Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

682 results about "Plasma technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

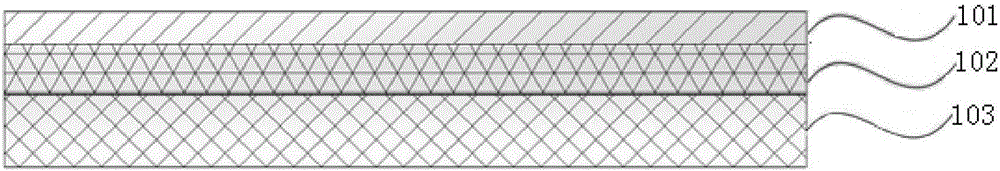

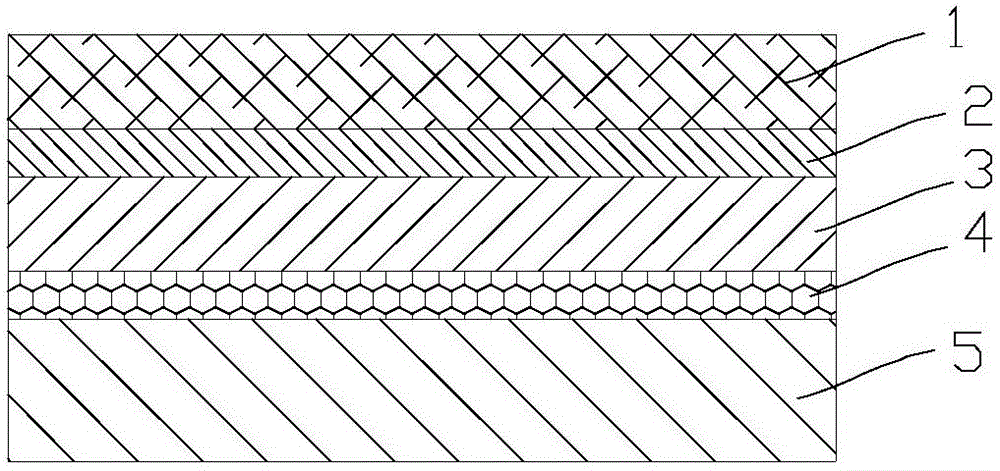

Aluminum-plastic membrane used for packaging lithium battery

ActiveCN101992570AImprove heat resistanceImprove wear resistanceCell component detailsMetal layered productsPlasma technologyAluminum foil

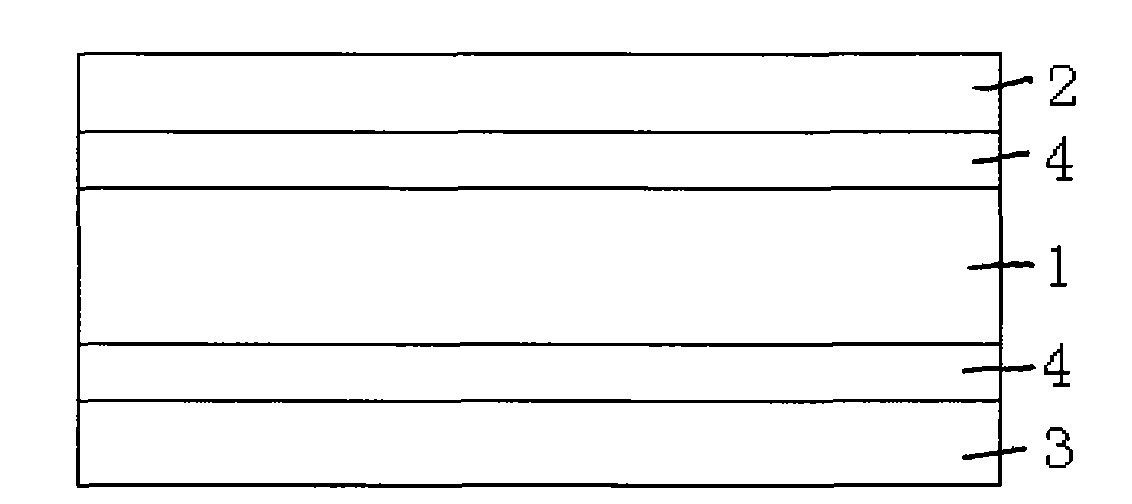

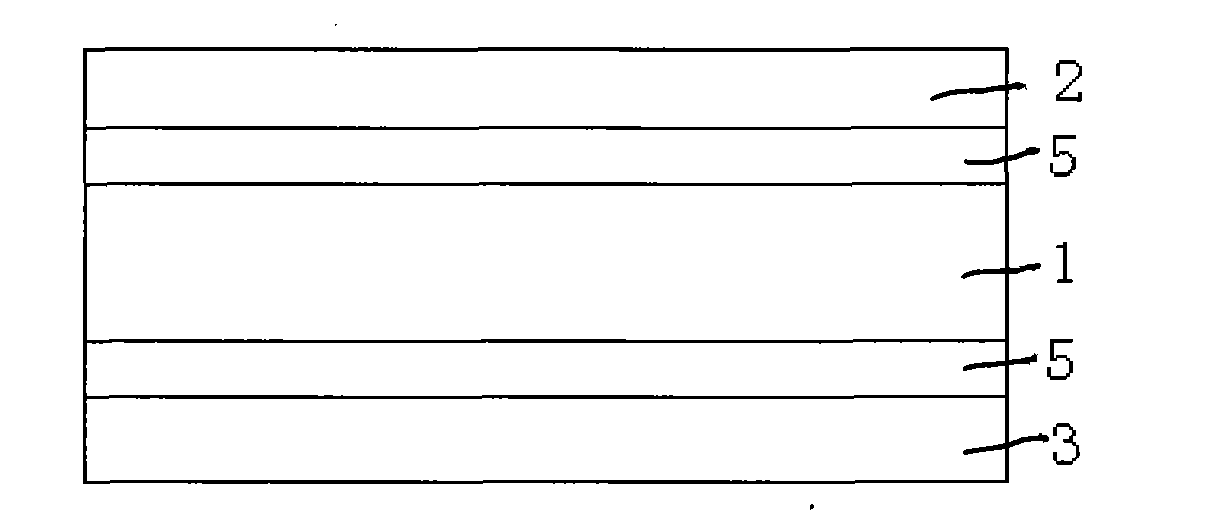

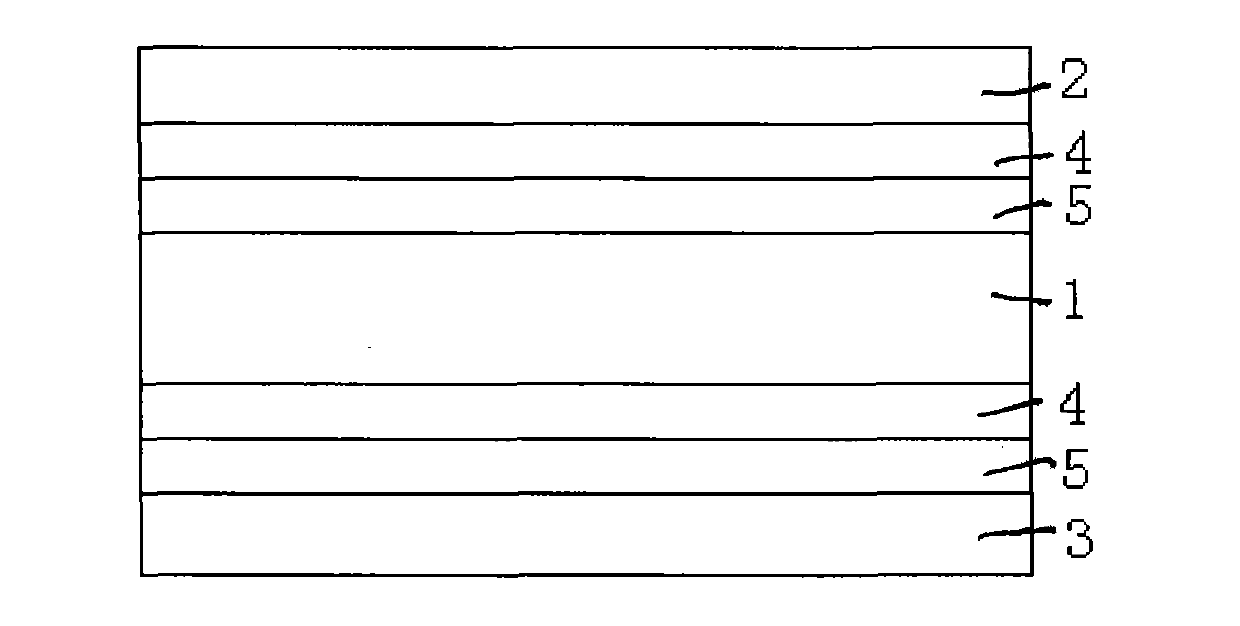

The invention discloses an aluminum-plastic membrane used for packaging the lithium battery. The aluminum-plastic membrane mainly comprises a protective layer, an aluminum foil layer and a heat sealing layer, wherein the protective layer is bound and combined with the aluminum foil layer through a glue layer, the heat sealing layer is bound and combined with the aluminum foil layer through a glue layer; before the binding and combining, the plasma technology is adopted to perform surface grafting treatment to the surfaces of the protective layer, the aluminum foil layer and the heat sealing layer; and then the protective layer and the aluminum foil layer are separately combined with the both sides of one glue layer through hot-pressing, and the aluminum foil layer and the heat sealing layer are are separately combined with the both sides of one glue layer through hot-pressing. The aluminum-plastic membrane has higher chemical resistance, moisture-proof property, oxygen-isolating property and packaging-binding property, also has explosion-proof property and is suitable for the soft package lithium battery.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

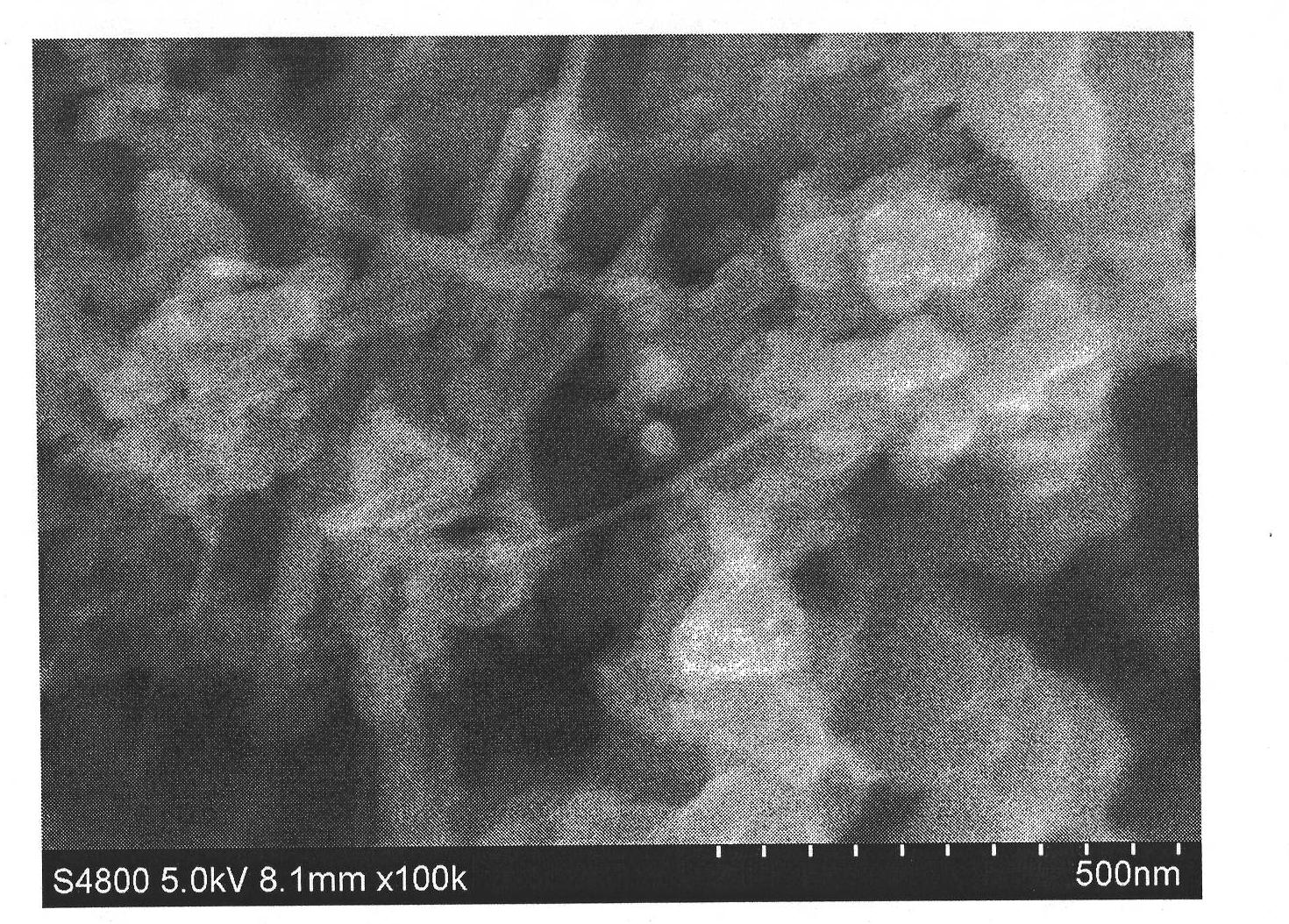

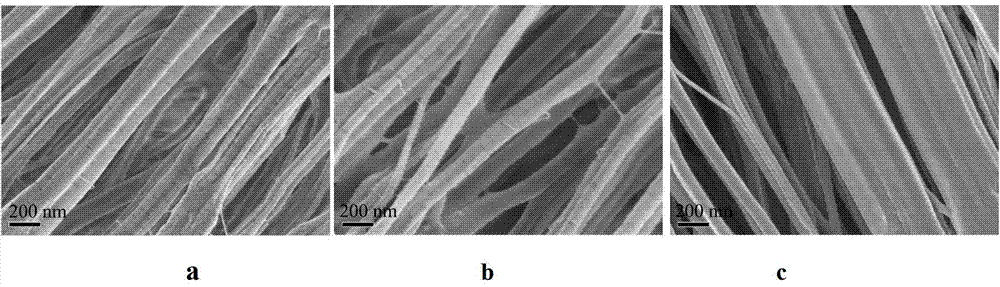

Method for thinning grapheme layer by layer

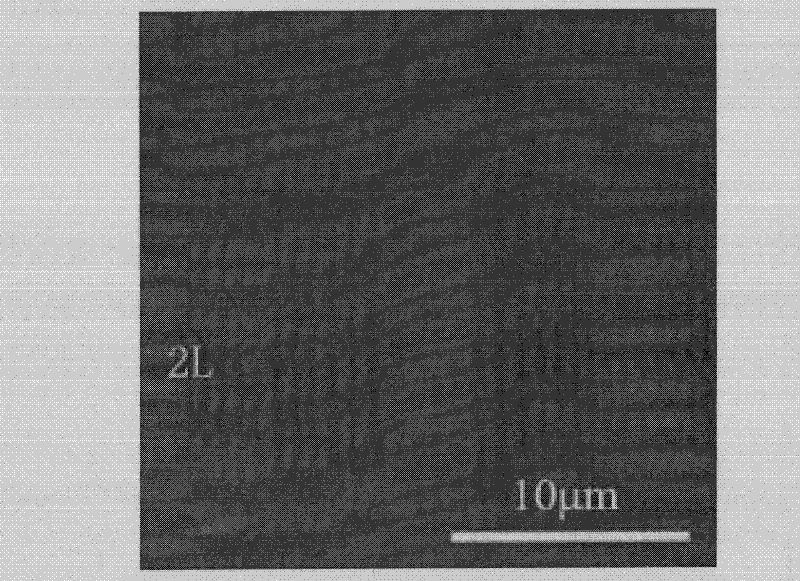

The invention relates to a method for thinning grapheme layer by layer, which is characterized in that the method comprises the following steps of: firstly utilizing the plasma ashing technology, bombarding multi-layer grapheme by plasma and then annealing in a high-temperature furnace to remove the grapheme on the top layer so as to realize the effect of precisely thinning the grapheme. Through more times of plasma bombarding and high-temperature annealing, the effect of thinning the multi-layer grapheme layer by layer can be realized. The method is characterized in that in combination with the grapheme modification and grapheme anisotropic oxidation process conducted by adopting the plasma technology, the method accurately etches the multi-layer grapheme and can realize the effect of precisely thinning the multi-layer grapheme on a monoatomic layer and keep the excellent performance of the thinned grapheme. The method is applied to the preparation of a grapheme nanostructure, a grapheme electronic device and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Process and apparatus for cleaning and/or coating metal surfaces using electro-plasma technology

A process for cleaning an electrically conducting surface (3) by arranging for the surface to form the cathode of an electrolytic cell in which the anode (1) is maintained at a DC voltage in excess of 30V and an electrical arc discharge (electro-plasma) is established at the surface of the workpiece by suitable adjustment of the operating parameters, characterized in that the working gap between the anode and the cathode is filled with an electrically conductive medium consisting of a foam (9) comprising a gas / vapor phase and a liquid phase. The process can be adapted for simultaneously coating the metal surface by including ions of the species required to form the coating in the electrically conductive medium. Apparatus for carrying out the process is also disclosed and, in particular, an anode assembly (1) which comprises a perforated anode plate (2) which is in communication with a chamber (4) adapted to receive a flow of a liquid electrolyte, means to supply the liquid electrolyte to the chamber, and means (7) to convert the liquid electrolyte received in the chamber into a foam.

Owner:CAP TECH LLC 50 DANILA VITALEVICH RYABKOV 50 +1

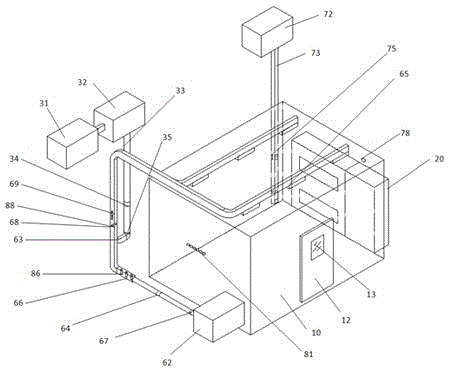

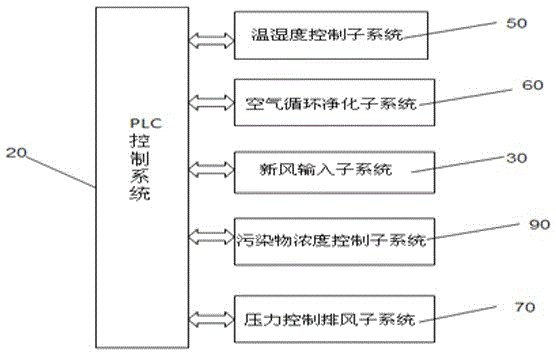

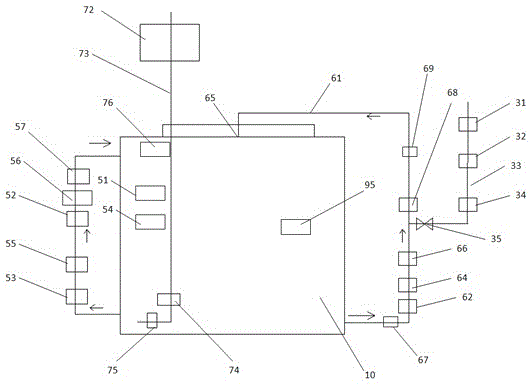

Multifunctional environment simulation cabin

InactiveCN105182889ALarge internal spaceEasy to testProgramme control in sequence/logic controllersPlasma technologyControl system

The invention relates to environment simulation laboratory equipment, especially to a multifunctional environment simulation cabin comprising a cabin body, a PLC control system installed at the outer wall of the cabin body, an air circulation and purification sub system for air circulation and purification inside the cabin body, a new air conveying sub system for inputting new air into the cabin body, a target gas concentration control sub system, and a pressure-control exhaust system. The PLC control system is connected with and controls a plurality of function sub systems by signals, thereby realizing simulation of the environment with different temperatures and humidity and target gas concentrations inside the cabin. According to the invention, an external circulating air hose is provided with different purification device interfaces to installed tested purification devices, so that dynamic testing of tested purifiers on the circulating air hose as well as testing of static environments with different monitoring gas concentrations can be simulated. Testing demands of various purifying devices like an adsorption type purifying device, a photocatalysis type purifying device, or a plasma-technology-based purifying device can be satisfied.

Owner:SHENZHEN XIBAO SHIP ELECTRONICS

Surface modification method of polymer microporous film

InactiveCN101439266AHigh activityHigh densitySemi-permeable membranesPolymer sciencePlasma technology

The invention discloses a microporous membrane surface hydrophilic modification method which comprises the following steps: (1) a polymer microporous membrane is pretreated by utilizing anatmospheric dielectric barrier discharge plasma technology; (2) the treated microporous membrane is arranged into the aqueous solution of a water-soluble polymer for dipping to lead the surface of the microporous membrane to absorb a polymer layer; (3) the microporous membrane is crosslinked and solidified under certain temperature. The method has the characteristics of simple technique, convenient operation, quick processing speed, good processing effect, low cost, being not easy to cause environment pollution, energy saving, and the like.

Owner:ZHEJIANG UNIV

Method for improving teflon adhesive property and method for producing pressure-sensitive adhesive tape

The invention discloses a method for improving a teflon adhesive property. The method comprises the following steps of washing, wherein at least one kind of methyl alcohol, methyl alcohol, isopropanol, acetone and methylbenzene is adopted, and teflon base materials are washed through ultrasonic oscillation; normal-pressure low-temperature plasma processing, wherein a normal-pressure low-temperature plasma technology based on barometric pressure glow is used for carrying out the normal-pressure low-temperature plasma processing on the washed teflon base materials. The invention further discloses a method for producing pressure-sensitive adhesive tape. The method for improving the teflon adhesive property has the advantages that the adhesive property of the teflon base materials can be effectively improved, the contact angle of the surfaces of the processed materials is 86 degrees, and the adhesive strength is larger than 5.0MPa.

Owner:成都同明创新科技有限公司

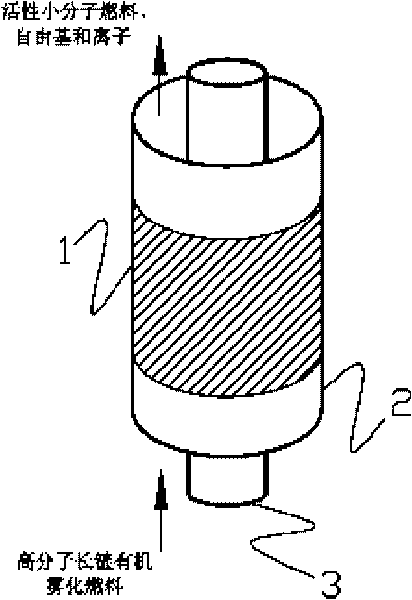

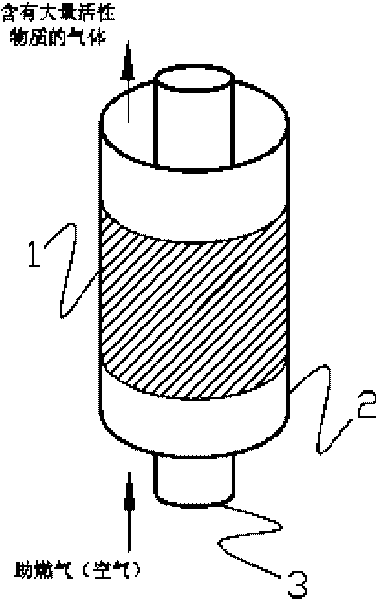

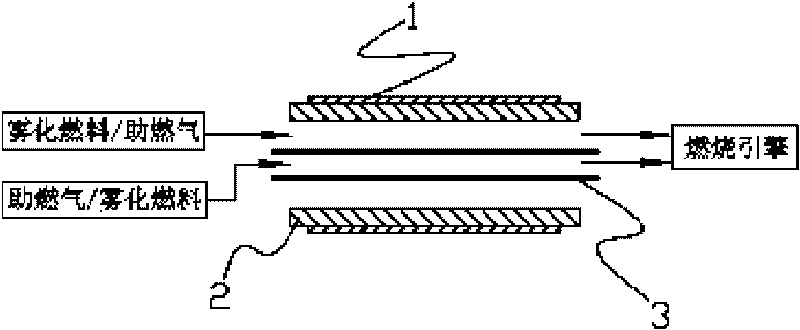

Method for increasing combustion efficiency of combustion engine

InactiveCN101701558ATake advantage ofIncrease the itineraryInternal combustion piston enginesCombustion-air/fuel-air treatmentJet aeroplanePlasma technology

The invention provides a new method for increasing combustion efficiency of a combustion engine; based on non equilibrium plasma technology, a non equilibrium plasma generator with low power is designed and applied, has small volume, can be widely applied to such as fuel power equipment such as automobiles, airplanes and the like and really realizes the combustion efficiency increase of the fuel equipment and exhaust emission reduction. The non equilibrium plasma generator provided by the invention is applied for carrying out controllable dielectric barrier discharge so as to activate fuel or combustion-supporting fuel, thus fundamentally improving combustion situation of the fuel, causing the fuel to fully and effectively burn and simultaneously achieving the effect of energy saving and emission reduction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Anticoagulation high polymer biomaterial as well as preparation method and application thereof

ActiveCN106730051AGuaranteed persistenceGuaranteed stabilityPharmaceutical containersMedical packagingPlasma technologyAnticoagulant

The invention discloses an anticoagulation high polymer biomaterial which comprises a substrate layer, an anticoagulation coating, and a plasma polymerization layer positioned between the substrate layer and the anticoagulation coating, wherein the substrate layer is made of a biomedical material; the plasma polymerization layer is an allylamine plasma polymerization membrane layer deposited on the substrate layer; the anticoagulation coating is an anticoagulant layer fixed on the plasma polymerization layer; and the anticoagulants comprise hirudin, heparin and the like. Anticoagulant molecules are fixedly grafted on the material surface by utilizing the pulsed plasma technology and surface heparin grafting method, and effective molecule orientation is remained by heparin molecules, so the anticoagulant performance is close to the performance of heparin molecules in the solution. Meanwhile, the heparin molecules are difficultly scoured off by blood, the persistence and stability of the anticoagulation effect are guaranteed, and the service life is long. The invention further discloses a preparation method and application of the anticoagulation high polymer biomaterial.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

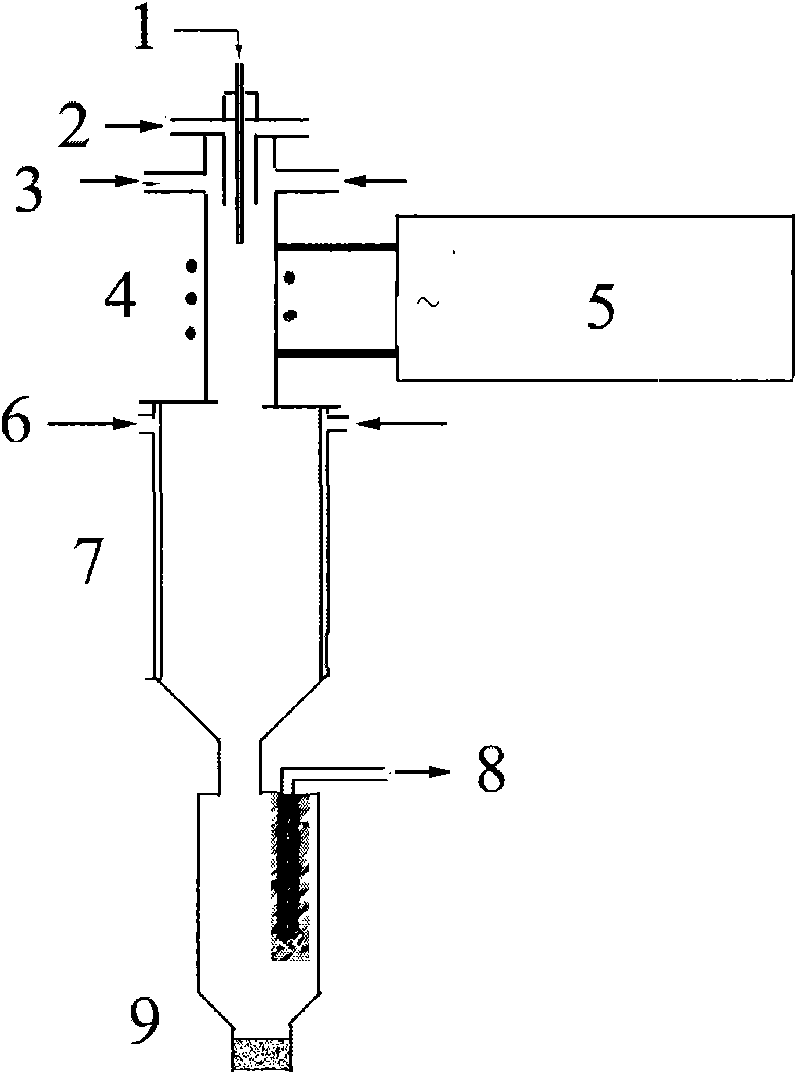

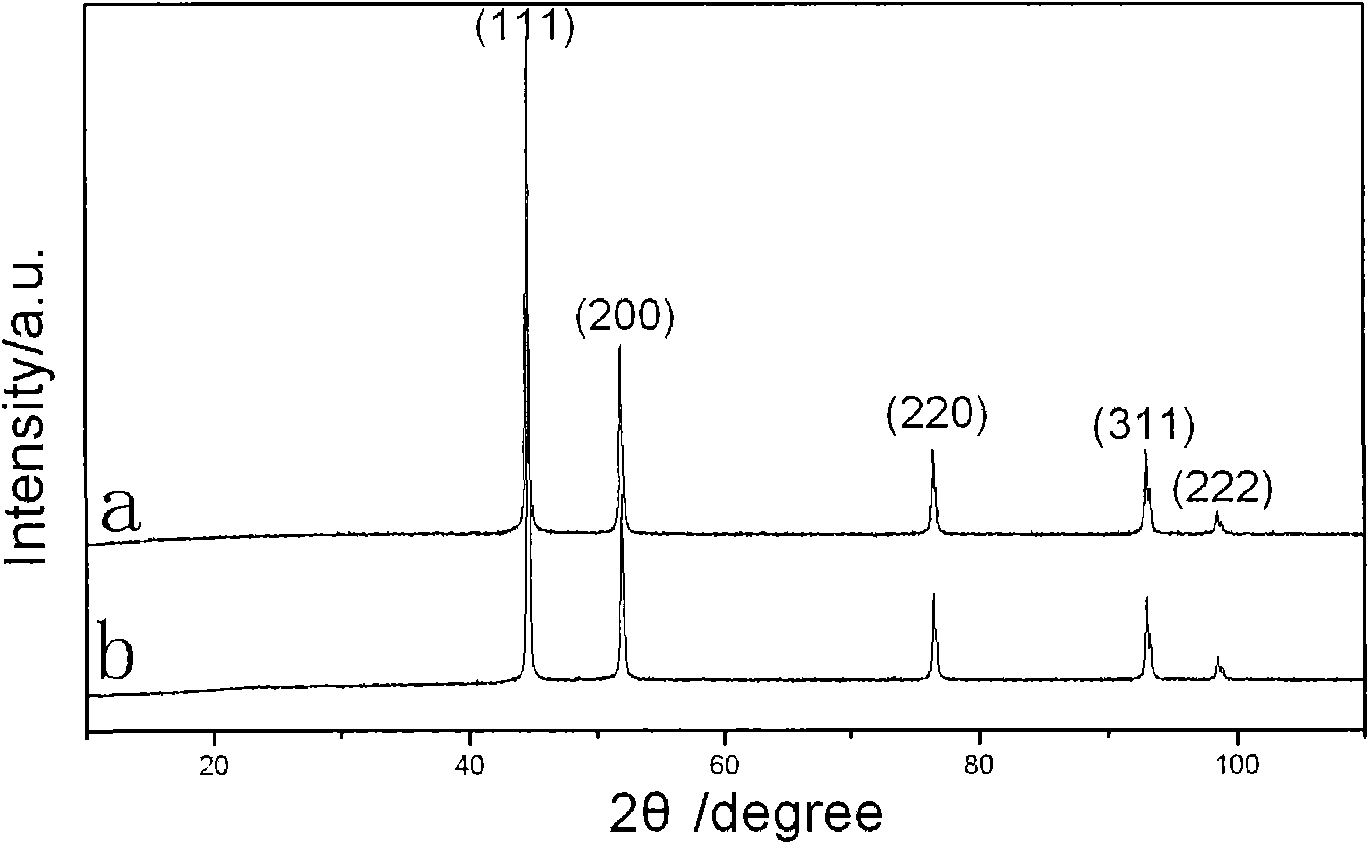

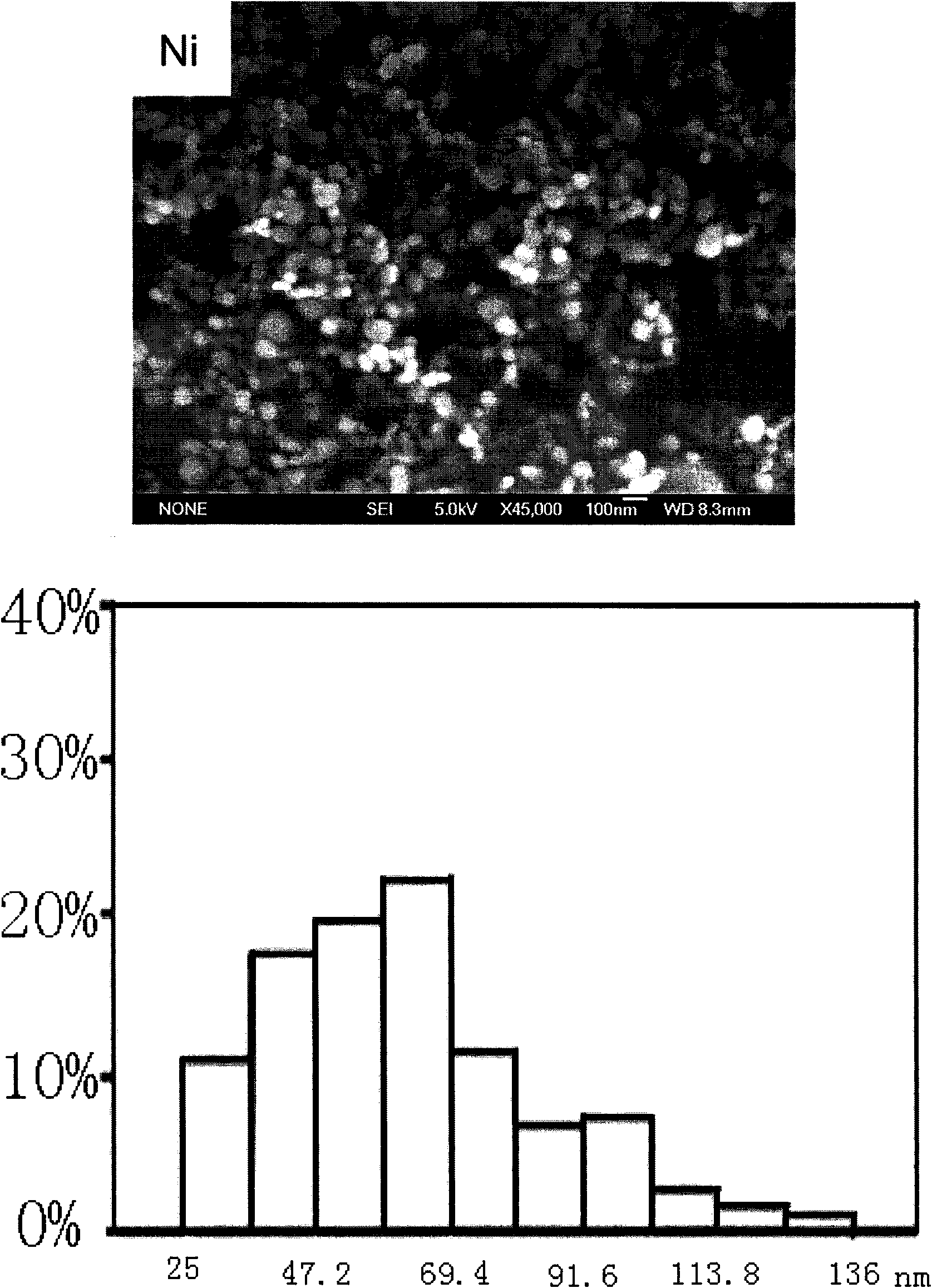

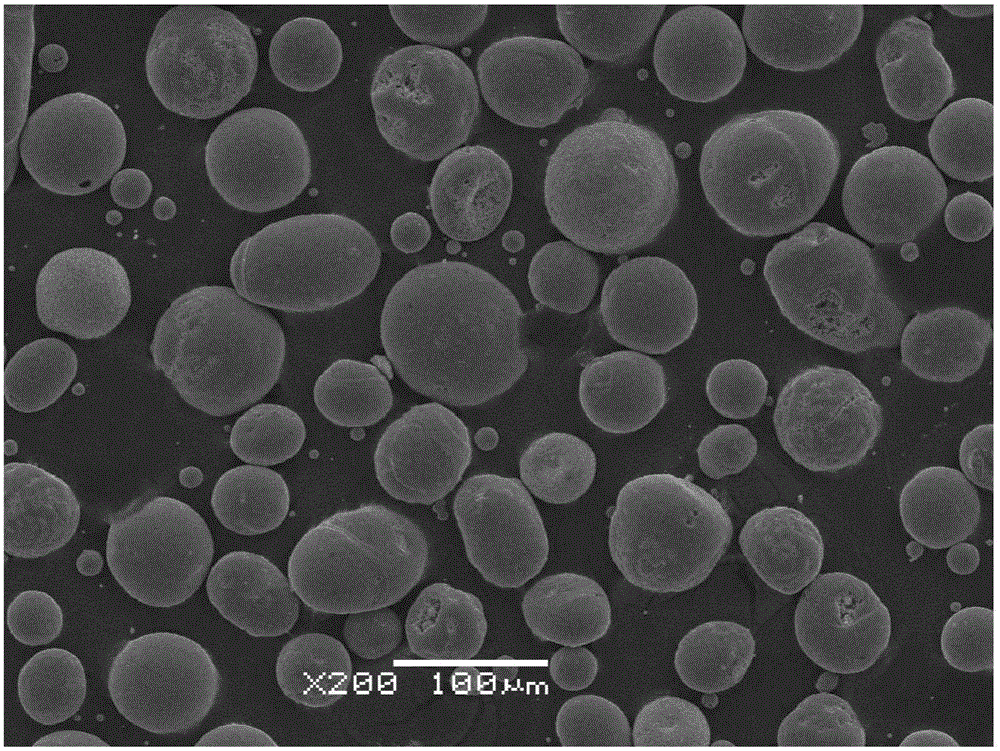

Method preparing superfine metallic nickel powder with high frequency plasma

The invention relates to a method preparing spherical metallic nickel powder with high frequency plasma. The method takes the hydrate of metallic nickel or subcarbonate as raw material and carries out hydrogen reduction through the high frequency plasma technology to prepare the superfine spherical nickel powder. Plasma arc is added to the raw material. The plasma is heated in high temperature through high frequency induction and generates reduction reaction with high-activity hydrogen plasma. The superfine spherical nickel powder can be obtained through a shape controller in the condensation process. The utility model is characterized in that the nickel hydroxide or the subcarbonate are used as the raw material, in the reduction process of the plasma, the particle size and the shape of the nickel powder can be controlled easily, the process flow is short and the production process is environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

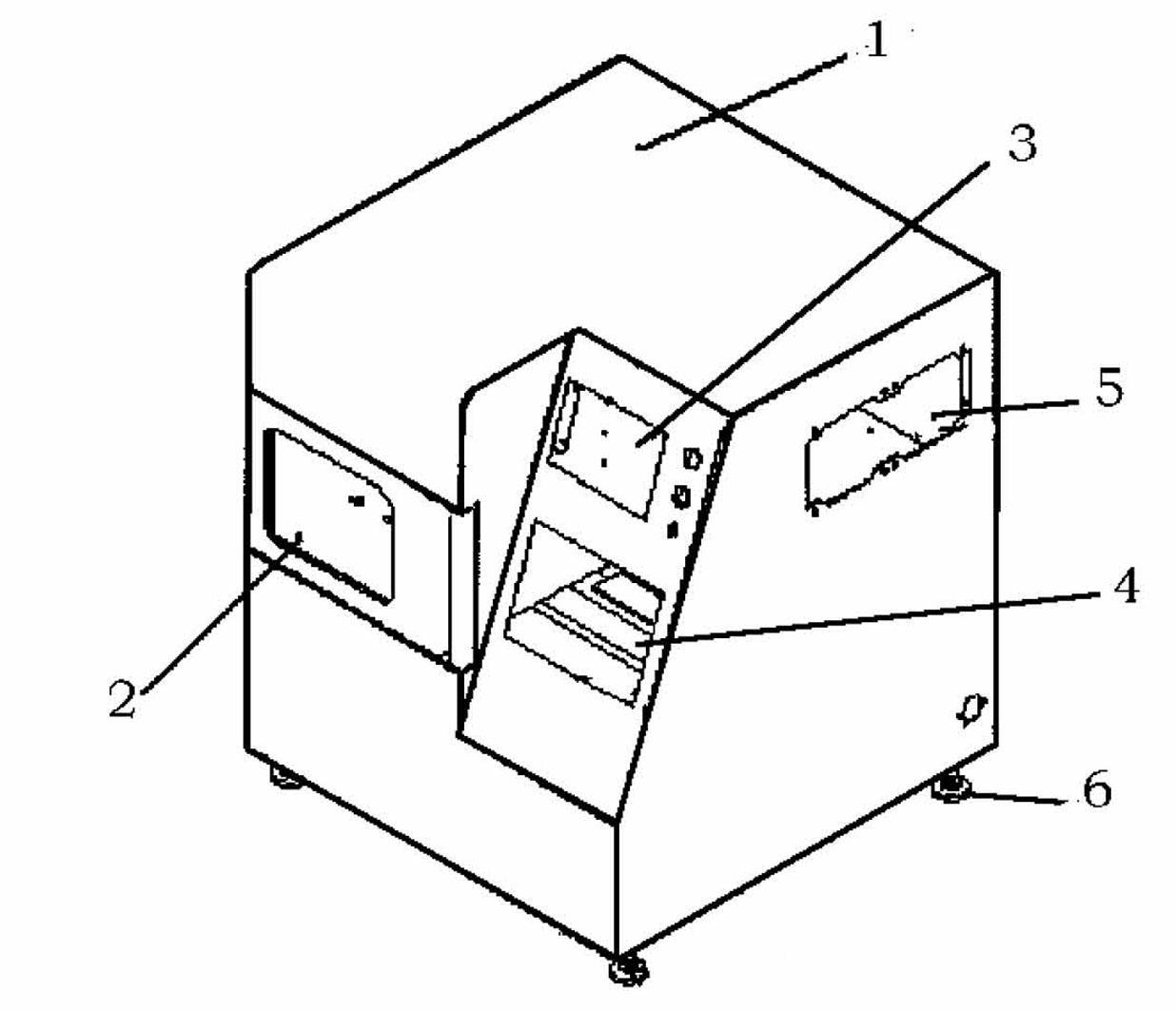

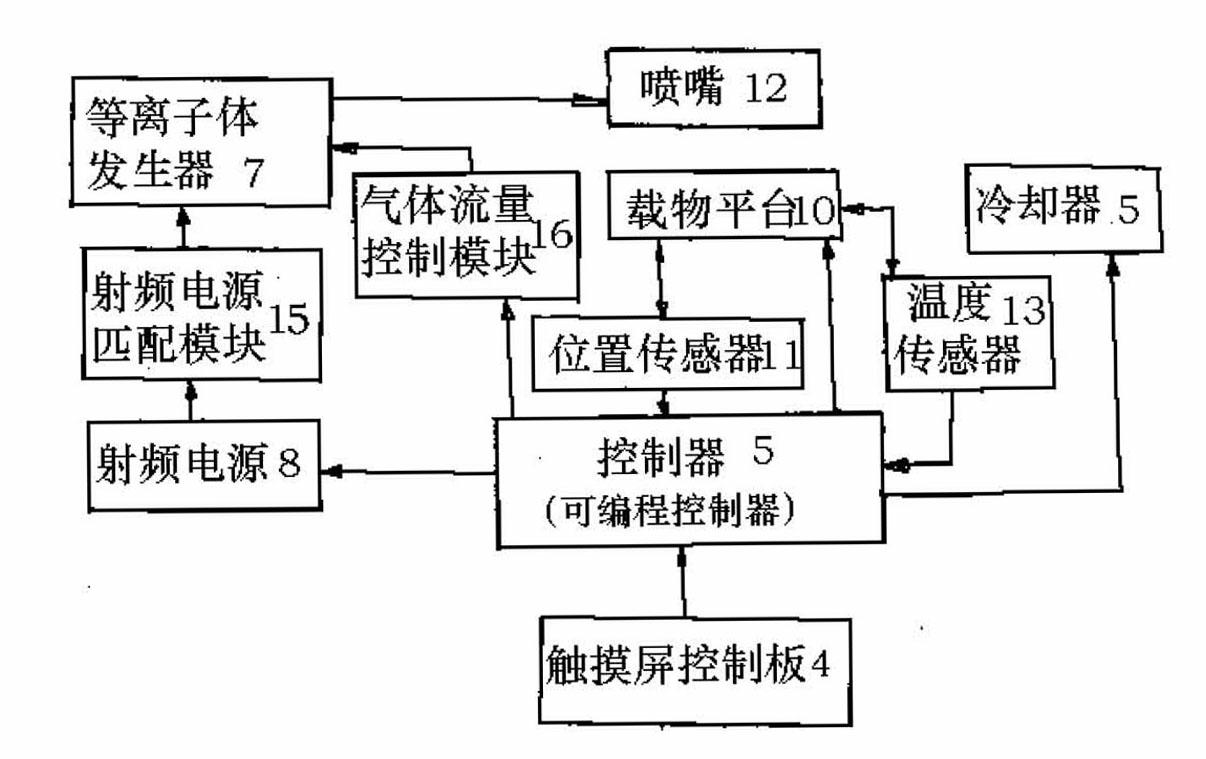

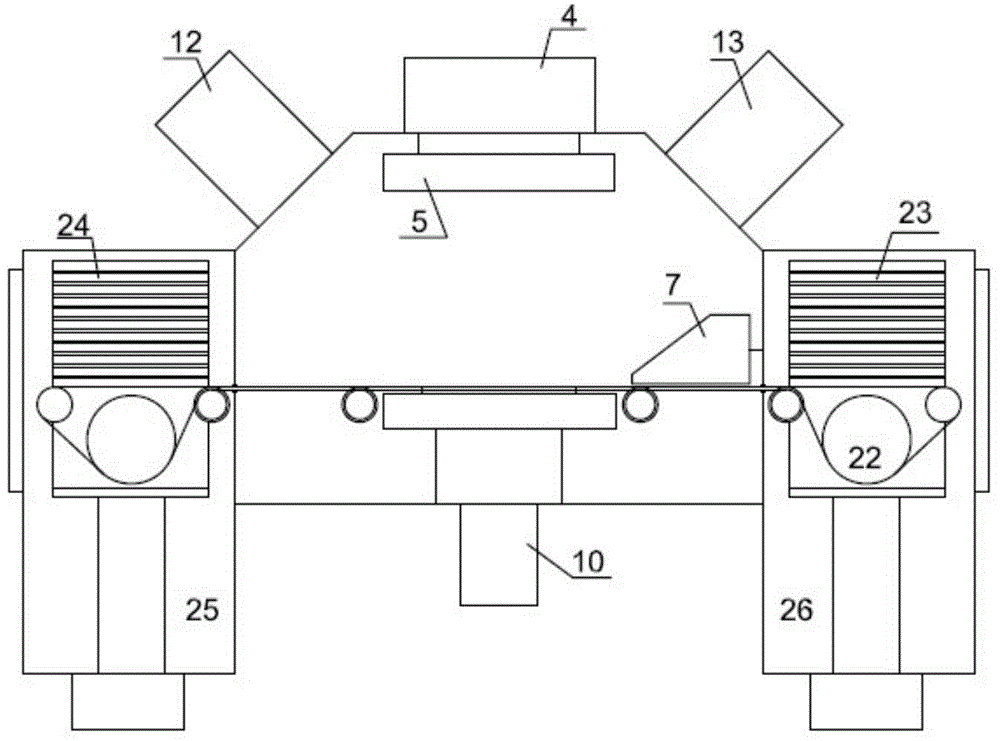

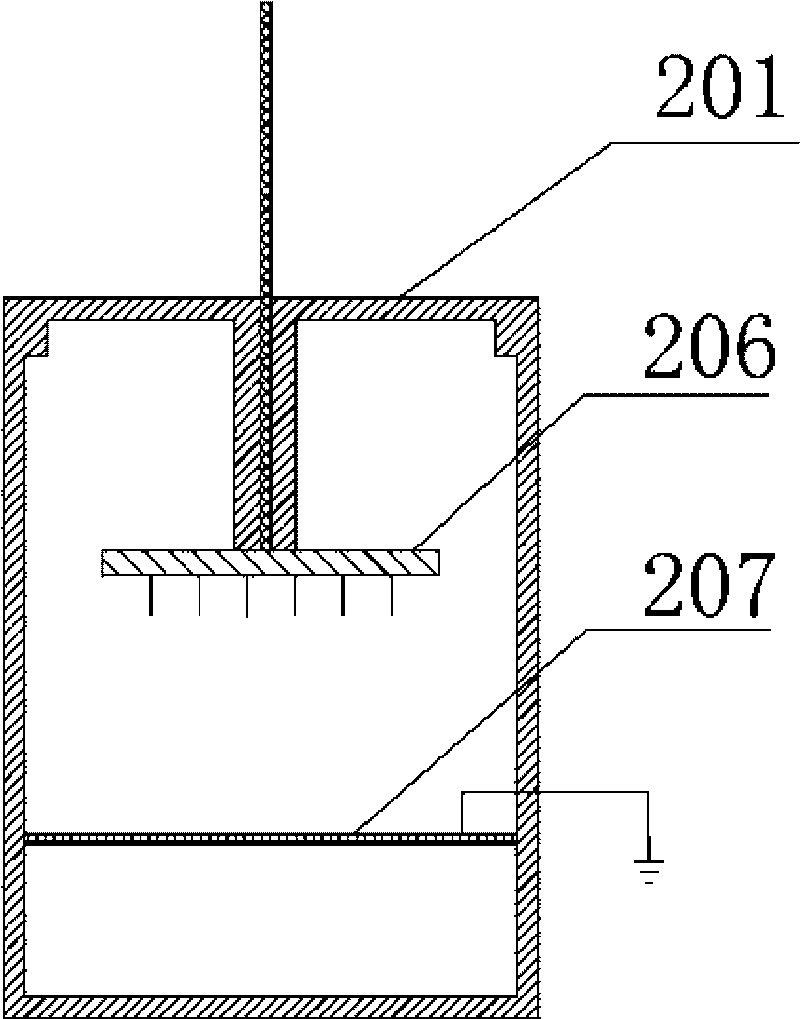

Plasma microbial mutagenic breeding equipment

InactiveCN102382763AControl processing timeControl processing powerBioreactor/fermenter combinationsBiological substance pretreatmentsPlasma jetMicroorganism

The invention discloses plasma microbial mutagenic breeding equipment, and belongs to the field of normal pressure plasma technology processing equipment. The plasma microbial mutagenic breeding equipment comprises a shell and a plasma generator arranged in the shell and used for processing samples; an operating room is formed on the left in the shell; a carrying platform for accommodating the samples is arranged in the operating room; a nozzle is connected with the plasma generator; a temperature sensor and a position sensor are fixed on the inner wall of the operating room; breeding samples are put on the carrying platform; and on the right in the shell, the plasma generator, a radio frequency power supply and a controller are arranged outside the operating room. A plasma jet generated by the plasma generator under the conditions of atmosphere and low voltage performs mutagenic breeding on biological samples, the uniformity is high, the temperature is low, and a phenomenon that a large number of biological samples are dead due to overhigh temperature of the jet is avoided; and the equipment has complete functions, is easy to operate, and has a good application prospect in the field of biotechnology.

Owner:BEIJING SIQINGYUAN BIO TECH

Method for preparing conductive carbon black and hydrogen by plasma technology

InactiveCN102108216AHigh yieldImprove protectionPigmenting treatmentHydrogenPlasma technologyThermal insulation

The invention discloses a low-cost, high-dispersibility and high-conductivity carbon black and hydrogen preparation method, which is characterized in that: a gas or gasifiable carbon-containing raw material is selected, hydrogen is used as a carrier gas, a gas hydrocarbon compound is added into the carrier gas, a secondary gas hydrocarbon compound is added into a plasma wake flame, and a high-voltage, low-current and long-gap-discharge mode is adopted; the gases in plasma generators have high space velocity and short reaction dwell time; the reactants are filled in a thermal-insulation fluid bed reactor, and the dwell time of carbon black in the thermal-insulation fluid bed reactor is several seconds to several minutes; after the separation of the carbon black from the gas, part of the gas circularly enters the first plasma generator and the first fluid bed reactor, and the rest gas enters a second plasma generator and a second fluid bed reactor; and if to obtain purer hydrogen, a third plasma generator and a third fluid bed reactor can be used to obtain low-cost, high-dispersibility, high-graphitization and high-conductivity conductive carbon black and pure hydrogen.

Owner:SUZHOU NAKANGNAMI MATERIALS

Gas turbine blade thermal barrier coating bonding layer and preparation method thereof

InactiveCN105132908ASimple processLow costMolten spray coatingPressure inorganic powder coatingPorosityPlasma technology

A gas turbine blade thermal barrier coating bonding layer is composed of powdery Co, Ni, Cr, Al and Y. The optimal range of the powder particle size is 10-50 micrometers. A preparation method comprises the steps that 1, oil removal, washing and drying are performed on the surface of a matrix before spraying is performed, 40-80-mesh corundum is used for sand-blasting roughening, and floating dust is removed to form the rough surface; 2, the powder forming the bonding layer is kept at the temperature of 200-300 DEG C for 4 h before spraying is performed, and the powder is sufficiently softened; 3, a cold spraying method is adopted for preparing the bonding layer on the surface of the matrix; 4, the surface of the bonding layer is sprayed through the plasma technology to obtain an 8YSZ ceramic surface layer; 5, a complete thermal barrier coating is kept at the temperature of 900-1100 DEG C in a vacuum heat treatment furnace for 4 h, and the vacuum degree is lower than 10<-3>Pa. The technology is simple and low in cost; the porosity of the bonding layer is controlled to be smaller than 1%, and the structure is compact; pressure stress exists inside the coating, and the thermal expansion matching in the coating service process can be relieved; the bonding strength of the coating is improved, and the oxidation resistance of the coating is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

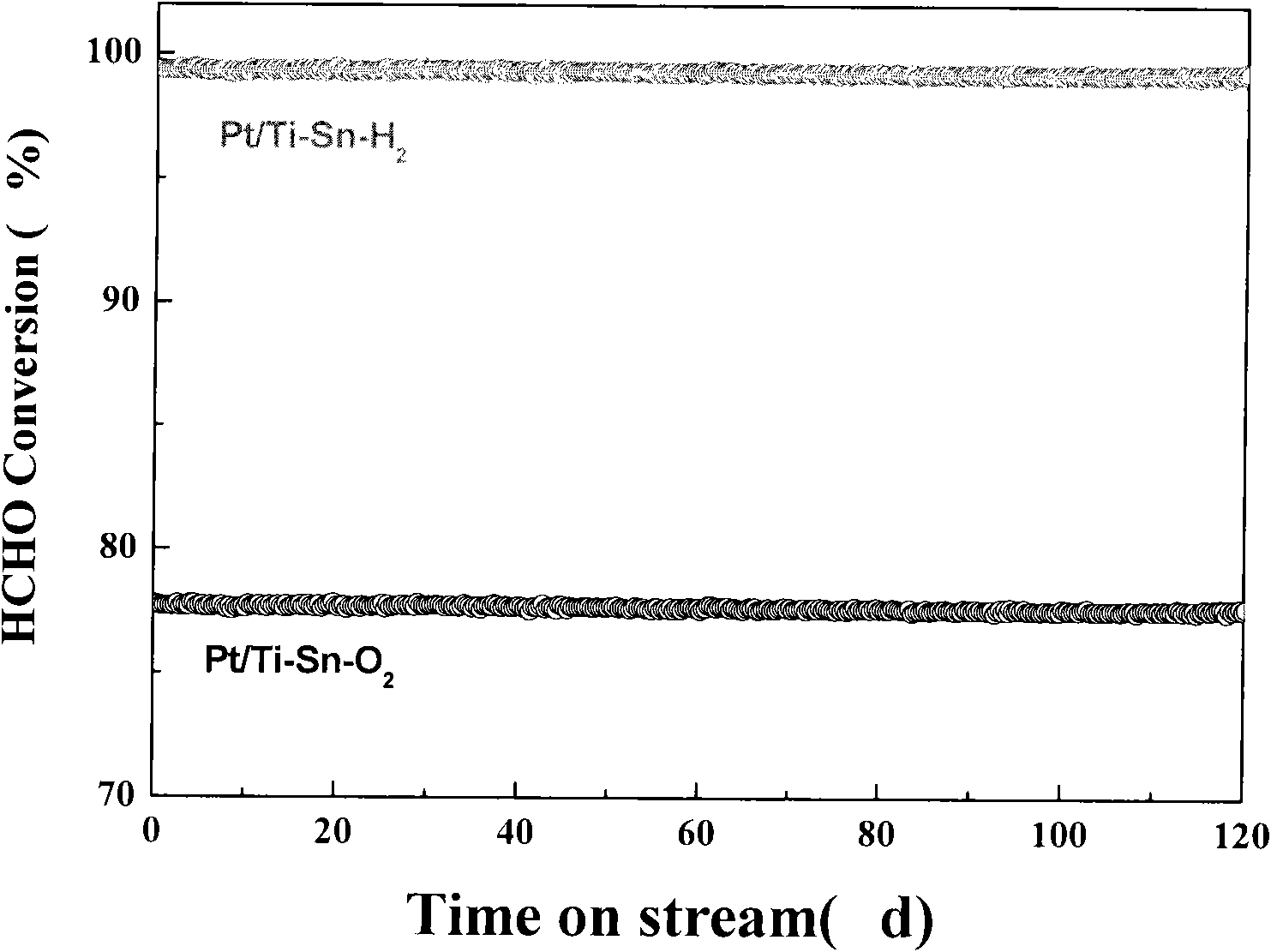

High-efficiency catalyst for removing formaldehyde at room temperature

InactiveCN102247842AReduce differential pressureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir volumeLiving room

The invention relates to a high-efficiency catalyst for oxidizing low-concentration formaldehyde in indoor air into carbon dioxide and water at room temperature and normal humidity and a preparation method of the catalyst. The catalyst is characterized in that: cordierite honeycomb ceramic coated with TiO2-SnO2 composite oxide is taken as a carrier, and 0 to 5 percent of Pt is taken as an active ingredient. The catalyst has the advantages that: energy such as light, heat, electricity and the like and a chemical reagent are not required to be added, the formaldehyde removing efficiency is far higher than that of a photocatalysis technology and a plasma technology under the conditions of large air quantity, high humidity and the like, byproducts are not generated, and the catalyst is suitable for efficiently removing formaldehyde in closed or semi-closed spaces such as artificial board production workshops, living rooms, automobiles and the like.

Owner:SHANGHAI NIUYI NEW ENERGY TECH

Photoelectric integrated processing device and photoelectric integrated processing technique for waste gases generated by spraying paint

InactiveCN104958990AImprove processing efficiencySolve secondary pollutionCombination devicesParticulatesActivated carbon

The invention discloses a photoelectric integrated processing device and a photoelectric integrated processing technique for waste gases generated by spraying paint. A washing processing unit, a low-temperature plasma processing unit and a photocatalytic processing unit are arranged inside a device casing and are sequentially connected. The photoelectric integrated processing technique comprises the following steps that the waste gases generated by spraying paint enter the washing processing unit through a pipeline for spraying at first to remove particulate matters in the waste gases generated by spraying paint; the waste gases generated by spraying paint then enter into a demisting unit for further removing paint mist; the waste gases generated by spraying paint are discharged into a plasma module for oxidizing organic matters in the gases; finally, the waste gases generated by spraying paint enter the photocatalytic processing unit, and by taking a carbon fiber adsorption layer as a catalytic carrier, the organic matters adsorbed in carbon fiber pores are oxidized and decomposed by using an ultraviolet lamp tube. According to the equipment, an absorption method, a low-temperature plasma technology, a photocatalytic technique and an activated carbon adsorption technique are effectively combined, so that the problems of secondary pollution, shorter operation cycle, short operation life and the like existing in single technique are solved while the treatment efficiency of the waste gases is improved.

Owner:杭州科瑞特环境技术有限公司

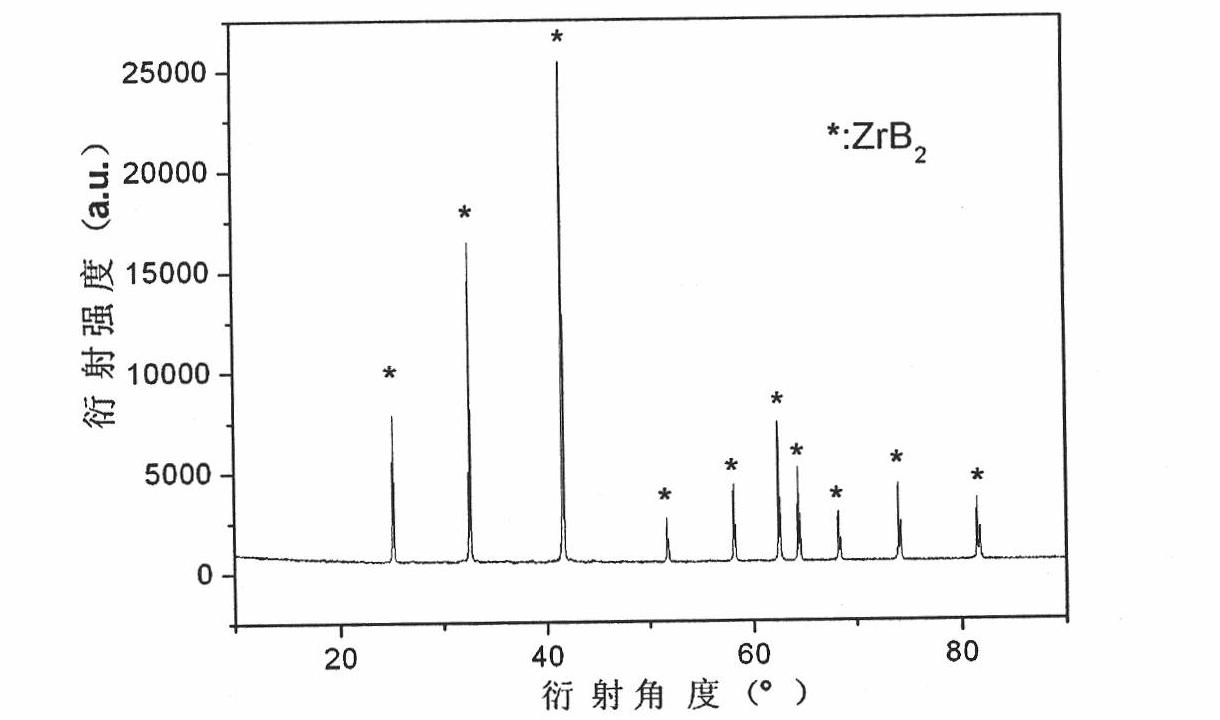

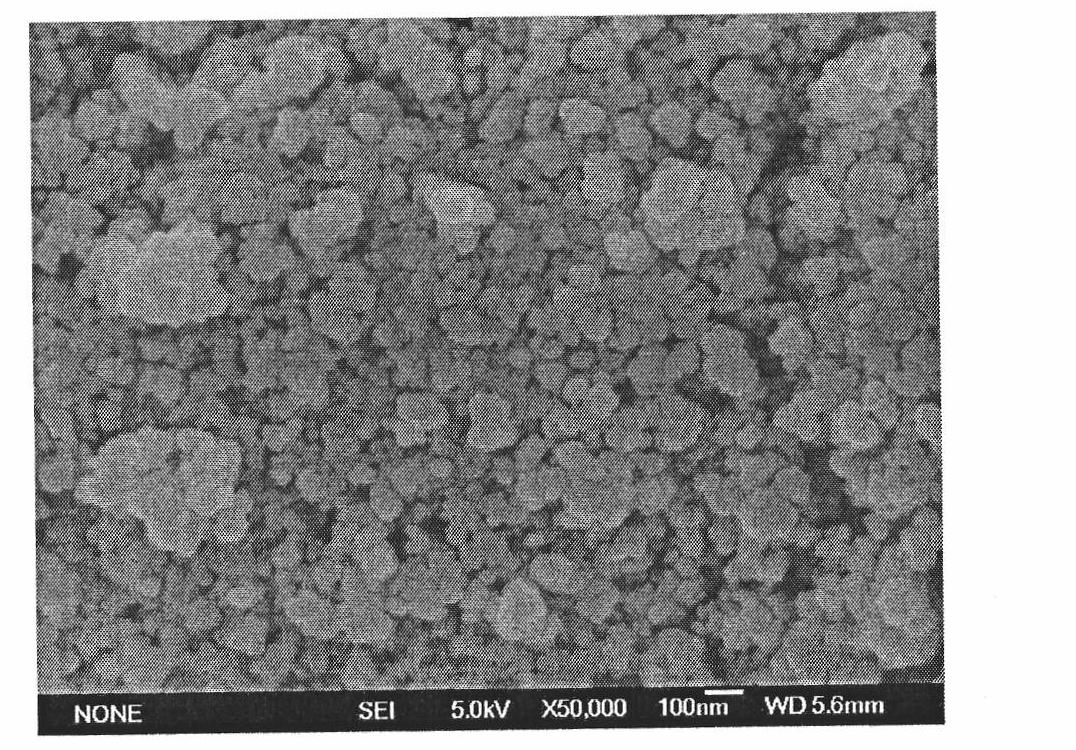

Method for preparing high-purity superfine zirconium boride powder by high-frequency plasma

The invention relates to a method for preparing a high-purity superfine zirconium boride powder by high-frequency plasma. A superhigh temperature heat source provided by a high-frequency plasma arc provides enough high temperature and energy for synthetic reaction; the electrodeless heating characteristic of the high-frequency plasma guarantees the high-purity quality of the product; particles freely deposit and grow in an airflow to obtain superfine particles with good dispersibility; and a reactor is designed to achieve a purpose of regulating product particle size. The zirconium boride powder prepared by the method provided by the invention has the advantages of high purity, good dispersibility and nano-scale size and is suitable for preparing high-temperature ceramic and compound material. The high-frequency plasma technology has a short flow and is suitable for large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of graphene foams

The invention relates to a preparation method of graphene foams. The preparation method of the graphene foams comprises the steps: carrying out plasma technology treatment on foamed nickel, and soaking in a graphene oxide solution; reducing graphene oxide coating the foamed nickel in the solution; placing the foamed nickel coated with graphene in the solution, removing the nickel template through metal corrosion, and repeatedly washing with absolute ethyl alcohol and water, and thus obtaining the graphene foams. The material not only has extremely low density, extremely high porosity and high specific surface area, but also has excellent conductivity of graphene. Compared with the prior art, the preparation method has the advantages of simple process, low cost, easy industrial popularization, and convenient industrialized mass production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Antibacterial composite nanofiber membrane as well as preparation method and application thereof

ActiveCN109675450AThe preparation process is safe and environmentally friendlyNothing producedMembranesSemi-permeable membranesFiberComposite nanofibers

The invention discloses an antibacterial composite nanofiber membrane as well as a preparation method and an application thereof. The antibacterial composite nanofiber membrane comprises a nanofiber membrane and g-C3N4 nanosheets distributed on the surface and inside of nanofiber membrane. The invention also discloses the preparation method of the antibacterial composite nanofiber membrane and theapplication of the antibacterial composite nanofiber membrane. Compared with the prior art, the nanofiber membrane with antibacterial and filtering functions can be prepared only from a graphite phase carbon nitride particle material with a plasma technology, and the nanofiber membrane with an antibacterial function and a filtering function can be prepared, and has low resistance and high efficiency. Meanwhile, the preparation process of the antibacterial composite nanofiber membrane is safe and environmentally friendly, and the preparation method is simple and feasible.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

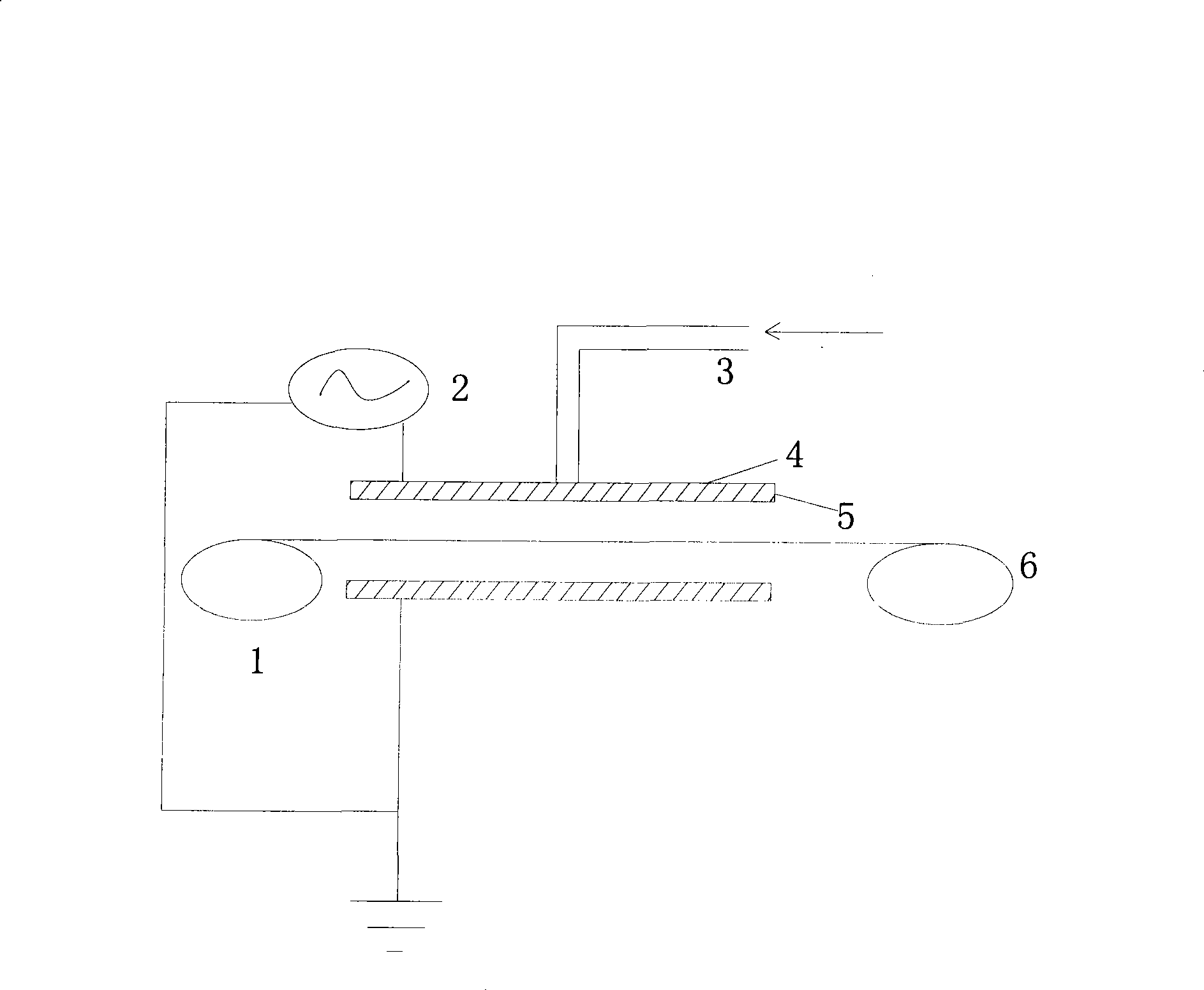

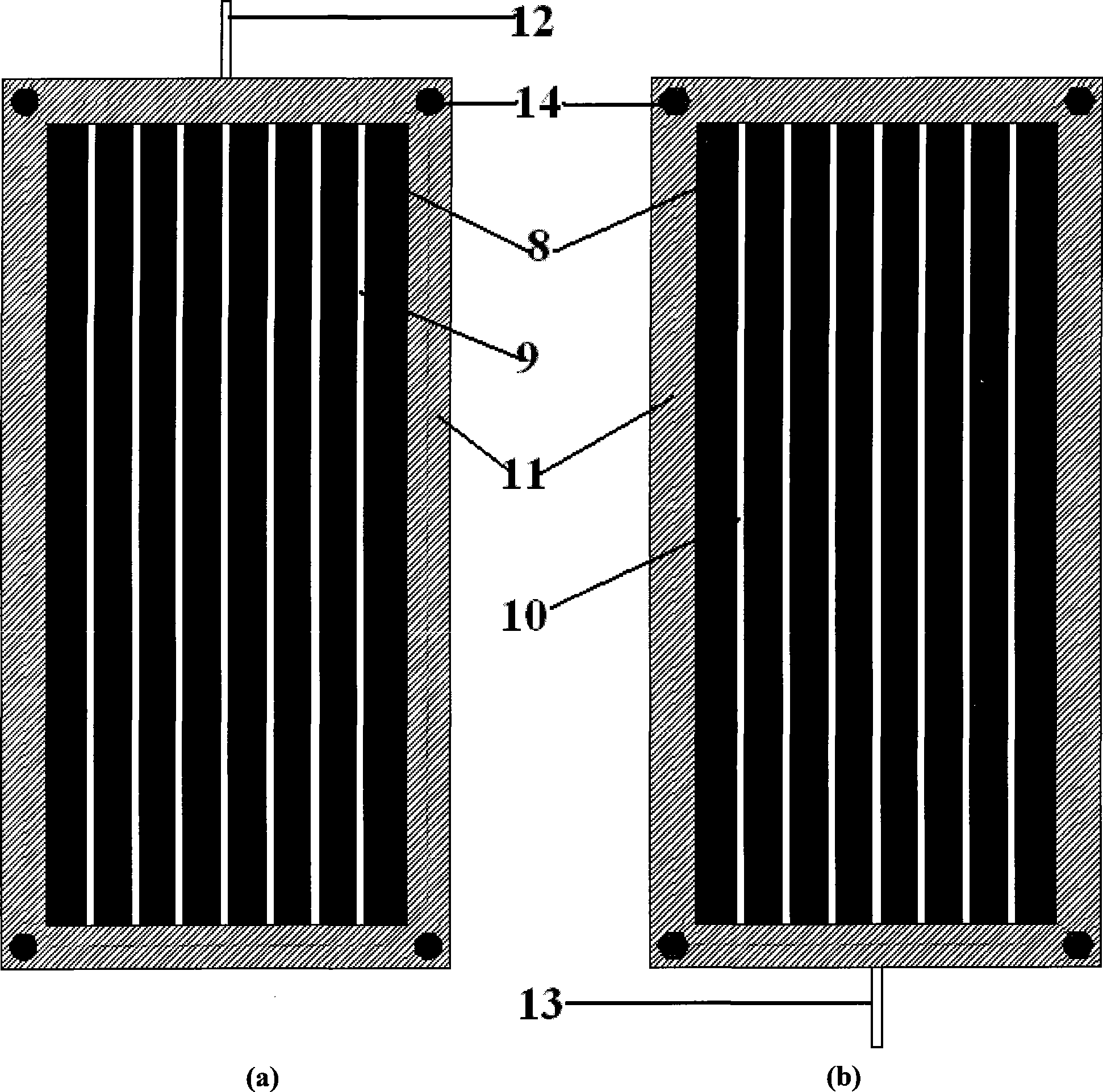

Inner air-cleaning system of vehicle

InactiveCN101474955ATo achieve the purpose of adsorption and regenerationExtended service lifeAir-treating devicesDeodrantsPlasma technologyTransformer

The invention relates to a vehicle air purification system, belongs to the field of air purifier and in particular relates to a vehicle air purification system integrating nanometer photocatalytic air purification technology, low-temperature plasma technology and active carbon adsorption technology into a whole. The system comprises a fan for introducing polluted air into the purification system; the inside of the purification system is provided with a plasma electrode structure and a catalyst membrane 5; an ultraviolet lamp 4 is arranged between the plasma electrode structure and the catalyst membrane 5 in parallel arrangement; and the outside of the purification system is provided with a transformer 3 and a ballast 7 which are connected with two electrodes of the electrode structure and the ultraviolet lamp. The system combines and applies the nanometer photocatalytic technology, the low-temperature plasma technology and the active carbon adsorption technology into the vehicle air purification system; and the synergistic action of three kinds of technology can overcome respective limitation so as to achieve the effect of removing pollutants at high efficiency.

Owner:中投亿星新能源投资有限公司

Magnetic MOFs adsorbent material for adsorbing antibiotics in water body

InactiveCN107570116AImprove adsorption capacityHigh porosityOther chemical processesWater contaminantsPorositySorbent

The invention discloses a magnetic MOFs adsorbent material for adsorbing antibiotics in a water body. A preparation process for the material comprises the following steps: preparing magnetic Fe3O4 particles; preparing a SiO2@Fe3O4 magnetic carrier; and preparing the magnetic MOFs adsorbent material UiO-66@SiO2@Fe3O4. The magnetic MOFs adsorbent material has the beneficial effects that: the magnetic carrier is added into an MOFs precursor solution, so that the magnetic MOFs adsorbent material is formed; the material has good adsorbing performances on antibiotics in the water body, has certain superparamagnetism, and has very great advantages in separating, recycling and repeatedly using the adsorbent; and a plasma technology is used to treat terephthalic acid, so that the prepared adsorbentmaterial has relatively high porosity; and a great number of carboxyl groups serving as function groups are formed on the surface of the material, so that the adsorbing performances, on antibiotics,of the adsorbent material are greatly improved.

Owner:ZHEJIANG OCEAN UNIV

Method for performing powder material surface modification through plasma

InactiveCN105312554AComposite functionIncrease surface specific surface areaVacuum evaporation coatingSputtering coatingPlasma technologyNew materials

The invention discloses a method for performing powder material surface modification through plasma. According to powder material surface modification, under a vacuum environment condition, one or more plasma technologies are used for combination to deposit one or more different characteristic materials on the surfaces of powder materials in different types. Meanwhile, one ore more gases can be selected for combination for micro-etching on the surface of powder in different materials according to the plasma appearance. Powder manufactured and processed through the technology is a novel modified powder material with one or more functional characteristics. The modified powder is changed into a single-metal or multiple-metal combined surface from a non-metal surface, vice versa, the metal surface can be modified into a non-metal ceramic surface. Meanwhile, the smooth powder surface can be subjected to micro roughening.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC +2

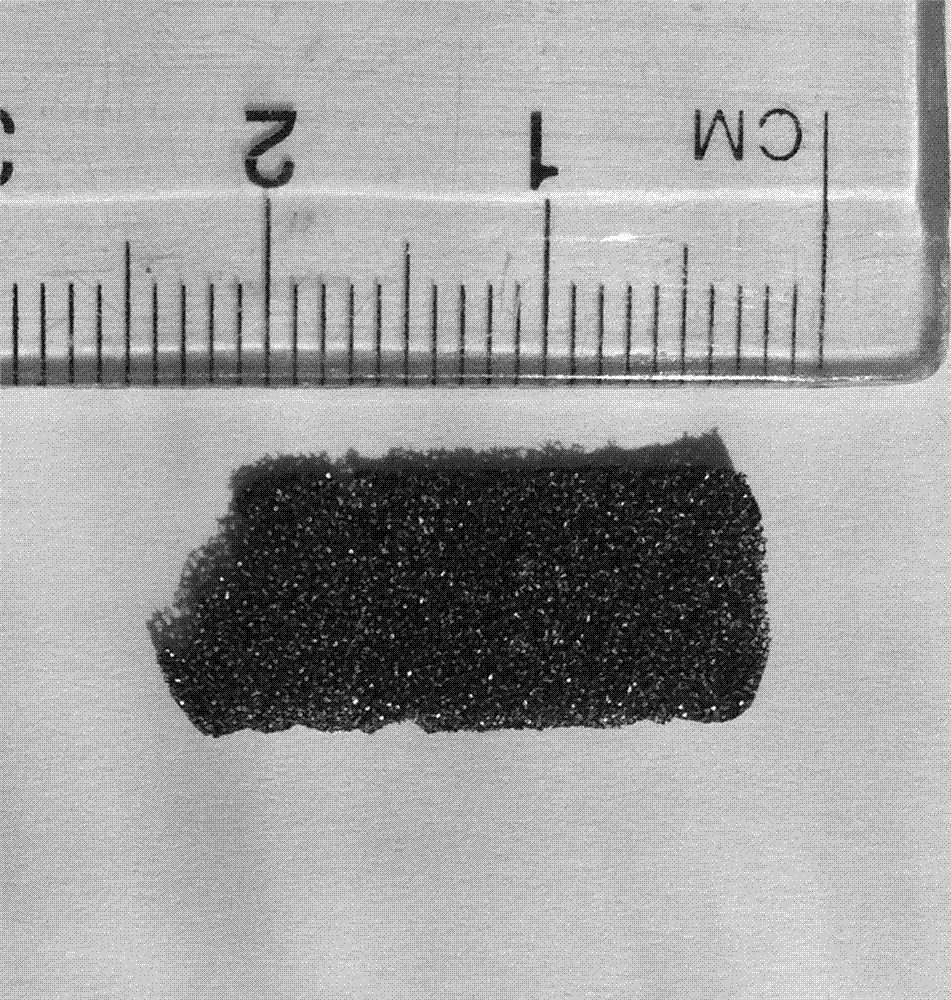

Preparation method of large-rate discharge porous diaphragm material and application of material

The invention relates to the film material field, and especially relates to a preparation method of a large-rate discharge porous diaphragm material and an application of the material. The preparation method of the large-rate discharge porous diaphragm material comprises the following steps: preparing a porous film through utilizing polyvinylidene fluoride (PVDF) or poly(vinylidene fluoride-co-hexafluoropropene) (PVDF-HFP) by adopting an immersion precipitation method or a thermotropic phase separation method; and carrying out post-treatment of the surface of the prepared PVDF or PVDF-HFP porous film through an ion technology to form a nano-micro hole controllable high-hole-ratio porous diaphragm having fingerlike tunnels penetrating to the bottom. The morphology of the porous film prepared in the invention is composed of a uniform nano / micro hole surface layer, thumb-like tunnels and a sponge hole bottom layer, and the porous film having the above structure provides an enough space for accommodating an electrolyte, so the tunnels are full of the electrolyte, the electrolyte and the PVDF form a gel electrolyte in a largest area mode, and the accommodating capability of the porous diaphragm to the electrolyte is increased.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

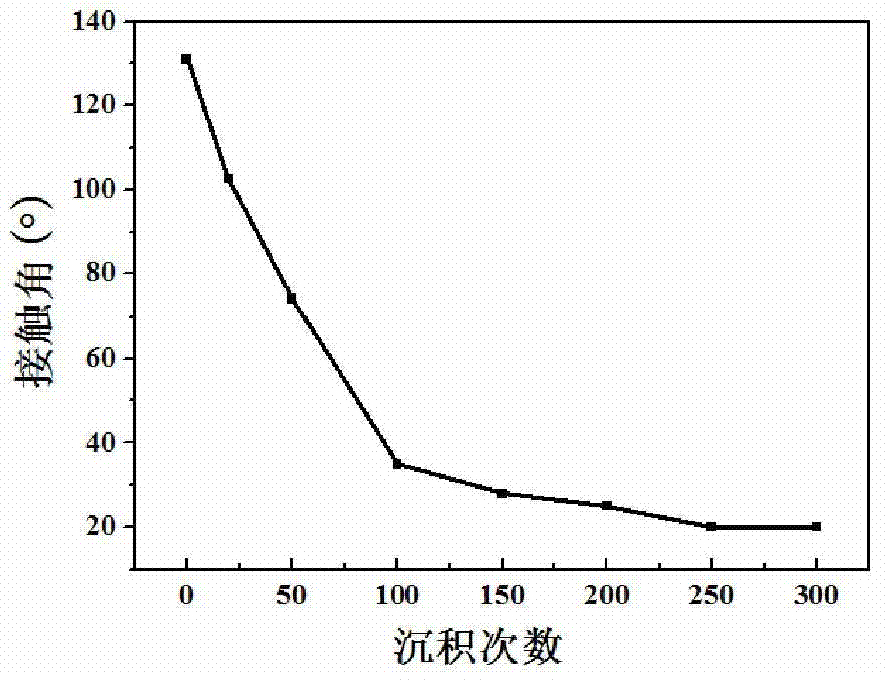

Surface modification method for polytetrafluoroethylene separation membrane

ActiveCN102773026AImprove performanceHigh retention rateSemi-permeable membranesThin oxidePlasma technology

The invention relates to a surface modification method for a polytetrafluoroethylene separation membrane. The method comprises the following steps of: activating the surface of the PTFE (polytetrafluoroethylene) membrane by virtue of a plasma technology, and then continuously depositing thin oxide layers on the surfaces of pore channels of the separation membrane by virtue of an atomic layer deposition technology to realize precise adjustment and control on pore diameter and surface properties of the separation membrane. According to the method, the plasma technology is used for pretreating, and then the atomic layer deposition is carried out, so that the growth mechanism of a deposition layer on the surface of the PTFE membrane is changed, the island type growthof the deposition layer is changed to conformal growth, the deposition layer is uniform and smooth, and the hydrophily, the pure water flux, the separating property and the anti-pollution capacity of the separation membrane are all obviously improved.

Owner:NANJING UNIV OF TECH

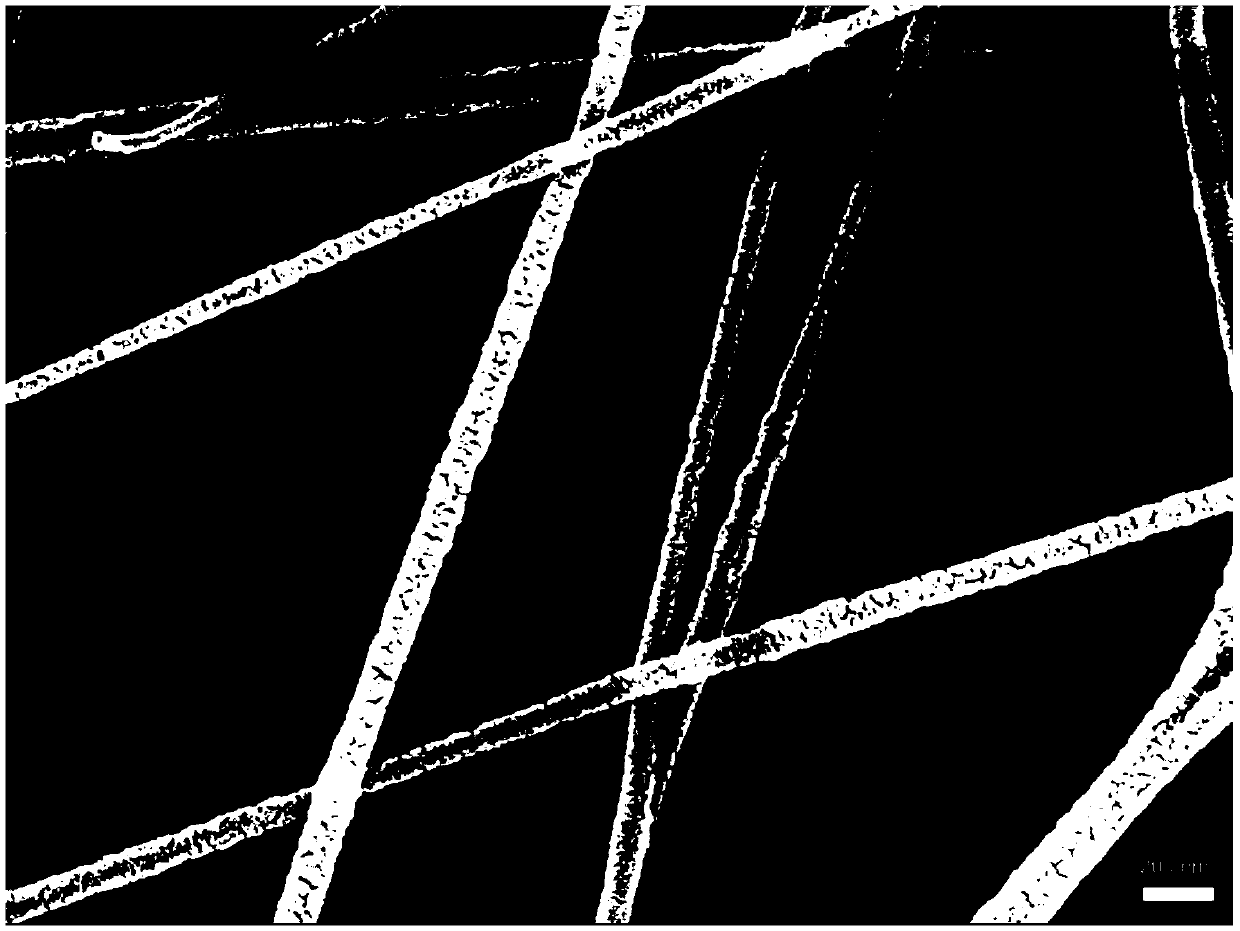

Nano silver in-situ formation silver-plating method based on plasma modification and silver-plated fabric

ActiveCN104988720AIncrease surface areaImprove wettabilityFibre typesUltrasonic/sonic fibre treatmentSilver plateSilver overlay

The invention relates to a nano silver in-situ formation silver-plating method based on plasma modification and a silver plated fabric. In the provided method, a plasma surface treatment modification technology is adopted to crack and etch the surface of synthetic fibers so as to form micro pits and fine cracks on the surface of fibers, thus the surface area of the fibers is enlarged, and the wettability of the fiber surface is improved. At the same time, the surface of the fibers is etched, and the binding strength between the metal coating and the fibers is enhanced. After the fibers are subjected to an oxygen gas plasma technology, hydrophilic and polar groups (-COOH, =C=O) are grafted on the fiber surface, thus silver ions can be adhered on the fiber surface more easily; in the presence of polyvinylpyrrolidone (PVC), sodium borohydride (NaBH4) is taken as the reducing agent to directly reduce the silver ions into nano silver particles, and a compact silver coating is in-situ generated on the etched fiber surface. The provided method has the advantages of simple technology, environment-friendliness, energy saving, and reduced cost. The silver coating on the produced silver-plated fabric is uniform and compact, the binding force between the silver coating and the fabric is strong, and the method is worth to promote.

Owner:SHANHAI CHENLONG TEXTILE NEW MATERIAL CO LTD

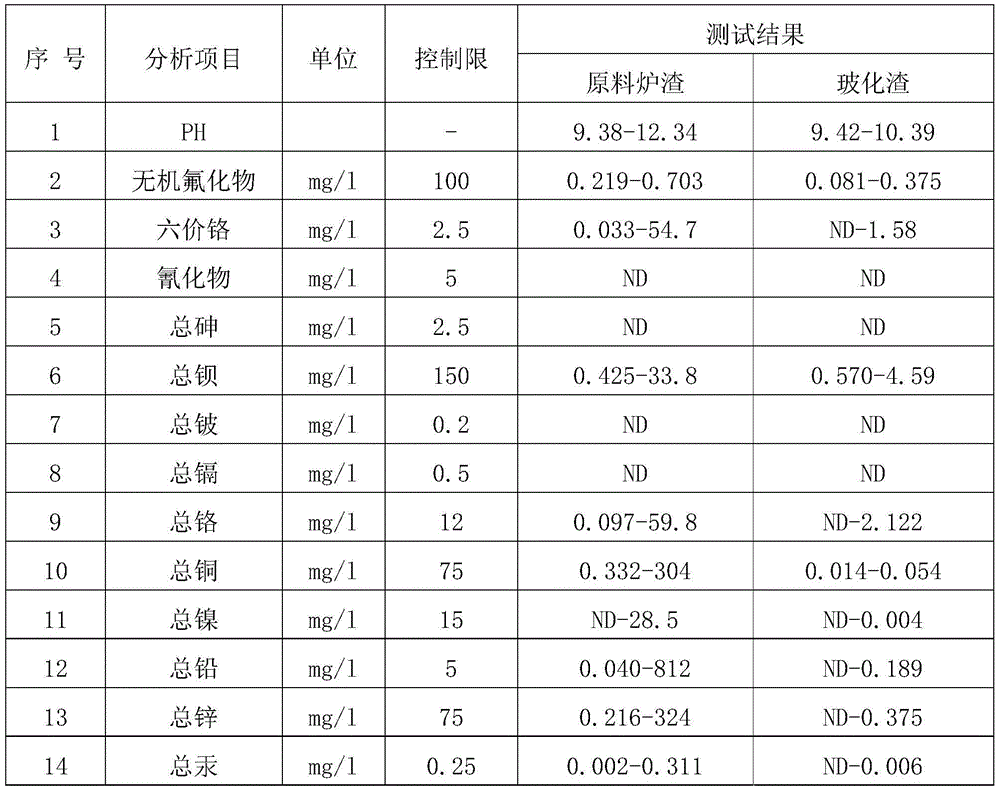

Method for treating hazardous waste incineration bottom ash by using plasma technology

InactiveCN105817459AHigh hardnessAvoid secondary pollutionSolid waste disposalTransportation and packagingPlasma technologySlag

The invention discloses a method for treating hazardous waste incineration bottom ash by using plasma technology. According to the invention, high temperature produced by plasma is utilized to decompose and destroy residual toxic organic matters including dioxin in the incineration bottom ash, and heating and cooling are carried out so as to form high-hardness high-strength vitrification slag of enclosed structure. As heavy metal ions included in the incineration bottom ash are immobilized, secondary pollution can be avoided, and technical requirements for ultralow leaching toxicity can be met, so hazardous wastes can be efficiently converted into non-hazardous wastes and do not need landfilling at great expense; and the vitrification slag formed after treatment can be converted into a road building material, constructional material or the like for comprehensive utilization, so the method has wide promotion space.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +1

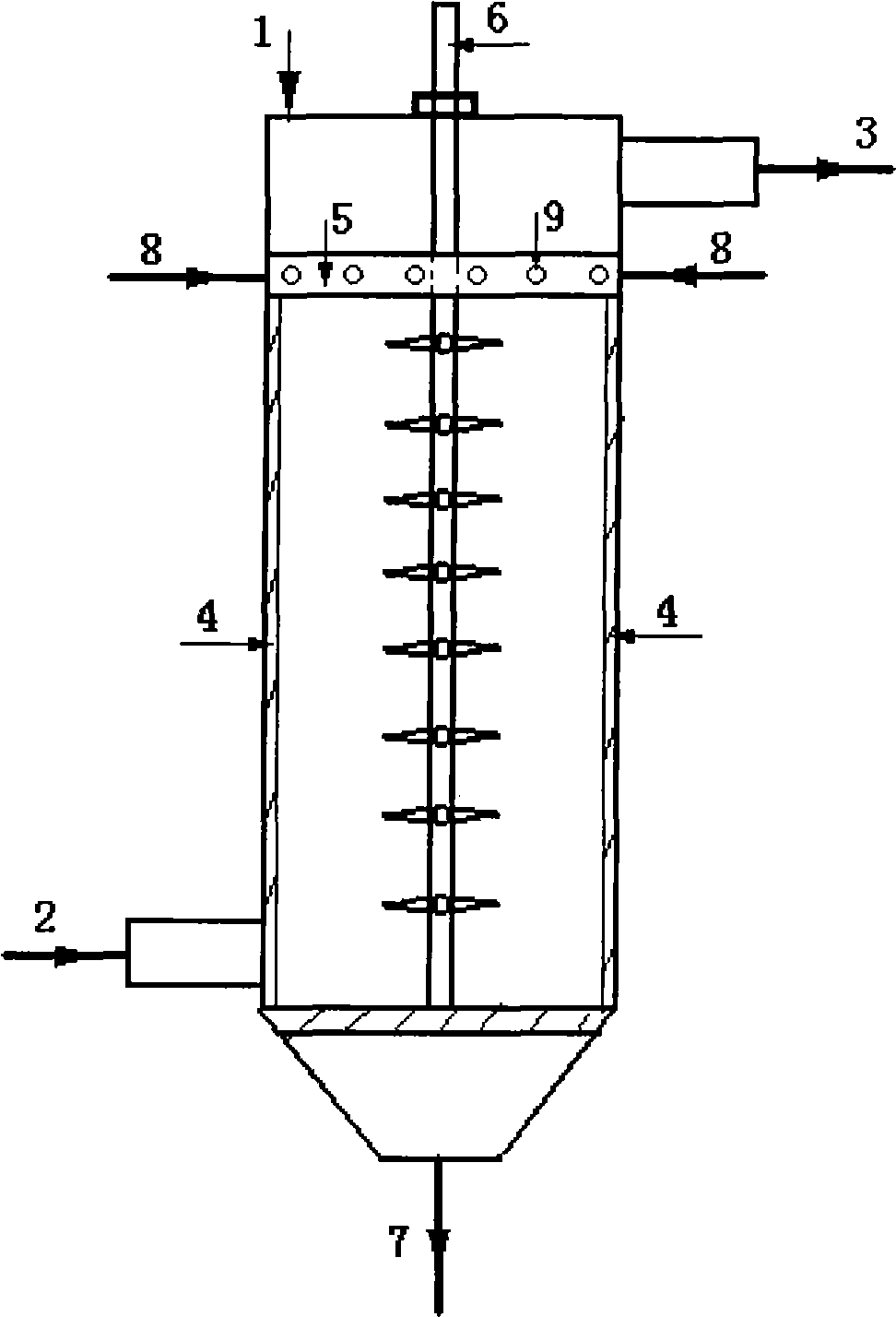

Wet-type flue gas treating reactor by pulse corona

InactiveCN101496987AReduce complexityLow investment costCombination devicesExternal electric electrostatic seperatorSorbentPlasma technology

The invention discloses a wet-type pulse corona smoke gas treatment reactor. The reactor comprises a shell; the lower end of the shell is provided with a gas inlet; the upper end of the shell is provided with a gas outlet; the inner wall of the shell clings to and is provided with a running water polar plate; the upper part of the running water polar plate is provided with a water sprayer; the bottom of the shell is provided with a water outlet; a sorbent is ejected from the water sprayer and flows from top to bottom along the running water polar plate; and finally, the sorbent is collected in the water outlet and flows to a feed discharge pool; the center of the shell is provided with an acicular corona wire; the acicular corona wire and the running water polar plate form two electrodes for corona discharging; the running water polar plate is connected with positive pulse high voltage; and the acicular corona wire is connected with negative pulse high voltage. The wet-type pulse corona smoke gas treatment reactor compounds non-thermal equilibrium plasma technology, physical adsorption technology and chemical absorption technology, realizes high-efficiency removing of PM2.5, SO2 and NOx in the same reactor, greatly simplifies a smoke gas treatment system and reduces investment and operating cost.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Biomolecule Immobilisation Using Atmospheric Plasma Technology

ActiveUS20070292972A1Material can be treatedReduce processing costsMicrobiological testing/measurementBiological testingPlasma technologyEngineering

The present invention is related to method for immobilising a biomolecule on a surface by generating and maintaining an atmospheric pressure plasma, said method comprising the steps of: introducing a sample in the space between two electrodes, a mixed atmosphere being present between said electrodes, applying an alternating voltage to said electrodes for generating and maintaining a plasma in the volumetric space between the electrodes, said voltage having a profile as a function of time, defined by a sequence of time periods during which a positive or zero voltage is applied, alternated with time periods during which a negative or zero voltage is applied, and depositing a coating on a surface of said sample, characterised in that said mixed atmosphere comprises an aerosol comprising a reactive precursor and an aerosol comprising a biomolecule, both of which are deposited and immobilised during the depositing step.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

Coaxial microwave plasma film-deposition equipment

InactiveCN104357810AIncrease the areaReal-time monitoring of electron densityChemical vapor deposition coatingPlasma technologyCoaxial line

The invention discloses coaxial microwave plasma film-deposition equipment, and belongs to the field of plasma technology. The equipment comprises a vacuum chamber, wherein a coaxial microwave plasma source is fixedly mounted on the vacuum chamber; the coaxial microwave plasma source comprises microwave generators, waveguides, coaxial line convertors, a quartz tube and an inner electrode; the quartz tube is located in the vacuum chamber and fixedly mounted on two side walls of the vacuum chamber; the coaxial line convertors are coaxially, symmetrically and fixedly mounted at the two ends of the quartz tube via the outer side wall of the vacuum chamber; the coaxial line convertors are connected with the microwave generators via the waveguides; the inner electrode penetrates through the quartz tube and is fixed on the coaxial line convertors; the inner electrode, the coaxial line convertors and the quartz tube are coaxial; the equipment is further provided with an instrument for testing the electron density and the electron temperature of plasmas and automatic power and air pressure control equipment and system, can obtain stable high-controllability plasmas, and can realize efficient, stable and uniform film deposition; the equipment has high production efficiency and is low in production cost.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Biological cell wall breaking system and biological effective component extracting system based on pulsed discharge plasma technology

ActiveCN101705182AEffective destructionHigh extraction rateBioreactor/fermenter combinationsBiological substance pretreatmentsShock waveBiological cell

The invention relates to a biological cell wall breaking system and a biological effective component extracting system based on the pulsed discharge plasma technology, solving the problems that the current traditional drug processing method is insufficient to break the biological cell walls and the extraction efficiency is low in the current methods for extracting the biological effective components. The biological cell wall breaking system first adopts high-voltage discharge to generate plasmas and then adopts the generated shock waves and living radicals to break the biological cell walls. The biological effective component extracting system first adopts the biological cell wall breaking system to break the biological cell walls to separate the biological effective components from the cells and then carries out filtration and concentration to obtain the biological effective components. The biological cell wall breaking system of the invention can be used in the technical field of breaking the biological cell walls and the biological effective component extracting system can be used in the field of extracting the biological effective components.

Owner:HARBIN INST OF TECH

Valve finisher surface modified processing method

InactiveCN1570192AHigh hardnessImprove stress resistanceMetal-working apparatusSolid state diffusion coatingThermal fatiguePlasma technology

The invention relates to a surface modification processing method for the engine critical component, which belongs to the field of the steel surface chemistry thermal treatment processing technology. The processing method comprises: nitriding for the air valve finisher by using the plasma technology, adding carbon-containing gas in the nitrogen-containing gas at the late stage of nitriding and carrying out the nitrocarburizing, and placing the mould in the steam oxidizing furnace for surface oxidizing treatment. The mould treated by said technology has excellent mechanical property, improved surface hardness, improved compression resistance, improved wear resistance and improved thermal fatigue resistance.

Owner:SHANGHAI UNIV

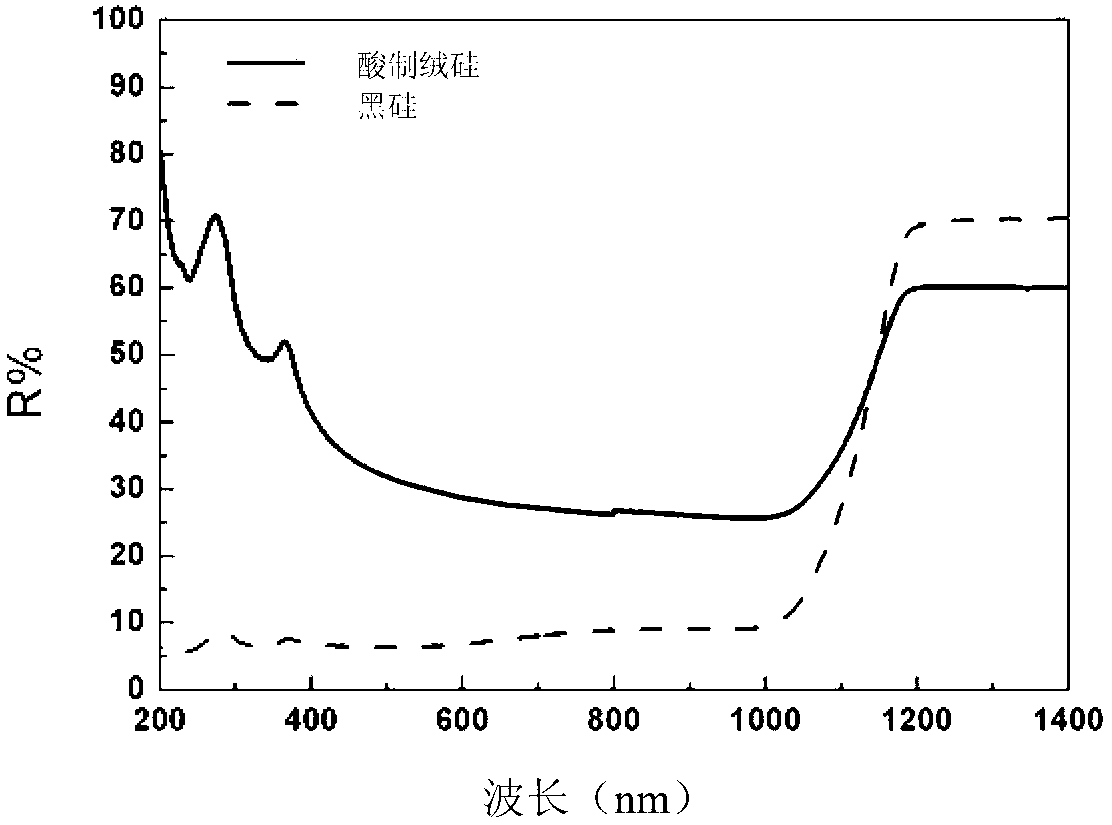

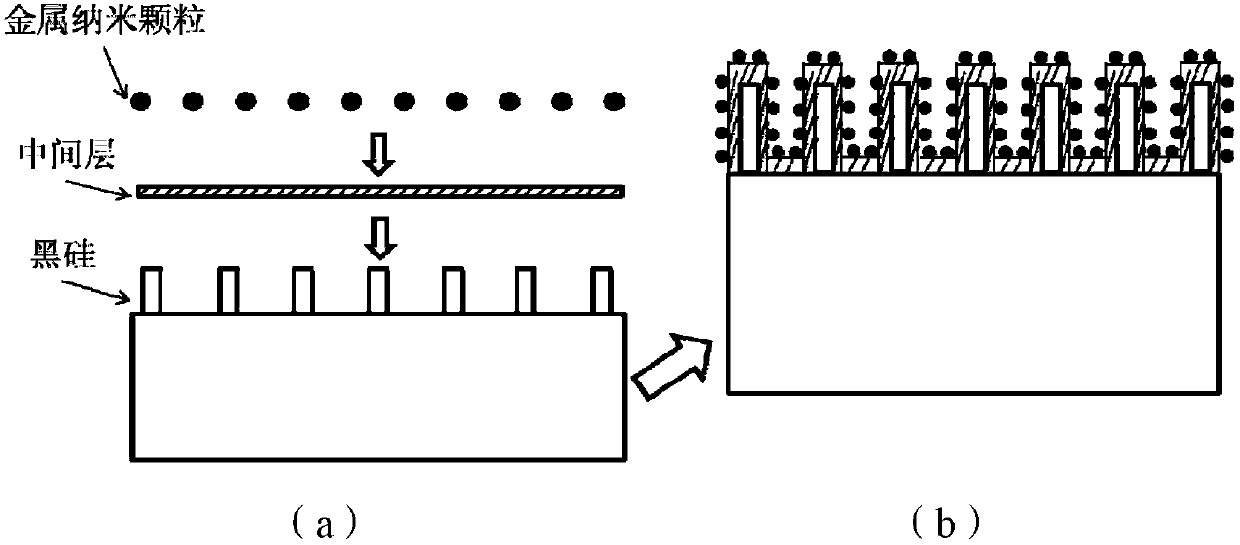

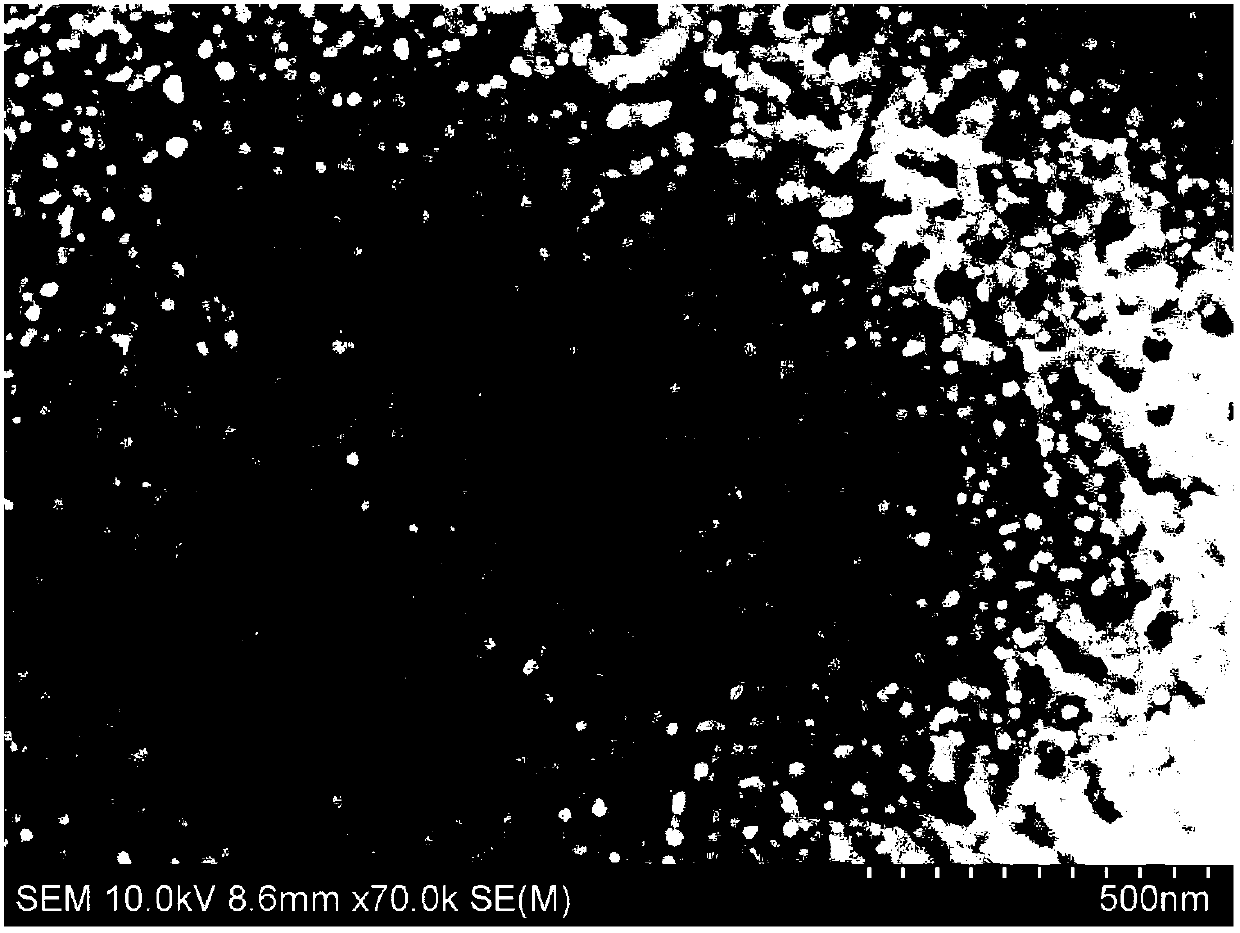

Method for reducing reflection of black silicon in wide band scope

ActiveCN102881769AInhibition reflexHigh outputFinal product manufactureSemiconductor devicesPlasma technologyTrapping

The invention provides a method for reducing reflection of black silicon in a wide band scope. The method comprises the following steps: 1) an intermediate layer is prepared on the surface of the black silicon, wherein the black silicon is silicon with a light trapping structure; 2) metal nanometer particles are deposited on the intermediate layer obtained in the step 1), and are not continuous or not in contact with one another; and 3) annealing processing is performed on a product obtained in the step 2). The method is simple in operation, low in cost, effectively combined with a black silicon technology, a surface isolation protection technology and a surface plasma technology to achieve a reflection reduction effect in the wide band scope, and conducive to the application in the industrial production of solar batteries.

Owner:深圳市石金科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com