Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Avoid uneven density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

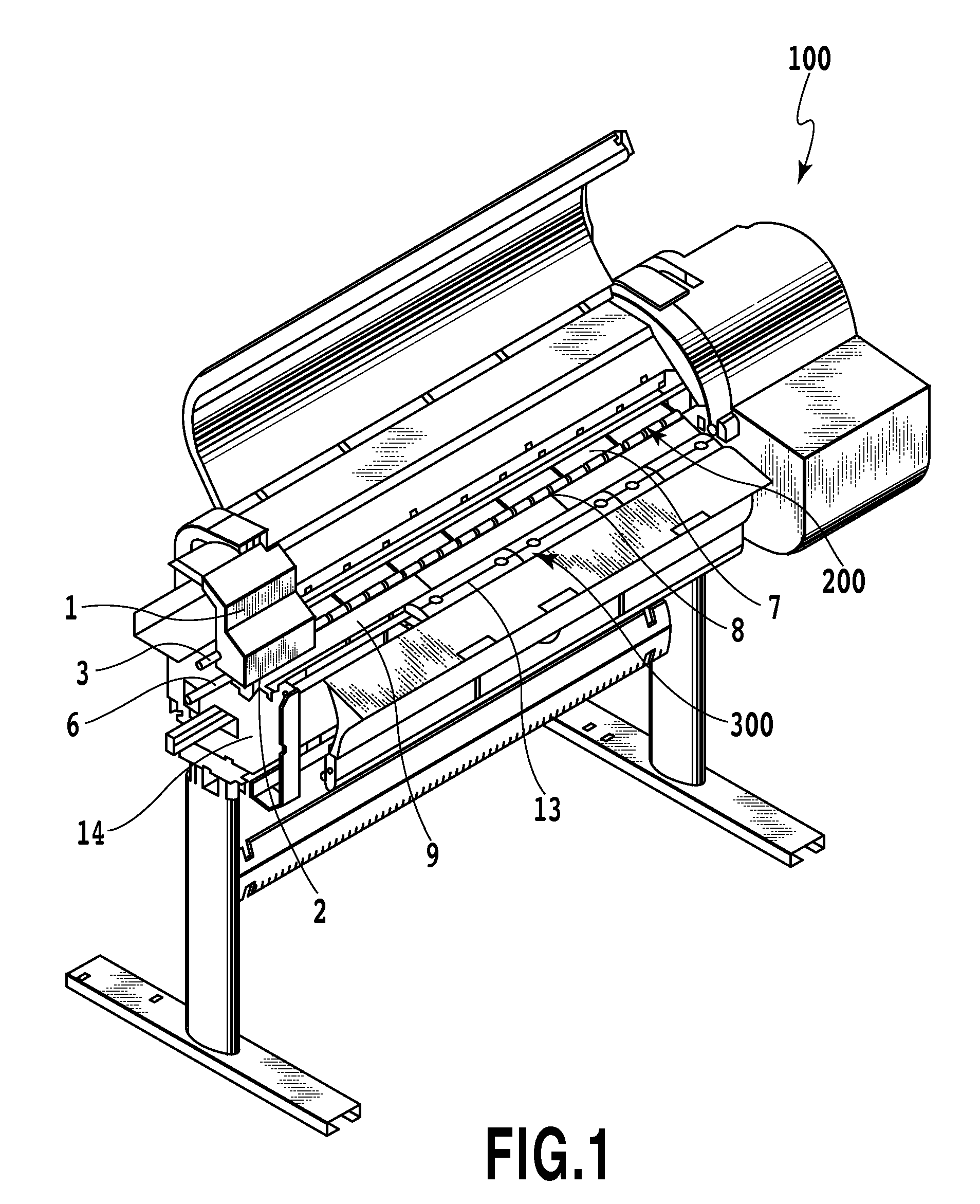

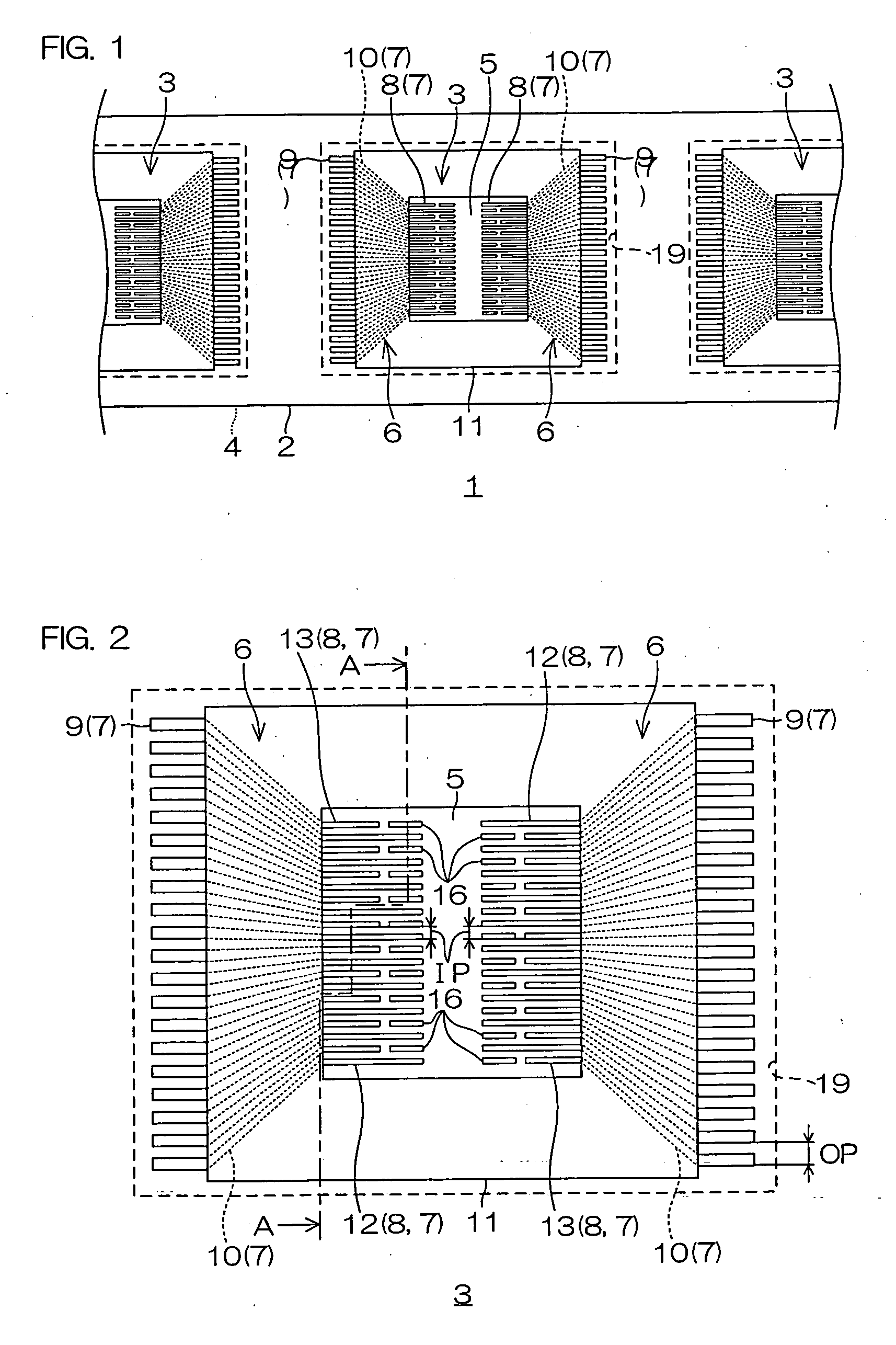

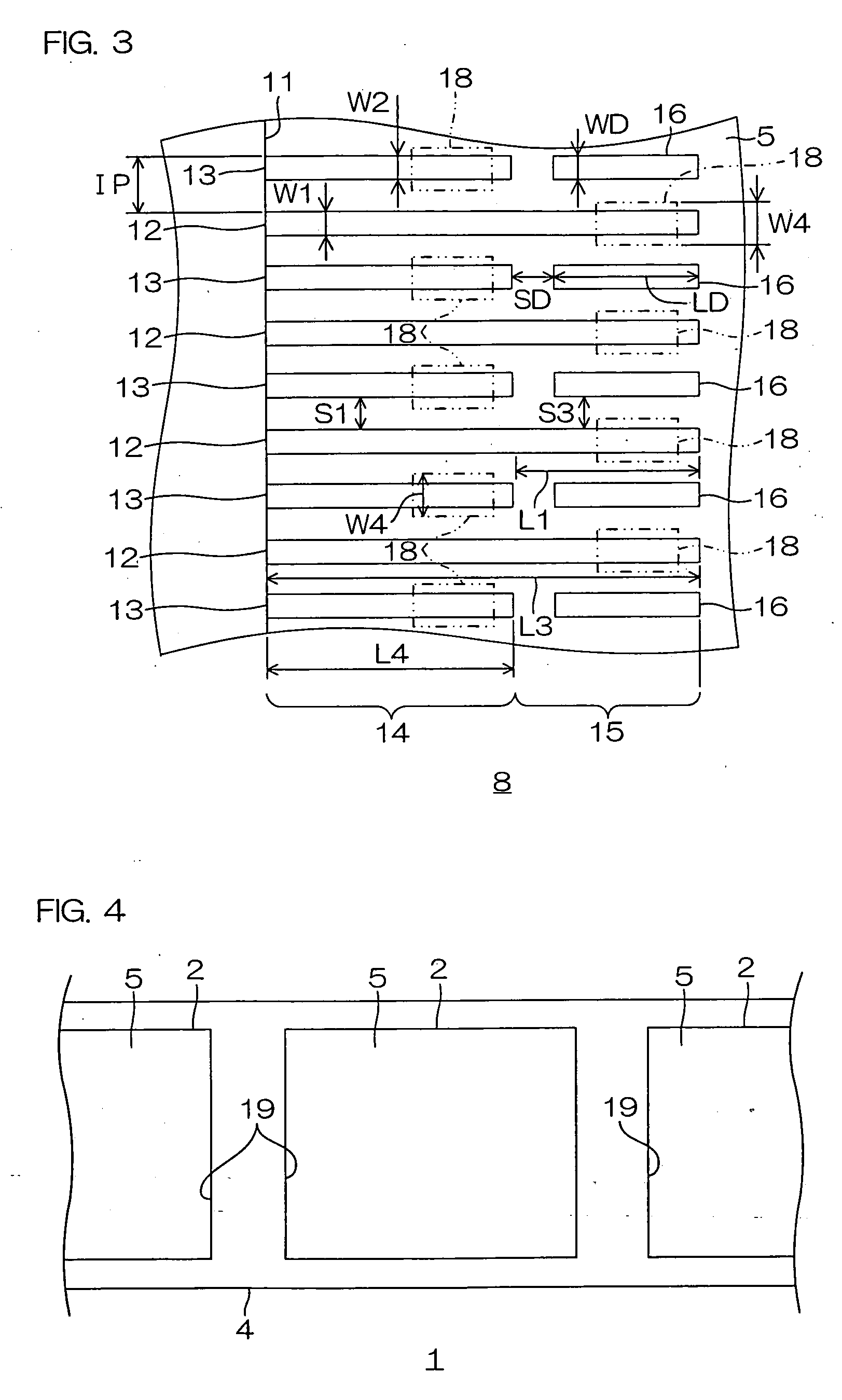

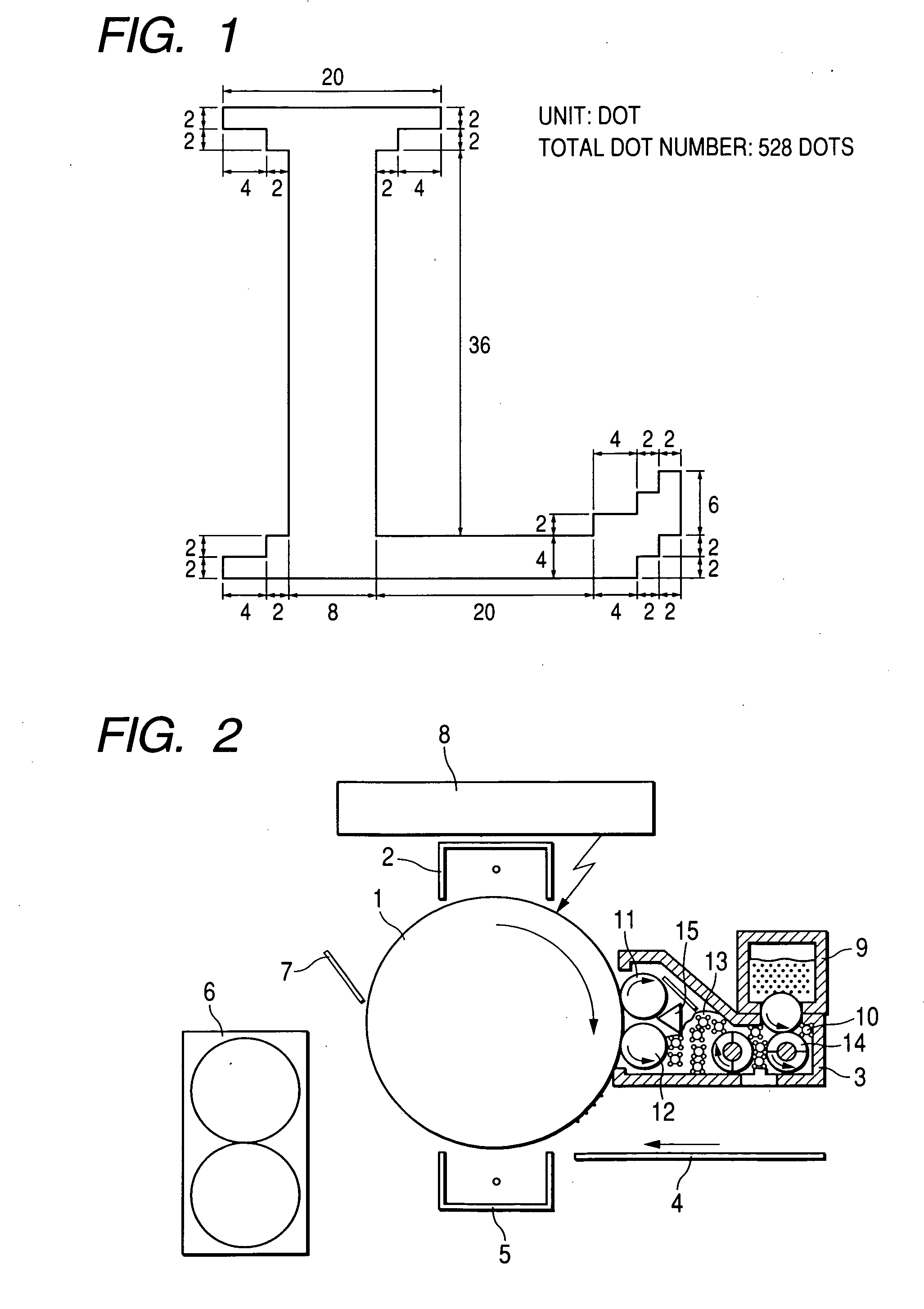

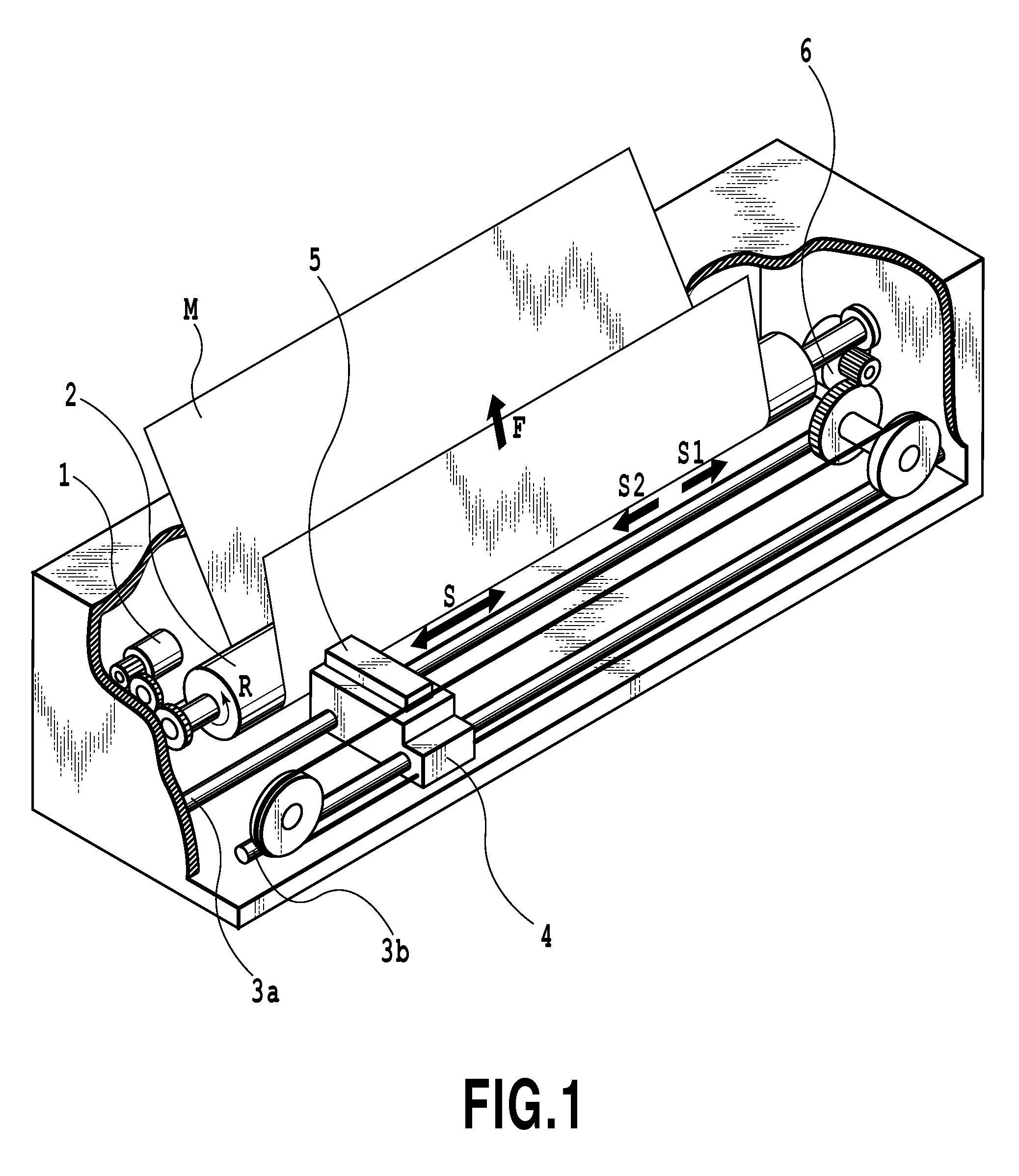

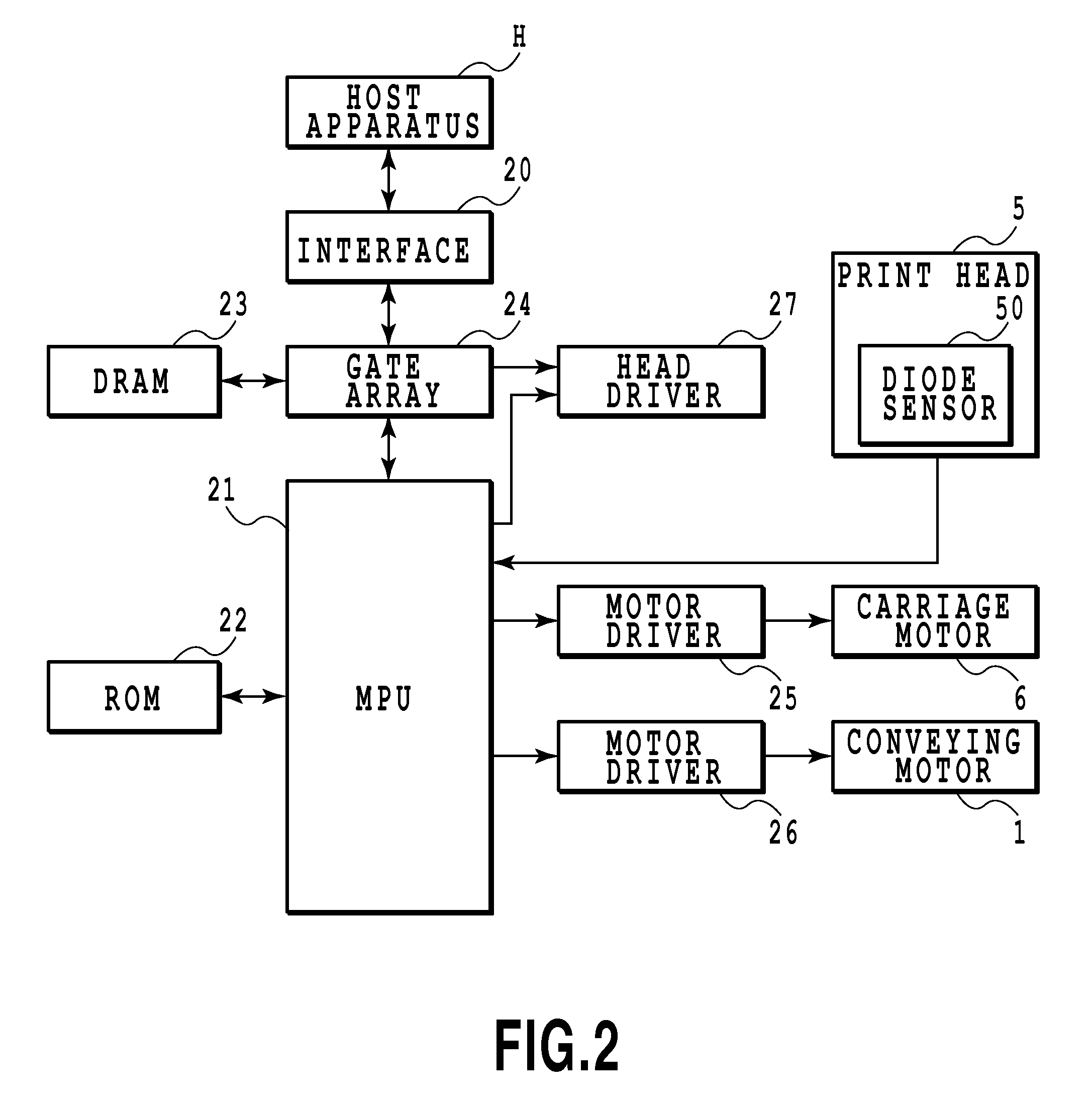

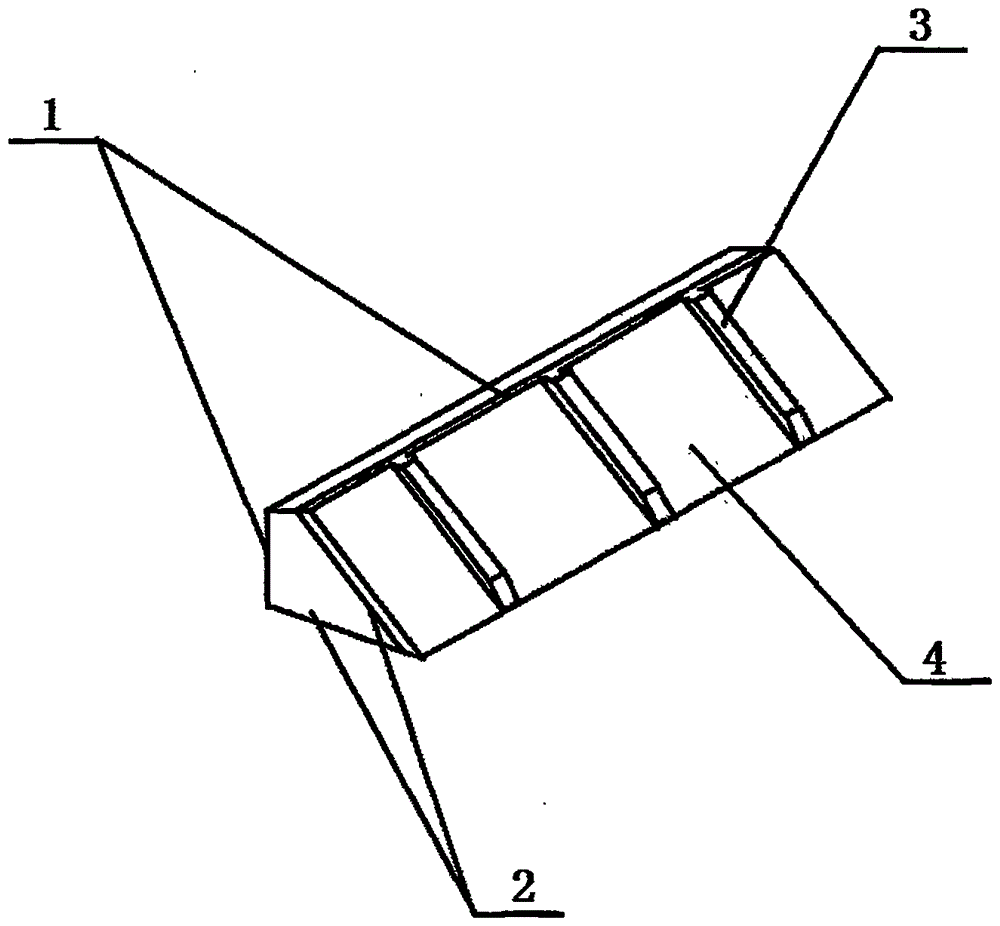

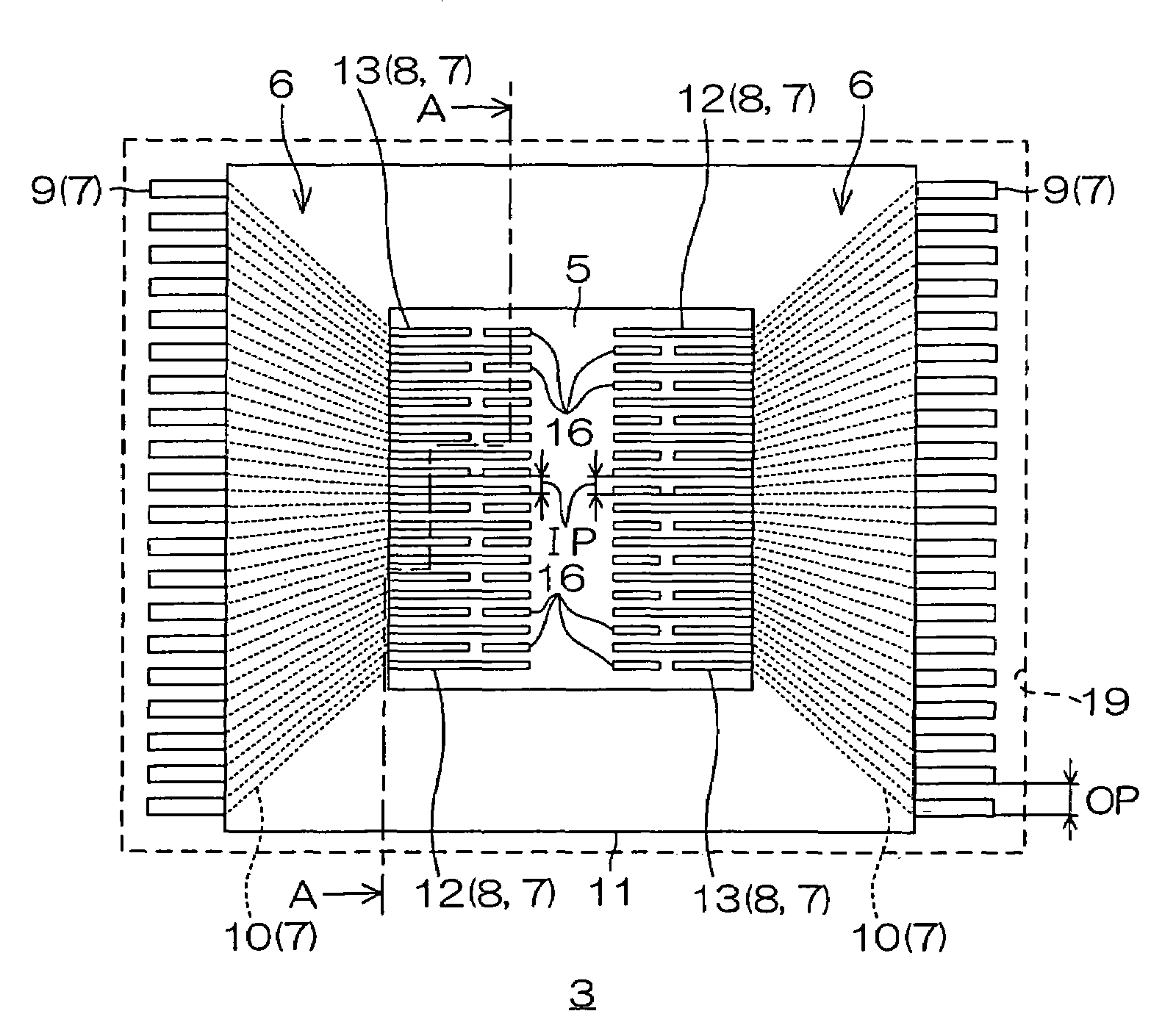

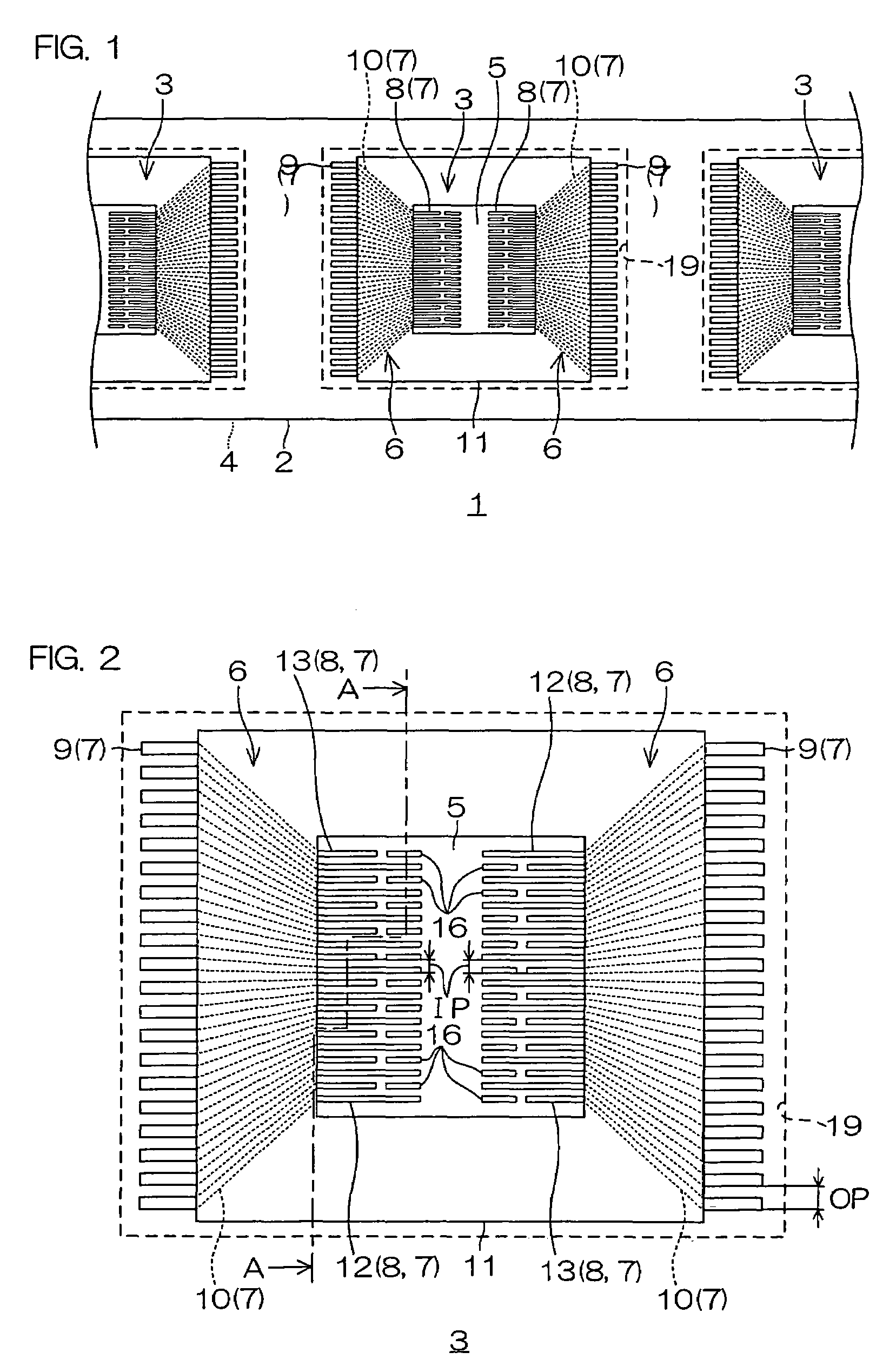

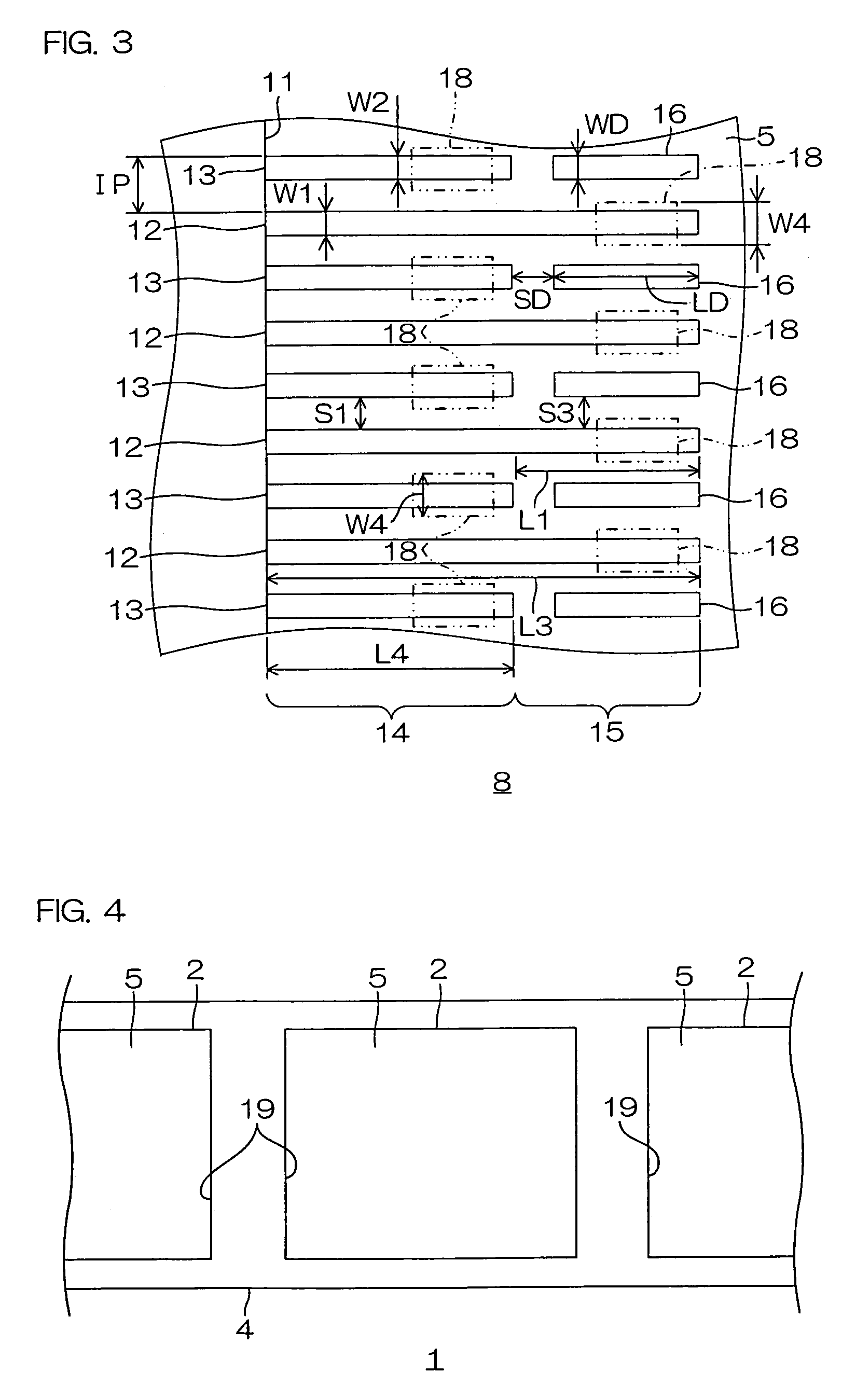

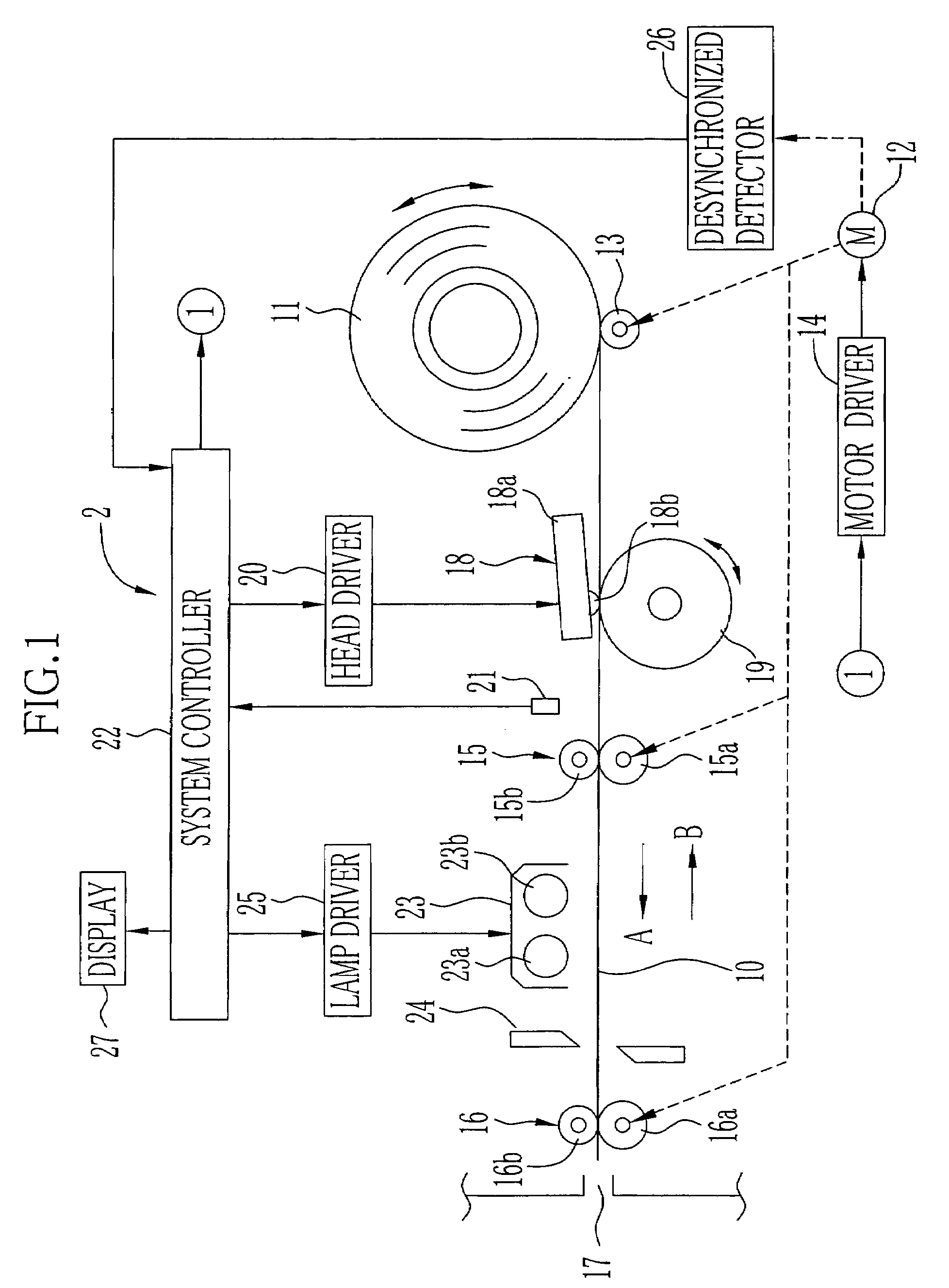

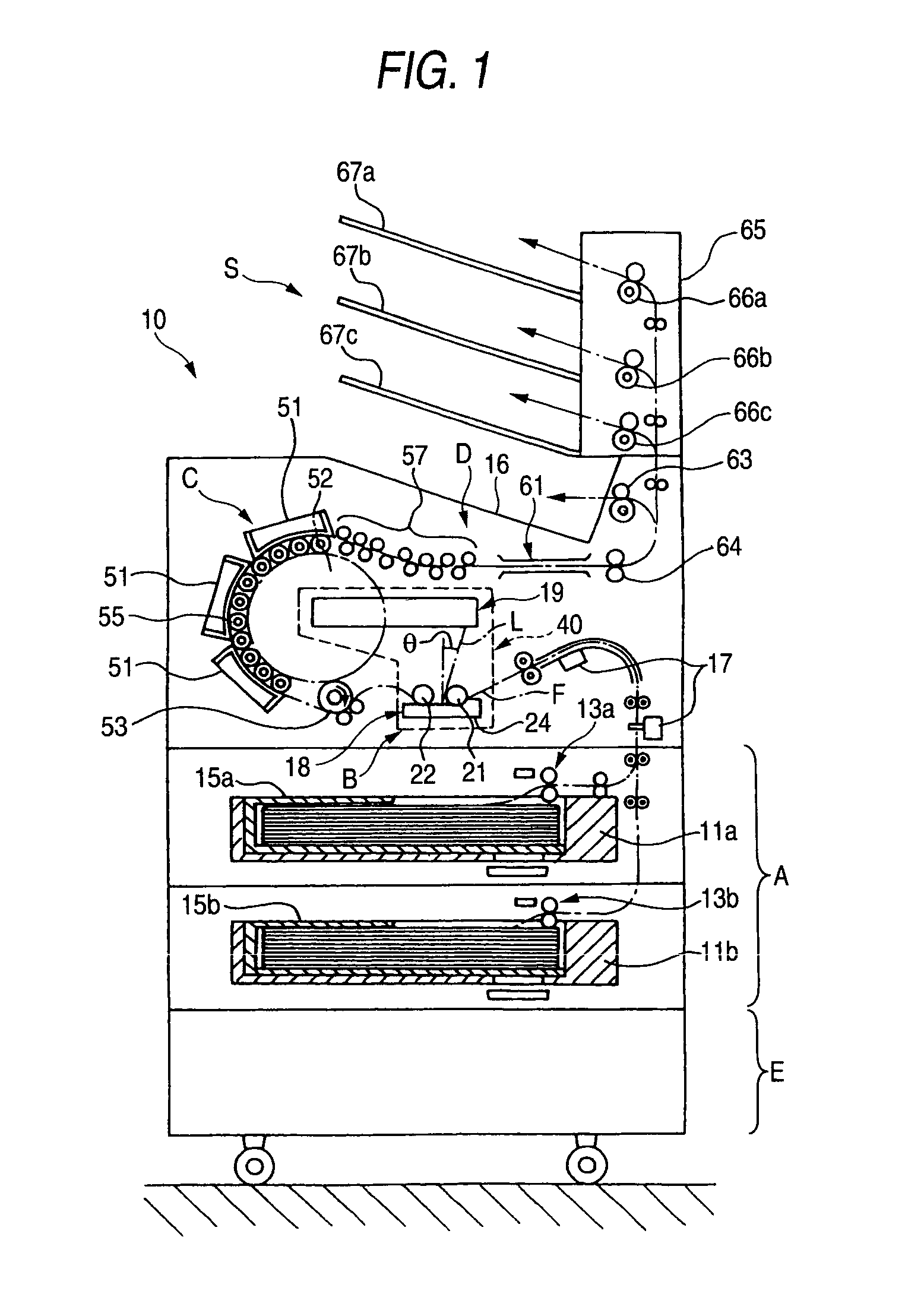

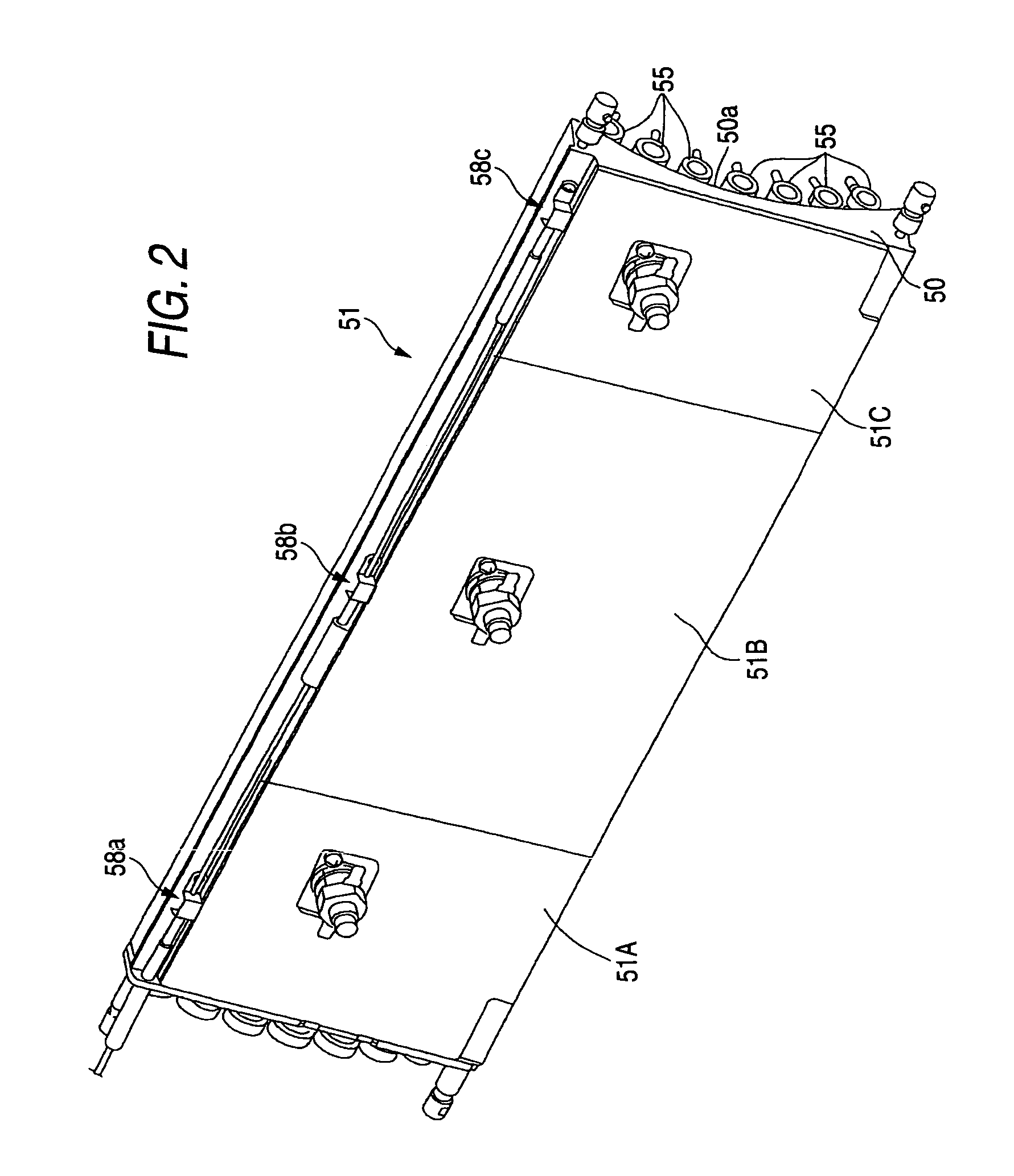

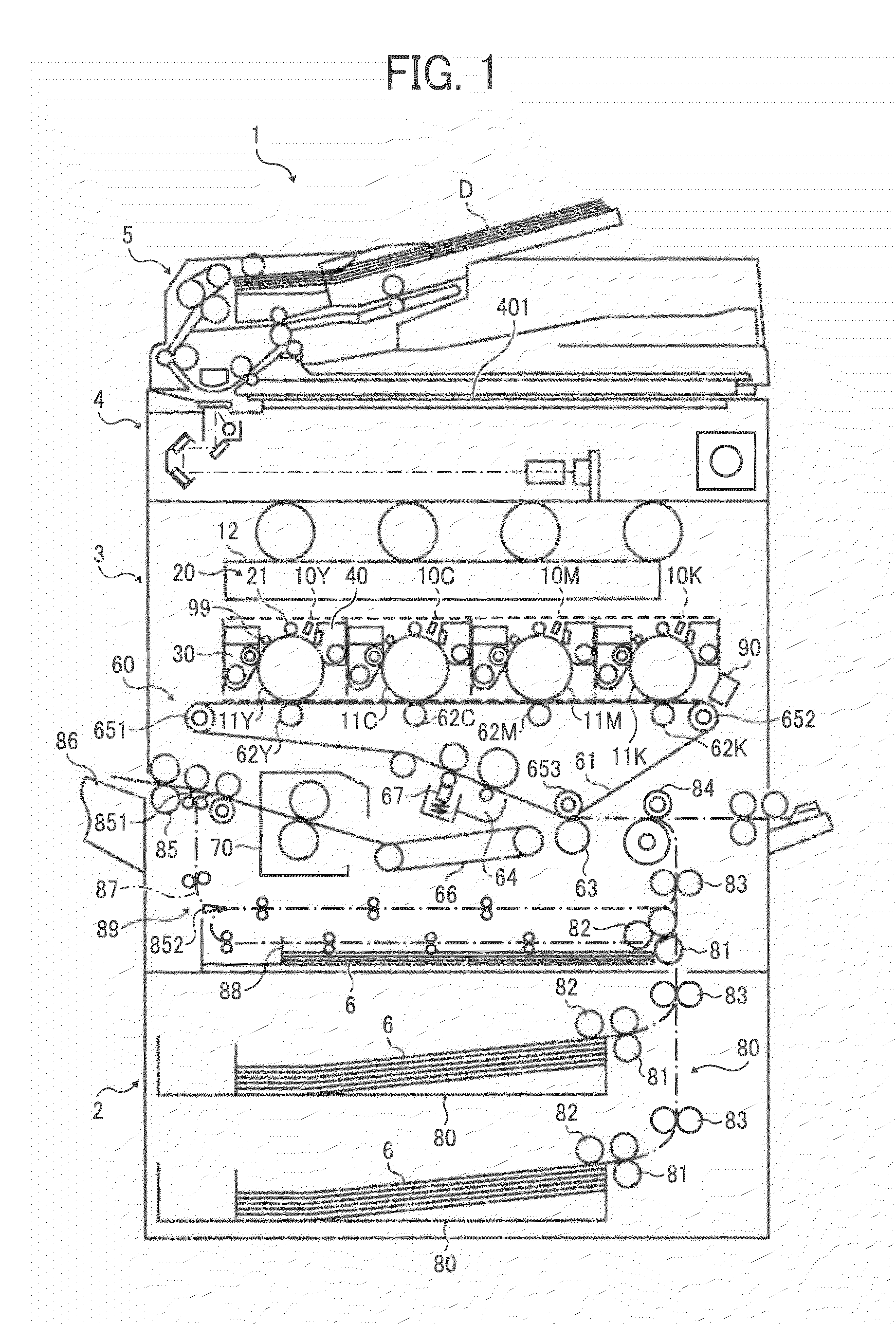

Ink jet printing apparatus and ink jet priting method

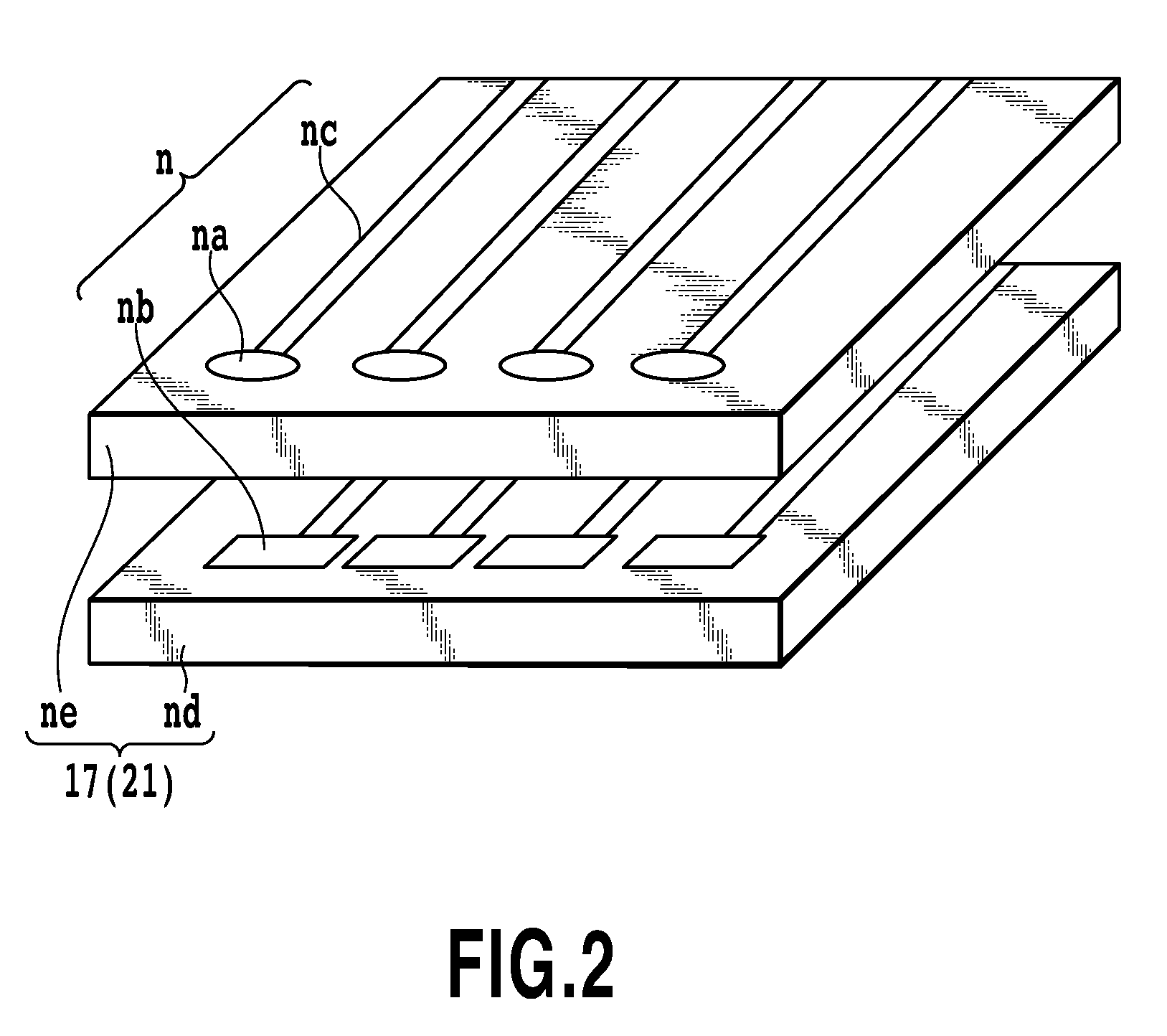

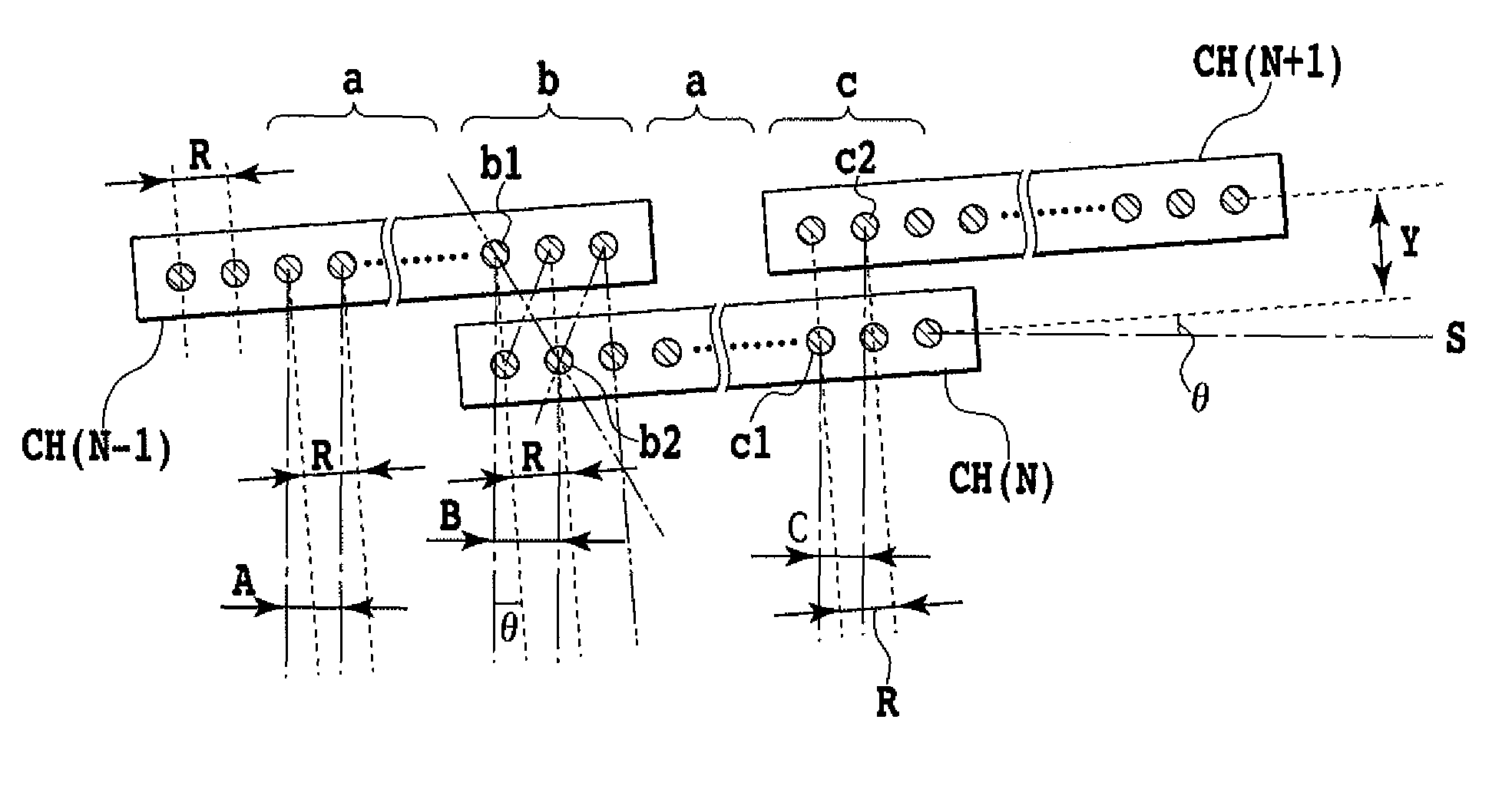

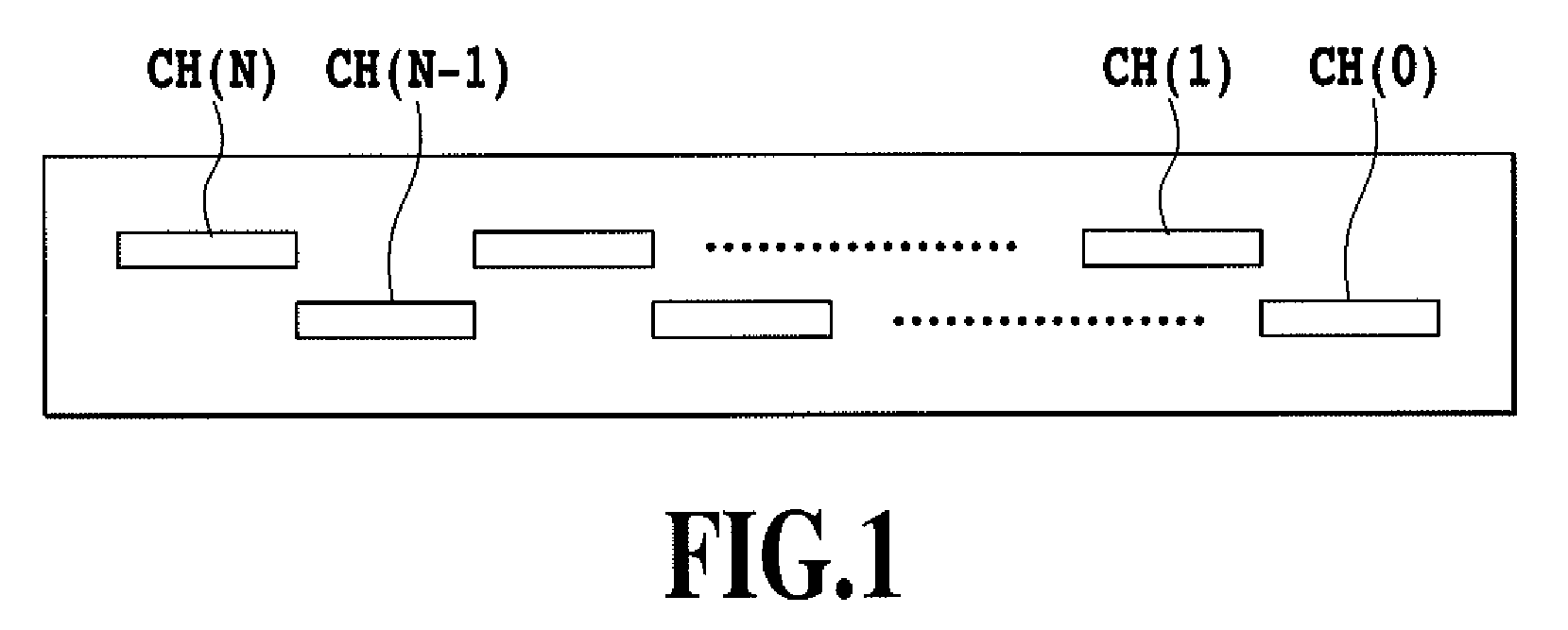

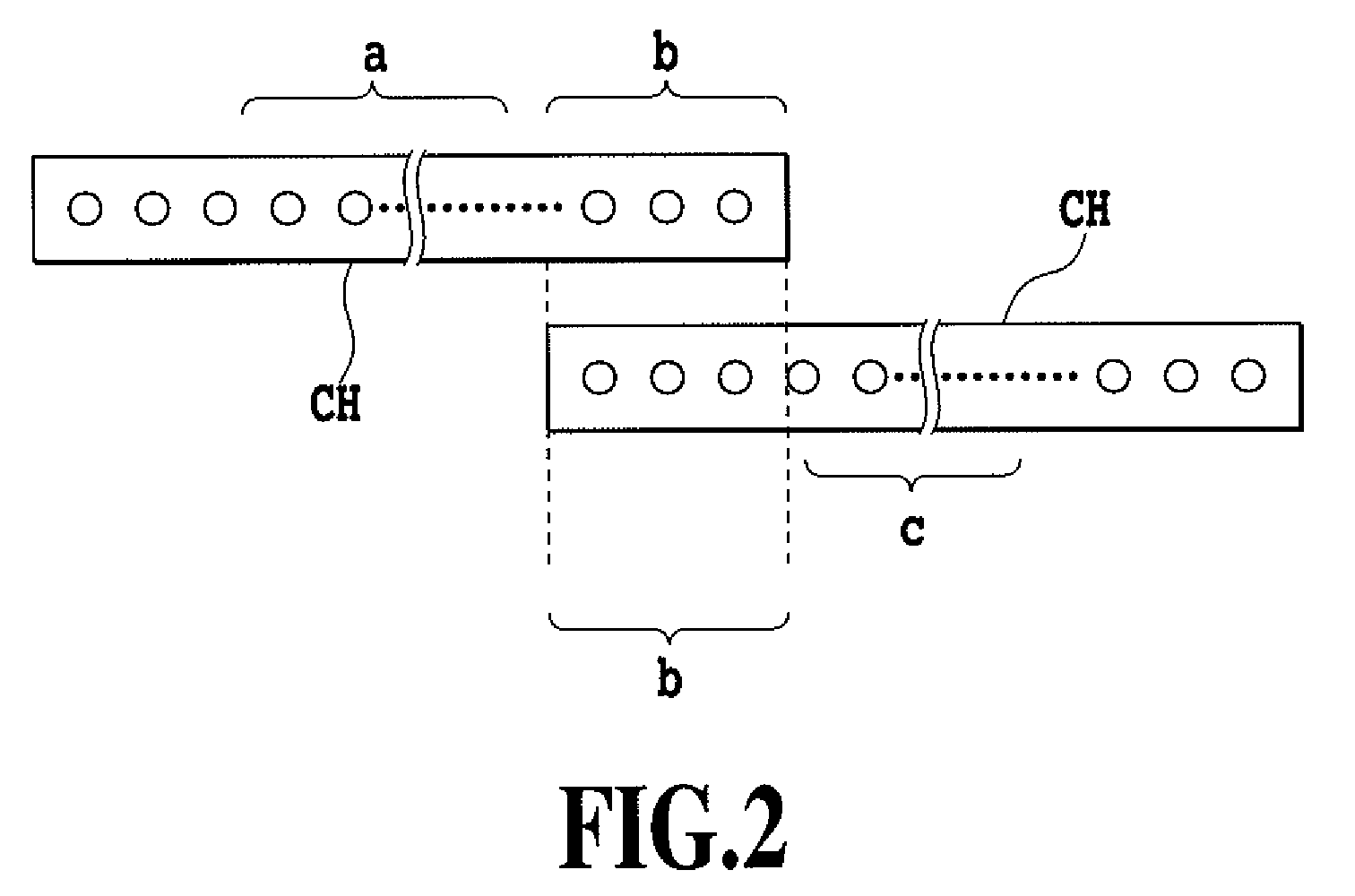

InactiveUS20080252673A1Avoid uneven densityImprove image qualityInking apparatusOther printing apparatusEngineeringHead moving

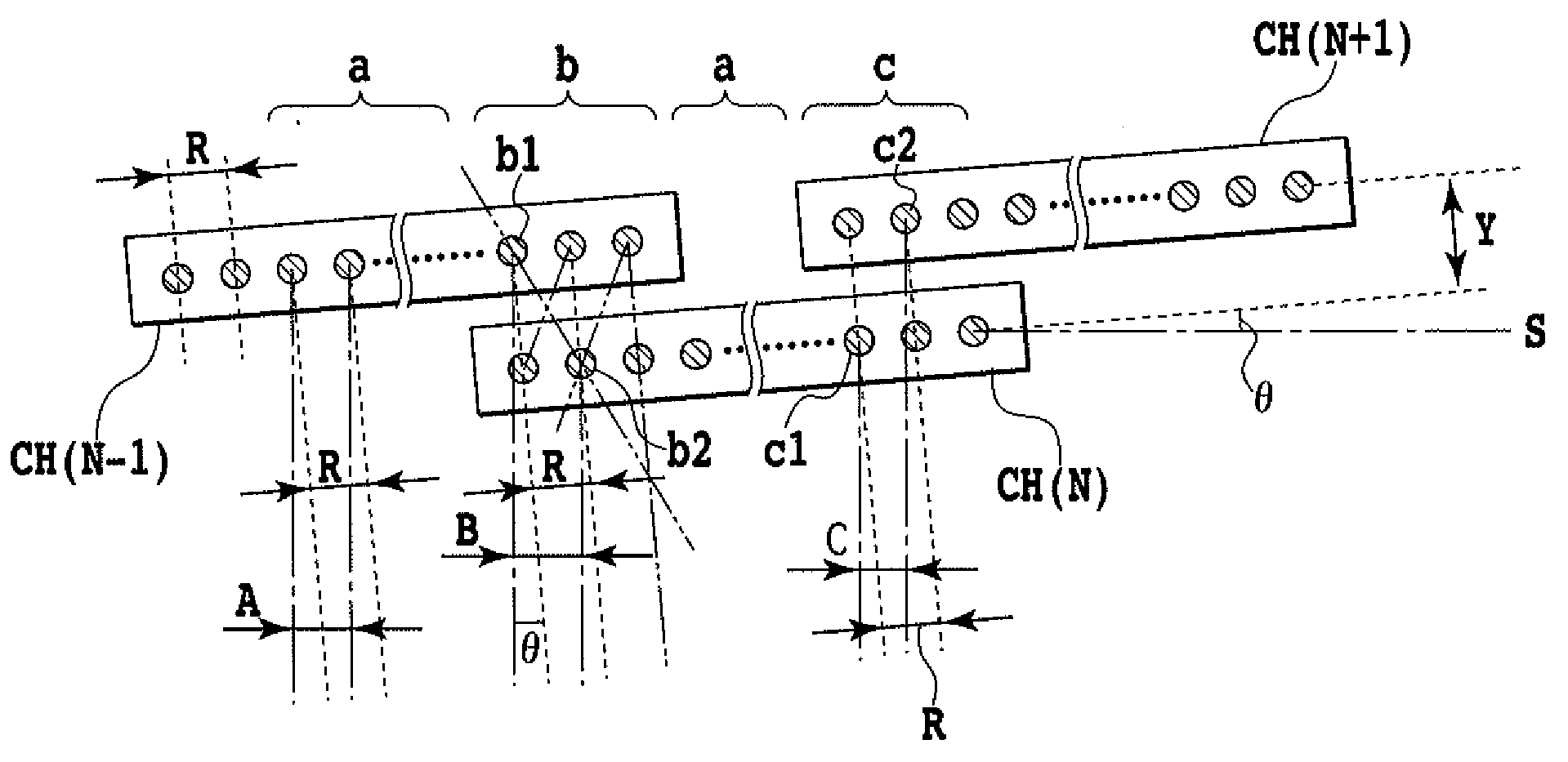

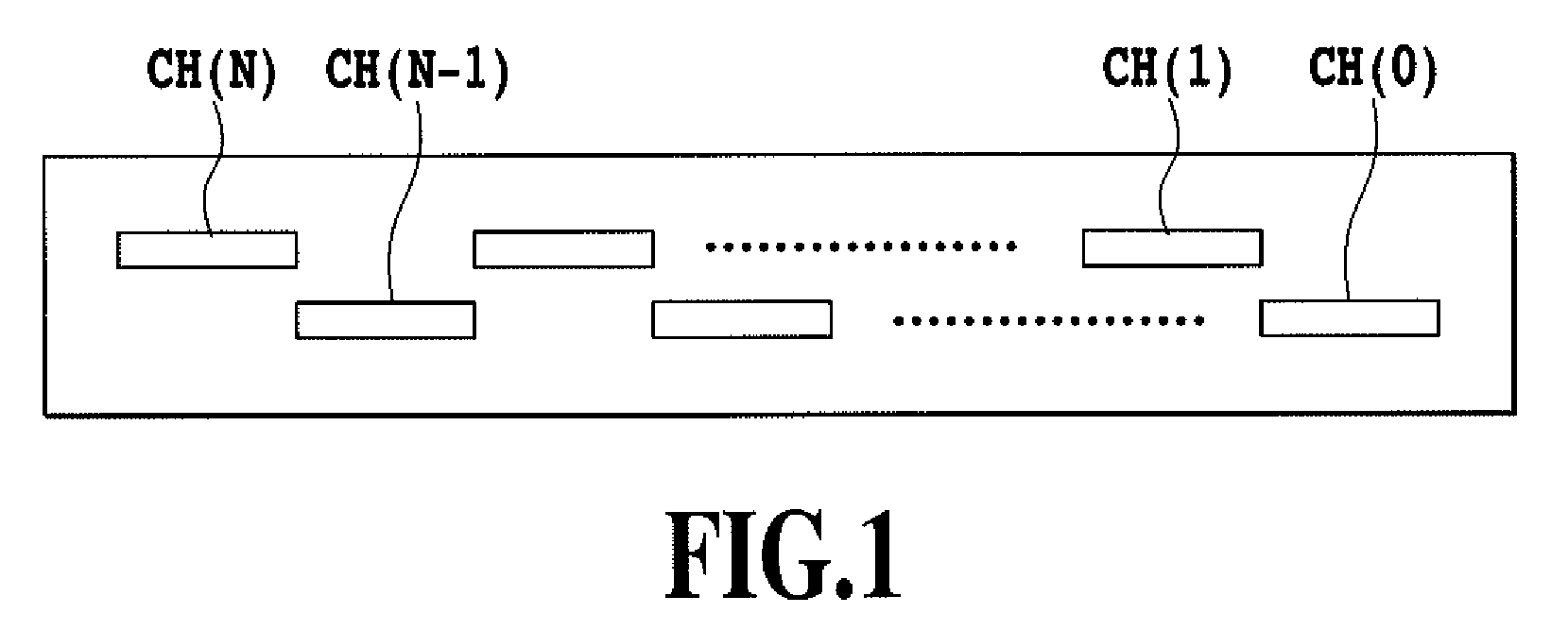

An object of the present invention is to provide an ink jet printing apparatus which can prevent possible stripe-like density unevenness in a joint in a print head constructed by joining a plurality of chips together even if the print head is inclined to the regular position of the print head. The present invention uses a print head having the nozzle arrays being shifted in a direction in which the nozzles are arranged, so as to have overlapping portions in a direction orthogonal to the nozzle arranging direction. The present invention controls an ink ejecting operation of the nozzles in the overlapping portions between the plurality of nozzle arrays on the basis of an angle between the nozzle array arranging direction and a direction orthogonal to the direction in which the print head moves relative to the print medium.

Owner:CANON KK

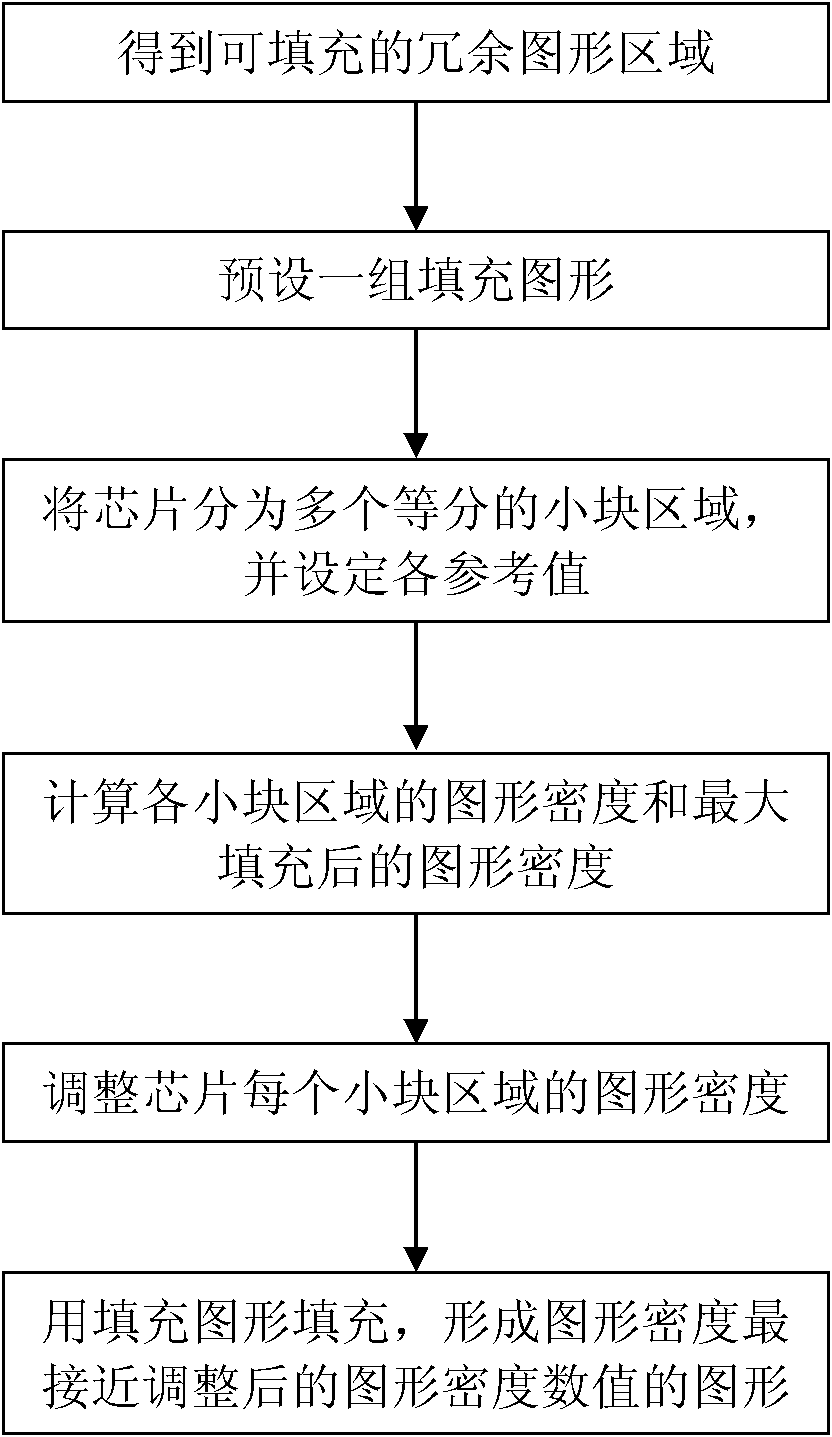

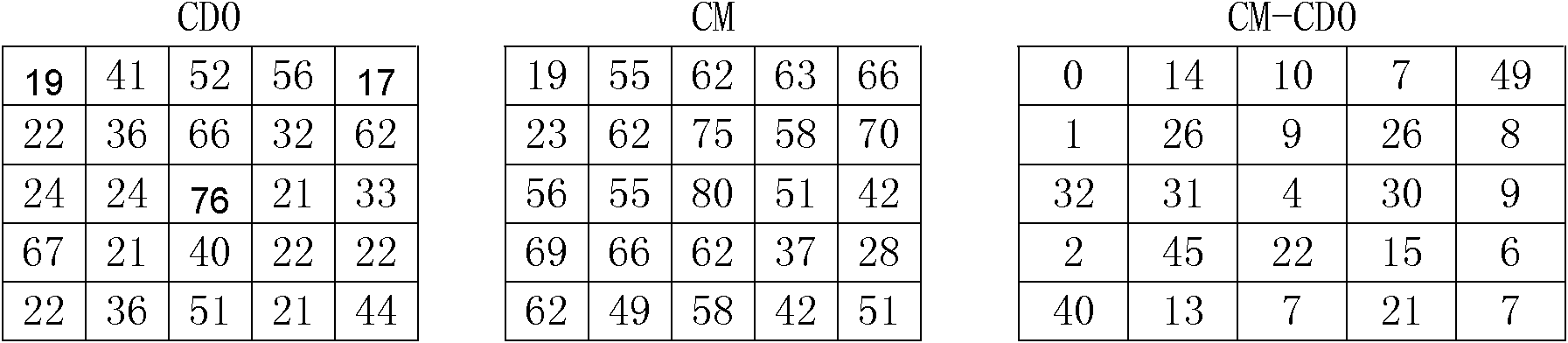

Method for adjusting chip graph density using redundancy graph insertion,

ActiveCN102468134AAvoid the problem of uneven pattern densityImprove uniformitySemiconductor/solid-state device manufacturingSpecial data processing applicationsDensity differenceAlgorithm

The invention discloses a method for adjusting graph density of a chip using redundancy graph filling, comprising the following steps: obtaining a fillable area in a certain graph layer of chip preparation; presetting a group of filling graphs with different graph densities; equivalently dividing into a plurality of small areas, and setting the graph density of the layer after filling, the minimal graph density value, the maximal graph density value of the small areas and the maximal graph density difference value between two adjacent small areas; calculating the initial graph density value of each small area; calculating the graph density value of the small area after filled with filling graph with maximal graph density; adjusting the graph density of each small area adopting virtual graph filling method; and filling the fillable areas of each small area to enable the graph density value of the filled small area to be close to the graph density value adjusted by Step (6). With the method, the uniformity of the graph densities of partial areas filled is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Manufacturing technique for EPE pearl wool

The invention discloses a manufacturing technique for EPE pearl wool. Jinpaomu serves as a raw material nucleating agent, a butane agent and monostearin serve as an accessory foaming agent and an anti-shrinking agent correspondingly, due to accessory matching, raw material foaming is sufficient, and accessories do not influence one another; raw materials are fed into the foaming agent for preheating treatment firstly, the preheating temperature is 50 DEG C, the preheated raw materials are subject to plasticizing heating, the plasticizing time can be shortened, and the problem of uneven melt density caused by uneven temperature during plasticizing heating can be solved; the mold opening temperature is 168 DEG C, the molding state of melt can be kept at the temperature, the amorphous form of the melt due to too high temperature can be prevented, and the condition that curing of the melt cannot be subject to traction due to too low temperature is avoided; after a sheet passes through a sizing drum, the width is 1.5 m through sizing, the width of the sheet is determined by the sizing drum, and the width facilities machining and treatment of the sheet in the later period; after the sheet is extended, burrs are removed, the step of removing the burrs is increased, and therefore the attractiveness of the sheet can be improved, and scrap edges can be removed.

Owner:ANQING SHENGHUA PAPER PACKAGING

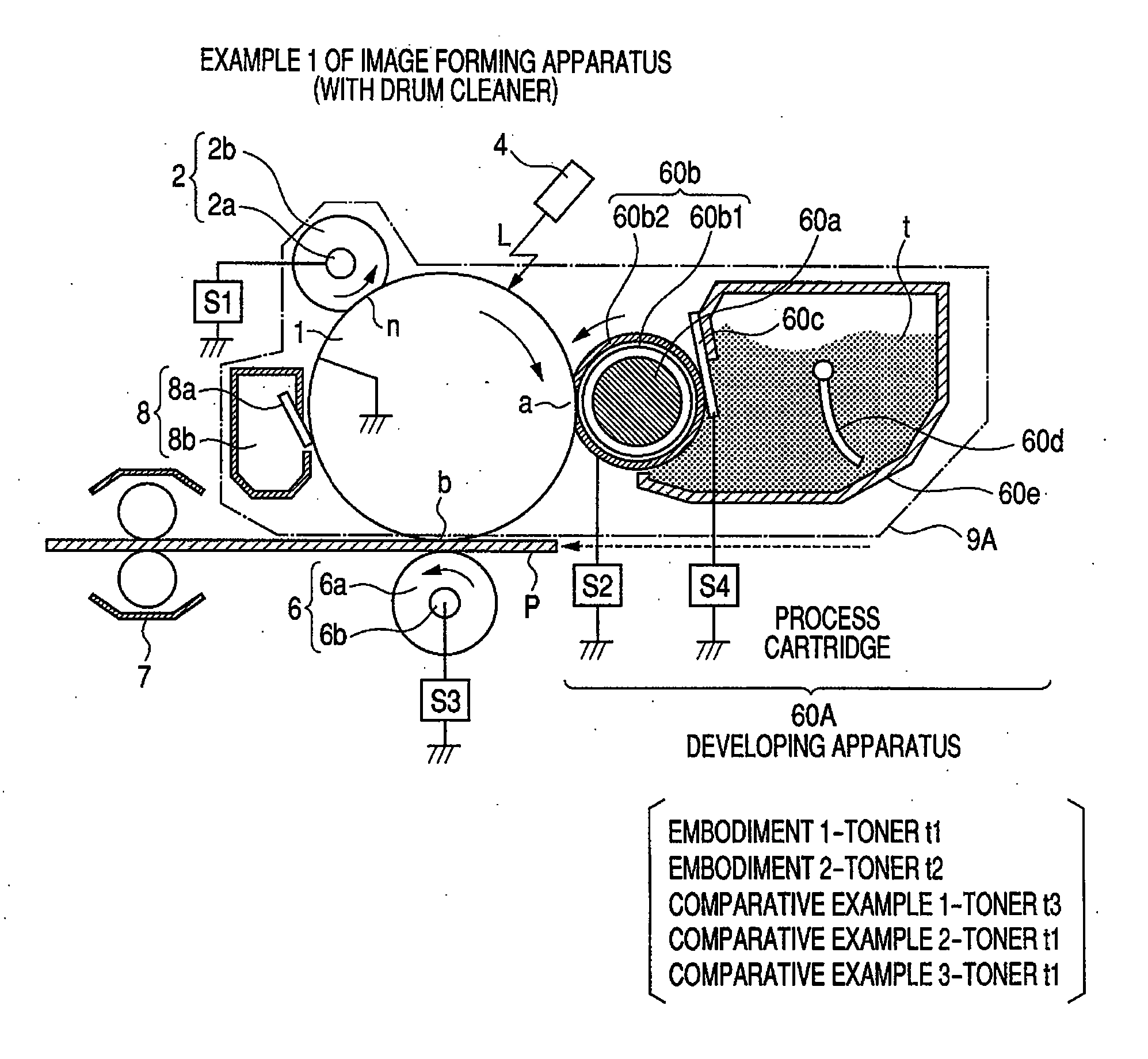

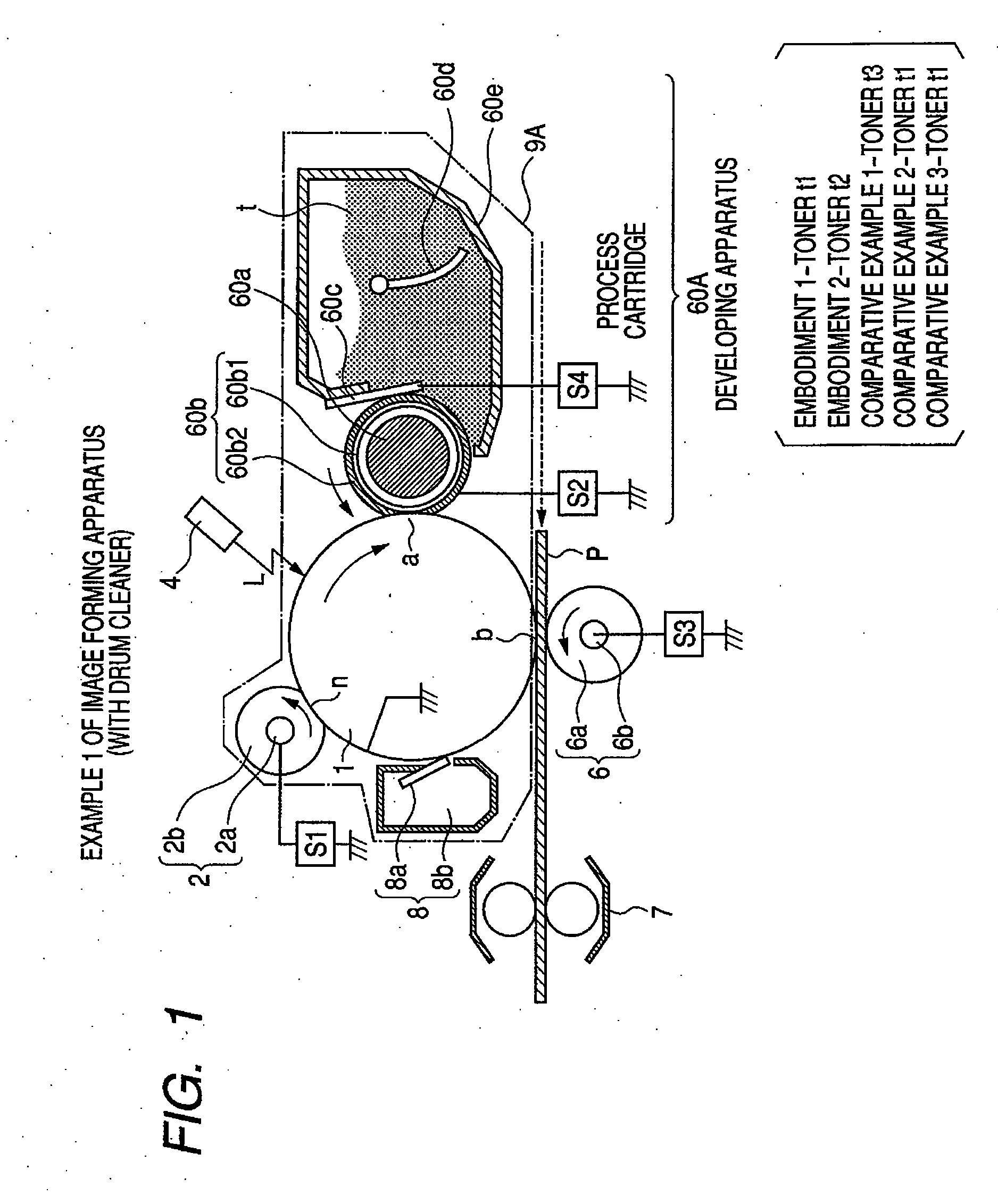

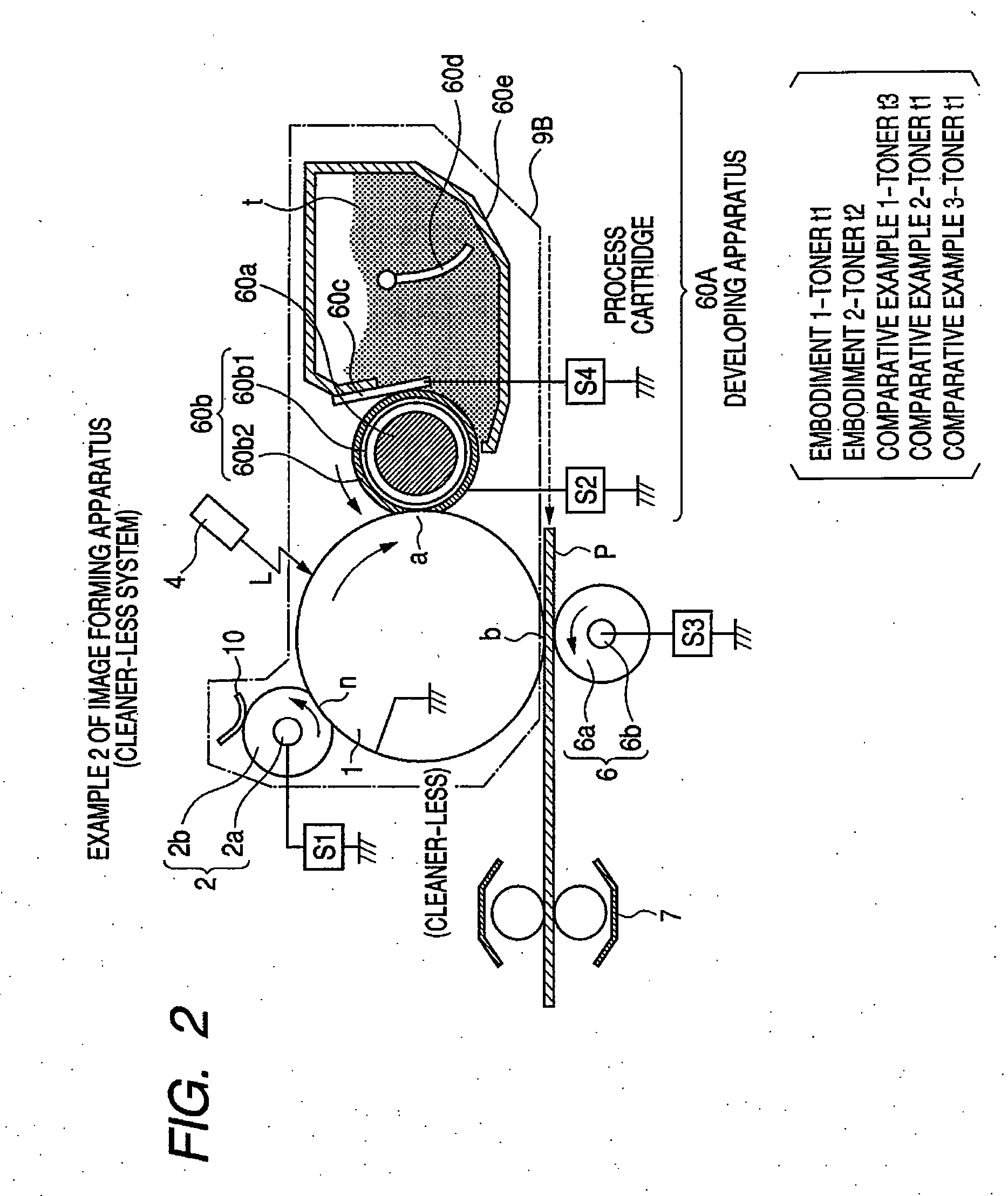

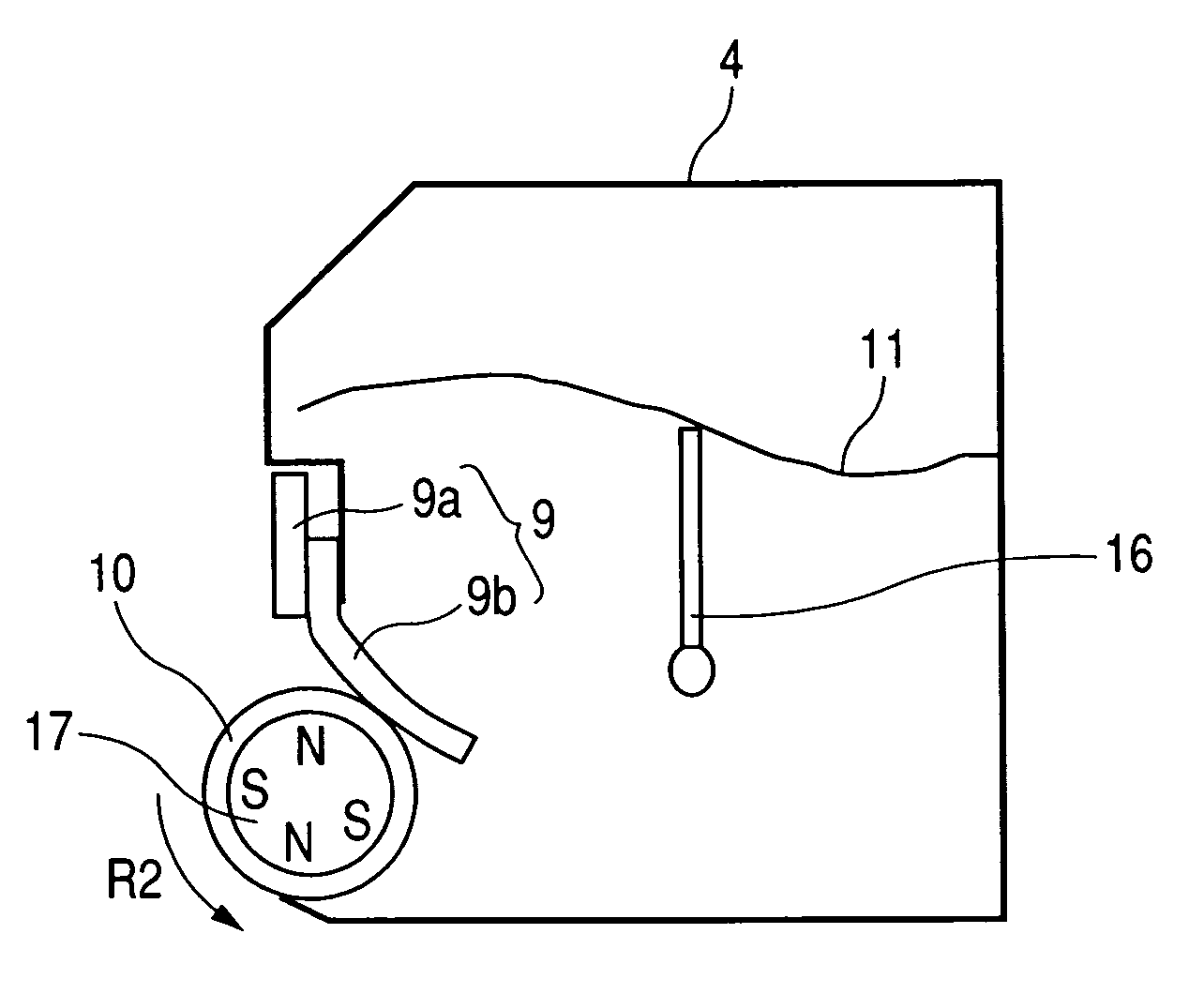

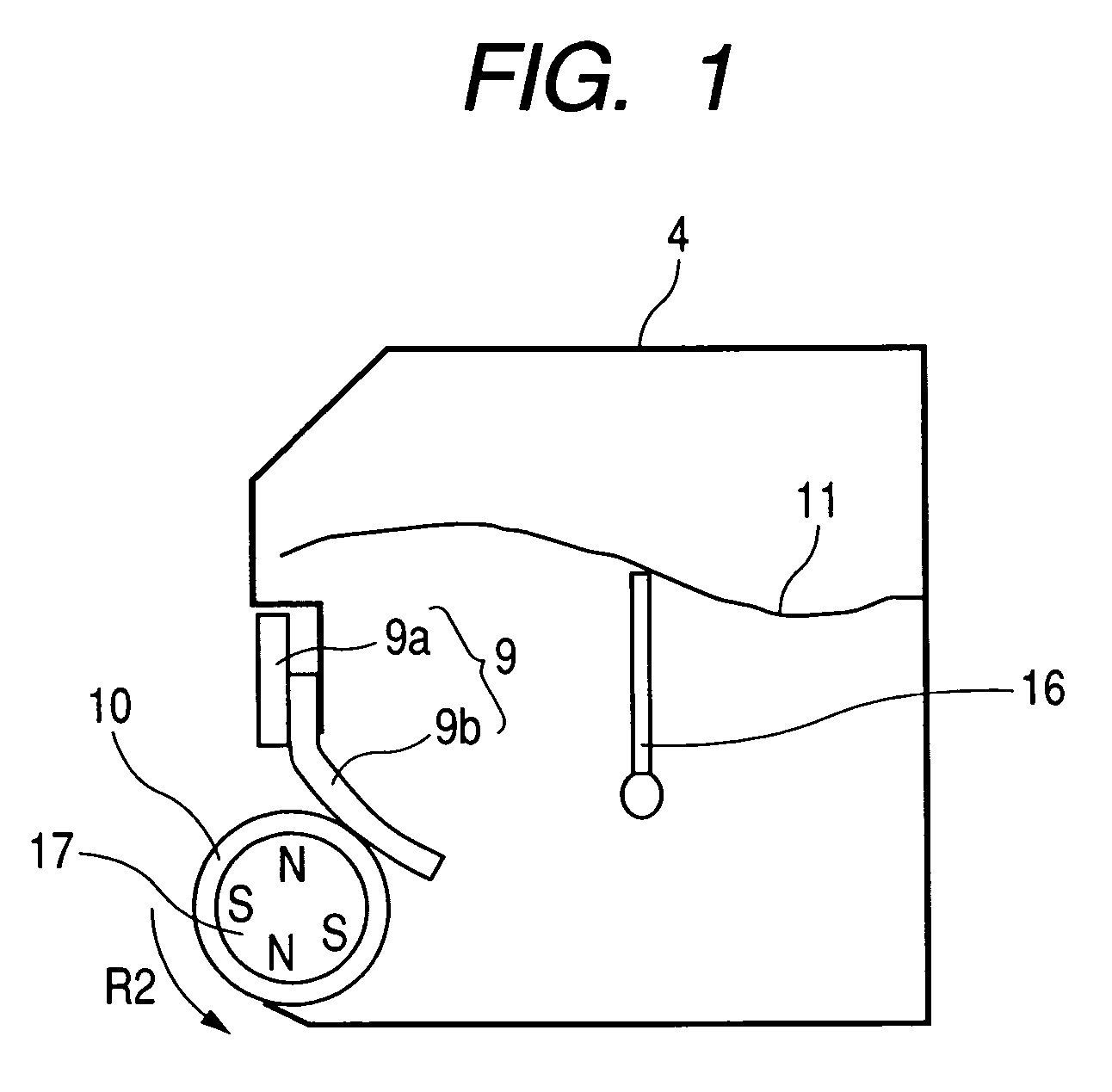

Developing apparatus

ActiveUS20060171745A1Prevent foggingAvoid it happening againElectrographic process apparatusMagnetic polesContact position

A developing apparatus having a developing sleeve provided with an elastic layer on its surface, and for developing an electrostatic image formed on an image bearing member with a mono-component magnetic toner having a mean degree of circularity of 0.965 or greater, a magnet provided in the developing sleeve, and a blade for regulating the amount of the developer carried on the developing sleeve satisfies the expressions |Br| / |B|≧0.5 and Nsb / (Bs×R)≦0.5, where B [G] is magnetic flux density formed on the surface of the developing sleeve by the magnet at the contact position between the blade and the developing sleeve, Nsb [mm] is the contact width between the blade and the developing sleeve, Br [G] is a component of magnetic flux density B [G] in a direction perpendicular to the surface of the developing sleeve, Bs [rad] is a half value width of the perpendicular component of the magnetic flux density of the nearest one of the magnetic poles of the magnet to the contact position on the surface of the developing sleeve, and R [mm] is the radius of the developing sleeve.

Owner:CANON KK

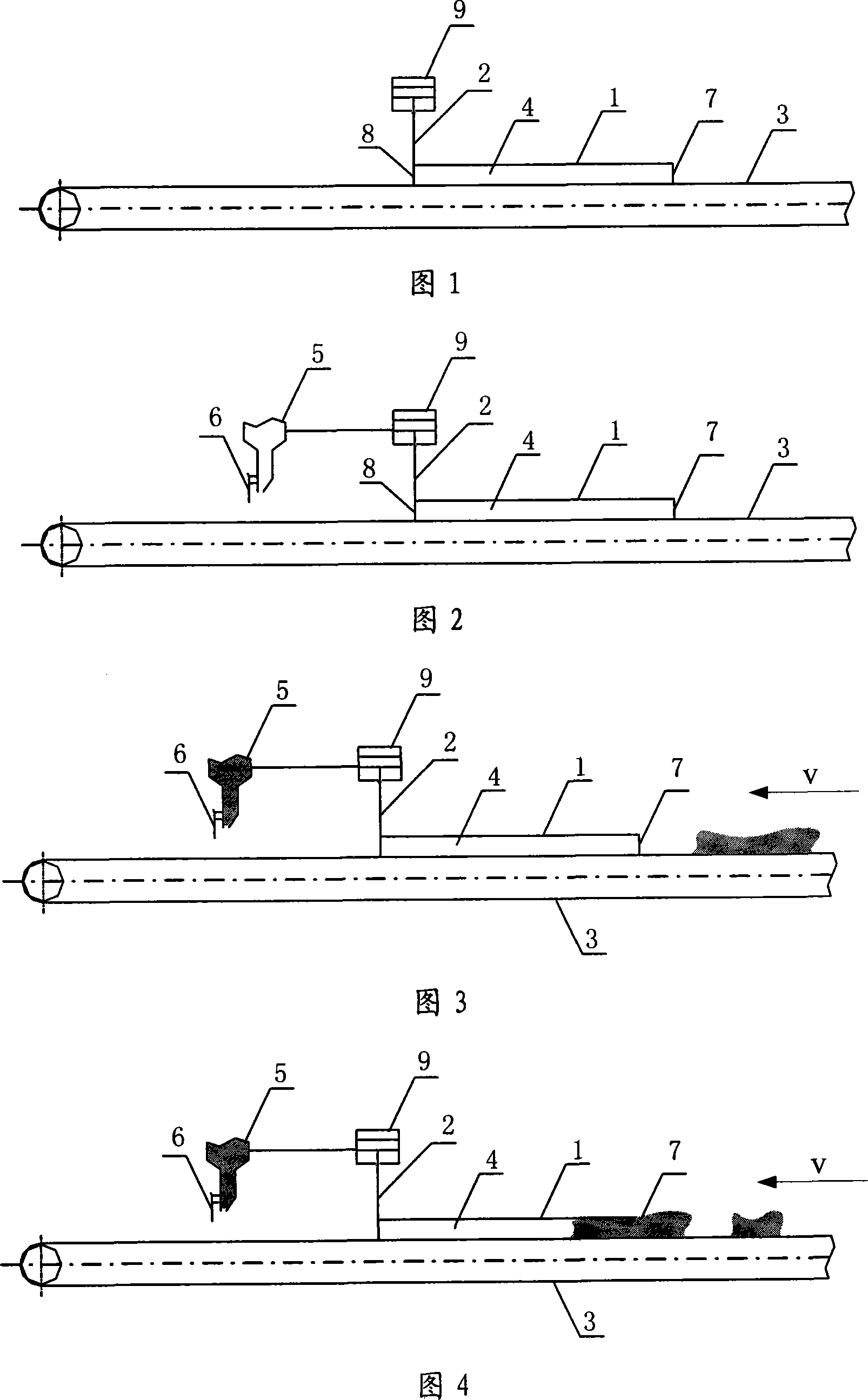

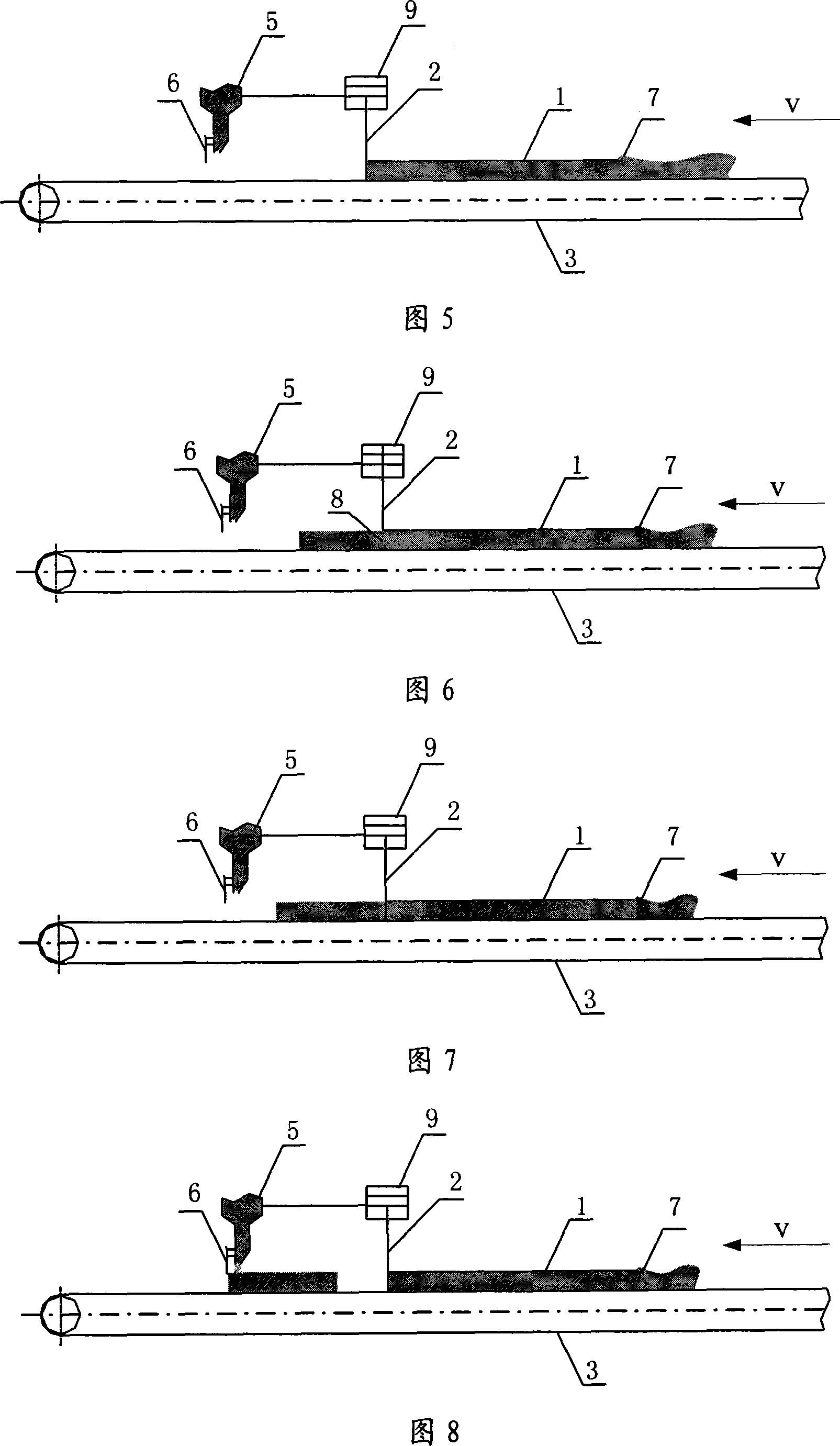

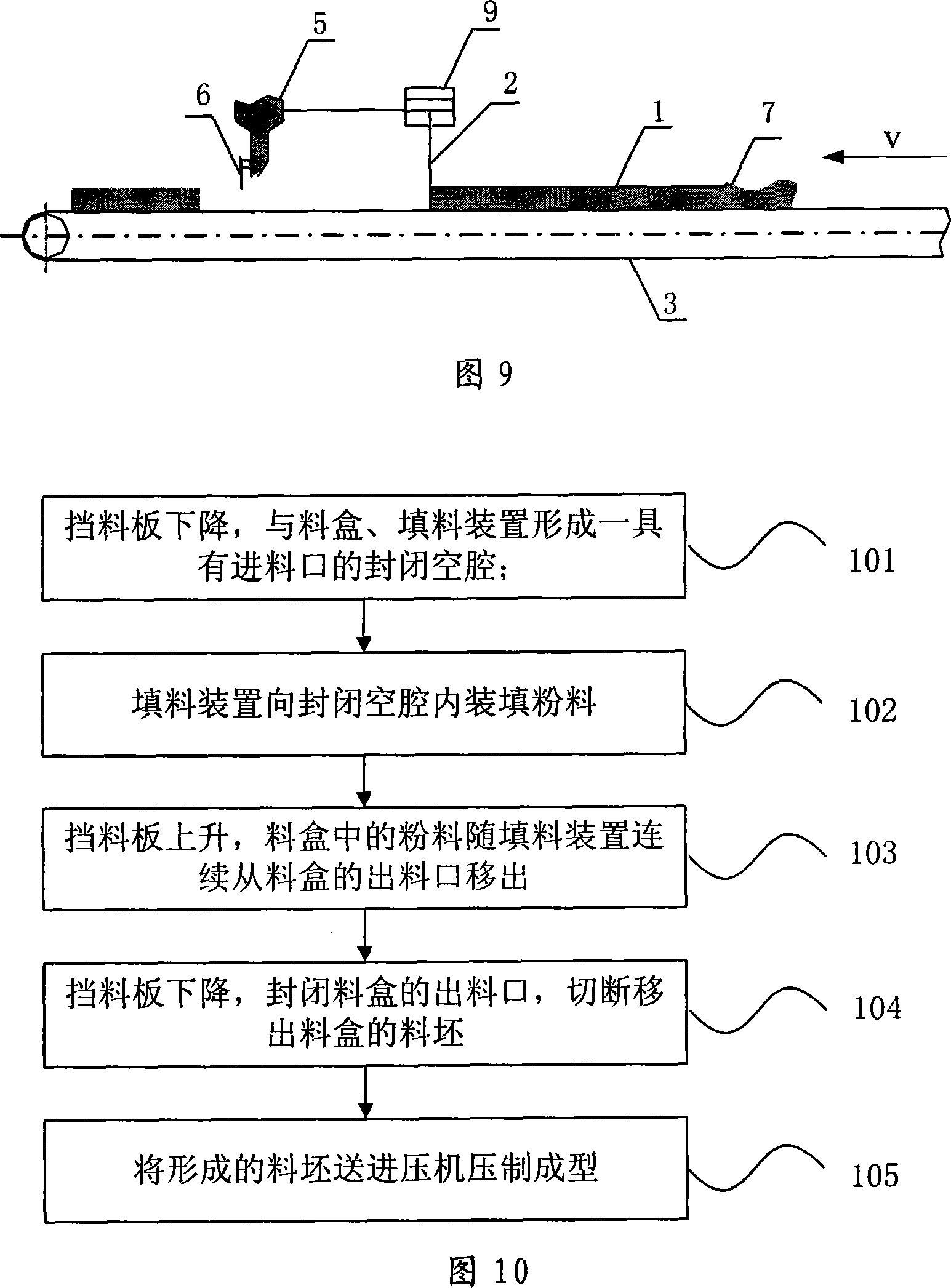

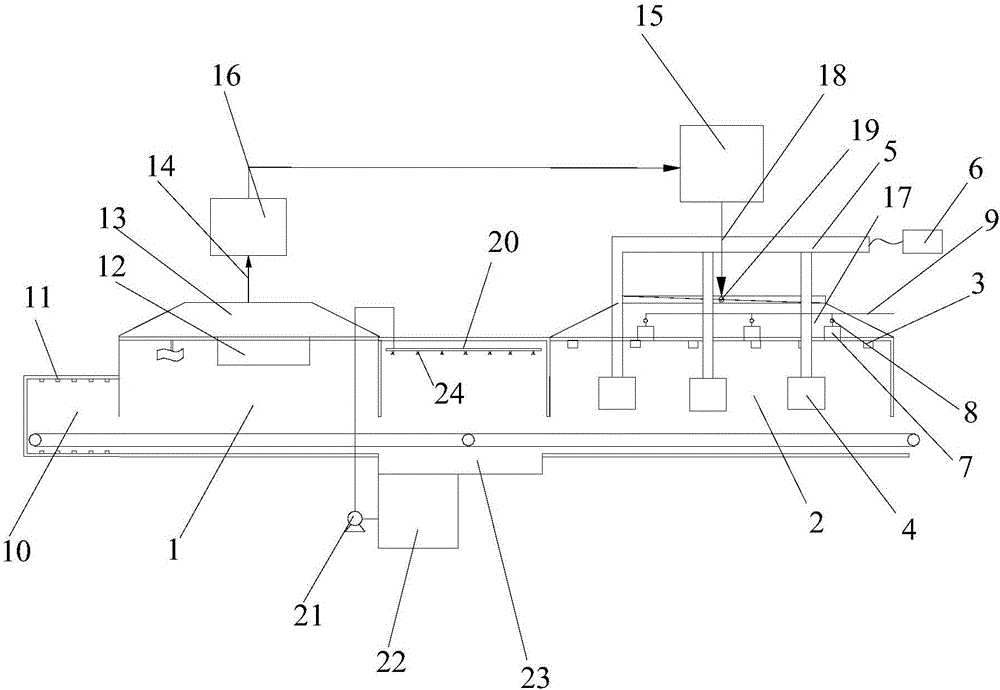

Cloth device and method

The present invention relates to material distributing mechanism and process. The mechanism includes one material box with material inlet and material outlet and fixed on the surface of one stuffing mechanism; one material keeping plate set to the material outlet of the material box capable of moving vertically and forming one closed cavity with material inlet together with the material box and the stuffing mechanism, and one stuffing mechanism for filling powdered material to the closed cavity and conveying formed material blank. The process includes the following steps: descending the material keeping plate for forming one cavity, filling powdered material to the cavity with the stuffing mechanism, ascending the material keeping plate to discharge the powdered material from the material box through the material outlet, descending the material keeping plate to shut up the material outlet and cutting and shifting out the material blank, and conveying the material blank to the press.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Optical pick-up

InactiveUS7012768B2High mechanical strengthImprove roundnessRecord information storageOptical beam guiding meansOptical pickupHigh density

An optical pick-up allows a lens to be supported at high dimensional accuracy for a high-density recording medium, and suppresses resonance for a high-speed access. The optical pick-up includes a supporting shaft, and a lens holder which fits on a supporting shaft rotatably, wherein the supporting shaft is formed of ceramics containing zirconia, and wherein the lens holder is formed of a liquid crystal resin composition. The optical-pickup includes a lens holder having a shaft hole which fits on a rotating shaft and a plurality of object lens holes, wherein the lens holder is a molded product of a resin composition of a liquid crystal resin or a polyphenylene ether resin mixed with a fibrous filler. The molded product has flexural elastic modulus of 10 GPa or more. The lens holder includes a bearing part formed vertically to a lens receiving surface with an excellent inner diameter roundness and excellent mechanical strength.

Owner:NTN CORP

Ink jet printing apparatus and method of controlling ink jet printing apparatus

InactiveUS20090122094A1Unevenness of image density is preventedAvoid unevennessPower drive mechanismsEngineeringMechanical engineering

Owner:CANON KK

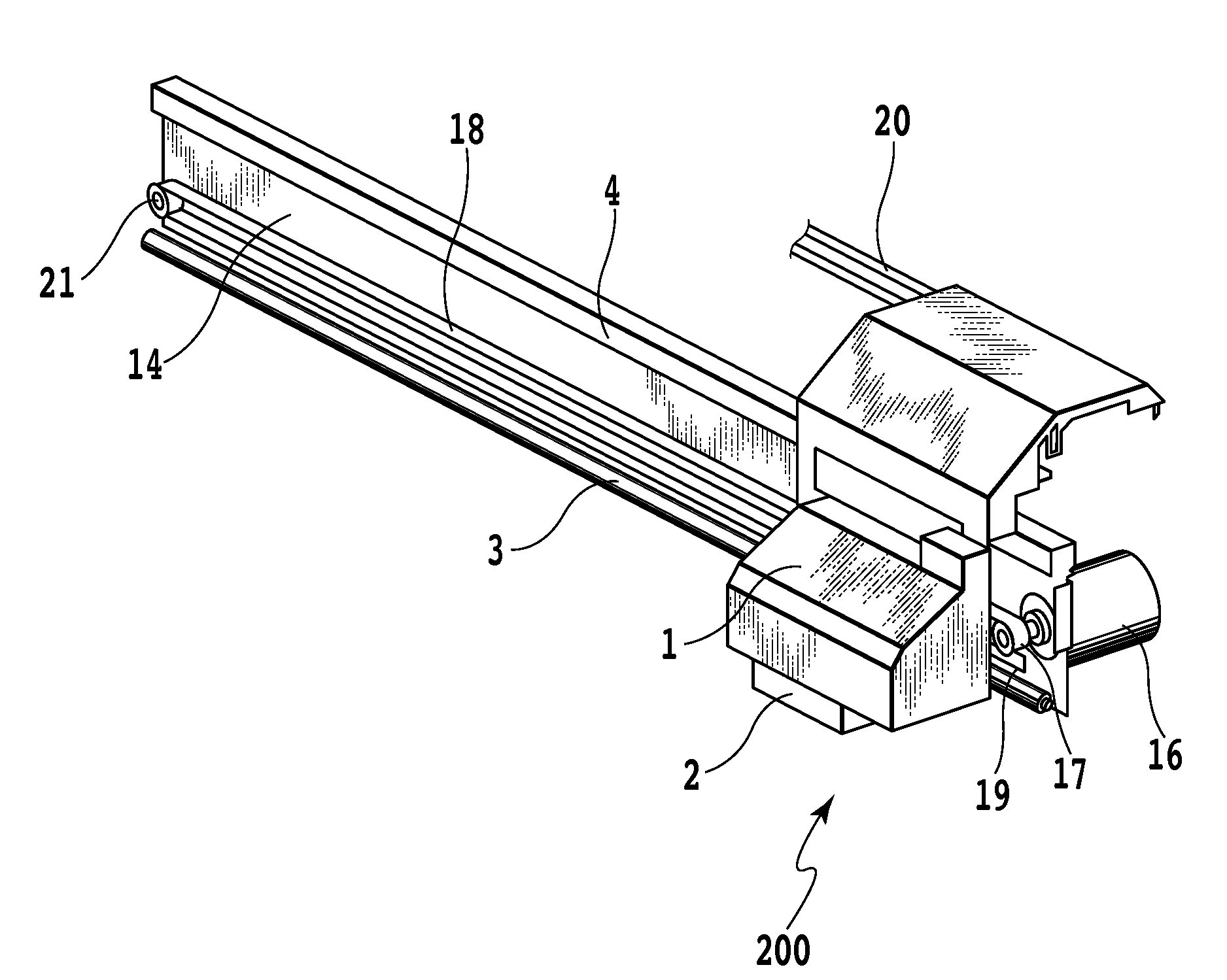

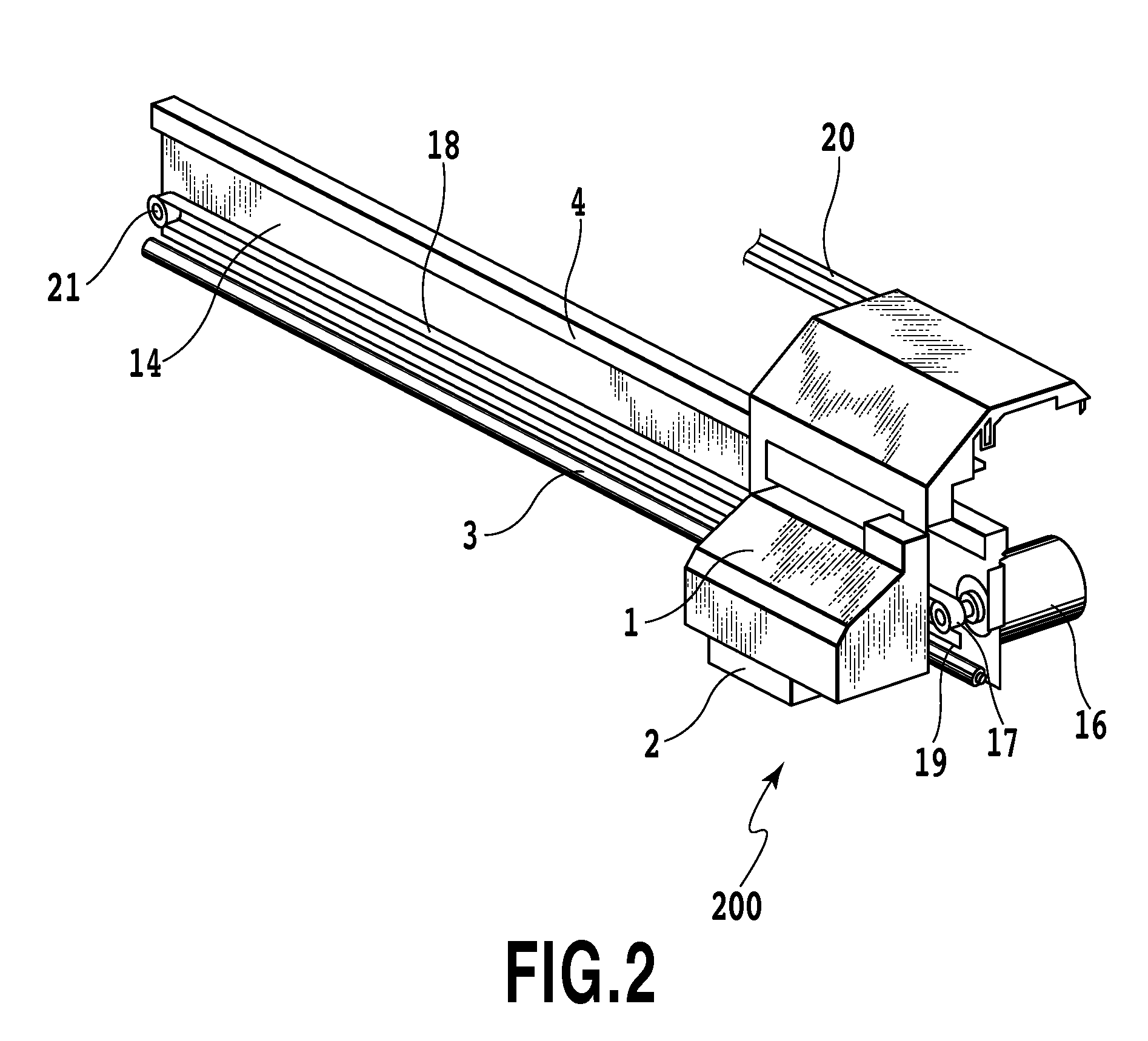

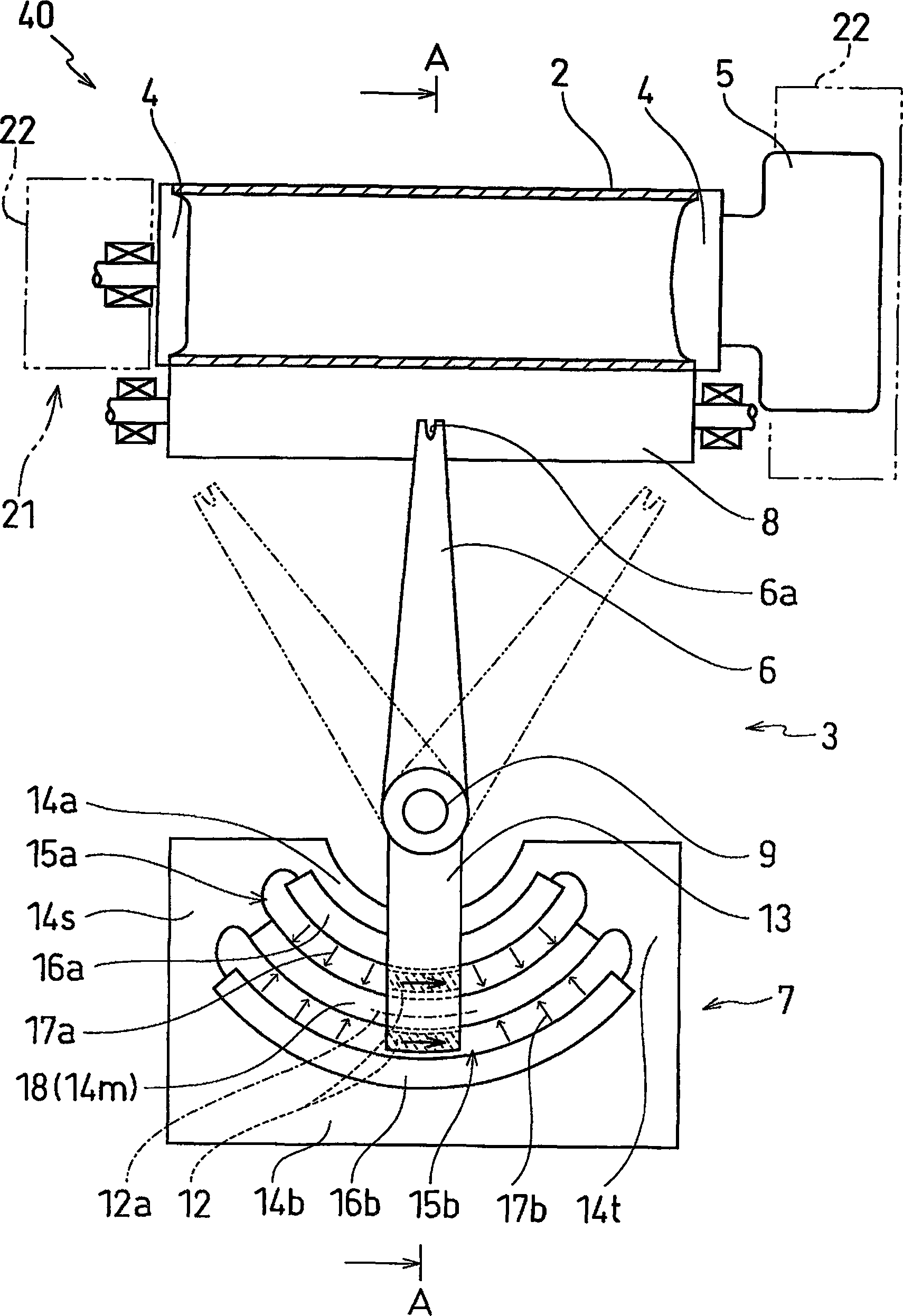

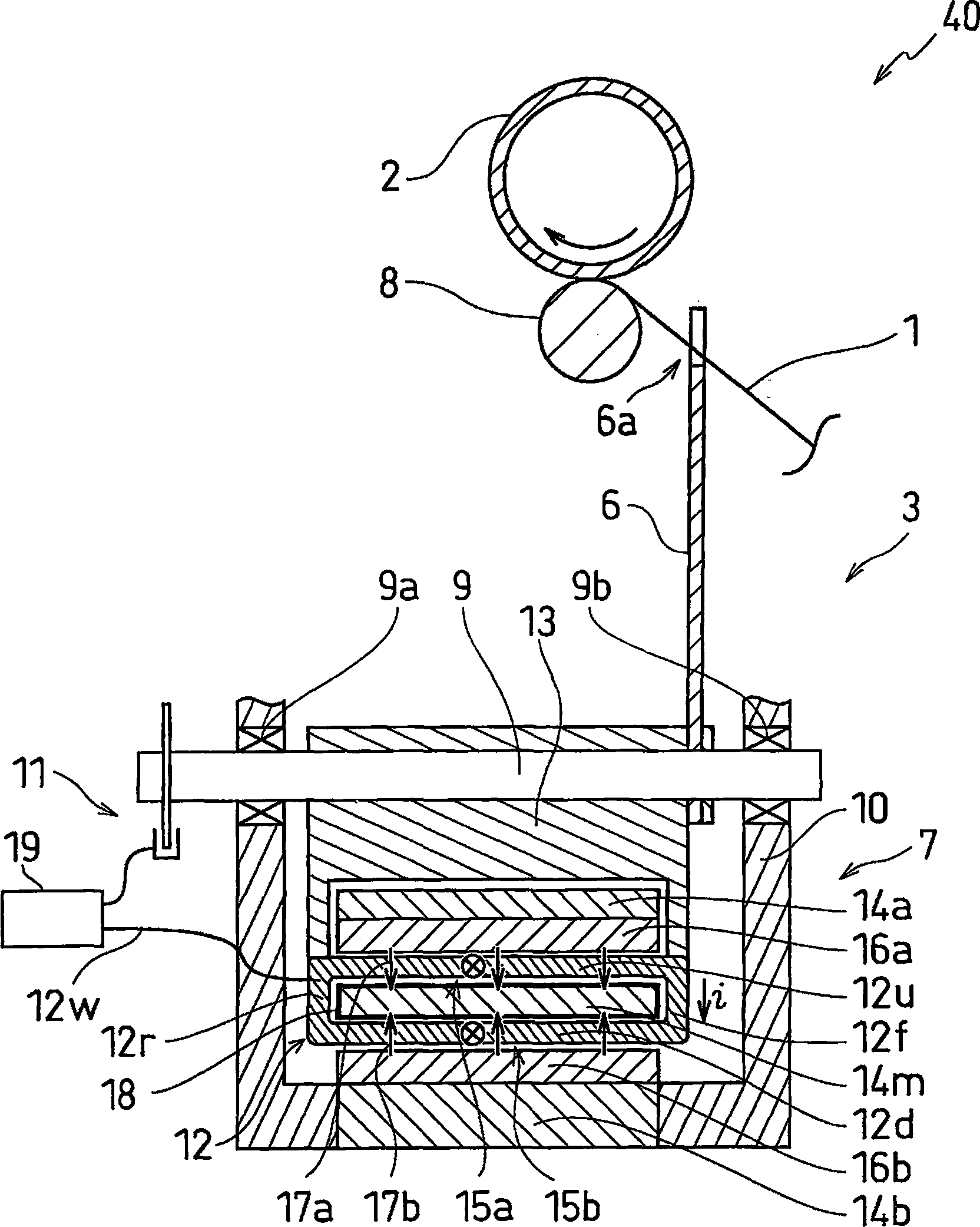

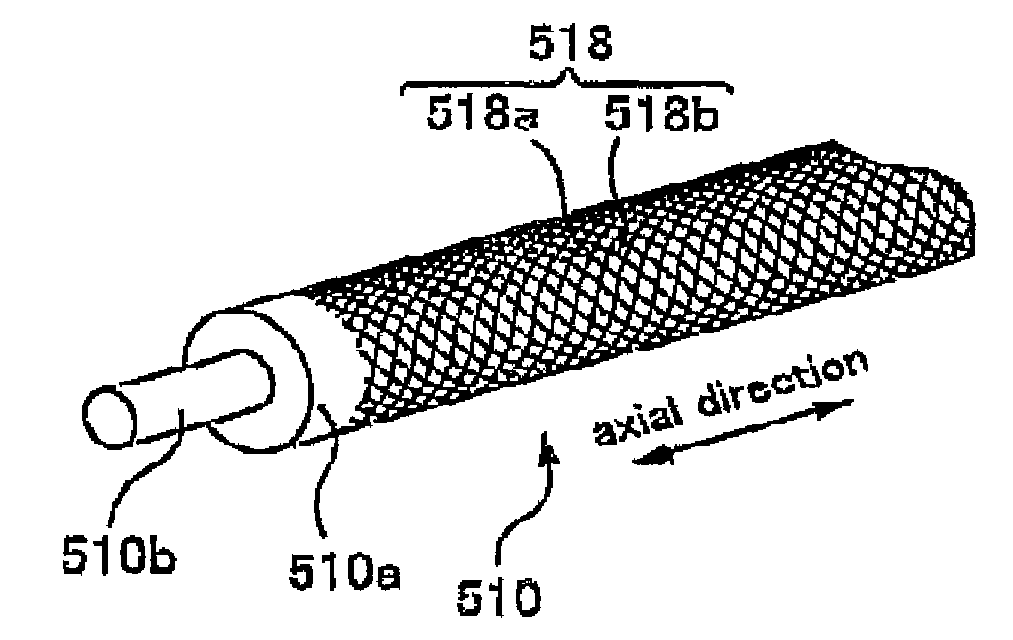

Traverse device for yarn, and textile machinery including the same

InactiveCN1872646ASmall inertiaImprove starting accelerationFilament handlingPropulsion systemsYarnBobbin

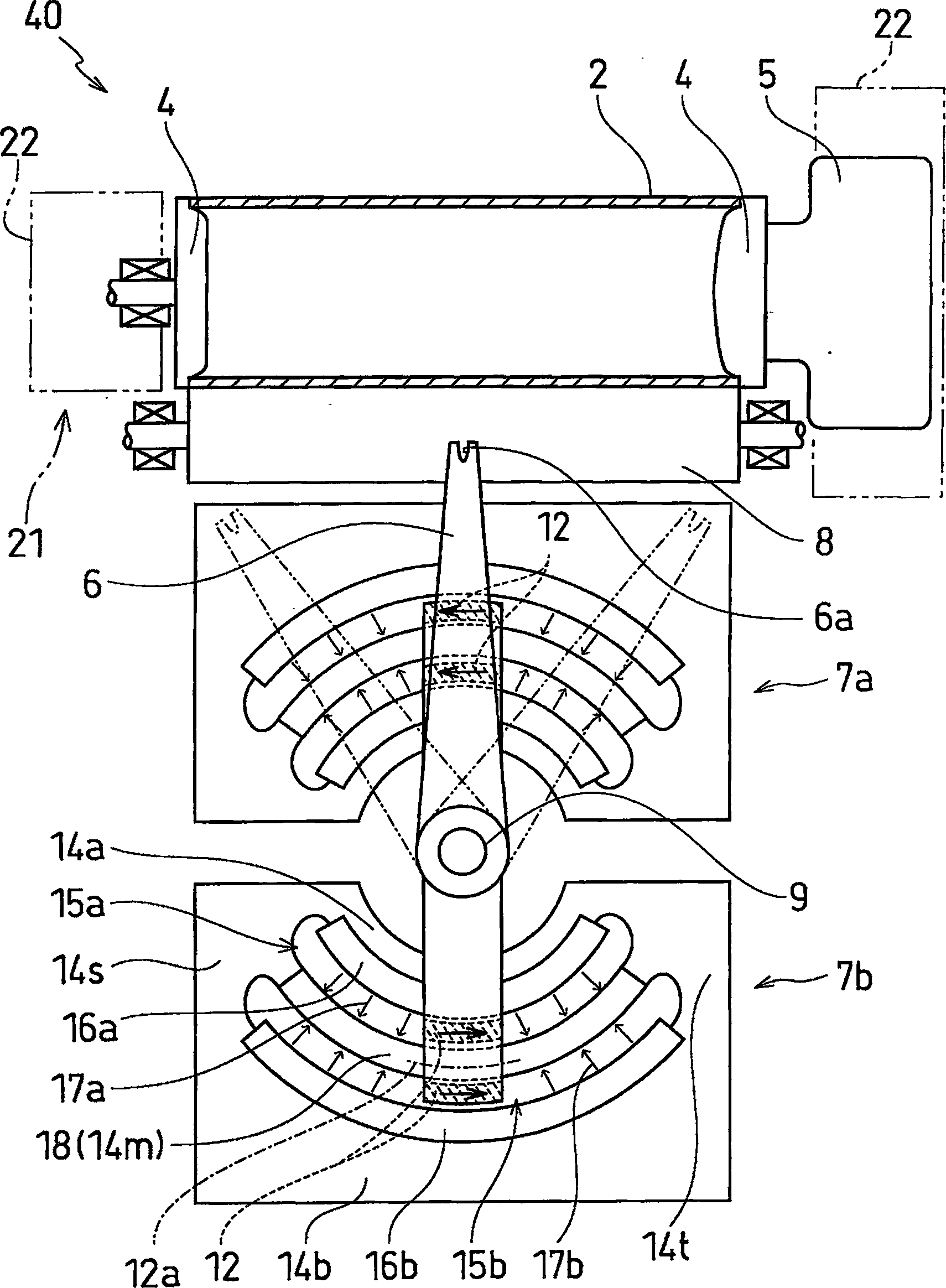

A traverse device (3) has an arm driving part (7) which rotatively reciprocates an arm (6) having a yarn guide (6a) to traverse a yarn (1) on a takeup bobbin (2) that winds the yarn (1). The arm driving part (7) comprises an electrical coil (12) provided in the arm (6), two yokes (14a, 14b) formed into arc shapes around the center of axis of an arm shaft (9) as the center of rotative movement of the arm (6), and an air gap (15) that is sandwiched between the two yokes (14a, 14b) and has magnetic fields formed inside, and a part of the electrical coil (12) is inserted in the air gap (15). The respective two yokes (14a, 14b) are provided with permanent magnets (16a, 16b), a central yoke (14m) that divides the air gap (15) into two rows is provided, and in the respective two-row air gaps (15a, 15b), magnetic lines (17a, 17b) turned in the radial direction and being opposite each other are formed by the permanent magnets (16a, 16b). A part of the electrical coil (12) is inserted in the respective two-row air gaps (15a, 15b) so as to surround the central yoke (14m).

Owner:MURATA MASCH LTD

Cof board

InactiveUS20090096069A1High densityImprove connection reliabilityFinal product manufactureSemiconductor/solid-state device detailsOn boardEngineering

Owner:NITTO DENKO CORP

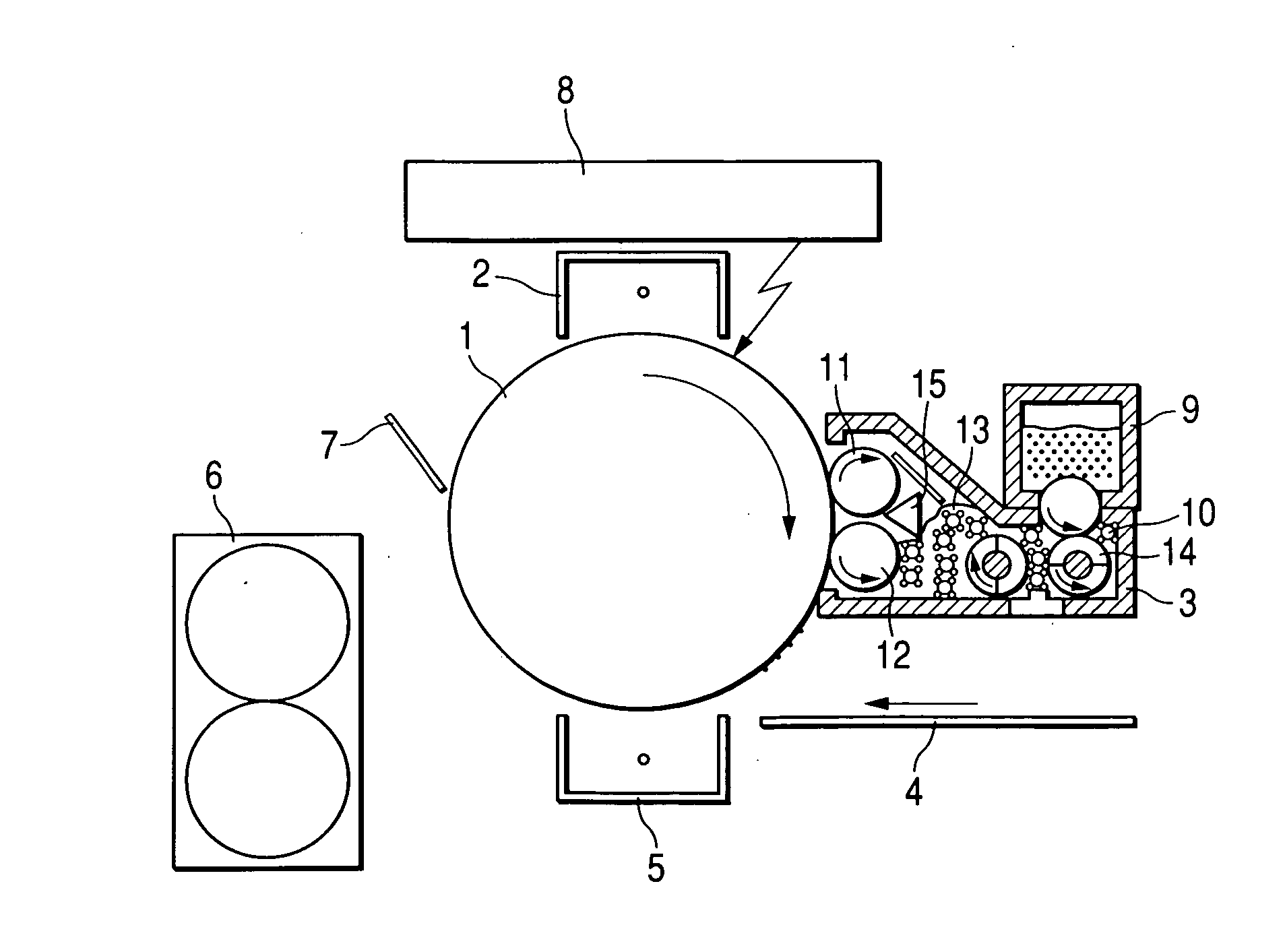

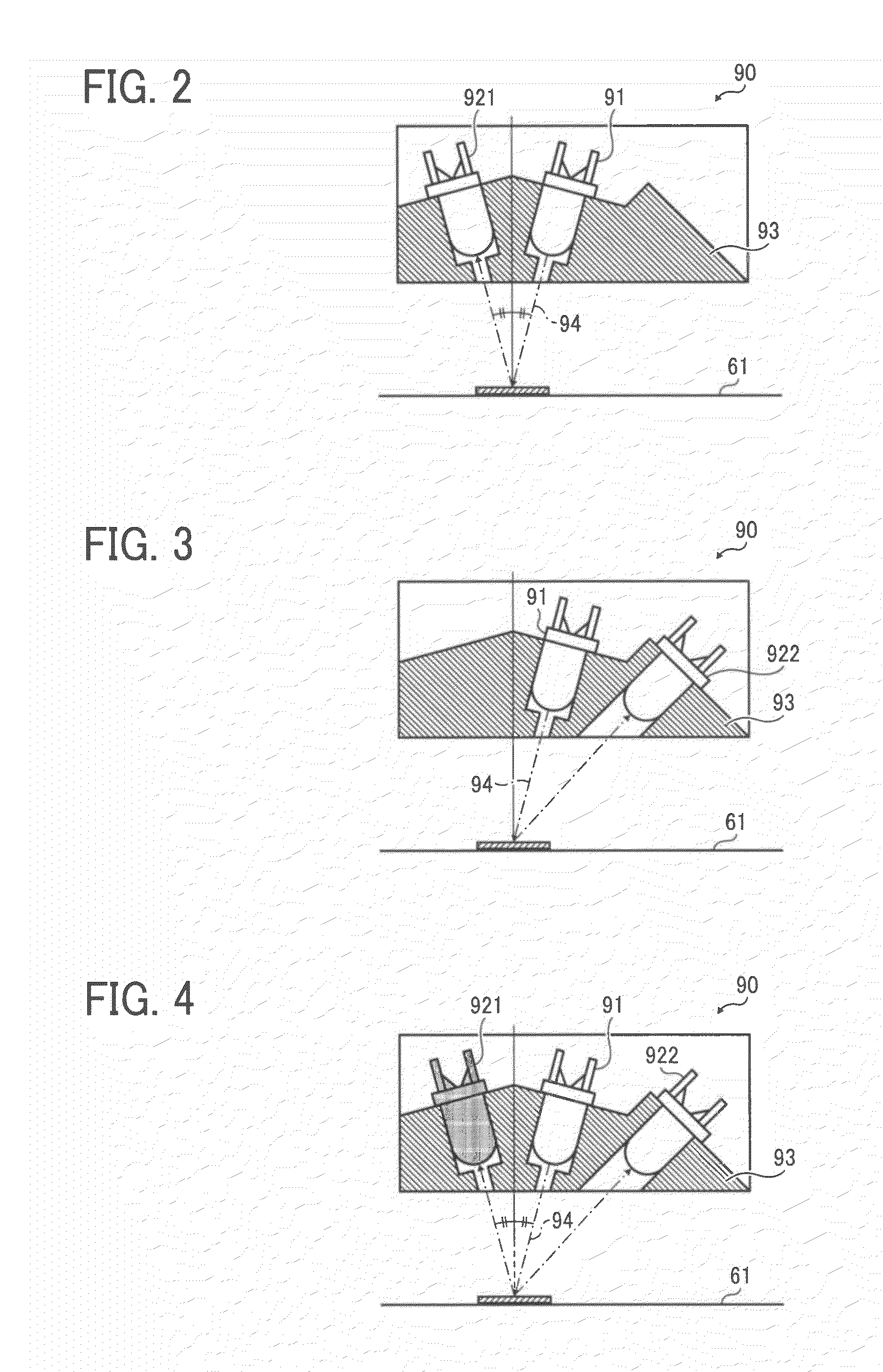

Image forming apparatus that prevents conspicuous unevenness in image density

An image forming apparatus includes: an image bearing body that is rotatable about a central axis thereof, and that bears a dot-like latent image, on a surface of the image bearing body, in each of a plurality of divided regions that are arranged in rows along a direction that intersects an axial direction of the central axis at a predetermined intersection angle; and a developer bearing roller that is rotatable in order to make visible, as a developer image, the dot-like latent images borne by the image bearing body, using a developer borne on a surface of the developer bearing roller, the developer bearing roller opposing the image bearing body such that an axial direction of the developer bearing roller is parallel to the axial direction of the image bearing body, and that includes a helical groove portion on the surface of the developer bearing roller, the helical groove portion being inclined at a predetermined inclination angle with respect to the axial direction of the developer bearing roller and being formed having a uniform pitch in the axial direction, wherein a value that is a tangent of the inclination angle divided by a ratio of a moving speed of the surface of the developer bearing roller to a moving speed of the surface of the image bearing body is different from a tangent of the intersection angle.

Owner:SEIKO EPSON CORP

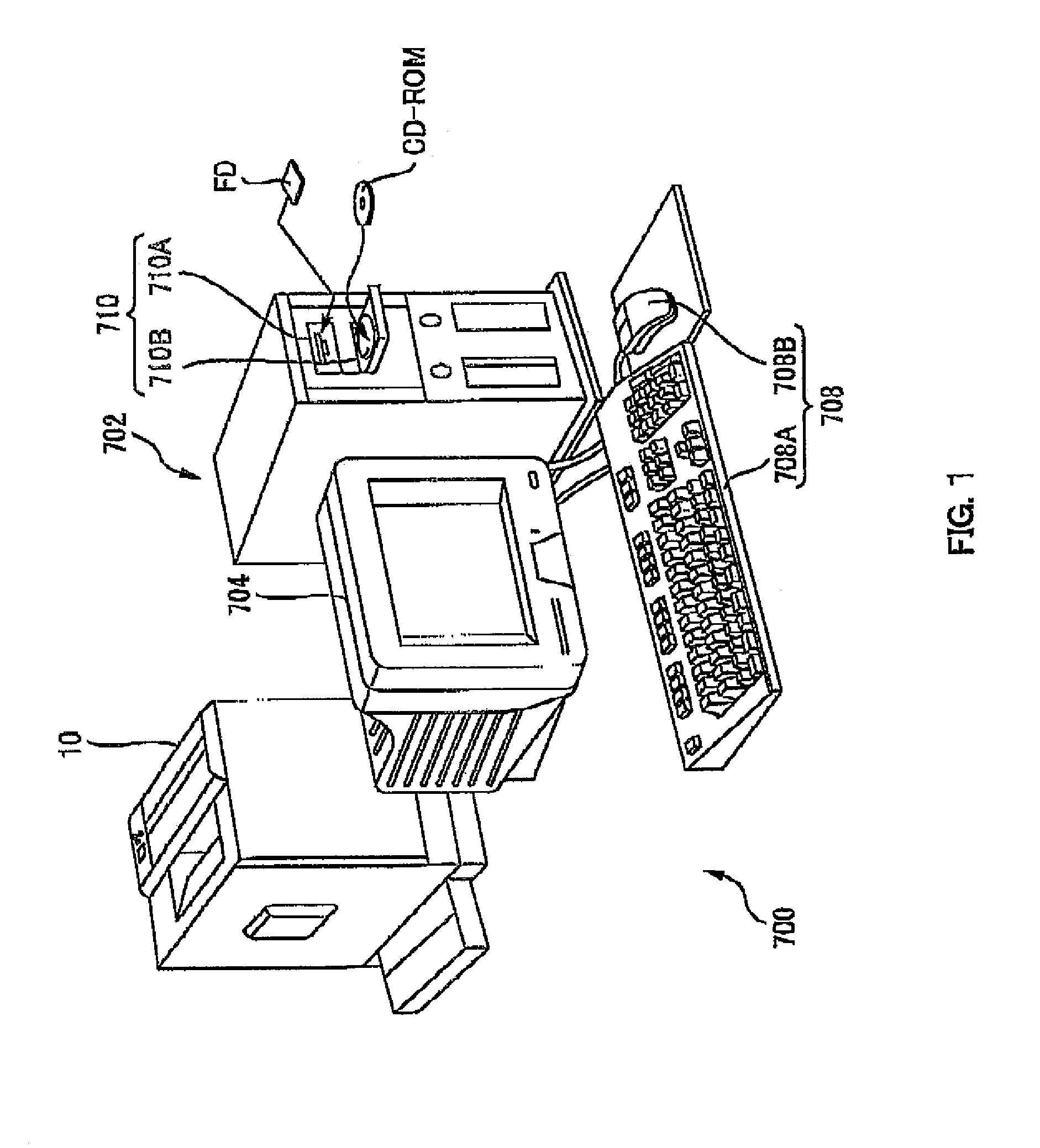

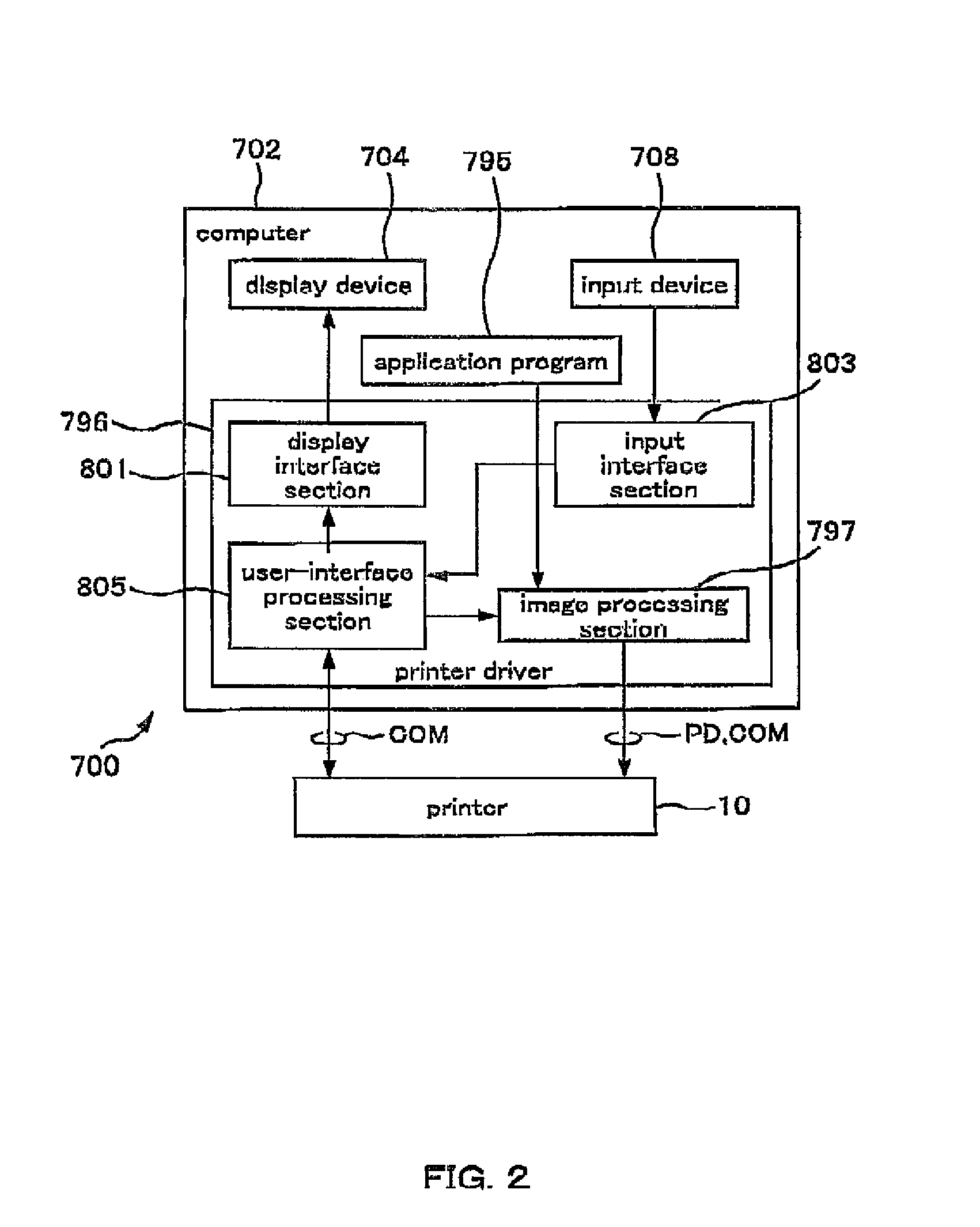

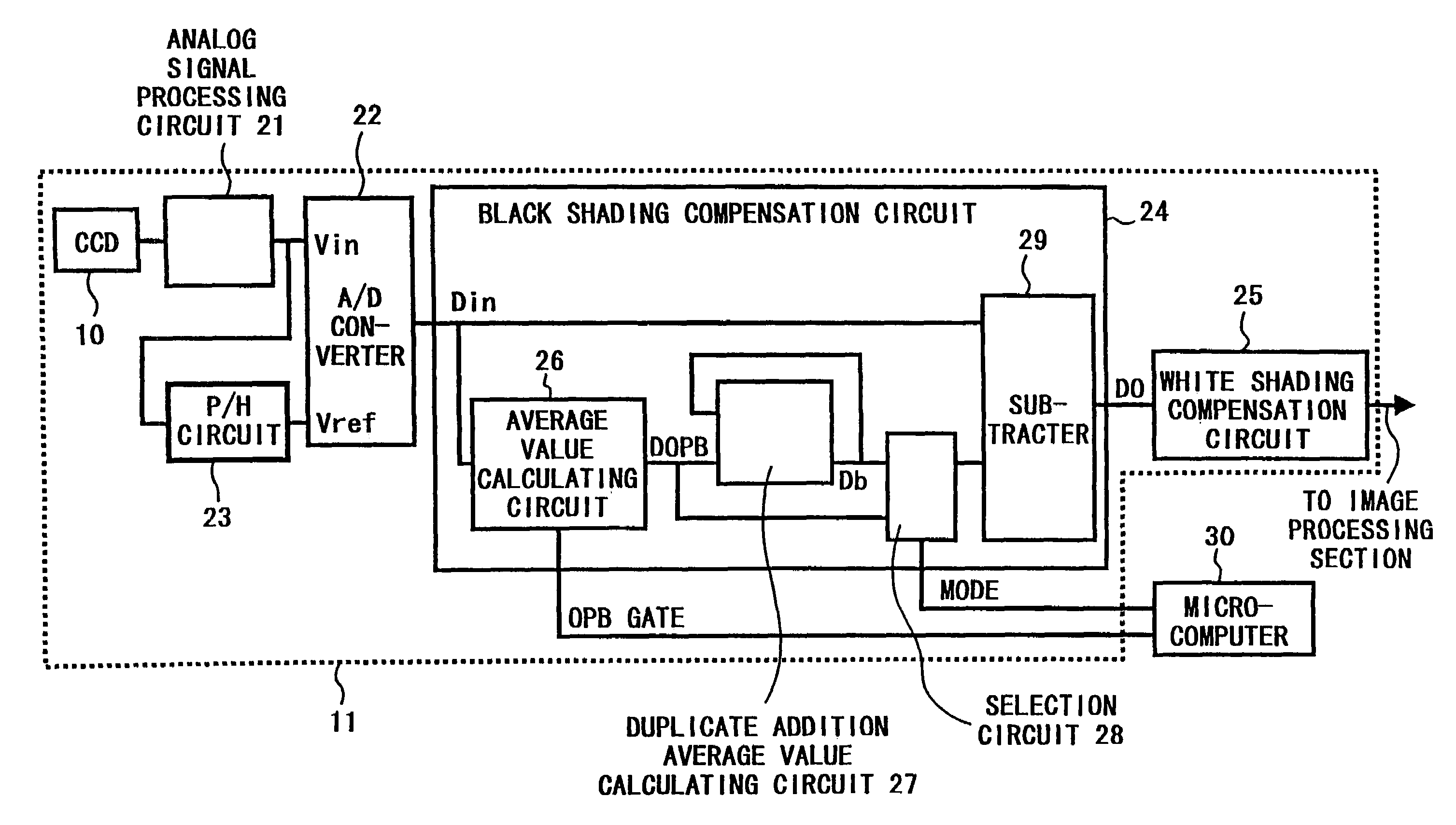

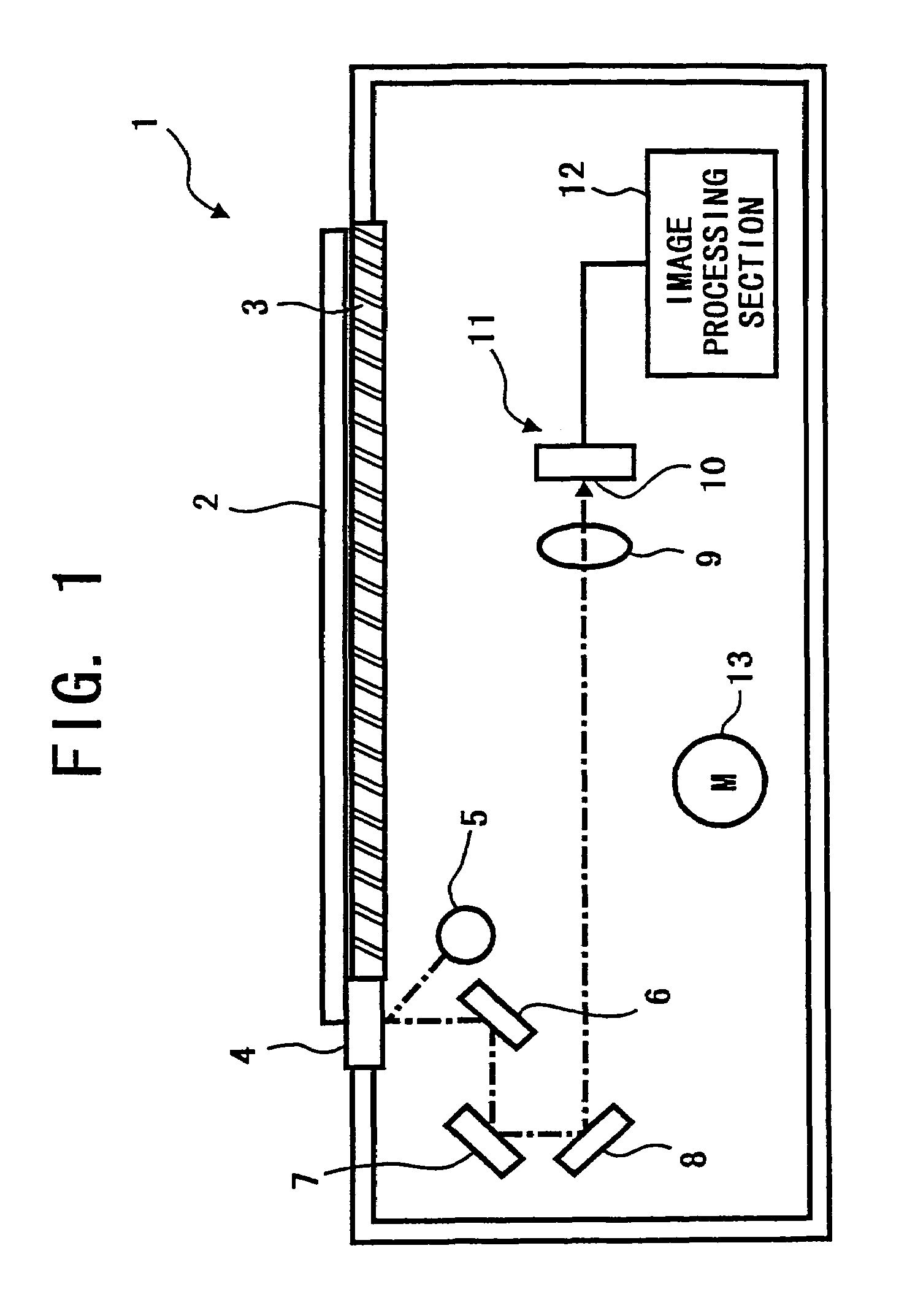

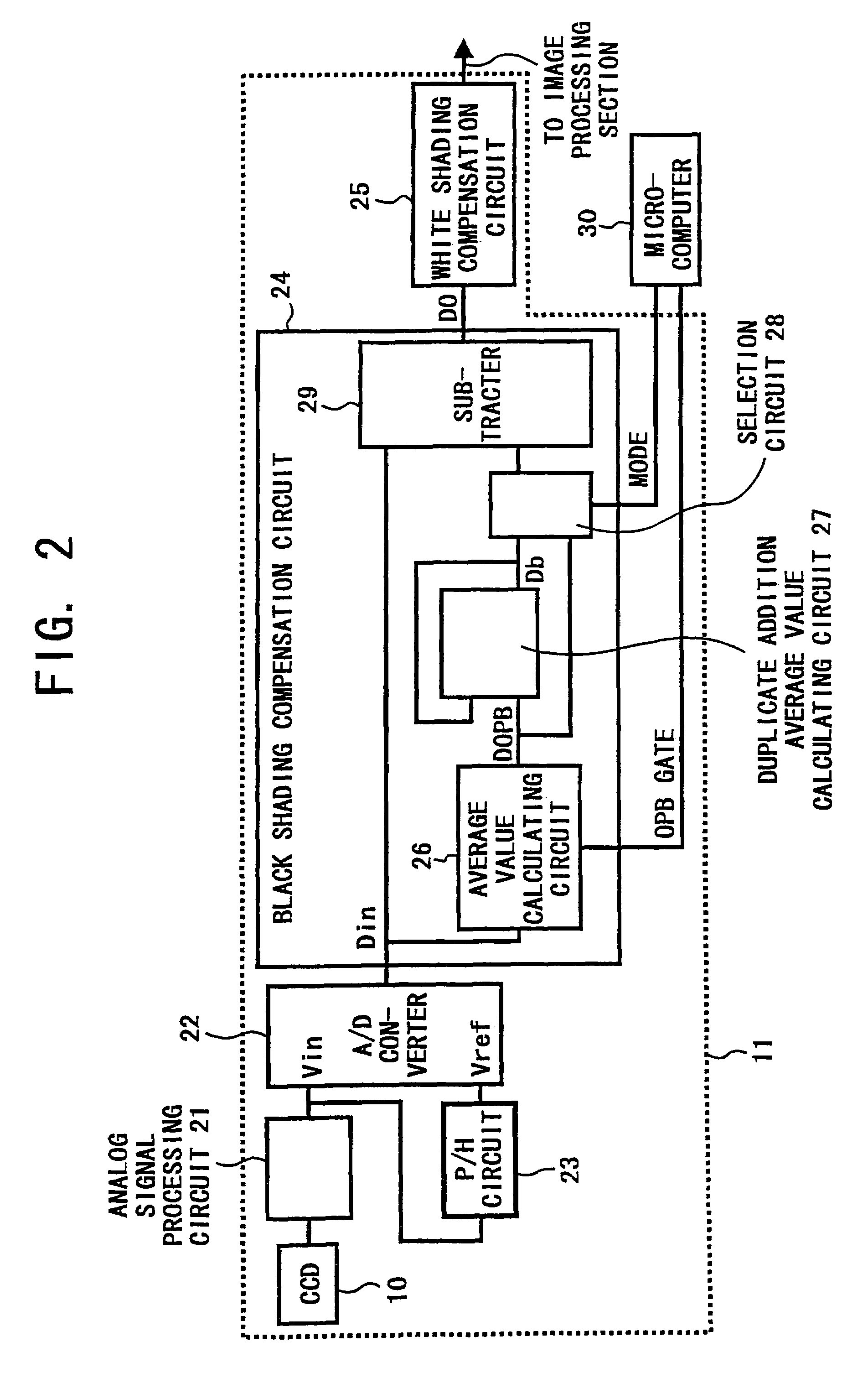

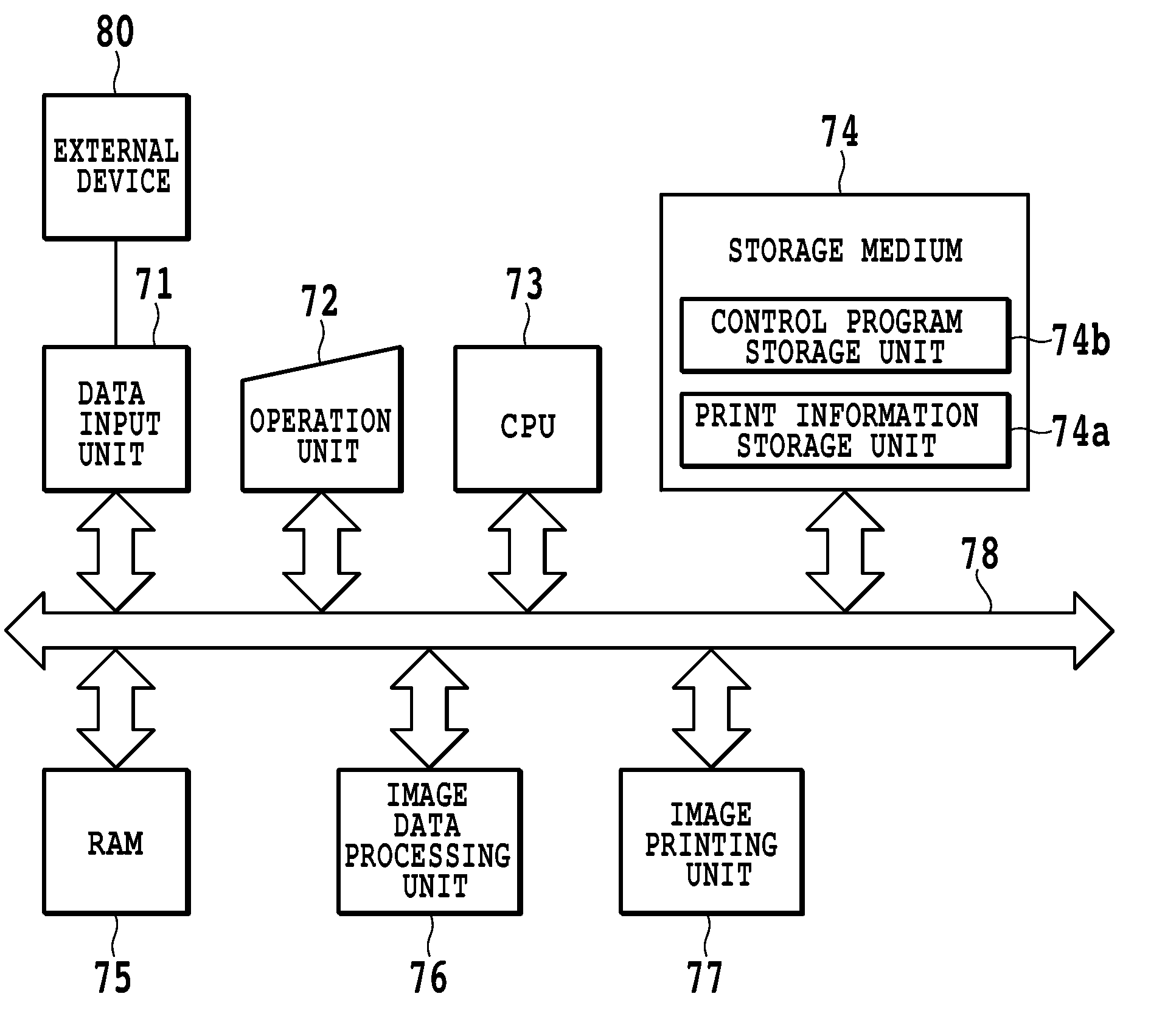

Image reading-out apparatus, copying machine and facsimile device utilizing the same, and method of reading out image

InactiveUS6961151B1Quality improvementAvoid it happening againImage enhancementVisual presentationA d converterPaper document

An image reading-out apparatus including a background level detecting circuit, an analog-to-digital converter, and a black-shading compensation circuit. The background level detecting circuit is configured to detect the background level of the original document from the image data. The analog-to-digital converter is configured to remove an influence due to the color of the background on the original document from the image data and configured to perform the analog-to-digital conversion of the image data in accordance with the detected background level. The black-shading compensation circuit is configured to perform black-shading compensation of the image data after the analog-to-digital conversion. The black-shading compensation circuit includes plural black level values calculating circuits which are configured to respectively obtain, per each one line, black level values employed for the black-shading compensation from the image data by use of respective different calculation members; a selection circuit which is configured to select and output one black level value among plural sorts of the black level values outputted by the plural black level values calculating circuits; and a subtracter which is configured to subtract the selected black level value from the image data after performing the analog-to-digital conversion and the black-shading compensation.

Owner:RICOH KK

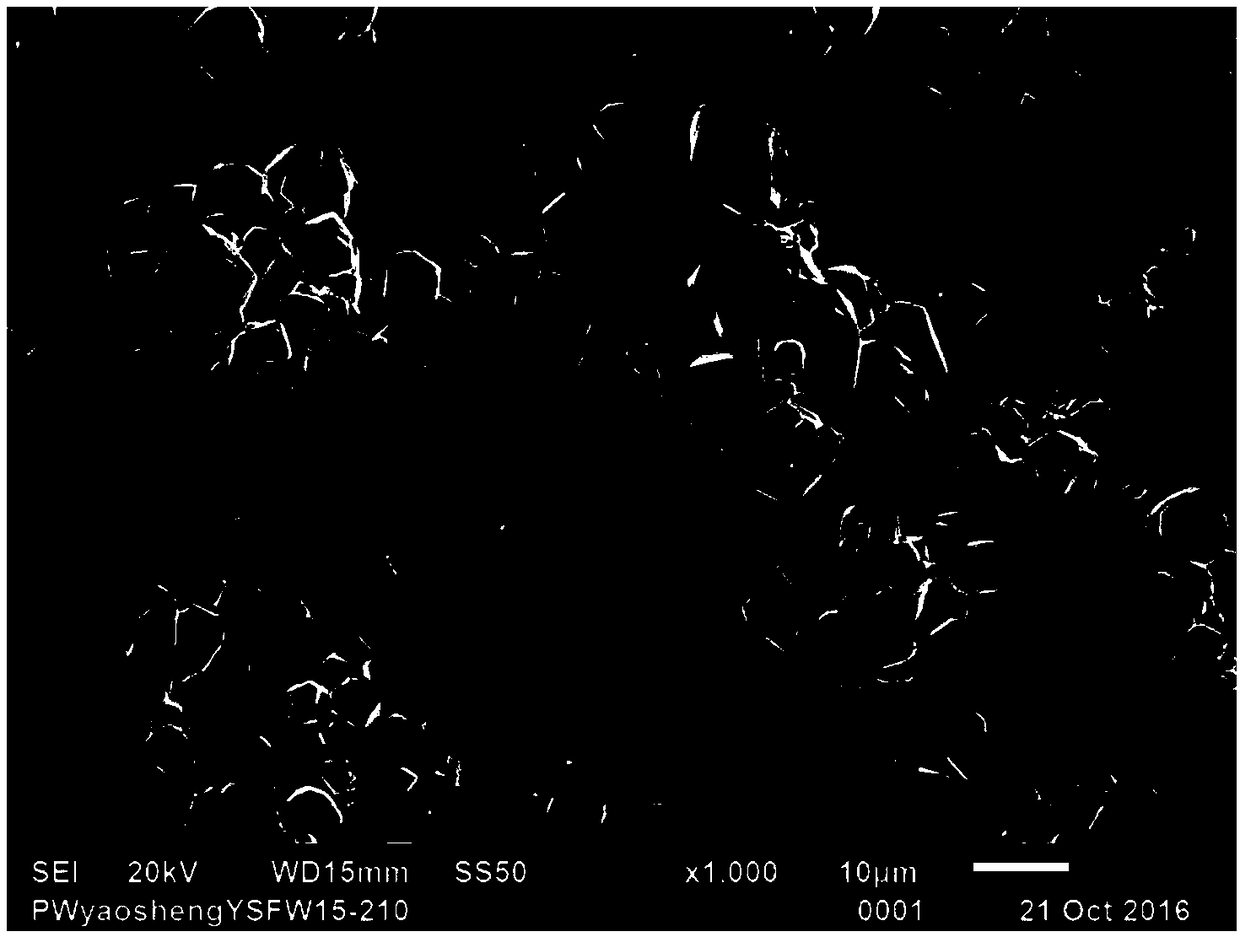

Ceramic bond CBN composite grinding wheel for grinding titanium alloys and preparation method

InactiveCN109465758AHigh bonding strengthImprovement effortsAbrasion apparatusGrinding devicesSurface finishTitanium

The invention belongs to the technical field of grinding, and in particular, relates to a ceramic bond CBN composite grinding wheel for grinding titanium alloys and a preparation method. The compositegrinding wheel comprises a basal body, and a composite patch fixed on the basal body by using an adhesive layer and used for grinding the titanium alloys. Through cooperation between ceramic microcrystal abrasives and CBN abrasives, the composite grinding wheel is prepared, sharp cutting edges can be continuously generated, more chip accommodating space is provided, the heat dissipating effect isimproved, the stable grinding effect is maintained, the finishing amount is reduced, and the production efficiency is improved; and through bonding and holding effects of low-temperature ceramic bondreinforcing abrasives with a specific ratio, the self-sharpening property is better, the chip accommodating space is larger, and the surface smoothness of grinded workpieces is further improved. Based on brand new raw material formulas, the preparation method forms a stable grid structure through low-temperature ceramic bonds, the CBN abrasives and the ceramic microcrystal abrasives to improve the mechanical strength of the composite grinding wheel.

Owner:SUZHOU FAR EAST ABRASIVES

Inkjet printing apparatus and inkjet printing method

InactiveUS20100328384A1Minimize air current disturbanceReduce density unevennessOther printing apparatusVolumetric Mass DensityEngineering

An inkjet printing apparatus and an inkjet printing method are provided which can minimize air current disturbances that occur between the print head and the print medium and also minimize density unevenness caused by mask patterns. For this purpose, the 2-pass printing is performed such that the high printing ratio region and the low printing ratio region are alternated every pixel in the nozzle-arrayed direction and that adjoining groups of high printing ratio regions are separated from one another by a group of low printing ratio regions that forms a passage wide enough for air currents to pass through.

Owner:CANON KK

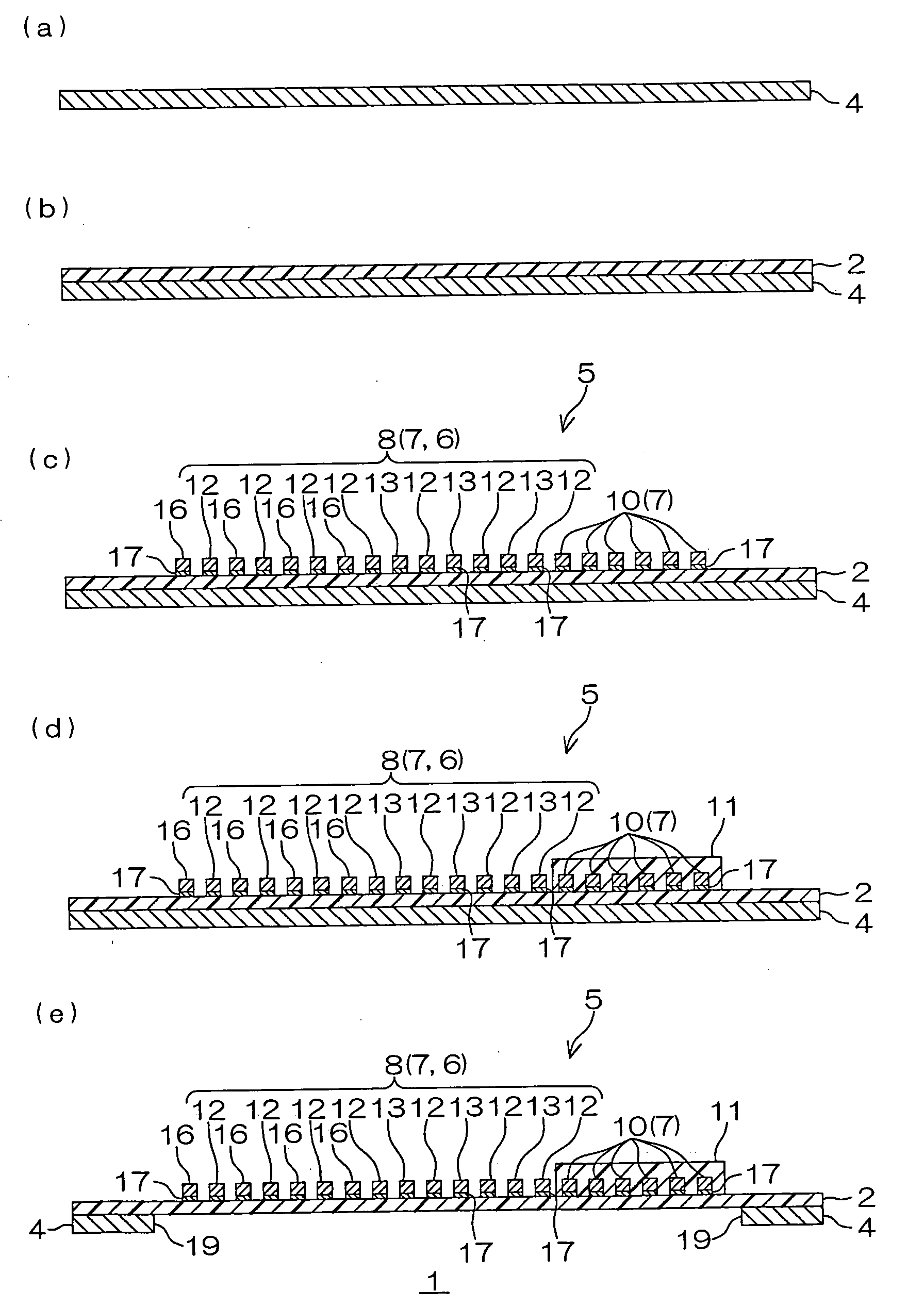

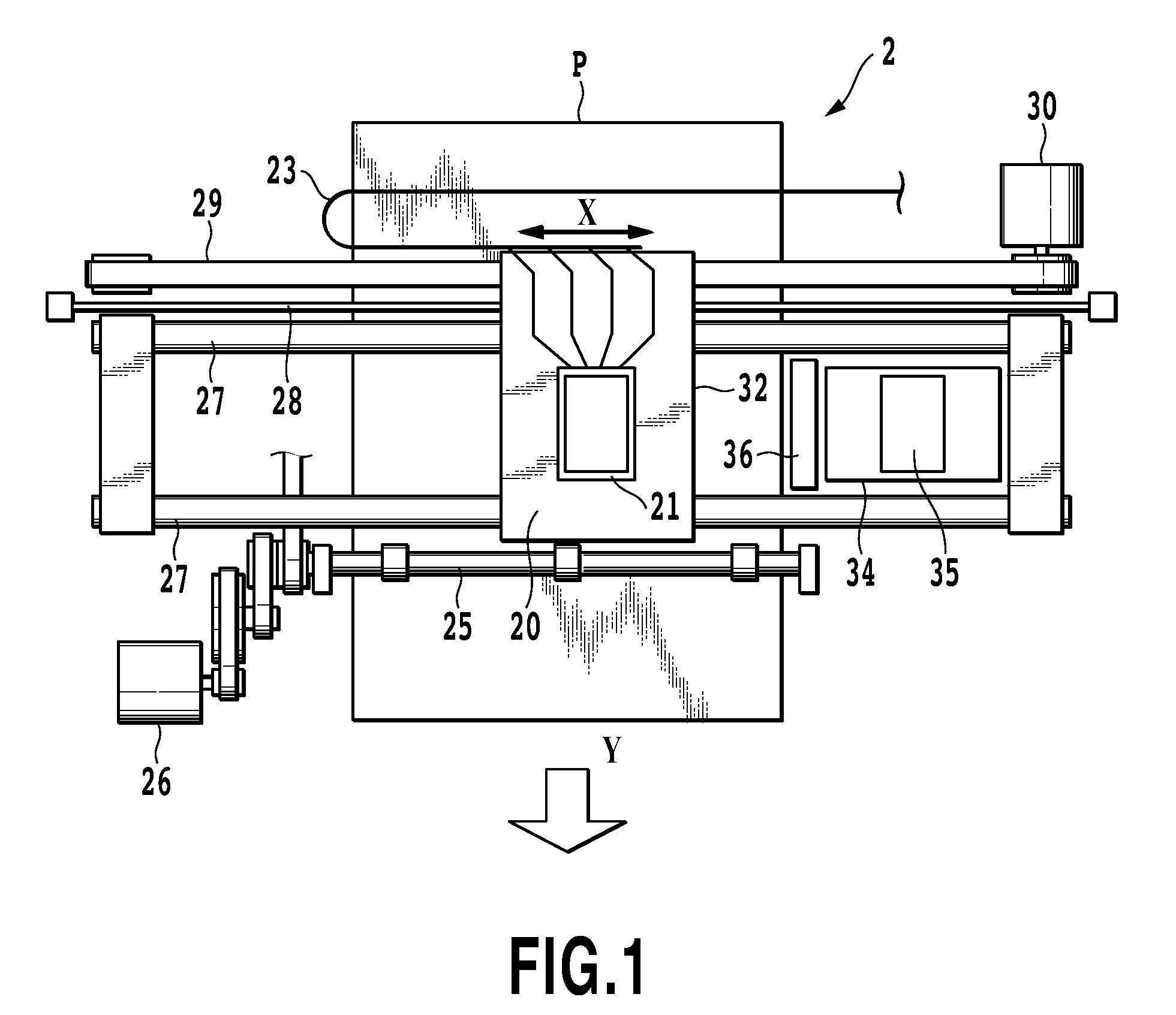

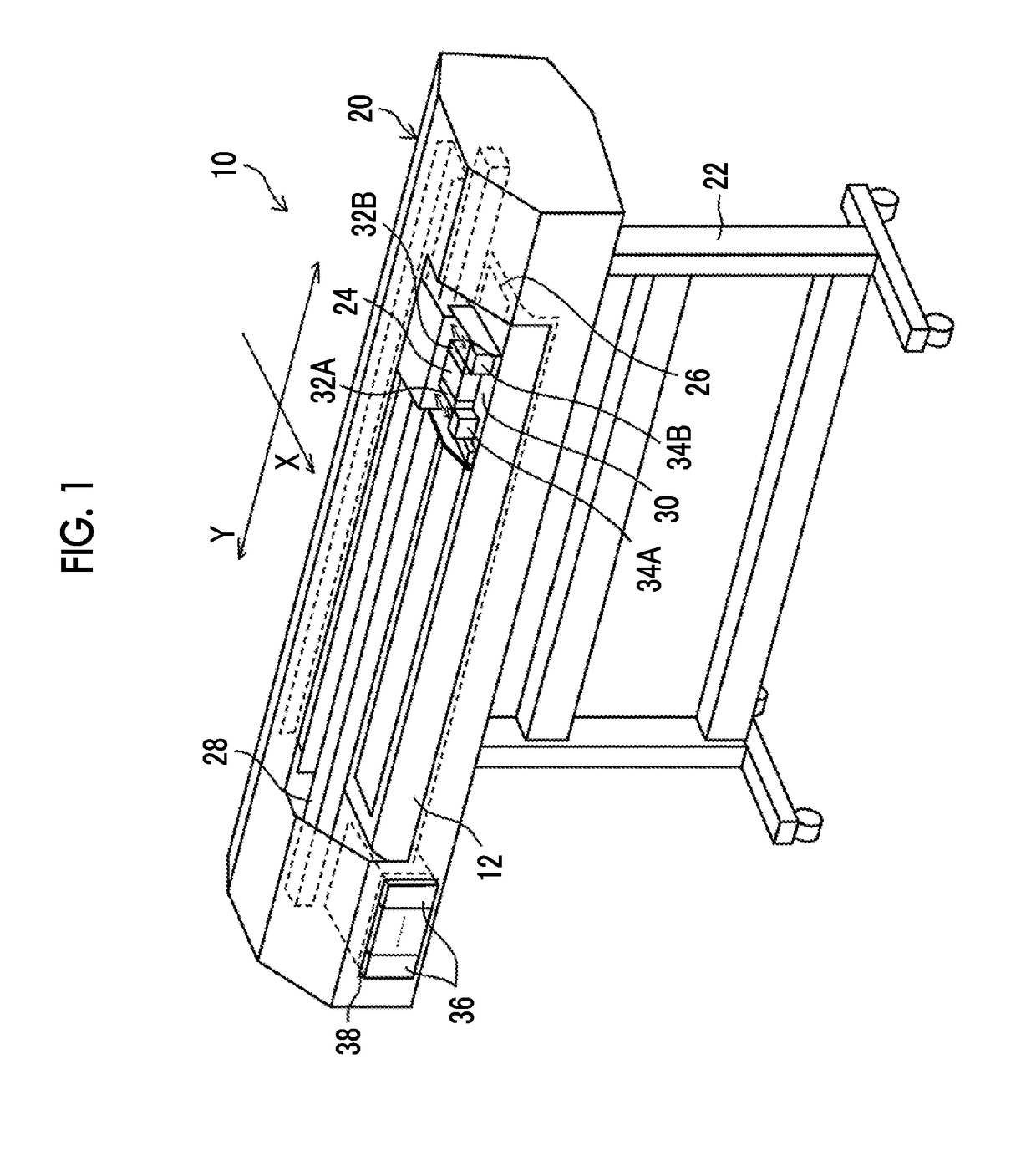

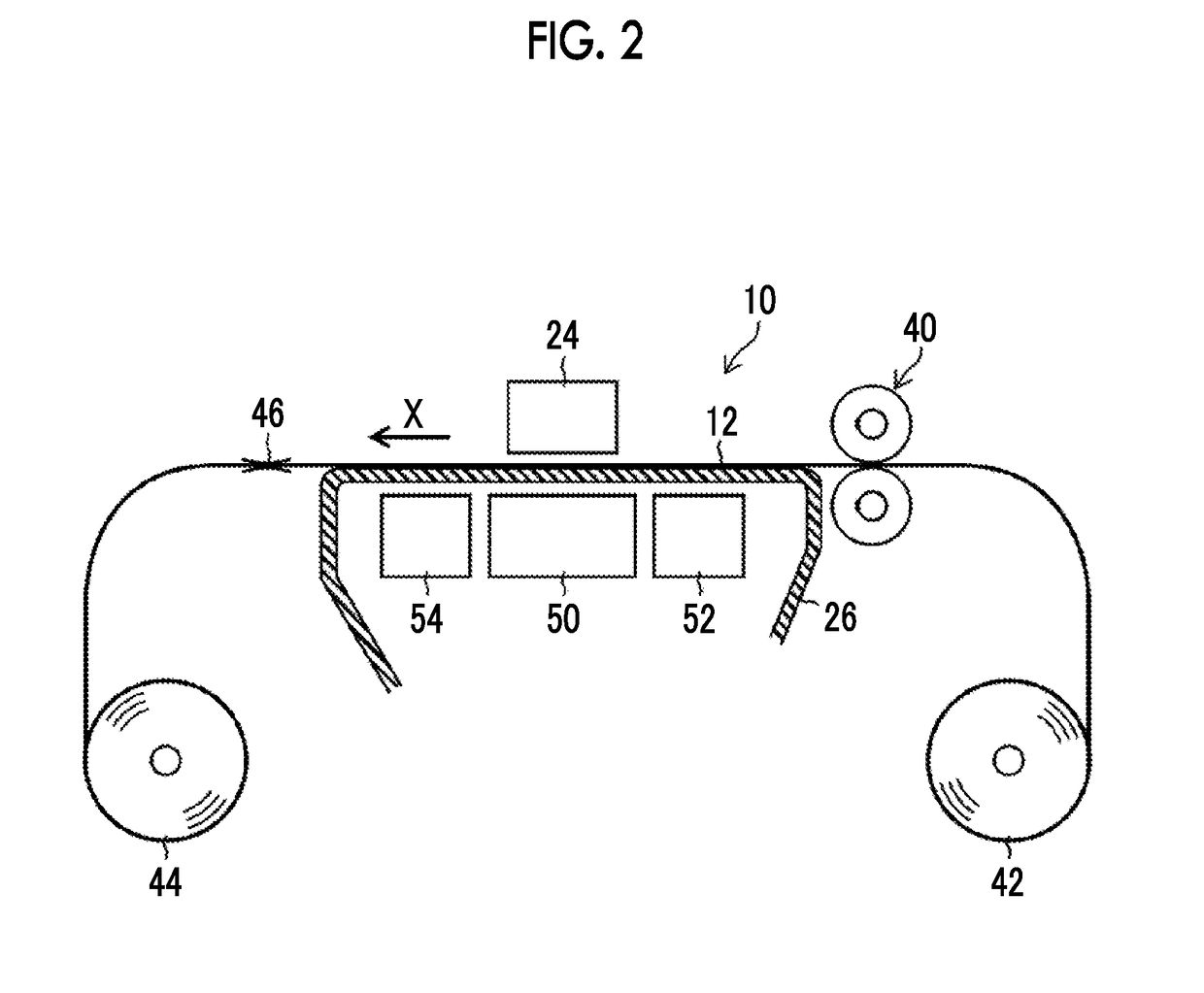

Ink jet printing apparatus and ink jet priting method

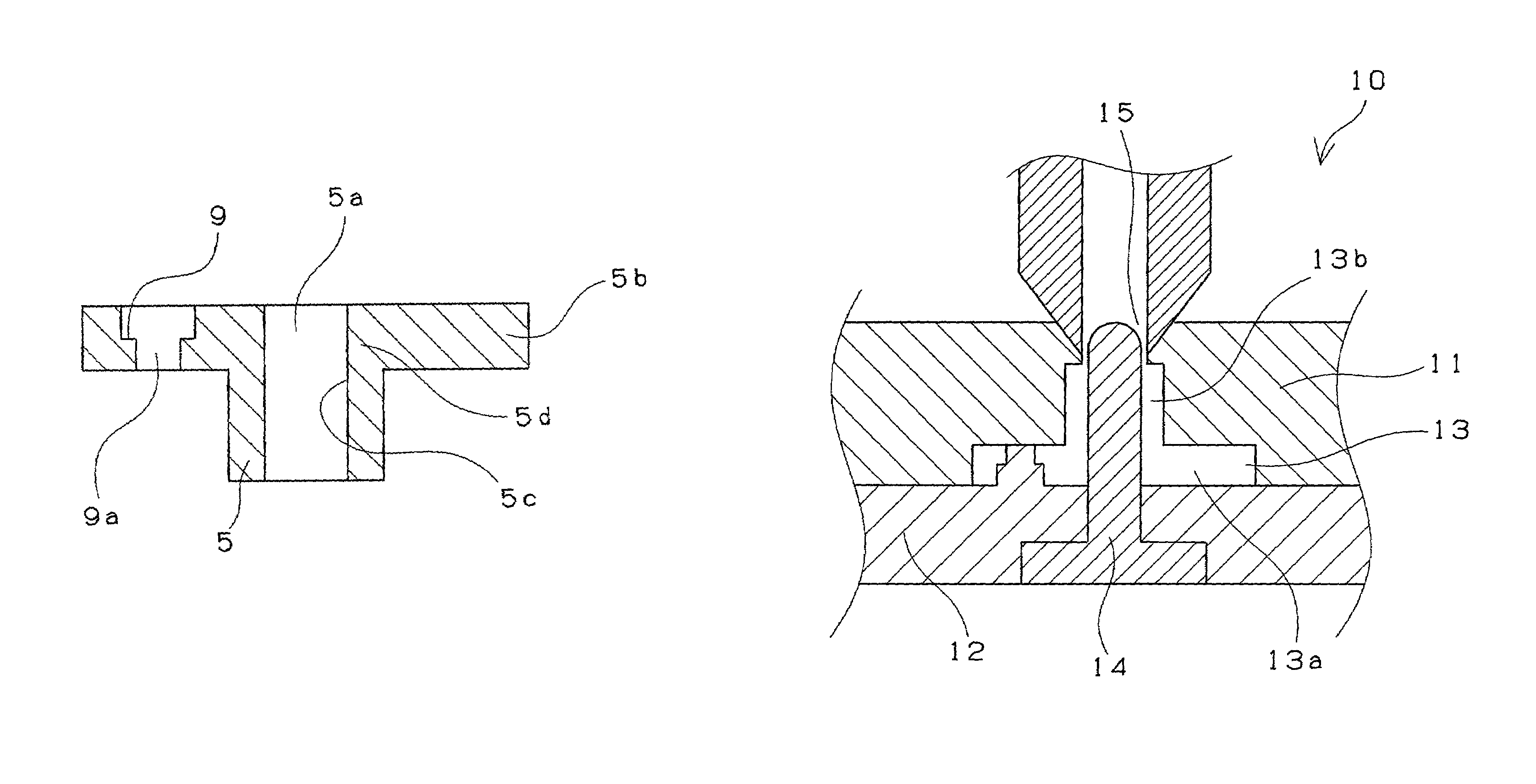

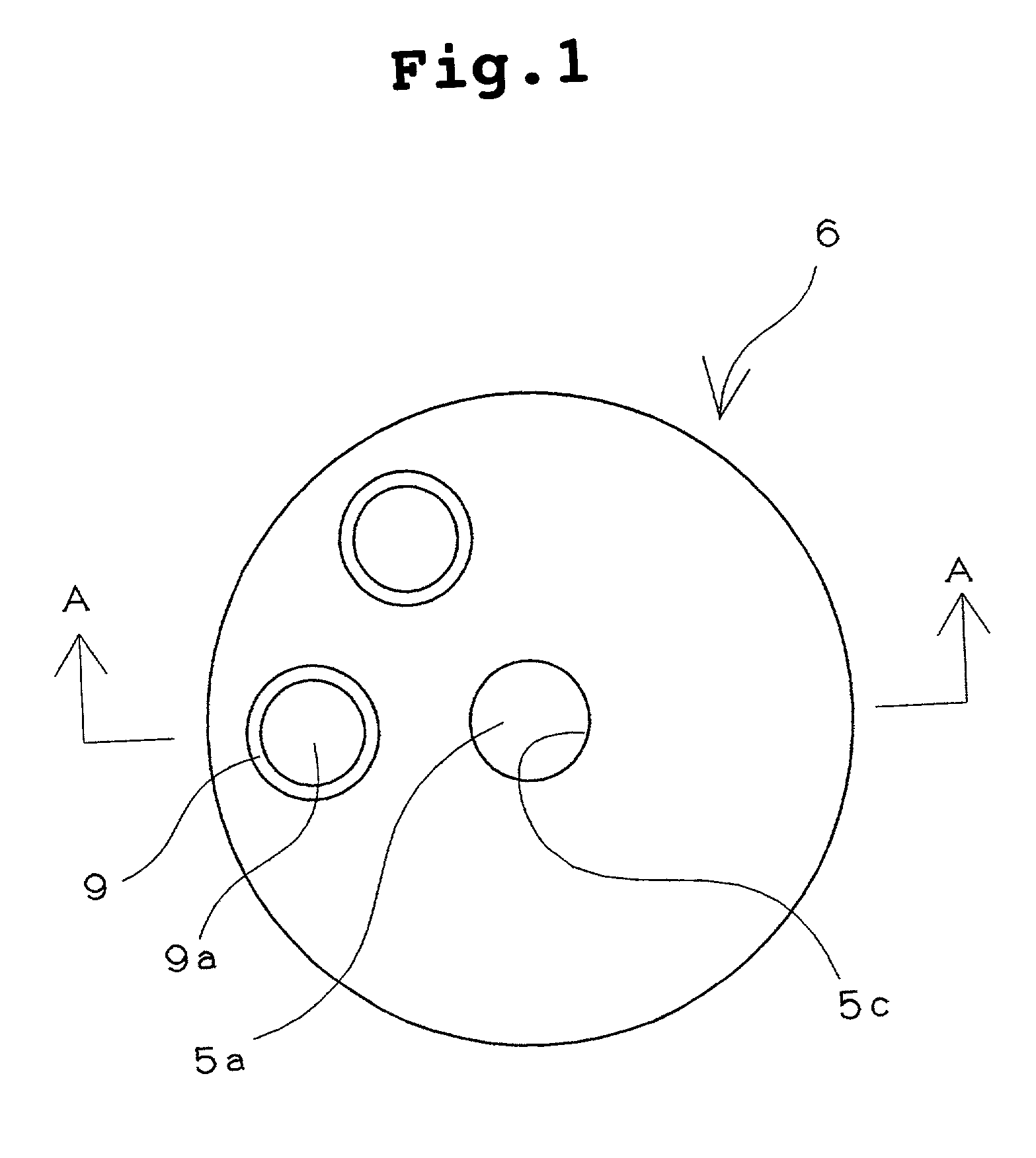

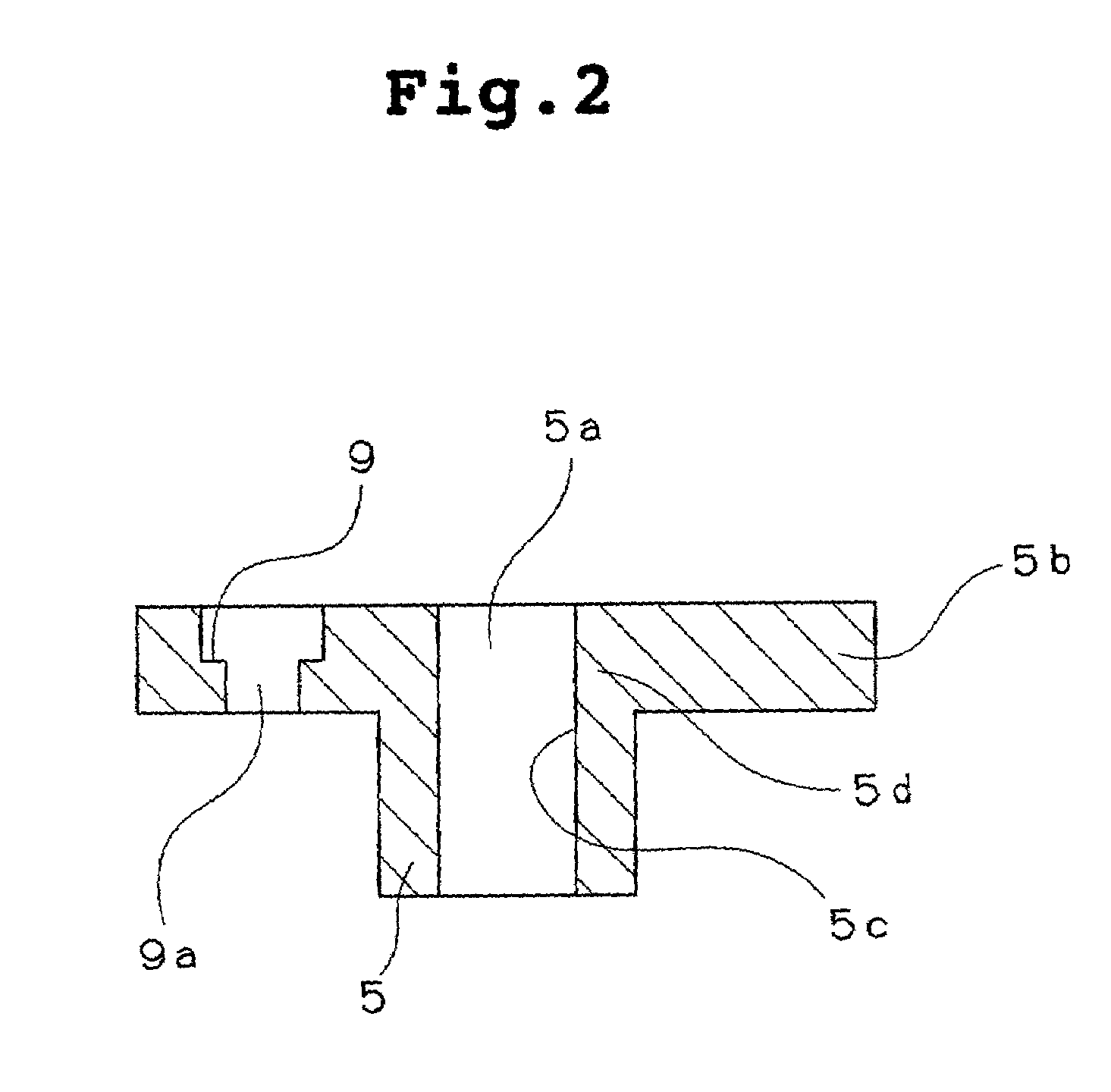

InactiveUS8210638B2Avoid uneven densityImprove image qualityInking apparatusOther printing apparatusSpray nozzleEngineering

An object of the present invention is to provide an ink jet printing apparatus which can prevent possible stripe-like density unevenness in a joint in a print head constructed by joining a plurality of chips together even if the print head is inclined to the regular position of the print head. The present invention uses a print head having the nozzle arrays being shifted in a direction in which the nozzles are arranged, so as to have overlapping portions in a direction orthogonal to the nozzle arranging direction. The present invention controls an ink ejecting operation of the nozzles in the overlapping portions between the plurality of nozzle arrays on the basis of an angle between the nozzle array arranging direction and a direction orthogonal to the direction in which the print head moves relative to the print medium.

Owner:CANON KK

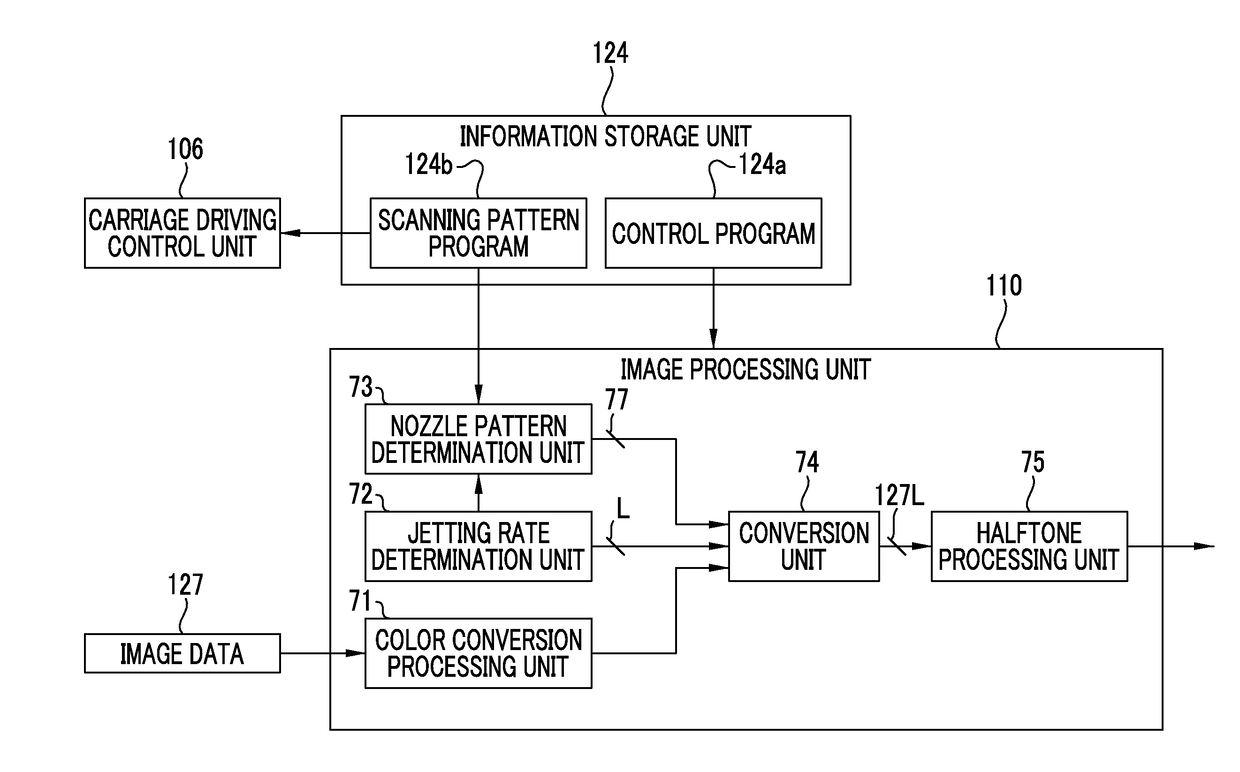

Image processing device, image processing method, and ink jet recording apparatus

ActiveUS20170157919A1Control granularityReduce granularityVisual presentationOther printing apparatusImaging processingComputer graphics (images)

Provided are an image processing device, an image processing method, and an ink jet recording apparatus that can prevent the occurrence of density unevenness, such as banding, regardless of a duty, without causing deterioration of image quality. A jetting rate indicating an ink jetting rate of each of a plurality of nozzles which jet ink in a recording head including the nozzles is determined. A nozzle pattern indicating which of the plurality of nozzles of the recording head is used to record each pixel of an image on a recording medium is determined. The jetting rate of the nozzle which records each pixel is reflected in a gradation value of each pixel of the image on the basis of the determination result of the jetting rate and the determination result of the nozzle pattern to convert the gradation value of each pixel.

Owner:FUJIFILM CORP

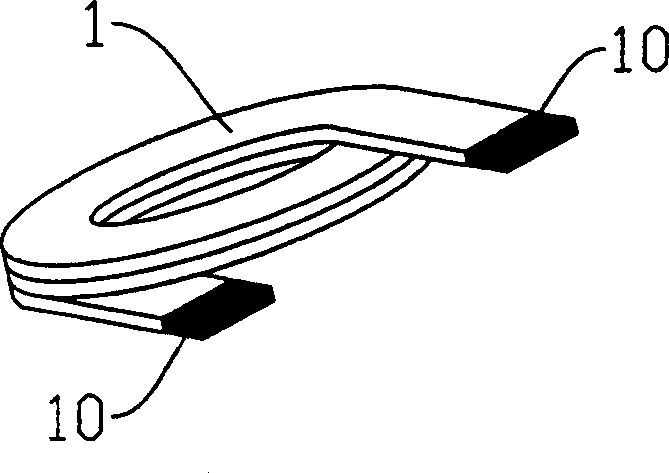

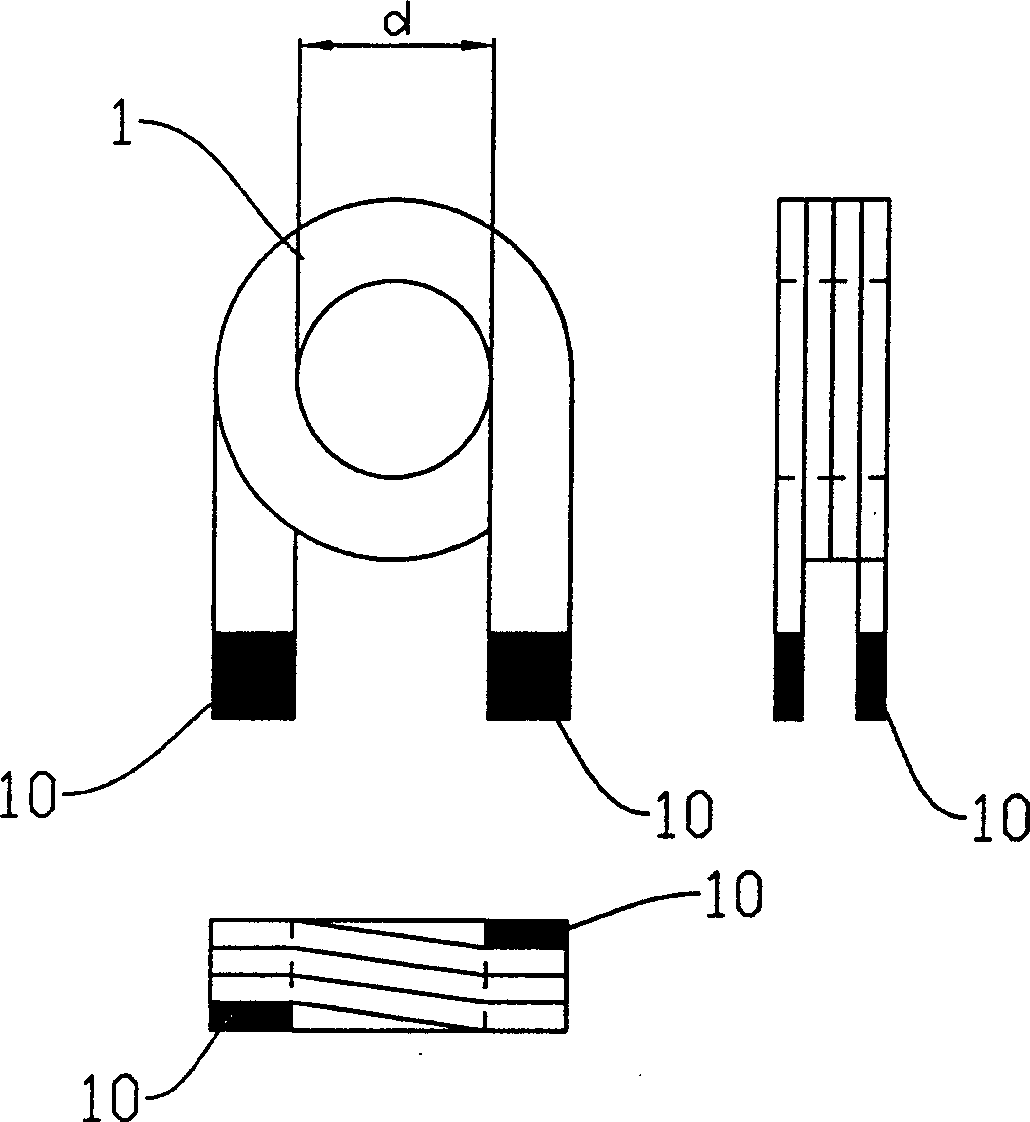

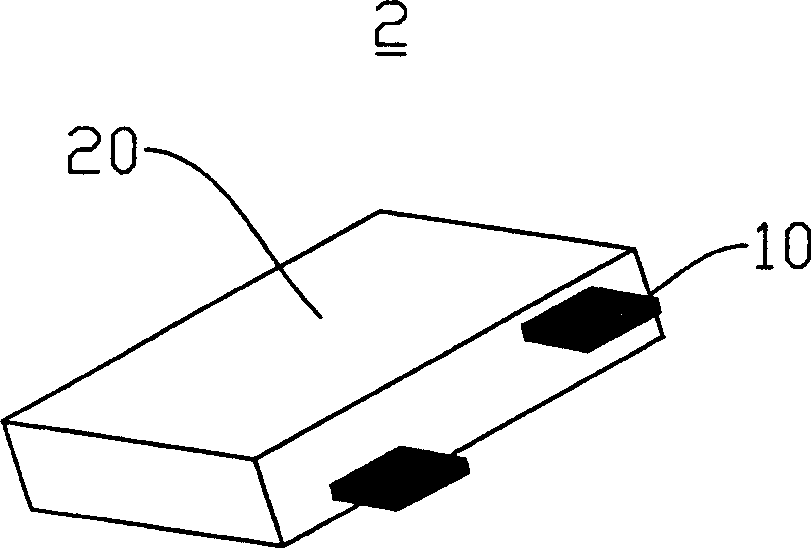

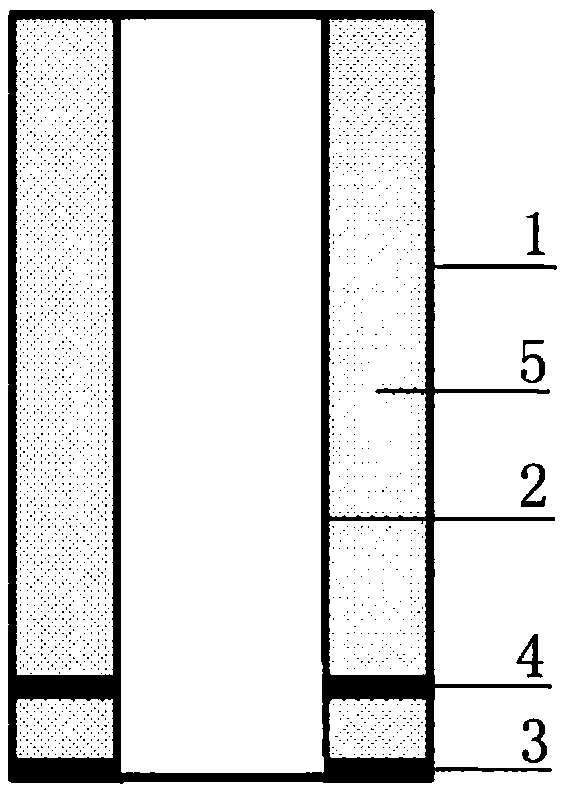

Method for manufacturing buried loop type inductor

InactiveCN1722320AAvoid uneven densityAvoid troubleInductances/transformers/magnets manufactureFixed signal inductancesInductorEngineering

This invention relates to a method for making imbed coil type inductor, which comprises the following steps: in the interval of twice powder-filling movements, inventing the integral mold, and avoiding twice compacting mixed powder to cause the density of magnetic core housing of imbed coil type inductor uneven. The invention is an imbed coil type inductor with uniform density of magnetic core housing, and can be applied in adopting different-height terminal of coil to make imbed coil type inductor.

Owner:DELTA ELECTRONICS INC

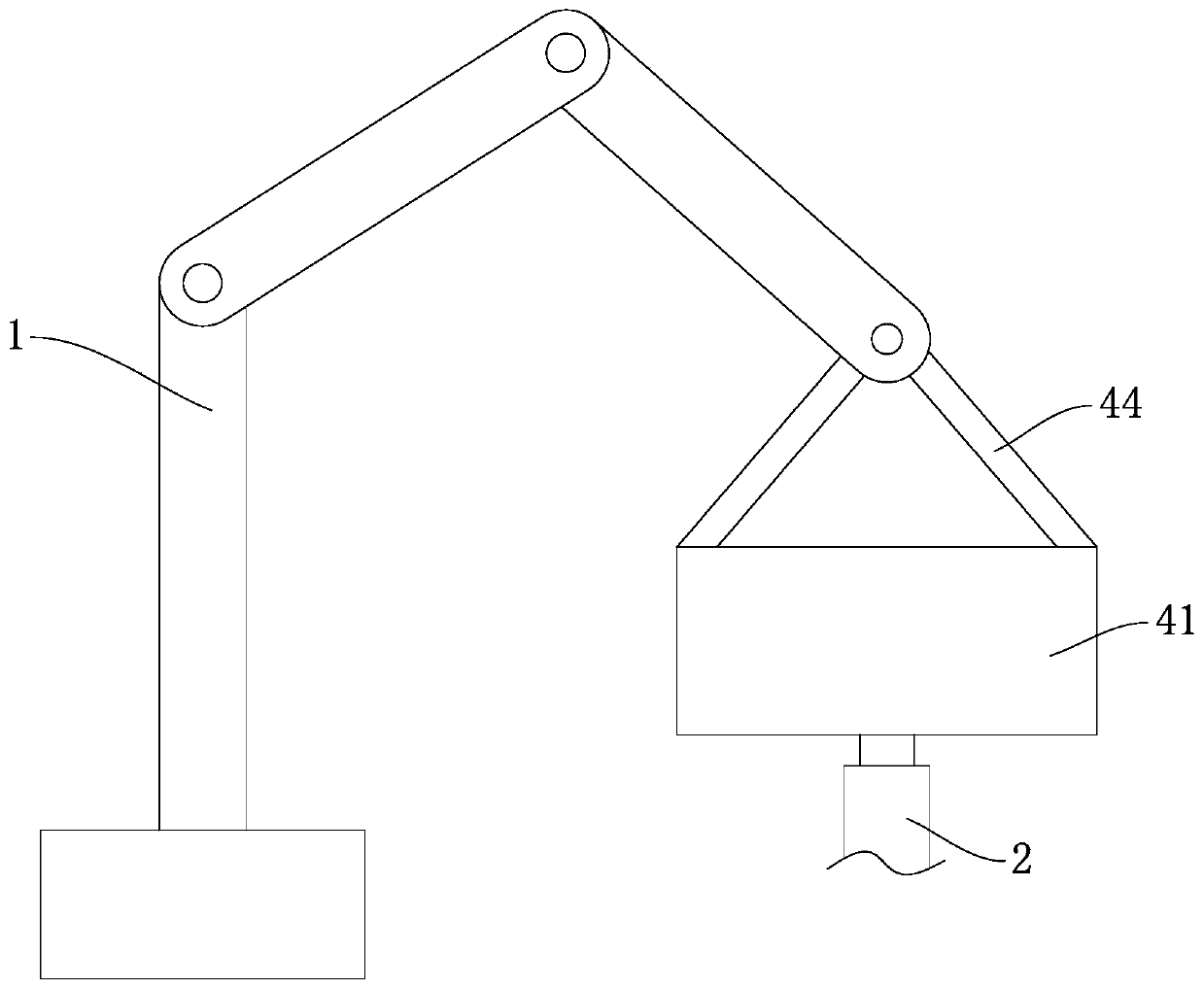

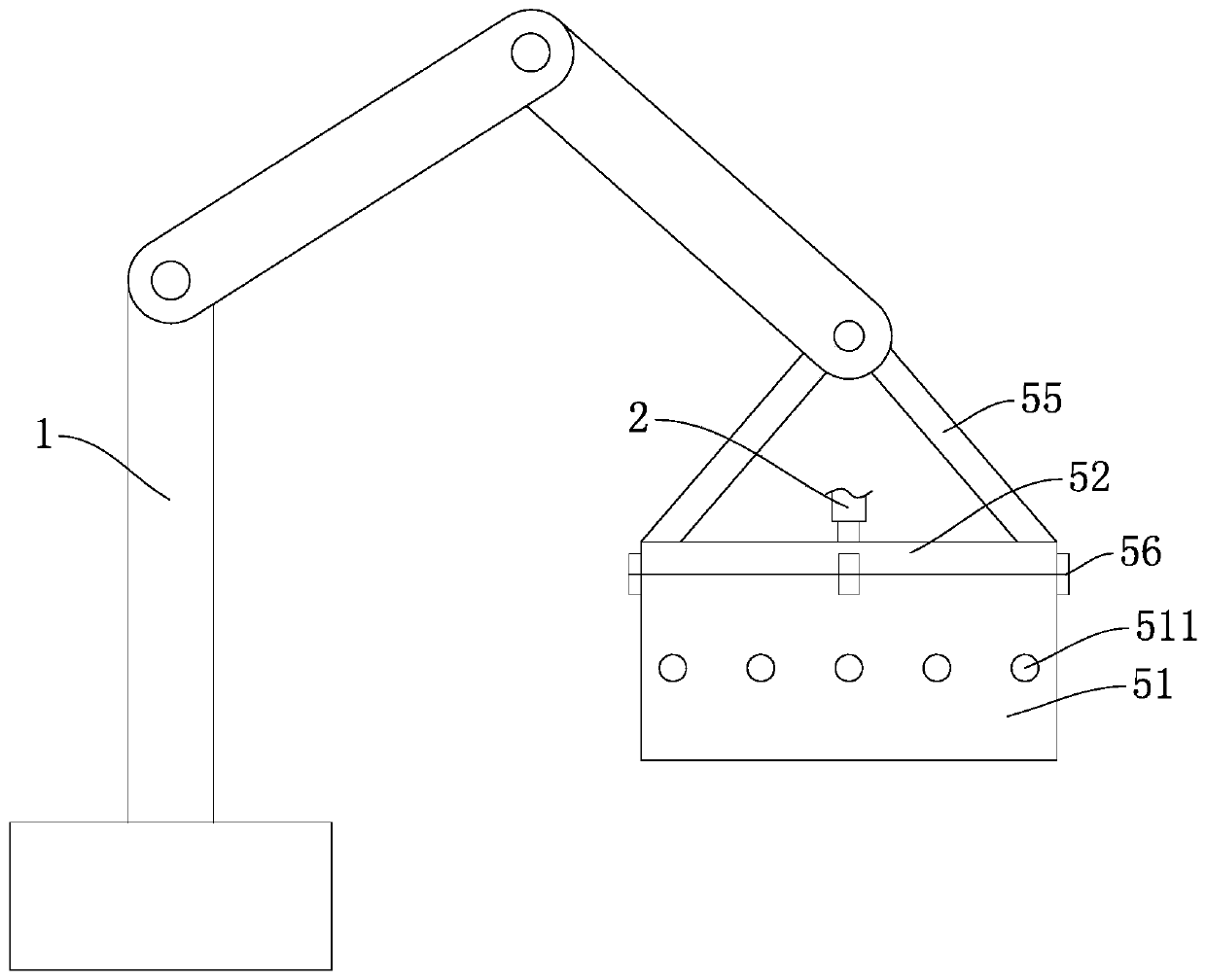

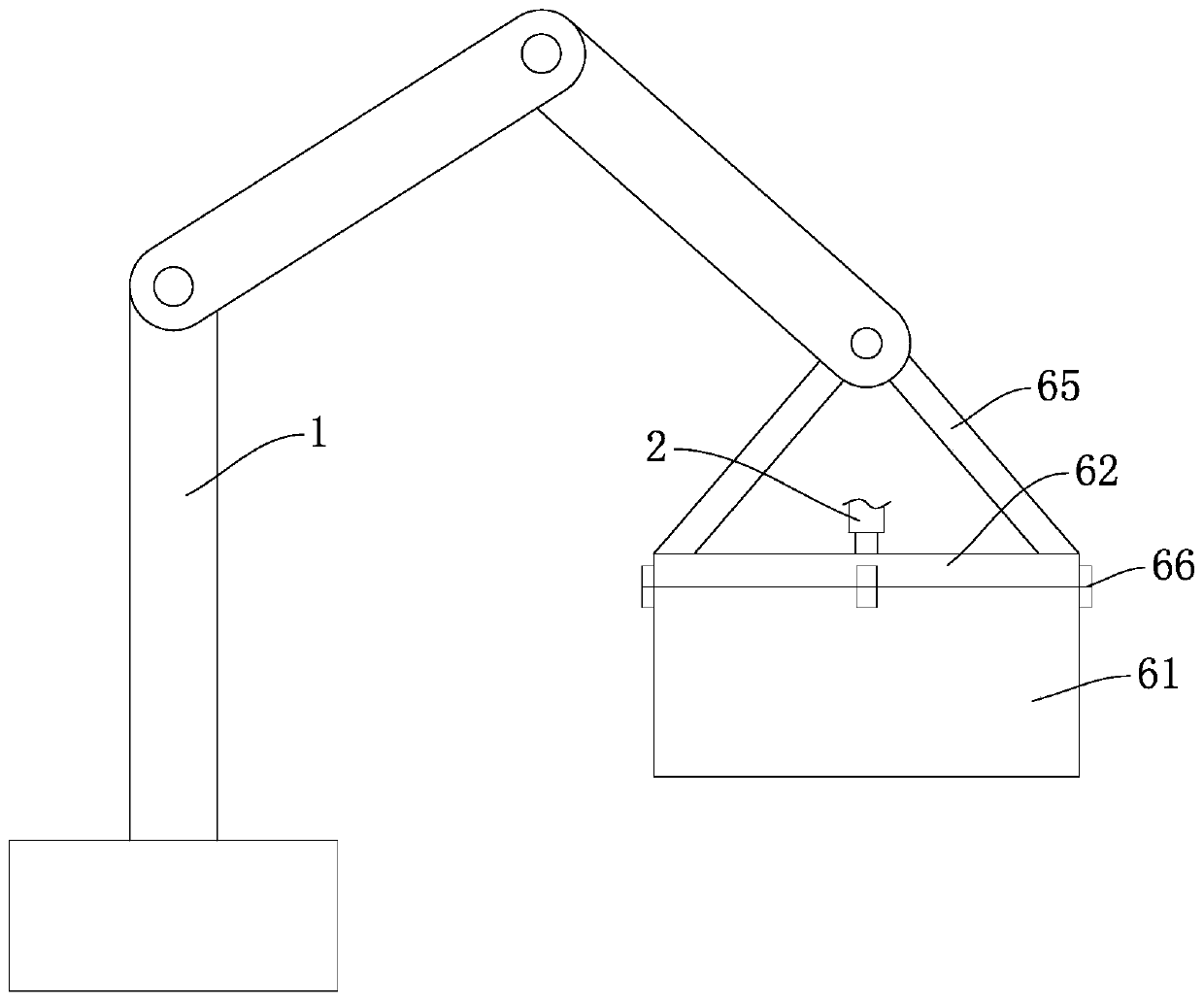

Foam concrete distributing machine and distributing method thereof

PendingCN110328738AReduce impactAvoid uneven pore sizeFeeding arrangmentsFoam concreteWaste management

The invention discloses a foam concrete distributing machine and a distributing method thereof. The machine comprises a mechanical arm, wherein a buffer decompression device is fixed on the front endof the mechanical arm; and the buffer decompression device communicates with a feeding pipe. The method comprises the following steps: 1, using foam concrete production equipment to convey foam concrete into the buffer decompression device; 2, using the mechanical arm to drive the buffer decompression device to move on a pouring area along the S-shaped direction; 3, determining whether a layer more needs to be poured or not by a worker, if yes, proceeding to step 4, if no, stopping the foam concrete production equipment from conveying the foam concrete into the buffer decompression device, andstopping the work of the mechanical arm; and 4, stopping the foam concrete production equipment from conveying the foam concrete into the buffer decompression device, using the mechanical arm to drive the buffer decompression device to move to the starting point of the last pouring, and returning to the step 1. By means of the machine and the method, the quality of a foamed concrete facility after pouring is improved.

Owner:卓建科

Image forming apparatus

InactiveUS20050271428A1Image stabilizationPreventing white spotDevelopersElectrographic process apparatusLatent imageImage formation

In the image forming apparatus by: visualizing an electrostatic latent image formed on an electrostatic charge carrying member; transferring a toner image, which is thus visualized, to a recording medium, or to a recording medium through an intermediate transfer material; and fixing the toner image, which is thus transferred to the recording medium, to obtain a recorded image, the toner includes at least a fixing resin, a colorant, a releasing agent, and an external additive, the toner has an average particle diameter in a range of from 4 to 12 μm and including no particle having a diameter of 45 μm or more, a ratio of a toner adhesion amount in a character part to a toner adhesion amount in a solid image part upon printing is more than 0. 5 and less than 4, and the toner adhesion amount in a character part is 1.6 mg / cm2 or less.

Owner:RICOH KK

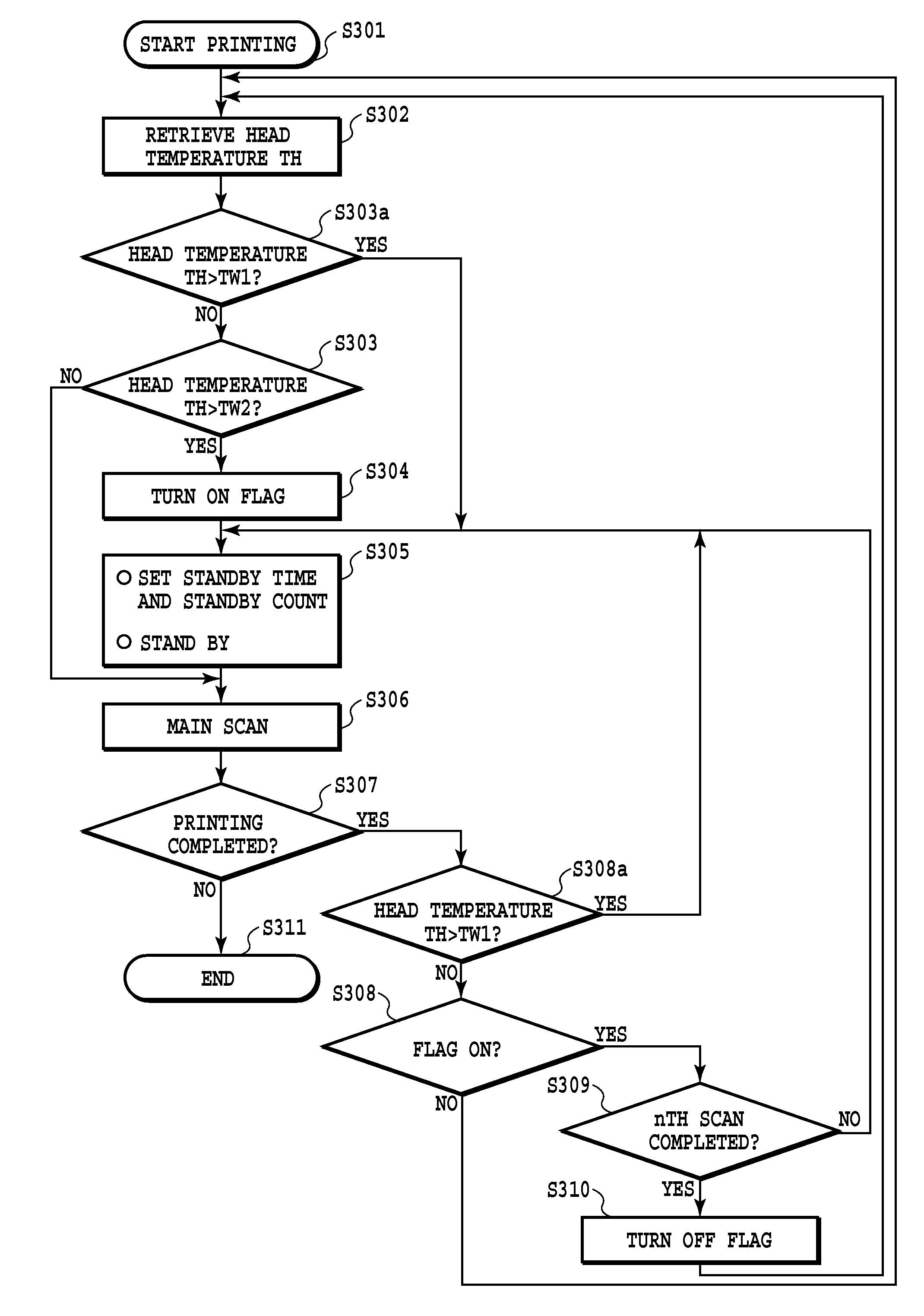

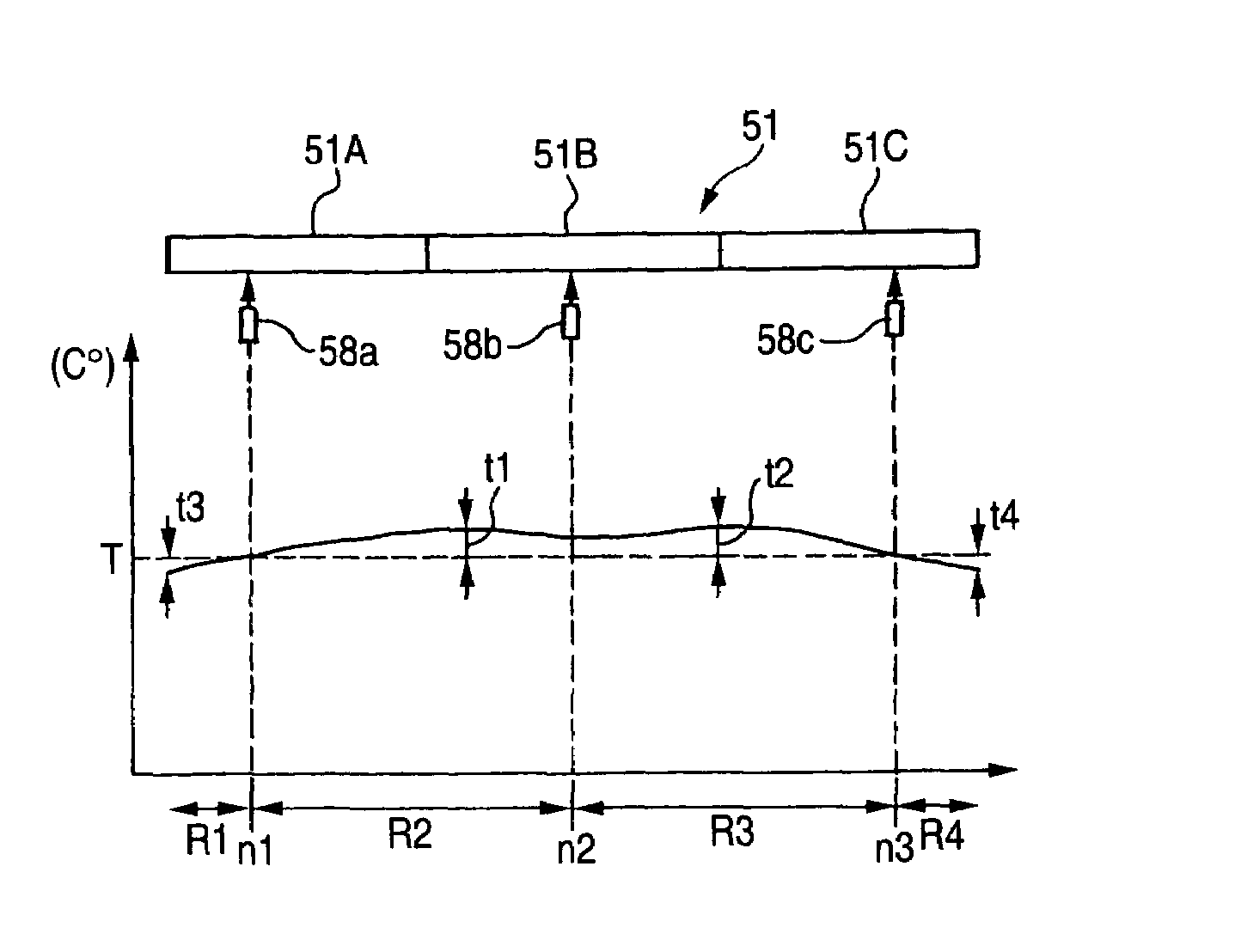

Ink jet printing apparatus and ink jet printing method

An object of the present invention is to provide an ink jet printing apparatus that inhibits the temperature of a print head from increasing excessively while preventing significant density or hue unevenness from occurring in images, without the need for a complicated structure or complicated control. Thus, the present invention detects temperature of the print head, and sets number of scans in which the print head is to stand by until start of scanning and a standby time for each of the set number of scans by the print head, on the basis of the detected temperature.

Owner:CANON KK

Melamine formaldehyde resin microwave foaming and after-treating device

The invention discloses a melamine formaldehyde resin microwave foaming and after-treating device and belongs to the technical field of resin microwave foaming devices. The device comprises a microwave cavity and a curing and drying cavity. A liquid ammonia spraying cavity is formed between the microwave cavity and the curing and drying cavity. Multiple drying microwave sources are arranged on the top of the curing and drying cavity, hot air diffusion pipe nets are arranged on the side wall of the curing and drying cavity and connected with a hot air pipeline, and the hot air pipeline is connected with a heating device. Air outlets are formed in the top of the curing and drying cavity, electric valves are arranged on the air outlets, and the air outlets are connected with an air outflow pipeline through the electric valves. Prepared melamine resin foam is low in brittleness, not prone to powder falling and high in stretch and tear strength, the problems in the prior art are effectively solved, and melamino-formaldehyde foam has good mechanical performance and anti-flaming and noise-reducing performance.

Owner:郑州峰泰纳米材料有限公司

Preparation method of large-porosity porous tungsten tube

ActiveCN108889953AUniform structureHigh strengthTransportation and packagingMetal-working apparatusProduct processingPowder metallurgy

The invention belongs to the field of preparation technologies of powder metallurgy porous metal materials, in particular to a preparation method of a large-porosity porous tungsten tube. The method comprises the following steps of tungsten powder and die preparation, die-filling, pre-sintering, demoulding, high-temperature sintering and finished product processing. The preparation method solves the problem that an existing isostatic cool pressing or die pressing, sintering and processing methods cannot prepare the large-porosity porous tungsten tube with high purity, a large length-diameter ratio, a thin wall and high strength, fills in the technical gap of a large-porosity porous tungsten tube material, the large-porosity porous tungsten tube material prepared by adopting the above process has a uniform structure, high strength, high purity, a large length-diameter ratio, a thin wall and high hardness, wherein the flexural strength can reach 16 MPa, the purity can reach 99.99%, the length-diameter (outer diameter) ratio can reach 10:1, the wall thickness can be as low as 1 / 15 of the diameter (outer diameter), the hardness HV30 can reach 280, the production process is reasonable,the production efficiency is high, and the production cost is low.

Owner:安泰天龙钨钼科技有限公司 +1

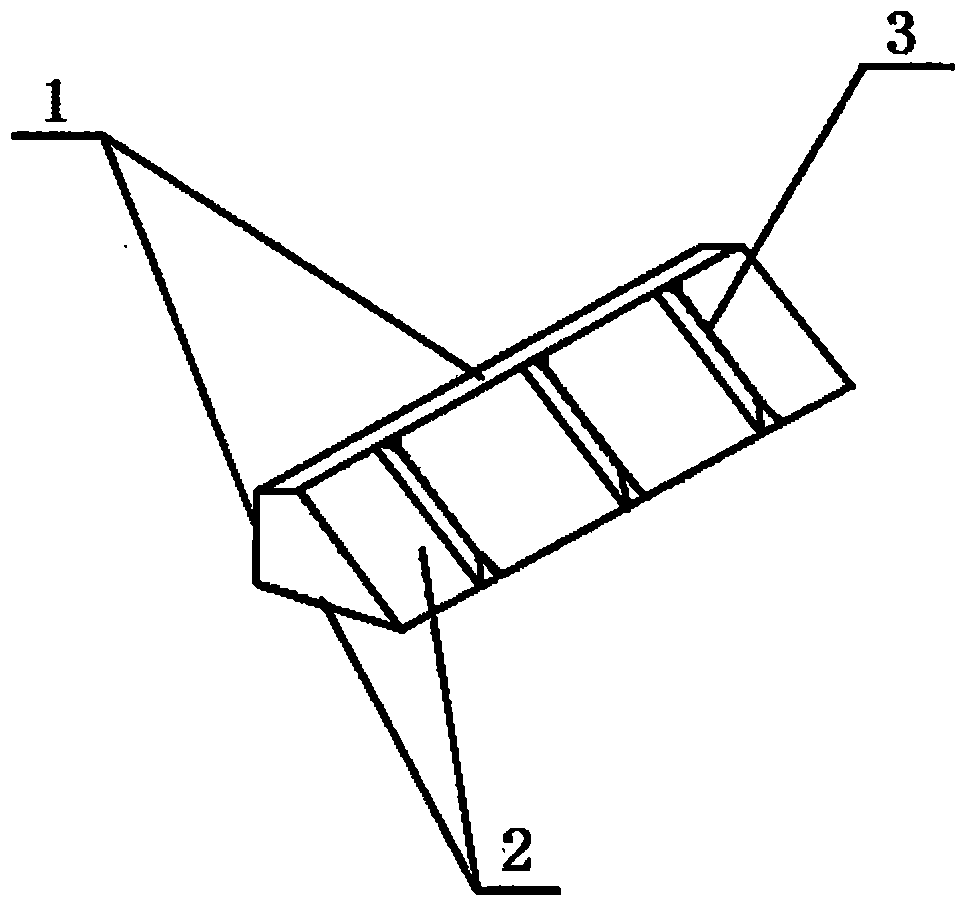

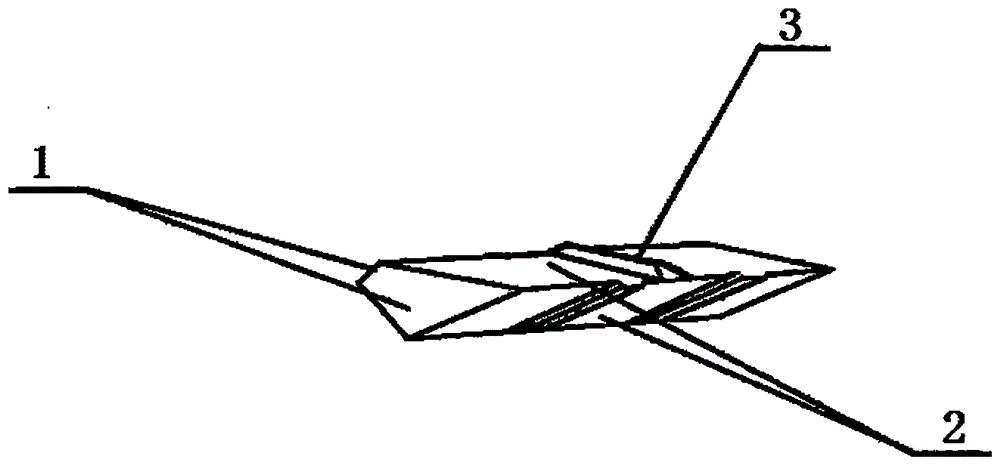

Zipper-type wall part and zipper key for producing the same

PendingCN105926841AAvoid uneven densityAvoid breakingMouldsBuilding componentsStress concentrationEngineering

The invention relates to a zipper-type wall part, also relates to a zipper key for the production of the zipper-type wall part. A zipper-type wall part is provided with a wedge groove in at least one corner of the part, and optionally the wedge groove edge is provided with a notch. The zipper-type wall part is characterized in that at least one side of the wedge groove is provided with one or more, preferably two or more than two grooves or protrusions. The invention can achieve the beneficial effects of: a pouring material in the zipper groove can be dispersed by gravity to each groove or protrusion, so as to avoid the uneven density in pouring; and stress between each layer of grooves or protrusions can be dispersed into the respective sides of the zipper groove, so as to avoid stress and rupture due to excessive local stress concentration and improve the overall quality of wall construction.

Owner:姚景祥

COF board

InactiveUS7659605B2High densityImprove connection reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical and Electronics engineering

Owner:NITTO DENKO CORP

Developing apparatus

A developing apparatus having a developer carrying member carrying developer including toner, a developer regulating member regulating the layer thickness of the developer carried on the developer carrying member, and a lubricant provided in a contact portion between the carrying member and the regulating member with the developer being not present on the carrying member, wherein the lubricant includes a first polymer particle which is of a spherical shape having an average degree of circularity of 0.90 or greater and is of a polarity opposite to the charging polarity of the toner, and a second polymer particle of a scalelike shape and of the same polarity as the charging polarity of the toner.

Owner:CANON KK

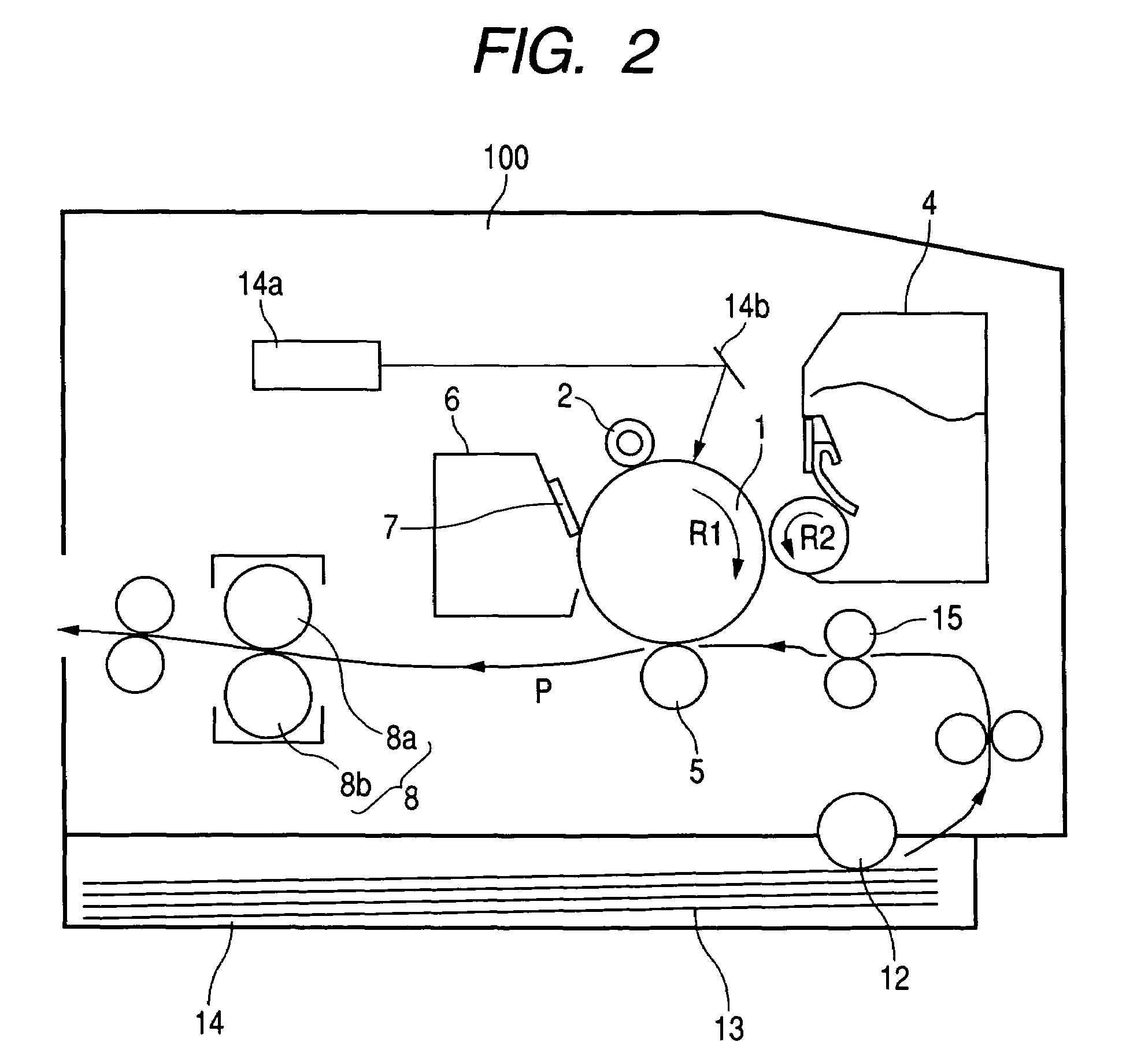

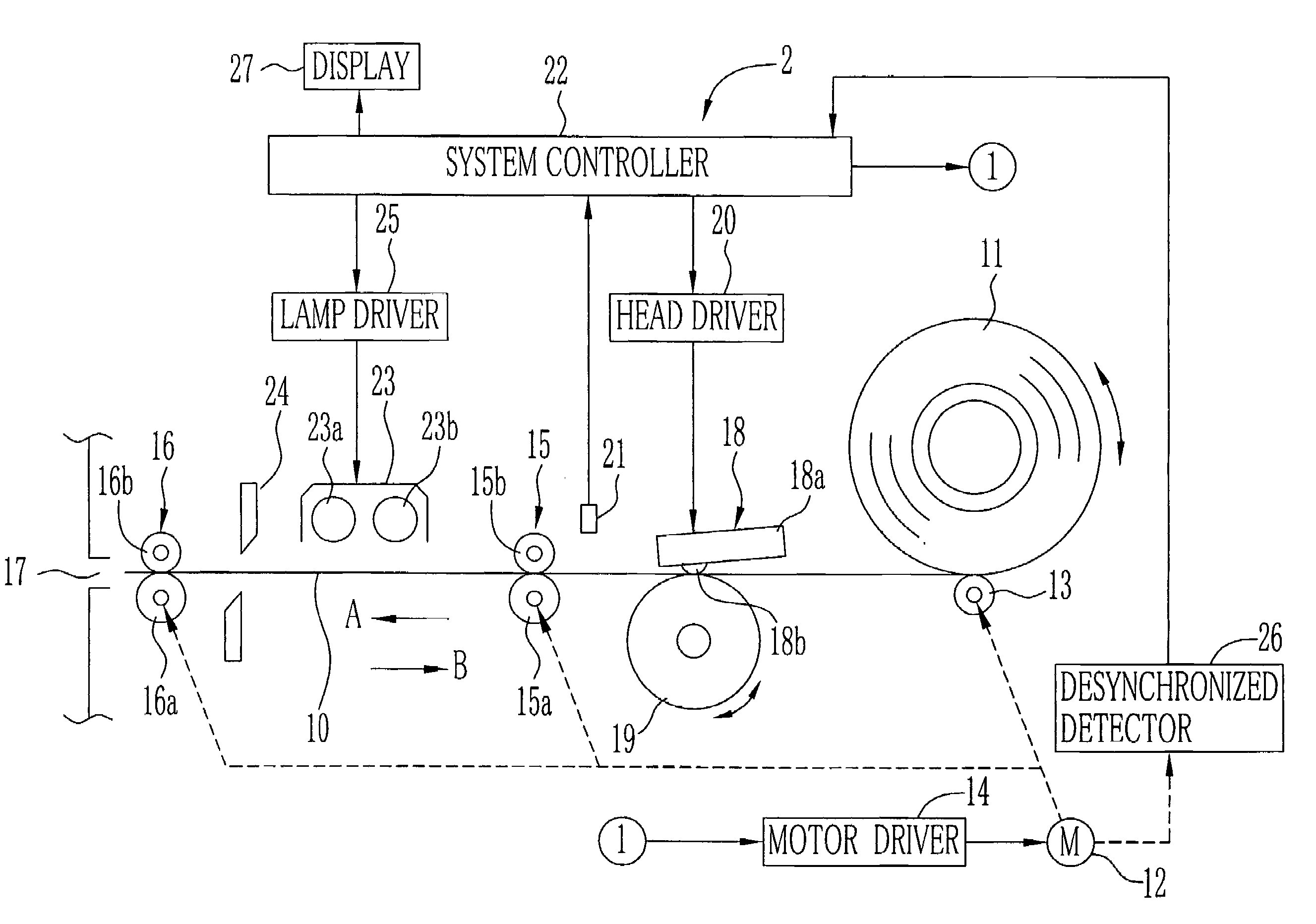

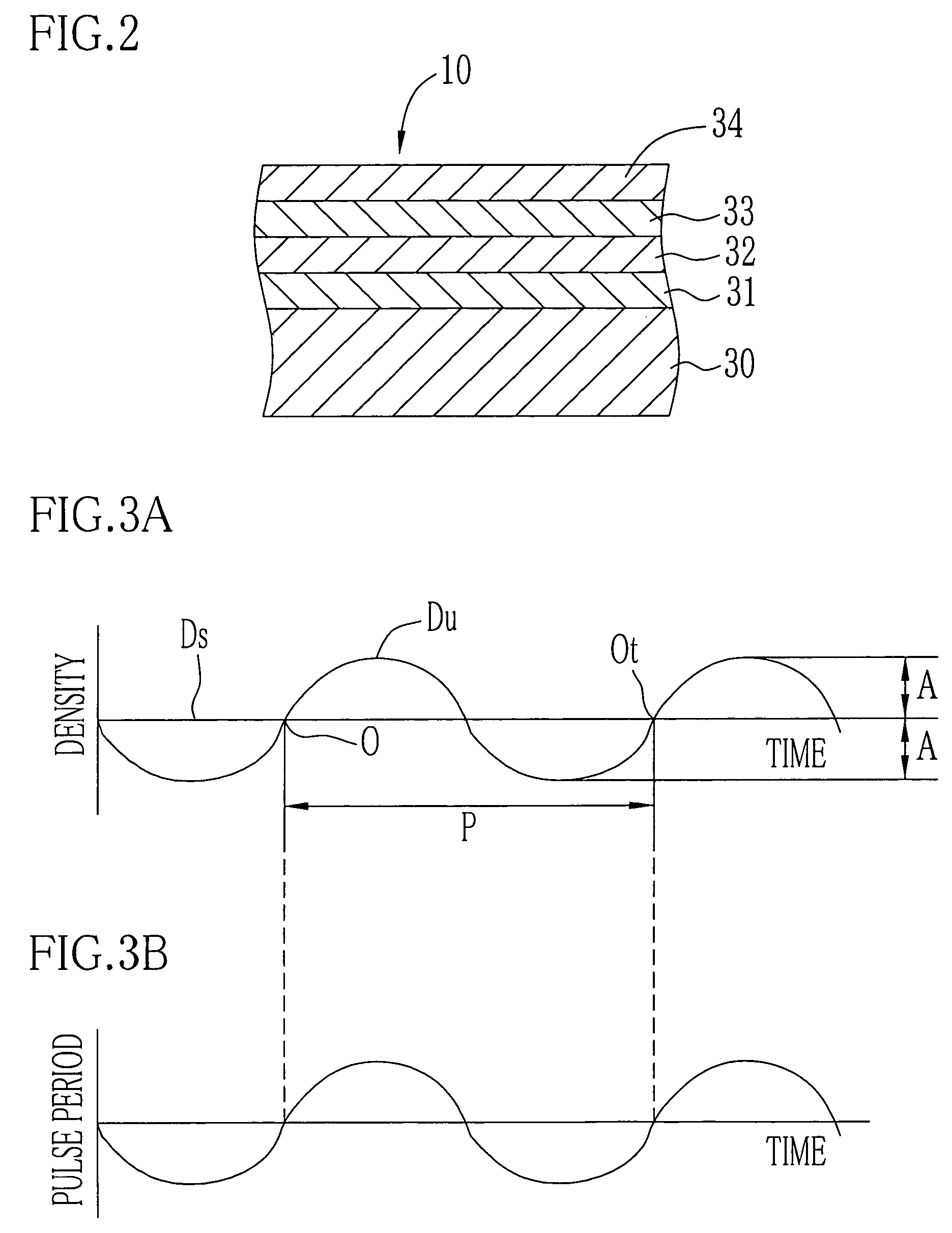

Image forming apparatus and density unevenness preventing method

InactiveUS7190384B2Increasing part costAvoid uneven densityOther printing apparatusLine sensorImage formation

A system controller of a color thermal printer obtains a density profile of an image with respect to a feeding direction of a color thermal recording paper based on density of a test print measured by a CCD line sensor, and then extracts a density unevenness component, which fluctuates periodically, from the density profile. The system controller relates the density unevenness component in one period to a rotating position of a feed motor so as to create a period profile of a driving pulse to offset the unevenness component. When recording the image, the driving pulse is given to the feed motor based on the period profile, so that the drive of the feed motor is controlled.

Owner:FUJIFILM HLDG CORP +1

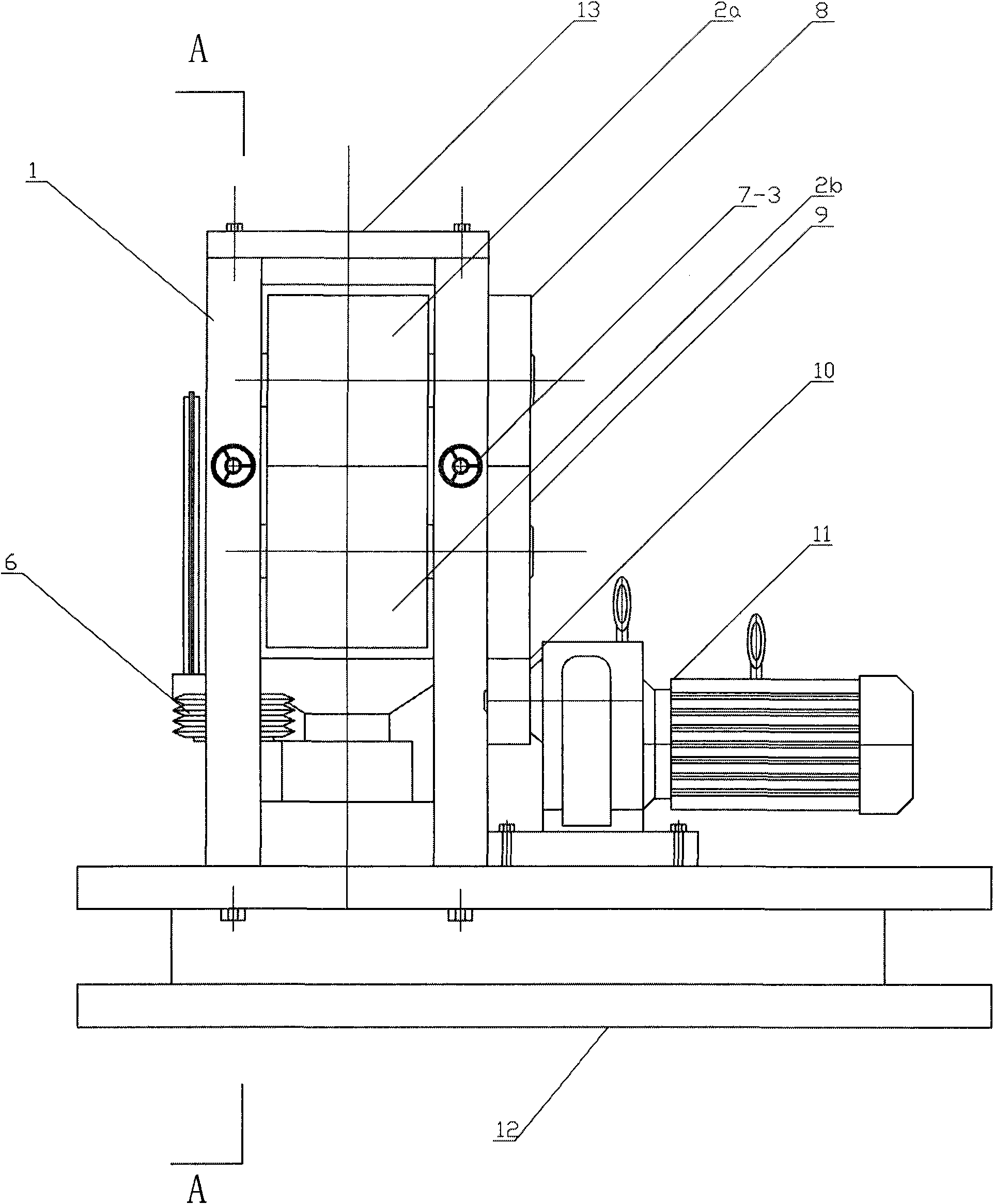

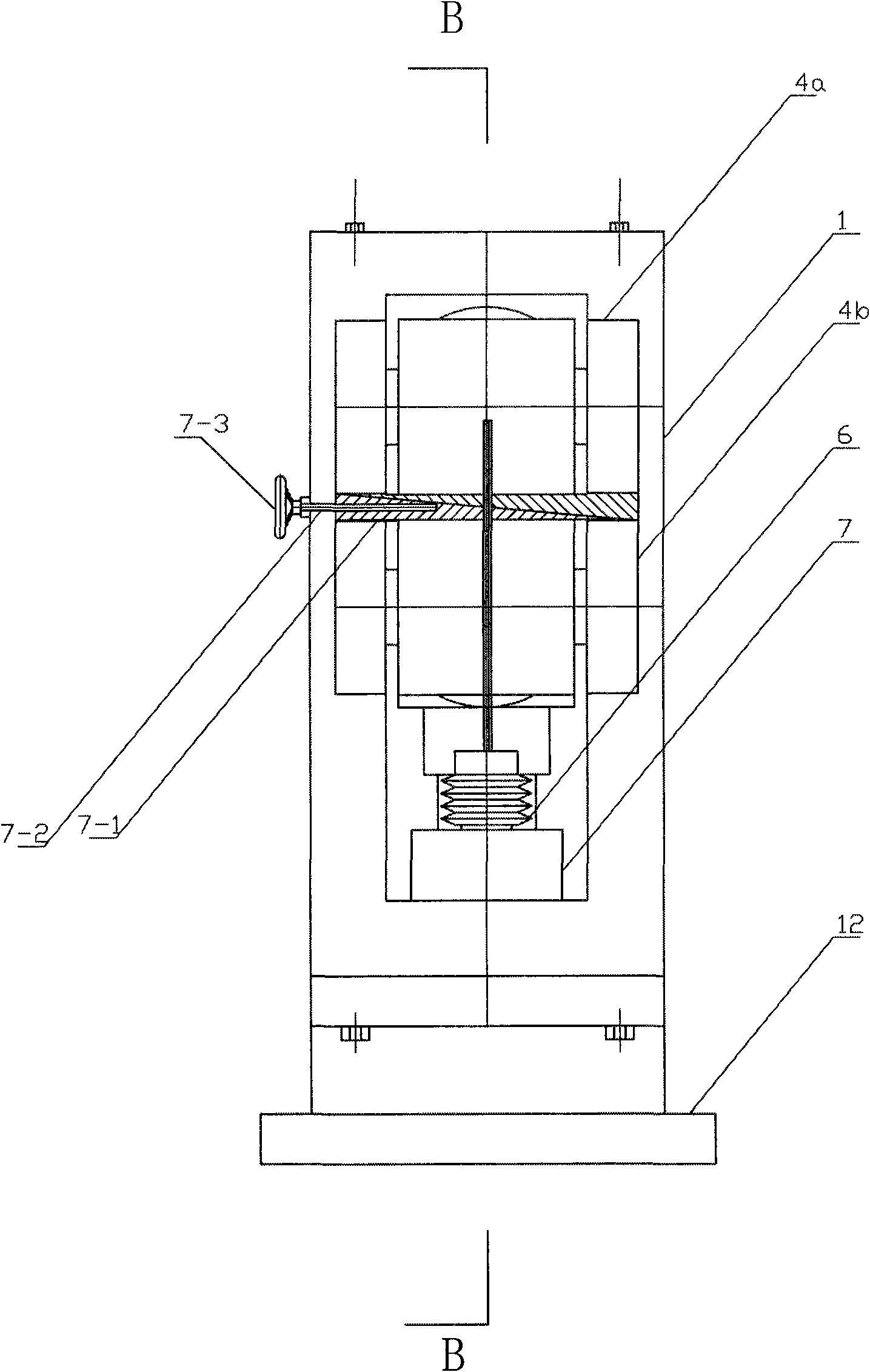

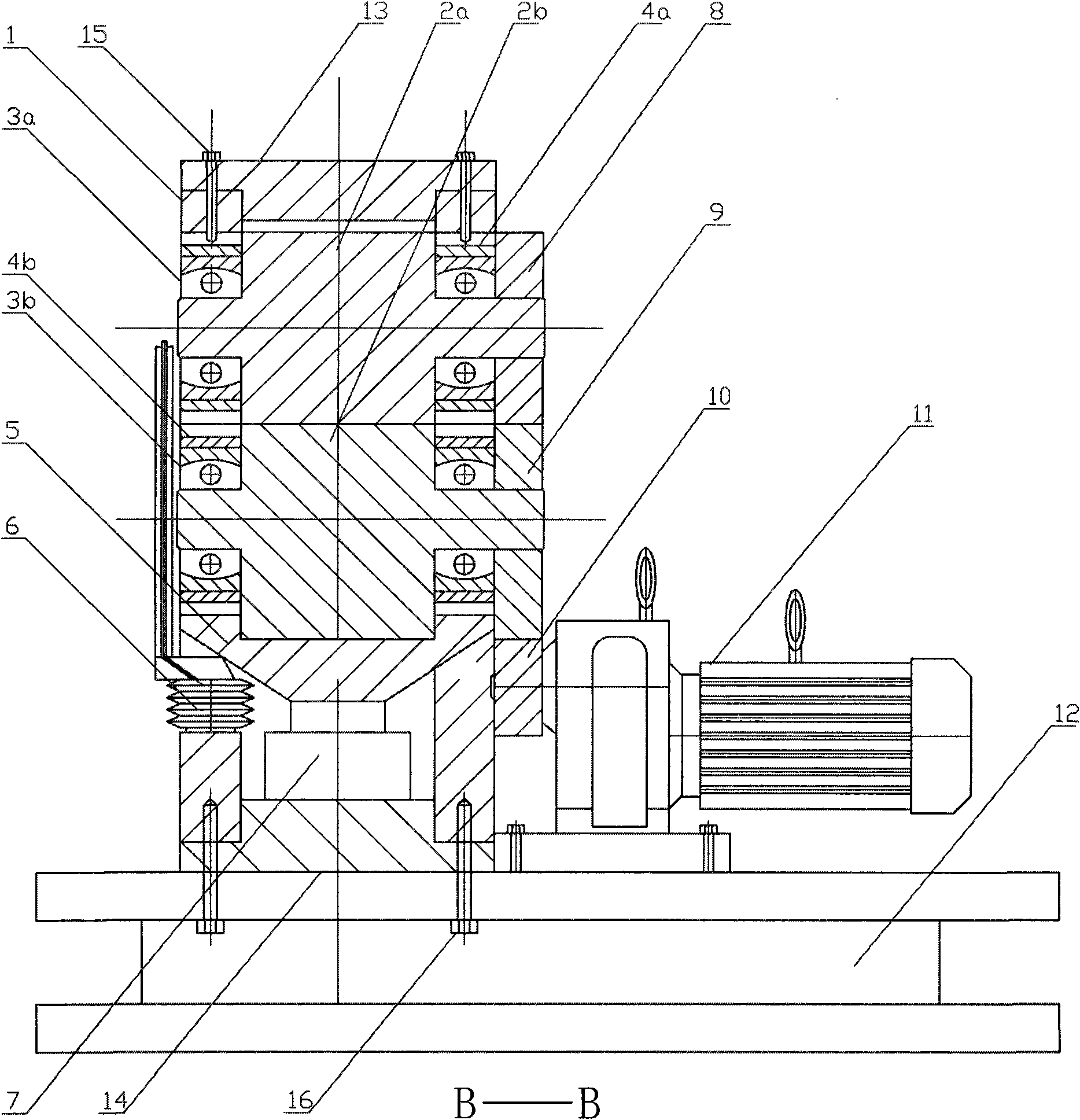

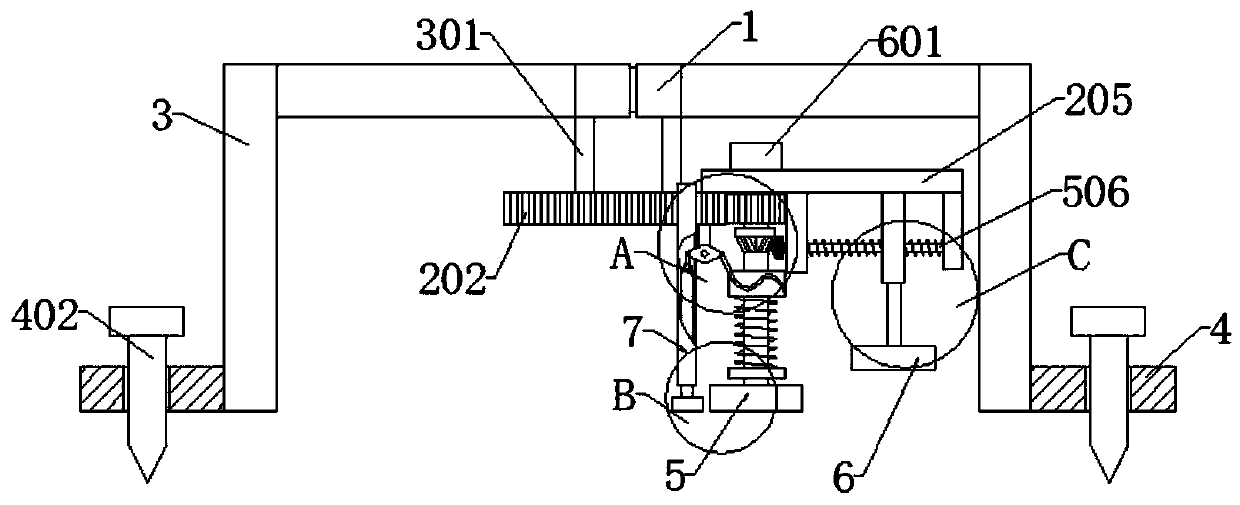

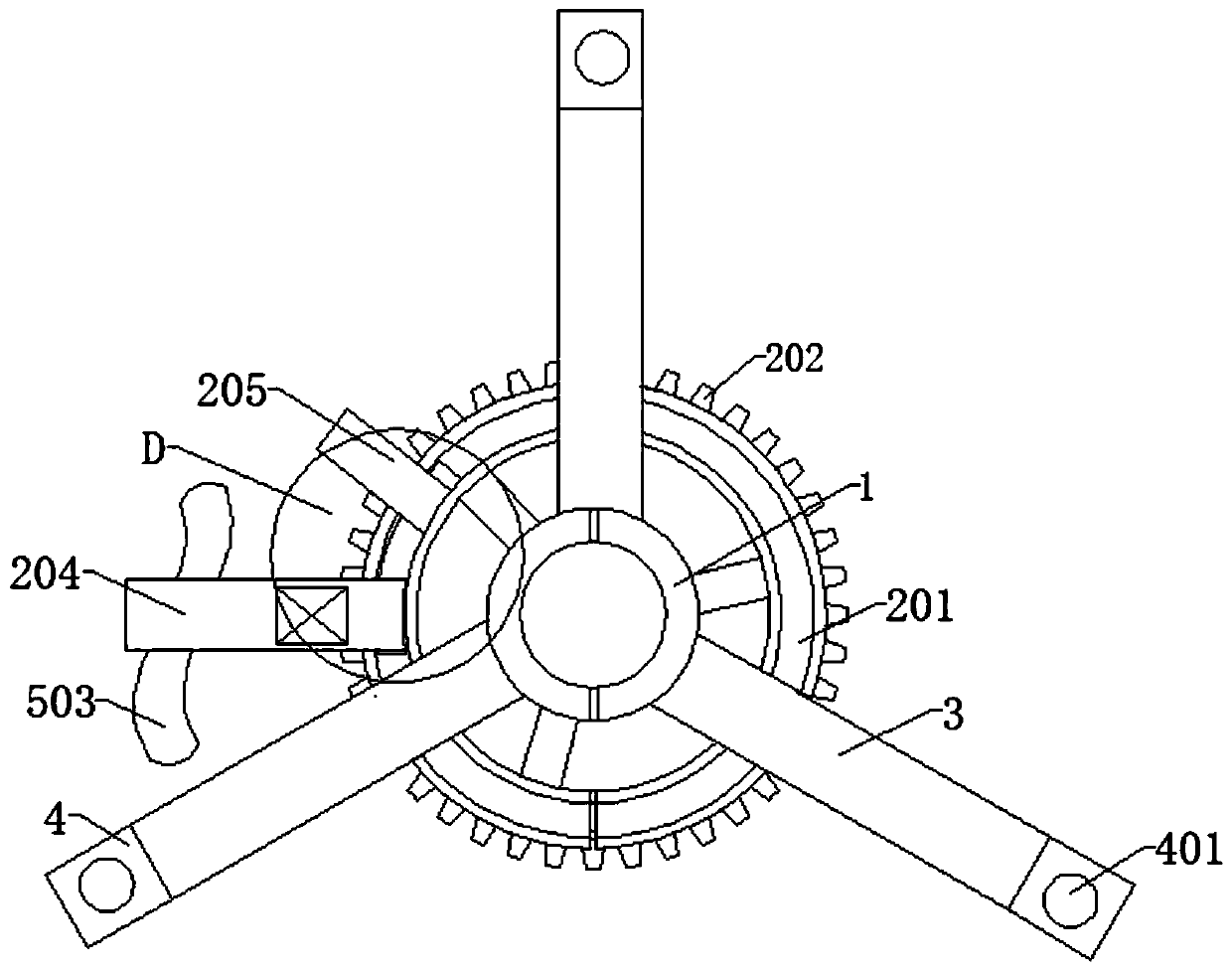

Single-point supporting film rolling mill capable of displaying roller gap

InactiveCN102049419AOvercome uneven thicknessAvoid uneven densityRoll force/gap control deviceMeasuring devicesGear wheelDisplay device

The invention discloses a single-point supporting film rolling mill capable of displaying a roller gap. The film rolling mill comprises a frame type bracket, an upper roller, an upper roller bearing, an upper roller bearing block, a lower roller, a lower roller bearing, a lower roller bearing block, an inverted prismatic table supporting seat, a roller gap change on-line sensing display, a slant wedge set, an oil cylinder, a driven gear pair, a driven gear, a main gear, a speed reduction motor, a base, an upper seat beam, a lower seat beam, a bolt, a bottom bolt, and the like. Compared with the prior art, the film rolling mill solves the problem of imbalance of supporting points at two ends, thus the problem of nonuniform thickness of a rolled lithium ion battery pole piece is solved; and the gap between two rollers can be displayed on line, and gap changes can be instantly corrected in a film rolling process so that the problem that the compactedness of the rolled roll lithium ion battery pole piece is nonuniform is solved.

Owner:赵宽 +1

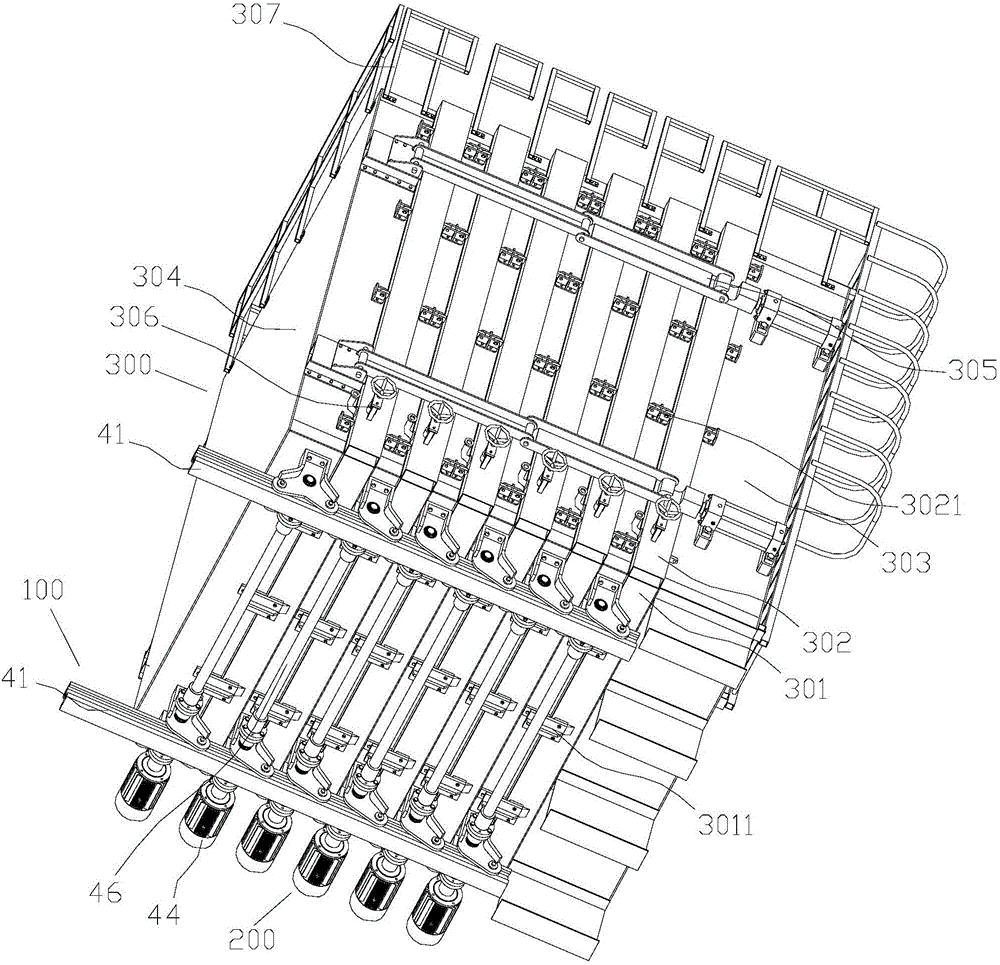

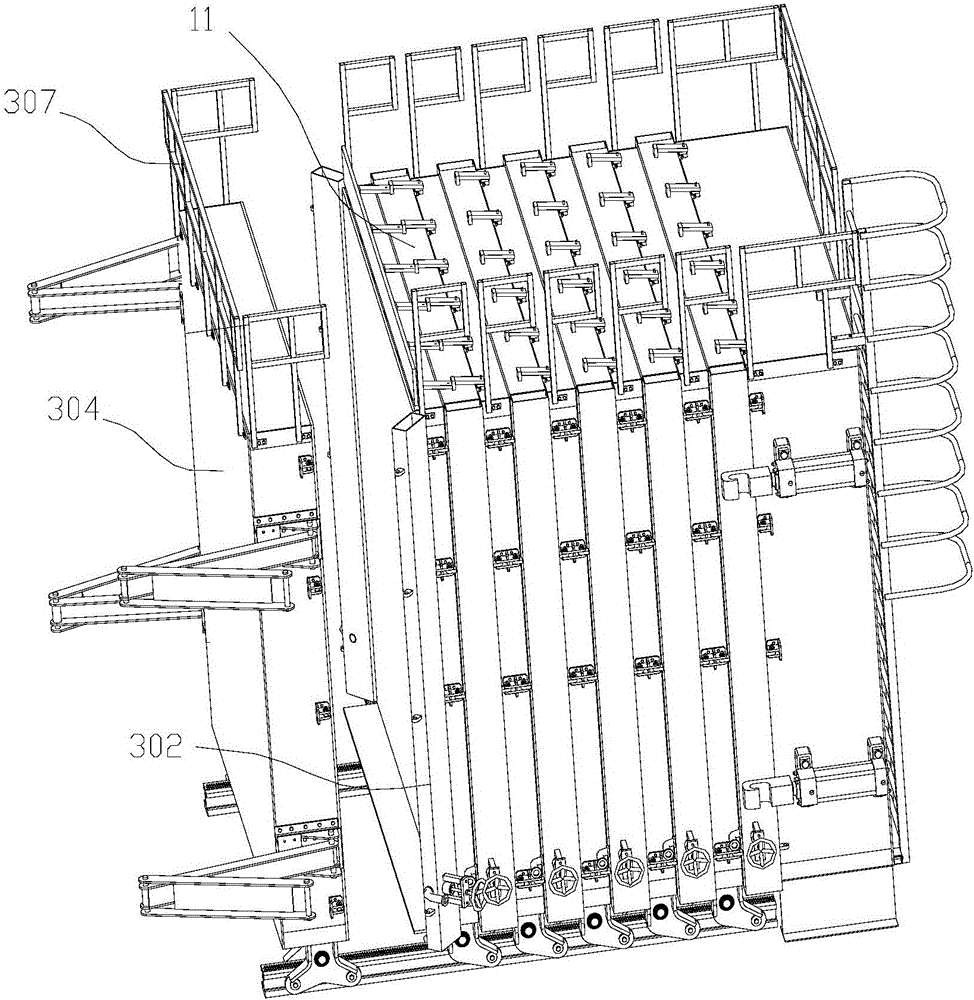

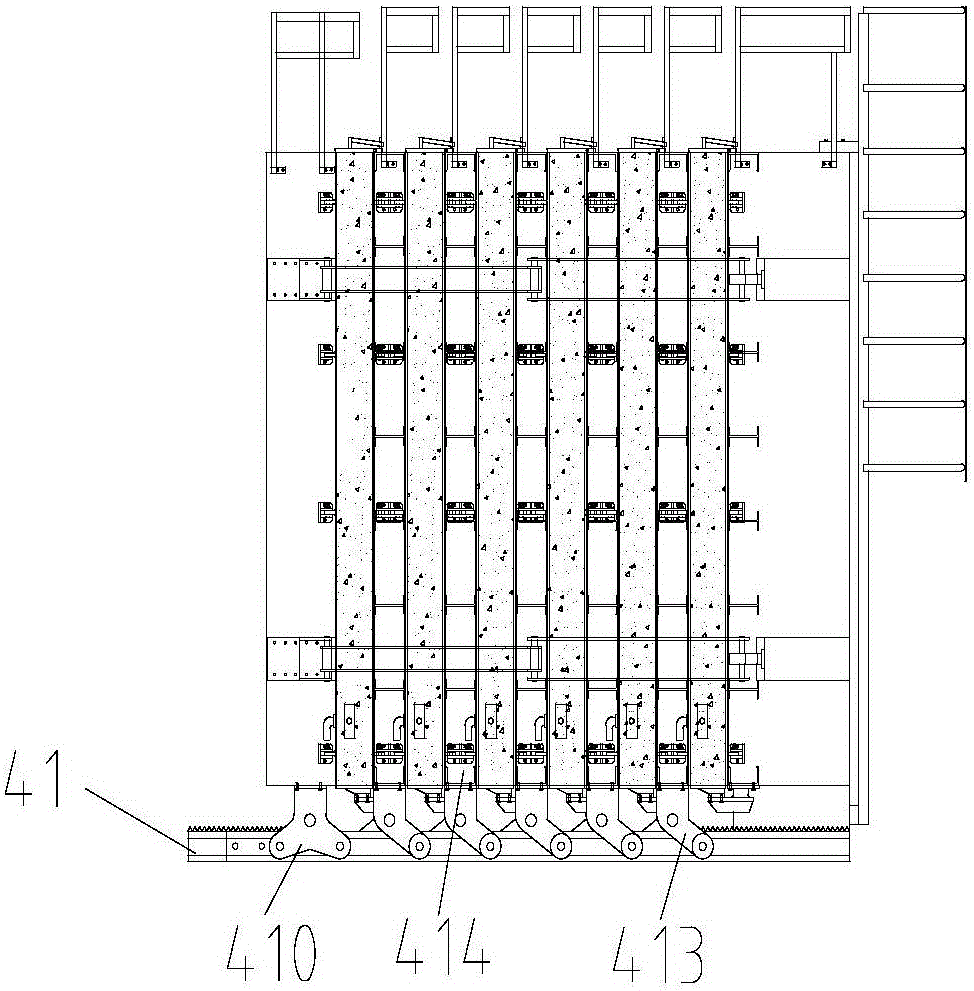

Prefabricated part group standing mould

InactiveCN104985676AImprove compactnessGuaranteed StrengthMouldsCeramic shaping mandrelsLap jointEngineering

The invention provides a prefabricated part group standing mould. The prefabricated part group standing mould comprises a track system, a drive system and a formwork system. The formwork system comprises a bottom mould, a top mould, a vertical mould and a side mould. The prefabricated part group standing mould further comprises a top mould pressing device. The top mould pressing device comprises a fixing seat, a pressing plate and a fixing insertion part. The fixing seat and the first end of the pressing plate are provided with connecting holes. The first end of the pressing plate is arranged on the fixing seat in a lap joint mode and the second end of the pressing plate is pressed on the top mould. The fixing seat is arranged on the top face of the vertical mould, and the fixing insertion part is inserted into the upper connecting hole and the lower connecting hole and used for connecting the pressing plate with the fixing seat. Thus, the formwork system can be driven to horizontally move on tracks for mould splicing and stripping, and production efficiency and the quality of concrete elements can be improved.

Owner:CHINA MINSHENG ZHUYOU

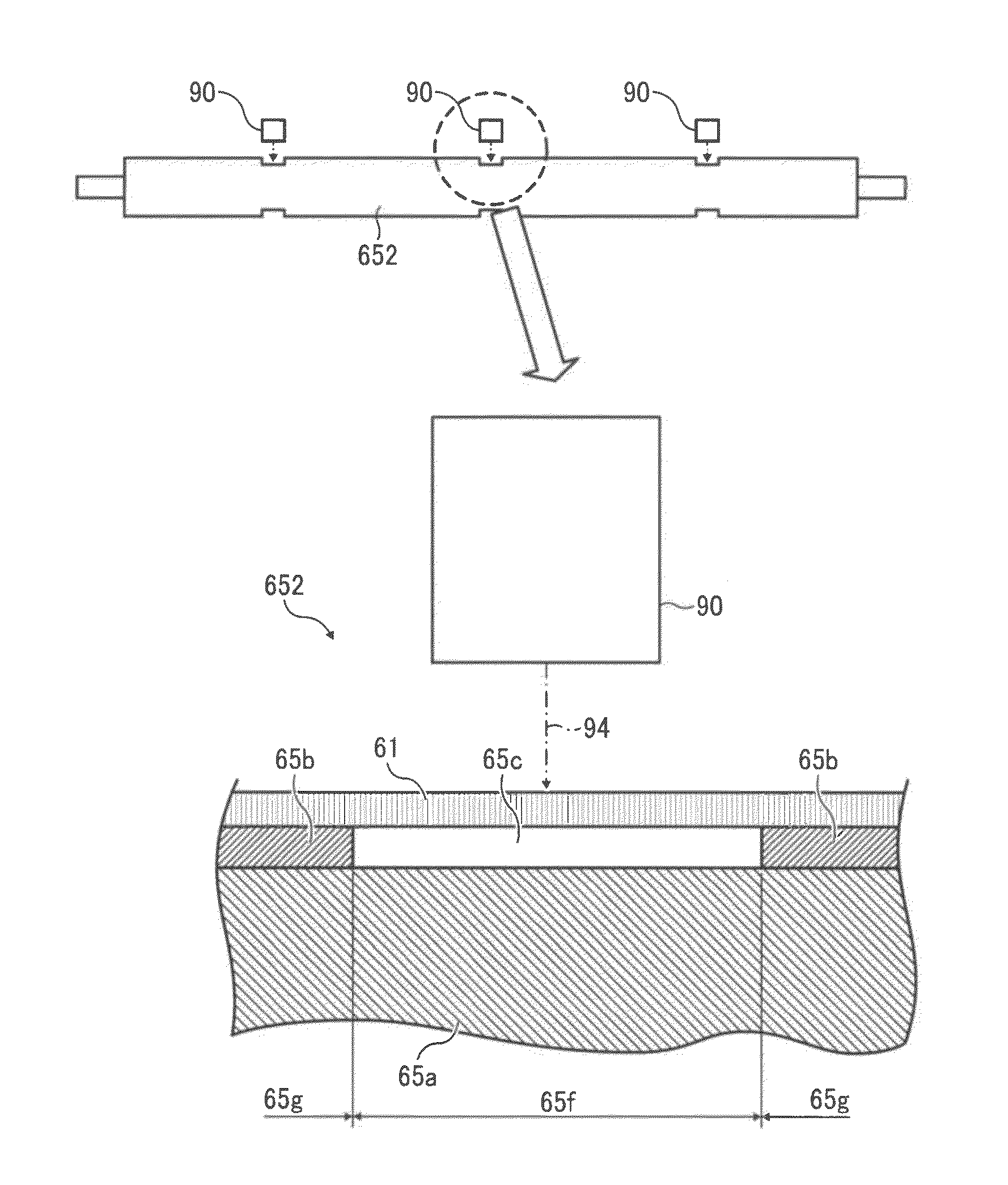

Thermal developing apparatus

InactiveUS7362344B2Avoid controlEliminate uneven temperature distributionX-ray/infra-red processesProcessingLatent imageEngineering

A thermal developing apparatus for thermally developing a latent image formed on a thermal developing recording material by a thermal developing portion, the apparatus comprising: a heating unit that heats the thermal developing recording material carried to the thermal developing portion, the heating unit comprising a plurality of heating portions that are aligned in a direction that intersects orthogonally with a carrying direction of the thermal developing recording material; and a plurality of temperature measuring portions that measure temperatures of the plurality of heating portions respectively, each of said plurality of temperature measuring portions being arranged to measure a center portion of a temperature distribution in each of said plurality of heating portions.

Owner:FUJIFILM HLDG CORP +1

Detector and roller arrangement for an image forming apparatus

ActiveUS8447198B2Avoid uneven densityImprove accuracyElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:RICOH KK

Filling-soil compactor for forestry afforestation use

InactiveCN111108875AReduce labor intensityImprove work efficiencySoil-working equipmentsClimate change adaptationForest industrySoil science

The invention discloses a filling-soil compactor for forestry afforestation use. The filling-soil compactor for the forestry afforestation use comprises a snap sleeve, a support frame, and a compaction mechanism; a connecting plate is connected to an outer wall of the snap sleeve; the snap ring is connected with one end, far away from the snap sleeve, of the connecting plate; a slider is connectedto an outer wall of the snap ring; a first support plate and a second support plate are separately connected to a top wall of the slider; a soil filling mechanism and a first compacting mechanism areseparately connected to a bottom wall of the first support plate; a second compacting mechanism is connected to a bottom wall of the second support plate; a third support plate is connected to an outer wall of the second compacting mechanism; a turning disk is connected to an outer wall of the third support plate; a first connecting rod and a second connecting rod are separately connected to an outer wall of the turning disk; the first connecting rod is connected with the second compacting mechanism; and the second connecting rod is connected with the first compacting mechanism. The filling-soil compactor for the forestry afforestation use is simple in structure, convenient to use, and capable of performing effective filling-soil compacting operation on a transplanting pit as well as achieving uniform soil compaction density so as to facilitate water penetration during watering; and moreover, the filling-soil compactor for the forestry afforestation use is also capable of effectivelyreducing labor intensity, and improving work efficiency.

Owner:李沙沙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com