Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3551results about How to "High color fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

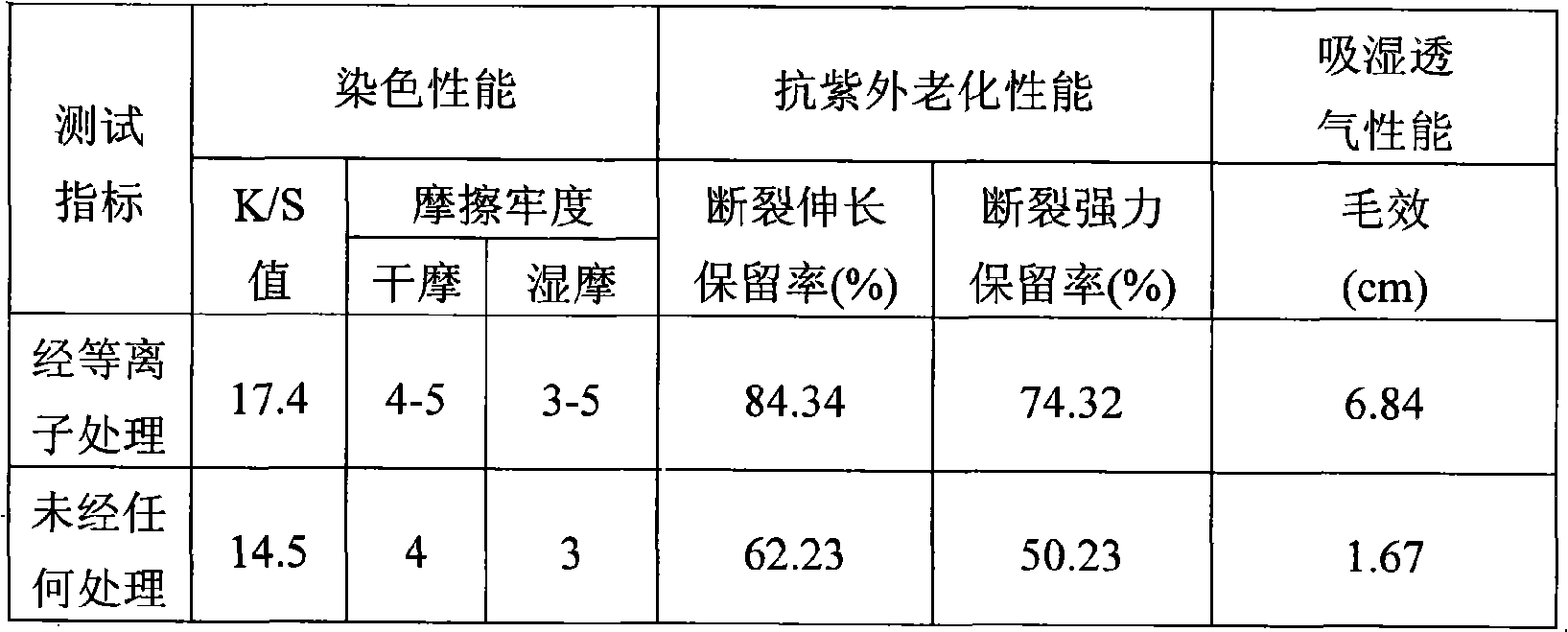

Ultra-high temperature high pressure dyeing method for aramid fiber textile

InactiveCN101235598AHigh color fastnessBright colorsPhysical treatmentDyeing processColour fastnessHigh pressure

The invention discloses a method for dying kevlar fabrics under ultrahigh temperature and high pressure, which comprises: a preprocessing procedure under the ultrahigh temperature and the high pressure and a dying procedure under the ultrahigh temperature and the high pressure, wherein in the preprocessing procedure under the ultrahigh temperature and the high pressure, atmospheric pressure plasmas are used to process the kevlar fabrics for 1-5min, the processing temperature is 100-150DEG C, while in the dying procedure under the ultrahigh temperature and the high pressure, the temperature is 160DEG C-190DEG C, and the pressure intensity is 0.8-0.9MPa, wherein the plasma preprocessing procedure is an important procedure before the dying procedure under the ultrahigh temperature and the high pressure, since the processing for the plasma produces a plurality of active groups on the kevlar fabrics, which enables carriers to be better absorbed on the kevlar baric and thereby is beneficial for dying dye on the kevlar fabrics, simultaneously, the kevlar fabrics after dying under the ultrahigh temperature and the high pressure has high fastness, fresh color and soft hand feeling, and the washing color fastness and the abrasion color fastness of the kevlar fabrics are improved better.

Owner:ZHEJIANG SCI-TECH UNIV

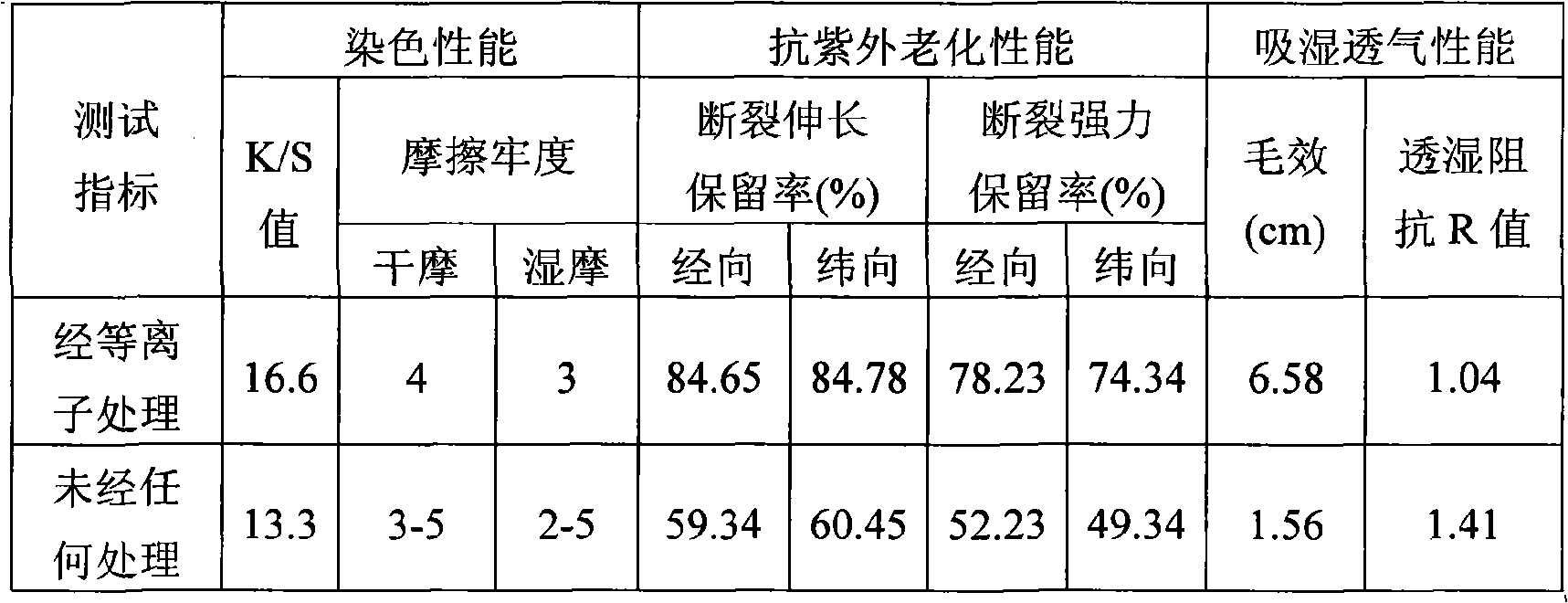

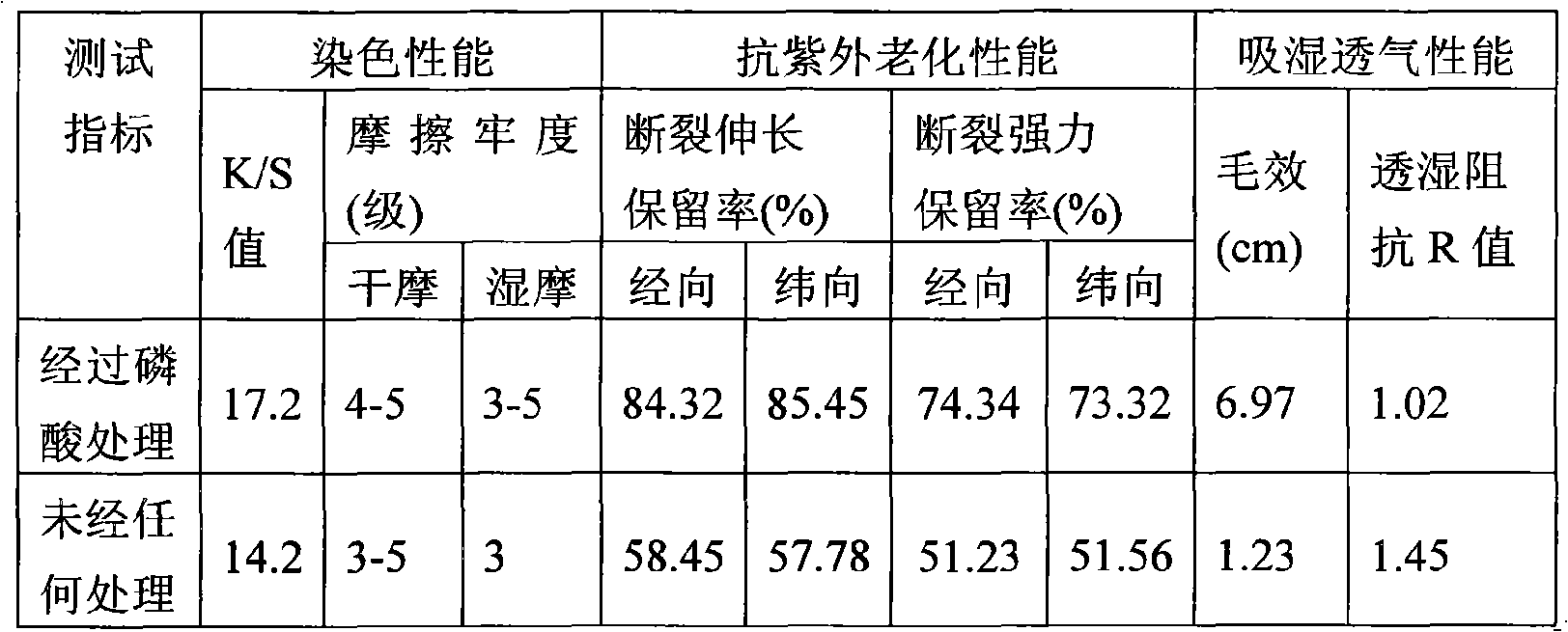

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

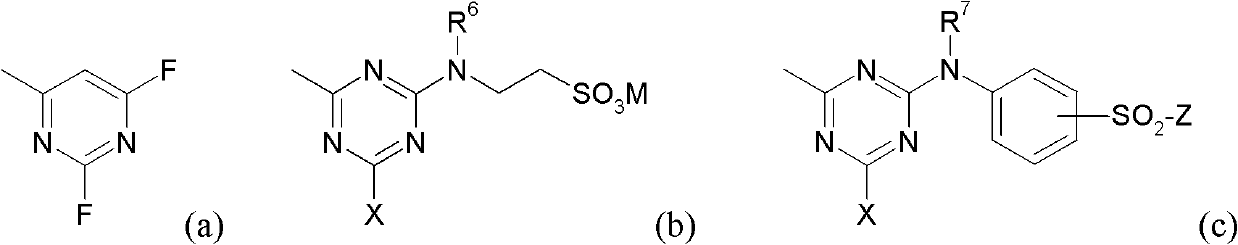

Method for preparing the reactive tinting compound and the tinted contact lens

A method for preparing the tinted contact lens with the covalently bonded novel reactive tinting compound is disclosed. The reactive tinting compound with mono vinyl functionality is prepared by reacting the reactive dye with a hydrophilic monomer containing both pendent hydroxyl and vinyl groups under an alkaline condition. The water soluble reactive dyes containing either difluoro-chloropyrimidine or β-sulphatoethylsulphone reactive groups are used for synthesis of the reactive tinting dye. The lens forming materials are photo-polymerized in the presence of the reactive tinting compound to prepare a tinted contact lens. The reactive tinting compound is copolymerized with the lens forming monomers in a single photo-polymerization step that requires no subsequently alkaline soaking or developing step as used in the prior art. In addition, the covalently bonded dye is stable and durable in the lens and does not fade or leach out after multiple high-pressure thermal sterilizations.

Owner:SMART PERFORMER

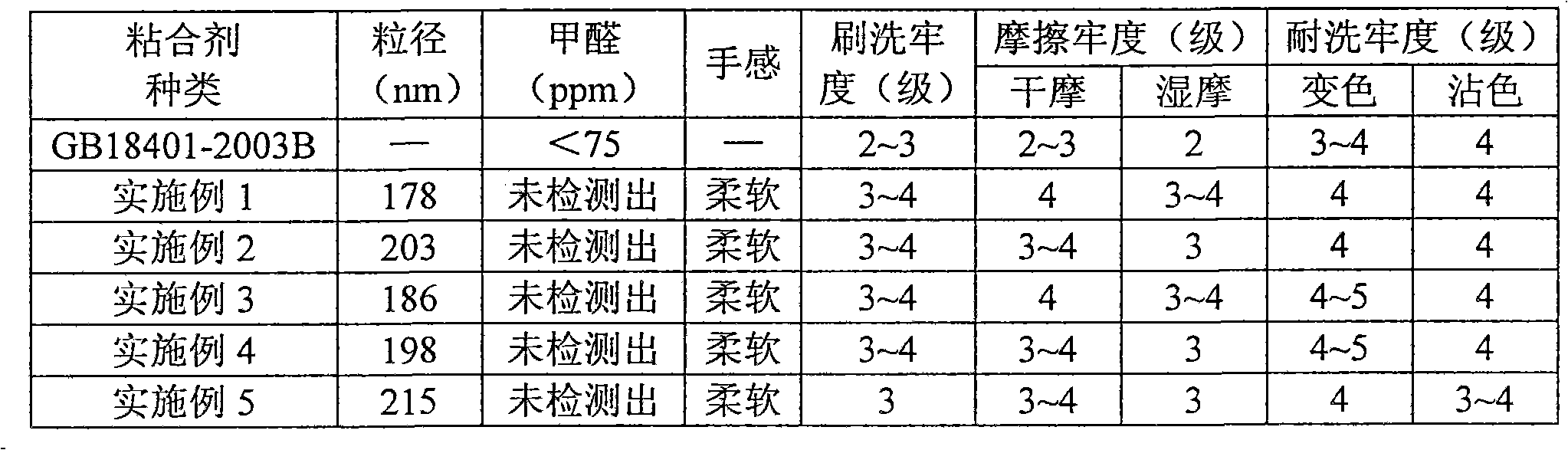

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

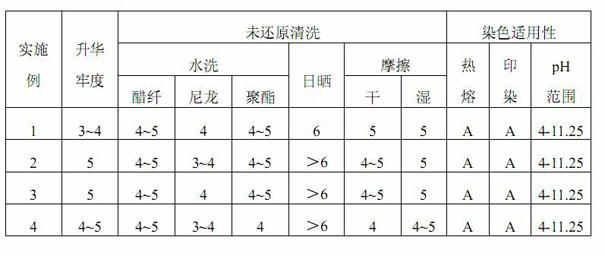

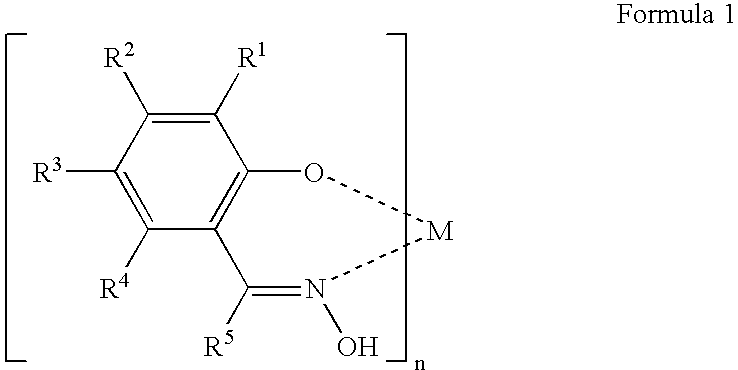

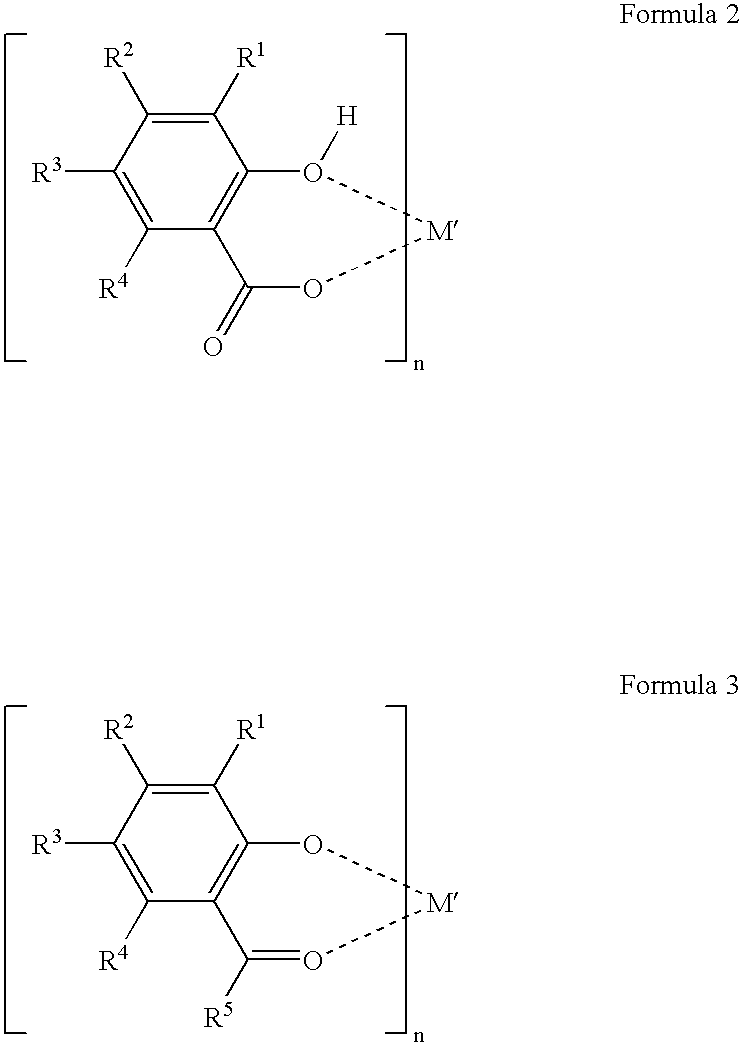

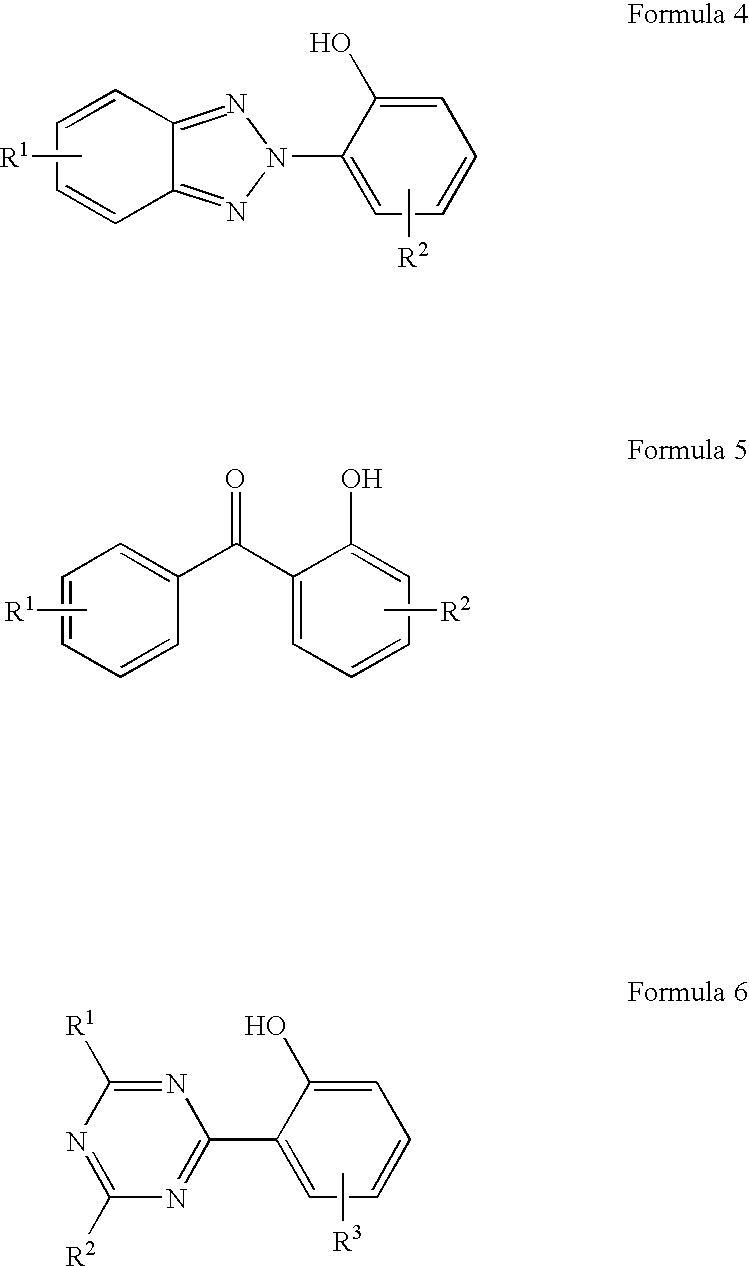

Alkali-resistant disperse dye complex

The invention discloses an alkali-resistant disperse dye complex, and relates to disperse blue BR-based alkali-resistant disperse dye complexes suitable for dyeing in a wide pH range. The complex comprises (1) alkali-resistant disperse dye blue complex, or (2) alkali-resistant disperse dye blue complex, or (3) alkali-resistant disperse dye black complex. The disperse dye complex of the invention has good dispersibility, dyeing stability and good reproducibility, and can effectively avoid the problems of stains, flaws, chromatic aberration and the like caused by dirt such as slurry, oil stain,wax and the like on fibers; and the pH value has wide range during use, dyeing can be performed in the pH range of 4.0 to 11.25, the dyed fabrics have full hue, and the dyed fabrics with predominant color fastness performance such as washing fatness, daylight fastness and the like can be obtained without reduction clearing.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

Fluorinated dye stabilizers in fluorinated dielectric solvent

InactiveUS7141688B2Improve quenching efficiencyImprove solubilityGroup 1/11 element organic compoundsReactive dyesSolubilitySolvent

The present invention is directed to novel fluorinated dye stabilizers having both high quenching efficiency and solubility in halogenated solvents. These dye stabilizers have shown a significantly effect on improving the dye fastness in hostile photooxidation conditions.

Owner:E INK CALIFORNIA

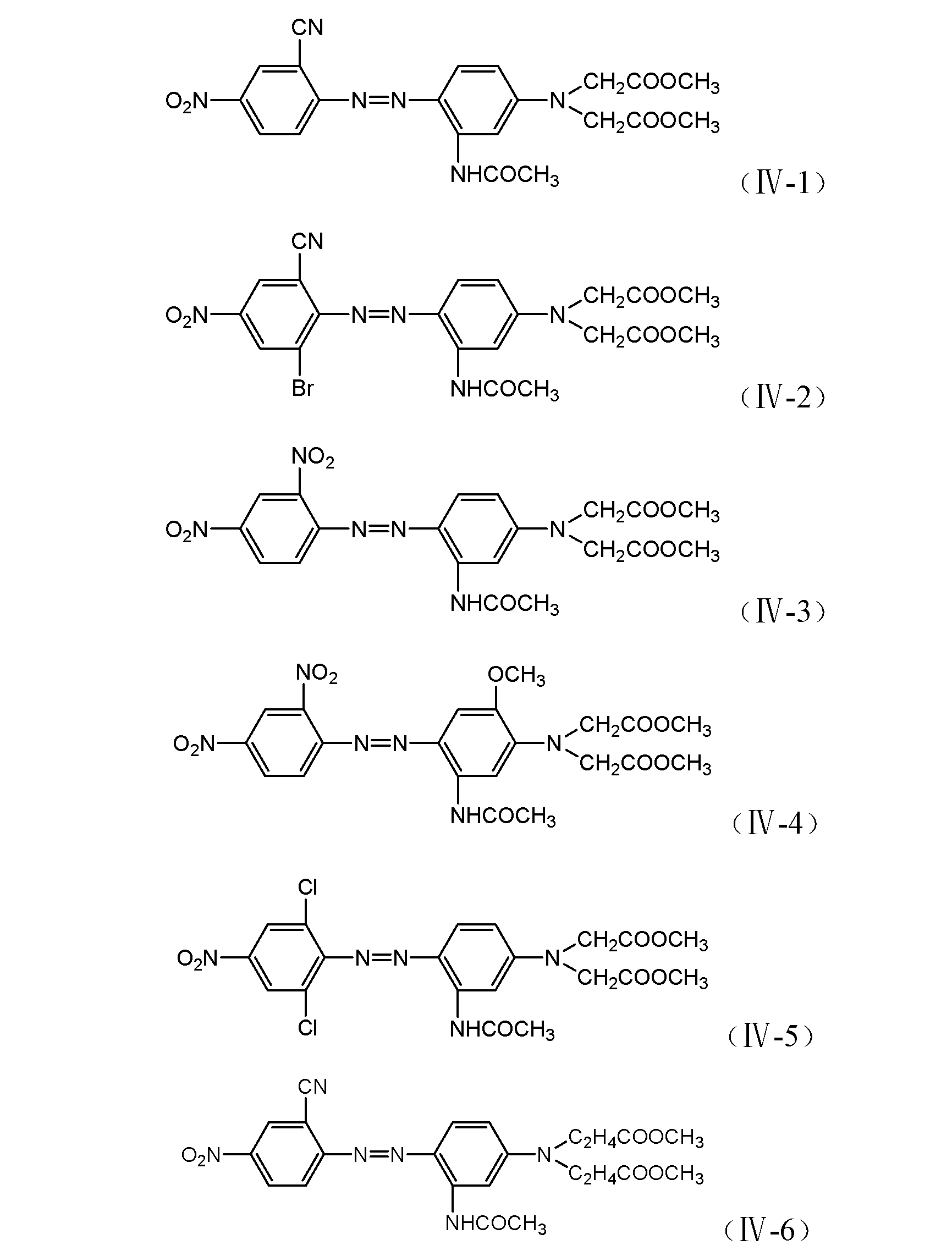

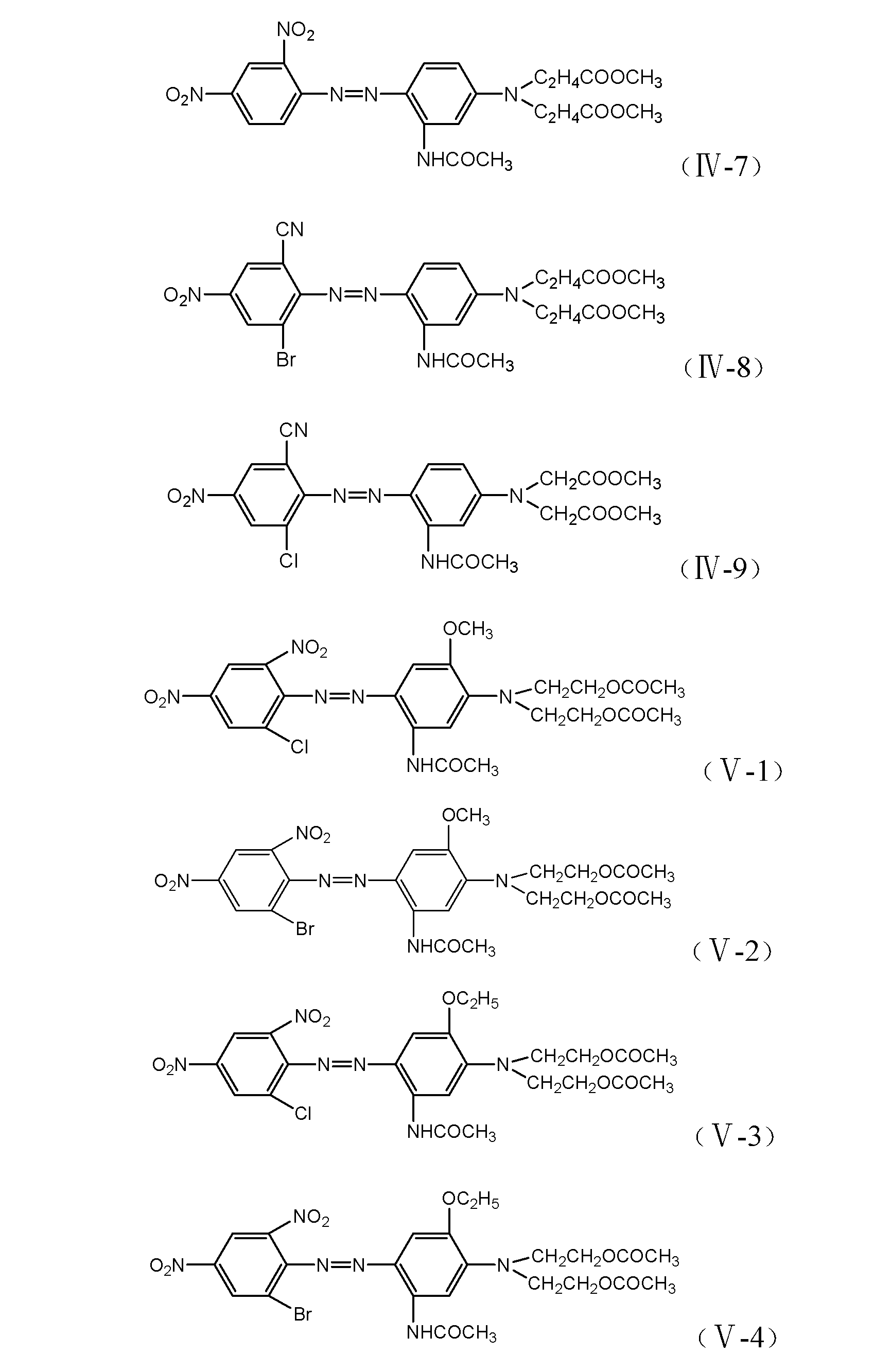

Disperse dye composition and application thereof

ActiveCN102031017AFull hueExcellent color fastnessOrganic dyesDyeing processPhotochemistryDisperse dye

The invention discloses a disperse dye composition and application thereof and particularly relates to a disperse dye which has good dyeing effect under an alkali condition and application thereof. The dye composition comprises a dye and an aid in a mass ratio of 1:1-1:2, wherein the dye is selected from any one or more of a dye I, a dye II, a dye III and a dye IV. The disperse dye composition can be widely applied to a full-polyester dyeing process, a synchronous polyester / cotton scouring, bleaching, dispersing and dyeing process, a polyester / cotton dispersing high-temperature active dye one-bath process, a polyester / cotton dispersing constant-temperature active dye one-bath two-step process and the like and has good dyeing effect. The disperse dye composition can realize synchronous performance of a pretreatment process and a dyeing process, can be used together with other active dyes, has wide application and contributes to shortening process time and lowering production cost.

Owner:浙江创元染料有限公司

Method for mordant printing on fabric dyed by natural vegetable dye

The invention discloses a mordant printing method on the natural plant dye dyeing cloth, which is characterized by the following: preparing printing slurry through mordant, thickener, penetrant and permeability-reducing agent; proceeding cleaning and printing disposal for slurry on the natural plant dye dyeing cloth; steaming at 120-160 deg.c for 1-5 min or baking at 130-160 deg.c at 1-5 min to fix color; proceeding watering disposal at 40-60 deg.c to dry in the 80-100 deg.c condition. The invention can improves quality of natural plant dyeing plant and added quality of cloth, which is a printing cloth with health function.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

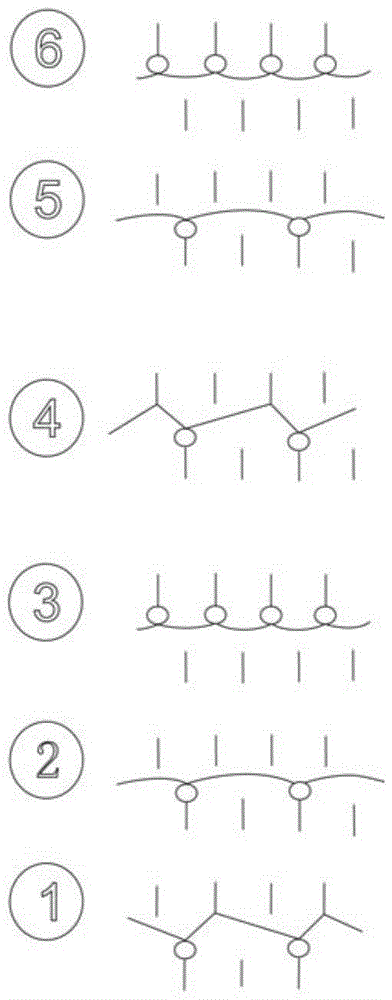

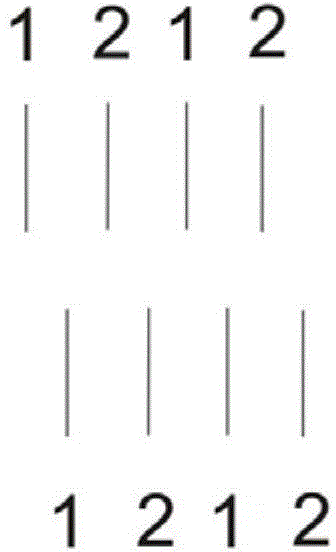

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

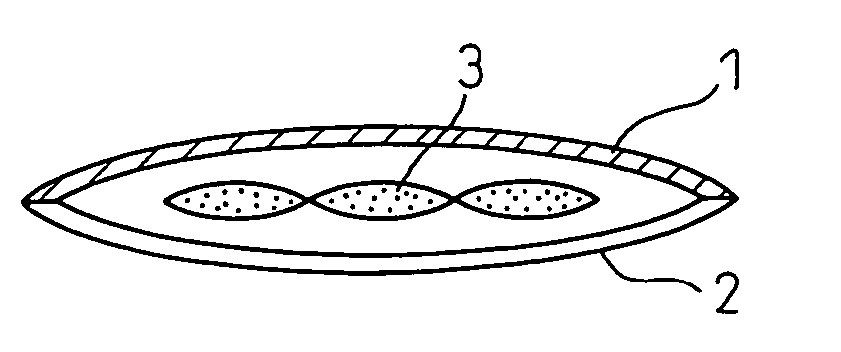

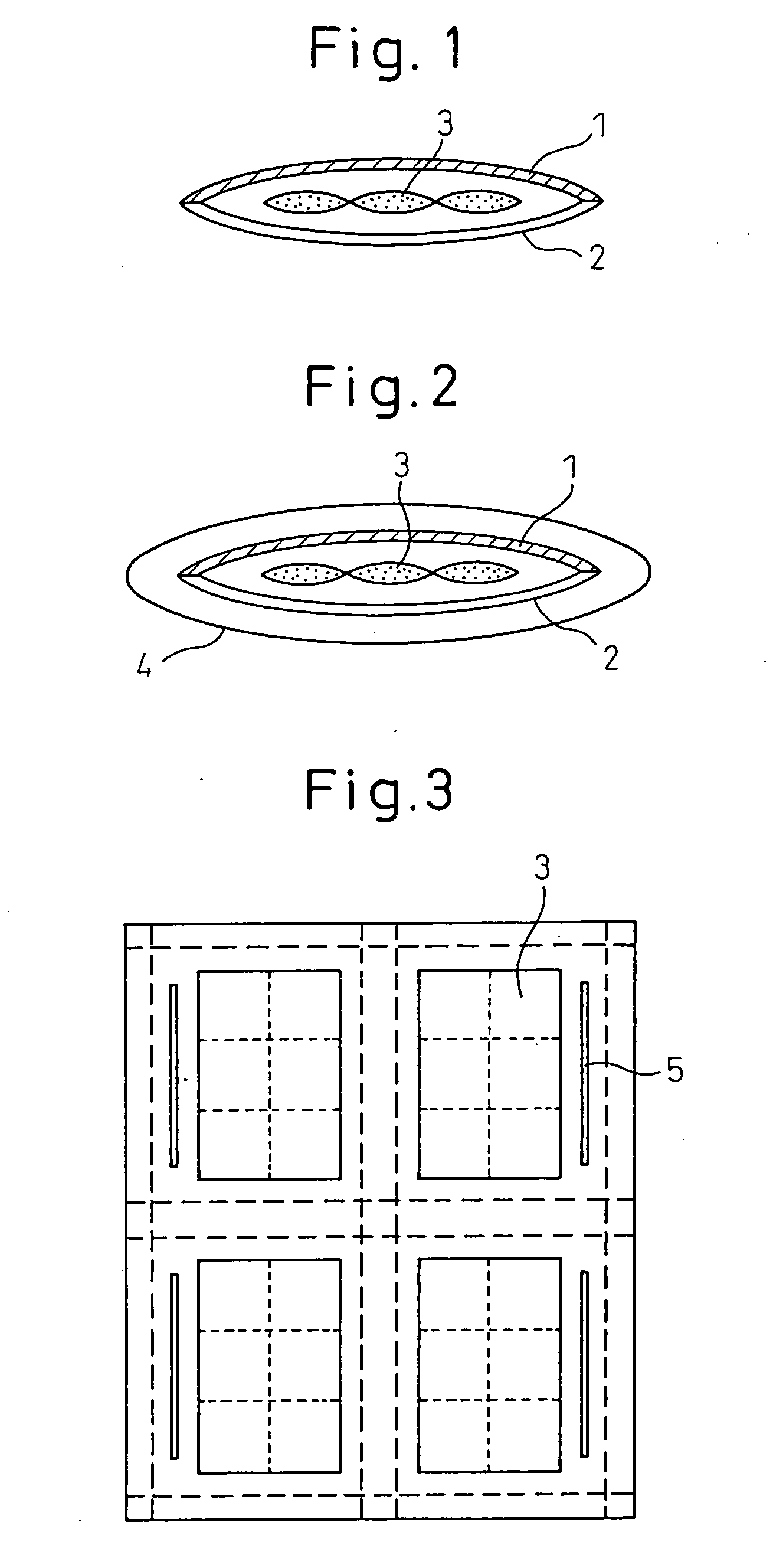

Simplified warm-keeping body and warm-keeping cloth

ActiveUS20060135016A1Conveniently carriedEasy to storeLayered productsWoven fabricsElectrical and Electronics engineeringTextile

Owner:ASAHI KASEI FIBERS CORPORATION

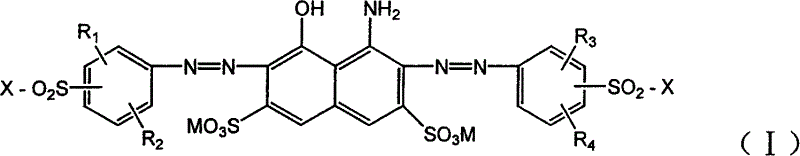

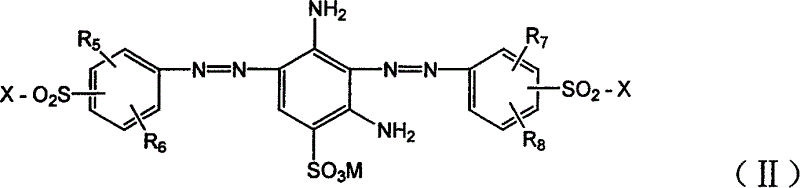

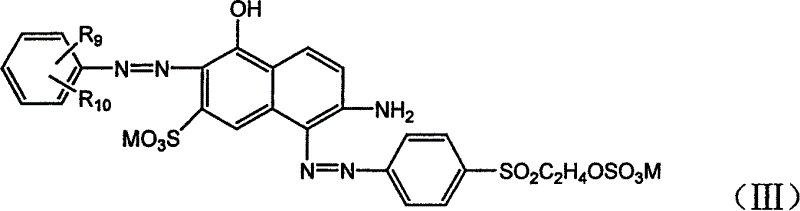

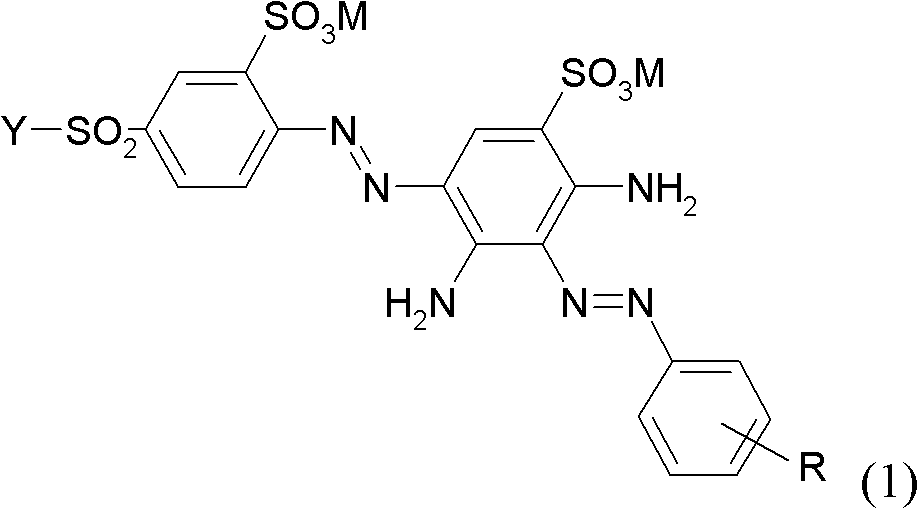

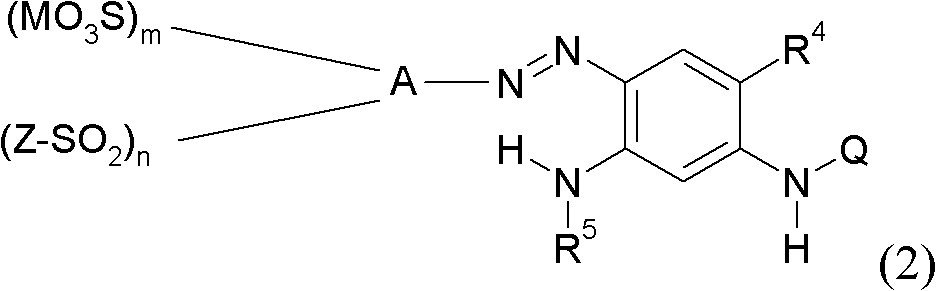

Composite active black dye

The present invention relates to a kind of disazo dyestuffs composition, the described composite active blank dyestuff mainly contains four dyestuffs, said invention also provides their structure formulas. The described composite dyestuff is suitable for dyeing dark colour fabrics, such as cellulose fibre, cotton fibre and synthetic fibre, etc., and has good level-dyeing property, repeatability, high dyeing fastness, fastness to washing and wet rubbing fastness.

Owner:SHANGHAI KEHUA DYESTUFF IND

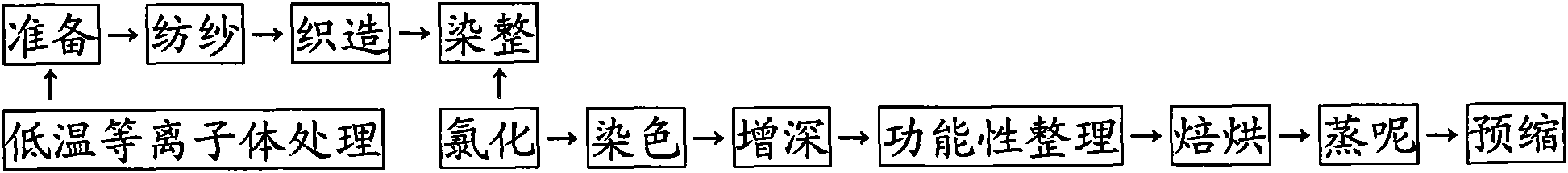

Piecedyed jet black fine-spun facing and preparation method thereof

InactiveCN101671950AImprove hydrophilicityImprove dye uptakePhysical treatmentDyeing processTextile technologyNatural fiber

The invention discloses a piecedyed jet black fine-spun facing and a preparation method thereof, and relates to the technical field of wool spinning. Raw fiber used comprises natural wool fiber. The preparation method comprises steps of preparation, spinning, weaving, dyeing, finishing and the like. The method is characterized in that the raw fiber used further comprises wool natural fiber, and non-wool natural fiber or / and chemical fiber blended spinning material. The preparation method comprises a step of wool top chlorination treatment in the preparation step, or fabric chlorination treatment in the step of dyeing and finishing, further comprises steps of low-temperature plasma treatment in the steps of preparation, spinning or dyeing and finishing to generate obvious dyed color to enhance effect, so even jet black wool and blended-spun and fine-spun facing without dyeing defect can be obtained. Detection by a computer color photometer shows that blackness of the facing is deep, L value is up to 3.5-9.5, chromatic aberration between pieces is small, and delta E is equal to or less than 0.5. No expensive piece goods treating machine is needed, and the method has the advantages oflow cost, simple process and stable quality.

Owner:JIANGSU DANMAO TEXTILE

Manufacturing process of antibacterial fiber

Tea polyphenol obtained by the extraction from tea has an antibacterial effect. In methods for producing an antibacterial fiber by fixing the tea polyphenol to fiber, the object of the present invention is to provide a process for manufacturing an antibacterial fiber capable of exerting an excellent antibacterial performance without the use of metal chelates potentially causing metal allergy and environmental problems. In order to achieve the above object, the present invention manufactures an antibacterial fiber by a process comprising the steps of contacting fiber with or immersing fiber in an aqueous solution in which a cationic surfactant with a quaternary ammonium salt group, a water-soluble protein, and an alkaline compound are dissolved; and separating said fiber from the aqueous solution, to immerse the fiber in another aqueous solution containing tea polyphenol.

Owner:SHOKUHIN SANGYO HIGH SEP

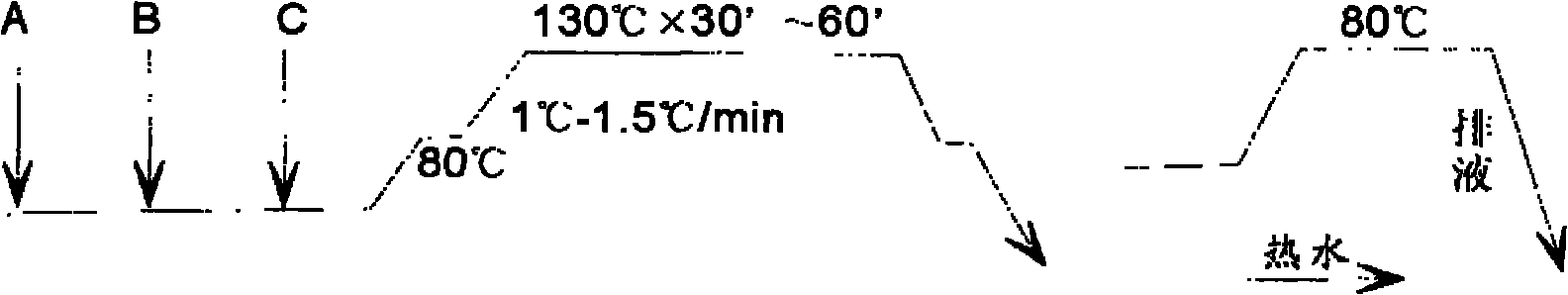

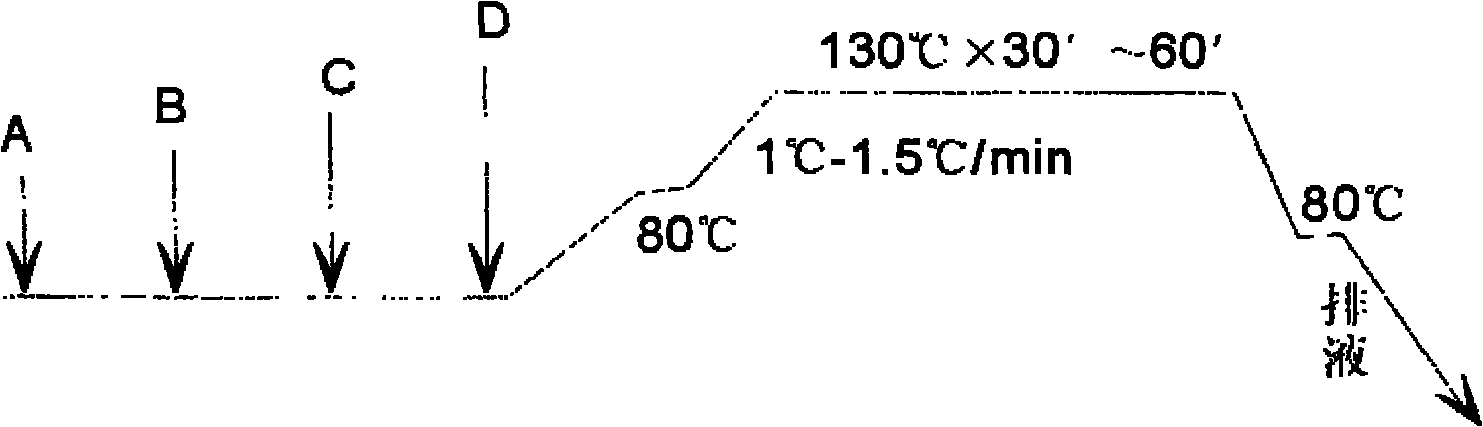

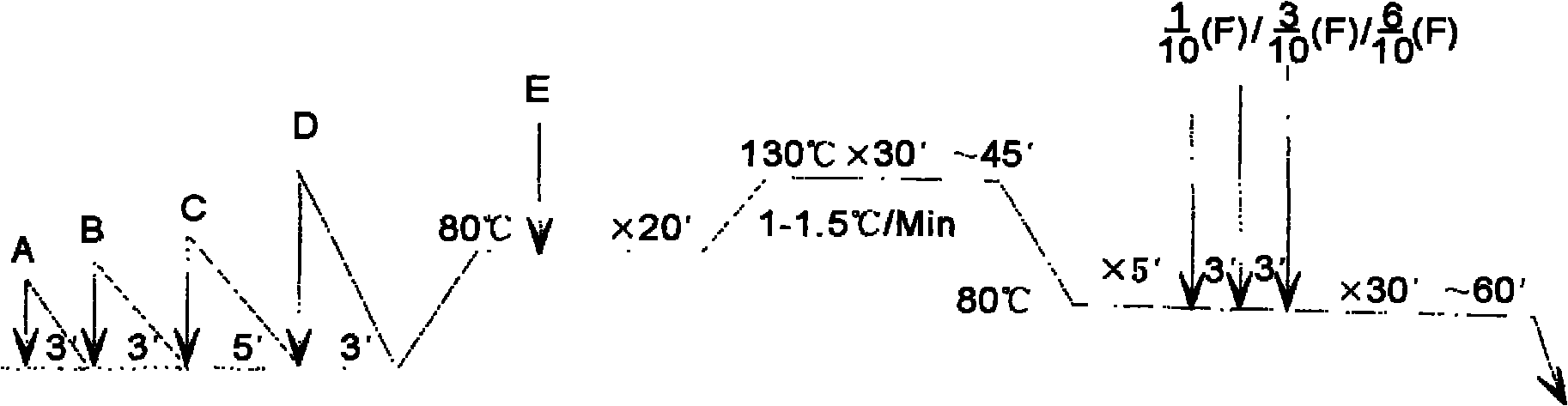

High-temperature high-pressure swelling dyeing method

InactiveCN101191306ASolving Dyeing PuzzlesIncrease profitSucessive textile treatmentsDyeing processPolymer scienceCrystallinity

The invention relates to a high temperature high pressure bulking dyeing method which comprises dyeing and after treatment. By adoption of the dyeing method of the invention, fibers or textile fabrics like aramid fibers, polysulfonamide fibers, polyphenylene sulfides, polybenzimidazole, poly-p-phenylene benzobisoxazole fibers, phenol formaldehyde resins, fibrilia and so on which have high crystallinity and high orientation degree or high glass transformation temperature can be dyed, and fibers after dyeing have the advantages of evenness, bright colors, high dyefastness, improvement of light fastness and little impact on physical properties.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

High-strength wear-resistant fabric for cases and production method thereof

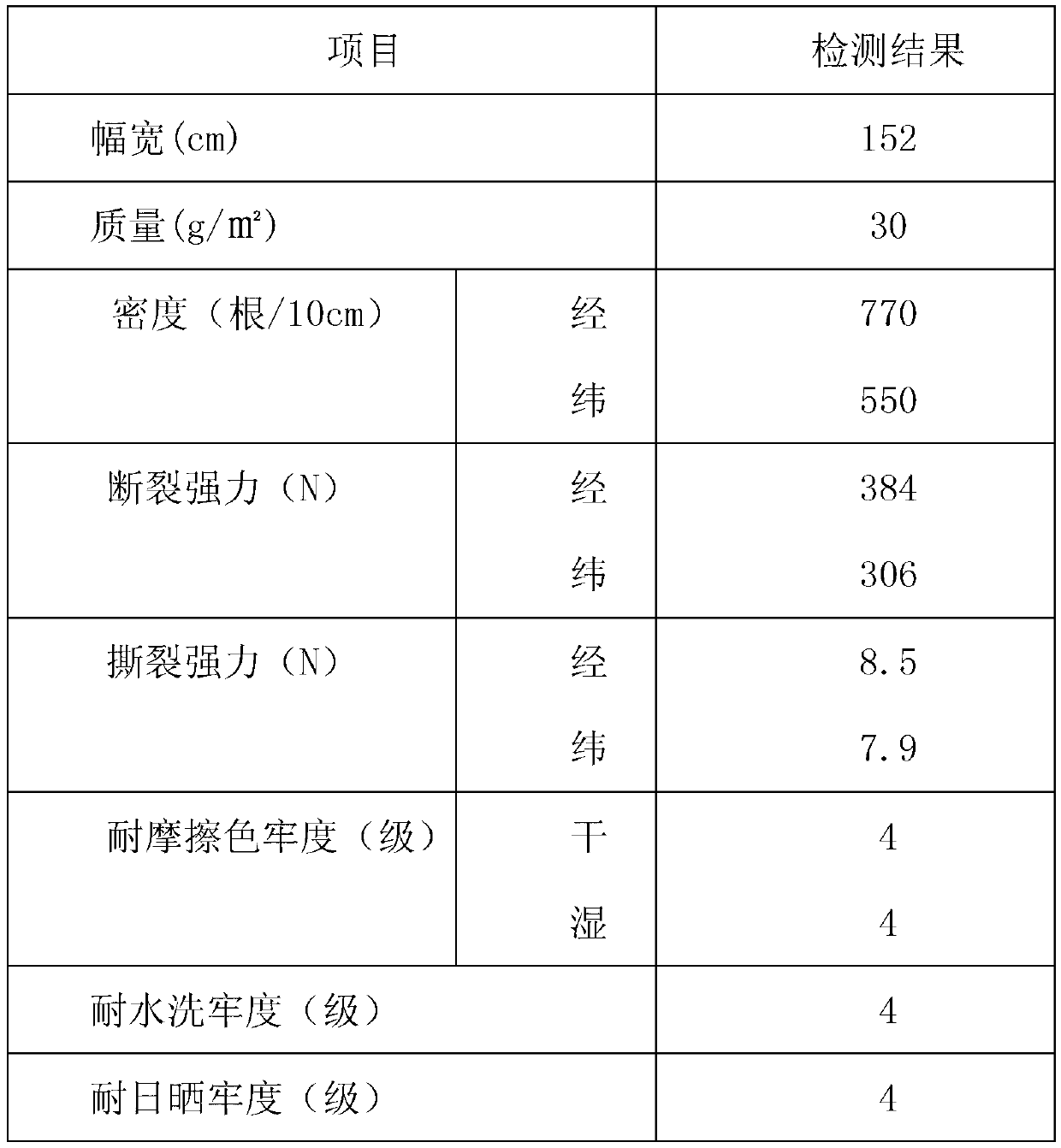

The invention relates to a high-strength wearable fabric for suitcases and bags and a manufacturing method thereof, which is characterized in that: the fabric is a coated fabric which is woven by adopting the high-strength polyester filament yarn with a strength indicator of more than 7.5cN / dtex and is made through a single-sided coating; the warp yarn adopts high-strength wearable polyester filament yarn air textured yarn, and the weft yarn can be in other filament yarn forms of high-strength polyester filament yarn. The high-strength wearable fabric has the advantages of high tensile strength, high tearing strength, high wear-resisting property, clear printing, good color fastness and good color tone; the fabric also has the properties of watertightness, inflaming retarding, camouflage and infrared ray prevention through the functional finishes. The overall performance of the high-strength wearable fabric is almost the same with that of foreign high-strength nylon fabric, but the price is quite low, thereby the high-strength wearable fabric has a higher cost performance.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Pigment ink for inkjet printing of high fastness textile and preparation method thereof

The invention discloses a pigment ink for inkjet printing of high fastness textile and a preparation method thereof. The ink comprises the following components by mass percent: 30-50% of pigment / branched polymer nano composite particle dispersoid, 10-50% of water soluble cosolvent, 1-5% of non-ionic surfactant, and the balance of deionized water. The preparation method comprises the following steps: sequentially adding the pigment / branched polymer nano composite particle dispersoid, a water-soluble cosolvent and a non-ionic surfactant into the deionized water in proportion, mixing uniformly, stirring by a stirrer at a speed of 500-1000rpm (revolutions per minute) for 20-40 minutes, regulating pH value of the ink to be 7-9, and filtering by virtue of a 500nm microfiltration membrane so as to obtain the coating ink. The ink needs no adhesive, the grain size of the pigment particle in the ink is less than 200nm, and the ink has good storage stability; after jet printing, the textile is baked so as to obtain good color fastness, thus improving the brightness.

Owner:JIANGSU GEMEIGAO DEV CO LTD

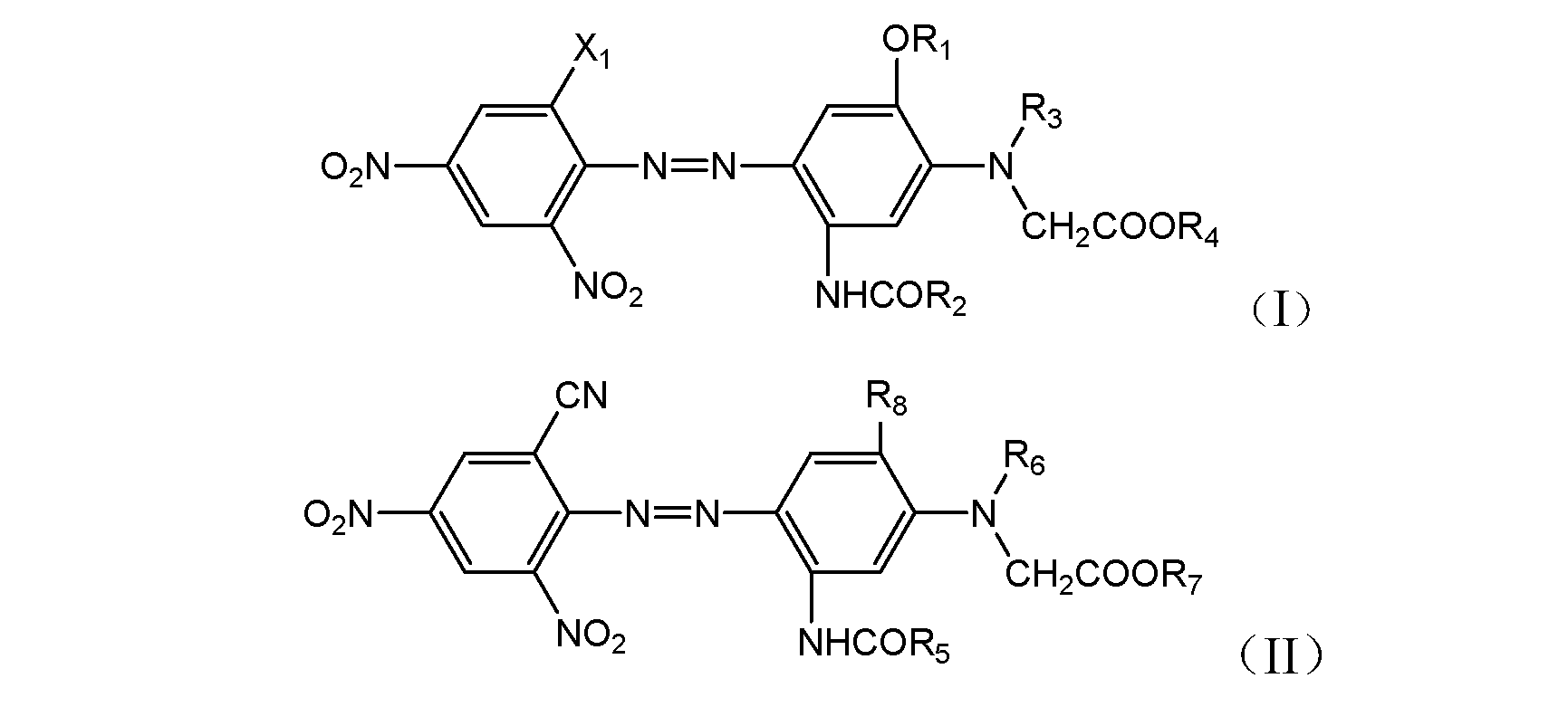

Dispersed dark dye composition

The invention provides a dispersed dark dye composition, which mainly comprises 5-95 parts by mass of one or more dye components A shown in formula (I) and 5-95 parts by mass of one or more dye components B shown in formula (2). When applied to a hydrophobic textile material, in particular to polyester material embossing or coloration, the dispersed dark dye composition provided by the invention has the characteristics of good dyeing depth, excellent lifting capacity, good color fastness and the like, therefore, the dye consumption during coloring is small, and the use cost of the dye is favorably saved.

Owner:ZHEJIANG LONGSHENG GROUP +1

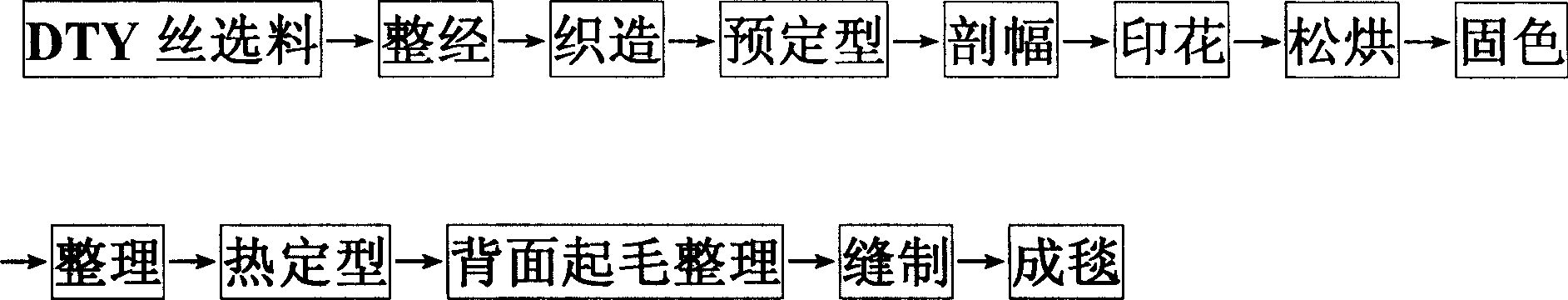

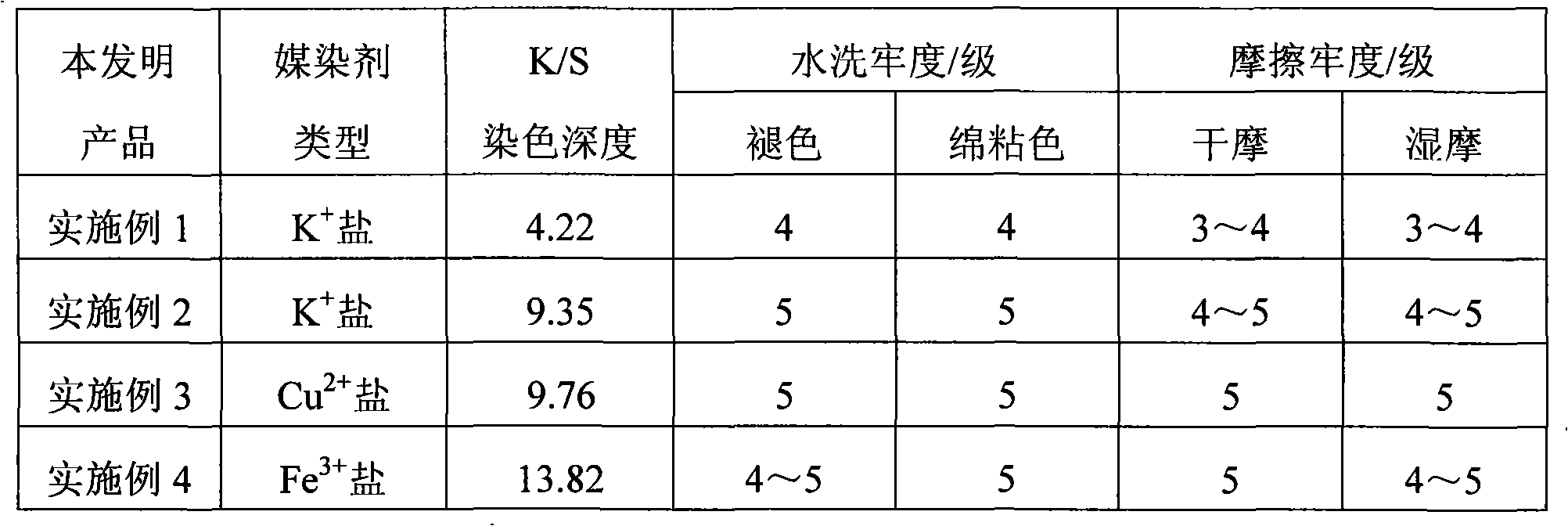

Process of machining full terylene ultrafine fiber coral fleece blanket

InactiveCN101016675ALongitudinal vertical stabilityHigh color fastnessWarp knittingHeating/cooling textile fabricsPolyesterColour fastness

The invention relates to a method for processing polyester ultra-fine fiber coral blanket comprises a DTY material selection, a warping process, a weaving process, a pre-shaping process, a cutting process, a printing process, a loosening drying process, a color fixing process, a finishing process, a thermal shaping process, a back furring finishing process, a sewing process, and final product outlet. The pre-shaping process comprises that pre-shaping the blank cloth in weaving process at high temperature before the cutting process. And the invention has the advantages that the invention can assure the contract homogeneity of blank fiber and stabilize the longitudinal verticality, to obtain better smooth, water adsorption and thermal insulation functions, and the invention can save cost, reduce SS degree of printed pollutant, and can improve the color stability of fabric.

Owner:常熟市锦绣经纬编有限公司

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

Natural dye mordanting dyeing or mordanting printing product and preparation method thereof

ActiveCN105113290AHigh color fastnessUniform base colorFibre treatmentDyeing processMordantNatural dye

The invention provides a method for preparing a natural dye mordanting dyeing or mordanting printing product. The preparation method comprises the steps of performing pretreatment on a fabric, using cation modified working solution to perform cation modification on the fabric, and obtaining cation-modified fabric; using natural dye to dye the cation-modified fabric and obtaining a natural dye dyeing fabric; using a mordant working solution or mordant working solution foam to perform mordanting dyeing or mordanting printing on the natural dye dyeing fabric at a predetermined area, performing steaming or baking at 80-180 DEG C for 10 s to 25 min, performing washing, softening and shaping, and obtaining the natural dye mordanting dyeing or mordanting printing product. The invention further provides the natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method. The natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method is good in color fastness and uniform in base color, the printing part is dark in color, the material loss is less, and a fabric is softer.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Aqueous jet ink printing pigment ink for textile and production method thereof

The invention discloses an aqueous jet ink printing pigment ink for textile and a production method thereof. The aqueous jet ink printing pigment ink for textile mainly consists of aqueous microcapsule pigment paste, a wetting agent, preservatives and de-ionized water. The invention has simple production process and low cost, and saves energy, reduces emission and accords with the requirements ofenvironment protection without pollution in the production process. The microcapsule technology is adopted to coat the grinded and comminuted pigments to make a functional high molecular dispersing agent, thereby effectively preventing the pigment particles from agglomerating for the second time and ensuring that the ink has better dispersing stability and storage stability.

Owner:李娟

Natural staining agent, preparation thereof and application thereof to silk dyeing

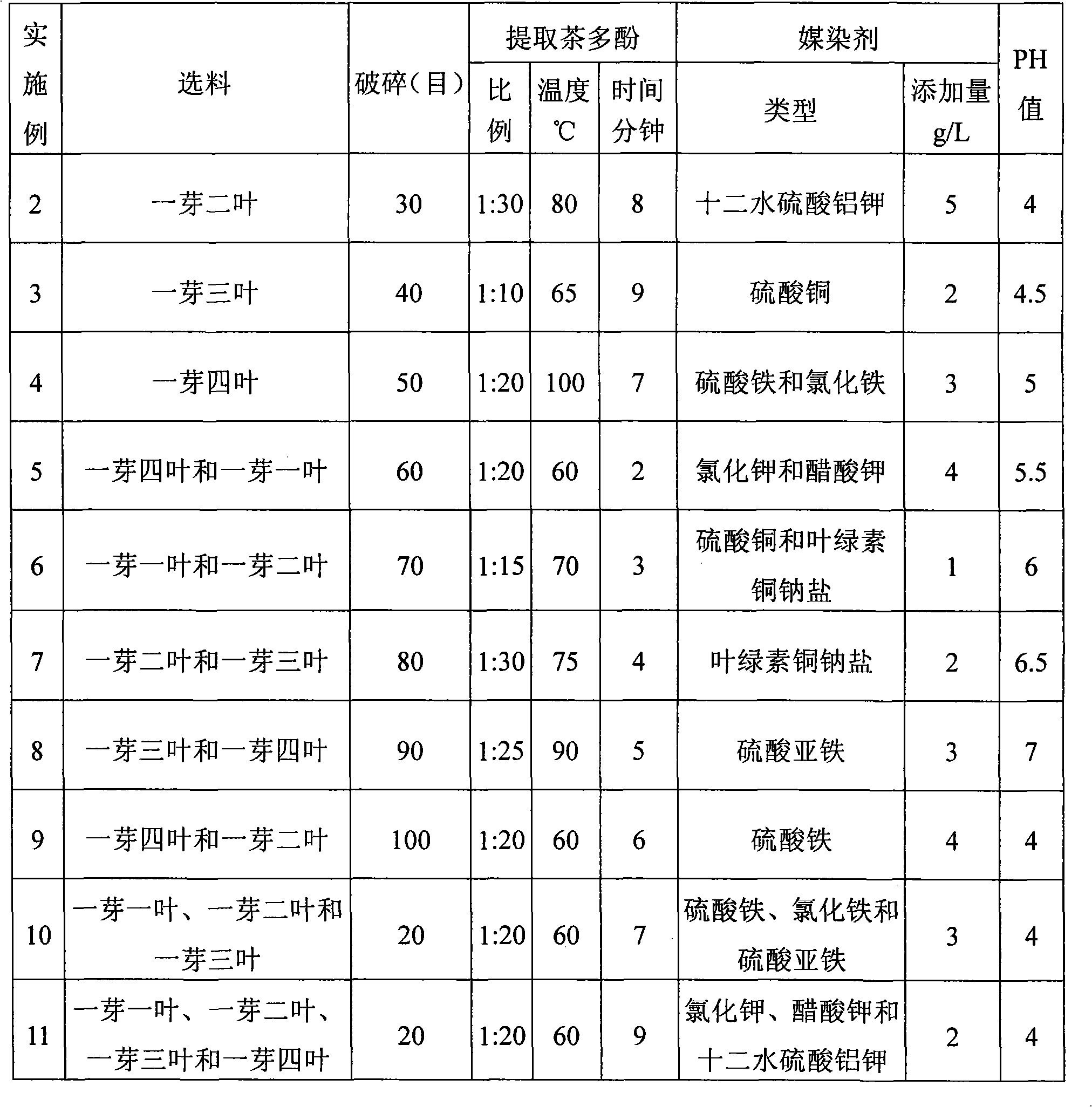

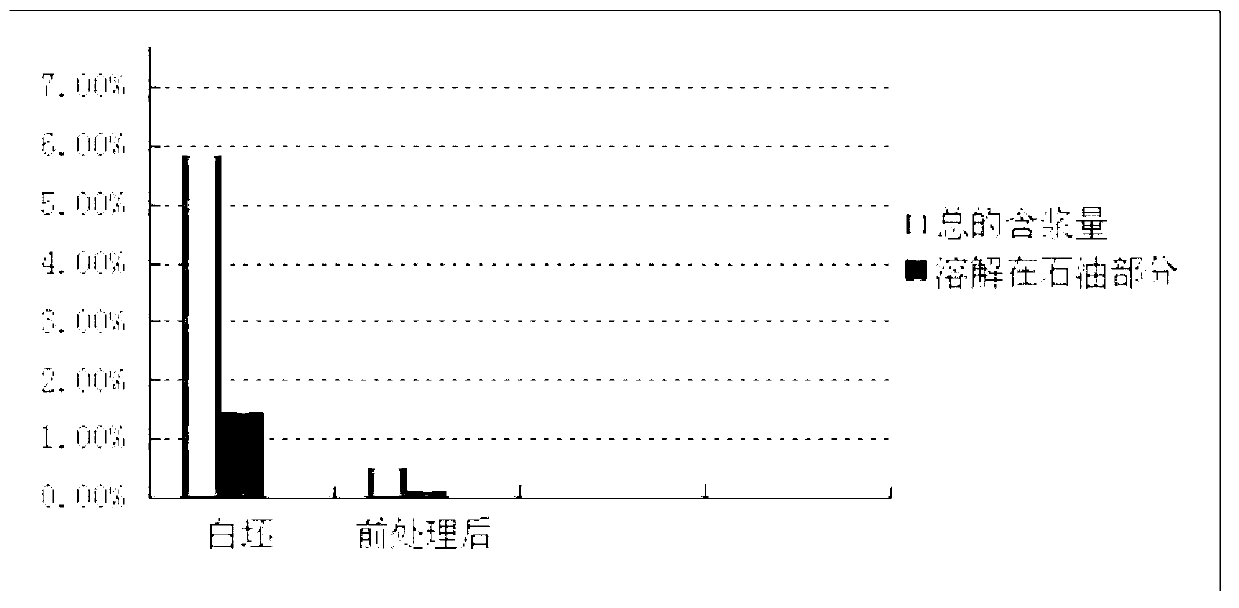

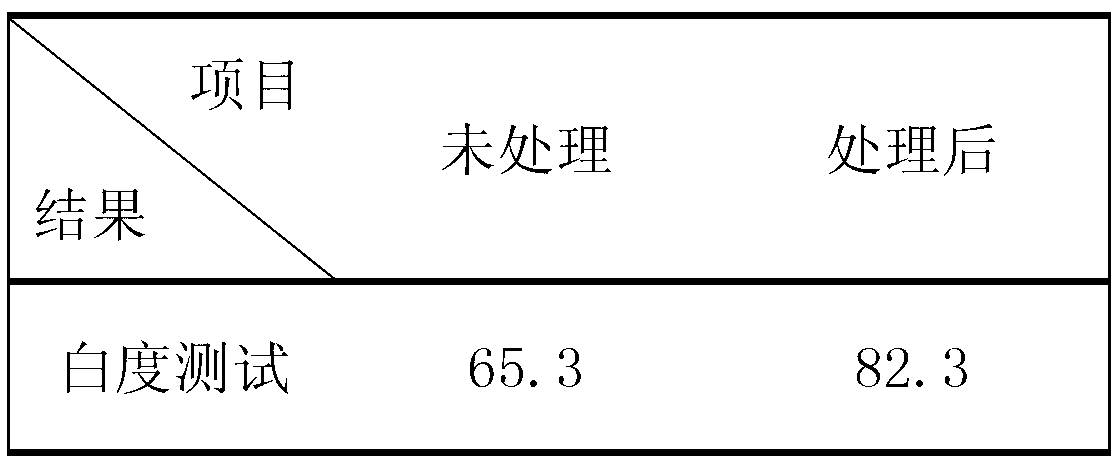

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Acid dyeing of polyurethane materials

ActiveUS20140250611A1Enhances color intensity obtainedHigh color fastnessOrganic dyesDyeing processOrganic solventAmmonium compounds

A polyurethane is dyed with an aqueous solution of an acid dye compound, a quaternary ammonium compound selected from soluble tetrabutylammonium compounds and tetrahexylammonium compounds, and, optionally, an water-soluble organic solvent.

Owner:NIKE INTERNATIONAL LTD

Dyeing and finishing method of superfine denier nylon fabric

ActiveCN103132349AHave affinityReduce initial dyeing speedFibre typesDry-cleaning apparatus for textilesCooking & bakingColour fastness

The invention discloses a dyeing and finishing method of superfine denier nylon fabric, belongs to the field of processing on the superfine denier nylon fabric, and aims at solving the problems that dyeing defect and uneven dyeing of the superfine denier nylon fabric are easily generated in the dyeing process. The method disclosed by the invention comprises the steps of: cold heaping, open-width desizing, pre-setting, dyeing, performing fixation, baking and molding a finished product. An anionic leveling agent disclosed by the invention has affinity on nylon, and can generate an unexpectedly dyeing effect on the fiber together with anionic dye. Thus, the initial dyeing speed of the dye is reduced, so as to achieve a uniform dyeing effect; and the fold resistance of the fabric is improved when the craping style of the fabric is kept by presetting the desized fabric. By using the dyeing and finishing method, the dyeing process is even, the color and the luster are good, the colour fastness is good, and the like; and the dyeing defect can not be generated, and the fabric processed by using the method accords with the requirements of superior products specified by the standard of GB / T17253-2008 'synthetic filament yarn fabric'.

Owner:SHENGHONG GRP CO LTD

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Brocade fabric active and neutral dye combination catalytic fixation printing technique

ActiveCN101597868AReasonable printing processClean and environmentally friendly productionDyeing processUreaAfter treatment

The invention relates to a brocade fabric active and neutral dye combination catalytic fixation printing technique. The technical problem to be solved is to provide a printing technique which can produce a brocade printing clothing plus material with top grade and light mass which is comfortable to wear. The technical proposal is that (1) textile pretreatment, the textile is pretreated by desizing, boiling, and bleaching; (2) presetting, technique conditions are that the temperature is 160 to 165 DEG C and the time is 30 seconds; (3)printing formulation preparation, 40 to 50 % of printing thickener, 0.05 to 1.0% of fixation catalytic agent, 1 to 1.5% of alkaline agent, 1% of reserve salt, 5% of urea, active dye and an amount of neutral dye and rest of water; (4)printing technique, according to the formulation in the step (3), the printing is carried out; the aging temperature is 102 to 105 DEG C, and the aging time is 18 to 20 min; (5) washing and soaping, fixing agent FRC is used for the after-treatment, afterboarding and tentering of the printing plus material. The technique is suitable for textile printing and dyeing industries.

Owner:浙江嘉欣兴昌印染有限公司

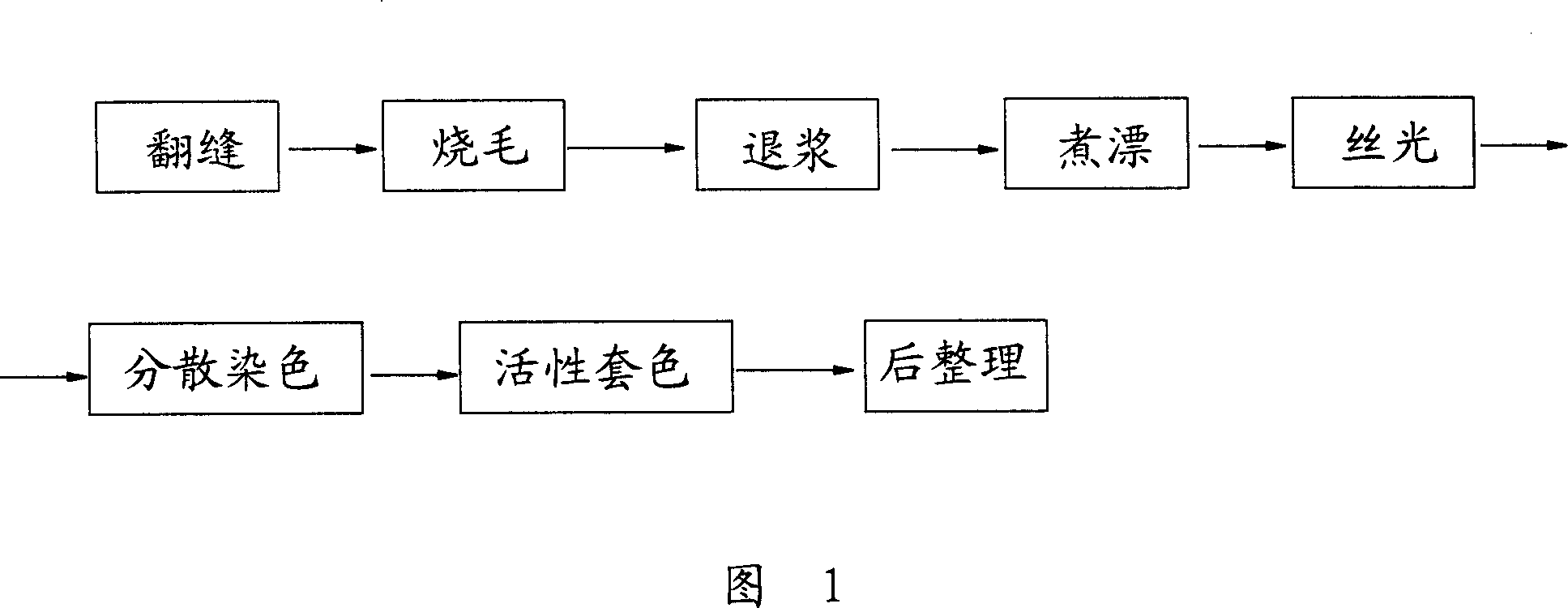

Dyeing technique for polylactic acid fabric/cotton blended shuttle weaving

InactiveCN101082154AHigh color fastnessBright colorMercerisingDyeing processDisperse dyeTextile dyeing

The process of dyeing woven polylactic acid fiber / cotton blended fabric belongs to the field of textile dyeing technology. The process of dyeing woven polylactic acid fiber / cotton blended fabric has China produced disperse dye and assistant adopted and improved steps of desizing, boiling and rinsing, mercerizing and dyeing. The dyed product has bright colors, proper shade and high color fastness. The present invention is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

Composition of a water-repellent agent

InactiveUS7396395B1Improve waterproof performanceHigh color fastnessGroup 4/14 element organic compoundsOther chemical processesEmulsionTear resistance

A composition of a water-repellent agent has a solvent and a solute. The solvent is water. The solute is dissolved in water and has isocyanate-acryl, non-ionic fluoro-acryl, 4,4-dipheylmethane diisocyanate, zinc acetate and polyethylene wax. Isocyanate-acryl has a concentration in a range of 10˜40 gram in per liter of the water-repellent agent (i.e. 10˜40%). Non-ionic fluoroacryl has a concentration in a range of 80˜150% t. 4,4-dipheylmethane diisocyanate has a concentration in a range of 5˜12%. Zinc acetate has a concentration in a range of 1˜20%. Polyethylene wax emulsion has a concentration in a range of 1˜40%. Therefore, a fabric treated with the present invention has good waterproof ability, widely enhanced color fastness in light and improved tear-resistance strength at the same time.

Owner:EVEREST TEXTILE CO LTD

Fiber-reactive azo dyes and dye mixtures, preparation thereof and use thereof

Owner:DYSTAR COLOURS DISTRIBUTION GMBH

Method for coloring alginate fiber stoste by adopting lake colors

ActiveCN104264280AIncrease profitHigh color fastnessAlginate artificial filamentsDye addition to spinning solutionSolventFine chemical

The invention discloses a method for coloring alginate fiber stoste by adopting lake colors, and belongs to the field of fine chemical engineering and material science. The method comprises the following steps: adding sodium alginate into deionized water, and stirring so as to dissolve sodium alginate fully to prepare alginate fiber spinning stoste; then adding lake colors into the alginate fiber spinning stoste, stirring and mixing uniformly, filtering and defoaming to obtain the lake color colored alginate fiber stoste, and preparing further to obtain lake color colored alginate fibers. The method overcomes the problem of damage of traditional dye dying on fibers; the prepared colored alginate fibers have the advantages of bright colors, high color fastness, good solvent mobility resistance and the like.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com