Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7702results about "Special paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

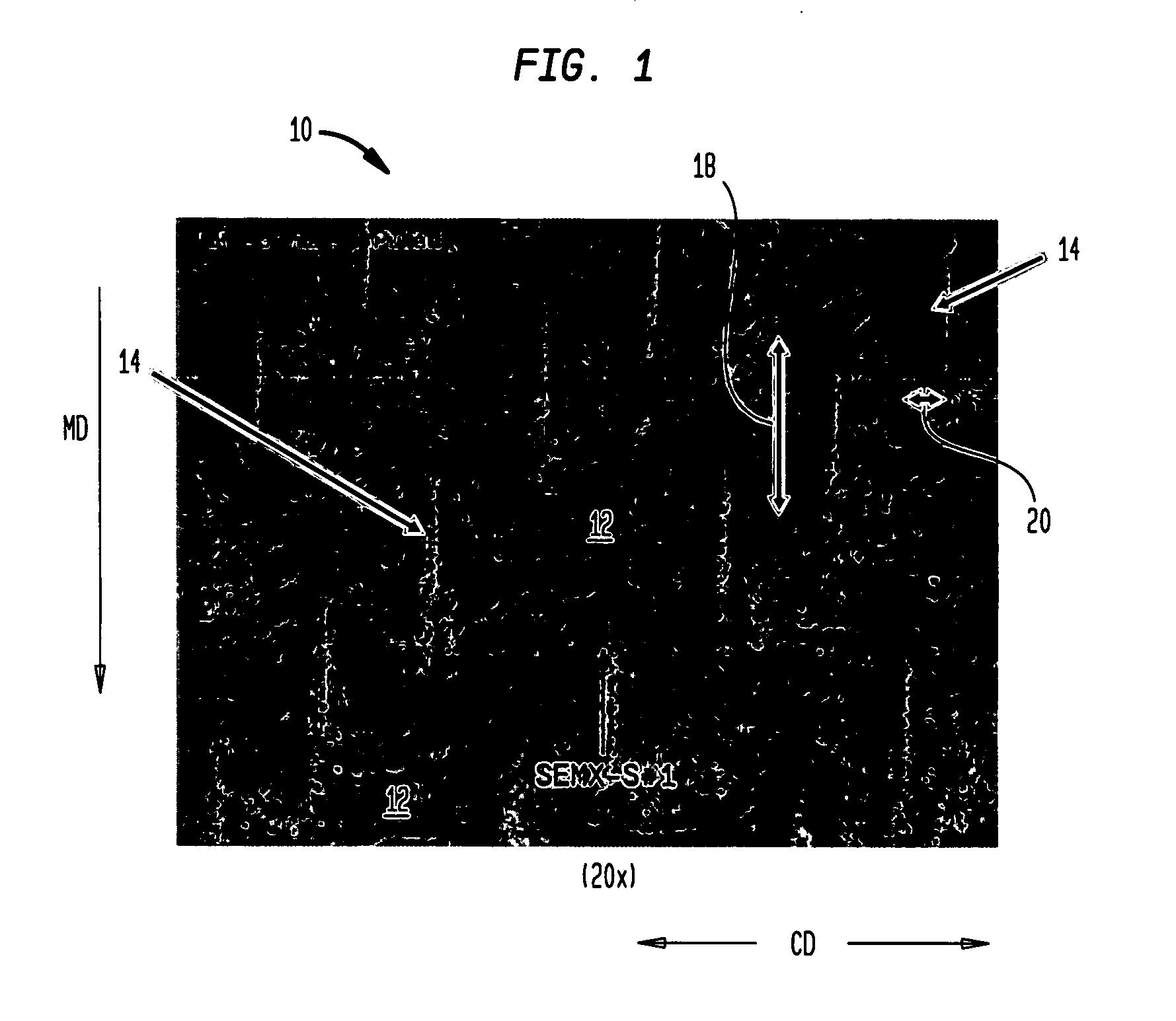

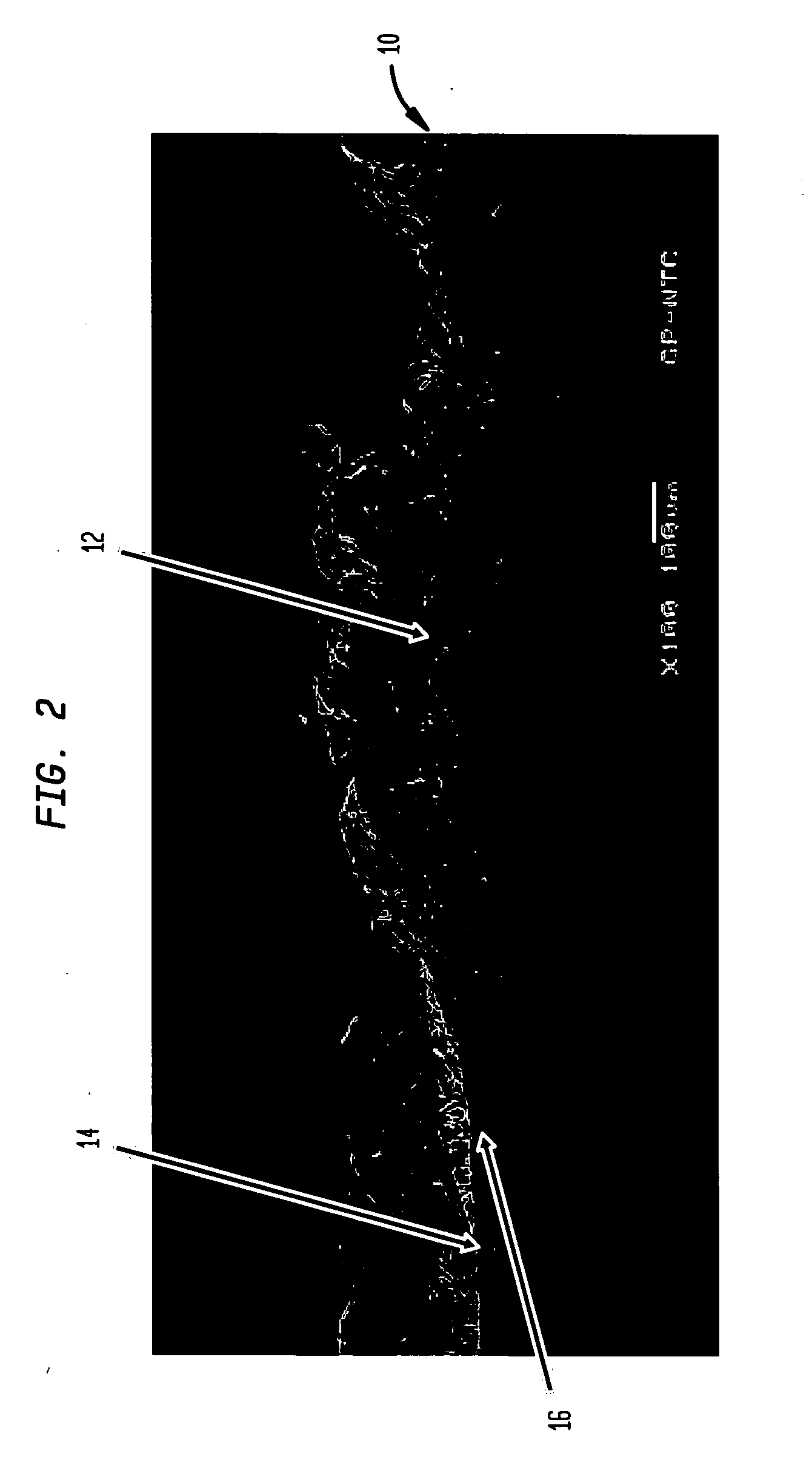

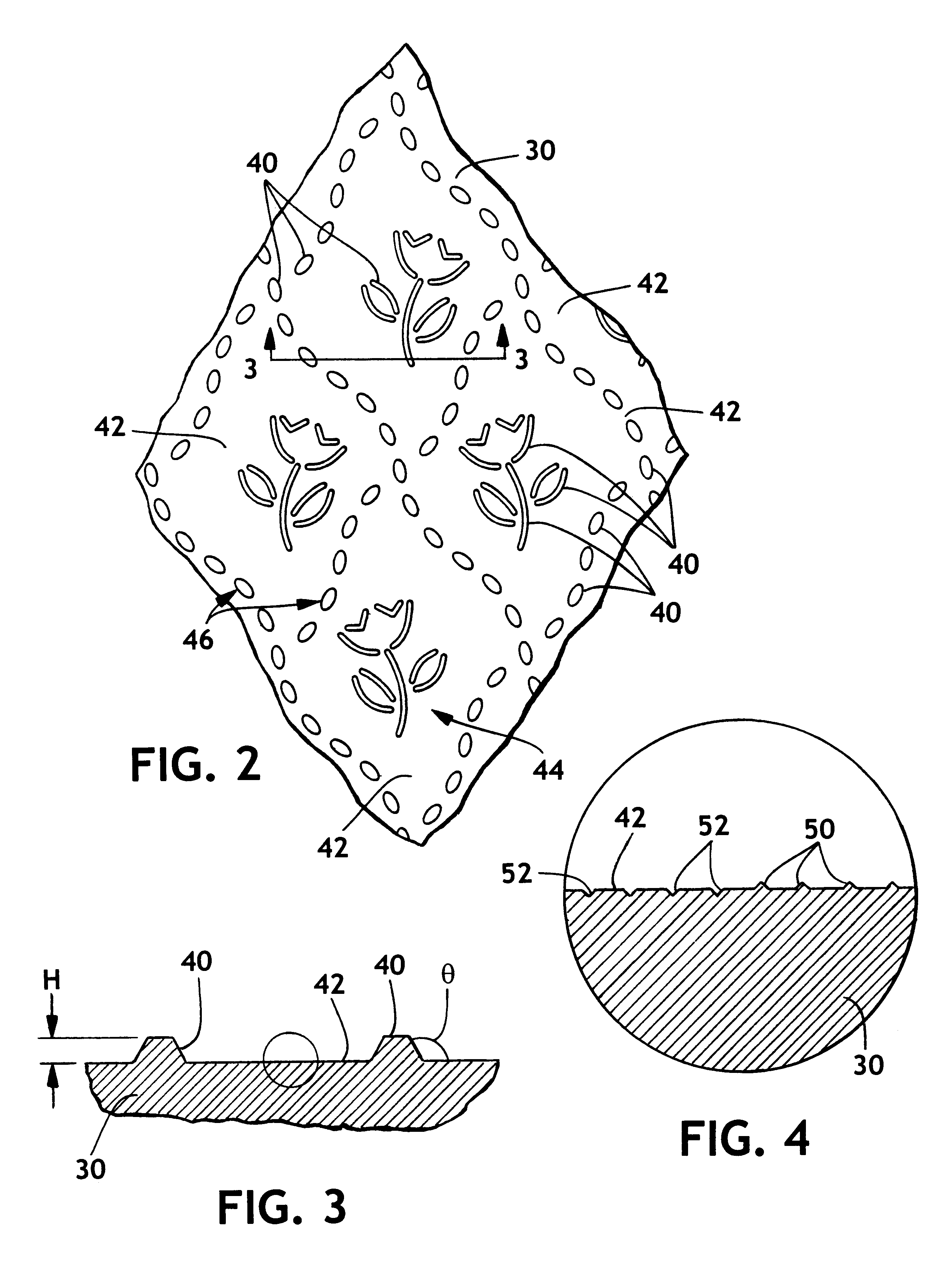

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

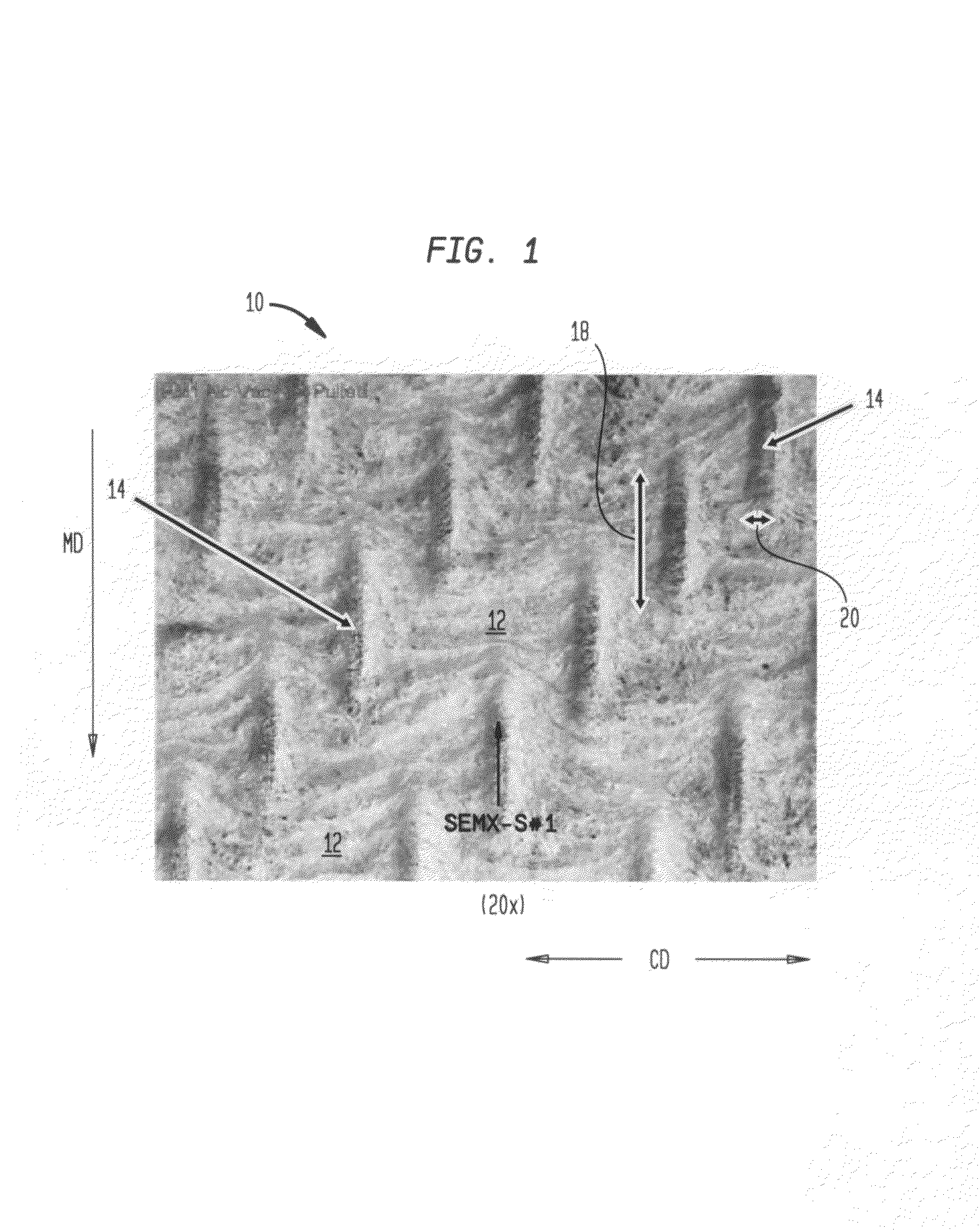

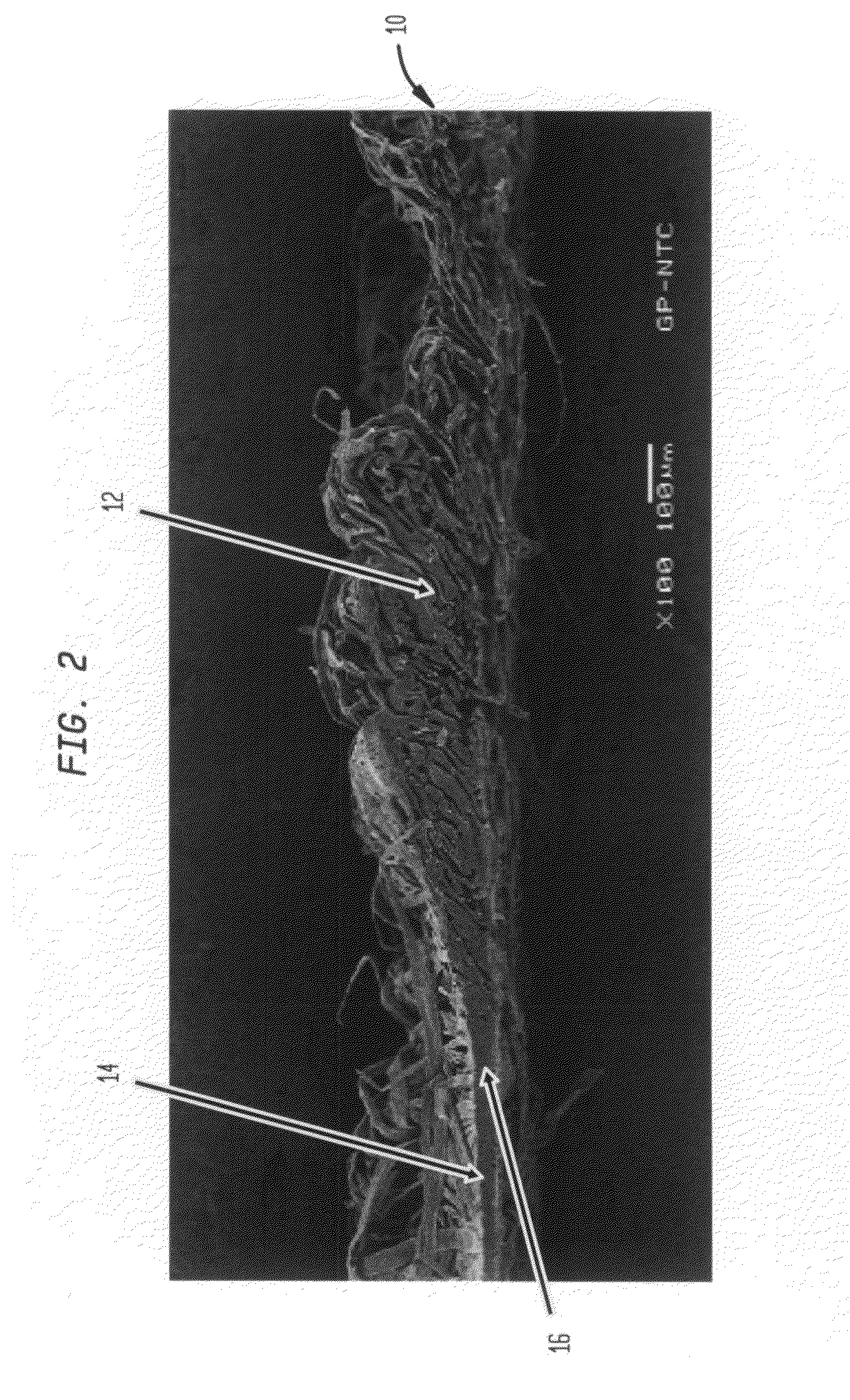

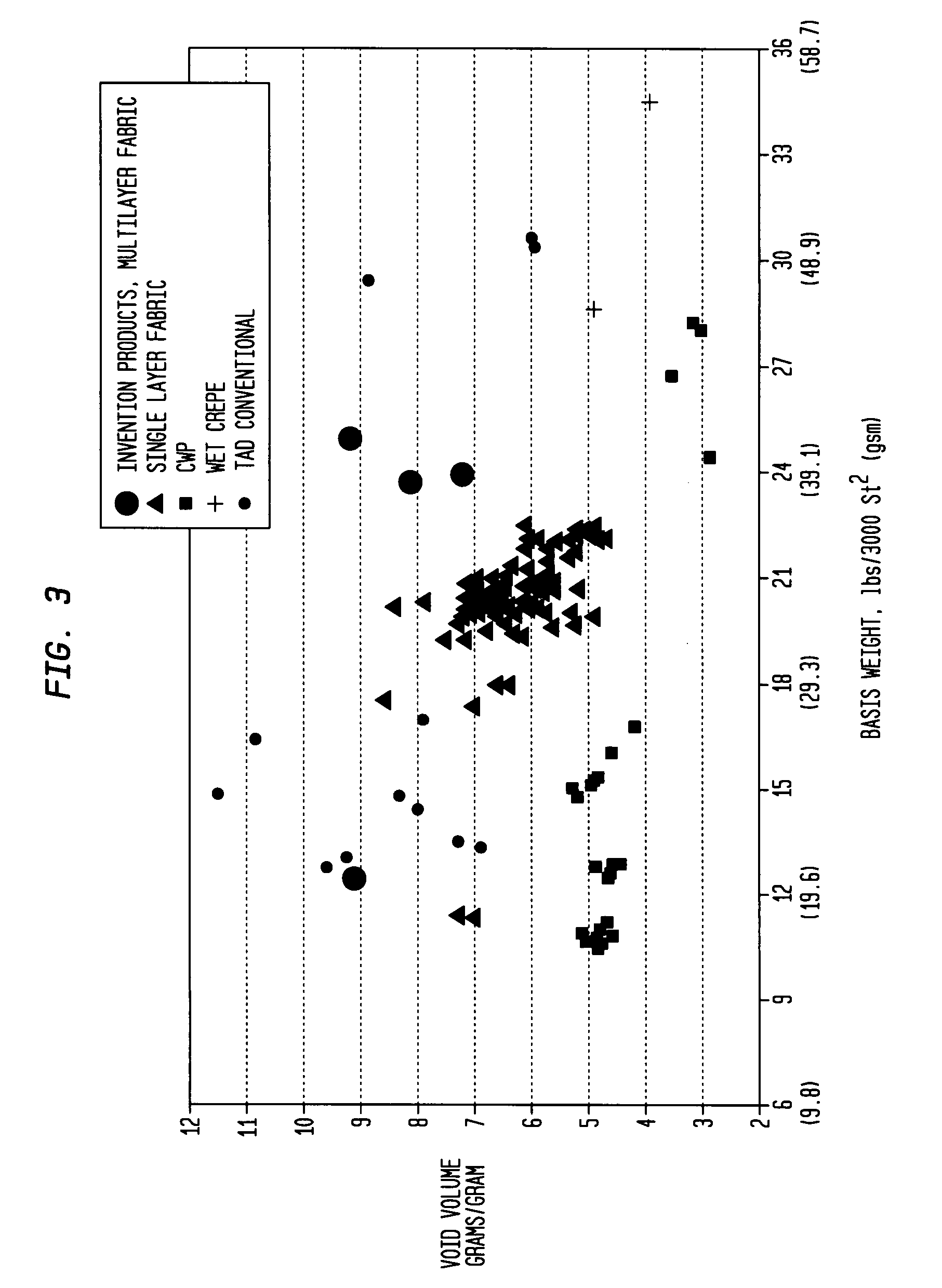

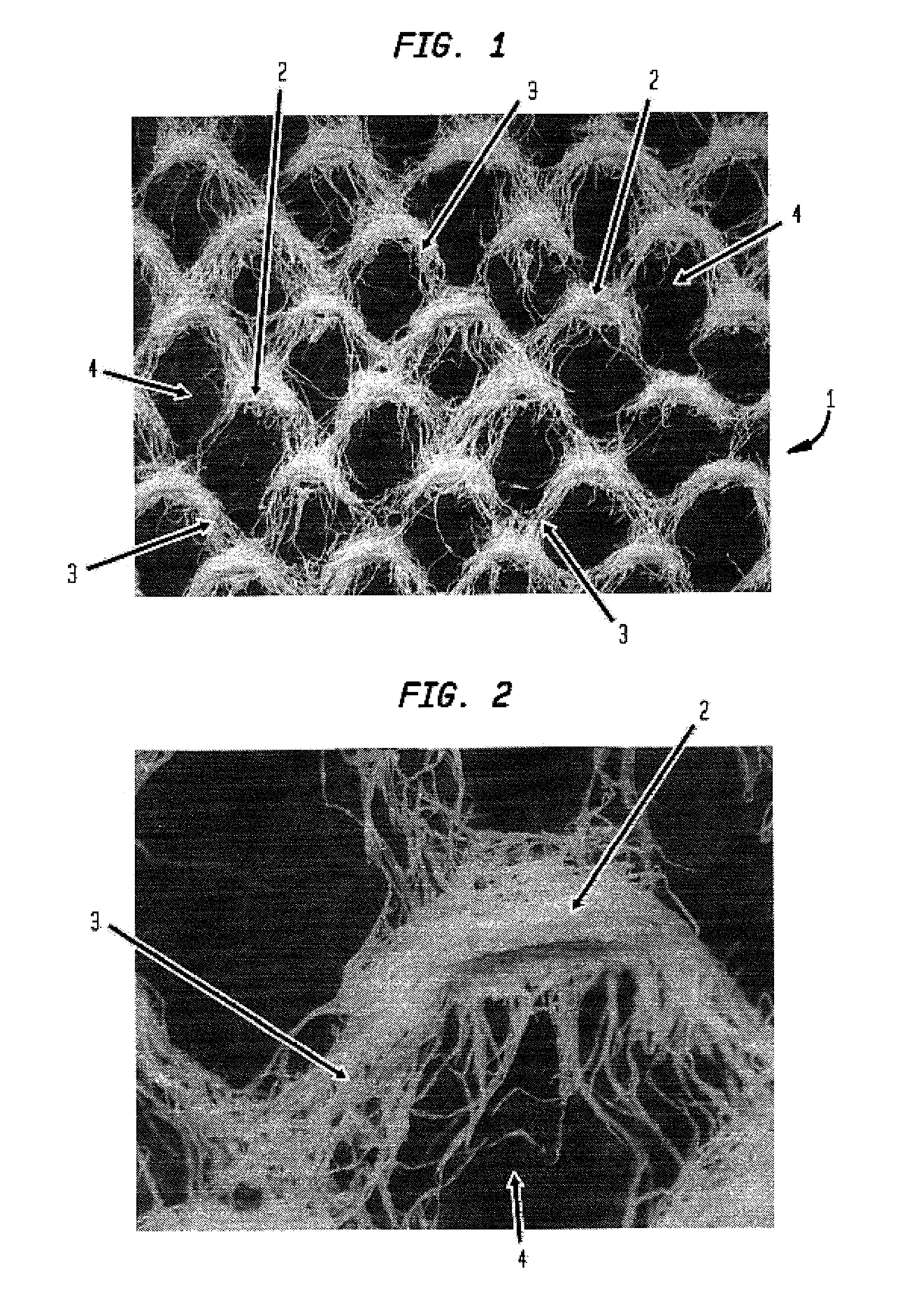

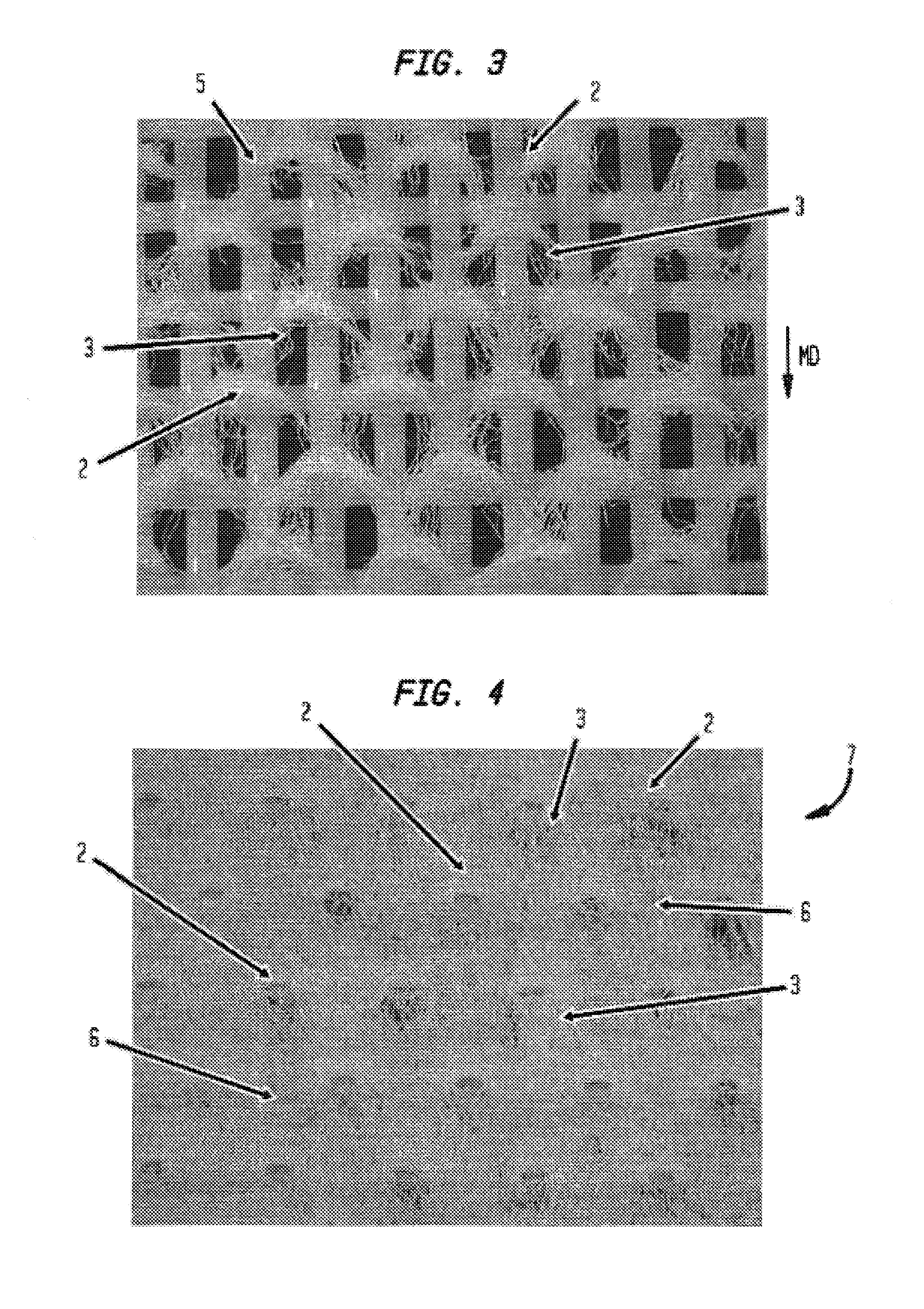

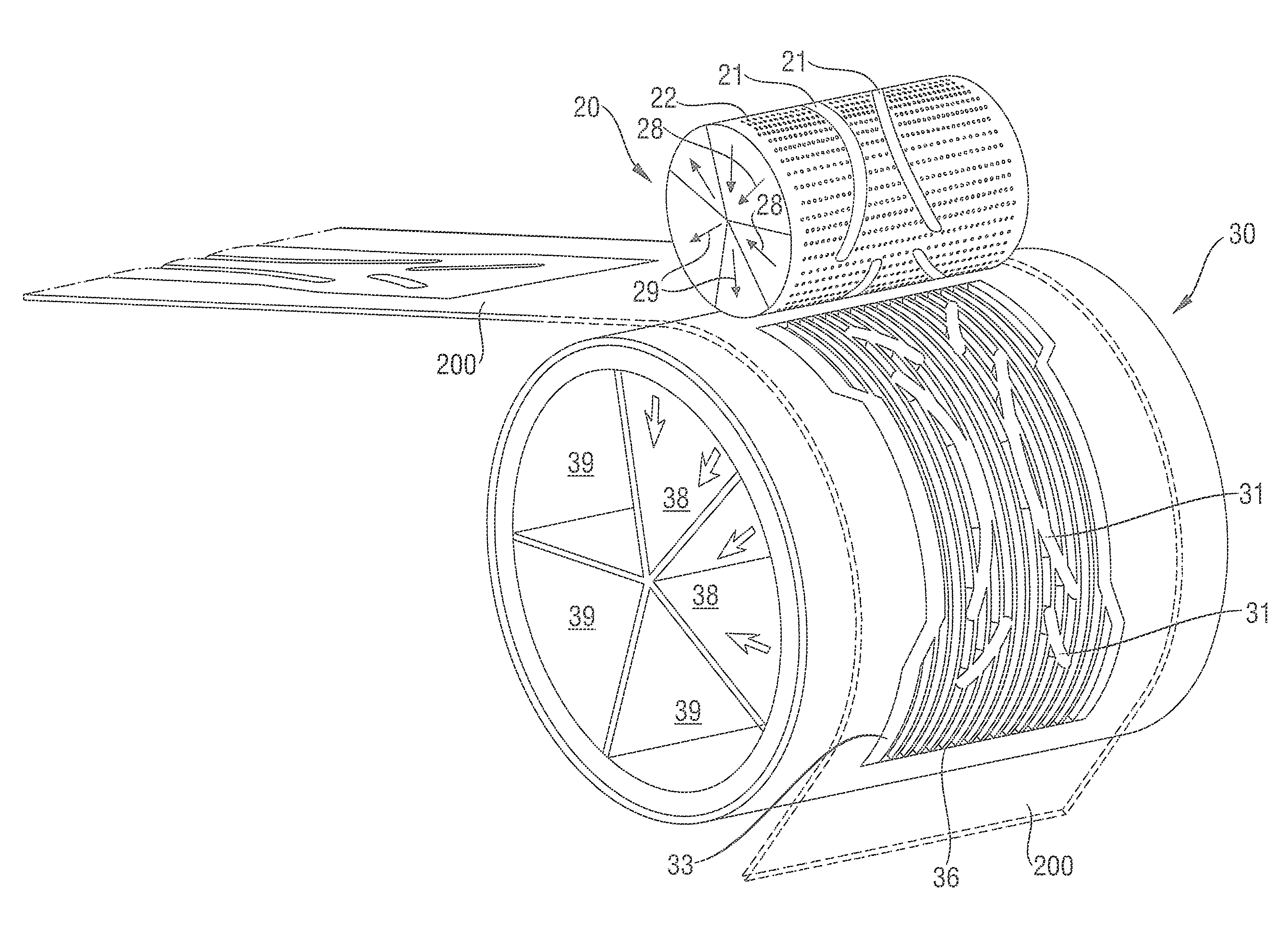

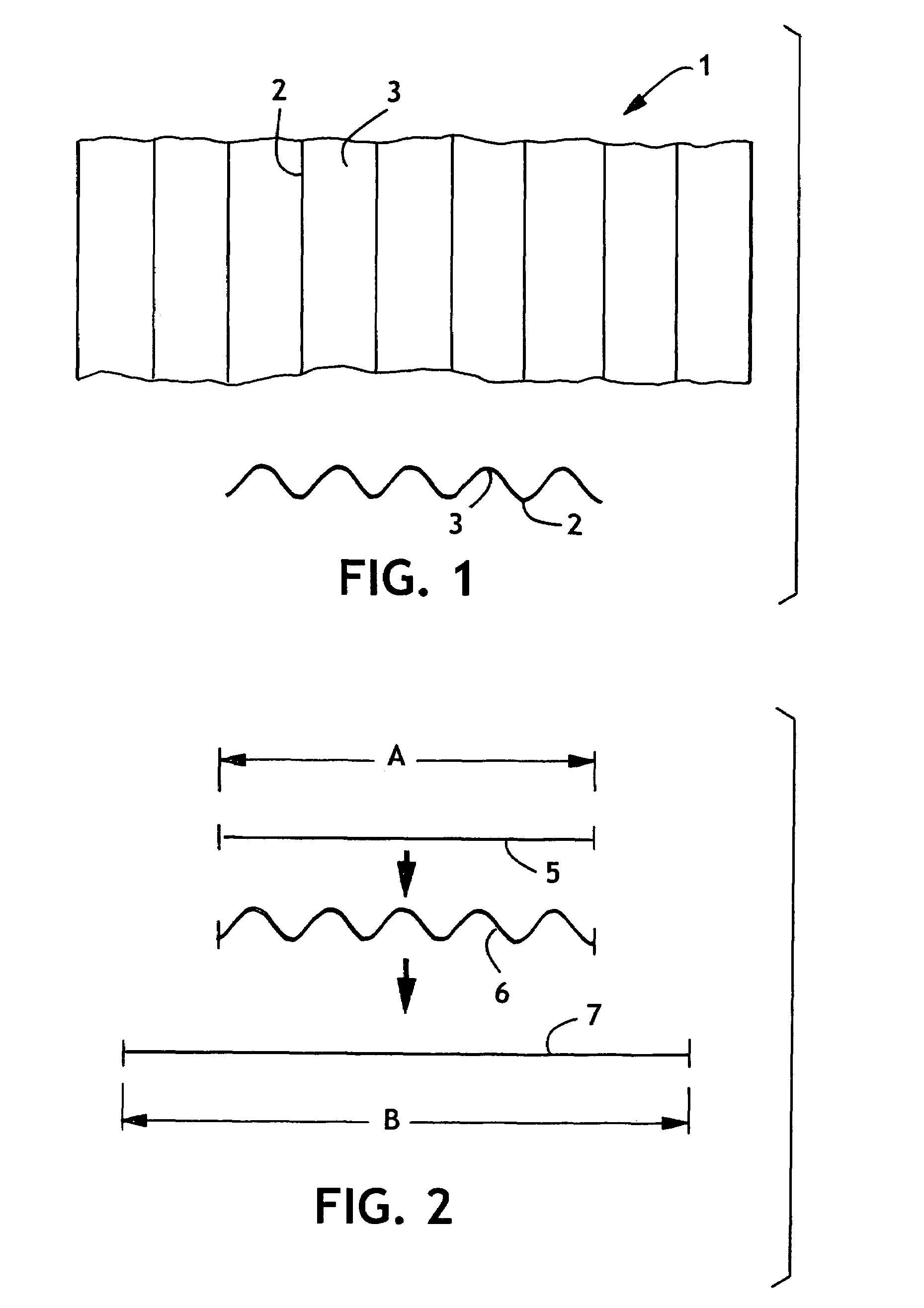

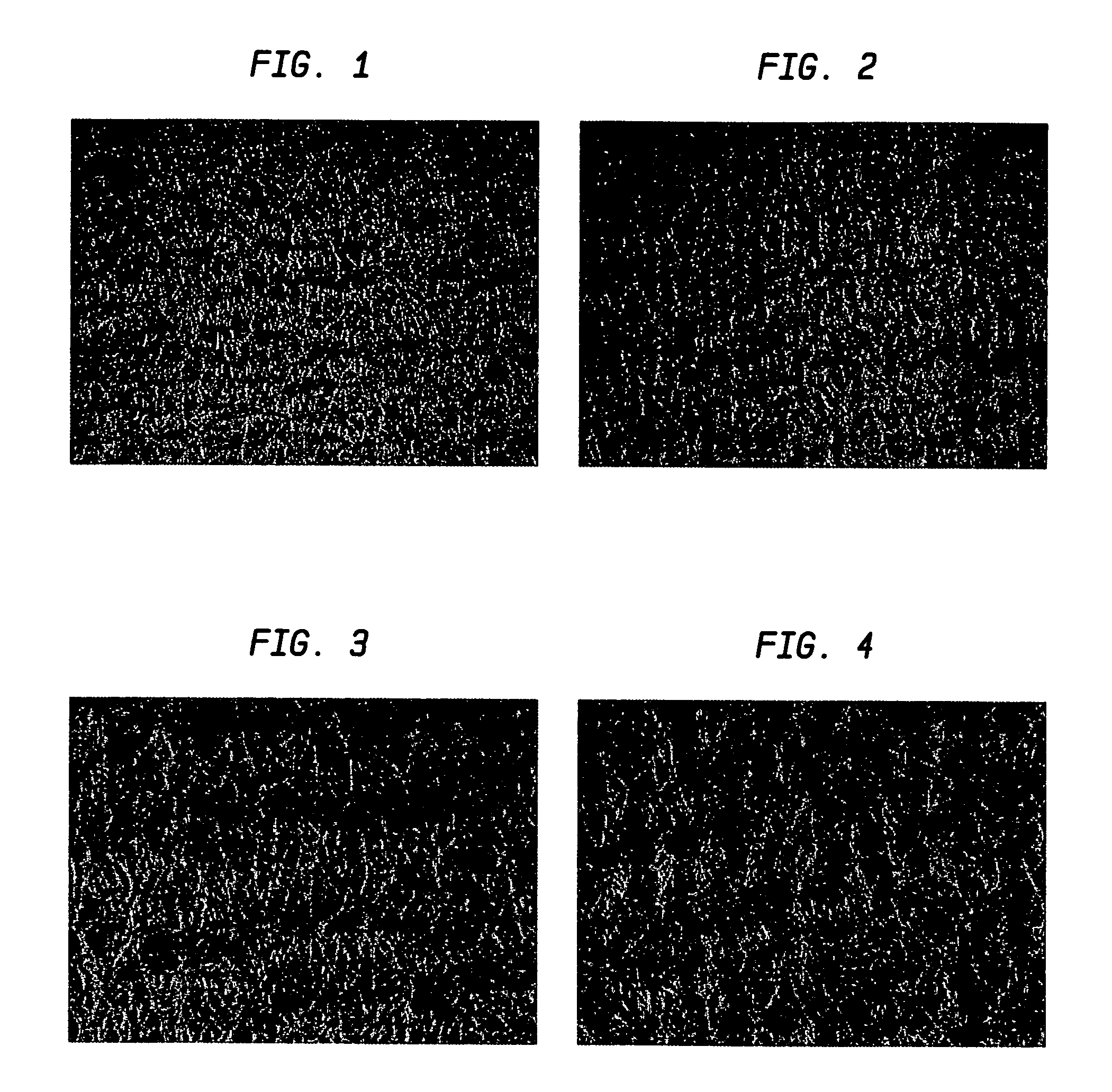

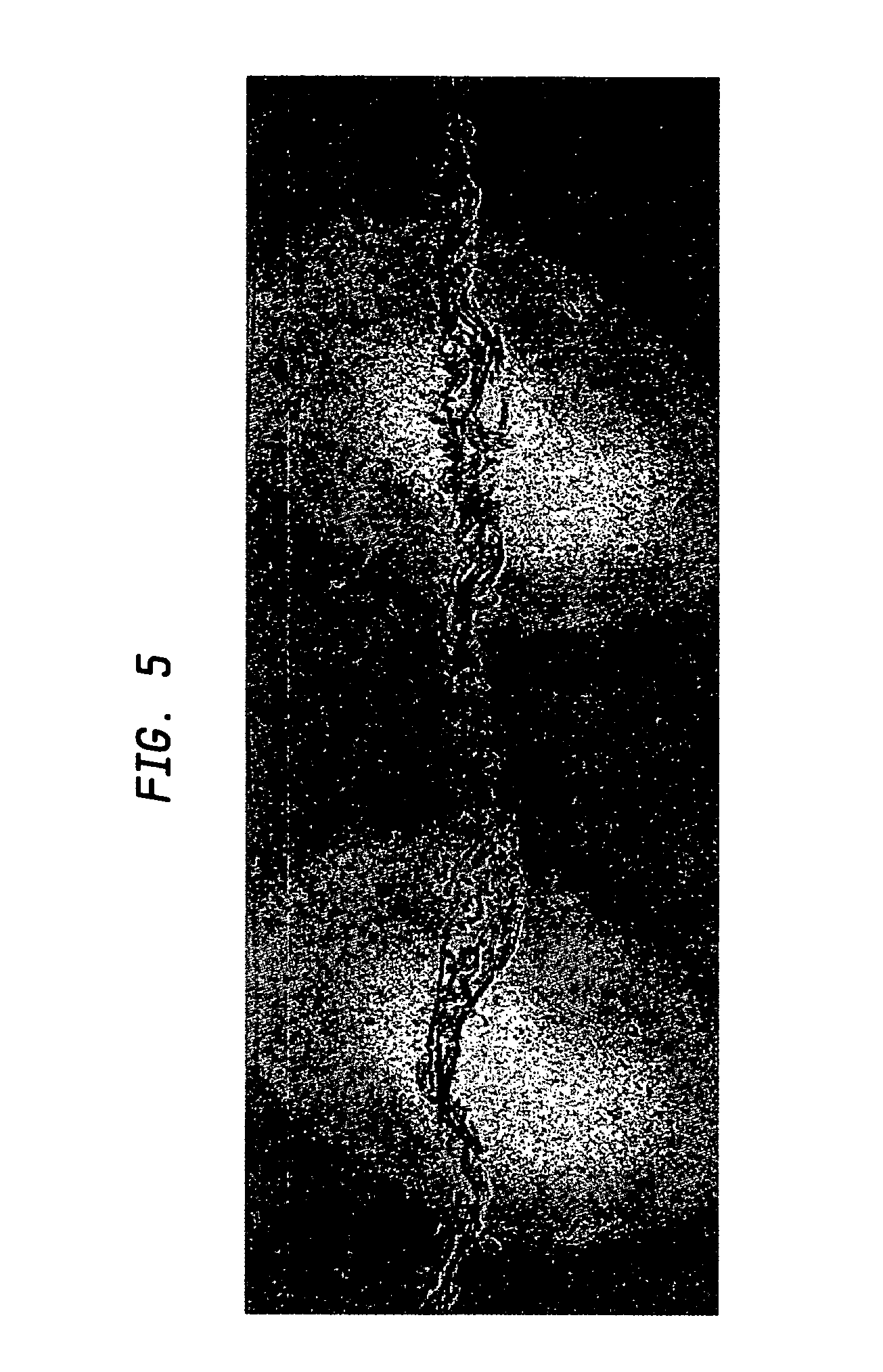

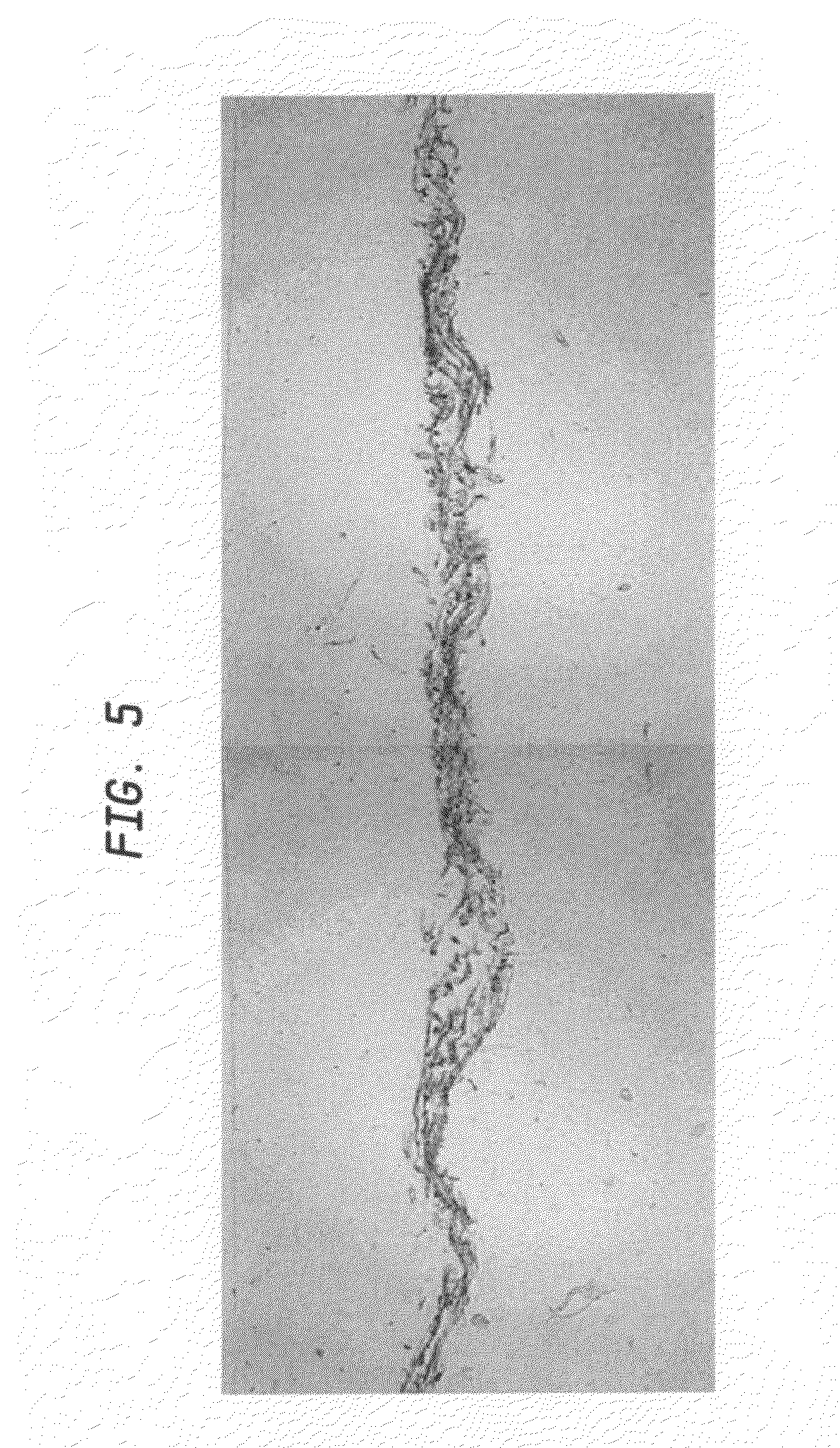

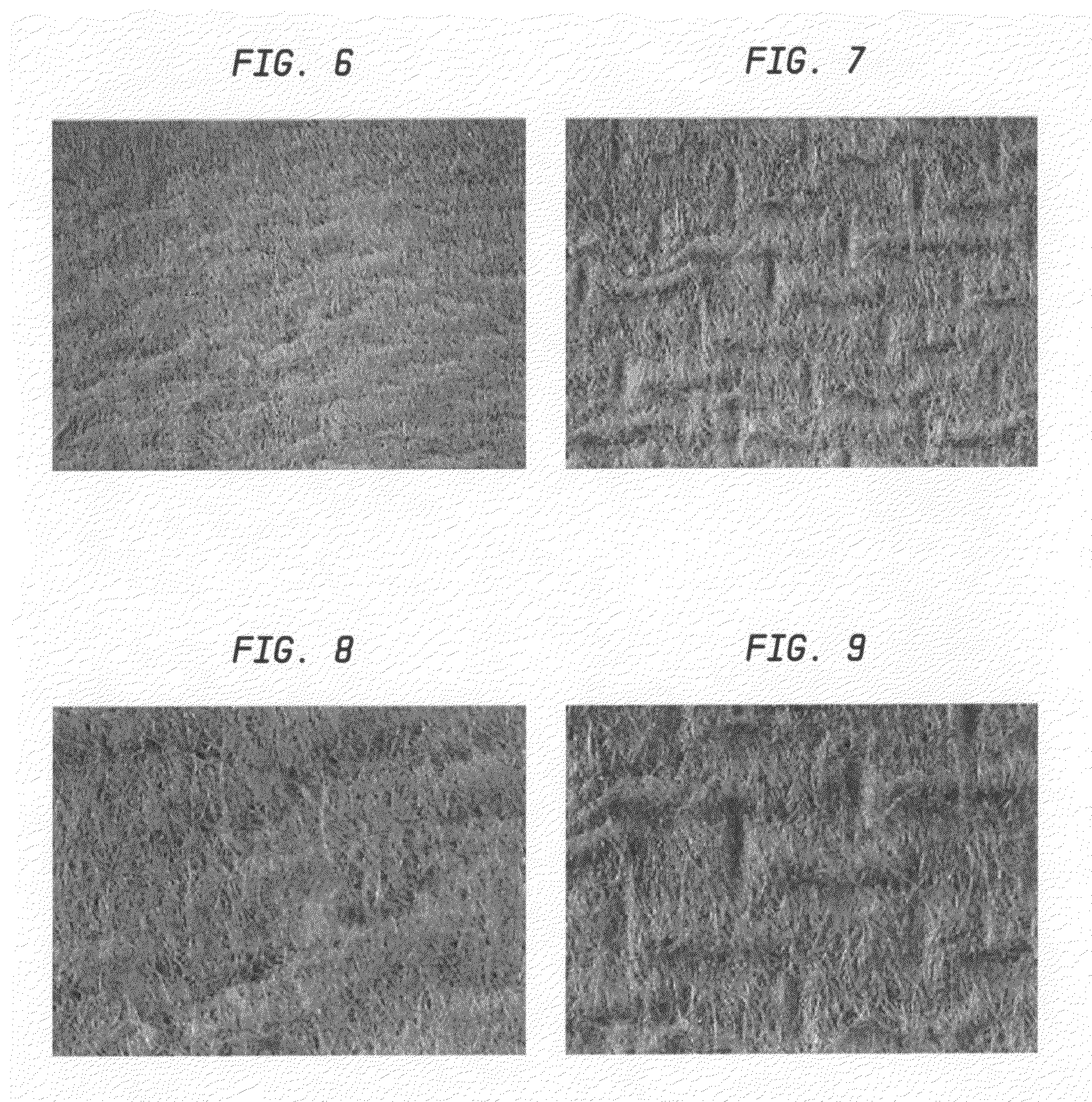

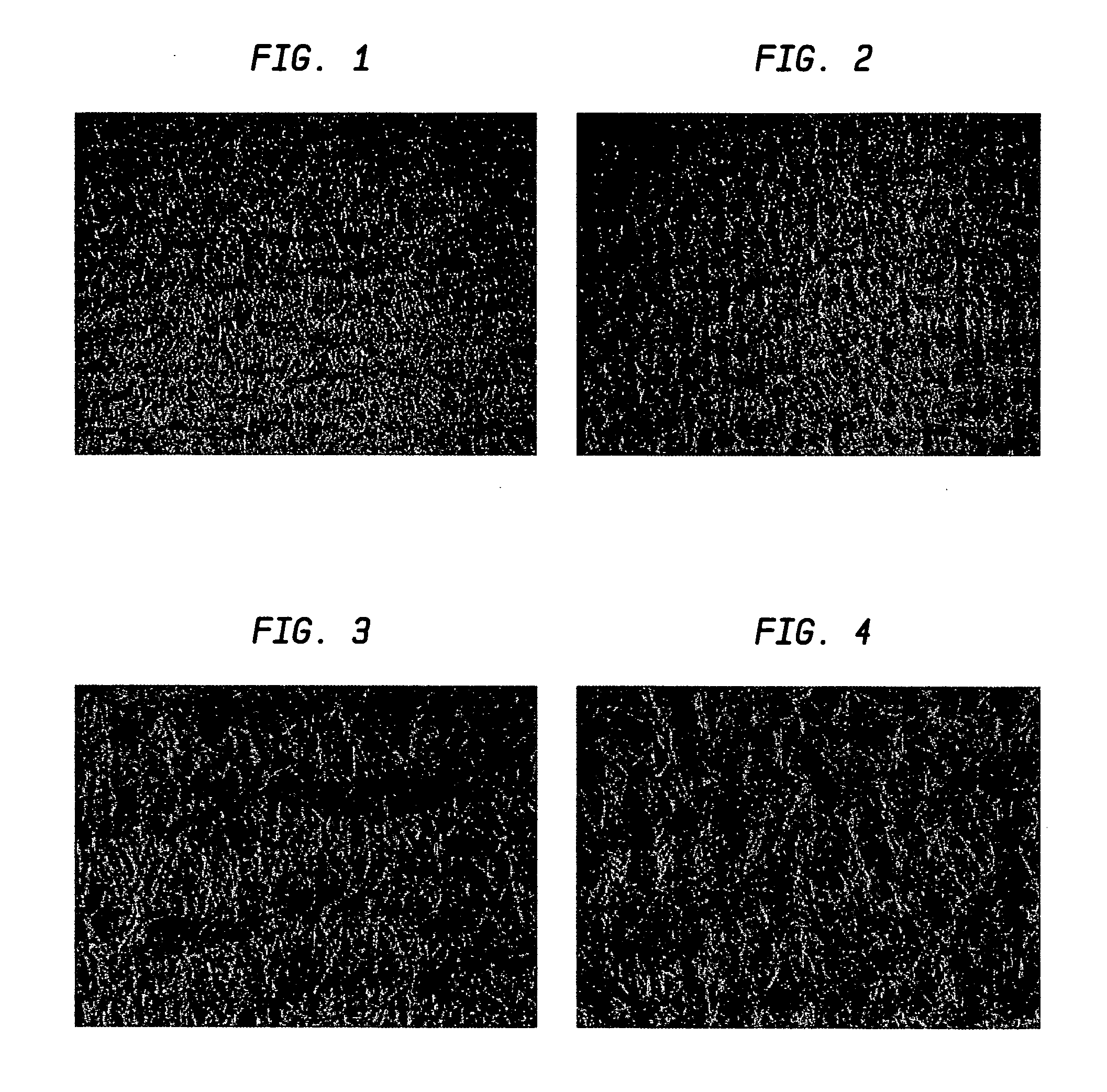

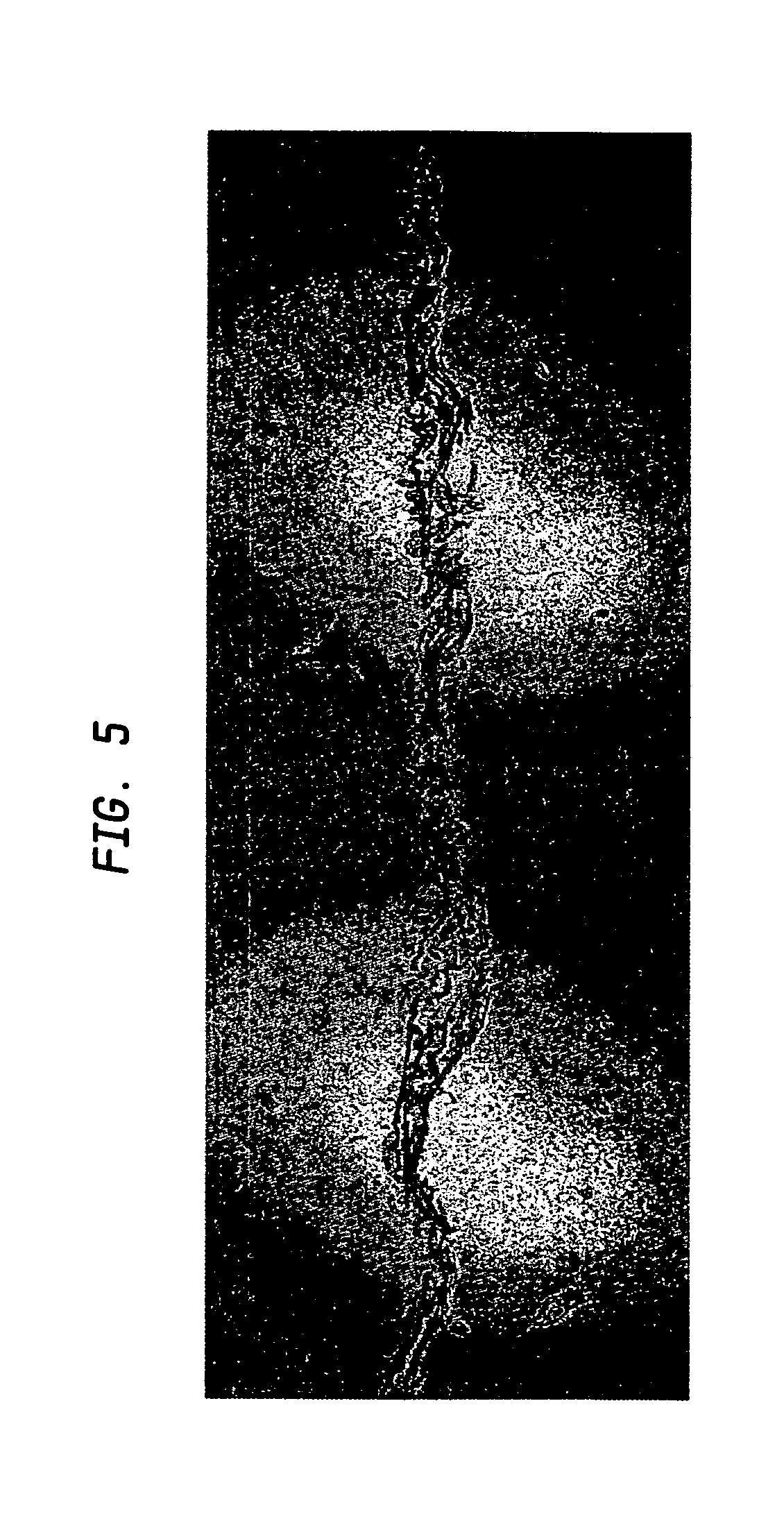

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

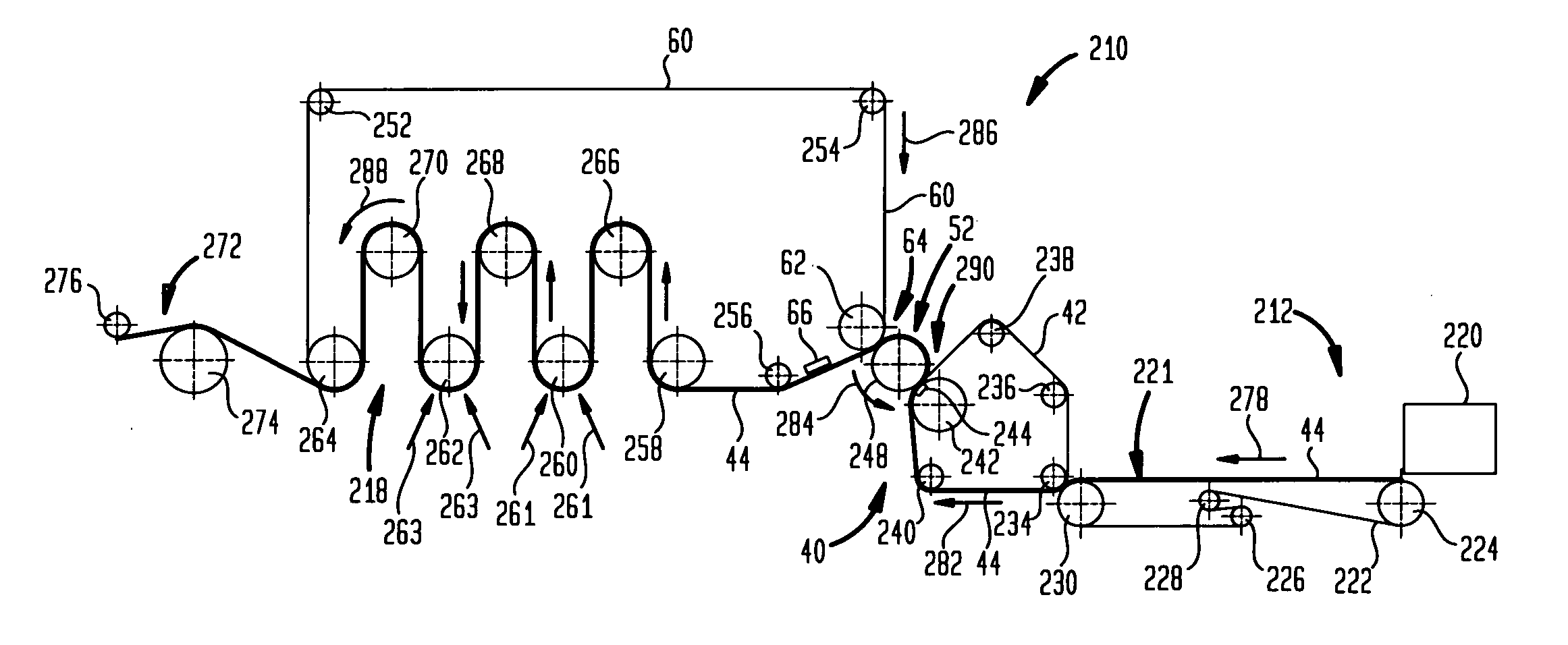

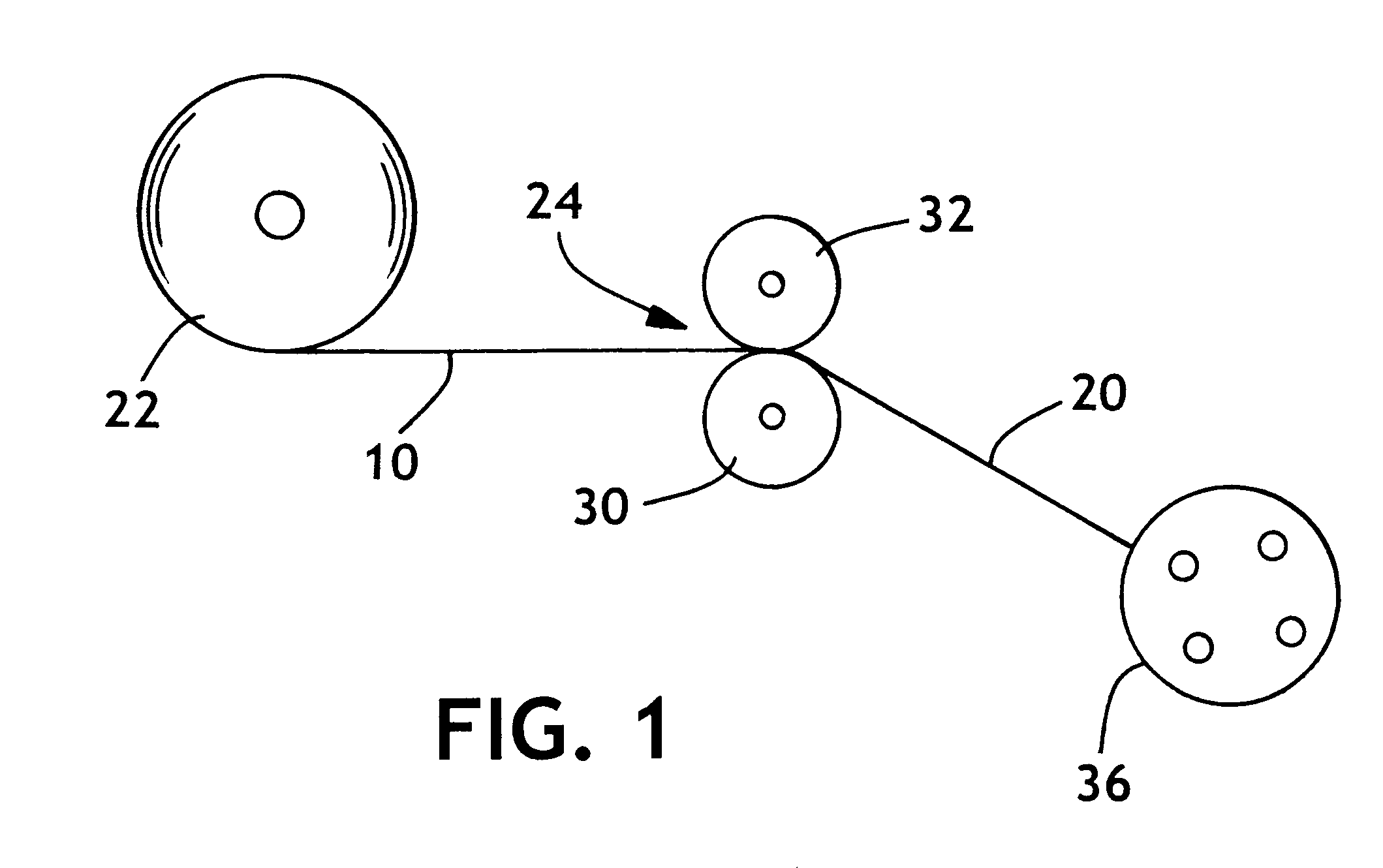

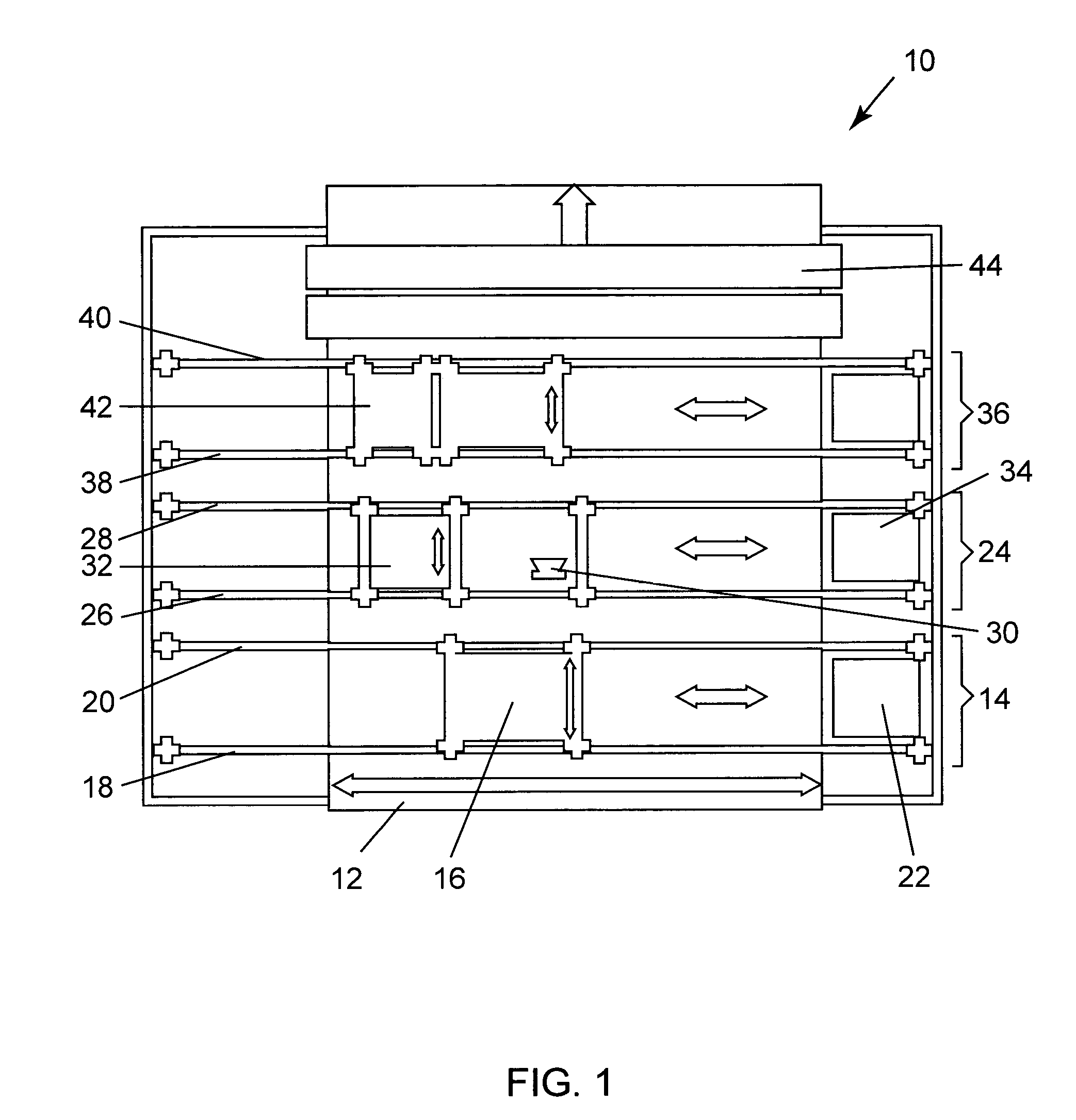

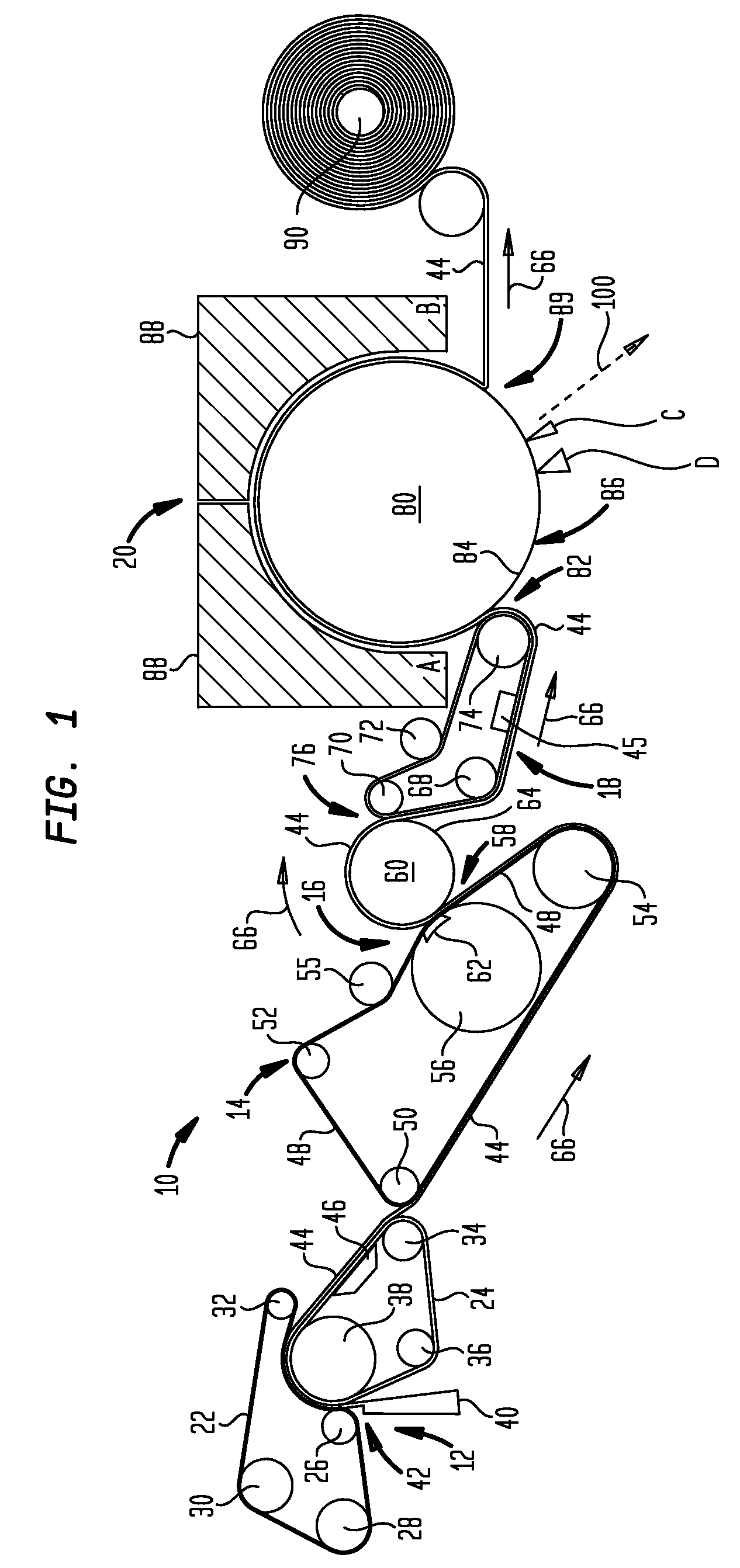

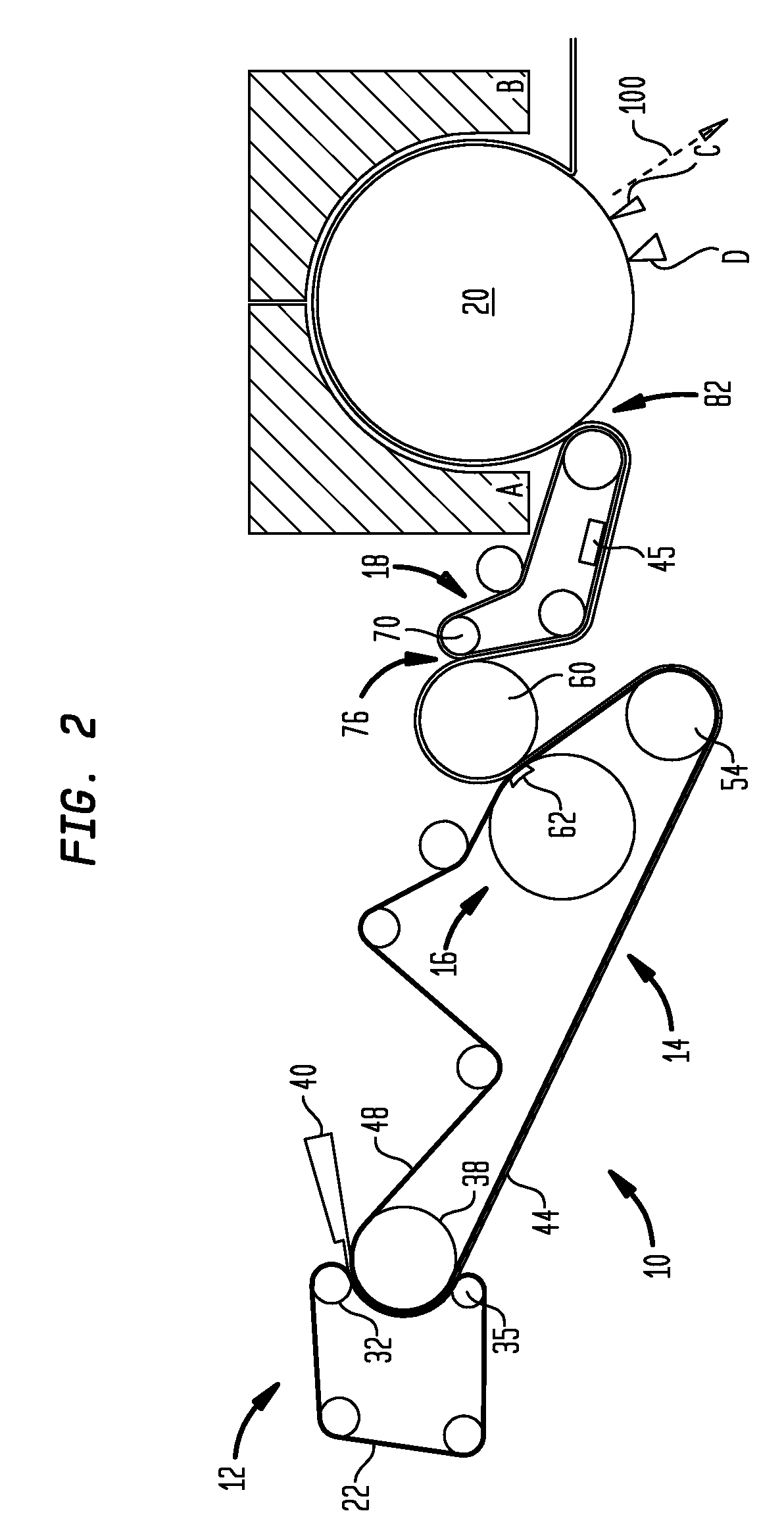

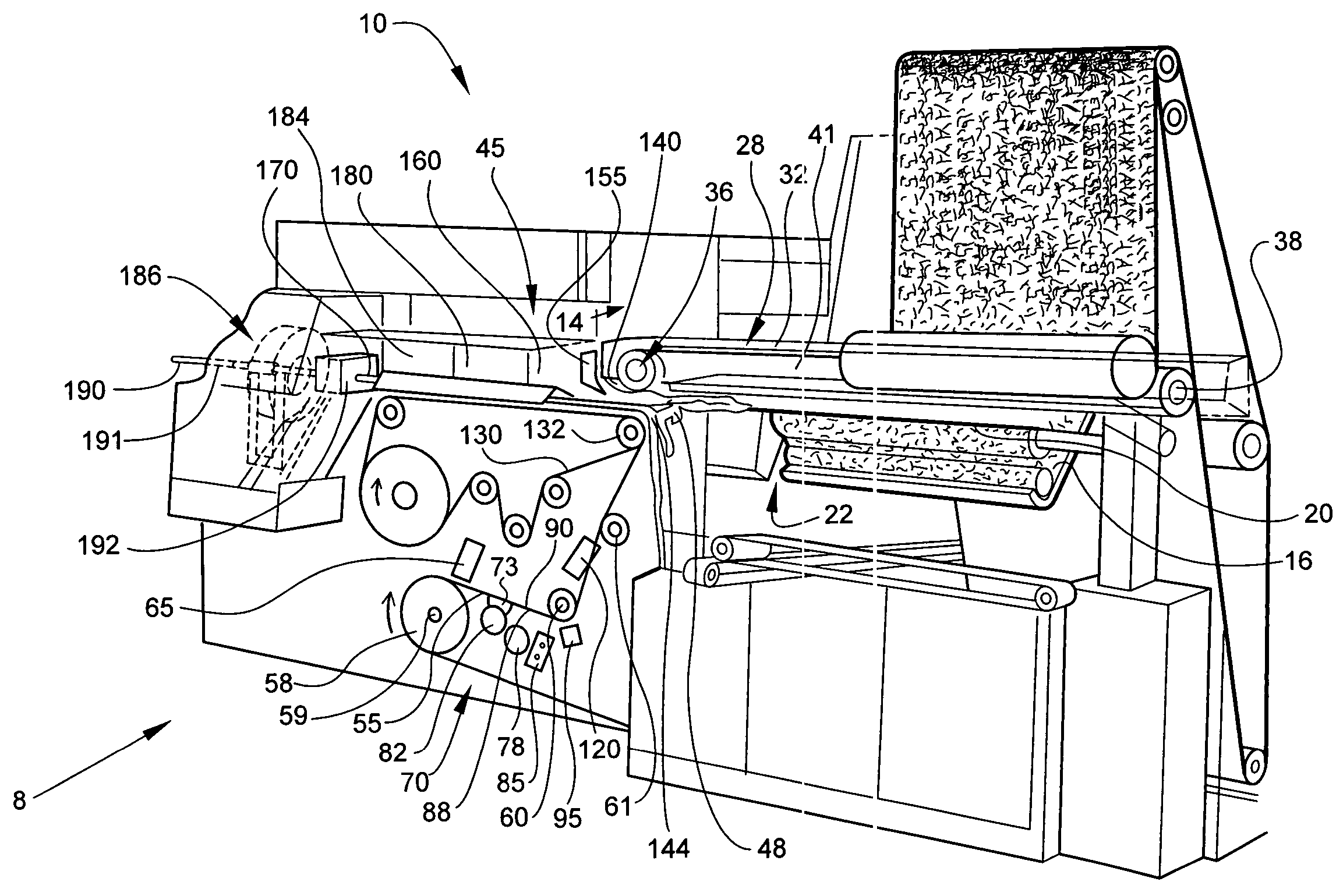

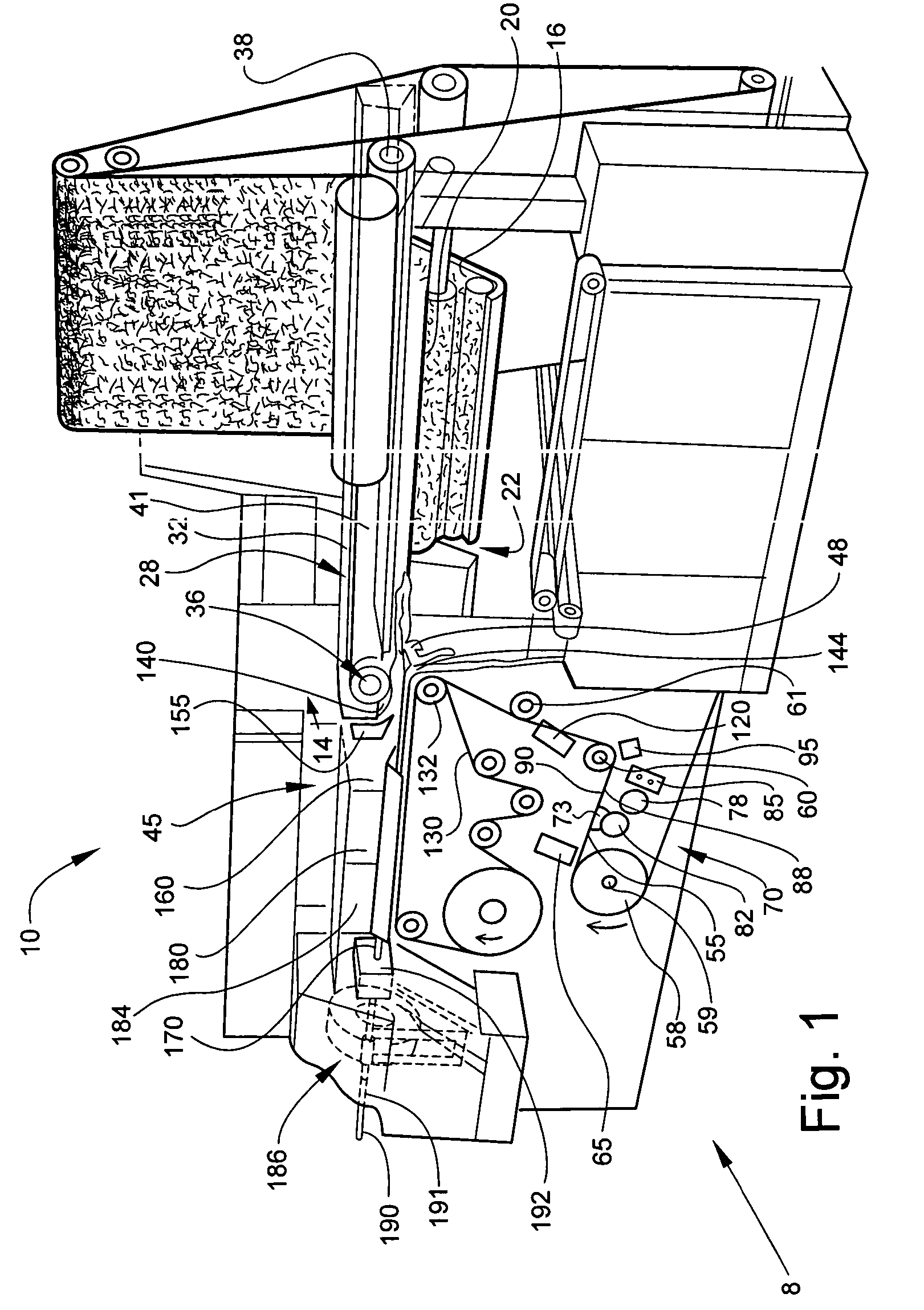

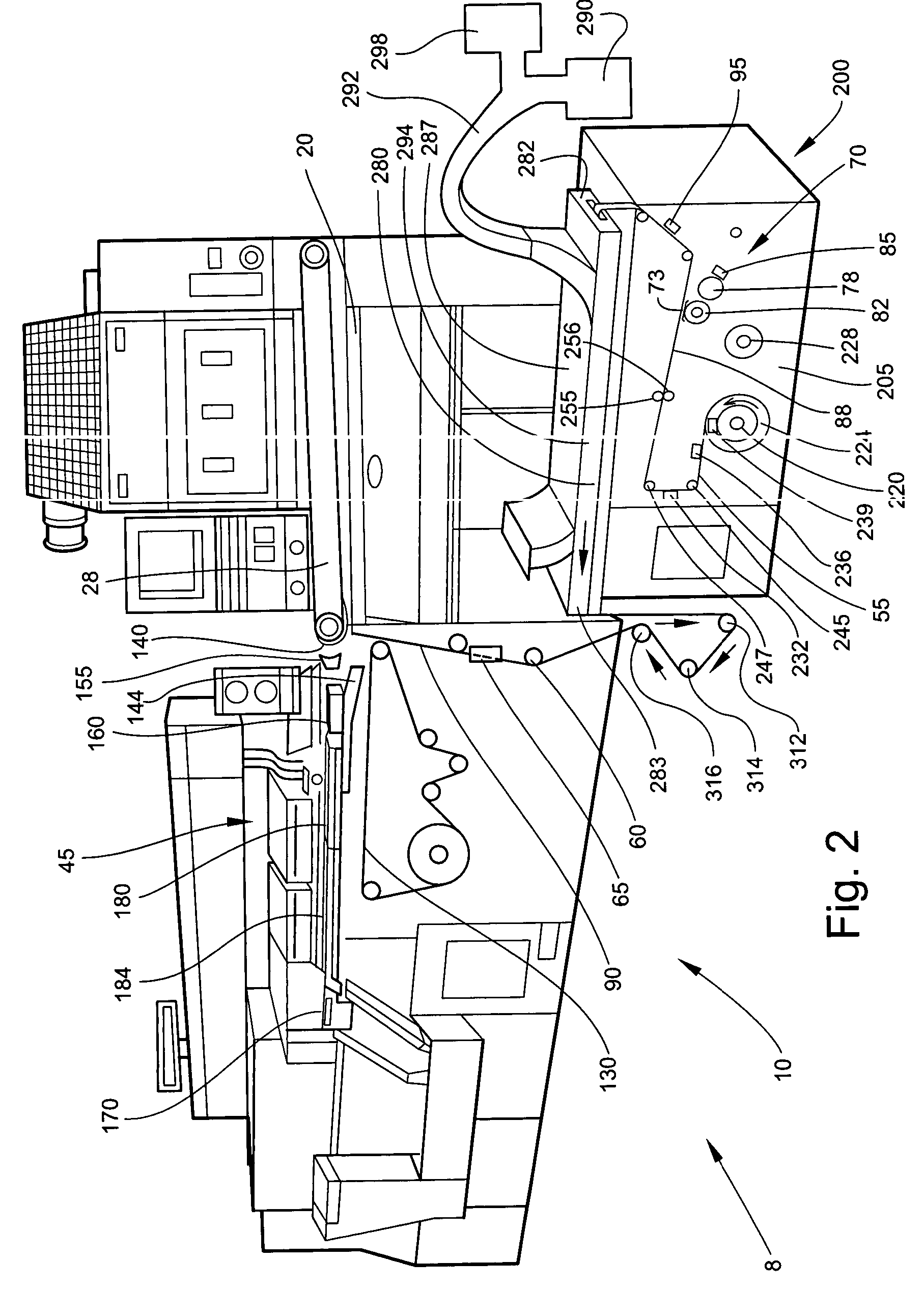

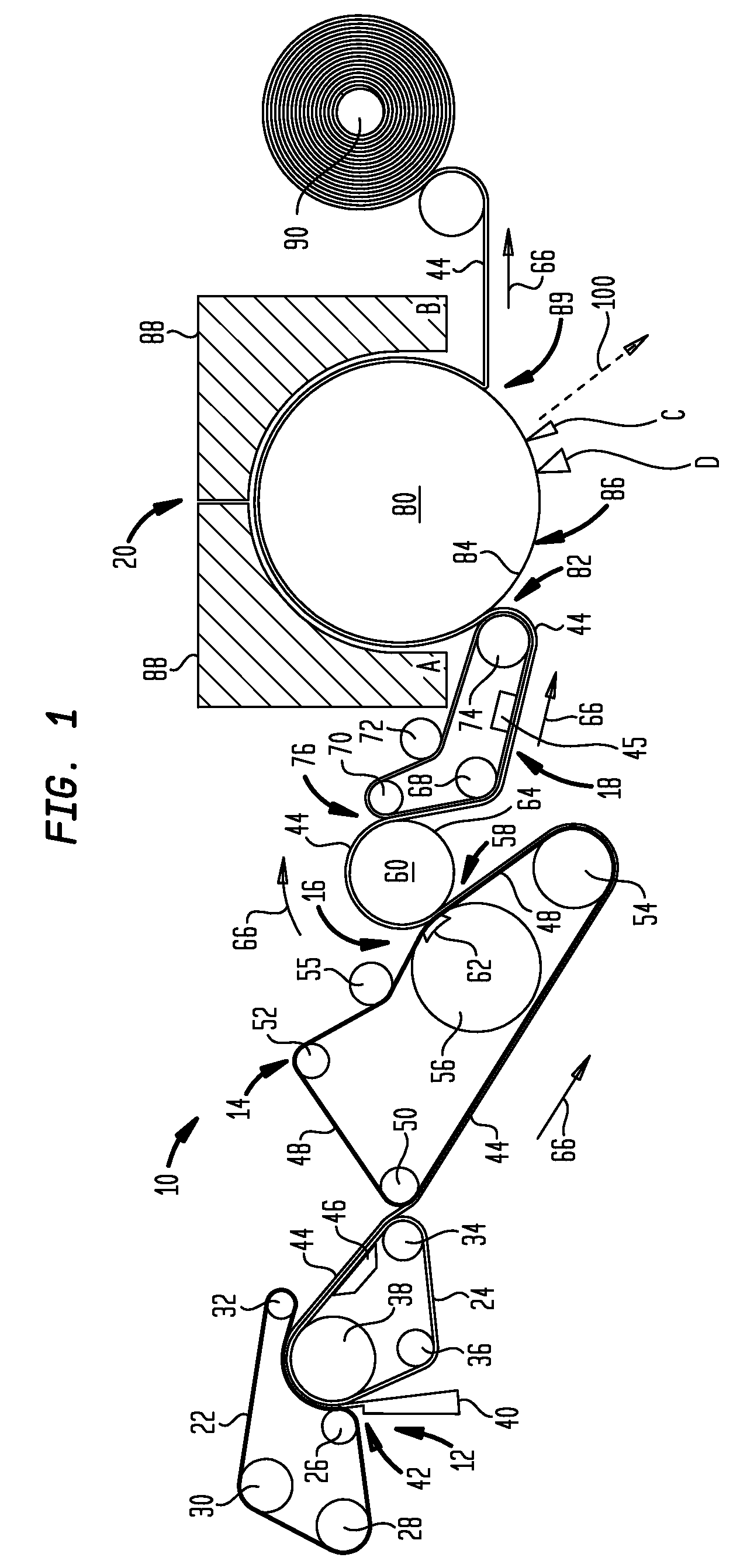

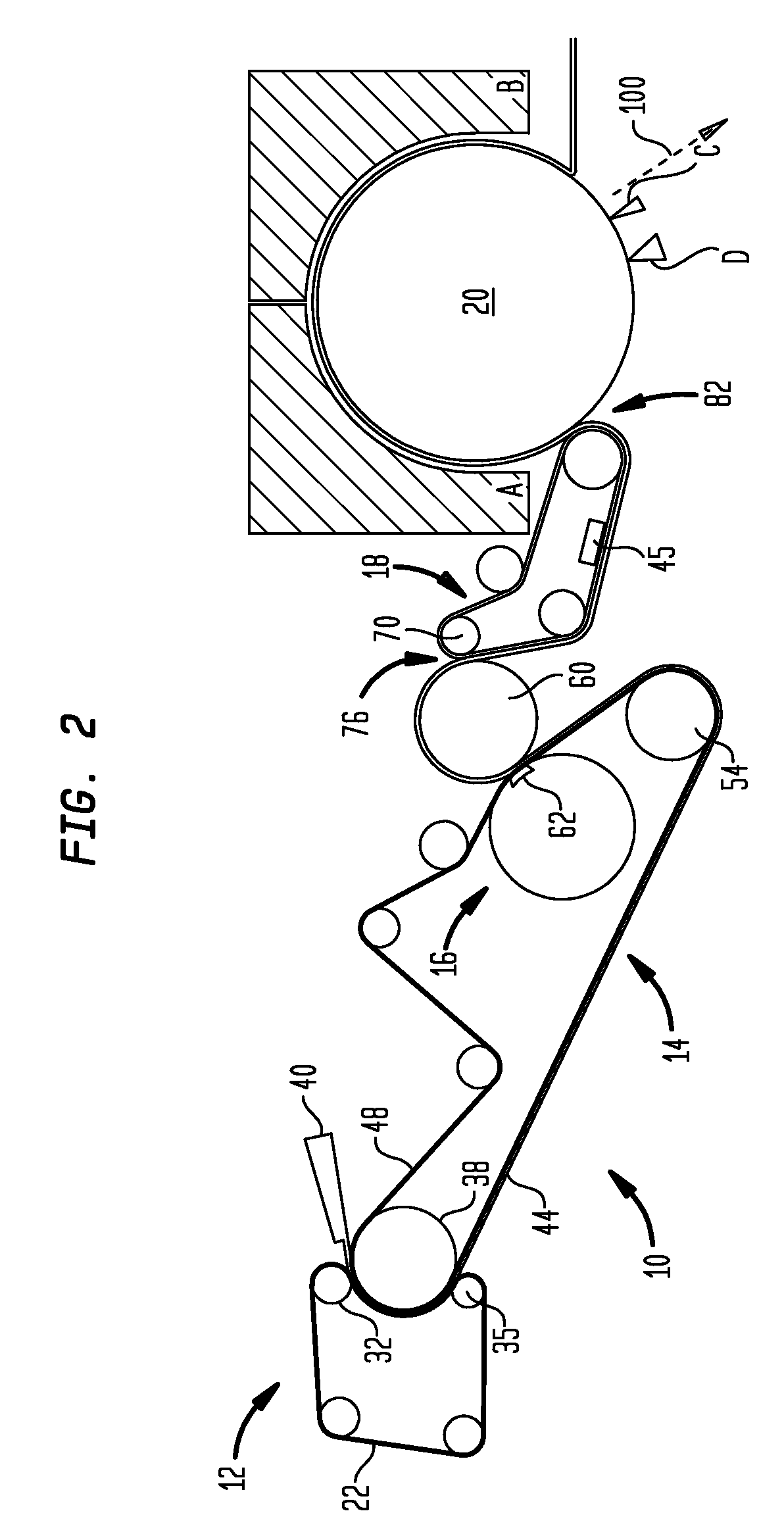

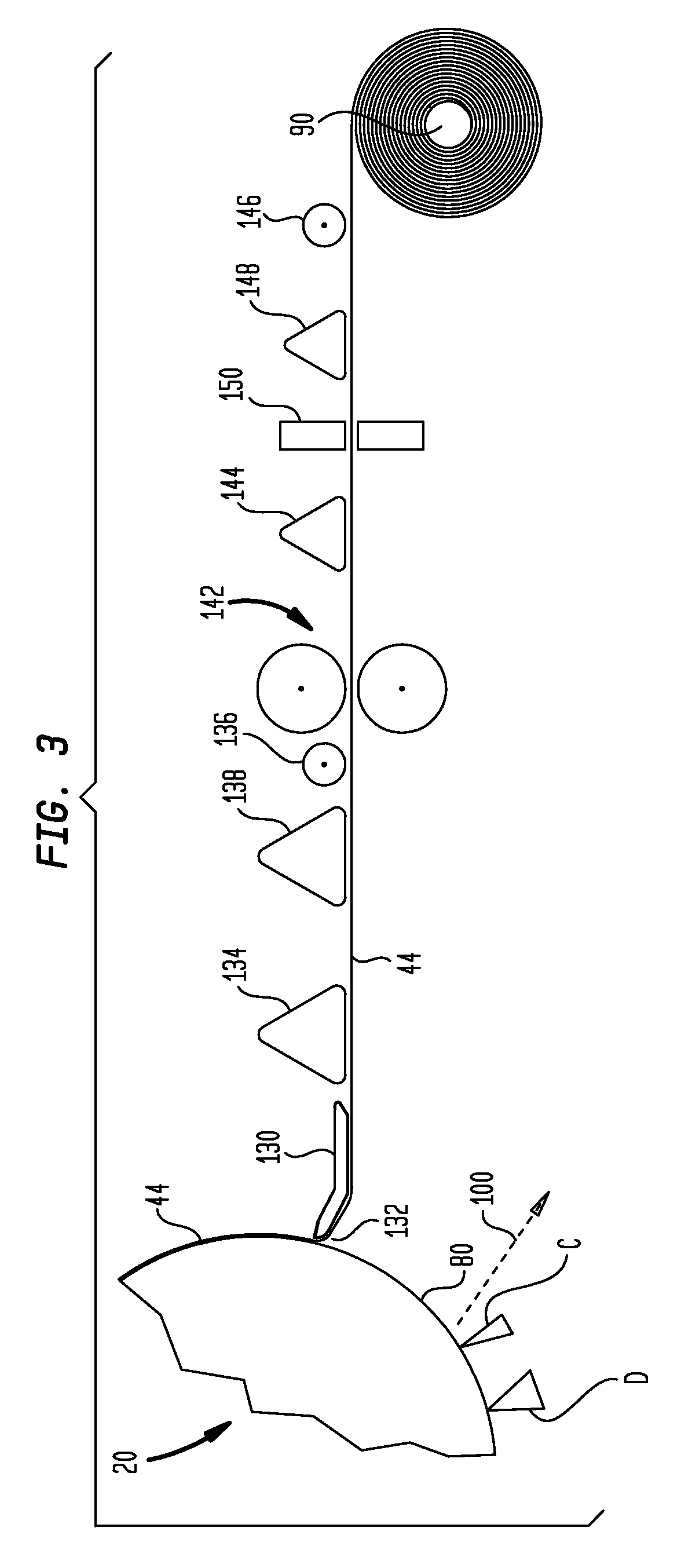

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

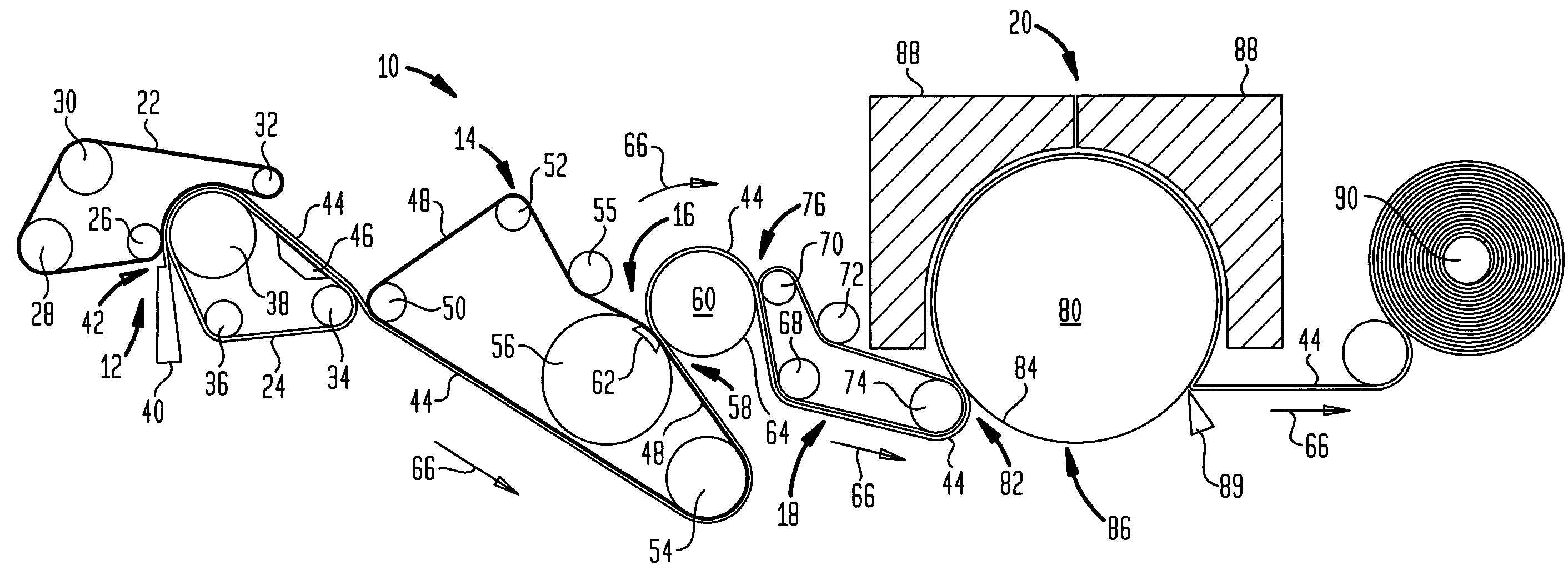

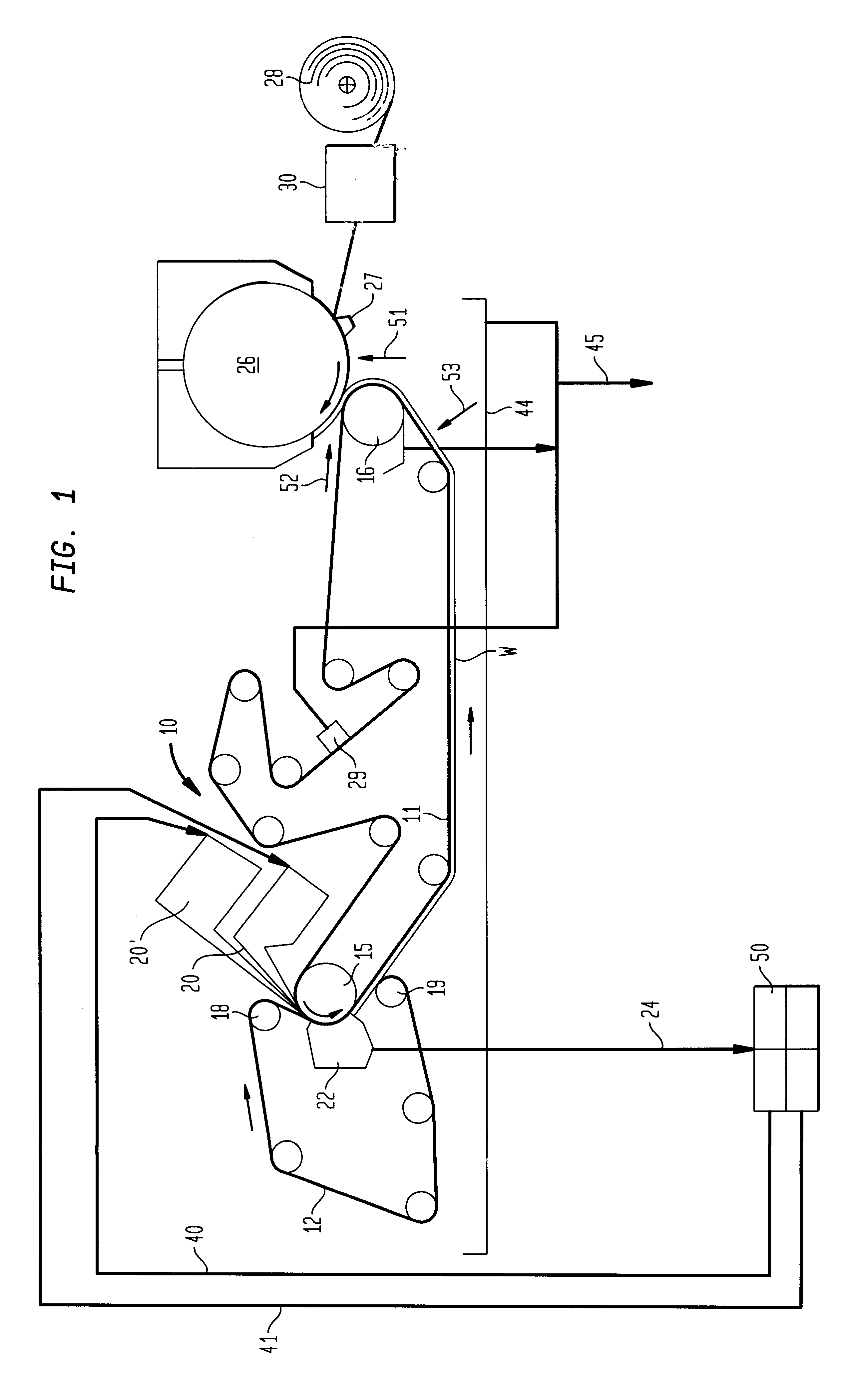

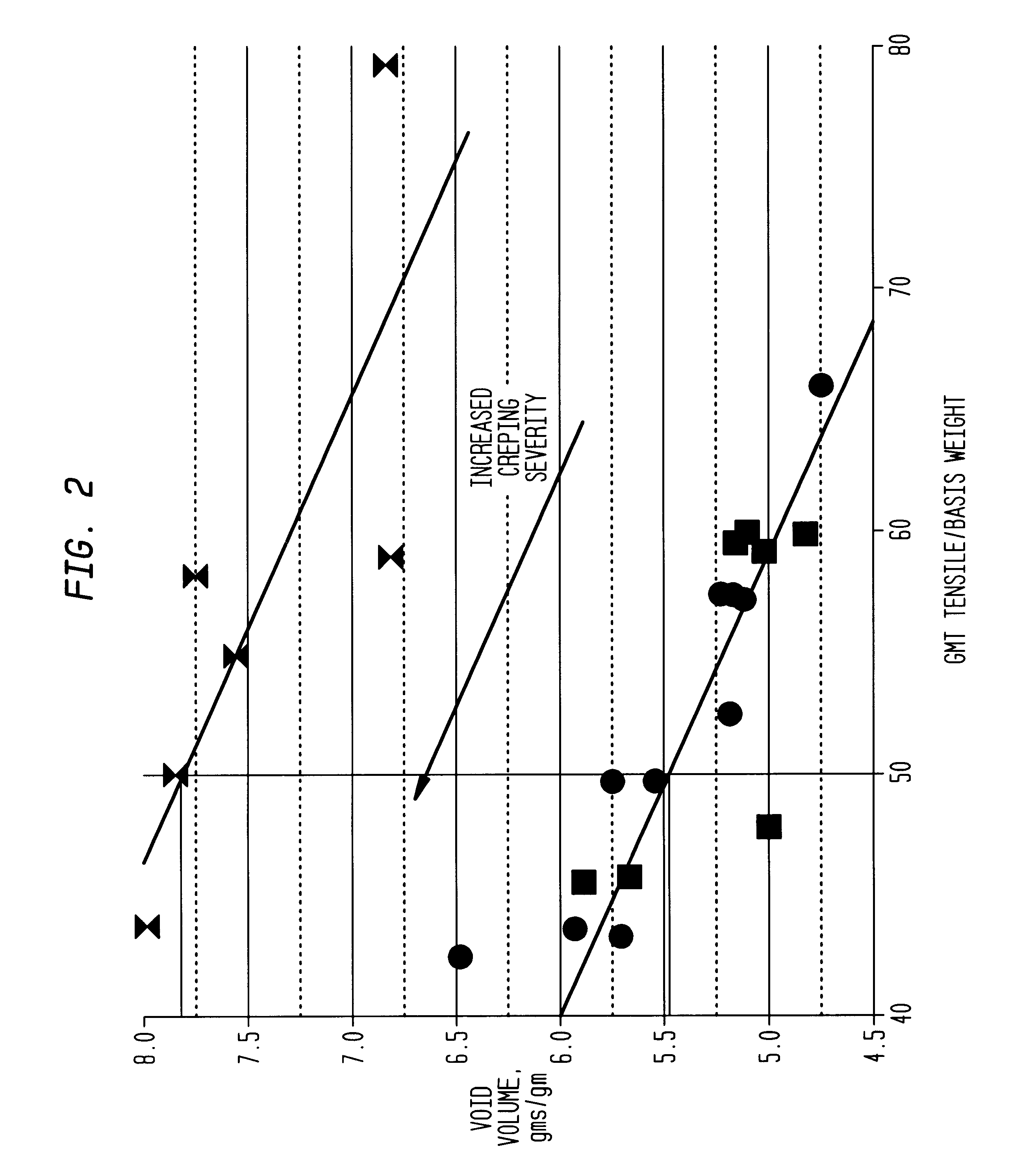

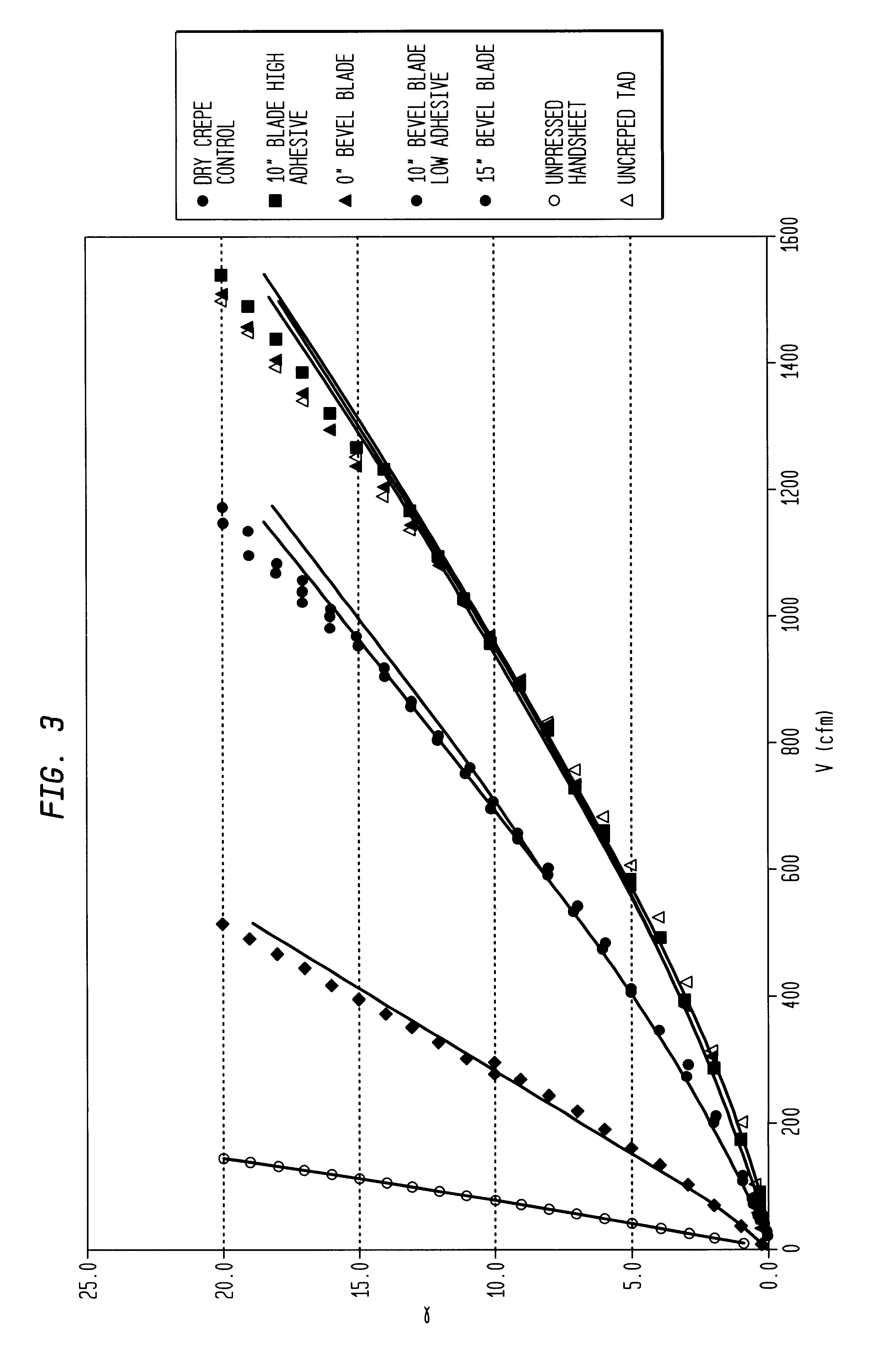

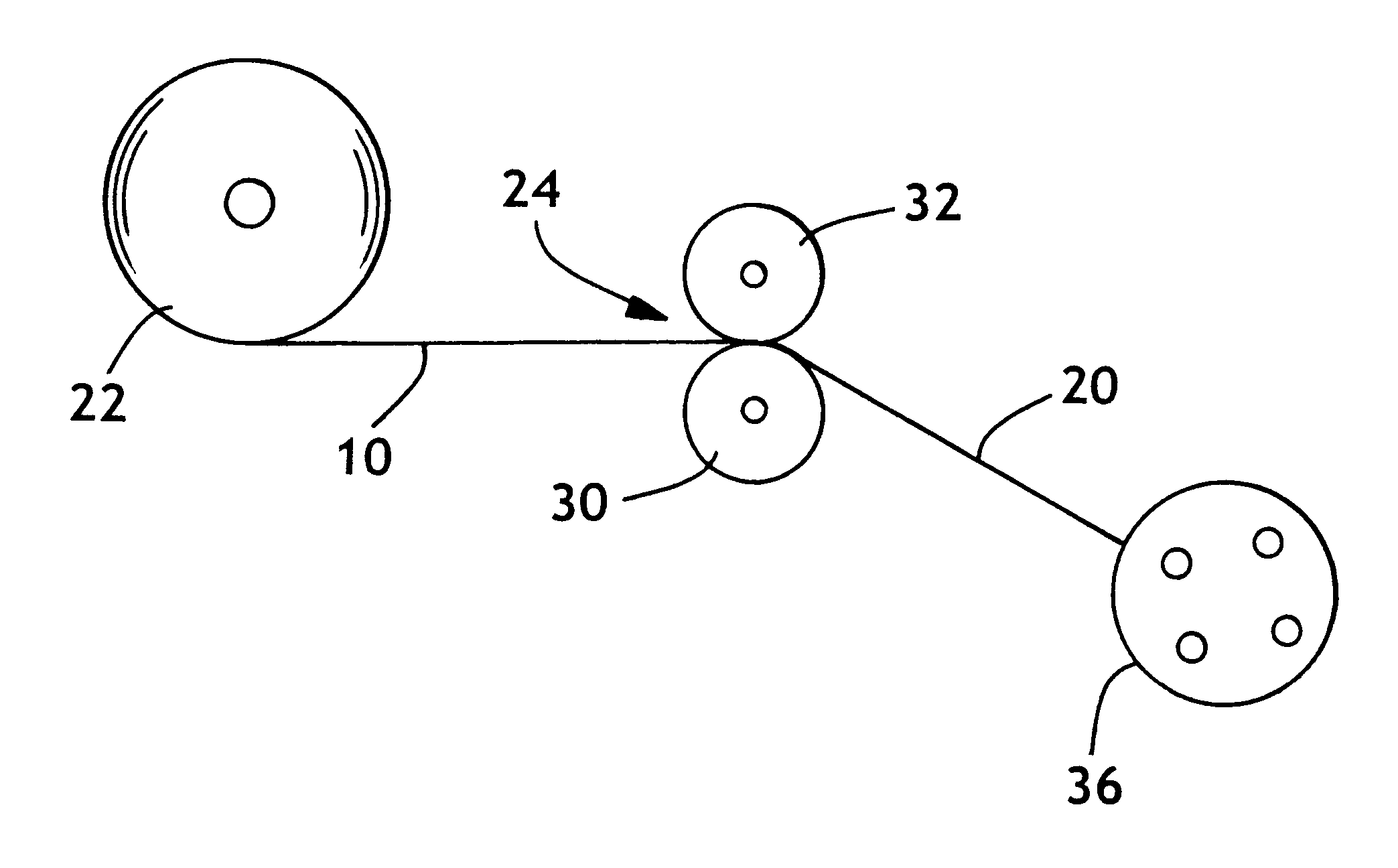

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

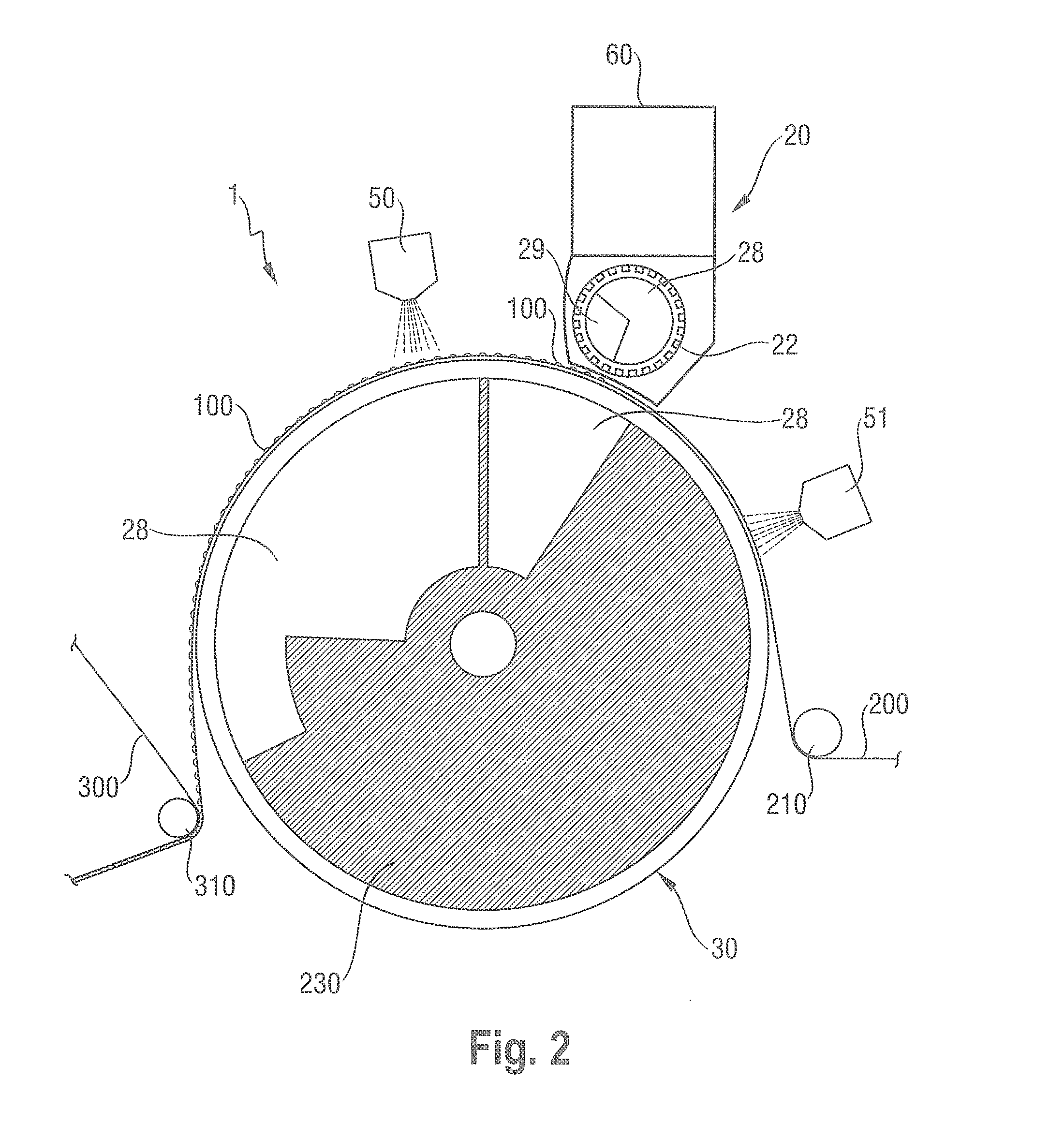

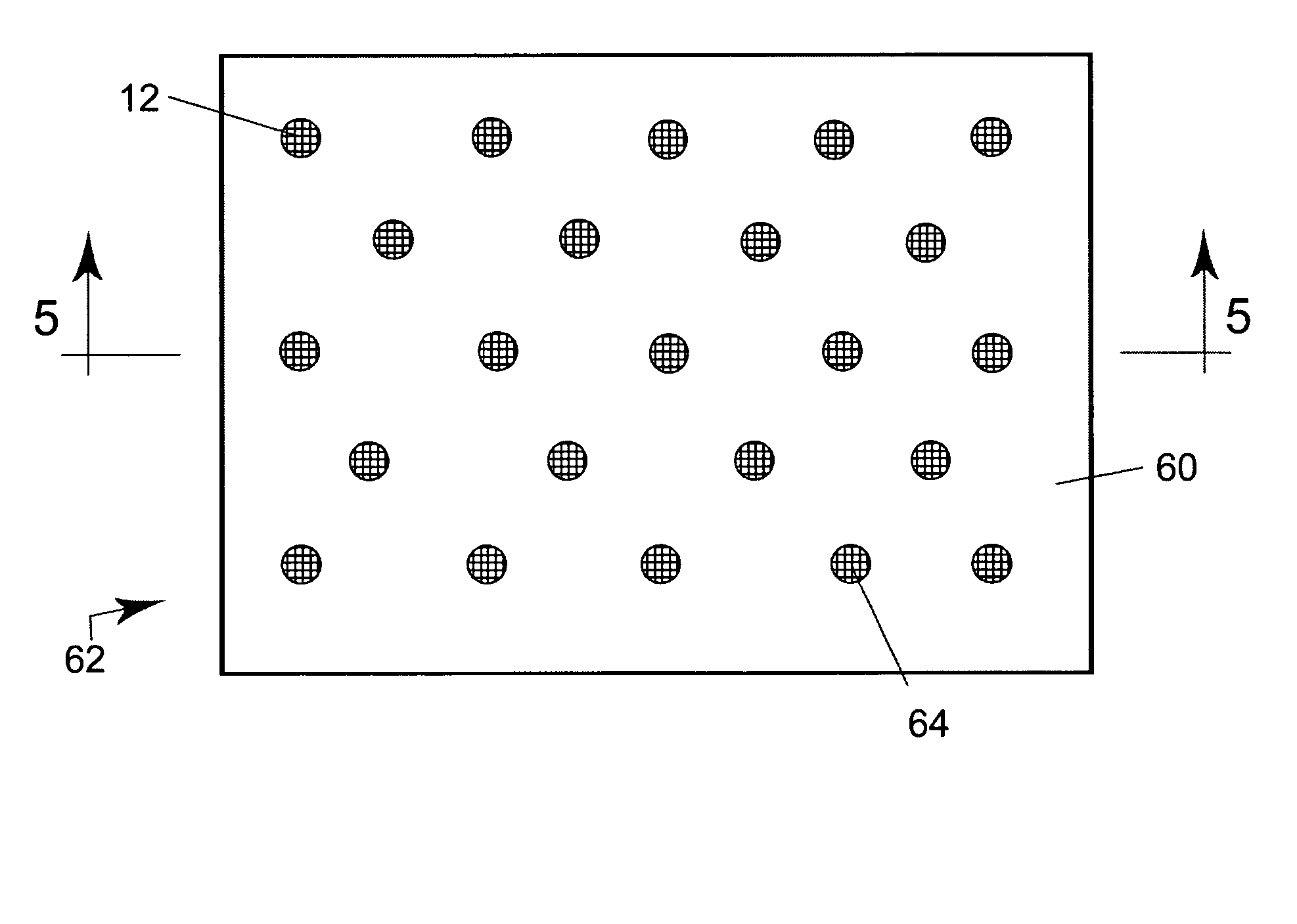

Method and Apparatus for Making Absorbent Structures with Absorbent Material

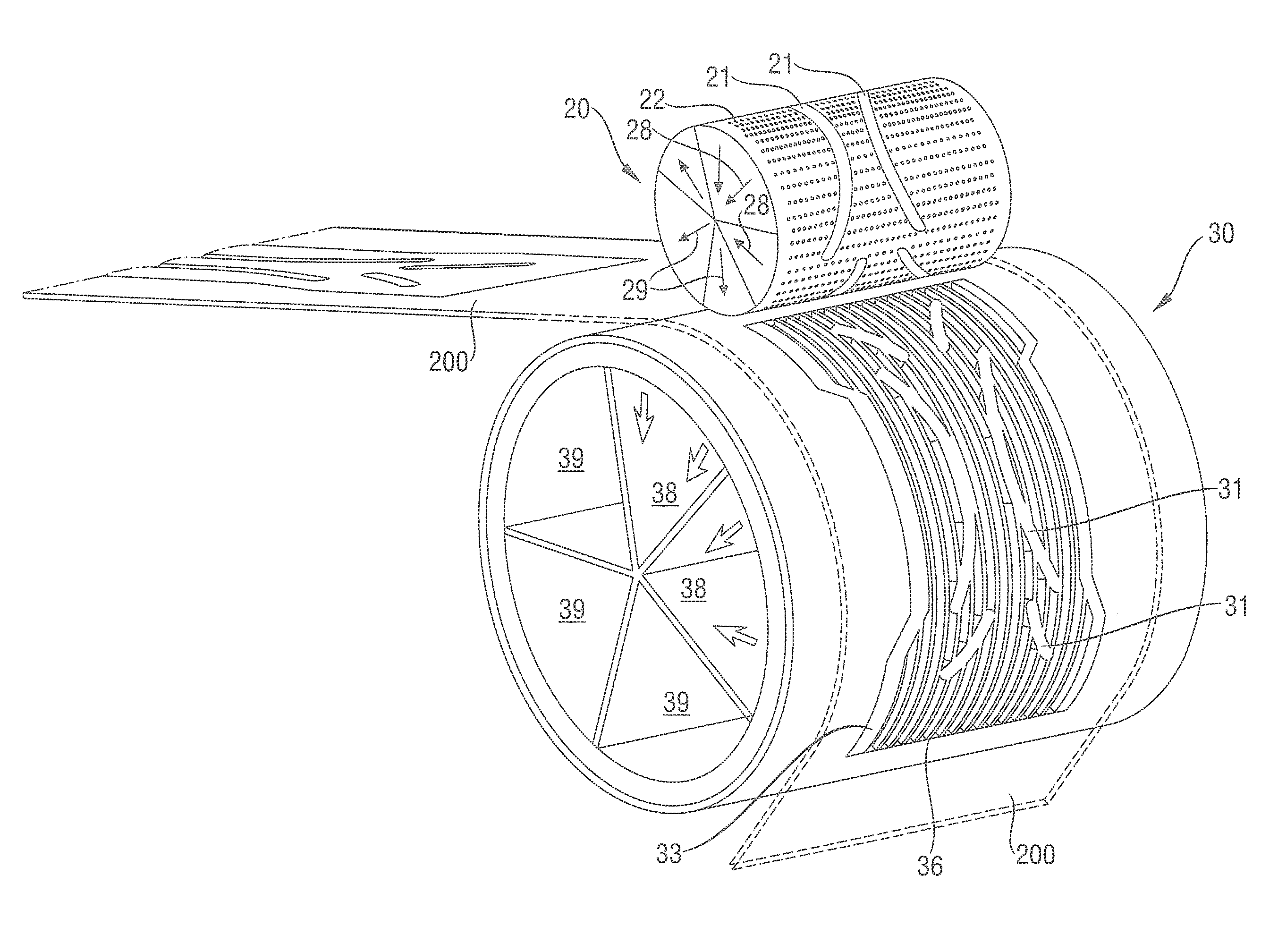

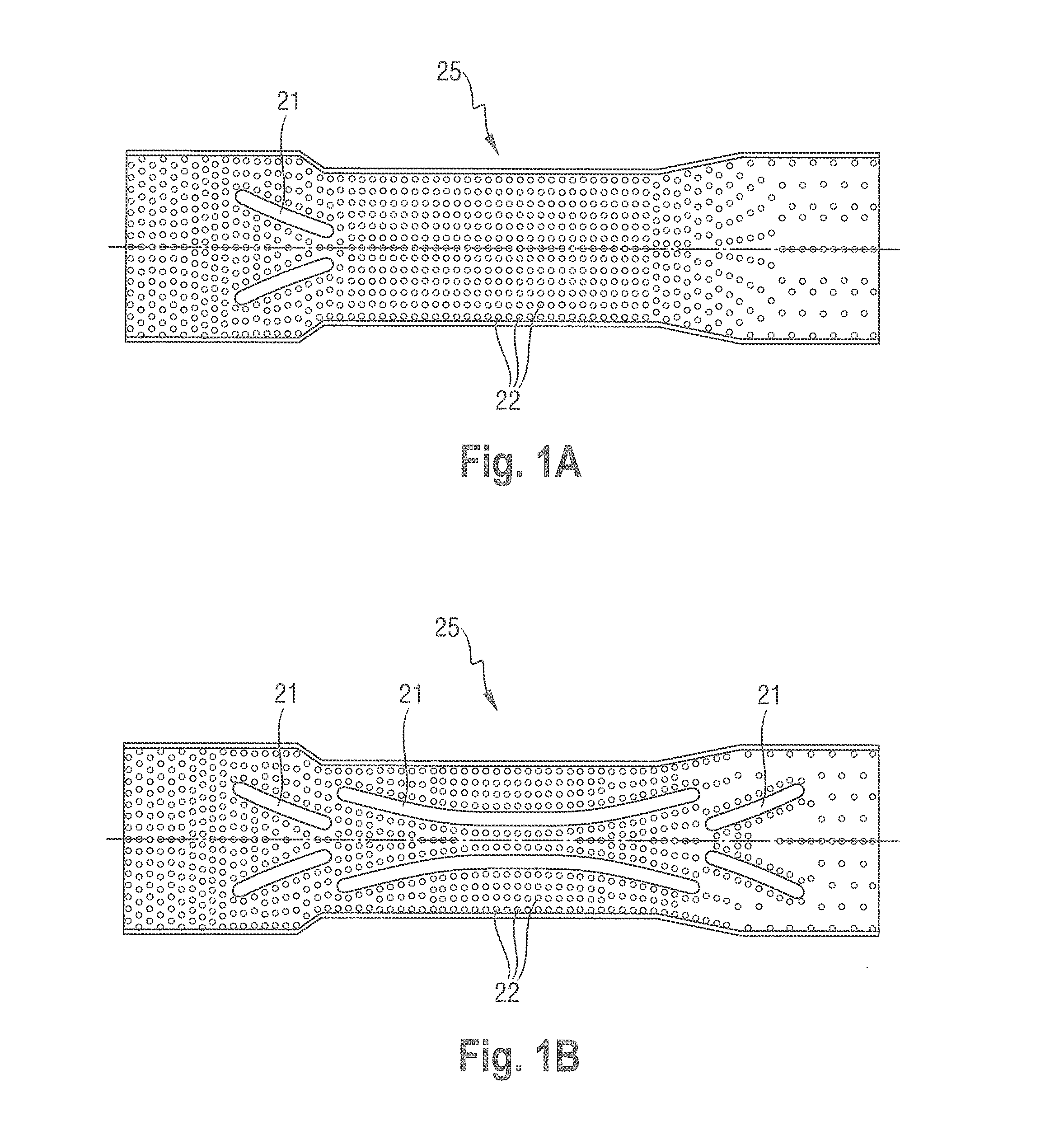

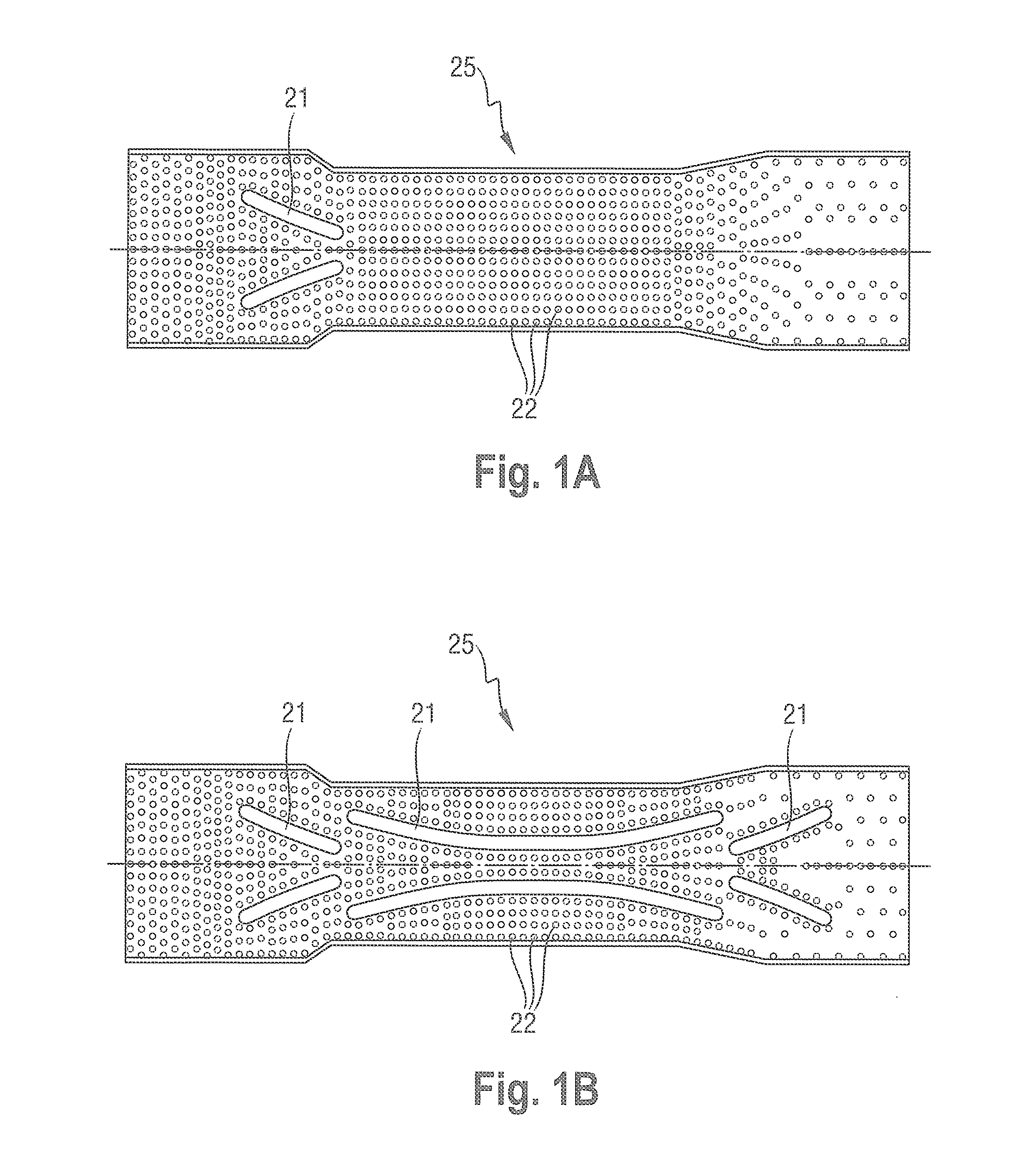

Apparatus and method for producing absorbent structures with absorbent layers with channel(s) without absorbent material, using a first moving endless surface with specific raised strip(s) and a second moving endless surface with specific mating strip(s).

Owner:THE PROCTER & GAMBLE COMPANY

Fabric creped absorbent sheet with variable local basis weight

InactiveUS20080029235A1Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

Paper tissue having enhanced softness

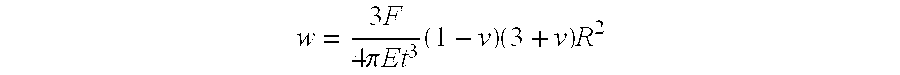

InactiveUS6344111B1Increase softnessMaintain tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

Method and apparatus for making absorbent structures with absorbent material

Owner:PROCTER & GAMBLE CO

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

Method for the production of a chafe resistant overlay

InactiveUS20090208646A1Avoid large quantitiesSpecial paperSpecial ornamental structuresBiochemical engineeringCorundum

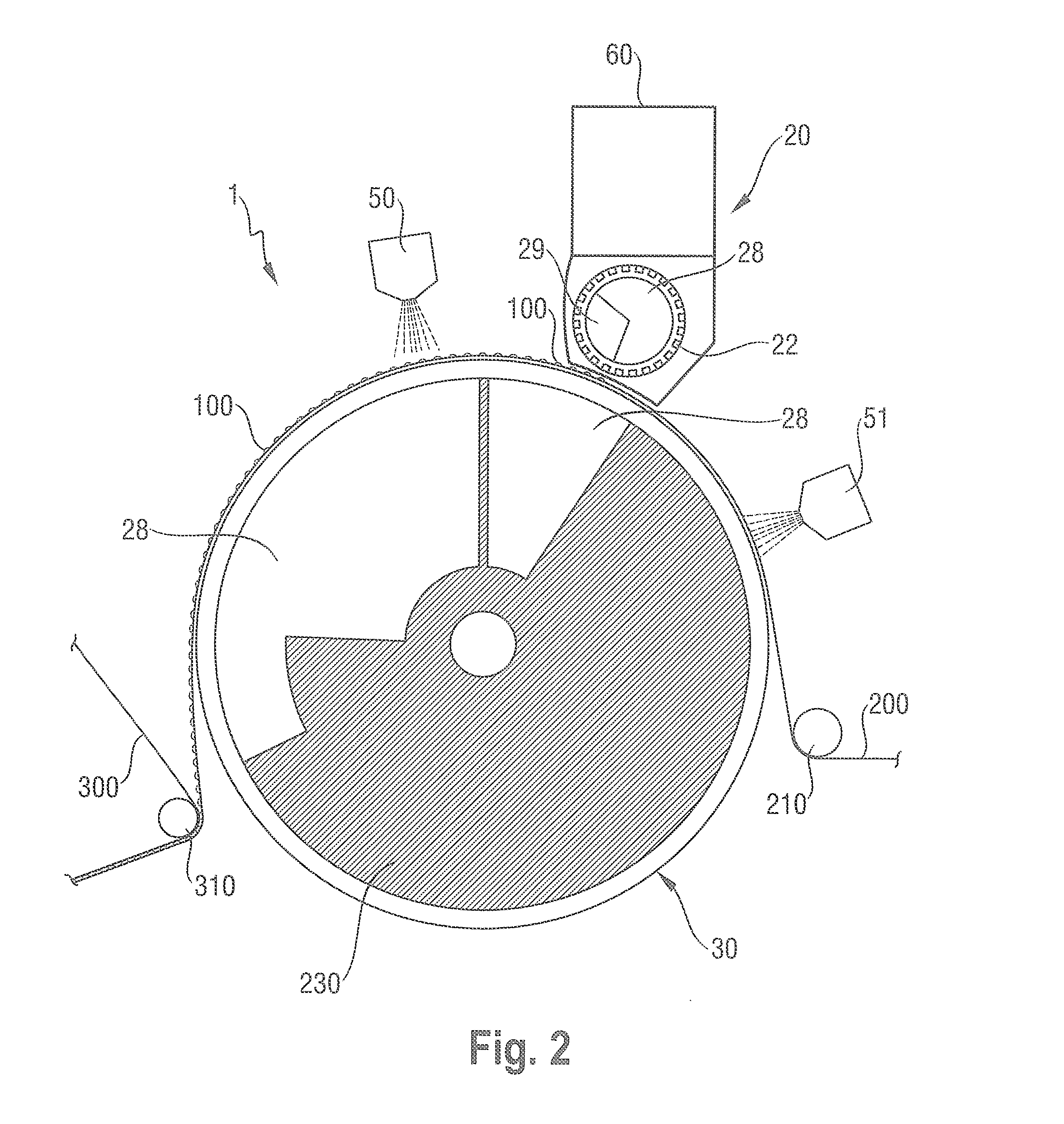

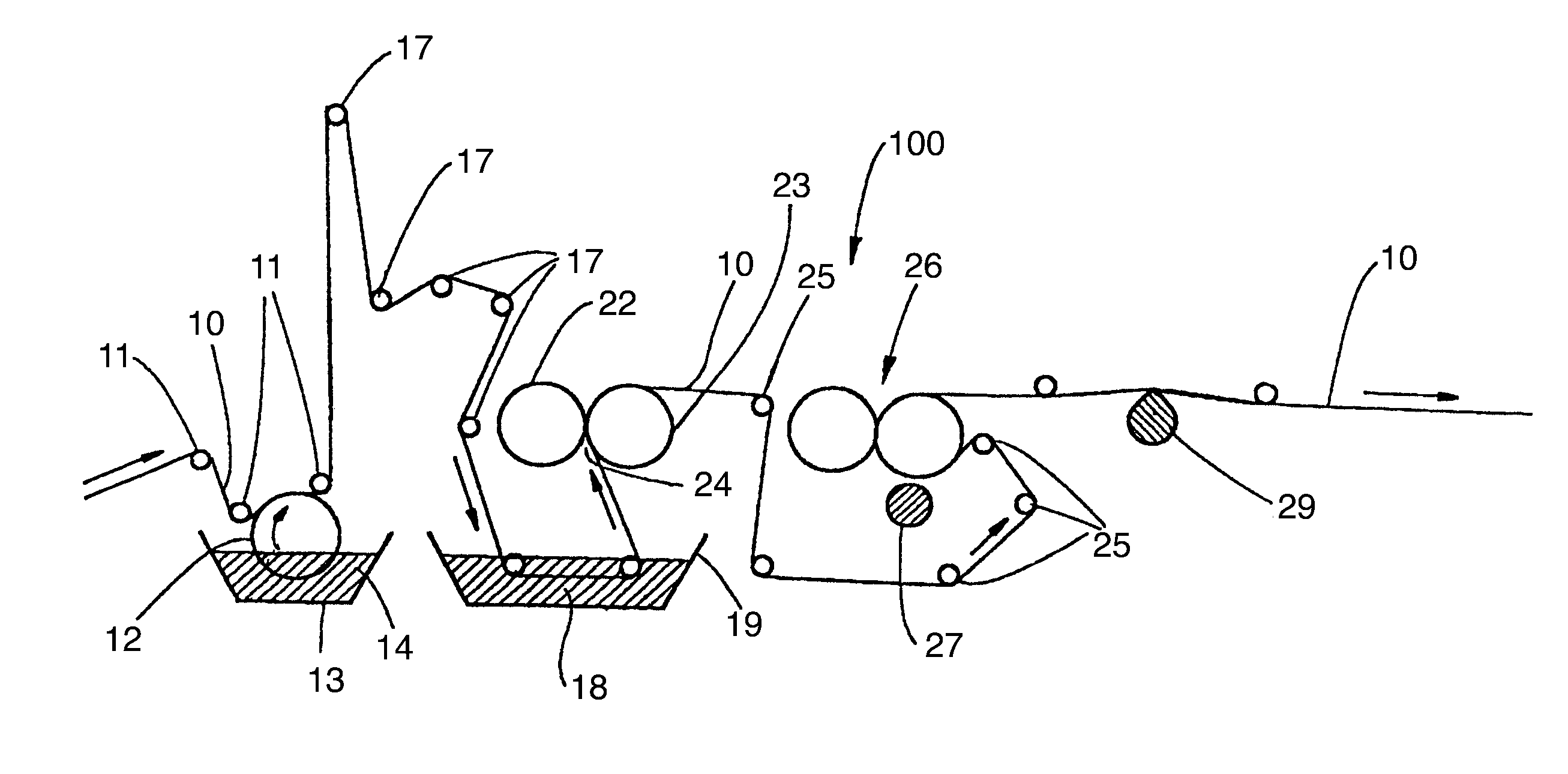

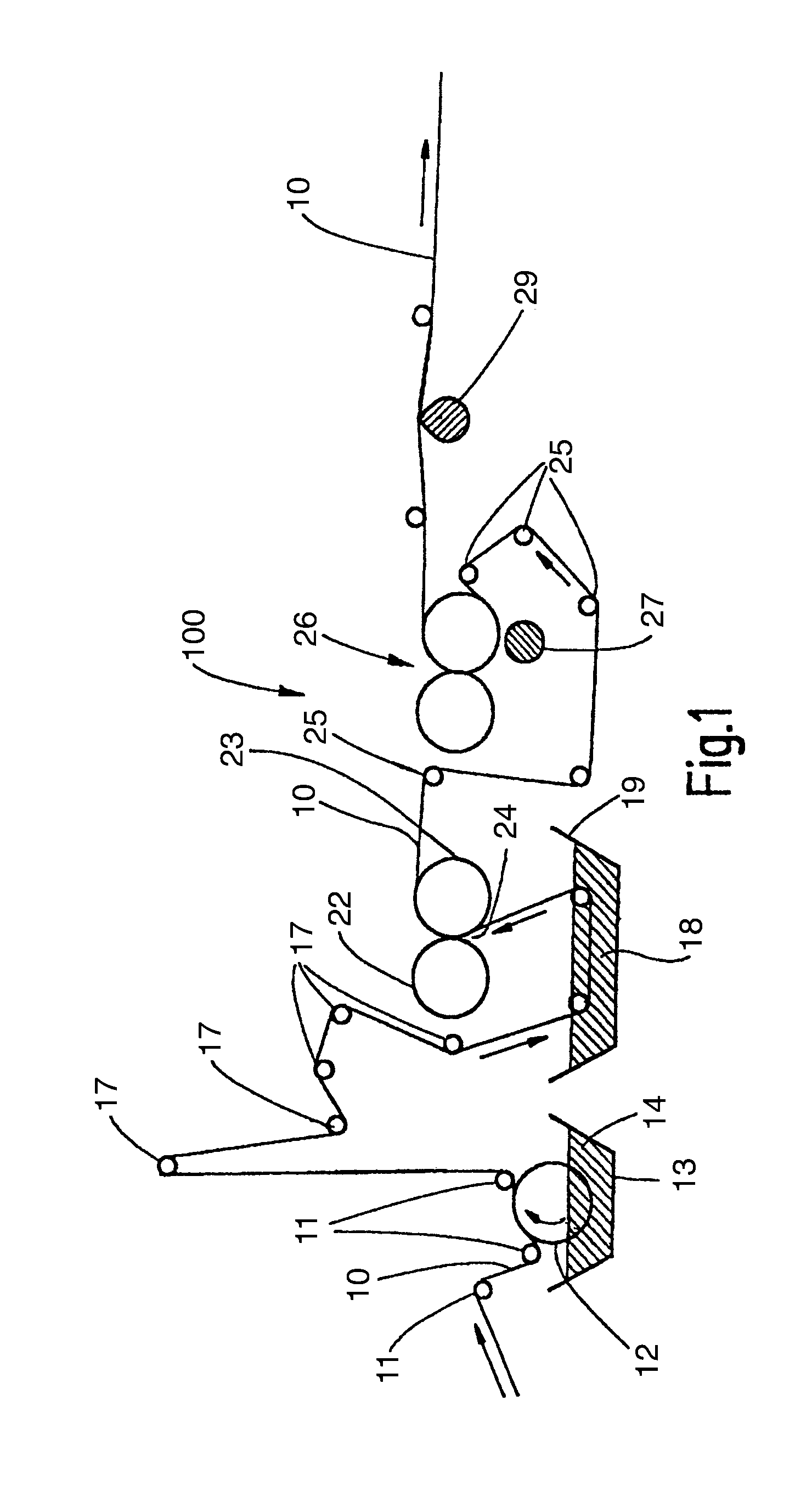

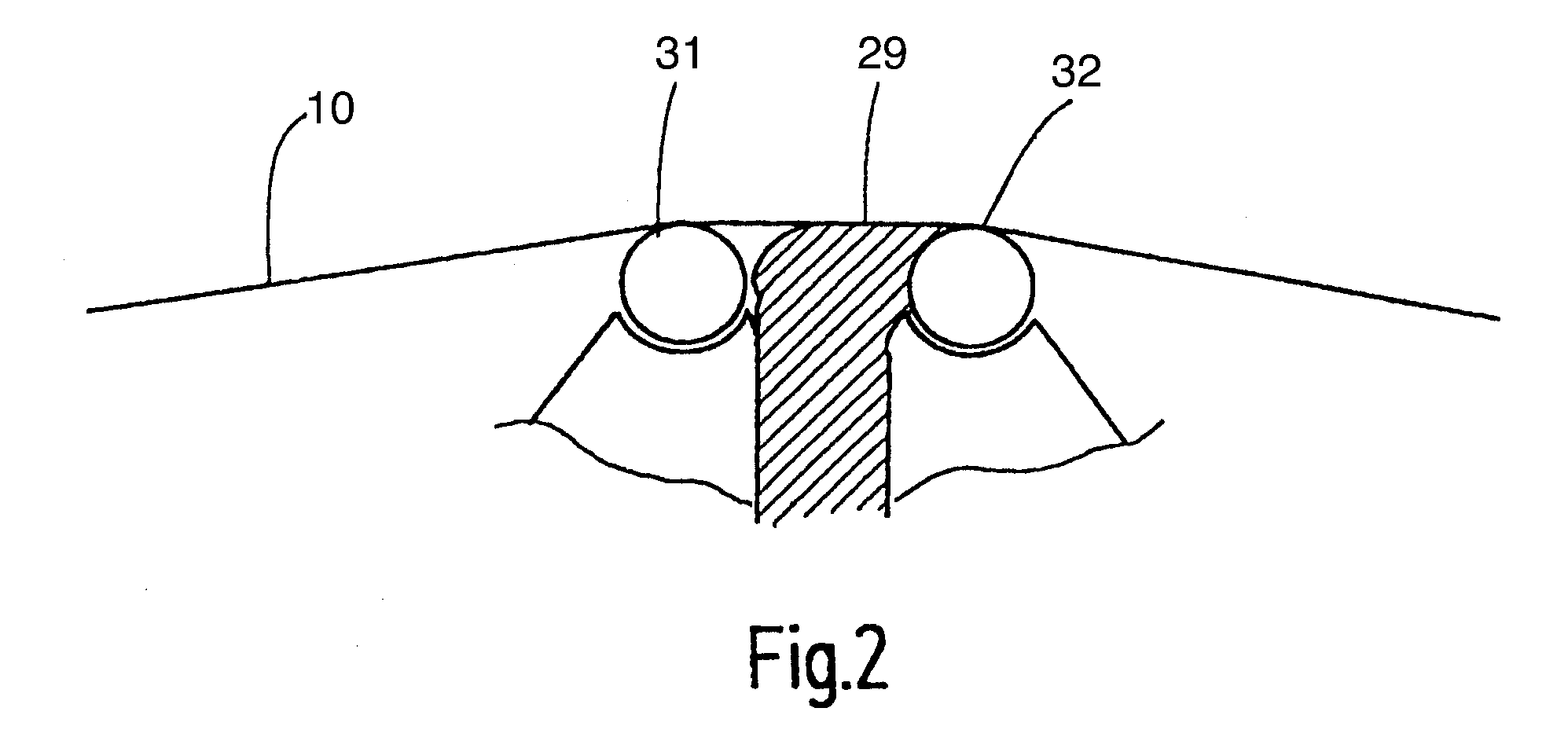

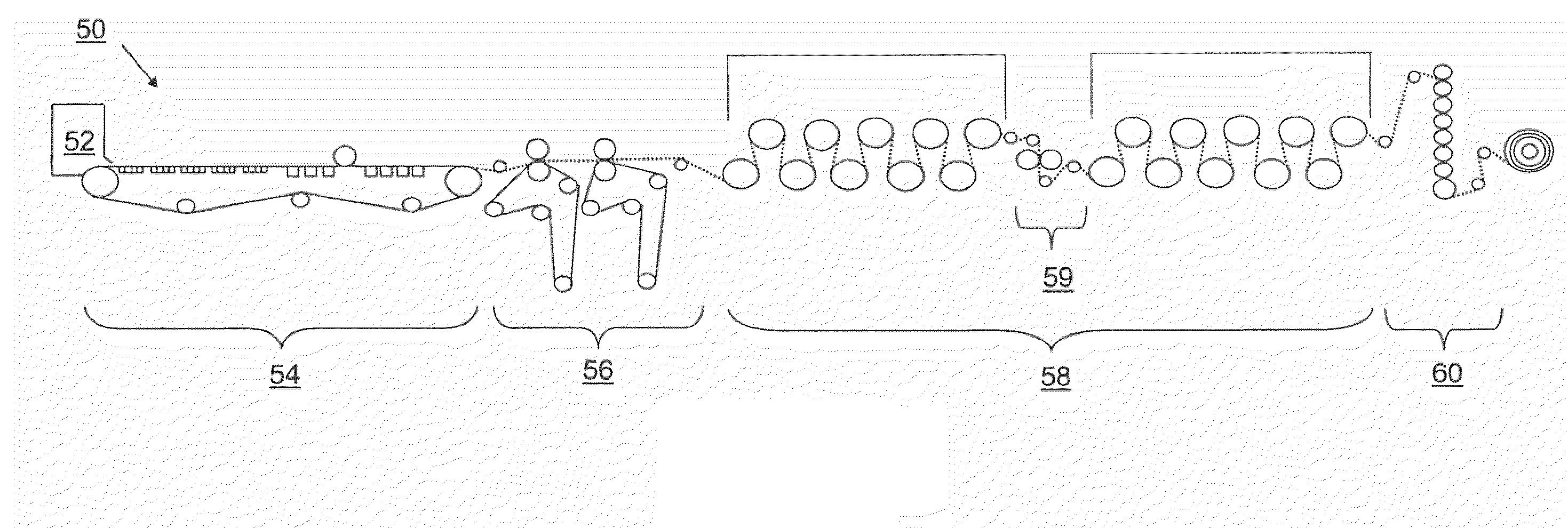

The invention relates to a method (100) for the production of an overlay, in particular for laminates. For this, firstly an overlay base paper (10) is impregnated in the usual manner and is coated on one side with a resin / coarse corundum application. In order to endow the overlay with additional characteristics, such as for example chafe resistance on the surface, in a further wet-in-wet application step a coating substance (29) is applied on the opposite side and is dosaged by a wiper (31).

Owner:DEKOR KUNSTE

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

Extracts from plant and non-plant biomass and uses thereof

Novel oil extracts from Angiosperm and Gymnosperm plants and other-plant biomass from human, veterinary, birds, aquatic species, microbial and mycological sources useful in human, veterinary and agricultural, mycological and microbiological applications are described. Methods of preparation of these extracts in oil and methods of application and administration are also described.

Owner:KANE SHANTARAM GOVIND

Method for purification of as-produced single-wall carbon nanotubes

InactiveUS20020127169A1High yieldNanostructure manufactureSpecial paperSolar cellSingle-Walled Nanotube

A method for purifying a mixture comprising single-wall carbon nanotubes and amorphous carbon contaminate is disclosed. The method includes the steps of heating the mixture under oxidizing conditions sufficient to remove the amorphous carbon, followed by recovering a product comprising at least about 80% by weight of single-wall carbon nanotubes. A method for producing tubular carbon molecules of about 5 to 500 nm in length is also disclosed. The method includes the steps of cutting single-wall nanotube containing-material to form a mixture of tubular carbon molecules having lengths in the range of 5-500 nm and isolating a fraction of the molecules having substantially equal lengths. The nanotubes may be used, singularly or in multiples, in power transmission cables, in solar cells, in batteries, as antennas, as molecular electronics, as probes and manipulators, and in composites.

Owner:RICE UNIV

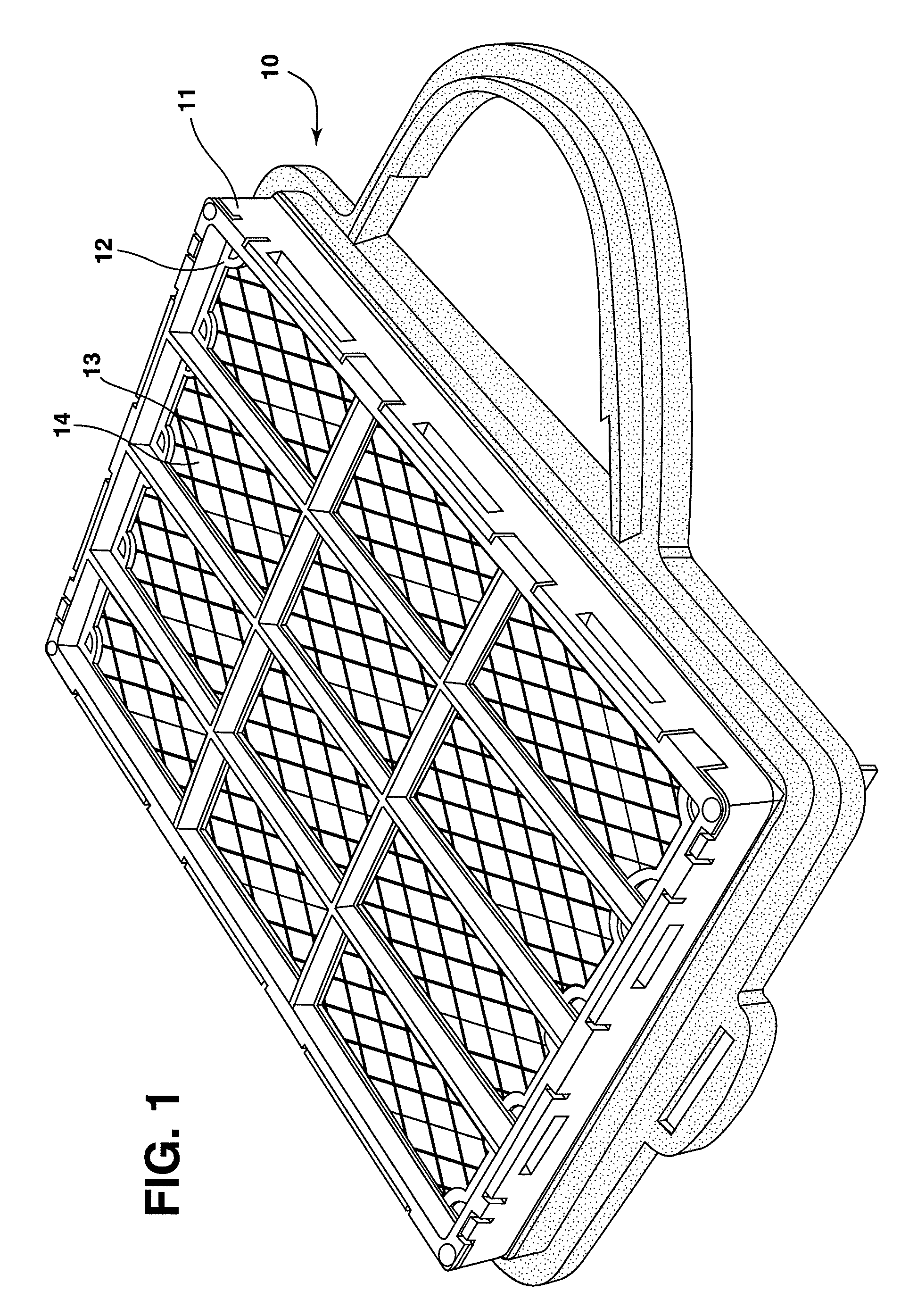

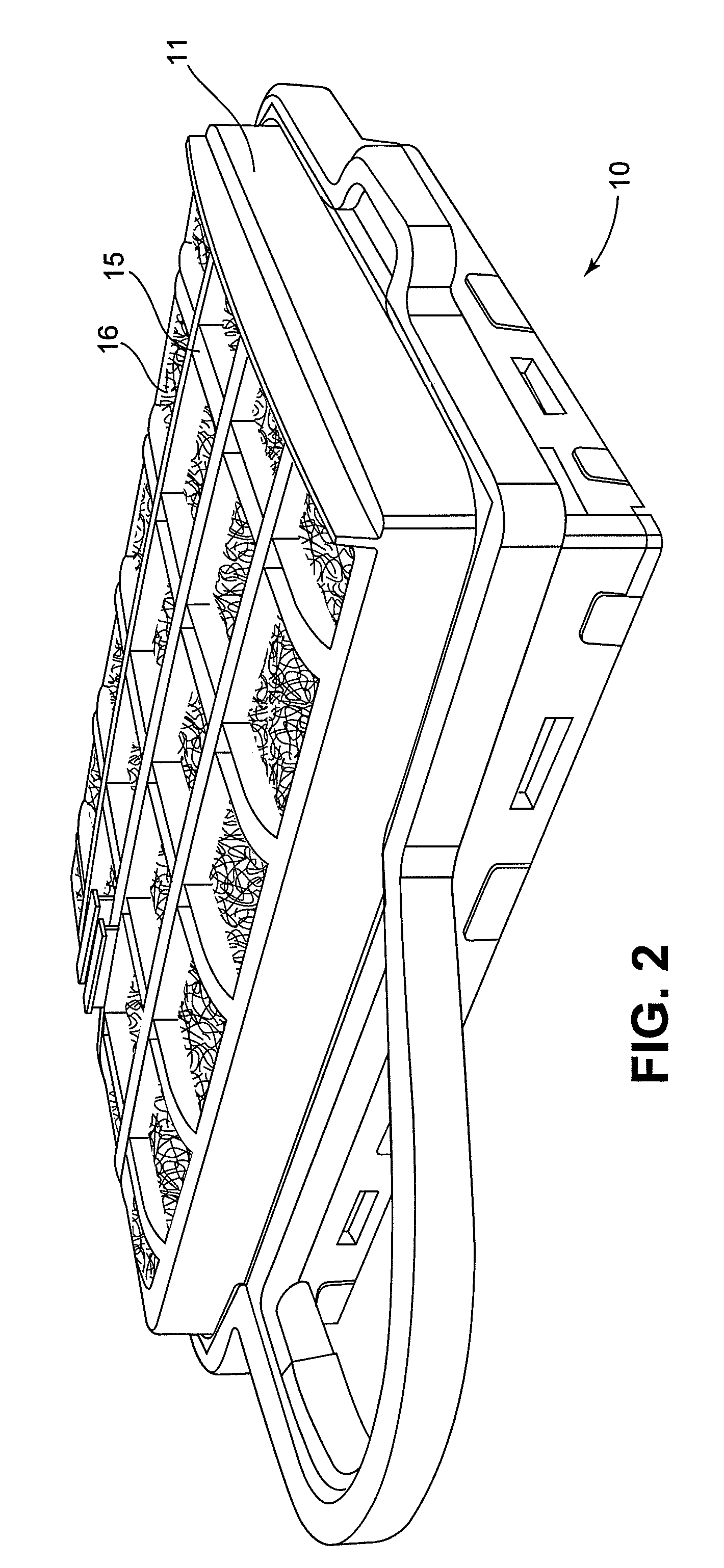

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

Paper manufacturing process

ActiveUS7419569B2High strengthNon-fibrous pulp additionNatural cellulose pulp/paperPre-conditionPre conditioning

A method of making soft, strong, high bulk tissue is disclosed. The method includes pre-conditioning a wet web by straining the wet web in the cross-machine direction prior to transferring the wet web to a throughdrying fabric. The pre-conditioned web provides improved sheet softness and conforms more readily to the surface contour of the throughdrying fabric, thereby creating greater caliper (bulk) in the resulting dried sheet. The bulk is maintained during a subsequent creping step by maintaining the dried sheet in registration with the throughdrying fabric when the dried sheet is applied to the surface of the creping cylinder.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of fabricating a belt and a belt used to make bulk tissue and towel, and nonwoven articles and fabrics

A method for manufacturing a belt and a belt for use in the production of bulk tissue and towel, and of nonwoven articles and fabrics, requires the application of a sacrificial material onto a base substrate in a predetermined pattern which is to be imparted onto products manufactured with the belt. The sacrificial material is deposited in droplets in a controlled manner so as to control the x, y, z dimension of the material deposited and preferably has having an average diameter of 10μ (10 microns) or more. A polymeric resin material is then deposited on the base substrate in all areas except those on which the sacrificial material has previously been applied. The polymeric resin material is then set by means appropriate to its composition, and the sacrificial material removed. Optionally, the polymeric resin material may then be abraded to provide the belt with a uniform thickness, and a smooth, macroscopically monoplanar surface.

Owner:ALBANY INT CORP

Fabric-creped sheet for dispensers

ActiveUS7585388B2More MD stretchMore lengthMechanical working/deformationSpecial paperBiomedical engineeringSheet material

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Fabric-creped sheet for dispensers

ActiveUS20060289133A1More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationThird generationEngineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

Method of making fabric-creped sheet for dispensers

ActiveUS7585389B2More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationWood veneerBiomedical engineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Method of making fabric-creped sheet for dispensers

ActiveUS20060289134A1More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationThird generationBiomedical engineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Composition for promotion of bone growth and maintenance of bone health

InactiveUS20050079232A1Accelerate bone regenerationInhibit bone resorptionBiocideNon-fibrous pulp additionDiseaseBone growth

The present invention relates to a composition for maintenance of bone health or prevention, alleviation and / or treatment of bone disorders. It also relates to the use of the composition in the manufacture of a nutritional product, a supplement, a treat or a medicament; and a method of promoting bone growth or for the maintenance of bone health, which comprises administering an effective amount of the composition.

Owner:NESTEC SA

Gypsum wood fiber product having improved water resistance

InactiveUS6010596AImprove water resistanceHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberWax

An improved water resistant gypsum board is made by adding an aqueous wax emulsion containing a cationic surfactant to an aqueous slurry containing calcium sulfate and host particles at a slurry temperature which maintains calcium sulfate hemihydrate crystals. The wax emulsion is stable at the temperature of slurry which maintains the calcium sulfate hemihydrate. The slurry is then dewatered and rehydrated to form a gypsum board and dried at a temperature to melt the wax.

Owner:UNITED STATES GYPSUM CO

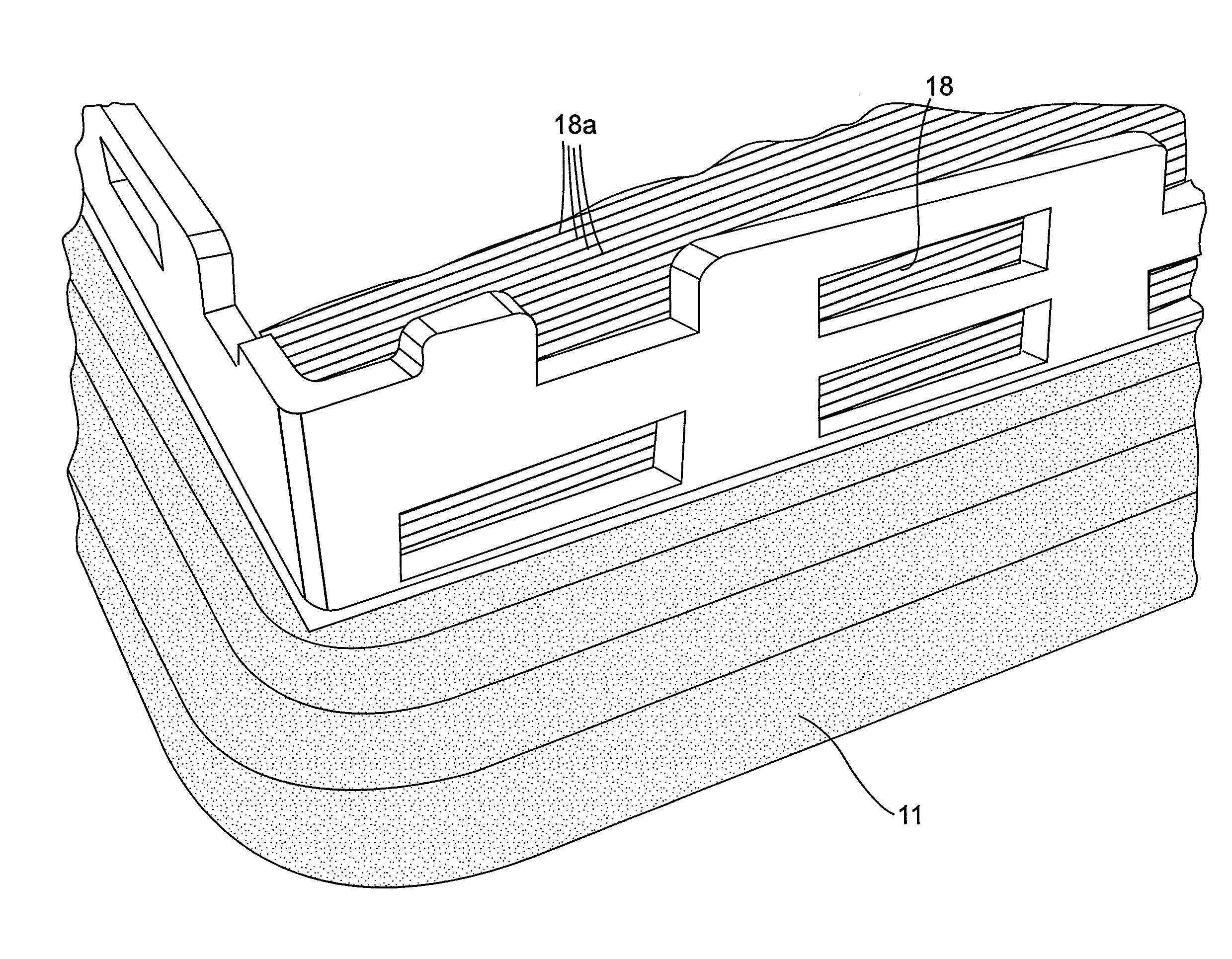

Industrial fabric for producing tissue and towel products, and method of making thereof

ActiveUS8454800B2Reduce the amount of solutionIncrease rangeNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

A nonwoven fabric includes a plurality of through voids, where each of the voids has a first opening associated with a top surface of the fabric and a first raised edge circumferentially adjacent to the first opening. The voids may each further include a second opening associated with a bottom surface of the fabric and a second raised edge circumferentially adjacent to the second opening, such that the first opening may have a surface area that is larger than or the same as the second opening.

Owner:ALBANY INT CORP

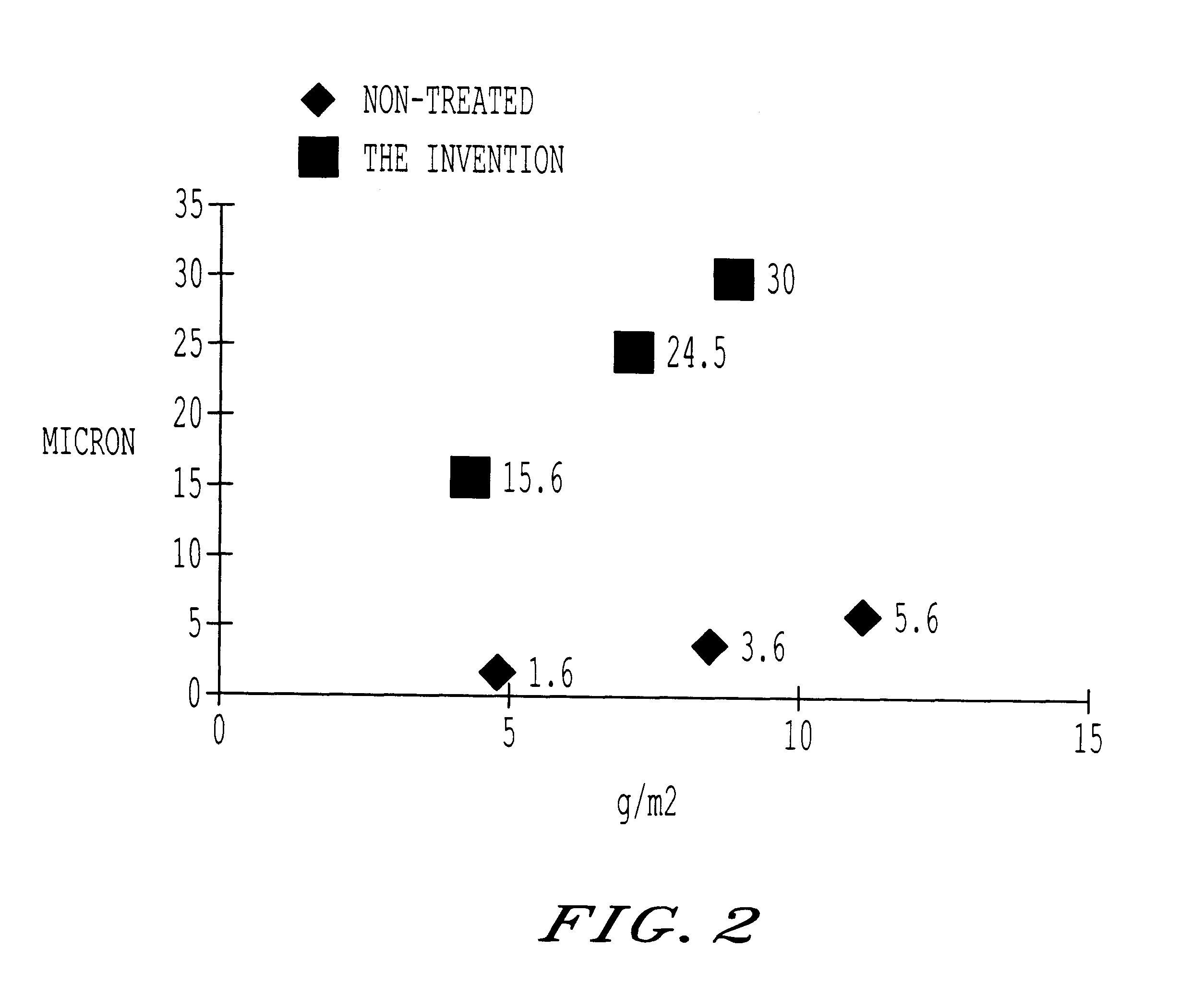

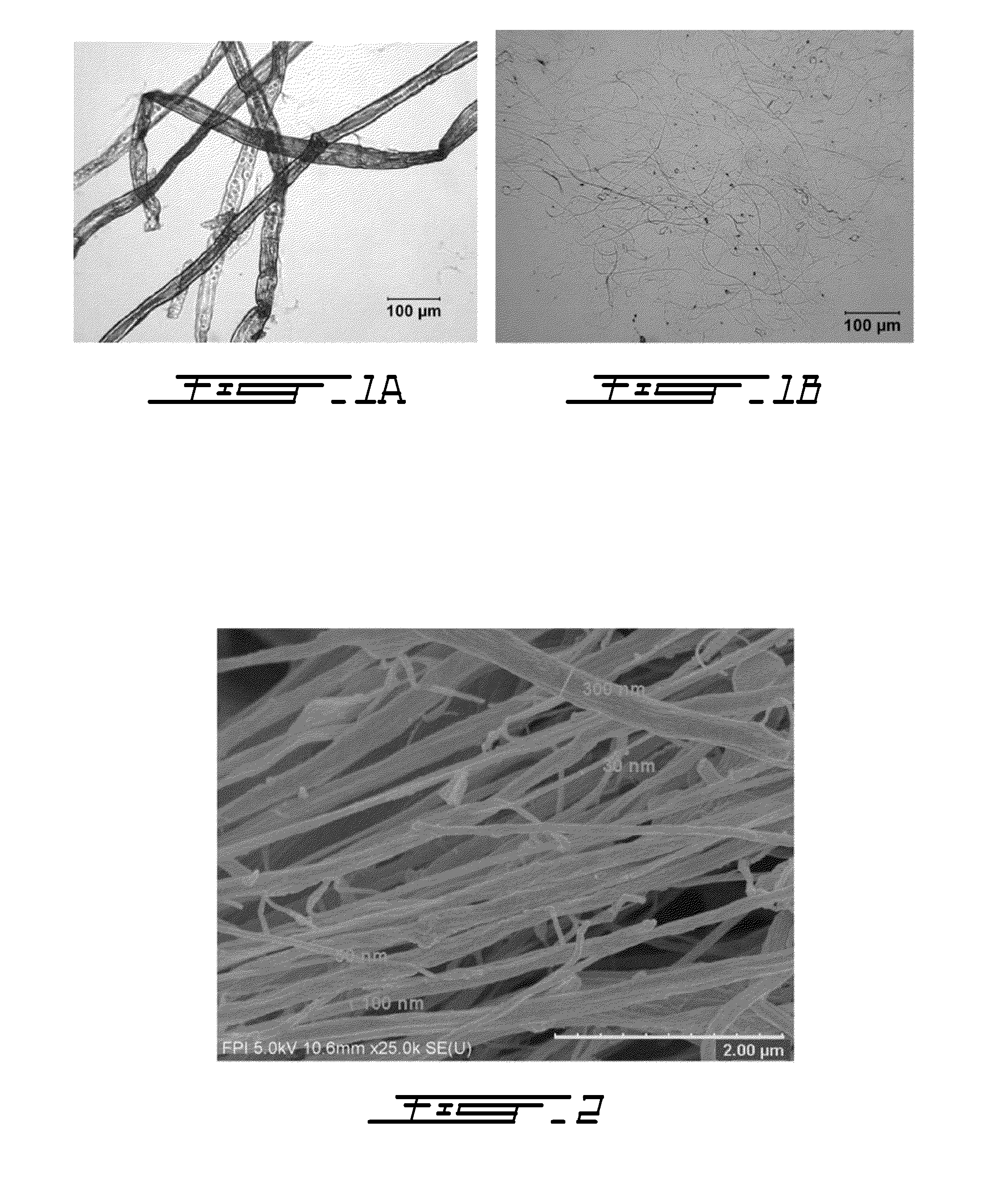

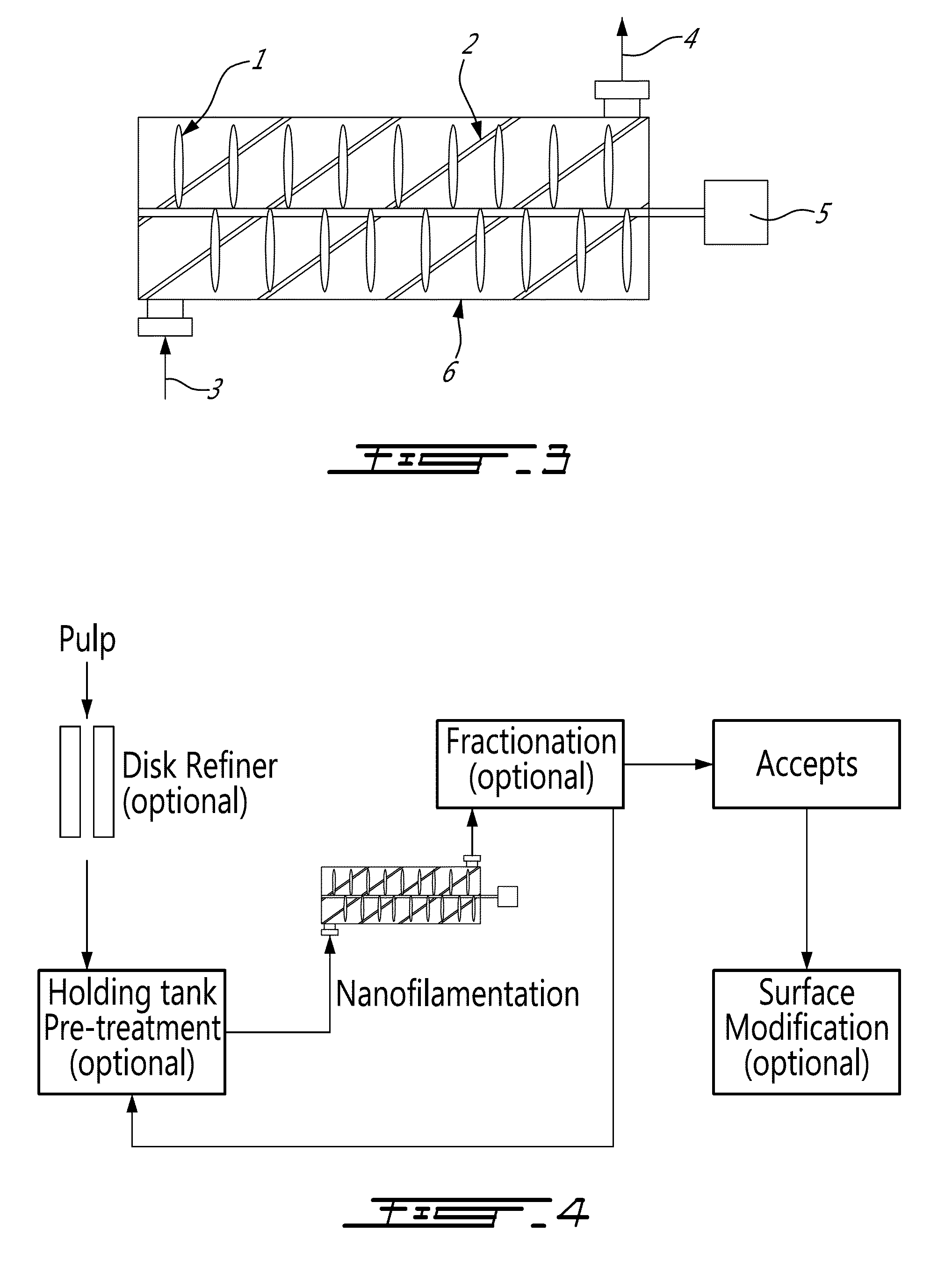

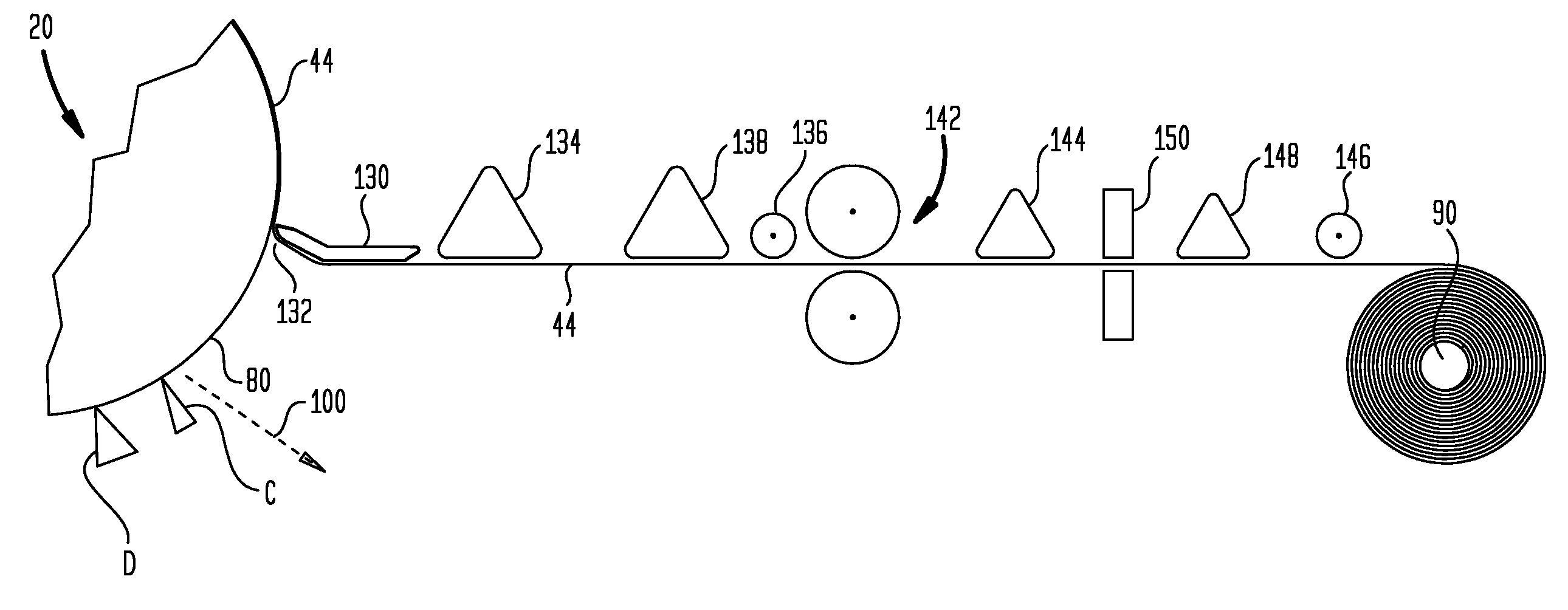

Cellulose nanofilaments and method to produce same

ActiveUS20110277947A1Improve strength propertiesMaterial nanotechnologyNatural cellulose pulp/paperPolymer sciencePaperboard

Cellulose nanofilaments from cellulose fibers, a method and a device to produce them are disclosed. The nanofilaments are fine filaments with widths in the sub-micron range and lengths up to a couple of millimeters. These nanofilaments are made from natural fibers from wood and other plants. The surface of the nanofilaments can be modified to carry anionic, cationic, polar, hydrophobic or other functional groups. Addition of these nanofilaments to papermaking furnishes substantially improves the wet-web strength and dry sheet strength much better than existing natural and synthetic polymers. The cellulose nanofilaments produced by the present invention are excellent additives for reinforcement of paper and paperboard products and composite materials, and can be used to produce superabsorbent materials.

Owner:FPINNOVATIONS INC

Method Of Controlling Adhesive Build-Up On A Yankee Dryer

ActiveUS20070204966A1Reducing steady-state tensionReduce tensionNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

An improved method of controlling build-up of adhesive coating on a Yankee drying cylinder preferably includes intermittently: (a) increasing the add-on rate of resinous adhesive to the drying cylinder substantially above the steady-state add-on rate; (b) segregating the absorbent sheet product produced while the add-on rate of resinous adhesive to the drying cylinder is elevated above the steady-state add-on rate from absorbent sheet product accumulated during steady-state operation; and (c) while the add-on rate of resinous adhesive to the drying cylinder is increased above the steady-state add-on rate, stripping at least a portion of the adhesive coating from the drying cylinder with a cleaning doctor.

Owner:GPCP IP HLDG LLC

Cigarette and wrapping materials therefor

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

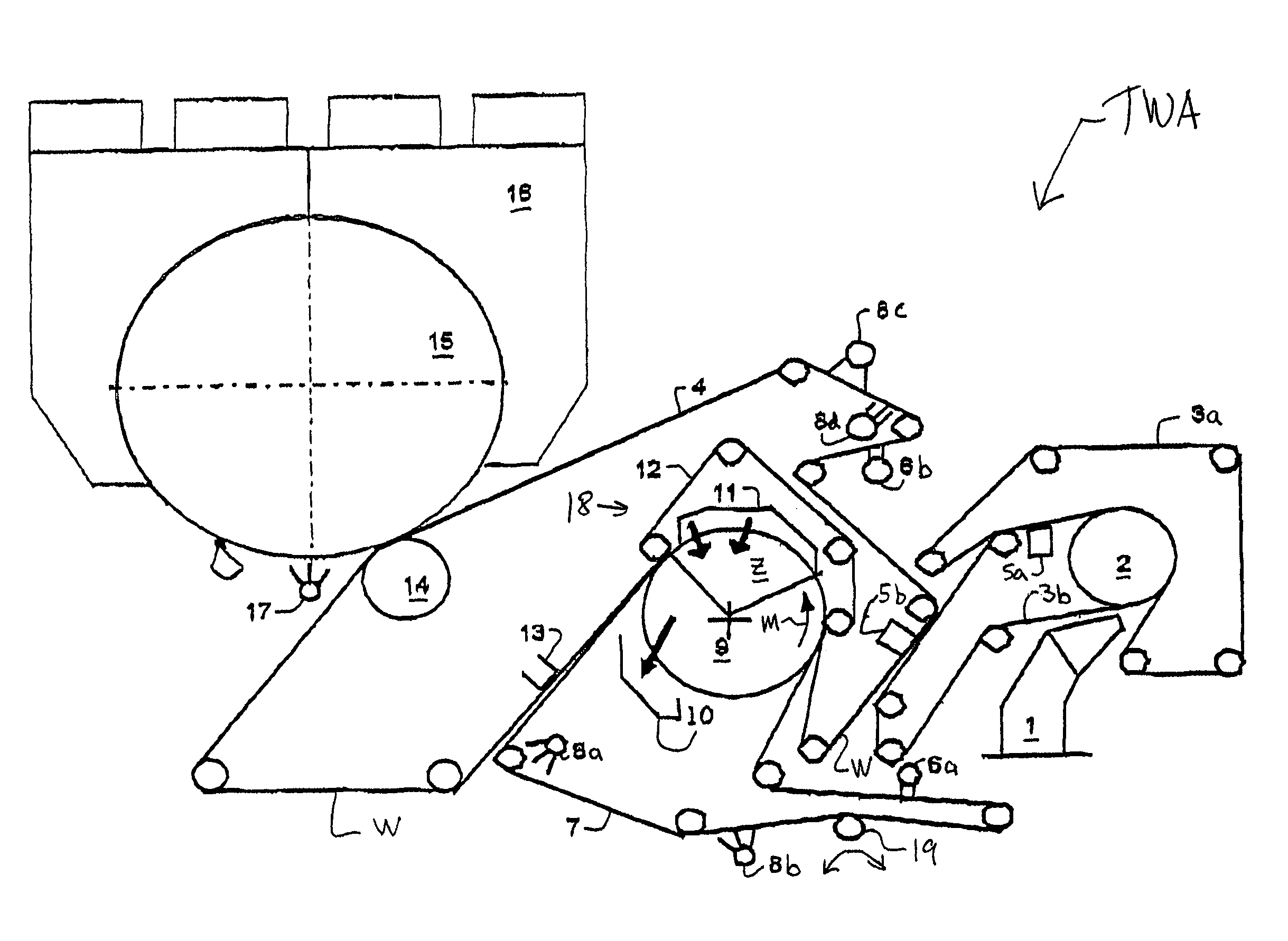

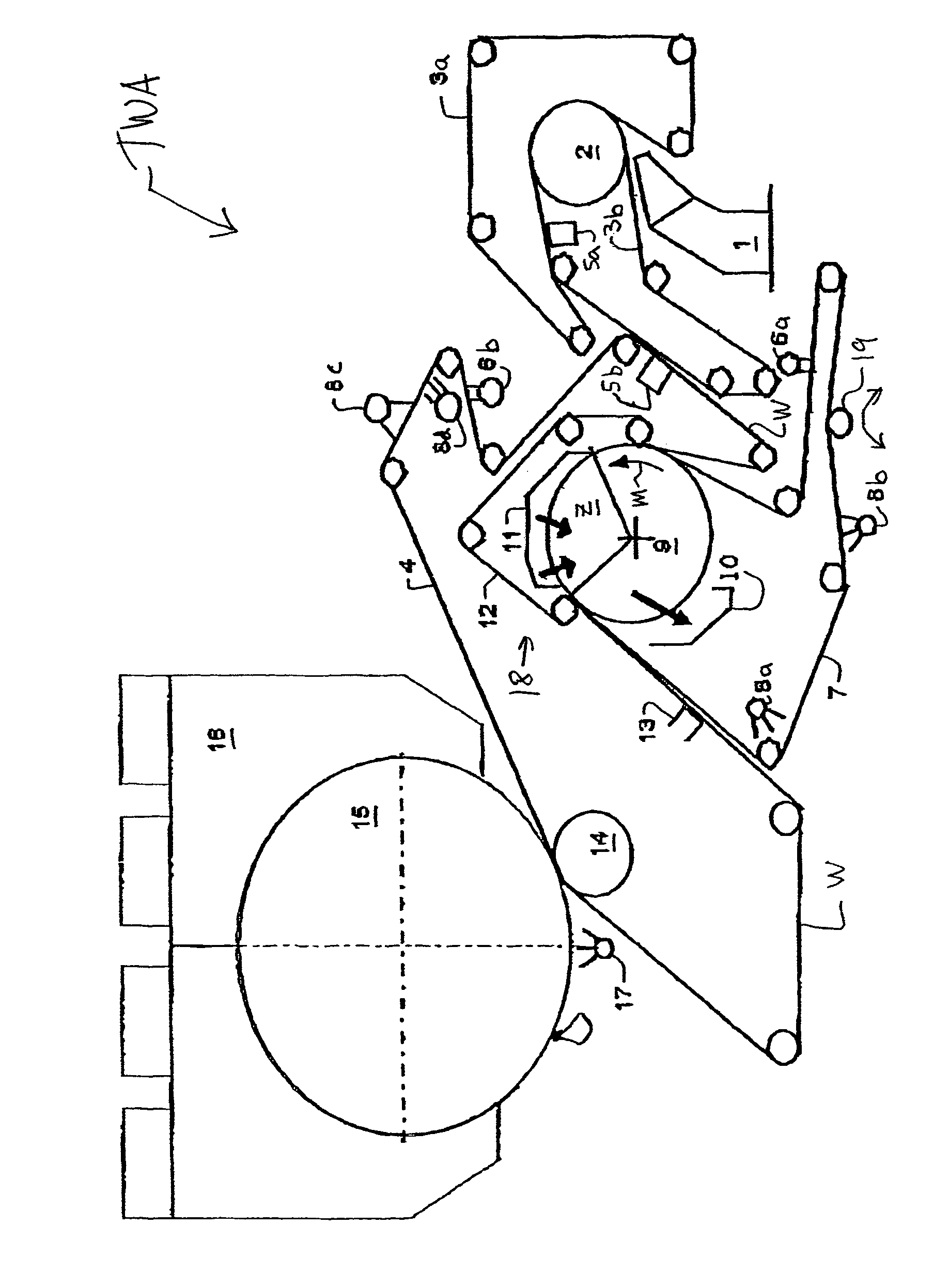

Twin wire for an ATMOS system

InactiveUS7744726B2Fill up the pillow areasIncrease contact areaNon-fibrous pulp additionNatural cellulose pulp/paperWire rodEngineering

Dewatering system for dewatering a web. The system comprises a former, a belt press, and a structured fabric comprising a paper web facing side and being guided over a support surface and through the belt press. The structured fabric runs at a speed differential relative to a wire of the former. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Method of controlling adhesive build-up on a yankee dryer

ActiveUS7850823B2Increase ratingsReduce the temperatureNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

Owner:GPCP IP HLDG LLC

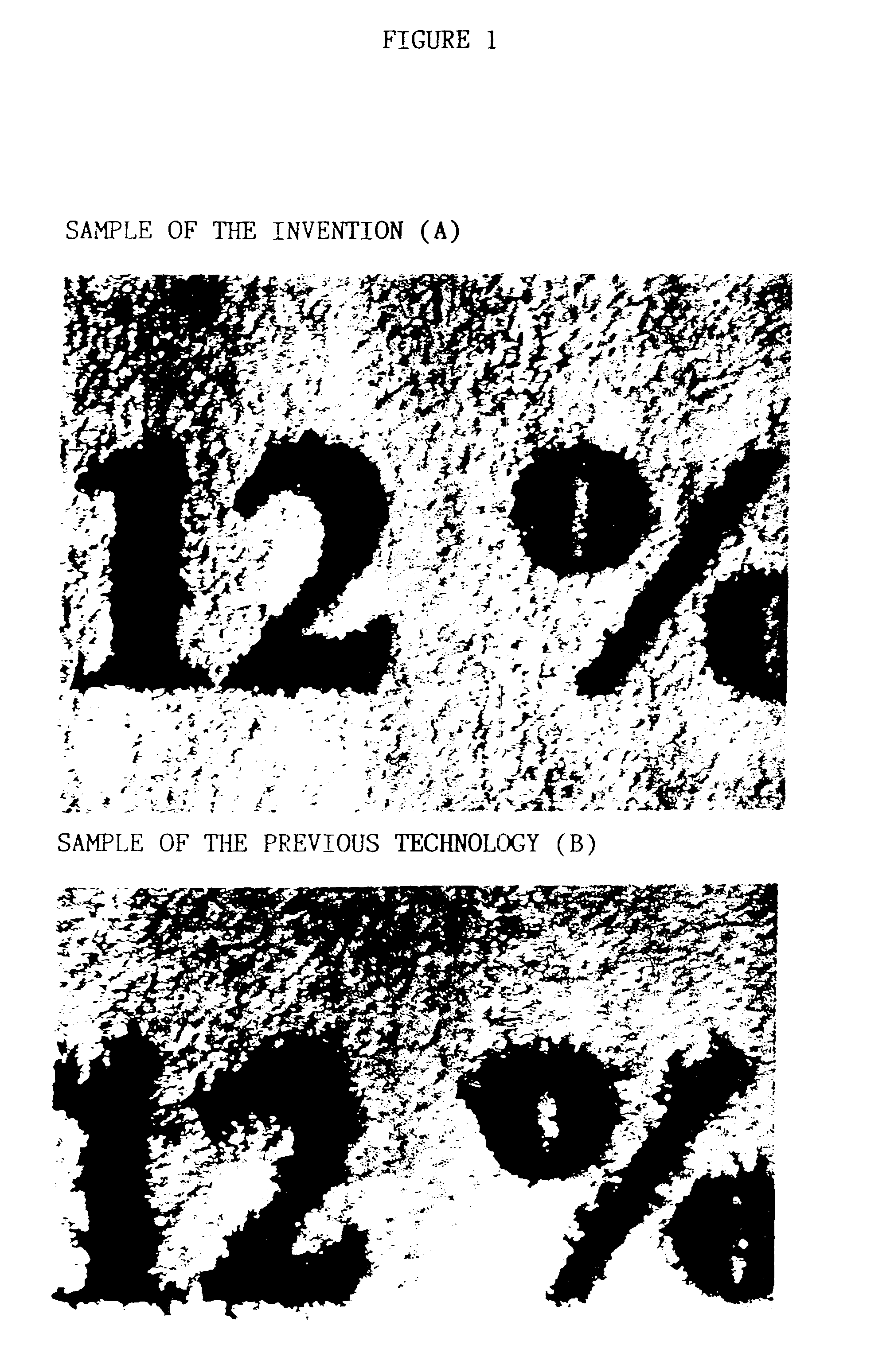

Method and composition for the sizing of paper with a mixture of a polyacid and a polybase

InactiveUS6171444B1Easy to produceHigh color fastnessNatural cellulose pulp/paperSpecial paperHueWater resistant

Compositions and methods are provided for the sizing of paper, to enhance the quality of images printed thereon. The novel sizing compositions contain as a sizing agent a mixture of a polyacid and a polybase. When applied to a paper substrate, such as in an internal or external sizing process, the sizing compositions result in a sized paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the sizing agent. Images printed on a paper substrate coated with the sizing compositions of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com