Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2237results about How to "Reduce unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

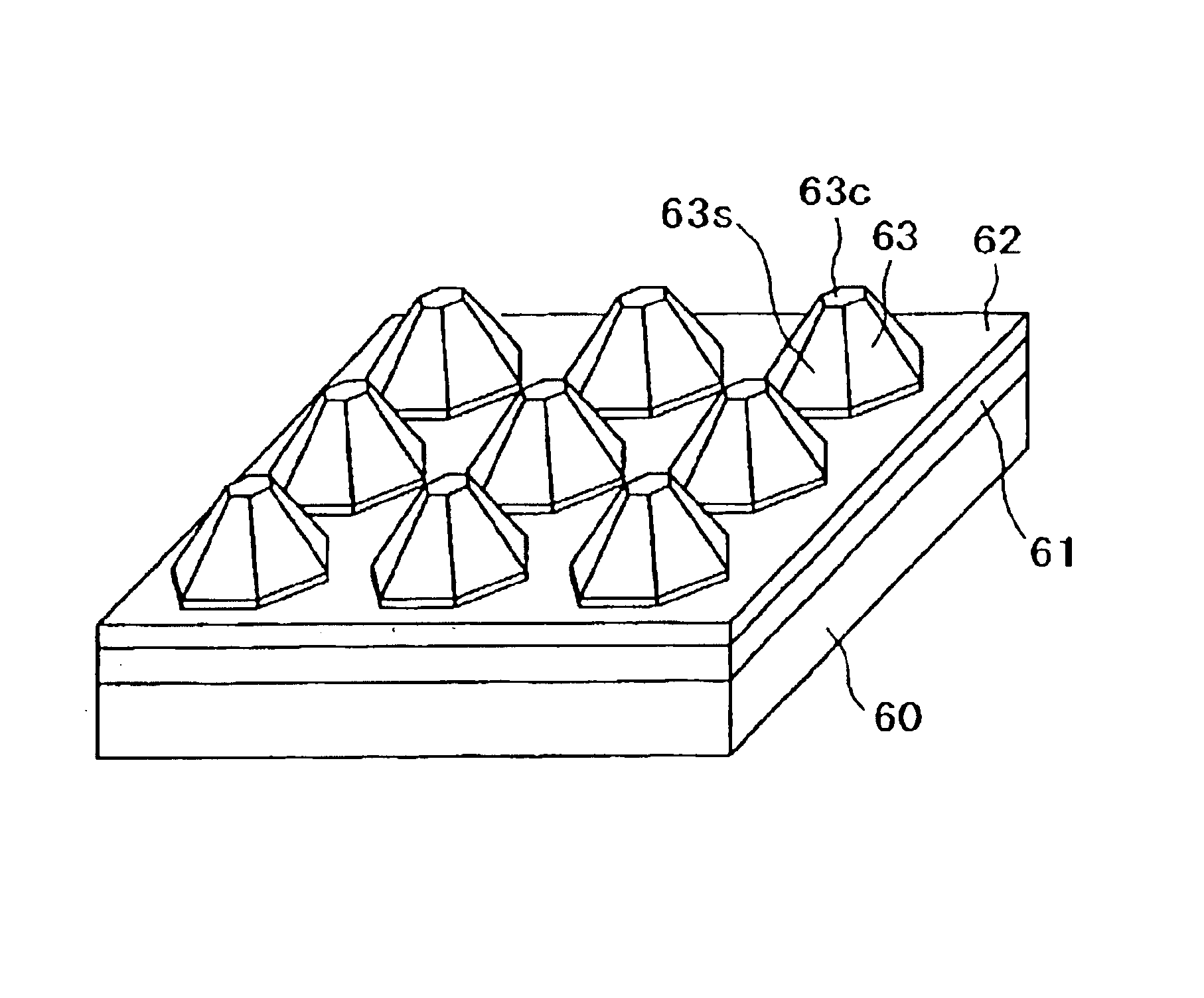

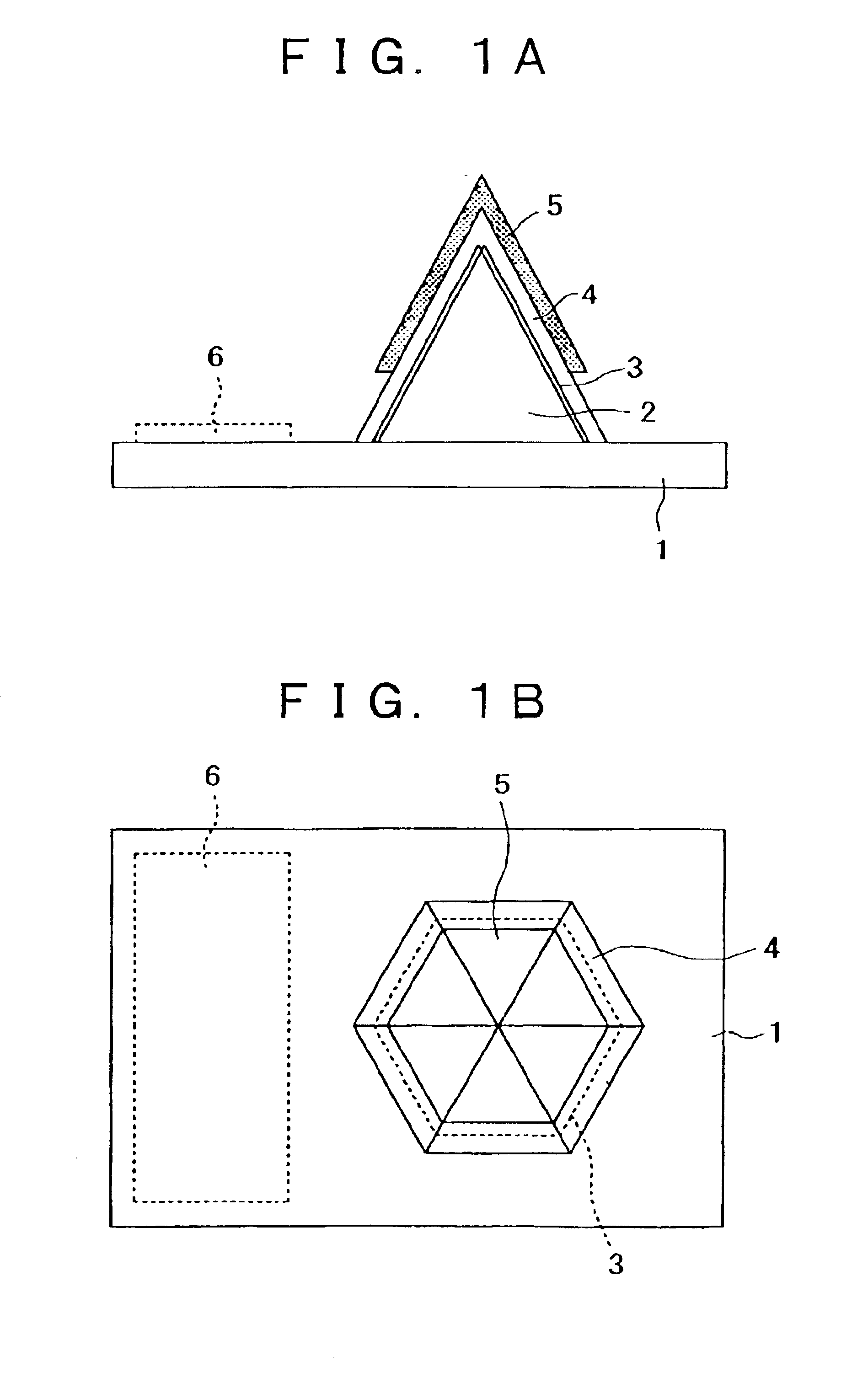

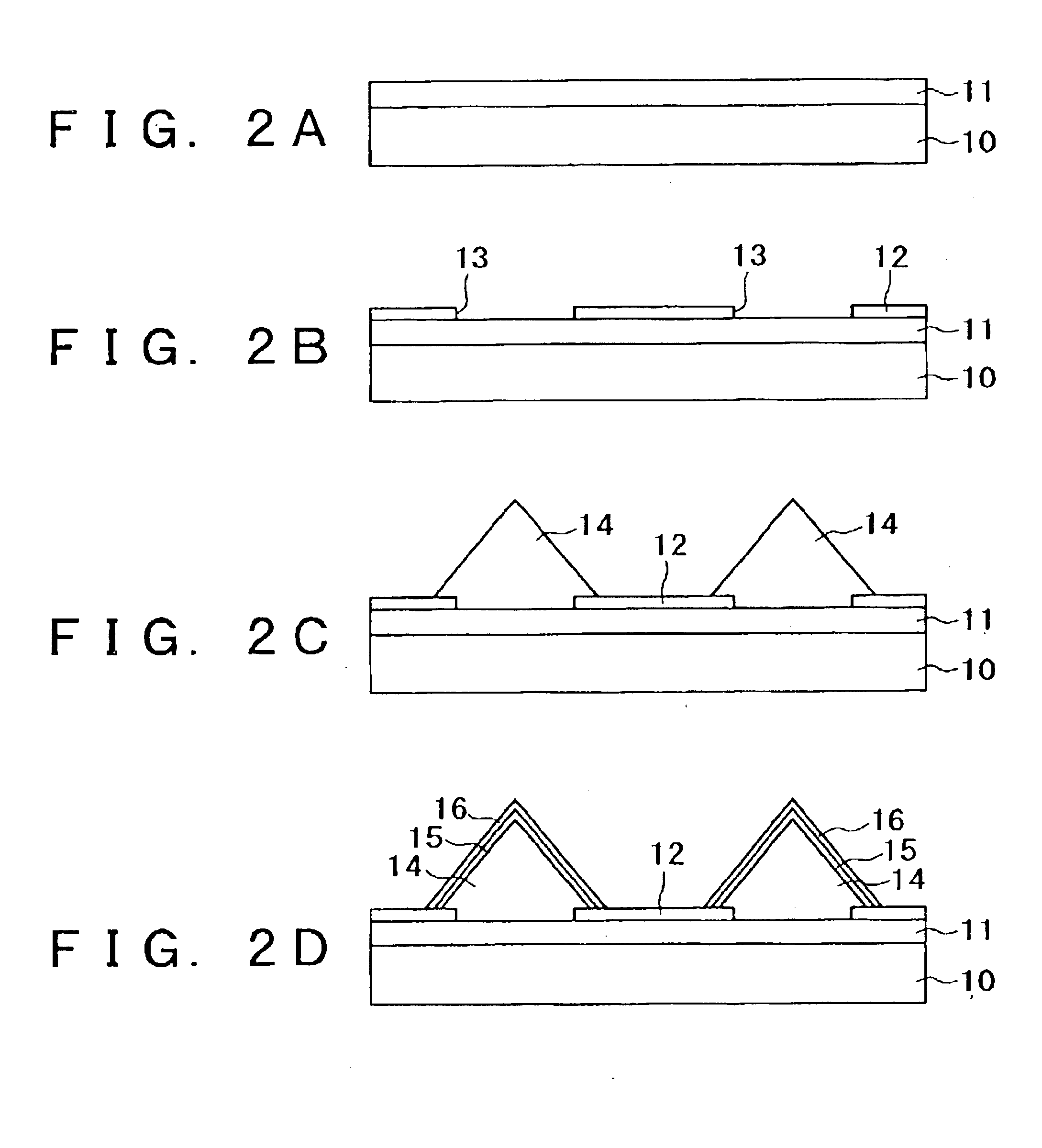

Selective growth method, and semiconductor light emitting device and fabrication method thereof

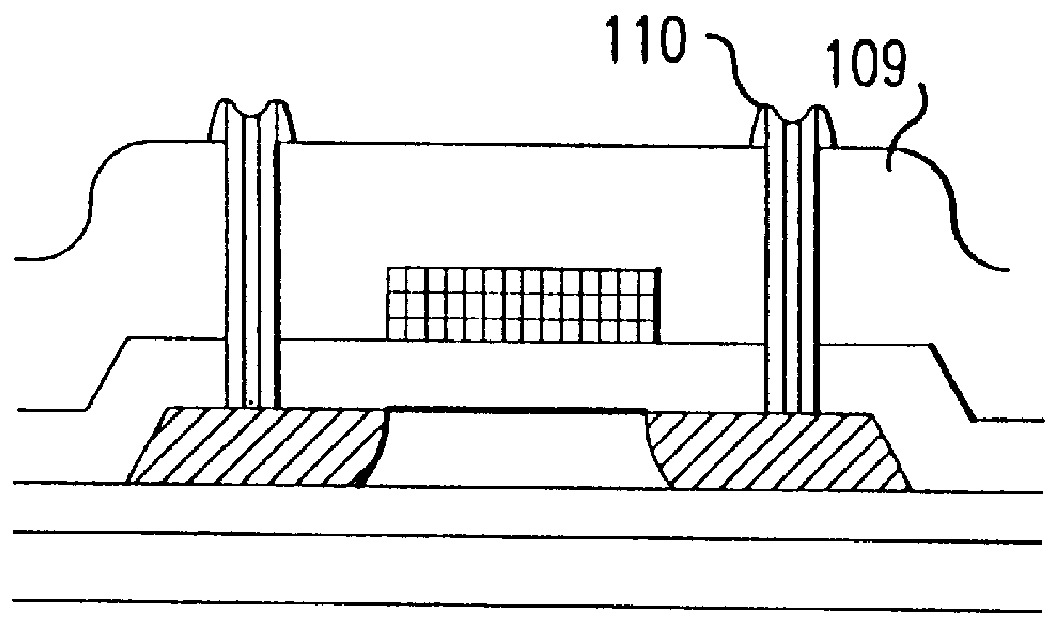

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

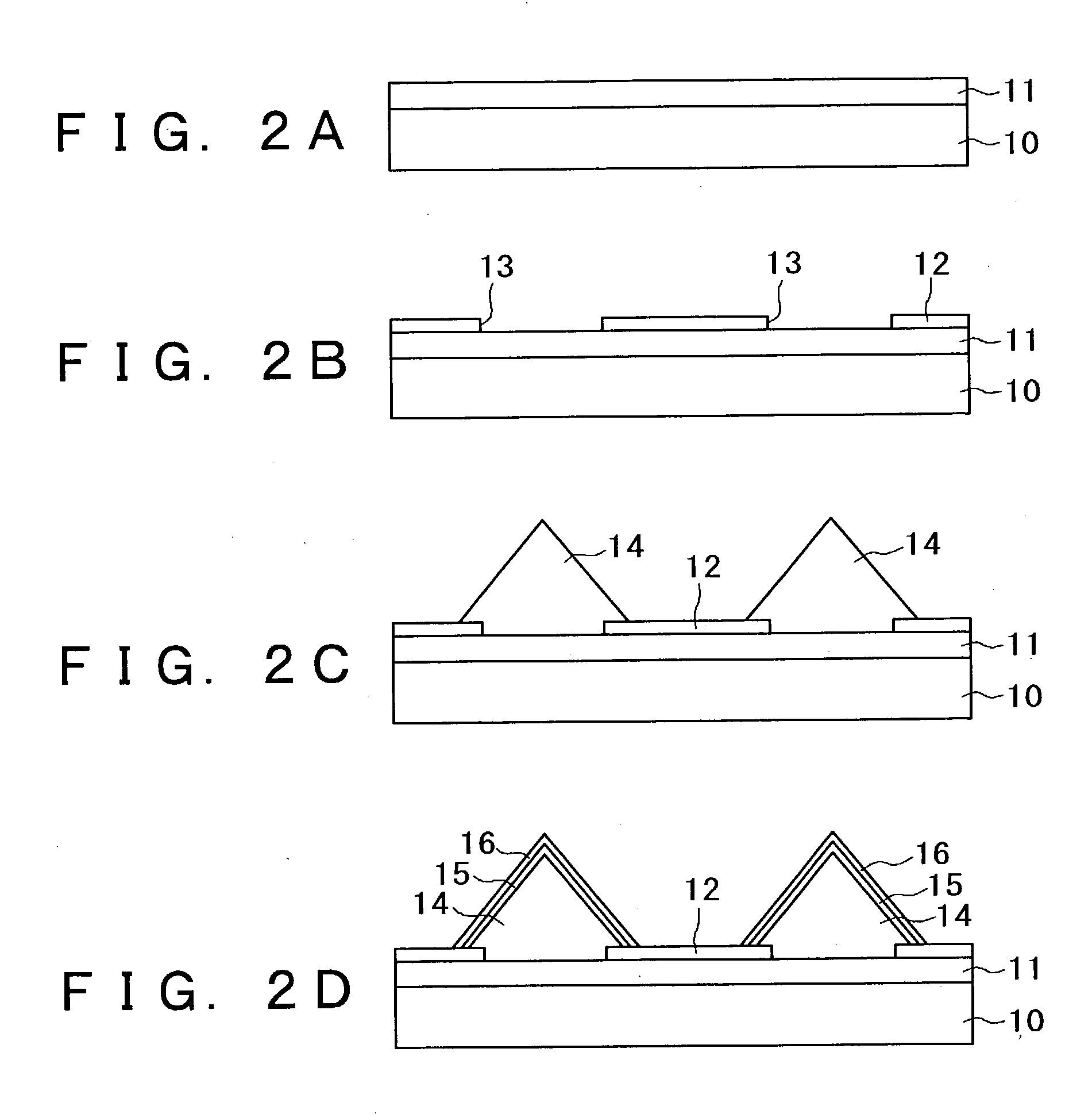

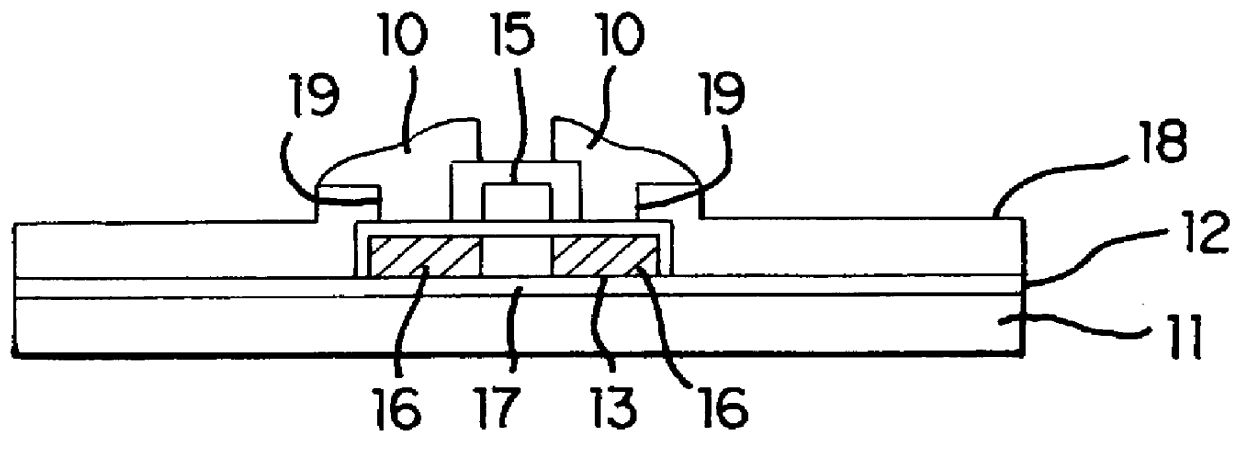

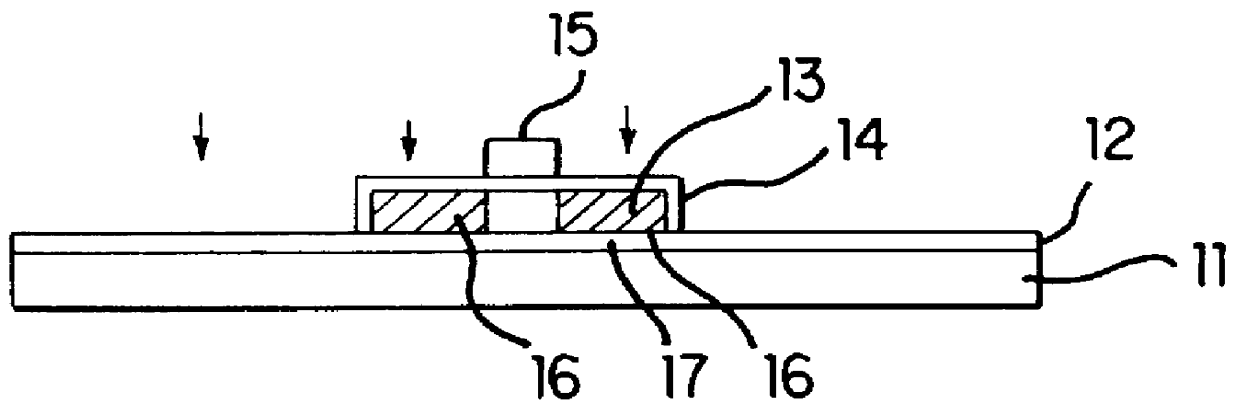

Fabrication method for a thin film semiconductor device, the thin film semiconductor device itself, liquid crystal display, and electronic device

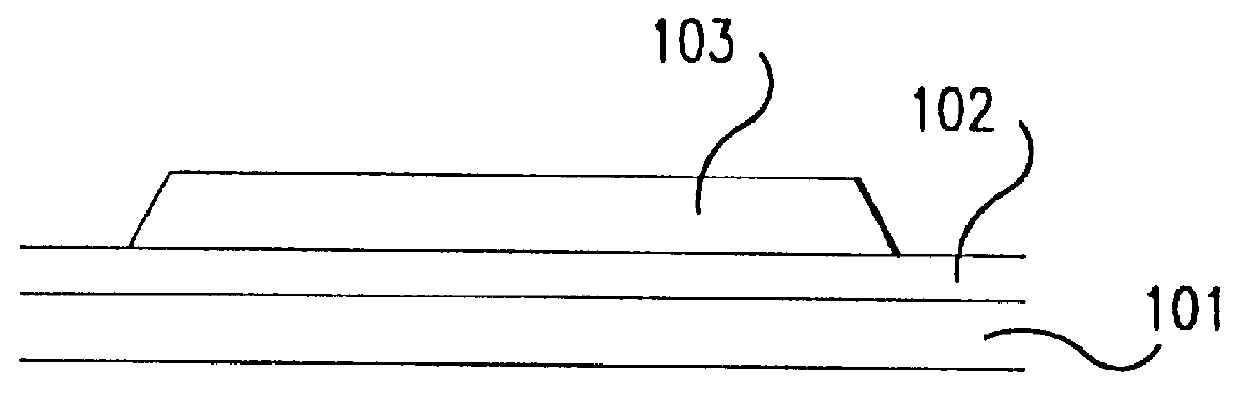

InactiveUS6017779AImprove propertiesWell formedTransistorLinear bearingsElectronic circuitLiquid-crystal display

In order to fabricate a high performance thin film semiconductor device using a low temperature process in which it is possible to use low price glass substrates, a thin film semiconductor device has been fabricated by forming a silicon film at less than 450 DEG C., and, after crystallization, keeping the maximum processing temperature at or below 350 DEG C. In applying the present invention to the fabrication of an active matrix liquid crystal display, it is possible to both easily and reliably fabricate a large, high-quality liquid crystal display. Additionally, in applying the present invention to the fabrication of other electronic circuits as well, it is possible to both easily and reliably fabricate high-quality electronic circuits.

Owner:INTELLECTUAL KEYSTONE TECH

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

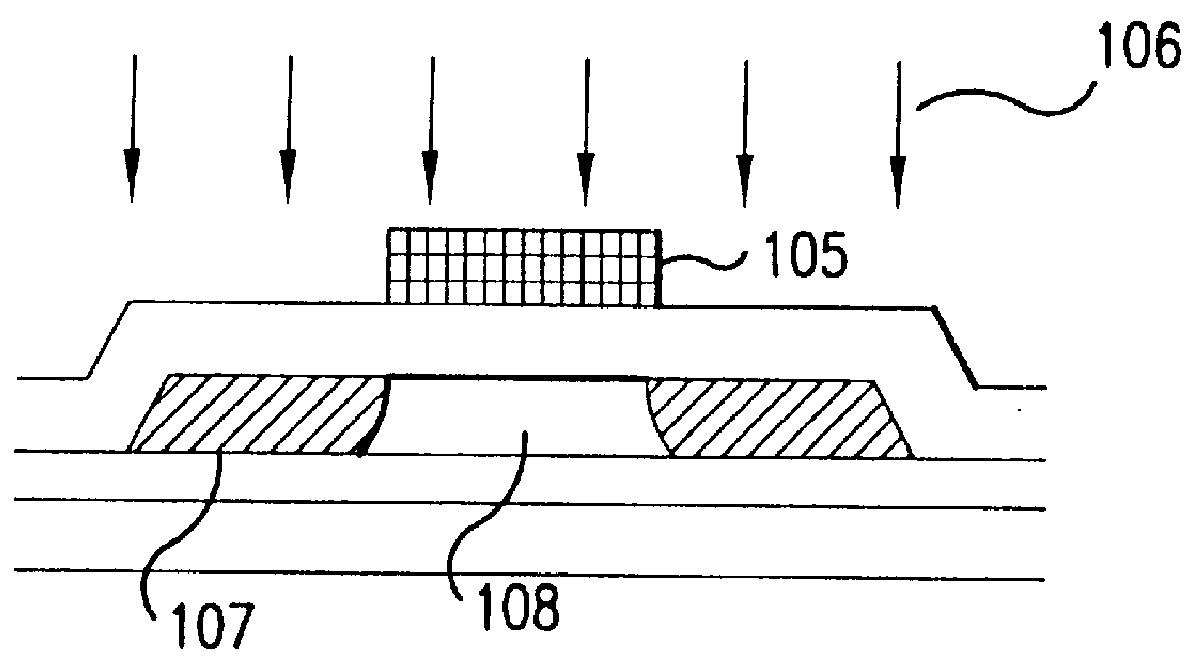

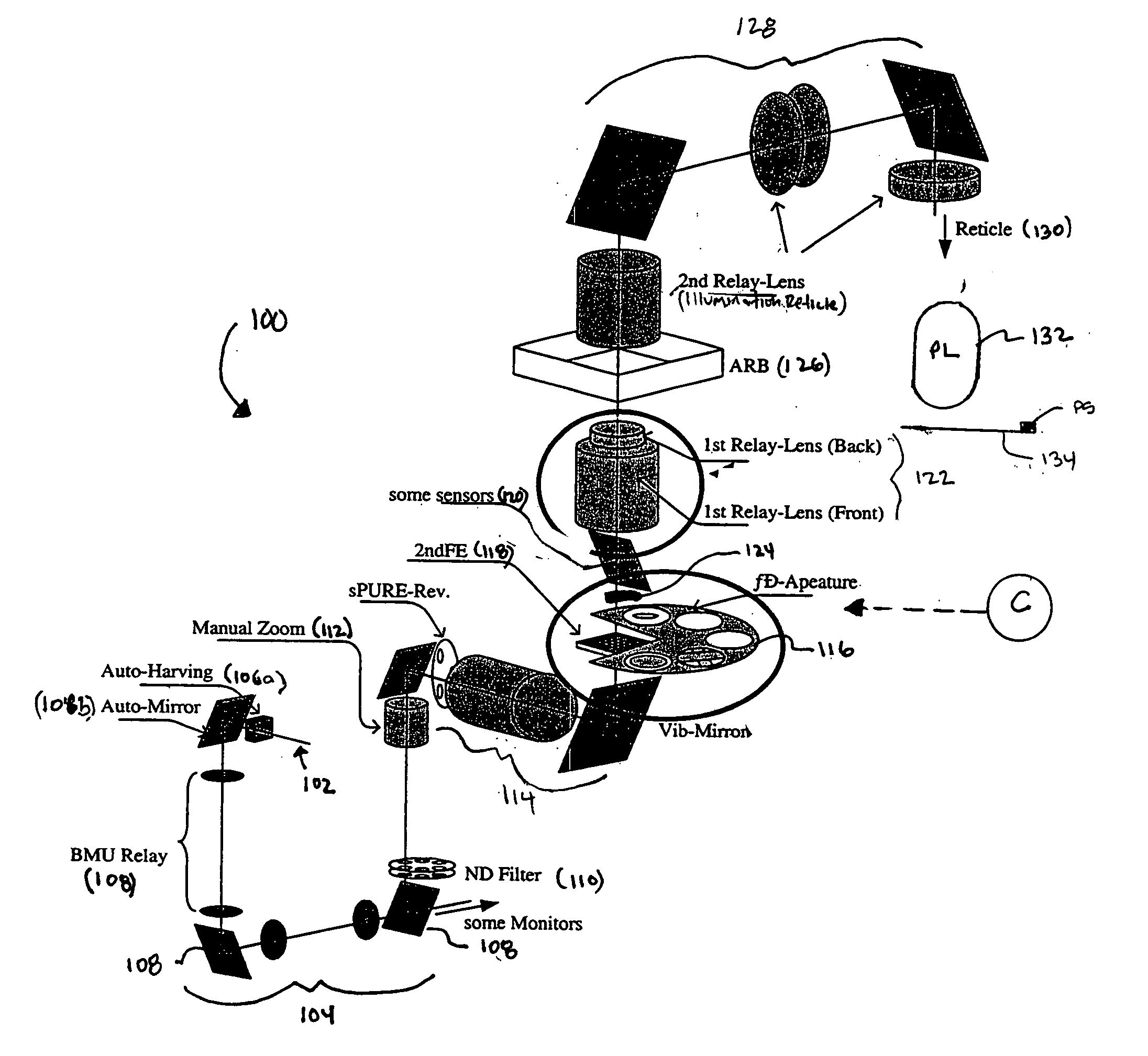

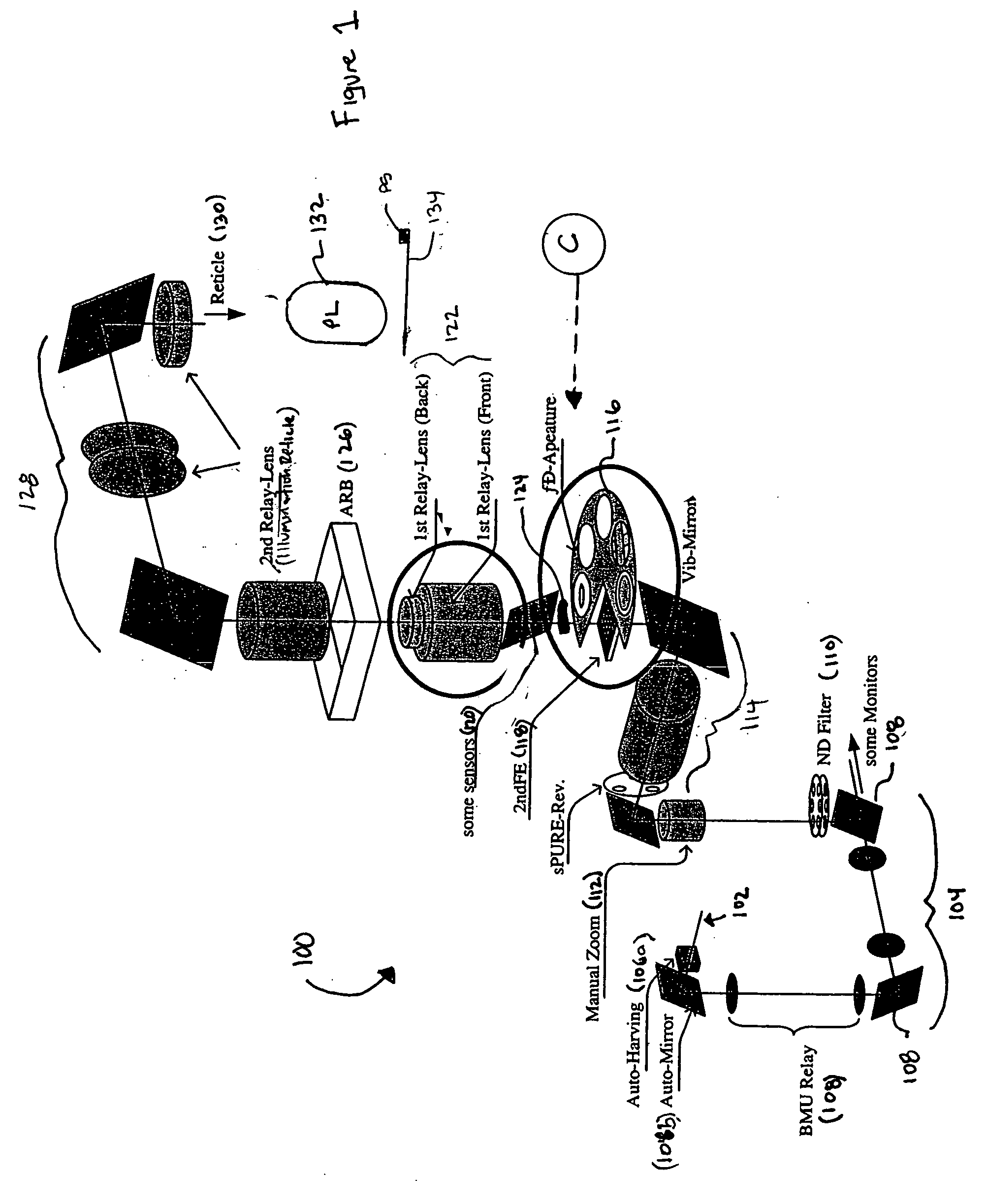

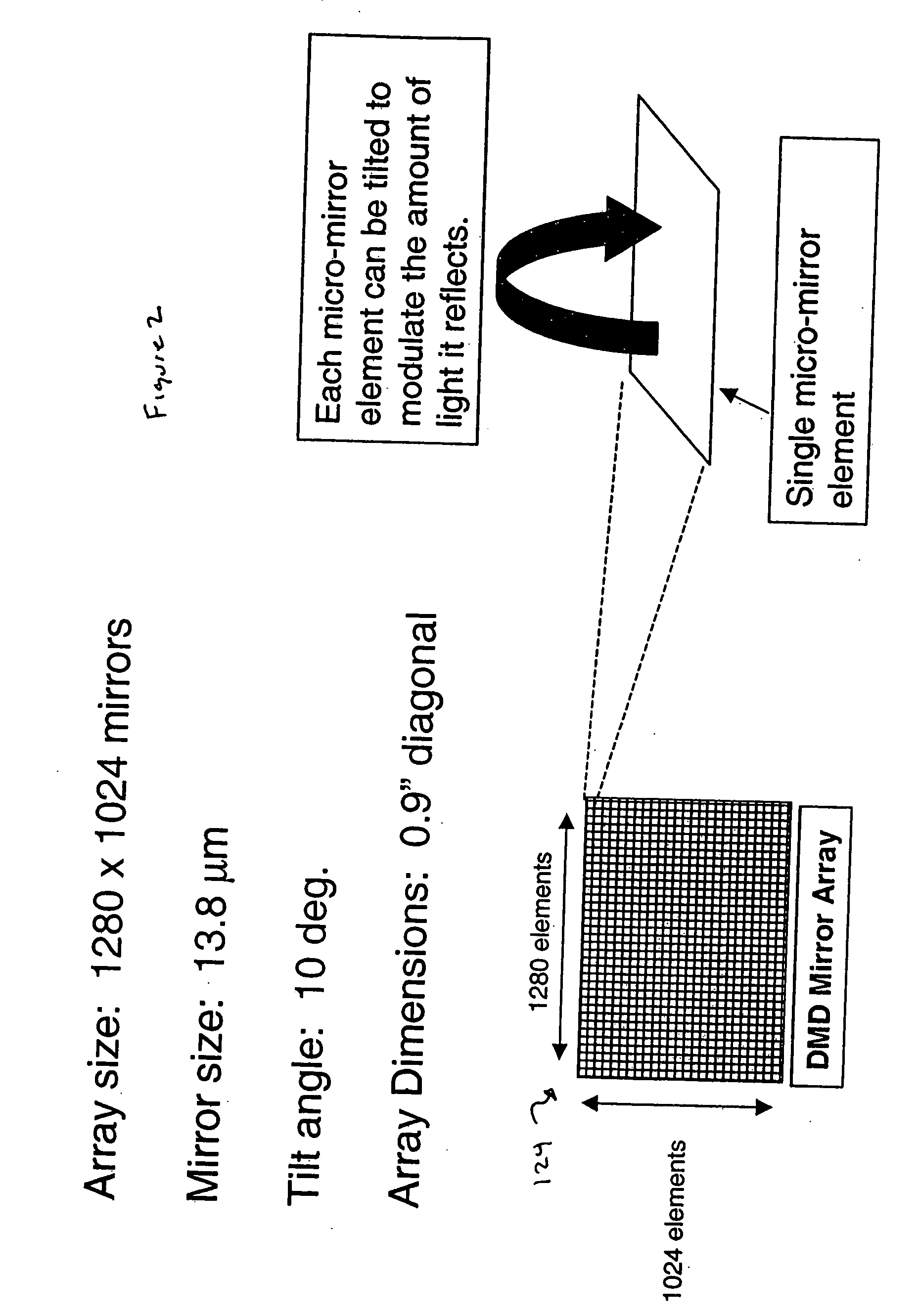

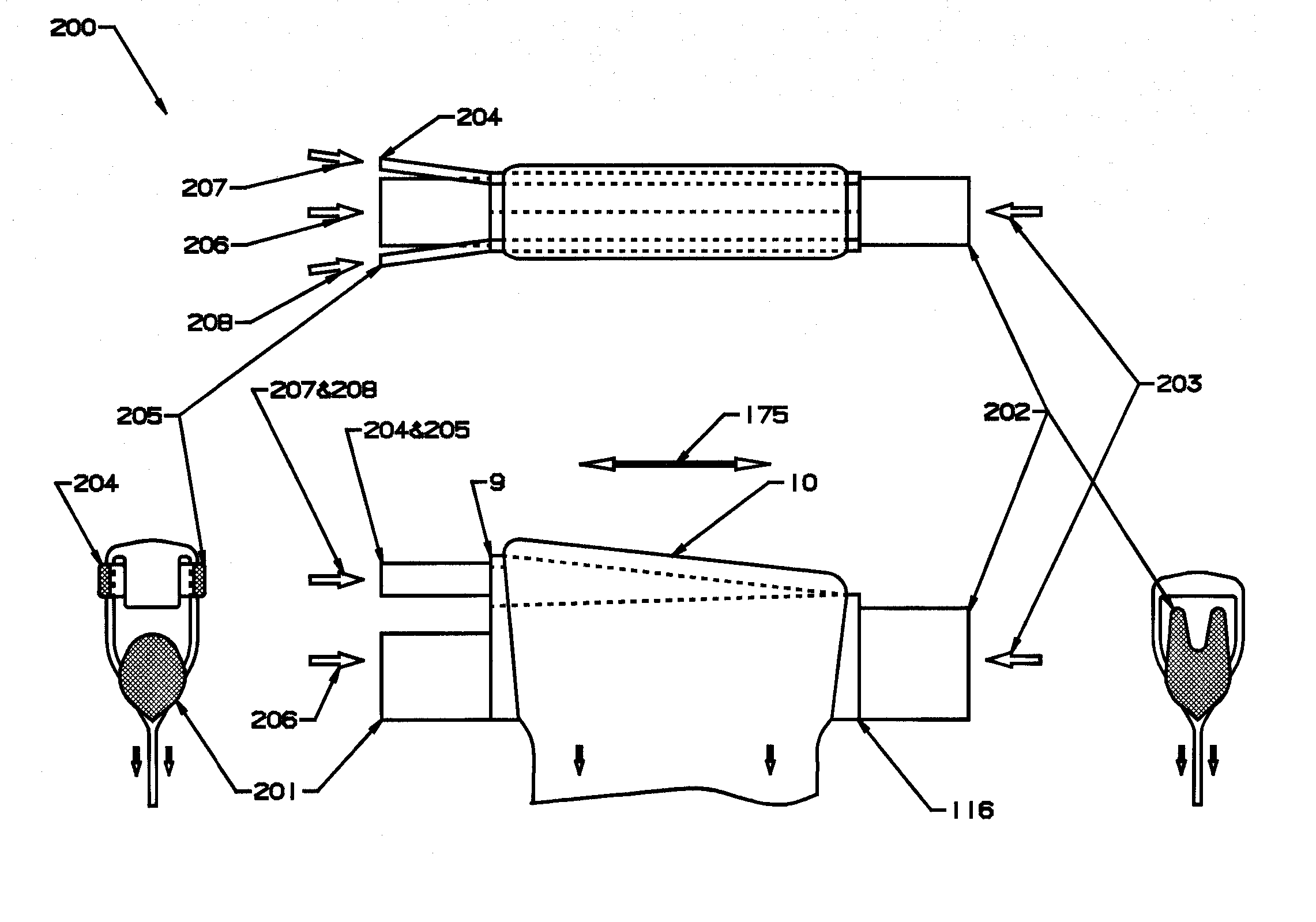

Dynamic illumination uniformity and shape control for lithography

InactiveUS20060087634A1Reducing illumination non-uniformityReduce illumination non-uniformityPhotomechanical apparatusPhotographic printingShape controlLight beam

A subsystem for an exposure apparatus has at least one array of tilting mirrors placed in either an image reticle plane or a conjugate image plane to provide dynamic control of an illumination beam through an exposure field. In the system, an optical subsystem and a plurality of mirrors directs light to a reticle and a sensor senses the illumination distribution of the light at a wafer stage. When the at least one array of tilting mirrors is placed in the image reticle plane, a control is used to interpolate data of the illumination distribution sensed by the sensor, and then control movement of at least one mirror of the array of mirrors based on the interpolated data.

Owner:NIKON PRECISION

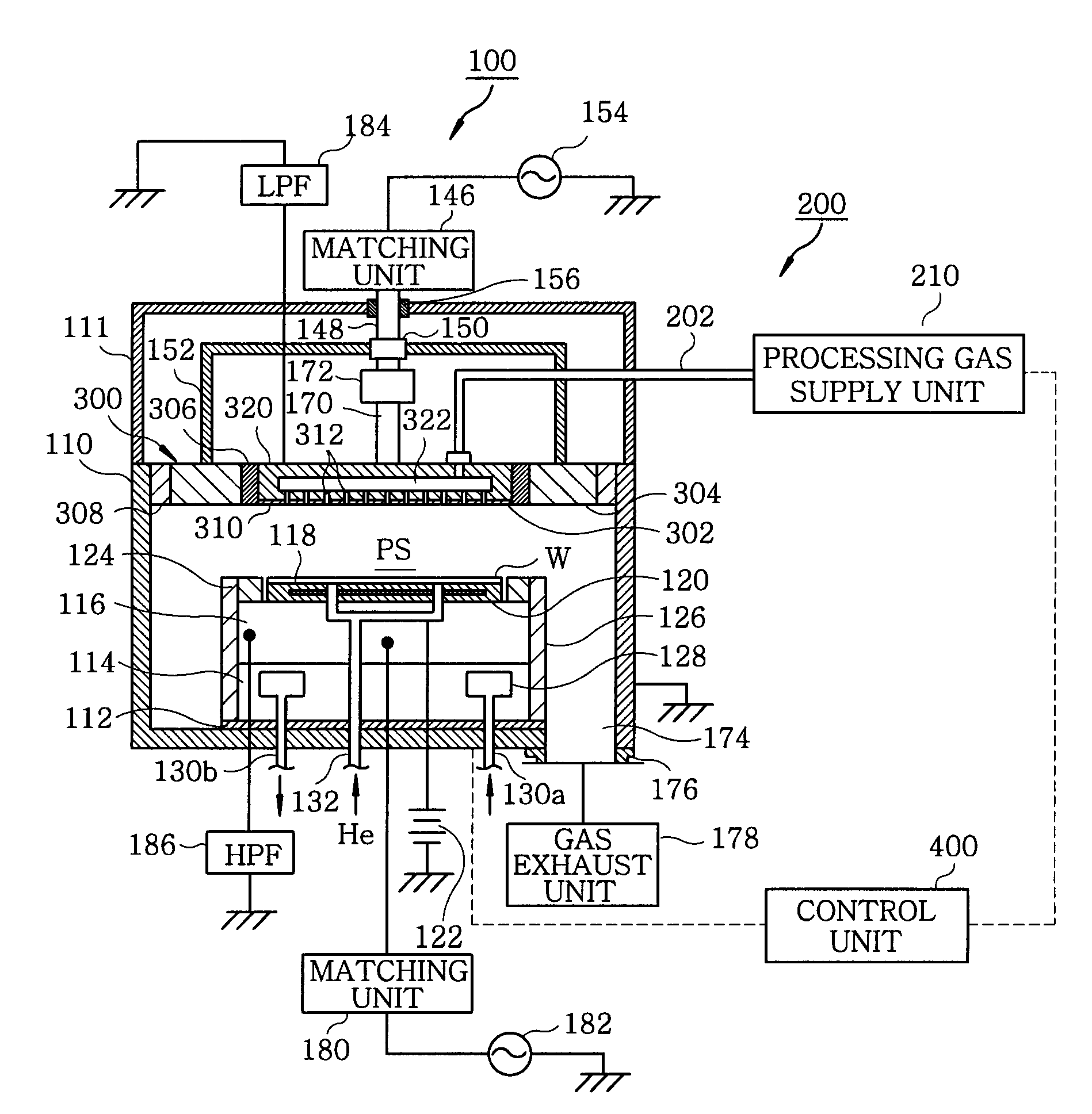

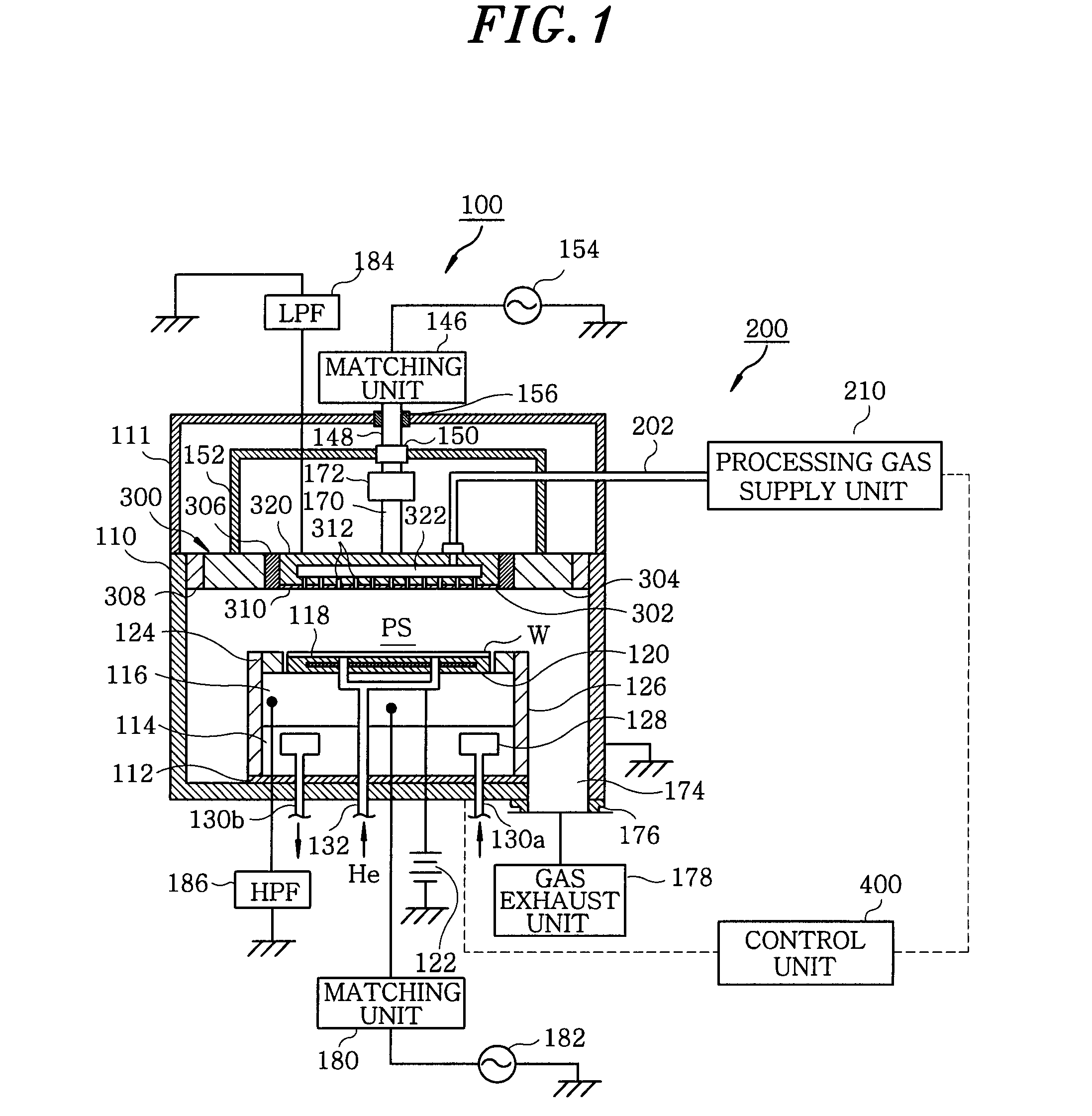

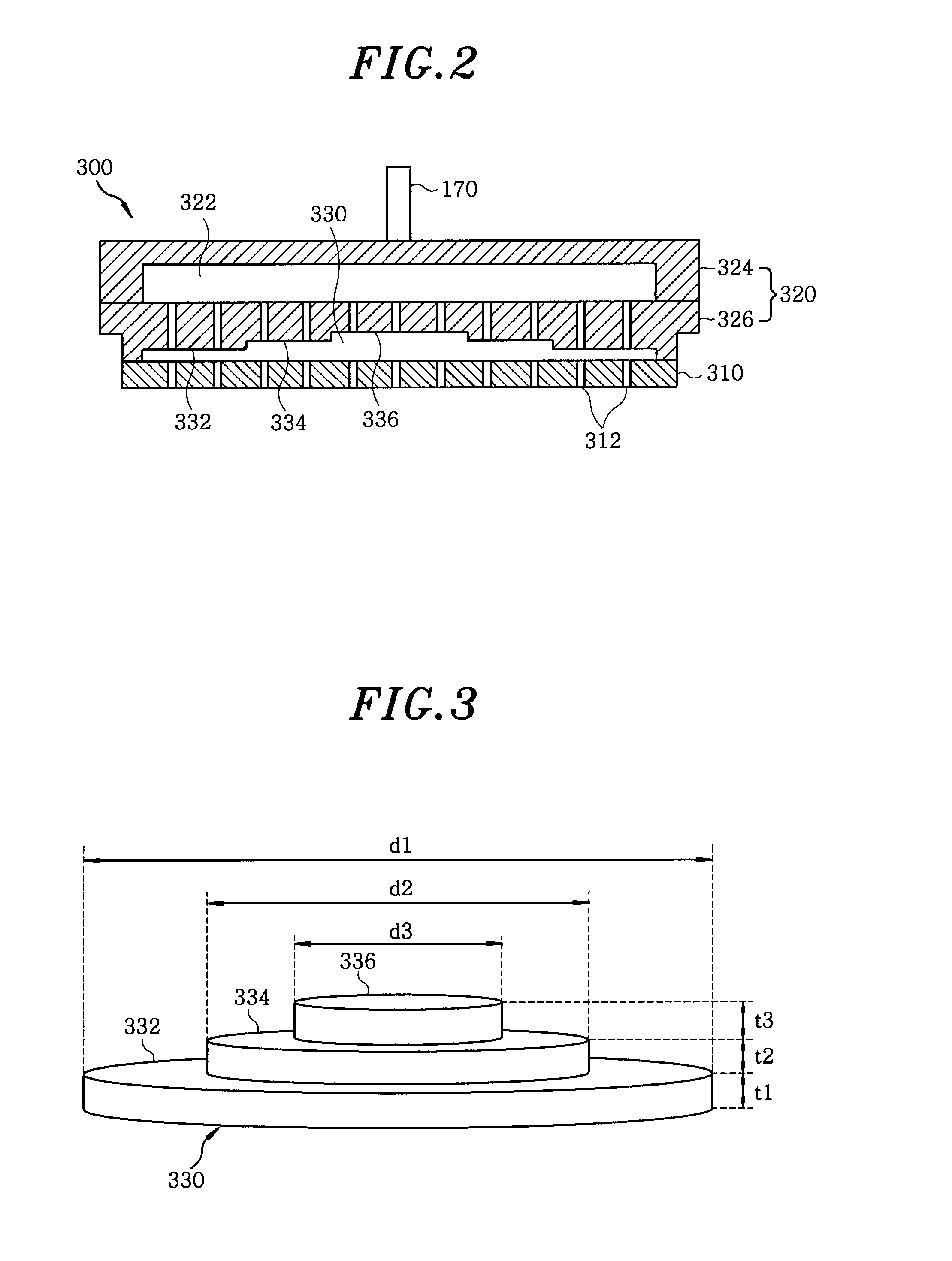

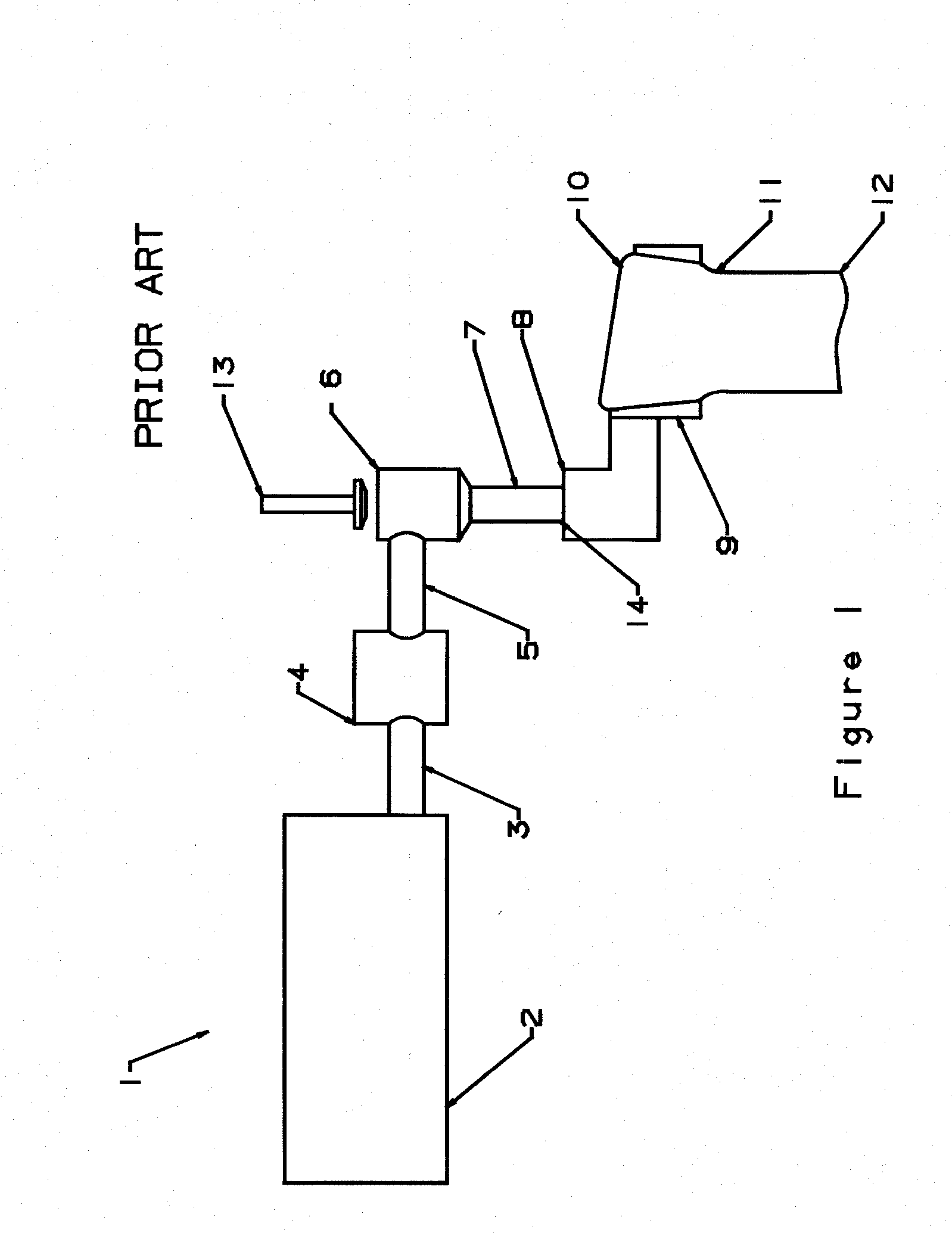

Plasma processing apparatus and electrode used therein

ActiveUS20070215580A1Improve uniformityReduce unevennessElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectric power

A plasma processing apparatus performs a specific plasma processing on a target substrate by disposing a first and a second electrode to face each other in a processing chamber, and supplying high-frequency electric power to at least one of the first and the second electrodes to thereby generate a plasma while introducing a processing gas onto the target substrate supported by the second electrode. The electrode for use as the first electrode includes: an electrode plate facing the second electrode; a support for supporting the electrode plate, wherein the support is in contact with a surface of the electrode plate and the surface is opposite to the second electrode; and a dielectric portion, provided on a contact surface of the support with the electrode plate, and having a shape in which a center portion thereof has a height different from that of an edge portion thereof.

Owner:TOKYO ELECTRON LTD

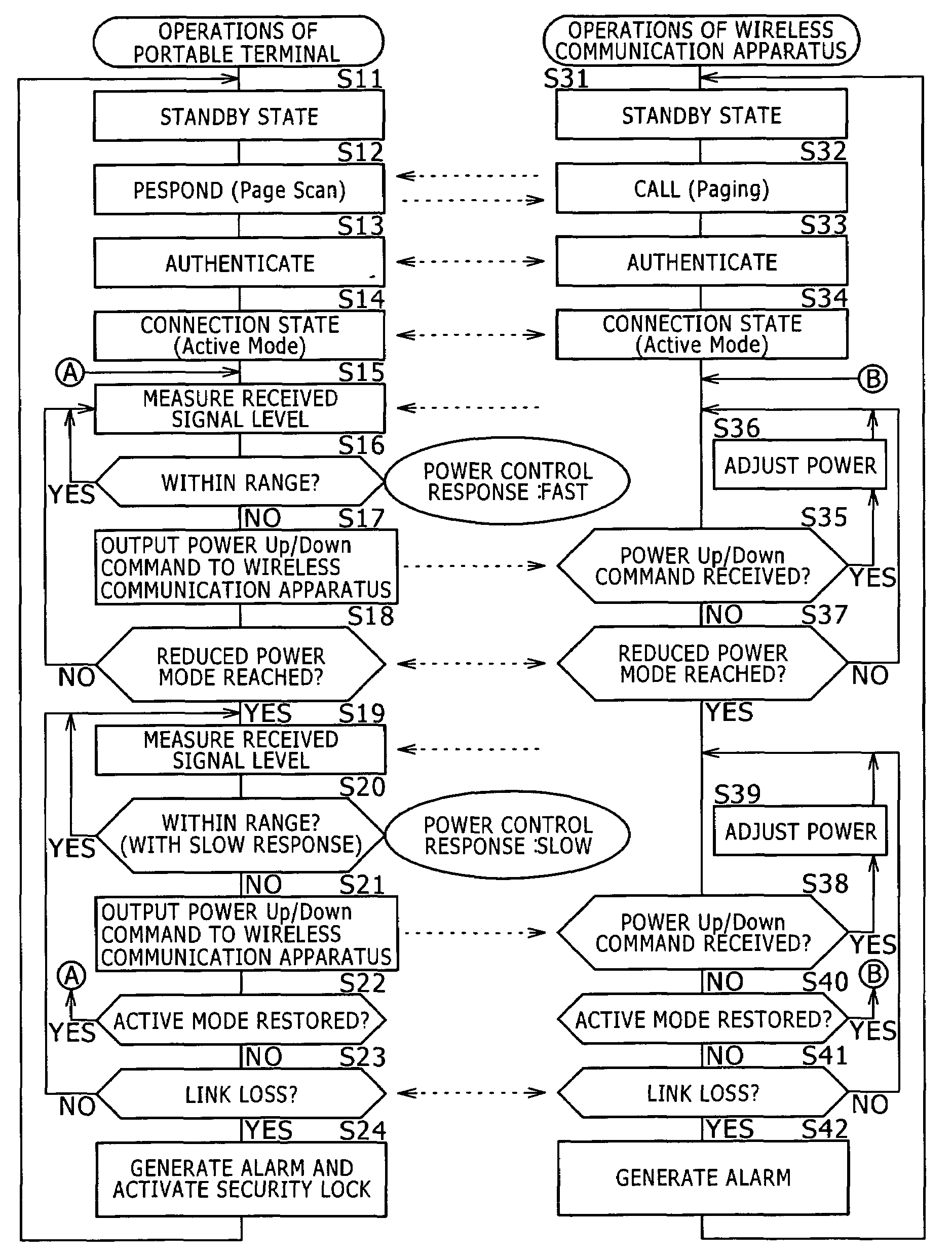

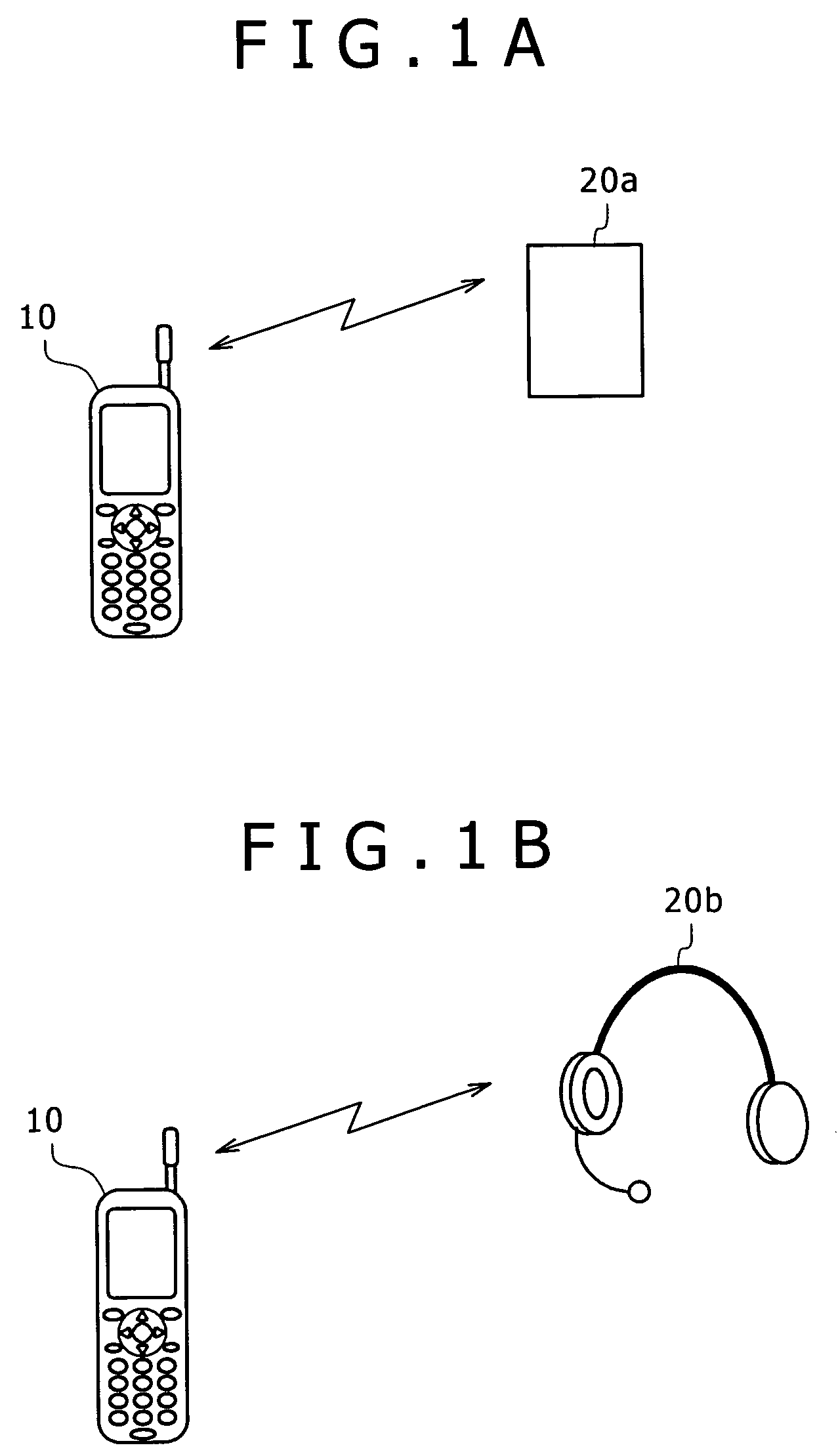

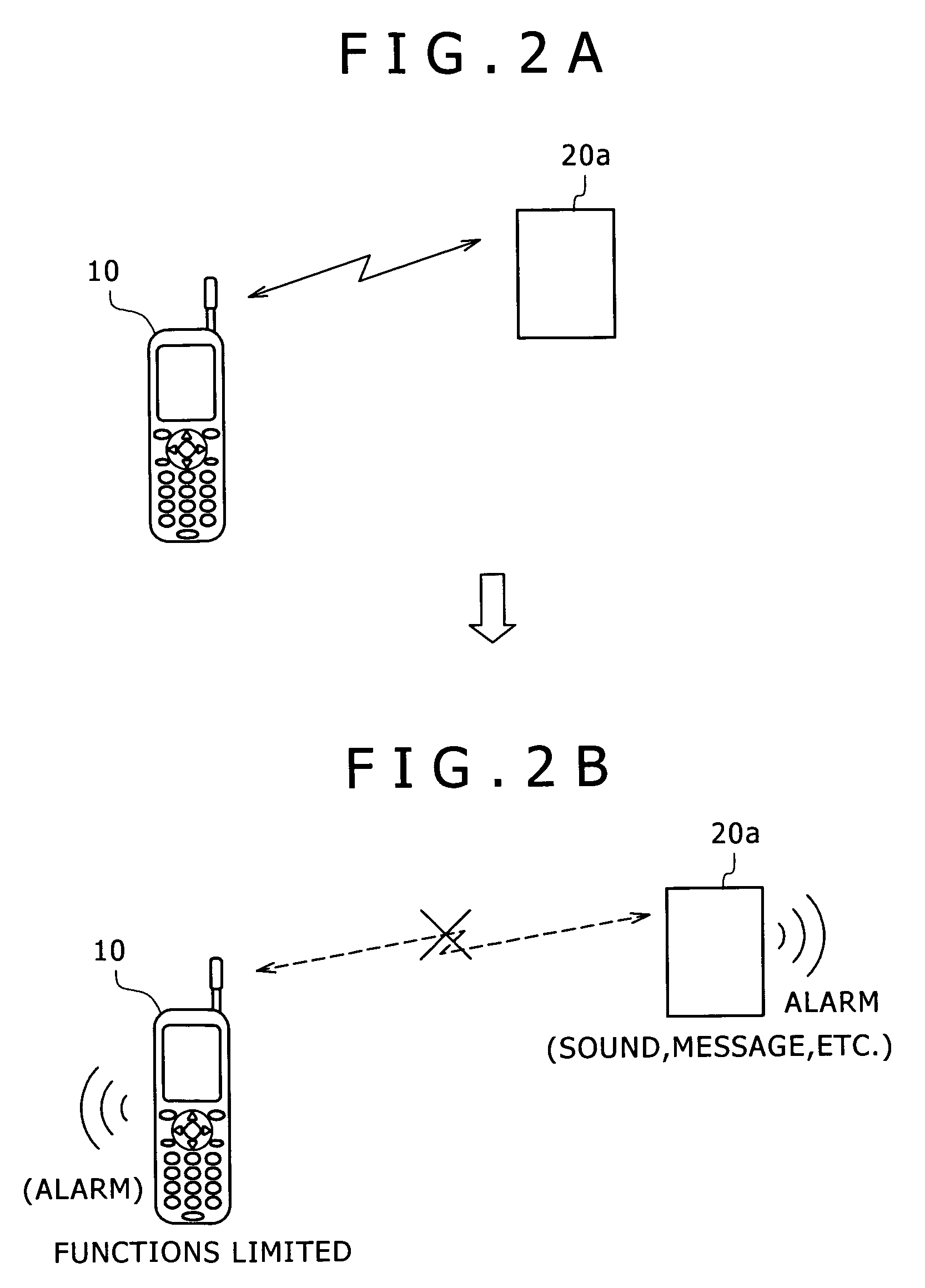

Short range wireless communication system, portable terminal apparatus, and wireless communication apparatus

ActiveUS7336929B2Increase transmit powerResponse speedEnergy efficient ICTTime-division multiplexCommunications systemTime segment

A portable terminal monitors a signal level of a short-range wireless signal from a wireless communication apparatus. If the signal level drops so low that a state of connection for short-range wireless communications cannot be maintained between the two apparatuses, use of predetermined functions of the portable terminal is limited. A short-range wireless communication facility of the portable terminal and the wireless communication apparatus move into a particular operation mode if communications do not occur therebetween at least for a predetermined time period. In monitoring the signal level of the wireless signal from the wireless communication apparatus in the particular operation mode, the portable terminal reduces a response speed at which to detect a signal level change. This causes the wireless communication apparatus to delay issuing a request for an increase in transmission power, thereby reducing unevenness of the working distance at which to alert a user to the unusual distance traveled between the two apparatuses or beyond which to limit the use of some functions of the portable terminal.

Owner:SONY CORP

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS6066516AGreat fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

PCT No. PCT / JP96 / 01775 Sec. 371 Date Jan. 31, 1997 Sec. 102(e) Date Jan. 31, 1997 PCT Filed Jun. 26, 1996 PCT Pub. No. WO97 / 01863 PCT Pub. Date Jan. 16, 1997A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

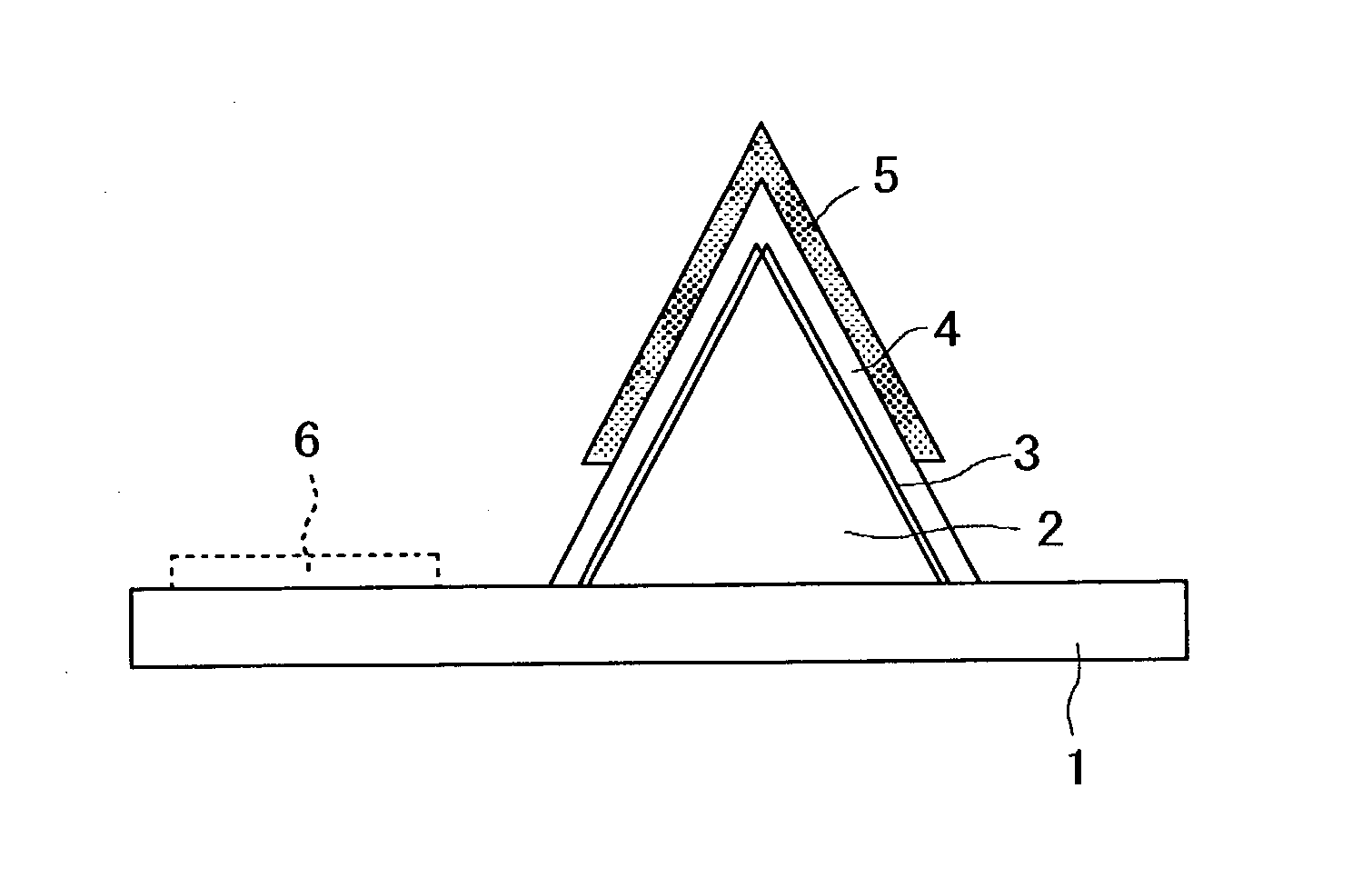

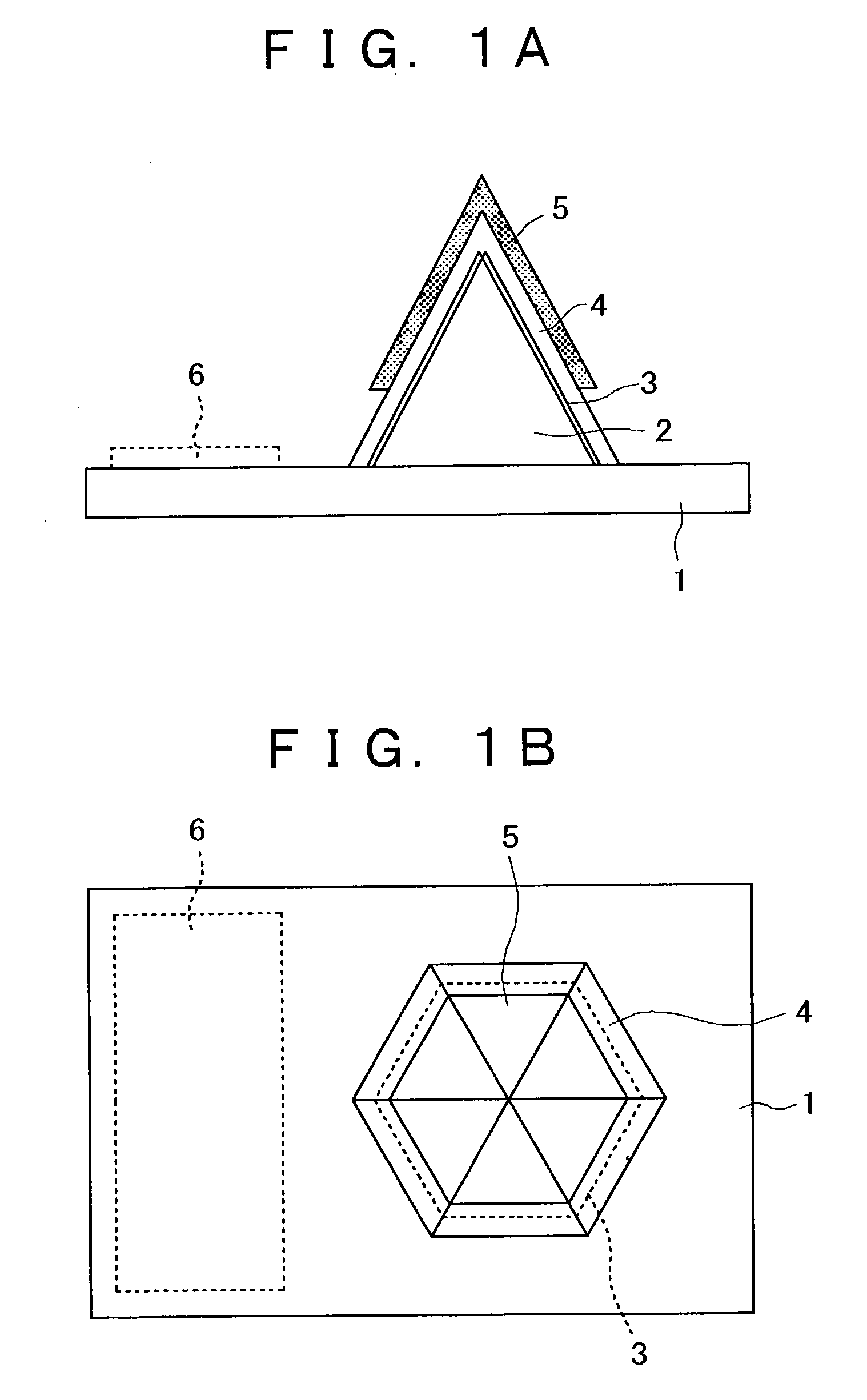

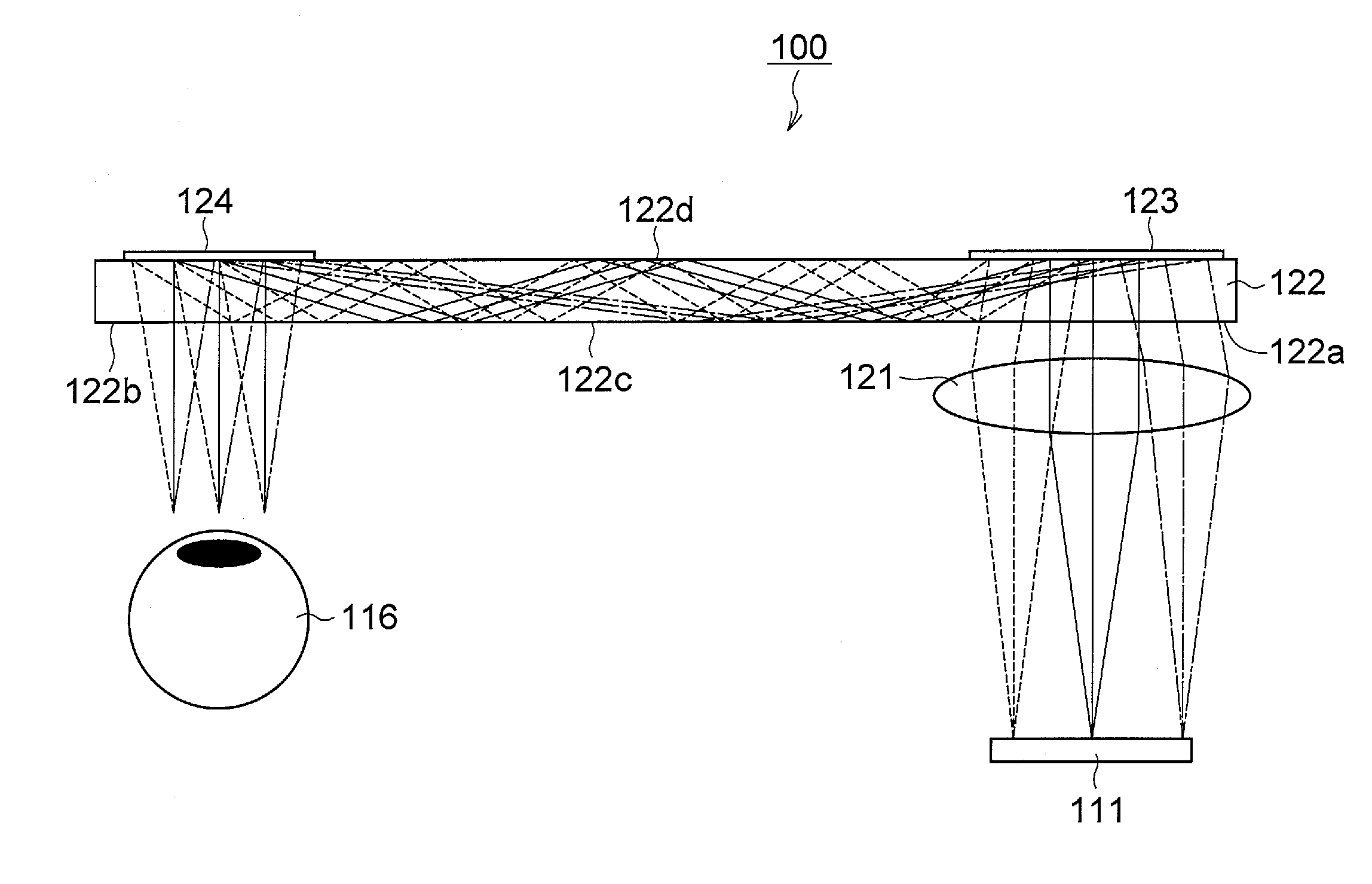

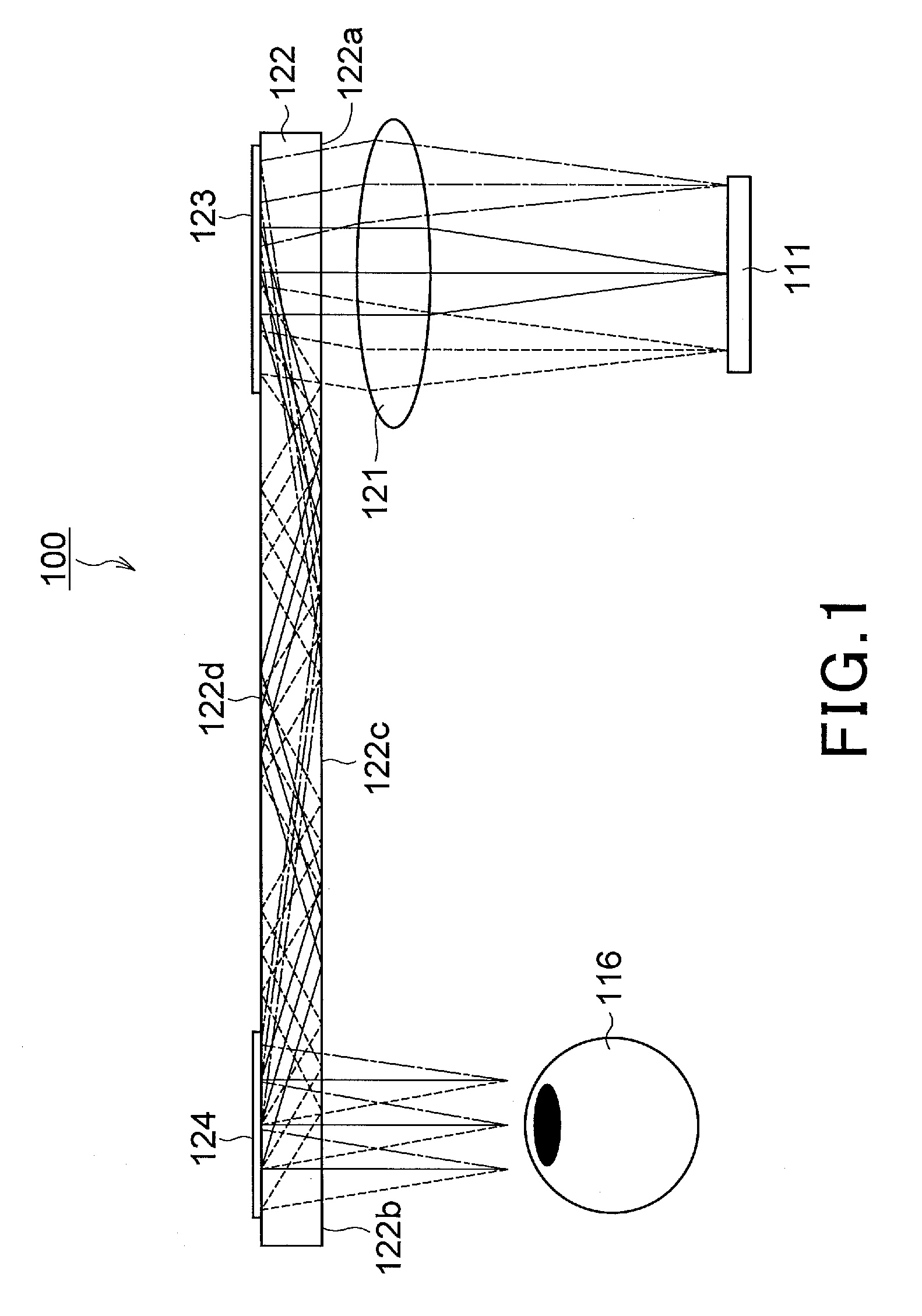

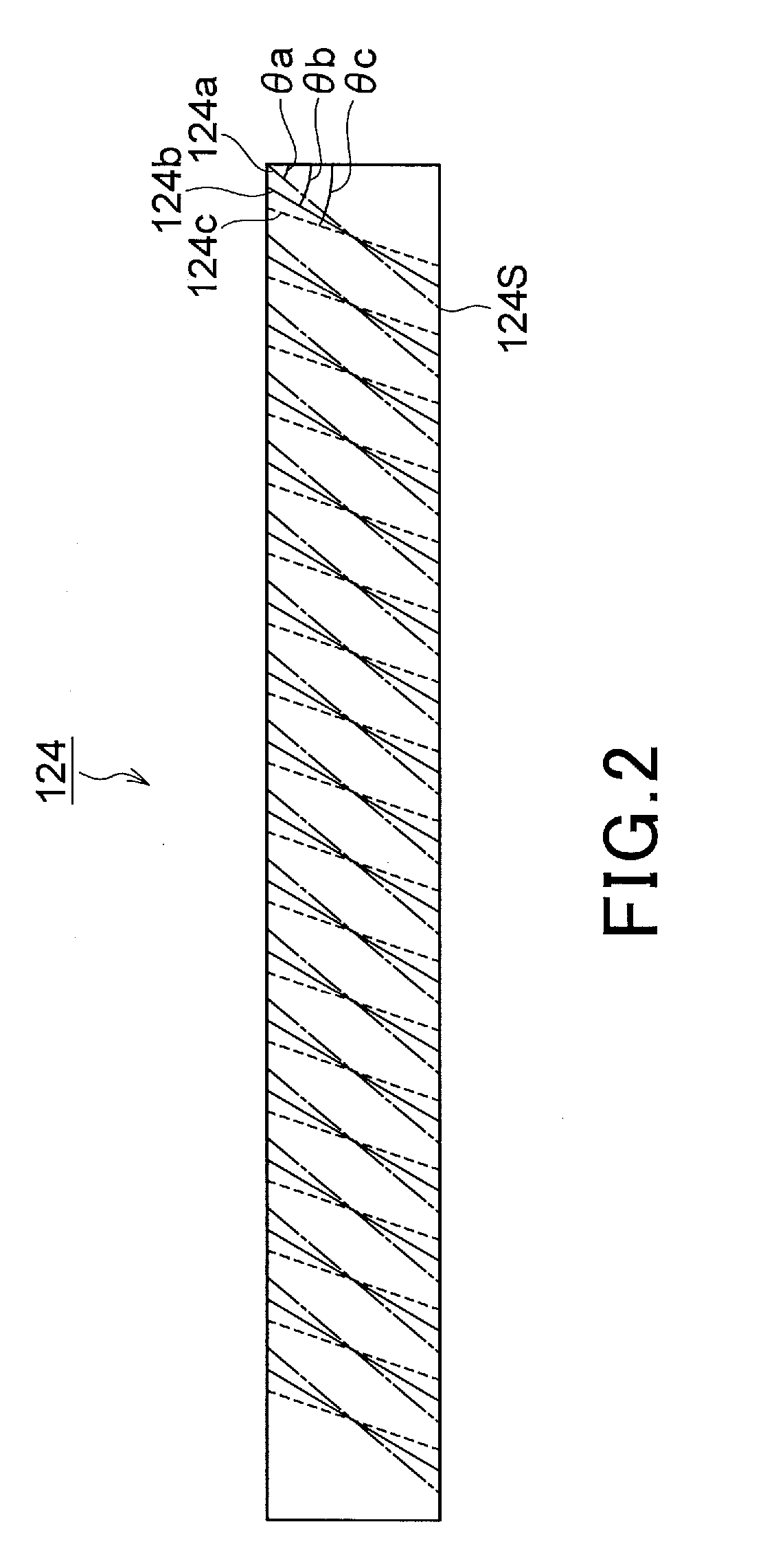

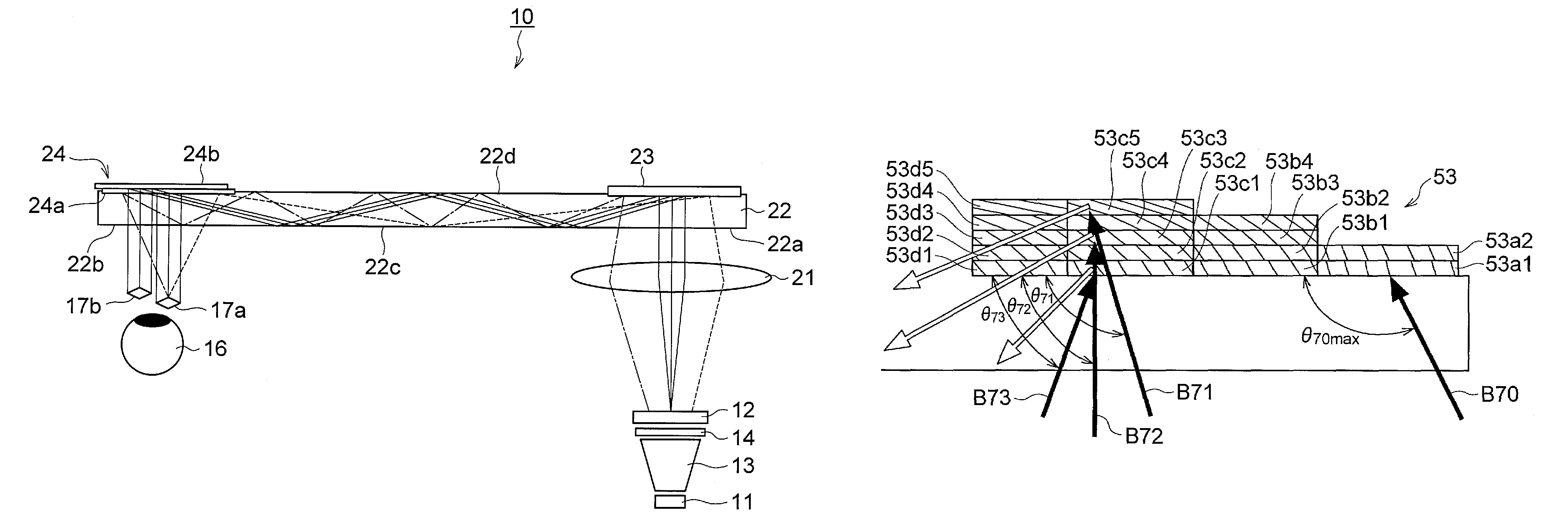

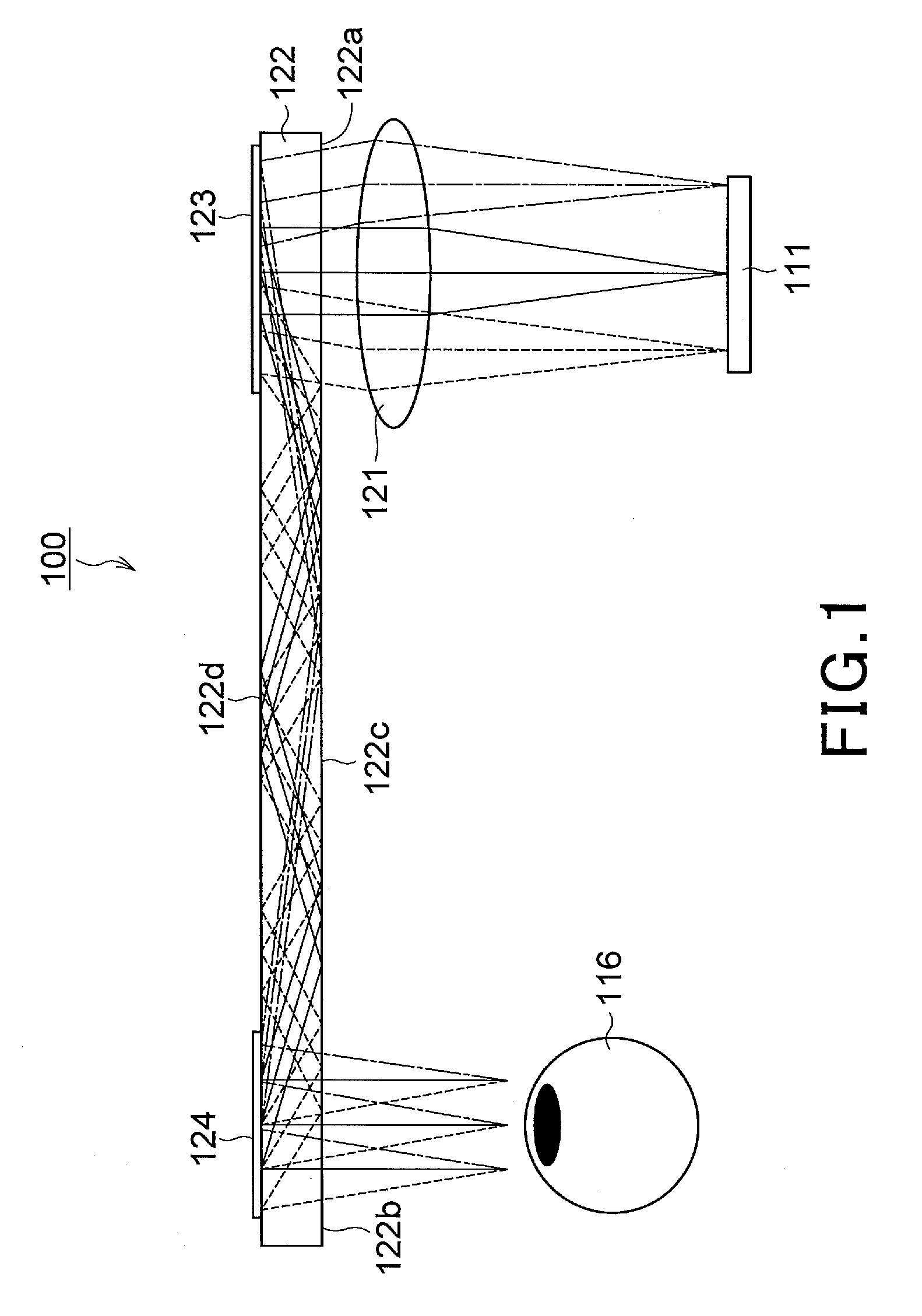

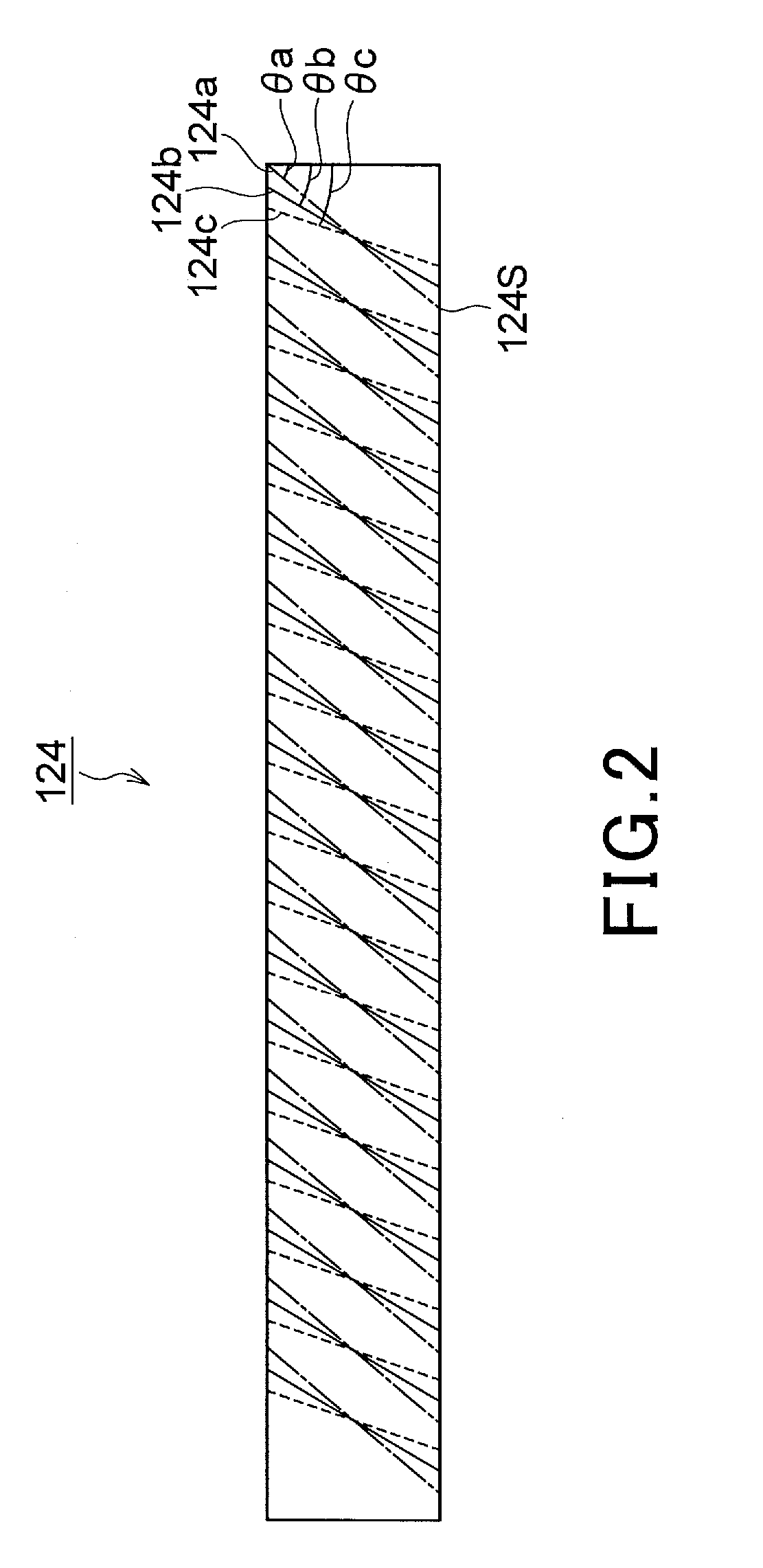

Optical device, and virtual image display

ActiveUS20060291021A1Reduce color unevennessReduce unevennessDiffraction gratingsOptical light guidesGratingLight beam

There is provided an optical device including an optical waveguide upon which a group of parallel light beams different in traveling direction from each other are incident and from which the group of parallel light beams go out after propagated by repeated total reflection through it. The optical waveguide includes a first reflection-type volume hologram grating, and a second reflection-type volume hologram grating. The pitches of interference fringes on the hologram surfaces of the first and second reflection-type volume hologram gratings are equal to each other. In at least the second reflection-type volume hologram grating, the angle formed between the interference fringes and hologram surfaces are varied continuously or stepwise within the hologram in relation to the main incident light beam so as to meet the Bragg condition. Therefore, it is possible to reduce the unevenness of color and brightness due to angles of view.

Owner:SONY CORP

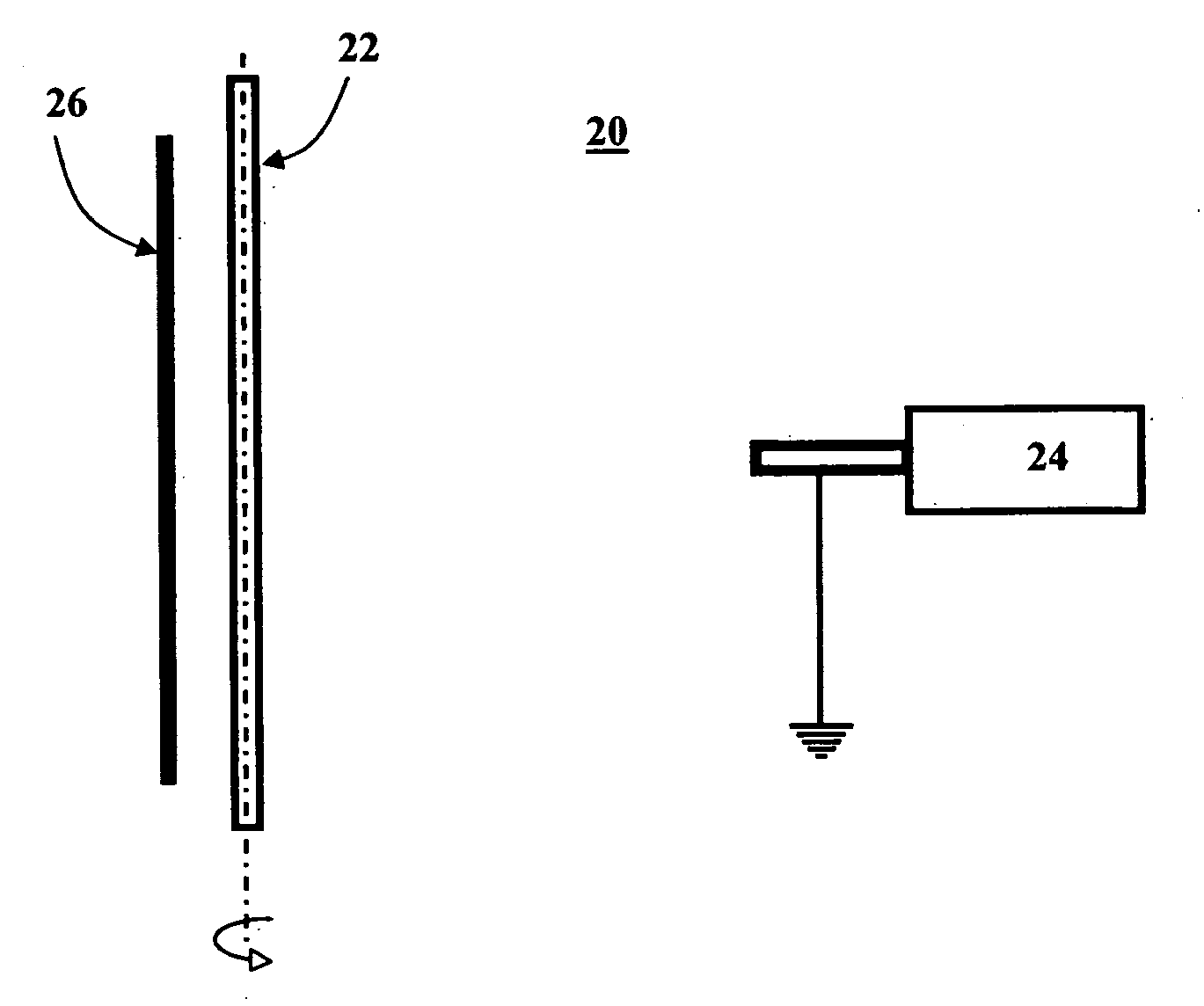

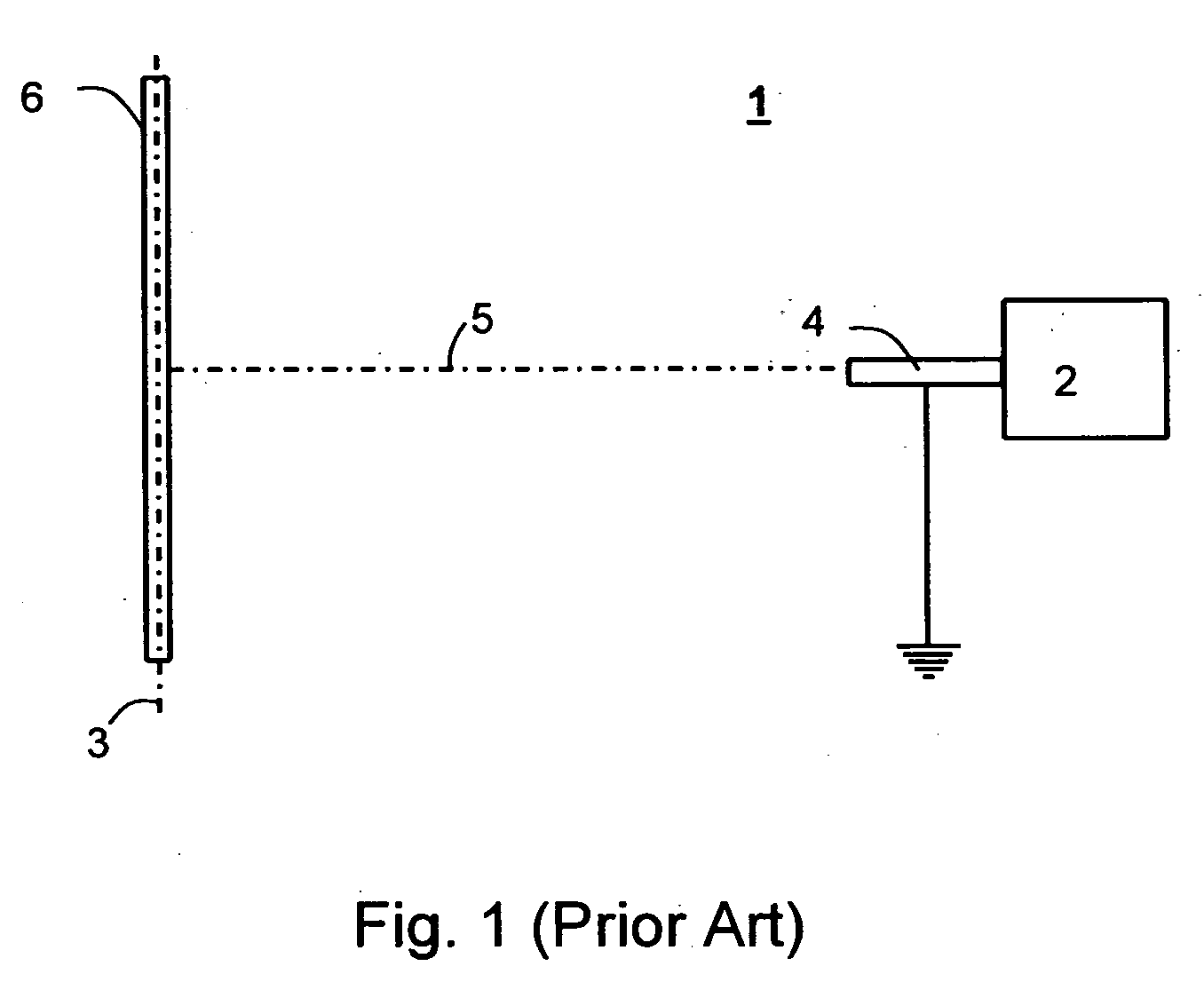

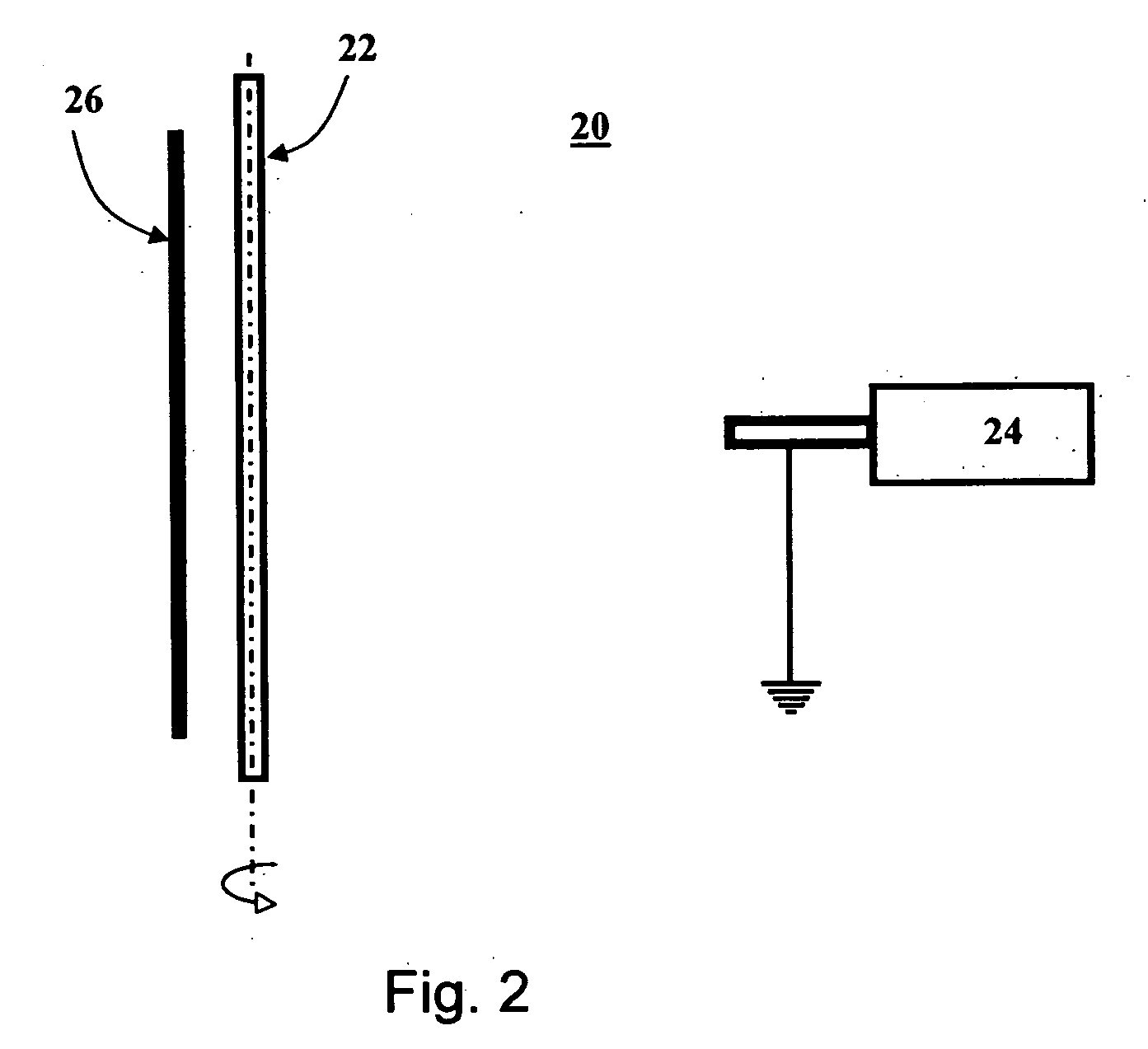

Method and apparatus for coating medical implants

InactiveUS20070031607A1Reduce unevennessMinimize volume chargeLiquid spraying plantsLiquid surface applicatorsFiberBiomedical engineering

A method of coating a non-rotary object with an electrospun coat, the method comprising, dispensing a charged liquefied polymer through at least one dispensing element within an electric field to thereby form a jet of polymer fibers, and moving the dispensing element relative to the object so as to coat the object with the electrospun coat.

Owner:NICAST LTD

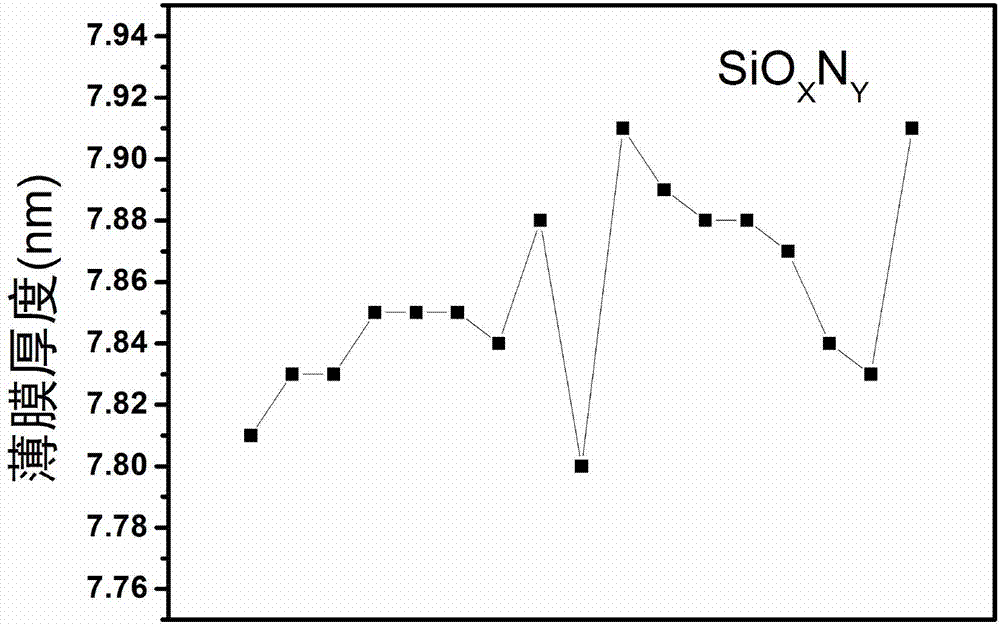

Ultrathin silicon oxynitride film material and preparation method and application thereof

ActiveCN104498895AGood uniformityImprove uniformityChemical vapor deposition coatingOperating temperatureFilm material

The invention discloses an ultrathin silicon oxynitride film material and a preparation method thereof. The preparation method comprises the following steps: placing a substrate in a chemical vapor deposition equipment cavity, introducing NH3, O2 gas and SiH4-containing gas as reactant gases, introducing a carrier and protective gas, performing vapor deposition, thereby obtaining the silicon oxynitride film material, wherein the operating temperature of the chemical vapor deposition equipment cavity is 100-260 DEG C, the working pressure is 1-4Pa, and the power is 200-450W; the vapor deposition time is 15-40 seconds; the volume ratio of the SiH4 gas to the O2 gas is 9-110; the volume ratio of the SiH4-containing gas to the NH3 gas is 3-11; and the volume ratio of the SiH4-containing gas to the carrier and the protective gas is 0.1-1. The thickness of the silicon oxynitride film material prepared on a four-inch silicon substrate is 6-9nm, and the non-uniformity of the film is lower than 0.7 percent.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

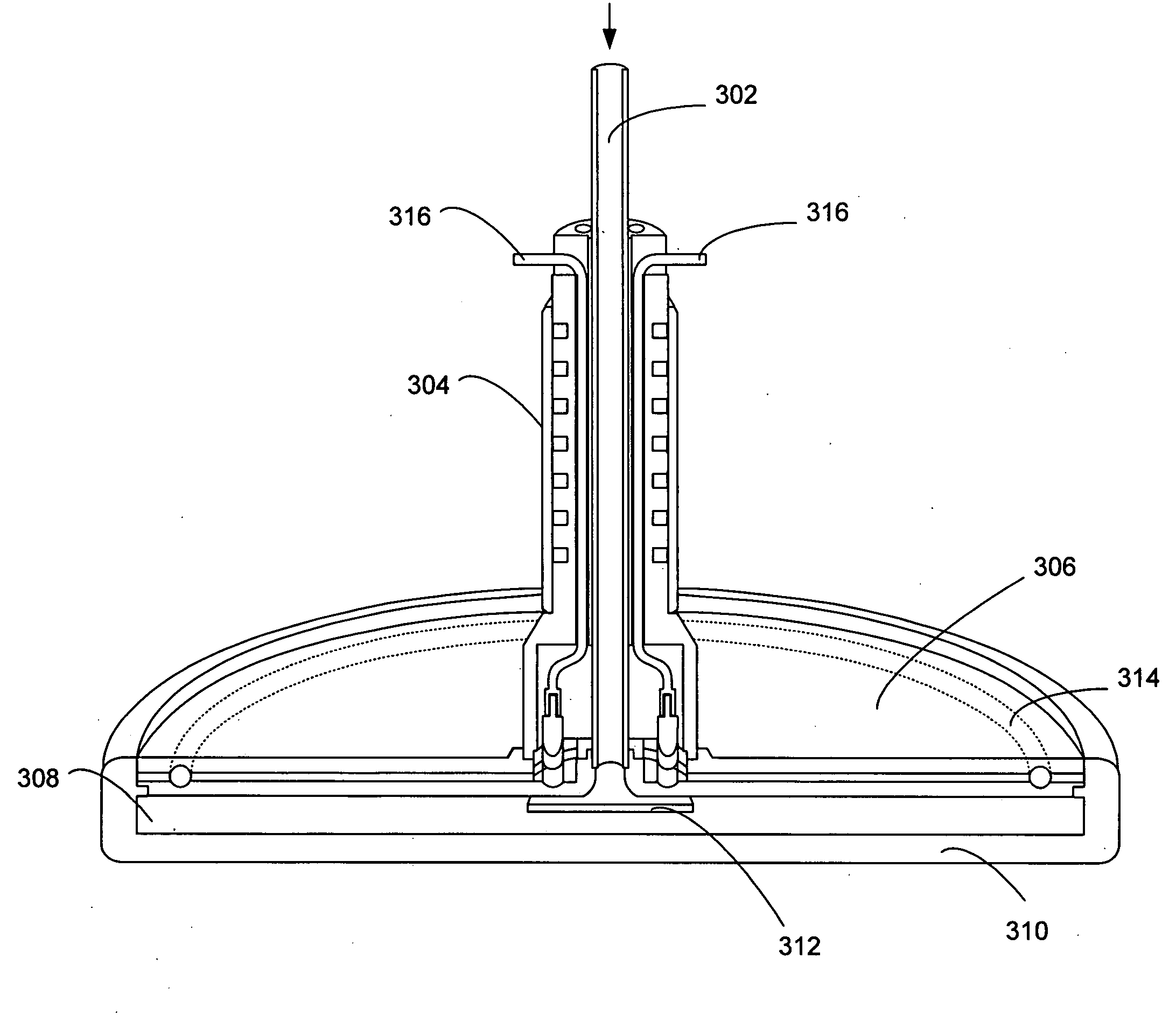

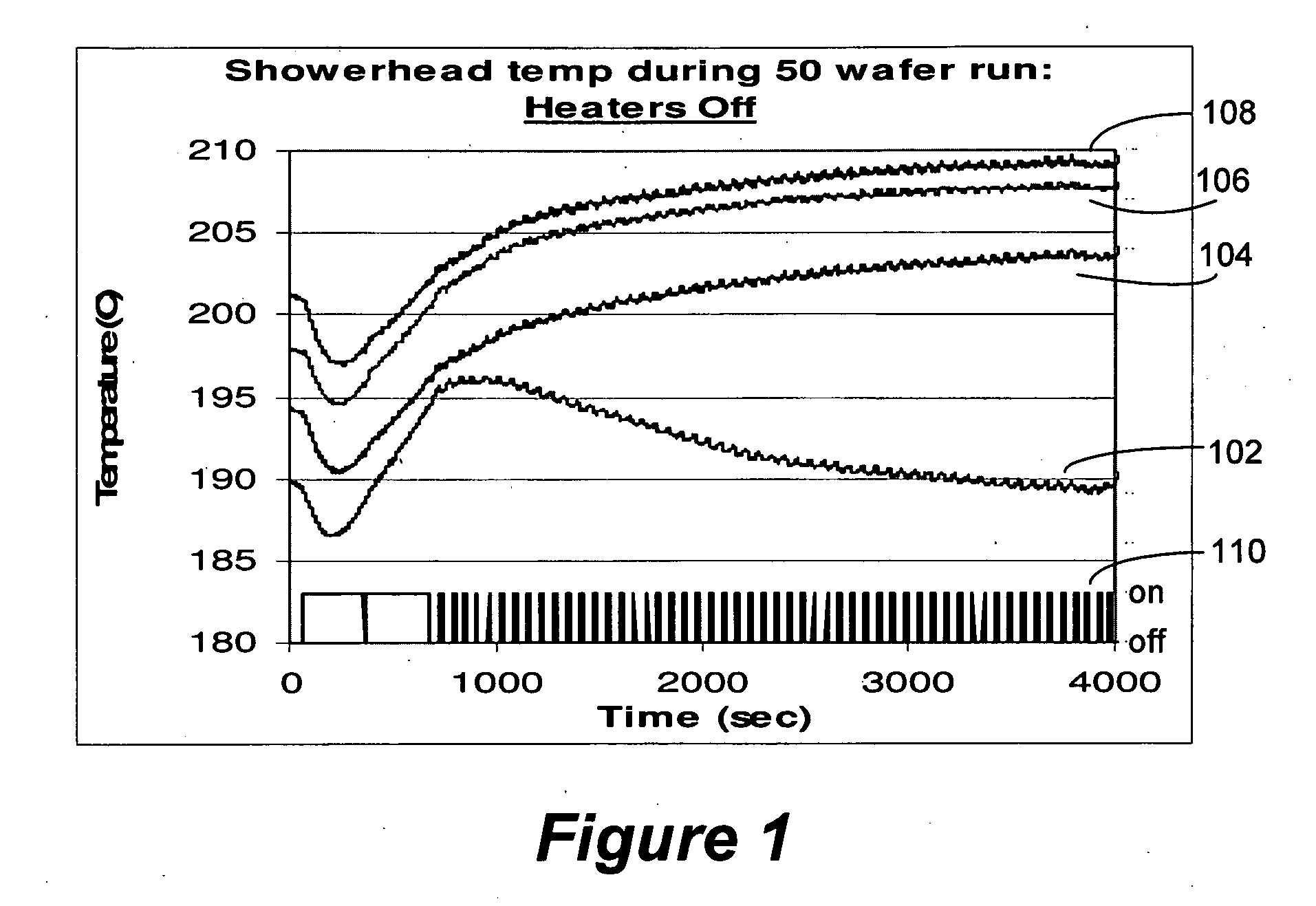

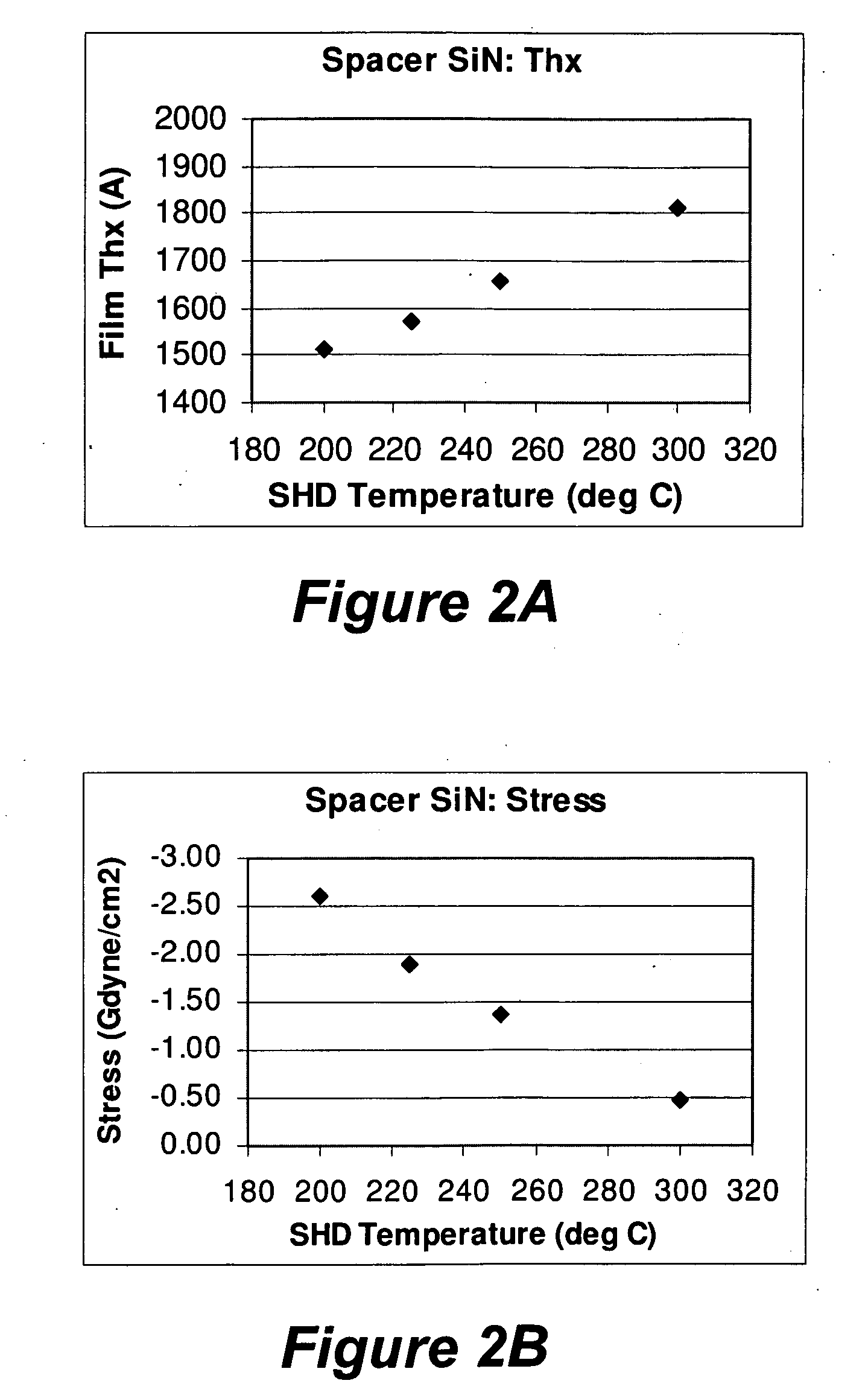

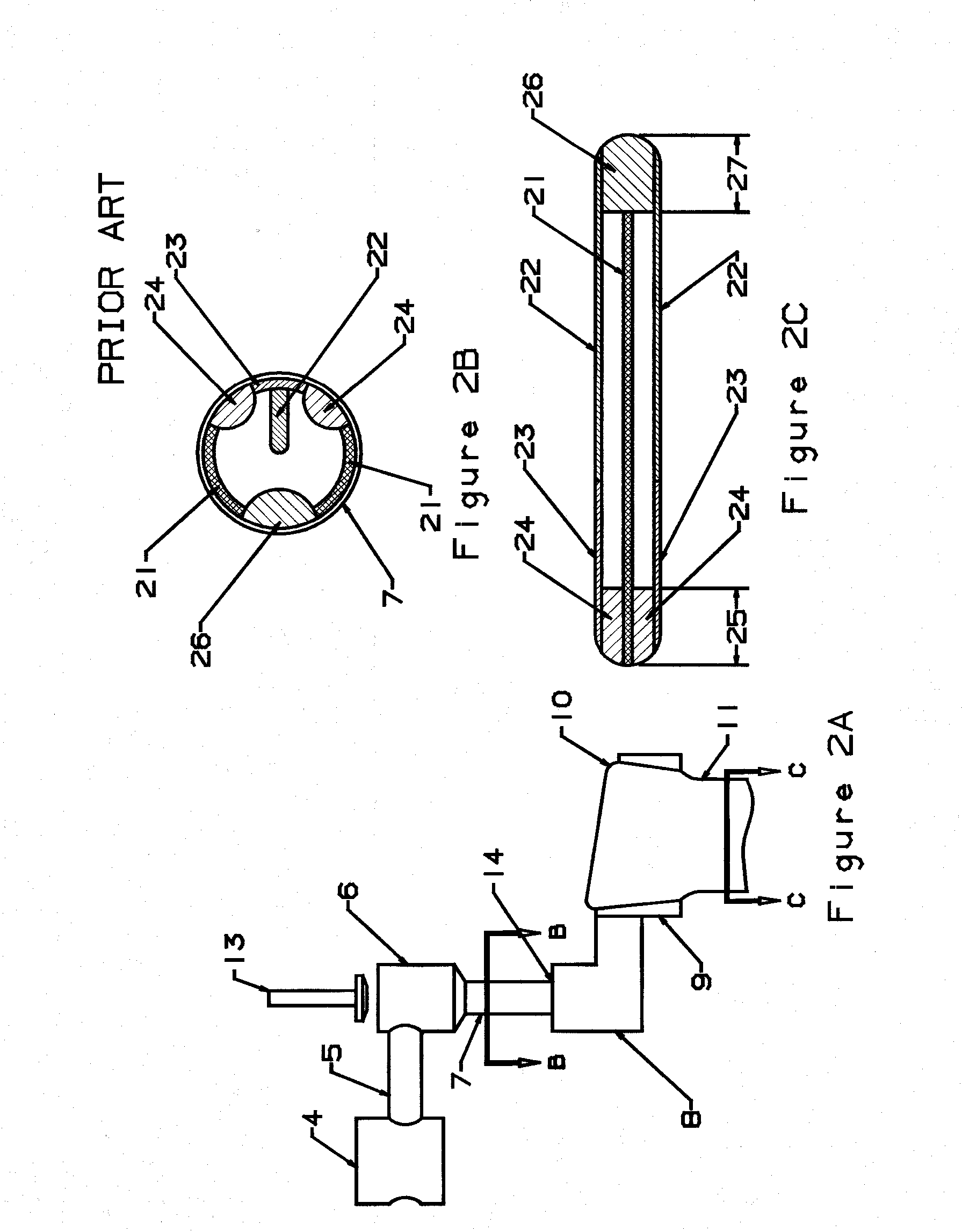

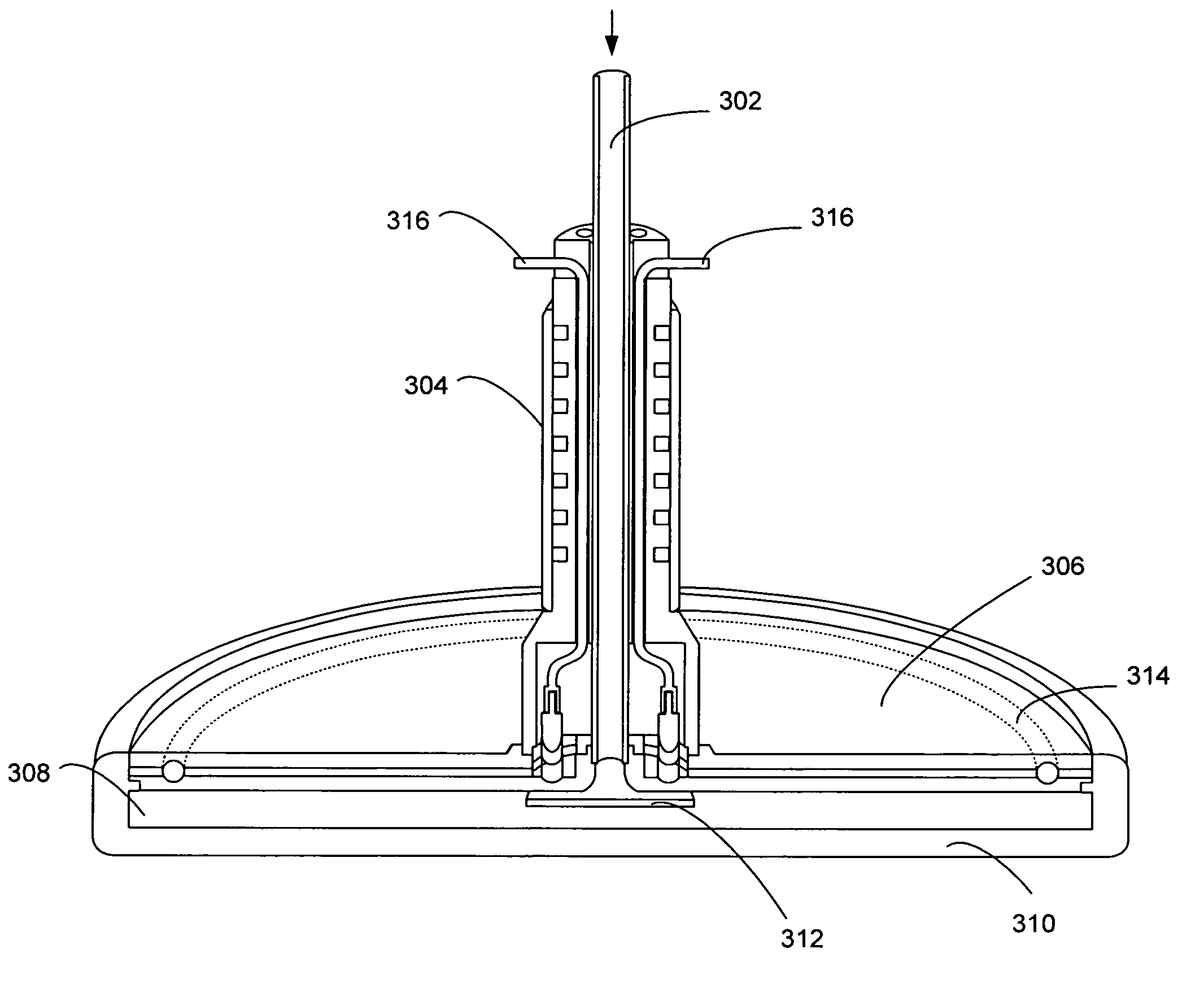

Temperature controlled showerhead

ActiveUS20090095220A1Precise and stable temperature controlRapid responseLiquid surface applicatorsElectric discharge tubesTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

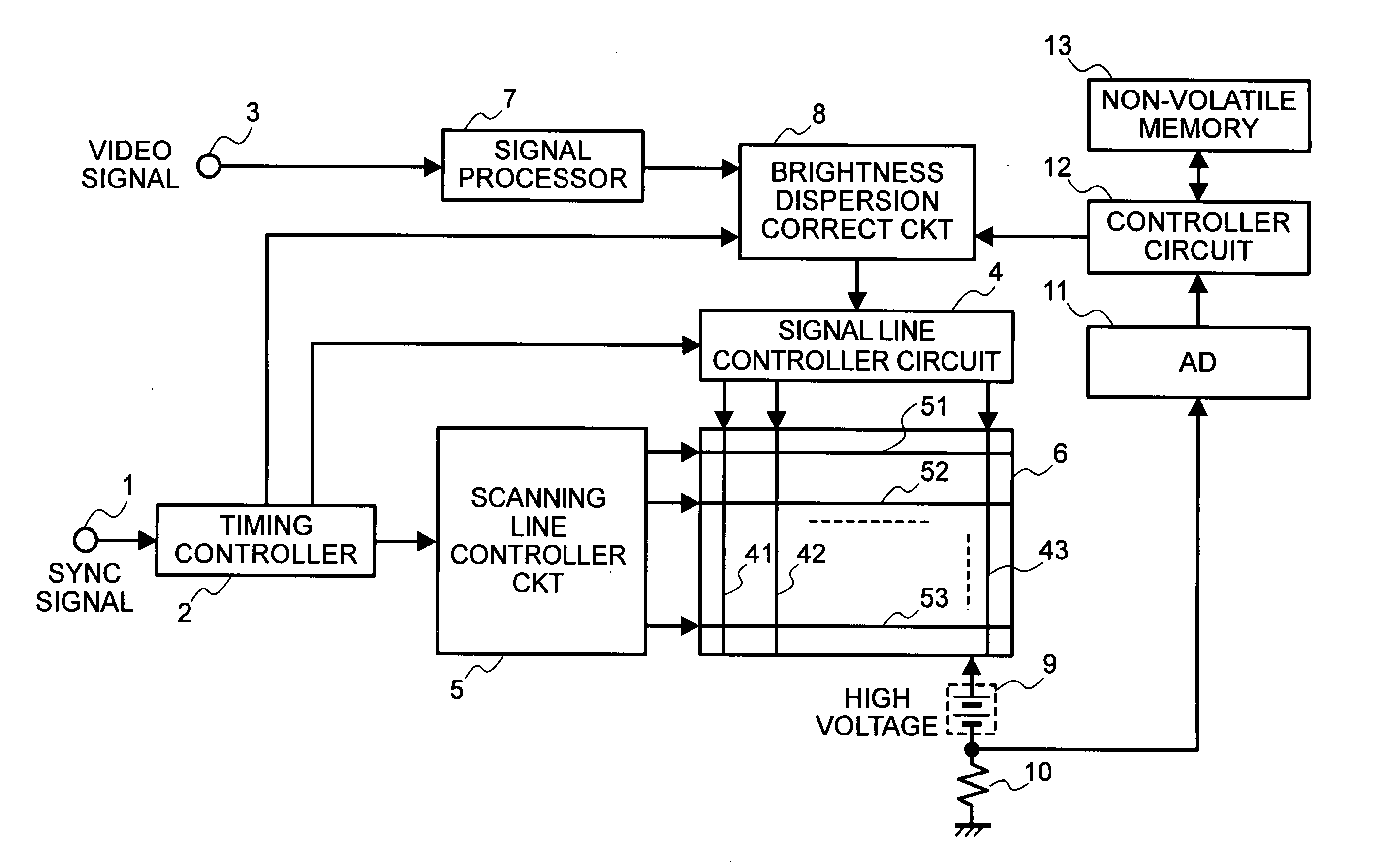

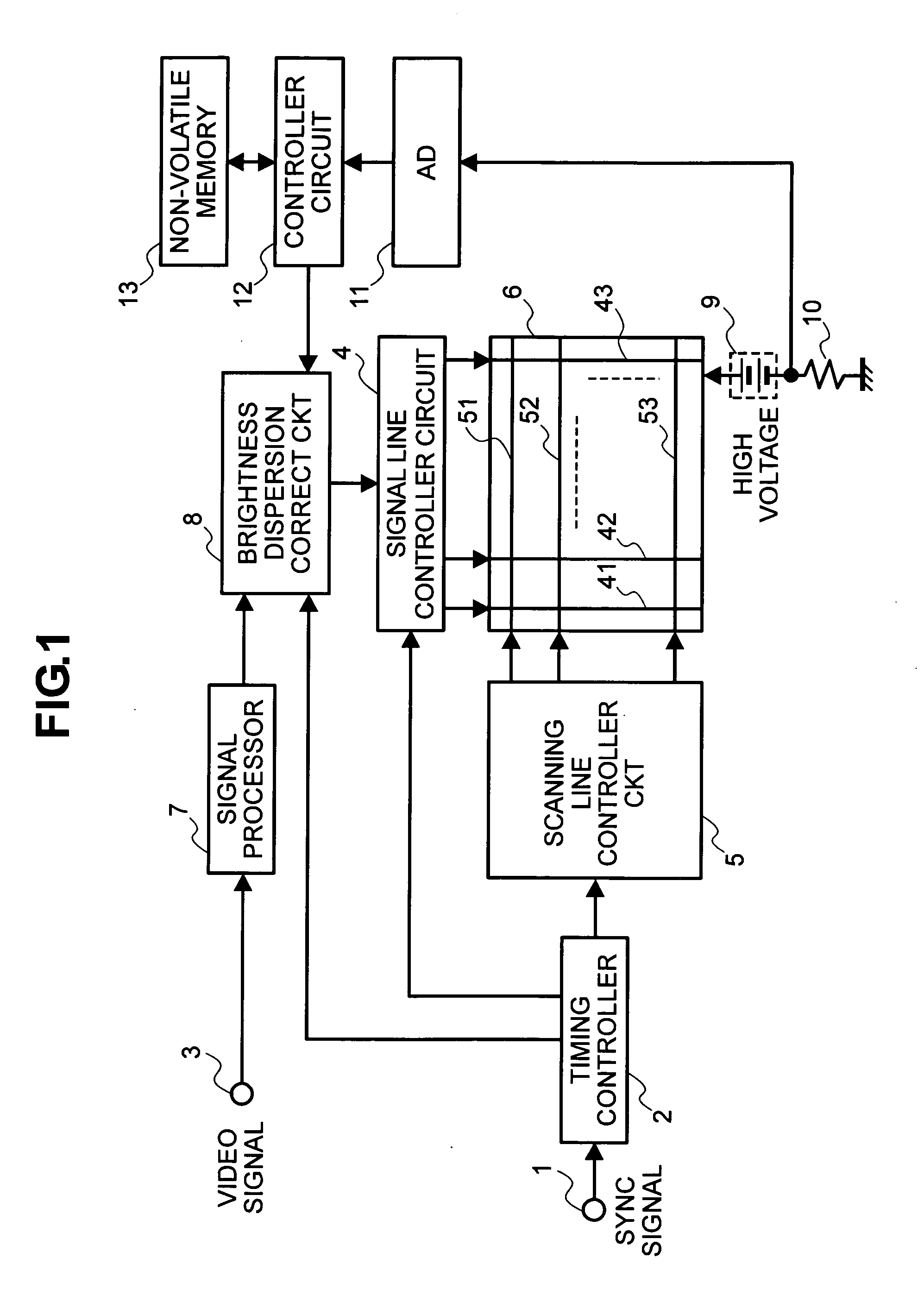

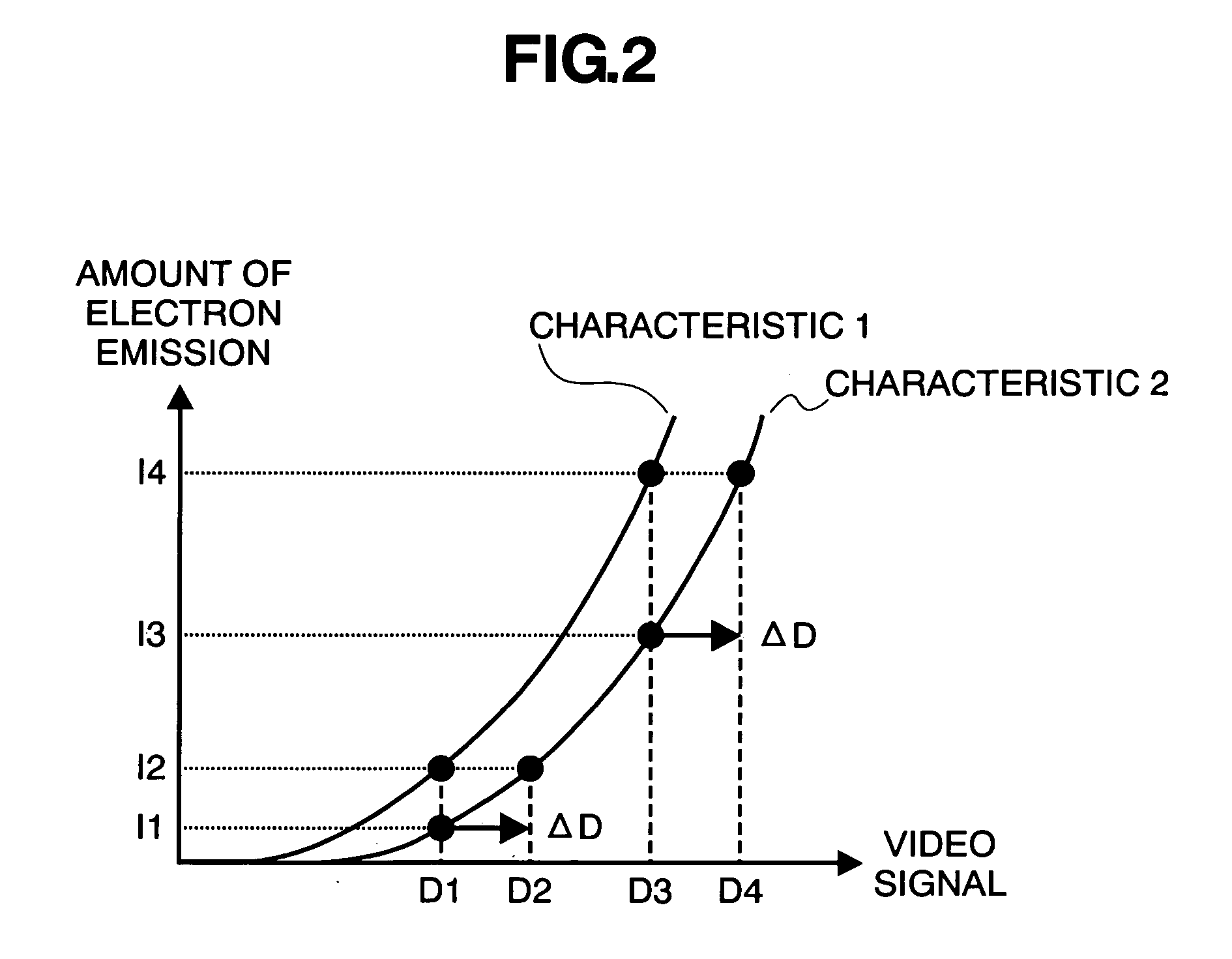

Image displaying apparatus

InactiveUS20060279481A1Reduce capacityShorten timeTelevision system detailsStatic indicating devicesSignal correctionVoltage

An image displaying apparatus, comprises: a plural number of electron sources, being disposed in matrix-like manner, each for emitting electrons therefrom; a driver for producing drive voltage for driving the electron sources upon basis of a video signal, to be supplied to the electron sources; and a correct circuit for correcting the video signal, wherein the correct circuit determines a predetermined number of correction points in horizontal and vertical directions, for the plural number of electron sources disposed in the matrix-like manner, corrects the video signal to the electron source corresponding to the correction point upon basis of a first correction value, which is determined in advance, and corrects the video signal corresponding to the electron source located between the correction points, upon basis of a second correction value, which is obtained through an interpolation calculation with using said first correction values, which are determined at each of the correction points, thereby correcting or compensating the unevenness in brightness, with using a small number of correction values therein.

Owner:HARUNA FUMIO +1

Optical device, and virtual image display

ActiveUS7453612B2Reduce color unevennessReduce unevennessDiffraction gratingsOptical light guidesGratingWaveguide

An optical device including an optical waveguide upon which a group of parallel light beams different in traveling direction from each other are incident and from which the group of parallel light beams go out after propagated by repeated total reflection through it. The optical waveguide includes a first reflection-type volume hologram grating, and a second reflection-type volume hologram grating. The pitches of interference fringes on the hologram surfaces of the first and second reflection-type volume hologram gratings are equal to each other. In at least the second reflection-type volume hologram grating, the angle formed between the interference fringes and hologram surfaces are varied continuously or stepwise within the hologram in relation to the main incident light beam so as to meet the Bragg condition. Therefore, it is possible to reduce the unevenness of color and brightness due to angles of view.

Owner:SONY CORP

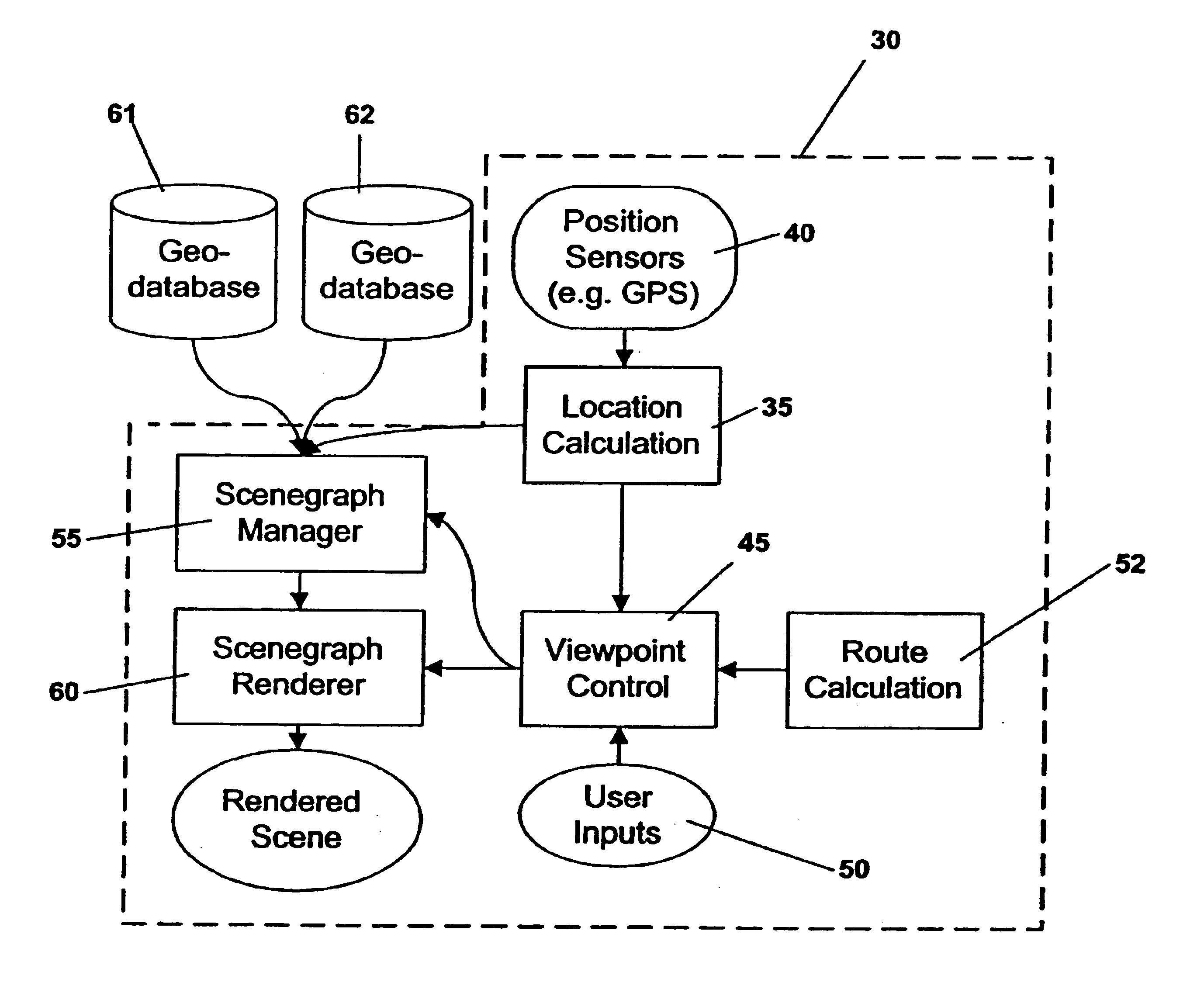

System and method for advanced 3D visualization for mobile navigation units

InactiveUS6885939B2Improve realismReduce unevennessInstruments for road network navigationRoad vehicles traffic controlMobile navigationViewpoints

A system providing three-dimensional visual navigation for a mobile unit includes a location calculation unit for calculating an instantaneous position of the mobile unit, a viewpoint control unit for determining a viewing frustum from the instantaneous position, a scenegraph manager in communication with at least one geo-database to obtain geographic object data associated with the viewing frustum and generating a scenegraph organizing the geographic object data, and a scenegraph renderer which graphically renders the scenegraph in real time. To enhance depiction, a method for blending images of different resolutions in the scenegraph reduces abrupt changes as the mobile unit moves relative to the depicted geographic objects. Data structures for storage and run-time access of information regarding the geographic object data permit on-demand loading of the data based on the viewing frustum and allow the navigational system to dynamically load, on-demand, only those objects that are visible to the user.

Owner:ROBERT BOSCH GMBH

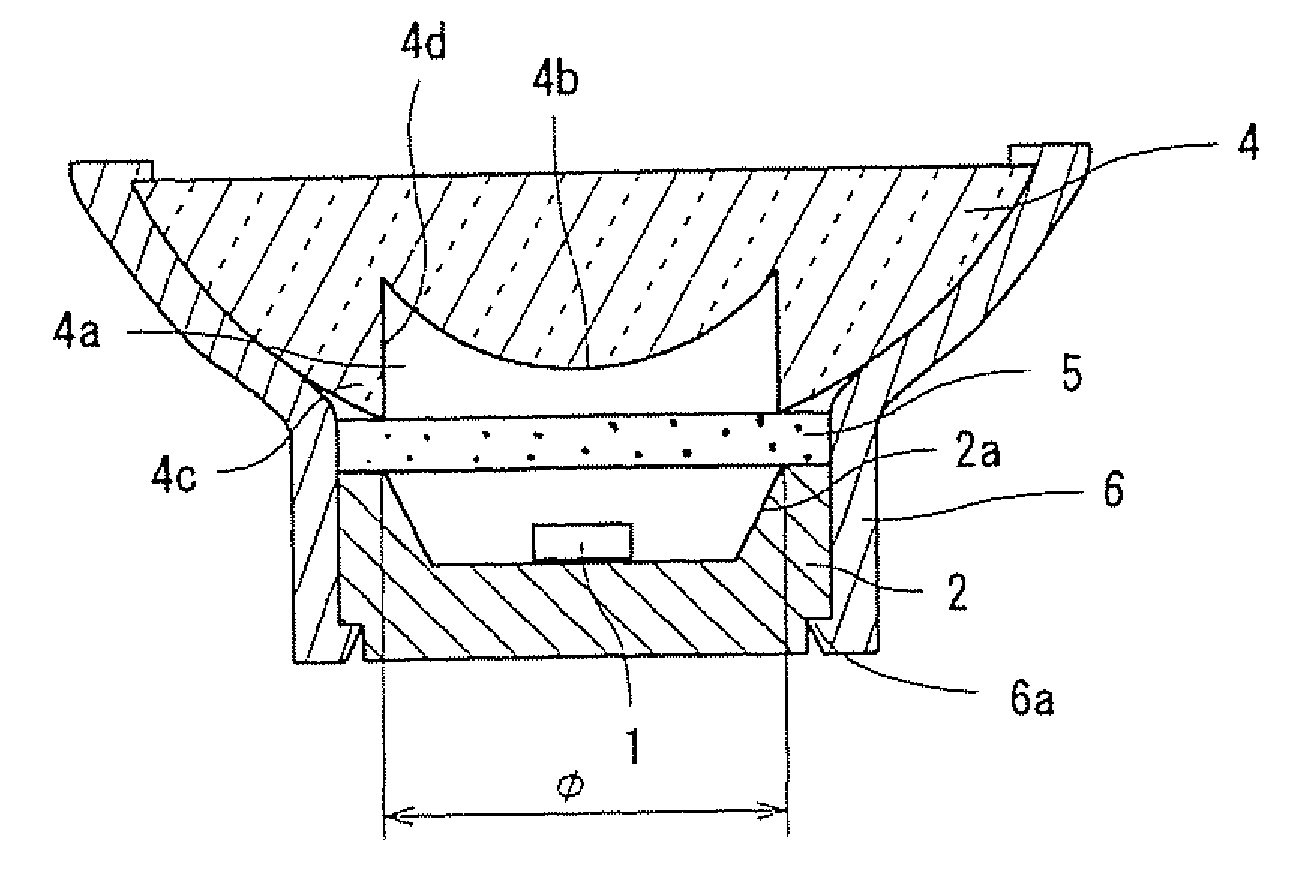

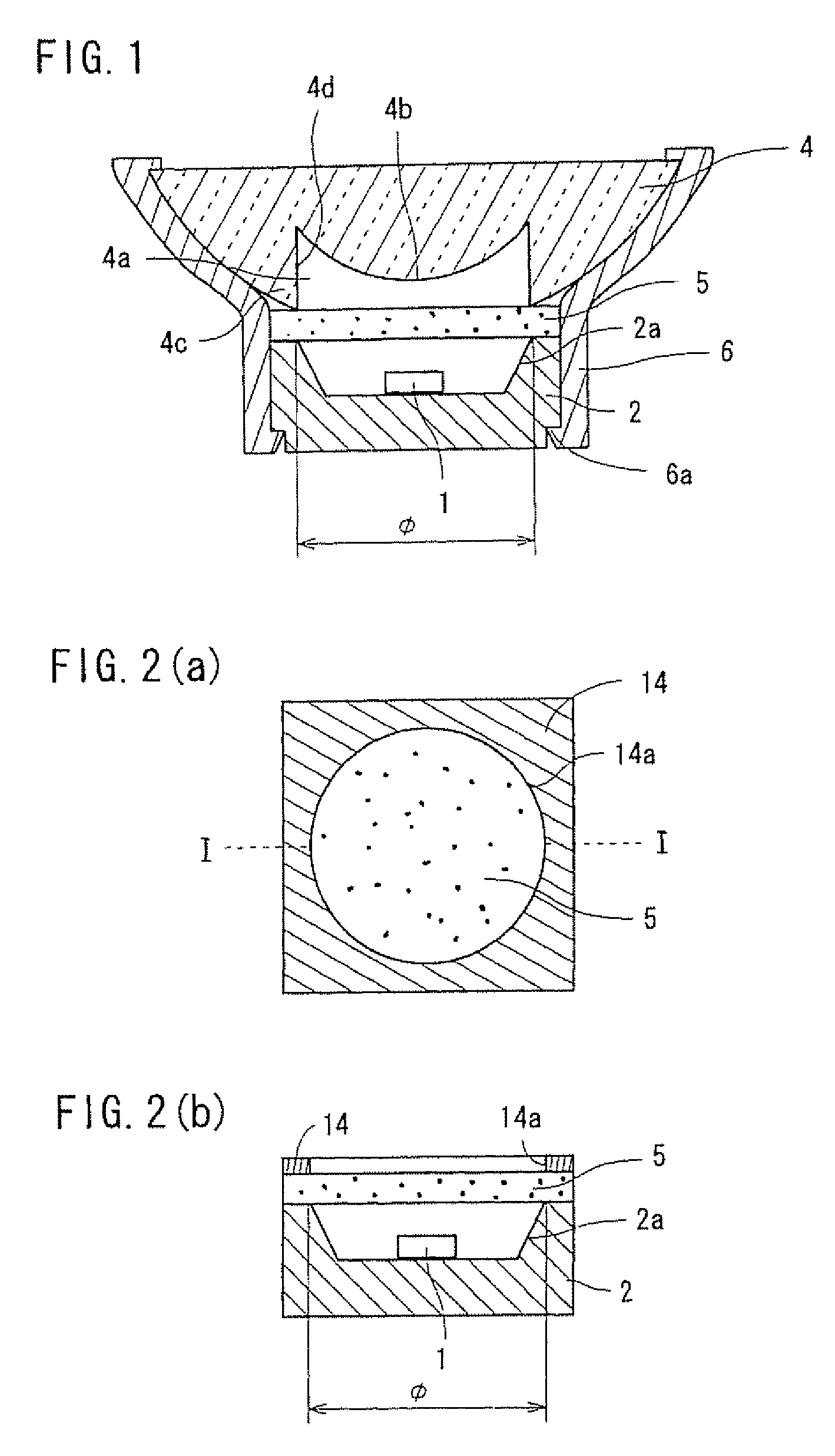

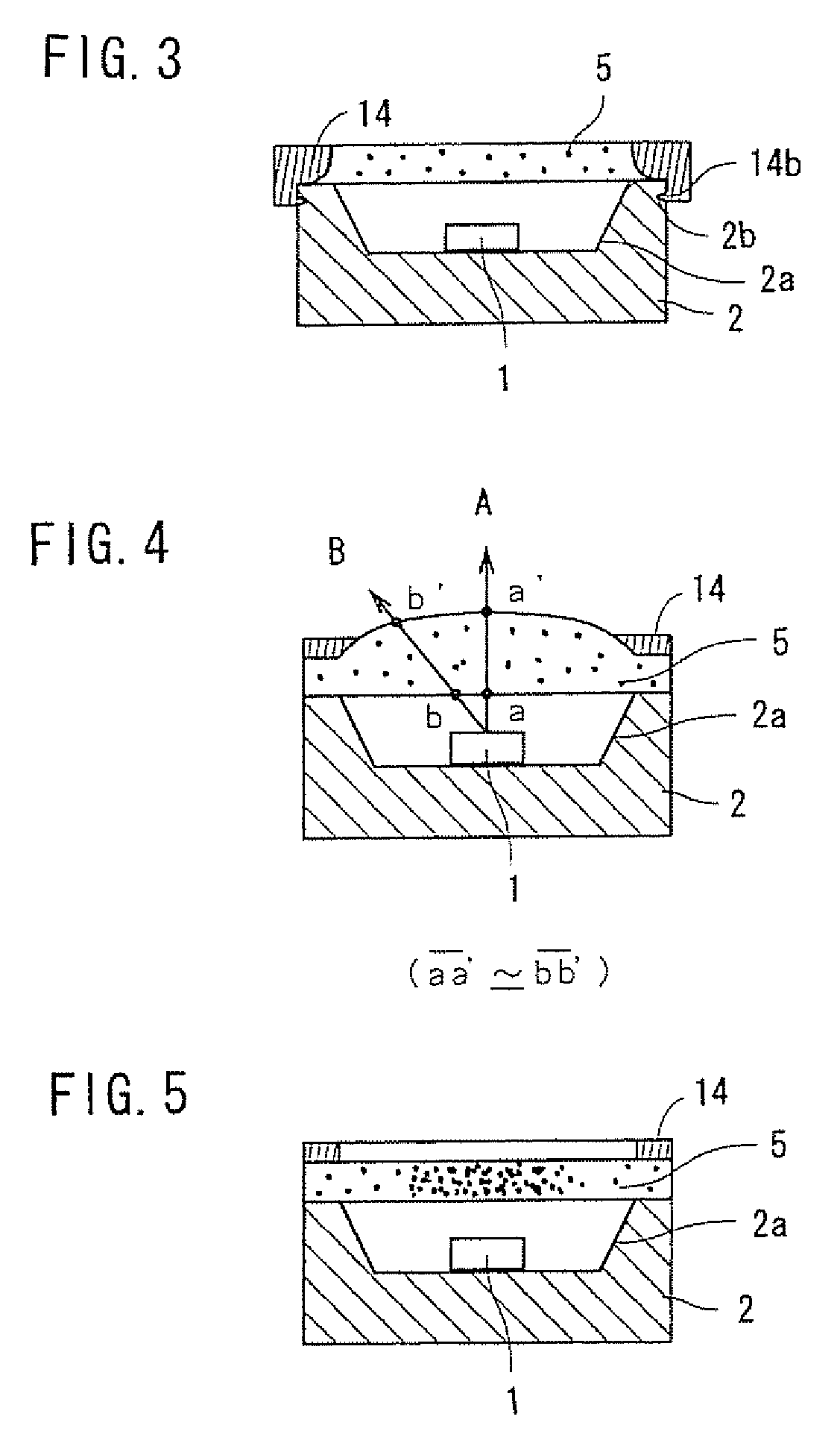

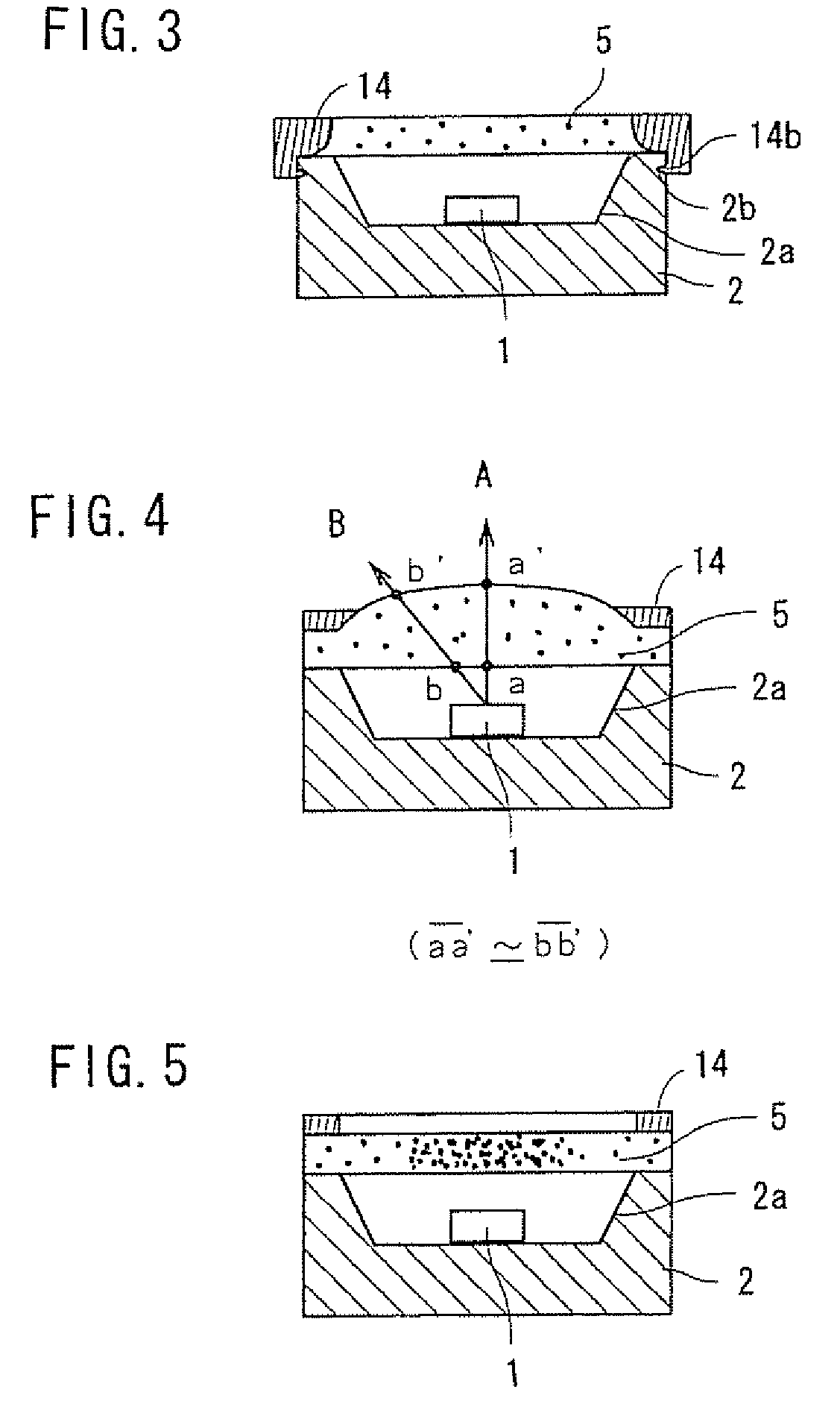

Light emitting device using light emitting diode chip

ActiveUS20070085103A1Improve efficiencyHigh elasticityDischarge tube luminescnet screensLamp detailsExcitation wavelengthEdge region

A light emitting device comprises: an LED chip mounted in a recess formed in a mounting substrate; a wavelength converting member that is disposed so as to cover the recess and the edge area around the recess and that is excited by light emitted from the LED chip to emit light of a wavelength different from an excitation wavelength; and an emission control member disposed at a light output side of the wavelength converting member so as to allow emission of light coming from an area of the wavelength converting member that corresponds to the recess and to prevent emission of light coming from an area of the wavelength converting member that corresponds to the edge area around the recess. This can prevent variations in color between light emitted from the central part of the wavelength converting member and light emitted from the part of the wavelength converting member that is located on the edge area around the recess of the mounting substrate, thereby reducing unevenness of color on the irradiation surface.

Owner:MATSUSHITA ELECTRIC WORKS LTD

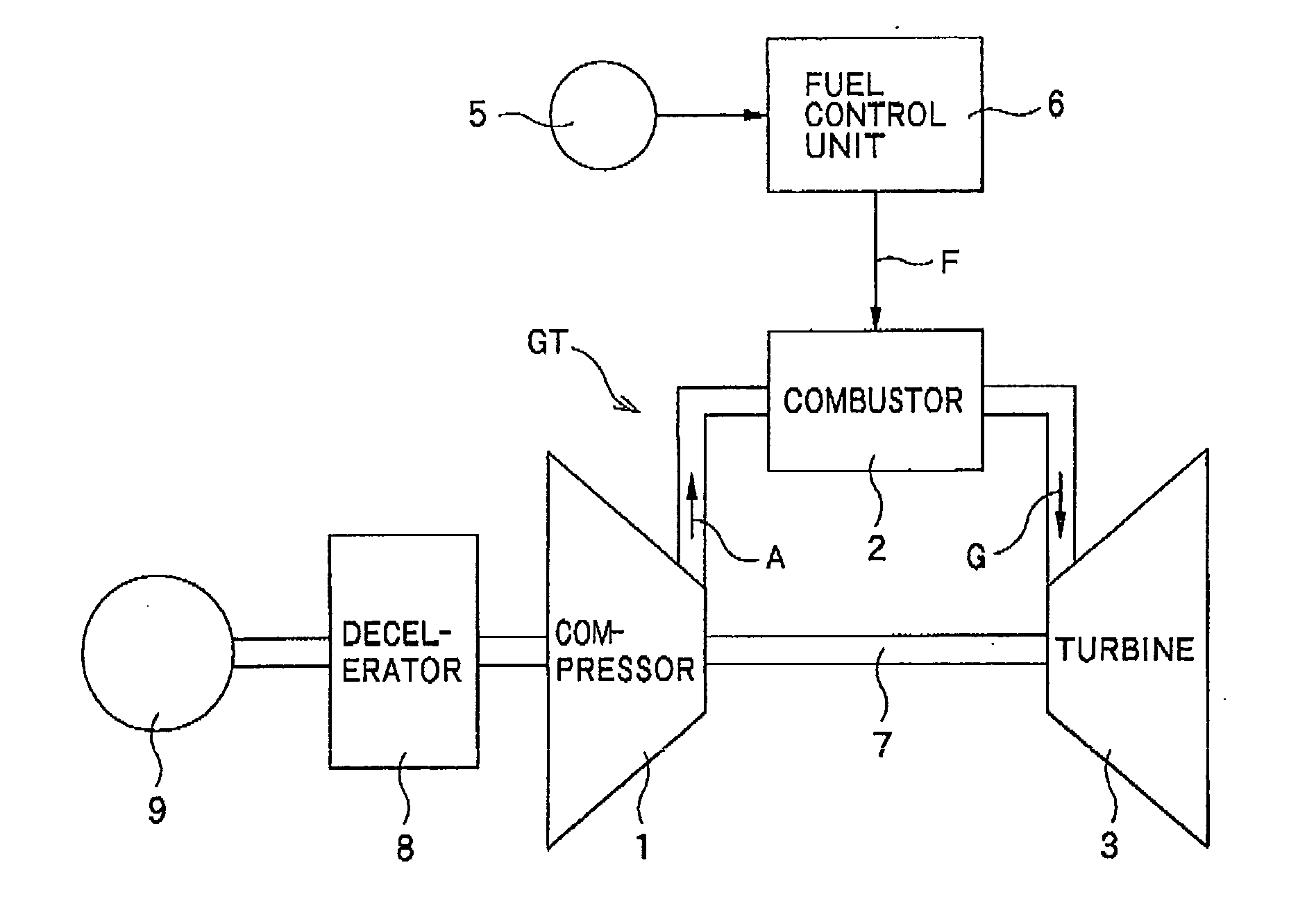

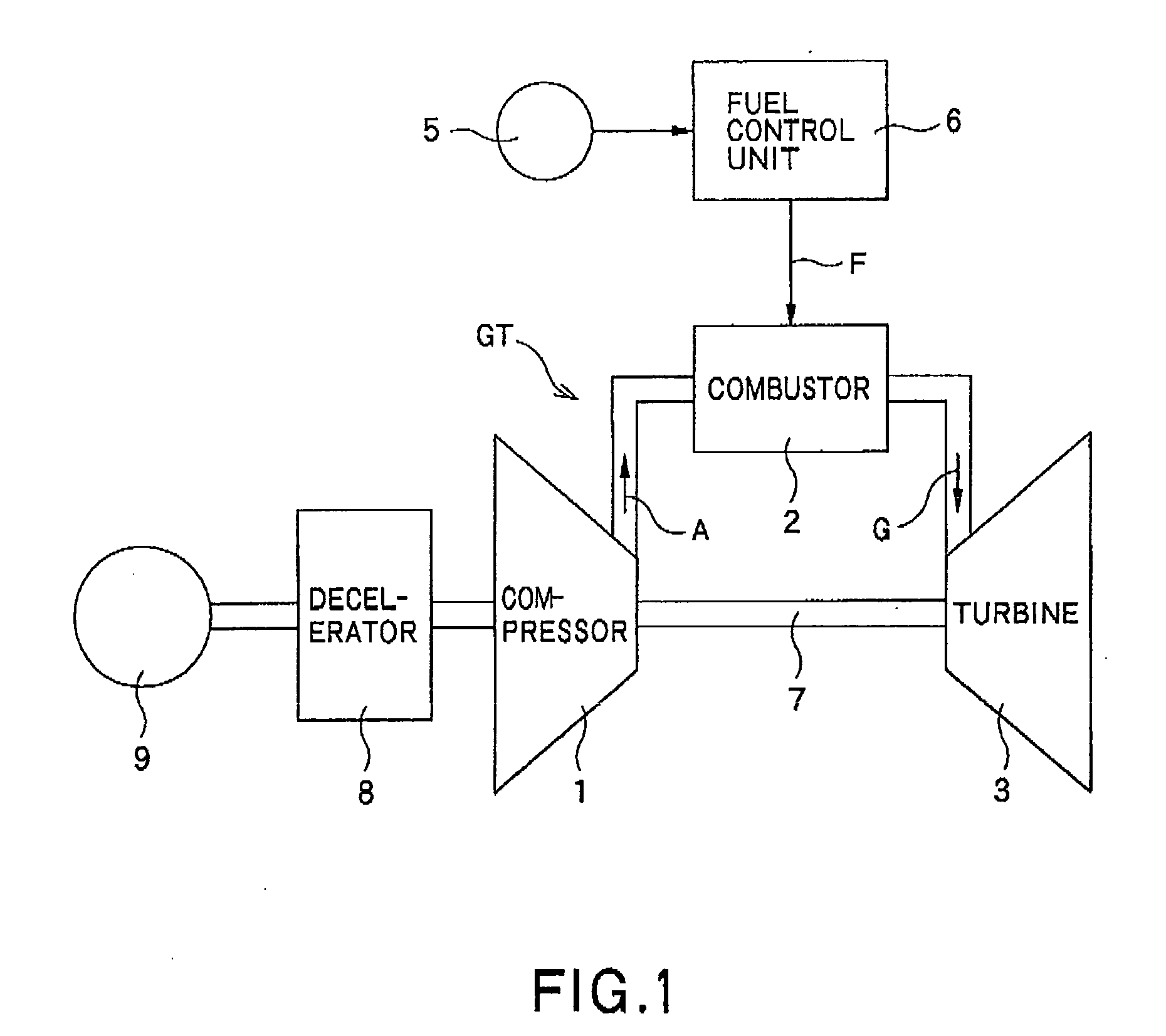

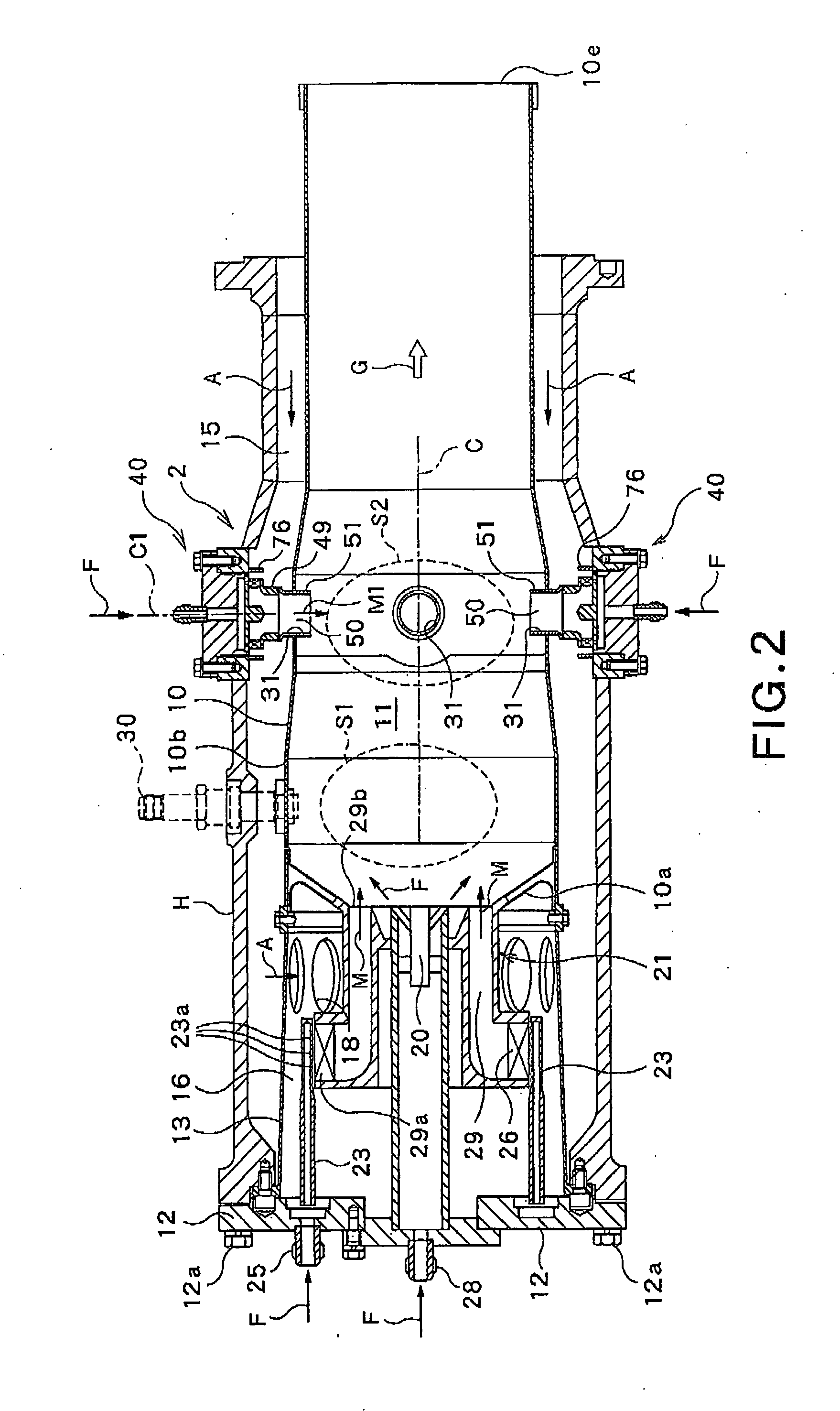

Gas turbine combustor

ActiveUS20100229557A1Reduce unevennessMixing effectContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCombustion chamber

This invention provides a gas turbine combustor including: a main burner at a head portion of a combustor cylinder; and a pre-mixing type supplemental burner at a downstream portion of the combustor cylinder and extending through a circumferential wall thereof. The supplemental burner includes: an introducing passage configured to deflect a part of the compressed air radially inward, the compressed air flowing from an air passage between the circumferential wall of the combustor cylinder and a housing surrounding the circumferential wall toward the head portion of the combustor cylinder, and introduce the compressed air into the combustor cylinder; and a fuel nozzle configured to supply the fuel from fuel injection holes to the compressed air introduced into the introducing passage to produce a pre-mixed gas in the introducing passage.

Owner:KAWASAKI HEAVY IND LTD

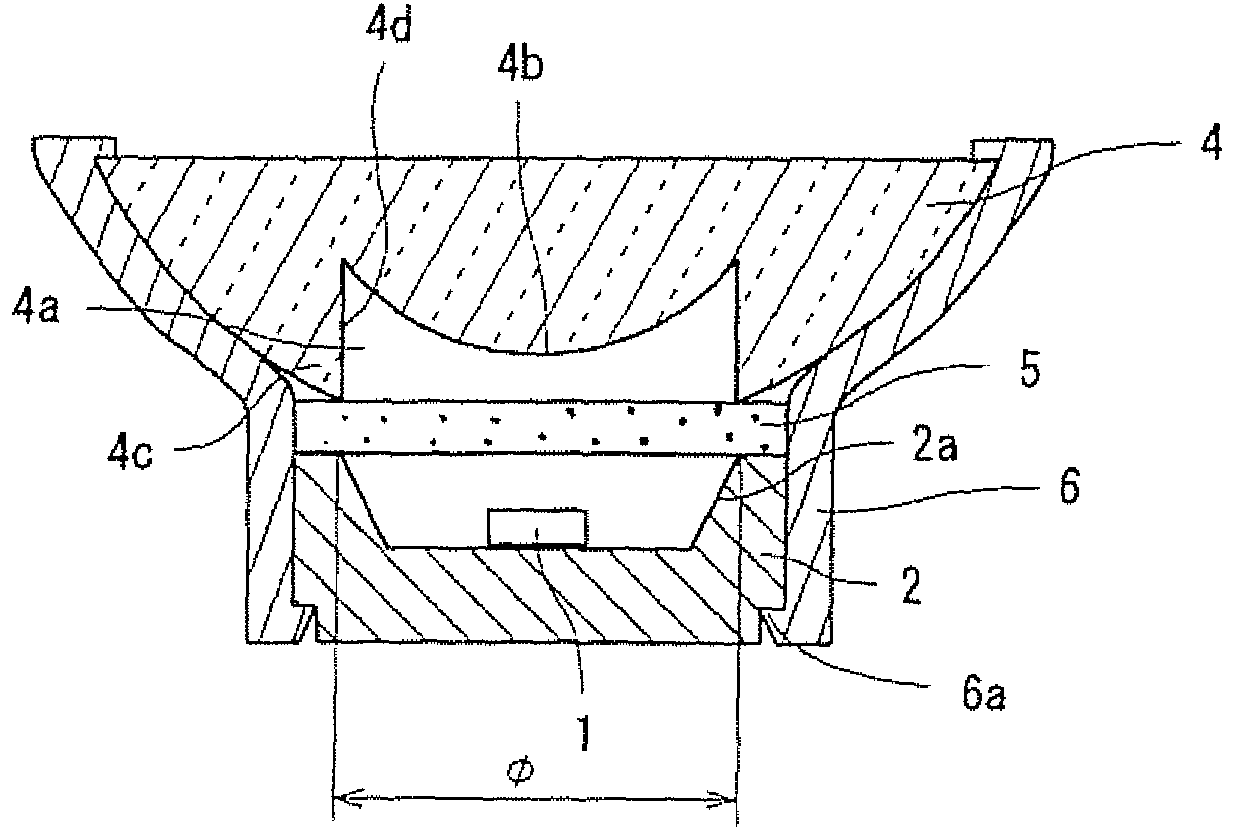

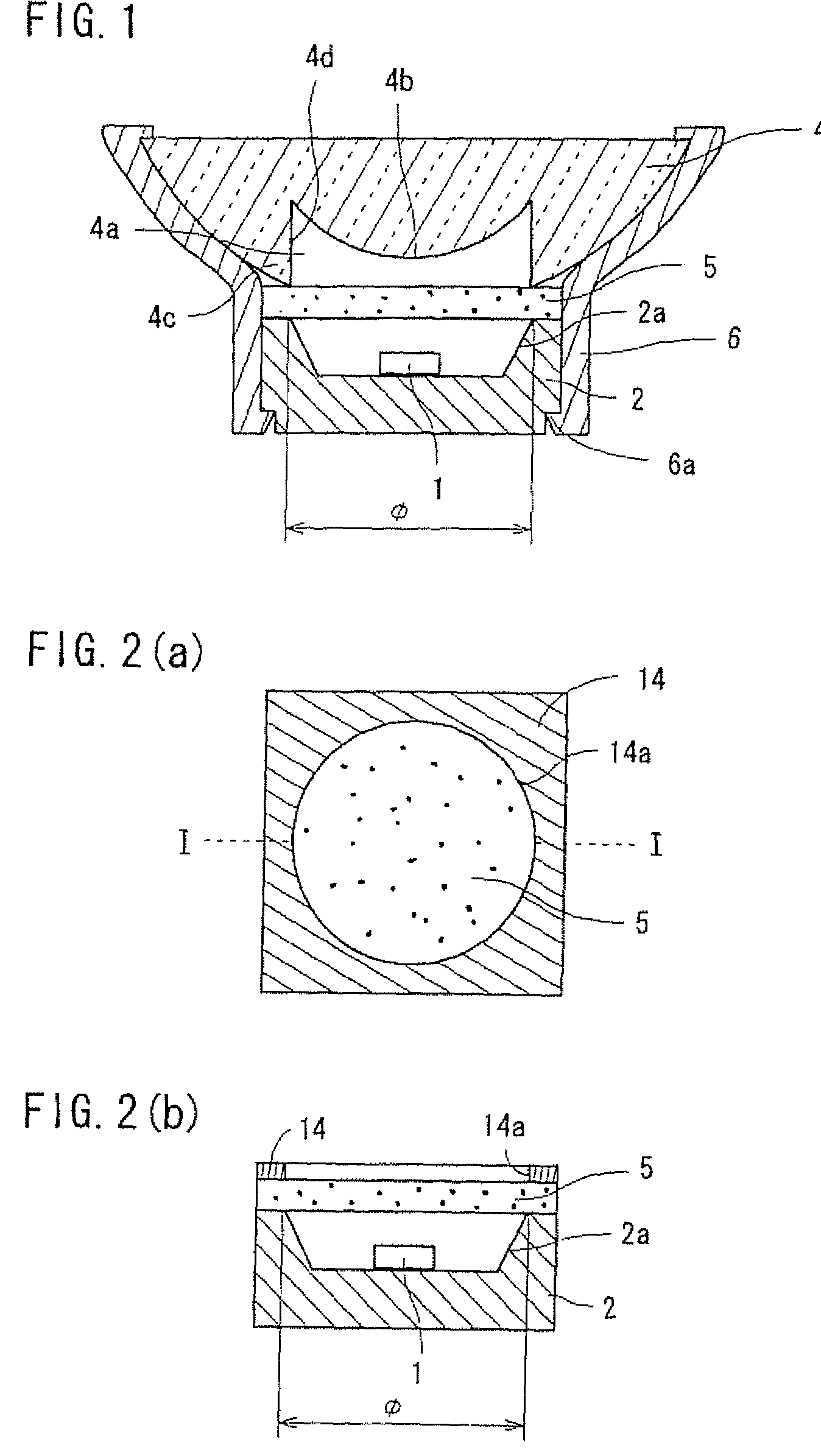

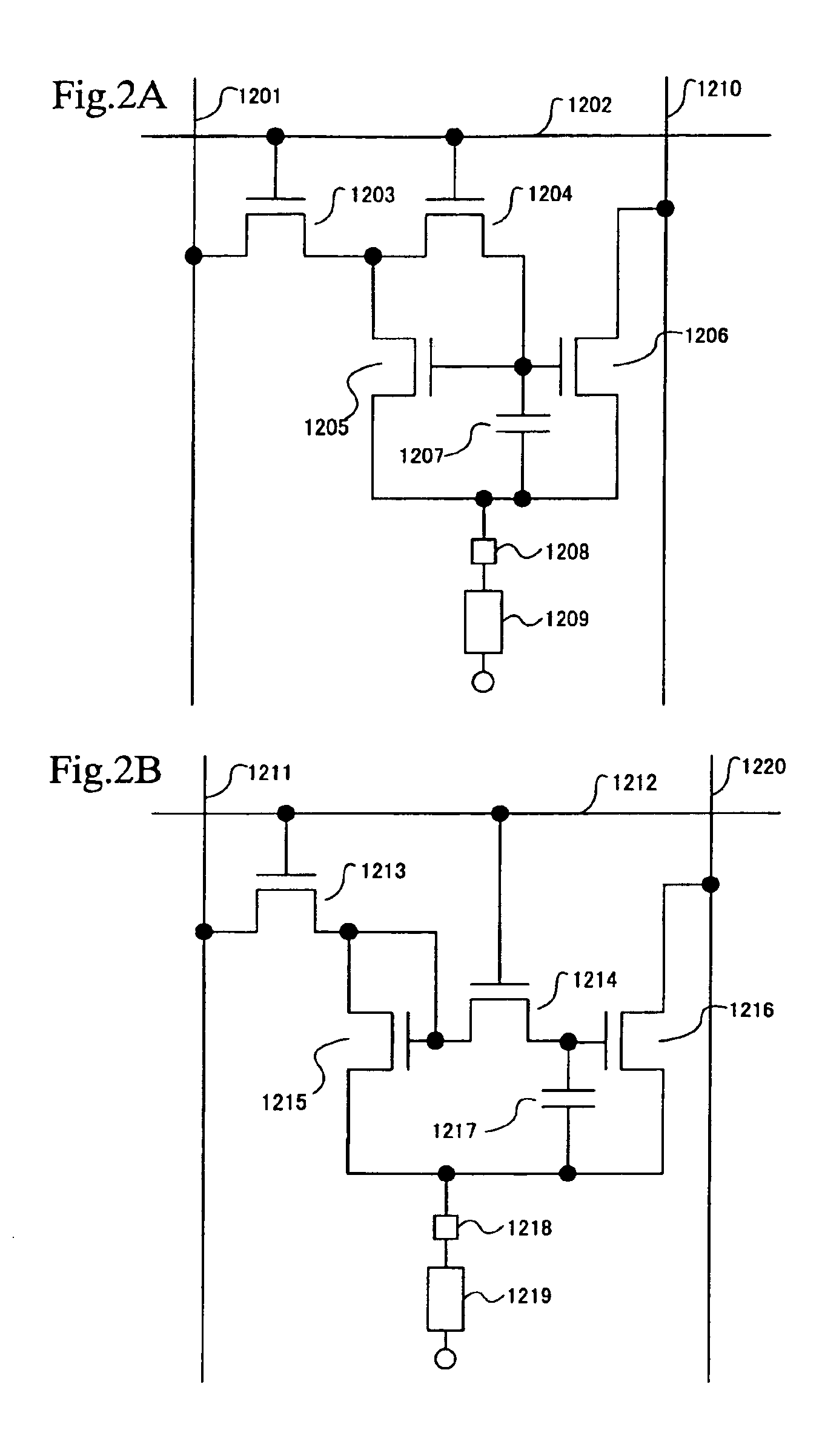

Light emitting device using light emitting diode chip

ActiveUS7717589B2Reduce unevennessSmall surface areaDischarge tube luminescnet screensLamp detailsLength waveIrradiation

A light emitting device comprises: an LED chip mounted in a recess formed in a mounting substrate; a wavelength converting member that is disposed so as to cover the recess and the edge area around the recess and that is excited by light emitted from the LED chip to emit light of a wavelength different from an excitation wavelength; and an emission control member disposed at a light output side of the wavelength converting member so as to allow emission of light coming from an area of the wavelength converting member that corresponds to the recess and to prevent emission of light coming from an area of the wavelength converting member that corresponds to the edge area around the recess. This can prevent variations in color between light emitted from the central part of the wavelength converting member and light emitted from the part of the wavelength converting member that is located on the edge area around the recess of the mounting substrate, thereby reducing unevenness of color on the irradiation surface.

Owner:MATSUSHITA ELECTRIC WORKS LTD

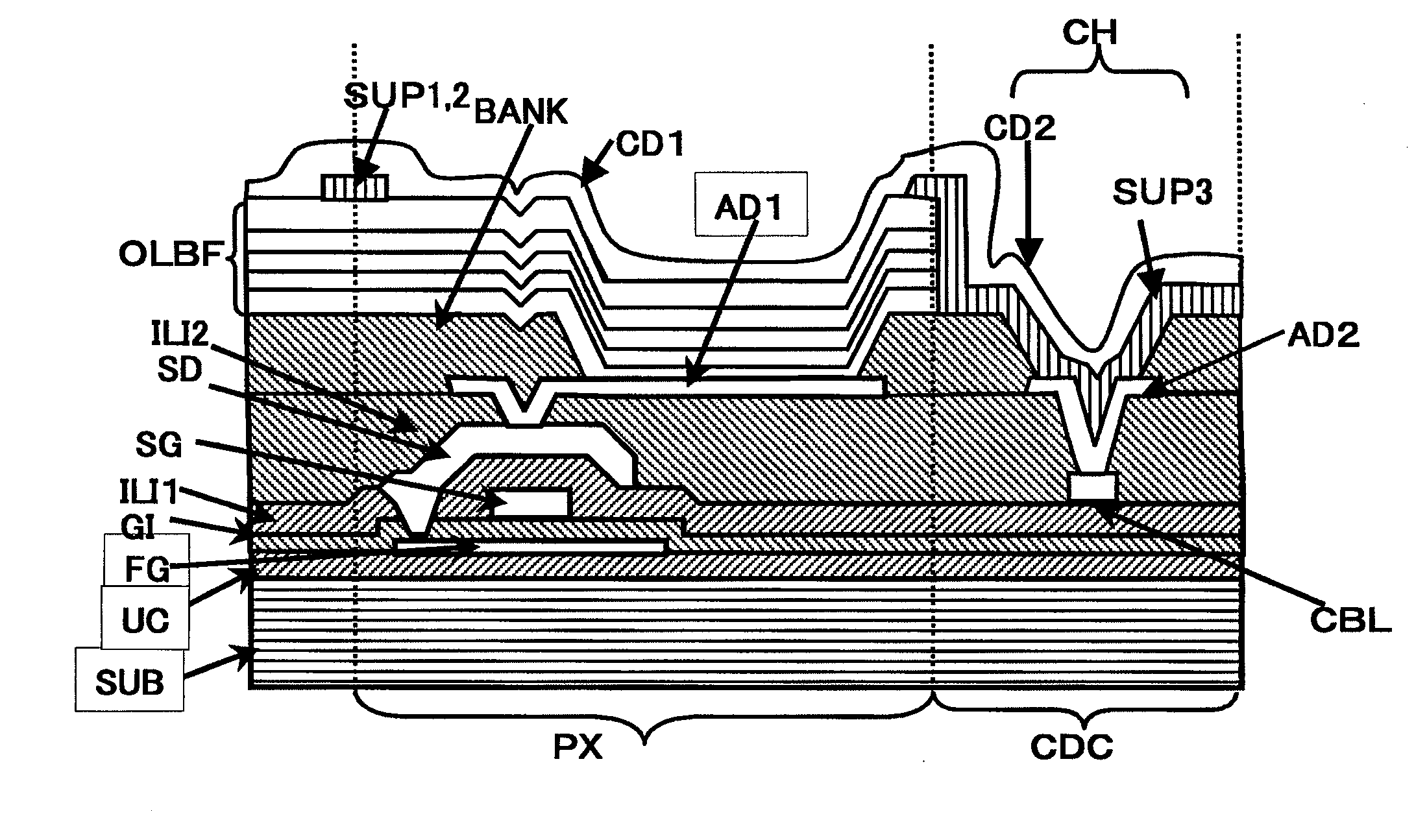

Organic Electroluminescence Display Device

InactiveUS20070241664A1Suppress on-screen luminance unevennessWithout reducing opening ratioDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerDisplay device

An organic electroluminescence display device with high luminescence and high display quality comprises a plurality of active elements, and a plurality of organic electroluminescence elements which produce luminescence through control by the active elements, on a substrate; wherein the organic electroluminescence element has a structure in which a lower electrode, an organic layer, and an upper electrode CD are laminated in this order from the substrate side; the upper electrode CD of the plurality of organic electroluminescence elements is formed as an electrode common to all the organic electroluminescence elements; an electrode is prepared between the upper electrode CD and the organic layer; and the sheet resistance between two points on the upper electrode CD which sandwich the electrode is lower than that between two points which do not sandwich the metal electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Laser sintering method with increased process precision, and particles used for the same

InactiveUS20060159896A1Reduces temperature inhomogeneityReduce laser powerGlass/slag layered productsWood layered productsMaterials scienceRapid prototyping

In the rapid prototyping method of selective laser sintering, temperature gradients occur inside and between individual layers, leading to component deformation which is intolerable at least for high-quality components. The air of the invention is to provide a method for selective laser sintering, whereby the temperature inside the built-up particle cake is as homogeneous as possible. To this end, particles containing at least one material having a maximum softening temperature of approximately 70° C. are used.

Owner:DAIMLER AG

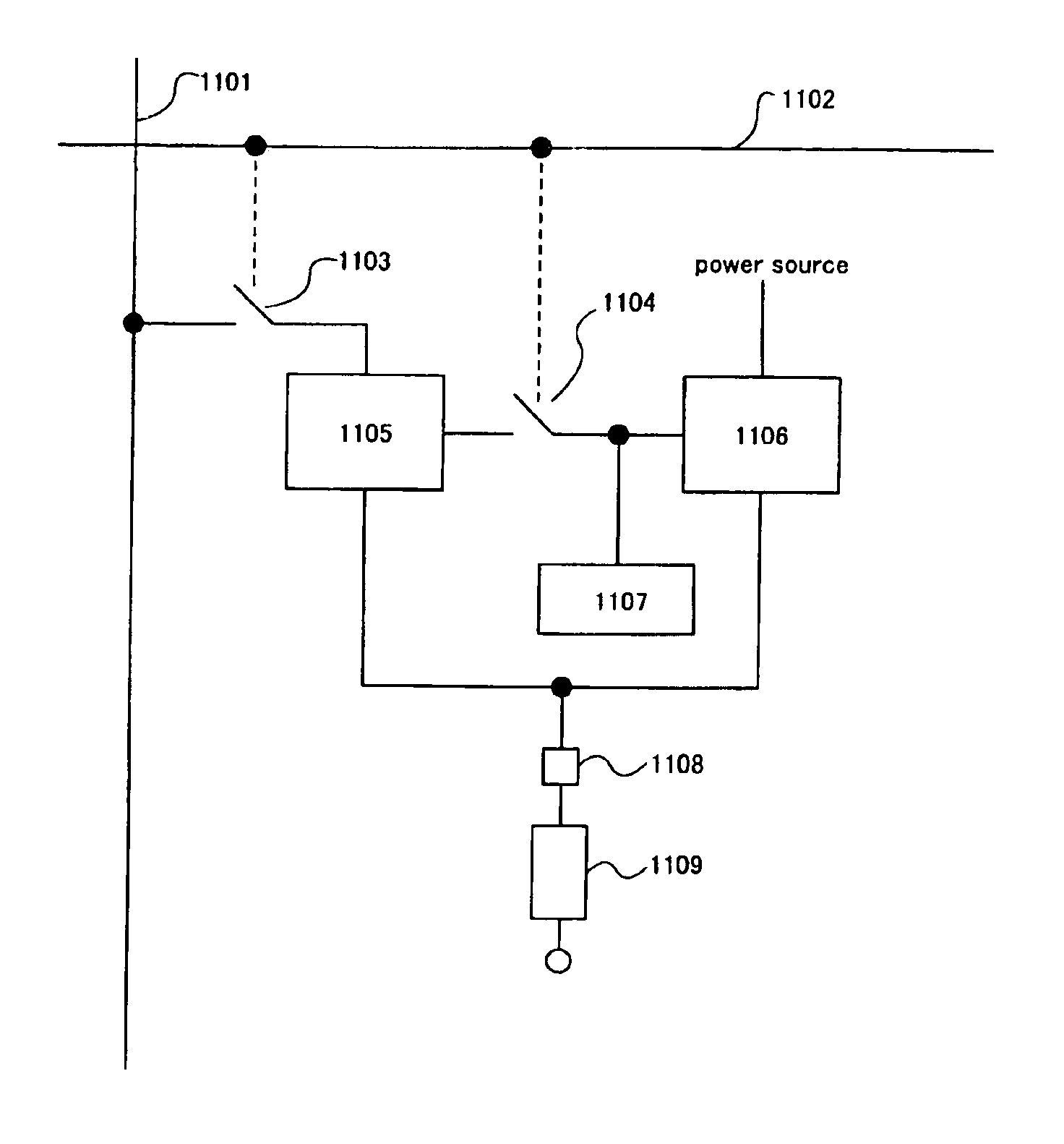

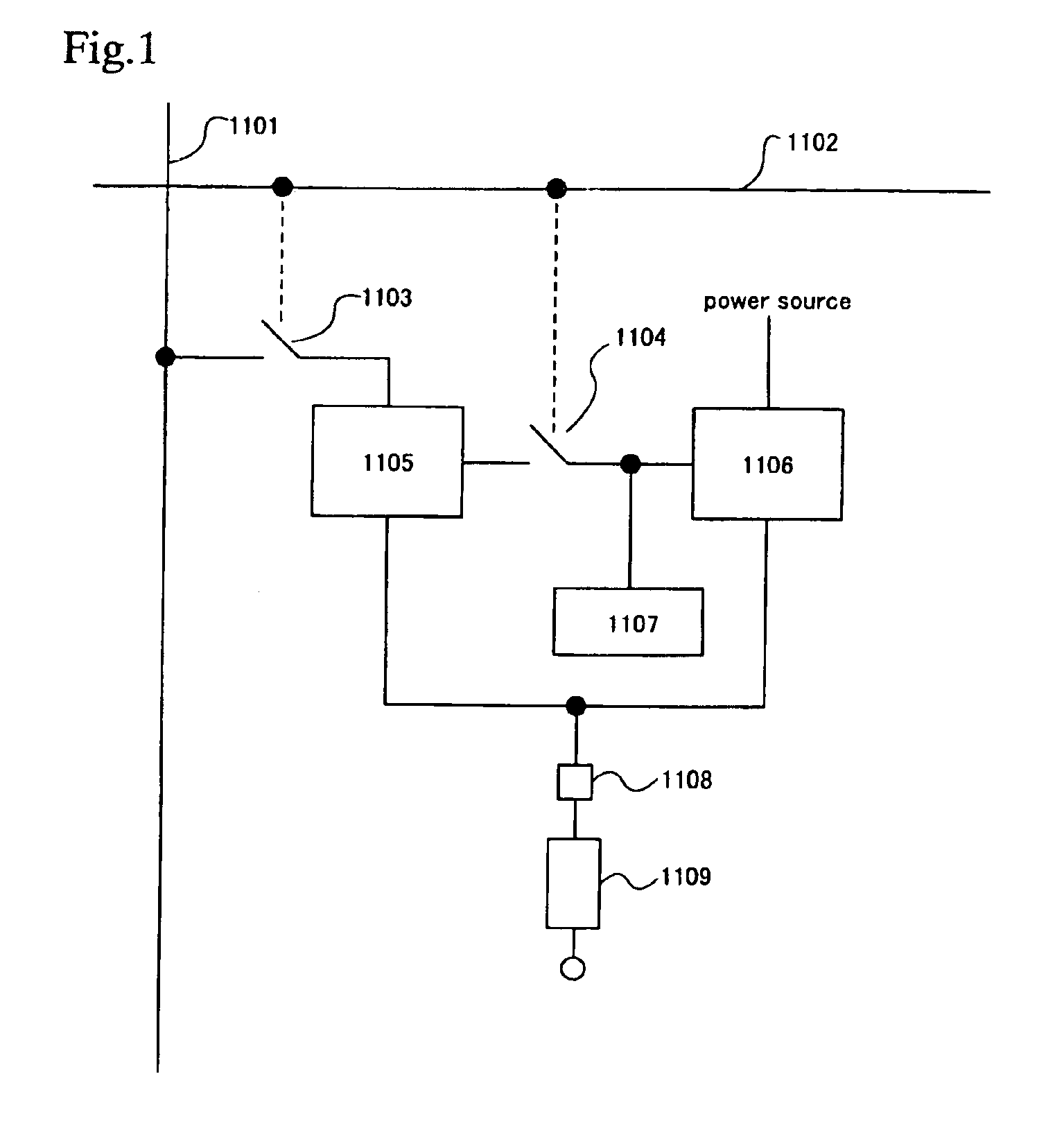

Display device and electronic equipment using the same

InactiveUS6876350B2Reduce conversionHigh current accuracyCathode-ray tube indicatorsInput/output processes for data processingActive matrixDisplay device

In an active matrix EL display device, pixels which are suitable for a constant current drive are structured. The pixel includes a first switch which has one end connected to a source signal line and the other end connected to a current-voltage conversion element, a second switch which has one end connected to the current-voltage conversion element and the other end connected to a voltage holding capacitor and to a voltage-current conversion element, and a pixel electrode connected to the current-voltage conversion element and to the voltage-current conversion element.

Owner:SEMICON ENERGY LAB CO LTD

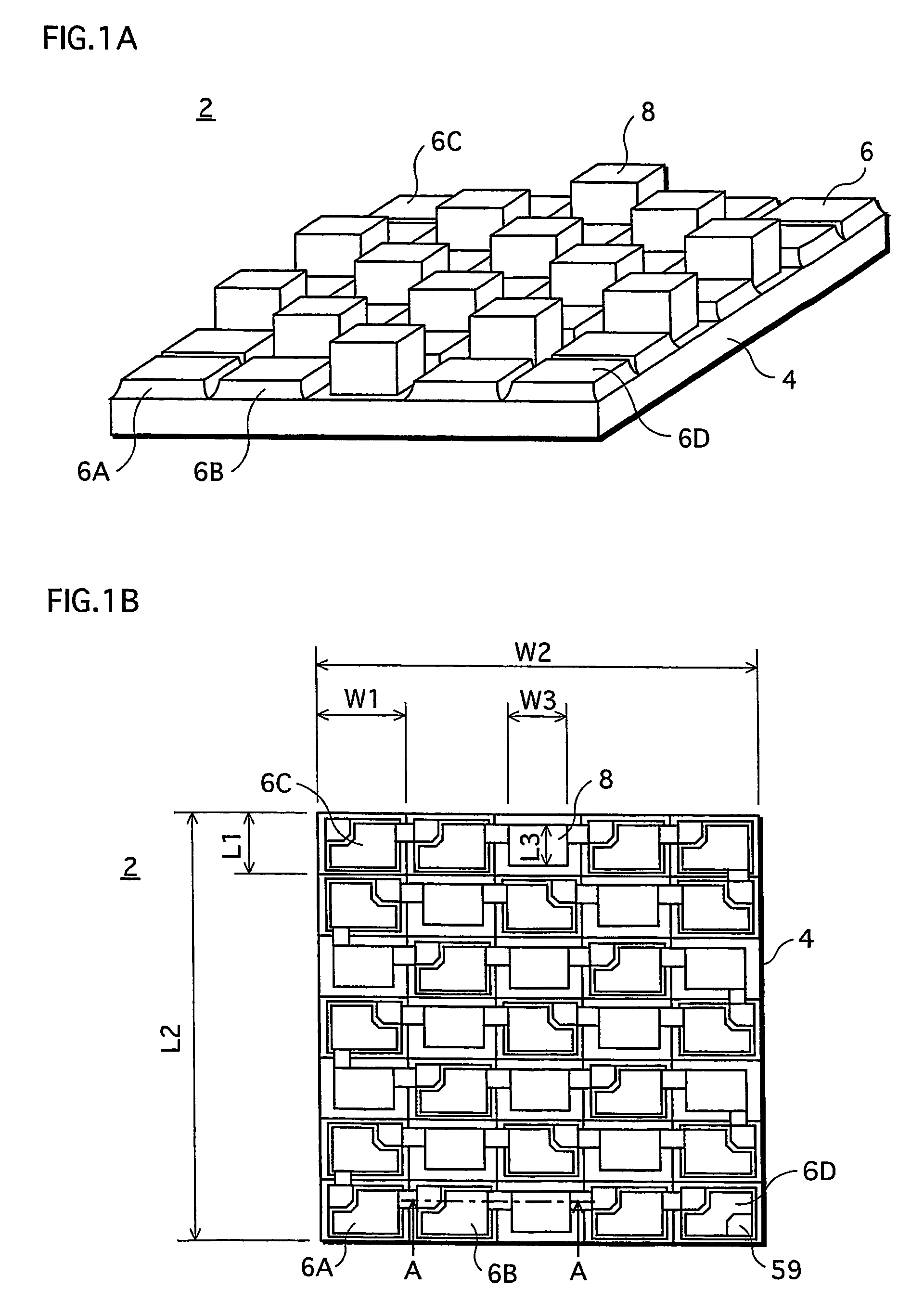

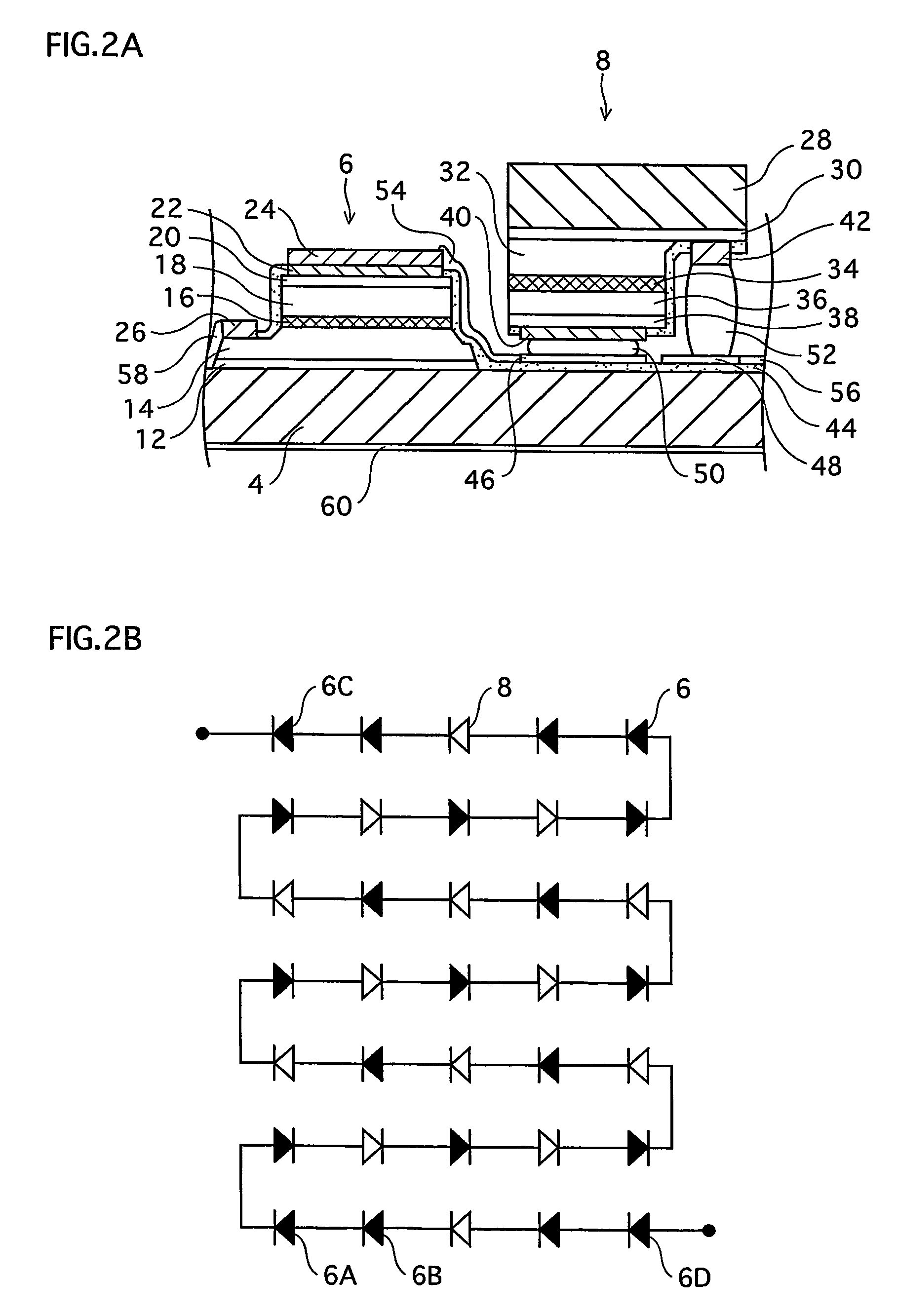

Semiconductor light emitting device, light emitting module and lighting apparatus

ActiveUS7473934B2Reduce color unevennessImprove manufacturing productivityPlanar light sourcesLight source combinationsLight equipmentLed array

An LED array chip (2) includes blue LEDs (6) and red LEDs (8). The blue LEDs (6) are formed by epitaxial growth on an SiC substrate (4). Bonding pads (46 and 48) are formed on the SiC substrate (4) in a wafer fabrication process. The red LEDs (8) are separately manufactured from the blue LEDs (6), and flip-chip mounted on the bonding pads (46 and 48) formed on the SiC substrate.

Owner:PANASONIC CORP

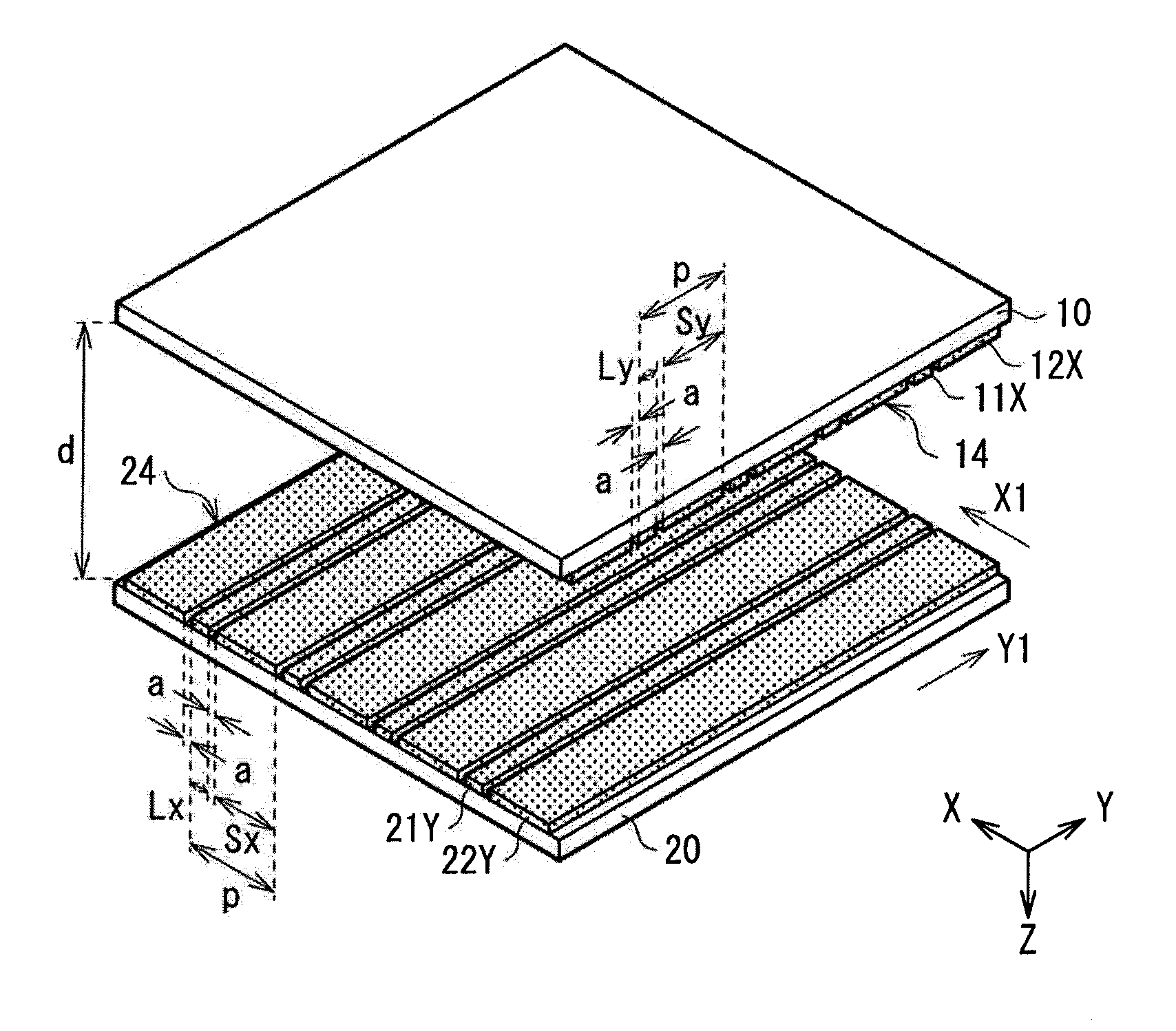

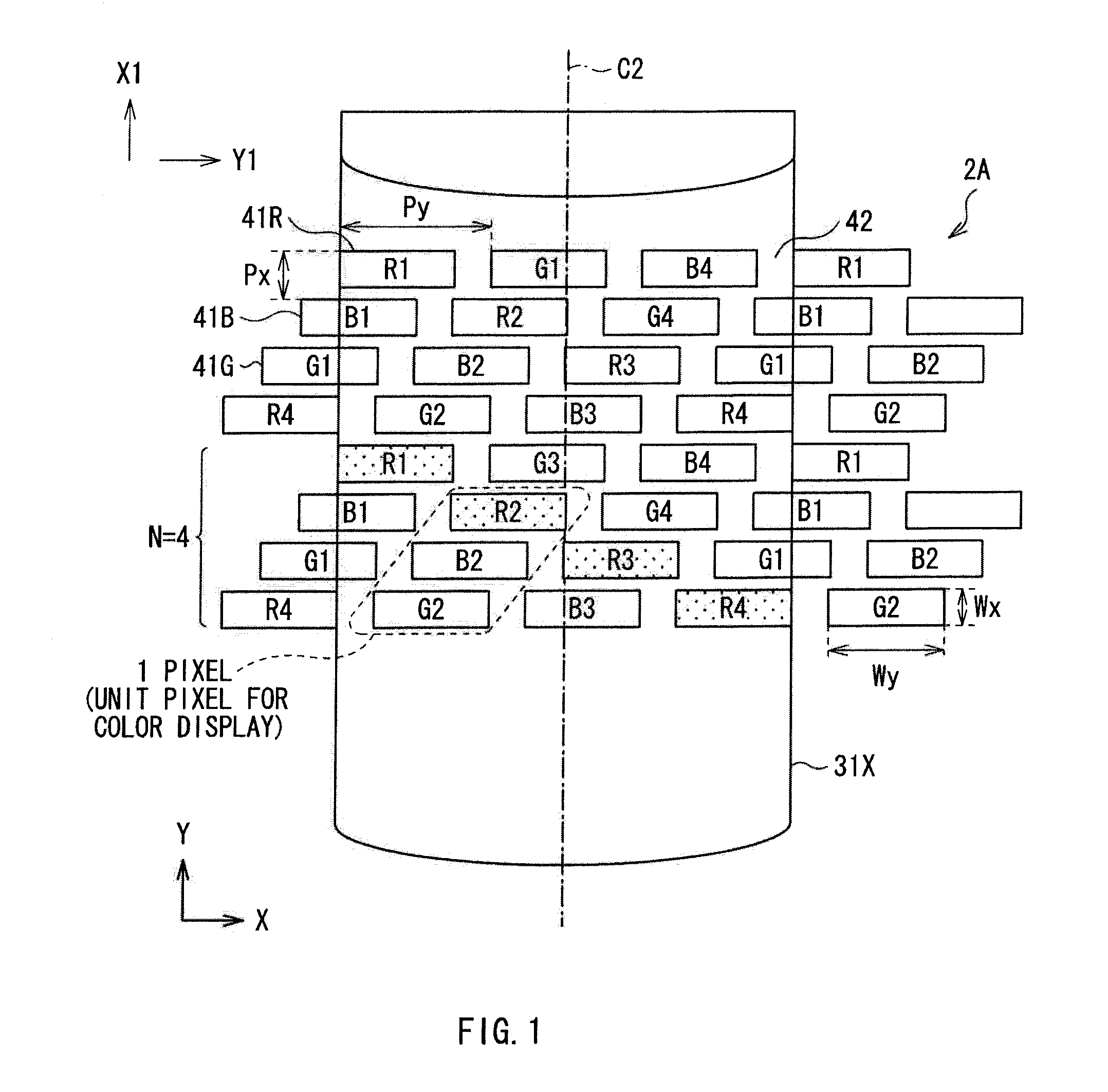

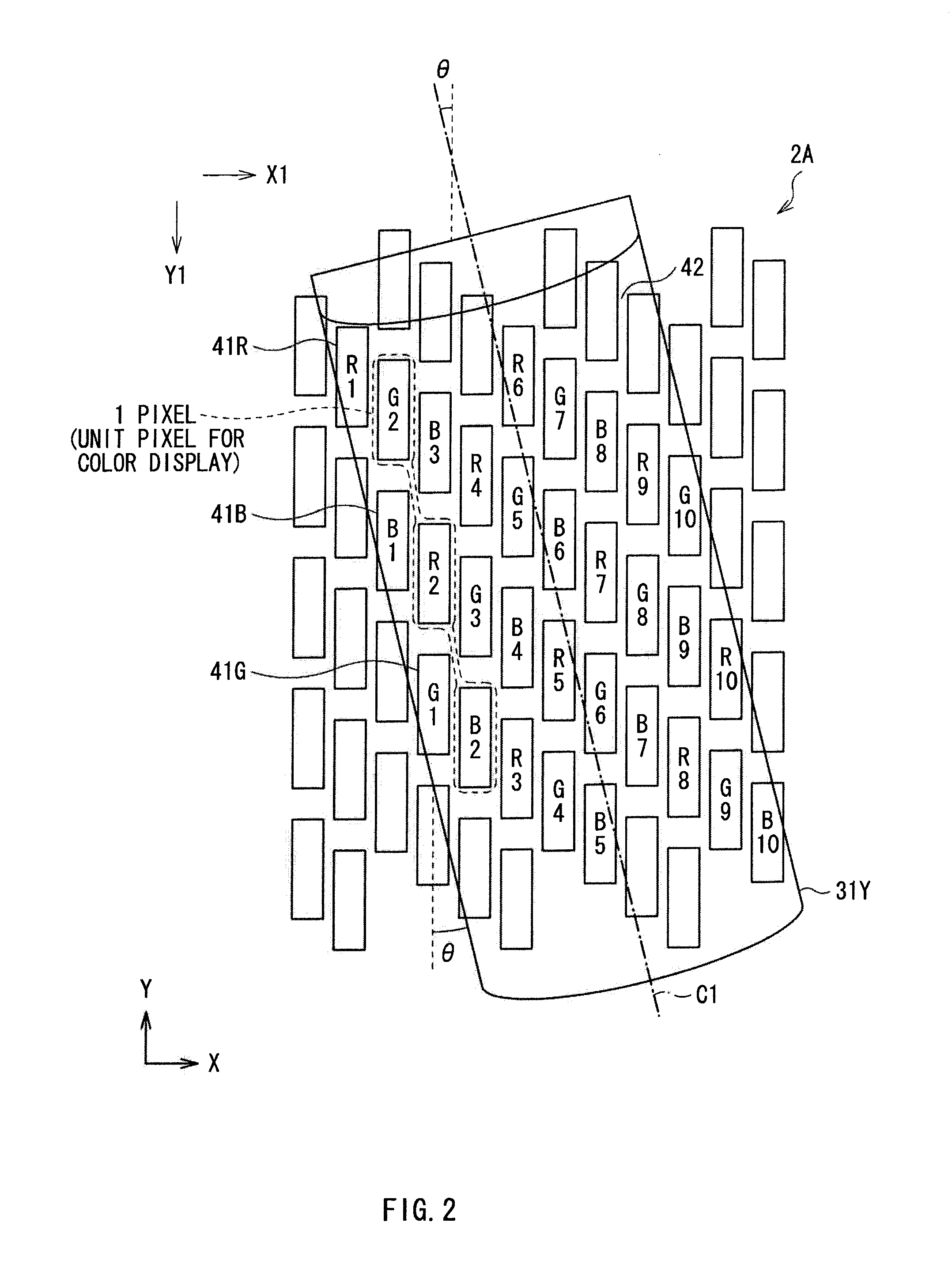

Stereoscopic display

InactiveUS20100259697A1Good stereo visionReduce brightness unevennessSteroscopic systemsNon-linear opticsComputer scienceLens effect

A stereoscopic display includes: a display panel configured to display an image in either one of two or more arrangement states including a first arrangement state and a second arrangement state which are switchable with each other; and a lens array device arranged to face a display surface of the display panel. The lens array device produces a lens effect in a direction, the direction of effect being changed between in the first arrangement state and in the second arrangement state. The display panel includes an array of a plurality of sub-pixels, and a combination of sub-pixels used as a unit pixel is changed between in the first arrangement state and in the second arrangement state.

Owner:SONY CORP

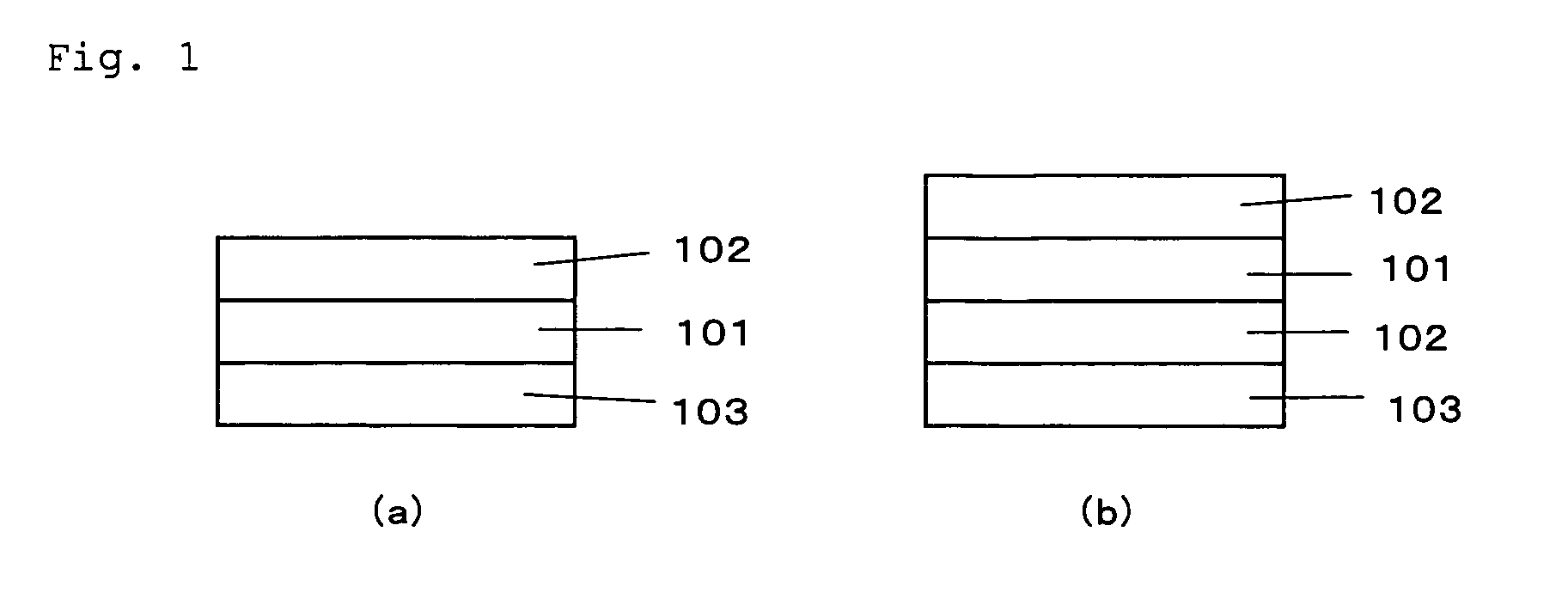

Polarizing plate and production process of the same

InactiveUS20050243245A1Improve adhesionStable productionNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentTectorial membranePolyvinyl alcohol

A novel polarizing plate is disclosed. The polarizing plate comprises a polyvinyl alcohol based polarizer, a protective film comprising a saturated alicyclic structure-containing thermoplastic polymer, and an adhesive layer comprising a water-soluble polymer between the protective film and the polarizer wherein the surface of the protective film contacting with the adhesive layer is subjected to a surface treatment.

Owner:FUJIFILM CORP

Organic electroluminescent element and lighting device using same

InactiveUS20120193619A1Reducing luminescence unevennessReducing thickness fluctuationSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeEngineering

An organic EL element having a high productivity and a multi-unit structure is produced by using an organic EL material which can meet the demands of an increased area and high productivity, uses a high-speed process at atmospheric pressure, that is, the non-discharge type coating process, and which has a high process adaptability. An organic electroluminescent element is provided, between a plurality of light-emitting units, with a charge generating layer which generates a hole and an electron by applying an electric field, wherein the charge generating layer comprises one or more layers, at least one layer of which is formed by means of the non-discharge type solution coating process, and the plurality of light-emitting units are formed by means of the non-discharge type solution coating process.

Owner:KONICA MINOLTA INC

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070068197A1Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Temperature controlled showerhead

ActiveUS8137467B2Improve cooling effectPrecise and stable temperature controlLiquid surface applicatorsSemiconductor/solid-state device manufacturingTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

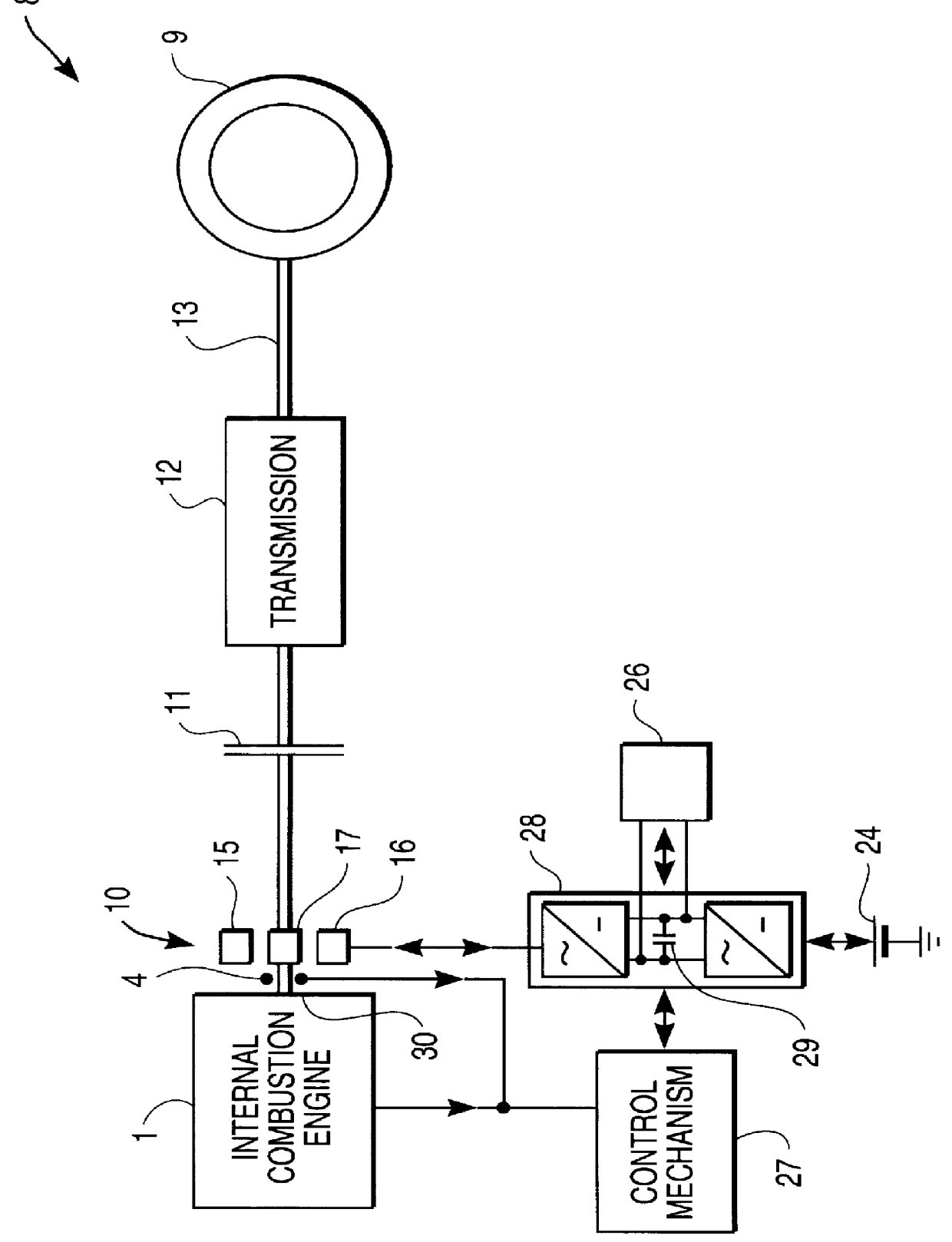

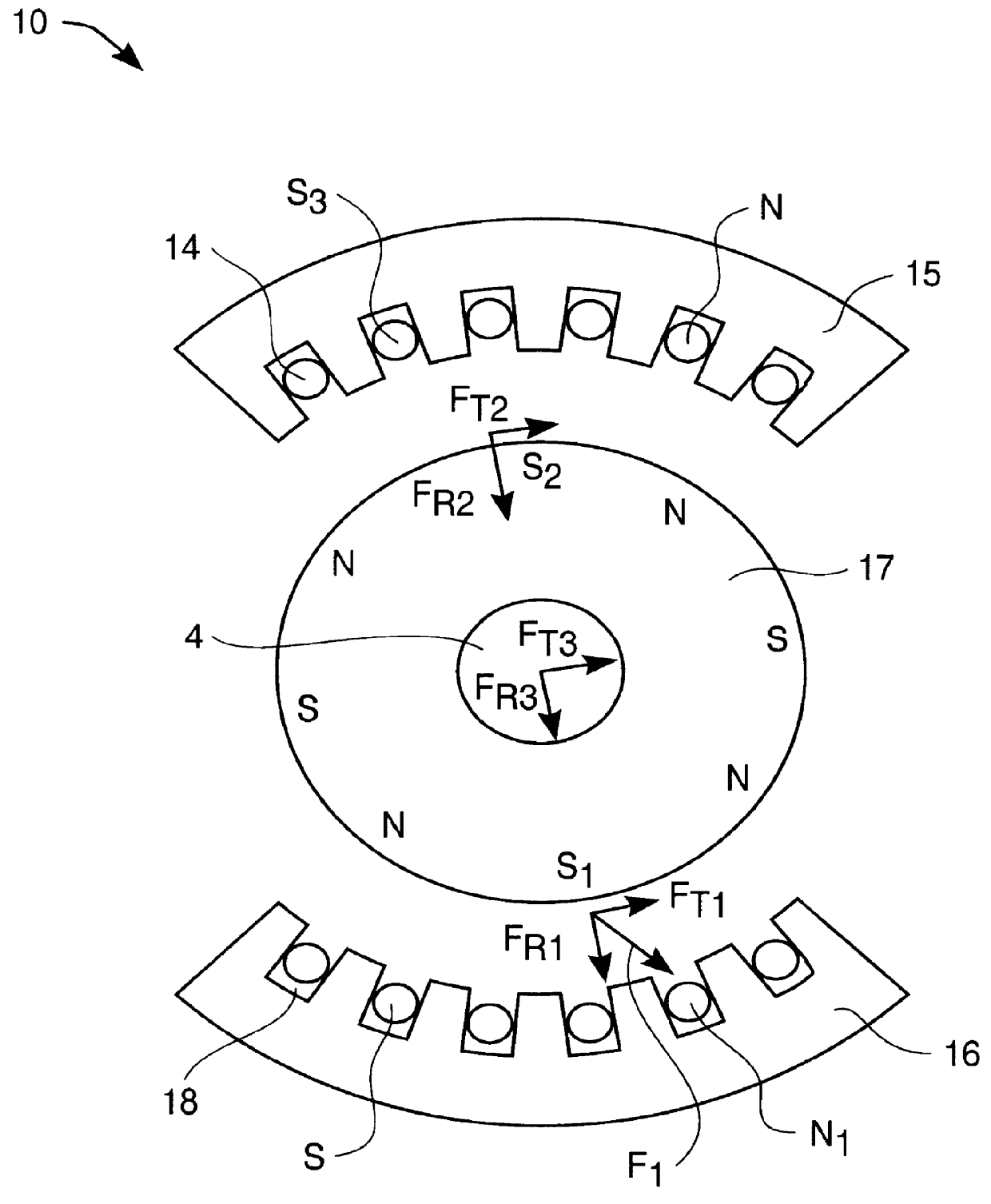

System for actively reducing radial vibrations in a rotating shaft, and method of operating the system to achieve this

InactiveUS6138629AReduce vibrationReduce unevennessRotating vibration suppressionBraking element arrangementsDrive shaftEngineering

PCT No. PCT / DE96 / 01665 Sec. 371 Date Jul. 23, 1998 Sec. 102(e) Date Jul. 23, 1998 PCT Filed Aug. 31, 1996 PCT Pub. No. WO97 / 08477 PCT Pub. Date Mar. 6, 1997The invention concerns a system for active reduction of radial vibrations of a rotating shaft (4), especially the drive shaft of an internal combustion engine (1), with at least one active electromagnetic device (7; 10; 15, 16), which is configured and controlled such that it applies radial forces to the shaft (4), which counteract the radial vibrations of the shaft (4).

Owner:CONTINENTAL ISAD ELECTRONICS SYST GMBH & CO KG

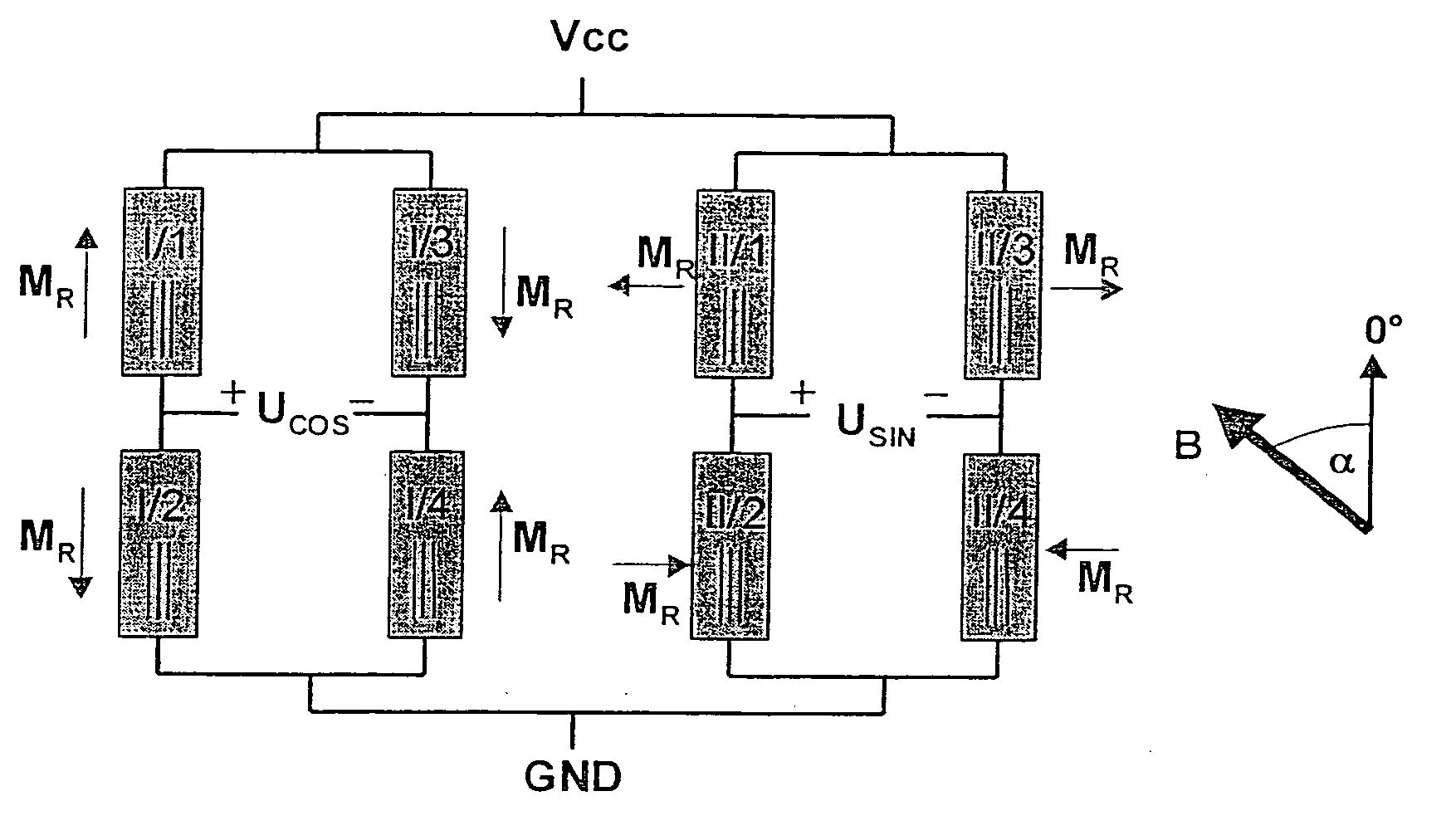

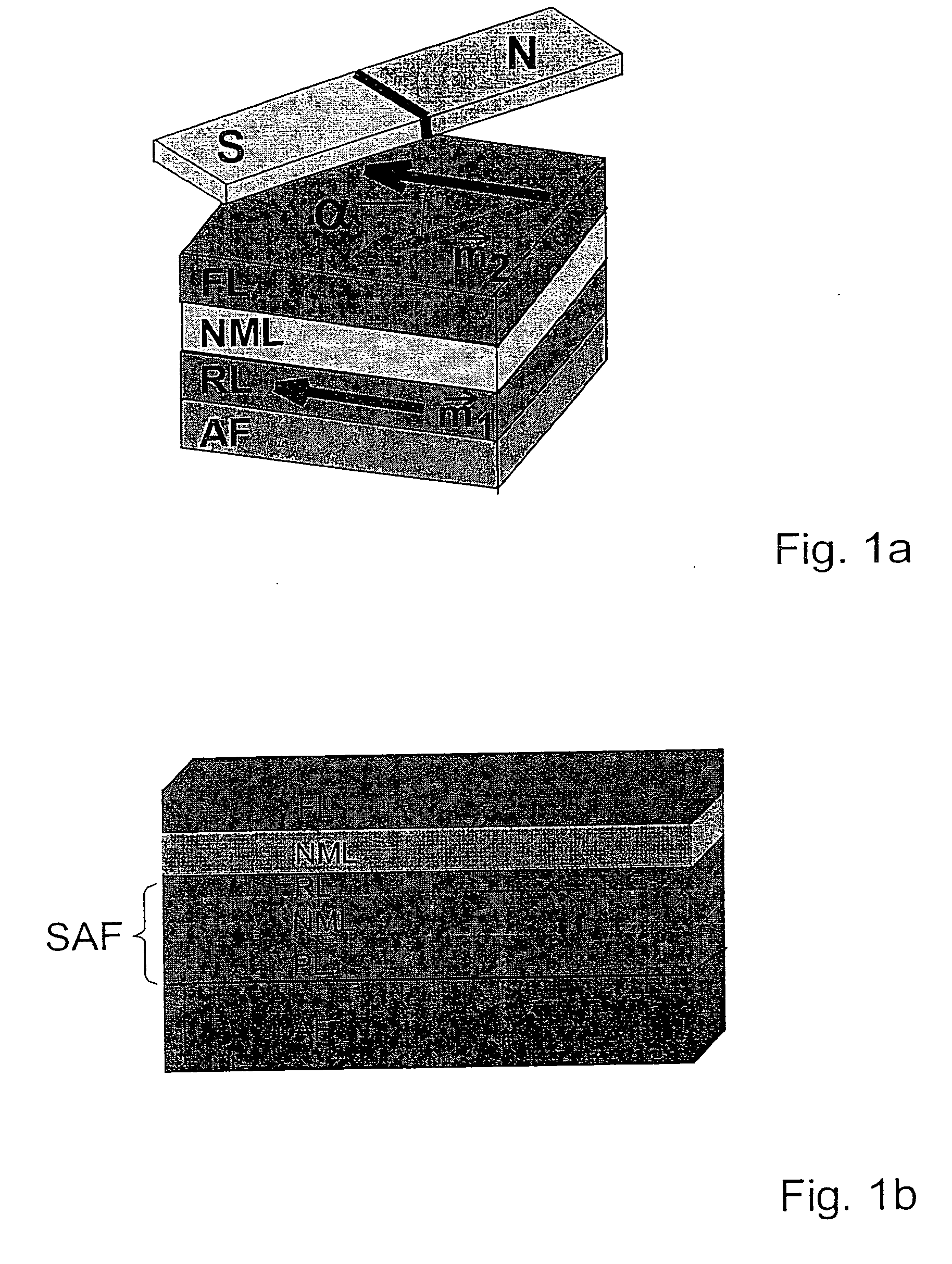

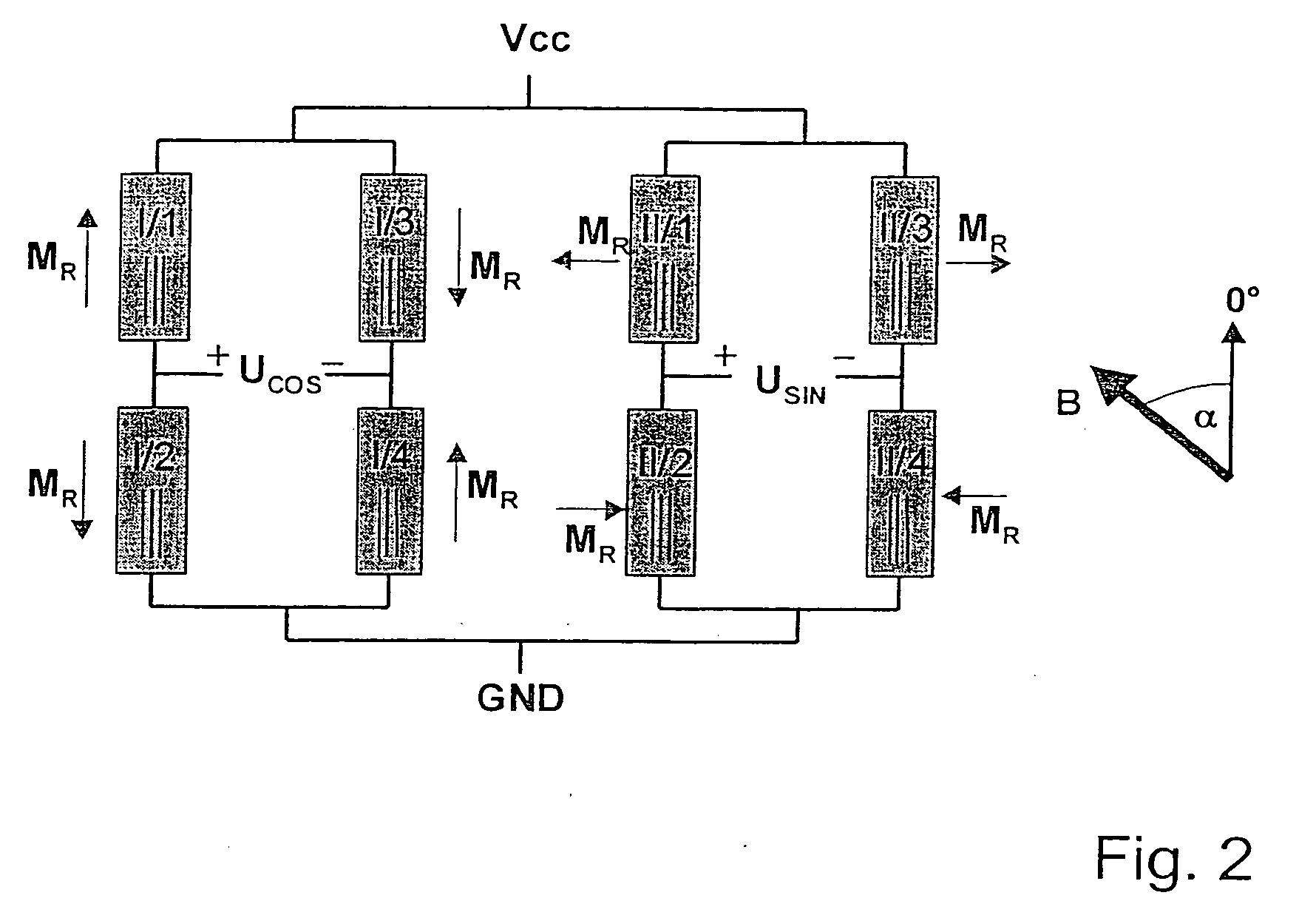

Gmr sensor element and its use

InactiveUS20060103381A1Improve long-term stabilityImprove signal stabilityValve arrangementsNanomagnetismSteering angleFull bridge

A GMR sensor element is proposed, having a rotationally symmetrical positioning of especially eight GMR resistor elements which are connected to each other to form two Wheatstone's full bridges. This GMR sensor element is especially suitable for use in an angle sensor for the detection of the absolute position of the camshaft or the crankshaft in a motor vehicle, particularly in the case of a camshaft-free engine having electrical or electrohydraulic valve timing, of a motor position of an electrically commutated motor, or of detection of a windshield wiper position, or in the steering angle sensor system in motor vehicles.

Owner:ROBERT BOSCH GMBH

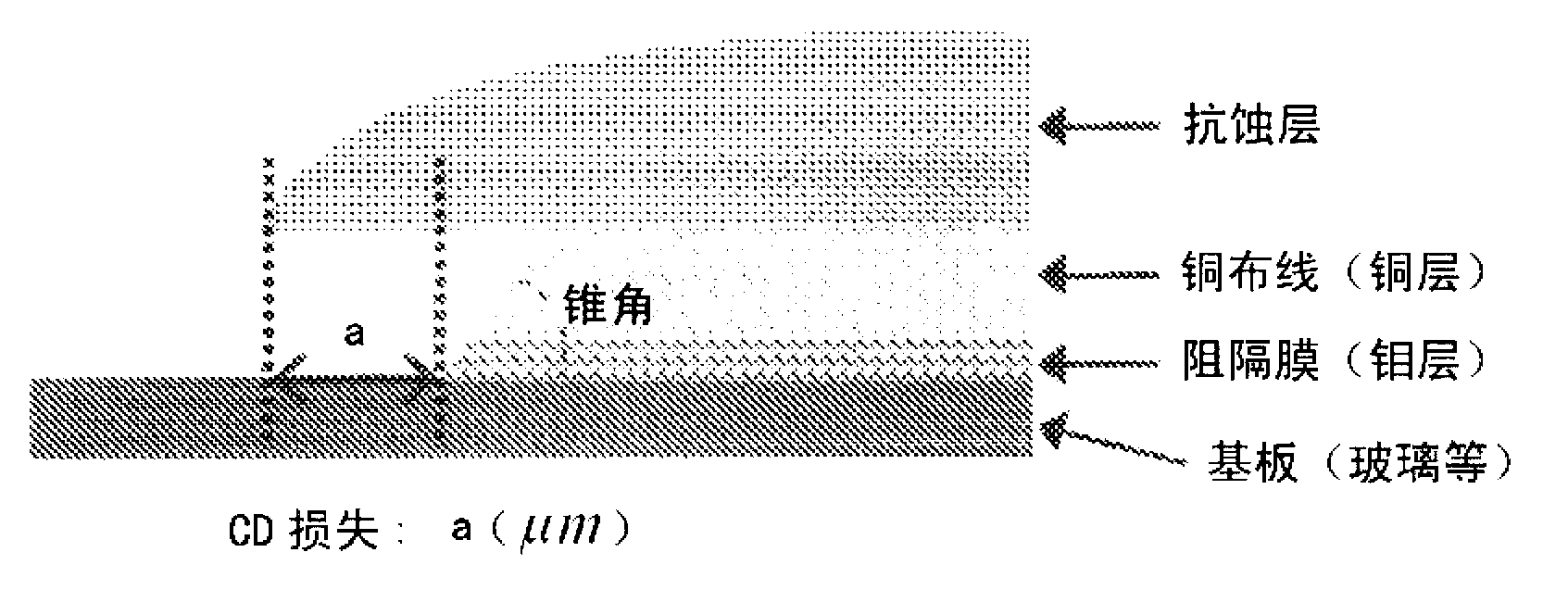

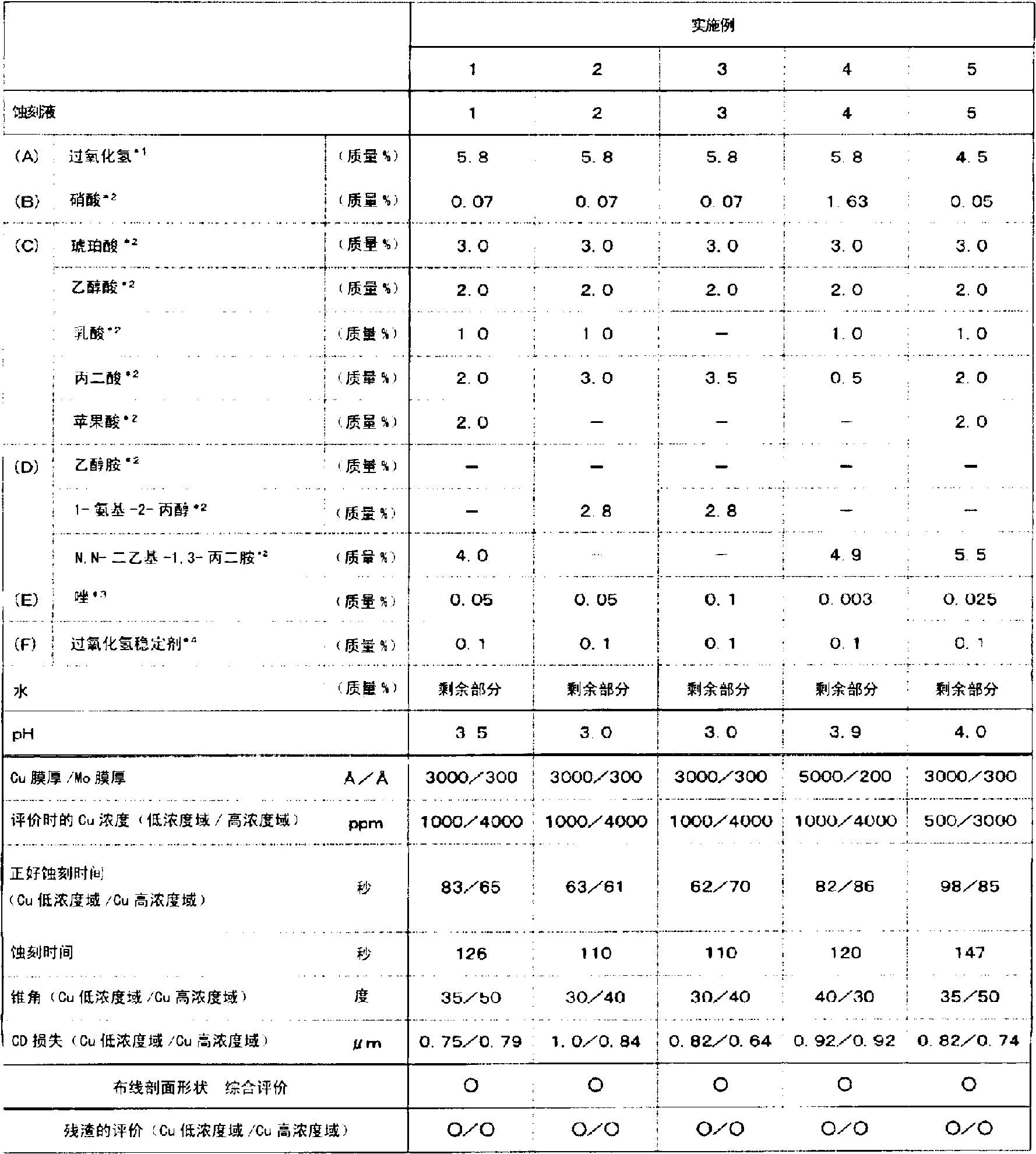

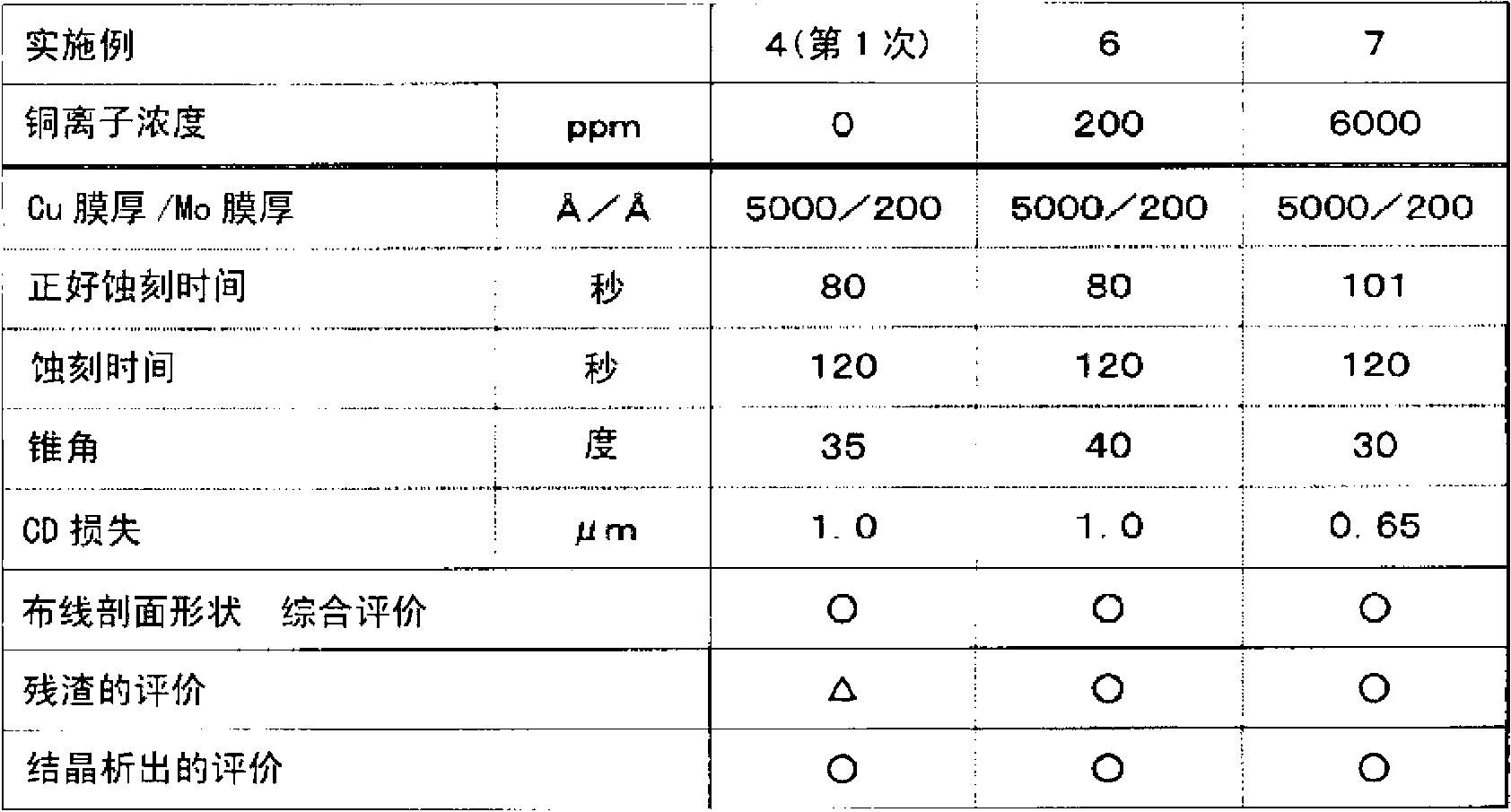

Etching solution for multilayer thin film having copper layer and molybdenum layer contained therein

ActiveCN102762770AExtend your lifeImprove machining accuracySemiconductor/solid-state device detailsSolid-state devicesOrganic acidCopper

Disclosed are: an etching solution for a multilayer thin film having a copper layer and a molybdenum layer contained therein; and a method for etching a multilayer thin film having a copper layer and a molybdenum layer contained therein using the etching solution. Specifically disclosed are: an etching solution for a multilayer thin film having a copper layer and a molybdenum layer contained therein, which comprises (A) hydrogen peroxide, (B) an inorganic acid having no fluorine atom, (C) an organic acid, (D) an amine compound having 2 to 10 carbon atoms and also having an amino group and a hydroxy group in the total number of two or more, (E) an azole, and (F) a hydrogen peroxide stabilizer, and which has a pH value of 2.5 to 5; and an etching method using the etching solution.

Owner:MITSUBISHI GAS CHEM CO INC

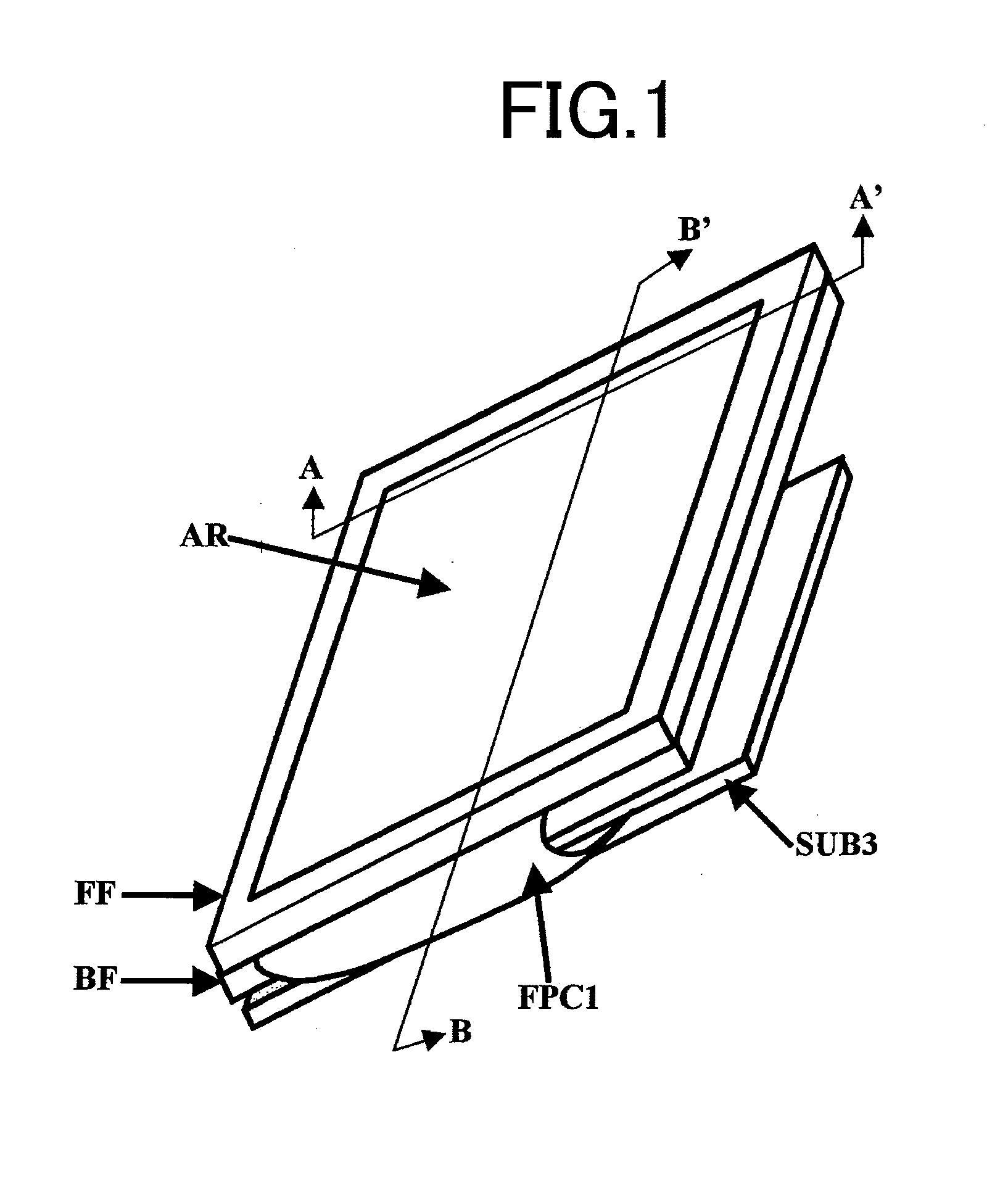

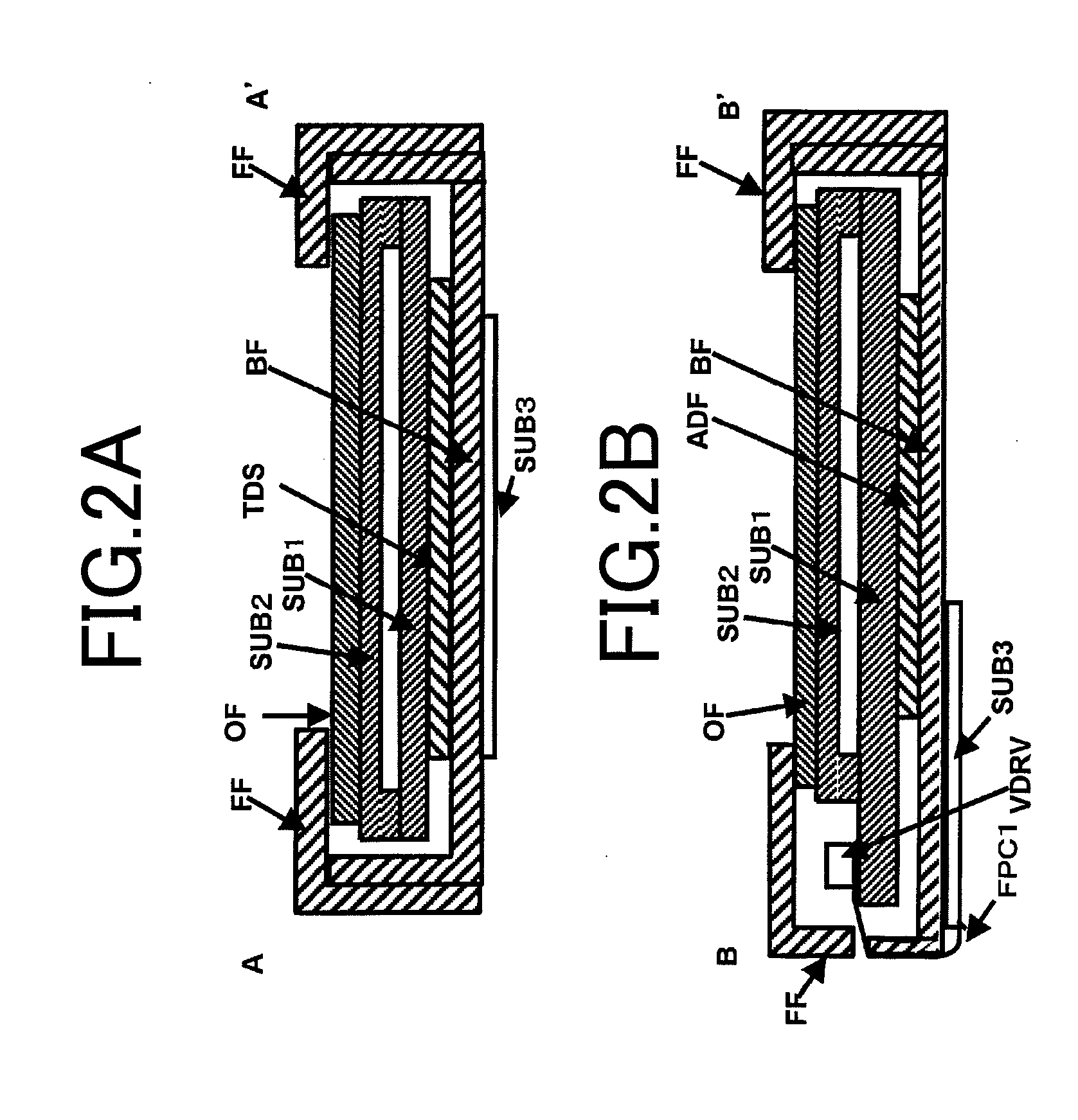

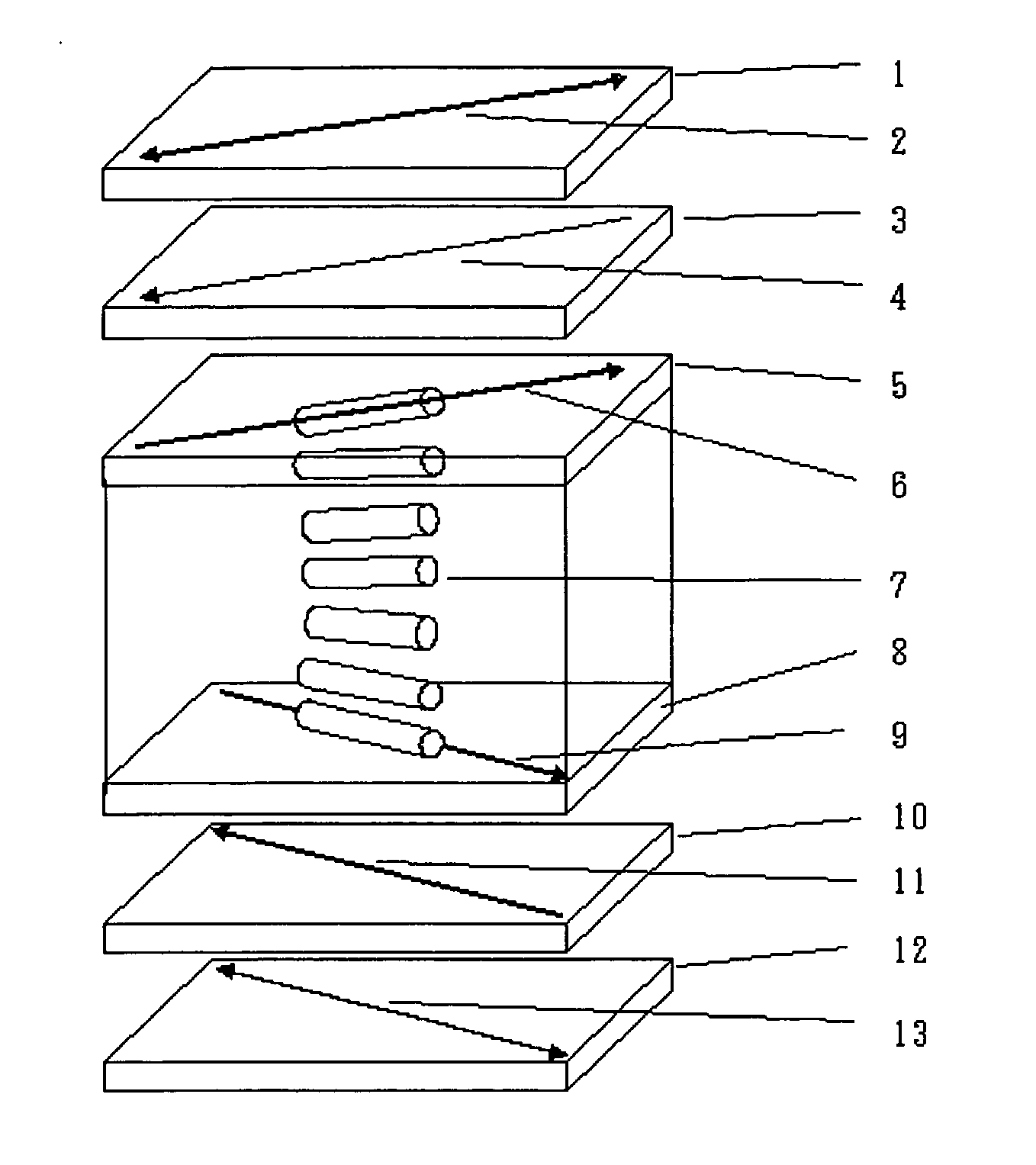

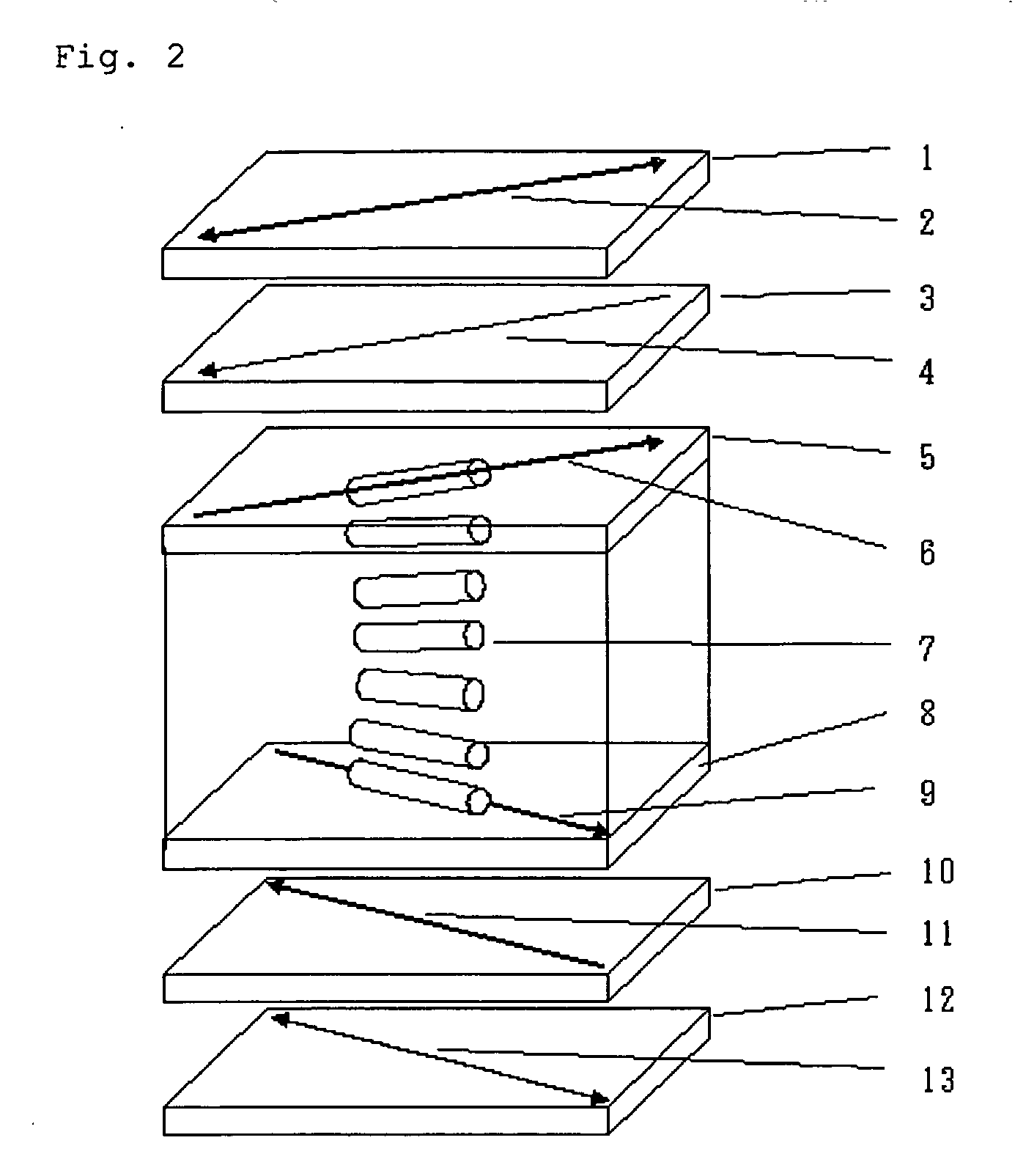

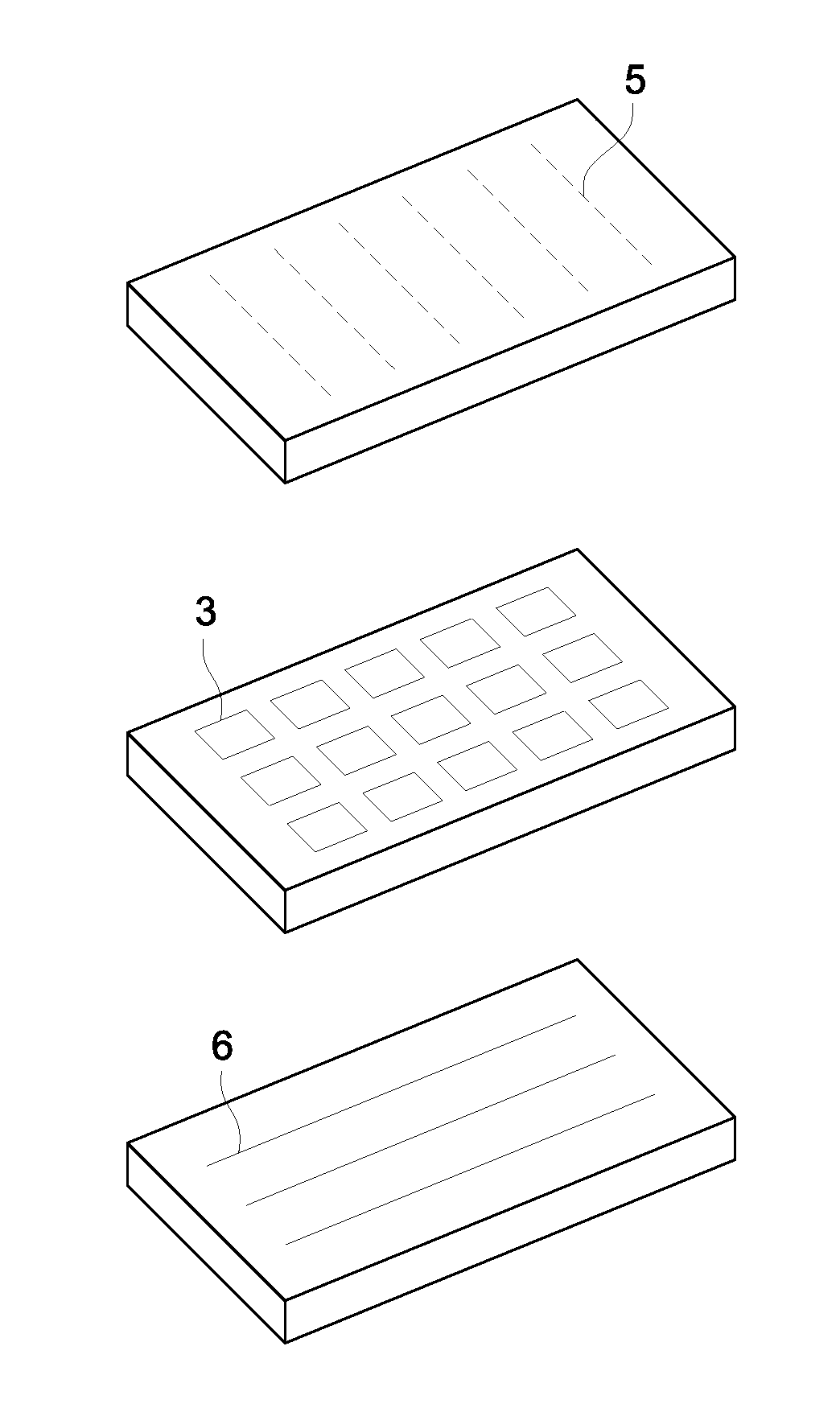

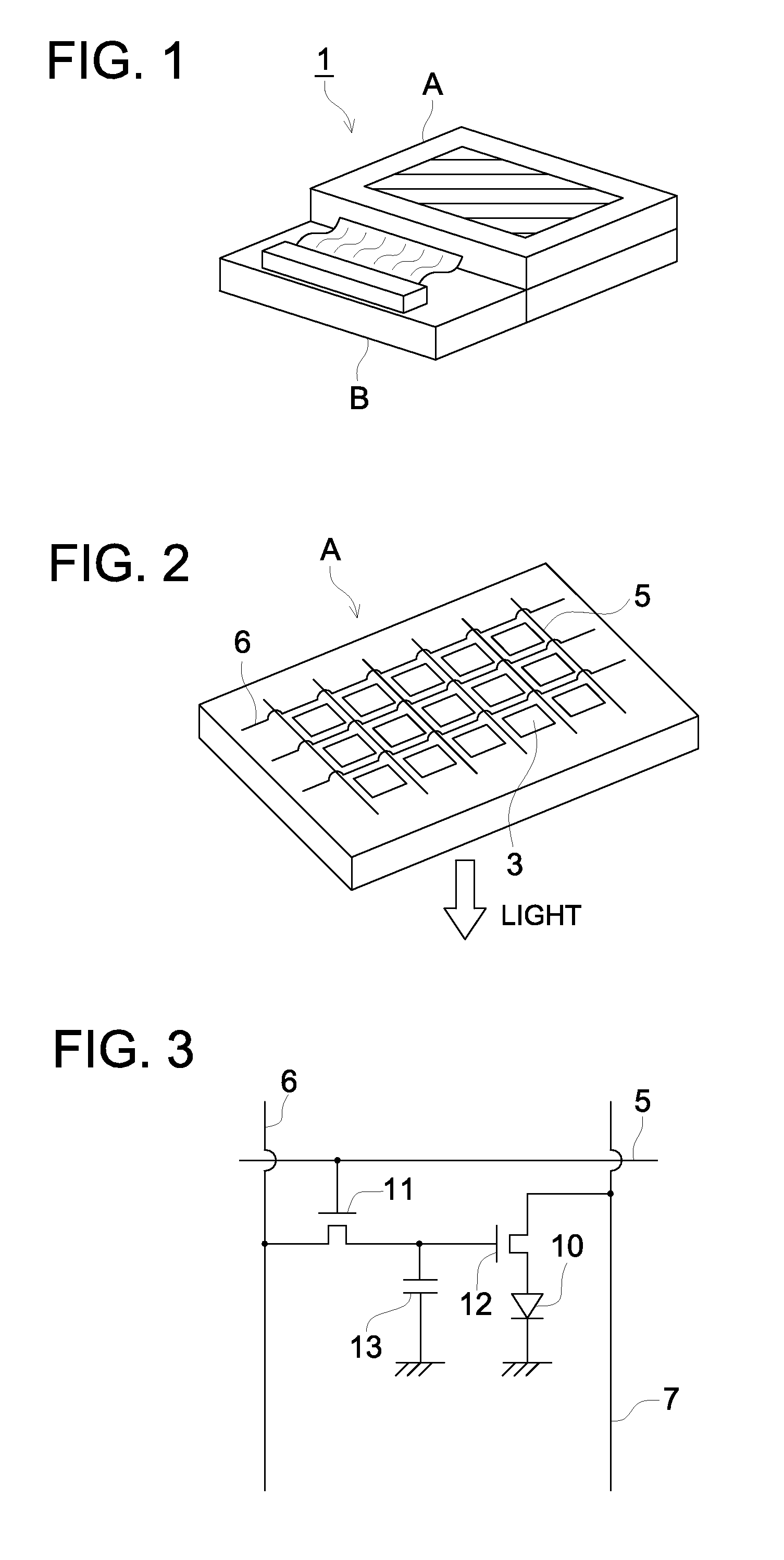

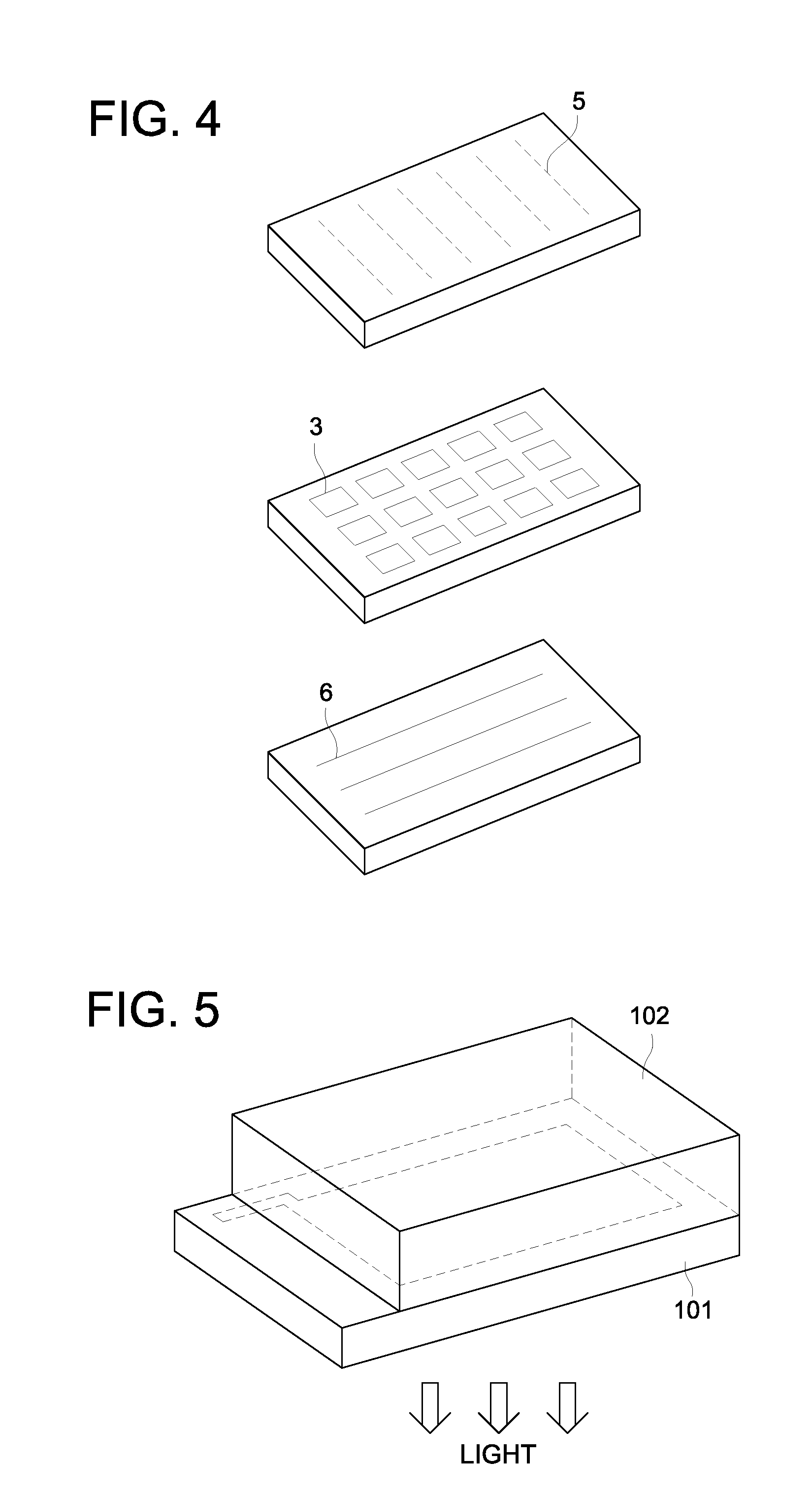

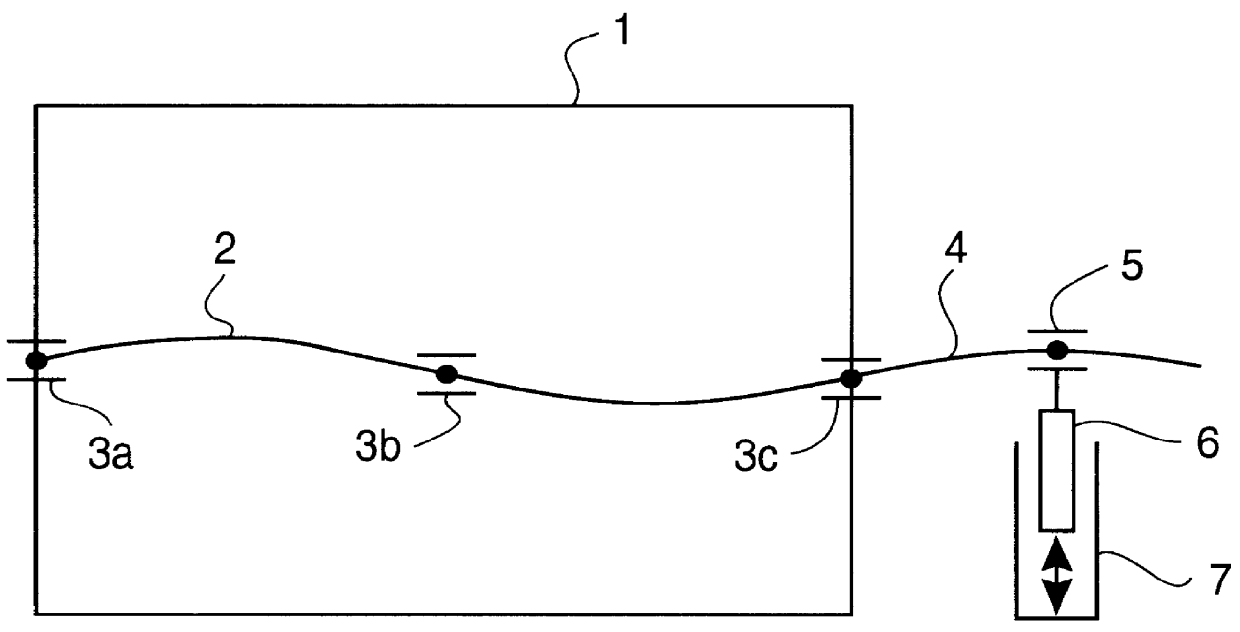

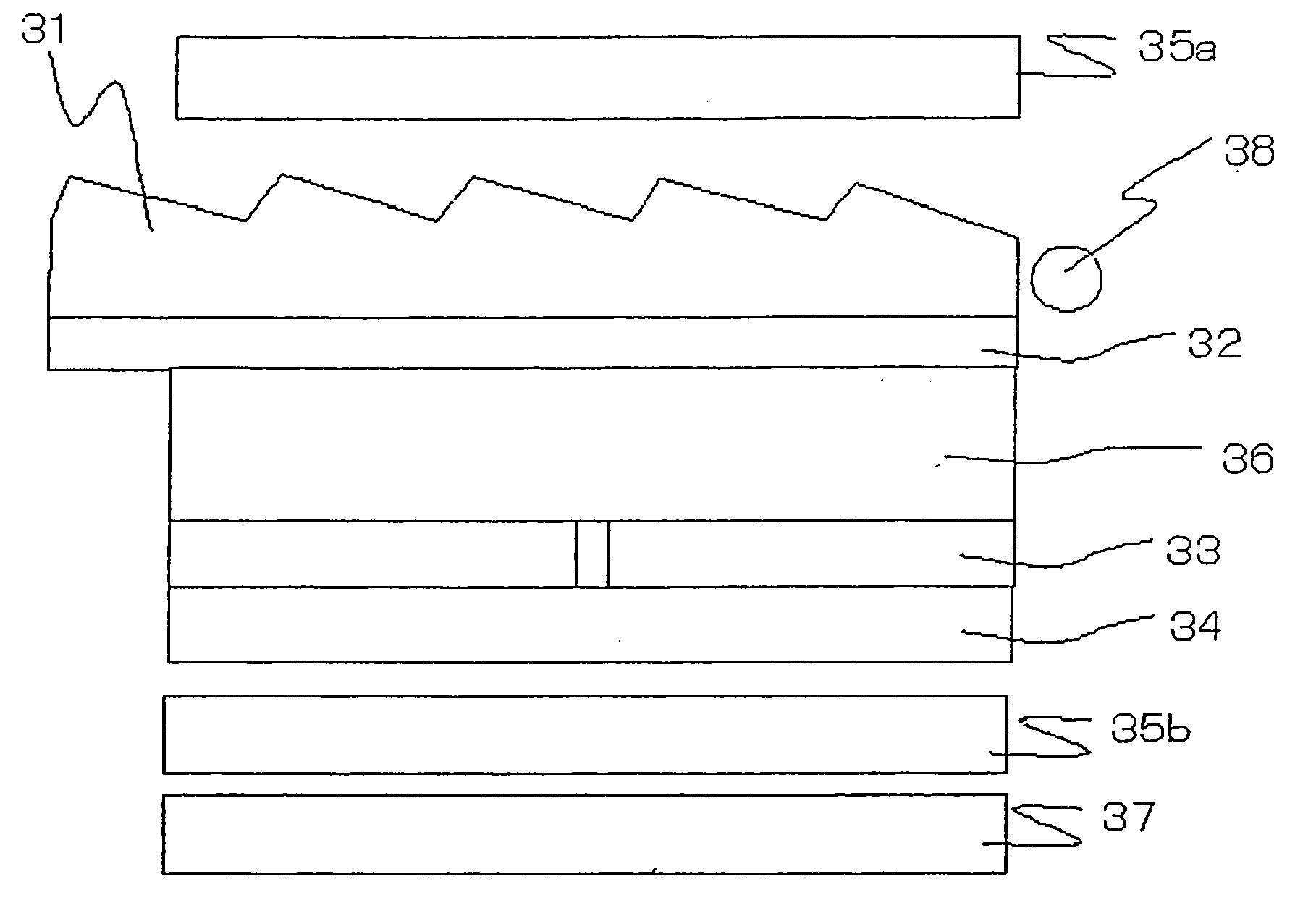

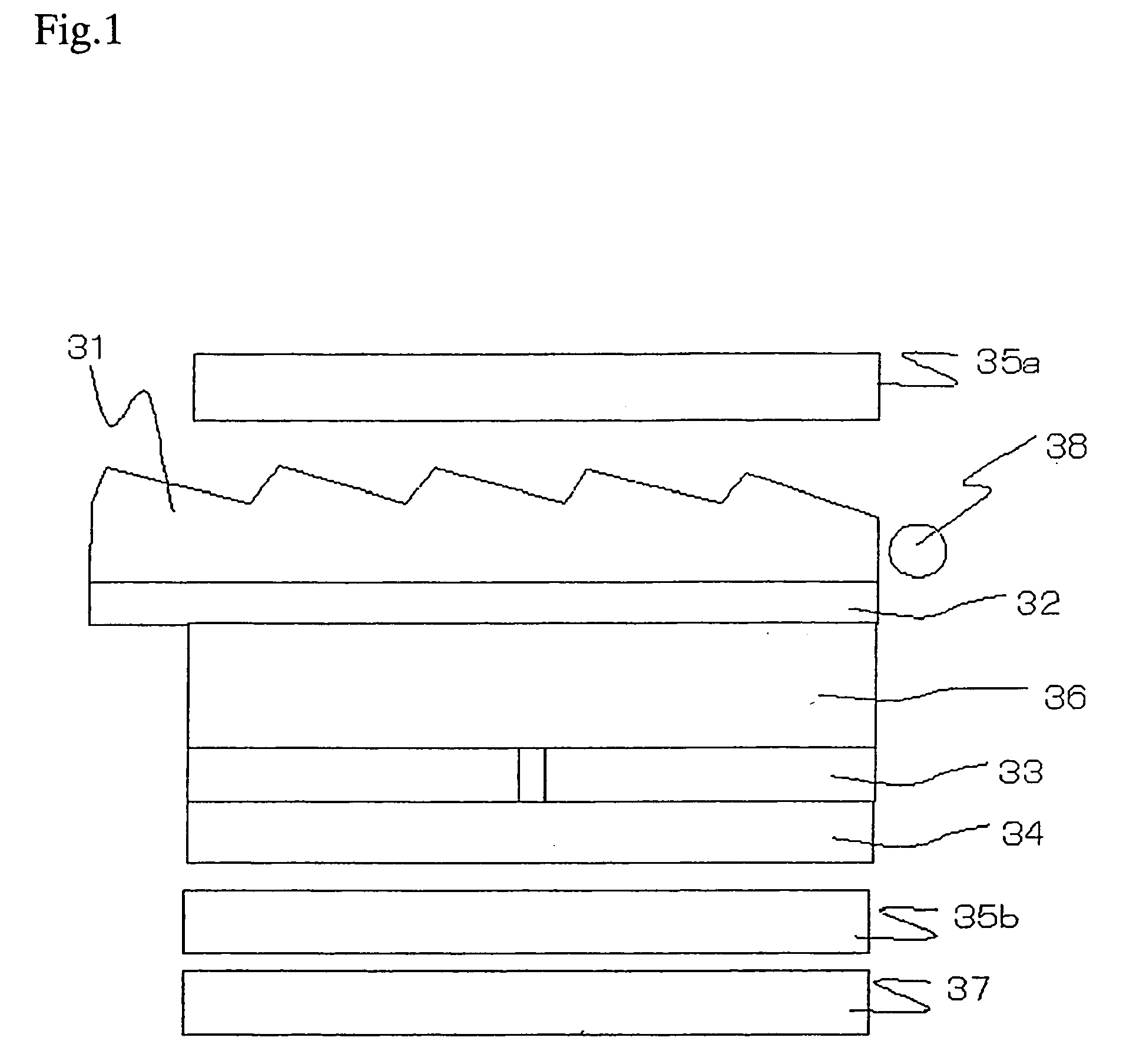

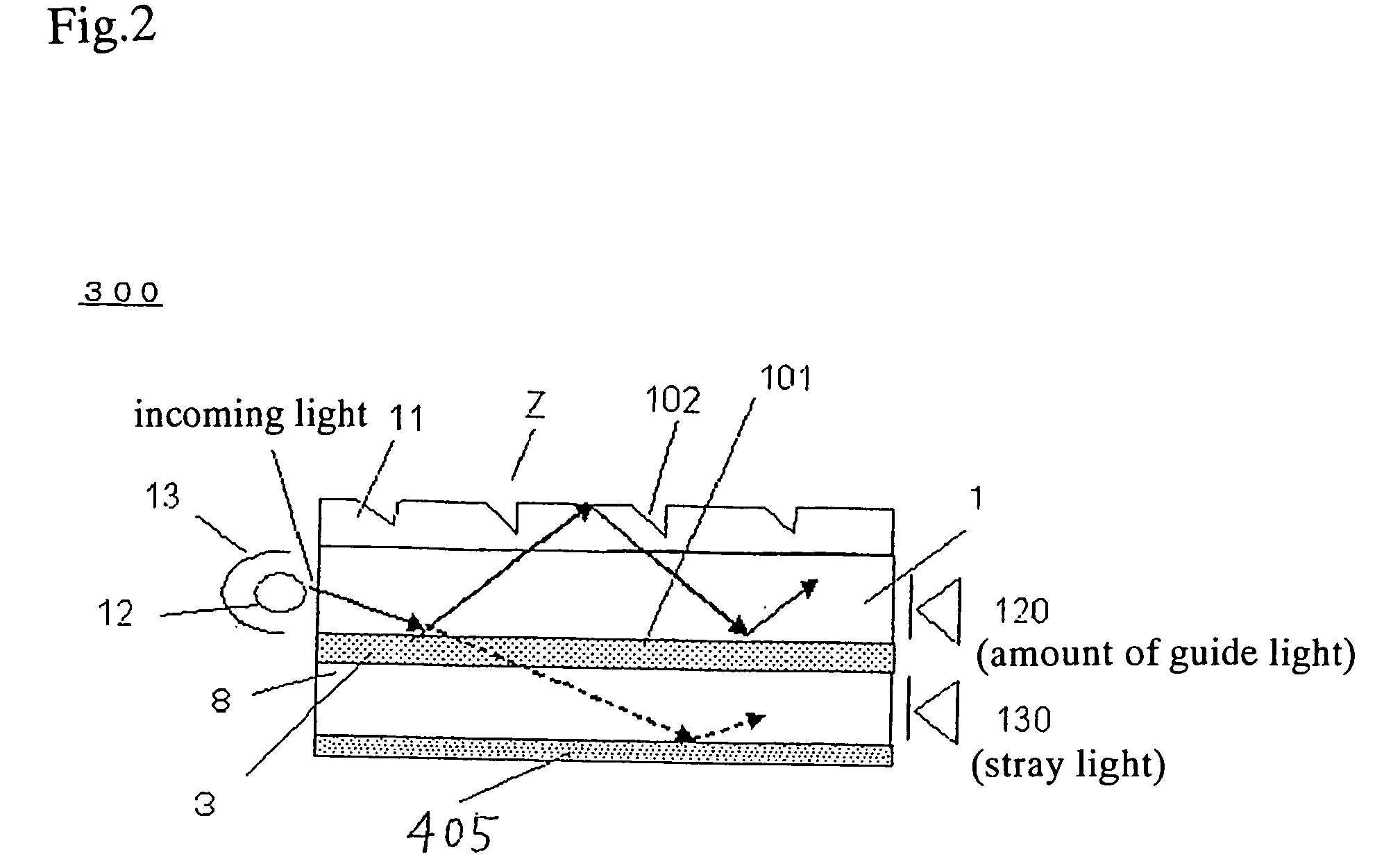

Optical modulating/display device and production method therefor and display apparatus mounting the optical modulating/displaying device thereon

InactiveUS20050146897A1Reduce unevennessMechanical apparatusLight guides for lighting systemsLiquid-crystal displayDisplay device

The present invention relates to an optical modulating display device (200) such as a liquid crystal displaying device provided with a front-light type planar illuminating device. The above front-light type planar illuminating device allows illuminating light to propagate inside a substrate (1), and is provided with a low refraction layer (3) being lower in refractive index than the substrate (1) and being in close contact with the inner surface of the substrate (1), and with reflection structure (11) on the outer surface of the substrate (1). The optical modulating display device (200) provided with the above front-light type planar illuminating device can ensure a sufficient amount of guide light propagating inside the substrate (1) and reduce non-uniformity in display illumination. And a display apparatus mounting the above optical modulating display device (200) thereon can be reduced in thickness and weight and provide a high quality display.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com