Super-hydrophobic coating, super-hydrophobic coating layer, and preparation method thereof

A technology of super-hydrophobic coatings and super-hydrophobic coatings, applied in pigmented coatings, coatings, separation methods, etc., can solve problems such as poor stability, high cost, and low separation efficiency, and achieve low cost, good friction resistance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A super-hydrophobic paint, the weight percentage content of each component is: 1% hydrophobic nano silicon dioxide particles, 1% methyl silicone resin, 98% xylene solution.

[0047] The method for preparing the above-mentioned super-hydrophobic coating: according to the mass fraction of the final solution, 1% of hydrophobic nano-silica particles and 1% of methyl silicone resin are dissolved in xylene solution for ultrasonic dispersion, and the mixture can be obtained after mixing evenly. Superhydrophobic coatings.

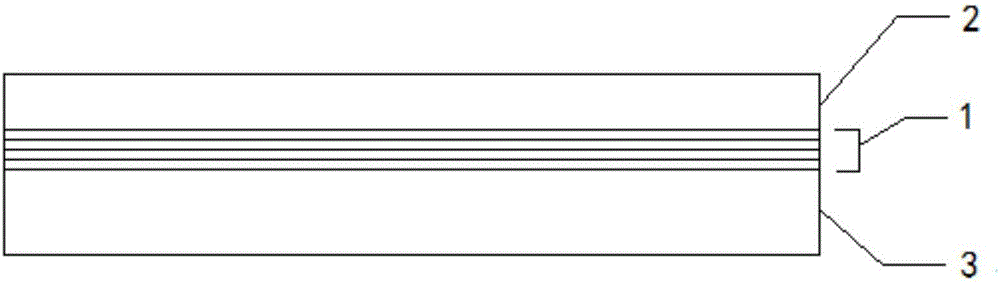

[0048] Such as figure 1 Shown, a kind of superhydrophobic coating, described superhydrophobic coating is a micro-nano composite rough structure, and this coating comprises hydrophobic nanoparticle layer 2, hydrophobic resin layer 1 and base material layer 3; Described hydrophobic nanoparticle layer 2. The hydrophobic resin layer 1 and the base material layer 3 are laminated, and the hydrophobic resin layer 1 wraps part of the hydrophobic nanoparticles in th...

Embodiment 2

[0059] This example is basically the same as that of Example 1, except that the polyurethane sponge is immersed in the preparation solution to obtain a superhydrophobic sponge. After testing, the contact angle of the superhydrophobic sponge is 159°. At the same time, the superhydrophobic sponge has a contact angle of 0° to oil (n-hexane, carbon tetrachloride, chloroform, gasoline, silicone oil, etc.), so it can also be used for oil-water separation. The superhydrophobic sponge has a separation efficiency of more than 99% for the mixture of oil (n-hexane, carbon tetrachloride, chloroform, gasoline, silicone oil, etc.) and water, and the superhydrophobic sponge can be squeezed to recover the oil, and it can be reused 10 times , the separation efficiency is still above 98%.

Embodiment 3

[0061] This embodiment is basically the same as the above-mentioned embodiment 1, except that the qualitative filter paper is used as the base material and immersed in the preparation solution to obtain the super-hydrophobic filter paper. After testing, the contact angle of the superhydrophobic filter paper to water is 156°; meanwhile, the contact angle of the superhydrophobic filter paper to oil (n-hexane, carbon tetrachloride, chloroform, gasoline, silicone oil, etc.) is 0°, so it is also Can be used for oil-water separation. The superhydrophobic filter paper has a separation efficiency of more than 99% for the mixture of oil (n-hexane, carbon tetrachloride, chloroform, gasoline, silicone oil, etc.) and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com