Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1364results about How to "Good self-lubricating performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

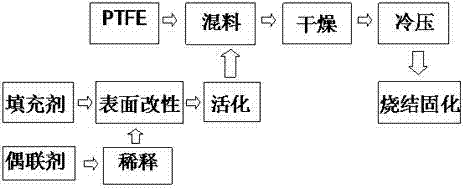

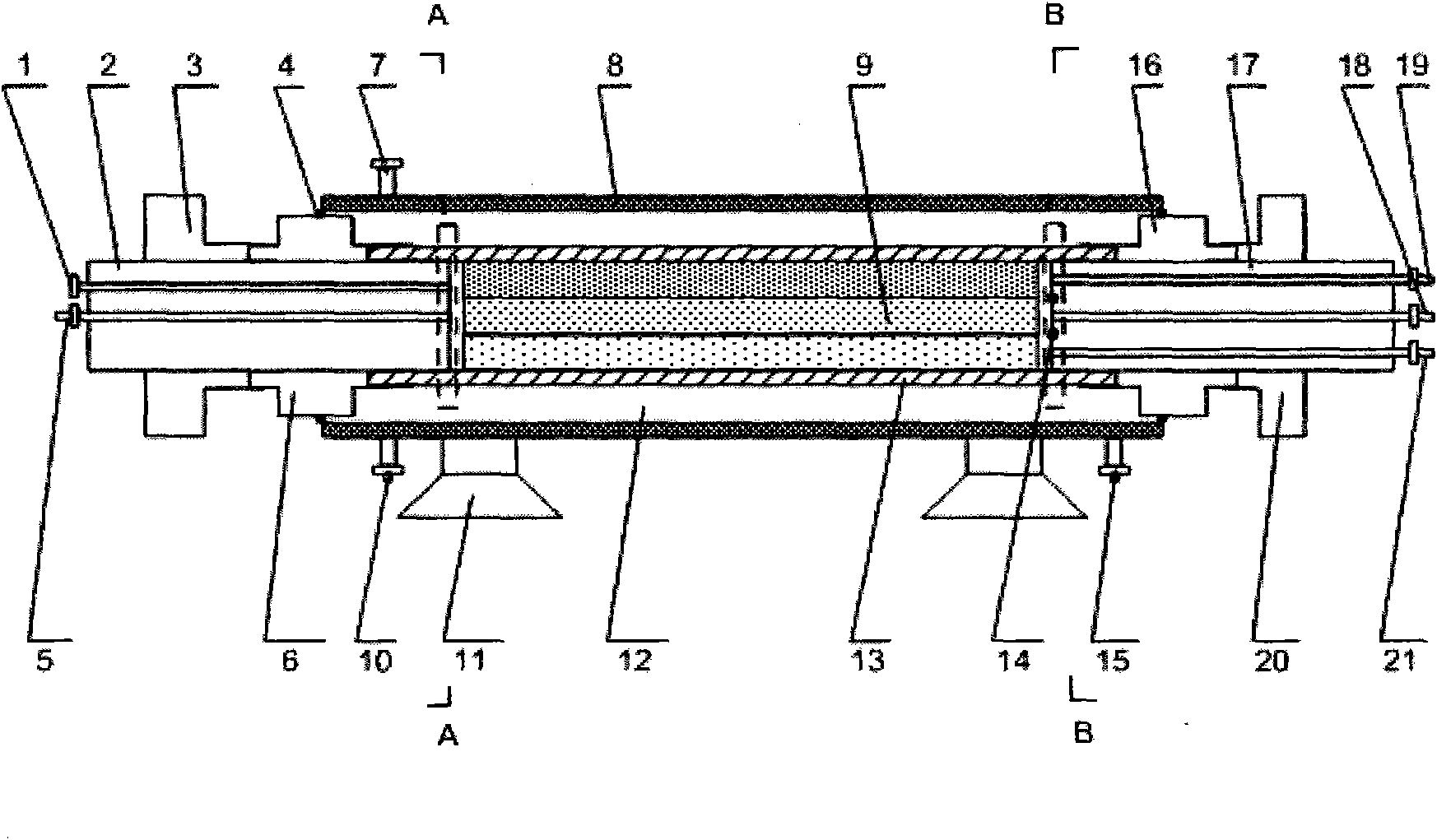

Fluorine-containing polymer mixing material and method for preparing bulb buffer ball keyway by same

InactiveCN102952360AGood chemical stabilityGood self-lubricating performanceControl armMixed materials

The invention discloses a fluorine-containing polymer mixing material and a method for preparing a bulb buffer ball keyway by the same. The fluorine-containing polymer mixing material is prepared by mixing fluorine-containing polymer resin with filler modified by a coupler, and comprises the materials in parts by mass as follows: 60-99 parts of fluorine-containing polymer resin and 1-40 parts of modified filler. The filler meets the condition that the filler is stably sintered at a temperature above the melting temperature of the resin and the granularity is smaller than or equal to 150 microns; the filler does not absorb moisture; and the filler is not clustered under the sintering condition and is not reacted with the polymer. The coupler accounts for 5-40% of the filler by mass percentage. The material has excellent chemical stability, self-lubricating property, noninflammability, resistance to atmospheric aging and high and low temperature adaptability and the like as well as higher mechanical strength. The hardness can be improved through modification and the material is used to prepare wear-resisting products. The bulb buffer ball keyway is prepared from the material so that a suspension type direction control arm assembly of an automobile with high mechanical strength, good wear-resistance and a long service life is further obtained.

Owner:浙江国威汽车配件有限公司

Low-VOC scratch-resistant modified polypropylene composite material and preparation method thereof

InactiveCN101787159AImprove adsorption capacityFully dispersedMolecular sievePolypropylene composites

The invention belongs to the field of modified polypropylene composite material, and relates to a low-VOC scratch-resistant modified polypropylene composite material which is applicable to manufacturing automobile interior trim parts, and comprises the components based on the parts by weight: 60-90 parts of polypropylene, 5-20 parts of toughening agent, 5-20 parts of mineral filler, 0.1-4 parts of odor adsorbent, 5-15 parts of wear-resistant agent / scratch-resistant agent and 0.1-3 parts of auxiliary agent, wherein the odor adsorbent is a mixture of three selected from clay, bentonite, porous silicon dioxide, activated aluminium oxide or molecular sieve; and the wear-resistant agent / scratch-resistant agent is one or a mixture of two in polytetrafluoroethylene micro powder or reaction-type polyorganosiloxane. The modified polypropylene composite material not only has better impact-resistant performance and strength, but also has excellent scratch-resistant performance and low-VOC diffusion characteristic; and the needed raw materials have wide source and can be conveniently and easily obtained.

Owner:SUZHOU SUNWAY POLYMER

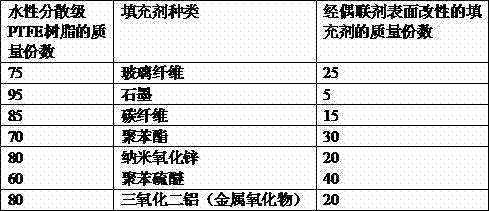

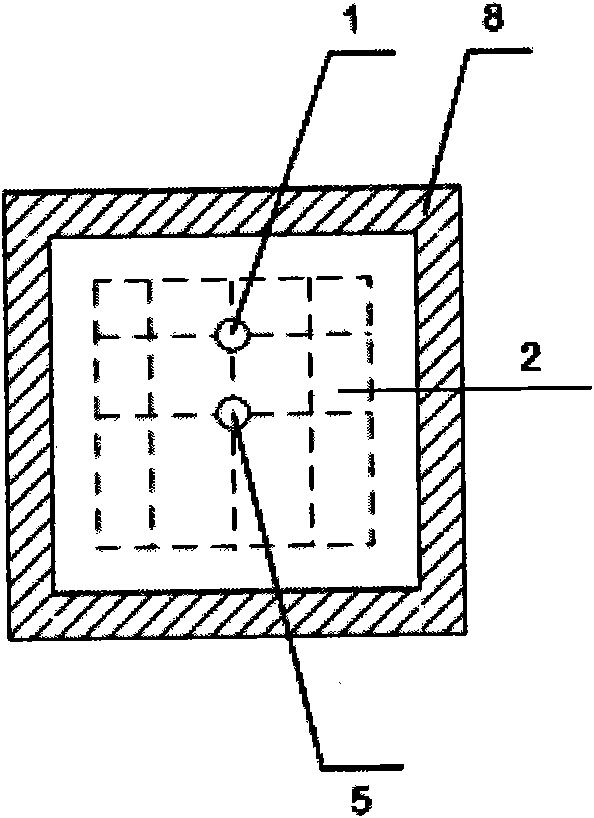

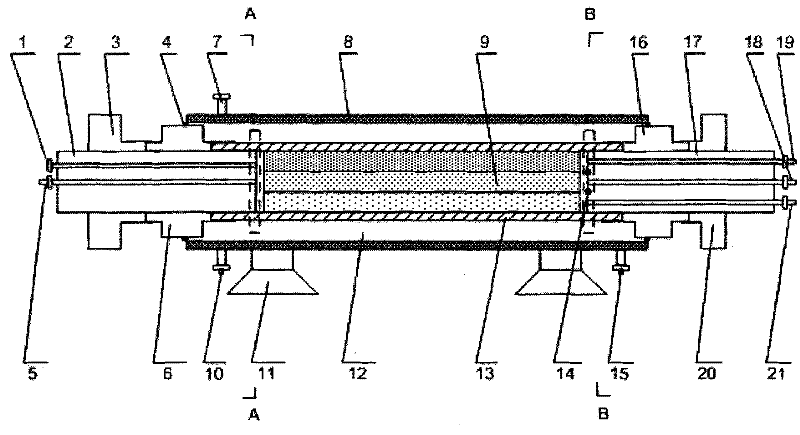

Computed tomography (CT) scanning heterogeneous model testing system

ActiveCN102095740AImprove mechanical propertiesPeel-resistantPermeability/surface area analysisMaterial analysis by transmitting radiationFluid saturationComputed tomography

The invention relates to a computed tomography (CT) scanning heterogeneous model testing system. The system comprises a CT scanning system, a displacement system, an overburden pressure system, a pressure measurement system, a heterogeneous multilayer core clamp holder and a metering system, wherein the heterogeneous multilayer core clamp holder consists of a shell, a rubber cylinder, a core left plug, a core right plug, a left fixing sleeve, a right fixing sleeve, a left fastening sleeve, a right fastening sleeve and a fixed bracket; the core right plug is provided with a plurality of liquid outlets; each liquid outlet is respectively aligned with one layer of core model; and a strip liquid outlet sealing gasket is formed on the core right plug, which correspond to a seam between two adjacent layers of core models, so that liquid flow passing through each layer of core model flows out from the corresponding liquid outlet of each layer of core model, and thus, intraformational heterogeneous water displacing oil layered measurement is realized. By the CT scanning system, the real-time on-line monitoring of the on-way distribution of saturation of fluid on each layer section in a heterosphere is realized so as to observe the interlayer communication phenomenon.

Owner:PETROCHINA CO LTD

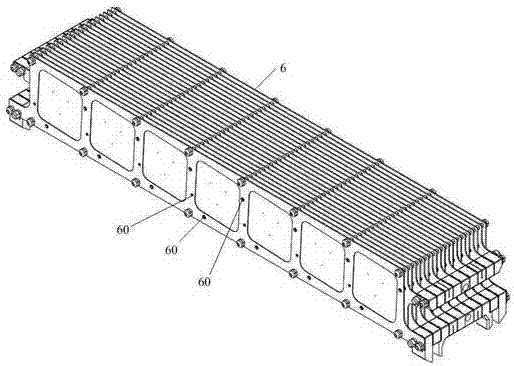

Electric locomotive pantograph copper-soaking carbon contact strip producing method

ActiveCN104774012AImprove conductivityHigh mechanical strengthPower current collectorsShock resistanceNitrogen gas

The invention discloses an electric locomotive pantograph copper-impregnated carbon contact strip producing method. The method comprises the steps that 1, pitch coke powder, graphite powder, siliconized graphite powder and high temperature pitch are mixed according to the proportion to be ground into powder; the mixed powder is prepressed into a stage stock column, and then the stage stock column is solidified and squeezed to be molded and roasted, so that a composite carbon contact strip is obtained; 2, the composite carbon contact strip is cleaned and dried, then is cooled and placed into a graphite crucible, and is placed in an electric furnace at temperature of 1300-1400 DEG C to be preheated; copper liquid is poured into the crucible to soak the composite carbon contact strip, then the crucible is placed in an oil press cover, nitrogen is led in, heat preservation is kept for 3-5 min under the specific intensity of pressure, and finally cooling is carried after pressure releasing. According to the electric locomotive pantograph copper-impregnated carbon contact strip producing method, the electroconductibility of the copper-impregnated carbon contact strip is improved, the electrical resistivity is lowered, the mechanical strength of the carbon contact strip and copper impregnated angle can be increased, then the carbon contact strip abrasive resistance and self-lubrication are improved, the copper-impregnated carbon contact strip is more resistant to abrasion, main line damage and block dropping are avoided, the shock resistance is high, and the service life of the copper-impregnated carbon contact strip is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Carbon nanotube reinforced aluminum based composite material and its vacuum hot pressing prepn. method

InactiveCN1834280AImprove wear resistanceImprove anti-friction performanceDistilled waterCarbon nanotube

This invention discloses a method for preparing carbon nanotube-reinforced aluminum-based composite by vacuum hot pressing. The composite, comprising carbon nanotubes 0.1-5 wt.% and aluminum alloy powders 95-99.9 wt.%, is prepared by: (1) immersing carbon nanotubes in mixed acids, and adding surfactant; (2) dispersing; (3) filtrating, and washing carbon nanotubes with distilled water to neutrality; (4) performing two-step ball milling; (5) vacuum drying; (6) hot pressing in vacuum; and (7) hot extruding to obtain carbon nanotube-reinforced aluminum-based composite. This invention improves the capacity of aluminum alloy matrix in resisting abrasion, reducing friction, self-lubricating, surface wettability and mechanical properties.

Owner:HARBIN INST OF TECH

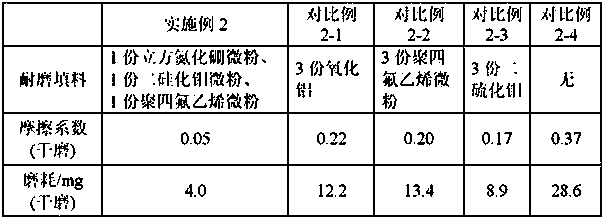

Wear-resistant filling material, wear-resistant composite material prepared from same and preparation method for composite material

The invention discloses a wear-resistant filling material, a wear-resistant composite material prepared from the same and a preparation method for the composite material. The wear-resistant filling material is prepared from the following components by weight: 0.15 to 7.5 parts of cubic boron nitride micro powder, 0.15 to 7.5 parts of molybdenum disilicide micro powder and 0.2 to 10 parts of polytetrafluoroethylene micro powder. The wear-resistant composite material is prepared from the following components by weight: 100 parts of a plastic resin, 0.5 to 25 parts of the wear-resistant filling material, 0 to 2 parts of a coupling agent and 0 to 2 parts of a processing aid. The preparation method for the wear-resistant composite material comprises the following steps: mixing the above-mentioned components at a high speed and carrying out extrusion with an extruder. According to the invention, cubic boron nitride micro powder, molybdenum disilicide micro powder and polytetrafluoroethylene micro powder are compounded to prepare the wear-resistant filling material which is applied to a plastic matrix, so the wear-resistant composite material with good wear resistance, a low friction coefficient and low dry grinding abrasion is prepared; and the application scopes of cubic boron nitride and molybdenum disilicide are broadened at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

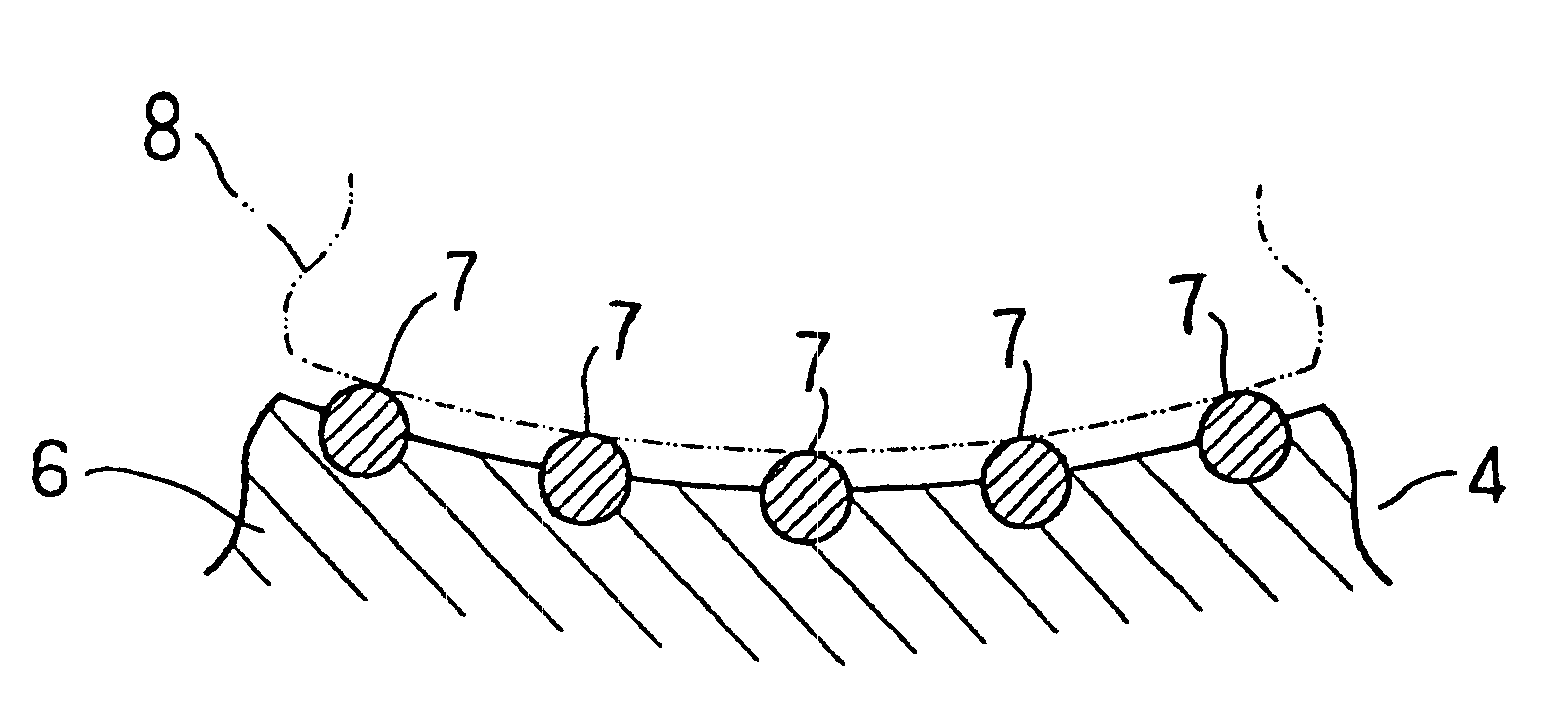

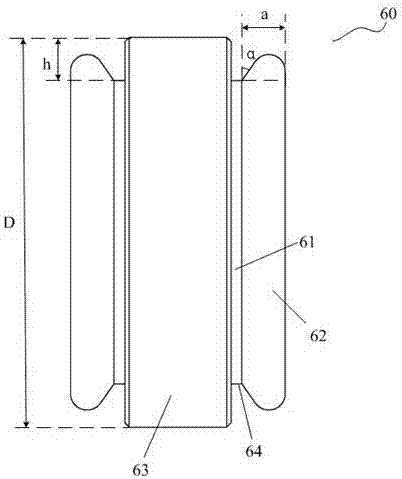

Polymer self-lubricating thin layer composite axle sleeve and its preparation method

ActiveCN101126418AImprove wear resistanceGood self-lubricating performanceBearing componentsMetal meshLubrication

The invention discloses a polymer self-lubrication thin layer composite shaft sleeve and the preparation method, which is rolled by a support skeleton made of metal mesh and a polymer composite. The formation of the metal mesh can be mesh-weaving forming, two-way stretching forming, punch forming or other forming modes; the shape of the mesh can be lozenge, hexagon, round or other shapes. The invention of shaft sleeve has excellent wear resistance, water corrosion resistance and good self-lubricating property and is especially suitable to be applied in the self-lubrication liner bushings of the automobile door hinge, footrest, joy stick and automatic door and window system.

Owner:COB PRECISION PARTS

Composite material and preparation method thereof

The invention provides a composite material which comprises the following components in parts by weight: 90-110 parts of rubber, 1-15 parts of nanometer titanium dioxide, 2-20 parts of glass fiber, 5-30 parts of ultra-high molecular weight polyethylene, 2-20 parts of polytetrafluoroethylene, 5-40 parts of nanometer silicon carbide, 0.5-5 parts of peroxide initiator, 4-30 parts of cross-linking agent, 0-15 parts of molybdenum disulfide, 0-15 parts of graphite, 0-10 parts of zinc oxide, and 0-10 parts of potassium hexatitanate. The invention further provides a preparation method of the composite material. The nanometer titanium dioxide, the nanometer silicon carbide, the polytetrafluoroethylene and the ultra-high molecular weight polyethylene are added in the composite material and form a crystallographic and covalent cross-linking composite material with the rubber through a cross-linking effect of the peroxide initiator and the cross-linking agent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

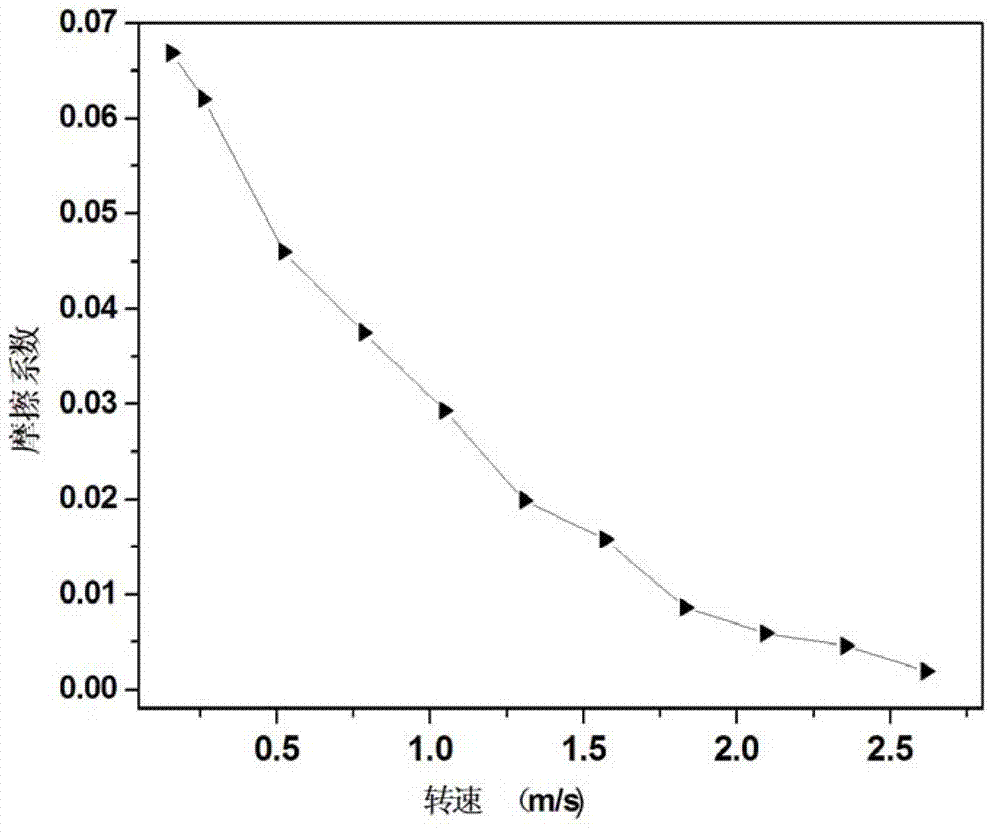

Copper alloy sliding material

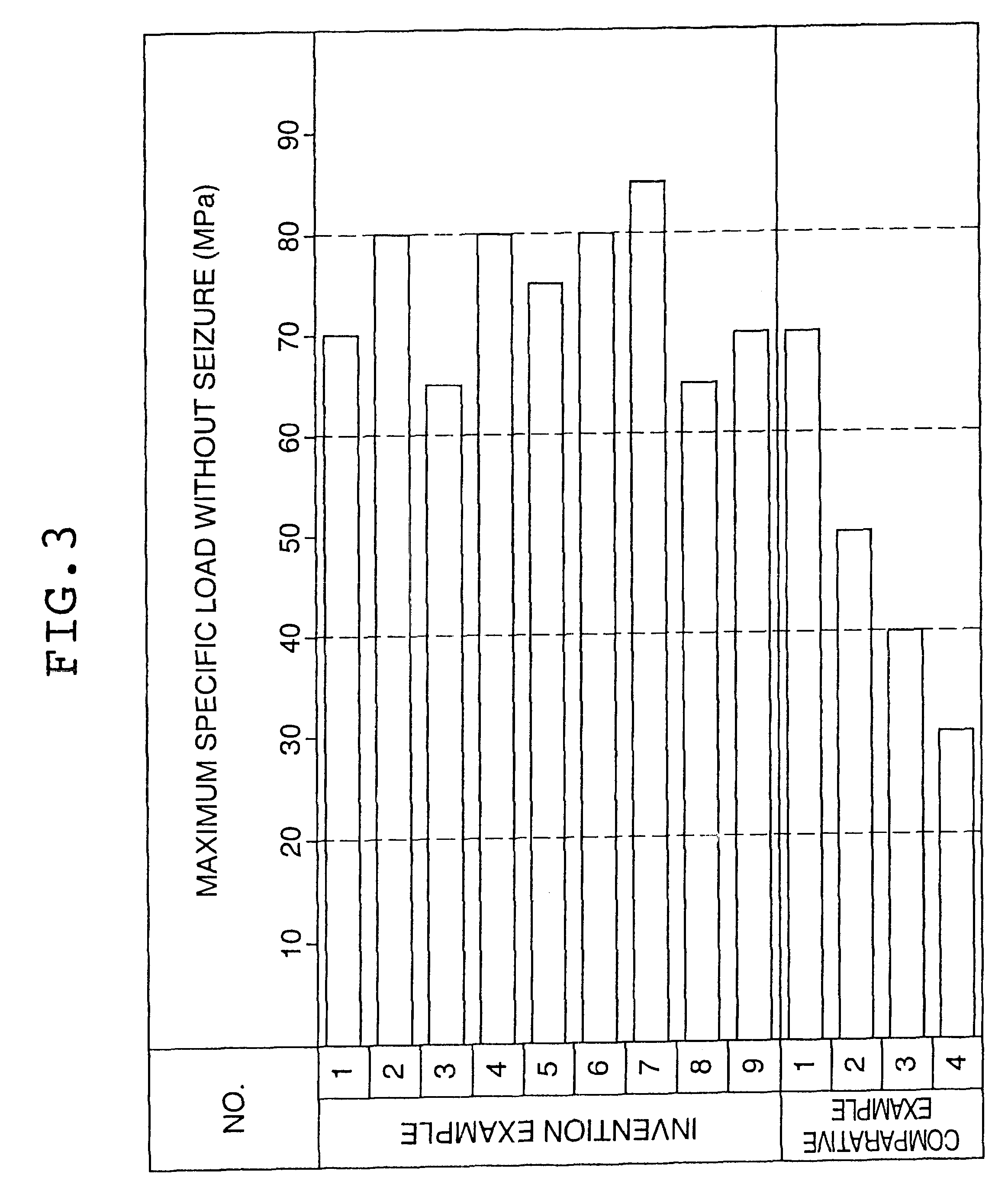

InactiveUS6334914B2Good self-lubricating performanceEasy to wearShaftsBearing componentsGraphiteSliding contact

Disclosed is a copper alloy sliding material comprising 0.5 to 15 mass % Sn and 0.1 to 10 vol % of hard particles consisting of one or more selected from WC, W2C and Mo2C. The hard particles have preferably an average particle size of 0.1 to 10 mum, whereby they are dispersed in the copper alloy matrix so as to make the sliding-contact surface uneven, from which the hard particles protrude partially. The sliding material comprises an amount or a total amount of not more than 40 mass % of one or more selected from Ni, Ag, Fe, Al, Zn, Mn, Co, Si and P, an amount or a total amount of not more than 10 mass % of Bi and / or Pb, and / or an amount or a total amount of not more than 10 vol % of a solid lubricant comprising BN, graphite, MoS2 and / or WS2.

Owner:DAIDO METAL CO LTD

Self-lubricating passivation solution and hot galvanizing self-lubricating coating steel sheet coated thereby

InactiveCN103289569AGood corrosion resistanceGood paintability and adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosion resistantLubrication

The invention discloses a self-lubricating passivation solution and a hot galvanizing self-lubricating coating steel sheet coated thereby. The self-lubricating passivation solution is formed by modified solid lubricants, a film forming matter, a film forming additive, an accelerant, a pH modifier, an organic solvent and deionized water through compounding. The solid content after compounding is 15-25%, and the modified solid lubricants are modified nanometer MoS2 and modified nanometer teflon particles. According to the total weight of 1000g, the self-lubricating passivation solution comprises the following components: 10-20g / kg of modified nanometer MoS2, 10-20g / kg of modified nanometer teflon particles, 80-120g / kg of film forming matter, 10-30g / kg of film forming additive, 5-15g / kg of the accelerant and the balance of mixed solution of the organic solvent and the deionized water; and the pH value is adjusted to 3-6 by the pH modifier. The hot galvanizing self-lubricating coating steel sheet coated by the self-lubricating passivation solution comprises a hot galvanizing substrate and a self-lubricating coating attached to the hot galvanizing substrate. The self-lubricating passivation solution does not contain Cr<6+> and other environmentally harmful substances and has environmental protection property, corrosion resistance, wear extreme pressure resistance as well as coating and self-lubrication properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Composite material sliding bearing with base of high-temp polymer

InactiveCN1431406AImprove thermal conductivityGood toughening effectBearing componentsFiberPolymer science

This invention discloses a high-temp polymer matrix compound material sliding bearing which is processed according to conventional formation method with the compound material made of high-temp polymer matrix resin with functional additives, reinforced fiber and agent. The said matrix resin is made by teflon mixed with and / or polyamide and modified and the said function additives are nm or mm level mineral nonmetal fillers in which, at least one kind is particle of nm level. This invention provides a low friction ratio, good wearness, long working time, high PV, value, self lubricating compound material sliding bearing.

Owner:UNIV OF JINAN

Ultrahigh-molecular weight polyethylene composite material and preparation method thereof

The invention discloses an ultrahigh-molecular weight polyethylene composite material and a preparation method thereof. The ultrahigh-molecular weight polyethylene composite material comprises the following component in parts by weight: 100 parts of ultrahigh-molecular weight polyethylene, 0.1-10 parts of a lubricating agent, 10-60 parts of a filling material, 5-40 parts of reinforcing fiber and 0.1-10 parts of nanometer inorganic filler. The ultrahigh-molecular weight polyethylene composite material overcomes the difficulty that the ultrahigh-molecular weight polyethylene is very high in melt viscosity and is difficult to prepare; the ultrahigh-molecular weight polyethylene composite material can be prepared into different products through extrusion moulding of an extruder; the modified ultrahigh-molecular weight polyethylene composite material not only has high strength, impact resistance, wear resistance, high rigidity, high surface hardness, chemical corrosion resistance and other performance, but also has good self lubrication and dimensional stability.

Owner:GUANGDONG TAUGHNESS CONVEYOR BELTING

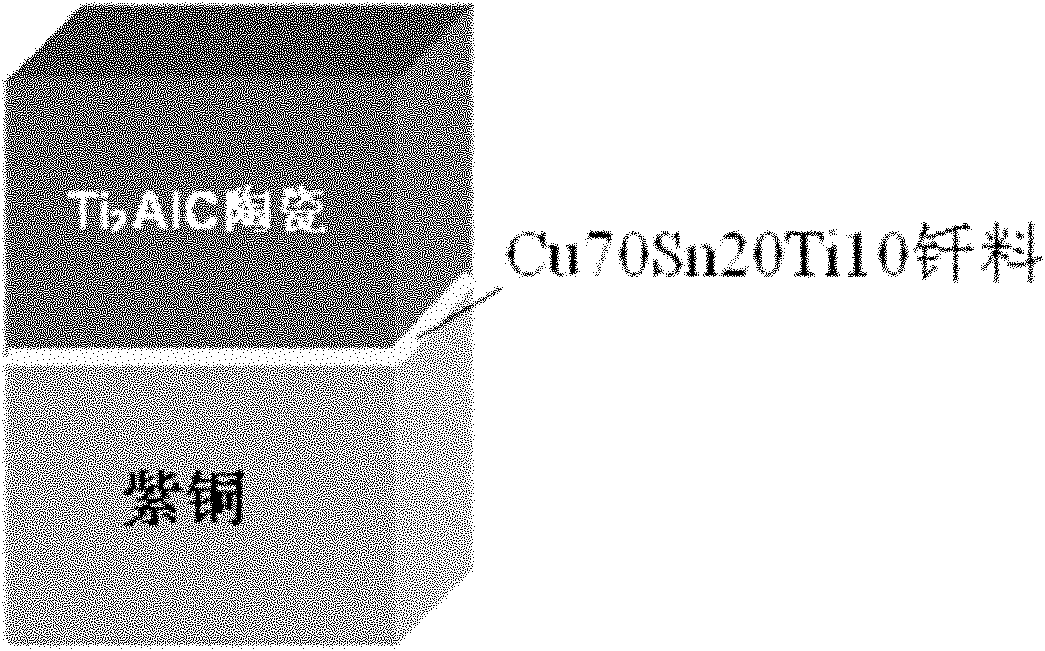

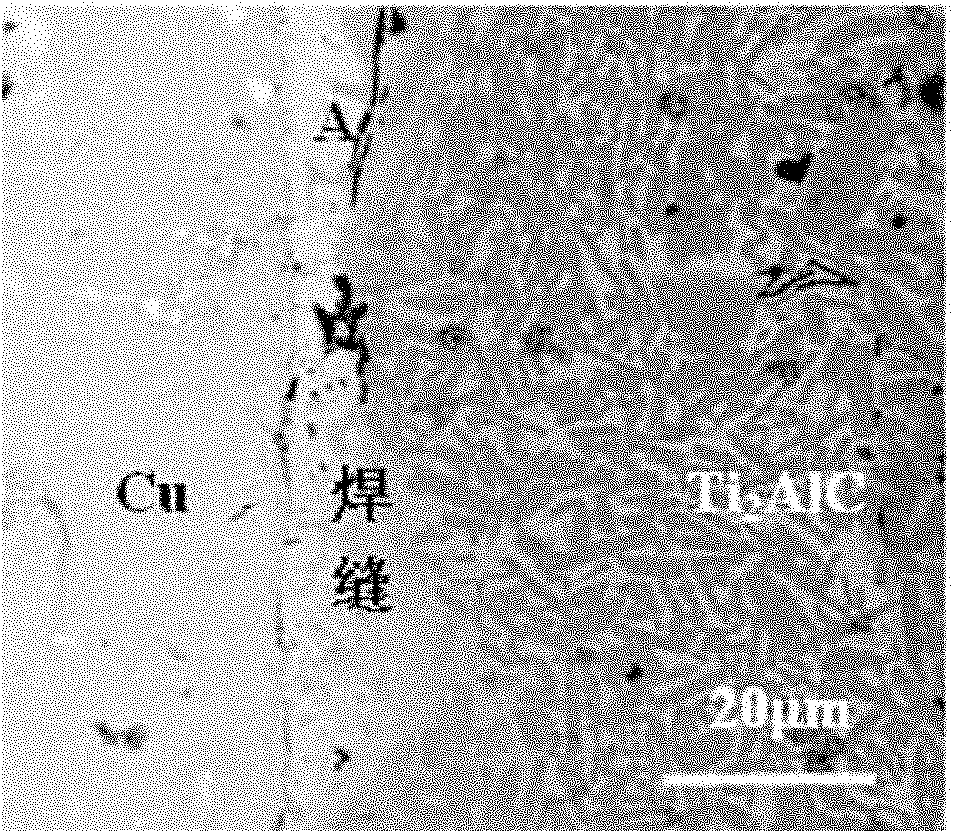

Cu-Sn-Ti solder and method for brazing Ti2AlC ceramics and Cu with same

InactiveCN101987402AHigh conductivity connectionGood electrical conductivityWelding/cutting media/materialsSoldering mediaCeramicHigh intensity

The invention relates to a Cu-Sn-Ti solder and a method for brazing Ti2AlC ceramics and Cu with the same, relating to a Cu-Sn-based solder and a method for brazing Ti2AlC ceramics and Cu with the same and realizing the high-strength and high-conductivity connection of the Ti2AlC ceramics and the Cu. The method comprises the following steps of: respectively grinding, polishing and clearing the Ti2AlC ceramics and the Cu and assembling the Ti2AlC ceramics, the Cu-Sn-Ti solder and the Cu into a brazing assembly unit; and then, brazing in a vacuum brazing furnace. The invention successfully realizes the connection between the Ti2AlC ceramics and the Cu and reaches the joint compression shearing strength of 40.53-187 MPa, the conductivity of 5.13*106-5.997*106 S / m, high joint strength and good electrical conductivity. The Ti2AlC ceramics and Cu connector is used for a carrier friction device and can solve the problems of high cost and shorter service life existing in the carrier friction device in traditional engineering applications.

Owner:HARBIN INST OF TECH

Carbon fiber reinforced copper-based composite material and preparation method thereof

The invention discloses a preparation method of a carbon fiber reinforced copper-based composite material. The preparation method comprises the following steps: I, weighing ingredients and carrying out ball-milling mixing for 3 hours, thereby obtaining a mixed material, and wrapping the surface of carbon fiber by a nickel layer, wherein the particle size of graphite powder is 50mu m, the graphite powder is subjected to chemical plating technical treatment, and a copper layer is plated on the surface of the graphite powder; II, pressing the mixed material prepared in the step I under the pressure of 700MPa, thereby obtaining a blank; III, performing secondary sintering on the blank prepared in the step II, thereby obtaining a sintered alloy block; and IV, performing thermal treatment on the alloy block treated in the step III, thereby obtaining the carbon fiber reinforced copper-based composite material. The carbon fiber reinforced copper-based composite material disclosed by the invention not only has excellent self-lubrication property, but also is particularly excellent in wearing resistance and mechanical property.

Owner:宁波新睦科技有限公司

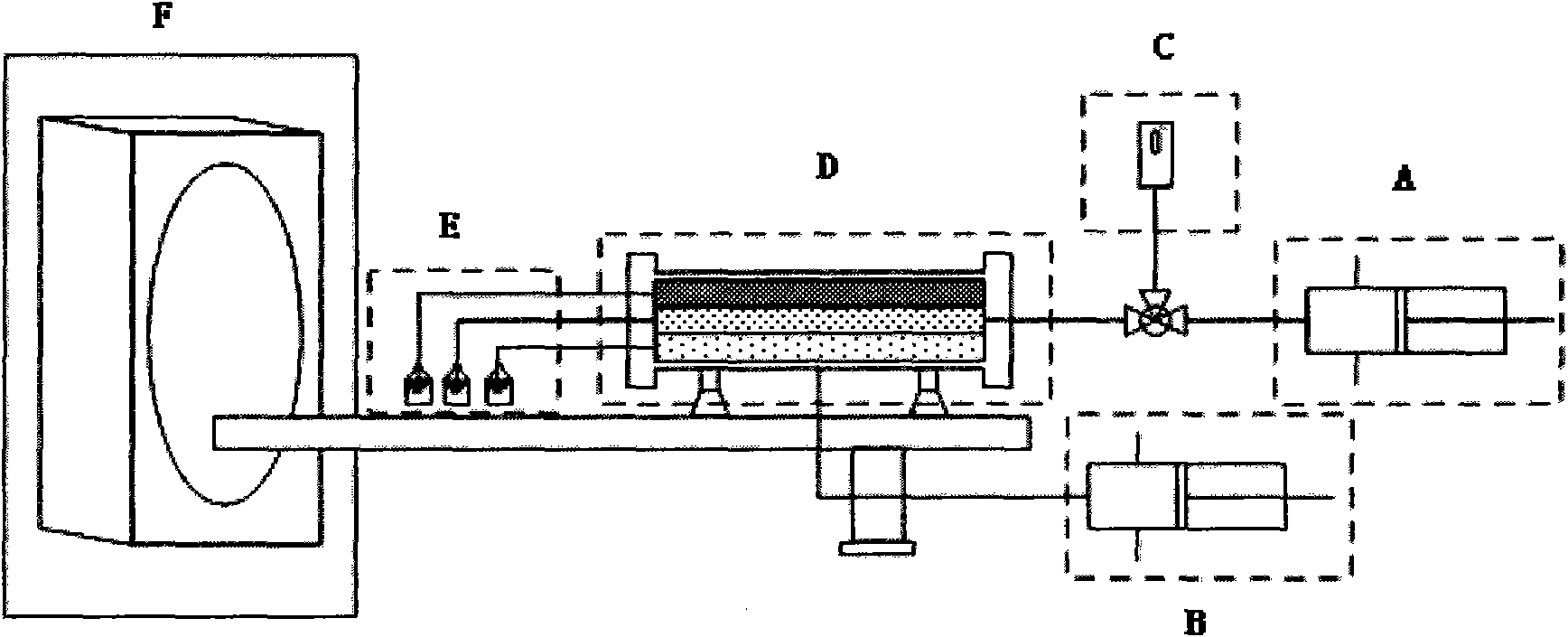

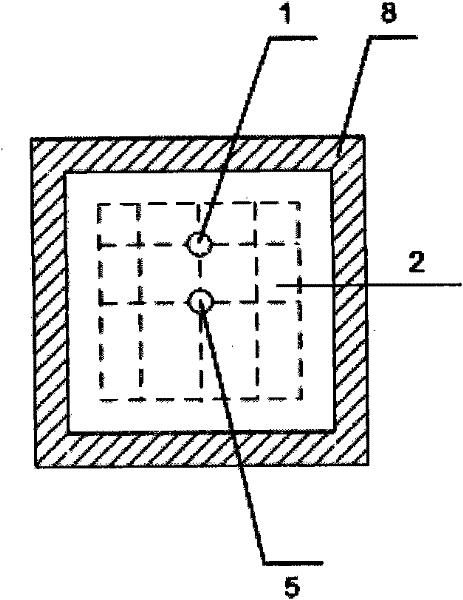

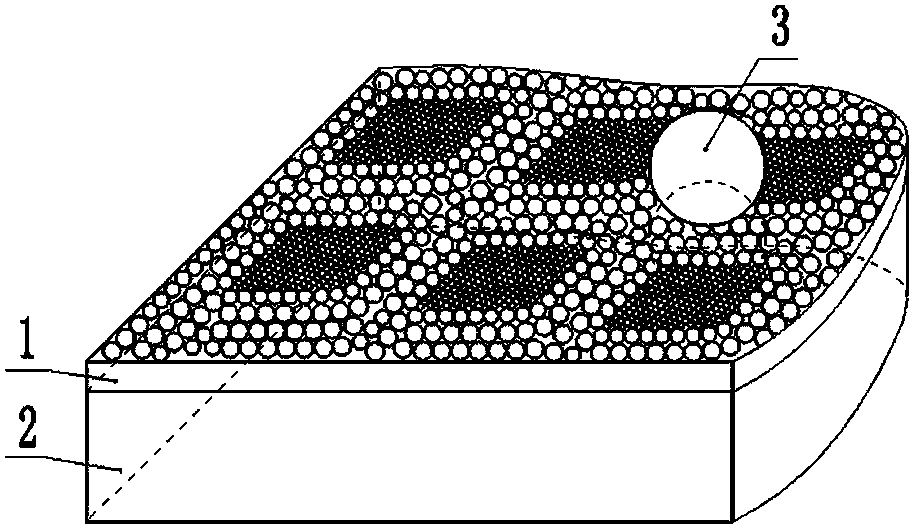

Non-homogenous multi-layer core holder for CT (computed tomography) scanning

ActiveCN102162784AImprove mechanical propertiesImprove insulation performanceMaterial analysis using wave/particle radiationPermeability/surface area analysisFluid saturationComputed tomography

The invention relates to a non-homogenous core holder for CT (computed tomography) scanning. A rubber cylinder is arranged in a shell; a core left top and a core right top arranged in the rubber cylinder and push against two ends of a multi-layer core mold; a core containing chamber which accommodates the multi-layer core mold is defined by the inner wall of the rubber cylinder, the core left top and the core right top; a left fixed sleeve and a right fixed sleeve are respectively sleeved on the core left top and the core right top; an enclosed annular confining pressure space is defined by the outer wall of the rubber cylinder, the left fixed sleeve, the right fixed sleeve and the inner wall of the shell; the shell is provided with a confining pressure interface, a confining pressure exhaust hole and a confining pressure discharging hole; the core left top is internally provided with a liquid inlet and a core exhaust hole; and the core right top is internally provided with a middle-layer liquid outlet, an upper-layer liquid outlet and a lower-layer liquid outlet. The holder can detect the on-way distribution of fluid saturation in each layer section in a non-homogenous layer on line in real time, and also can observe fluid channeling among layers.

Owner:PETROCHINA CO LTD

Steel bonded hard alloy and preparation method thereof

The invention provides steel bonded hard alloy which comprises the following components: 1.5wt%-6.0wt% of refractory carbide, 1.0wt%-3.0wt% of WS2, 1.0wt%-3.0wt% of C, 0.1wt%-0.5wt% of Mn, 10.0wt%-18.0wt% of Cr, 1.0wt%-5.0wt% of Mo, more than 0 but less than or equal to 1.8wt% of Si, more than 0 but less than or equal to 5.0wt% of Ni, and the balance of Fe. The invention also provides a preparation method for the steel bonded hard alloy. The raw materials, such as refractory carbide, tungsten disulfide, carbon and chromium are added in the steel bonded hard alloy, and a powder metallurgy sintering technology and a thermal treatment technology are adopted, so that the strength and hardness of the steel bonded hard alloy are increased, the abrasive resistance of the steel bonded hard alloy is increased and the service life of a stirring shaft abrasion-resisting sleeve prepared from the steel bonded hard alloy is prolonged.

Owner:CHANGSHA WEISITAN METALLURGY PRODS

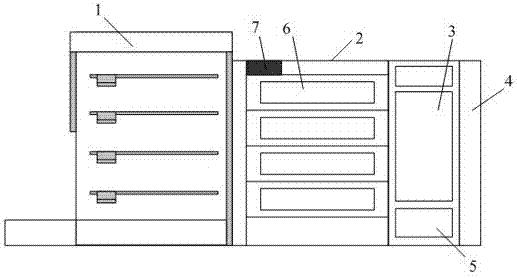

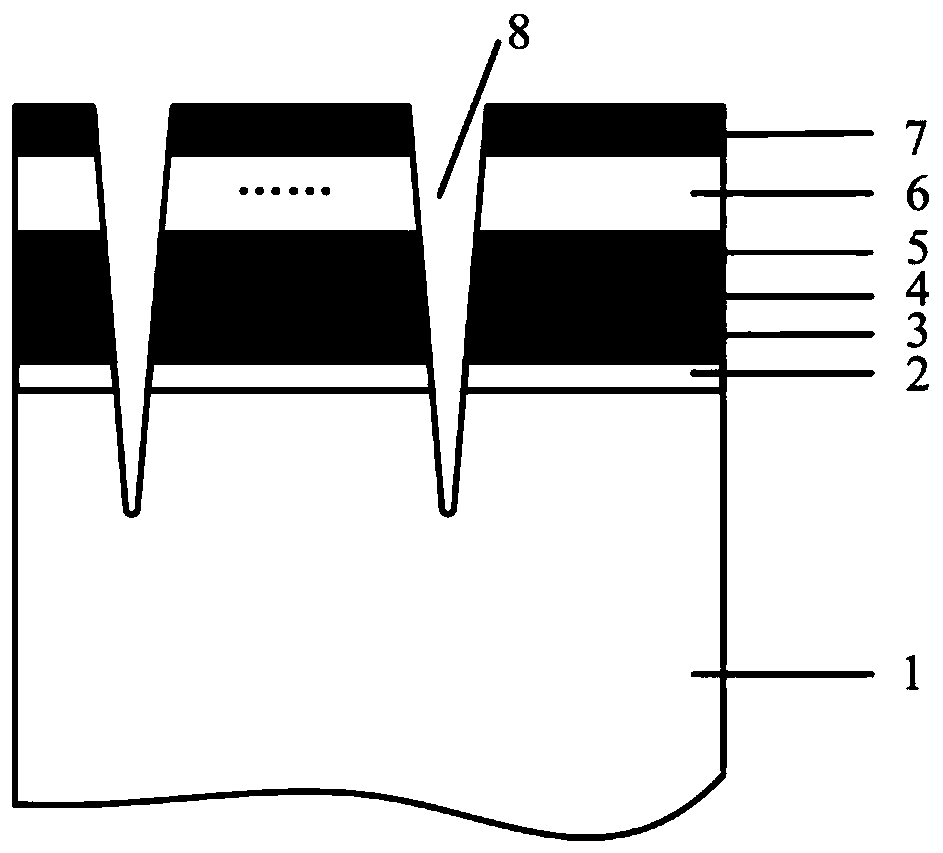

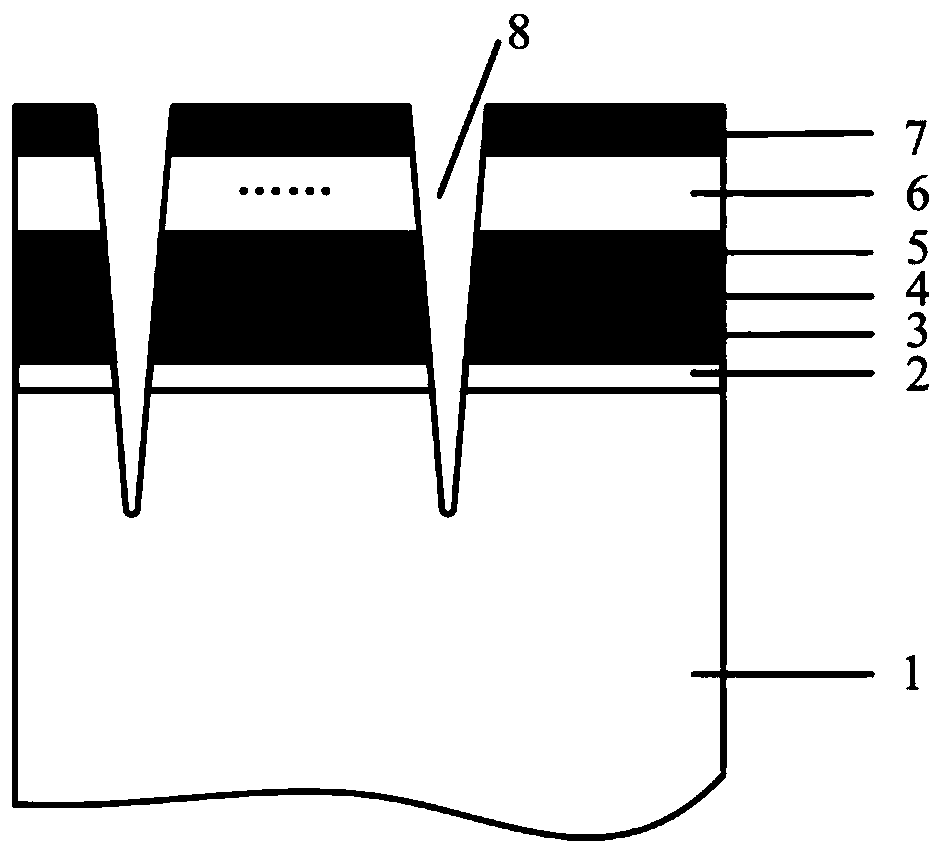

Coating equipment and method for tube-type PERC solar cells

ActiveCN107287579AReduce depthReduce gap sizeFinal product manufactureChemical vapor deposition coatingSilanesSolar cell

The invention discloses coating equipment for tube-type PERC solar cells. The coating equipment comprises a wafer loading region, a furnace body, a gas cabinet, a vacuum system, a heating system, a control system and a graphite boat; the gas cabinet is provided with a first gas pipeline for introducing silane, a second gas pipeline for introducing ammonia, a third gas pipeline for introducing trimethylaluminum, a fourth gas pipeline for introducing laughing gas and a fifth gas pipeline for introducing methane; the graphite boat is used for loading or unloading a silicon wafer; before being used or after being coated many times, the graphite boat needs to be subjected to pretreatment comprising the steps: drying the graphite boat; and coating at least one layer of silicon carbide film on the surface of the dried graphite boat. Correspondingly, the invention further discloses a coating method for tube-type PERC solar cells. By using the coating equipment and method, the pretreatment step of the graphite boat is simplified, the consumption of the silicon wafer is reduced, the silicon wafer is prevented from being scratched, and the EL yield of the cells is increased.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

Wear-resistant self-lubricating nylon composite material, and preparation method and application thereof

The invention relates to a wear-resistant self-lubricating nylon composite material, and a preparation method and application thereof. The nylon composite material is composed of a nylon resin, a reinforcing fiber, a hydrophobic material, an anti-wear agent, a lubricant, an ultraviolet-resistant light absorber, an antioxidant and a compatilizer. The preparation method comprises the following steps: mixing the nylon resin, hydrophobic material, anti-wear agent, lubricant, ultraviolet-resistant light absorption agent, antioxidant and compatilizer, adding into a charging hopper, continuously metering and feeding into a double screw extruder, feeding the reinforcing fiber into the double screw extruder through a side feed metering screw, merging with the main materials, sending into a compounding region for blending, cooling, granulating and drying. The nylon composite material prepared by the method has the characteristics of high strength, low hydroscopic property, wear resistance, moisture resistance, weather resistance, excellent self-lubricating and the like, has the advantages of favorable dimensional stability and long service life, and can be widely used in the fields of lubricating bearings, shaft sleeves, mechanical gears, mine support rollers and the like.

Owner:长沙五犇新材料科技有限公司

Nano-graphene loaded wax liquor, and preparation method and use thereof

ActiveCN103468004AGood electrical and thermal conductivityGood self-lubricating performanceFibre treatmentInksTotal solid contentCvd graphene

The invention belongs to the technical field of fine chemical engineering polymer materials, and specifically relates to nano-graphene loaded wax liquor, and a preparation method and a use thereof. The wax liquor is a wax dispersion which is formed by loading ultrafine nano-graphene particles having the particle size in the range from 20 to 40 nm on wax particles having the particle size in the range from 200 to 800 nm; and the total solid content of the wax liquor is 15-25%. The preparation method provided by the invention is used for successfully solving the dispersion and aggregation problems of graphene while being used for a paint or an ink body; and the nano-graphene loaded wax liquor prepared by the preparation method is used for paint, ink or leather finishing, and has the effects of rub resistance, static resistance and electromagnetic wave blocking.

Owner:NANJING TIANSHI NEW MATERIAL TECH

Cutting tool with micro textures and gradient coatings as well as preparation method of cutting tool

ActiveCN110016642AHigh hardnessGood self-lubricating performanceVacuum evaporation coatingSputtering coatingPlasma technologyHardness

The invention discloses a cutting tool with micro textures and gradient coatings as well as a preparation method of the cutting tool. The base material of the cutting tool is high-speed steel, hard alloy or ceramic. Firstly, a laser-induced plasma technology is used to form micro textures of different patterns and sizes on the front and back surfaces of the cutting tool; and a method of multi-arcion plating and medium-frequency magnetron sputtering co-deposition is used to prepare Zr+ZrN transition layers, nano laminated layers consisting of alternating ZrVCN+TiSiNbC hard coatings and a WBSesoft coating on the surfaces of the cutting tool. The cutting tool has the advantages of the micro textures, the hard coatings, the soft coating, the nano layers and the laminated structure, and thushas high hardness and good self-lubricating property. During dry cutting, effective continuous lubricating films can be formed on the surfaces of the cutting tool, and the micro textures on the surfaces can perform the functions of reducing friction and collecting wear debris; and the nano laminated coating layers increase the binding force between the coating layers and reduce the internal stressof the coating layers. The cutting tool can be widely used in dry cutting and the cutting of difficult-to-machine materials.

Owner:SOUTHEAST UNIV

Bearing retainer material and preparation method thereof

ActiveCN101696311AImprove thermal stabilityWide temperature rangeBearing componentsMaterials scienceMetal

The invention discloses a bearing retainer material and a preparation method thereof. The material is prepared from the following raw materials in percentage by weight: 2 to 5 percent of molybdenium disulfide, 8 to 12 percent of polyimide, 9 to 15 percent of polybenzoate, the balance of polytetrafluoroethylene. The preparation method comprises the following steps of: weighting the raw materials; mixing the raw materials; grinding the mixture; loading the mixture into a mould; pressurizing to prepare a blank; sintering the blank; and processing the blank into a finished product. The retainer material has the advantages of high temperature resistance, low temperature resistance, dimension stability, small erosion to metal and rubbed surfaces and good abrasion resistance. A retainer made of the bearing retainer material can be used under harsh conditions of no magnetism, ambient temperature changed between -19 and +55 DEG C, and rotation speed up to 7,200r / min so as to improve the performance of bearings.

Owner:LUOYANG BEARING RES INST CO LTD

Treating agent for forming a protective coating and metallic materials with a protective coating

InactiveUS7651556B2Maintain good propertiesReduce complicated treatment solution controlAlkali metal silicate coatingsPretreated surfacesGallingMetallic materials

A protective coating is formed on a metallic material surface by applying a treating agent comprising water, an alkali silicate, and, optionally, a lubricating component to the surface and drying the treating agent. The coating film thereby formed has excellent anti-galling and rust preventive properties. If a lubricating component is present, the coating film also has excellent self-lubricating properties.

Owner:HENKEL KGAA

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

Powder metallurgy duplicate gear and preparation method thereof

The invention provides a powder metallurgy duplicate gear which is prepared by pressing the following raw powder materials in parts by weight: 100 parts of ferrous powder, 1.8-2.0 parts of copper powder, 0.5-0.8 parts of molybdenum powder, 0.1-0.3 parts of vanadium powder, 0.8-1.2 parts of nickel powder, 0.5-0.8 parts of graphite powder, 0.1-0.3 parts of modified wood ash, 0.2-0.6 parts of rare earth ferrosilicon alloy, 0.1-0.3 parts of zinc stearate, 0.1-0.2 parts of ethylene bis stearamide, 0.1-0.3 parts of molybdenum disulfide, 0.2-0.4 parts of aluminum oxide, 0.2-0.4 parts of boron nitride and 0.4-0.5 parts of LiF. During preparation, the raw powder materials are mixed step by step, then pressed, sintered, and subjected to heat treatment and surface treatment to form a finished duplicate gear. The produced powder metallurgy duplicate gear has the characteristics that the powder metallurgy duplicate gear is good in abrasive resistance, high in strength, high in hardness, good in machinability, long in service life, corrosion-resistant, and not easy to break.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Surface texture of indium-iron grid-shaped spherical composite microcrystal composite layer

The invention discloses a surface texture of an indium-iron grid-shaped spherical composite microcrystal composite layer. A surface material layer is arranged on a part and mainly comprises larger indium-iron composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and iron exceeds 55% (Wt%), each larger indium-iron composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, the larger indium-iron composite spherical microcrystal units are distributed regularly to form a grid, multiple single crystal grains or smaller indium-iron microcrystal units are closely distributed in the grid, each smaller indium-iron microcrystal unit is formed by close connection of at least two spherical crystal grains or nearly-spherical crystal grains, and the surface material layer and a base body material of the part are integrated to form the indium-iron grid-shaped spherical composite microcrystal composite layer; then a surface texture is machined on the part surface provided with the indium-iron grid-shaped spherical composite microcrystal composite layer and consists of multiple surface texture units, and the surface texture of the indium-iron grid-shaped spherical composite microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

Solid lubricating composite material and manufacturing method thereof

InactiveCN101717682AReduce lubricationLow self-lubricating propertiesBase-materialsElectricityCarbon nanotube

The invention discloses a solid lubricating composite material and a manufacturing method thereof. Raw materials for the solid lubricating composite material comprise carbon nano tube, boron oxide and polytetrafluoroethylene. The manufacturing method comprises the following steps: grinding the carbon nano tube in a ball mill to form sectional structures, adding ethanol and surface dispersant into the carbon nano substances of the sectional structures, and treating the mixture by ultrasonic wave to obtain carbon nano liquid; taking boron oxide powder, polytetrafluoroethylene powder and the carbon nano liquid in percentage by weight, and mixing the three substances and stirring the mixture at a high speed to disperse the carbon nano liquid into the boron oxide and polytetrafluoroethylene powder so as to obtain a mixture; and die-pressing and molding the mixture, and demoulding the mixture to obtain the finished product solid lubricating composite material. The solid lubricating composite material prepared from the combination of the carbon nano tube and the polytetrafluoroethylene with self-lubricating property greatly improves the technical indexes such as low friction coefficient, self-lubricating property, abrasion resistance and the like, can conduct heat and electricity and eliminate static electricity produced by friction, and can be continuously produced in batch with lower cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wind driven generation set main shaft self-aligning slide bearing

ActiveCN1904400AGuaranteed uptimeExtended maintenance intervalsBearing componentsMachines/enginesWind drivenWind force

In the invention are disposed an outer ring and an inner race. The inside diameter of the outer ring is an internal spherical surface and the outside diameter of the inner race is an external spherical surface. On the outside diameter of the inner race are uniformly set blind holes with solid lubricant inside and is set a circular recess. A rolling body and a floating spacing pin are disposed between the circular recess and the outer ring. On the inside diameter surface of the inner race is covered a frictional layer made of self-lubricating composite material.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV +1

Basalt fiber filled ultrahigh molecular weight polyethylene composite material and preparation method thereof

InactiveCN102181089AReduce coefficient of frictionGood self-lubricating performanceHot pressHardness

The invention discloses a basalt fiber filled ultrahigh molecular weight polyethylene composite material and a preparation method thereof, and belongs to a polymer composite material and a preparation method thereof. The material consists of the following components in percentage by mass: 65 to 95 percent of ultrahigh molecular weight polyethylene, 5 to 35 percent of basalt fibers and 0 to 2 percent of coupling agent. The preparation method comprises the following steps of: mixing the ultrahigh molecular weight polyethylene, the basalt fibers and the coupling agent to form a uniform mixture; and performing hot press molding, namely preserving the heat for 1 to 2 hours at the temperature of between 180 and 220 DEG C, pressing the mixture for 20 to 60 minutes under the pressure of 10 to 30MPa, and finally cooling the pressured mixture to room temperature to prepare the basalt fiber filled ultrahigh molecular weight polyethylene composite material. The modified material has good abrasionresistance and self-lubricating performance and high compressive strength, hardness and creep deformation resistance.

Owner:CHINA UNIV OF MINING & TECH

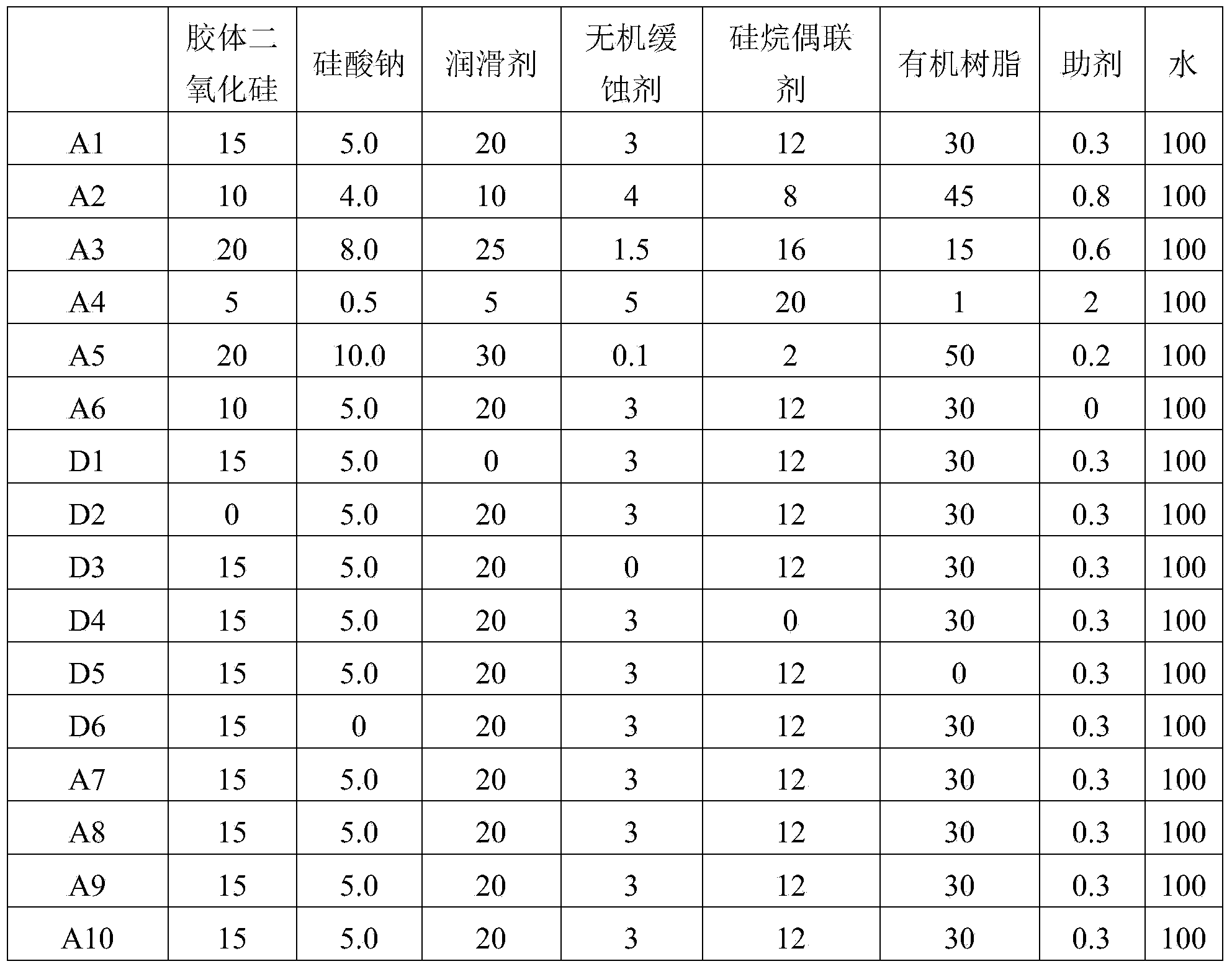

Self-lubricating treating agent composition, hot aluminum/zinc-plated sheet and preparation method thereof

ActiveCN103911063AGood self-lubricating performanceEnvironmentally safePolyurea/polyurethane coatingsMetal layered productsHeat resistanceZinc

The invention discloses a self-lubricating treating agent composition which contains water, colloidal silicon dioxide, sodium silicate, lubricant, inorganic inhibitor, silane coupling agent and organic resin. The invention also discloses a hot aluminum / zinc-plated sheet which comprises a hot aluminum / zinc-plated sheet substrate and a coating attached to the surface of the substrate, wherein the coating is formed by the self-lubricating treating agent composition. The invention the invention also discloses a preparation method of the hot aluminum / zinc-plated sheet, which comprises the following steps: preparing the self-lubricating treating agent composition into a coating solution, coating the coating solution on the hot aluminum / zinc-plated sheet substrate, and curing. The coating formed by curing the self-lubricating treating agent composition has favorable corrosion resistance, heat resistance, water resistance and adsorptivity, and has especially excellent fingerprint resistance and self-lubricating property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com