Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1857results about How to "Improve friction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

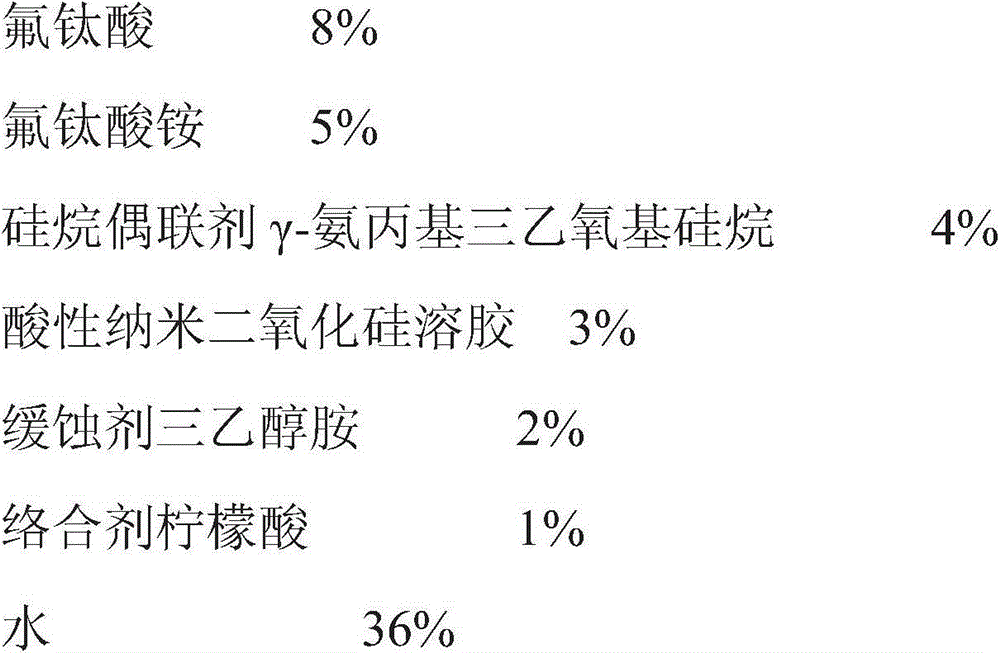

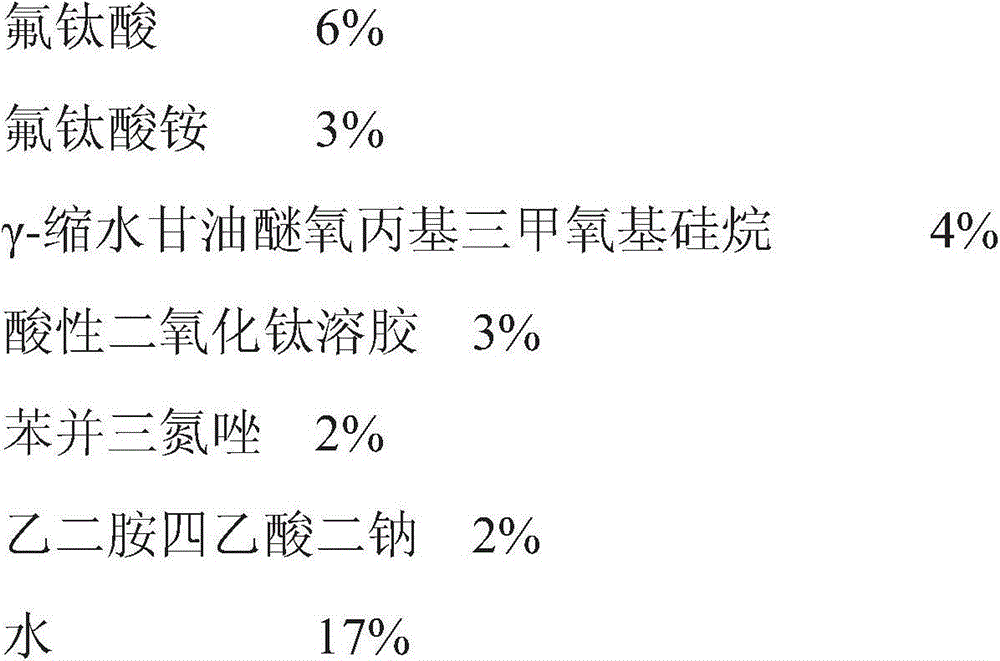

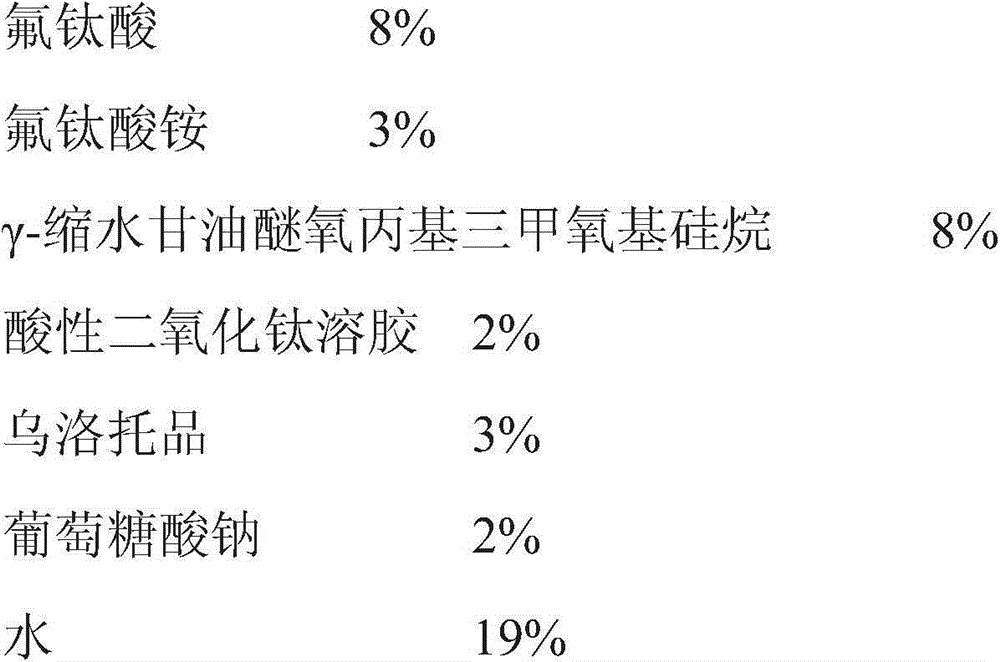

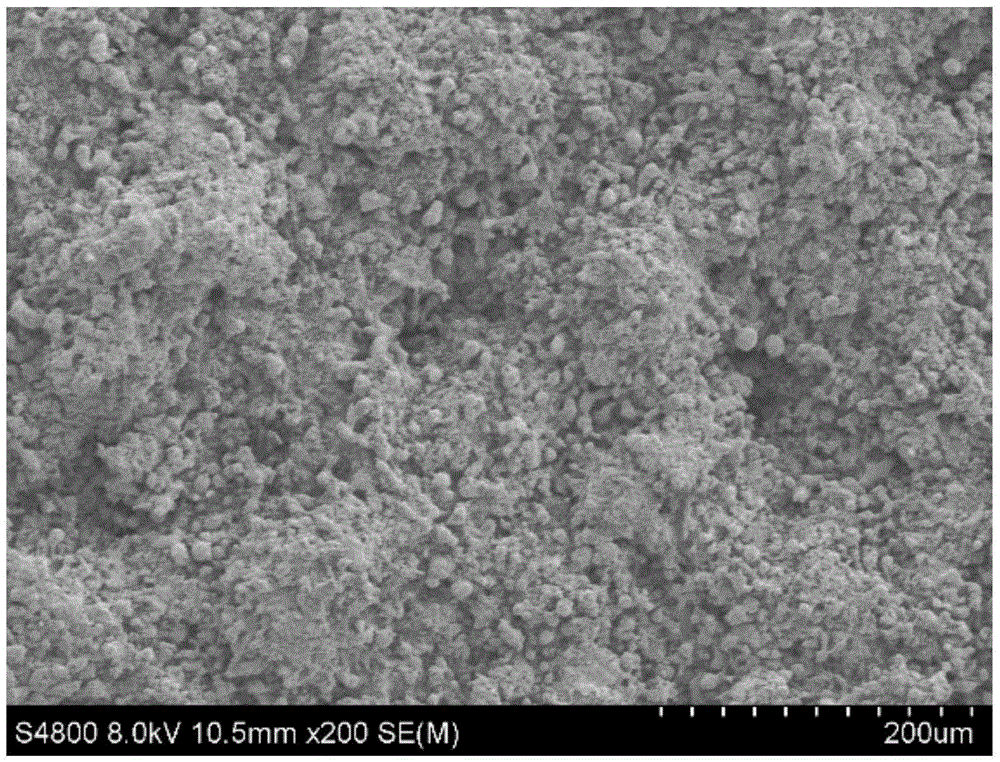

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

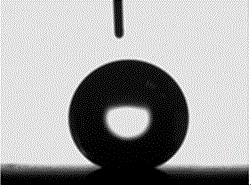

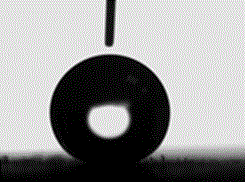

Method for preparing wear-resisting super-hydrophobic coating through cold spraying technology and product of method

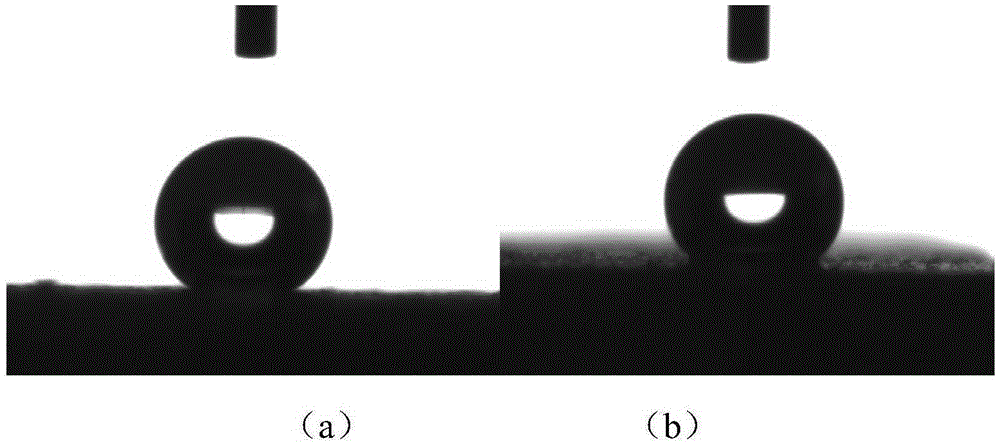

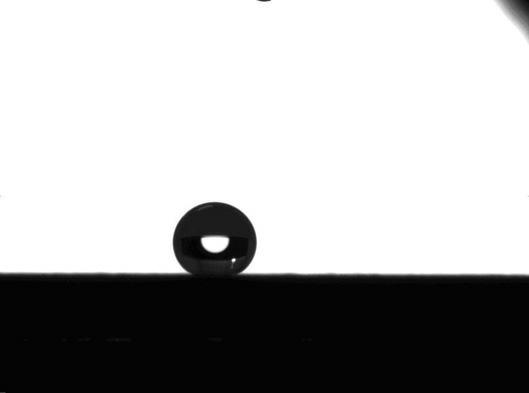

ActiveCN105386032APreserve physicochemical propertiesFast depositionPressure inorganic powder coatingWear resistanceRolling angle

The invention discloses a method for preparing a wear-resisting super-hydrophobic coating through a cold spraying technology and a product of the method. The method comprises the following steps that firstly, the surface of a base body is roughened; secondly, sprayed powder is modified with low-surface-energy matter; and thirdly, the wear-resisting super-hydrophobic coating is prepared on the surface of the base body through the cold spraying technology. The static contact angle of the coating prepared through the method can be 150-180 degrees, the rolling angle of the coating is smaller than 10 degrees, and good super-hydrophobicity is achieved. According to the method, the product of a non-stick pan is prepared and has good wear resistance and non-stick performance, and compared with non-stick pans in the market, the product is more resistant to wear and has the great competitive potential in the field. In addition, the method can be used for preparing different wear-resisting super-hydrophobic coatings based on different base materials (such as metal, ceramic, glass and plastic), and the application range is wide.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

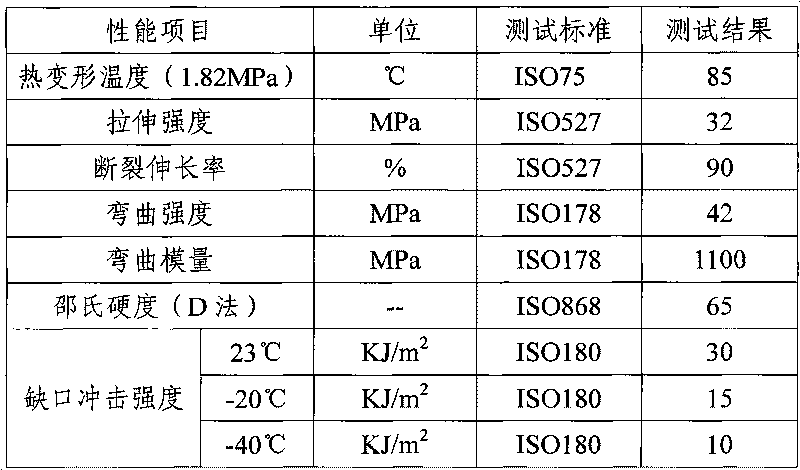

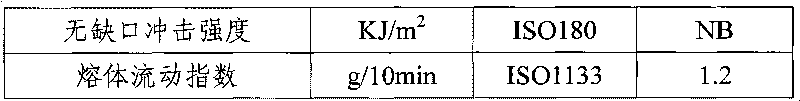

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

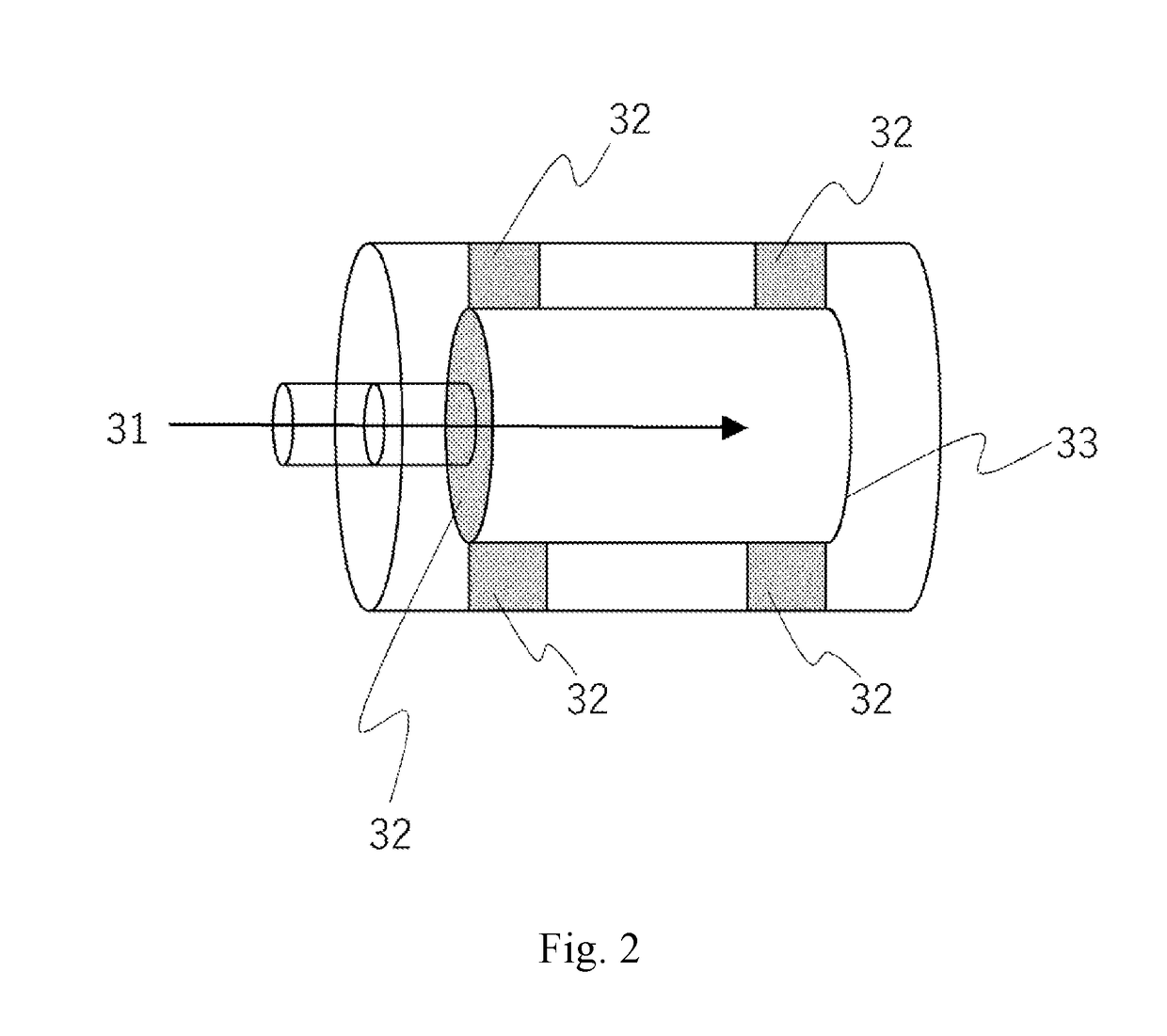

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Graphene-modified fluororesin coating material

The present invention discloses a graphene-modified fluororesin coating material, which comprises a film forming substance, commonly used additives, a solvent and graphene, wherein the amount of the added graphene is 0.001-10% of the mass of the fluororesin coating material, the fluororesin coating material is further added with the first additive and the second additive, and the addition amount of the first additive and the second additive is 0.1-3.5% of the mass of the fluororesin coating material. According to the present invention, the graphene is adopted to improve the strength of the fluororesin coating material, wherein the friction resistance, the adhesion of the fluororesin coating material and the substrate, the impact resistance and the thermal conductivity of the fluororesin coating material are significantly increased; and the fluororesin coating material has characteristics of low cost, less use amount, durable effect and simple and convenient use, and can be used in a plurality of fields of building industry, household non-stick cookware, marine life fouling resistance fields, high temperature resistance fields, national economy and national defense construction fields and the like.

Owner:NINGBO MORSH NEW MATERIALS

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

Expansion type flame-retardant coatings glue and use thereof in textile finishing

ActiveCN101498100AImprove washing resistanceResistance to Mechanical ImprovementVegetal fibresCross-linkPolymer science

The invention discloses an intumescent flame retardant coating gum and the application thereof on fabric finishing. When the traditional intumescent flame retardant is applied to fabric, the fabric is not resistant to water rinse, water immersion or transfer, the flame retardant can lose or degrade under the action of luminous rays, heat, moisture and mechanical external force, and the flame retardant properties are reduced. The intumescent flame retardant coating gum comprises a flame retardant coating base gum and a carbon source, and is characterized in that the flame retardant coating base gum is prepared by mixing ammonium polyphosphate, melamine and 4A zeolite, adding organic alcohol, coating the mixture by more than two silane coupling agents for modification, drying the mixture after removing the organic alcohol to obtain a composite flame retardant, adding water, a non-ionic surface active agent, a binding agent and a cross-linking agent to the composite flame retardant, and grinding and dispersing the mixture; the carbon source is aqueous polyacrylic ester containing hydroxyl groups or aqueous polyurethane containing hydroxyl groups or a modifier of the former two. The invention obviously improves the performance of the flame retardant coating gum on flame retardant fabric for resistance to water rinse, transfer, light, heat and friction.

Owner:传化智联股份有限公司 +2

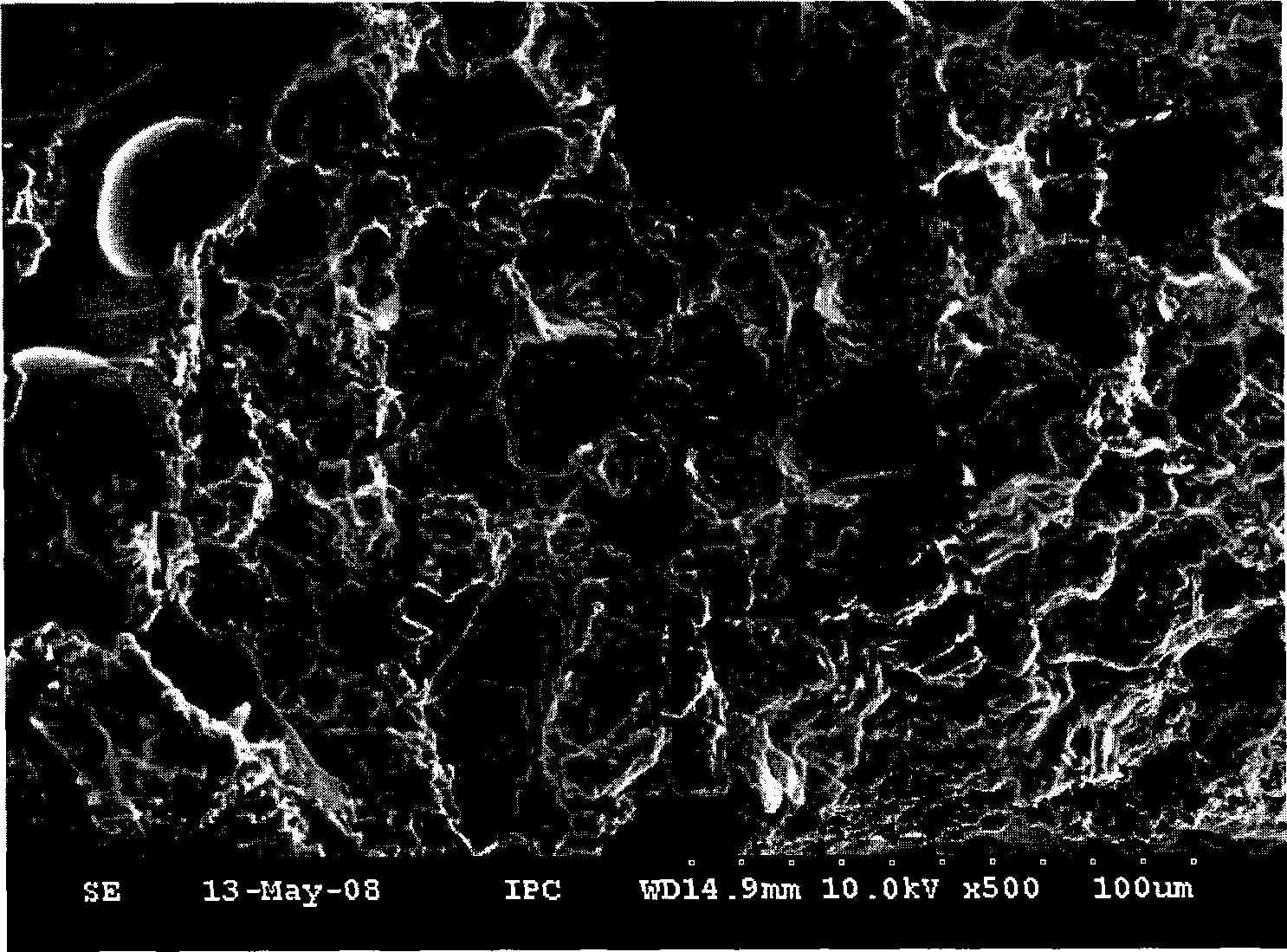

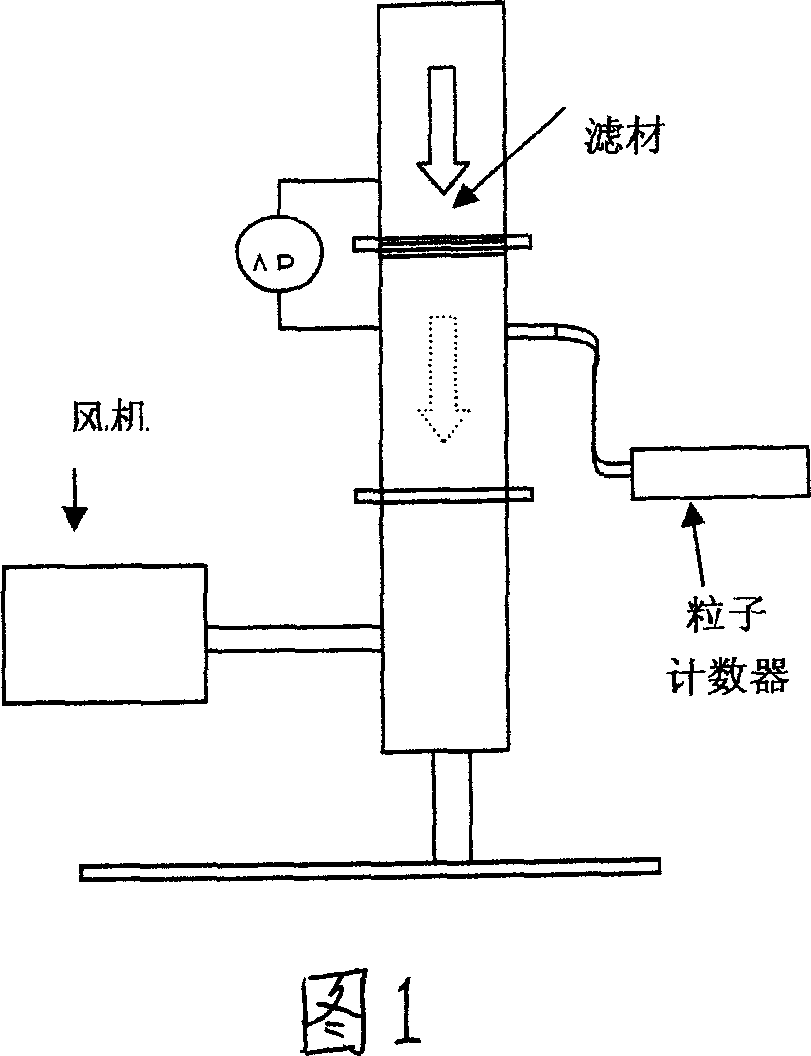

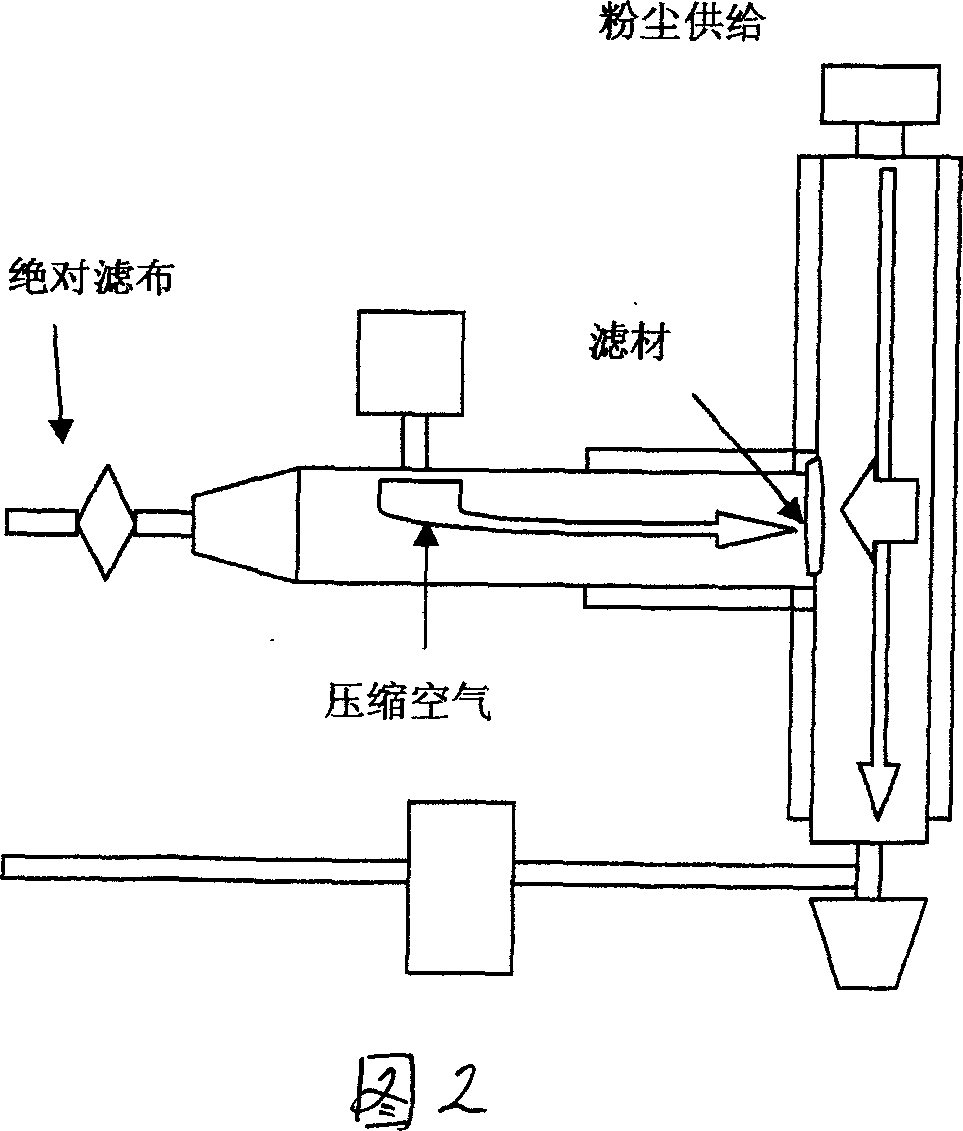

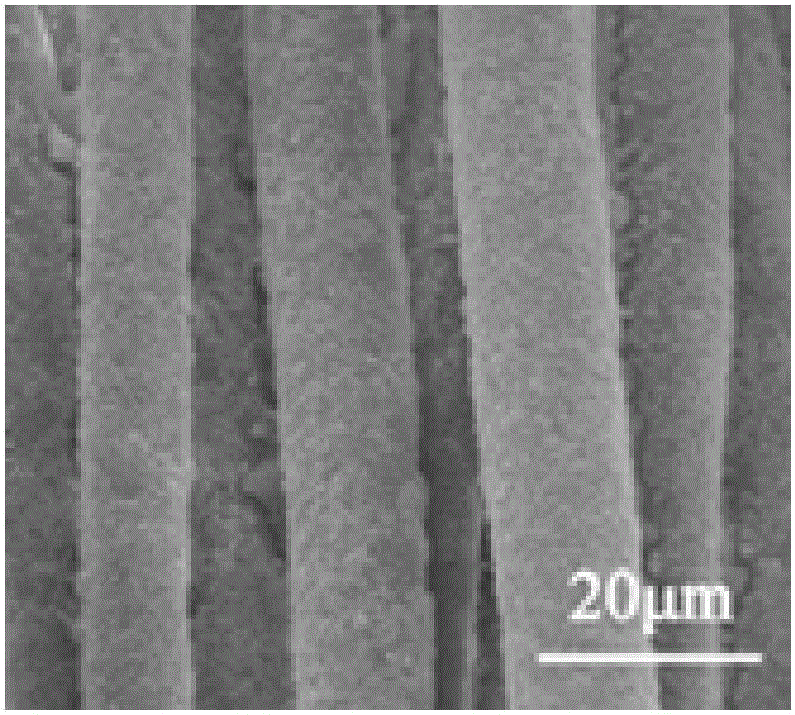

Filtering material of thermal stability and the purpose thereof

InactiveCN101032674AHigh mechanical strengthReduce thermal shrinkageFiltration separationFiberHeat resistance

The present invention discloses one kind of heat resistant filter material and its use. The heat resistant filter material consists of one base material layer and one combined filter layers, the base material layer is made of inorganic fiber and / or heat resistant organic fiber, and at least one filter layer contains both inorganic fiber and heat resistant organic fiber, with the diameter of the inorganic fiber being smaller than that of the heat resistant organic fiber. The heat resistant filter material is used in filter. It has excellent complexing performance between the inorganic fiber and the heat resistant organic fiber, high dust collecting efficiency, high dust impact resistance, high antiwear performance, high heat shrinkage tolerance, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

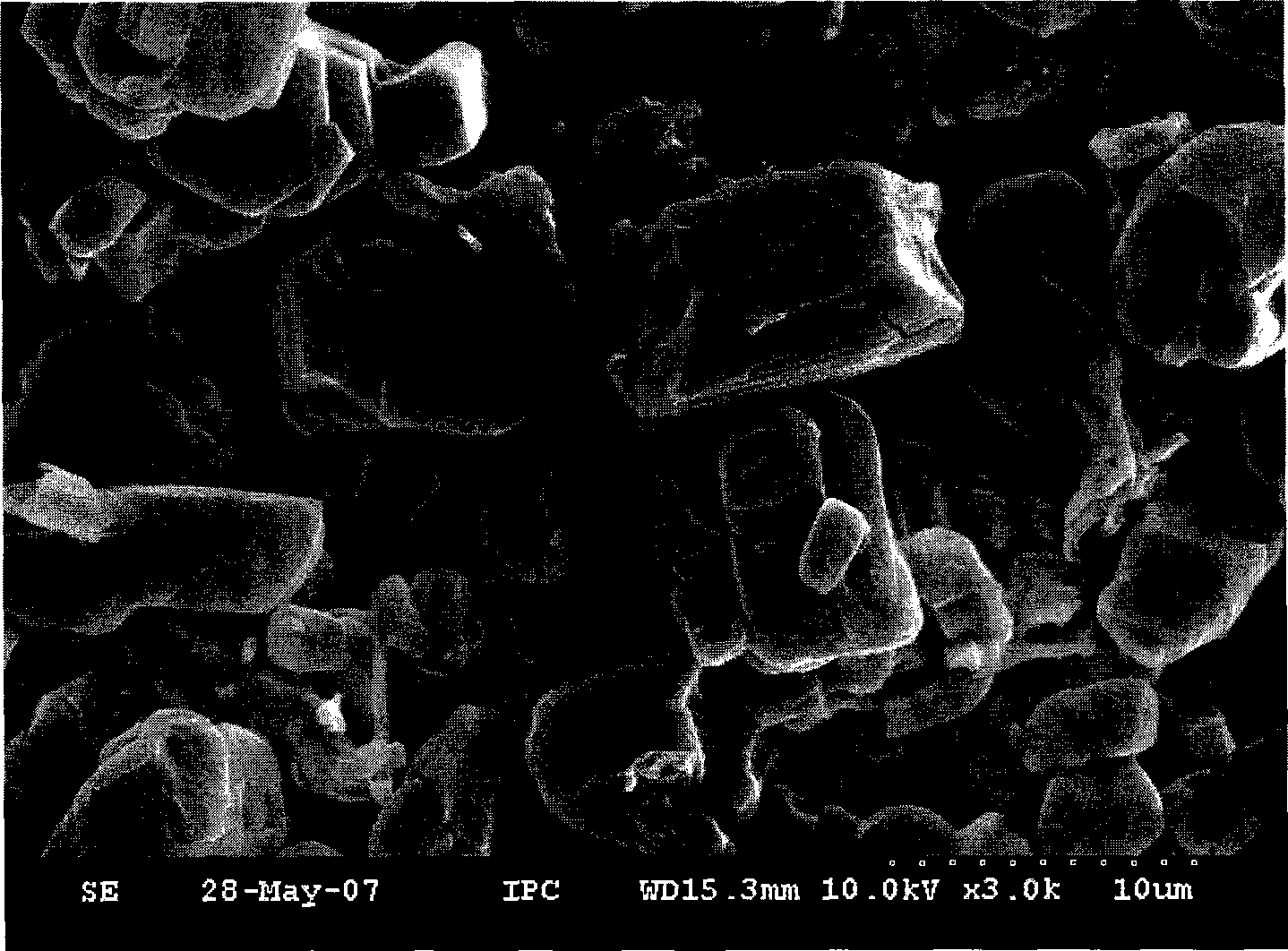

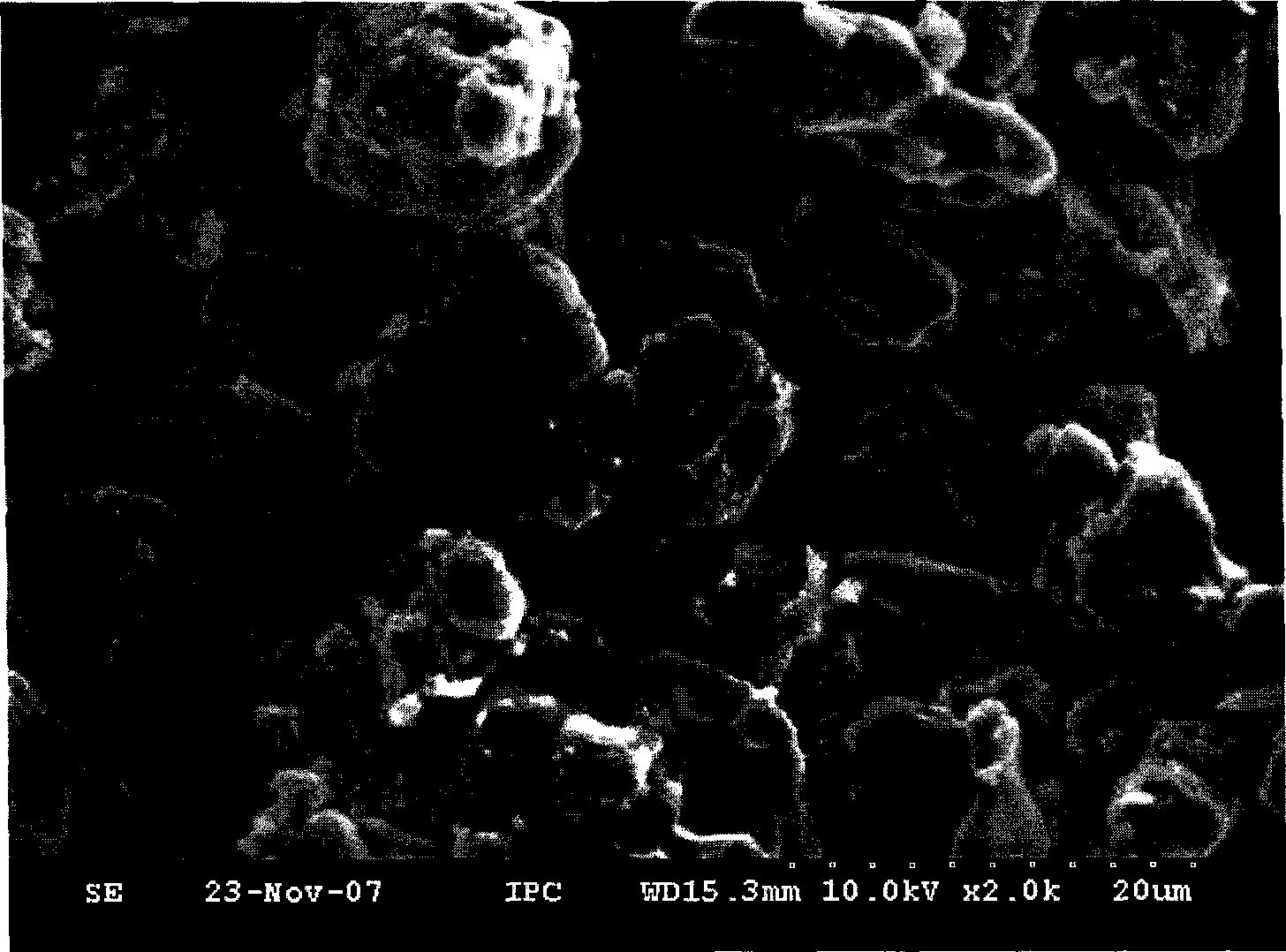

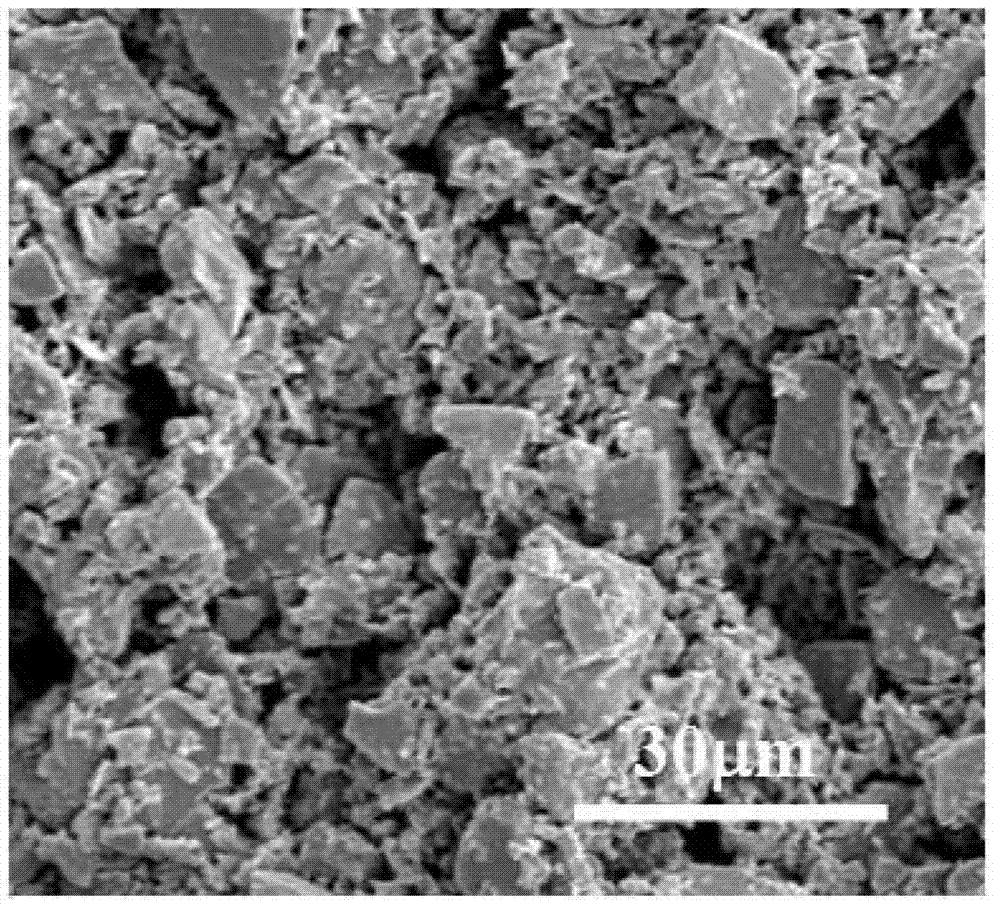

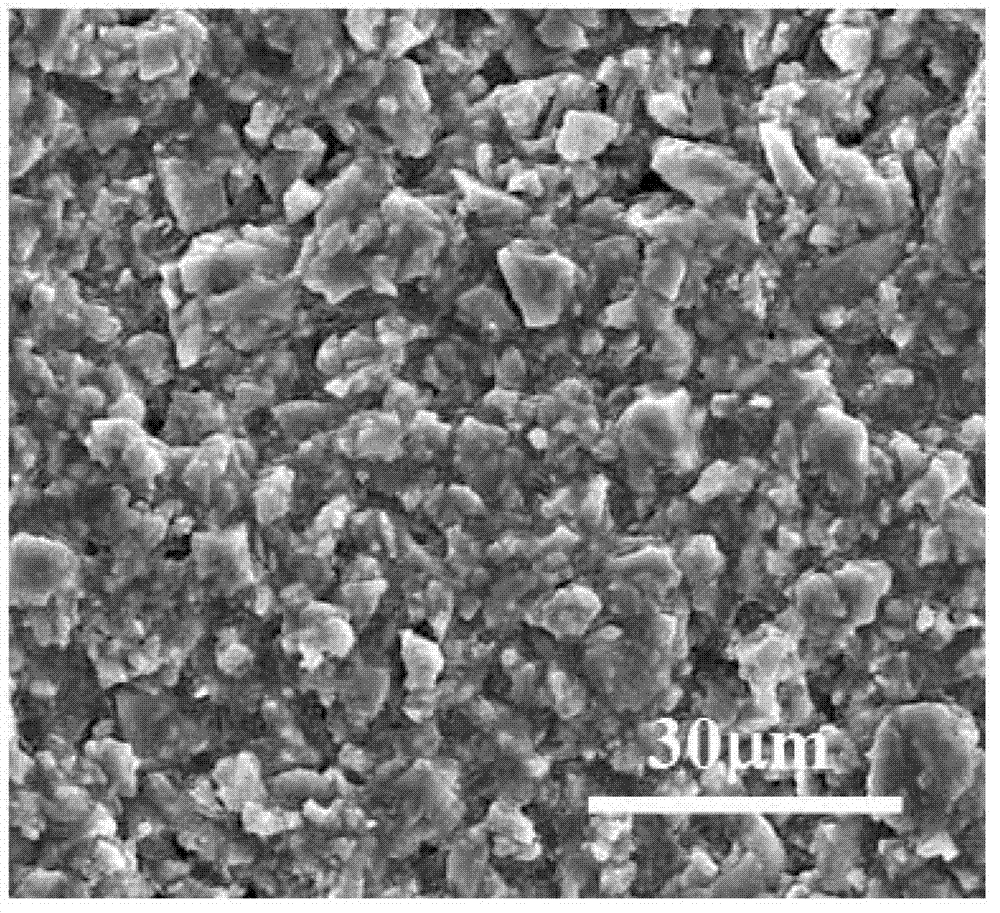

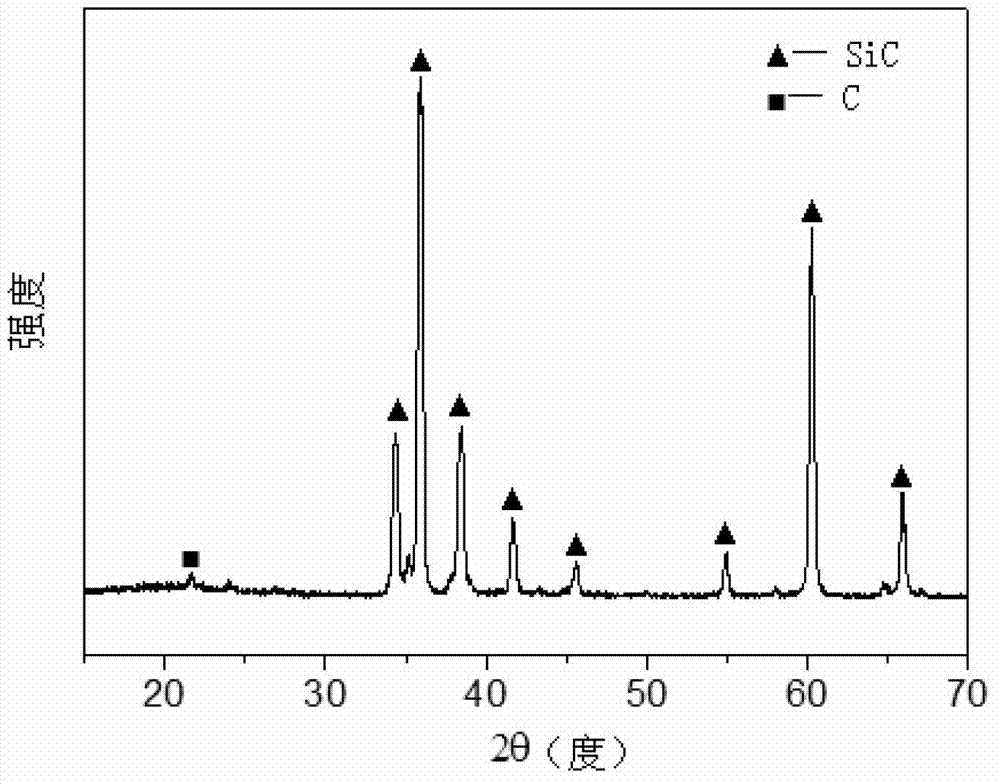

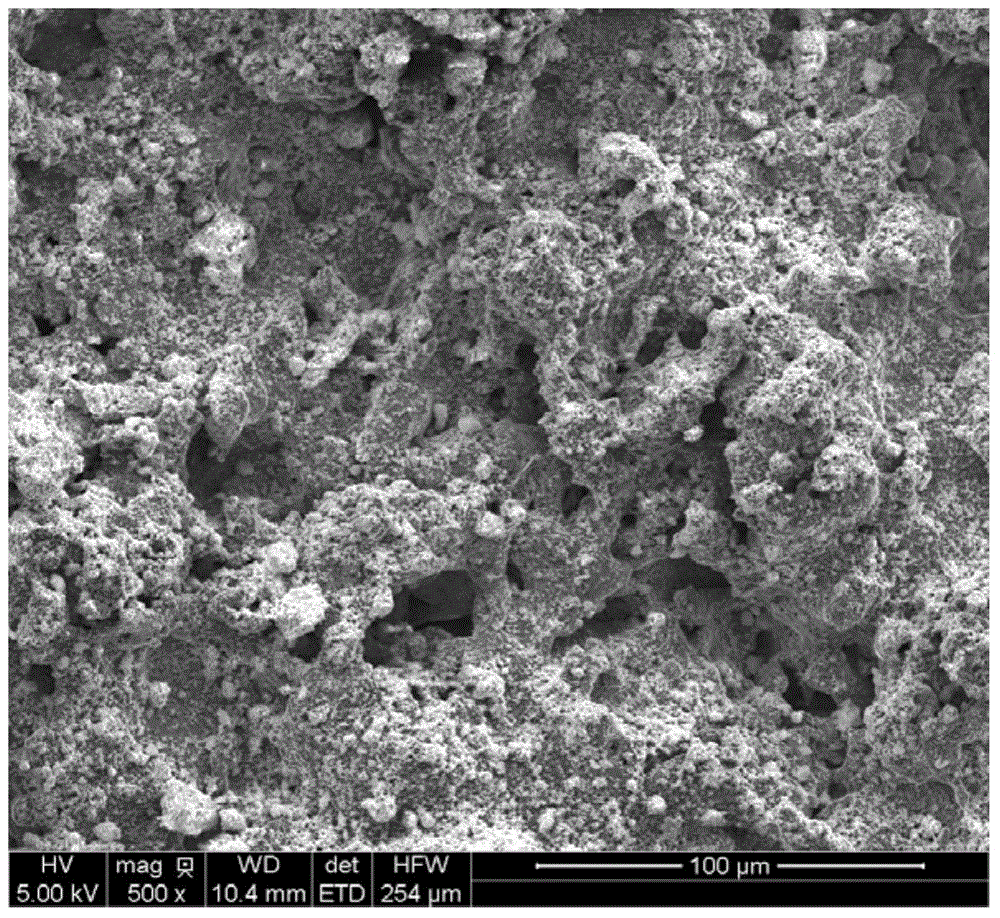

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

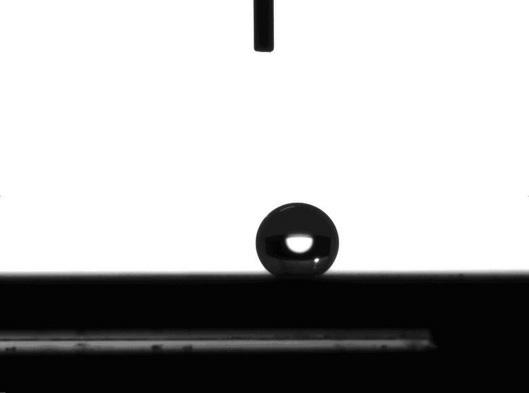

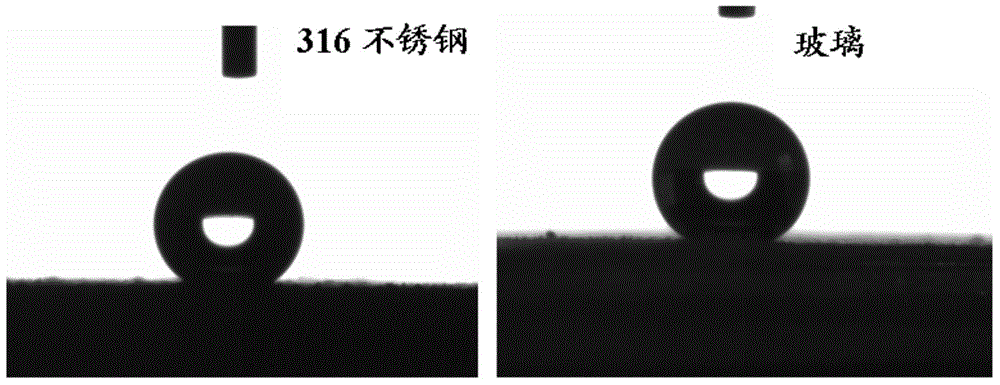

Method for preparing superhydrophobic coating by adopting supersonic electric arc spaying technique

The invention discloses a method for preparing a superhydrophobic coating by adopting a supersonic electric arc spaying process. The method comprises the following steps of: firstly, roughening the surface of a substrate; then preparing a coating on the surface of the substrate by adopting a supersonic electric arc spaying technique; and finally, modifying the surface of the coating with a substance with low surface energy, and drying to form a superhydrophobic surface. The method disclosed by the invention has the advantages of easy operation, low cost and good repeatability and is suitable for industrial production. In addition, the method can be used for preparing superhydrophobic coatings on a variety of surfaces such as metal surfaces, glass surfaces and tile surfaces, thus the scope of application of the superhydrophobic coating can be broadened, and large-scale production with high market value can be archived.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

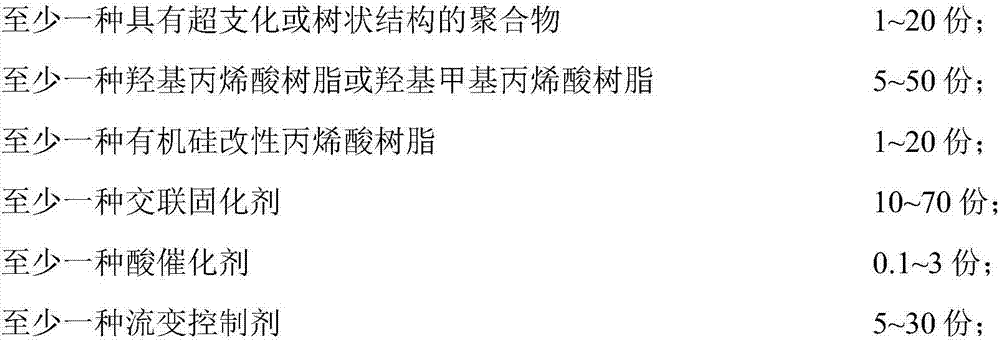

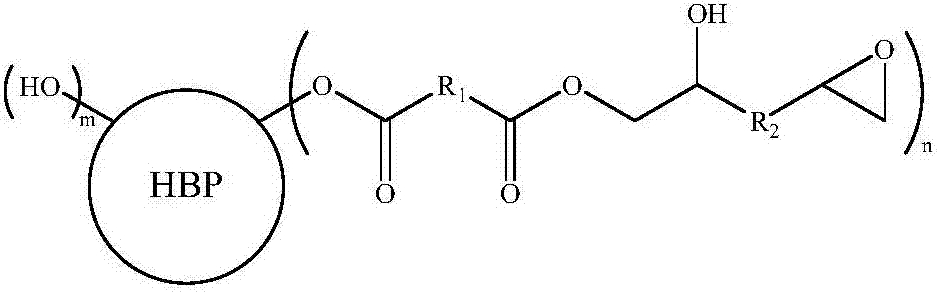

Mono-component varnish composition, preparation method and purpose thereof

ActiveCN106916503AImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

The invention discloses a mono-component varnish composition, which comprises at least a polymer having a hyper branched or dendritical structure; at least one type of hydroxyl acrylic resin or hydroxyl methacrylate resin; at least one type of organosilicon-modified acrylic resins; at least a crosslinking curing agent; at least an acid catalyst; at least a rheological control agent; at least an auxiliary agent and at least a solvent; and the mono-component varnish composition has the advantages of high scratch resistance and high weather resistance. The provided mono-component varnish composition can effectively increase the smoothness of the surface of a varnish composition film, and increases the rub resistance of the film; in addition, the introduction of the organosilicon-modified acrylic resin can further increase the weatherability of the varnish composition film.

Owner:LANGFANG NIPPON PAINT +2

Super-hydrophobic coating, super-hydrophobic coating layer, and preparation method thereof

InactiveCN106366907AImprove environmental adaptabilityImprove friction resistanceCoatings with pigmentsFiltration separationFiberSolvent

The invention provides a preparation method of a super-hydrophobic coating layer. The preparation method includes the steps of: 1) according to mass percentage of a final solution, dissolving 0.5-10% of hydrophobic nano particles and 1-15% of hydrophobic resin in a solvent, performing ultrasonic dispersion for 15-60 min to obtain a mixed solution; 2) forming the mixed solution on the surface of a substrate material and in internal microstructures of the substrate material; 3) naturally air-drying the substrate material to form the super-hydrophobic coating layer. According to the method, the preparation process of the coating layer is free of assistance of external equipment, such as heating and the like, so that the method is simple and low-cost. The method can achieve preparation of the super-hydrophobic coating layer on various fiber surfaces and porous material surfaces, has excellent universality and is easy to achieve in industrial large-area preparation.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Graphene-modified wear-resistant rubber

The invention relates to a graphene-modified wear-resistant rubber. The graphene-modified wear-resistant rubber comprises, by weight, 48.9 to 56.5% of synthetic rubber, 1.5 to 2.5% of a sulfuration promoter, 8 to 18% of graphene, 25 to 30% of a filling material, 1.5 to 5% of a plasticizer and 0.1 to 3% of an auxiliary agent. According to the invention, graphene is added into the rubber so as to improve strength of the rubber, and since graphene has good lubrication effect, wear resistance of the rubber can be improved; and addition of asbestos fiber and polyimide fiber enables heat resistance of the rubber to be substantially improved.

Owner:余姚市振大塑胶有限公司

Toner

ActiveUS20180329327A1Increase freedomExcellent charge riseDevelopersEngineeringElectrical and Electronics engineering

A toner comprising a binder resin and a colorant, wherein the toner has a Martens hardness, as measured at a maximum load condition of 2.0×10−4 N, of from 200 MPa to 1,100 MPa.

Owner:CANON KK

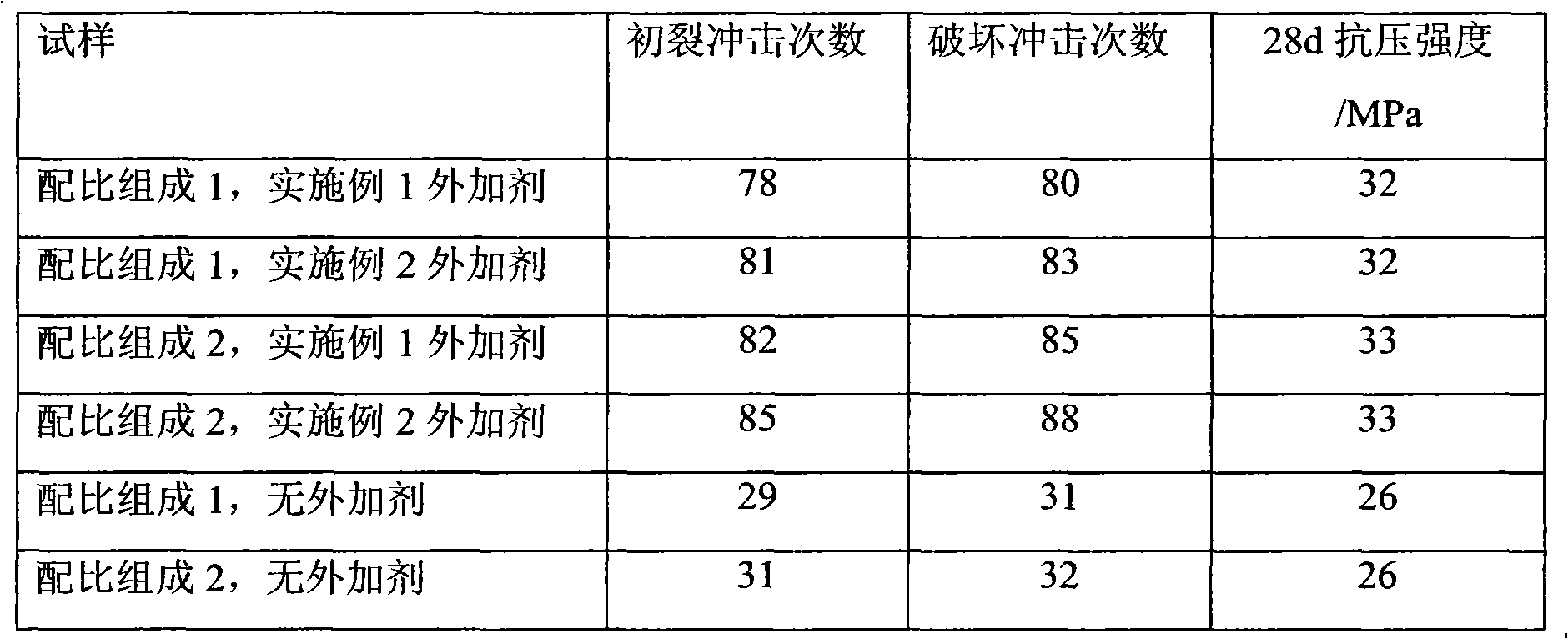

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

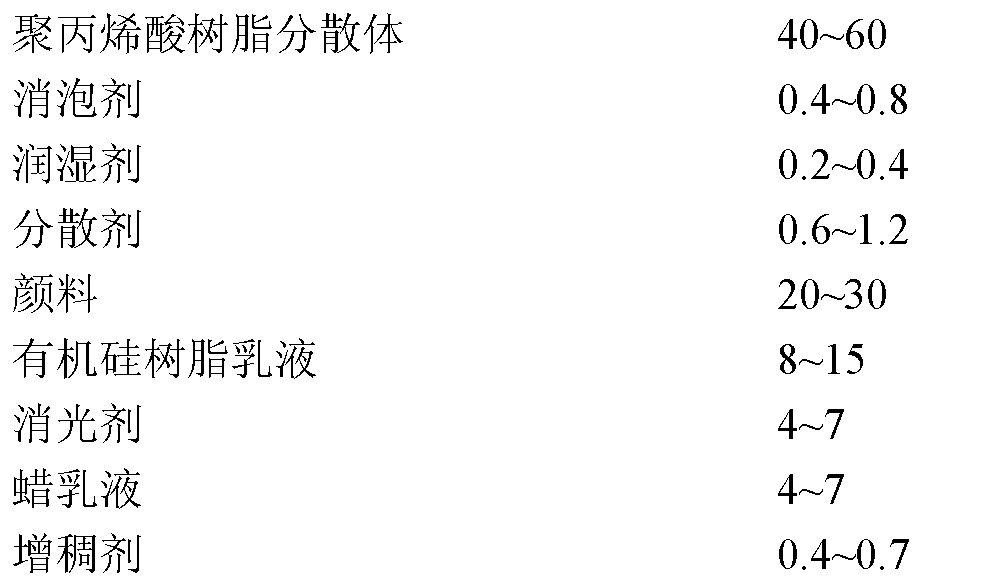

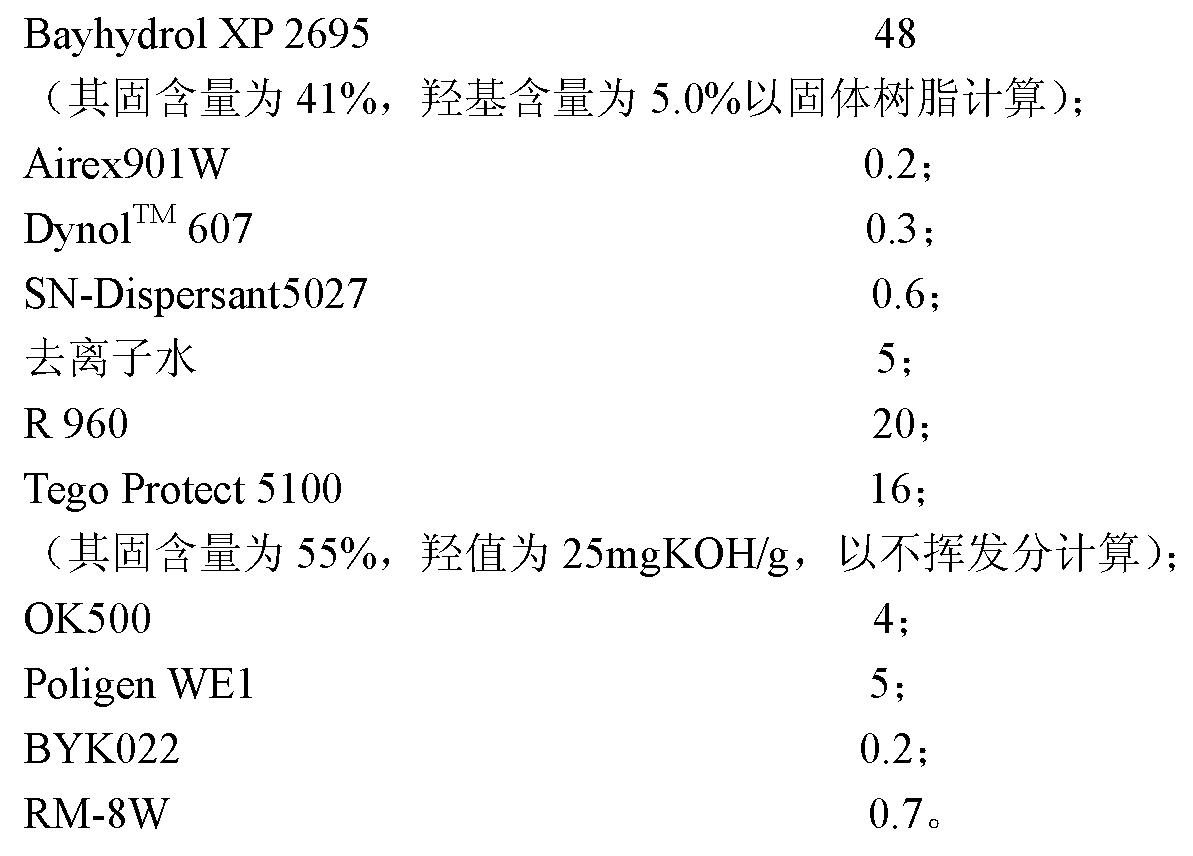

Dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance and preparation thereof

InactiveCN102516858AImprove scratch resistanceImprove friction resistancePolyurea/polyurethane coatingsWaxChemistry

The invention discloses a dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance, and a preparation method thereof. The dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance is prepared by using aqueous hydroxy-containing polyacrylic resin dispersion and fatty group polyisocyanate as main film forming substances, adding organosilicon resin emulsion, deionized water, antifoaming agent, wetting agent, dispersant, pigment, dulling agent, wax emulsion and thickening agent and carrying out high speed disperse. The paint has characteristics of high crosslinking density, low surface tension, strong permeability resistance, good scratch resistance, substantial scrawling resistance and pasting resistance, excellent performances of low VOC content, high hardness, good weatherability, brushing resistance and chemical resistance, and is suitable for application fields of municipal public facility, building paint and terrace paint coating, etc.

Owner:CENT SOUTH UNIV +1

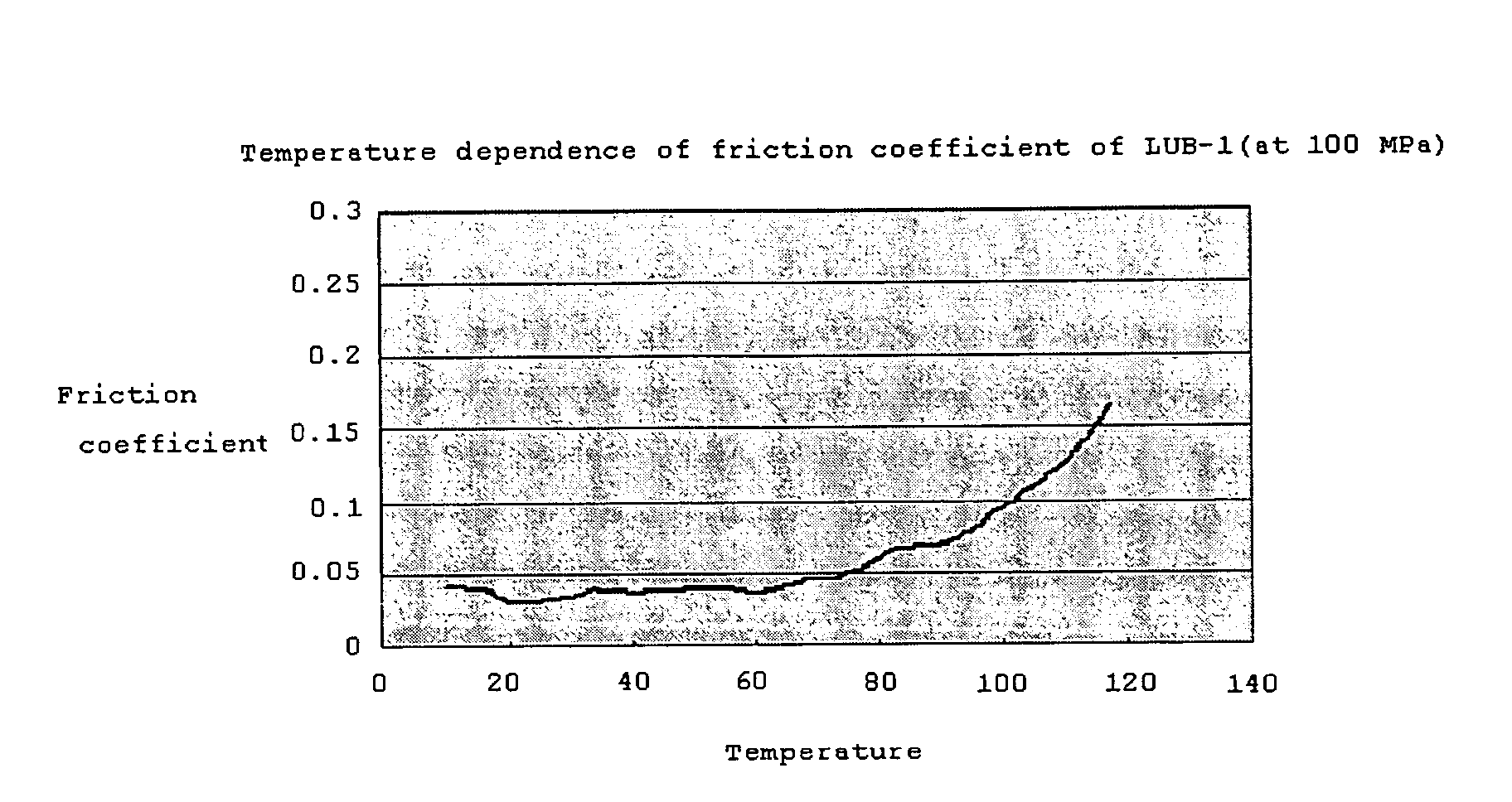

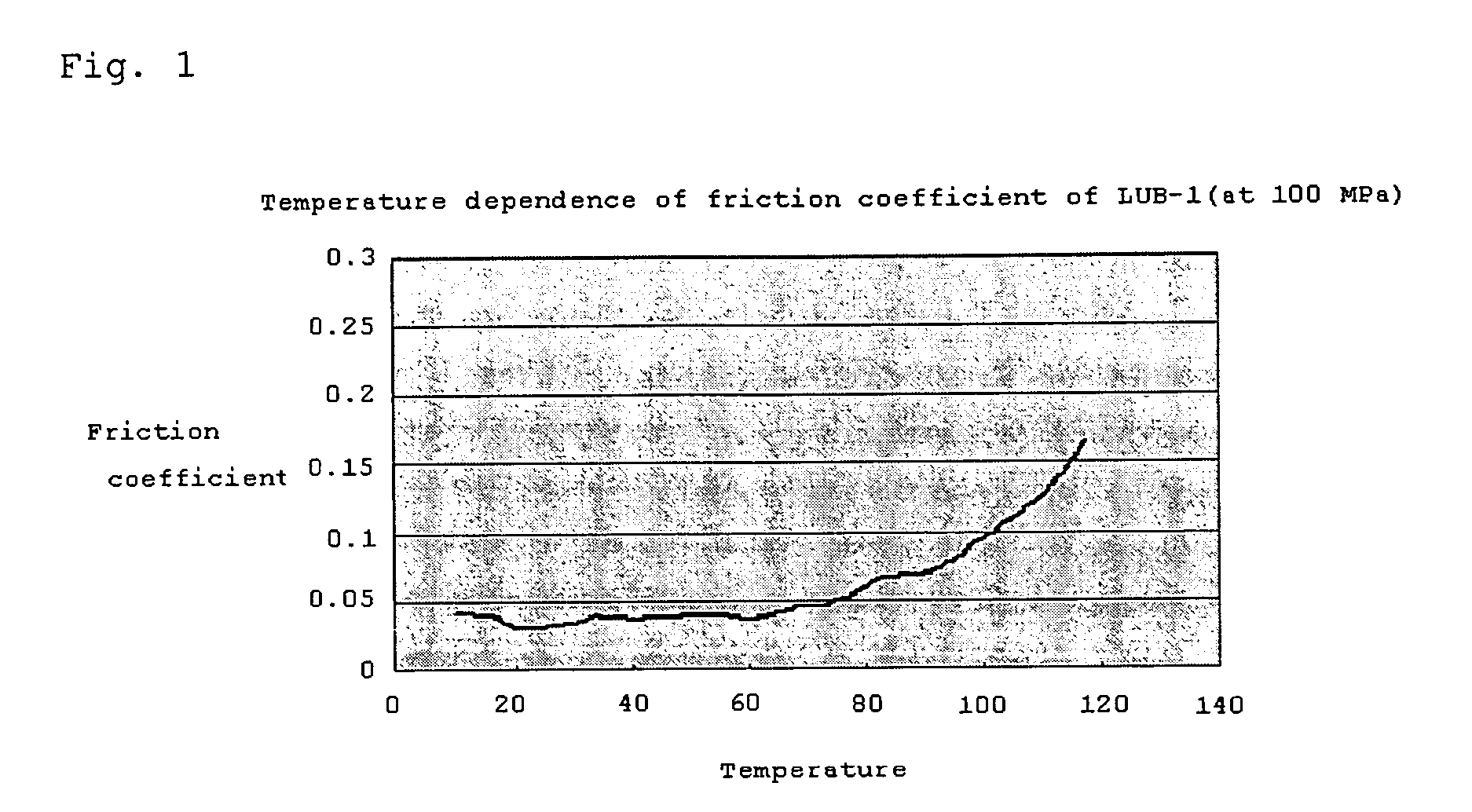

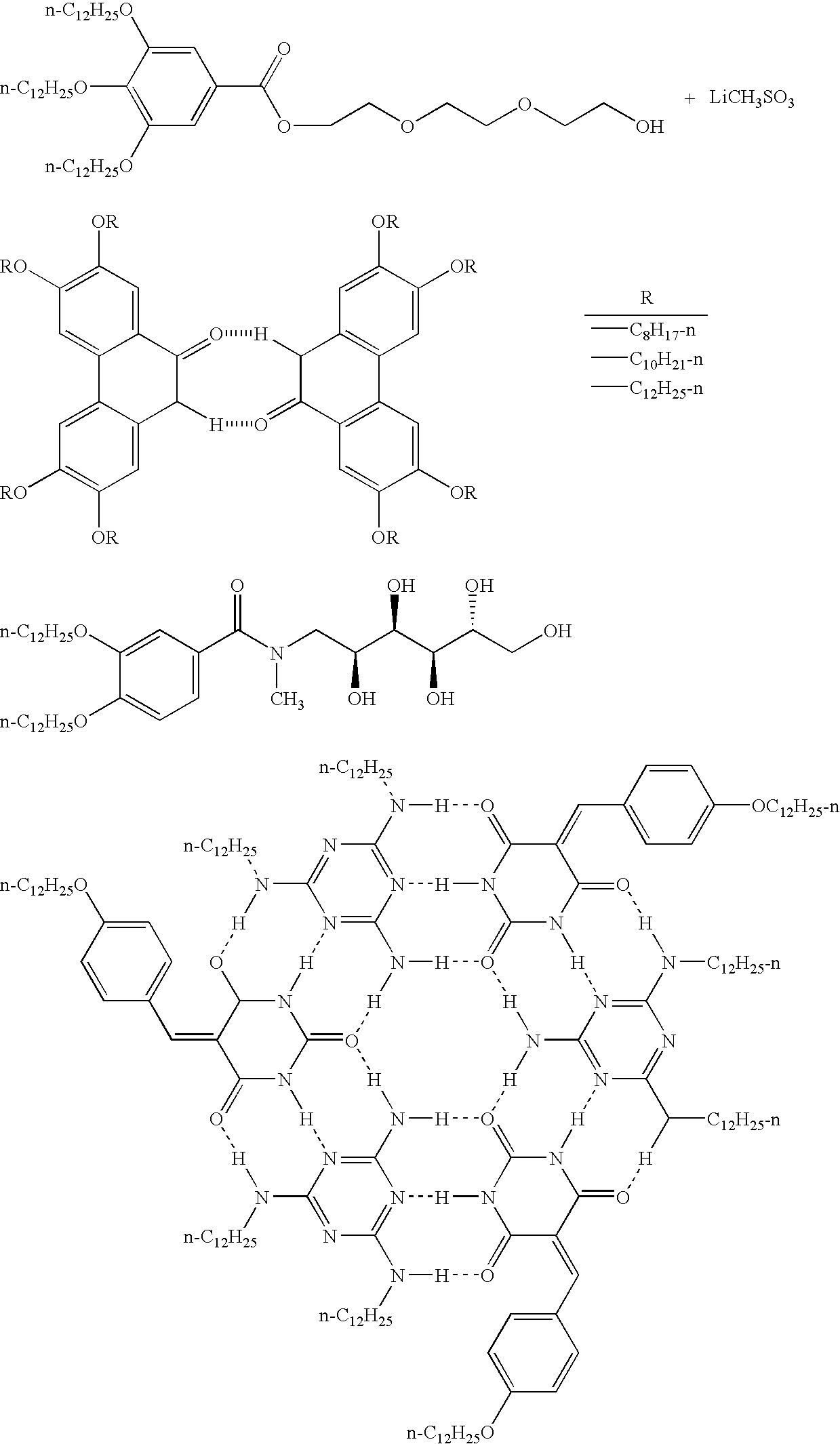

Lubricant composition and mechanical element

InactiveUS20060270568A1Low viscosityImprove friction resistanceLiquid carbonaceous fuelsAdditivesOrganic compoundLamellar phase

A novel lubricant composition is disclosed. The lubricant composition comprises at least one organic compound, and, when disposed between two surfaces moving at peripheral speeds differing from each other, is capable of exhibiting a discotic columnar phase or a discotic lamellar phase in which a plurality of molecules of said organic compound is assembled.

Owner:FUJIFILM CORP

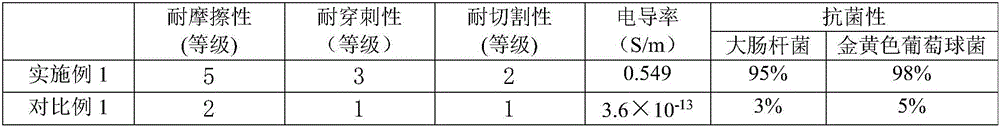

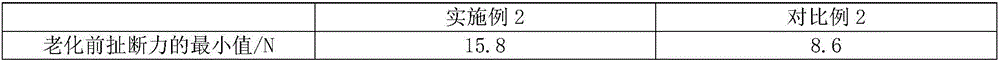

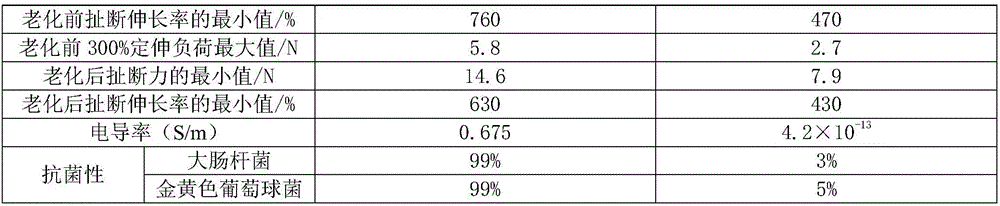

Graphene-latex functional high-strength protection glove and production method thereof

InactiveCN106065095AComfortable to wearImprove friction resistanceGlovesBulk chemical productionElectricityAviation

The invention discloses a graphene-latex functional high-strength protection glove and a production method thereof. The method comprises the following steps: (1) immersing a glove blank in a coagulating agent, immersing the glove blank in a graphene-latex composite liquid, and drying the immersed glove blank to obtain the glove; or (2) immersing the glove blank in the coagulating agent, drying the immersed glove blank, immersing the dried glove blank in the graphene-latex composite liquid, leaching the immersed glove blank, crimping the leached glove blank, drying the crimped glove blank, vulcanizing the dried glove blank, leaching the vulcanized glove blank, and drying the leached glove blank to obtain the glove. Compared with gloves in the prior art, the graphene-latex functional high-strength protection glove produced in the invention fully performs the advantages of high electricity conductivity, high strength, friction resistance and strong bacteriostasis of graphene, and has wide uses in the fields of the manufacturing industry, the medical industry, the chemical engineering industry and the space flight and aviation industry.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Aluminum-base alloy self-lubricating material and preparation method thereof

A aluminum-based alloy self-lubricating materials and method for making same relates to the technology for preparing composite metal materials. Aimming at the evil of large gas cavity amount in aluminum-based alloy self-lubricating materials, there is disclosed a aluminum-based alloy self-lubricating materials and method for making same. Said scheme is as follows: selecing aluminium alloy as a basal body alloy, adding a slipping agent into the aluminium alloy fused mass, wherein said slipping agent is composed of one of copper facing mineral carbon or one mixture of copper facing mineral carbon and copper facing carbon fabric or one mixture of copper facing mineral carbon and nickel plating carbon fibre and is prepared through stirring-mixing, vacuum outgassing and casting, and the basal body aluminium alloy comprises (based on mass percent) Si of 6.5-9.0, Mg of 0.8-1.2, Mn of 0.1-0.5, Ti of 0.1-0.25, Zn of not more than 0.3, Fe of not more than 0.5, Cu of not more than 0.3, Ni of not more than 0.1, in which the allowance is Al. The weight of the added substance is 7-12%, 10-18% and 10-17 of the total weight of the aluminum-based alloy respectively when copper facing mineral carbon, the mixture of copper facing mineral carbon and copper facing carbon fabric and the mixture of copper facing mineral carbon and nickel plating carbon fibre are adopted. There is less gas cavities existing in said material.

Owner:NORTHEASTERN UNIV

Nano-silica/polyacrylate organic and inorganic hybrid water-dispersible resin and preparation method thereof

InactiveCN105061700AGood storage stabilityInhibit aggregationAntifouling/underwater paintsPaints with biocidesWater dispersibleIn situ polymerization

The invention discloses nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin and a preparation method thereof. According to the method, a silane coupling agent is adopted to modify a methyl methacrylate dispersion liquid of silica at first, and then in-situ polymerization of the modified methyl methacrylate dispersion liquid of silica and acrylate monomers is carried out in a solvent. The nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin comprises the following ingredients in parts by mass: 20-40 parts of a solvent, 10-40 parts of a modified methyl methacrylate dispersion liquid of silica, 8-14 parts of acrylate monomers, 2-6 parts of acrylic acid, 0.15-0.5 part of an initiator, 1.5-5.5 parts of a pH regulator and 10-30 parts of deionized water. The water-dispersible resin is a pale yellow or pale yellow and slightly-blue semitransparent liquid, is favorable in storage stability, high in coating transparency and good in stain resistance and water resistance, the hardness can be 4H or above and the adhesion can be 1 grade.

Owner:SOUTH CHINA UNIV OF TECH

Filter material containing polyphenyl thioether fiber and use

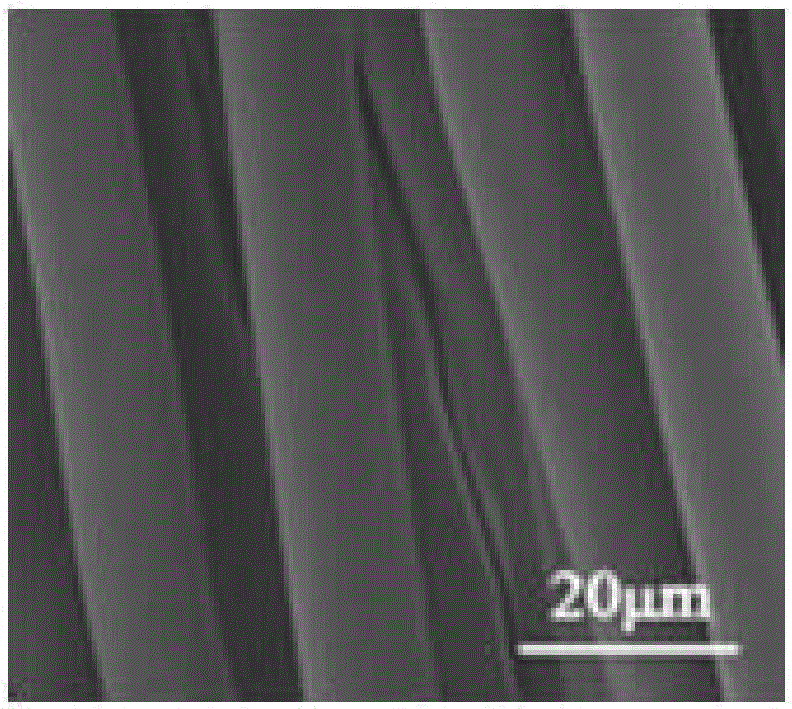

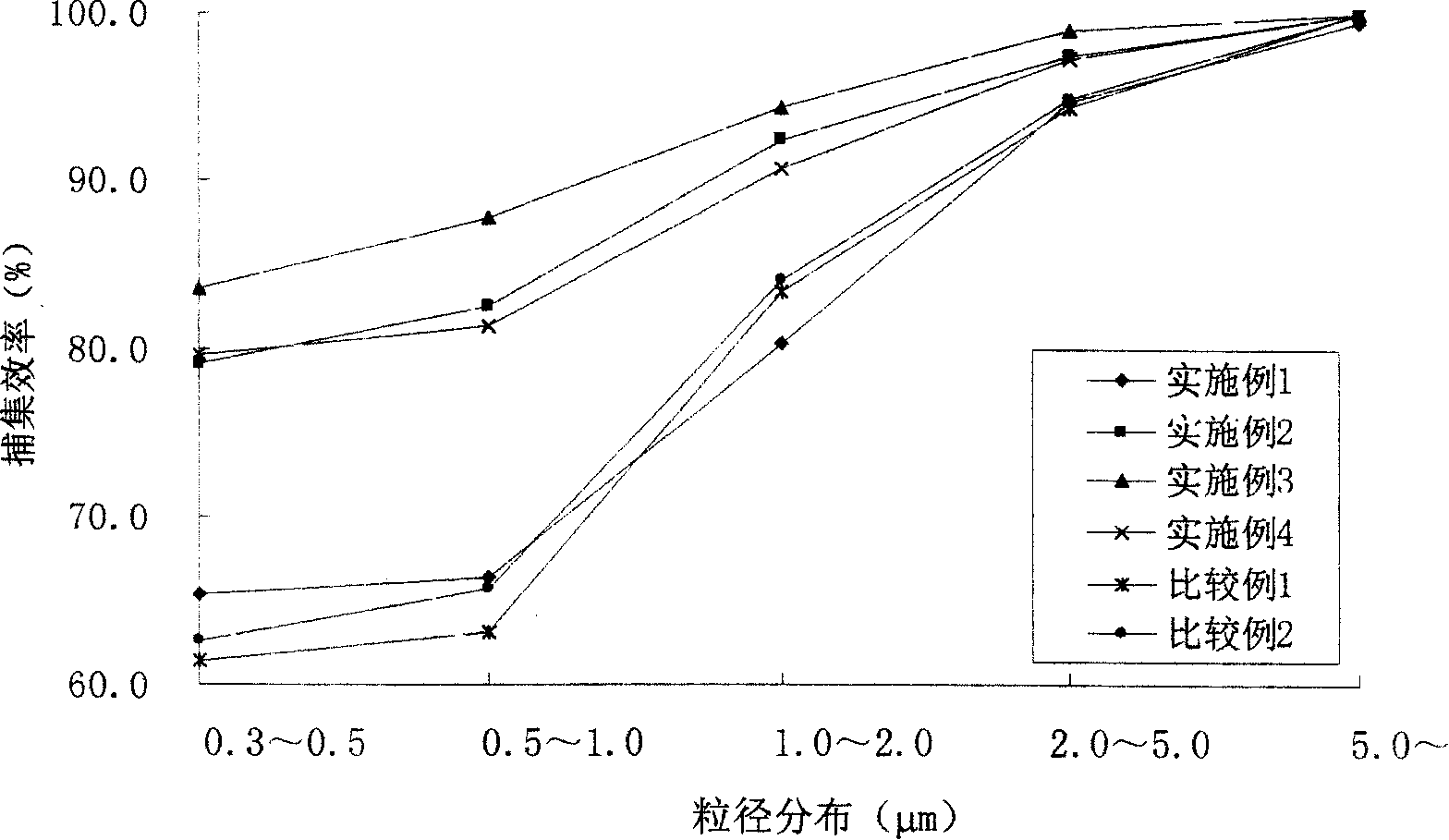

InactiveCN101168112AImprove capture efficiencyAvoid damageDispersed particle filtrationFiltration separationFiberMicrometer

The invention discloses filtering materials with polyphenylene sulfide fiber and the usage of the filtering materials. The filtering materials are composed of three layers of a filtering veneer, a non filtering veneer and a middle fabric reinforcing layer, wherein the filtering veneer is a fiber netting which is composed by mixing the fiber with 30wt% to 70wt% of which the average diameter is below 10 micrometers and the fiber with 30wt% to 70wt% of which the average diameter is 10 to 20 mum, the non filtering veneer is a fiber netting formed by fiber of which the average diameter is above 20 micrometers, and the middle layer is the fabric reinforcing layer. At least the fiber of the filtering veneer and the non filtering veneer employ the polyphenylene sulfide fiber within the filtering materials which form the filtering veneer, the non filtering veneer and the middle fabric reinforcing layer. The products of the invention have the advantages of high efficiency of dust arrestment and perfect frictional resistance, and can be used as the materials of filtering bags.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

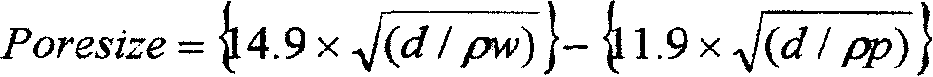

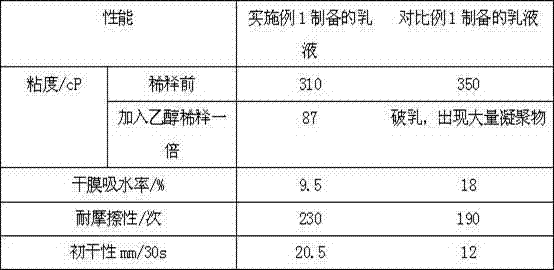

Room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution and preparation method for same

The invention discloses a room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution and a preparation method for the same. The room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution comprises the following components: styrene, an acrylate monomer A, an acrylate monomer B, a hydrophilic monomer, a crosslinking monomer, an emulsifier, an initiator, a pH value buffer, a neutralizer and water; and in the preparation method disclosed by the invention, the room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution is prepared by adding a seed emulsion and using semicontinuous polymerization process. The acrylate monomer A containing a long-chain ester group is added during synthesis, so that the prepared styrene-acrylic emulsion can be directly diluted by adding ethanol; and the crosslinking monomer is added during synthesis, so that the solvent resistance, wear resistance and drying speed of emulsion dry film can be improved and increased. The room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution disclosed by the invention can be used for preparing water-based ink and water-based gloss oil satisfying medium-speed and high-speed printing requirements.

Owner:FOSHAN SOUTHERN PACKAGING +1

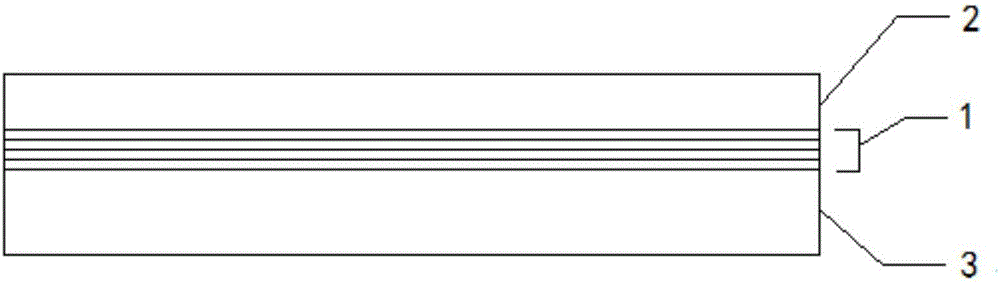

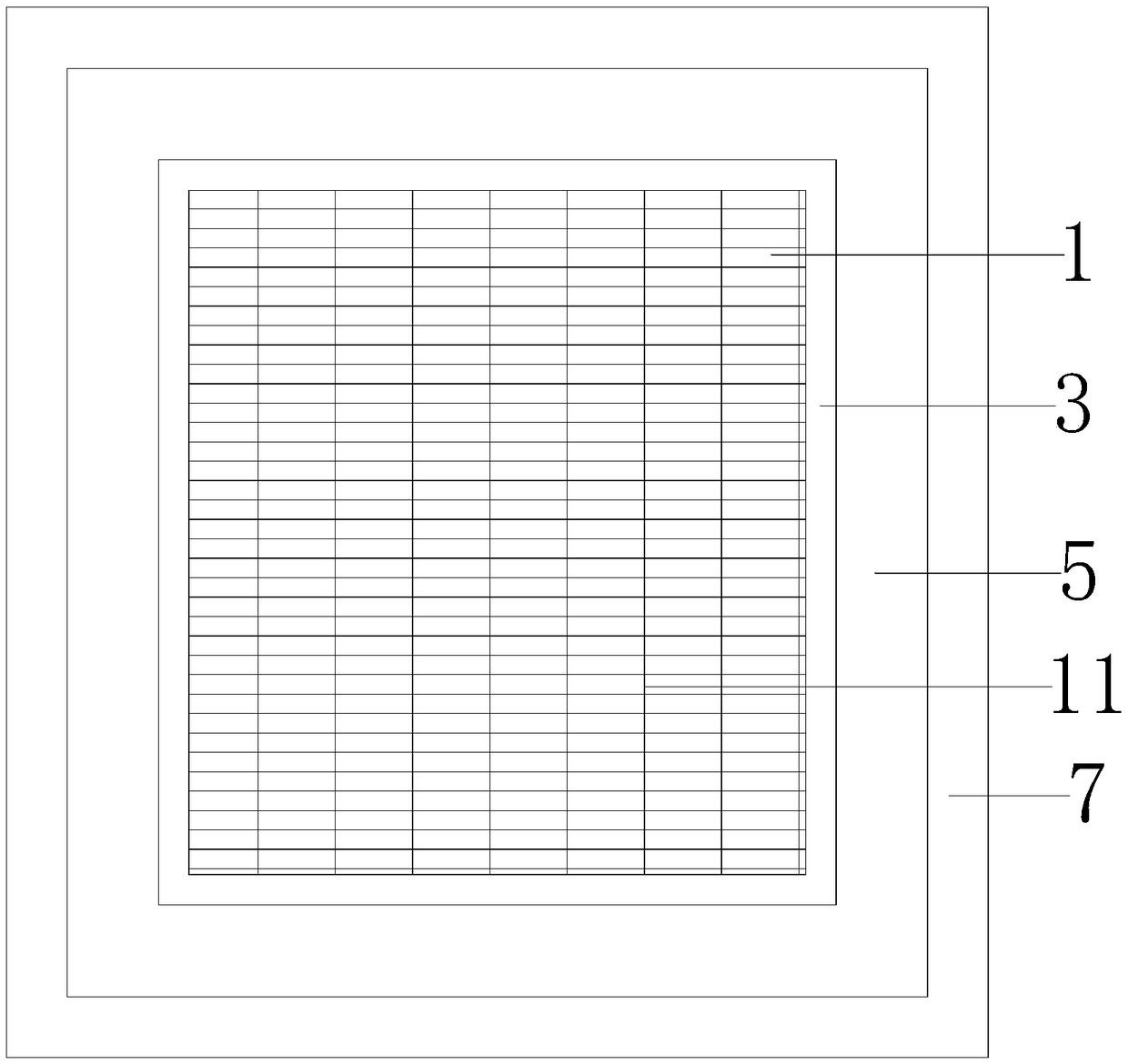

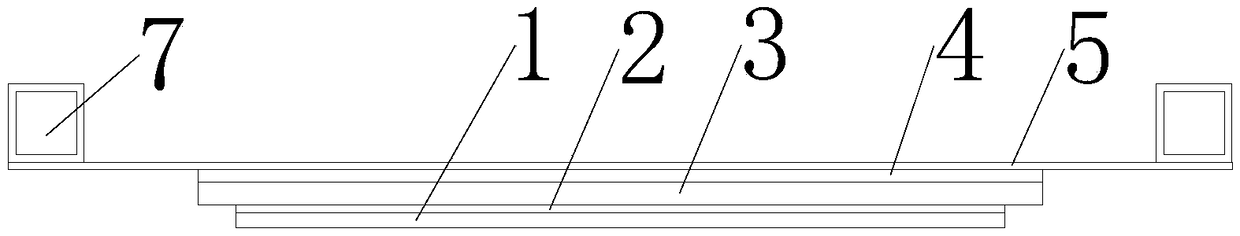

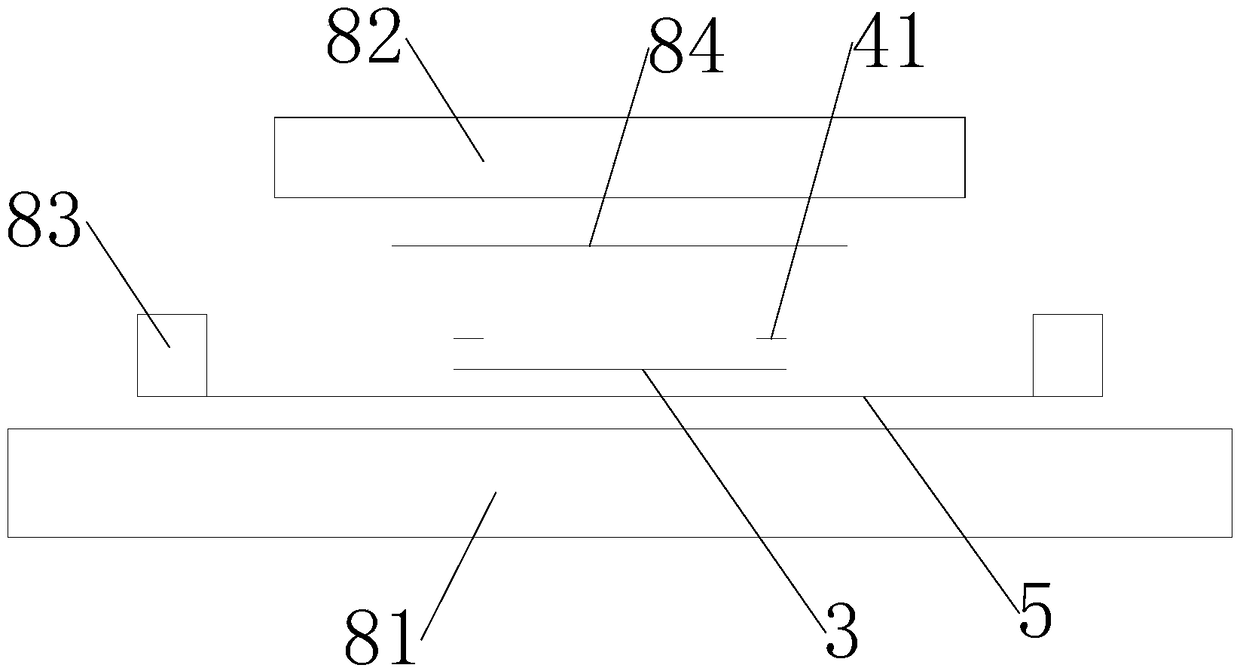

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

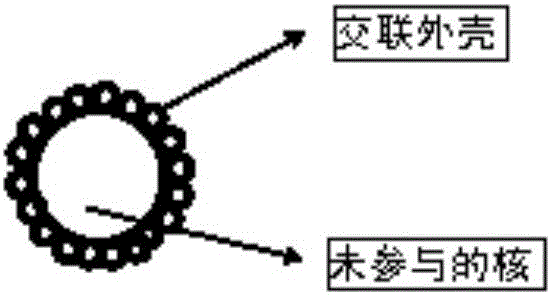

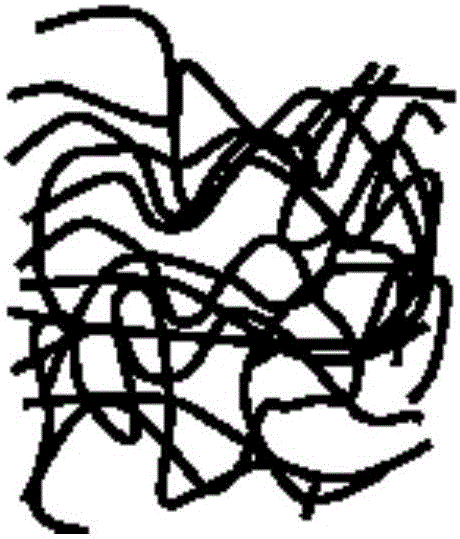

Compositions and Methods to Improve the Setting Properties and Rub Resistance of Printing Inks

ActiveUS20130324653A1Easy to processQuick set upLiquid surface applicatorsInksPolymer sciencePrinting ink

Provided are high viscosity essentially non-aqueous dispersions containing acrylic core / shell polymer particles in a non-aqueous solvent; sheetfed, heatset and coldset lithographic ink compositions containing the dispersions; and methods of printing with ink containing the dispersions to improve the setting and drying properties and rub resistance of sheet fed offset, heatset and coldset lithographic inks. The lithographic inks containing the dispersions set quickly enough to allow processing of printed sheets soon after printing.

Owner:SUN CHEM CORP

Metal super-hydrophobic surface and preparation method thereof

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

Nano-graphene loaded wax liquor, and preparation method and use thereof

ActiveCN103468004AGood electrical and thermal conductivityGood self-lubricating performanceFibre treatmentInksTotal solid contentCvd graphene

The invention belongs to the technical field of fine chemical engineering polymer materials, and specifically relates to nano-graphene loaded wax liquor, and a preparation method and a use thereof. The wax liquor is a wax dispersion which is formed by loading ultrafine nano-graphene particles having the particle size in the range from 20 to 40 nm on wax particles having the particle size in the range from 200 to 800 nm; and the total solid content of the wax liquor is 15-25%. The preparation method provided by the invention is used for successfully solving the dispersion and aggregation problems of graphene while being used for a paint or an ink body; and the nano-graphene loaded wax liquor prepared by the preparation method is used for paint, ink or leather finishing, and has the effects of rub resistance, static resistance and electromagnetic wave blocking.

Owner:NANJING TIANSHI NEW MATERIAL TECH

Method for making hydrophobic solution and hydrophobic glass

A process for preparing a hydrophobic solution and a hydrophobic glass used for the windscreen of car is disclosed. Said hydrophobic solution is prepared from CF3(CF2)5C2H4Si(OC2H5)3, Si(OC2H5)4, C2H5OH, deionized water, and hydrochloric acid through proportional mixing, and stirring for 5-20 hr. Said hydrophobic glass is prepared through cleaning glass, preparing said hydrophobic solution, coating it on the surface of glass, and solidifying at 250-350 deg.C for 10 min -72 hr to form a firm hydrophobic film.

Owner:FUYAO GLASS IND GROUP CO LTD

Graphene-modified building coating material

ActiveCN103740158AImprove adhesionHigh contrast ratioPolyurea/polyurethane coatingsFiberCarbon fibers

The present invention discloses a graphene-modified building coating material, which comprises a solvent, a commonly used additive and a main film forming substance, and further comprises graphene for modification, wherein the amount of the added graphene is 0.001-20% of the weight of the building coating material, the building coating material can further be added with the auxiliary additive, and the amount of the added auxiliary additive is 0-8% of the weight of the building coating material. According to the present invention, graphene is added to the existing building coating material so as to modify the water resistance mechanical strength of the building coating material and increase adhesion of the building coating material and the substrate, the contrast ratio and the scrubbing resistance; the bamboo carbon fibers are added to the building coating material so as to provide effects of bacterial inhibition, antibacterial and anti-ultraviolet light, such that the building coating material has the characteristic of green environmental protection; and the bone glue is added to the building coating material so as to improve bonding property and increase adhesion.

Owner:NINGBO MORSH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com