least one flexible or inflexible eccentric enlarged abrading and cutting head attached thereto which comprises an abrasive surface. When placed against stenotic tissue and rotated at high speed, the eccentric nature of the abrading and cutting head moves along an orbital path, opening the lesion to a diameter larger than the resting diameter of the enlarged abrading and cutting head. Preferably the abrading and cutting head has a center of mass spaced radially from the rotational axis of the drive shaft, facilitating the ability of the device to travel along an orbital path. The abrading and cutting head comprises proximal and / or distal radiused surfaces that facilitate cutting difficult stenosis material while minimizing trauma to the vessel.

Owner:CARDIOVASCULAR SYST INC

Eccentric abrading and cutting head for high-speed rotational atherectomy devices

ActiveUS20100100110A1Improve abilitiesEasy to cutCannulasExcision instrumentsRotational axisHigh speed rotational atherectomy

The invention provides a rotational atherectomy device having, in various embodiments, a flexible, elongated, rotatable drive shaft with at least one flexible or inflexible eccentric enlarged abrading and cutting head attached thereto which comprises an abrasive surface. When placed against stenotic tissue and rotated at high speed, the eccentric nature of the abrading and cutting head moves along an orbital path, opening the lesion to a diameter larger than the resting diameter of the enlarged abrading and cutting head. Preferably the abrading and cutting head has a center of mass spaced radially from the rotational axis of the drive shaft, facilitating the ability of the device to travel along an orbital path. The abrading and cutting head comprises proximal and / or distal radiused surfaces that facilitate cutting difficult stenosis material while minimizing trauma to the vessel. In some cases, the abrading and cutting head is made from a relatively dense metal.

Owner:CARDIOVASCULAR SYST INC

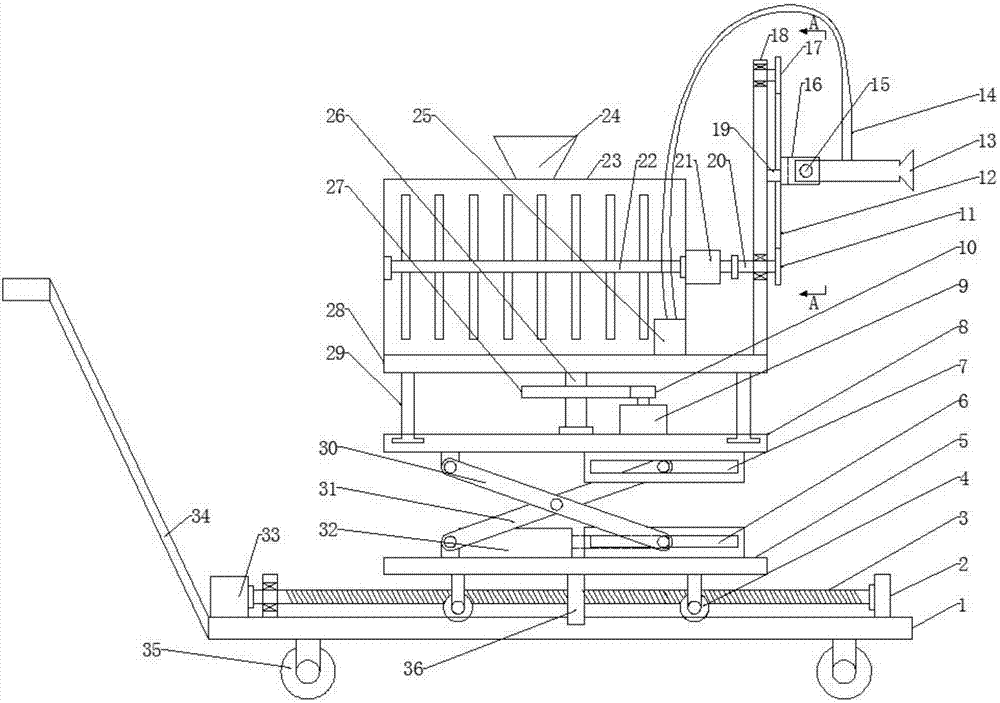

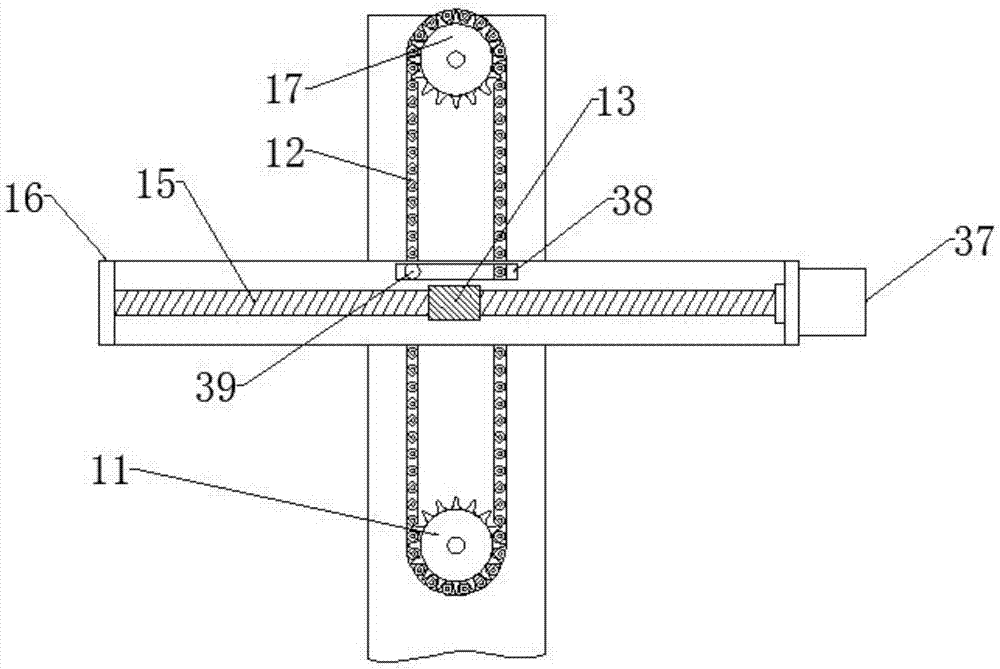

Building construction wall body spraying device

InactiveCN107542253AEasy to spraySpray evenlyBuilding constructionsArchitectural engineeringSprocket

The invention discloses a construction wall spraying device, which comprises a bottom plate, a first threaded rod, a first motor, a lifting mechanism, a first rotating shaft, a first gear, a second gear, a second motor, a biaxial motor, a second Two rotating shafts, the first sprocket, chain, the second sprocket, U-shaped mounting plate, the second threaded rod, the third motor and the nozzle, the present invention is provided with a lifting mechanism, which can adjust the height of the nozzle, and is convenient for different heights The wall is sprayed, and the second motor, the first gear and the second gear are provided. Through cooperation, the steering of the nozzle can be adjusted to facilitate spraying on irregular walls. There are a first sprocket, a chain, a second sprocket and The U-shaped mounting plate drives the nozzle to move up and down through cooperation to spray the wall with uniform spraying and high efficiency. It is equipped with a third motor and a second threaded rod, which drives the nozzle to move the position through cooperation, avoiding back and forth when spraying the wall. Moving the whole device has high efficiency and reduces the labor intensity of workers.

Owner:李小强

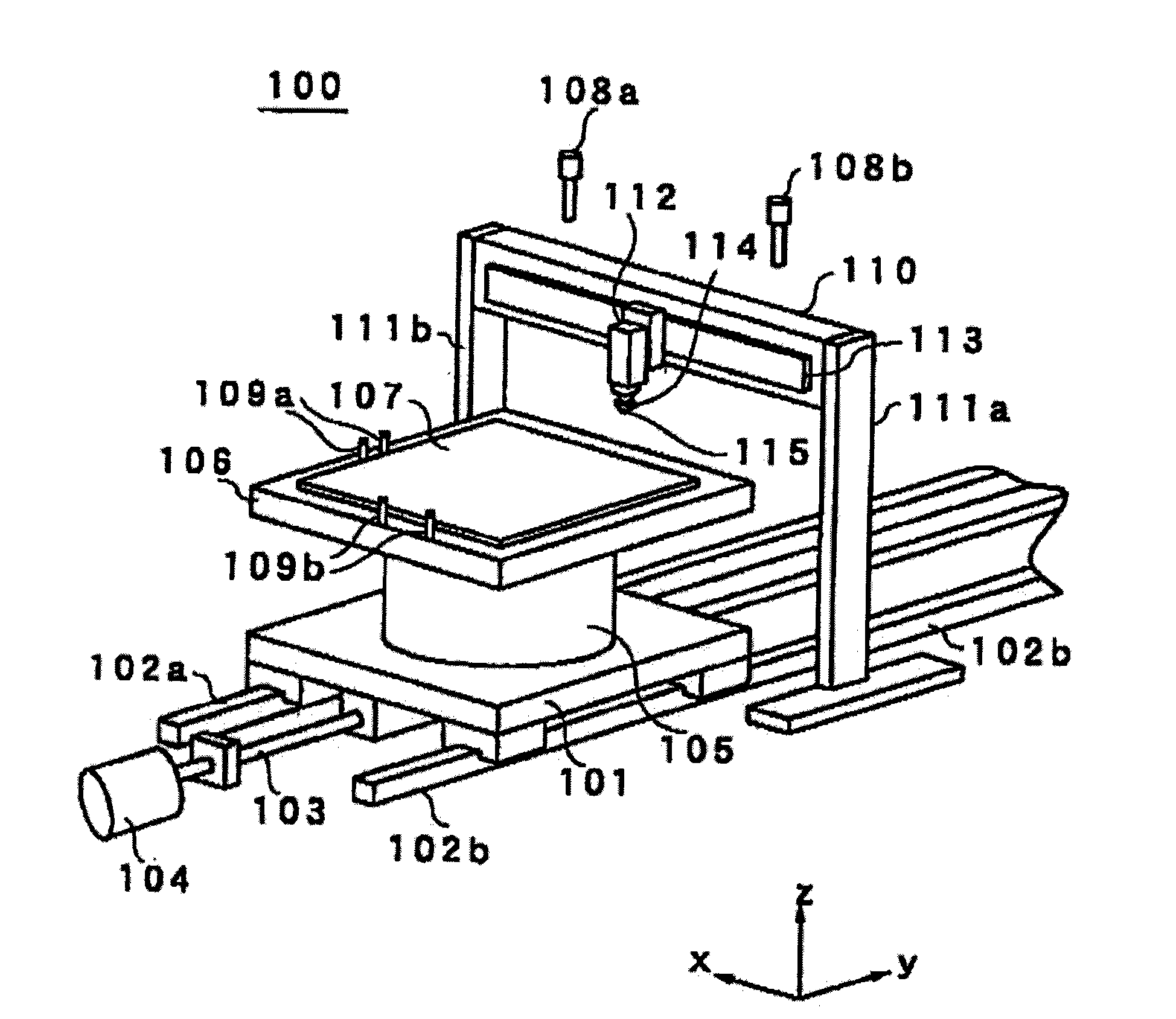

Three-dimensional printer and printing method thereof

ActiveCN103786347ASimple structureEasy to controlAdditive manufacturing apparatusHollow article cleaningEngineeringElectrical and Electronics engineering

The invention provides a three-dimensional printer and a printing method of the three-dimensional printer. The three-dimensional printer comprises at least two print cartridges, a print cartridge installation rack, a movable frame, a driving head, at least two printing heads and at least two shifters. The print cartridges are installed on the print cartridge installation rack. The driving head is installed on the movable frame. Each printing head receives consumable items from the corresponding print cartridge. The printing heads are detachably connected with the driving head through first connecting devices. Each shifter is detachably connected with the corresponding printing head through a second connecting device. The printing method of the three-dimensional printer comprises the following steps: the driving head moves one printing head connected with the driving head to the corresponding shifter, each shifter is connected with the corresponding printing head, and the driving head is detached from the printing head; the driving head moves to the other printing head, the driving head is connected with the printing head, and the corresponding shifter is detached from the printing head. The three-dimensional printer and the printing method of the three-dimensional printer have the advantages that the structure is simple, control is easy, and cost is low.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

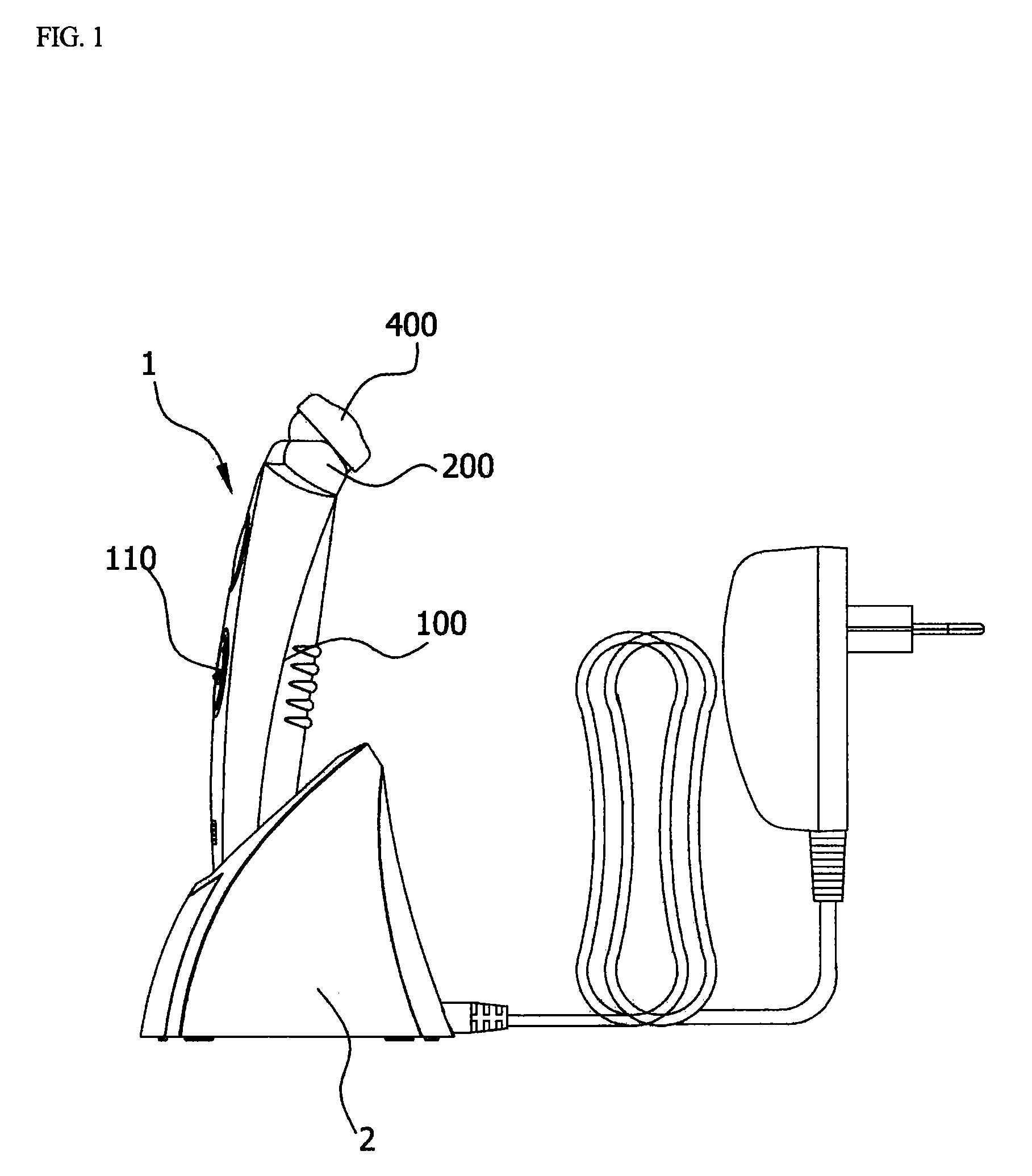

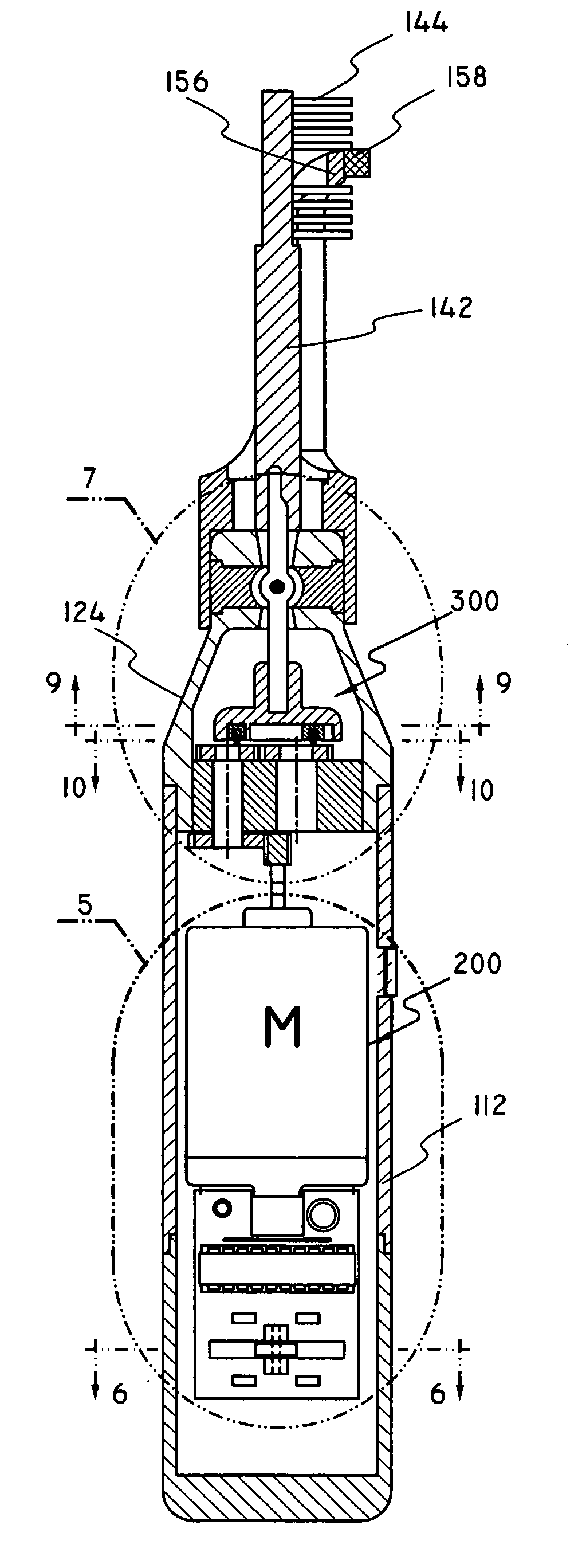

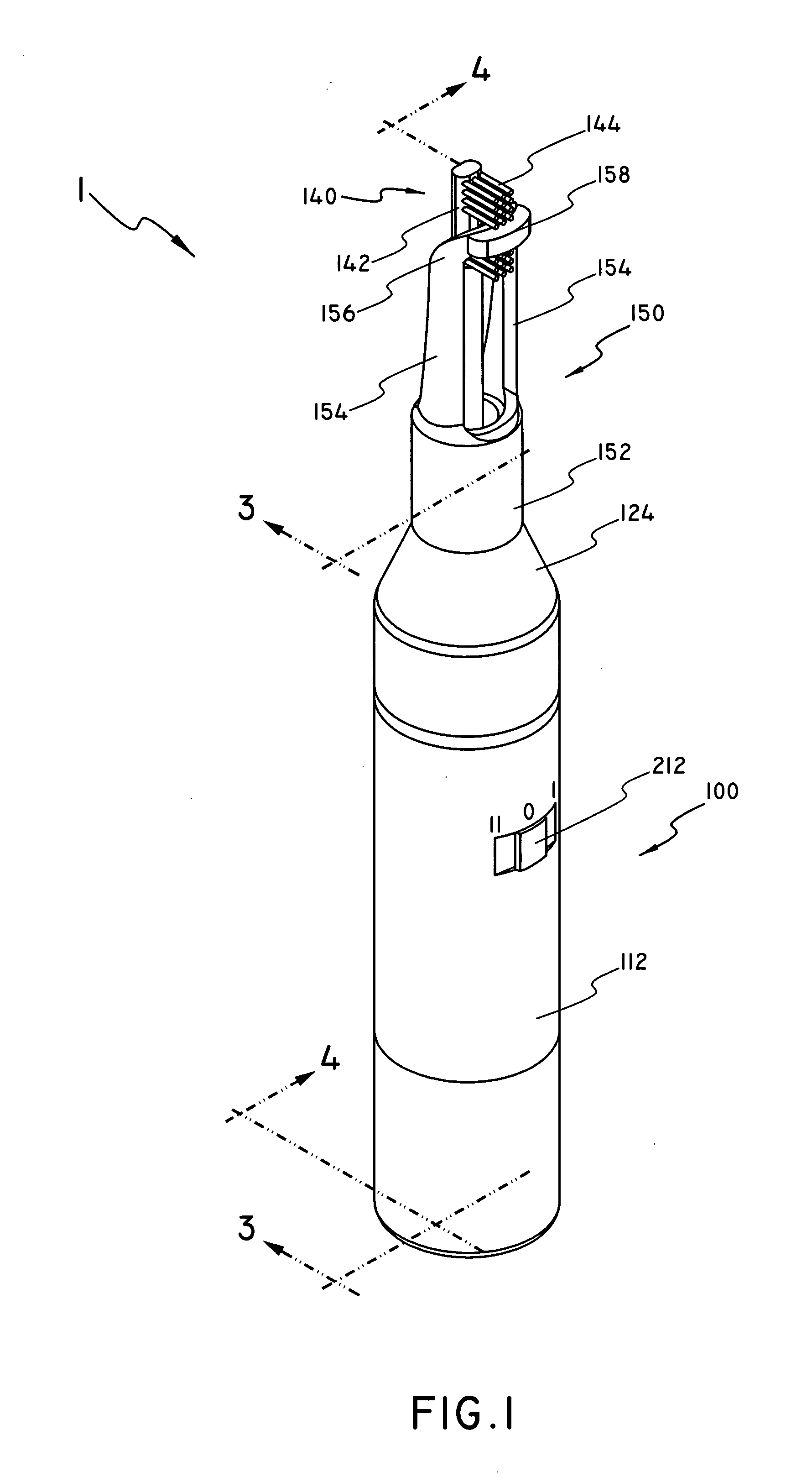

Electric toothbrush

An electric toothbrush in which the brushing head moves in an elliptical motion such that, on the brushing stroke, the bristles are proximate the teeth, and in the recovery portion of the cycle the bristles are pulled away from the teeth. A position sensitive switch automatically switches from a forward to a reverse operation of the electric motor, depending on the positioning of the toothbrush in a user's hand, allowing the user to brush both the upper and lower teeth using a stroke carrying the bristles from the gum line to the ends of the teeth, as is recommended by dental professionals, without having to move the toothbrush from hand to hand or manually move the switch from the forward to the reverse positions. A bridge pad engages the face of the teeth, maintaining a proper distance between the teeth and bristles during the elliptical rotation of the brush head.

Owner:FILSOUF EHSAN

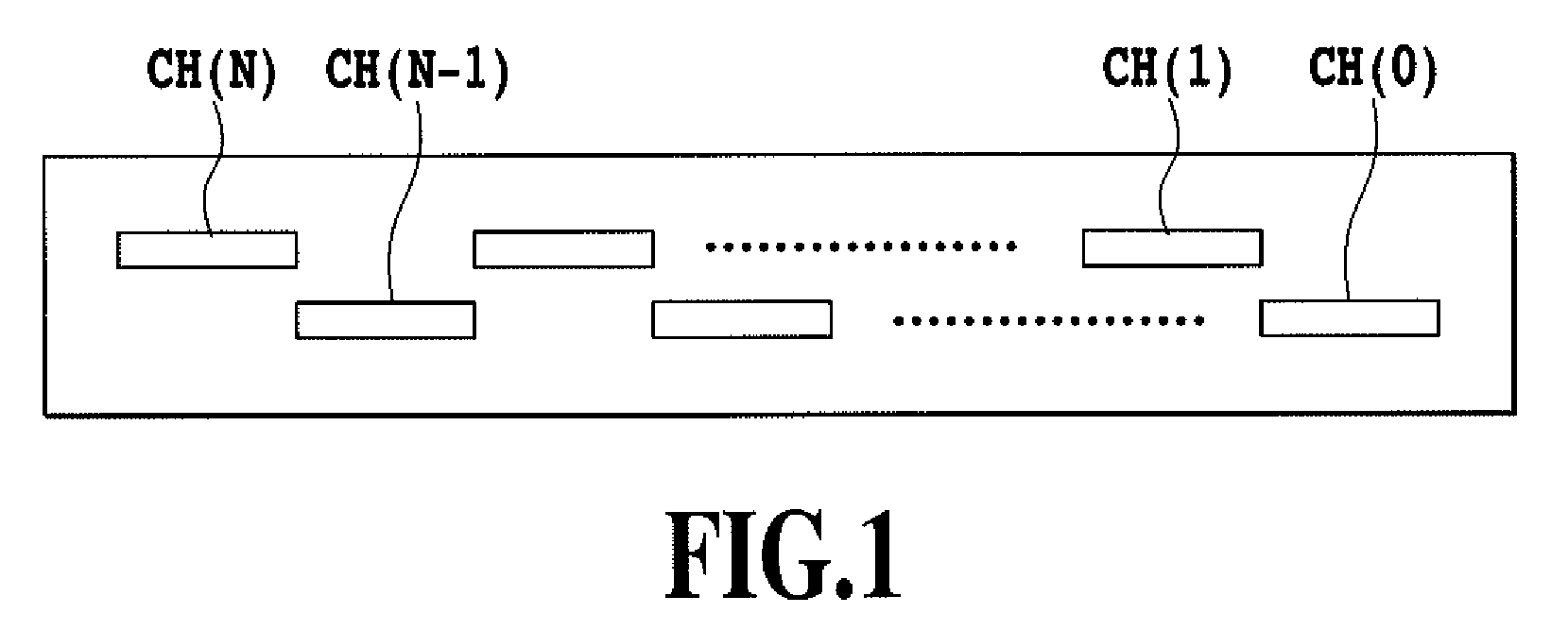

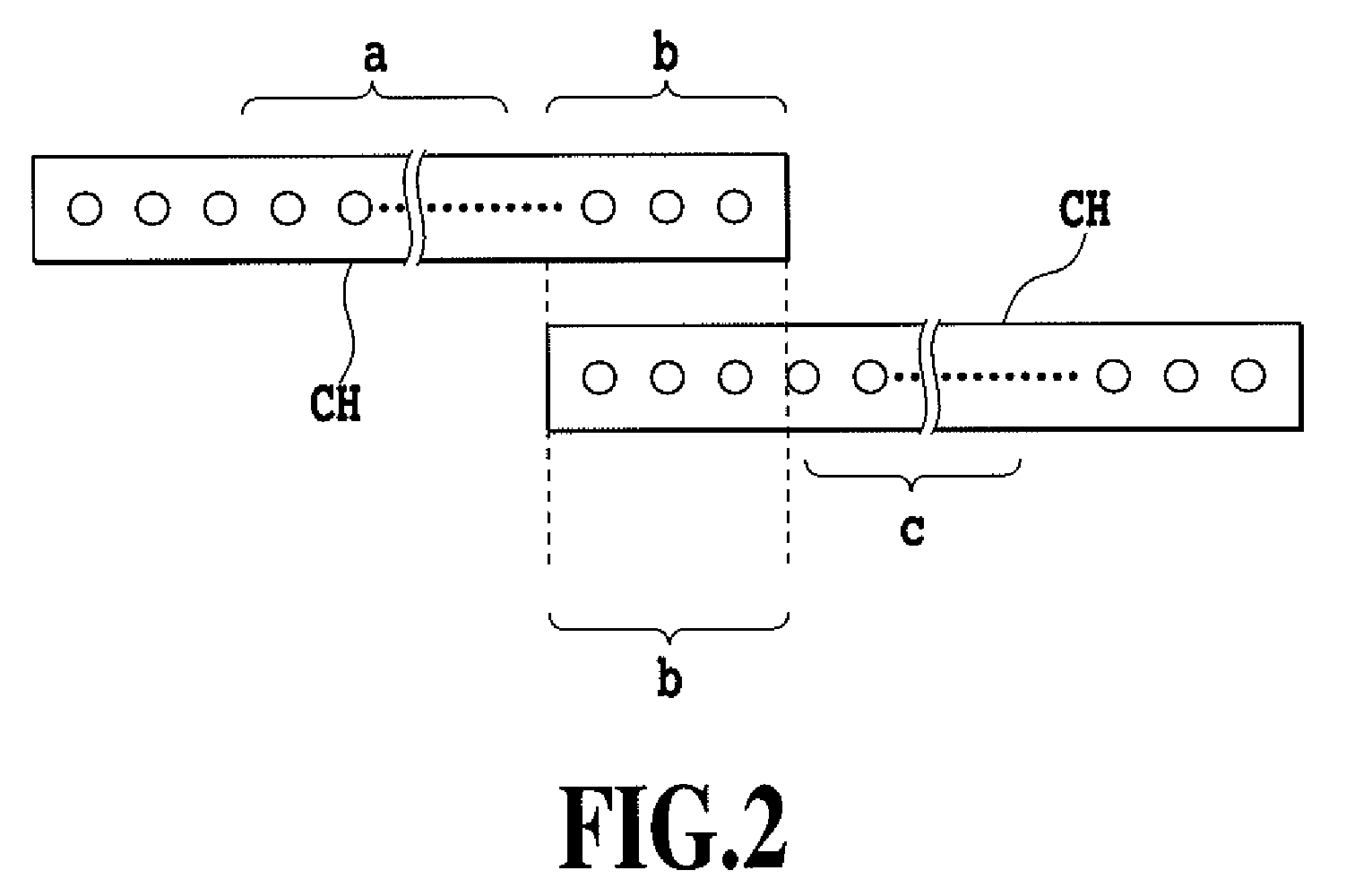

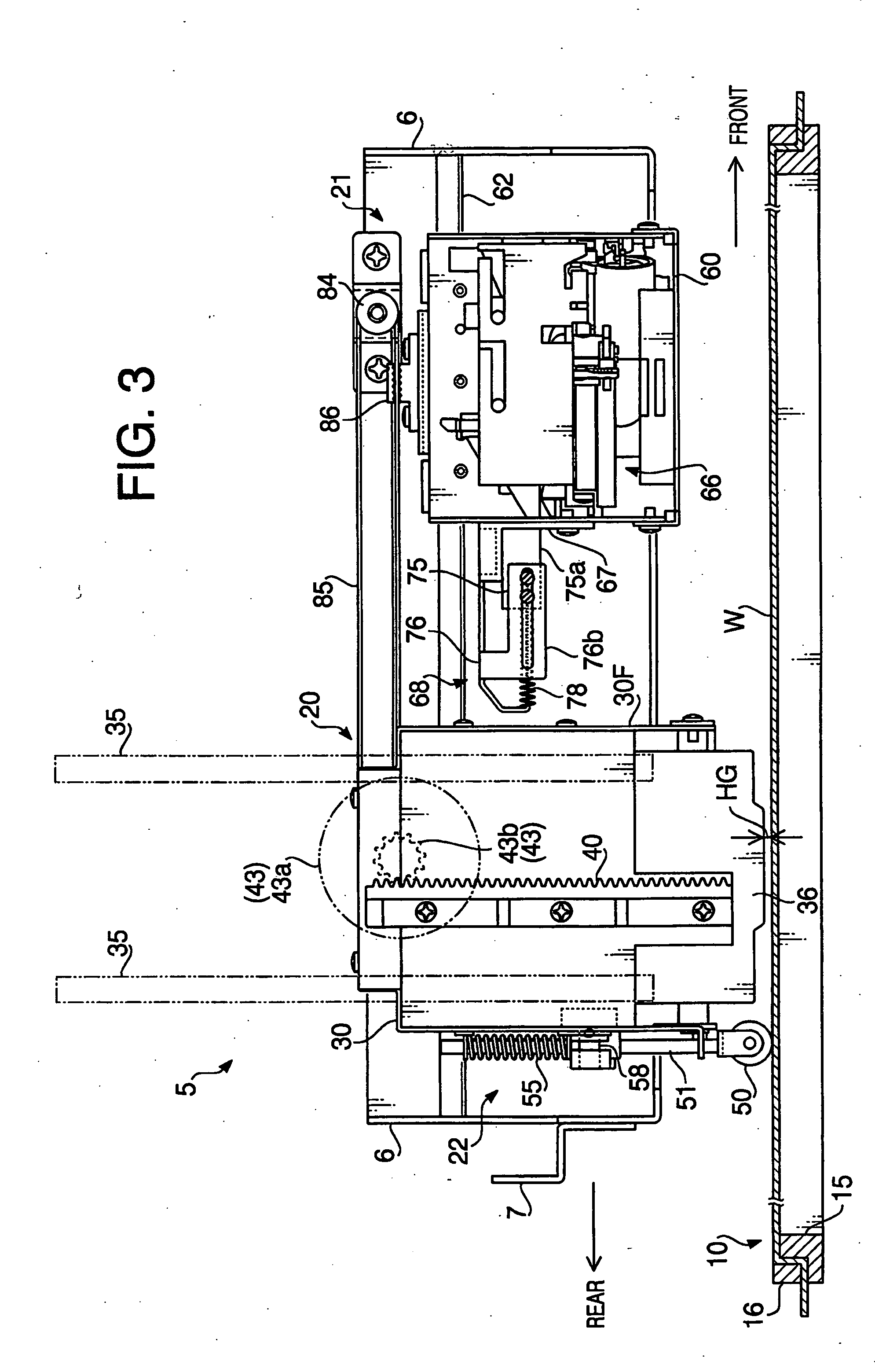

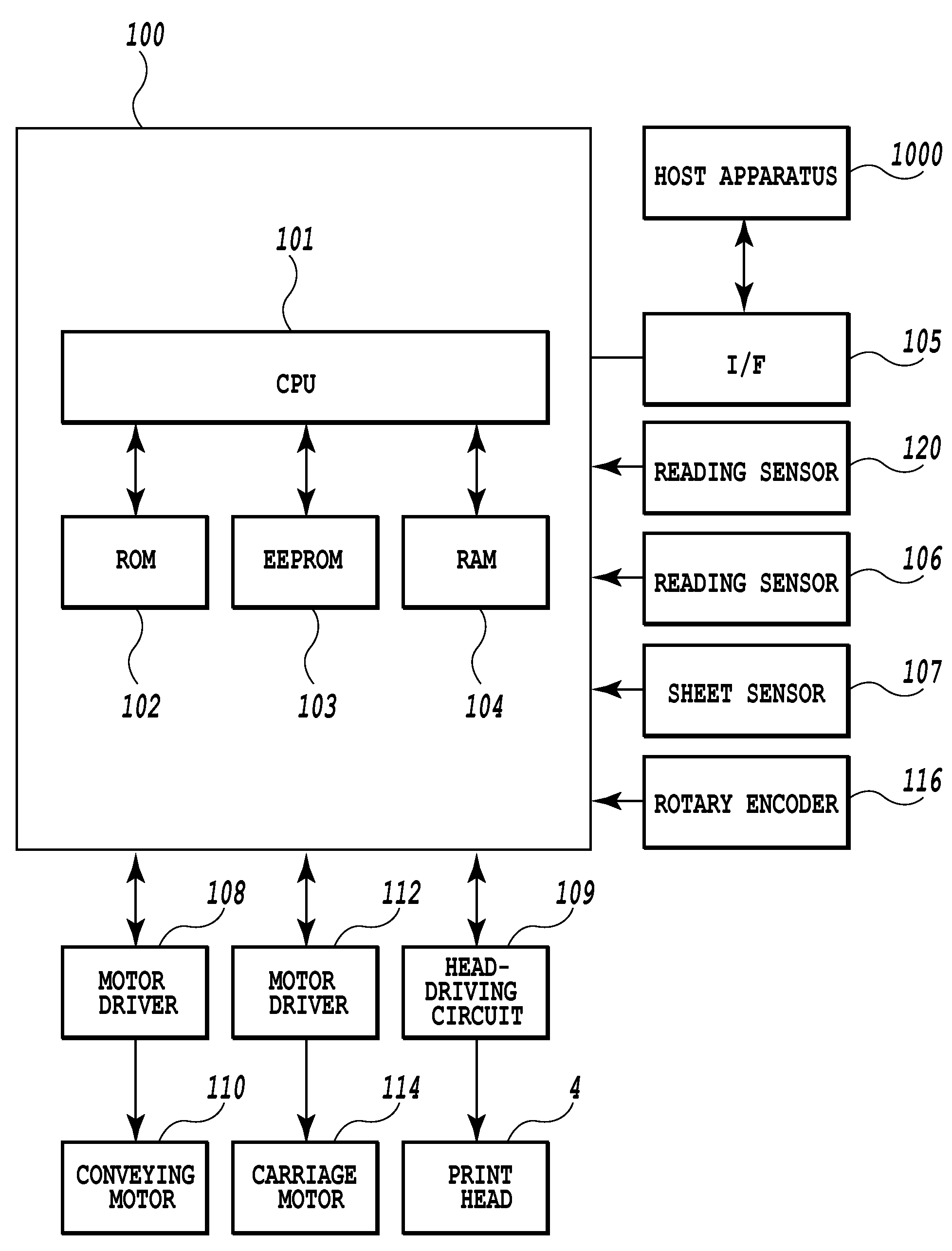

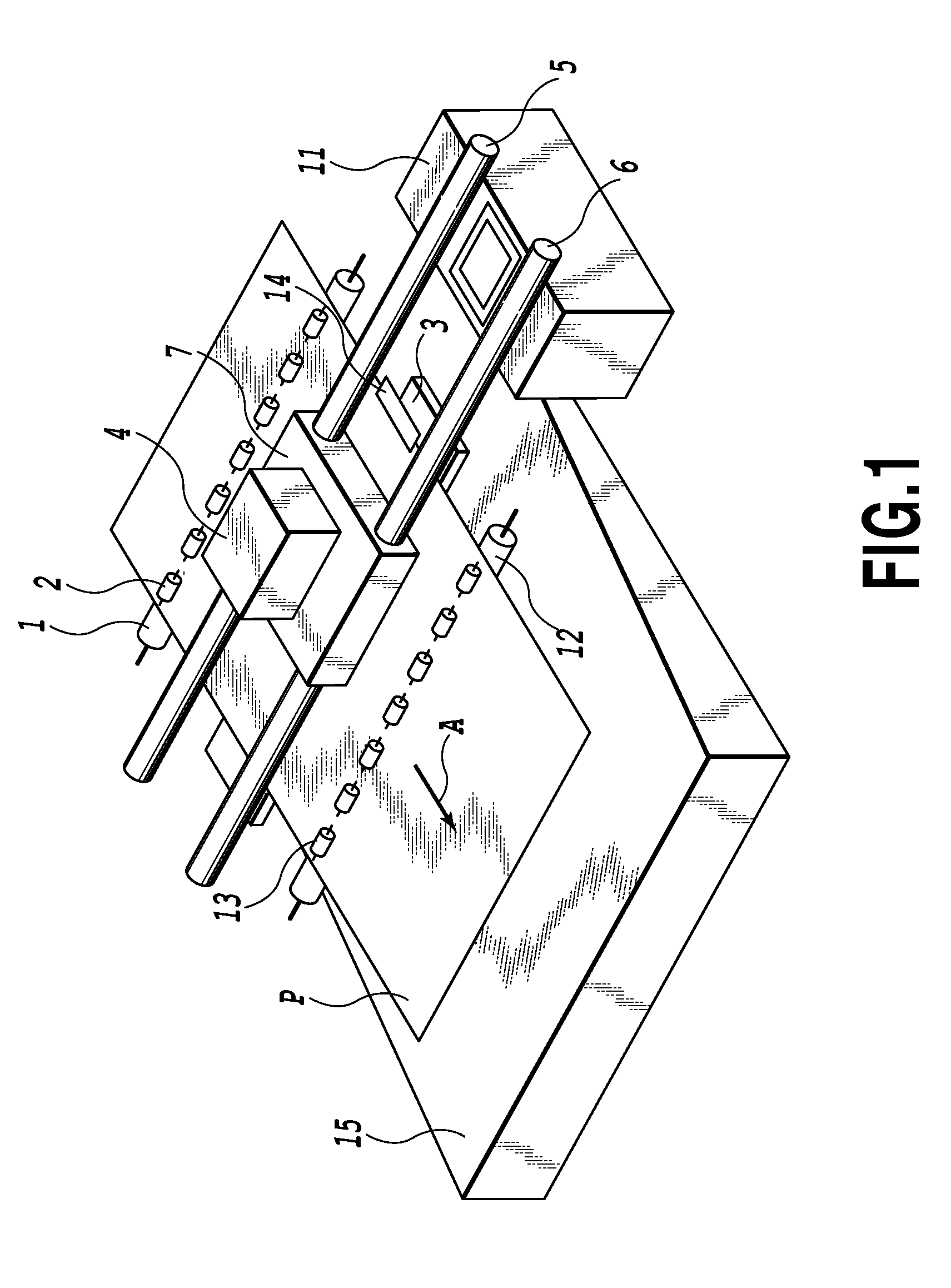

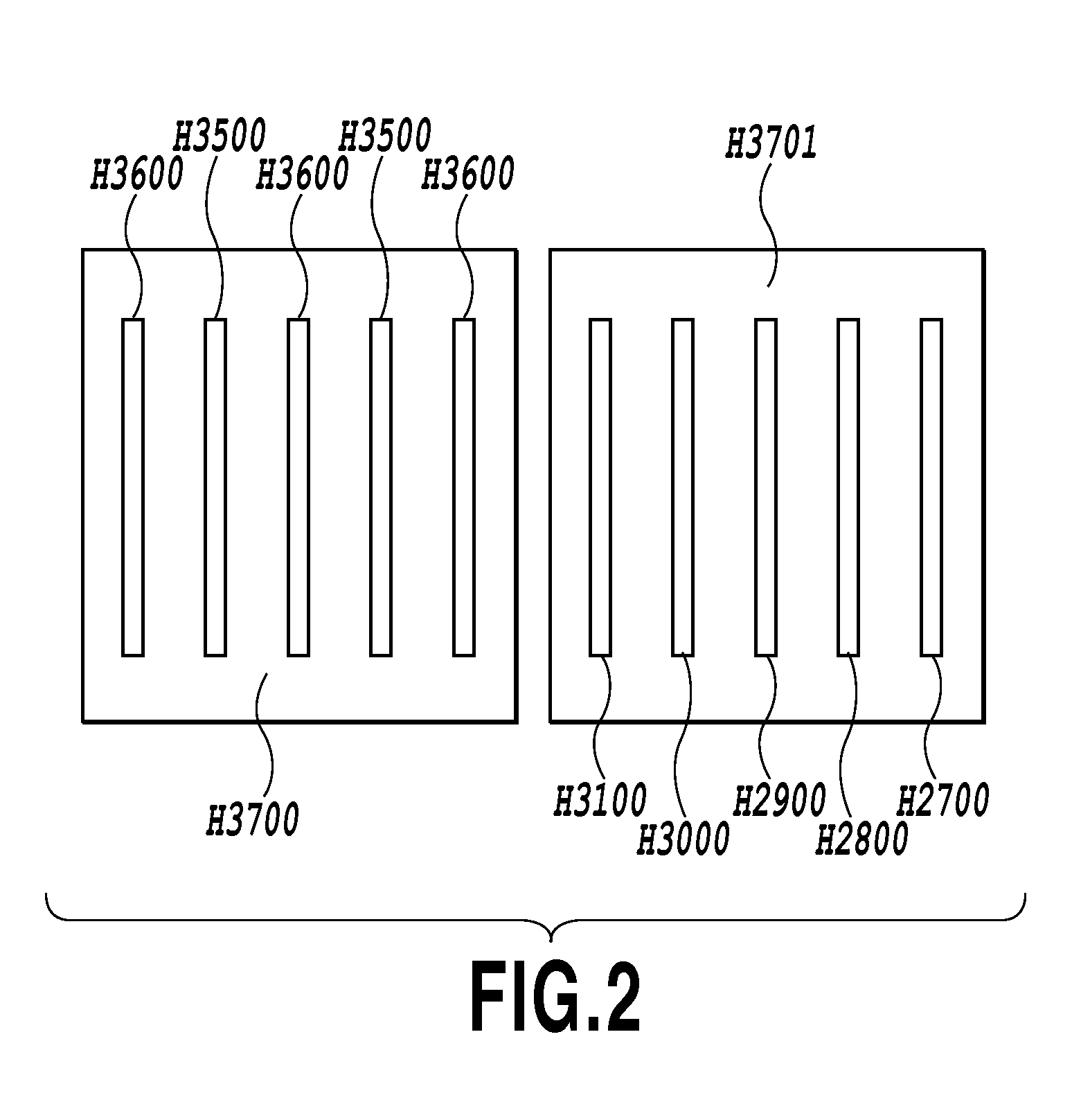

Ink jet printing apparatus and ink jet priting method

InactiveUS20080252673A1Avoid uneven densityImprove image qualityInking apparatusOther printing apparatusEngineeringHead moving

An object of the present invention is to provide an ink jet printing apparatus which can prevent possible stripe-like density unevenness in a joint in a print head constructed by joining a plurality of chips together even if the print head is inclined to the regular position of the print head. The present invention uses a print head having the nozzle arrays being shifted in a direction in which the nozzles are arranged, so as to have overlapping portions in a direction orthogonal to the nozzle arranging direction. The present invention controls an ink ejecting operation of the nozzles in the overlapping portions between the plurality of nozzle arrays on the basis of an angle between the nozzle array arranging direction and a direction orthogonal to the direction in which the print head moves relative to the print medium.

Owner:CANON KK

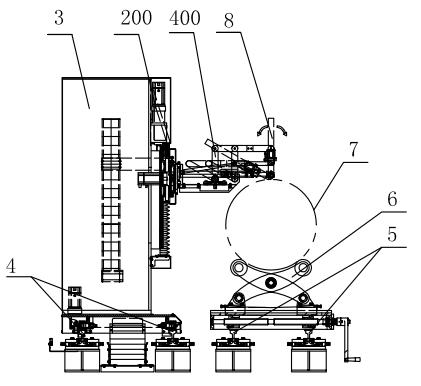

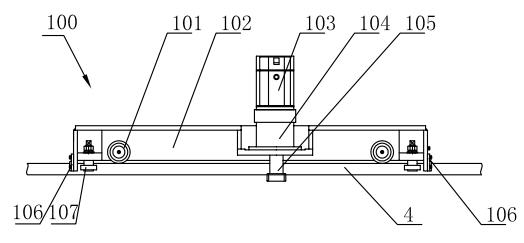

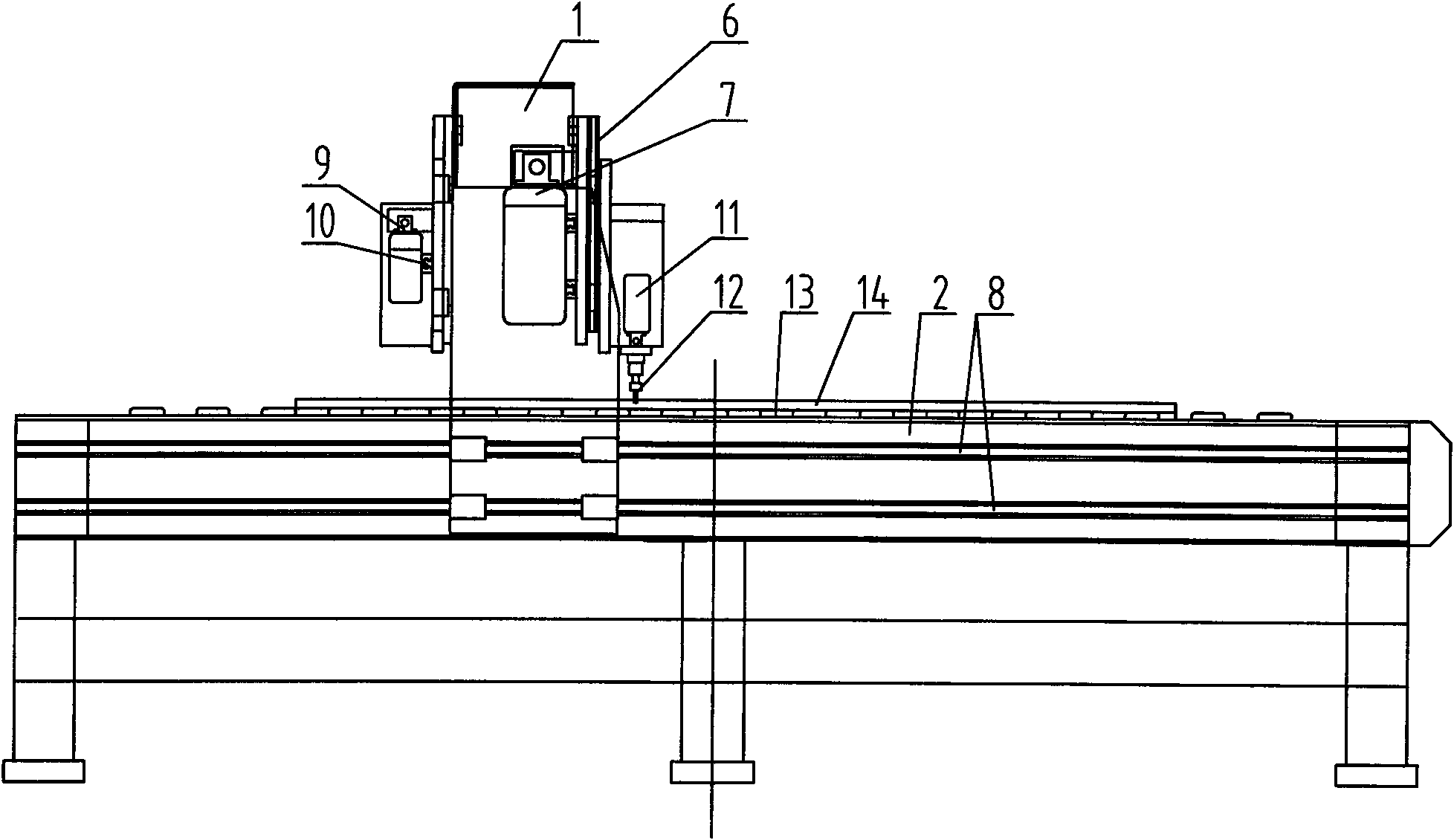

Five-axis steel pipe intersecting line cutter

ActiveCN101954558AMeet high precision cutting requirementsWelding/cutting auxillary devicesAuxillary welding devicesLine tubingEngineering

The invention relates to a five-axis steel pipe intersecting line cutter. The cutter comprises a main spindle box, wherein the main spindle box is positioned at one end of the cutter; the output end of the main spindle box is connected with a rotary chuck; the pedestal of the cutter is provided with two parallel tracks; one track is positioned on the lower part of a machined pipe; a plurality of steel pipe support brackets are arranged on the track; a cutting head moving component is movably arranged on the other track and connected with the power part and the control part of the cutter by pipelines; and the cutting head moving component comprises a cutting head longitudinal moving part, a cutting head lifting part, a cutting head left-and-right swinging part and the cutting head front-and-back connecting rod swinging part. The five-axis steel pipe intersecting line cutter has the advantages of rational structure, convenient operation, and capability of efficiently and accurately cutting complicated steel pipe intersecting lines and machining welding grooves at one time in the cutting process.

Owner:WUXI HUALIAN SCI & TECH GROUP

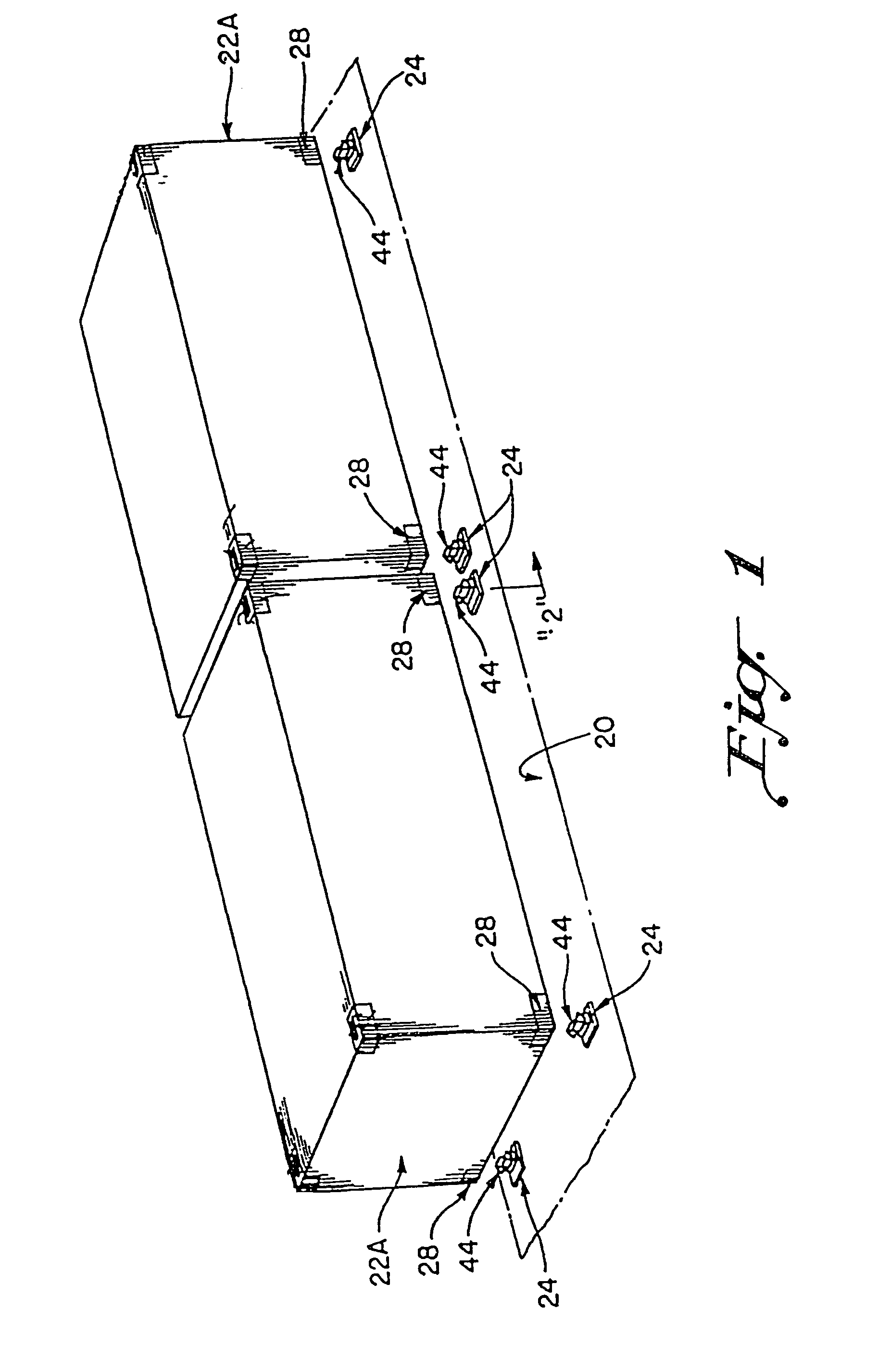

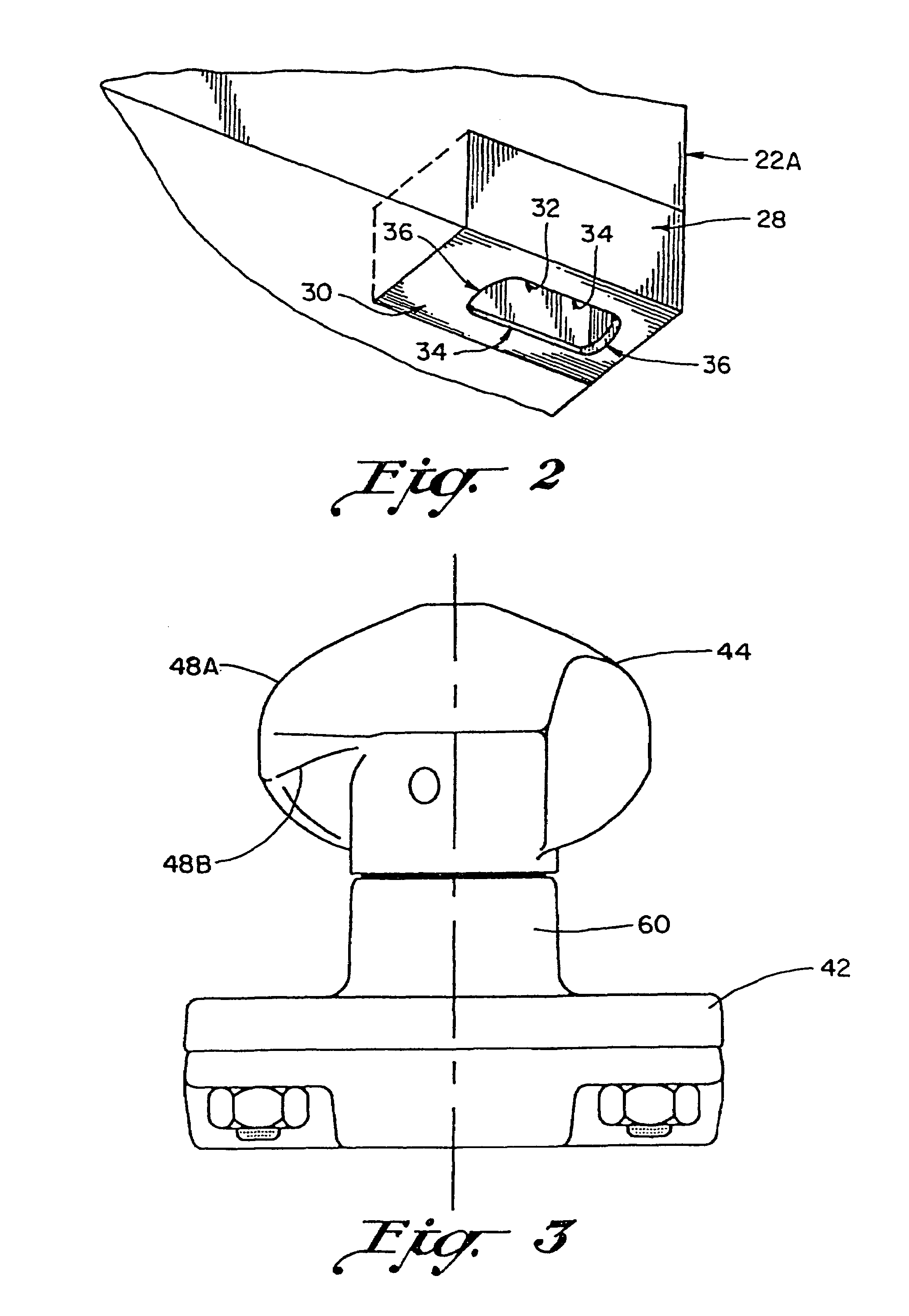

Container securement device and system

A container securement device enables a user to secure a cargo container to a carrier deck. The device includes a base having a projecting shear block received in the lock-actuating opening of the container. A shaft-mounted head rotates between an unlocked or loading position in which the head moves through the locking opening and a locked position in which the container is secured. Automatic entry and release are provided by a selected interchangeable spring element within the base biasing the head to the locked position but permitting movement to the unlocked position when torque is applied by engagement of the container with a cam surface on the head. The spring element may be interchanged as may be required by anticipated climactic and / or temperature conditions. Each spring element is actuable by a uniquely configured shaft member having a spring-receiving end capable of cooperating with at least two types of springs.

Owner:HOLLAND CO

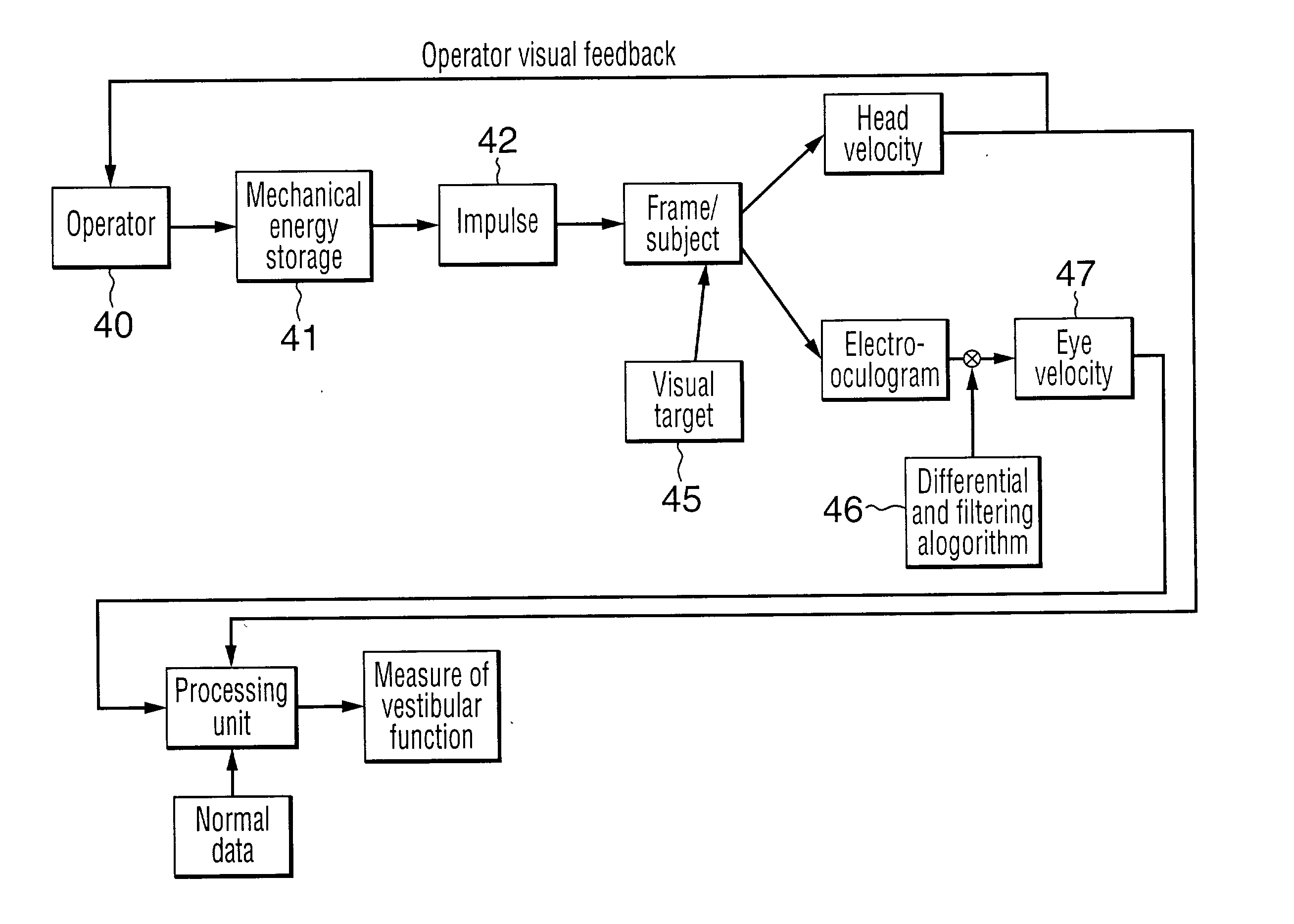

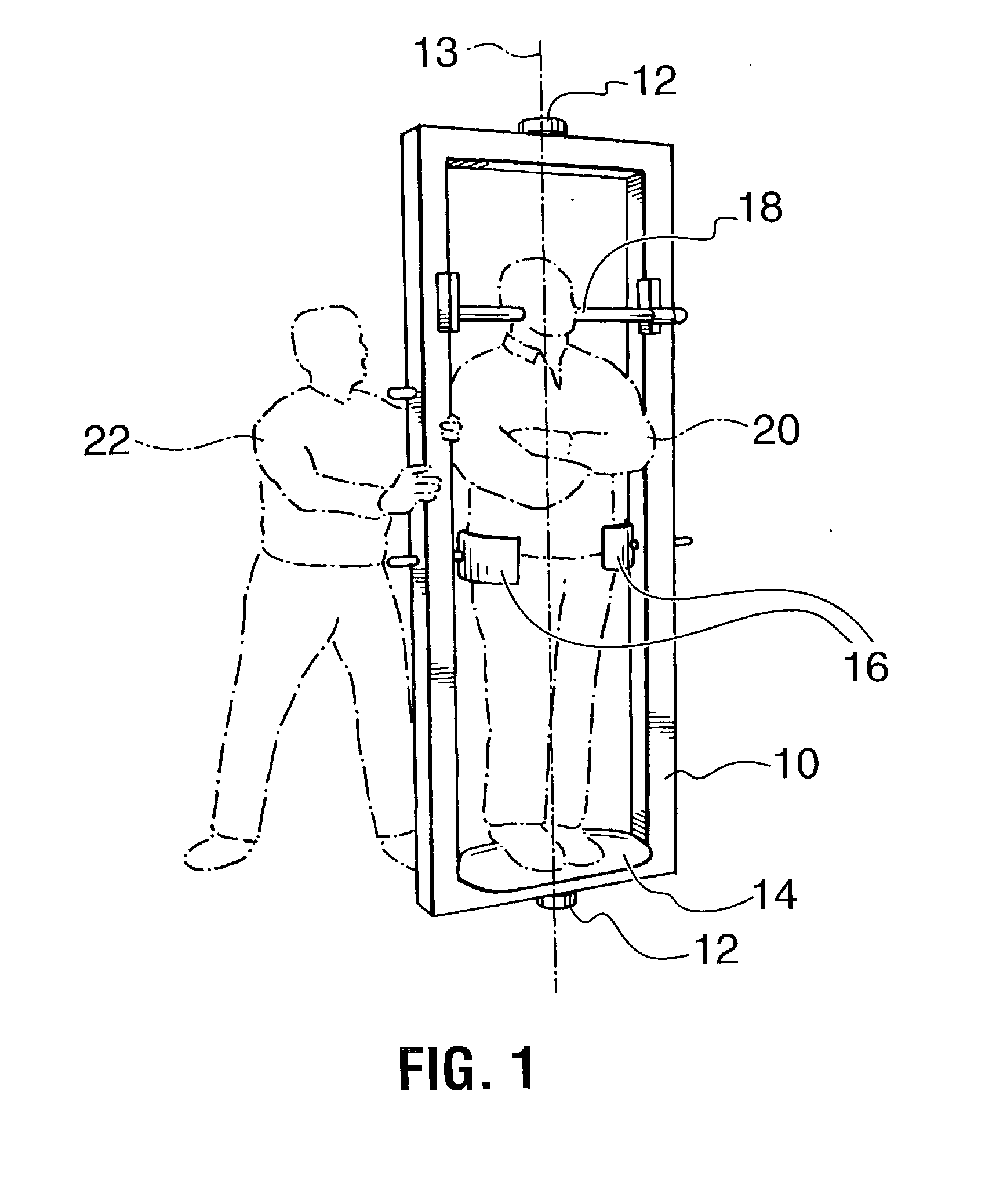

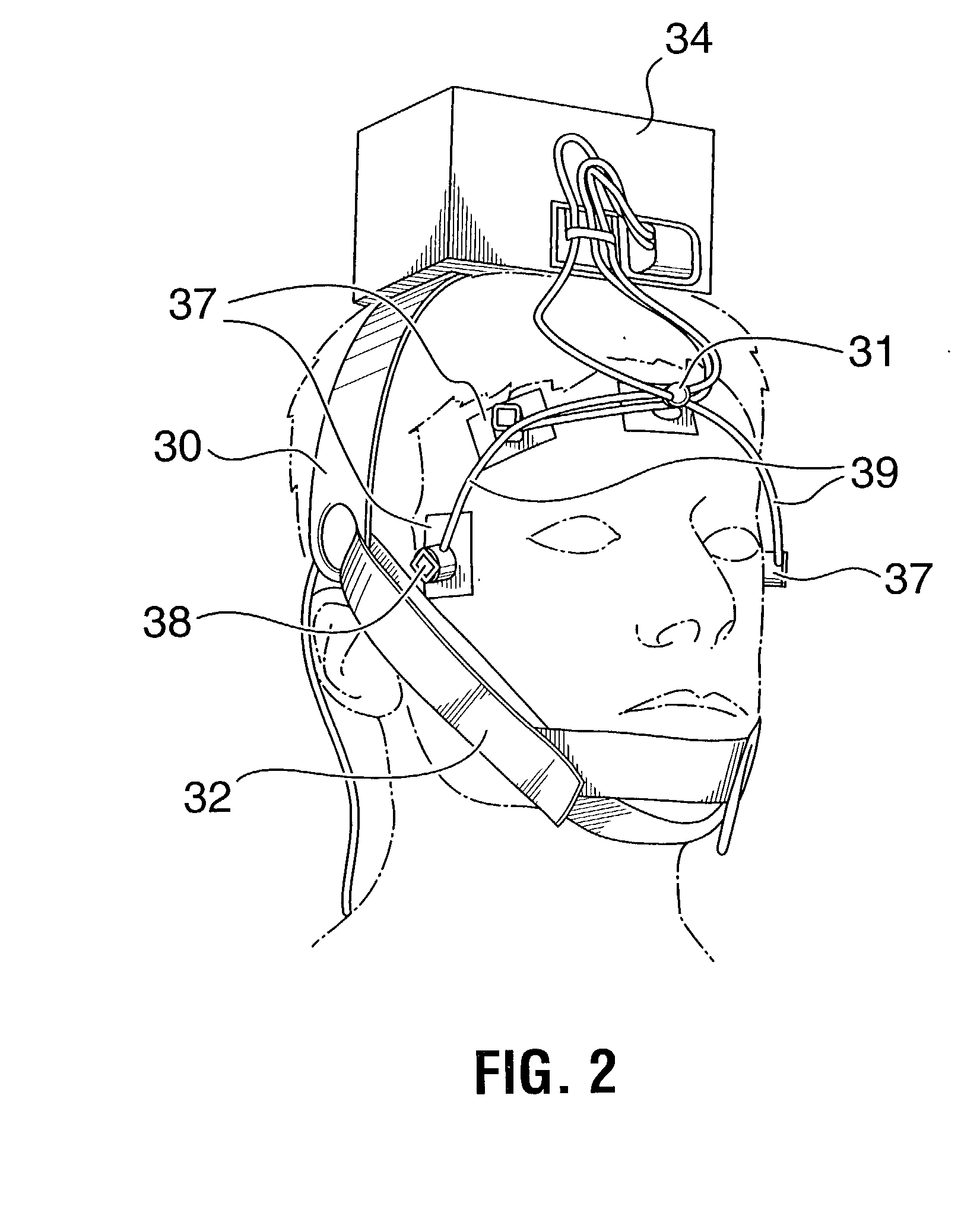

Method for evaluating vestibular response

InactiveUS20020151818A1Accurate measurementConveniently performedElectro-oculographySensorsMedicineUnison

A method is disclosed for evaluating the vestibular function in a human subject. The subject is constrained in a substantially erect position so that the head moves in unison with the rest of the body. A controlled stimulus in the form of a sudden angular acceleration is imparted to the body, and the subject's ocular response to the controlled stimulus is measured. The vestibular function is evaluated from the ocular response and the angular velocity of the head.

Owner:CANADIAN SPACE AGENCY

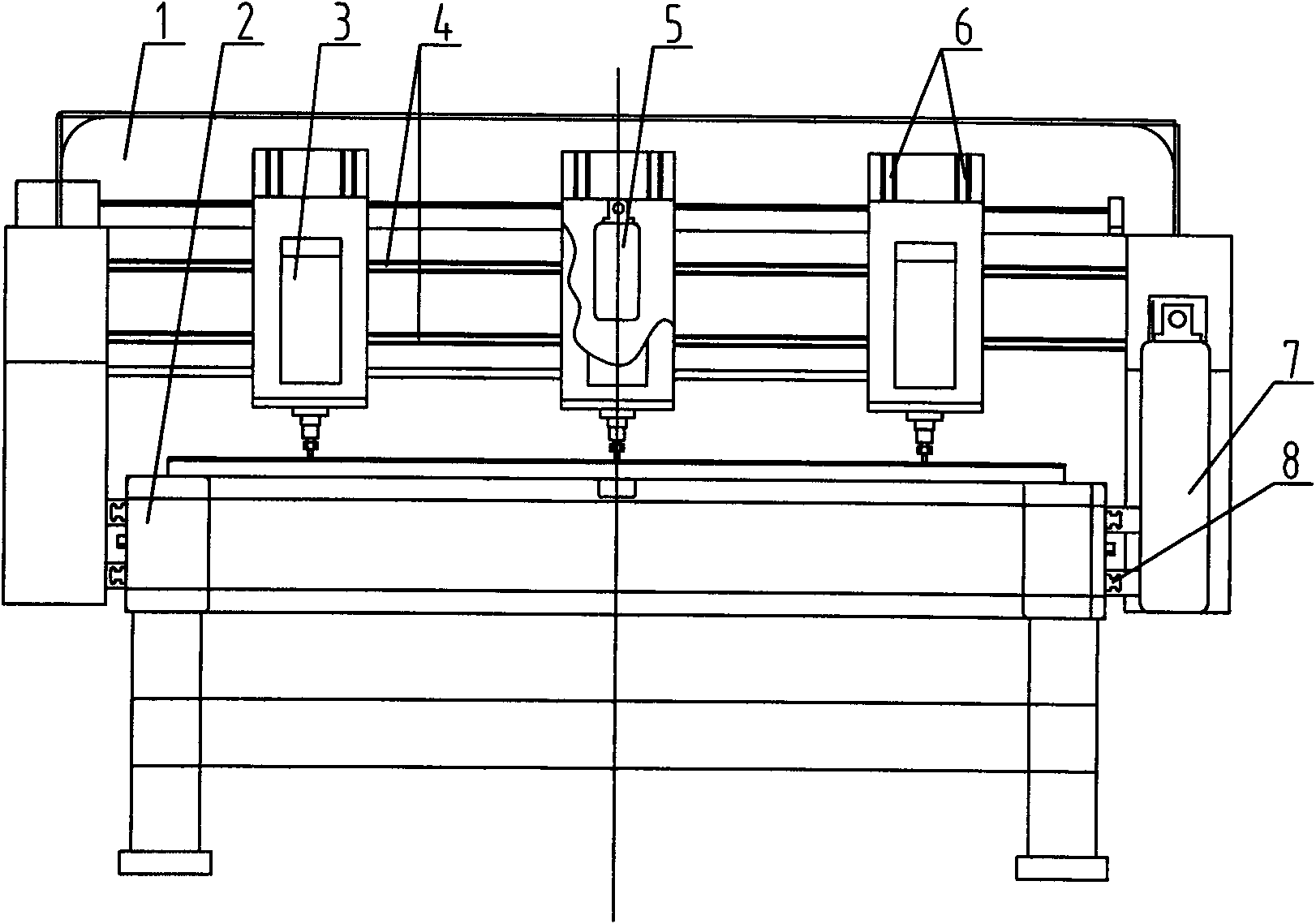

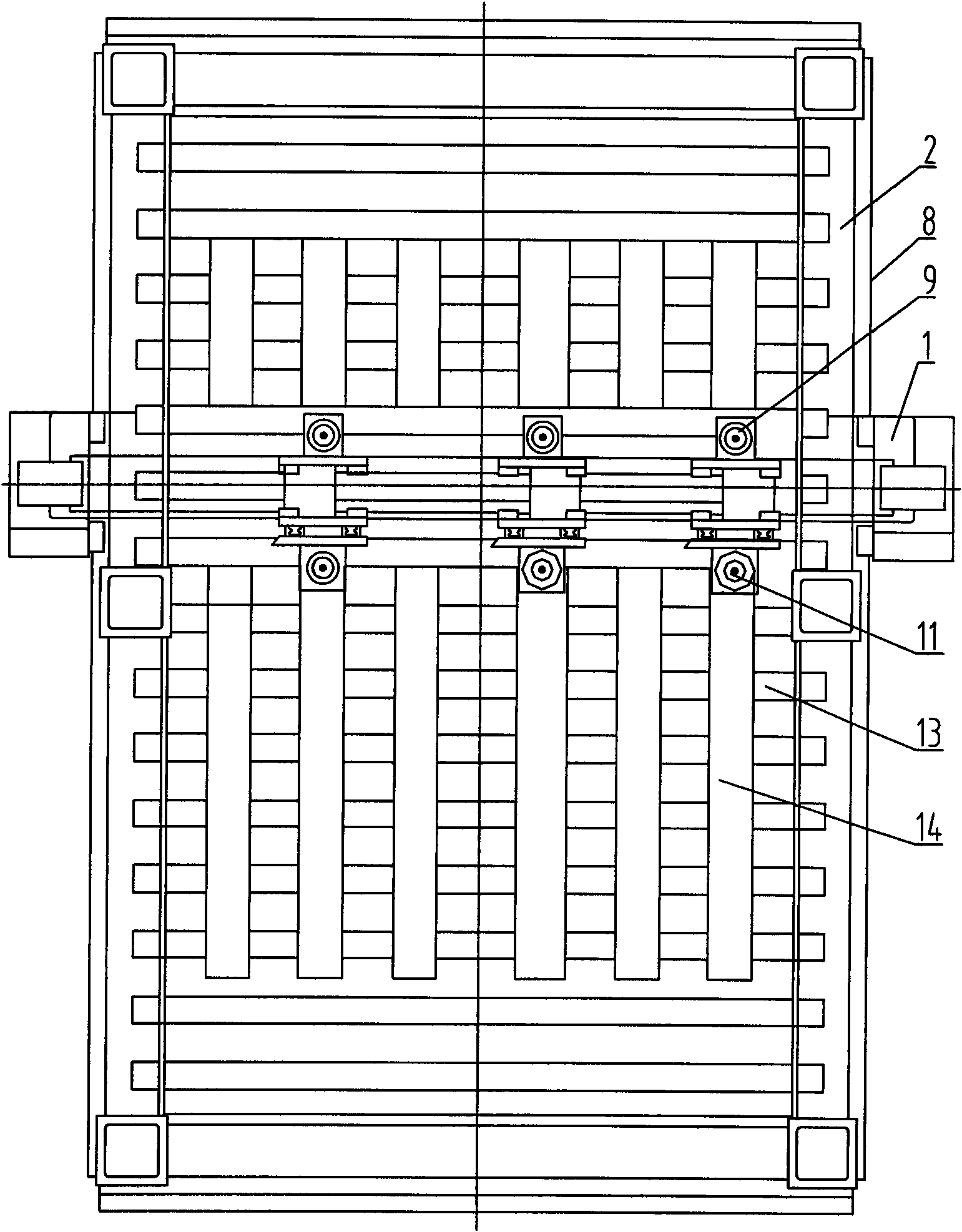

Multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment

InactiveCN102151883ASimple structureLow costMilling machinesLarge fixed membersNumerical controlControl system

The invention discloses multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment which comprises a portal frame, a lathe bed, a numerical control unit, a transmission system and x-axle, y-axle and z-axle guide rails, wherein the numerical control unit comprises an x-axle drive motor, a y-axle drive motor and a z-axle drive motor which are arranged on the portal frame. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment is characterized in that left and right sides of the portal frame are respectively provided with two y-axle guide rails, and the portal frame is also provided with 2-6 independent synchronous or asynchronous power heads and multiple sets of tools matched with the power heads, a lathe generates a three-dimensional processing figure by using a computer, the computer controls each power head respectively for processing after processing coordinates are input, a corresponding control system is provided with a servo motor or a stepping motor, the power heads move on the three guide rails along the x-axle direction, three points are fixed; and a screw or rack structure is adopted in the transmission system. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment has the advantages of simple structure, low cost, high processing accuracy, good stability, high processing efficiency, wide application range and the like.

Owner:ALNAN ALUMINIUM CO LTD

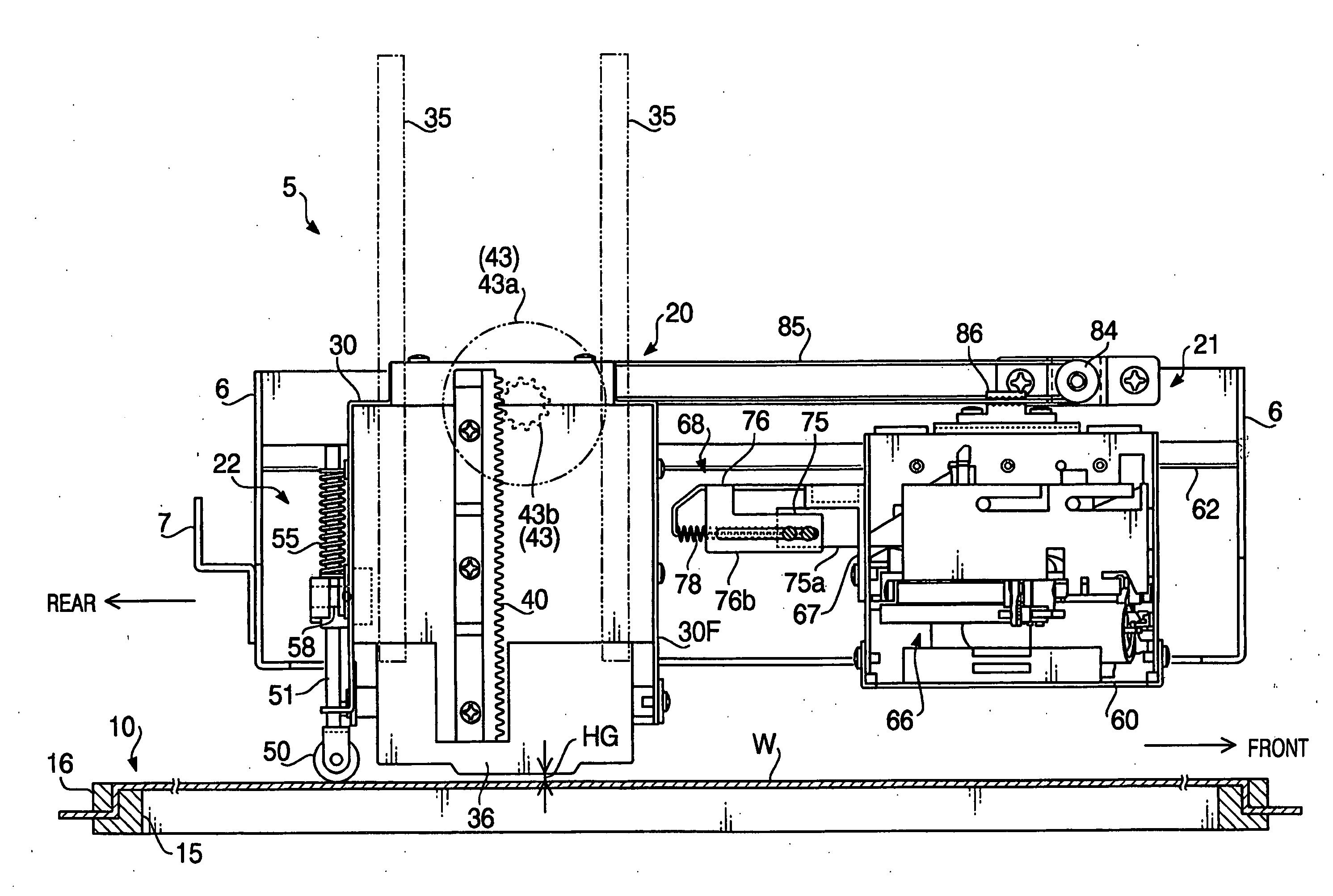

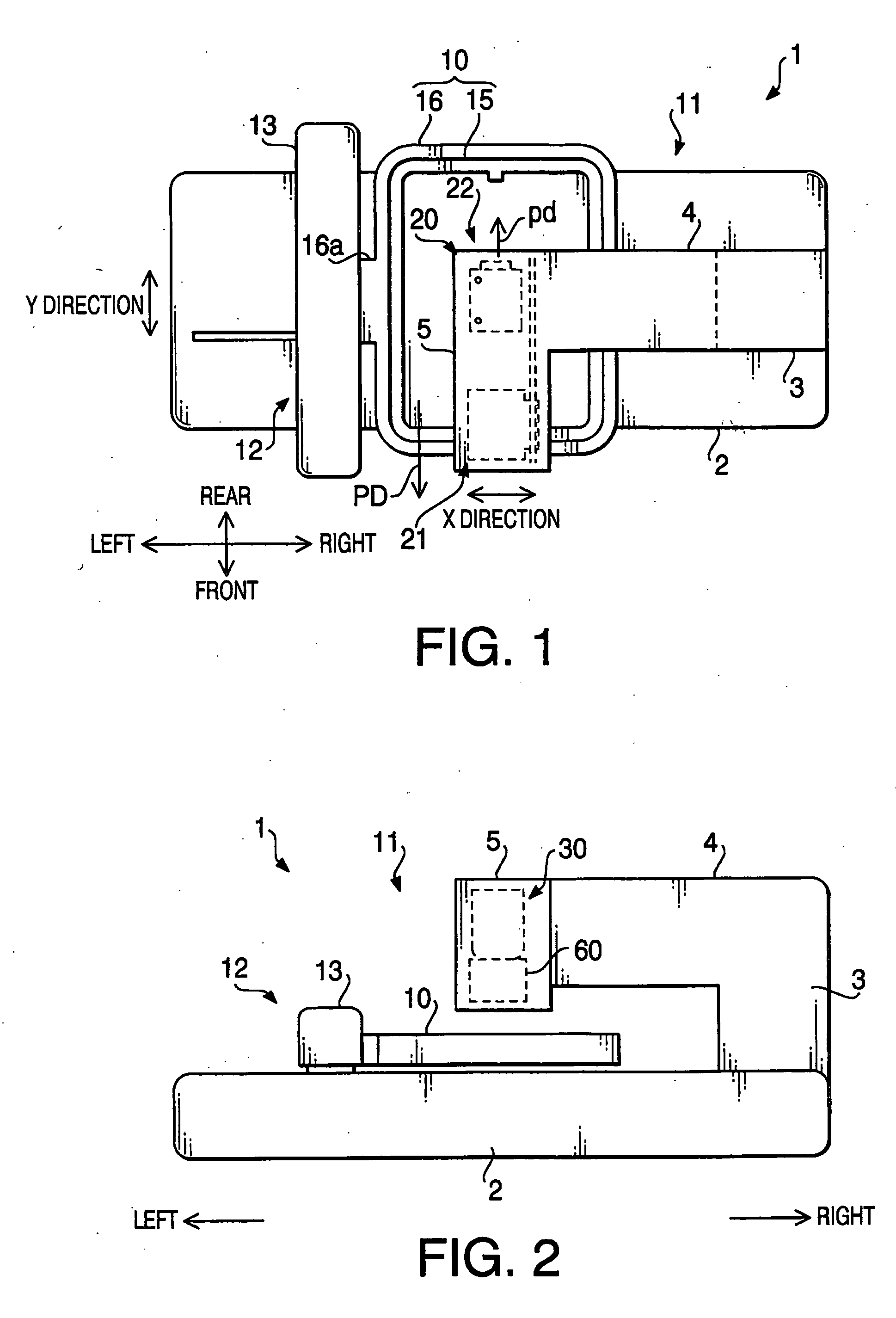

Printer

ActiveUS20060192798A1Accurate detectionPower drive mechanismsOther printing apparatusFree rotationComputer printing

Owner:BROTHER KOGYO KK

Printing apparatus and conveying control method

Provided are a printing apparatus and a conveying-error controlling method capable of printing a high-quality image by correction reflecting the conveying amount of a printing medium. A provided inkjet printing apparatus prints images by printing scans for actual printing and by conveying the printing medium with a roller orthogonally to the printing-scan direction. In each printing scan, the printing medium is scanned with a print head having an array of nozzles from which the ink is ejected. The print head moving direction differs from the arranging direction of the nozzles in the array. The apparatus includes a conveying controller to control the conveying of the printing medium on the basis of a correction value used to correct a conveying error of the roller. The conveying controller changes the correction value to be applied in accordance with the conveying amount of the printing medium between two scans with the print head.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com