Aluminum-plastic membrane used for packaging lithium battery

A technology of aluminum-plastic film and lithium battery, which is applied in the field of packaging aluminum-plastic film, can solve the problems of poor toughness of the bonding layer and poor heat-sealing bonding strength, and achieve high chemical resistance and explosion-proof packaging adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

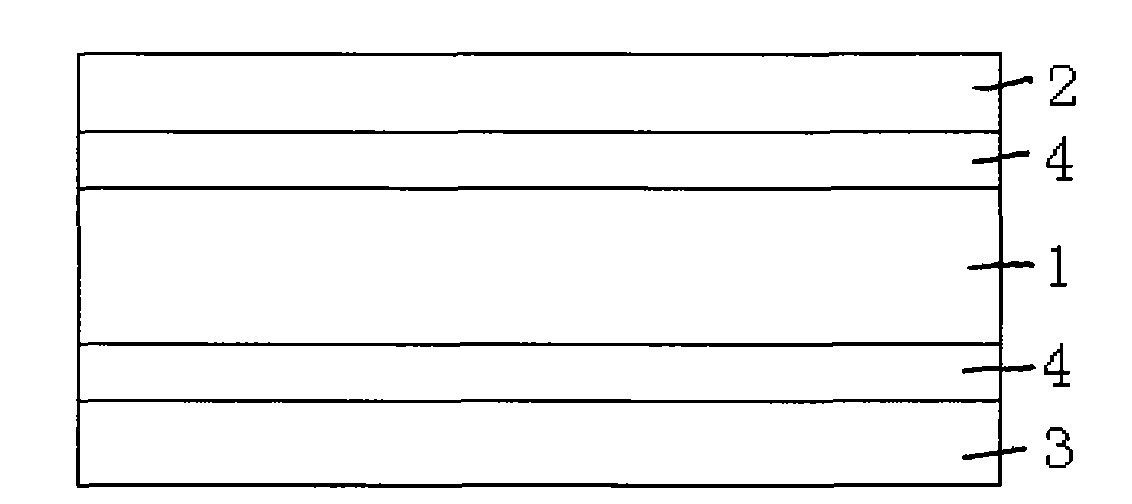

[0032] Using a 40um thick high-toughness aluminum foil 1, the surface of the aluminum foil is grafted with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6, and then a thermosetting adhesive is applied to the treated surface of the aluminum foil. On the surface, bake at 40-100°C for 1-5 minutes to make a thermosetting adhesive layer 4 with a thickness of 3-10um, and then perform surface grafting treatment with argon and nitrogen with a volume ratio of 3:7 to achieve high wear resistance. The tough polyamide film is compound coated on the treated surface of the aluminum foil with a temperature of 40-100°C and a pressure of 0.2-1kgf to form an outer protective layer 2; then the aluminum foil is treated with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6 the other surface, and apply a thermosetting adhesive on the other treated surface of the aluminum foil, bake at 40-100°C for 1-5 minutes to form another thermosetting adhesive layer 4 with a thicknes...

Embodiment 2

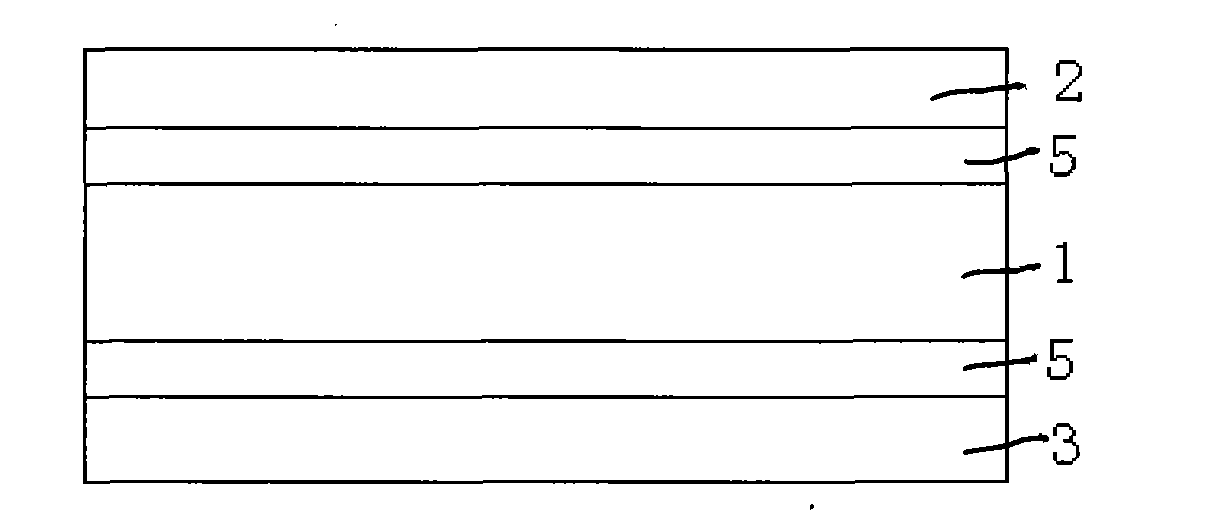

[0034] Adopt 40um thick high tenacity aluminum foil 1, carry out surface graft treatment to one surface of aluminum foil with the plasma gas of the volume ratio of oxygen and nitrogen of 4:6; The plasma gas with a nitrogen volume ratio of 3:7 is used for surface grafting treatment. Blend low-density polyethylene and ethylene vinyl acetate copolymer at a mass fraction of 1:1 and extrude a coating film 10-20um thick on the treated surface of aluminum foil to form a thermoplastic cushioning adhesive layer 5, and then polyamide film treated One surface is attached to the extruded film, and the protective layer 2 is compounded at a temperature of 100-160°C and a pressure of 0.5-1.5kgf; then the other surface of the aluminum foil is treated with a plasma gas with a volume ratio of oxygen and nitrogen of 4:6, and the low Density polyethylene and ethylene vinyl acetate copolymer are blended and extruded with a mass fraction of 1:1 to coat the other surface of the aluminum foil with a ...

Embodiment 3

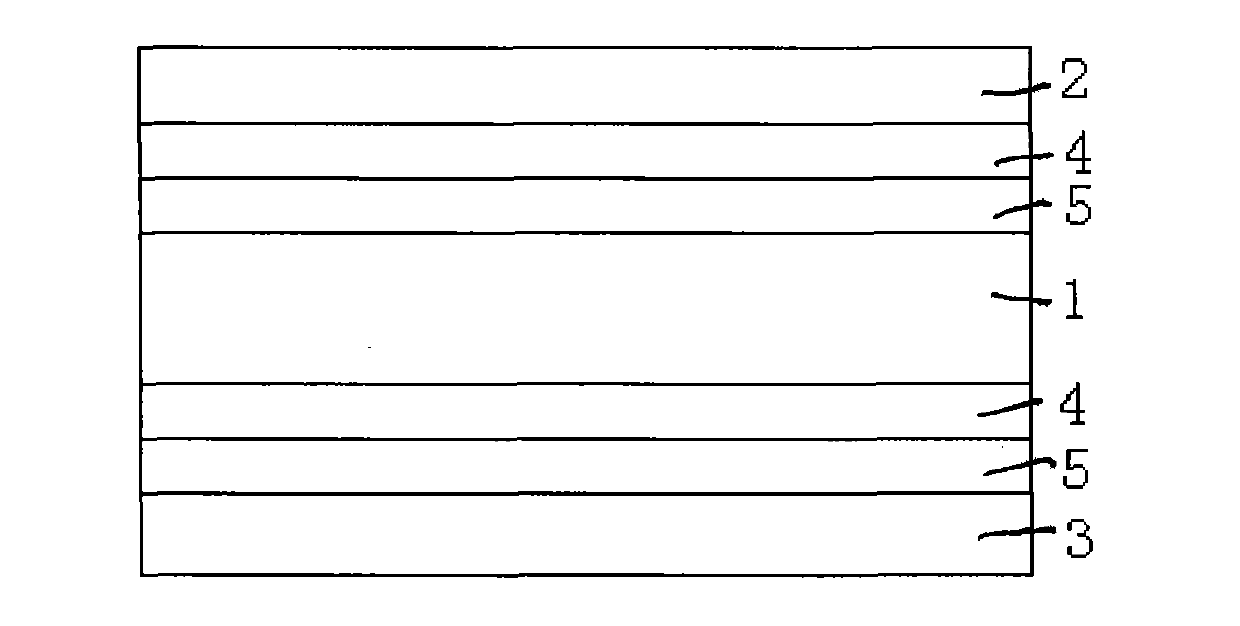

[0036] A 25um thick polyamide film with high wear resistance and toughness is used as the protective layer 2, and the surface of the film is grafted with a plasma gas with a volume ratio of argon and nitrogen of 3:7, and then the thermosetting adhesive is coated. Spread it on the treated surface of the polyamide film, bake it at 40-100°C for 1-5 minutes, and make a 3-10um thick thermosetting adhesive layer 4; use a 50um thick unsaturated acid anhydride modified polypropylene film as the heat-sealing layer 3. Carry out surface grafting treatment on one surface of the polypropylene film with a plasma gas with a volume ratio of argon and nitrogen of 3:7, and then apply a thermosetting adhesive on the treated surface of the polypropylene film to Bake at 40-100°C for 1-5 minutes to form another thermosetting adhesive layer 4 with a thickness of 3-10um; use a 40um-thick high-toughness aluminum foil 1, and use a plasma gas with a volume ratio of oxygen and nitrogen of 4:6 to treat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com