Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1823 results about "Synthetic rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic rubber is any artificial elastomer. These are mainly polymers synthesized from petroleum byproducts. About fifteen billion kilograms (thirty-three billion pounds) of rubbers are produced annually, and of that amount two thirds are synthetic. Global revenues generated with synthetic rubbers are likely to rise to approximately US$56 billion in 2020. Synthetic rubber, like natural rubber, has uses in the automotive industry for tires, door and window profiles, hoses, belts, matting, and flooring.

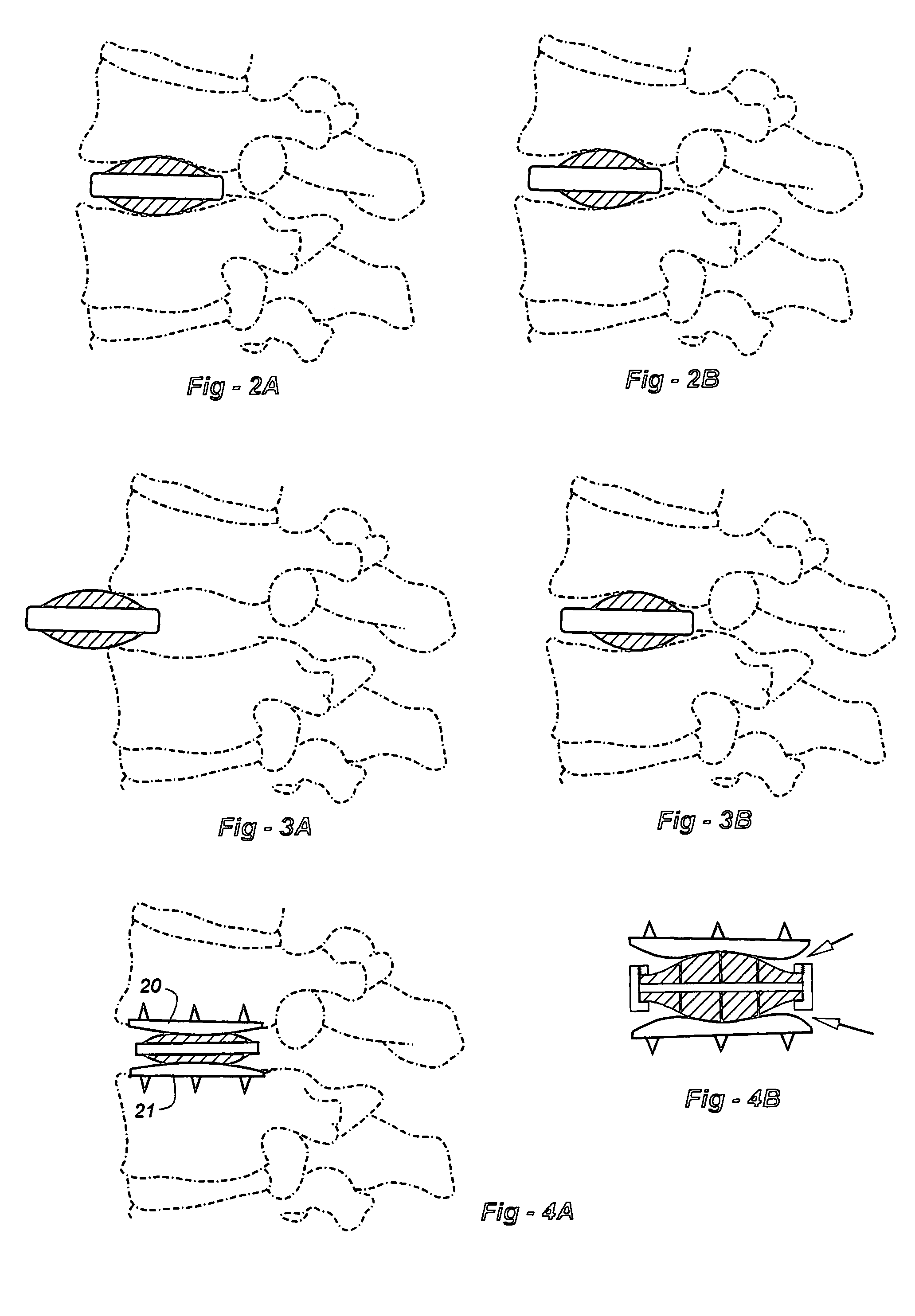

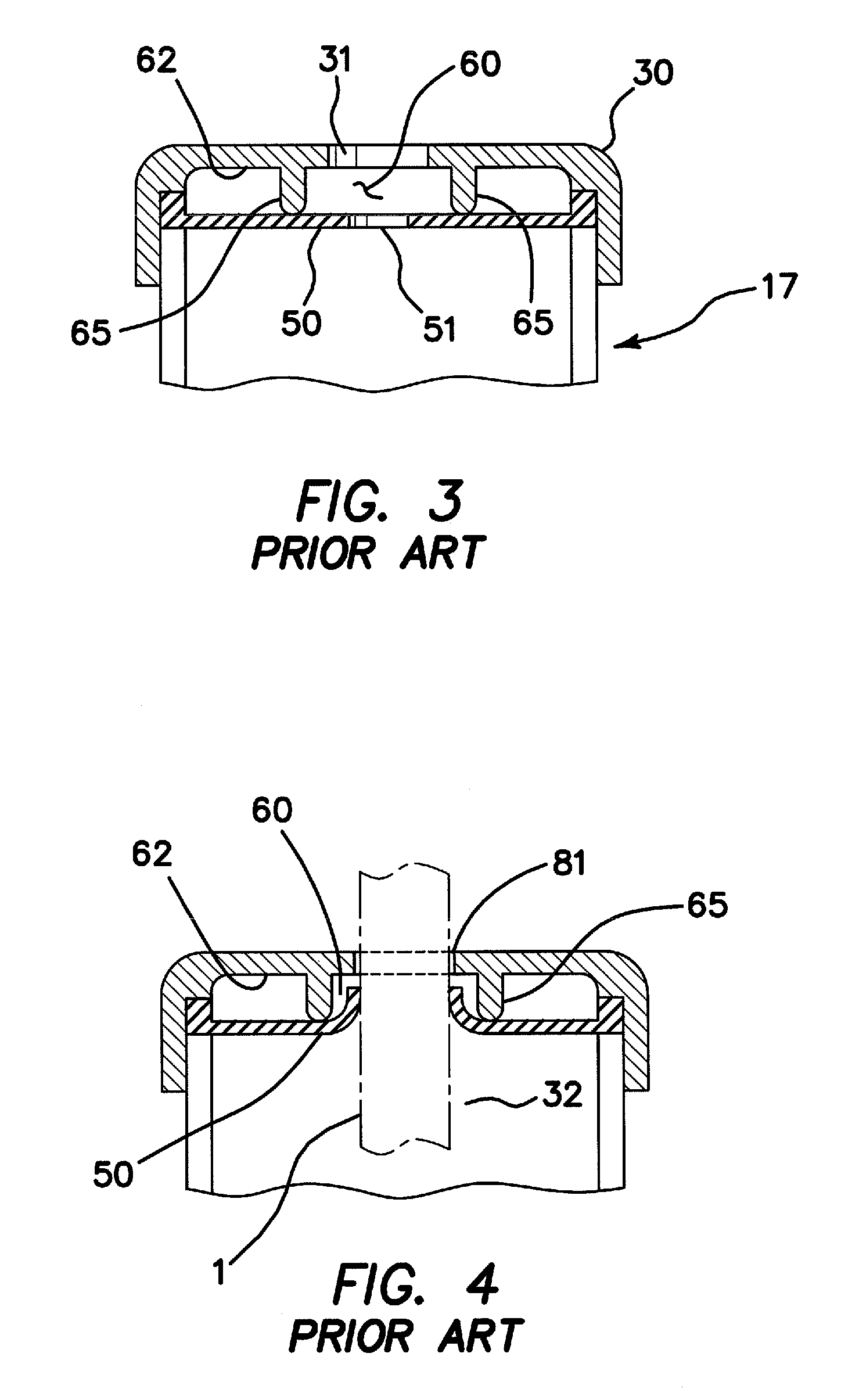

Prosthetic components with partially contained compressible resilient members

InactiveUS7066958B2Improve protectionEliminate shear stressJoint implantsSpinal implantsElastomerShape-memory alloy

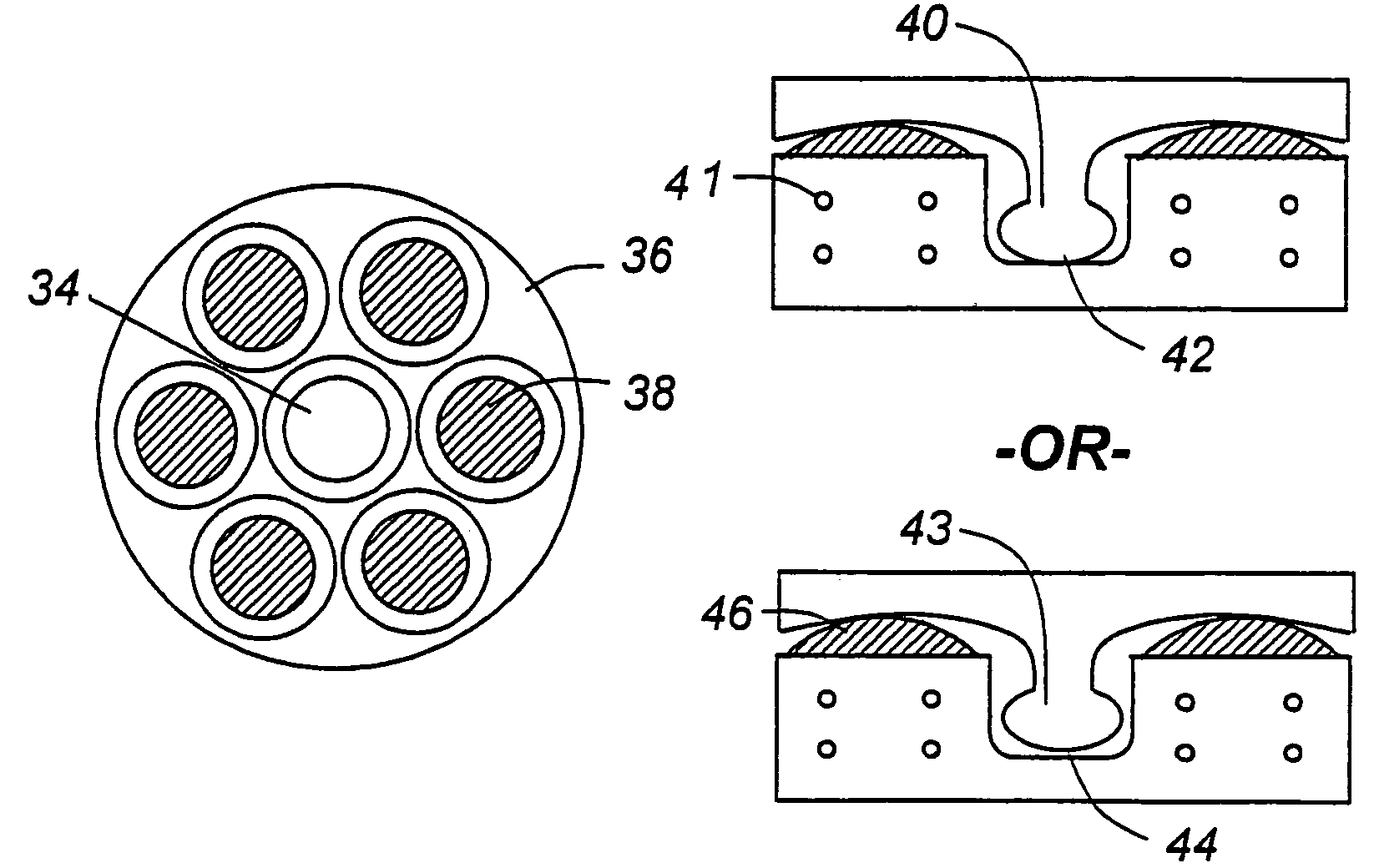

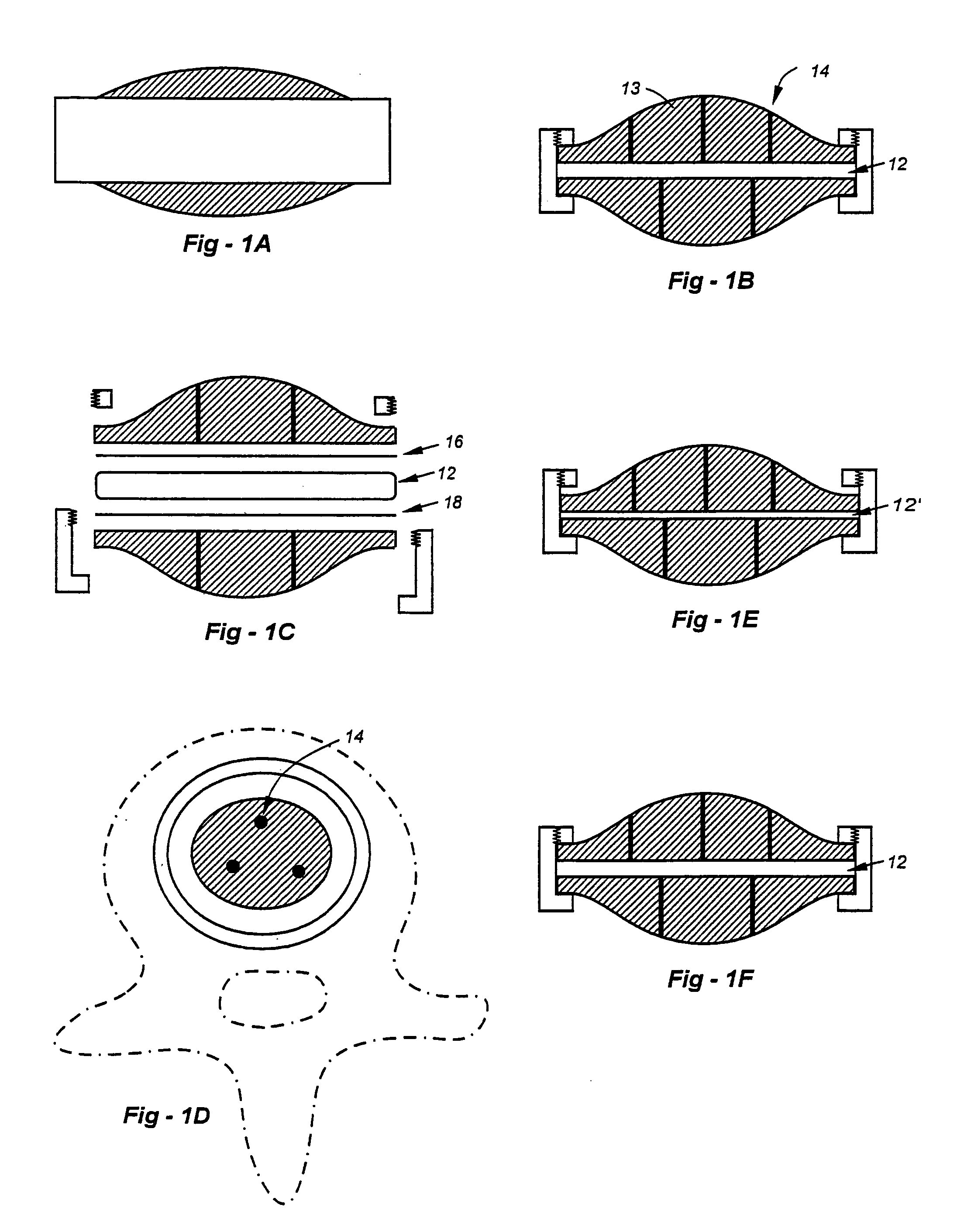

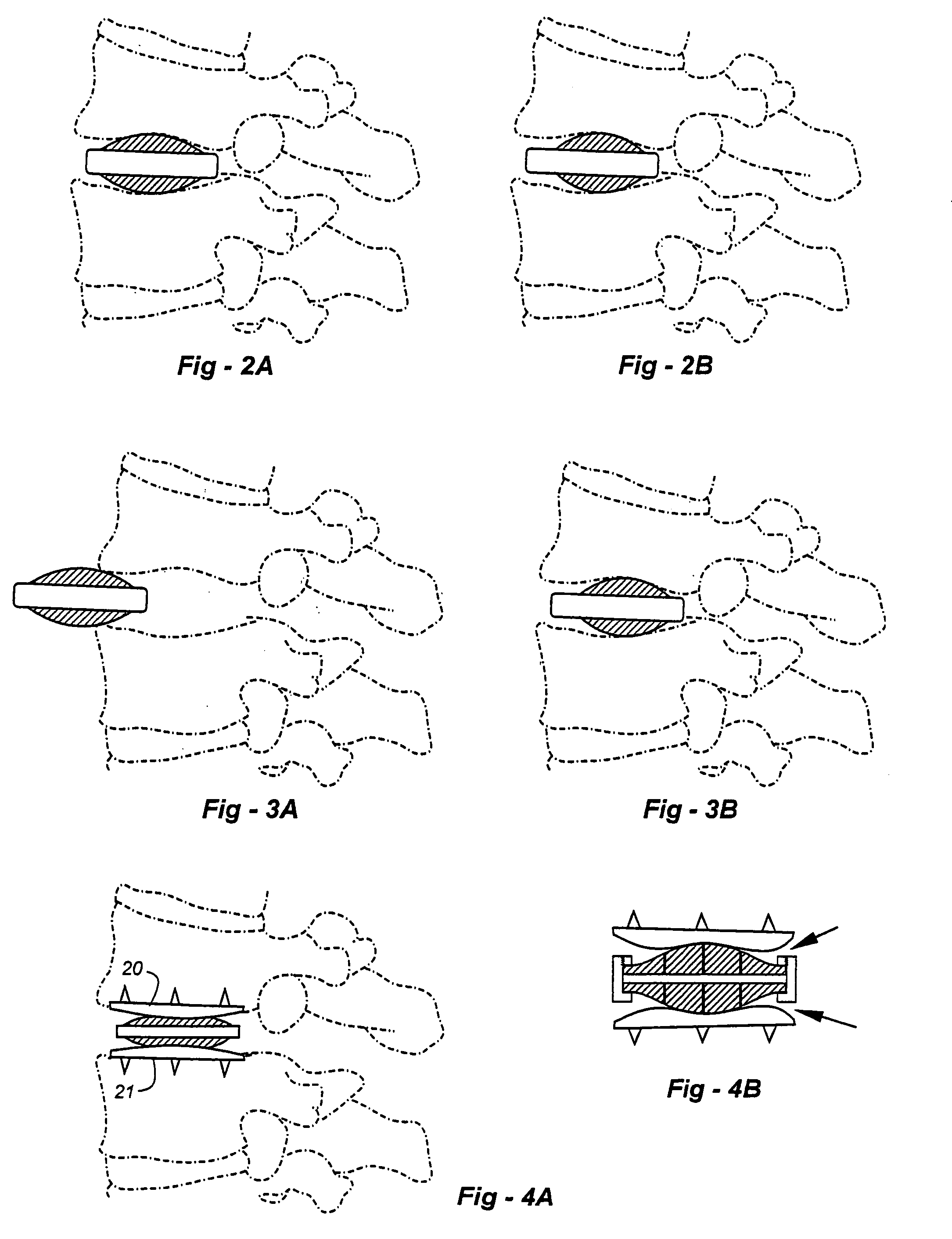

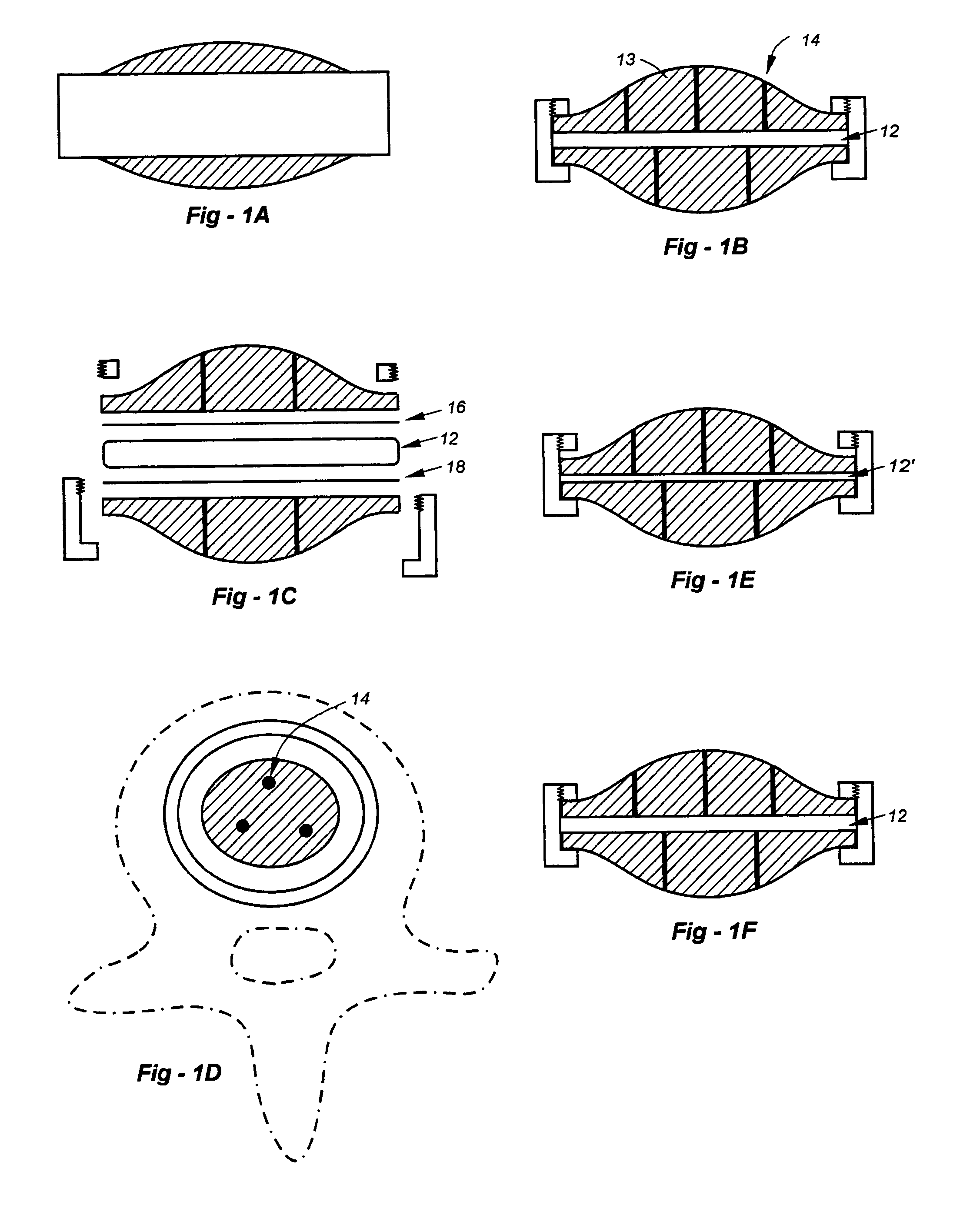

One or more rigid components associated with an articulating bone are used to encase, encapsulate, contain, or otherwise protect a compressible / resilient member. The embodiments are applicable not only to artificial disc replacement (ADR) devices, but also to joint situations including total knee and hip arthroplasty. The cushion elements in the preferred embodiments include synthetic rubbers, hydrogels, elastomers, and other polymeric materials such as viscoelastic polymers and foam polyurethanes. The invention effectively combines the advantages of such materials (cushioning, shape memory, and expansion after insertion in the case of hydrogels), while providing increased protection, particularly the elimination of shear stresses. When applied to an ADR, the invention also minimizes the risk of extrusion.

Owner:FERREE BRET A

Resilient flooring compositions

InactiveUS20120276348A1Improve wear resistanceReduce the possibilityCovering/liningsSpecial ornamental structuresWood veneerNatural fiber

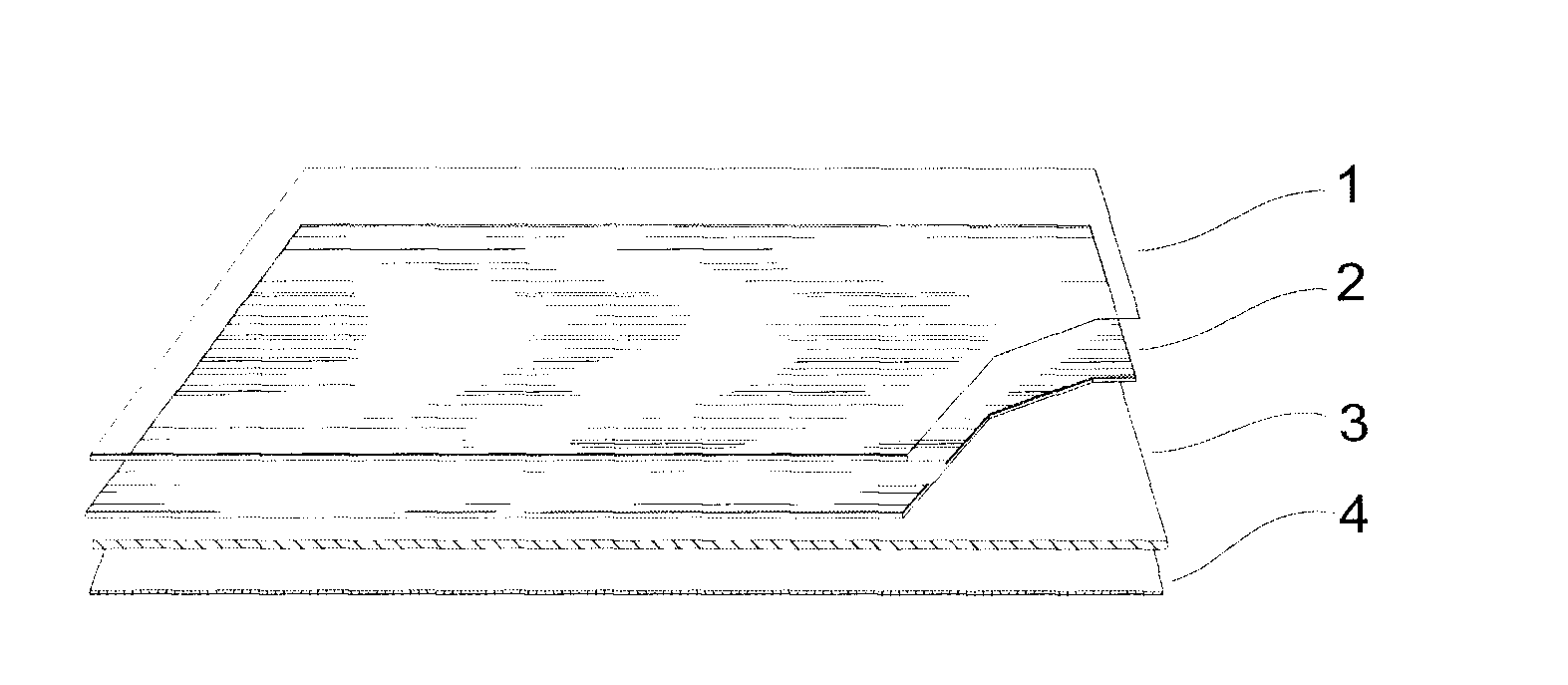

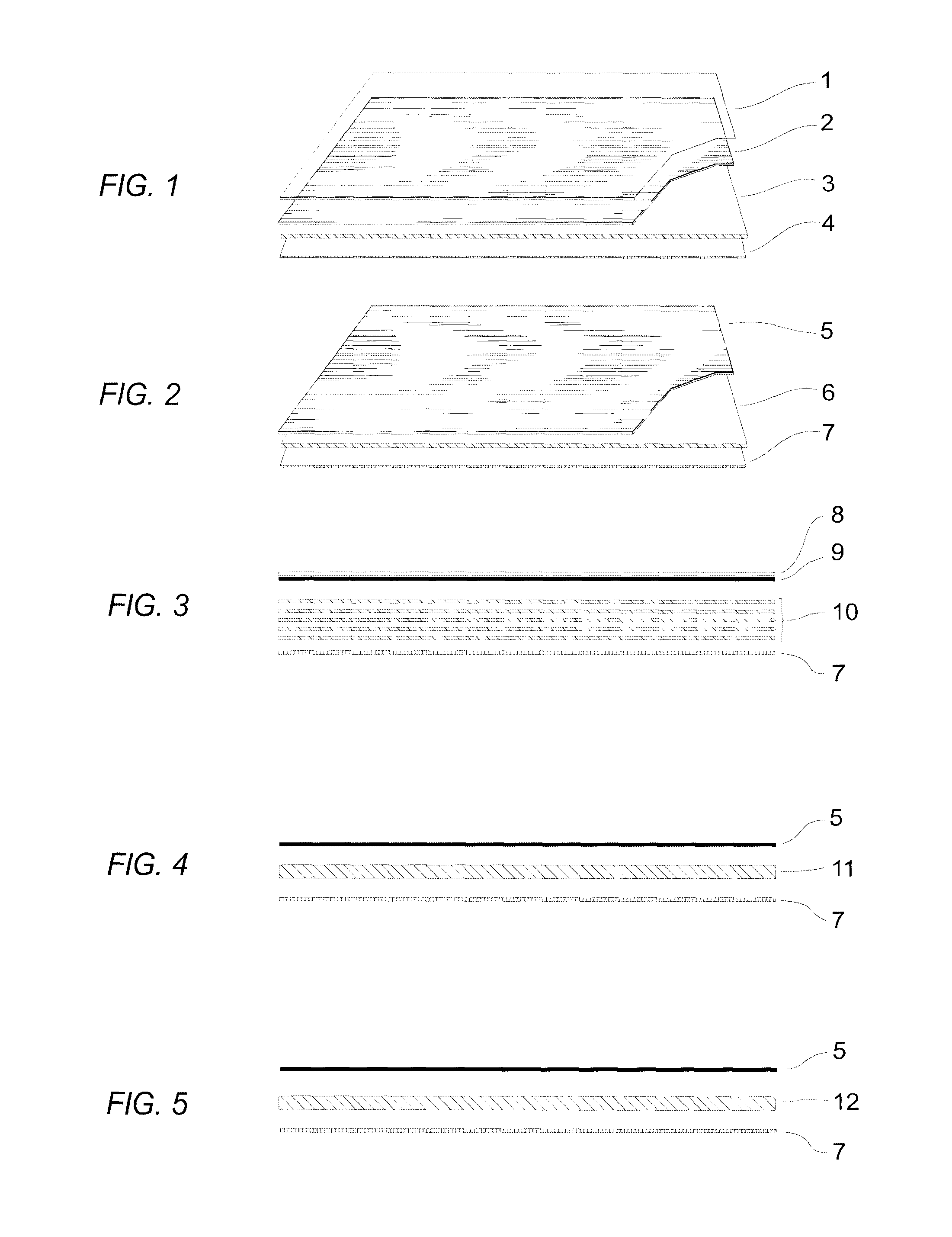

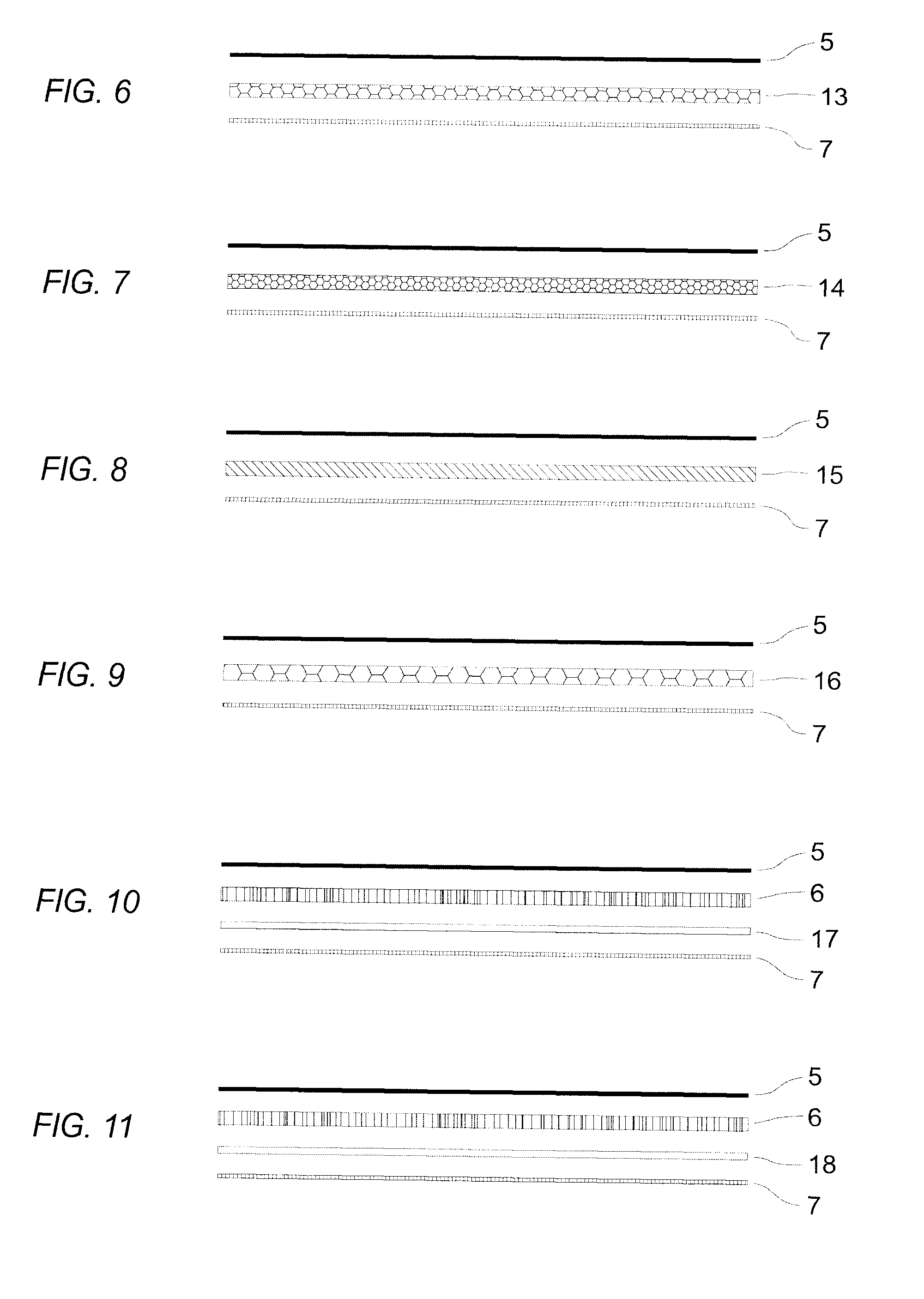

Resilient flooring materials made from impregnated papers or foils and core materials are provided. As well, the methods for producing such products are provided. In particular, panels, with a layered structure, created by forming an assembly which consists of laminating a heat-activated resin impregnated decorative layer with printed graphics or a wood veneer decorative layer, a core material made up of one or more heat-activated resin-impregnated papers or other materials including linoleum, natural or synthetic rubber, cork, flexible natural fiber composites or other core materials, and a heat-activated resin impregnated paper backing layer. The heat-activated resin also acts to waterproof each of the layers and abrasion particles may be incorporated to improve wear properties. The panels may also be formed into three-dimensional products.

Owner:CLAUSI ROBERT N +1

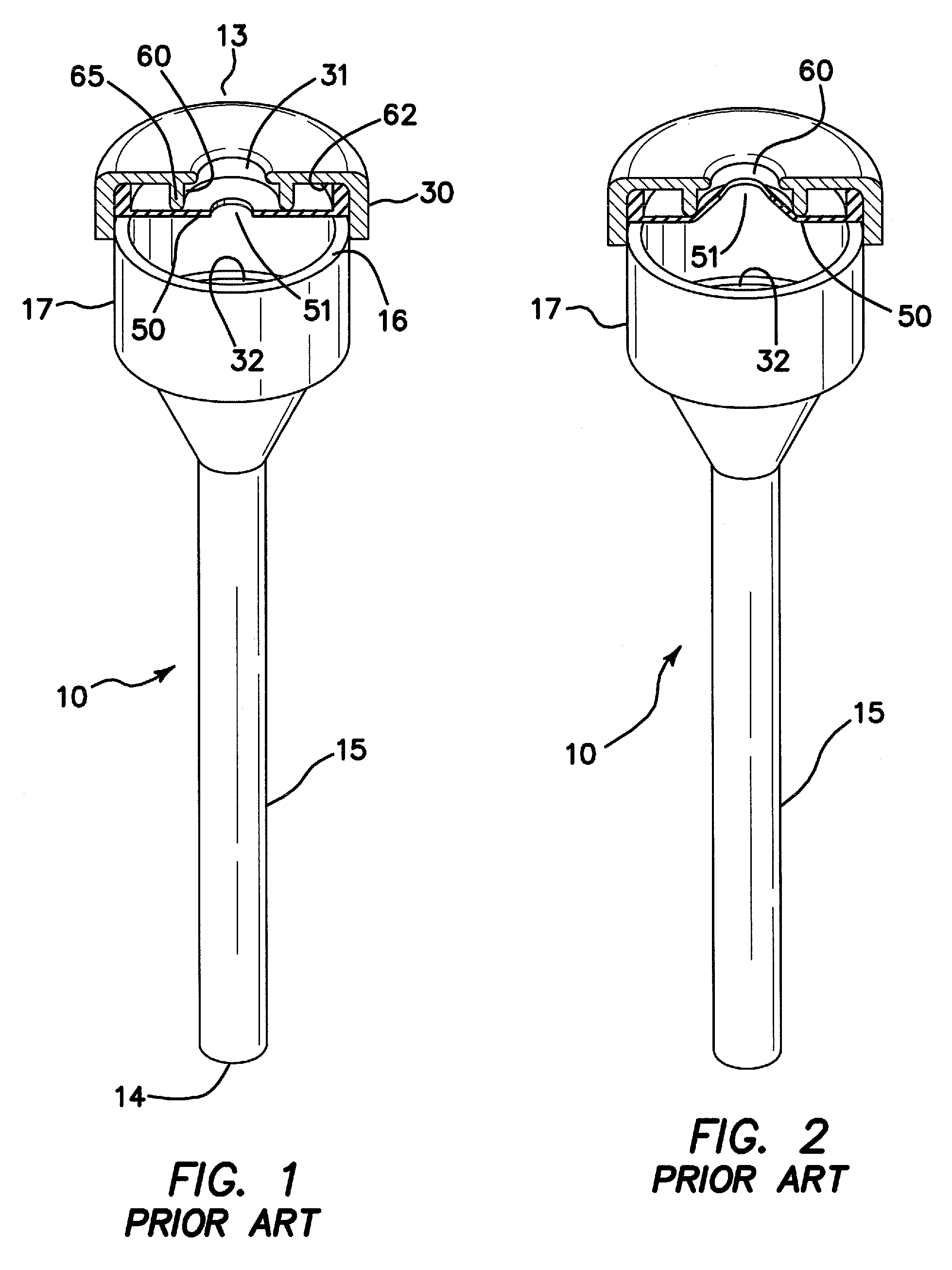

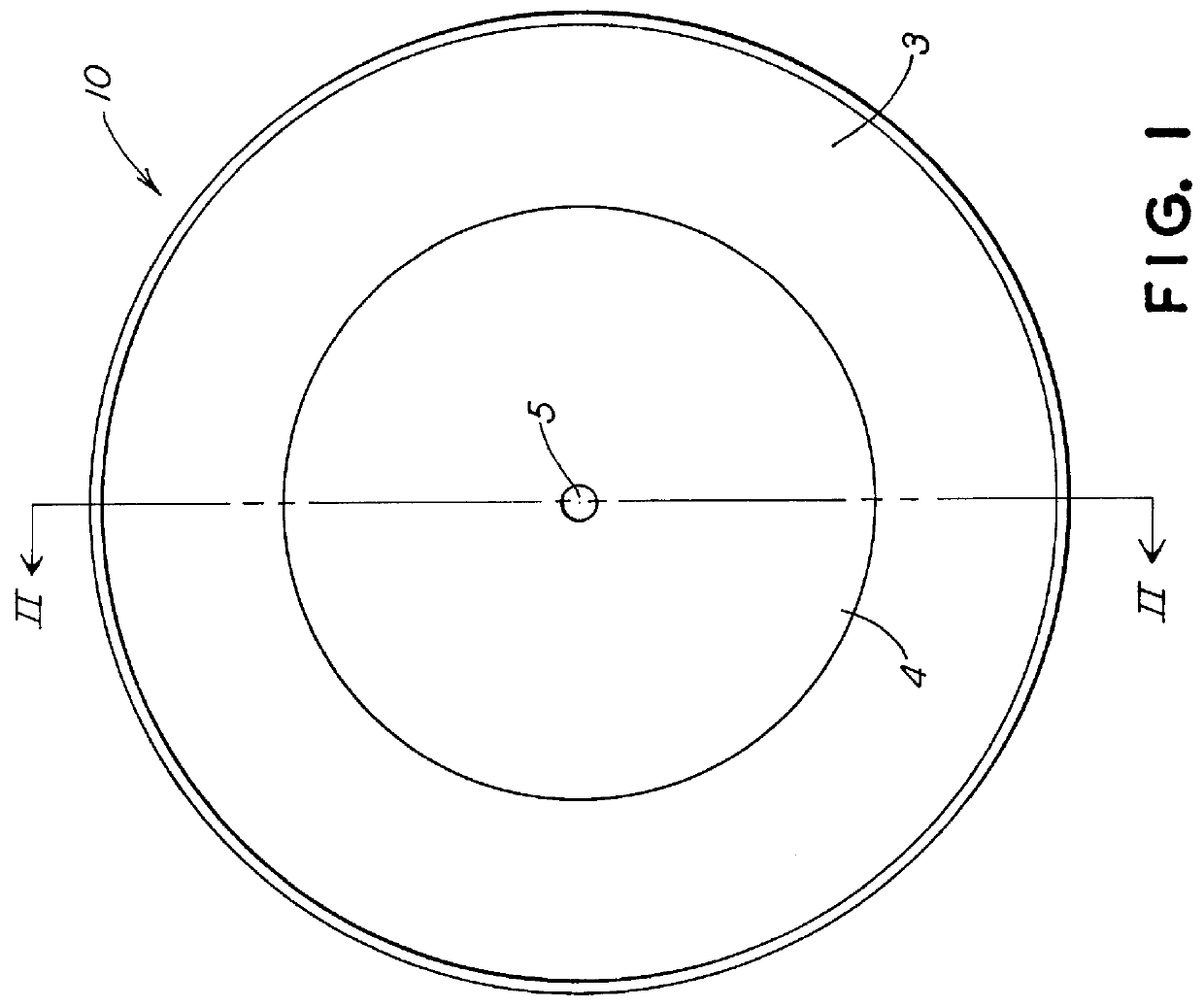

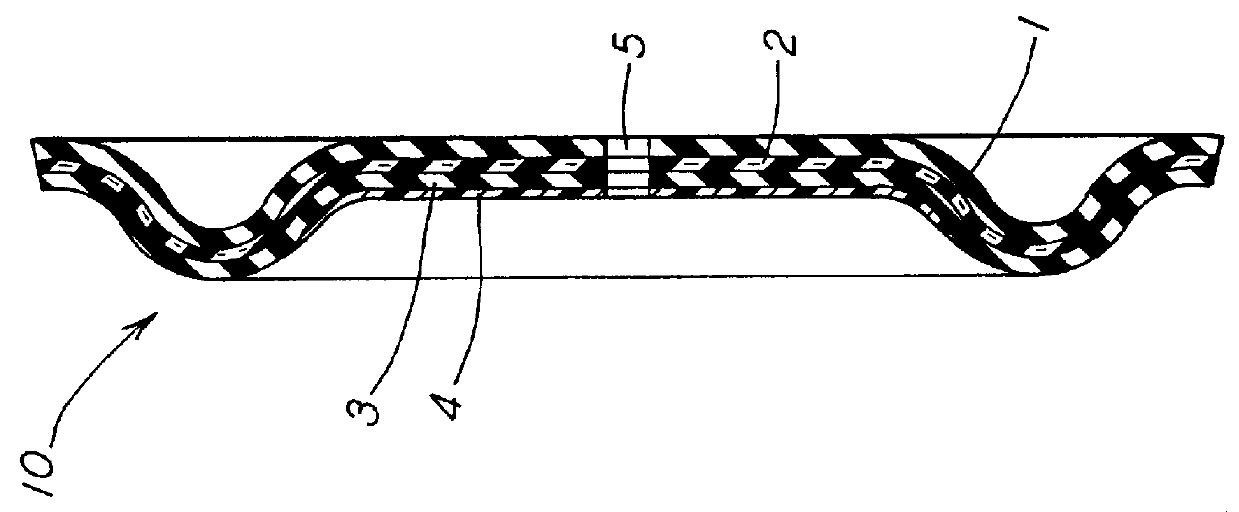

Prosthetic components with contained compressible resilient members

InactiveUS7235102B2Improve protectionEliminate shear stressJoint implantsSpinal implantsElastomerShape-memory alloy

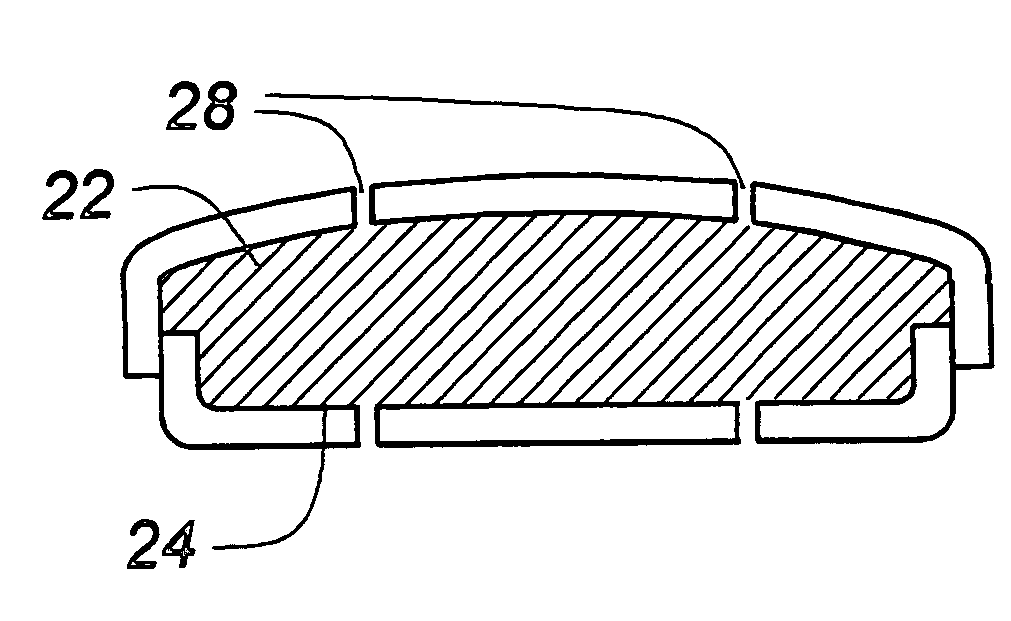

One or more rigid components associated with an articulating bone are used to encase, encapsulate, contain, or otherwise protect a compressible / resilient member. The embodiments are applicable not only to artificial disc replacement (ADR) devices, but also to joint situations including total knee and hip arthroplasty. The cushion elements in the preferred embodiments include synthetic rubbers, hydrogels, elastomers, and other polymeric materials such as viscoelastic polymers and foam polyurethanes. The invention effectively combines the advantages of such materials (cushioning, shape memory, and expansion after insertion in the case of hydrogels), while providing increased protection, particularly the elimination of shear stresses. When applied to an ADR, the invention also minimizes the risk of extrusion.

Owner:ANOVA

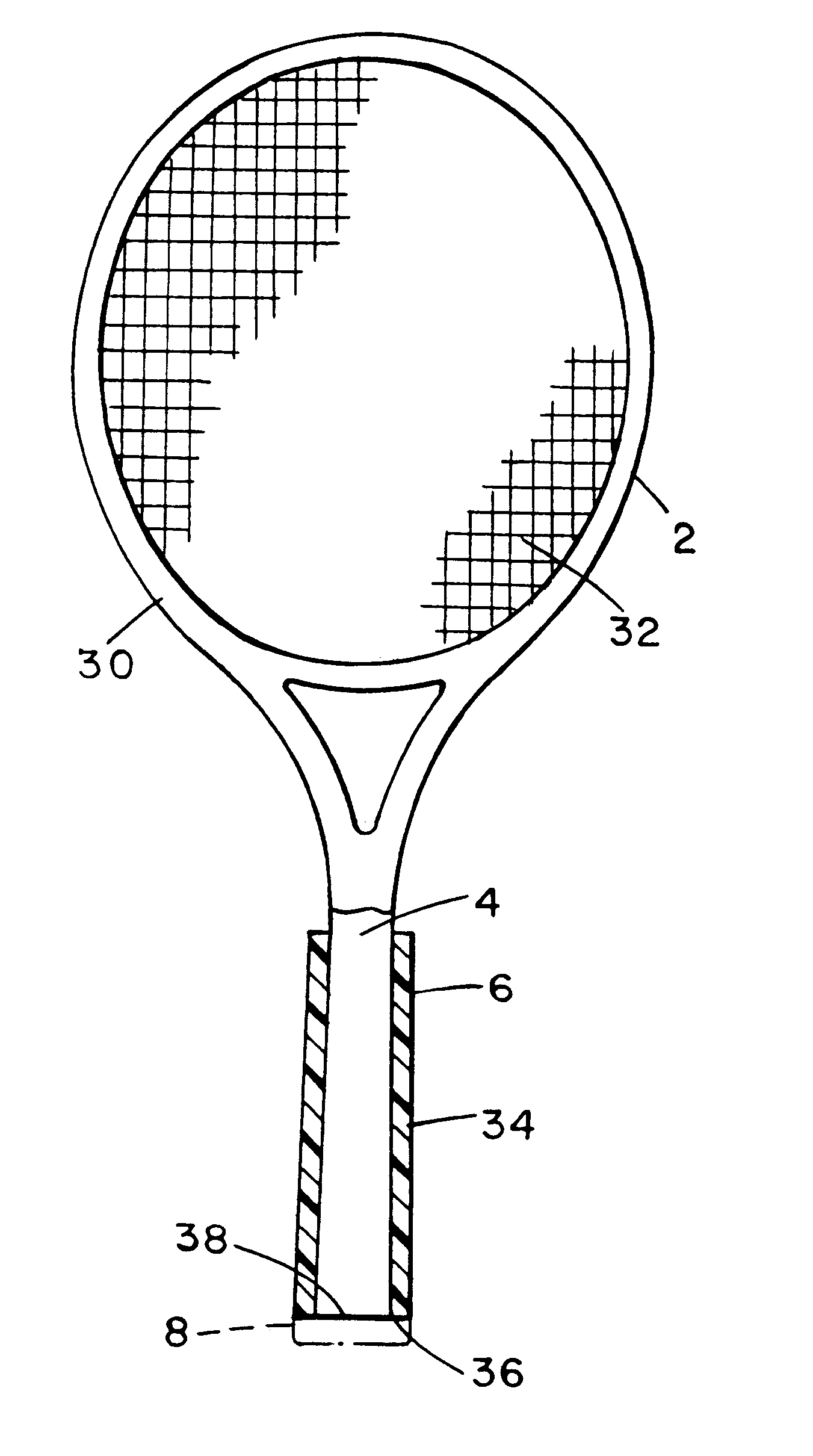

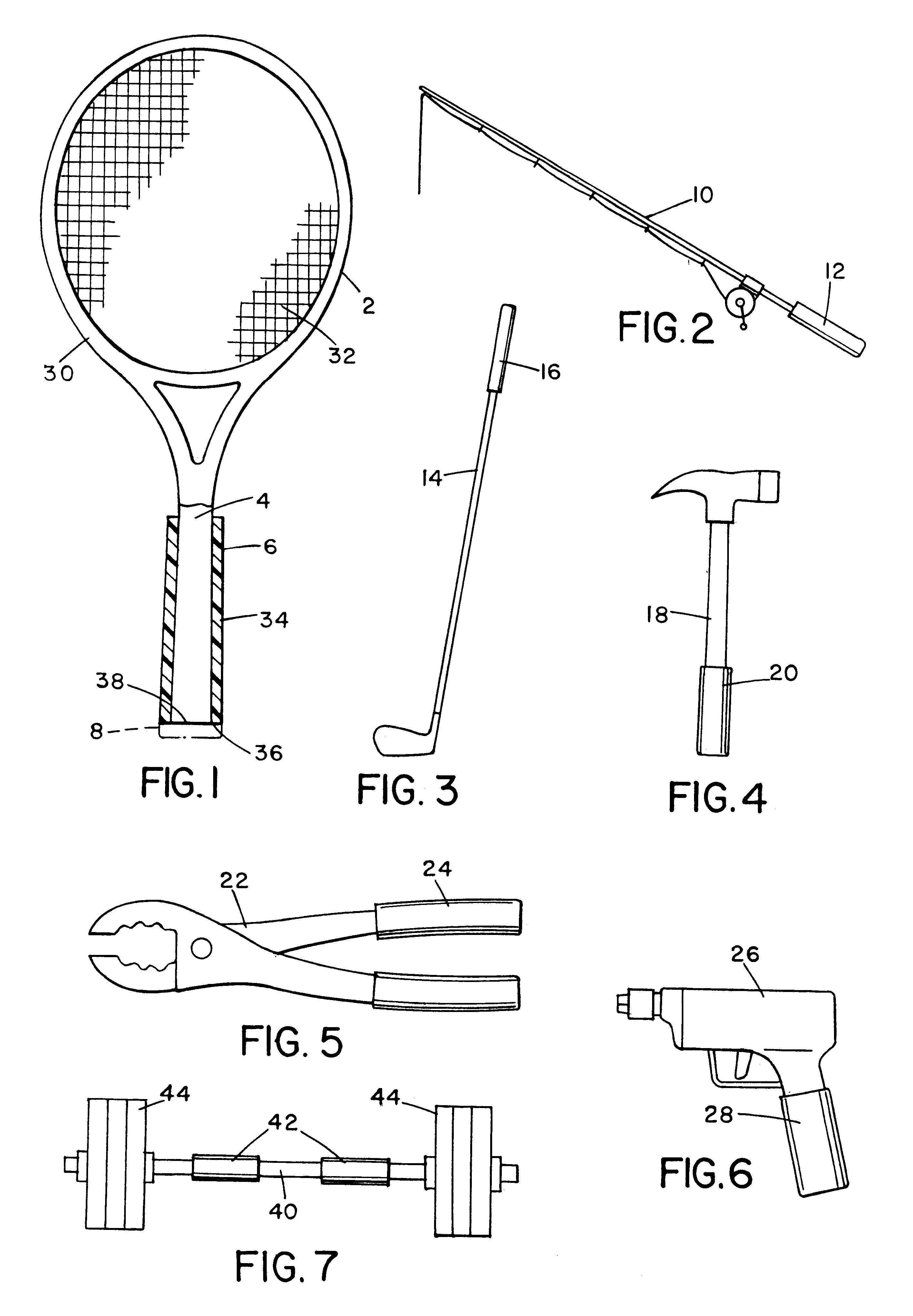

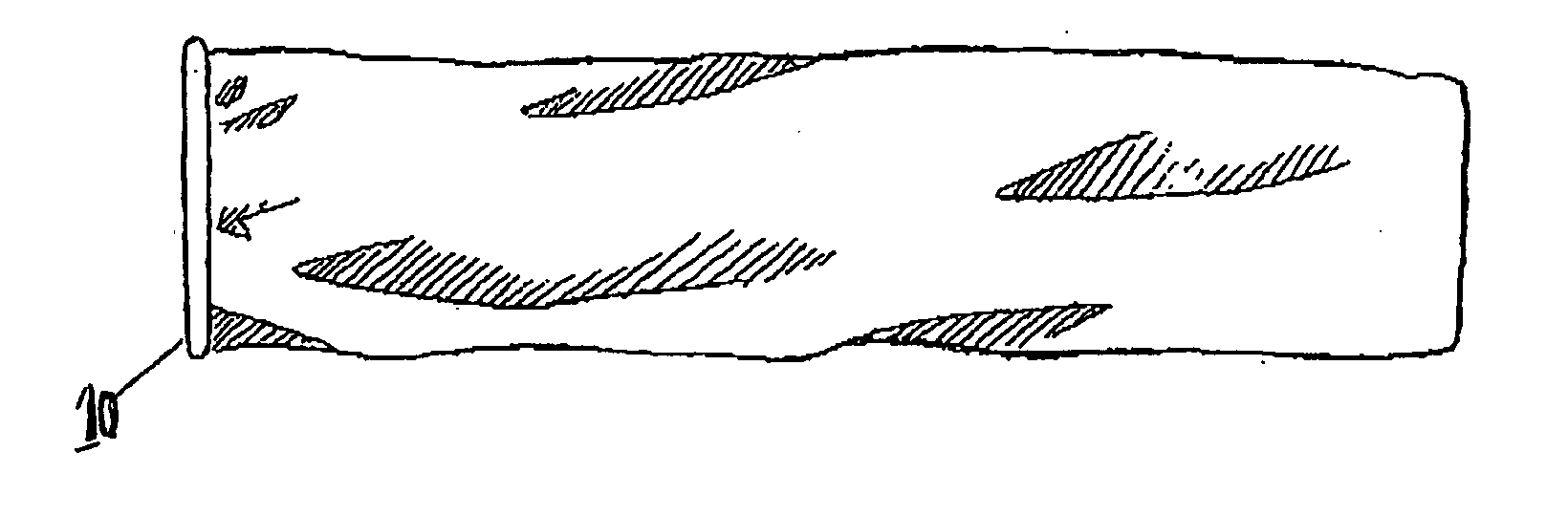

Low-odor single element equipment grip

A low odor grip is disclosed for a handle of a hand-held implement such as a sports implement or a manual or electric tool which is essentially free of disagreeable odors, which can be installed and quickly shrunk into a tight vapor resistant grip within a matter of a few minutes rather than requiring extended periods of time, and can be installed without the need for any application of heat or use of special tools, equipment or materials. The present device is therefore easy to install, merely sliding over the handle while in dilated state and then allowed to shrink and set by evaporation of the solvent, and thus can be satisfactorily installed in both fabrication facilities and in the field either as an original or replacement grip. The invention also includes an implement fitted with such grip. Representative implements include sports implements such as golf clubs, tennis racquets, weight bars and fishing poles, as well as tools such as hammers, drills, pliers, shovels, axes, and the like. The grip is preferable made of a swellable elastomeric material, preferably a natural or synthetic rubber. Suitable rubbers include EPDM rubber, neoprene or chlorosulfonate polyethylene (Hypalon(TM)) rubber, of which EPDM rubber is preferred.

Owner:JONES MICHAEL G

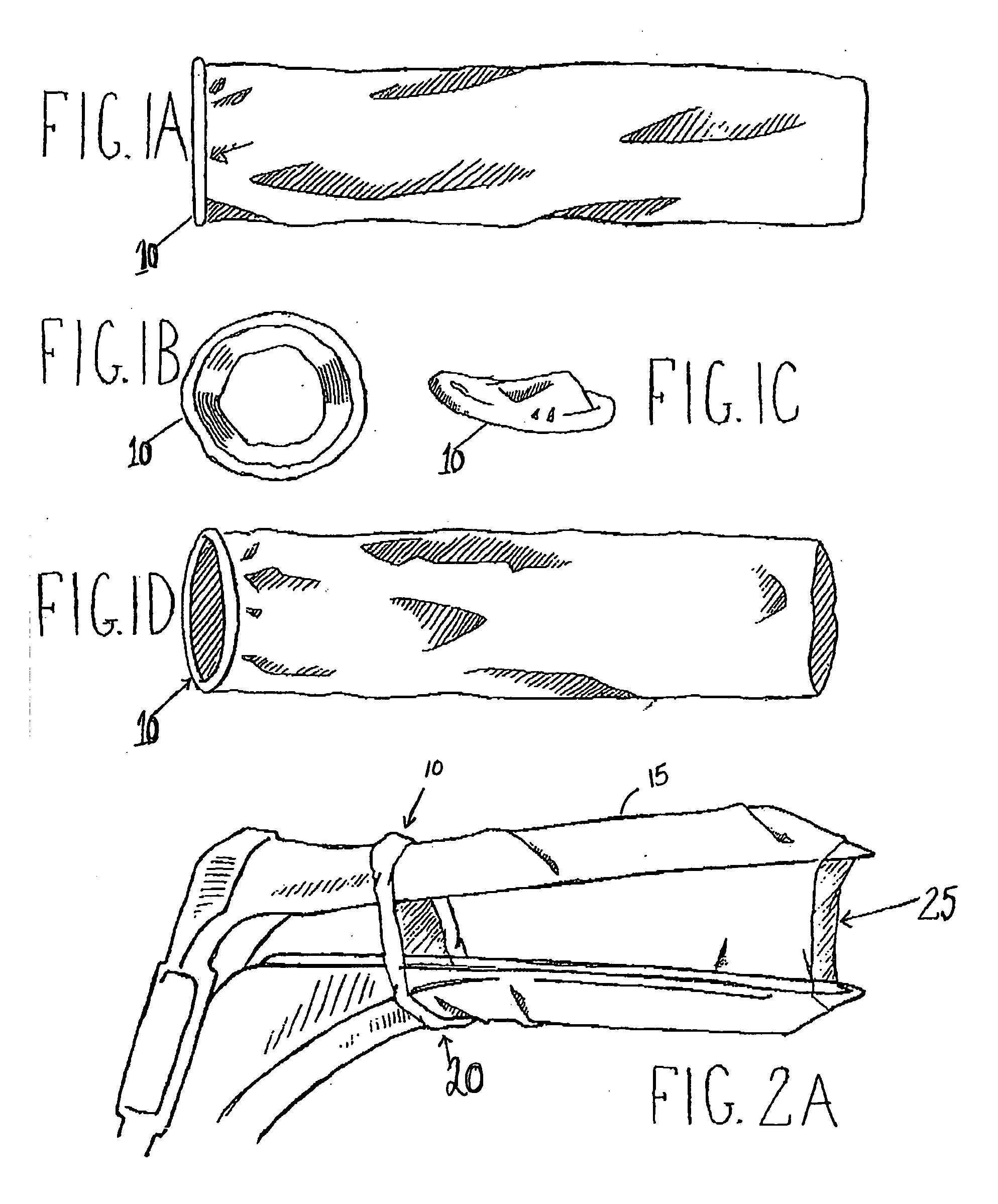

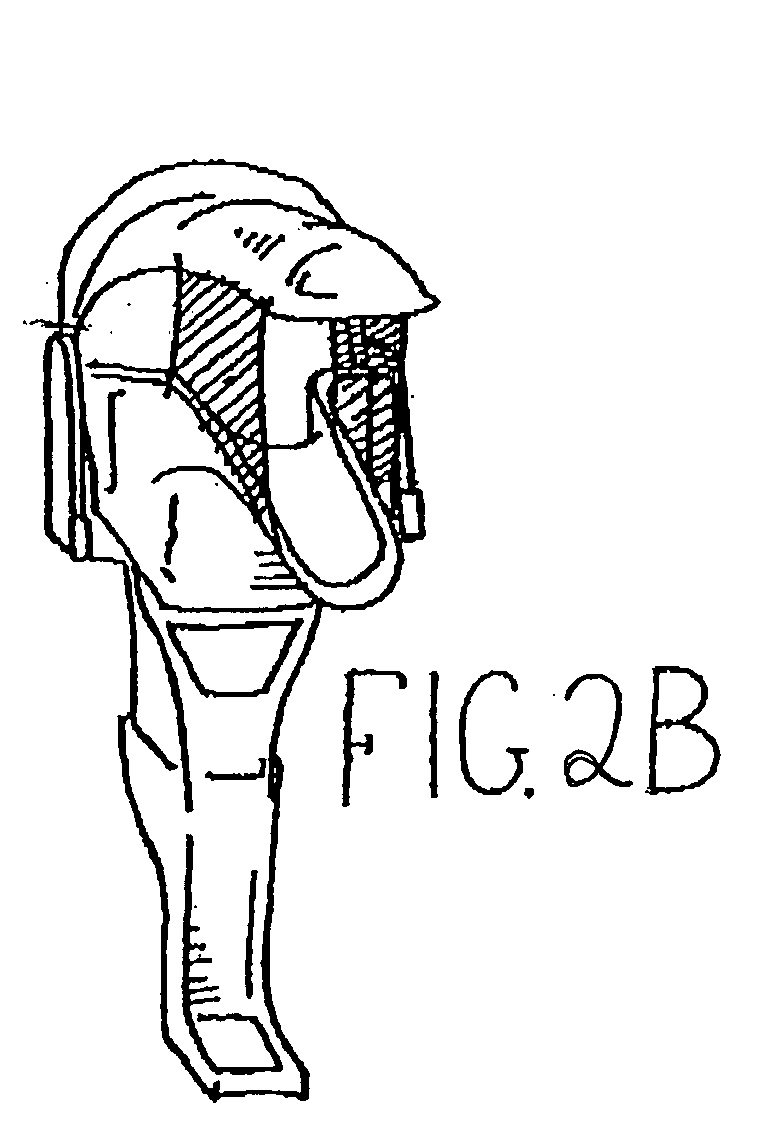

Disposable sheath for specula

A speculum sheath which covers a speculum and methods for using the sheath are described herein. A variety of different types of specula may be covered with the sheath, including anal, vaginal, ear, and nasal specula. The sheath is made of a compliant or partially compliant material, including latex, vinyl, natural and synthetic rubbers, silicone, nylon, polyethylene, polypropylene, and non-degradable or degradable elastomers. The material may be transparent or opaque. In the preferred embodiment, the material is transparent. The sheath may contain one or two openings. Optionally, the sheath contains an affixing means on the inside of or at least one of the openings on the sheath to prevent slippage when in contact with the speculum. Optionally, the sheath contains an active agent, such as hemostatic agents, anti-infectives, antibiotics, antimitotics anti-inflammatory, or other chemotherapeutic agents. In the preferred embodiment, the sheath is placed on a vaginal speculum and supports loose vaginal tissue when inserted into a patient. In the most preferred embodiment, the material is transparent so that medical provider may view the lumen.

Owner:ENDOLUMINAL THERAPEUTICS

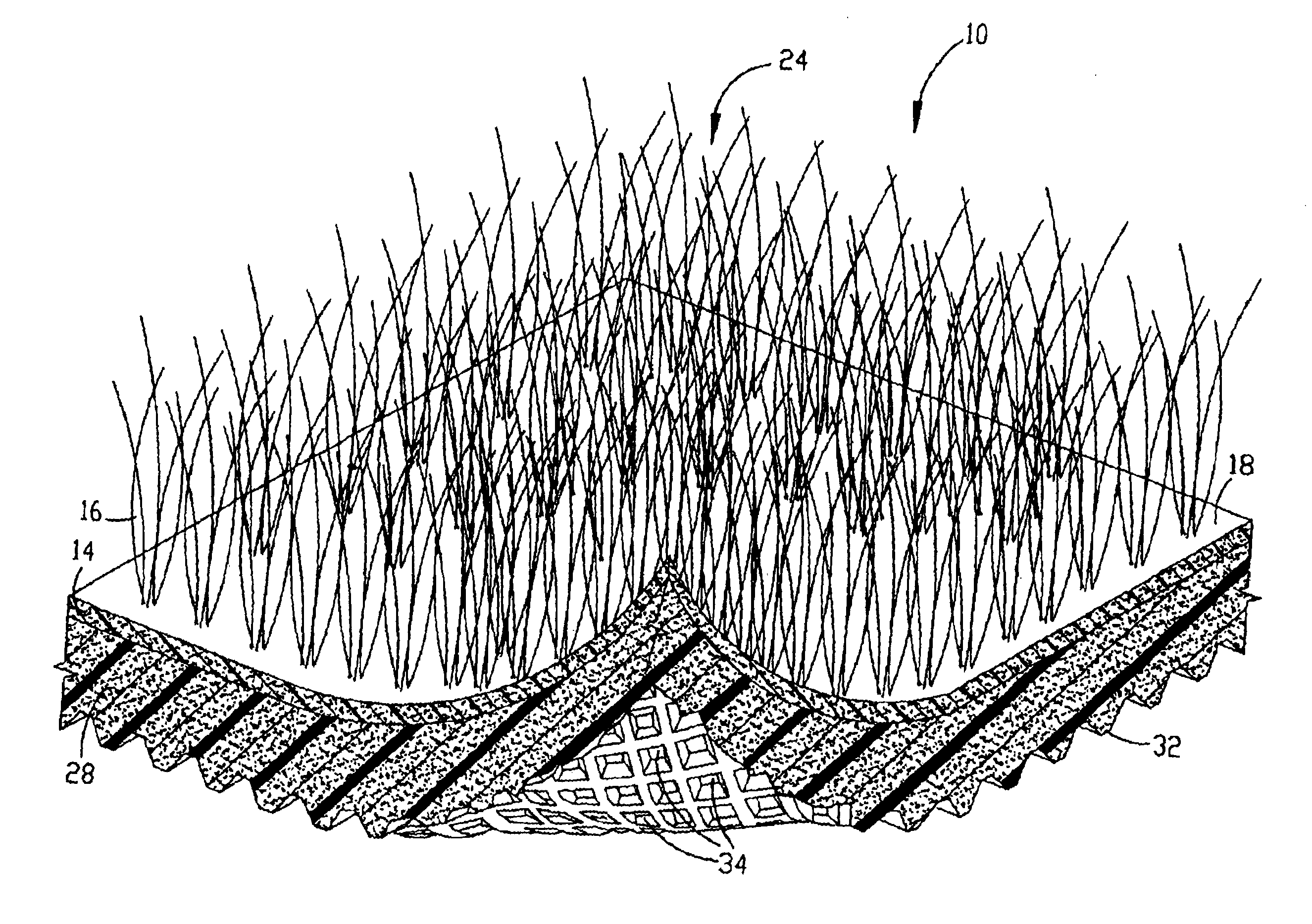

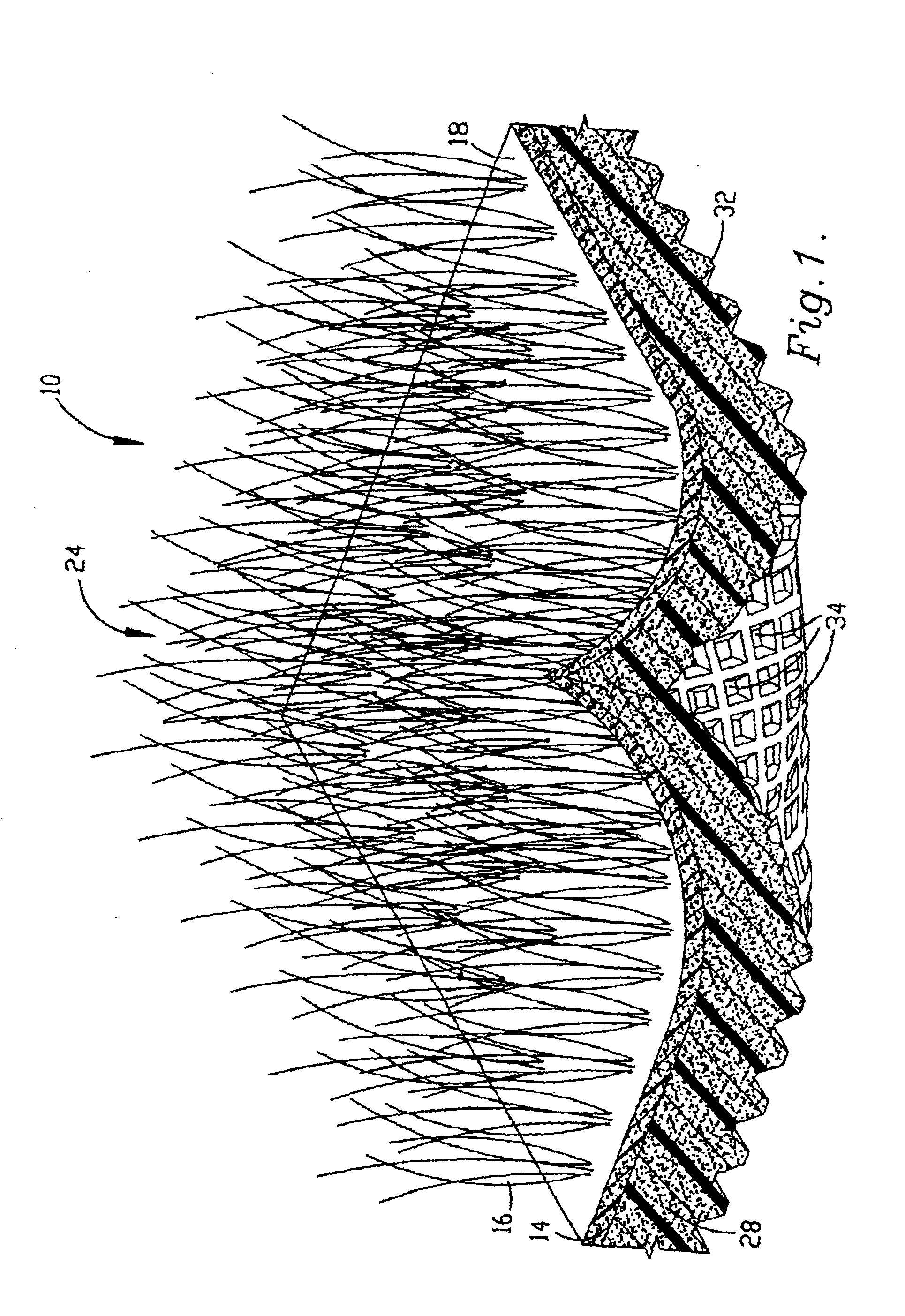

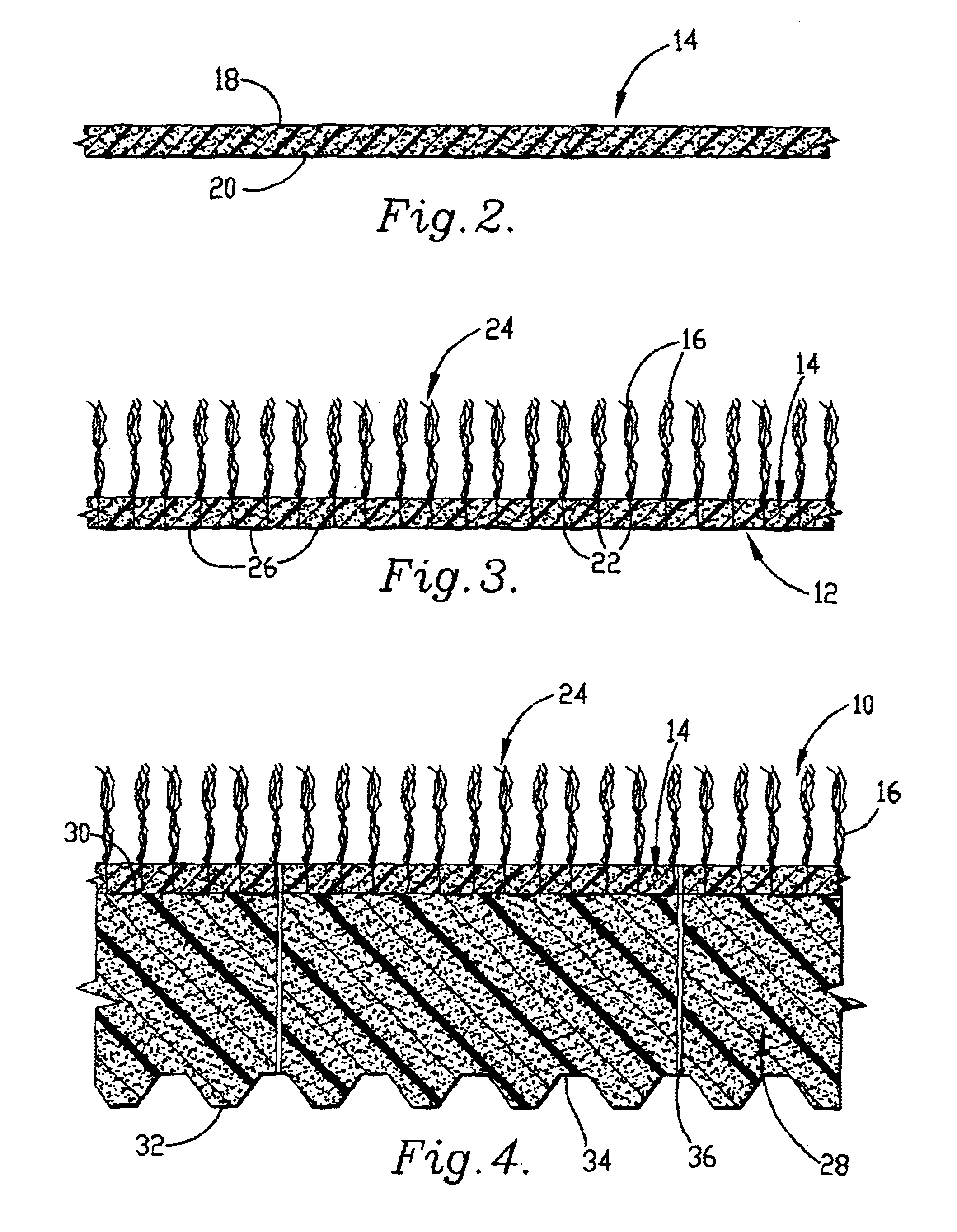

Tufted surface covering and method

The tufted surface covering includes a base formed from particles of a thermosetting polymer compound mixed with a particle binding agent causing a portion of the particles to bind together to form a self supporting web. The base is tufted with a tufting material. Thermosetting vulcanized natural and / or synthetic rubber compounds are employed. The polymer layer is tufted with a tufting material and heated to a temperature of from about 110° C. to about 220° C. at an elevated pressure of up to two tons per square inch, to cause the particles to bind together at elevated temperature and pressure to anchor and seal the tufts in place. Cross-linking agents and polar polymer containing compounds may be employed as particle binding agents. In another aspect of the invention, a second layer of particles of a thermosetting polymer mixed with a particle binding agent may be joined together with the particles of the first layer at elevated temperature and pressure. A series of spaced apertures extends through the first and second layers to enable free draining of the surface covering. The lower surface of the covering includes spaced indentations to reduce the weight of the covering.

Owner:WALTERS IAN D

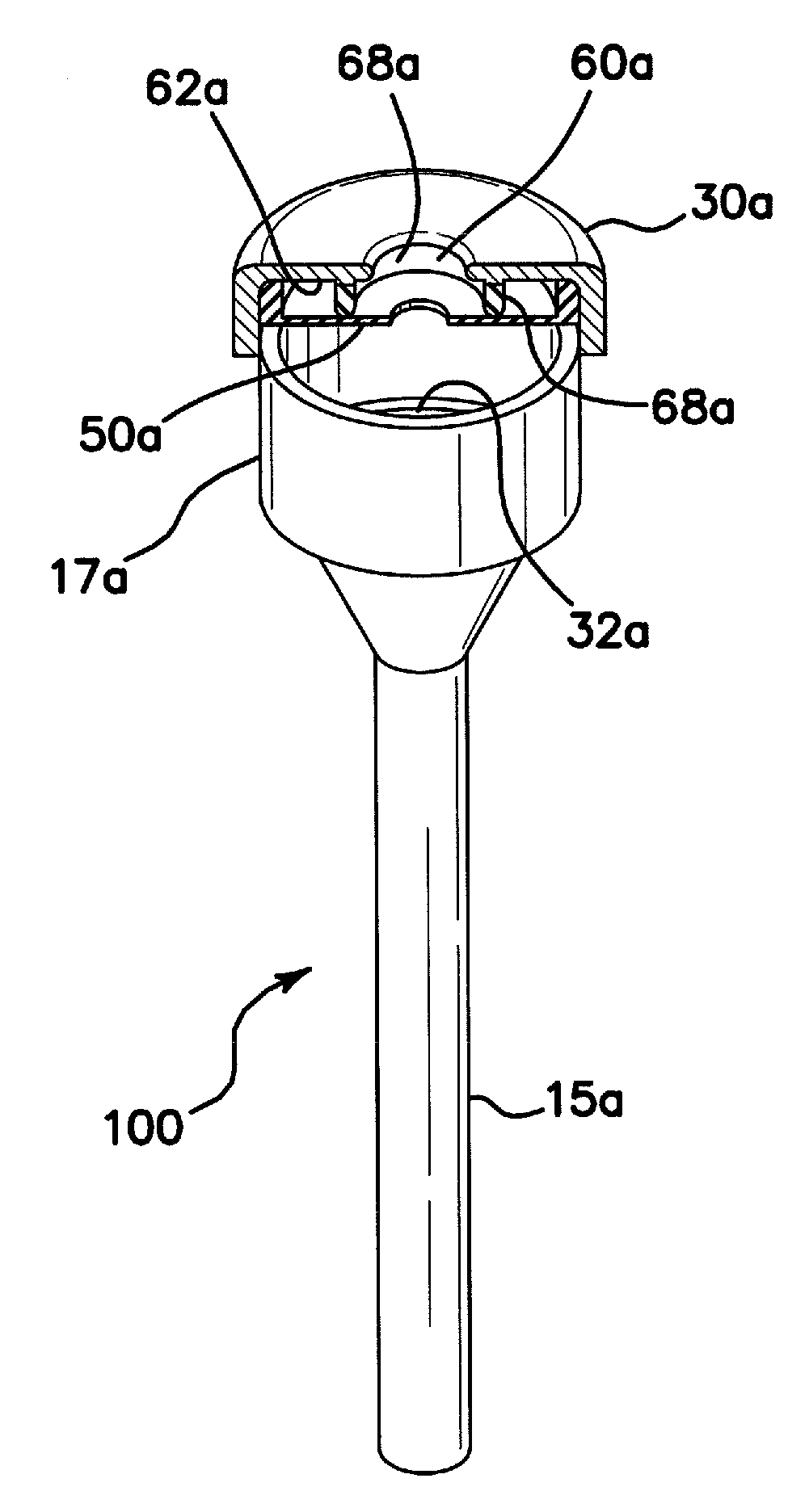

Seal housing having anti-inversion features

InactiveUS7591802B2Avoid excessive wearFacilitates over-center positioningEar treatmentCannulasDiaphragm sealEngineering

The invention is directed to a trocar adapted to form a seal around a surgical instrument, the trocar comprising a cannula having an axis extending between a proximal end and a distal end; a housing having a proximal wall and forming with the cannula a working channel sized and configured to receive the instrument; a septum seal disposed in the housing and extending transverse to the axis of the cannula across the working channel, the septum seal having a normal state when the instrument is absent from the working channel and a stretched state when the instrument is being withdrawn from the working channel; portions of the proximal wall of the housing defining an orifice sized and configured to receive the instrument into the working channel; and an elastomeric ring-shaped projection extending axially distally between the proximal wall and the septum seal, the ring-shaped projection having an axial length adapted to deform to prevent inversion and binding of the septum seal and the orifice upon withdrawal of the surgical instrument. In particular, the septum seal is prevented from reaching the orifice in the proximal wall of the housing when the instrument is withdrawn. The projection may be bonded, insert-molded, or compressively fitted to the proximal wall of the housing. The projection may be formed of an elastomeric material such as natural or synthetic rubber. The projection may further comprise a plurality of portions or fingers extending axially distally from the proximal wall, each of the extending portions or fingers may further include a living hinge. In another aspect, the ring-shaped projection may be formed on the surface of the septum seal instead of the proximal wall of the housing. That is, the ring-shaped projection may be formed to extend axially proximally from the surface of the septum seal toward the proximal wall of the housing.

Owner:APPL MEDICAL RESOURCES CORP

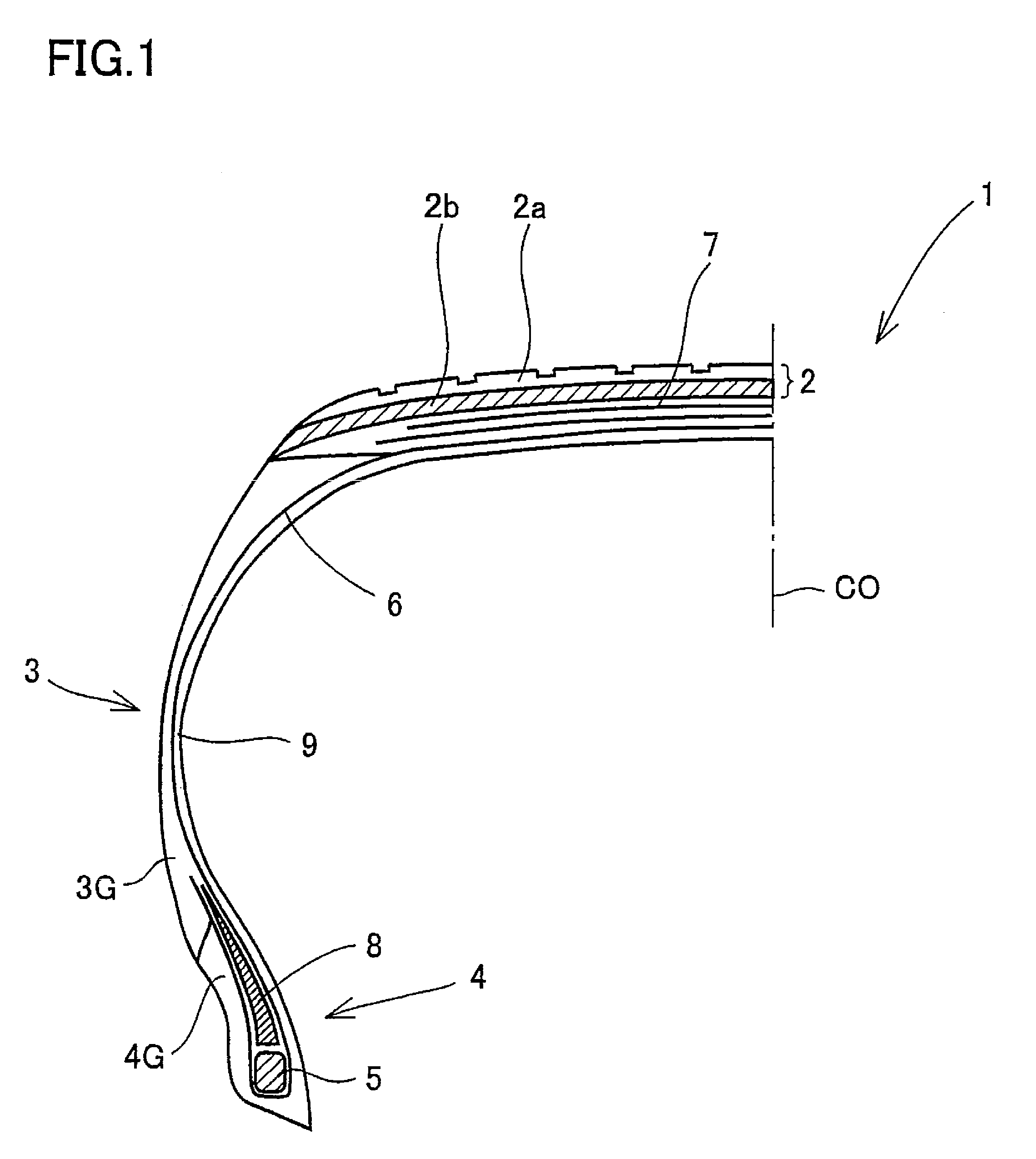

Vulcanized rubber composition, pneumatic tire and the process of producing the same

InactiveUS8022136B2Improve featuresReduce energy lossSpecial tyresPneumatic tyre reinforcementsPolymer scienceRolling resistance

By using a vulcanized rubber composition containing a rubber component composed of at least any one of a natural rubber, a modified natural rubber and a synthetic rubber, and chemically modified microfibril cellulose, it is possible to provide a vulcanized rubber composition that is environmentally conscious and that exhibits excellent rupture characteristics and a low energy loss, and a pneumatic tire that is excellent in rolling resistance property, steering stability and durability.

Owner:SUMITOMO RUBBER IND LTD +1

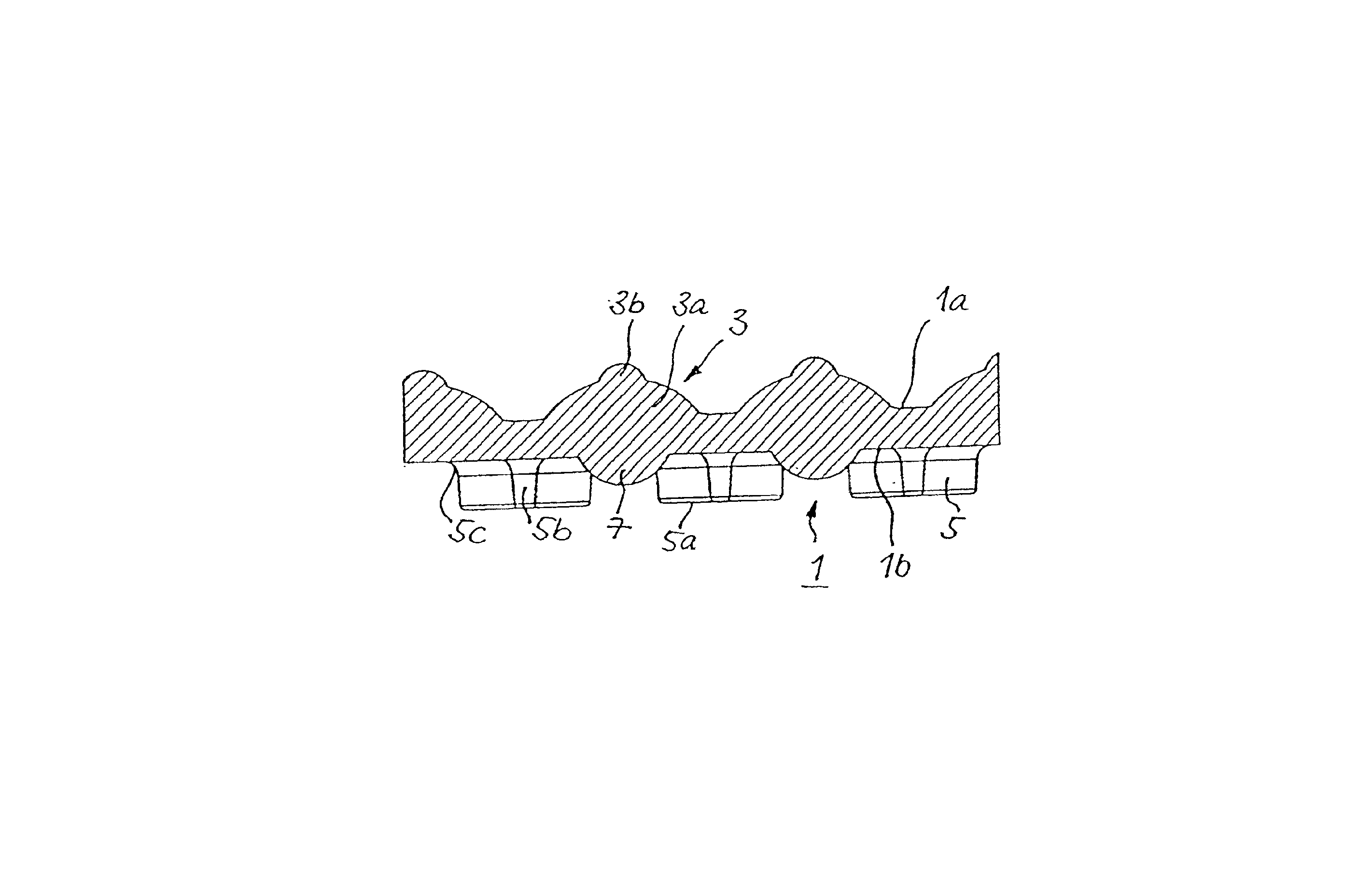

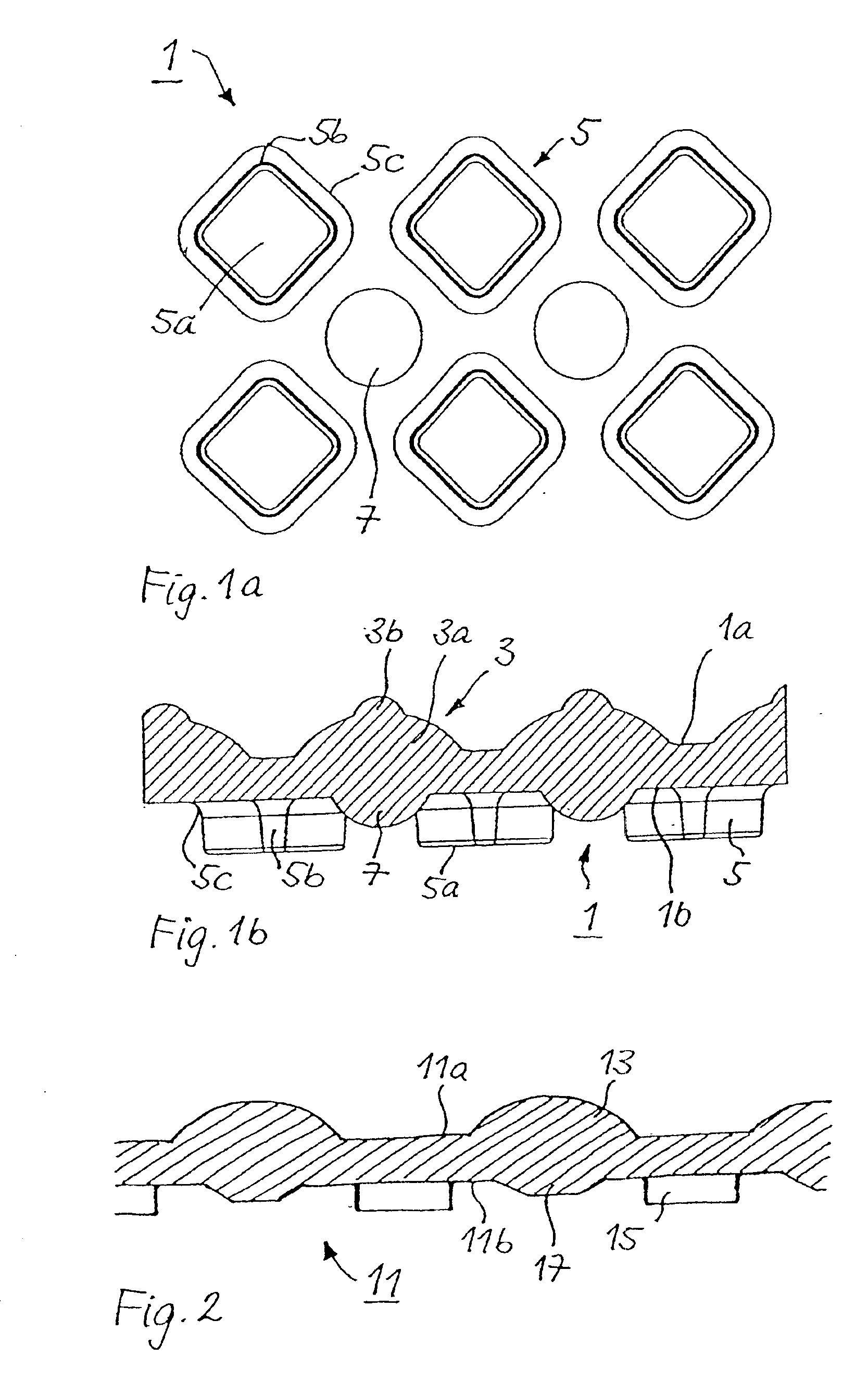

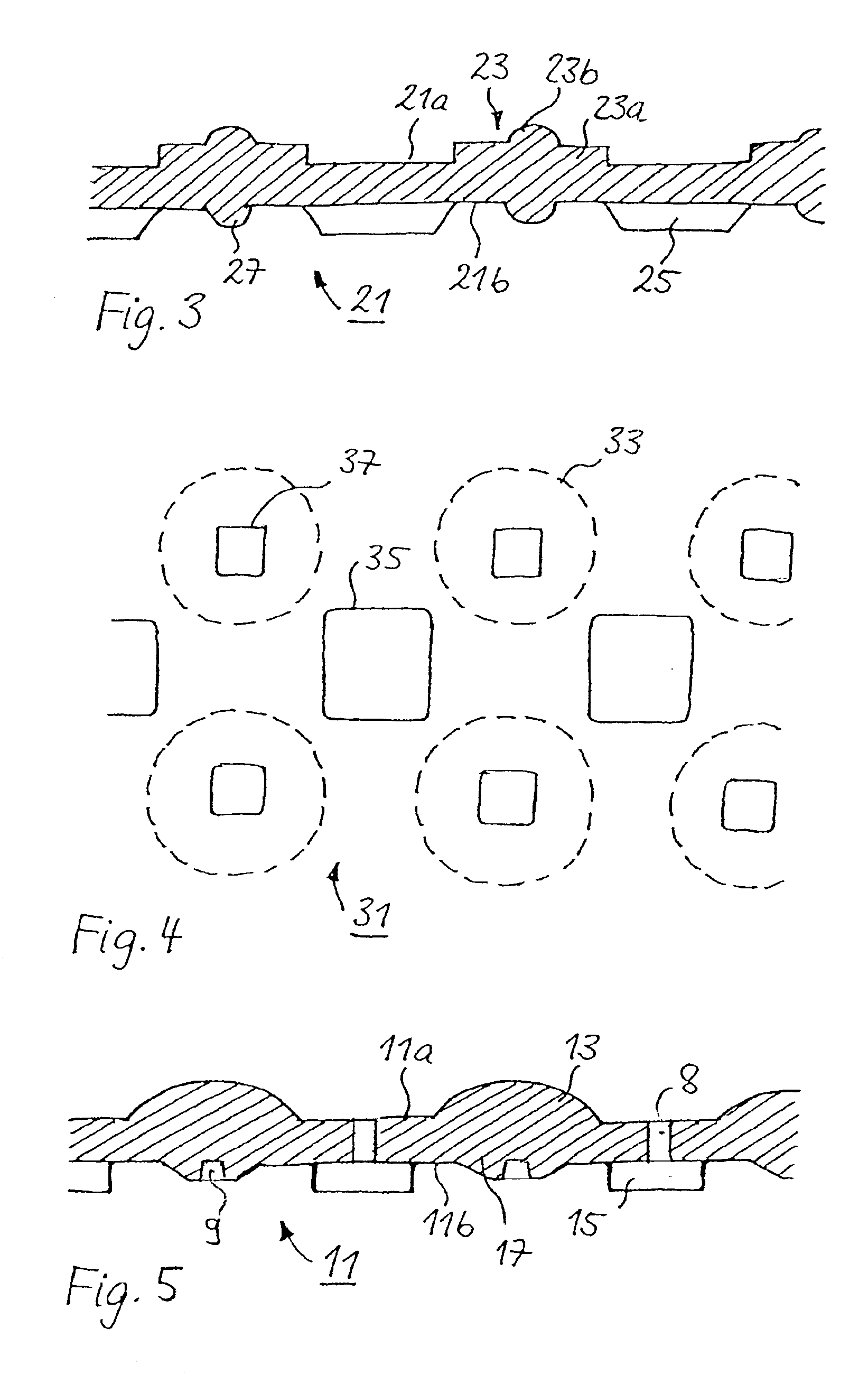

Floor covering of an elastically deformable material

InactiveUS6878430B2Easy to cleanImprove skid resistanceTreadsVehicle arrangementsEngineeringSynthetic rubber

A floor covering (1) made of an elastically moldable material, in particular from a synthetic rubber, which is provided with a regular arrangement consisting of first projections (3) on the upper side (1a) and with a regular arrangement of second projections (5) on the underside (1b), the projections of the first projections and of the second projections not exhibiting any overlapping area on the plane of the covering and that, on the underside within the projections of the first projections, third projections (7) are provided in each case which have a smaller height vis-à-vis the second projections such that the floor covering only touches a floor with the second projections when it is in an unloaded state, however, when a preset load is exceeded locally, the third projections come in contact with the floor.

Owner:WERKSITZ W MILEWSKI

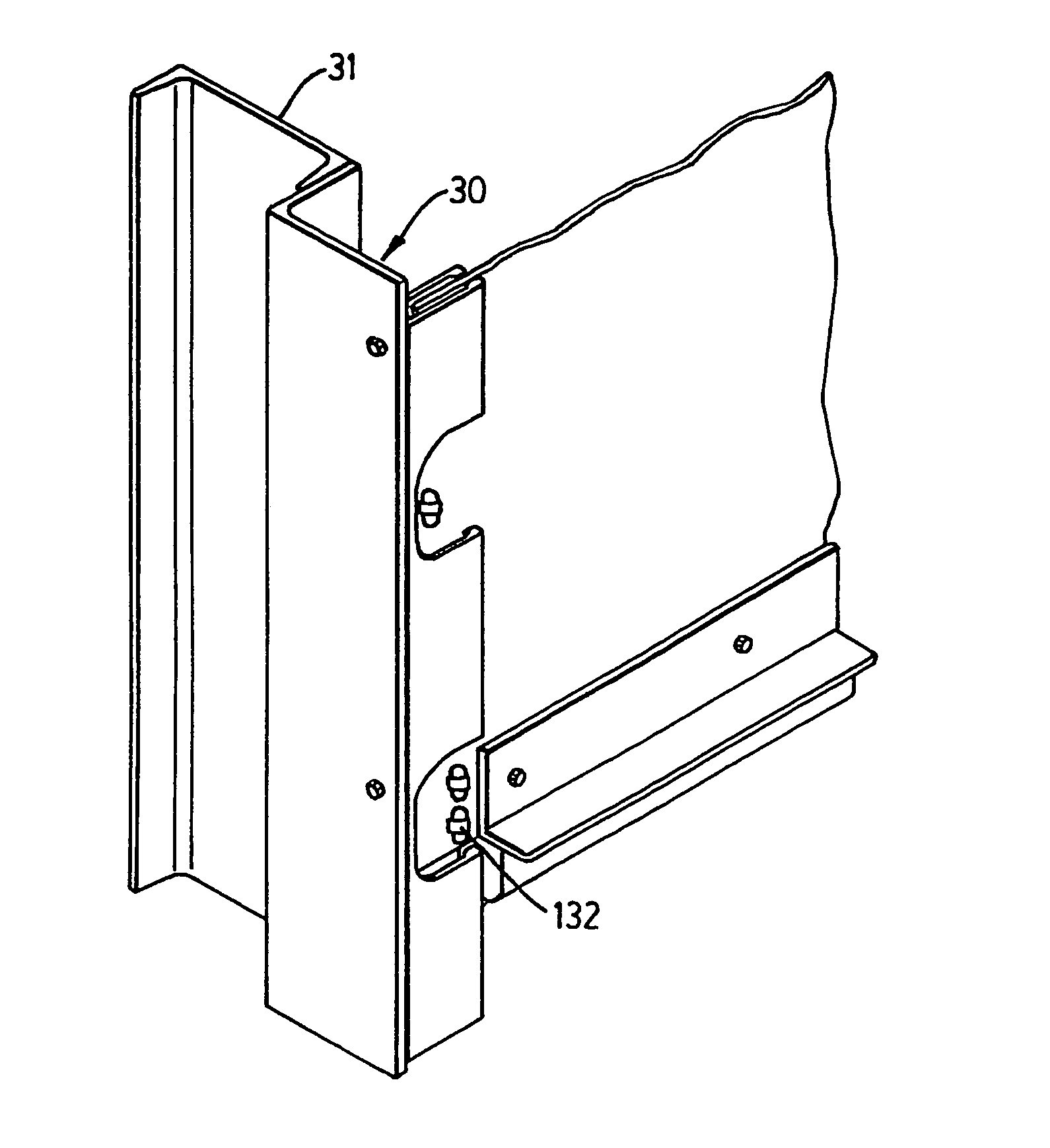

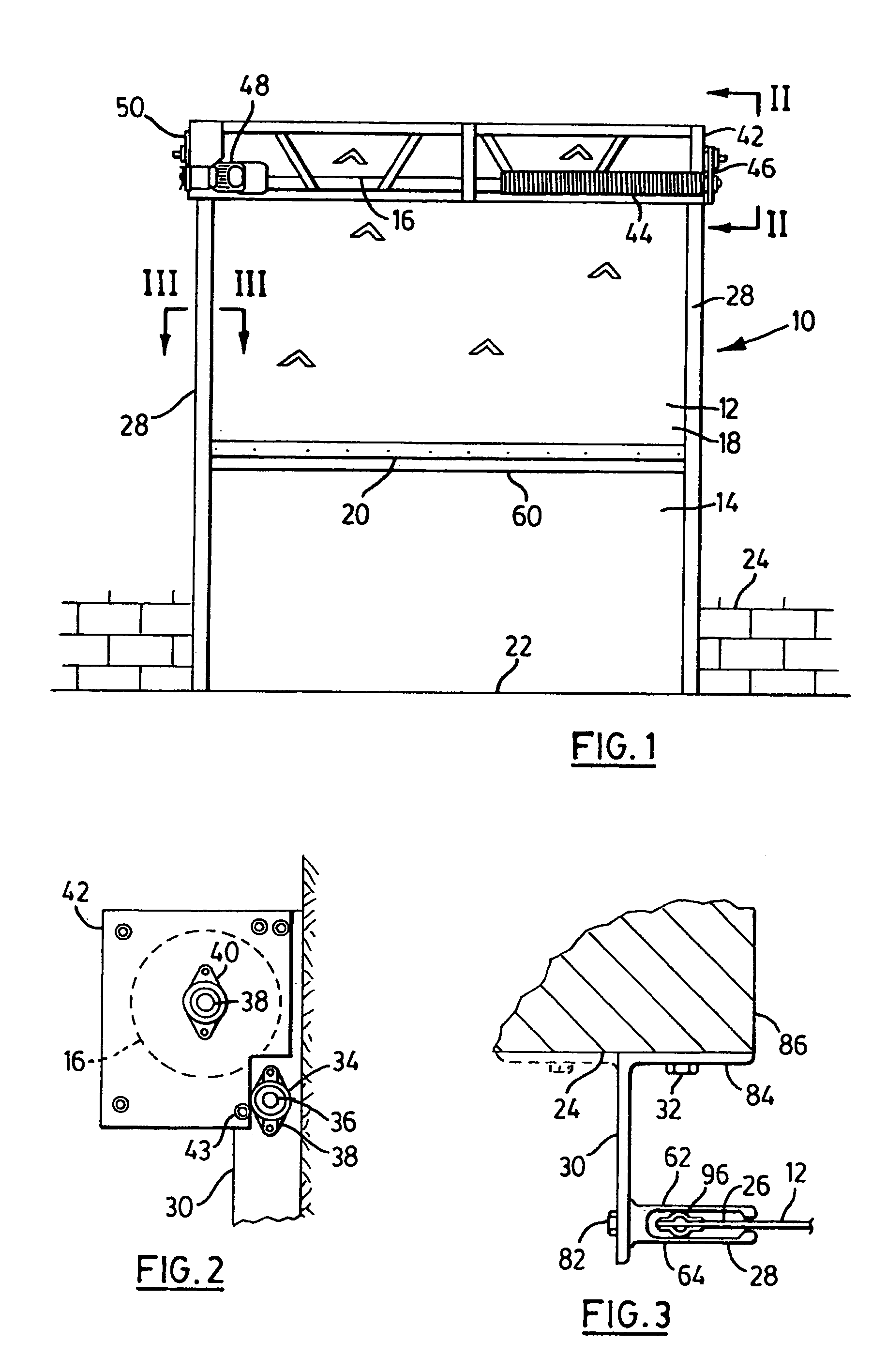

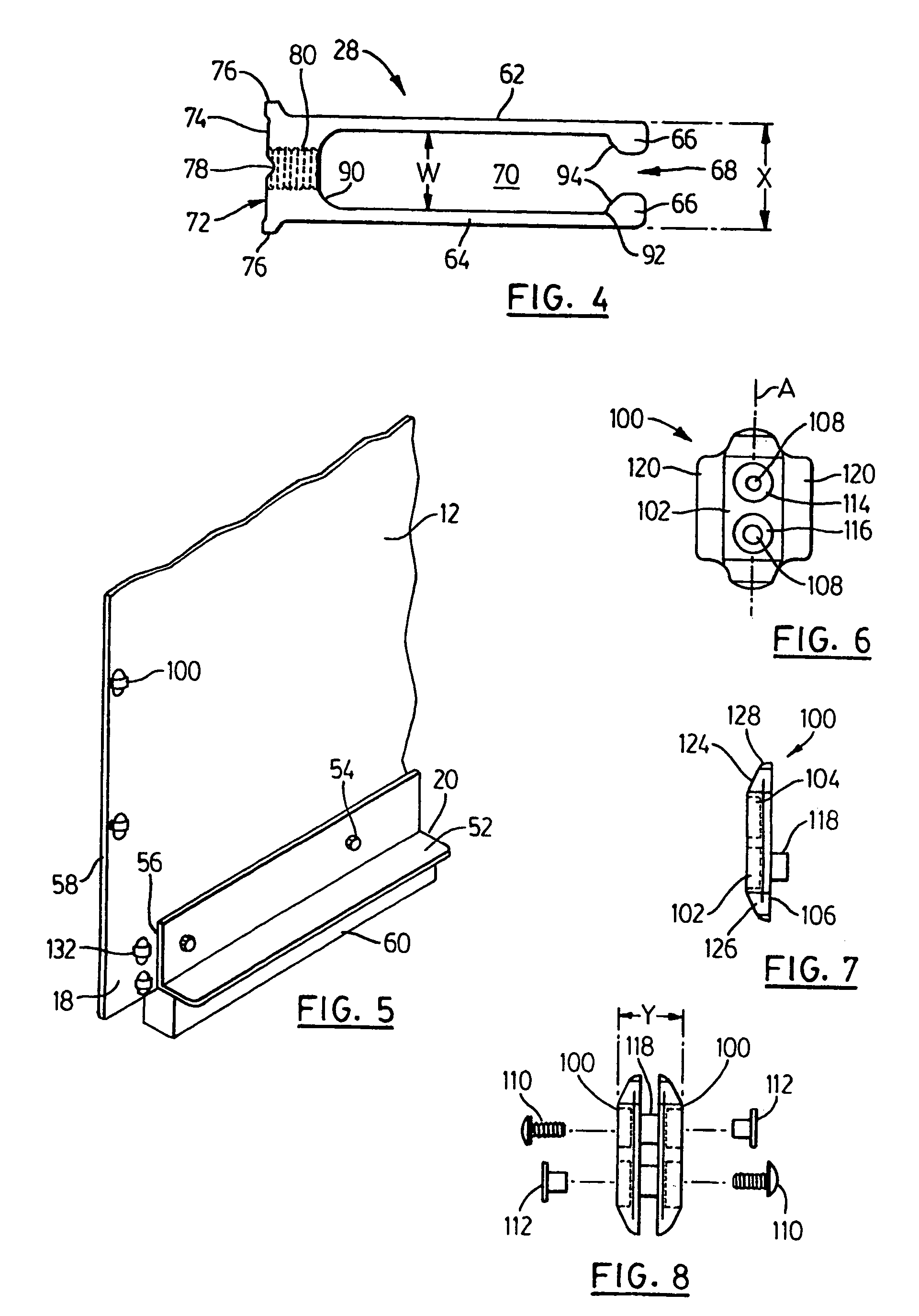

Roll-up flexible door and guides therefor

ActiveUS7516770B2Avoid damagePrevent escapeScreensExtensible doors/windowsSynthetic rubberMechanical engineering

A roll-up door assembly including a flexible curtain made of synthetic rubber or fabric, a curtain winding mechanism and two guide members which extend vertically on opposite sides of the doorway. Side edge sections of the curtain are movable in respective guide members. Each guide has inner and outer wall sections with each wall section having an inwardly projecting, longitudinal rib. The two ribs of each guide form an elongate slot that receives a side edge section of the curtain. Spaced-apart pairs of curtain lock members are mounted on and distributed along each side edge section of the curtain. The lock members of each pair are positioned opposite one another on front and rear surfaces of the curtain respectively. The combined thickness of each pair of lock members and the curtain exceeds the width of the elongate slot.

Owner:TNR INDAL DOORS

Using a cleaning cloth impregnated with coupling agent for adhesive films

InactiveUS6106953AAdhesive processes with surface pretreatmentGlass/slag layered productsSolventSynthetic rubber

Use of a prior-cleaning cloth for an adhesive bond brought about by means of an adhesive film which is rereleasable without damage by pulling in the direction of the bond plane and which has an adhesive composition based on polymers and / or copolymers of synthetic rubber and / or natural rubber, characterized in that the substrate to be bonded is rubbed with a prior-cleaning cloth of this kind which is impregnated with a moisture-reactive organosilane, the organosilane being dissolved in a solvent or solvent mixture and being present therein in a concentration of 0.1-3% by weight, whereupon, following a waiting time of a few minutes, the adhesive film is pressed onto the treated area and then an article, hook or the like is bonded to the other side of the adhesive film, or else in that, after a waiting time of a few minutes, the adhesive film is pressed onto the treated area, an article, hook or the like already being located in bonded-on form on the reverse of the adhesive film.

Owner:TESA SE

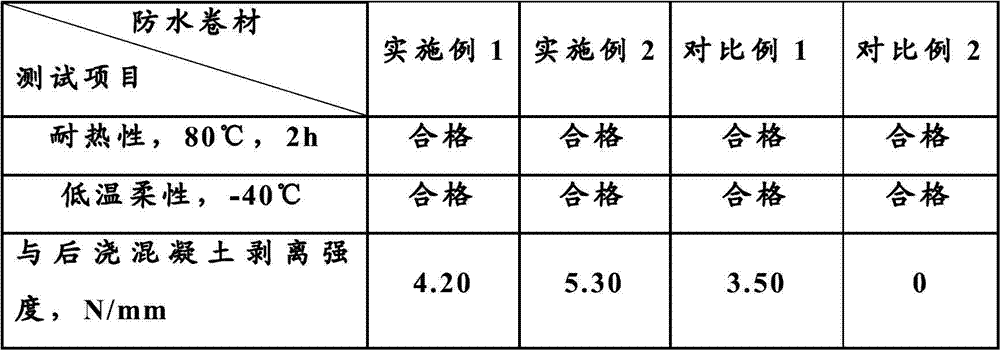

Waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement

ActiveCN103333555AImprove adhesionGood extensibilityRosin coatingsConjugated diene hydrocarbon coatingsMortise and tenonSynthetic rubber

The invention provides a waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement. The waterproof coating is characterized by comprising the following raw materials by weight: 20-50 parts of a synthetic rubber latex, 20-50 parts of emulsified asphalt, 0.5-2 parts of a functional additive and 0.5-2 parts of a dispersant, 20-40 parts of a filler and 10-25 parts of water. The principle is that through coupling effect of the functional additive, part of the molecules in the synthetic rubber and most molecules in the asphalt couple into large molecules with reaction activity; when the large molecules contact with a base plane, the non-reactive molecule segments of the rubber and asphalt and the base plane form physical adsorption, and the molecular segments with reaction activity conduct react with the base plane to form chemical bond effect, so as to generate strong adhesive force; and after bonding, the coating is hardly influenced by environmental factors. Therefore, the waterproof coating provided by the invention has excellent waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

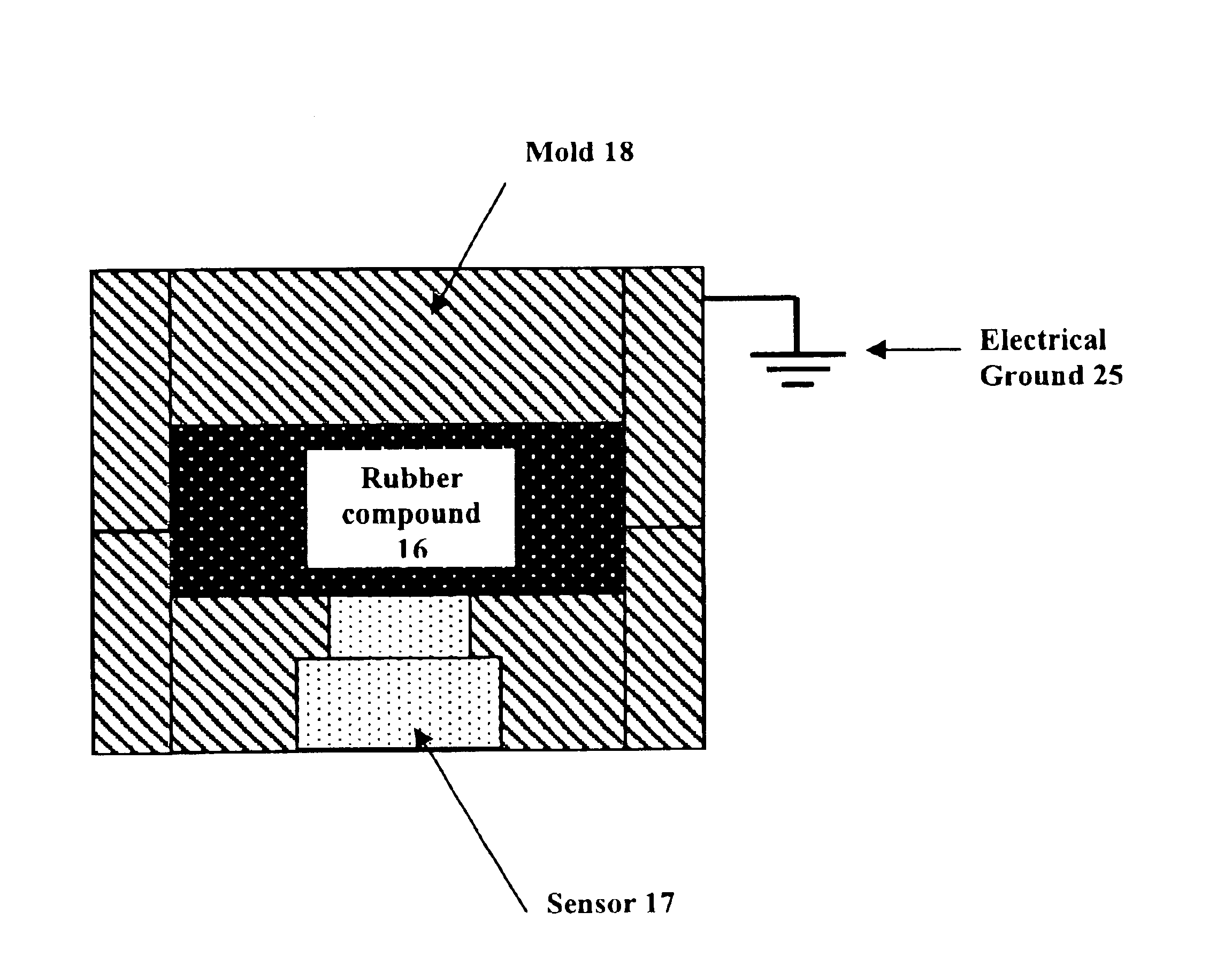

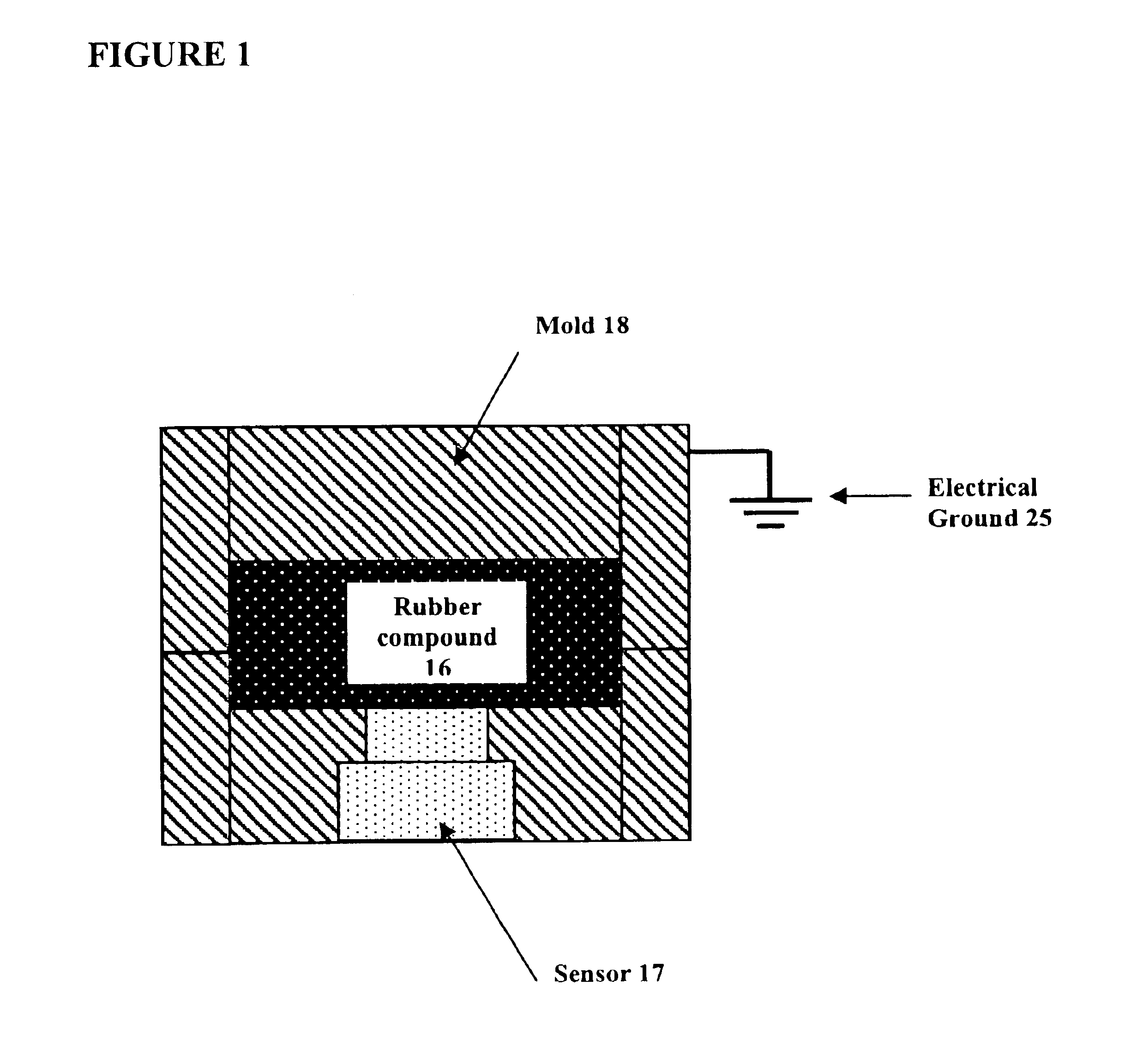

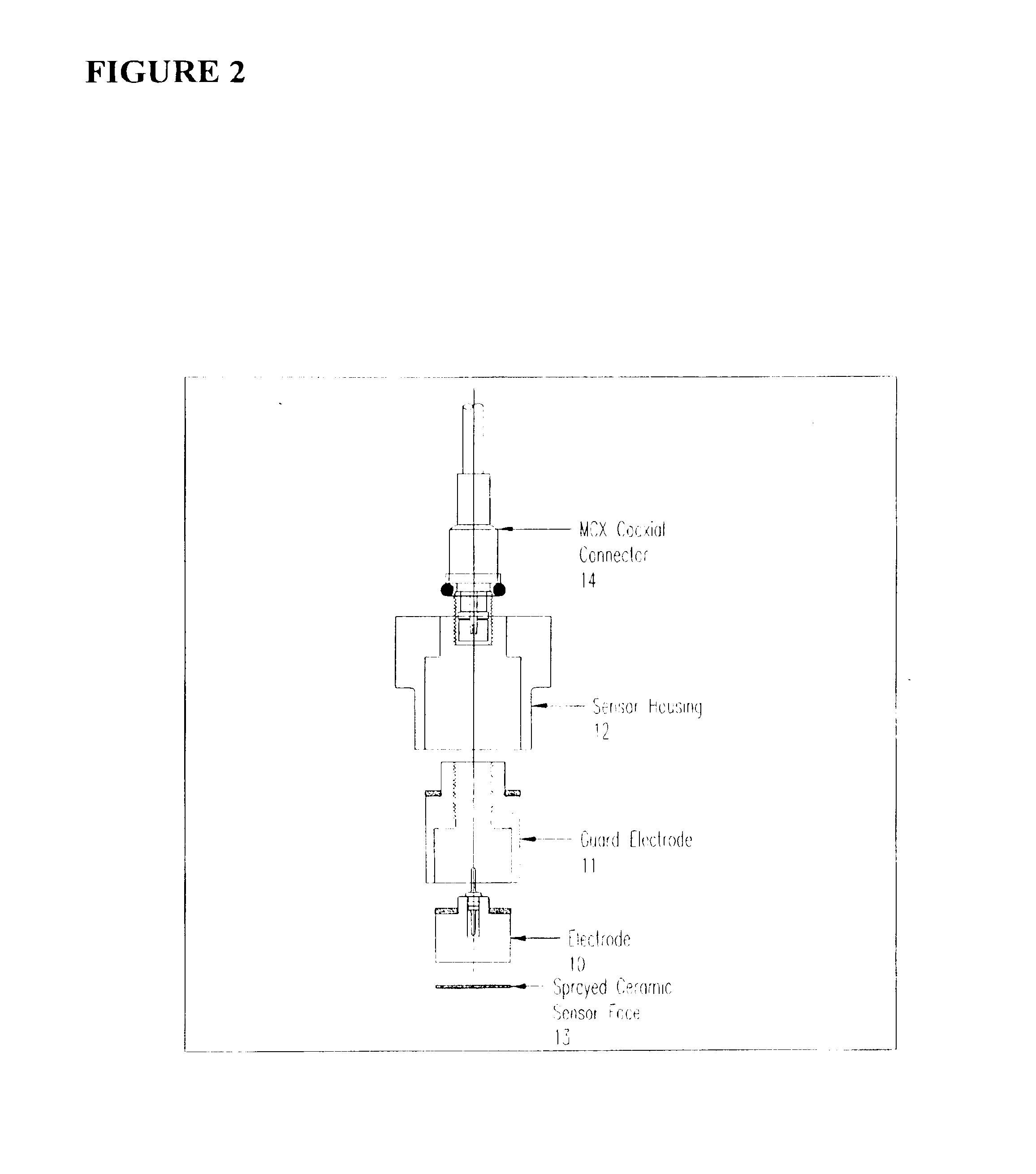

Process and apparatus for improving and controlling the vulcanization of natural and synthetic rubber compounds

InactiveUS6855791B2Unique shapeQuality improvementFlow propertiesThermometer testing/calibrationCompound aElectricity

A process for curing a natural or synthetic rubber includes the measuring of curing conditions by dielectric or impedance means to produce a process curve (impedance property data versus time) followed by analyzing the process curve with a software algorithm which defines and statistically quantifies the correlation between the process curve and the desired part properties. The correlation relationship is applied in real time to end the curing process at the optimum time and to produce rubber parts of uniform quality and with reduced process cycle time.

Owner:SIGNATURE CONTROL SYST

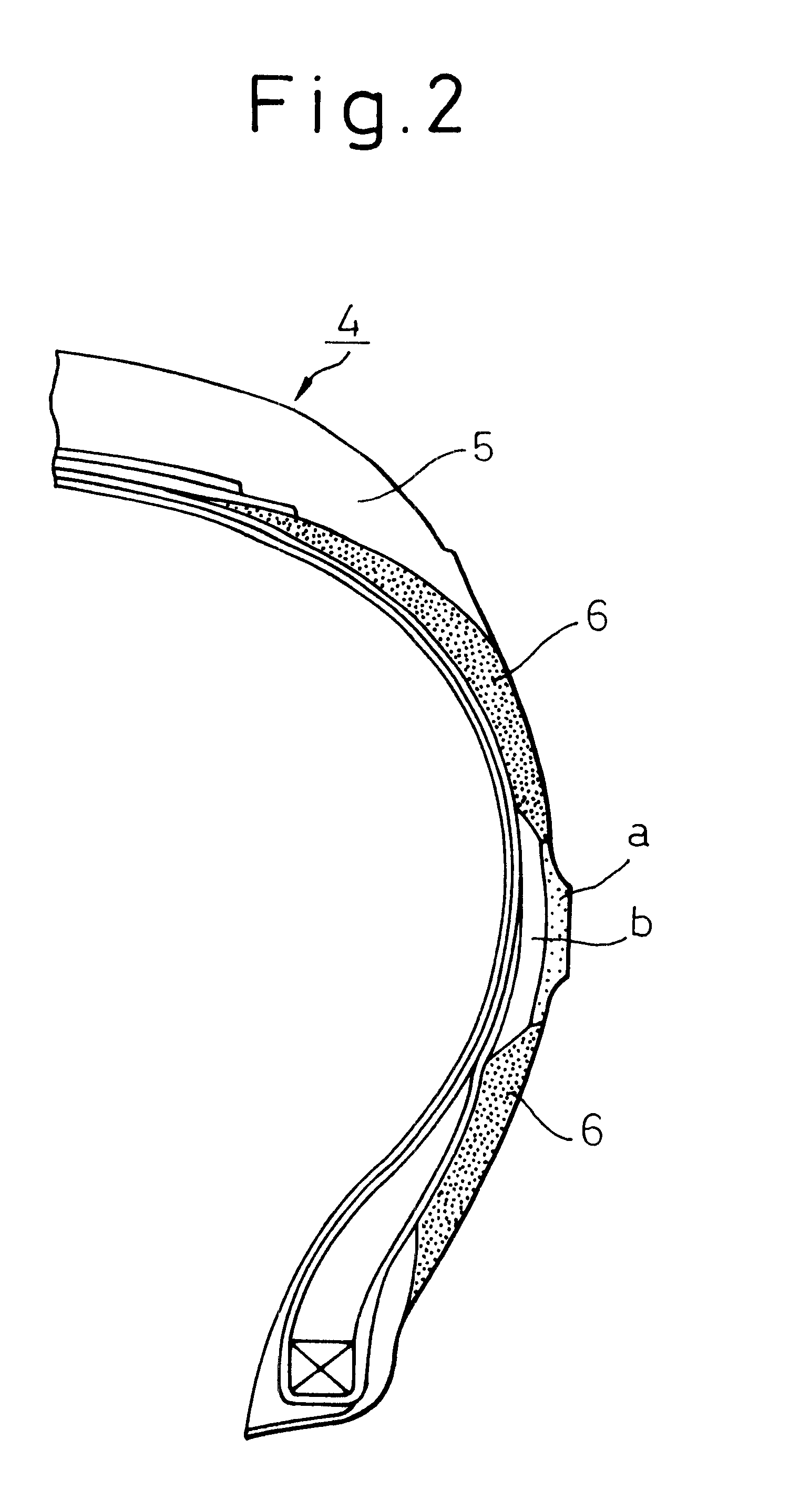

Pneumatic tire using long afterglow phosphorescent rubber composition

InactiveUS6431236B1Improve fatigue resistanceMinimizes strainSpecial tyresInflatable tyresPolymer scienceSurface layer

Owner:YOKOHAMA RUBBER CO LTD

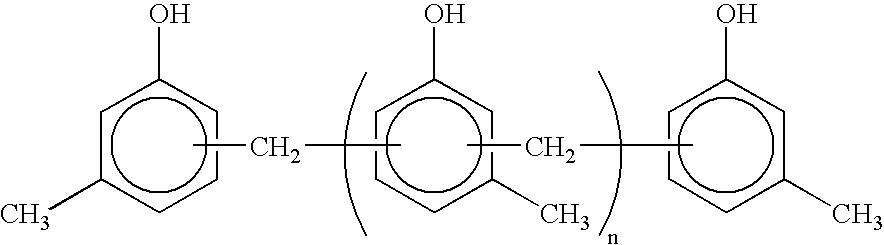

Rubber composition and tire using same

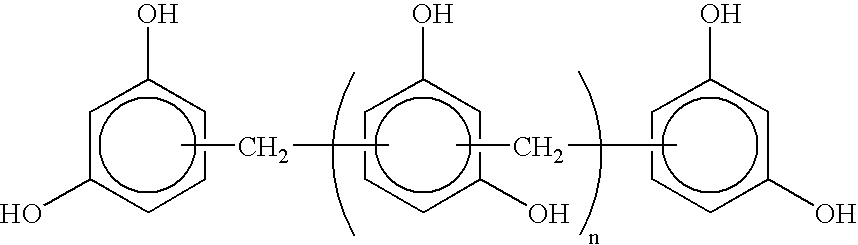

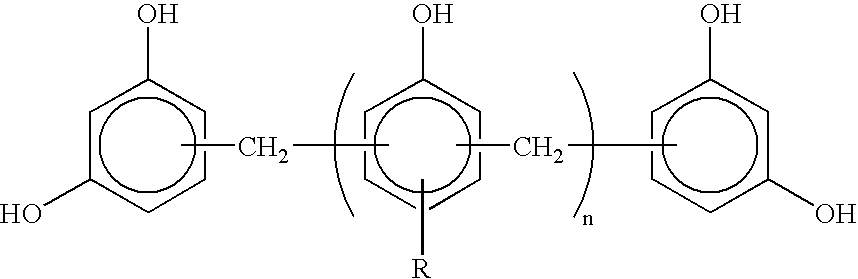

InactiveUS20080009570A1Solve the lack of hardnessReduce consumptionOrganic chemistrySpecial tyresPolymer scienceCresol

The present invention provides a rubber composition with superior properties with respect to processability, low fuel consumption, complex modulus, and durability, and tires prepared by using the rubber composition. The rubber composition of the present invention comprises: 2 to 2.9 parts by weight of (B) sulfur, 0.6 to 10 parts by weight of (C) at least one compound selected from the group consisting of a cresol resin, a resorcin condensate, and a modified resorcin condensate, and 10 to 55 parts by weight of (D) a carbon black and / or silica, based on 100 parts by weight of (A) a rubber component comprising a natural rubber and / or isoprene rubber and at least two kinds of synthetic rubbers selected from the group consisting of butadiene rubber, modified butadiene rubber, styrene-butadiene rubber, and modified styrene-butadiene rubber. The tire of the present invention is prepared by using the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

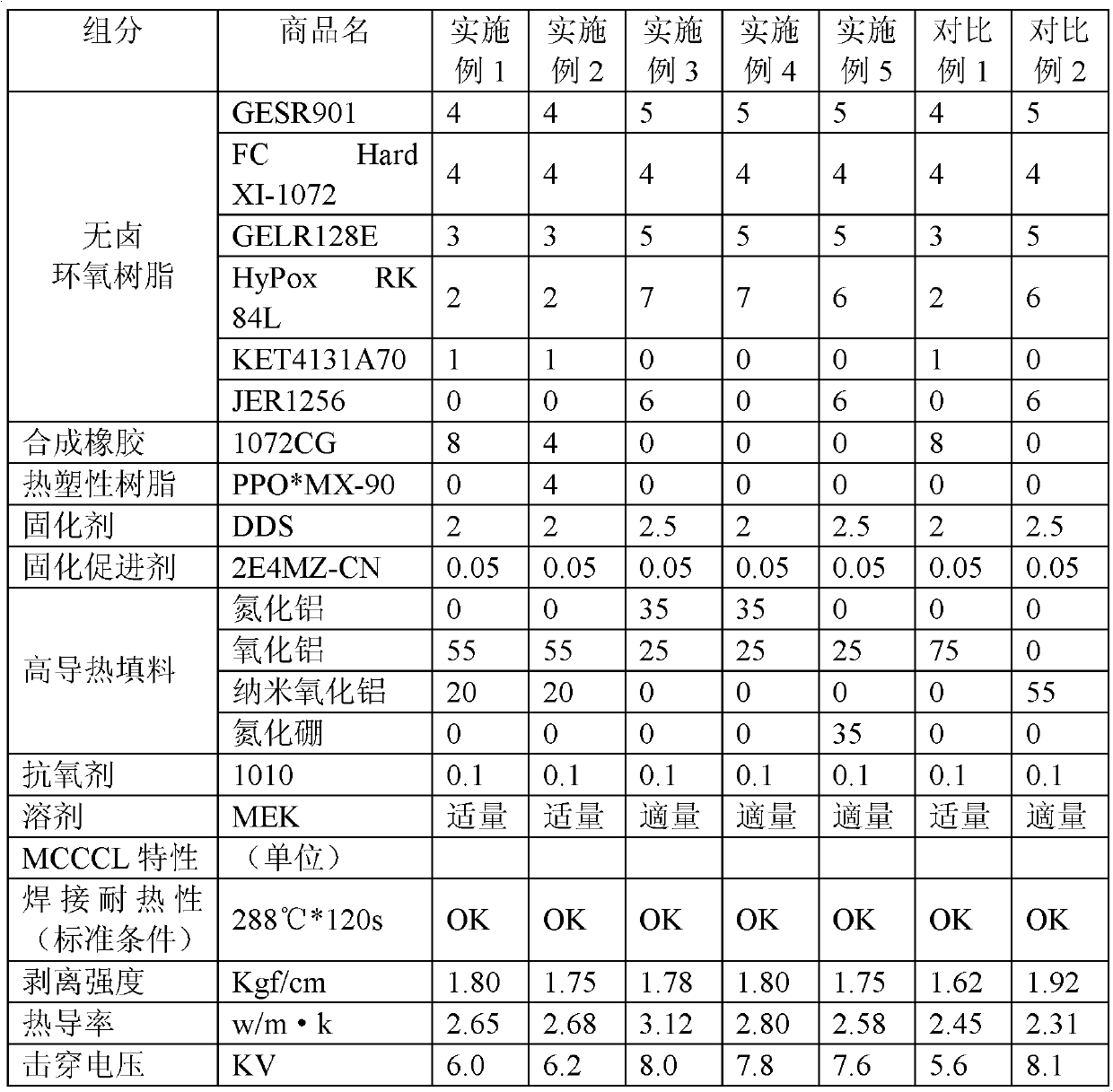

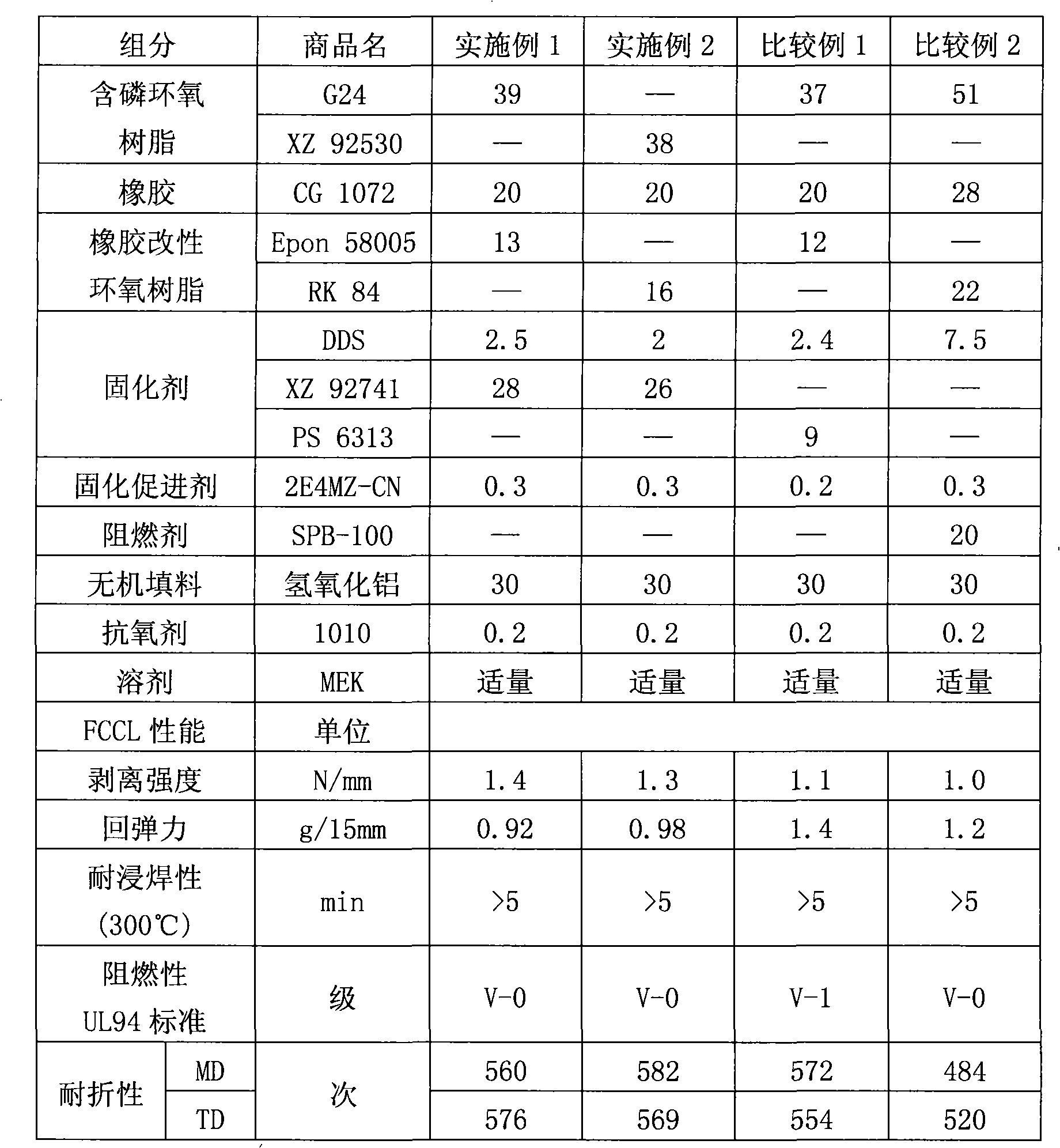

Halogen-free fire-retardant high heat conducting insulating resin composition and heat dissipation metal-base copper clad plate

ActiveCN102558765AImprove heat resistanceHigh peel strengthSynthetic resin layered productsEpoxy resin adhesivesEpoxyHeat conducting

The invention discloses a halogen-free fire-retardant high heat conducting insulating resin composition and a heat dissipation metal-base copper clad plate (CCL). The composition comprises the following components in parts by weight: 10-45 parts of halogen-free epoxy resin, 0-15 parts of thermoplastic resin and / or synthetic rubber, 0.1-5 parts of curing agent, 0.02-1 parts of accelerator, 0.5-1 parts of antioxidant and 25-80 parts of heat conducting filler. The halogen-free fire-retardant high heat conducting insulating resin composition of the invention adopts high heat conducting filler, and the cured composition shows good thermal conductivity, electric insulativity and welding heat resistance as well as high adhesive force. The invention also discloses a heat dissipation metal-base CCL prepared by using the above halogen-free fire-retardant high heat conducting insulating resin composition, which has high thermal conductivity and high peel strength, does not have the problems of peel-off and deterioration even being subjected to thermal cycle of quick heating and quick cooling, and also has high electrical breakdown resistance, good heat resistance and soldering resistance and the like, and the flame retardant rating of the heat dissipation metal-base CCL reaches UL-94V0.

Owner:ALLSTAE TECH ZHONGSHAN

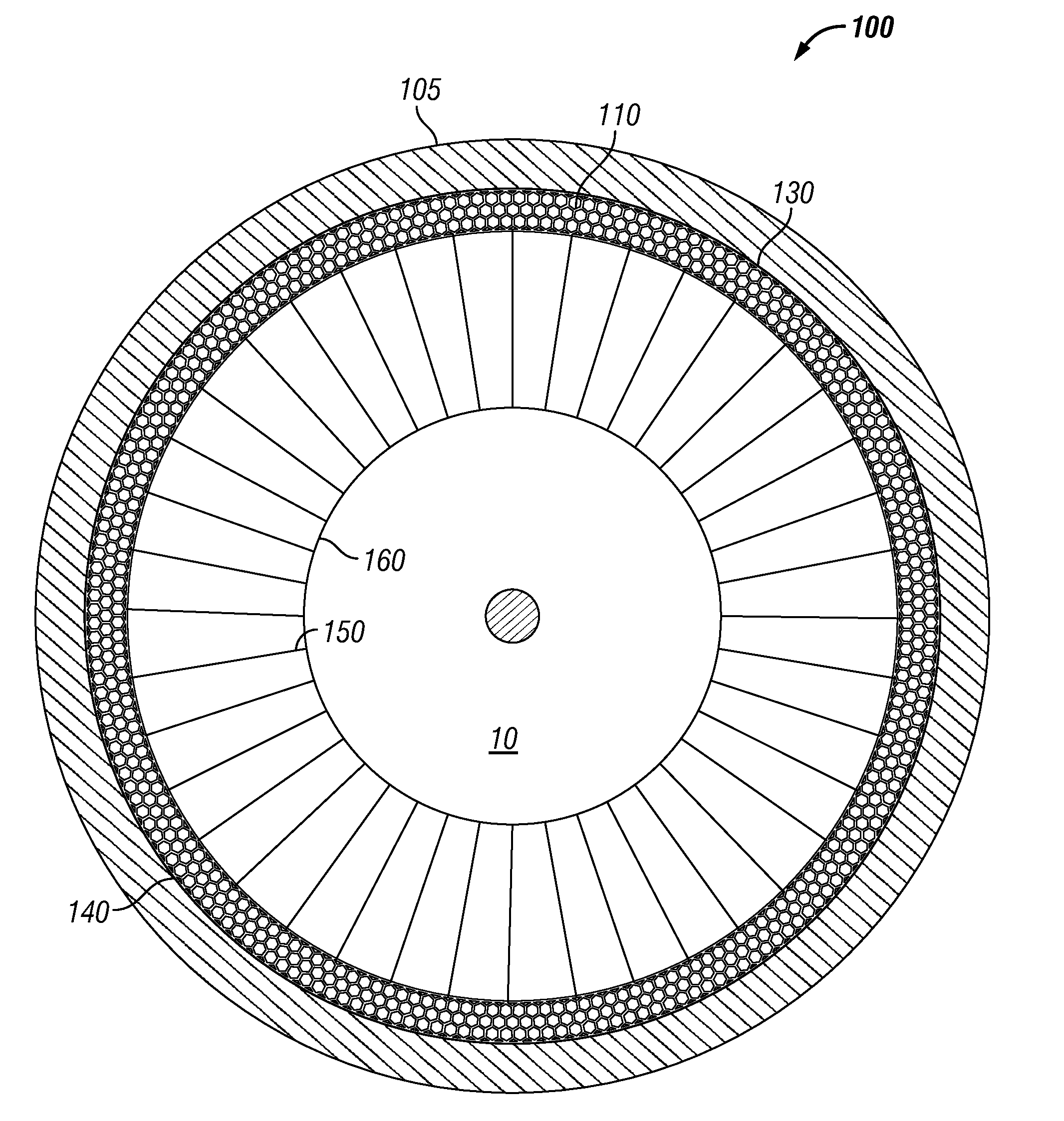

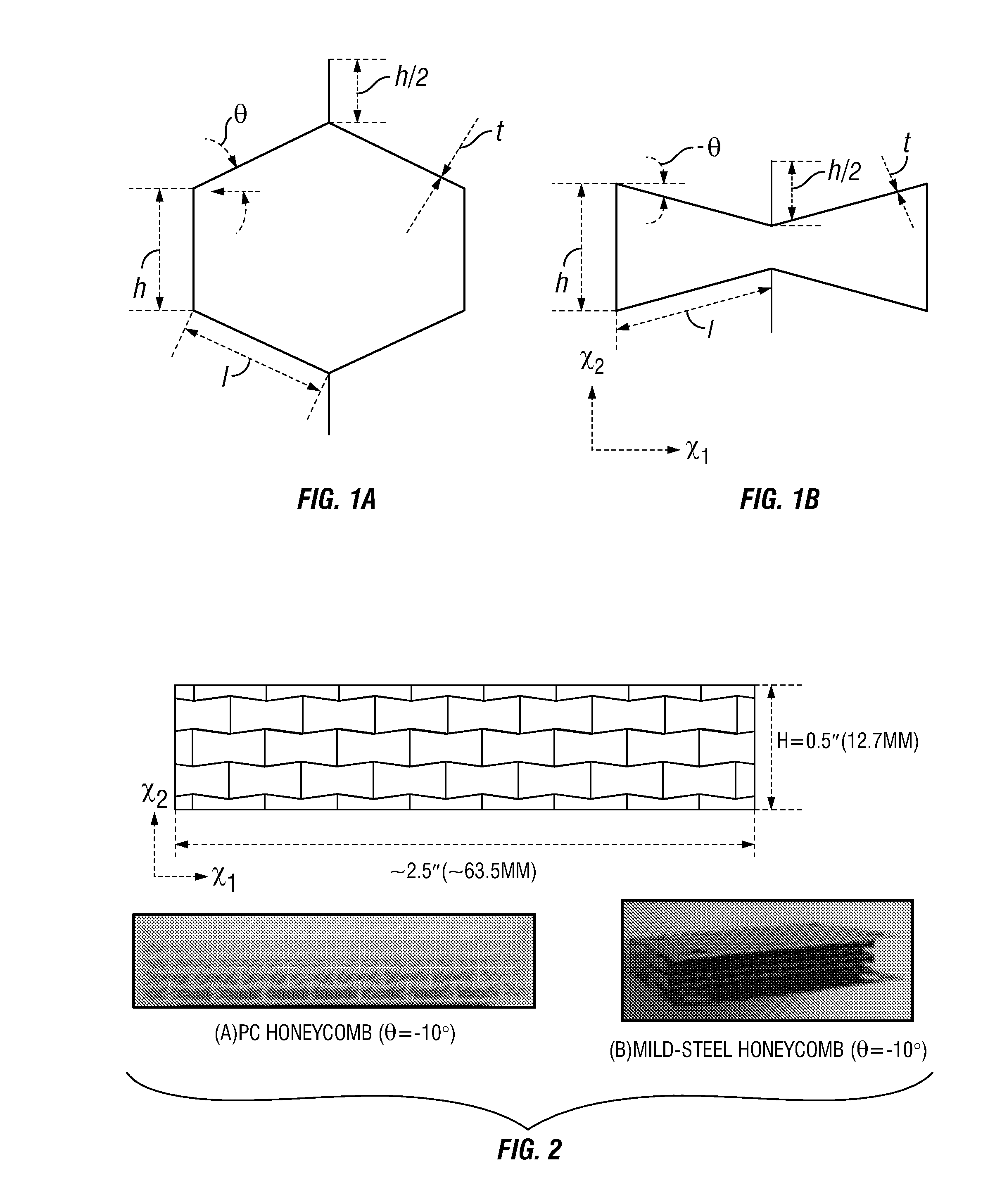

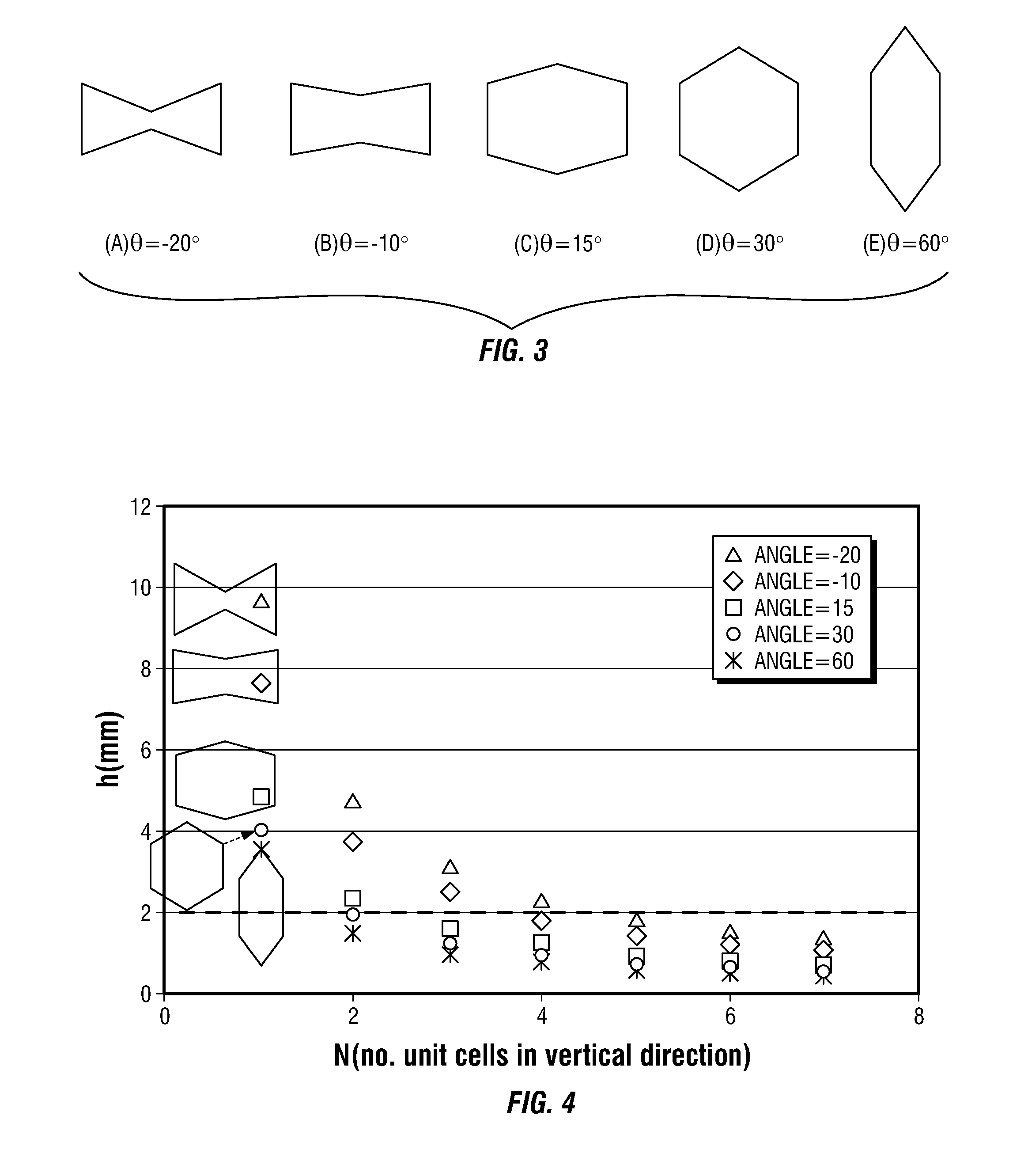

Honeycomb structures for high shear flexure

The present invention provides an improved shear band for use in non-pneumatic tires, pneumatic tires, and other technologies. The improved shear band is uniquely constructed of honeycomb shaped units that can replace the elastomeric continuum materials such as natural or synthetic rubber or polyurethane that are typically used. In particular, honeycomb structures made of high modulus materials such as metals or polycarbonates are used that provide the desired shear strains and shear modulus when subjected to stress. When used in tire construction, improvements in rolling resistance can be obtained because of less mass being deformed and reduced hysteresis provided by these materials. The resulting mass of the shear band is greatly reduced if using low density materials. Higher density materials can be used (such as metals) without increasing mass while utilizing their characteristic low energy loss.

Owner:MICHELIN NORTH AMERICA

Abrasion resistant plastic bonded to a diaphragm

InactiveUS6080685AWithout substantially affecting such diaphragm's flexibilityFlexible wall reciprocating enginesEngine diaphragmsEngineeringReinforced rubber

An improved diaphragm substantially resistant to abrasive wear for use in certain applications in which at least a portion of such diaphragm is in contact with another surface which would tend to abrade such diaphragm, such diaphragm comprising at least one layer of a flexible material selected from a group including natural rubber, synthetic rubber, fabric reinforced rubber, plastic and mixtures thereof and an abrasion resistant polymeric material having a predetermined thickness. This abrasion resistant polymeric material is adhered to such diaphragm at least in the portion that such diaphragm is in contact with another surface and is subject to abrasion. This type of abrasion generally occurs in the flange area of the diaphragm.

Owner:WESTINGHOUSE AIR BRAKE CO

Halogen-free flame-retardant epoxy resin composition, flexible copper clad laminate made therefrom and preparation of the flexible copper clad laminate

InactiveCN101280093AGood compatibilityImprove mechanical propertiesCircuit susbtrate materialsSolid componentEpoxy

The invention relates to a halogen-free flame-retardant epoxy resin composite, the flexible copper clad laminate made from the epoxy resin composite and the production method. The halogen-free flame-retardant epoxy resin composite is composed of solid components and organic solvents, wherein, the solid components include: phosphorus epoxy resin, synthetic rubber, rubber-modified epoxy resin and composite curing agent. The flexible copper clad laminate made from the halogen-free flame-retardant epoxy resin composite is a three-layer flexible copper clad laminate, including a polyimide insulation film, a coating of halogen-free flame-retardant epoxy resin composite coated on the polyimide insulation film, and a copper foil pressed on the coating of halogen-free flame-retardant epoxy resin composite. The resin composite of the invention is halogen-free and dispenses with other organic phosphorus flame retardants; the flexible copper clad laminate made from the composite has the flame retardancy up to UL94 V-0-level and has the advantages of high peeling strength, excellent dimensional stability, softness, good ion migration resistance and processing performance.

Owner:GUANGDONG SHENGYI SCI TECH

Vulcanized rubber composition, pneumatic tire and the process of producing the same

ActiveUS20100076118A1Improve featuresReduce energy lossSpecial tyresTyre tread bands/patternsPolymer scienceRolling resistance

By using a vulcanized rubber composition containing a rubber component composed of at least any one of a natural rubber, a modified natural rubber and a synthetic rubber, and chemically modified microfibril cellulose, it is possible to provide a vulcanized rubber composition that is environmentally conscious and that exhibits excellent rupture characteristics and a low energy loss, and a pneumatic tire that is excellent in rolling resistance property, steering stability and durability.

Owner:SUMITOMO RUBBER IND LTD +1

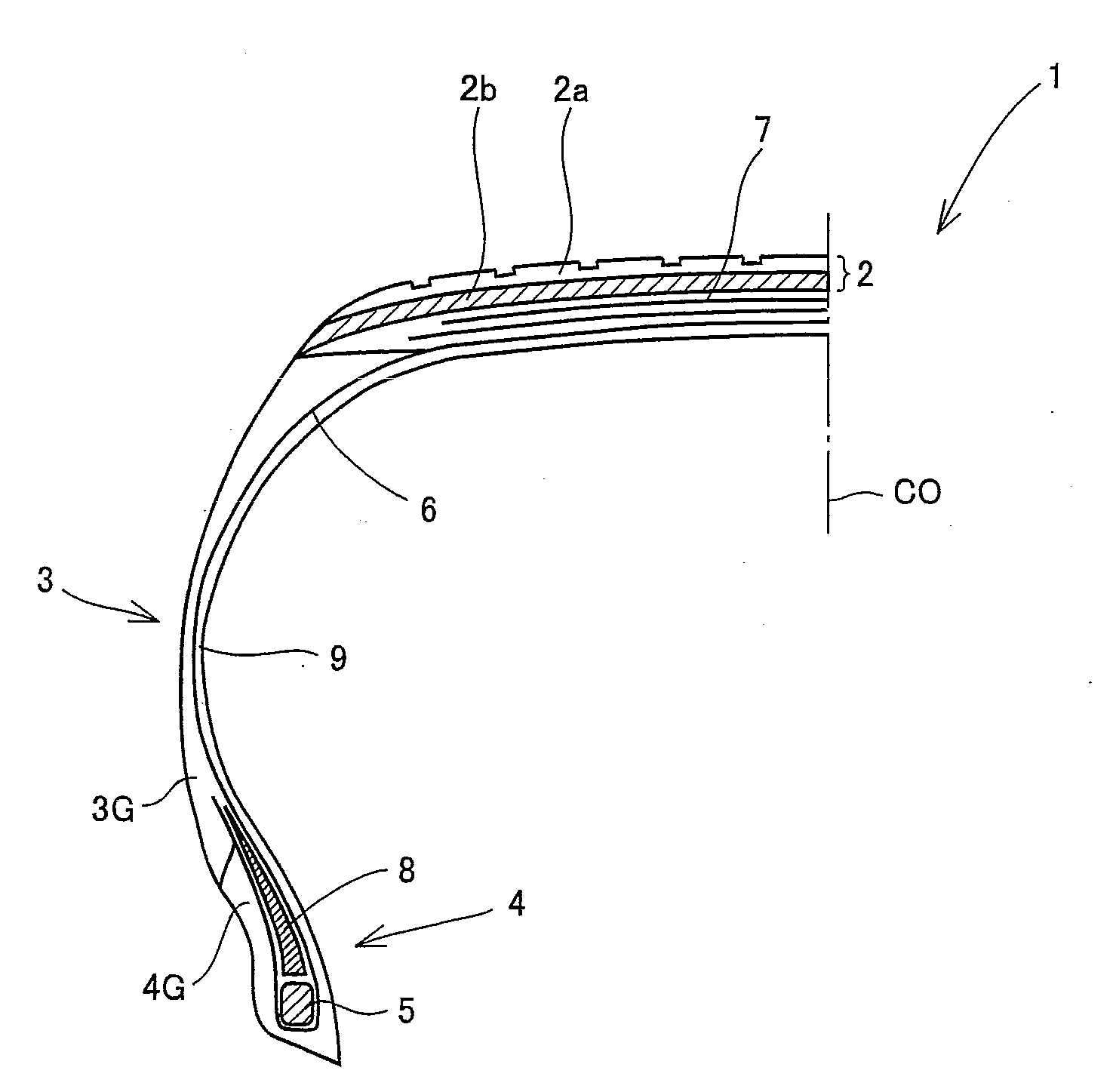

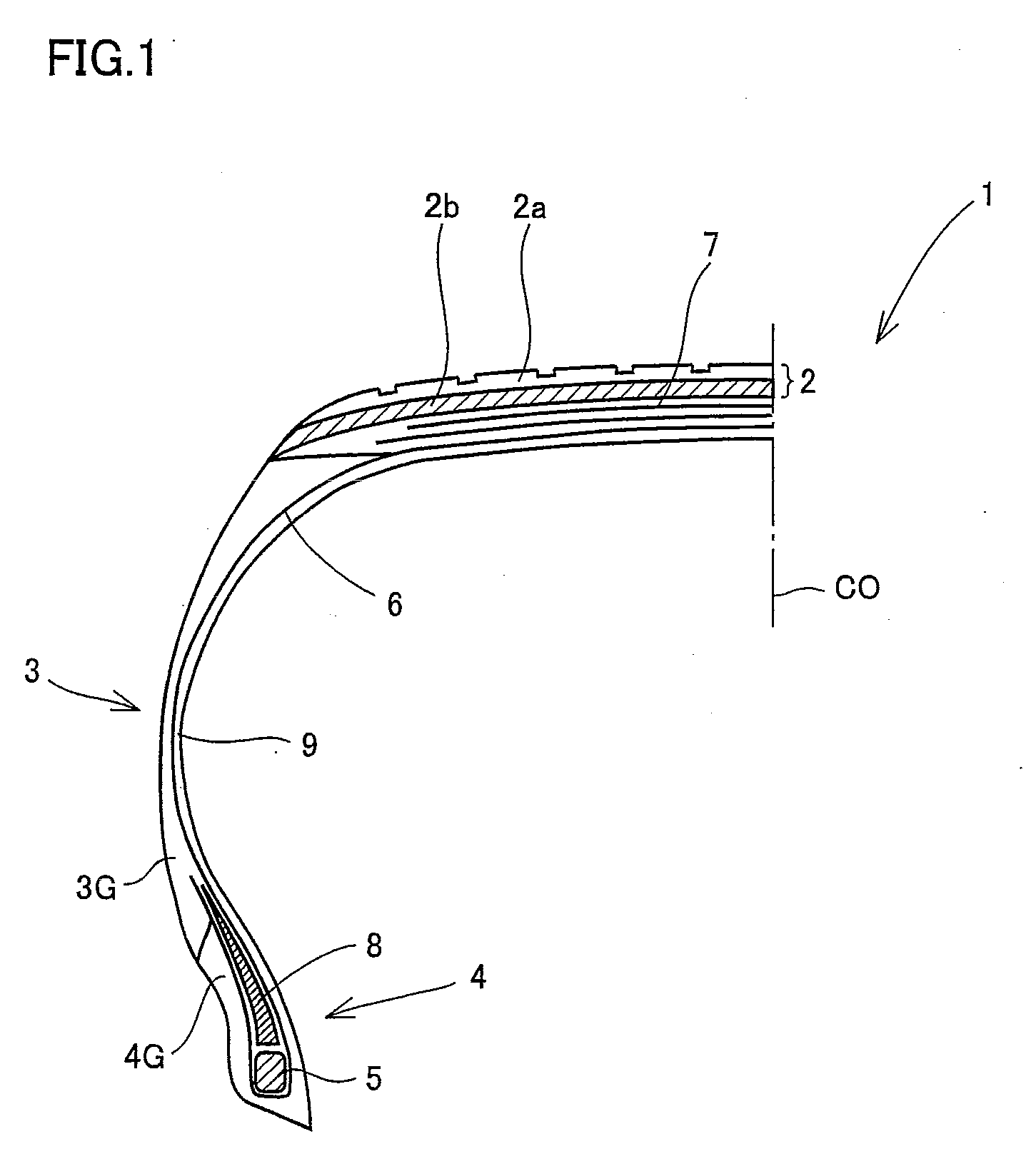

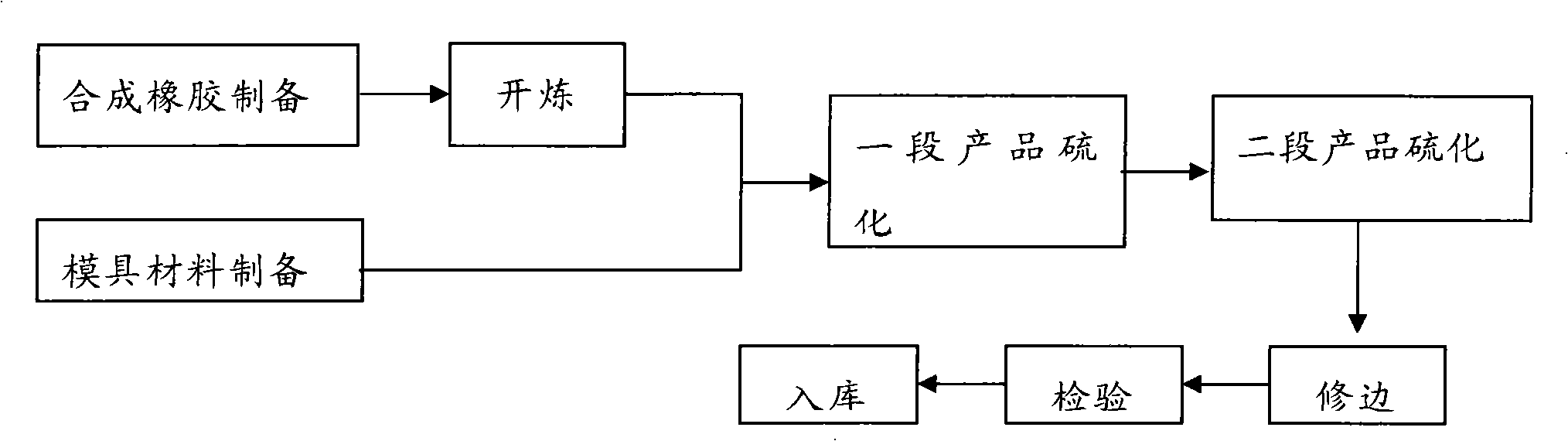

Rubber packing ring and manufacturing technology thereof

InactiveCN101315144AMedium resistantHigh tensile strengthFluid pressure sealed jointsPolymer scienceManufacturing technology

The invention provides a rubber sealing ring and a production method thereof. The rubber sealing ring is prepared from the following components of (by weight parts): ethylene propylene diene monomer (EPDM) 80-120, carbon black 55-75, paraffin oil 15-25, indirect process zinc oxide 4-6, stearic acid 0.2-1, anti-aging agent 2-4, sulfur S-80 0.1-0.35, vulcanizing agent dicumyl peroxide (DCP) 3-5, and lubricating agent 1-3. The production method comprises the steps of: synthesizing rubber with a Banbury mixer, forming the synthetic rubber with a mixing mill, first-stage vulcanizing in a mold of a vulcanizing device, second-stage the product from the first-stage vulcanization in an oven, trimming, testing, and storing. The inventive rubber sealing ring has improved tensile strength, extensibility, tear strength, self-lubrication effect, compression and deformation resistance, heat resistance and aging resistance, good medium resistance, and prolonged service life. The inventive production method is simple and reasonable.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Tread rubber composite material and preparation method thereof

ActiveCN102050973ALow costSimple processSpecial tyresTyre tread bands/patternsInorganic particlePolymer science

The invention provides a tread rubber composite material and a preparation method thereof, relating to the technical field of tyres, wherein the tread rubber composite material is prepared from 100 parts by weight of rubber and 2-30 parts by weight of composite powder. The composite powder comprises inorganic particles and rubber particles, wherein the weight ratio of the rubber particles to the inorganic particles is 1:6 to 6: 1. The composite powder is prepared by uniformly mixing and drying raw materials including irradiated synthetic rubber latex and slurry liquid of the inorganic particles. The composite powder can excellently reinforce the rubber so that the tread rubber composite material has the advantages of better mechanical property after aging, lower abrasion consumption, lower fatigue compression themogenesis and higher slippery-resistant performance and higher tearing intensity. Meanwhile, the preparation method of the tread rubber composite material has the advantages of simple process, easiness for operation and industrialization, low cost and wide use range.

Owner:CHINA PETROLEUM & CHEM CORP +1

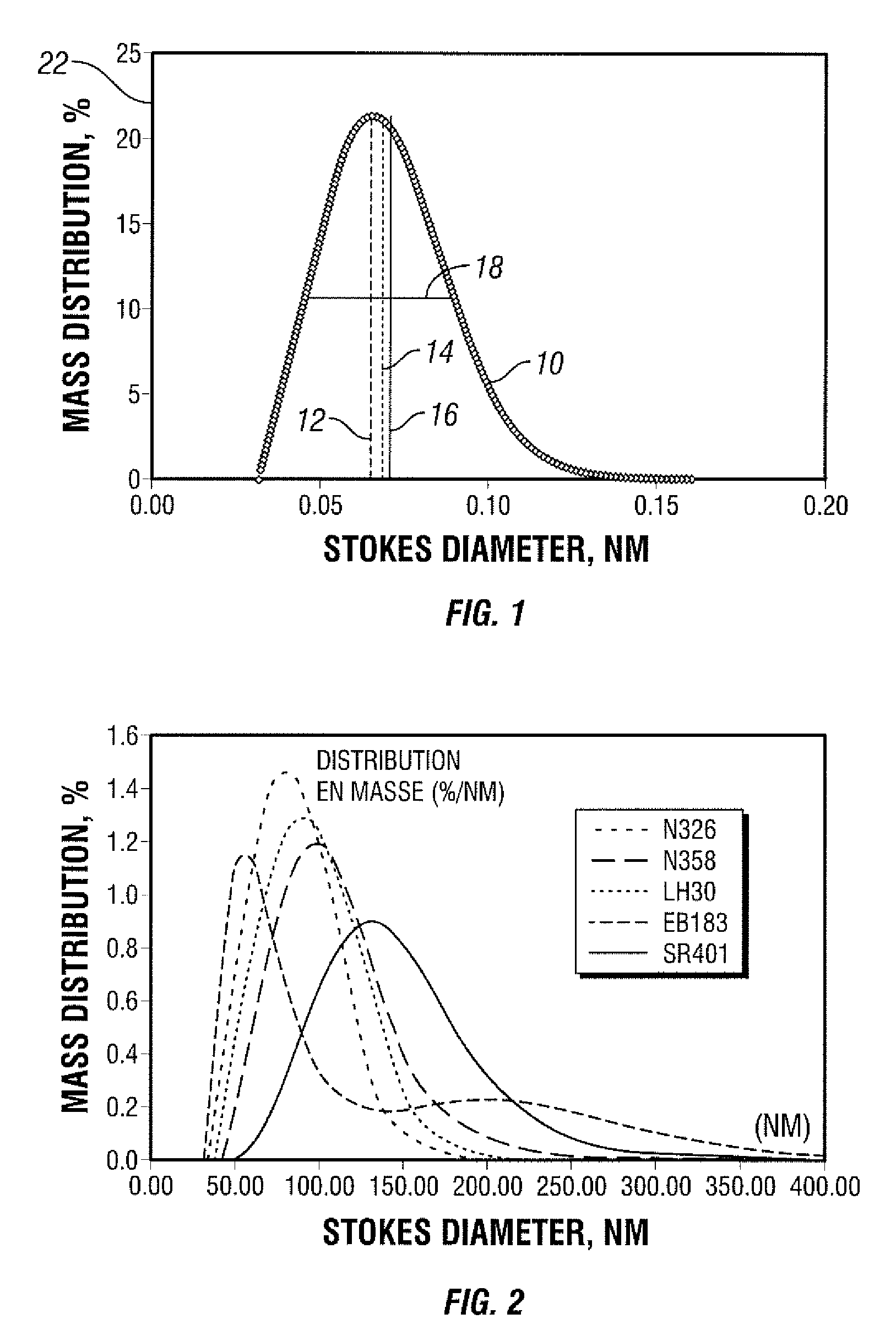

Elastomer compositions with carbon black

An elastomer composition includes an elastomer and a carbon black, wherein the carbon black is characterized as having a COAN of between about 90 and 150 ml / 100 g, a BET of between 50 and 69 m2 / g and a distribution index DI that is greater than 1.15, wherein the DI is a ratio of dw to dmode. In particular embodiments, the elastomer may be selected from one or more natural rubbers, one or more synthetic rubbers or combinations thereof For example, the one or more synthetic rubbers may be selected from styrene butadiene rubber, butadiene rubber, polyisoprene rubber, butyl rubber or combinations thereof. Products made from the elastomer composition include tires and other products, particularly tires that include a sidewall, a carcass, a carcass reinforcement, tread and / or an undertread comprising the elastomeric composition.

Owner:MICHELIN RECH & TECH SA +1

Fluidtight zip fastener

InactiveUS6343408B1Improve sealingAvoid wear and tearSnap fastenersSlide fastenersLongitudinal planeCoupling

The fluidtight zip fastener comprises a pair of fluidtight zip fastener carrying tapes carrying the zip fastener coupling member rows and which are in each case formed by a base tape with a soft, synthetic rubber or similar covering layer. They engage on one another by their edge portions. The pair of continuous coupling member rows is sewn to the zip fastener carrying tapes in a spaced offset position transversely to the longitudinal edges of said carrying tapes in such a way that the press-contact edge portions of the soft covering layers are in contact with one another along a longitudinal plane, which intersects the zip fastener at a central axis thereof and runs at right angles to the zip fastener principal plane. The press-contact edge portions project over said longitudinal plane, when the coupling member rows are disengaged. The edge portions, when the coupling member rows are engaged, are bent away from the side carrying the coupling member rows so as to extend roughly at right angles to the zip fastener principal plane. The soft covering layers of the press-contact edge portions engage on one another under pressure action when the zip fastener is closed and thus ensure the fluidtightness condition.

Owner:YKK CORP

Anode composition for lithium battery, and anode and lithium battery using the same

InactiveUS7459235B2Good dispersionImprove adhesionSilver accumulatorsNegative electrodesCellulosePolyelectrolyte

Provided are an anode composition for a lithium battery, and an anode and a lithium battery using the same. The anode composition can improve anode and battery characteristics while using water as a solvent that is harmless to humans. The anode composition includes an anode active material, a synthetic rubber binder, a cellulose-based dispersing agent, and a water-soluble anionic polyelectrolyte.

Owner:SAMSUNG SDI CO LTD

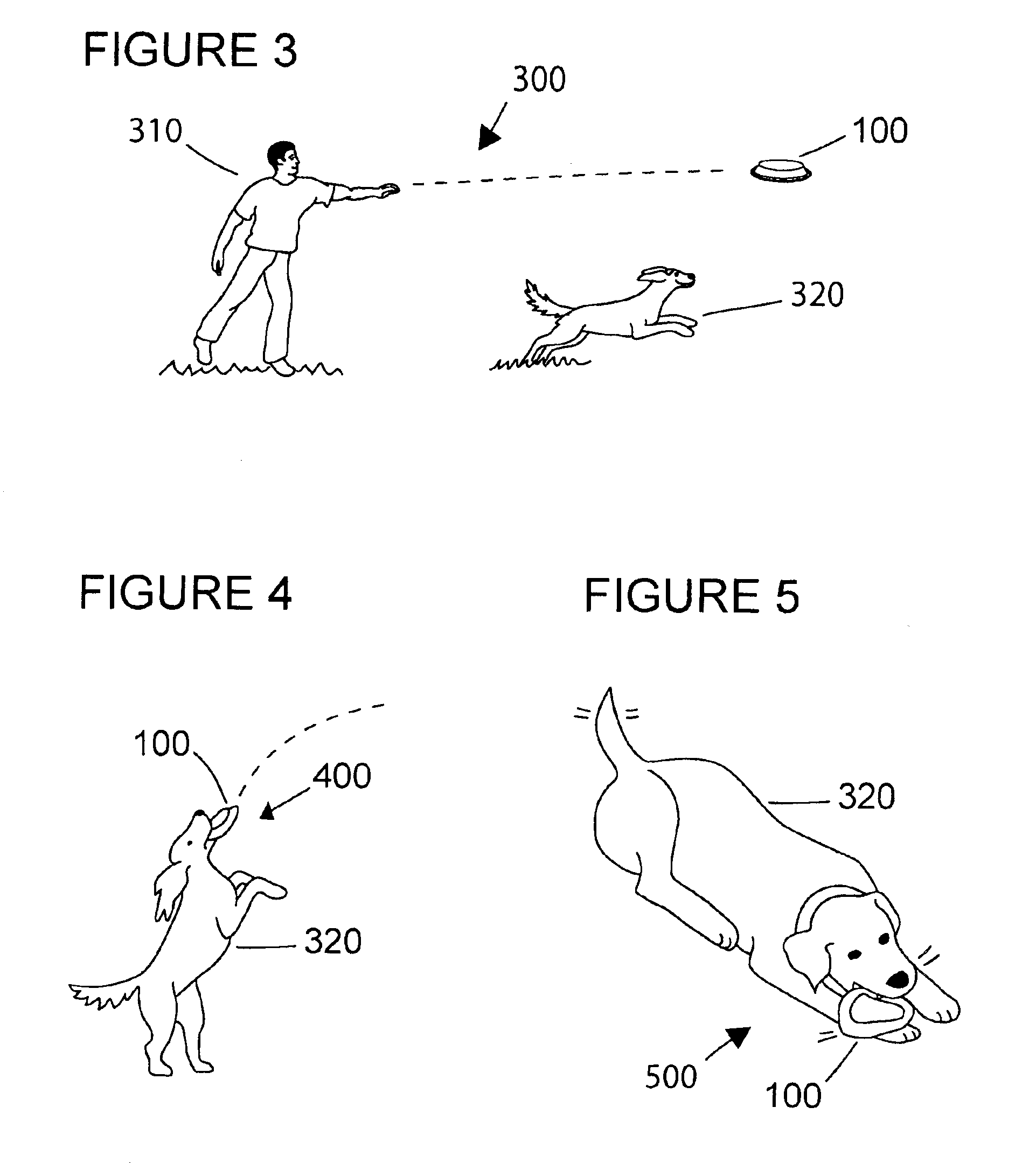

Multipurpose disc toy

A multipurpose disc useful as a throw, tug, and chew toy for play involving pets and for play involving pets and people, and useful as a water and food dish for pets, the disc comprising: a circular top portion; an annular sidewall portion that merges with the circular top portion; an annular flange portion that merges with the annular sidewall portion, the annular flange and circular top portions being disposed in parallel spaced planes; a convex outer side; and, a concave inner side. The multipurpose disc has a flat top, annularly depressed trough formed in the annular flange, an internal flexible woven fabric re-enforcing member, and is composed of a resilient, waterproof, durable, and flexible material such as natural or synthetic rubber.

Owner:PERSALL STANLEY EDWIN

Graphene-modified wear-resistant rubber

The invention relates to a graphene-modified wear-resistant rubber. The graphene-modified wear-resistant rubber comprises, by weight, 48.9 to 56.5% of synthetic rubber, 1.5 to 2.5% of a sulfuration promoter, 8 to 18% of graphene, 25 to 30% of a filling material, 1.5 to 5% of a plasticizer and 0.1 to 3% of an auxiliary agent. According to the invention, graphene is added into the rubber so as to improve strength of the rubber, and since graphene has good lubrication effect, wear resistance of the rubber can be improved; and addition of asbestos fiber and polyimide fiber enables heat resistance of the rubber to be substantially improved.

Owner:余姚市振大塑胶有限公司

Modified rubber composition and preparation method thereof

The invention provides a rubber composition and a preparation method thereof. The rubber composition comprises the following components according to parts by weight: 100 parts of rubber and 40 to150 parts of composite powder; the composite powder includes inorganic nanoparticles and rubber particles; the method for preparing the composite powder comprises the following steps of evenly mixing the irradiated synthetic rubber latex and the serosity of the inorganic nanoparticles to obtain the mixed latex, and then drying the mixed latex; the weight ratio between the rubber particles and the inorganic nanoparticles is 70:30 to 30:70; the composite powder has good rubber reinforcement effect to rubber, and the unmodified inorganic nanoparticles in the composite powder can be evenly dispersed in the rubber; and meanwhile, the method for preparing the rubber composition is simple in process, easy to operate, low in cost, wide in application range and feasible for industrialization.

Owner:CHINA PETROLEUM & CHEM CORP +1

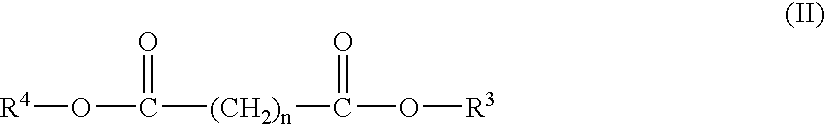

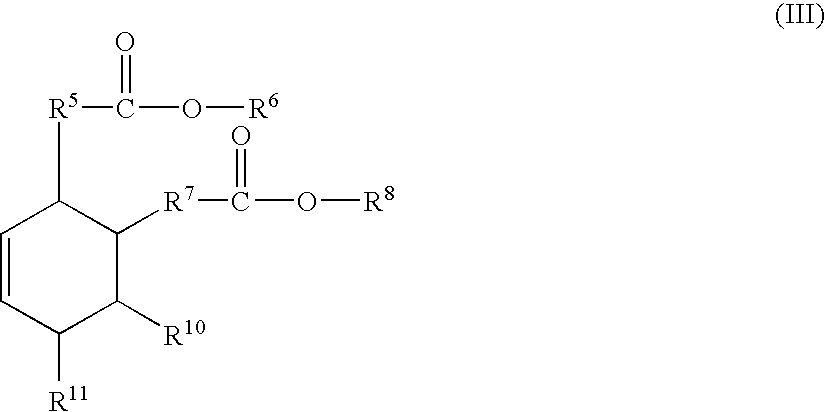

Adhesion promoter for cord-reinforced rubber and metal or polymer substrate/rubber composites

A rubber composition including a natural or synthetic rubber, and an adhesive resin capable of unexpected adhesion to metal, polymer and glass substrates, particularly cords in radical tires, hoses, conveyor belts, transmission belts, and the like by the addition of long chain esters, including mono, di- and tri-esters.

Owner:LASALLE BANK NAT ASSOC

Macromolecule pre-laid waterproof coiled material

ActiveCN102774057AAvoid the disadvantages of poor high and low temperature resistanceImprove peel adhesion performanceSynthetic resin layered productsConjugated diene hydrocarbon adhesivesPolyethylene glycolCarboxylic acid

The invention relates to a macromolecule pre-laid waterproof coiled material which comprises a sheet-shaped macromolecule base material and a macromolecule adhesive layer formed on the macromolecule base material; and the macromolecule pre-laid waterproof coiled material is characterized by further comprising a protective layer coated on the macromolecule adhesive layer, wherein the macromolecule base material is high-density polyethylene, and polyethylene glycol terephthalate or ethylene-vinyl acetate copolymer; synthetic rubber is the main component of the macromolecule base material; and the material of the protective layer is silicon-containing unsaturated carboxylic acid modified butyl rubber which is prepared by the steps of grafting unsaturated carboxylic acid on butyl rubber molecule and then mixing with active silica. The macromolecule pre-laid waterproof coiled material has good high and low-temperature resistance and high adhesion peeling strength, and is easy to construct.

Owner:中建材苏州防水研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com