Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329 results about "Methacrylic acid copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methacrylic acid copolymer, also known as Methacrylic acid - ethyl acrylate copolymer is an excipient used in pharmaceutical manufacturing. It is a solid white powder with dissolution above pH of 5.5, and is used in enteric coatings for fast dissolution in the upper bowel, for granulation of drug ...

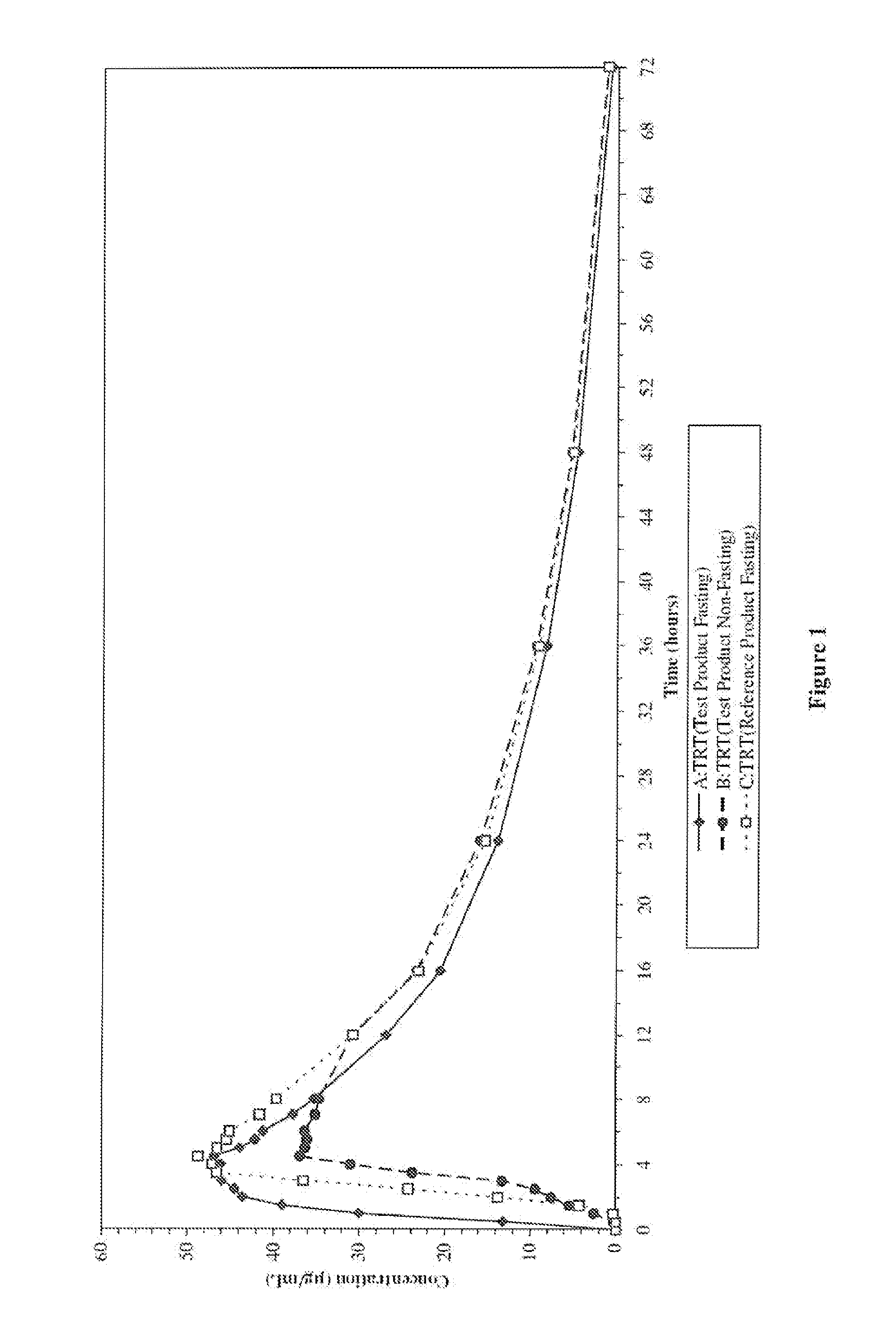

Stabilized extended release pharmaceutical compositions comprising a beta-adrenoreceptor antagonist

InactiveUS20070092573A1Well formedStrengthen matrixBiocideOrganic active ingredientsGreek letter betaAdrenergic receptor sites

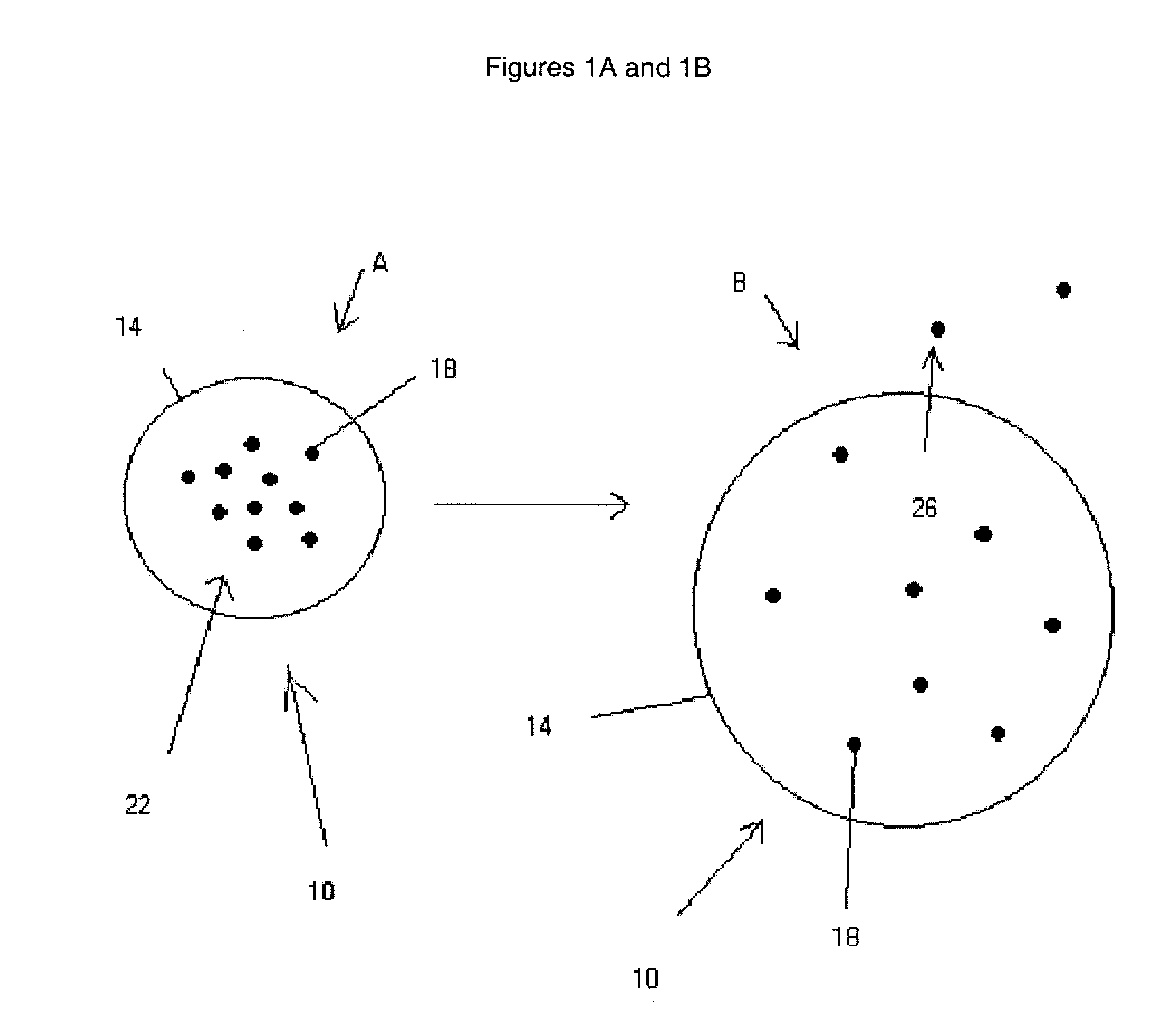

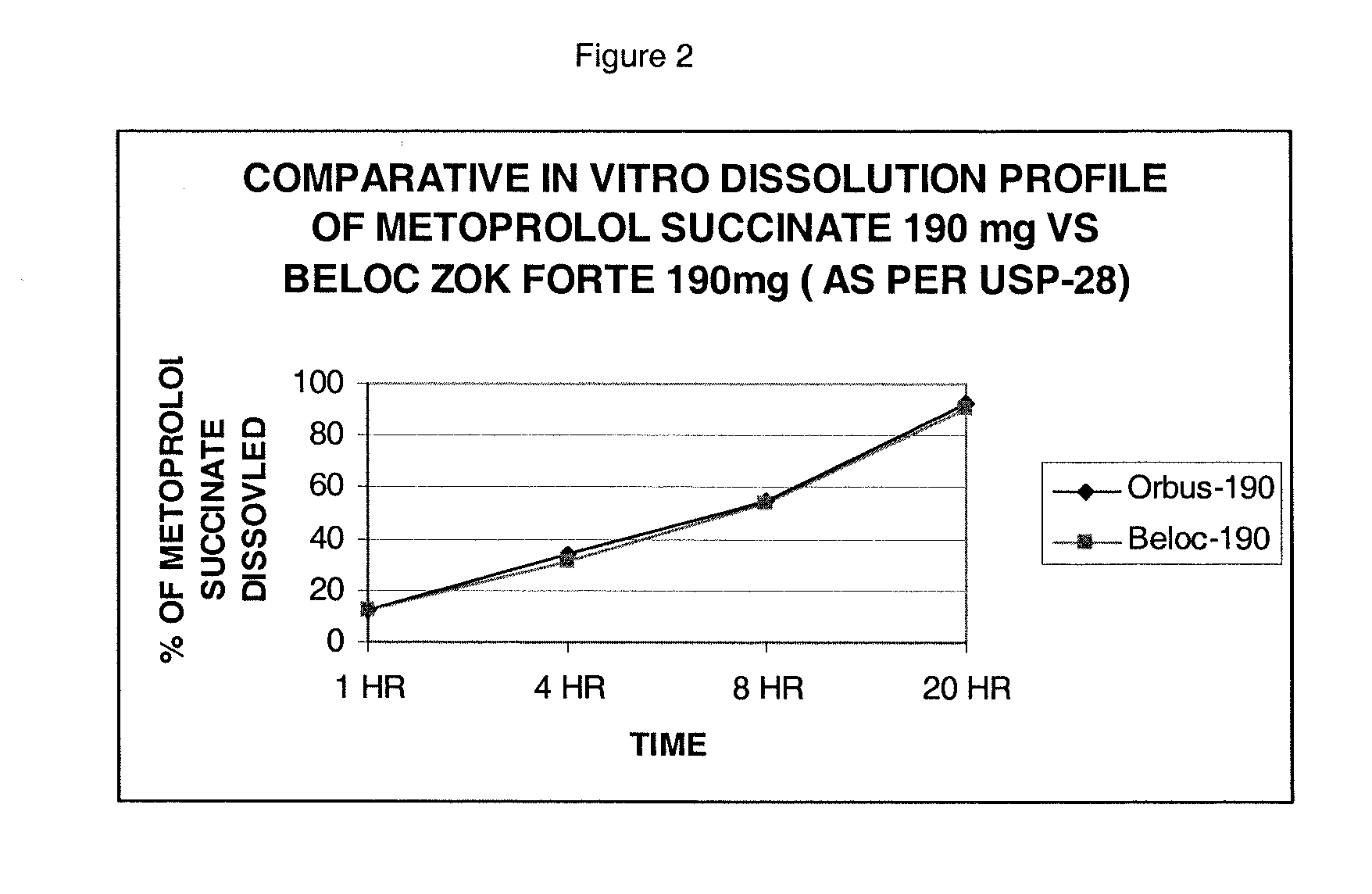

The present invention is a new stable extended release drug composition particularly suitable for use as a beta-adrenoreceptor antagonist agent. The present invention is specifically a drug composition comprising a pharmaceutical, a methacrylic acid copolymer and a matrix forming agent, and a method for manufacturing same. When applied to highly soluble drugs like metoprolol succinate, the resulting drug composition is characterized by an extended-release profile.

Owner:ORBUS PHARMA INC

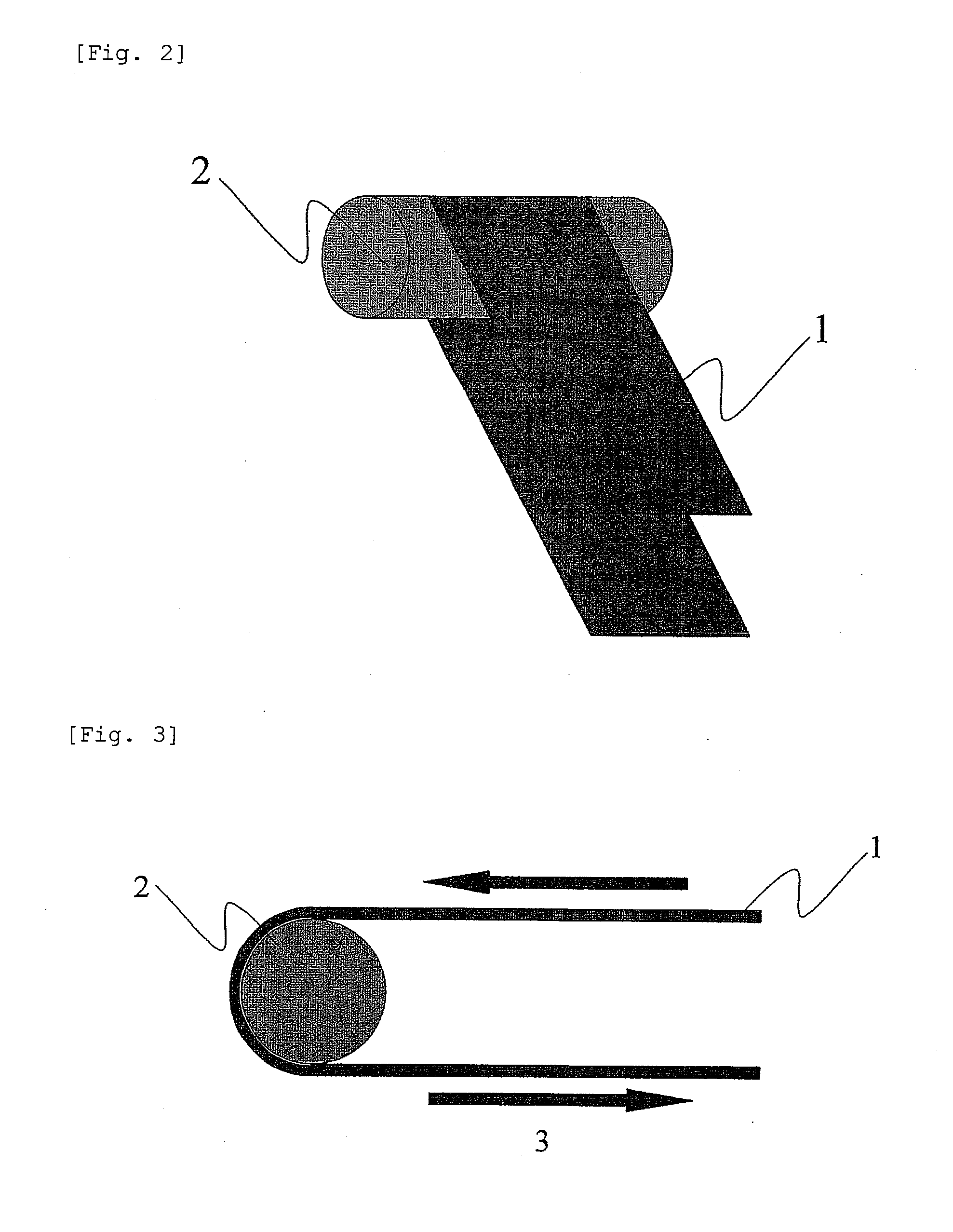

Aqueous paste for electrochemical cell, electrode plate for electrochemical cell obtained by applying the aqueous paste, and battery comprising the electrode plate

InactiveUS20120231337A1Improve cycle performanceSolve the lack of adhesionConductive materialSpecial tyresStructural unitElectrochemical cell

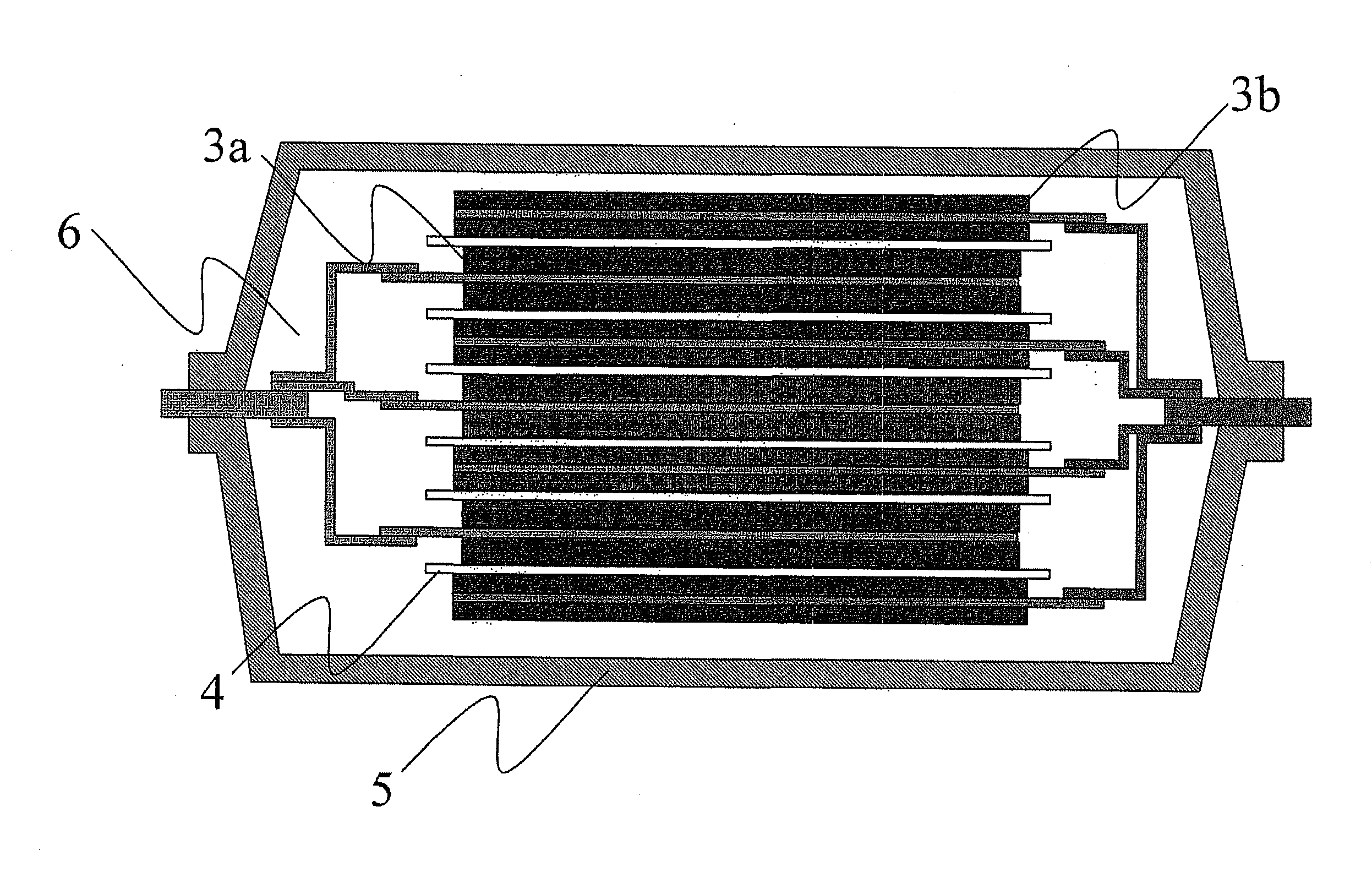

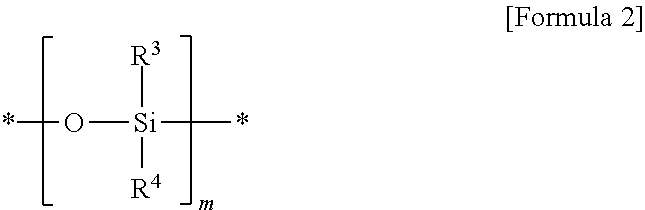

The aqueous paste for an electrochemical cell of the present invention comprises an aqueous dispersion for an electrochemical cell that comprises an olefin copolymer (a); an active material; and a conductive assistant, wherein the olefin copolymer (a) has a weight average molecular weight of not less than 50,000 and is at least one kind selected from a random propylene copolymer (a-1) containing 50% by weight to less than 85% by weight of a structural unit derived from propylene; an acid-modified random propylene copolymer (a-2) obtained by modifying the copolymer (a-1) with an acid; and an ethylene-(meth) acrylic acid copolymer (a-3) containing 5% by weight to less than 25% by weight of a structural unit derived from (meth) acrylic acid.

Owner:MITSUI CHEM INC +1

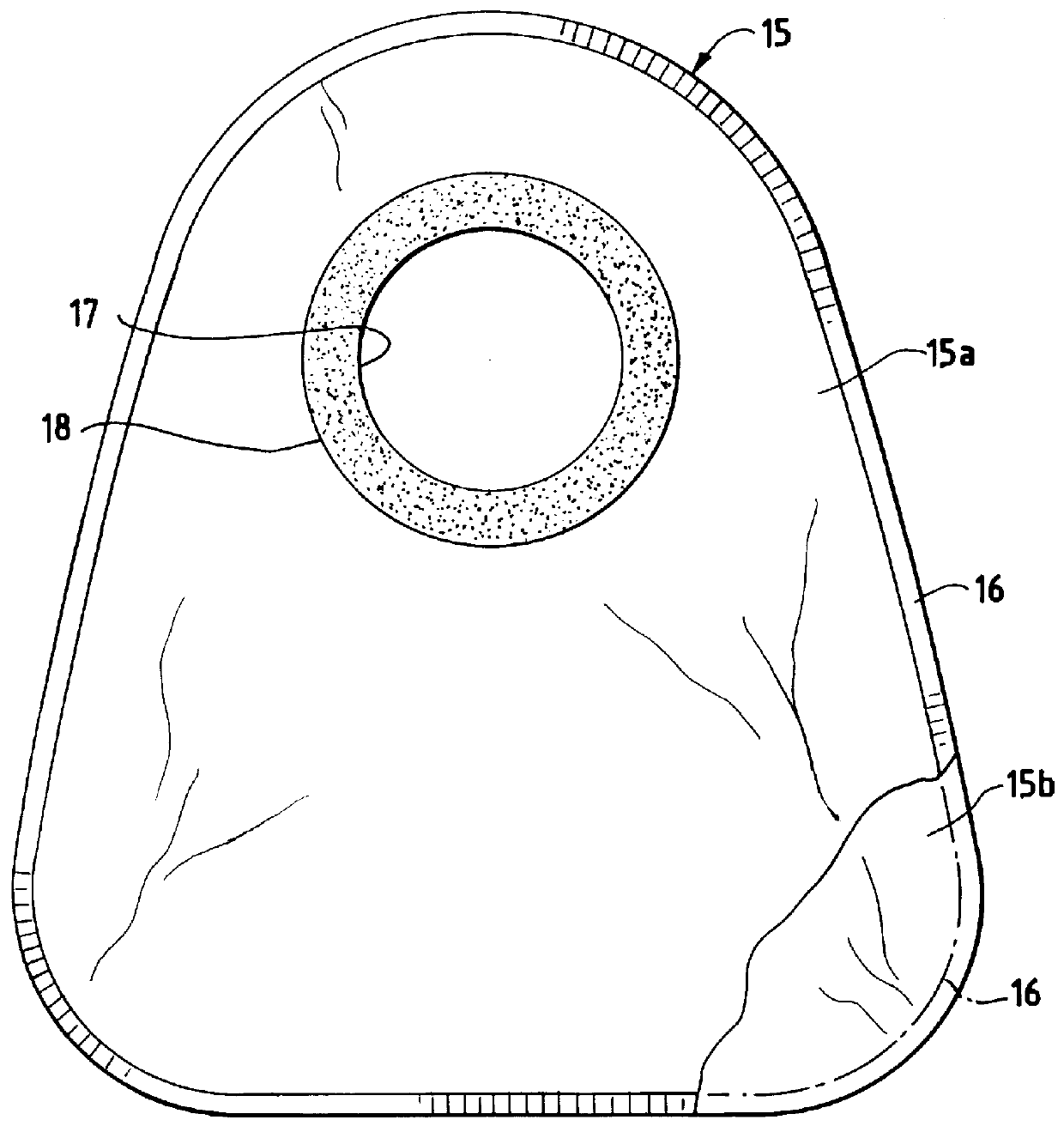

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS6143383AGood odor barrier propertyMinimal noiseSynthetic resin layered productsBagsHigh resistanceLow noise

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film includes an odor barrier layer and at least one directly adjoining heat-sealable skin layer. The barrier layer is composed of either an aliphatic or partially aromatic polyamide resin, or a blend thereof, blended with an ionomer resin consisting essentially of a partially neutralized ethylene-methacrylic acid copolymer, and the heat-sealable skin layer or layers bonded directly to the barrier layer are composed of copolymers of ethylene and an ester-containing comonomer. High resistance to delamination of the barrier layer and skin layer(s) is achieved without tie layers therebetween. Pouches formed of such multilayer chlorine-free films are also disclosed.

Owner:HOLLISTER INCORPORAED

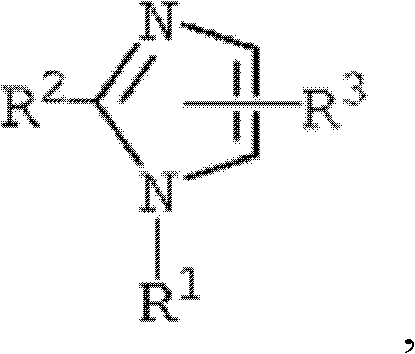

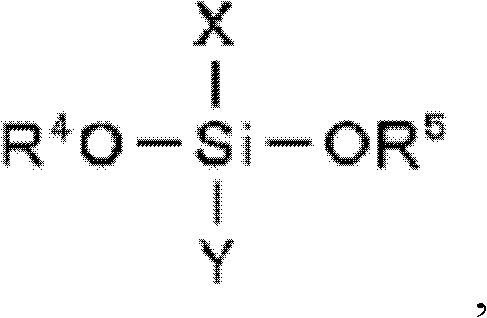

Gastric retentive tablet compositions

The present invention relates to a gastric retentive tablet composition comprising: (1) coated particles essentially consisting of a drug and an amino methacrylate copolymer, (2) a methacrylic acid copolymer and (3) an excipient, wherein items 1, 2, and 3 are blended together, and then compressed into a gastric retentive tablet. Thus, the coated particles (item 1), a methacrylic acid copolymer and the excipient are evenly distributed in the tablet. The excipient is selected from a group consisting of a retarding agent, a binder, a filler, a chelating agent, a diluent, a disintegrant, a lubricant, a colorant, a solubilizing agent, or a mixture thereof. The coated particles (item 1) do not contain methacrylic acid polymer.

Owner:WONG DAVID

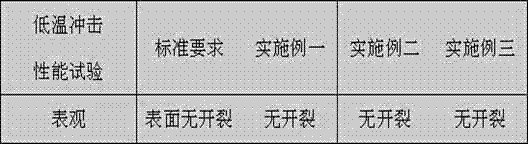

Golf ball

ActiveUS20100009776A1Increase elasticityImproves low temperature durabilityGolf ballsSolid ballsMeth-Flexural modulus

An object of the present invention is to provide a golf ball having an excellent properties like flight distance and low temperature durability. The present invention provides a golf ball comprising: a core consisting of a center and one or more intermediate layers covering the center; and a cover covering the core, wherein at least one piece or one layer of said intermediate layers is formed from a highly elastic intermediate layer composition that contains (A) a highly elastic polyamide resin having a flexural modulus in a range from 700 MPa to 5,000 MPa; (B) a metal-neutralized product of ethylene-(meth)acrylic acid copolymer and (C) a resin having a polar functional group in a specific way.

Owner:SUMITOMO RUBBER IND LTD

Negative electrode for lithium ion secondary battery, method for producing the same, lithium ion secondary battery and method for producing the same

InactiveUS20100009258A1Excellent cycle characteristicsElectrode manufacturing processesFinal product manufactureLithiumEthylene

A negative electrode for a lithium ion secondary battery, including: a negative electrode material mixture including an active material powder capable of reversibly absorbing and desorbing lithium, and a binder, wherein the active material includes at least one element selected from the group consisting of Si and Sn, and the binder includes at least one selected from the group consisting of an ethylene-acrylic acid copolymer and an ethylene-methacrylic acid copolymer.

Owner:PANASONIC CORP

Flame Retardant Polycarbonate Resin Composition and Molded Product Made Using the Same

A flame retardant polycarbonate resin composition that can have excellent scratch resistance and impact resistance includes: (A) about 10 to about 89 wt % of a polycarbonate resin; (B) about 10 to about 89 wt % of a polycarbonate-polysiloxane copolymer; (C) about 1 to about 70 wt % of a modified (meth)acrylic copolymer resin; and (D) about 1 to about 50 parts by weight of a phosphorus-based flame retardant, based on about 100 parts by weight of components (A)+(B)+(C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Reactive hot melt adhesive

The invention is a reactive hot melt composition which has excellent adhesion and curing properties, and can be formulated into free-flowing pellets or beads, by using an ethylene-acrylic acid copolymer, and athylene-methacrylic acid copolymer, and / or an ethylene-acrylic acid methacrylic acid terpolymer as a component of the composition along with free radical crosslinking initiators. The incorporation of a foaming agent enables the production of compositions which are useful in space-filling applications, (i.e., as so-called "anti-flutter" compositions).

Owner:DOW GLOBAL TECH LLC +1

Aqueous primer surfacer compositions

ActiveUS20060003166A1Fast curingEarly assembly stabilitySynthetic resin layered productsPretreated surfacesEpoxyMeth-

The invention relates to aqueous coating compositions for producing primer and / or filler layers in a multi-layer coating, in particular in vehicle coating, comprising the following components: A) at least one water-dilutable epoxy resin, B) at least one polyamine curing agent, C) optionally, at least one water-dilutable polyurethane resin, D) water and E) optionally, pigments, fillers, conventional paint additives and / or organic solvents, wherein the polyamine curing agent B) comprises: B1) 5-95% by weight of at least one amino functional compound with at least two secondary and / or primary amino groups and B2) 95-5% by weight of at least one water-dilutable (meth)acrylic copolymer, wherein the percentages by weight of components B1) and B2) are based on the solids and add up to 100% by weight.

Owner:AXALTA COATING SYST IP CO LLC

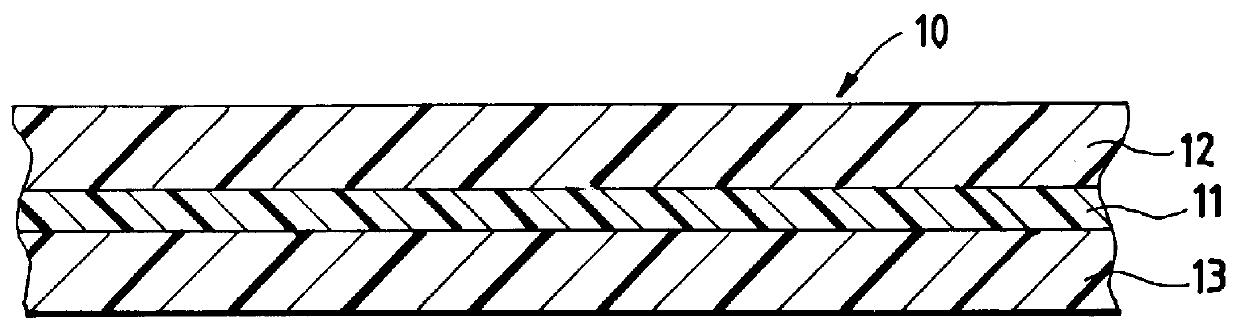

Ethylene acid copolymer with enhanced adhesion

InactiveUS6500556B1Improve adhesionMonocarboxylic acid ester polymer adhesivesSynthetic resin layered productsPolymer scienceMetal foil

The present invention relates to an adhesive useful as a tie layer between a metal foil and polyethylene film that is a blend of two ethylene acrylic or methacrylic acid copolymers, one having a high-acid and a high-melt index and the other having a lower acid content and a lower melt index.

Owner:PERFORMANCE MATERIALS NA INC

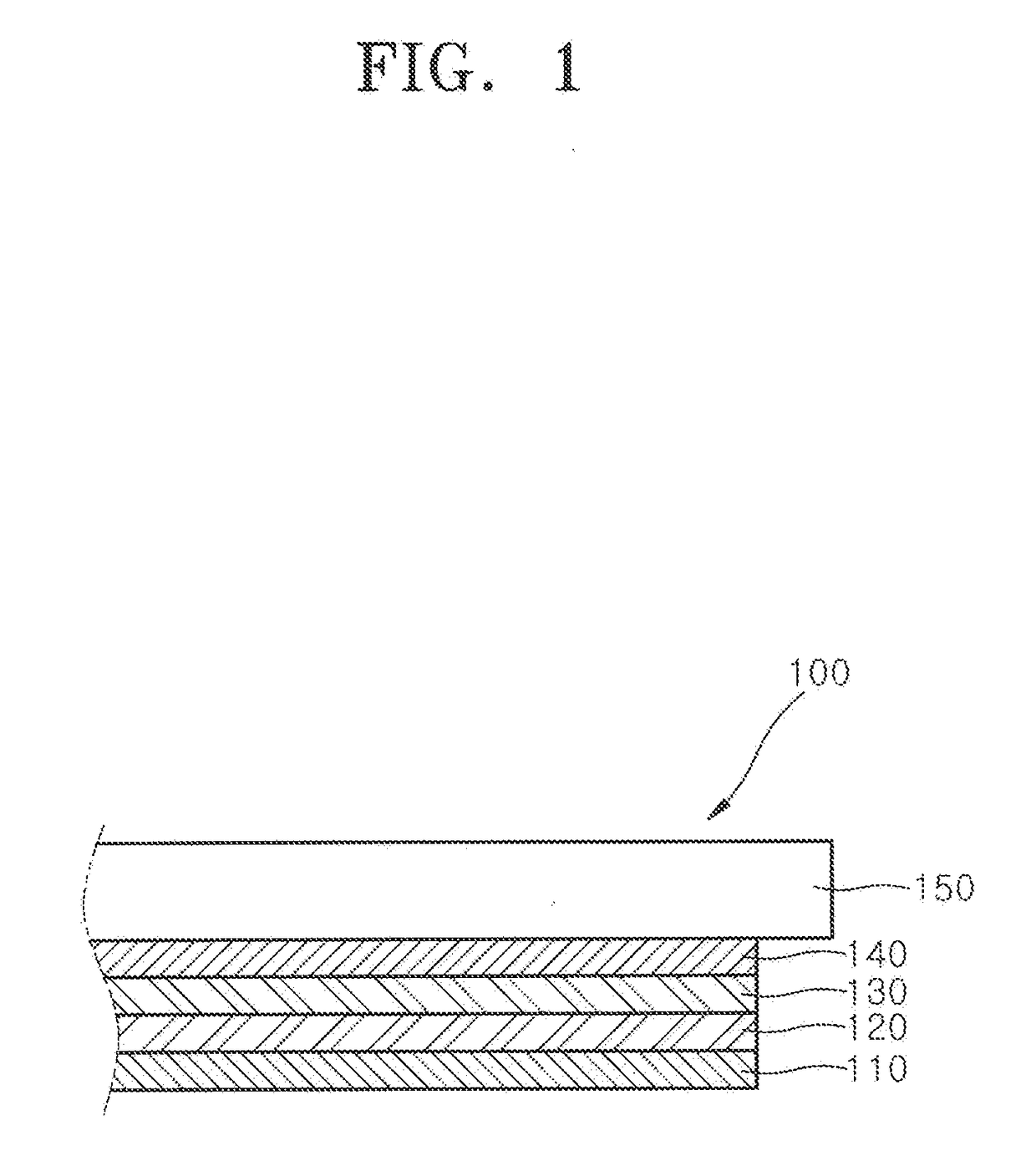

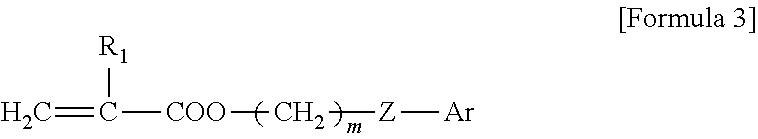

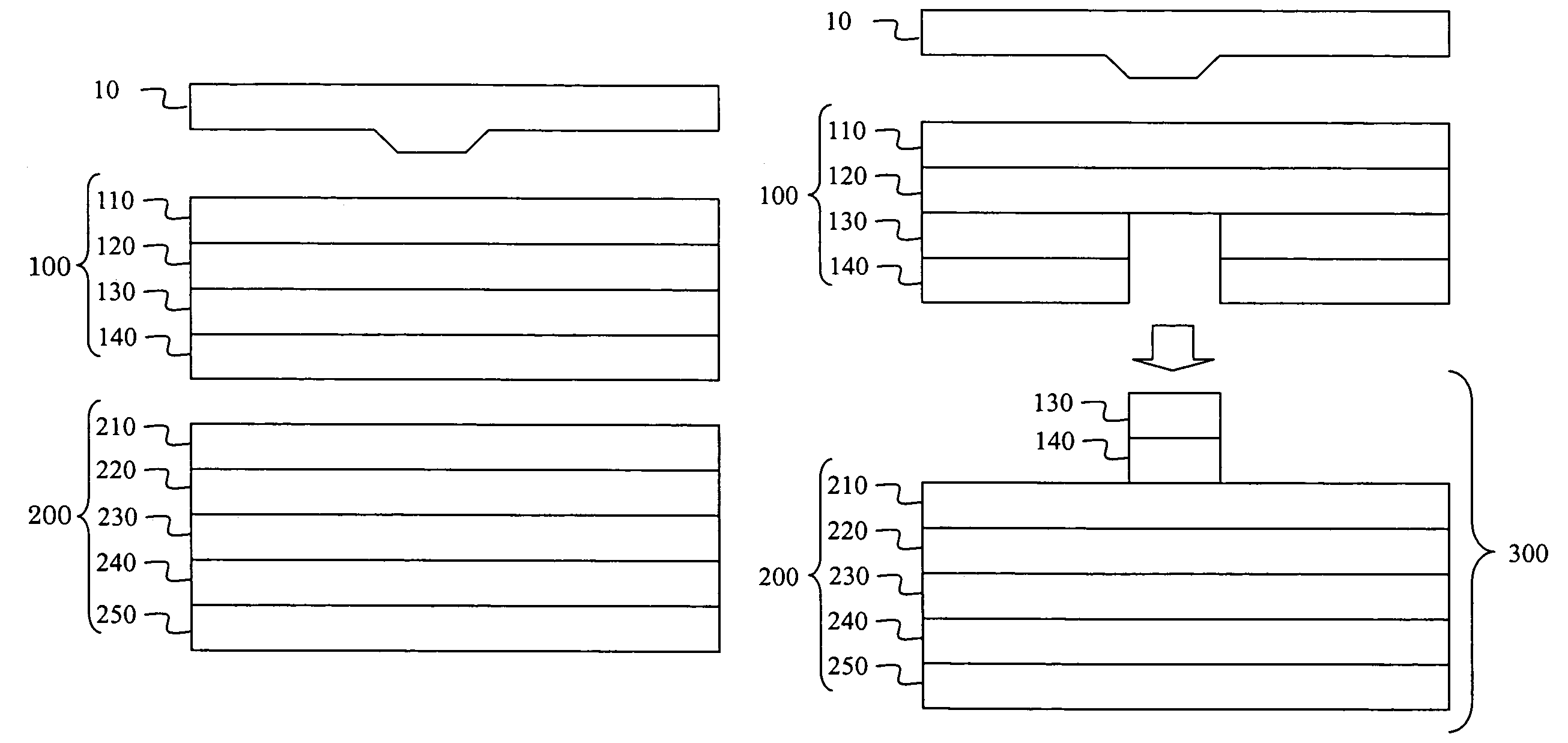

Adhesive film, optical member comprising the same and optical display comprising the same

PendingUS20170306194A1Synthetic resin layered productsCellulosic plastic layered productsVitrificationMeth-

An adhesive film, an optical member including the same, and an optical display including the same are provided. An adhesive film includes a (meth)acrylic copolymer including a hydroxyl group and formed of a monomer mixture including a hydroxyl group-containing (meth)acrylate and an alkyl group-containing (meth)acrylate. The adhesive film has a glass transition temperature of about −35° C. or less and allows about 50,000 cycles or more of bending before delamination between the adhesive film and a PET film, cracking, or bubble generation occurs in a specimen as described herein.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Reactive hot melt adhesive

ActiveUS7271202B2Excellent adhesion and curing propertyImprove adhesionAbsorbent padsBaby linensFoaming agentHot melt

The invention is a reactive hot melt composition which has excellent adhesion and curing properties, and can be formulated into free-flowing pellets or beads, by using an ethylene-acrylic acid copolymer, and athylene-methacrylic acid copolymer, and / or an ethylene-acrylic acid methacrylic acid terpolymer as a component of the composition along with free radical crosslinking initiators. The incorporation of a foaming agent enables the production of compositions which are useful in space-filling applications, (i.e., as so-called “anti-flutter” compositions).

Owner:DOW GLOBAL TECH LLC +1

High-temperature-resistant soft double-shield instrument cable for maritime oil and gas engineering and manufacturing method thereof

InactiveCN102969043AImprove high temperature resistanceImprove aging resistanceFlexible cablesCable/conductor manufactureCopper conductorCross-link

The invention relates to a high-temperature-resistant soft double-shield instrument cable for maritime oil and gas engineering and a manufacturing method thereof. The cable is characterized in that a chemical cross-linked polyolefin insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form a power cable insulation wire core; every two insulation wire cores are stranded, and then wrapped with a wire core copper foil polyester composite tape shielding layer and a wire core polyester tape, and then the insulation wire cores are stranded to form a cable core; and the periphery of the cable core is successively provided with an extruded cable core copper foil polyester tape and cable core polyester tape, an extruded inner sheath, a clad copper alloy wire weaving armor layer, a wrapped water-proof wrapping tape, and an extruded outer sheath. The insulation layer comprises the following raw material components: 12 parts of ethylene / vinyl acetate copolymer, 6 parts of high density polyethylene, 2 parts of ethylene-methacrylic acid copolymer, 0.5-1 part of cross-linking agent DCP (Dicumyl Peroxide), 0.4-0.9 part of antioxidant 1076, 0.2-0.4 part of antioxidant DNP, 0.2-1 part of lubricant stearic acid, 25-30 parts of aluminum hydroxide, 0.6-1 part of red phosphorus; and 0.05-0.1 part of ultraviolet ray absorber UV-326. The insulation layer of the cable is excellent in high-temperature resistance and ageing resistance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

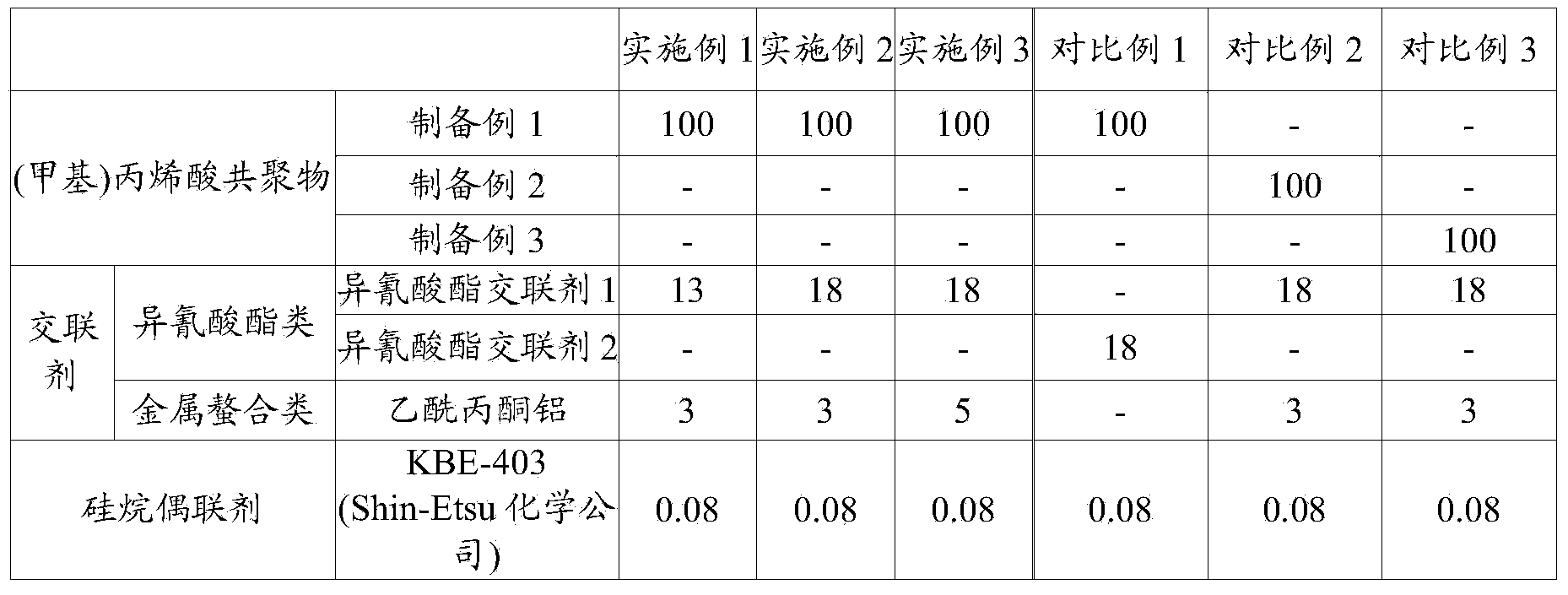

Adhesive film for polarizing plate, polarizing plate and optical display

An adhesive film for a polarizing plate is disclosed. The adhesive film includes a cured product of a composition including a (meth)acrylic copolymer and a cross-linking agent, and has a peel strength ratio of about 6 or more, as represented by Equation 1. An adhesive composition for the adhesive film, a polarizing plate including the adhesive film, and an optical display including the adhesive film are also described.

Owner:CHEIL IND INC

Pharmaceutical compositions of duloxetine

The present invention relates to solid oral pharmaceutical compositions of duloxetine, process for preparing such compositions and method of using such compositions. Preferably, the invention relates to a delayed release composition of duloxetine comprising a core comprising duloxetine, optional separating coat and an enteric coat, wherein the enteric coat comprises methacrylic acid copolymer.

Owner:TORRENT PHARMA LTD

Thermoplastic resin composition and molded products thereof

ActiveUS20140371375A1Maintain good propertiesImprove impact resistanceOrganic dyesHeat resistanceRefractive index

A thermoplastic resin composition according to the present invention is characterized by comprising: (A) a polycarbonate resin; and (B) a biphenyl group-containing (meth)acrylic copolymer. As such, the refractive index of the biphenyl group-containing (meth)acrylic copolymer (B) can be approximately from 1.495 to 1.640. The thermoplastic resin composition exhibits superior balance of material properties such as impact strength, internal scratch resistance, transparency, thermal resistance and appearance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Thermal transfer recording medium, method of recording same, recorded medium and recorded label

ActiveUS7081284B2Improved chemical solvent resistanceGood solvent resistanceStampsInk ribbonsWaxDiol

A thermal transfer recording medium is provided wherein the thermal transfer recording medium has a substrate; a separation layer on the substrate, wherein the separation layer contains a resin and a wax; and an ink layer on the separation layer, wherein the ink layer contains a colorant and a metal salt of an ethylene-methacrylic acid copolymer, and, optionally, one or more diols or diol derivatives containing an acetylene group, a thermal transfer recording method using the medium, and a recorded medium and recorded label prepared therefrom.

Owner:RICOH KK

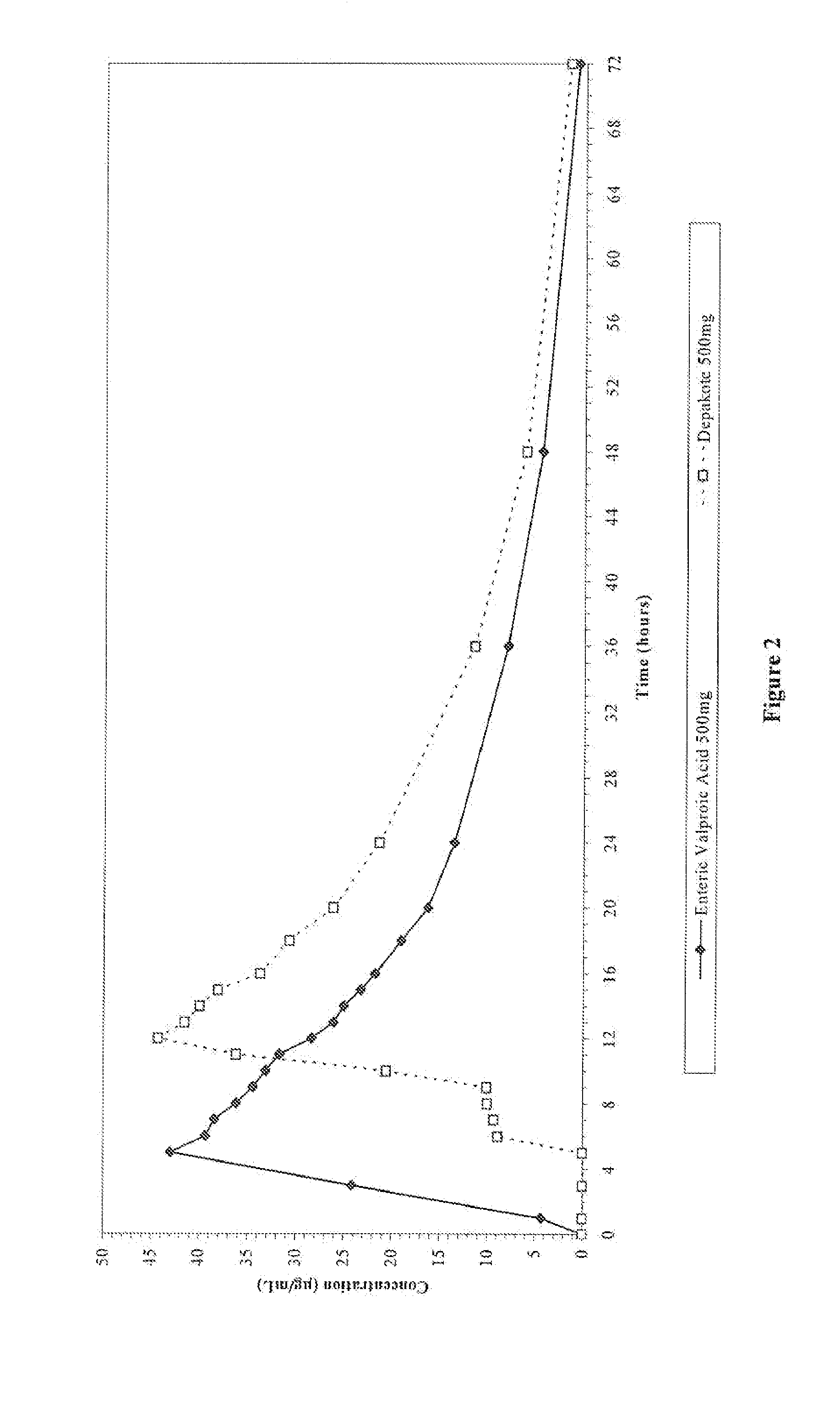

Enteric valproic acid

An enteric valproic acid soft gelatin capsule, in which the enteric polymer is a component of the capsule shell rather than a coating, has been developed. The fill material comprises valproic acid or divalproex sodium and, optionally, one or more pharmaceutically acceptable excipients such as corn oil. The capsule shell is prepared from a mass comprising a film-forming polymer, an acid insoluble polymer, an aqueous solvent, and optionally a plasticizer. Suitable film-forming polymers include gelatin. Suitable acid-insoluble polymers include acrylic-acid / methacrylic acid copolymers. The acid-insoluble polymer is present in an amount from about 8% to about 20% by weight of the wet gel mass. The weight ratio of acid-insoluble polymer to film-forming polymer is from about 25% to about 50%. The aqueous solvent is water or an aqueous solution of alkalis such as ammonia or diethylene amine or hydroalcoholic solutions of the same. Suitable plasticizers include glycerin and triethylcitrate. The enteric soft gelatin capsule does not require an enteric coating and thus is not susceptible to the processing problems associated with enteric coated dosage forms. Enteric valproic acid soft gelatin capsules may be smaller in size and thus easier to swallow than currently available enteric coated tablets due to the presence of fewer ingredients, as well as smaller amounts of ingredients in the capsule shell.

Owner:PATHEON SOFTGELS INC

Duloxetine hydrochloride delayed release formulations

Delayed release formulations of duloxetine hydrochloride and methods for its manufacture are described. A preferred formulation includes an inert core, a drug layer comprising duloxetine hydrochloride, a separating layer and an enteric layer comprising at least one of methacrylic acid copolymer and hydroxypropyl methyl cellulose phthalate.

Owner:TEVA PHARM USA INC

Coating compositions and process for the production of multilayer coatings

An aqueous coating composition, comprising A) at least one water-dilutable hydroxy-functional binder and B) at least one polyisocyanate crosslinking agent with free isocyanate groups, wherein component A) comprises A1) 40-95 wt. % of at least one water-dilutable hydroxy-functional (meth)acrylic copolymer with a hydroxyl value of 60-250 mg of KOH / g and an acid value of 5-50 mg of KOH / g, which is obtained by free-radical copolymerization performed in a non-aqueous phase, wherein the ratio of primary hydroxyl groups to secondary hydroxyl groups in the (meth)acrylate copolymer A1) is 1:0.1 to 1:1.2 and at least 80% of the secondary hydroxyl groups result from reaction products of a monoepoxy ester and an unsaturated acid-functional monomer, and A2) 5-60 wt. % of at least one water-dilutable polyester oligomer, wherein the total of the weight percentages of component A1) and A2) add up to 100 wt. % and wherein the free-radical polymerization for the production of component A1) is performed at least in part in the presence of component A2) and / or wherein component A2) is added during polymerization or after completion of polymerization.

Owner:AXALTA COATING SYST IP CO LLC

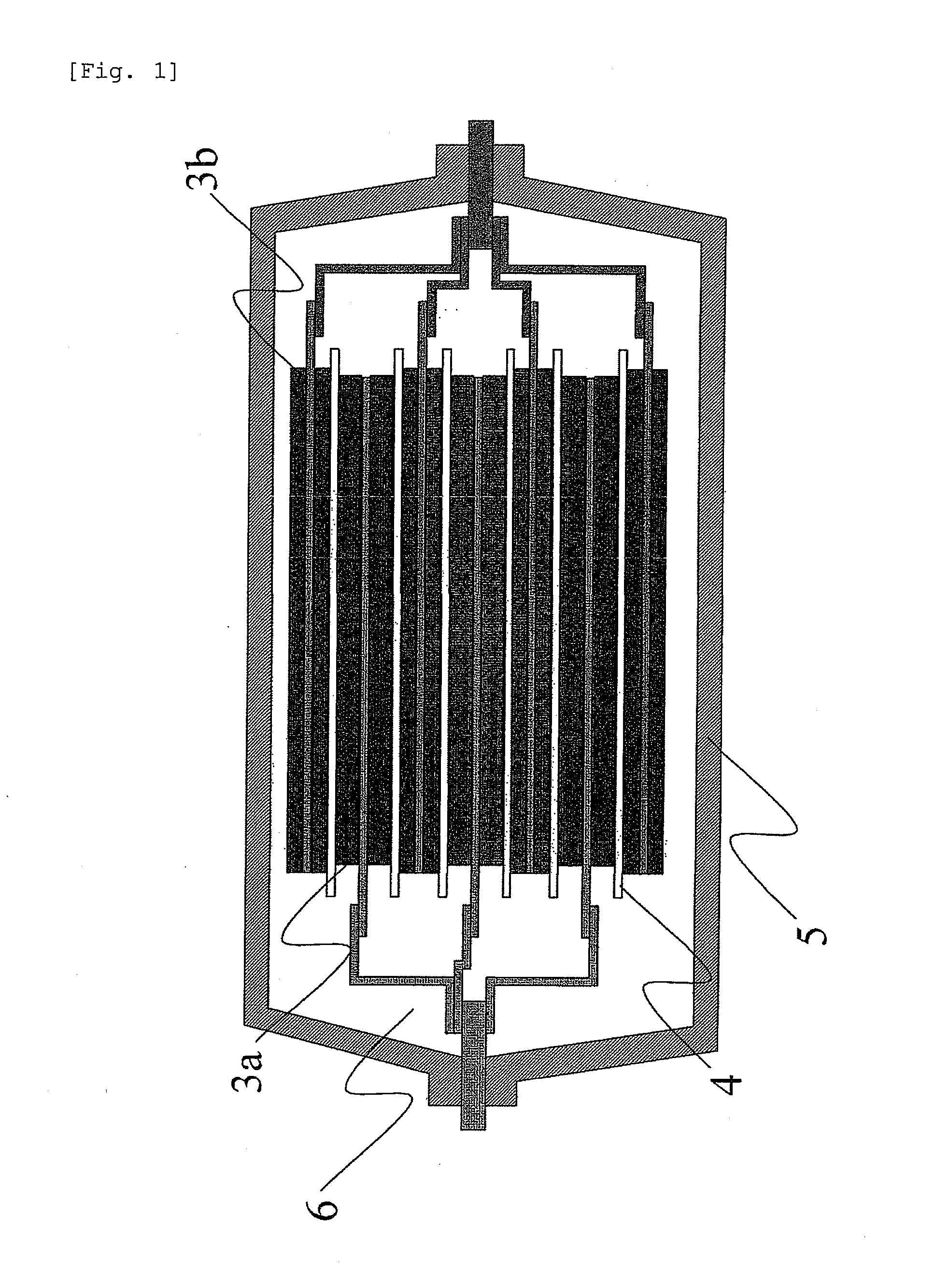

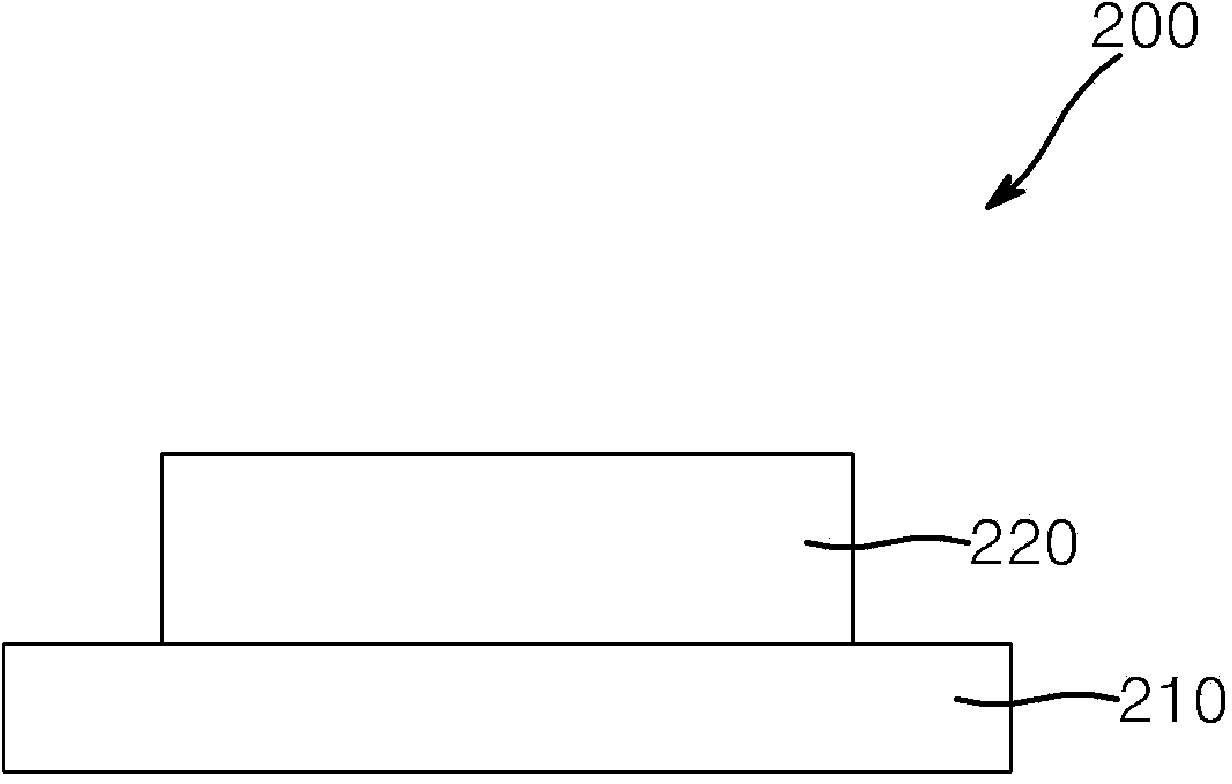

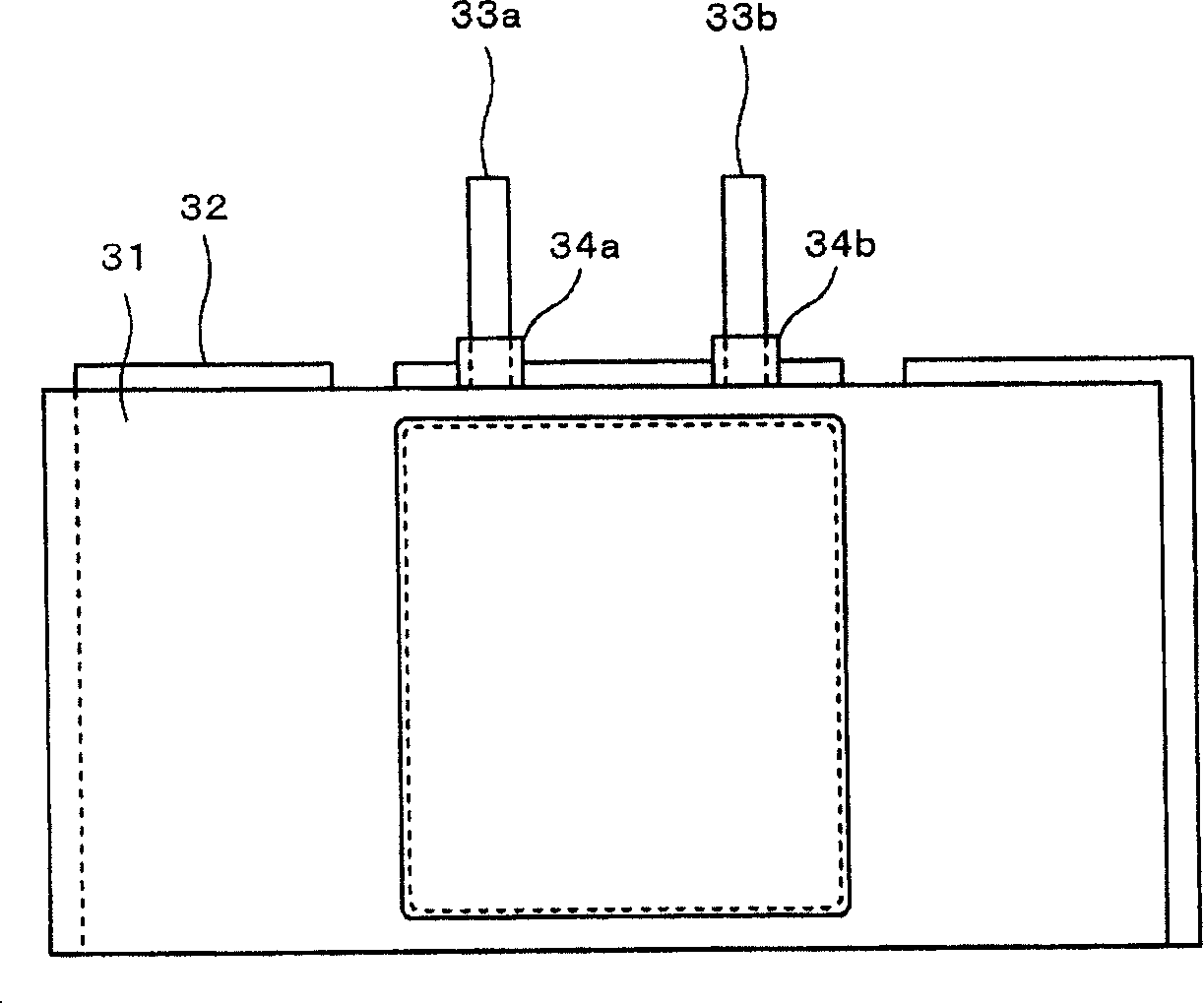

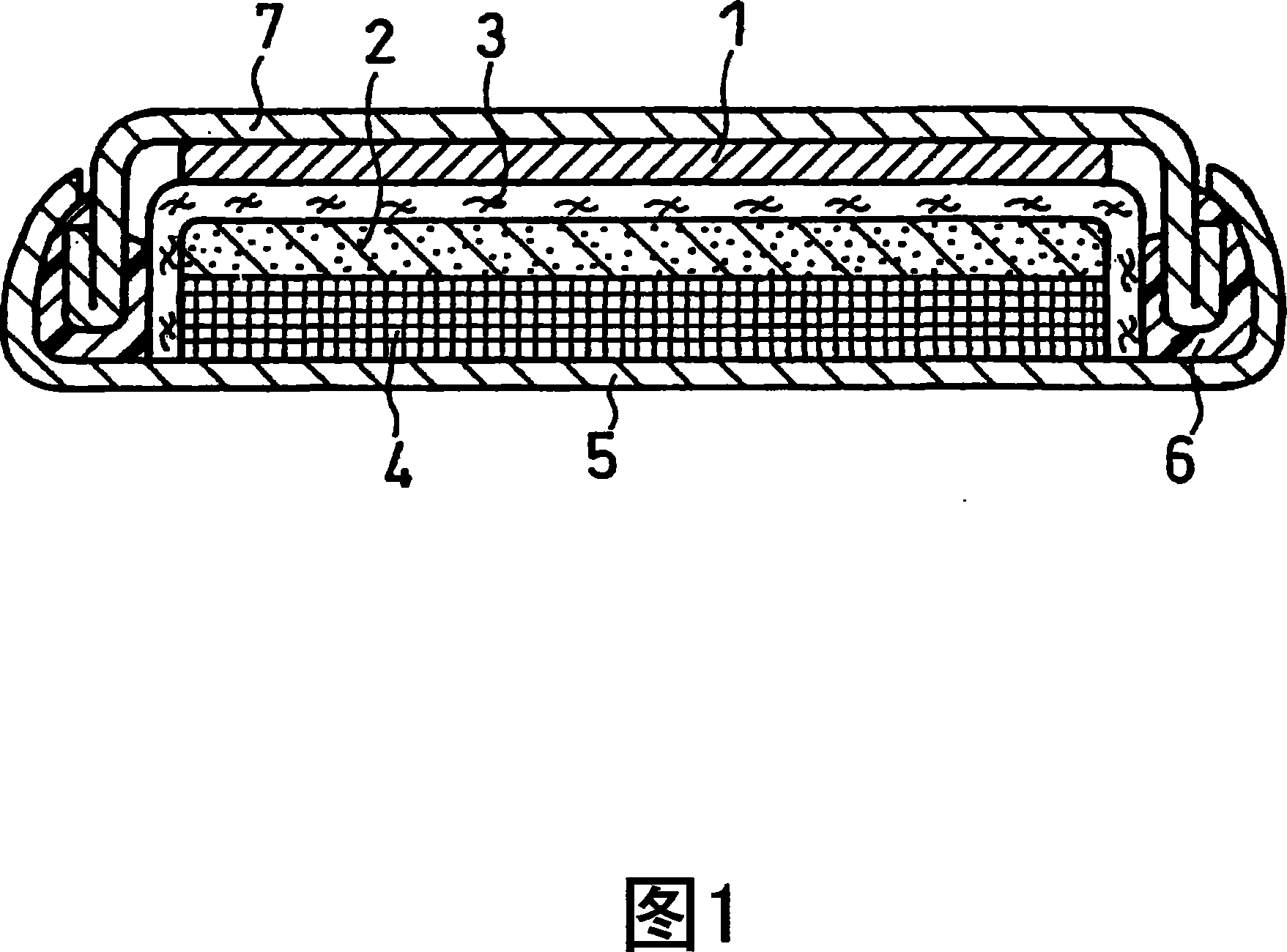

Battery pack

ActiveCN101197431AAdhesiveExcellent adhesionSmall-sized cells cases/jacketsWound/folded electrode electrodesEngineeringCarvacryl acetate

A battery pack is provided. The battery pack includes: a generator device having a battery element disposed on a flexible covering material folded to cover the battery element, wherein three sides of the flexible covering material around the battery element are sealed; a rigid covering material for covering the generator device, having an opening and being bonded to the flexible covering material of the generator device; and a cover fitted into the opening of the rigid covering material, wherein the rigid covering material has a three-layer structure having an outer packaging layer, a metal layer, and a heat-bonding layer which are stacked on one another, and the heat-bonding layer is one selected from an ethylene-vinyl acetate copolymer, an ethylene-acrylic acid copolymer, an ethyl acrylate copolymer, a methyl acrylate copolymer, a methacrylic acid copolymer, a methyl methacrylate copolymer, polyacrylonitrile, an ethylene vinyl alcohol resin, a polyamide resin, a polyester resin, acid-modified polypropylene, or an ionomer.

Owner:MURATA MFG CO LTD

Adhesive composition, optical member, surface protective film, and adhesive sheet

The present invention provides an adhesive composition, an optical member, a surface protective film, and an adhesive sheet, wherein the adhesive composition includes 100 parts by weight of a (meth)acrylic copolymer having a weight average molecular weight of about 100,000 to about 2,000,000 g / mol; about 0.01 to about 5 parts by weight of a peroxide crosslinking agent; and about 0.001 to about 5 parts by weight of a carbodiimide.

Owner:CHEIL IND INC

Preparation method for acrylonitrile/methacrylic acid copolymer foamed plastic

The invention discloses a preparation method for acrylonitrile / methacrylic acid copolymer foamed plastic. The preparation method comprises the following steps: adding deionized water, a suspending agent and an aqueous phase inhibitor into a reactor, and uniformly agitating; uniformly mixing monosomic acrylonitrile, methacrylic acid and an initiator, adding the mixture into the reactor, agitating the mixture at the room temperature so as to obtain a stable suspension, rising the temperature to a reaction temperature, and performing free radical suspension polymerization under the condition of agitation; drying a slurry-shaped mixture obtained after the reaction; uniformly mixing copolymer powder, a carbamide foaming agent and a bismaleimide (BMI) crosslinking agent which are obtained after drying; performing hot-pressing foaming formation of the mixture, and otaining polymethacrylimide foamed plastic via heat treatment. The technical scheme provided by the invention is high in production efficiency and yield, can obtain a product with stable performance, is simple and convenient to operate and environmental-friendly, and realizes a beneficial implement effect.

Owner:HAOBO FUJIAN NEW MATERIAL TECH

Coating agent, the manufacture and uses thereof

InactiveUS6200639B1High hardnessImprove application reliabilityPretreated surfacesPolyester coatingsPolyesterMeth-

Coating composition suitable for multi-layer lacquerings, with a binder composition which comprises: A) 25 to 75 wt. % of carboxyl-functional (meth)acrylic copolymers and / or carboxyl-functional polyesters, the carboxyl functionality of which corresponds to an acid number of 15 to 300 mg KOH / g, B) 25 to 75 wt. % of epoxide-functionalized crosslinker resins, at least one of which is a (meth)acrylic copolymer which has been prepared co-using tert-butyl (meth)acrylate, C) 0 to 50 wt. % of polyols which have at least two hydroxyl functions in the molecule, D) 0 to 40 wt. % of components which crosslink with hydroxyl groups to form ethers, and / or of a crosslinking agent based on triazine, E) 0 to 40 wt. % of polyisocyanates, F) 0 to 50 wt. % of at least one organic polyanhydride with at least two cyclic carboxylic acid anhydride groups per molecule, G) 0 to 20 wt. % of reactive thinners with an epoxide function, H) 0 to 10 wt. % of one or more catalysts for the reaction of carboxyl and epoxide groups.

Owner:HERBERTS GMBH

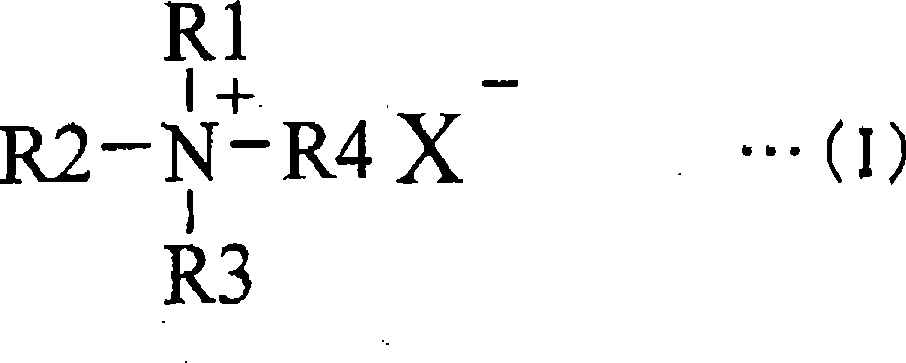

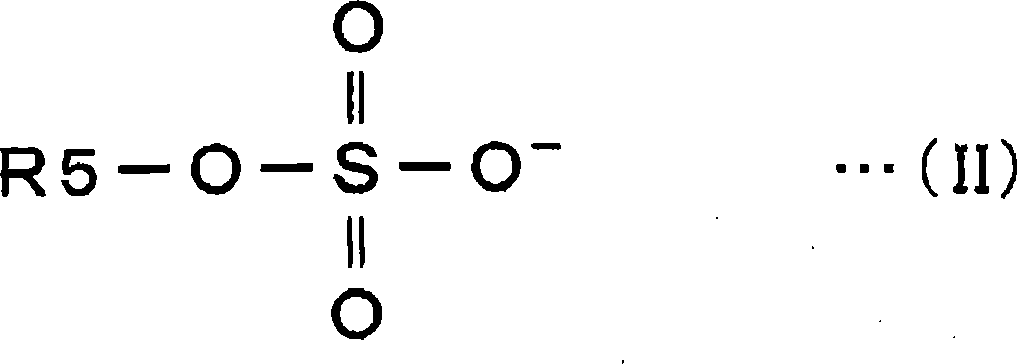

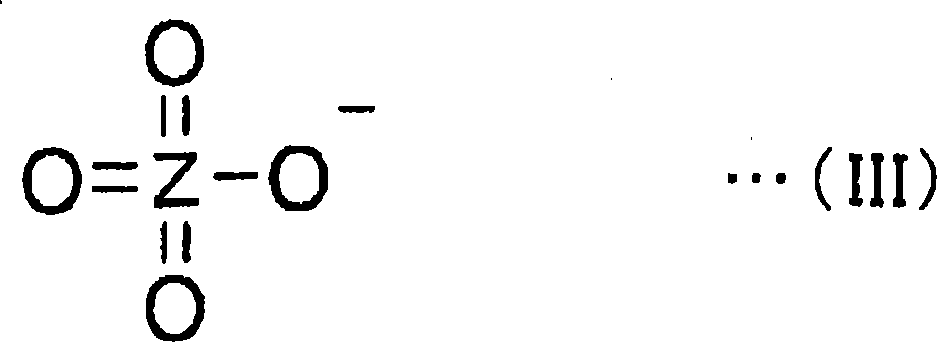

Antistatic agent composition

InactiveCN101089112AIncreased durabilityHigh color fastnessOther chemical processesOptical elementsEpoxyChemical structure

The present invention provides an antistatic agent composition which attains sufficient antistatic properties and also has antistatic properties having excellent durability against high temperature, high humidity and ultraviolet irradiation. The antistatic agent composition of the present invention comprises a water-soluble resin having a carboxyl group, a crosslinking agent having a functional group capable of reacting with a carboxyl group, and an ammonium salt having a specific chemical structure. One or more crosslinking agents selected from a carbodiimide resin, an epoxy resin, an isocyanate resin and a zirconium salt are preferably used as the crosslinking agent. At least one kind of a water-soluble resin selected from the group consisting of polyacrylic acid and an acrylic acid-methacrylic acid copolymer is preferably used as the water-soluble resin.

Owner:SUMITOMO CHEM CO LTD

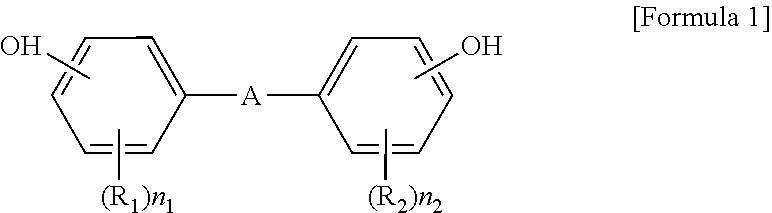

Methacrylic Copolymer, Method for Preparing the Same, and Methacrylic Resin Composition Including the Same

InactiveUS20100197850A1High refractive indexGood compatibilityOrganic dyesPolycarbonatePolymer chemistry

Disclosed herein is a methacrylic copolymer which is a polymer of a monomer mixture comprising about 20 to about 99.9% by weight of a C6-20 aromatic methacrylate, an aliphatic methacrylate, or a combination thereof, and about 0.1 to about 80% by weight of a mono-functional unsaturated monomer. The methacrylic copolymer can have a high refractive index of about 1.495 to about 1.59, and thus when it is blended with polycarbonate resin, it is possible to obtain a methacrylic resin composition having improved compatibility without any other compatibilizer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Coating material, protective coating and construction method of protective coating

InactiveCN106752410AImprove insulation effectImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsThermoplasticFoaming agent

The invention provides a coating material, a protective coating and a construction method of the protective coating, which relate to the field of anticorrosion and heat insulation. The coating material is prepared from the following raw materials: 100 to 500 parts of base material, 1 to 50 parts of foaming agent and 2 to 200 parts of additive. The base material comprises one or more of thermosetting plastic, thermoplastic plastic and rubber. The additive comprises an inorganic and / or organic additive(s); the organic additive comprises an ethylene-methacrylic acid copolymer and / or an ethylene-acrylic copolymer; the inorganic additive comprises one or more of TiO2, silicon-based oxide and Al2O3. With the additive and the foaming agent, the coating material has an anticorrosion function and a heat insulation function at the same time. The construction method of the protective coating comprises the steps of distributing a mixture, formed by mixing the base material, the foaming agent and the additive, onto a substrate material to be protected, foaming, and forming the protective coating on the substrate material. The protective coating has a certain thickness so as to achieve better anticorrosion and heat insulation effects on the substrate material.

Owner:河南中和信建筑安装有限公司

Method for preparing polymer retanning fat-liquoring agent and retanning fat-liquoring agent

InactiveCN101831024AMeet the protection requirementsWith retanningTanning treatmentLeather impregnationOrganic solventSodium methacrylate

The invention discloses a method for preparing a polymer retanning fat-liquoring agent and the retanning fat-liquoring agent. The preparation method comprises the following steps of: preparing long-chain fatty alcohol maleic acid monoester by adopting C8-C18 long-chain fatty alcohol and maleic anhydride, preparing the long-chain fatty alcohol maleic acid monoester into long-chain fatty alcohol maleic acid monoester salt, and then dripping methacrylic acid octadecyl ester, aqueous solution of sodium methacrylate and aqueous solution of initiator into the long-chain fatty alcohol maleic acid monoester salt to perform aqueous emulsion copolymerization to form the polymer retanning fat-liquoring agent. The polymer retanning fat-liquoring agent contains terpolymer of the methacrylic acid octadecyl ester, the long-chain fatty alcohol maleic acid monoester and the methacrylic acid. The preparation method saves an organic solvent during synthesizing the retanning fat-liquoring agent so as to reduce environmental pollution, and meanwhile overcomes the defect of insufficient fat-liquoring performance of a long-chain fatty alcohol maleic acid monoester and methacrylic acid copolymer by introducing oleophilic methacrylic acid octadecyl ester monomer into the polymer.

Owner:甘肃宏良皮业股份有限公司

Negative electrode for lithium ion secondary battery, process for producing the same, lithium ion secondary battery and process for producing the same

InactiveCN101103475AExcellent cycle characteristicsElectrode manufacturing processesFinal product manufactureLithiumEthylene

A negative electrode for lithium ion secondary battery, comprising a negative electrode mixture containing a powdery active material capable of reversible lithium occlusion and release and a binding agent, wherein the active material contains at least one element selected from the group consisting of Si and Sn, and wherein the binding agent contains at least one member selected from the group consisting of an ethylene-acrylic acid copolymer and an ethylene-methacrylic acid copolymer.

Owner:PANASONIC CORP

Production method of ionic middle membrane laminated glass

InactiveCN103011624AWon't scatterDurableSynthetic resin layered productsGlass/slag layered productsShear modulusUltimate tensile strength

The invention discloses a production method of ionic middle membrane laminated glass. The method comprises the steps of earlier stage glass processing, glass lamination, and glass doping, an ionic middle membrane is an ethylene and methacrylic acid copolymer, about 1% of metal sodium ions contained are bonded with the glass by ionic bonds, the bonding strength is larger compared with the strength of PVB (Polyvinyl butyral), the shearing modulus is more than 50 times that of the PVB / PU (polyurethane), the tearing strength is 5 times higher than that of the PVB / PU, and the transparency is good.

Owner:SUZHOU SHINWU OPTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com