Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1592results about "Adhesive processes with surface pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

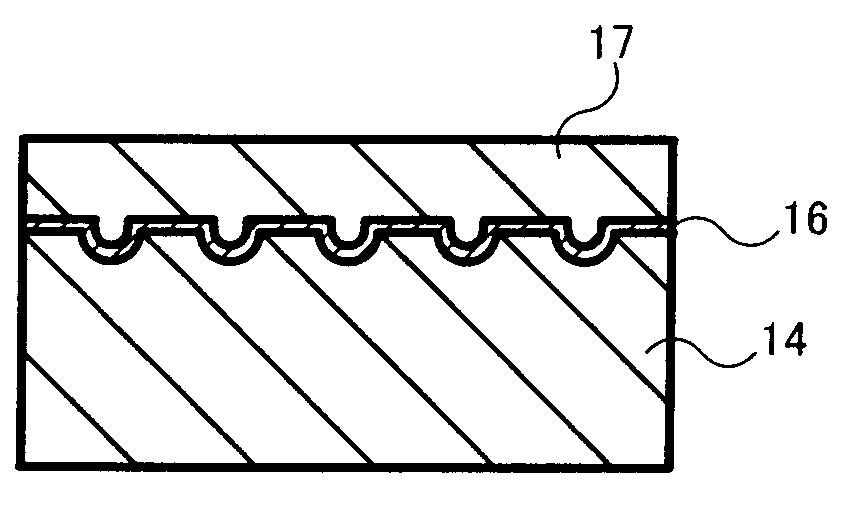

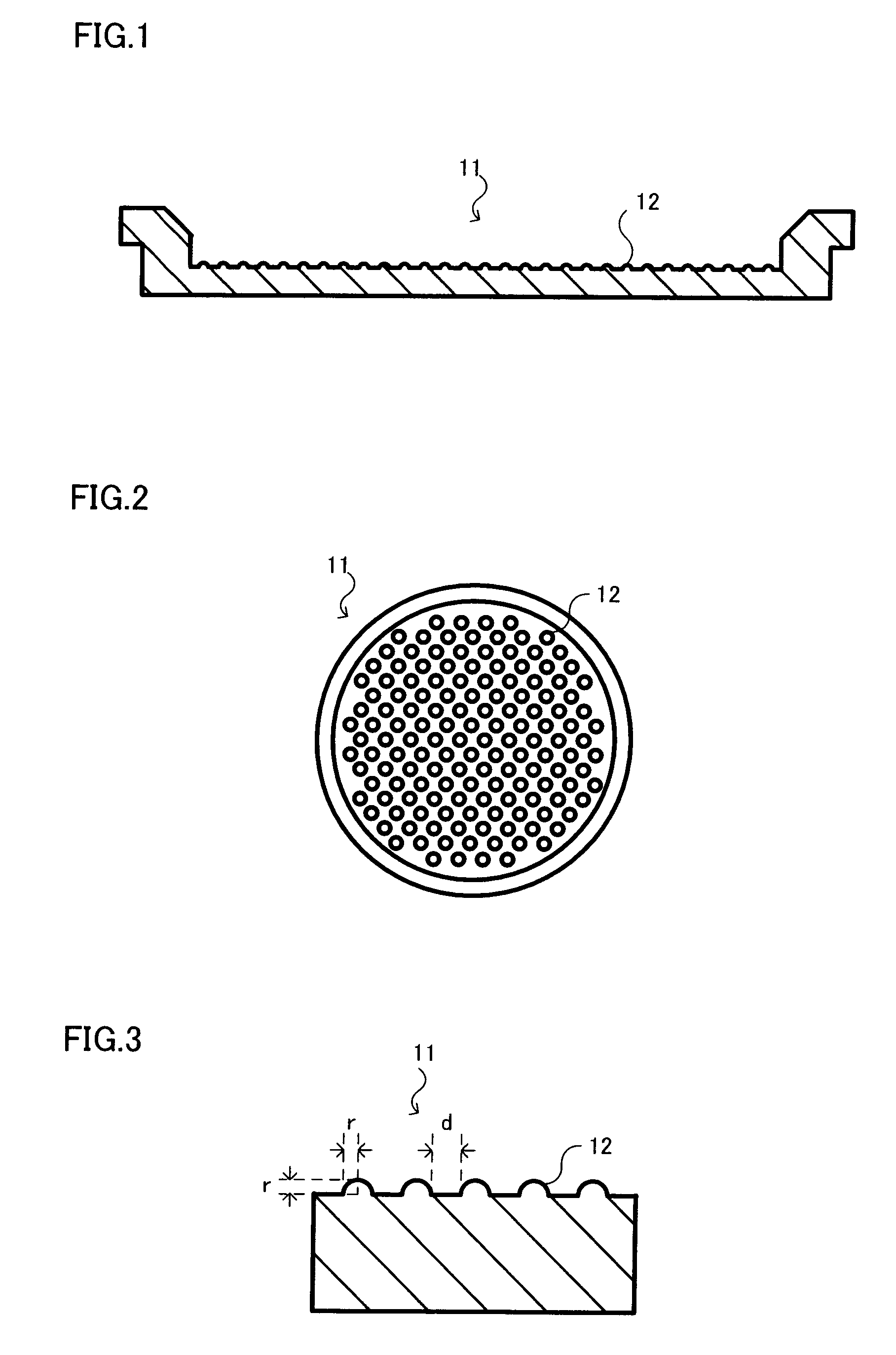

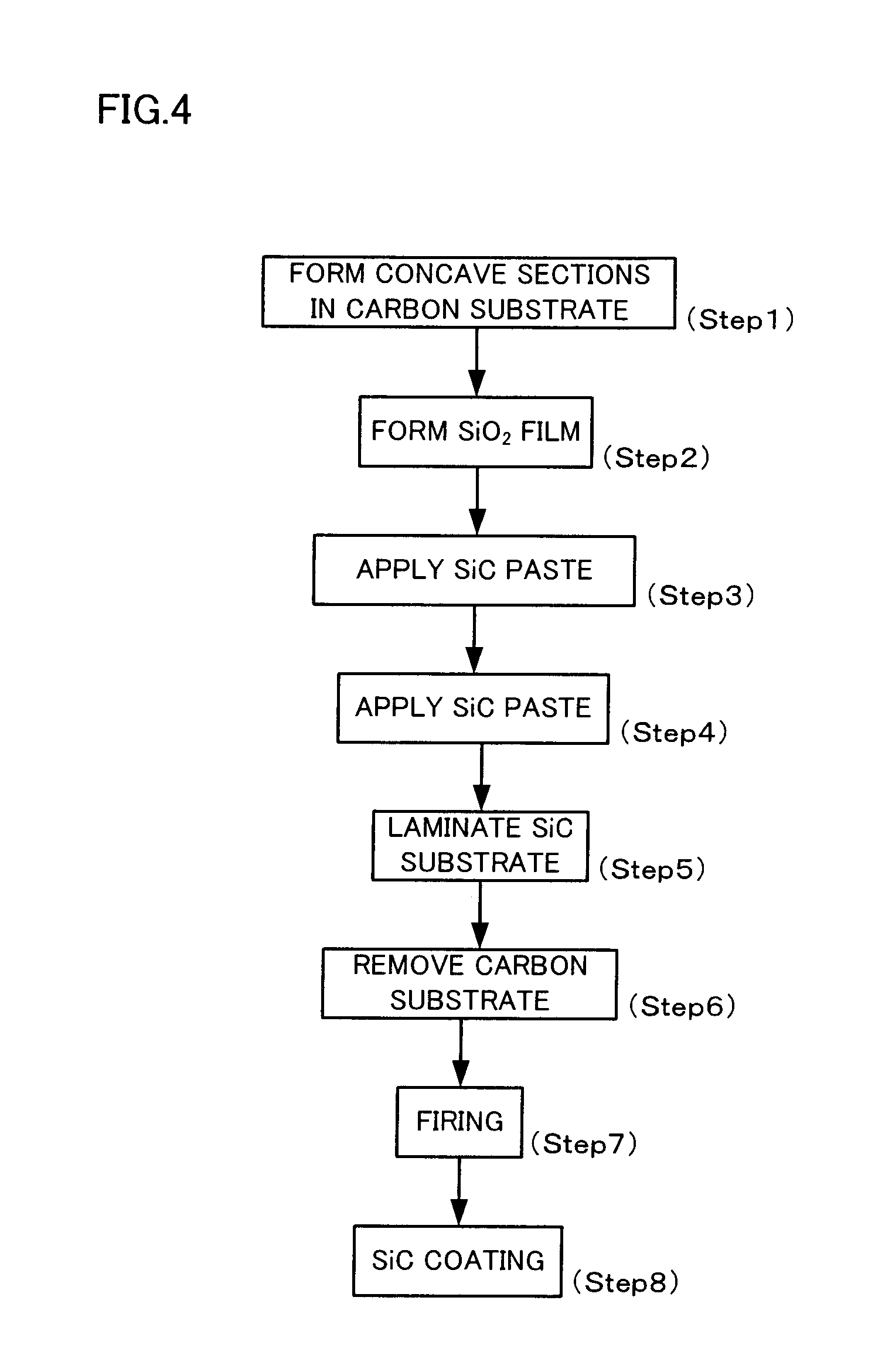

Method for manufacturing susceptor

ActiveUS20100163524A1Decorative surface effectsSemiconductor/solid-state device manufacturingSusceptorMetallurgy

A method for manufacturing a susceptor includes: forming a concave pattern in a surface of a substrate to be processed; applying a SiC paste containing a SiC powder and a sintering agent to the surface of the substrate to be processed to fill the concave pattern to form a SiC coating layer; laminating a SiC substrate on the SiC coating layer; and firing the SiC coating layer to form a SiC layer having at least one convex section on the surface of the SiC substrate.

Owner:NUFLARE TECH INC

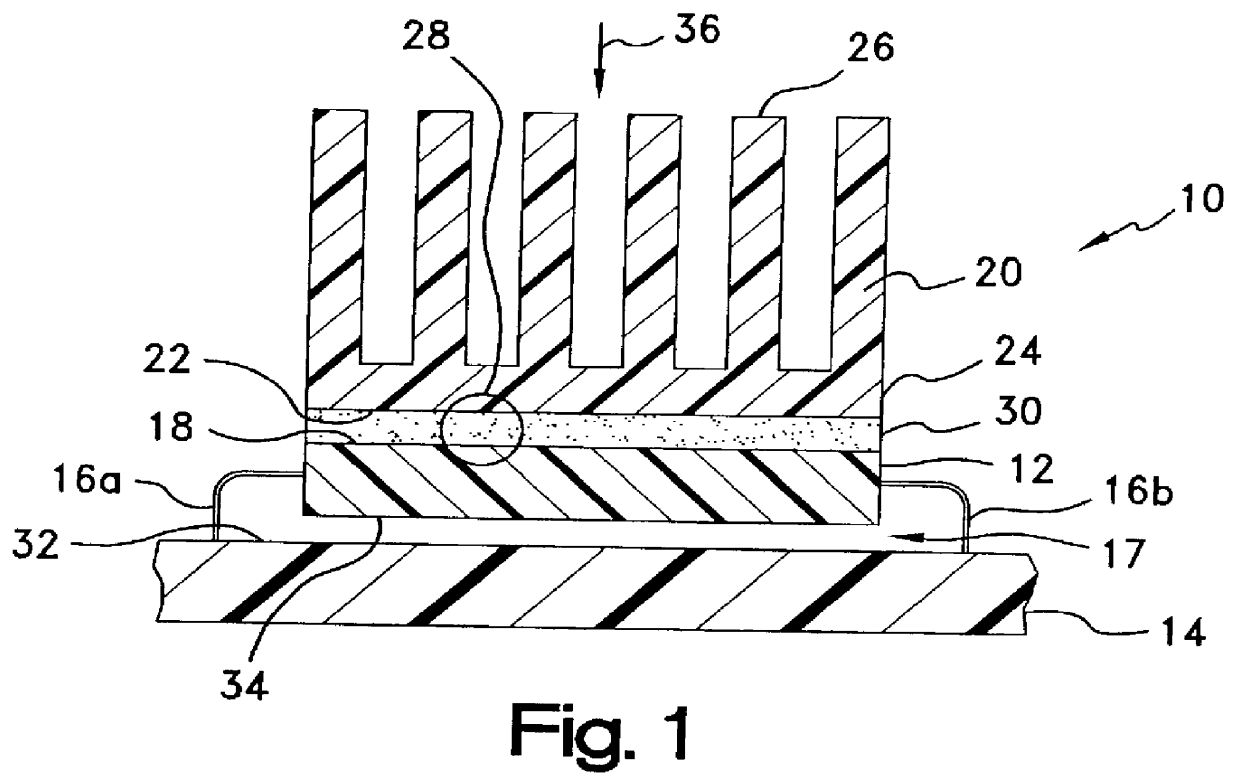

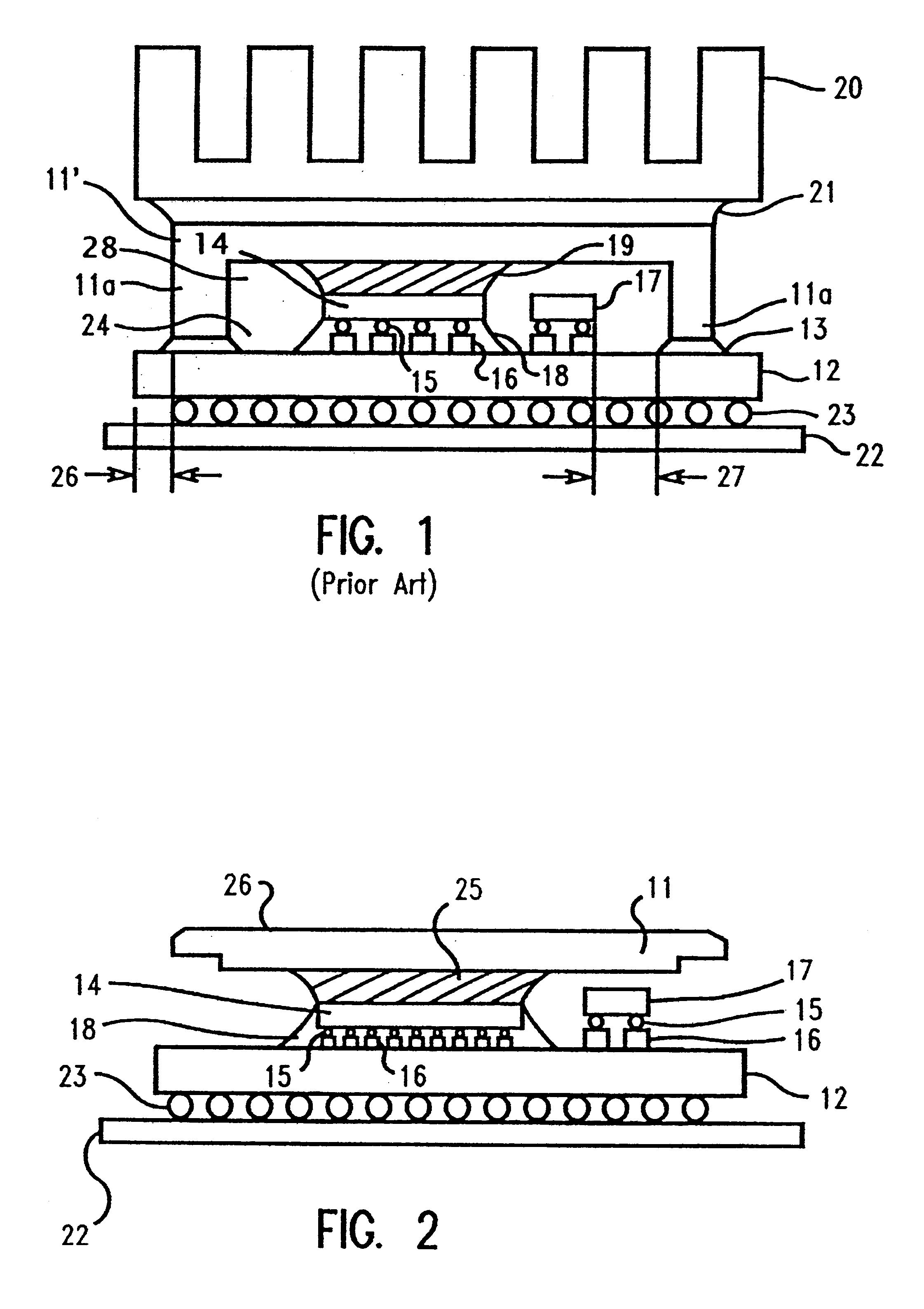

Conformal thermal interface material for electronic components

InactiveUS6054198AOptimize allocationReadily apparentSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureConductive materials

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:PARKER INTANGIBLES LLC

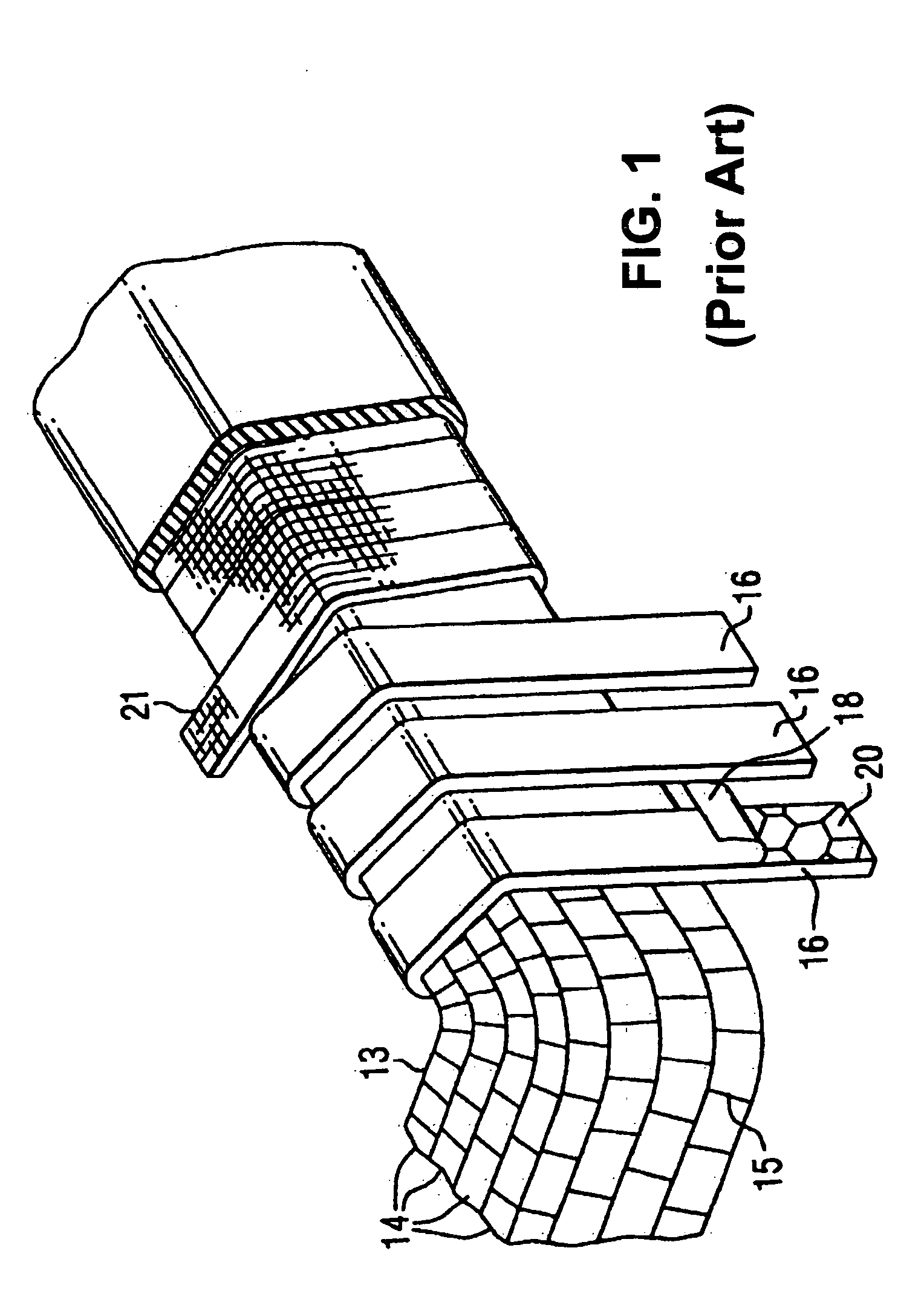

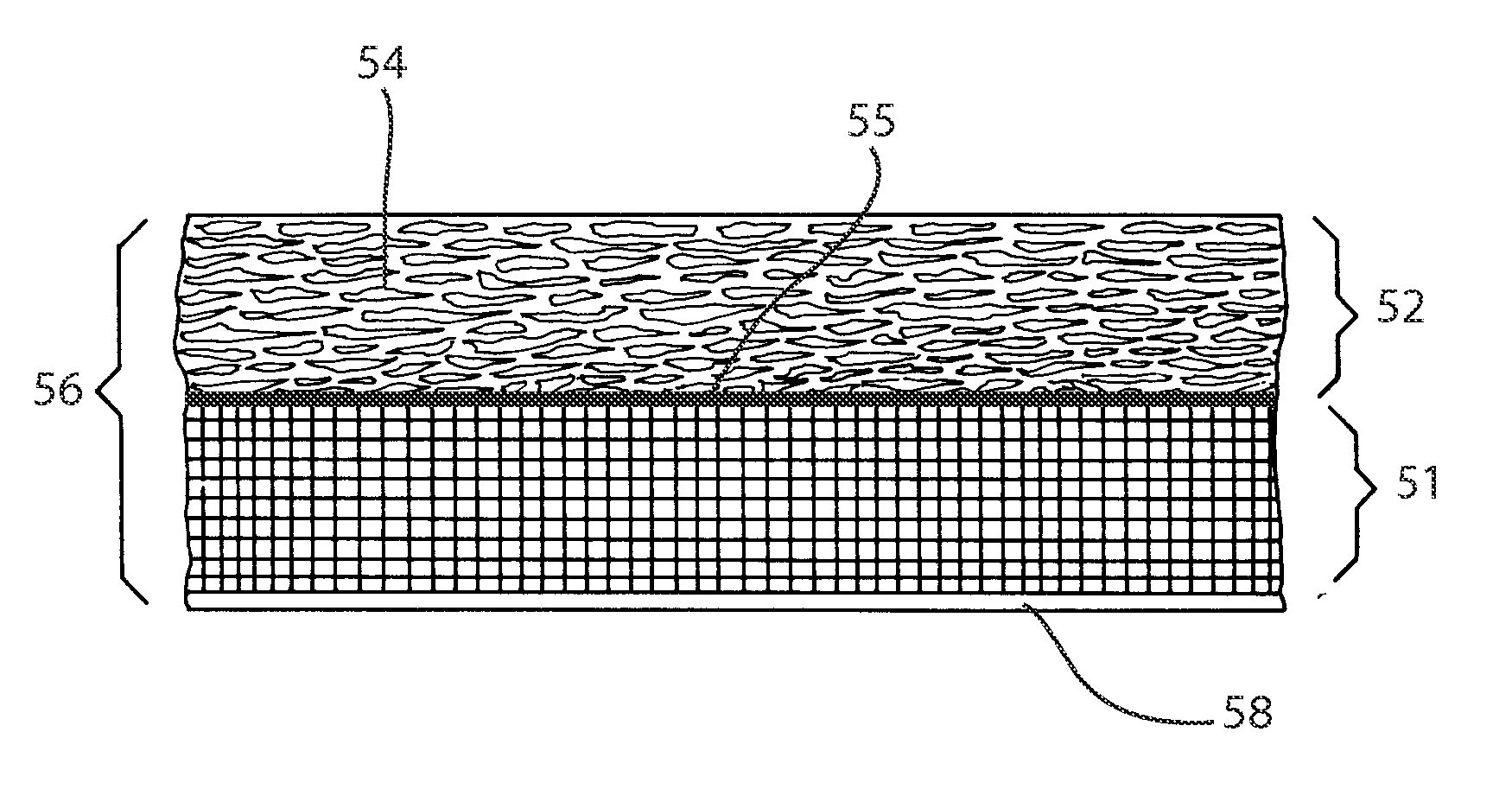

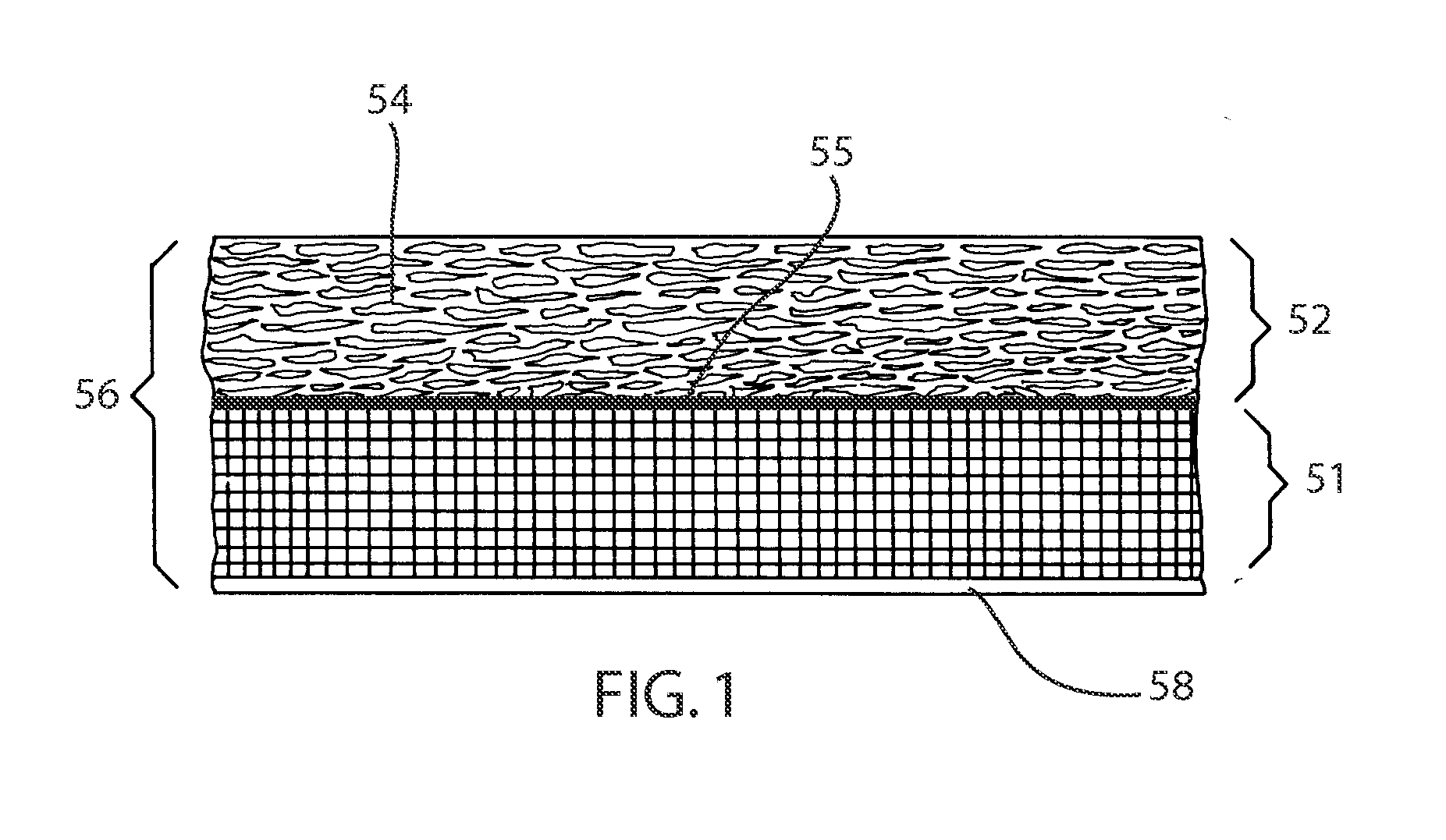

Thermoplastic planks and methods for making the same

InactiveUS7211310B2Improve moisture resistanceEasy flexibilityCovering/liningsTraffic signalsThick plateEngineering

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

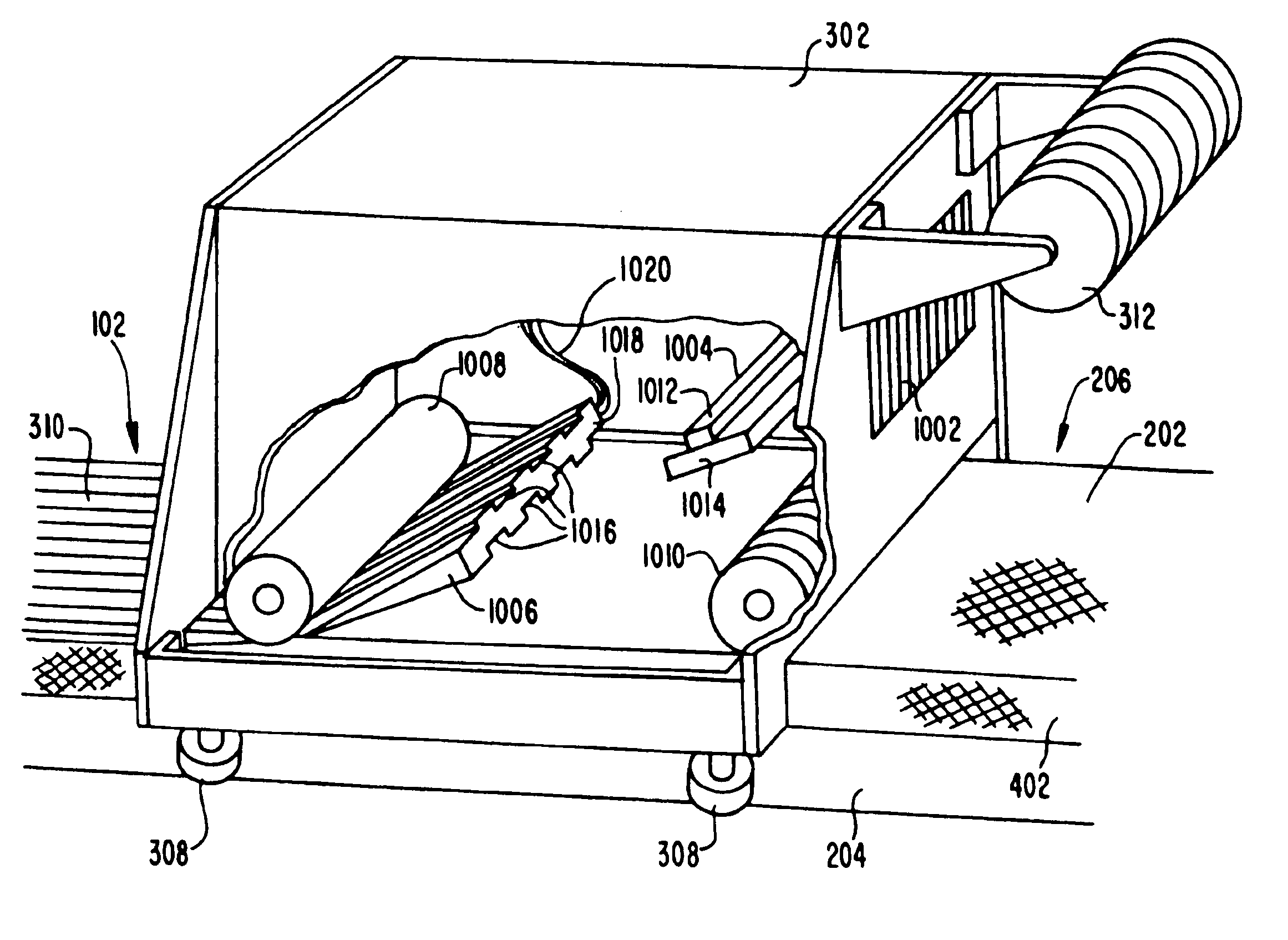

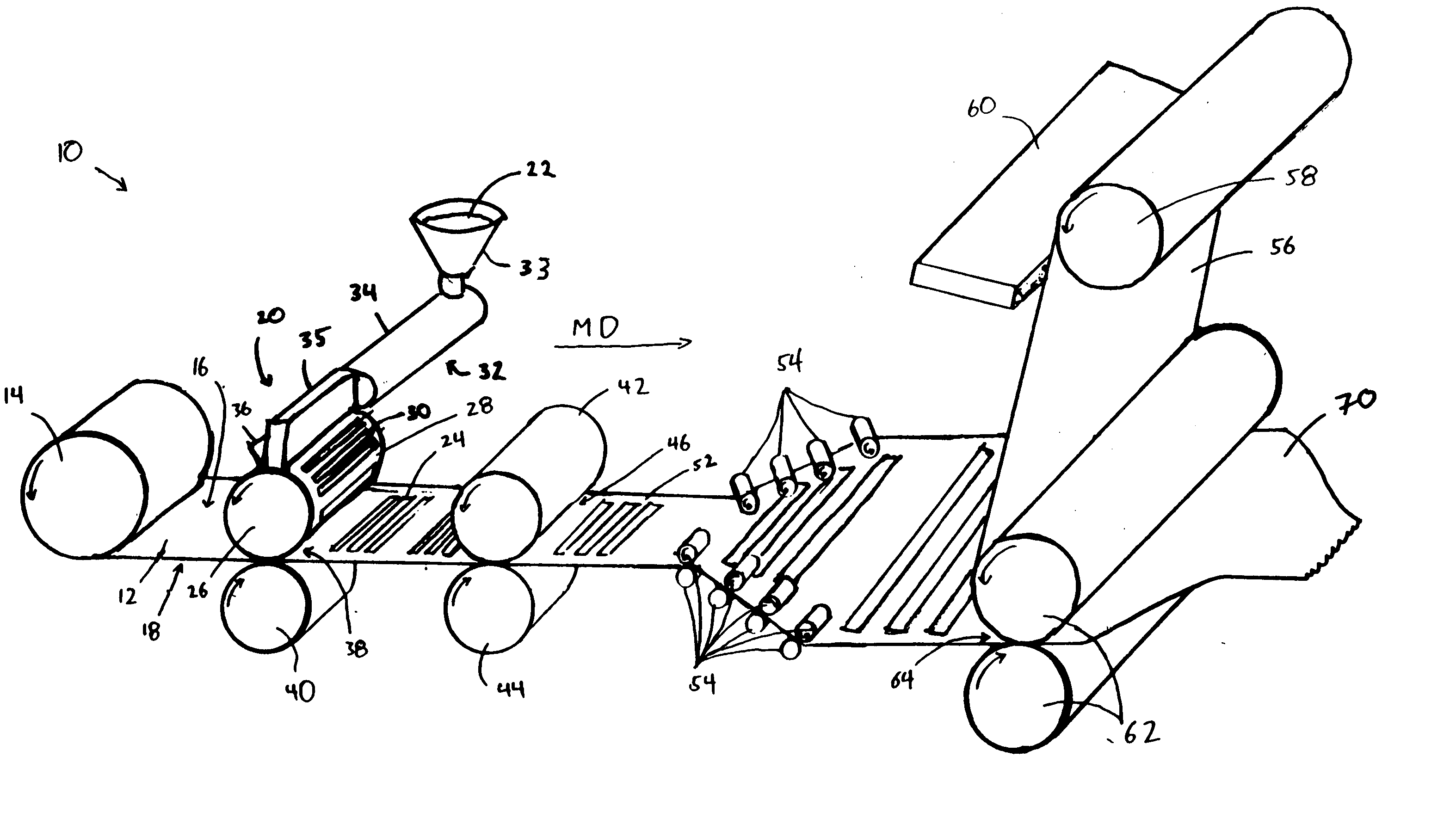

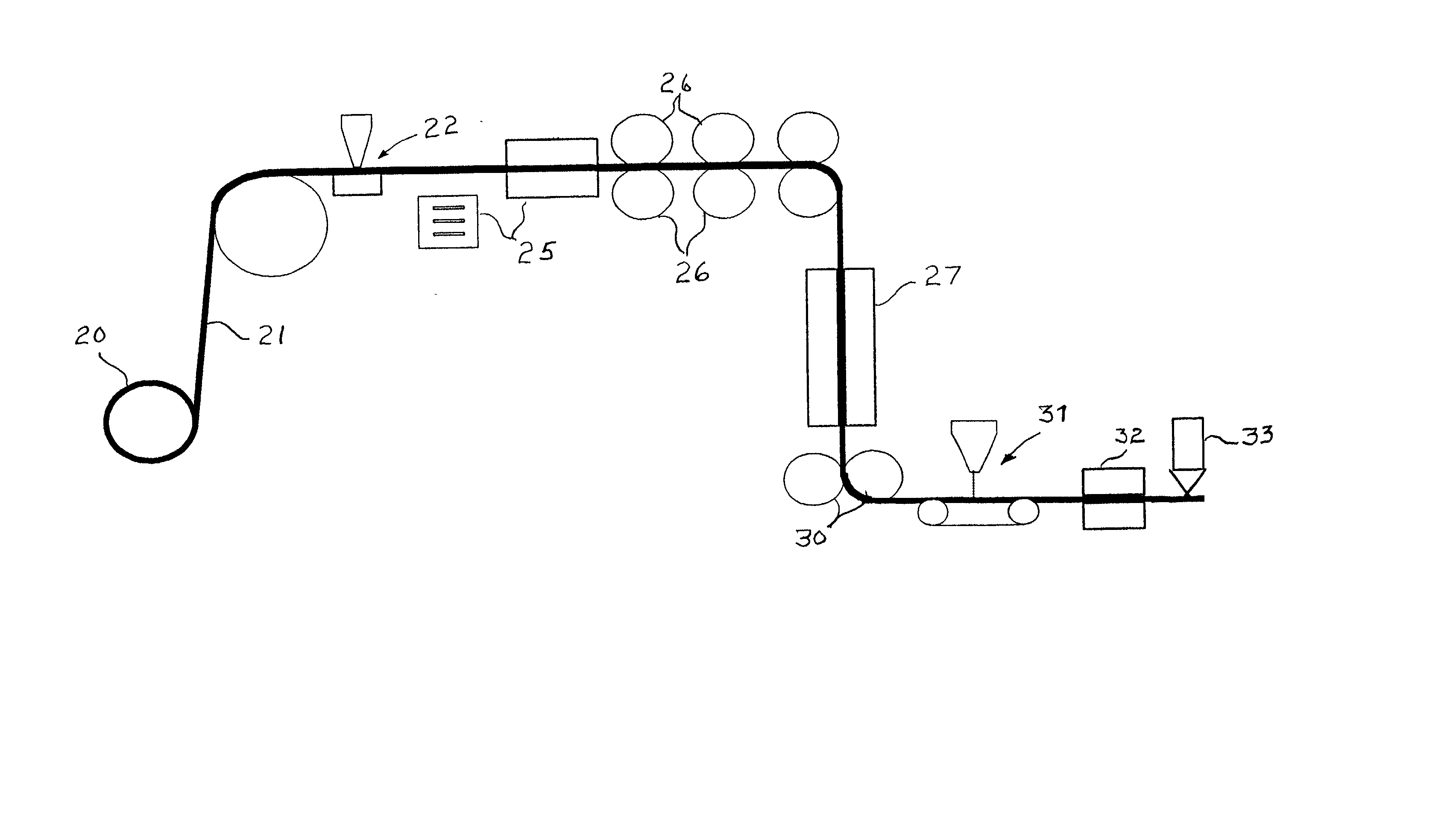

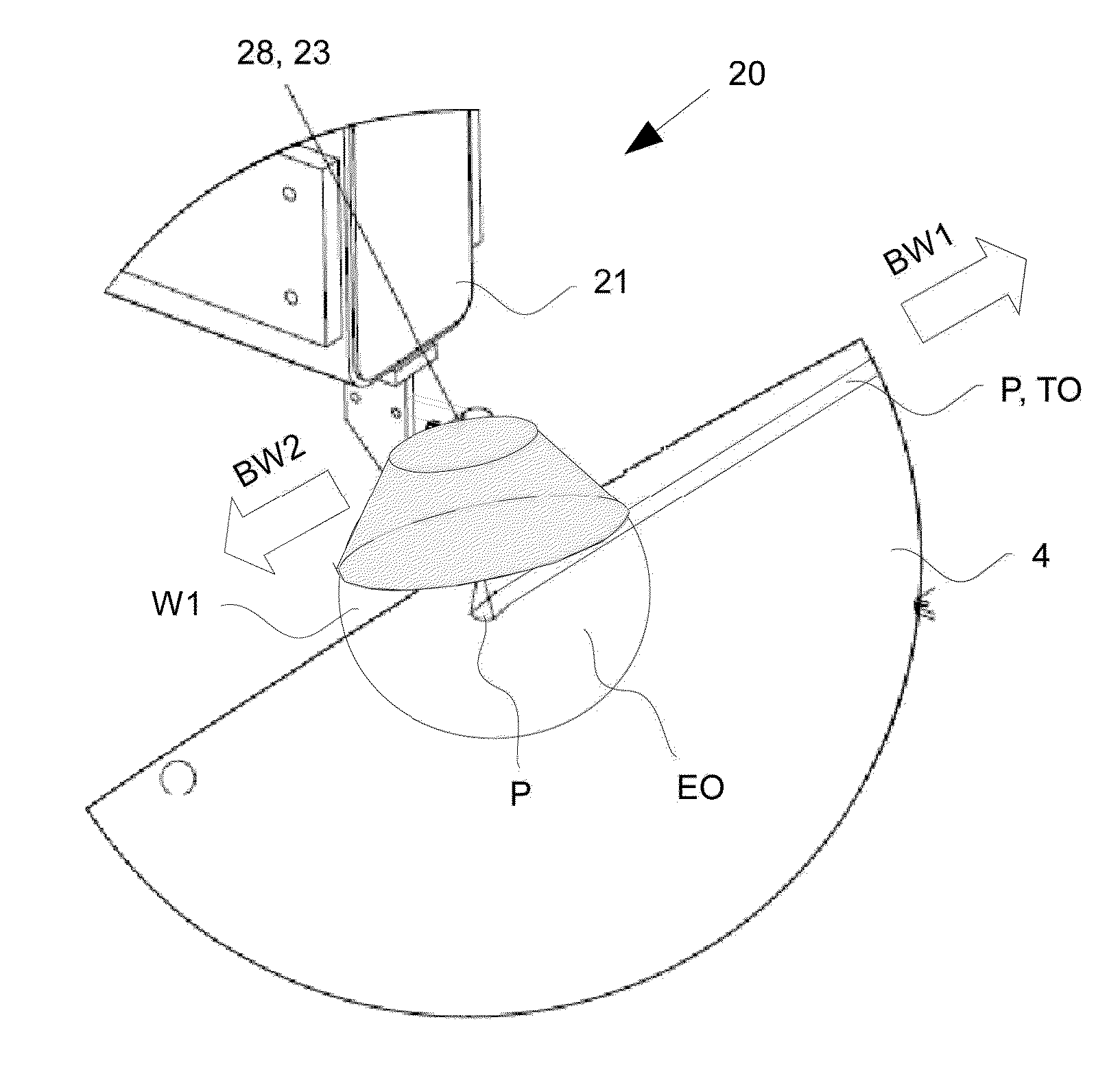

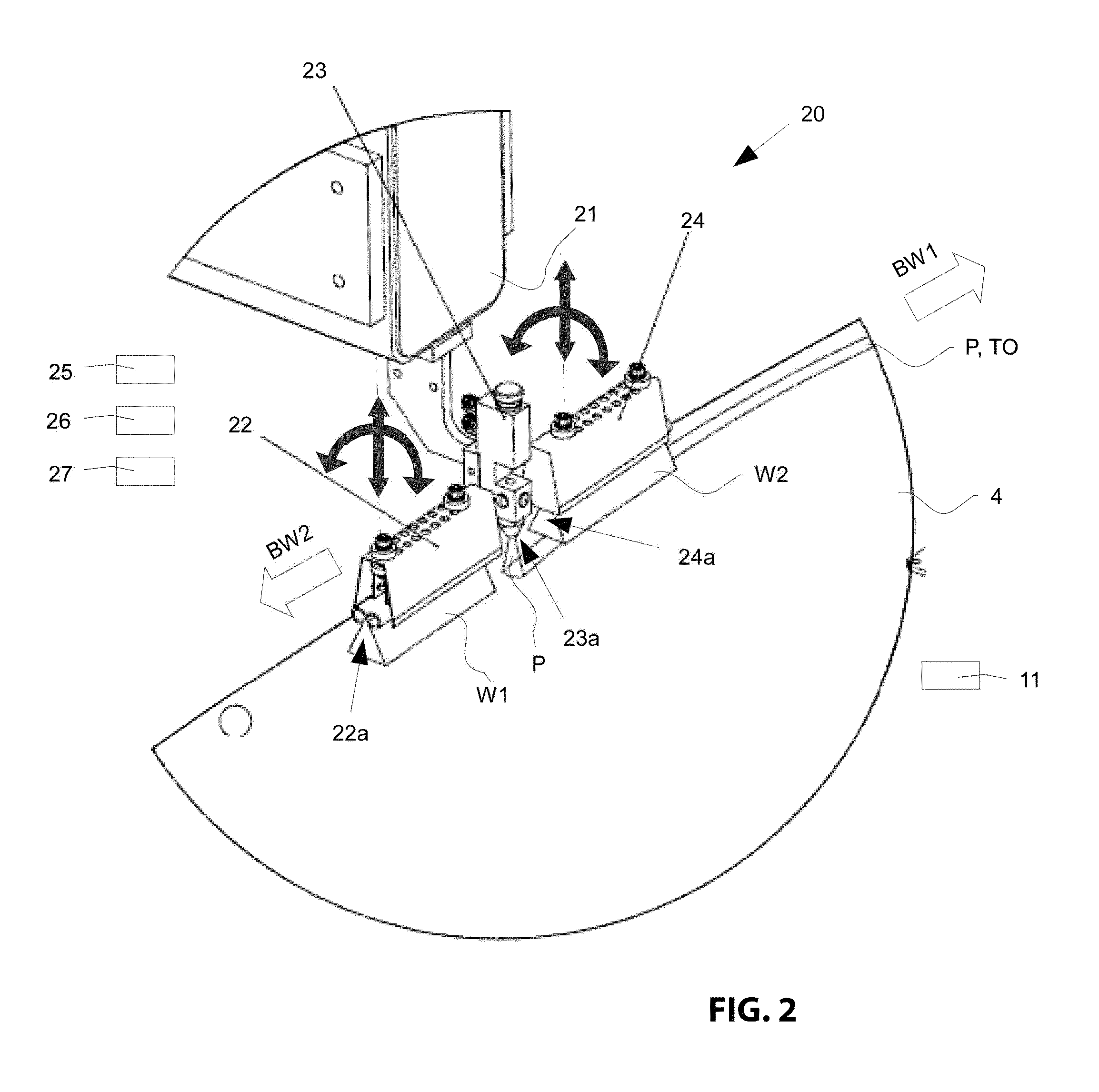

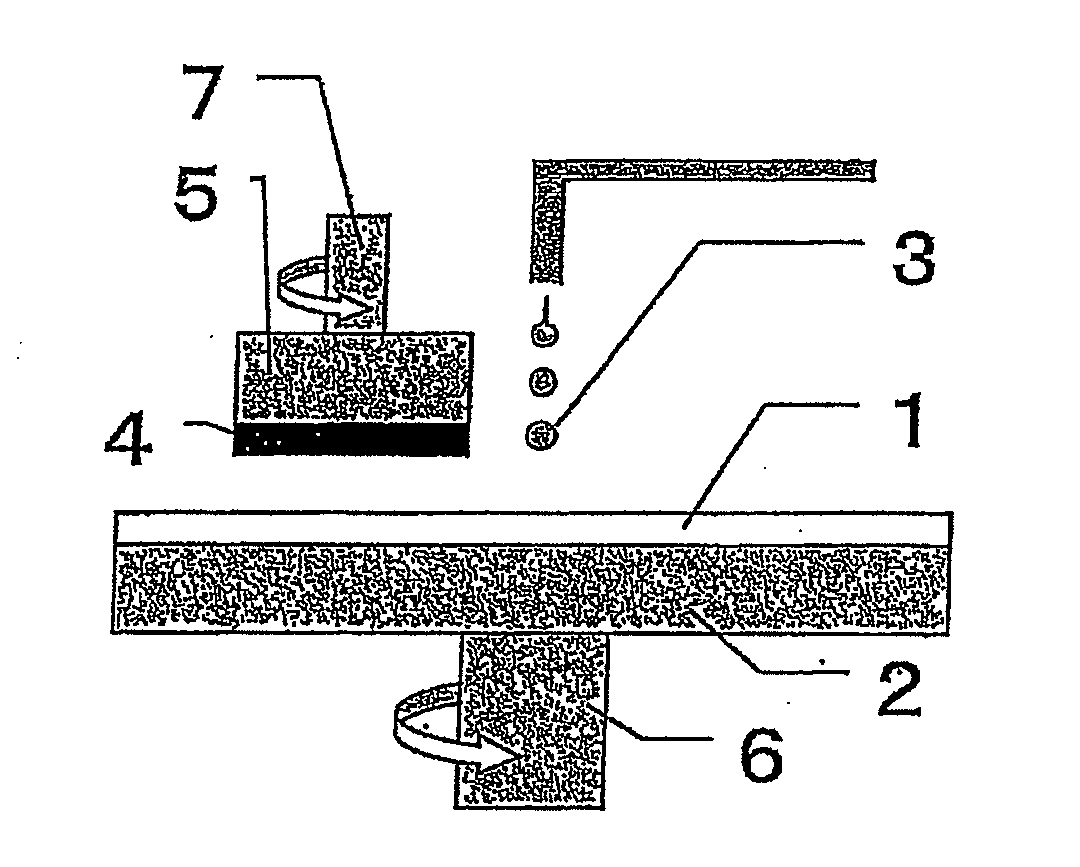

Composite structural element fabricating device and method

ActiveUS20070029038A1Easy to produceAdhesive processes with surface pretreatmentWelding/cutting auxillary devicesEngineeringMechanical engineering

To fabricate a composite item, a device places a composite ply on a curved form at about 0° relative to a longitudinal axis of the form. The form includes a web surface and a cap surface. The device includes a web compaction roller and a set of guides. The web compaction roller compacts a composite material upon the web surface and generate a web ply. The set of guide rollers urges against the cap surface. The compaction roller is directed along the form by the guide rollers.

Owner:THE BOEING CO

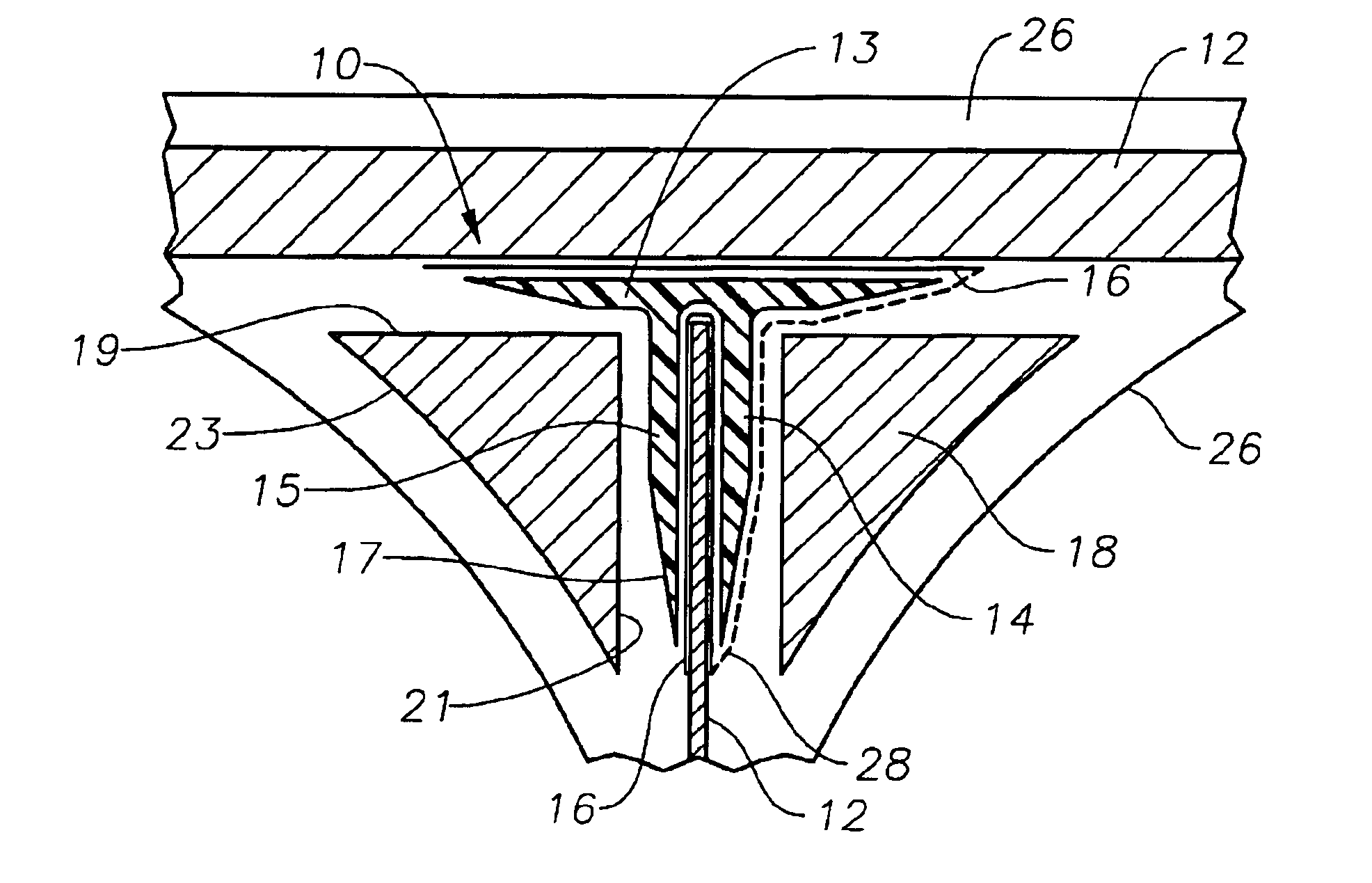

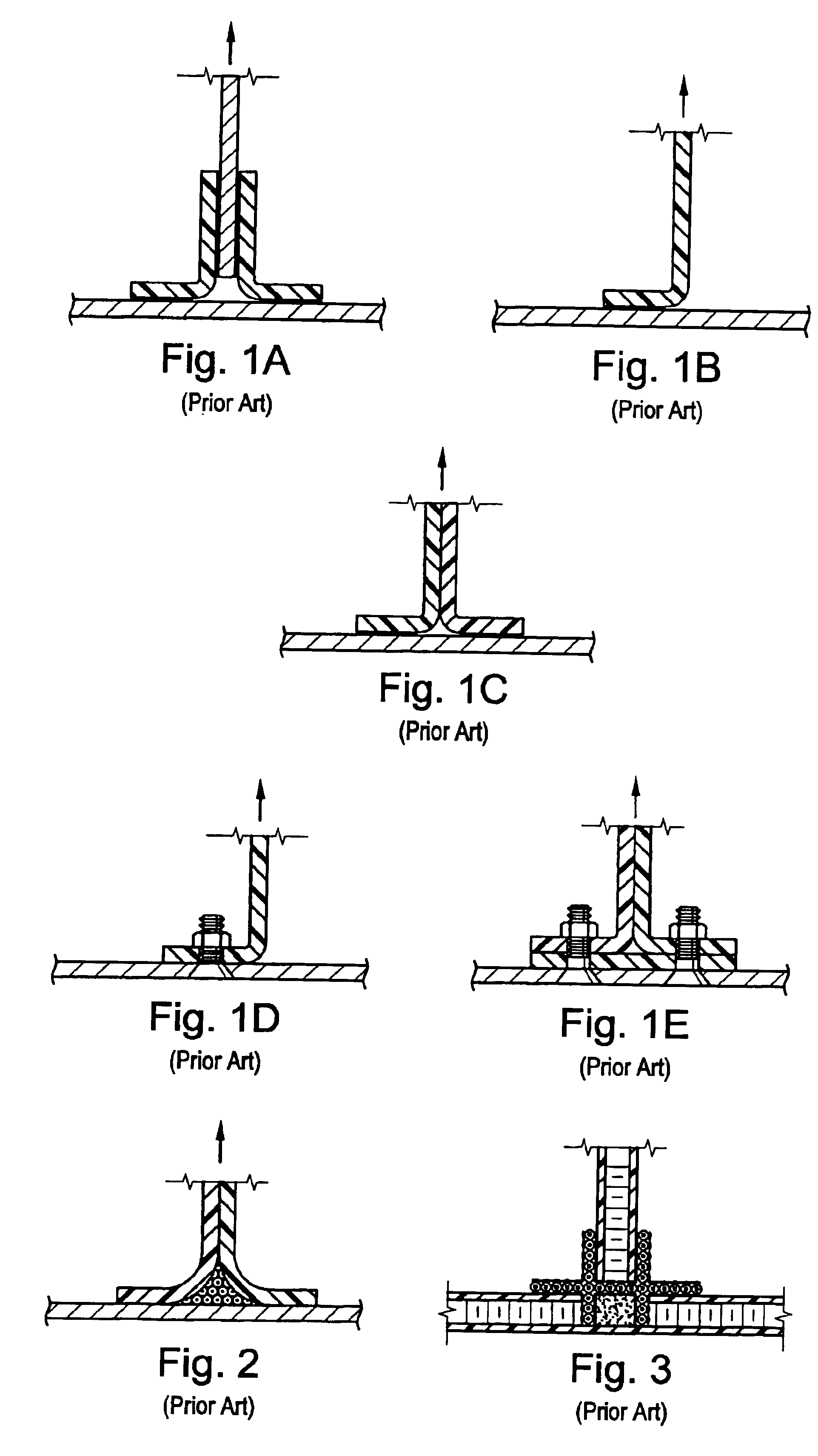

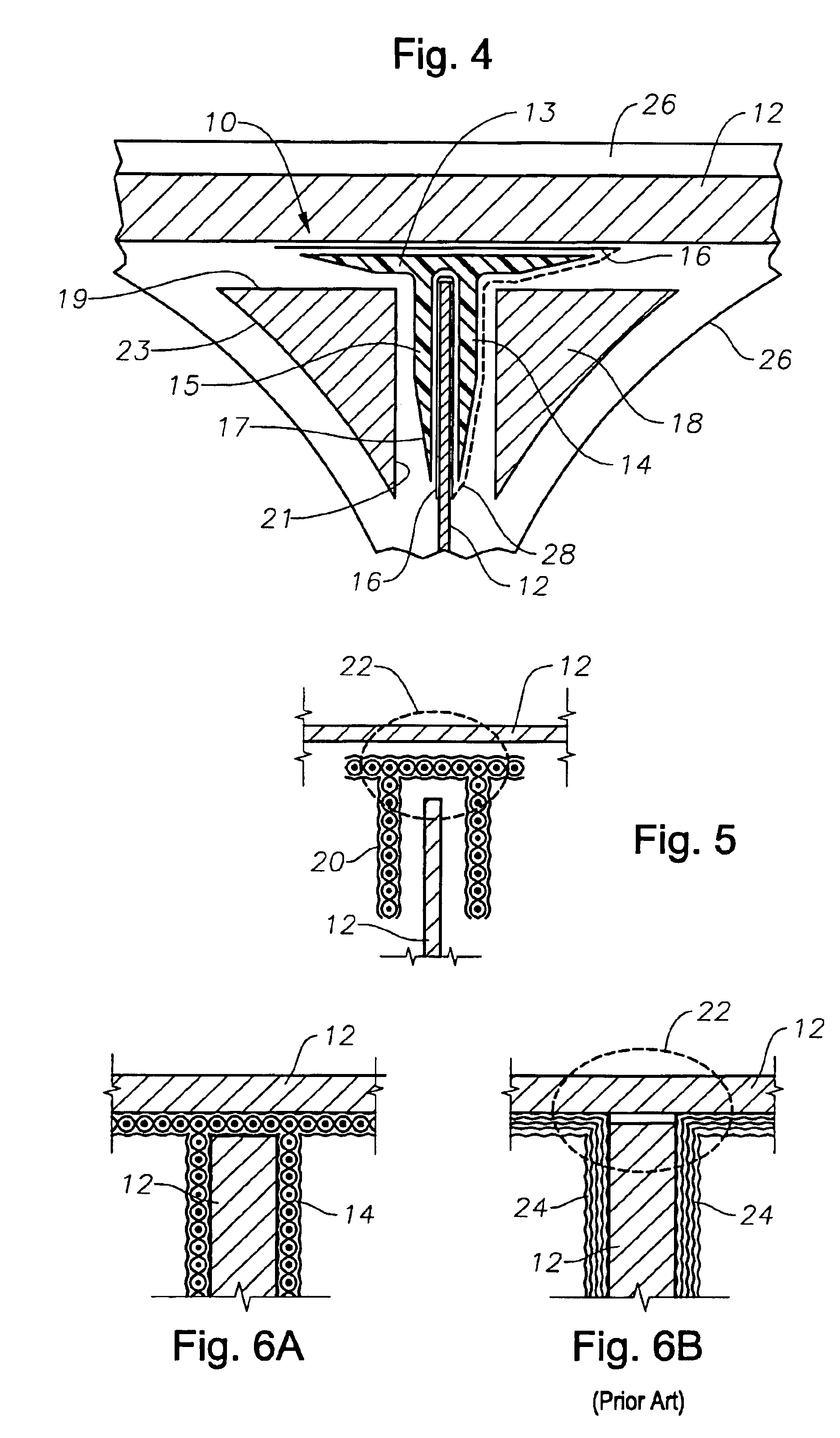

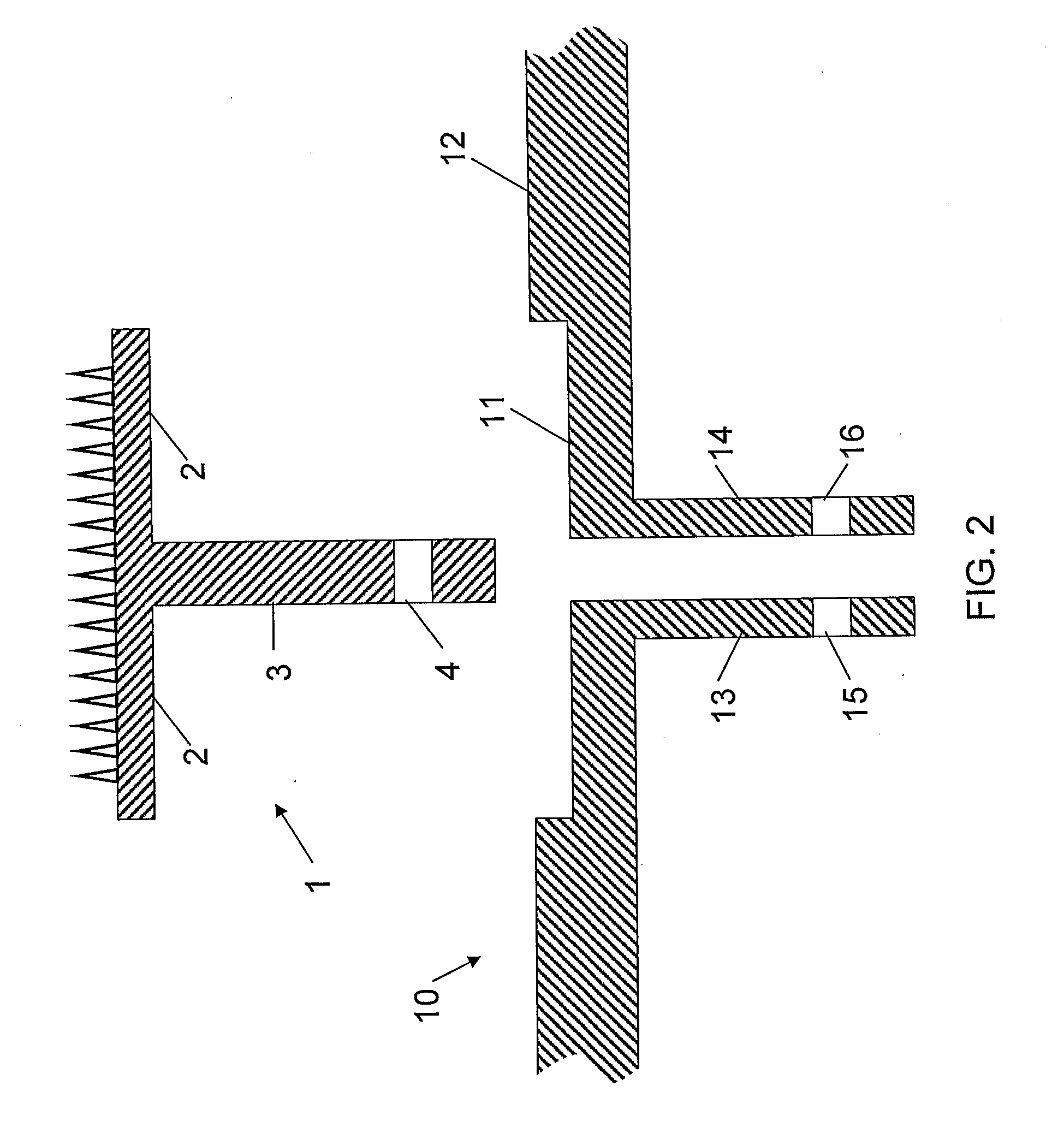

System and method of forming structural assemblies with 3-D woven joint pre-forms

InactiveUS6849150B1Improve structural strengthEliminate needFuselage framesCylinder headsAdhesiveEngineering

A system and method for forming structural assemblies with 3-D woven joint pre-forms. The method of the present invention forms complex structural assemblies with pre-formed structures. Adhesive is applied between the preformed structures and uncured 3-D woven textile pre-forms. Then together the preformed structures and uncured resin impregnated 3-D woven textile are cured with heat and / or pressure to form the larger complex structural assemblies.

Owner:LOCKHEED MARTIN CORP

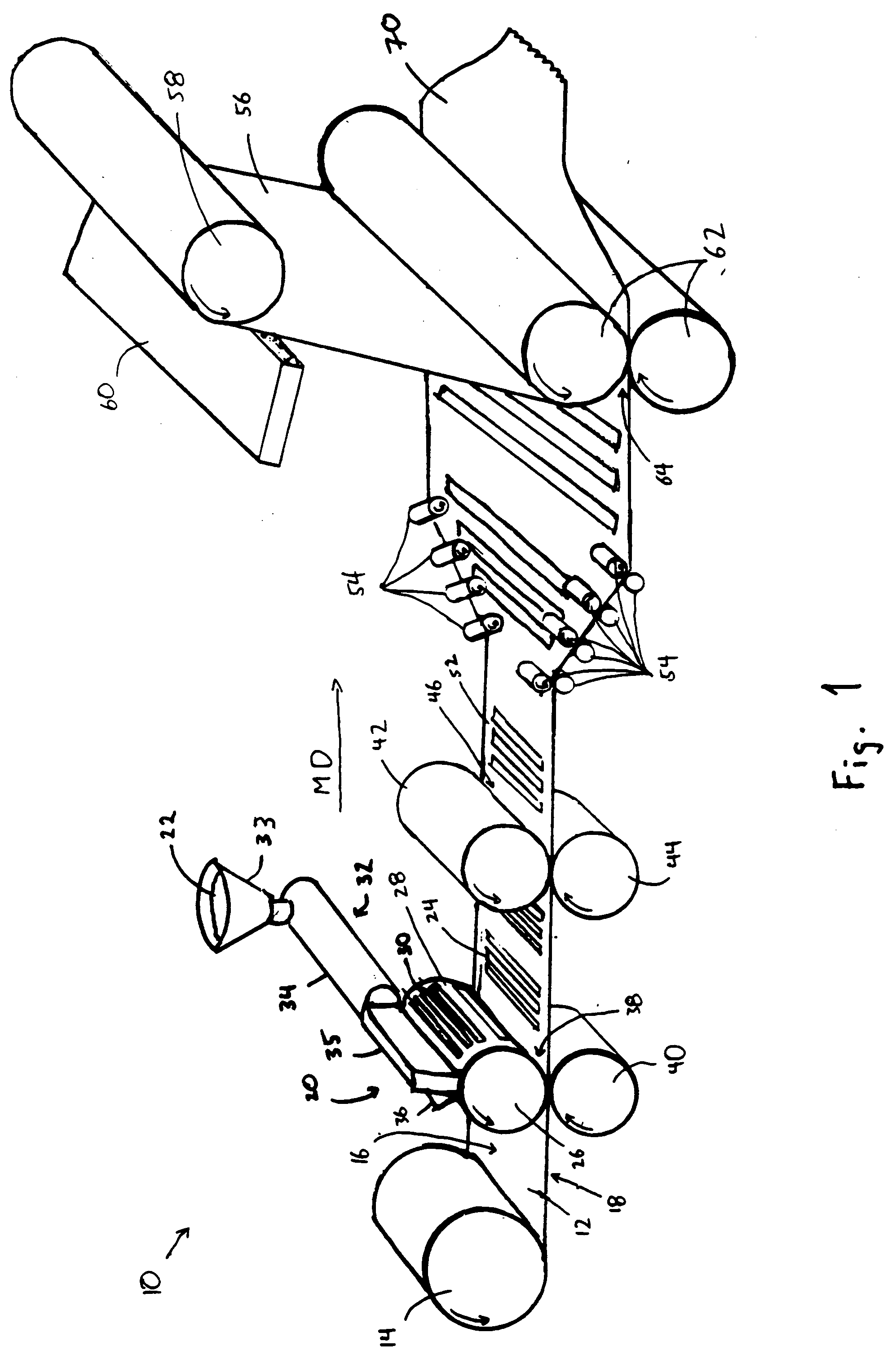

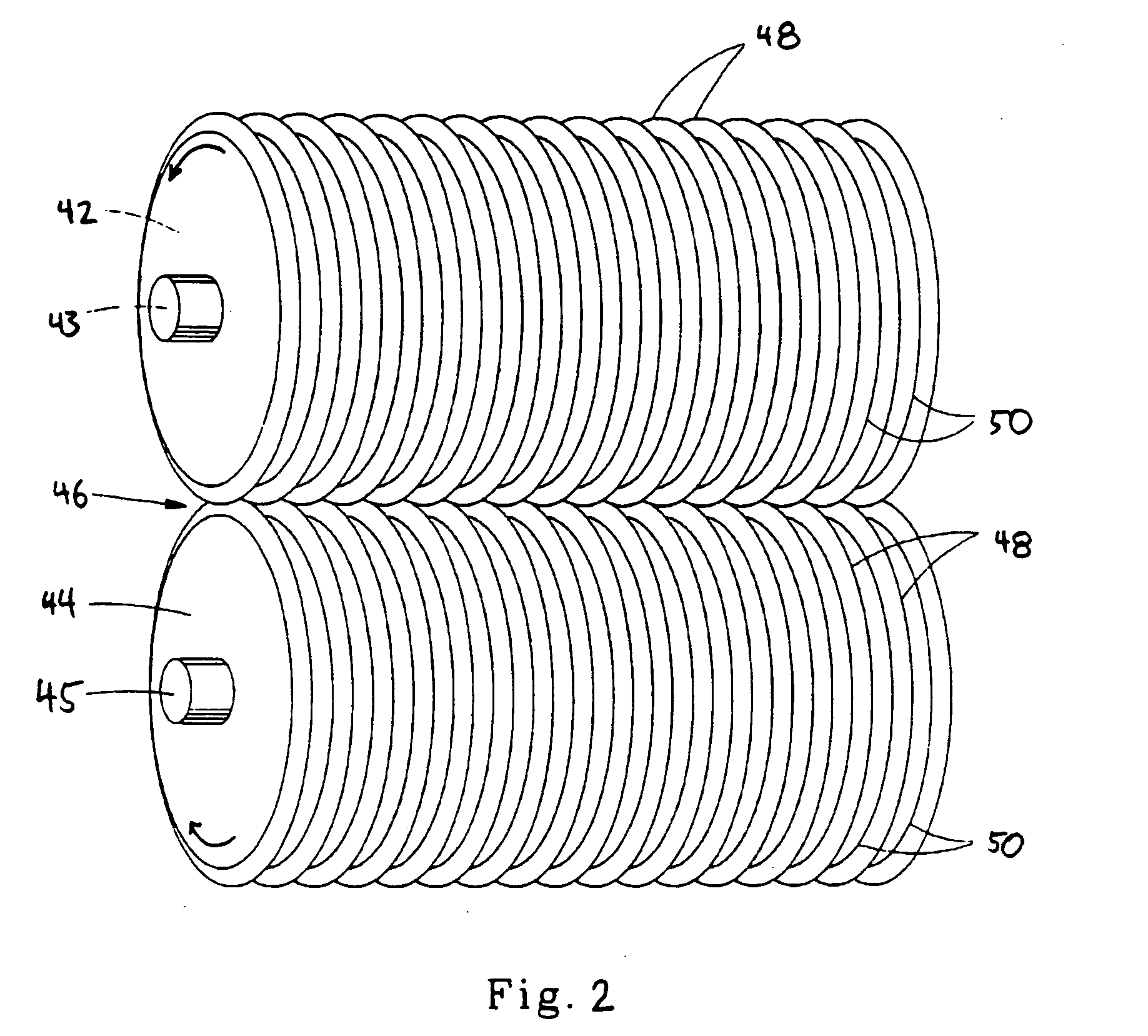

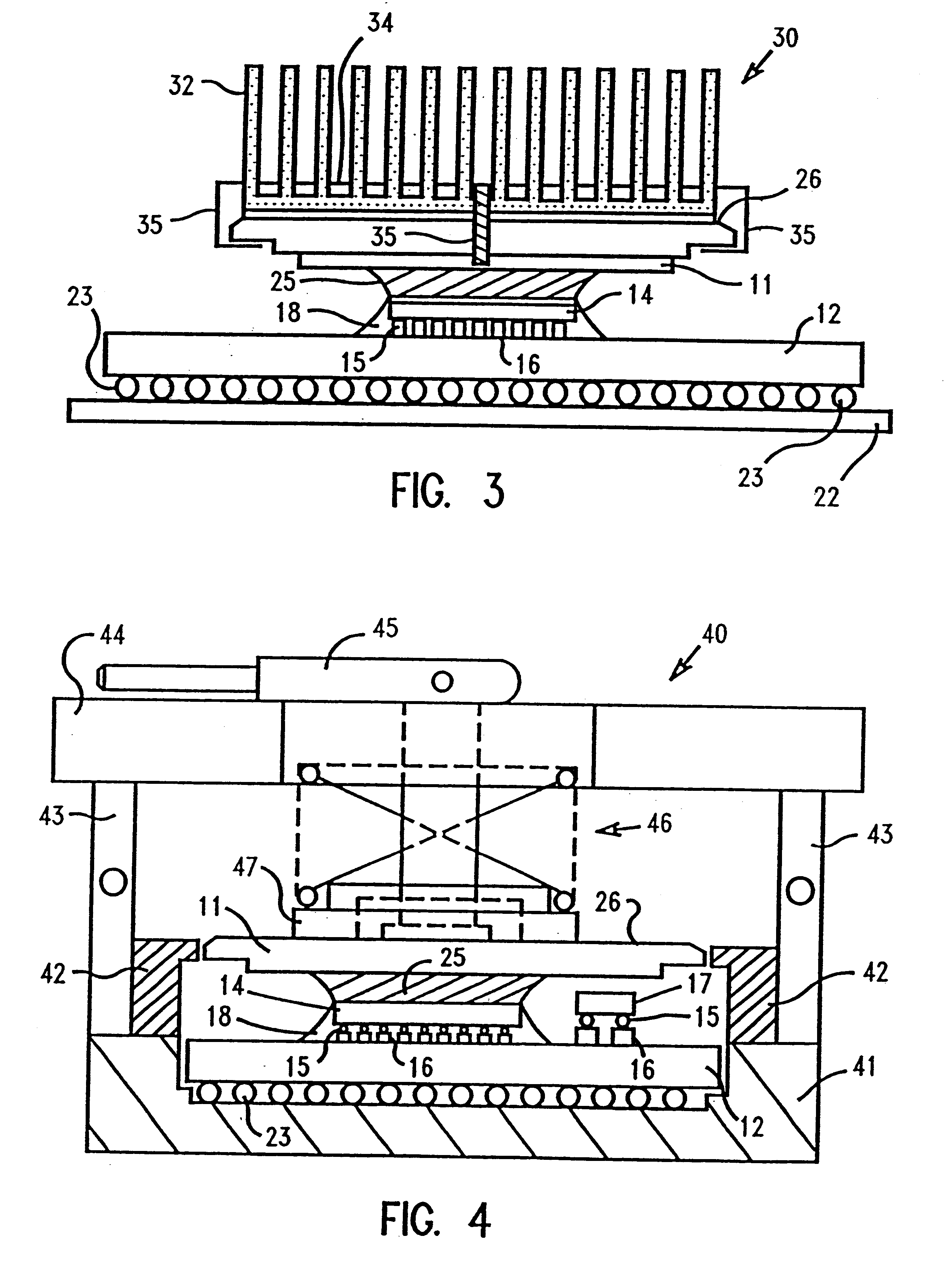

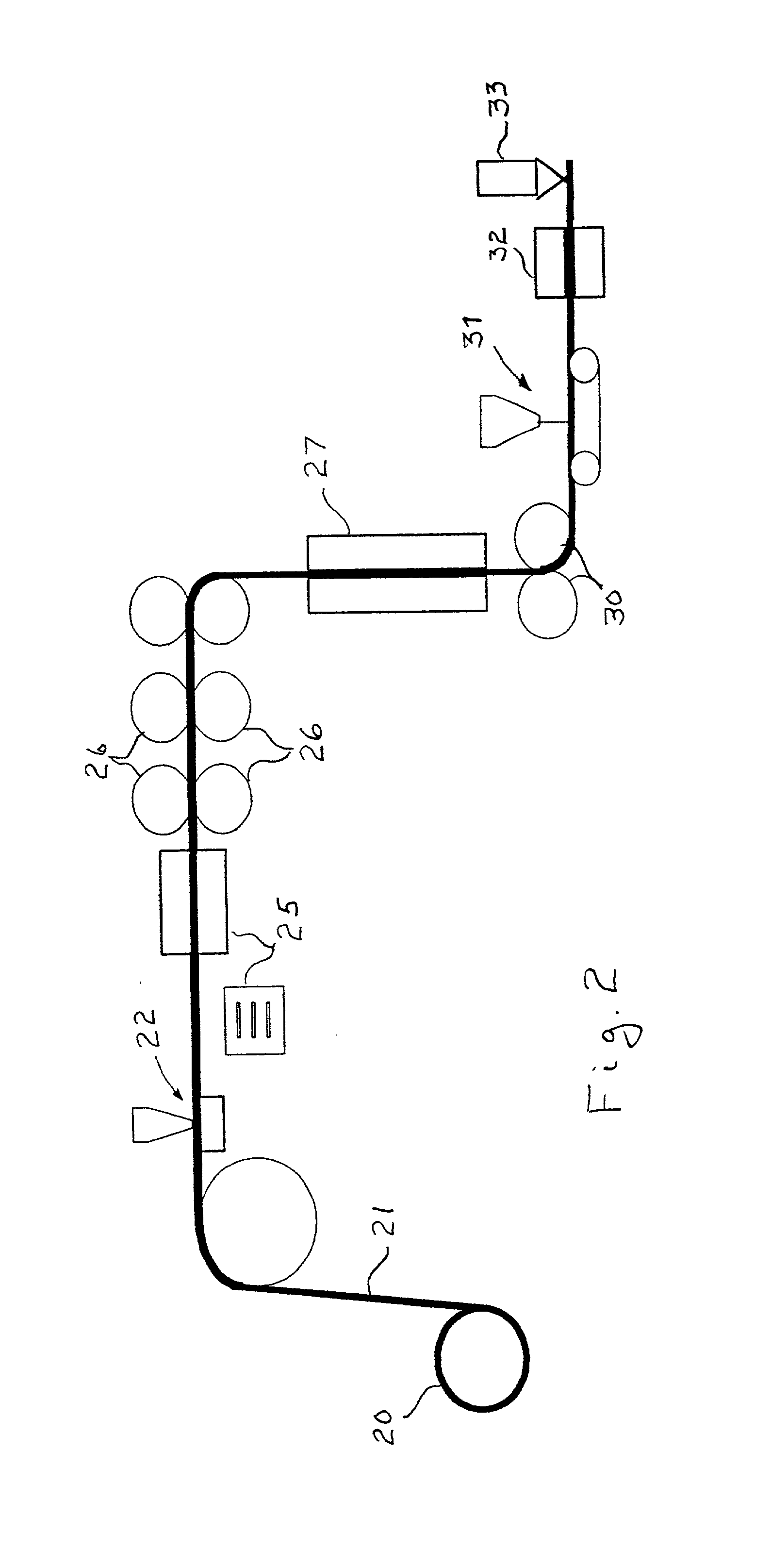

Method for producing a corrugated stretch laminate

InactiveUS20060083900A1Mechanical working/deformationAdhesive processes with surface pretreatmentMolten stateElastomer

A process for making a corrugated stretch laminate comprising the steps of providing a first carrier web having a first surface and a second surface; applying a first elastomeric composition in a fluid or molten state to the first surface of the carrier web to form at least one first elastic member; incrementally stretching in a first direction at least a portion of the carrier web to form a stretch composite preform; elongating the stretch composite preform in the first direction; joining a first substrate to the elongated stretch composite preform; and allowing the elongated stretch composite preform to recover to form said corrugated stretch laminate.

Owner:THE PROCTER & GAMBLE COMPANY

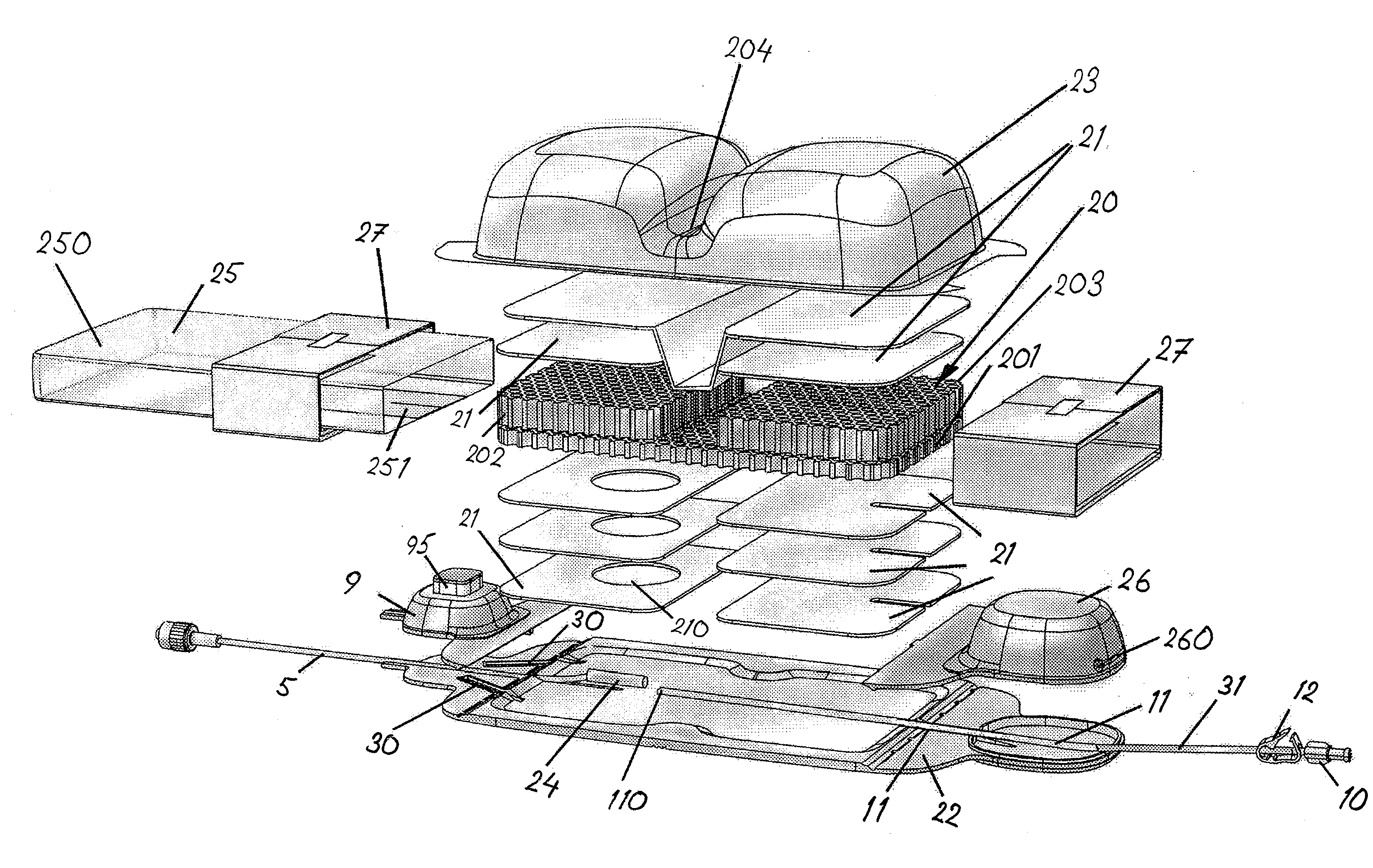

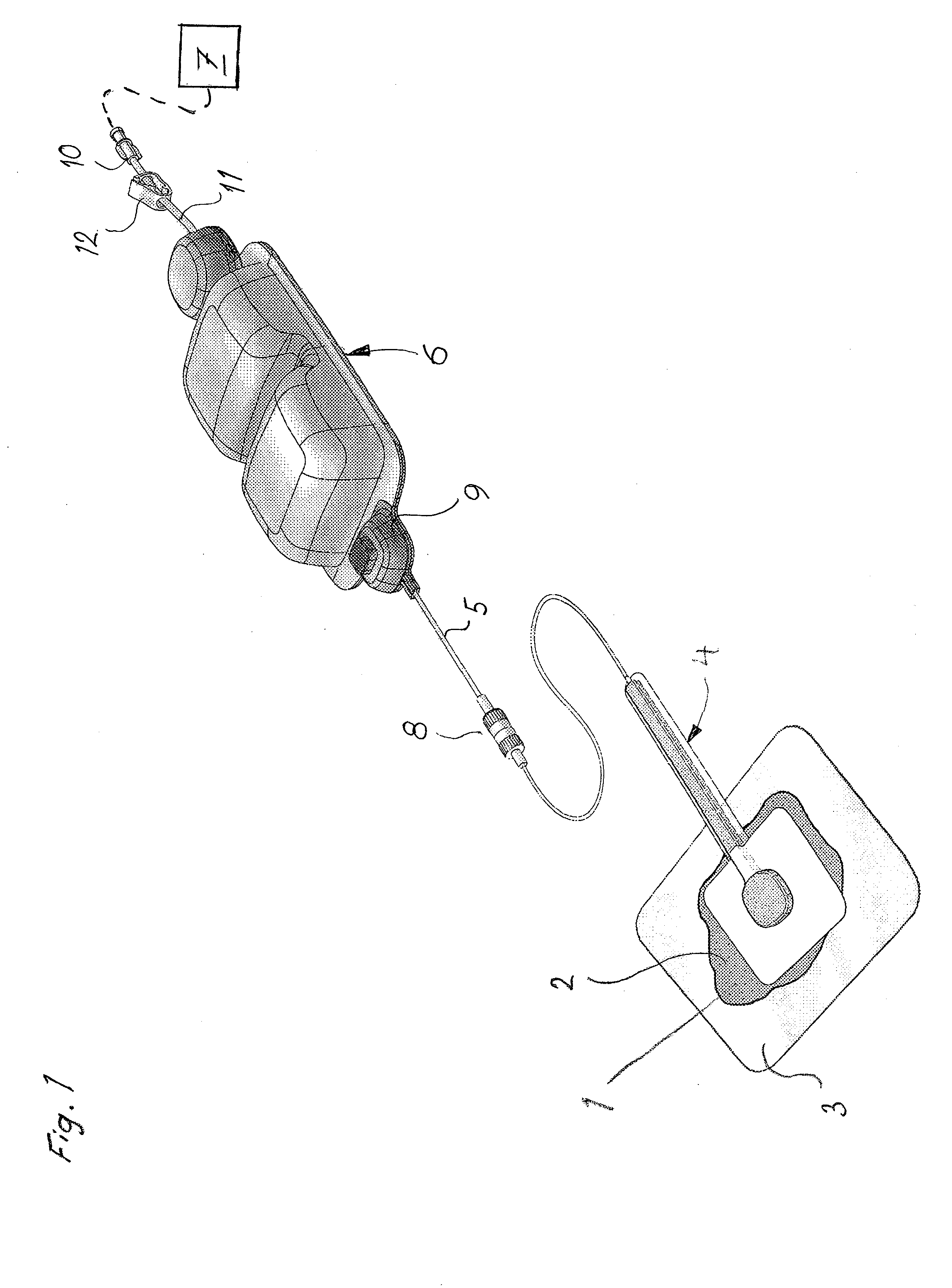

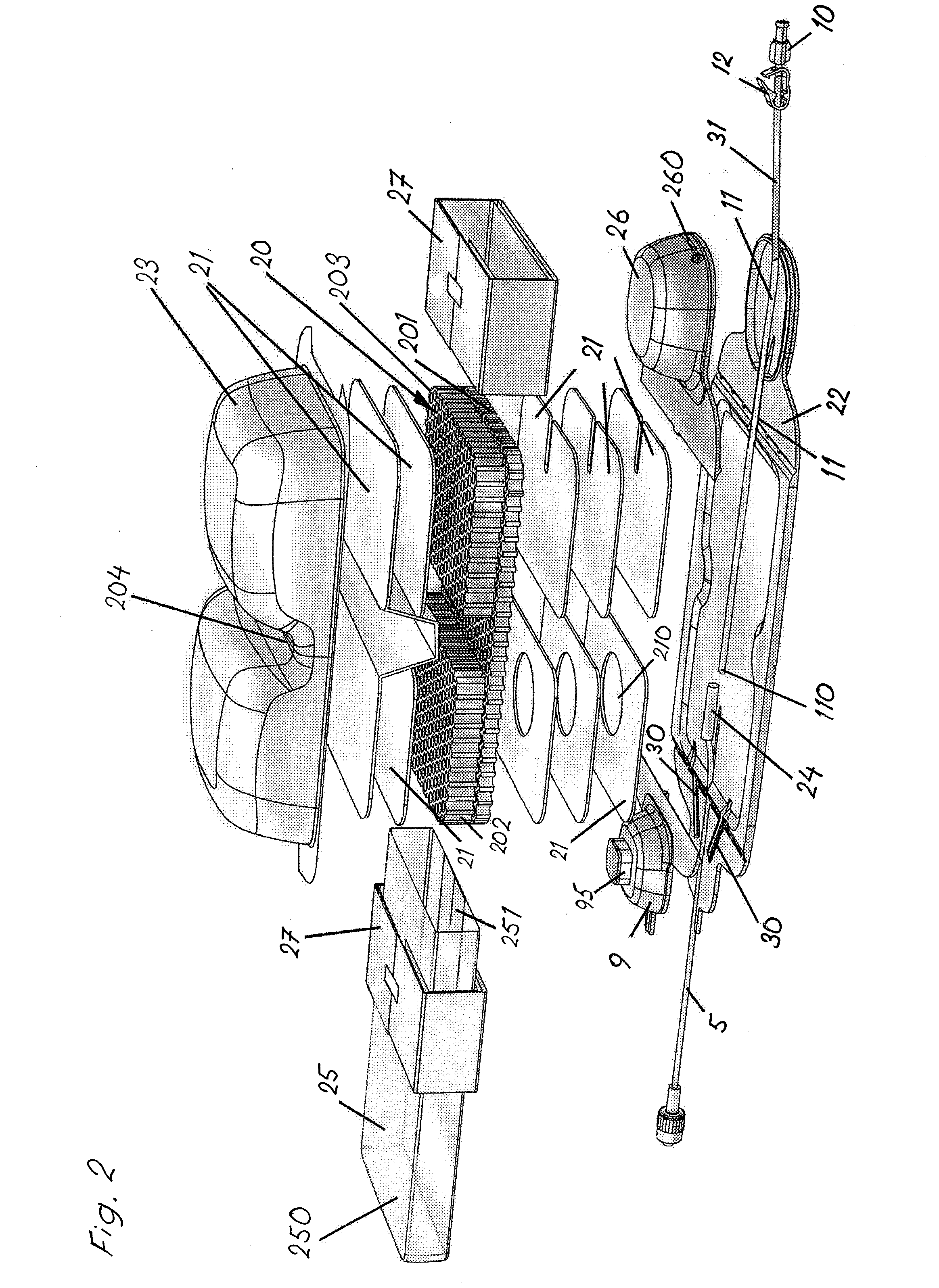

Device for treatment of wounds and a method for manufacturing of wound pads

ActiveUS20110028919A1Adjustable pressureExcellent impregnationElectrotherapyNon-adhesive dressingsSilicone GelsMedicine

A device for treatment of wounds using reduced pressure, said device comprisinga pumpa reservoir connected to said pump for collecting exudate from a wound (1),an inlet to the reservoir for connecting the reservoir with the wound so as to allow the pump to expose the wound to the reduced pressure, a wound pad to be arranged in the wound cavity and a sealing covering the wound and said wound pad.The wound pad consist of an open-cell polyurethane foam which is fully impregnated with a soft hydrophobic silicone gel, and that the foam has a hardness of 1.0-6.0 kPa measured according to ISO 3386-1 at 40% compression. The invention also concerns such a wound pad to be used with an absorbent member. In addition the invention concerns a method for manufacturing the wound pad.

Owner:MOLNLYCKE HEALTH CARE AB

Process for making a foam component

Process for making a foam component by obtaining a first and a second wet foam shape, then drying, partially or completely, the first foam shape and second foam shape and then superposing the dry or partially dry first and second foam shapes and attaching the first and second foam shapes to one another. The invention also provides foam components obtained by such a process.

Owner:THE PROCTER & GAMBLE COMPANY

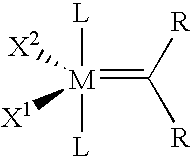

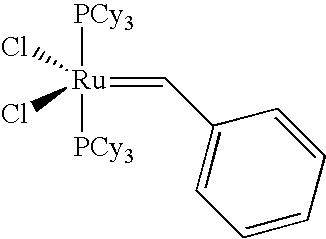

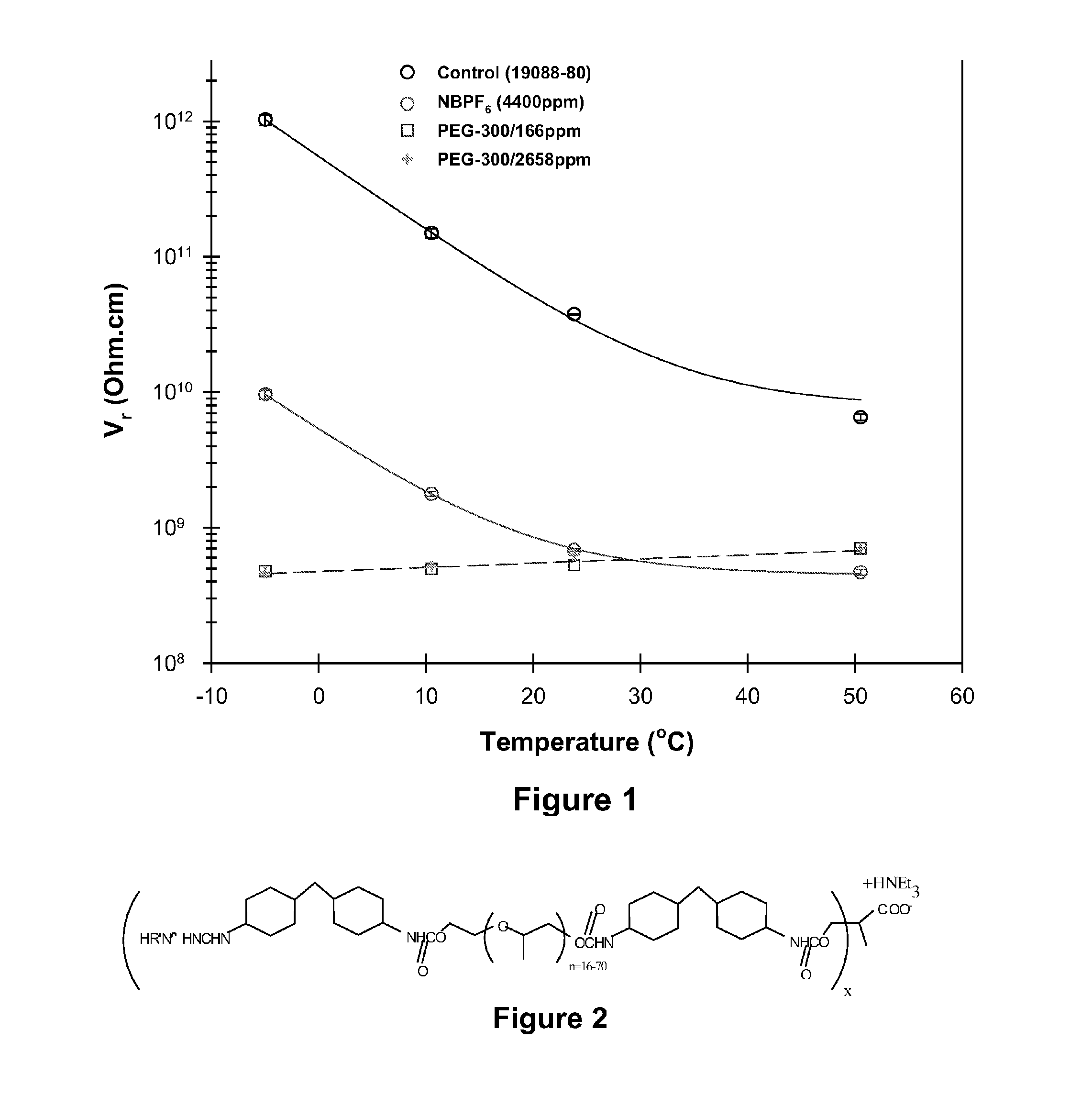

Catalyst systems and their use for metathesis reactions

ActiveUS20090069516A1Narrow molecular weight distributionReduce molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsAdhesive processes with surface pretreatmentNitrile rubberInorganic chemistry

Novel catalyst systems for metathesis reactions, in particular for the metathesis of nitrile rubber, which contain a specific salt additive in addition to the metathesis catalyst are provided.

Owner:ARLANXEO DEUT GMBH

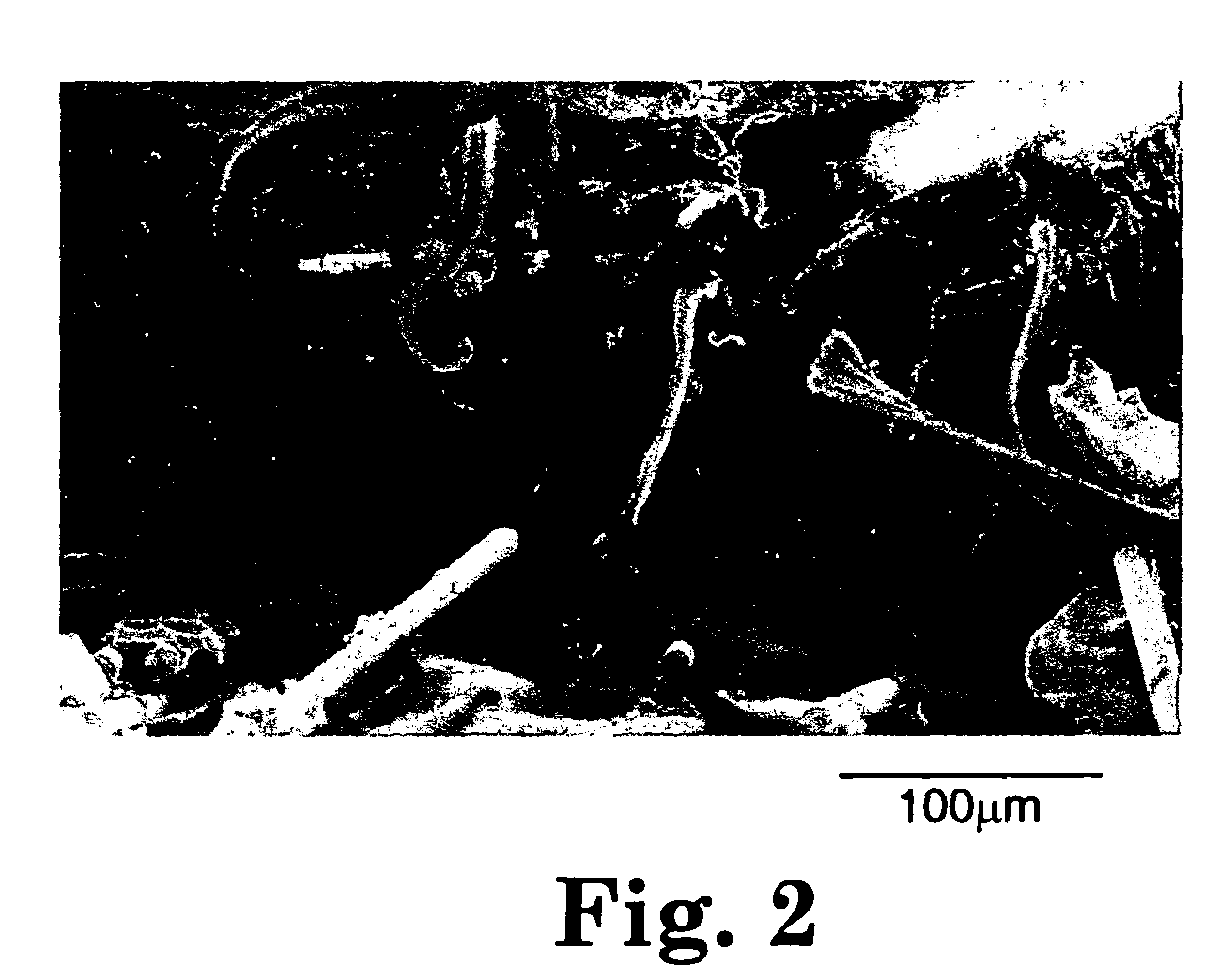

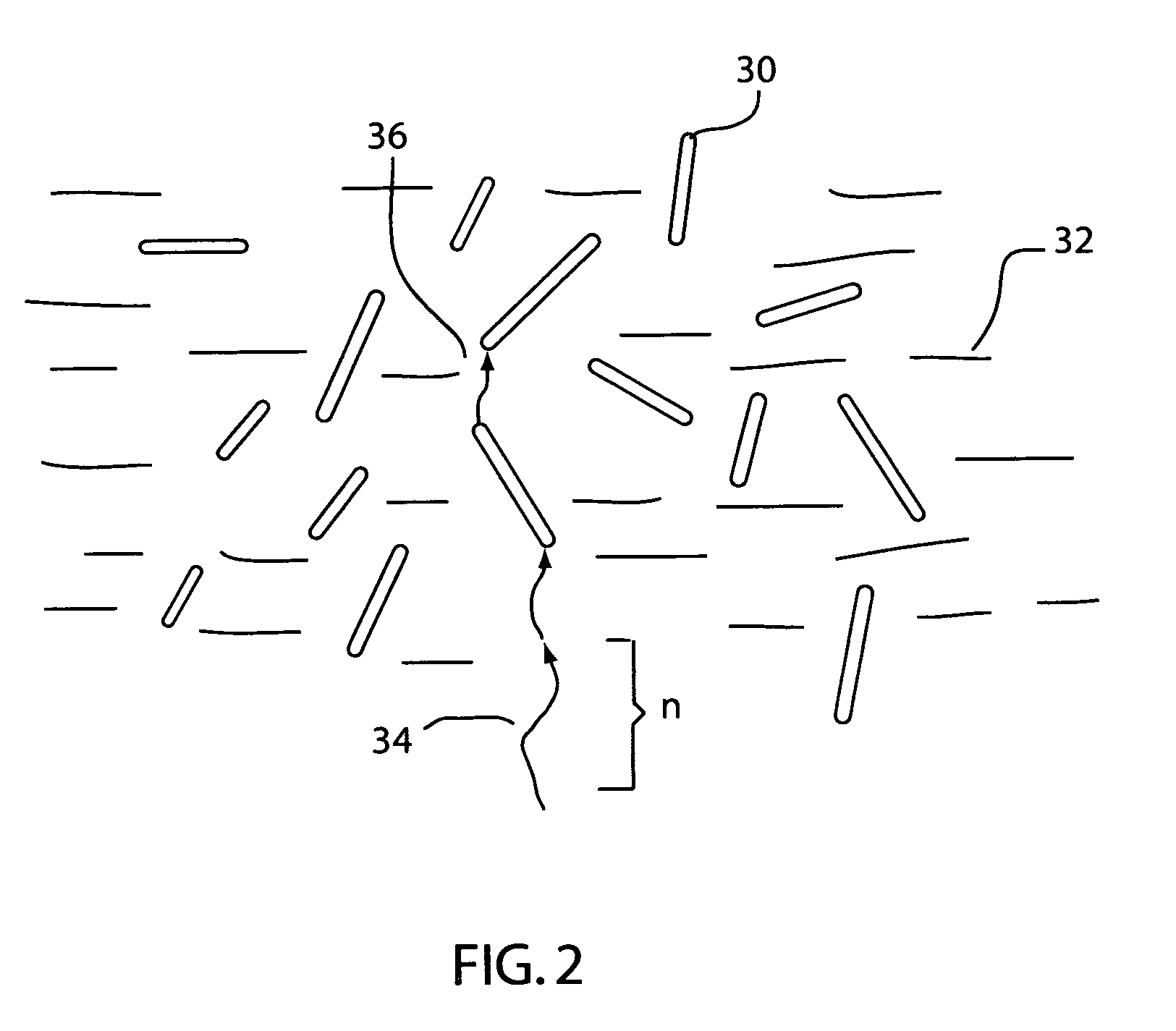

Composite articles reinforced with highly oriented microfibers

InactiveUS7014803B2Improve toughnessAdded strength and stiffnessFilament/thread formingWood working apparatusMaterial typePolymer science

A composite formed of a polymer matrix phase having a reinforcement phase including polymeric microfibers. The microfibers are preferably formed of a highly oriented polymer, having a high modulus value and a large surface area. The large surface area can serve to tightly bind the microfibers to the polymer matrix phase. The microfibers can be provided as a fully- or partially-microfibrillated film, as a non-woven web of entangled microfibers, or as a pulp having free fibers. The microfibers can be embedded in, or impregnated with, a polymer or polymer precursor. Some composite articles are formed from thermoset resins cured about a highly oriented polypropylene microfiber reinforcement phase, providing a strong, tough, moisture resistant article. One composite includes a matrix and reinforcement formed of the same material type and having substantially equal refractive indices, allowing the composite to be optically clear.

Owner:3M INNOVATIVE PROPERTIES CO

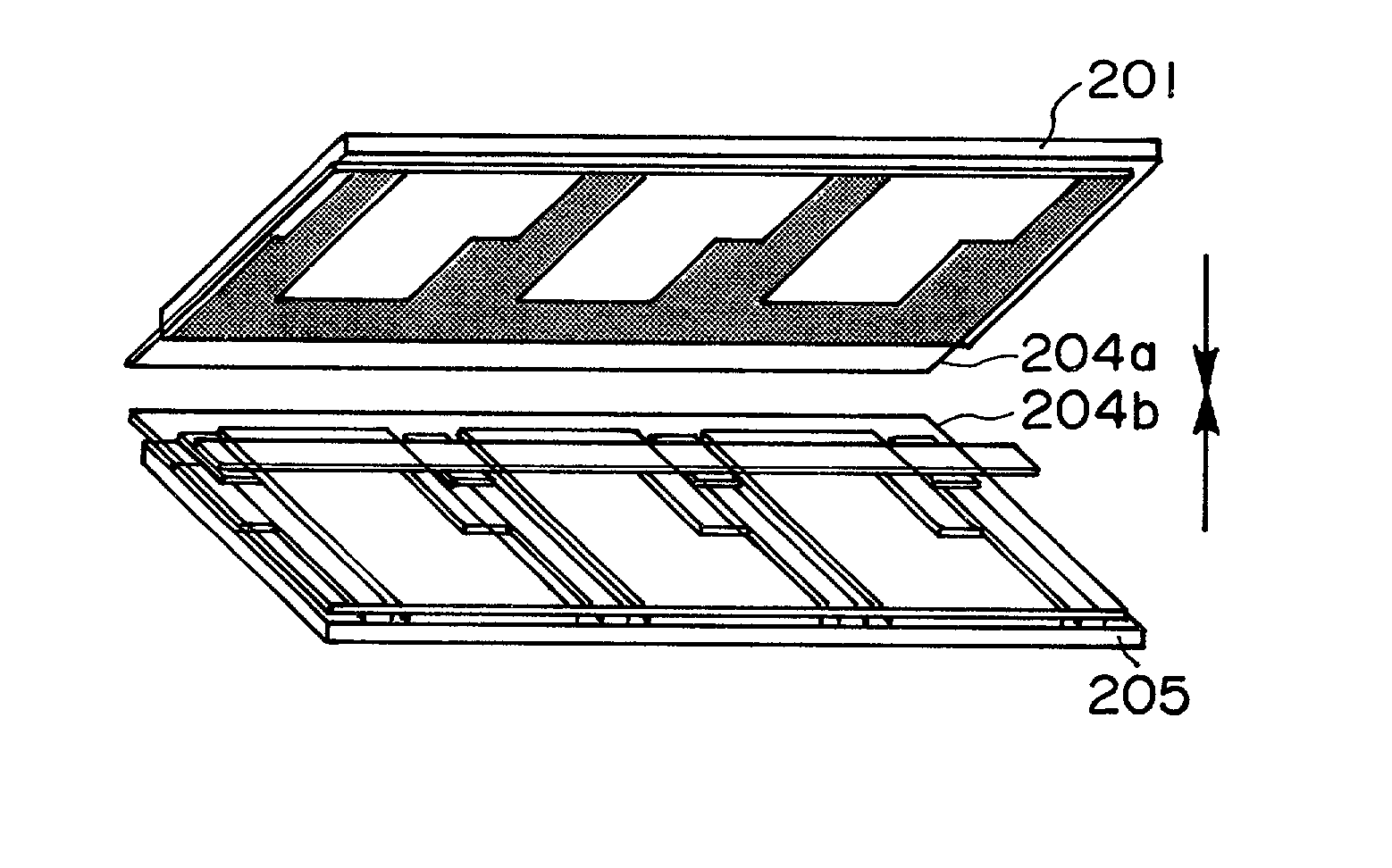

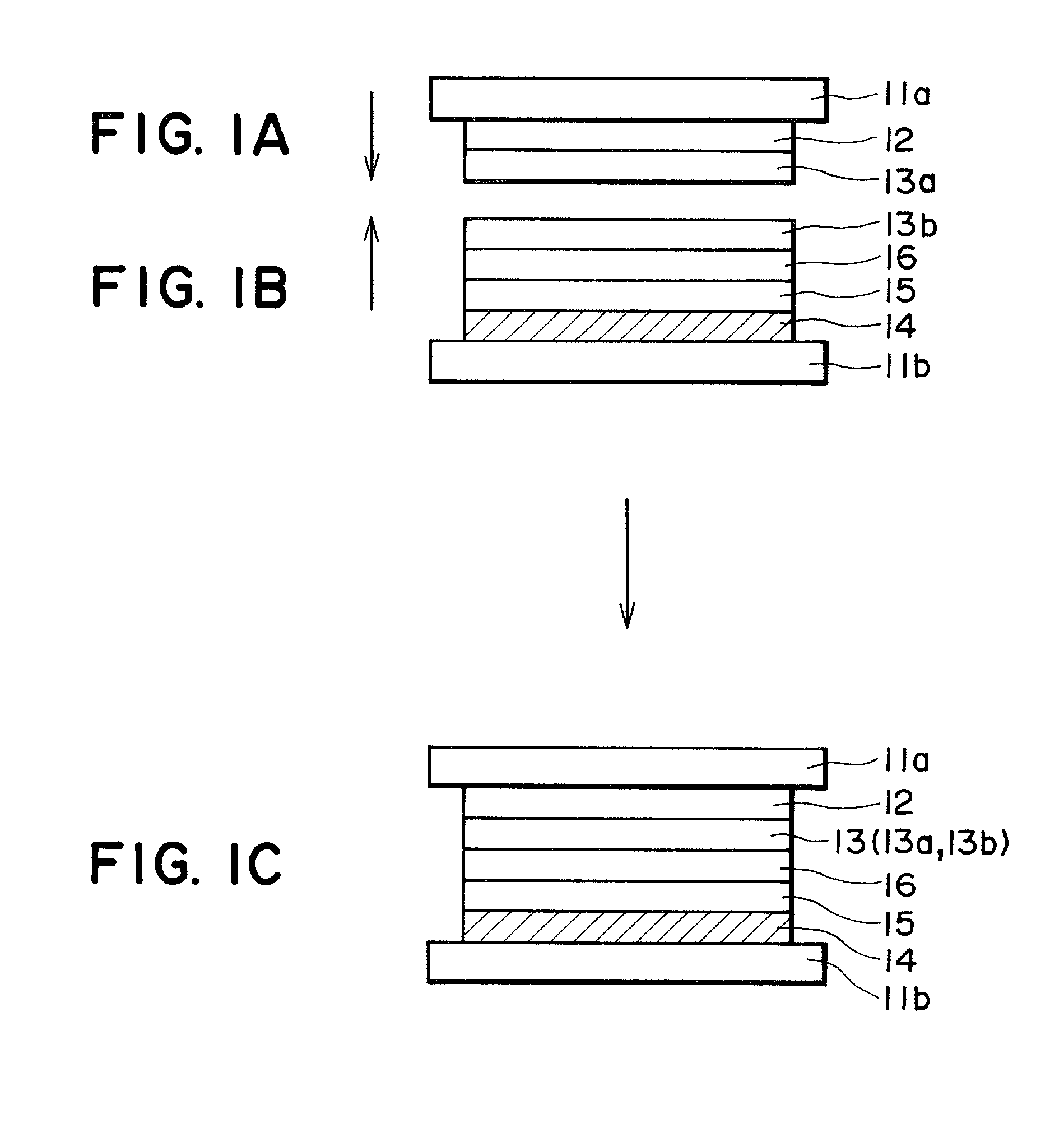

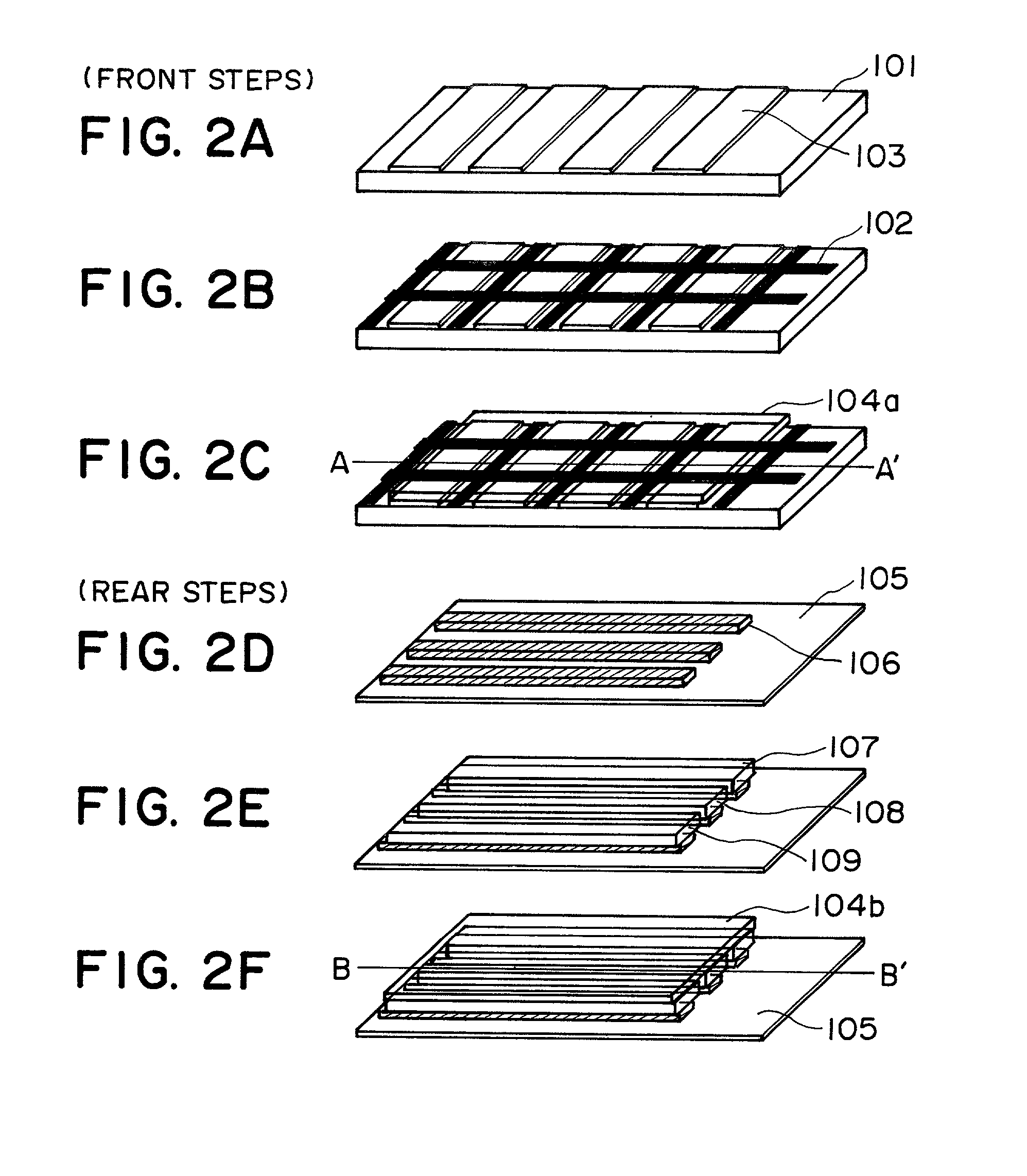

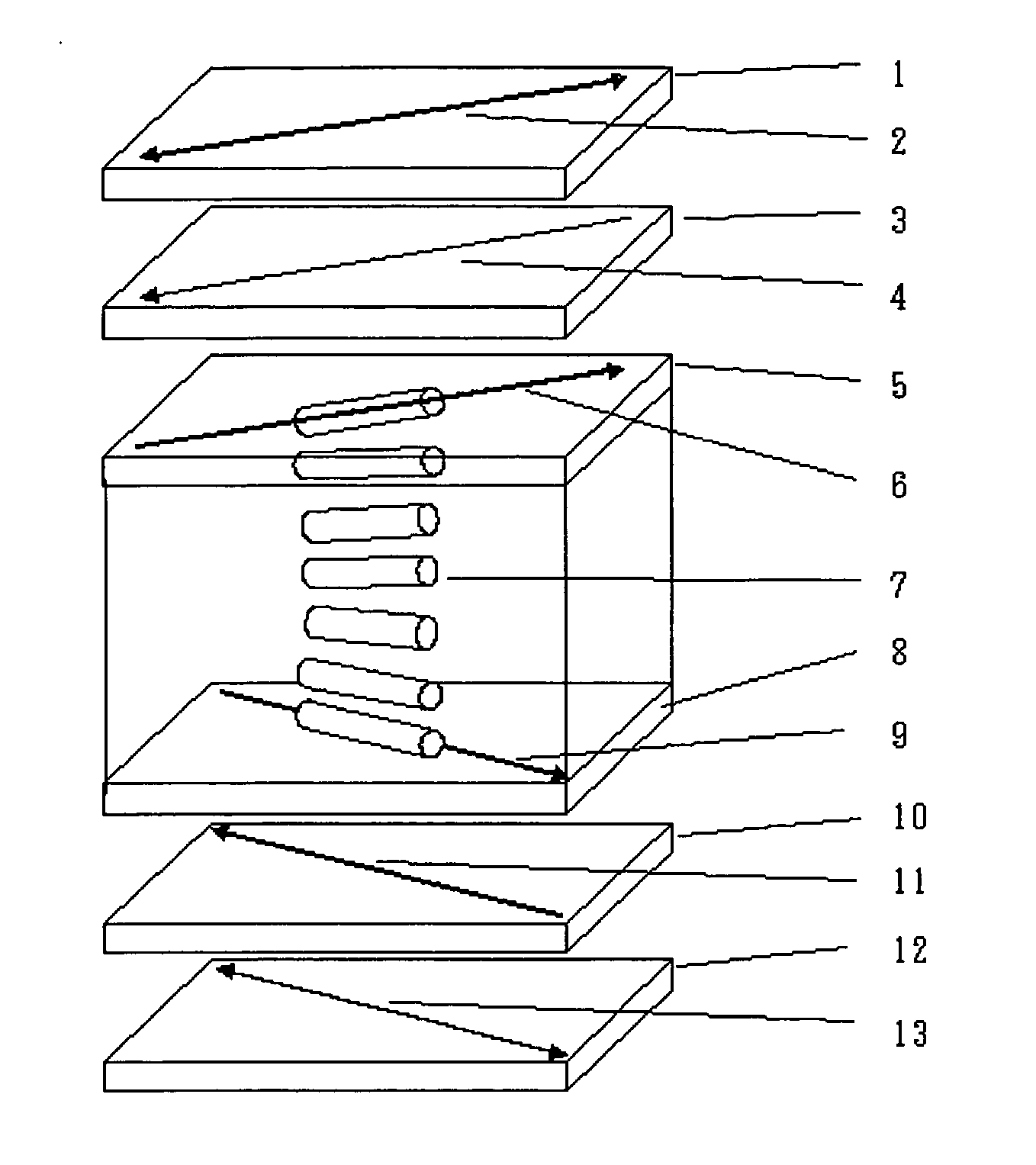

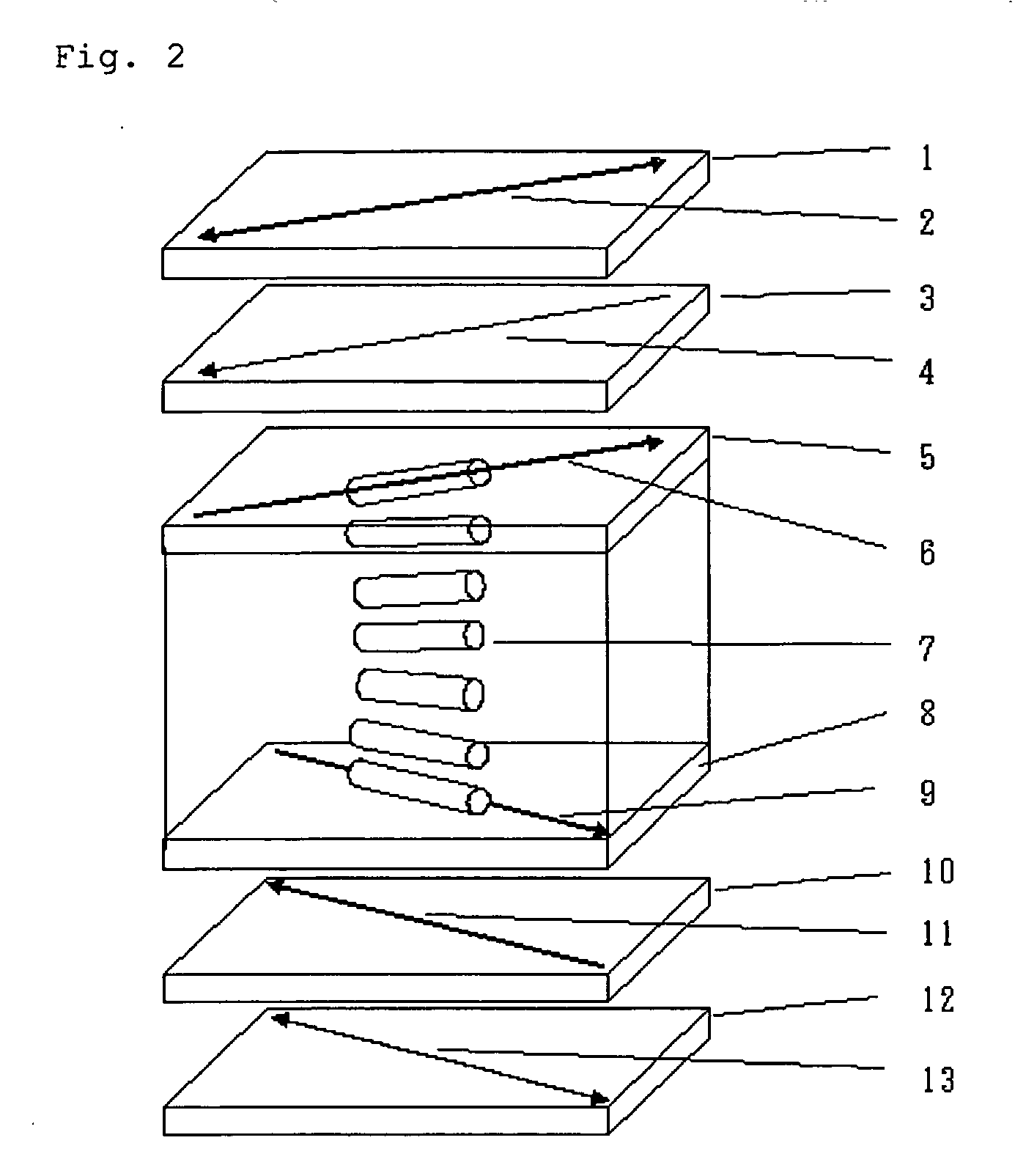

Organic luminescence display device and process for production thereof

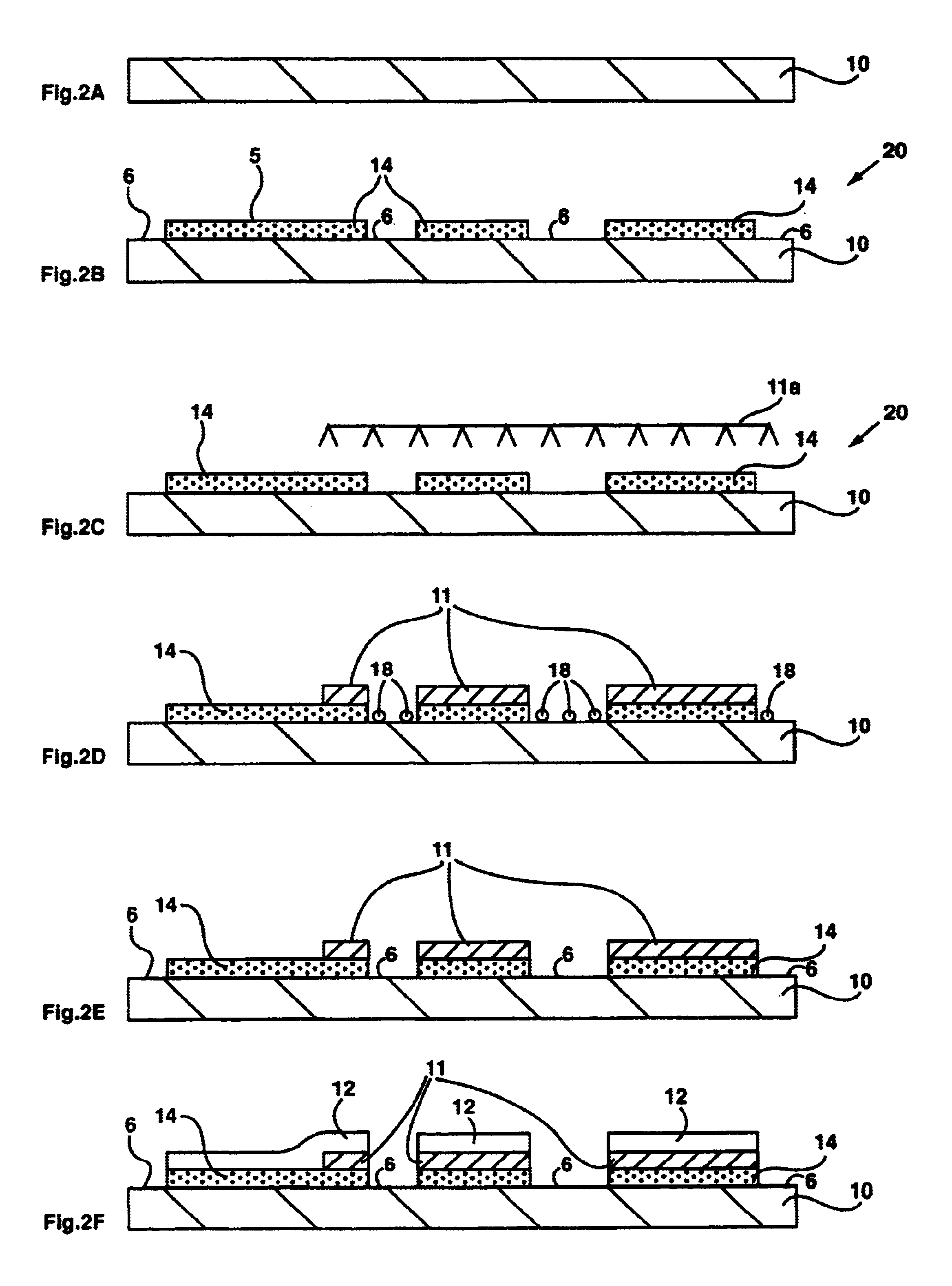

InactiveUS20020053401A1Electroluminescent light sourcesAdhesive processes with surface pretreatmentOrganic light emitting deviceOrganic layer

An organic luminescence device including organic layers disposed between an anode and a cathode is produced through a process including: a step of forming a first organic layer over an anode already formed on a first substrate; a step of forming a second organic layer comprising an identical material forming the first organic layer over a cathode already formed on a second substrate; and a combining step of disposing the first and second organic layers opposite to each other and applying the first and second organic layer to each other under pressure, followed by baking, to form a laminate organic luminescence device. A step of pre-baking at least one of the first and second organic layers is preferably included prior to the combining step. As a result, the organic layers in the luminescence device can be formed free from binders and yet in a good adhesion therebetween.

Owner:CANON KK

Method for direct attachment of a chip to a cooling member

InactiveUS6413353B2High bonding strengthAdequate flowSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentHeat flowSilanes

A semiconductor chip module uses a silicone adhesive between the semiconductor chip and a cap, said adhesive having sufficient bond strength to secure said cap to said chip without additional mechanical constraint while providing a direct thermally conductive path and permitting sufficient heat flow from said chip to said cap to maintain steady state operation of said semiconductor chip. The preferred silicone adhesive comprises a primerless, two-part polysiloxane-based adhesive made by reacting polydimethyl siloxane, an organosilicon compound, a polysiloxane, and a silane, in the presence of a catalyst.

Owner:IBM CORP

Gas diffusion electrode manufacture and MEA fabrication

InactiveUS20020134501A1Final product manufactureAdhesive processes with surface pretreatmentTetrafluoroethyleneEmulsion

A method for producing a gas diffusion electrode in which a slurry of carbon black, alcohol, water and a tetrafluoroethylene emulsion is applied as a layer a non-Teflonized carbon cloth substrate, which is then heated to remove water. The dried coated carbon cloth is then rolled followed by heating to remove wetting agents present in the tetrafluoroethylene emulsion. The coated carbon cloth is then cooled and rolled again to produce the final end product.

Owner:GAS TECH INST

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

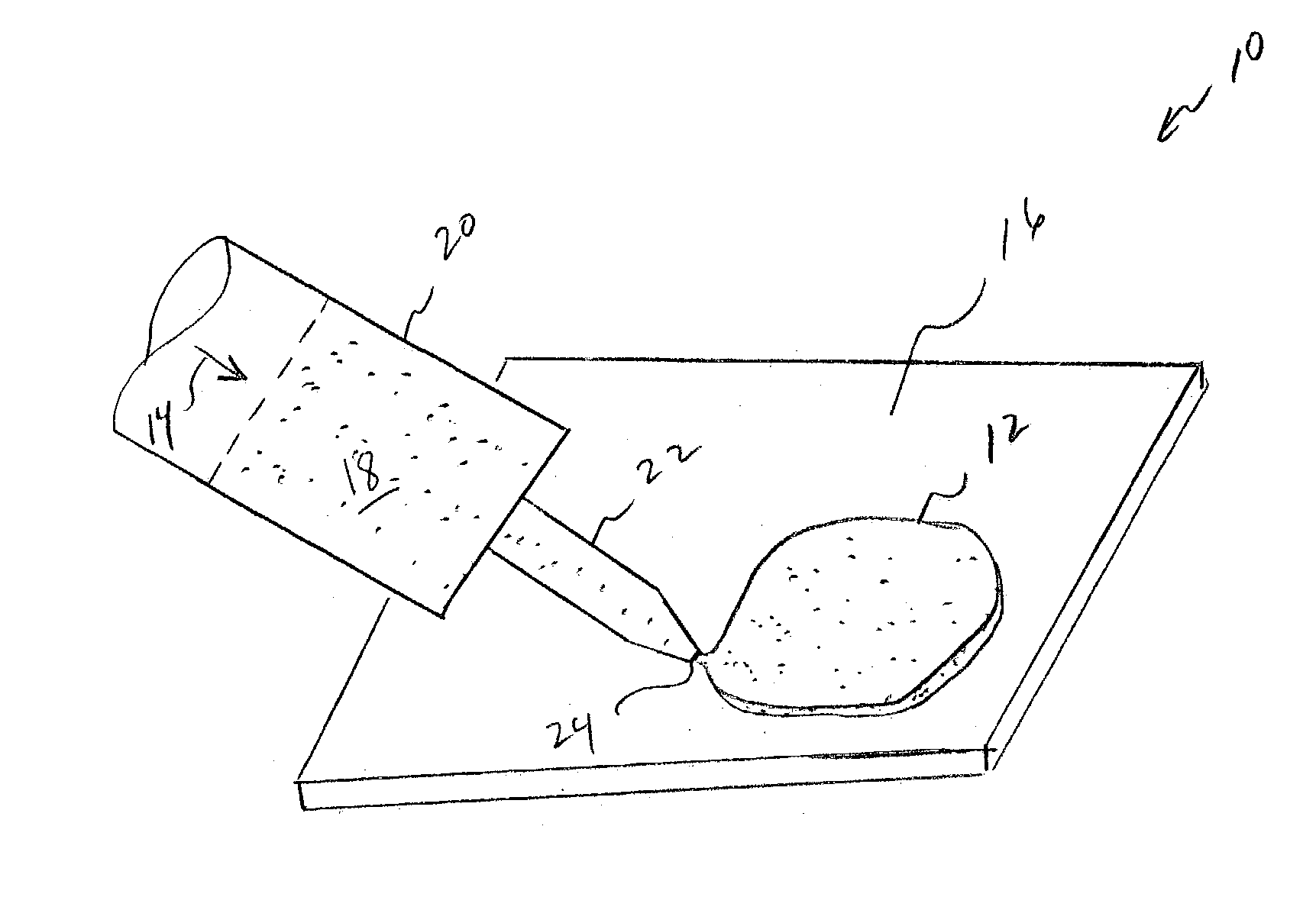

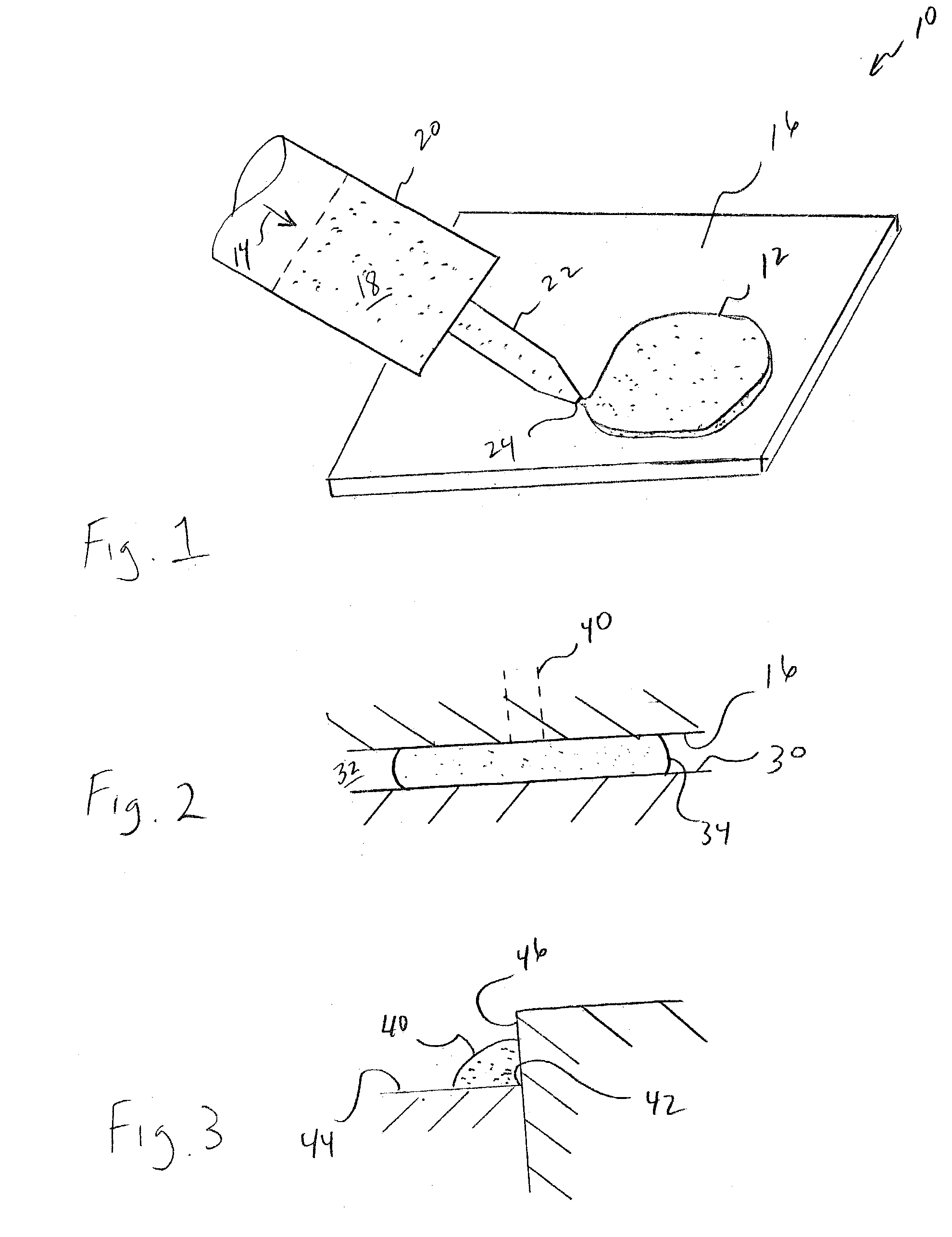

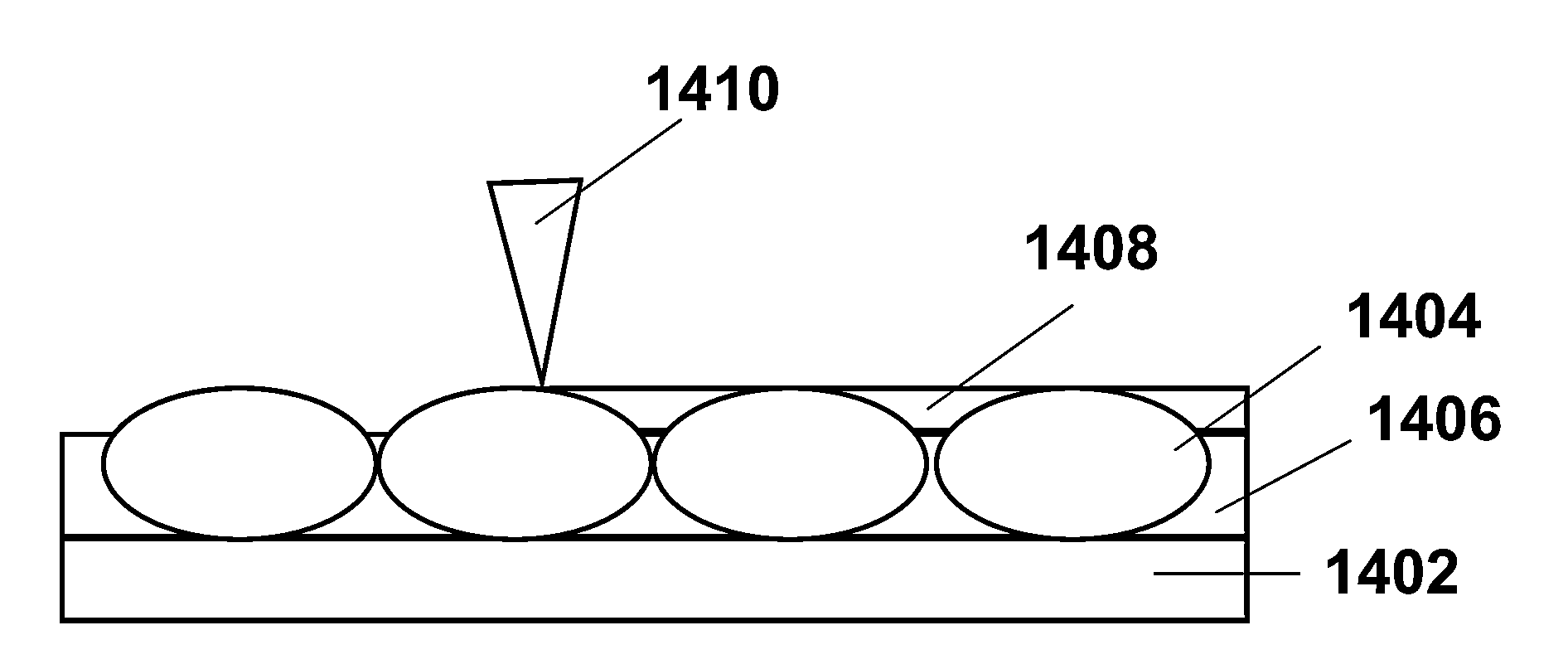

Thermally or electrically-conductive form-in-place gap filter

ActiveUS7208192B2Magnetic/electric field screeningSemiconductor/solid-state device detailsParticulatesEngineering

Application of a thermally and / or electrically conductive compound to fill a thermal and / or EMI shielding gap between a first and a second surface. A supply of a fluent, form-stable compound is provided as an admixture of a cured polymer gel component, and a particulate filler component. An of the compound is dispensed from a nozzle or other orifice under an applied pressure onto one of the surfaces which, when opposed, form the gap, or into the gap formed between the surfaces. The gap is at least partially filled by at least a portion of the dispensed compound.

Owner:PARKER INTANGIBLES LLC

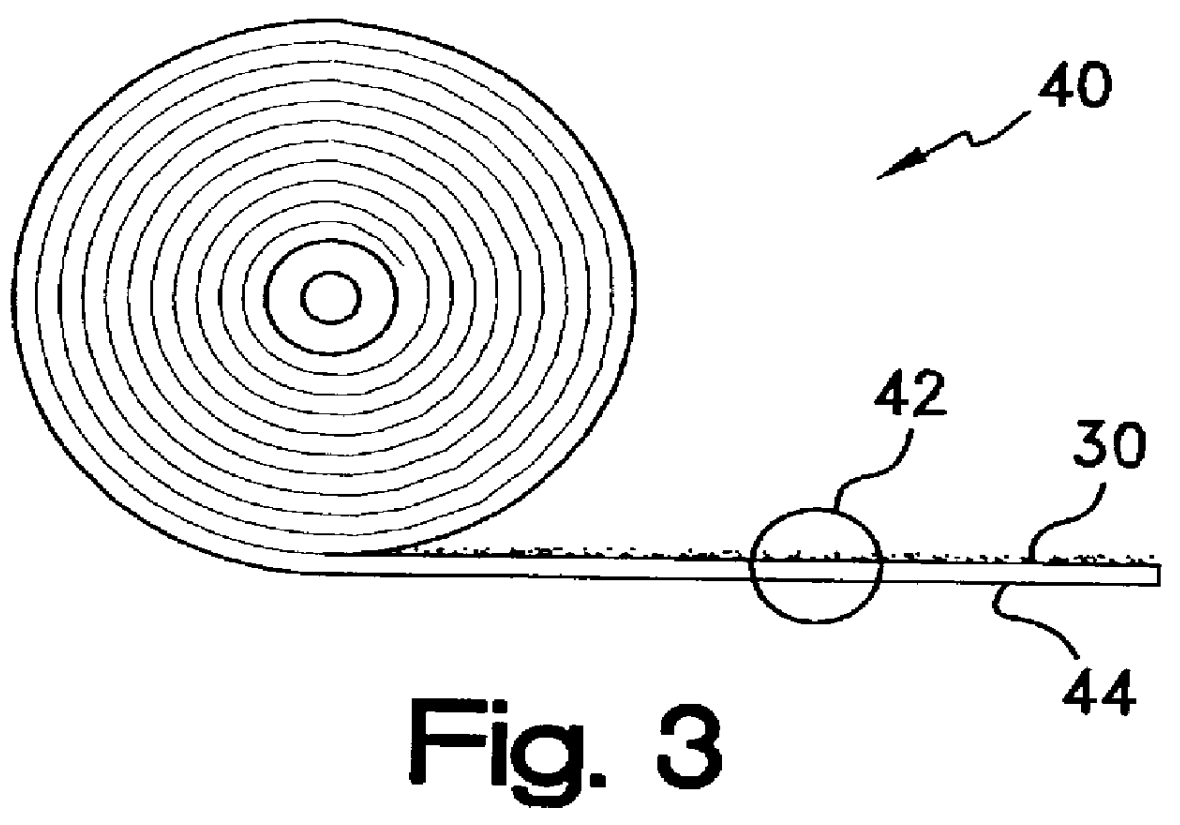

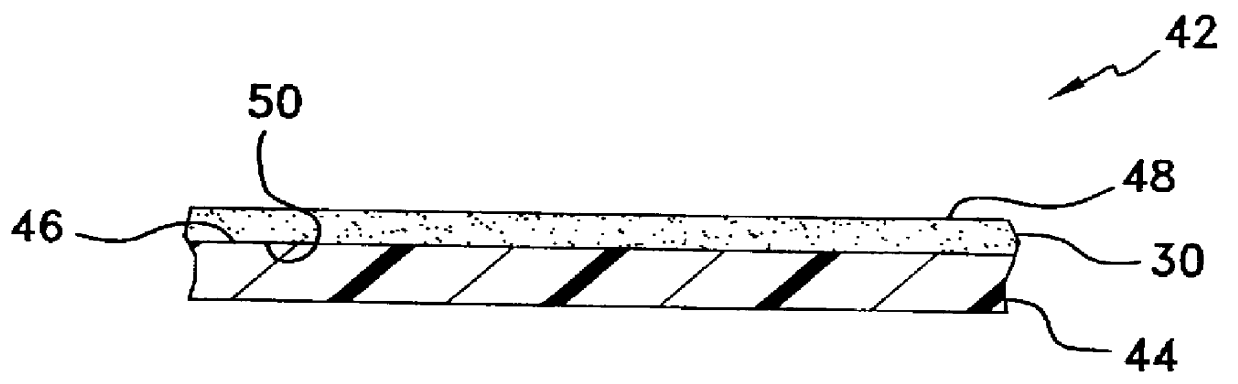

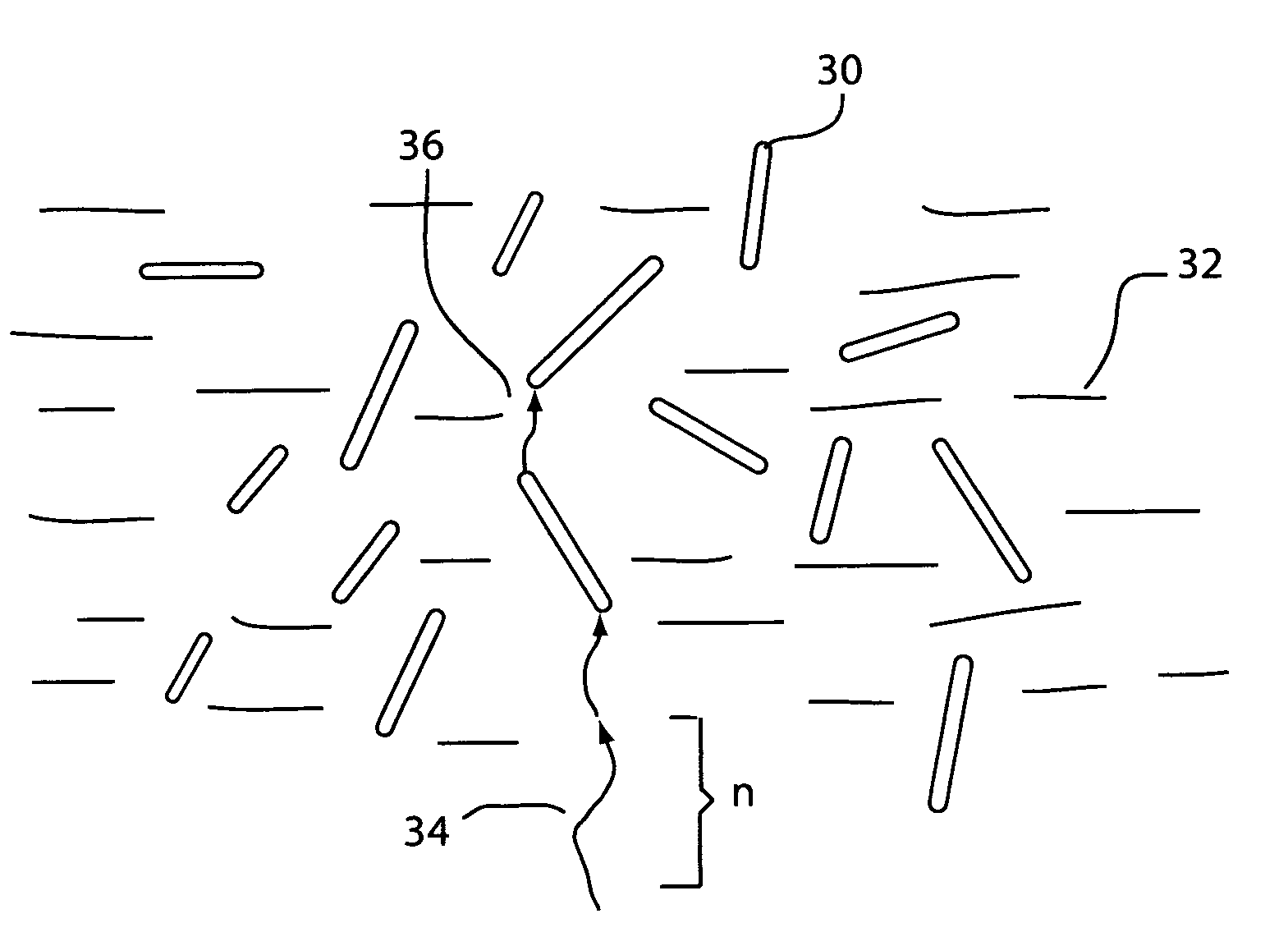

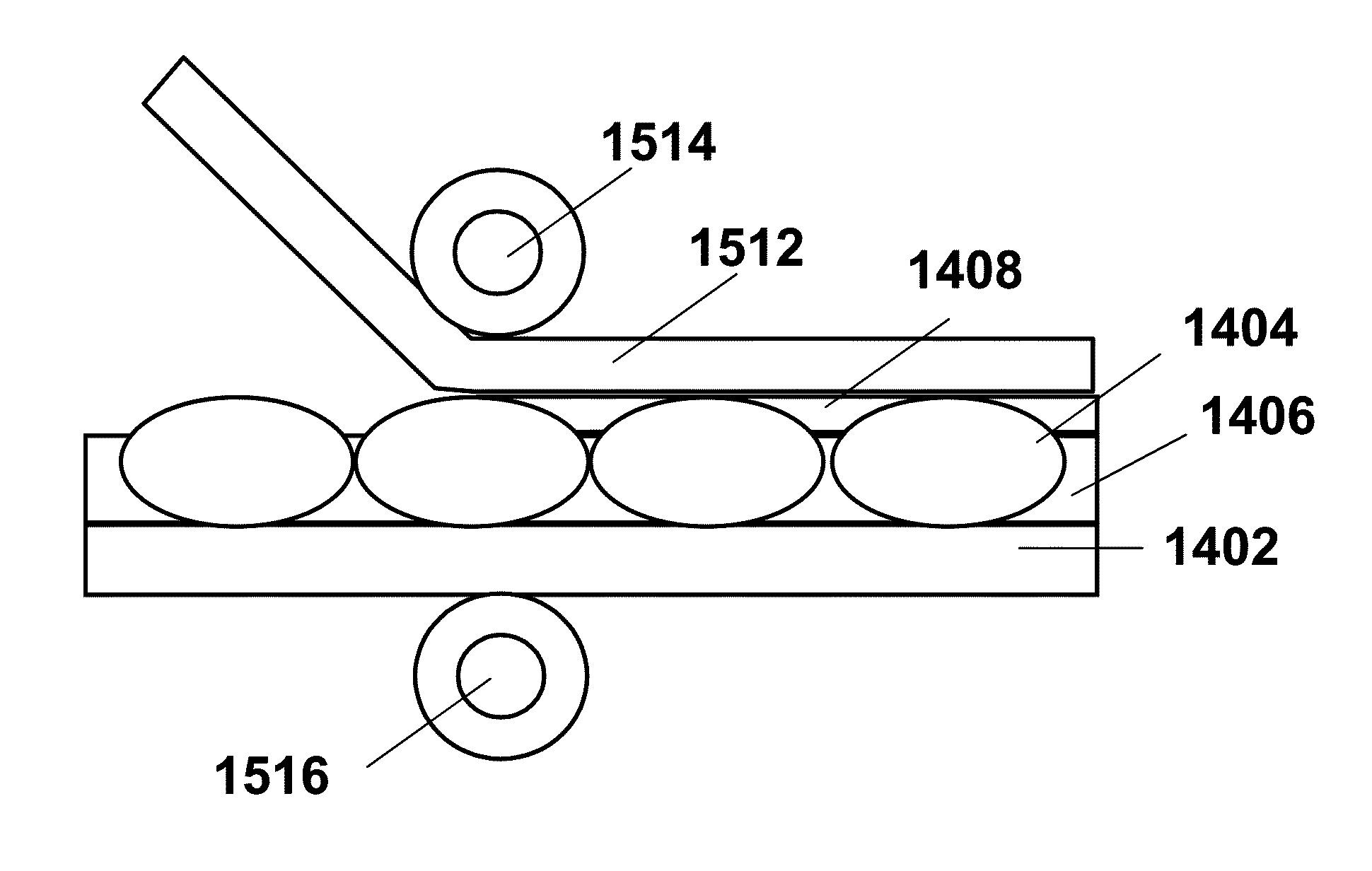

Compression of resin impregnated insulating tapes

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

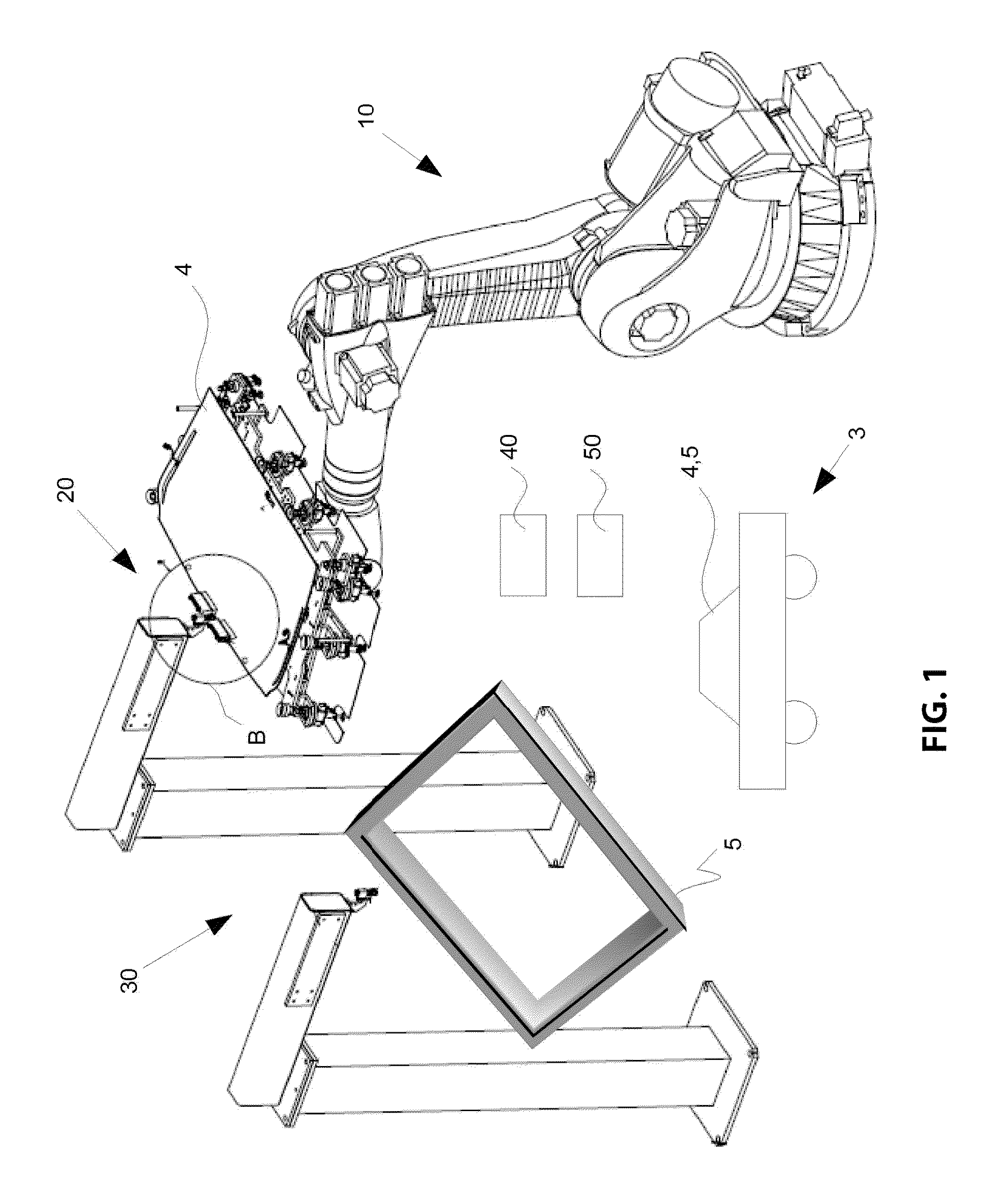

Joining surface treatment device and method

ActiveUS8678060B2Avoid heatingEnergy of of minimizedLamination ancillary operationsManual label dispensersBiomedical engineering

Owner:FFT PRODIONSSYST

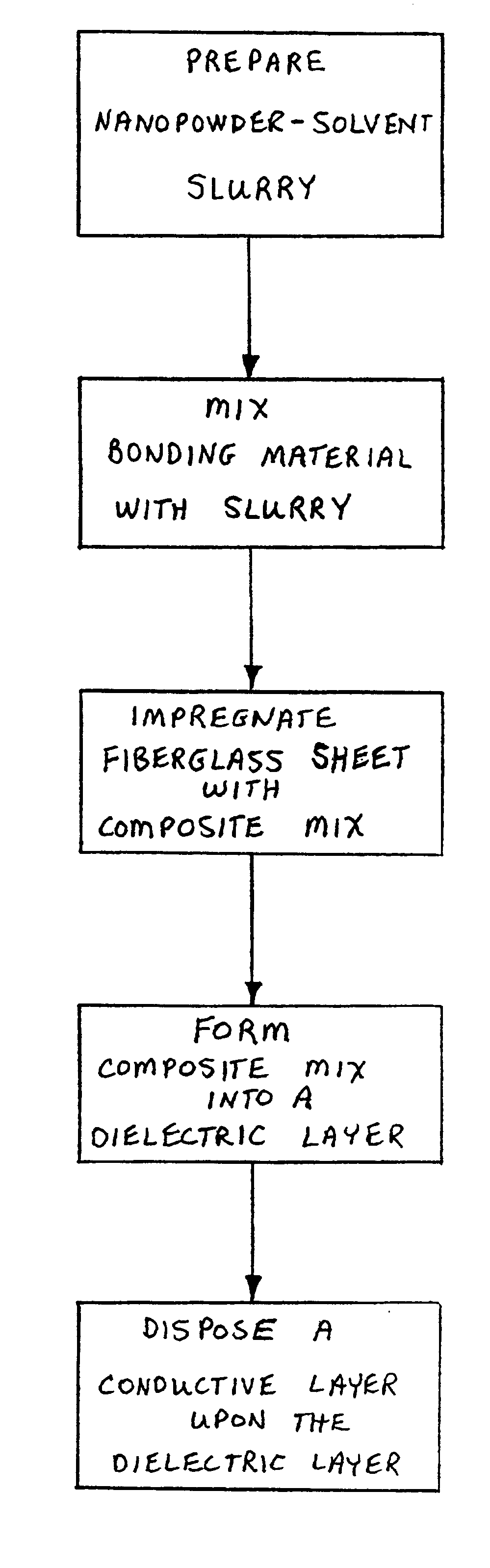

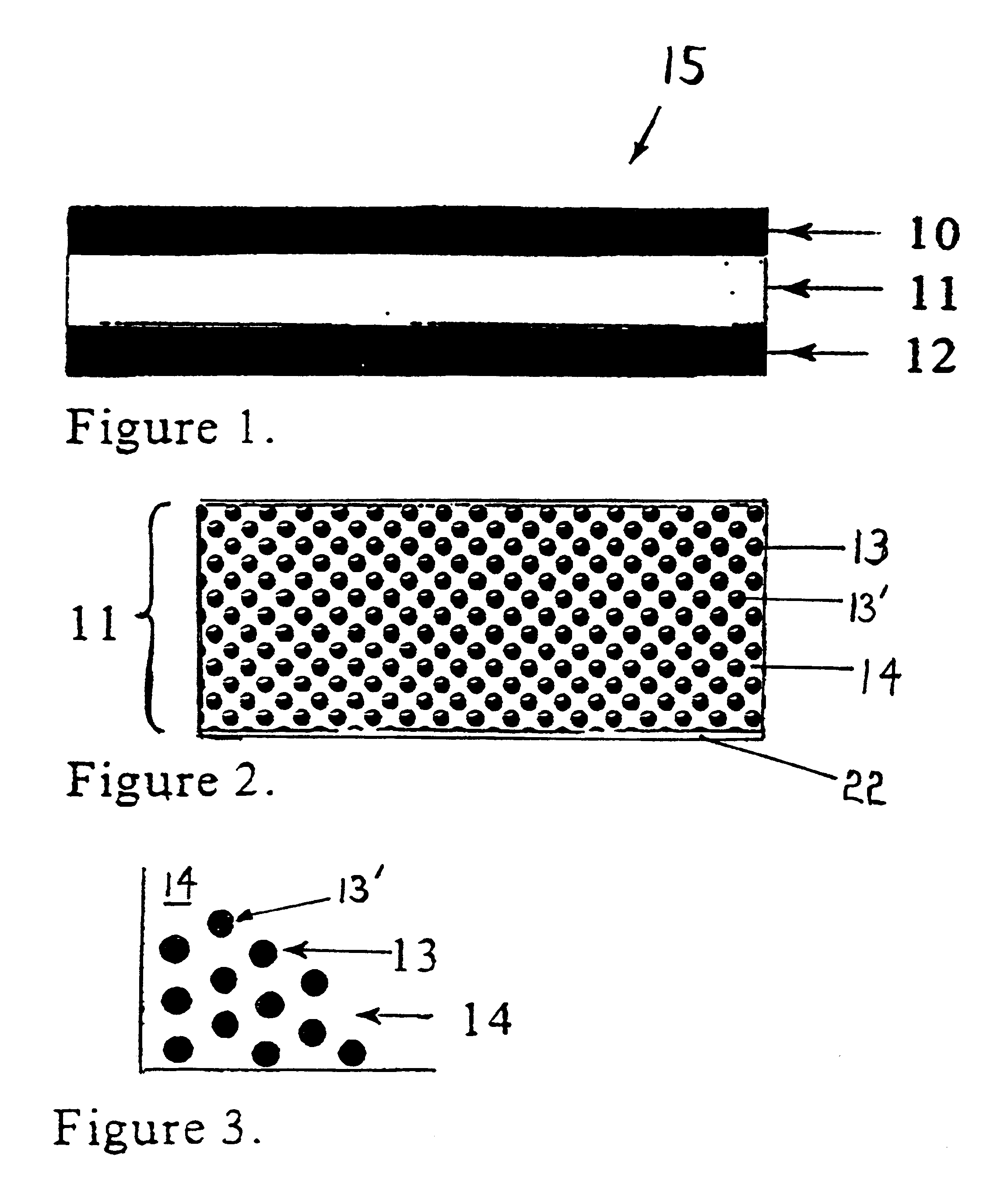

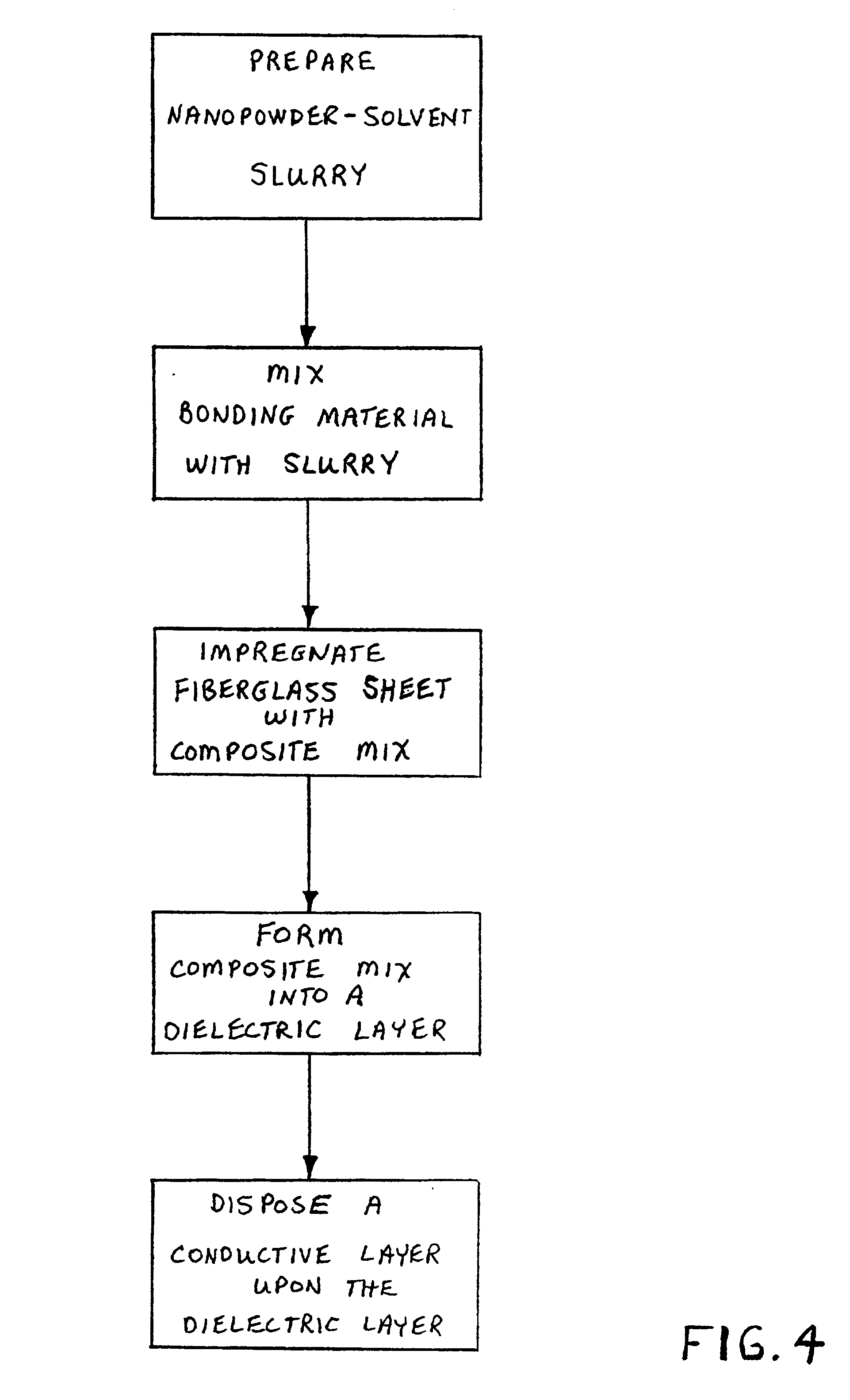

Integral capacitance for printed circuit board using dielectric nanopowders

InactiveUS6616794B2Adhesive processes with surface pretreatmentPrinted circuit aspectsCapacitanceSputtering

A method for producing integral capacitance components for inclusion within printed circuit boards. Hydrothermally prepared nanopowders permit the fabrication of a very thin dielectric layers that offer increased dielectric constants and are readily penetrated by microvias. Disclosed is a method of preparing a slurry or suspension of a hydrothermally prepared nanopowder and solvent. A suitable bonding material, such as a polymer is mixed with the nanopowder slurry, to generate a composite mixture which is formed into a dielectric layer. The dielectric layer may be placed upon a conductive layer prior to curing, or conductive layers may be applied upon a cured dielectric layer, either by lamination or by metallization processes, such as vapor deposition or sputtering.

Owner:TPL INC

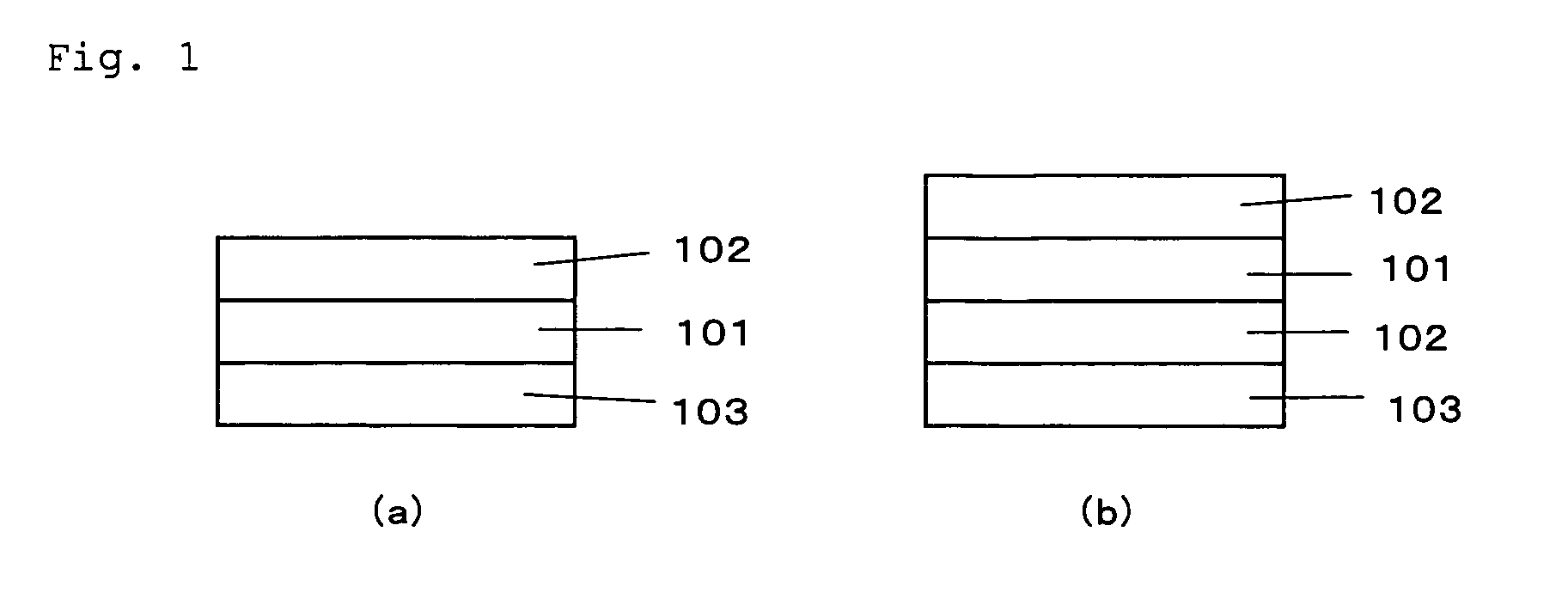

Polarizing plate and production process of the same

InactiveUS20050243245A1Improve adhesionStable productionNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentTectorial membranePolyvinyl alcohol

A novel polarizing plate is disclosed. The polarizing plate comprises a polyvinyl alcohol based polarizer, a protective film comprising a saturated alicyclic structure-containing thermoplastic polymer, and an adhesive layer comprising a water-soluble polymer between the protective film and the polarizer wherein the surface of the protective film contacting with the adhesive layer is subjected to a surface treatment.

Owner:FUJIFILM CORP

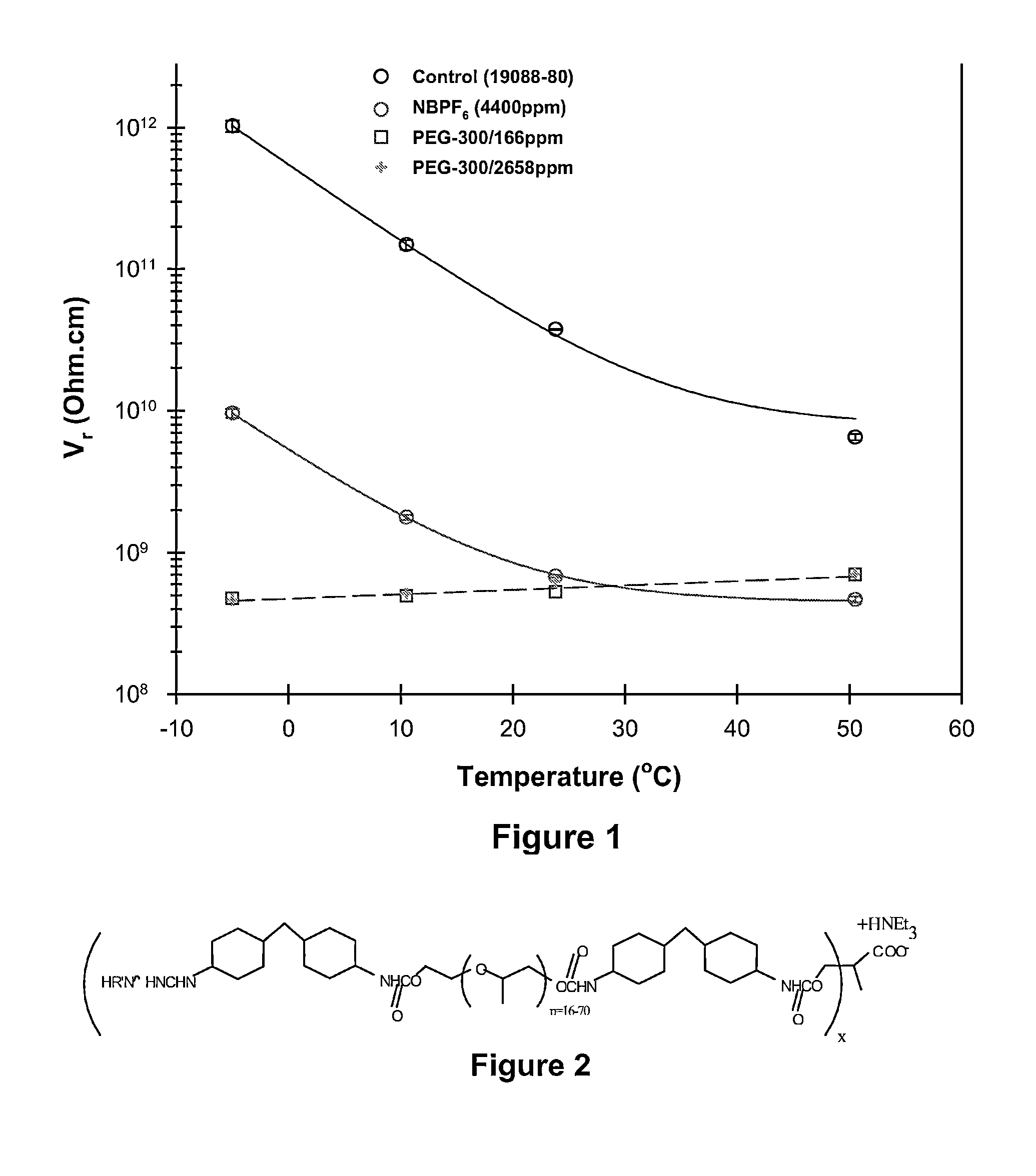

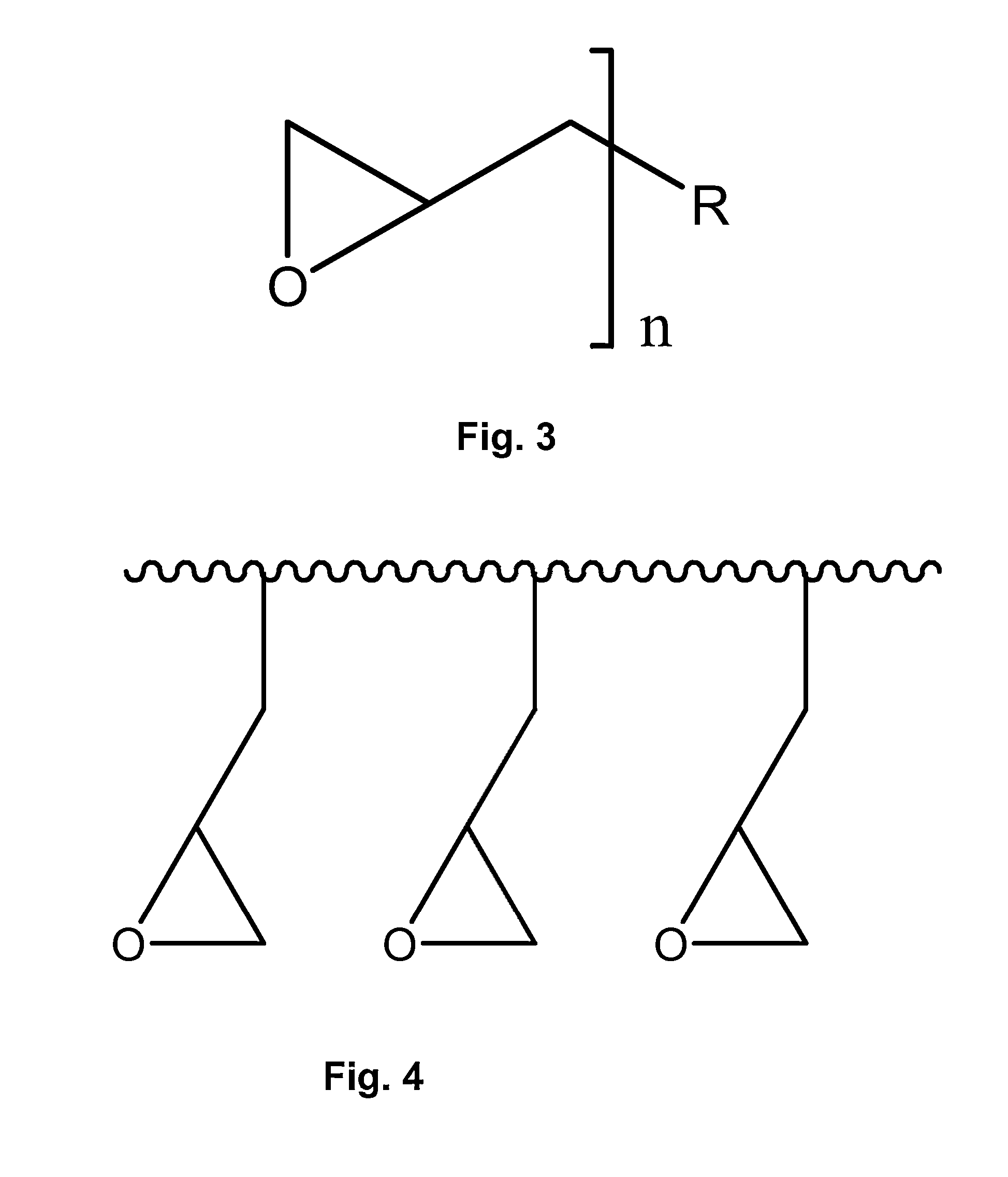

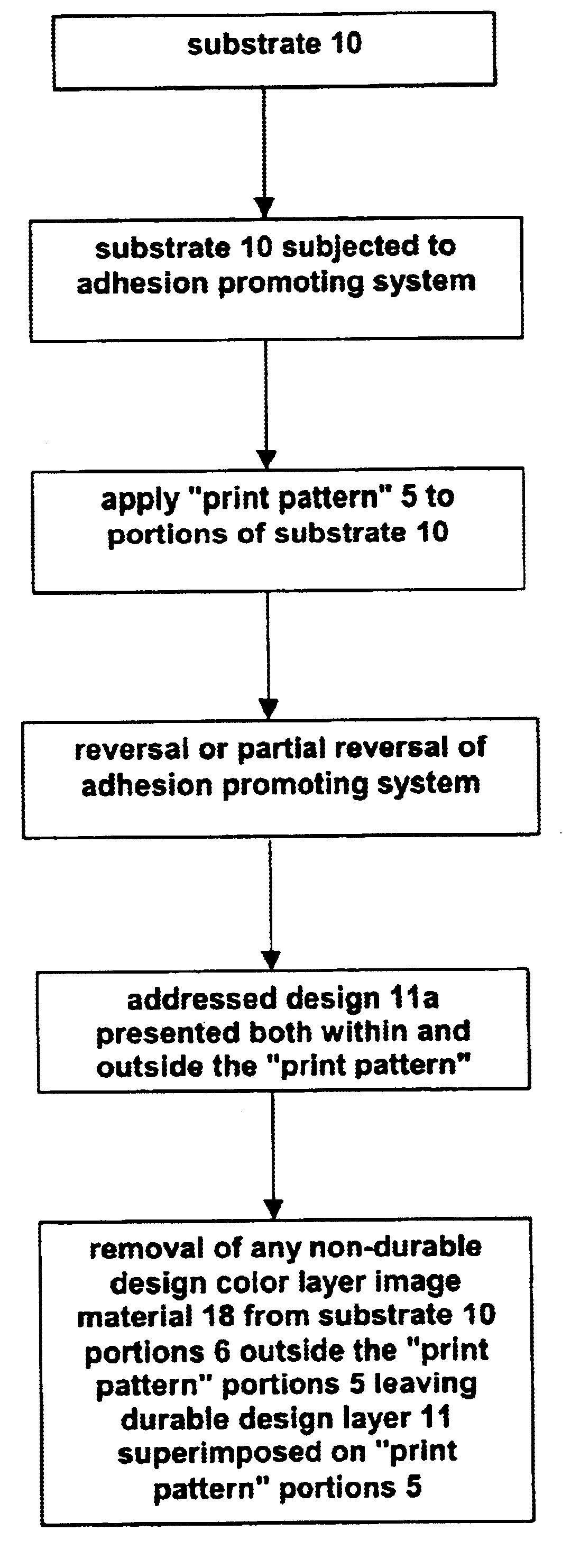

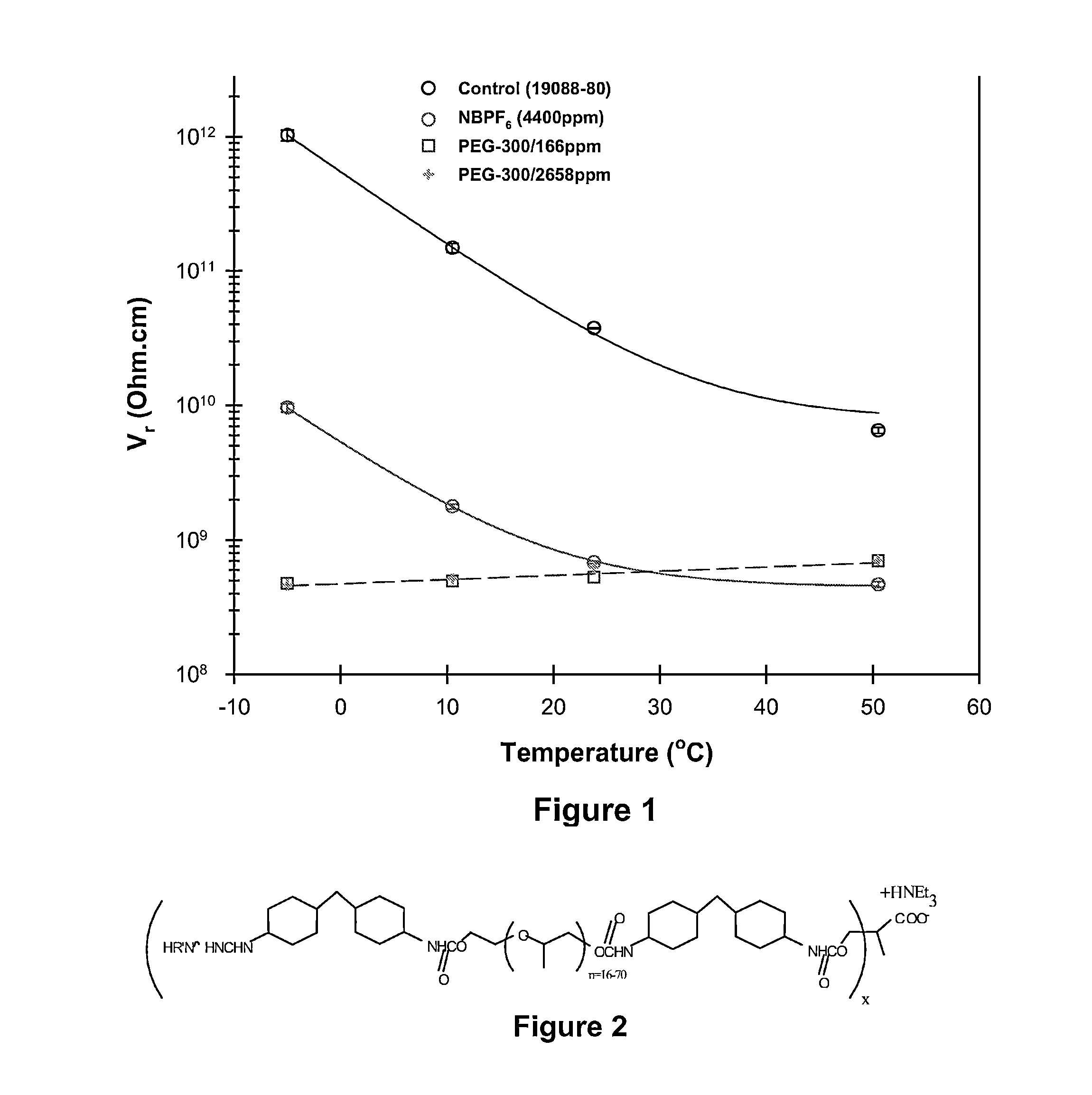

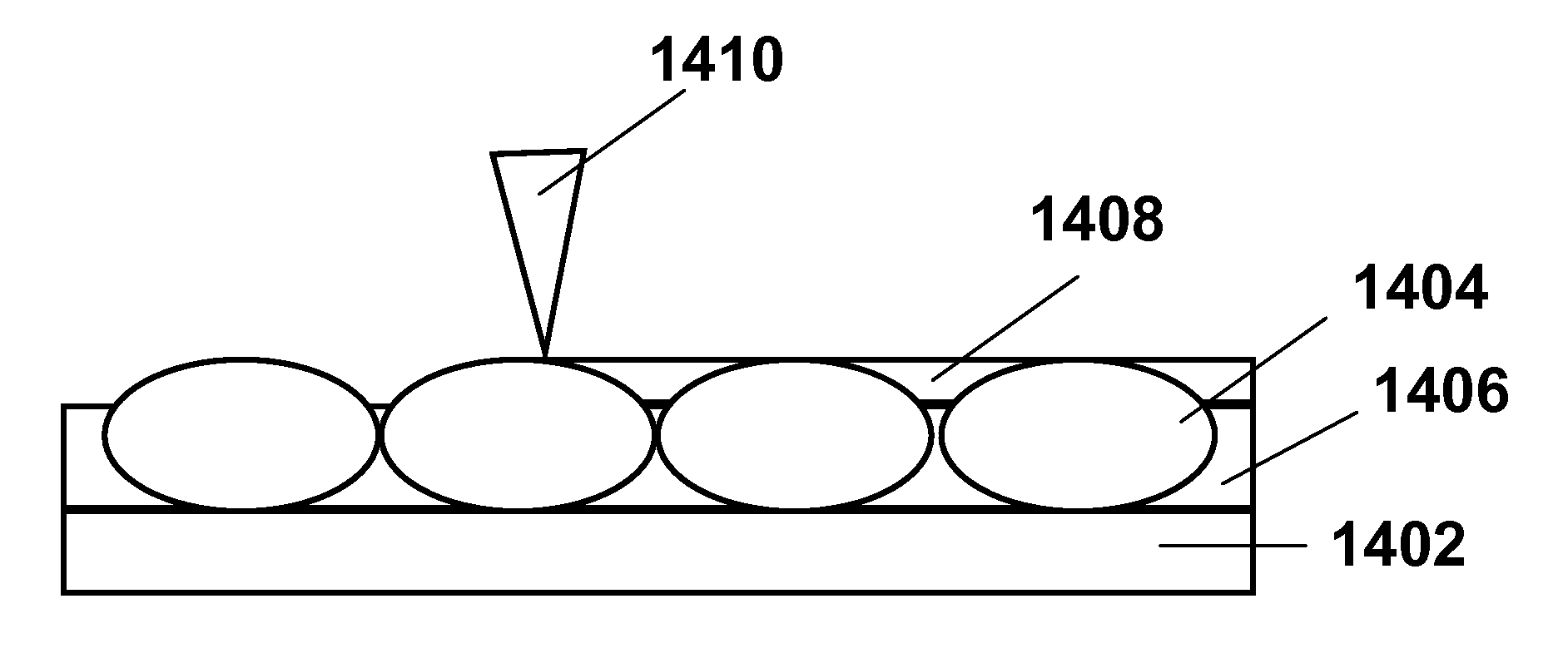

Electro-optic displays, and materials for use therein

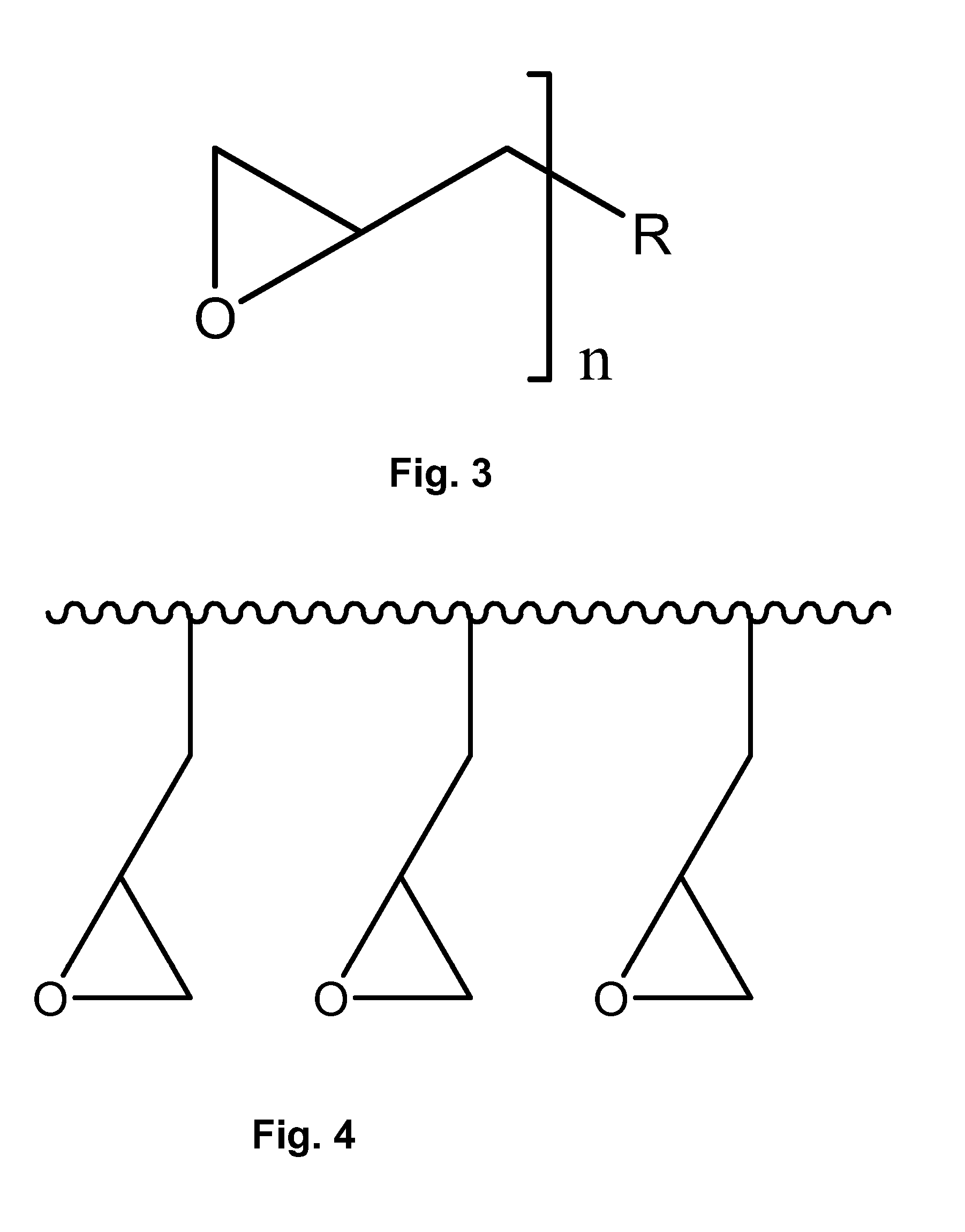

ActiveUS20150226986A1Polyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

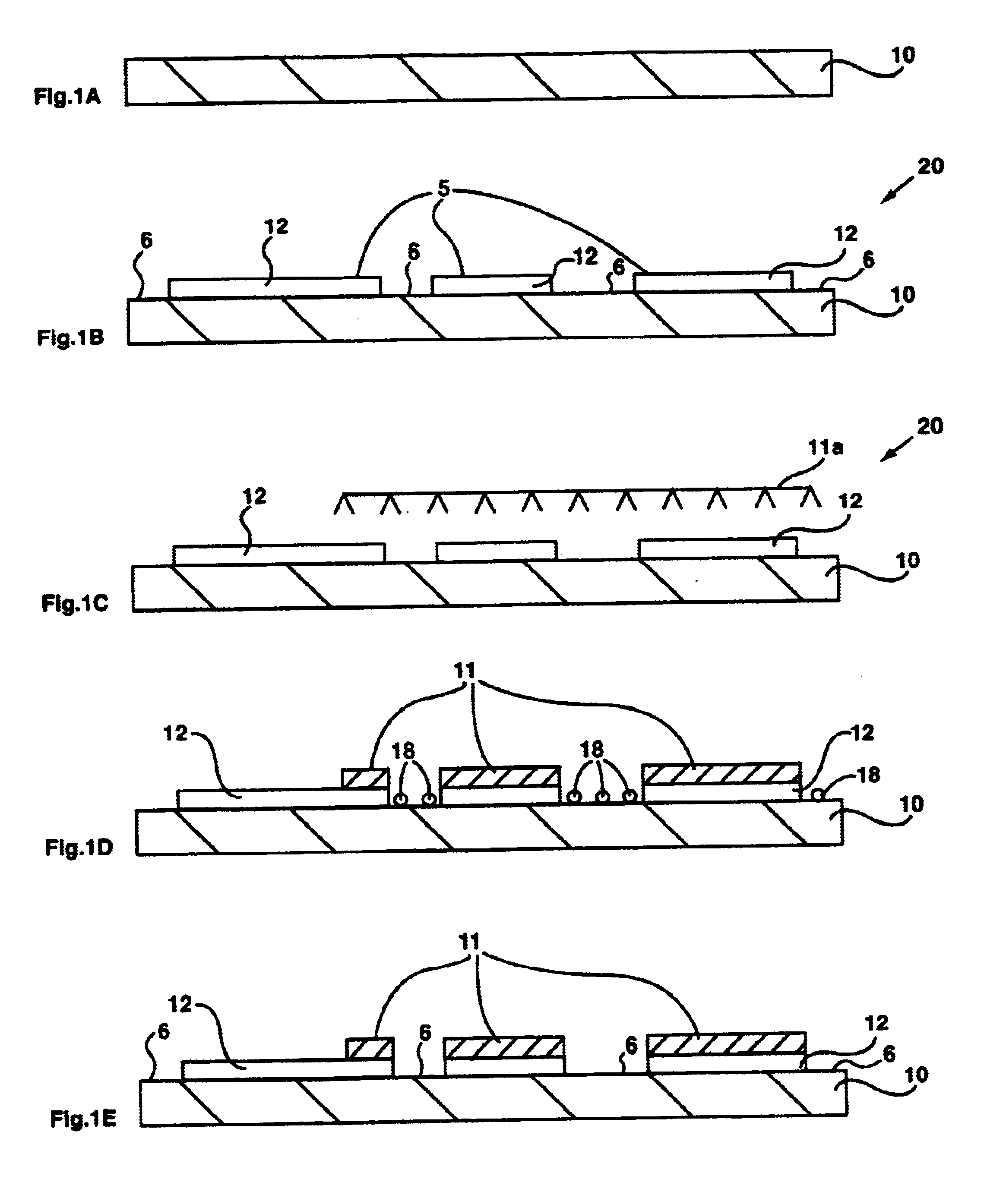

Printing with differential adhesion

InactiveUS6899775B2Facilitates subsequent removalLower surface energyElectric discharge heatingRadiation applicationsEngineeringHigh surface

This invention relates to the printing of a substrate having a pre-printed “print pattern” with a “design layer” of ink where there is differential adhesion within and without the print pattern. The print pattern is receptive to an ink, and the design layer ink forms a durable image material with good bond to the print pattern, but the ink does not form a durable image material on the portions of the substrate outside the print pattern. The design layer ink is a UV-curable ink, and the print pattern may have a higher surface energy than the portions of the substrate outside the print pattern.

Owner:CONTRA VISION

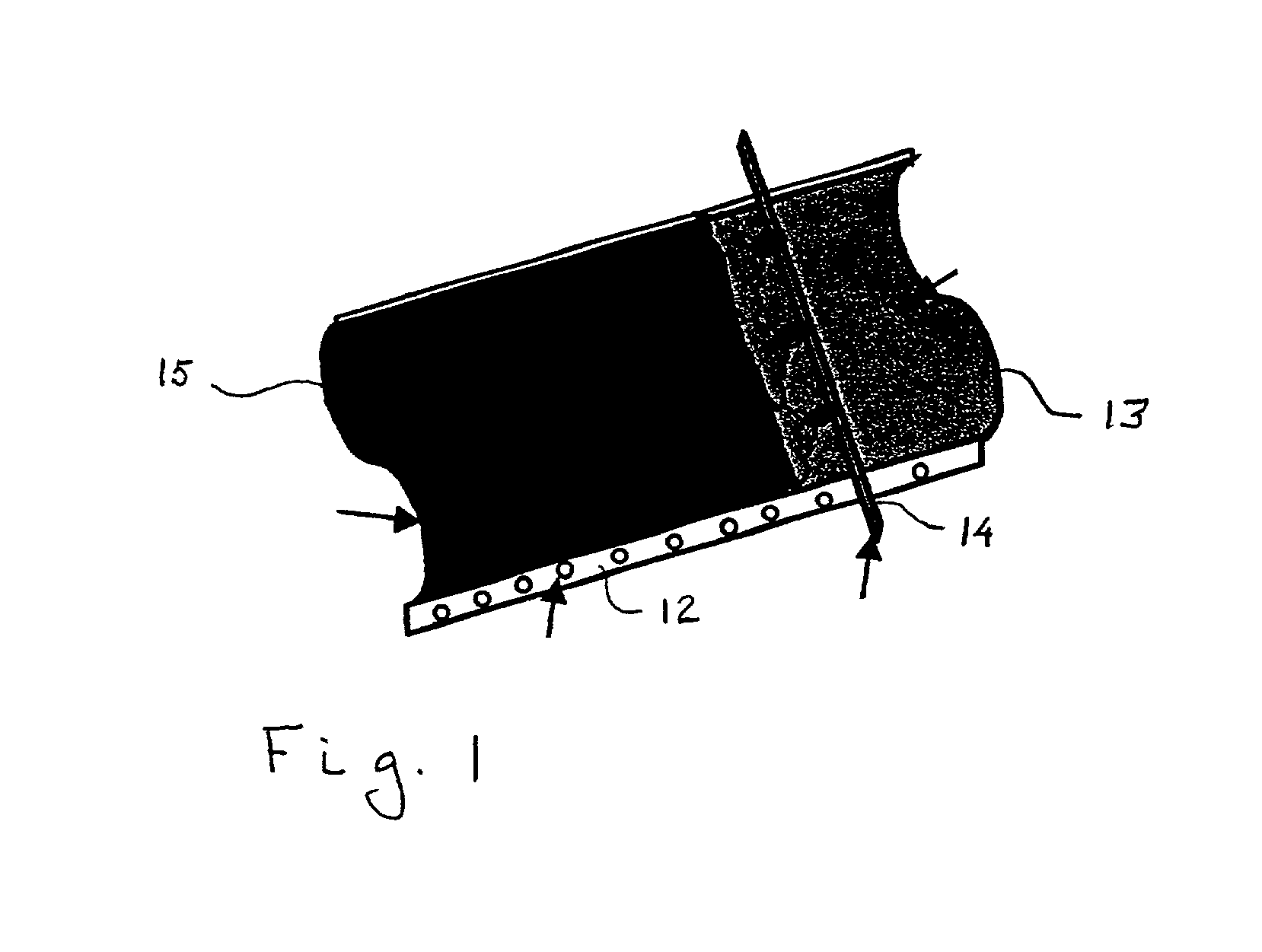

Surface for use on implantable device

InactiveUS6911249B2Reduce air resistancePromote absorptionLayered productsDecorative surface effectsImplanted deviceMaterials science

An attachment surface for an implantable device has an irregular pattern formed through a process including masking, chemical or electrochemical etching, blasting and debris removal steps. Surface material is removed from the implant surface without stress on the adjoining material and the process provides fully dimensional fillet radii at the base of the surface irregularities. This irregular surface is adapted to receive the ingrowth of bone material and to provide a strong anchor for that bone material which is resistant to cracking or breaking. The surface is prepared through an etching process which utilizes the random application of a maskant and subsequent etching in areas unprotected by the maskant. This chemical etching process is repeated a number of times as necessitated by the nature of the irregularities required in the surface. The blasting and debris removal steps produce microfeatures on the surface that enhance the ingrowth of bone material.

Owner:TITAN SPINE

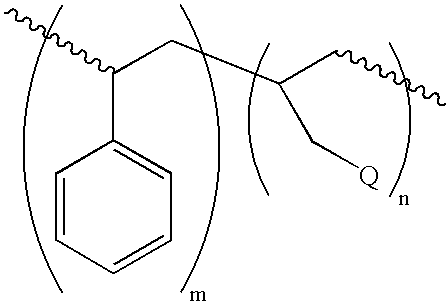

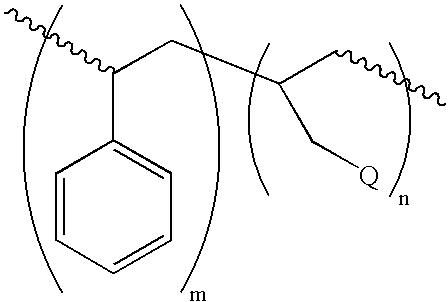

Derivatives of poly(styrene-co-allyl alcohol) and methods for use thereof

ActiveUS20080017308A1Low in ionic impurityEasy to convertAdhesive processes with surface pretreatmentSolid-state devicesCombinatorial chemistryMonomer

The invention provides derivatives of poly(styrene-co-allylalcohol). These materials are useful as thermosetting monomers that can be incorporated into adhesive compositions. In some embodiments, the adhesive compositions are useful in the microelectronic packaging industry.

Owner:DESIGNER MOLECULES

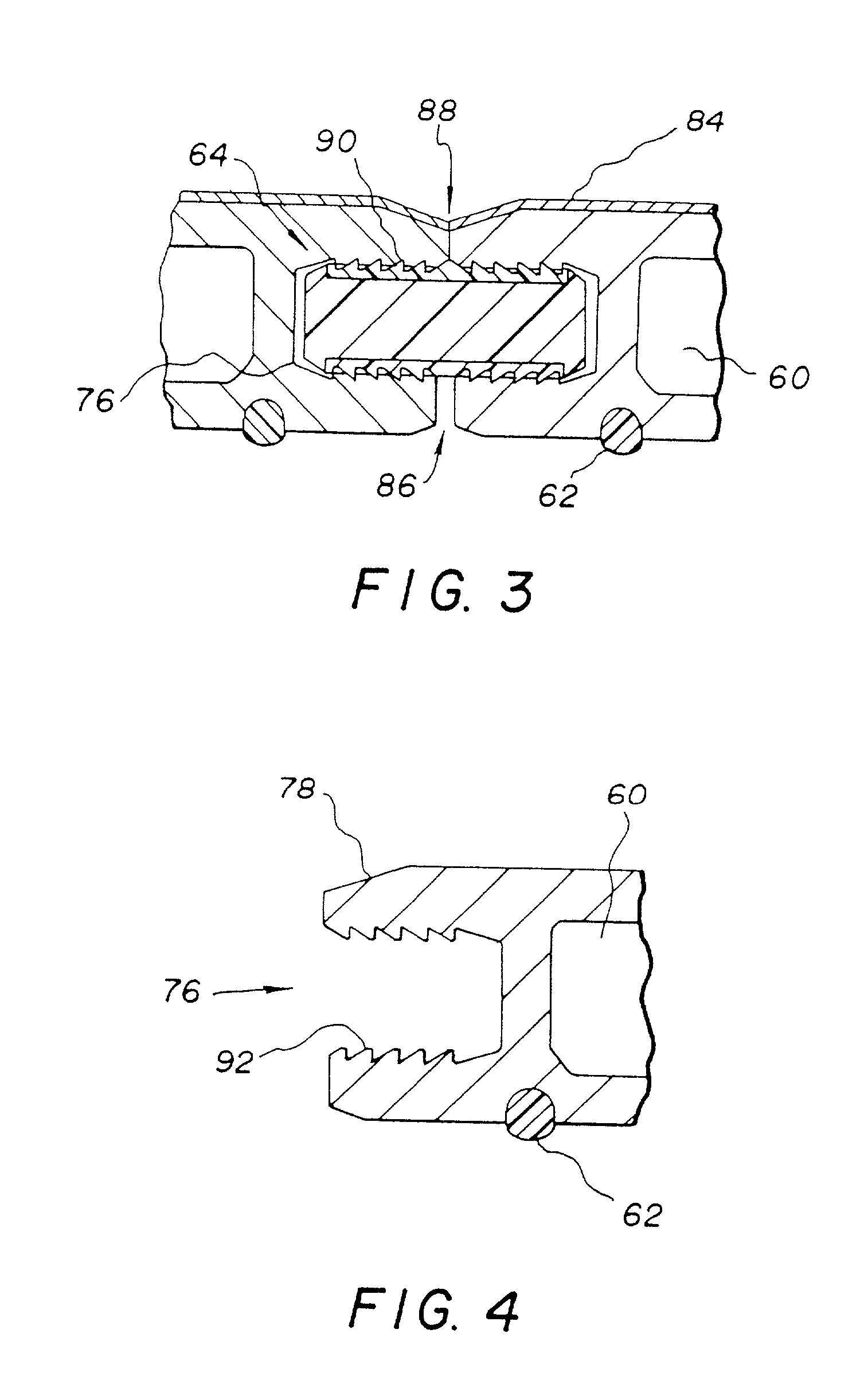

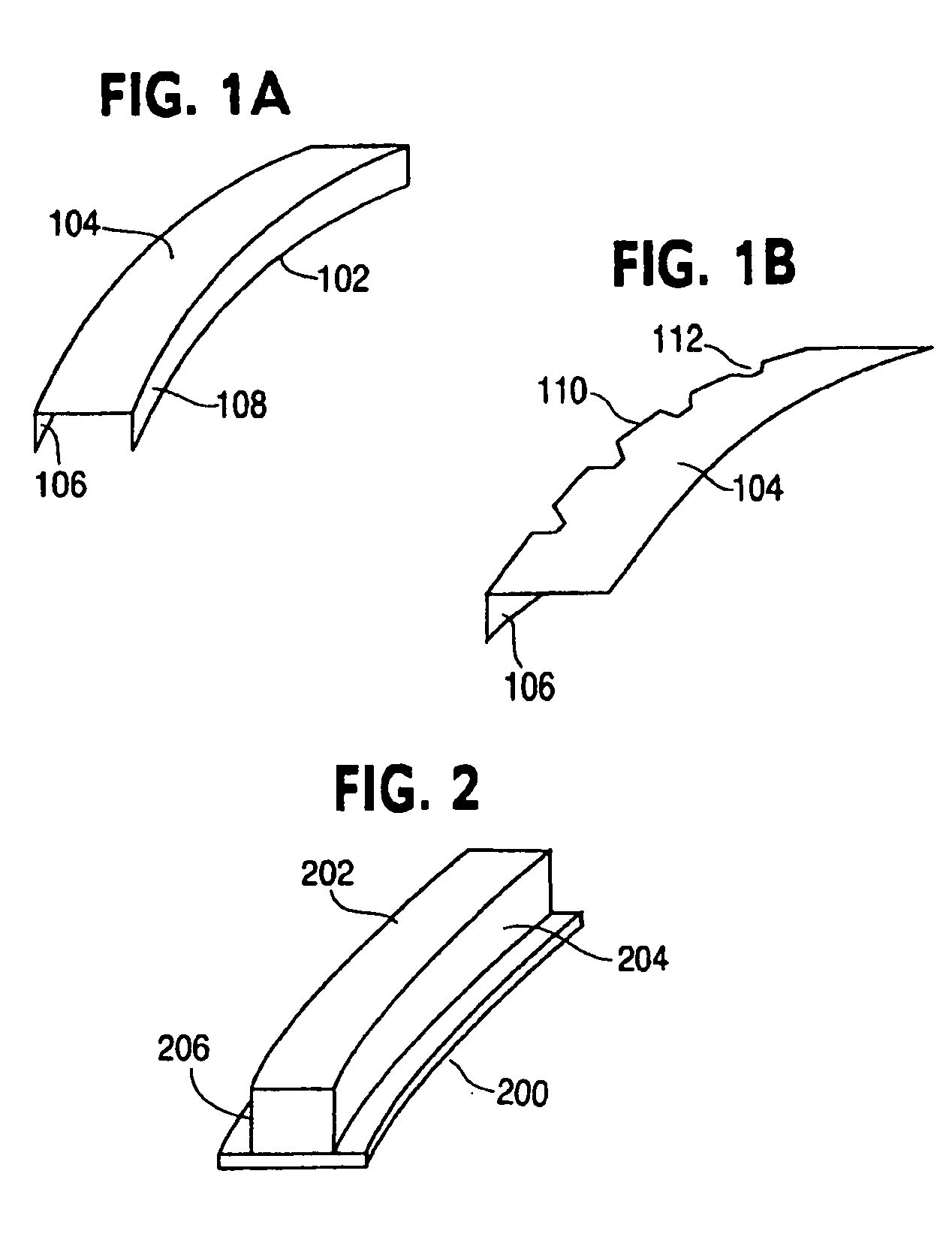

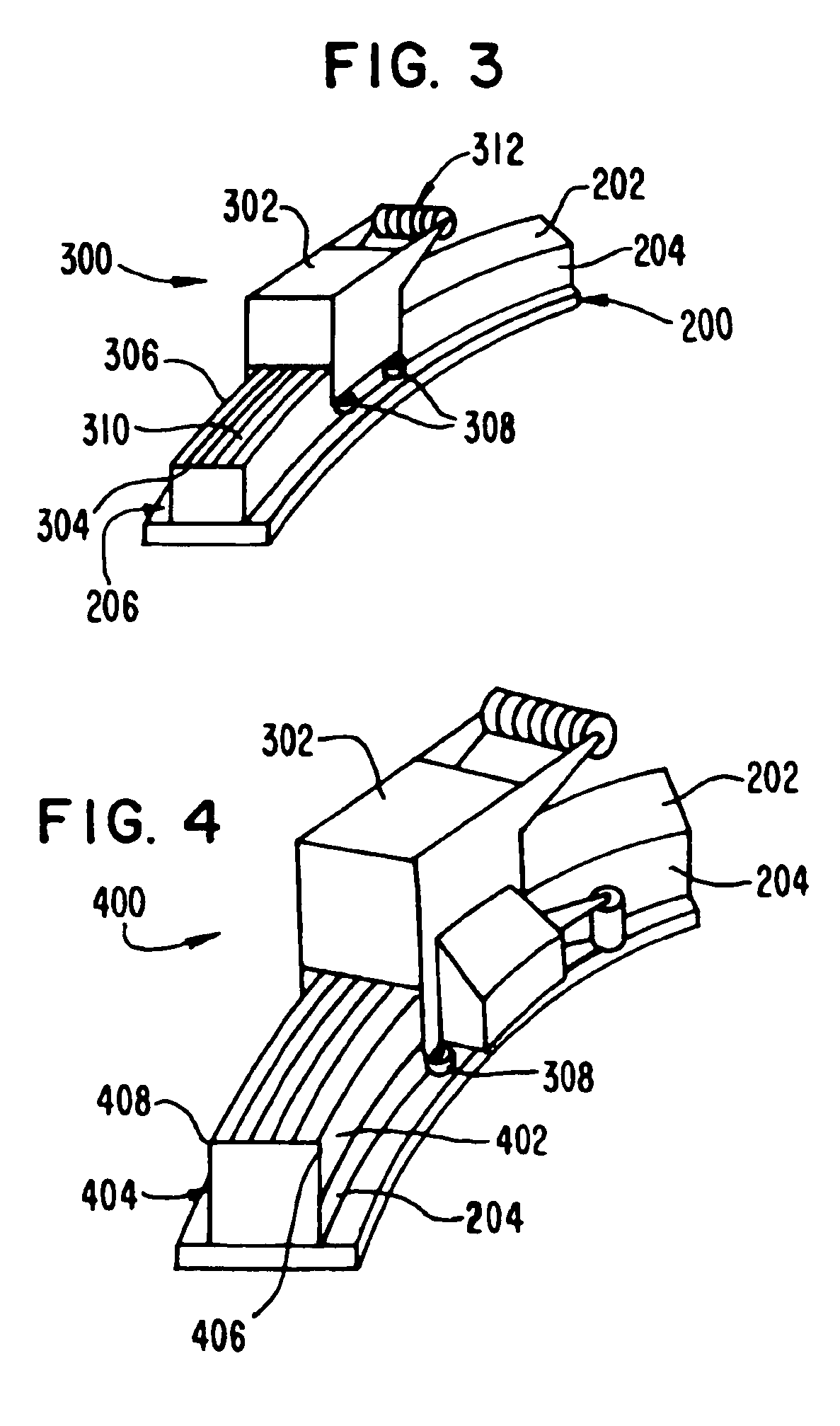

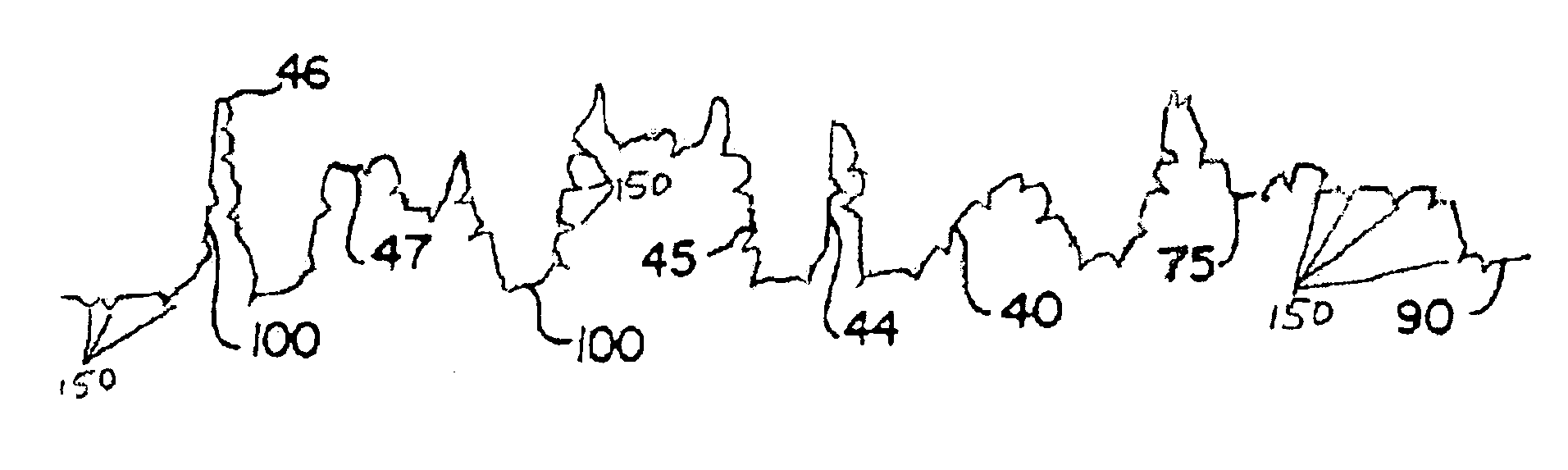

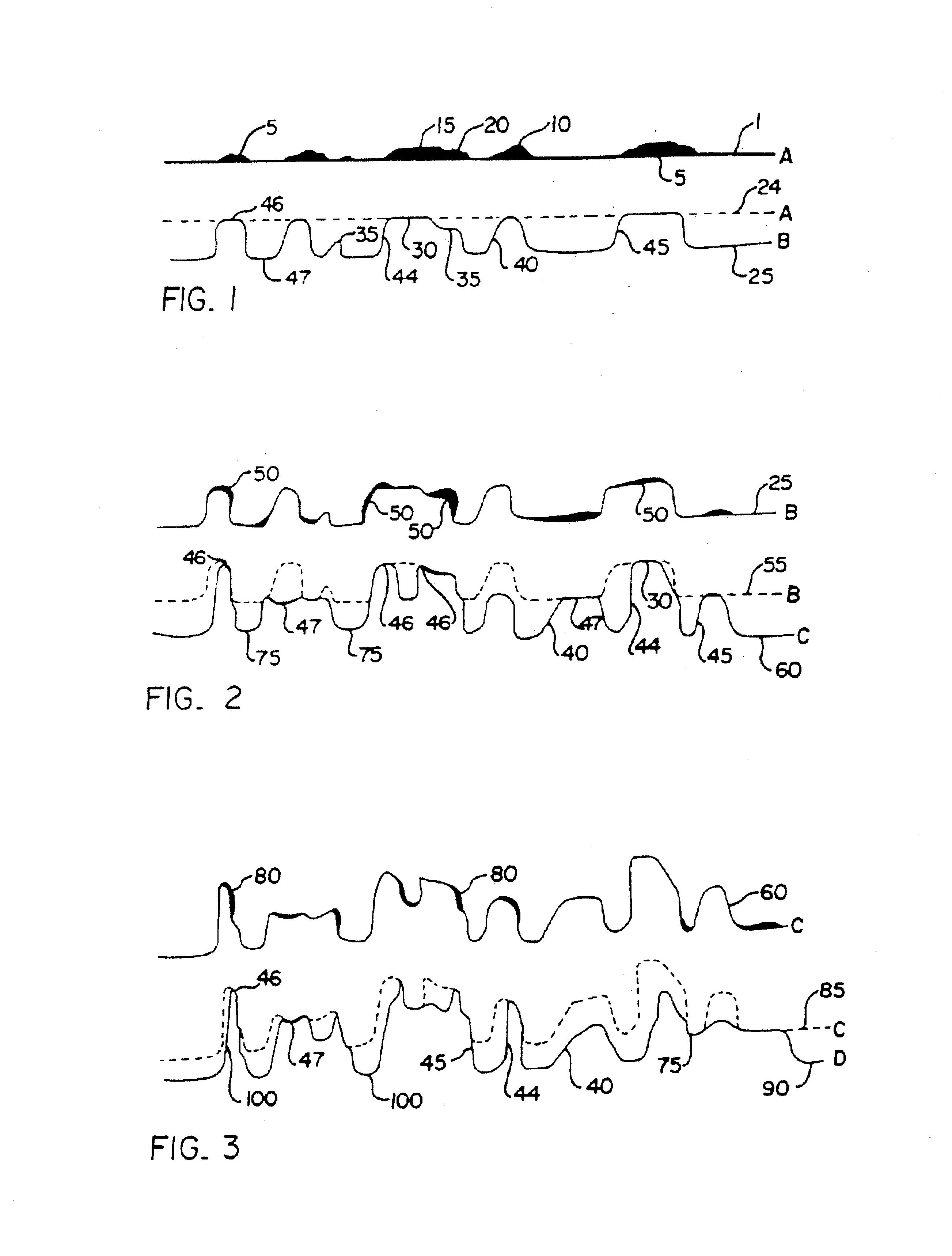

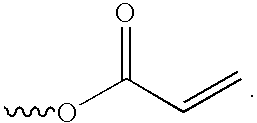

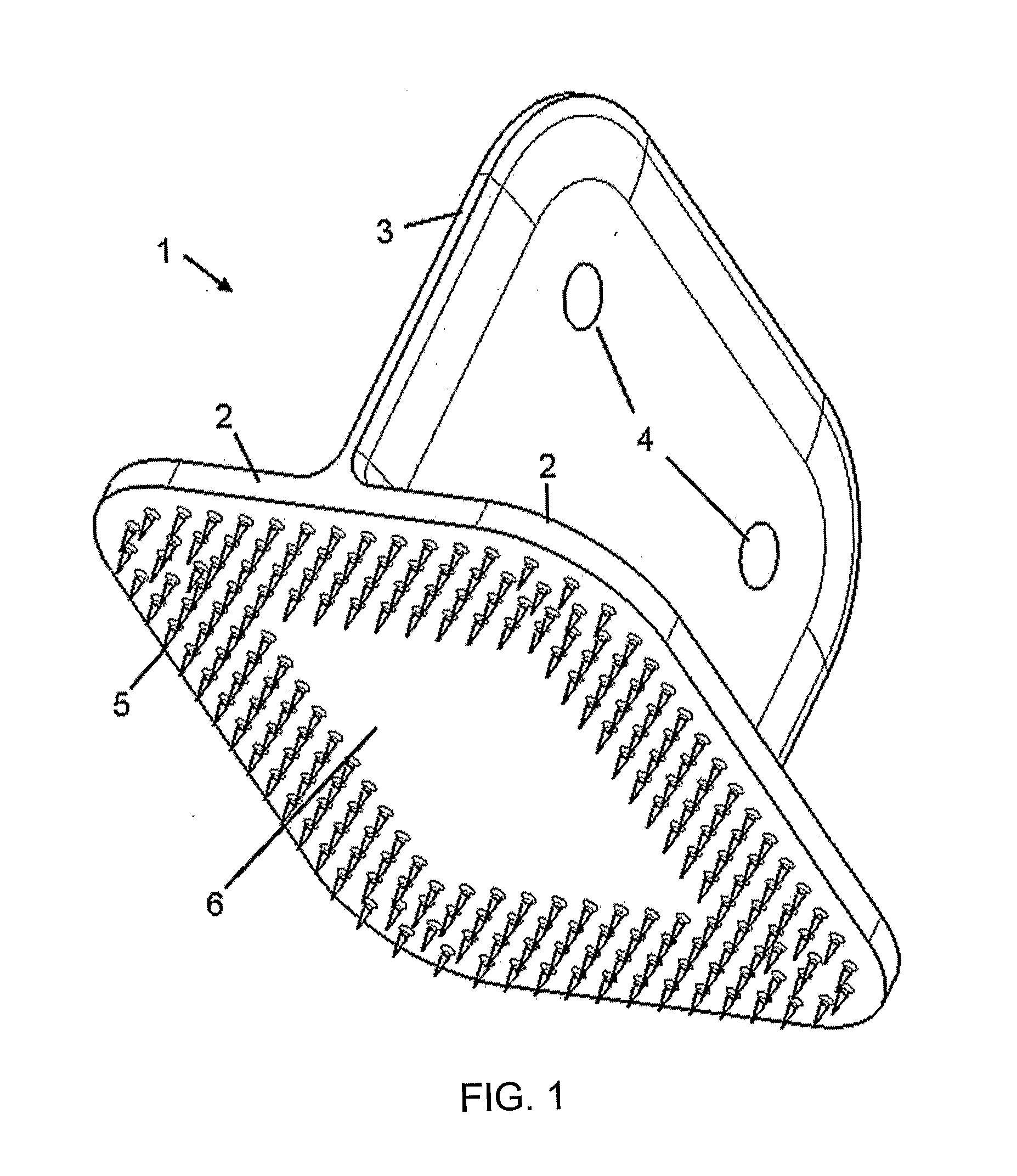

Preparation of a component for use in a joint

ActiveUS20100068464A1Reduce riskReduce risk of damageCeramic layered productsAdditive manufacturing with solidsEngineeringFuselage

A method of preparing a component (60) to be joined to another component (55). The method comprises growing an array of projections (56, 57) on a bond region of the component (55) in a series of layers, each layer being grown by directing energy and / or material from a head to selected parts of the bond region. The joint may be used to join a pair of structural components, for instance in an aerospace application. For instance the joint may be used to join a reinforcing plate, floating rib foot, or stringer to a panel such as a wing or fuselage cover. Alternatively the joint may be used to join adjacent layers in a laminate structure.

Owner:AIRBUS OPERATIONS LTD

Electro-optic displays, and materials for use therein

ActiveUS20150227018A1Lamination ancillary operationsPolyureas/polyurethane adhesivesCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

Polyurethane reaction system having a blocked catalyst combination

InactiveUS6348121B1Long open timeFast curing timePolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentPolyolMetal catalyst

Disclosed is a polyol / polyisocyanate adhesive system having an isocyanate component and a catalyzed component which form a heat-cured composition when admixed and heated above a threshold temperature. The catalyzed component has a hydroxyl-functional component catalyzed with a catalyst combination of a heat-activatable amine or amine-like catalyst which is activated at temperatures above the threshold temperature, and an activatable complexed metal catalyst comprising the reaction product of tin or bismuth catalysts, or a mixture thereof, and a molar excess of a mercapto compound complexing agent. The catalyst combination is effective to maintain the processibility of the system at ambient temperatures while promoting the rapid cure of the system when heated above the threshold temperature.

Owner:ASHLAND LICENSING & INTPROP LLC

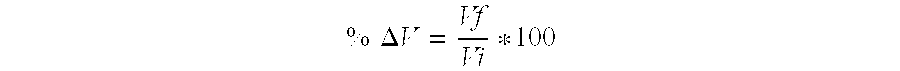

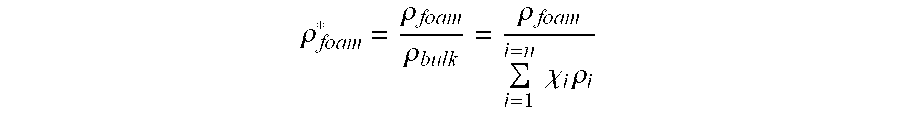

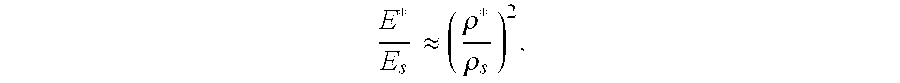

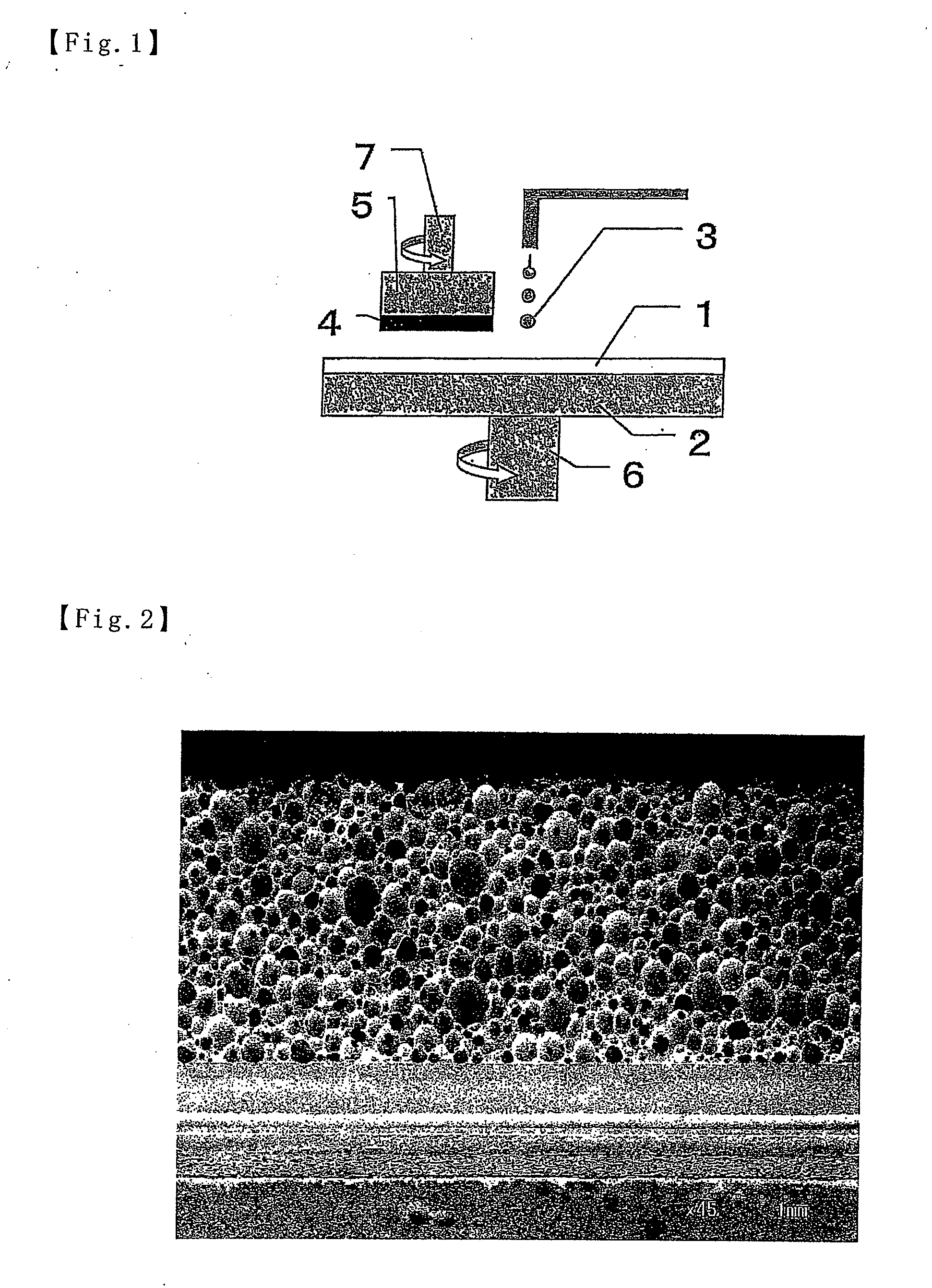

Polishing pad and a method for manufacturing the same

ActiveUS20100029185A1Good adhesivenessIncreased durabilityAdhesive processes with surface pretreatmentAbrasion apparatusHydrogenChemical compound

An object of the invention is to provide a polishing pad excellent in durability and in the adhesiveness between a polishing layer and a base material layer. The first invention relates to a polishing pad comprising a polishing layer arranged on a base material layer, wherein the polishing layer comprises a thermosetting polyurethane foam having roughly spherical interconnected cells having an average cell diameter of 20 to 300 μm, the polyurethane foam comprises an isocyanate component and an active hydrogen-containing compound as starting components, and the active hydrogen-containing compound comprises 30 to 85% by weight of a high-molecular-weight polyol having 2 to 4 functional groups and a hydroxyl value of 20 to 100 mg KOH / g.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Electro-optic displays, and materials for use therein

InactiveUS20110164301A1Lamination ancillary operationsPolyureas/polyurethane adhesivesCross-linkDisplay device

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

Using a cleaning cloth impregnated with coupling agent for adhesive films

InactiveUS6106953AAdhesive processes with surface pretreatmentGlass/slag layered productsSolventSynthetic rubber

Use of a prior-cleaning cloth for an adhesive bond brought about by means of an adhesive film which is rereleasable without damage by pulling in the direction of the bond plane and which has an adhesive composition based on polymers and / or copolymers of synthetic rubber and / or natural rubber, characterized in that the substrate to be bonded is rubbed with a prior-cleaning cloth of this kind which is impregnated with a moisture-reactive organosilane, the organosilane being dissolved in a solvent or solvent mixture and being present therein in a concentration of 0.1-3% by weight, whereupon, following a waiting time of a few minutes, the adhesive film is pressed onto the treated area and then an article, hook or the like is bonded to the other side of the adhesive film, or else in that, after a waiting time of a few minutes, the adhesive film is pressed onto the treated area, an article, hook or the like already being located in bonded-on form on the reverse of the adhesive film.

Owner:TESA SE

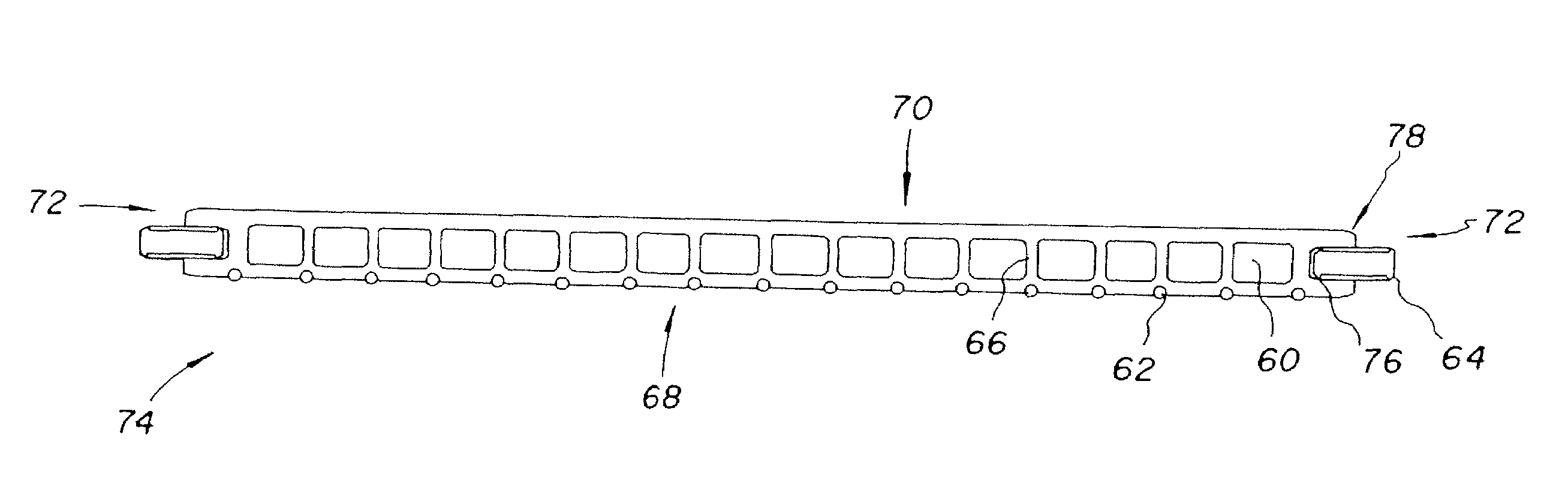

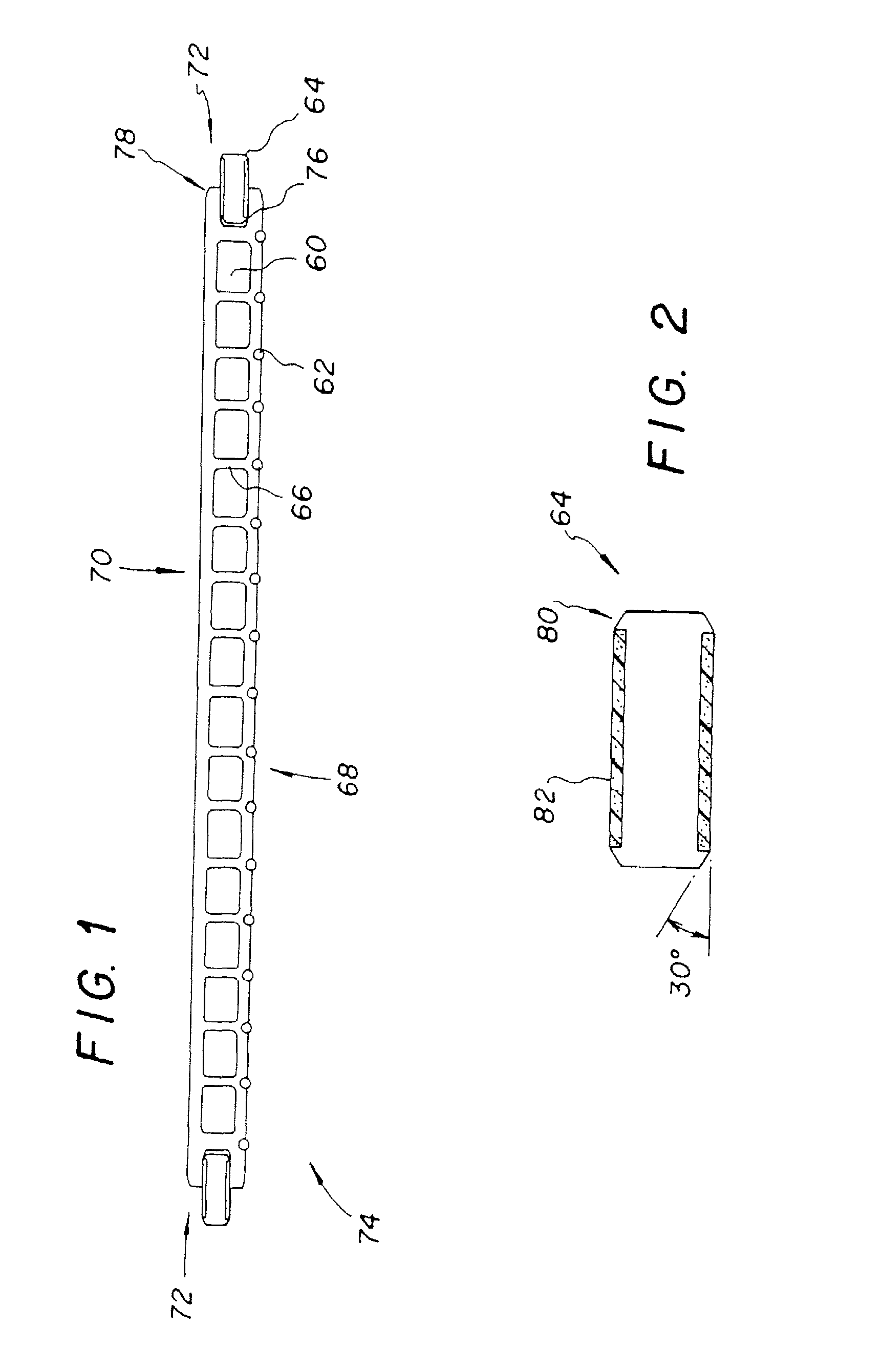

High Thermal Conductivity Mica Paper Tape

InactiveUS20080050580A1Improve thermal conductivityHigh materialDomestic sealsAdhesive articlesPaper tapeOptoelectronics

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com