Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1316results about "Leather impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing detachable dirt- and water-repellent surface coatings

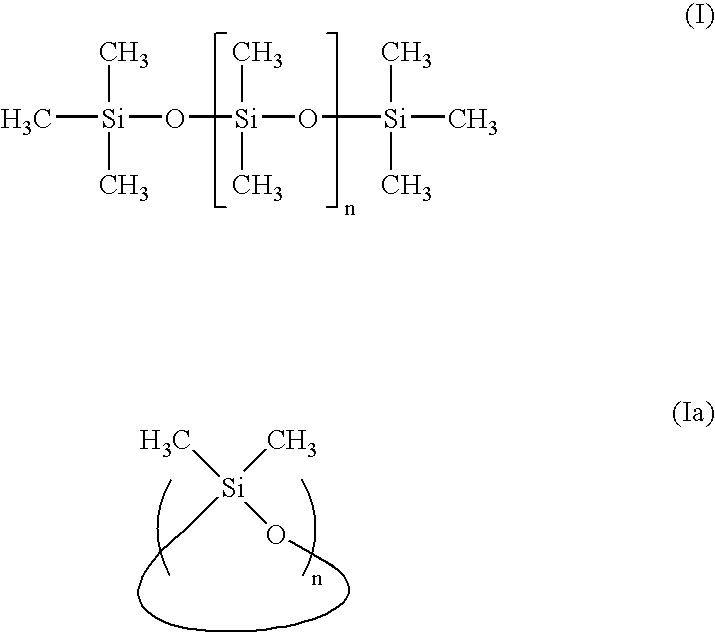

ActiveUS7083828B2Good removal effectSimple wayFouling preventionSolid waste managementWaxSurface structure

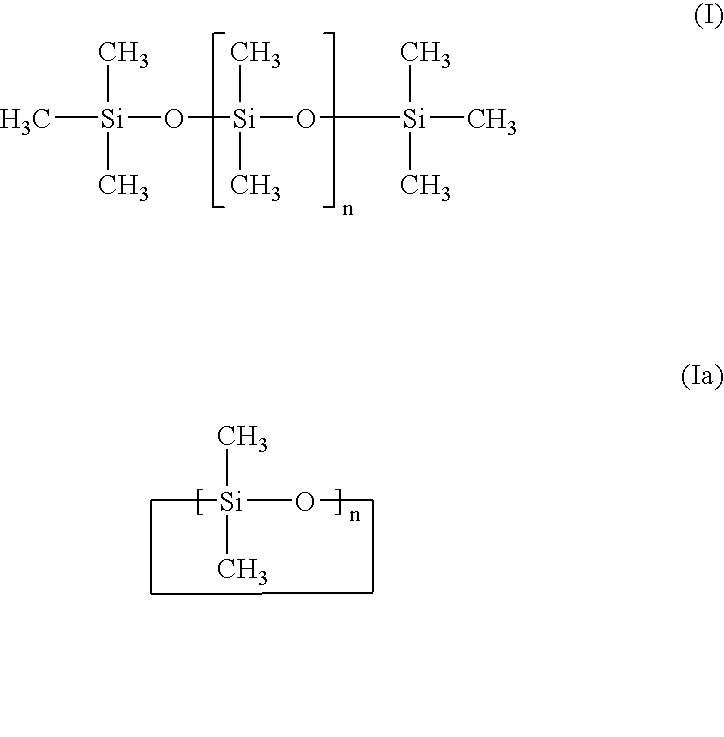

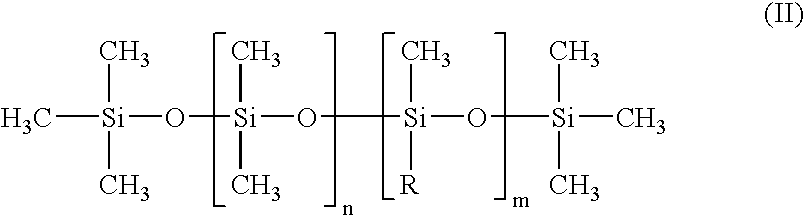

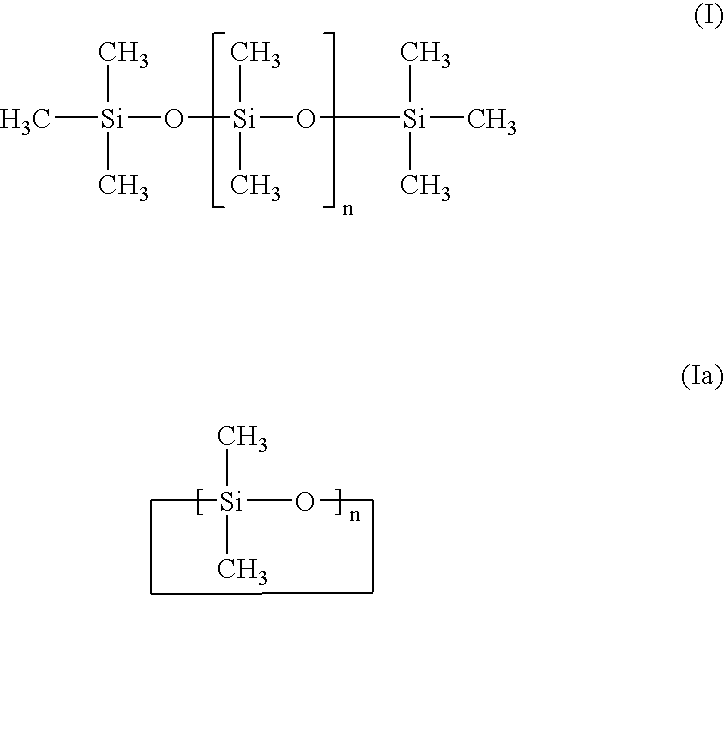

Process for producing detachable dirt- and water-repellent surface coatings on articles, wherein during the coating process, hydrophobic particles are applied to the surface of the articles, thus generating a surface structure with elevations on that surface of the articles that has dirt- and water-repellent properties, which comprises suspending the hydrophobic particles in a solution of a silicone wax in a highly volatile siloxane, and applying this suspension to at least one surface of an article, and then removing the highly volatile siloxane.

Owner:EVONIK DEGUSSA GMBH

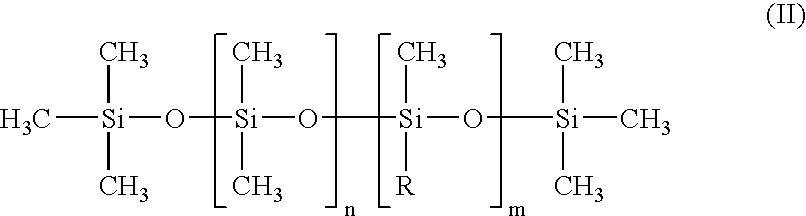

Compositions comprising anionic functionalized polyorganosiloxanes for hydrophobically modifying surfaces and enhancing delivery of active agents to surfaces treated therewith

InactiveUS7166235B2Highly effectiveEasy to cleanCosmetic preparationsImpression capsPersonal careActive agent

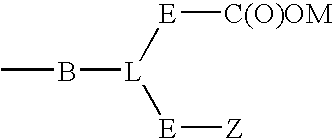

Disclosed are compositions and methods for treating and modifying surfaces and for enhancing delivery of active agents to surfaces treated therewith, wherein the compositions comprise siloxane polymers functionalized with pendant moieties comprising two or more anionic groups, at least one anionic group being a carboxy group. When applied to a suitable surface, the present composition forms a substantially hydrophobic coating of the anionic functionalized siloxane polymer on the treated surface. These polymers effectively deposit on surfaces that have cationic sites, which are capable of forming bonds or linkages with the anionic groups of the polymer. The treated surface becomes hydrophobic due to the deposition of the anionic functionalized siloxane polymer, which then imparts a variety of end use benefits to that surface such as ease of cleaning, soil release, stain removal and prevention, conditioning, etc. The anionic functionalized siloxane polymer further acts as a carrier to deposit active agents onto the surface and to improve retention and efficacy of the active agents on the treated surface. The present compositions are useful in a variety of applications including oral care, hair and skin care, personal care, cosmetics, and fabric and hard surface cleaning and conditioning.

Owner:THE PROCTER & GAMBLE COMPANY

Hydrocarbon extenders for surface effect compositions

Owner:THE CHEMOURS CO FC LLC

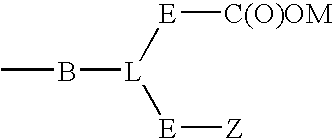

Engineered leather and methods of manufacture thereof

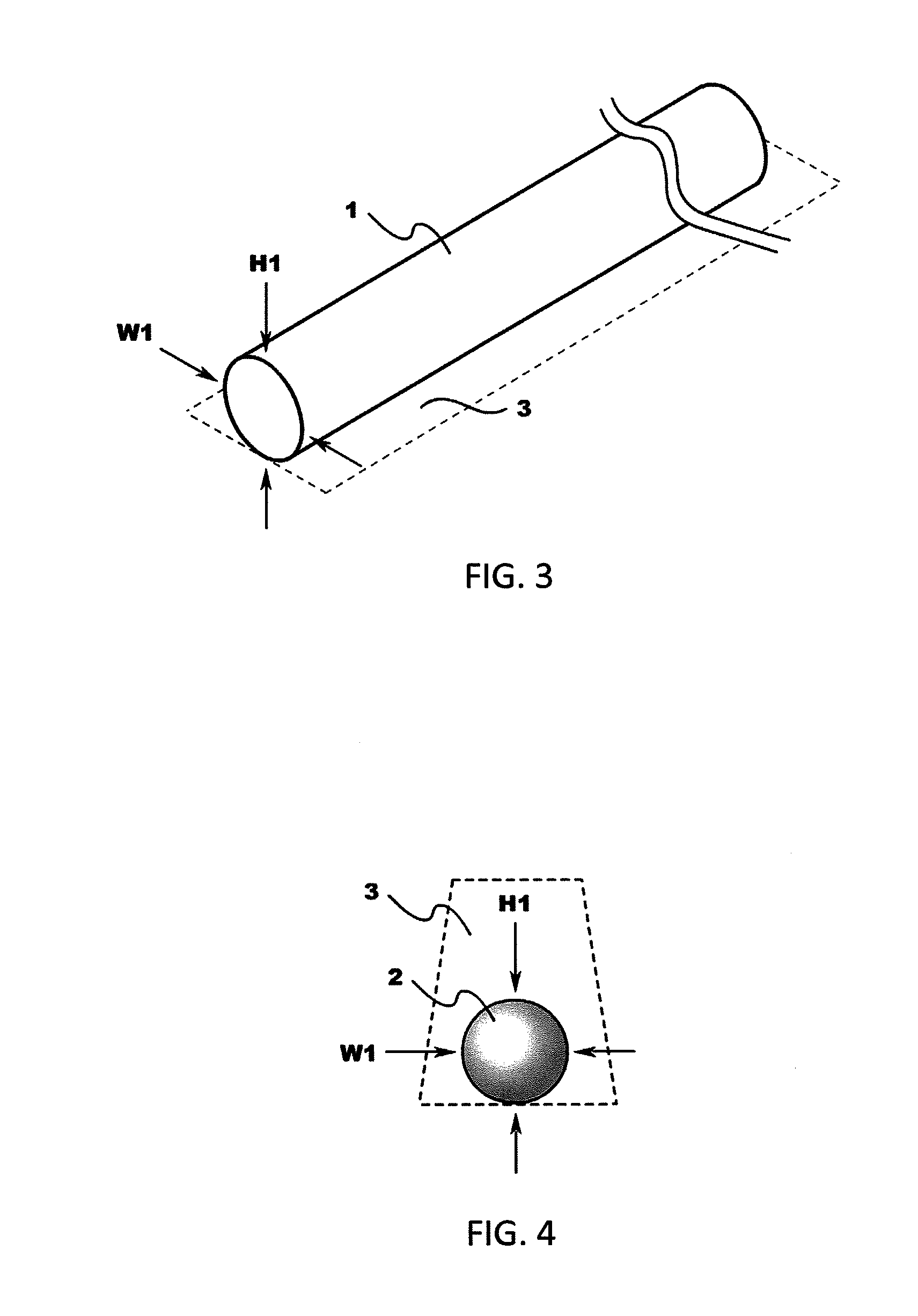

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Metal oxide dispersion

ActiveUS20050069648A1Low costLess resourcesMolten spray coatingPhotosensitive materialsDispersed mediaMaterials science

The present invention relates to a metal oxide dispersion, which can form a metal thin film onto a substrate by heat treatment at a low temperature, wherein a metal oxide having a particle diameter of less than 200 nm is dispersed in the dispersion medium. By heat treating the dispersion after applying it onto a substrate, a metal thin film is formed.

Owner:ASAHI KASEI KK

Photostable cationic organic sunscreen compounds and compositions obtained therefrom

InactiveUS6936735B2Stabilizing the sunscreen formulation against photodegradationImprove light resistanceCosmetic preparationsBiocidePhotochemistryPolymer

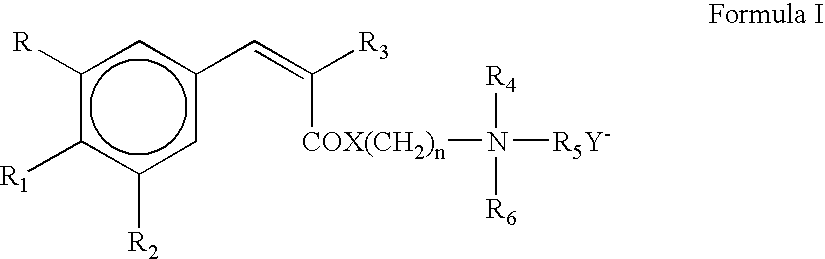

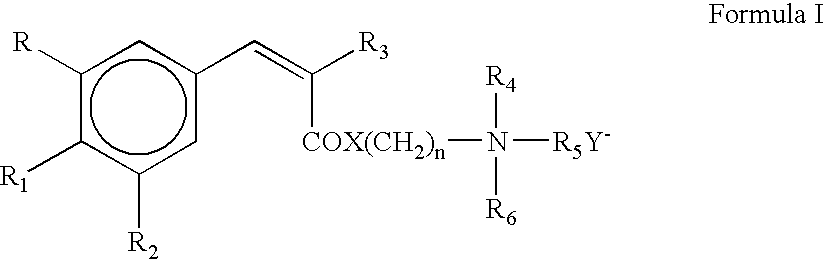

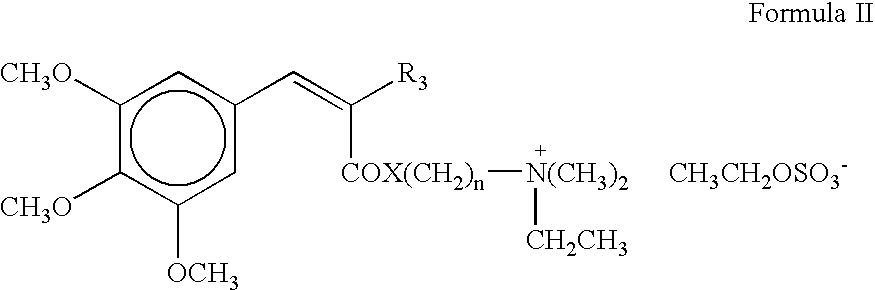

Compounds of Formula I: whereinR, R1 and R2 are each independently hydrogen or linear or branched C1 to C10 alkyl, or linear or branched C1 to C10 alkoxy;R3 is selected from the group consisting of COCH3, CO2R7, CONH2, CON(R8)2, CN, COX(CH2)n-N—(R4)(R5)(R6), and the quaternized salt form of the formula COX(CH2)n-N—(R4)(R5)(R6)+Y−;X is O or NH;n is an integer of 1 to 5;Y is an anion;R4, R5 and R6 are independently linear or branched C1 to C30 alkyl; andR7 and R8 are independently hydrogen or linear or branched C1-C30 alkyl.Sunscreen formulations containing compounds of Formula I, and methods for protecting hair, skin and substrates such as polymers, textiles, fabrics, leathers and paints using the compounds herein.

Owner:EMD CHEM

Production technology of cow skin nappa leather

ActiveCN105132596AUniform leatherImprove leather yieldLeather manufacturingTanning treatmentFiberManufacturing technology

The invention relates to the technical field of the leather manufacturing technology, and provides a production technology of cow skin nappa leather. A series of problems that due to the fact that the structure of the abdomen and the part between the ribs and the hips of the cow skin is thin and fiber is woven loosely, in the processing process, the part of the abdomen and the part between the ribs and the hips are prone to being excessively loose, the part deviation is large, and face loosening is likely to happen are solved through the production process of the cow nappa soft-face leather. The integral procedure of the technology is simple, easy to achieve, convenient to operate and practical. The grain on the abdomen and the part between the ribs and the hips is easy to open in the tan preprocessing working section of the cow skin through tanning preprocessing, retanning processing and post-tanning mechanical processing, and the whole skin body fiber is even and loose. Even and slow tanning is carried out in the tanning working section, step-by-step and multi-time even filling is carried out in the retanning working section, the whole cow skin leather is even and consistent in the manner that filling is conducted after loosening, the leather is soft but not loose, and the leather yield and the utilization rate of finished cow skin are greatly increased.

Owner:XINGYE LEATHER TECH CO LTD

Chrome-free tannage producing technique for goat glove leather

The invention relates to a processing technique of leather, in particular to a chrome-free tannage manufacturing technique of goat glove leather, aims at solving the problem of heavy environment pollution caused by the chrome sewage in the prior art of chrome tannage. The processing technique of leather adopts a technical proposal that the chrome-free tannage manufacturing technique of goat glove leather comprises a plurality of successively steps as followings: softening, dipping in acid, organophosphor tanning, oxidation, stacking, sammying and extension, shaving, washing, degreasing, rinse, washing, retanning and stuffing, washing, and routine following chrome tanning technique. The processing technique of leather has the advantages of eliminating the environment pollution caused by the heavy metal chrome, reducing the cost of sewage treatment, producing environment-friendly goat glove leather with soft, plumpy, highly resilient, and flowing hand feeling, smooth grain, brilliant color, qualified formaldehyde content as ecological leather, over 88 DEG C shrinkage temperature, and completely same mechanical property as routine chrome tannage leather.

Owner:HAINING SHANGYUAN LEATHER

Methods and compositions for improving light-fade resistance and soil repellency of textiles and leathers

ActiveUS20050022313A1Easy to useImpart propertyDispersed particle filtrationPhysical treatmentAdditive ingredientChemical compound

One method includes applying to a post-manufactured textile material a liquid composition resulting from a combination of ingredients. The ingredients include one or more anti-fading compounds, one or more anti-soiling compounds, one or more silicon-based compounds, and one or more carrying media. One composition is a liquid composition resulting from a combination of ingredients, with the ingredients including a benzotriazole, a fluorocarbon, an organosiloxane, and odorless mineral spirits.

Owner:SCHEIDLER KARL J

Hydrocarbon extenders for surface effect compositions

ActiveUS20060052556A1Comparable and superior durabilityFibre treatmentPaper coatingPolymer scienceMonomer

A polymer extender composition for use with fluorochemical repellents, said composition comprising monomers copolymerized in the following percentages by weight: (a) from about 60% to about 94% of a monomer, or mixture of monomers, of the formula I: [CH3—(CH2)p][CH3(CH2)n]CHCH2—OC(O)—C(R)═CH2 (I), and (b) from about 5% to about 20% of a monomer, or mixture of monomers, of the formula II: H—(OCH2CH2)m—O—C(O)—C(R)═CH2 (II) wherein each R is independently H or CH3; n is 1 to 10; p is 1 to 20 and m is 2 to 10 is disclosed.

Owner:THE CHEMOURS CO FC LLC

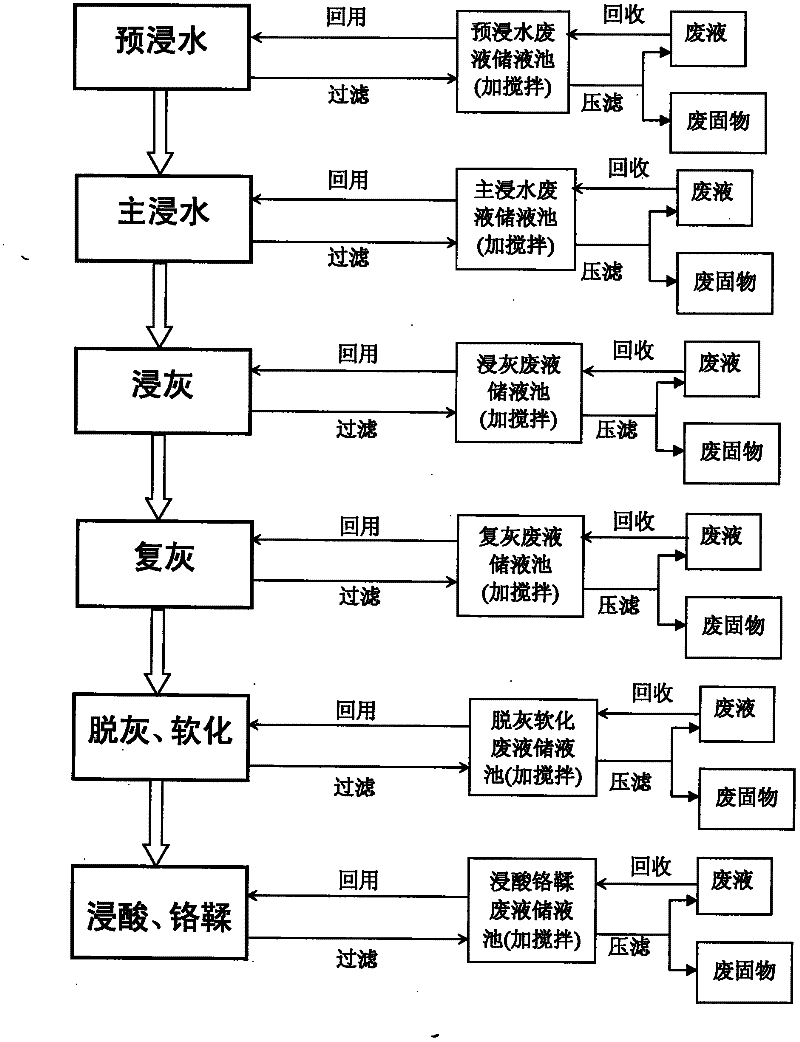

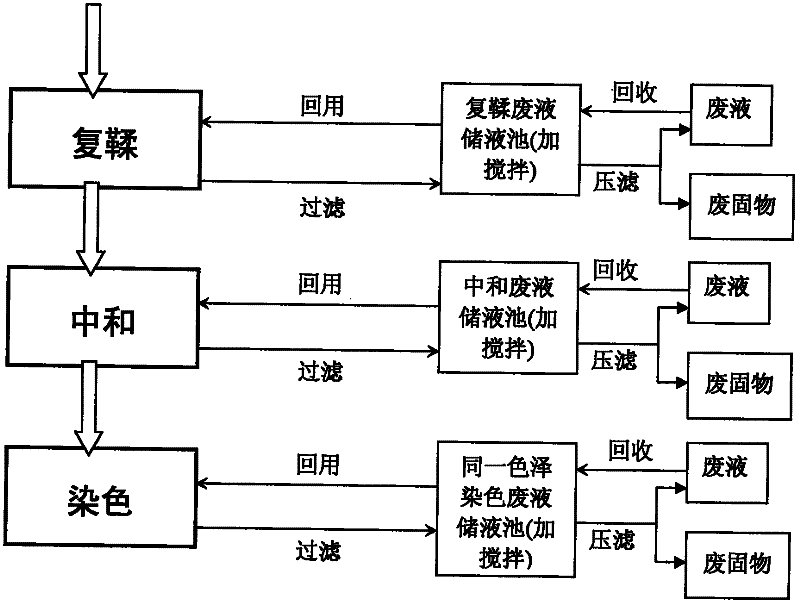

Tanning production process capable of recycling waste water repeatedly from soaking to dyeing

ActiveCN102534056AImprove firmnessHigh fullnessTanning treatmentPre-tanning chemical treatmentWastewaterSewage

The invention provides a tanning production process capable of recycling waste water repeatedly from soaking to dyeing, which is characterized in that waste liquid recycling is conducted in procedures of pre-soaking, main-soaking, liming, deliming and softening, pickling and chrome tanning, retanning, neutralizing and dyeing step by step, and waste liquid in all the procedures achieves full-closed circulation recycling. The technology is tested and verified in actual production in a tanning workshop of BIOSK (sq) Chemicals Co. Limited. The process achieves recycling of waste water from the pre-soaking to the dyeing, sewage discharging is greatly reduced, a problem of tanning pollution is solved thoroughly, quality of finished leather can be guaranteed simultaneously, loose side rate of the finished leather is effectively reduced, degree of compacting and fullness of the finished leather is improved, chemical materials can be saved by 15% to 55%, for example, chromium powder is saved by 35% to 65%, partial chemical materials can be saved by more than 90%, and exceptional chemical materials such as salt can be saved by 100%.

Owner:宝斯卡(商丘)化工有限公司

Process for producing detachable dirt- and water-repellent surface coatings

ActiveUS20060235143A1Good removal effectSimple wayFouling preventionSolid waste managementWaxSurface structure

Process for producing detachable dirt- and water-repellent surface coatings on articles, wherein during the coating process, hydrophobic particles are applied to the surface of the articles, thus generating a surface structure with elevations on that surface of the articles that has dirt- and water-repellent properties, which comprises suspending the hydrophobic particles in a solution of a silicone wax in a highly volatile siloxane, and applying this suspension to at least one surface of an article, and then removing the highly volatile siloxane.

Owner:EVONIK DEGUSSA GMBH

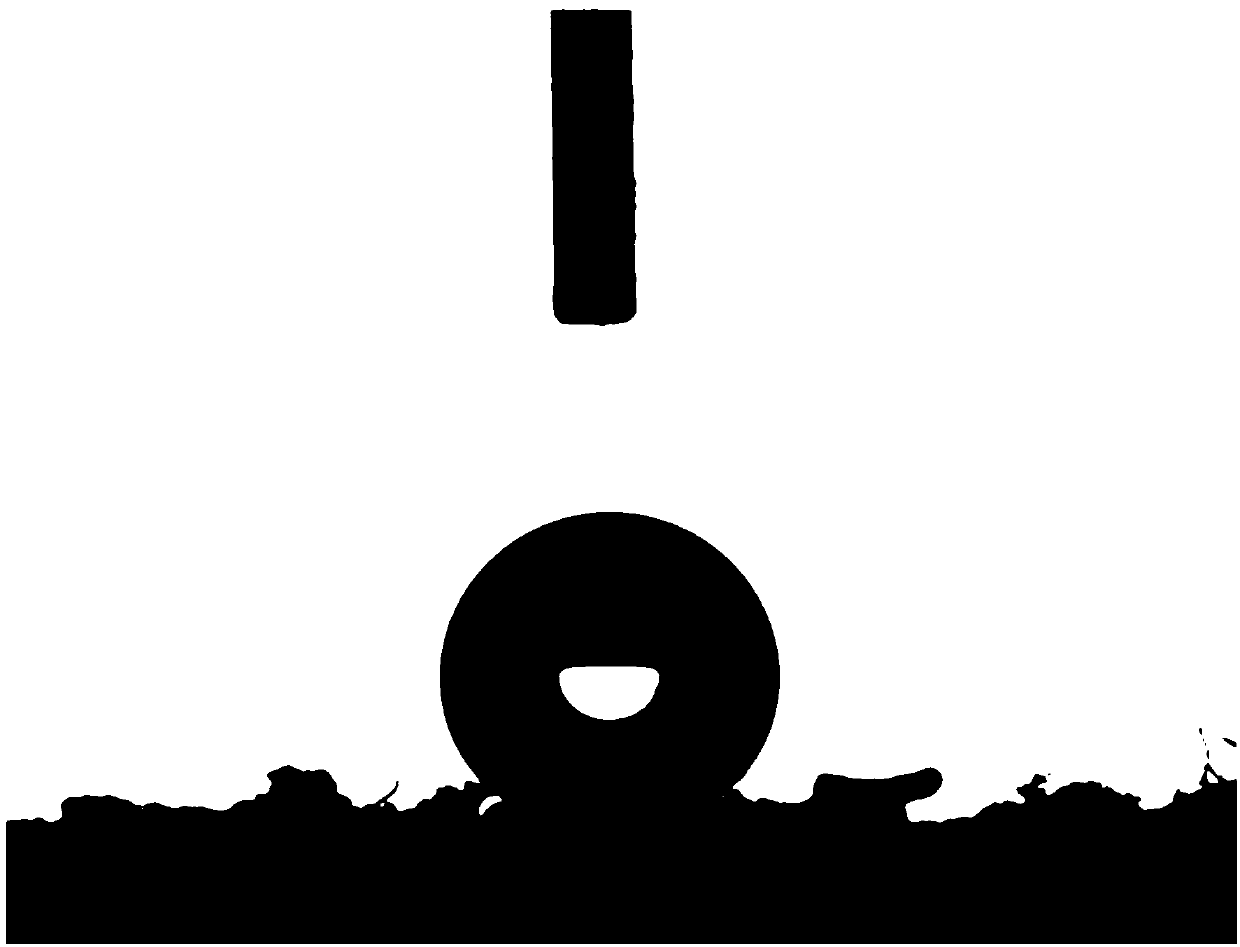

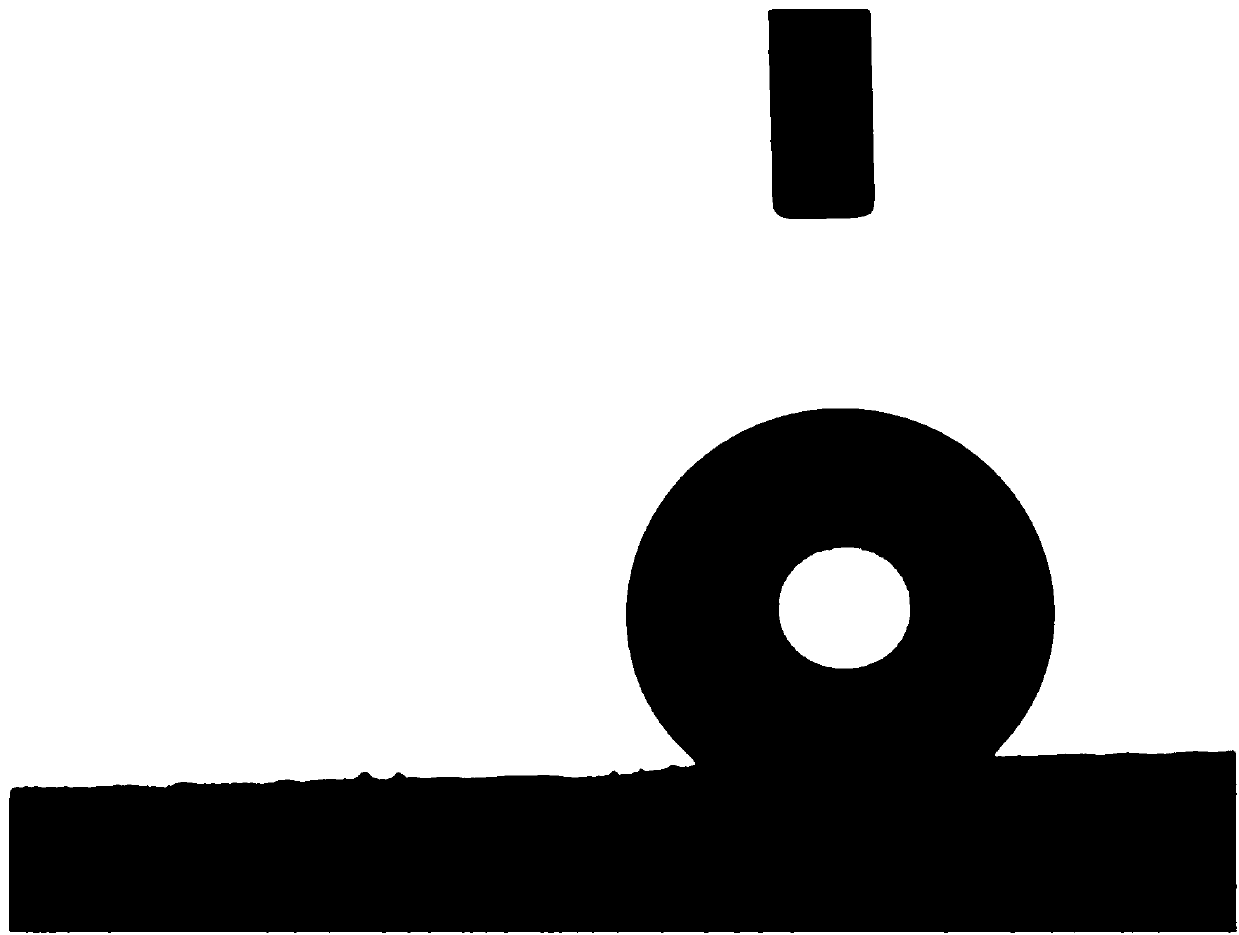

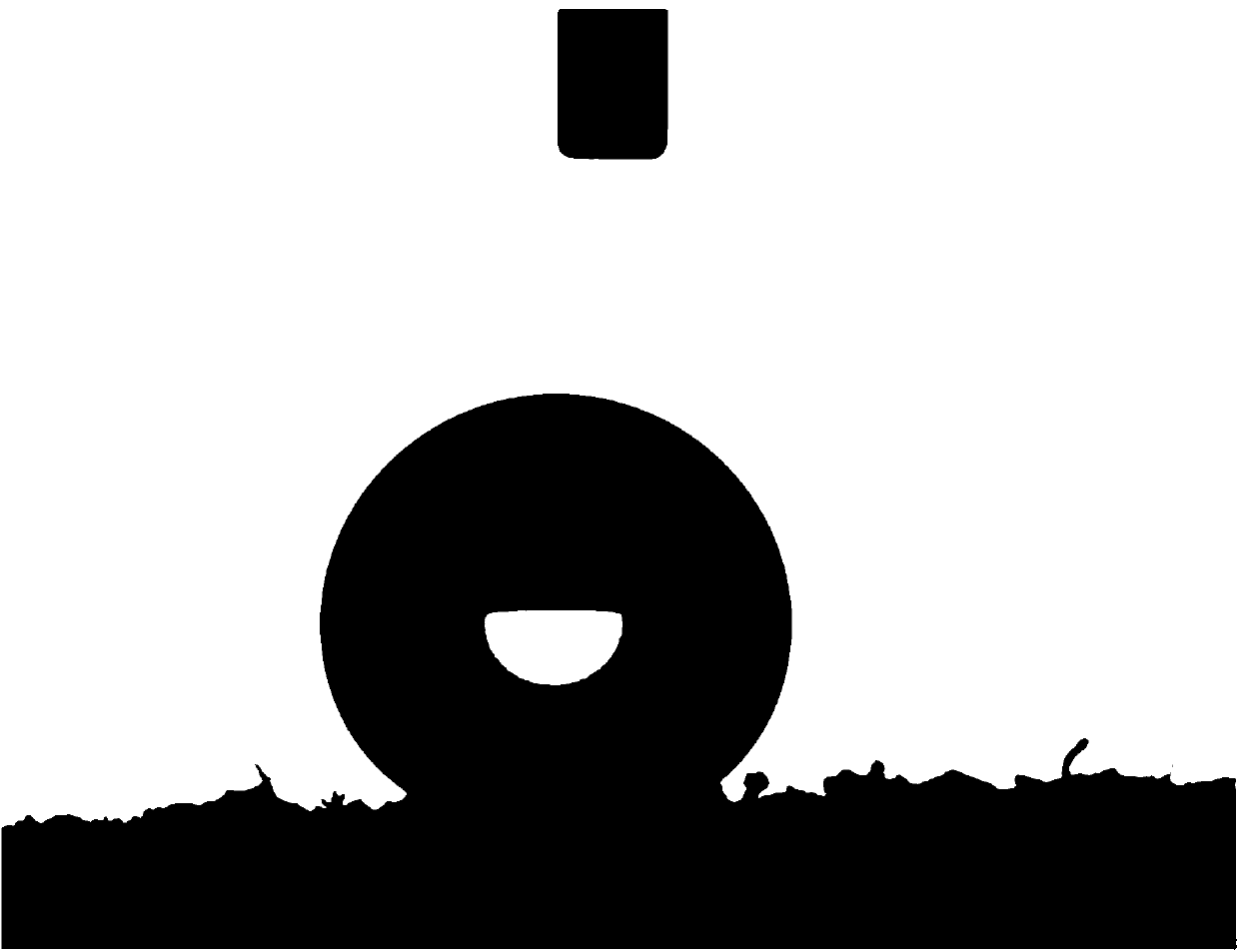

Preparation method for super-hydrophobic material

The invention provides a preparation method for a super-hydrophobic material. The method comprises the following steps: (1) modifying the integral three-dimensional structure of a substrate material by using a nanomaterial with a nanotechnology, so that the roughness of the integral three-dimensional structure of the material is increased; (2) coating the material with a low-surface-energy substance through a surface modifying technology to obtain the super-hydrophobic material. The static contact angle between the super-hydrophobic material and water is 152-158 degrees. The prepared super-hydrophobic material has superior hydrophobicity, the preparation process is simple, the reaction conditions are mild, and special machining equipment is not needed.

Owner:SICHUAN UNIV

Manufacturing process of semi-vegetable tanned wrinkled leather of cow leather

InactiveCN102080134AQuality assuranceReduce contentTanning treatmentPre-tanning chemical treatmentPulp and paper industryHexavalent chromium

The invention relates to a manufacturing process of the semi-vegetable tanned wrinkled leather of cow leather, which comprises the working procedures of initial tanning, deacidifying, vegetable tanning, filling and dry finishing. In the method provided by the invention, firstly tanning is carried out on raw hide by a small quantity of chromium tanning agent and then by a vegetable tanning agent, thereby under the premise of guaranteeing the quality of the leather, greatly reducing the content of chromium in tanning waste liquid, lightening the pollution of the chromium to the environment and effectively inhibiting the generation of hexavalent chromium through the vegetable tanning agent in the leather; and meanwhile, the granule surface of the leather is tightened through the working procedures of dry finishing and coating, and natural winkles are formed on the granule surface, thereby covering the injury of the granule surface of the leather and improving the additional value of the leather.

Owner:锦兴皮业科技有限公司

Hot melt adhesives for roll-applied labels

ActiveUS20100112250A1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolyesterTriethylene glycol

Disclosed are hot-melt adhesives prepared from polyesters containing 1,4-cyclohexane-dicarboxylic acid as a diacid component and a diol component containing at least two diols chosen from 1,4-cyclohexanedimethanol, triethylene glycol, and diethylene glycol. These adhesives set up rapidly within a well-defined temperature window. The hot-melt adhesives can be used in a variety of applications, but are especially suited as seaming adhesives for roll-applied labels. These adhesives have melting temperatures and crystallization properties that allow their application at temperatures cool enough to prevent curling and premature shrinkage of the shrink label during seaming, and yet produce strong label seams that can withstand the elevated temperatures of a shrink tunnel without sacrificing line speed. Also disclosed are labeled containers and a process for applying a roll-on, shrink label to a container using the hot-melt adhesives of the invention.

Owner:EASTMAN CHEM CO

Ionic liquid flame retardants

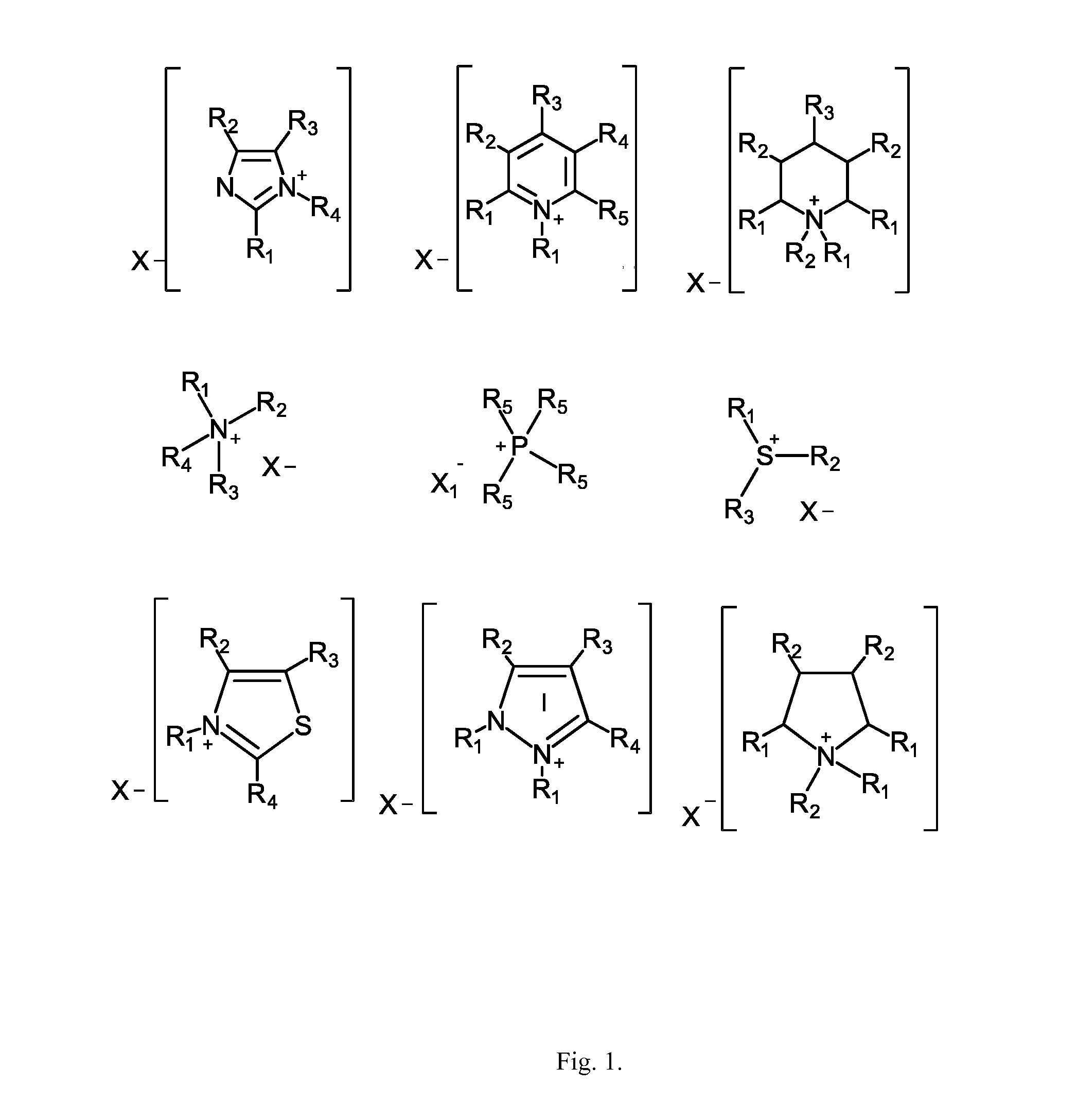

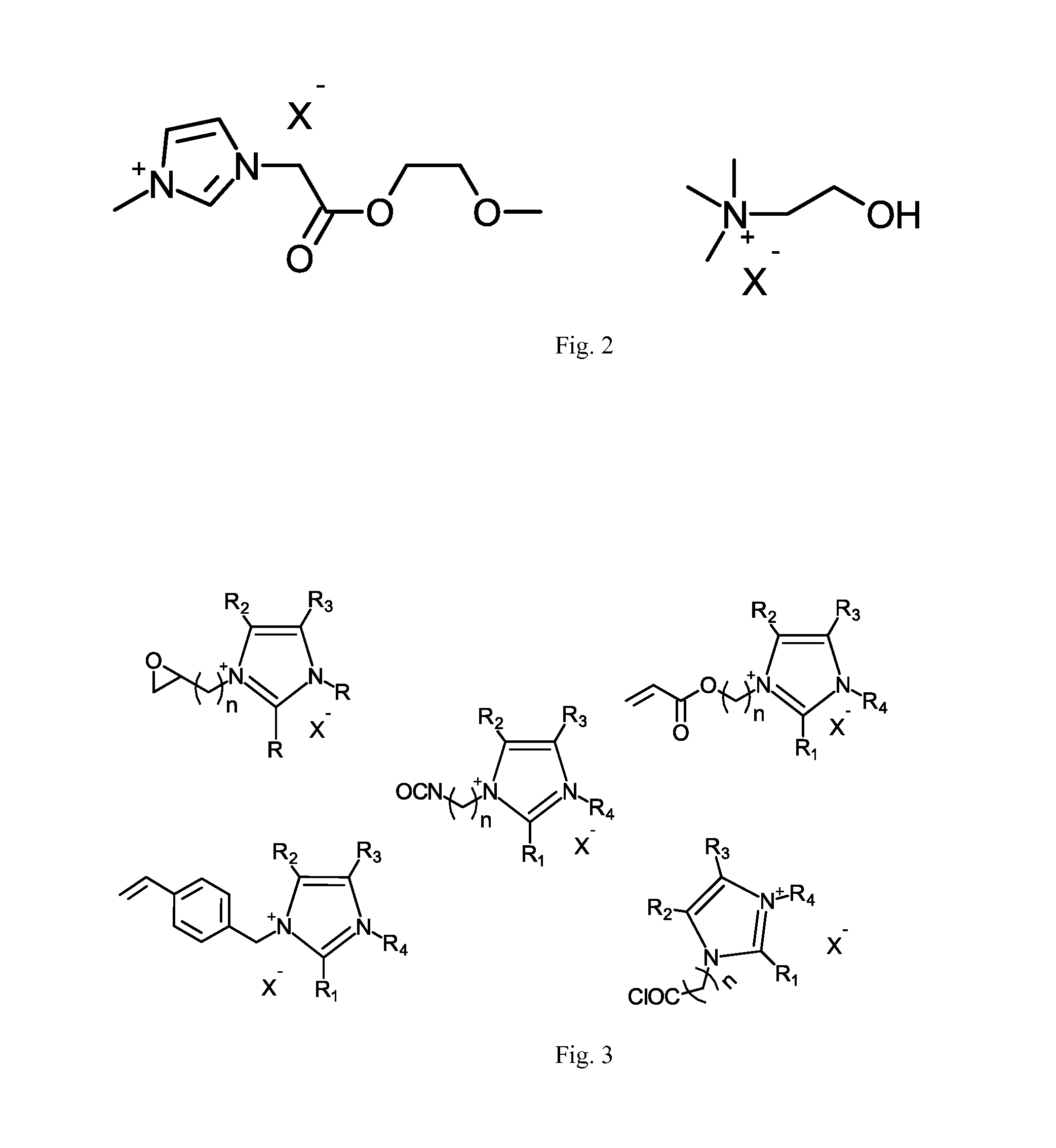

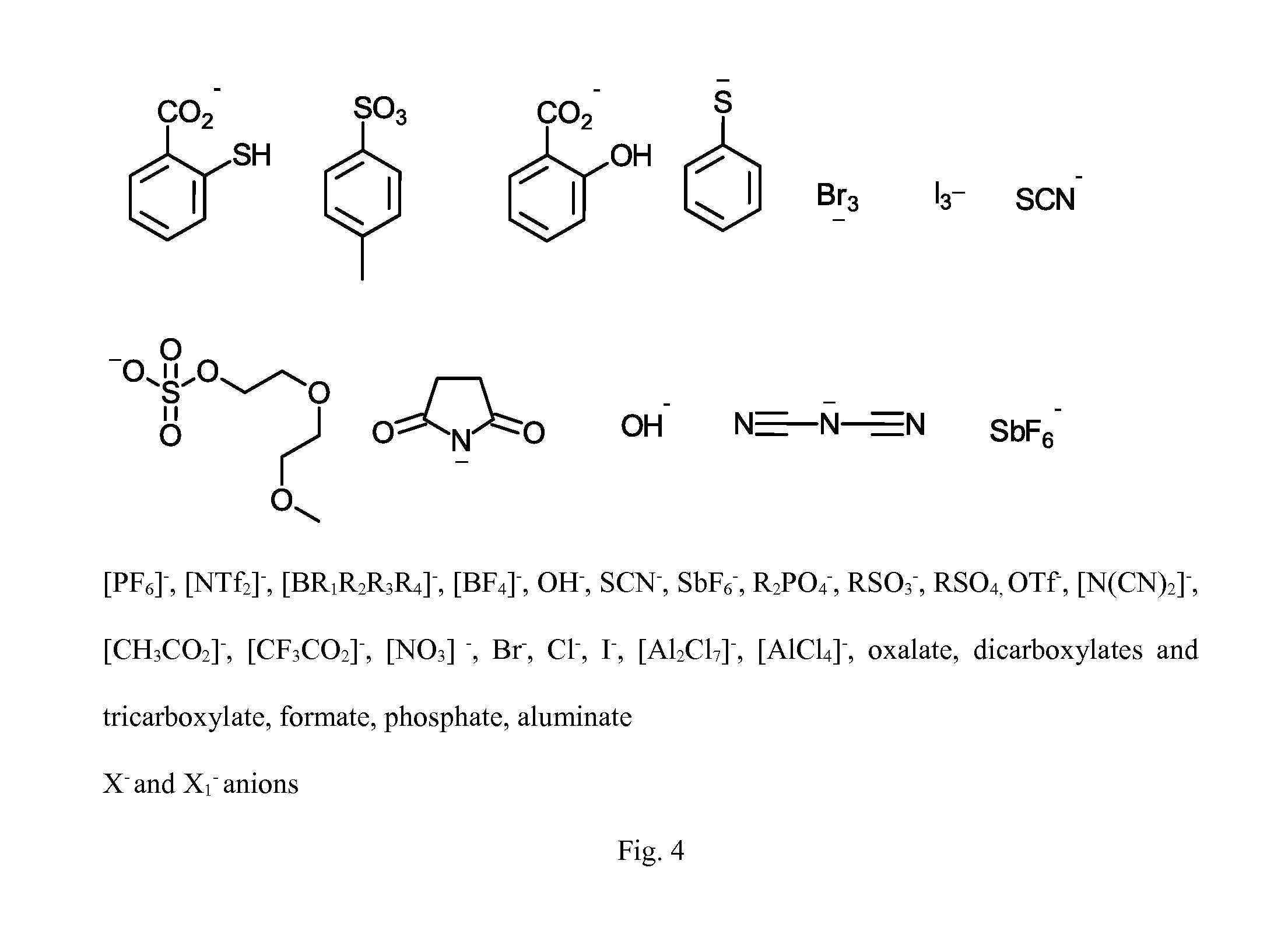

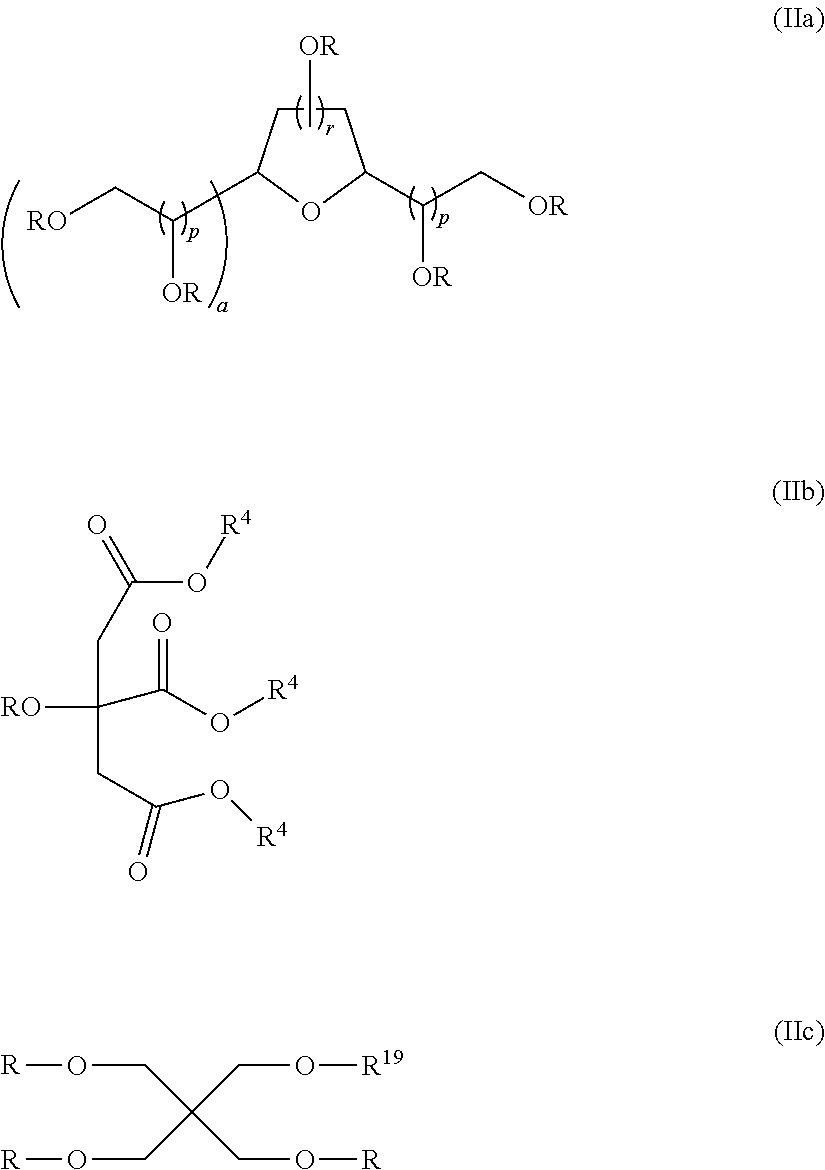

InactiveUS20110039467A1Excellent resistance to migrationPromote leachingNatural cellulose pulp/paperSpecial paperFire retardantIonic liquid

The present invention relates to the use of ionic liquids as flame retardants. The compounds of the invention may be used as flame retardants in various materials without causing damage to the environment and or health of humans or animals. Ionic liquid flame retardants maybe applied alone or in combination with traditional flame retardants. Ionic liquid flame retardants can be applied to finish textile, plastic, leather, paper, rubber, or as wild fire flame retardants.

Owner:H&C CHEM

Environment-friendly type crust leather production method

ActiveCN103060488AEmission reductionCreate pollutionTanning treatmentPre-tanning chemical treatmentChromiumIon

The invention discloses an environment-friendly type crust leather production method, and aims at solving the problems that in a crust leather production method using conventional chrome tanning as basis, plenty of chromium ions are contained in waste water and cannot be effectively processed, plenty of leather wastes with chrome are also generated, and the environment is seriously polluted. The production method comprises the following steps of non-pickling tanning, retanning filling, dyeing fat liquoring and chrome retanning. The method adopts non-pickling non-chrome tanning technology, so solid wastes with the chrome cannot be generated. At the same time, through mutual matching with other procedures, finished leather shrinkage temperature and performance can be effectively improved so as to meet demands of leather production. At the last, the chrome retanning is adopted, only a path of waste water with the chrome is generated, waste water quantity is small, and the waste water is easy to recover and process. Therefore, compared with an existing crust leather production method using a chrome tanning method as basis, cleaning degree is high, the waste water quantity with the chrome can be effectively reduced, and the waste water is convenient to recover and process. At the same time, the leather wastes with the chrome cannot be produced, and the method is environment-friendly.

Owner:四川亭江新材料股份有限公司 +1

Non-fluorinated urethane based coatings

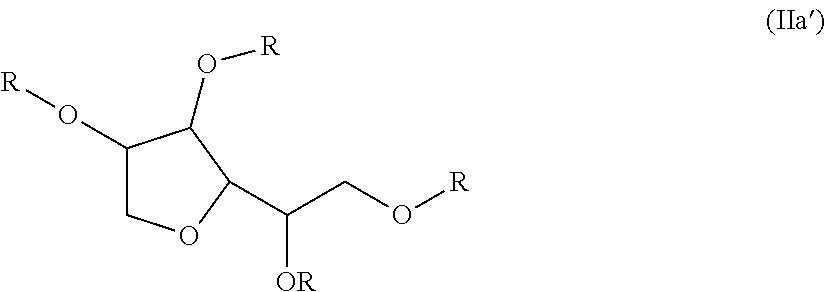

ActiveUS20160090508A1Imparting durable water repellencyIncreased durable water repellencyWater-repelling agents additionSynthetic fibresSaccharic acidPolymer science

The present invention is an aqueous composition comprising at least one hydrophobic compound having at least one linkage of Formula I:—NHC(O)—X— (I)wherein X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; or mixtures thereof; where the cyclic or acyclic sugar alcohol is selected from a saccharide, reduced sugar, aminosaccharide, aldonic acid, or aldonic acid lactone; wherein each n is independently 0 to 20; each m is independently 0 to 20; m+n is greater than 0; each R1 is independently a linear or branched alkyl group having 5 to 29 carbons optionally comprising at least 1 unsaturated bond; each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

Reducing leather and preparation method thereof

ActiveCN101851828ARandom croppingNo location differenceNon-adhesive dressingsTanning treatmentFiberApparent density

The invention discloses reducing leather and a preparation method thereof. The leather is mainly and three-dimensionally weaved by collagenous fiber obtained by defibrination of leather materials, and the apparent density thereof is 0.35g / cm3-1.4g / cm3. The preparation method of the leather comprises the steps: carrying out defibrination on the leather materials to prepare the collagenous fiber, forming web, carrying out hydroentanglement and wet-hot shrinkage and forming. The leather is reducing leather, the weaving structure, the apparent density, all strength indexes and wear resistance of which are approximate to those of true leather. Compared with the true leather, the reducing leather has the advantages that the leather is large and tidy and can be cut randomly, the weaving apparent density is consistent without location difference; and simultaneously, the raw materials of the reducing leather mainly adopt corner wastes in the leather-working industry. The promotion of the method can enhance the circulation and reutilization of resources in the leather-working industry, and is beneficial to realizing transformation from the traditional leather-working industry to the energy-saving and environment-friendly industry.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Clean process for producing leather by using sturgeon skin

The invention discloses a clean process for producing leather by using sturgeon skin, which comprises the following steps of: immersing sturgeon into water, manual meat removing, degreasing, oil slick scratching, ash immersing, dying, ash immersing, oil slick scratching, ash restoring, oil slick scratching, deliming without ammonium, oxidation bleaching, acid etching, reduction bleaching, softening, organophosphorus tanning or oxazolidine tanning, dyeing and fat-liquoring, aluminum retanning or zirconium retanning, washing, hung airing and drying and finishing. According to the clean process, the sturgeon skin is tanned by adopting an organophosphorus tanning or oxazolidine tanning agent and a chrome-free tanning process; a less-sulfur liming and deliming without ammonium clean process is adopted in the tanning process, so that the harm of heavy metal chromium to the environment and a human body can be avoided, the emission of sulphide and the consumption of lime are reduced, the content of ammonia nitrogen in wastewater is reduced and the cost of sewage treatment of enterprises is saved; in addition, the produced environmentally-friendly sturgeon skin is soft in hand feeling, plump, rich in elasticity and flat and fine in particle surfaces, and keeps beautiful and complete natural squama.

Owner:王学川 +1

Process for producing leather

ActiveCN102586497ARelieve pressureLow costLeather manufacturingPre-tanning chemical treatmentEngineering

The invention relates to the field of the manufacture of leather and provides a process for producing the leather. The production cost is reduced by changing the formula of the process. The process comprises the following steps of: preparing a crust, milling the crust, toggling, tumbling, trimming, patching, buffing, blowing dust and cleaning, spraying cations, tumbling for the second time, spraying, repairing corners, tumbling for the third time, trimming for the second time, rolling, obtaining G gloss, pressing a plate, spraying for the second time, obtaining water gloss, tumbling for the fourth time, milling for the second time, staking, tumbling for the fifth time, and spraying a handle agent.

Owner:XINGYE LEATHER TECH CO LTD

Compositions for improving the light-fade resistance and soil repellancy of textiles and leathers

ActiveUS7157018B2Easy to useConveniently preparedDispersed particle filtrationLight resistant fibresBenzotriazoleOdorless mineral spirits

Owner:SCHEIDLER KARL J

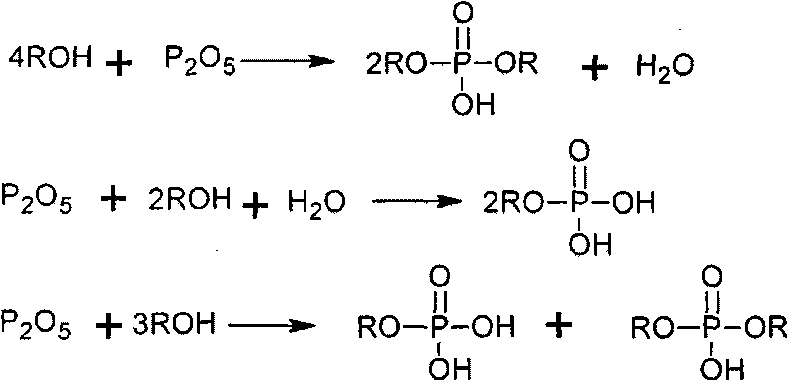

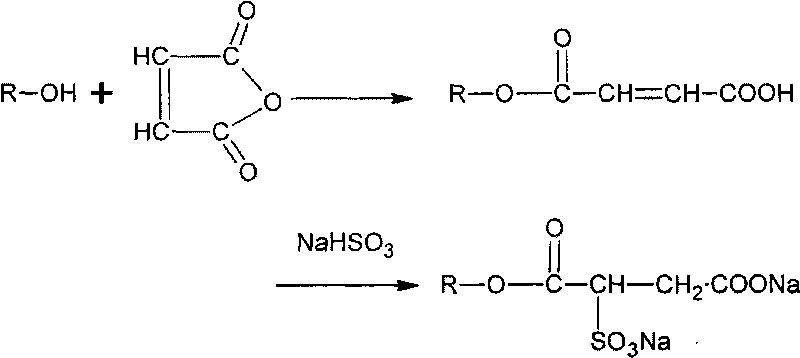

Composite leather greasing agent and preparation method thereof

InactiveCN101760570AHigh content of active substancesExcellent comprehensive fatliquoring performanceLeather impregnationVegetable oilAlkylphosphate

The invention provides a composite leather greasing agent used for a leather greasing work procedure and a preparation method thereof. The composite greasing agent comprises two ingredients: alkyl phosphate and disodium sulfosuccinate. The preparation method comprises the following steps: making hydroxylated animal and vegetable oil and modifiers thereof take phosphorylation reaction with phosphorus pentoxide; then, making obtained materials take monoester reaction with maleic anhydride; and next, making obtained materials take sulphitation reaction with sodium bisulfite to obtain the composite leather greasing agent with the two ingredients of alkyl phosphate and disodium sulfosuccinate. The composite leather greasing agent has the characteristics of high active matter content, strong combination capability with leather and good comprehensive greasing performance. The production process of the composite leather greasing agent is simple, and the discharge of the three wastes does not occur in the production process.

Owner:WENZHOU UNIVERSITY

Sturgeon skin chrome tanning leather production process

InactiveCN102199676ALow fat contentImprove use valueTanning treatmentPre-tanning chemical treatmentSturgeonLeather production processes

The invention discloses a sturgeon skin chrome tanning leather production process, which comprises the following steps: immersing in water; removing meat manually; degreasing; scraping oil slick; liming; scraping oil slick; liming again; scraping oil slick; deliming and softening; bleaching by oxidization; pickling; bleaching by reduction; chrome tanning; dyeing and greasing; re-tanning; washing; hanging and drying; and coating. In the invention, when the sturgeon skin chrome tanning leather production is adopted, the grease content in the sturgeon skin can be reduced obviously and the color of particle surface of the back of the sturgeon skin can be lightened; and thus, dyeing or production of light leather can be facilitated, the finished leather retains the natural attractive scales and special textures of sturgeon skin, the utilization value of the sturgeon skin is improved greatly, and the added value of the product is increased obviously.

Owner:王学川 +1

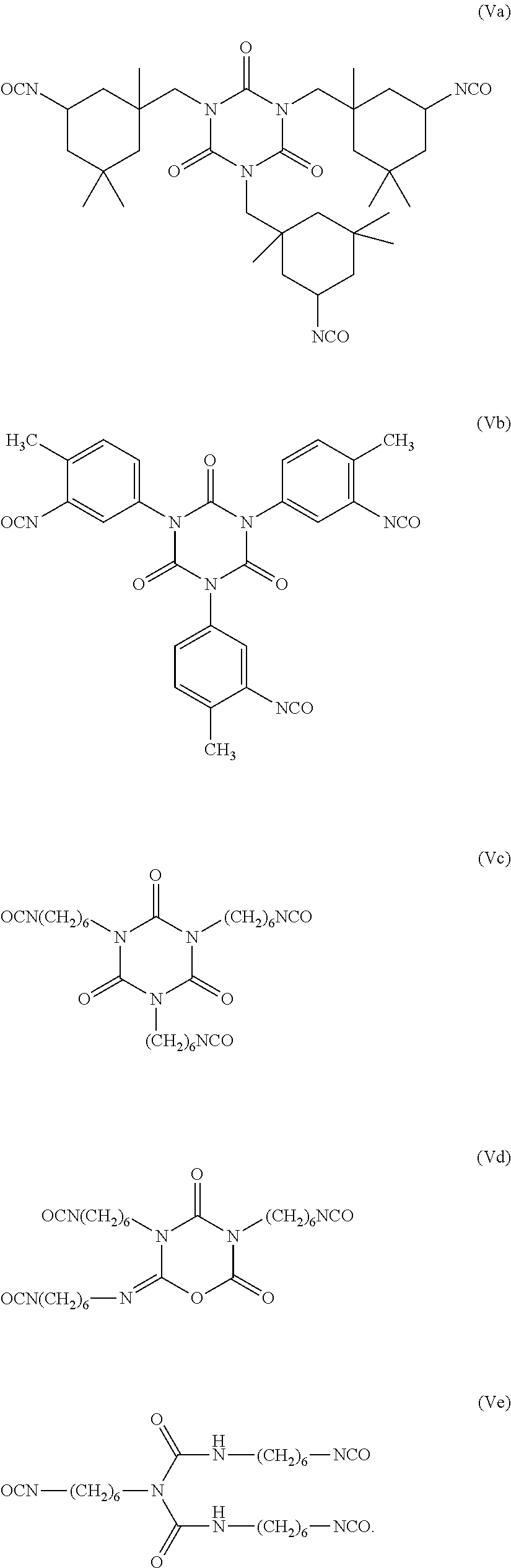

Topcoat

InactiveUS20100310882A1Preventing generation of squeak noiseSoftness and flexibility and smoothness and slick touchSynthetic resin layered productsPretreated surfacesCross-linkEmulsion

This invention provides a natural leather having a coating film as a topcoat layer that can suppress and prevent the occurrence of an uncomfortable squeak noise and, at the same time, has softer feeling, soft and smooth feeling, and slick feeling, a composition for the formation of a coating film on a natural leather, and a process for producing a natural leather. The natural leather comprises, as a topcoat layer, a coating film comprising 48 to 55% by weight of a two-component aliphatic polyurethane, 3 to 7% by weight of silica fine particles, 23 to 37% by weight of a cross-linking agent, and 7 to 13% by weight of a silicone touch agent (the total of the components being 100% by weight), wherein, in the coating film as the topcoat layer, the two-component aliphatic polyurethane contains 12 to 25% by weight, based on the solid content, of a polyurethane resin matting agent, or wherein, in the coating film as the topcoat layer, the two-component aliphatic polyurethane is contained in an amount of 51 to 55% by weight based on the solid content and further contains 6 to 10% by weight, based on the solid content, of a two-component aliphatic polyurethane / acryl emulsion.

Owner:MIDORI HOKUYO CO LTD

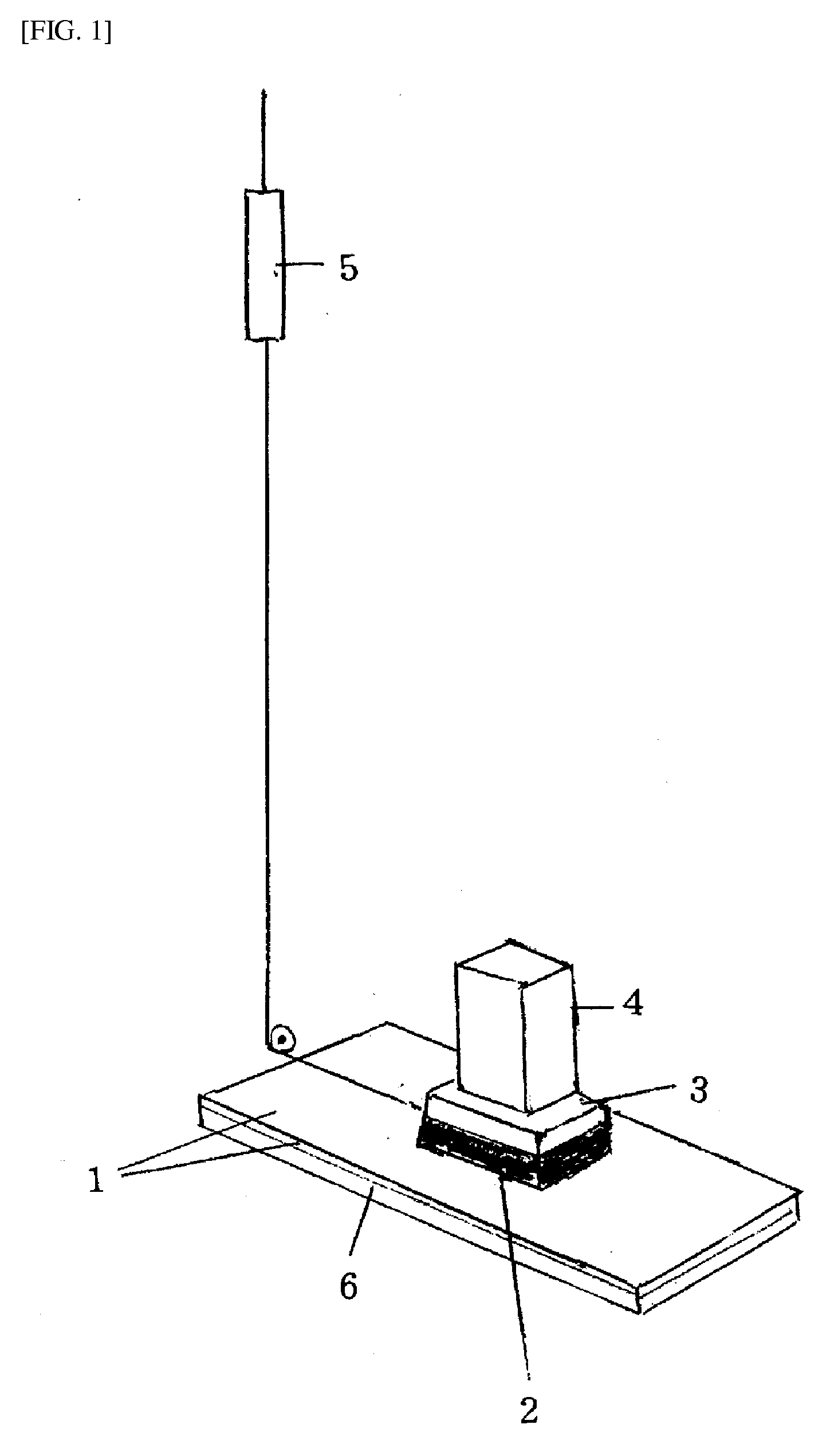

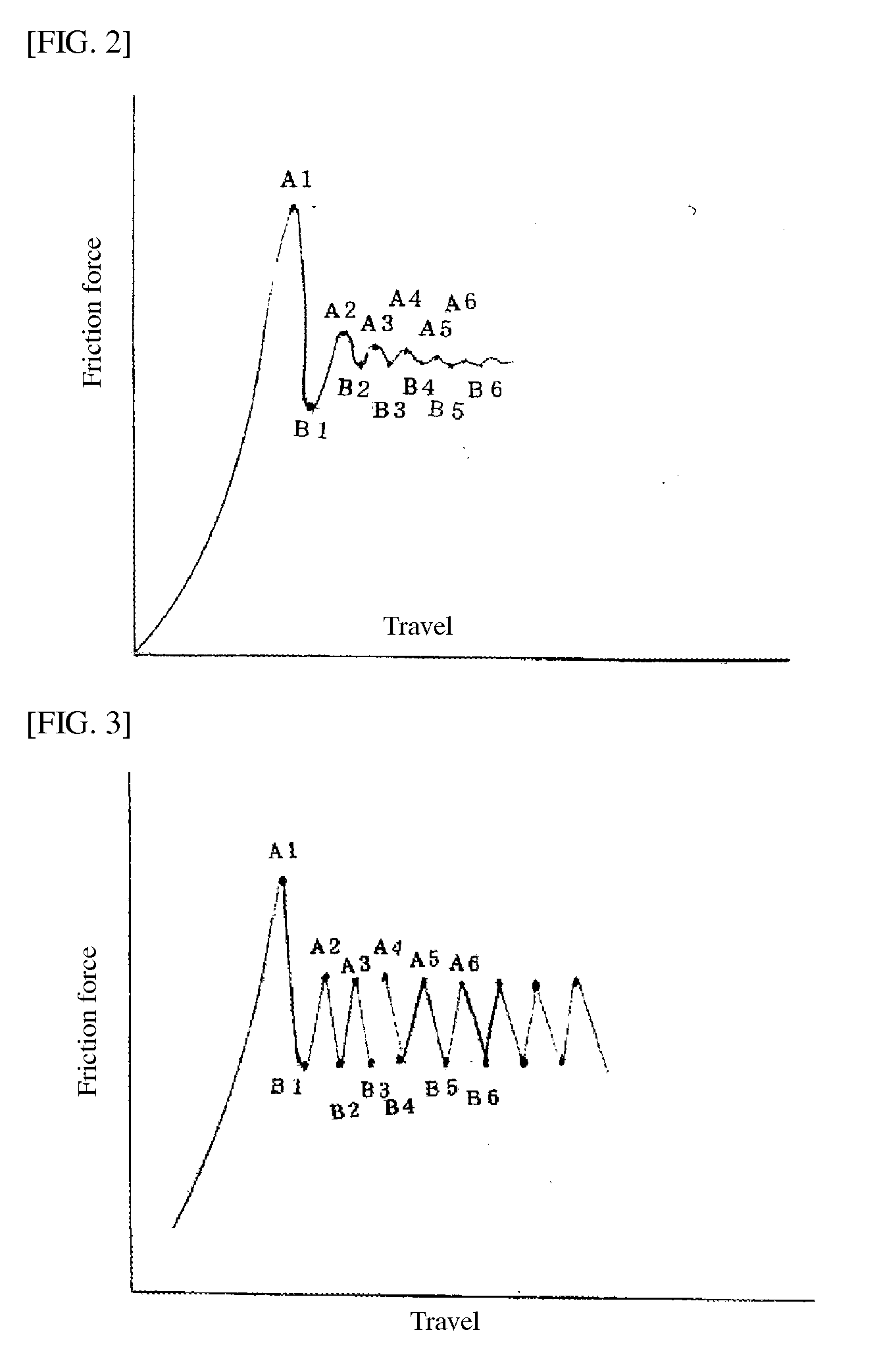

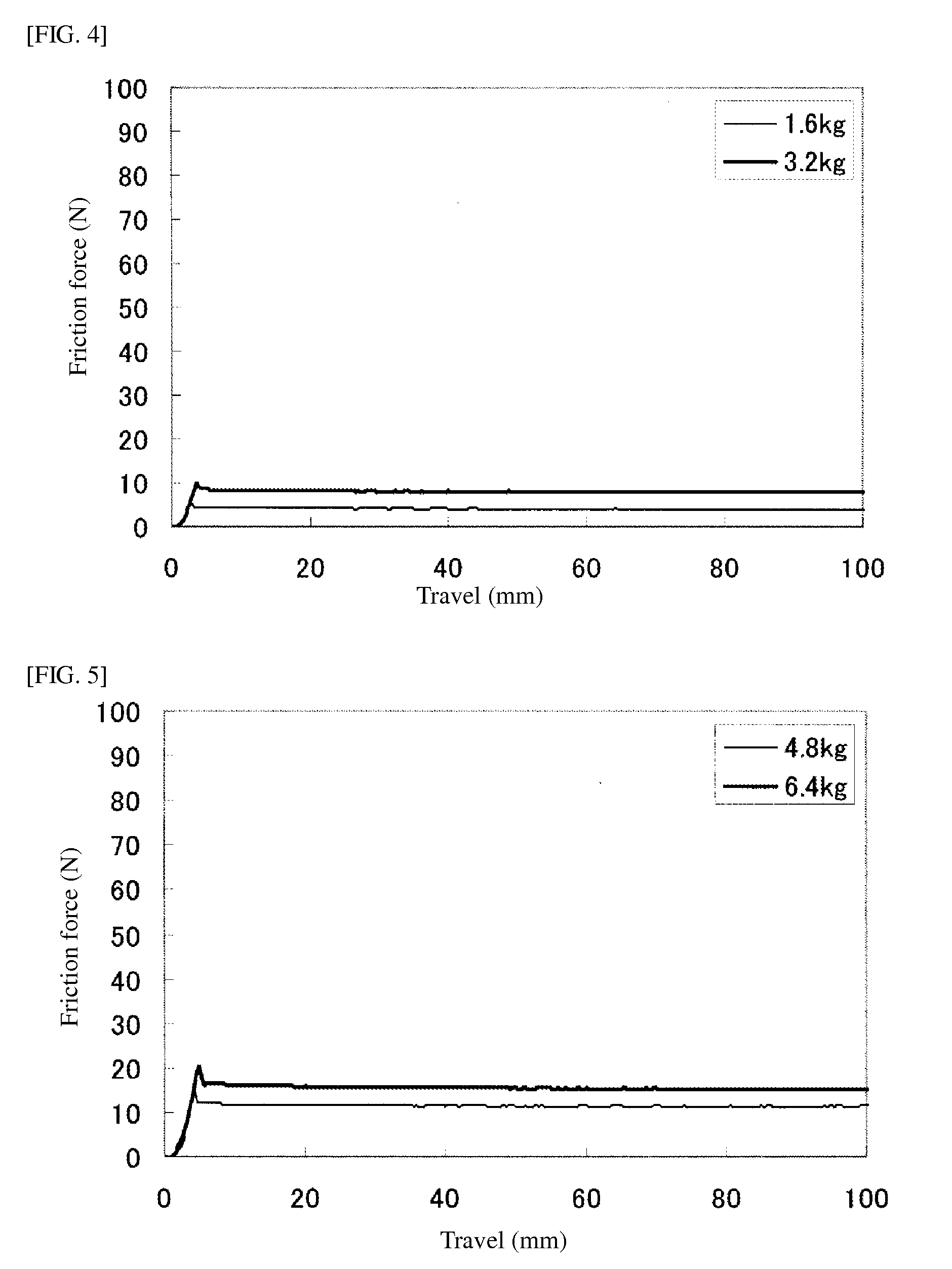

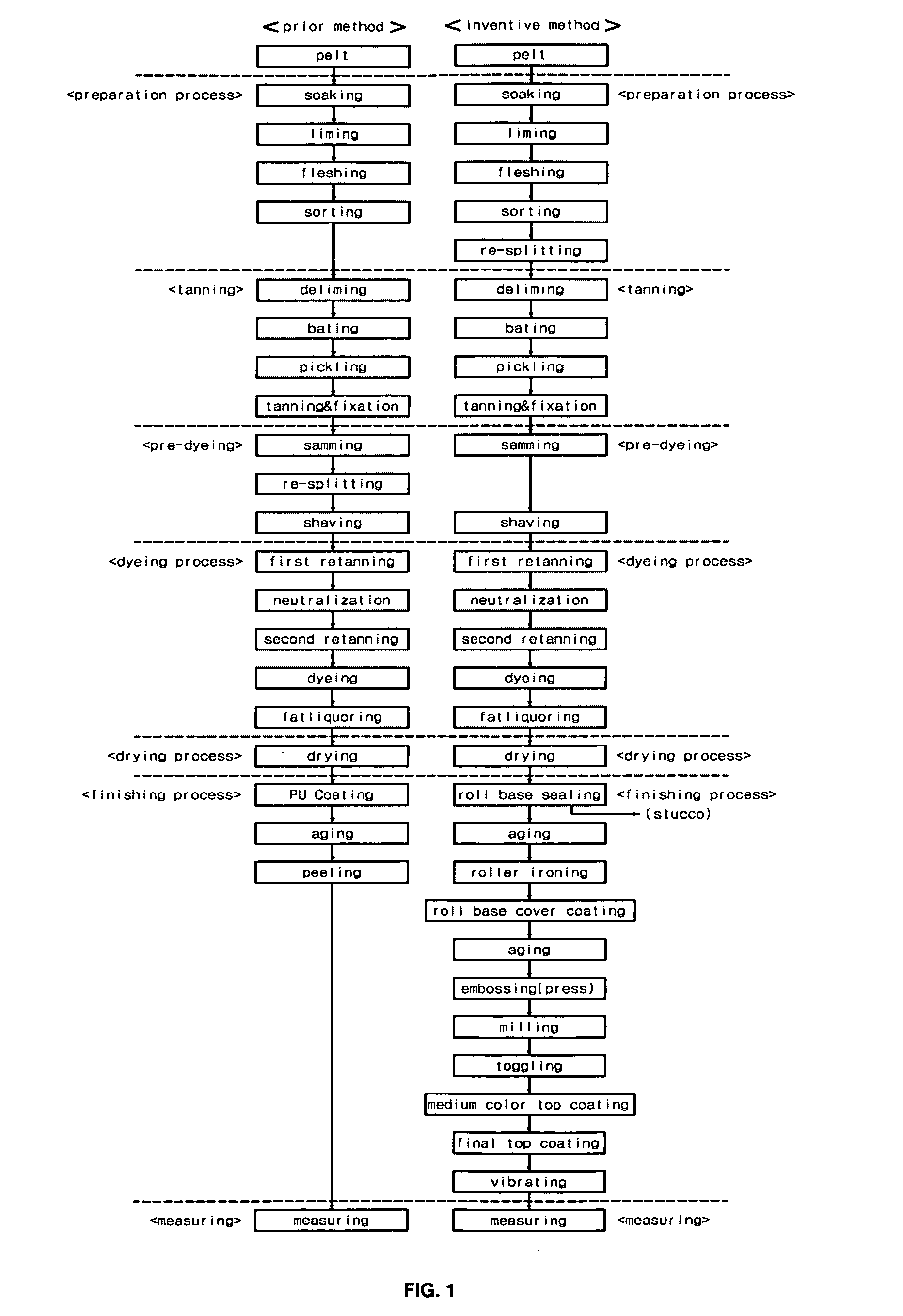

Split Leather for Car Seats and Manufacturing Method Thereof

InactiveUS20080299406A1Maximally maintain propertyCost advantageVehicle seatsTanning treatmentCar seatEngineering

Disclosed herein are split leather for car seats and a manufacturing method thereof. The method comprises a preparation process, a tanning process, a pre-dyeing process, a dyeing process, a drying process and a finishing process, wherein the method comprises, after the preparation process, but before the tanning process, a re-splitting process of splitting pelt into an upper grain layer and a split layer, having a thickness of 2.5-4 mm, and re-splitting the split layer to have a thickness of 1.8-2.5 mm starting from the upper side thereof, thus obtaining split leather, and the finishing process comprises sequentially forming a roll base sealing layer, a roll base cover layer, a medium color top coating layer and a final top coating layer on the split leather, thus treating the surface of the split leather. The split leather for car seats has a luxuriousness close to that of full-grain leather and a soft touch and feel, and can give customers a cost advantage. Also, the range of selection of raw material for manufacturing car seat leather can be widened, and waste can be recycled to thus reduce the generation of waste, thus being helpful to the environment. In addition, leather seats can be diversified and a new product group can be created.

Owner:NAM CHUNG

Method for preparing cleaned three-proofing cow split leather and prepared cleaned three-proofing cow split leather

ActiveCN102676710AGood flexibilityReduce Chromium PollutionTanning treatmentPre-tanning chemical treatmentWater solubleFluoride

The invention discloses a method for preparing cleaned three-proofing cow split leather and prepared cleaned three-proofing cow split leather. Cow split blue wet leather serving as a raw material is subjected to the steps of water return, preliminary fat-liquoring chromium-free retanning, neutralization, filling, dyeing, fat liquoring, fixing, fireproof treatment, drying and the like to prepare the cleaned three-proofing cow split leather. A waterproof anti-fouling agent and a flame retardant are added in the preparation process to enable the three-proofing cow split leather to have waterproof, anti-fouling and fireproof functions, wherein the waterproof anti-fouling agent is a water-soluble fluoride, and the flame retardant is an inorganic flame retardant. The method has the advantages of being high in cleaning degree, small in water discharge amount, short in production period and low in cost, and the three-proofing cow split leather is good in waterproof, anti-fouling and fireproof effects.

Owner:JINAN LURI JUNDA LEATHER

Shoe and leather care product

ActiveUS7229486B2Excellent characteristicsMaintain good propertiesOther chemical processesMixing methodsWater basedOrganic solvent

Owner:SC JOHNSON & SON INC

Method for manufacturing leather fattening agent

InactiveCN1580288ALow iodine valueReduce organic chlorine contentLeather impregnationHydrogenAlcohol

The invention includes : A. preparation of sulfonation compound fat, put vegetable oil, animal oil and wool fat together, add hydrogen under catalyst reaction, after sulfonation treatment, and gain sulfonation compound fat; B. preparation of amphoteric phosphorated fat, add low carbon alcohol to ester change nature, add active hydrogen compounds, adding ester acidifying reagent gain anion phosphorated vegetable oil, adding cation reagent gain amphoteric phosphorated fat; C. mix sulfonation compound fat and amphoteric phosphorated fat and add additives to match leather greasing agent. Because compound fat's hydrogenation puts double bond to single bond, lows iodine number, fat not only is difficult to oxy peroxid by oxygen in the air, results chromic adding fat : in addition the invention of compound fat agent excludes chlorparaffins and is low of organochlorine, belonging to environment fat agent.

Owner:阮文娟

Method for manufacturing washable cow split leather

ActiveCN107502685AFully rehumidifiedImprove washing resistanceTanning treatmentPre-tanning chemical treatmentSofteningChemistry

The invention relates to a method for manufacturing washable cow split leather and belongs to the technical field of manufacture of leather. The method comprises the following steps: taking a cow split leather blank subjected to wringing and shaving, and sequentially performing re-wetting, primary washing, retanning, neutralizing, secondary washing, filling, dyeing, stuffing, acid solidification, thrice washing, fixing, quartic washing, drying, hanging and airing, vibratory softening, leather fluffing and milling. The washable cow split leather manufactured by the method has favorable washability, and is high in leather yield.

Owner:漳州香洲皮革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com