Formaldehyde-free fixing agent and preparation method thereof

An aldehyde-free color-fixing agent and regulator technology, which is applied in the field of printing and dyeing auxiliaries, can solve the problems of uneven color-fixing agents and no solution to the fastness to immersion in boiling water, so as to improve the color fastness of various colors and improve the color fastness to washing Fastness and fastness to immersion in boiling water, good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

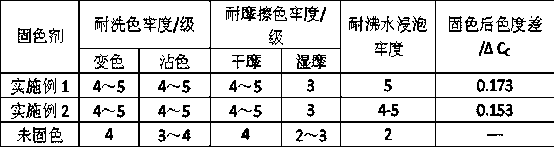

Examples

Embodiment 1

[0030] An aldehyde-free color fixing agent, comprising the following components by weight: 80 parts by weight of cationic monomers, 5 parts by unsaturated higher organic amine monomers, 3 parts by dicyandiamide, 4 parts by pH regulator, Metal ion chelating agent is 0.001 part, initiator is 0.5 part, epichlorohydrin is 2 parts, and deionized water is 20 parts.

[0031] The cationic monomers include dimethyl diallyl ammonium chloride, methacryloxyethyl trimethyl ammonium chloride, diethyl diallyl ammonium chloride and acryloxy ethyl trimethyl One or two of ammonium chloride.

[0032] The unsaturated higher organic amine monomers include allylamine, diallylamine or triallylamine.

[0033] The pH adjusting agent includes citric acid, glacial acetic acid or hydrochloric acid.

[0034] The metal ion chelating agent includes the sodium salt of ethylenediaminetetraacetic acid, the sodium salt of ethylenediaminetetramethylenephosphonic acid, or the sodium salt of aminotriacetic acid.

[0035] ...

Embodiment 2

[0047] The rest is the same as the above embodiment, the difference is that an aldehyde-free color fixing agent includes the following components by weight: 120 parts by weight of cationic monomer, 20 parts by unsaturated higher organic amine monomer, and dicyandiamide It is 10 parts, pH adjuster is 18 parts, metal ion chelating agent is 0.05 parts, initiator is 1 part, epichlorohydrin is 10 parts, and deionized water is 50 parts.

Embodiment 3

[0049] The rest is the same as the above embodiment, the difference is that an aldehyde-free color fixing agent includes the following components by weight: 90 parts by weight of cationic monomer, 9 parts by unsaturated higher organic amine monomer, and dicyandiamide It is 4 parts, pH adjuster is 6 parts, metal ion chelating agent is 0.01 parts, initiator is 0.6 parts, epichlorohydrin is 3 parts, and deionized water is 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com