Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

412 results about "Instantaneous speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The instantaneous speed is the speed of an object at a certain instant of time. If the position is a function of time, then the speed depends on the change in the position as time changes. The instantaneous speed can be found as this change in time becomes small.

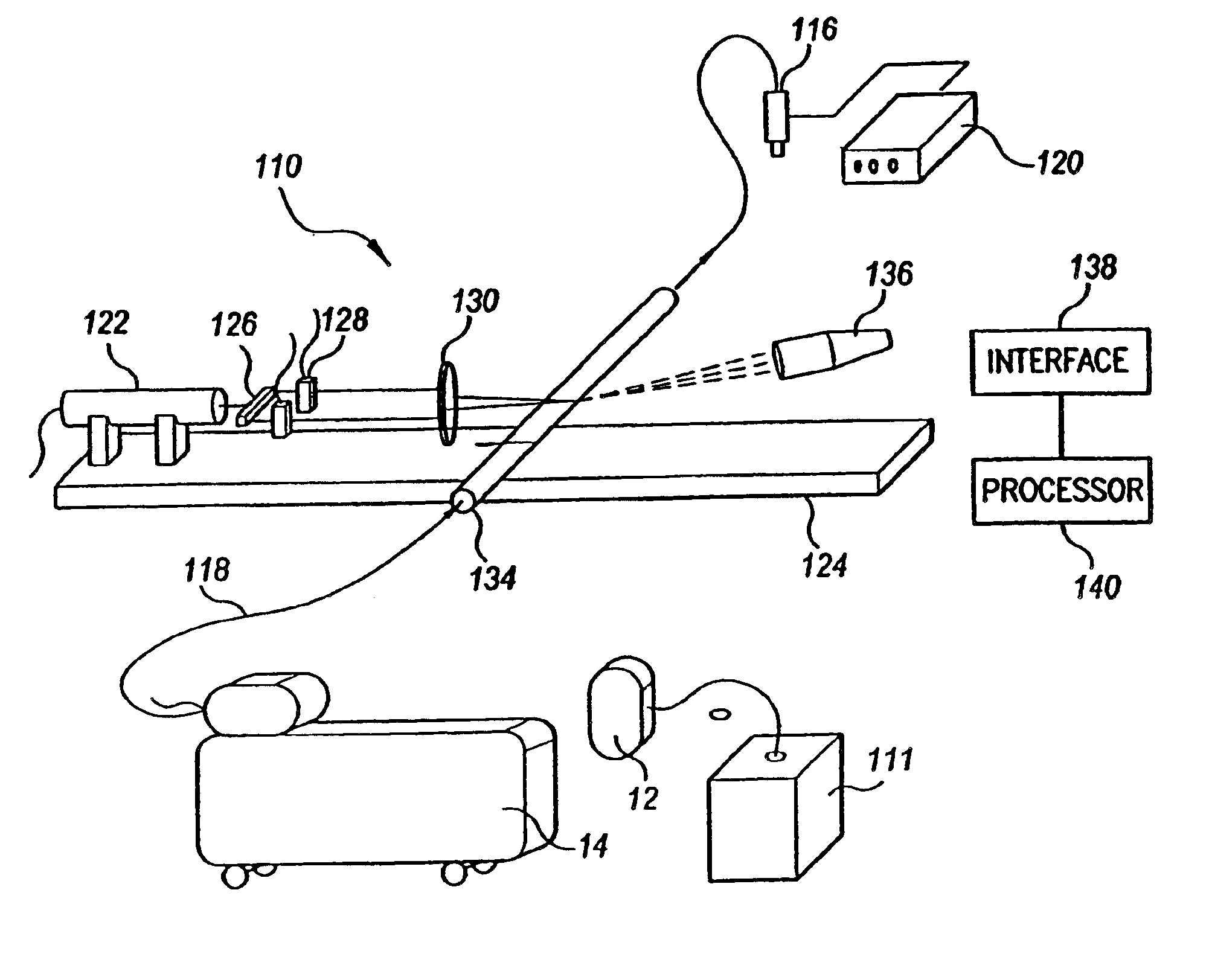

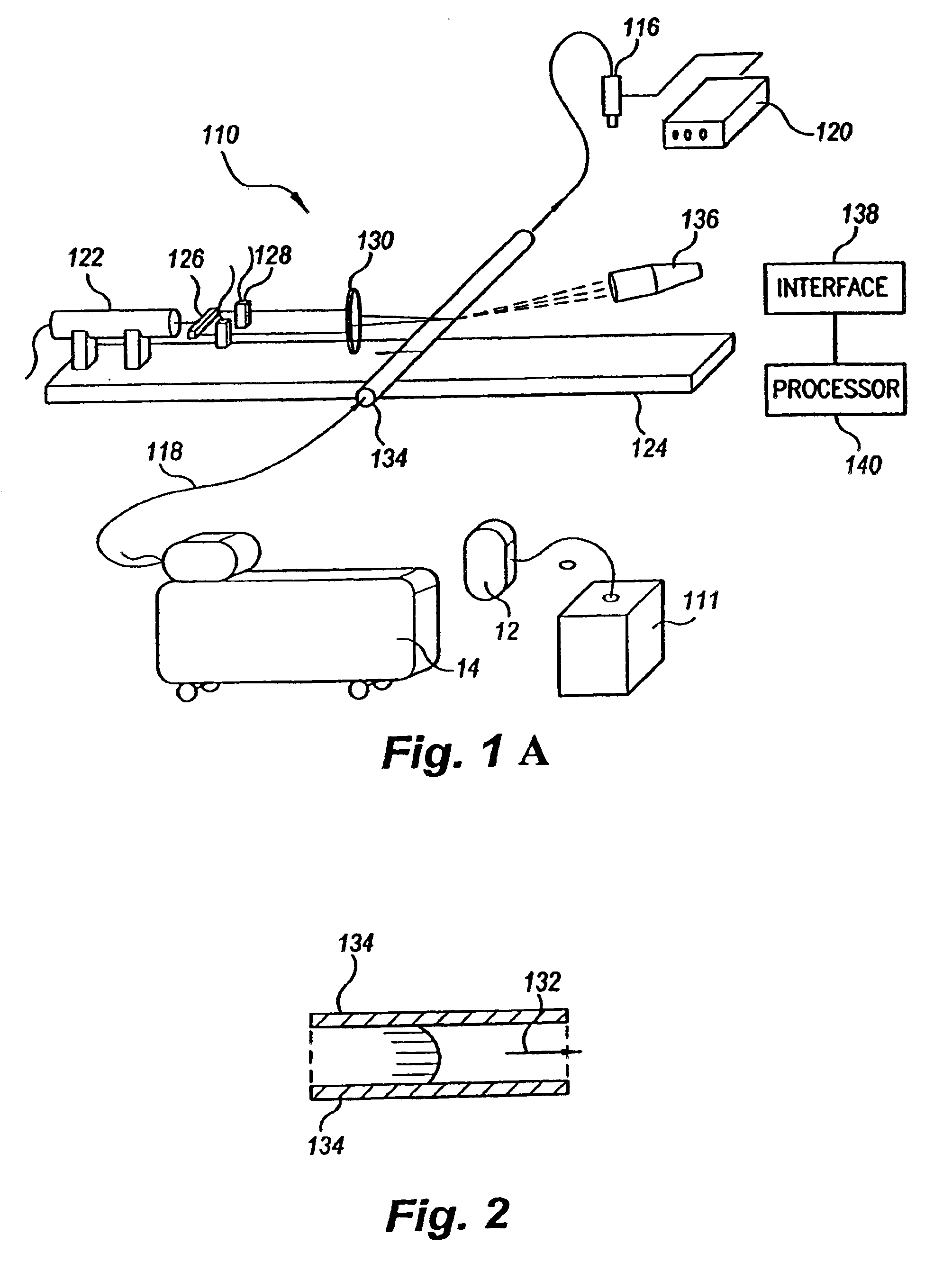

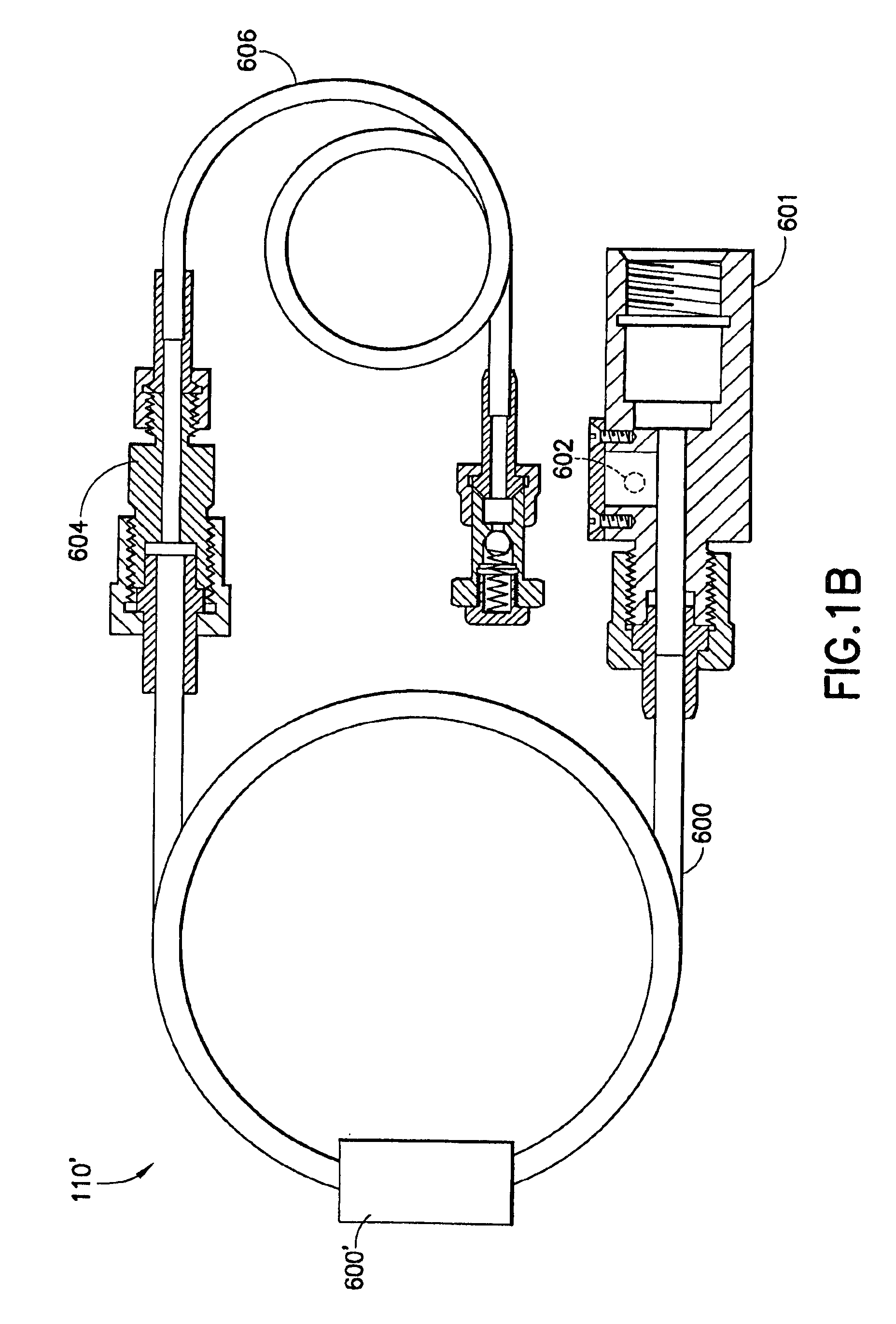

Flow meter

Various embodiments of the present invention provide a flow meter device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe. The flow meter may process the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and / or other flow characteristics (e.g., as instantaneous quantities and / or integrated over a time interval) The flow meter may use an electronic processing method. The electronic processing method may provide essentially an exact solution to the Navier-Stokes equations for any periodically oscillating flow.

Owner:COMBUSTION DYNAMICS

Cursor motion blurring

An electronic device for displaying a cursor with a trail is provided. The user may control electronic device operations by navigating the cursor on a display. To assist the user in identifying the current location of the cursor, the electronic device may define and display a trail indicating the prior positions of the cursor. For example, the electronic device may identify previous cursor positions and draw a curve, for example a spline, connecting the previous cursor positions and the current cursor position. The curve may have a varying width, thus forming a trail for which the wider portion is adjacent the cursor, and for which the narrower portion is adjacent the tip of the curve. The electronic device may instead or in addition modify the opacity of the curve, for example based on the instantaneous speed of the cursor. In some embodiments, other trail characteristics (e.g., size, color, opacity, path) may be modified based on prior cursor movements or cursor speed.

Owner:APPLE INC

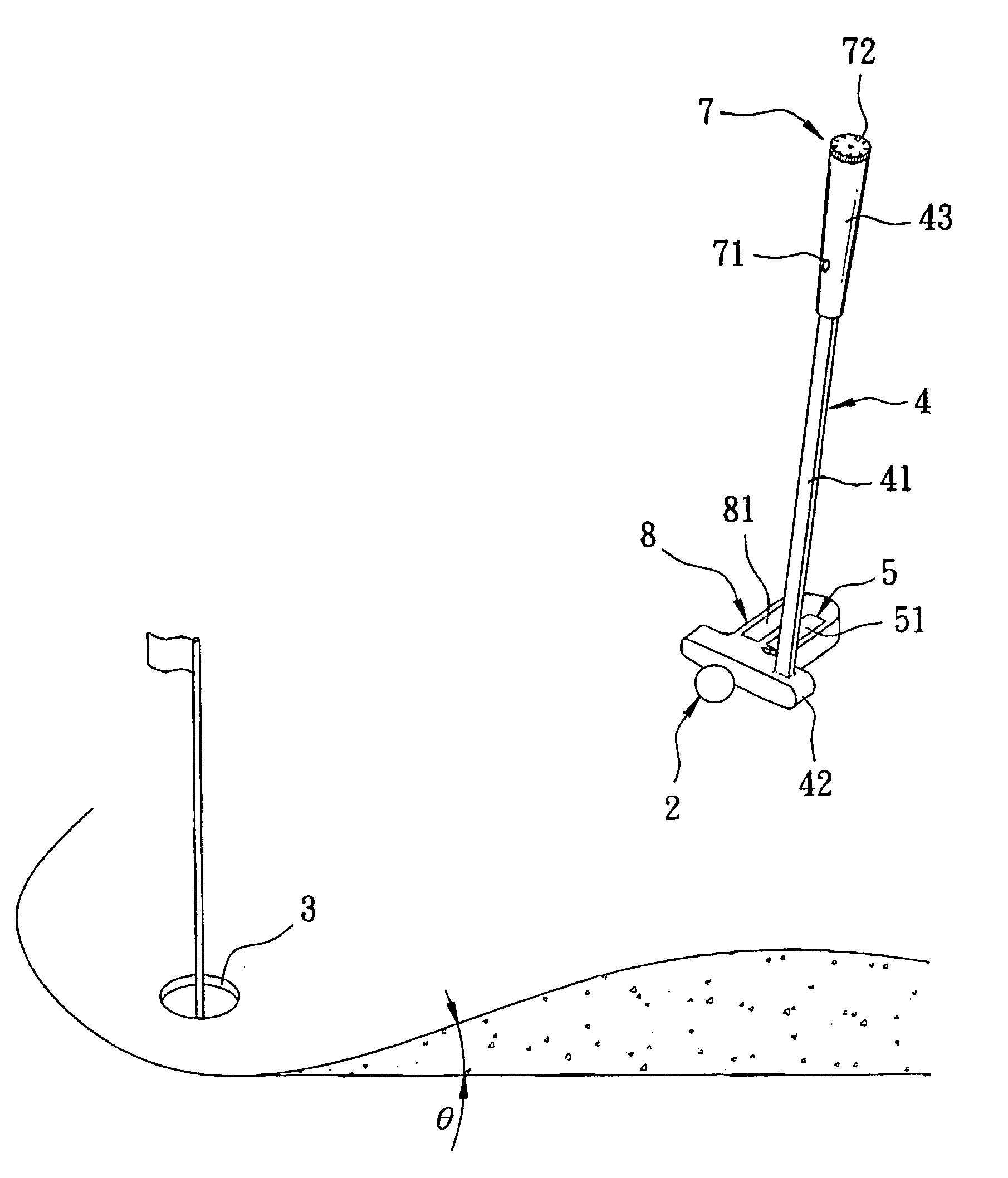

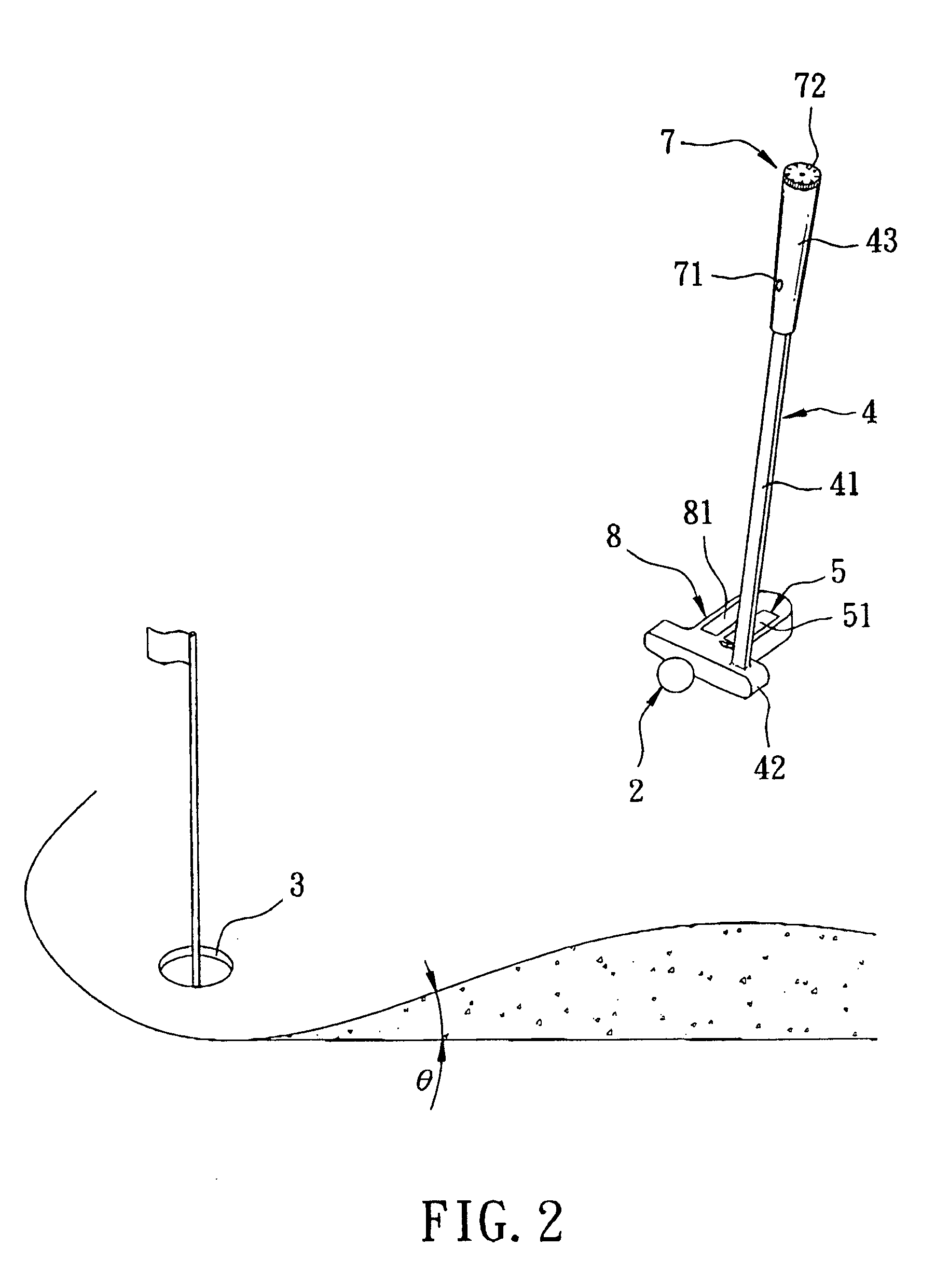

Golf putter assembly

A golf putter assembly includes a putter including a head, a display unit disposed in the putter, and a detecting unit disposed in the putter and electrically coupled to the display unit. The detecting unit is operable to detect and record a stationary starting position of a golf ball. The detecting unit is further operable to detect, during a practice swing, an instantaneous speed of the head as the head moves past the starting position, and to calculate what would be an initial speed of the golf ball if the golf ball was actually hit by the head with reference to the instantaneous speed of the head detected thereby. The detecting unit further performs control such that the initial speed of the golf ball as calculated is displayed on the display unit.

Owner:LIN CHIH CHIEN +1

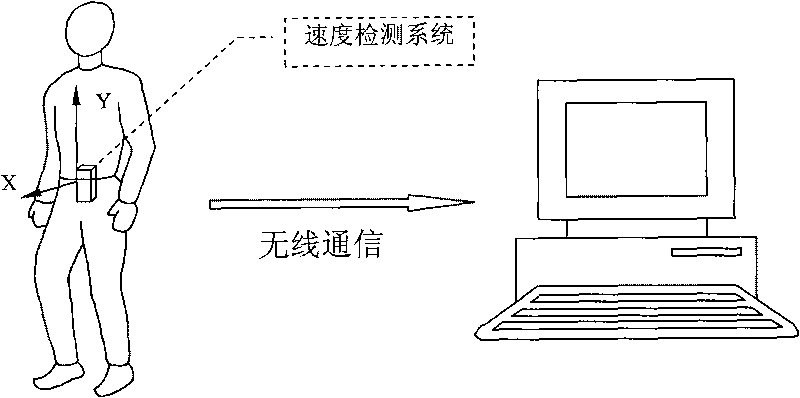

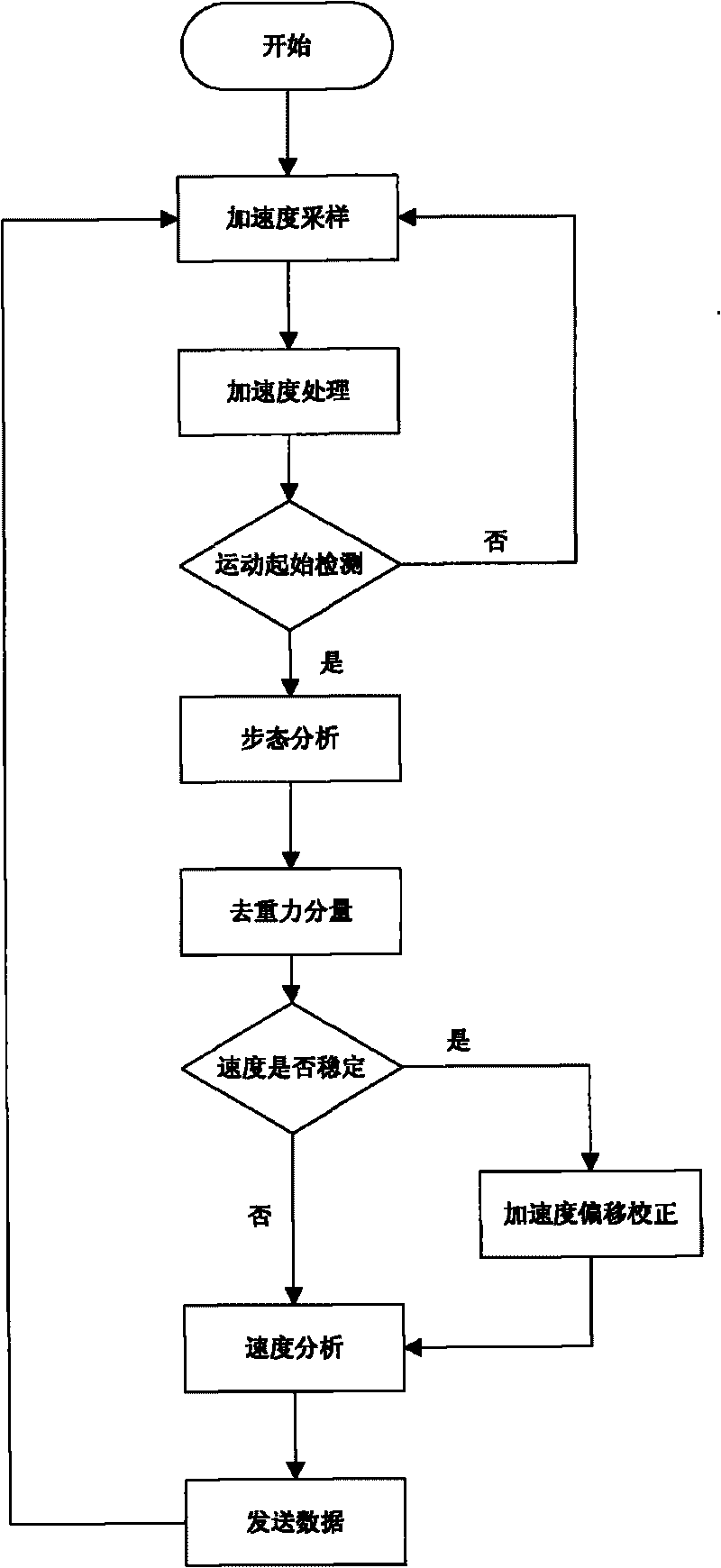

Pedestrian gait detection-based system and method of walking speed measurement and transmission

InactiveCN101694499ALow costEasy to useAcceleration measurement using interia forcesSpeed measurement using accelerationGait analysisComputer terminal

The invention relates to system and method of walking speed measurement and transmission and aims at providing a pedestrian gait detection-based system and a method of walking speed measurement and transmission. The system comprises an acceleration detection unit comprising a double-spindle acceleration sensor and peripheral circuits, an acceleration processing unit, a gait analysis unit, a speed analysis unit, a wireless communication emission unit, a wireless communication receiving unit and an output terminal. The speed detection system has the advantages of lower cost, convenient use and installation, basically no limitations in use, and better real-time performance and external interfaces in comparison with the prior art. Gait characteristics can be extracted from acceleration data during human movement so as to detect the instantaneous speed, the average speed, the displacement distance, the movement time of and the step number.

Owner:ZHEJIANG UNIV

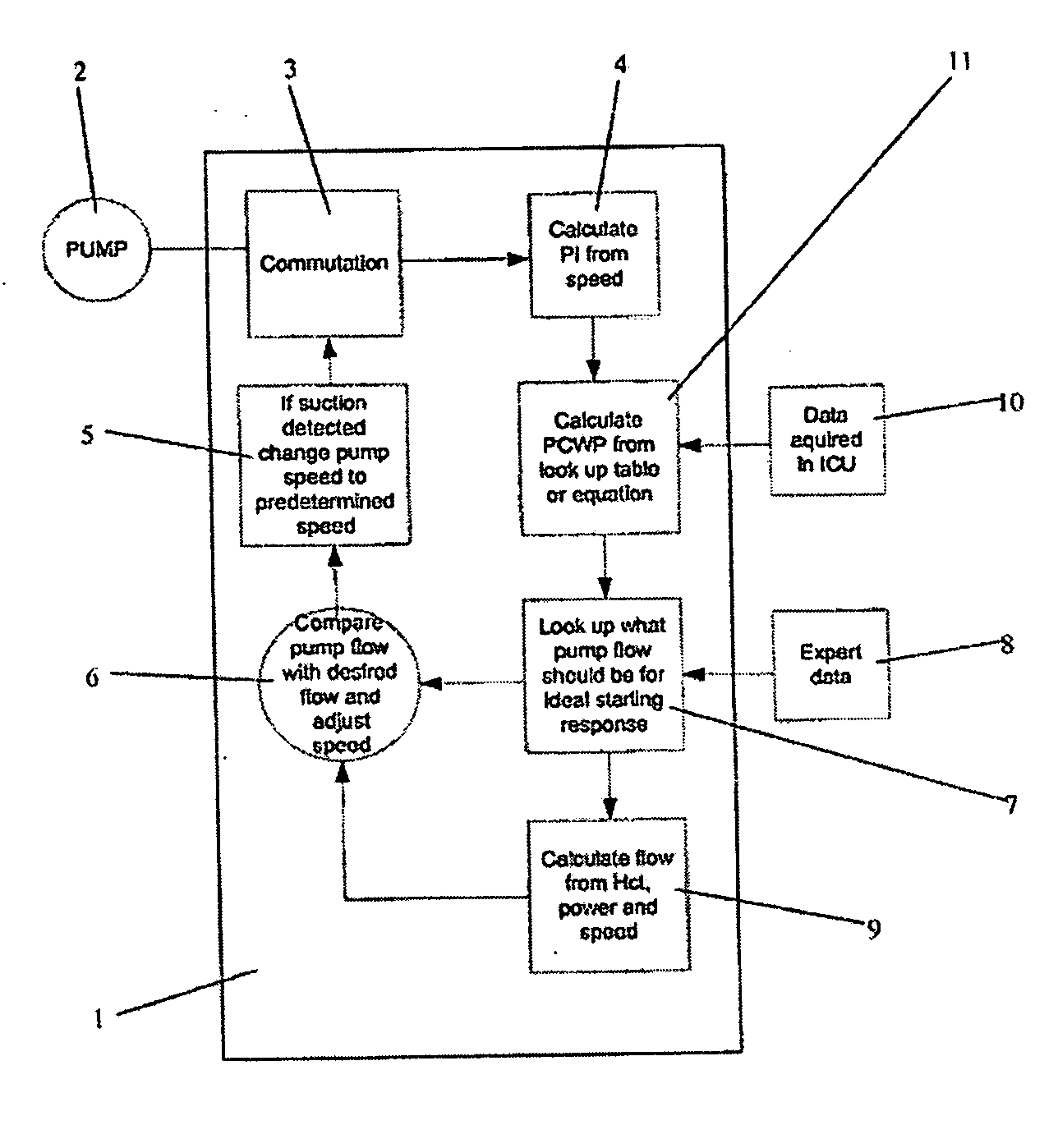

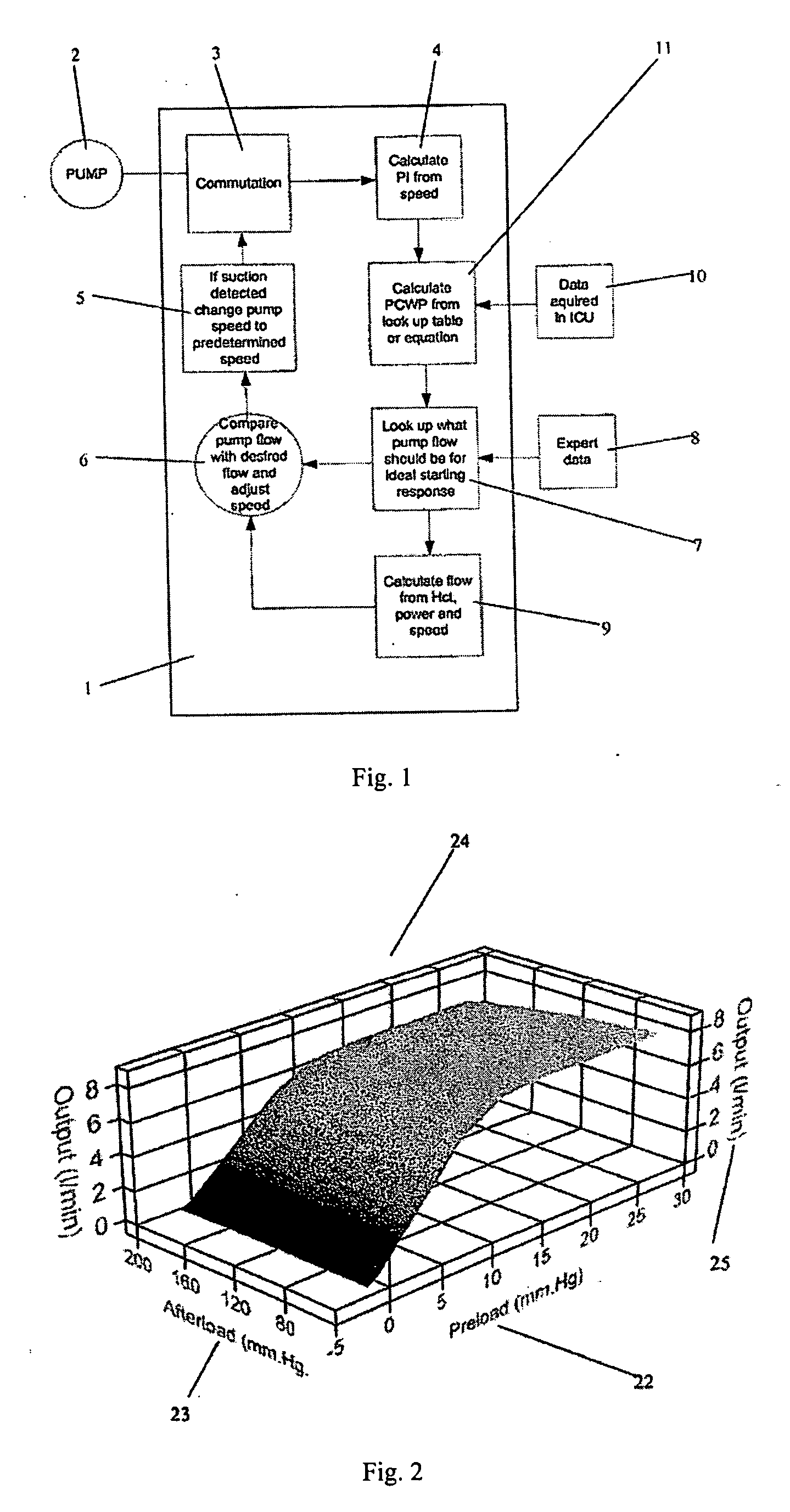

Control systems for rotary blood pumps

InactiveUS20070142923A1Minimises target pump speedPrevent backflowControl devicesBlood pumpsControl systemBlood pump

The present invention generally relates to a control system for a rotary blood pump adapted to move blood in a patient. The control system comprises a means for measuring and varying the speed of the pump and a means for measuring the pulsatility index of a patient, and the control system is adapted to maintain the pulsatility index at or near a predetermined value by varying the speed of the pump. The pulsatility index is derived from the amplitude of the actual pump speed over a predetermined time period. Optionally, also, the control system can calculate the second derivative of instantaneous speed of the rotary blood pump and use the calculation of the second derivative of instantaneous speed to detect a suction event, and help prevent it.

Owner:TC1 LLC

Self-powered wireless sensor assembly for sensing angular position of the engine crankshaft in a vehicle

A self-powered, wireless sensor assembly is provided for sensing crankshaft position of an engine comprising a rotatable flywheel having a ring gear. The sensor assembly includes an electromagnetic sensor responsive to structural features on the ring gear when the ring gear rotates. A power supply is coupled to generate a direct current in response to the output signal from the electromagnetic sensor. A transceiver is coupled to one of the following sensors: a magnetostatic sensor energized by the power supply and responsive to the structural features on the ring gear to generate an output signal when the ring gear rotates, and the electromagnetic sensor. The transceiver is configured to wirelessly transmit the output signal from that one sensor, wherein the output signal from that one sensor comprises information indicative of the instantaneous speed of said engine.

Owner:DELPHI TECH INC

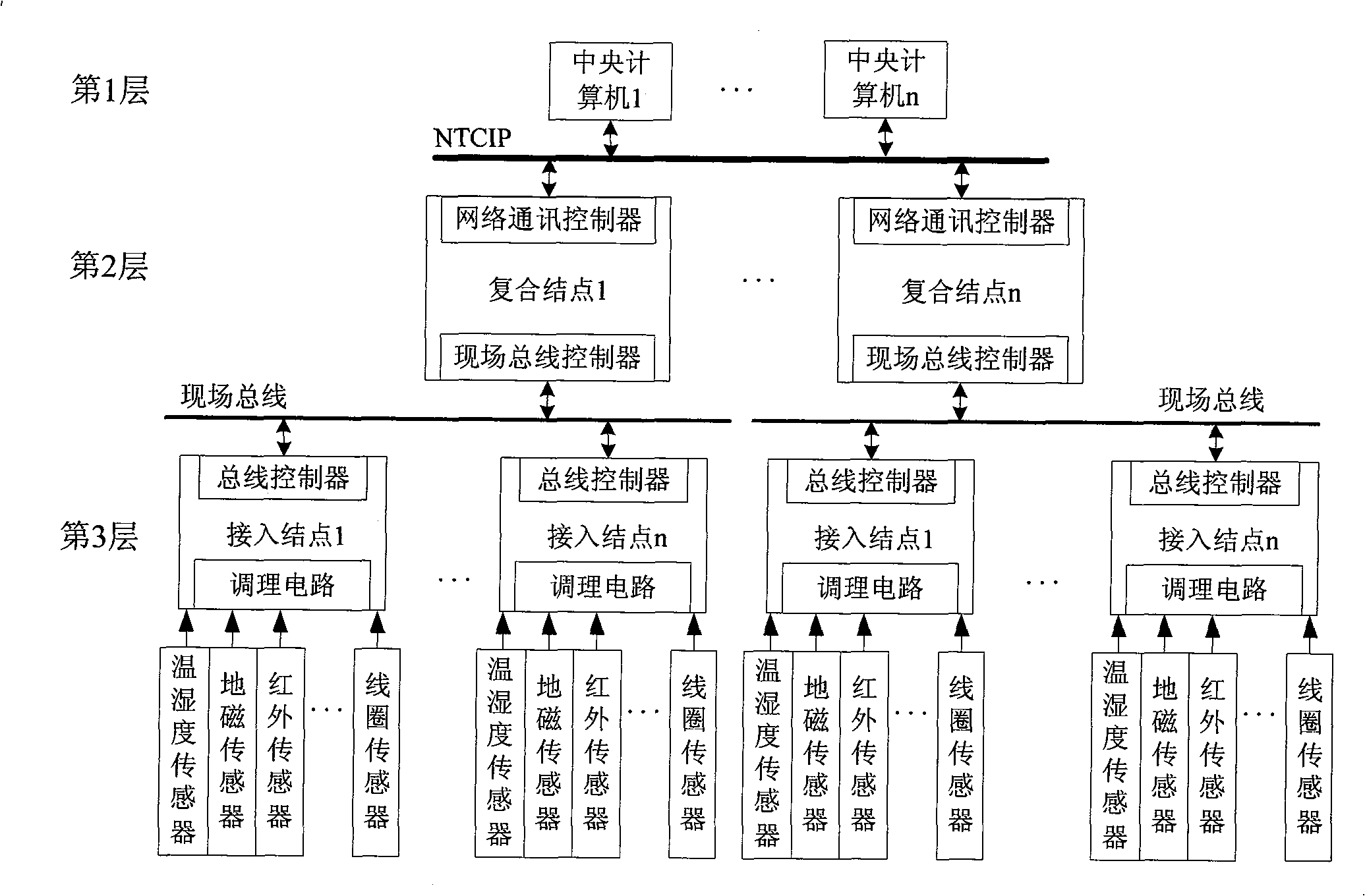

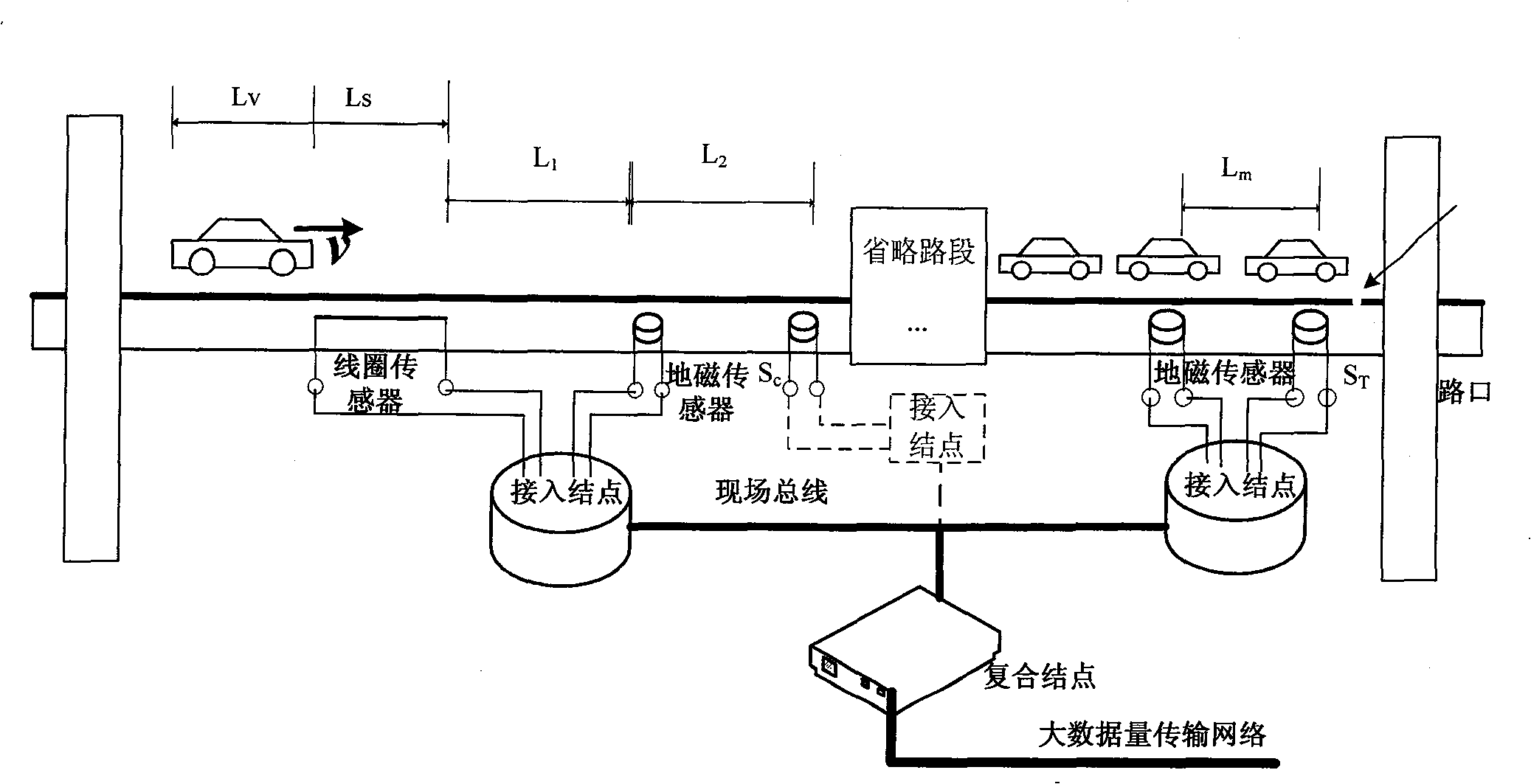

Method and device for obtaining traffic status based on sensor network

InactiveCN101493991AReduce delivery pressureReduced processing power requirementsDetection of traffic movementState parameterDelayed time

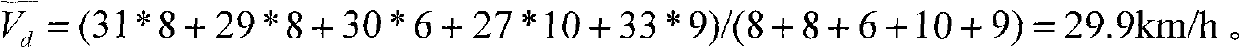

The invention relates to a method for obtaining traffic status based on a sensor network and a device thereof. The method and the device adopt a transmission mode where a site bus is combined with a mass-data transmission network to form the sensor network for obtaining the traffic status. A sensor access node and a compound node have data processing capability. Such traffic status parameters, which reflect the traffic status at the section, as traffic flow, time occupancy factor, vehicle instantaneous speed, average speed at a section, and distribution feature of flow at the section over time, are obtained at the access node of the sensor network; fusion of logistic level is finished at the compound node to obtain such parameters reflecting zone traffic status as delay time, saturation flow rate, average queue length, average queue time at a road section, average driving time, average journey time, average driving speed, traffic coefficient, and average delay time at a small granule area; and fusion of business level is finished in a central computer to obtain such parameters reflecting large granule traffic status as average journey time at different routes, traffic coefficient at different routes and zone traffic jam degree.

Owner:BEIJING JIAOTONG UNIV

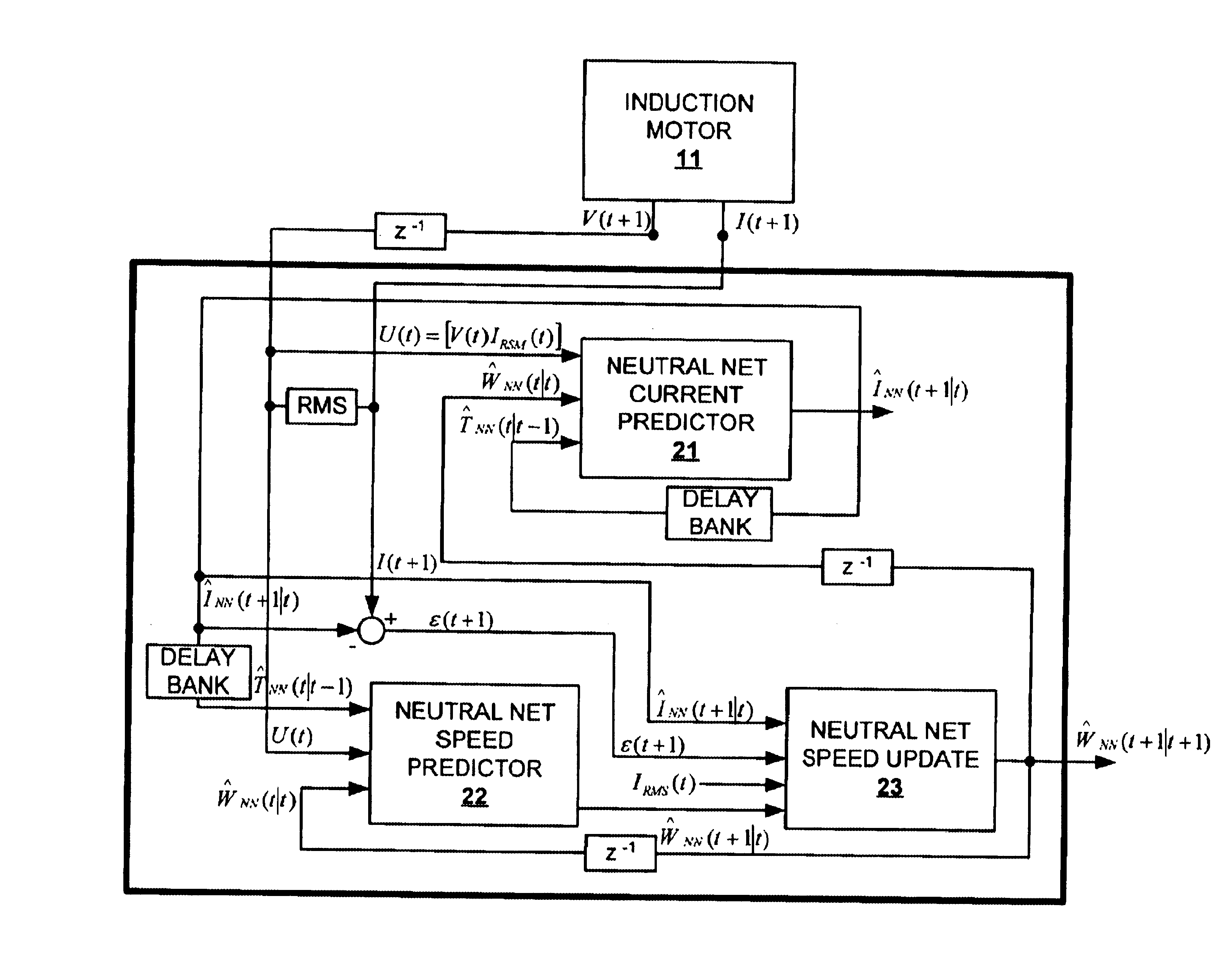

Method and system for determining induction motor speed

A non-linear, semi-parametric neural network-based adaptive filter is utilized to determine the dynamic speed of a rotating rotor within an induction motor, without the explicit use of a speed sensor, such as a tachometer, is disclosed. The neural network-based filter is developed using actual motor current measurements, voltage measurements, and nameplate information. The neural network-based adaptive filter is trained using an estimated speed calculator derived from the actual current and voltage measurements. The neural network-based adaptive filter uses voltage and current measurements to determine the instantaneous speed of a rotating rotor. The neural network-based adaptive filter also includes an on-line adaptation scheme that permits the filter to be readily adapted for new operating conditions during operations.

Owner:TEXAS A&M UNIVERSITY

Downhill auxiliary driving device for electrically-driven automobile, and control method

InactiveCN106427600AImprove battery lifeSave energyElectrodynamic brake systemsElectricityBrake torque

The invention discloses a downhill auxiliary driving device for an electrically-driven automobile, and a control method. The downhill auxiliary driving device comprises a switch module, a target speed module, a speed control module and a braking force distribution module, wherein the switch module is used for starting or stopping the downhill auxiliary driving device according to operations of a driver and the traveling condition of the automobile; the target speed module is used for recording an instantaneous speed when the downhill auxiliary driving device is started by the switch module, as a target speed,; the speed control module is used for calculating target braking torque required for maintaining the target speed according to a difference value between a current real-time speed and the target speed; and the braking force distribution module is used for controlling power recovery of a drive motor so as to provide braking torque the same as the target braking torque. According to the downhill auxiliary driving device disclosed by the invention, the braking torque in a downhill gliding process is produced through the kinetic energy recovery function of the drive motor, so that energy consumed through friction braking is reduced, and the driver can conveniently control and change the speed in the downhill gliding process through operations the same as ordinary driving habits.

Owner:SCHAEFFLER TECH AG & CO KG

Method and system for determining induction motor speed

A non-linear, semi-parametric neural network-based adaptive filter is utilized to determine the dynamic speed of a rotating rotor within an induction motor, without the explicit use of a speed sensor, such as a tachometer, is disclosed. The neural network-based filter is developed using actual motor current measurements, voltage measurements, and nameplate information. The neural network-based adaptive filter is trained using an estimated speed calculator derived from the actual current and voltage measurements. The neural network-based adaptive filter uses voltage and current measurements to determine the instantaneous speed of a rotating rotor. The neural network-based adaptive filter also includes an on-line adaptation scheme that permits the filter to be readily adapted for new operating conditions during operations.

Owner:TEXAS A&M UNIVERSITY

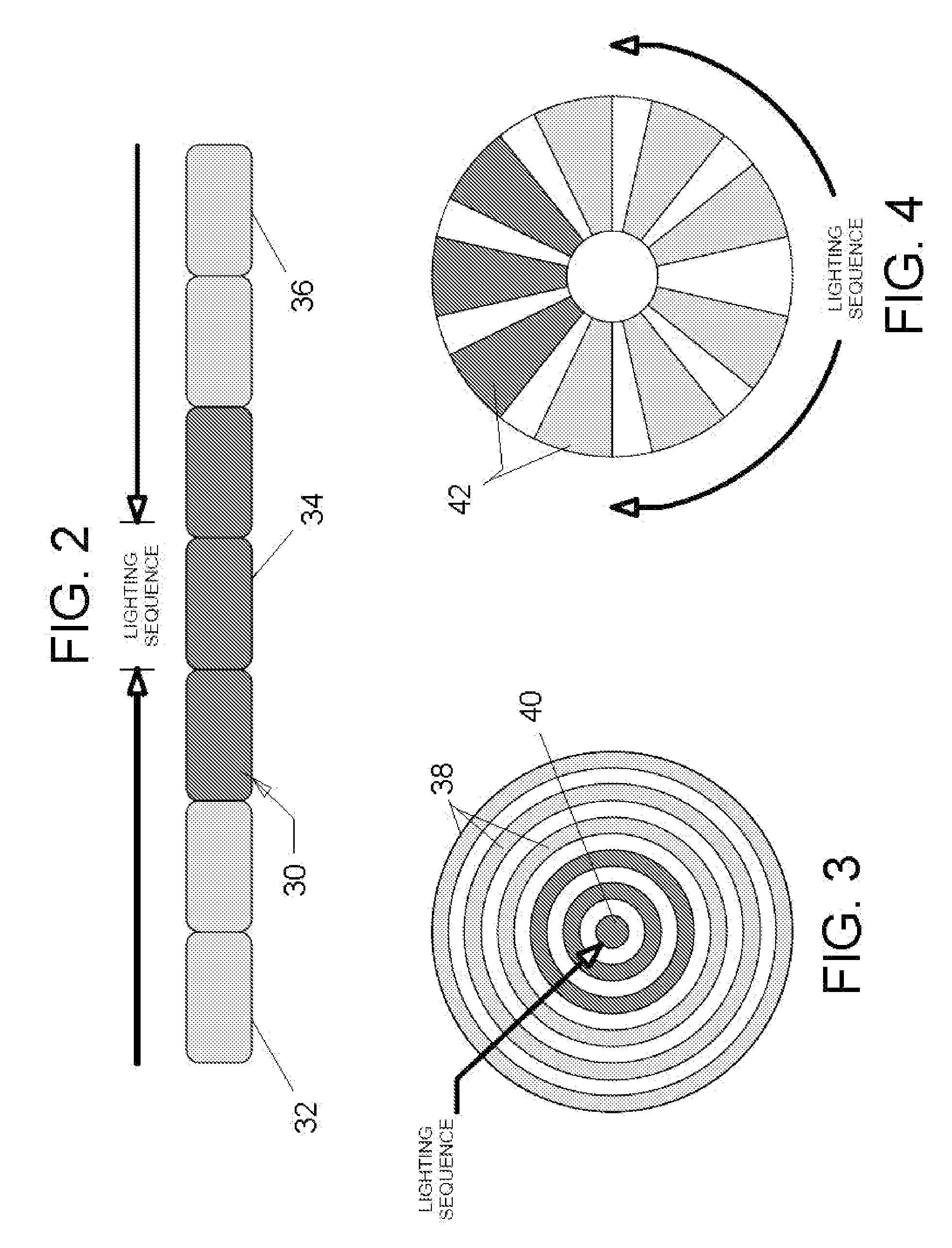

Sequential brake light system

InactiveUS20080309478A1Enough timeReduce in quantityFrequency-division multiplex detailsIndication of parksing free spacesAccelerometerMaster controller

A sequential brake light system for road vehicles has a brake light array of plural lights in a linear, concentric or radial series. A master and slave controllers are connected to the array for lighting the lights in sequence and repeatedly at a rate that is proportional to a deceleration of the vehicle upon braking. A speed sensor senses the instantaneous vehicle speed and deactivates the master controller if the speed is below a threshold value so that the array is not powered in stop-and-go traffic. A brake position sensor senses a position of the vehicle brake pedal and an accelerometer measures deceleration of the vehicle, so that the master controller receives signals corresponding to the instantaneous speed of the vehicle, a signal corresponding to the position of the brake pedal and a signal corresponding to the deceleration of the road vehicle for properly warning a trailing drive of the braking condition of the road vehicle.

Owner:MORALES CHARLES J

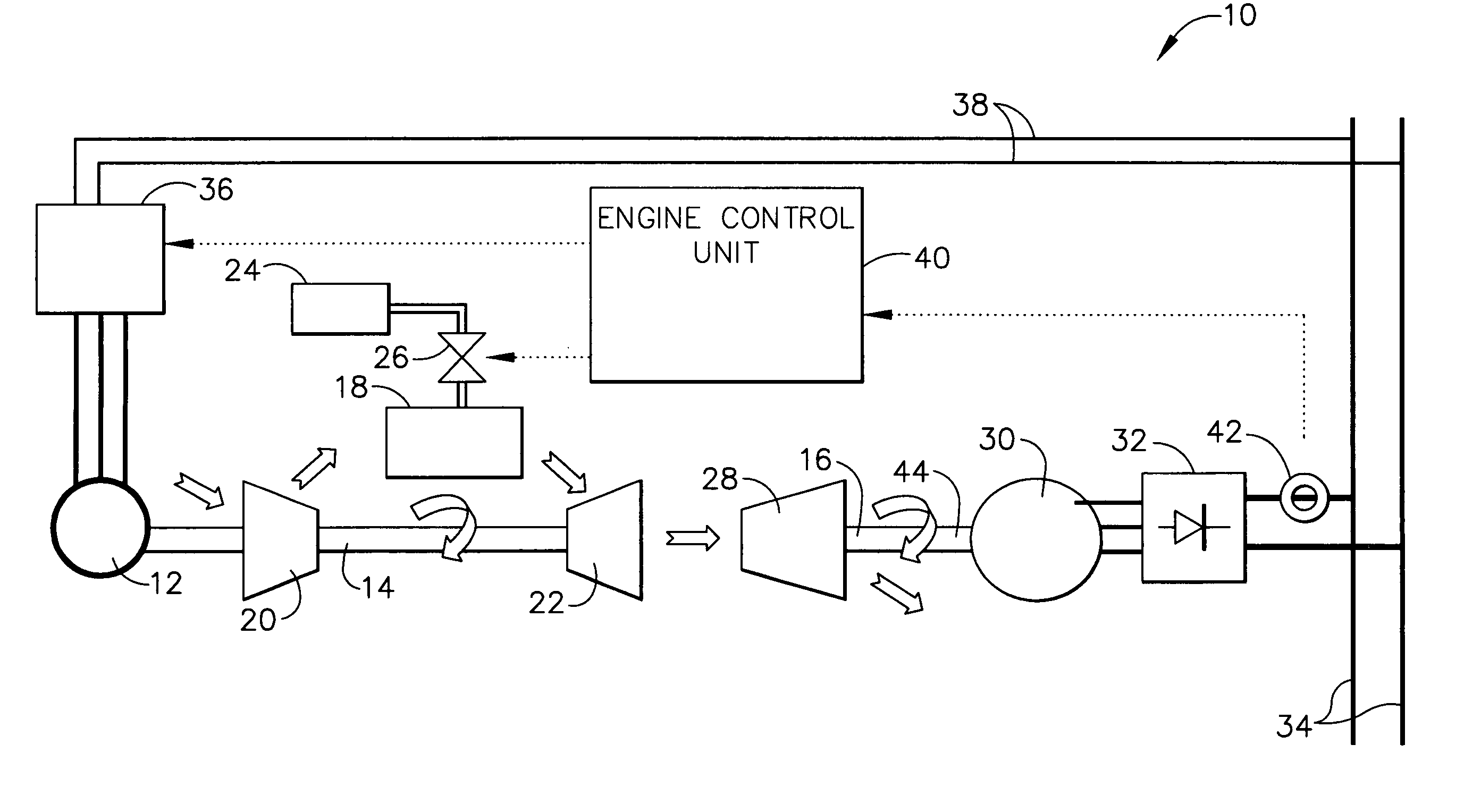

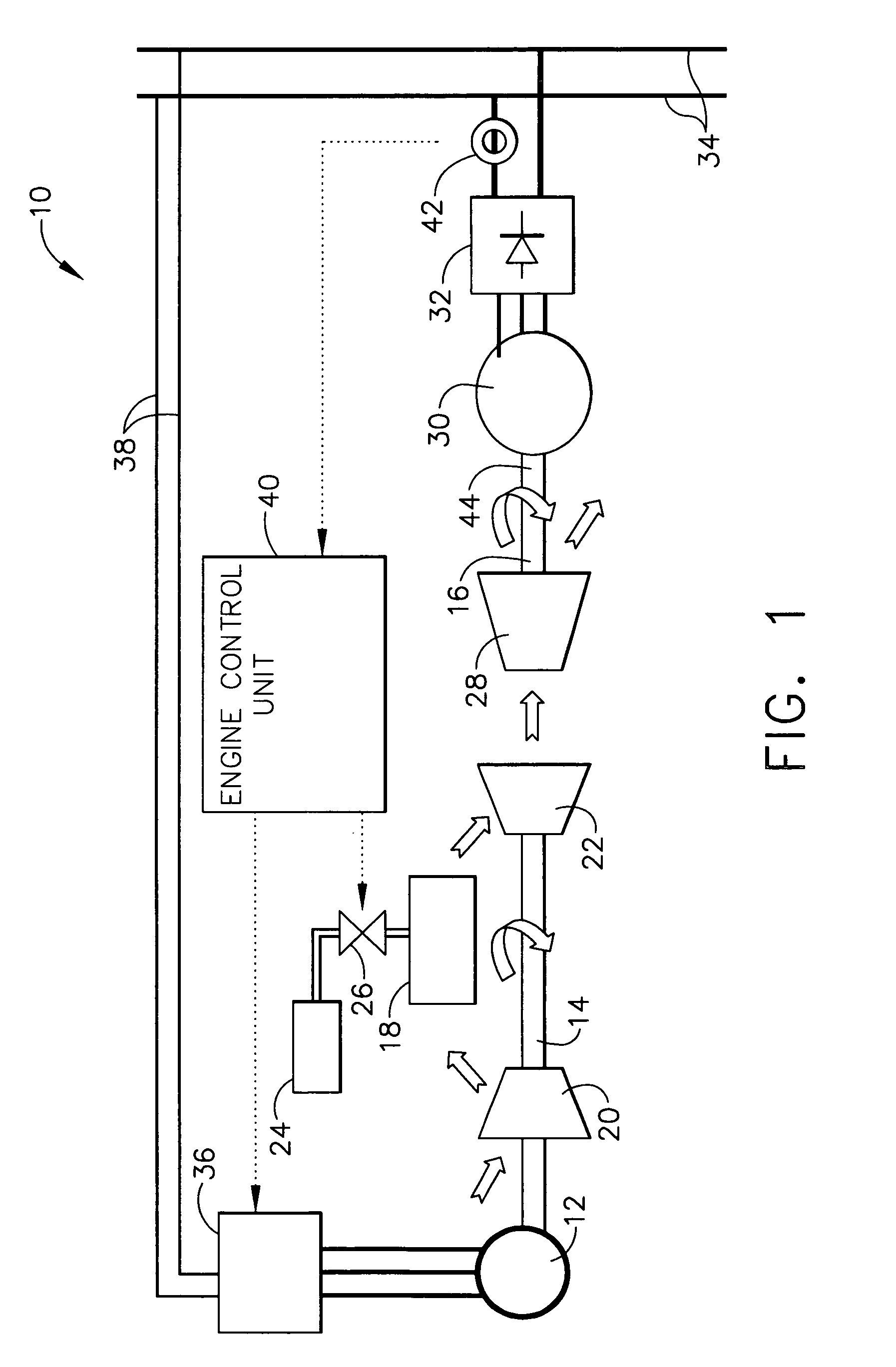

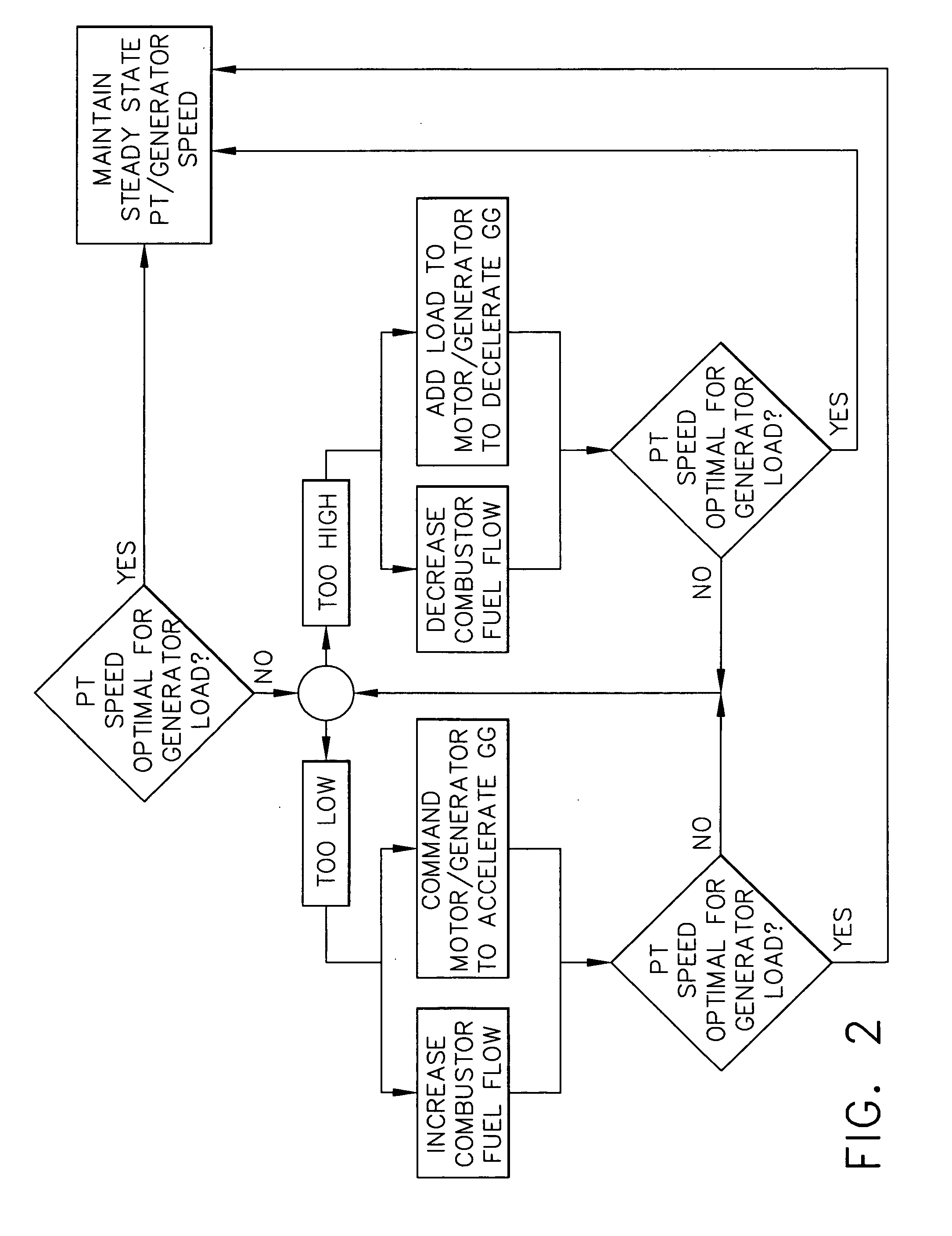

Starting and controlling speed of a two spool gas turbine engine

Two spool gas turbine engines are often used to drive variable speed loads, such as an electric generator, or the fan / propeller of aircraft engines. The gas turbine engine must be designed to withstand transient speed and temperature conditions which are encountered when sudden changes to the load on the generator, fan, or propeller occur. By adding a relatively small motor / generator to the gas generator spool of the gas turbine engine, the compressor speed and airflow can be quickly adjusted to compensate for external load changes. This reduces the severity and duration of the transient conditions, resulting in decreased operation and reliability problems such as overspeed, compressor surge, and high turbine temperature. The motor / generator may also be used as an engine starting device.

Owner:HONEYWELL INT INC

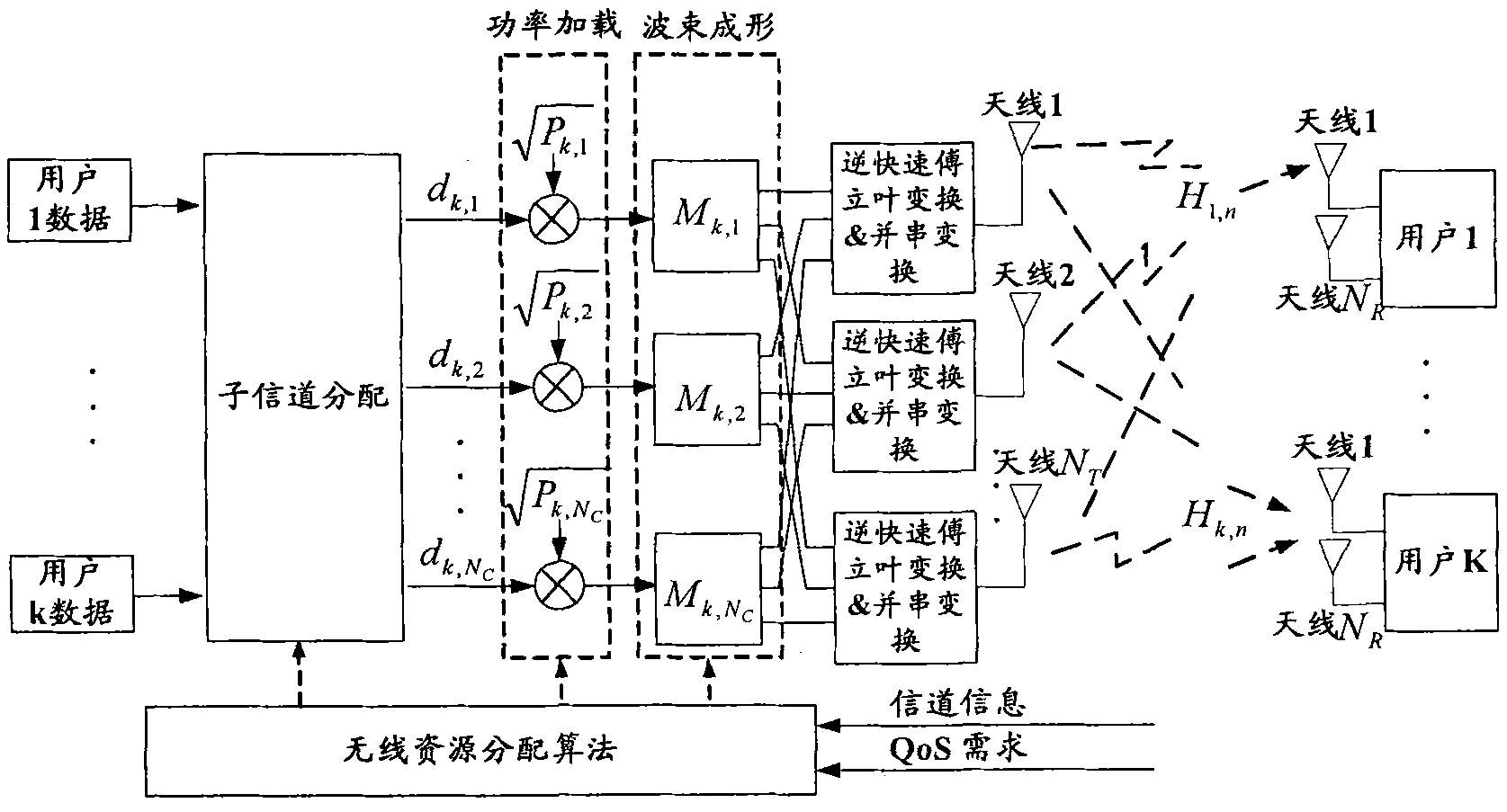

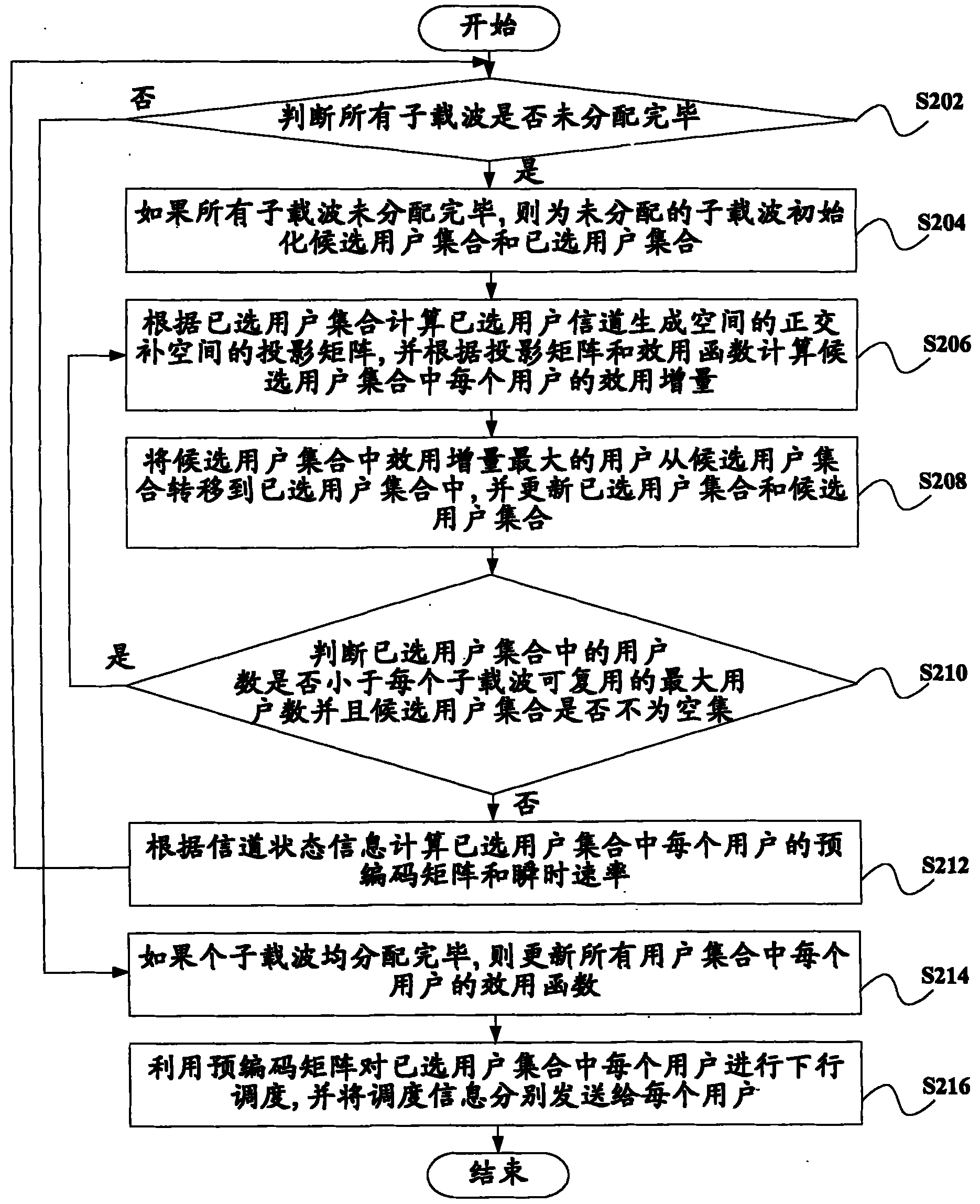

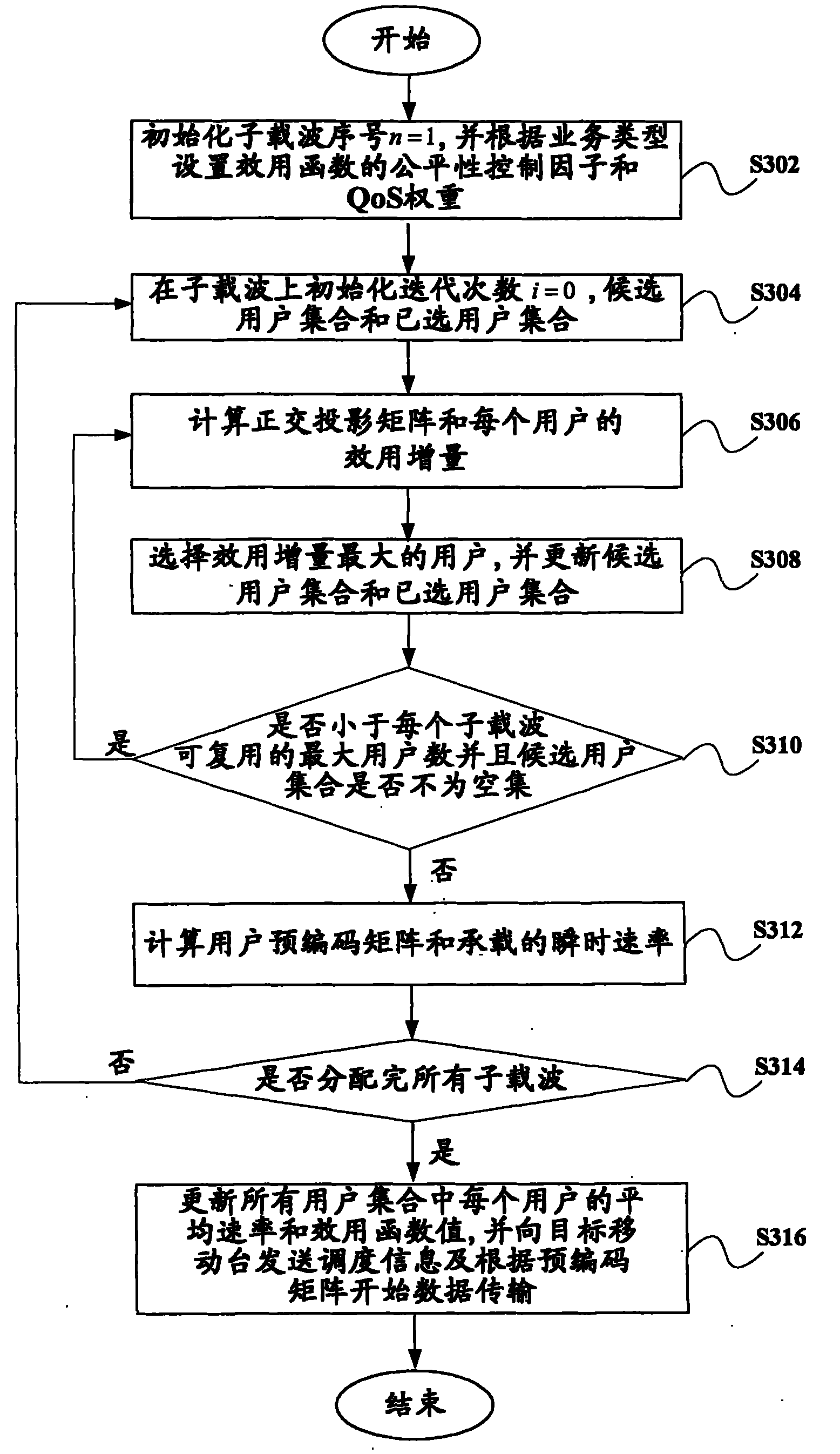

Downlink multiuser scheduling method, device and base station

InactiveCN101841916AMeet QoS requirementsImprove spectrum utilizationMulti-frequency code systemsWireless communicationHat matrixOrthogonal complement

The invention discloses a downlink multiuser scheduling method, a device and a base station. The method comprises the following steps: judging whether NC subcarriers are allocated or not; if not, initializing a candidate user set and the selected user set for the unallocated subcarriers; calculating a projection matrix of an orthogonal complement space of a channel generation space of the selected user and the utility increment of each user in the candidate user set; transferring the user with maximum effective increment to the selected user set; judging whether the user number in the selected user set is less than the maximum number multiplexed by each subcarier or not and the candidate user set is not an empty set or not; if yes, returning to the step of calculating the projection matrix and otherwise calculating a precoding matrix and instantaneous speed of each user in the selected user set; updating a utility function of each user in all user sets K being from 1, 2 to k if the NC subcarriers are allocated; and downlink scheduling each user in the selected user set by using the precoding matrix.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Driving behavior analysis system

PendingCN104786967ARegistering/indicating working of vehiclesElectric/fluid circuitComputer terminalReal-time computing

The embodiment of the invention discloses a driving behavior analysis system and belongs to the field of automobiles. The driving behavior analysis system can be used for analyzing driving behaviors. The system comprises a vehicle-mounted terminal, a remote server and a mobile terminal. The vehicle-mounted terminal obtains first driving data and transmits the first driving data to a communication module, wherein the first driving data comprise real-time instantaneous speeds of vehicles; the remote server conducts driving behavior analysis according to the real-time instantaneous speeds to obtain driving behavior analysis results; the remote server sends the driving behavior analysis results to the mobile terminal; the mobile terminal displays the driving behavior analysis results.

Owner:BEIJING YESWAY INFORMATION TECH

Time-based servopositioning systems

InactiveUS6999258B2High bandwidthAlignment for track following on tapesRecord information storageData recordingPositioning system

Servo positioning systems, methods, formats, and data recording media used in association with the same, employing additional timing reference information to improve immunity to time-based errors caused by instantaneous speed variations.

Owner:IMATION

Methods for building power consumption factor model and estimating following-up driving range of electric car

InactiveCN103234544AGuaranteed accuracyImprove practicalityNavigational calculation instrumentsEstimation methodsElectric cars

The invention discloses methods for building a power consumption factor model and estimating following-up driving range of an electric car. The model building method comprises the following steps of: introducing aggregate variable, calculating a comprehensive variable value of per second based on the instantaneous speed and acceleration of the electric car obtained in advance; forming a basic database by combining corresponding power consumption rate of per second; dividing a driving segment according to a certain time interval; counting the mean speed of each segment; merging the comprehensive variable value of the driving segment at the same mean speed; counting a distribution law, and calculating the average power consumption rate of per kilometer, namely a power consumption factor; and determining the final electric car power consumption factor model based on the mean speed by applying a mathematical statistic method according to the counted mean speed and the power consumption factor. The invention simultaneously discloses a method for estimating following-up driving range of the electric car.

Owner:BEIJING JIAOTONG UNIV

Floating car data processing device and method

ActiveCN102013167AReduce the impactReduce mistakesDetection of traffic movementInformation processingSimulation

The invention discloses a floating car data processing method and a floating car data processing device, which relate to the field of traffic road condition information processing, and solve the problem of large error existing in the current average speed calculation methods. The floating car data processing method comprises the following steps: firstly, calculating the average speed of a floating car according to the effective GPS point data recorded by the floating car on a traveling road; then, calculating the average instantaneous speed of the floating car according to the instantaneous speeds included in all effective GPS point data on the traveling road; and finally, when the sum of the average speed and a preset speed is less than the average instantaneous speed, correcting the average speed by using the average instantaneous speed so as to obtain a corrected average speed. The method and the device disclosed by the invention have the advantages that: because the average speed is corrected by using the average instantaneous speed, the influence of special GPS point data on the average speed is reduced, thereby reducing the error of the average speed, and then improving the accuracy of calculation on the road condition information. The method and the device disclosed by the invention are used for dynamically acquiring traffic jam information in real time.

Owner:CENNAVI TECH

Positioning method and device

ActiveCN103558617AGuaranteed accuracyInstruments for road network navigationSatellite radio beaconingLandmarkMotion sensors

The invention provides a positioning method and device. The positioning method comprises the following steps: an instantaneous acceleration measurement volume of a mobile terminal is acquired; an instantaneous speed of the mobile terminal is acquired; a GPS signal is received; a positioning point track is acquired; the strength of the received GPS signal is contrasted with a preset threshold value; when the strength of the GPS signal is higher than the preset threshold value, instantaneous speed calculation adjustment parameters and displacement calculation adjustment parameters are acquired; the instantaneous speed, the instantaneous speed calculation adjustment parameters and the displacement calculation adjustment parameters of the mobile terminal are corrected; whether landmark information is perceived is judged; if yes, the perceived landmark information is verified with standard map information, and the positioning track of the mobile terminal is corrected. According to the positioning method and device, a motion sensor is used for calculating the state of the mobile terminal in real time, positioning accuracy is adjusted in real time by means of perceiving special landmarks in the running process, and therefore the requirement for positioning a vehicle accurately in real time in a city is met.

Owner:苏州美信互联信息技术有限公司

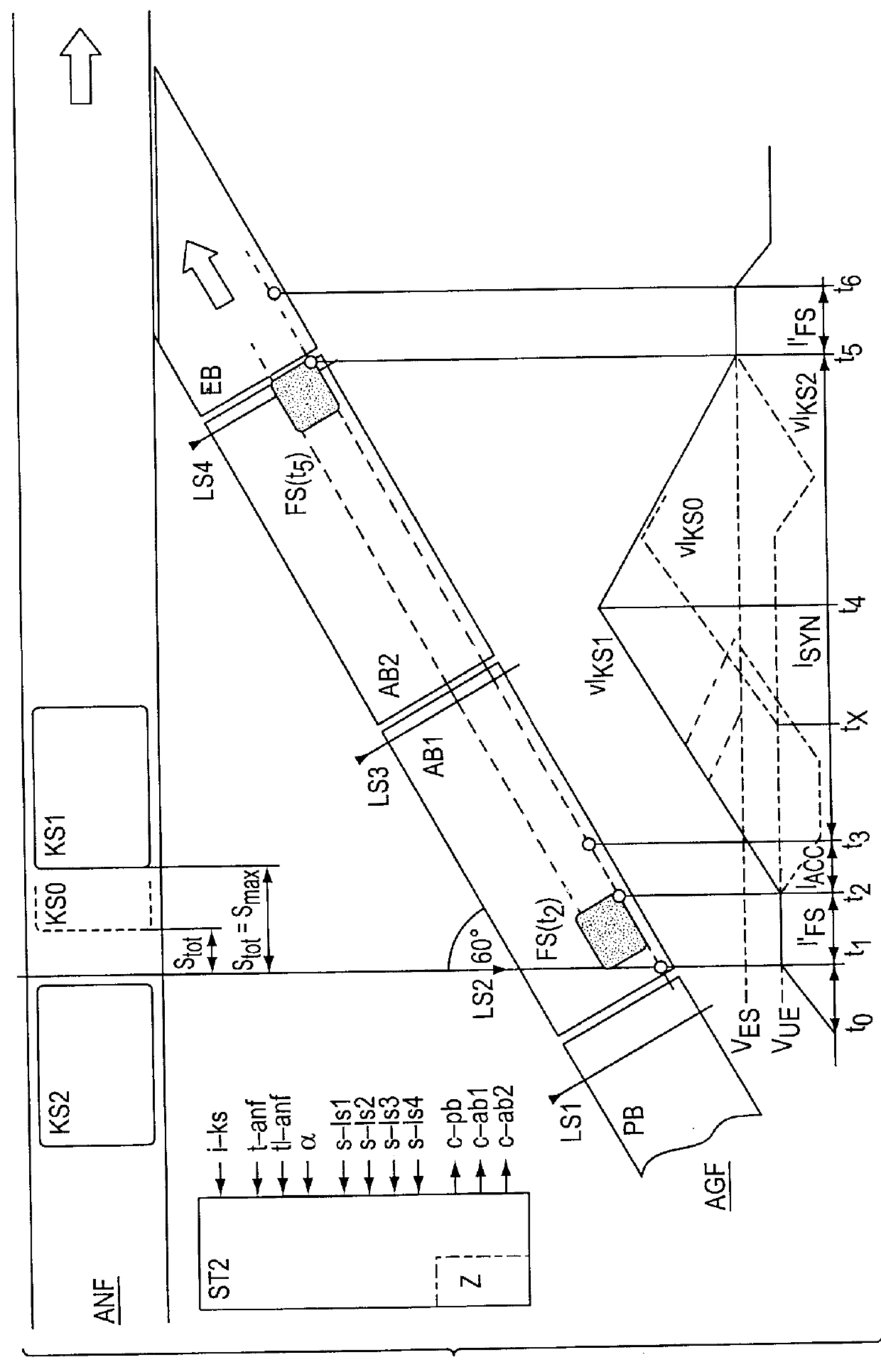

Method and device for channeling parceled goods

InactiveUS6129199AReduce processReduce idle timeControl devices for conveyorsMechanical conveyorsEngineeringPosition control

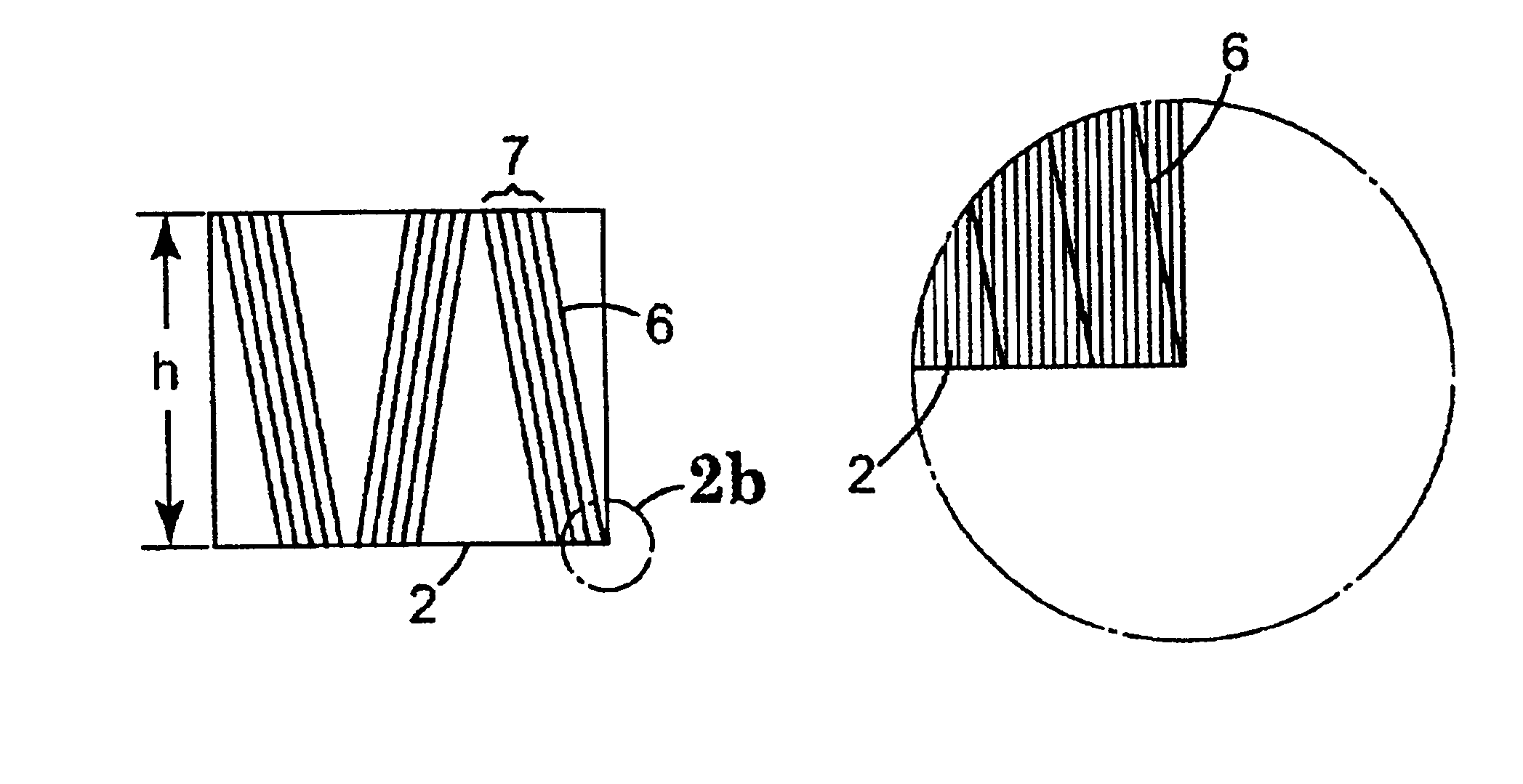

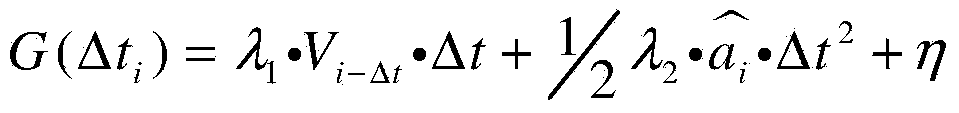

PCT No. PCT / CH96 / 00305 Sec. 371 Date Jun. 26, 1997 Sec. 102(e) Date Jun. 26, 1997 PCT Filed Sep. 5, 1996 PCT Pub. No. WO97 / 09256 PCT Pub. Date Mar. 13, 1997Process and apparatus for controlling the channeling of parceled goods to be delivered via a delivery conveyor, which includes at least one buffer conveyor, a call-up conveyor, and a channeling conveyor, to free locations on an acceptance conveyor running at a constant speed. The acceptance conveyor and the delivery conveyor are arranged to encompass an angle alpha , and the delivery conveyor is provided with a parcel measuring device. The process includes measuring a length of a parcel to be channeled, determining a length of time t2 utilized in measuring the length of the parcel, and determining a momentary parcel speed; a speed of the channeling conveyor to which the parcel will be transferred; a distance on the call-up conveyor on which acceleration of the parcel occurs prior to a transfer of the parcel to the channeling conveyor; and a position of a next free space on the acceptance conveyor. The process also includes synchronizing movement of the parcel to the next free space by one of (a) accelerating and decelerating and (b) decelerating and accelerating the parcel on the call-up conveyor at a constant acceleration a, and without intermediate stopping of the call-up conveyor, transferring the parcel from the call-up conveyor to the channeling conveyor, and synchronously transferring the parcel to the next free space on the acceptance conveyor. The apparatus includes a measuring device to measure a length of a parcel to be transferred from the delivery conveyor to the acceptance conveyor, wherein the measurement of the length occurs in a time t2, a control device provided for determining a momentary speed of parcel; a speed of the channeling conveyor to which the parcel will be transferred; a distance on the call-up conveyor on which acceleration of the parcel occurs prior to a transfer to the channeling conveyor; and a position of a next empty space on the acceptance conveyor. The control device also is provided to adjust one of (a) an acceleration and deceleration and (b) a deceleration and acceleration of the parcel on the call-up conveyor, without intermediate stopping of the call-up conveyor, to synchronize the movement of the parcel to the next empty space on the acceptance conveyor.

Owner:SIEMENS SWITZERLAND +1

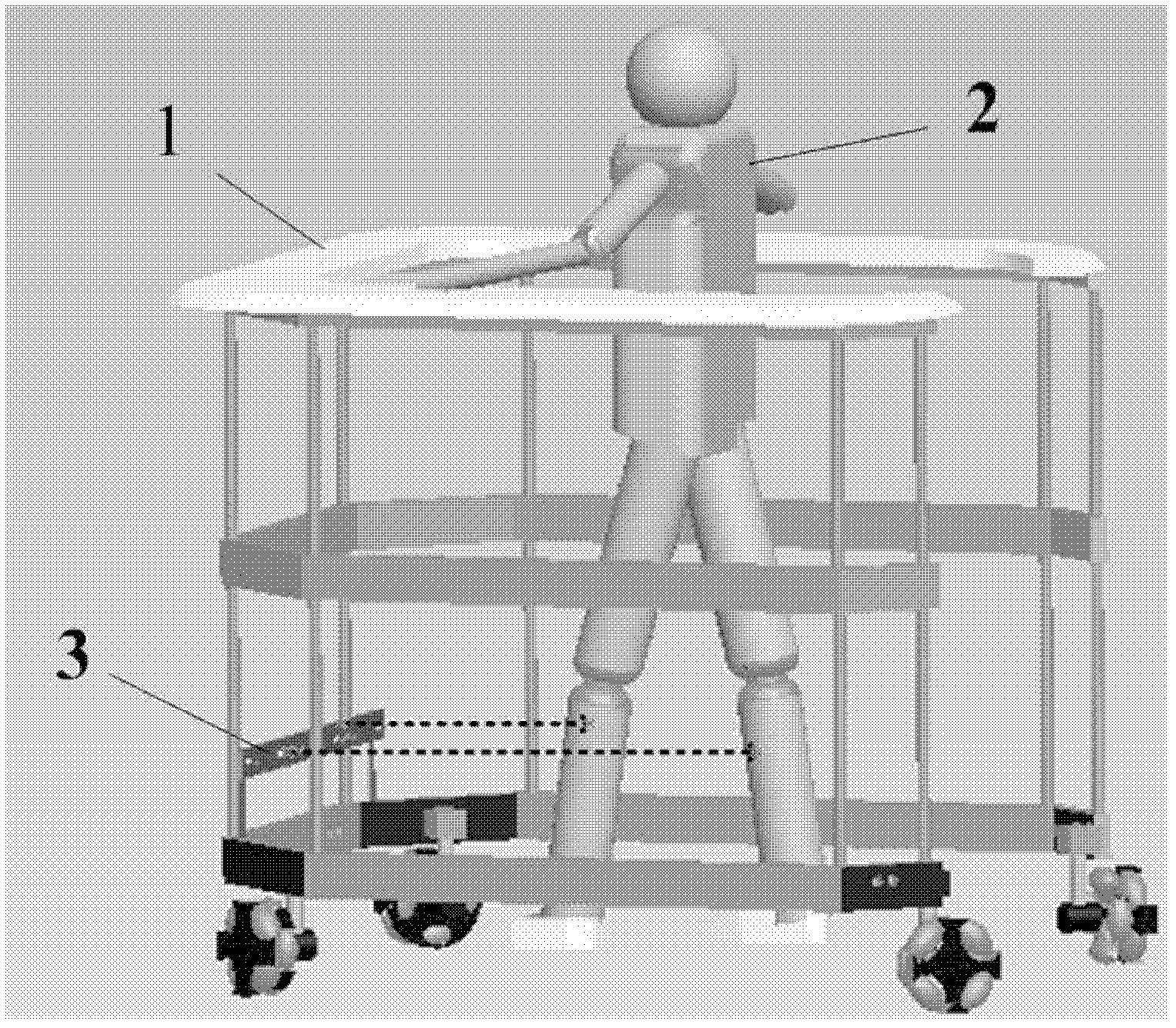

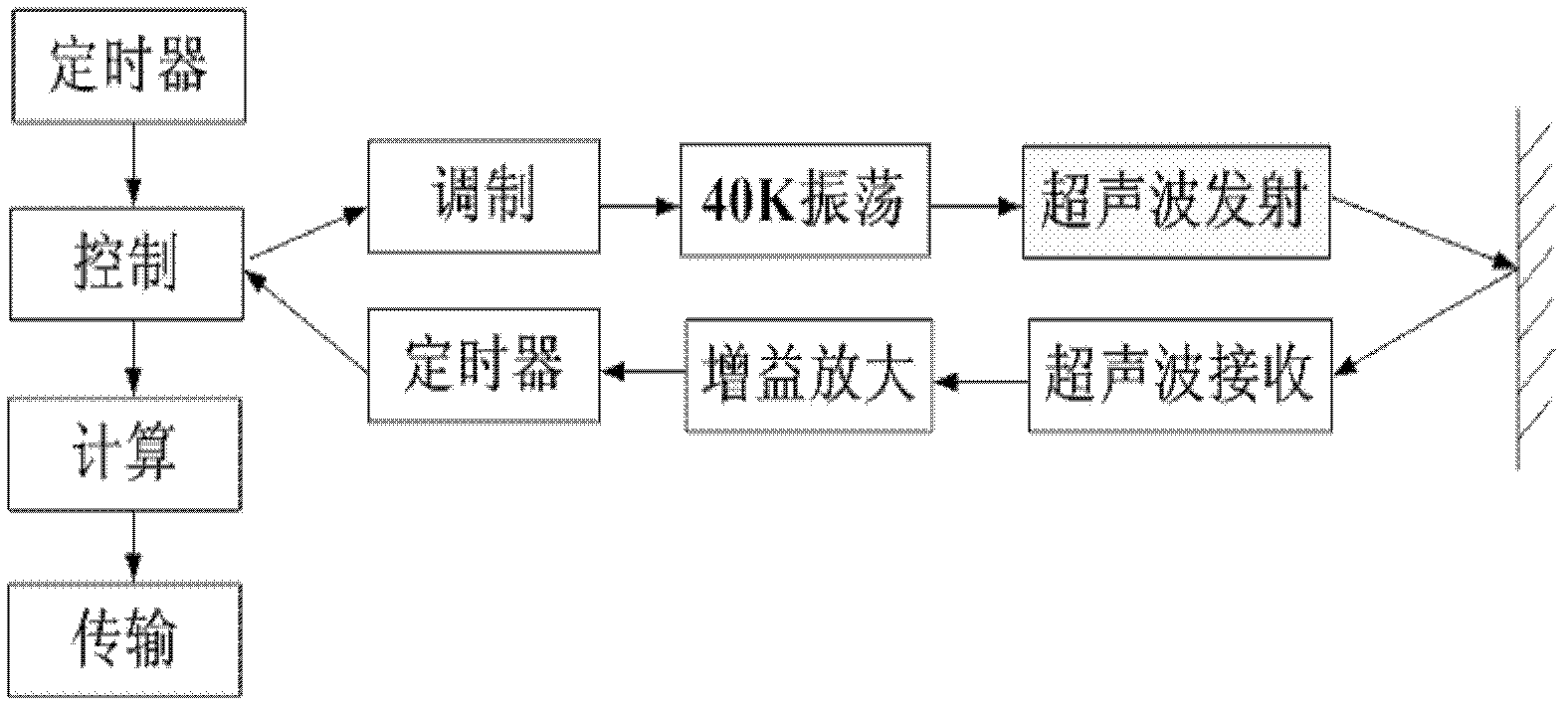

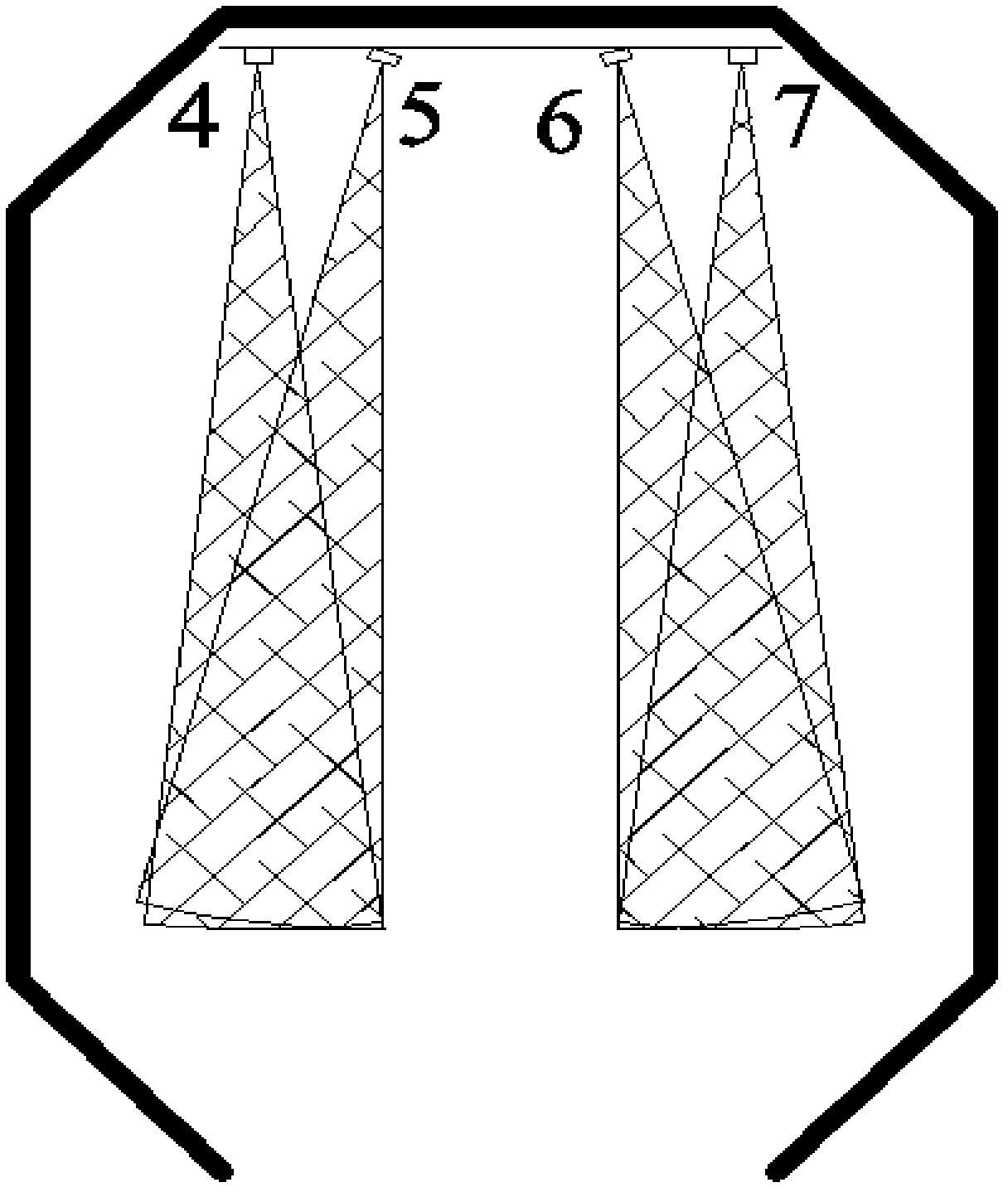

Ultrasonic gait detection device and method

ActiveCN102499692AAvoid interferenceReduce distractionsDiagnostic recording/measuringSensorsHuman bodyTransceiver

The invention discloses an ultrasonic gait detection device and method. The method is characterized by comprising the following steps: installing an ultrasonic detection system in front of a walking aid robot platform, respectively detecting the distance between the left and right legs of the testee and the ultrasonic detection platform by multiple ultrasonic sensors, extracting gait information in the walking process of the human body, and analyzing and calculating gait parameters, including average step length, average pace, step frequency, instantaneous speed and the like. The device comprises an ultrasonic transceiver, a data acquisition and transmission device, a gait data processing unit and a gait characteristic parameter calculation and analysis unit. The detection device is installed on the walking aid robot platform, and no device is installed on the testee body, so that the ultrasonic gait detection device can detect the gait of the testee without any restriction, thereby reducing the mental load of the testee in the gait detection process; the extracted gait characteristic parameters are more accurate; and the detection system has the advantages of simple structure and low cost, and is convenient to use and install.

Owner:SHENYANG POLYTECHNIC UNIV

Laser confocal scanning microscope and methods of improving image quality in such microscope

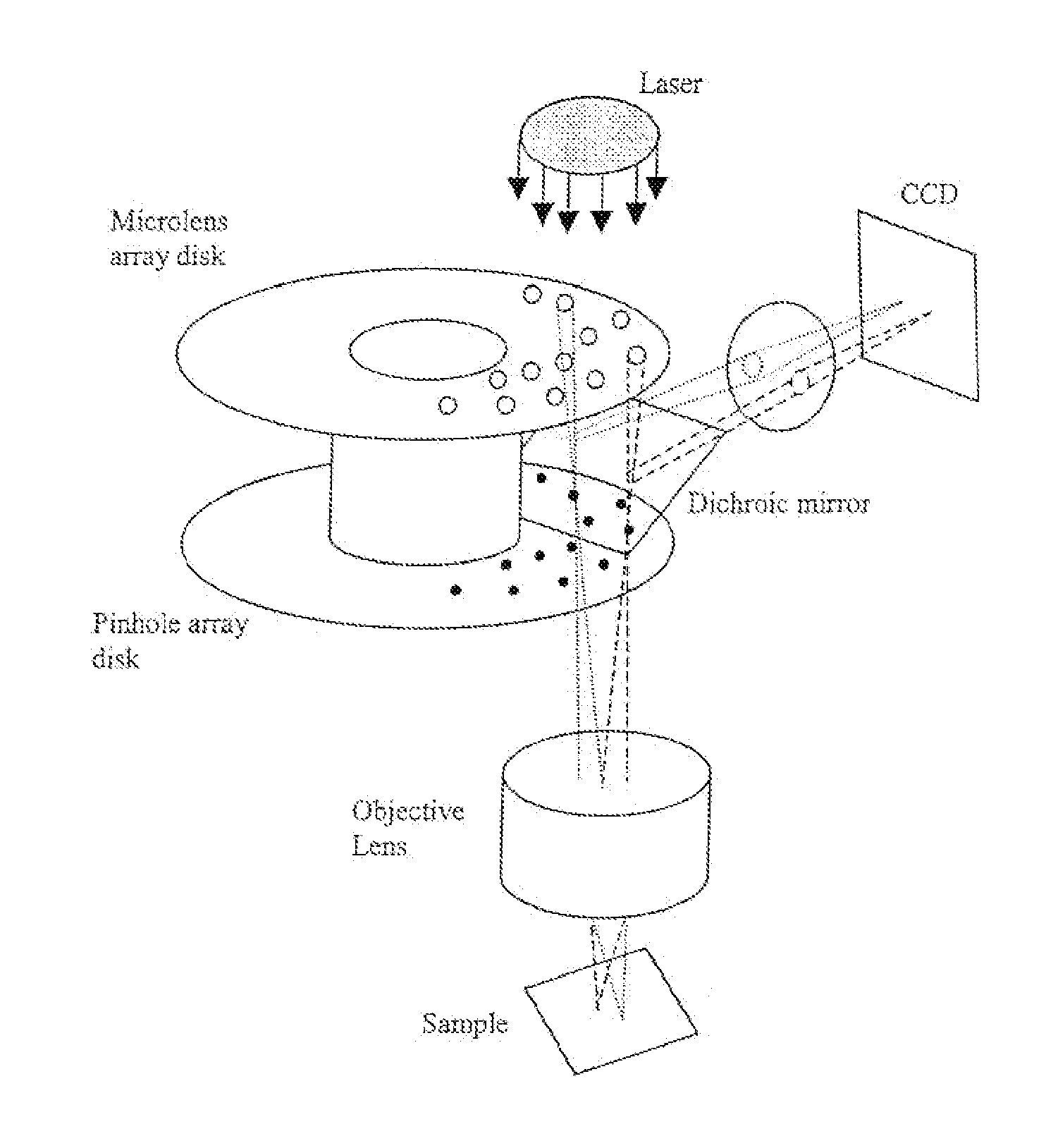

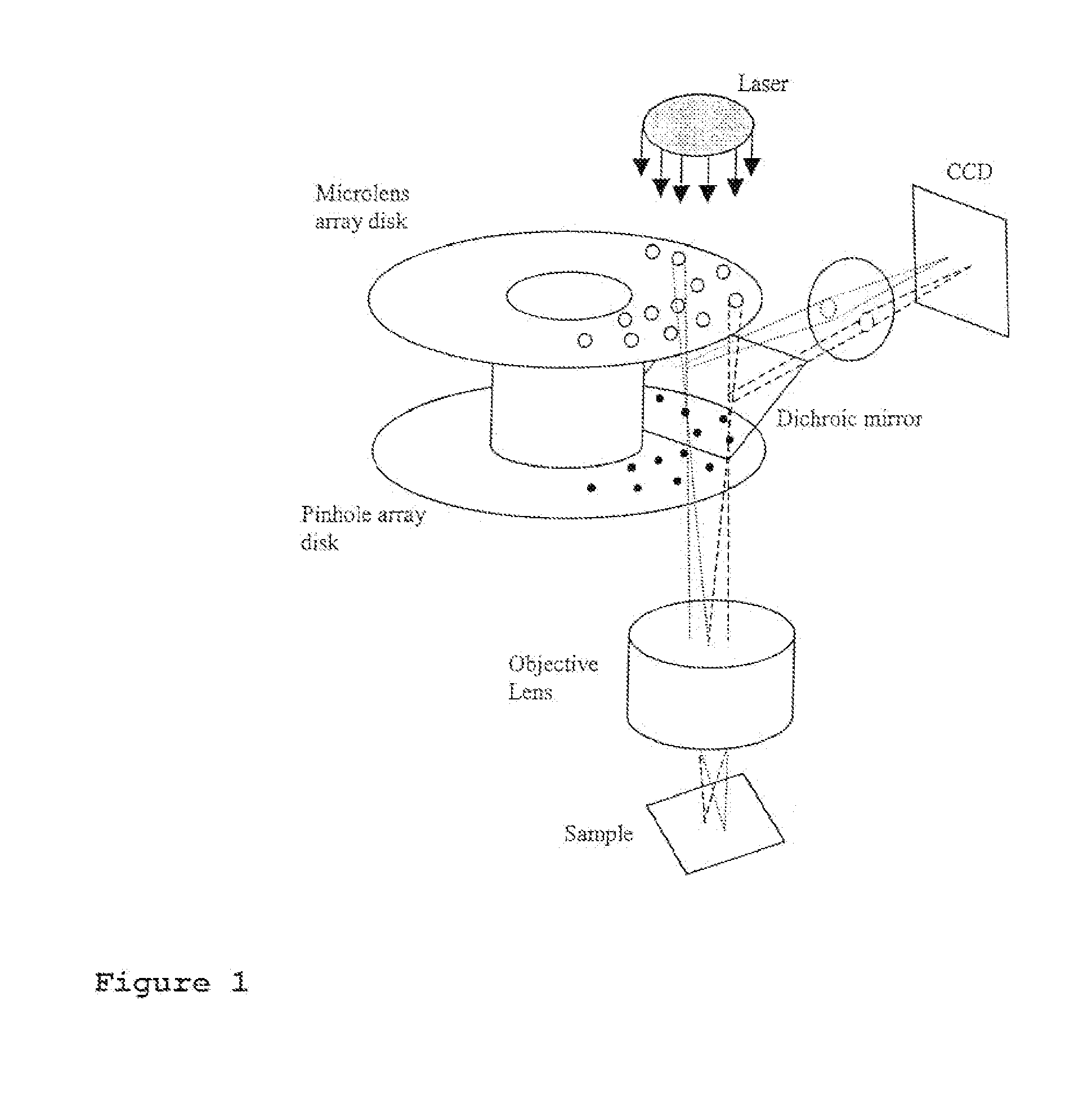

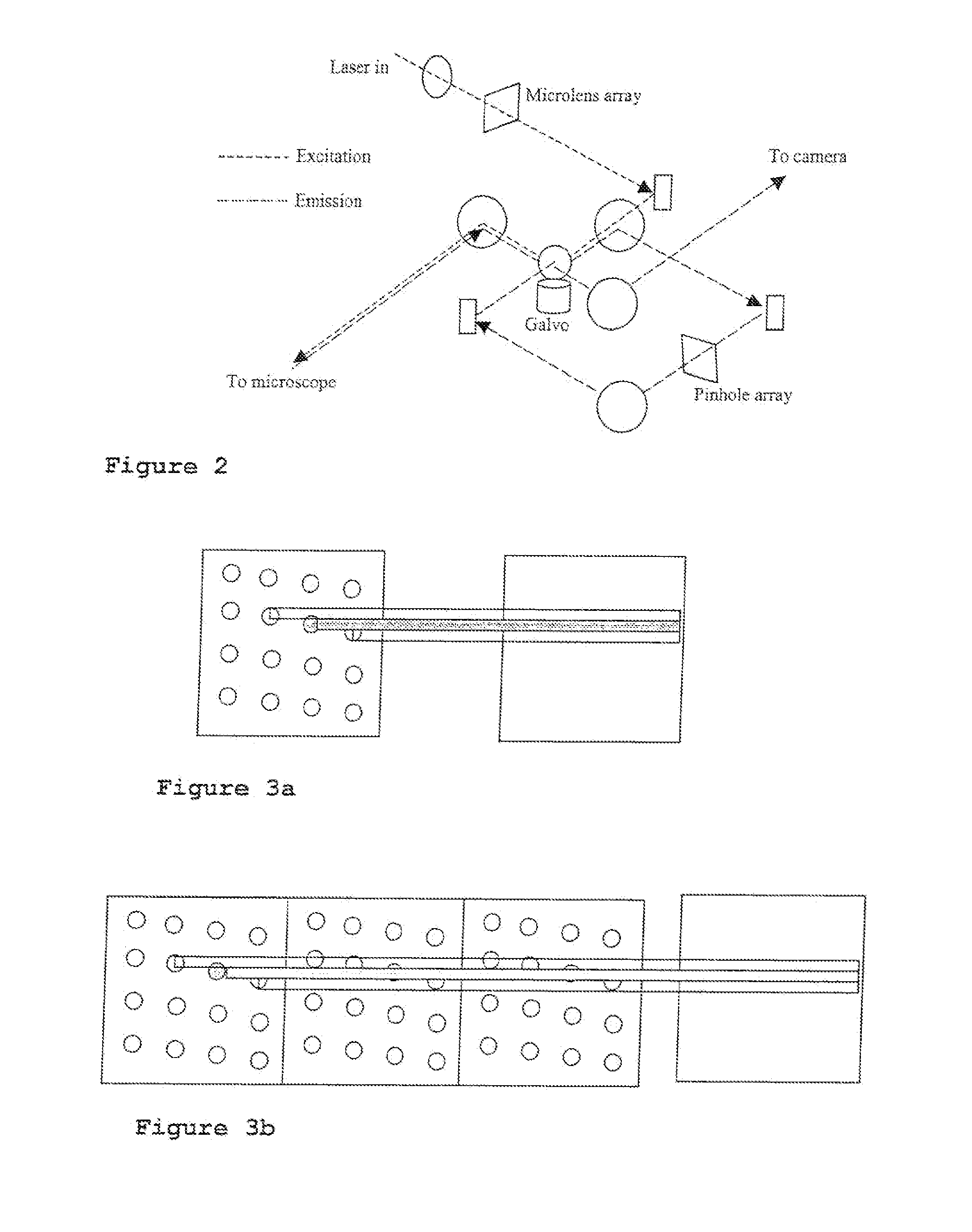

InactiveUS20080037114A1High strengthReduce appearance problemsMicroscopesModulation functionImaging quality

According to a first embodiment the invention provides for increasing the throughput and reducing the striping due to imperfections in the microlens and / or confocal aperture arrays of a Laser Confocal Scanning Microscope by increasing the number of repeat patterns in the microlens and confocal aperture arrays to more than one, and incorporating an intensity modulation function that ensures constant integrated image intensities at the image detector independent of the instantaneous speed of scanning. According to a second embodiment the invention provides for reducing the striping in a Laser Confocal Scanning Microscope by introducing a second galvanometer mirror such that the emitted laser light beam is descanned at the image (sample) plane. According to embodiments three to five, striping in a Laser Confocal Scanning Microscope is also reduced by destroying coherency in the emitted light beam by insertion of a small angle diffuser, by flattening the Gaussian intensity distribution of the emitted laser light beam and changing the characteristics of the beam expander. According to embodiment six the invention provides for changing the degree of confocality of a Laser Confocal Scanning Microscope by inserting a mechanism that offers a range of selectable confocal aperture sizes.

Owner:VISITECH INT LTD

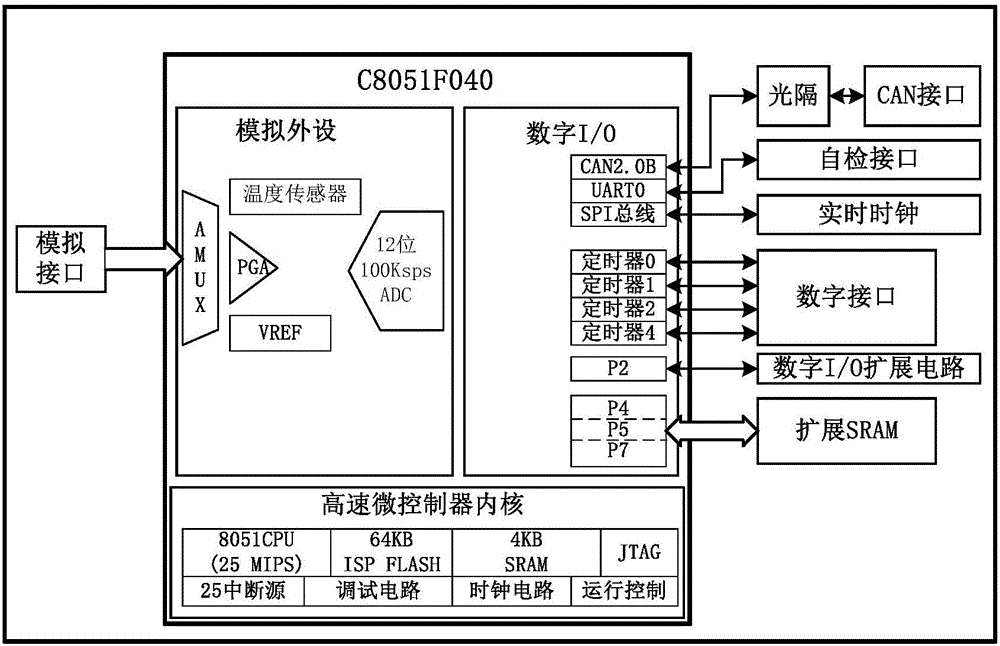

Monitoring device based on digital monitoring heavy equipment engine and monitoring method thereof

ActiveCN106444489ARealize online monitoringSolve the problem of poor testabilityProgramme controlInternal-combustion engine testingTransceiverComputer module

The invention discloses a monitoring device based on a digital monitoring heavy equipment engine. The device comprises a main control computer, a CAN bus communication circuit, an engine monitoring module and a meter parameter monitoring module. The main control computer is used for conducting monitoring on the heavy equipment engine; the CAN bus communication circuit comprises a CAN bus controller and a CAN bus transceiver, wherein the CAN bus controller conducts data transmission with the main control computer through the CAN bus transceiver; the engine monitoring module is connected to the CAN bus communication circuit, and used for acquiring engine vibration data, fuel capacity data and instantaneous speed data; the meter parameter monitoring module is connected to the CAN bus transceiver, and used for conducting data transmission on an inputting signal with the main control computer through the CAN bus controller. The invention further discloses a monitoring method based on the digital monitoring heavy equipment engine.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

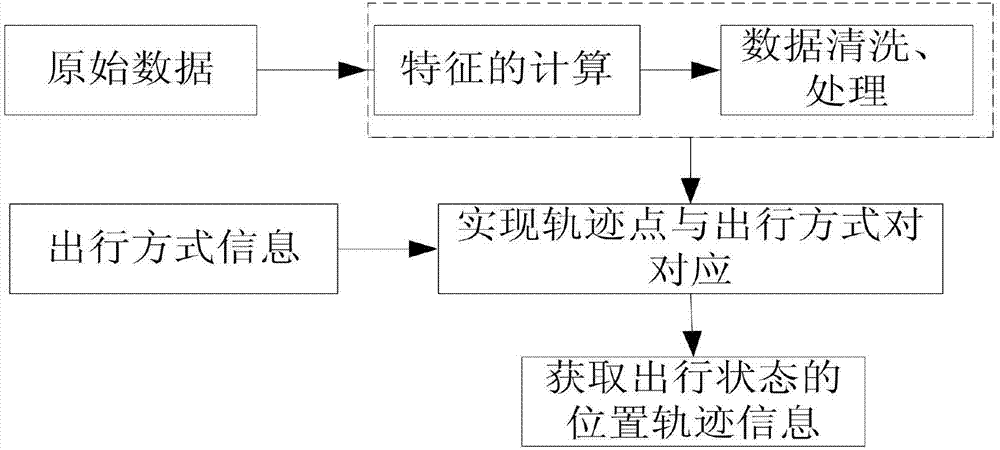

Position-trajectory-based travel state splitting method

InactiveCN104504099AGeographical information databasesSpecial data processing applicationsLongitudeSimulation

The invention belongs to the technical field of analysis over travel behaviors of residents, and particularly relates to a position-trajectory-based travel state splitting method, which comprises the following steps of performing GPS (Global Positioning System) positioning to obtain latitude and longitude coordinates of a position trajectory; calculating the distances of trajectory points, instantaneous speed and instantaneous acceleration; performing data cleaning and abnormal data processing; matching a manually identified travel manner; selecting different time intervals T, and splitting a travel state; performing characteristic extraction and sequential storage; performing Euclidean-distance-based similarity measurement on adjacent segments by taking characteristics of the travel segments as characteristic vectors, determining a proper time interval, and determining splitting points to realize the splitting of the travel state according to distance similarity measurement. According to the method, key points of the travel state can be determined more accurately, and the travel state can further be better split; compared with a conventional fixed time period and key point travel state splitting method, the method is more objective and reliable.

Owner:BEIJING JIAOTONG UNIV

Speed measurement system and method of servo motor

ActiveCN103048484AInstantaneous speed values are reliableLinear/angular speed measurementLow speedElectric machine

The invention provides a speed measurement system of a servo motor. The speed measurement system of the servo motor comprises an encoder counting module, a rotate speed judging module, a first speed measurement module and a second speed measurement module, wherein the first speed measurement module is used for measuring speed by adopting an M / T method when the rotate speed of the motor is greater than or equal to a first threshold value, and outputting a speed measurement result as a speed feedback; the second speed measurement module is executed when the rotate speed of the motor is less than the first threshold value and comprises a first unit and a second unit; the first unit is used for measuring the speed by using a T method and outputting the speed measurement result as the speed feedback; and the second unit is used for predicting the speed of the current sampling period and outputting the predicted speed of the current sampling period as the speed feedback. The invention also provides a corresponding method. According to the speed measurement system of the servo motor, the predicted rotate speed is used as the speed feedback when a rotor runs at an ultra-low speed, and therefore, the instantaneous speed value of a speed control period at a low speed can be relatively reliable.

Owner:SUZHOU INOVANCE TECH CO LTD +1

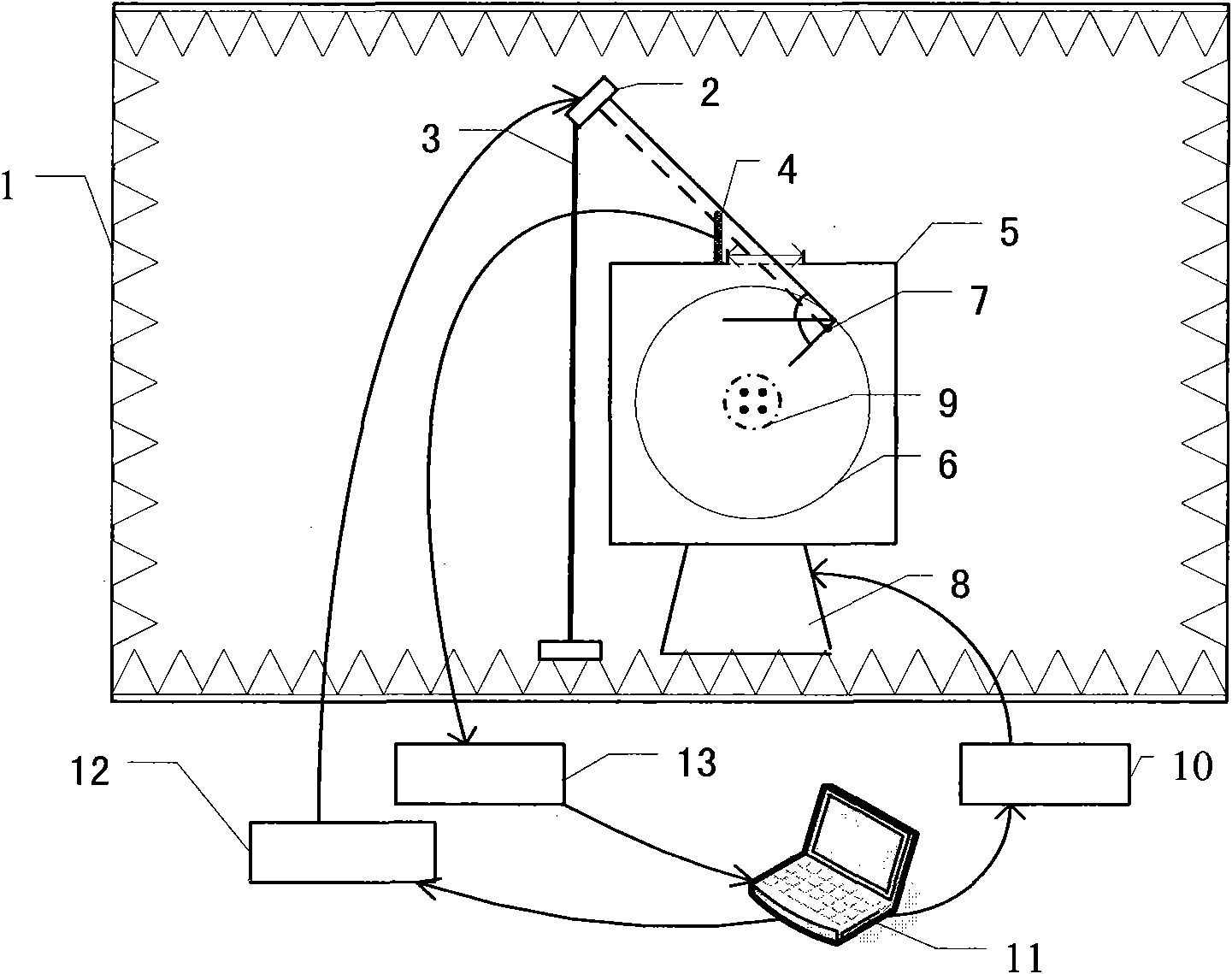

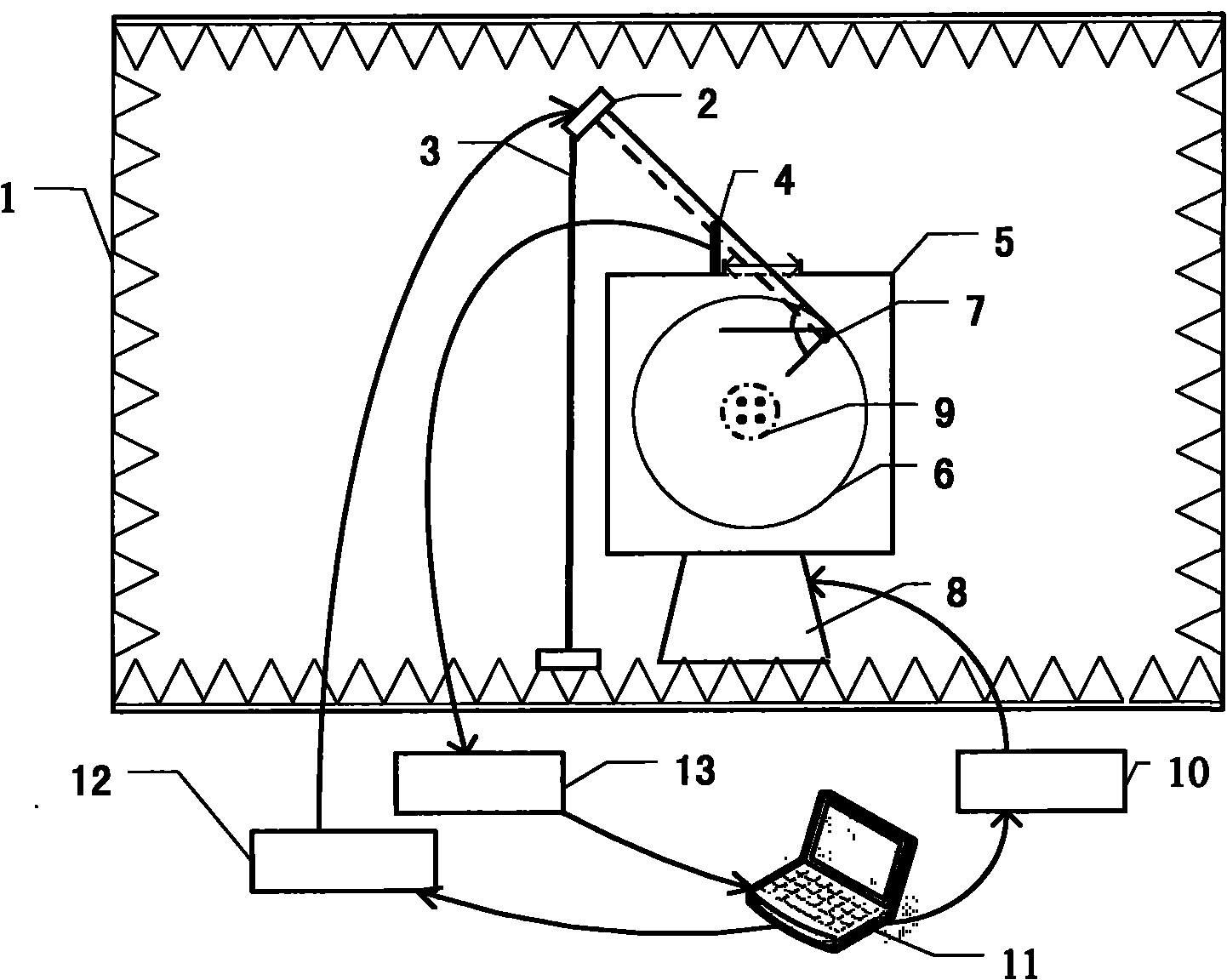

Response frequency benchmark test system and method for electronic tag in high-speed motion state

ActiveCN101980252AScientific automated testingRepeatable automated testingCo-operative working arrangementsSpectrum analyzerResponse Frequency

The invention relates to a response frequency benchmark test system and a response frequency benchmark test method for an electronic tag in a high-speed motion state. The system consists of a standard test environment, a signal source transmitting antenna, a signal source antenna bracket, a spectrum analyzer receiving antenna, a protective cover, a turntable, the electronic tag to be tested, a support table, a driving motor, a driving motor controller, a control computer, a signal source and a spectrum analyzer. In the method, a frequency domain range in which the electronic tag to be tested in the motion state can normally respond to the signal of a reader-writer is obtained by analyzing the response characteristics of an electronic tag product to be tested in the high-speed motion statein different test frequency bands; linear direction speed is simulated by instantaneous speed in the tangential direction of the turntable to realize the high-speed motion of the electronic tag to betested; the frequency response performance benchmark test of the tag in the motion state is realized by simulating the reader-writer to read the signal of the electronic tag to be tested; and a radiofrequency identification (RFID) automatic testing tool and a benchmark test method which are simple, clear and effective can be provided for users.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

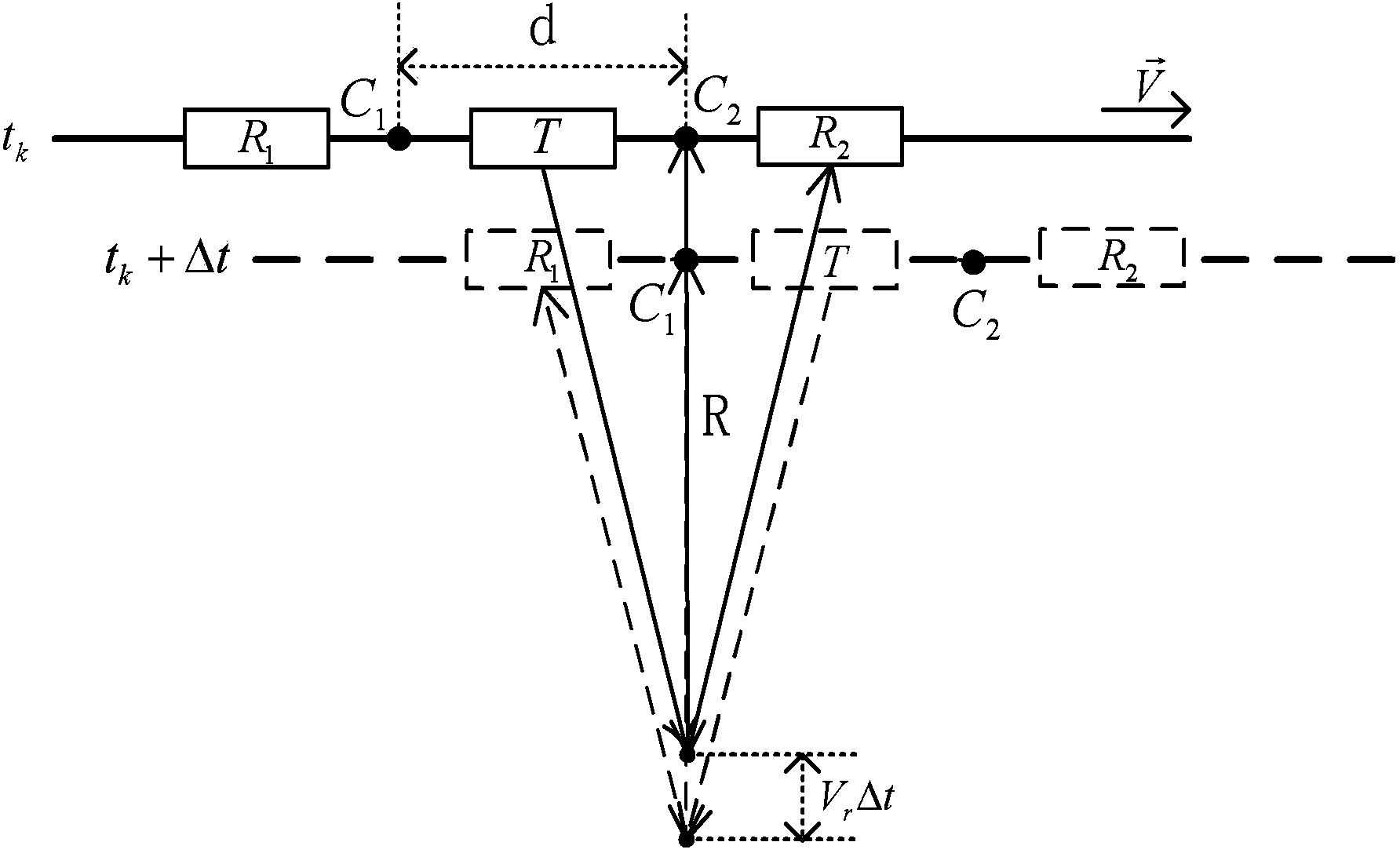

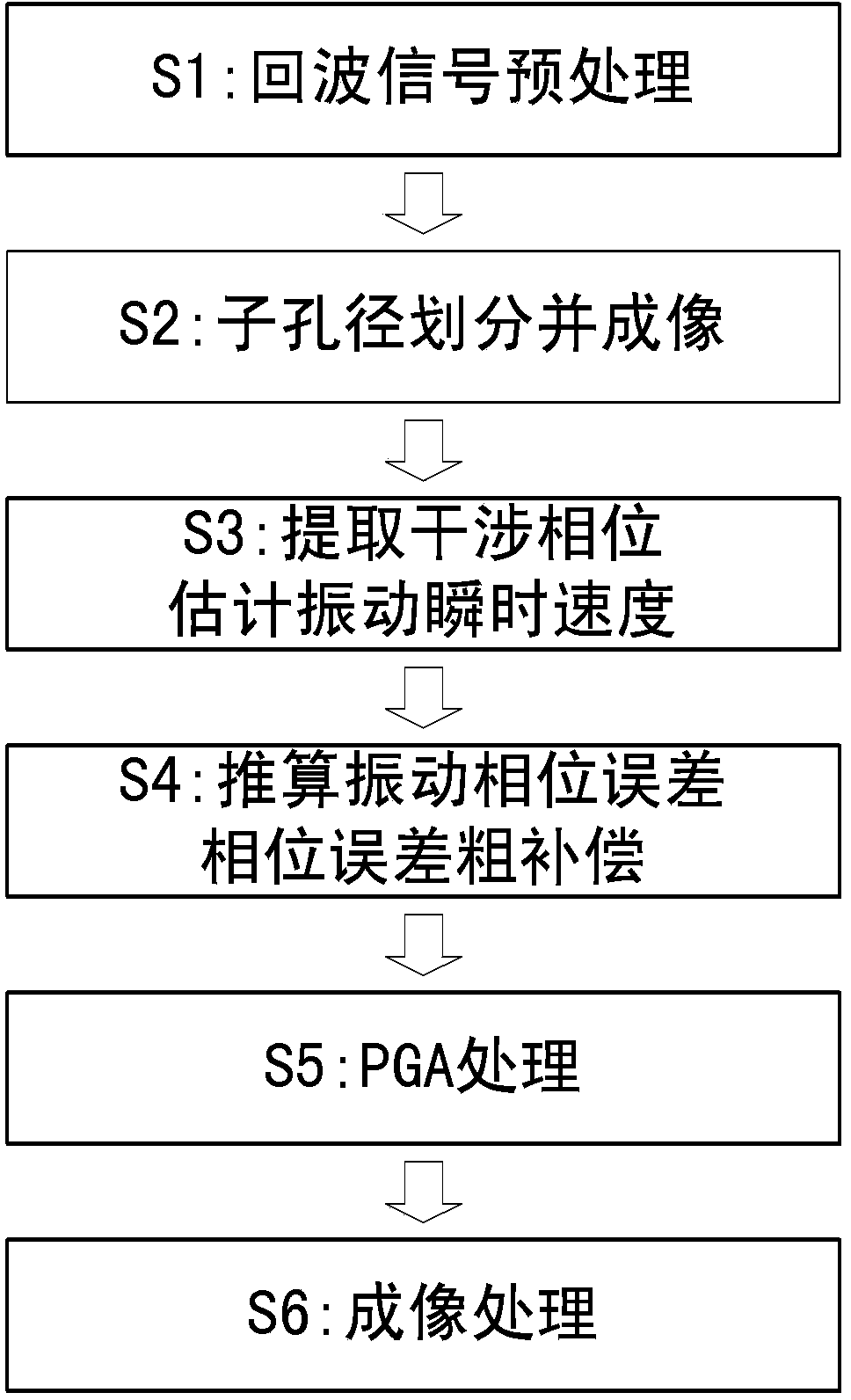

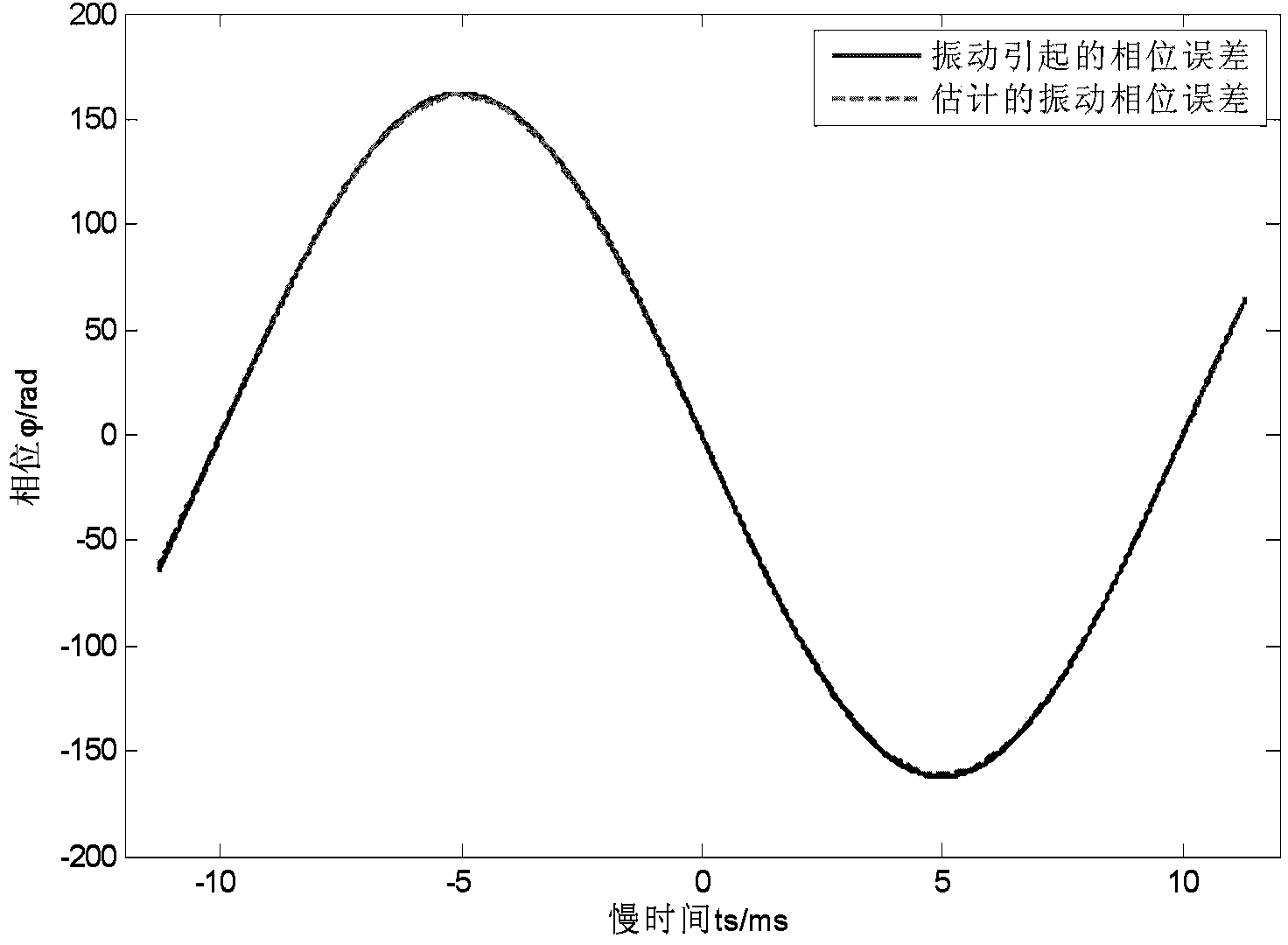

Onboard SAL imaging method adopting along-track interference to inhibit platform vibration

ActiveCN103728621AReduce vibrationReduce constraints on isolated strong pointsRadio wave reradiation/reflectionHigh resolution imagingSlow time

The invention discloses an onboard SAL imaging method adopting along-track interference to inhibit the platform vibration. The method comprises the steps: pre-processing an echo signal, dividing a slow time subaperture and imaging the subaperture; processing an image of the subaperture by means of the interference, extracting an interferometric phase, and estimating the instantaneous speed of a platform in vibration; calculating a phase error caused by the vibration, and performing coarse compensation on the phase error; processing the phase-compensated data by means of PGA (Programmable Gain Amplifier) treatment to obtain a final imaging result. Based on an along-track multi-detector observing structure, the onboard SAL vibration inhibition and imaging method can effectively inhibit influences caused by the platform vibration, and realizes the high-resolution imaging of an onboard SAL azimuth.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

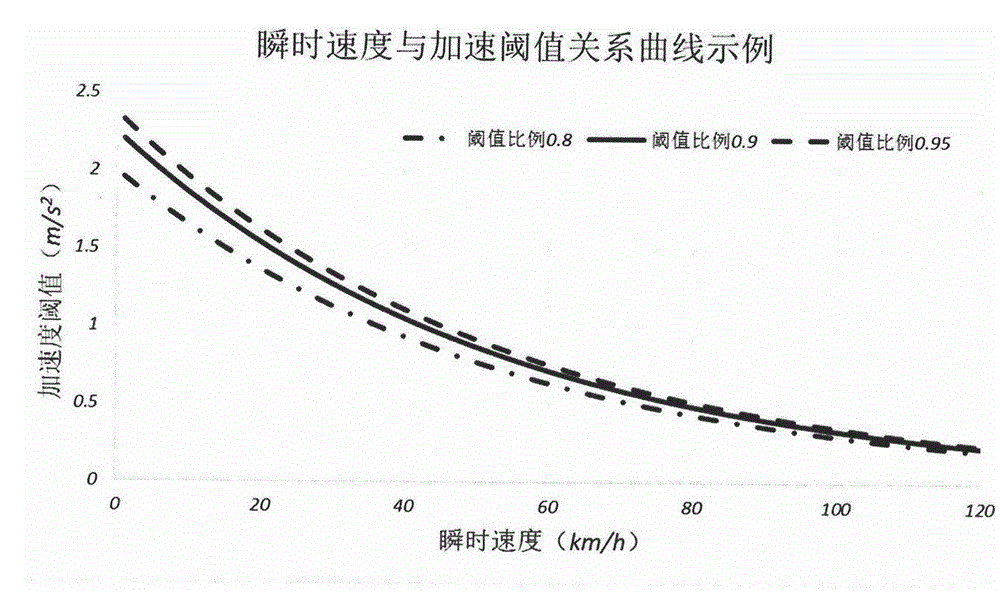

Driving behavior analysis method

The embodiment of the invention discloses a driving behavior analysis method and belongs to the field of cars. Driving behavior can be analyzed. According to the method, car running data are obtained, the running data comprise car real-time instant speed, and according to the real-time instant speed, driving behavior analysis is carried out. The driving behavior analysis method comprises the steps that the running data comprising the car real-time instant speed are obtained, and according to the real-time instant speed, driving behavior analysis is carried out. Therefore, driving behavior analysis is carried out according to the car running data.

Owner:BEIJING JIAOTONG UNIV +1

Speed dependent service availability in a motor vehicle

InactiveUS20060250226A1Improve convenienceRelieve pressureInstrument arrangements/adaptationsCathode-ray tube indicatorsMobile vehicleDriver/operator

A method for operating multimedia and / or telematics services and associated user interfaces in a motor vehicle, featuring speed-dependent control of the selection of the services and of the representation of the services at the user interfaces. A speedometer-coupled service management unit controls automatic adaptation of the representation and use of the services in a manner adapted to the instantaneous speed of the motor vehicle. This reduces stress on the driver, the risk of accident, and increases convenience.

Owner:ROBERT BOSCH GMBH

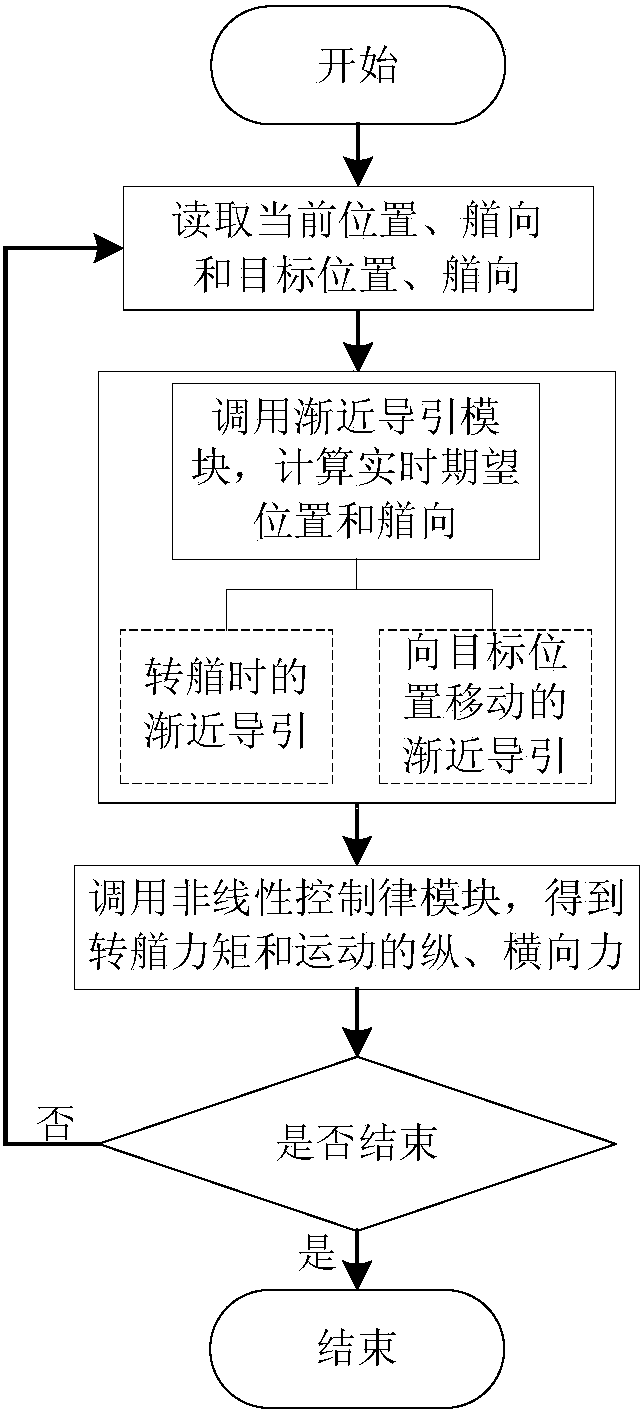

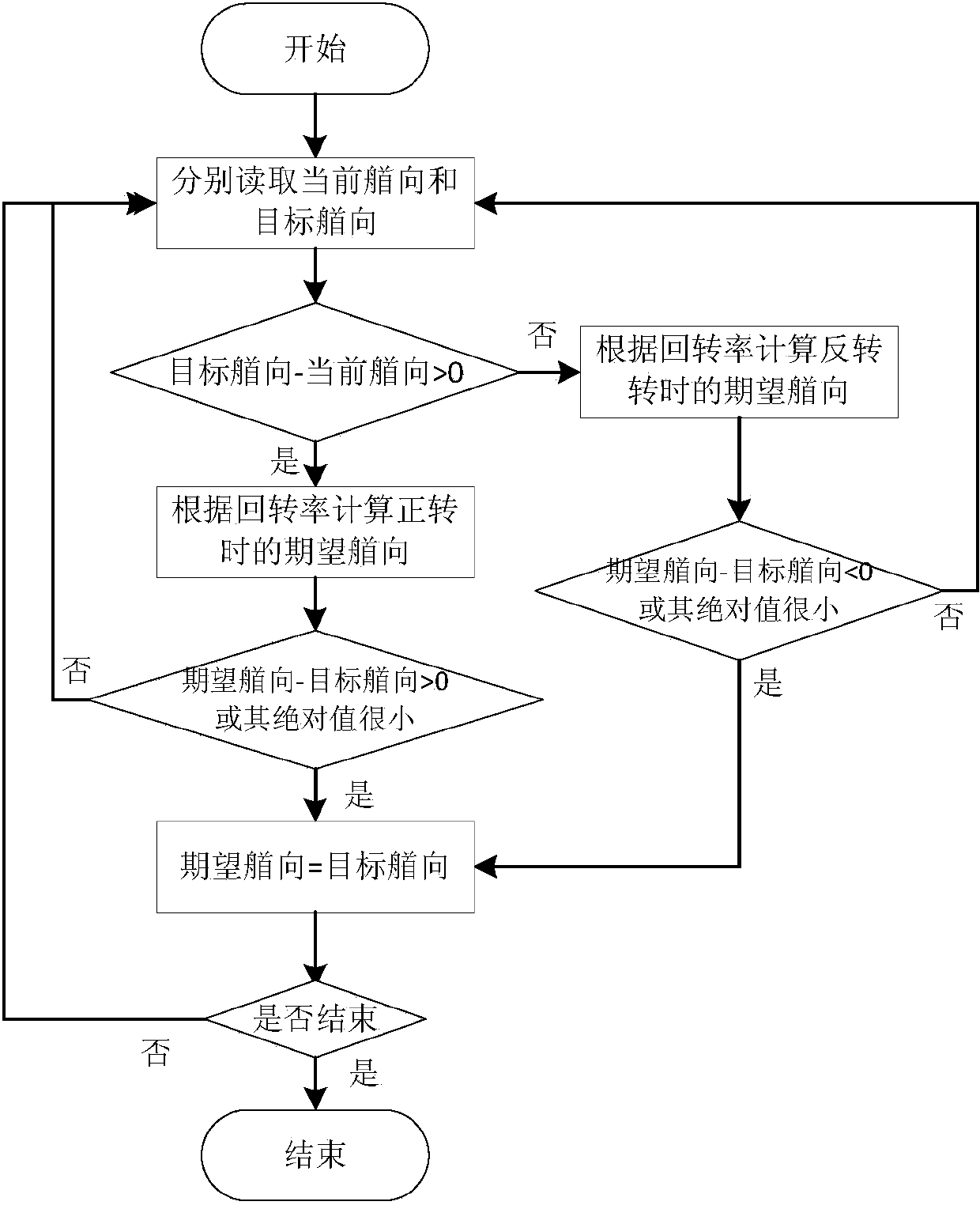

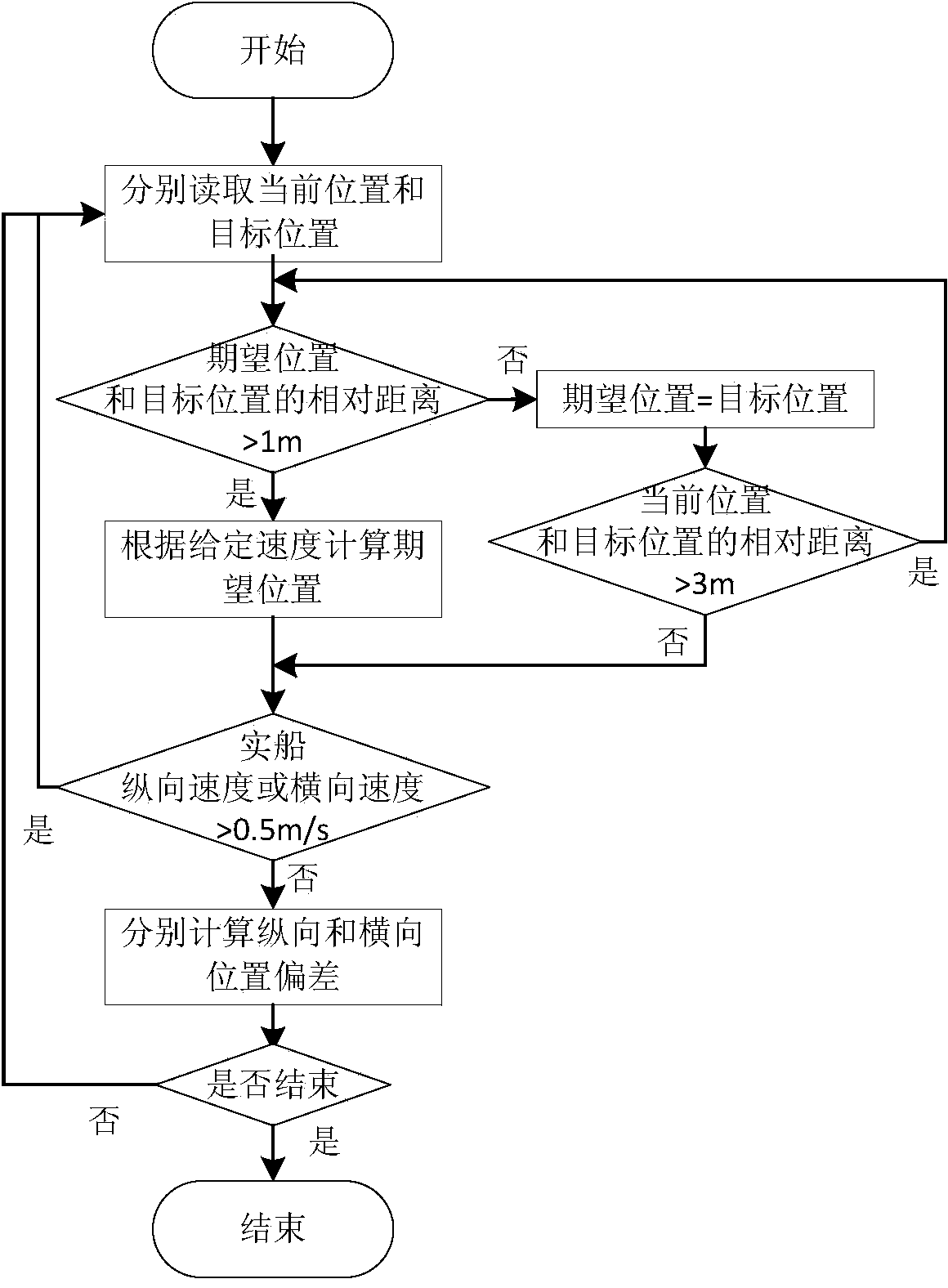

Ship positioning control method based on progressive guidance

ActiveCN103529842ASmooth torqueNo oscillationPosition/course control in two dimensionsPropellerDynamic positioning

The invention belongs to the field of dynamic positioning ship control and particularly relates to a ship positioning control method based on progressive guidance. The ship positioning control method comprises the following steps: (1) determining the target heading and the target position of a ship; (2) calculating real-time expected positions and the heading; (3) calculating required longitudinal force, lateral force, moment required during bow rotating, a north position deflection, an east position deflection and a bow direction deflection according to the current north position, the current east position, the current heading, a target north position, a target east position, a target heading, the longitudinal instantaneous speed of the ship, the lateral instantaneous speed of the ship, clockwise rotating rate, and longitudinal force, lateral force and moment which are generated by ambient disturbance. The positioning control method is designed based on progressive guidance and control. The moment and thrust which are obtained by the method gradually vary and can be ensured within the limit range of a propeller, so that the ship can stably arrive in the target position without oscillation, and the positioning precision is higher.

Owner:HARBIN ENG UNIV

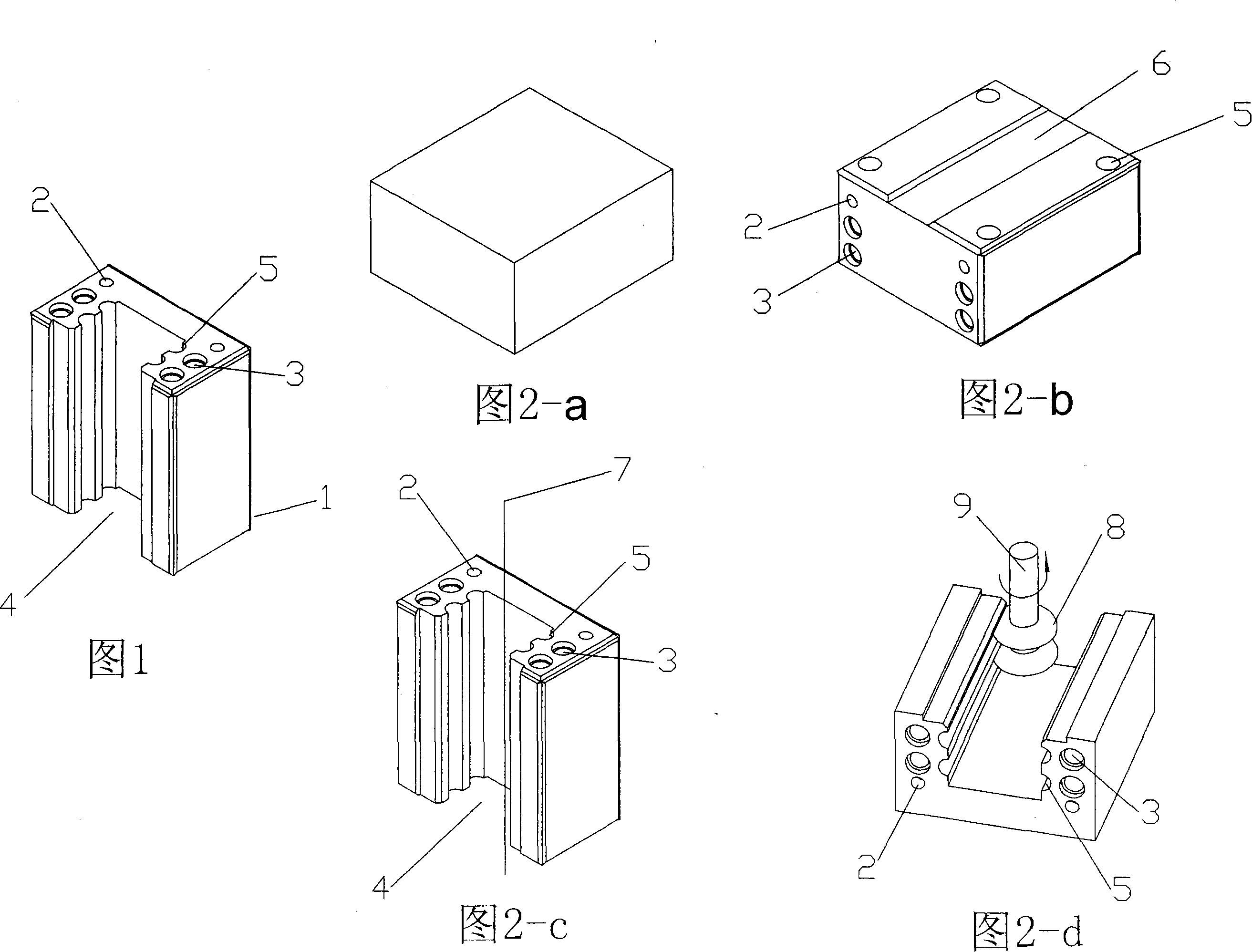

Straight-line rolling slipper block and method of manufacture

InactiveCN101235847AImprove compactnessStable and precise upper and lower contactLinear bearingsSEMI-CIRCLESteel bar

The invention relates to a linear rolling slider, which comprises a rolling steel ball which is arranged in the slider, an upper raceway groove and a lower raceway groove which are parallel are arranged on the inner walls of the two sides of an inner concave slider, and a raceway cavity which is reversely connected with the upper raceway groove and the lower raceway groove is horizontally arranged on the inner walls of the two sides of the inner concave slider. The method for preparation comprises that a round steel bar is thermally forged into a square green body, the square green body is milled and processed into cut angle end surfaces which are mutually vertical, and relative surfaces are hexahedron which are mutually parallel. The hexahedron is flatly ground and processed to achieve the required precision of parallelism and reference location, the hexahedron is cut and processed into a concave slider body by a wire electrical discharge, and an upper semi-circle raceway groove and a lower semi-circle raceway groove which are parallel and are arranged on the two sides of the inner concave slider are ground in high speed. A steel ball in the raceway groove not only operates in high speed not to block, but also is not bore in long time operation and not produces frictional heating. The friction coefficient is capable of being reduced to fiftieth of the original friction coefficient, the instantaneous speed is increased for 10 times, the linear rolling slider uses a double-row raceway groove, thereby being capable of greatly increasing carrier loads, achieving steady operation, and prolonging the service life.

Owner:宁波恒力汽配轴承有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com