Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2791 results about "Reactive dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a reactive dye, a chromophore (an atom or group whose presence is responsible for the colour of a compound) contains a substituent that reacts with the substrate. Reactive dyes have good fastness properties owing to the covalent bonding that occurs during dyeing. Reactive dyes are most commonly used in dyeing of cellulose like cotton or flax, but also wool is dyeable with reactive dyes. Reactive dyeing is the most important method for the coloration of cellulosic fibres. Reactive dyes can also be applied on wool and nylon; in the latter case they are applied under weakly acidic conditions. Reactive dyes have a low utilization degree compared to other types of dyestuff, since the functional group also bonds to water, creating hydrolysis.

Method and composition for the sizing of paper with a mixture of a polyacid and a polybase

InactiveUS6171444B1Easy to produceHigh color fastnessNatural cellulose pulp/paperSpecial paperHueWater resistant

Compositions and methods are provided for the sizing of paper, to enhance the quality of images printed thereon. The novel sizing compositions contain as a sizing agent a mixture of a polyacid and a polybase. When applied to a paper substrate, such as in an internal or external sizing process, the sizing compositions result in a sized paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the sizing agent. Images printed on a paper substrate coated with the sizing compositions of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

Dye polymers

The present invention relates to polymeric shading dye and their use in laundry applications. The polymers are polyethylene imines and the dyes are reactive dyes.

Owner:CONOPCO INC D B A UNILEVER

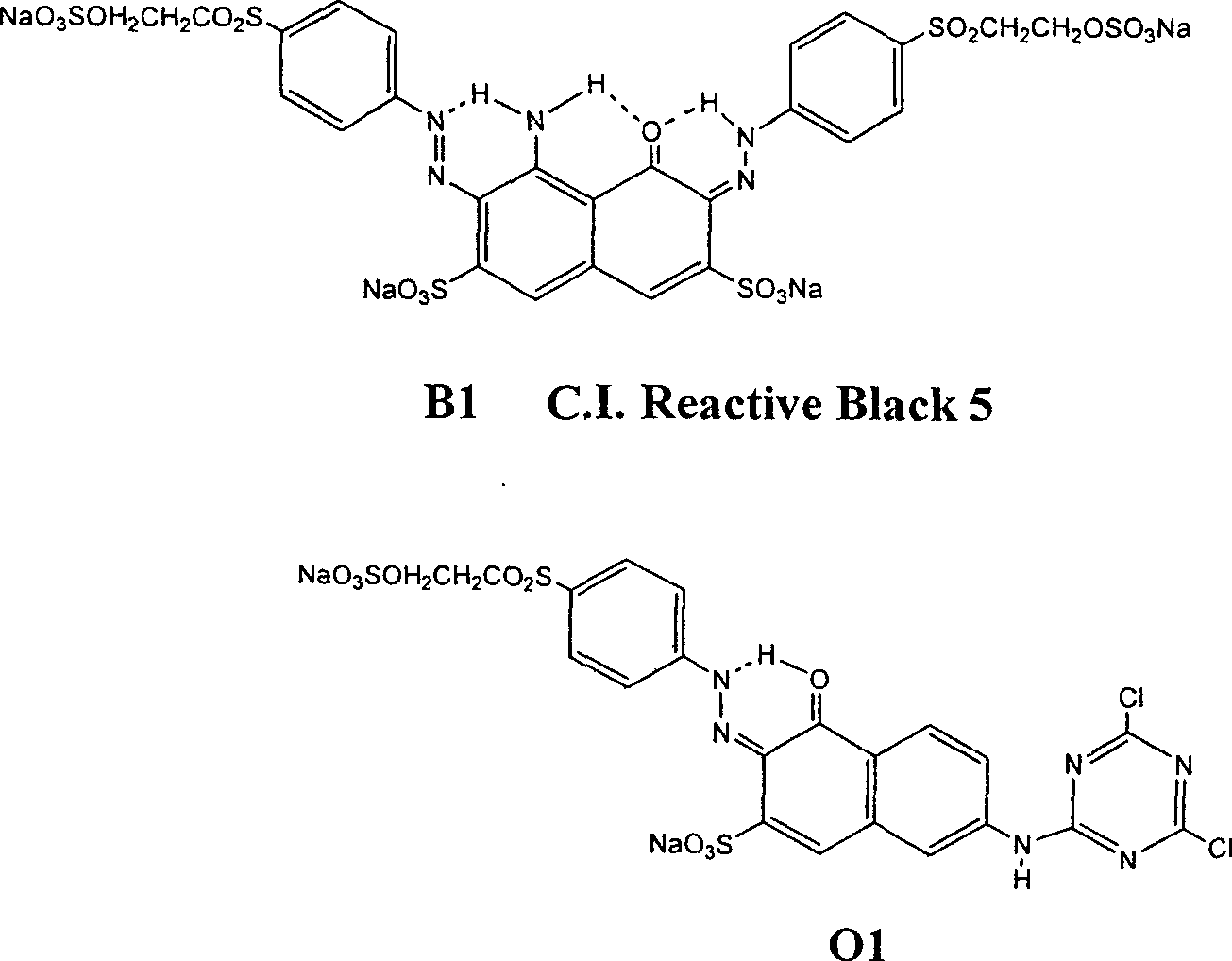

Black and active dye

The invention provides a black composite reactive dye having three primary color constituents comprising, green disazo dye employing ethylene sulfone series arylamine or aniline derivative as diazo component and H acid as coupling component, one ore more red disazo dyes employing sulfoalkyl J acid or carboxymethyl J acid derivatives as coupling components, one ore more yellow bisazo or polyazo dyes employing sulfochlorinated 3,5-diaminobenzoic acid or sulfoalkyl derivatives as coupling components. The dye can be applied to intermittent and continuous dyeing for cellulose fiber, protein fiber, poly nylon and their fiber mixed fabrics.

Owner:DALIAN UNIV OF TECH

Method for preparing the reactive tinting compound and the tinted contact lens

A method for preparing the tinted contact lens with the covalently bonded novel reactive tinting compound is disclosed. The reactive tinting compound with mono vinyl functionality is prepared by reacting the reactive dye with a hydrophilic monomer containing both pendent hydroxyl and vinyl groups under an alkaline condition. The water soluble reactive dyes containing either difluoro-chloropyrimidine or β-sulphatoethylsulphone reactive groups are used for synthesis of the reactive tinting dye. The lens forming materials are photo-polymerized in the presence of the reactive tinting compound to prepare a tinted contact lens. The reactive tinting compound is copolymerized with the lens forming monomers in a single photo-polymerization step that requires no subsequently alkaline soaking or developing step as used in the prior art. In addition, the covalently bonded dye is stable and durable in the lens and does not fade or leach out after multiple high-pressure thermal sterilizations.

Owner:SMART PERFORMER

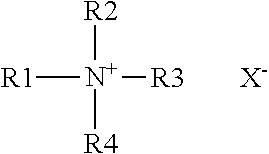

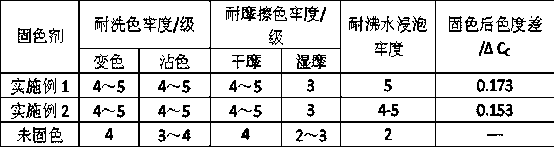

Preparation method and application of terminated-type cation water-borne polyurethane color fixing agent

The invention relates to a preparation method of a terminated-type cation water-borne polyurethane color fixing agent, belonging to the field of organic adhesives. The terminated-type cation water-borne polyurethane color fixing agent with solid content of 20-40% of and transparent or translucent yellowish appearance can be prepared by the following steps of: (1) polyurethane prepolymer reaction, (2) terminated reaction, and (3) acid neutralization and ionization reactions. In the invention, partial terminating after prepolymerization is adopted, a small number of isocyanate groups is inactivated and a self-emulsifying method is adopted to synthesize the water-borne polyurethane color fixing agent; in the color fixing process, closed active groups are released through baking at high temperature and are carried out crosslinking reaction with hydroxyl and amino groups on textile fabrics and reactive dyes so that the color fastness to washing of the textile fabric is improved.

Owner:溧阳常大技术转移中心有限公司

Limited play data storage media and coating formulations thereon

The present invention provides a formulation for a reactive dye layer for a limited-play optical storage medium, the reactive formulation including at least one carrier material or curable acrylate monomer, at least one reactive material disposed within the carrier material or acrylate monomer, and at least one photo-bleaching retarder material disposed within the at least one adhesive material. The at least one photo-bleaching retarder material includes at least one polymeric polyhydroxy compound selected from the group consisting of polyhydroxystyrenes, cellulose, and functionalized cellulose derivatives.

Owner:FLEXPLAY TECH INC +1

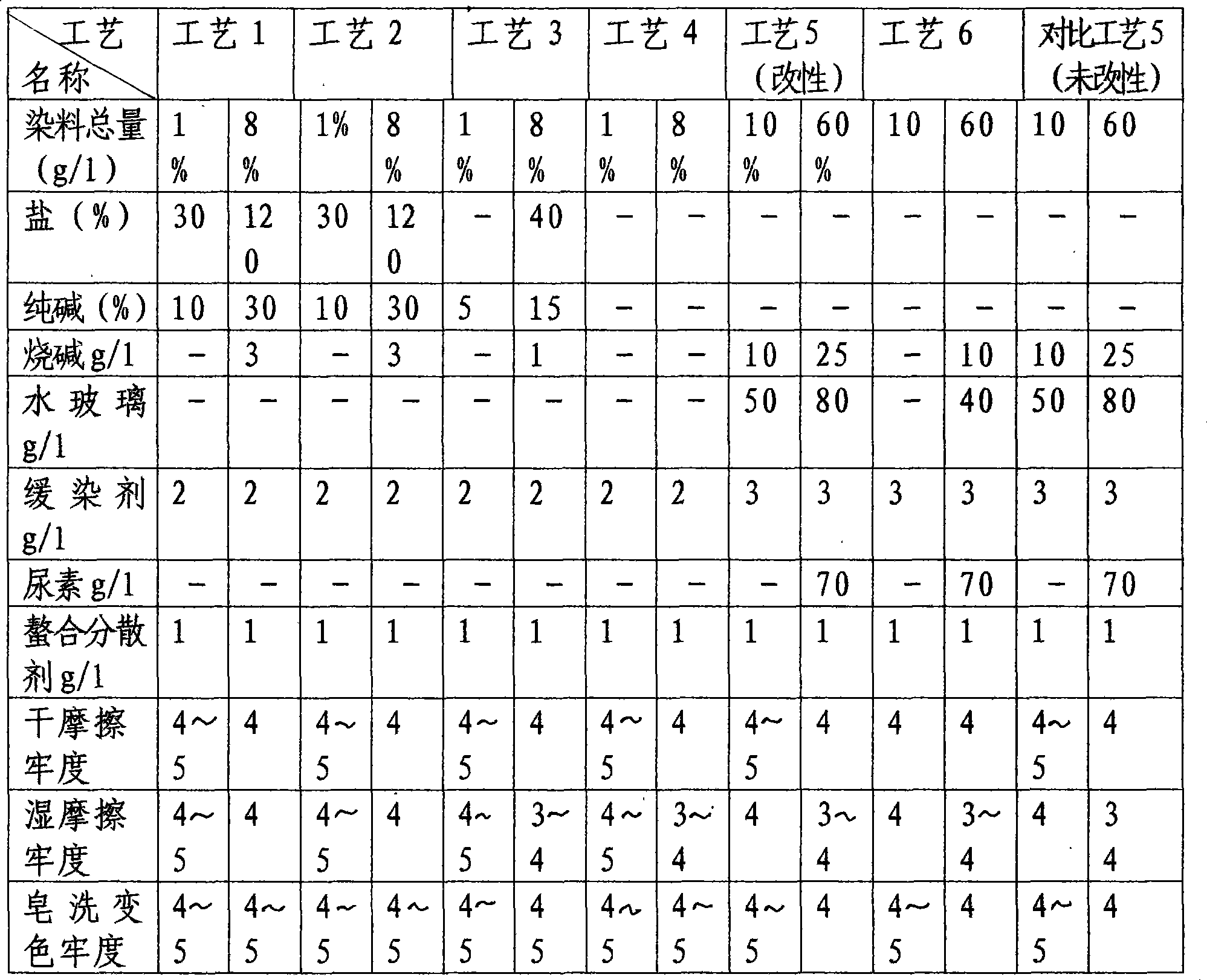

Method for dip-dyeing polyamide/cotton (viscose) fabrics with acid or neutral and reactive dyes in one-bath way

The invention discloses a method for dyeing polyamide / cotton (viscose) fabrics with acid (neutral) and reactive dyes in a one-bath way. The method comprises the following steps of: adding alkali in reactive dyes till pH value is 11-11.5 and dyeing cotton fibers with the reactive dyes at the low temperature of 60-65 DEG C or two temperature ranges of 60-65 DEG C and 80-85 DEG C; and then adding acid until the pH value is 5-6, and raising the temperature to 95-98 DEG C and dyeing the polyamide fibers with the acid (neutral) dyes; and meanwhile, fixing the colour of the acid (neutral) dyes in the reactive dye soaping process. According to the invention, as the one-bath two-step dyeing technology is used for replacing the traditional two-bath process, the dyeing time is shortened, the yield is increased and the consumption of energy and water and the alkali usage are reduced, thus lowering the production cost and protecting the environment; when the acid (neutral) dyes are used for dyeing, the dye liquid is a buffer system formed by sodium acetate and acetic acid and can improve the dye reproducibility (dyeing right first time) and reduce rehandling. The method has very obvious practical value.

Owner:ZHEJIANG SCI-TECH UNIV

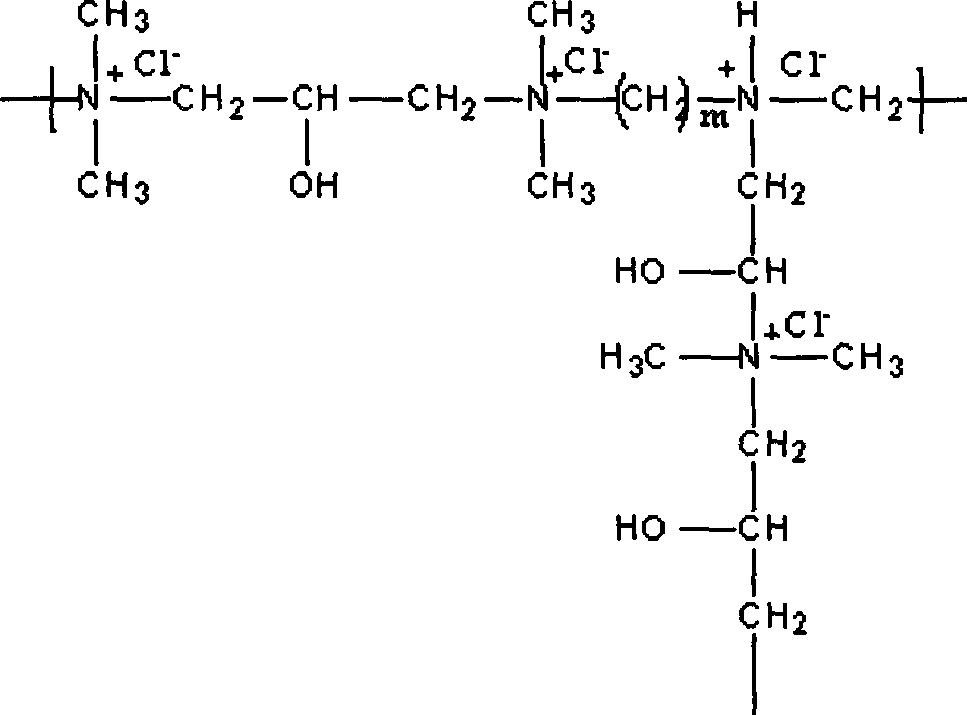

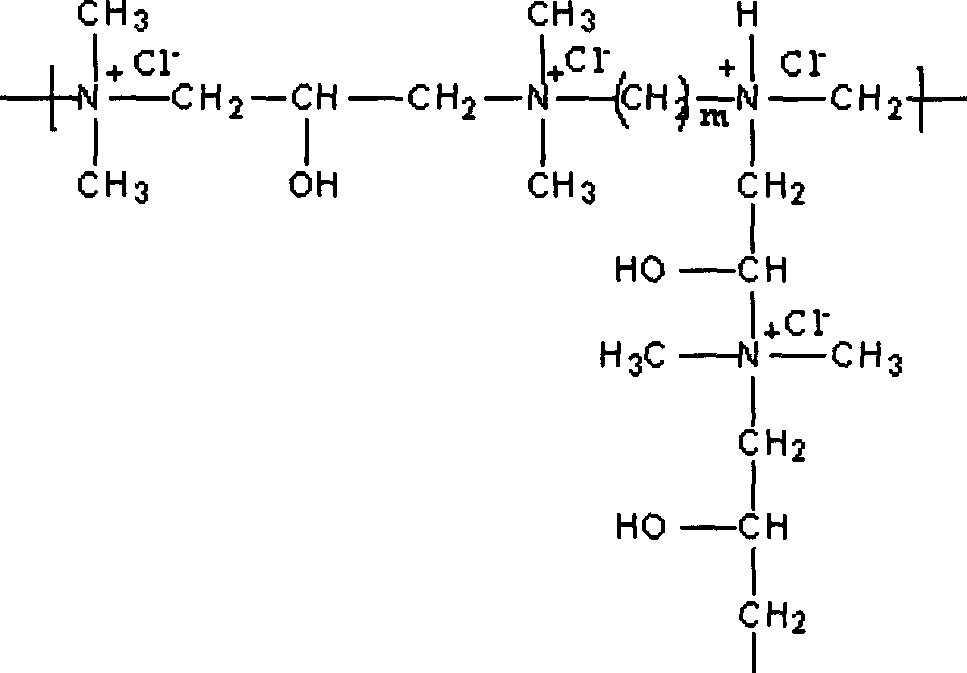

Ecological low-salt dyeing and finishing agent for reactive dyes and preparation method and applications thereof

The invention discloses an ecological low-salt dyeing and finishing agent for reactive dyes, which comprises a crosslinking cationic modifier A and a branched cationic modifier B, wherein the weight ratio of the crosslinking cationic modifier A to the branched cationic modifier B is (30-50): 50. The ecological low-salt dyeing and finishing agent for reactive dyes disclosed by the invention has the advantages that in the process of treating cotton fibers by using the crosslinking cationic modifier and the branched cationic modifier, the inner portions and surfaces of the fibers can be modified through cationization, therefore, the utilization rate of reactive dyes can be improved, and the dye-uptake rate and fixation rate of cotton fabrics are significantly higher than those in conventional dyeing; salt-free low-alkali dyeing even salt-free alkali-free dyeing can be achieved, and dyeing wastewater can be recycled for secondary utilization; and the color fastness to washing and the color fastness to rubbing are consistent with those of conventional cotton fabrics.

Owner:南通曙光染织有限公司

Reactive dyestuff dyeing and fixing technique and printing and dyeing auxiliary agent used for the same

The invention relates to a dyeing and fixation process technical method of an activated dye and a textile auxiliary used in the method. The textile auxiliary or the substance or additive having the similar function like the textile auxiliary includes inorganic substance, organic substance, additive and adjusting ingredient; the raw materials are packed directly or packed after being smashed after the measurement, or heated to above 110 DEG C in water to be prepared into different products; in conventional equipment and without the modification of the fiber to be dyed, firstly, through only adding one of the products no more than the quantity of sodium carbonate to realize completely abandoning or no longer mainly relying on the sodium carbonate for fixing; secondly, meanwhile the normal contents of various salts are substantially reduced by 15 to 100 percent; therefore, thirdly, after getting rid of the restriction of relying on the sodium carbonate and the salt in the traditional process, the invention can substantially reduce the resources irrationally wasted in each process of dyeing such as water, power and vapor, etc. More particularly, the process operation is simplified, the processing cycle is shortened, and the effects of substantial energy saving and exhaust reducing, and effect strengthening and consumption reducing can be realized.

Owner:罗海航 +1

Formaldehyde-free fixing agent and preparation method thereof

The invention discloses a formaldehyde-free fixing agent, which comprises the following components in parts by weight: 80 to 120 parts of cationic monomer, 5 to 20 parts of unsaturated high-grade organic amine monomer, 3 to 10 parts of dicyandiamide, 4 to 18 parts of pH regulator, 0.001 to 0.05 part of metal ion chelating agent, 0.5 to 1 part of initiator, 2 to 10 parts of epichlorohydrin and 20 to 50 parts of deionized water. The formaldehyde-free fixing agent provided by the invention does not contain formaldehyde and alkylphenol ethoxylates (APEO); and meanwhile, the film-forming property of the fixing agent is utilized, a meshed film layer can be formed on the surface of the fiber, so that the dye dissolution is reduced, the color fastness of reactive dye dyed fabrics is improved, a fixing effect is good, the formaldehyde-free fixing agent can be applied to fixing colors of the reactive dye dyed fabrics, and the washable color fastness and boiling water soaking fastness of the fabrics are improved.

Owner:苏州联胜化学有限公司

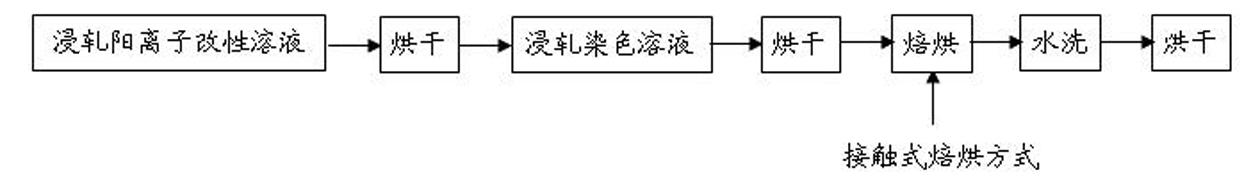

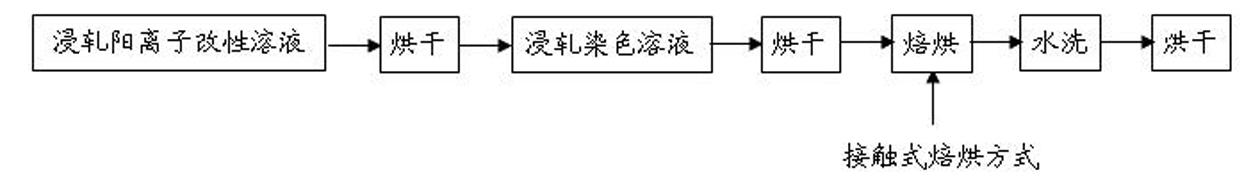

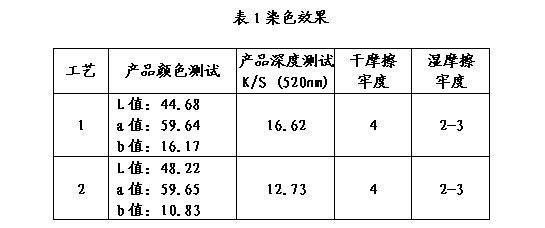

Method for dyeing yarn containing cellulose fiber by reactive dye

The invention relates to a method for dyeing a yarn containing cellulose fiber by reactive dye. In the method, the following processes are carried out on the yarn which is warped into a beam by a continuous pad dyeing mode: padding with cationic modified solution, drying, padding with staining solution, drying, baking, washing and drying, wherein, a drying cylinder is adopted in the baking process for baking in a contact manner, and the yarn is directly contacted with a high-temperature outer wall of the drying cylinder. By means of the method, continuous pad dyeing of the yarn containing cellulose fiber can be carried out by the reactive dye; the dyeing process has the advantages of relatively low baking temperature, simple baking mode and less broken yarns which are easily handled by an operator; and the adopted dye has the advantages of being free from restriction of K-type reactive dye, comprehensive color spectrum, wide selection range, simple auxiliaries without salt, urea and the like, less dye hydrolysis consumption, low wastewater chromaticity and stable dyeing quality, and deep, medium and light color can be dyed.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

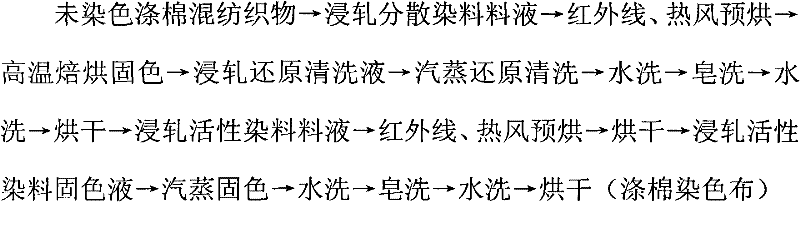

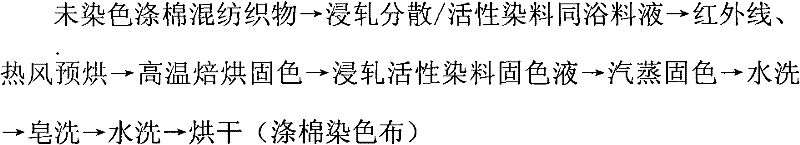

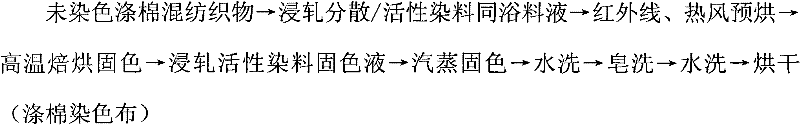

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

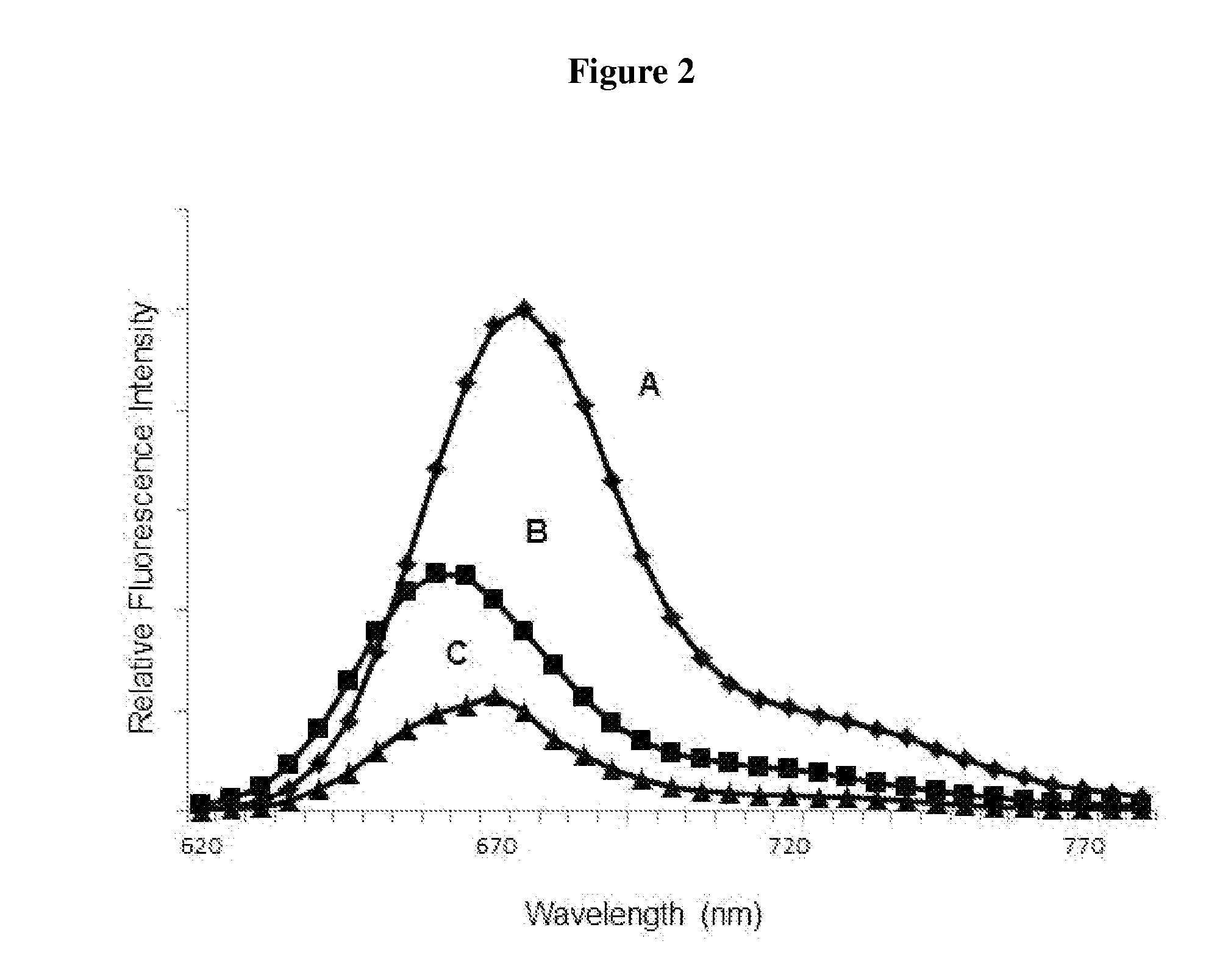

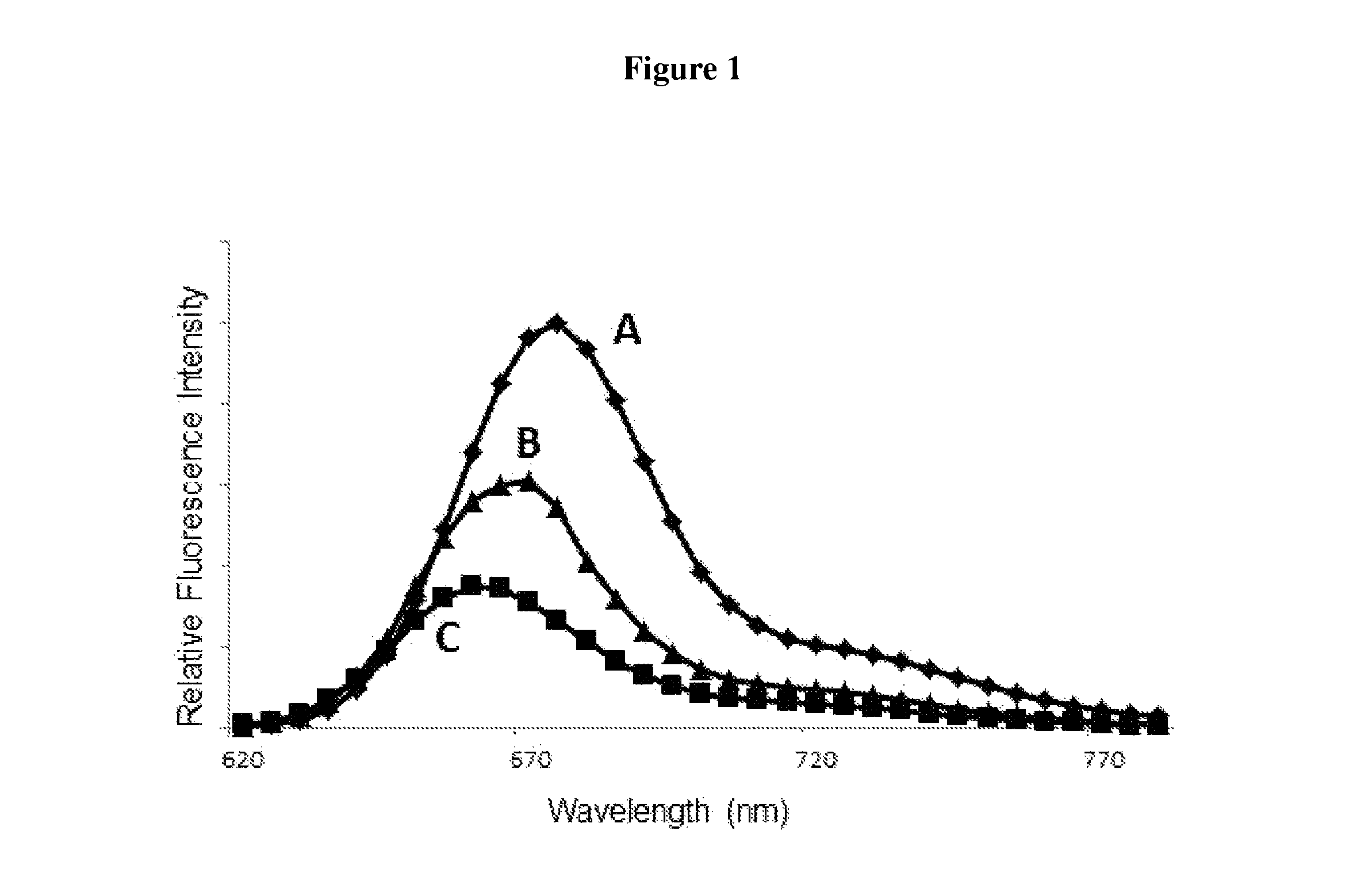

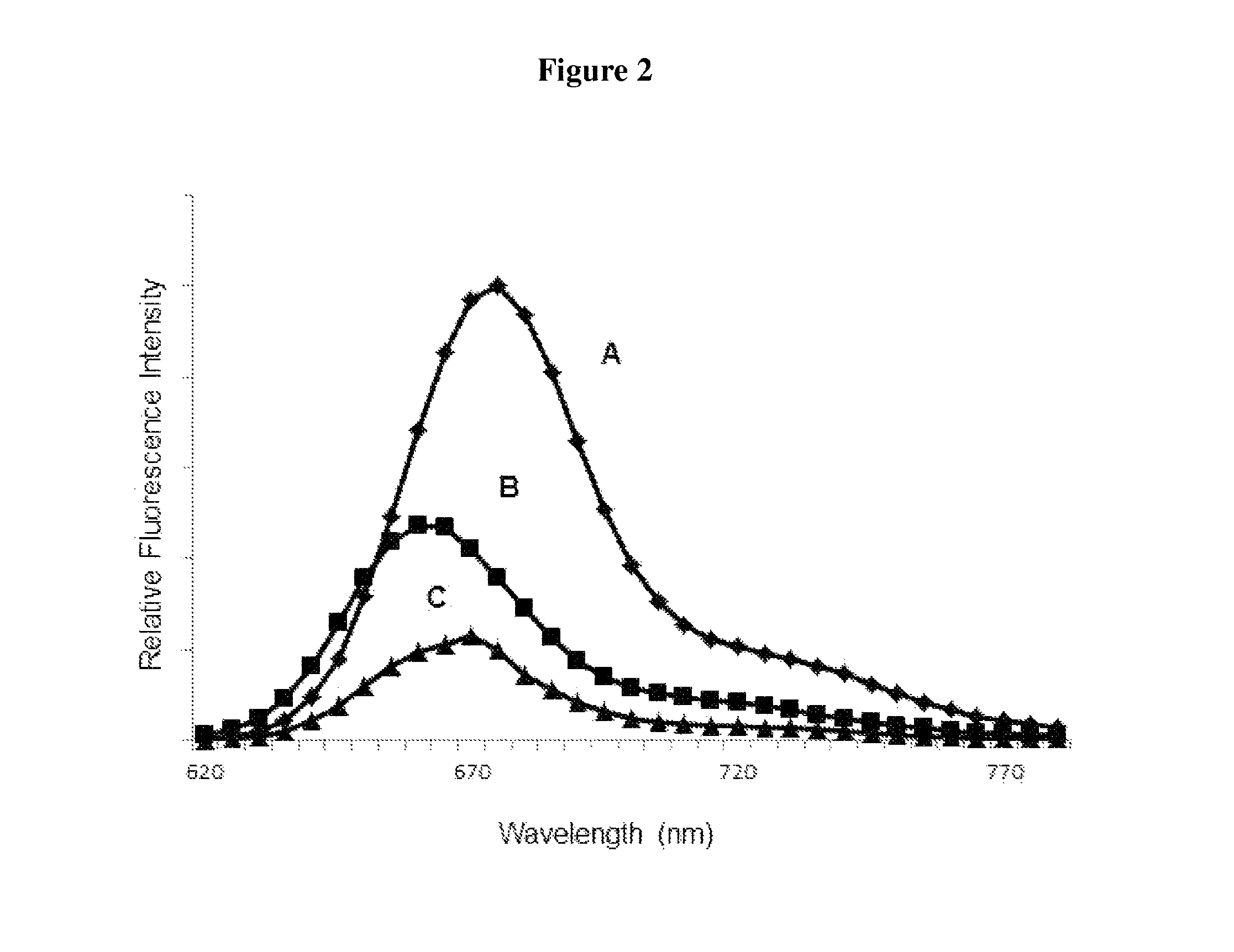

Luminescent dyes with a water-soluble intramolecular bridge and their biological conjugates

ActiveUS20120183954A1High luminous intensityHigh detection sensitivityMethine/polymethine dyesMammal material medical ingredientsFluorescenceWater soluble

Owner:AAT BIOQUEST +1

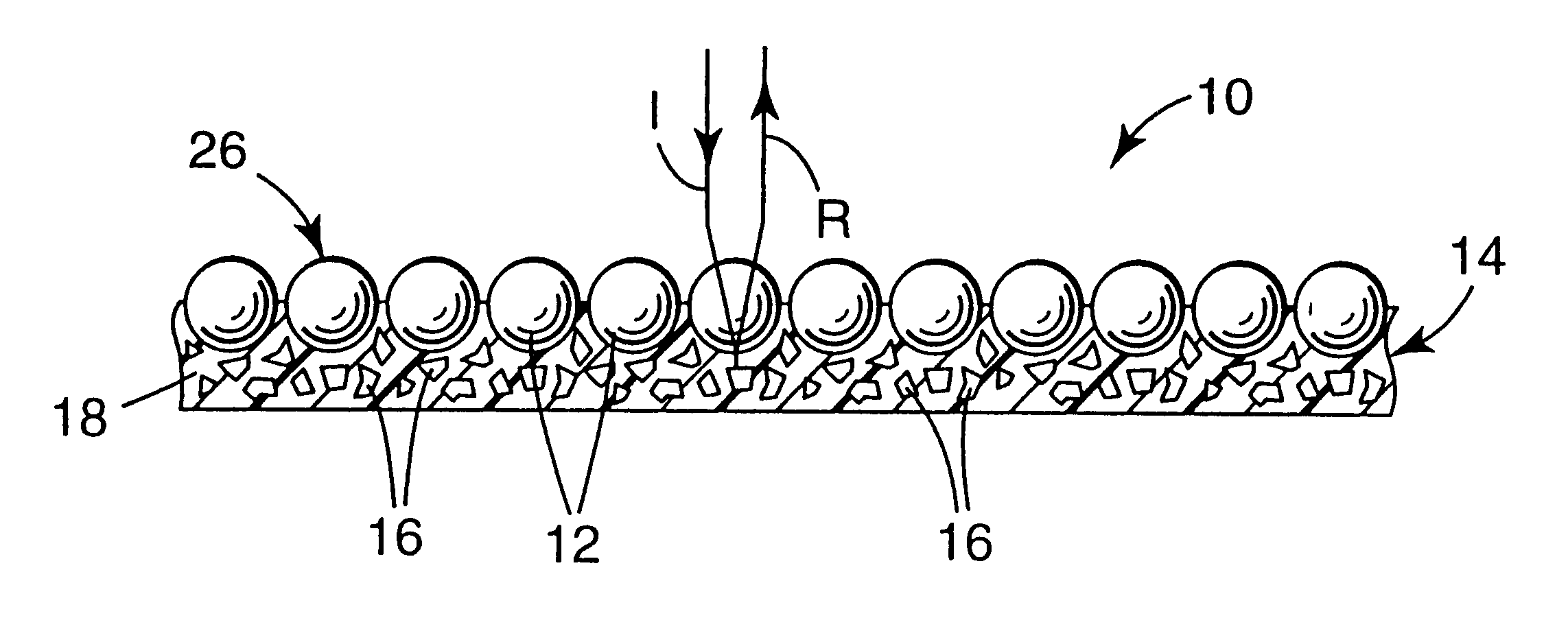

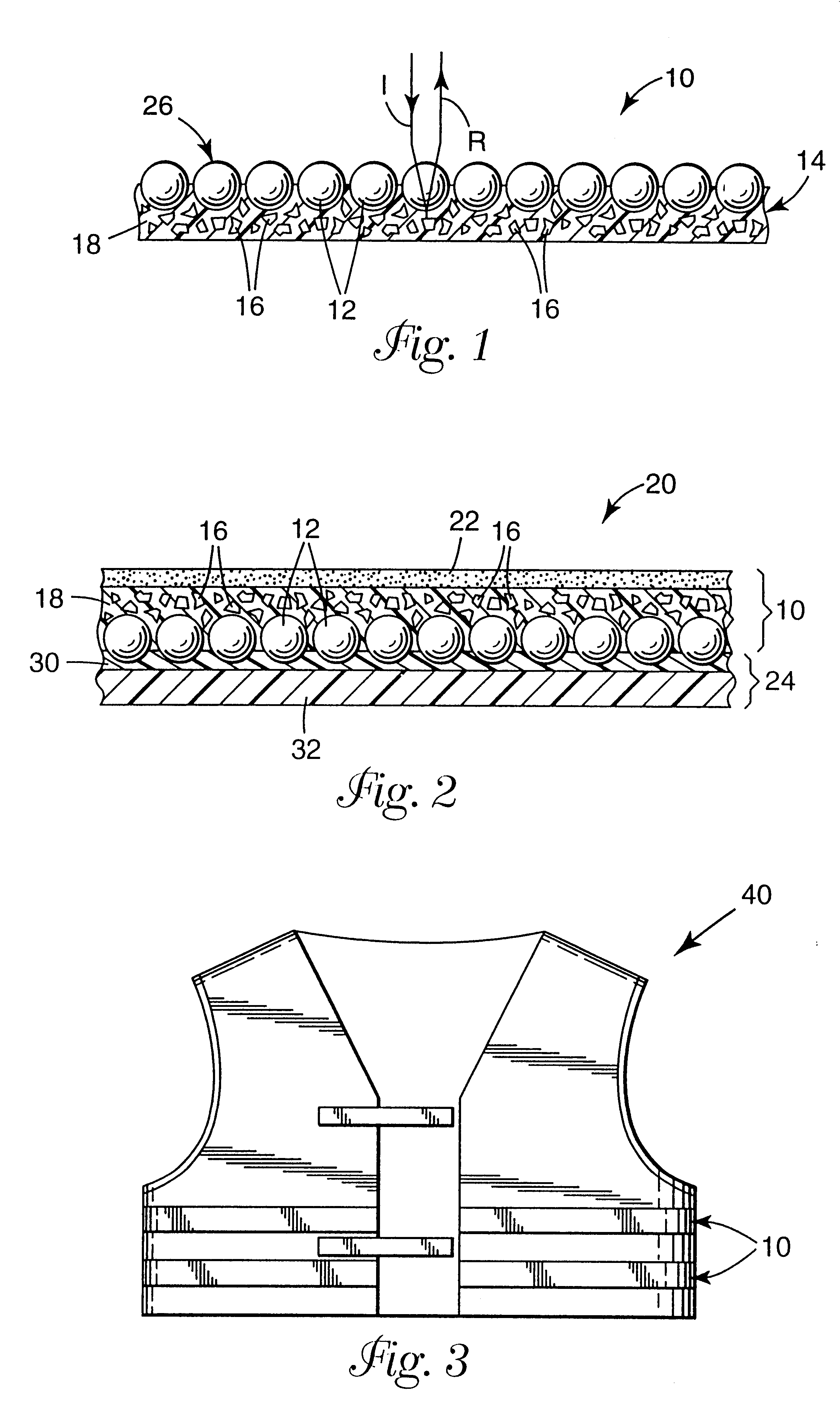

Retroflective article having a colored layer containing reflective flakes and a dye covalently bonded to a polymer

Exposed lens retroreflective article 10 that comprises a colored layer 14 and a layer of optical elements 12 that are partially embedded in the colored layer 14. The colored layer 14 comprises reflective flakes 16 and a dye that is covalently bonded to a polymer 18. The articles can retain their color after multiple industrial wash cycles. The use of a reactive dye, reflective flakes, and / or polymer precursor during the preparation of the colored layer enables a launderably-durable colored retroreflective article to be made without the use of a solvent and without the use of a temporary carrier.

Owner:3M INNOVATIVE PROPERTIES CO

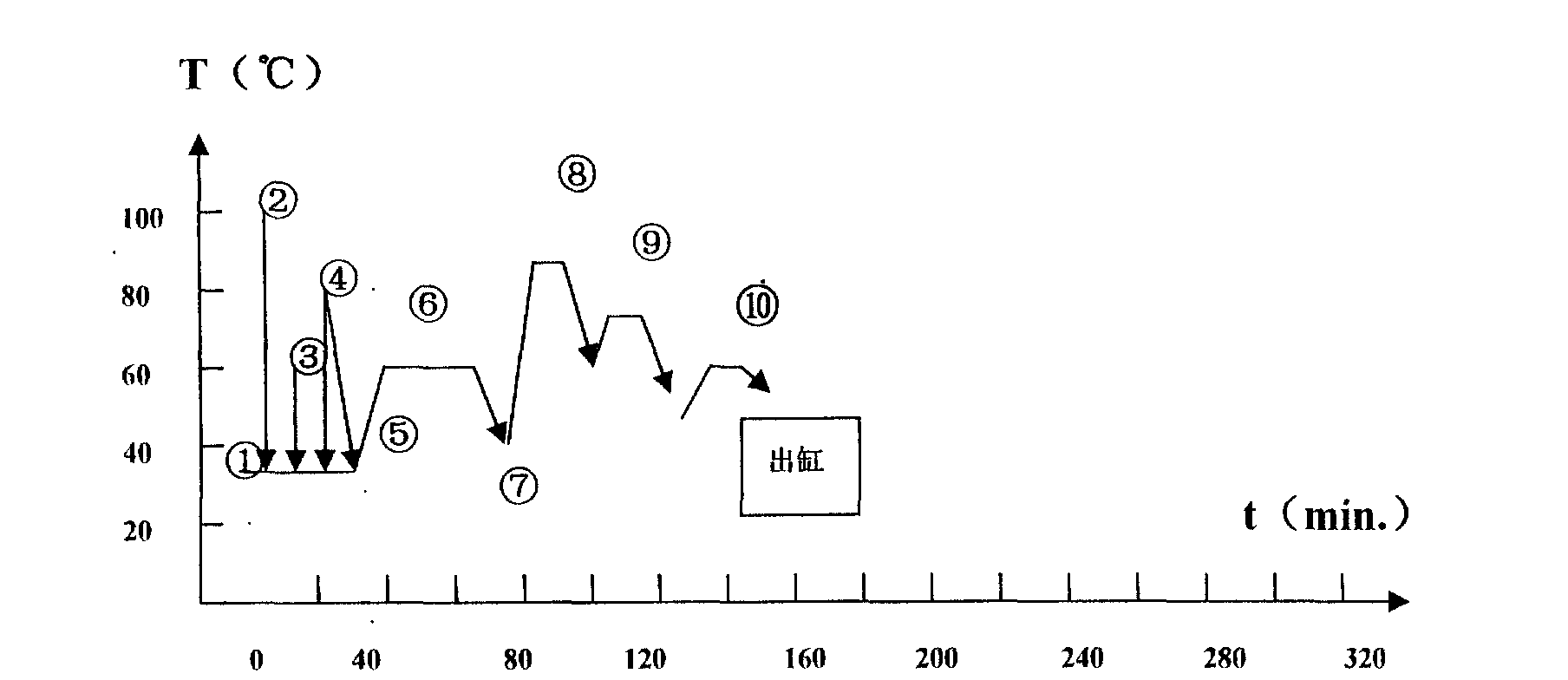

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

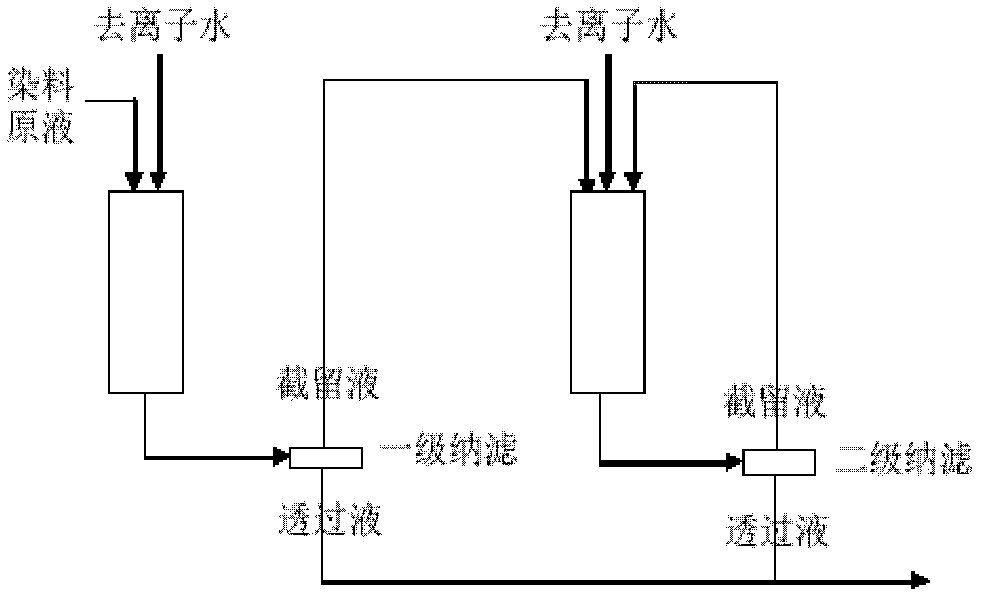

Active dye ink-jet printing ink and preparation method thereof

InactiveCN102504648AImprove washing fastnessGood storage stabilityInksDyeing processDisinfectantFiltration

The invention relates to active dye ink-jet printing ink and a preparation method thereof. The active dye ink-jet printing ink comprises the following components by mass percent: active dye concentrated solution 25 to 50 percent, humectant 5 to 15 surfactant 0.1 to 3 pH regulator 0.5 to 3 disinfectant 0.1 to 1 water-soluble cosolvent 5 to 10 and deionized water in balancing amount. The active dye ink-jet printing ink is prepared through the following steps: adding the active dye concentrated solution, the humectant, the surfactant, the water-soluble cosolvent, the pH regulator and the disinfectant into the deionized water, stirring and then continuing to stir through an emulsifying machine; still standing; and finally filtering through a filtration film. The active dye concentrated solution (the concentration is greater than 20 percent) is obtained through refining with a two-stage nano-filtration device, so that the purity is very high; and invention is environmental-friendly, and the prepared active dye ink-jet printing ink has the advantages of high printing smoothness, storage stability, pattern printing accuracy and color fastness and is washable.

Owner:DONGHUA UNIV +1

Salt free dyeing with reactive dye

The invention provides a reactive dye salt-free dyeing process for cotton fiber, which comprises the following steps of pre-treatment, modified treatment, dyeing, post-treatment and so on. The modified treatment is that a copolymer of poly epichlorohydrin and polyamine used for cotton fiber is pretreated and cleaned under high temperature and alkali conditions before a special reactive dye used for a leveling agent is added to dye the cotton fiber, and the dyeing process is completed under salt-free, alkali-free or low-alkali conditions, thereby improving dyeing and fixing rate of the dye. The reactive dye salt-free dyeing process simplifies the prior dyeing process, is simple and easy to understand for operators, reduces influences of human operation factors on dyeing process and dyeing quality, and lowers production cost and sewage treatment cost overall.

Owner:胡红湘

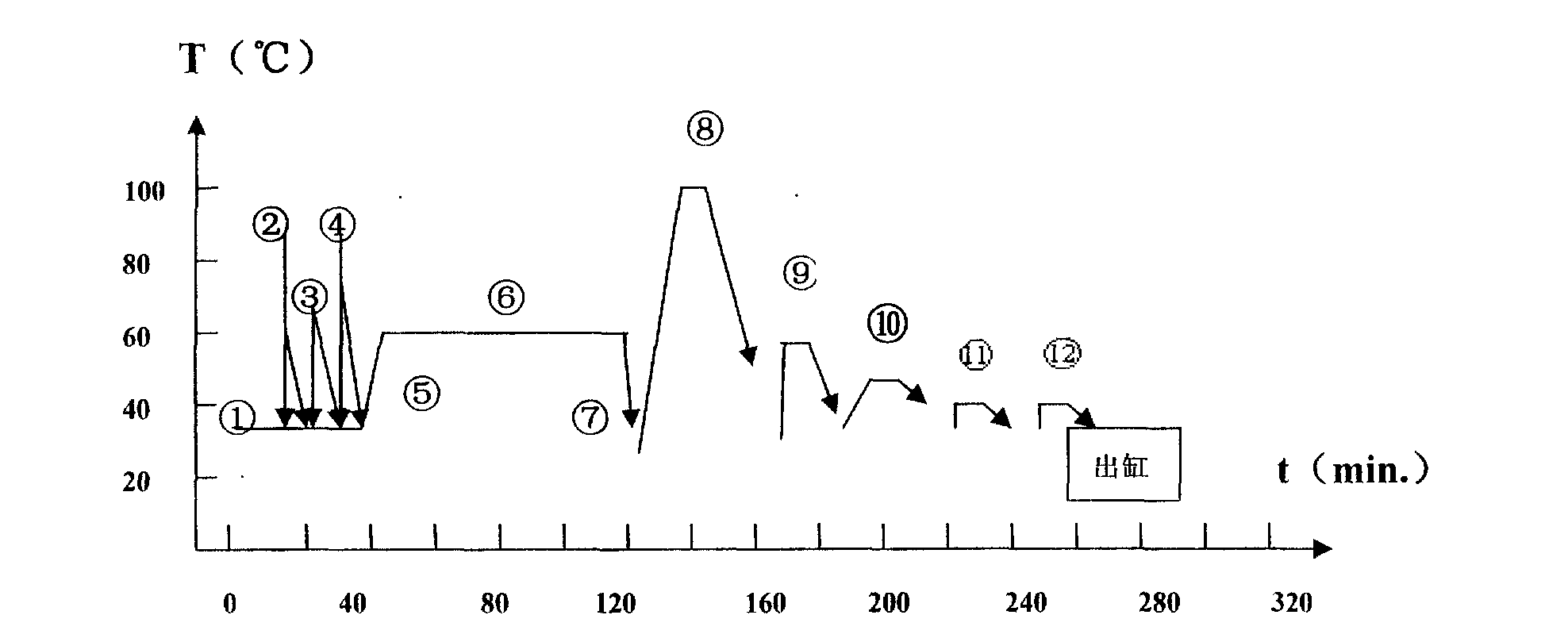

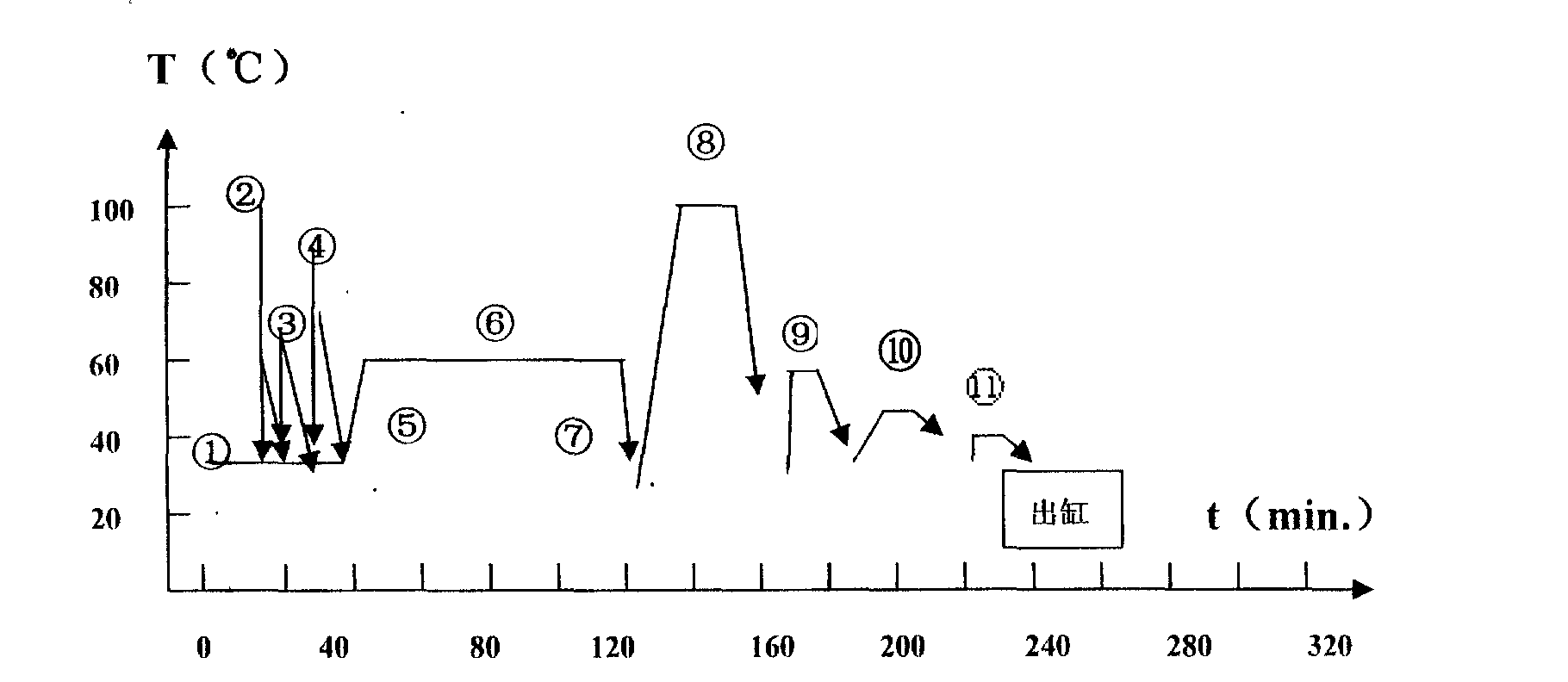

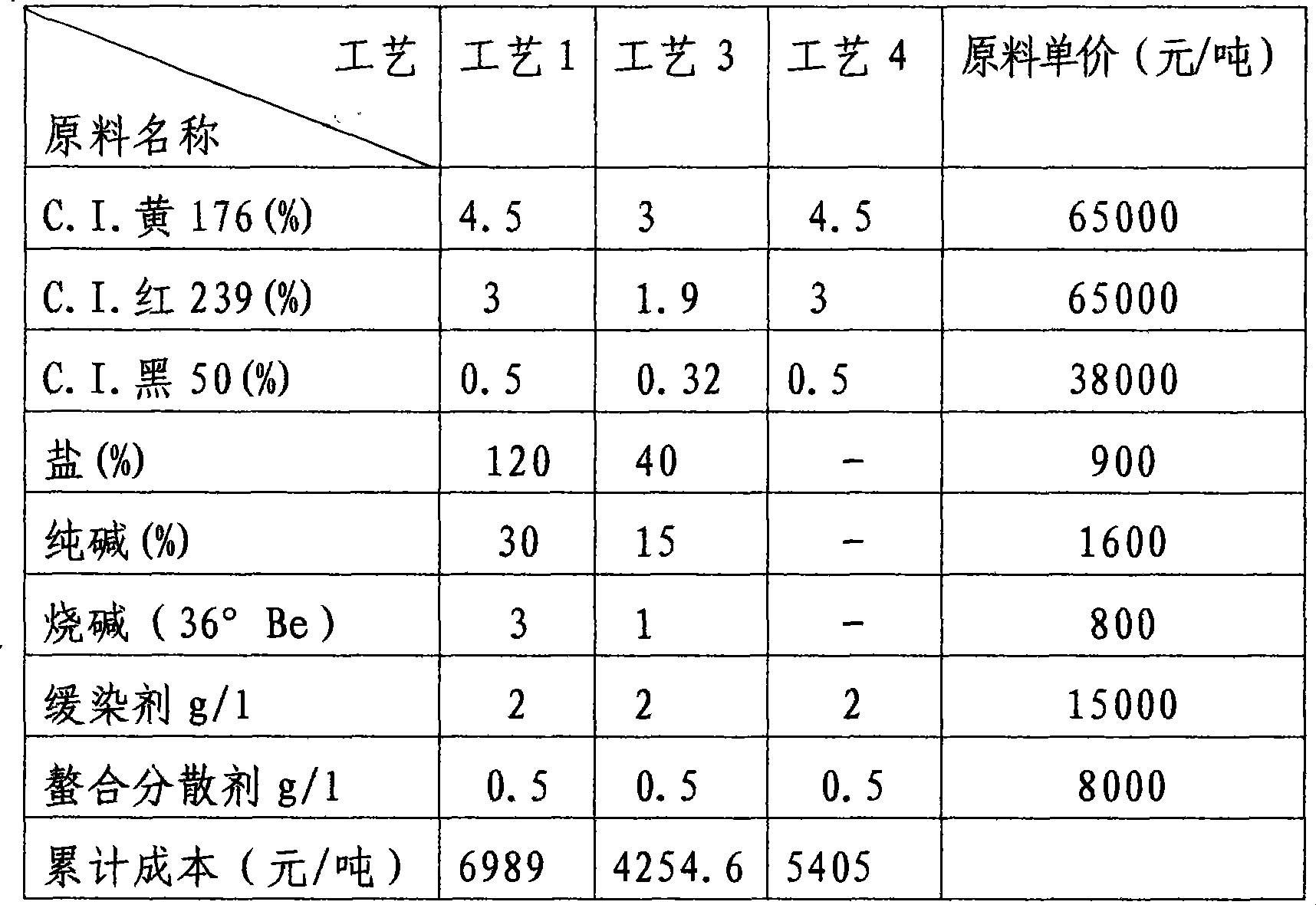

Terylene/cotton/chinlon/spandex polycomponent seamless underwear dyeing process

The invention discloses a terylene / cotton / chinlon / spandex polycomponent seamless underwear dyeing process, which belongs to the technical field of pretreatment, dyeing and afterfinish processes of knitgoods. The process comprises the following steps: performing oxygen bleaching refining on cotton and refining oil removal on terylene / cotton / chinlon / spandex according to the prior oxygen bleaching refining and oil removing technological requirements; respectively adding various dyes and auxiliary agents to perform one-bath dyeing on the terylene / the cotton / the chinlon / the spandex; and finally performing softening treatment according to the prior softening treatment technological requirements, wherein the dyes and the auxiliary agents consist of a dispersing dye, a high-temperature neutral fixing reactive dye, a weak acidic or neutral dye, a chelating dispersant, sodium sulfate, a disperse leveling agent, a pH regulator P-7 and the like. The process reasonably selects the low-temperature dispersing dye and the high-temperature neutral fixing reactive dye, adopts one-bath process for dyeing, shortens the process flow and the dyeing time, reduces the using amount of steam and water, reduces pollution discharge, improves the production efficiency, and reduces the dyeing cost.

Owner:ZHEJIANG QIAOERTINGTING FASHION

Laser reactive dyes for DVD copy protection system

A method and system for providing copy-protected optical medium using transient optical state change security materials capable of changing optical state when exposed to a wavelength of about 630 nm to about 660 nm and software code to detect such change in optical state.

Owner:VERIFICATION TECH INC

Salt-free pad steam continuous dyeing method for active dye

InactiveCN101200859AFor quick replacementGood reproducibilityDyeing processLiquid/gas/vapor textile treatmentTextile printerSalt free

The present invention relates to a continuous saltless pad-steam dyeing method with reactive dyes, which belongs to the novel technical field of textile printing and dyeing. After being singed, desized, boiled, bleached and mercerized, the half-finished product of cellulosic fibre woven fabric is dyed in the process of the continuous dyeing technique of padding, steam fixation, water washing, soaping, water washing and drying by the reactive dyes. The half-finished product of the preprocessed cellulosic fibre woven fabric is produced by pad dyeing, steaming and water washing, wherein, dyeing solution is composed of M reactive dyes, leveling agent, fixation alkali agent and water, and the mixture ratio is as follows: M reactive dyes: 0.01 percent to 10 percent, leveling agent: 0.1 percent to 0.2 percent, fixation alkali agent: 1.5 percent to 4 percent, and water: balance. The method is different from the conventional continuous dyeing technique of padding, drying, padding and steaming, which uses reactive dyes, and also different from the shortened wet-steaming technique with reactive dyes. On the conventional continuous padding machine, the novel method can fulfill the whole process of reactive dyeing without a hot-air padding machine and only with a developing and soaping range, thus greatly saving energy and reducing cost.

Owner:SHANXI CAIJIA PRINTING & DYEING

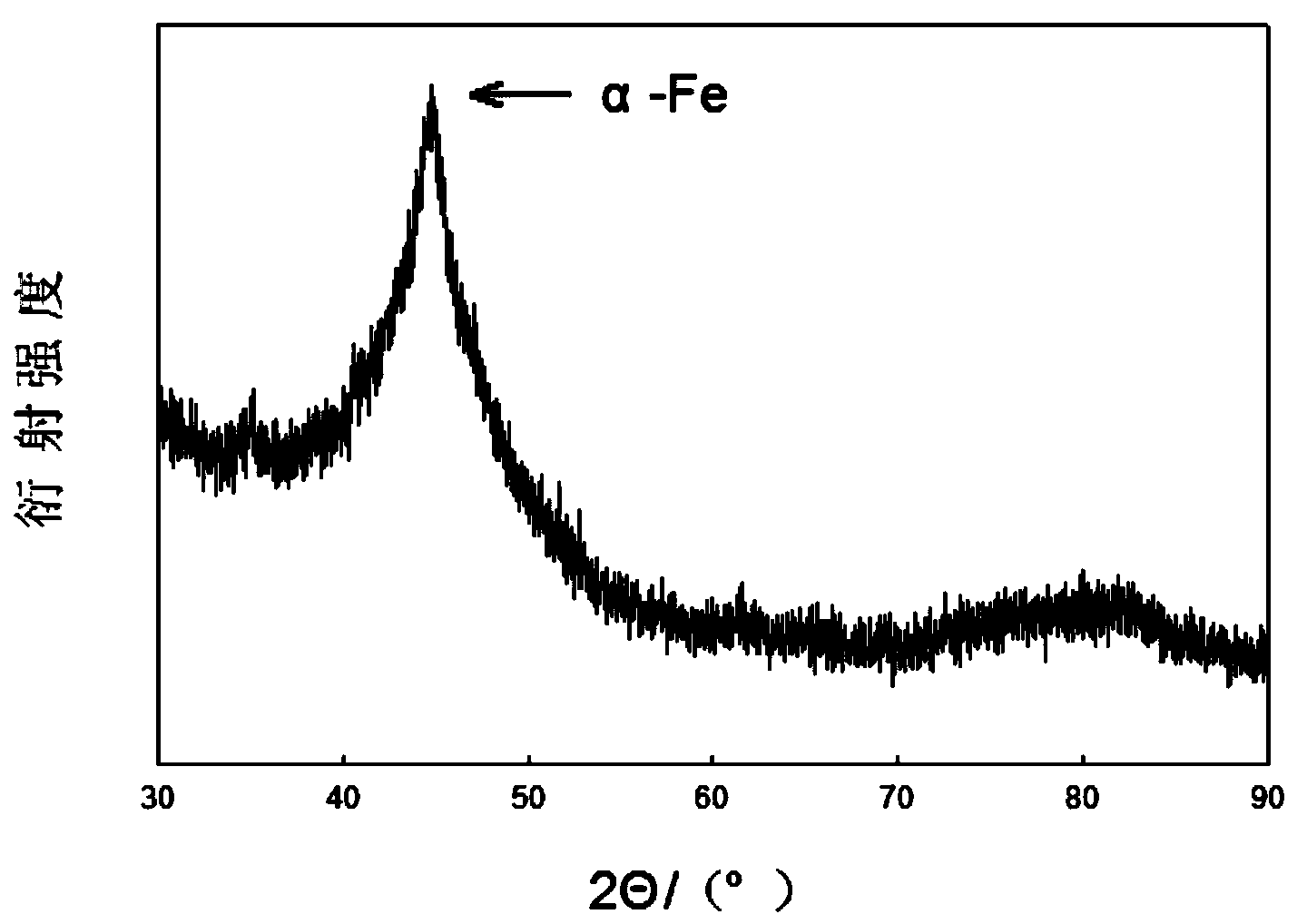

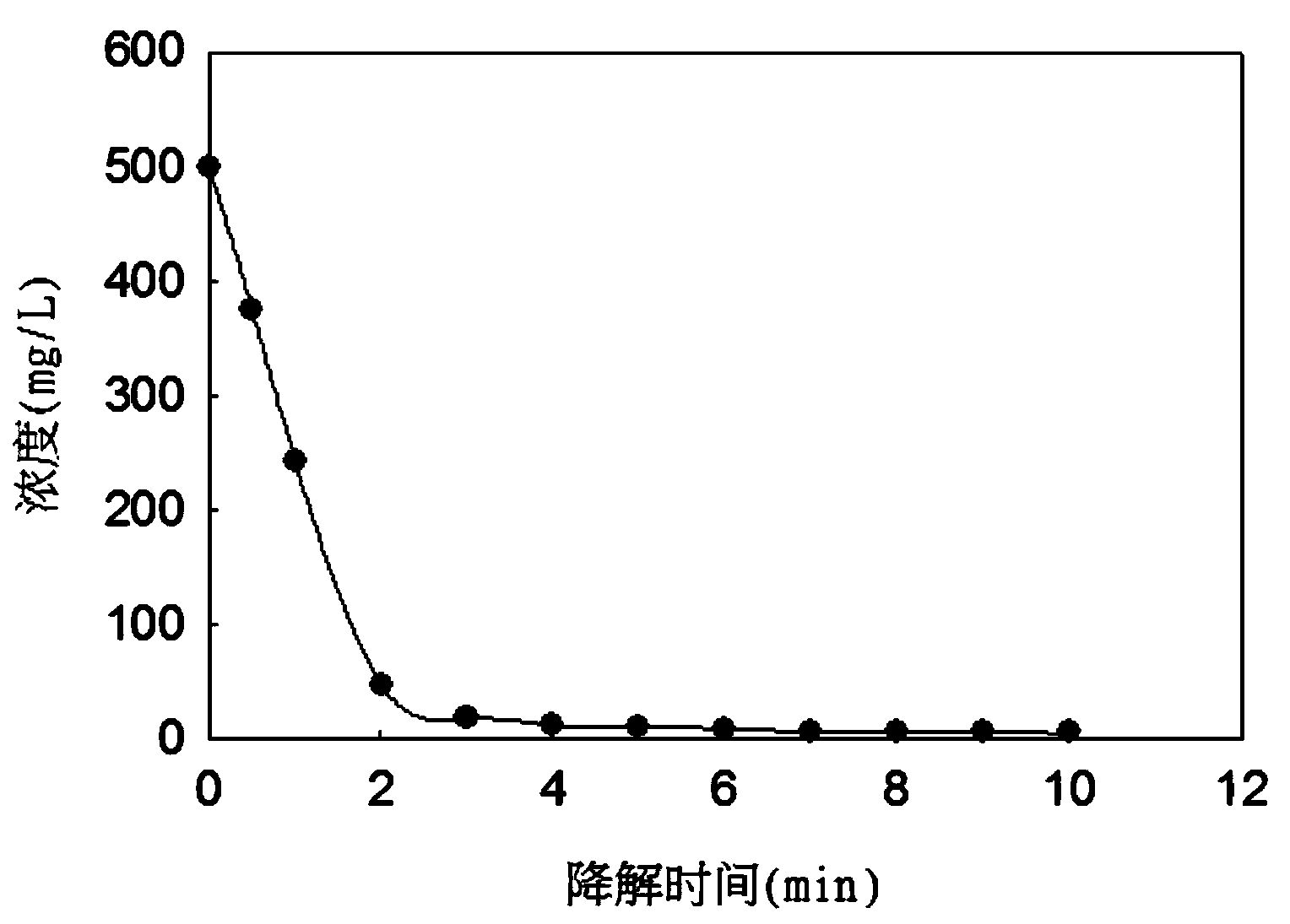

Green synthesis method for nanometer zero-valent iron by utilizing grape seeds and application thereof

ActiveCN104174870AThe method works wellGood effectMaterial nanotechnologyWater/sewage treatment by oxidationBrilliant RedGrape seed

The invention relates to a green synthesis method for nanometer zero-valent iron by utilizing grape seeds and an application, and belongs to the field of nanometer material and wastewater treatment. The preparation method is characterized in that nanometer zero-valent iron particles are prepared by taking waste grape seed extracting solution as dispersing agent and antioxidant under the condition of room temperature, and the nanometer zero-valent iron particles prepared through the method has good dispersibility and stability. The nanometer zero-valent iron particles prepared by the method are used for catalytically degrading reactive dye in wastewater, under the condition that the pH of the dye wastewater is equal to 2 to 10, more than 98% of azo-dye reactive brilliant red K-2G is degraded in 9min, more than 95% of anthraquinone dye reactive brilliant blue KN-R is degraded in 30min, and the environmental adaptability is high, and the degrading efficiency is high. The method is simple in technology, economic and efficient, resource utilization of grape seeds is realized, the synthetic nanometer zero-valent iron has extremely high activity, and the method has wide application prospect.

Owner:BEIJING UNIV OF TECH

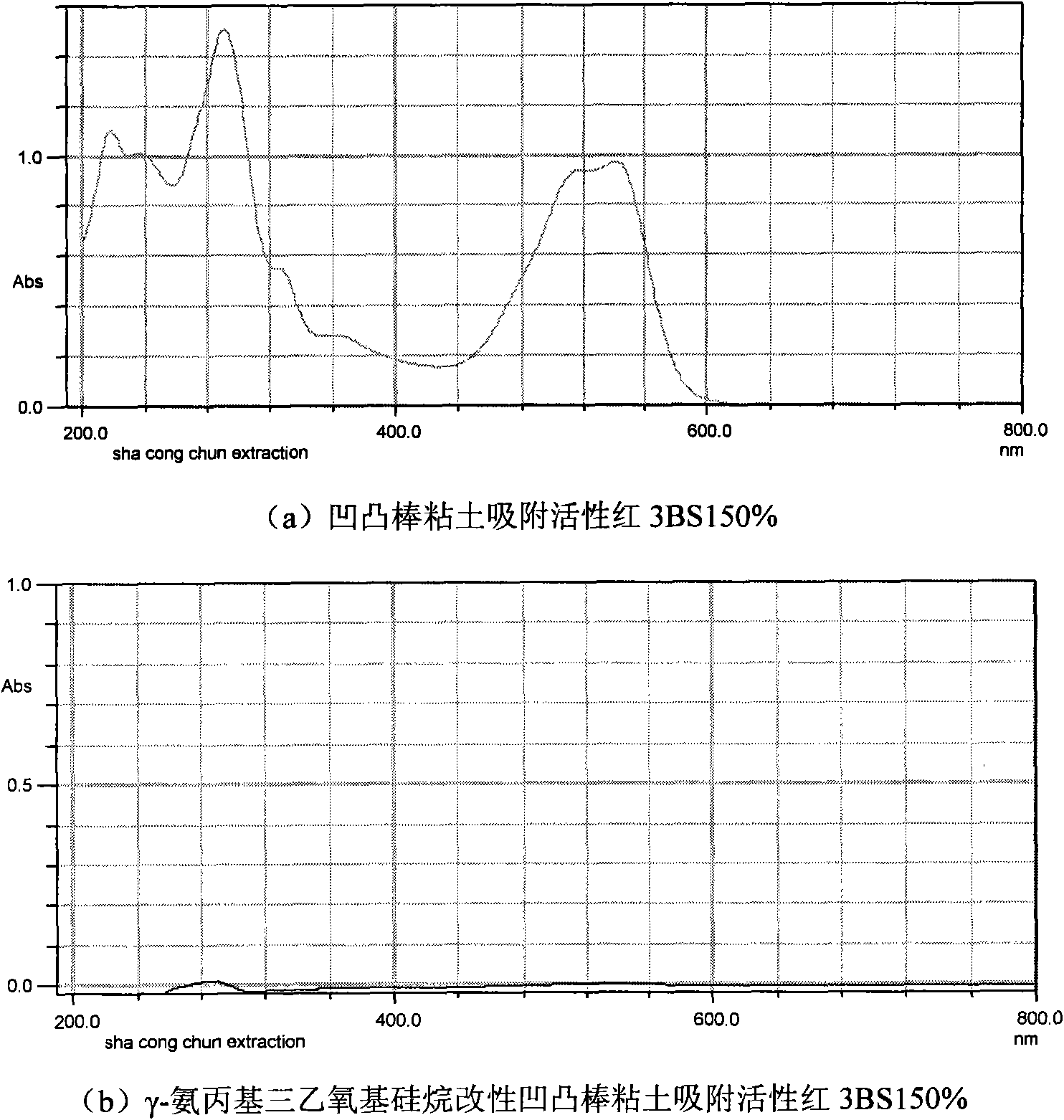

Method for preparing adsorbent by modifying attapulgite clay

InactiveCN101658782AReduce manufacturing costShort production processOther chemical processesOrganic acidSorbent

The invention discloses a method for preparing an adsorbent by modifying attapulgite clay. A silicon hydroxyl group on the surface of the attapulgite clay is used to react with an amino silane coupling agent to obtain the adsorbent the surface of which has an amino functional group. The preparation method is simple and easy to operate, as well as has wide application prospect. The adsorbent has excellent adsorption property for reactive dye, heavy metal, a dye intermediate with a sulfonic acid group and organic acid.

Owner:HUAIYIN TEACHERS COLLEGE

Dark black active dyestuff having high colour fixing rate

The invention provides an dark black reactive dye having high color fixation rate and compounded of three-primary color components: dark blue, fuchsine and orange components and the synthesizing method thereof, where the weight percents of the navy, fuchsine and orange components are (40-85)%, (5-30)%, and (5-25)%, respectively. And it has characters: it has very high blackening; color fixation rate up to above 80% at standard color and cplor of dyeing liquor residue is low, having good environmental benefits; dyeing curves of component to fiber are completely consistent; the dyed fabrics have good color uniformity. And it is especially applied to exhaustive dyeing of fibrin, protein fibre and polyarmide fiber.

Owner:大连华成中瑞科技有限公司

Luminescent dyes with a water-soluble intramolecular bridge and their biological conjugates

ActiveUS8623324B2Methine/polymethine dyesMammal material medical ingredientsFluorescenceWater soluble

Owner:AAT BIOQUEST +1

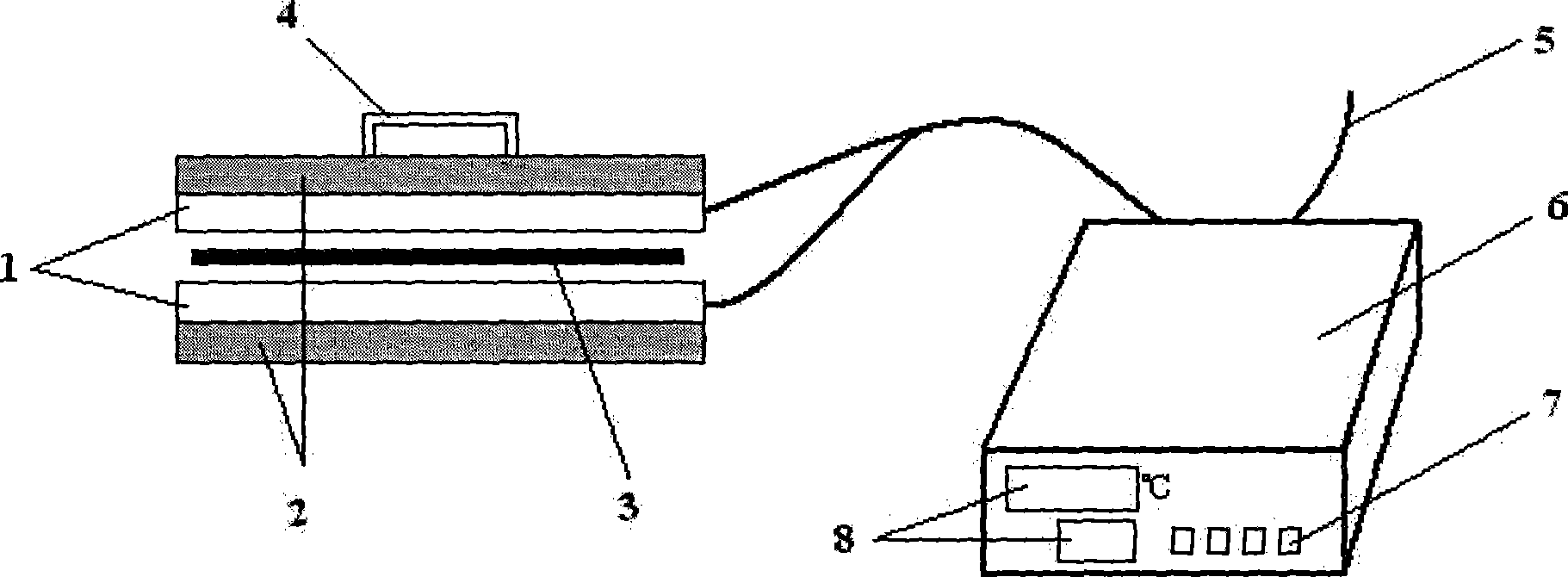

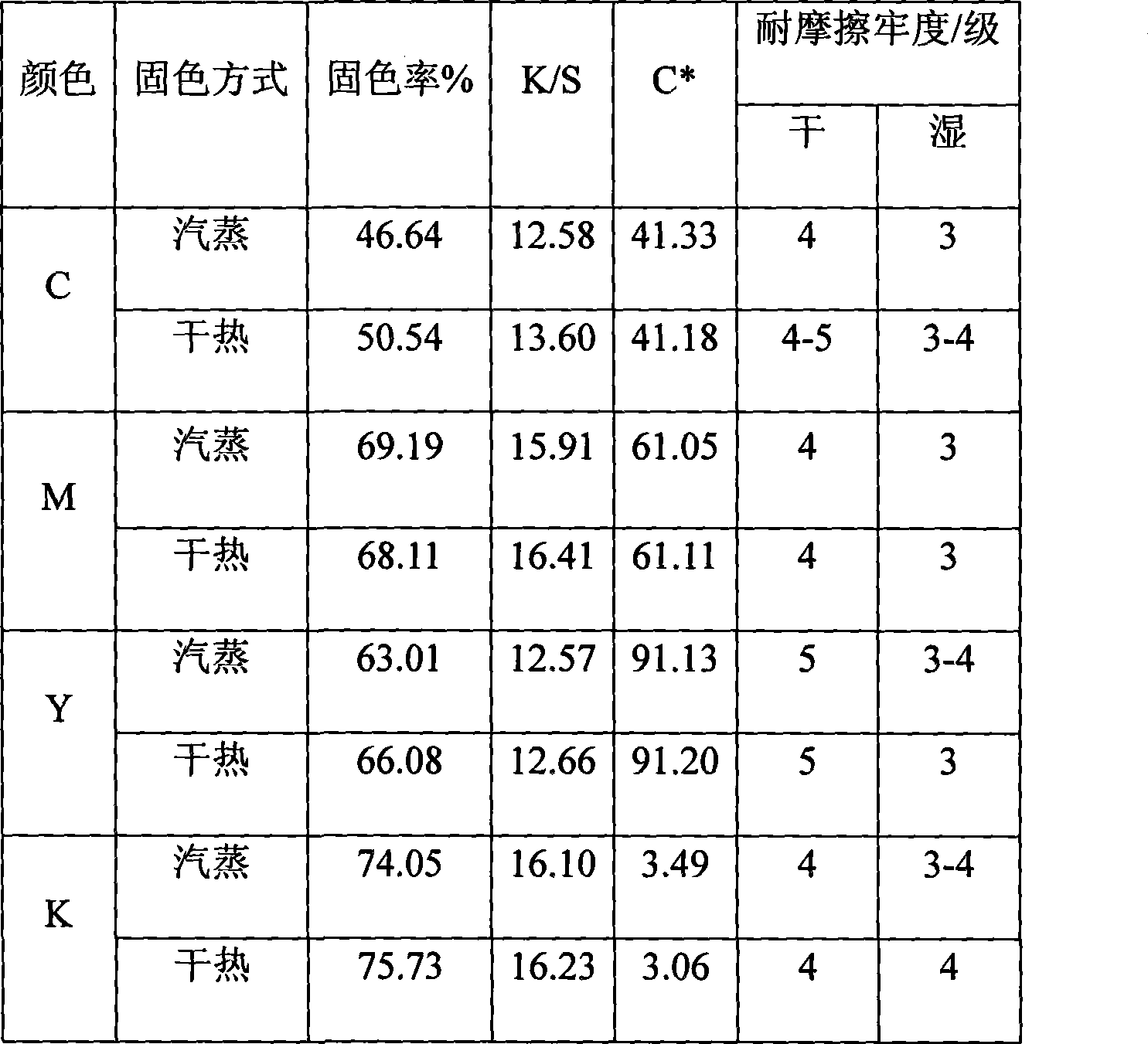

Fixation method and apparatus for inking and printing on cotton with active ink

InactiveCN101381934AHigh color fixing rateImprove color vividnessHeating/cooling textile fabricsDyeing processEngineeringDry heat

The invention relates to a method and a device for fixing cotton fabric reactive ink inkjet printing. The method comprises the following: (1) a step of pretreating fabric, which is to make thickener into stock thickener, dissolve alkaline agent, urea and antifoaming agent in water, add the alkaline agent, the urea and the antifoaming agent to the stock thickener, evenly mix the mixture so as to form a pretreatment solution, pad the fabric with the pretreatment solution and then dry the fabric; (2) a step of performing inkjet printing, which is to adopt reactive dye ink to perform inkjet printing to the pretreated fabric on a digital inkjet printing machine; and (3) a step of after-treating the fabric, which is to adjust humidity of the jet-printed fabric for 4 hours, adopt a contact-type dry-heat fixation device, regulate the temperature of a heating plate to be between 150 and 160 DEG C, set the treatment time to be between 40 and 80 seconds, complete fixation through contact-type dry-heat treatment, wash and dry or air the fabric, so as to obtain a finished product. The invention has the advantages of convenient operation of technological process, strong flexibility and high fixation rate, and solves the problems existing in small-batch steaming fixation.

Owner:DONGHUA UNIV

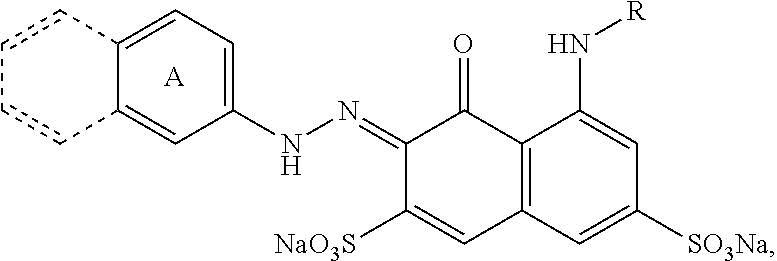

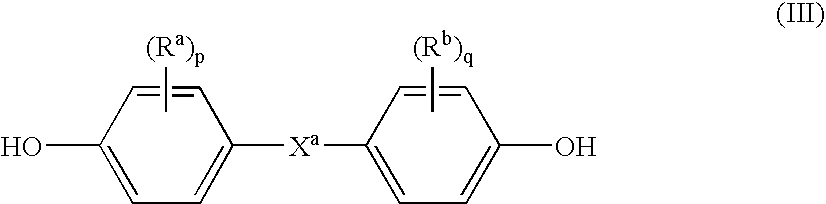

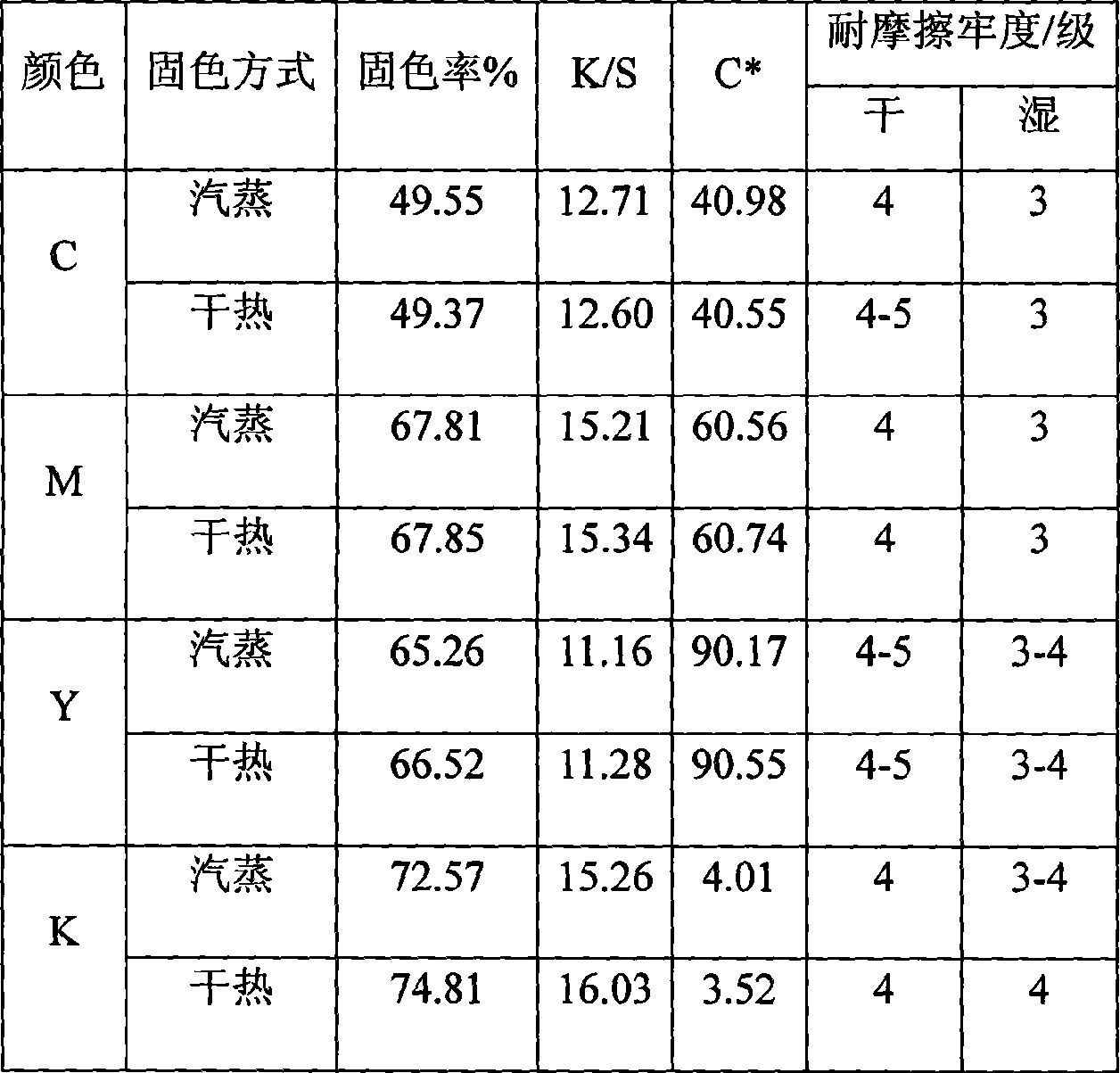

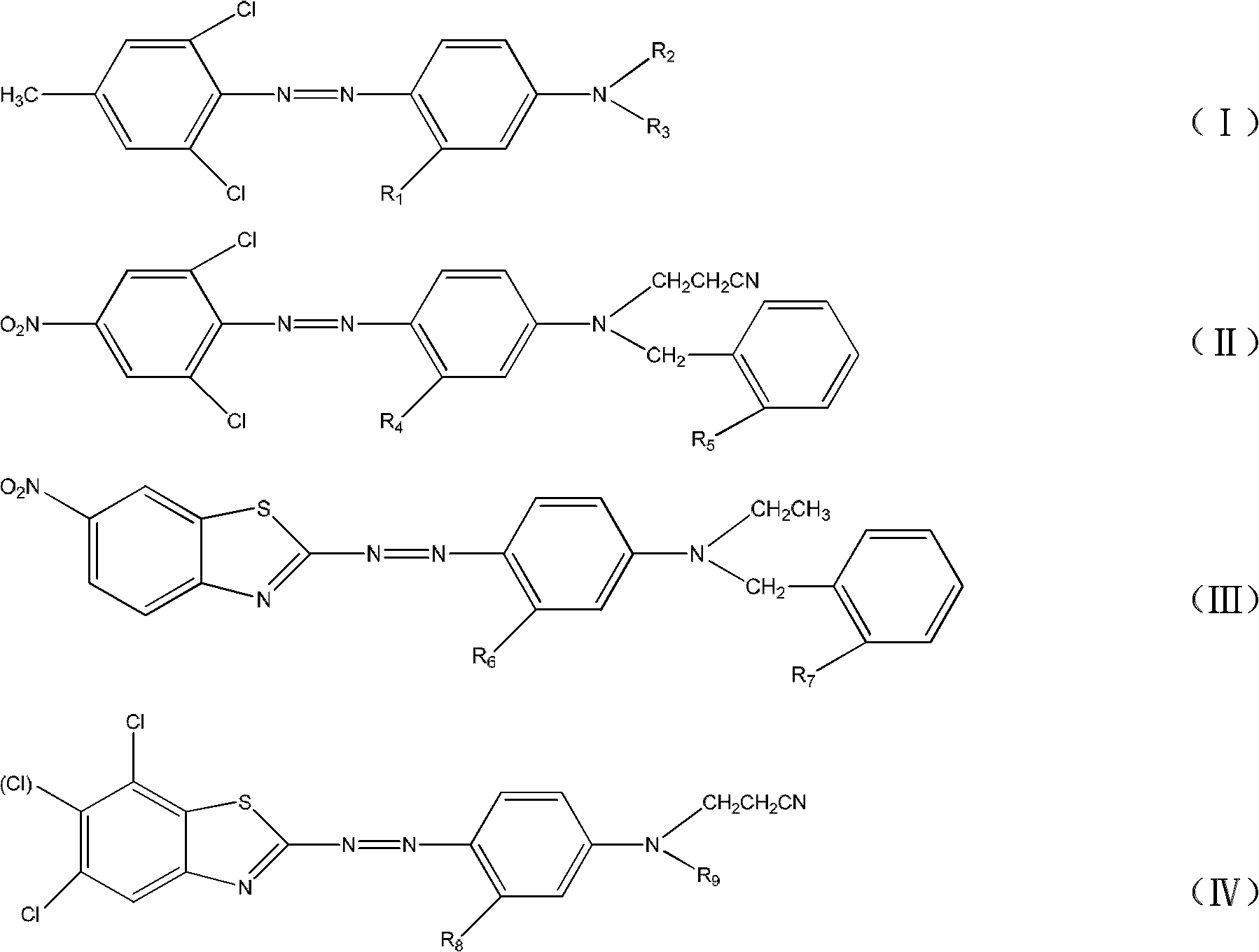

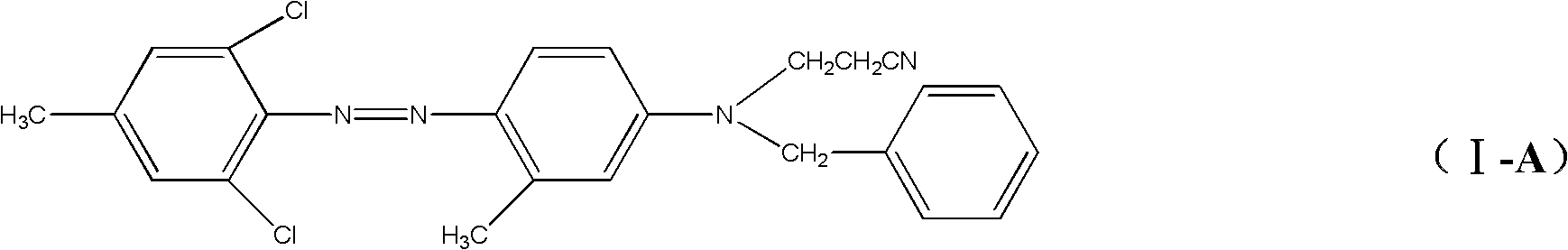

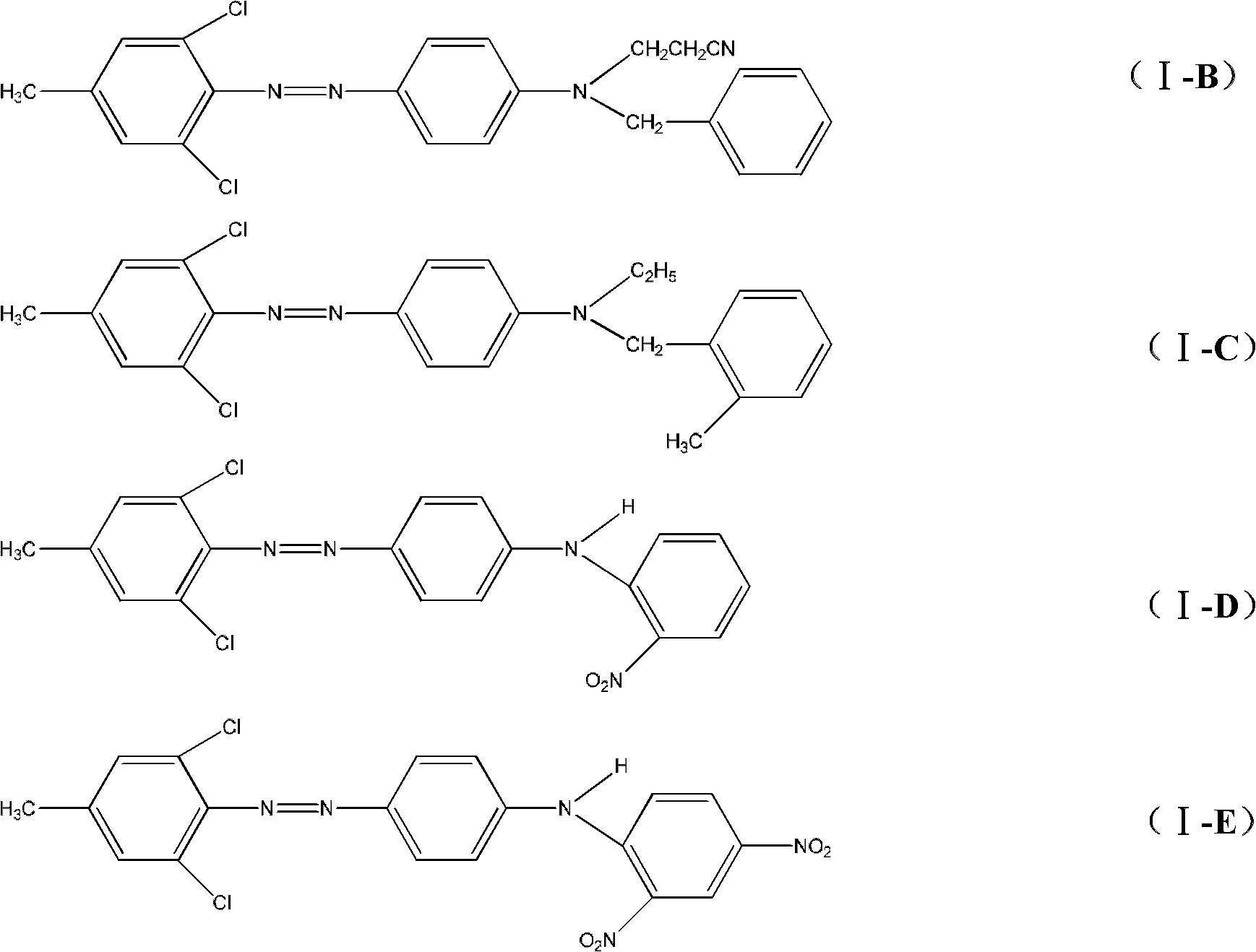

Disperse dye composition for disperse/reactive dye combination printing, and preparation and application thereof

ActiveCN102660145AAchieve one-step printing technologyImprove cleanlinessOrganic dyesDyeing processDisperse dyeYELLOW DYE

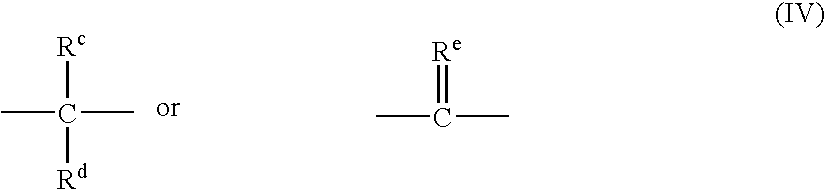

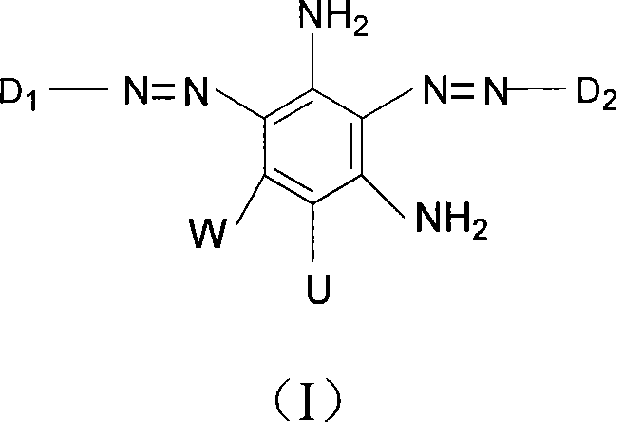

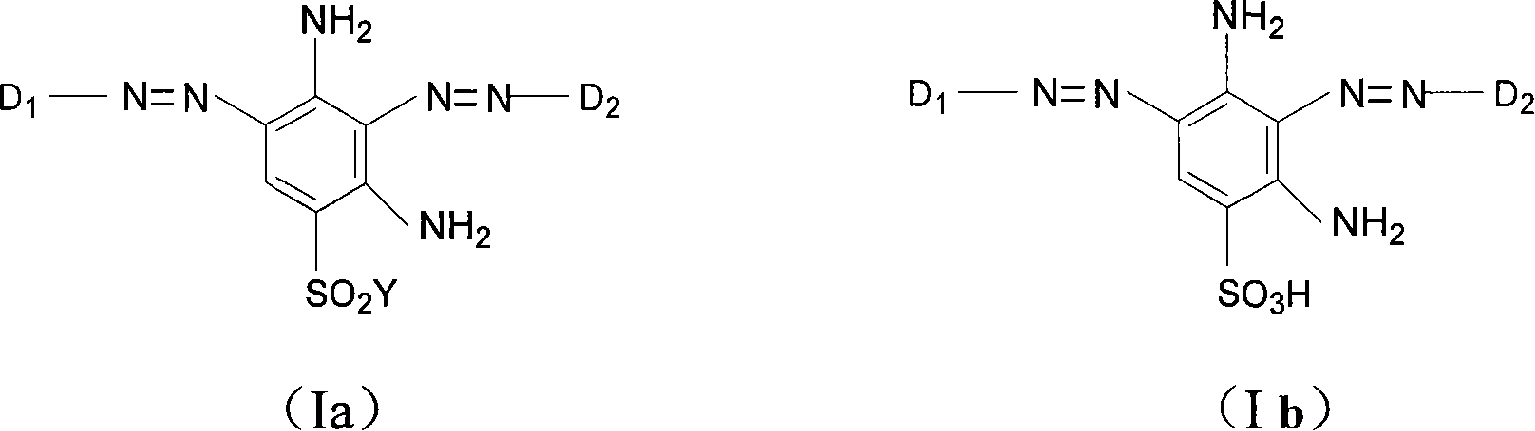

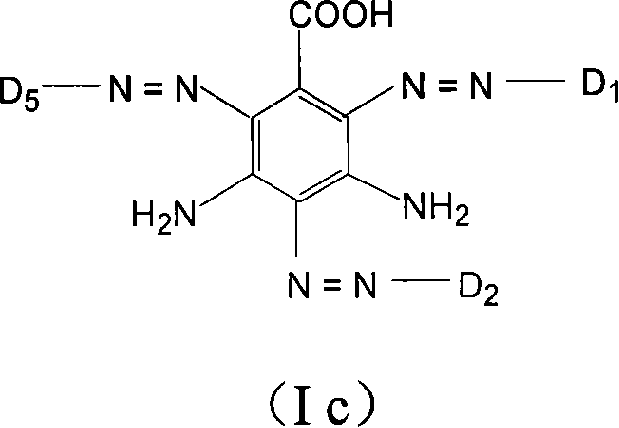

The invention relates to a disperse dye composition for disperse / reactive dye combination printing, and preparation and application thereof. The disperse dye composition comprises 2-4 of yellow dyes disclosed as a general formula (I), orange dyes disclosed as a general formula (II), blue dyes disclosed as a general formula (III) and red dyes disclosed as a general formula (IV), wherein the number of dyes disclosed as each general formula does not exceed two. The disperse dye composition is used for a disperse / reactive dye combination printing method. The disperse dye composition is suitable for disperse / reactive dye combination printing technique of terylene / cotton and terylene / viscose blend fabrics, and has the advantages of simple technological process, higher production efficiency, lower production cost and less printing wastewater; the printed fabric has the advantages of smooth cloth cover and favorable fabric style; and Compared with the traditional printing, the invention implements disperse / reactive dye one-step printing technology of terylene / cotton and terylene / viscose blend fabrics.

Owner:ZHEJIANG WANFENG CHEM

Method and composition for coating pre-sized paper with a mixture of a polyacid and a polybase

InactiveUS6197383B1Quality improvementHigh color fastnessCoatings with pigmentsWater-repelling agents additionHueWater resistant

The present invention features coating compositions and methods for improving the quality of images printed on a paper substrate. The novel coating compositions contain a coating agent comprising a mixture of a polyacid and a polybase. When applied to a sized paper substrate, the coating compositions provide a coated paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the coating agent. Images printed on a paper substrate coated with the coating composition of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

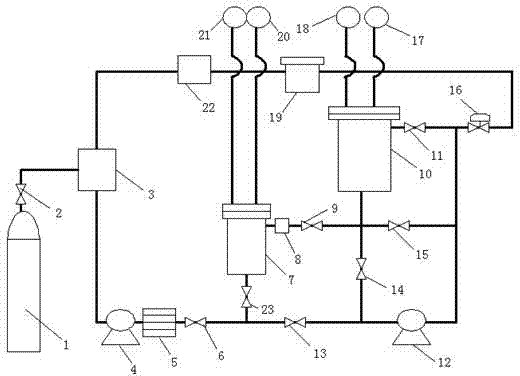

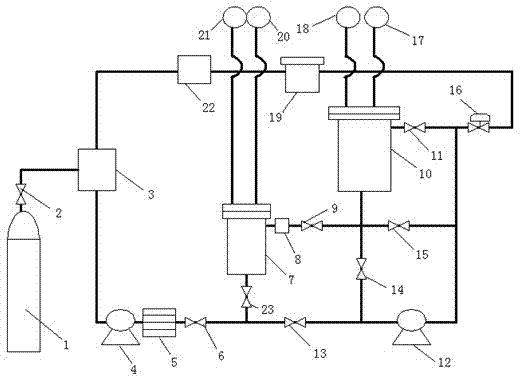

Dyeing method of natural fibers in supercritical carbon dioxide fluid

ActiveCN102296469AIncrease profitInhibit side effectsDyeing processLiquid/gas/vapor textile treatmentPtru catalystNatural fiber

The invention discloses a natural fiber dyeing method in a supercritical carbon dioxide fluid. A natural fiber textile is placed in a supercritical carbon dioxide dyeing unit, which is dispersed with reactive dyes and in a dissolving state; the dyes are adsorbed uniformly on the fiber, and fully diffused in the fiber; and a catalytic fixation of the dyes on the fiber is realized in a 1.0-6.0 MPa carbon dioxide gas medium and with existence of a dye fixation catalyst. According to the invention, dye up-take and dye fixation reaction are conducted in different units and under different conditions, so a side reaction between a large amount of dyes, which are not absorbed, in a fluid and the dye fixation catalyst is avoided, when a dyeing and a dye fixation are carried out in a same bath. Therefore, utilization rate of the dyes and dye fixation catalysis efficiency of the catalyst to the dyes on the fiber during the dye fixation reaction are both increased. The technical method of the present invention has advantages of high dye fixation efficiency, high dye utilization rate, simple technology, green and environment friendliness.

Owner:SUZHOU UNIV

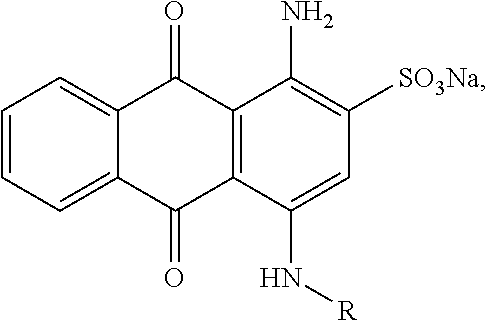

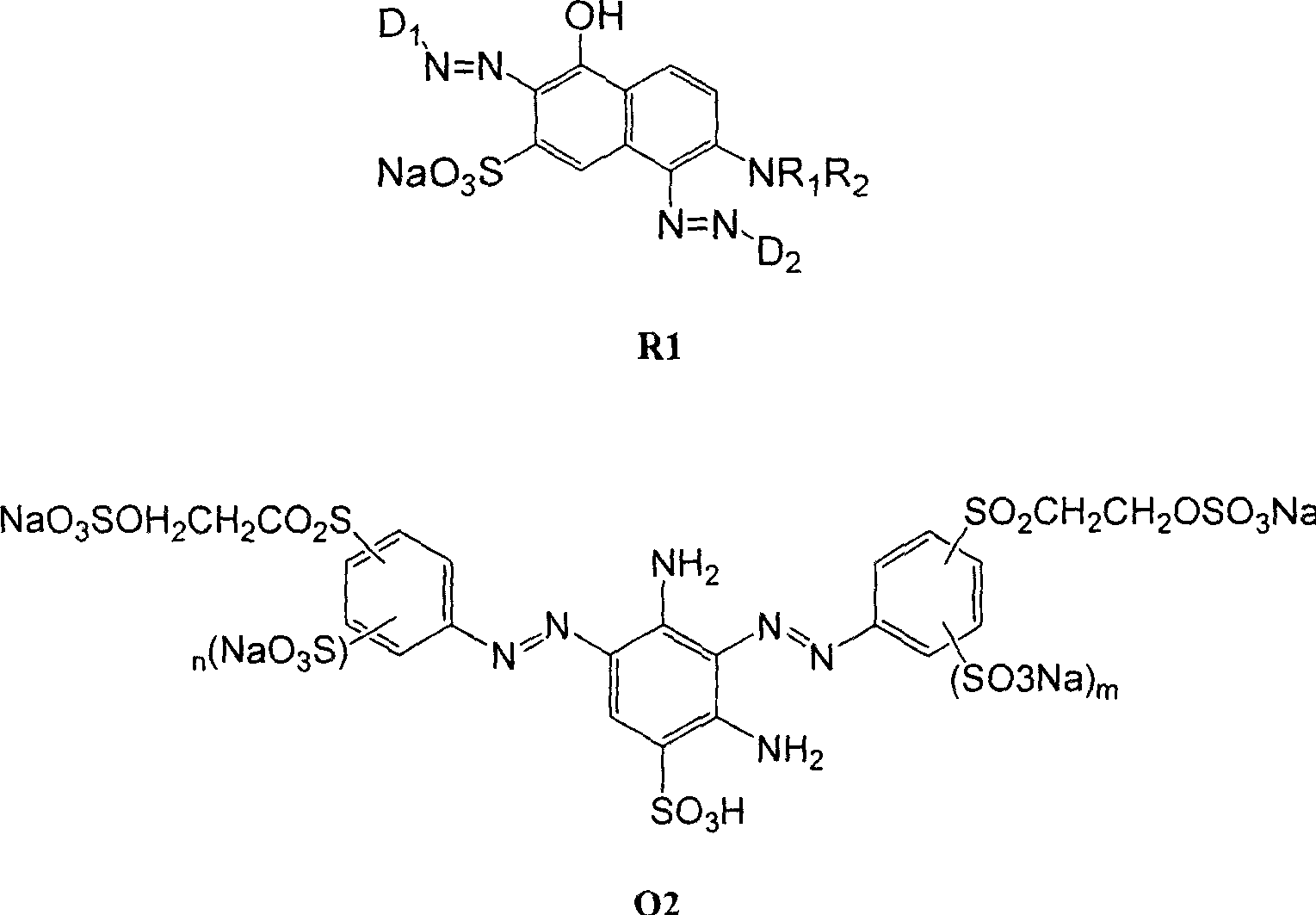

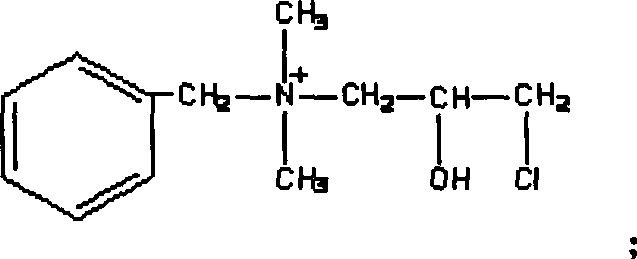

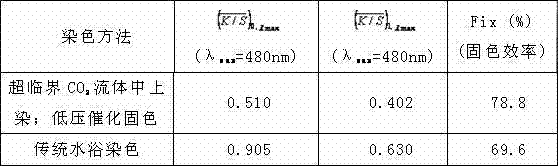

Antibacterial cation reactive dye and preparation and application thereof

InactiveCN101768372AImprove antibacterial propertiesHigh affinityReactive dyesDyeing processFiberChemical structure

The invention relates to an antibacterial cation reactive dye, which comprises 3-phenyl-azo-4-hydroxy-5-[(4,6-dichloro)-1,3,5-triazine]amino-2,7-naphthalene disulfonate as a dye matrix, monochlorotriazine as a reactive group and a long carbon chain quaternary ammonium structure as a water soluble group. The chemical structure is as follows. The preparation method comprises the following steps: stirring and adding the 3-phenyl-azo-4-hydroxy-5-[(4,6-dichloro)-1,3,5-triazine]amino-2,7-naphthalene disulfonate to a polyethylene imine water solution, and isothermally reacting for 2-5 hours to obtain XPEI; then reacting with propylene oxide while stirring at a temperature of 0-5 DEG C for 5-8 hours to obtain TXPEI; and finally adding benzyl chloride, stirring and reacting at a constant temperature of 48-52 DEG C for 6-8 hours, layering the reaction liquid after reaction, and removing unreacted benzyl chloride by extraction to obtain the antibacterial cation reactive dye QXPEI. The antibacterial cation reactive dye has good antibacterial effect, good color fastness, good application prospects on dyeing and antibacterial finish of various fibers, simple preparation method, low cost, environment protection of raw materials, small environment pollution and industrial application prospects.

Owner:DONGHUA UNIV

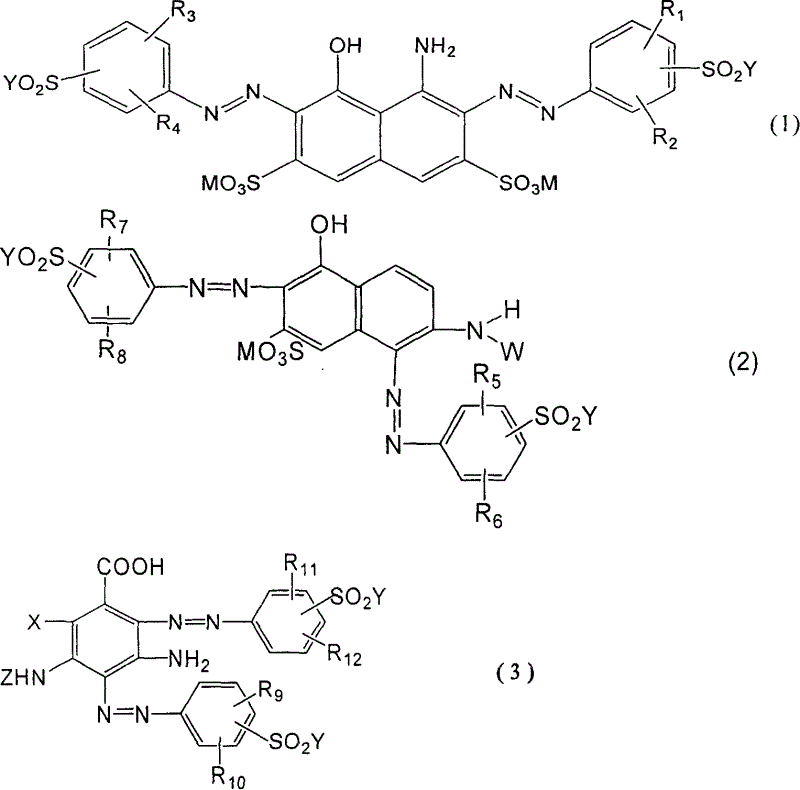

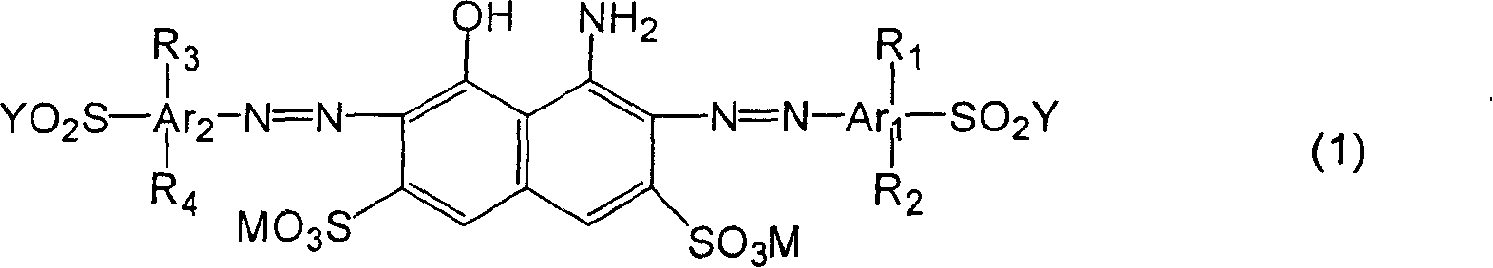

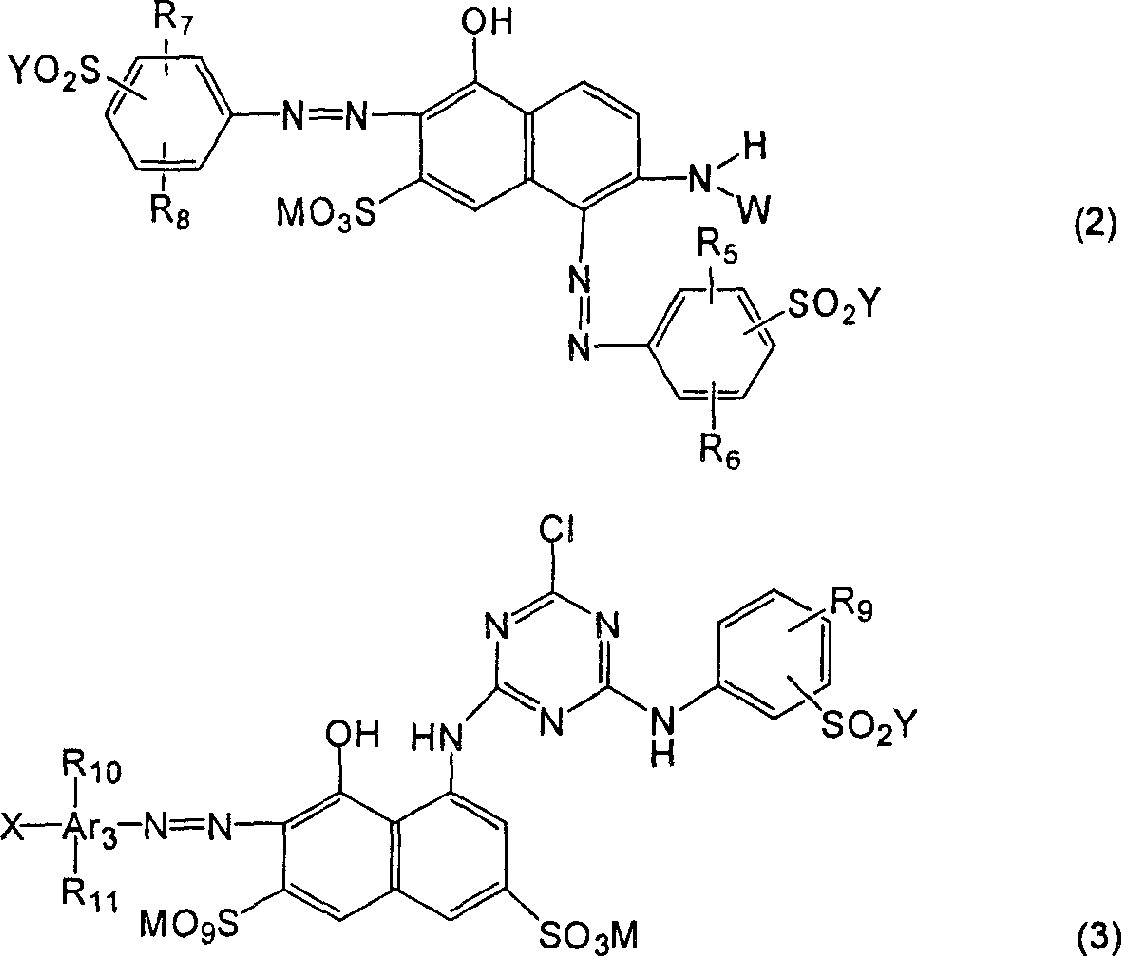

High-concentration composite reactive dye

InactiveCN101117449AImprove dyeing effectHigh color fixing rateOrganic dyesDyeing processHigh concentrationCellulose fiber

A high-concentration composite reactive dye belongs to the fine chemical field, relating to the preparing method of the high-concentration composite reactive dye. The invention is characterized in that: the invention discloses a high-concentration composite reactive dye, which comprises any type or more types of compound formula (I), any type or more types of compound formula (II), any type or more types of compound formula (III) and any type or more types of compound formula (IV); according to the percentage by weight, I to II to III is equal to (5-55) to (20-85) to (0-25), and (I plus II plus III) to IV is equal to (100-50) to (0-50). The invention has the beneficial effects that: remixed black and brown dyes possess high exhaust dyeing rate and color fixing rate and excellent level dyeing property, build-up property and repeatability, thereby the dye is particularly suitable to be used in short liquor ratio dyeing of cellulose fiber and polyamide fiber.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com